Patents

Literature

17462results about How to "Short process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chip for processing of gene and apparatus for processing of gene

InactiveUS20050048540A1Short processBioreactor/fermenter combinationsHeating or cooling apparatusInjection portGene

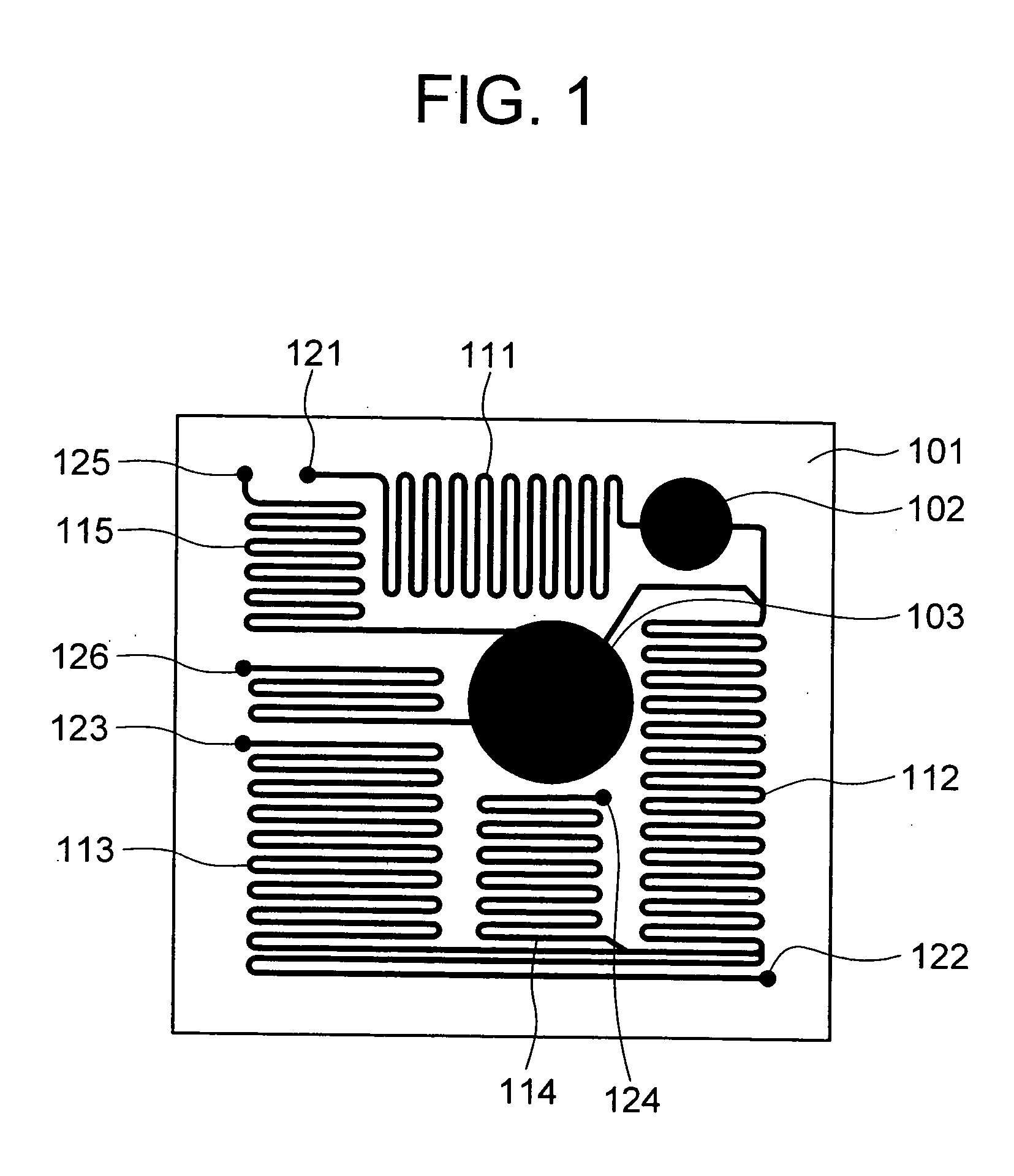

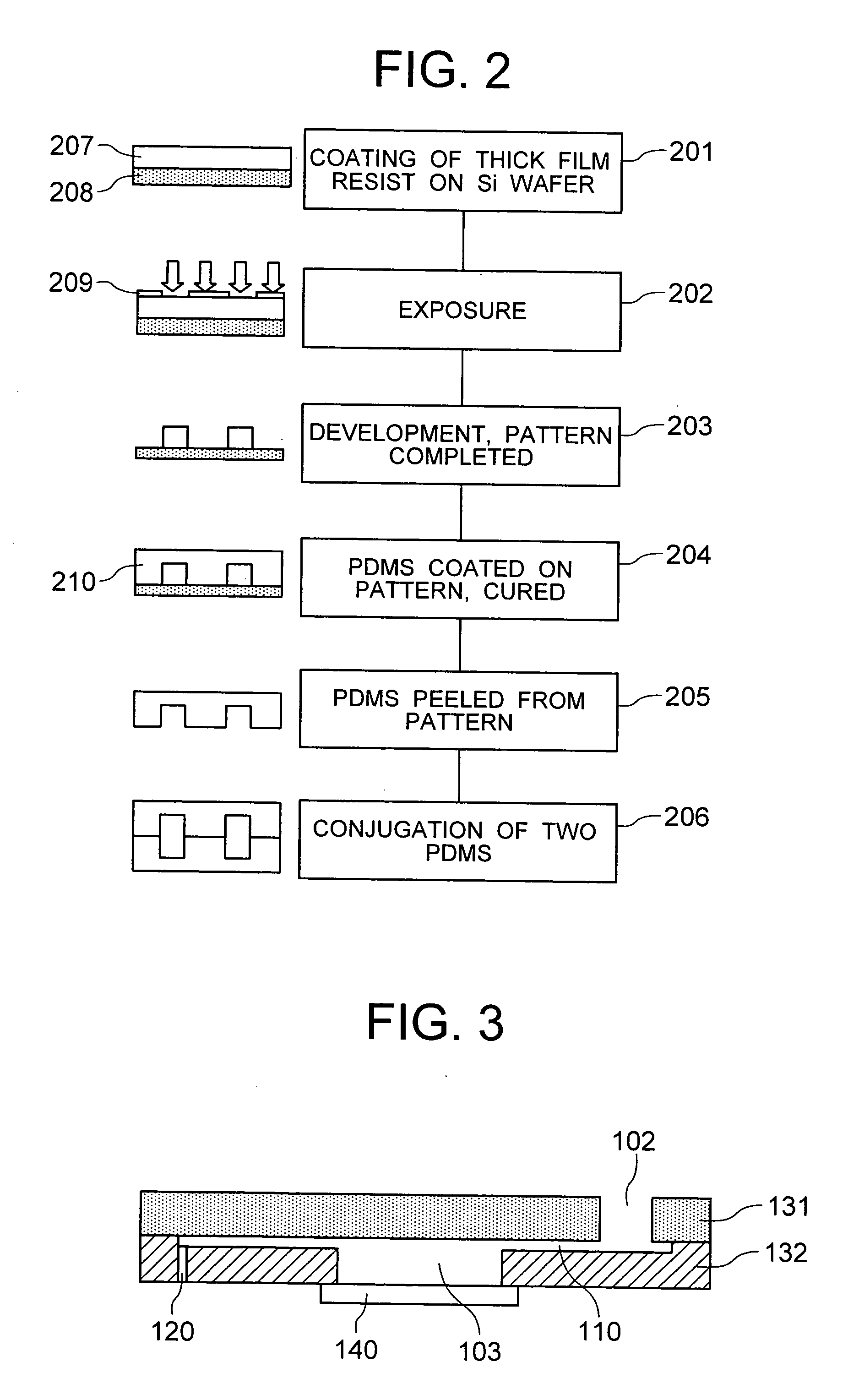

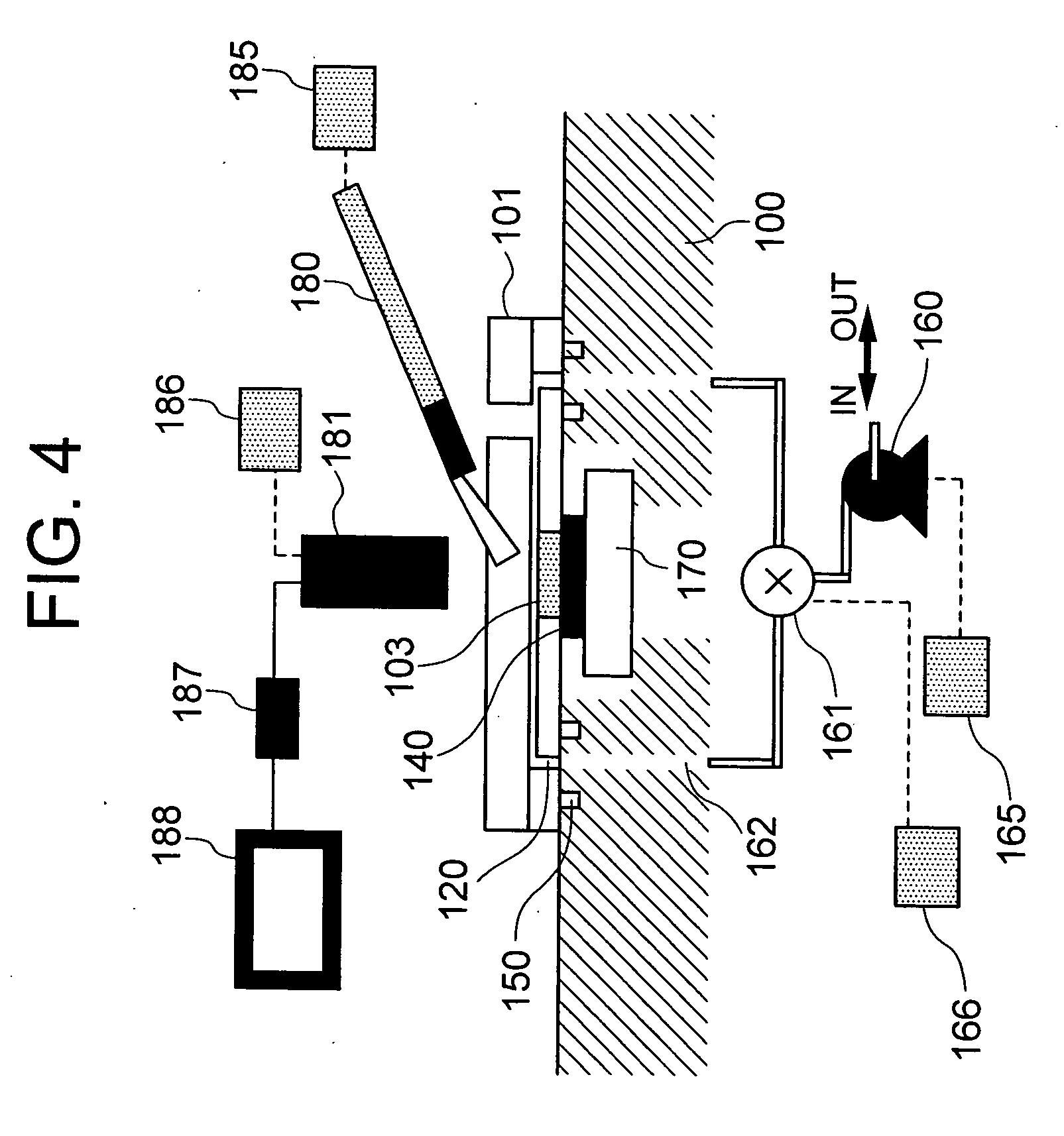

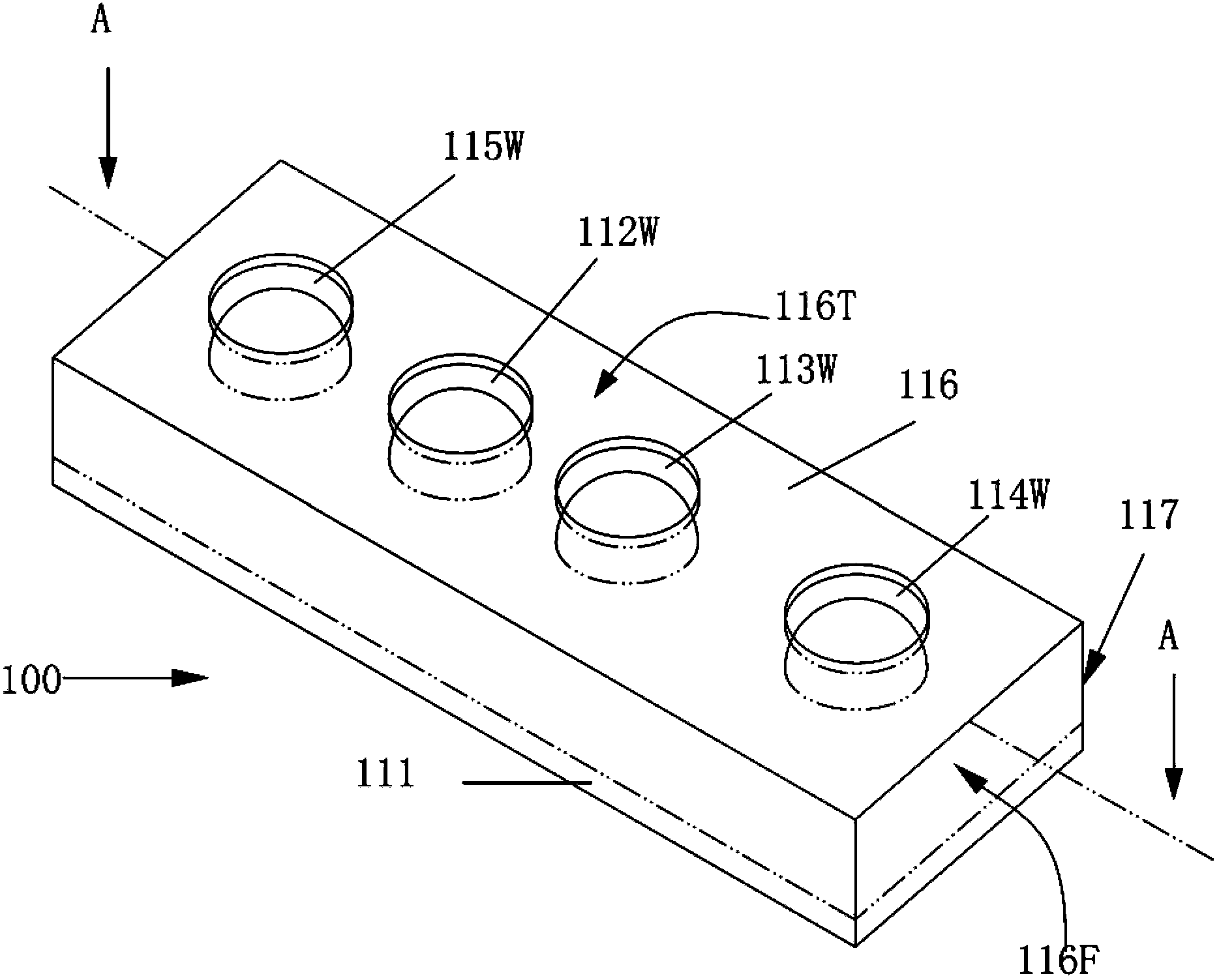

The present invention provides an analytical chip that is easy to handle, inexpensive, and for which the extraction of gene from a sample and analysis thereof can be automated to one process, and a small-sized and portable analytical apparatus equipped therewith. The chip for processing of gene that is equipped with an injection port into which a sample containing gene is delivered, a gene extraction part into which a solution containing said sample is introduced and which has a gene-binding carrier that binds to said gene, a washing solution-storing part that stores the washing solution to be introduced into said gene extraction part, and a reaction part into which said gene captured in said extraction part is introduced, wherein a fluid channel through which said washing solution is introduced from said washing solution-storing part has been connected to a region more remote from said injection port than from a region into which a solution containing said sample is introduced in said gene extraction part is obtained.

Owner:HITACHI LTD

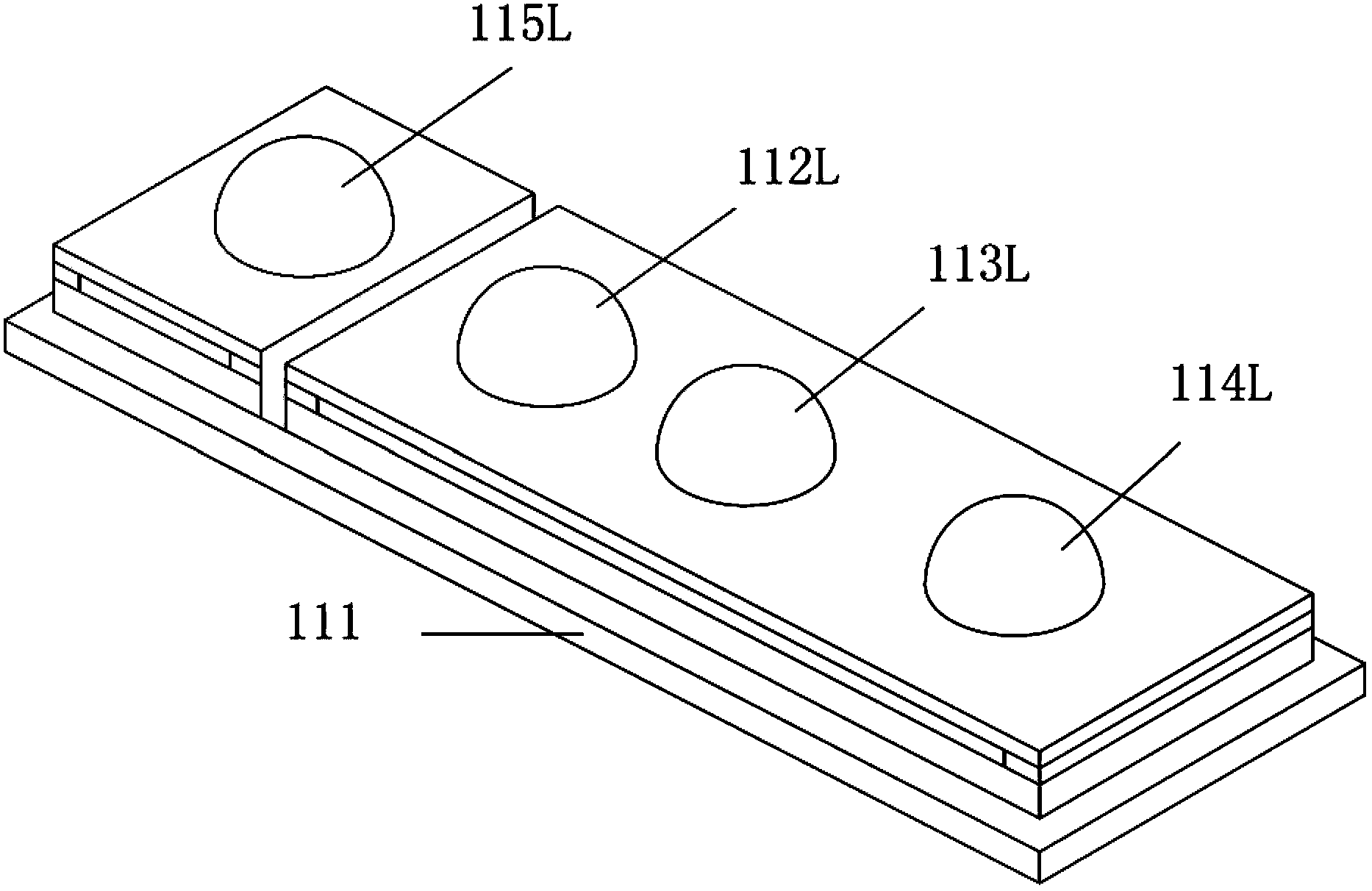

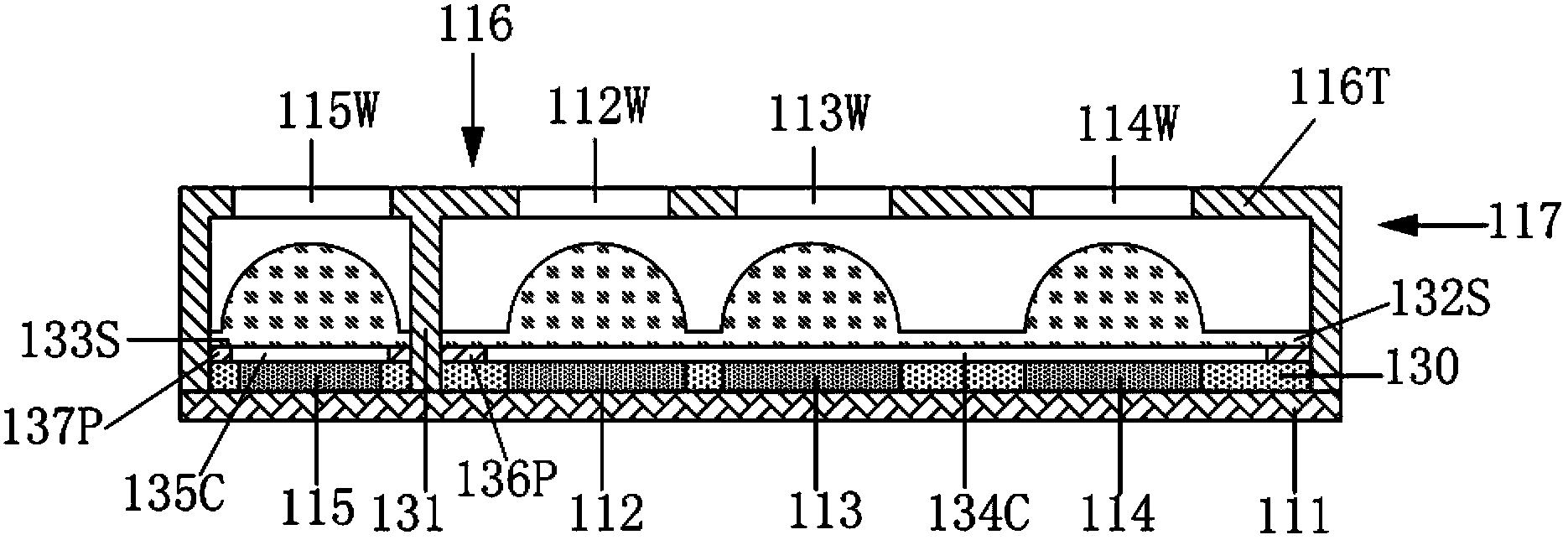

Integrated optical sensor package

ActiveCN103515371AReduce volumeReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesManufacturing cost reductionOptoelectronics

The invention relates to an integrated optical sensor package. The integrated optical sensor package comprises a package substrate, an ambient light sensor, a proximity optical sensor, an image sensor and a package cover, wherein the package substrate is positioned at the bottom; the ambient light sensor, the proximity optical sensor and the image sensor are arranged on the package substrate; and the package cover is mutually sealed with the package substrate so that a package housing is formed. The integrated optical sensor package provided by the invention can reduce the package volume and reduce the manufacturing cost.

Owner:GALAXYCORE SHANGHAI

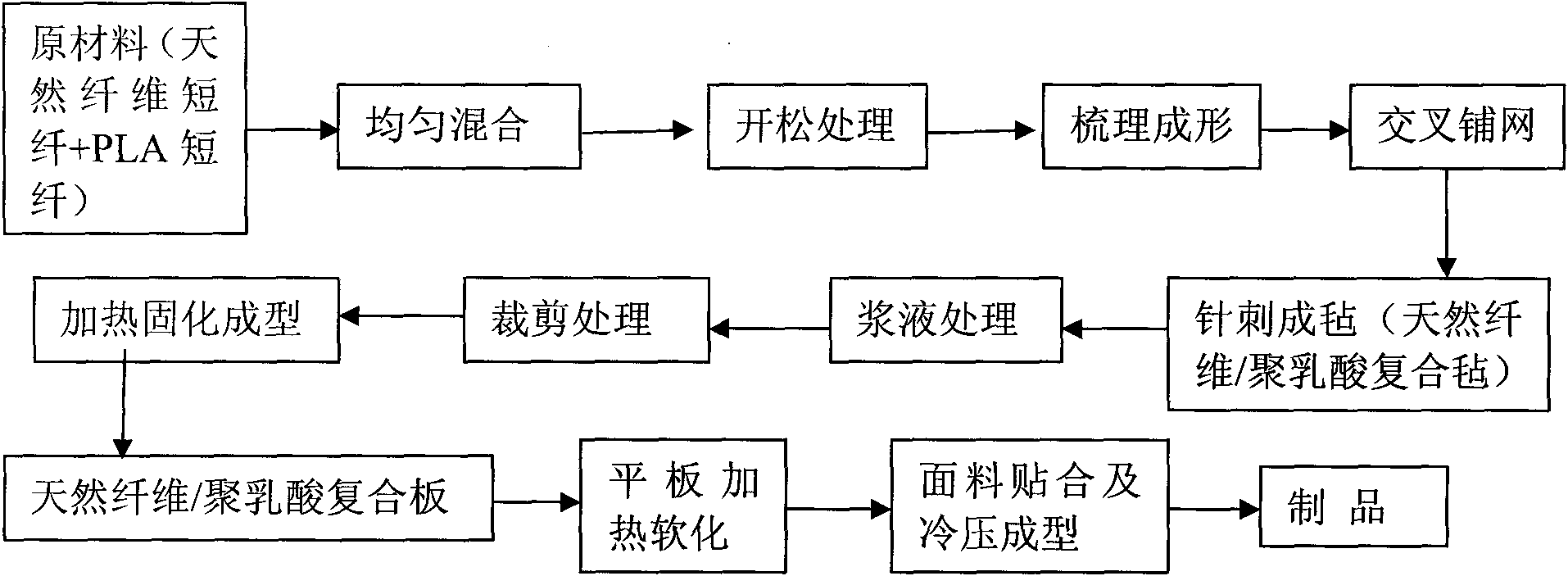

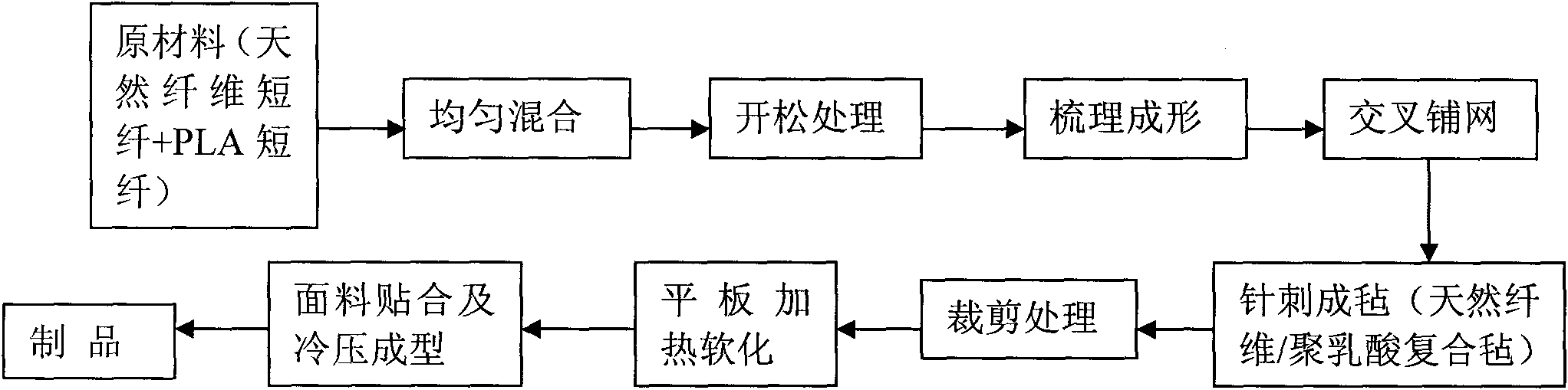

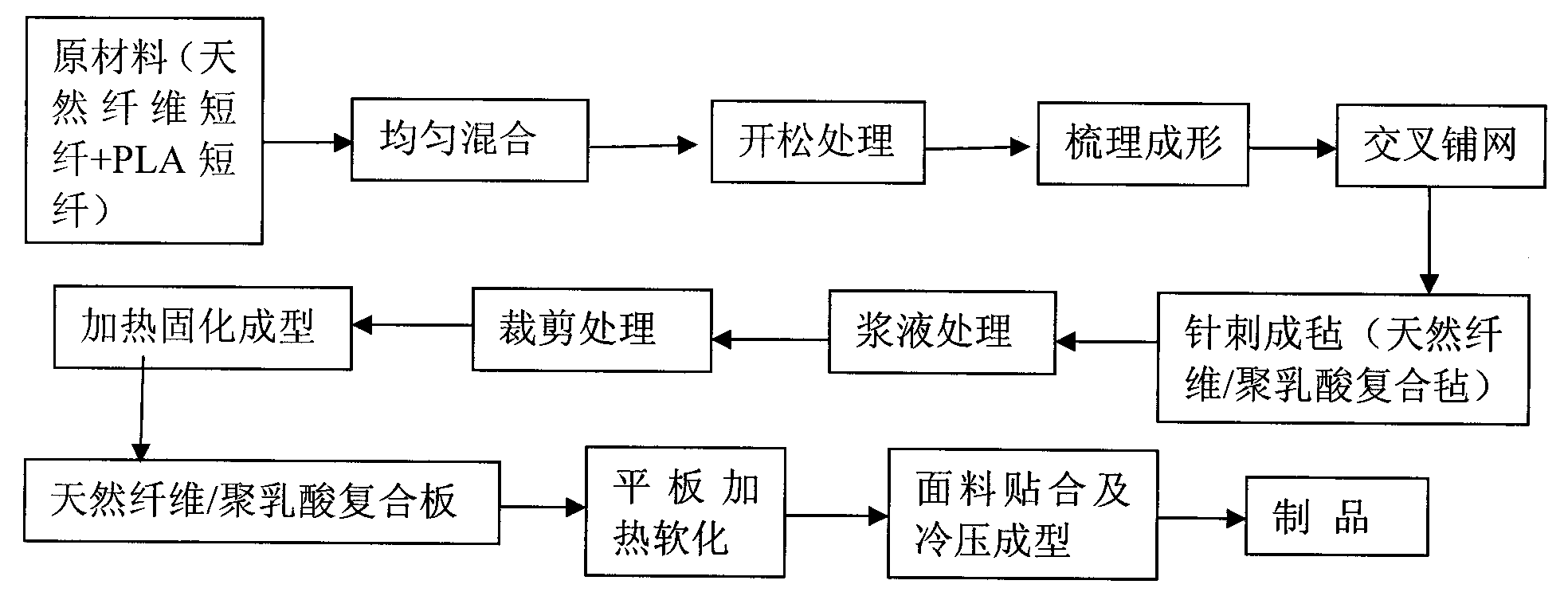

Composite material for automobile interior part and production method thereof

ActiveCN101812773ANo pollution in the processReduce lossVehicle componentsNon-woven fabricsMetallurgySlurry

The invention discloses a formula of a composite material for an automobile interior part. The formula consists of the following materials in percentage by weight: 40 to 60 percent of polylactic acid fiber and 40 to 60 percent of natural fiber. The production method of the invention comprises the following steps: uniformly mixing the raw materials; putting the mixture into an opener for opening, combing and shaping the obtained product, feeding the product into a lapping machine for cross lapping and feeding the cross-lapped product into a needling machine for needling to form a felt; immersing the fiber felt into a processing slurry; drying the immersed coiled material through hot blast and cutting the dried material into pieces of required size; placing the cut material into a mould for curing and shaping by heating; demoulding the material to form a composite plate; and softening the composite plate by flat panel heating, covering the plate with a surface decorative layer and performing cold molding on the plate through a product mould to manufacture the finished product finally; or softening the cut fiber felt by the flat panel heating directly, covering the plate with the surface decorative layer and performing the cold molding to manufacture the finished product finally. The composite material for the automobile interior part of the invention has the advantages of no toxicity, no pollution, simple processing technique, small energy consumption and high environment protection performance.

