Patents

Literature

5681 results about "Xylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Xylene (from Greek ξύλο, xylo, "wood"), xylol or dimethylbenzene is any one of three isomers of dimethylbenzene, or a combination thereof. With the formula (CH₃)₂C₆H₄, each of the three compounds has a central benzene ring with two methyl groups attached at substituents. They are all colorless, flammable liquids, some of which are of great industrial value. The mixture is referred to as both xylene and, more precisely, xylenes.

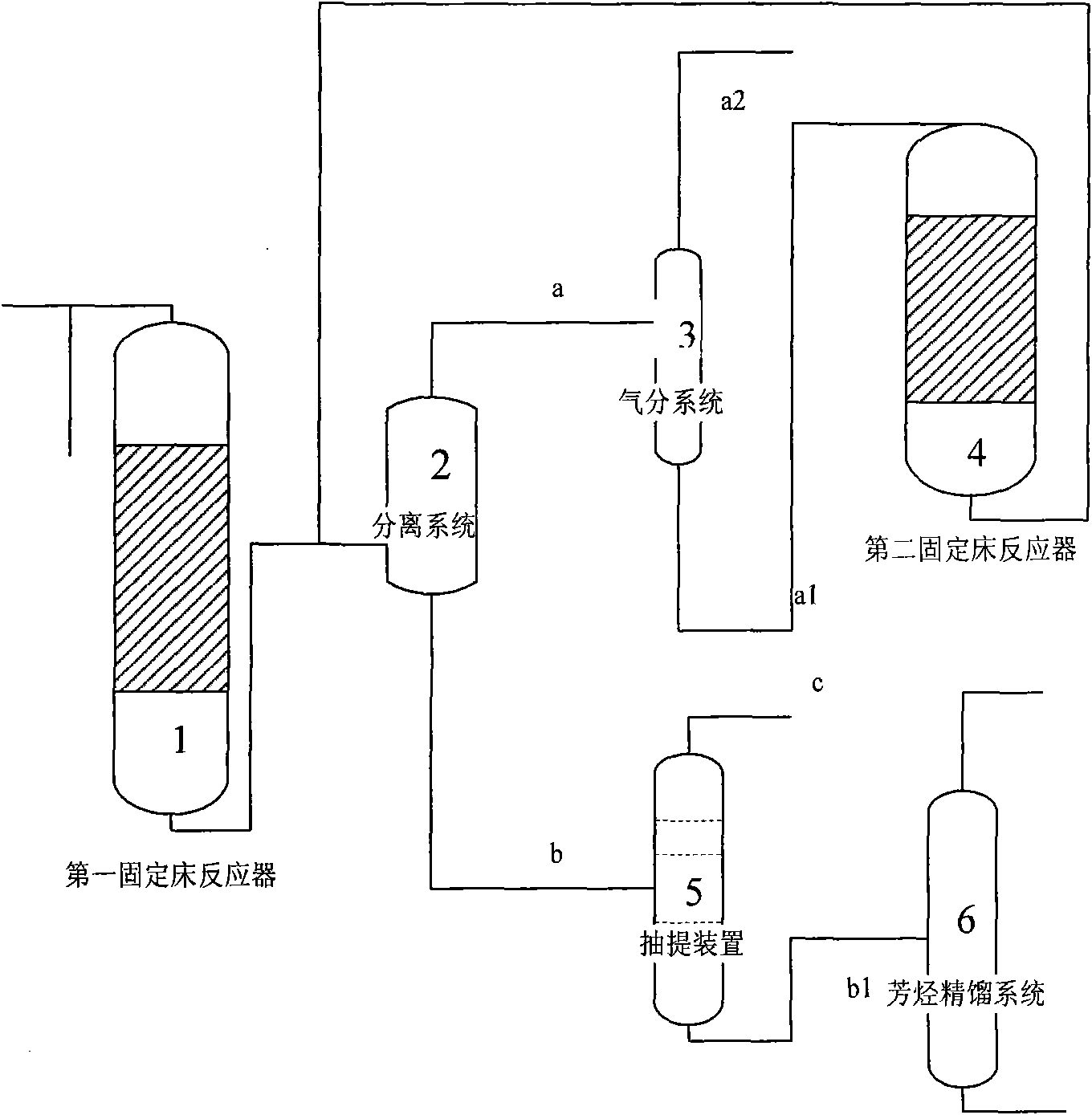

Method for preparing aromatic hydrocarbons and propylene simultaneously employing methanol/dimethyl ether

InactiveCN101607858AHigh selectivityIncrease added valueMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveFixed bed

The invention discloses a method for preparing aromatic hydrocarbons and propylene simultaneously employing methanol / dimethyl ether, comprising the following steps: 1) placing raw materials containing methanol or / and dimethyl ether, metals and molecular sieve based catalyst which is modified through silanizing in a first fixed bed reactor to perform catalytic reaction; 2) separating the products obtained in step 1) to obtain propylene, then placing propylene in a second fixed bed reactor with molecular sieve based catalyst which is modified by using metals to react, then performing aromatization on the obtained product in step 1) and obtaining aromatic hydrocarbons; then separating to obtain toluene and sending toluene back to the outlet of the first fixed bed reactor as a raw material. In the method, methanol is converted and prepared to aromatic hydrocarbons while propylene is produced at the same time and the content of paraxylene in aromatic hydrocarbons is high. In the products prepared by the method, the content of propylene can reach above 20%, the content of aromatic hydrocarbons can reach above 58wt% and the content of paraxylene in aromatic hydrocarbons is more than 35wt%.

Owner:CHINA NAT OFFSHORE OIL CORP +2

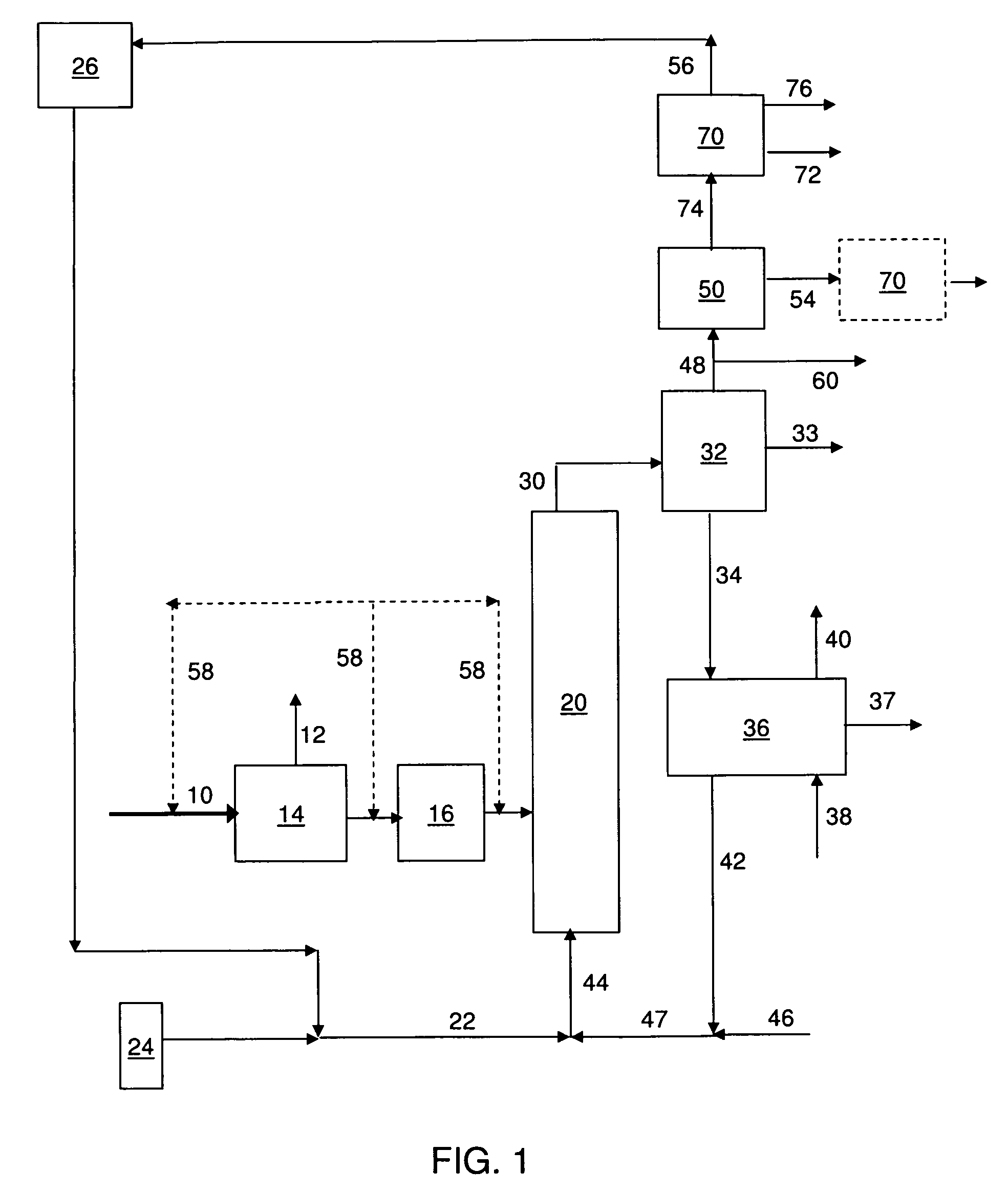

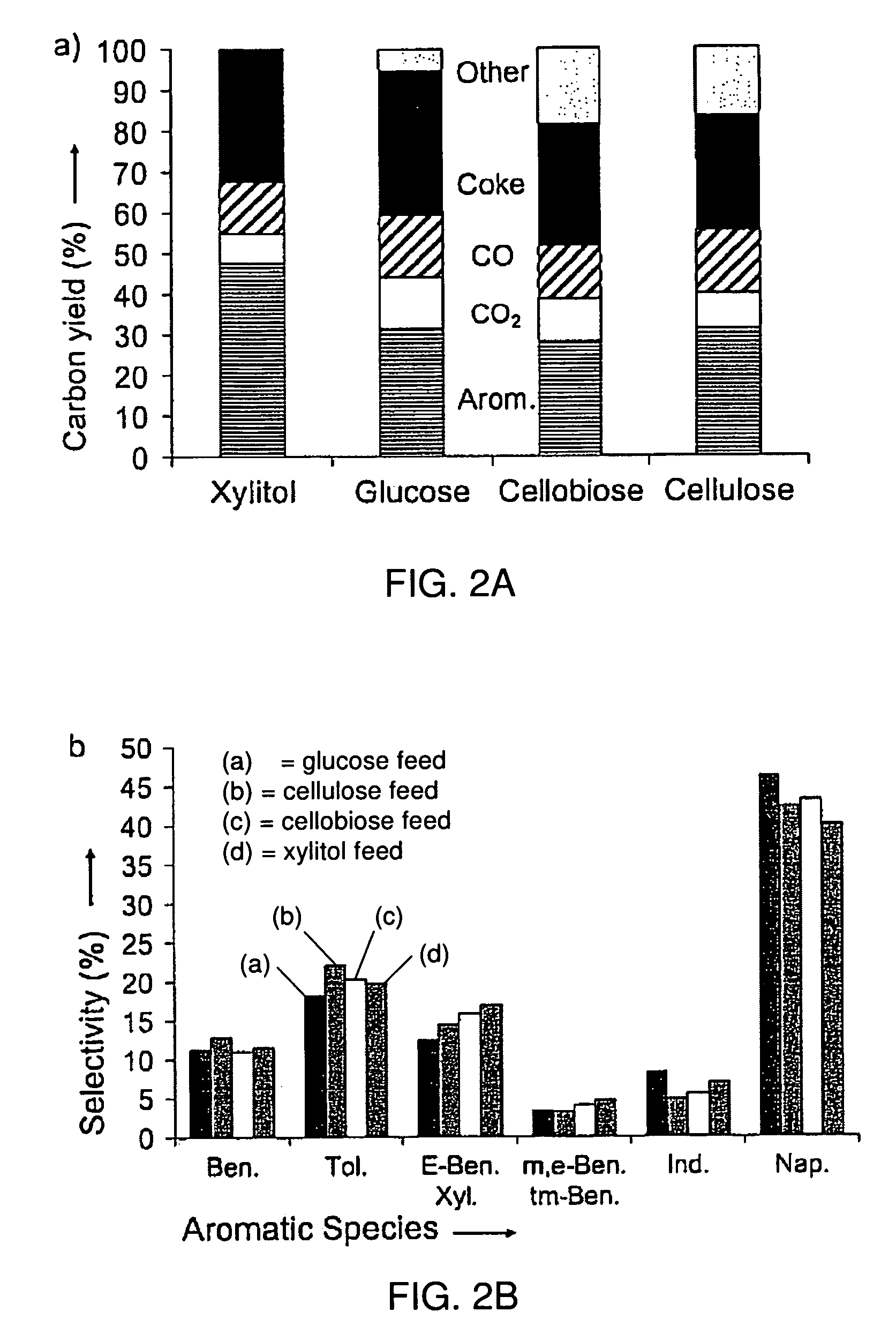

Catalytic pyrolysis of solid biomass and related biofuels, aromatic, and olefin compounds

ActiveUS8277643B2Minimize coke productionSolid fuelsHydrocarbon from oxygen organic compoundsCatalytic pyrolysisHigh rate

This invention relates to compositions and methods for fluid hydrocarbon product, and more specifically, to compositions and methods for fluid hydrocarbon product via catalytic pyrolysis. Some embodiments relate to methods for the production of specific aromatic products (e.g., benzene, toluene, naphthalene, xylene, etc.) via catalytic pyrolysis. Some such methods may involve the use of a composition comprising a mixture of a solid hydrocarbonaceous material and a heterogeneous pyrolytic catalyst component. In some embodiments, the mixture may be pyrolyzed at high temperatures (e.g., between 500° C. and 1000° C.). The pyrolysis may be conducted for an amount of time at least partially sufficient for production of discrete, identifiable biofuel compounds. Some embodiments involve heating the mixture of catalyst and hydrocarbonaceous material at high rates (e.g., from about 50° C. per second to about 1000° C. per second). The methods described herein may also involve the use of specialized catalysts. For example, in some cases, zeolite catalysts may be used; optionally, the catalysts used herein may have high silica to alumina molar ratios. In some instances, the composition fed to the pyrolysis reactor may have a relatively high catalyst to hydrocarbonaceous material mass ratio (e.g., from about 5:1 to about 20:1).

