Patents

Literature

1330 results about "Clinker (cement)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the manufacture of Portland cement, clinker occurs as lumps or nodules, usually 3 millimetres (0.12 in) to 25 millimetres (0.98 in) in diameter, produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stage.

Sludge curing agent and application thereof

ActiveCN101081718AGood boardIncreased durabilitySludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

The present invention is sludge curing agent and its application, and belongs to the field of soil treating chemicals technology. The sludge curing agent includes powdered components and liquid components, the powdered components include cement clinker 30-60 weight portions, slag 30-60 weight portions, lime 3-8 weight portions, gypsum 1-7 weight portions and other sulfates 1-7 weight portions; and the liquid components include polyacrylamide 5-30 weight portions, polyaluminum chloride 0-20 weight portions, mannitol 0-30 weight portions, lignosulfonate 20-80 weight portions, lignosulfonate-iron or chromium ion complex 0-30 weight portions, alkylphenol ethoxylate 0.2-2 weight portions, tannin 0-10 weight portions, humate 0-10 weight portions, and alpa-olefin sulfonate 0.2-2.5 weight portions. The sludge curing agent has low cost, small consumption, high cumulate strength and high cumulate water tolerance, and may be applied widely.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

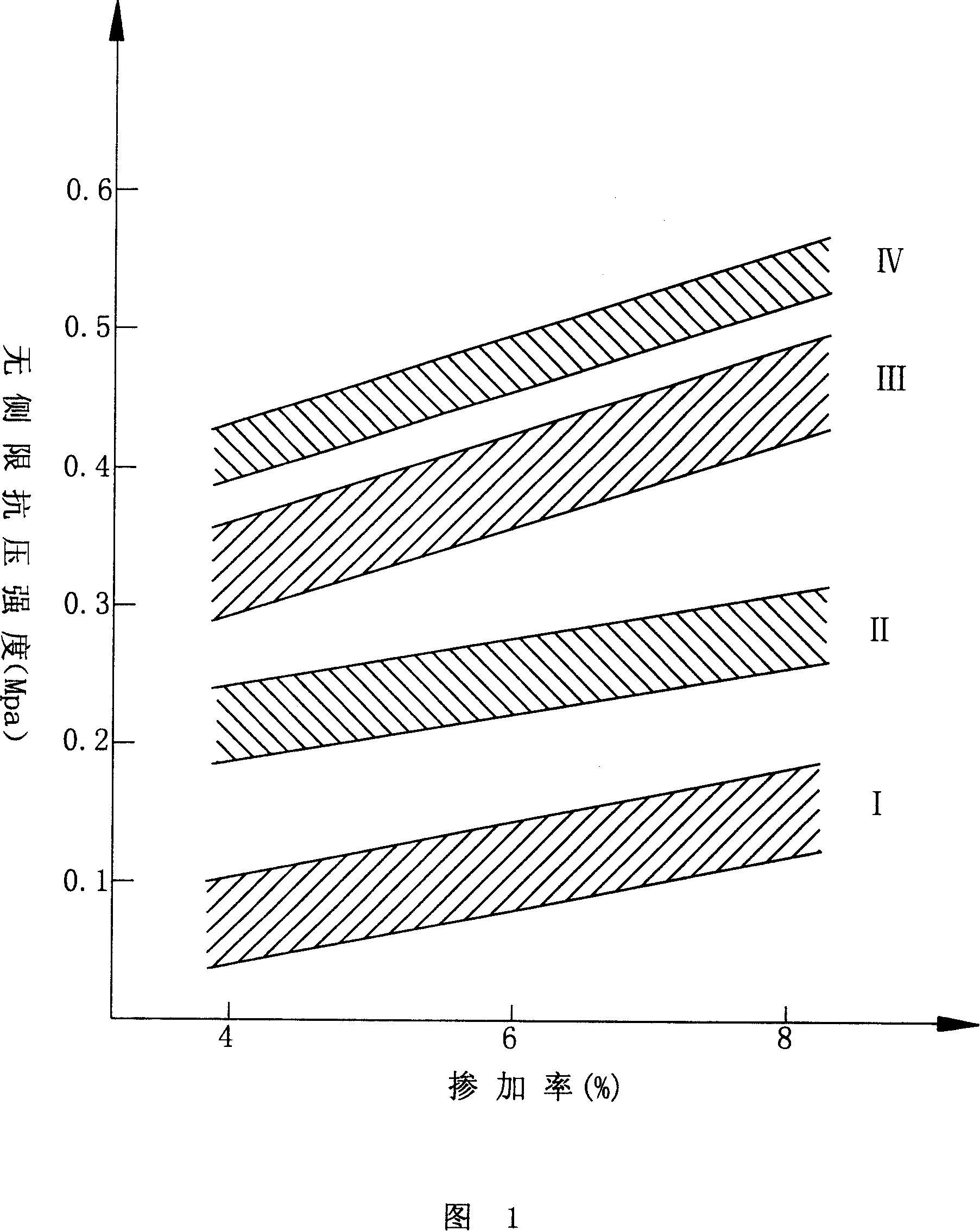

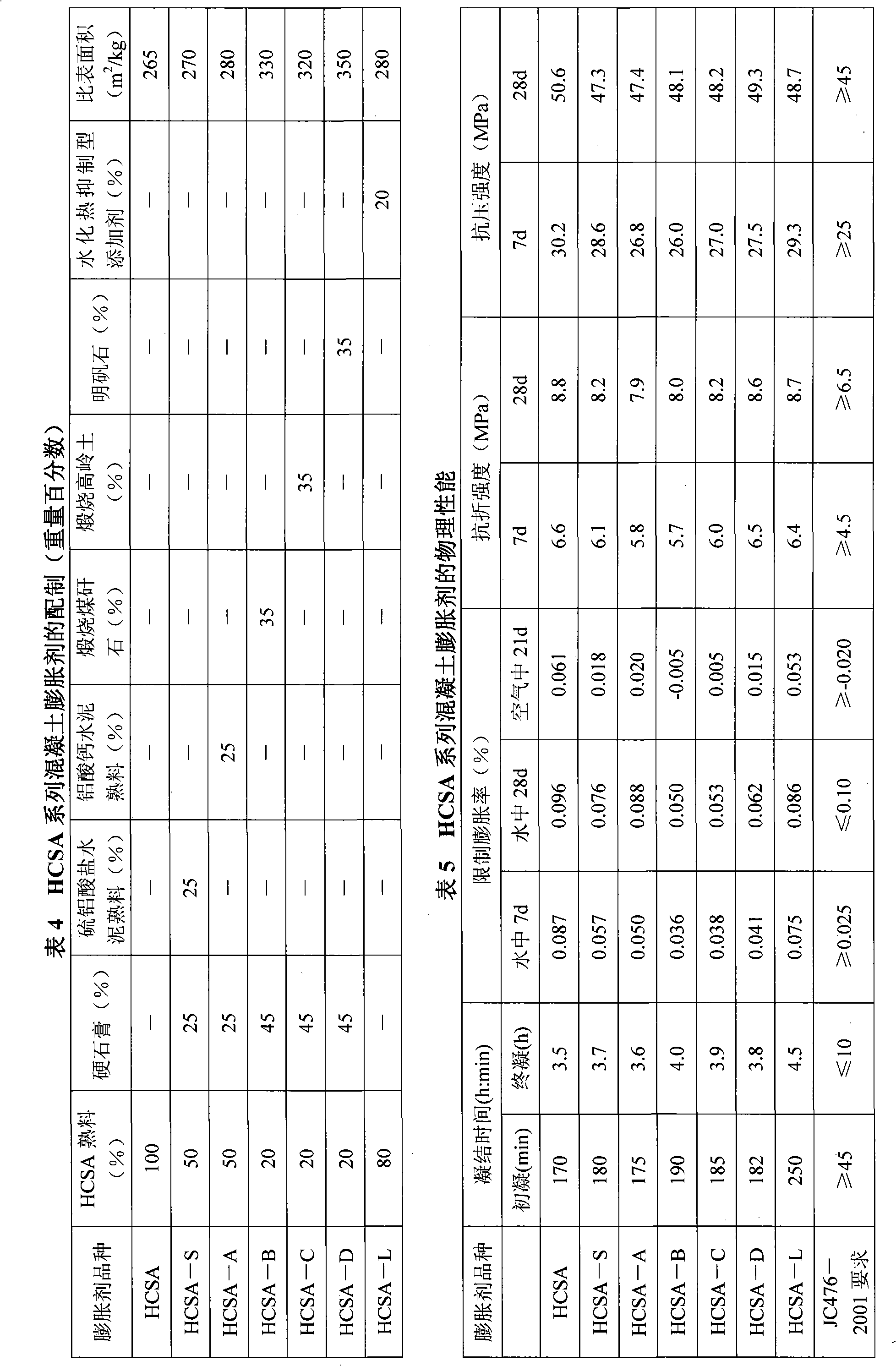

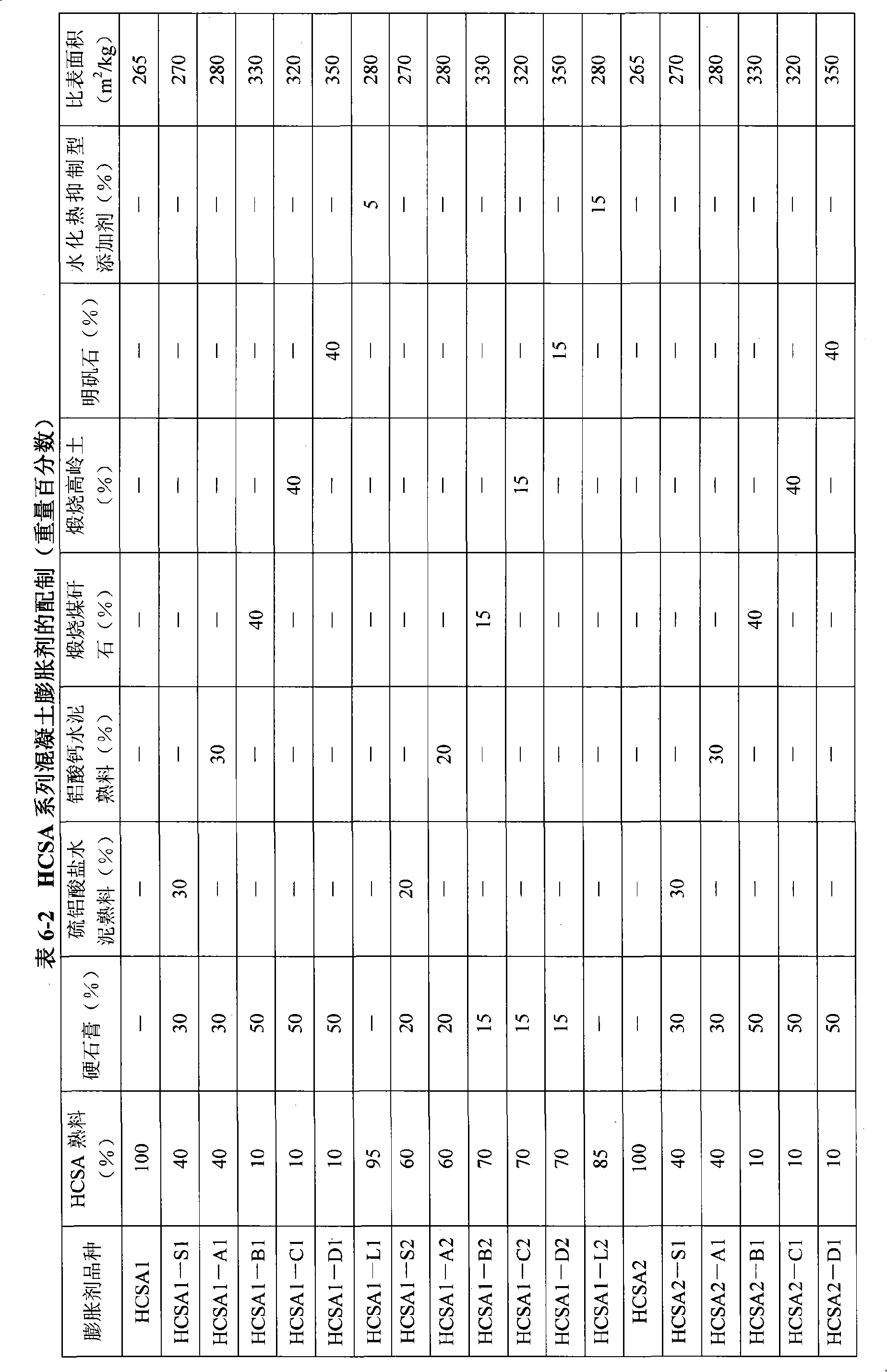

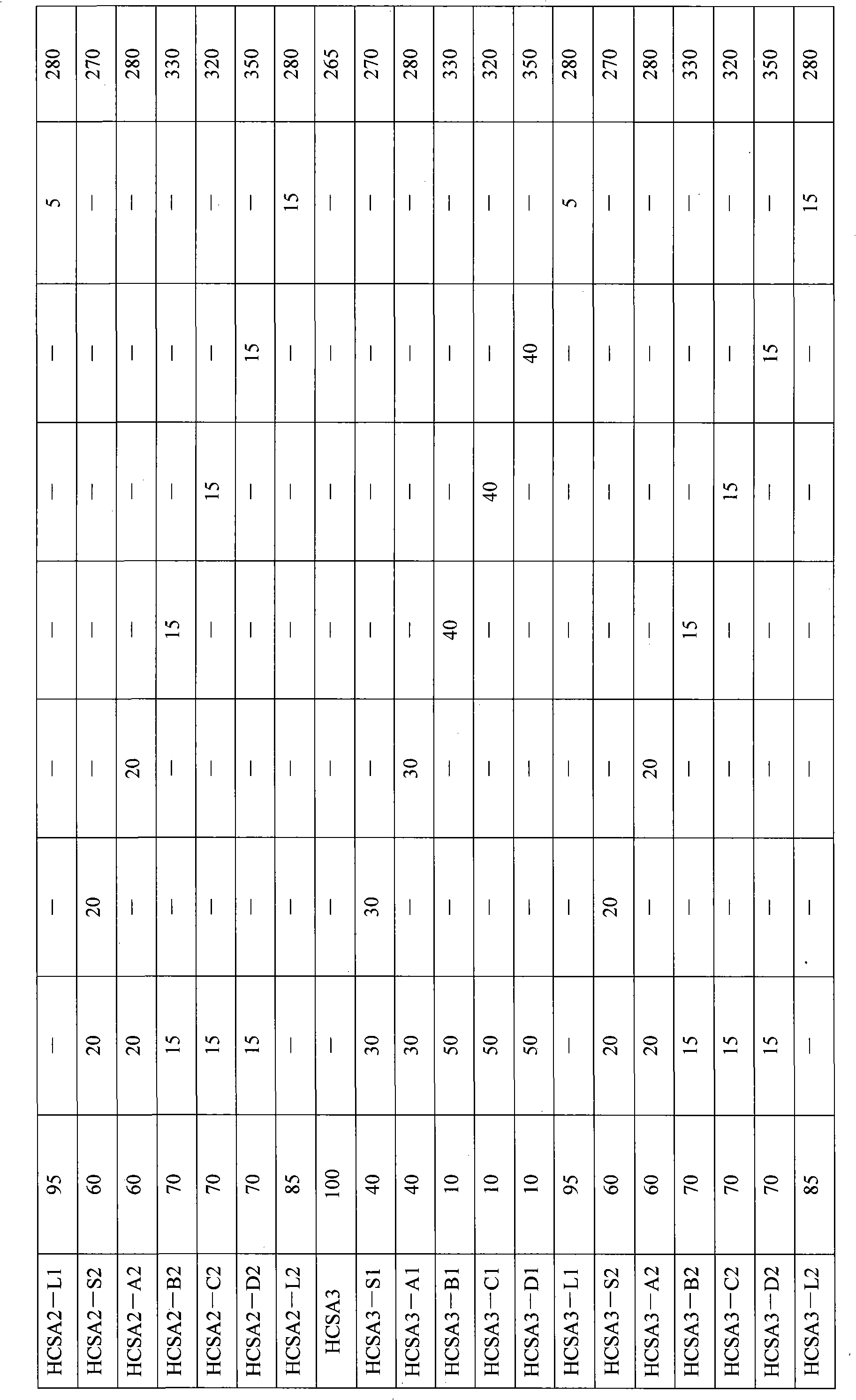

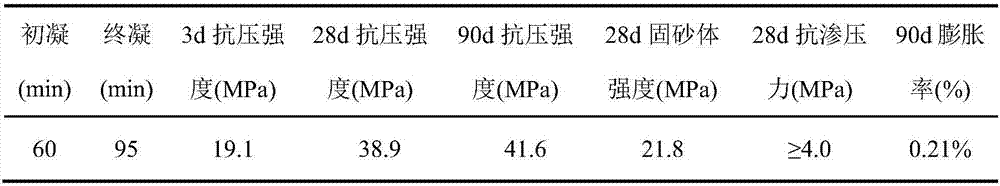

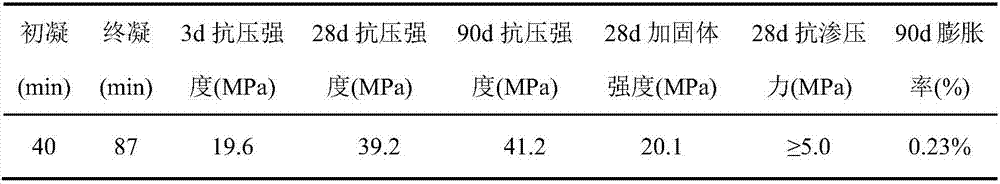

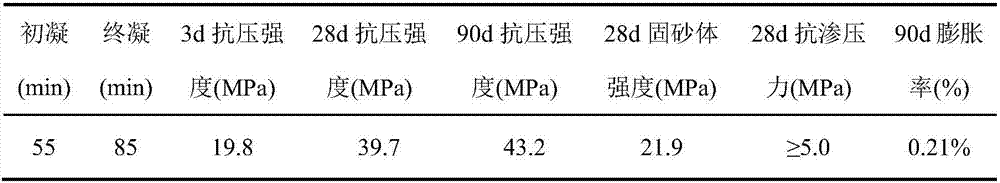

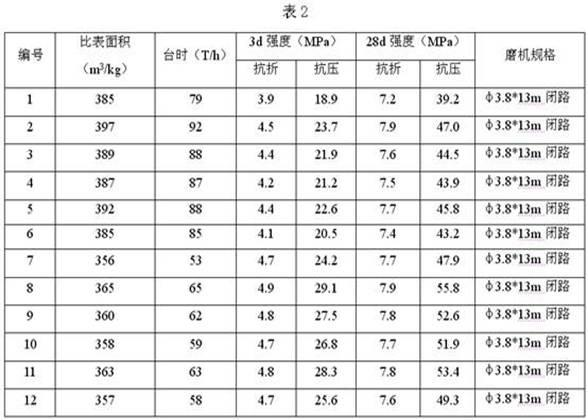

High performance expansible cement clinker expansion agent series prepared thereby

Disclosed are a high-performance expansion cement clinker, a manufacturing method of the cement clinker, a series concrete expansion agent and a manufacturing method of the concrete expansion agent. The high-performance expansion cement clinker is made as follows: firstly, 50-90 wt% of limestone, 1-20 wt% of bauxite, 5-30 wt% of gypsum and 1-5 wt% of iron powder are grinded together into raw meal, then the raw meal is calcined at 1250-1400 DEG C in a rotary kiln, a tunnel kiln or a roller kiln to get the cement clinker. The cement clinker is milled alone or in combination with sulfur calcium aluminate cement clinker, calcium aluminate cement clinker, anhydrite, calcined gangue, alunite, calcined kaolin and hydration heat inhibiting additives until the specific surface area reaches 200-400m2 / kg, so as to get the series concrete expansion agent. The high-performance expansion cement clinker disclosed in the invention is calcium hydroxide-hydrated calcium aluminate sulfate double-expansion source expansion clinker, which is fast in expansion rate and high in expansion efficiency and uses less bauxite of scarce resources; besides, the calcination temperature is low to avoid calcium oxide dead burning, so the preparation is safe and reliable.

Owner:CHINA BUILDING MATERIALS ACAD

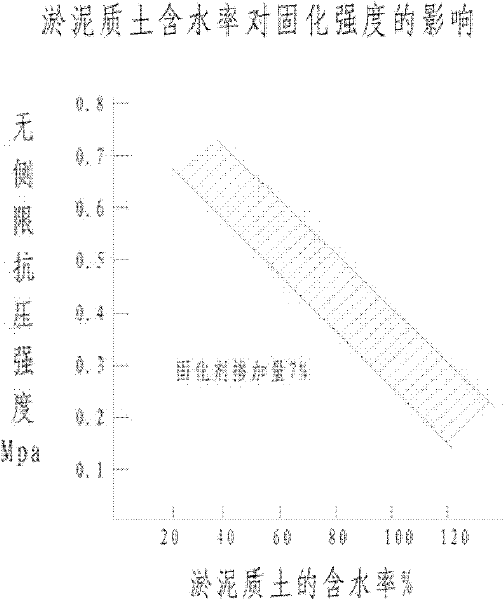

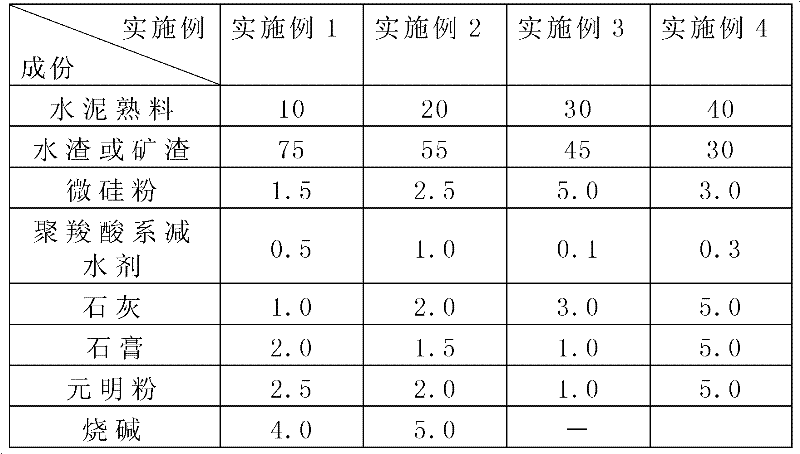

Curing agent for curing marine poor subsoil

ActiveCN102344813ASimple ingredientsCompatibility is reasonableBuilding constructionsOrganic fertilisersSlagSodium silicate

The invention relates to a curing agent for curing marine poor subsoil, which belongs to the technical field of poor subsoil curing. The curing agent for curing the marine poor subsoil is composed by the components of cement clinker, granulating slag or slag, silica fume, polycarboxylic acid type water-reducer, lime, plaster, anhydrous sodium sulphate, caustic soda, sodium silicate and sodium fluosilicate. The adulteration amount of the poor subsoil curing agent is 5%-12% in application, good curing functions can be realized, and the curing agent for curing the marine poor subsoil can be applied in the poor soil curing of building sites, road embankments, roadbeds and ground base layers. The invention has the advantages that: the components of the curing agent are simple, the compatibility is reasonable, the doping amount is less, and the curing effect is good; and during the application process, the construction period is short, the construction cost is low, the induration bearing capacity is high, the induration compression modulus is strong, and the induration permeable resistance is strong.