Owner:CHERY COMML VEHICLE ANHUI

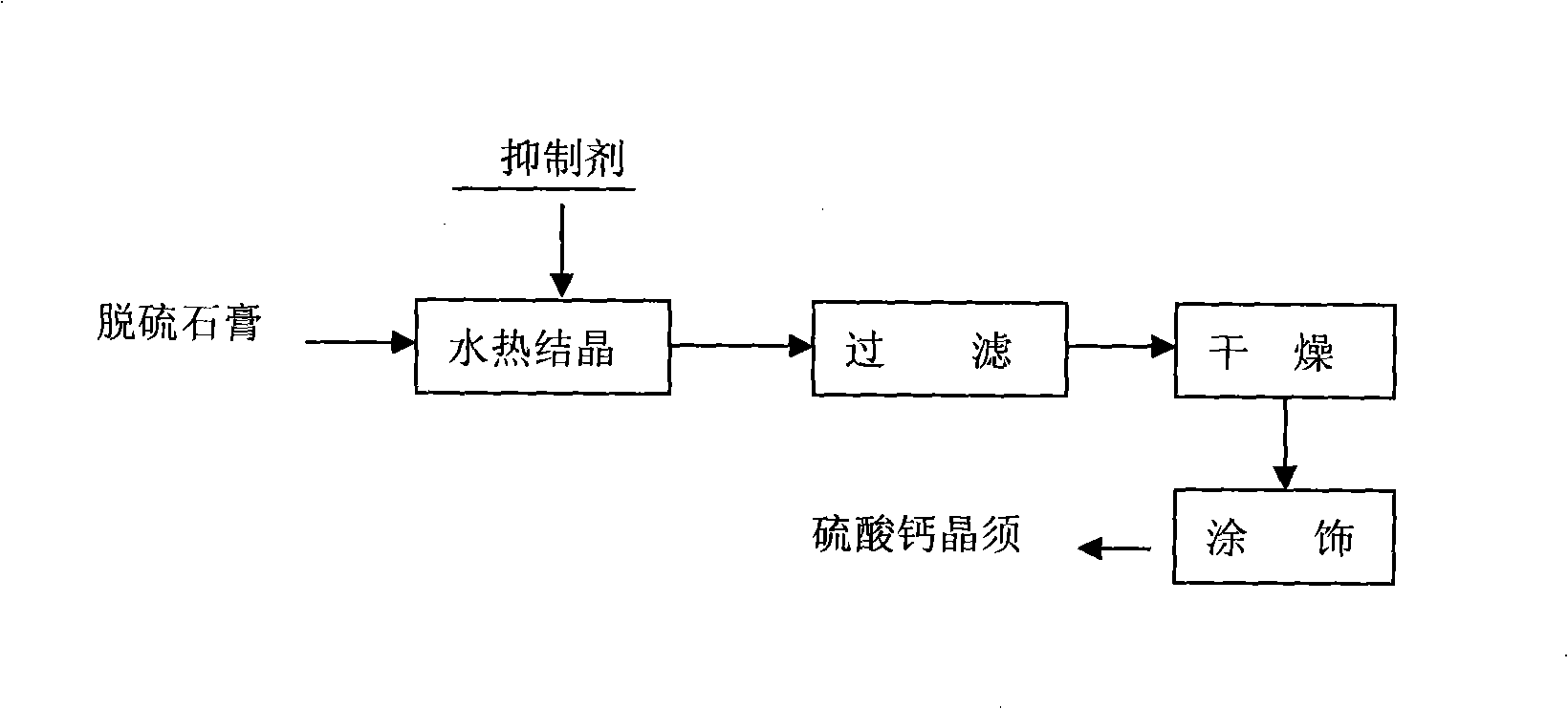

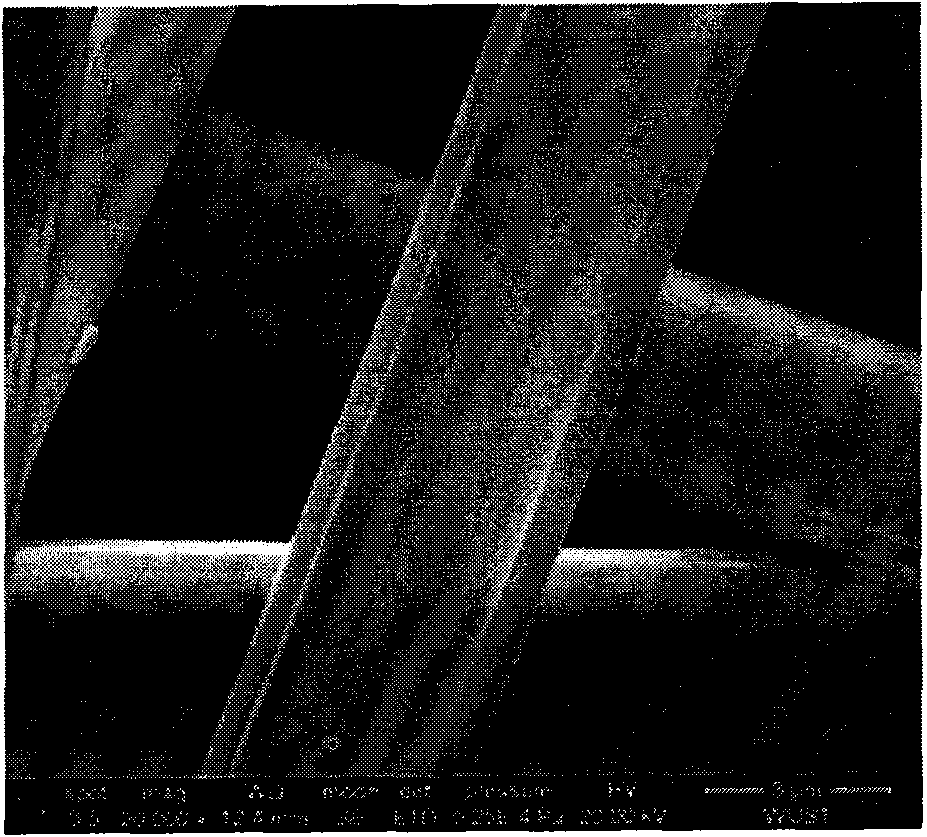

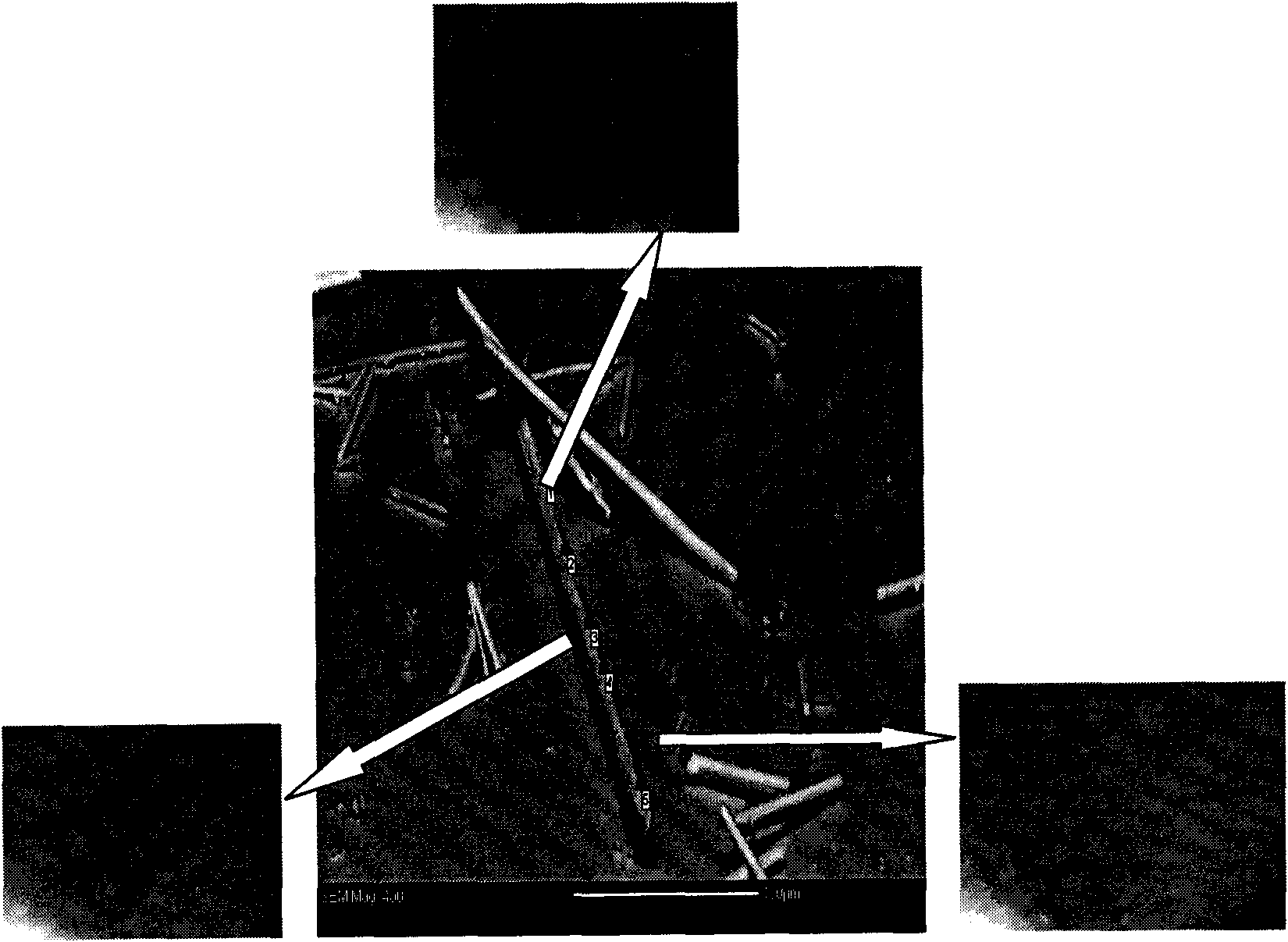

Process for preparing calcium sulphate whiskers by using flue gas desulfurization gypsum

InactiveCN101311337AReduce environmental problemsMitigation resourcesPolycrystalline material growthFrom normal temperature solutionsGlass fiberSulfate

The invention discloses a method for using flue gas desulfurization gypsum to prepare calcium sulfate whisker, comprising process steps of size mixing, high-temperature crystallization, drying and coating, etc. The method utilizes the flue gas desulfurization gypsum as the raw material, which has low production cost, short technological process and saves natural gypsum mine and effectively relieves the environmental pollution problem of the flue gas desulfurization gypsum. The product purity can be up to more than 98 percent, which can be used as filler with medium intensity or as friction material, building material or insulating material, and the like, instead of asbestos. The product can also partly replace organic macromolecular compounds such as glass fiber, resin, rubber and plastic, and the like, and has good describability.

Owner:NORTHEASTERN UNIV

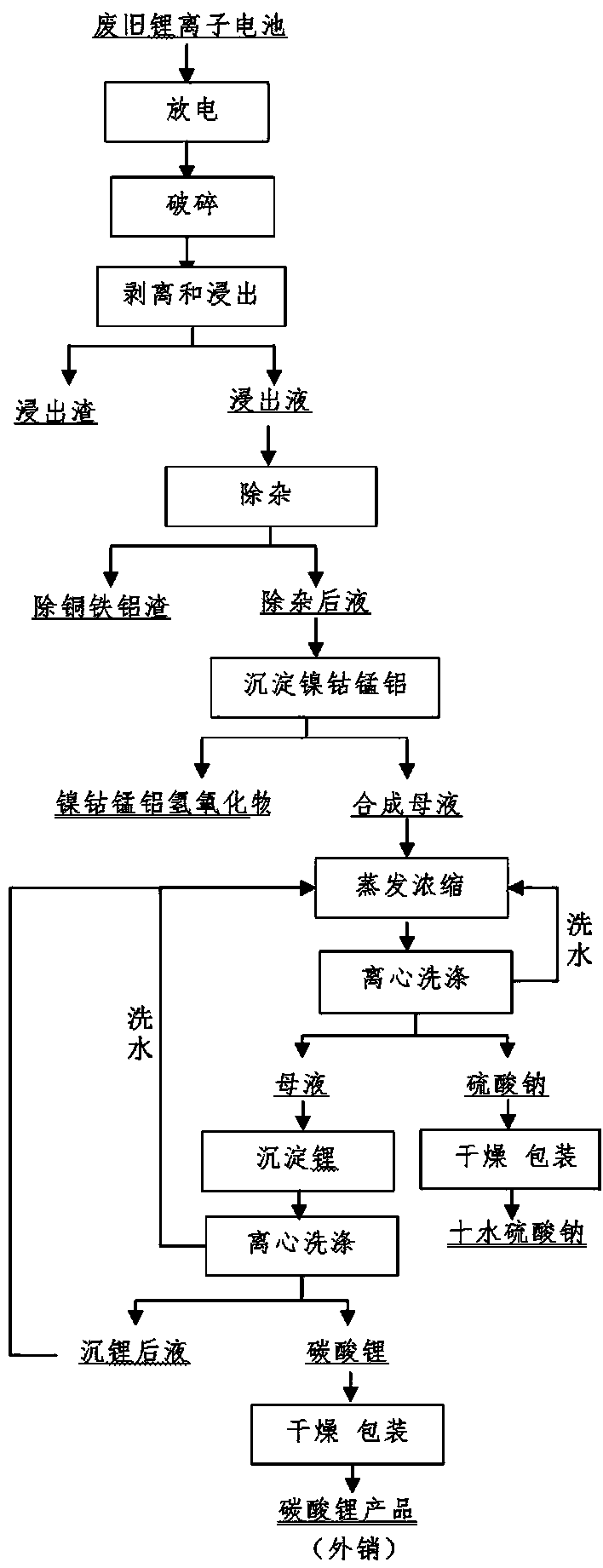

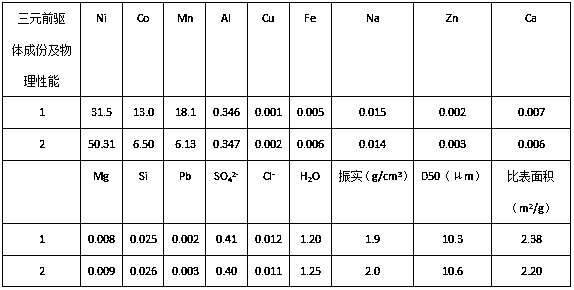

Recycling method for valuable metal from waste nickel-cobalt-manganese lithium ion battery

InactiveCN107653378AReduce lossesLess investmentWaste accumulators reclaimingProcess efficiency improvementSlagManganese

The invention relates to a method for recycling valuable metal from a waste nickel-cobalt-manganese lithium ion battery. The method comprises the following steps of: dismounting, discharging and crushing the battery, soaking crushed waste nickel-cobalt-manganese lithium ions into sulfuric acid with certain concentration, adding a reducing agent to strip positive and negative pole pieces, and leaching valuable metals of nickel, cobalt, manganese and lithium; and replacing leach liquor with iron powder to remove copper, carrying out hydrolyzing to remove iron and aluminum, and dosing an impurity-removed solution to synthesize an aluminum coated nickel, cobalt and manganese ternary positive electrode material precursor, evaporating and concentrating the synthesized solution, adding carbonateor introducing carbon dioxide to recycle lithium. According to the method disclosed by the invention, stripping and leaching are synchronously completed, chemical precipitation is performed to removecopper, iron and aluminum, slag amount is small, slag filter performances are good, and the impurity-removed solution is used for synthesizing the aluminum coated nickel, cobalt and manganese ternaryprecursor, so that the recovery rate of valuable metal is increased; and the recovery rate for nickel, cobalt and manganese is 96% or higher in the whole process, the total recovery rate of lithium is90% or higher, the technological process is short, operation is simple, equipment is less, and the cost is low.

Owner:JINCHUAN GROUP LIMITED +1

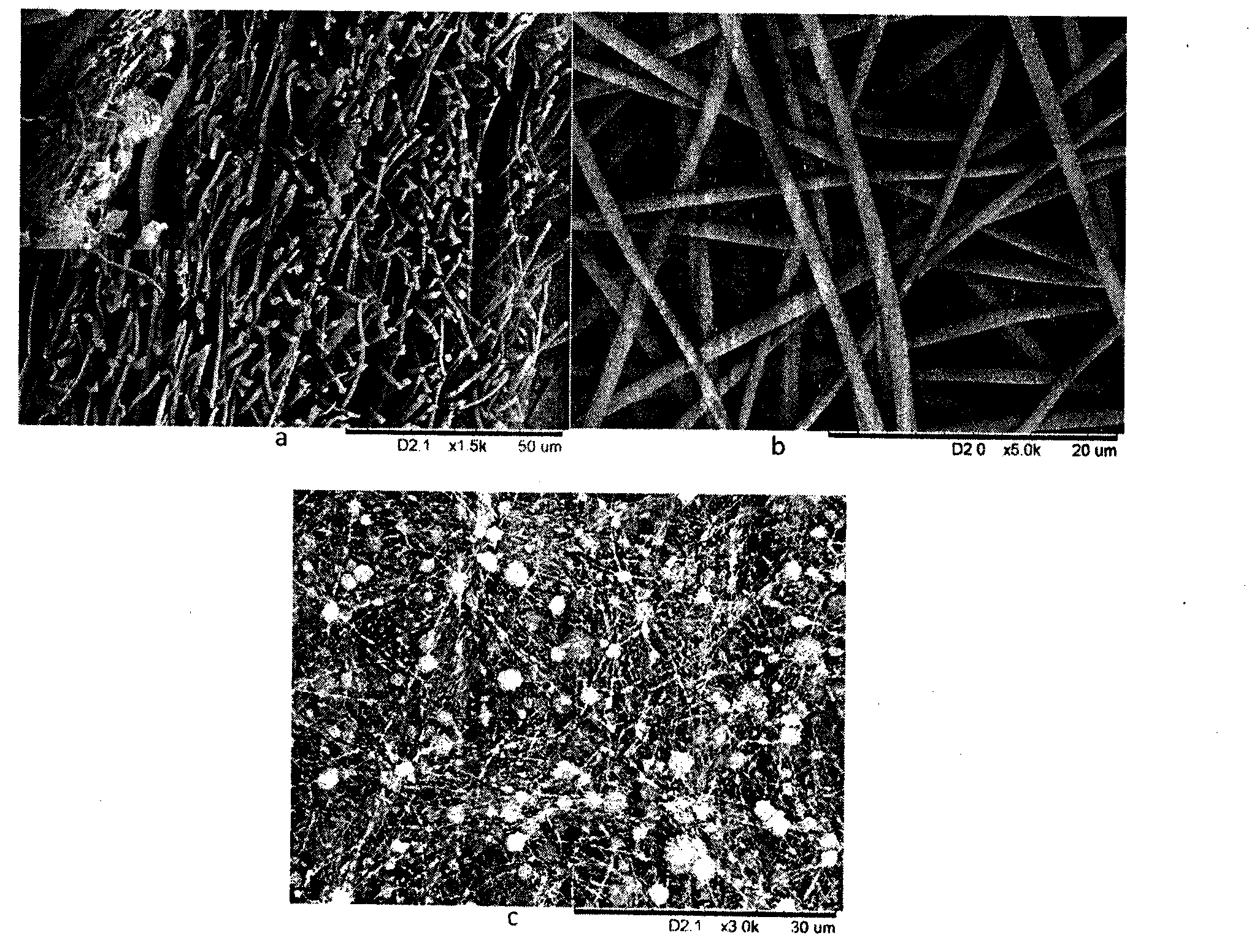

Preparation method of polytetrafluoroethylene superfine fiber porous membrane

InactiveCN101530750AUniform pore sizeHigh porositySemi-permeable membranesHigh concentrationVoid ratio

The invention discloses a preparation method of polytetrafluoroethylene superfine fiber porous membrane. In the method, high concentration polytetrafluoroethylene aqueous emulsion is mixed with matrix polymer uniformly to prepare spinning solution. With the effect of high voltage electric field, polytetrafluoroethylene / matrix polymer composite superfine fiber porous membrane with the diameter of 100 nm to 2 [mu]m is obtained by electrostatic spinning, and then polytetrafluoroethylene superfine fiber porous membrane is formed at the conditions of sintering temperature being 330 to 500 DEG C and the sintering time lasting 30s to 5min so that the aperture diameter is 100 nm to 10 [mu]m and the porosity is 50% to 80%. The polytetrafluoroethylene superfine fiber porous membrane prepared by using the method has uniform aperture diameter and high porosity, and can be widely applied to filter material. Compared with the existing technology, the preparation method has the characteristics of simple processing technology, short process and low cost.

