Patents

Literature

61results about How to "Good dehydrogenation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion

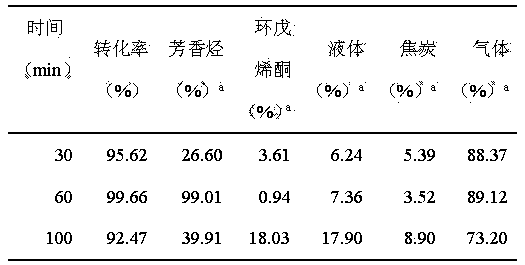

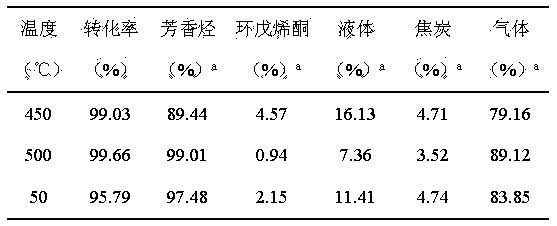

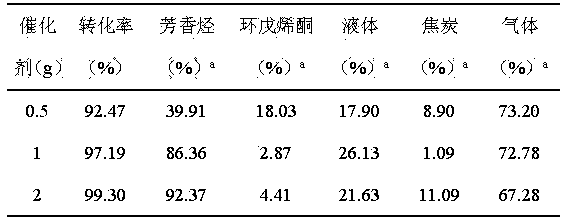

InactiveCN104230615AGood dehydrogenation performanceInhibition of partial polymerizationHydrocarbonsPreparation from heterocyclic compoundsLiquid productReaction temperature

The invention relates to a method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion, which comprises the following steps: (1) using biomass derivative gamma-valerolactone as a raw material, which is prepared by carrying out hydrogenation reaction on levulinic acid; (2) introducing one or more transition metals into a zeolite molecular sieve, and preparing a reaction catalyst at the reaction temperature of 350-550 DEG C by using a fixed bed or fluid bed as a reactor; (3) in an inert or reducing atmosphere, carrying out contact reaction on the raw material gamma-valerolactone and catalyst under the reaction pressure of 0-10 MPa; and (4) after the pyrolysis gas is condensed, collecting the liquid product in the condensation receiver, thereby obtaining the aromatic hydrocarbon product (of benzene, toluene and xylene) and the cyclopentenone product. By using the renewable biomass derivative gamma-valerolactone as the raw material, the method has the advantage of milder reaction conditions, and the catalyst is simple to prepare and easy to recover and reuse.

Owner:湖南清欣绿色环保有限公司

High-hardness self-protecting flux-cored welding wire for overlaying repair of continuous casting roller

InactiveCN104690451AHigh hardnessImprove wear resistanceArc welding apparatusWelding/cutting media/materialsArc stabilityHigh carbon

The invention discloses a high-hardness flux-cored welding wire for overlaying repair of a continuous casting roller, and belongs to the technical field of welding in material processing engineering. An H08A cold-rolled steel strip is adopted as an outer cover, a flux core comprises the following components in percentage by weight: 20-40% of TiO2, 5-15% of high-carbon ferrochrome, 12-30% of low-carbon ferrochrome, 0.5-5% of Mn-Si alloy, 0.5-5% of Al-Mg alloy, 5-15% of Ni, 0.5-2.5% of fluoride, 5-15% of Mo, 0.5-2.5% of V, 2-10% of Cr, 0.5-5% of Al2O3 and the balance of iron powder. The filling rate of the traditional Chinese medicine core of the flux-cored welding wire is 20-35%. The welding wire has the advantages that the flux-cored welding wire adopts a self-protecting overlaying manner, and shielding gas and welding flux are not needed in the overlaying repair process of the continuous casting roller, so that the repair cost can be greatly reduced, the manual labor intensity is lowered, and the production efficiency is improved; the welding wire has good arc stability, excellent abrasion-proof property and excellent thermal fatigue resistant property, and the service life of the continuous casting roller is effectively prolonged.

Owner:SHOUGANG CORPORATION

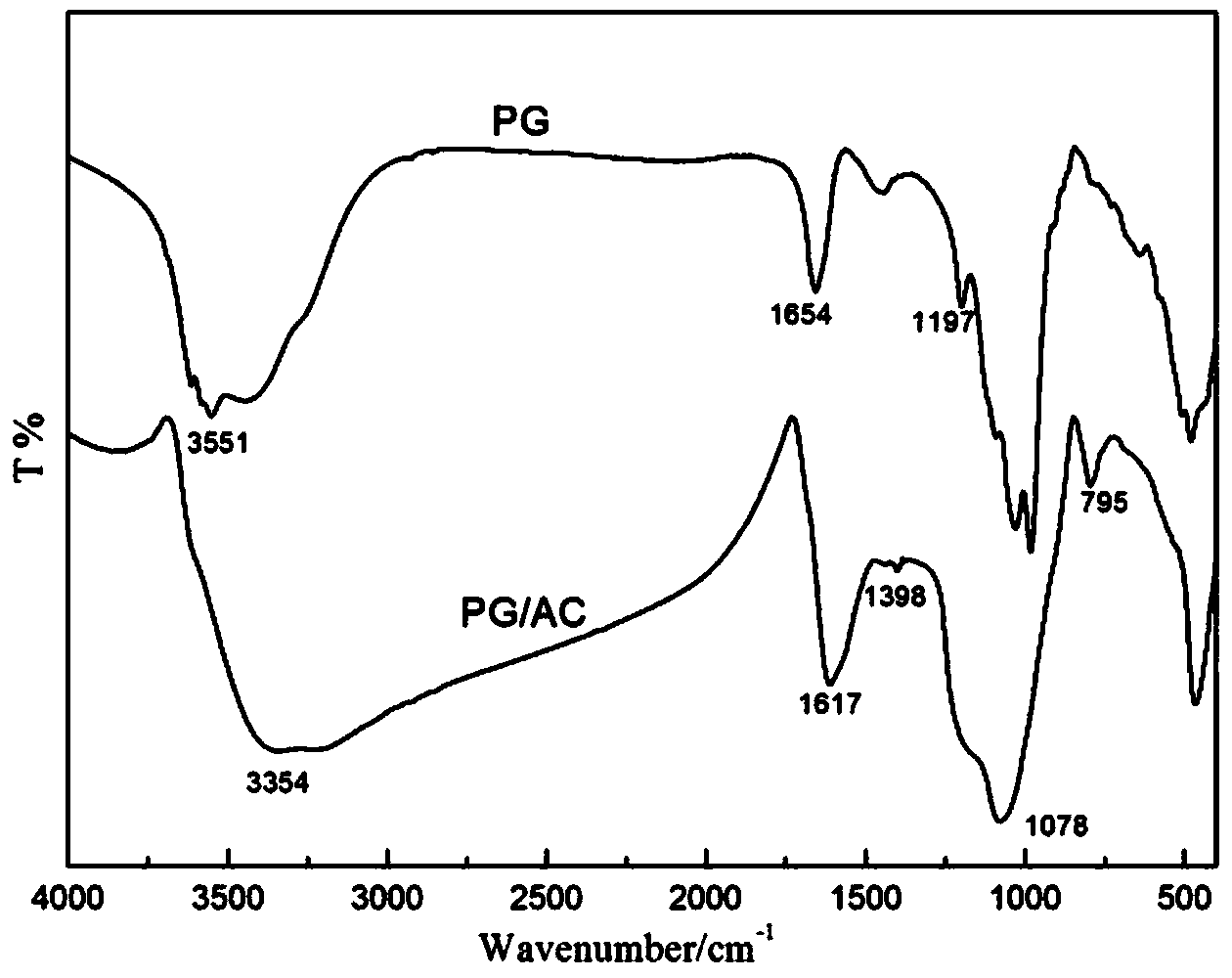

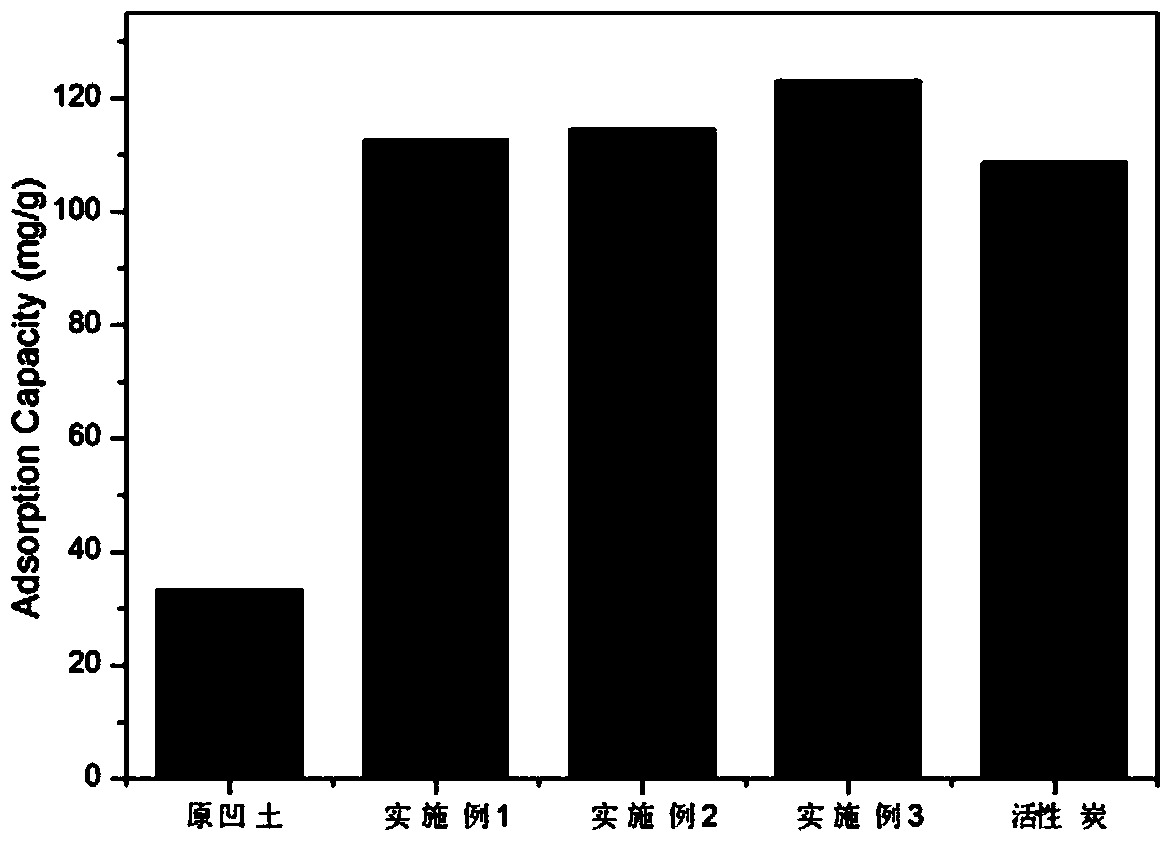

Method for preparing attapulgite/carbon composite adsorbent by one-step carbonization-activation

ActiveCN104289179ALarge specific surface areaHigh yieldOther chemical processesWater/sewage treatment by sorptionCarbon compositesCellulose

The invention discloses a method for preparing an attapulgite / carbon composite adsorbent by one-step carbonization-activation. According to the method, nature attapulgite clay with low cost and a biomass cellulose carbon source are taken as raw materials, ZnCl2 is taken as an activating agent, and the attapulgite / carbon composite adsorbent is prepared by a one-step calcination method. According to the method, amorphous carbon with an organophilic property can be supported on the surfaces of attapulgite crystals, and the specific surface area of a composite can be further greatly enlarged by activation and pore-forming effects of ZnCl2. Compared with the natural unmodified attapulgite clay, the removal rate against pollutant methylene blue in water of the composite adsorbent after activation is greatly improved. According to the method disclosed by the invention, the sources of the raw materials are extensive, the price is low, the preparation process is simple, and the reaction conditions are mild; and the adsorption capability of the attapulgite / carbon composite adsorbent prepared by the method disclosed by the invention against pollutants in water is obviously upgraded, and the attapulgite / carbon composite adsorbent can be used for advanced treatment of the organic pollutants in the water.

Owner:HEFEI UNIV OF TECH

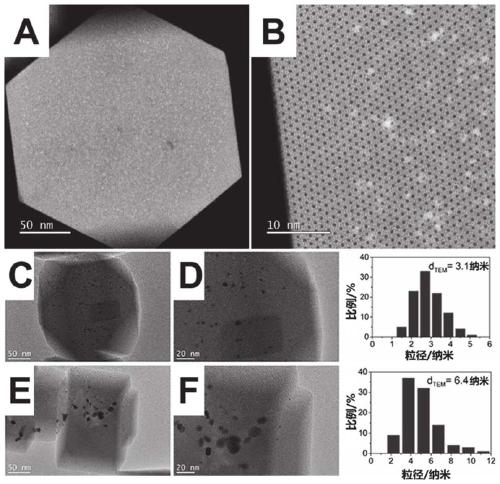

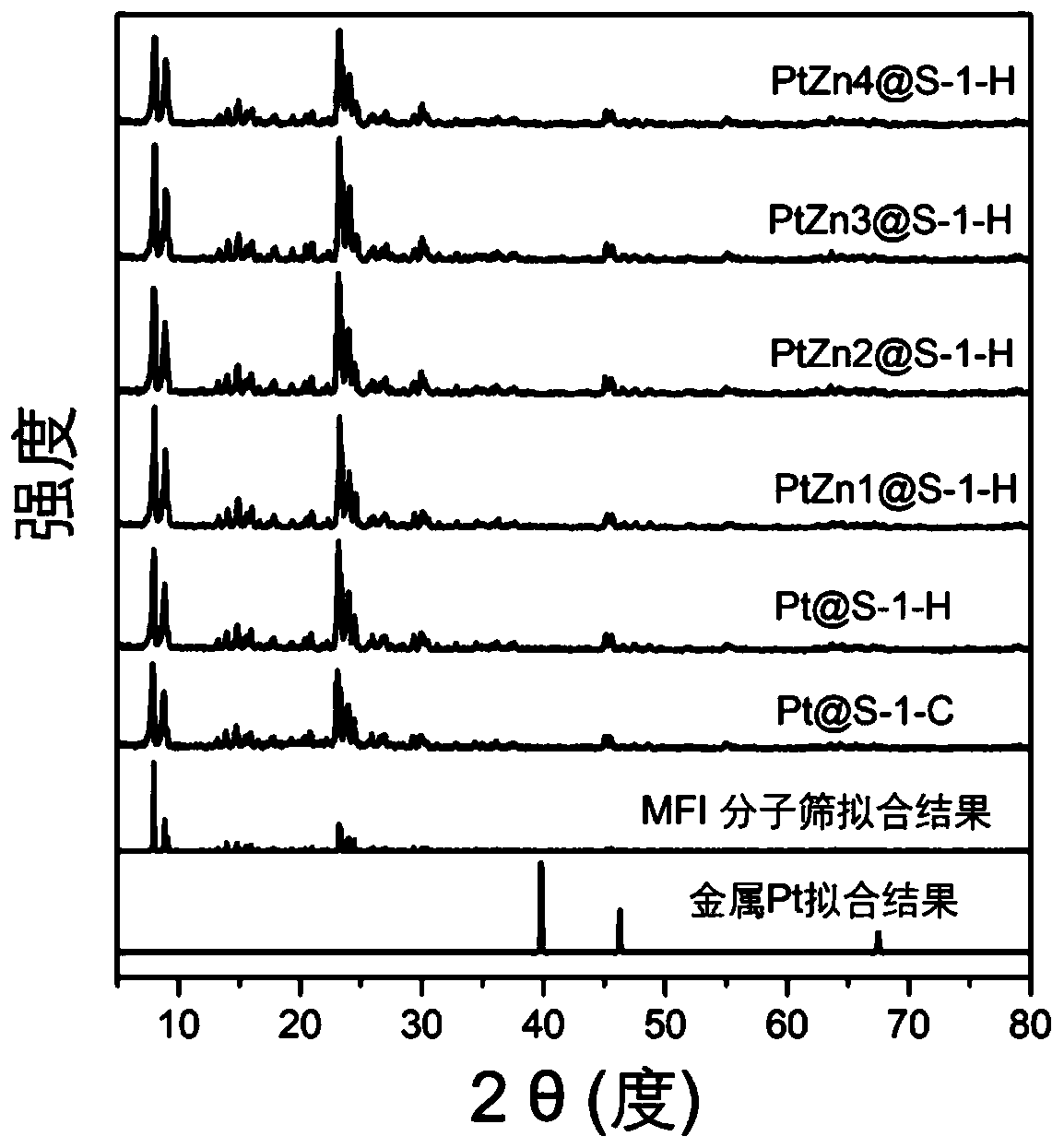

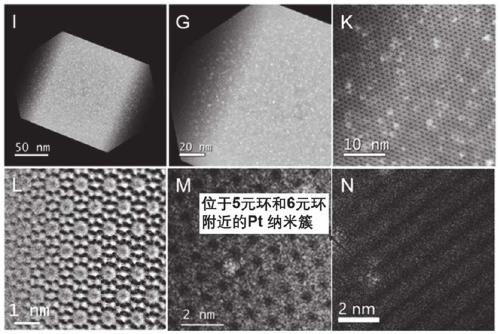

Catalyst and preparation method and application thereof

ActiveCN110479353AGood dehydrogenation performanceEasy to fixMolecular sieve catalystsCatalyst activation/preparationMolecular sieveHydrogen

The invention discloses a catalyst as well as a preparation method and application thereof. The catalyst comprises a carrier and an active component, the carrier is a pure silicon molecular sieve, andthe active element in the active component comprises Pt,wherein Pt is loaded in the carrier in the form of a sub-nano Pt cluster (the number of Pt atoms in the cluster is 1-10, and the average numberof Pt atoms is 3), zn is linked with the carrier through a Zn-O-Si bond in the form of unit point + divalent Zn ions, and is connected with the platinum cluster through a Zn-O-Pt bond. The preparation method of the catalyst adopts the direct hydrogen reduction, the prepared catalyst encapsulates the sub-nano platinum clusters and the unit point Zn <2 +> ions into a pure silicon molecular sieve, and the catalyst is applied to the propane dehydrogenation catalytic reaction and shows the performance far higher than that of other catalysts.

Owner:JILIN UNIV

Flux-cored wire for non gas shielded welding

InactiveCN106695171AImproved arc stabilityImprove low temperature impact toughnessWelding/cutting media/materialsSoldering mediaArc stabilityIron powder

The invention discloses a flux-cored wire for non gas shielded welding and belongs to the technical field of welding. The flux-cored wire comprises an outer skin and a flux core. The outer skin is a SPCC cold-rolled strip; the flux core comprises the following components in percentage by weight: 12-25% of CaF2, 10-20% of TiO2, 5-10% of Mn, 5-15% of CaO, 2-10% of MgO, 1-5% of zircon sand, 0.5-5% of Al-Mg, 3-10% of Ni and the balance of iron powder; and the filling rate of the flux core in the flux-cored wire is 15-25%. The flux-cored wire has excellent electric arc stability and low-temperature impact toughness; and the impact toughness of welding line metal is greater than 60 J at minus 40 DEG C.

