Patents

Literature

2050 results about "Chemical technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

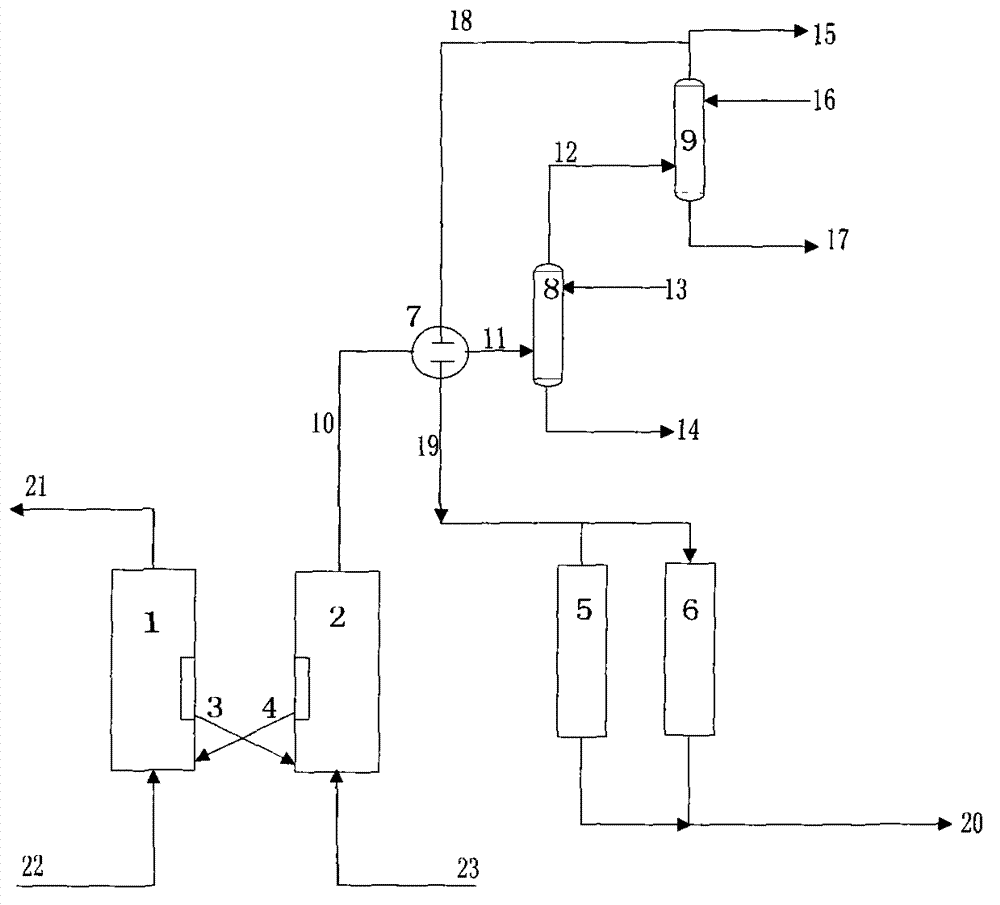

Multifunctional methanol processing method and apparatus

InactiveCN102775261AFlexible planningShort processHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionGasolinePetrochemical

Owner:李小燕

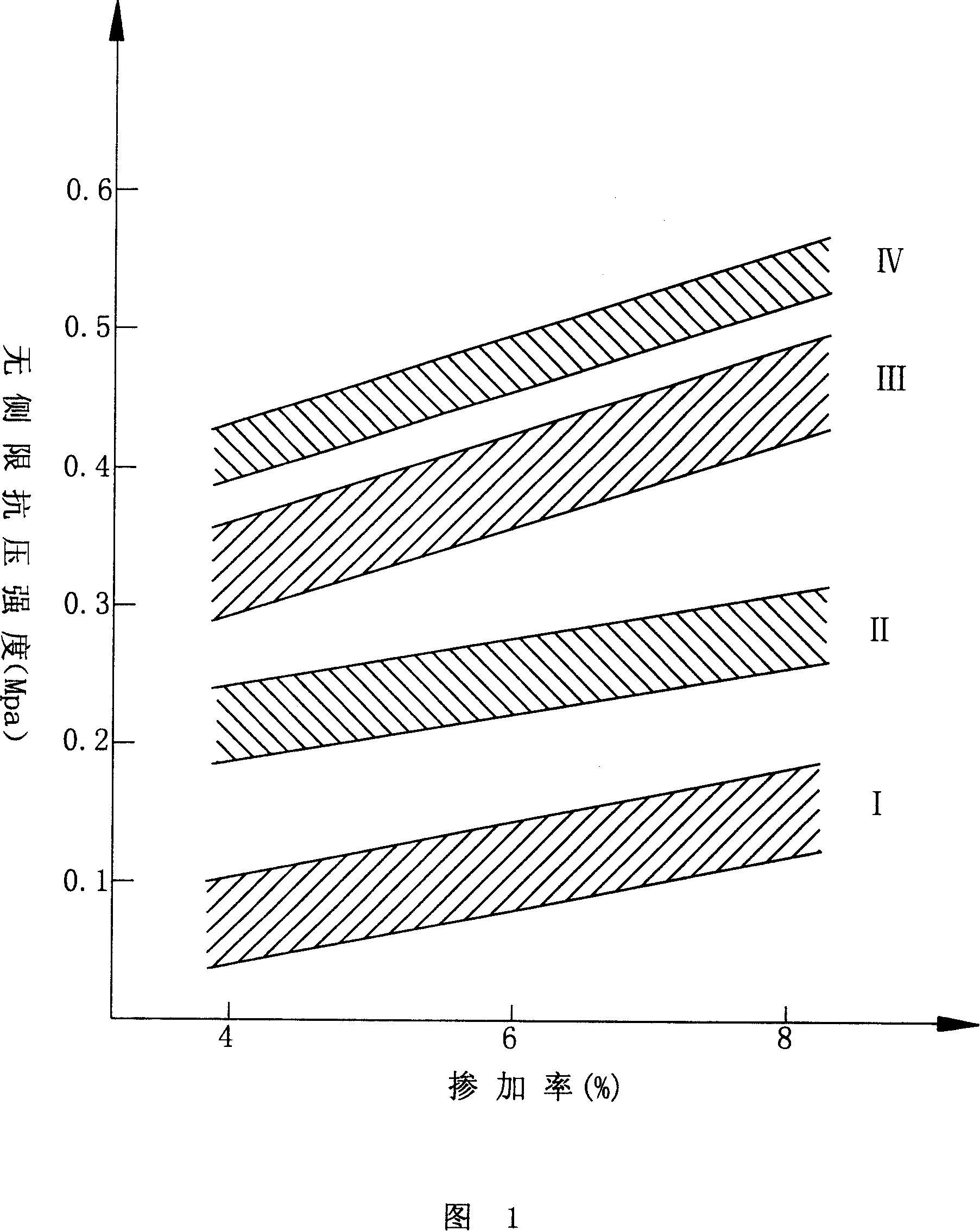

Sludge curing agent and application thereof

ActiveCN101081718AGood boardIncreased durabilitySludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

The present invention is sludge curing agent and its application, and belongs to the field of soil treating chemicals technology. The sludge curing agent includes powdered components and liquid components, the powdered components include cement clinker 30-60 weight portions, slag 30-60 weight portions, lime 3-8 weight portions, gypsum 1-7 weight portions and other sulfates 1-7 weight portions; and the liquid components include polyacrylamide 5-30 weight portions, polyaluminum chloride 0-20 weight portions, mannitol 0-30 weight portions, lignosulfonate 20-80 weight portions, lignosulfonate-iron or chromium ion complex 0-30 weight portions, alkylphenol ethoxylate 0.2-2 weight portions, tannin 0-10 weight portions, humate 0-10 weight portions, and alpa-olefin sulfonate 0.2-2.5 weight portions. The sludge curing agent has low cost, small consumption, high cumulate strength and high cumulate water tolerance, and may be applied widely.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

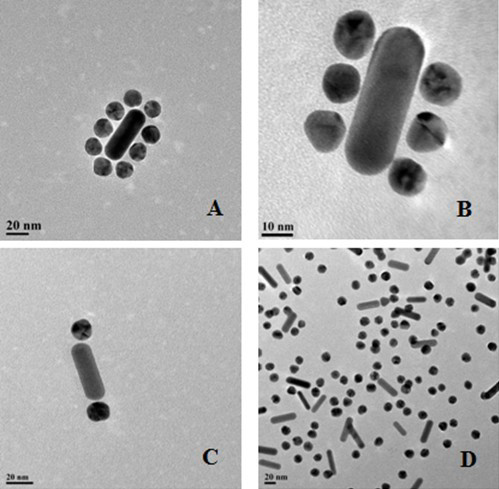

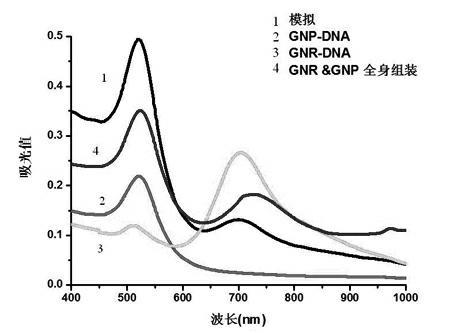

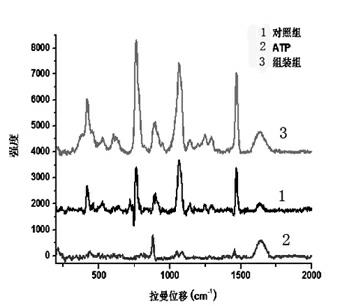

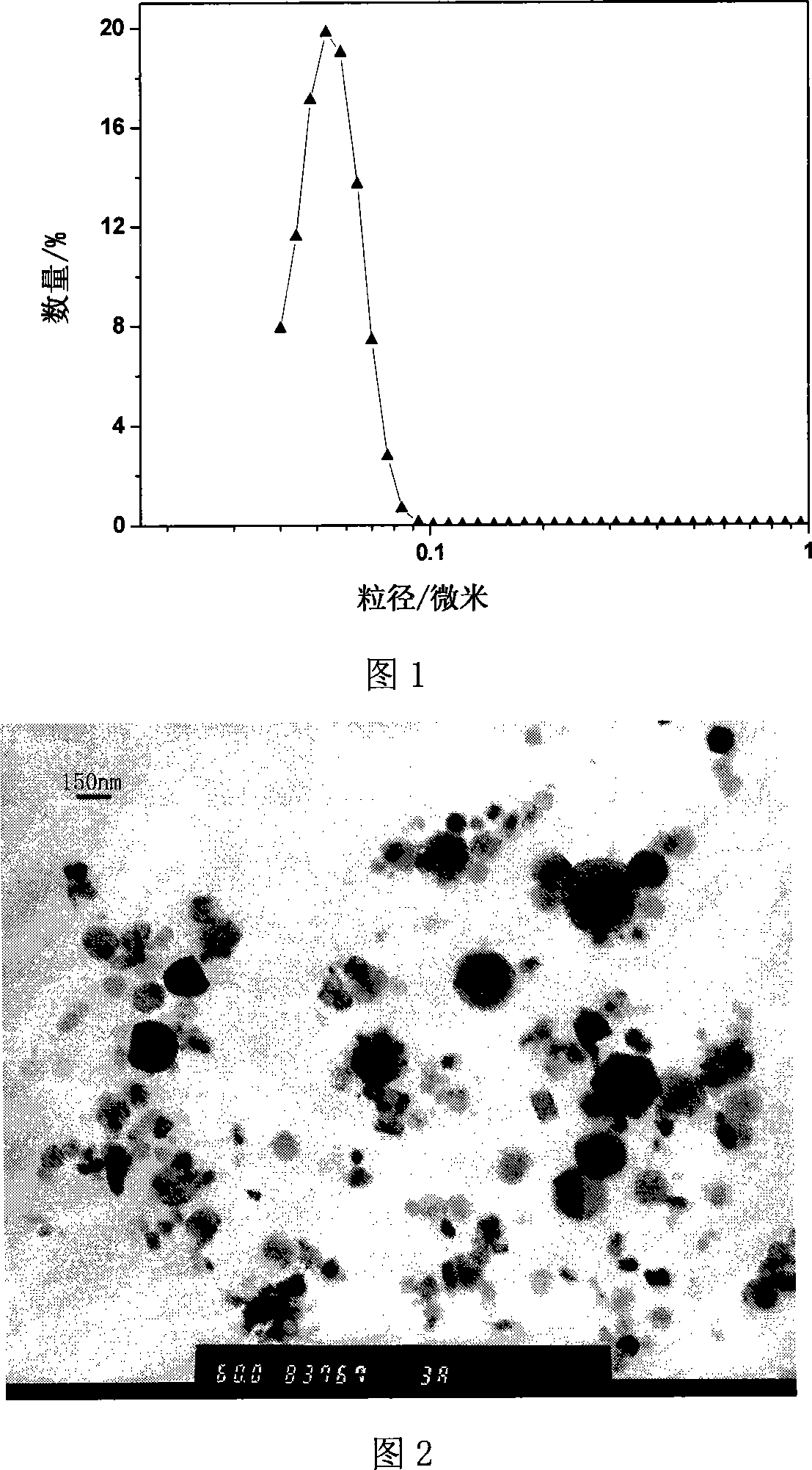

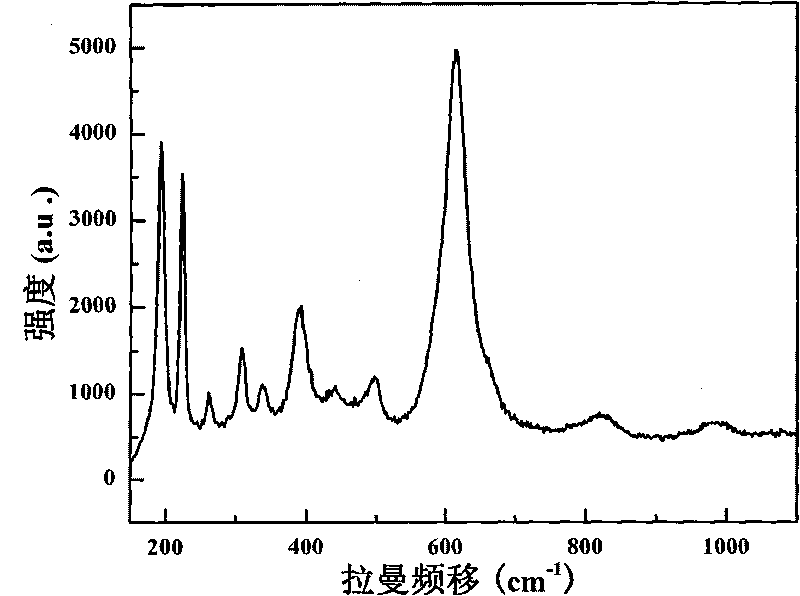

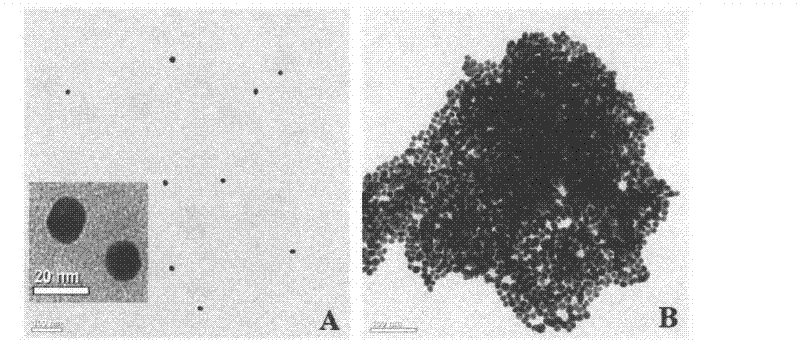

Preparation method of self-assembly material having surface-enhanced Raman activity

InactiveCN102127542AUniform assembly structureRaman activeDNA/RNA fragmentationModified dnaSelf-assembly

The invention relates to a preparation method of a self-assembly material having surface-enhanced Raman activity, belonging to the technical field of material chemistry. The preparation method comprises the following steps: synthesizing gold nano particles; synthesizing gold nano rods; modifying DNA (deoxyribonucleic acid) 1 with the gold nano particles; modifying DNA 2 with the gold nano rods; coupling the gold nano rods with Raman beacon molecules; and assembling and characterizing the gold nano rods and the gold nano particles. The nano material assembly body prepared by the invention has a uniform and controllable assembly structure and has Raman activity, thereby making monomolecular detection possible.

Owner:JIANGNAN UNIV

Formaldehyde scavenging agent with oil solubility and preparation method

InactiveCN103055465AImprove purification efficiencyImprove practicalityPreparation by ester-hydroxy reactionPolyester coatingsSocial benefitsSolubility

The invention relates to the chemical technology field, and concretely relates to a formaldehyde scavenging agent with oil solubility and a preparation method and a usage method. The formaldehyde scavenging agent with oil solubility can be prepared to paint, and can be used for coating on the furniture, floor or other decoration sheet materials, and has good purification efficiency on indoor free formaldehyde, and no secondary pollution can be generated. On the premise of no change of the sheet material application and construction technology in the prior art, and the release of indoor formaldehyde can be fundamentally controlled. The preparation method is simple, the usage is convenient, and the formaldehyde scavenging agent is suitable for large-scale production and business application for enterprises, has good application prospect, and has obvious economy and social benefit.

Owner:上海格伦化学科技有限公司

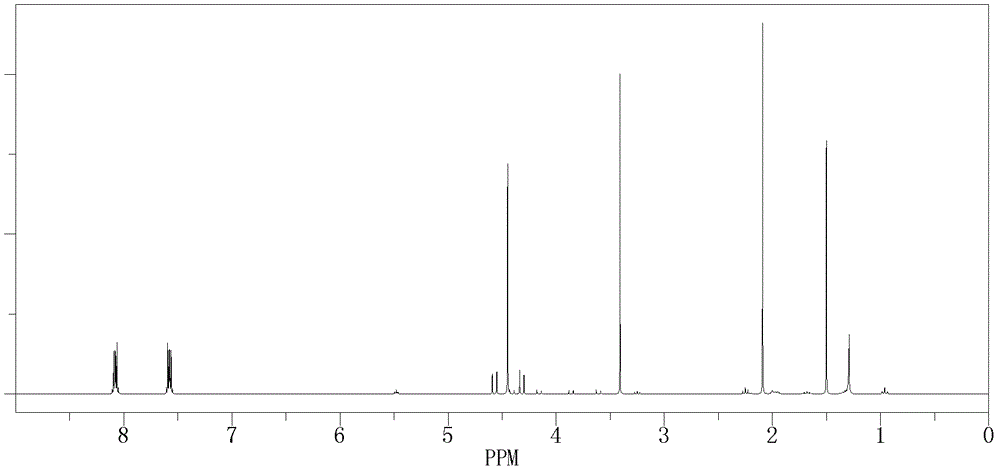

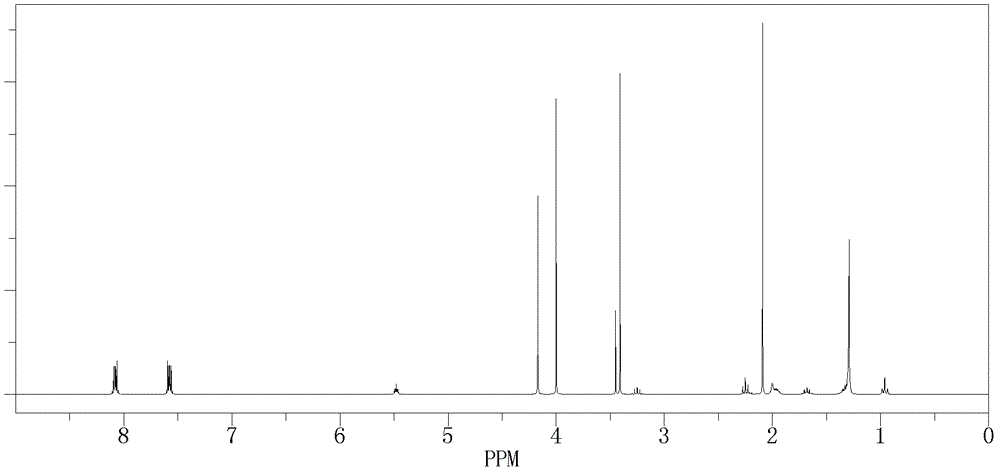

Benzimidazole derivatives, preparation method and medicinal use thereof

ActiveCN103709154AEnhanced antihypertensive activityEnhance antihypertensive effectOrganic active ingredientsOrganic chemistryBenzimidazole derivativeLiver and kidney

The invention belongs to the technical field of the pharmaceutical chemistry, and concretely discloses benzimidazole derivatives, and a preparation method and a medicinal use thereof. The benzimidazole derivatives comprise ligustrazine and NO donor derivatives, and the benzimidazole derivatives can rapidly release ligustrazine or NO in vivo, so there is an effective synergistic effect between the benzimidazole derivatives and azilsartan, thereby the benzimidazole derivatives enhances the antihypertension effect, reduces untoward effects, has an ideal protection effect on the liver and kidney of a patient, and fills a gap in the prior art.

