Patents

Literature

57results about How to "Avoid bulk accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

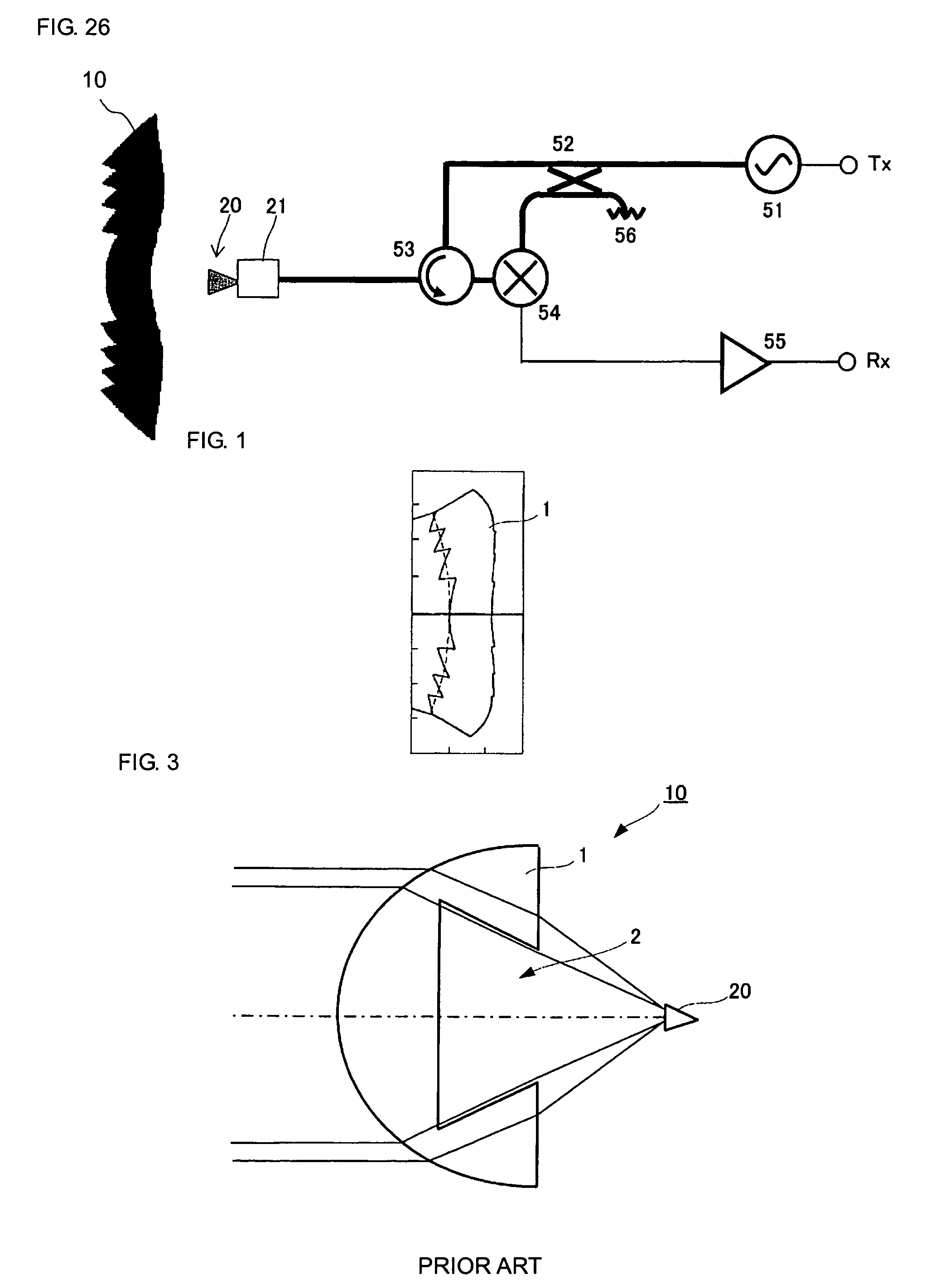

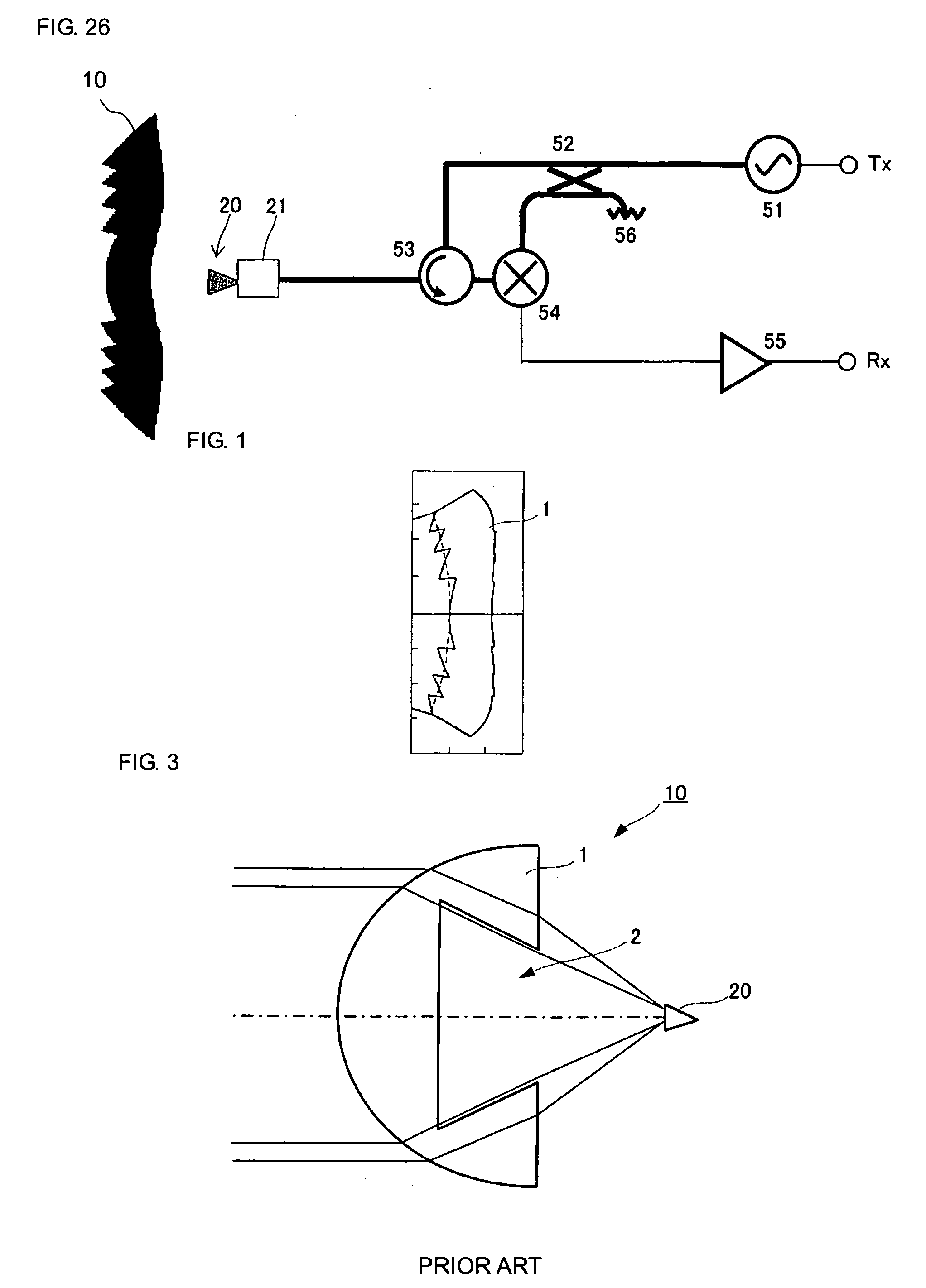

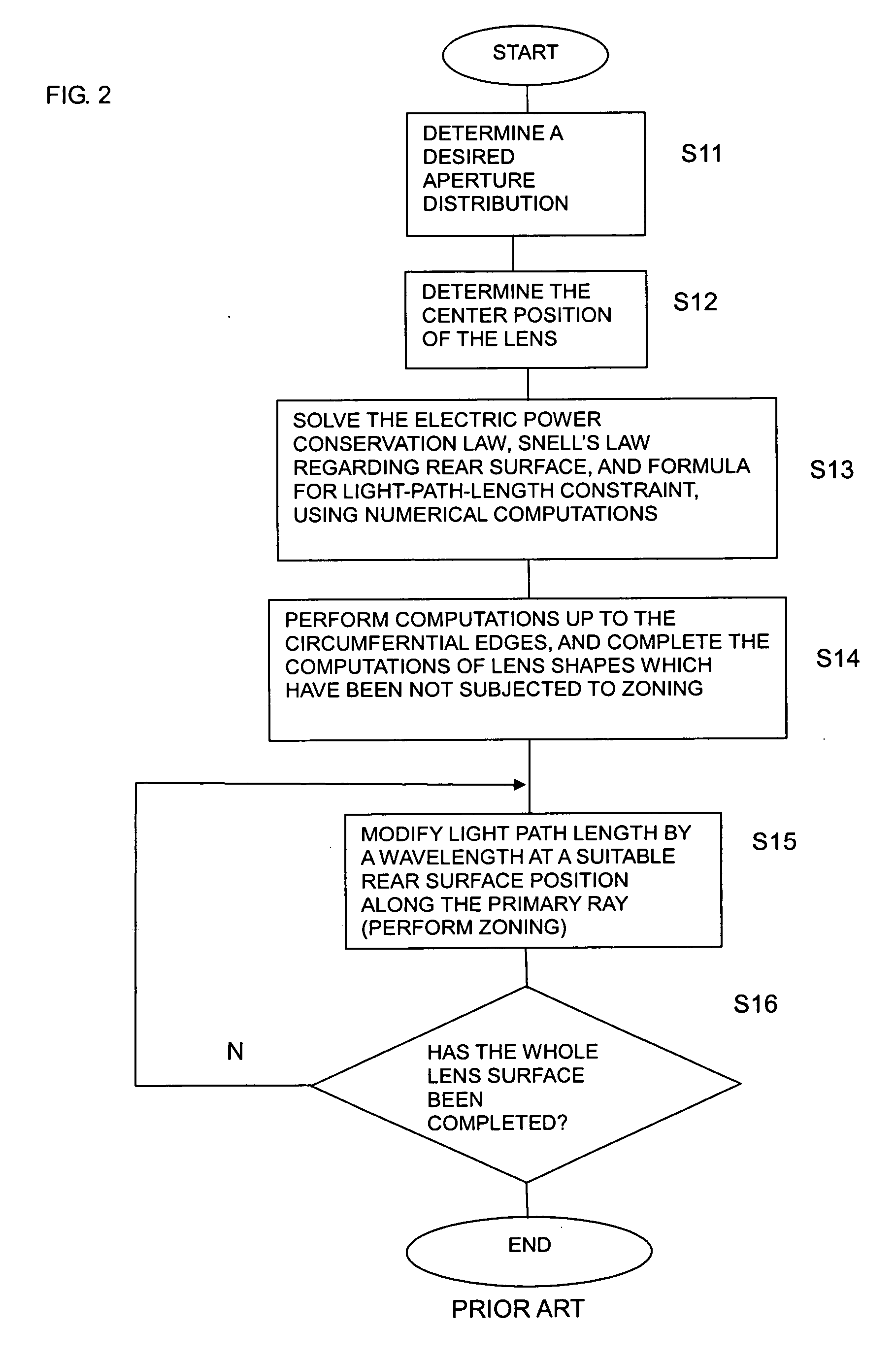

Dielectric lens, dielectric lens device, design method of dielectric lens, manufacturing method and transceiving equipment of dielectric lens

InactiveUS7355560B2Reduce weight and sizeEliminate the problemAntennasPath lengthSimultaneous equations

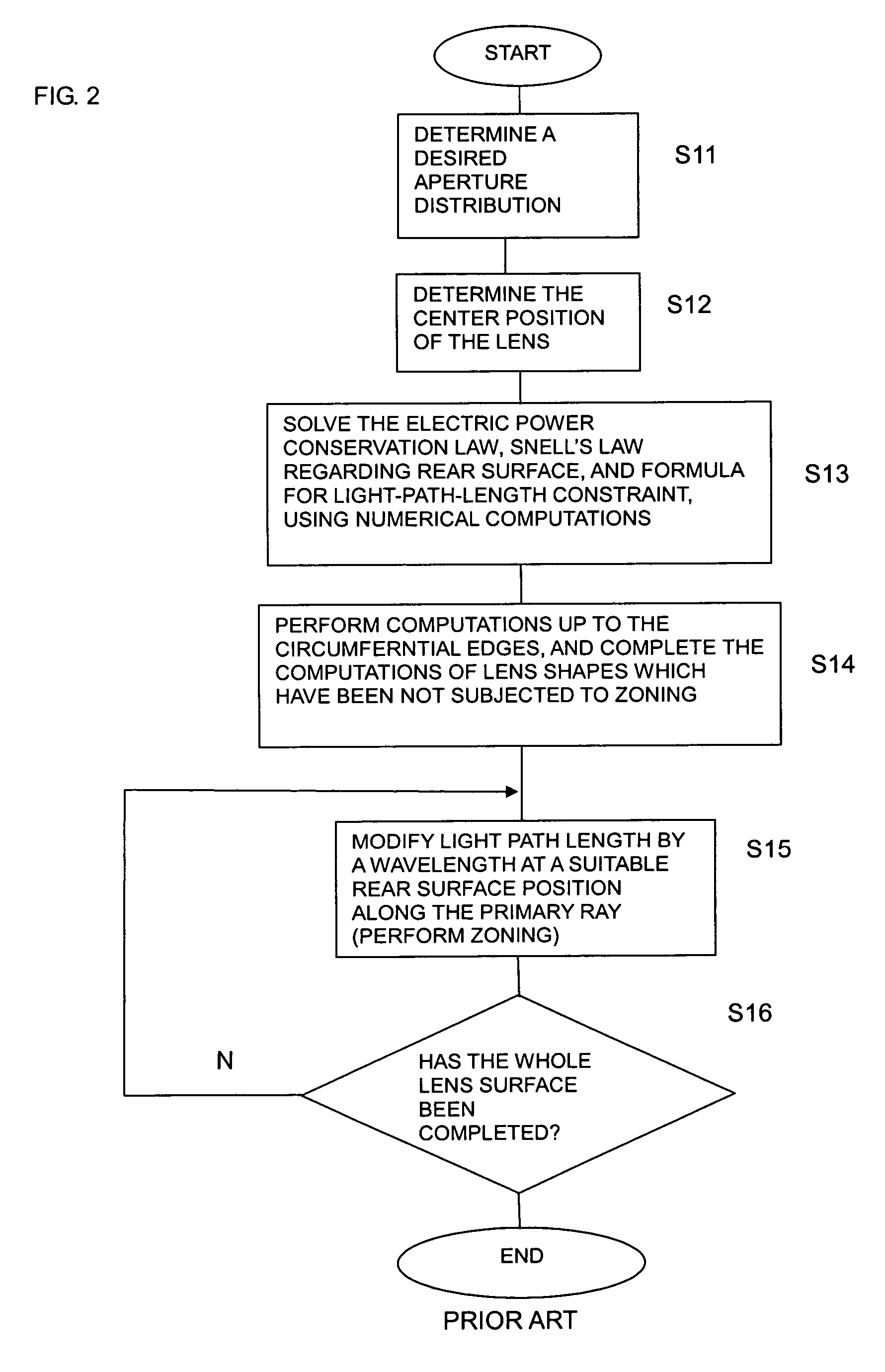

A design process first determines a desired aperture distribution, then converts the electric power conservation law, Snell's law on the rear face side of a dielectric lens, and the formula representing light-path-length constraint, into simultaneous equations, and computes the shapes of the surface and rear face of the dielectric lens depending on the azimuthal angle θ of a primary ray from the focal point of the dielectric lens to the rear face of the dielectric lens, and then reduces the light path length in the formula showing light-path-length constraint by an integral multiple of the wavelength when the coordinates on the surface of the dielectric lens reach a predetermined restriction thickness position. A dielectric lens is designed by sequentially changing the lazimuthal angle θ from its initial value, and also repeating the second and third steps. Thus, downsizing and quantification is realized by zoning while keeping antenna properties at the time of constituting a dielectric lens antenna in a good condition.

Owner:MURATA MFG CO LTD

Dielectric lens, dielectric lens device, design method of dielectric lens, manufacturing method and transceiving equipment of dielectric lens

InactiveUS20060202909A1Preventing antenna propertyAvoiding characteristicAntennasPath lengthSimultaneous equations

A design process first determines a desired aperture distribution, then converts the electric power conservation law, Snell's law on the rear face side of a dielectric lens, and the formula representing light-path-length constraint, into simultaneous equations, and computes the shapes of the surface and rear face of the dielectric lens depending on the azimuthal angle θ of a primary ray from the focal point of the dielectric lens to the rear face of the dielectric lens, and then reduces the light path length in the formula showing light-path-length constraint by an integral multiple of the wavelength when the coordinates on the surface of the dielectric lens reach a predetermined restriction thickness position. A dielectric lens is designed by sequentially changing the lazimuthal angle θ from its initial value, and also repeating the second and third steps. Thus, downsizing and quantification is realized by zoning while keeping antenna properties at the time of constituting a dielectric lens antenna in a good condition.