Owner:SHOUGANG CORPORATION +1

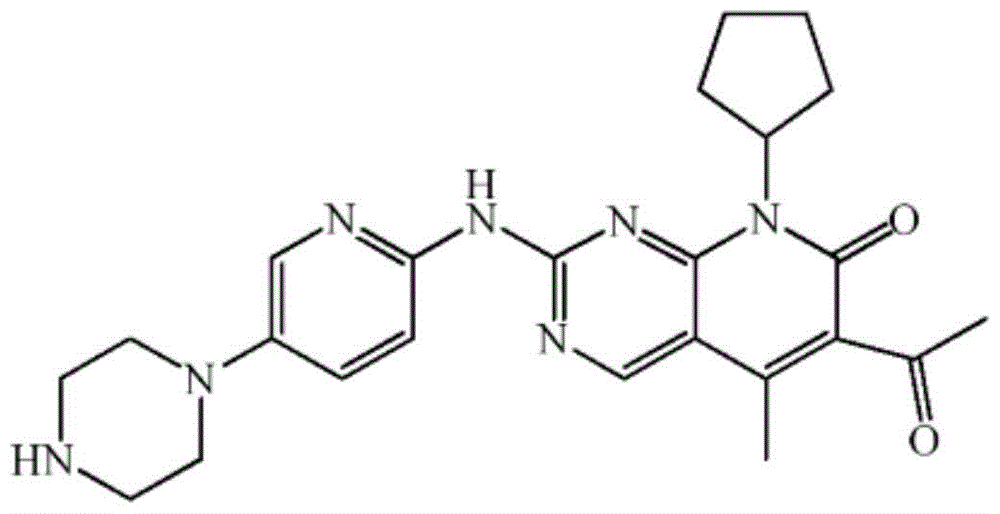

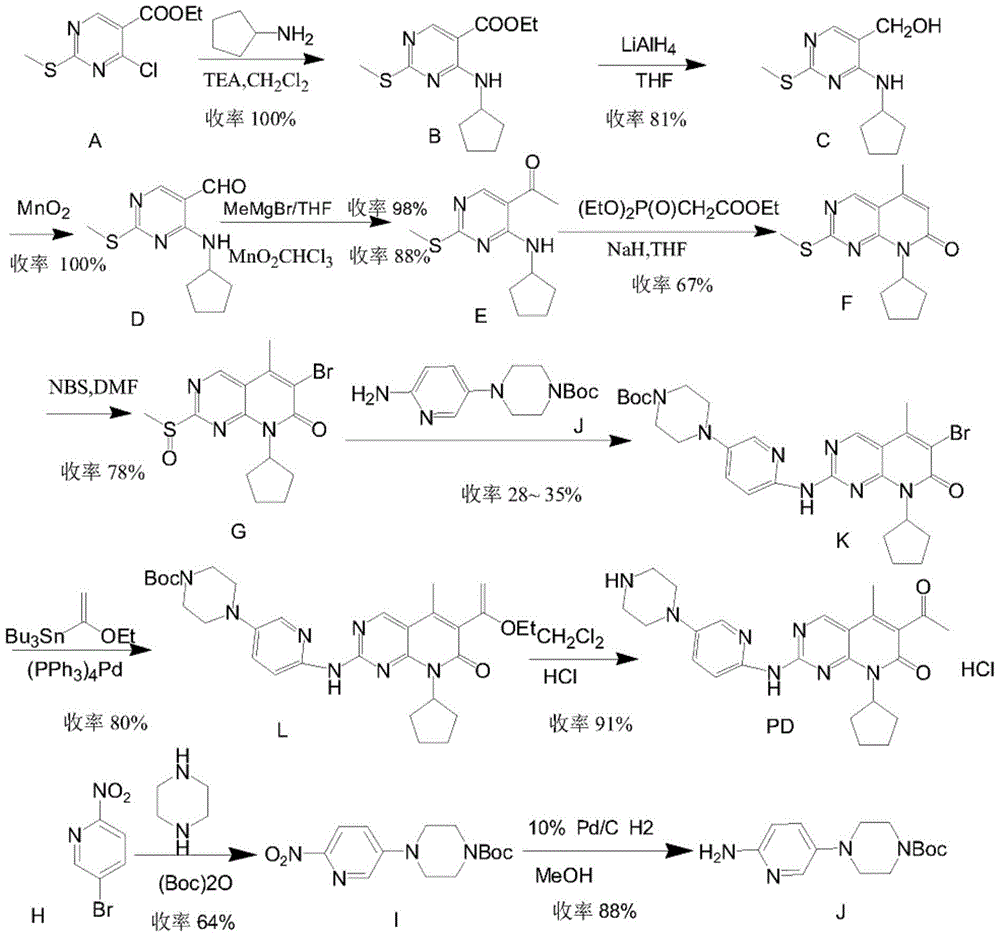

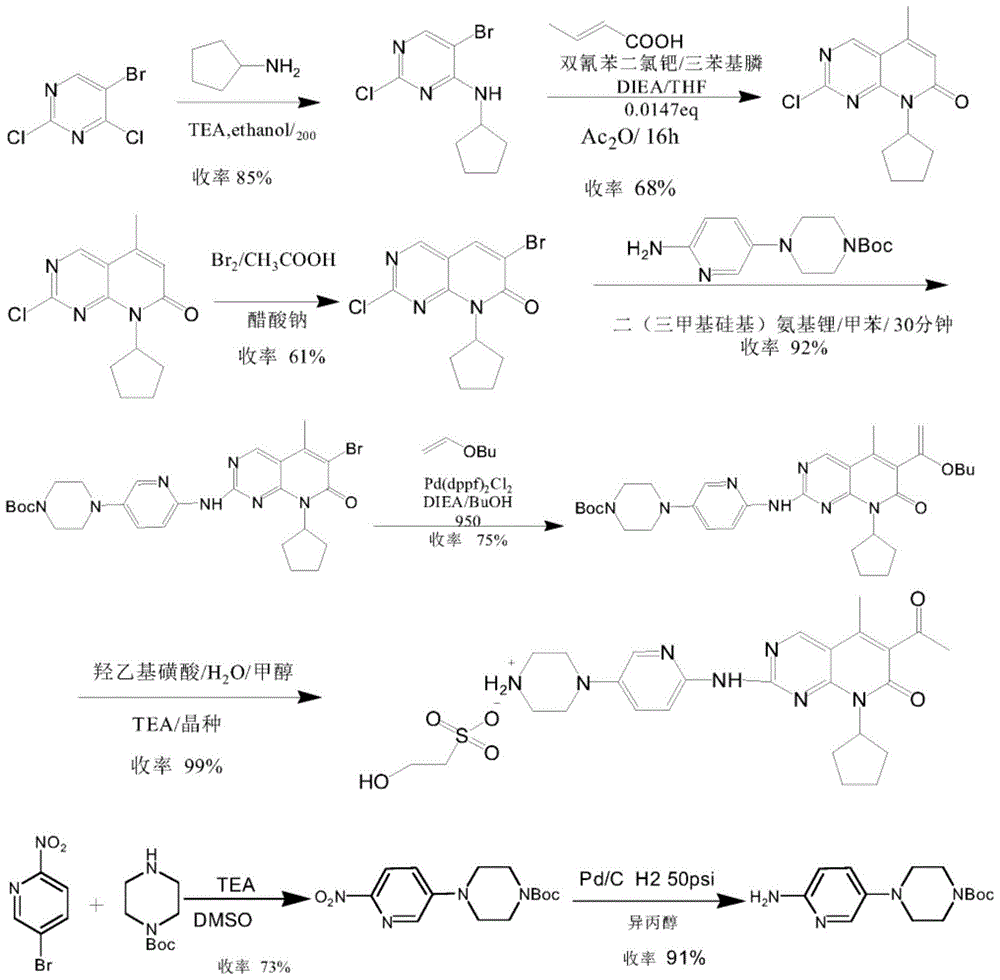

A kind of preparation method of palbociclib

The invention belongs to the field of pharmaceutical and chemical engineering, and particularly relates to a preparation method of palbociclib. 2-acetyl-2-butenoic acid methyl ester, malononitrile and a guanidino compound III are reacted together according to an ultrasonic-microwave assisted synthesis method, and a compound IV is rapidly obtained with a high yield; then, sodium nitrite and hypophosphorous acid are subjected to a deamination reduction reaction to generate a compound V; then, the compound V and cyclopentane halide are subjected to a coupled reaction under the action of a catalyst to generate a compound VI; finally, a dehydrogenation reaction is conducted under the action of a catalyst TPND to obtain the palbociclib. The method has the advantages that reaction conditions are mild, the technological process is simple and reasonable, reaction time is short, aftertreatment is easy, product quality is high, and the yield is high.

Owner:SHANDONG LUOXIN PHARMA GRP CO LTD

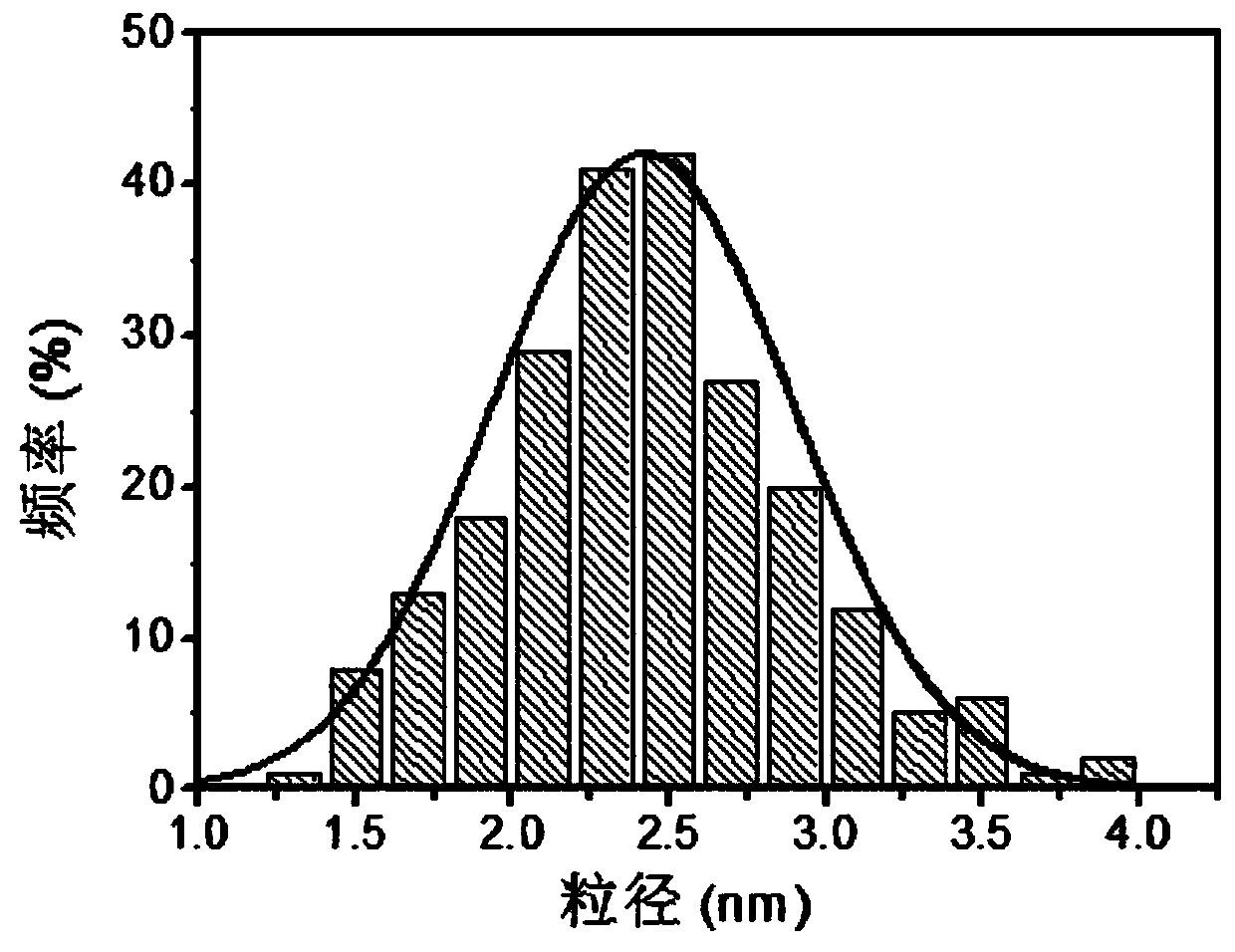

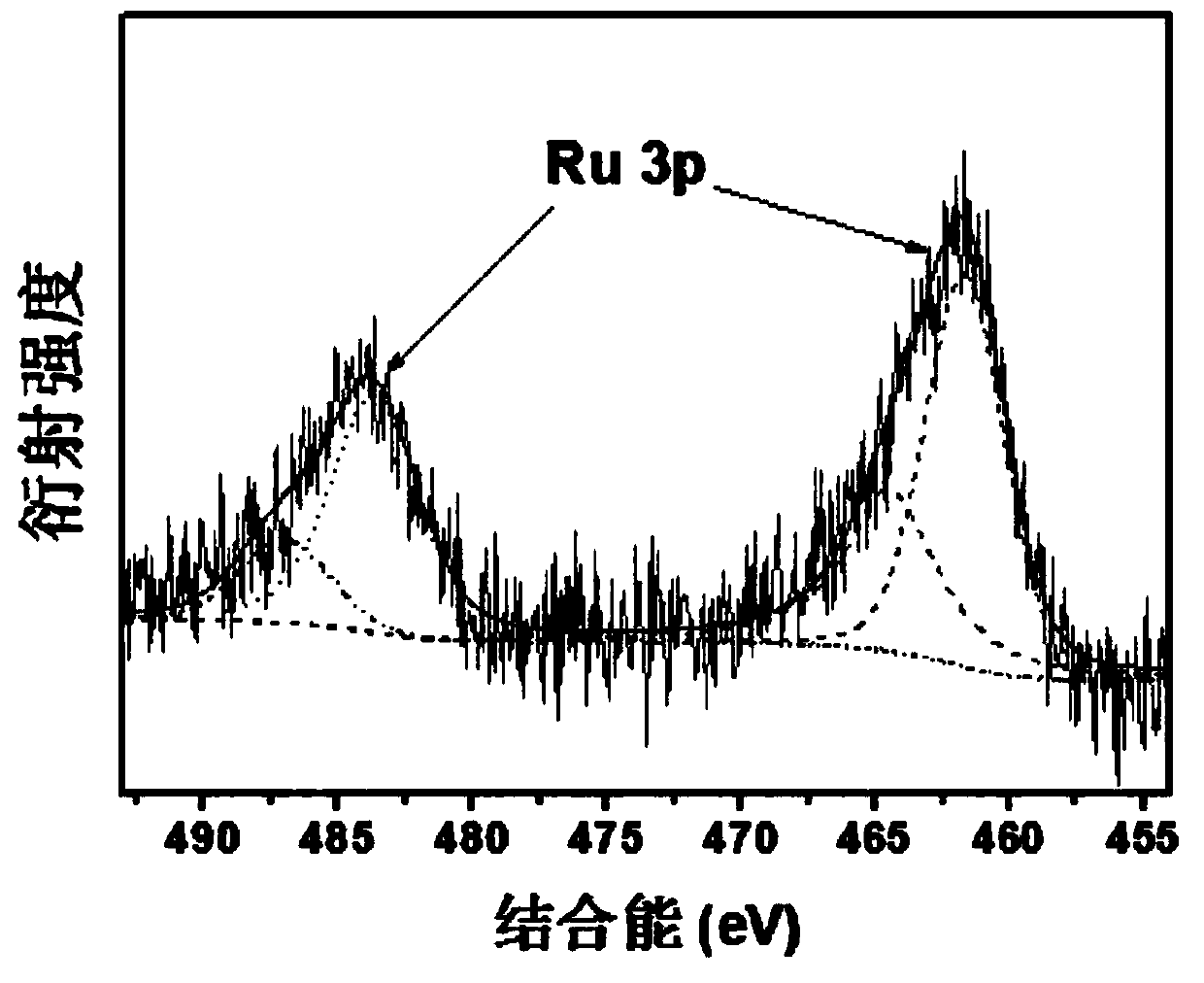

Carbon-supported ruthenium phosphide nanocluster dual-functional catalyst, and preparation method and application thereof

ActiveCN110639567AImprove stabilityHigh activityPhysical/chemical process catalystsOrganic chemistryActivated charcoal powderPtru catalyst

The invention discloses a carbon-supported ruthenium phosphide nanocluster dual-functional catalyst, and a preparation method and application thereof. The preparation method of the catalyst comprisesthe following steps: dispersing active carbon powder and an Ru precursor in water, carrying out stirring to ensure that the Ru precursor is fully adsorbed on the surface of the active carbon, then carrying out evaporating to remove moisture, mixing and grinding the obtained solid powder with sodium hypophosphite, placing the mixture in a tubular furnace, carrying out high-temperature calcination in an inert atmosphere to enable the Ru precursor supported on the active carbon and the sodium hypophosphite to react at high temperature to be converted into a ruthenium phosphide active component, washing the calcined product with water, and carrying out drying to obtain the carbon-supported ruthenium phosphide nanocluster dual-functional catalyst. The carbon-supported ruthenium phosphide nanocluster dual-functional catalyst disclosed by the invention can be used for catalyzing a hydrogenation reaction of quinoline and catalyzing a dehydrogenation reaction of 1,2,3,4-tetrahydroquinoline. Thecatalyst disclosed by the invention is high in catalytic activity and good in stability; and the preparation method of the catalyst is simple, and is easy for industrial mass production.

Owner:ZHEJIANG UNIV OF TECH

Welding method for low-carbon high-strength steel

ActiveCN103008846AImprove efficiencyHas a stirring effectArc welding apparatusLaser beam welding apparatusStress concentrationGas metal arc welding

The invention provides a welding method for low-carbon high-strength steel. The welding method for the low-carbon high-strength steel comprises the following steps of: 1) forming a welding groove on the low-carbon high-strength steel with a laser blanking method, and forming a welding line between the welding grooves of two pieces of low-carbon high-strength steel to be welded; and 2) welding the welding line by consumable electrode mixed gas metal arc welding, filling a welding wire in the welding process, and ensuring that the welding environment temperature is higher than 5DEG C. Specifically, the step 2) comprises the following steps of: 21) carrying out backing weld to the welding line by non-pulse consumable electrode mixed gas metal arc welding, forming a backing weld layer on the bottom of the welding line, and filling the welding wire in the welding process; and 22) carrying out cosmetic welding to the welding line by pulse consumable electrode mixed gas metal arc welding, forming a plurality of cosmetic layers above the backing weld layer, ensuring that two adjacent cosmetic layers are provided with overlay regions, and filling welding wire in the welding process. According to the welding method for the low-carbon high-strength steel, the stress concentration is lowered, and the welding quality of the low-carbon high-strength steel is improved.

Owner:青岛中车四方轨道车辆有限公司

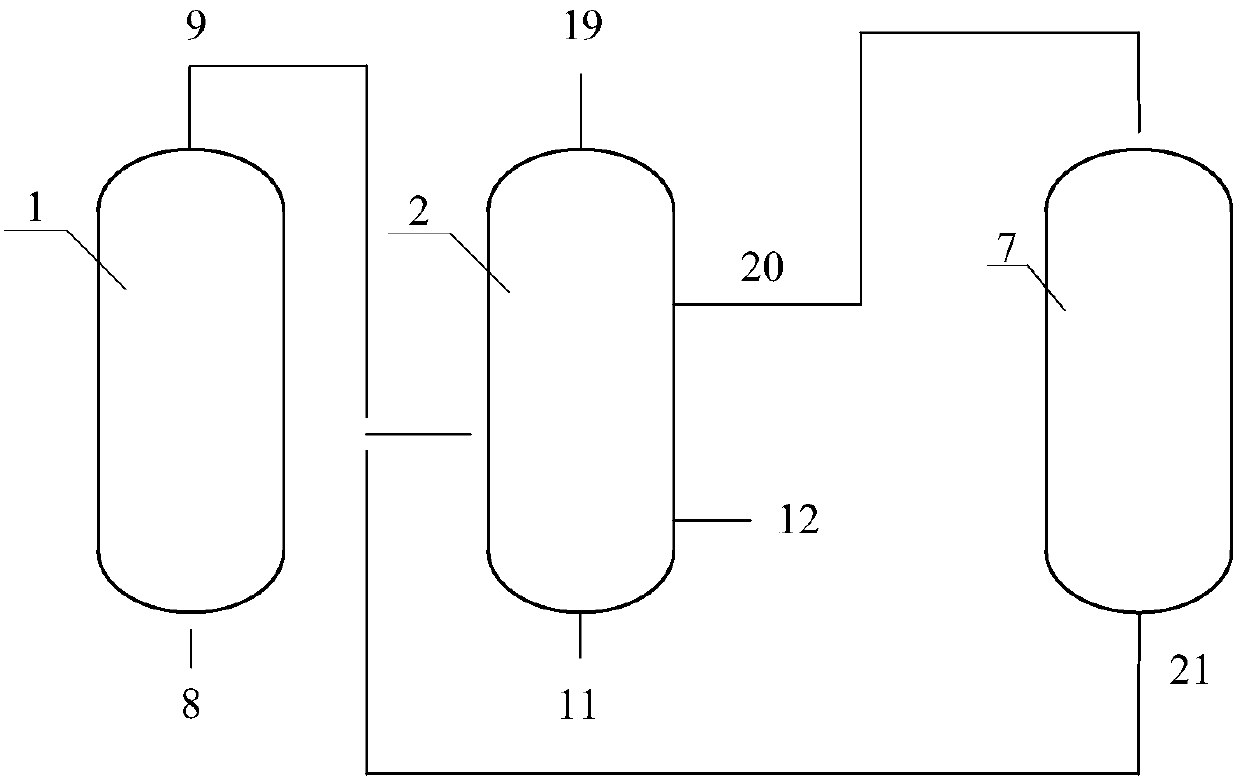

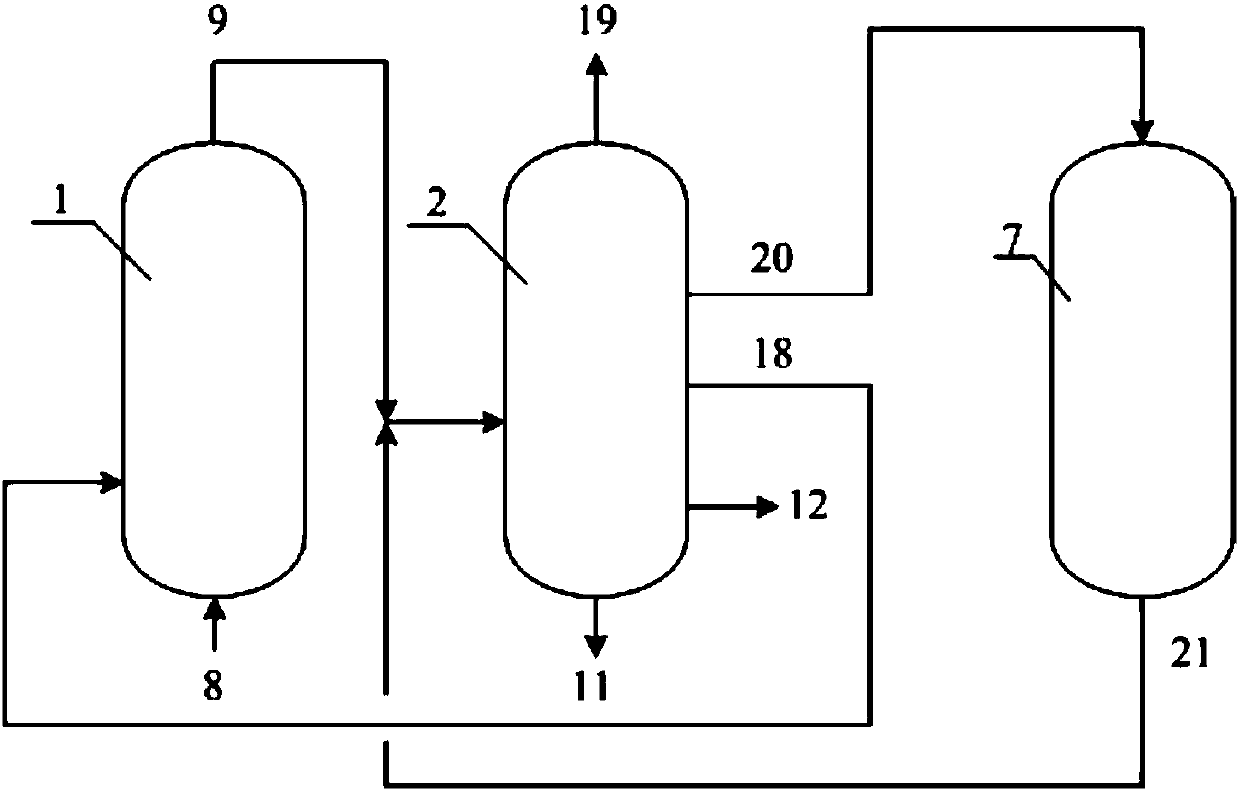

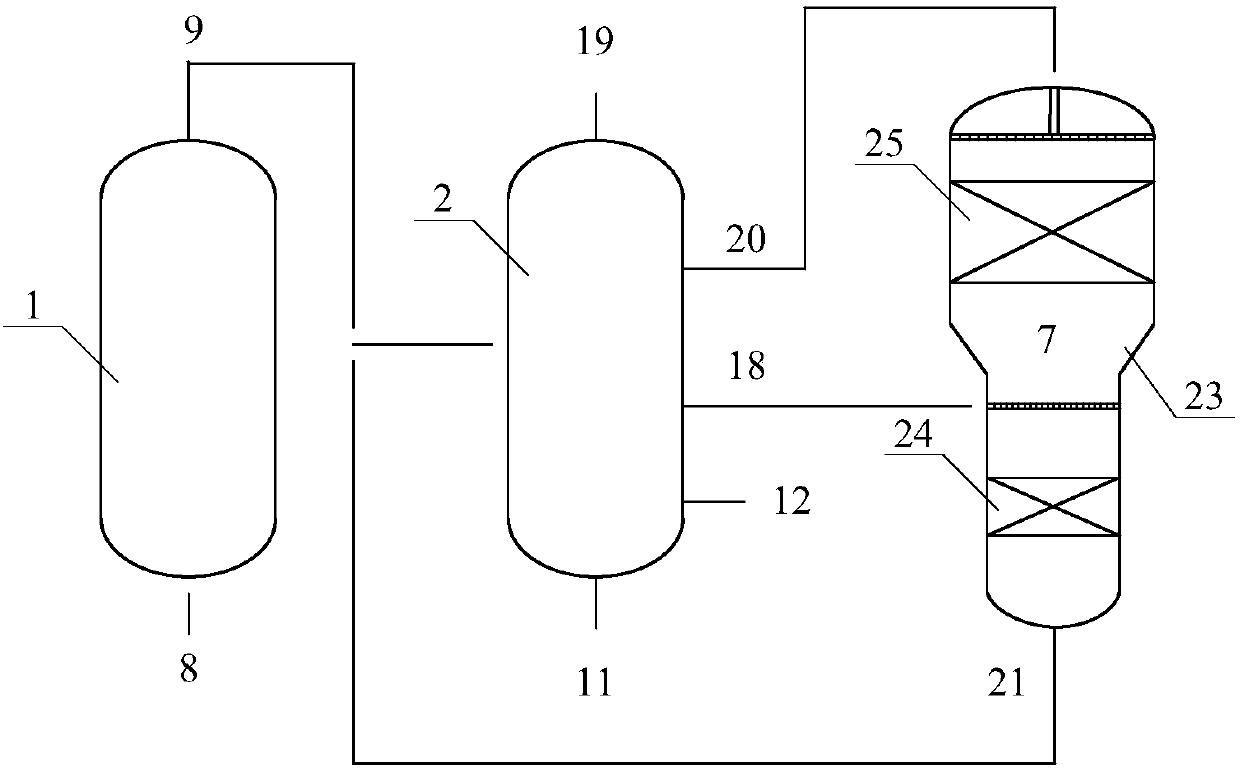

Method for preparing aromatic hydrocarbons through catalytic conversion of oxygenated compound-containing raw material