Owner:徐辰楚 +1

Biomass-derived grinding aids

Compositions and methods for increasing grinding efficiency of cement, cement clinker, raw materials for cement, and other inorganic particles. Use of biomass-derived polyols such as diols, triols, or mixtures thereof, optionally with a conventional grinding aid, cement quality improver, and / or hexavalent chromium reducer, are believed to provide less risk of sludging when compared to glycerides obtained from fossil fuel sources.

Owner:GCP APPL TECH INC

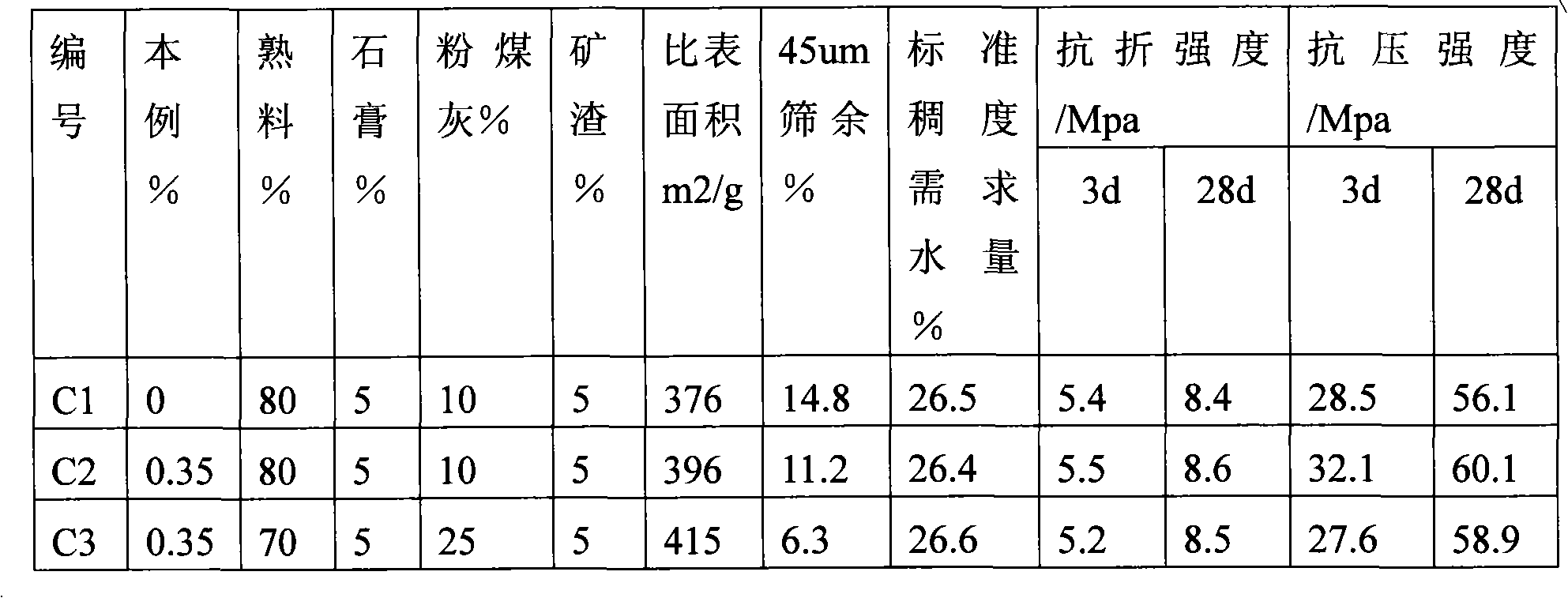

Chlorine-free powdery cement grinding aid and preparation method thereof

InactiveCN101665338AHigh strengthStrong compound synergistic effectCement productionSulfateLignosulfonates

The invention discloses a chlorine-free powdery cement grinding aid suitable for fly ash, which comprises the following components in parts by weight: 0-5 parts of alkanolamine, 2-5 parts of polylol,15-75 parts of sulfate, 5-20 parts of acetate, 0-5 parts of lignosulphonate, 2-6 parts of carbohydrate organic matter, 5-25 parts of miltonite, 0-25 parts of carbamide and 5-50 parts of inorganic carrier material. The invention also discloses a preparation method of the chlorine-free powdery cement grinding aid suitable for the fly ash. A compound grinding aid can lower the cement cost and uses the fly ash for replacing partial clinker to save the clinker dosage by 10-15 percent on the premise of keeping the cement strength unchanged, and uses extra 10-15 parts of fly ash without increasing the required water amount of cement standard consistency; the cost of the cement per ton is lowered by more than 10 Yuan.

Owner:NANJING ZHUJI ENERGY SAVING TECH

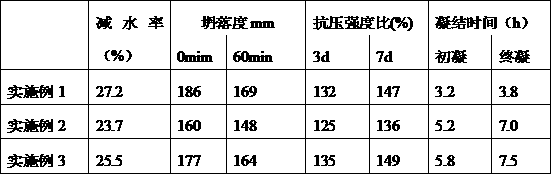

Alkali-activated high-performance water reducer and preparation method thereof

ActiveCN103011662AHigh water reduction rateEnhancement effect is goodBlack liquorProcess engineering

The invention discloses an alkali-activated high-performance water reducer and a preparation method thereof. The alkali-activated high-performance water reducer comprises a composite alkali-activator, a composite water reducer, black liquor of a paper mill, a composite retarder, a composite air entraining agent, a composite thickener, a composite regulator and the balance of water. The preparation method for the alkali-activated high-performance water reducer comprises the following steps of: adding the components and water to a reaction kettle in sequence; and mixing and carrying out a reaction on the components and the water under the room-temperature environment to obtain the finished product. The alkali-activated high-performance water reducer disclosed by the invention can activate the cementitious activity of the mixed materials such as slag, coal ash, gangue and the like, has excellent adaptability to different cements and highly doped concrete, and can greatly reduce the adding amount of cement clinker. The alkali-activated high-performance water reducer has the characteristics of a high water-reducing agent, good peaceability, a remarkable reinforcing effect, a good collapse preventing effect, adjustable setting time and the like. Moreover, the external additive has a simple production process, no pollution, low energy consumption and low cost, can solve an environmental pollution problem of the black liquor of the paper mill, and has good practicability.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

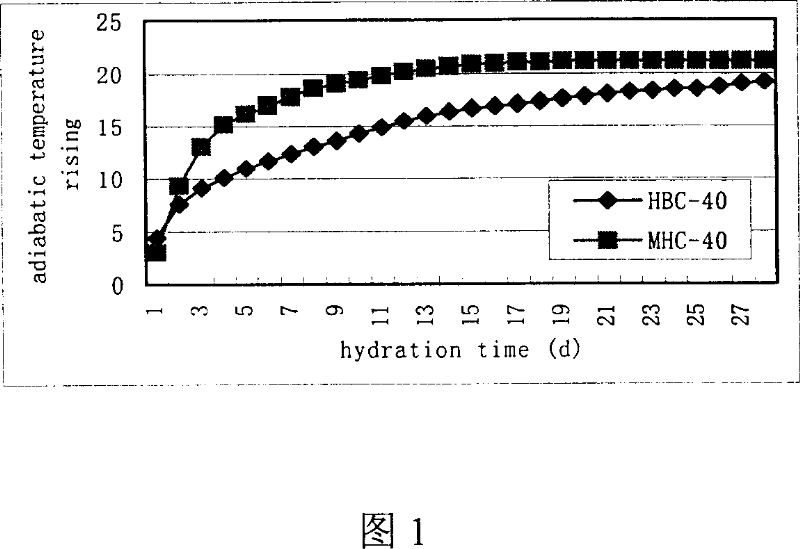

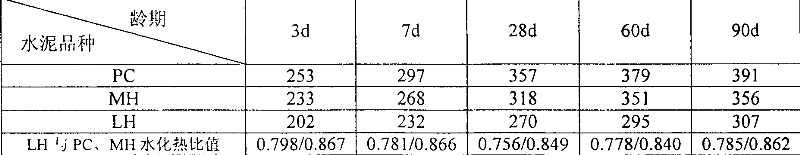

High-magnesium low-heat portland cement clinker aggregate and preparation method thereof

InactiveCN101041560AImprove crack resistanceLow heat of hydrationClinker productionHigh magnesiumPortland cement

The invention discloses a high-magnesium lower thermal silicate cement clinker, making mineralogical composition at (mass percent): 40 -65% C2S, 15-40% C3S, 1-8% C3A, 10-25% C4AF and content of MgO at 2.0-6.0%. The invention also discloses a preparing method of high-magnesium lower thermal silicate cement clinker, including indispensable steps of producing cement clinker with raw materials and controlling content of MgO of cement clinker at 2.0-6.0%.