Owner:UNIV OF MASSACHUSETTS

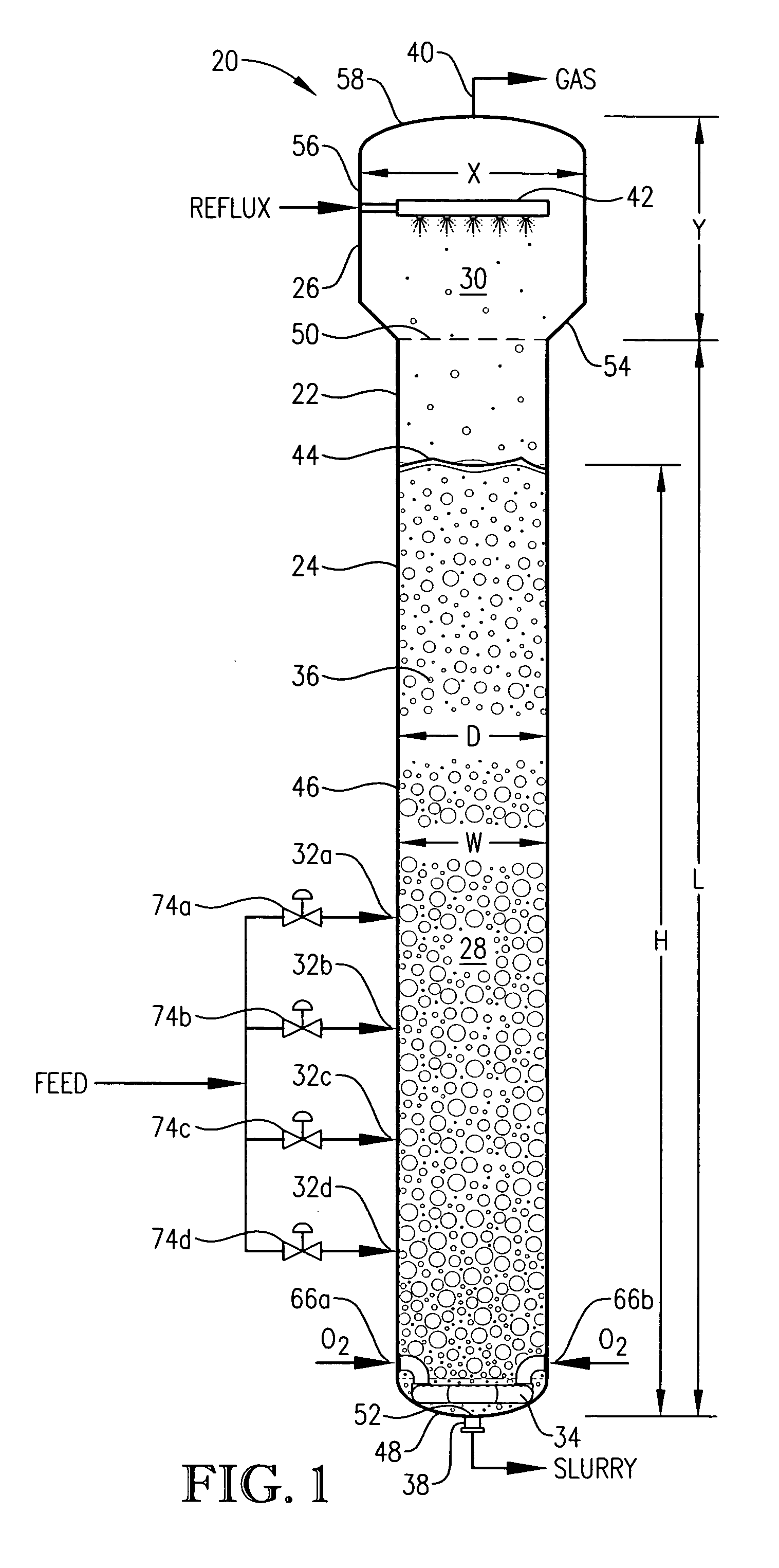

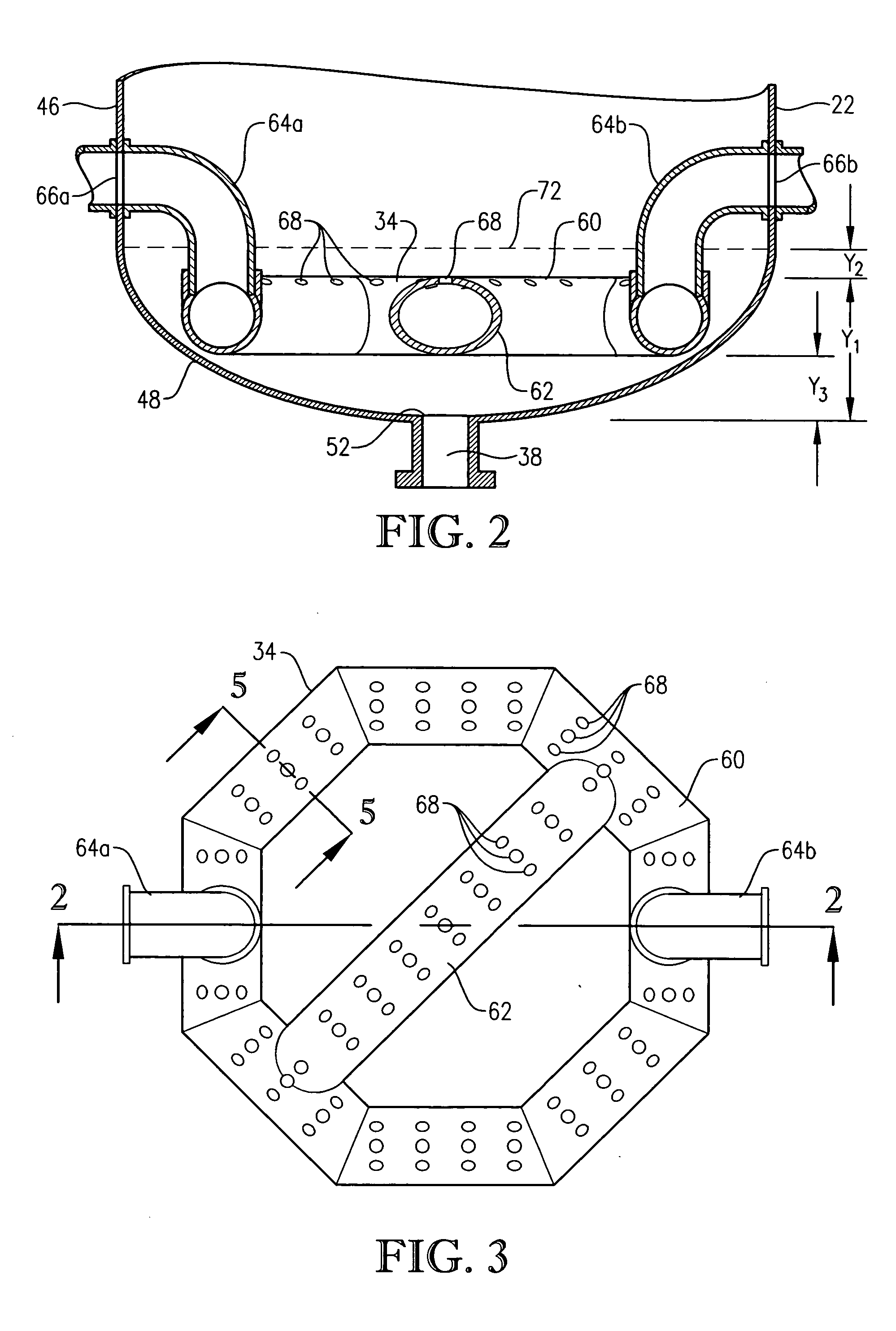

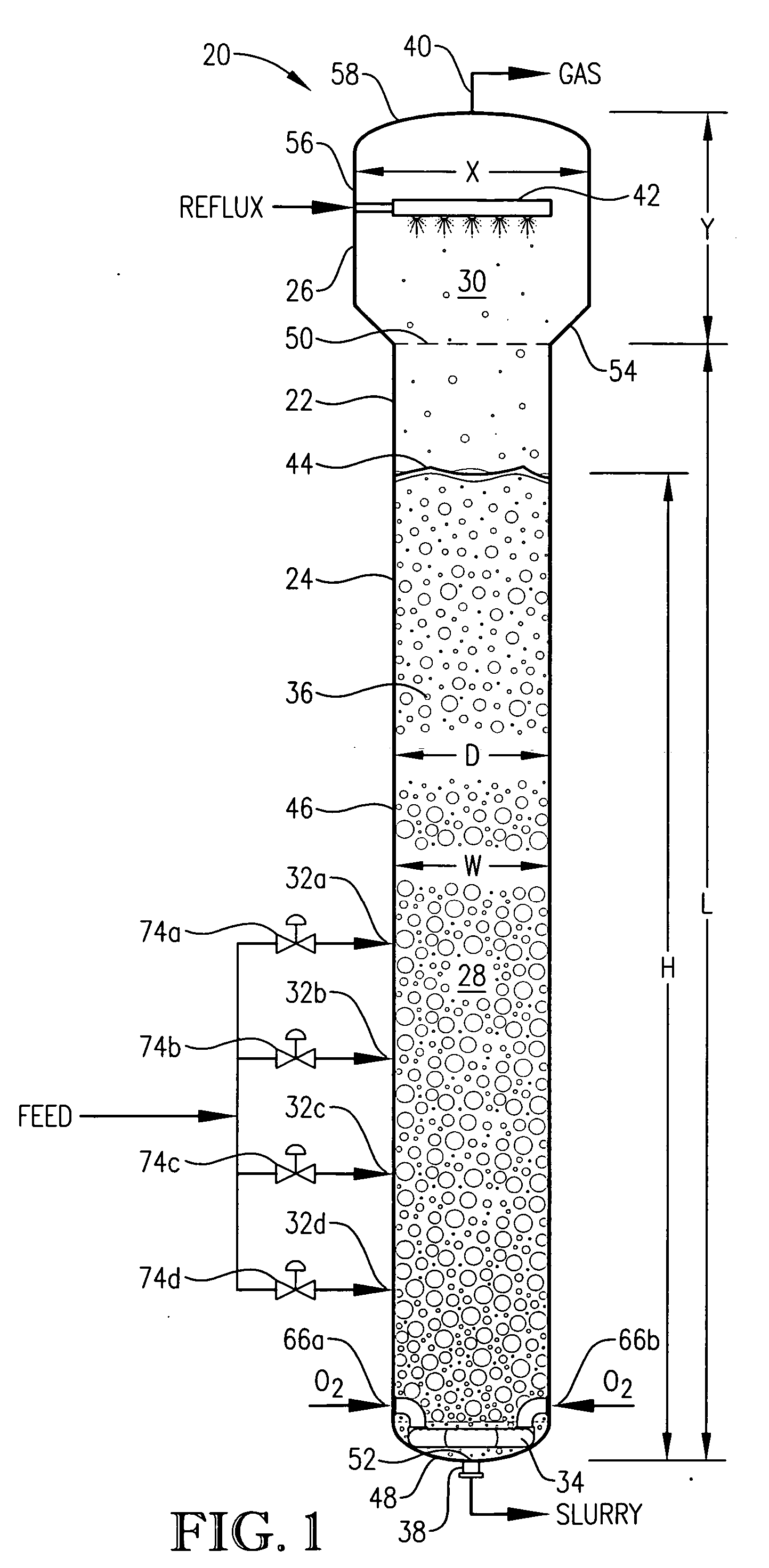

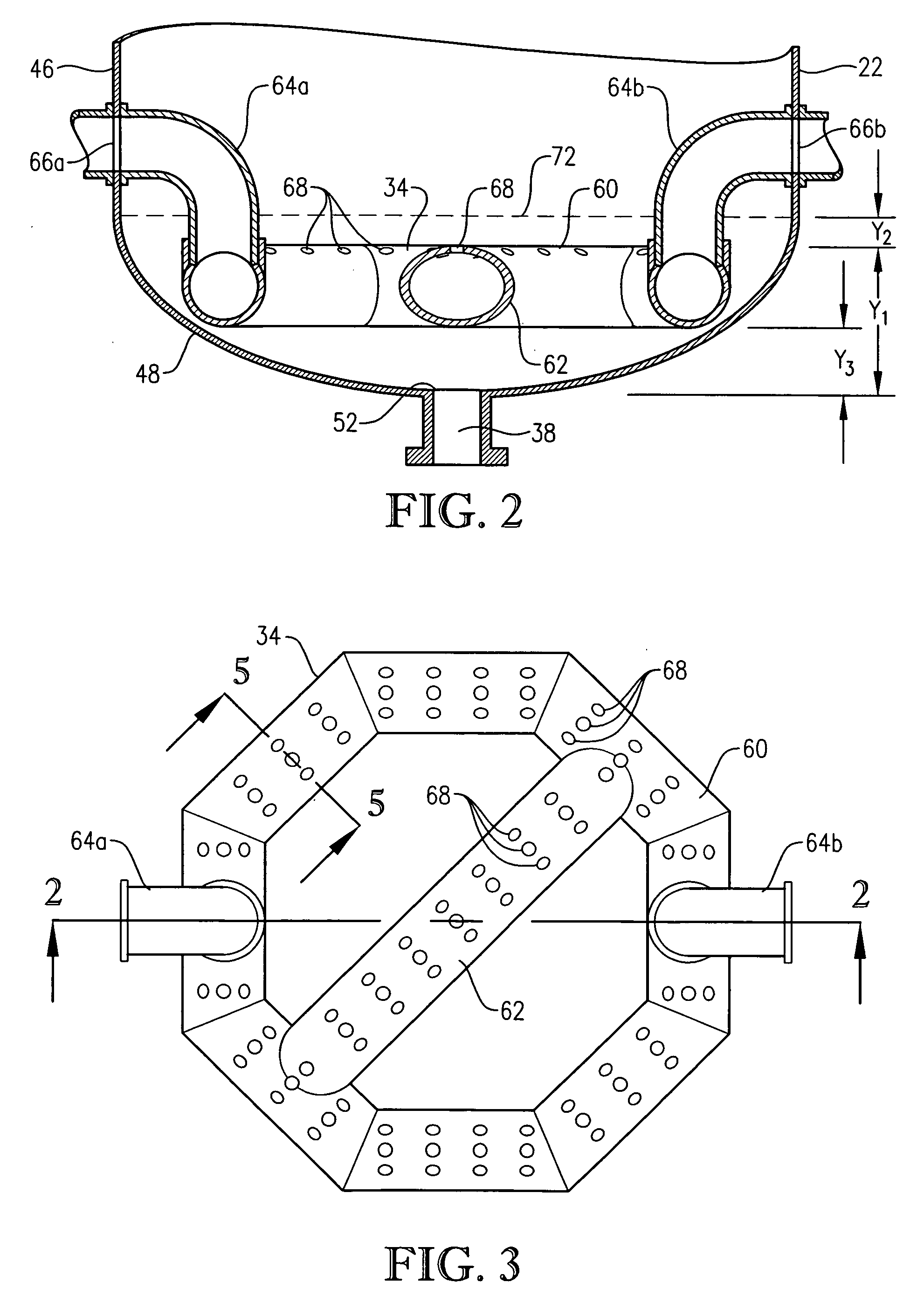

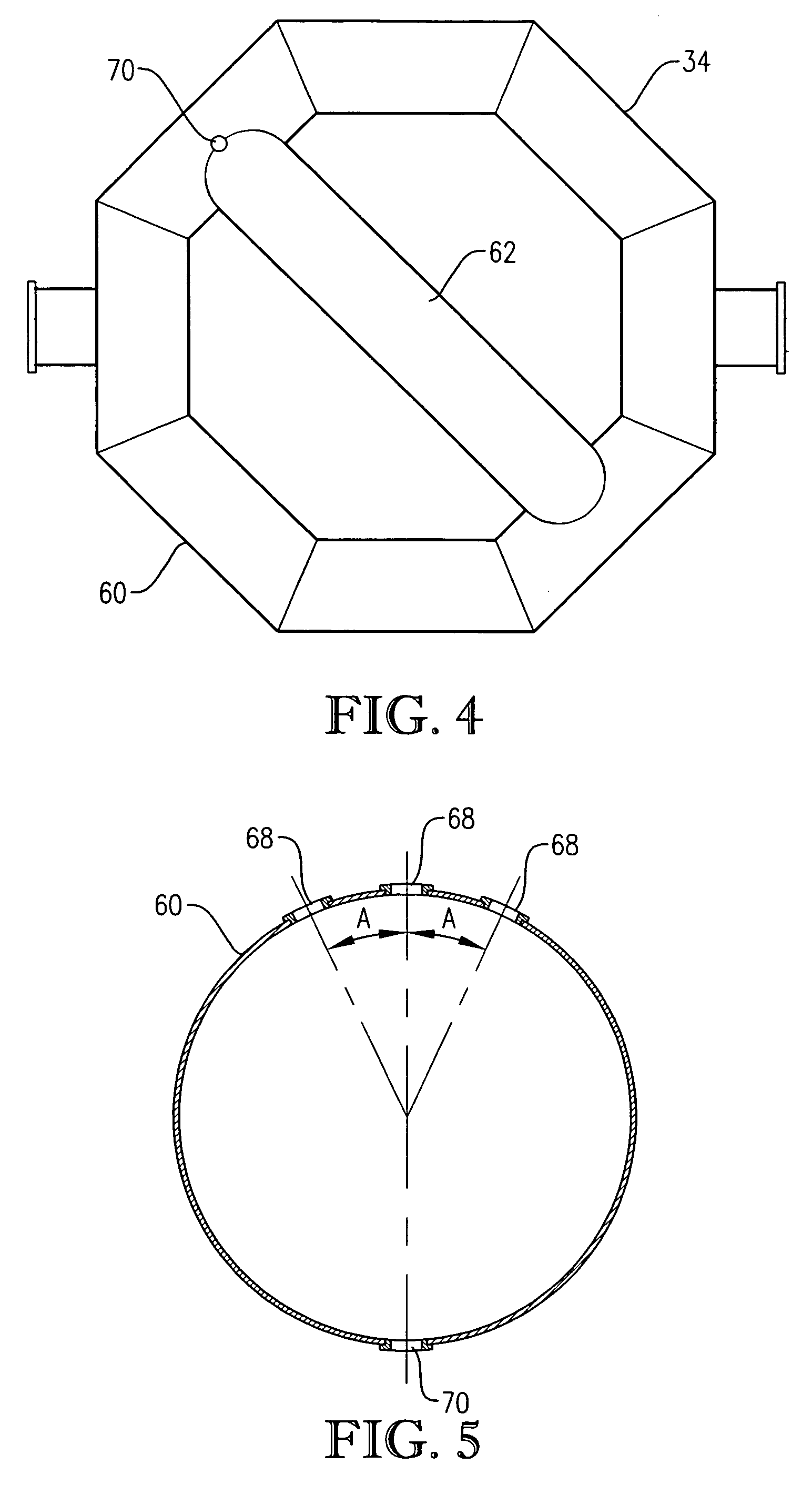

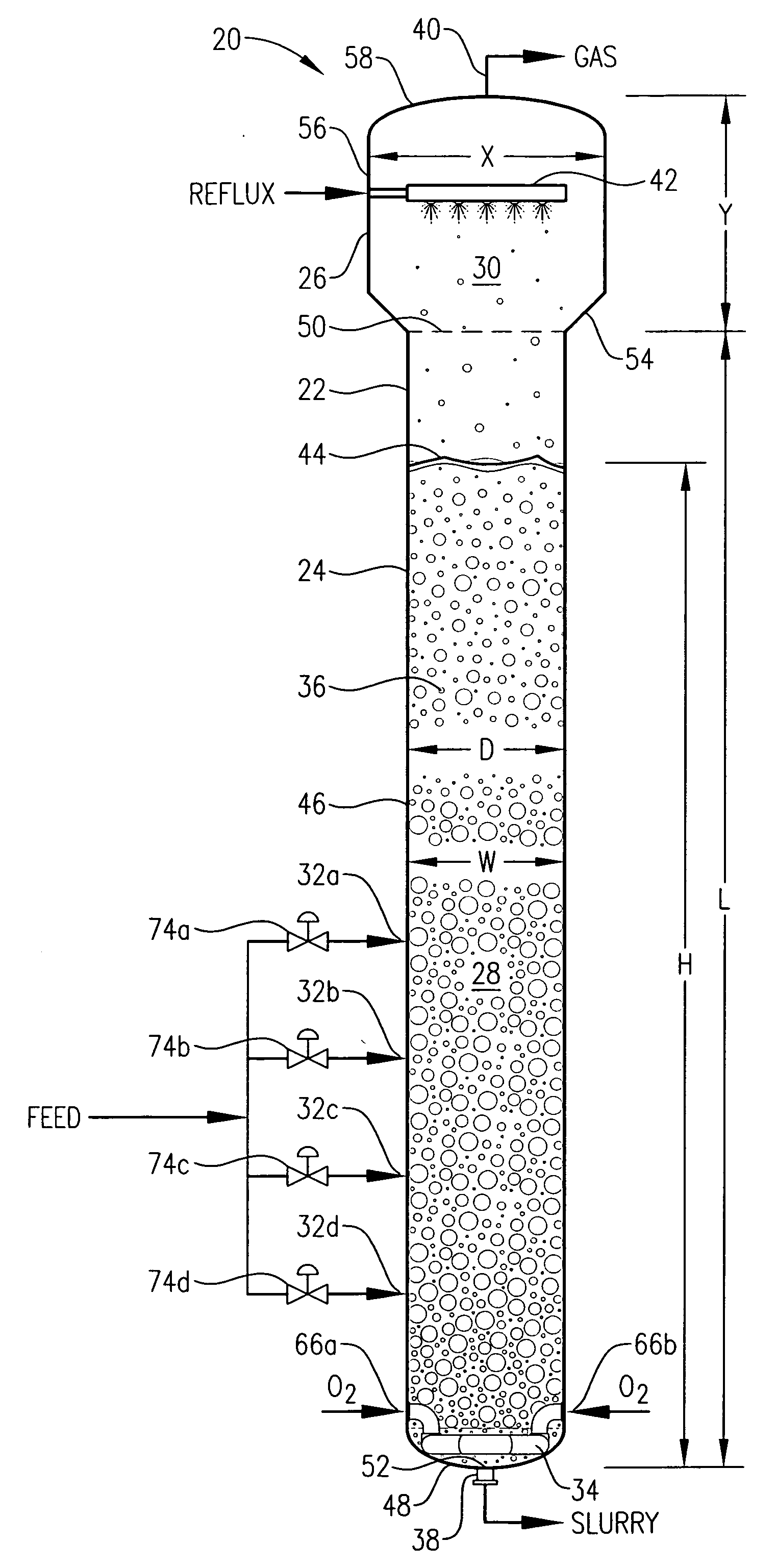

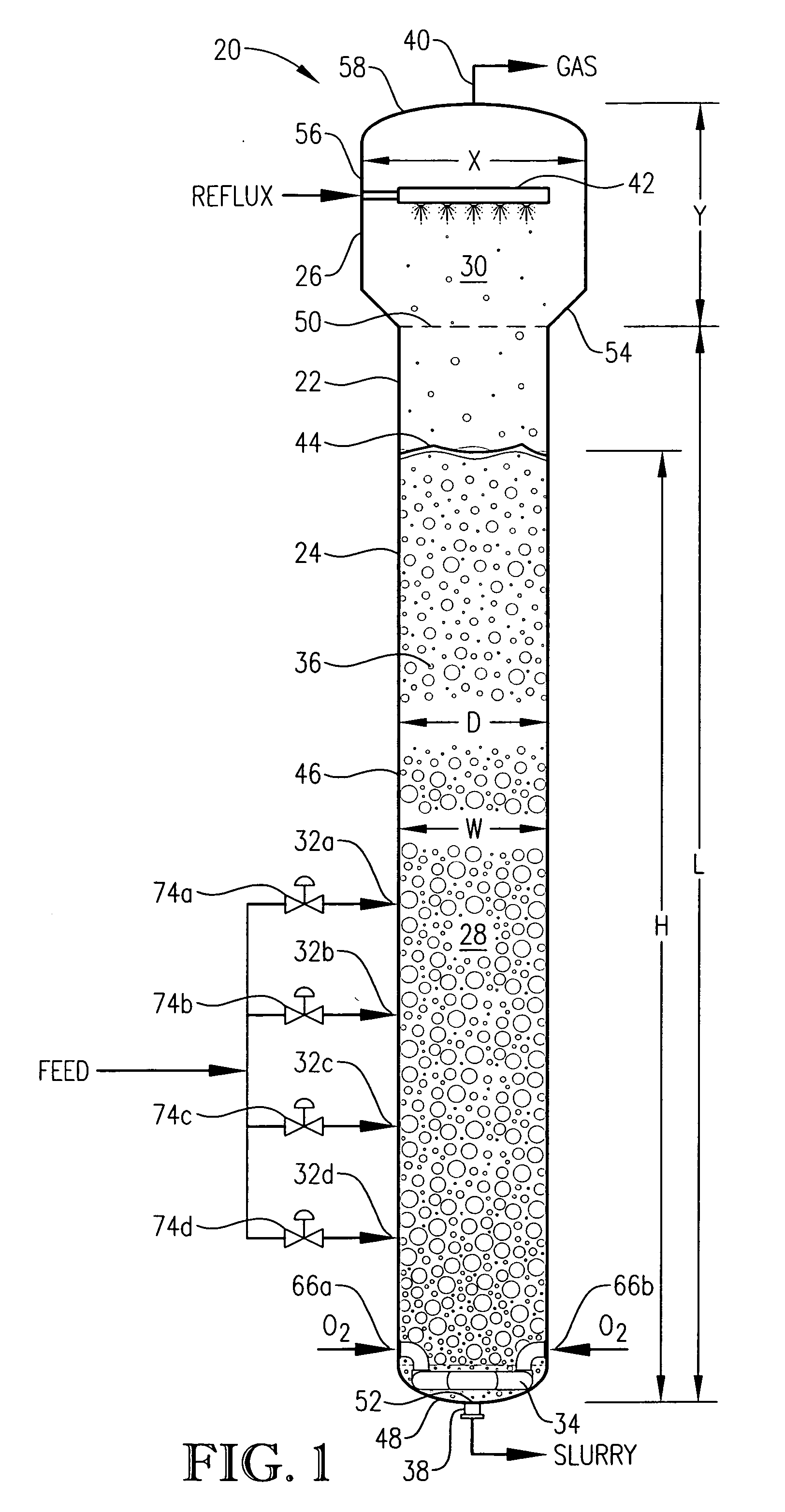

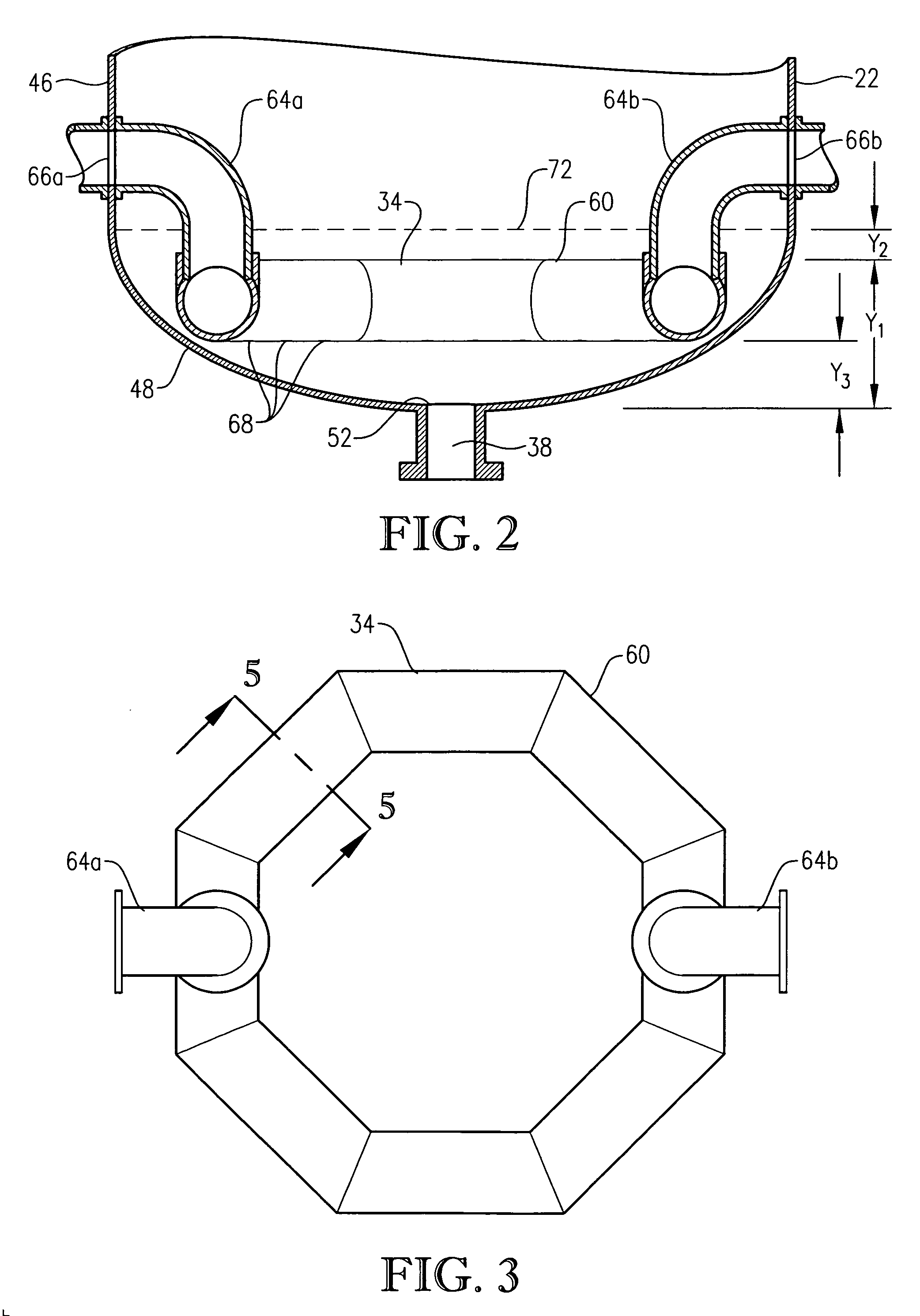

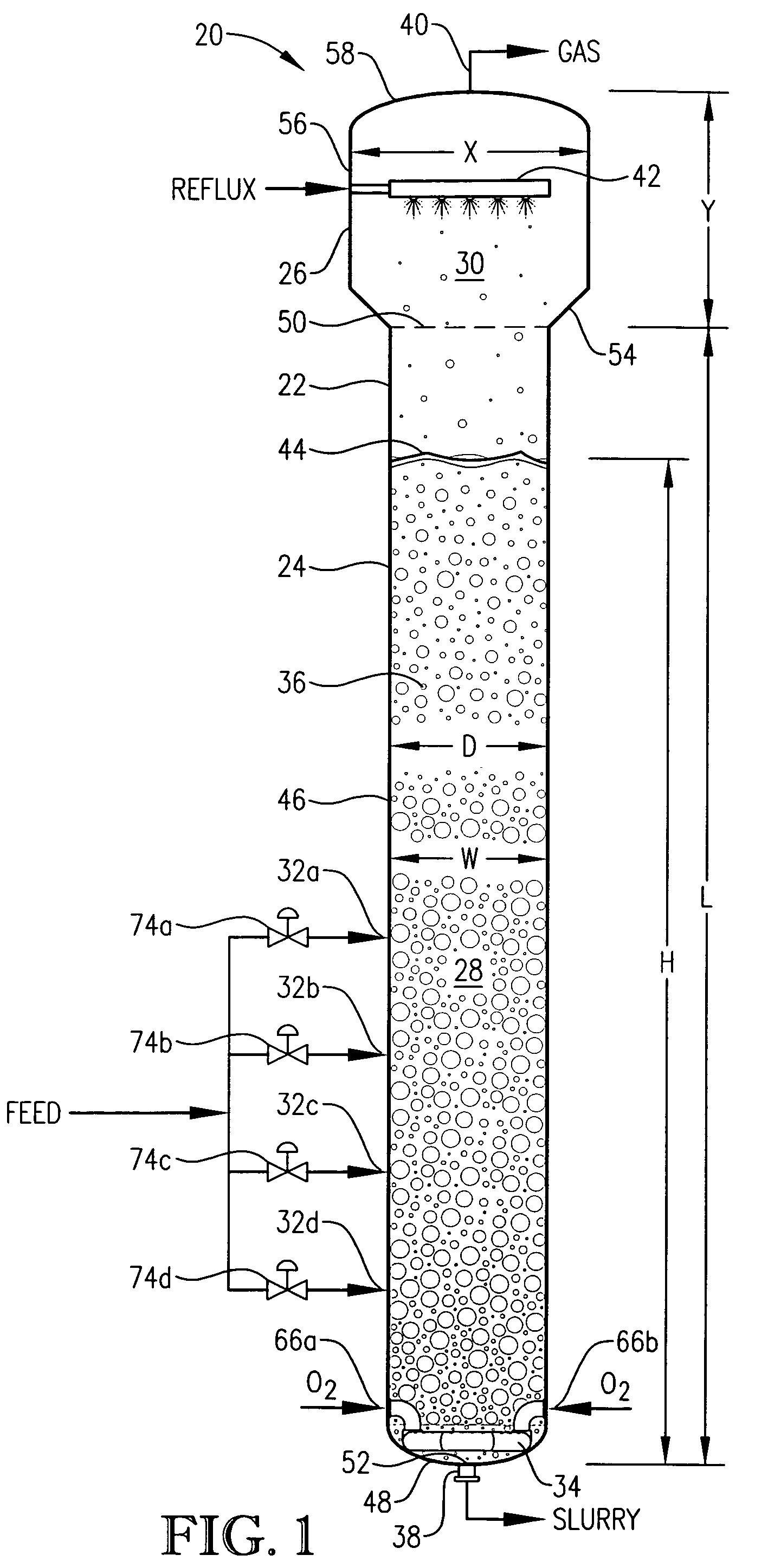

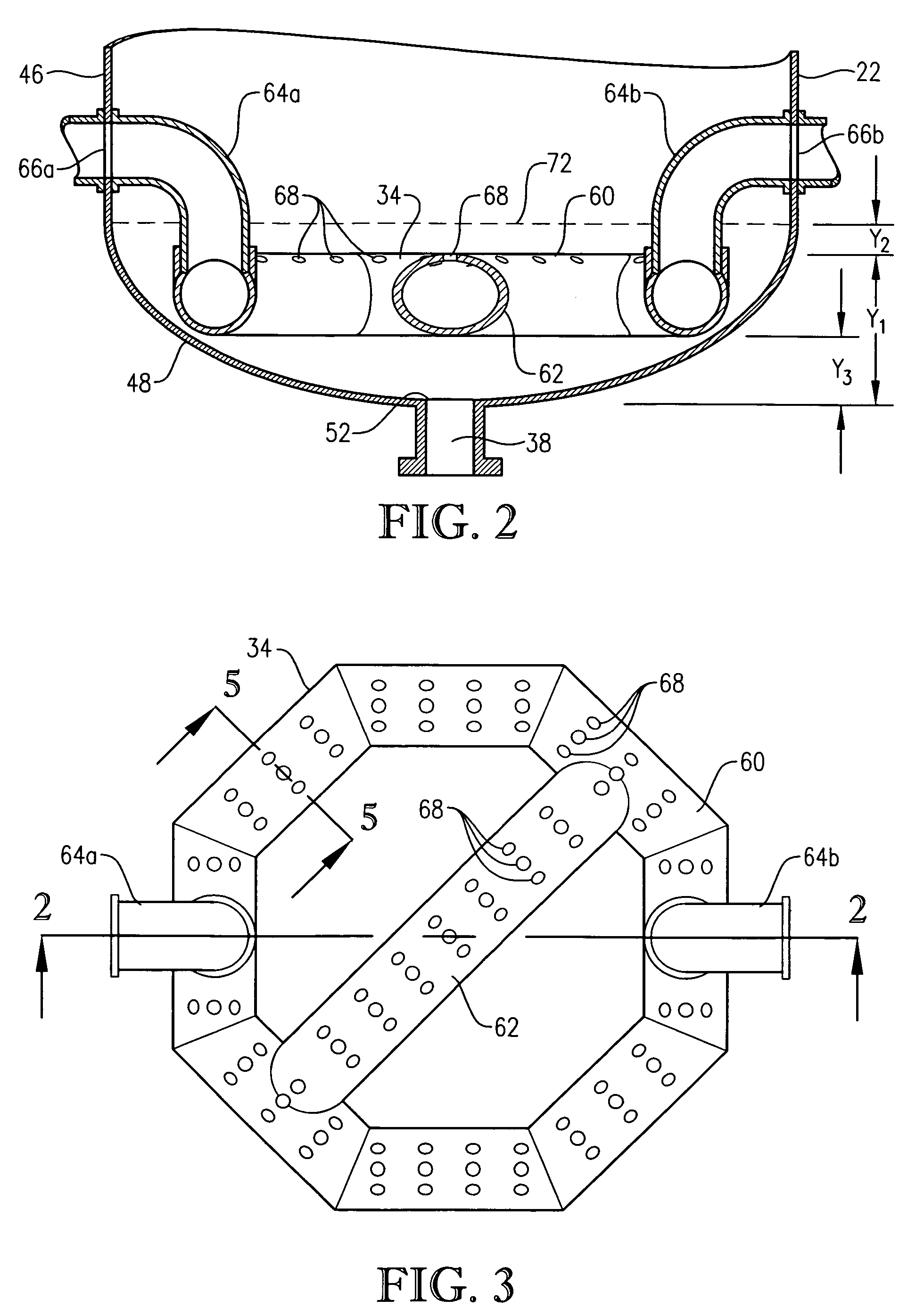

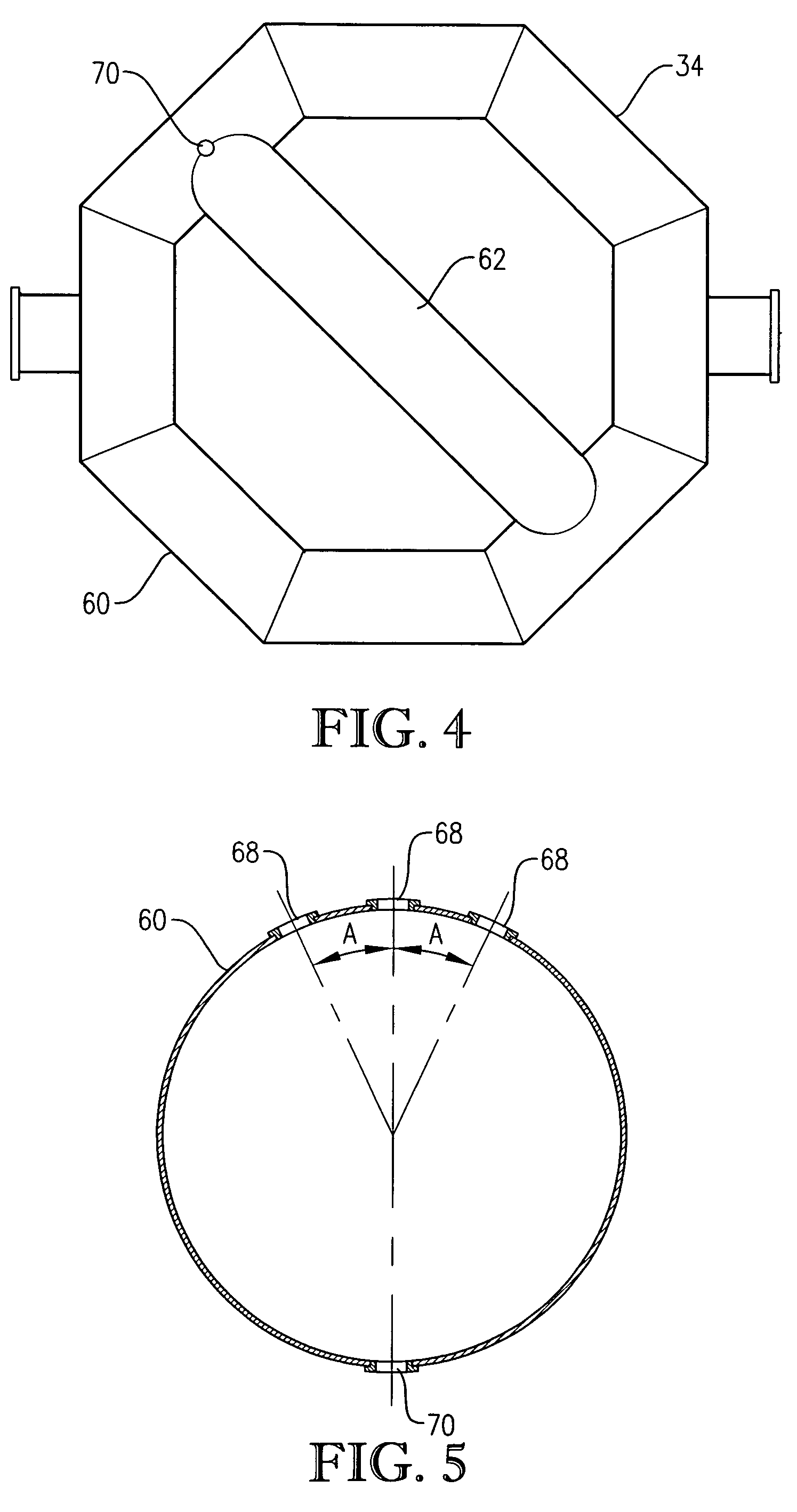

Optimized liquid-phase oxidation

ActiveUS20060047163A1Effective and economicalReduce formationOrganic oxidationOrganic compound preparationOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

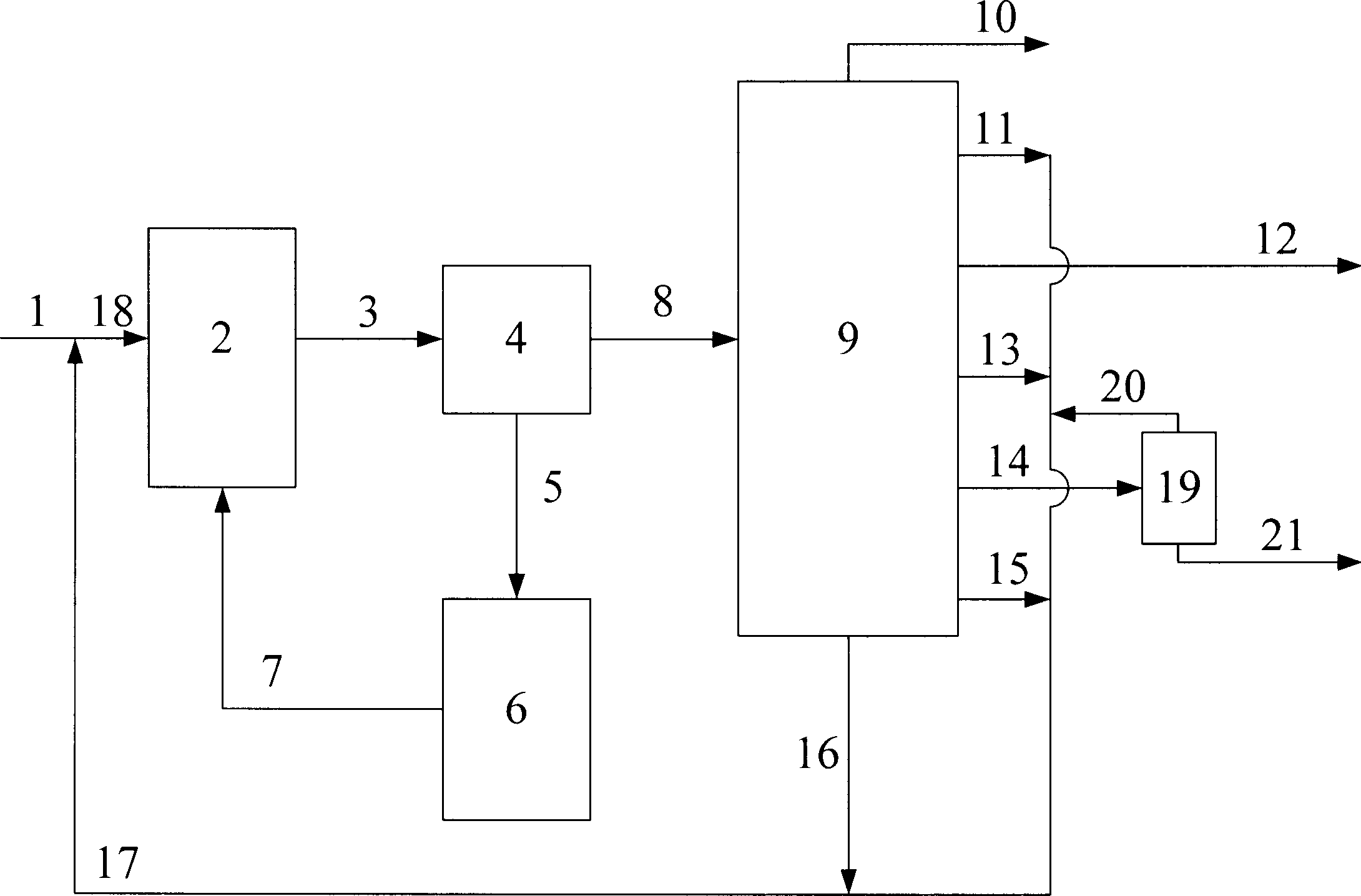

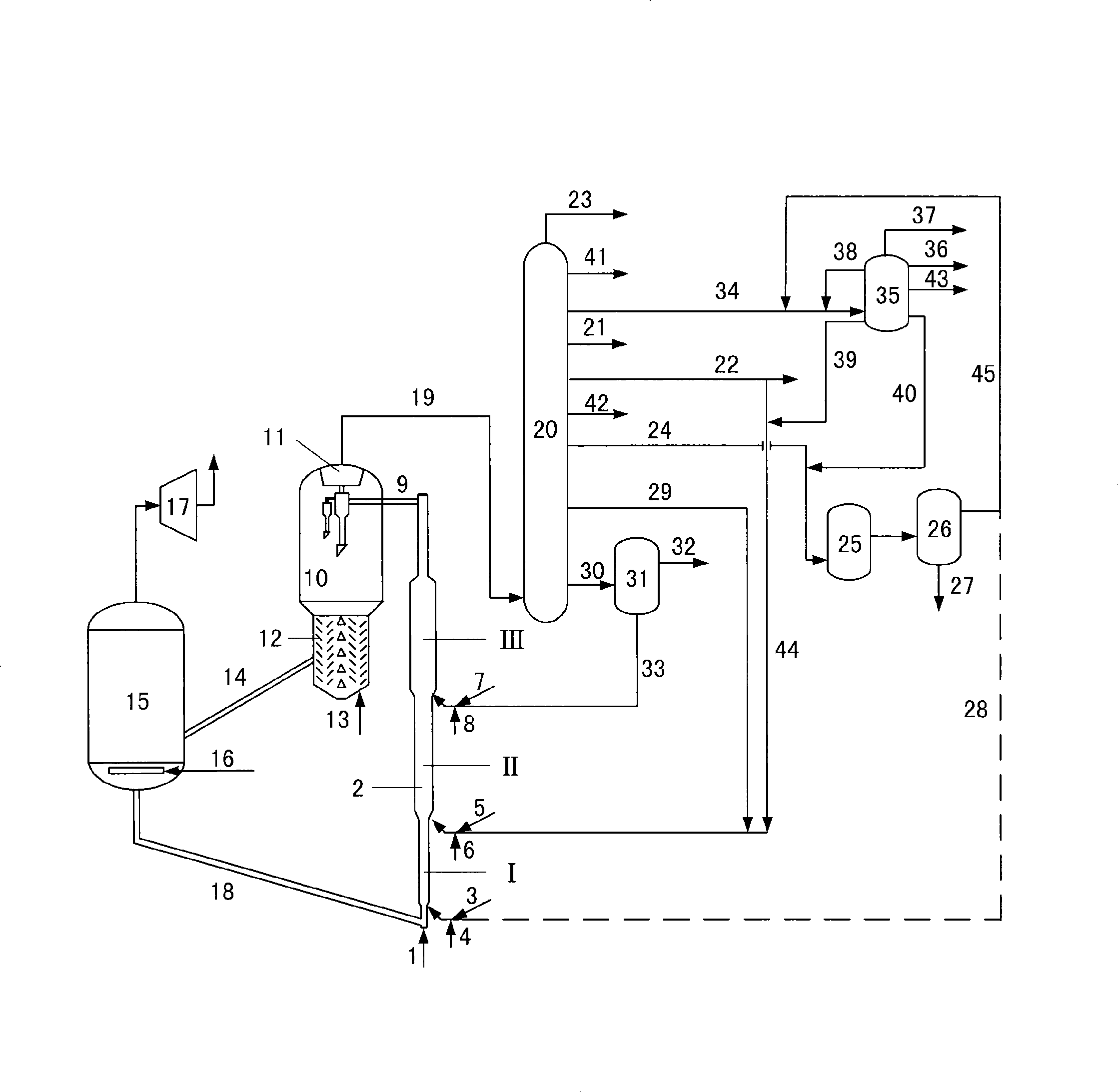

Chemical oil-refining method for preparing low carbon olefin and arene

This invention is a chemical oil refining method of generating low carbon alkene and arene. Material oil, regenerated catalytic cracking catalyst and vapor are contact to each other in cracking device. On condition of 500~7000C, pressure 0.15~0.4MPa, weight ratio of catalytic cracking catalyst and material oil is 5~50, weight ratio of vapor and material oil is 0.05~0.6, catalyst and reaction oil gas are separated, the catalyst go back to reaction device after regenerated, then the low carbon alkene and arene are got after separating the reaction oil gas. Propylene, ethane and other low carbon alkene is got from heavy feed stock at maximum limit, yield of propylene exceed 30%, and toluene, xylene and other arene are generated at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