Owner:WUHAN LL SCI & TECH DEV

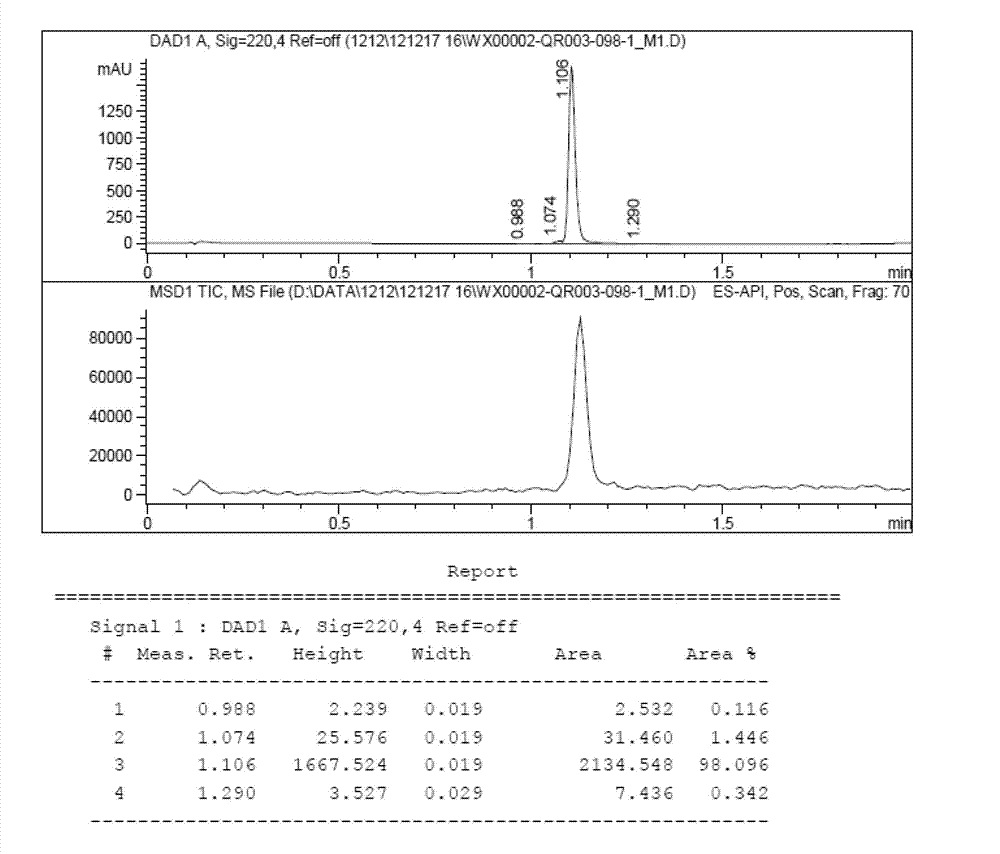

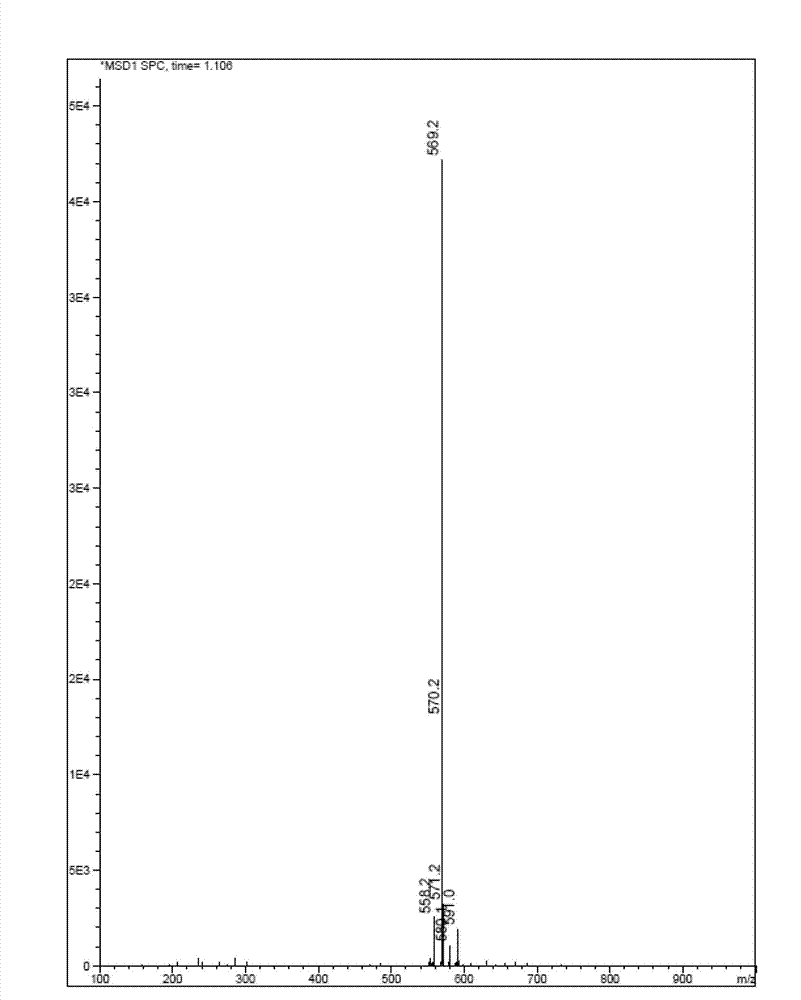

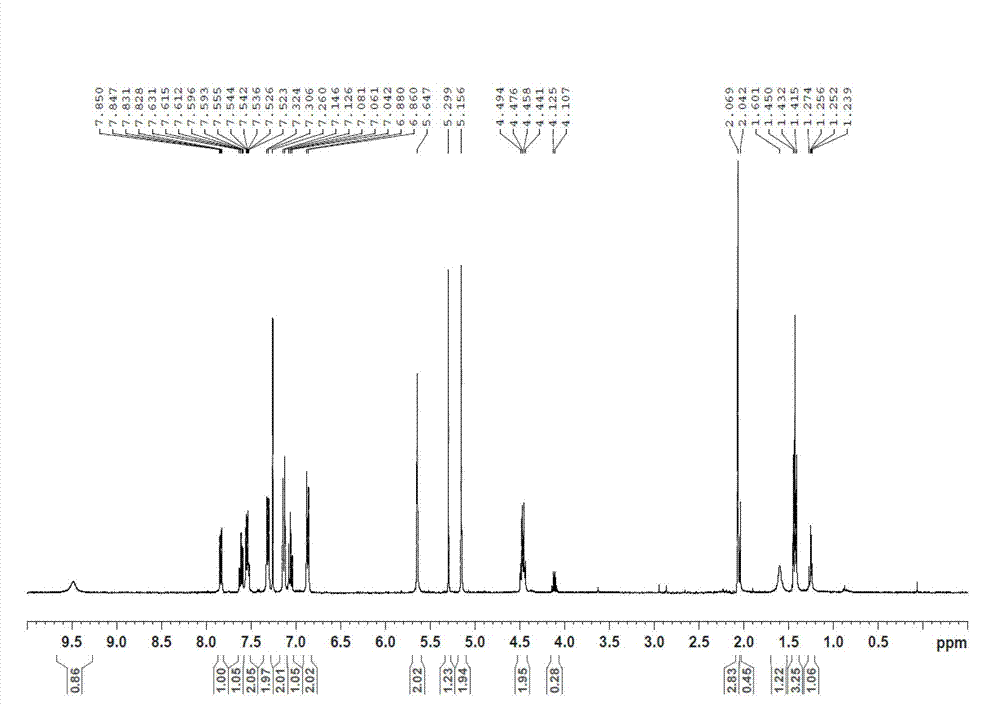

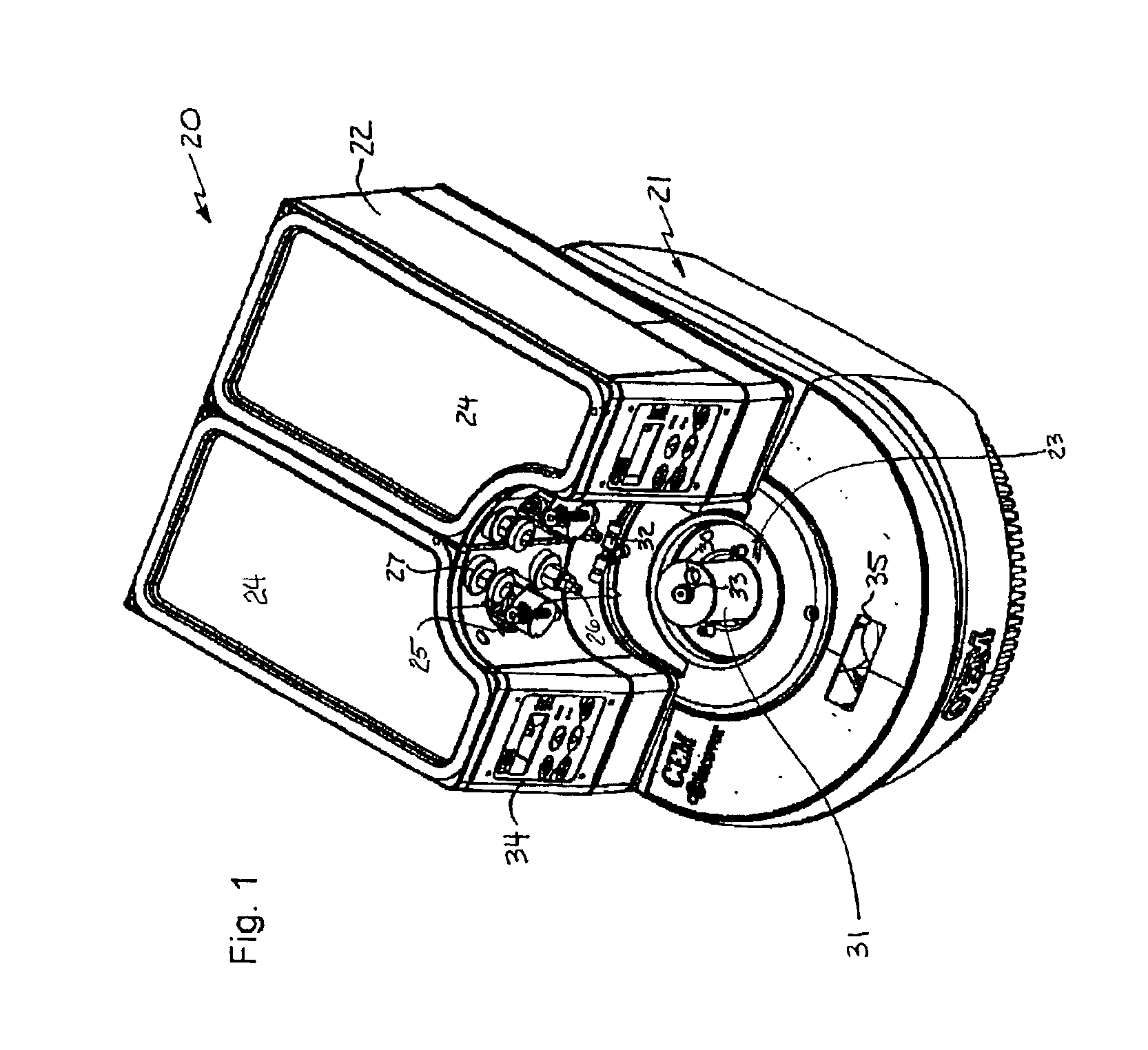

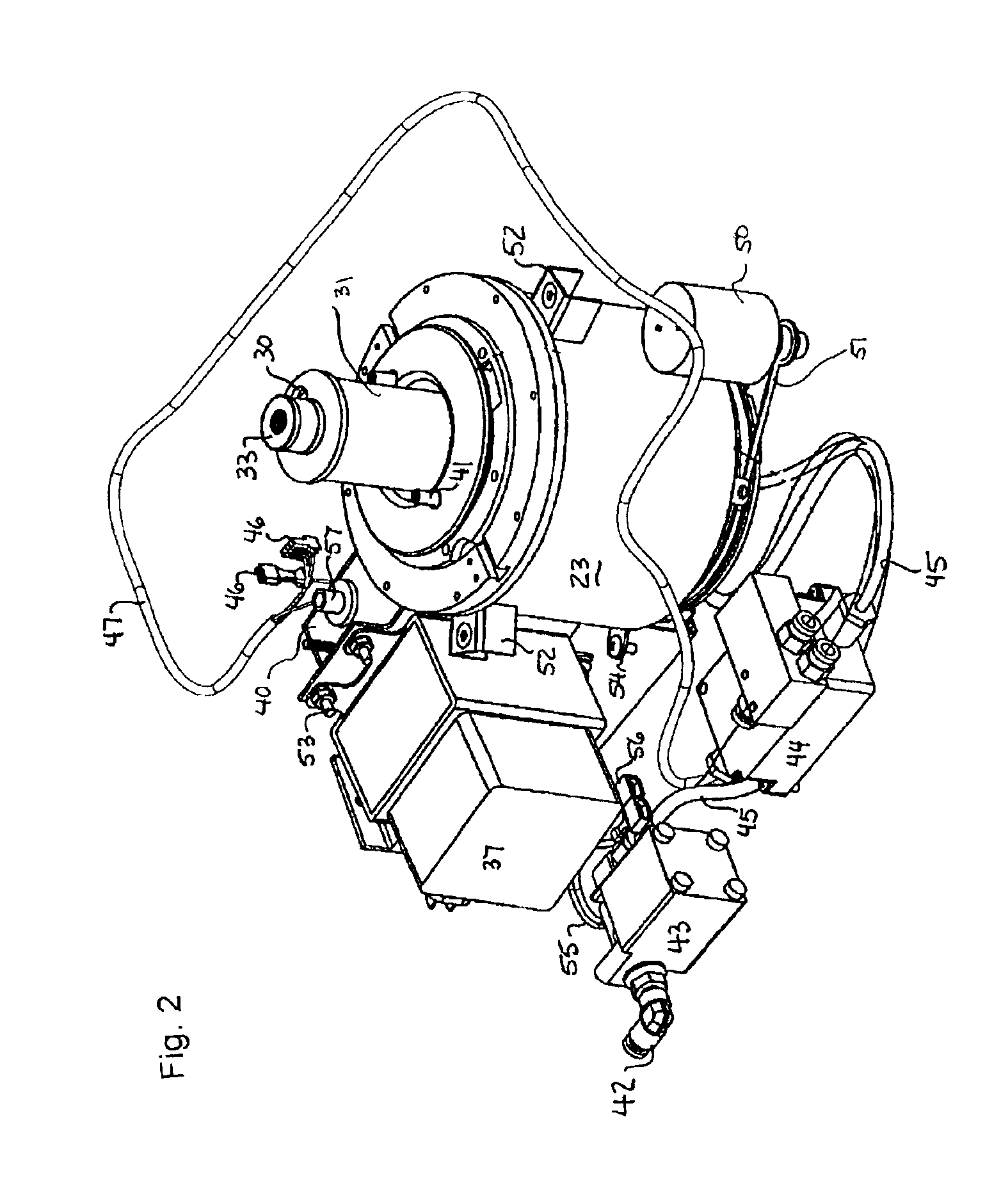

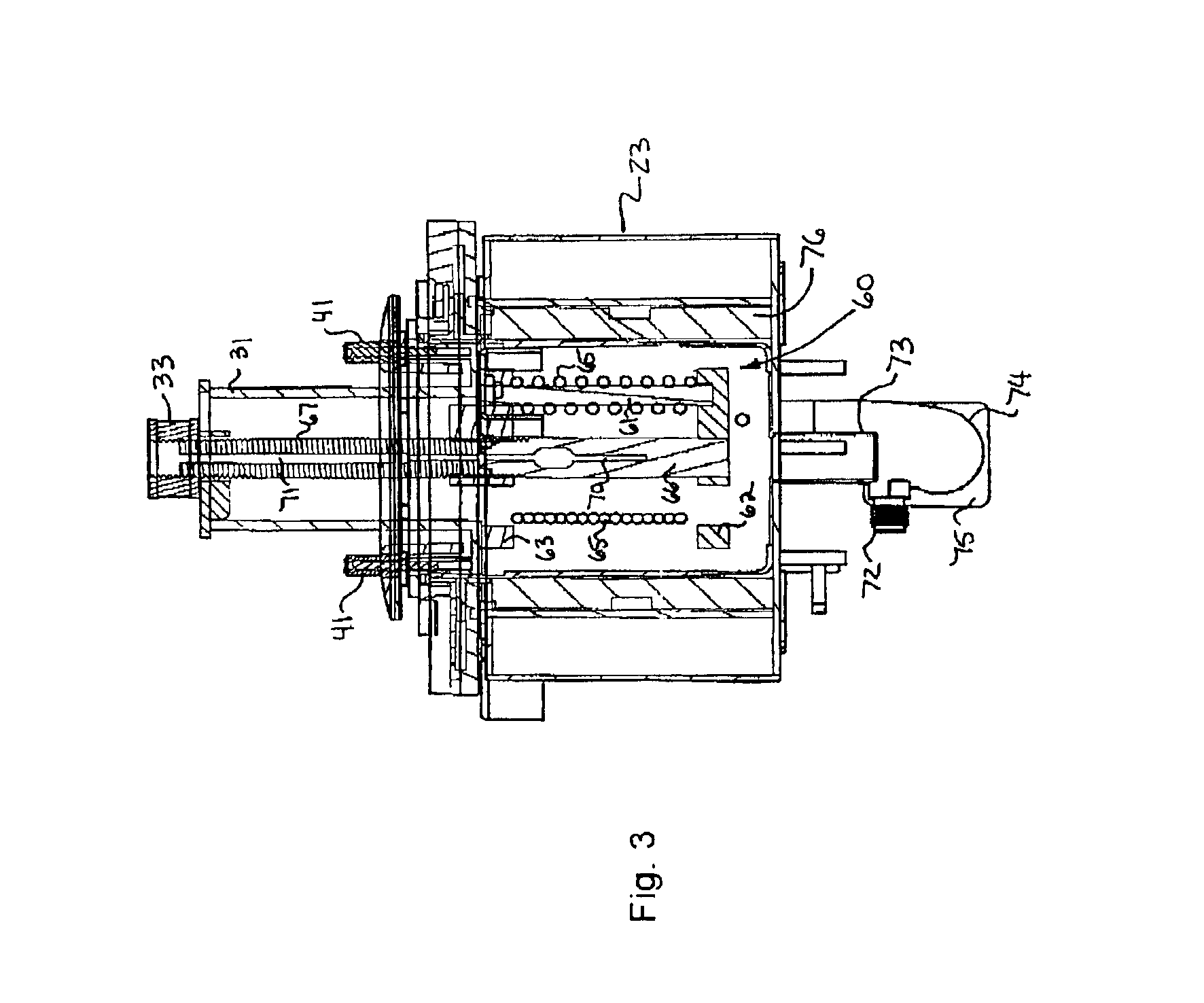

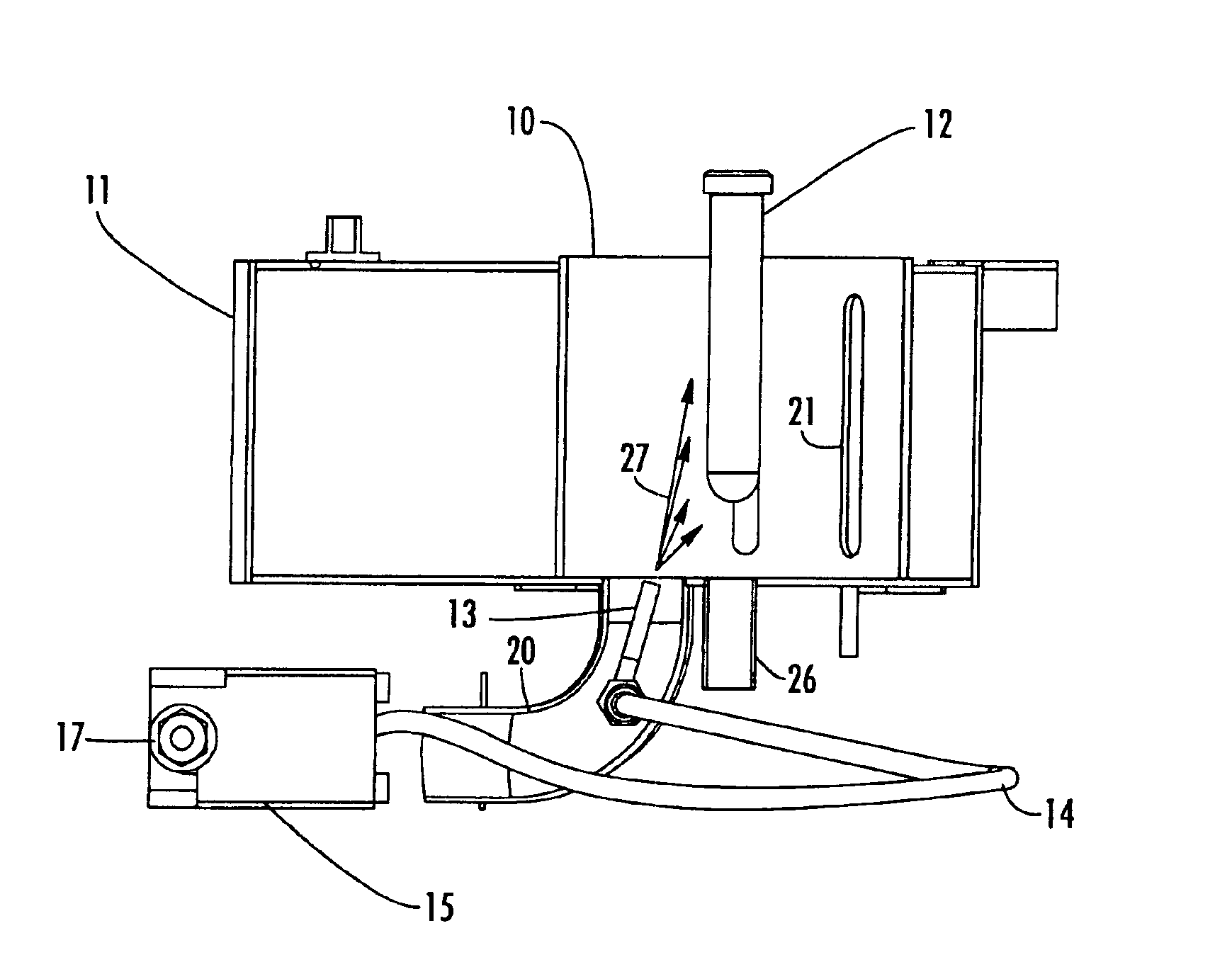

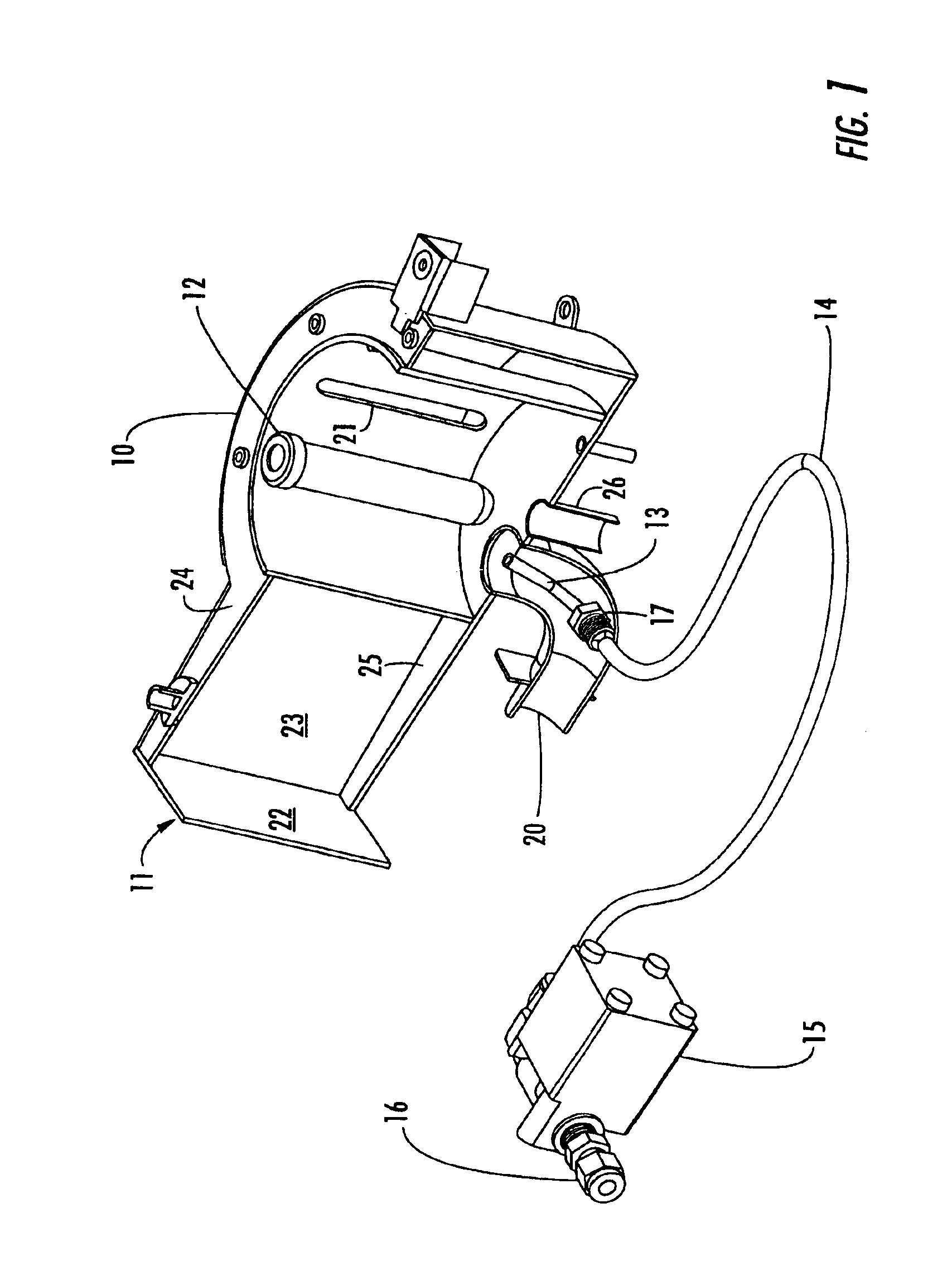

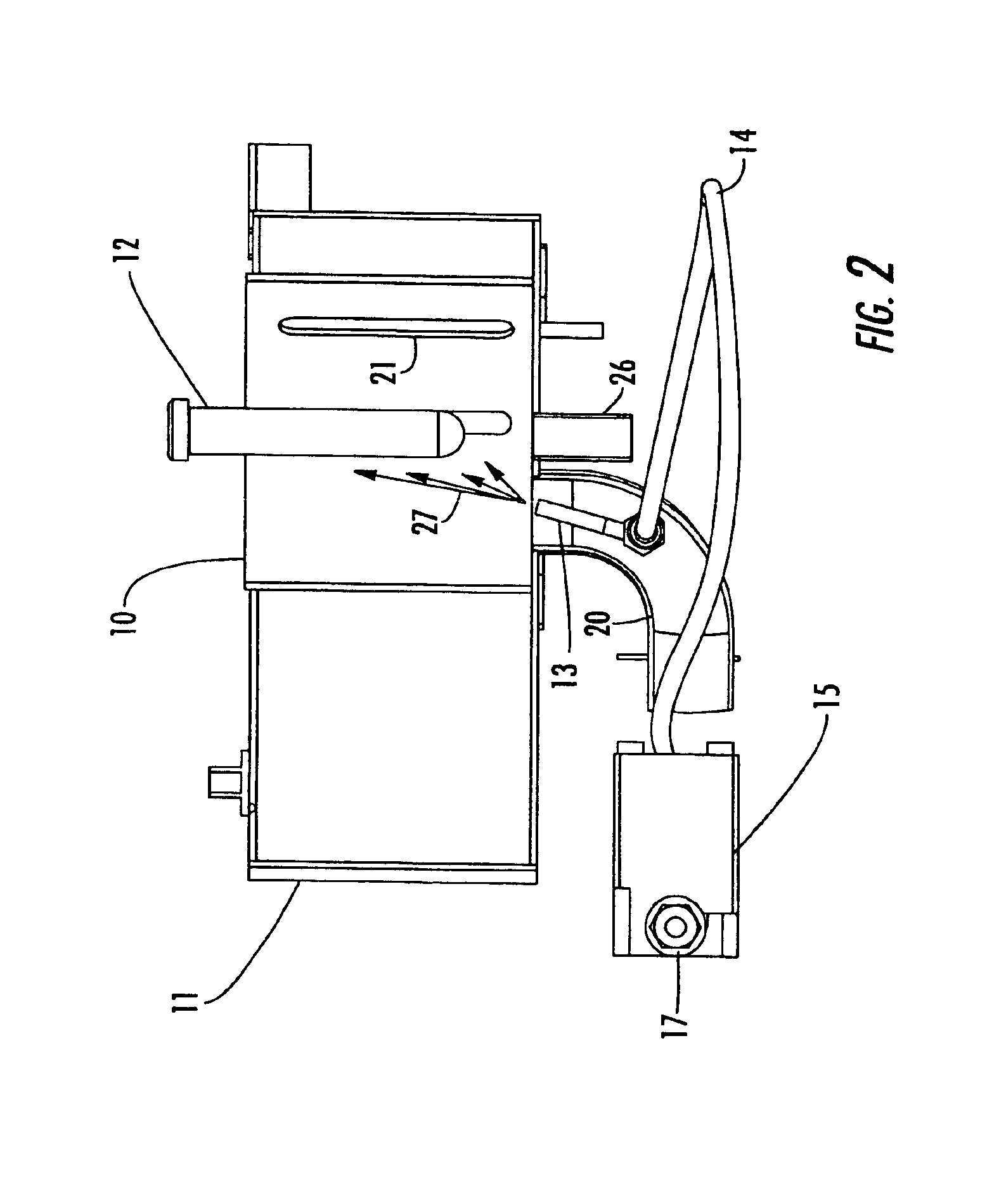

Method and apparatus for continuous flow microwave-assisted chemistry techniques

InactiveUS6867400B2Increase temperaturePreparation by ester-hydroxy reactionOrganic compound preparationMicrowave cavityContinuous flow

The invention is a method and associated instrument for microwave assisted chemistry. The invention includes the steps of directing a continuous flow of fluid through a microwave cavity while applying microwave radiation to the cavity and to the continuous flow of materials therein, monitoring the pressure of the fluid in the cavity; and cooling the fluid in the cavity when the pressure exceeds a predetermined setpoint pressure.

Owner:CEM CORP

Water polyurethane electric conduction paint containing carbon nano-tube and preparation method thereof

InactiveCN101165127AImprove dispersion uniformityNo subsidencePolyurea/polyurethane coatingsEmulsion paintsPolyesterCarbon nanotube

The present invention belongs to the field of chemical technology, and is especially one kind of conducting water soluble polyurethane paint containing carbon nanotube and its preparation process. The conducting paint is prepared through the first modifying carbon nanotube chemically for the surface to carry hydroxyl group, carboxyl group or amino group; the subsequent introducing to polyester polyol or isocyanate terminated polyurethane pre-polymer through chemical bonding and self-emulsifying to prepare water soluble polyurethane dispersoid containing carbon nanotube; and final adding