Owner:ZHEJIANG SCI-TECH UNIV

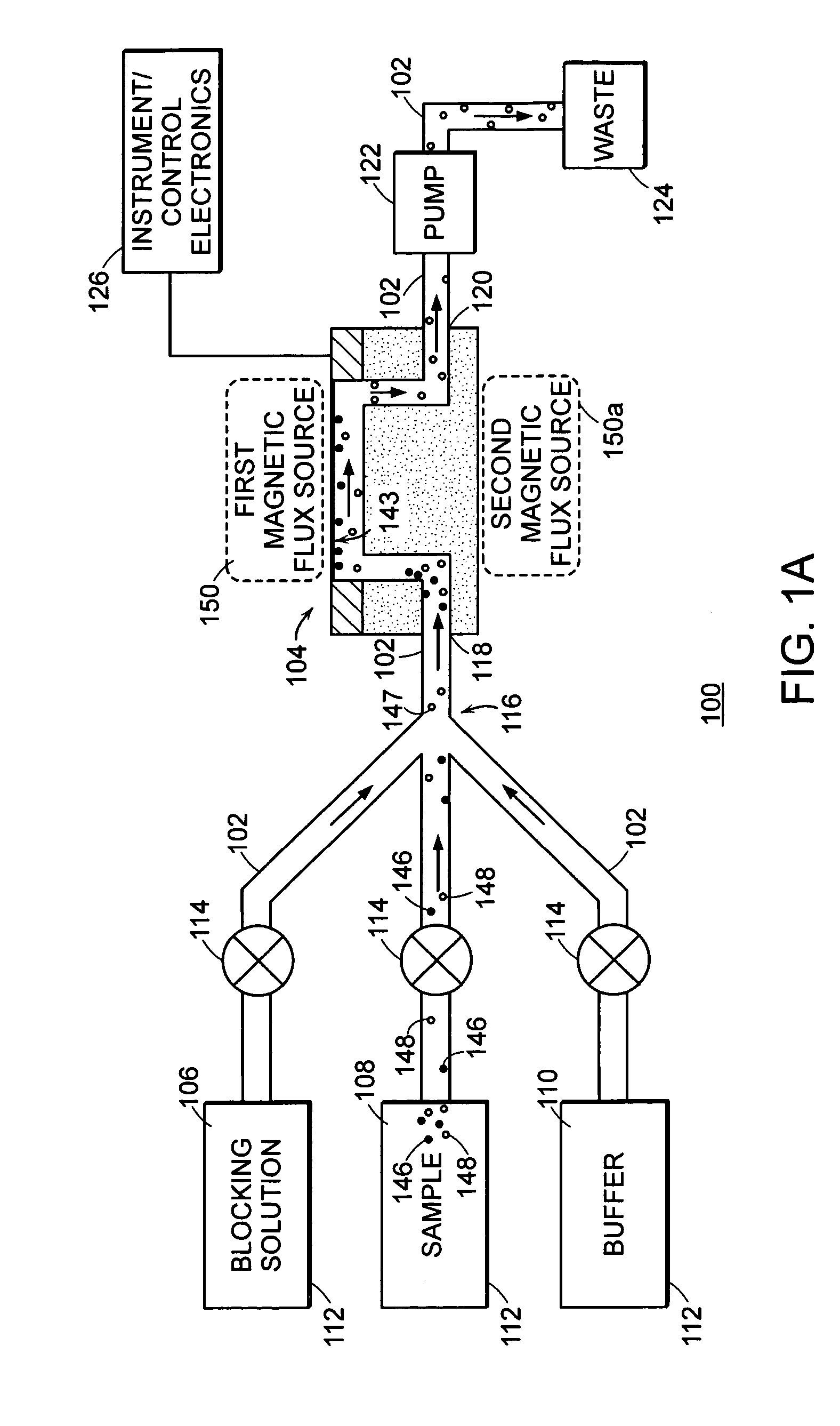

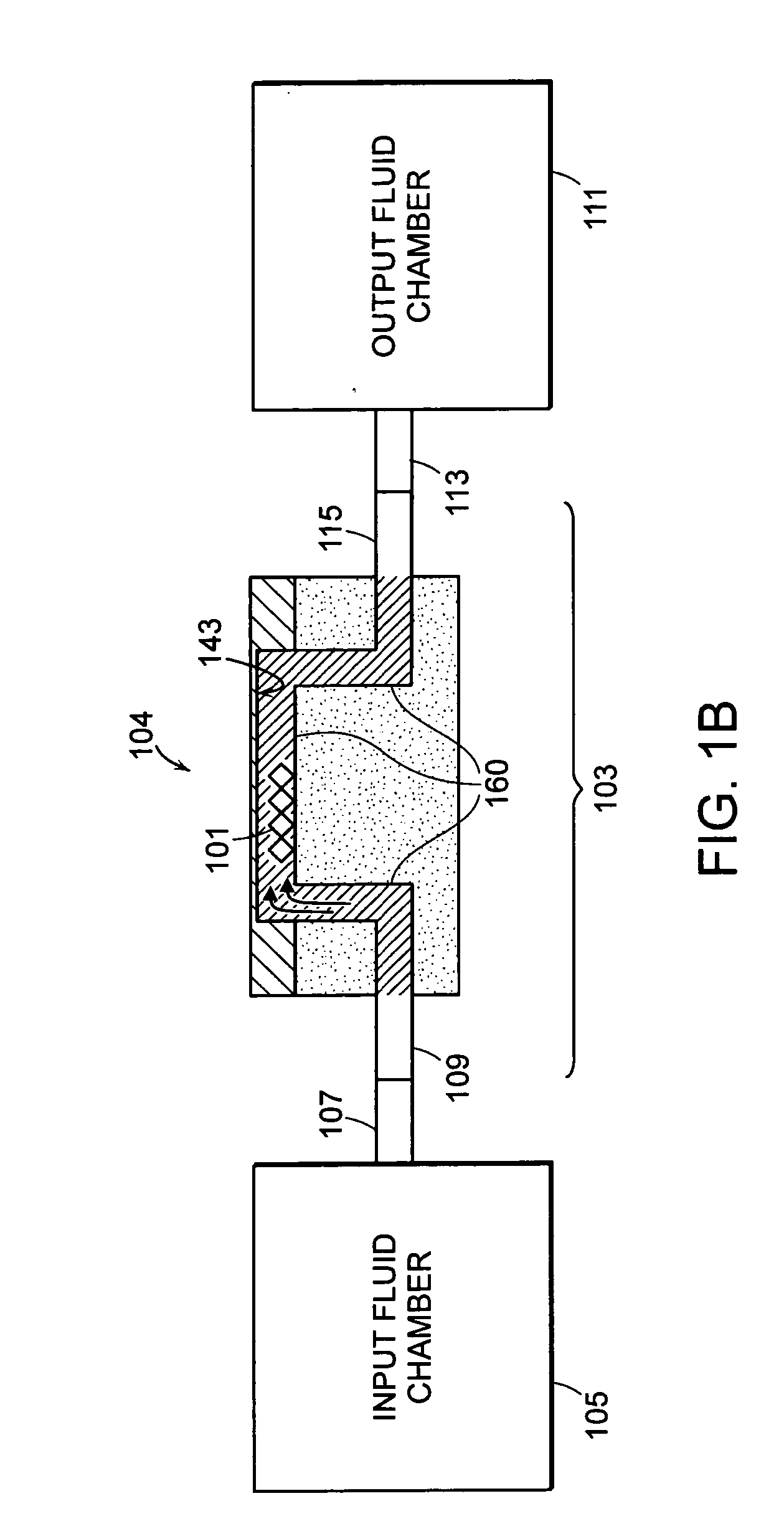

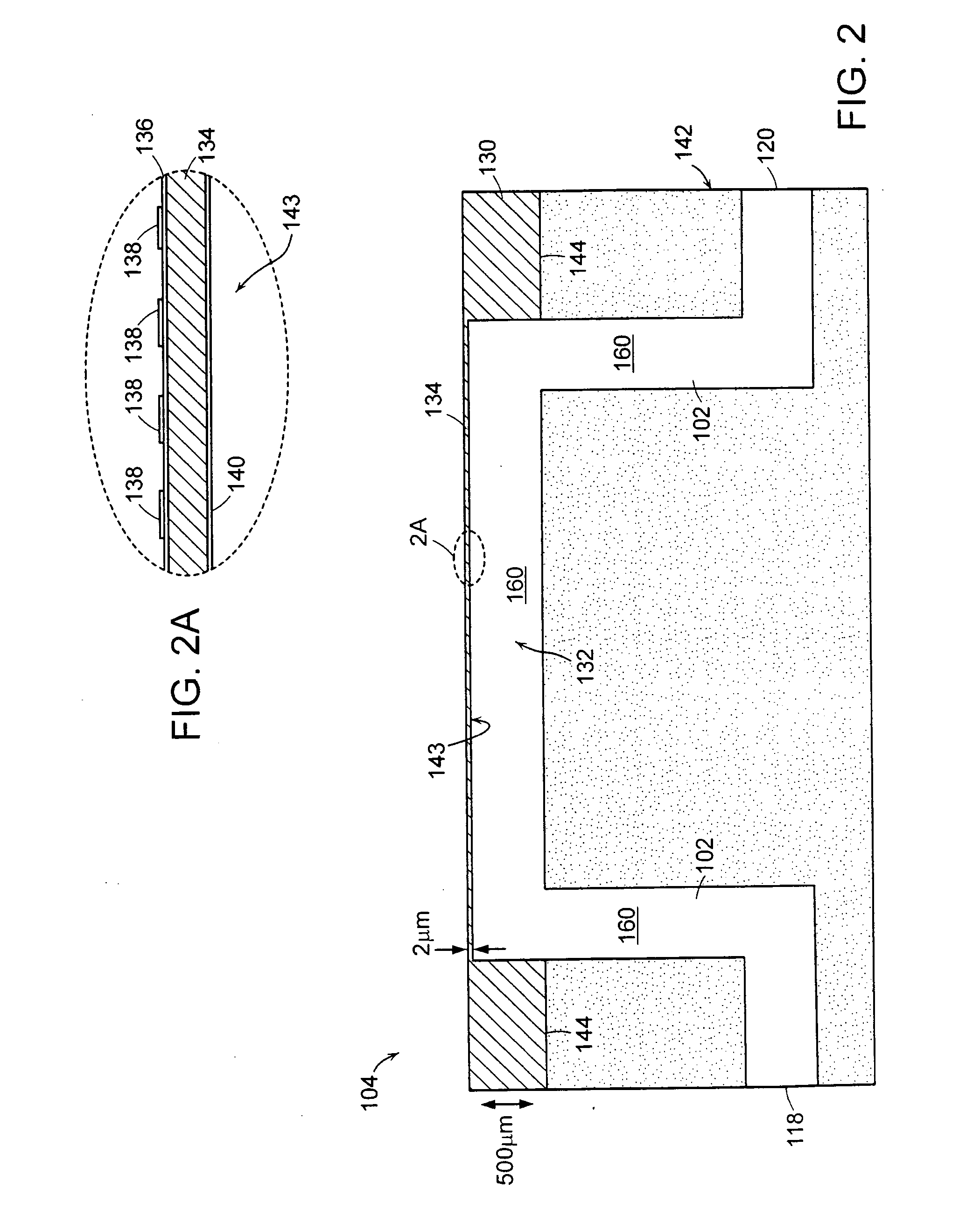

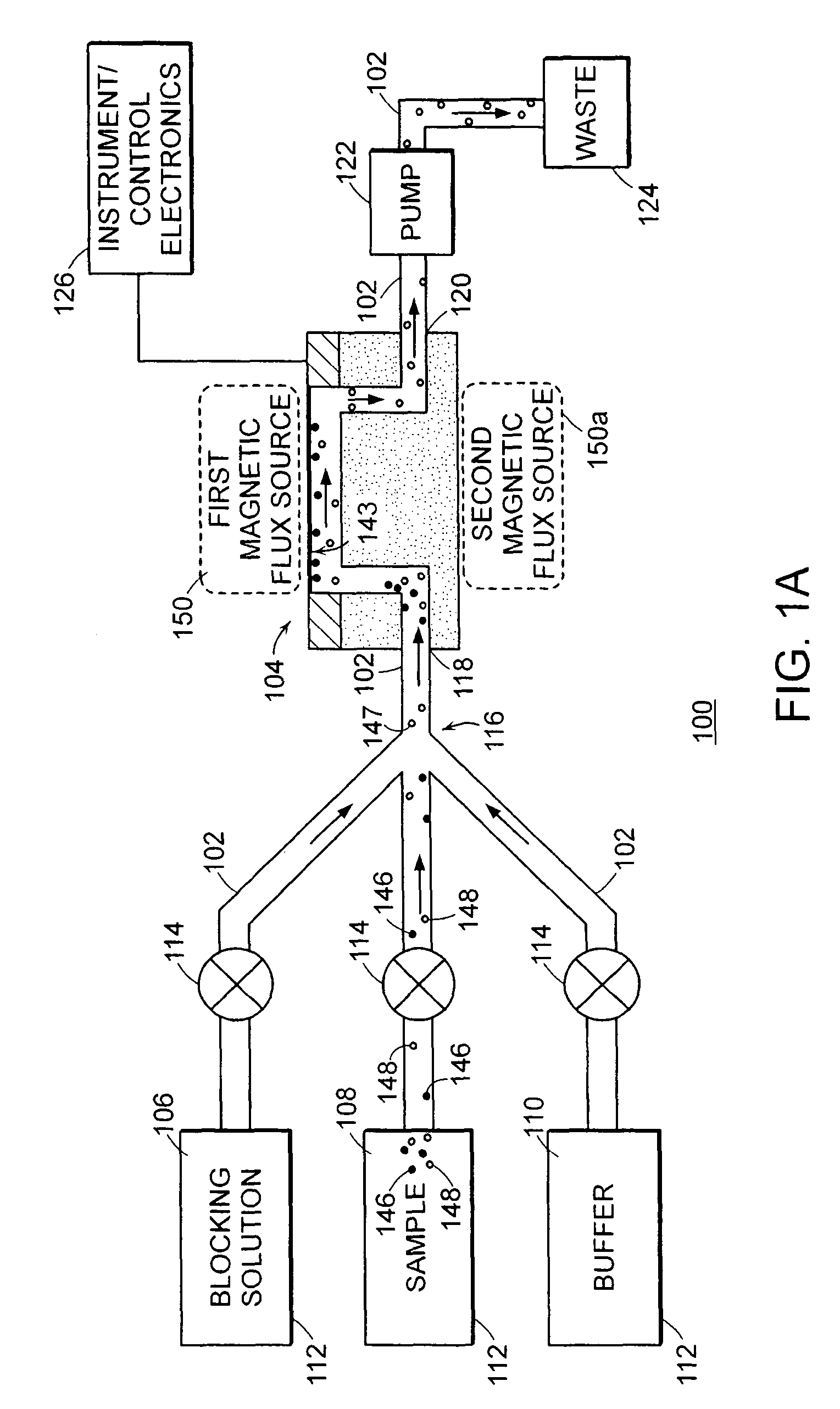

Methods and apparatus for detecting cardiac injury markers using an acoustic device

InactiveUS20060257945A1Improve the level ofAvoid delayBioreactor/fermenter combinationsMaterial nanotechnologyAnalyteResonant sensor

Methods for detecting cardiac injury by detecting one or more cardiac markers are provided. A plurality of particles, each of which is coated with a capture agent having an affinity for a cardiac marker, is combined with the sample to form a plurality of analyte-particle complexes. The system also includes a transport arrangement for transporting the sample to the sensor surface, and optionally a magnetic field inducing structure constructed and arranged to establish a magnetic field at and adjacent to the sensor surface. The resonant sensor produces a signal corresponding to an amount of analyte-particle complexes that are bound to the sensor surface.

Owner:BIOSCALE

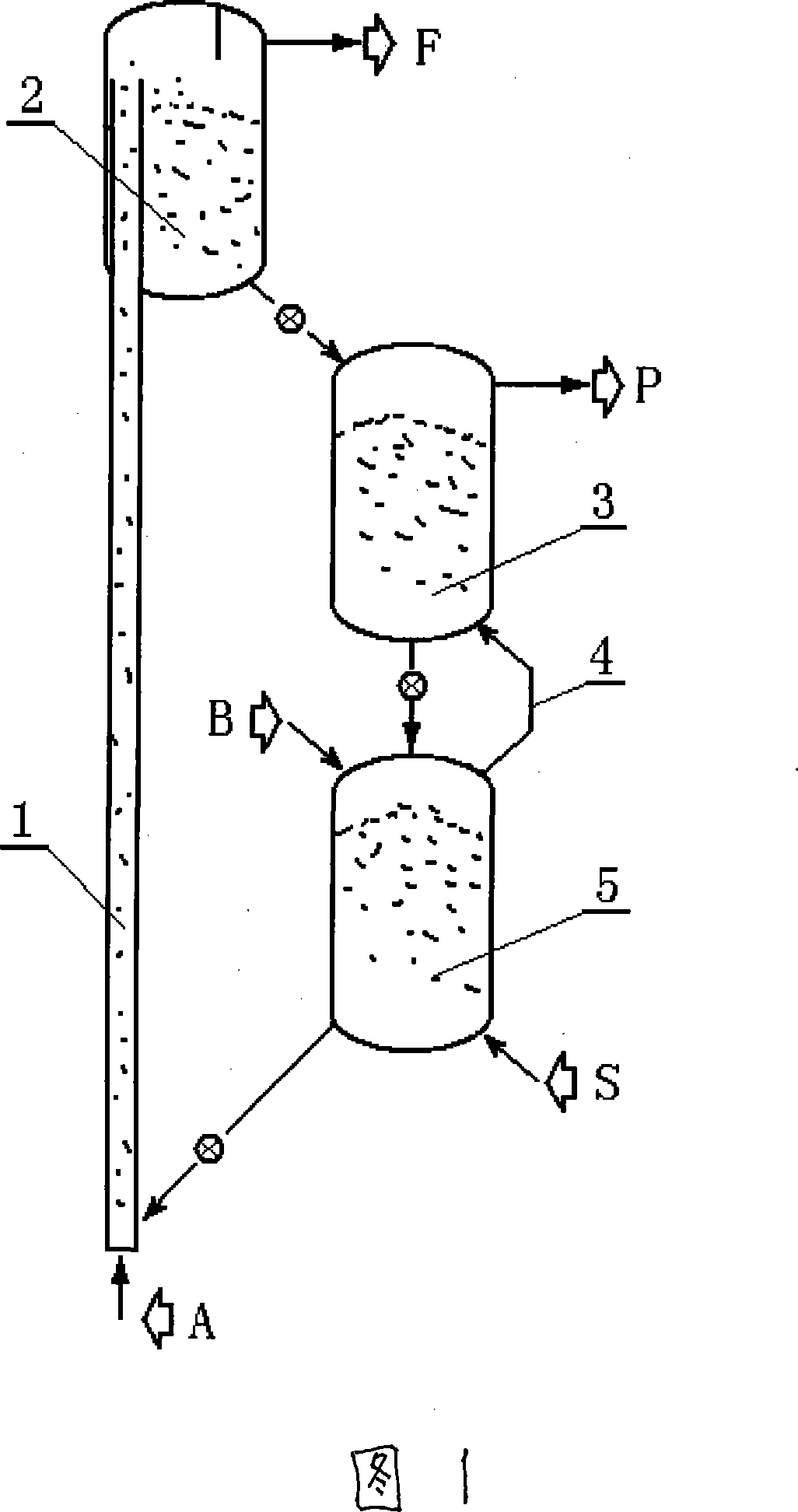

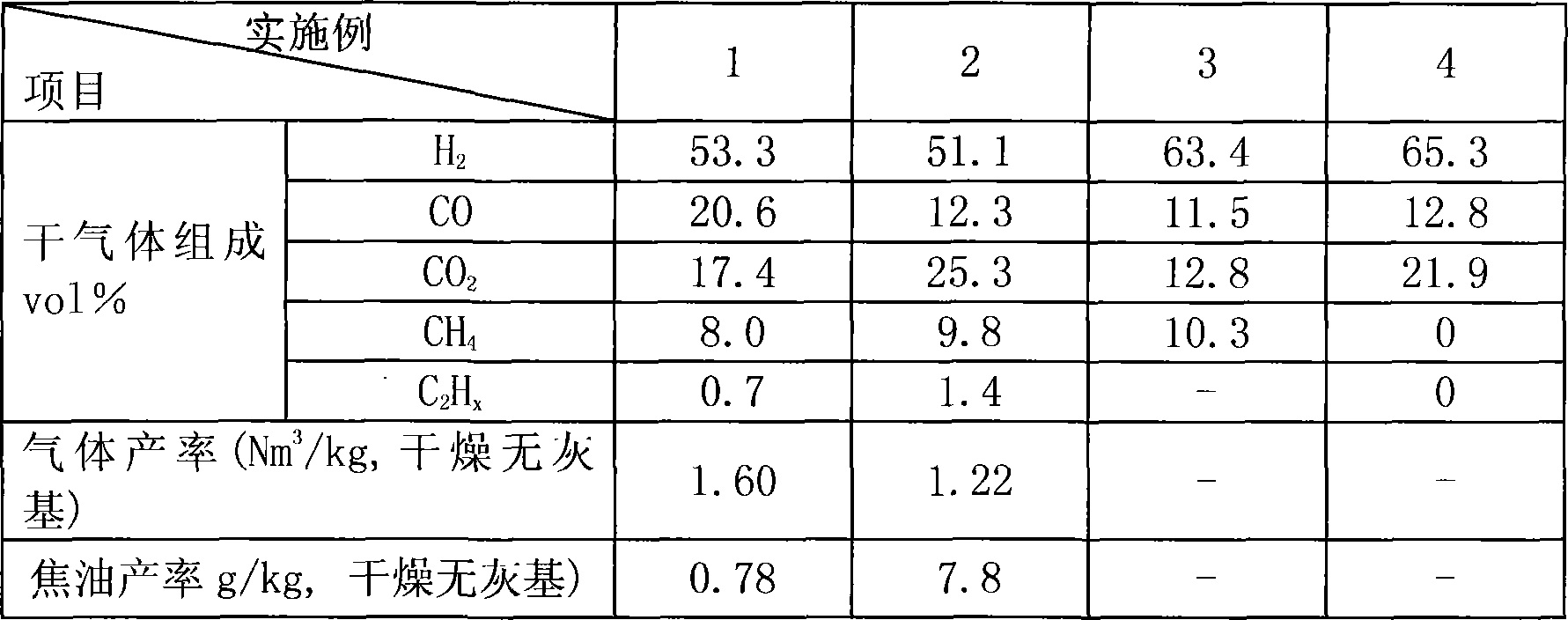

Method for preparing hydrogen-riched gas by solid fuel catalytic gasification

InactiveCN101045524AReasonable temperature distributionReduce the temperatureDirect heating destructive distillationHydrogen productionCatalytic reformingHeat carrier

A process for preparing the H2-enriched gas by catalytic gasification of solid fuel features that the solid catalyst used also as the heat carrier is circulating through riser combustion reactor, solid catalyst storage tank, catalytic reforming reactor and pyrolyzing reactor. In said pyrolyzing reactor, the biomass or coal and the solid heat carrier (catalyst) take part in fast pyrolytic reaction. Its resultant and the water steam take part in catalytic decomposing and reforming reaction to generate H2-enriched gas or synthetic gas.

Owner:DALIAN UNIV OF TECH

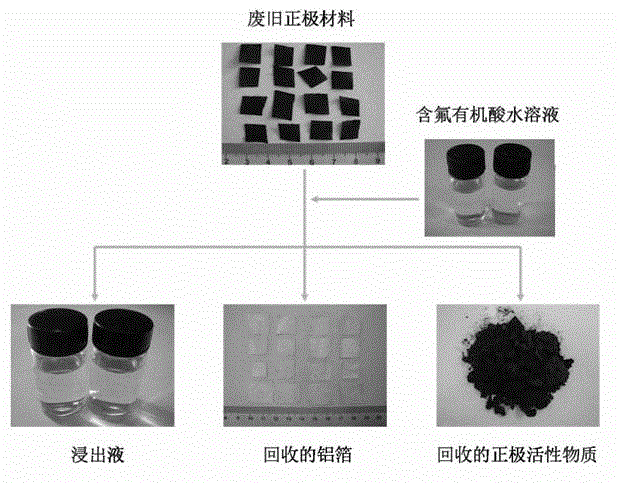

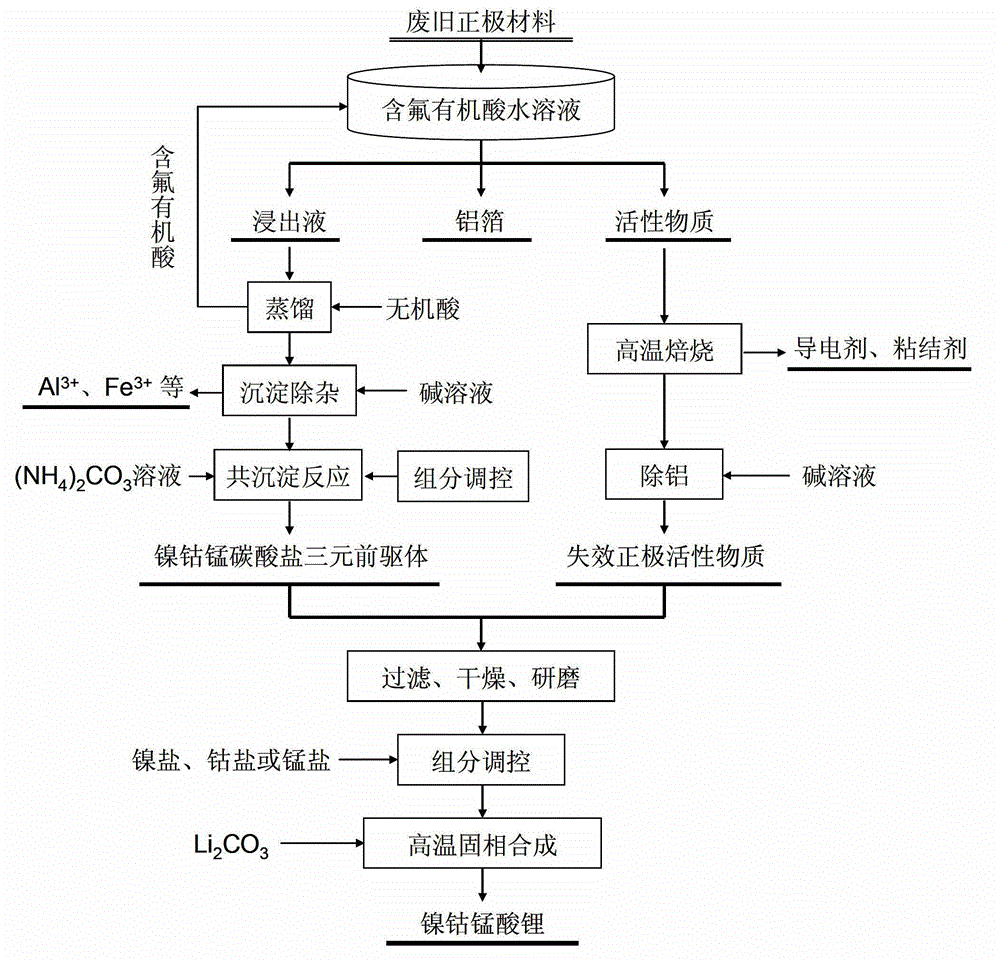

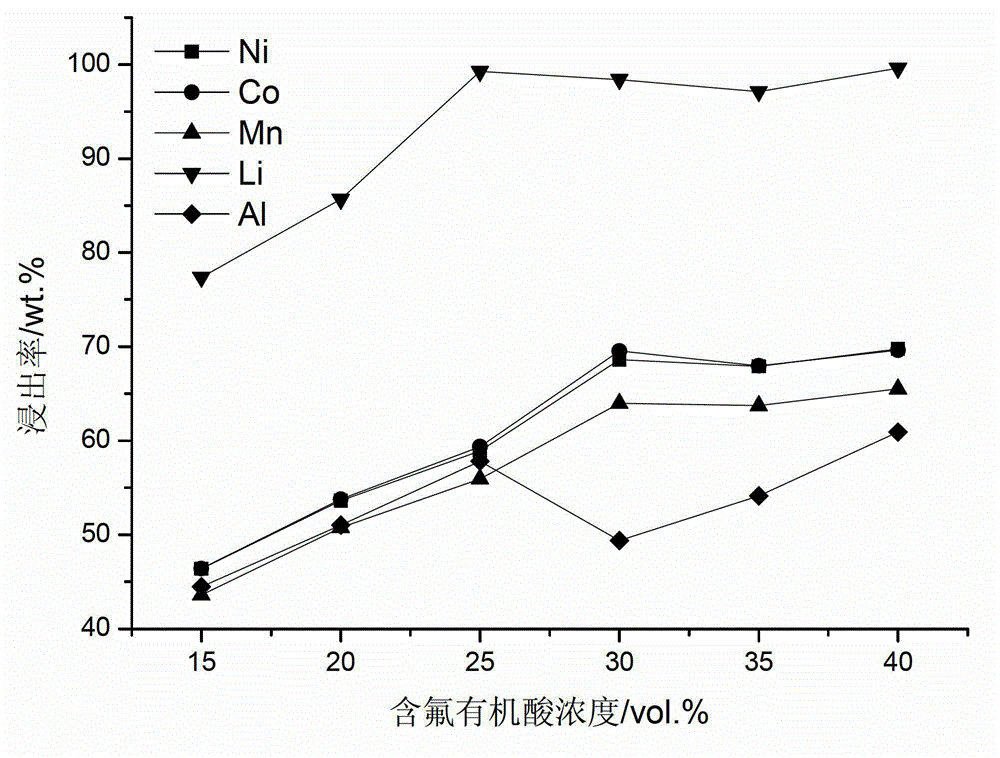

Full-component resource reclamation method for waste positive electrode materials of lithium ion batteries

ActiveCN102751549AAvoid secondary pollutionImprove separation efficiencyWaste accumulators reclaimingBattery recyclingRecovery methodDistillation

The invention provides a full-component resource reclamation method for waste positive electrode materials of lithium ion batteries. The method comprises the following steps: 1) separating active substances and aluminum foils in waste positive electrode materials of lithium ion batteries by using an aqueous solution of fluorine-containing organic acid and carrying out liquid-solid-solid separation so as to obtain leachate, the lithium-containing active substances and the aluminum foils; 2) respectively carrying out high temperature roasting and impurity removal with alkali liquor on the lithium-containing active substances; 3) respectively carrying out recovery of the fluorine-containing organic acid through addition of acid and distillation, deposition of impurity ions through addition of alkali and ammonium carbonate coprecipitation on the leachate so as to prepare nickel-cobalt-manganese carbonate ternary precursor; and 4) carrying out component regulation on a mixture of the treated active substances and the nickel-cobalt-manganese carbonate ternary precursor, adding lithium carbonate in a certain proportion and carrying out high temperature solid phase sintering so as to prepare a lithium nickel cobalt manganese oxide ternary positive electrode material. The method provided in the invention has the following advantages: the application scope of the method is wide; separation efficiency of the lithium-containing active substances and the aluminum foils is high; short-flow direct re-preparation of positive electrode materials in waste lithium ion batteries is realized; and the method is applicable to large-scale resource reclamation of waste lithium ion batteries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