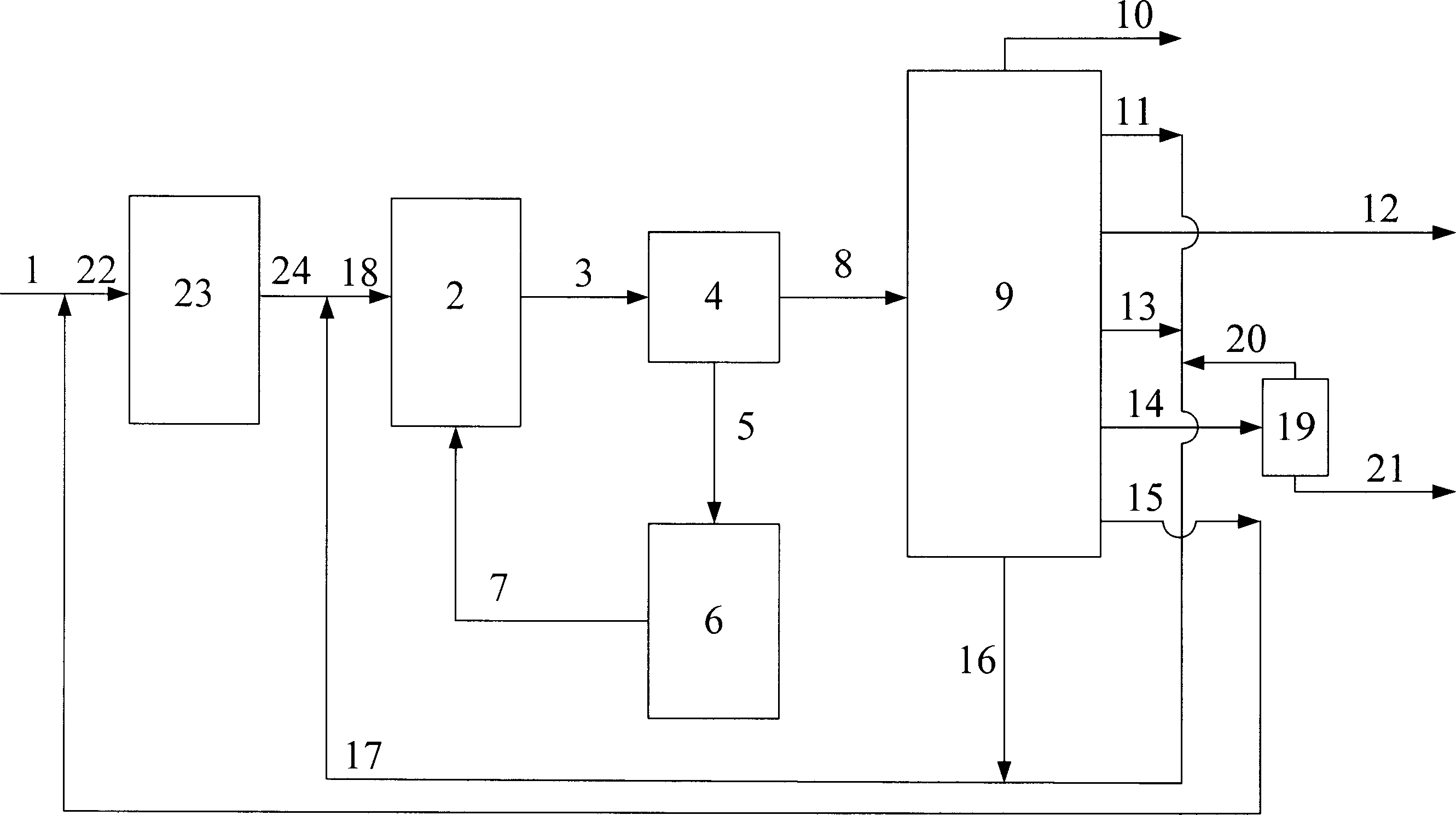

Catalytic conversion method of ethylene, propylene and aromatic hydrocarbon preparation

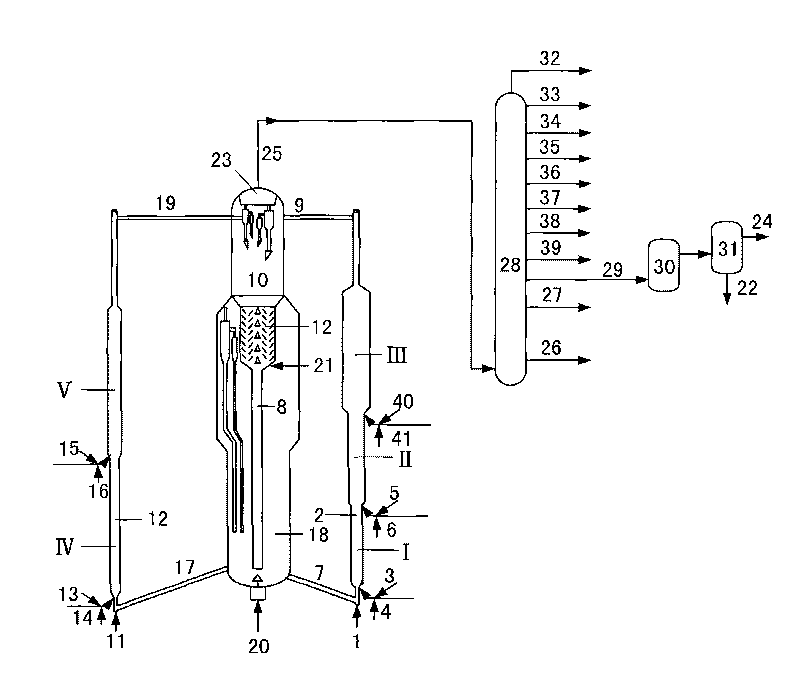

The invention discloses a catalytic conversion method for preparing ethylene, propylene and aromatic hydrocarbon. Hydrocarbon raw material with different cracking performances is contacted with a catalytic cracking catalyst, and cracking reaction is carried out in a fluidized bed reactor under the conditions that the temperature is 550 DEG C to 800 DEG C, the weight hourly space velocity is 0.1-800h<-1>, the reaction pressure is 0.10MPa to 1.0MPa, the weight ratio of the catalytic cracking catalyst and the raw material is 10-150, and the weight ratio of steam and the raw material is 0.15-1.0.Then a spent catalyst and reaction oil gas are separated, the spent catalyst returns to the reactor after regeneration, and the target products comprising low carbon olefin and the aromatic hydrocarbon are obtained by separating the reaction oil gas, wherein, fraction with the temperature to be 160 DEG C to 260 DEG C returns for catalytic cracking as circulating material, and the ethylene and the propylene are further obtained by cracking of ethane, propane, butane, and the steam entered. Low carbon olefin such as ethylene, propylene, and the like, is produced from heavy feedstock to the utmost extent in the method, and the yield of the ethylene and the propylene is over 20% by weight, in addition, the aromatic hydrocarbon such as toluene, xylene, and the like, are produced in an integrated way.

