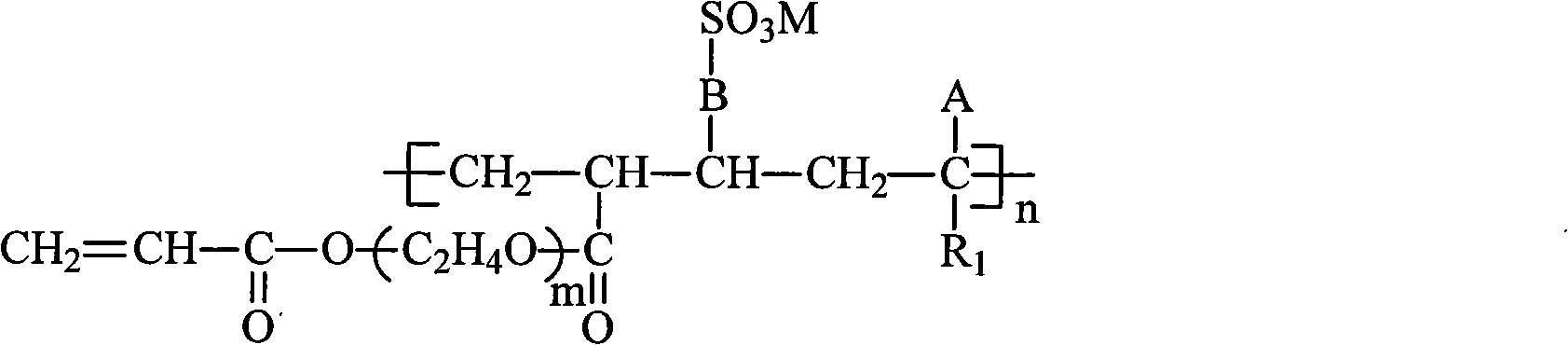

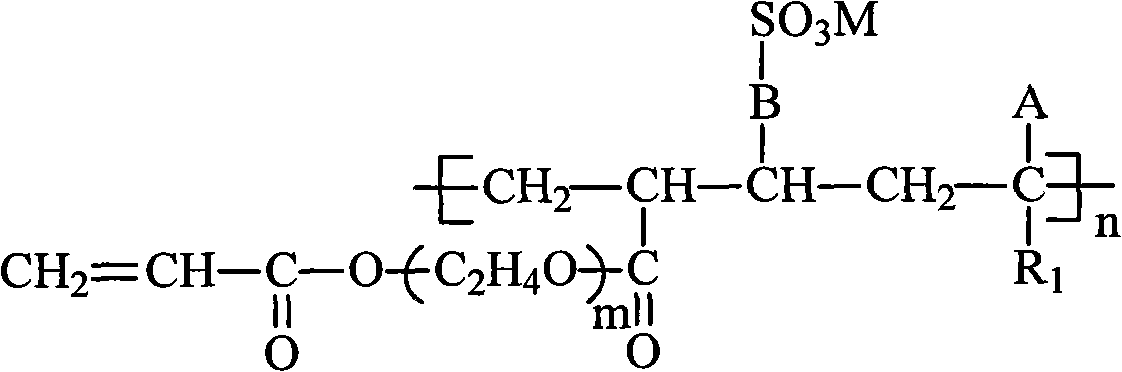

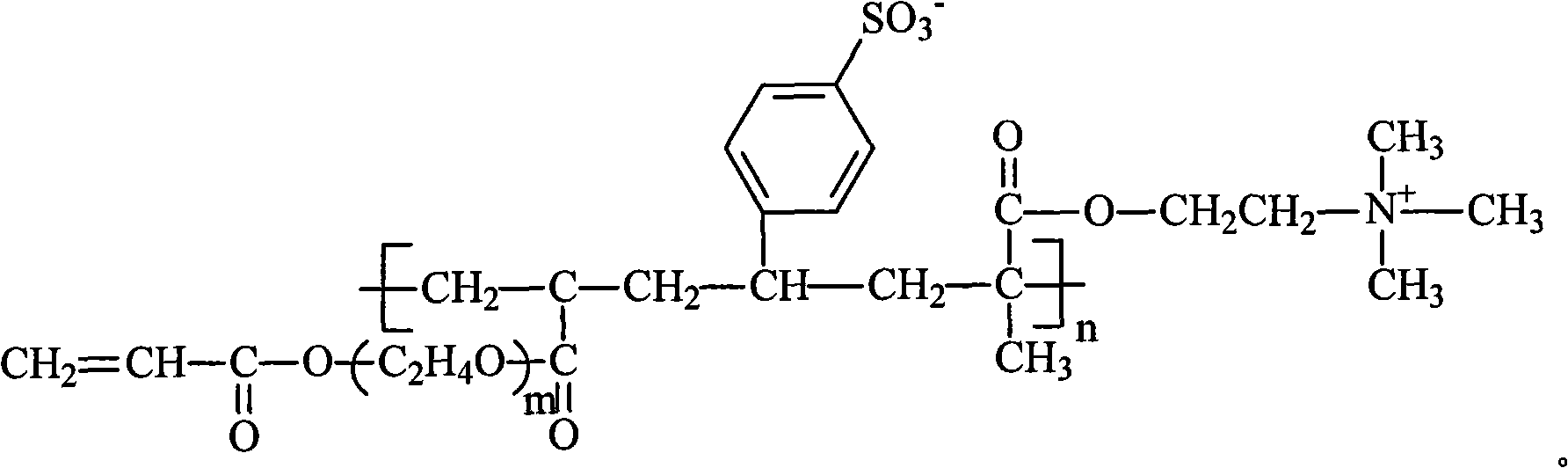

Amphoteric water-coal-slurry dispersing agent and preparation method thereof

A technology of coal-water slurry and dispersant, which is applied in chemical instruments and methods, liquid carbon-containing fuels, transportation and packaging, etc., can solve problems such as easy formation of sedimentation, high price, and unsatisfactory flow pattern of coal-water slurry, and achieve Good viscosity reduction effect, increase the effect of variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: at first in the there-necked flask that thermometer, stirrer and oil-water separator are housed, add the polyoxyethylene glycol of 70g and the polymerization inhibitor hydroquinone of 0.45g, be warming up to 80 ℃, treat polyethylene glycol and hydroquinone After diphenol is stirred evenly, add 30.2g of acrylic acid, 2.1g of catalyst p-toluenesulfonic acid and 30.1g of water-carrying agent xylene in turn, continue to heat up to 110°C, and react when no more water is generated in the oil-water separator At the end, when the temperature is lowered to 90°C, distill under reduced pressure to remove unreacted acrylic acid and water, and the catalyst and polymerization inhibitor are separated out as colorless crystals to obtain a brown-yellow transparent liquid;

[0024] The brownish-yellow transparent liquid was treated with 5% Na 2 CO 3 The solution was adjusted to neutrality, then washed with a saturated NaCl solution, extracted with 30 ml of ether, the organ...

Embodiment 2

[0028]Embodiment 2: first in the there-necked flask that thermometer, stirrer and oil-water separator are equipped with, add the polyoxyethylene glycol of 70g and the polymerization inhibitor hydroquinone of 0.45g, be warming up to 80 ℃, wait for polyethylene glycol and hydroquinone After diphenol is stirred evenly, add 30.2g of acrylic acid, 2.1g of catalyst p-toluenesulfonic acid and 30.1g of water-carrying agent xylene in turn, continue to heat up to 140°C, and react when no more water is generated in the oil-water separator At the end, when the temperature is lowered to 90°C, distill under reduced pressure to remove unreacted acrylic acid and water, and the catalyst and polymerization inhibitor are separated out as colorless crystals to obtain a brown-yellow transparent liquid;

[0029] The brownish-yellow transparent liquid was treated with 5% Na 2 CO 3 The solution was adjusted to neutrality, then washed with a saturated NaCl solution, extracted with 30 ml of ether, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com