Method for preparing aromatic hydrocarbons through catalytic conversion of oxygenated compound-containing raw material

A technology for catalytic conversion and compounding, which can be used in the production of hydrocarbons from oxygen-containing organic compounds, carbon compound catalysts, hydrocarbons, etc., and can solve problems such as low yield of aromatics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

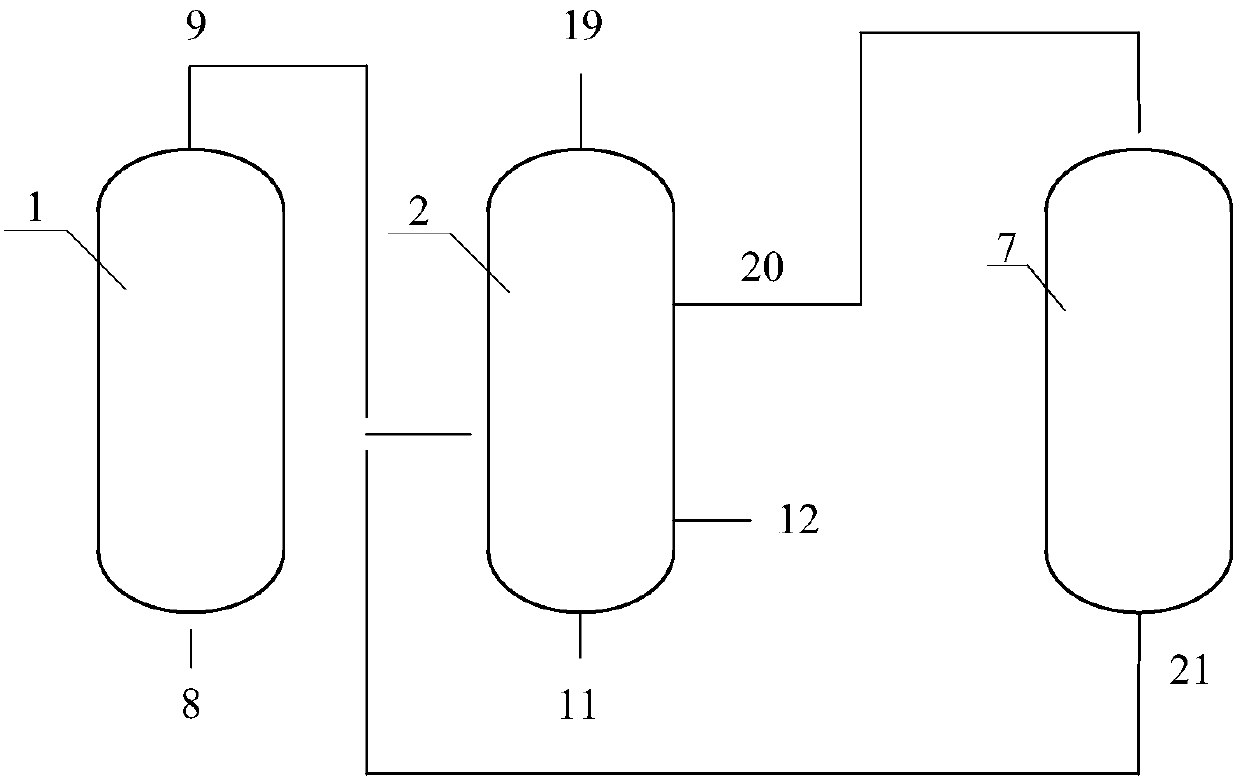

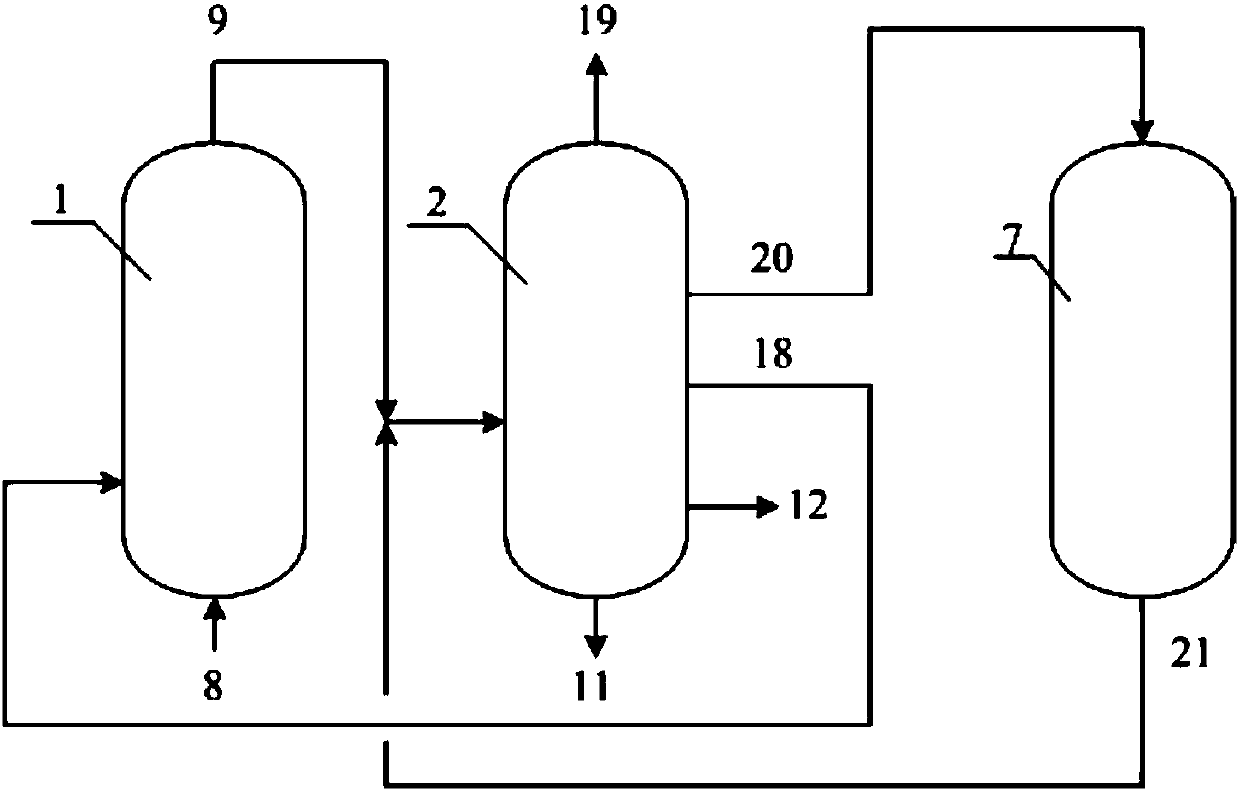

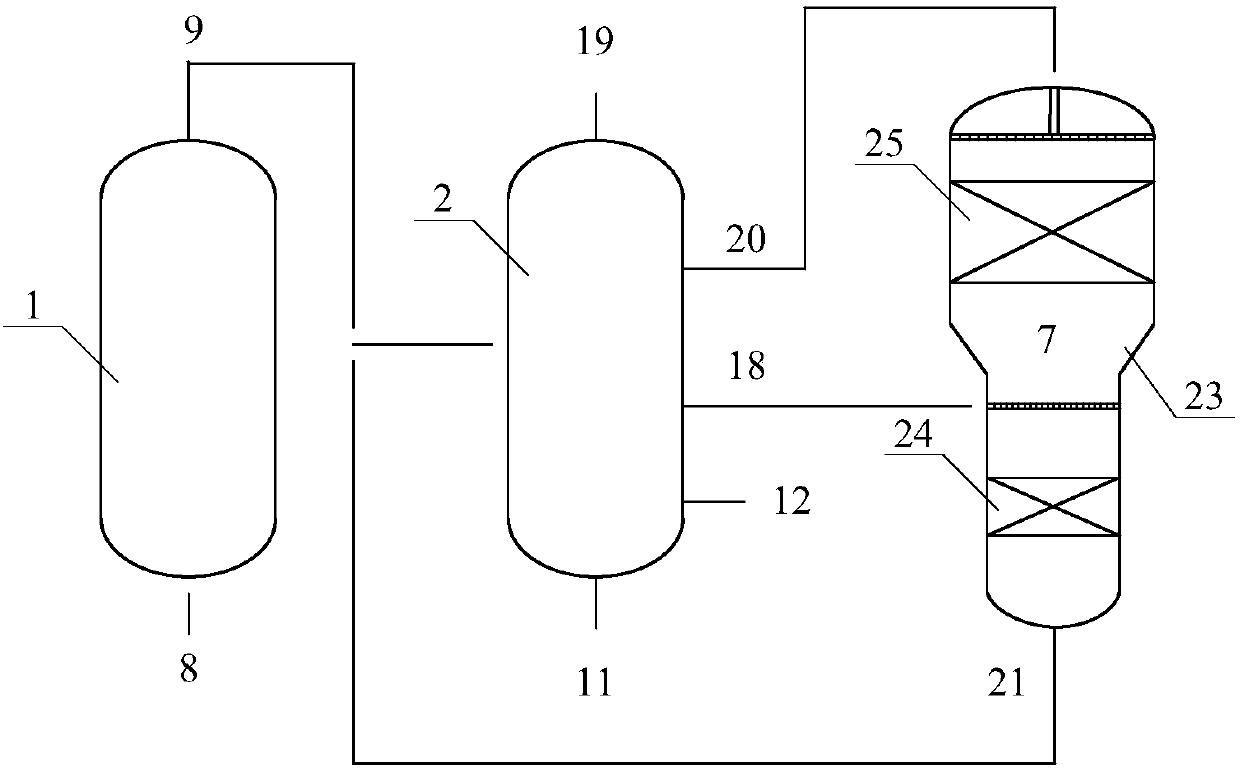

[0042] according to figure 1 In the shown device, the raw material with a methanol weight percentage of 95% enters the catalytic conversion reaction system (1) containing the oxygen-containing compound raw material to obtain a reaction product (9) rich in aromatics; the catalytic conversion reaction system (1) containing the oxygen-containing compound raw material ) is a circulating fluidized bed for catalyst continuous reaction-regeneration; the reaction product (9) rich in aromatics is separated by a separation system (2) to obtain a water phase product (11), an oil phase product (12), and light hydrocarbon effluent materials ( 19). Light