Owner:CHINA PETROLEUM & CHEM CORP +1

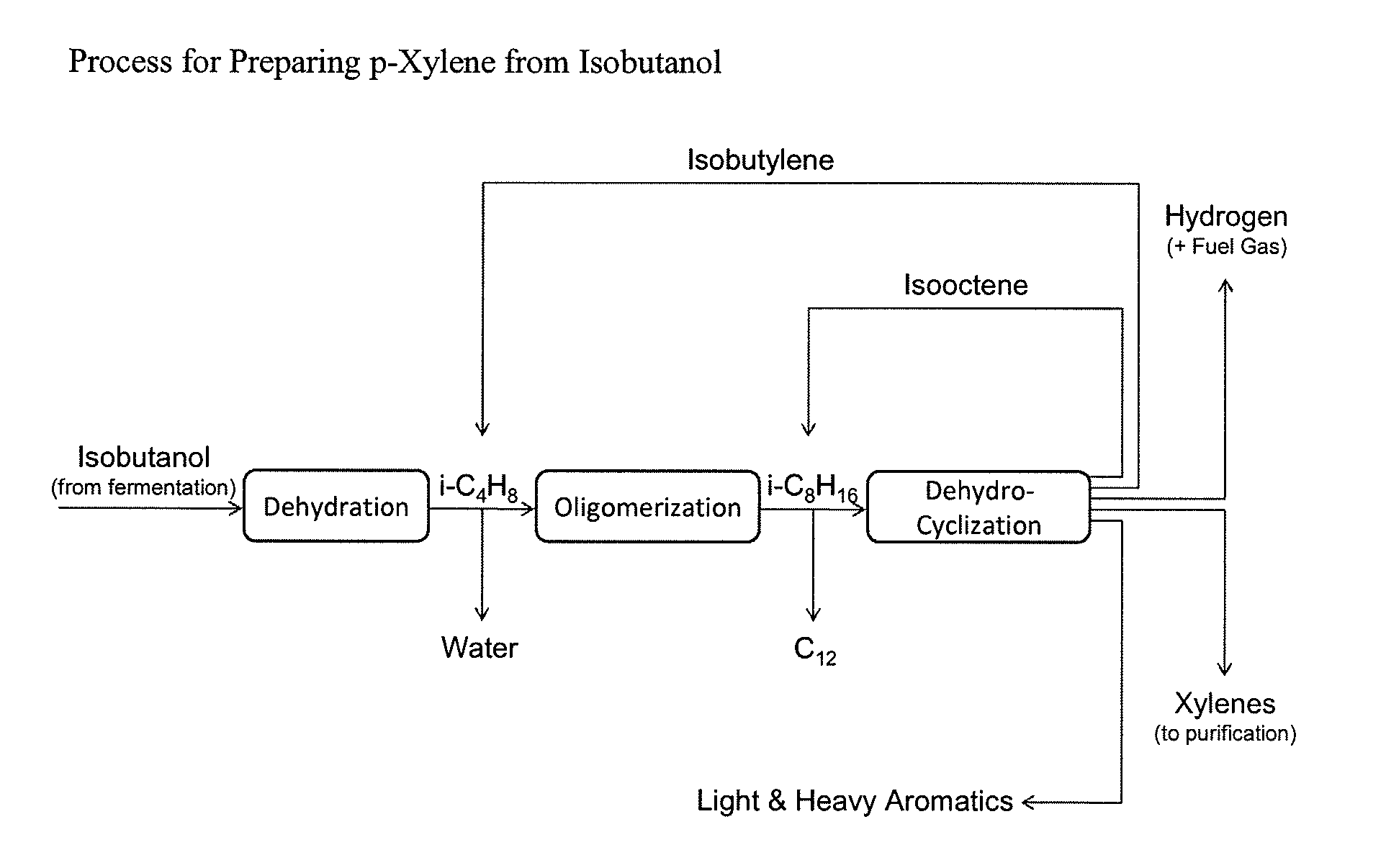

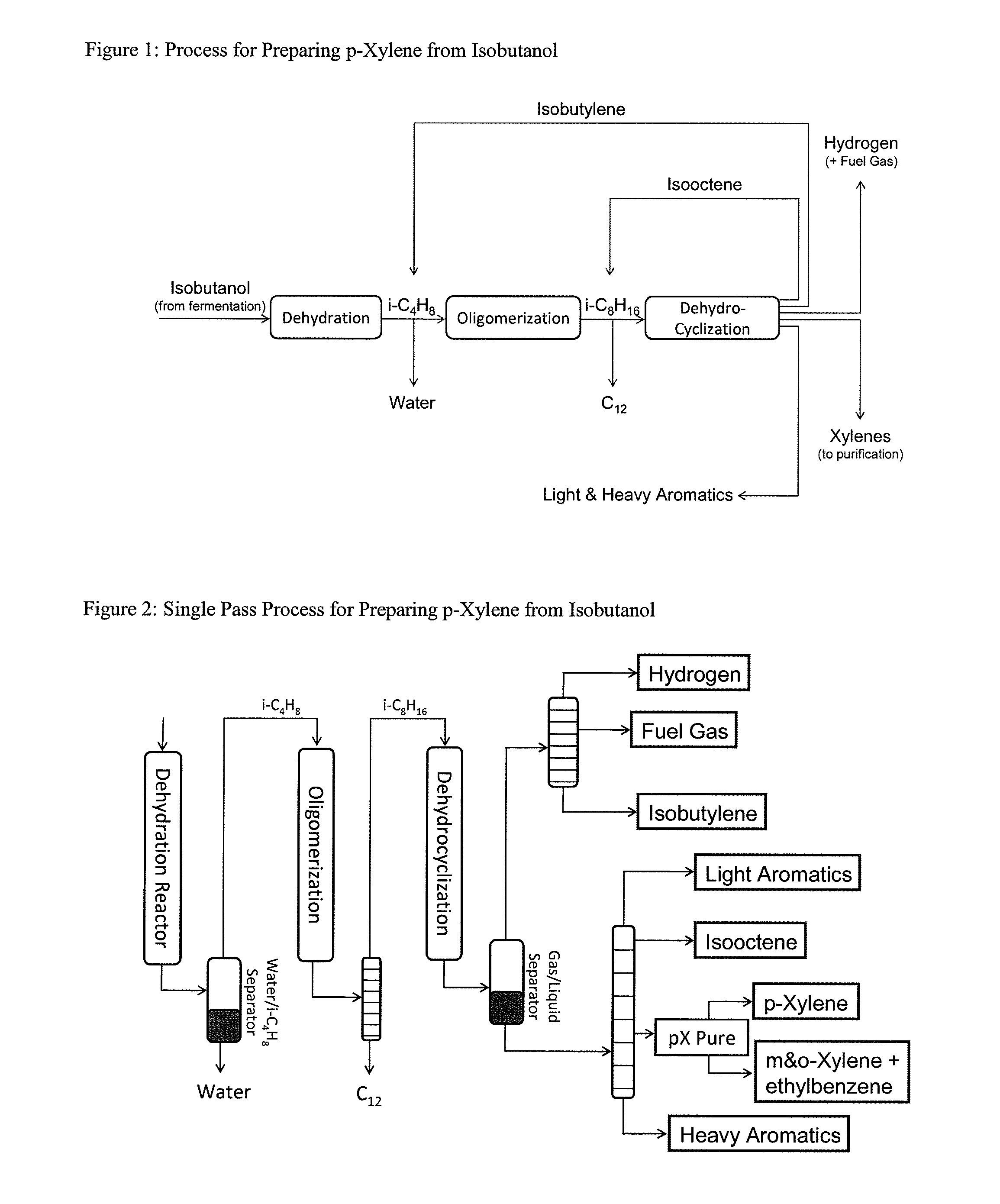

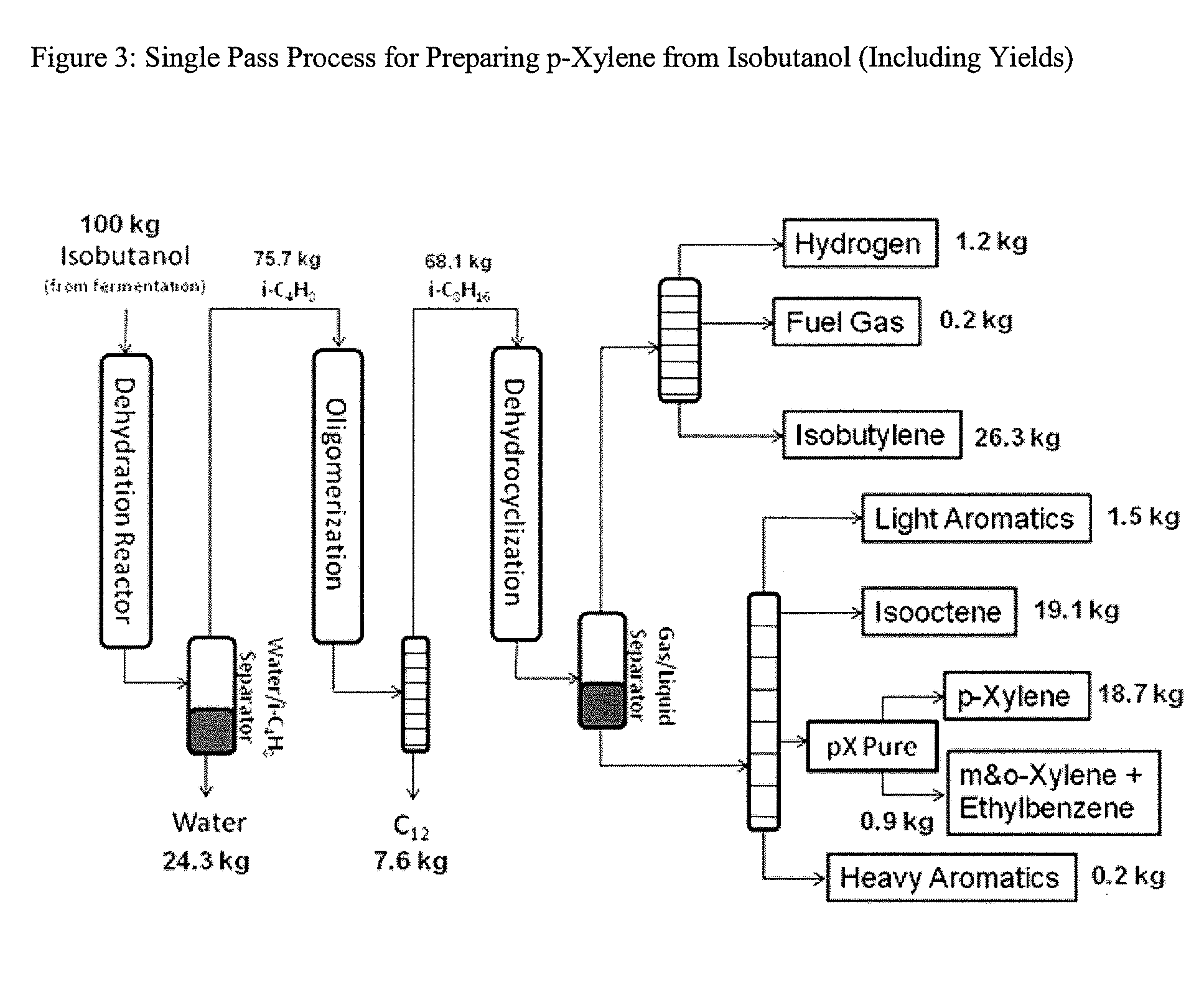

Integrated Process to Selectively Convert Renewable Isobutanol to P-Xylene

The present invention is directed to a method for preparing renewable and relatively high purity p-xylene from biomass. For example, biomass treated to provide a fermentation feedstock is fermented with a microorganism capable of producing a C4 alcohol such as isobutanol, then sequentially dehydrating the isobutanol in the presence of a dehydration catalyst to provide a C4 alkene such as isobutylene, dimerizing the C4 alkene to a form one or more C8 alkenes such as 2,4,4-trimethylpentenes or 2,5-dimethylhexene, then dehydrocyclizing the C8 alkenes in the presence of a dehydrocyclization catalyst to selectively form renewable p-xylene in high overall yield. The p-xylene can then be oxidized to form terephthalic acid or terephthalate esters.

Owner:GEVO INC

Optimized liquid-phase oxidation

ActiveUS20060047147A1Effective and economicalReduce formationOrganic compound preparationChemical/physical/physico-chemical stationary reactorsOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

Liquid phase process for C8 alkylaromatic isomerization

InactiveUS6872866B1Saving considerable capitalImprove stabilityHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationAcid washing

A liquid or partially liquid phase process for isomerizing a non-equilibrium mixture of xylenes and ethylbenzene uses a zeolitic catalyst system preferably based on zeolite beta and on pentasil-type zeolite. The invention obtains an improved yield of para-xylene from the mixture relative to prior art processes in a more economical manner. A preferred beta zeolite is a surface-modified zeolite beta resulting from acid washing of a templated native zeolite at conditions insufficient to effect bulk dealumination. A preferred pentasil zeolite is a MTW-type with a silica-to-alumnina ratio between 20 and 45.

Owner:UOP LLC

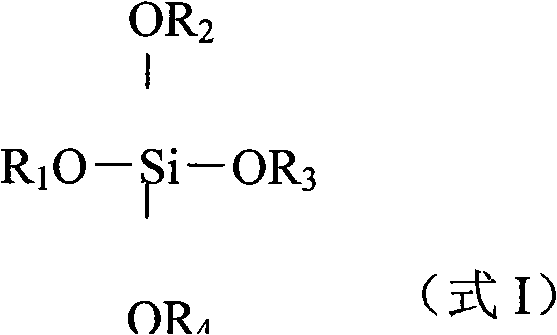

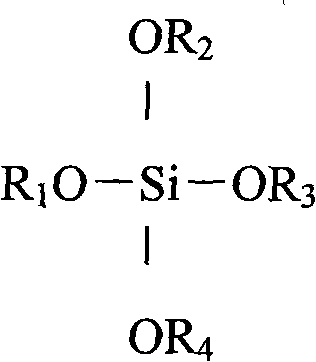

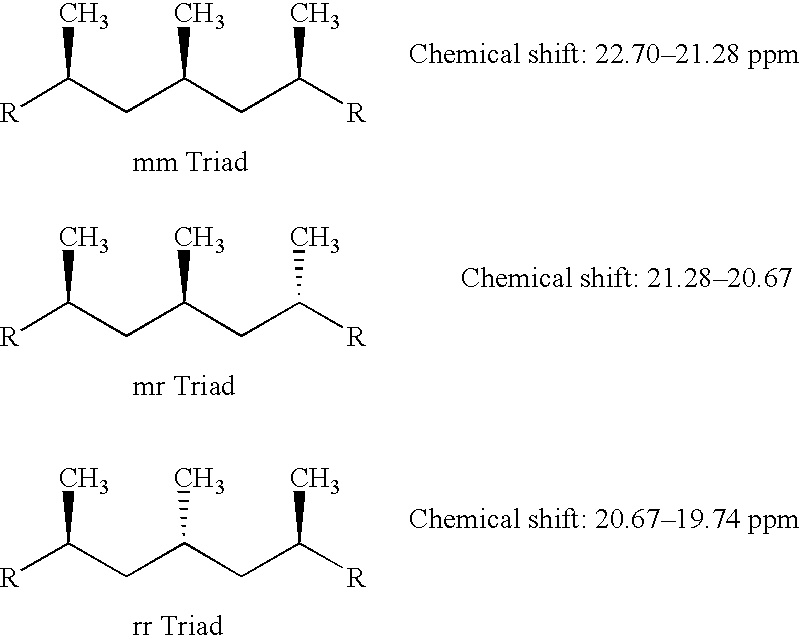

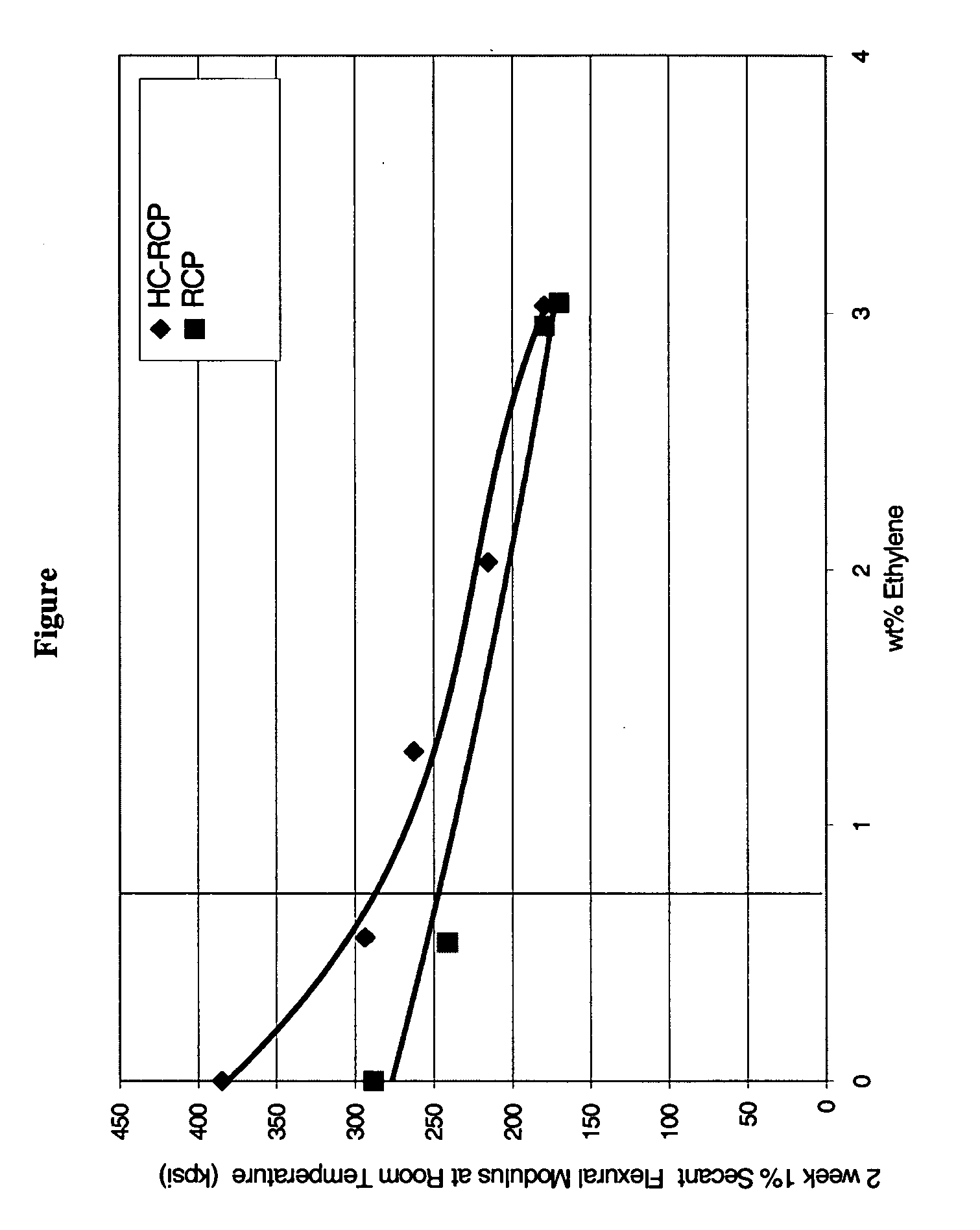

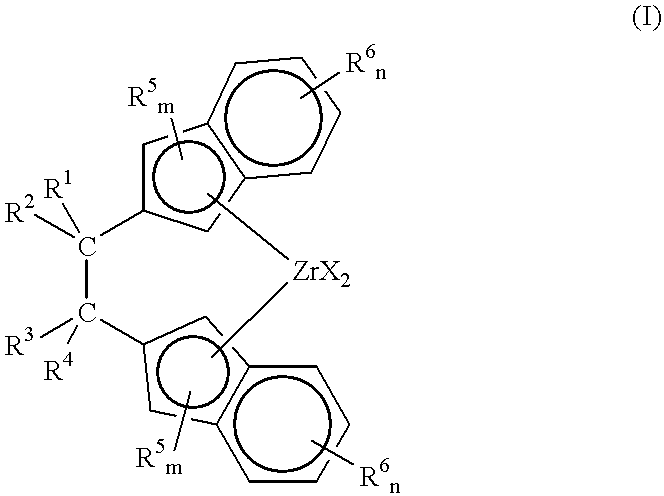

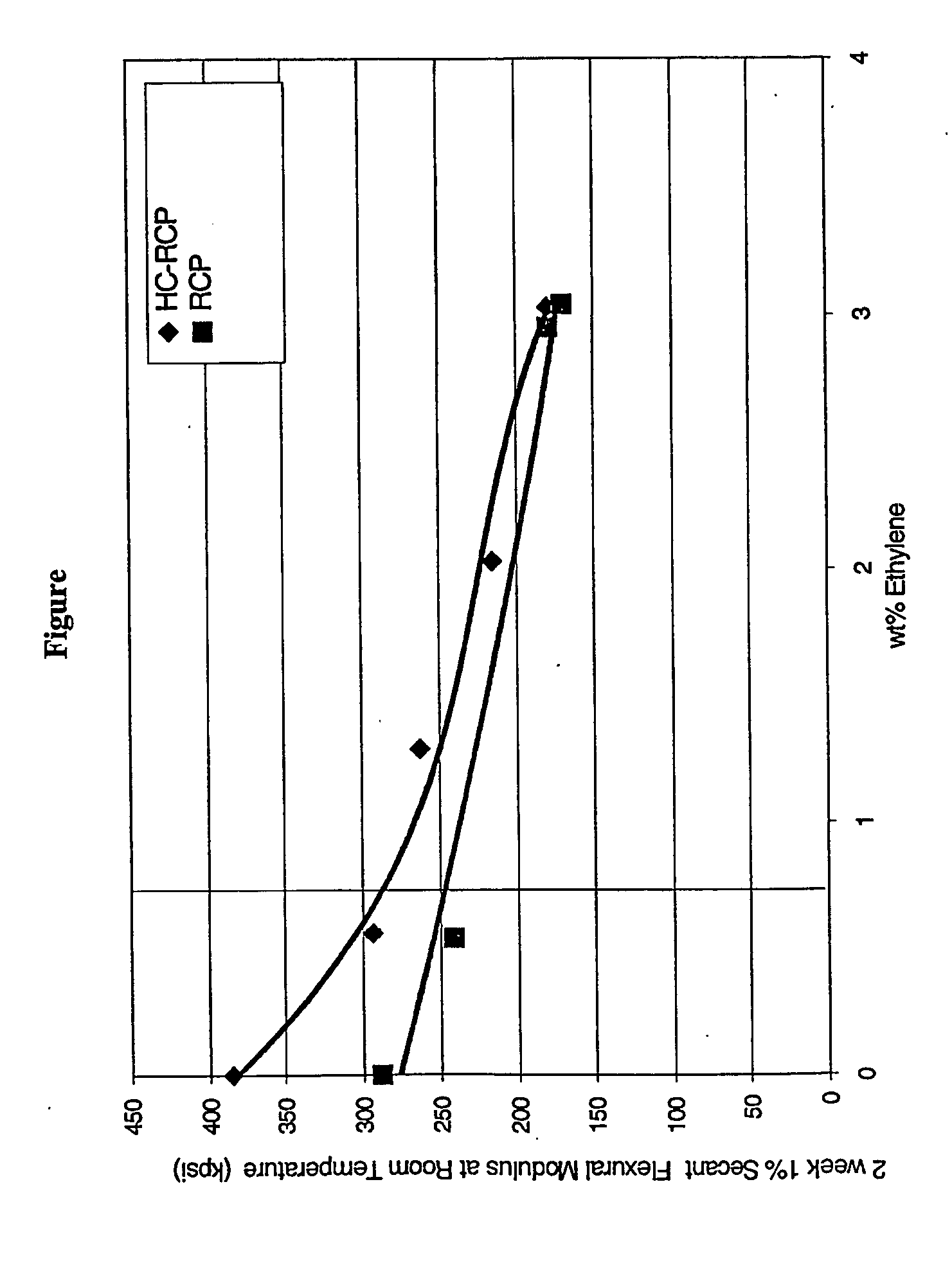

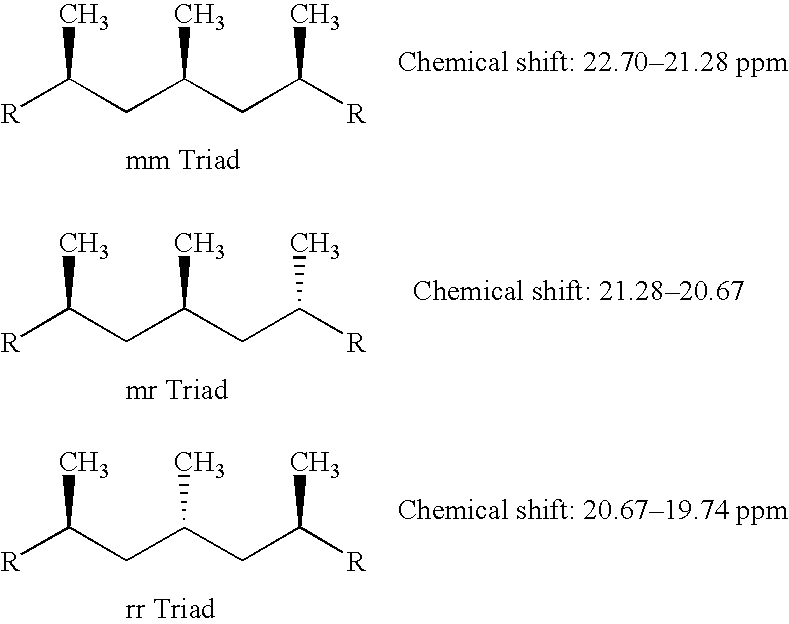

Highly crystalline polypropylene with low xylene solubles

ActiveUS20040122196A1Narrow molecular weight distributionLow melt flow rateFlexural modulusPolypropylene

The invention is directed to a polypropylene resin which has a Mw / Mn of less than 5, a melt flow rate of less than 7 g / 10 min., a 1% secant flexural modulus of greater than 300,000 psi and less than 2 wt. % xylene solubles.