deionized water and assistants through high speed stirring to obtain the conducting paint. The conducting paint can form coating with volume resistivity of 1x10<-5>-4x10<-4. ohm.cm, surface resistivity of 1x10<-1>-2x10<2> ohm, adhesion of 0 grade, shielding effectiveness of 70-85 dB, and long term stability, and has wide application.

Owner:SHANGHAI SAFEGREEN TECH

Vanadium dioxide precursor liquid and method for preparing thin-film material by using the same

ActiveCN101760735ALow costGood film formingSolid/suspension decomposition chemical coatingVanadium dioxidePeak value

The invention belongs to the technical field of material chemistry, in particular relates to a vanadium dioxide precursor liquid and a method for preparing a thin-film material by using the same. The vanadium dioxide precursor liquid of the invention comprises a soluble vanadium salt, a film forming accelerator and a solvent. The invention further provides a method for preparing a vanadium dioxide thin film by using the vanadium dioxide precursor liquid. The invention overcomes the shortages of the prior preparation technique of liquid-phase vanadium dioxide, reduces the cost of raw materials, and can previously reduce or oxidize the vanadium raw material in the raw materials to quadrivalence so that vanadium element is not necessarily subjected to an oxidation-reduction reaction in the process of thermal treatment. The vanadium dioxide thin film prepared by the invention has uniform phase, good purity and intelligent response to temperature. The vanadium dioxide thin film prepared ona glass substrate has a light transmittance peak value up to 70% at most in a visual light region and an infrared light regulating performance up to 60% at most, and has wide application prospect in the fields of optical functional materials and electric functional materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

