Patents

Literature

661 results about "Bisulfate salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium bisulfate, also known as sodium hydrogen sulfate, is the sodium salt of the bisulfate anion, with the molecular formula NaHSO4. Sodium bisulfate is an acid salt formed by partial neutralization of sulfuric acid by an equivalent of sodium base, typically either in the form of sodium hydroxide or sodium chloride.

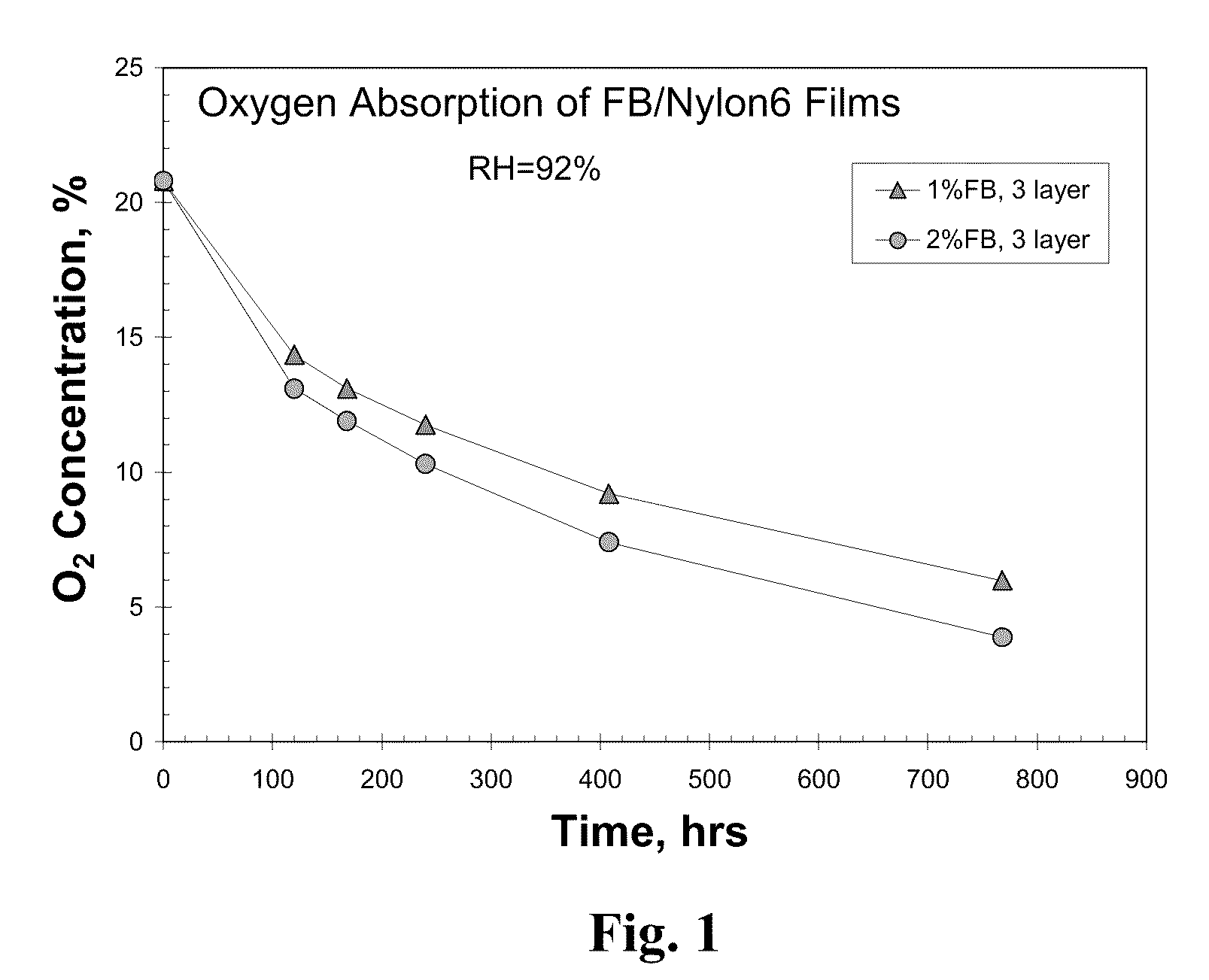

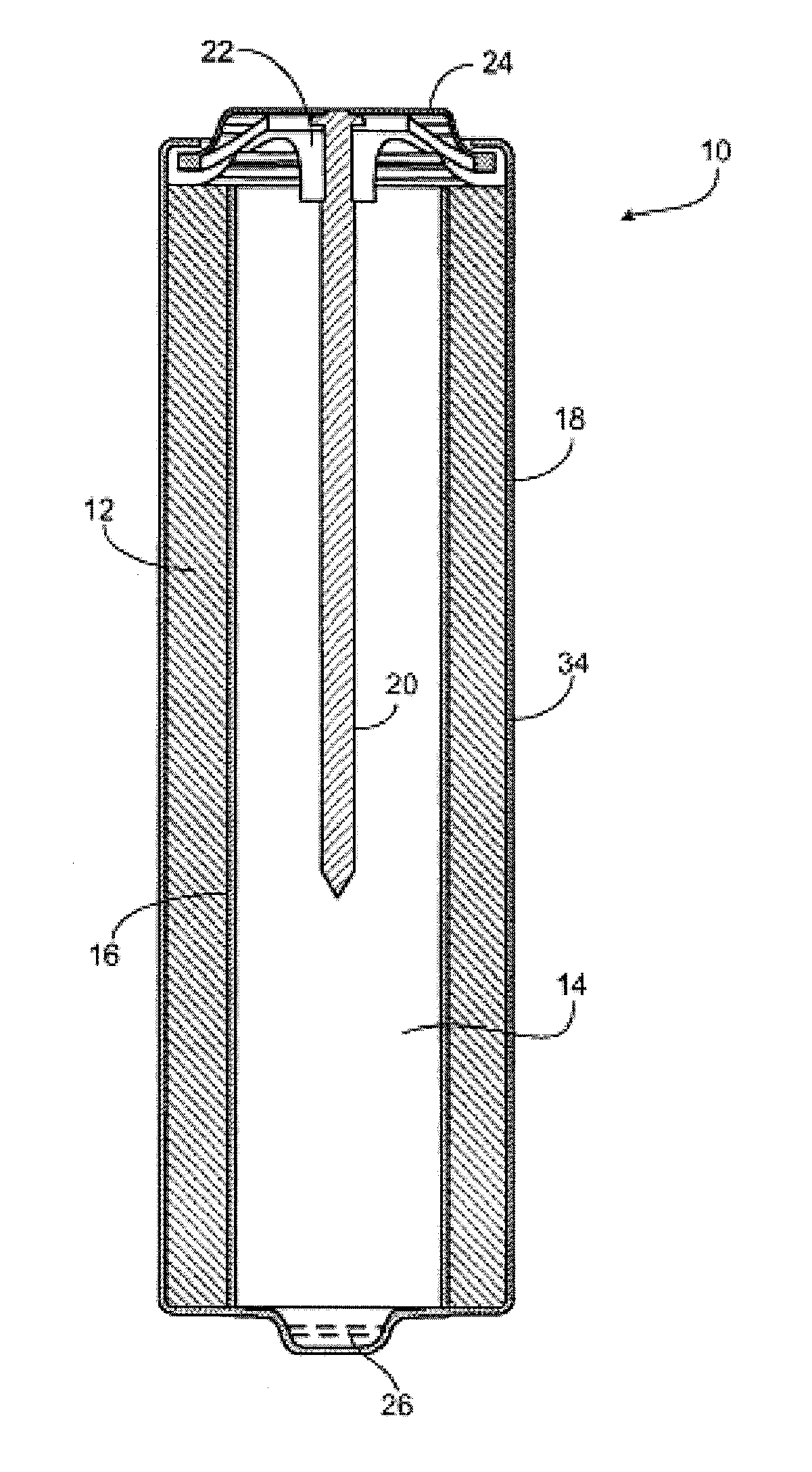

Oxygen scavenging films

InactiveUS20100255231A1Metal-working apparatusGlass/slag layered productsParticulatesAlkaline earth metal

A well dispersed oxygen scavenging particulate compounded in a polymer matrix. The oxygen scavenging formulation consists of iron powder with a mean particle sizes within 1-25 um and pre-coated with at least one or more activating and acidifying powdered compounds, usually in the form of solid organic and inorganic salts of alkaline and alkaline earth metals such as sodium chloride and sodium bisulfate. The pre-coated iron particulate is dispersed into a polymer resin by using a conventional melt processing method such as twin-screw extrusion. The oxygen scavenging compound is mixed with polymer pellets in the solid state prior to melting. The polymer resin pellets and the coated iron powder are preferably treated with a surfactant in the dry state to help dispersing the iron / salt powder with the resin pellets. The melt extruded compounds are pelletized and kept in the dry state to prevent premature activation.

Owner:MULTISORB TECH INC

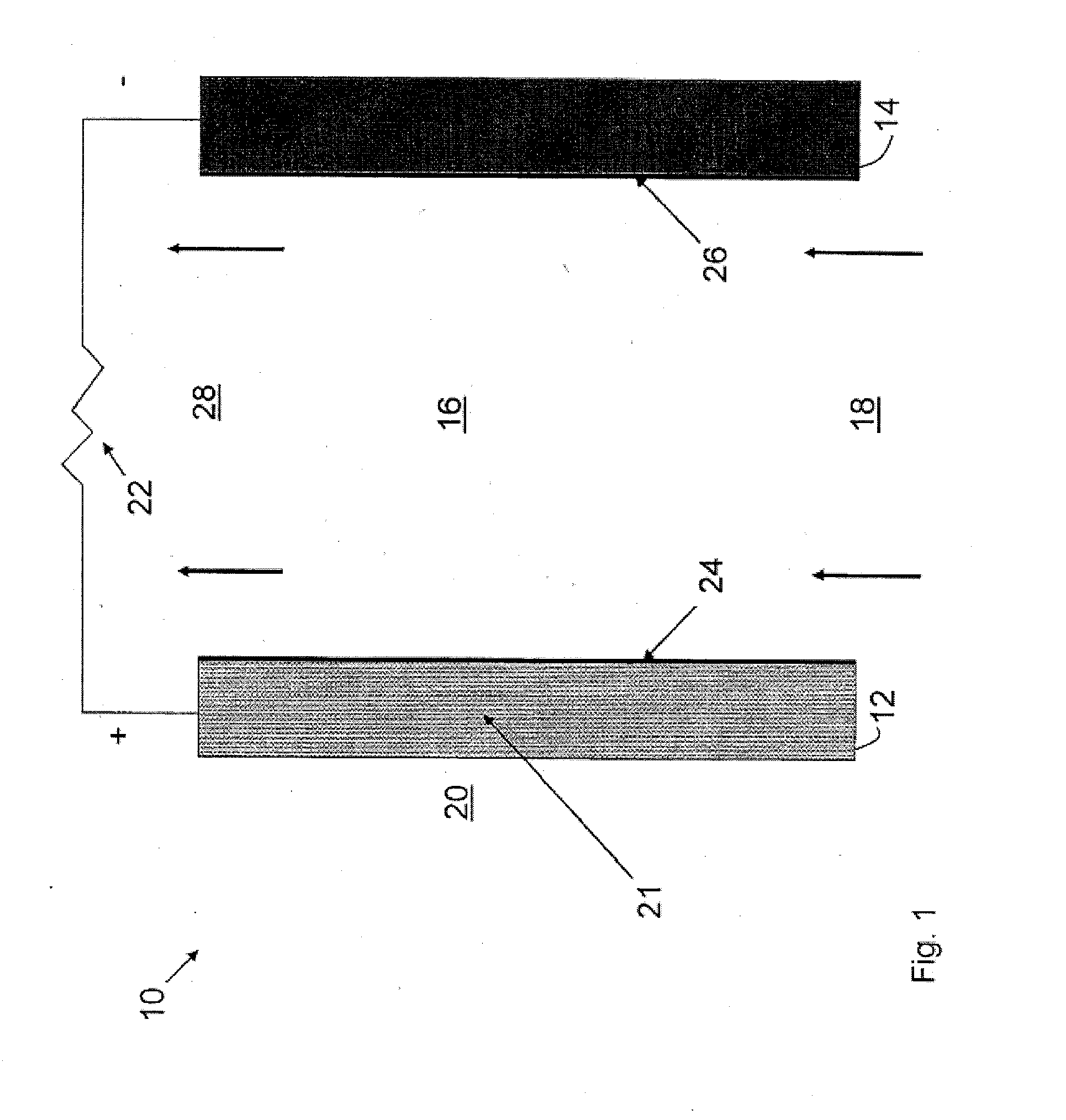

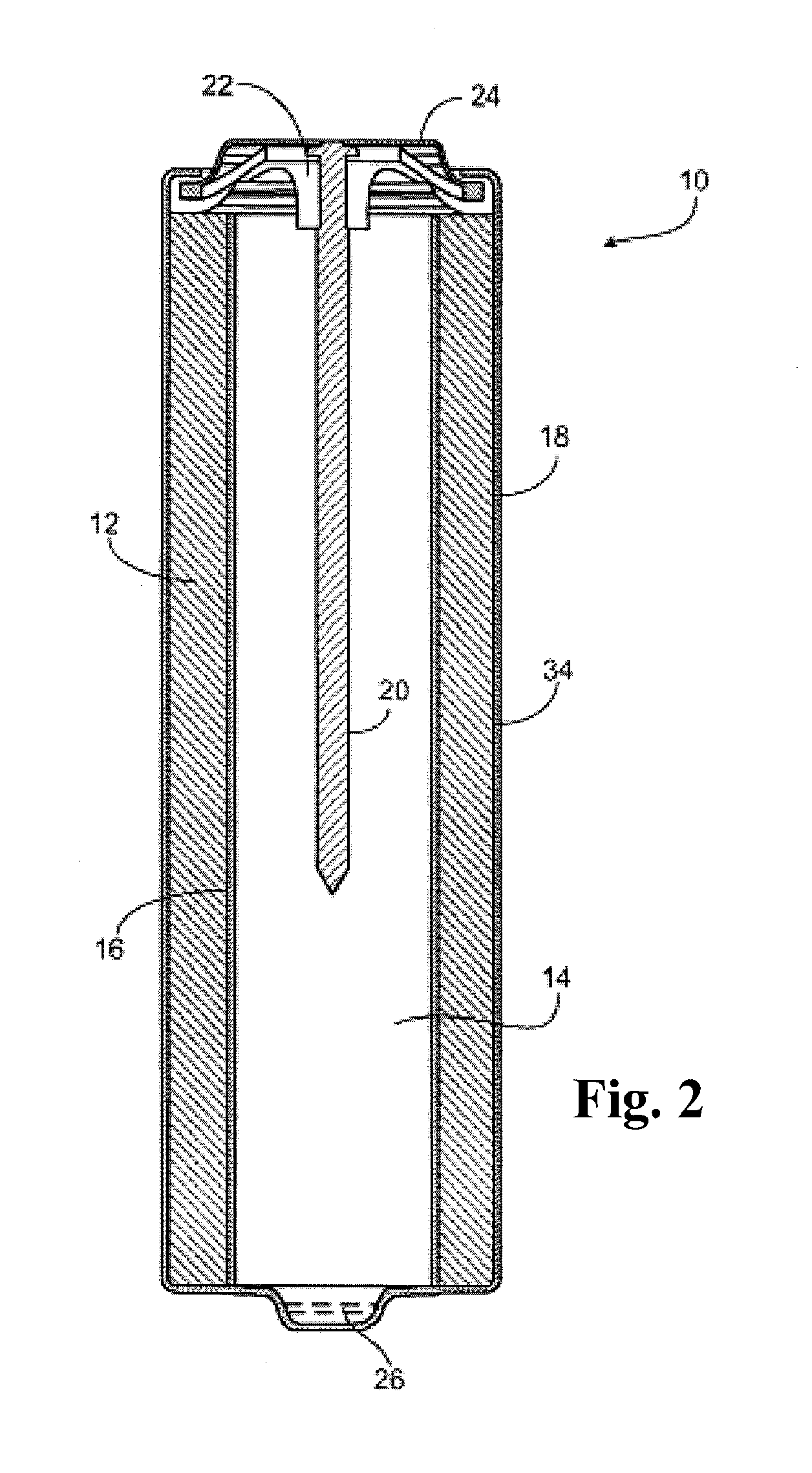

Synthesis of hetero compounds using dialkylcarbonate quaternation

Methods of preparing hetero ionic complexes, and ionic liquids from bisulfate salts of heteroatomic compounds using dialkylcarbonates as a primary quaternizing reactant are disclosed. Also disclosed are methods of making electrochemical cells comprising the ionic liquids, and an electrochemical cell comprising an alkaline electrolyte and a hetero ionic complex additive.

Owner:FORM ENERGY INC

Dimensionally Stable Solid Rinse Aid

ActiveUS20080293615A1Reduced water solid filming in waterReduce spotting and water solids filmingOrganic detergent compounding agentsDrying soapAlcoholPreservative

The present invention is a solid rinse aid composition and methods of making and using the same. The solid rinse aid composition generally includes sodium sulfate and urea as solidification agents and an effective amount of an alcohol ethoxylate compound sheeting agent component and an effective amount of defoamer component. The solid rinse aid composition may also incorporate a preservative system including sodium bisulfate. The solid rinse aid composition may be phosphate-free, aminocarboxylate-free, and GRAS if desired.