Owner:BRASKEM AMERICA

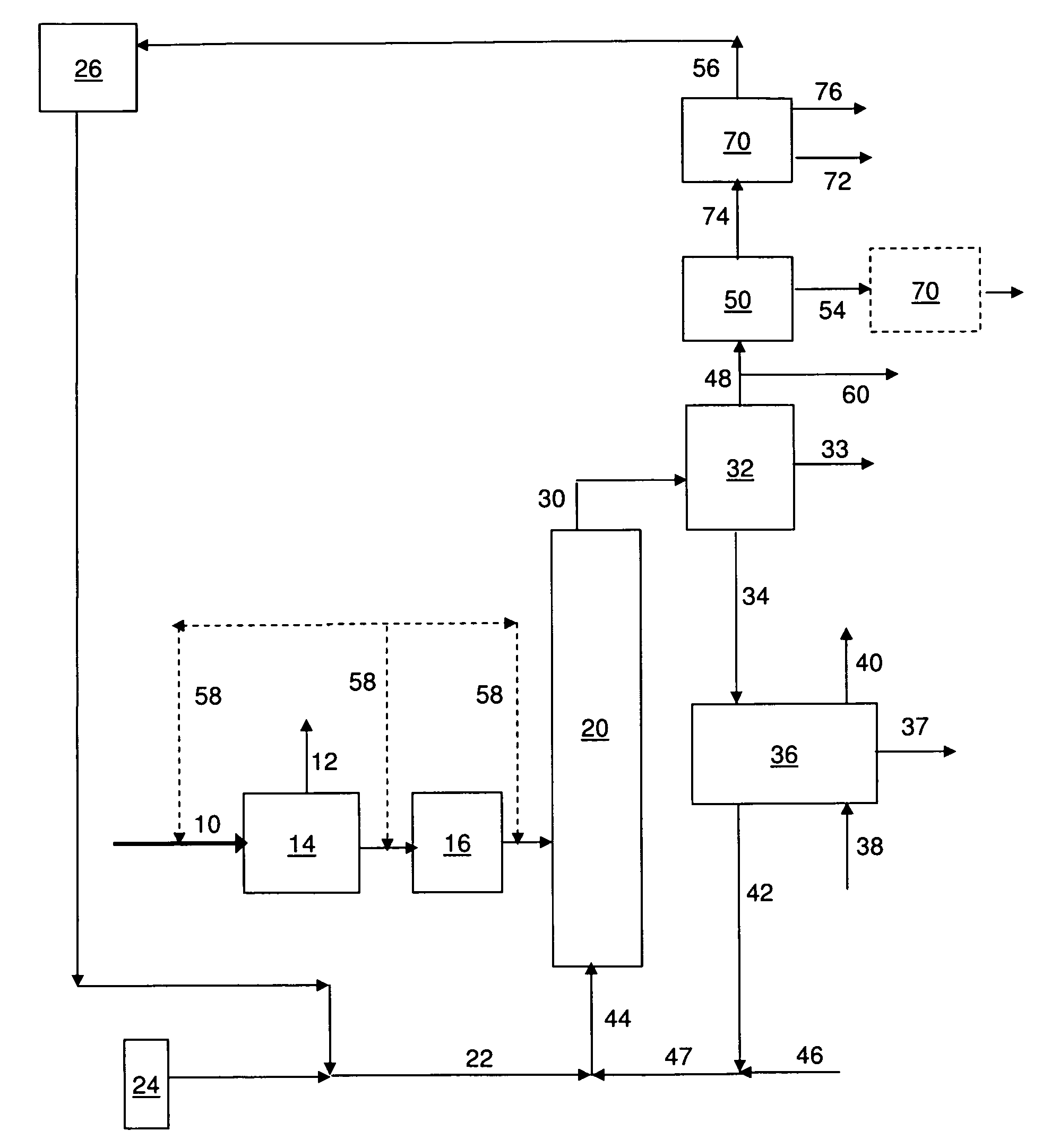

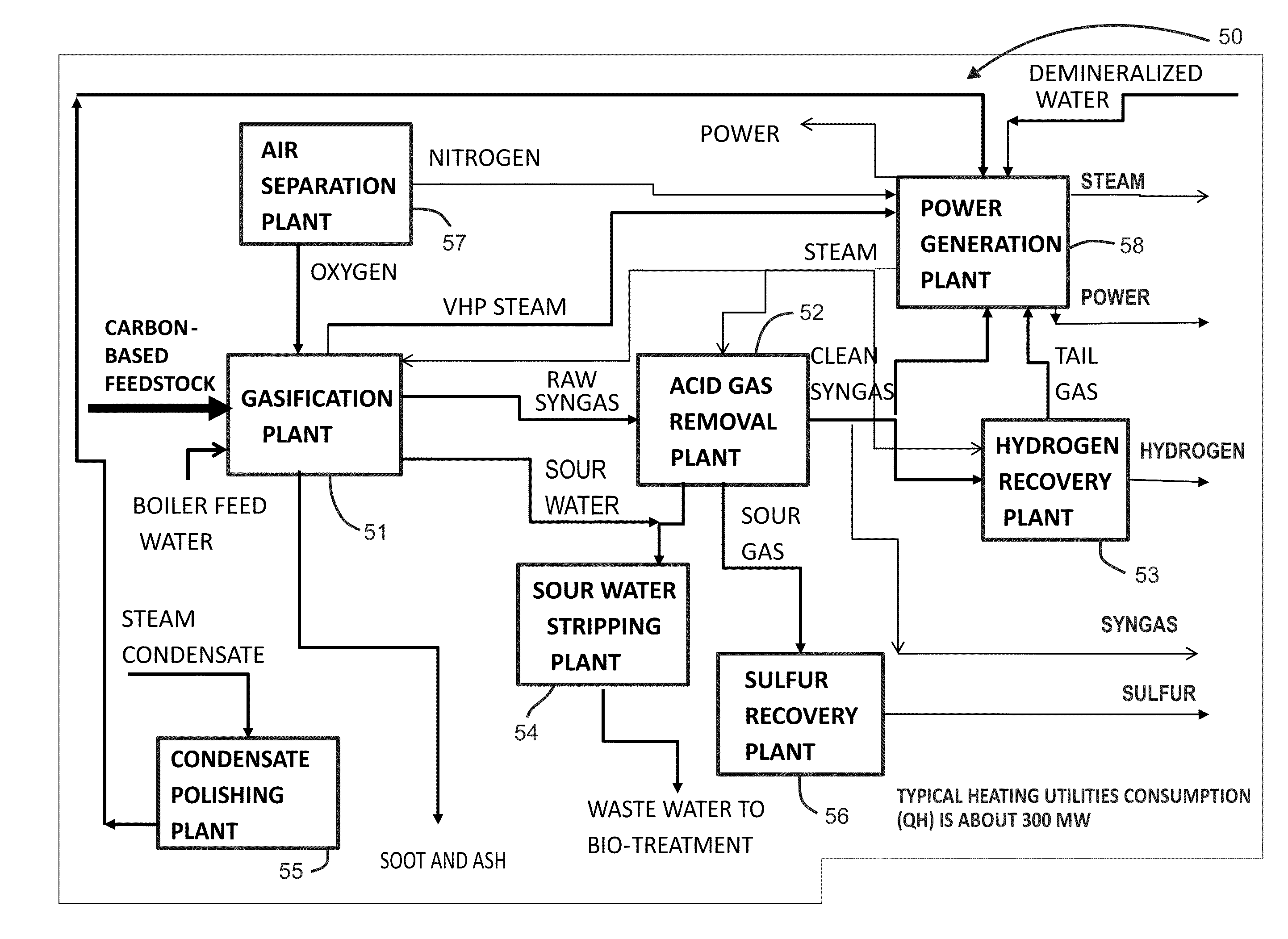

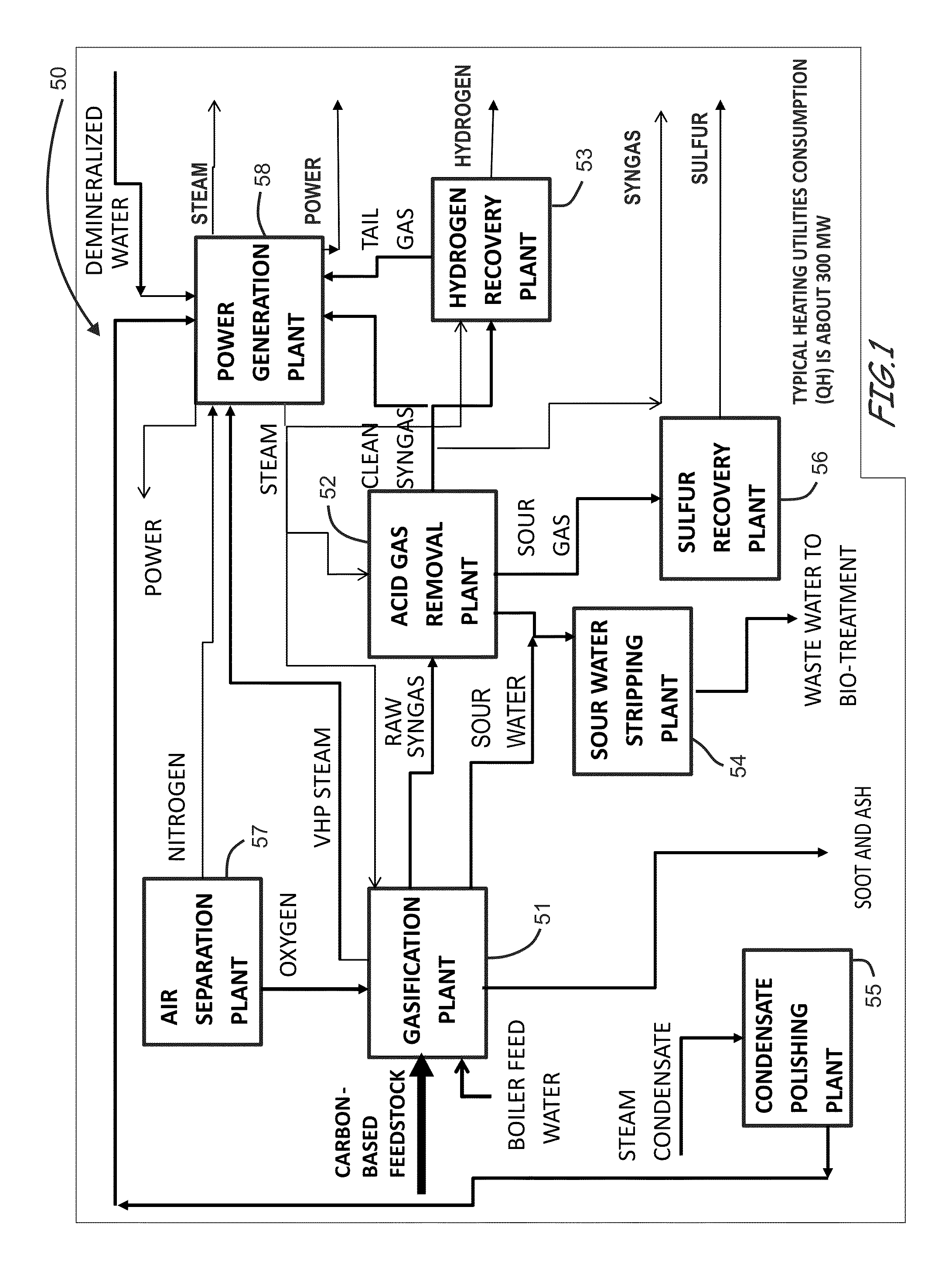

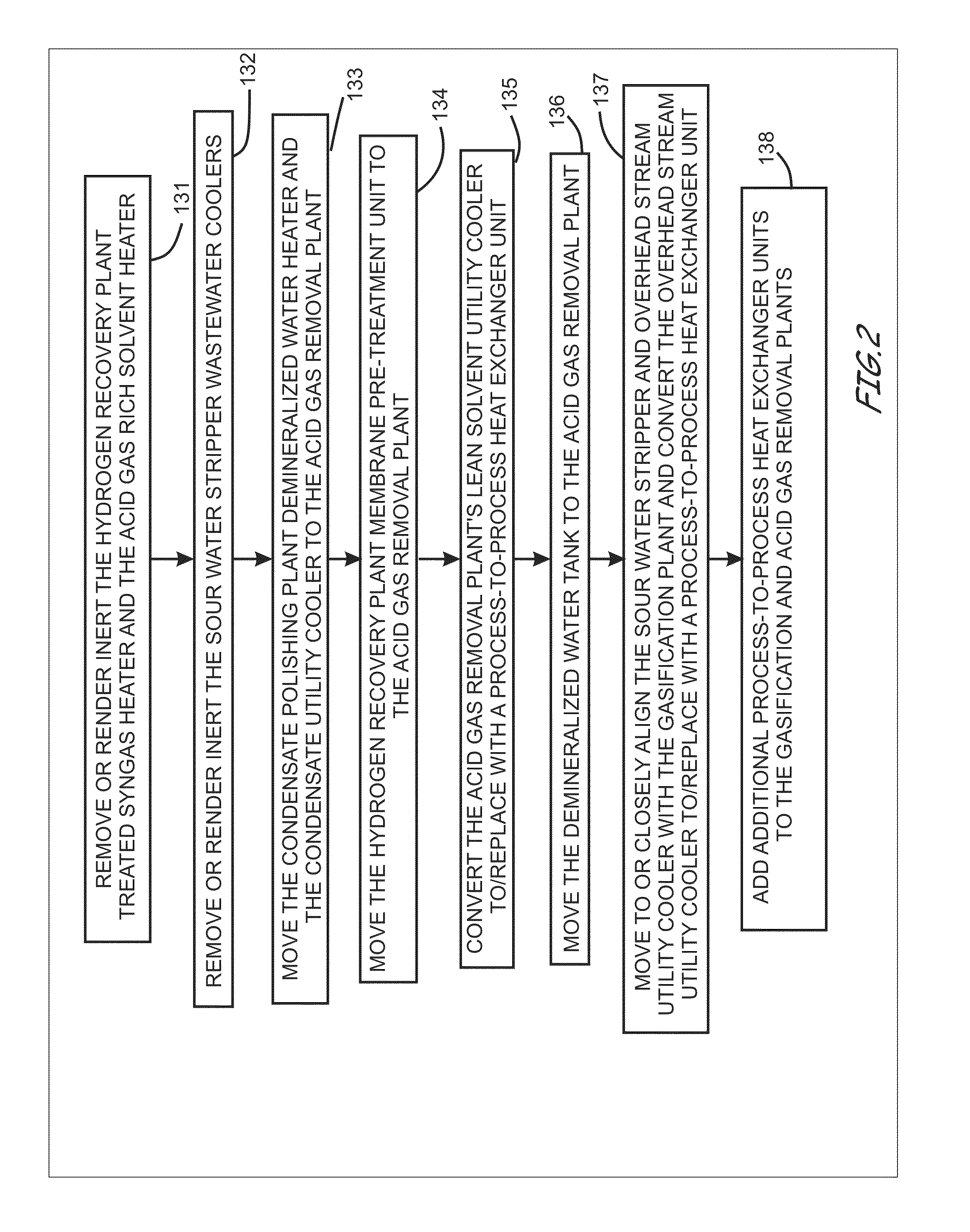

Energy efficient apparatus employing energy efficient process schemes providing enhanced integration of gasification-based multi-generation and hydrocarbon refining facilities and related methods

ActiveUS20150377079A1Less pollutionEasy to modifyProcess control/regulationGasifier mechanical detailsSolventMulti generation

Energy-efficient gasification-based multi-generation apparatus, facilities, or systems, and methods of modifying existing gasification-based multi-generation apparatus and the various conventional thermal coupling arrangements, are provided. Apparatus for managing waste heat recovery through integration of a gasification-based multi-generation facility or other multi-generation system with a hydrocarbon refining facility or other hydrocarbon refining system and methods of providing the respective integration are also provided. An exemplary apparatus includes an integrated site energy management system configured according to one or more process-based thermal coupling schemes comprising one or more thermal coupling arrangements between a gasification-based multi-generation system or facility and a hydrocarbon refining system or facility. The gasification-based multi-generation system or facility can include an acid gas removal system or plant configured to remove acidic contaminants from a raw syngas feed to thereby provide a treated syngas feed, the acid gas removal system or plant containing a separation section including a solvent regenerator, and a gasification system configured to generate the raw syngas feed from a carbon-based feedstock. The hydrocarbon refining system or facility can include an aromatics system or plant containing a xylene products separation section including one or more of the following: an Extract column and a Raffinate column. The integrated site energy management system can include a hot-water system extending between the separation section of the acid gas removal system or plant and the xylene products separation section of the aromatics system or plant, and a plurality of added heat exchanger units providing various advanced thermal coupling arrangements.

Owner:SAUDI ARABIAN OIL CO

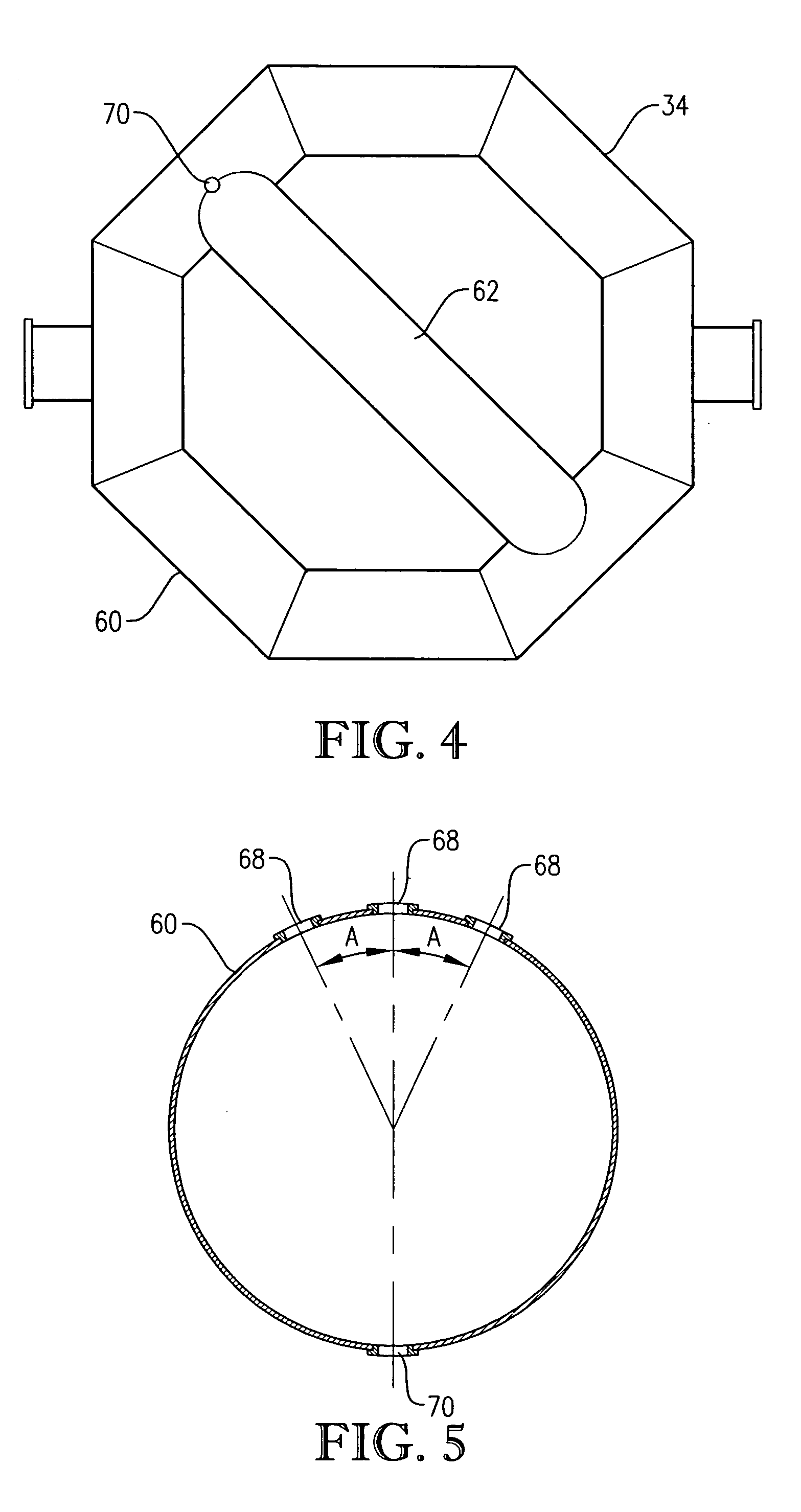

Oxidation system with internal secondary reactor

ActiveUS20070155985A1Effective and economicalReduce formationLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

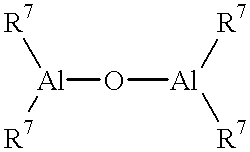

Multi-stage process for the polymerization of olefins

A multi-stage process for preparing ethylene (co)polymers having broad molecular weight distributions is disclosed, said process comprising:(A) a first polymerization stage in which, in the presence of a Ti or V catalyst, a first ethylene polymer is prepared;(B) a treatment stage in which the catalyst used in the first stage is deactivated and in which a bridged bis-2-indenyl zirconocene is supported on the ethylene polymer produced in stage (A), optionally in the presence of a suitable cocatalyst; and(C) a second polymerization stage in which ethylene is polymerized in the presence of the product obtained from stage (B).Furthermore, polyethylene obtainable by the above process is disclosed, having intrinsic viscosity ranging from 0.5 to 6 dl / g, Mw / Mn>8 and cold xylene solubility<1.2% wt.

Owner:MONTELL TECH CO BV

Fuel additive composition and method for treatment of middle distillate fuels and gasoline

InactiveUS6923838B2Increase and improvement of performanceIncrease and improvement of and lubricityLiquid carbonaceous fuelsFuel additivesVegetable oilAntioxidant

A fuel additive for middle distillate fuels is a mixture of at least one methyl, ethyl, propyl or butyl ester of a vegetable oil or a C16-C18 fatty acid, at least one alkyl ether of propylene glycol, a surfactant, and an antioxidant. A fuel additive for gasoline is a mixture of ligroin or toluene / xylene, at least one alkyl ether of propylene glycol, a surfactant, and tertiary amyl methyl ether.

Owner:ADVANCED COMBUSTION TECH

Selective xylenes isomerization and ethylbenzene conversion

This invention is drawn to a process for isomerizing a non-equilibrium mixture of xylenes and ethylbenzene using an oil-dropped catalyst comprising a zeolite, a platinum-group metal and an aluminophosphate binder, resulting in a greater yield of para-xylene at favorable conditions compared to processes of the known art.

Owner:UOP LLC

Process for alkane aromatization using platinum-zeolite catalyst

InactiveUS20050143610A1Formation is suppressedHigh selectivityMolecular sieve catalystsMolecular sieve catalystAlkanePlatinum

Aromatization of alkanes having one to four carbon atoms per molecule to aromatics, such as benzene, toluene and xylenes (BTX), uses a catalyst of a crystalline zeolite on which platinum has been deposited, specifically a platinum-containing ZSM-5. A byproduct of the process is a light gas fraction of methane and ethane. The use of a platinum-containing ZSM-5 catalyst in an alkane aromatization process, such as the Cyclar process, suppresses the formation of methane and increases selectivity to BTX. The high content of ethane relative to methane in the light gas fraction allows this process effluent to be a feedstream for a cracker.

Owner:SAUDI BASIC IND CORP SA

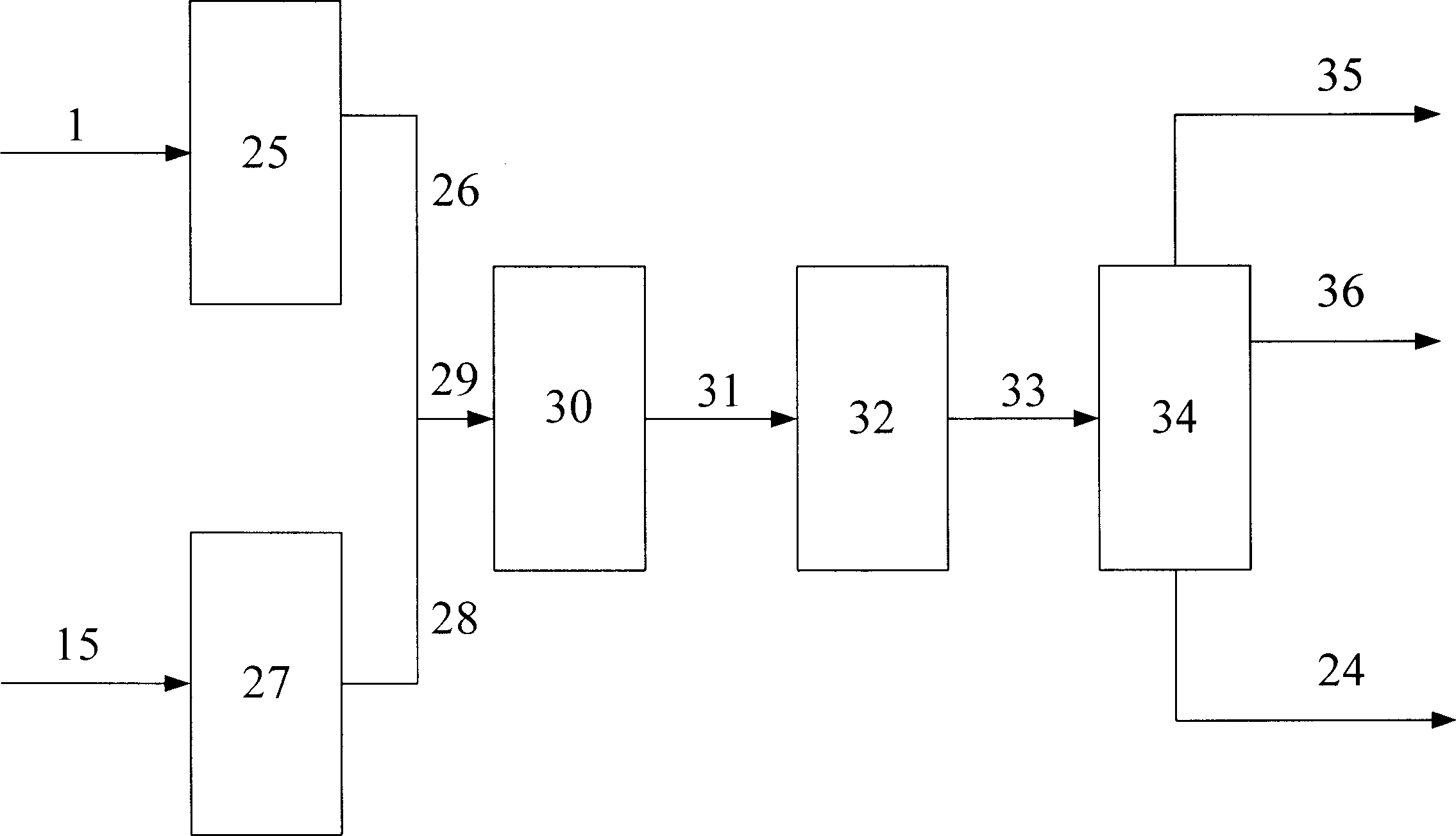

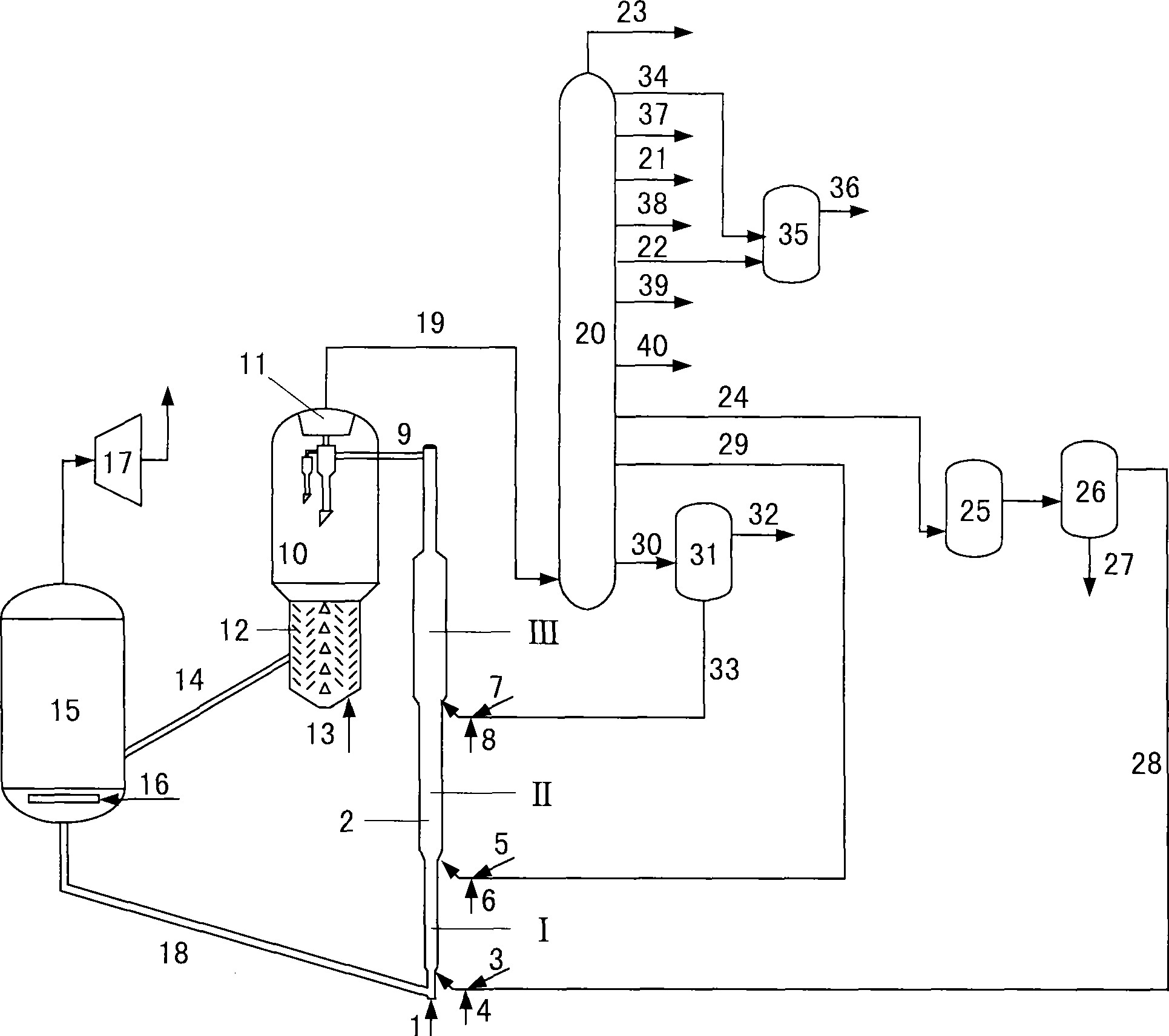

Catalytic conversion method for preparing propylene and aromatic hydrocarbons

ActiveCN101531558AHydrocarbon purification/separationHydrocarbon oil crackingWater vaporFluidized bed