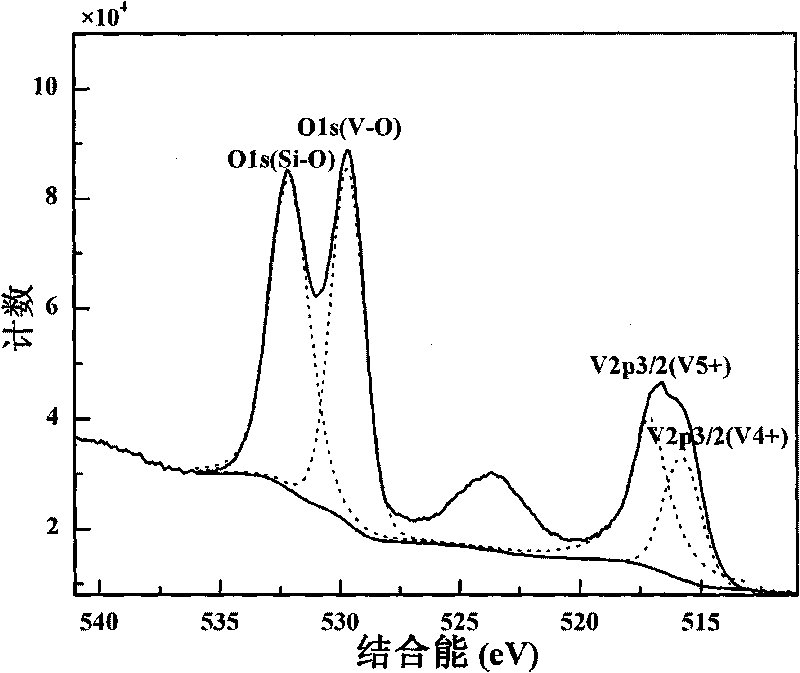

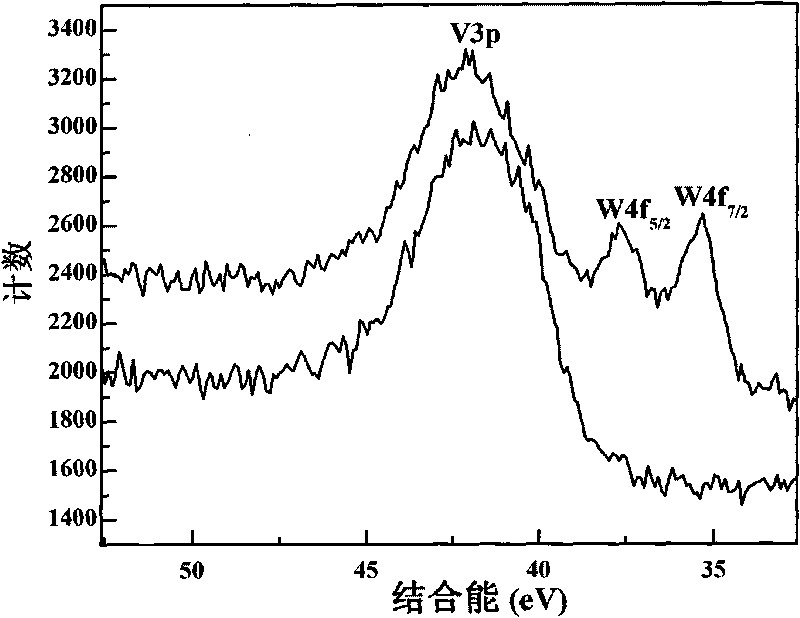

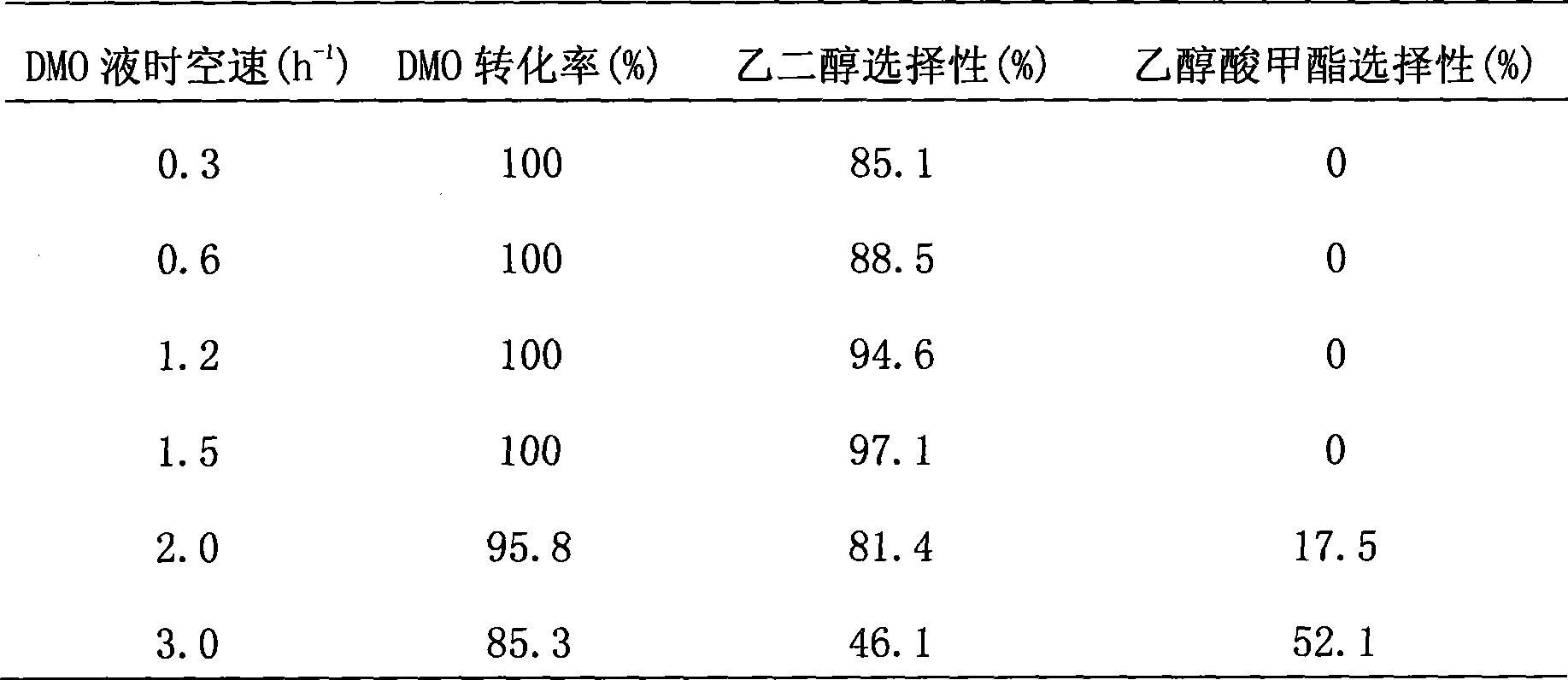

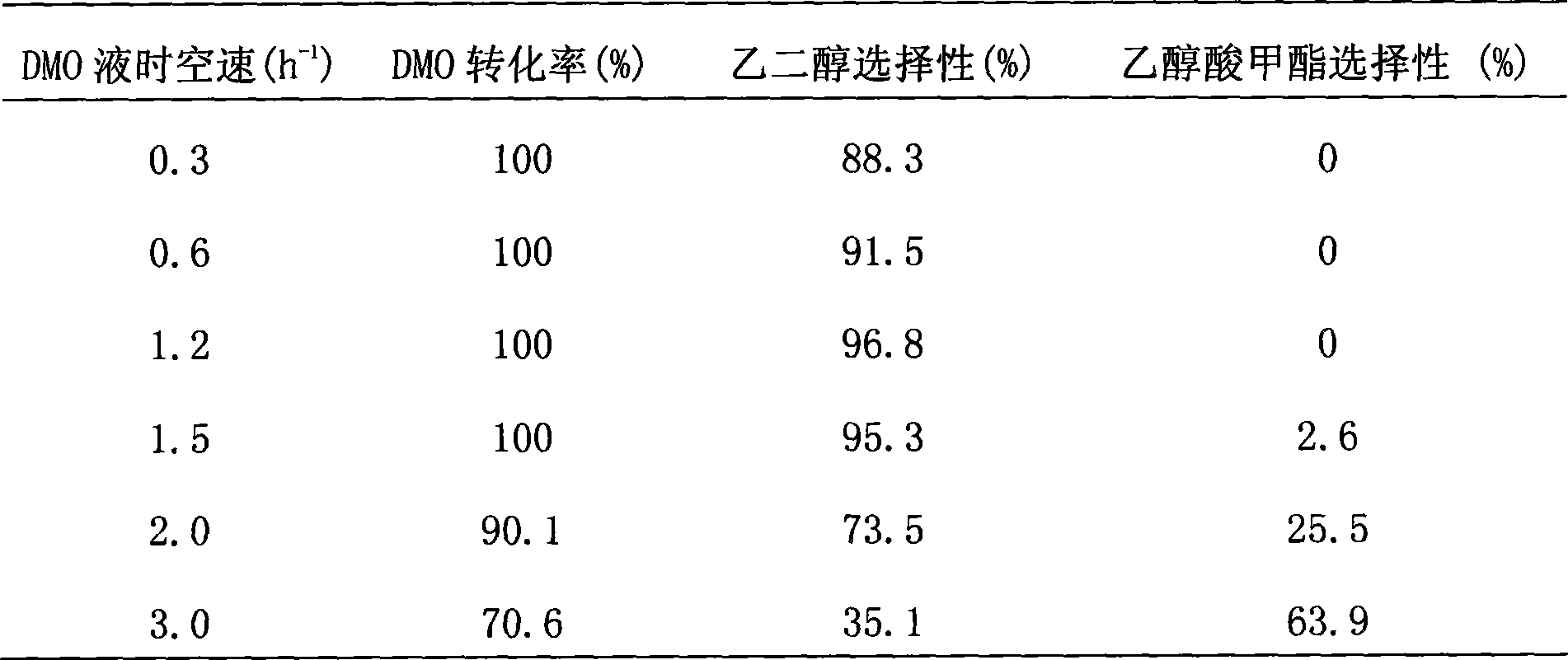

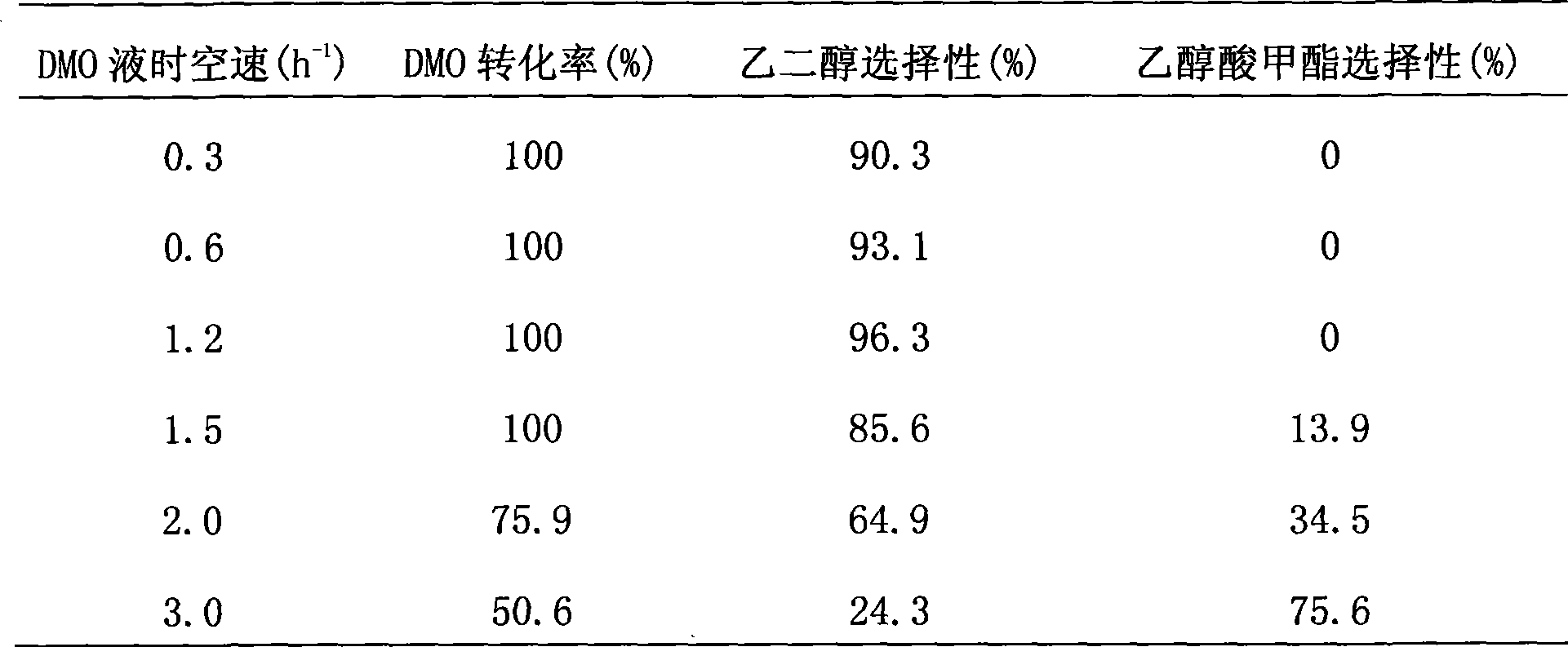

Method for preparing catalyst used in method for preparing ethanediol by dimethyl oxalate hydrogenation

InactiveCN101411990AHigh catalytic activityImprove catalytic selectivityMolecular sieve catalystsOrganic compound preparationCopper nitrateMesoporous silica

The invention relates to the field of chemical technology, in particular to a method for preparing a catalyst for hydrogenating dimethyl oxalate to prepare glycol. The method comprises the following steps: step one, copper nitrate is used to prepare a cuprammonium complex compound; step two, the cuprammonium complex compound is added with a mesoporous silica molecular sieve, is dripped with distilled water, and is filtered, washed, dried and roasted to prepare a catalyst precursor; and step three, the catalyst precursor is reduced in a hydrogen-nitrogen mixed atmosphere to prepare the catalyst. In the catalyst, according to mass percentage, the content of copper is between 5 and 40 percent; and the content of the mesoporous silica molecular sieve is between 60 and 95 percent. The method has the advantages that a silicon copper catalyst prepared through the new method has high catalytic activity and glycol selectivity in the reaction of hydrogenating the dimethyl oxalate to prepare the glycol, has long service life, smooth reaction performance and easy control.

Owner:FUDAN UNIV

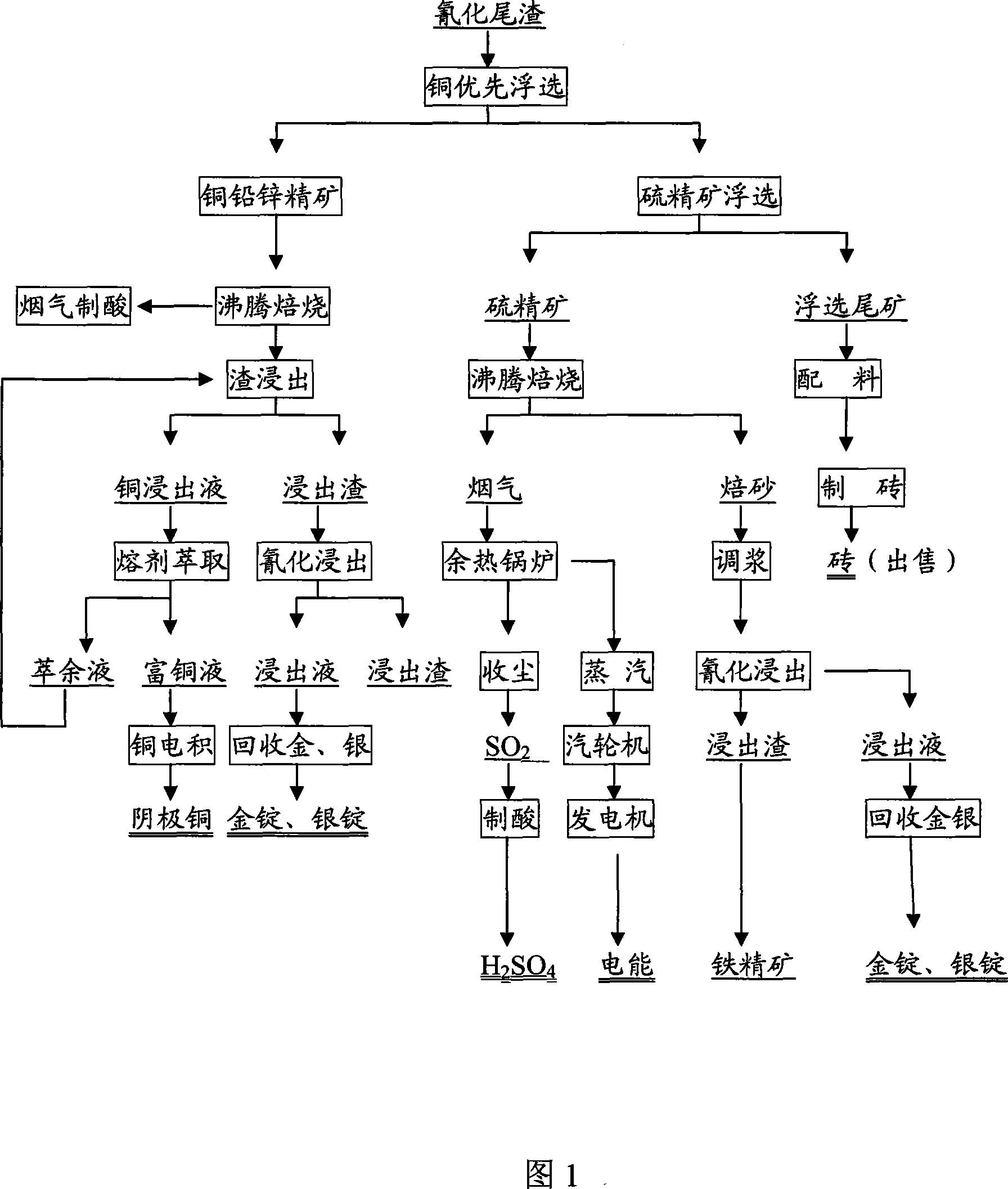

Integrated utilization technique for cyanidation gold-extracted waste slag

InactiveCN101078051AReduce energy consumptionTake advantage ofSolid waste managementSulfur compoundsBrickSlag

The invention relates to a method of complex utilization of the waste residue that from gold extraction with cyanidation. This invention belongs to the field of metallurgy and chemical technology. Firstly, the waste residue that from gold extraction with cyanidation is pretreated with acid. The floatation process is adopted here. The first step is to concentrate cuprum, plumbum, zincum and argentum; Secondly, collect 47%-52% of the high-grade sulfur and concentrate gold and argentums; Then roast the high-grade sulfur concentrate, the gas is utilized to produce acid, and the waste heat is utilized to produce electricity, and the waste residue is utilized to extract gold with cvanidation. After washing by water, the leavings which contains 62%-68% iron can be used as iron concentrate. Finally, produce slag brick with the refuse. The technology which could reclaim the elements, such as Fe, S, Cu, Pb, Zn, Au, Ag, complex utilizes the waste residue that from gold extraction with cyanidation. The invention takes full advantage of resource. The effect of integrated utilization of resource and the economic benefit are enhanced and the environmental pollution is lessened by this way.

Owner:SHANDONG GUODA GOLD

Reaction and temperature control for high power microwave-assisted chemistry techniques

InactiveUS6917023B2Organic chemistry methodsDielectric heating circuitsMicrowave cavityTemperature control

A method is disclosed for carrying out microwave assisted chemical reactions. The method includes the steps of placing reactants in a microwave-transparent vessel, placing the vessel and its contents into a microwave cavity, applying microwave radiation within the cavity and to the vessel and its contents while concurrently externally cooling the vessel conductively.

Owner:CEM CORP

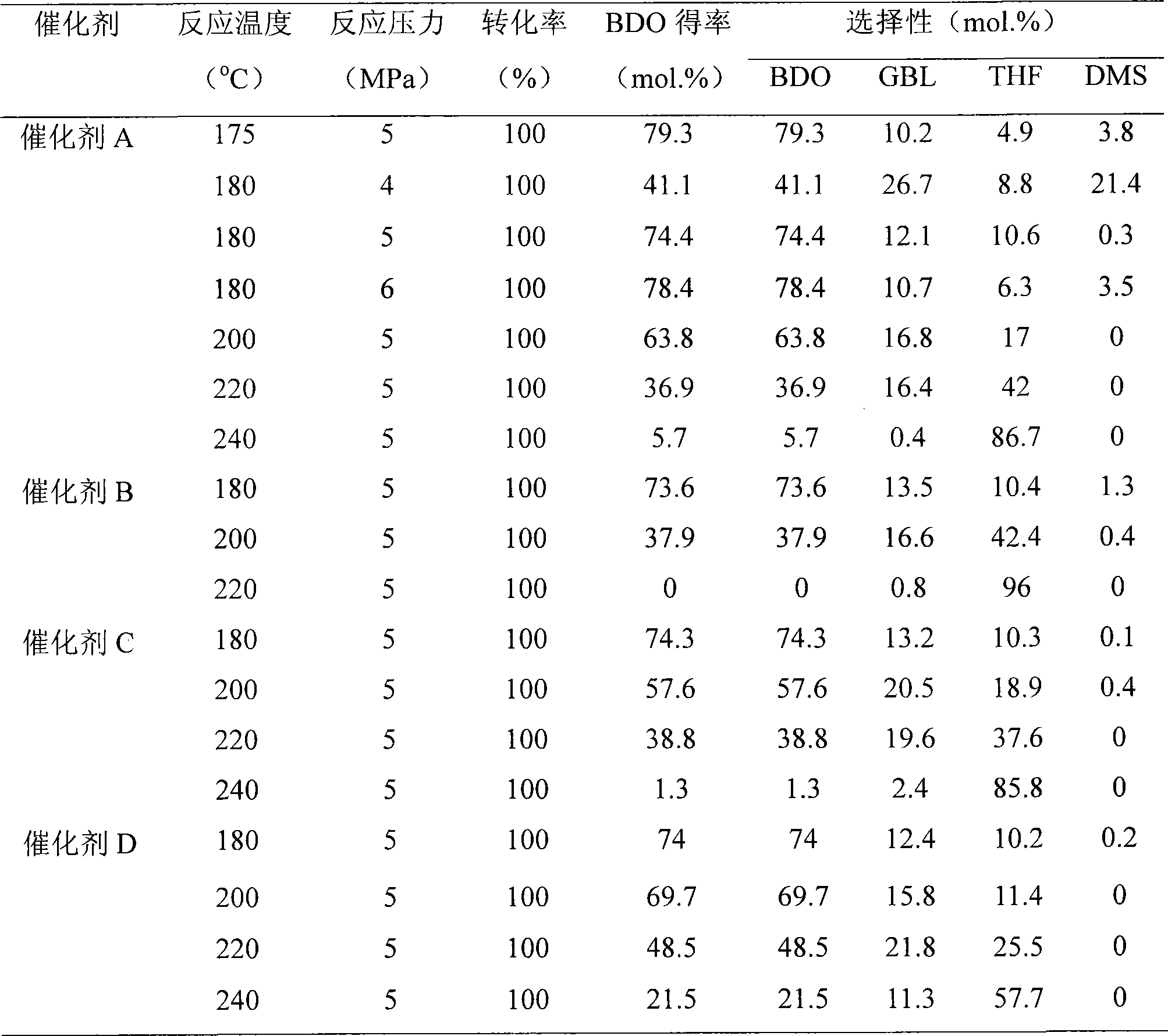

Catalyst for preparing 1,4-butanediol or tetrahydrofuran from selective hydrogenation of dimethyl maleate and preparation method thereof

ActiveCN101502803AHigh selectivitySolve filterabilityOrganic compound preparationHydroxy compound preparationMonoethyl maleateHydrogenation reaction

The invention belongs to the field of chemical technology, and in particular relates to a catalyst for preparing 1, 4-butanediol or tetrahydrofuran by selective hydrogenation of dimethyl maleate and a preparation method thereof. The catalyst consists of Cu, Zn, Al, M and O, and the mol content of each metal element is as follows: 30 to 60 percent of Cu, 10 to 50 percent of Zn, 5 to 20 percent of Al and 0 to 10 percent of M, wherein M is any one of Mn, Mg and Cr. The preparation method for the catalyst comprises precipitation, ageing, washing, drying and baking of a catalyst precursor, and reduction activation before use. The catalyst is applied to the hydrogenation reaction of the dimethyl maleate, and the yield of the 1, 4-butanediol at a reaction temperature of 180 DEG C is 73.6 percent; and the yield of the tetrahydrofuran is 96 percent at a reaction temperature of 220 DEG C. Product composition of the catalyst can be well adjusted by changing the reaction condition to adapt to different market demands, and the catalyst has extremely high industrial application value.

