Cementing material prepared from fly ash and preparation method thereof

A technology for cementitious materials and fly ash, applied in the field of building materials, can solve the problems of less fly ash consumption, high fly ash quality requirements, poor product performance, etc., to achieve less emissions, improve production efficiency and equipment The effect of using efficiency and equipment requirements is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

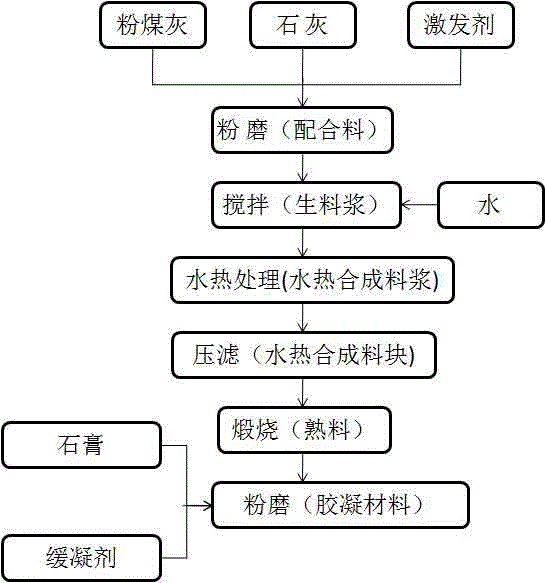

Method used

Image

Examples

Embodiment 1

[0030] A cementitious material using fly ash as a raw material, wherein the batch material contains the following components in parts by mass:

[0031] 78 parts of fly ash

[0032] Lime 22 parts

[0033] Sodium hydroxide 0.5 parts

[0034] Weigh fly ash, lime, and sodium hydroxide according to the above mass ratio, and grind them together until the fineness is 80 μm and the sieve residue is 4.3%. Pour the batch into a mixer, add 150 parts of water and stir for 3 minutes to obtain raw Slurry: hydrothermally treat the raw slurry at 90°C for 14 h in a hydrothermal reaction tank to obtain a hydrothermally synthesized slurry, filter and dehydrate the hydrothermally synthesized slurry to obtain a hydrothermally synthesized block, and calcinate the block at 750°C for 120min Then blow air to cool to obtain clinker; take 92 parts of clinker, 8 parts of dihydrate gypsum, and 0.2 part of sodium gluconate to grind together to 3.4% of the 80 μm sieve to obtain a gelled material. The wat...

Embodiment 2

[0036] A cementitious material using fly ash as a raw material, wherein the batch material contains the following components in parts by mass:

[0037] 62 parts of fly ash

[0038] Lime 38 parts

[0039] Sodium carbonate 2.0 parts

[0040] Weigh fly ash, lime, and sodium carbonate according to the above mass ratio, and grind them together until the fineness is 80 μm, and the sieve residue is 2.8%. Pour the batch into a mixer, add 250 parts of water, and stir for 3 minutes to obtain a raw meal Slurry: hydrothermally treat the raw slurry in a hydrothermal reaction tank at 98°C for 16 h to obtain a hydrothermally synthesized slurry, press filter and dehydrate the hydrothermally synthesized slurry to obtain a hydrothermally synthesized block, and calcinate the block at 950°C for 30 min Then blow air to cool to obtain clinker; take 95 parts of clinker, 5 parts of anhydrous gypsum, and 1.5 parts of sodium phosphate to grind together to 2.9% of the 80 μm sieve to obtain a gelled ma...

Embodiment 3

[0042] A cementitious material using fly ash as a raw material, wherein the batch material contains the following components in parts by mass:

[0043] 70 parts of fly ash

[0044] Lime 30 parts

[0045] Sodium hydroxide 1.0 parts

[0046]Weigh fly ash, lime, and sodium hydroxide according to the above mass ratio, and grind them together until the fineness is 80 μm, and the sieve residue is 3.6%. Pour the batch into a mixer, add 200 parts of water and stir for 3 minutes to obtain raw Slurry: The raw slurry was hydrothermally treated at 95°C for 12 h in a hydrothermal reaction tank to obtain a hydrothermally synthesized slurry, and the hydrothermally synthesized slurry was press-filtered and dehydrated to obtain a hydrothermally synthesized block, which was calcined at 850°C for 60 After 1 min, blow air to cool to obtain clinker; take 94 parts of clinker, 6 parts of anhydrous gypsum, and 1.2 parts of sodium pyrophosphate to grind together to 3.5% of the 80 μm sieve to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com