Owner:MURATA MFG CO LTD

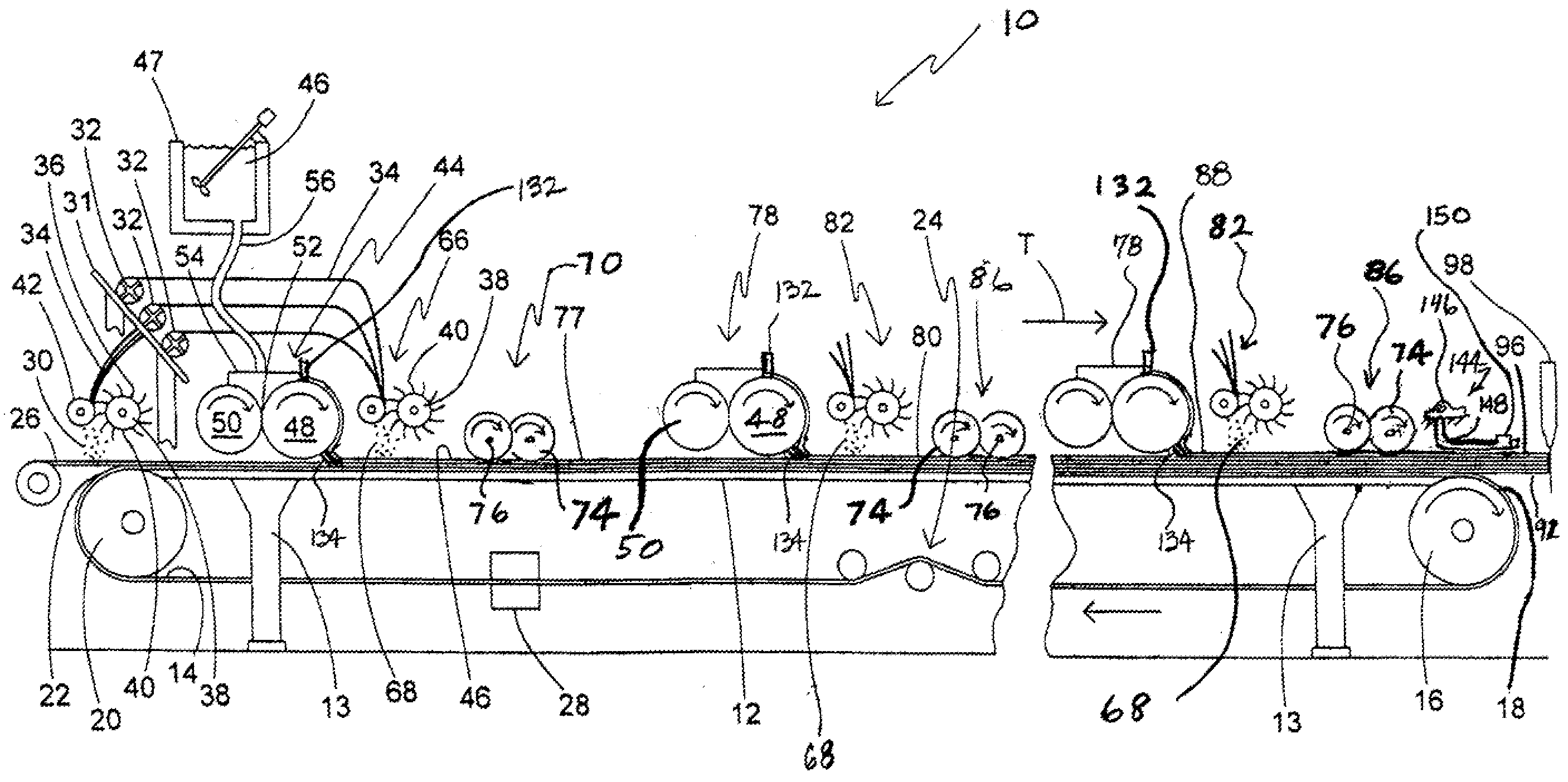

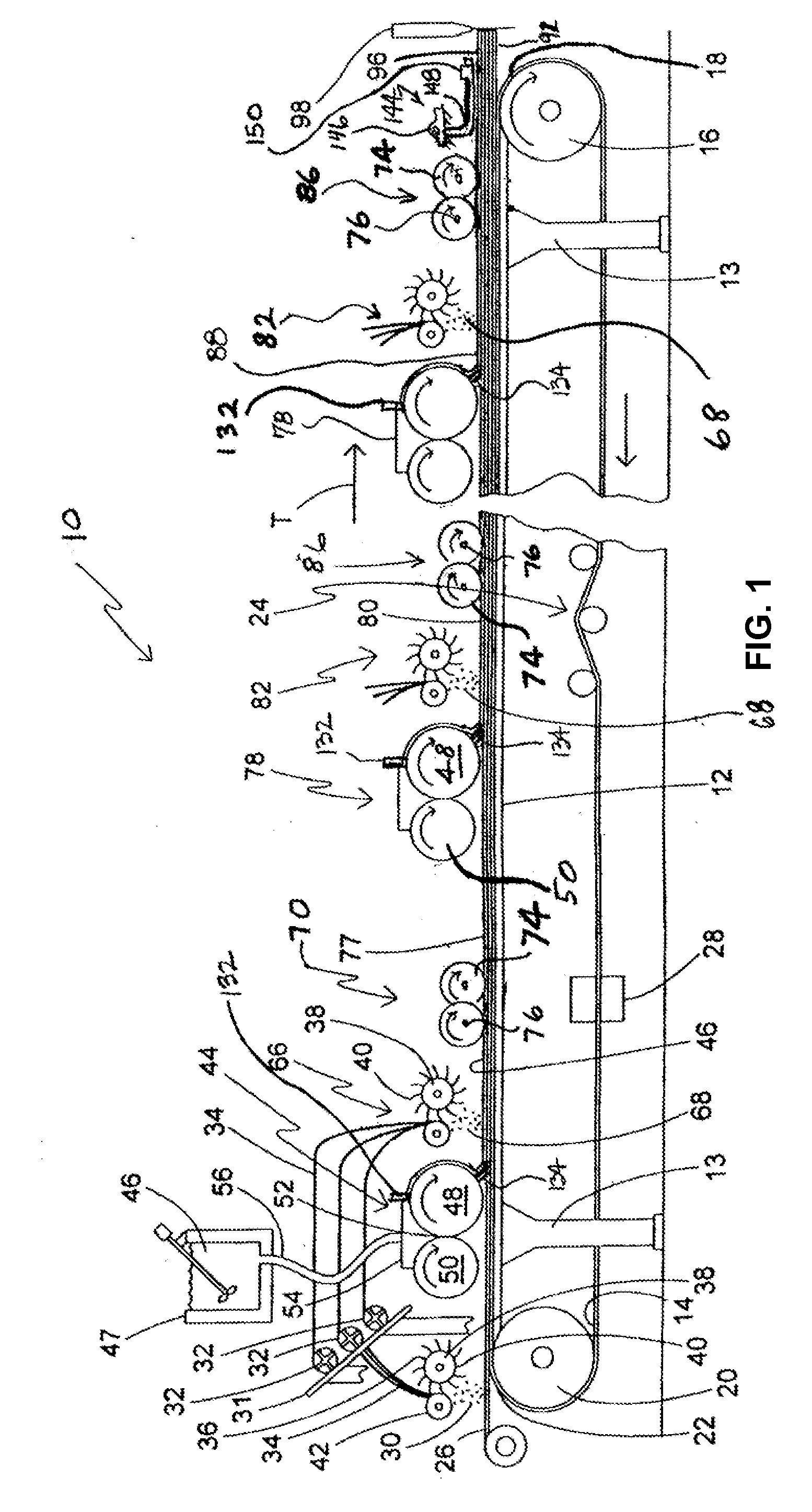

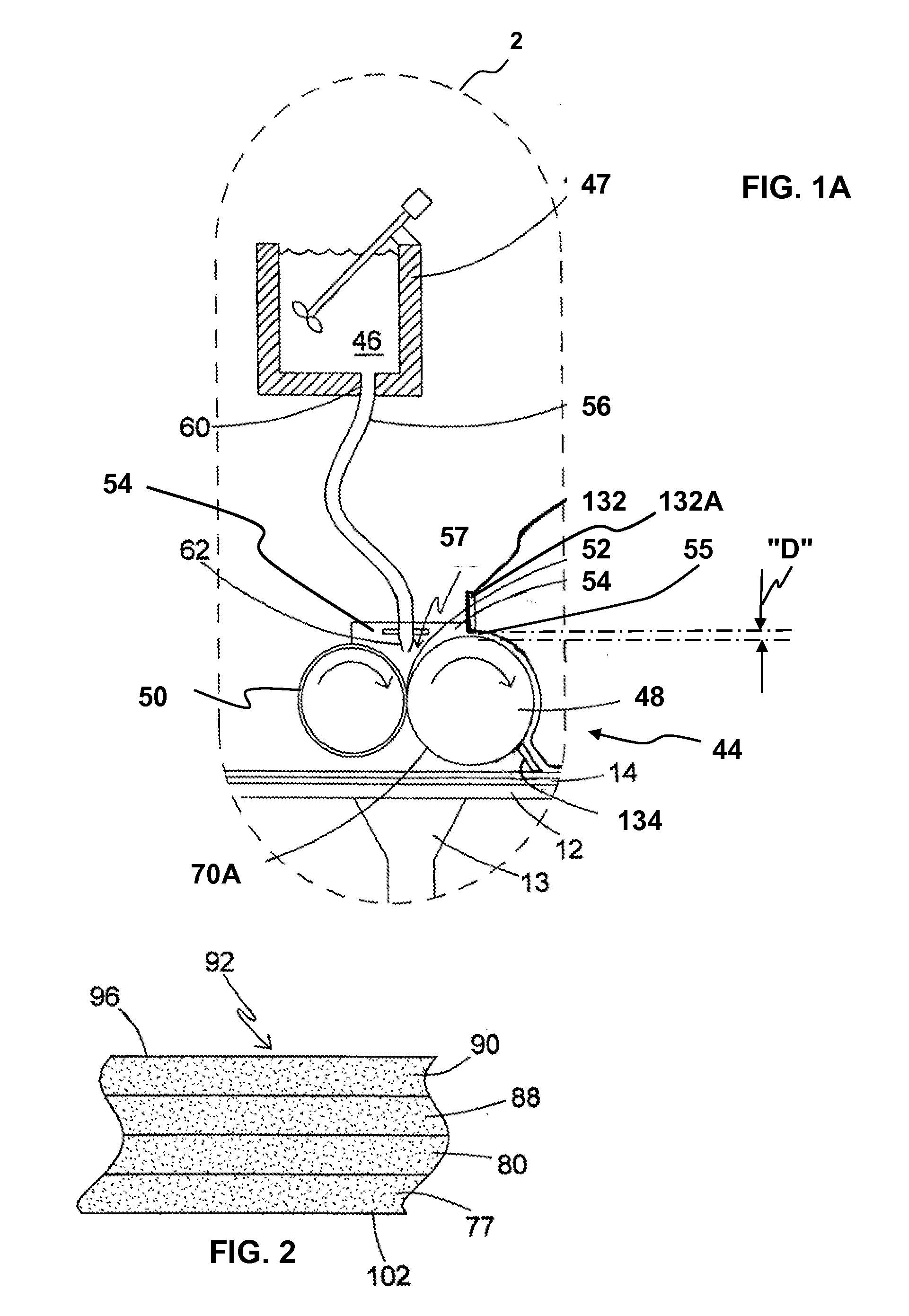

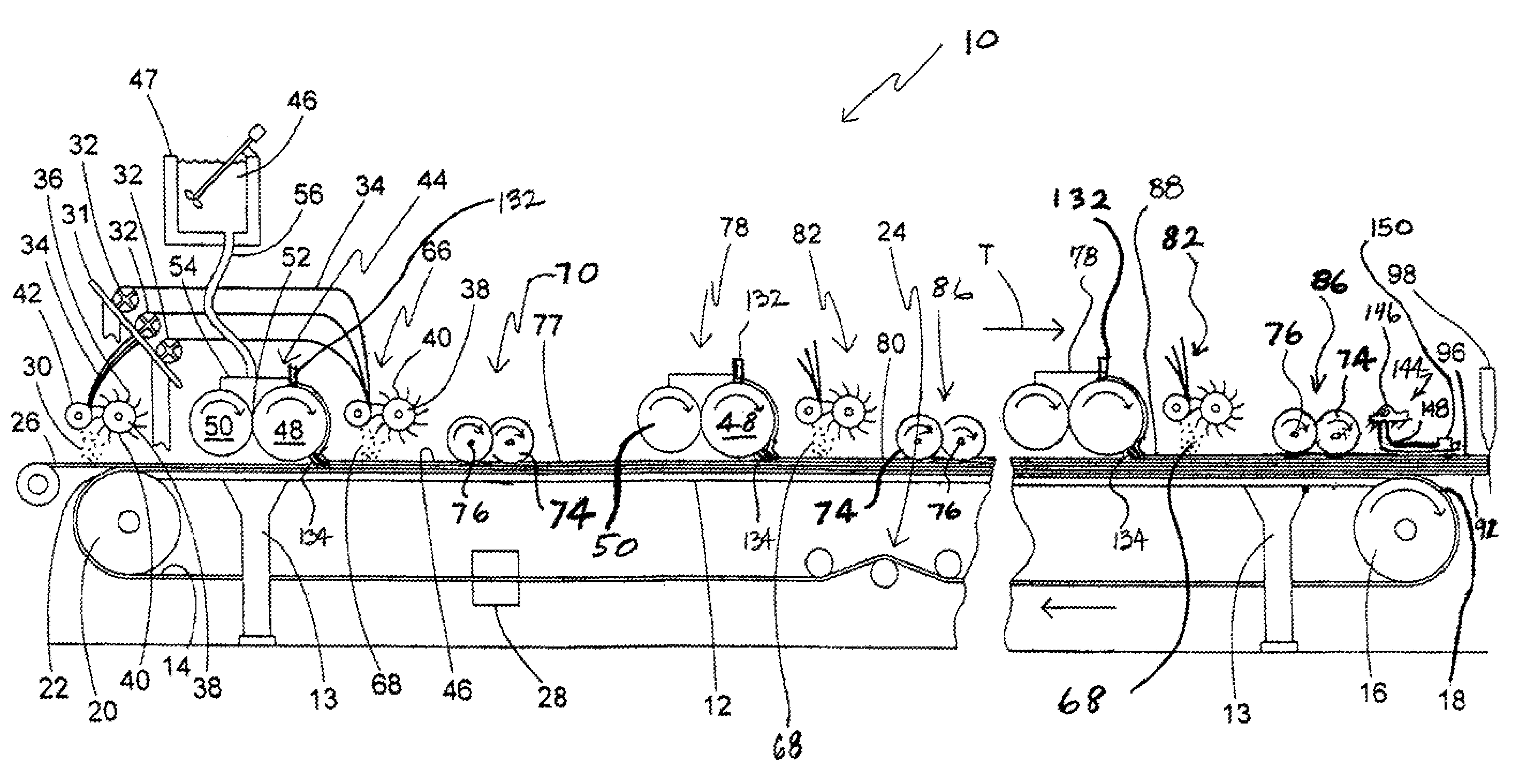

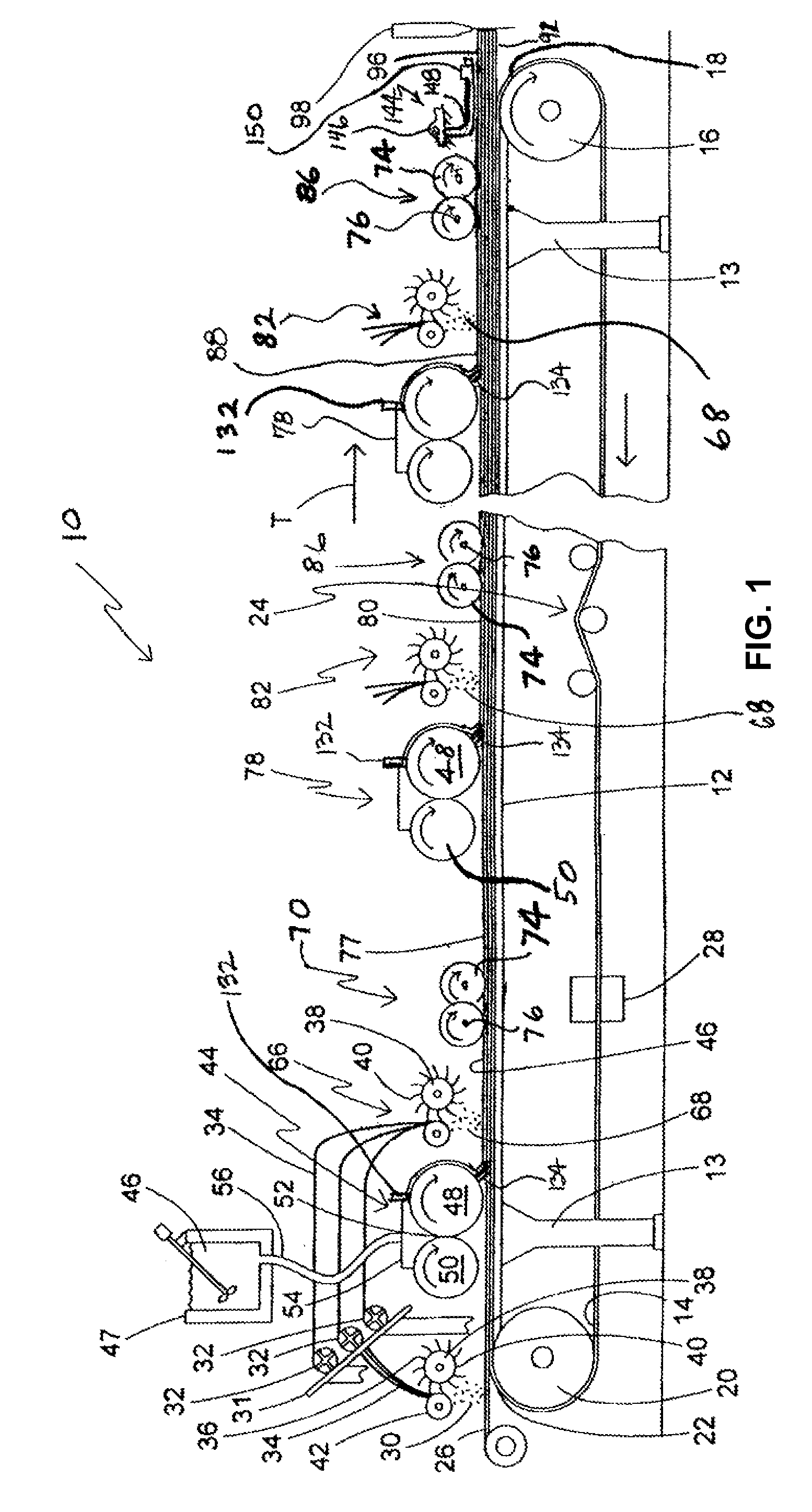

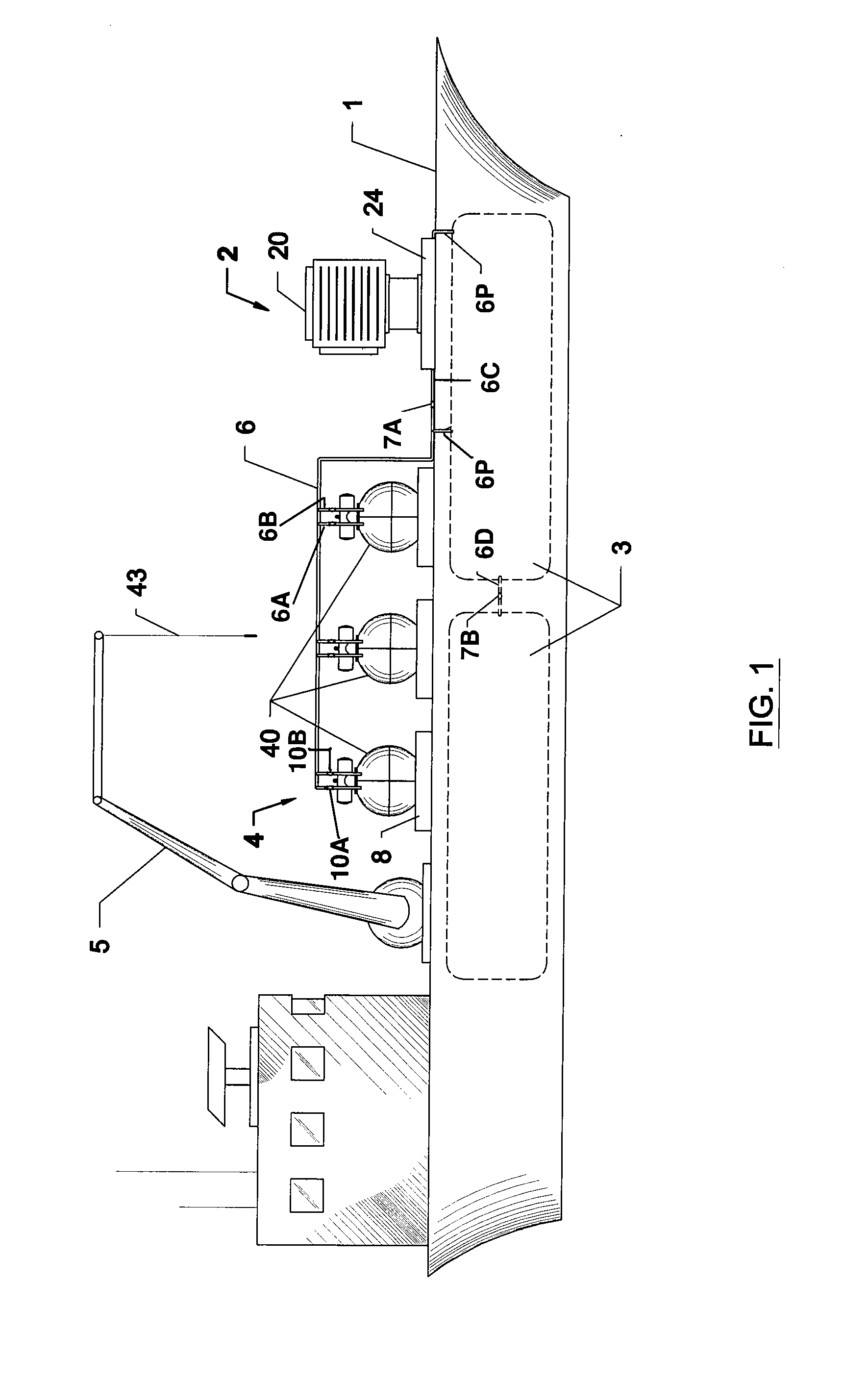

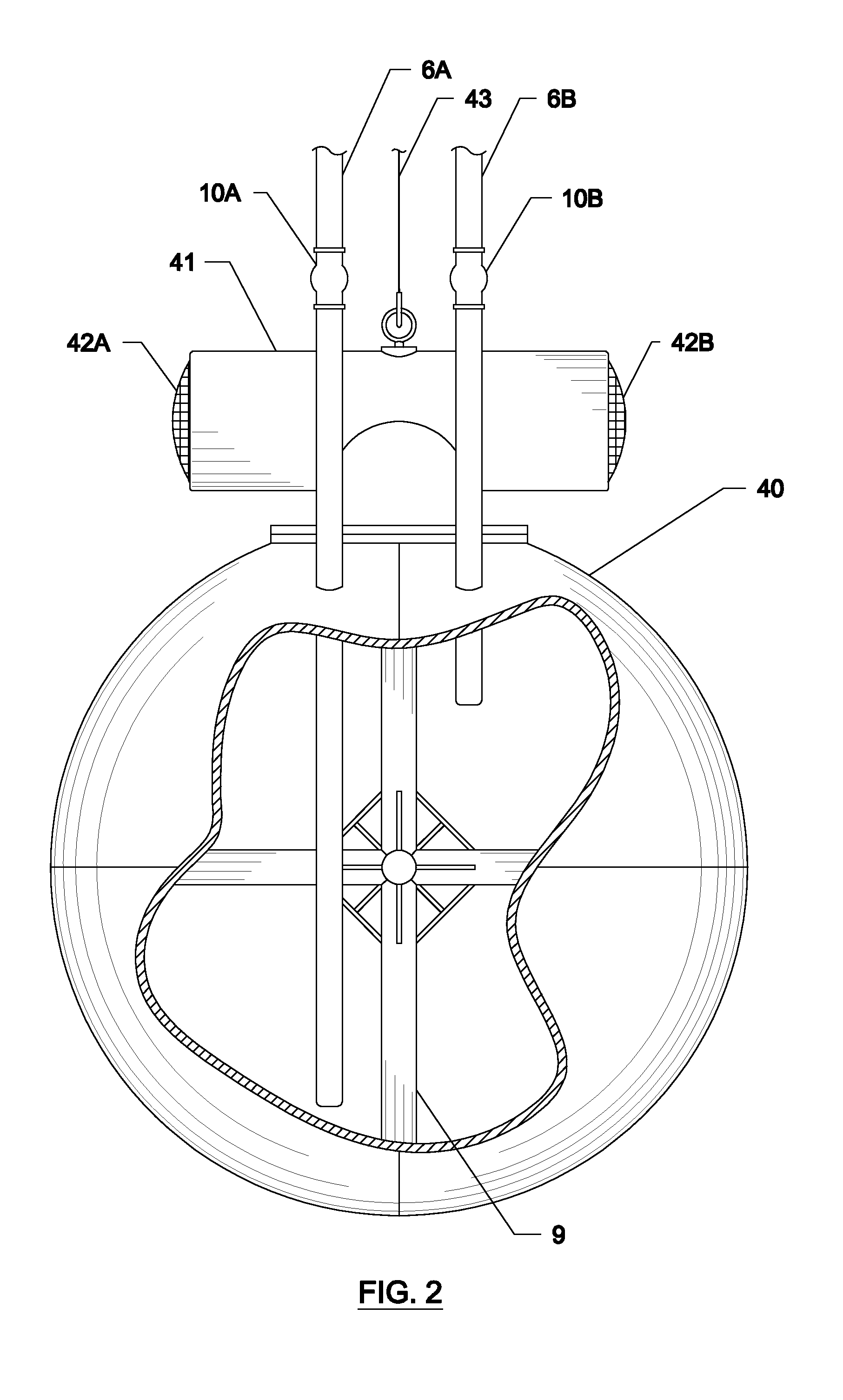

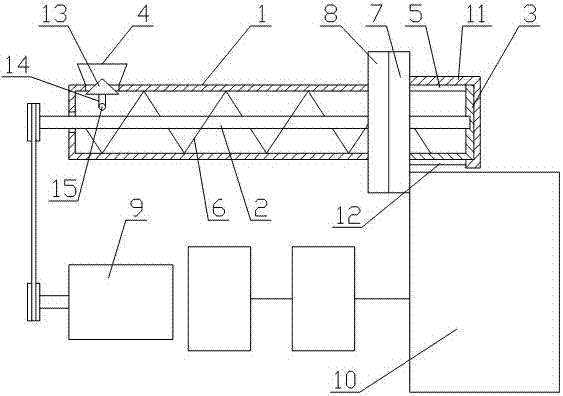

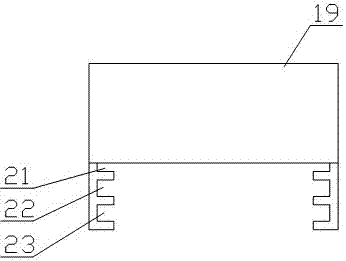

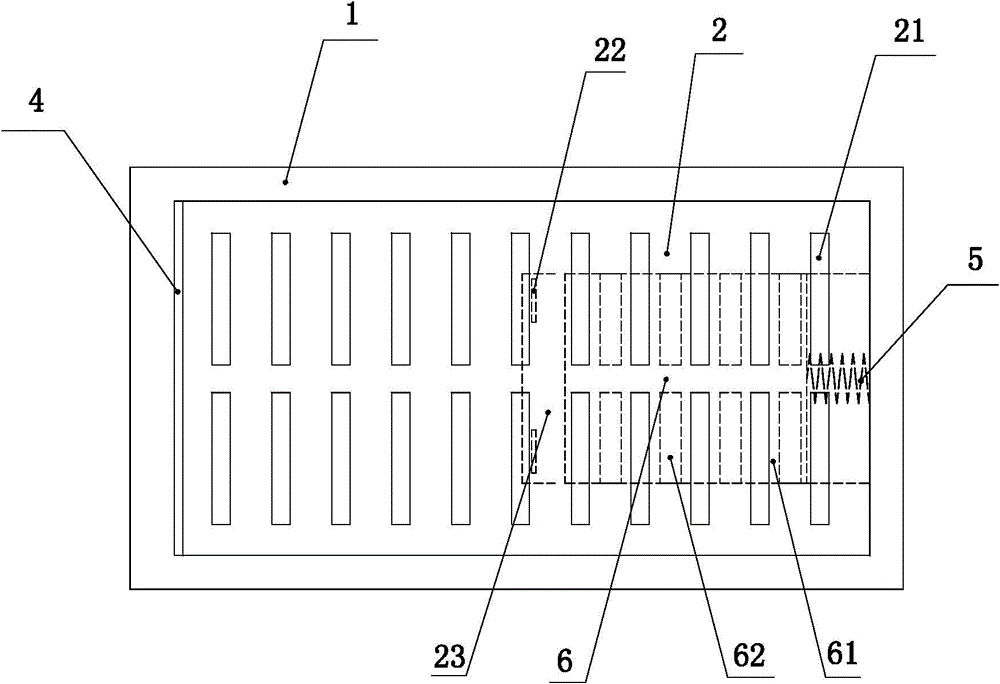

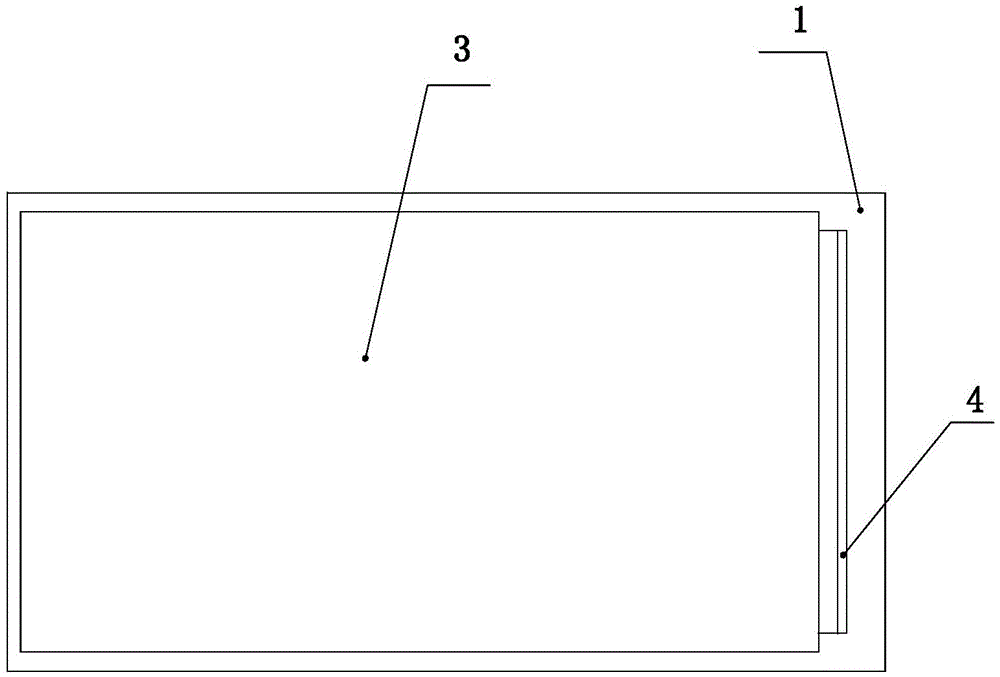

Process and apparatus for feeding cementitious slurry for fiber-reinforced structural cement panels

ActiveUS20080099171A1Good strength propertiesA large amountNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringFibre reinforcement

A head-box for depositing slurry upon a moving web including a main metering roll, a companion roll disposed in closely spaced relation to the metering roll and a vibrating gate which forms a nip between the metering roller and the gate. The nip is arranged to retain a supply of the slurry, and the rolls are driven so slurry retained in the nip progresses over an upper outer peripheral surface of the metering roll to be deposited upon the web. Also, preferably included is a doctor blade disposed in operational relationship to the metering roll for directing the slurry downwardly from the outer metering roll surface to a point above the surface of a carrier for a fiberglass layer upon which the slurry layer is deposited. The vibrating gate and doctor blade may be pivotally mounted to either side of the surfaces of the head-box.