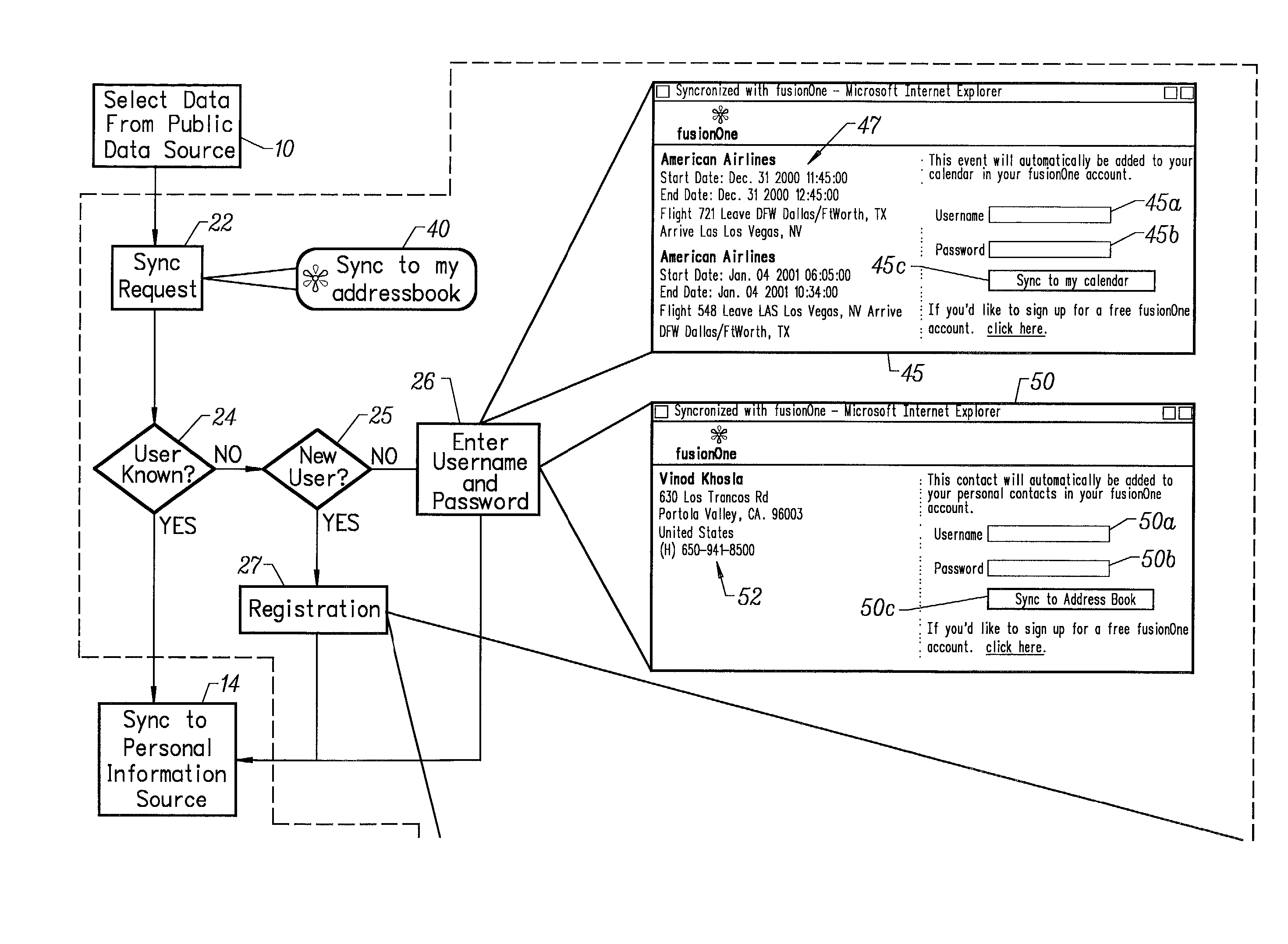

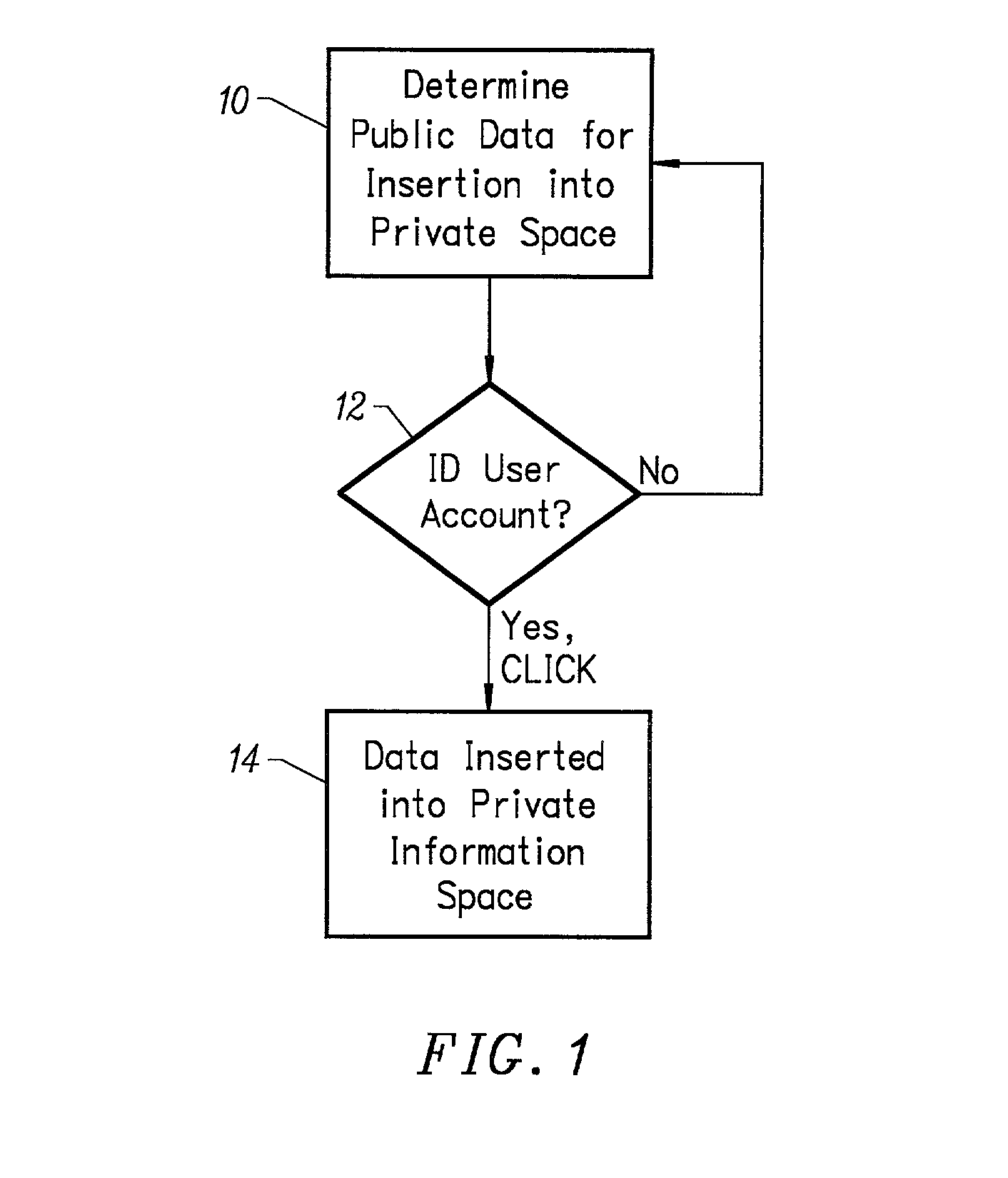

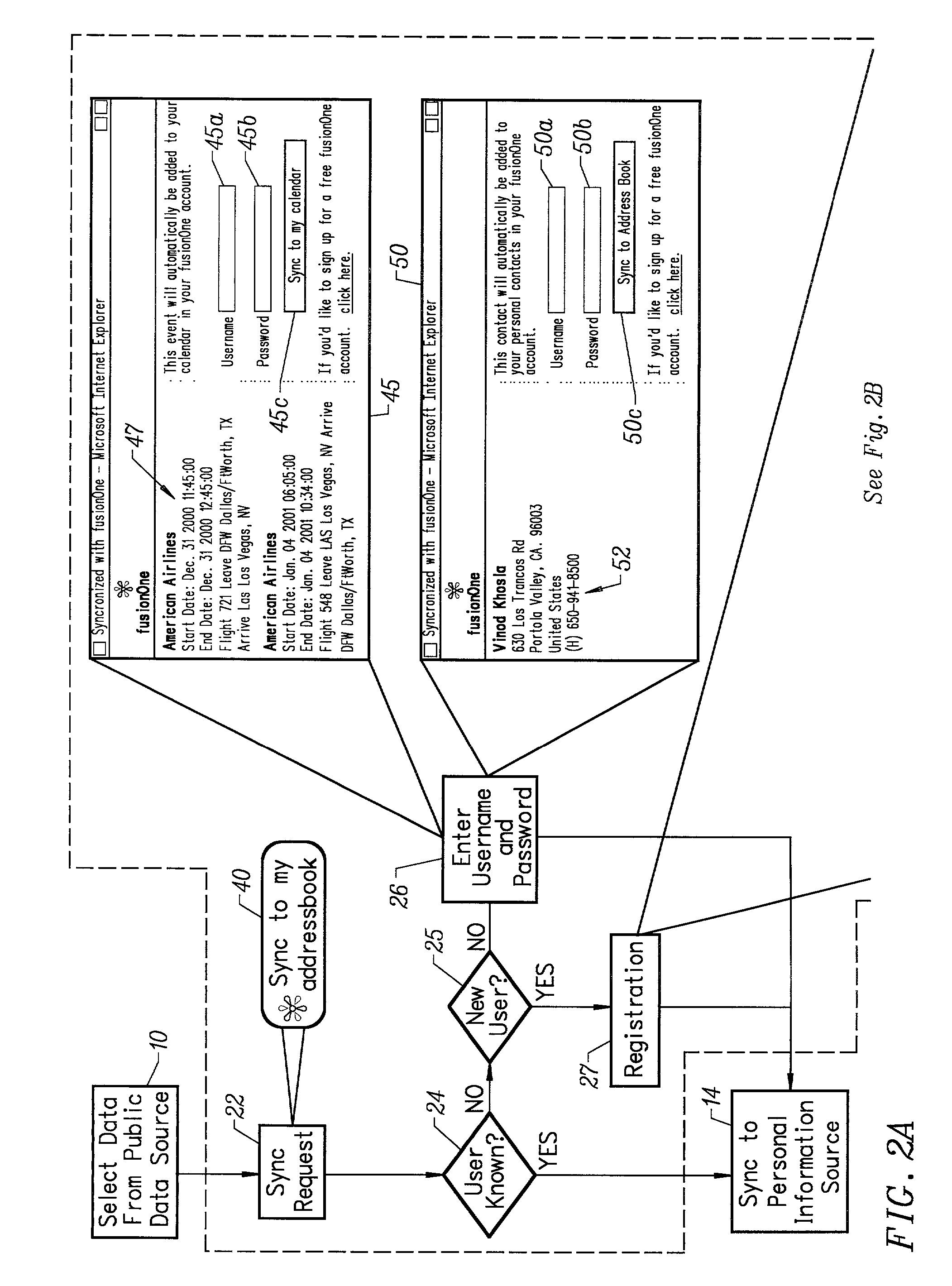

Single click data synchronization of public and private data

ActiveUS20020038316A1Improve usabilityReturn quicklyMultiple digital computer combinationsWeb data navigationClient-sideData synchronization

A method for transferring public information to a private information store maintained by a private information space manager. The method may include the steps of selecting public information from a public information source; initiating a sync request by selecting a sync request button on the public information web site; and identifying the private information space were the public information is to be stored. In a further aspect, the invention comprises a system for synchronizing public content from a public information web site to a private information store. The system may include a sync enable button on the public information web site; a pop-up window provided by a private information store provided responsive to the sync enable button on the public information web site; and a sync interface transfer button on the pop-up window initiating transfer of the public information to the private information store. In a further aspect, the public information web site is provided by an affiliate server and said affiliate server includes code enabling said sync button by directing a client web browser to the private information store provider. The system may further include at least one synchronization routine synchronizing the public information data with the private information space.

Owner:SYNCHRONOSS TECH

Fruit and vegetable soybean milk drink and preparation method thereof

InactiveCN104997103AGreat tasteRetain nutritional valueFood ingredient functionsOligosaccharide food ingredientsBiotechnologyNutritive values

The present invention discloses a fruit and vegetable soybean milk drink which is prepared from the following raw materials in parts by weight: fruit juice 10-15 parts, vegetable juice 5-10 parts, Chinese red date soybean milk 3-5 parts, white granulated sugar 3-5 parts, high glucose syrup 2-3 parts, xylo-oligosaccharide 1-2 parts, malic acid 2-5 parts, citric acid 0.1-0.2 part, stabilizer 0.1-0.15 part and pure water 77.15-87.3 parts. The preparation method of the fruit and vegetable soybean milk drink comprises the following steps: (1) preparing the fruit juice; (2) preparing the vegetable juice; (3) preparing the Chinese red date soybean milk; (4) blending; (5) homogenizing and degassing; and (6) sterilizing and bottling. The prepared fruit and vegetable soybean milk drink increases the taste, improves the mouthfeel, maintains the nutritional values and increases the nutrients of the soybean milk, not only satisfies the people's pursuit for taste preferences, but also maintains and adds more nutrients, and has higher nutritional values.

Owner:HEILONGJIANG TIANYI AGRI TECH DEV

Copper bismuth catalyst and preparation method thereof

ActiveCN102658158AImprove wear performanceExtended service lifeOrganic compound preparationHydroxy compound preparationCooking & bakingAlcohol

The invention relates to a copper bismuth catalyst for combining chemically into 1, 4-butynediol with formaldehyde and ethyne and a preparation method thereof. The preparation method comprises the following steps of: preparing mixed solution which contains copper salt, bismuth salt, magnesium salt and dispersant; dropping alcoholic solution with an organic silicon source into the mixed solution; adjusting a pH value of the mixed solution with alkaline solution to obtain mixed precipitate; and further aging, washing, drying and baking in inert atmosphere to obtain the copper bismuth catalyst with C-MgO-SiO2 a carrier, in the catalyst, the content of CuO accounts for 25-50 weight percent, and the content of Bi2O3 accounts for 2-6 weight percent. The catalyst is applied in a reaction of combining chemically into 1, 4-butynediol with formaldehyde and ethyne, and has high catalytic activity and high selectivity.

Owner:SHANXI UNIV

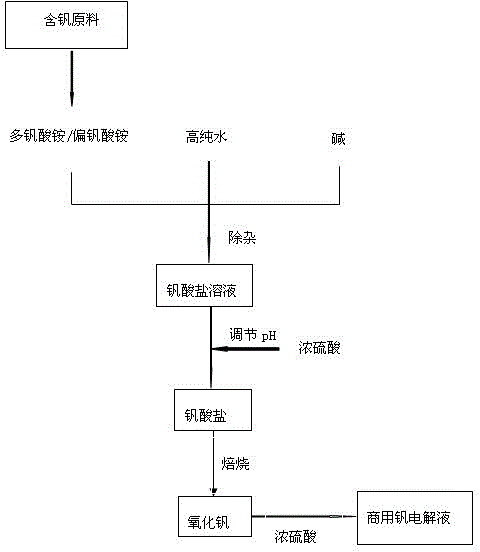

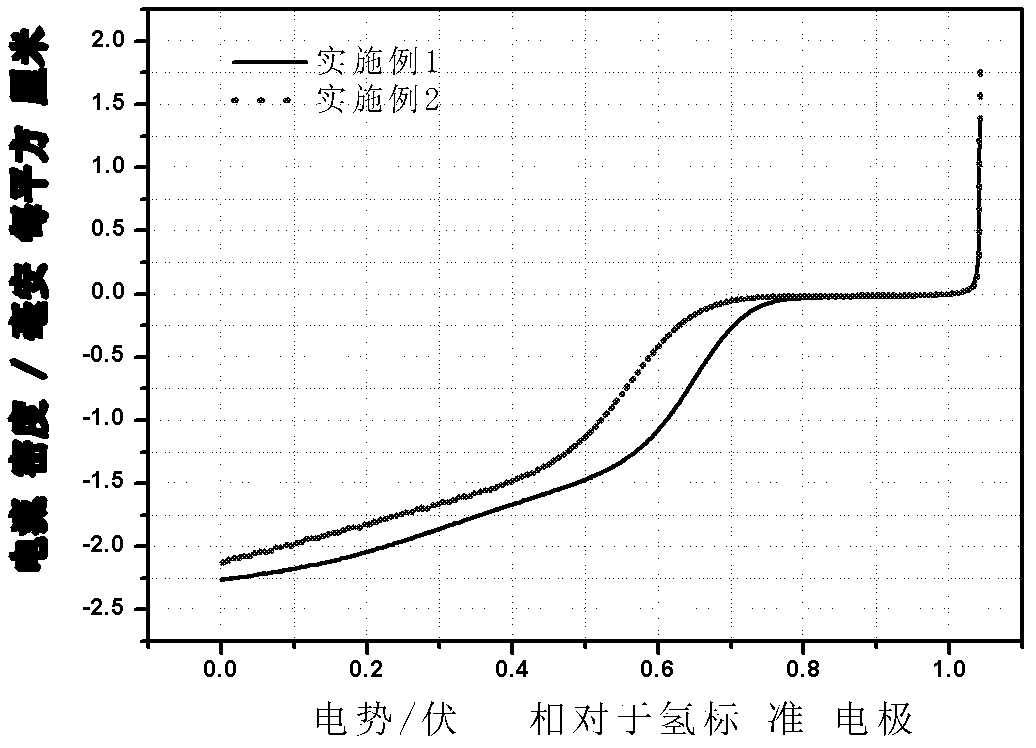

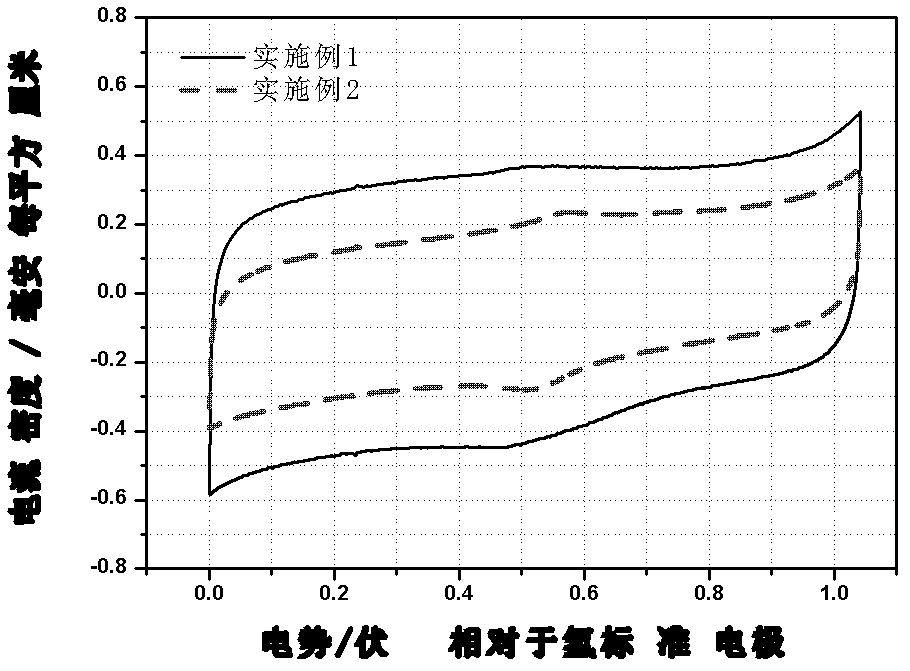

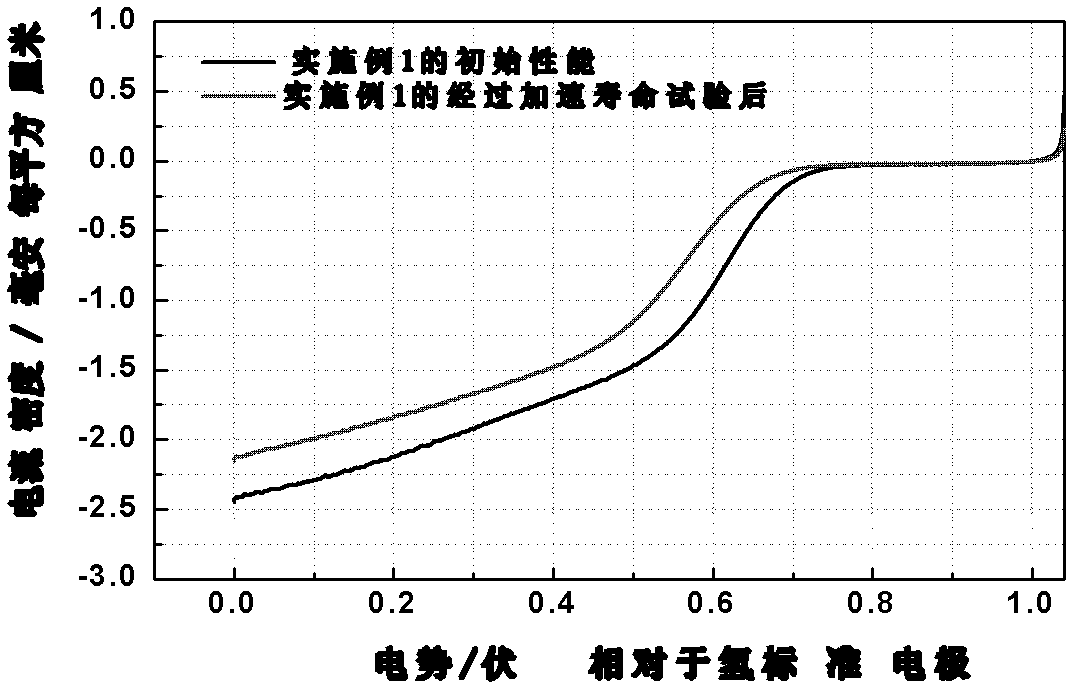

Preparation method for commercial vanadium battery electrolyte

ActiveCN103606694AHigh purityLimited service lifeIndirect fuel cellsAcid electrolytesSocial benefitsHydrogen

The invention discloses a preparation method for commercial vanadium battery electrolyte. According to the preparation method, vanadium electrolyte is prepared by one step through a chemical method; the preparation method comprises the following steps: dissolving raw materials containing vanadium by using an alkali; adjusting a pH (Potential of Hydrogen) value by acid-alkali regulation; repeatedly precipitating the vanadium to remove impurity elements; then roasting to obtain an oxide of the vanadium; finally, dissolving the oxide of the vanadium by using concentrated sulfuric acid to obtain the vanadium electrolyte. With the adoption of the method, impurities including iron, chrome, silicon, manganese and the like can be removed effectively and a process flow is shortened; the vanadium yield is improved, the impurity content is reduced and the process flow is shortened; the product purity can also be improved. The preparation method for the commercial vanadium battery electrolyte has important meanings on production technology levels and market competitiveness of the vanadium electrolyte; the method has good economic benefits and social benefits.