Owner:ECOLAB USA INC

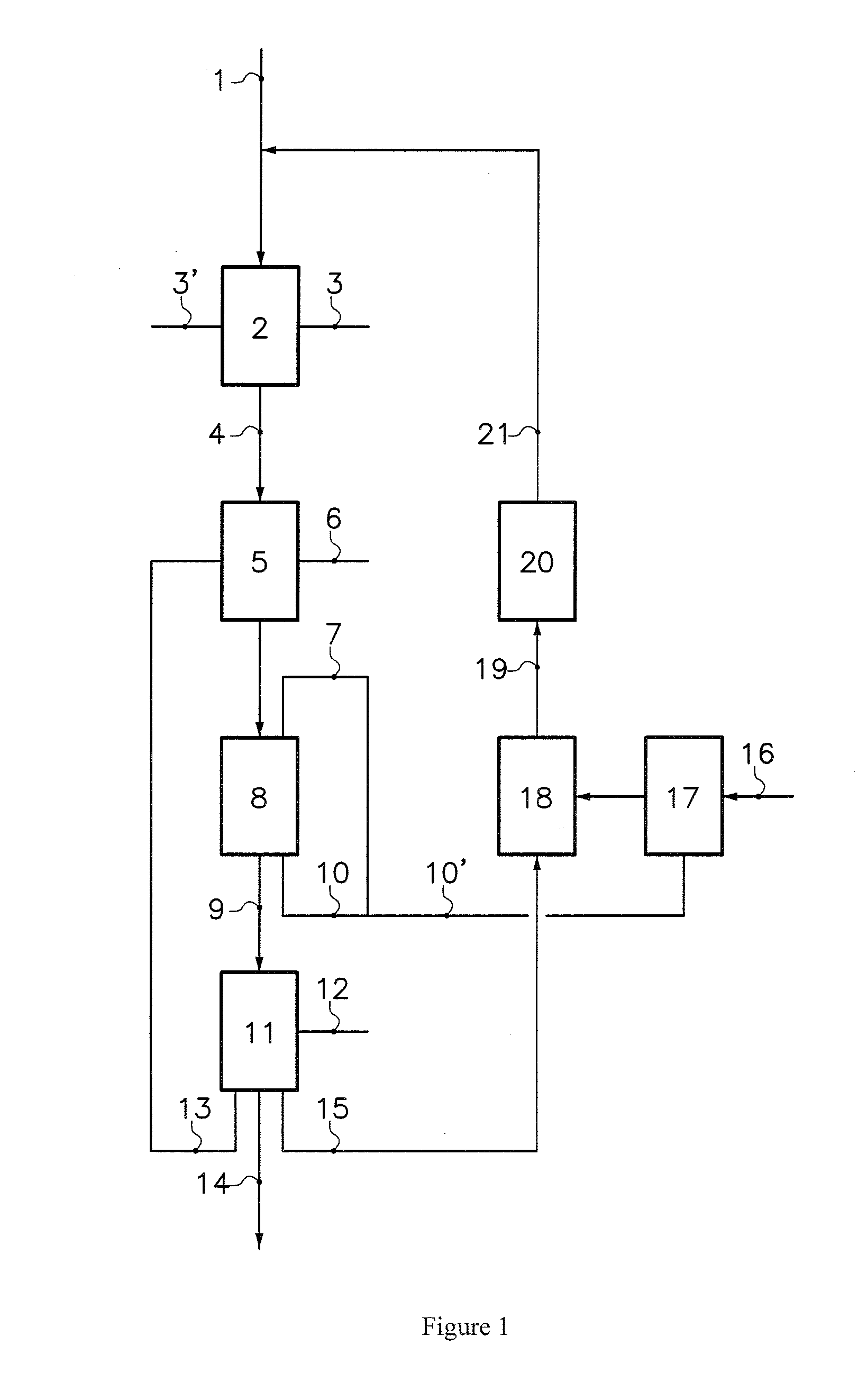

Process for producing sodium bicarbonate for flue gas desulphurization

InactiveUS20100290967A1Electrolysis componentsVolume/mass flow measurementSodium bicarbonateFlue gas

Process for producing sodium bicarbonate for purifying flue gases, according to which an aqueous solution containing sodium sulfate is subjected to electrodialysis to produce a sodium hydroxide solution and a sodium bisulfate solution, the sodium hydroxide solution being carbonated in order to obtain sodium bicarbonate.

Owner:SOLVAY SA

Massive bodies containing free halogen source for producing highly converted solutions of chlorine dioxide

InactiveUS7182883B2Increase conversion rateImprove permeabilityBiocideOrganic chemistryHalogenLiquid water

A massive body, e.g., a tablet, for producing a solution of chlorine dioxide when the massive body is added to liquid water. The massive body comprises a metal chlorite such as sodium chlorite, an acid source such as sodium bisulfate and a source of free halogen such as the sodium salt of dichloroisocyanuric acid or a hydrate thereof. The concentration of free halogen in the solution will be:(a) less than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.25:1 by weight; or(b) equal to or greater than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.50:1 by weight.

Owner:ENGELHARD CORP

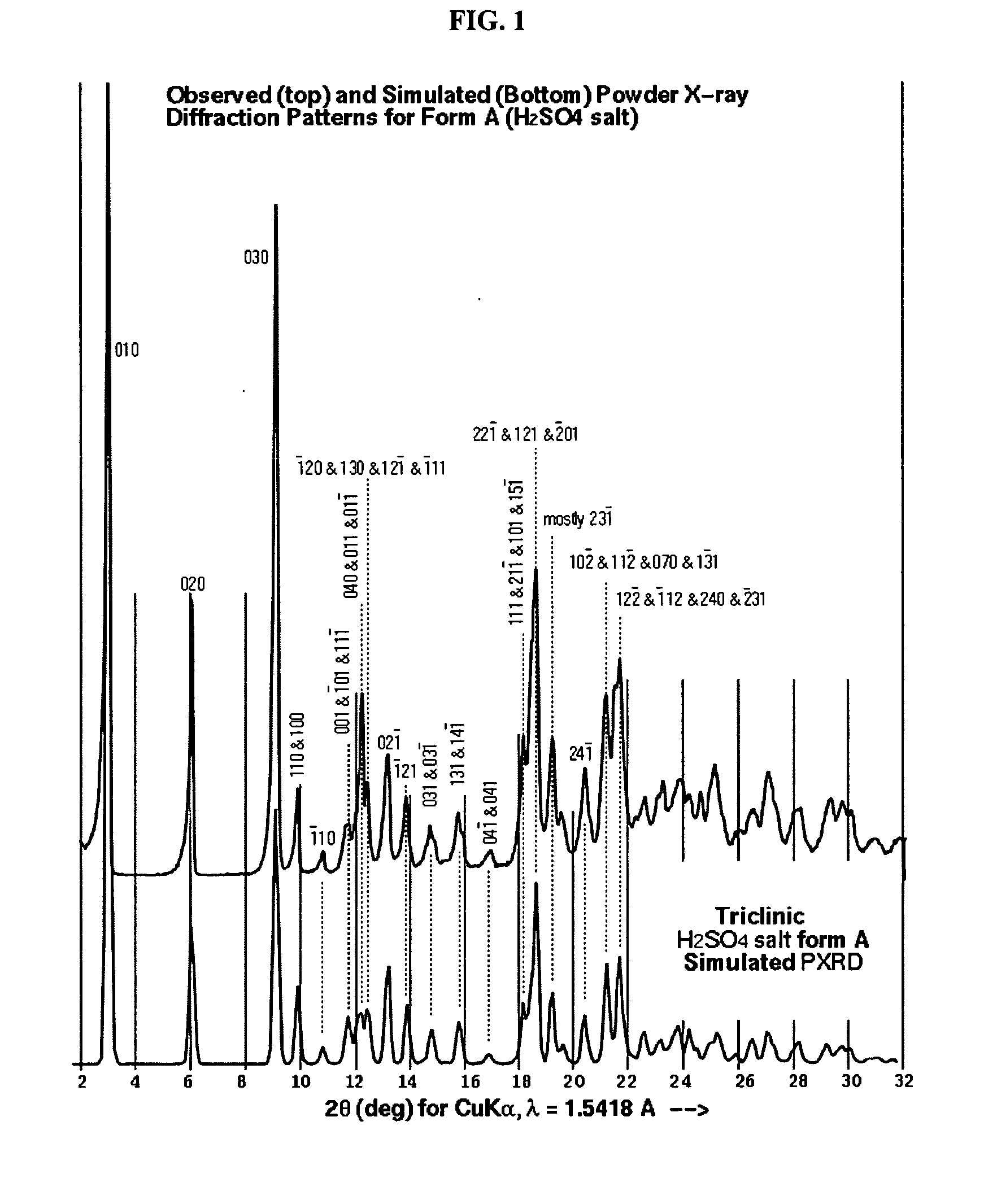

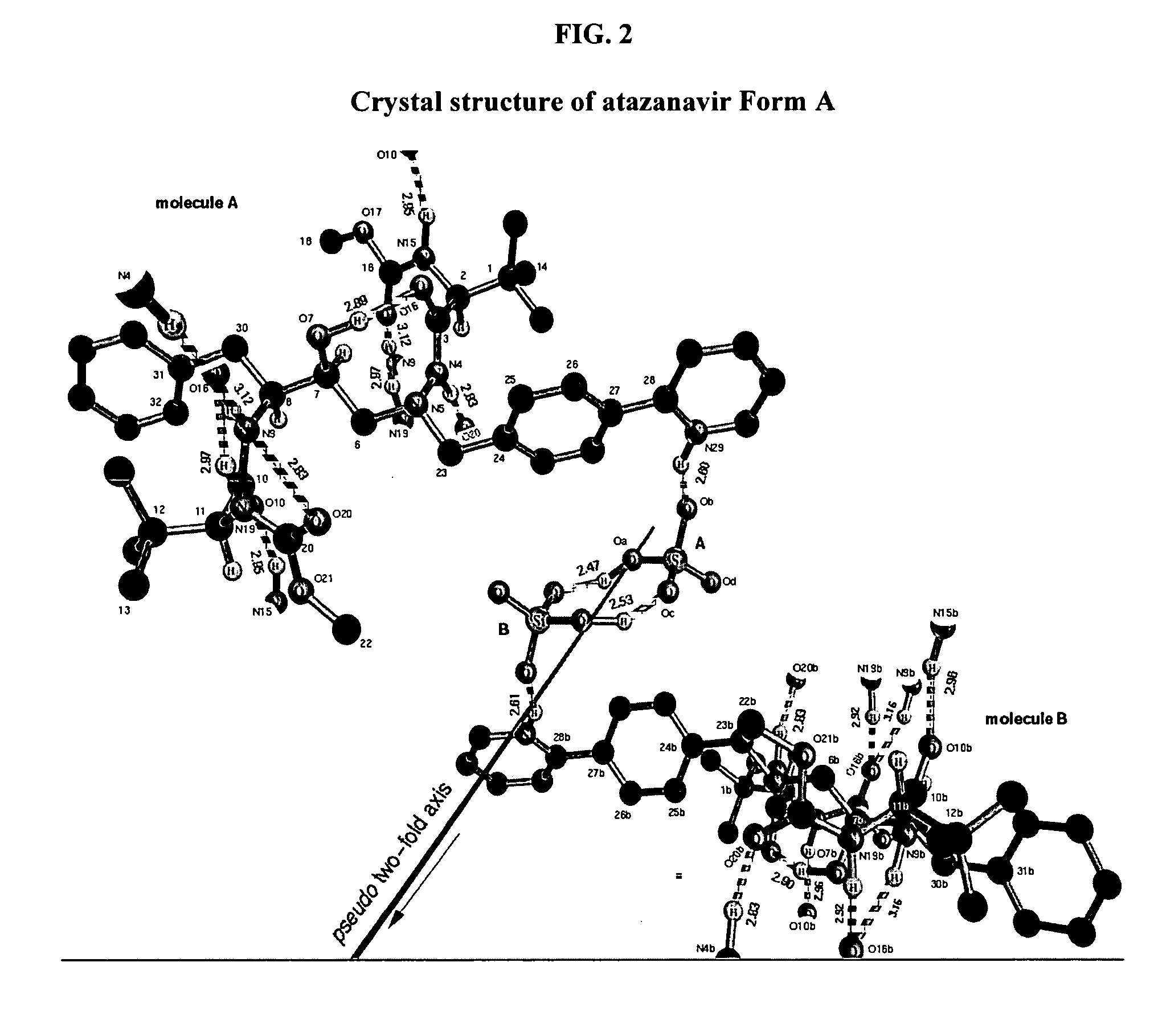

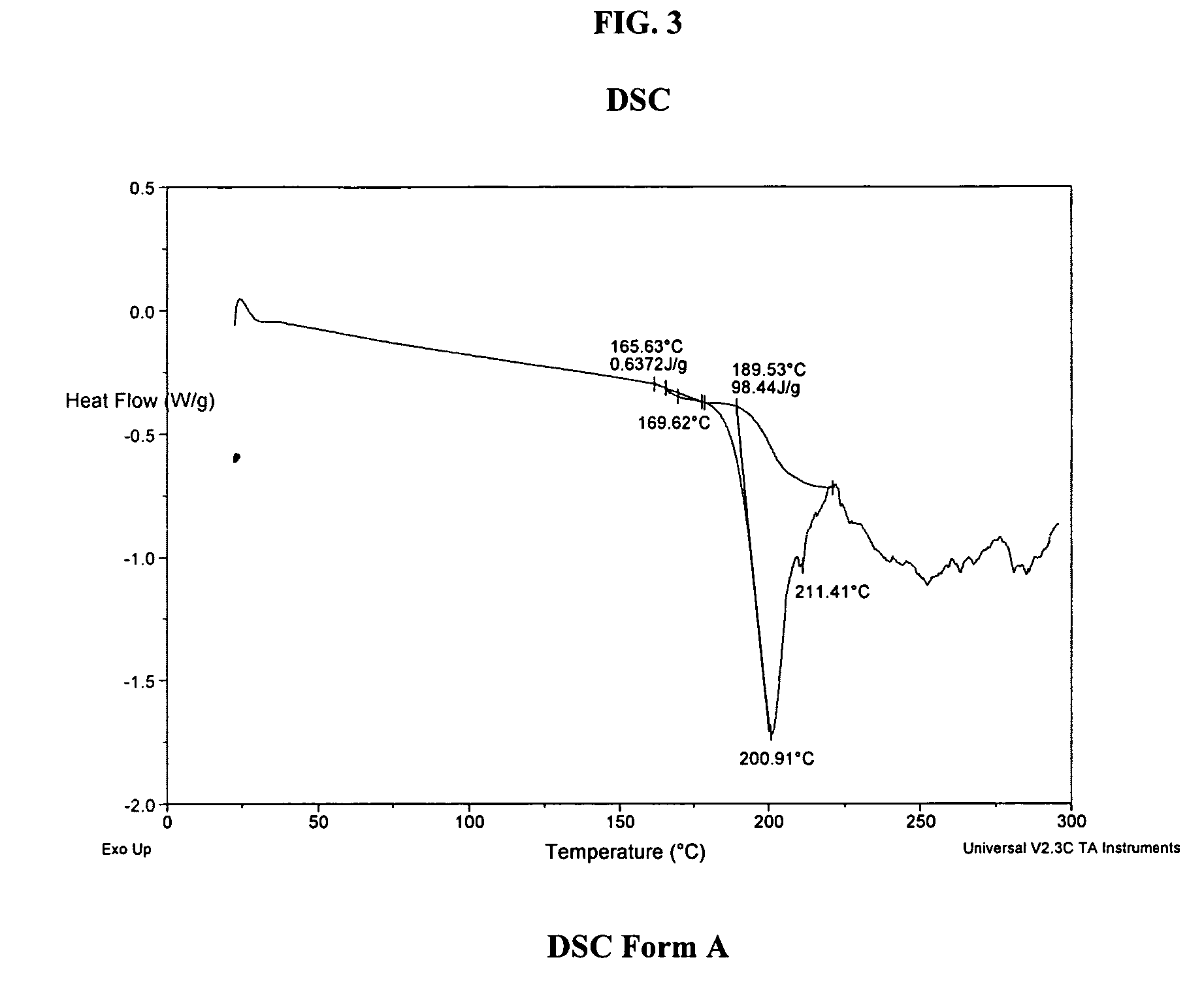

Process for preparing atazanavir bisulfate and novel forms

A process is provided for preparing the HIV protease inhibitor atazanavir bisulfate wherein a solution of atazanavir free base is reacted with concentrated sulfuric acid in an amount to react with less than about 15% by weight of the free base, seeds of Form A crystals of atazanavir bisulfate are added to the reaction mixture, and as crystals of the bisulfate form, additional concentrated sulfuric acid is added in multiple stages at increasing rates according to a cubic equation, to effect formation of Form A crystals of atazanavir bisulfate. A process is also provided for preparing atazanavir bisulfate as Pattern C material. A novel form of atazanavir bisulfate is also provided which is Form E3 which is a highly crystalline triethanolate solvate of the bisulfate salt from ethanol.