Owner:UNITED STATES GYPSUM CO

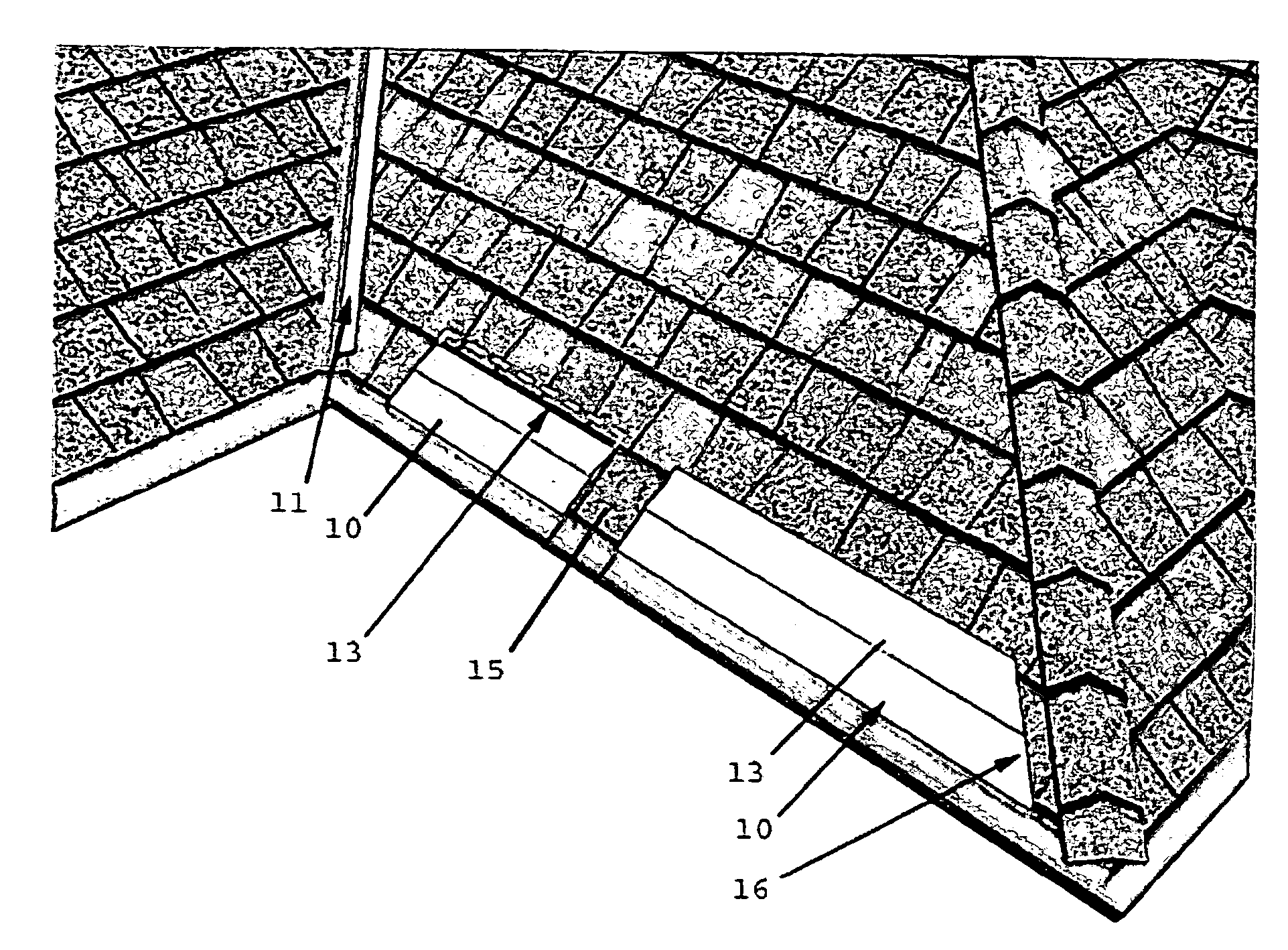

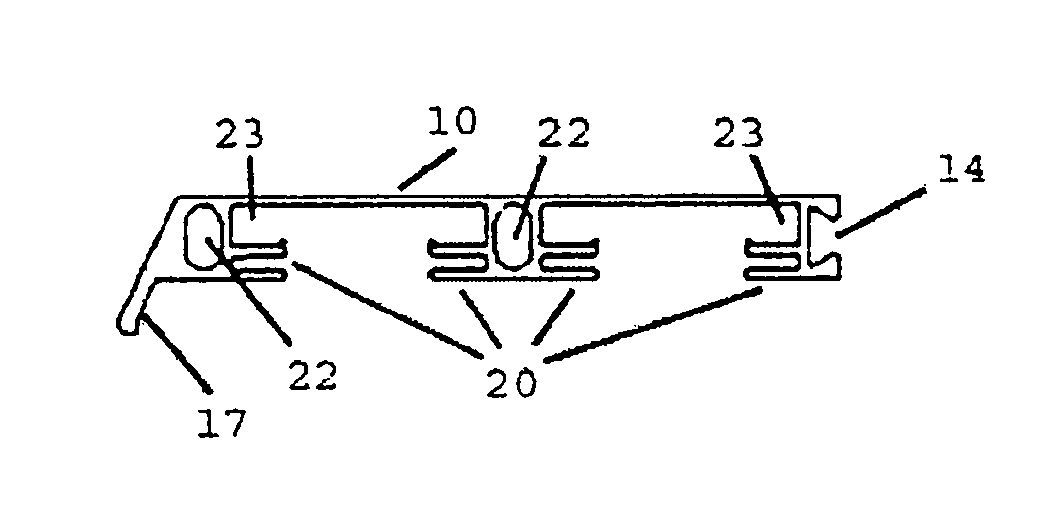

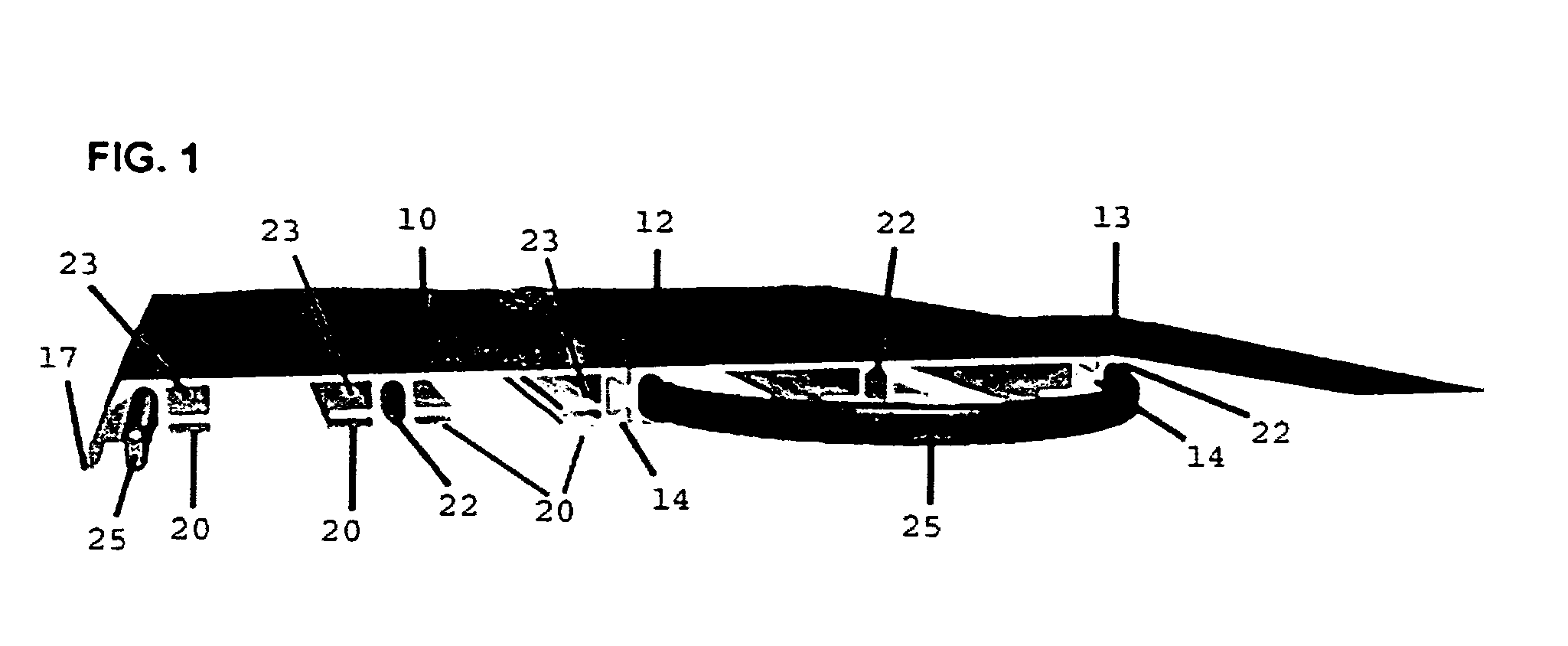

Roof ice and snow melt system

ActiveUS20060288652A1Eliminate buildupEliminates formationPhotovoltaic supportsBuilding roofsSnow meltingEngineering

A snow and ice melting device adapted to rest on a roof; having a flat plate with a series of channels therethrough containing a heating element to heat the flat plate and melt the ice and snow on the roof.

Owner:ENGINEERED ROOF DE ICING

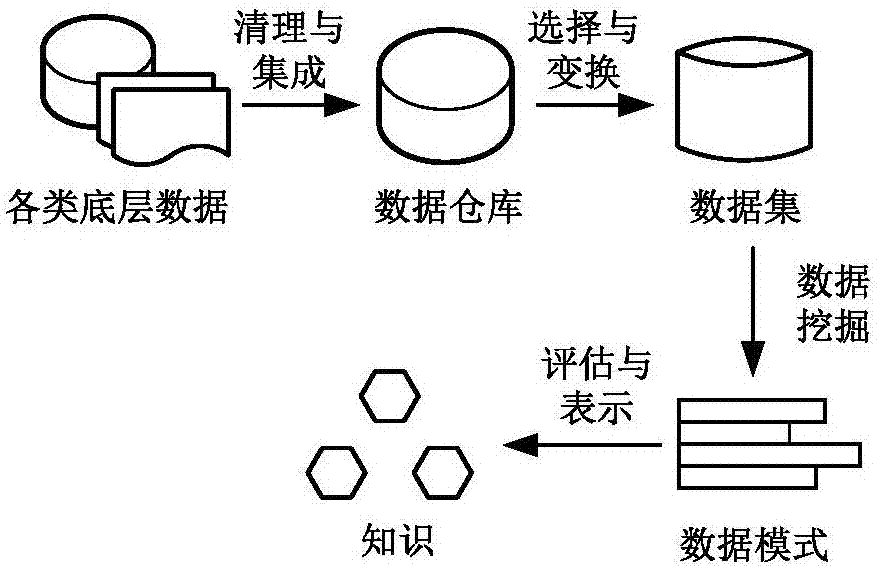

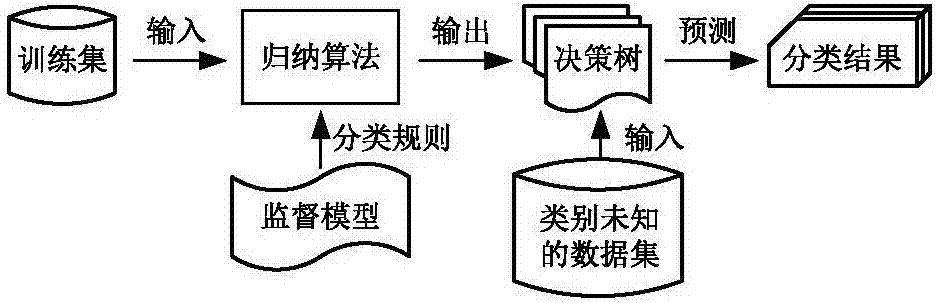

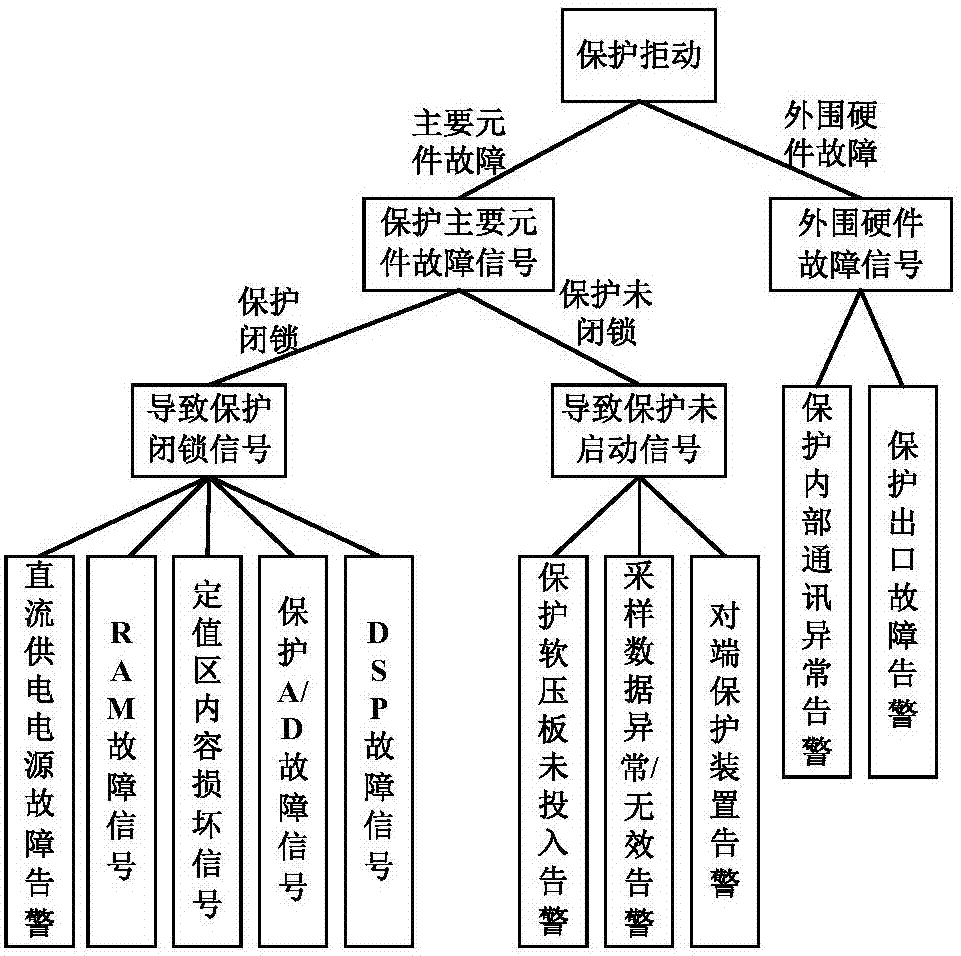

Power grid fault tracking method based on data mining technology

InactiveCN107016507AAvoid bulk accumulationTightly boundCharacter and pattern recognitionResourcesSelf-healingData set

The invention discloses a power grid fault tracking method based on data mining technology. The method includes taking various types of data acquisition systems of an intelligent substation as an original data source; selecting a decision tree to classify the information in the station, and providing decision support for the fault tracking program on a dispatching side; classifying the data filtered by the decision tree according to the supervision model into three classes: protection rejection signals, signal channel fault signals, and breaker rejection signals; and after the classification algorithm of the decision tree on the training samples is completed, predicting the data set in the unknown class, and corresponding to the power grid fault tracking process, namely, analyzing the various kinds of data of the transformer station layer to give the protection or breaker rejection reasons. The power grid fault tracking method can monitor the other data of the lower transformer station layer at the dispatching center, for example, the general level and forecasting level alarm data, can determine the condition of protection and breaker rejection according to the data, timely know the condition of the power system, and saves time for the power grid fault self-healing.

Owner:STATE GRID OF CHINA TECH COLLEGE +1

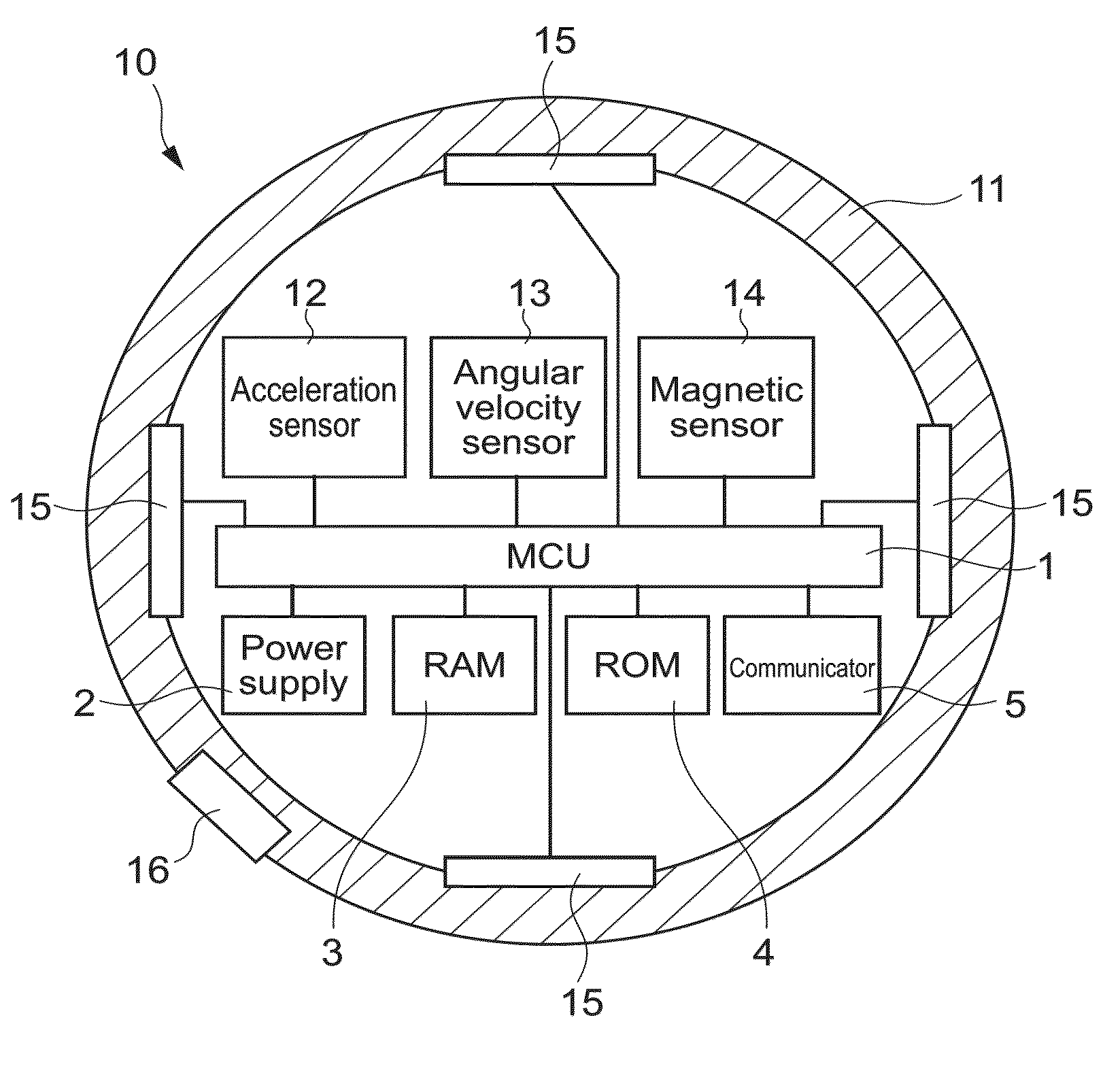

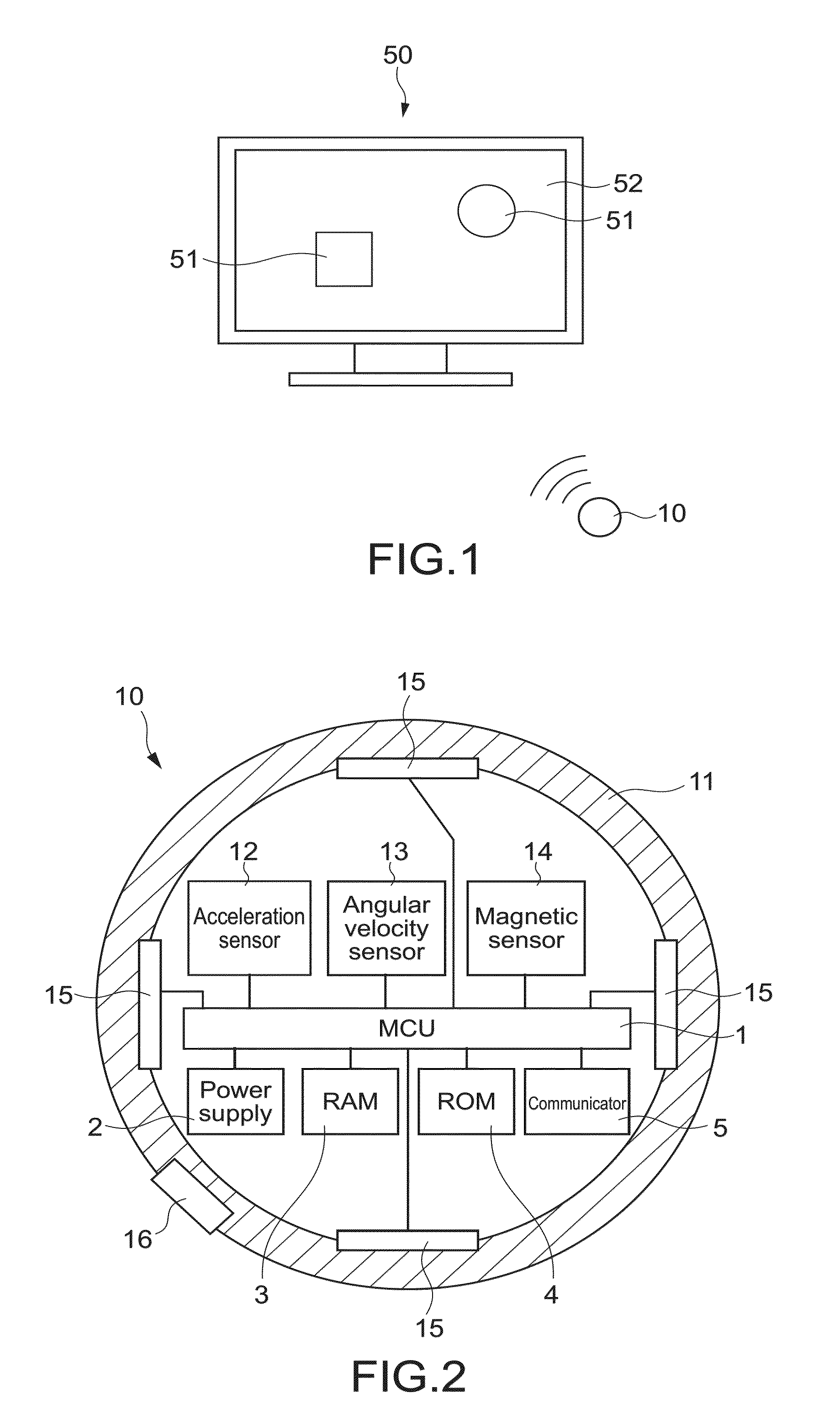

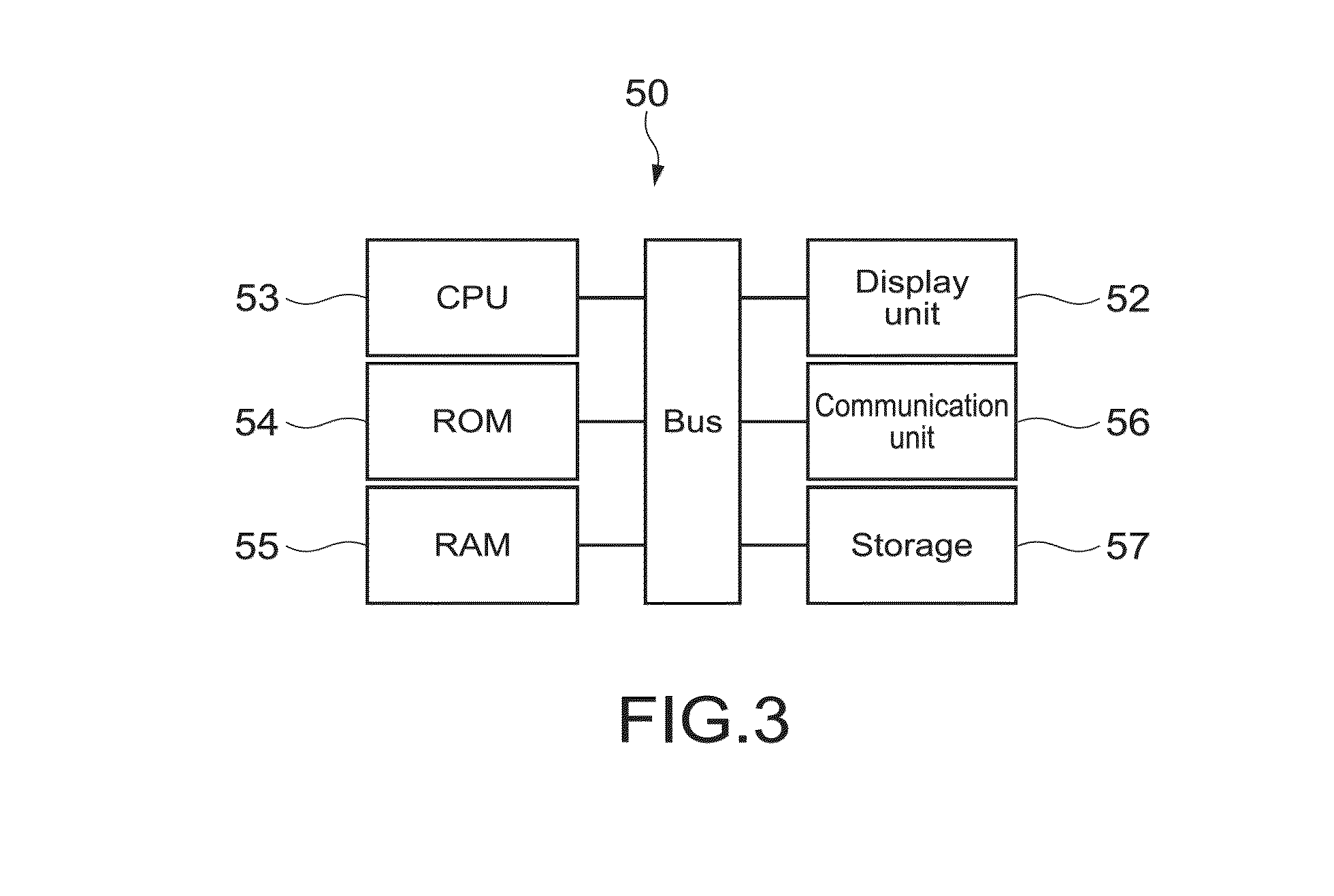

Information processing apparatus, information processing system, and information processing method

ActiveUS20120179408A1Move preciselyImprove accuracyTesting/calibration apparatusSpeed measurement using gyroscopic effectsInformation processingStart time

An information processing apparatus includes: an operation unit configured to calculate, based on information on an acceleration detected by an acceleration sensor included in an operation device that is operated by a user, movement information as information on one of a velocity and a movement distance of the operation device; and a correction unit configured to correct, based on information obtained by the acceleration sensor within an acceleration period as a period between an acceleration start time and an acceleration end time of the operation device, the movement information of the operation device within a period between the acceleration end time of the operation device and a movement end time at which the movement ends, that is calculated by the operation unit.