Owner:CHINA BUILDING MATERIALS ACAD

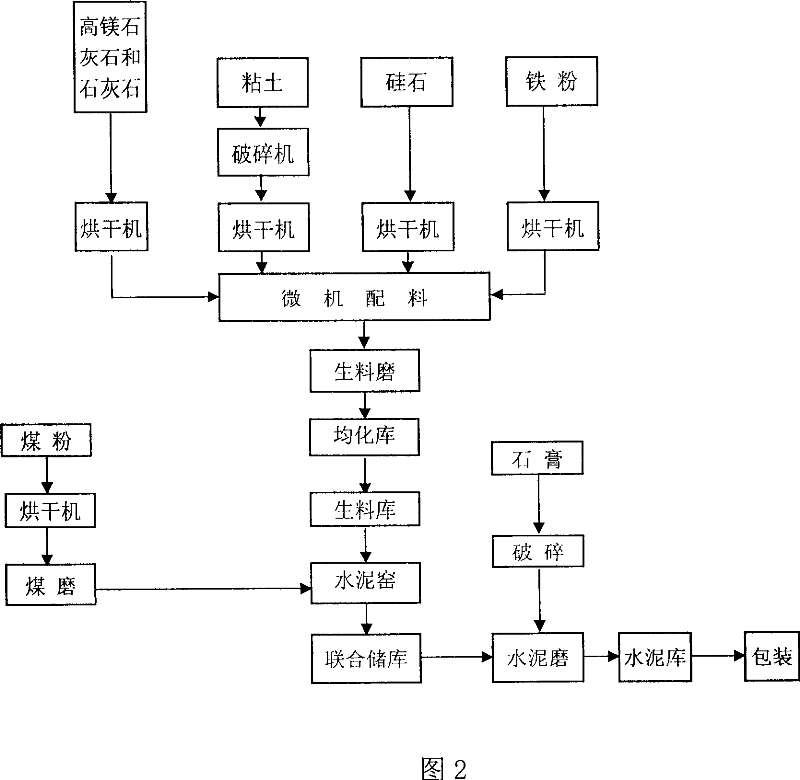

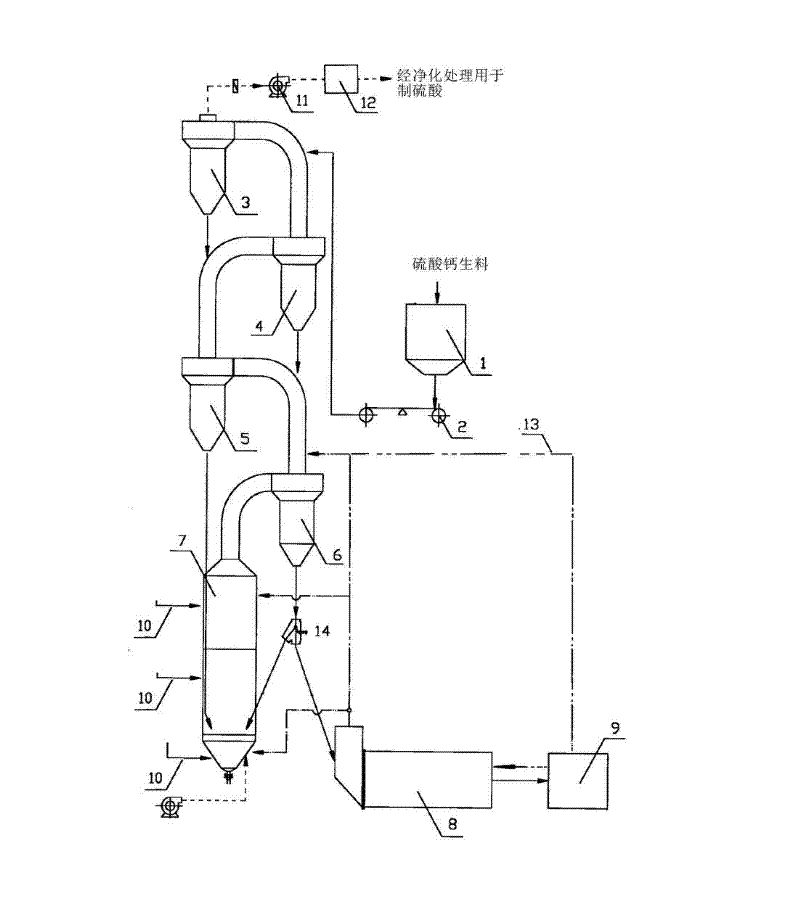

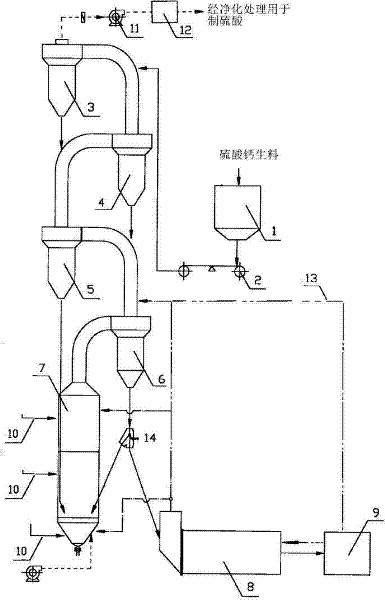

Method for producing sulphate aluminum cement

The invention relates to a method for producing sulphate aluminum cement. The method comprises the following steps: preparing cement raw meal by proportioning limestone, phosphogypsum, low grade alumina and coke; uniformly grinding and calcining at high temperature; in the calcining process, promoting phosphogypsum to be decomposed as much as possible; replacing partial limestone by calcium oxide generated by decomposition; collecting sulfur dioxide to prepare sulfuric acid; and adding natural dihydrate gypsum in the cement clinker and grinding to prepare a cement product. Compared with the existing conventional production methods, according to the method, the utilization of phosphogypsum can be greatly improved, the utilization concentration of sulfur dioxide discharged by decomposition of little gypsum in the production process can be guaranteed to be reached, the use level of limestone is further reduced and emission of carbon dioxide is reduced. Cement calcined is wide in adaptability, can be widely applied to production of sulphate aluminum cement by phosphogypsum, and further can be suitable for producing high early strength cement, expansive cement and the like.

Owner:CHONGQING UNIV

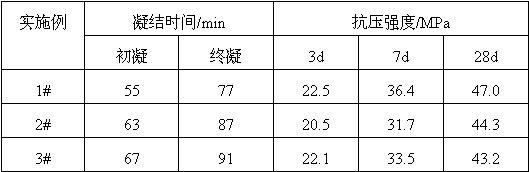

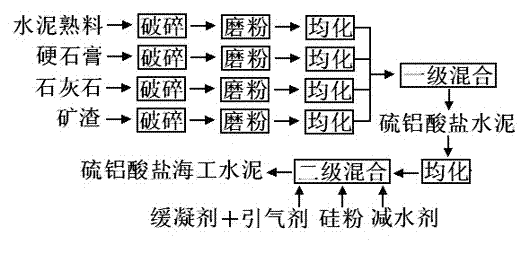

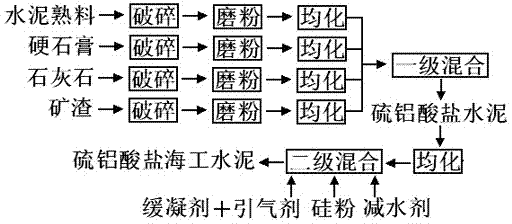

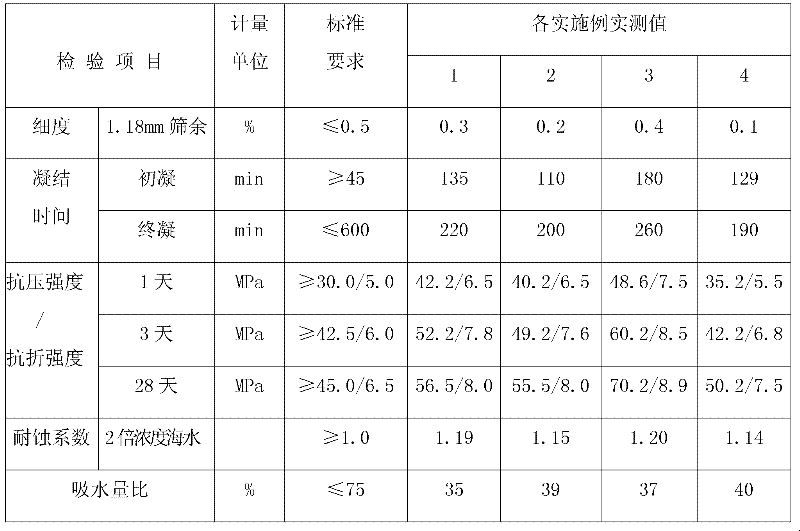

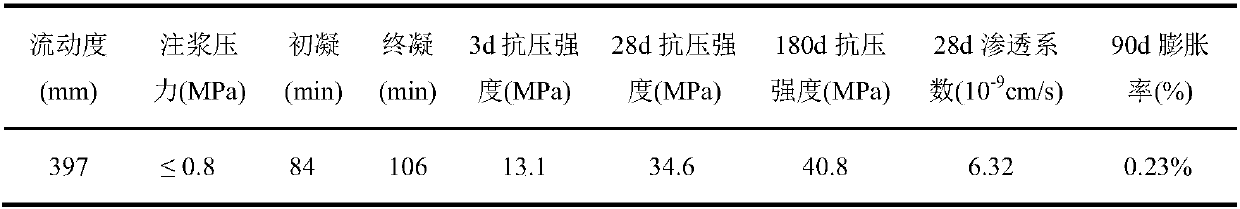

Sulphoaluminate maritime work cement and preparation method thereof

The invention discloses sulphoaluminate maritime work cement and a preparation method thereof. The sulphoaluminate maritime work cement comprises the following main raw materials in parts by weight: 50-80 parts of cement clinker, 8.0-20 parts of anhydrite, 0-30 parts of limestone, 0-30 parts of slag, 0.1-0.5 part of water reducing agent, 0.001-0.005 part of air entraining agent, 0.1-0.5 part of retarder and 2-5 parts of silicon powder. The preparation method comprises the following steps of: respectively smashing, grinding and homogenizing the sulphoaluminate cement clinker, the anhydrite, the limestone and the slag; then, burdening at a ratio, and evenly mixing; adding the water reducing agent, the air entraining agent, the retarder and the silicon powder; and mixing and homogenizing to obtain the product. The concrete mixed by the sulphoaluminate maritime work cement has the advantages of small bleeding rate and high slurry viscidity. The slurry has strong covering and supporting action on aggregate. The concrete keeps good homogeneity and has the advantages of hard and quick early strength, continuously-increased later strength, good slurry structure compactness and high volume stability and is convenient to use and operate for constructing.

Owner:广西云燕特种水泥建材有限公司

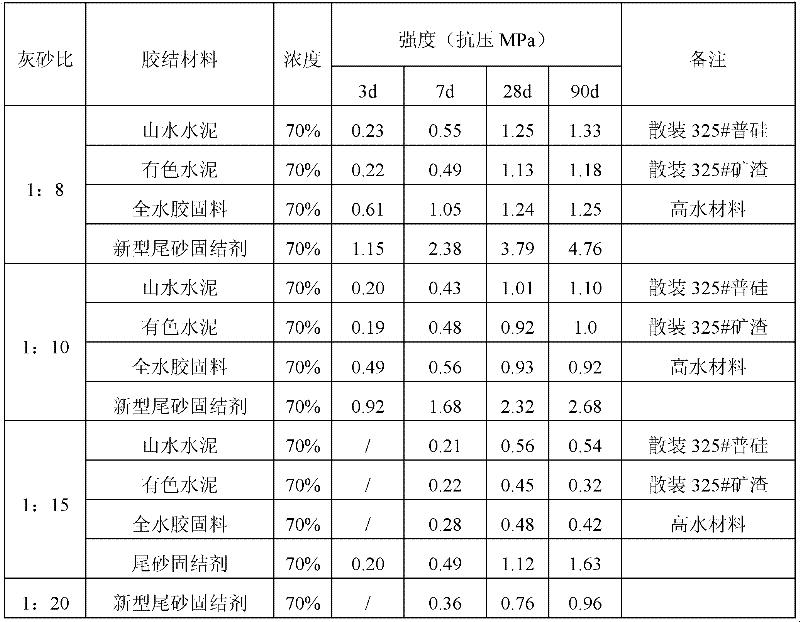

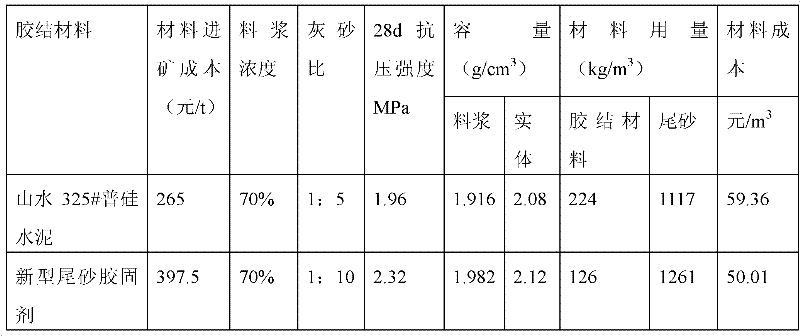

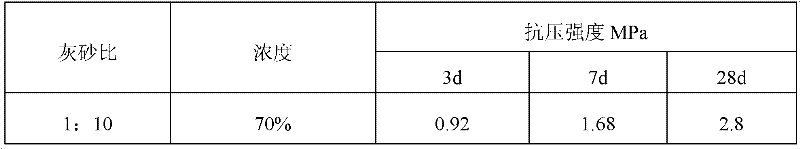

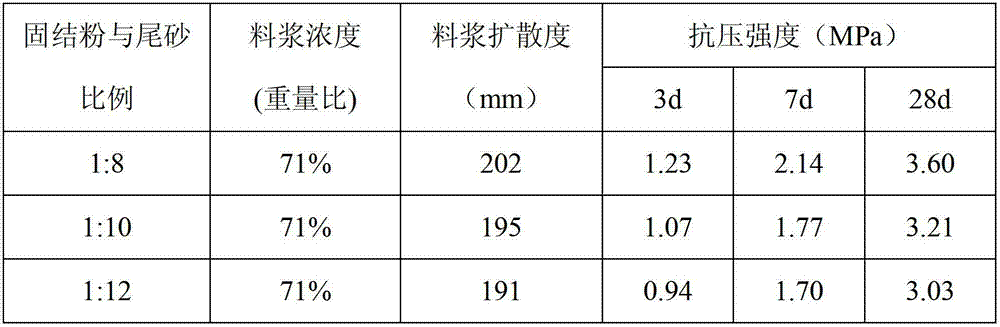

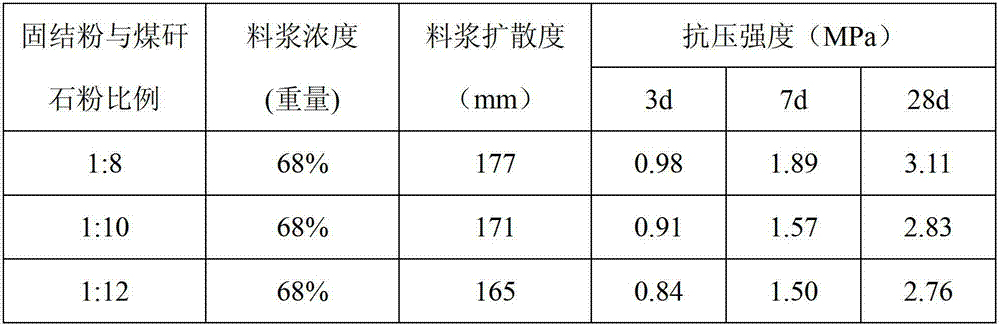

Novel tailing consolidator and preparation method thereof

The invention concretely relates to a novel tailing consolidator which uses fine powder ground from blast furnace water quenching slag as a main raw material and a preparation method of the consolidator. The consolidator is characterized in that the consolidator comprises, by mass concentration, 9 % to 17.54% of portland cement clinker, 10% to 17.54% of anhydrite, 6% to 10% of quicklime, 0.2 to 6 thousandths of Na2SO4, 0.2 to 0.5 thousandths of carboxymethyl cellulose, 5% to 10% of coal ash and 43.65% to 69.96% of the fine powder ground from the blast furnace water quenching slag. Each above component is dried by a dryer, put in a mixer to be evenly stirred, and conveyed to a bowl mill by a belt conveyer to be ground. The blast furnace slag discharged from a smeltery is used as the main raw material in the invention to reduce the cost and solve slag processing, so the consolidator has the advantages of low production cost, simple processing, and agile and convenient usage. A usage amount of the consolidator in the present invention is half or less than the usage amount of common cement under the same conditions with the same backfilling intensity.

