Safe and environment-friendly method for protecting storage tanks

A safe, environmentally friendly, storage tank technology, applied in containers, packaging, transportation and packaging, etc., can solve the problems of high cost, large amount of nitrogen protection gas, and difficult to deal with odorous gases such as sulfur, so as to reduce production costs and reduce gas. Treatment process, the effect of reducing nitrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

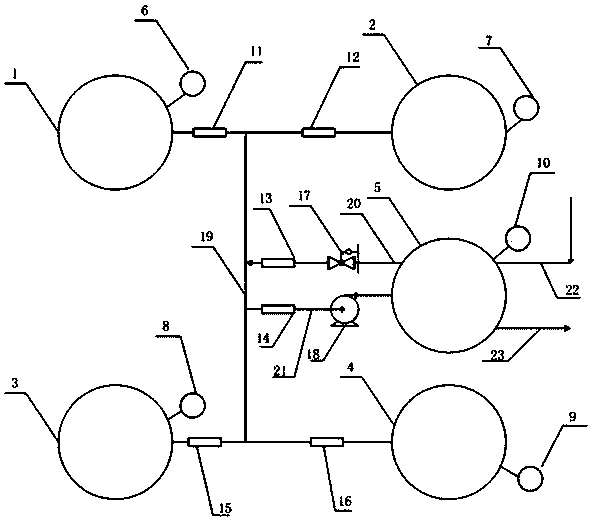

[0016] The purpose of the present invention is to protect the safety of the storage tank by using the sulfur-containing gas produced by the liquid itself in the storage tank and part of the external nitrogen, and send the excess gas to the torch or incinerator for treatment, so as to protect the safety and environmental protection of the storage tank.

[0017] The schematic flow diagram of the present invention is as figure 1 As shown, it includes four storage tanks (1, 2, 3, 4), a gas buffer tank (5), pressure gauges (6, 7, 8, 9, 10) on each tank, and resistors on each gas phase pipeline. Firearms (11, 12, 13, 14, 15, 16), pressure relief valve (17), compressor (18), gas main pipe (19).

[0018] The four storage tanks (1, 2, 3, 4) and the buffer tank (5) are connected by gas phase pipelines to form a gas main pipe (19), and the gas charging pipe (21) of the gas main pipe passes through the compressor (18) and the buffer tank (5 ), the return pipe (20) of the gas main pipe is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com