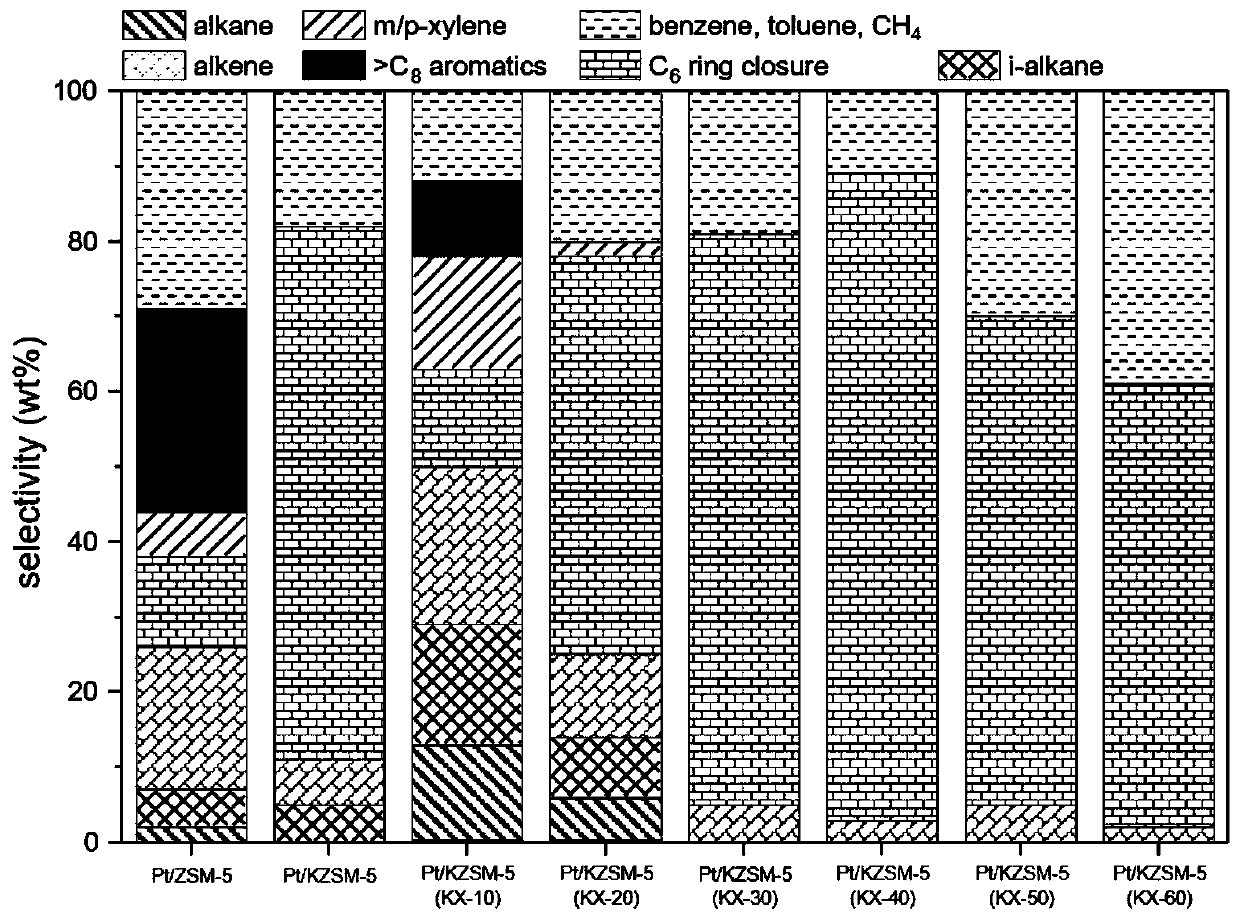

ActiveCN108017490AHigh selectivityAvoid bulk accumulationHydrocarbon by isomerisationMolecular sieve catalystHydrogenAromatization

The invention relates to a method for preparing aromatic hydrocarbons through catalytic conversion of an oxygenated compound-containing raw material. The method mainly solves the problem of low yieldof aromatic hydrocarbons in the prior art. The oxygenated compound-containing raw material enters an oxygenated compound-containing raw material catalytic conversion reaction system to obtain a reaction product rich in aromatic hydrocarbons; the reaction product rich in aromatic hydrocarbons goes through a cooling and separating system to obtain a water phase product and an oil phase product, thewater phase product and the oil phase product are discharged from the system, obtained hydrogen, methane and C2 hydrocarbons are discharged from the system, and at least parts of obtained C3 or more non-aromatic hydrocarbons enter a light hydrocarbon aromatization reaction system; and the obtained light hydrocarbon aromatization reaction product returns to the cooling and separating system. The method adopting the above technical scheme well solves the problem, and can be used in the industrial production of the aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

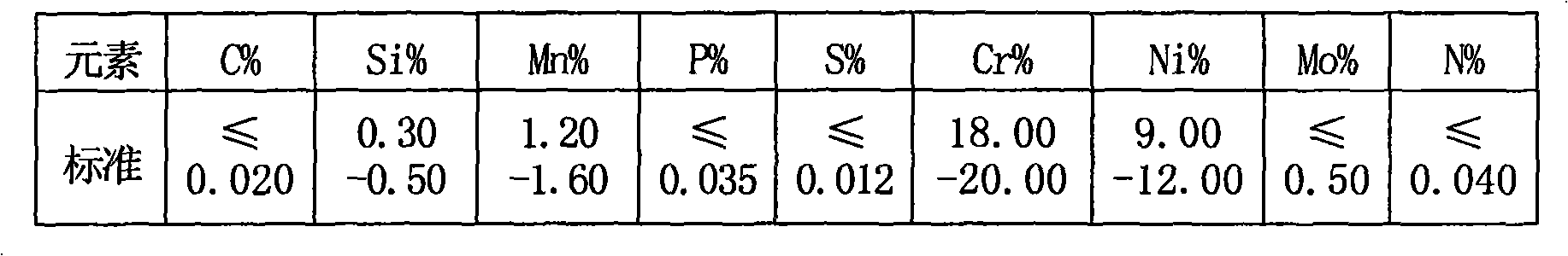

Corrosion-resistant high-toughness flux-cored wire

InactiveCN106514046AReduce oxygen contentGood dehydrogenation performanceWelding/cutting media/materialsSoldering mediaHardnessWear resistance

The invention discloses a corrosion-resistant high-toughness flux-cored wire. The corrosion-resistant high-toughness flux-cored wire is composed of a flux core and a stainless steel outer skin coating the outer side of the flux core. The flux core comprises the components in percentage by mass: 0.1-0.2% of C, 0.6-0.9% of Si, 0.1-0.3% of Mg, 0.2-0.4% of Al, 0.3-0.6% of B, 1.2-2% of Mn, 3.5-5% of Ni, 14.5-19% of Cr, 1.8-2.5% of Ti, 0.05-0.15% of Sr, 0.08-0.15% of Mo, 0.04-0.12% of V, 0.02-0.35% of Zr, 0.08-0.15% of Nd, 0.01-0.02% of Sc and the balance Fe and inevitable impurities. The corrosion-resistant high-toughness flux-cored wire disclosed by the invention is good in toughness, hardness, strength, corrosion resistance and wear resistance, and the service life of a metal member is prolonged.

Owner:天长市通联焊业有限公司

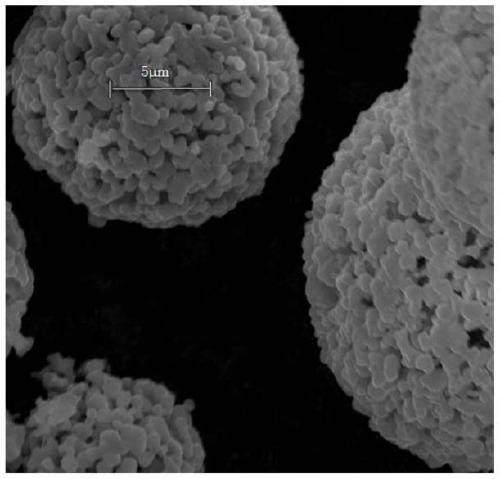

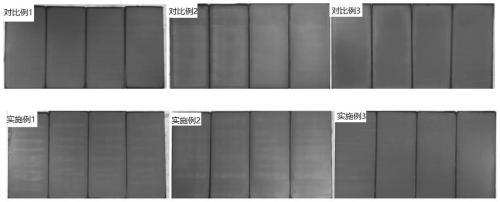

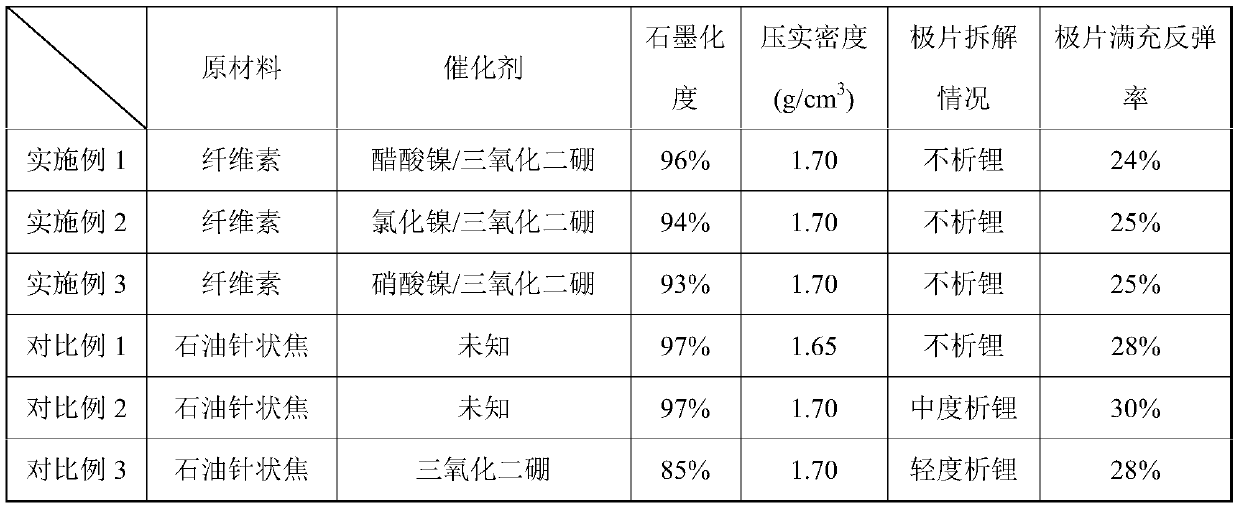

Graphite negative material, preparation method thereof and cell

The invention relates to a graphite negative material, a preparation method thereof and a cell. The preparation method of the graphite negative material comprises the following steps that a celluloseraw material, a catalyst and a dispersant are mixed, ball-milled and dried to obtain nanocrystal spheroidized precursor particles; and the nanocrystal spheroidized precursor particles are burned and then graphitized to prepare the graphite negative material. The catalyst is composed by a combination of a nickel compound and an electron deficiency compound. The graphite negative material has high electrochemical performance, and can reduce the production cost substantially.