Owner:淄博乾耀固结材料有限公司

Calcium-based catalytic desulfurization agent for cement kiln

ActiveCN105779074AGuarantee high temperature sulfur fixationReduce pollutionSolid fuelsFuel additivesIron oxideMagnesium

The invention discloses a calcium-based catalytic desulfurization agent for a cement kiln.The calcium-based catalytic desulfurization agent comprises calcium hydroxide, calcium oxide, iron oxide, magnesium oxide, barium carbonate and a rare element compound, and the desulfurization agent is added into the kiln together with cement raw materials so as to lower the concentration of SO2 generated by flue gas emission of the cement kiln.According to the calcium-based catalytic desulfurization agent, a tiny amount of the calcium-based catalytic desulfurization agent is blended into the raw materials, potential of pulverized coal combustion of the new dry process cement kiln can given fully play, high temperature sulfur fixation of the cement kiln is guaranteed, meanwhile, SO2 emitted into air due to the high sulfur content of the raw materials can be effectively lowered, air pollution is reduced, and in addition, no adverse impact is generated to performance of cement clinker; meanwhile, the calcium-based catalytic desulfurization agent is easy to produce and operate, and great practical significance is achieved for solving the problems of cement industry energy crisis and environmental pollution.

Owner:广东万引科技股份有限公司

Light thermal-shield refractory castable

InactiveCN101792294ALight weightImproved thermal shock stabilitySolid waste managementCapacitanceMullite

The invention relates to a light thermal-shield refractory castable comprising the following components in percentage by weight: 40-60% of light aggregate, 10-20% of capacitance mullite, 5-10% of kyanite powder, 5-10% of high-aluminium clinker powder, 3-8% of silica micro powder, 3-8% of alpha-Al2O3 micro powder, 5-10% of high-aluminium cement, 0.5-10% of high-aluminium refractory fibre containing zirconium, 1.5-4% of thermal-shield steel fibre, 0.1-1% of melamine and 0.05-0.1% of organic anti-explosion fibre, wherein the granularity of the capacitance mullite is less than or equal to 1 mm, both the granularity of the silica micro powder and the granularity of the alpha-Al2O3 micro powder are less than or equal to 5 mu m, and the chemical modified light aggregate is obtained by drying after the light aggregate is dipped in inorganic chemical solution or sol. The light thermal-shield refractory castable of the invention can improve the service life of a furnace roller, lowers production consumption cost, reduces non-working hours caused by exchanging rollers and improves production efficiency.

Owner:武钢集团有限公司

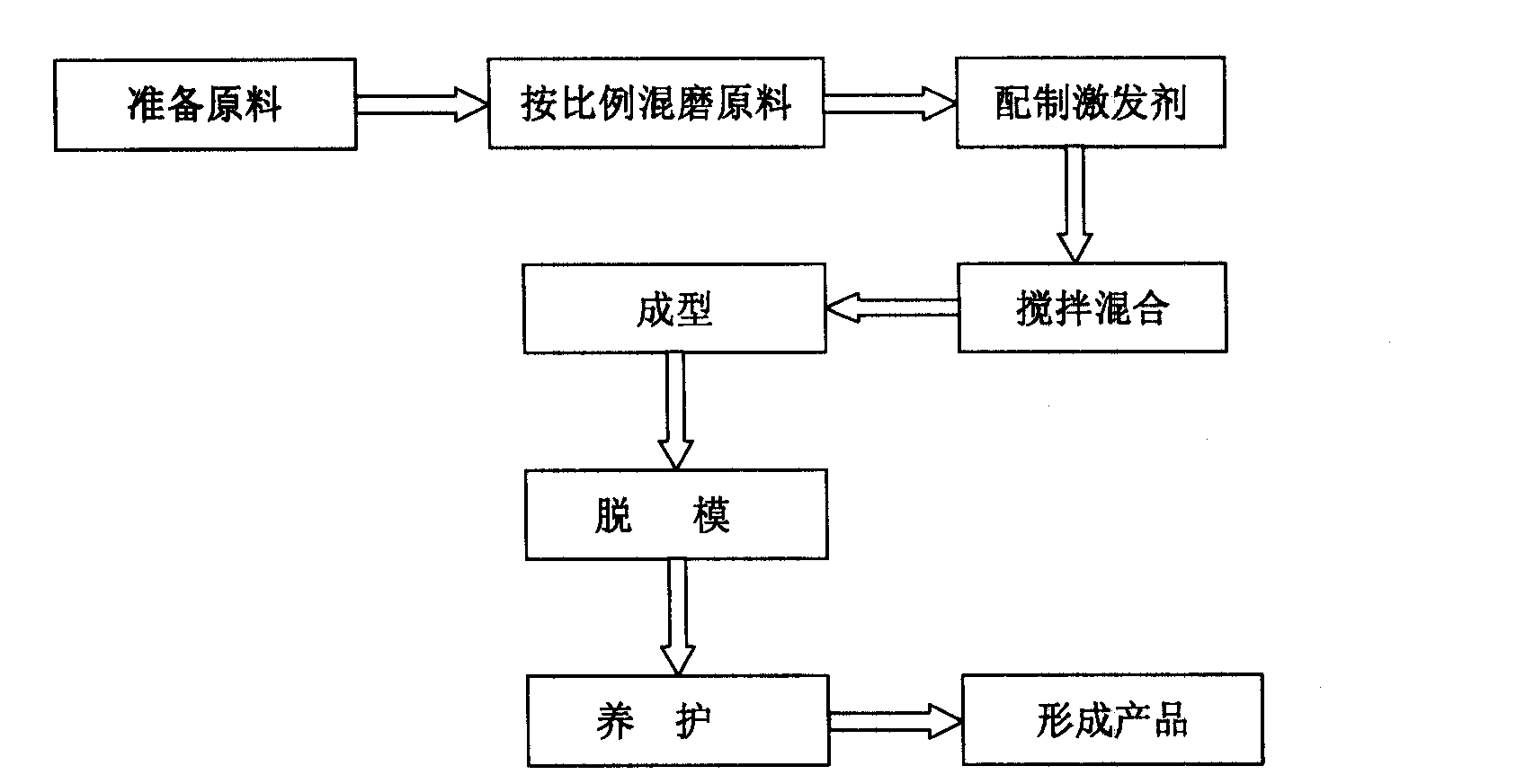

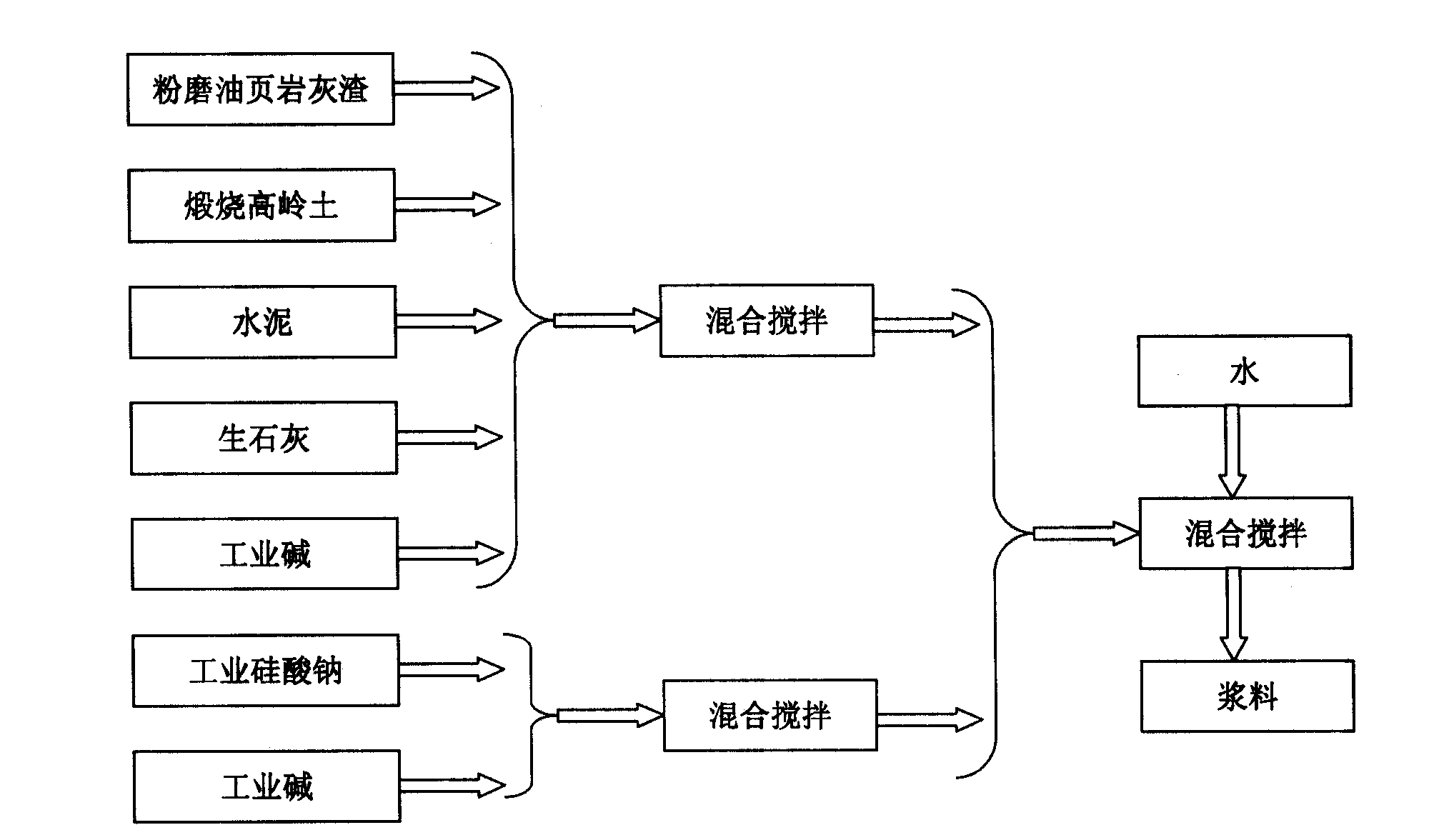

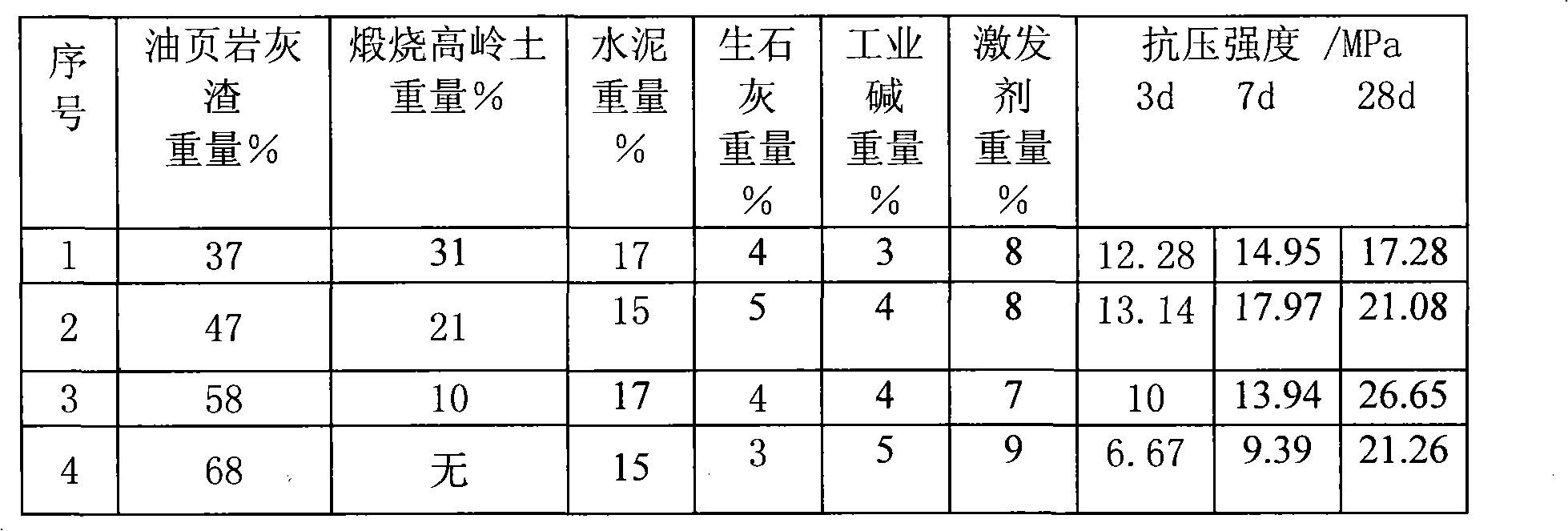

Wax shale gray slag base polymer gelled material

The invention relates to a cementing material of an oil shale clinker matrix polymer and a preparation method thereof, and belongs to the field of environment-friendly materials. The cementing material comprises the following components in percentage by weight: 30 to 70 percent of oil shale clinker with the particle diameter of 200 meshes, 0 to 70 percent of low-temperature calcined kaolin with particle diameter of 200 meshes, 0 to 10 percent of calcium lime with the fineness of 150 meshes, 5 to 30 percent of P32.5 cement, and 5 to 10 percent of exciting agent, wherein the exciting agent is a mixed solution of industrial sodium silicate of which modulus M is 3.3 and industrial alkali. The cementing material can replace the prior cementing material gypsum and cement, and is suitable for manufacturing stone imitated artworks, embossing wall bricks, sculptures and ground tiles for building decoration and products such as hollow bricks, light bricks, and the like for building materials. The cementing material has low cost and performance superior to the prior material.