Owner:FUDAN UNIV +1

Method for extracting rose damascana and rose flower water from roses

InactiveCN101691522AReduce lossesImprove qualityCosmetic preparationsToilet preparationsWater vaporPetal

The invention relates to a method for extracting rose damascana and rose flower water from roses, belonging to the technical field of natural product chemistry. In the invention, the picked fresh roses and saline solution are placed into a pulp refiner with a certain ratio of material to liquid for homogenization and crushing after the stamens of the roses and impurities are removed, the sample is poured into a distillation still for dipping, a vent valve is opened, water steam flow rate is adjusted to carry out steam distillation, the temperature of a condenser is adjusted, oil-water mixed steam is condensed, the flowing-out liquid is collected until the volume of the flowing-out liquid and the weight of rose leaves form a certain proportion, the flowing-out liquid is placed still and layered at low temperature, rose damascana dehydrating agents are added in an upper layer of oil, and then the rose damascana is obtained after being dehydrated; the solution at the lower layer is the rose flower water. Compared with the prior art, the method has the advantages of little loss of top note of the extracted rose damascana, high product quality, simple operation and low production cost.

Owner:INST OF MEDICINAL PLANTS YUNNAN ACAD OF AGRI SCI

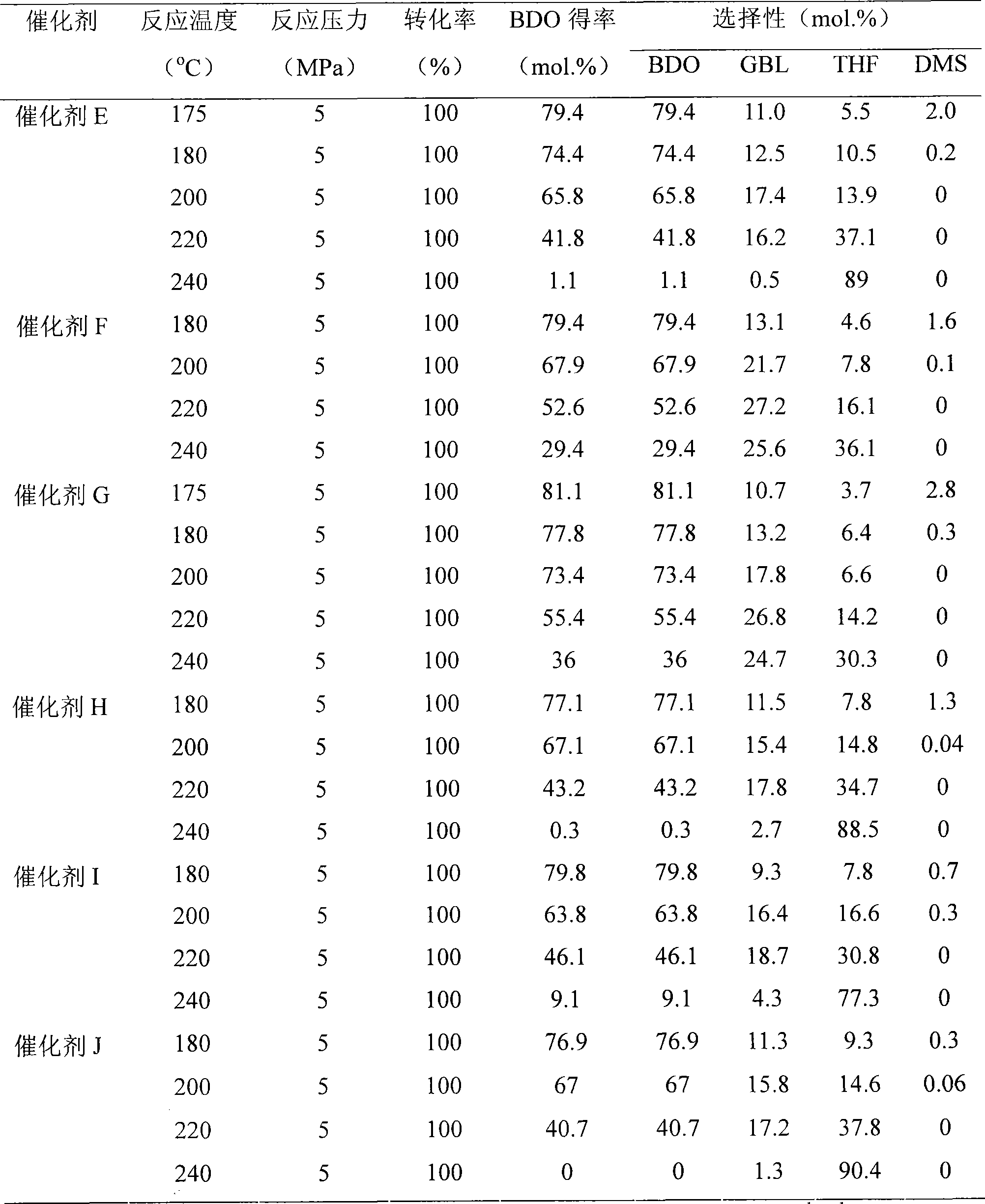

Prepn of nano barium sulfate

InactiveCN1398789AStable operating conditionsGood resolubility and dispersibilityMaterial nanotechnologyCalcium/strontium/barium sulfatesSal ammoniacSulfate radicals

The present invention belongs to the field of chemical technology and is especially a complexing process of preparing nanometer BaSO4. The process includes two main steps of complexing reaction and deposition reaction. Specifically. Ba2+ ion solution and EDTA complexing agent solution produce complexing reaction in a reactor to produce complex solution with certain stability and ammonia water being used for regulating system pH value. The complex solution is made to react with sulfate radical solution while stirring to prepare nanometer level BaSO4 particles as precipitate. The nanometer level BaSO4 product is hexagonal crystal and blue in color, and has grain size of 20-40 nm and average grain size of 25 nm. The process is stable in operation, and the product has high quality and dispersivity.

Owner:ZHONGBEI UNIV

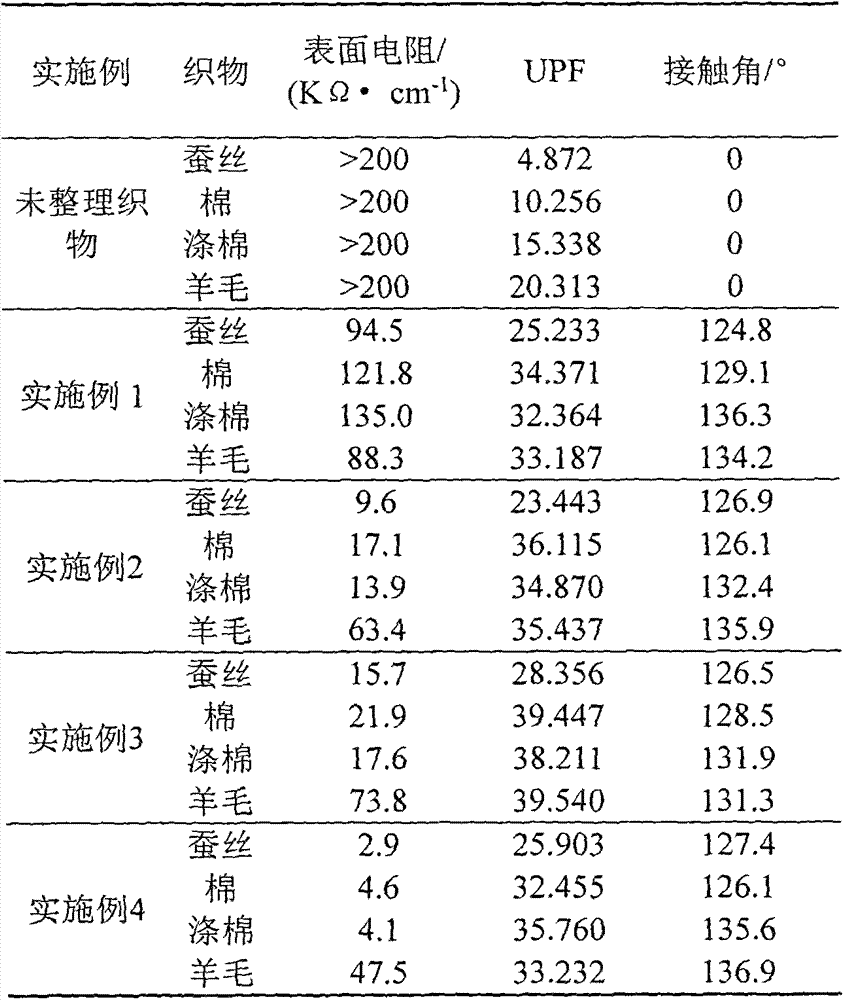

Method for multifunctional sorting of textile by using graphene oxide derivative

ActiveCN104328653ASimple technical solutionEasy to operateVegetal fibresAnimal fibresUltravioletSmart transducer

The invention discloses a method for multifunctional sorting of a textile by using a graphene oxide derivative, belonging to the technical field of textile chemistry. The method comprises the following steps: immersing the textile with a graphene oxide derivative water solution; drying the textile and carrying out reduction so that the surface of the textile is covered with one layer of a reduced graphene oxide derivative; and repeating the steps to obtain the multifunctional textile with good conductive, anti-ultraviolet and water-repelling functions. By virtue of the method, the textile can obtain a lot of functions by one type of sorting and the multifunctional sorting of common textiles including cotton, wool, silk, dacron, chinlon and the like, and blended textiles or intertextures thereof can be realized; and the textile can be used for the fields including medical treatment, intelligent sensors, mobile power generation, military affairs and the like.

Owner:JIANGNAN UNIV

Gel foam selective water blockoff agent and use thereof

InactiveCN101481604AImprove stabilityLong water blocking periodDrilling compositionFoaming agentHexamethylenetetramine

The invention relates to gel-foam selective plugging agent and the application thereof, belonging to the technical field of oilfield chemistry. The plugging agent comprises the components: 30-50% of acrylamide, 20-40% of hexamethylenetetramine, 5-15% of phenol, 5-15% of tetraethylene pentamine and 5-15% of foaming agent. The aqueous solution with the mass ratio of 0.5-2% can be prepared in site and is injected into a well after being evenly dissolved, so that the plugging agent is used for plugging water in the oil well at the temperature of 90-150 DEG C. The plugging agent uses organic cross linker for cross bonding polymer to form gel foam under the condition of high temperature, so as to be resistant to the high temperature of 90-150 DEG C and have long period of validity in plugging water.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

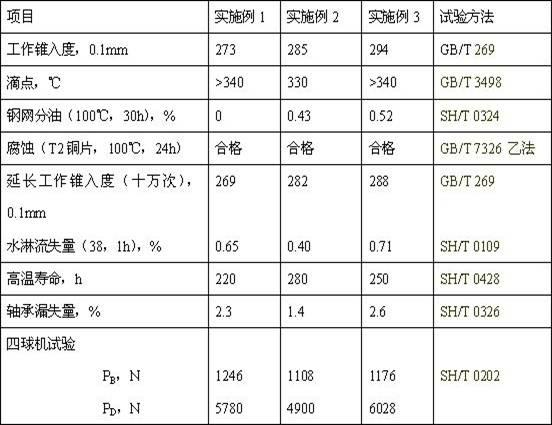

High-performance calcium sulfonate complex grease and preparation method thereof

ActiveCN102634400AImprove high temperature resistanceGood mechanical stabilityThickenersAntioxidantHydroxystearic Acid

The invention relates to grease and a preparation method thereof, in particular to calcium sulfonate complex grease and a preparation method thereof, which belong to the field of chemical technology. A formula of the calcium sulfonate complex grease includes, in weight percentage, 23.5-35.5% of base oil, 32.0-45.4% of high alkalinity calcium sulfonate, 5-15% of calcium carbonate, 1.1-1.5% of alkyl benzene sulfonic acid, 2.5-3.5% of isopropanol, 3-6% of water, 1.9-2.7% of calcium hydroxide, 2-4% of 12-hydroxystearic acid, 1.75-2.25% of inorganic acid, 0.5-3.5% of thickening agent, and 0.1-5% of antioxidant. The calcium sulfonate complex grease has the advantages of high dropping point, fine rust and corrosion resistance, extreme pressure and wear resistance, fine mechanical stability, no hardening in long-term storage and long service life.

Owner:JIANGSU LOPALTECH

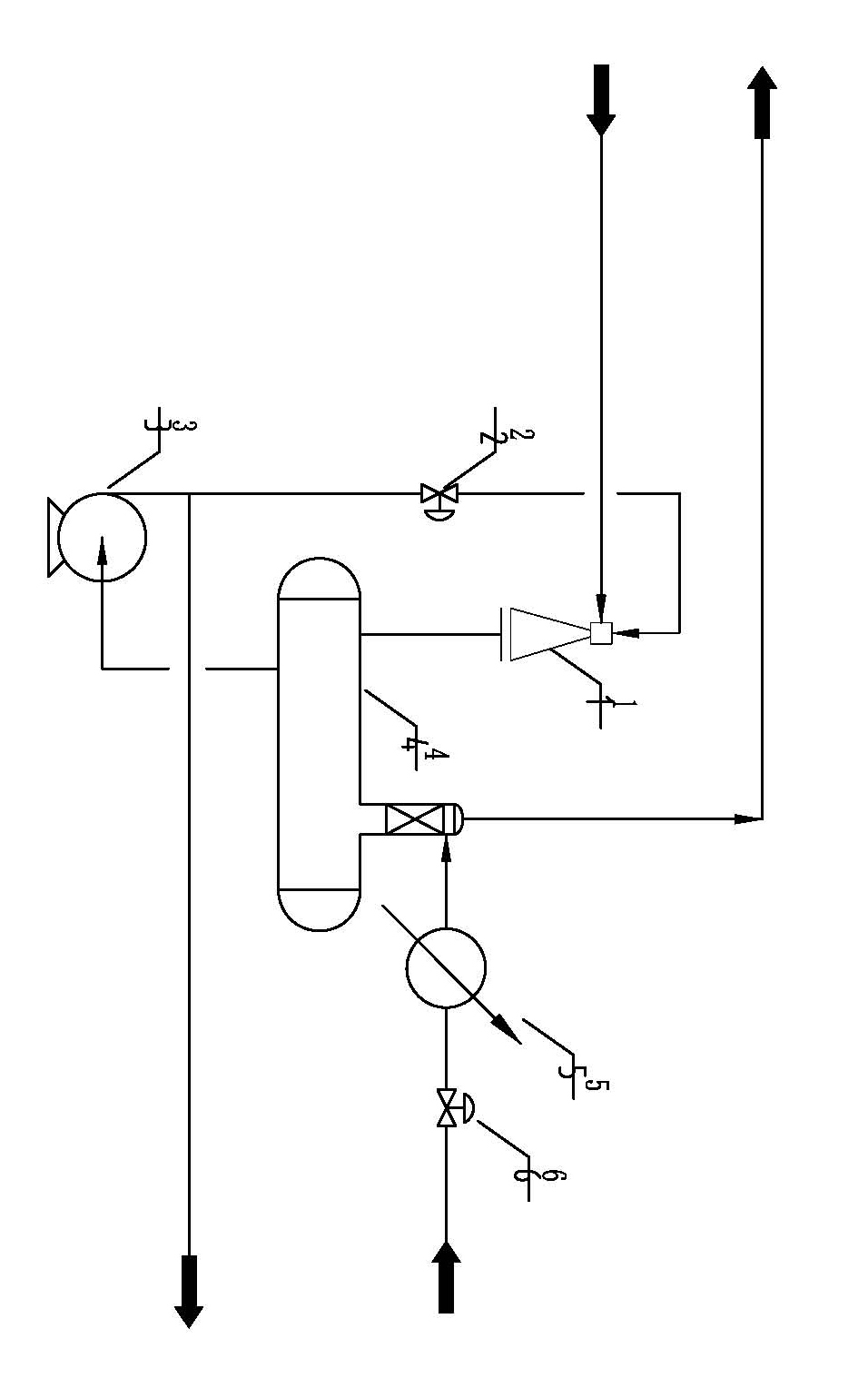

Pressure reduction gas desulfurization method

The invention relates to a pressure reduction gas desulfurization method which belongs to the technical field of chemical technology. The pressure reduction gas desulfurization method comprises the following steps of: firstly, performing injection desulfurization with an absorbent; secondly, performing absorption desulfurization with an absorbent in a recycling tank; and then performing absorption again with absorbing structured packing after absorption desulfurization. In the specific operations of the vacuum gas desulfurization method, the absorbent is recycled through a circulation line; a circulating pump and the recycling tank are connected to the circulation line; an injector is connected to an upstream circulation line of the recycling tank; sulfur-contained gas is connected to the injector; and the top of the recycling tank is provided with a clean gas outlet. The pressure reduction gas desulfurization method has the advantages of simple process, convenience of operation, low construction investment and low failure rate. Moreover, the content of hydrogen sulfide after gas desulfurization can be reduced to be less than 500ppm, thus the desulfurization and purification effects are good and the desulfurization efficiency is high.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

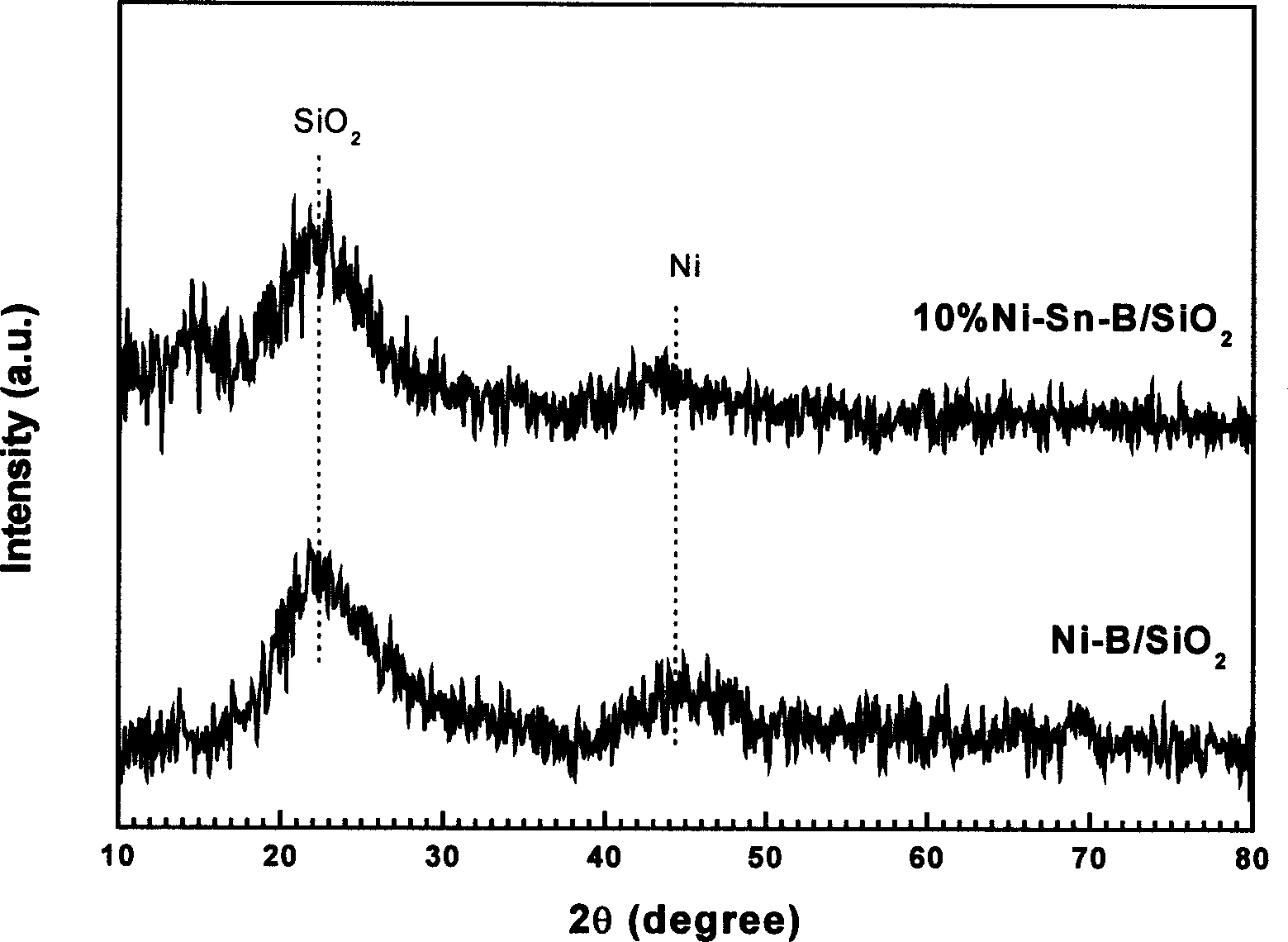

Amorphous nickel boron catalyst for hypnone hydrogenation and its preparation method

The present invention belongs to the field of chemical technology, and is new type of amorphous catalyst for acetophenone hydrogenating process to prepare phenethyl alcohol and its preparation process. The catalyst consists of Ni, B, metal additive M and carrier material L, where, Ni exists mainly in Ni-B or Ni-M-B amorphous alloy form and the metal additive M is one of Sn, Cr, Mo, W, Fe, Co and La. The catalyst is prepared through reducing metal ion and subsequent impurity elimination. The catalyst is used for acetophenone hydrogenating process to prepare phenethyl alcohol, and has simple preparation process, relatively low cost and much higher acetophenone hydrogenating activity and selectivity compared with traditional industrial Rancy Ni catalyst.