Owner:SONY CORP

Method for preparing zeolite molecular sieve by using oil shale residues

ActiveCN101723397AAvoid bulk accumulationReduce occupancySolid waste disposalCrystalline aluminosilicate zeolitesMolecular sieveEconomic benefits

The invention discloses a method for preparing a zeolite molecular sieve by using oil shale residues. The method comprises the following steps: separating SiO2 in the oil shale residues to be solid phase by adopting acid dipping, changing Al2O3 into aluminum salt to be dissolved in a liquid phase, adding alkali into the solution to make the solid phase and the liquid phase generate water glass and sodium metaaluminate solution respectively, and finally dehydrating silicon-aluminum gel formed by mixing the water glass and the sodium metaaluminate solution to form transition metacolloid so as to form stable authigenic mineral, namely the zeolite molecular sieve. The method can make full use of the oil shale residues so as to increase the utilization rate, increase the economic benefit, avoid mass accumulation of the residues at the same time of changing waste into valuable, reduce the occupation amount of the land and reduce the environment pollution. The method has the advantages of simple process, less investment and low cost, and is an industrialized method of fine chemical engineering and comprehensive utilization of the oil shale residues with good prospect.

Owner:FUSHUN MINING IND GROUP

Method for preparing cement clinker by using oil shale waste residues

The invention discloses a method for preparing cement clinker by using oil shale waste residues. The method comprises the following steps of: 1, mixing the following components according to the following proportions: 81 to 84 percent of limestone, 12 to 15 percent of shale waste residues, 1 to 2 percent of iron tailings sand and 2 to 4 percent of moulding sand; and 2, grinding the mixture obtained in the step 1 to obtain raw materials which is screened by a 80um square-hole sieve of which the screen residue is less than 5 percent, calcining the raw materials at temperature of between 1,350 and 1,450 DEG C for 15 to 20 minutes, and cooling to obtain the cement clinker. The method is used for preparing the cement clinker by using the oil shale waste residues replacing clay, so that a large quantity of clay resources are saved, and the production cost of the cement is reduced; furthermore, the doped quantity of the oil shale waste residues is large and up to 13 percent, so that the oil shale waste residues are used fully; therefore, the economic benefit is increased, wastes are turned into treasures, a large quantity of stacked residues are avoided, the land occupied amount is reduced, and the environment pollution is reduced.

Owner:FUSHUN MINING IND GROUP

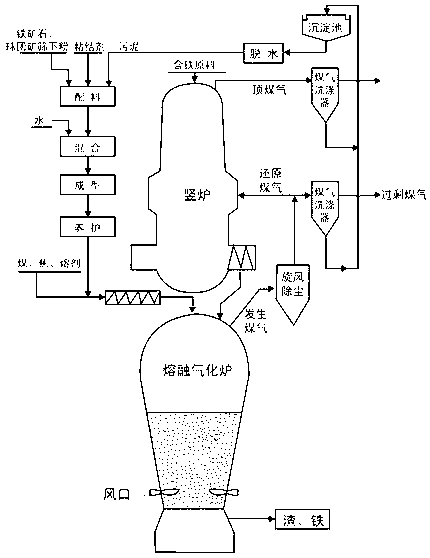

Method for recovering sludge from smelting ironmaking

ActiveCN102925675AAchieve recyclingReduce pollutionProcess efficiency improvementIronstoneMixed materials

The invention relates to a method for recovering and utilizing dewatered sludge from smelting reduction ironmaking process. A method for recovering sludge from smelting ironmaking comprises the following steps: firstly, dewatering ironmaking sludge to obtain a water content of 10-25%; secondly, mixing the sludge, a binder, minus sieve powder of iron ore or pellet ore, or a mixture of the two types of minus sieve powder according to the following weight percents, that is, 30-55% of the sludge, 10-15% of the binder, and 30-60% of the minus sieve powder of iron ore or pellet ore, or a mixture of the two types of minus sieve powder; during mixing, additionally adding 1-15% of water to maintain the water content of the mixed materials to be 10-18%; thirdly, pressing and molding the well mixed materials by a press; fourthly, curing the mixed materials after molding; fifthly, briquetting the cured mixed materials, feeding the briquetted mixed materials with coal, coke, and flux into a smelting gasifier through a screw feeder. The invention realizes the recovery and utilization of sludge from smelting ironmaking, reduces molten iron cost, and reduces environment pollution.