Owner:BRISTOL MYERS SQUIBB CO

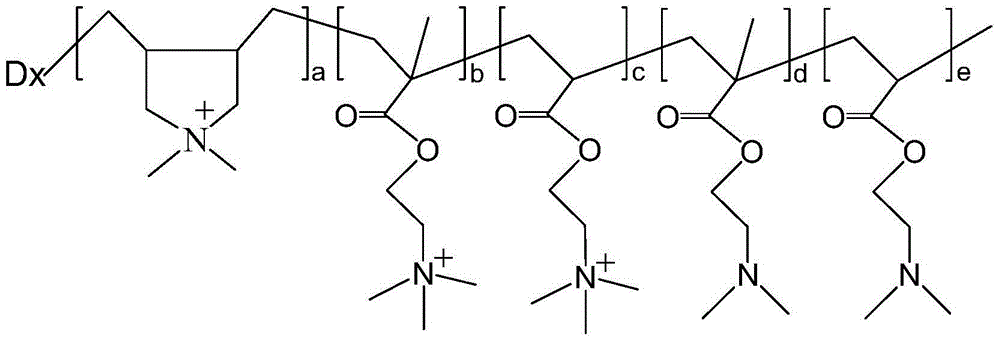

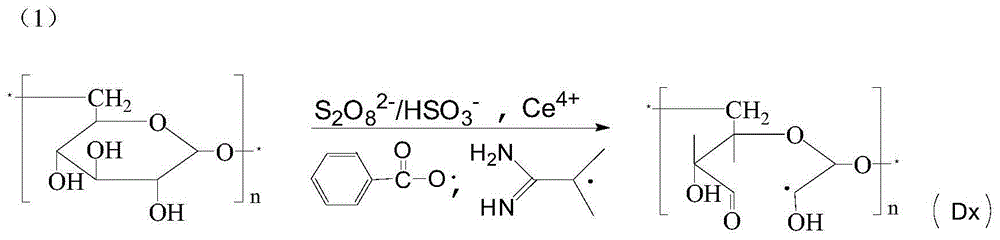

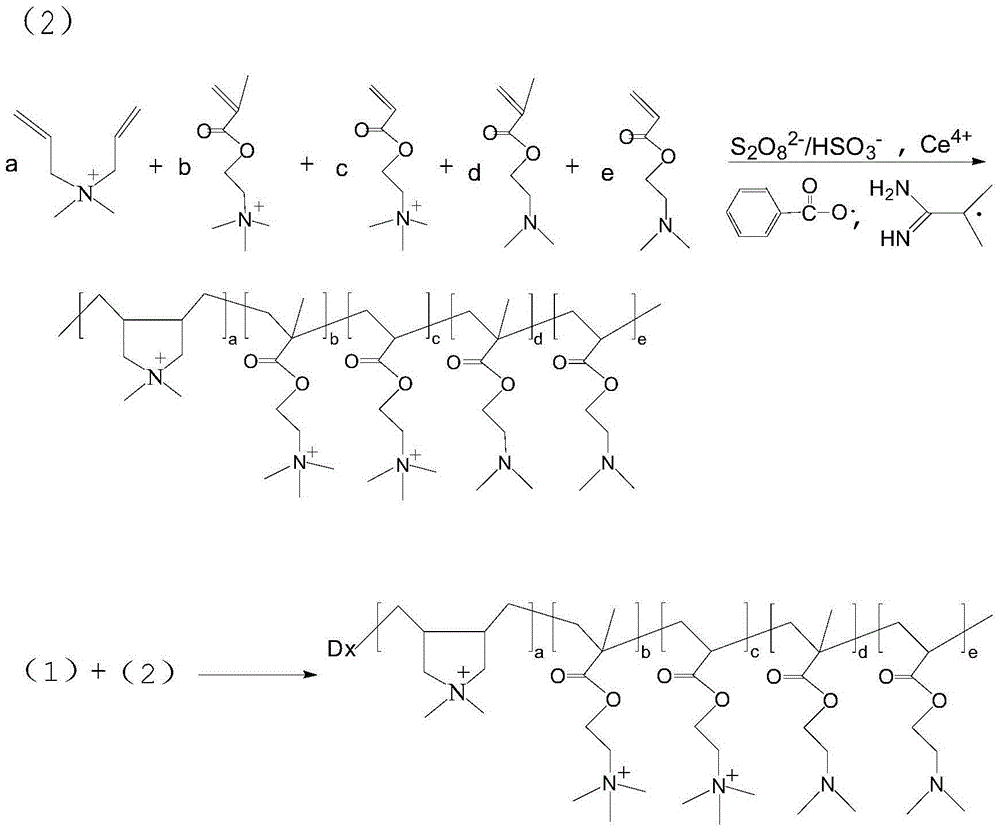

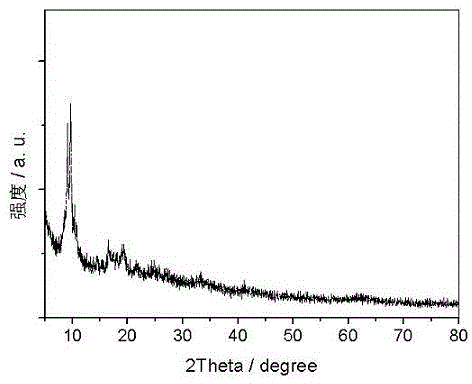

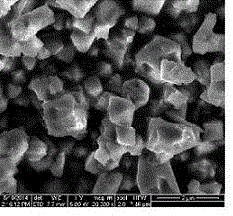

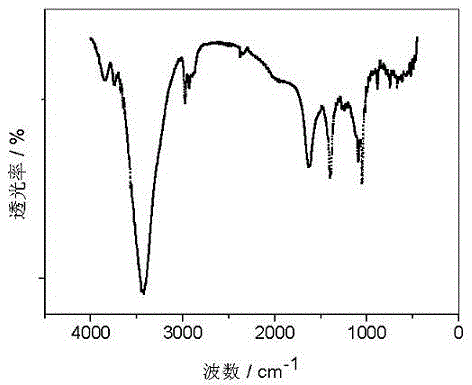

Grafted copolymerized cationic polysaccharide bioflocculant and preparation method thereof

ActiveCN104130351AImprove adsorption capacityHigh positive charge densityWater/sewage treatment by flocculation/precipitationMethacrylateSodium bisulfate

The invention relates to a grafted copolymerized cationic polysaccharide bioflocculant and a preparing method thereof. A product with the cationic degree (DC) of 3-63% is finally prepared through an aqueous solution polymerization technology with a present nonionic polysaccharide bioflocculant (Dx) as a raw material, one or more of dimethyl diallyl ammonium chloride (DMDAAC), methacryloxyethyltrimethyl ammonium chloride (DMC), acryloyloxyethyltrimethyl ammonium chloride (DAC), dimethylaminoethyl methacrylate (DMAEMA), dimethylaminoethyl acrylate (DMAEA) as a monomer, and one or two of ammonium persulfate / sodium bisulfate and dibenzoyl peroxide (BPO) (AIBA) as an initiator. The preparation method is simple, and is easy to control, and the product obtained in the invention has good flocculation effect and high treatment efficiency, and can be widely used in the field of treatment various sewages, the sludge dewatering field and the like.

Owner:威海汉邦生物环保科技股份有限公司

Method of treating organic wastewater based on Fenton-like reaction of iron-based organic-framework material

InactiveCN104310565AIncrease the areaLarge apertureWater treatment compoundsWater contaminantsSulfate radicalsPtru catalyst

The invention discloses a method of treating organic wastewater based on Fenton-like reaction of an iron-based organic-framework material. The method comprises the following steps: by taking the iron-based organic-framework material as a catalyst and taking persulfate or hydrogen persulfate as an oxidant, degrading organic pollutants by virtue of sulfate radicals formed in a reaction process. The iron-based organic-framework material has a relatively great specific surface area and a relatively great bore diameter, is regular in metal ion spatial arrangement, uniform in distribution, high in active point location density, high in catalytic activity, environmentally friendly, easy to recycle and capable of being recycled. And moreover, the method is simple in equipment, convenient to operate, capable of efficiently degrading organic pollutants in water within a relatively wide pH value range, and very great in application prospect.

Owner:UNIV OF JINAN

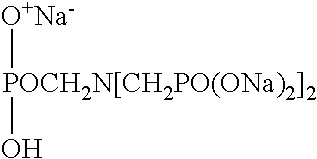

Polyethyleneimine jelly profile-control water-blocking agent

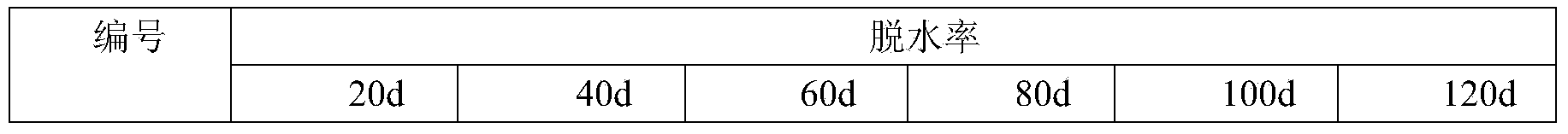

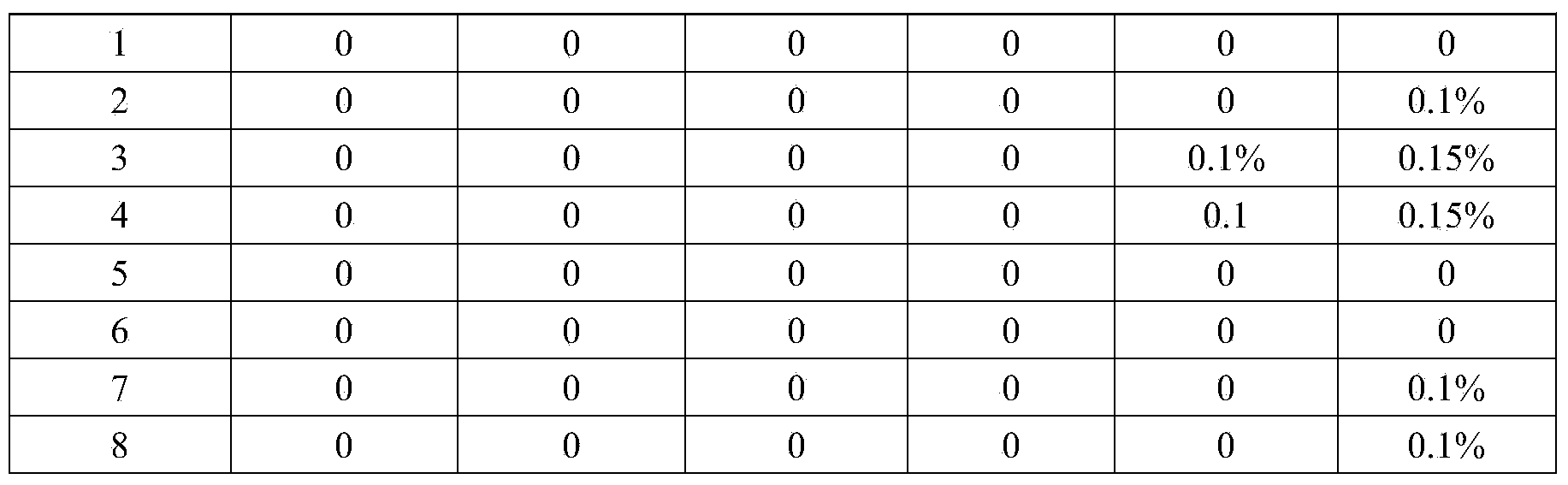

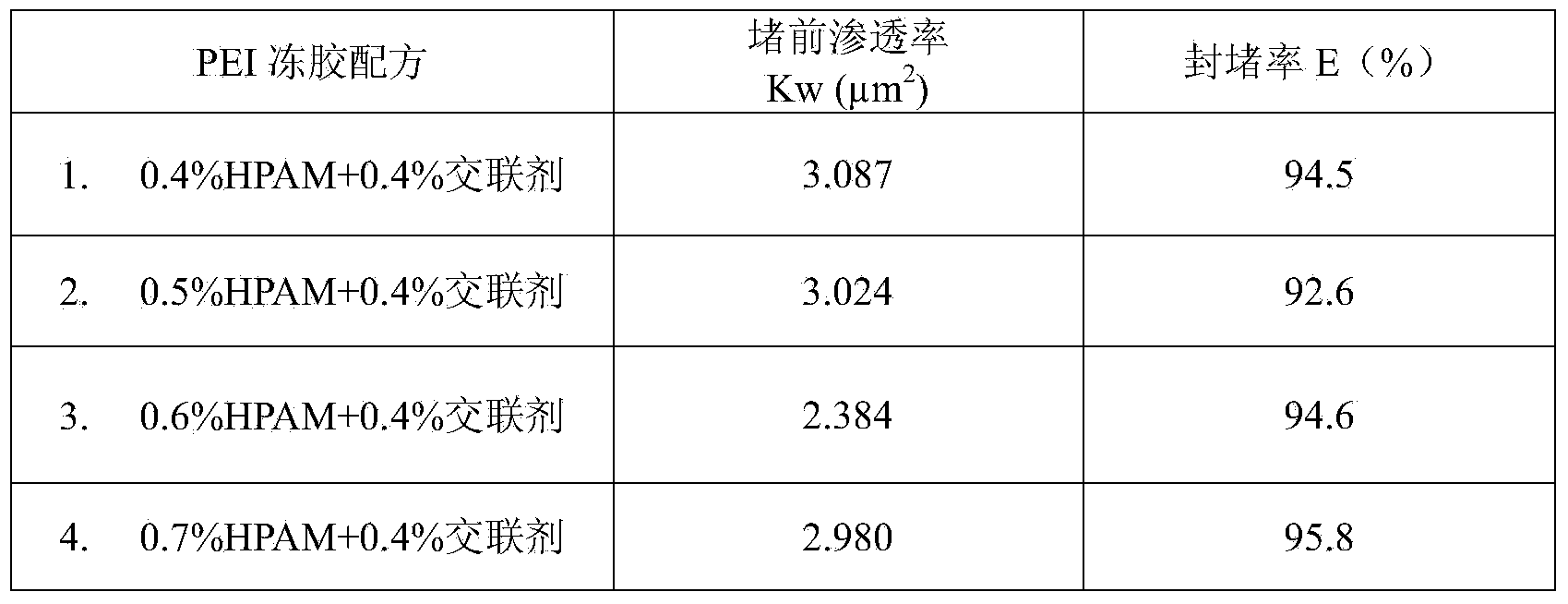

The invention provides a polyethyleneimine jelly profile-control water-blocking agent. The profile-control water-blocking agent is prepared by reacting partially-hydrolyzed polyacrylamide and a cross-linking agent polyethyleneimine. The profile-control water-blocking agent comprises following components by weight: 0.3-0.8% of the partially-hydrolyzed polyacrylamide, 0.2-0.5% of the cross-linking agent polyethyleneimine and 0.3-0.8% of an additive, with the balance being water, wherein the partially-hydrolyzed polyacrylamide adopts anionic polyacrylamide, and the additive is one compound selected from a group of sodium sulfite, sodium bisulfate, and sodium hyposulfite or thiourea, or is a mixture of several compounds selected from the group. The jelly forming time of the profile-control water-blocking agent is adjustable and the jelly has high strength. The profile-control water-blocking agent can block underground water having a temperature lower than 110 DEG C and a NaCl mineralization degree of 50000 mg / L. The profile-control water-blocking agent has good temperature toleration and cannot be dehydrated for 120 days.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Novel process for preparation of clopidogrel bisulfate polymorph - Form I

A process for making Clopidogrel Bisulfate Form I which comprises dissolving Clopidogrel Bisulfate Form II in a solublizing solvent at room temperature to form a solution; adding an anti-solvent to the said solution till turbid; stirring the said turbid solution; collecting the precipitated solid and drying the final solid product, form I.

Owner:SAWANT KAMLESH DIGAMBAR +2

Non-fluorescence collapse-proof fluid loss additive for oil exploration drilling fluid

The present invention discloses petroleum exploration well-drilling liquid used non-blooming anti-collapse and anti-falling filtration agent, which is confected by coal gangue 500Kg, waste orlon thread 270Kg, sodium hudroxide 100Kg, formaldehyde 20Kg, sodium nitrite 30Kg, sodium bisulfate 30Kg, phenol 50Kg, and water 3000Kg. The cost of the processing raw material of the product of the present invention is low, compared with the same kind of the product, the cost of the well-drilling slurry can be lowered by 30 percent, during the well-drilling process, the using volume is less, in the fresh water, 1 percent volume can be added, in the sea water, 3percent volume can be added, the performance is better than the performance of all the lignite resin products, the circumference of the drilling tool can form smooth and hard filtration cake to prevent the well wall from collapsing, to control the mudstone and the clay shale from swelling by absorbing water, to control the water lost volume, so as to improve the well-drilling schedule. The raw material adopted by the present invention is all non-blooming material, which has no interference to geological log, the product petroleum field is large in demand volume, and great in market potential. The present invention also discloses the preparation method for above anti-collapse and anti-falling filtration agent.

Owner:图们市方正化工助剂厂

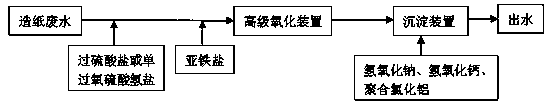

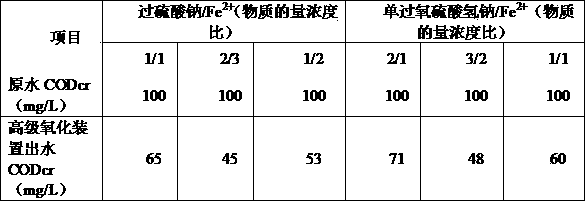

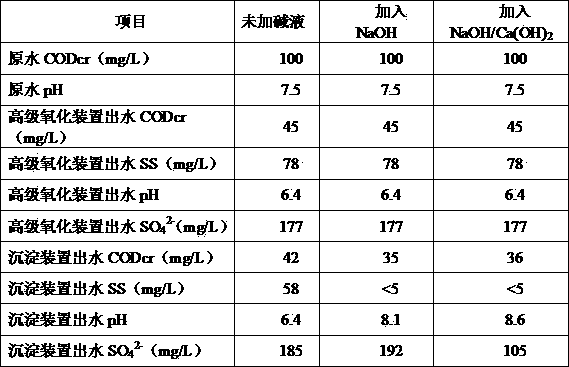

Method for processing papermaking wastewater by advanced oxidation treatment of activating persulfate or monoperoxy-hydrosulfate with ferrous salt

InactiveCN103818993AImprove applicabilityStrong oxidation abilityWater treatment parameter controlSpecific water treatment objectivesAluminium chlorideSulfate radicals

The invention discloses a method for processing papermaking wastewater by an advanced oxidation treatment of activating persulfate or monoperoxy-hydrosulfate with ferrous salt. The method is divided into two phases, namely an oxidation phase and a precipitation phase; wherein the oxidation phase is carried out in advanced oxidation equipment where wastewater is prone to mix, the hydraulic retention time is more than 0.5 hour, then persulfate or monoperoxy-hydrosulfate is subjected to carry out reactions with ferrous salt to generate sulfate free radicals with a strong oxidizing property, the sulfate free radicals can degrade organisms in the wastewater; the precipitation phase is carried out in precipitation equipment, the hydraulic retention time is more than 1.5 hours, and an alkaline solution or polymerized aluminum chloride is added so as to promote the flocculation and sedimentation of iron mud. The papermaking wastewater processing method is based on sulfate free radical advanced oxidation treatment, and the processed wastewater is clear and has a low COD value and a low Cr content. The method has the advantages of high efficiency, easy operation, and wide applicable pH range, and is especially suitable for processing papermaking wastewater having complicated components and high requirements on advanced treatment.