Owner:FUDAN UNIV

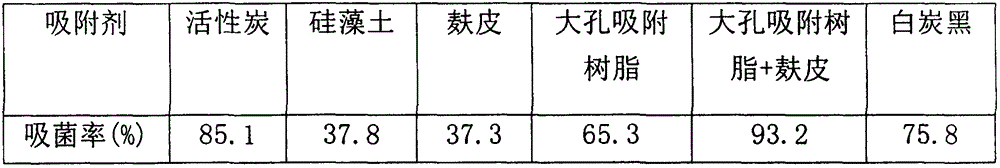

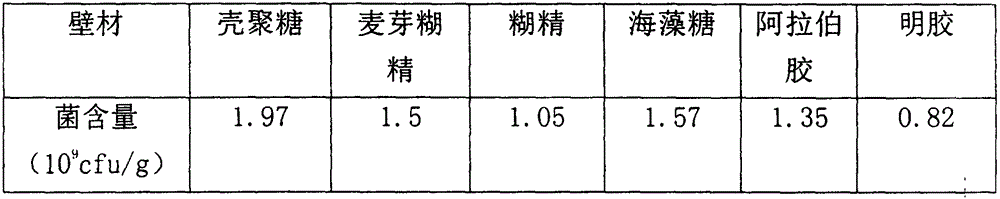

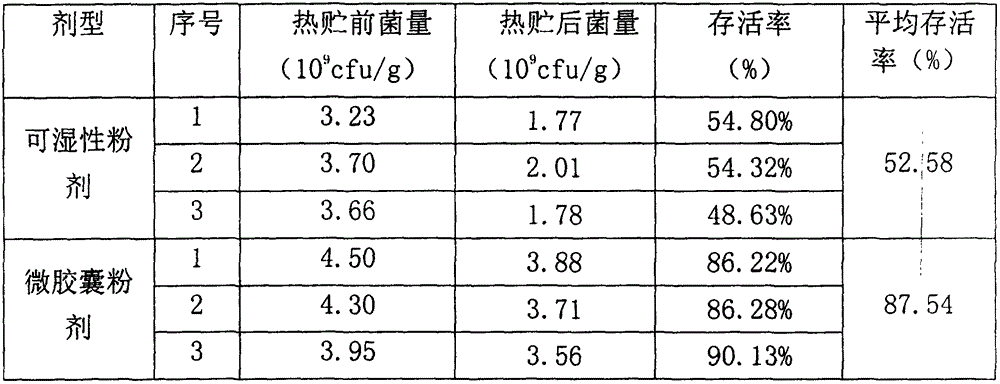

Preparation of microcapsules of viable microbe biopesticide

The invention relates to microcapsules prepared from viable microbes such as pseudomonas, bacillus and paenibacillus serving as main active components, belonging to the technical field of microorganism and biochemistry. The method for preparing microcapsules of viable microbe biopesticide comprises the following steps of: adsorbing microbial fermentation culture solution through an adsorption effect to prepare capsule cores and solidifying the capsule cores, and adding wall materials, so as to prepare a microcapsule preparation. The microcapsule preparation prepared by adopting the method has high content of viable microbes, high storage property and strong high-temperature and ultraviolent resistances, and stable and good prevention and control effect on plant diseases and insect pests.

Owner:成都特普生物科技股份有限公司

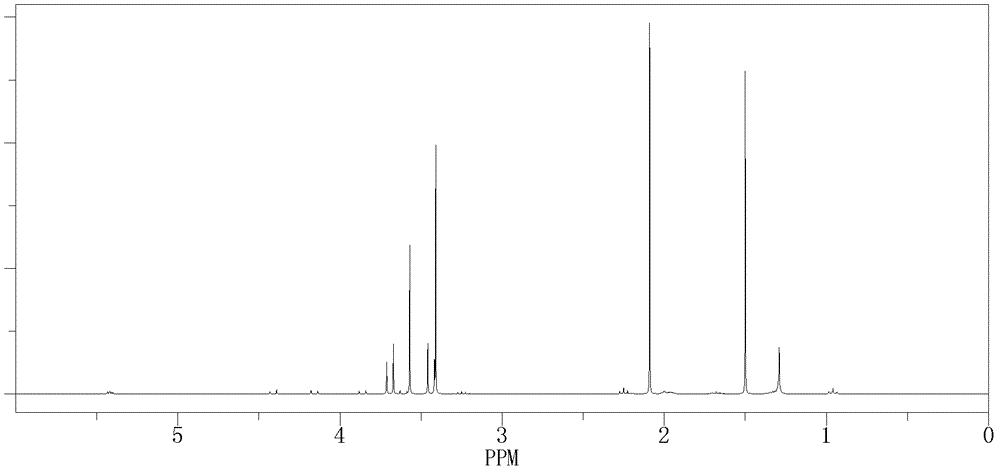

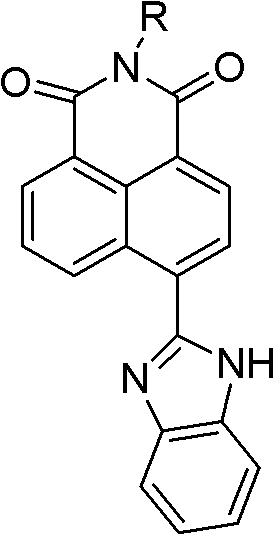

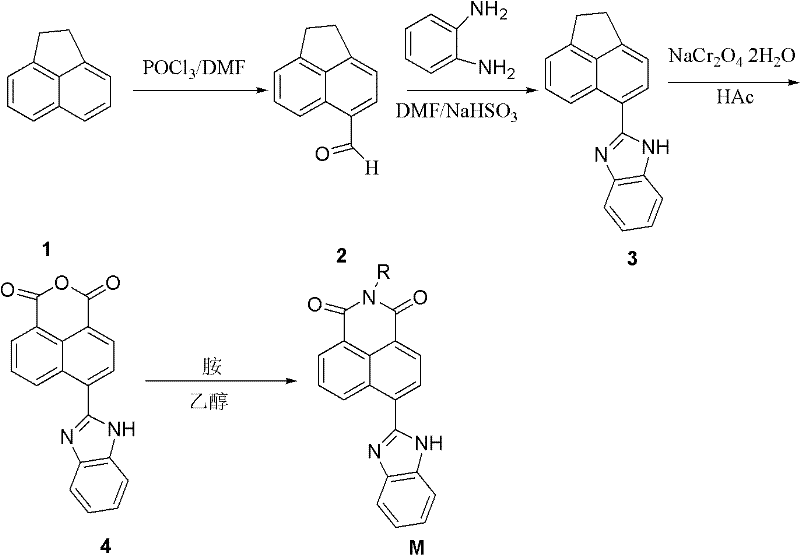

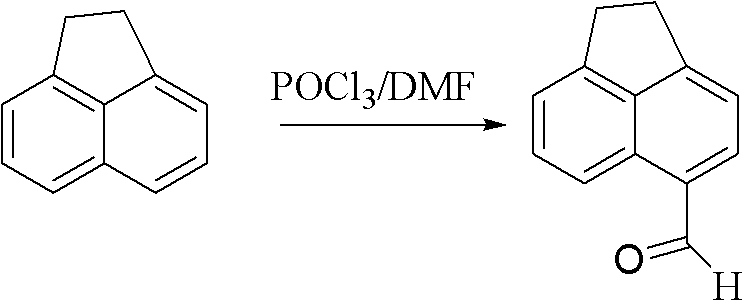

Synthesis of benzimidazole-containing naphthalimide derivatives and applications of benzimidazole-containing naphthalimide derivatives on cancer resistance

InactiveCN102206203AGood choiceGood tumor suppressor activityOrganic active ingredientsOrganic chemistryPheochromocytomaOrganic synthesis

The invention relates to synthesis of benzimidazole-containing naphthalimide derivatives and applications of the benzimidazole-containing naphthalimide derivatives on cancer resistance, and belongs to the field of organic synthesis and pharmaceutical chemistry technology. The benzimidazole-containing naphthalimide derivatives are obtained through a method that a benzimidazole group is introduced into a fourth position of a naphthalene ring of naphthalimide. Experiments of proliferation inhibiting effects of the benzimidazole-containing naphthalimide derivatives on cancer cells adopt a microculture tetrozolium (MTT) reduction method and aim at MCF-7 human breast cancer cells, Hela human cervical cancer cells and PC12 rat adrenal medullary pheochromocytoma differentiated cells. Results of the experiments show that the benzimidazole-containing naphthalimide derivatives have the advantages of good inhibitory activity against cancer cells and good selectivity on cancer cells.

Owner:DALIAN UNIV OF TECH

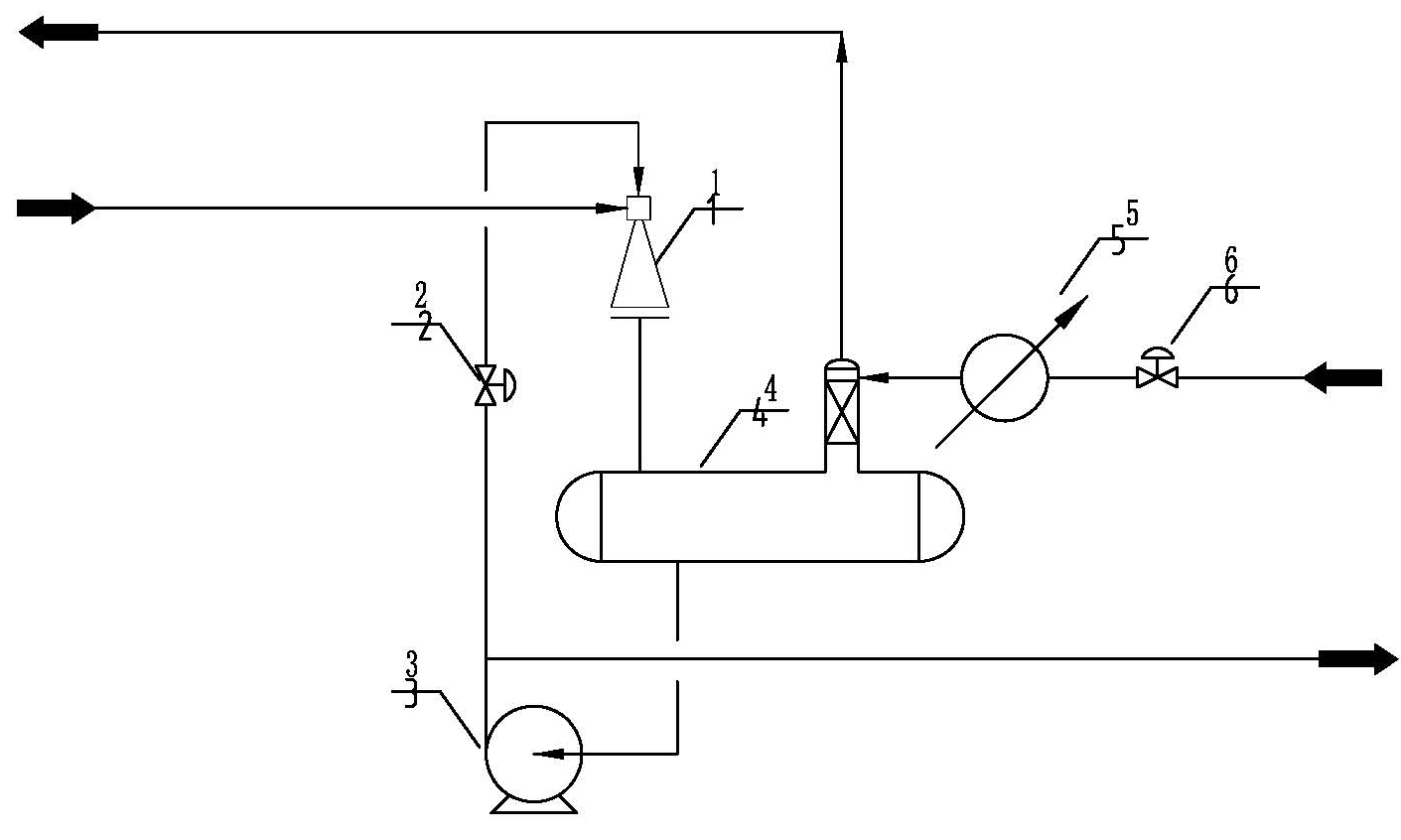

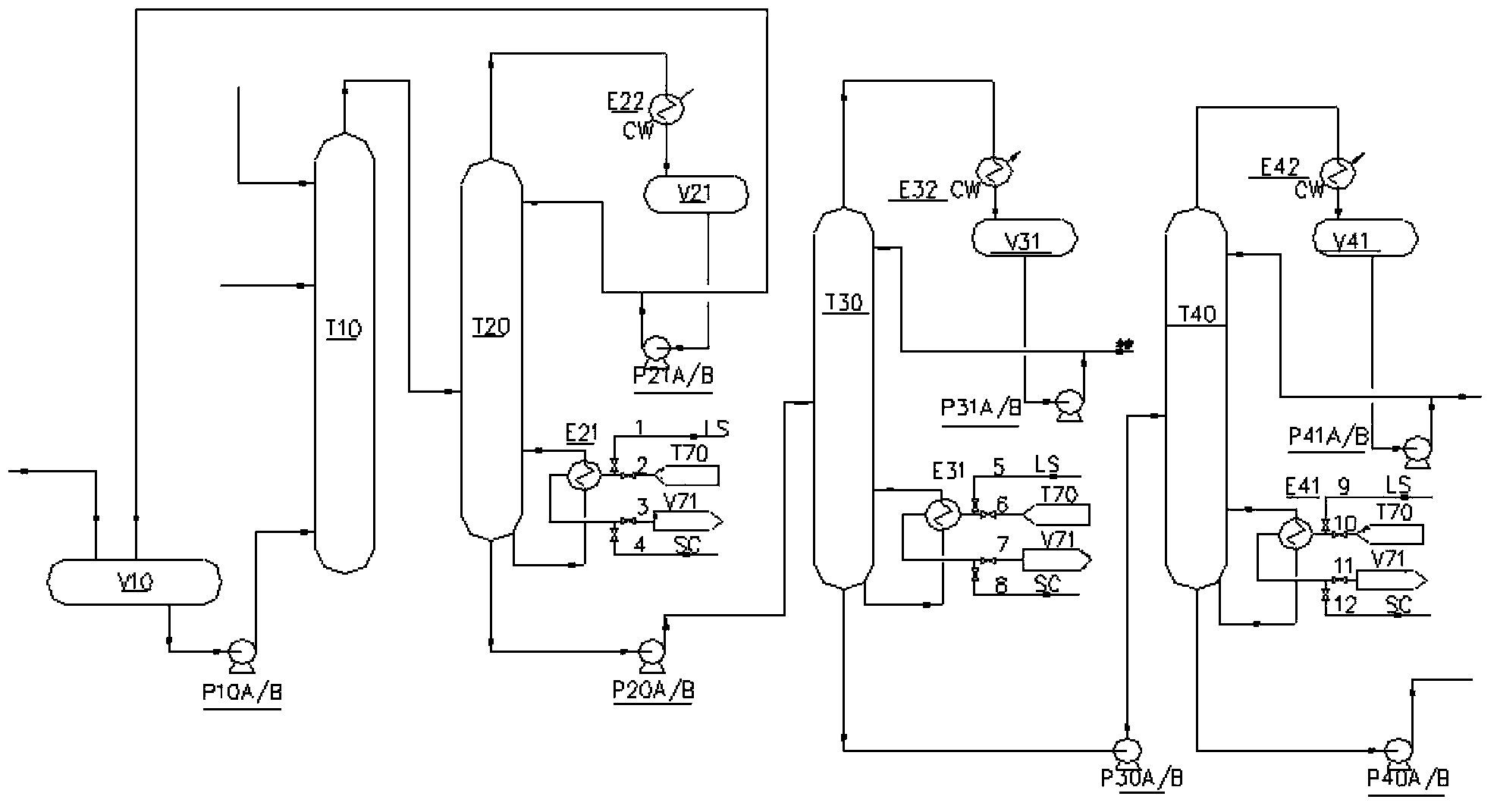

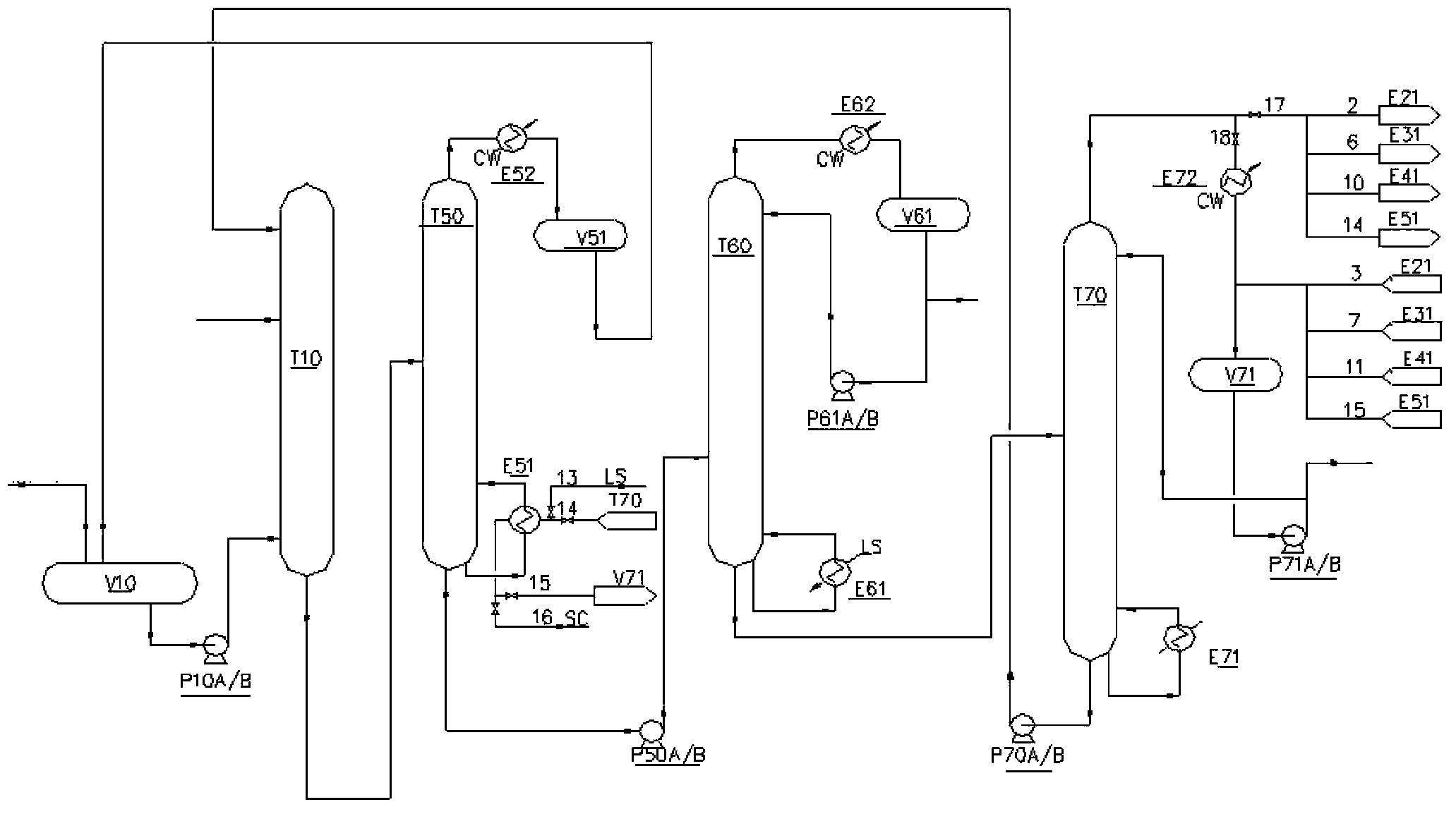

Separation equipment and separation method of methyl methacrylate (MMA)

InactiveCN103833551AReduce energy consumptionLess investmentOrganic compound preparationCarboxylic acid esters separation/purificationSolventTower

The invention relates to the field of chemical technology, and particularly relates to separation equipment and separation method of methyl methacrylate (MMA). The separation equipment of MMA comprises a separation device, and the separation device comprises a solvent tank, an extraction tower, a solvent recovery tower, an impurity ester removal tower and an MMA refining tower. The separation method of MMA comprises a separation process and is operated by the separation equipment by the following steps: 1) extracting the MMA reaction liquid with washing water and n-hexane in the extraction tower to obtain an extract phase from the tower top; 2) heating and refining the extract phase through the solvent recovery tower to obtain coarse MMA from the tower kettle and n-hexane from the tower top; 3) recycling the n-hexane obtained from the tower top in the solvent tank. After the coarse MMA is subjected to impurity ester removal in the impurity ester removal tower and then is processed by the MMA refining tower to obtain the purified MMA product. According to the separation equipment and separation method provided by the invention, the common easily-available n-hexane with a wide source is used as an MMA extraction agent, and the n-hexane is recycled through an MMA refining process.