Owner:HEBEI IRON AND STEEL

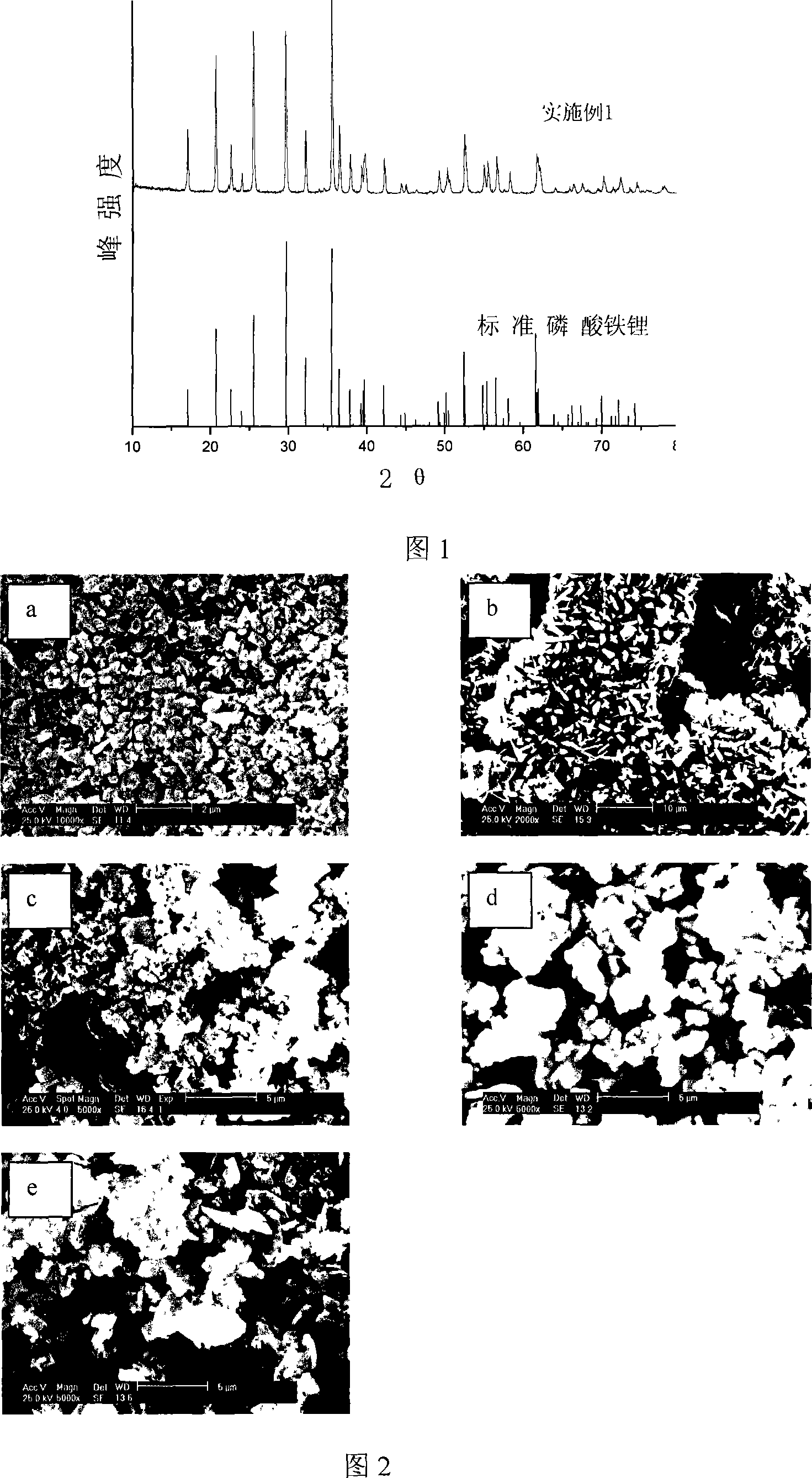

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

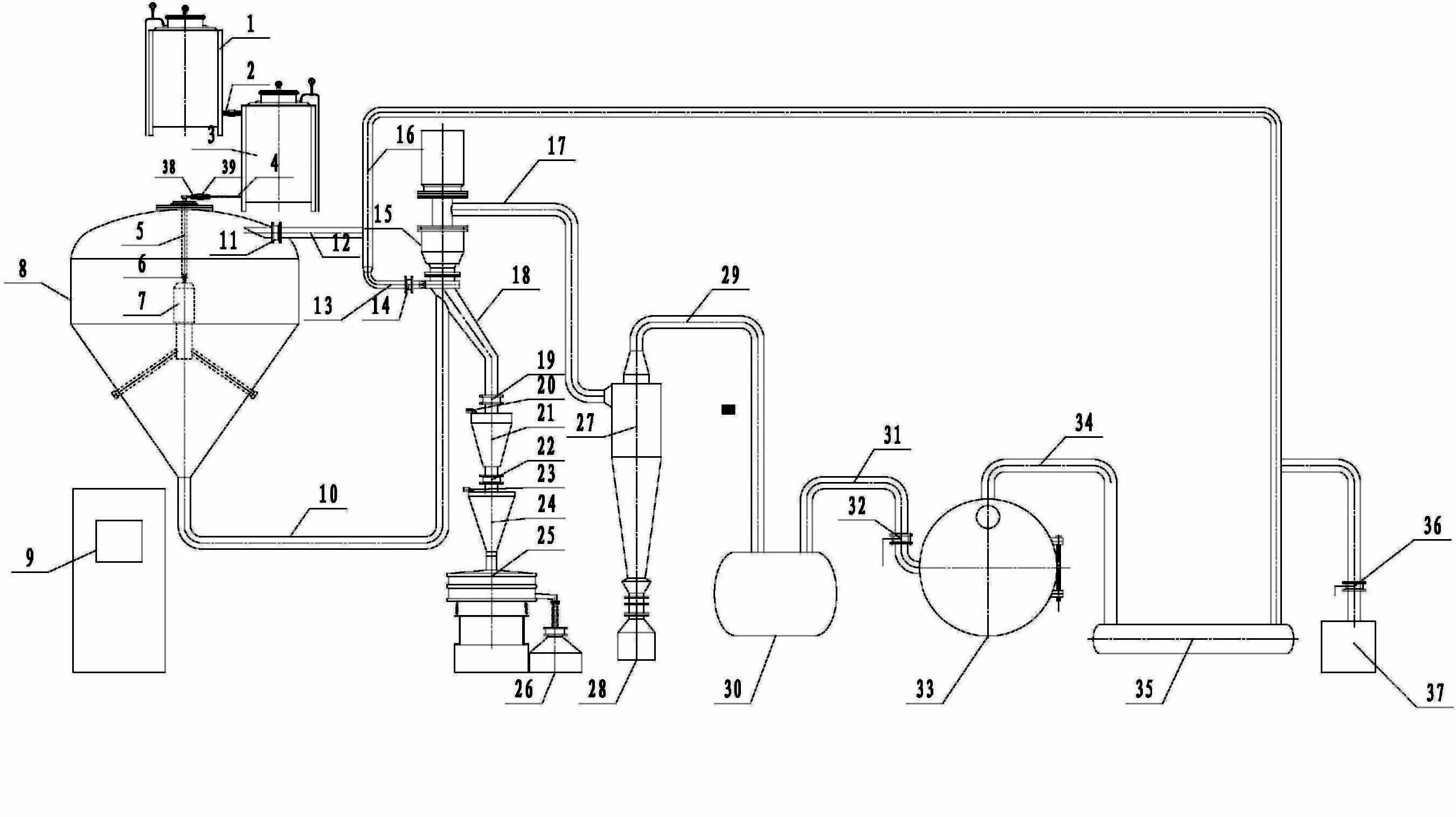

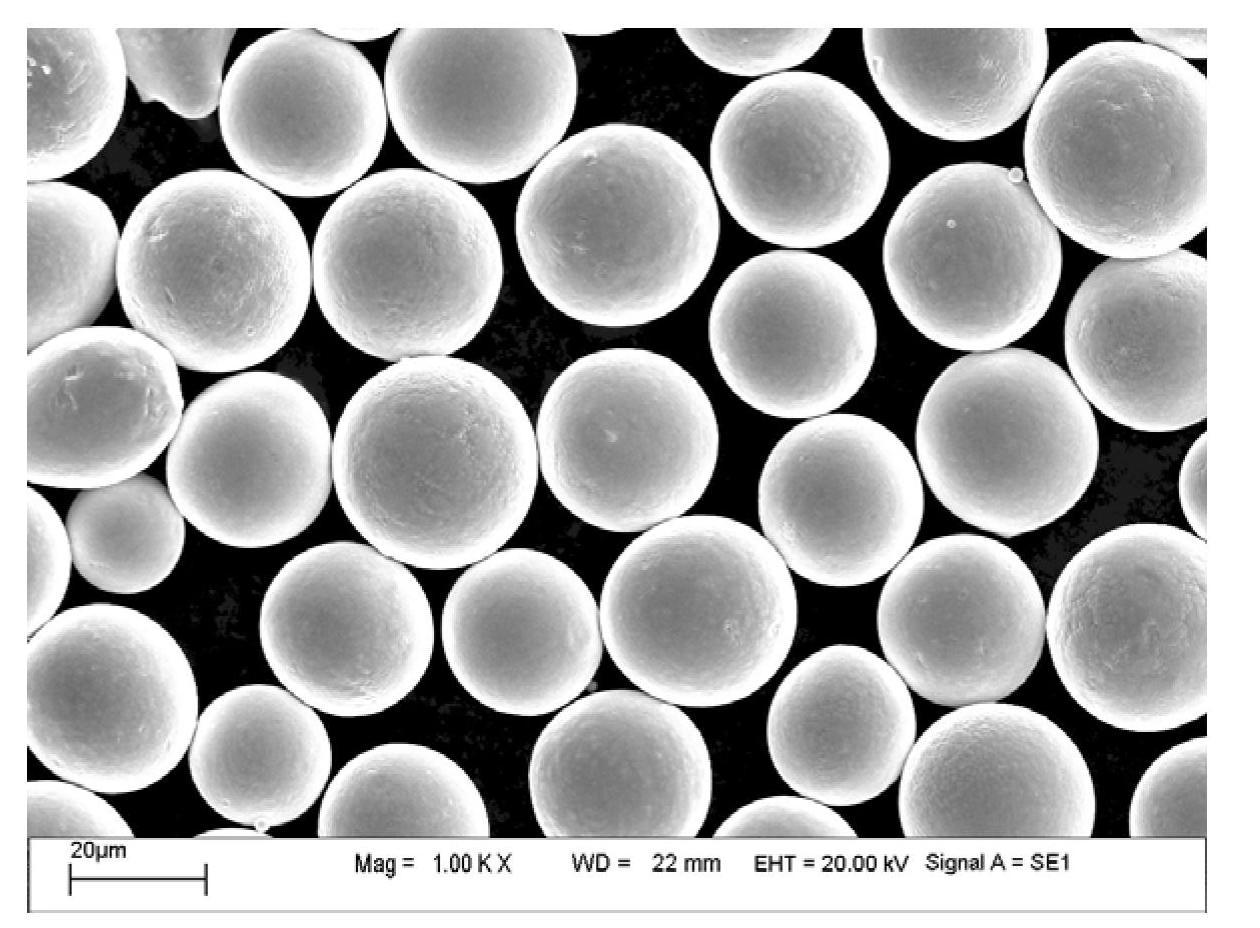

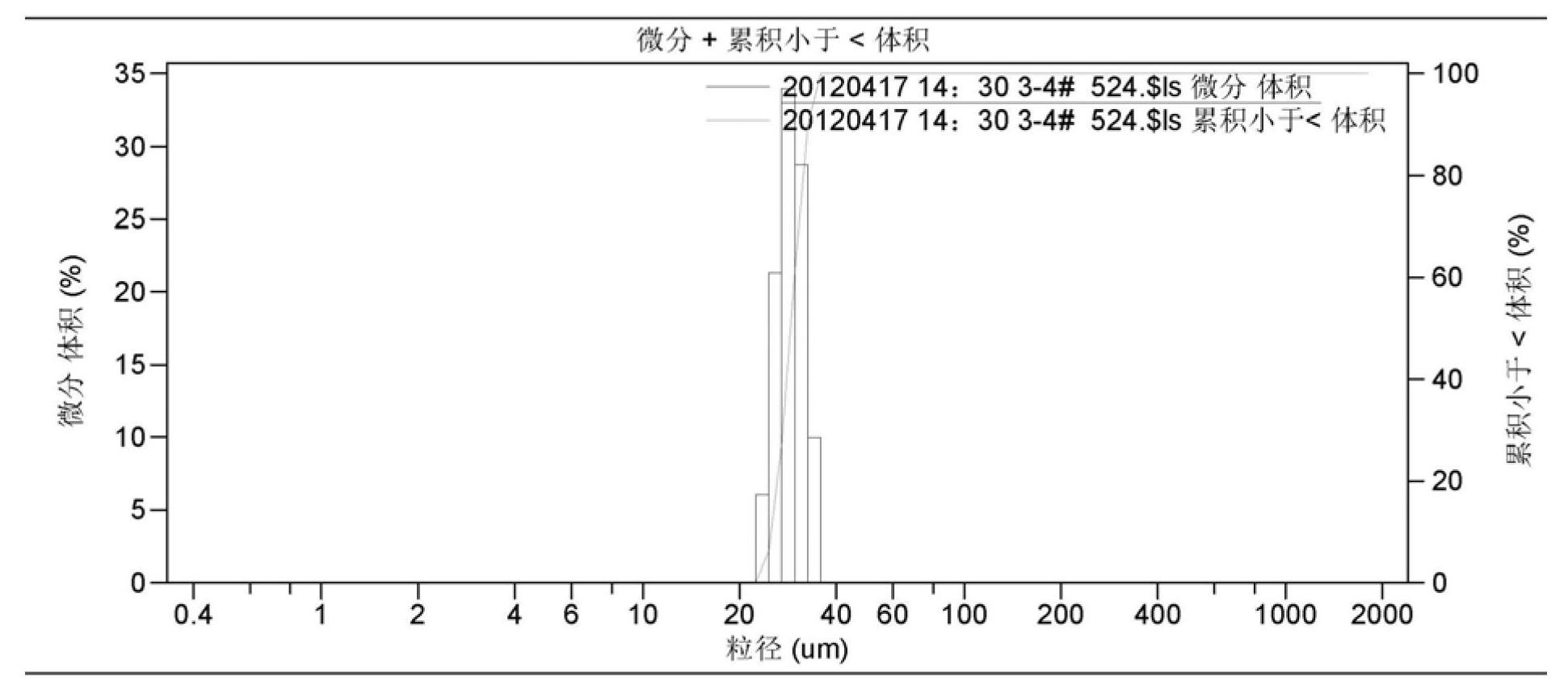

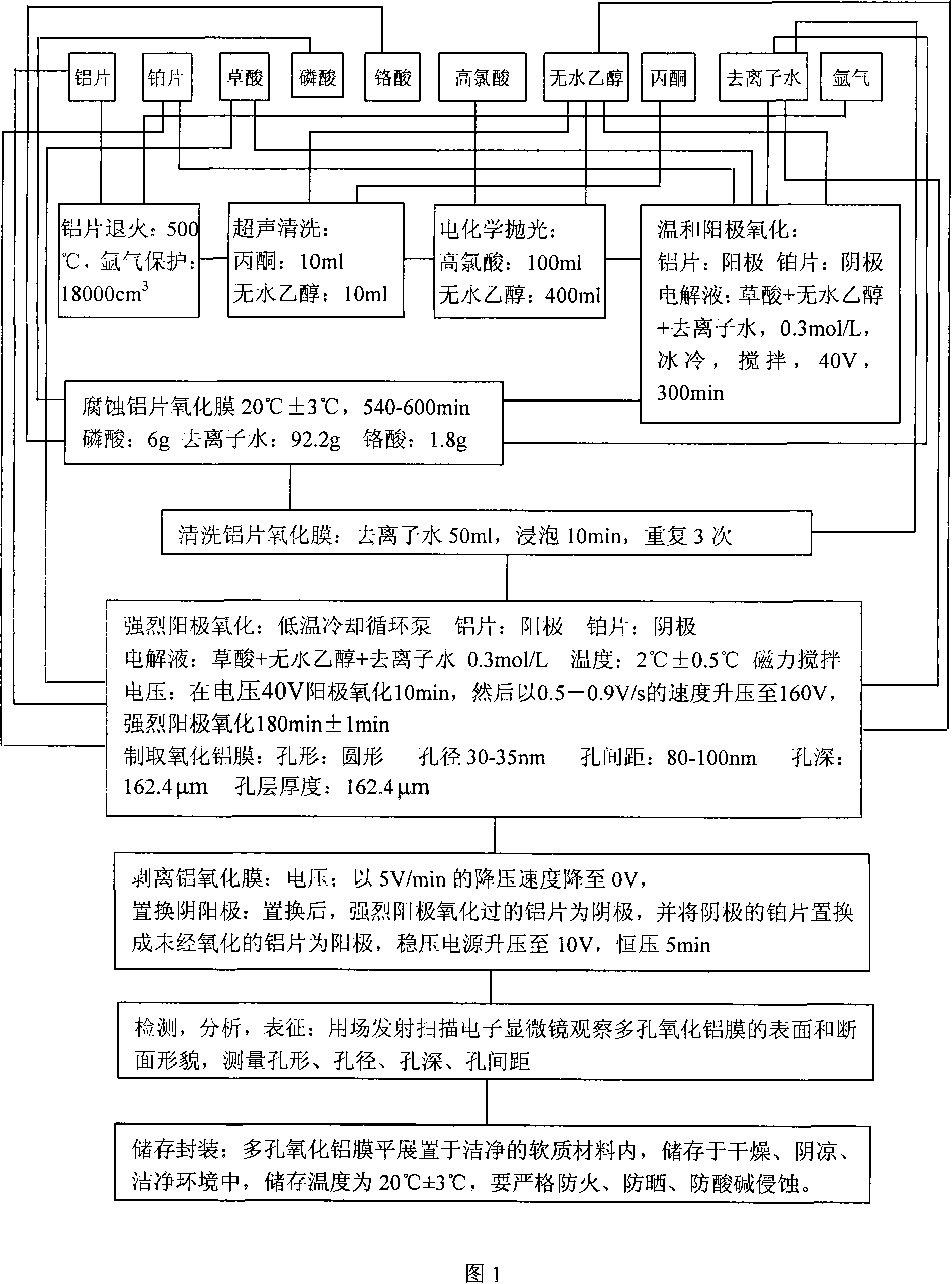

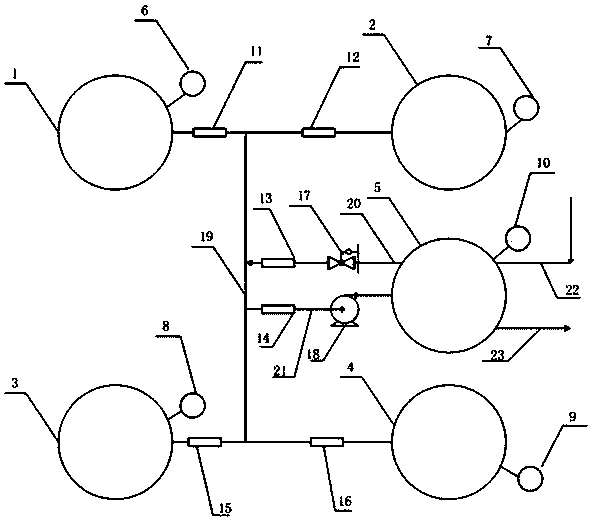

Metal powder preparation device and method therefor

The invention relates to a metal powder preparation device and method therefor. The device comprises an atomization furnace, a heater, a cooler, an atomization chamber, an atomizer, a pneumatic classifier, a middle bin, a sieving funnel, a screening machine, a deduster, a balance tank, a shell-and-tube heat exchanger, a vacuum obtaining device, a control system, an infusion tube, a conduit, a pipeline, a gas channel, a pneumatic butterfly valve, an electromagnetic valve and the like. The method comprises atmosphere preparation, metal smelting, infusion, centrifugal atomizing, pneumatic classification, mechanical screening, gas purification, cooling and the like, the metal is smelted and treated so as to be poured onto the atomizer for centrifugal atomization to form powder, the powder is classified by the pneumatic classifier, after classification, rough powder is screened by the mechanical screening so as to obtain the finished powder, fine powder is sent into the deduster by airflow for purification, the purified gas is driven by a high pressure centrifugal fan so as to be speeded up to be atomized and classified again after being subjected to heat exchange through the shell-and-tube heat exchanger. The device can be used for continuous production of spherical powder below -320 meshes, and the oxygen content is less than or equal to 80ppm.

Owner:BEIJING COMPO ADVANCED TECH

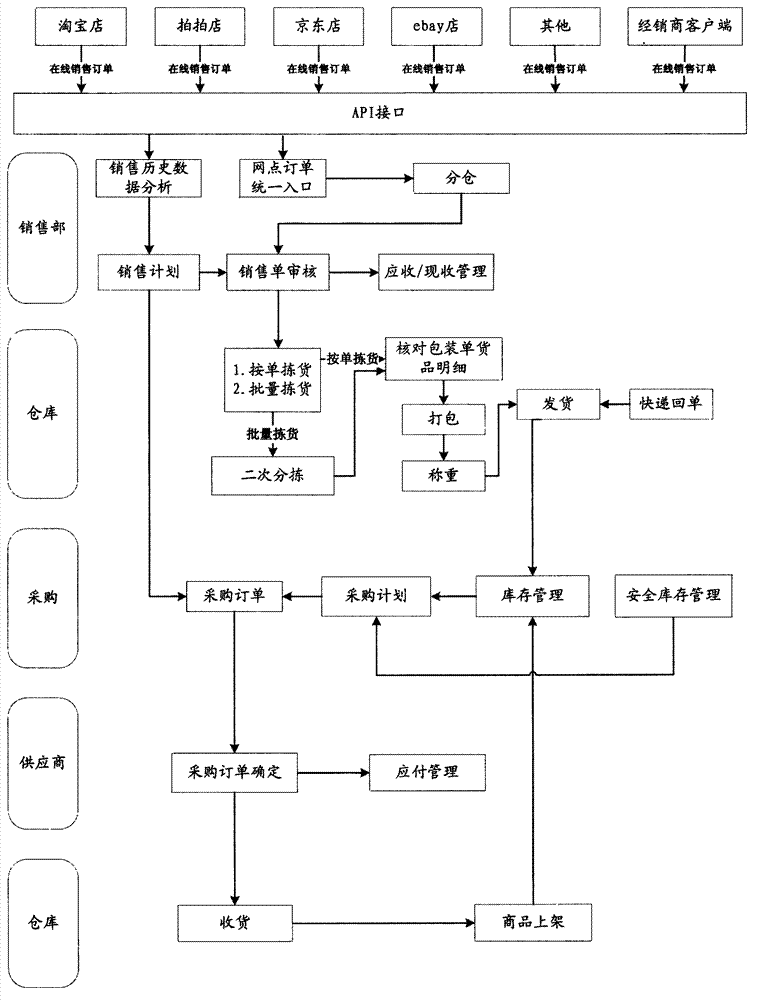

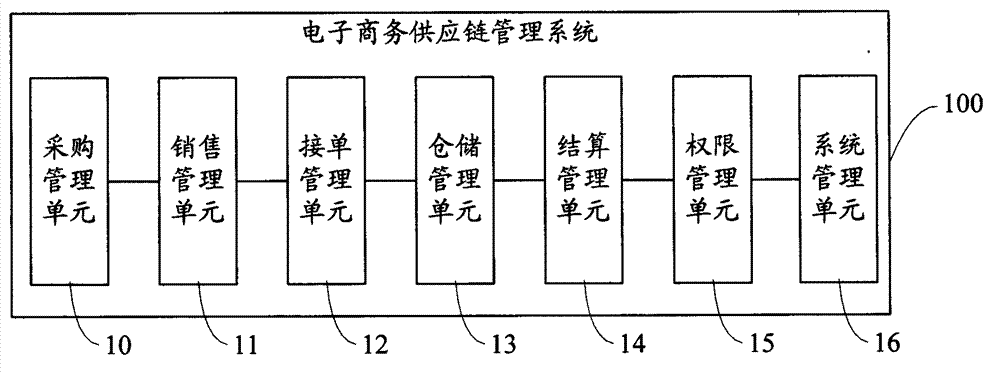

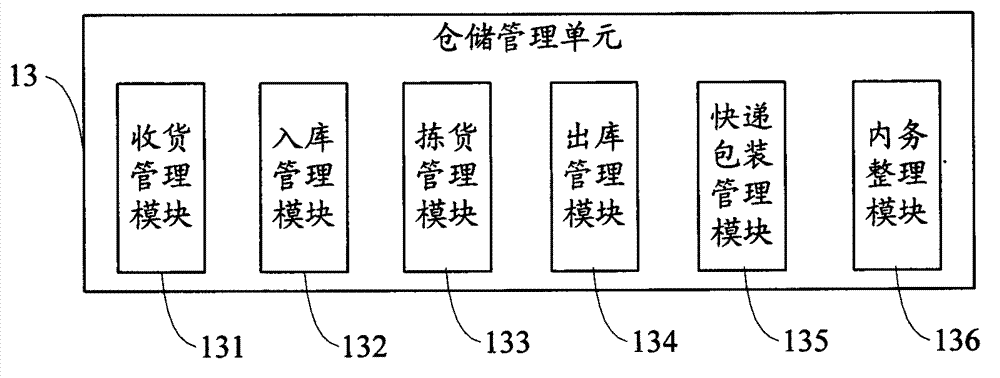

Electronic commerce supply chain management system

ActiveCN102819789AComplete faster and saveSave manpower and material resourcesResourcesSystems managementMaterial resources

The invention relates to an electronic commerce supply chain management system, comprising a purchasing management unit, a marketing management unit, an order-receiving management unit, a warehousing management unit, an authority management unit and a system management unit, wherein the electronic commerce supply chain management system performs unified and coordinated management on the purchasing, marketing, order-receiving, warehousing, settlement, authority-controlling, basic information, and internal and organizational structures of the system of commodities, and completes the corresponding function by each executing unit, so that the purchasing, marketing, warehousing and inventory become very clear; the electronic commerce supply chain management system does not only save a lot of manpower and material resources, but also shortens a large amount of process, and optimizes the picking, allocation and delivery procedures, so that the user saves a lot of staff and express costs; and the electronic commerce supply chain management system further greatly shortens the delivery cycle, and improves the delivery efficiency, so that the user can complete the whole logistics procedure from purchasing to delivering of the commodities more rapidly and frugally.