Owner:SOUTH CHINA UNIV OF TECH

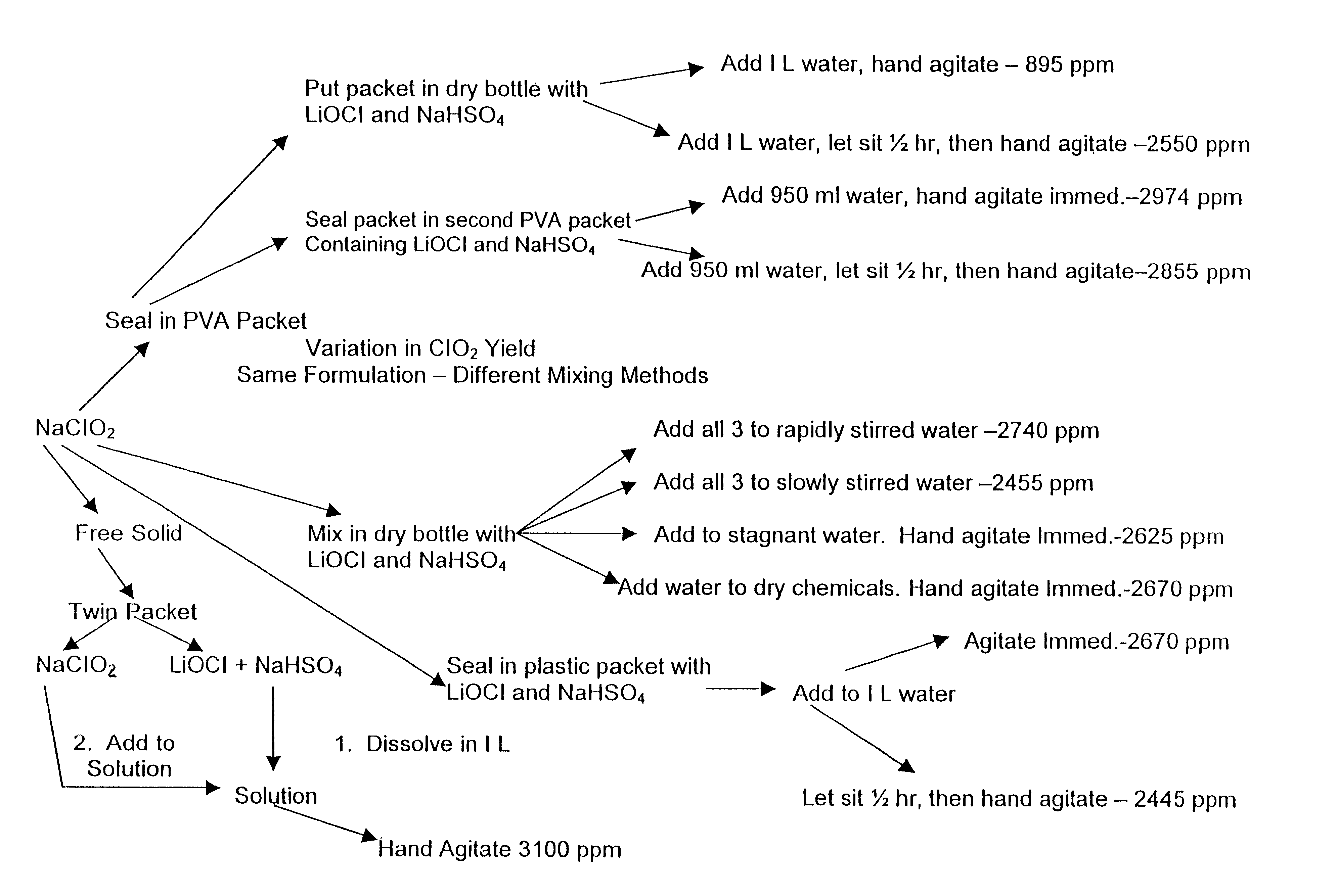

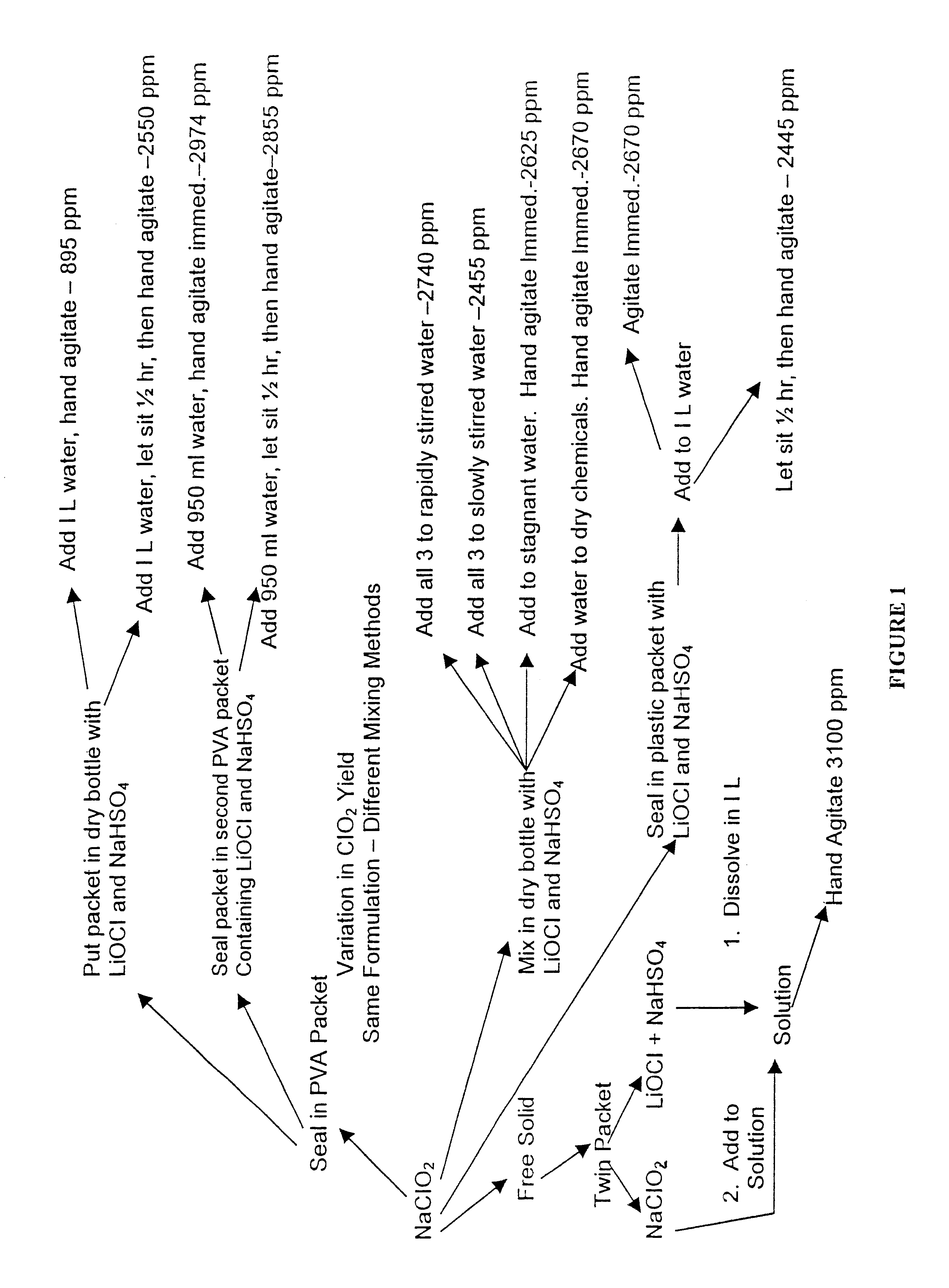

Composition for generating chlorine dioxide

InactiveUS6602442B1Transportation safetyMade preciselyBiocidePeroxide active ingredientsLithium hypochloriteSodium bisulfate

A dry disinfectant composition for the production of aqueous solutions of chlorine dioxide of predetermined concentration is formulated of a mixture of lithium hypochlorite, sodium bisulfate and sodium chlorite. Special liquid and dry formulations are also contemplated for convenience of use, for quality assurance and for safety.