Owner:XINJIANG BAYI IRON & STEEL

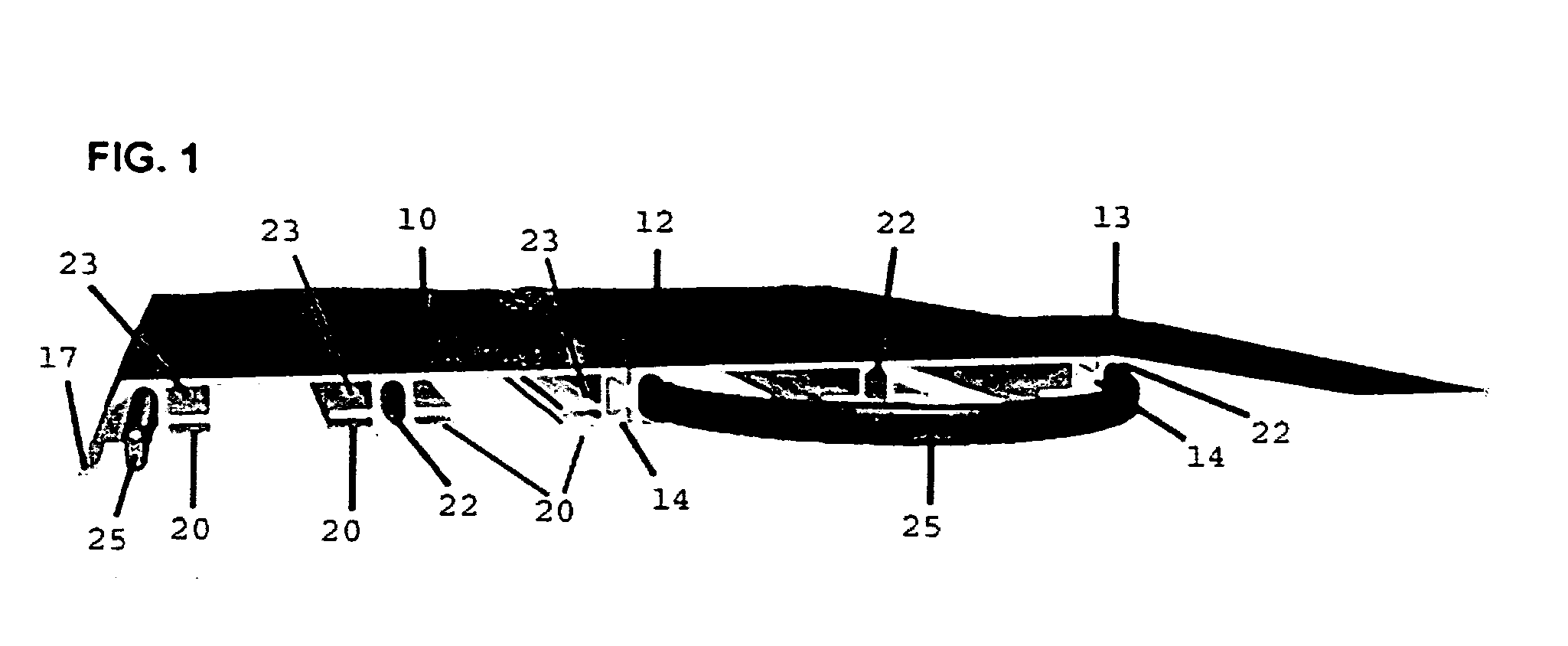

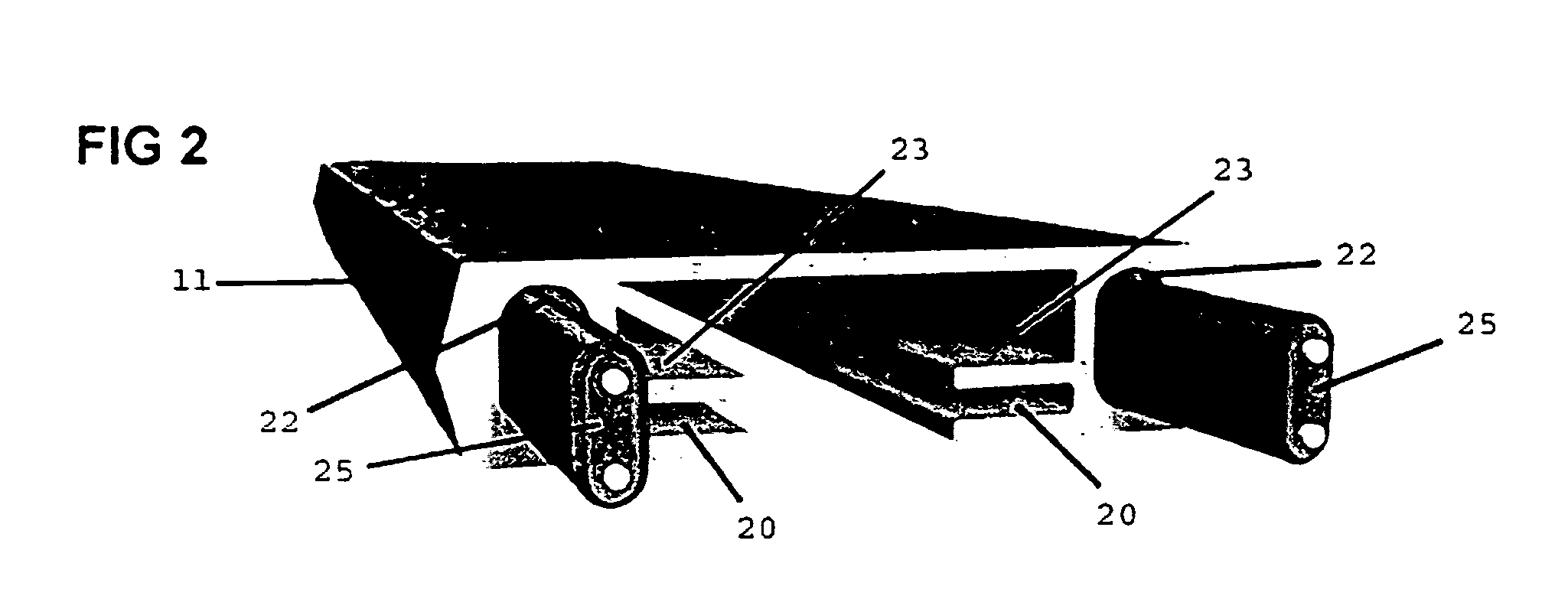

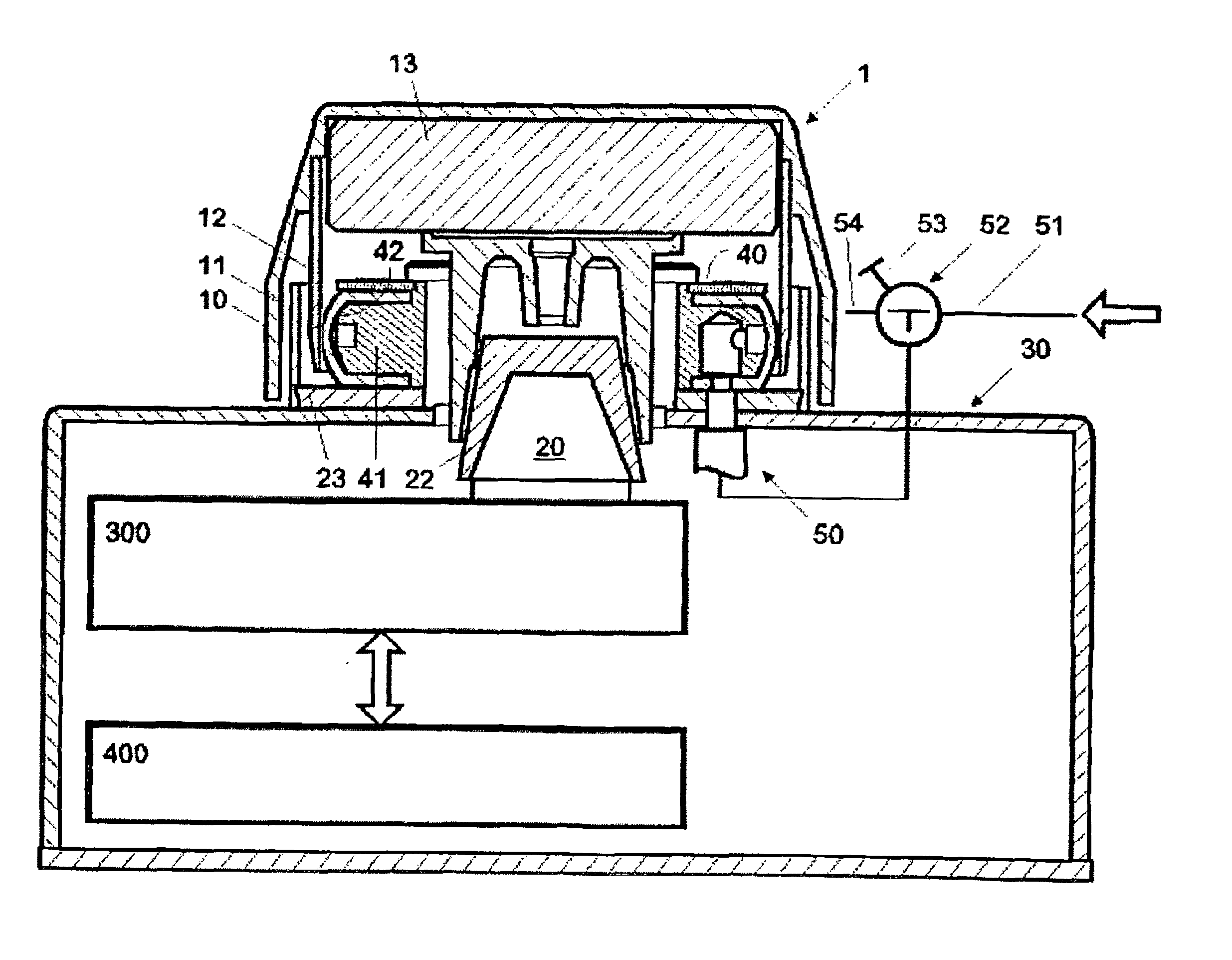

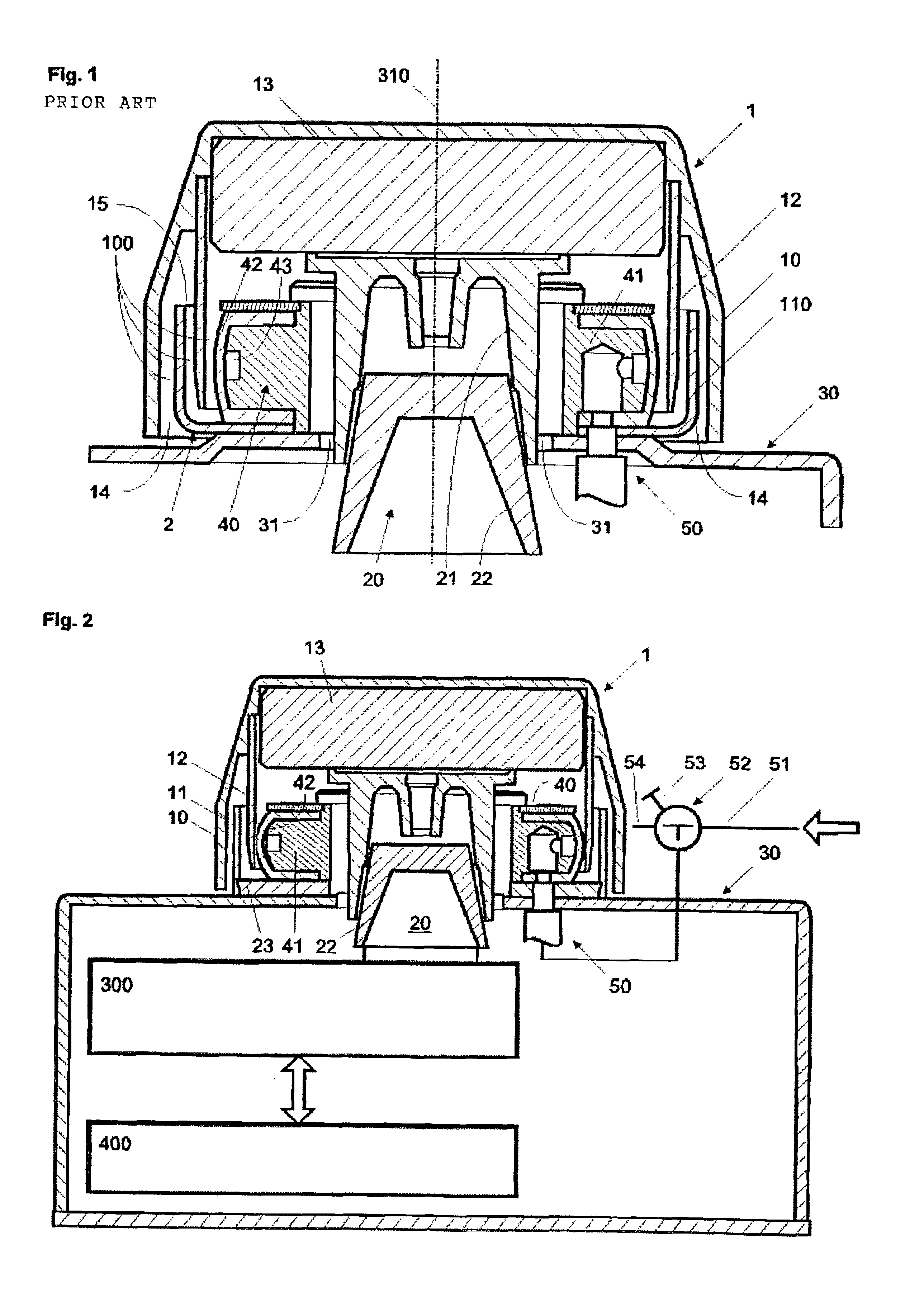

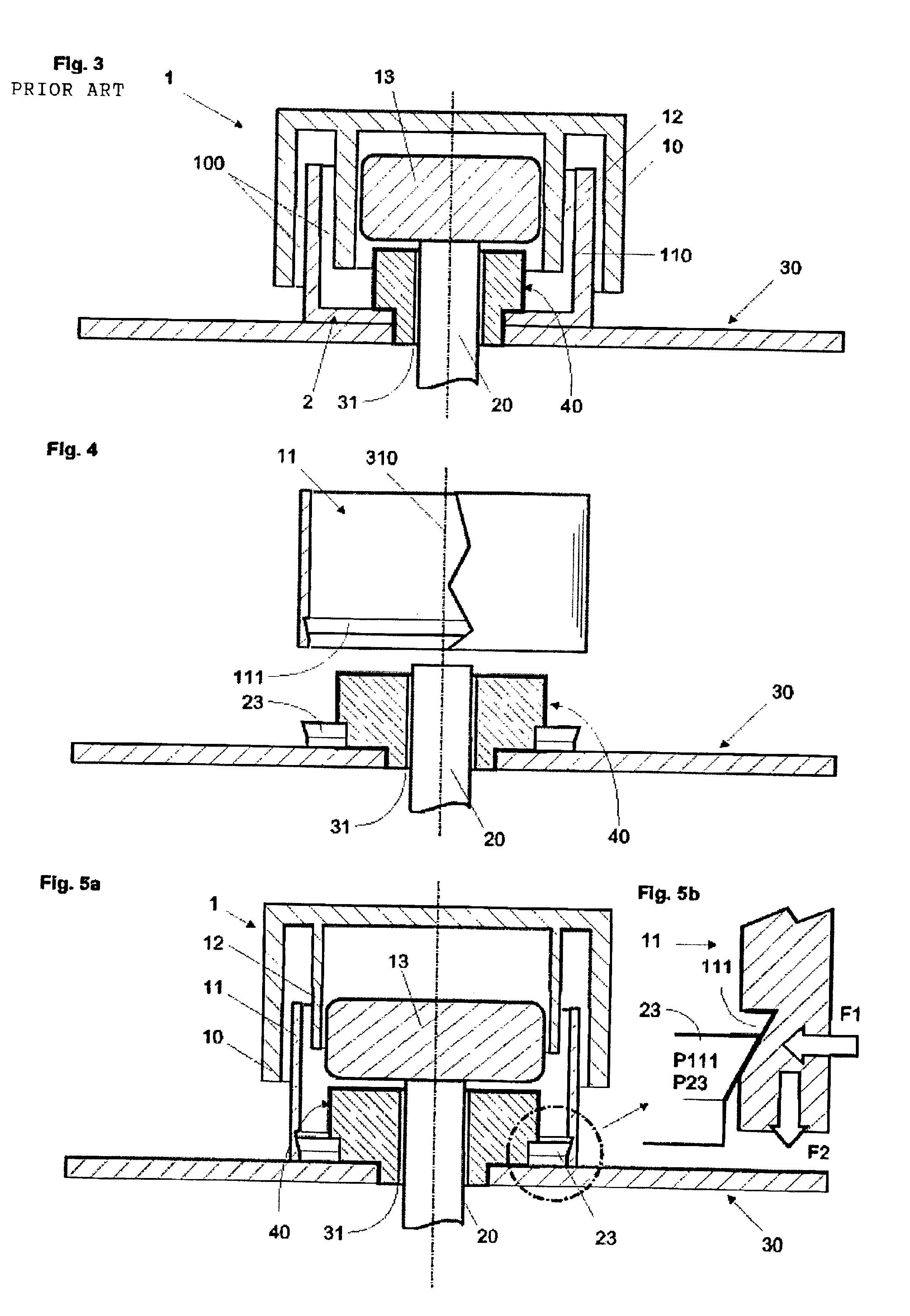

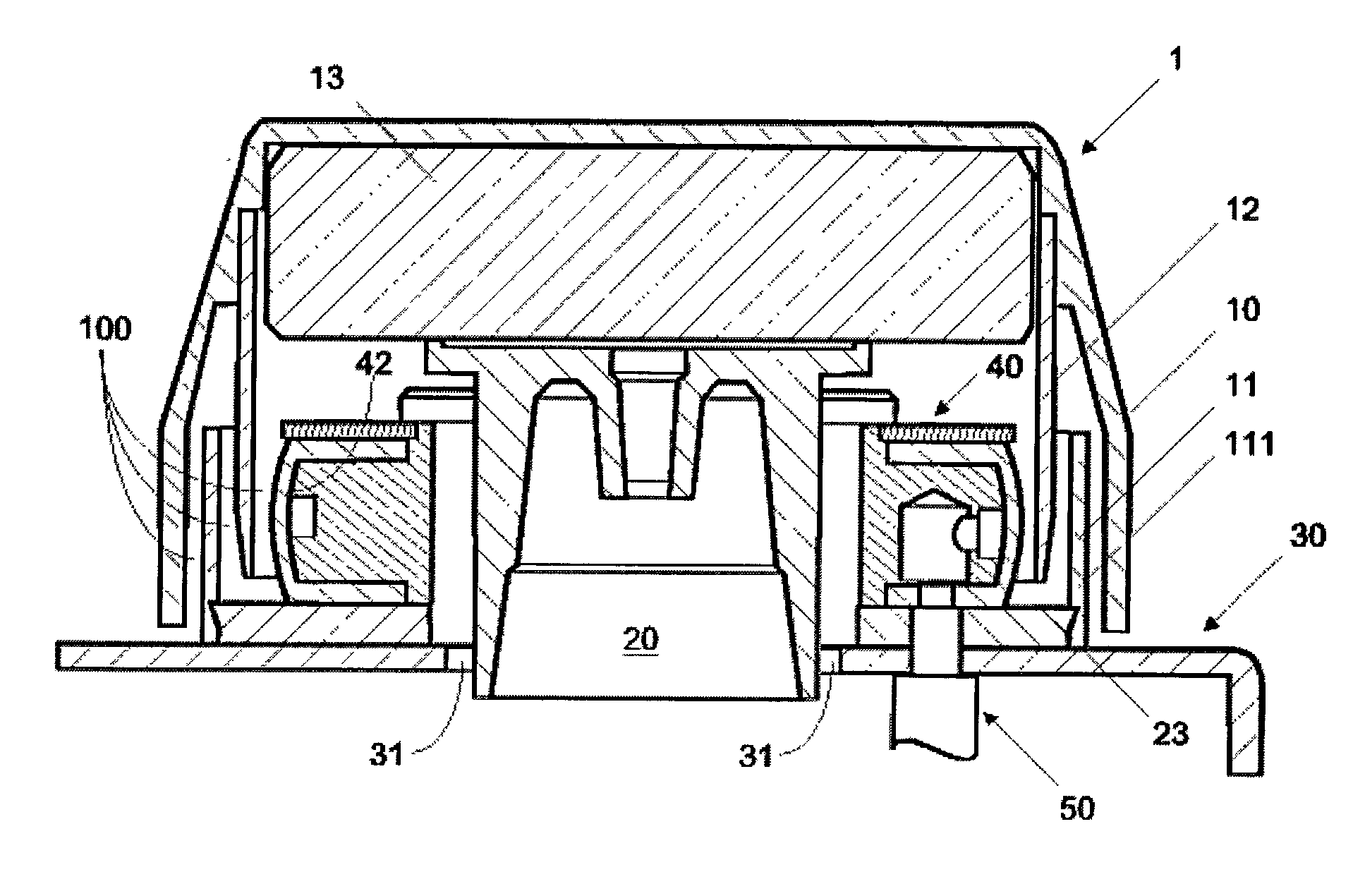

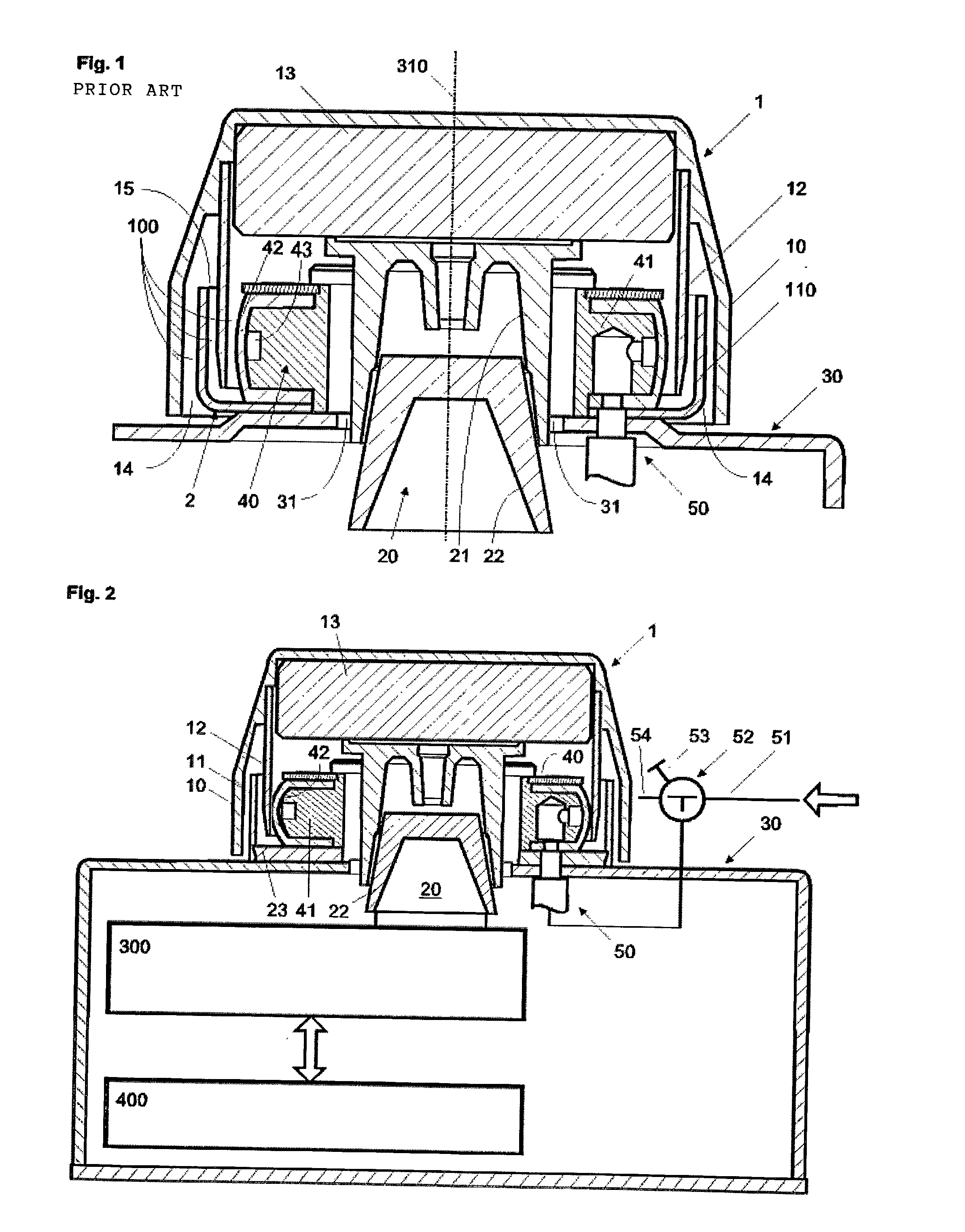

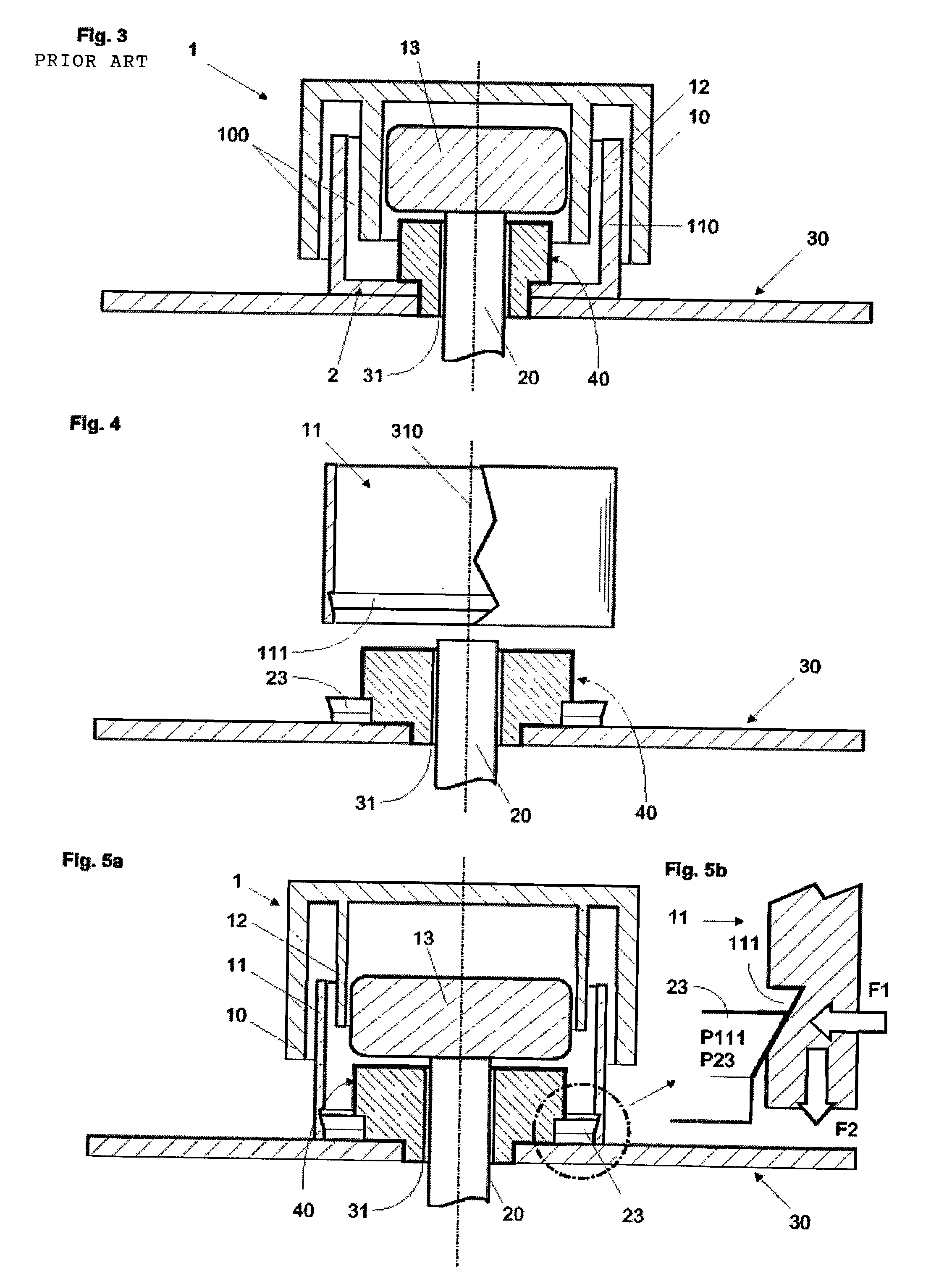

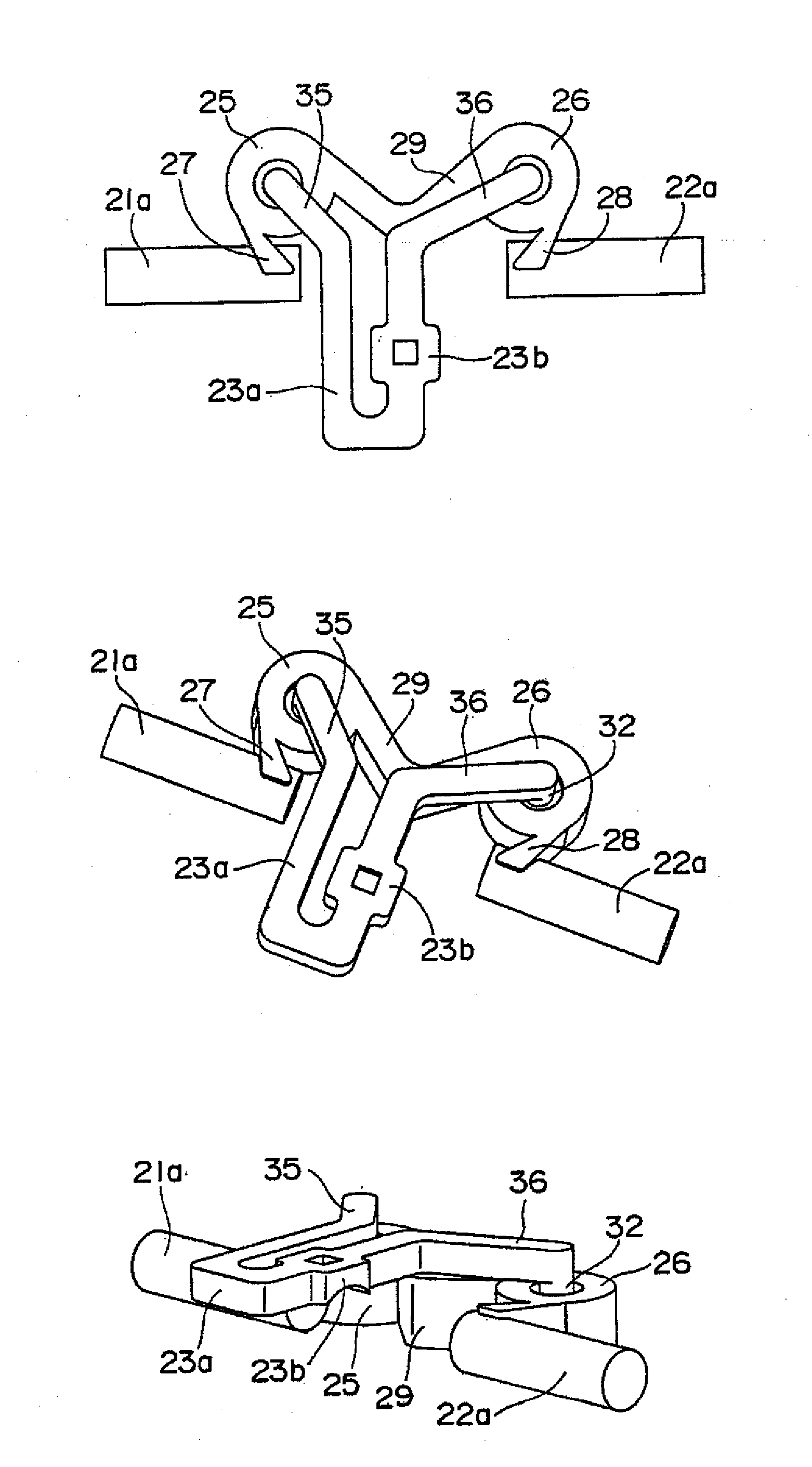

Baffle seal with removable ring element, and balance equipped with the baffle seal

InactiveUS6923449B2Thorough and fast cleaningAvoid bulk accumulationEngine sealsClosuresEngineeringFastener

Owner:METTLER TOLEDO GMBH

Baffle seal with removable ring element, and balance equipped with the baffle seal

InactiveUS20030067119A1Facilitate quick and thorough cleaningImprove sealingEngine sealsWeighing apparatus detailsFastenerRing element

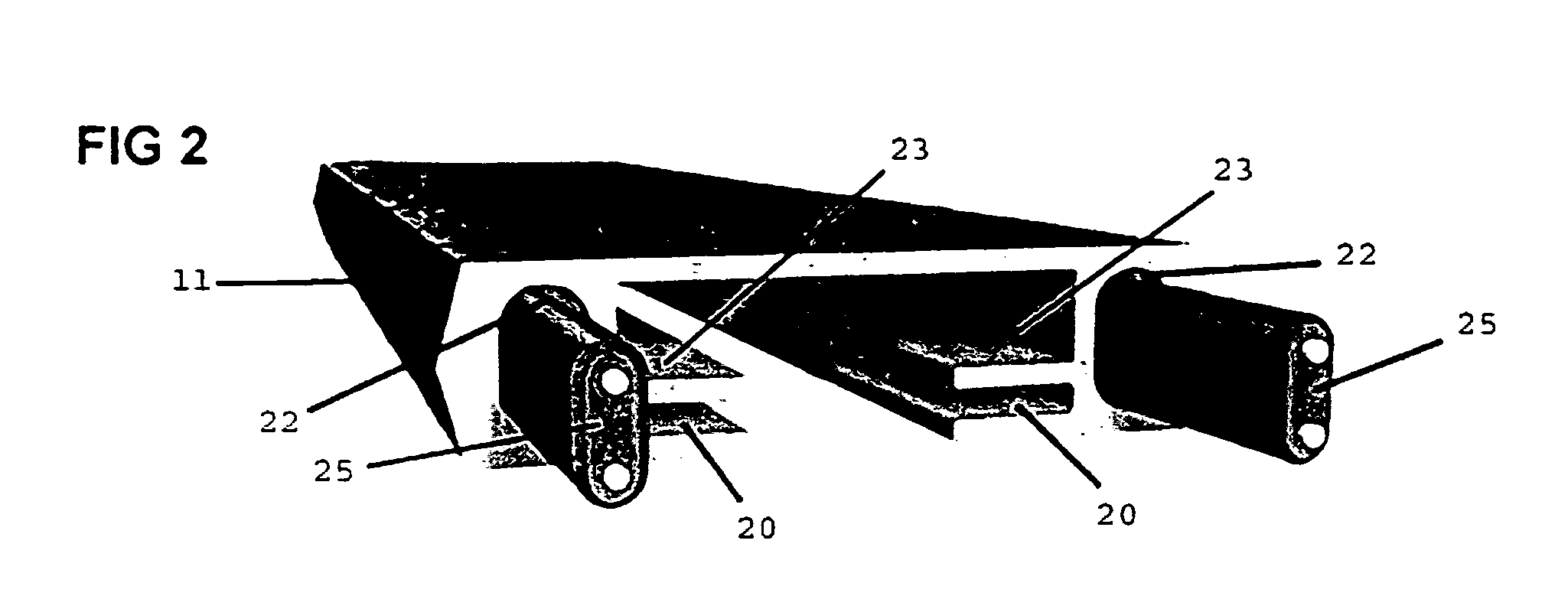

A baffle seal at the opening (31) for the load-transmitting member (20) in a balance housing (30) has at least one sleeve-shaped ring element (11, 110), fastener means (23) attached to the housing (30) and serving to hold the sleeve-shaped ring element in a stationary working position surrounding the opening, and a cover cap (1) with at least one sleeve-shaped ring (10, 10', 12) that is axially movable relative to the sleeve-shaped ring element. The ring element is releasable so that it can be separated from the balance without dismantling other parts.

Owner:METTLER TOLEDO GMBH

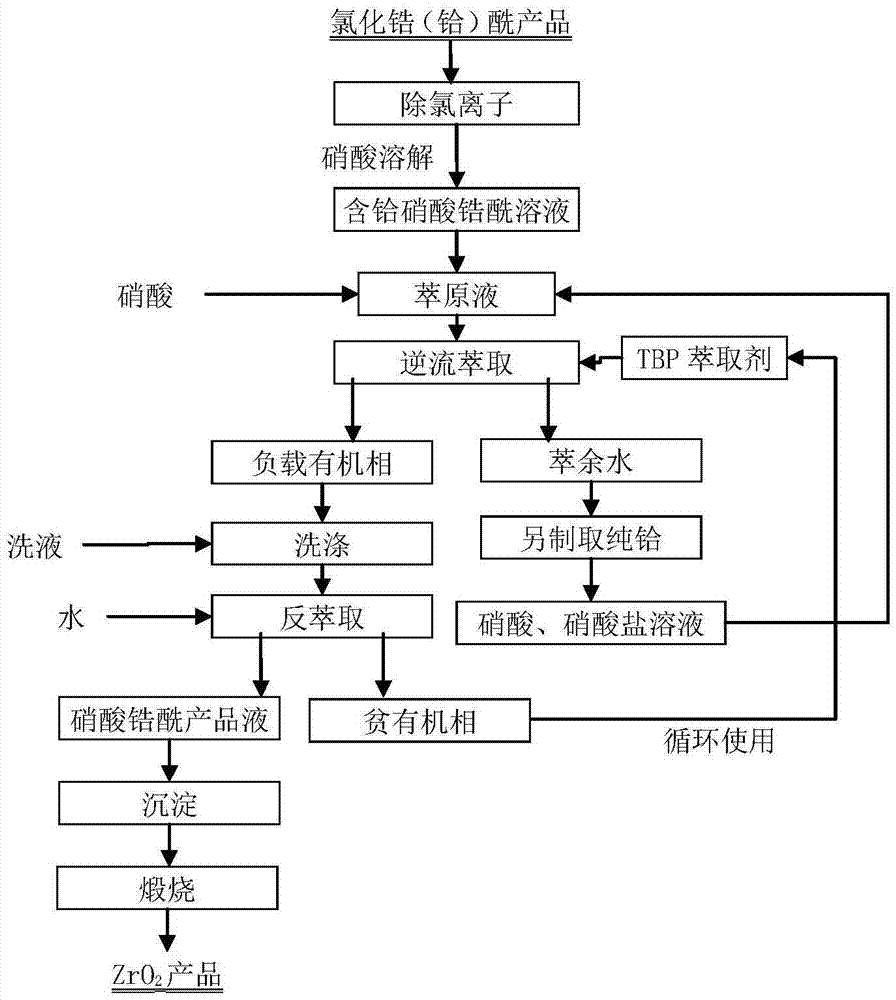

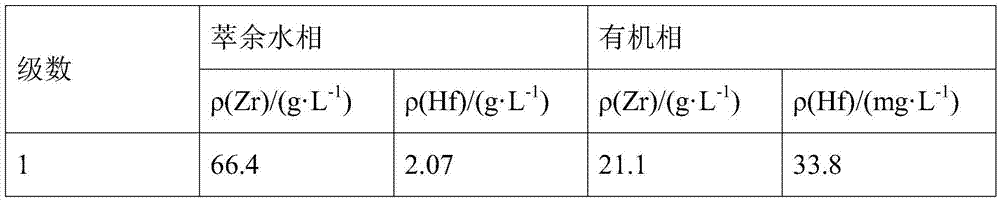

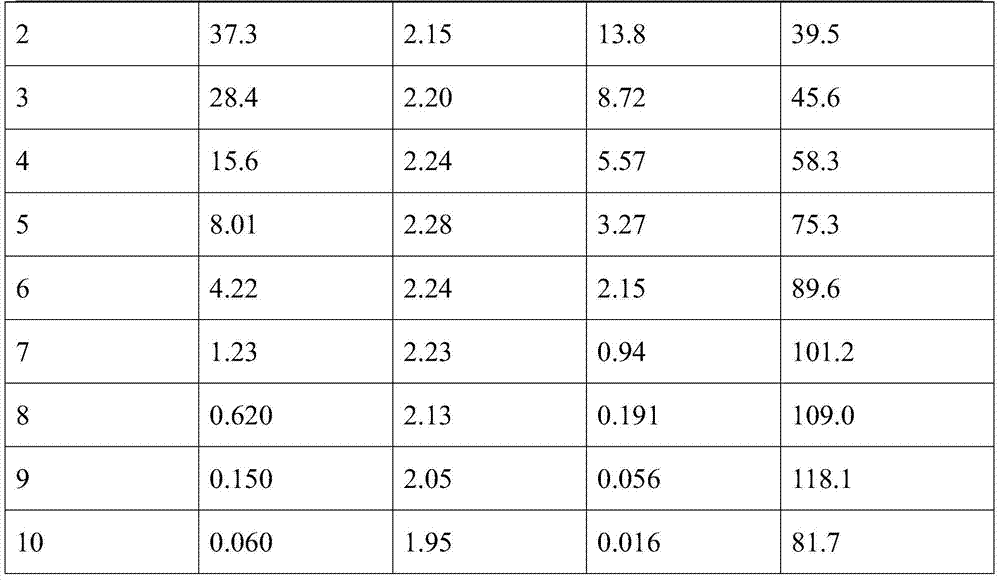

Process for separating zirconium and hafnium by solvent extracting method

ActiveCN106929695AFulfil requirementsImprove product qualityProcess efficiency improvementZirconium oxidesKeroseneHydrometallurgy