Owner:SHENZHEN HULIANTONG SCI & TECH

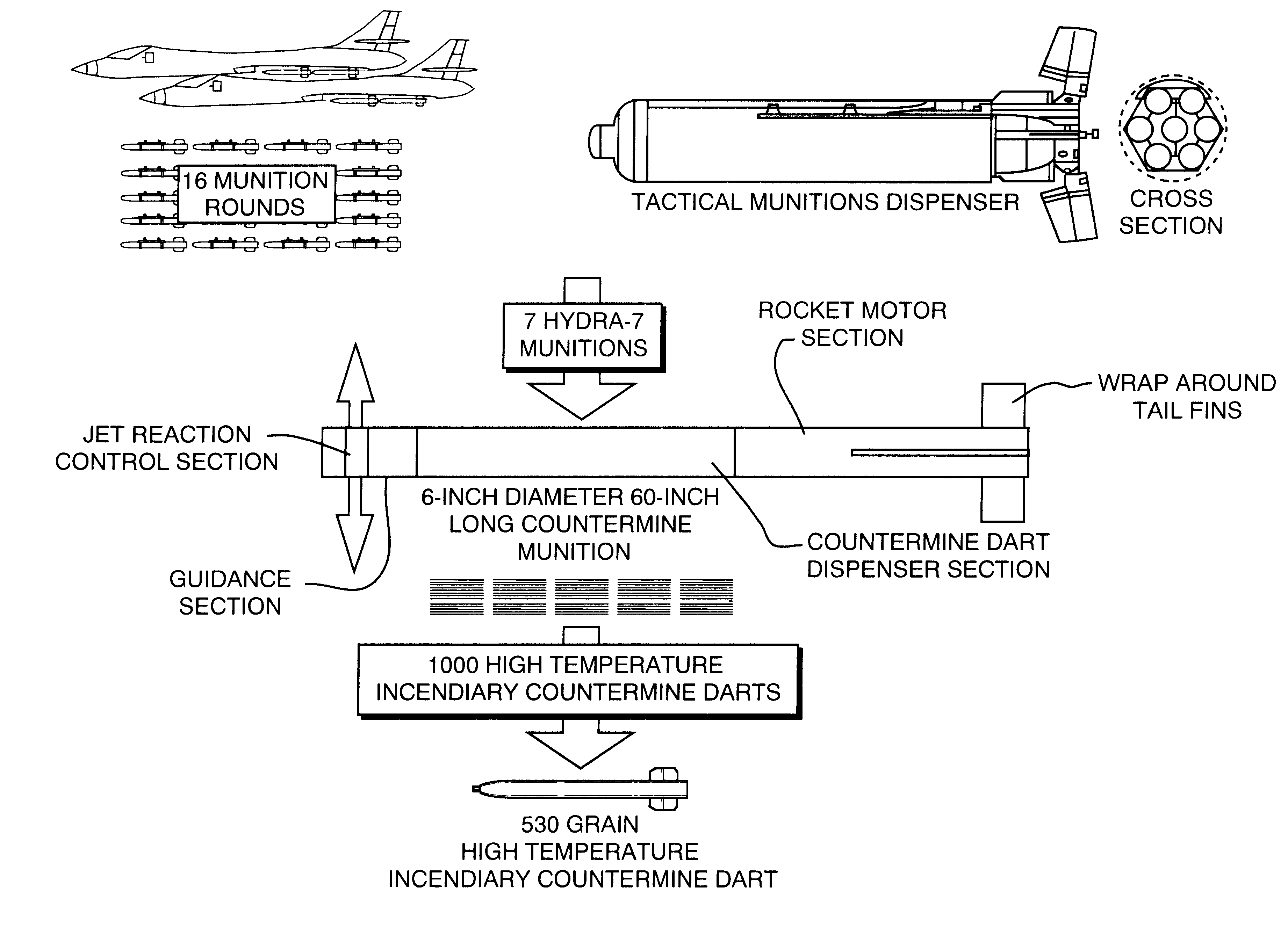

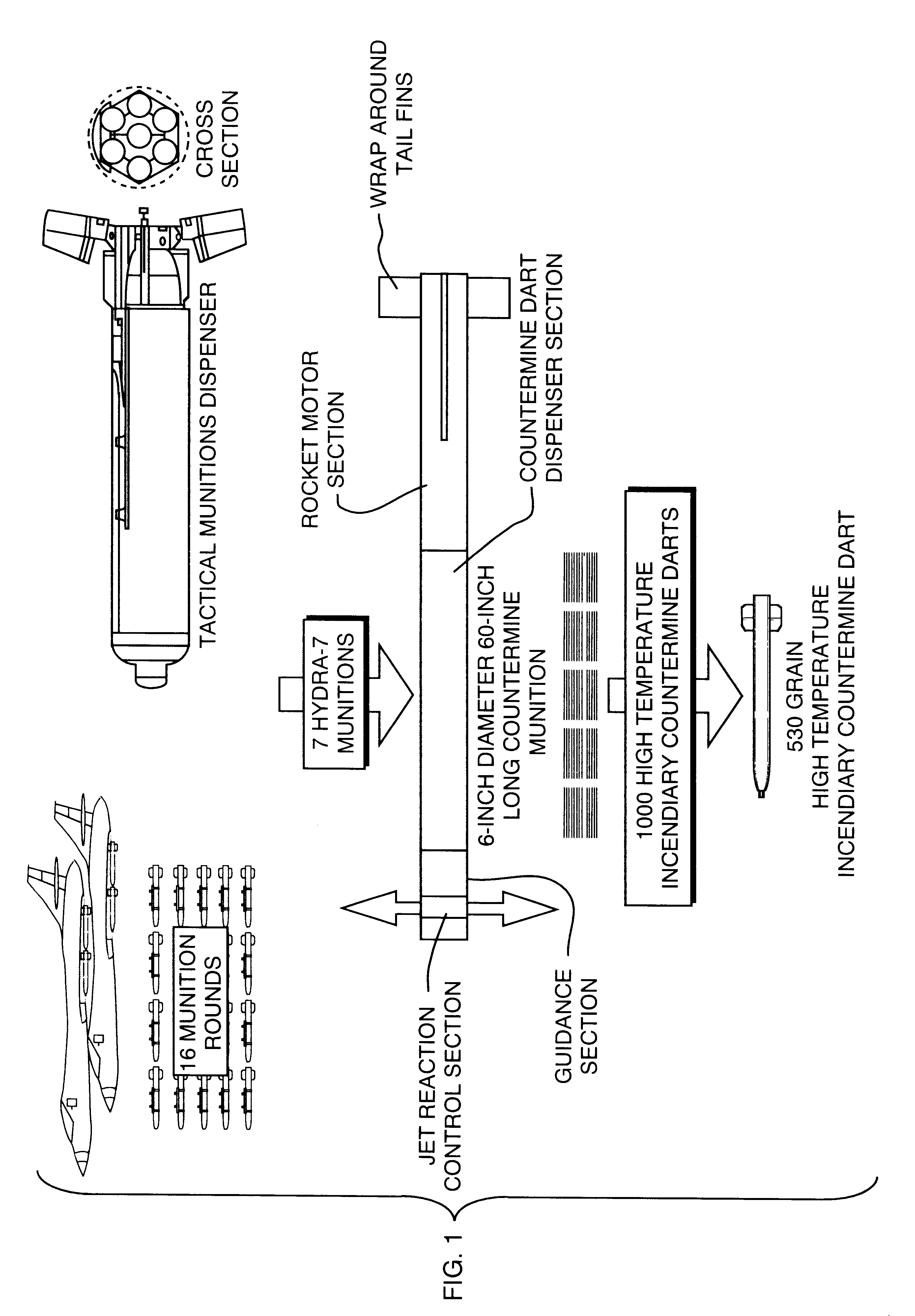

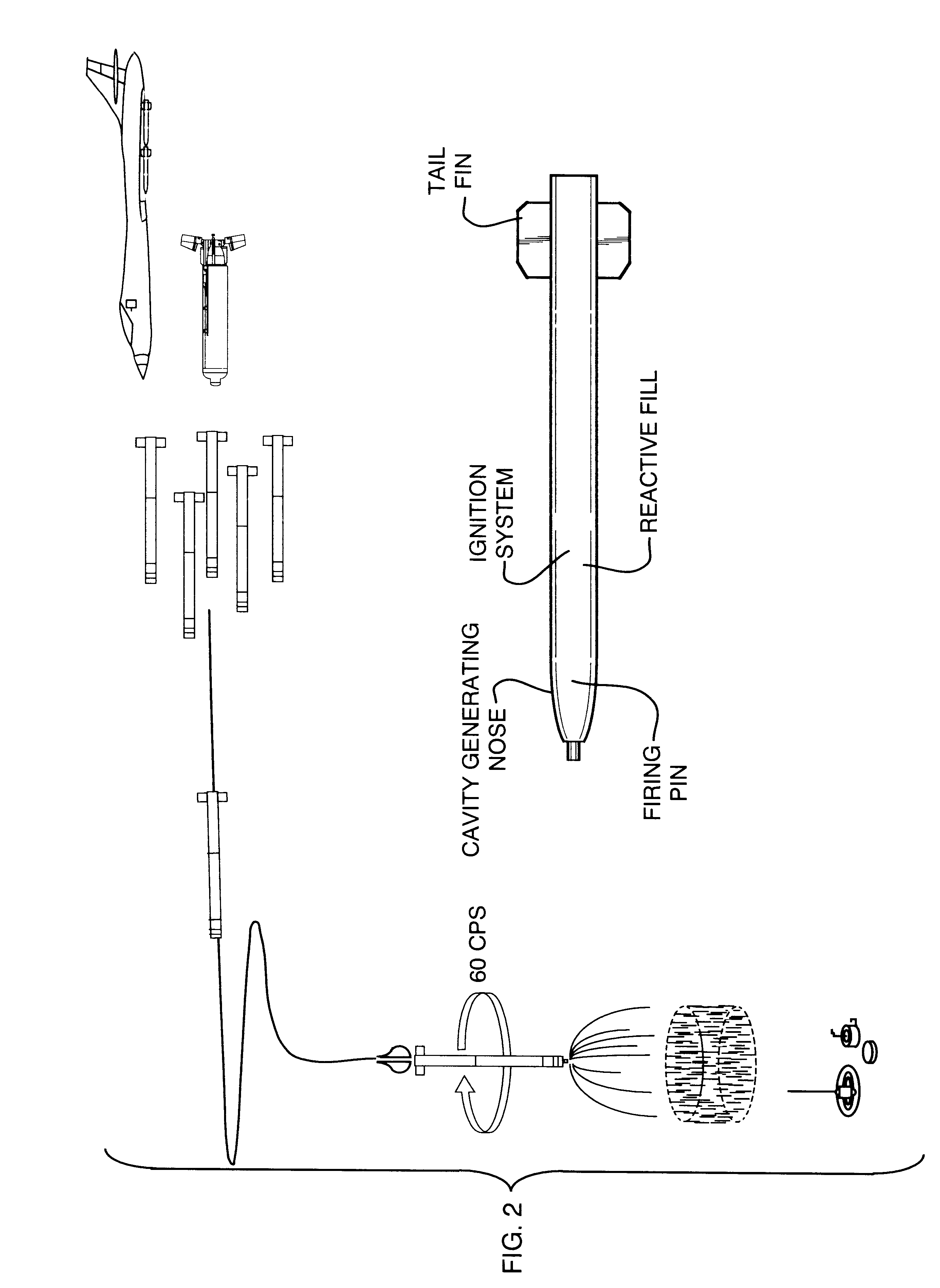

System for clearing buried and surface mines

Owner:LOCKHEED MARTIN ADVANCED PROJECTS

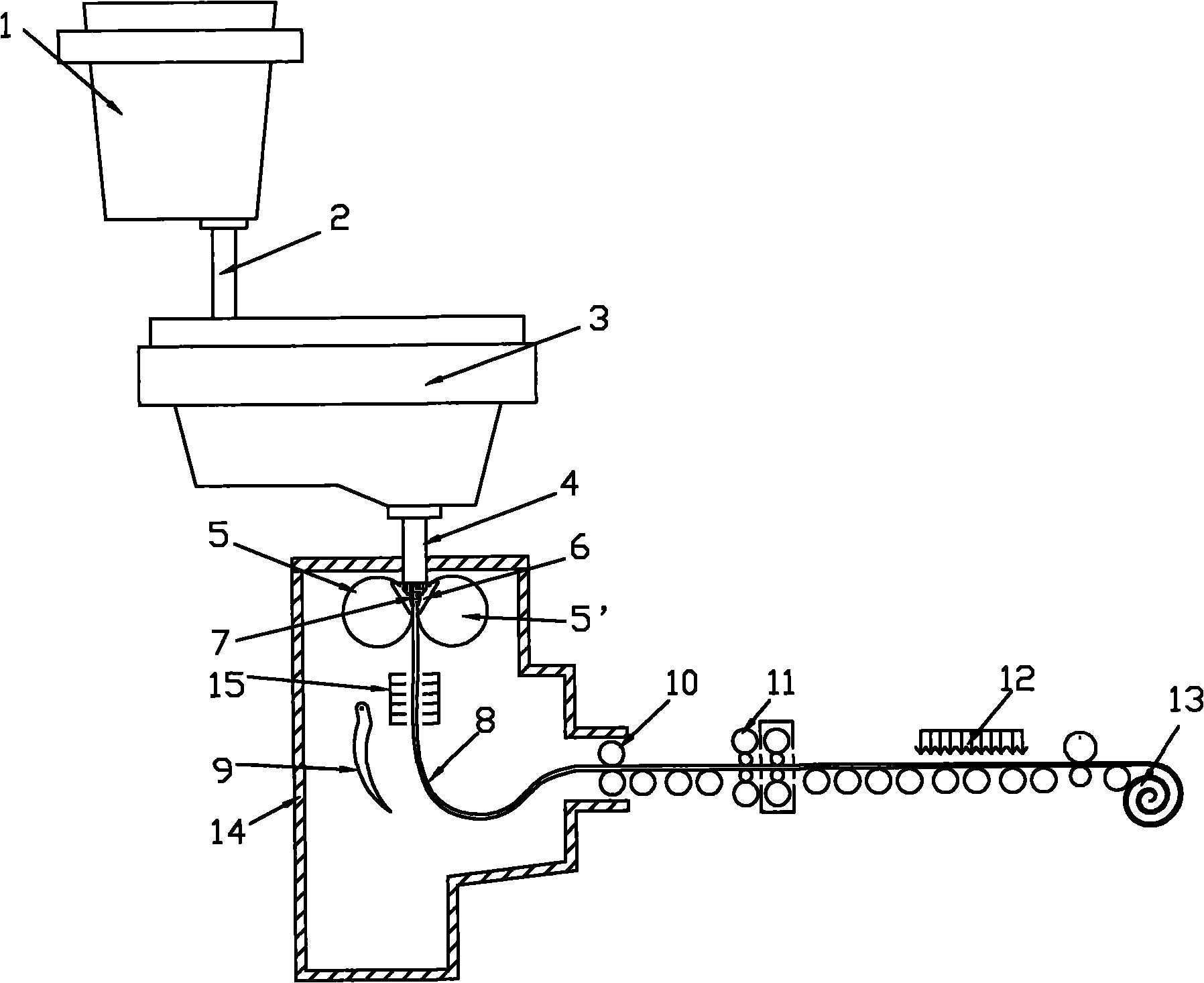

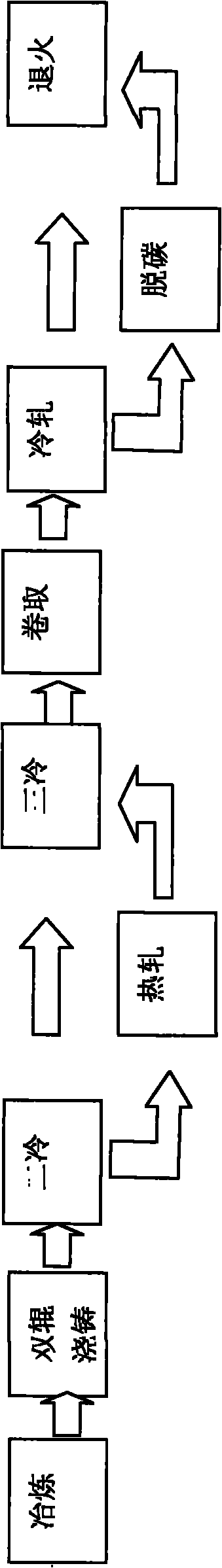

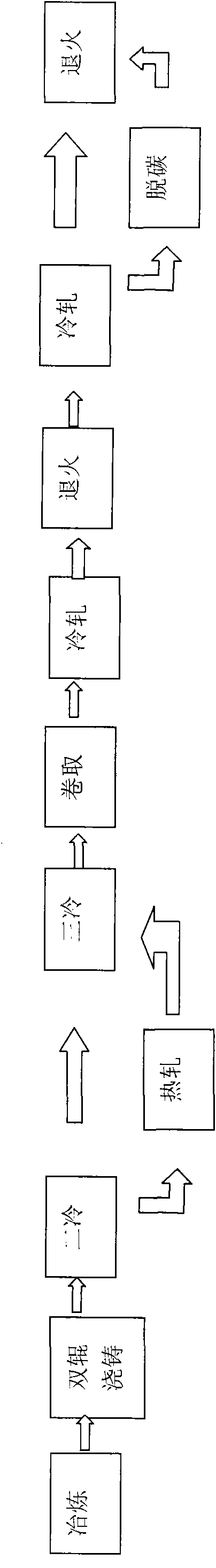

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367AMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time, hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improve the medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

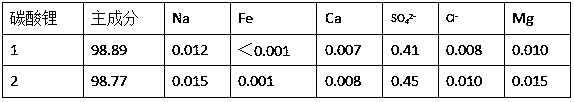

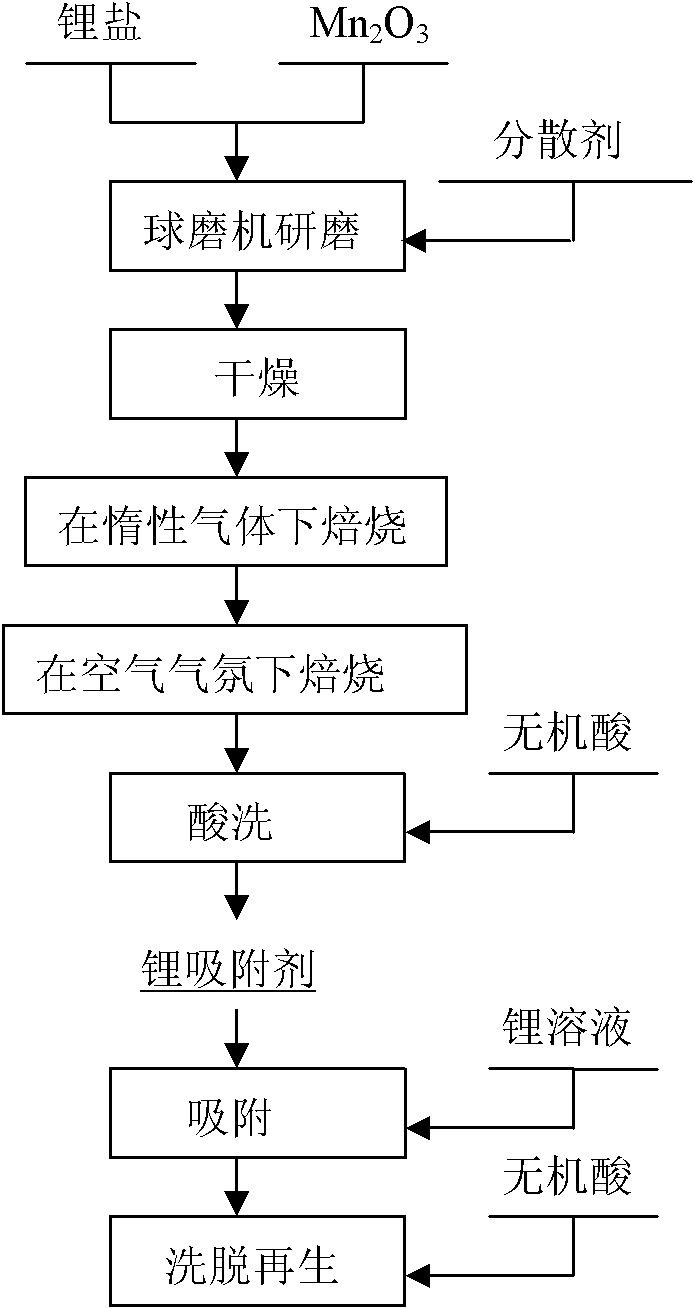

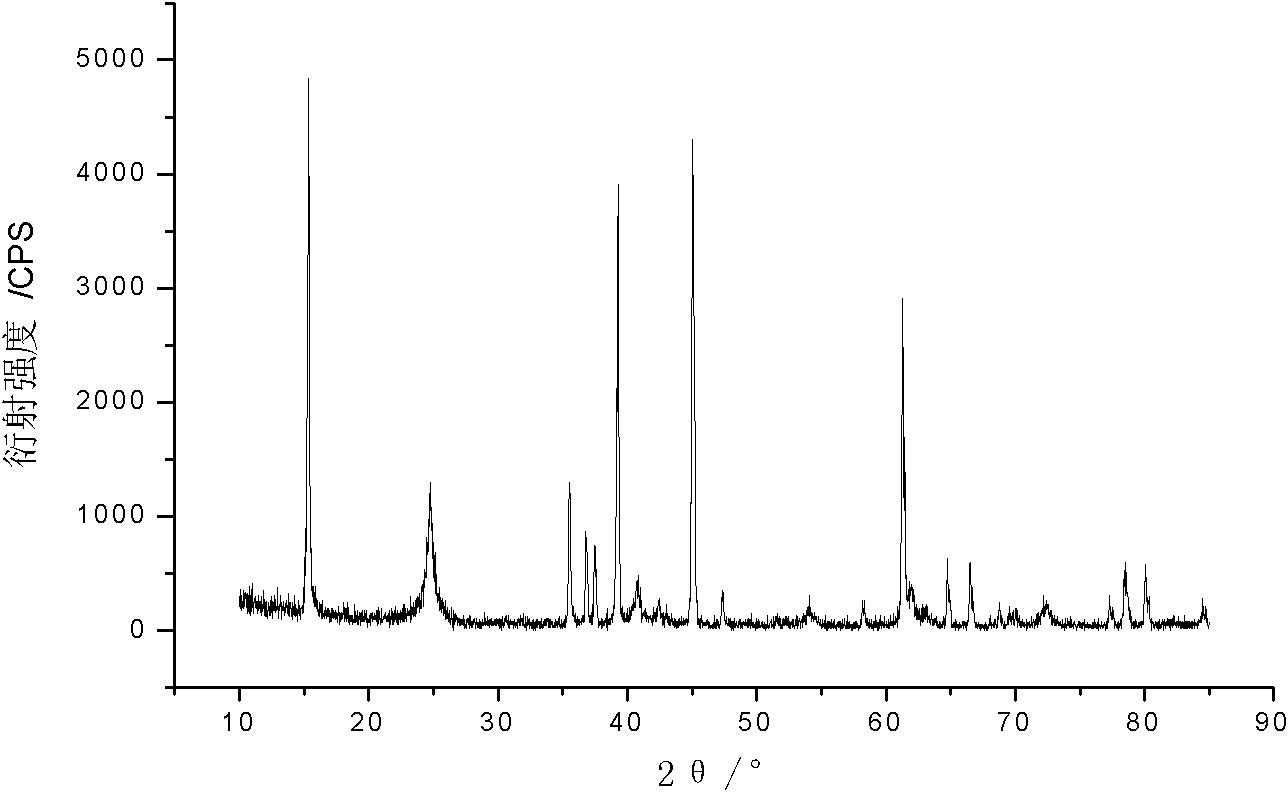

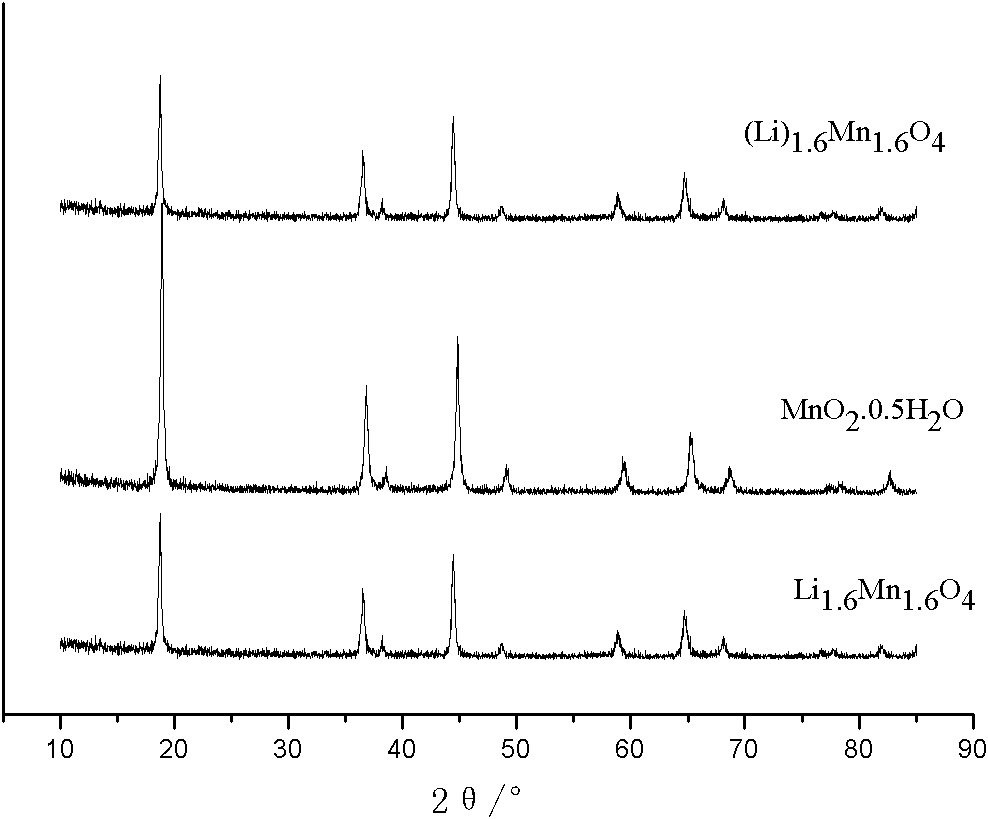

Manganese series lithium ion sieve adsorbent and preparation method of precursor thereof

ActiveCN101961634ALow priceThe ratio is easy to controlOther chemical processesManganese oxides/hydroxidesSorbentManganese

The invention discloses a method for preparing a manganese series lithium ion sieve adsorbent, and relates to a method for preparing an inorganic adsorbent for adsorbing lithium from liquid lithium resources such as brine of salt lake, seawater and the like. In the method, a cubic crystal ion sieve precursor Li1.6Mn1.6O4 is prepared from Mn2O3 and LiOH or Li2CO3 serving as raw materials by using two sections of solid-phase reactions, wherein the precursor also can be used as an anode material of a lithium ion battery. The precursor is acidized to obtain a lithium ion sieve adsorbent MnO2.0.5H2O (or expressed as H1.6Mn1.6O4), and the ion sieve is the lithium adsorbent which has high selectivity on lithium. The method has the advantages of simple and readily available raw materials, simple process, high adsorption capacity of the ion sieve, low cost, high purity of products and is easy to realize industrial production.

Owner:CENT SOUTH UNIV +1

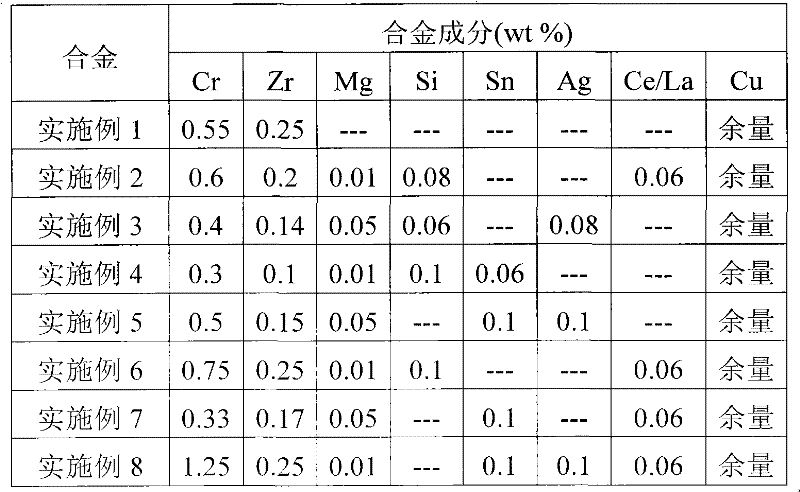

CuCrZr alloy with high strength and high conductivity, and preparation and processing method thereof

The invention relates to a CuCrZr alloy with high strength and high conductivity, and a preparation and processing method thereof. The alloy comprises the basic ingredients in percentage by mass: 0.3 percent to 1.4 percent of Cr, 0.02 percent to 0.25 percent of Zr and the balance Cu, wherein the ingredients in the CuCrZr alloy are needed to meet the following requirements: (a) Cr / Zr is less than or equal to 5 and is greater than or equal to 1.9; and (b) Cr+Zr is less than or equal to 1.5 percent and is greater than or equal to 0.4 percent. The preparation and processing method comprises the following steps of: a, compounding, feeding, smelting and casting according to mass percent; b, surface milling; c, hot rolling; d, solution treatment; e, primary cold rolling; f, primary aging; g, secondary cold rolling; and h, secondary aging. The CuCrZr alloy has the tensile strength sigma b being 600-700 MPa, the plasticity elongation rate delta being 4-10 percent, and the conductivity being greater than 80 percent of IACS (International Annealed Copper Standard), can be widely applied to occasions with high strength and high conductivity for preparing resistance welding electrodes, liners of crystallizers of continuous casting machines, integrated circuit lead frame and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