A catalytic conversion method for preparing propylene and aromatic hydrocarbons comprises the following steps: hydrocarbon raw materials with different cracking performances are contacted with a catalytic cracking catalyst to carry out cracking reaction in a fluidized-bed reactor under the conditions that the temperature is 450-750 DEG C, the weight hourly space velocity is 0.1-800h<-1>, the reaction pressure is 0.10-1.0MPa, the weight ratio of the catalytic cracking catalyst to the raw materials is 1-150 and the weight ratio of water vapor to the raw materials is 0.05-1.0, the spent catalyst and reaction oil and gas are separated, the spent catalyst returns to the reactor after the regeneration, the separated reaction oil and gas are separated to obtain target products of low-carbon olefins, aromatic hydrocarbons and the raw materials for re-cracking, wherein the raw materials for re-cracking are re-cracked after hydrotreating. The method can product the propylene and other low-carbon olefins from the heavy raw materials to the maximum extent, wherein the yield of the propylene is more than 40 percent by weight; meanwhile, the method can co-produce toluene, xylene and other aromatic hydrocarbons, and the yield of the dry gas is unexpectedly reduced by more than 80 percent by weight.

Owner:CHINA PETROLEUM & CHEM CORP +1

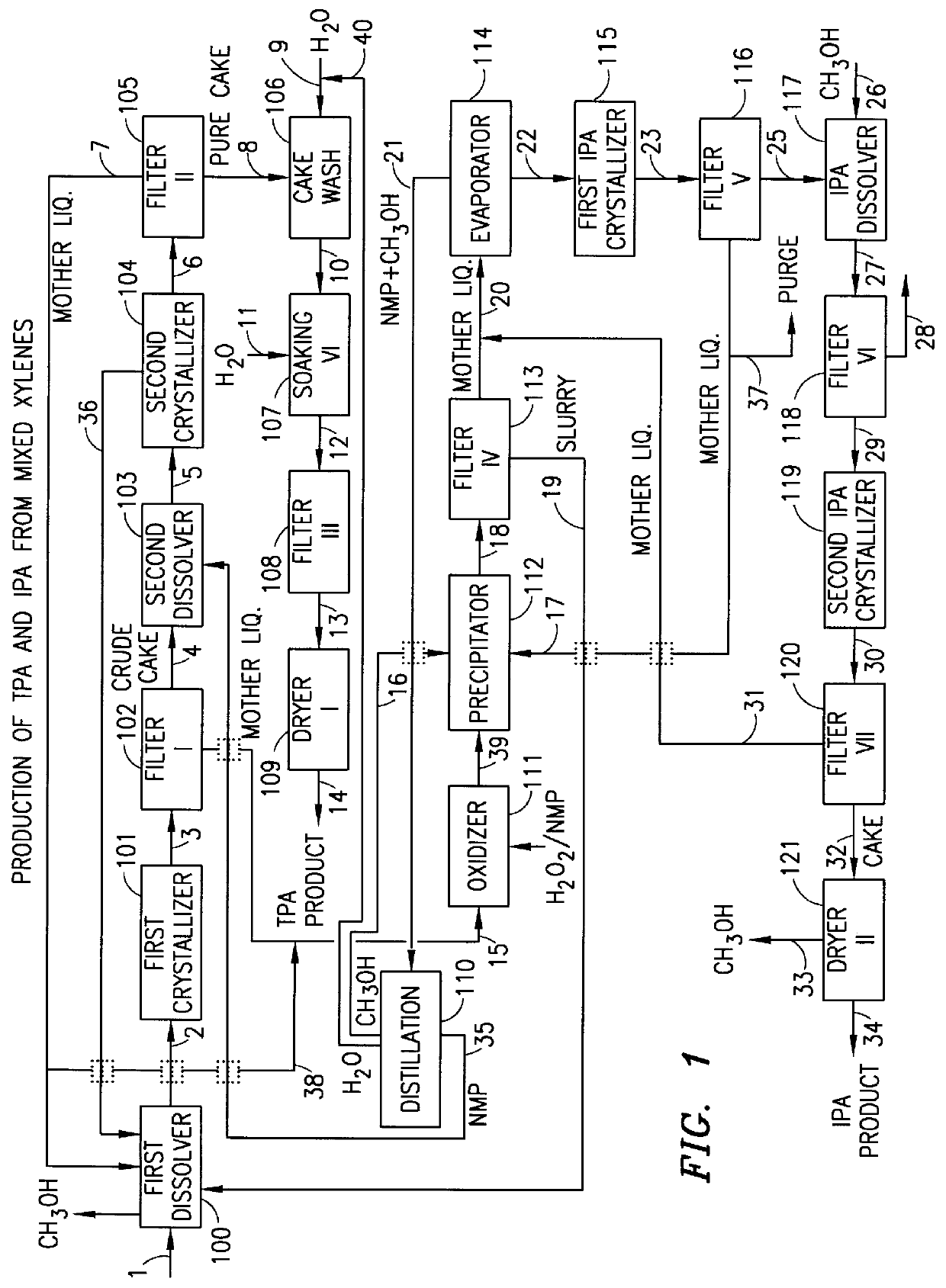

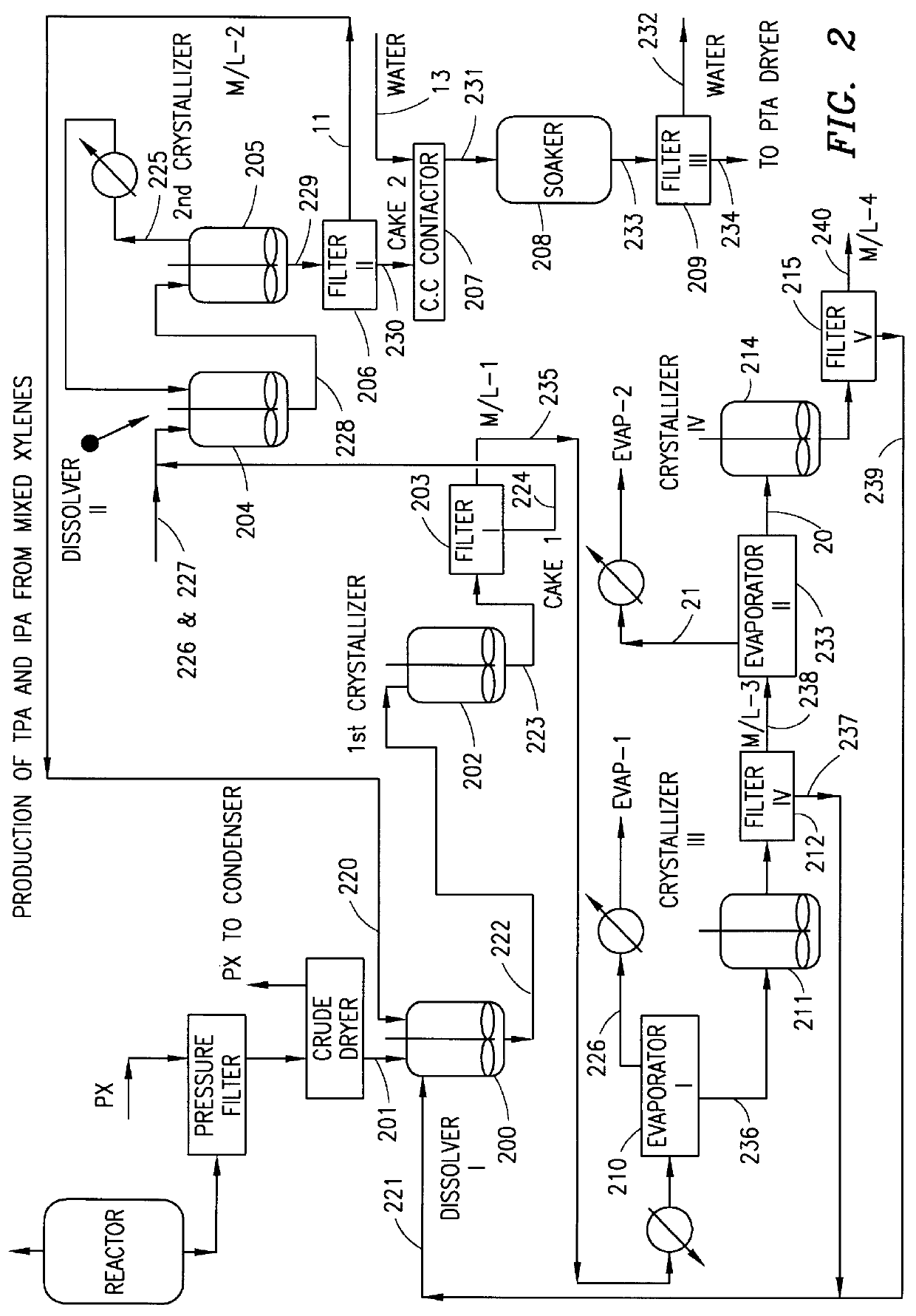

Method and apparatus for preparing purified terephthalic acid and isophthalic acid from mixed xylenes

InactiveUS6054610AReduce pressureReduce the temperatureOrganic compound preparationChemical industryIsophthalic acidXylene

A method and apparatus for preparing purified terephthalic acid and, optionally, isophthalic acid from mixed xylenes. The method of the present invention purifies the oxidation reactor effluent containing a mixture of terephthalic acid and isophthalic acid as well as minor amounts of 4-carboxybenzaldehyde (4-CBA), 3-carboxybenzaldehyde (3-CBA), and toluic acid isomers, to produce purified terephthalic acid and, optionally, purified isophthalic acid in an integrated process.

Owner:GTC TECHNOLOGY INC

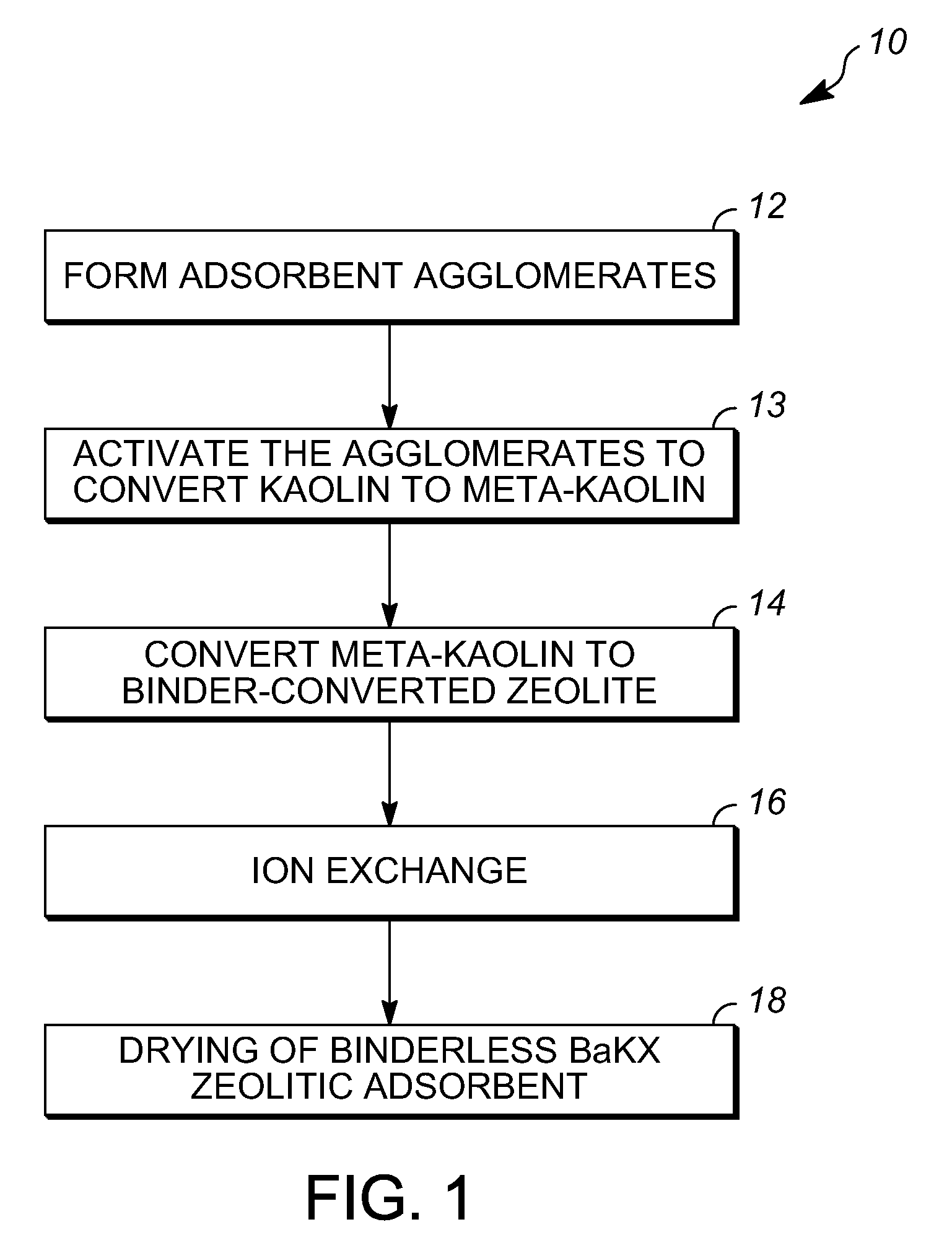

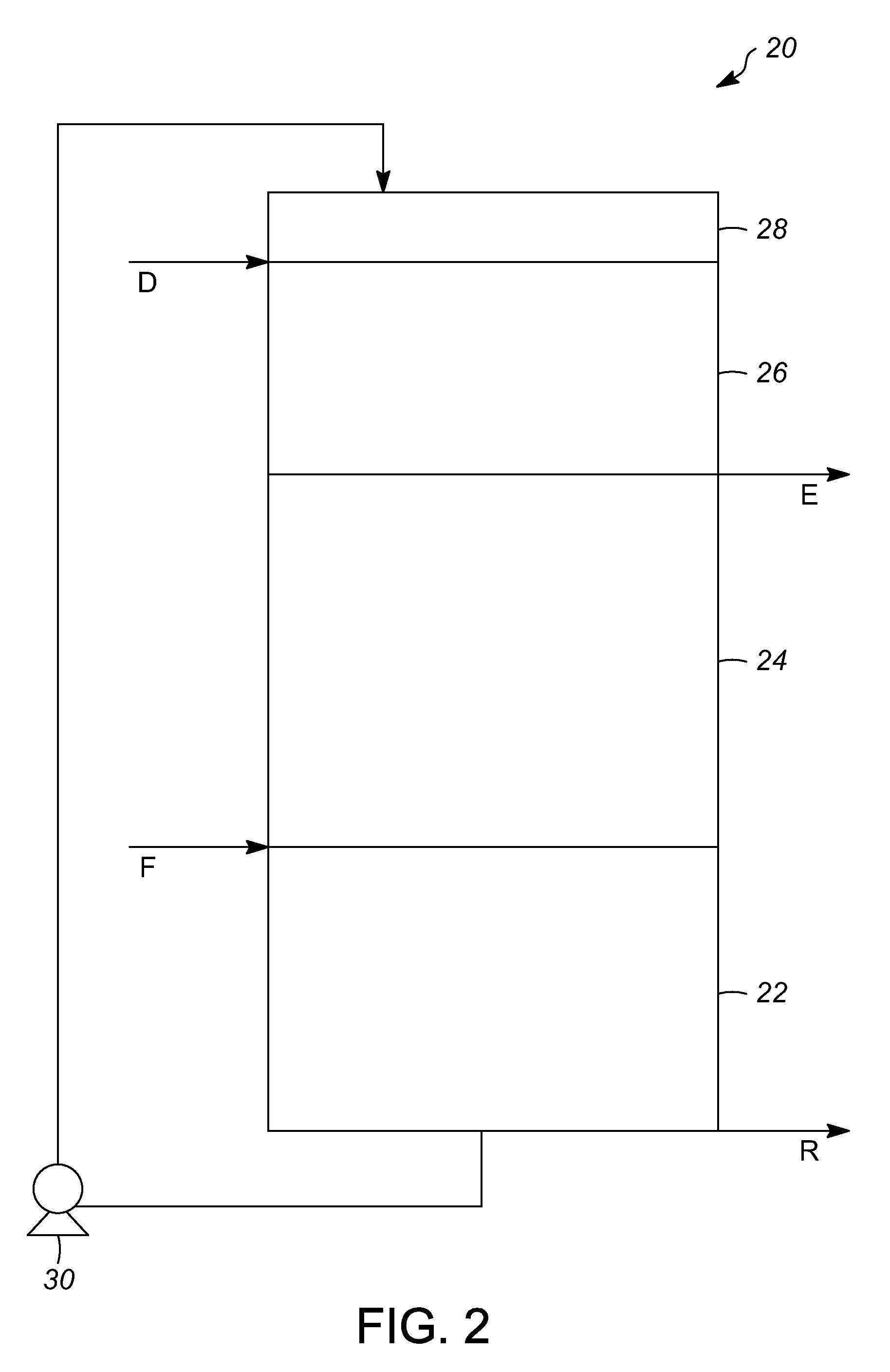

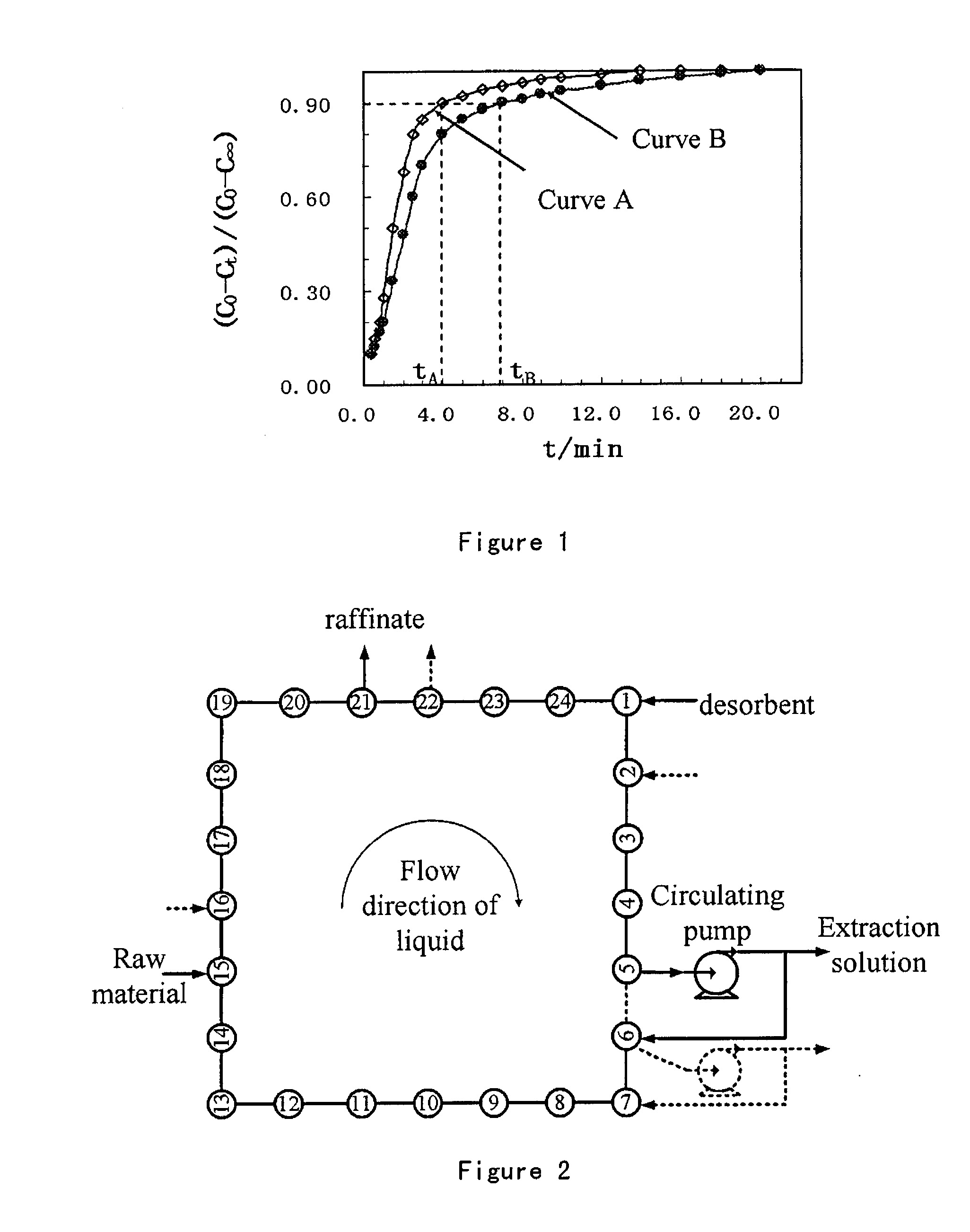

Binderless zeolitic adsorbents, methods for producing binderless zeolitic adsorbents, and processes for adsorptive separation of para-xylene from mixed xylenes using the binderless zeolitic adsorbents