Owner:FUSHUN MINING IND GROUP

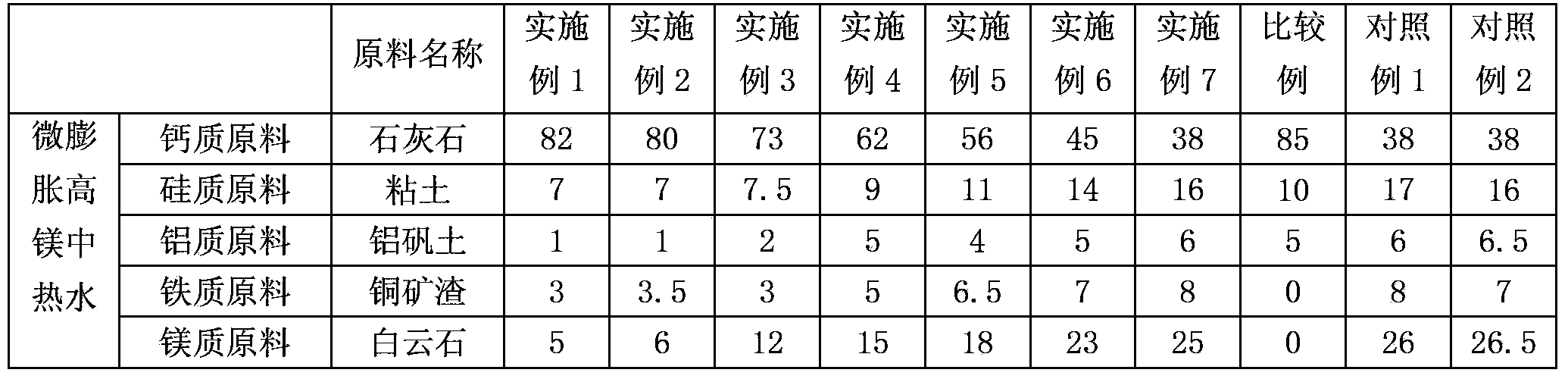

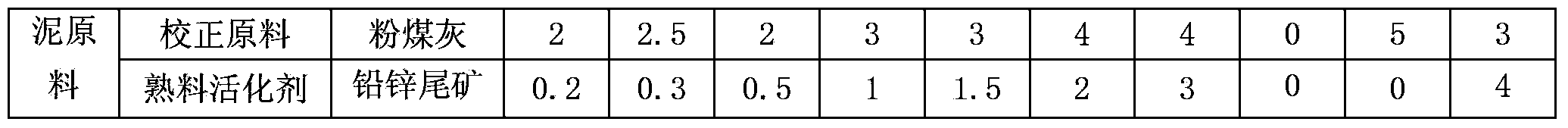

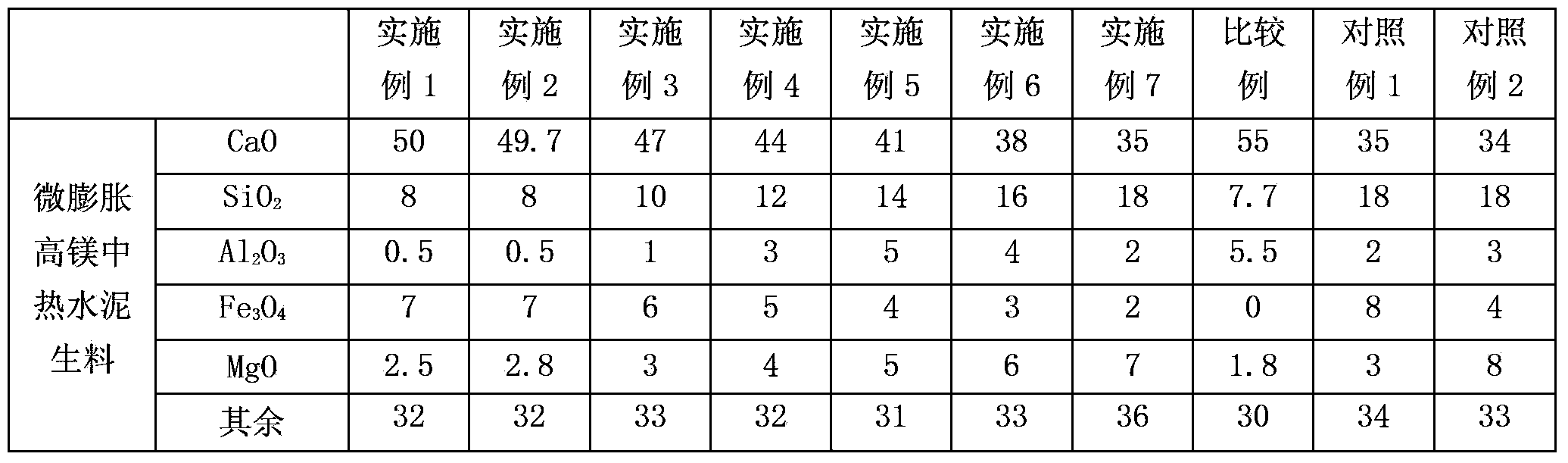

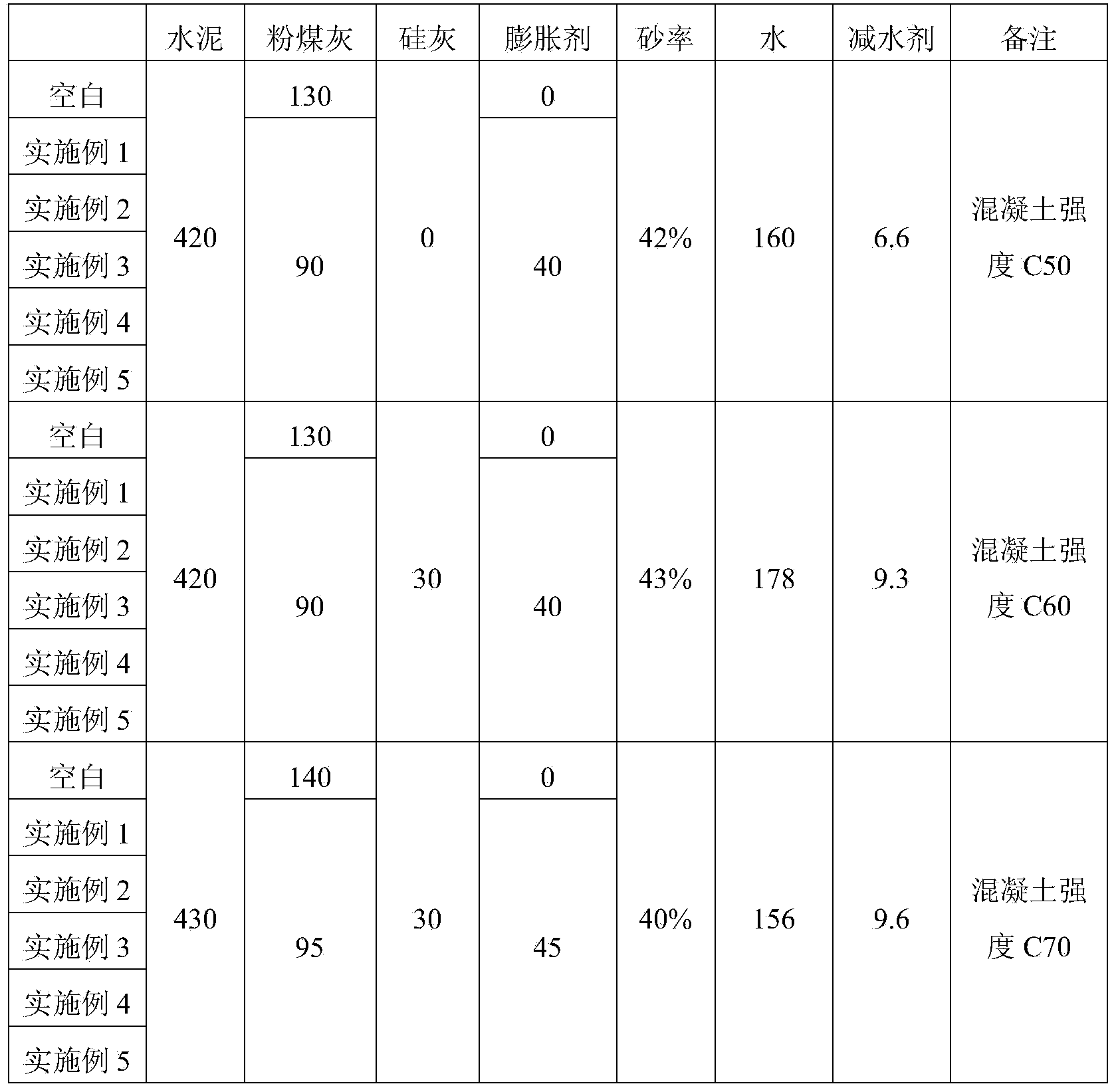

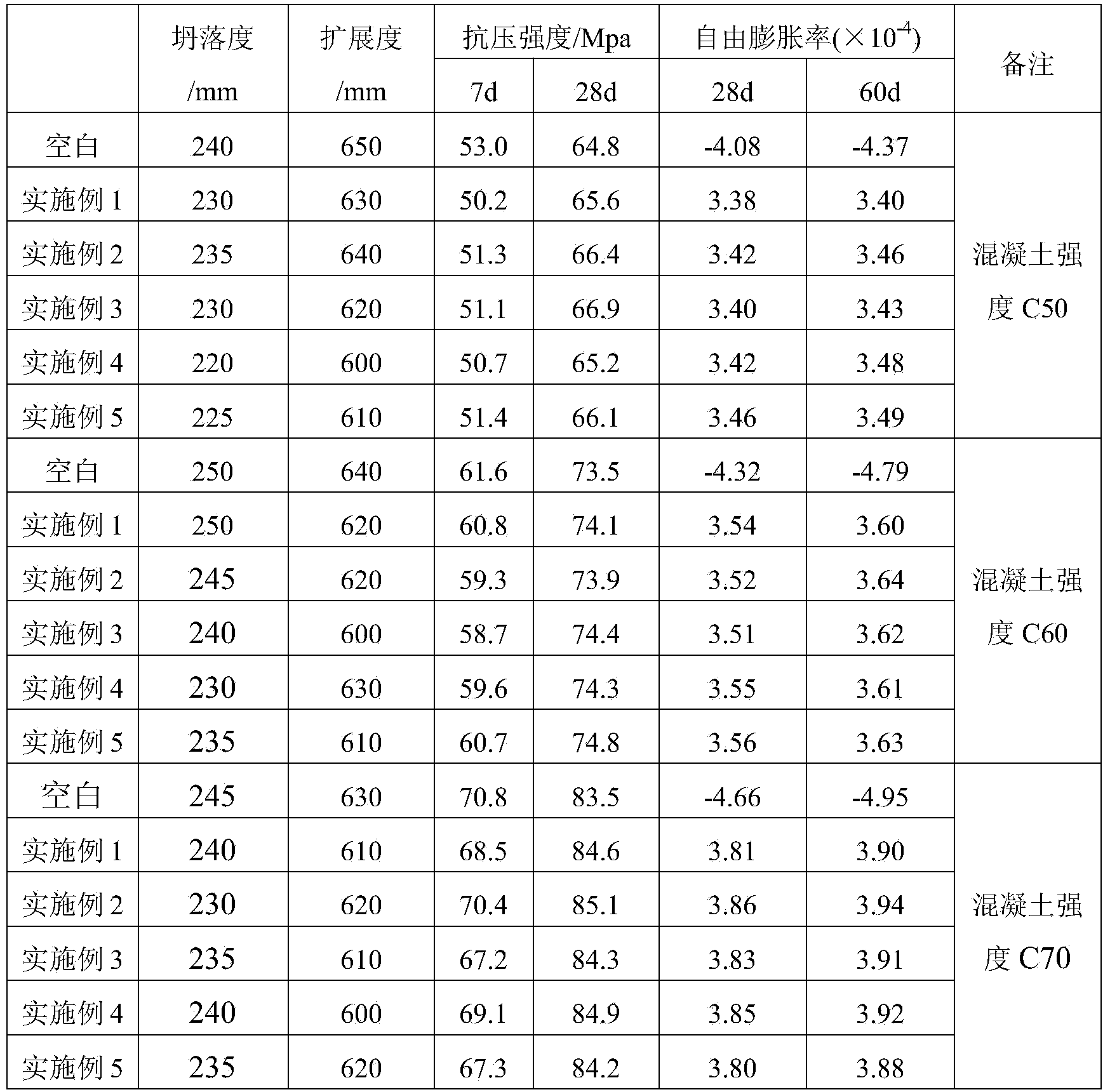

Minimum inflation high magnesium moderate heat cement, production method therefor and applications thereof

The invention discloses a kind of minimum inflation high magnesium moderate heat cement, a production method therefor and applications thereof. The cement is prepared from calcium raw materials, silicon materials, aluminum raw materials, iron raw materials, magnesium raw materials, correction raw materials and clinker activating agents through two-grinding and one-burning process. The content of MgO in the clinkers is raised to 6-9%, the content of periclase is controlled to 2-8%, the minimum inflation performance of periclase can be used fully, the contraction of mass concrete can be compensated, concrete cracks can be decreased, and therefore the volume stability and safety of concrete are raised.

Owner:CHINA BUILDING MATERIALS ACAD

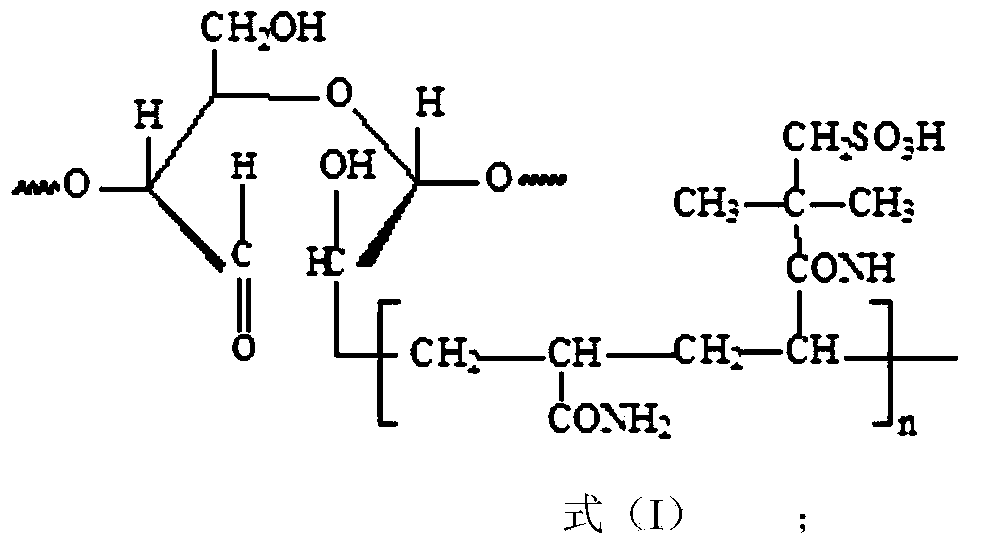

Compound expanding agent for inhibiting temperature rising in early stage and promoting hydration in later stage and preparation method thereof

The invention belongs to the field of building material, and particularly relates to a compound expanding agent for inhibiting temperature rising in the early stage and promoting hydration in the later stage. The compound expanding agent comprises the following raw materials by weight: 10 to 30 % of calcium oxide, 28 to 43 % of sulphate aluminium cement clinker, 25 to 40 % of anhydrite, 5 to 15 % of magnesium oxide, 0.3 to 0.5 % of boric acid, 1 to 1.5 % of zinc sulfate and 0.2 to 0.5 % of ICA. The compound expanding agent has the advantages of high early stage expanding capacity, sustainable expansion and long expanding stable period, can effectively compensate self-constriction and drying shrinkage of concrete, enables the synergetic development of the volume expansion and the strength increase of concrete, and is very suitable for being applied to steel pipe concrete and mass concrete.