Owner:OCCIDENTAL CHEM CORP

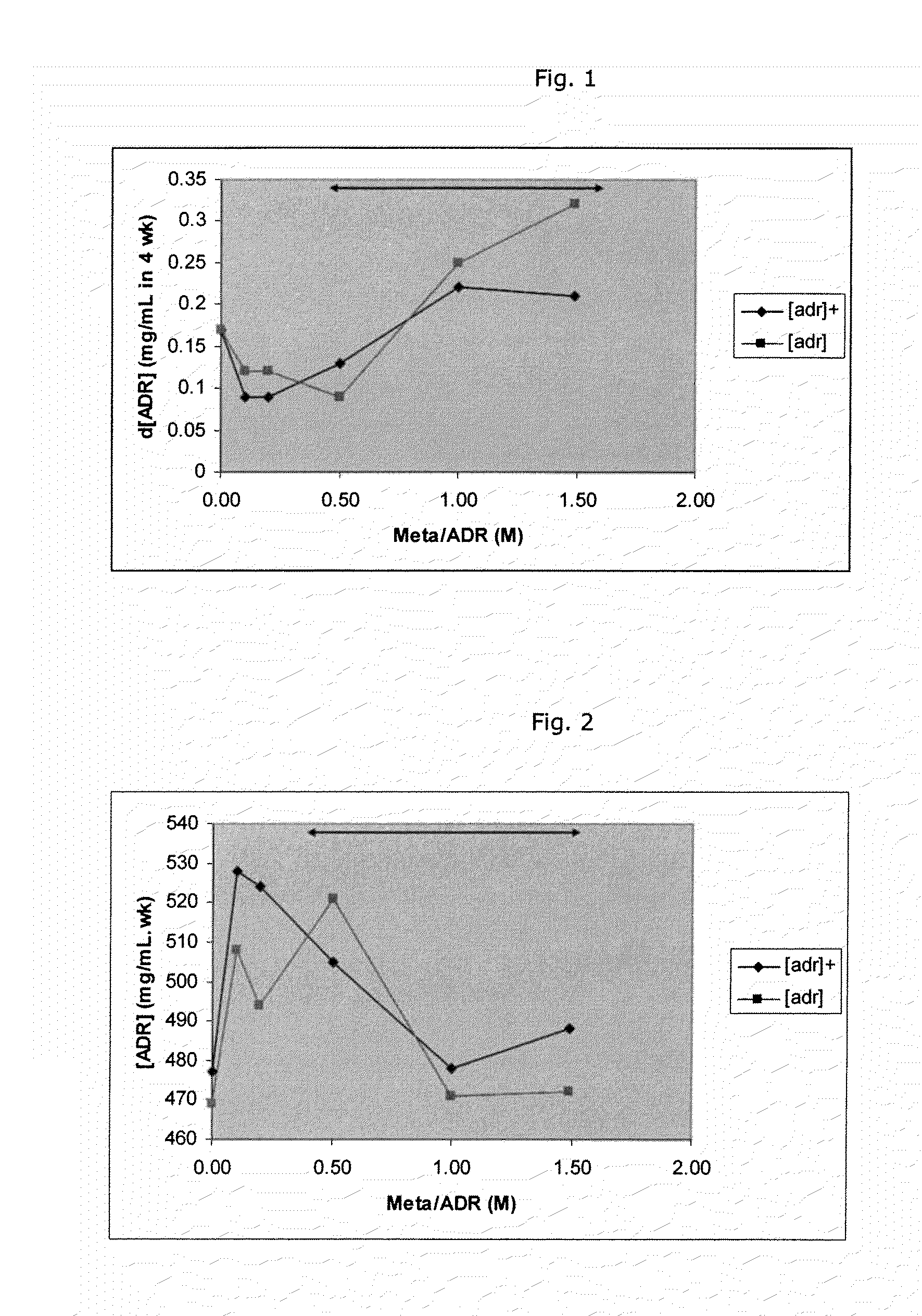

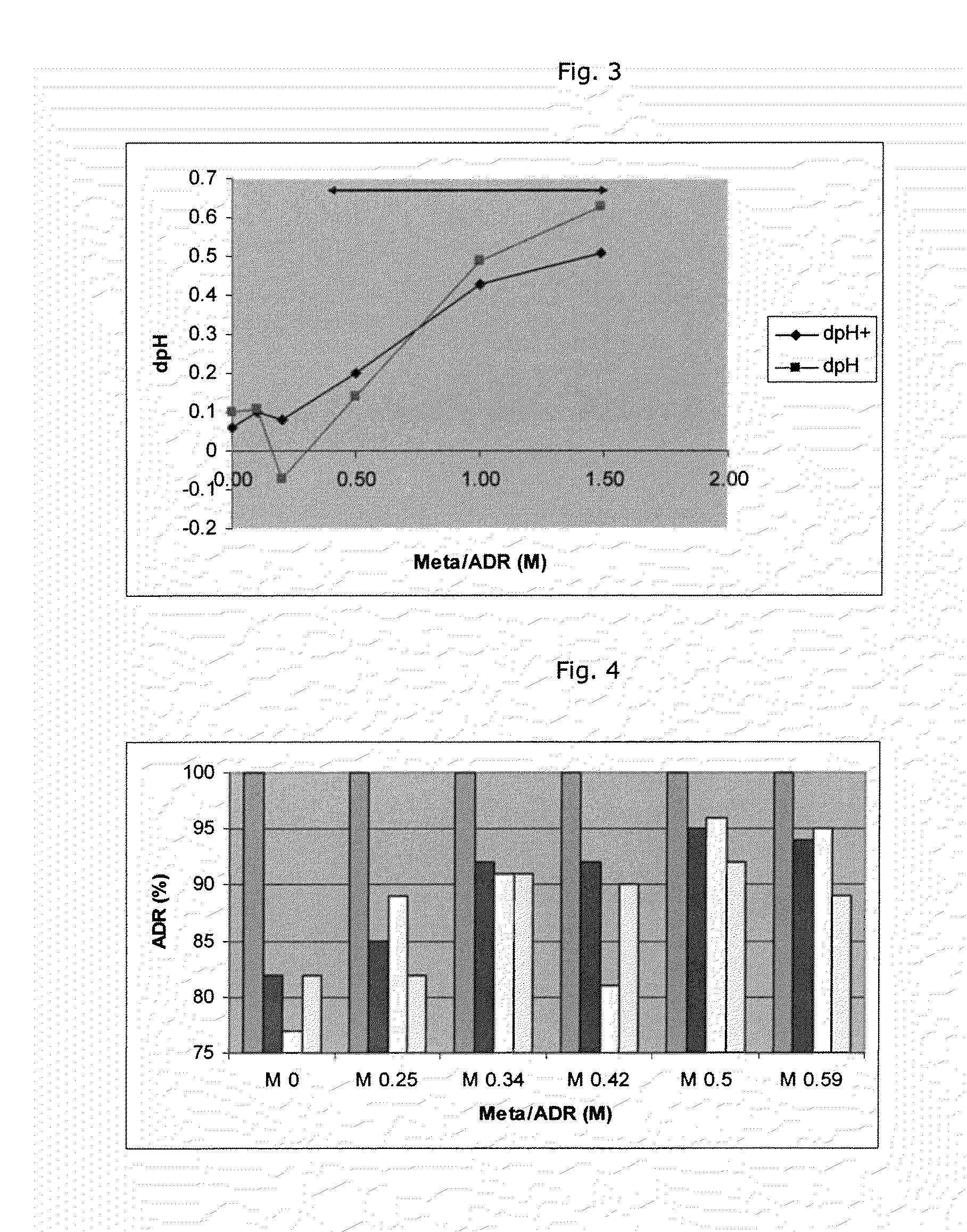

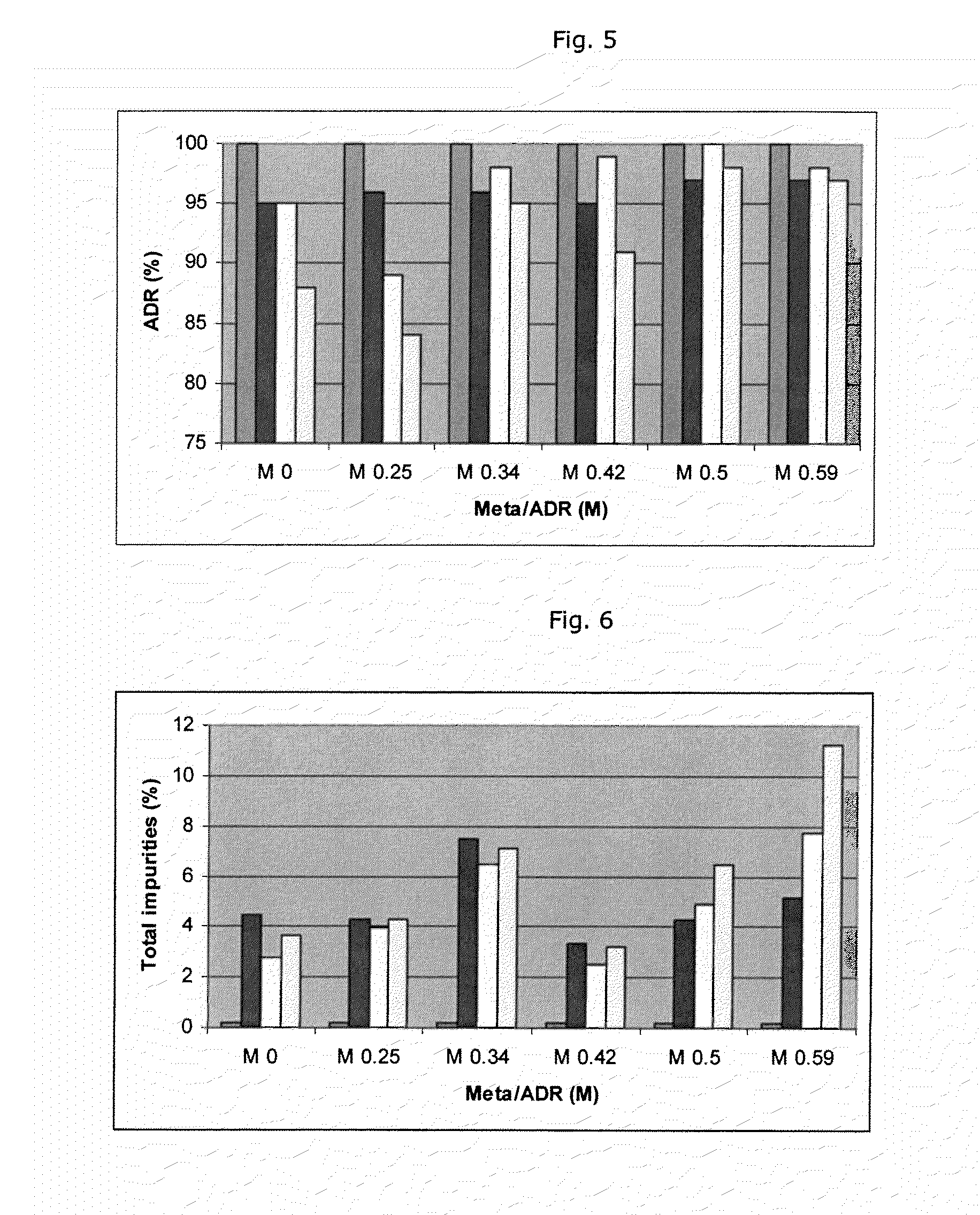

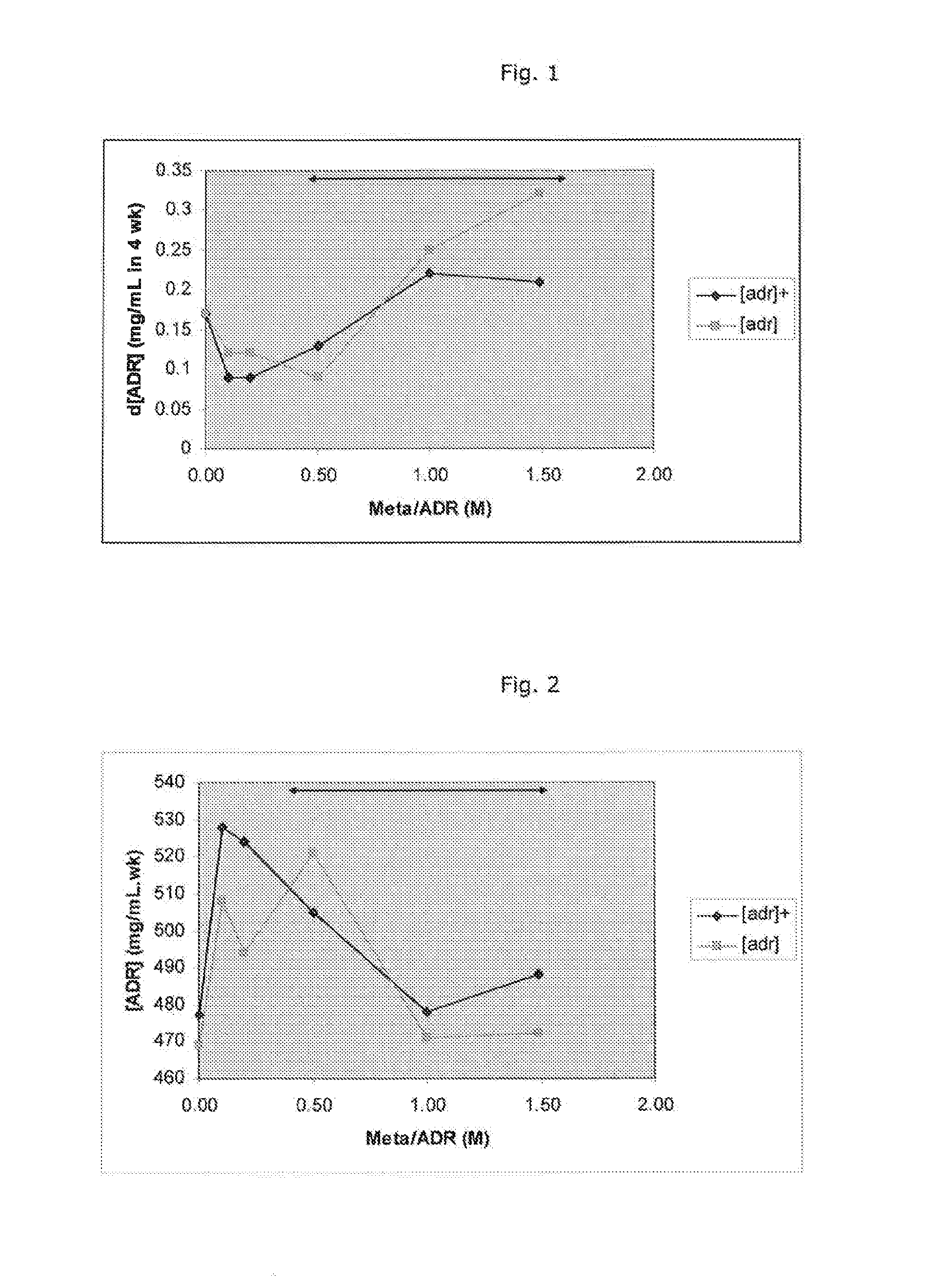

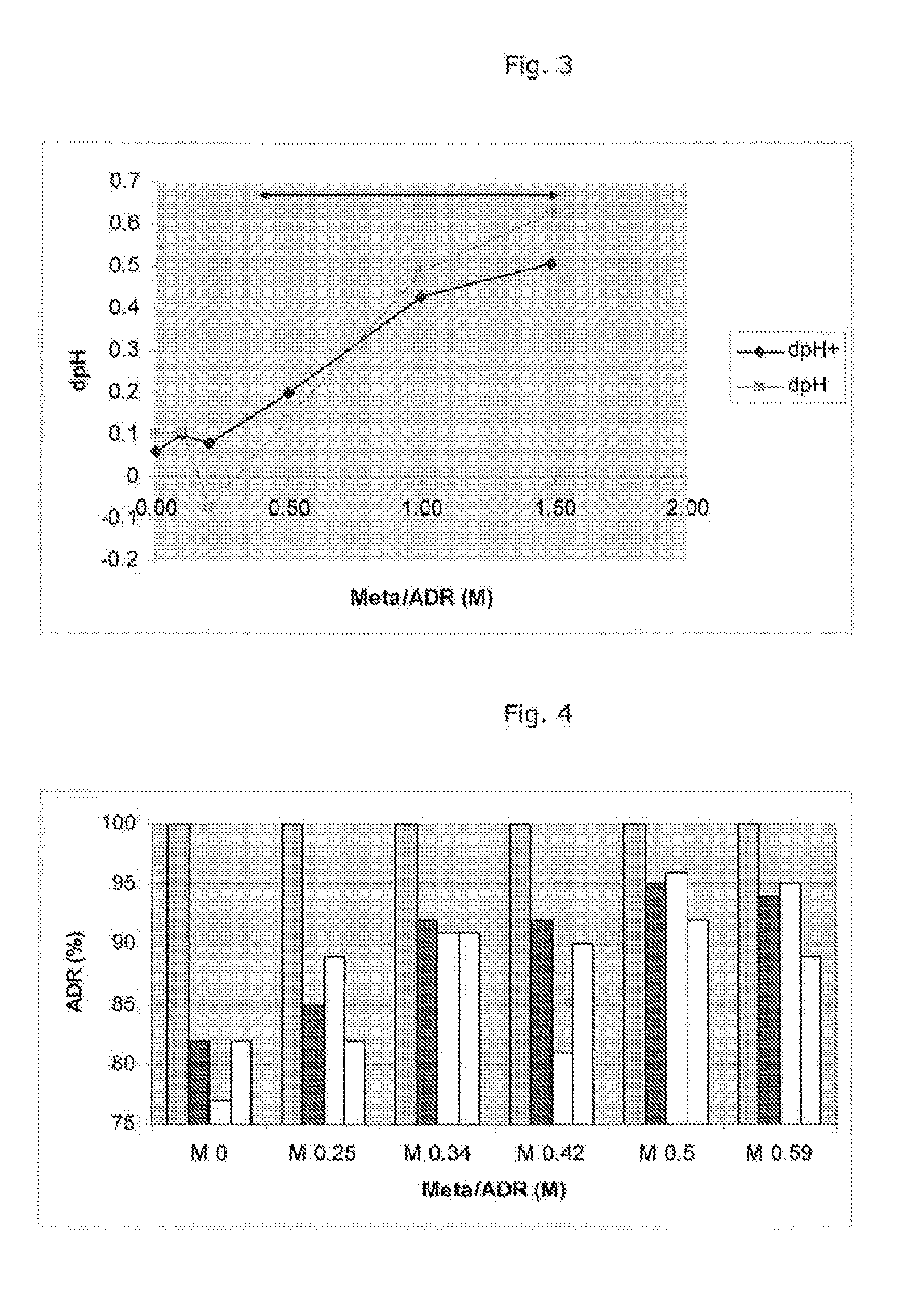

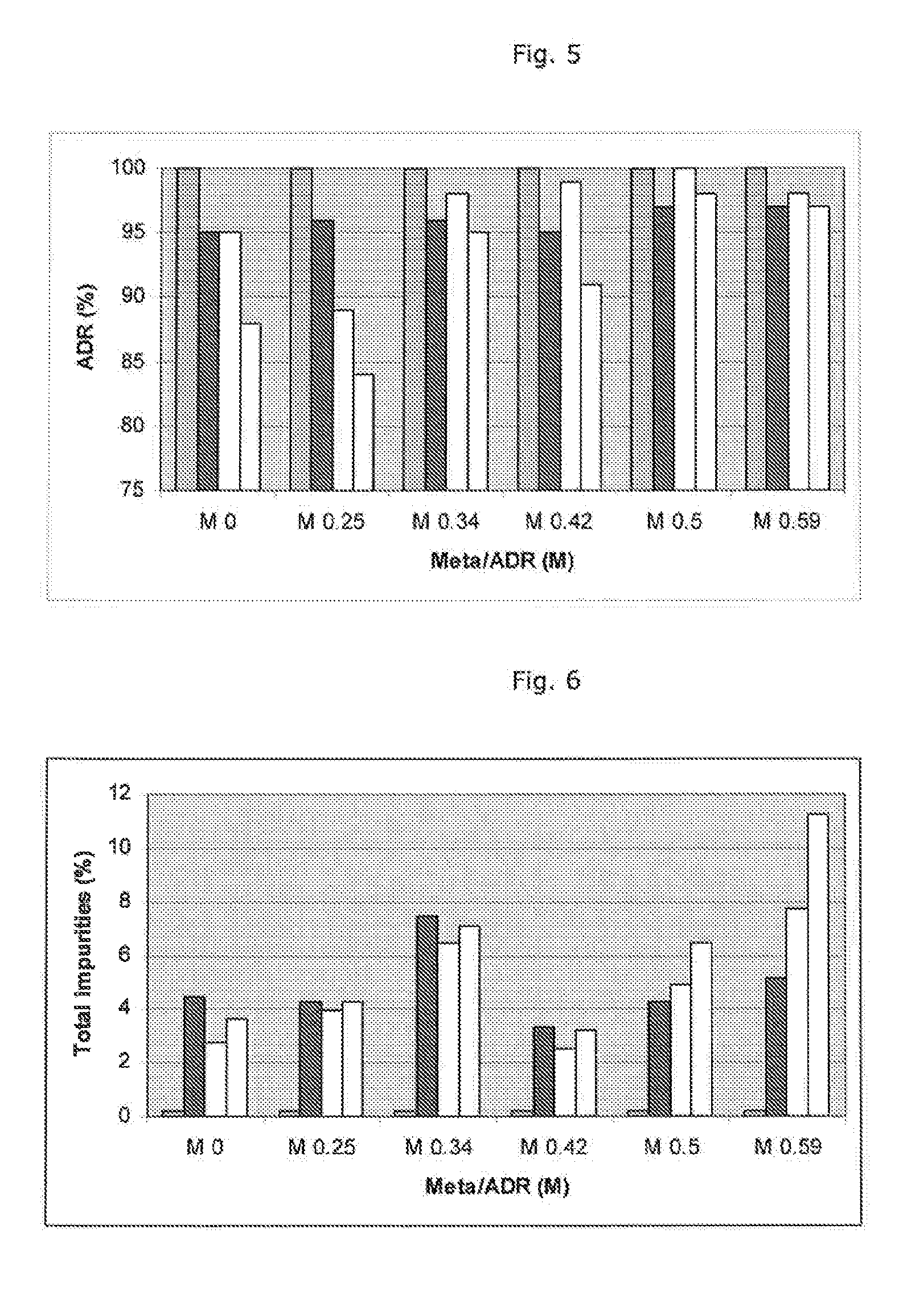

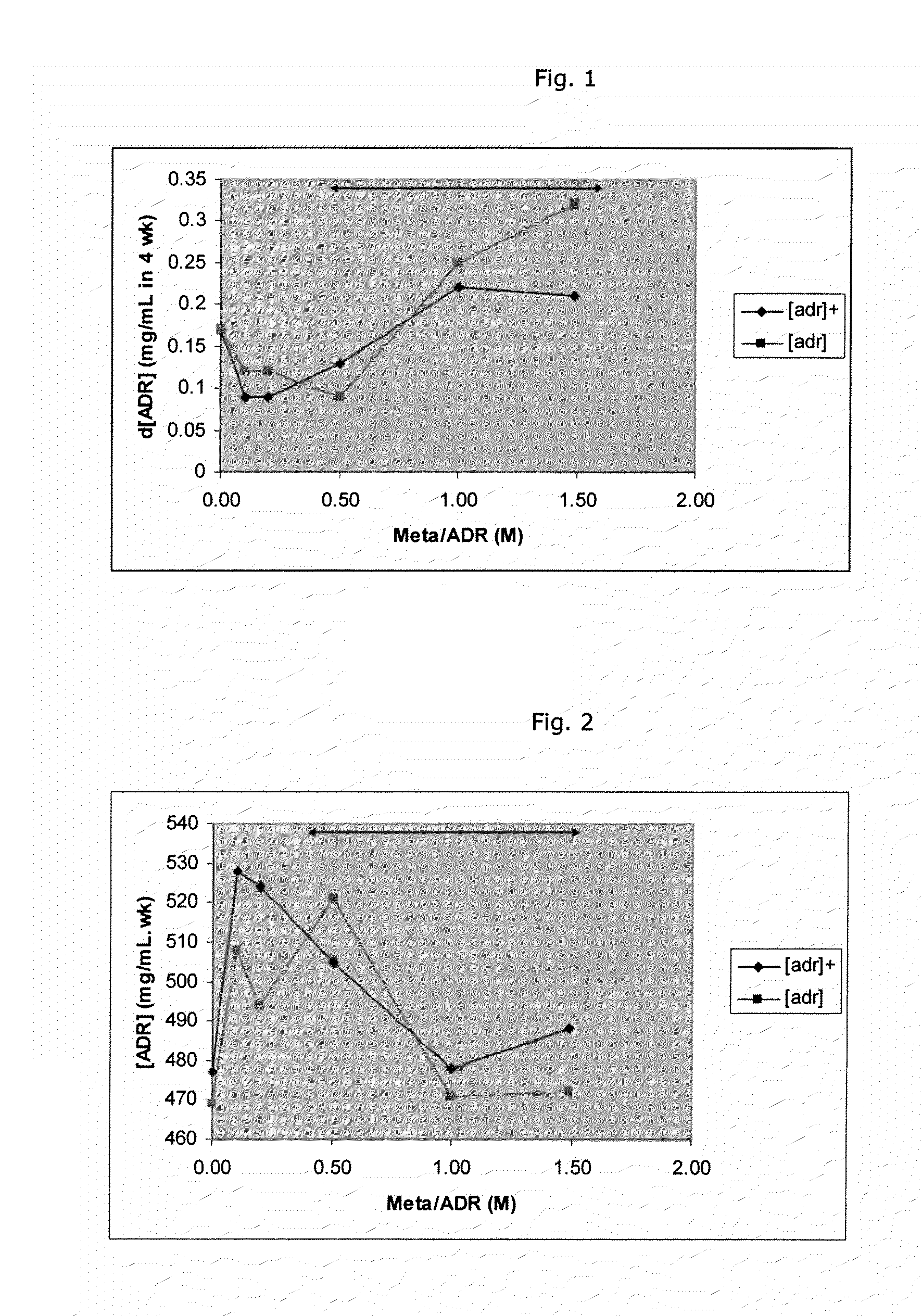

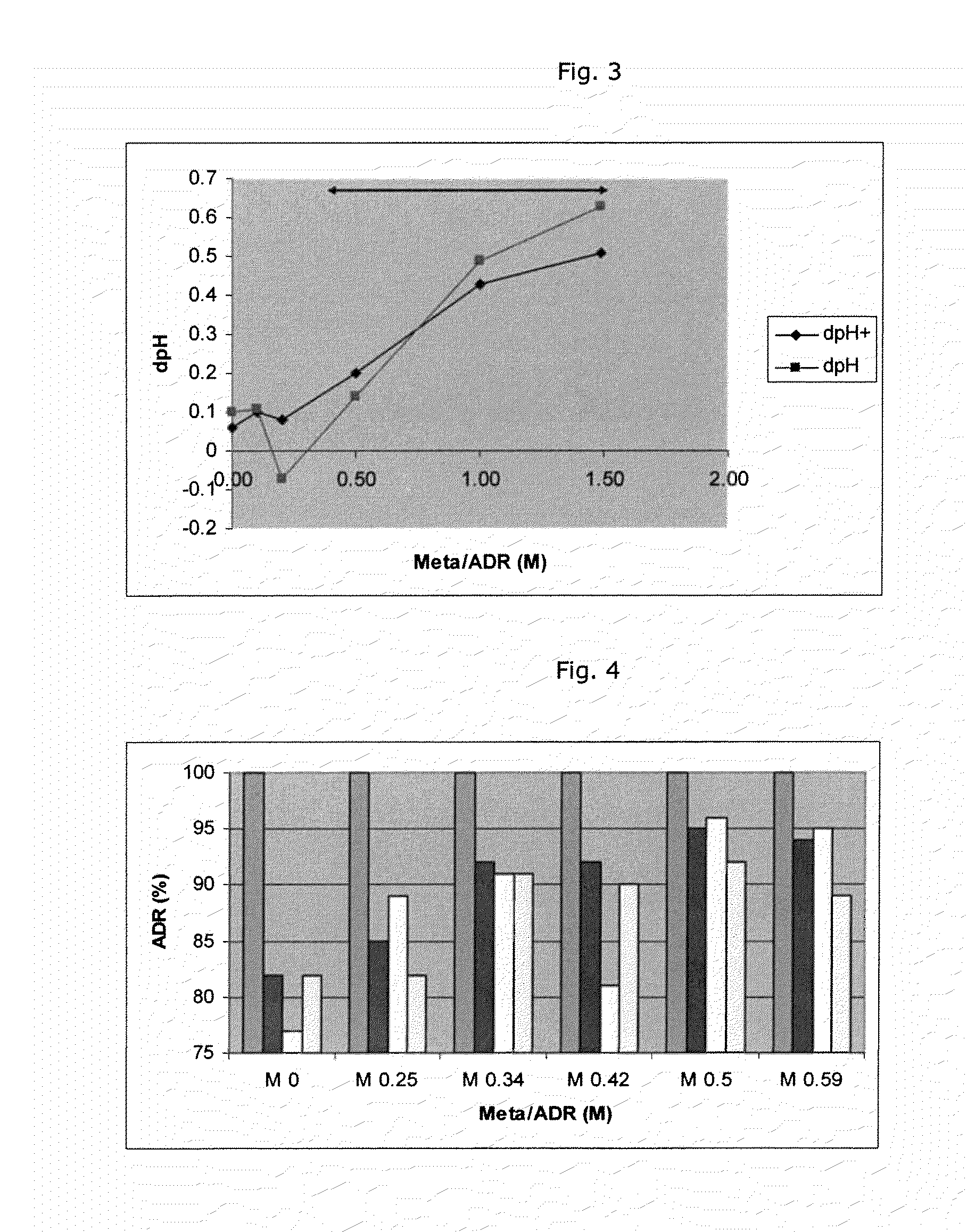

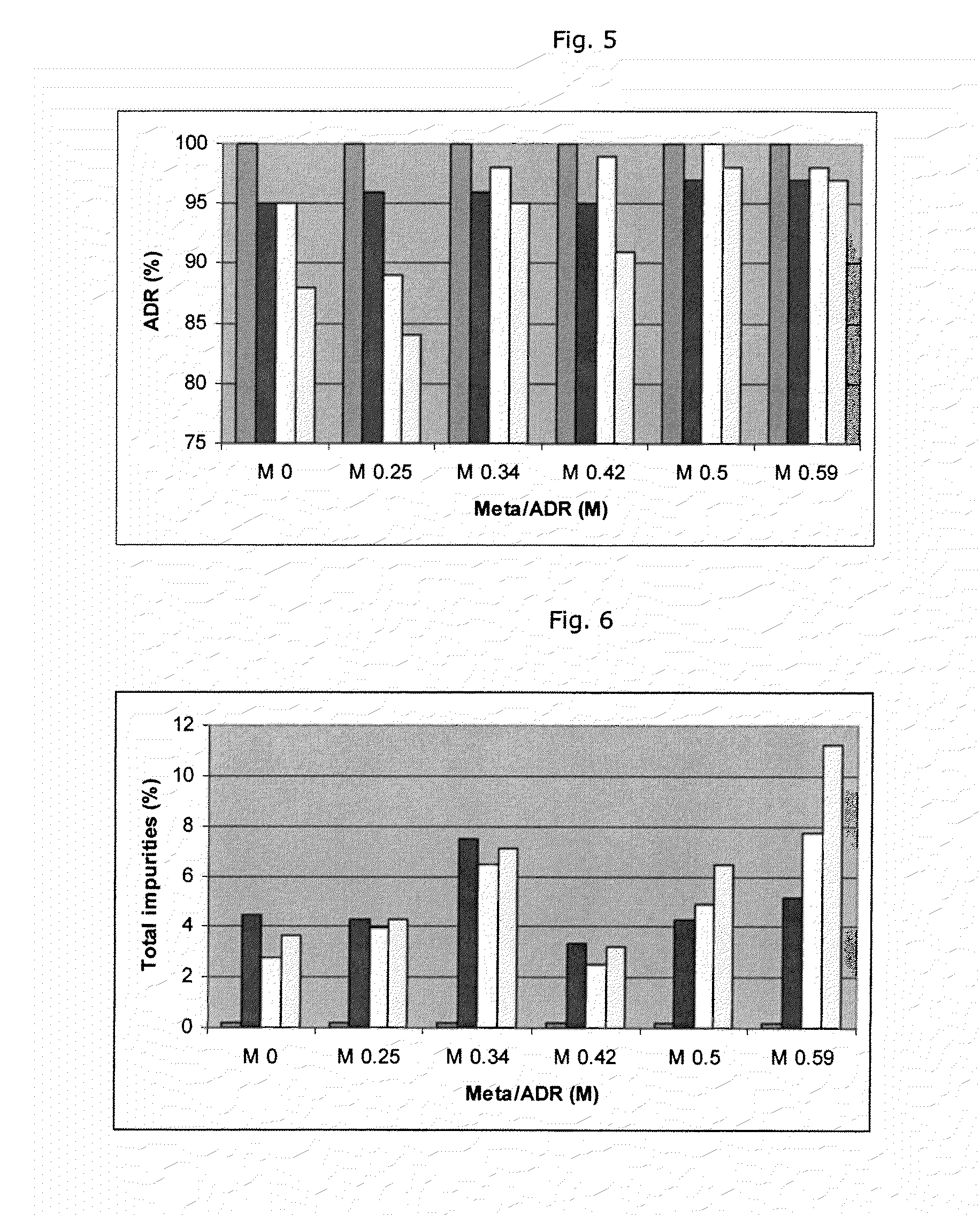

Stabilized composition comprising at least one adrenergic compound

InactiveUS20110003015A1Improve stabilityExtended shelf lifeOrganic active ingredientsBiocideCompound aAntioxidant

A stabilised composition comprising at least one adrenergic compound and at least one antioxidant selected from the group consisting of a bisulfate, a metabisulfite and a sulfite compound.

Owner:ALK ABELLO SA

Synergistic peroxide based biocidal compositions

InactiveUS20100092574A1Good curative effectBiocidePeroxide active ingredientsHydrogenChemical composition

Disclosed is a method for controlling microbial growth in an aqueous system containing sulfite and / or bisulfite residues by addition of a peroxy compound at a pH of greater than 5. Also disclosed is a method for stabilizing an active halogen biocide in an aqueous system containing peroxide residues by addition of an N-hydrogen compound to the active halogen biocide before combining it with the peroxide containing aqueous system. Further disclosed is an optimized papermaking biocide program consisting of initially treating sulfite bleached pulp with peroxide followed by application of an N-hydrogen-stabilized active halogen compound to the paper producing white waters and an analytical method for determining peroxide concentrations in aqueous systems in the presence of sulfite and / or bisulfite.

Owner:LONZA INC

RNA virus inactivation preservation solution and application thereof

ActiveCN111363729AAchieve immediate lysis and inactivationHigh sensitivityMicrobiological testing/measurementInactivation/attenuationLithium chlorideActive agent

The present invention discloses an RNA virus inactivation preservation solution. The inactivation preservation solution comprises ammonium salt, 1-ethyl-3-methylimidazolium bisulfate, lithium chloride, ethylenediaminetetraacetic acid, an RNase inhibitor, a surfactant, a reducing agent, a buffer agent and water. The present invention also provides an RNA virus sample inactivation and preservation method and an RNA virus detection method, and the method is conducted by using the inactivation preservation solution. The preservation solution has low cost, inhibits RNase activity, preserves RNA integrity, realizes preservation and transportation of samples at room temperature, can also quickly inactivate pathogens at room temperature, reduces infection risks of medical personnel, and reduces false negatives in detection. At the same time, the inactivation preservation solution can realize a lysis function, does not contain chaotropic reagents and alcohols, is compatible with mainstream nucleic acid extraction kits on the market, greatly saves time of an entire process, and is particularly suitable for 2019 new coronavirus (COVID-19) inactivation and lysis steps after swab sampling.

Owner:苏州白垩纪生物科技有限公司

Industrial stereospecific synthesis of beta-artemether by using artemisinin as raw material

InactiveCN101857599AReduce usageReduce intermediate processOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSodium bisulfateBeta-Artemether

The invention discloses stereospecific synthesis of beta-artemether by using artemisinin as a raw material through a one-pot method, which comprises the following steps of: in a system of alkaline solution of dichloromethane, taking sodium borohydride as a reducing agent and aluminium tert-butoxide as a catalyst, and reducing to obtain dihydroartemisinin; and separating out a water phase, adding methanol, sodium acid sulfate, aluminum perchlorate nonahydrate, nickelousperchlorate and the like serving as catalysts for methyl etherification, and reacting at room temperature for 2 hours to obtain the beta-artemether, wherein the maximum yield rate of the beta-artemether is 85 percent and the maximum total yield rate of artemether is 93.5 percent. The method has the characteristics of low cost, high yield, short time and simple and safe operation, and is completely suitable for industrial production.

Owner:GUANGZHOU SWELLXIN SCI & TECH

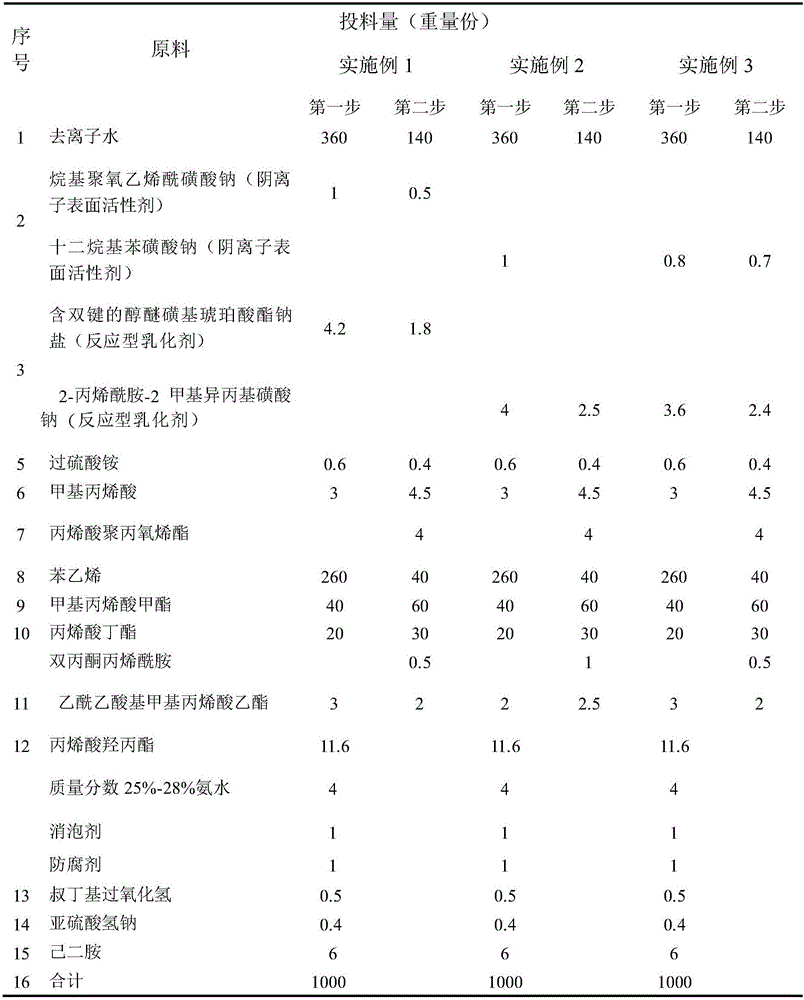

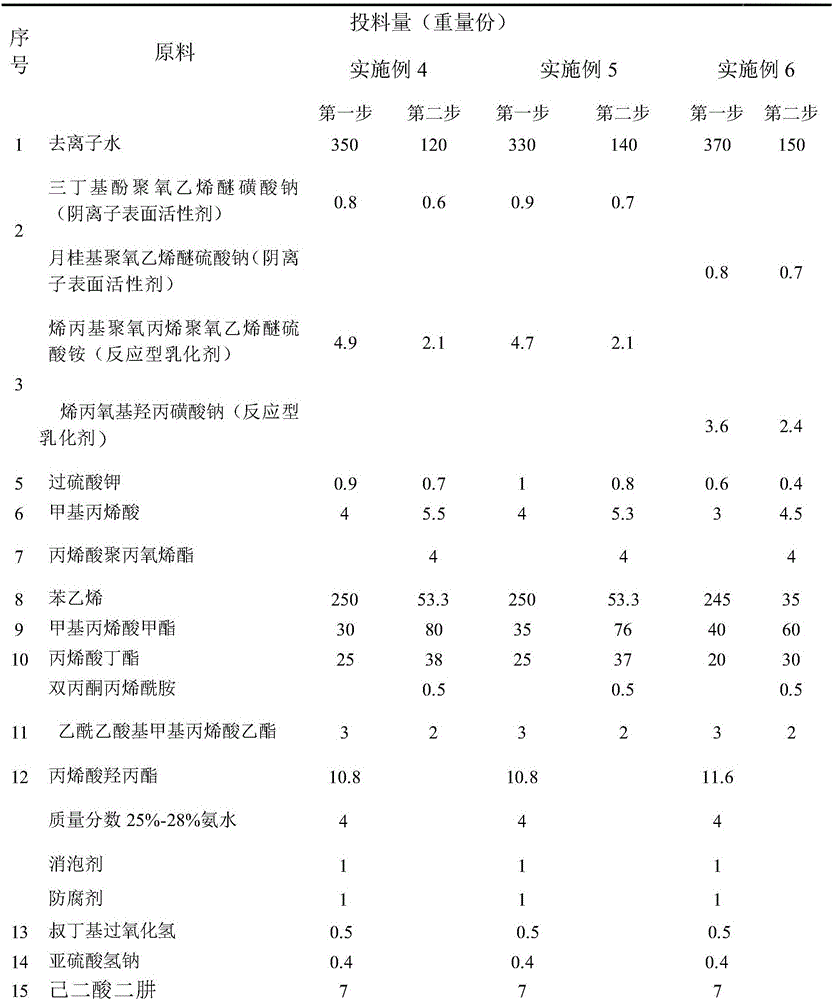

Acrylate copolymer emulsion, and aqueous industrial anticorrosive paint adopting acrylate copolymer emulsion as film forming substance