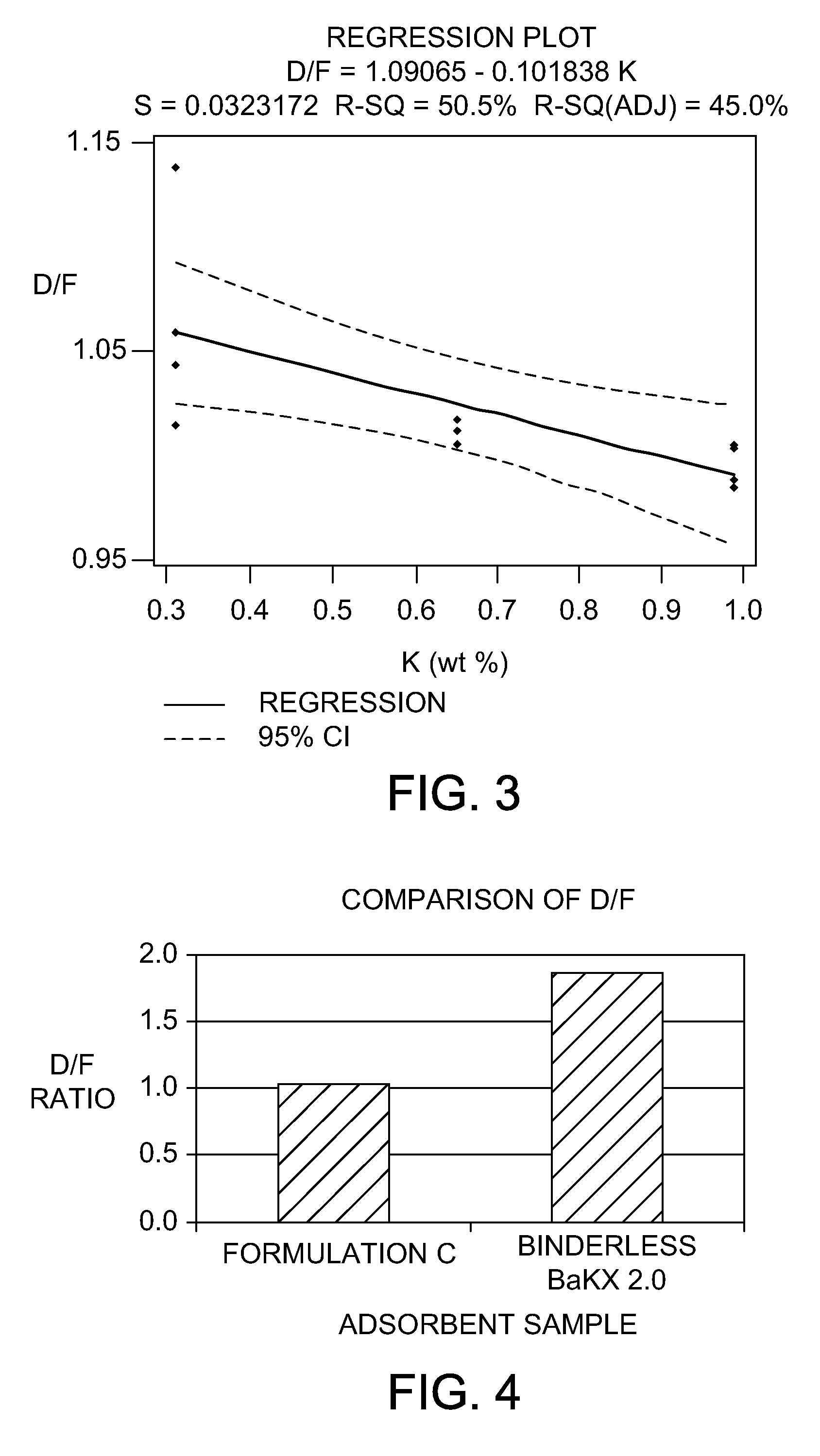

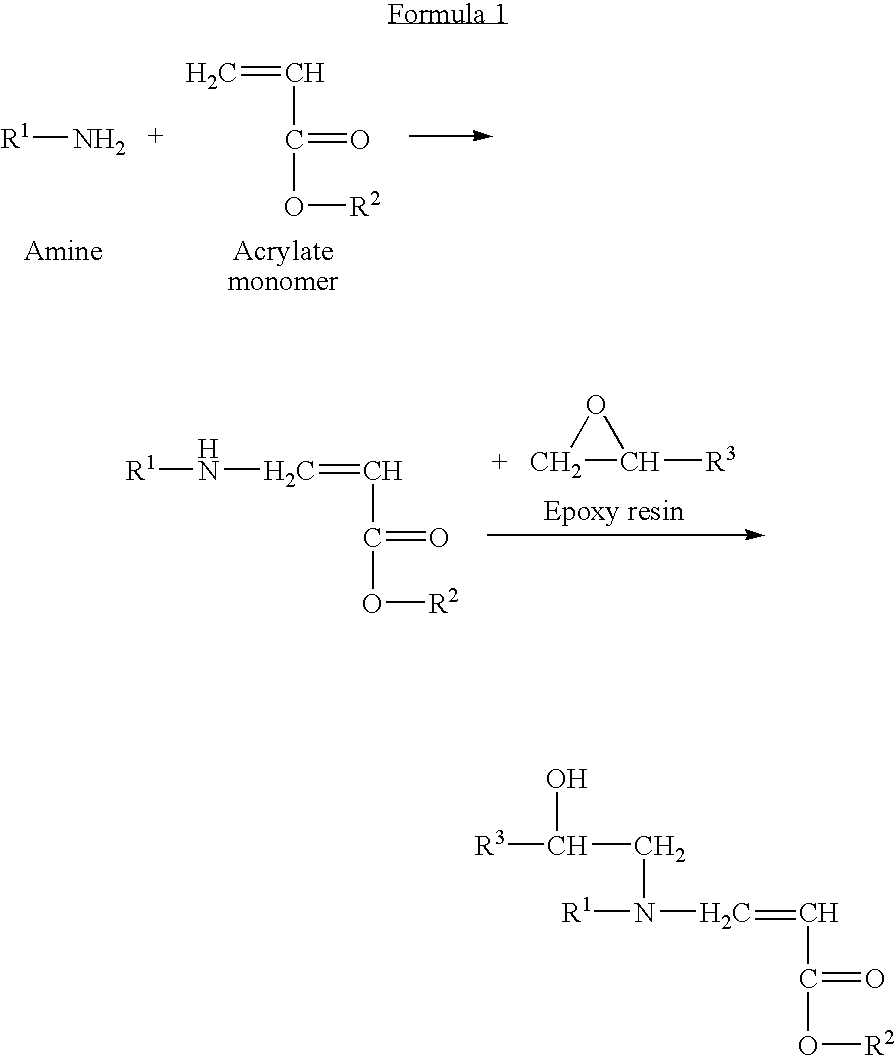

Binderless BaKX zeolitic adsorbents, methods for their production, and processes for their use in a liquid phase adsorptive separation process are provided. An adsorbent includes a binder-converted zeolite portion formed from x wt % kaolin clay binder and (100-x) wt % unconverted Zeolite X with a silica:alumina molar ratio of about 2.5. The kaolin clay binder is in the range of about 10 to about 20 wt %. Ba and K occupy cationic exchangeable sites within the adsorbent. K is in the range of about 0.25 to about 0.9% by weight and Ba is greater than about 31.6% by weight of the binderless BaKX zeolitic adsorbent. Cornstarch may be added to the Zeolite X and kaolin clay binder to increase adsorbent macro-porosity and pore volume. Productivity of the adsorbent is improved decreasing process operating costs. The mechanical strength of the adsorbent is also improved.

Owner:UOP LLC

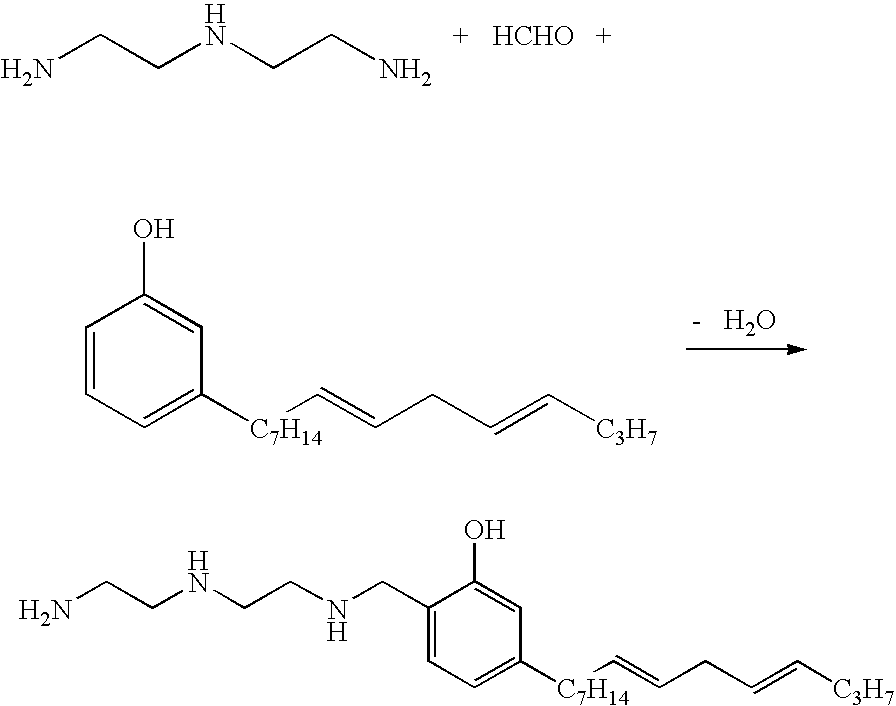

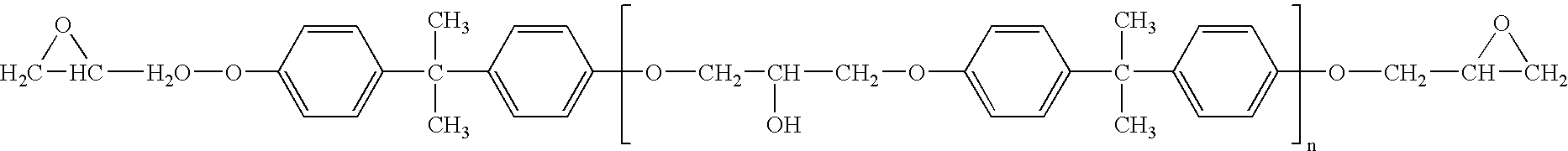

High-solid anticorrosive coating composition, high-solid rapidly-curable anticorrosive coating composition, method of coating ship or the like, high-solid anticorrosive film and rapidly cured high- anticorrosive film obtained, and coated ship and underwater structure coated with these coating films

InactiveUS20090226729A1Improve anti-corrosion performanceIncrease contentLiquid surface applicatorsAntifouling/underwater paintsOrganic solventBoiling point

A high-solids anticorrosive coating composition which comprises a main ingredient (A) comprising an epoxy resin (a1) and a hardener ingredient (B) comprising an alicyclic amine hardener (b1) and / or a Mannich type hardener (b2), the ingredient (A) and / or the ingredient (B) containing at least either of an additive (a2) selected among epoxidized reactive diluents and modified epoxy resins and a coating film modifier (ab) selected among petroleum resins, xylene resins, coumarone resins, terpene phenol resins and vinyl chloride copolymers. The high-solids anticorrosive coating composition especially of the rapidly curable type is characterized by containing a high-boiling organic solvent having a boiling point exceeding 150° C. and containing substantially no organic solvent having a boiling point of 150° C. or lower.

Owner:CHUGOKU MARINE PAINTS

Agglomerated zeolite adsorbents, process for their preparation, and their use for adsorbing paraxylene from aromatic C8 fractions

InactiveUS6410815B1Improve efficiencyImproved kineticsMolecular sieve catalystsOther chemical processesSorbentPotassium

The present invention relates to agglomerated zeolite adsorbents based on faujasite with an Si / Al ratio such that 1<=Si / Al<=1.15, at least 70% exchanged with barium and optionally with potassium, and on a binder, preferably a zeolitizable binder.They are obtained by agglomerating zeolite powder with a binder, followed by exchange of the zeolite ions for barium ions and activation of the adsorbents thus exchanged.These adsorbents are particularly suitable for the adsorption of the para-xylene contained in aromatic C8 hydrocarbon fractions in the liquid phase, in processes of simulated fluid-bed type.

Owner:INST FR DU PETROLE +1

Highly crystalline polypropylene with low xylene solubles

InactiveUS20050272858A1Narrow molecular weight distributionLow melt flow rateGranular deliveryFlexural modulusPolypropylene

The invention is directed to a polypropylene resin which has a Mw / Mn of less than 5, a melt flow rate of less than 7 g / 10 min., a 1% secant flexural modulus of greater 5 than 300,000 psi and less than 2 wt. % xylene solubles.

Owner:BRASKEM AMERICA

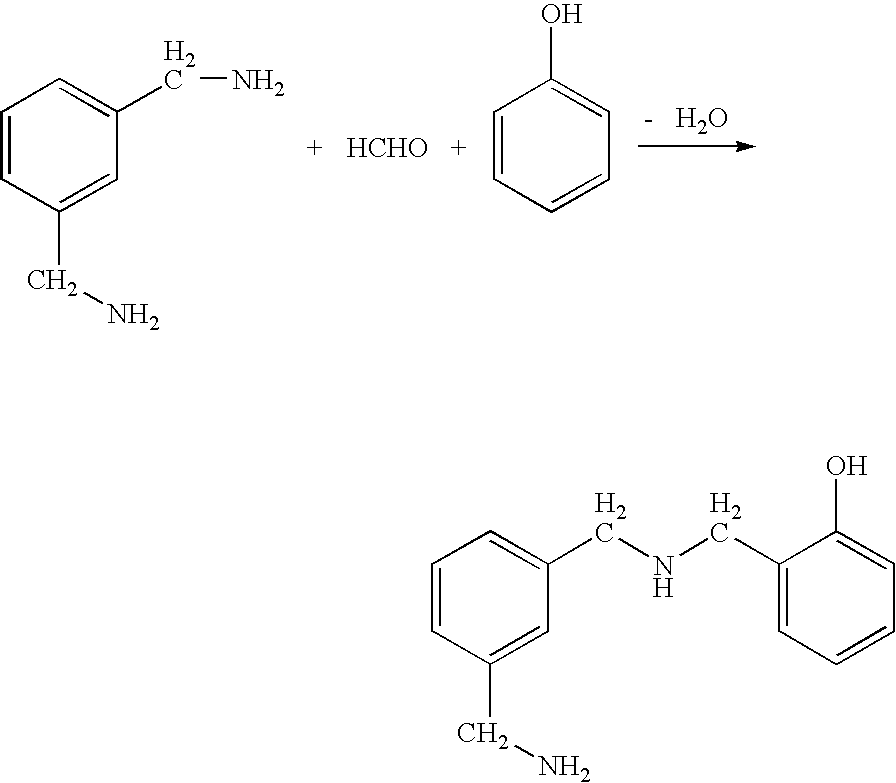

Coating composition and article coated therewith

InactiveUS20050215670A1Improve corrosion resistancePlastic/resin/waxes insulatorsAnti-corrosive paintsEpoxyTriazole antifungals

A coating composition used for coating of a steel material and / or aluminum material comprises a corrosion inhibitor, a base resin and a curing agent. The corrosion inhibitor may be selected from cerium compounds, lanthanum compounds, molybdate salt compounds, gluconic acid derivative salts, porous base materials, triazole compounds, thiazole compounds, tetracyclines, and metal phosphate salt compounds of ascorbic acid. The base resin may include a xylene-formaldehyde-resin-modified amino-containing epoxy resins obtained by reacting an epoxy resin having an epoxy equivalent of from 180 to 2500 with a xylene formaldehyde resin and an amino-containing compound. The curing agent may be a blocked polyisocyanate compound obtained by blocking an isocyanate group of a polyisocyanate compound with a blocking agent.

Owner:KANSAI PAINT CO LTD

Thermocured, heat conductive and heat radiating paint for LED lamp and preparation method thereof

InactiveCN103555094AExtended service lifeImprove fullnessPolyurea/polyurethane coatingsEthyl acetateColor changes

A thermocured, heat conductive and heat radiating paint for an LED lamp is prepared by the following raw materials by weight: 40-45 parts of polyacrylic resin, 5-8 parts of polyurethane resin, 4-6 parts of polyacrylamide, 6-8 parts of isophorone diamine IPDA, 20-24 parts of xylene, 2-3 parts of silane coupling agent KH550, 1-2 parts of aluminium powder, 8-12 parts of ethyl acetate, 2-4 parts of benzyltrimethylammonium tribromide, 10-12 parts of aluminium nitride, 2-3 parts of beryllia, and 4-5 parts of film forming auxiliary agent. Aluminium nitride powder, the beryllia and the aluminium powder are added, so as that the paint has high heat conduction rate and good heat radiation effect, and can be long-term used under 200 DEG C without change of mechanical property; polyacrylic resin is used, so as that the paint has advantages of excellent fullness, glossiness, hardness, solvent resistance and weatherability, without color change and brightness reversion when high temperature baked; and the paint has advantages of large adhesion stress, not-easy shedding, aging resistance and long usage life.

Owner:天长市天泰光电科技有限公司

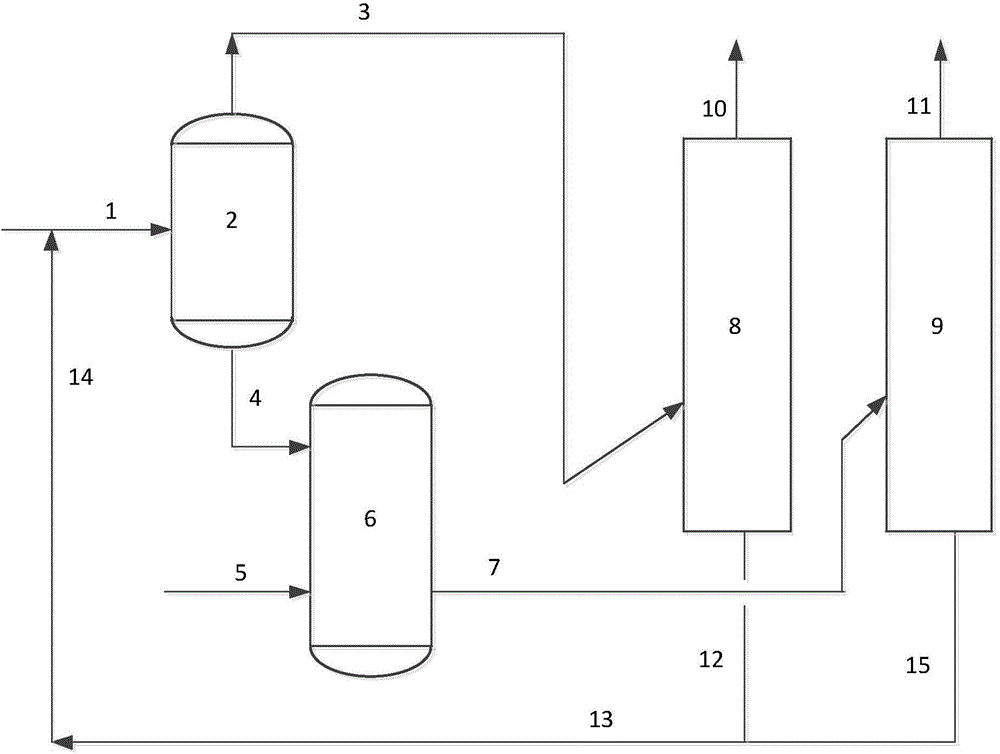

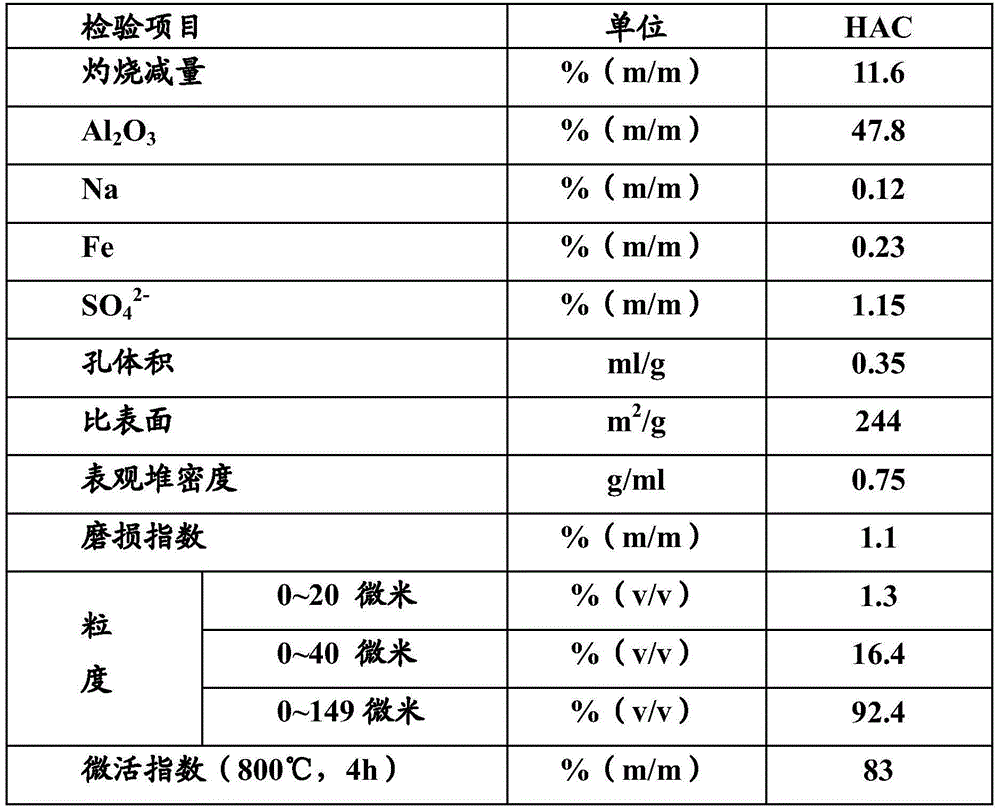

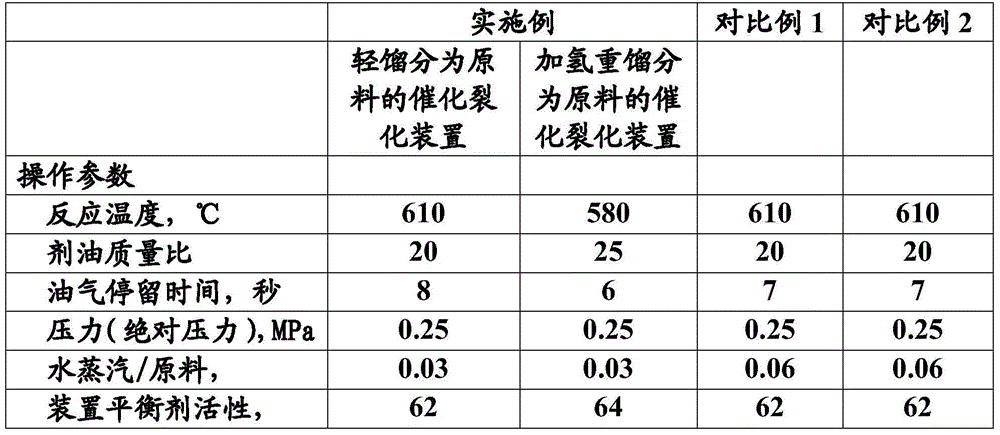

Catalytic conversion method for producing gasoline containing rich aromatic hydrocarbon

ActiveCN104560187AReduce hydrogen consumptionImprove harsh conditionsTreatment with hydrotreatment processesHydrocarbon oils treatment productsPolycyclic aromatic hydrocarbonGasoline

The invention provides a catalytic conversion method for producing gasoline containing rich aromatic hydrocarbon. The catalytic conversion method comprises the following steps: cutting catalytic cracking light cycle oil to obtain a light fraction and a heavy fraction, performing hydrogenation treatment on the heavy fraction to obtain a hydrogenated heavy fraction, singly and respectively conveying the light fraction and the heavy fraction into different riser reactors of catalytic cracking devices, performing a cracking reaction in the presence of a catalytic cracking catalyst, and separating reaction products to obtain a product containing the gasoline which contains rich aromatic hydrocarbon and the light cycle oil. According to the method, single catalytic cracking devices are used for processing the light fraction and the hydrogenated heavy fraction of the light cycle oil to satisfy harsh conditions necessary for the catalytic cracking reaction of different fractions of the light cycle oil to the maximum, so as to produce catalytic gasoline containing rich benzene, toluene and xylene to the maximum.