Owner:WUHAN UNIV OF TECH

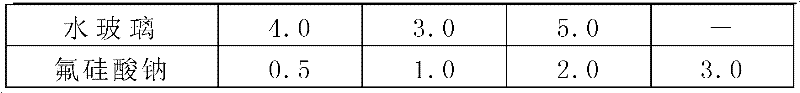

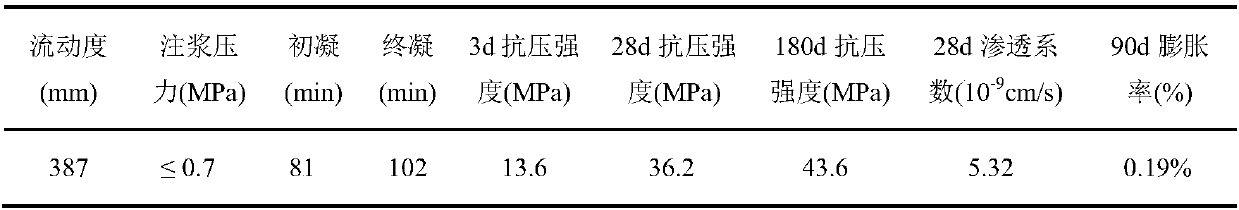

High-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment and application of grouting material

The invention discloses a high-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment, and application of the grouting material. The grouting material comprises the following ingredients in parts by weight: 50-79 parts of Portland cement clinker, 19-48 parts of an auxiliary cementing material and 2-7 parts of desulfurized gypsum, whereinthe auxiliary cementing material comprises the following ingredients in parts by weight: 25-57 parts of mineral slag, 8-21 parts of steel slag, 18-36 parts of pulverized fuel ash, 6-12 parts of limestone flour, 1-8 parts of silica fume and 2.5-12.8 parts of a high-performance composite regulator; the high-performance composite regulator comprises the following ingredients in parts by weight: 5-16parts of sodium hydroxide, 4-12 parts of sodium silicate, 4-14 parts of potassium metaaluminate, 12-21 parts of calcium chloride, 11-18 parts of lithium chloride, 4-12 parts of triethanolamine, 21-27parts of alum, 18-29 parts of aluminum sulfate, 0.2-1.5 parts of hydroxypropyl methyl cellulose, 0.1-3.0 parts of viscous polymer, 0-0.8 parts of polypropylene fiber and 0.5-3.0 parts of a superplasticizer; and the viscous polymer is an acrylic ester polymer or an ethylene-vinyl acetate copolymer.

Owner:SHANDONG UNIV

Crack-resistant waterproof cement-based permeable composite repairing material and method for preparing same

InactiveCN101531497AEffective protectionPromotes secondary hydrationSolid waste managementFiberSuperplasticizer

The invention discloses a crack-resistant waterproof cement-based permeable composite repairing material and a method for preparing same. The crack-resistant waterproof cement-based permeable composite repairing material of the invention comprises the following components by the mass fraction: 20% to 40% of Portland cement clinker, 3% to 20% of fly ash, 2% to 10% of gypsum, 2% to 10% of high-alumina cement, 1% to 4% of sodium silicate, 0.1% to 1.5% of high-efficiency naphthalene-based water-reducing agent, 0.1% to 2.0% of sodium carbonate, 40% to 70% of shaping quartz sand, 0.1% to 3.0% of polypropylene staple fiber and 0.05% to 1.0% of sodium carboxymethyl cellulose. The high-performance material of the invention is free from toxicity and pollution, and further has the characteristics of solid cementation, good penetration depth, good waterproof, anti-permeability and crack-resistant effects and the like; and meanwhile, the invention has the advantages of low production cost, simple preparation process and construction method and wide applicable range.

Owner:TIANJIN URBAN CONSTR COLLEGE

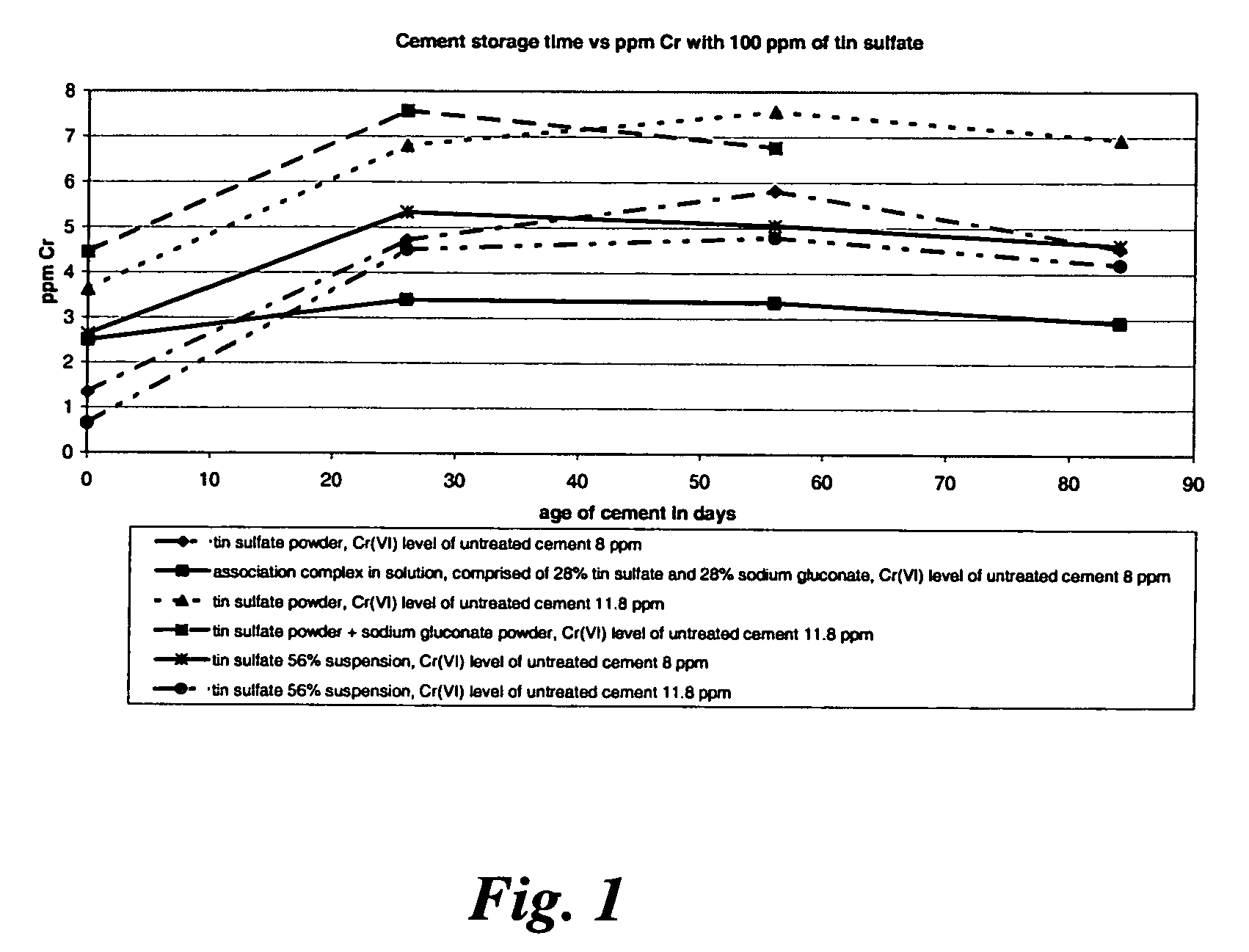

Dosage efficient, storage stable compositions for reducing chromium (VI) in cement

InactiveUS20070034118A1Maintain curative effectMaintaining the efficacy of chromium reducers in cement over timeHydration reactionSulfonate

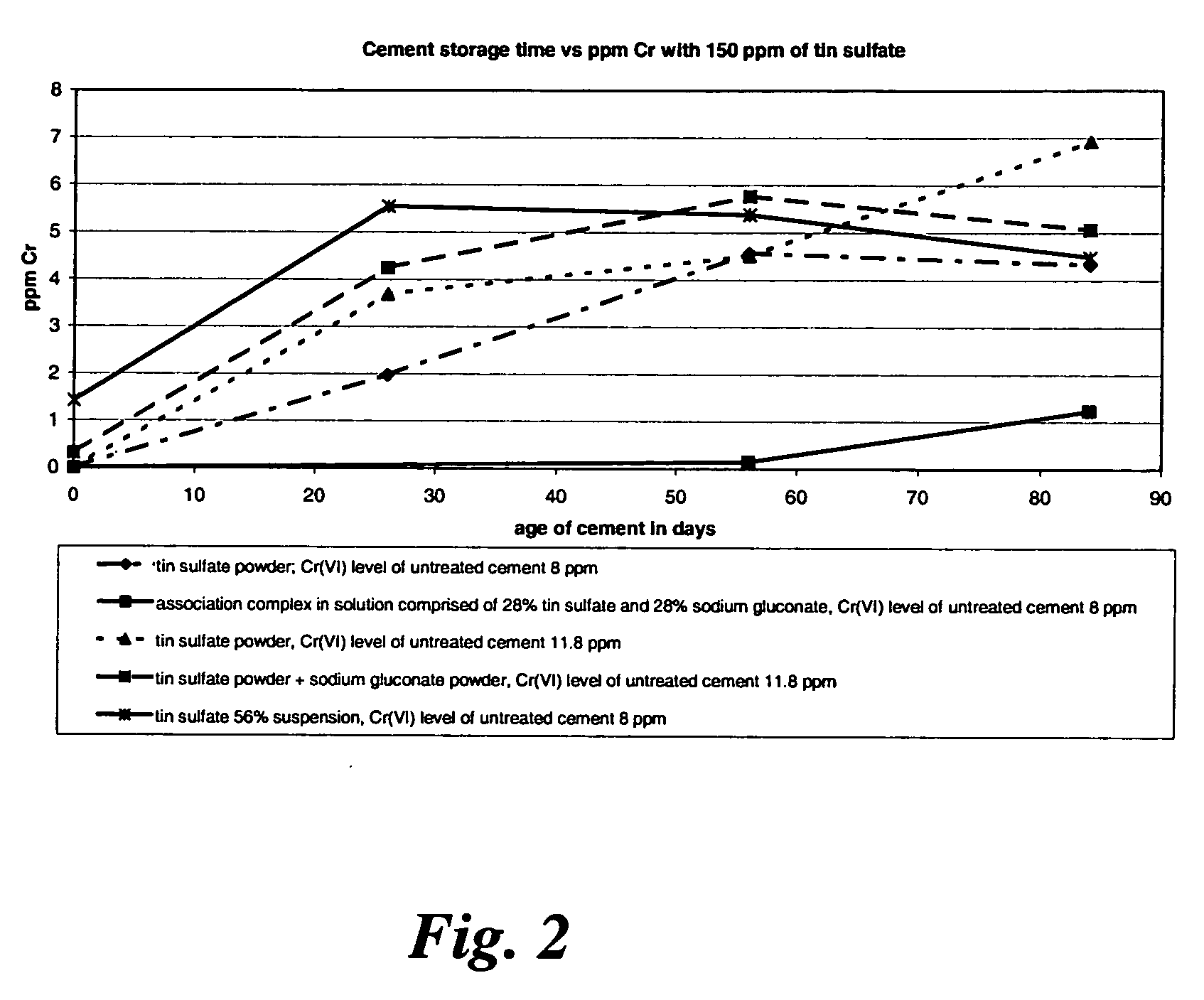

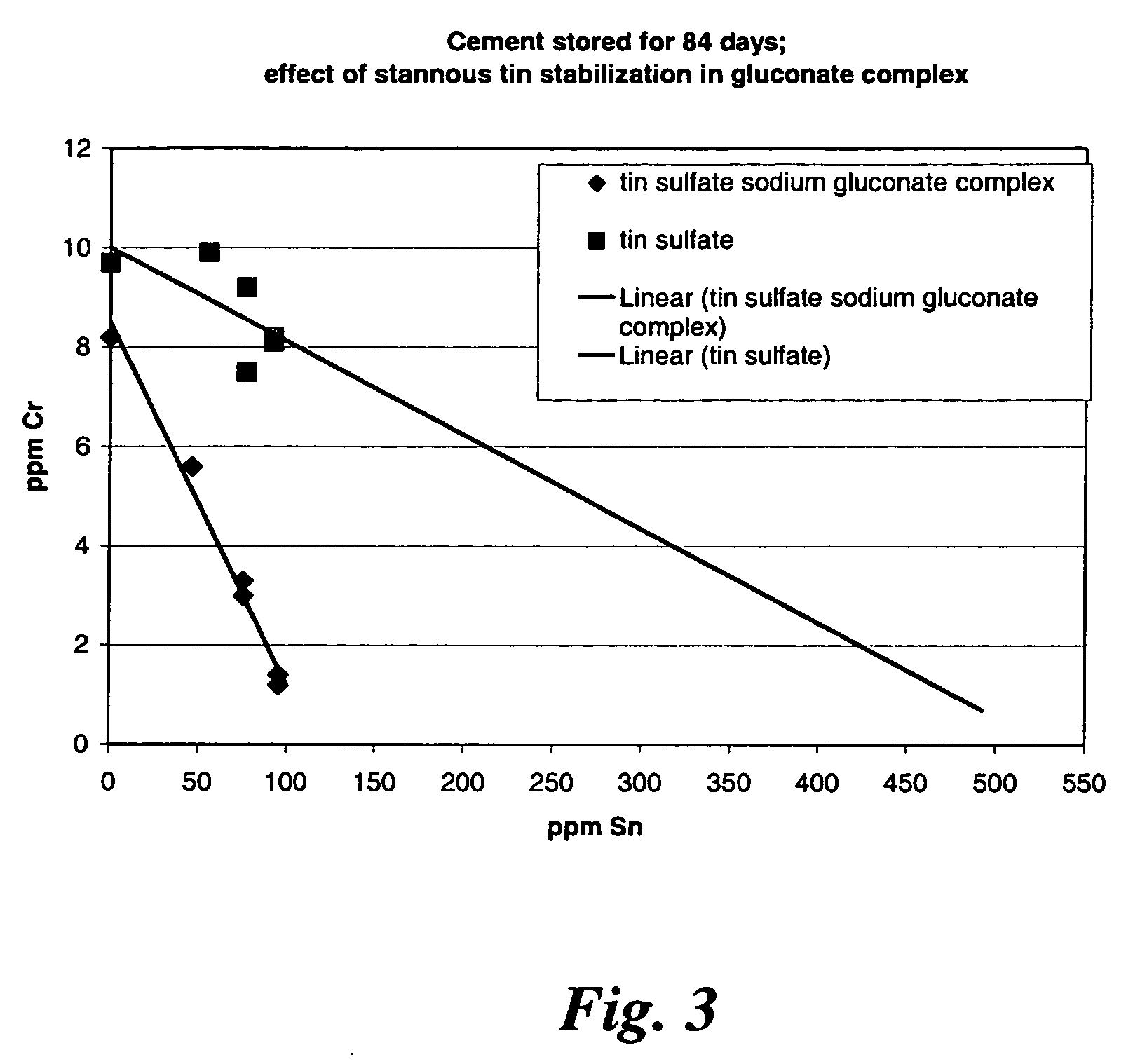

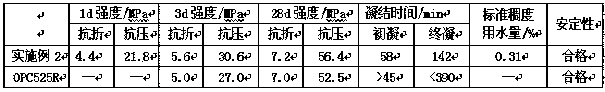

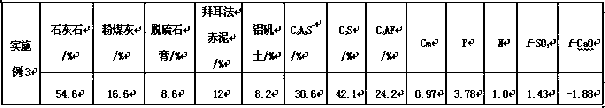

An association complex formed in a liquid environment from a metal-based chromium (VI) reducer and a non-lignosulfonate-based complexing agent is introduced into cement clinker or hydratable cement particles. In preferred embodiments, the formation of the association complex provides storage stability to the chromium reducer within the cement, such that the level of chromium (VI) after water is added to the cement remains less than 2 ppm for certain duration after mixing with water and without the necessity for further additions of chromium reducer during said duration (e.g., 26-84 or more days after addition). Compositions having the association complex are also described.