ActiveCN105859936AReduce the temperatureGuaranteed compactnessAnti-corrosive paintsCross-linkSodium bisulfate

The invention discloses an acrylate copolymer emulsion, and belongs to the technical field of aqueous coatings. The acrylate copolymer emulsion comprises, by weight, 450-550 parts of deionized water, 1-2 parts of an anionic surfactant, 5-8 parts of a reactive emulsifier, 3-15 parts of hydroxypropyl acrylate, 50-160 parts of methyl methacrylate, 20-75 parts of butyl acrylate, 200-410 parts of styrene, 5-10 parts of methacrylic acid, 3-10 parts of an adhesion function monomer, 2-9 parts of a cross-linking monomer, 3-10 parts of a cross-linking agent, 0.1-3 parts of an antifoaming agent, 0.8-2 parts of an initiator, 3-5 parts of ammonia water, 0.8-2 parts of an antiseptic, 0.1-1 part of tert-butyl hydroperoxide and 0.1-0.8 parts of sodium bisulfate. The invention also discloses an aqueous industrial anticorrosive coating adopting the acrylate copolymer emulsion as a film forming substance. The coating has the advantages of high adhesion to a substrate, high water resistance and high salt spray resistance.

Owner:HENGSHUI XINGUANG CHEM

Dimensionally stable solid rinse aid

ActiveUS20120231992A1Reduced stabilityReduced water solid filming in waterOrganic detergent compounding agentsDrying soapAlcoholPreservative

The present invention is a solid rinse aid composition and methods of making and using the same. The solid rinse aid composition generally includes sodium sulfate and urea as solidification agents and an effective amount of an alcohol ethoxylate compound sheeting agent component and an effective amount of defoamer component. The solid rinse aid composition may also incorporate a preservative system including sodium bisulfate. The solid rinse aid composition may be phosphate-free, aminocarboxylate-free, and GRAS if desired.

Owner:ECOLAB USA INC

Device for generating aqueous chlorine dioxide solutions

InactiveUS7150854B2Fast formingPromote rapid formationBiocideWater softeningAlkaline earth metalLiquid water

The invention pertains to a device for generating aqueous chlorine dioxide solutions when the device is contacted with liquid water. The device comprises an alkali metal or alkaline earth metal chlorite, e.g., sodium chlorite, and a chemical reagent comprising an acid or a material capable of releasing an acid upon exposure to liquid water, e.g., sodium bisulfate. The chlorite and the reagent are either combined as a mixture or are disposed as separate components adhered to the surface of one or more substrates. Upon exposure to liquid water, the chlorite and the reagent produce boundary layers. The chlorite and the reagent are disposed upon, and adhered to, the surface(s) of the substrates in a manner such that upon exposure to liquid water, the chlorite boundary layer comes into contact with the reagent boundary layer to thereby produce an aqueous chlorine dioxide solution.

Owner:BASF CATALYSTS LLC

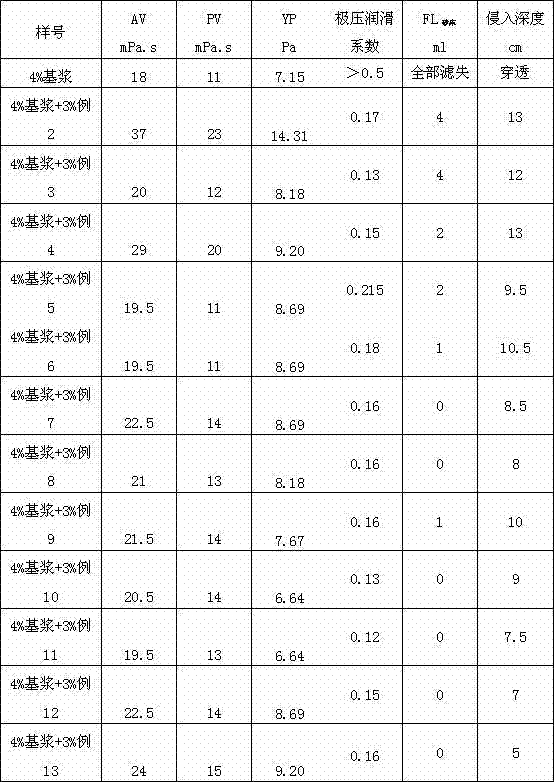

Temperature-resistance drilling fluid drill-feeding plugging agent and its preparation method

InactiveCN103937471AEffective blockingDoes not affect rheological parametersDrilling compositionSodium bisulfateVegetable fibers

The invention relates to a temperature-resistance drilling fluid drill-feeding plugging agent and its preparation method, the drill-feeding plugging agent comprises the following components by weight: 30-80 parts of vegetable fiber, 10-40 parts of mineral fiber, 10-40 parts of fruit shell, 0-10 parts of powdered steatile, and 3-10 parts of silicon-based gel deformation particles. The silicon-based gel deformation particles enable emulsification and dispersion of 1.4-2.5 parts of vinyltriethoxysilane monomer according to weight to an aqueous solution composed of 18-24 parts of acrylamide, 0.0025-0.005 parts of N,N'-methylene bisacrylamide, 0.7-1.25 parts of OP-10 and 0.1-0.17 parts of sodium dodecyl benzene sulfonate, 0.003 parts of disodium ethylene diamine tetraacetate, 0.009-0.12 parts of ammonium persulfate and 0.009-0.012 parts of sodium bisulfate, a process of micellar copolymerization is carried out, a polymer is dried, granulated and crushed to obtain the silicon-based gel deformation particles with average particle size of 80-200 meshes; easy-leakage highly-permeable stratum and micro crack are effectively plugged, rheological parameter of the drilling fluid is not influenced, frictional resistance coefficient of the drilling fluid is reduced, a storage layer is protected, and the drill-feeding plugging agent is suitable for plugging the easy-leakage stratum and the storage layer.