The invention belongs to the field of wet metallurgy and the technical field of zirconium and hafnium separation, and in particular, relates to a process for separating zirconium and hafnium by a solvent extracting method. Industrial products containing hafnium zirconium chloride acetyl are used as raw materials for such procedures as water solution, alkali sinking, washing and nitric acid dissolving to prepare zirconium (hafnium) nitrate acetyl solution; TBP kerosene solution of adding phase modifying agent octanol is used as an extracting agent; most zirconium and less hafnium are extracted into an organic phase through multistage counter-current extraction by using the characteristic of TBP priority extraction of zirconium; the loaded organic phase is washed by nitric acid solution with a certain concentration to further remove most hafnium in the organic phase; the acid-washed loaded organic phase is reversely extracted by water to obtain zirconium nitrate acetyl solution; the solution is precipitated in ammonia, dried and calcined to obtain zirconium dioxide powder, and the mass of the zirconium dioxide powder accords with the atomic energy-level zirconium dioxide standard; less zirconium and most hafnium only remained in residual water phase of zirconium after reverse extraction are extracted; the content of zirconium in hafnium meets the requirements on impurity zirconium by atomic energy-level hafnium; and atomic energy-level hafnium can be directly prepared by enrichment.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Process and apparatus for feeding cementitious slurry for fiber-reinforced structural cement panels

ActiveUS7754052B2Prevent buildupImprove liquidityNon-fibrous pulp additionNatural cellulose pulp/paperGlass fiberCement board

Owner:UNITED STATES GYPSUM CO

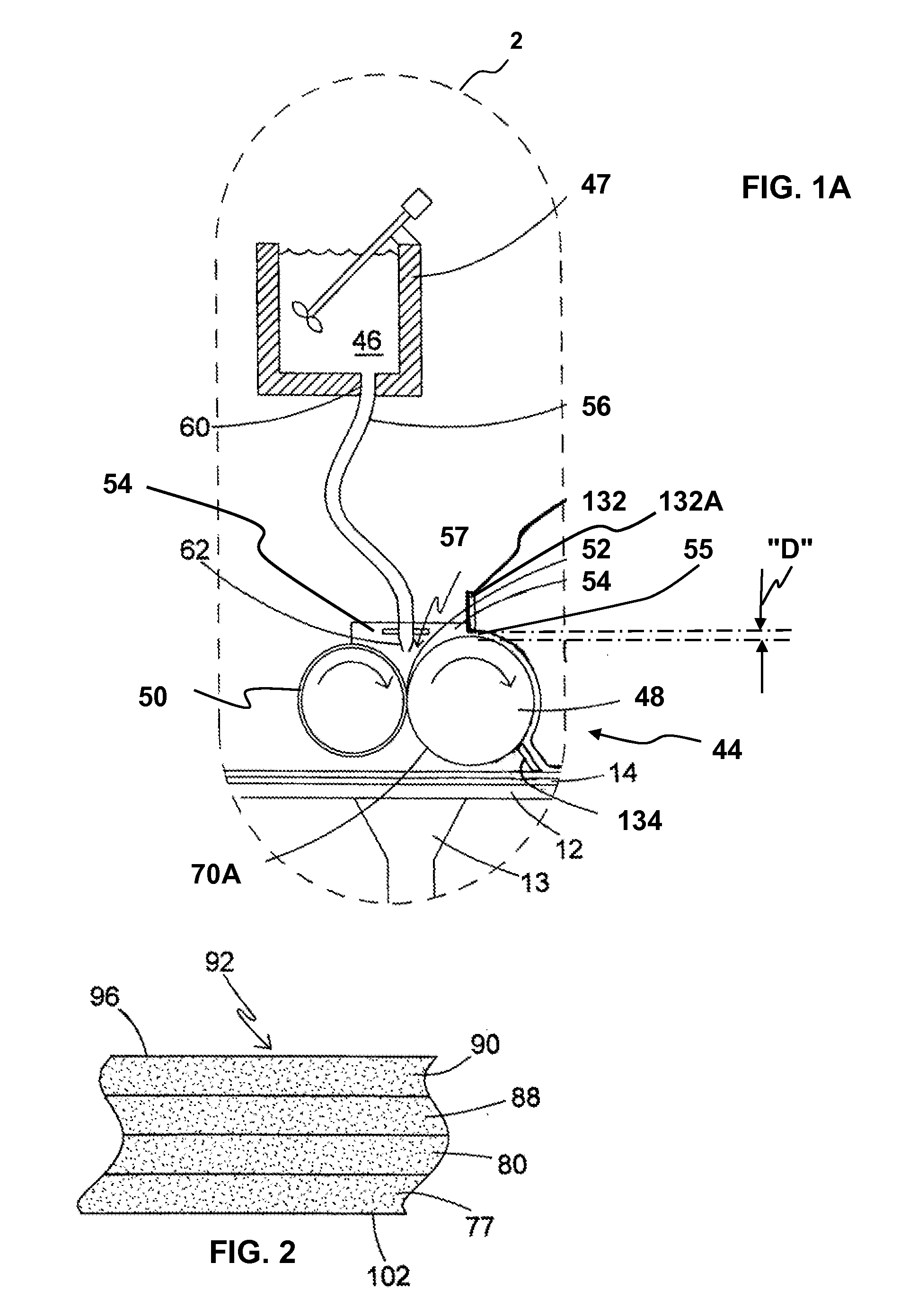

Method, apparatus, and processes for producing potable water utilizing reverse osmosis at ocean depth in combination with shipboard moisture dehumidification

InactiveUS20110132842A1Reduce salt contentReduce riskGeneral water supply conservationAuxillariesSaline waterWater source

Devices and methods for producing purified water. The device includes a reverse osmosis subsystem, a dehumidification subsystem and a purified water storage tank fluidly coupled to the subsystems such that purified water produced by each can be locally stored. A vehicular platform, such as a ship, can be used to locate the device adjacent a supply of saline water and humid air. A saline water inlet, membrane and purified water outlet cooperate in the reverse osmosis subsystem to allow preferential passage of water relative to salt in a saline water supply, while the dehumidification subsystem includes a heat exchanger that extracts moisture from the ambient humid air. Purified water produced by each of the subsystems can be used as a potable water source. When used in conjunction with a ship, part or all of the reverse osmosis subsystem can be submersed to a depth sufficient to generate a hydrostatic pressure that is in turn sufficient to passively operate the reverse osmosis membrane such that additional pressurizing equipment, such as a pump, is not needed. Furthermore, the temperature of the water purified by the reverse osmosis subsystem may be low enough to be used as a condensing agent for the ambient humid air passing through the dehumidification subsystem.

Owner:SALYER IVAL O

Roof ice and snow melt system

ActiveUS8607509B2Eliminates buildup formationEliminate the problemRoof covering using slabs/sheetsRoof covering using tiles/slatesSnow meltingEngineering

Owner:ENGINEERED ROOF DE ICING

Method for producing heat storage brick by magnesite tailing

The invention discloses a method for producing a heat storage brick by the magnesite tailing, which improves the heat storage capability and the thermal shock stability of the heat storage brick. The method for producing the heat storage brick by the magnesite tailing comprises the following steps of: mixing 55-65wt% of magnesite tailing and 35-45wt% of iron powdered ore; carrying out ball milling to mixed materials in a ball mill; adding 5wt% of water into the ball-milling material in a mixing mill for mixing to obtain aggregate; breaking and screening the prepared aggregate; adding 5wt% of sulphurous acid paper pulp waste liquor as binder; then adding 1-1.5wt% of steel fiber to evenly mix; and mixing by the mixing mill; and pressing the mixed material into the heat storage brick under the pressure of 1000-1200KN. The method disclosed by the invention is characterized in that the magnesite tailing which is the waste after the magnesite tailing is adopted for mineral separation serves as raw material, the magnesite resource is effectively utilized, the phenomenon that a great quantity of magnesite tailing is accumulated is avoided, and the environment is improved. Meanwhile, the mafic heat storage material produced by the magnesite tailing has strong heat storage capability, the compression strength can reach 50-60MP, and the bulk density reaches 2.5-4g / cm<3>.

Owner:UNIV OF SCI & TECH LIAONING

Method for preparation of faujasite from oil shale residue

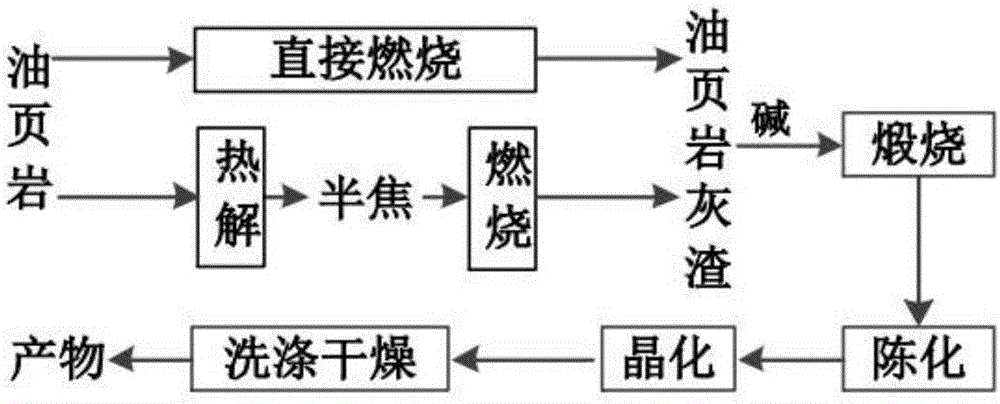

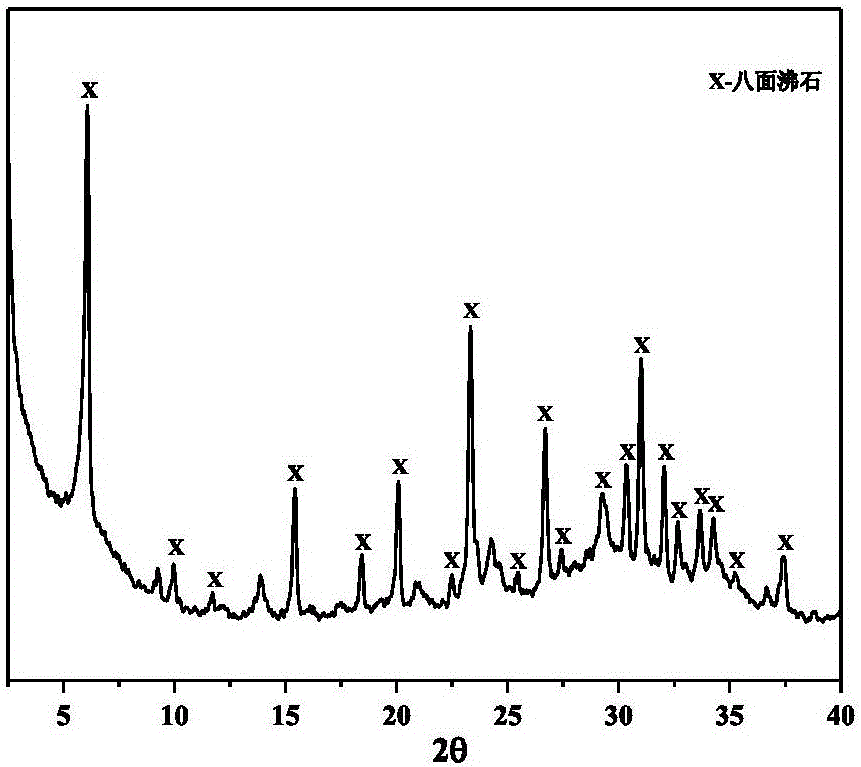

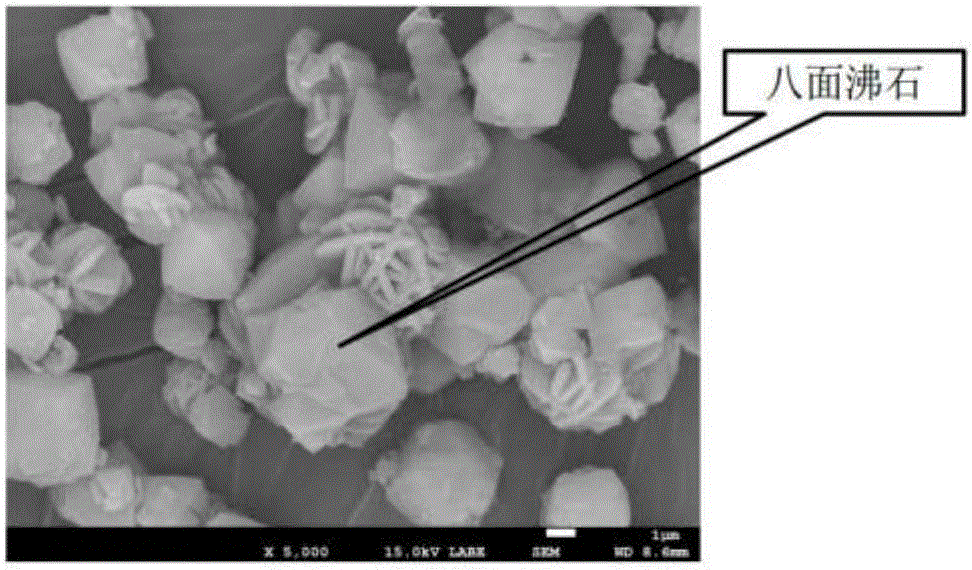

InactiveCN106241829ASimple processLow costFaujasite aluminosilicate zeoliteResource utilizationFixed bed

The invention relates to a method for preparation of faujasite from oil shale residue. The method comprises the steps of: subjecting the semi-coke generated by pyrolysis of oil shale at 300-700DEG C to combustion in an industrial boiler like circulating fluidized bed and the like or directly subjecting oil shale to combustion in an industrial boiler like a fixed bed or circulating fluidized bed and the like, and taking the generated oil shale residue as the raw material, taking oil shale residue below 200 meshes, fully grinding and mixing the oil shale residue with alkali in a mass ratio of 1: 0.8-1:1.5 evenly, then calcining the mixture at 550-700DEG C for 0.5-2h, letting the calcined object cool naturally to room temperature, then performing grinding, adding distilled water according to a liquid-solid ratio of 3:1-7:1 (ml / g), fully stirring the substances at room temperature for 3-24h, conducting sealing and carrying out crystallization at 60-110DEG C for 6-48h, washing the crystallization product with distilled water until the pH value of the washing liquid reaches 7-8, and performing drying so as to obtain a faujasite product. The method for synthesis of faujasite has the advantages of simple process, low cost and good repeatability, and the prepared faujasite has perfect crystal form and good crystallinity, thus providing a new way for high grade resource utilization of oil shale residue.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

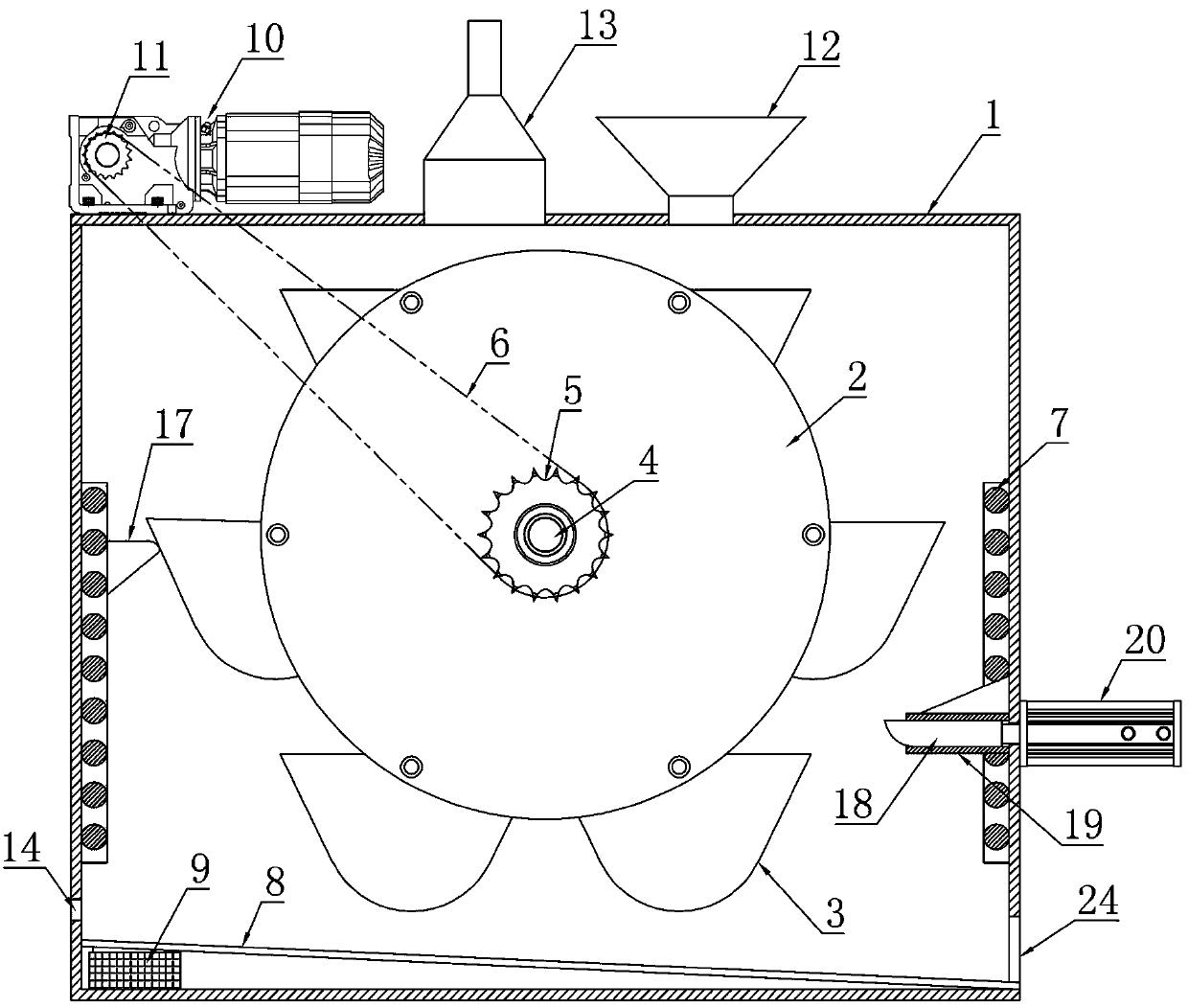

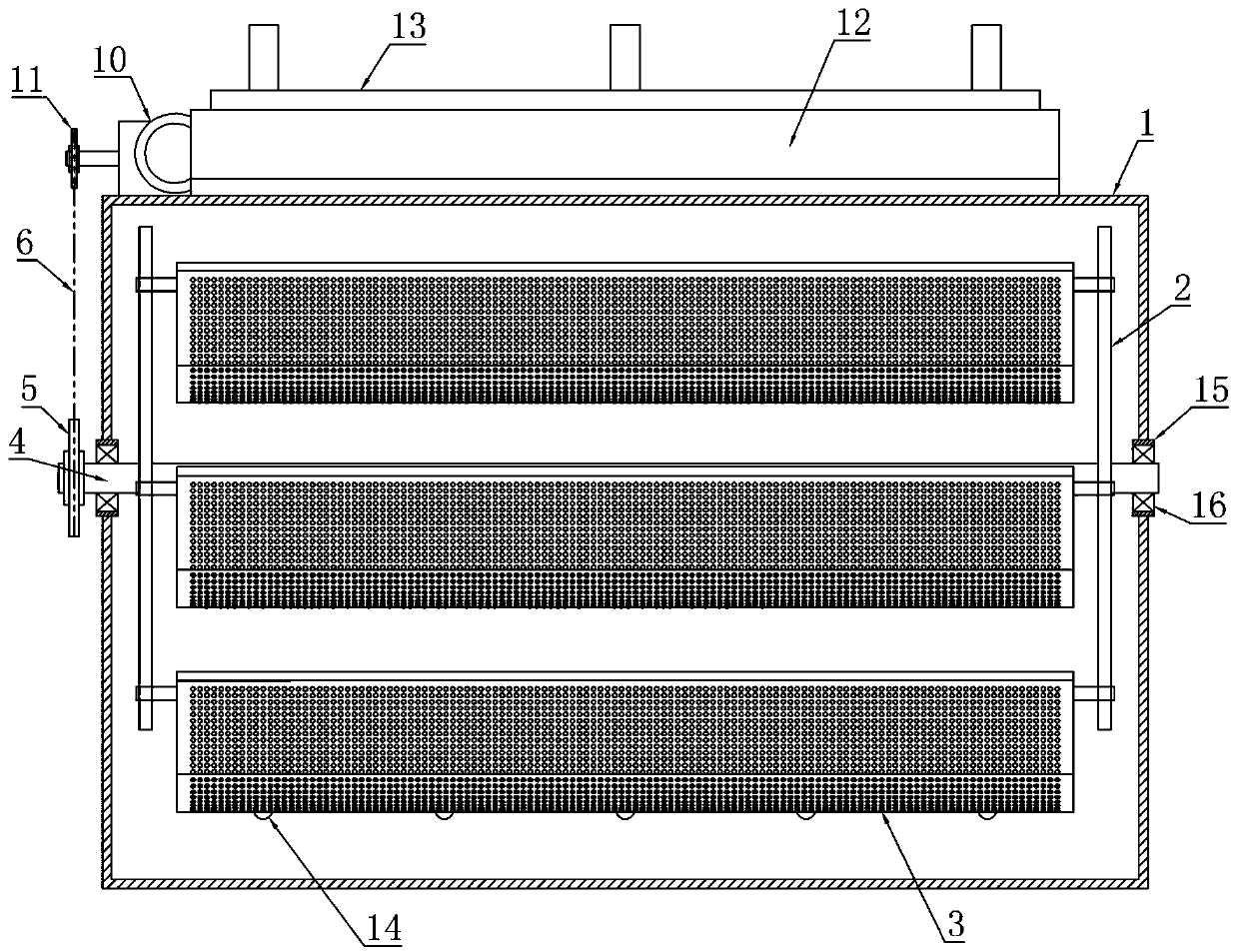

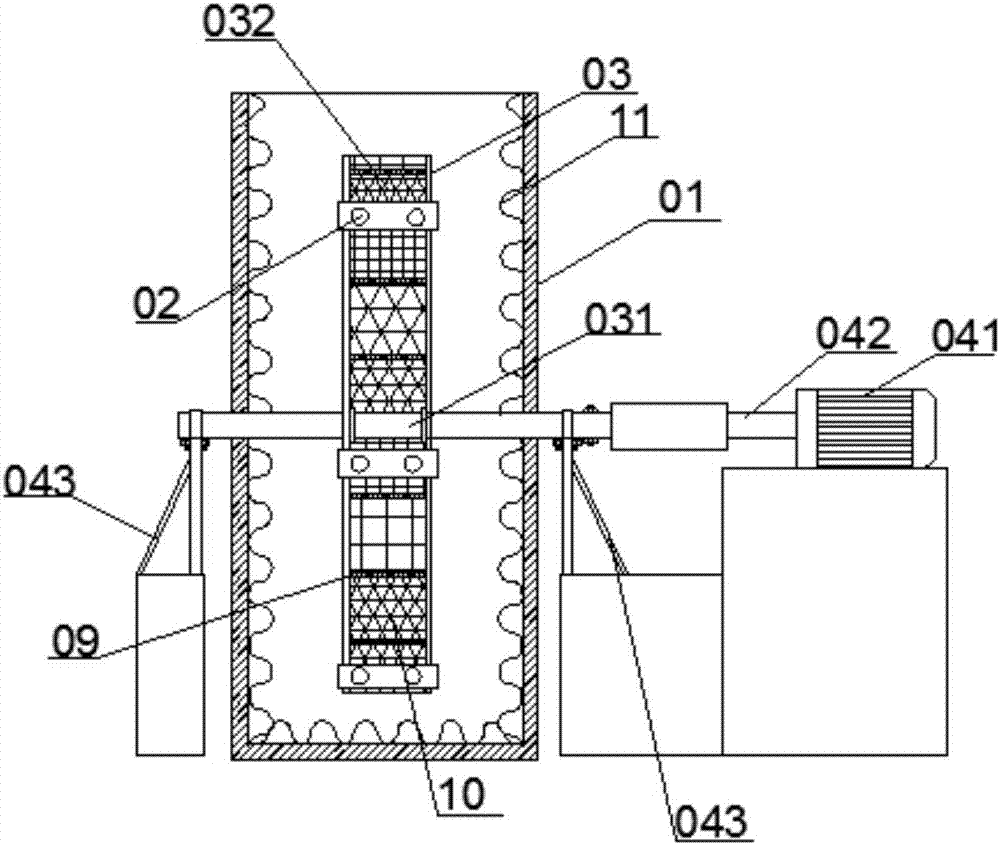

Vegetable dehydrating and drying device

ActiveCN110574949AAvoid colliding with each otherAvoid bulk accumulationFood dryingFruits/vegetable preservation by dehydrationEngineeringDehydration

The invention relates to a vegetable dehydrating and drying device. A rotating shaft is installed in a box, and one end of the rotating shaft penetrates out of the box to be connected with a rotationdriving mechanism; two rotary discs are fixedly installed on the rotating shaft; a plurality of hoppers used for containing materials are rotatably installed between the two rotary discs and evenly distributed along the circumferences of the rotary discs; the hopper is of a structure with an opening in the top and a screen-shaped bottom; the hoppers rotate along with the rotary discs, and ports are kept upward; a plurality of electric heating devices are installed in the box; and the box is provided with a feed inlet and a discharging port. A batch of materials can be contained in multiple hoppers to be dried, such that mutual collision of the materials can be avoided, the situation that a large number of materials are accumulated can also be avoided, and the ventilation effect is improved. The dehydration and drying efficiency of materials can be improved, and the materials can be prevented from continuously rolling and stirring, so that the generation of chippings can be reduced. Dueto the fact that the hoppers rotate continuously, it can be guaranteed that the drying degrees of the materials are the same, and then the consistency of the quality of the materials is guaranteed.