Owner:SOUNDON NEW ENERGY TECH CO LTD

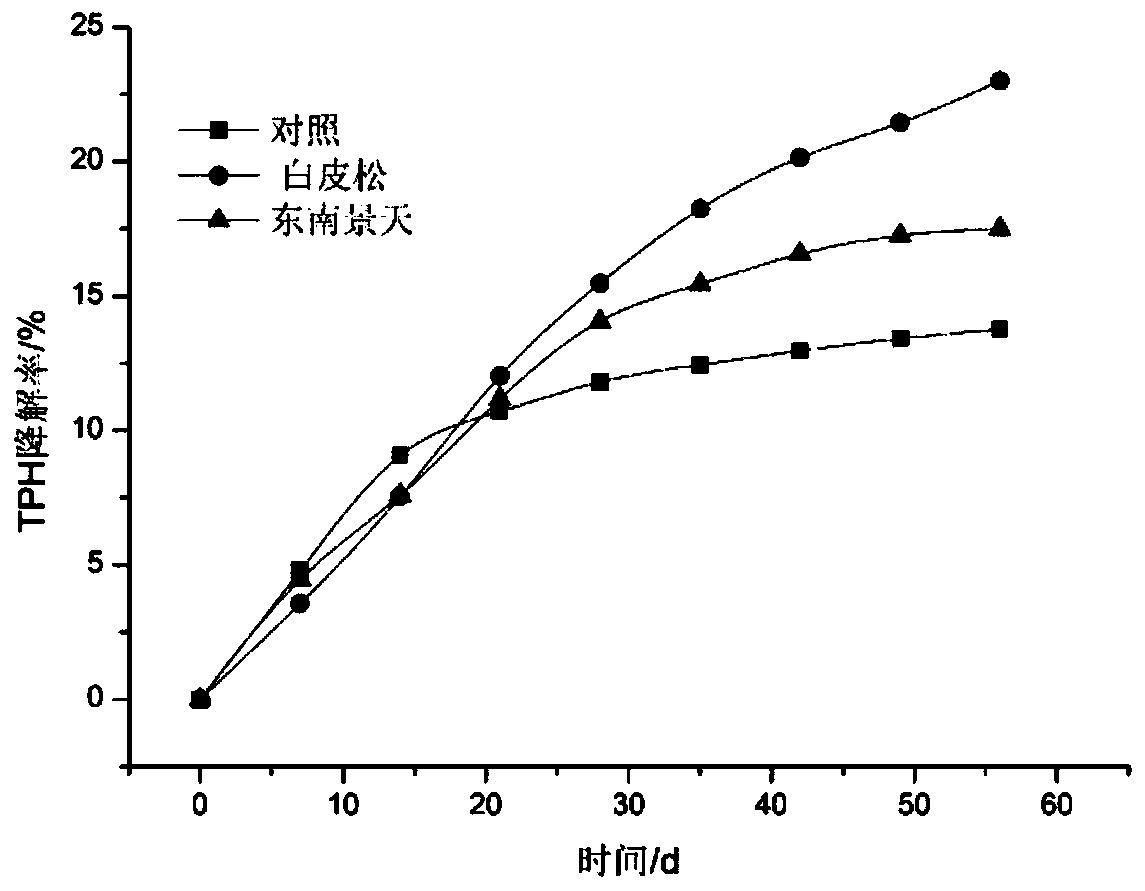

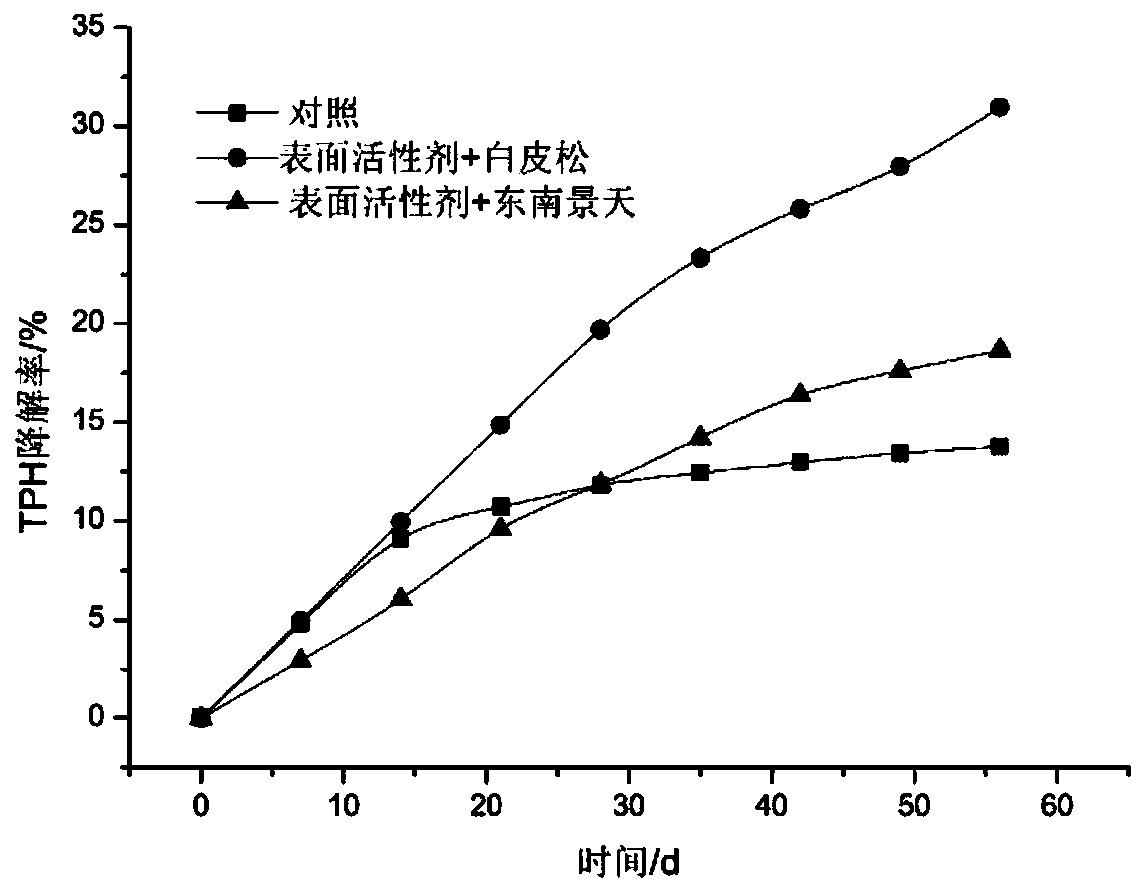

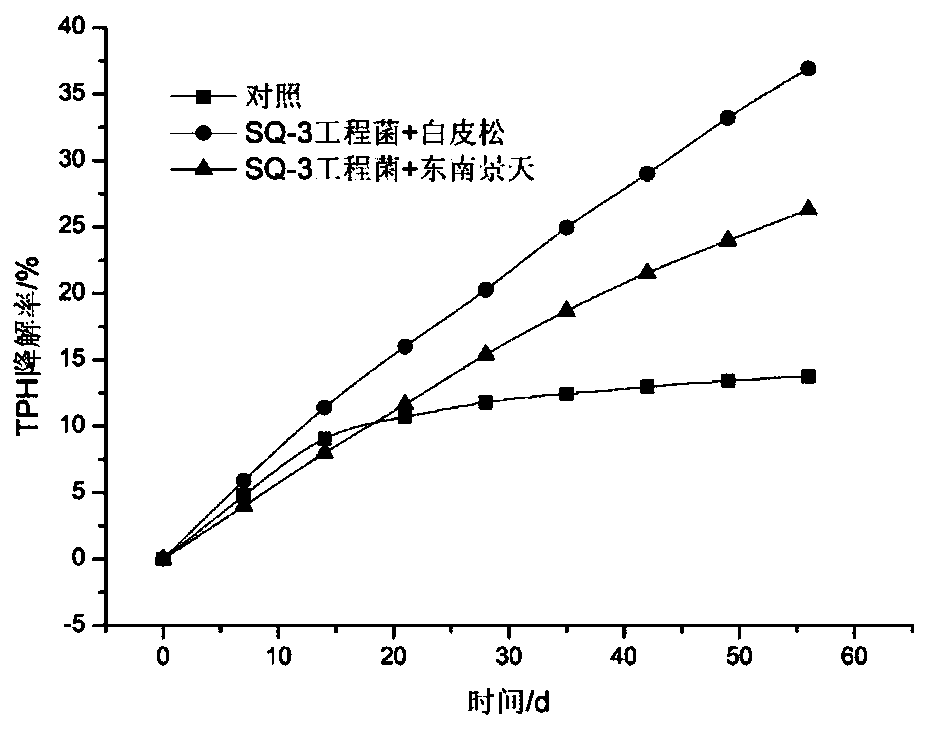

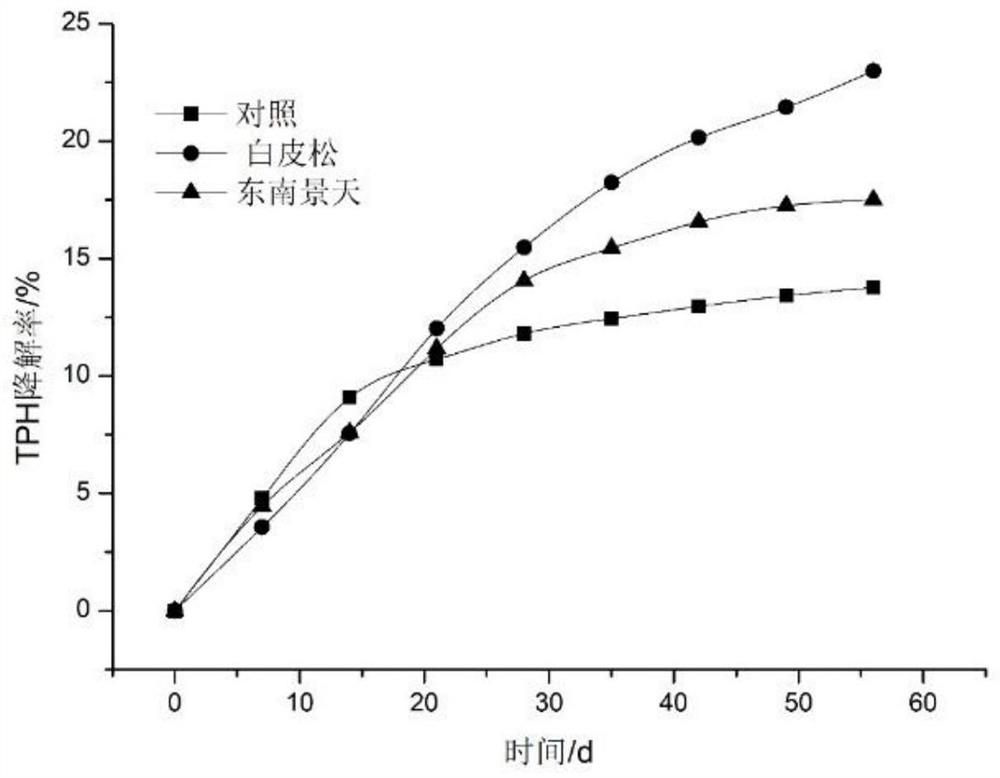

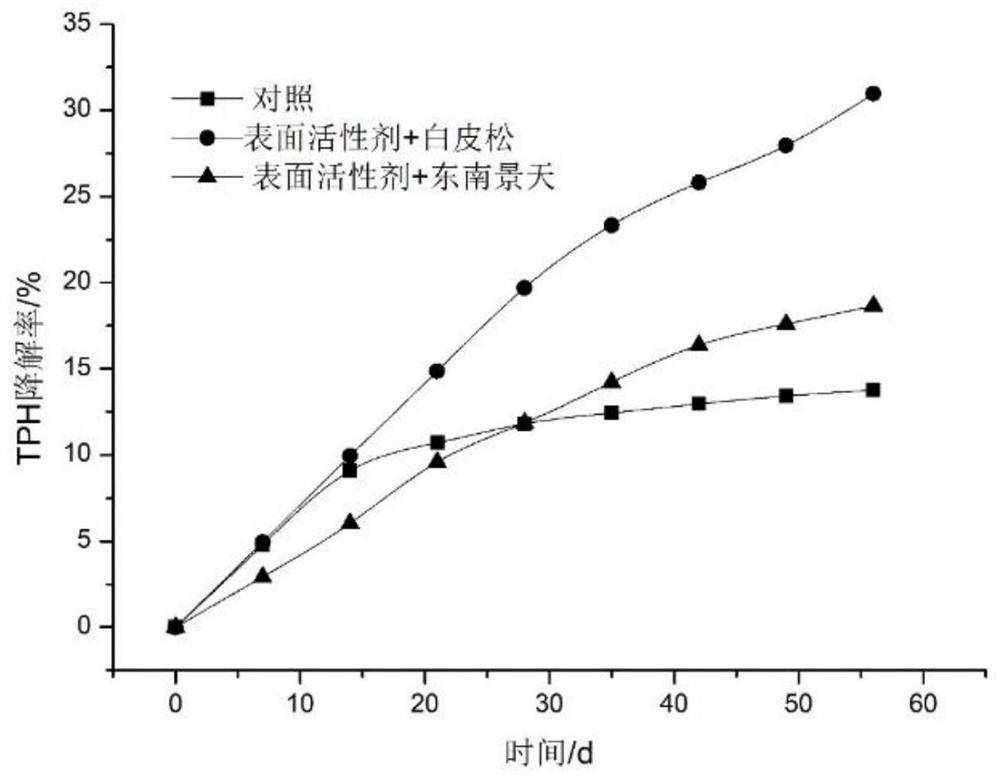

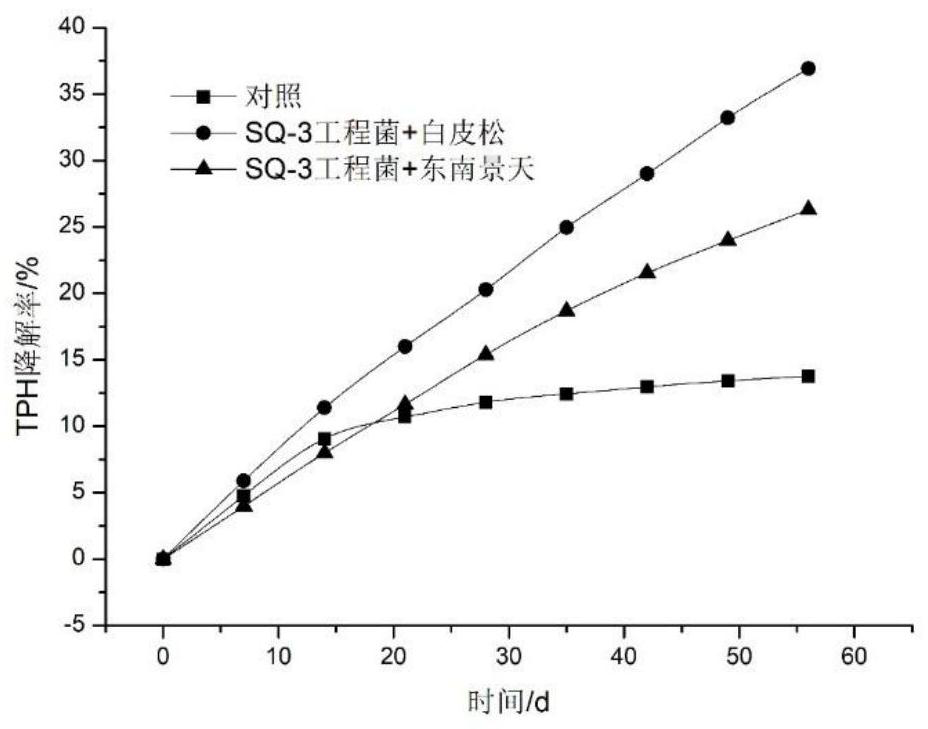

Method for remediate waste oil-based drilling fluid sediments through combination of engineering bacteria and plants

InactiveCN109926440AImprove processing efficiencyWill not cause secondary pollutionContaminated soil reclamationSedimentBiology

The invention discloses a method for repairing waste oil-based drilling fluid sediments through engineering bacterium-plant combination. The method comprises the following steps: firstly, processing clean soil and the waste oil-based drilling fluid sediments into mixed soil; pre-planting the plants for 20 days; adding two types of engineering bacteria, NH4NO3, KH2PO4, and a surfactant into the mixed soil; then, planting plants for 30-300 days; within 7 to 10 days after planting, processing NH4NO3 solid powder and KH2PO4 into water solutions with the concentration of 0.05-1.2 mg / kg and 0.05-1.5mg / kg respectively, then uniformly spraying the aqueous solution into the soil, wherein 0.5-2.0 L of the aqueous solution is sprayed to 1 m<3> of the mixed soil. The problems that in the prior art, the treatment efficiency is low, and secondary pollution is likely to be caused can be solved.

Owner:SOUTHWEST PETROLEUM UNIV

Method for dehydrogenating low-carbon stainless steel in refining furnace

The invention relates to a method for dehydrogenating low-carbon stainless steel in a refining furnace. The method comprises the following steps of: carbon deoxidization in a vacuum state and strong stirring for dehydrogenating in a vacuum state after reduction; the steps are characterized in that: in the first step, at the early stage of molten steel processing, the molten steel dehydrogenated by utilizing high-carbon deoxidization boiling under a high vacuum degree in a VOD (vacuum oxygen decarburization) refining furnace has not more than 6ppm of initial hydrogen content and 0.25-0.35 percent of carbon content, and under the condition that the vacuum degree is not more than 3*10<2>Pa, the carbon deoxidization boiling time is 15-20min; and in the second step, after reduction, strong stirring for dehydrogenating is carried out by utilizing steel ladle bottom argon blowing under the high vacuum degree, after all reduction materials are added for 2min and under the condition that the vacuum degree is not more than 3*10<2>Pa, steel ladle bottom argon blowing is carried out, the argon intensity is not less than 12L / min, and stirring dehydrogenating is carried out for 16-20min. According to the method disclosed by the invention, the dehydrogenating effect is enhanced, the dehydrogenating rate can reach 50-80 percent so that the hydrogen content in the stainless steel is completely reduced to 1.5ppm-0.5ppm from the initial 2-6ppm, and the requirements of the low-carbon stainless steel for the hydrogen content are achieved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Copper oxide catalyst for preparing isobutene through isobutane dehydrogenation and preparation method and application of copper oxide catalyst

Provided is a copper oxide catalyst for preparing isobutene by isobutane dehydrogenation, which takes nitrogen doped mesoporous carbon as a carrier and comprises 2-20% by mass of copper oxide as an active component, preferably 5-15%, being balanced with nitrogen doped mesoporous carbon. The preparation method comprises the following steps: mixing a copper-containing compound and citric acid at a mol ratio of 1:0.5-1:3; dissolving by adding water to prepare a blue solution with the copper concentration of 0.2-2.2 mol / L; adding nitrogen doped mesoporous carbon at a ratio of 319-3898 grams of nitrogen doped mesoporous per mol of copper into the aqueous solution; stirring at a constant temperature, drying, and roasting; and to obtain obtaining the copper oxide catalyst. The catalyst is used for preparing isobutene by isobutane dehydrogenation through oxidation by carbon dioxide, the conversion rate of isobutane can reach 25-70%, and the selectivity of isobutene can reach 70-96%. The catalyst free of noble metal and highly toxic chromium metallic oxide is low in cost, environment-friendly, easy to prepare, and suitable for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Welding wire for low alloy steel

InactiveCN106695168AReduce oxygen contentImprove crack resistanceWelding/cutting media/materialsSoldering mediaSlagMechanical property

The invention discloses a welding wire for low alloy steel. The welding wire is prepared from components as follows: C, Si, Cu, Mg, Nb, Al, K, Mn, Ni, Cr, Ti, Sr, Mo, V, Nd, Ce and the balance of Fe and inevitable impurities. The welding wire for low alloy steel has good welding performance, during welding, electric arc is stable, small splashing is produced, welding fluid liquidity is good, the weld surface is uniformly covered with welding slag, so that interfacial tension of the welding slag and deposited metal is increased, slag detachability is improved, formation of the obtained weld is good, the weld surface is free of cracks and pores, and the deposited metal has good mechanical properties.

Owner:天长市通联焊业有限公司

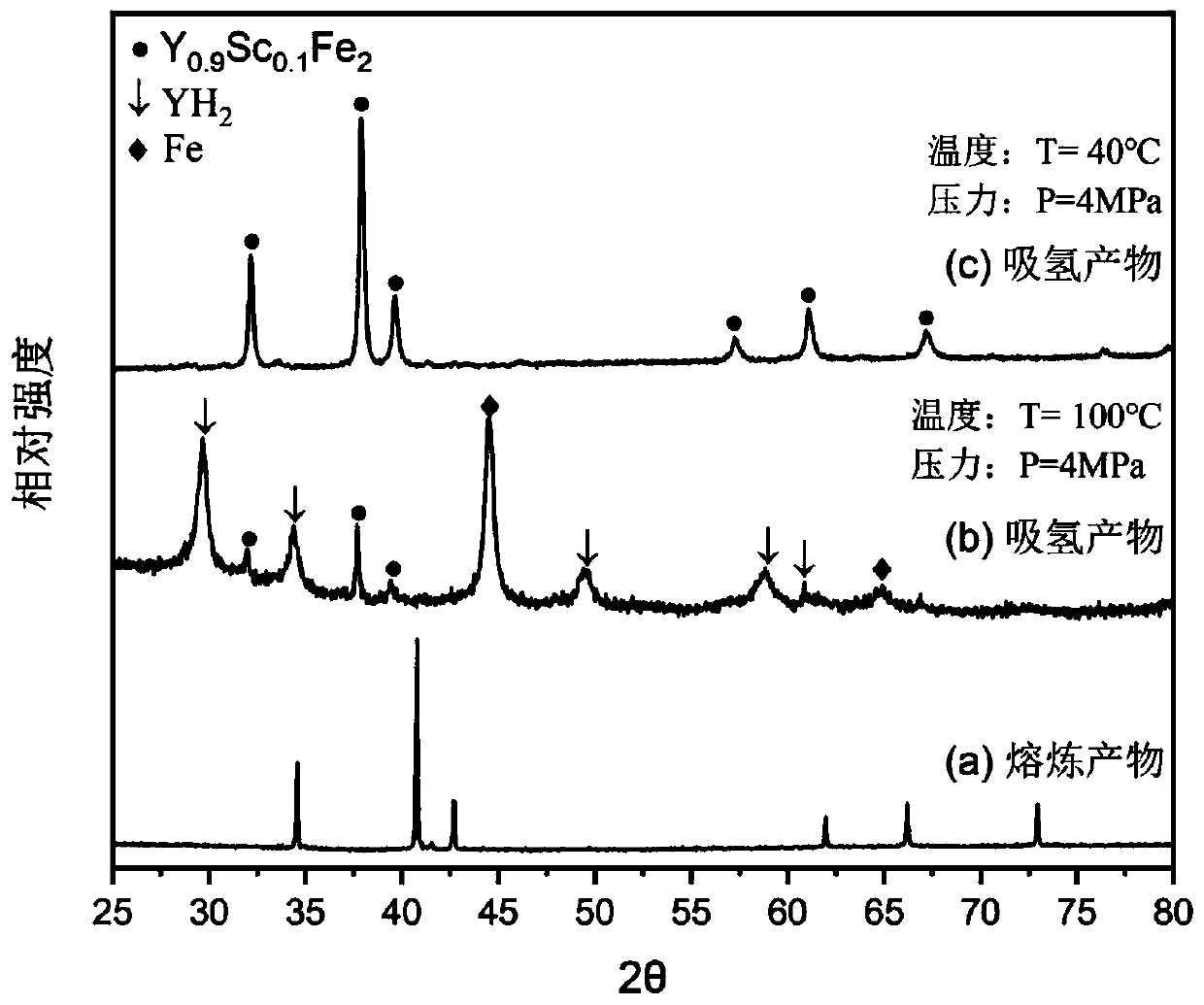

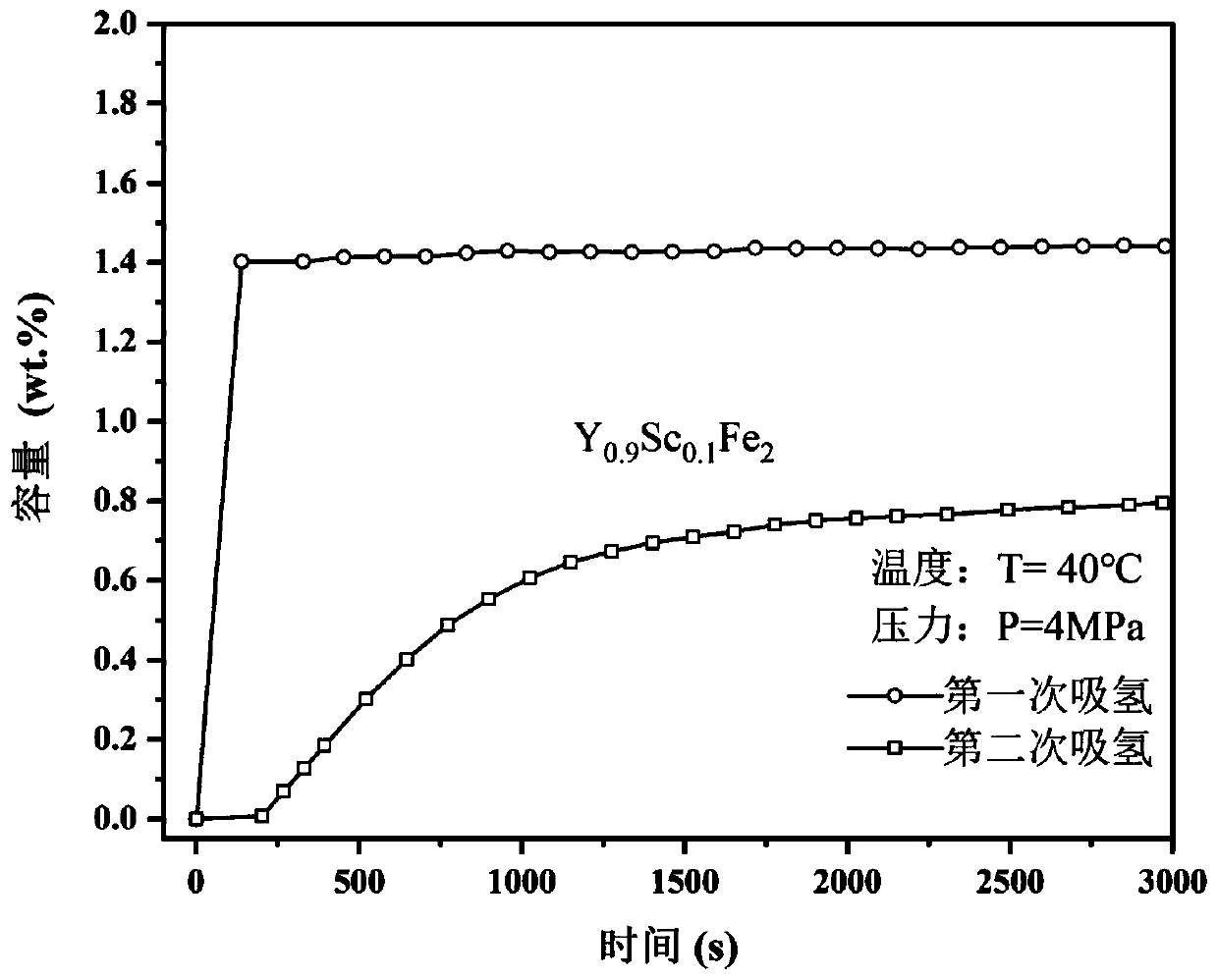

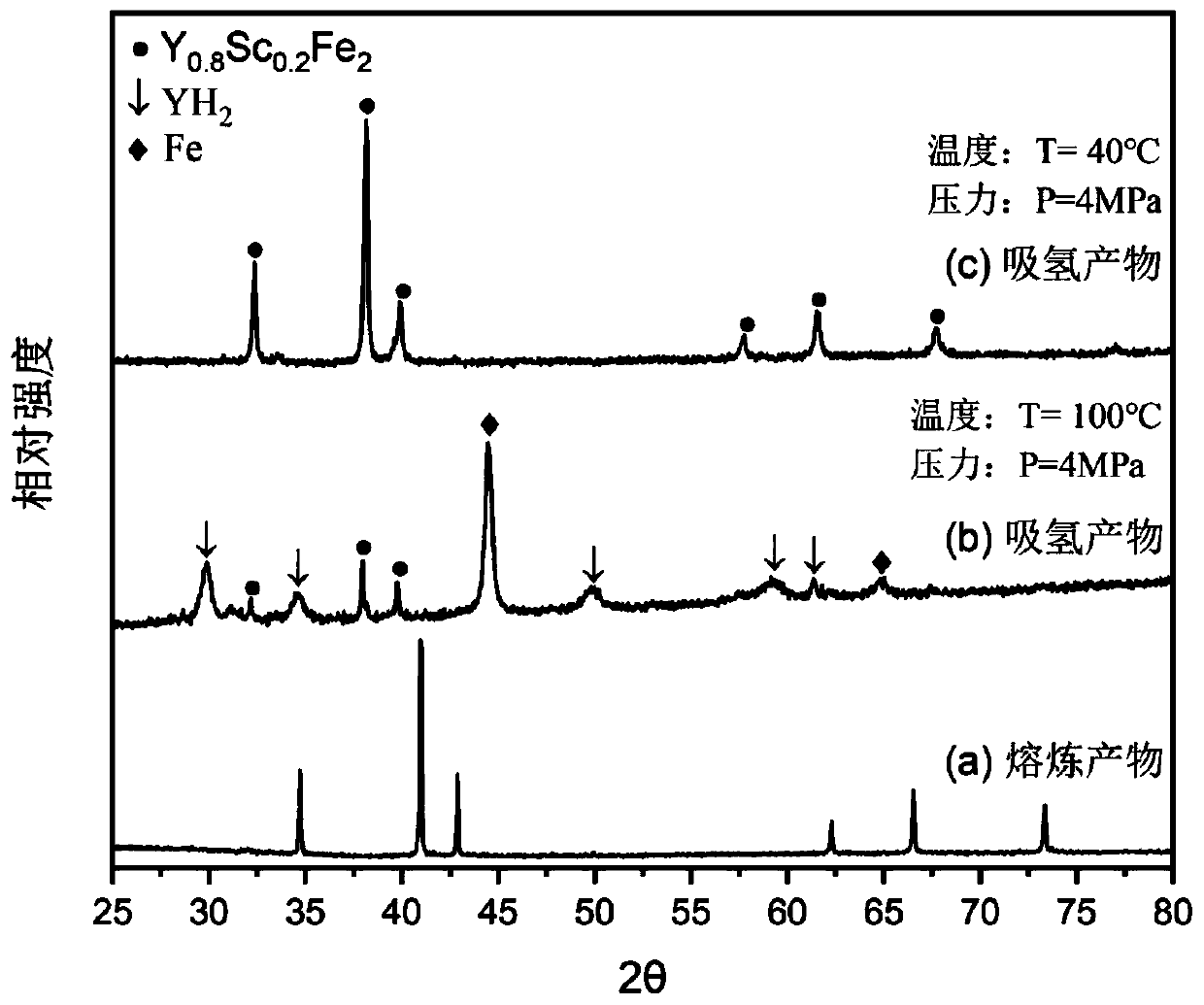

Yttrium-scandium-iron alloy material, yttrium-titanium-scandium-iron alloy material, preparation method and application

ActiveCN111485165AHigh hydrogen storage capacityLow hydrogen absorption temperatureCell electrodesIngotTitanium

The invention relates to the field of hydrogen storage alloy materials, in particular to an yttrium-scandium-iron alloy material and an yttrium-titanium-scandium-iron alloy material. The chemical general formulas of the yttrium-scandium-iron alloy material and the yttrium-titanium-scandium-iron alloy material are respectively Y<1-x>ScxFe2 and Y<1-x-y>TiyScxFe2, wherein x is greater than or equal to 0.1 and is less than or equal to 0.5, and y is greater than or equal to 0.1 and is less than or equal to 0.2. The invention also discloses the preparation methods of the yttrium-scandium-iron alloymaterial and the yttrium-titanium-scandium-iron alloy material. The preparation method comprises the following steps of: weighing and mixing metal block materials according to the mass ratio of the general chemical formula, smelting at the temperature of higher than 1,600 DEG C, and cooling to obtain an alloy ingot; placing and sealing the alloy ingot in an annealing container, and vacuumizing theannealing container; placing the annealing container under preset conditions for sealing, and taking out an alloy block from the annealing container after cooling; and crushing the alloy block into apowder state, thereby obtaining the alloy material. The alloy material provided by the invention has a stable structure, high hydrogen storage capacity, low hydrogen absorption temperature, excellenthydrogen absorption and desorption performances, and a significantly improved dehydrogenation performance, and is beneficial to the further practical application of the alloy material in the hydrogenstorage field and the nickel-hydrogen battery field.