Owner:WR GRACE & CO CONN

Method for preparing belite-sulphate aluminium cement by using coal ashes and bayer-process red mud

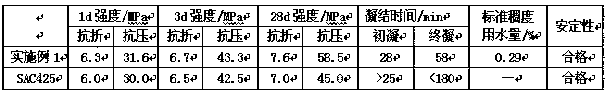

The invention discloses a method for preparing belite-sulphate aluminium cement by using coal ashes and bayer-process red mud. The method comprises the following steps: separately crushing and grinding limestone, coal ashes, bayer-process red mud, flue gas desulfurization gypsum and bauxite and sieving; preparing raw materials according to the rate value of the clinker in which Cm is 0.95-1.0, P is 3.50-3.82 and N is 0.8-1.1, wherein the f-(SO3) content in a clinker controlled to be 1-1.5% and f-(CaO) content is controlled to be greater than -2.0%; mixing and tabletting the prepared raw materials; carrying out heat preservation at 1250-1300 DEG C for 0.5-1 hour, and then quenching to obtain the clinker; crushing the clinker and grinding the crushed clinker, gypsum and portland cement clinker together into the specification of 400+ / -10m<2> / kg and preparing into cement. The mechanical property and the setting time of the cement disclosed by the invention can meet the requirements of 425 early-strength sulphoaluminate cement, and the belite-sulphate aluminium cement is good in grindability, and has good anti-freezing and anti-permeability performances. The resource utilization rate of the coal ashes and the flue gas desulfurization gypsum can be improved by application of the technology, and especially, a new way is provided for solving comprehensive control problems of the bayer-process red mud.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

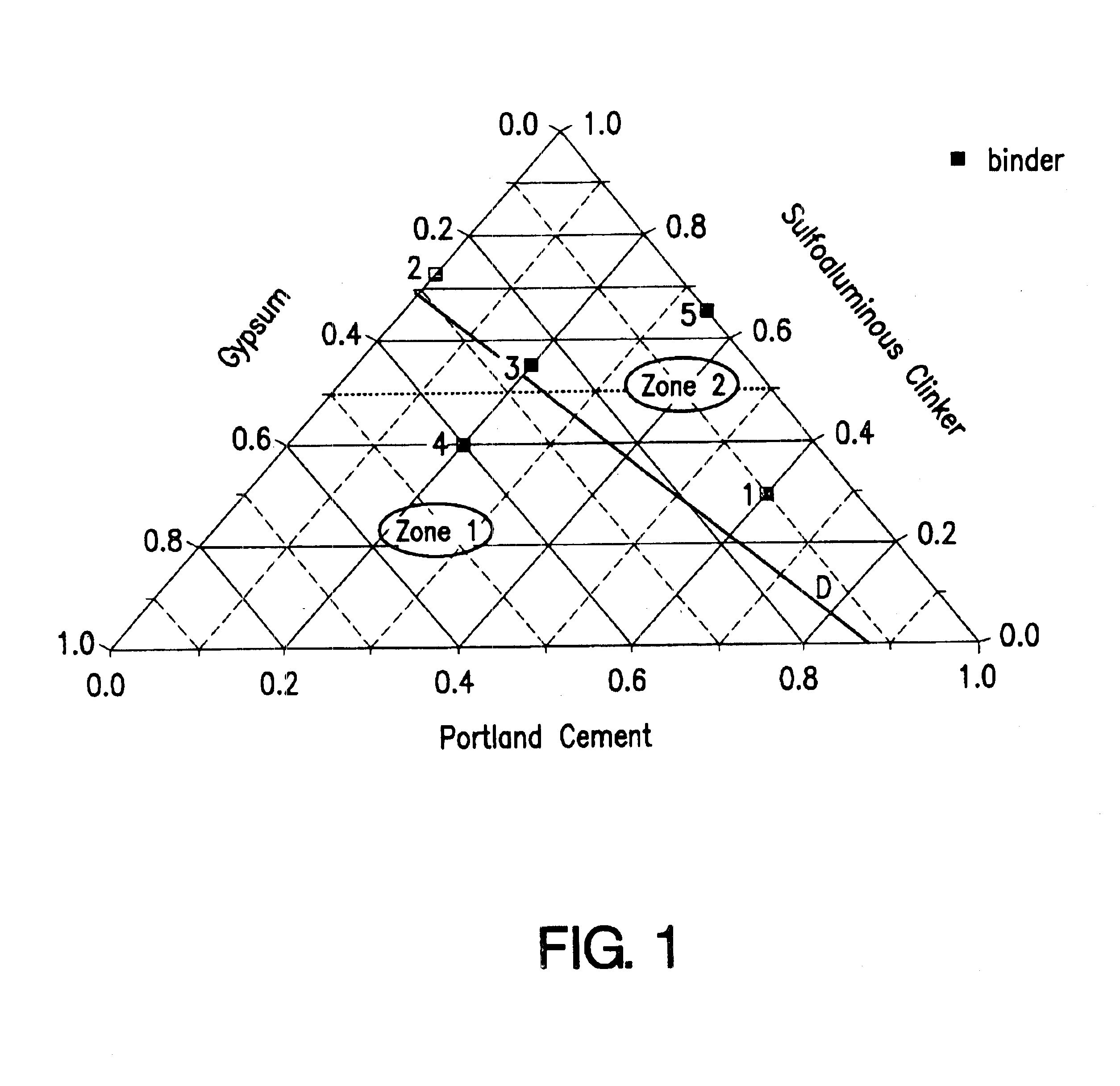

Sulfoaluminous clinker without iron and without free lime, its process of preparation and its use in white binders

The lightly colored sulfoaluminous clinker contains: more than 55% by weight of calcium sulfoaluminate phase (C4A3S), more than 10% by weight of belite phase (C2S), less than 10% by weight of anhydrite (C{overscore (S), and contains practically no ferrite phase, nor a gehlenite phase (C2AS), nor free lime. It is prepared by a process of roasting carried out at temperatures comprised between about 1250° C. and 1350° C. It can be used for a wide range of applications by combining it with a source of calcium sulfate and / or Portland cement, to obtain binders having specific properties (color, setup time, mechanical strength, expansion or contraction . . . ).

Owner:SOC DES CIMENTS FR

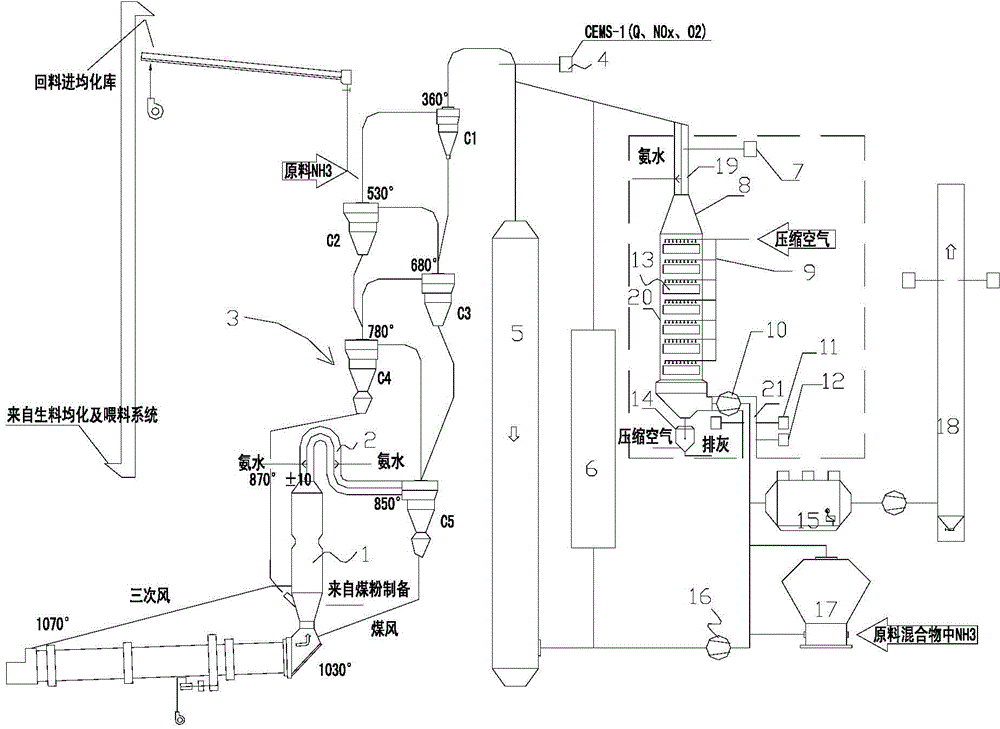

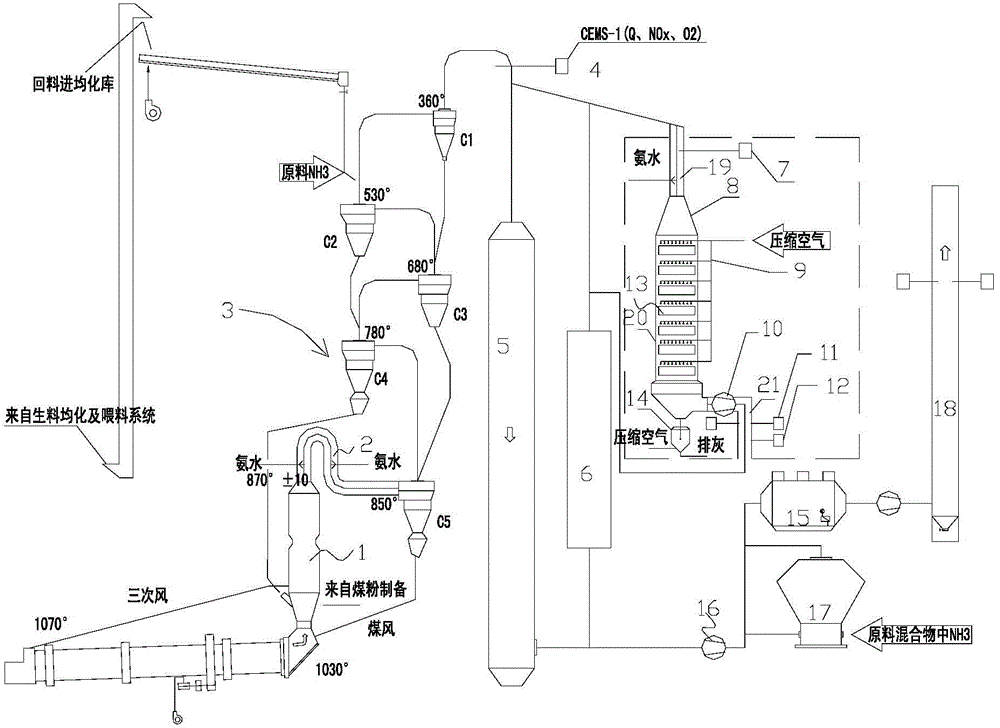

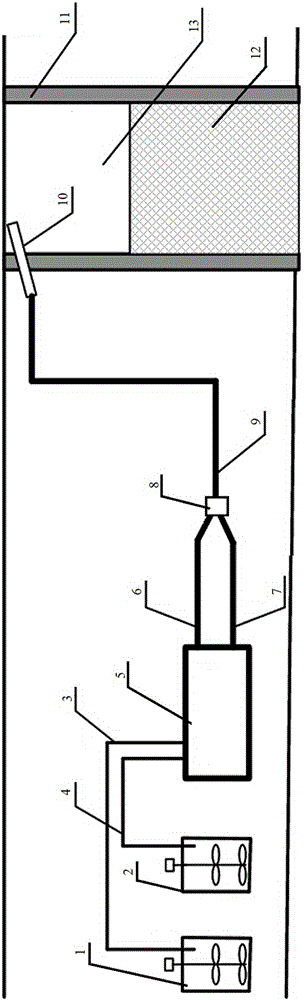

SCR denitration device and method applied to high-dust-content smoke from kiln tail of cement clinker production line

ActiveCN104645828AFlow field stabilityDoes not affect thermal efficiencyNitrous oxide captureDispersed particle separationProduction lineSprayer

The invention discloses an SCR (selective catalytic reduction) denitration device and an SCR denitration method applied to high-dust-content smoke from a kiln tail of a cement clinker production line. The device comprises a cement kiln decomposing furnace, a preheater, an afterheat boiler, a raw mill, an electric dust remover and a kiln tail chimney which are connected in sequence along the smoke direction, and further comprises an SCR reactor, wherein the SCR reactor comprises a reactor shell; an inlet divergent section is arranged at the top of the reactor shell, and an ash bucket is arranged at the bottom of the reactor shell; an inlet flue of the SCR reactor is connected with the preheater and the inlet divergent section and is provided with a reducer sprayer; a plurality of catalyst layers are arranged in the reactor shell in sequence from top to bottom; a plurality of steam ash blowers correspond to the catalyst layers one to one and are arranged above the corresponding catalyst layers; an outlet flue of the SCR reactor is connected with the bottom of the reactor shell and an upstream flue or a downstream flue of the afterheat boiler and is additionally provided with a high-temperature fan. On the basis that a high-temperature dust remover is not arranged, the SCR denitration device can handle with the smoke characteristics of high NOx load fluctuation, temperature fluctuation and high dust content.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE +1

Soil stabilizer, and preparation and application method thereof

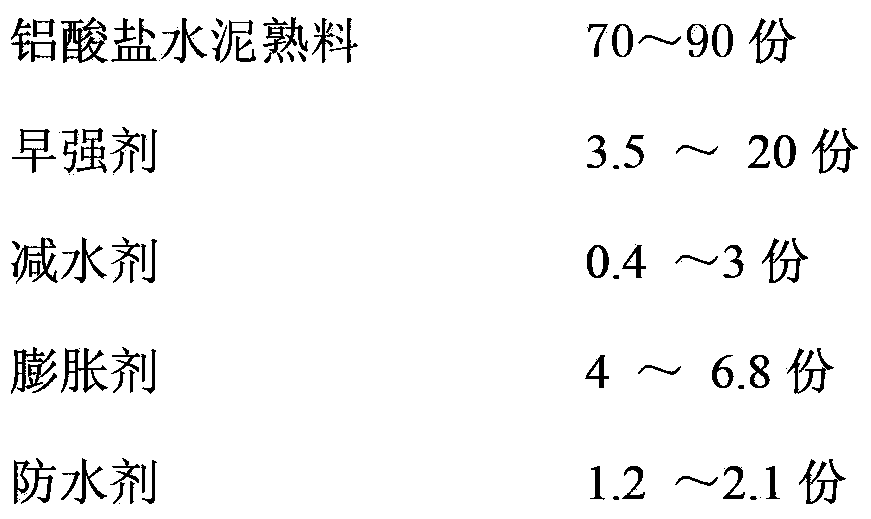

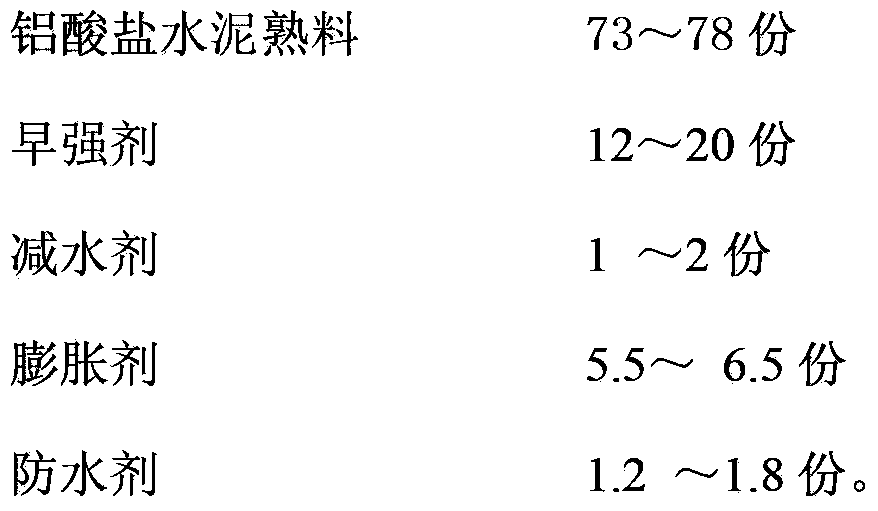

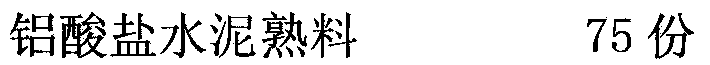

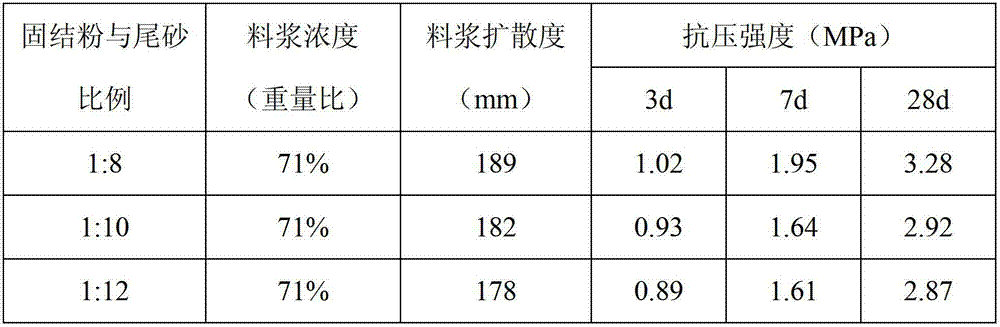

The invention relates to a soil stabilizer, and a preparation and application method thereof, belonging to the field of building materials. The invention aims to provide a soil stabilizer, and a preparation and application method thereof. The soil stabilizer is composed of the following substances in parts by weight: 70-90 parts of aluminate cement clinker, 3.5-20 parts of early-strength admixture, 0.4-3 parts of water reducing agent, 4-6.8 parts of expanding agent and 1.2-2.1 parts of waterproofing agent. The soil stabilizer has favorable stabilization effect; the strength of the soil body treated by the soil stabilizer is up to 3.728 MPa; and the curing period of the soil body treated by the soil stabilizer is shorter than the curing time of the soil stabilizer mainly comprising Portland cement clinker. The soil stabilizer is convenient to use and simple to operate.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Filling and consolidating powder for mining purposes and use thereof