Owner:HANDAN COLLEGE +1

Antifouling material and production method thereof

InactiveUS7955687B2Avoid depositionAvoid bulk accumulationLiquid surface applicatorsRecord information storageMetallurgyTitanium oxide

The subject of the invention is the use of a material composed of a substrate equipped with a coating based on titanium oxide surmounted by a thin hydrophilic layer forming at least one part of the outer surface of said material and that is not composed of titanium oxide, as a material that prevents the deposition of mineral soiling on said outer surface in the absence of water runoff.

Owner:SAINT-GOBAIN GLASS FRANCE

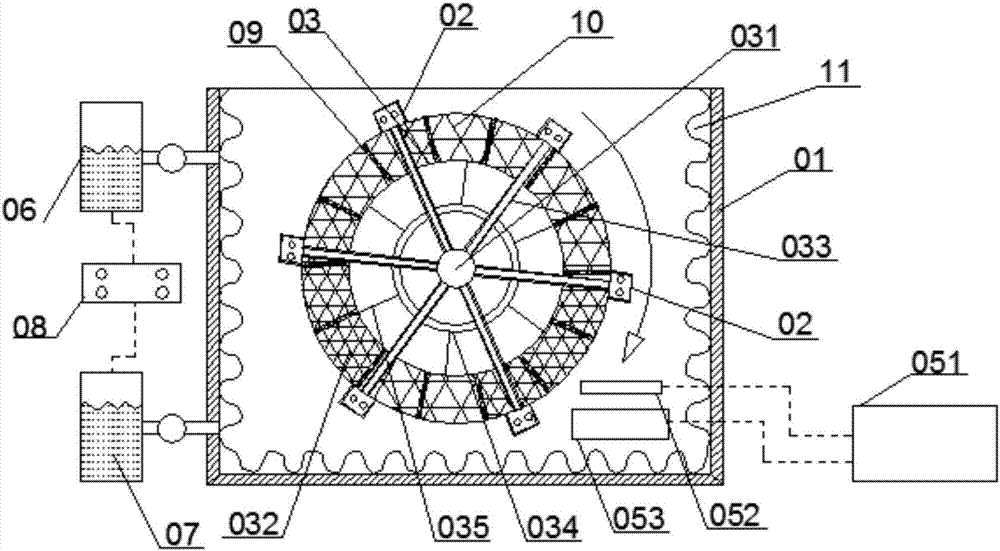

Ultrasonic medical apparatus cleaning device

InactiveCN107497777APlay the role of stirring and cleaningWide range of radiationLavatory sanitoryCleaning using liquidsEngineeringMechanical engineering

The invention provides an ultrasonic medical appliance cleaning device, which includes a cleaning and disinfection tank, an ultrasonic generator and a cleaning solution disposed in the cleaning and disinfection tank. A classification mechanism and a driving mechanism for driving the classification mechanism to rotate are arranged inside the cleaning and disinfection tank. The classification mechanism includes The central axis and a plurality of fan-shaped cleaning baskets arranged equidistantly around the central axis are used to classify and store different medical devices. A plurality of support columns are arranged along the radial extension of the central axis. The ends of the plurality of support columns are far away from the central axis All parts are equipped with ultrasonic generators, and multiple fan-shaped cleaning baskets are arranged in sequence and connected in a circular shape to be erected on the support column; when cleaning, the driving machine can drive the central shaft to rotate horizontally in the cleaning and disinfection tank. By implementing this technical solution, the problem in the prior art that the instruments to be cleaned close to the ultrasonic generator have a better cleaning effect than those far away from the ultrasonic generator can be avoided, and the medical instruments can be classified and cleaned to improve the cleaning efficiency and achieve more Good cleaning effect.

Owner:弘毅天承知识产权股份有限公司

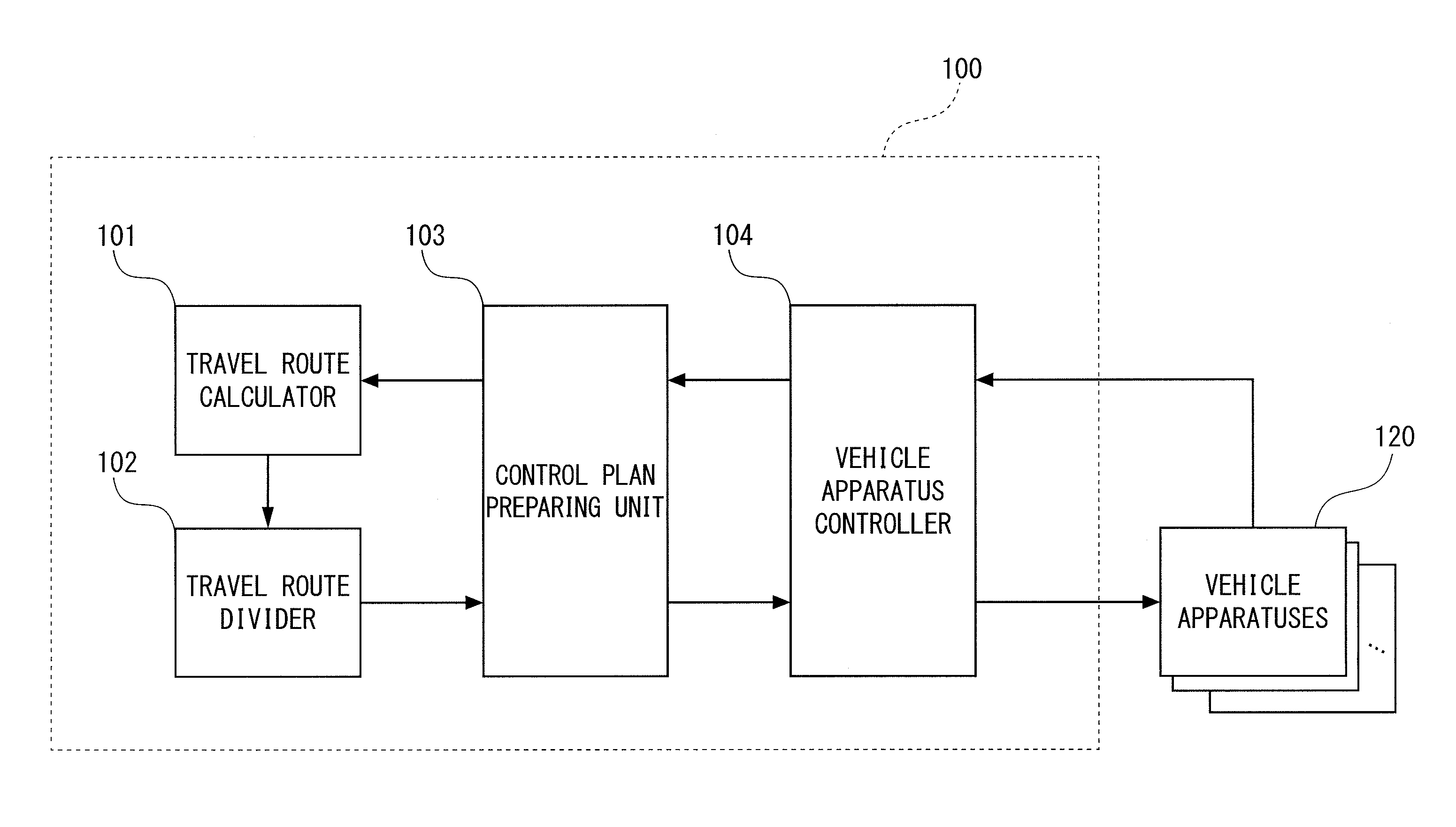

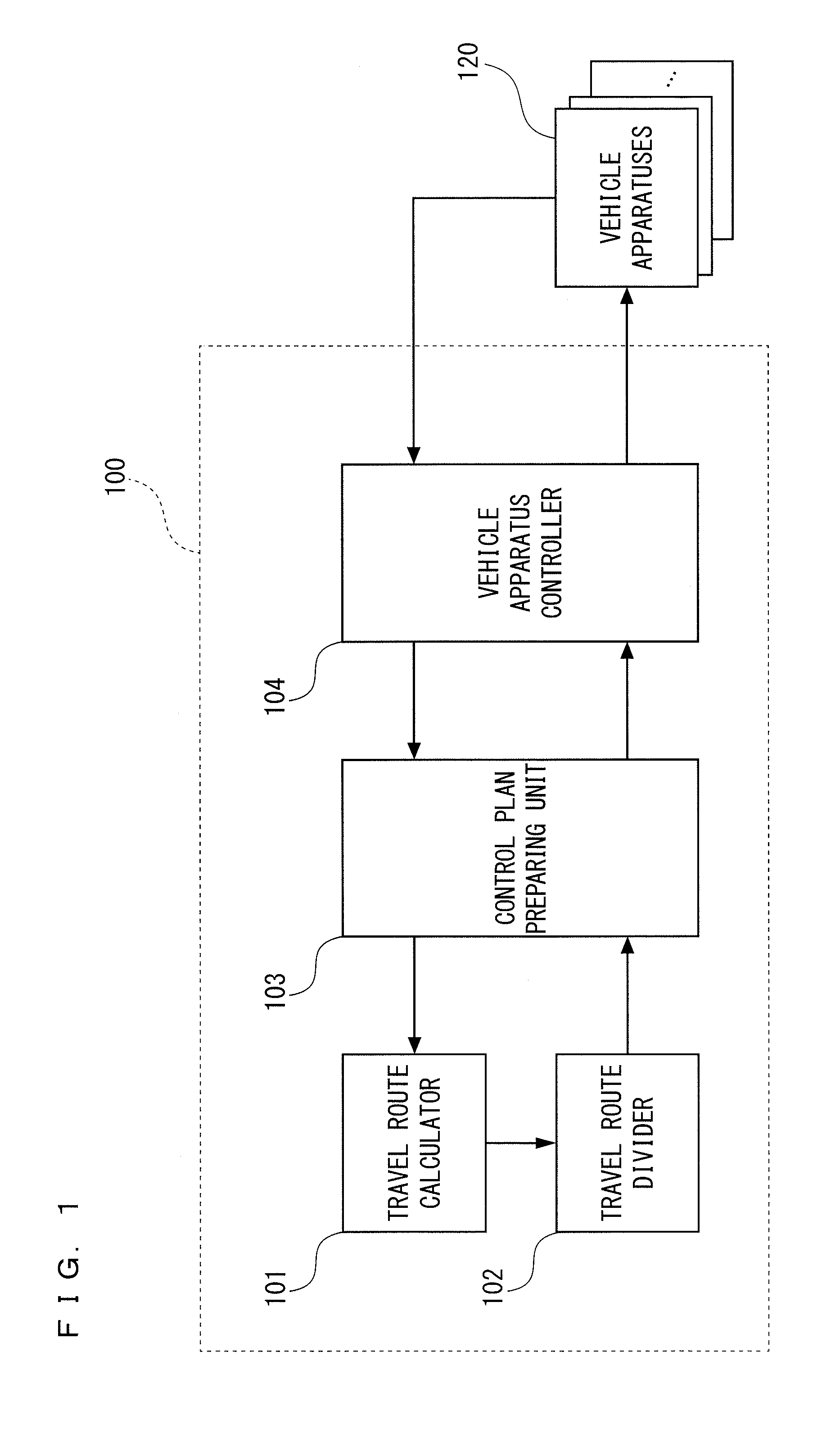

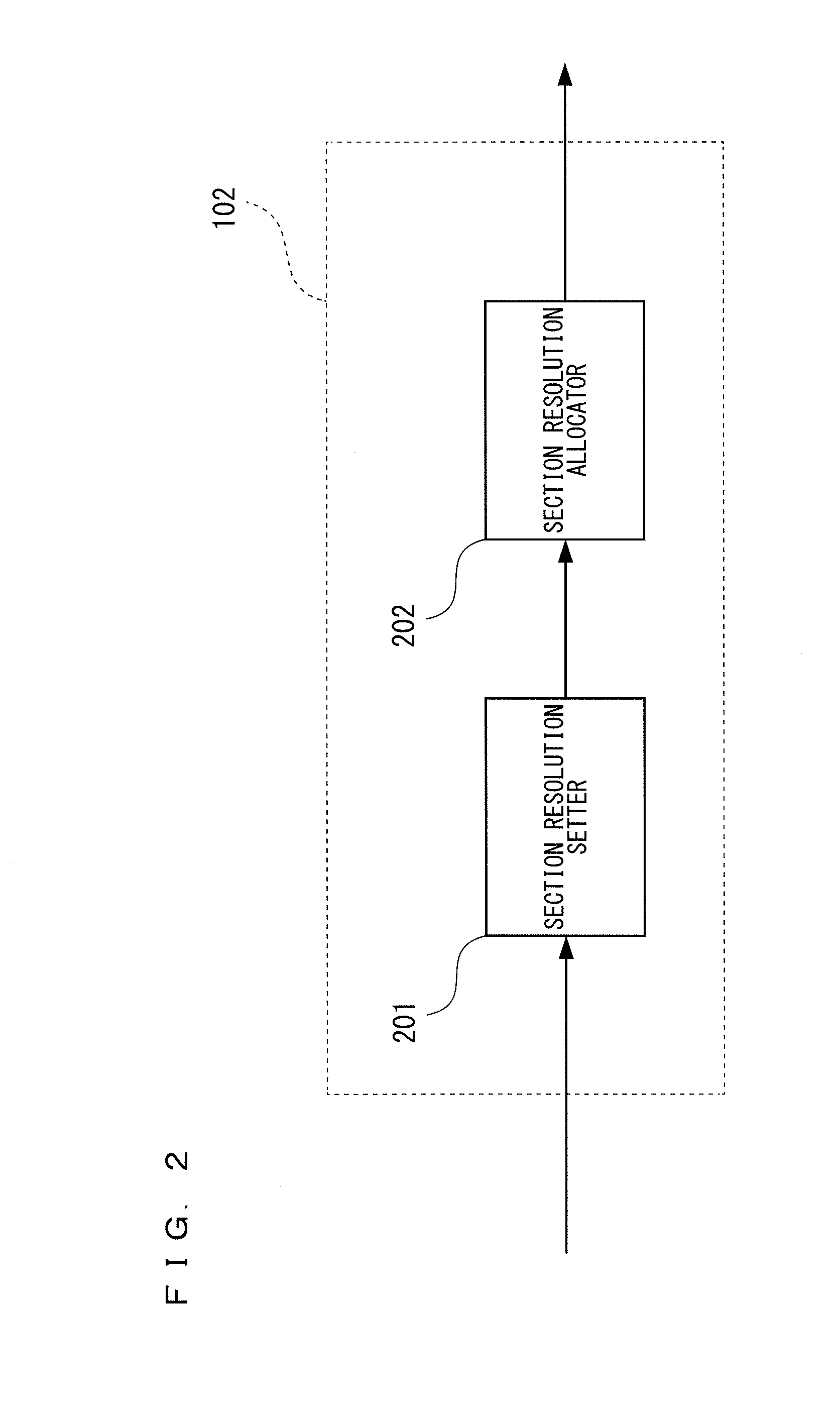

Vehicle energy-management device

ActiveUS20150258979A1Improve energy efficiencySuppress computing loadHybrid vehiclesDigital data processing detailsImage resolutionCalculator

A vehicle energy-management device is used for a vehicle that is equipped with a plurality of vehicle apparatuses driven by different energy sources. The vehicle energy-management device includes a travel route calculator that calculates a travel route of the vehicle, a travel route divider that divides the travel route into a plurality of sections, a control plan preparing unit that prepares, for each of the plurality of sections, a control plan for the plurality of vehicle apparatuses, and a vehicle apparatus controller that controls the plurality of vehicle apparatuses according to the control plan. The travel route divider determines a length of each of the sections such that a resolution is higher for a section closer to the vehicle and divides the travel route.

Owner:MITSUBISHI ELECTRIC CORP

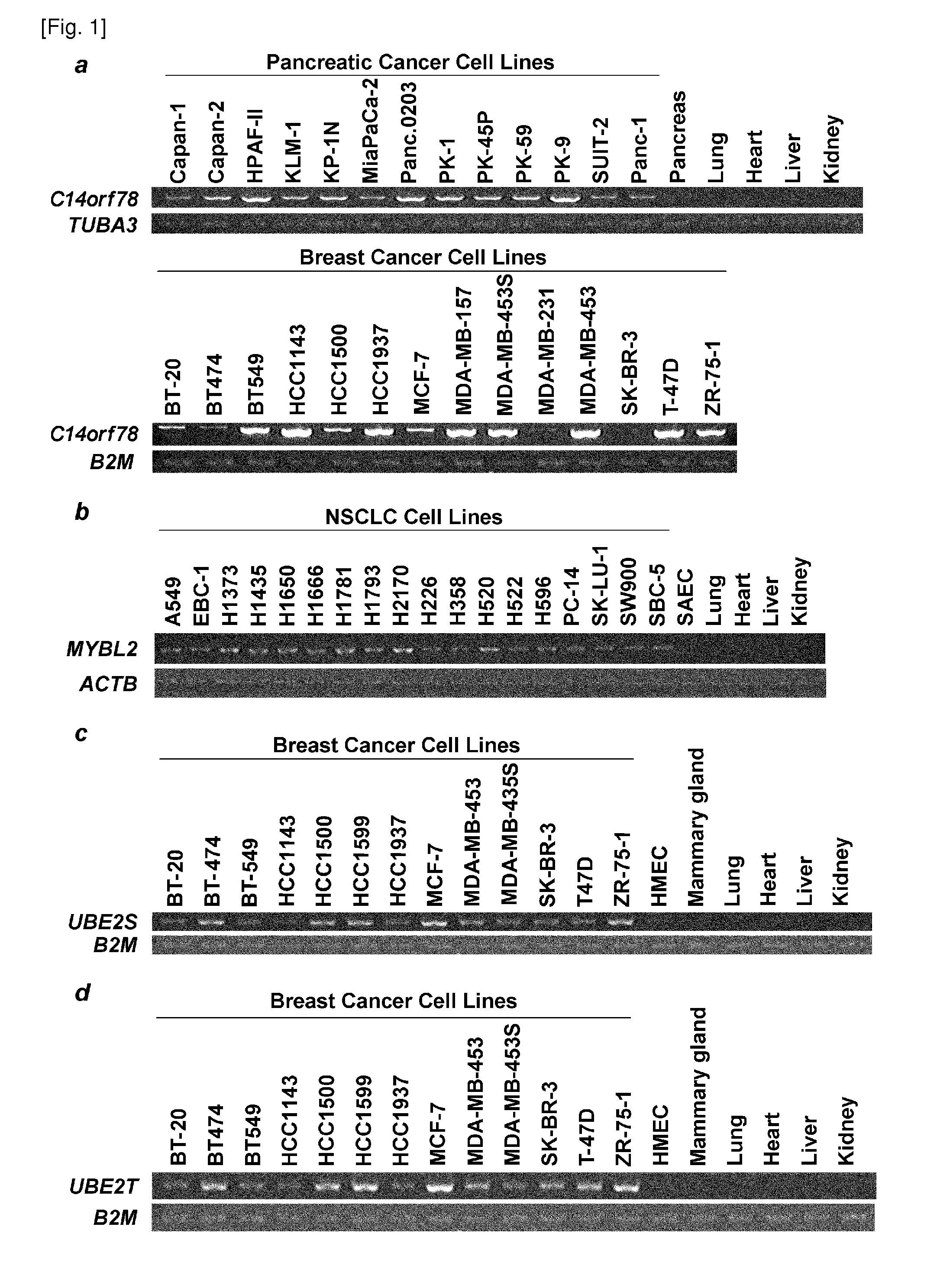

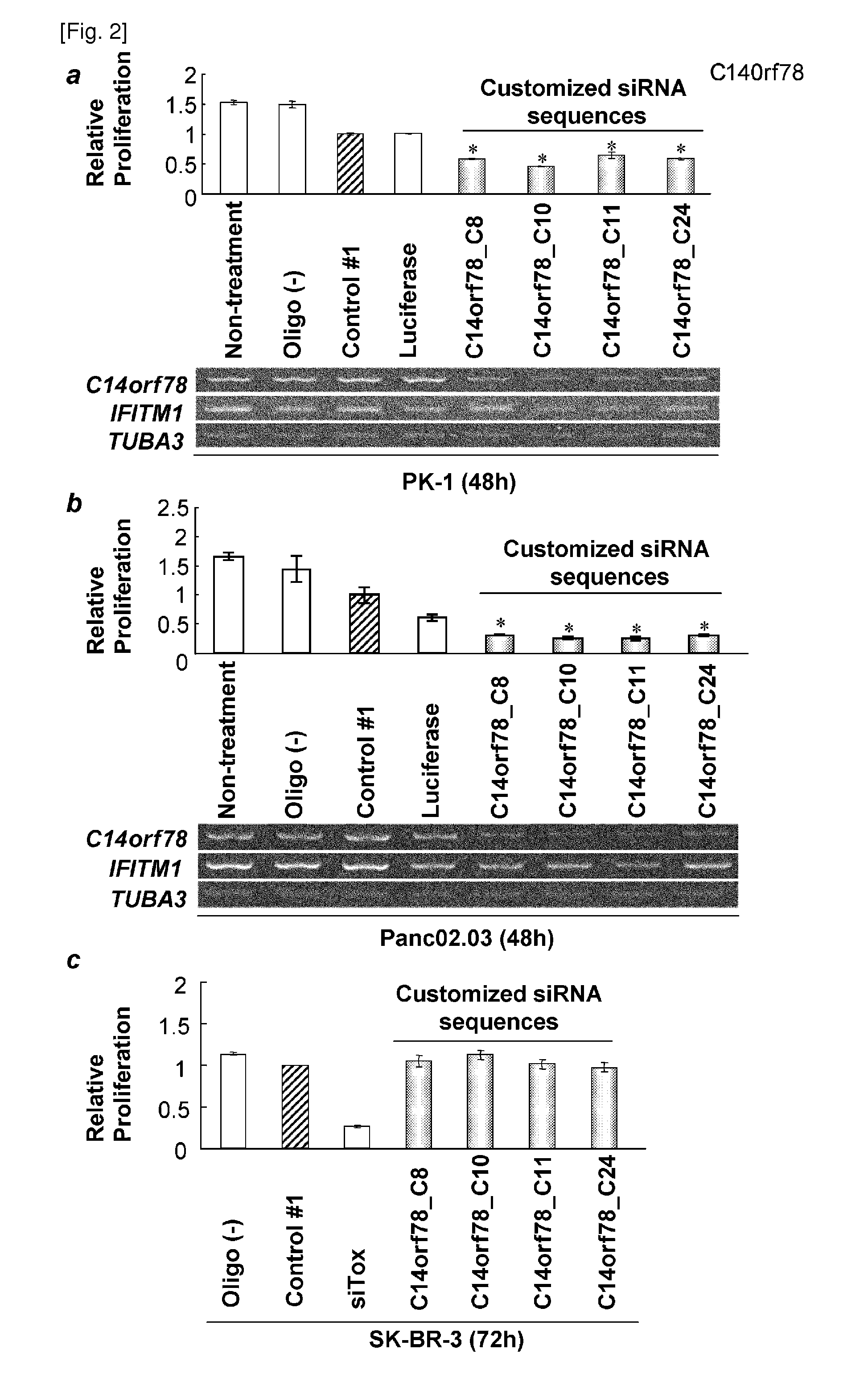

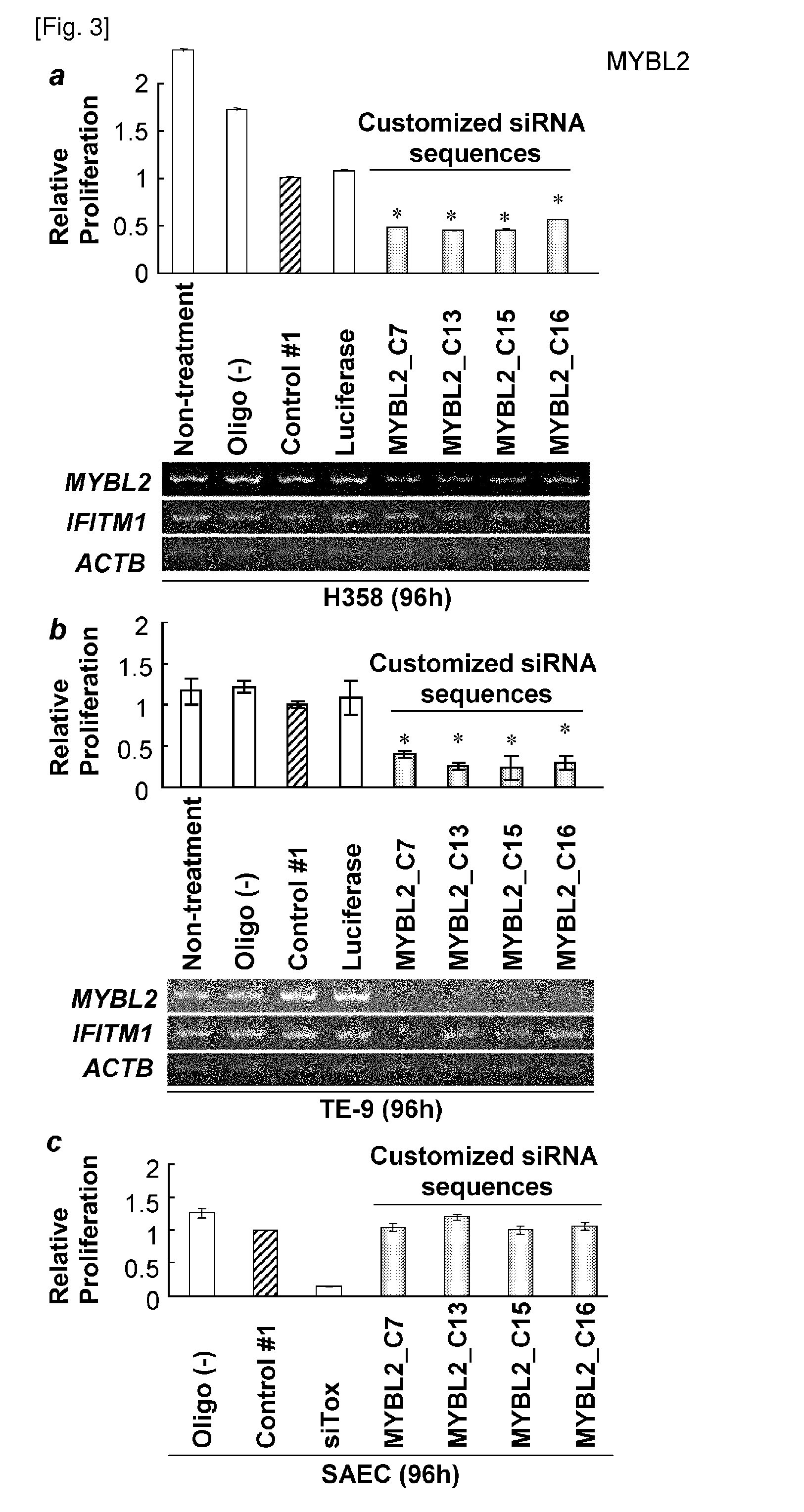

Compositions and methods of treating cancer

InactiveUS20100273855A1Inhibit cell growthTreat cancerOrganic active ingredientsSugar derivativesBladder cancerTesticular seminoma

The invention features a method for treating cancer by administering a double-stranded nucleic acid molecule against a CX gene selected from the group consisting of C14orf78, MYBL2, UBE2S and UBE2T. The invention also features products, including the double-stranded nucleic acid molecules and vectors encoding them, as well as compositions comprising the molecules or vectors, useful in the provided methods. The methods of the invention are suited for the treatment of cancers including lung cancer, breast cancer, bladder cancer, esophagus cancer, prostate cancer, cholangiocellular carcinoma and testicular seminoma.