Owner:SOUTH CHINA UNIV OF TECH

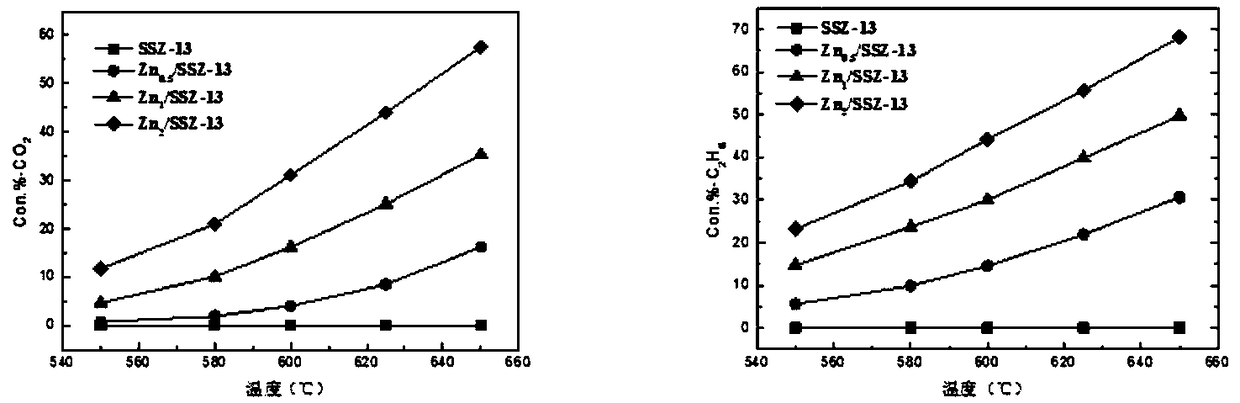

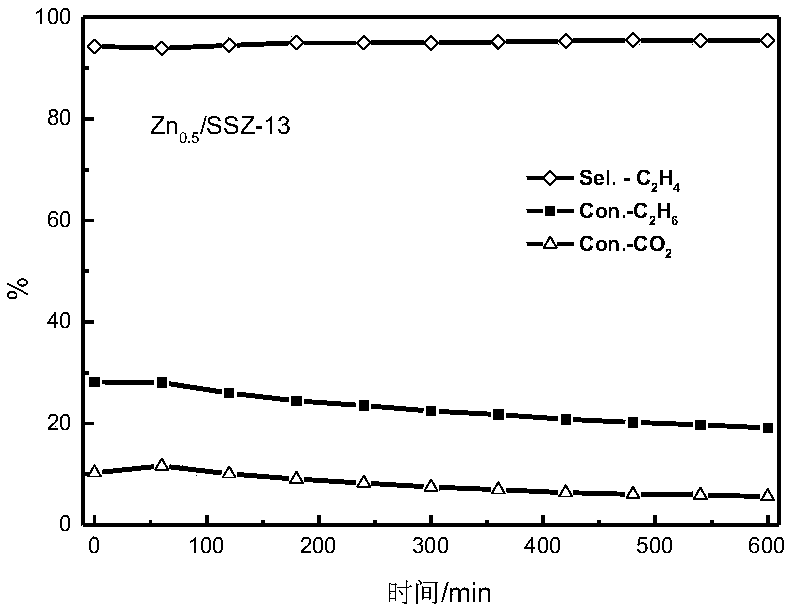

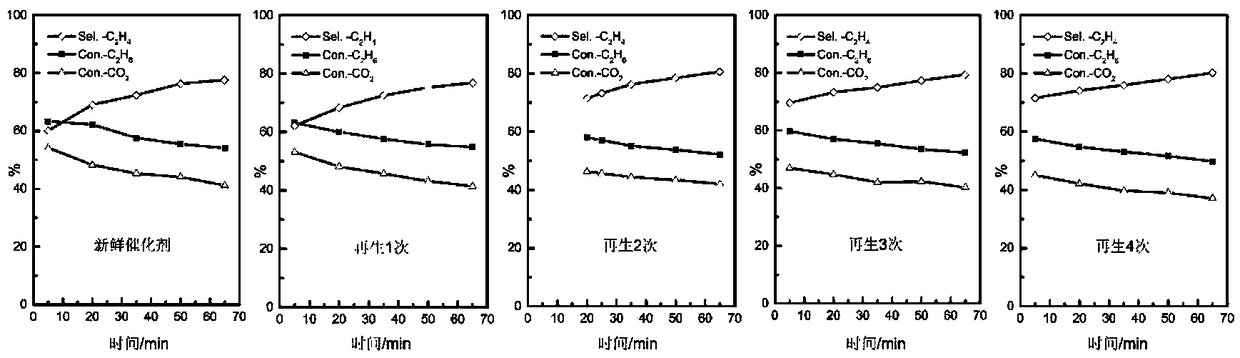

Catalyst for preparing C2H4 by oxidative dehydrogenation of C2H6 by CO2 and preparation method of catalyst

ActiveCN109433252AHigh selectivityLarge specific surface areaMolecular sieve catalystsMolecular sieve catalystActive componentDehydrogenation

The invention provides a catalyst for preparing C2H4 by oxidative dehydrogenation of C2H6 by CO2 and a preparation method of the catalyst. The catalyst comprises a support and an active component, wherein the support is a microporous zeolite molecular sieve with pore size distributed in the range of 0.2-0.4 nm, the active component is zinc ions, in terms of weight of zinc, the catalyst contains 0.5%-15% by mass of zinc, and the microporous zeolite molecular sieve is at least one of SAPO-34 and SSZ-13. The support has the advantages of high hydrothermal stability, high specific surface area, more surface protonic acid sites, exchangeable cations and the like, and the problem that the catalyst support is poor in hydrothermal stability in the prior art can be effectively solved. The zinc ionstaken as the active substance are non-toxic and have better dehydrogenation capability, and generation of H2 by a reaction is facilitated. CO2 adsorbability of the catalyst can be improved effectively by the zinc ions, so that CO2 conversion rate and C2H4 selectivity are increased.

Owner:DALIAN UNIV OF TECH

High-tenacity anti-cracking aluminum alloy welding stick

InactiveCN107175424AGood casting performanceImprove welding effectWelding/cutting media/materialsSoldering mediaArc stabilityBonding strength

The invention discloses a high-tenacity anti-cracking aluminum alloy welding stick. The high-tenacity anti-cracking aluminum alloy welding stick comprises components including, by mass percent, Mg, Be, Si, Mn, Cr, Cu, Ti, Sr, Mo, W, V, Nb, Zr, Nd, Sc, Ce, Eu, Y and the balance Al and inevitable impurities. The provided high-tenacity anti-cracking aluminum alloy welding stick is reasonable in formula, arc stability is good, welding line forming is attractive, strength is high, low-temperature resistance and impact resistance are good, the bonding strength between the welding stick and a mother material is large, and performance is stable.

Owner:安徽飞弧焊业股份有限公司

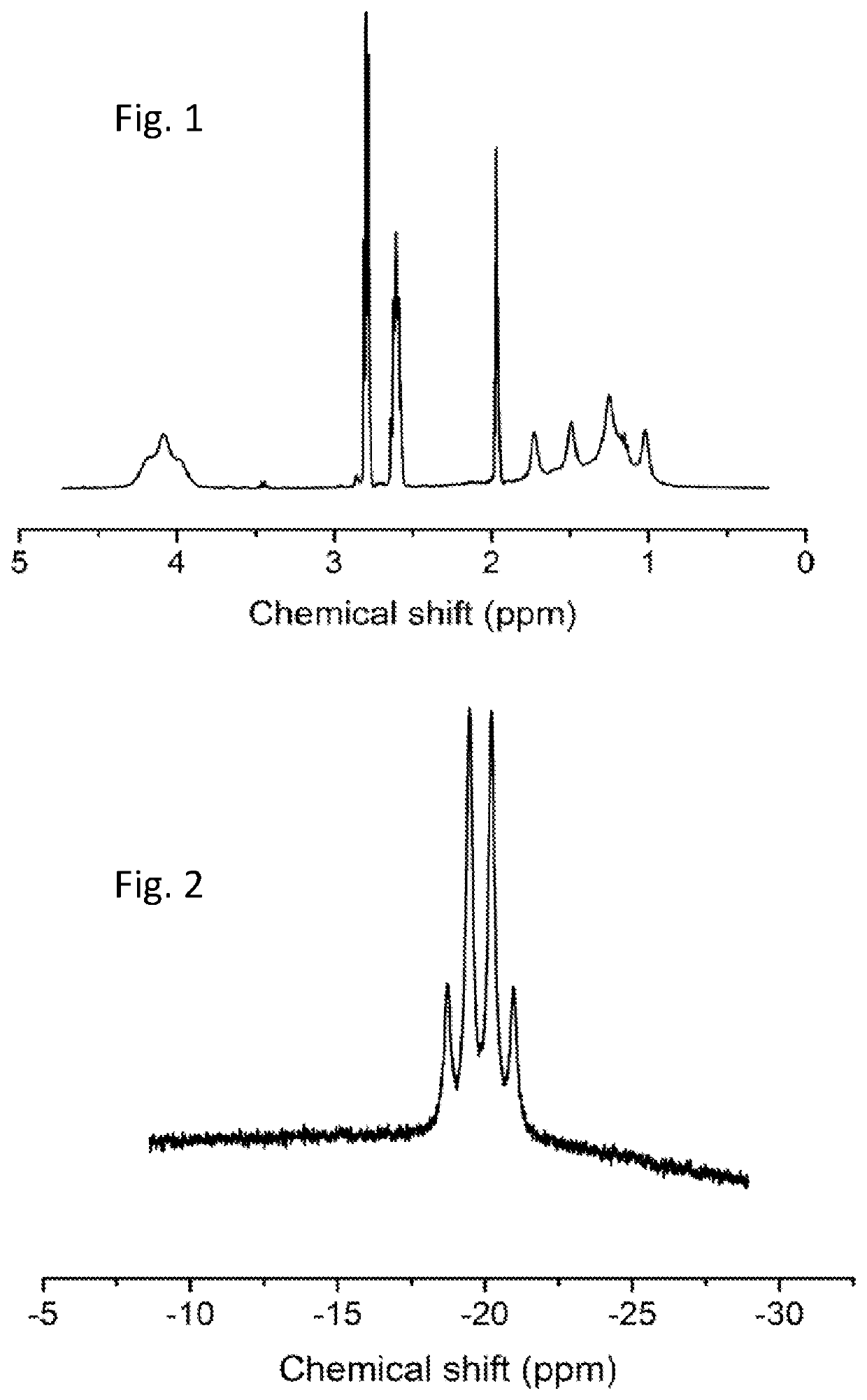

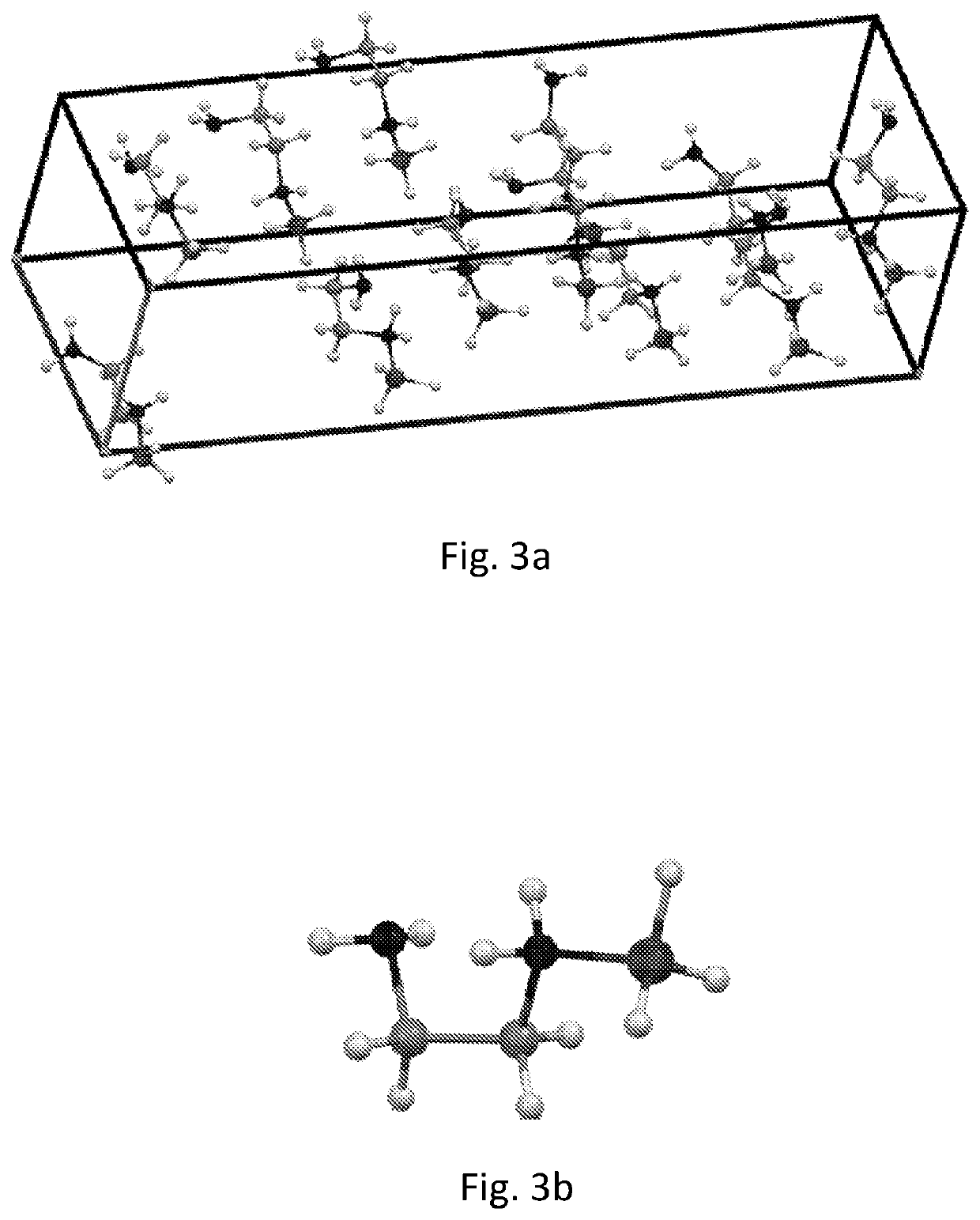

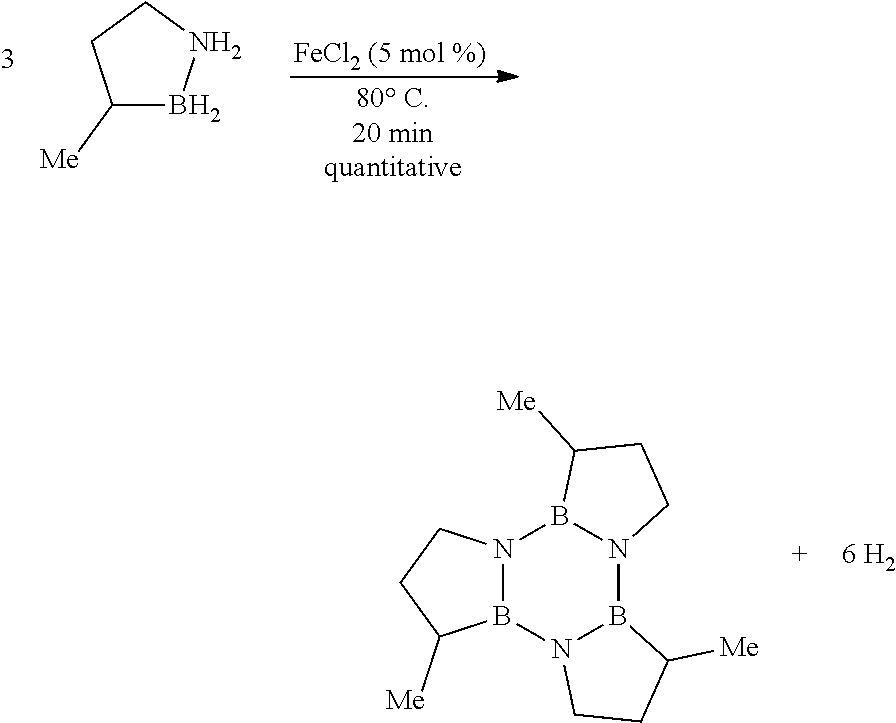

Hydrogen storage and delivery material

InactiveUS20190359483A1High H storage capacityPromote regenerationHydrogenReactant parameters controlHydrogen purityChemical synthesis

The present invention provides novel diamine-monoborane liquid organic hydrogen carriers with hydrogen storage capacities at least equivalent to prior art hydrogen carriers. The novel diamine-monoboranes of the invention provide advantages over the prior art including low cost due to the simple one-step chemical synthesis method between a diamine and a borane complex, and that the starting materials are inexpensive compared to the prior art. The novel diamine-monoboranes of the invention provide excellent dehydrogenation performance. With the presence of inexpensive and readily-available commercial catalysts, dehydrogenation occurs at ambient temperatures and pressures with high hydrogen purity. The resulting 1,3,2-diazaborolidines (cyclic diaminoboranes) are readily hydrogenated to produce the novel diamine-monoboranes of the invention. The invention also provides use of the diamine-monoboranes of the invention in a fuel cell or a portable power cell, or cell installed in conjunction with a hydrogen-burning engine. Other uses relate to transport down pipelines and in tankers.