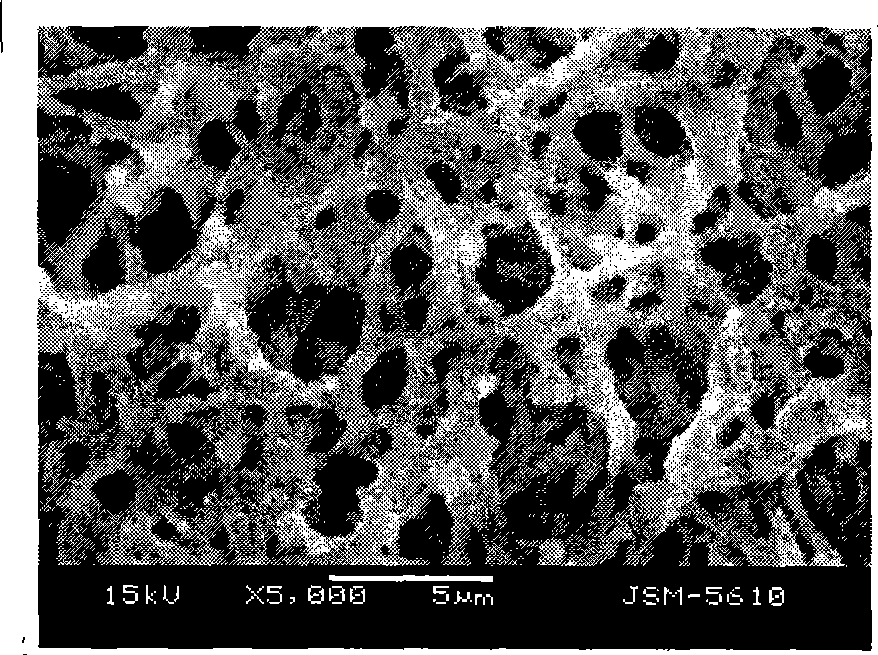

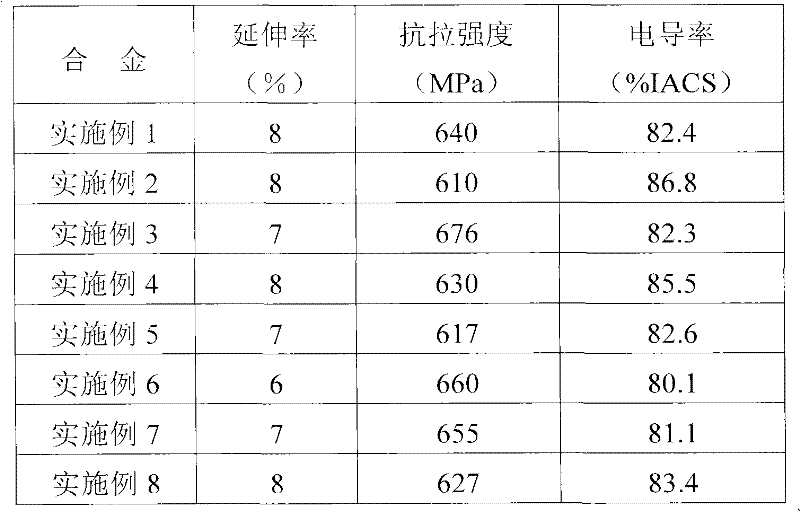

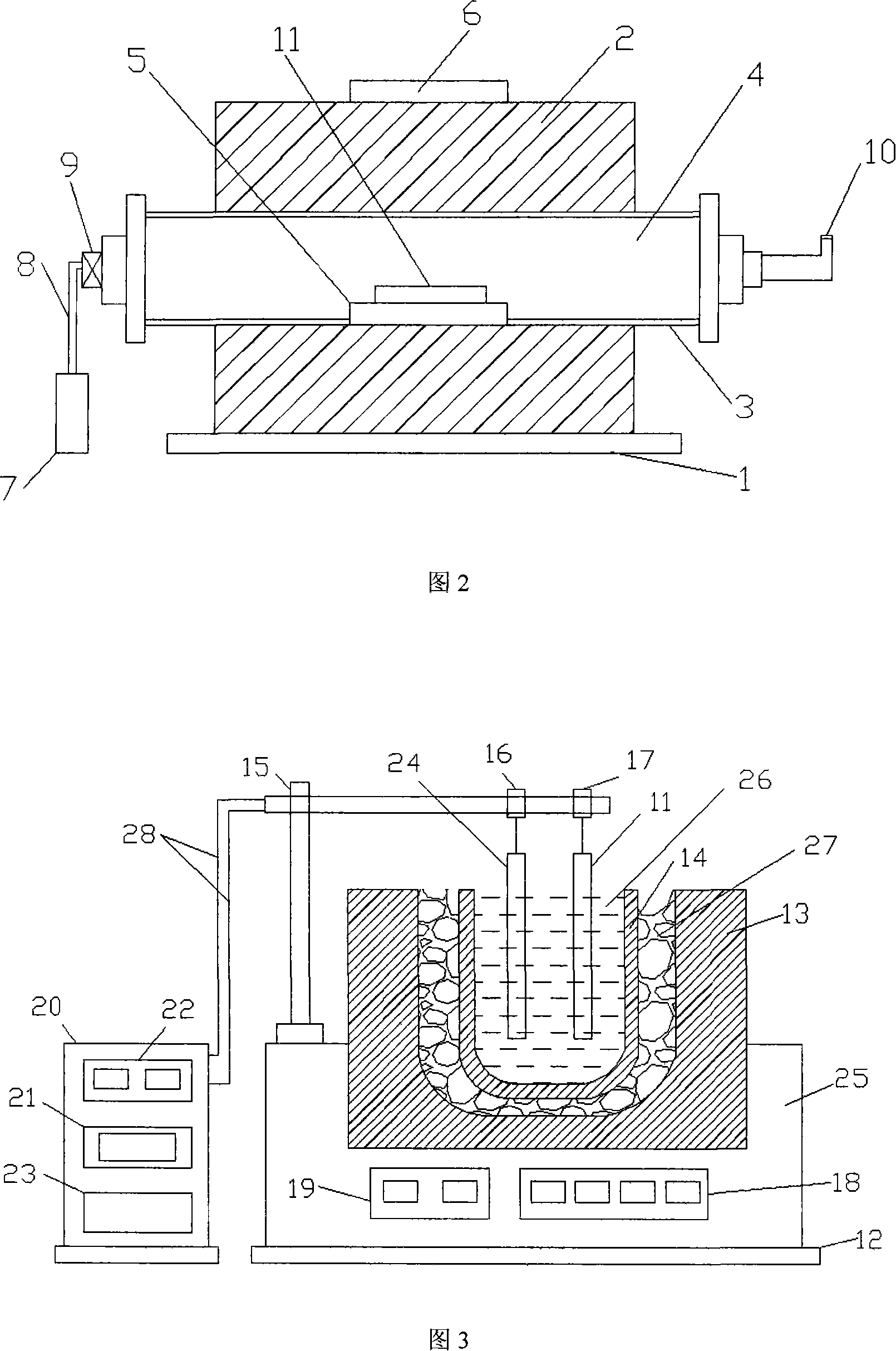

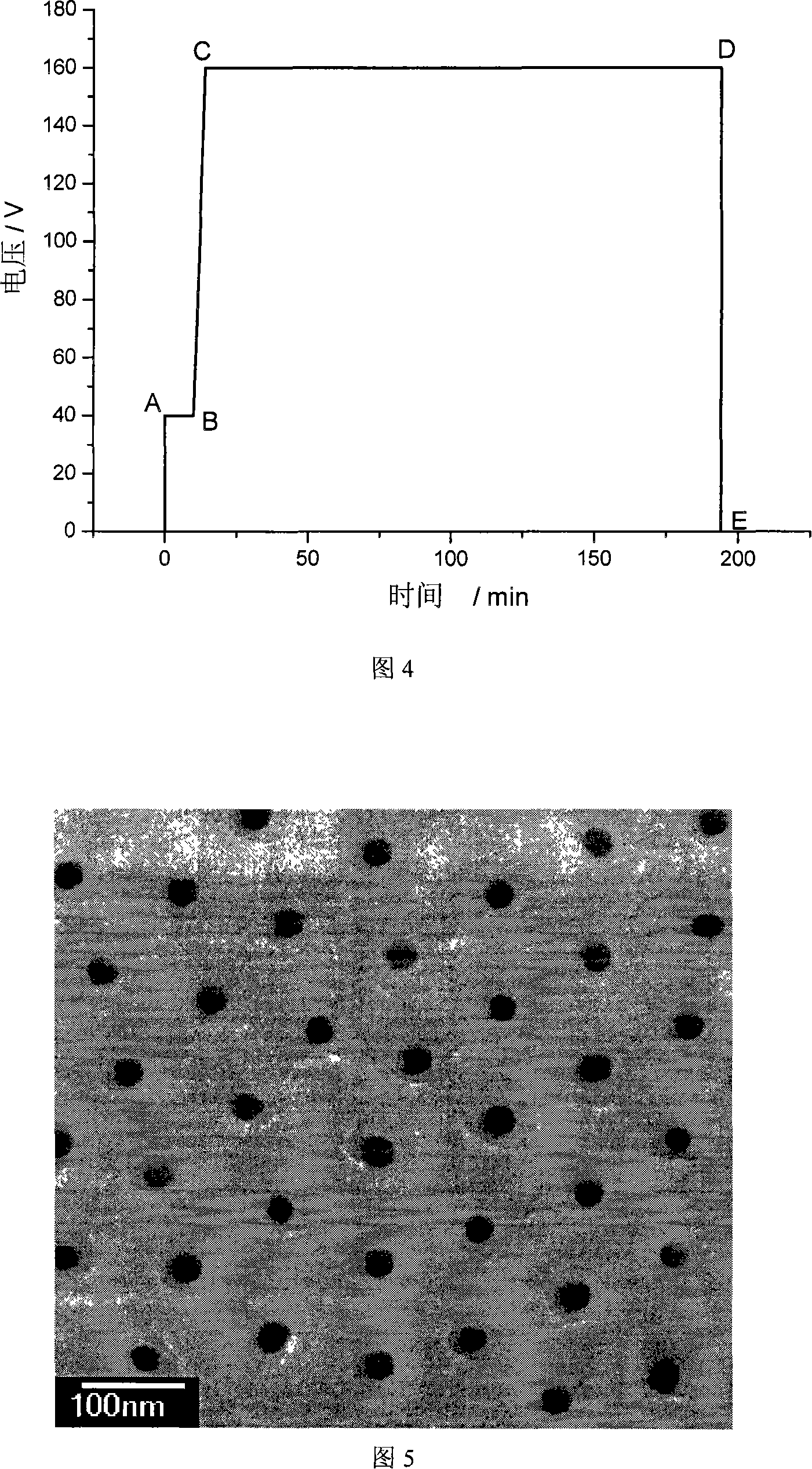

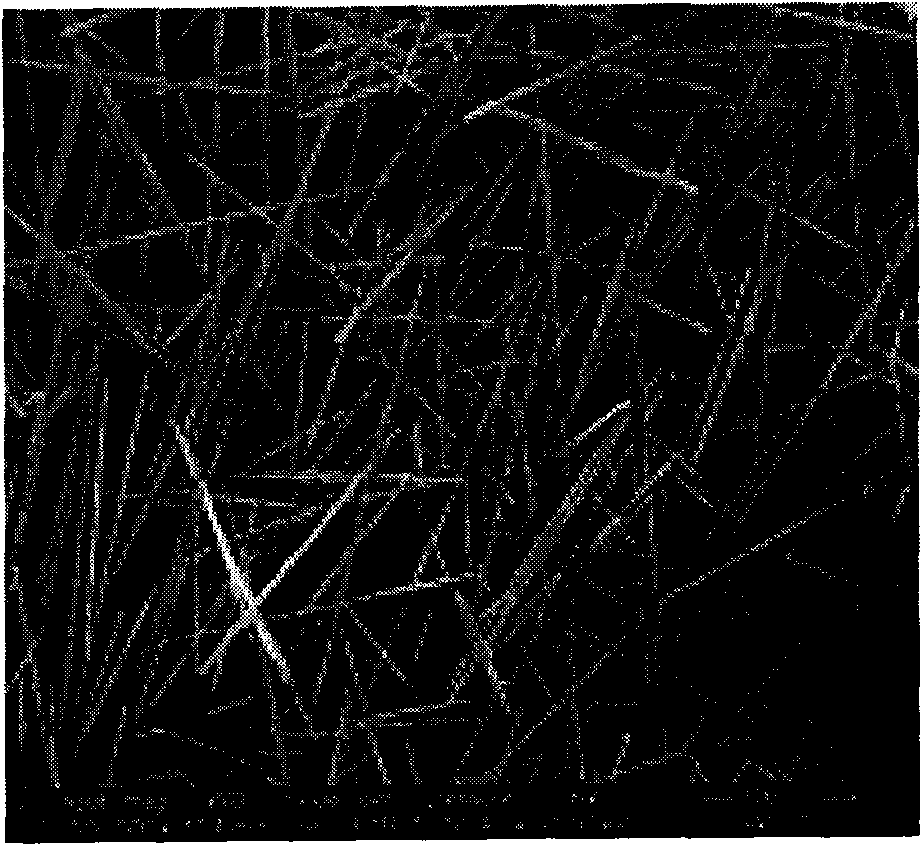

Strong anodic oxidation method for preparing porous pellumina

InactiveCN101139730AReduce pollutionRich sourcesSurface reaction electrolytic coatingShielding gasPhosphoric acid

The invention relates to an intensive anodic oxidation process to prepare porous anodic alumina film. An aluminum sheet is as an anode; a platinum sheet as a cathode; argon as shielded gas; mixed solution of perchloric acid with absolute alcohol as electrochemical polishing compound for the aluminum sheet; mixed solution of oxalic acid, absolute alcohol and deionized water as electrolyte; and mixed solution of phosphoric acid, chromic acid and deionized water as alumina film corrodent. Through aluminum sheet annealing, purging, electrochemical polishing, mild anodic oxidation, corrosion on aluminum sheet oxide film, intensive anodic oxidation and stripping oxide film, and finally, pale yellow, high purity and ordered porous-structured nanometer-leveled alumina film is achieved; The alumina film pore is in circular shape sized in 30 to 35nm, pore distance in 80 to100nm and pore depth in 162.4 micrometers; growth rate of the alumina film is 54 micrometers / h, which is 27 times higher than 2 micrometers / h of growth rate of anodic oxidation aluminum film prepared through mild anodic oxidation process.

Owner:TAIYUAN UNIV OF TECH

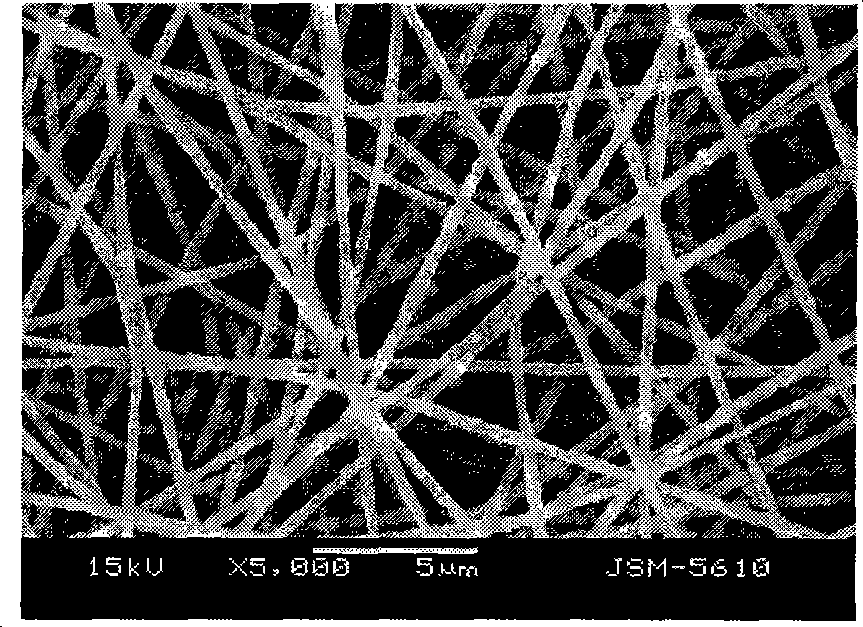

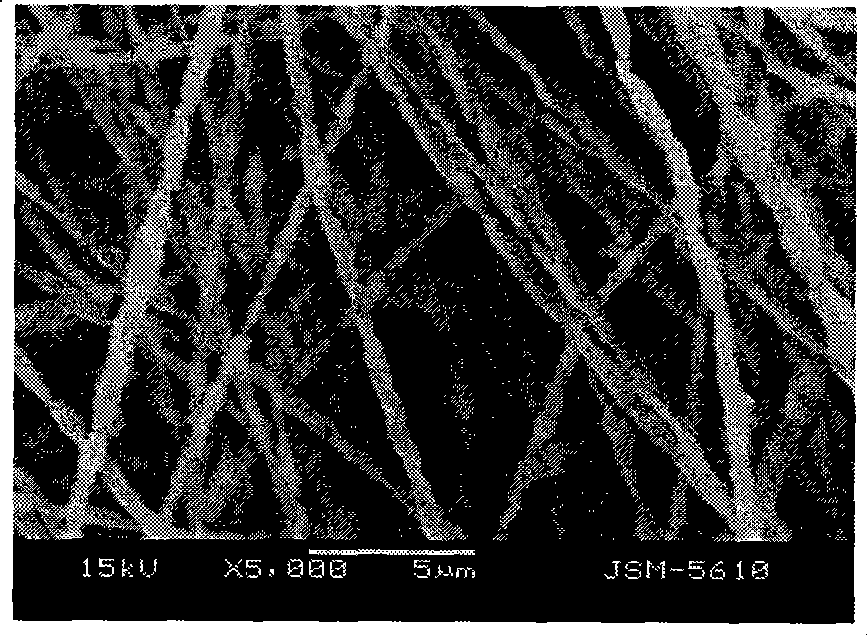

CaSO* crystal whisker with desulfurized gypsum as raw material and preparing method

InactiveCN101550602AReduce pollutionShort processPolycrystalline material growthFrom solid stateWhiskersCalcium sulphate crystals

The present invention relates to a CaSO4 crystal whisker with desulfurized gypsum as raw material and a preparing method. A technical scheme includes: mixing desulfurized gypsum, water and habit modifier fully for forming suspension; wherein, mass concentration of desulfurized gypsum is 1-8%, mass concentration of habit modifier is 5-20%; or stirring the above suspension 1-3 hours under conditions of normal pressure, 100-128 deg c and 120-210 r / min stirring speed, adding calcium sulphate crystal whisker by weight of 0.5-1% as inoculating crystal, reacting 1-3 hours, adding modifying agent, or stirring the above suspension 3-8 hours, adding the modifying agent directly; or stirring the above suspension 3-8 hours, and adding the modifying agent directly, the amount of the modifying agent is 0.4-1% of the suspension weight, stirring 0.5-1 hours; then pump filtering, washing and three-section drying for obtaining three various type calcium sulphate crystal whisker. The method uses a normal pressure salt solution crystallization method for preparing CaSO4 crystal whisker which has short process flow, geniality condition and low cost, and is an efficient purpose for realizing resource utilizing.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing polyester filament capable being dyed by continuous condensed direct-spinning cation dye

InactiveCN101070642AReasonable workmanshipShort processMelt spinning methodsMonocomponent polyesters artificial filamentFiberEther

A method for making a continuous polycondensation direct spinning cationic dye and tinctable polyester filament, it pertains to chemical art. Refining terephthalic acid and Glycol Monomer are raw materials, also including the preparation continuous polycondensation cationic dye and can-be-stained polyester and direct spinning dye tinctable polyester filament. In the present continuous polyester device, first beat the refining terephthalic acid and Glycol, then add Benzene PTA acid Glycol ester-5-Sodium and Ether-agent and stabilizer to get cationic dye tinctable polycondensation melt, then through pipeline, after measure, extrude, draw, wind to obtain cationic dye tinctable polyester pre-orientation silk or cationic dye can-be-stained polyester all-orientation silk. The invention has a short and less process, reasonable art. The quality of product is stable. And the fiber gained has high intensity, small deviation, and is dyed well-distributed, and has a better spinning quality. It can decrease production cost.

Owner:ZHEJIANG CHEM FIBER UNITED GROUP

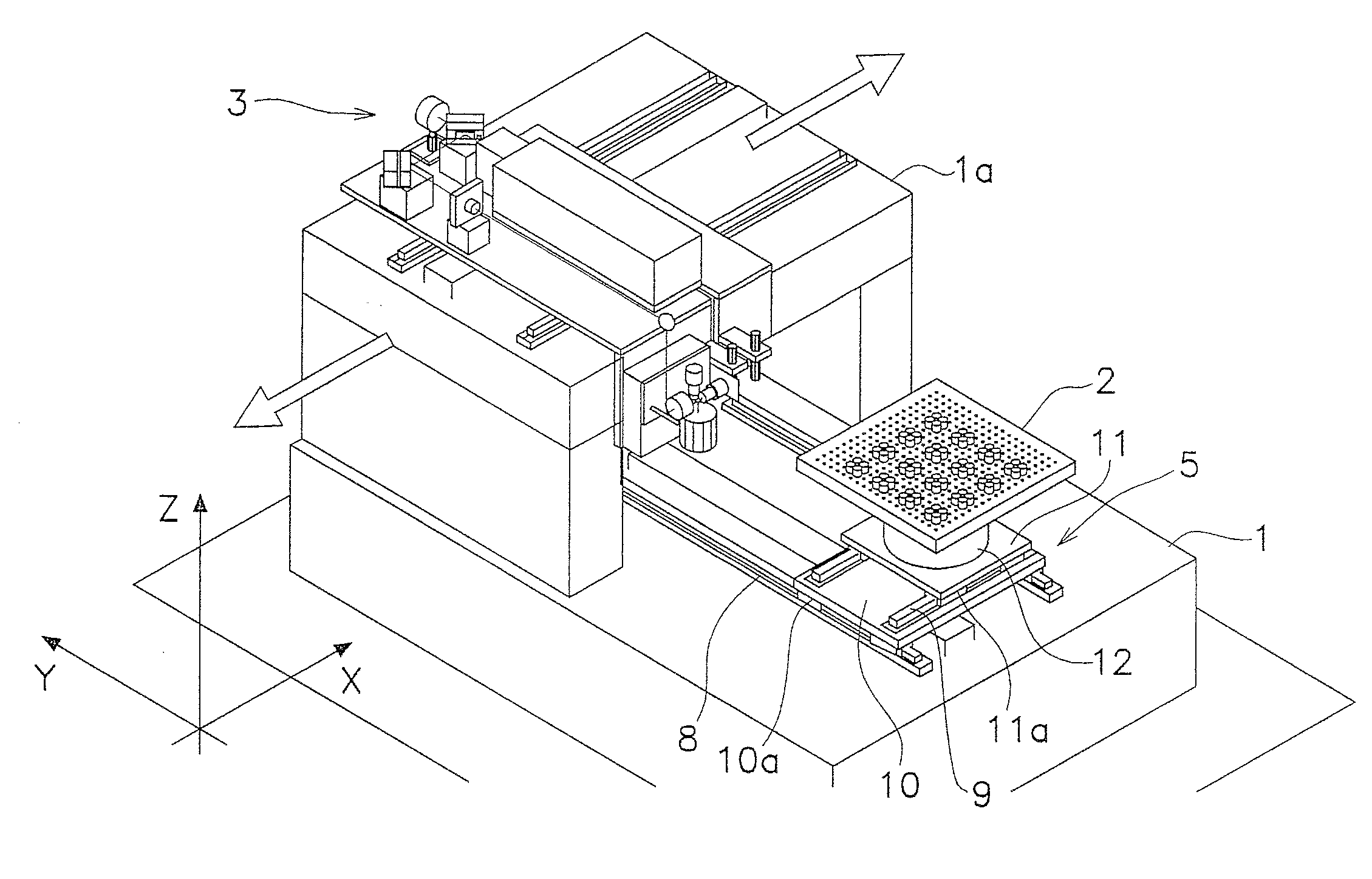

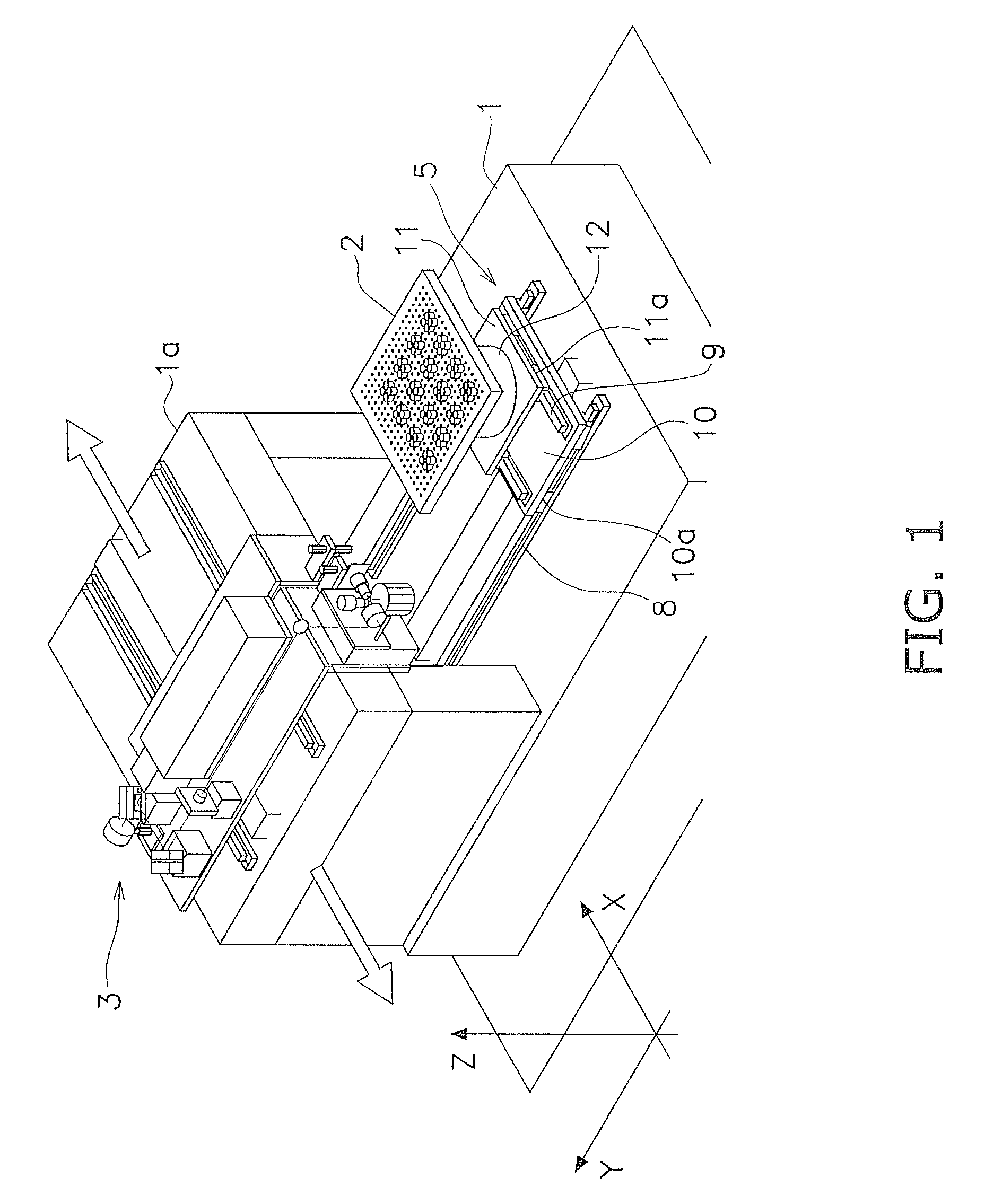

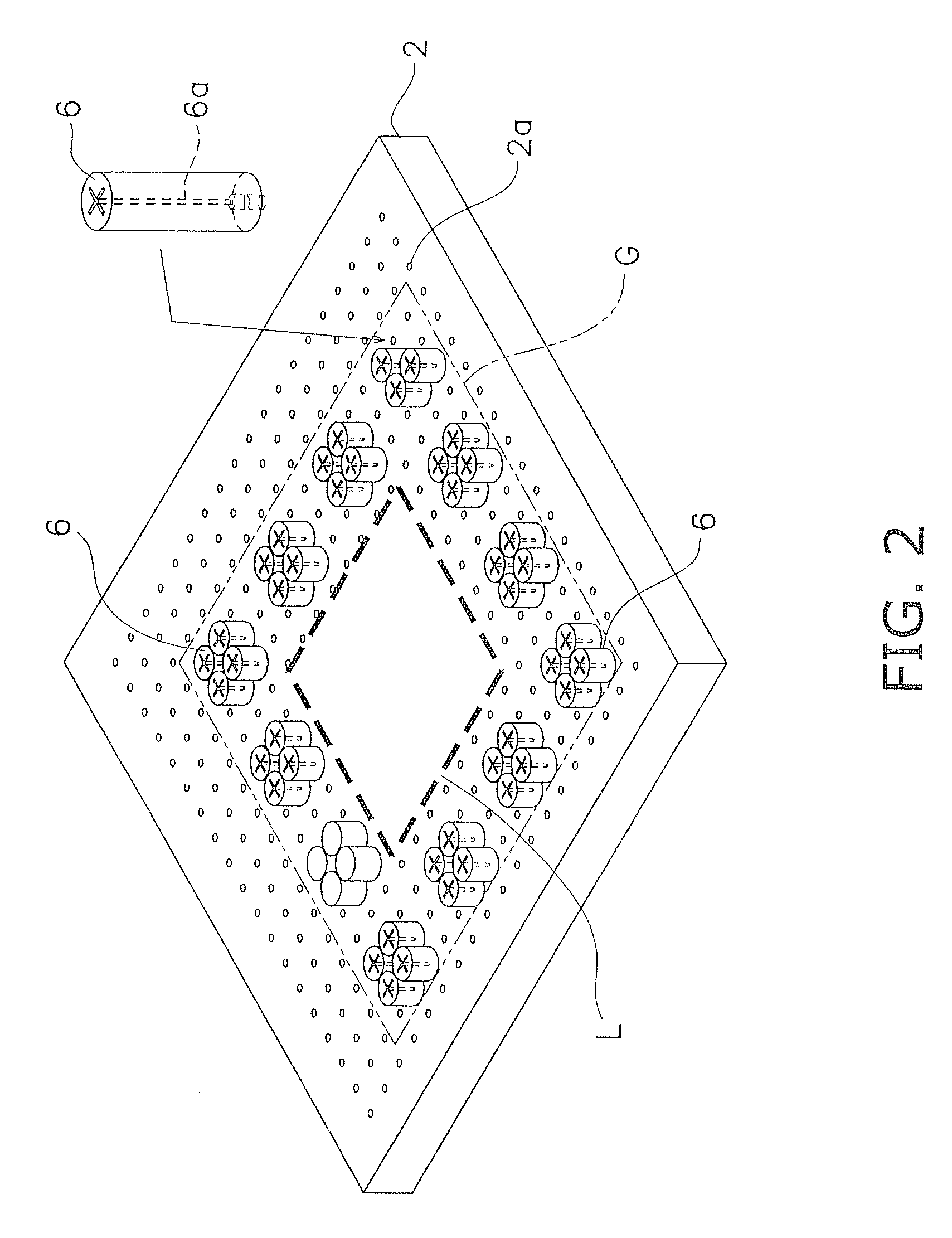

Glass substrate processing device using laser beam

ActiveUS20100326138A1Low costShort timeGlass reforming apparatusGlass severing apparatusLight beamComputational physics

A processing device is configured to irradiate a laser beam onto a glass substrate for processing. The processing device has a work table, a laser beam output section, a multi-spot focus section, a rotation drive mechanism, an optical system, and a laser beam scan section. The multi-spot focus section receives a laser beam, and splits and focuses the laser beam inputted therein into a plurality of beam focus spots. The rotation drive mechanism rotates the plurality of beam focus spots about a single center axis that is arranged in a center of the plurality of beam focus spots. The optical system guides the laser beam to the multi-spot focus section. The laser beam scan section moves all the plurality of beam focus spots rotating about the single center axis in a desired direction within a predetermined range of a plane arranged along a surface of the glass substrate.