Owner:中国石油天然气股份有限公司冀东油田分公司钻采工艺研究院

Stabilized composition comprising at least one adrenergic compound

ActiveUS20120129944A1Improve stabilityExtended shelf lifeBiocideOrganic active ingredientsCompound aBisulfide

A stabilised composition comprising at least one adrenergic compound and at least one antioxidant selected from the group consisting of a bisulfite, a metabisulfite and a sulfite compound.

Owner:ALK ABELLO SA

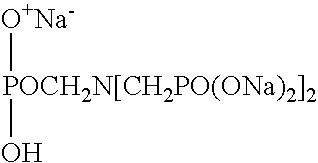

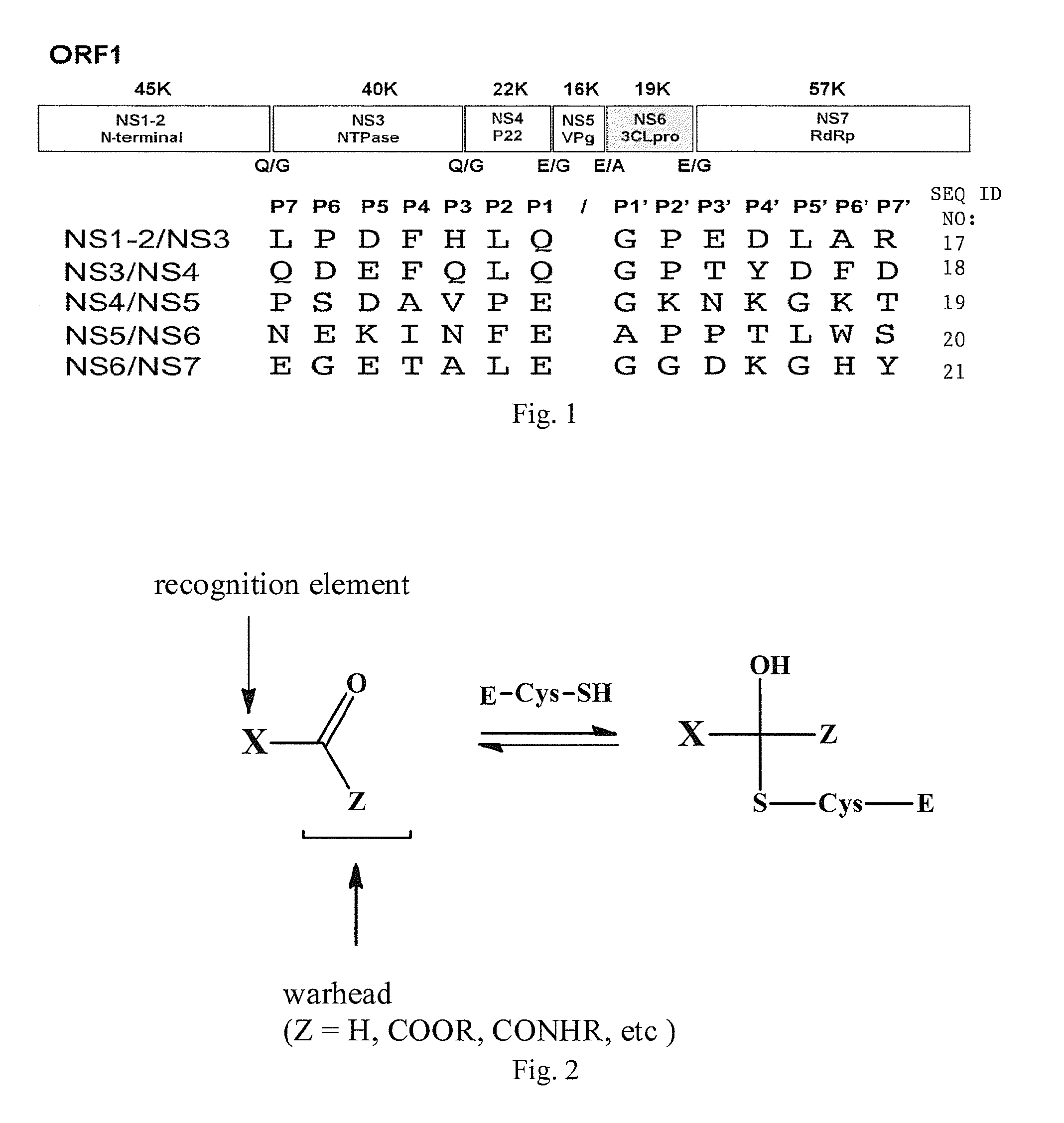

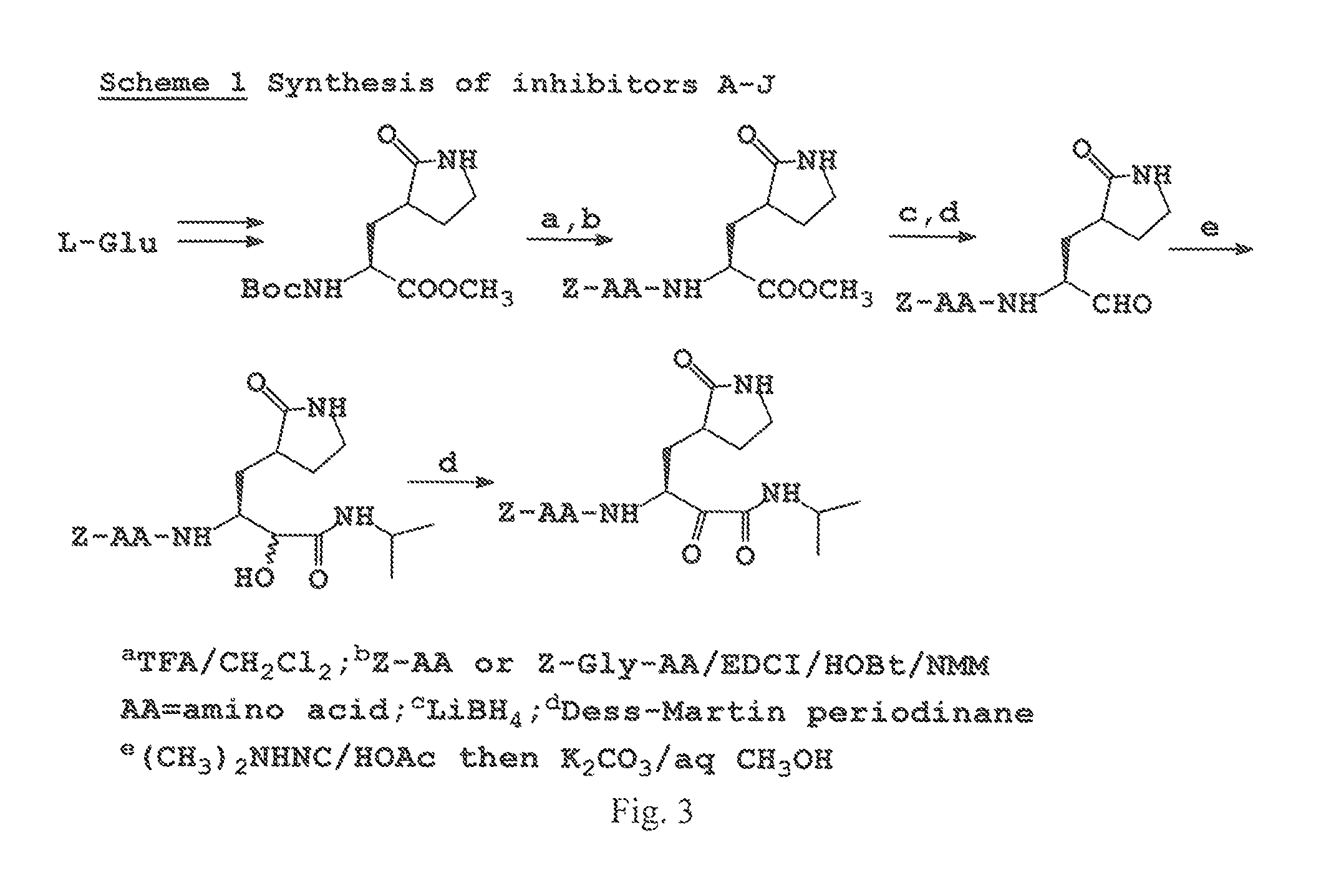

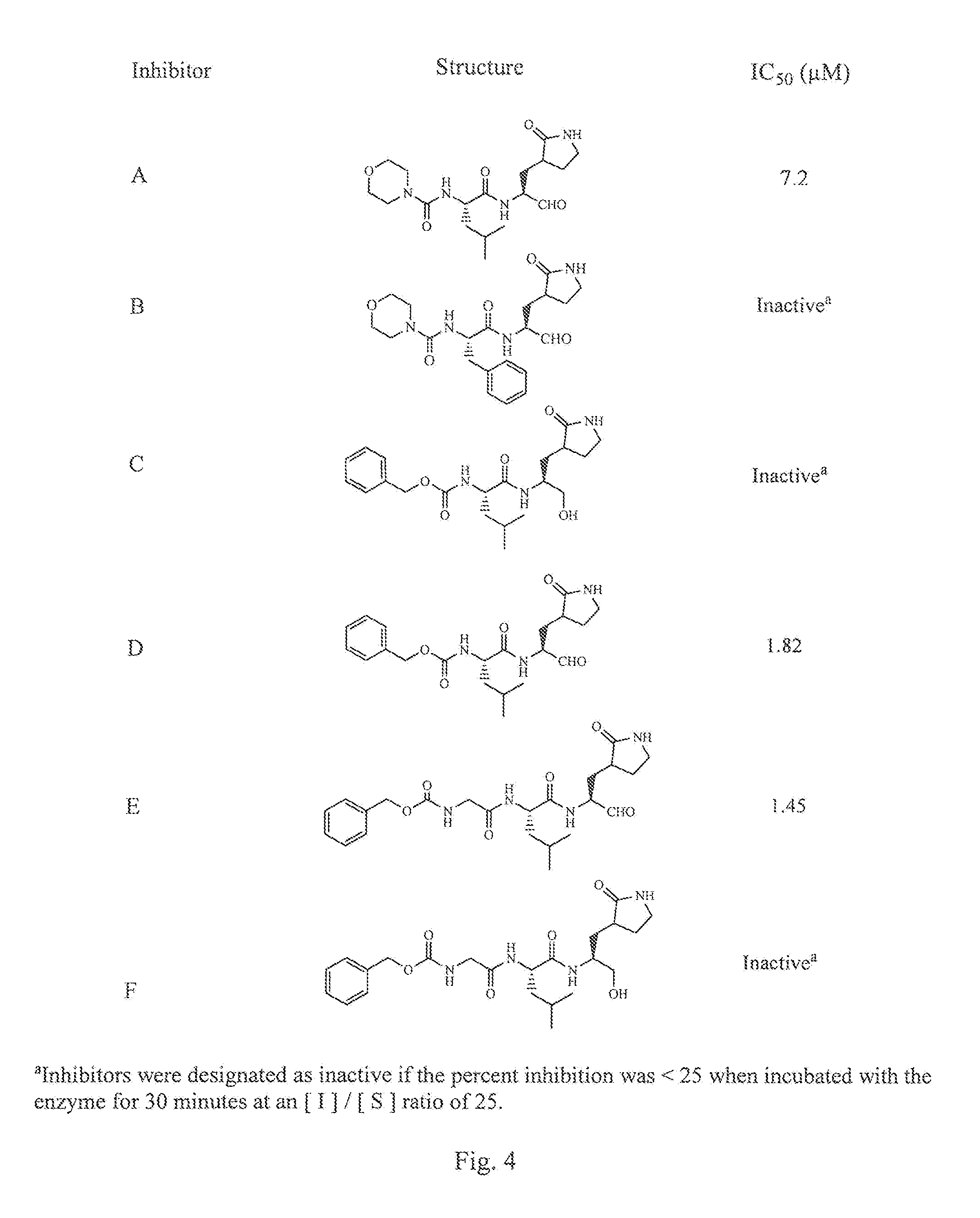

Broad-spectrum antivirals against 3C or 3C-like proteases of picornavirus-like supercluster: picornaviruses, caliciviruses and coronaviruses

Antiviral protease inhibitors, including peptidyl aldehydes, peptidyl α-ketoamides, peptidyl bisulfate salts, and peptidyl heterocycles, are disclosed, along with related antiviral compounds, and methods of using the same to treat or prevent viral infection and disease. The compounds possess broad-spectrum activity against viruses that belong to the picornavirus-like supercluster, which include important human and animal pathogens including noroviruses, enteroviruses, poliovirus, foot-and-mouth disease virus, hepatitis A virus, human rhinovirus (cause of common cold), human coronavirus (another cause of common cold), transmissible gastroenteritis virus, murine hepatitis virus, feline infectious peritonitis virus, and severe acute respiratory syndrome coronavirus.

Owner:WICHITA STATE UNIVERSITY +2

Composition with capability of providing thermal stability for polymer and application of composition

The invention relates to a composition with the capability of providing the thermal stability for polymer and application of the composition. The composition is prepared from the following raw materials: (1) hindered phenol, (2) phosphate or thioester, (3) an acid-removing agent and (4) sulfite, bisulfate or sulfide, wherein the mass ratio of hindered phenol, phosphate or thioester, the acid-removing agent and sulfite, bisulfate or sulfide is 1:(1-4):(0.5-2):(0.5-3). The invention also provides the application of the composition serving as an antioxidant in polymer resin. The composition is capable of lowering the melt index of polyolefin, eliminating a quinones compound serving as an intermediate and lowering the yellow index of polyolefin.

Owner:INST OF CHEM CHINESE ACAD OF SCI

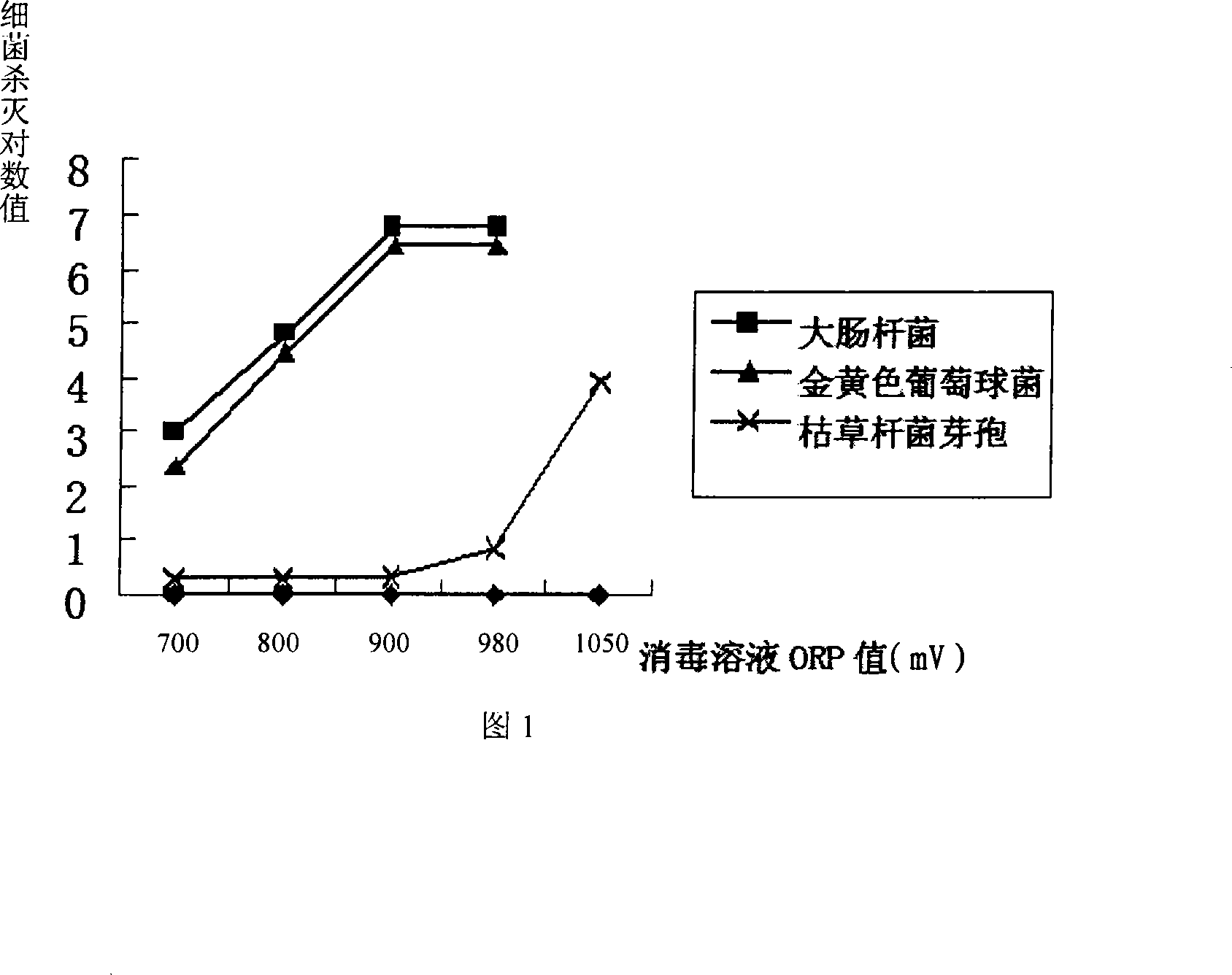

Disinfection effervescence tablet capable of continuously generating high oxidation-reduction potential