Owner:UNIV OF TECH SYDNEY

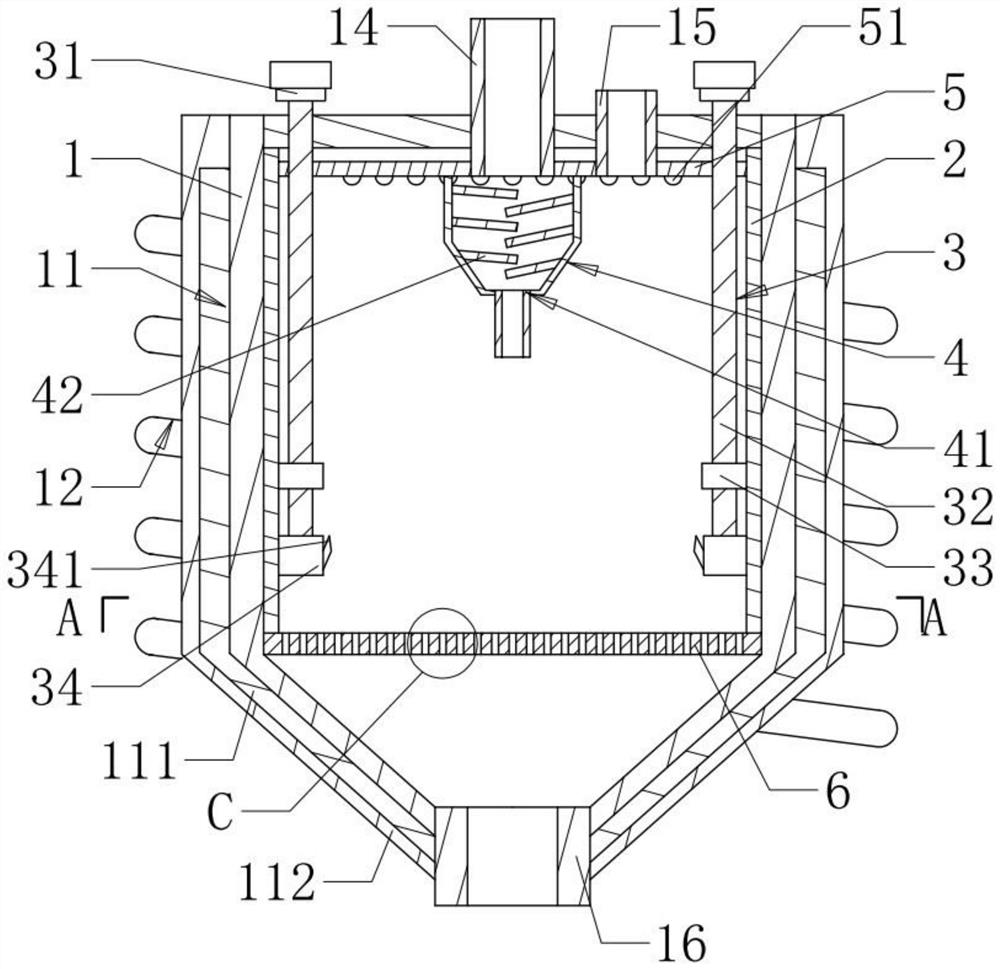

Dehydrogenation catalyst, preparation method and hydrogen release method

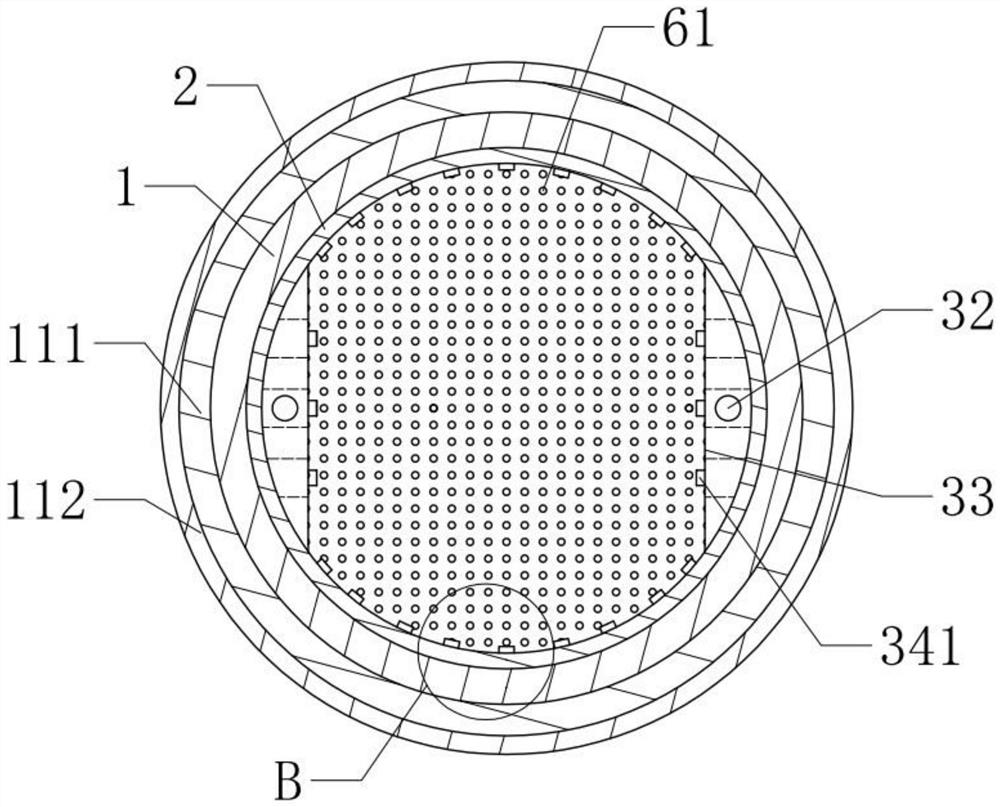

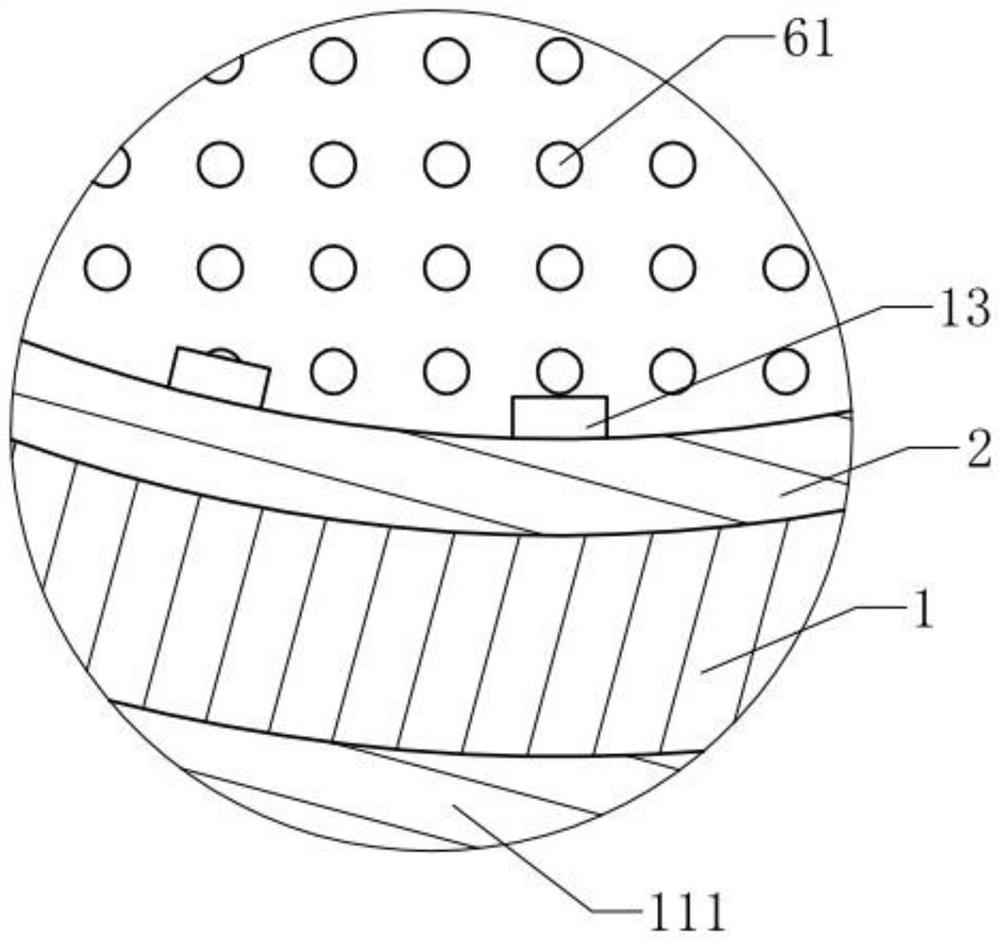

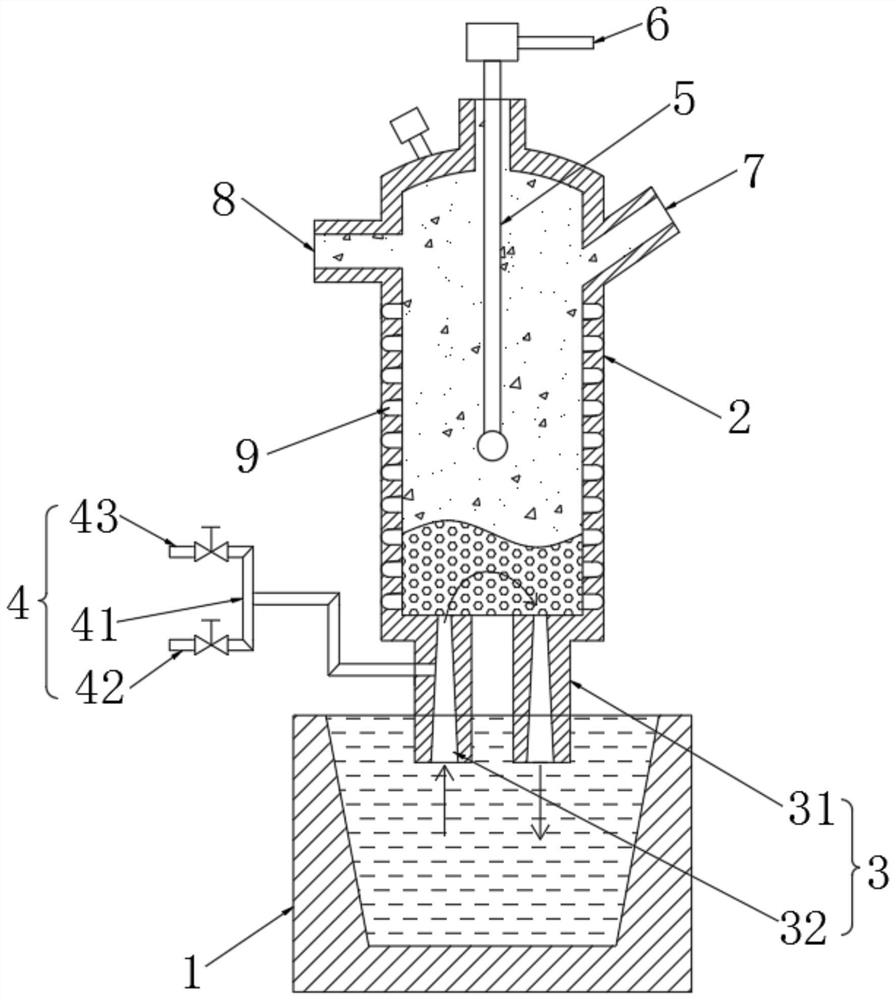

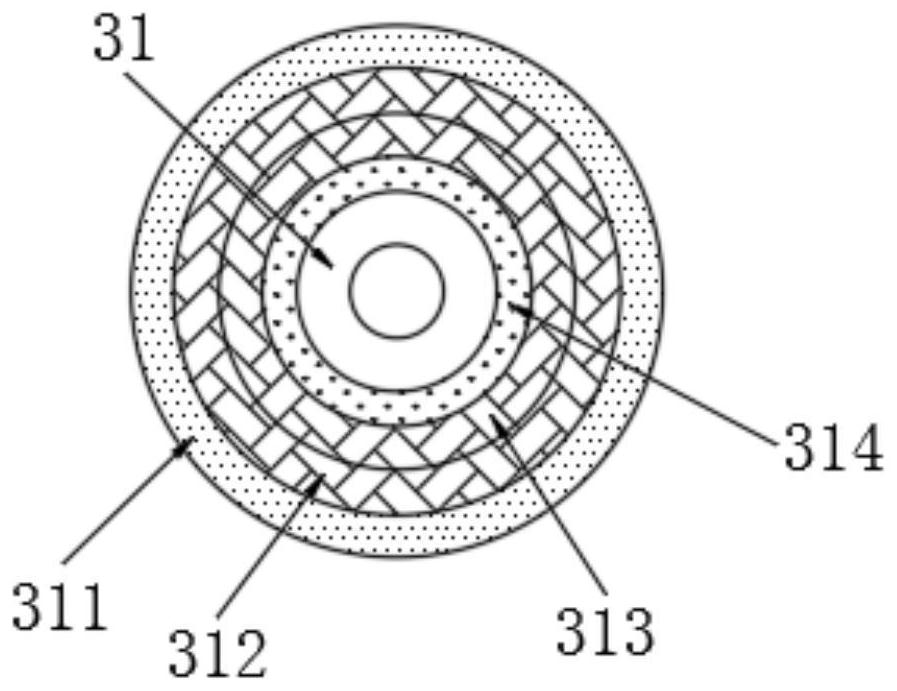

InactiveCN113649023AGood dehydrogenation performanceReduce surface acidityHydrogen separation using liquid contactCatalyst activation/preparationPtru catalystPhysical chemistry

The invention discloses a dehydrogenation catalyst, a preparation method and a hydrogen release method. A barrel is included, a heating device and a cooling device are arranged on the outer surface of the barrel; a baffle is arranged on the inner side wall of the barrel; two corresponding inner side walls of the baffle are connected with sliding devices; a plurality of bulges are arranged on the other two corresponding inner side walls of the baffle; a gas outlet pipe and a feeding pipe are arranged over the barrel; a gas inlet pipe is arranged under the barrel; a separating device and a bubble breaking plate are arranged in the upper of the interior of the barrel, the bubble breaking plate is fixedly connected with the baffle, the separating device is located under the bubble breaking plate, one end of the separating device is suspended in the barrel, the other end of the separating device is fixedly connected with the bubble breaking plate and communicated with the gas outlet pipe, a gas distributing plate is arranged in the barrel, the gas distributing plate is fixedly connected with the lower end of the baffle, and the gas distributing plate is located over the gas inlet pipe. The catalyst has the beneficial effects that the active components of the catalyst can be highly uniformly dispersed, the dehydrogenation effect is remarkably improved, and carbon deposition is effectively inhibited.

Owner:浙江理谷新能源有限公司

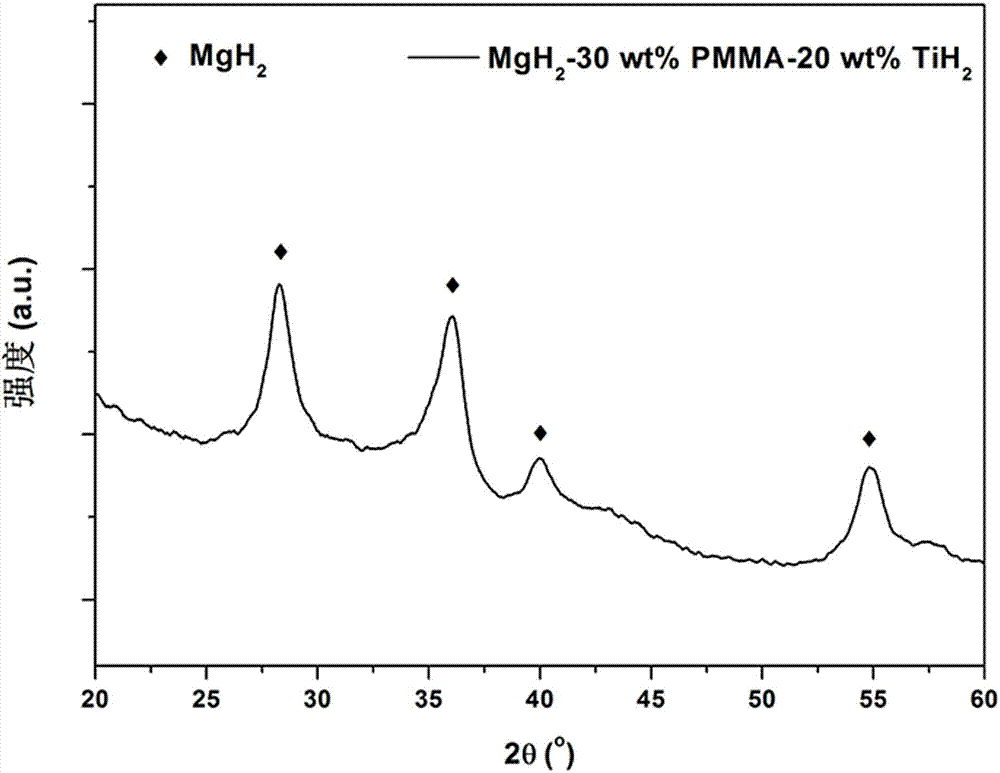

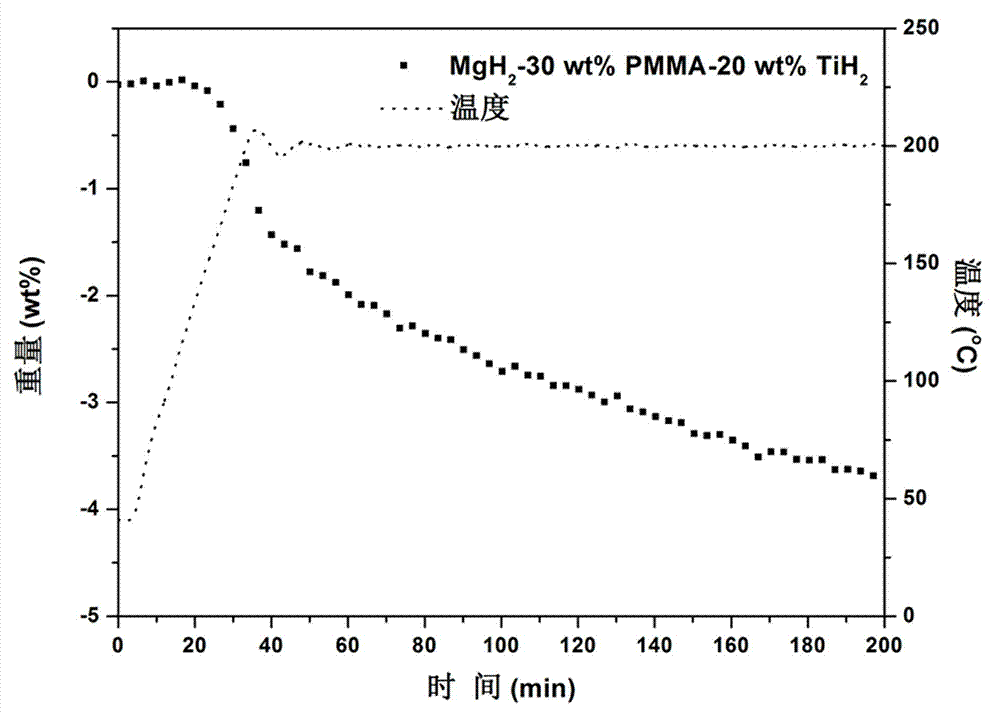

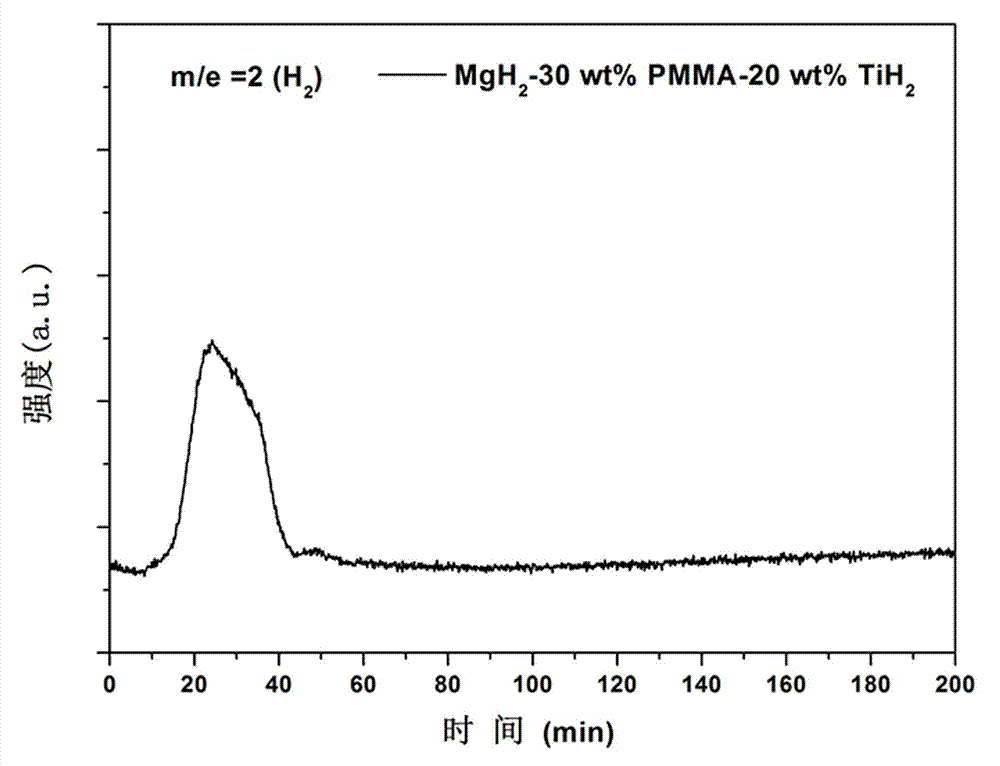

TiH2 doped Mg/ polymethyl methacrylate (PMM) composite material and preparation method

ActiveCN104741095AEasy to prepareEasy to operateOther chemical processesMethyl methacrylateFluid phase

The invention relates to a preparation method for doping an MgH2 / polymethyl methacrylate (PMMA) composite hydrogen storage material with TiH2 as a catalyst, particularly relates to a method for improving the dehydrogenation performance of the MgH2 / PMMA composite hydrogen storage material by doping the material with TiH2 as a catalyst, and belongs to the field of material invention. The preparation method comprises the following steps: firstly, preparing a TiH2-MgH2 material by a solid-phase ball milling method; then performing ultrasound treatment on the TiH2-MgH2 material in a tetrahydrofuran (THF) solution in which PMMA is dissolved by a liquid-phase ultrasound method; and finally, carrying out temperature controlled vacuum drying so as to prepare the TiH2@MgH2 / PMMA composite hydrogen storage material. The composite hydrogen storage material prepped by solid phase ball milling and liquid phase ultrasound treatment has good dehydrogenation performance. When the amount of the doped catalyst TiH2 is 10wt%-30wt%, the initial dehydrogenation temperature of the material is 120 DEG C; the constant-temperature dehydrogenation amount at 200 DEG C within 200 minutes reaches 3.7wt% (except for the mass ratio of a composite agent PPMA), and reaches 72.5% of the theoretical hydrogen content.