Owner:华东理工大学工程设计研究院有限公司

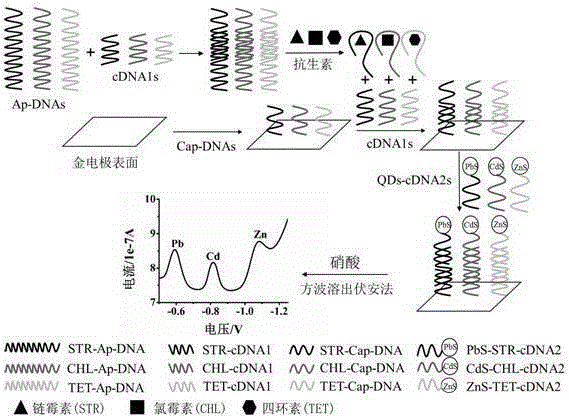

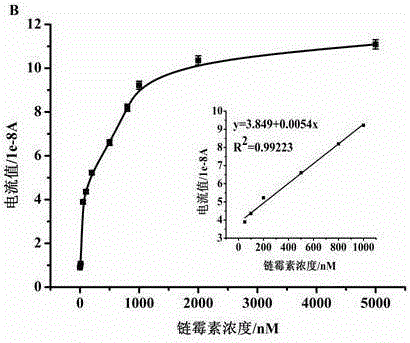

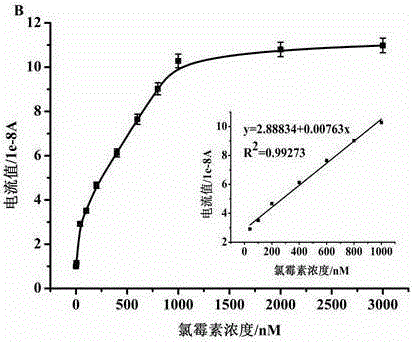

Method for simultaneously detecting three antibiotic residues including streptomycin, chlorampenicol and tetracycline based on nucleic acid aptamer and quantum dots

ActiveCN105301085AEasy to manufactureEasy to retouchMaterial electrochemical variablesDissolutionAntibiotic Y

The invention relates to a method for simultaneously detecting three antibiotic residues including streptomycin, chlorampenicol and tetracycline based on nucleic acid aptamers and quantum dots and belongs to the technical field of analytical chemistry. Three-section complementary cDNA 1 sequences are designed and synthesized and are complemented with three antibiotic aptamers DNA sequences and are further complemented with respective capturing probe DNA sequences of three antibiotics and complementary cDNA 2 sequence part. The three cDNAs 1 are first hybridized with aptamer DNAs supplemented with each other to form double-stranded DNAs. When target antibiotics exist in a sample, the aptamer DNAs are combined with corresponding antibiotics as a priority to cause the double-stranded DNAs to be de-hybridized and release cDNAs 1. The free cDNAs 1 are combined with capturing probe DNAs modified on the surface of a gold electrode, and cDNAs 2 modified with three quantum dots are hybridized with the other end of each cDNA 1. The three quantum dots on the surface of the gold electrode generate dissolution volt-ampere peaks corresponding to the target antibiotics. The three antibiotics are detected by utilizing the relations of changes of peak current values and antibiotic concentration. The method is good in repeatability and stability and high in sensitivity and can be used for directly measuring the three antibiotic residues in samples such as milk.

Owner:ANHUI HUATENG AGRI TECH CO LTD

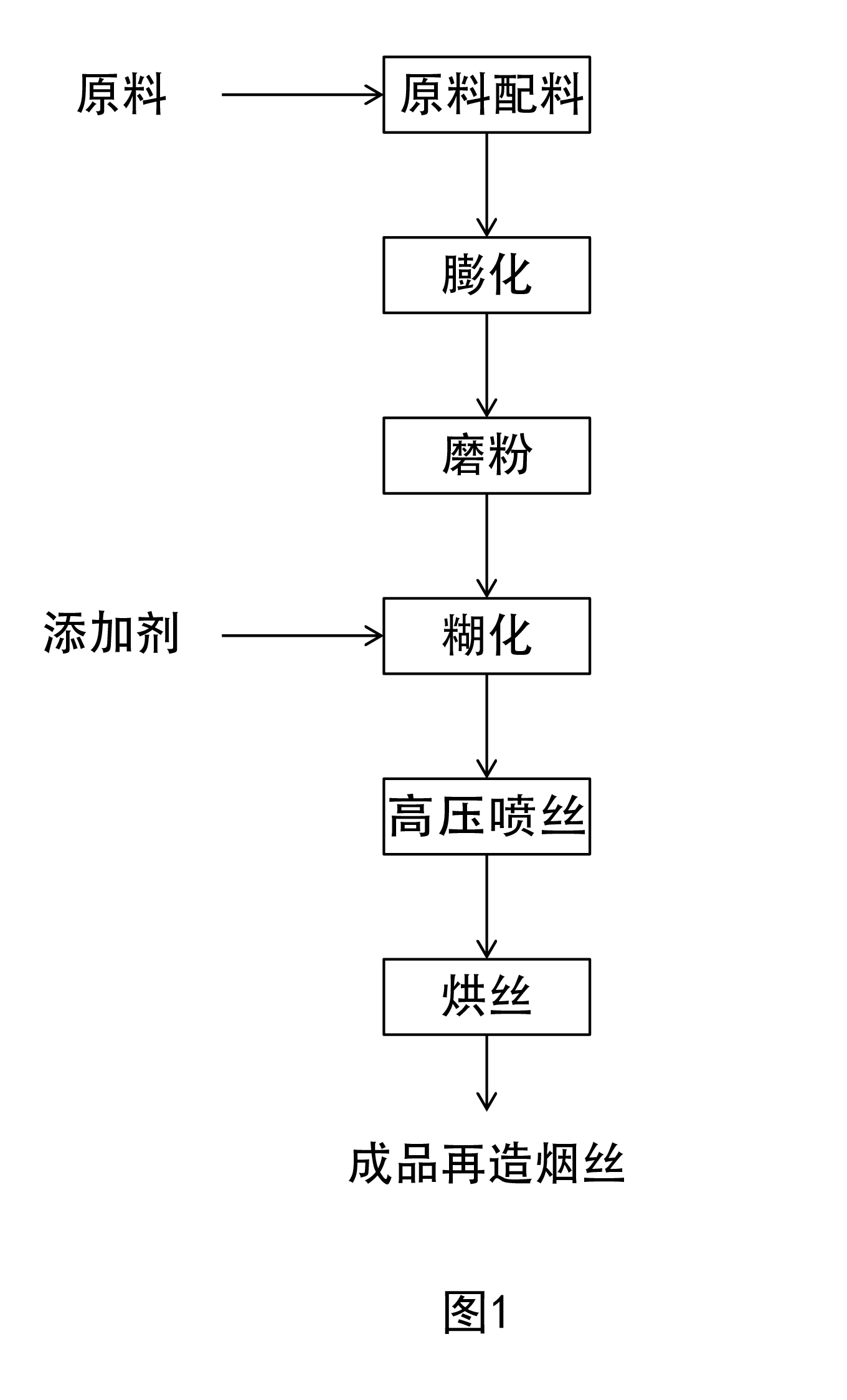

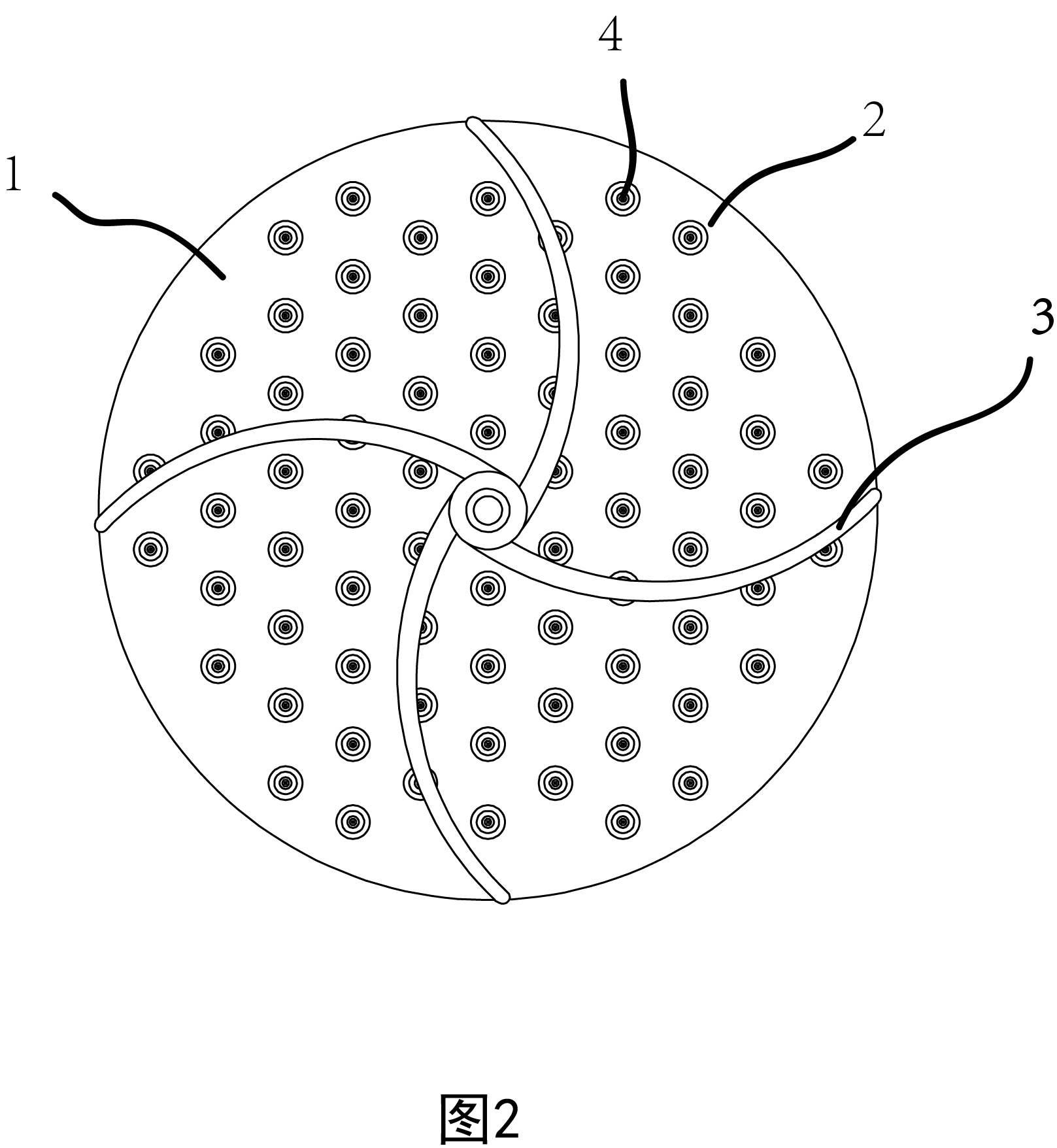

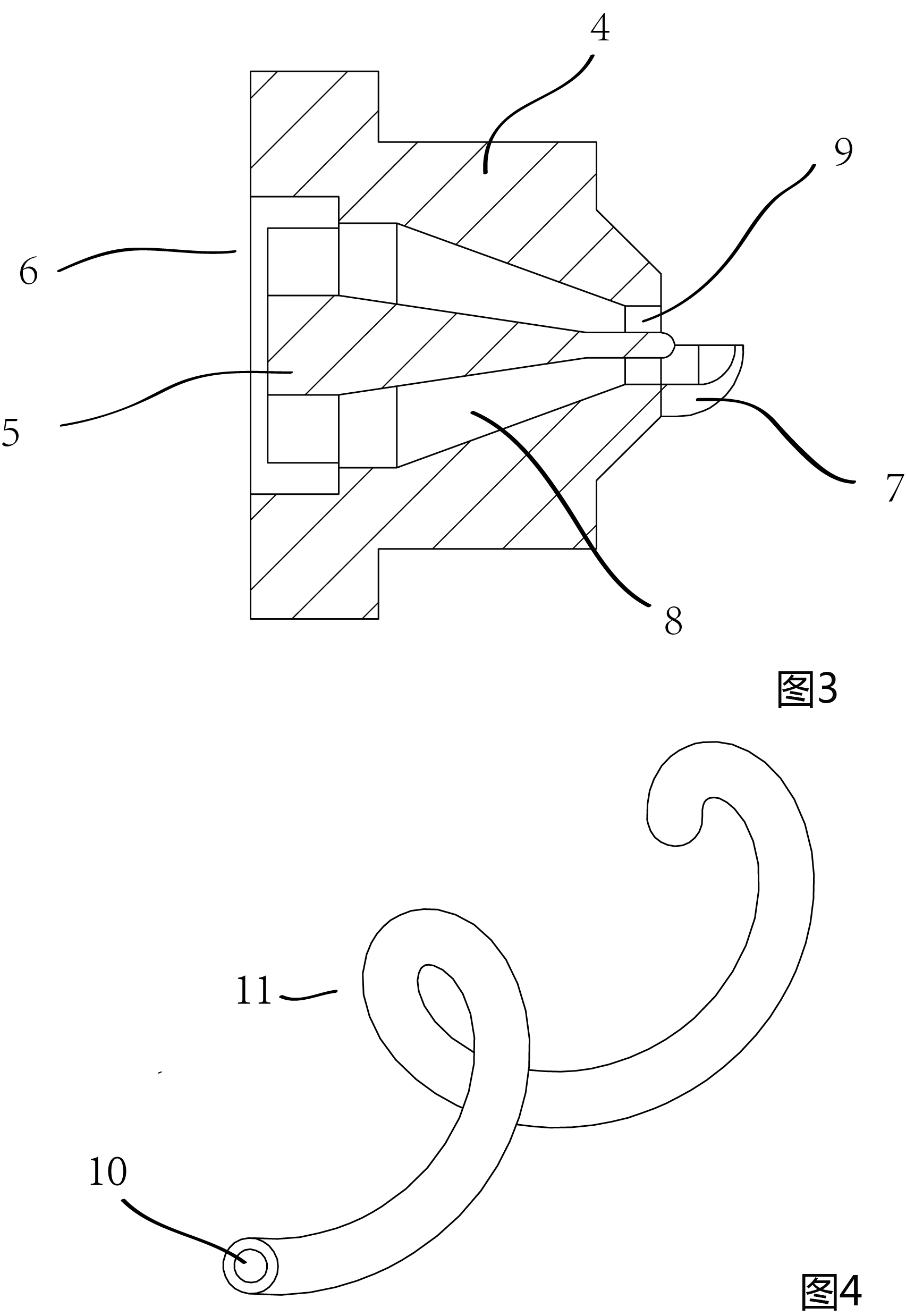

Tobacco remanufacturing process by spinning method

The invention relates to a tobacco remanufacturing process by a spinning method, belonging to the chemical technology of tobacco, in particular to a tobacco remanufacturing process for remanufacturing the tobacco and tobacco shreds by utilizing smoked sheets, tobacco waste and tobacco stalks. The tobacco remanufacturing process is characterized in that the remanufactured tobacco shreds with different shapes and structures are produced by carrying out the procedures of blending, bulking, grinding, gelatinizing, high-pressure spinning and shred baking on raw materials, and comprise hollow remanufactured tobacco shreds. Compared with the traditional processes such as a thick slurry method, a rolling method and a papermaking method, the tobacco remanufacturing process has the benefits that the utilization ratio of the tobacco is improved from 85%-95% to be close to 100%, no sewage and waste are discharged, the quality of the tobacco shreds is improved, the application range of the remanufactured tobacco shreds is expanded, the process flow is simple and easy to control, the automatic production is easy to be realized and the sensing quality and the production efficiency are improved.