hydrocarbon aromatization material (20). The light hydrocarbon aromatization material (20) all enters the light hydrocarbon aromatization reaction system (7), and the light hydrocarbon aromatization reaction product (21) obtained in the light hydrocarbon aromatization reaction system (7) returns to the The deactivated catalyst in the separ...

Embodiment 2

[0048] According to the conditions and steps described in Example 1, the raw material with a weight percentage of methanol of 10% enters the catalytic conversion reaction system (1) containing oxygenate raw material to obtain a reaction product (9) rich in aromatics; by weight, the 10% of the light hydrocarbon aromatization material (20) enters the light hydrocarbon aromatization reaction system (7).

[0049] Catalytic conversion reaction system containing oxygen-containing compound raw materials (1) P-modified Zn-ZSM-5 molecular sieve catalyst is used, Zn loading mass percentage is 10%, the catalyst bed temperature is 550 °C, and the weight space velocity is 6h -1 , The reaction pressure is 0.5 MPa in gauge pressure.

[0050] The light hydrocarbon aromatization reaction system (7) adopts ZSM-22 molecular sieve catalyst loaded with Zn, In, La, and the total content of loaded metal is 15% based on the mass percentage of the catalyst; the catalyst bed temperature is 600°C, and t...

Embodiment 3

[0054] According to the conditions and steps described in Example 1, the raw material (the weight ratio of n-propanol and ethanol is 1:1) that the total weight percentage of n-propanol and ethanol is 70% enters the catalytic conversion reaction system containing oxygenate raw material ( 1) A reaction product (9) rich in aromatics is obtained; by weight, 100% of the light hydrocarbon aromatization material (20) enters the light hydrocarbon aromatization reaction system (7).

[0055] Catalytic conversion reaction system containing oxygen-containing compound raw materials (1) P-modified Zn-ZSM-5 molecular sieve catalyst is used, Zn loading mass percentage is 5%, the catalyst bed temperature is 500 °C, and the weight space velocity is 2h -1 , The reaction pressure is 0.2 MPa in gauge pressure.

[0056] The light hydrocarbon aromatization reaction system (7) adopts ZSM-5 molecular sieve catalyst loaded with Zn, Ga, La, and the total content of loaded metal is 5% based on the mass p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com