Owner:GUILIN UNIV OF ELECTRONIC TECH

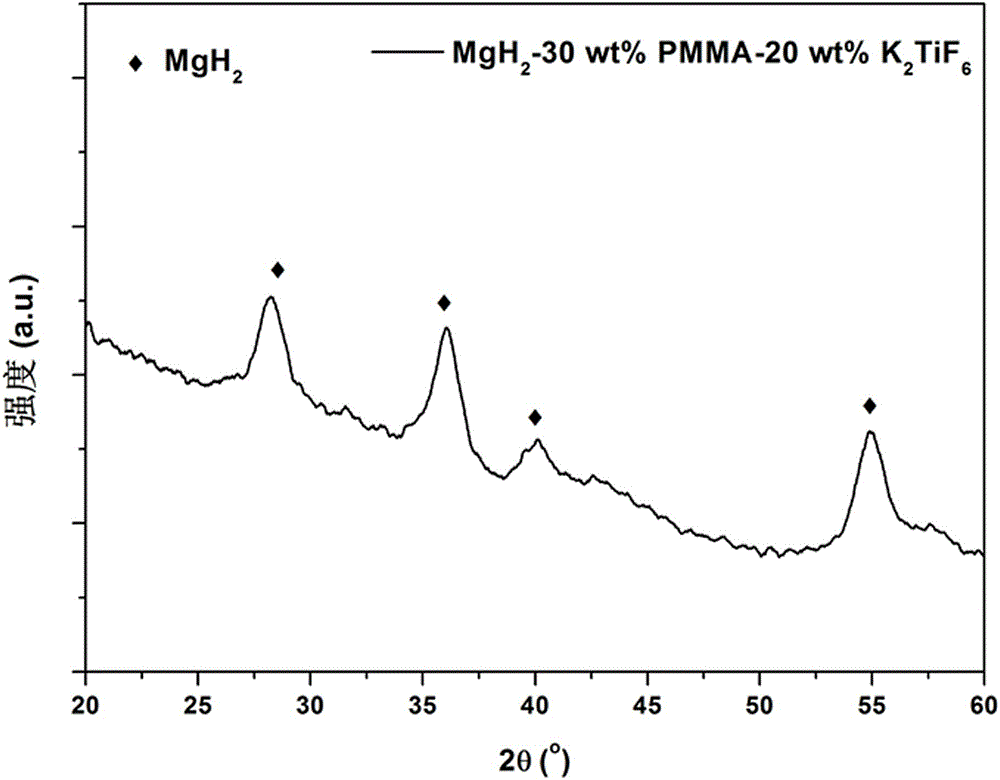

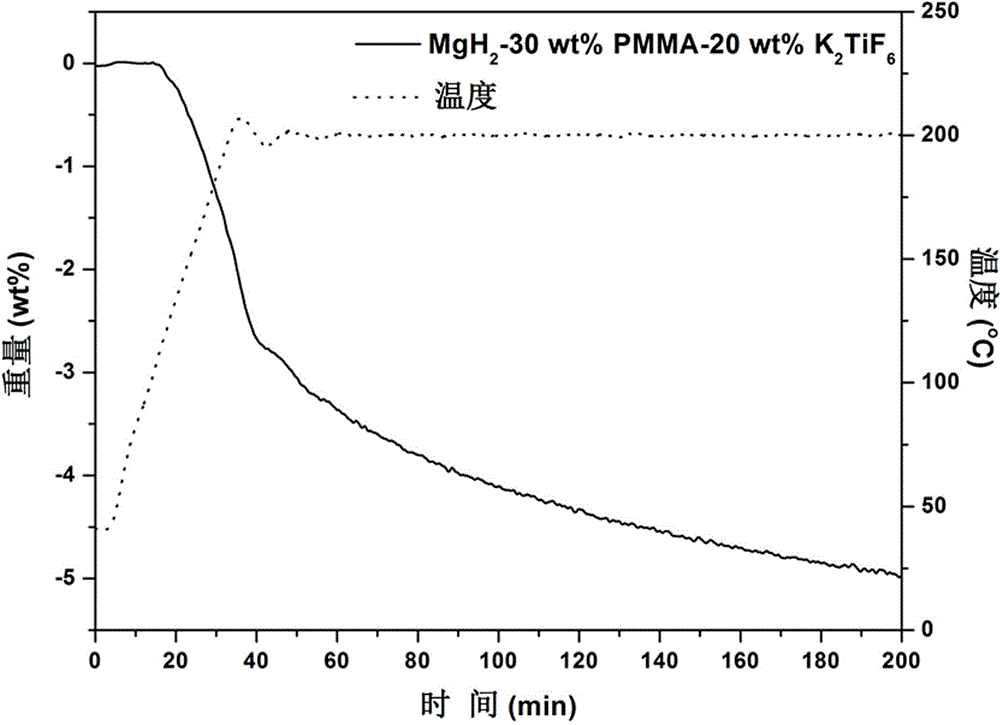

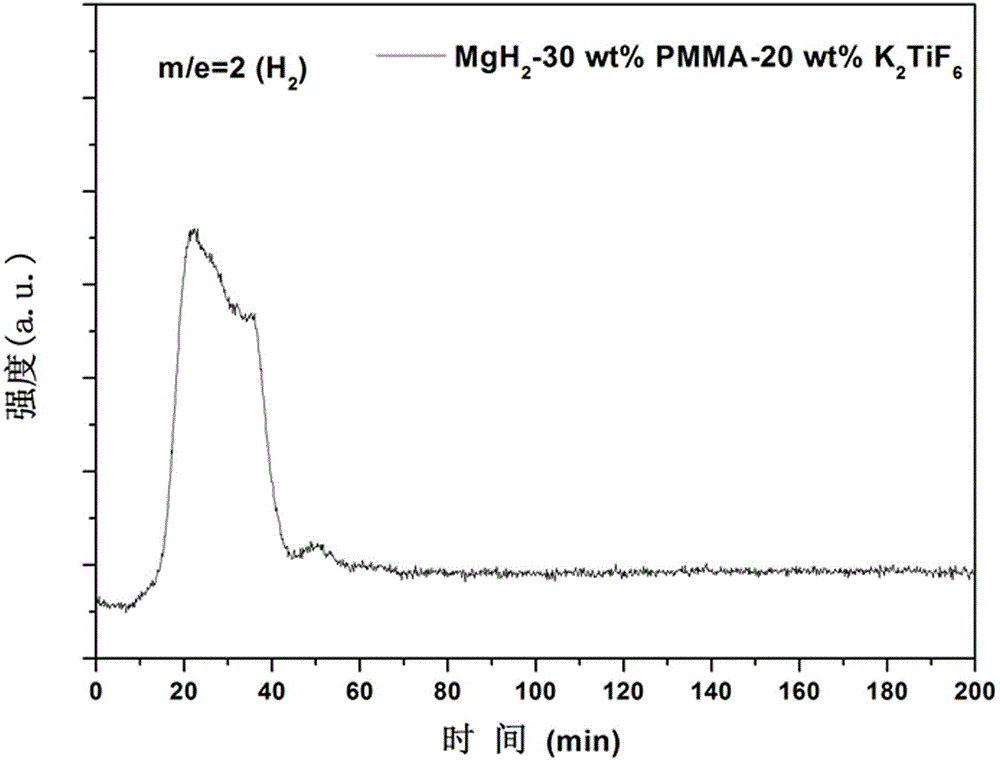

K2TiF6 doped Mg/PMMA composite material and preparation method thereof

The invention provides a K2TiF6 doped Mg / PMMA composite material and a preparation method thereof. The invention relates to a preparation method for doping a MgH2 / polymethyl methacrylate (PMMA) composite hydrogen storage material by using K2TiF6 as a catalyst, in particular relates to a method for improving the dehydrogenation property of the MgH2 / PMMA composite hydrogen storage material by virtue of doping with the K2TiF6 as the catalyst, and belongs to the field of material invention. The composite material is prepared by virtue of the following steps: firstly, preparing a K2TiF6-MgH2 material by use of a solid-phase ball milling method; secondly, performing ultrasonic treatment, by use of a liquid-phase ultrasonic method, on the K2TiF6-MgH2 material in a tetrahydrofuran (THF) solution in which the PMMA is dissolved; finally, preparing the K2TiF6@MgH2 / PMMA composite hydrogen storage material by use of a temperature-controlled vacuum drying method. The composite hydrogen storage material prepared by virtue of solid-phase ball milling and liquid-phase ultrasonic treatment has excellent dehydrogenation property. When the doping amount of the catalyst K2TiF6 is 10-30wt%, the starting dehydrogenation temperature of the material is 120 DEG C, and at 200 DEG C, the constant-temperature dehydrogenation amount in 200 minutes reaches 4.9wt% (the complexing agent PMMA mass ratio deducted), which is 96% of the theoretical hydrogen content of the material.

Owner:GUILIN UNIV OF ELECTRONIC TECH

RH furnace dehydrogenation method and device

The invention discloses an RH furnace dehydrogenation method and device, and relates to the technical field of RH refining. The RH furnace dehydrogenation method specifically comprises the following steps: 1, initial conditions; 2, baking; 3, vacuumizing treatment; 4, vacuum heating; 5, vacuum dehydrogenation treatment; 6, vacuum decarburization treatment; 7, measuring; and 8, vacuum breaking. TheRH furnace dehydrogenation method is simple in process, convenient to operate and lower in cost, molten steel can be heated at the same time in RH vacuum treatment, the degassing temperature of the molten steel is guaranteed, the dehydrogenation efficiency is improved, each of an ascending pipe and a descending pipe in a dehydrogenation device is of a conical structure with a large bottom openingand a small top opening, scouring of the molten steel to the inner wall of a vacuum chamber can be reduced, the dehydrogenation effect of the device is effectively improved, the ascending pipe and the descending pipe in the design are good in corrosion resistance and high temperature resistance, and the service life is longer.

Owner:河北敬业精密制管有限公司

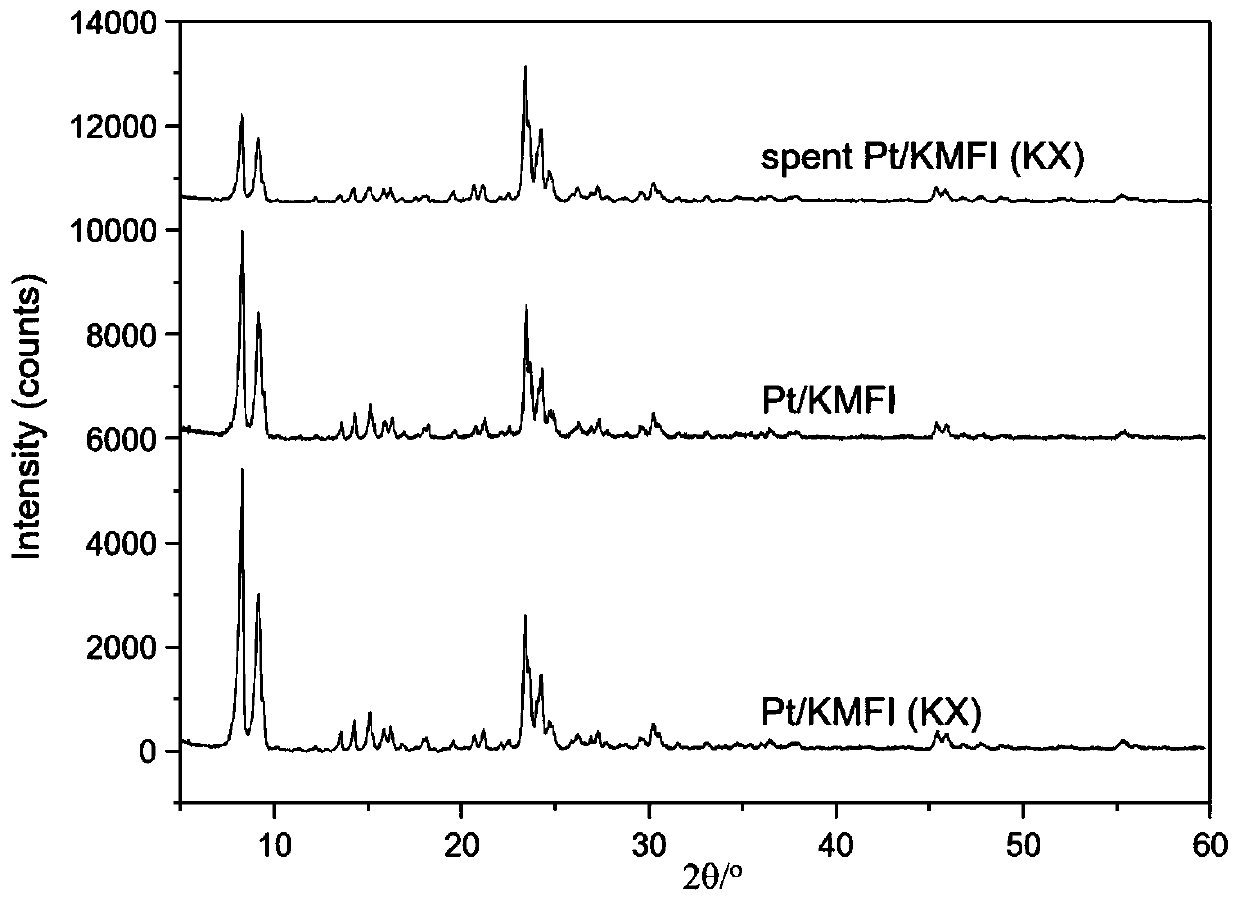

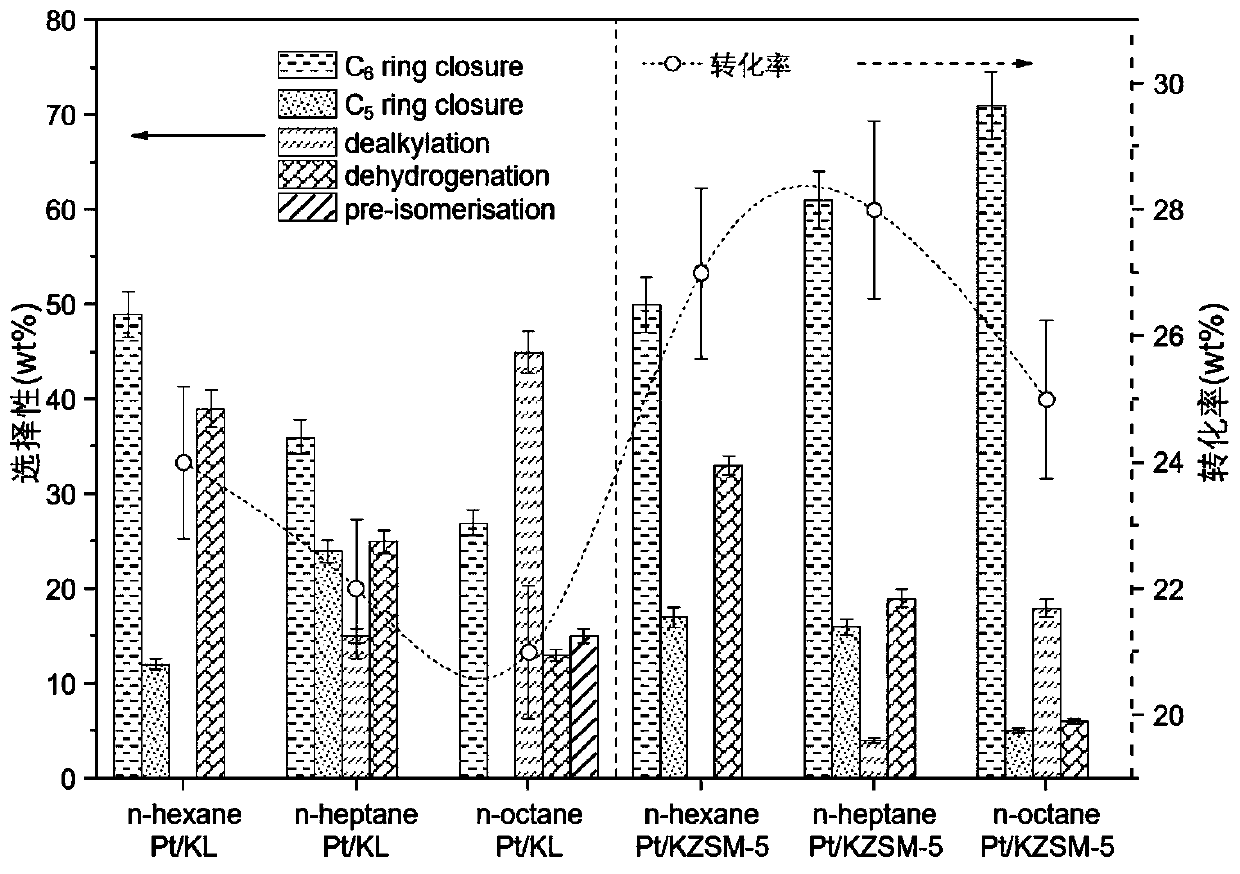

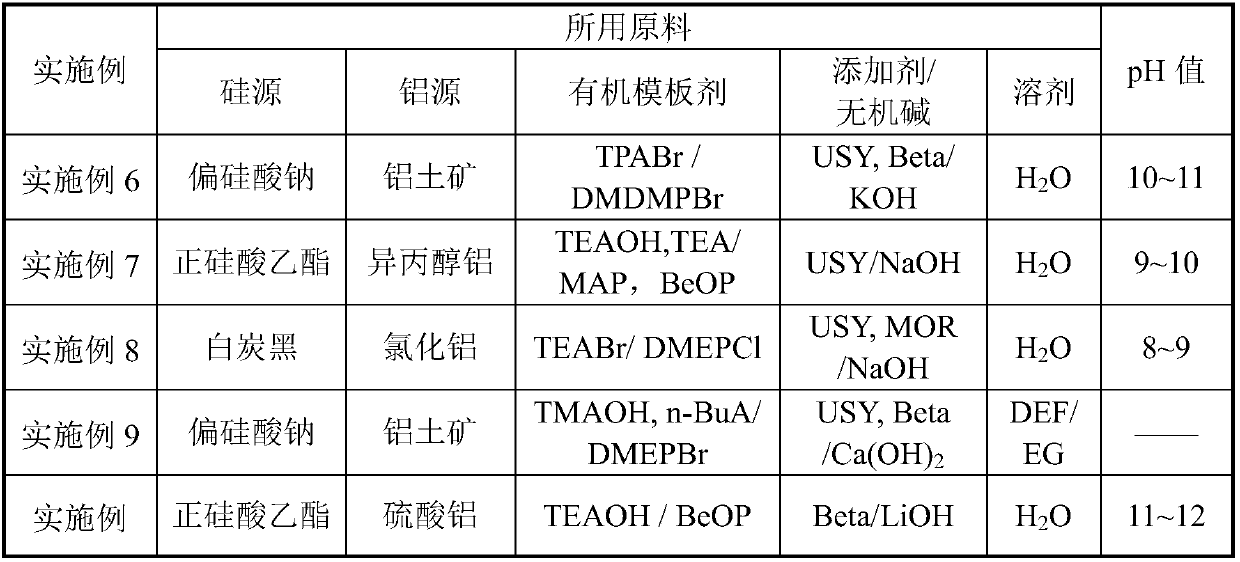

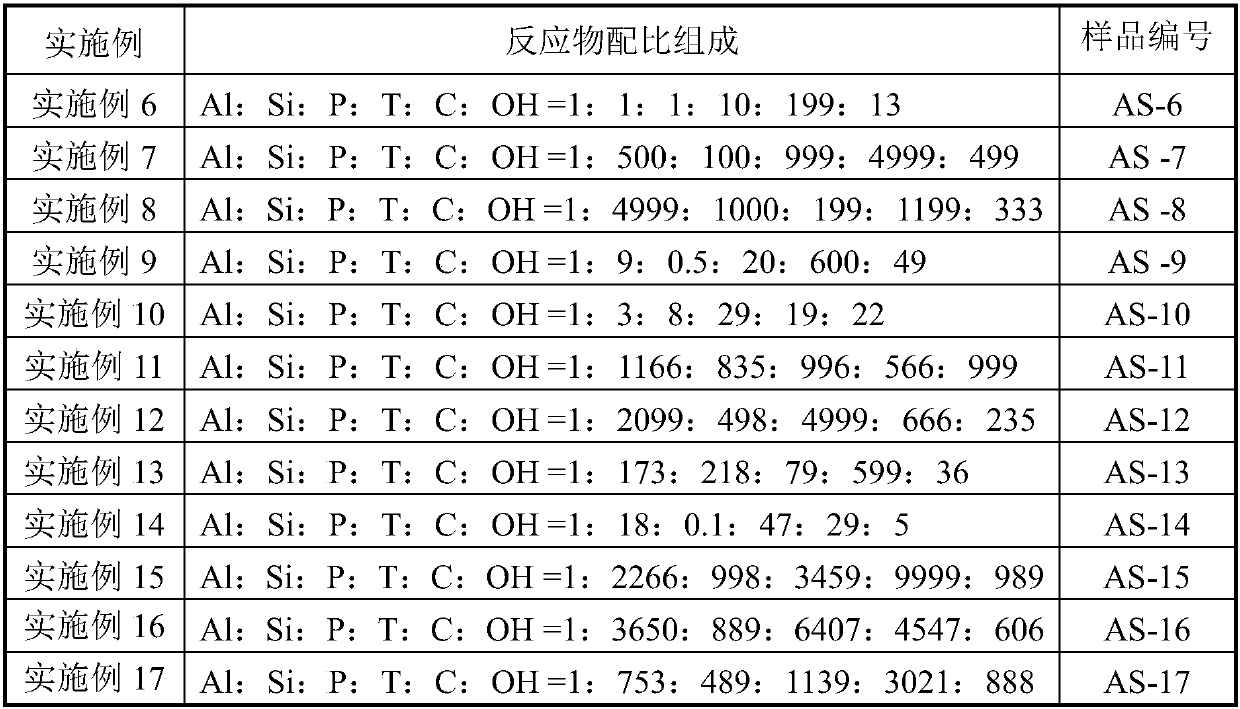

Bimetallic acid-free aluminosilicate porous composite material for direct aromatization of n-alkanes as well as preparation method and application of bimetallic acid-free aluminosilicate porous composite material

PendingCN111420698ALess cokeLow focusMolecular sieve catalystsHydrocarbon by hydrocarbon condensationMolecular sieveAlkane

The invention discloses a bimetallic acid-free aluminosilicate porous composite material for direct aromatization of n-alkanes as well as a preparation method and application of the bimetallic acid-free aluminosilicate porous composite material. The bimetallic acid-free aluminosilicate porous composite material is composed of metal with active sites and a matrix material of non-acidic porous aluminosilicate, wherein the matrix material is a molecular sieve including ZSM-5 type molecular sieve, the metal with the active sites is one or a mixture of more of Pt, Pd, Na, K, Ca and Ba, and the loading amount of each metal on the matrix material is 0.1-10% of the mass of the matrix material. The bimetallic acid-free aluminosilicate porous composite material prepared by the method can realize conversion of various alkanes (C6-C10) into aromatic hydrocarbon and other chemicals with high added value, and produces less coke.

Owner:广西华睿能源科技有限公司

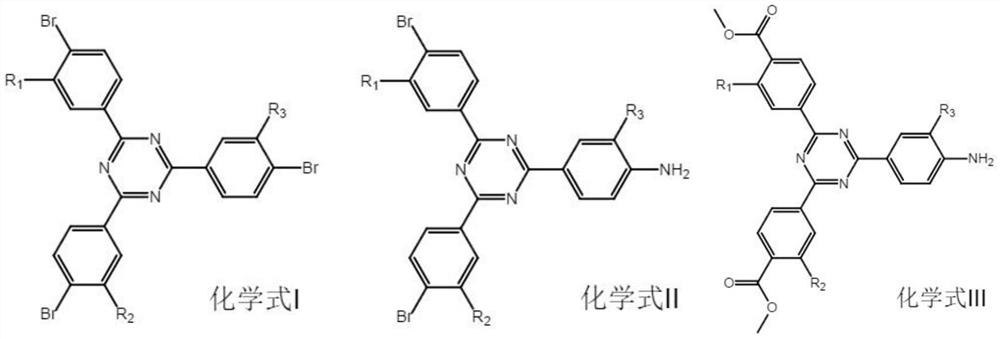

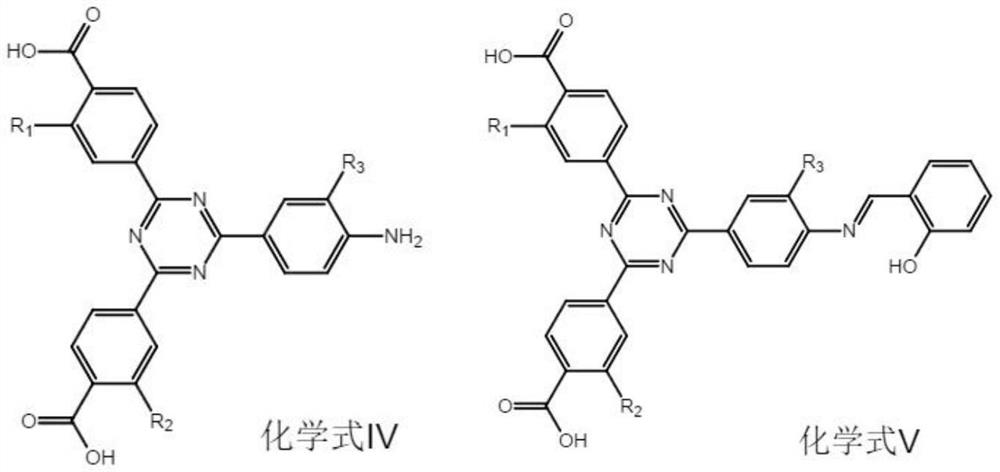

Hydrogenation and dehydrogenation catalyst as well as preparation method and application thereof

PendingCN114054089AMany active sitesThe active site hasHydrocarbon by dehydrogenationOrganic compound preparationBenzoic acidPtru catalyst

The invention discloses a preparation method of a hydrogenation and dehydrogenation catalyst, which comprises the following steps: S1, by taking tri(4-bromophenyl)triazine as a raw material, converting one bromophenyl group into an aniline group through amination reaction; s2, under light promotion with carbon monoxide and methanol as raw materials, carrying out catalytic reaction, so that the remaining two bromophenyl groups are converted into methyl benzoate groups; s3, performing saponification and acidification reactions in sequence, so that the methyl benzoate group is converted into a benzoic acid group; s4, adding 2,5-dihydroxy benzaldehyde, and enabling a benzaldehyde functional group to react with amido to finally generate an organic ligand with a Schiff base functional group; s5, sequentially adding active nanoparticles and metal salt, and reacting the materials to obtain the catalyst which takes the active nanoparticles as an active center and takes the metal organic framework as a carrier. The catalyst is suitable for hydrogenation and dehydrogenation reaction processes of an organic liquid phase hydrogen storage material, and has the advantages of high hydrogen storage energy density, low dehydrogenation temperature and high dehydrogenation speed.