Owner:MITSUBOSHI DIAMOND IND CO LTD

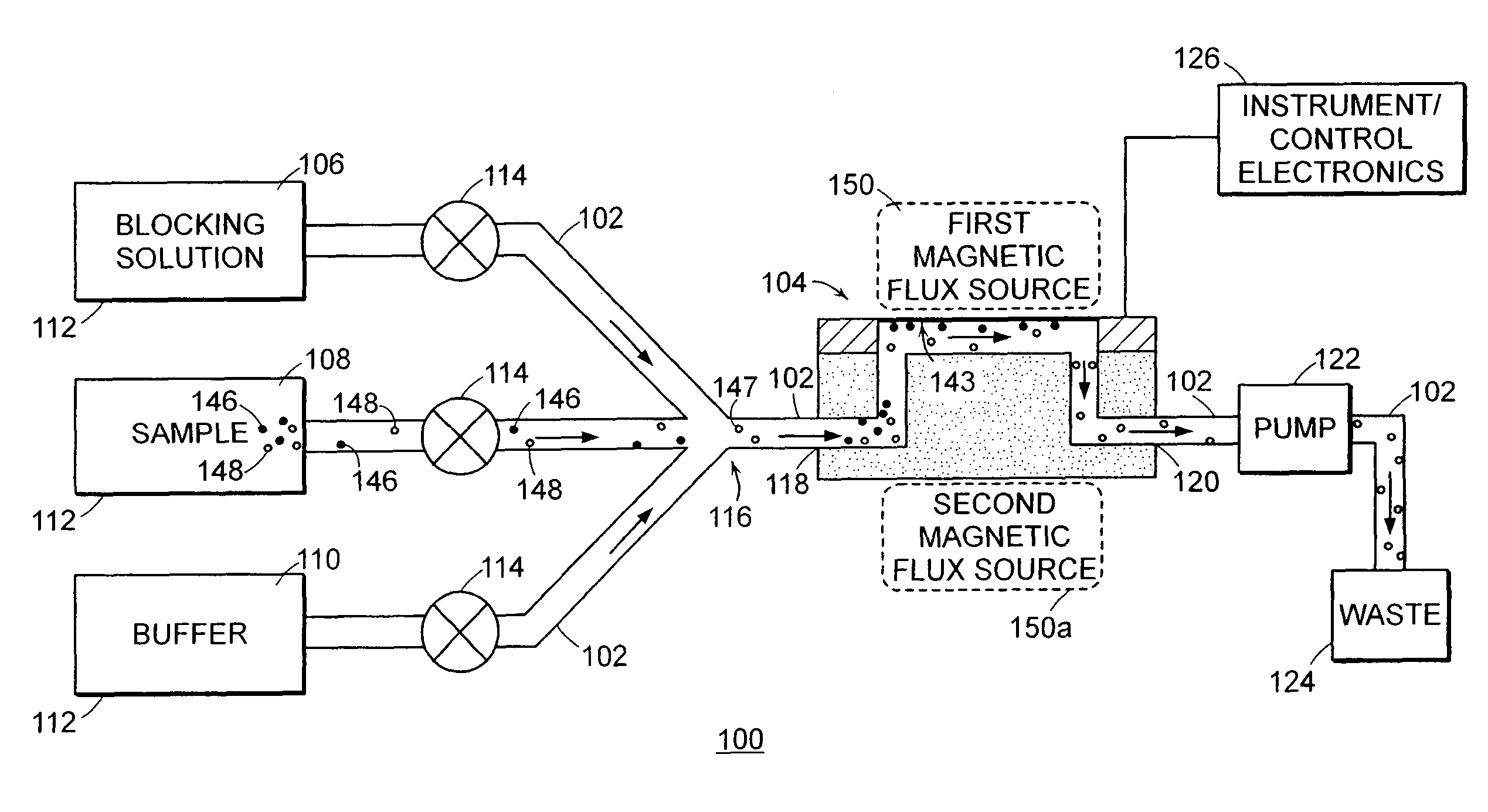

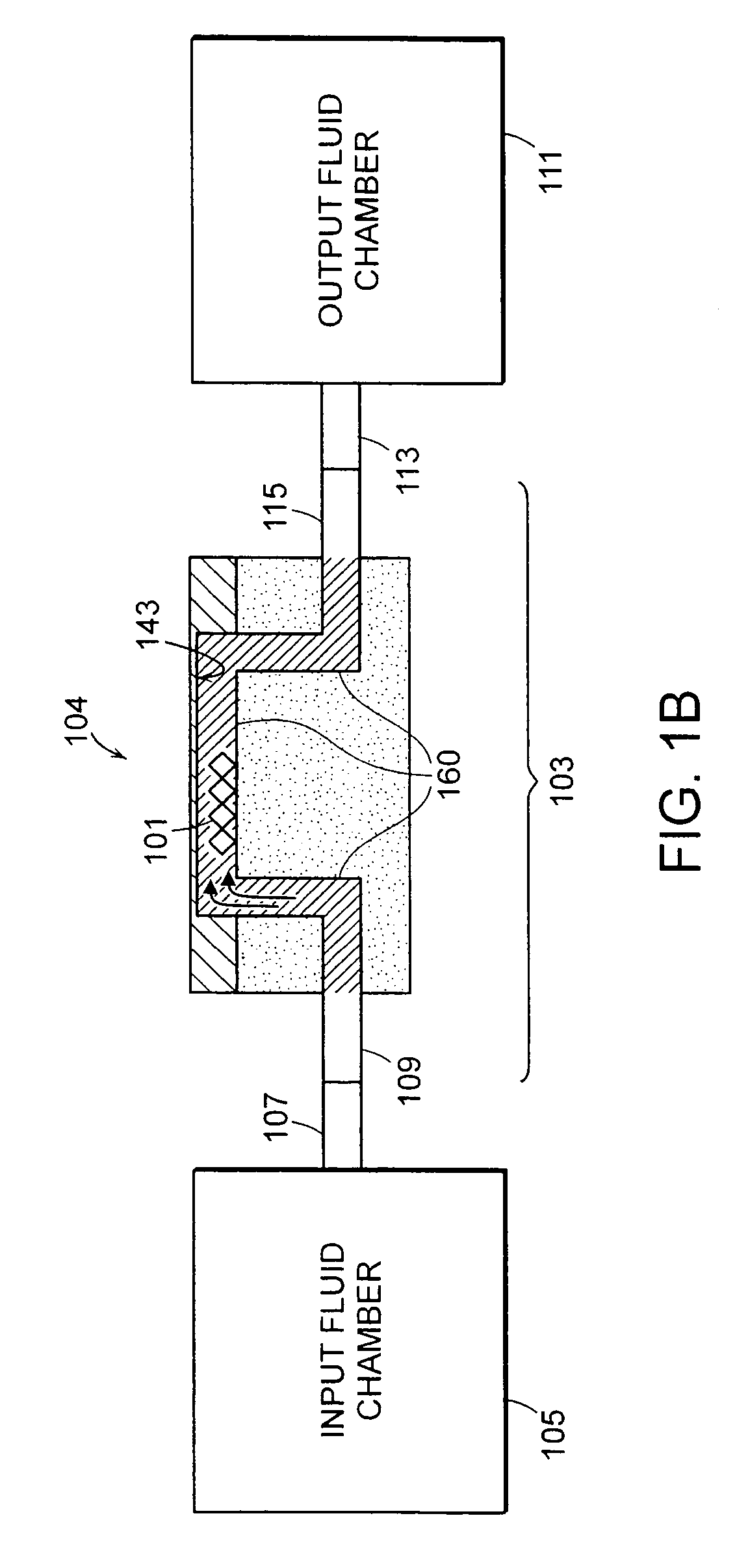

Method and apparatus for analyzing bioprocess fluids

InactiveUS7749445B2High fractional captureLarge gradientMaterial nanotechnologyBioreactor/fermenter combinationsAnalyteResonant sensor

Methods and apparatus for analyzing bioprocess fluids are provided. A plurality of particles coated with a plurality of capture agents having an affinity for one or more biological markers is combined with bioprocess fluid to form a plurality of analyte-particle complexes. The system also includes a transport arrangement for transporting the sample to a sensor surface, and optionally a magnetic field inducing structure constructed and arranged to establish a magnetic field at and adjacent to the sensor surface. The resonant sensor produces a signal corresponding to an amount of analyte-particle complexes that are bound to the sensor surface.

Owner:BIOSCALE

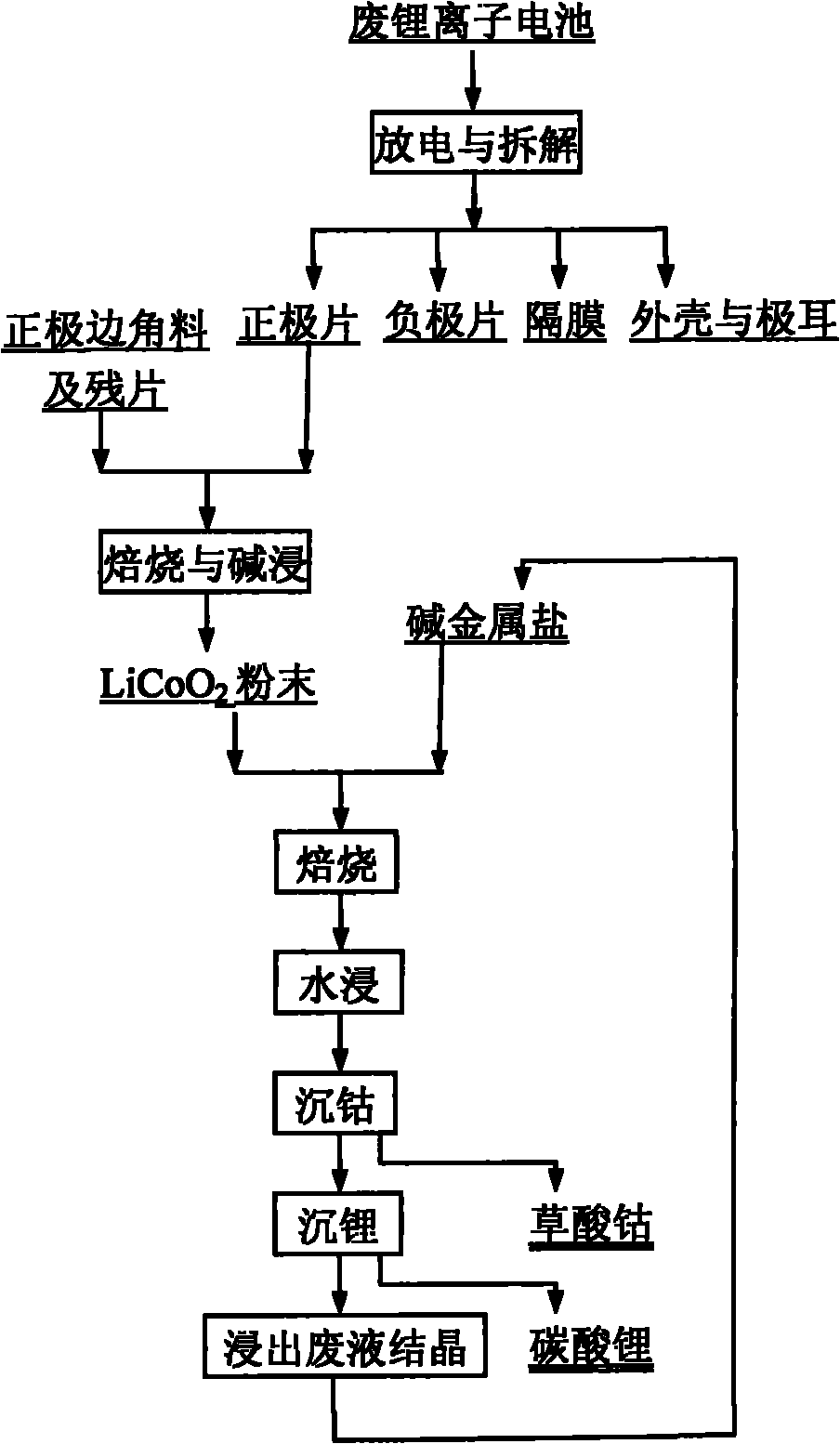

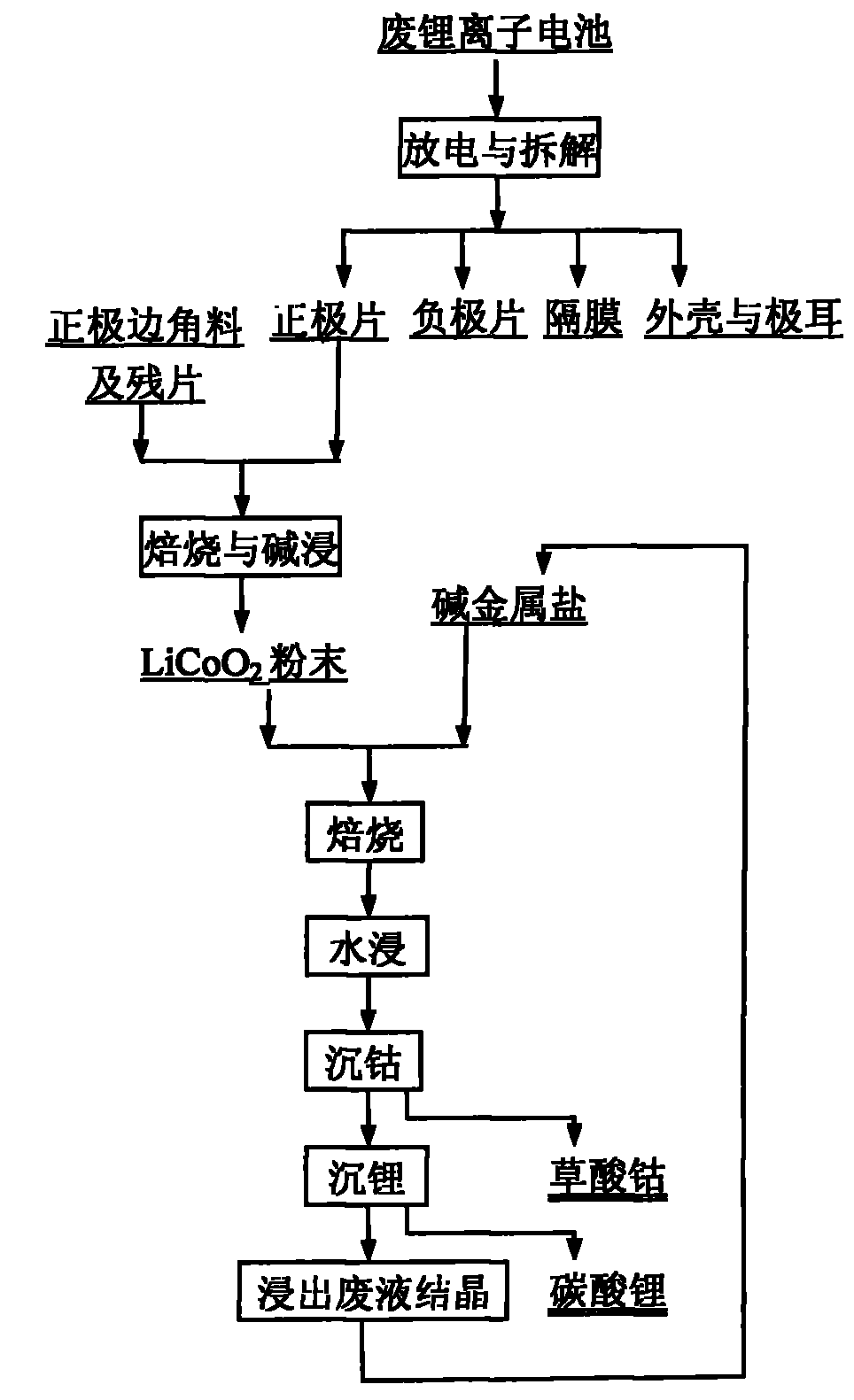

Method for recovering cobalt and lithium from waste lithium ion batteries

The invention relates to a method for recovering cobalt and lithium from waste lithium ion batteries, which aims to prevent metals in waste lithium ion batteries from generating secondary waste gas pollution to the environment and lower the requirement on anticorrosion of equipment in the leaching process. The method comprises the following steps of: firstly, discharging and disassembling waste lithium ion batteries; carrying out alkali leaching and filtering treatment on waste positive plates to obtain LiCoO2 powder; fully mixing the LiCoO2 powder and the salts of alkali metals (sodium and potassium) in the mass ratio of 1:3-9, and then, roasting the mixture for 0.2-3 hours at the temperature of 500 DEG C-750 DEG C; leaching the roasted products with water for 5-30 minutes at the temperature of 40 DEG C-70 DEG C; depositing cobalt and lithium in the leaching solution to obtain cobalt oxalate and lithium carbonate; and adjusting components of the leaching waste solution with sulfuric acid, and carrying out crystallization treatment to obtain sodium bisulfate and potassium bisulfate, wherein the sodium bisulfate and the potassium bisulfate can be recycled in the roasting process.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

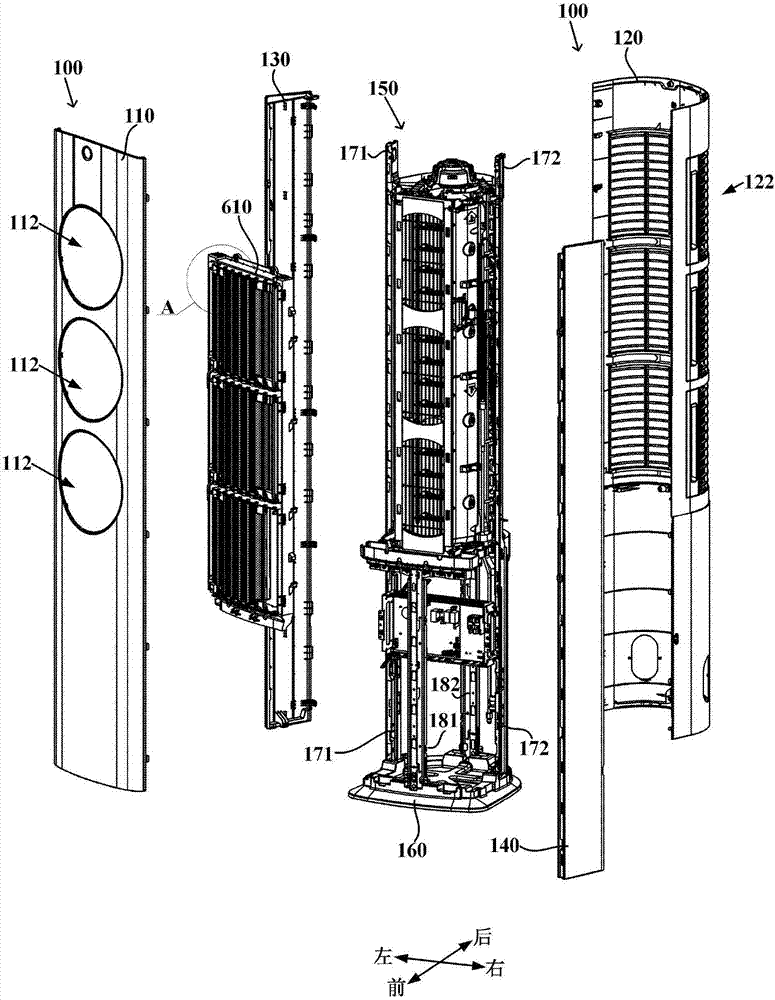

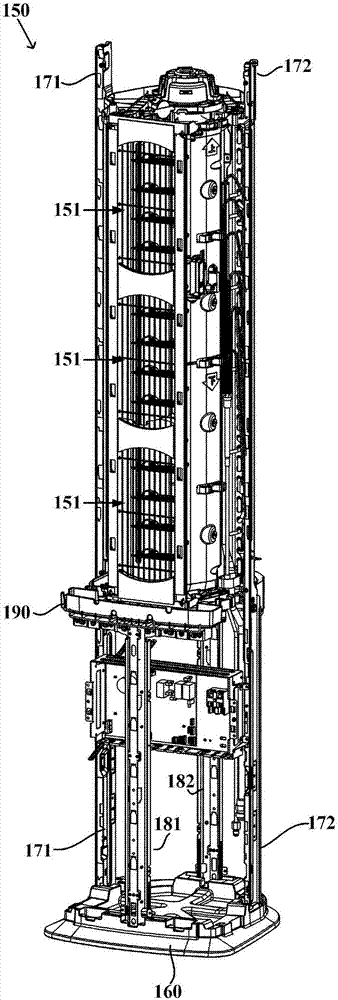

Indoor unit of vertical air conditioner

ActiveCN107289516AImprove energy efficiencyShort processDucting arrangementsLighting and heating apparatusEngineeringHeat exchanger

The invention provides an indoor unit of a vertical air conditioner. The indoor unit comprises a machine shell, a heat exchanger, a first cross flow fan and a second cross flow fan; the heat exchange is arranged in the machine shell; the first cross flow fan and the second cross flow fan are arranged up and down in the machine shell, vertically extend along an axis and are arranged collinearly; the machine shell comprises a framework, a bottom plate, a front upright post, a rear upright post, a left upright post, a right upright post and a shell; the framework is used for mounting the heat exchanger, the first cross flow fan and the second cross flow fan; the bottom plate is arranged below the framework and is used for supporting the indoor unit of the vertical air conditioner; the front upright post and the rear upright post respectively extends upwards from the front and rear sides of the bottom plate to the bottom end of the framework to support the framework; the left upright post and the right upright post respectively extend upwards from the left and right sides of the bottom plate to the top end of the framework to fix the framework; and the shell surrounds the outer side of the framework, the lower end of the shell extends to the edge of the bottom plate, a plurality of air outlets are formed in the front side of the shell, and an air inlet is formed in the rear side of the shell. The indoor unit of the vertical air conditioner, provided by the invention, is relatively low in fan air pressure loss and capable of saving more energy during operation and has various air supply modes, so that the user experience is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

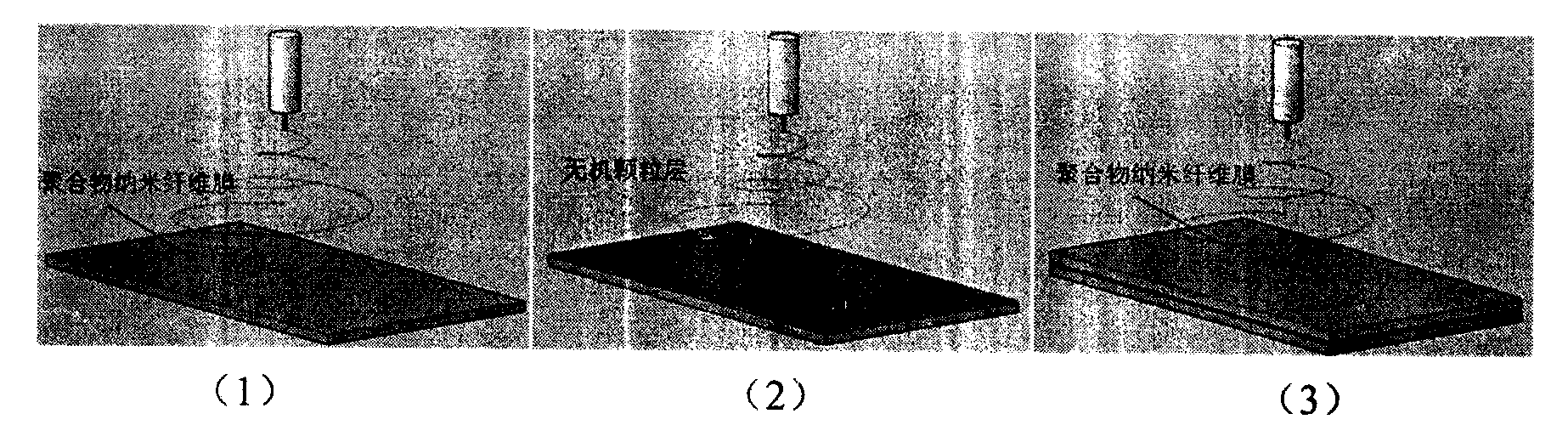

Method for preparing composite lithium-ion battery separator through electrostatic spinning/electrostatic spraying

InactiveCN103474610AExcellent heat shrinkage resistanceIncrease fluid retentionCell component detailsNon-woven fabricsFiberOrganic solvent

The invention relates to the field of lithium-ion batteries, in particular to a method for preparing a composite lithium-ion battery separator through electrostatic spinning / electrostatic spraying. The method specifically includes the steps of firstly, adding high molecular polymer into an organic solvent, dissolving the high molecular polymer through mechanical stirring to form a transparent solution, and obtaining an electrostatic spinning solution; secondly, mixing inorganic nanometer particles with the high molecular polymer and adding the mixture into the organic solvent, and conducting mechanical stirring to obtain inorganic nanometer particle suspension liquid; thirdly, conducting electrostatic spinning on the spinning solution prepared in the first step to prepare a lower layer nanometer fiber film, and enabling the inorganic nanometer particle suspension liquid prepared in the second step to be deposited on the lower layer nanometer fiber film through electrostatic spraying to obtain an interlayer; finally, receiving an electrostatic spun nanometer fiber layer on an inorganic particle layer to obtain the composite lithium-ion battery separator. The composite lithium-ion battery separator has the high imbibing rate and good electrochemical stability under the room temperature and has good heat shrinkage resistance performance at the same time.

Owner:TIANJIN POLYTECHNIC UNIV

Safe and environment-friendly method for protecting storage tanks

InactiveCN104370000AShort processReduce dosageLarge containersEnvironmental resistancePositive pressure

The invention relates to a safe and environment-friendly method for protecting storage tanks to mainly solve the problems that in the prior art, the gas consumption of nitrogen protection is excessively large, cost is high, and sulfur-containing gas and other peculiar smell gas are hard to treat. According to the safe and environment-friendly method for protecting the storage tanks, the gas produced by liquid in the storage tanks enters a compressor (18) through a main gas pipe (19) and an inflation pipe (21), the gas is pressurized by the compressor (18) and stored in a buffering tank (5) to serve as one part of positive-pressure protection gas, when the gas stored in the buffering tank (5) cannot meet the positive-pressure protection of all storage tanks, the nitrogen from a nitrogen inlet pipeline (22) is used for performing supplementation, and when the pressure stored in the buffering tank (5) exceeds the designed pressure, the residual gas is sent to a torch or combustion furnace through a torch or combustion furnace leading pipeline (22), the problems are well solved through the technical scheme, and the method can be used in storage tank protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano carbon doped electrocatalyst for fuel cell, and application of nano carbon doped electrocatalyst

InactiveCN103050714AChange the microstructureChange Edge Face DefectsPhysical/chemical process catalystsCell electrodesMicrowave radiometryHigh heat

The invention relates to a nano carbon doped electrocatalyst for a fuel cell, and application of the nano carbon doped electrocatalyst. The electrocatalyst is prepared by adopting the steps of: complexing a nitrogen-containing and / or boron-containing organic precursor and a transition metal salt to form a composite; adding nano carbon as a carrier, and heating and reacting a mixture by adopting a microwave radiation method; and after the reaction is complete, filtering and drying, placing a product obtained after the reaction in an inert atmosphere and / or reducing atmosphere, and treating at a high temperature of 500-1500 DEG C to obtain the nano carbon doped electrocatalyst. The nano carbon doped electrocatalyst is very low in cost, high in activity and stability and excellent in anti-poisoning capacity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com