The invention discloses filling and consolidating powder for mining purposes and a use thereof. The filling and consolidating powder comprises the following raw materials in percentage by weight: 3-5% of portland cement clinker, 8-10% of metakaolin, 5-15% of carbide slag, 18-24% of phosphogypsum, 18-22% of fly ash, 9-14% of red mud, 15-19% of blast furnace slag, 4-10% of limestone, 0.8-1.2% of polycarboxylic acid type water reducing agent and 0.4-0.7% of sodium hydroxide and is prepared by uniformly mixing and grinding to get fine powder with 400 meshes-600 meshes. When the filling and consolidating powder is used, mining tailing or coal gangue is firstly mixed with water according to a proportion in a mixing machine for forming uniform slurry, and then the consolidating powder is further added, uniformly mixed and then conveyed to a downhole place by a pipeline for filling. The cost of the filling material blended by the consolidating powder disclosed by the invention is 50-70 yuan / ton, while the cost of the similar filling and consolidating powder is 90-110 yuan / ton; and compared with the prior art, the cost is greatly reduced and the filling effect is good.

Owner:ZIBO GEOLOGICAL MINE TECH SERVICE CENT

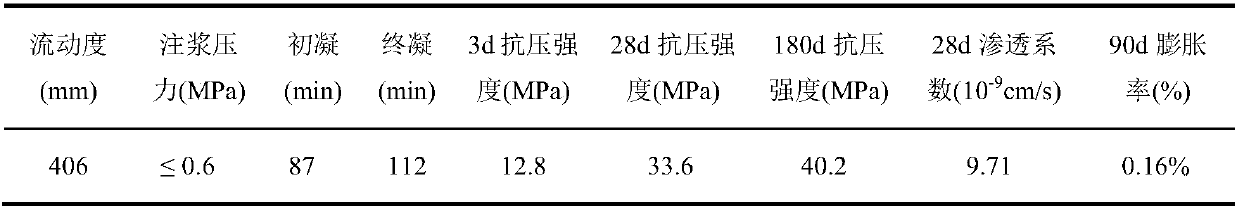

Efficient superfine cement based composite grouting material for grouting treatment of water-rich sand layer, preparation process and application

ActiveCN107572994AEasy to operateImprove applicabilityDrilling compositionSealing/packingMicrofine cementAluminate

The invention discloses an efficient superfine cement based composite grouting material for grouting treatment of a water-rich sand layer, a preparation process and application. The efficient superfine cement based composite grouting material is prepared from the following components in parts by weight: 40 to 80 parts of portland cement clinker, 10 to 45 parts of coal ash, 5 to 30 parts of superfine slag micro powder, 2 to 6.5 parts of desulphurization gypsum, 1 to 10 parts of silica fume, 0.51 to 2.10 parts of first mixed composite modifier, 0.4 to 2.4 parts of second mixed composite modifierand 5.5 to 8.9 parts of third mixed composite modifier; the coal ash is prepared from the following components in parts by weight: 50 to 100 parts of high-calcium coal ash and 0 to 50 parts of low-calcium coal ash; the first mixed composite modifier is prepared from the following components in parts by weight: 96 to 99 parts of super plasticizer and 1 to 4 parts of hydroxypropyl methyl cellulose;the second mixed composite modifier is prepared from the following components in parts by weight: 20 to 32 parts of sodium hydroxide, 21 to 28 parts of sodium carbonate, 18 to 32 parts of sodium sulfate and 18 to 36 parts of sodium metaaluminate; the third mixed composite modifier is prepared from the following components in parts by weight: 12 to 25 parts of calcium chloride, 8 to 21 parts of lithium chloride, 10 to 23 parts of triethanolamine and 32 to 68 parts of sulphoaluminate cement clinker.

Owner:SHANDONG UNIV

Cement grinding aid and preparation method thereof

ActiveCN102126843AImprove performanceNo adverse side effectsSolid waste managementCelluloseCarbamate

The invention discloses a cement grinding aid. The cement grinding aid comprises the following components in percentage by weight: 8 to 20 percent of triethanolamine, 0 to 10 percent of triisopropanolamine, 8 to 20 percent of diol byproduct, 0 to 10 percent of synthetic glycerine, 0 to 25 percent of molasses, 0 to 5 percent of calcium lignosulfonate, 0 to 15 percent of polyurethane, 0 to 10 percent of cystine, 3 to 5 percent of sorbitol, 5 to 10 percent of sodium carboxymethylcellulose, 0 to 5 percent of citric acid, 0 to 5 percent of silica powder, 0 to 5 percent of fly ash and the balance of water. The invention also discloses a preparation method of the cement grinding aid. The grinding aid can effectively improve the equipment-hour yield of a cement grinding mill, reduce energy consumption and remarkably improve cement performance, does not have adverse side effects on cement, reduces the using amount of cement clinkers by 4 to 10 percent, improves the equipment-hour yield of cement production by 6 to 10 percent, and has a good effect. The method has a unique process, a part of raw materials are treated by ultrasound, and the prepared grinding aid has high performance.

Owner:CHINA UNITED CEMENT LUNAN

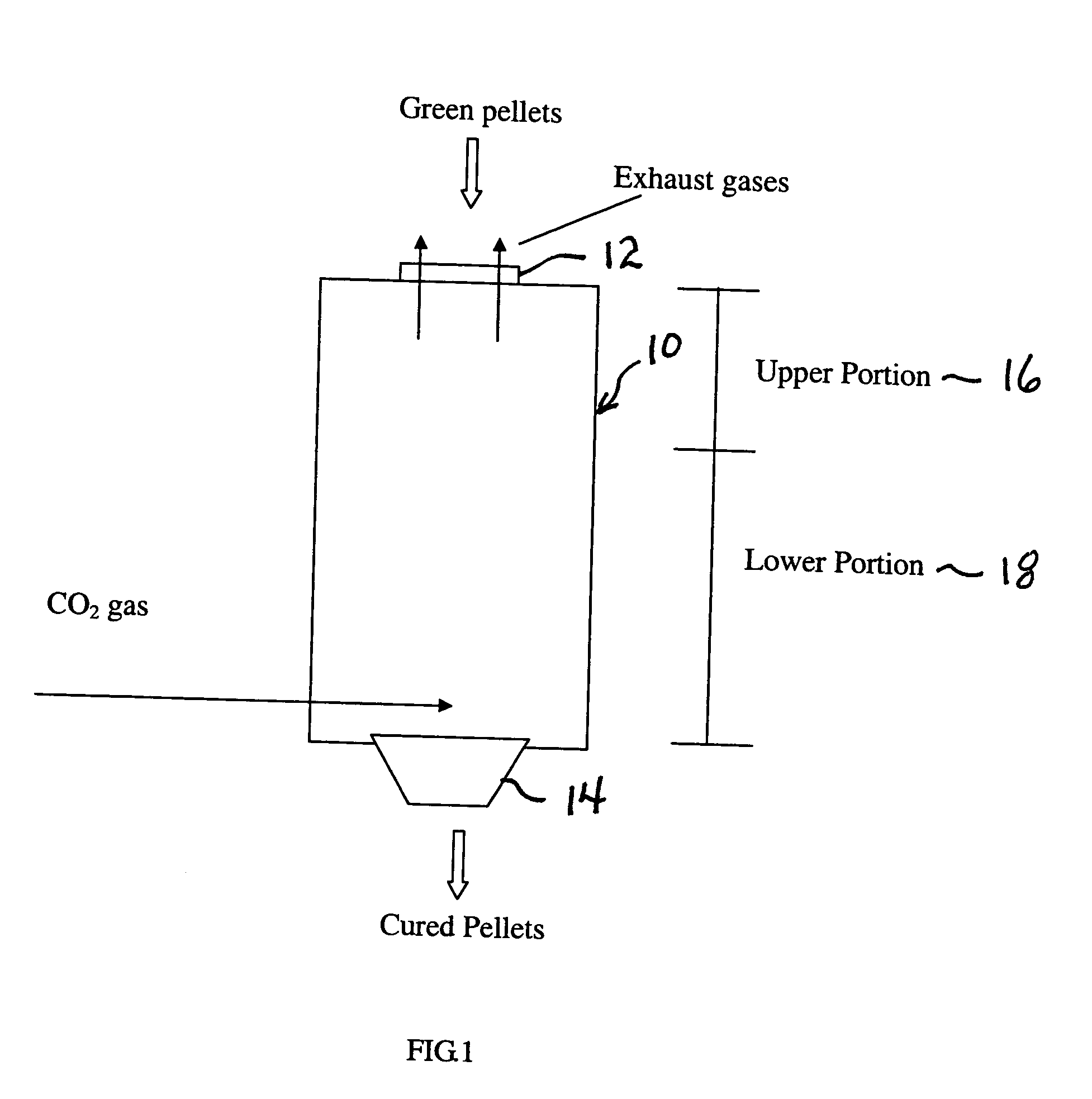

Self-reducing, cold-bonded pellets

ActiveUS20050061207A1Lower production costHigh flexibilityCeramic shaping apparatusCarbon dioxidePortland cement

Self-reducing, cold-bonded pellets and a method for their production for smelting a great variety of steels, including blast furnace iron-making, non-blast furnace iron-making, and all sorts of steelmaking in steel smelting furnaces, etc. The self-reducing, cold-bonded pellets comprise iron ore concentrate, carbonaceous reducing agent, and finely divided Portland cement clinker with special requirements as binder. The components are combined together to form a mixture. Pellets are produced when the mixture is placed into a balling disc or rotating drum and water is added. Pellets with predetermined size normally ranging from about 8-16 mm are obtained by using roller screens. The pellets are then continuously placed into a curing device. Inside the curing device, the pellets will then be hydrated and carbonated by using hot gases containing carbon dioxide with a temperature range of about 100-300° C. Thereafter, after drying, the dried pellets are discharged from the curing device and will be ready for use.

Owner:HANQING LIU

Inflaming retarding high-temperature-resisting foam concrete and preparation method thereof

The invention discloses inflaming retarding high-temperature-resisting foam concrete and a preparation method thereof. The concrete is prepared by mixing a gel material, heat-resisting aggregates, a liquid-state composition, an admixture and a foaming agent, wherein the gel material is slag silicate cement and grade-I fly ash; the heat-resisting aggregates comprise vitrified micro-beads, crushed clay clinkers, nano clay and corundum sand; the liquid-state composition comprises a water reducing agent, water and acrylic resin; and the admixture comprises phosphate, an inorganic fire retardant, glass fibers and calcium carbonate crystal whiskers. The inflaming retarding high-temperature-resisting foam concrete prepared by the preparation method has the advantages of small density, relatively high strength, low heat conductivity coefficient, good heat insulation performance and the like; and the combustion performance is grade A, and the fireproof limit can reach 4 hours so that the inflaming retarding high-temperature-resisting foam concrete is a fireproof heat-insulation material with a good comprehensive performance.

Owner:CHINA MCC17 GRP +1

Method for producing sulfur dioxide from calcium sulfate and sulfur

ActiveCN102502524AQuick responseImprove heat utilizationChemical industrySulfur compoundsClinker (cement)Sulfur dioxide

The invention provides a method for producing sulfur dioxide from calcium sulfate and sulfur and relates to a chemical production process for producing sulfuric acid and cement clinker by adopting calcium sulfate. The method comprises the following steps: a, drying wet calcium sulfate into semi-hydrated gypsum, mixing other correction raw materials into the semi-hydrated gypsum to prepare a raw material, adding the raw material into a material preheating system consisting of multiple stages of cyclone preheaters, preheating, and then feeding into a reduction furnace; b, spraying liquid sulfur into the reduction furnace; c, controlling the content of oxygen in the reduction furnace to be less than 1.5%, and reducing calcium sulfate to generate calcium sulfide; and d, controlling the molar ratio of calcium sulfide generated in the step c to unreacted calcium sulfate to be (1:2)-(9:1), feeding a mixture of calcium sulfide and unreacted calcium sulfate into a rotary kiln and then reacting at oxidation atmosphere at the temperature of 900-1450 DEG C so as to obtain SO2 and the cement clinker. The method is rapid in reaction speed (the reaction time is only few seconds under fluidization), high in heat utilization rate, simple in process, and easily controllable in reaction condition.

Owner:YUNNAN YUNTIANHUA

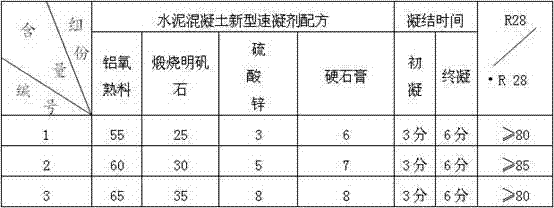

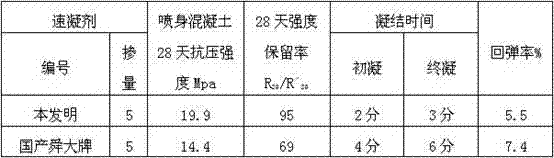

Cement concrete accelerator

The invention relates to a cement concrete accelerator. The accelerator comprises 50-65% of aluminium-oxygen clinker, 25-35% of calcined alunite, 3-8% of zinc sulfate and 6-8% of anhydrite. According to the accelerator, the resilience rate is low, the later strength is high, the compression strength retention rate for 28 days can reach more than 90%, and the alkali charge is low, and harm to an operating worker can be reduced greatly.

Owner:贵州遵辉环保科技有限公司

Rapid-hardening inorganic filling support material for mine and using method of support material

The invention discloses a rapid-hardening inorganic filling support material for mine. The support material consists of a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 93-97 parts of sulphoaluminate cement clinker, 2-5 parts of an XWZ-A type compound admixture, 0.01-0.1 part of an air entraining agent, 0.0-0.05 part of an air entraining admixture, 0.2-1.0 part of a foam stabilizer and 0.25-2 parts of fibers; and the component B comprises the following raw materials in parts by weight: 75-88 parts of gypsum, 10-25 parts of lime, 2-5 parts of an XWZ-A type compound admixture, 0.01-0.1 part of an air entraining agent, 0.0-0.05 part of an air entraining admixture, 0.2-1.0 part of a foam stabilizer and 0.25-2 parts of fibers. The prepared filling support material disclosed by the invention has the characteristics of quick setting property, lightweight, rapid hardening property, early strength, high compressibility, high residual strength, good gas tightness and the like, and is particularly suitable for the mine filling support aspect.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com