Owner:苏州倍友环保科技有限公司

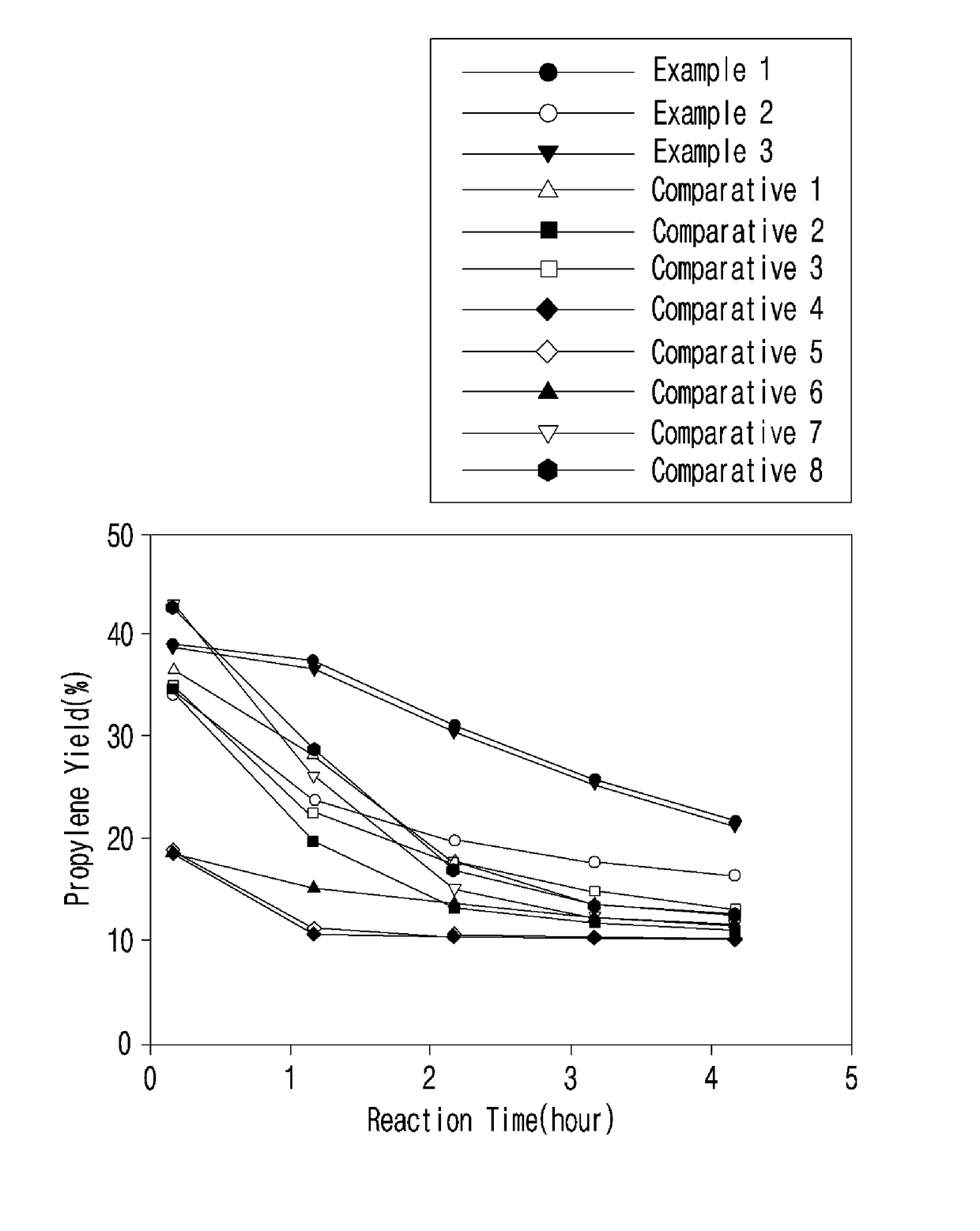

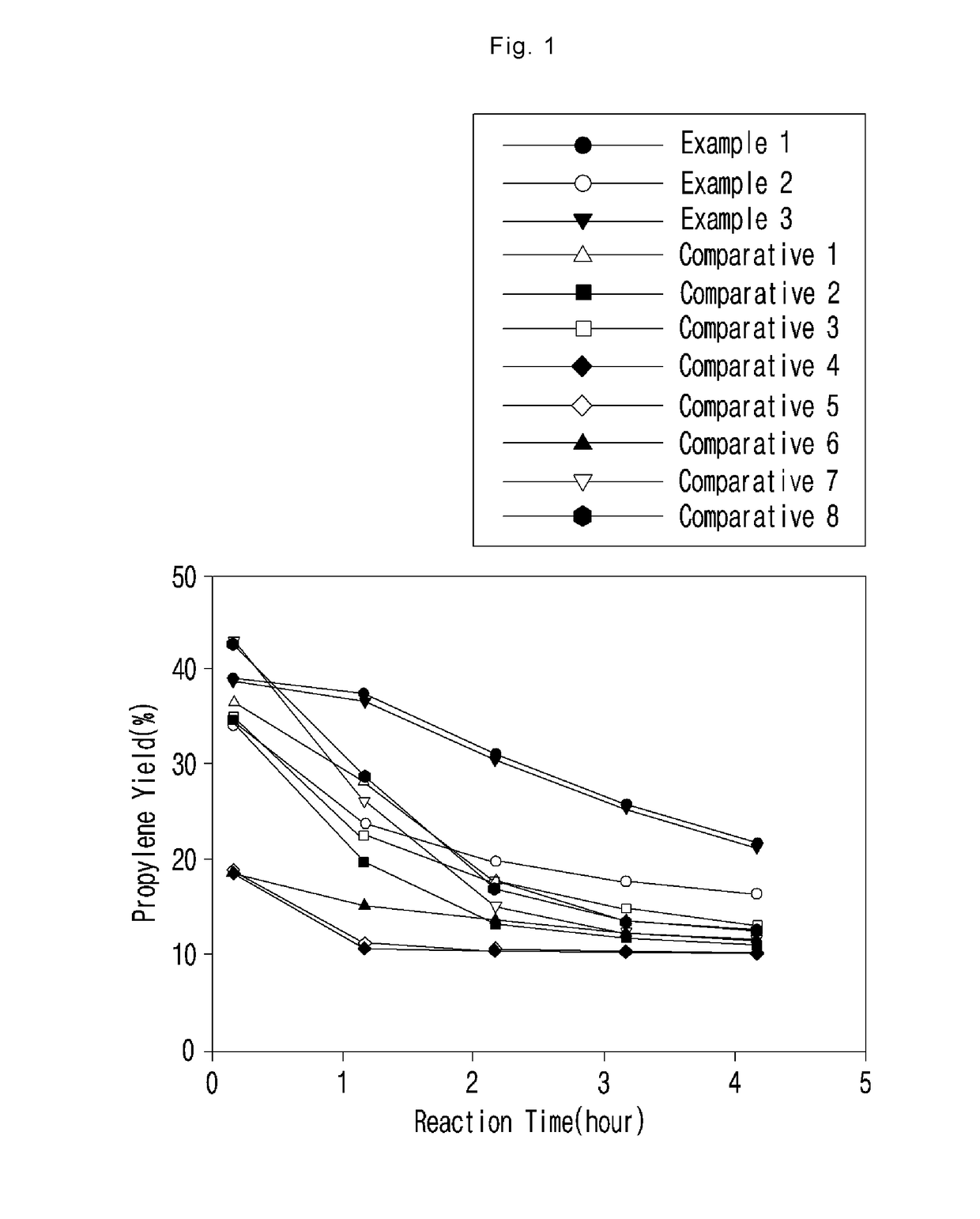

Metal-loaded zeolite catalyst for dehydrogenation of light alkane and preparation method thereof

ActiveUS20180297913A1Increase surface areaImprove thermal stabilityMolecular sieve catalystsMolecular sieve catalystAlkaneIndium

The present invention relates to a zeolite catalyst for preparing light alkene by dehydrogenation of light alkane including a cocatalyst metal selected from tin (Sn), germanium (Ge), lead (Pb), gallium (Ga) and indium (In), and a preparation method of the same. The catalyst of the present invention is prepared by using the zeolite having a relatively high pore diameter, a structure of at least 12-membered ring, and a low acidity due to a SiO2 / Al2O3 ratio of at least 50, so that it can suppress the inactivation of a catalyst caused by pore clogging due to the formation of coke. Therefore the catalyst of the present invention can be effectively used as a catalyst for the preparation of light alkene by dehydrogenation of light alkane.

Owner:KOREA RES INST OF CHEM TECH

A combined engineering bacteria-plant method for remediating waste oil-based drilling fluid deposits

InactiveCN109926440BImprove processing efficiencyWill not cause secondary pollutionContaminated soil reclamationSoil scienceEnvironmental engineering

A method for jointly repairing waste oil-based drilling fluid deposits with engineering bacteria-plants. First, clean soil and waste oil-based drilling fluid deposits are made into mixed soil; plants are pre-planted for 20 days; two kinds of engineering materials are added to the mixed soil Bacteria and NH 4 NO 3 , KH 2 PO 4 and surfactants; then plant the plants for 30 to 300 days, and within 7 to 10 days after planting, the NH 4 NO 3 Solid powder and KH 2 PO 4 Prepared into aqueous solutions with concentrations of 0.05-1.2mg / kg and 0.05-1.5mg / kg respectively, and sprayed evenly into the soil with a spraying amount of 1m 3 The mixed soil is sprayed with 0.5~2.0L of aqueous solution. The invention can solve the problems of low treatment efficiency and easy to cause secondary pollution in the prior art.

Owner:SOUTHWEST PETROLEUM UNIV

Liquid catalyst and application thereof

PendingCN111632616AAvoid inactivationHigh reactivityHydrogenPhysical/chemical process catalystsSide productMaterials science

The invention discloses a liquid catalyst and application thereof. The liquid catalyst is used for catalytic cracking of hydrocarbons, and is composed of a first component and a second component, wherein the first component is selected from a metal simple substance or alloy, and the second component is selected from a metal carbide. When the liquid catalyst is used for catalytic cracking of hydrocarbons, carbon and hydrogen are generated, products can be directly separated and utilized in the whole catalytic cracking reaction process, no by-product is generated, the catalytic efficiency of theliquid catalyst is high, and the hydrocarbon conversion rate is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

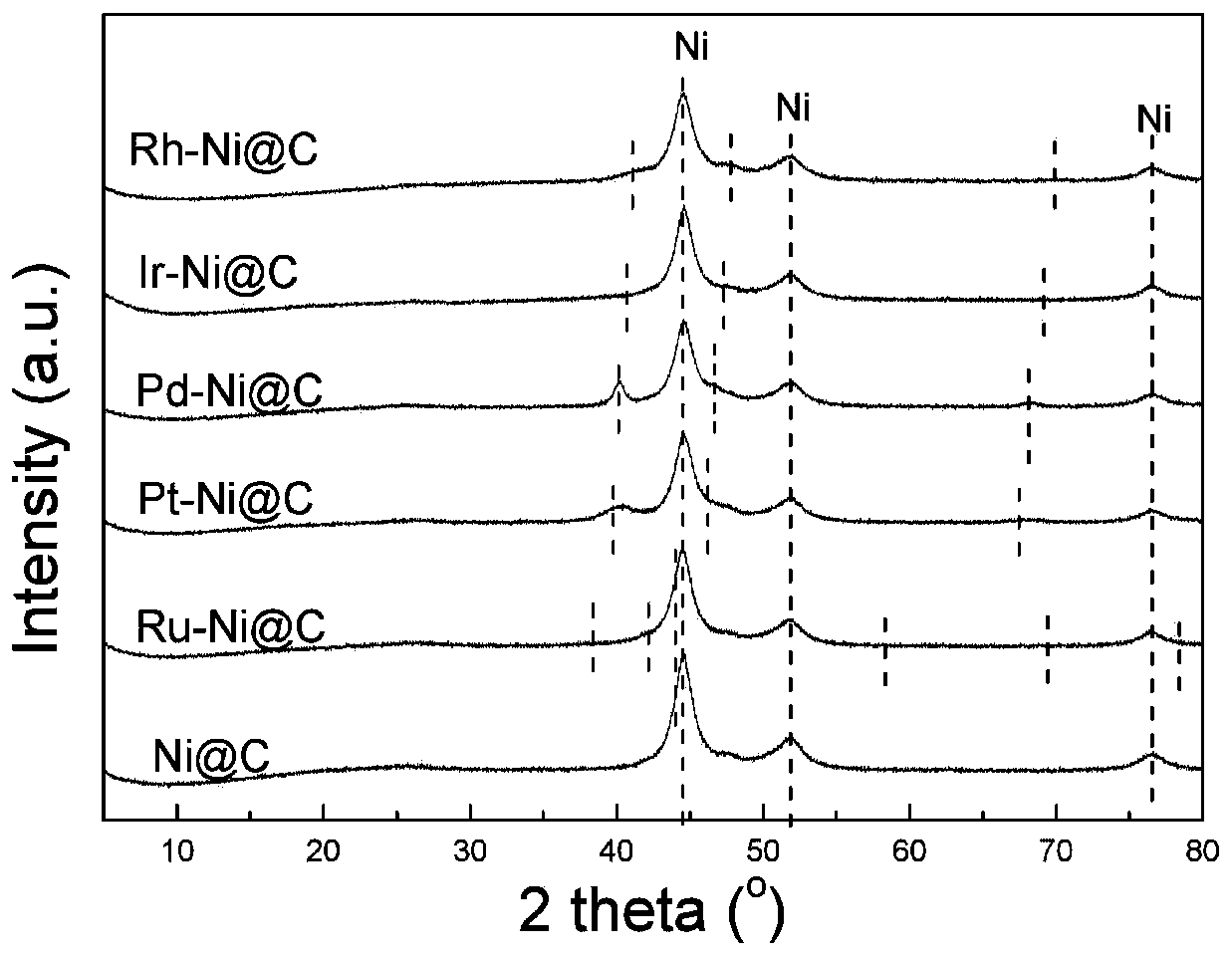

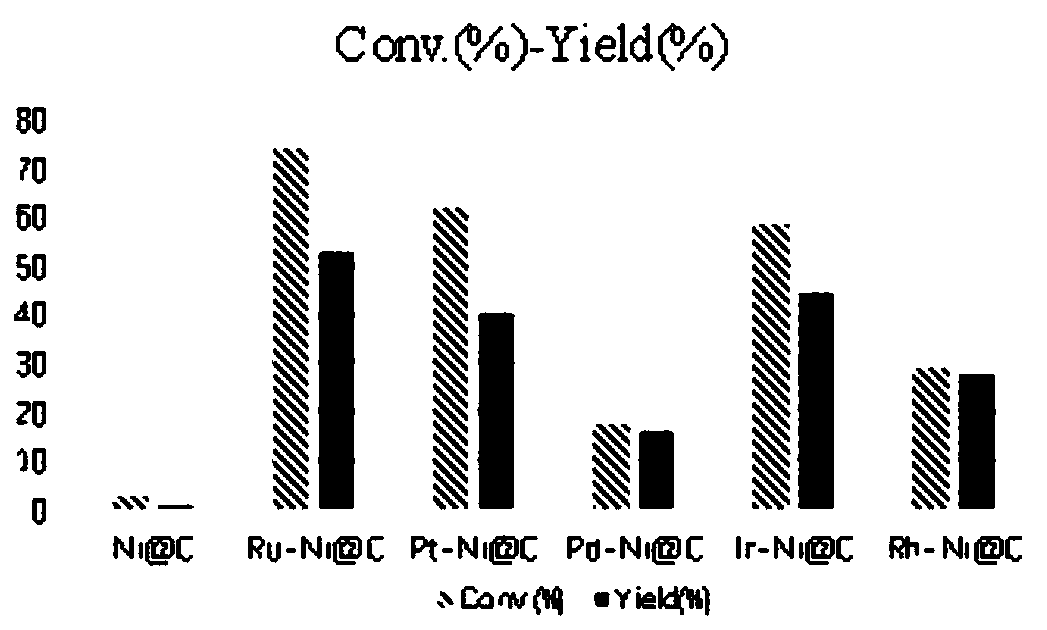

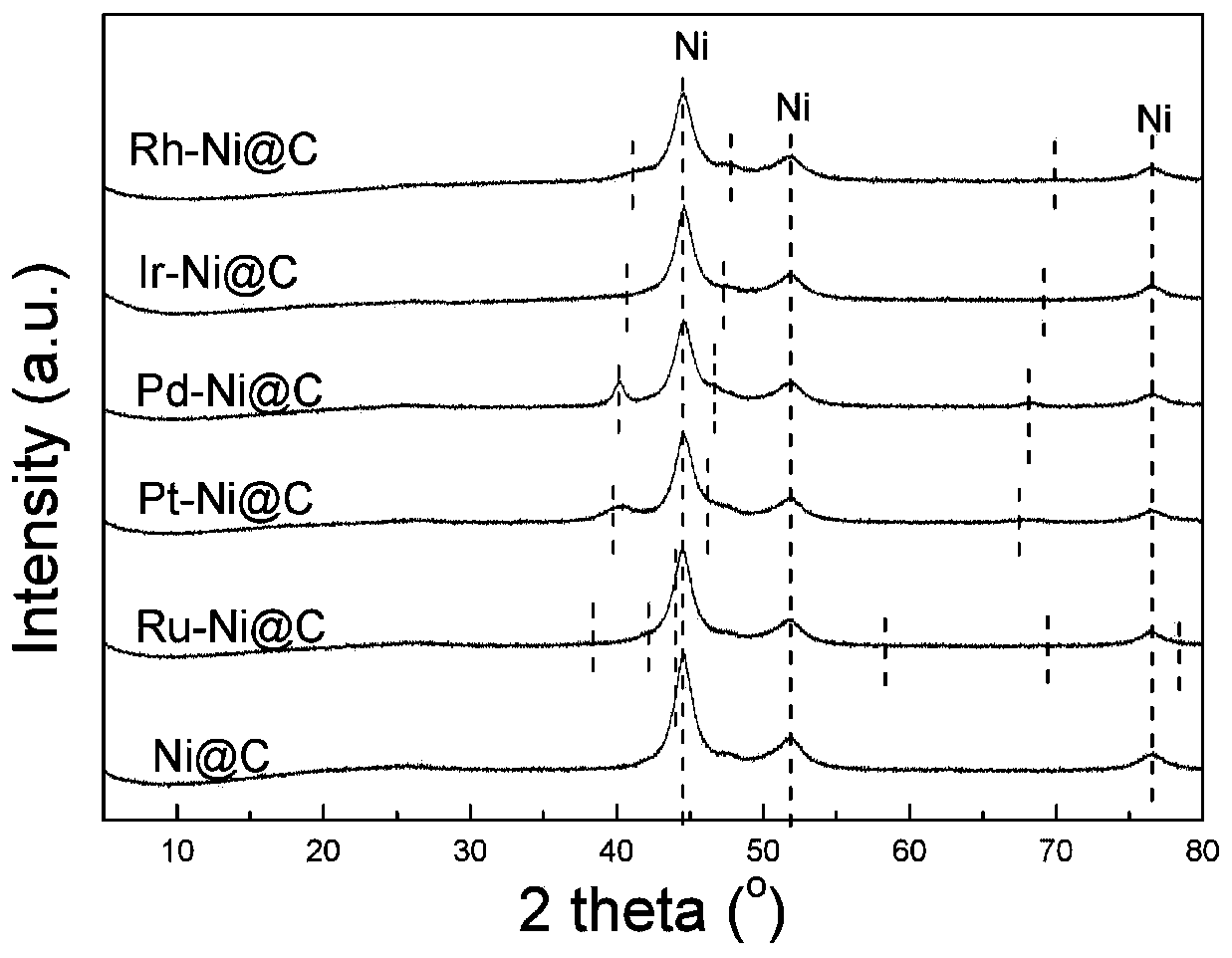

Preparation method and application of bimetallic catalyst for preparing alanine through lactic acid amination

ActiveCN111111689AReduce usageShort reaction timeOrganic compound preparationCatalyst activation/preparationPtru catalystCombinatorial chemistry

The invention discloses a preparation method and an application of a magnetic bimetallic catalyst for preparing alanine through lactic acid amination. The obtained magnetic bimetal M-Ni@C is used as acatalyst, ammonia water is used as a solvent, efficient conversion of alanine can be realized by carrying out reductive amination reaction under the action of H2, byproducts are few, the catalyst iseasy to separate and recover and is suitable for industrial production, and the problems of single reaction catalytic system, difficulty in catalyst separation and poor cyclic utilization in the priorart are solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

AEI composite molecular sieve catalyst and preparation method and application thereof

ActiveCN109701609AImprove anti-carbon performanceInhibition of dealuminationHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveEthylene

The invention relates to an AEI composite molecular sieve catalyst and a preparation method and application thereof, and mainly solves the problems that the stability of the catalyst for preparing low-carbon olefins by using methanol in the prior art is not high, and the selectivity and yield of isobutene in the low-carbon olefins excluding ethylene and propylene are low. The AEI composite molecular sieve catalyst is characterized by comprising the following components in percentage by weight: a) 10-100% of an AEI composite molecular sieve; and b) 0-90% of a binder, the problems are well solved, and the AEI composite molecular sieve catalyst can be applied to methanol-to-hydrocarbon industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com