Owner:侯明

Method for rapidly detecting residuals of organophosphorus pesticides in vegetables by utilizing Au nano-particle colorimetric method

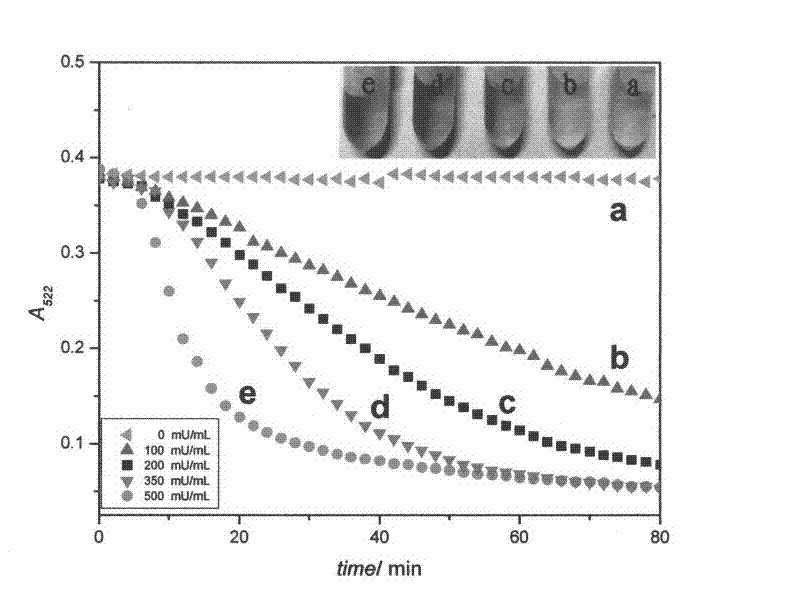

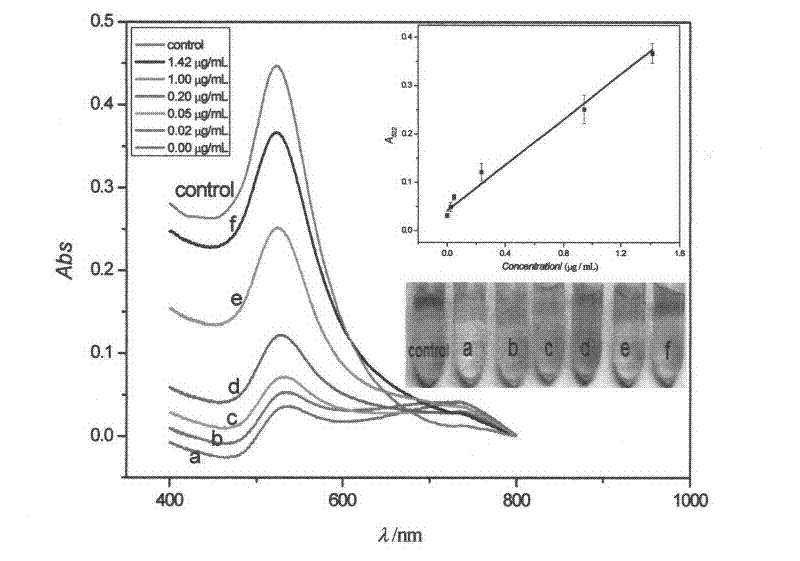

InactiveCN102221529AEasy to detectQuick checkColor/spectral properties measurementsColor changesOrganophosphorus pesticides

The invention relates to a method for rapidly detecting the residuals of organophosphorus pesticides in vegetables by utilizing an Au nano-particle colorimetric method, which belongs to the technical field of analytical chemistry. The method provided by the invention comprises the following detection steps: preparation of Au nano-particles (AuNps); establishment of a method for detecting organophosphorus pesticides, actual sample detection and the like. The method provided by the invention can simply, rapidly and sensitively detect methamidophos in the organophosphorus pesticides according to the color change of an Au nano-particle system, has high sensitivity and provides convenience for further research, production, supervision and the like.

Owner:JILIN UNIV

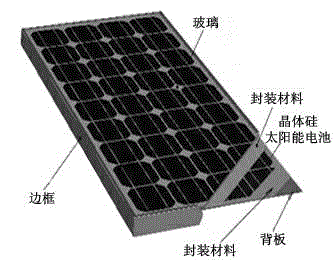

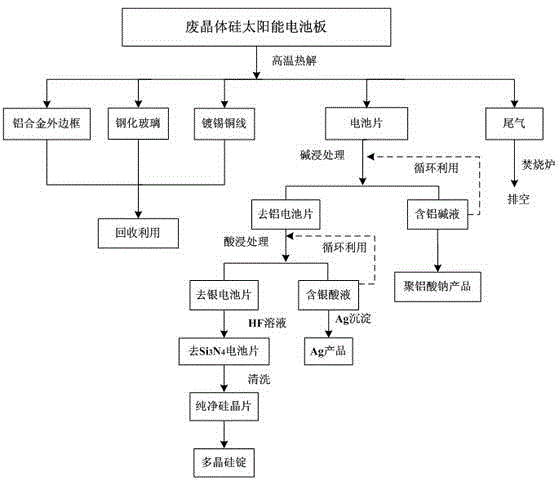

Waste crystalline silicon solar cell panel disassembling and recovering method

ActiveCN103978021AIncrease added valueRealize sorting and recyclingWaste processingSolid waste disposalWaferingPhysical chemistry

The invention discloses a waste crystalline silicon solar cell panel disassembling and recovering method. The method can realize the classification recovery of aluminum frames, toughened glass, silicon wafers, aluminum, silver and copper of waste crystalline silicon solar cell panels. The method adopts a heat treatment technology and a chemical technology combination technique to realize the frame and glass recovery of the waste crystalline silicon solar cell panels, the silicon wafer separation, and the valuable metal and silicon wafer recovery. The method has the advantages of recovery treatment difficulty reduction, tail gas harmlessness realization, secondary pollution control and environment protection; and an alkali dipping treatment and acid dipping treatment solution can be recycled, so the reagent consumption is reduced, the waste acid and waste alkali generation amount is reduced, and the final waste treatment cost is reduced.

Owner:刘景洋

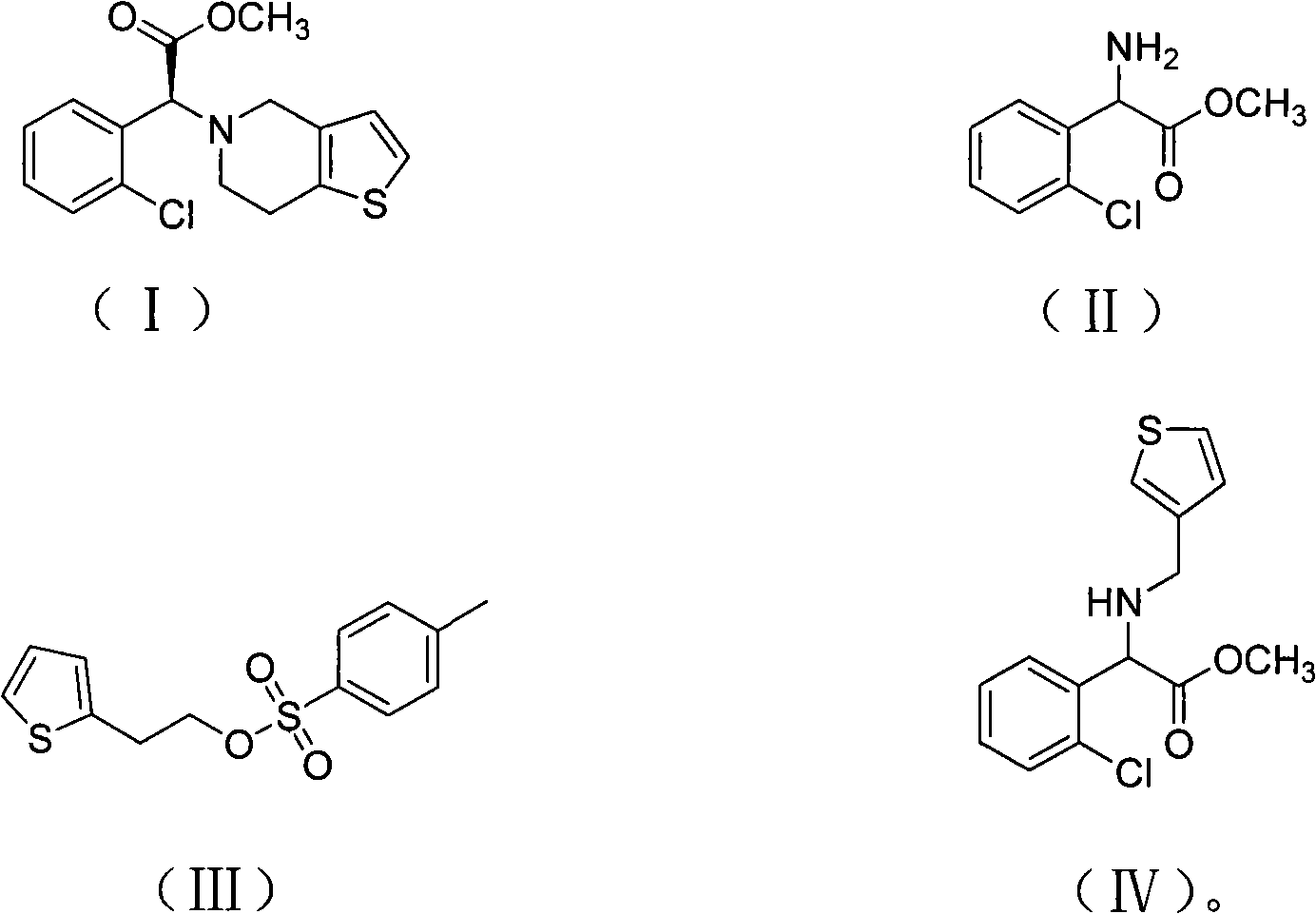

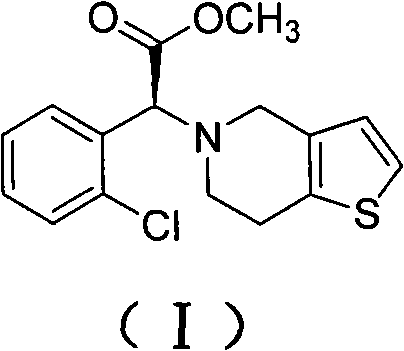

Method for preparing clopidogrel and salts thereof

The invention provides a preparation method for clopidogrel and the salts of clopidogrel, belonging to the field of medical and chemical technology. The invention solves the problems of more reaction steps, long technical route, high cost and low purity of the existing preparation method for clopidogrel. The preparation method for clopidogrel comprises the following steps: a. synchronous resolution and racemization; b. preparation of (plus) alpha-(2 - thiophene triethylamine yl) -2 - (2 - chlorophenyl) methyl acetate; c. preparation of target product clopidogrel through cyclization reaction. The clopidogrel can generate medicinal salt with acids in a solvent. The preparation method for clopidogrel and the salts of clopidogrel has simple technology, easy operation, lower costs and higher product purity.

Owner:江苏八巨药业有限公司

Nano copper-tin alloy conductive ink and preparation method and usage of nano copper-tin alloy conductive ink

ActiveCN102675960ALower sintering temperatureImprove antioxidant capacityInksMetallic pattern materialsRare earthElectron scattering

The invention belongs to the technical field of material chemistry, relates to conductive ink, and particularly relates to nano copper-tin alloy conductive ink and a preparation method and usage of the nano copper-tin alloy conductive ink. Nano copper-silver alloy is replaced by nano copper-tin alloy to be used as conductive filler in the conductive ink, sintering temperature of the conductive ink is lowered, and when the nano copper-tin alloy conductive ink is compared with nano copper-silver alloy conductive ink, antioxidant capacity of the conductive ink during sintering is improved, mechanical property and solderability of a conductive circuit formed after sintering of the conductive ink are improved, and the problem of silver ion migration is avoided. Further, since rare earth metal elements are doped in the nano copper-tin alloy, grain boundary of the nano copper-tin alloy is increased, electron scattering power is increased, and conductivity is improved as compared with that of nano copper alloy. On the other hand, tin is much cheaper than silver, so that raw material cost of the nano copper-tin alloy conductive ink is reduced.

Owner:深圳市尊业纳米材料有限公司

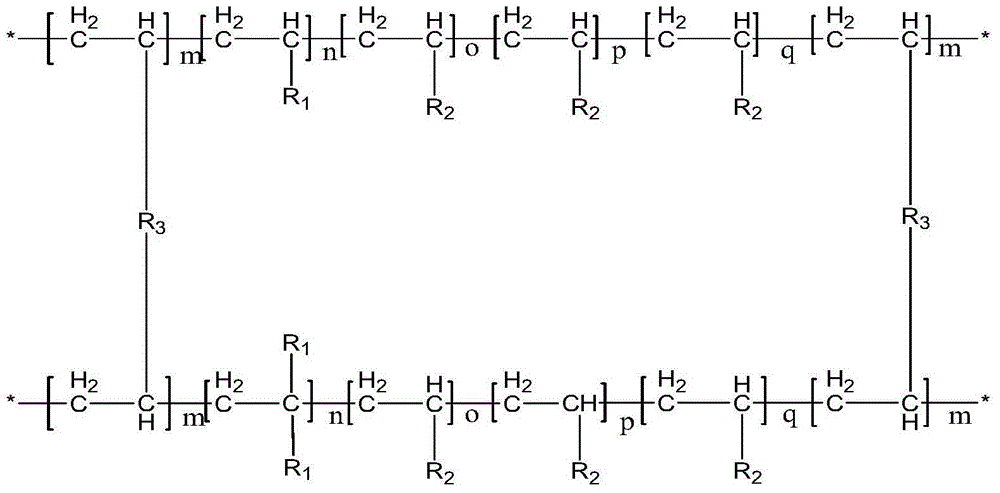

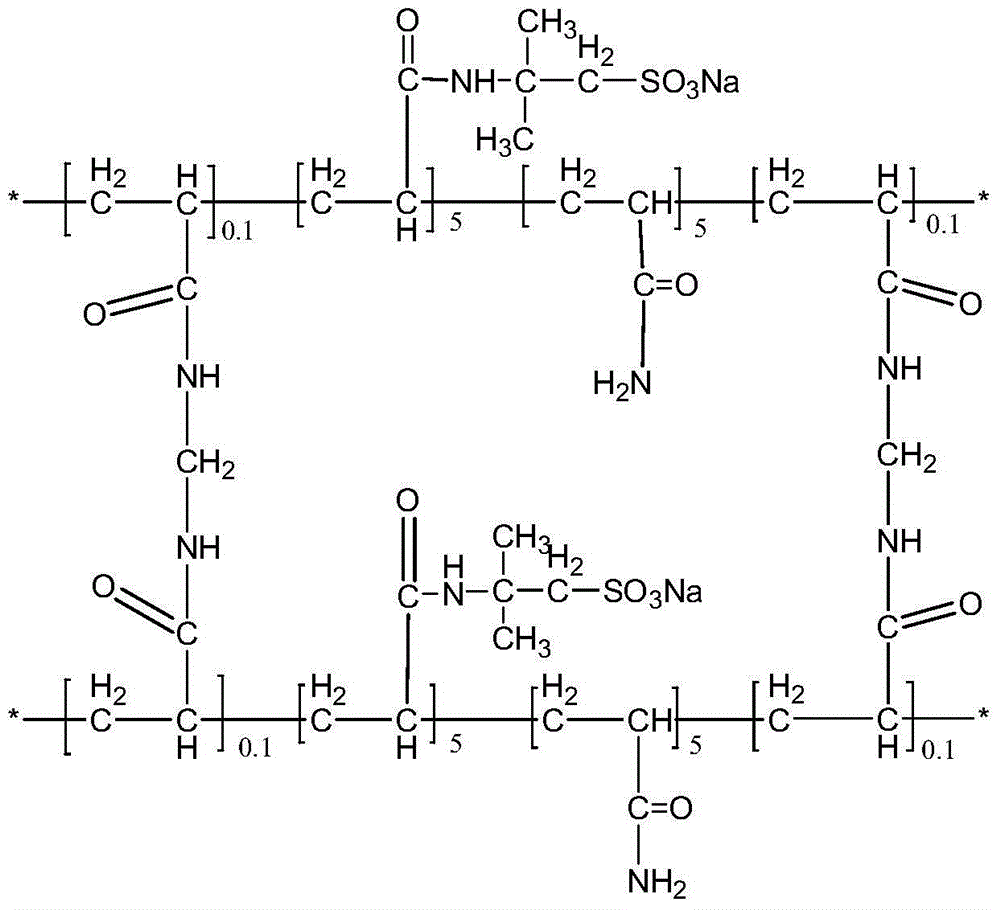

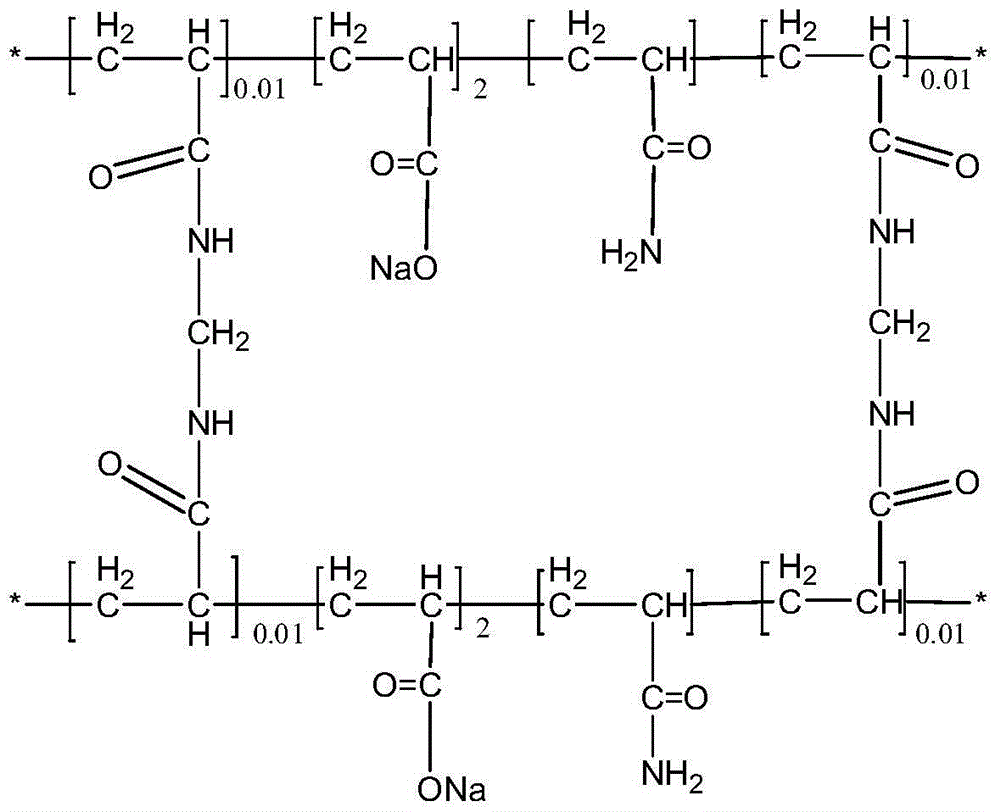

Water-absorbent resin temporary plugging agent and preparation method thereof

InactiveCN104449613AImprove adaptabilityWith elastic deformation functionDrilling compositionSolubilityAbsorption capacity

The invention relates to a water-absorbent resin temporary plugging agent and a preparation method thereof, belongs to the technical field of oilfield chemistry, and in particular relates to a petroleum drilling plugging agent. The water-absorbent resin temporary plugging agent is prepared by performing aqueous solution polymerization reaction on an acrylic acid monomer A, an acrylamide monomer B, a powdery acid-soluble inorganic filling material C and a crosslinking agent in the presence of an oxidization-reduction initiating system; the obtained gel-like product is pelletized and dried to obtain the water-absorbent resin temporary plugging agent for drilling solutions. The water-absorbent resin temporary plugging agent has acid solubility of more than 85 percent in 15 percent hydrochloric acid, temperature resistance of 150 DEG C, saturated water absorption capacity of 5-8 times and high self-adaption ability for leaking channels with different shapes and different sizes, and is high in toughness; moreover, the tensile elongation rate is up to 800-1,200 percent, and the tensile breaking strength is up to more than 2MPa. The water-absorbent resin temporary plugging agent is applied to plugging in a drilling and completion process, in particular to a reservoir drilling and completion process, and plugging of leaking reservoirs with different well depths under a hypersalinity condition.

Owner:CHINA PETROCHEMICAL CORP +1

Method of preparing high viscosity carboxymethyl cellulose by slurry method

This invention relates to a preparation method of carboxymethyl cellulose with special high viscosity, in particular belonging to polymer chemistry technology, which technical program includes four steps namely cellulose activating reaction, etherification, neutralization reaction and cleaning. The key points of this invention are that slurry method can prepare the carboxymethyl cellulose with high degree of substitution and high viscosity, without the addition of cross-linker or hydrophobic reagent. The practical significance of this invention is that it can improve product performance, namely viscosity and substitution, so that it can be better used in oil drilling, textile, sewage treatment, food processing and other fields.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com