InactiveCN101233851AReduce concentrationAvoid disadvantagesBiocideDisinfectantsSide effectIrritation

The invention relates to a disinfectant effervescent tablet which can generate continuously high redox potential. The disinfectant effervescent tablet comprises the following components by weight portions: 4-8 portions of inorganic chloride salt, 8-12 portions of organic acid, 3-5 portions of one or more selected from carbonate, sodium bisulfate and hydroxylamine hydrochloride, 1-2 portions of stabilizing agent and 1-2 portions of corrosion inhibitor. The disinfectant effervescent tablet also comprises 1-2 portions of synergistic agent. An effervescent tablet of 1g / tablet is put in water and completely dissolved in 5-10 minutes to obtain 100ml-1,000ml solution; pH value of the dissolved solution is 3-7; redox potential is 800-1,200mv and concentration of available chlorine is 1000-3,000mg / L. The disinfectant of the invention is put in water; the inorganic chloride salt reacts with the organic acid to generate hypochlorous acid, nascent state chlorine, nascent state oxygen and high redox potential which interact with each other so as to greatly improve the bactericidal function; when in use, the consentration of available chlorine falls below 280ppm, which reduces side effects such as residue and irritation. The disinfectant effervescent tablet is a monobasic solid tablet, overcomes the shortcomings existing in liquid disinfectant and binary packing disinfectant, and improves largely convenience of use.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Method for synthesizing acetyl tributyl citrate by using ion type catalyst

ActiveCN101125814AEasy to makeLow pricePhysical/chemical process catalystsOrganic compound preparationAcetic anhydrideSodium bisulfate

The invention relates to a method for synthesizing acetyl tributyl citrate through electrophoretic catalyst. The method comprises the steps: step one: citric acid, butanol and sodium bisulfate monohydrate are added into a reactor, and the catalyst is recycled and filtered after the cooling of the stirring reflux reaction, filtrate is neutralized by adding alkaline solution and rinsed till neutral state, then the butanol is distilled and recycled under normal pressure, and the residual water is steamed under reduced pressure to acquire crude tirbutyl citrate, and the compound decolurant of acticarbon and aluminum oxide is added into the crude tirbutyl citrat for decoloring treatment, thereby, the finished tirbutyl citrat is acquired; step two: the finished tirbutyl citrate, acetic anhydride and the sodium bisulfate monohydrate are added into the reactor, and the catalyst is filtered , cooled and recycled after 1.0-3.0 hours of stirring reaction under the temperature of 50-90 DEG C; filtrate is neutralized by adding alkaline solution and rinsed till neutral state; acetyl tributyl citrate is acquired after water phase is separated and n-butyl acetate is distilled under reduced pressure and recycled. The catalyst of the method of the invention is easily separated and recycled, the esterification process is not easily influenced by by-product, emulsification is not easy during the rinsing process and the product yield is high.

Owner:李祥庆

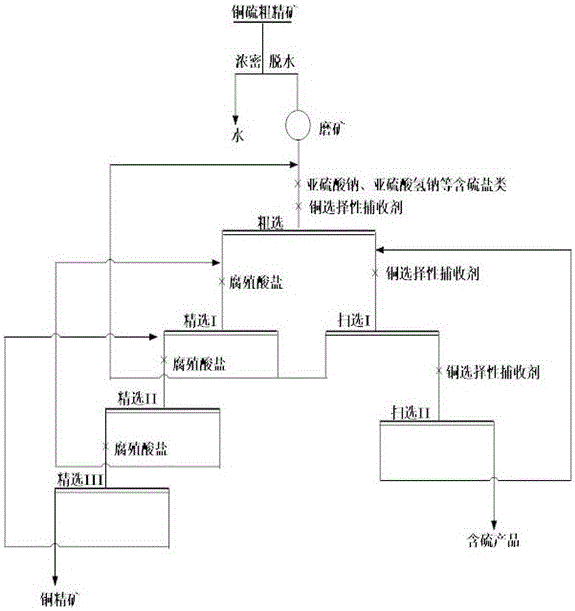

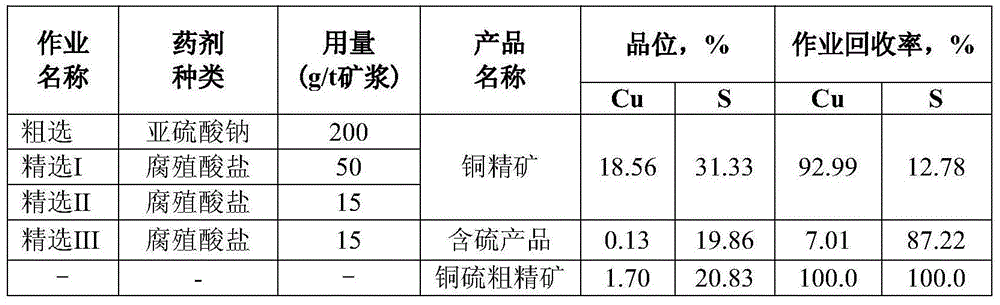

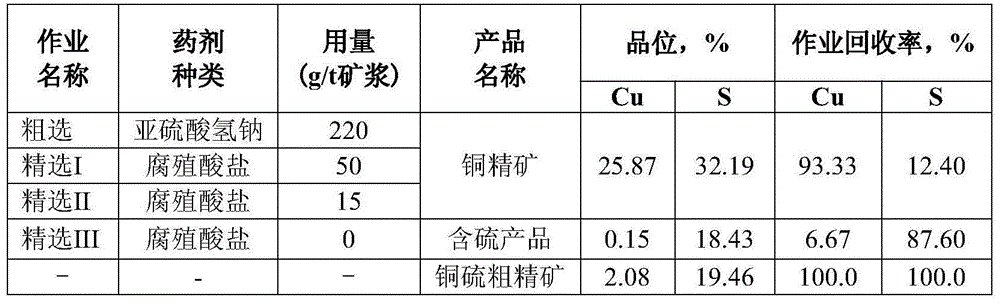

Copper and sulphur separation method for copper-sulphur ore

The invention provides a copper and sulphur separation method for copper-sulphur ore and relates to a method for separating copper from sulphur in copper-sulphur ore flotation rough concentrate. The copper and sulphur separation method for the copper-sulphur ore is characterized in that the steps of a treating process comprise that (1) ore grinding is conducted on copper-sulphur rough concentrate obtained through flotation; (2) after the ore grinding, a sulfur inhibitor selected from sodium sulfite, sodium metabisulfite, sodium bisulfate and sodium thiosulfate is added to the copper-sulphur rough concentrate, and a sulfur inhibition reaction is conducted; (3) a copper selective collector is added, and flotation is conducted; (4) a humate inhibitor is added to a flotation froth product; after an reaction with mixing is conducted, concentration is conducted; and (5) a humate inhibitor is added to a concentration froth product; after an reaction with mechanical mixing, concentration is conducted again, and copper concentrate separated from the sulphur is obtained. The copper and sulphur separation method for the copper-sulphur ore is simple in technology; lime and other highly alkaline inhibitors are not required to be added; required reagents are extensive in source and easy to prepare and add; the prepared reagents are good in flowability, easy to control, and not liable to block pipelines. The copper and sulphur separation method for the copper-sulphur ore is a novel copper and sulphur separation method.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Stabilized composition comprising at least one adrenergic compound

InactiveUS8628805B2Improve stabilityExtended shelf lifeOrganic active ingredientsBiocideCompound aAdrenergic

A stabilized composition comprising at least one adrenergic compound and at least one antioxidant selected from the group consisting of a bisulfate, a metabisulfite and a sulfite compound.

Owner:ALK ABELLO SA

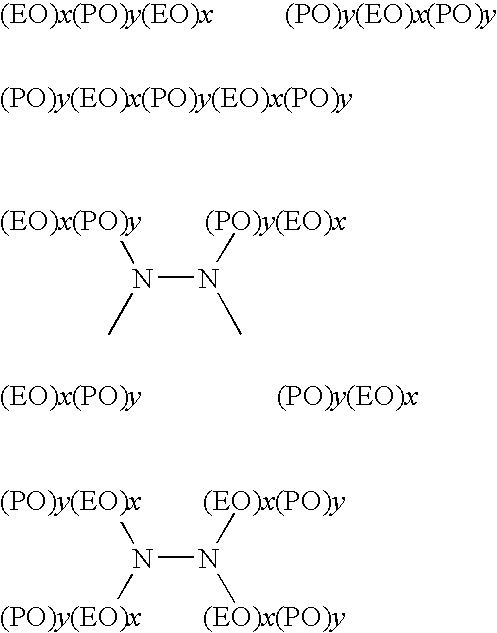

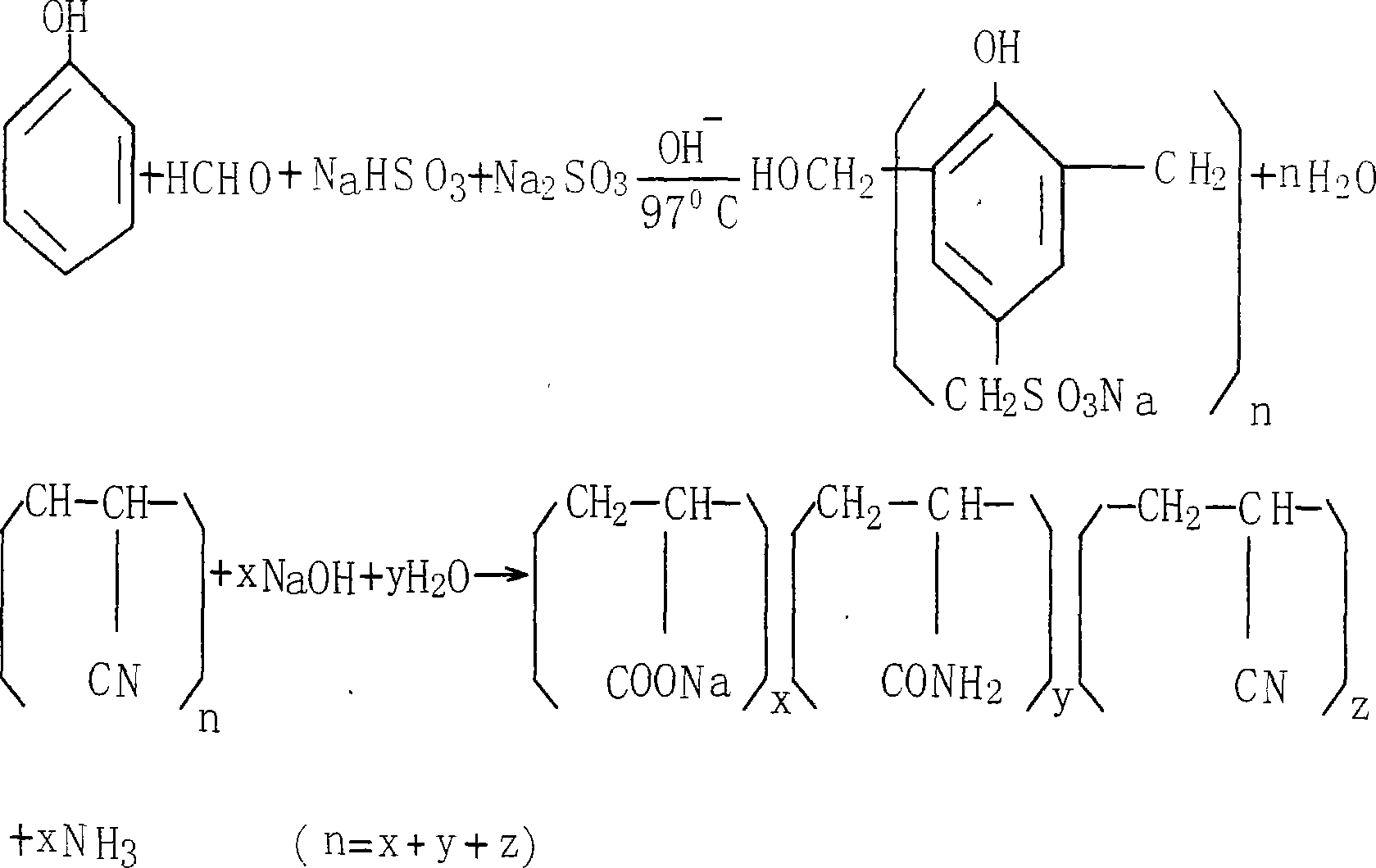

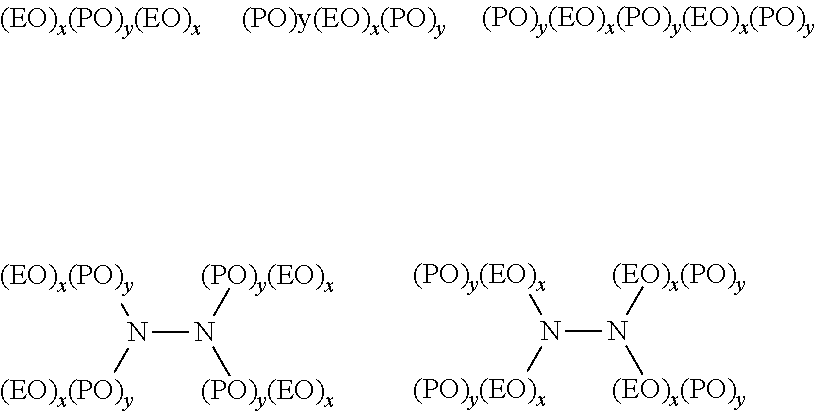

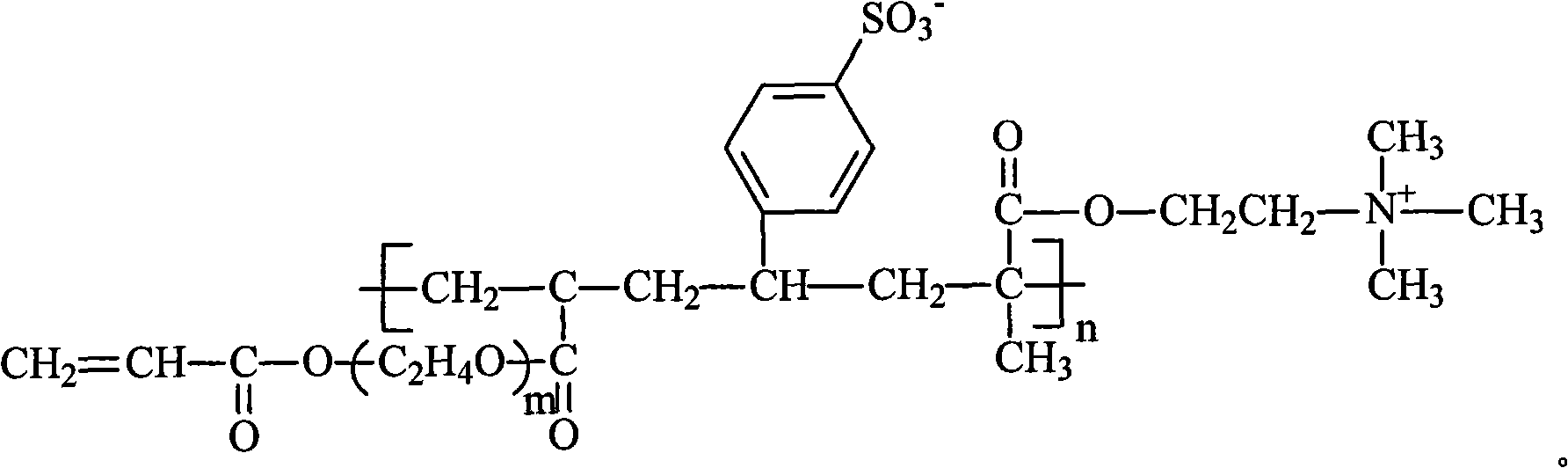

Amphoteric water-coal-slurry dispersing agent and preparation method thereof

InactiveCN101564663AImprove charge conditionChange hydrophobicityTransportation and packagingMixingPersulfatePolyethylene glycol

The invention provides an amphoteric water-coal-slurry dispersing agent and a preparation method thereof. The method comprises that: after polyethyleneglycol and polymerization inhibitor hydroquinone are mixed, acrylic acid, catalyst paratoluenesulfonic acid and a water-carrying agent dimethylbenzene are sequentially added to the mixture, are heated to react and are decompressed and distilled to obtain pale brown transparent liquid; the pale brown transparent liquid is adjusted to neutrality by Na2CO3 solution, is washed by saturated NaCl solution, and is extracted by 30ml aether to obtain an intermediate product I; deionized water, sulphonate or sulfoacid, cationic monomer and sodium bisulfate are stirred and dissolved; and the intermediate product I is dripped into persulfate aqueous solution to react to obtain polymer solution of an amphoteric ionic dispersing agent. The amphoteric water-coal-slurry dispersing agent synthesized by the preparation method introduces a long-chain group on the premise that the amphotericity of the dispersing agent is maintained, and can obviously improve the electric charge condition of coal particle surface so as to change the hydrophobic property of coal surface, thereby playing an excellent effect of viscosity reduction.

Owner:SHAANXI YI HAI CHENG CHEM TECH

High-efficient formaldehyde remover and preparation method thereof

The invention relates to a high-efficient formaldehyde remover and a preparation method thereof. The high-efficient formaldehyde remover is used for efficiently removing formaldehyde remained after interior decoration. The formaldehyde remover consists of a component A and a component B, wherein the component A is a chlorine dioxide matrix component and is prepared from the following raw materials in parts by weight: 0.5-10 sodium chlorite, 40-120 water and 0.2-5 agar; the component B is a slowly-released activating agent component and is prepared from the following raw material in parts by weight: 0.5-18 slowly-released activating agent which is one or mixture of boric acid, citric acid, tartaric acid, oxalic acid, dihydric phosphate, sodium bisulfate and sulfamic acid. The high-efficient formaldehyde remover has easily realized preparation process, simple components, low cost, convenient use, safety and effectiveness; the releasing time of chlorine dioxide gas is long, and the released chlorine dioxide gas can rapidly oxidize the formaldehyde in the air and also have the purifying efficacy of sterilizing, deodorizing and the like.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com