Owner:CHINA PETROLEUM & CHEM CORP +1

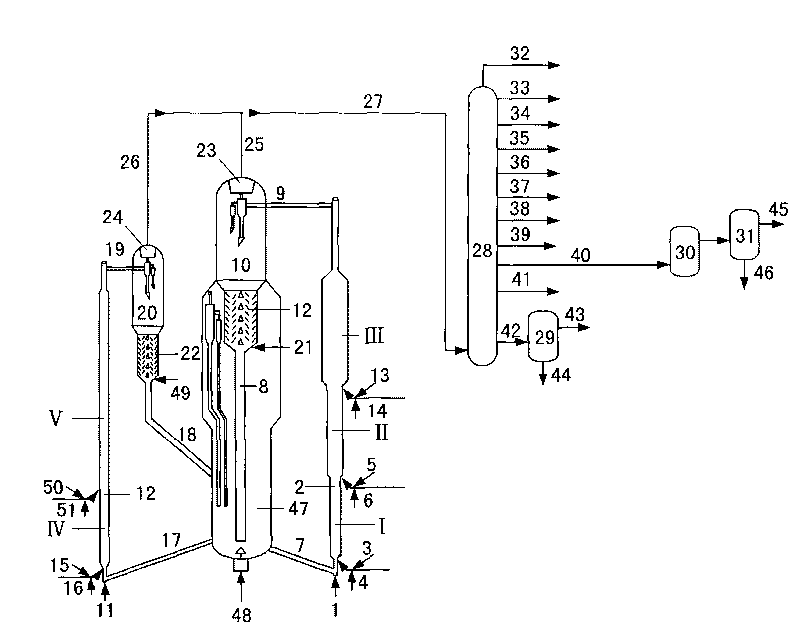

Catalytic conversion method for preparing lower olefins and aromatics

The invention relates to a catalytic conversion method for preparing lower olefins and aromatics. Raw oil with different cracking performances enters different reaction zones of a first riser reactor to contact with a catalytic cracking catalyst for cracking reaction to separate a spent catalyst from reaction oil gas, wherein the reaction oil gas is separated to obtain a product containing lower olefins, gasoline, distillates with distillation range of 180-250 DEG C and catalytic wax oil, wherein the gasoline is extracted by light aromatics to obtain light aromatics and gasoline raffinate; the raw materials are cracked to be sent into a second riser reactor to contract with a hot regenerated catalyst for catalytic conversion; and the spent catalysts of the two riser reactors are burned and regenerated in the same one regenerator and then returns to the two riser reactors. The method uses heavy raw materials to furthest produce the lower olefins, such as propylene, ethylene, and the like, particularly the propylene, the production rate can exceed 40 wt%, and at the same time the method can coproduce the aromatics, such as toluene, xylene, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

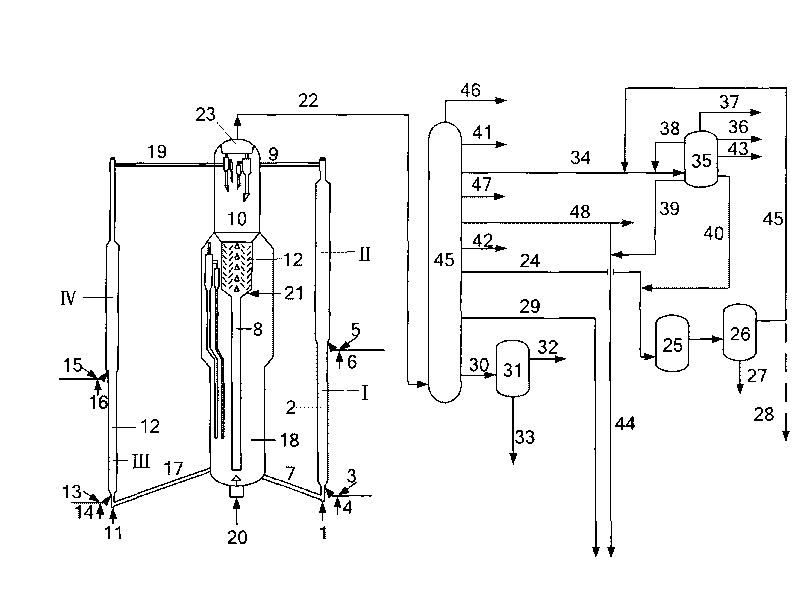

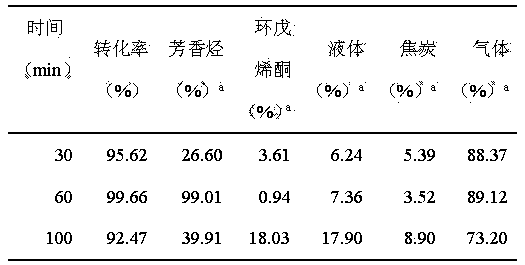

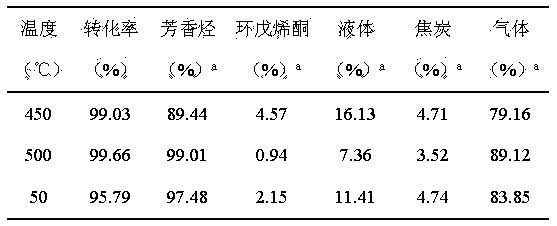

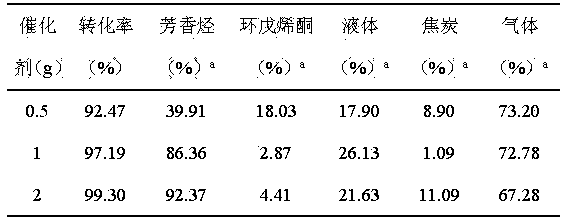

Method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion

InactiveCN104230615AGood dehydrogenation performanceInhibition of partial polymerizationHydrocarbonsPreparation from heterocyclic compoundsLiquid productReaction temperature

The invention relates to a method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion, which comprises the following steps: (1) using biomass derivative gamma-valerolactone as a raw material, which is prepared by carrying out hydrogenation reaction on levulinic acid; (2) introducing one or more transition metals into a zeolite molecular sieve, and preparing a reaction catalyst at the reaction temperature of 350-550 DEG C by using a fixed bed or fluid bed as a reactor; (3) in an inert or reducing atmosphere, carrying out contact reaction on the raw material gamma-valerolactone and catalyst under the reaction pressure of 0-10 MPa; and (4) after the pyrolysis gas is condensed, collecting the liquid product in the condensation receiver, thereby obtaining the aromatic hydrocarbon product (of benzene, toluene and xylene) and the cyclopentenone product. By using the renewable biomass derivative gamma-valerolactone as the raw material, the method has the advantage of milder reaction conditions, and the catalyst is simple to prepare and easy to recover and reuse.

Owner:湖南清欣绿色环保有限公司

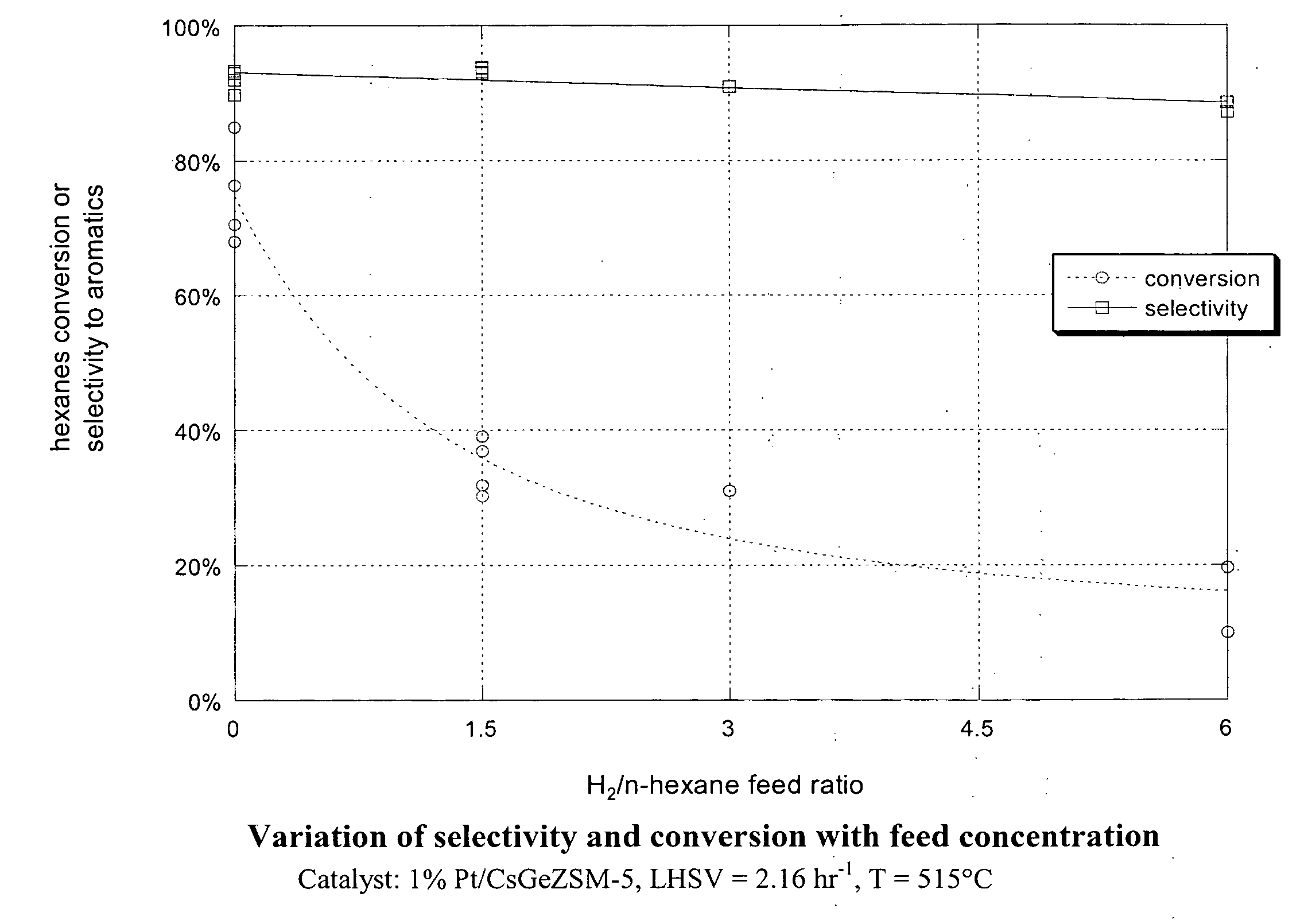

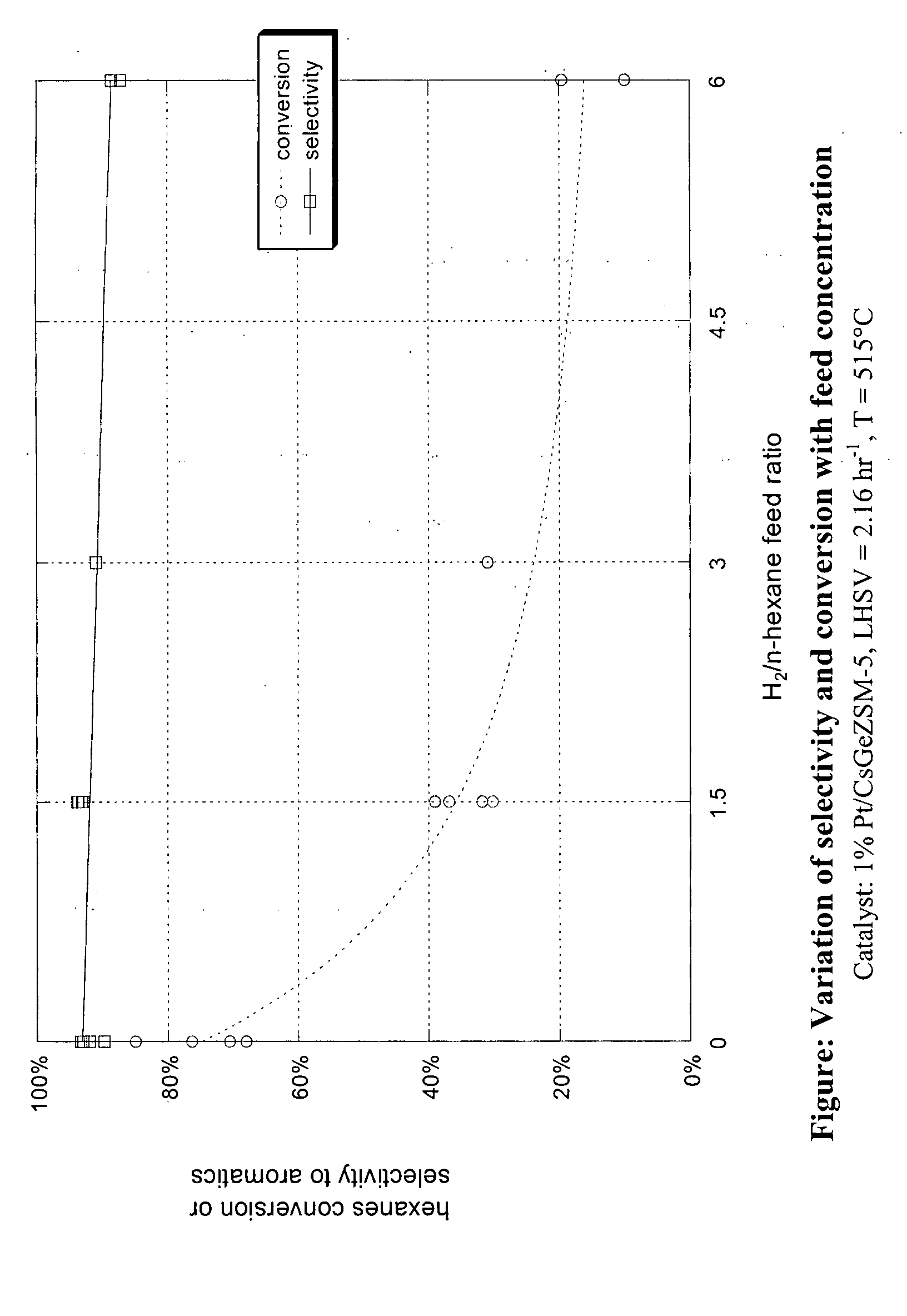

Aromatization of alkanes using a germanium-zeolite catalyst

ActiveUS20080255398A1Molecular sieve catalystsRefining to change hydrocarbon structural skeletonAlkaneAlkaline earth metal

This invention relates to a process for the aromatization of C6 to C12 alkanes, such as hexane, heptane and octane, to aromatics, such as benzene, ethyl benzene, toluene and xylenes, with a germanium-containing zeolite catalyst. The catalyst is a non-acidic aluminum-silicon-germanium zeolite on which a noble metal, such as platinum, has been deposited. The zeolite structure may be of MFI, BEA, MOR, LTL or MTT. The zeolite is made non-acidic by being base-exchanged with an alkali metal or alkaline earth metal, such as cesium, potassium, sodium, rubidium, barium, calcium, magnesium and mixtures thereof, to reduce acidity. The catalyst is sulfur tolerant and may be pretreated with a sulfur compound, i.e., sulfided. The hydrocarbon feed may contain sulfur up to 1000 ppm. The present invention could be applicable to a feedstream which is predominantly paraffinic and / or low in naphthenes. Lowering the hydrogen to hydrocarbon ratio increases conversion and aromatics selectivity.

Owner:SAUDI BASIC IND CORP SA

Optimized liquid-phase oxidation

ActiveUS7692036B2Effective and economicalReduce formationOrganic compound preparationCarboxylic preparation by oxidationOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

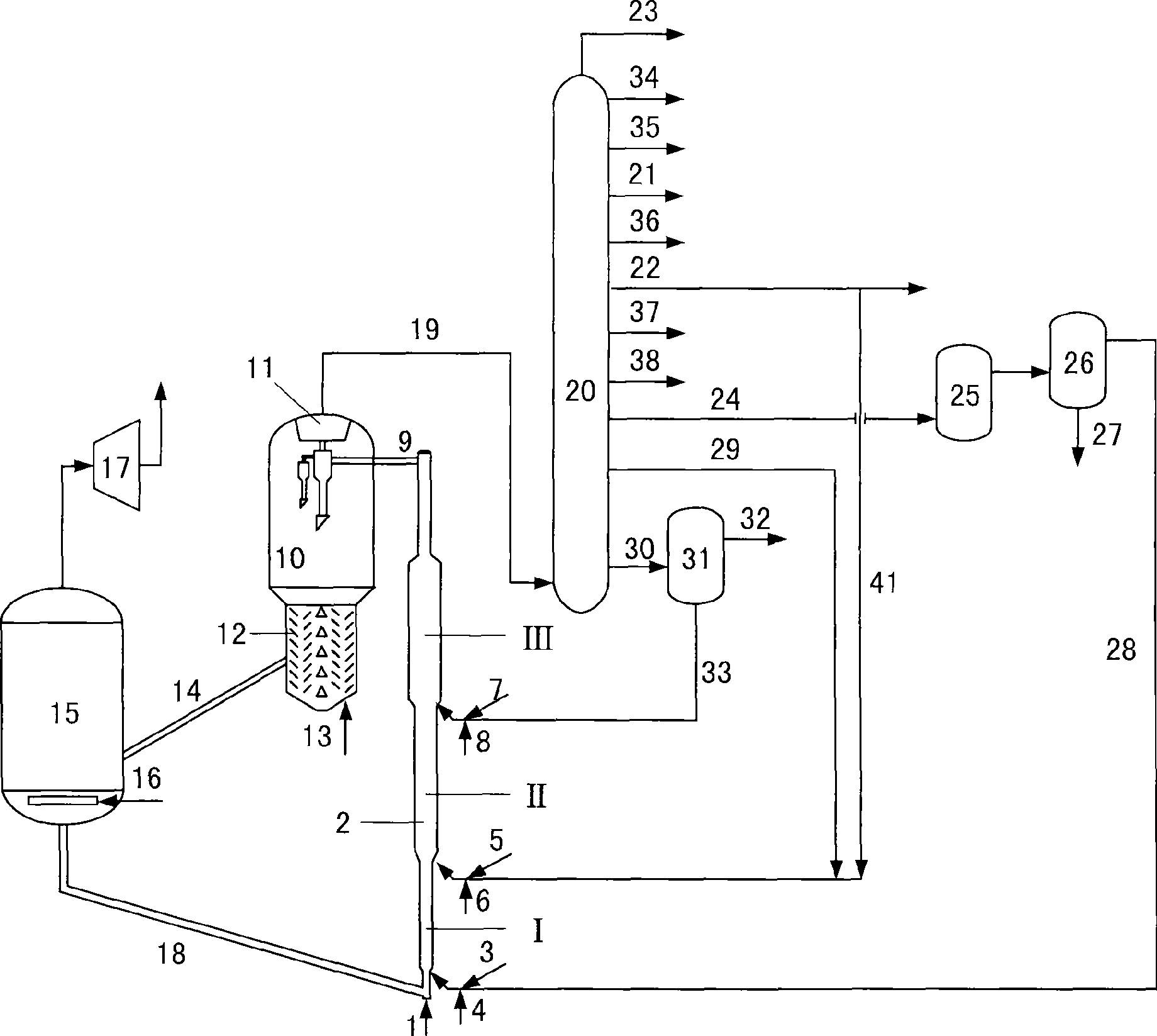

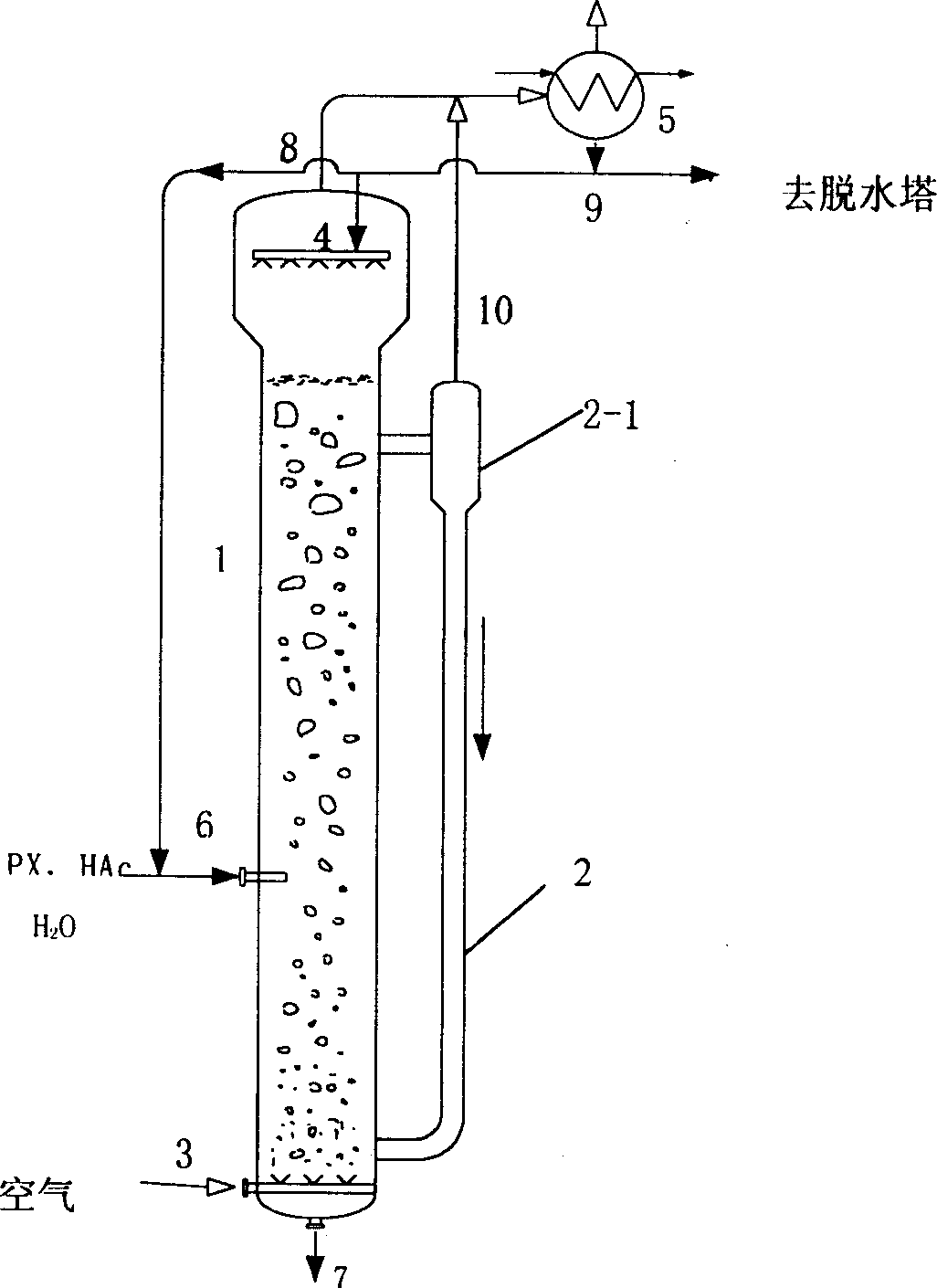

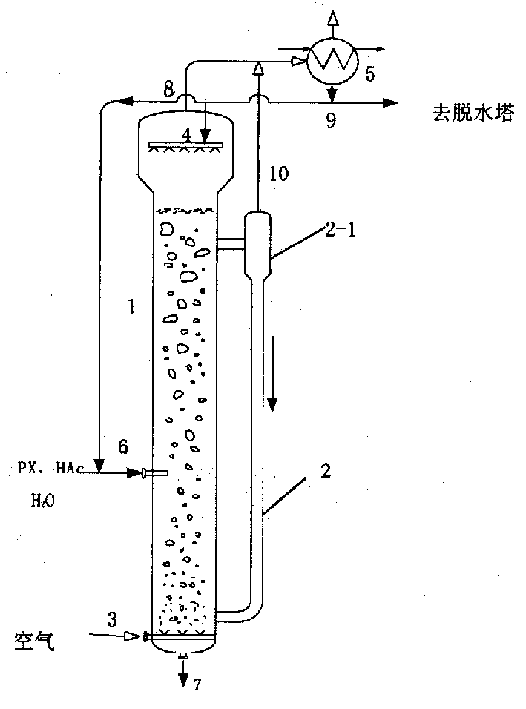

Air lift externally circulating bubble fower oxidation unit for producing terephthalic acid

InactiveCN1486968ASimple structureLow costOrganic compound preparationCarboxylic compound preparationCatalytic oxidationEngineering

The air lift externally circulation bubble tower oxidation apparatus includes cylinder bubble tower with top expanded section, outer circulating pipe, gas distributor, reflux liquid distributor and condensator. The outer circulating pipe has its upper end and lower end communicated with the upper part and the lower part of the bubble tower reaction section separately and is used to lead slurry from the upper part of the tower to the lower part via air lift effect so as to form the fluid circulation in the whole tower and complete the liquid phase catalytic oxidation of xylene. The bubble tower has relatively high height / diameter ratio and thus reinforced gas-liquid mass transfer and the air lift outer circulation pipe improves the temperature distribution and concentraion distribution inside the tower. The tower has no moving part, simple structure and low cost and is suitable for oxidizing xylene to prepare terephthalic acid via different technological processes.

Owner:CHINA TEXTILE IND ENG INST +2

Agglomerated zeolite adsorbents and process for producing the same

ActiveUS20110105301A1Large hole volumeImprove mass transfer effectMolecular sieve catalystsOther chemical processesSorbentIon exchange

An agglomerated zeolite adsorbent which comprises 95-99.5 mass % of X zeolite and 0.5-5.0 mass % of binder, wherein the exchangeable cationic sites of said X zeolite are occupied by Group IIA metal and / or K, the total pore volume of said adsorbent is no less than 0.26 mL / g as measured by mercury porosimetry, the volume of pores with pore diameters from 100 to 500 nm is at least 60% based on the total pore volume. During shaping, a pore-forming agent is added to this adsorbent, and then the adsorbent is alkali treated for in-situ crystallization, followed by ion exchange. Said adsorbent has high adsorption capacity, fast mass transfer rate and good mechanical strength. Said adsorbent is suitable for liquid phase adsorptive separation of para-xylene from C8 aromatic hydrocarbons and is also suitable for adsorptive separation of other alkyl aromatic hydrocarbons isomers.

Owner:CHINA PETROCHEMICAL CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com