Owner:ONCOTHERAPY SCI INC

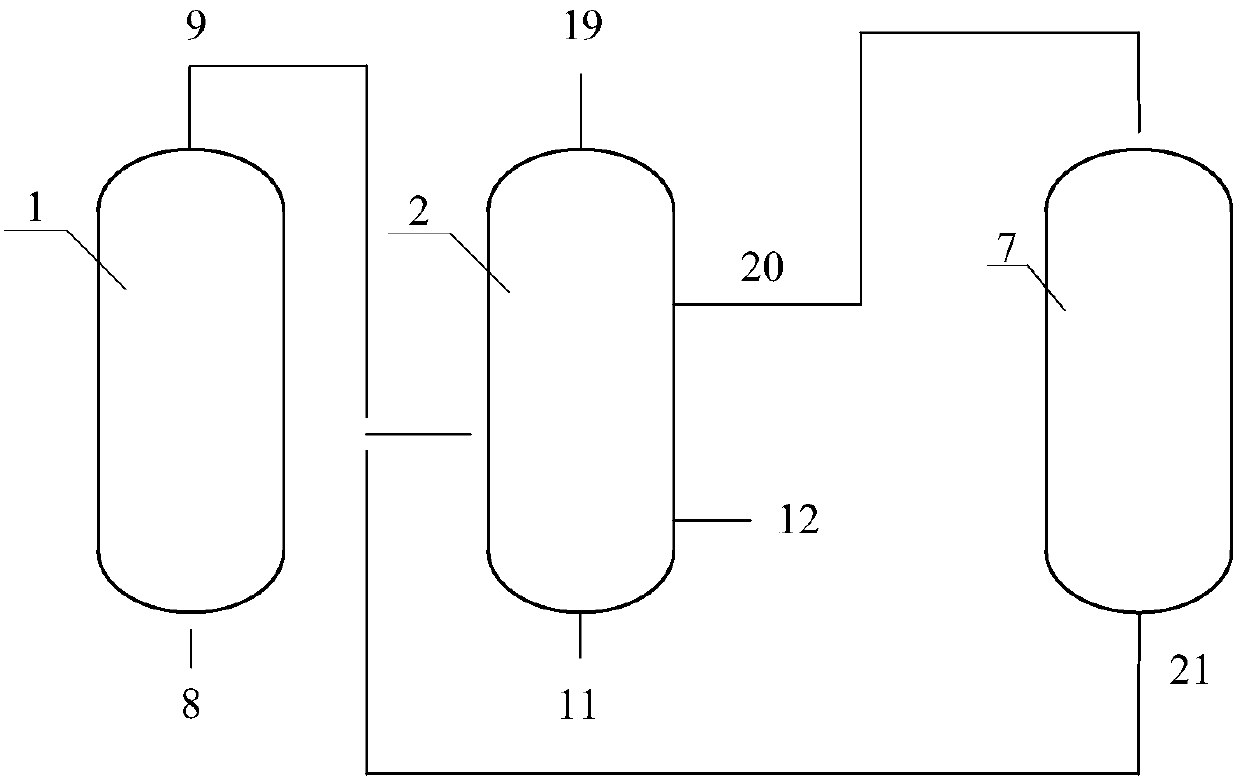

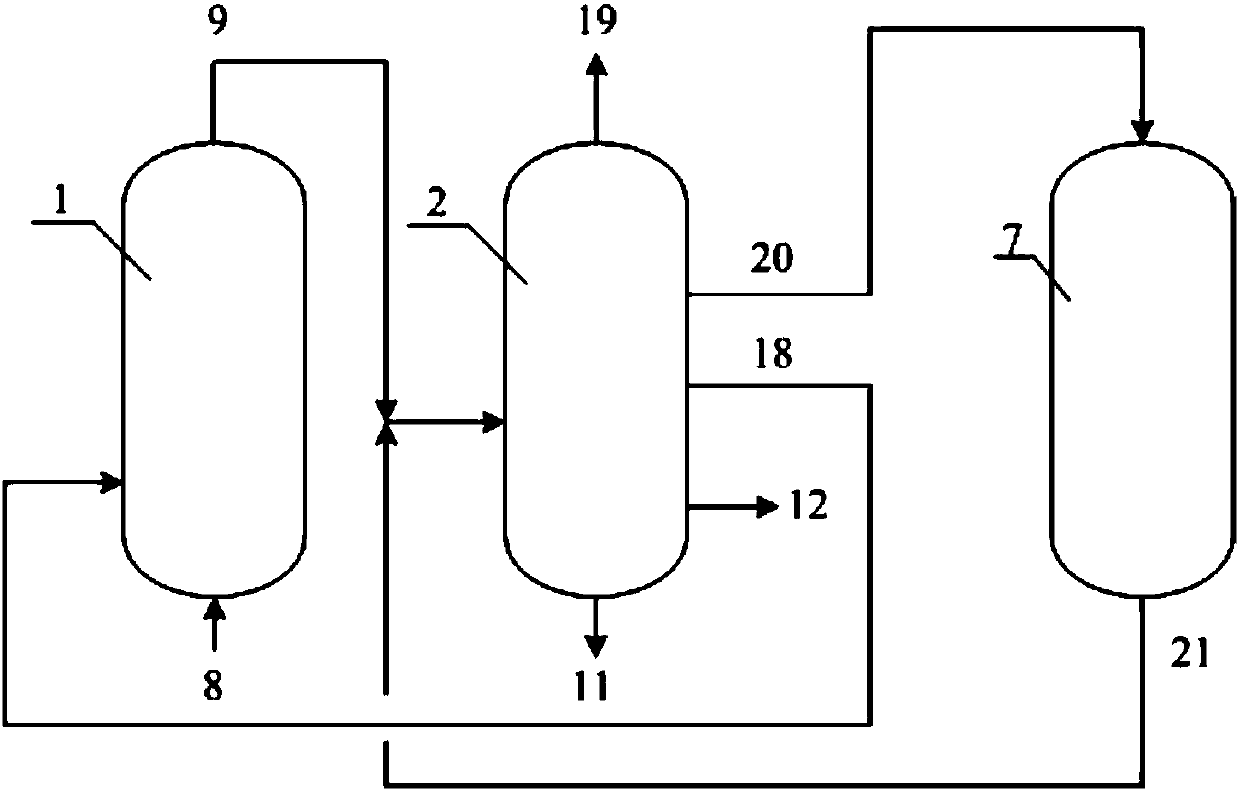

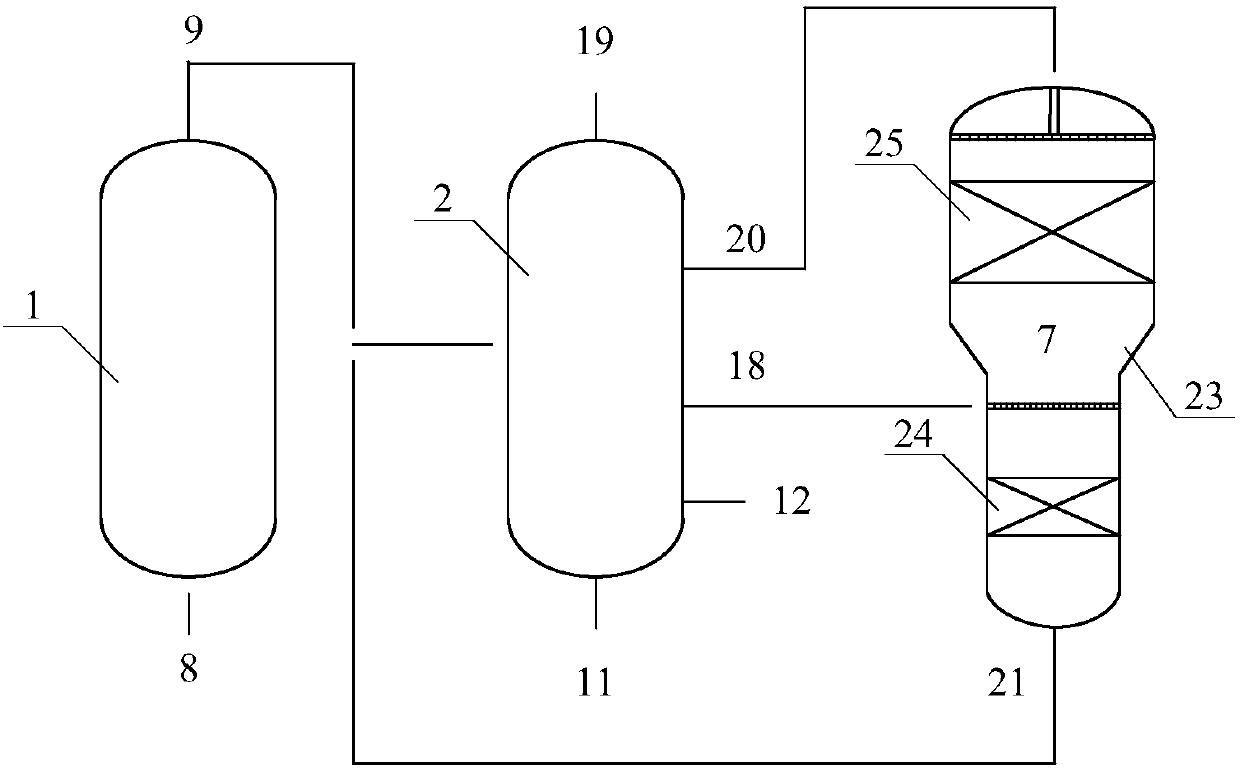

Method for preparing aromatic hydrocarbons through catalytic conversion of oxygenated compound-containing raw material

ActiveCN108017490AHigh selectivityAvoid bulk accumulationHydrocarbon by isomerisationMolecular sieve catalystHydrogenAromatization

The invention relates to a method for preparing aromatic hydrocarbons through catalytic conversion of an oxygenated compound-containing raw material. The method mainly solves the problem of low yieldof aromatic hydrocarbons in the prior art. The oxygenated compound-containing raw material enters an oxygenated compound-containing raw material catalytic conversion reaction system to obtain a reaction product rich in aromatic hydrocarbons; the reaction product rich in aromatic hydrocarbons goes through a cooling and separating system to obtain a water phase product and an oil phase product, thewater phase product and the oil phase product are discharged from the system, obtained hydrogen, methane and C2 hydrocarbons are discharged from the system, and at least parts of obtained C3 or more non-aromatic hydrocarbons enter a light hydrocarbon aromatization reaction system; and the obtained light hydrocarbon aromatization reaction product returns to the cooling and separating system. The method adopting the above technical scheme well solves the problem, and can be used in the industrial production of the aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

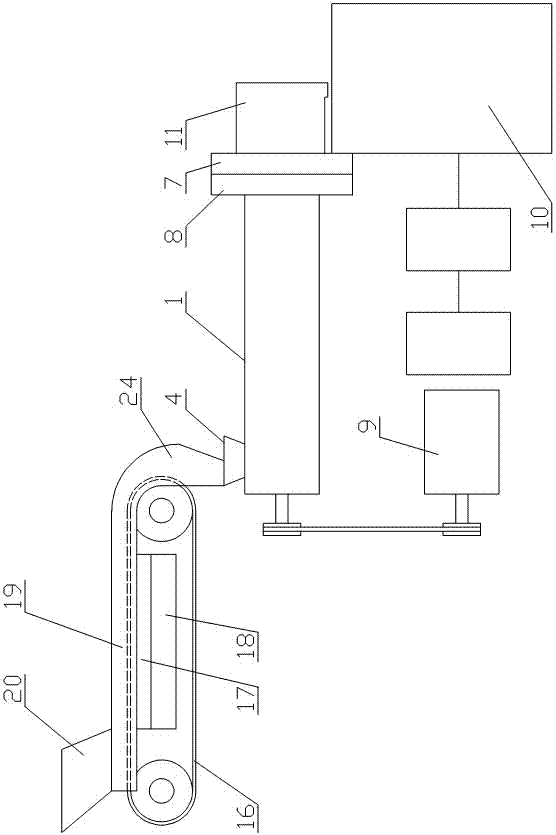

Biomass burning power generation device

PendingCN107990306AAvoid bulk accumulationImprove combustion efficiencyFuel feeding arrangementsSolid fuel pretreatmentBiomass boilerCombustion chamber

Disclosed is a biomass burning power generation device. The biomass burning power generation device comprises a belt conveying device, a spiral feeding device, a biomass boiler, a steam turbine and agenerator, wherein the belt conveying device, the spiral feeding device, the biomass boiler, the steam turbine and the generator are connected in sequence. The belt conveying device and the spiral feeding device are horizontally arranged. The belt conveying device comprises a feeding bin, a conveying belt and a drying box, wherein the conveying belt is horizontally arranged, and the drying box isturned over on the conveying belt and arranged in the conveying direction. The spiral feeding device comprises a feeding cylinder and a discharging cylinder, wherein the feeding cylinder and the discharging cylinder are connected together in a butt-joint mode. According to the biomass burning power generation device, the spiral conveying mode is adopted, materials can be intermittently supplied toa combustion chamber of the biomass boiler, accumulation of a large amount of biomass fuel in the combustion chamber is avoided, and the burning efficiency of the boiler is remarkably improved.

Owner:衡水亚菲材料科技有限公司

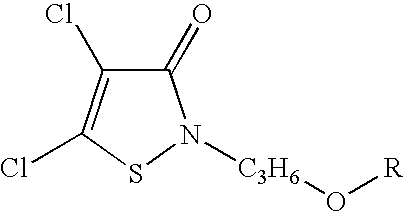

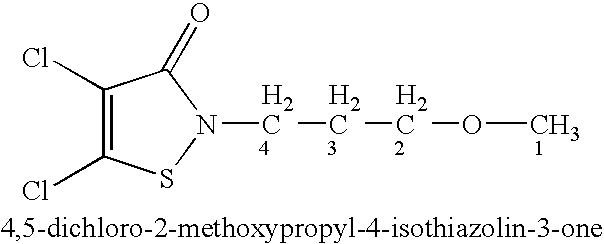

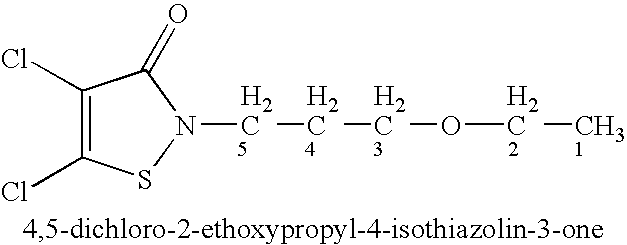

Alkoxylpropylisothiazolinone and preparation method and use thereof

ActiveUS7442240B2Reduced bioavailabilityImprove efficiencyFireproof paintsBiocideIsothiazolinonePropylamine

An alkoxylpropyl isothiazolinone of formula: C6H6Cl2NO2SR, in which R is CH3, CH2CH3, CH(CH3)2, CH2CH2CH2CH3, CH2CH2OCH3 or CH2CH2OC6H5Cl. A method for preparing the isothiazolinone by reacting sodium polysulphide with methyl acrylate to obtain dimethyl dithiodipropionate, followed by aminolysis with alkoxyl propylamine to obtain N,N′-dialkoxylpropyldithio-dipropionamide, which is then reacted with sulfuric chloride. The alkoxylpropyl-isothiazolinone of the invention can be used for preparing marine antifouling paint coating as antifoulant, and also used as bactericide.

Owner:OCEAN UNIV OF CHINA

Method for preparing mullite multiphase ceramic by low-temperature sintering of bauxite tailings

The invention discloses a method for preparing mullite multiphase ceramic by low-temperature sintering of bauxite tailings, and belongs to the technical field of high-value utilization of the bauxite tailings and ceramic preparation. According to the invention, bauxite tailings, bauxite clinker and lithium chinastone are adopted as main raw materials, and the mullite multiphase ceramic is prepared through the processes of batching, ball milling, molding and low-temperature sintering. The mullite multiphase ceramic material prepared by low-temperature sintering of the bauxite tailings has the characteristics of high compressive strength, small linear shrinkage rate, high volume density and simple preparation process, and can be used in industries such as high-value utilization of the bauxite tailings and ceramics. The required raw materials are easy to obtain, the preparation process is simple, the utilization amount of the bauxite tailings is high, the problems of massive accumulation of the bauxite tailings and pollution and damage to the environment can be solved, and waste is turned into wealth; and by adding the bauxite tailings, the sintering temperature of the mullite multiphase ceramic can be reduced, the cost and the energy consumption are low, and high-value utilization of the bauxite tailings is realized.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

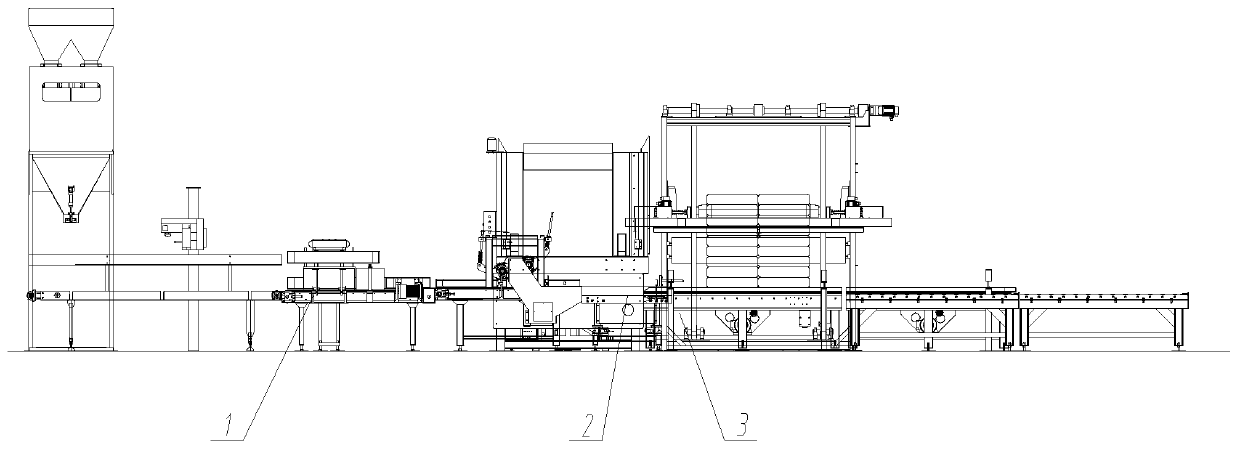

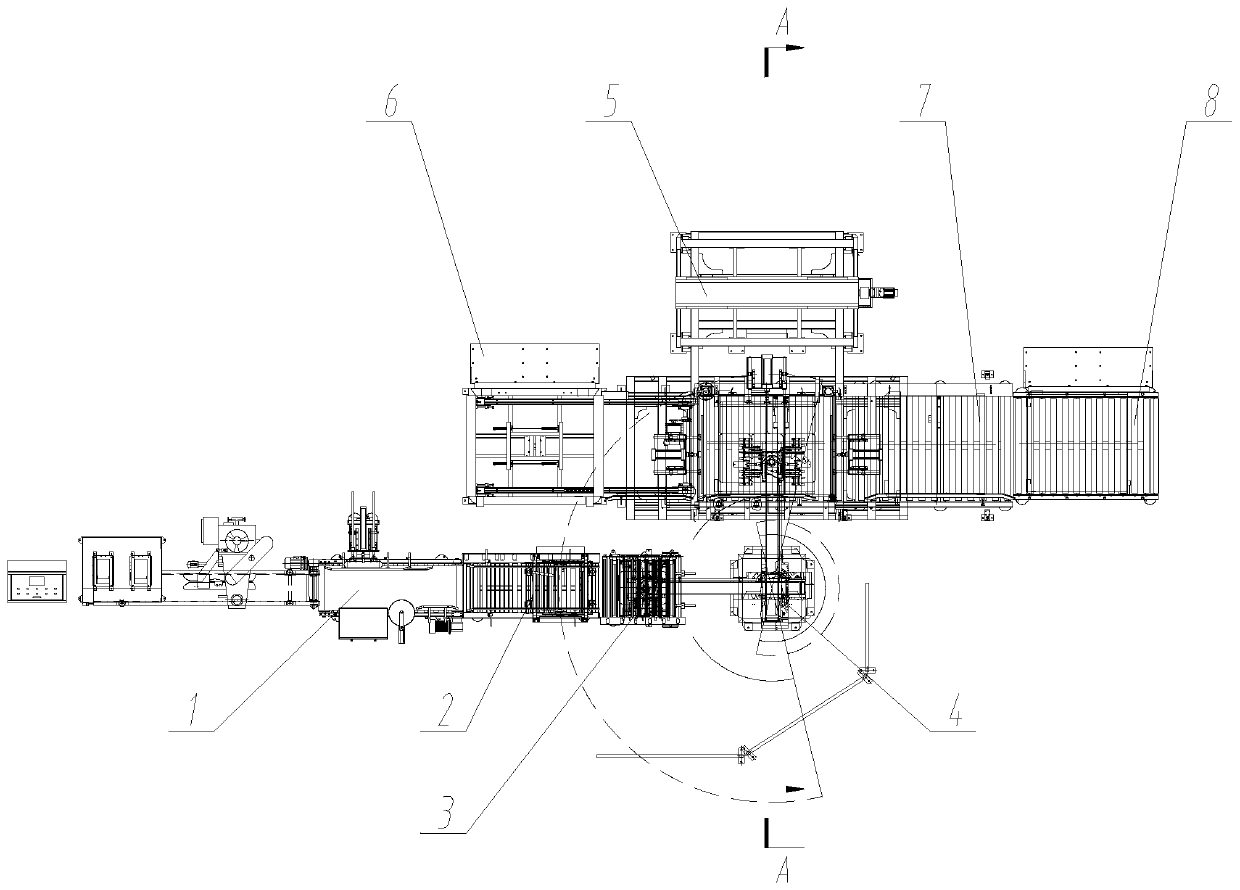

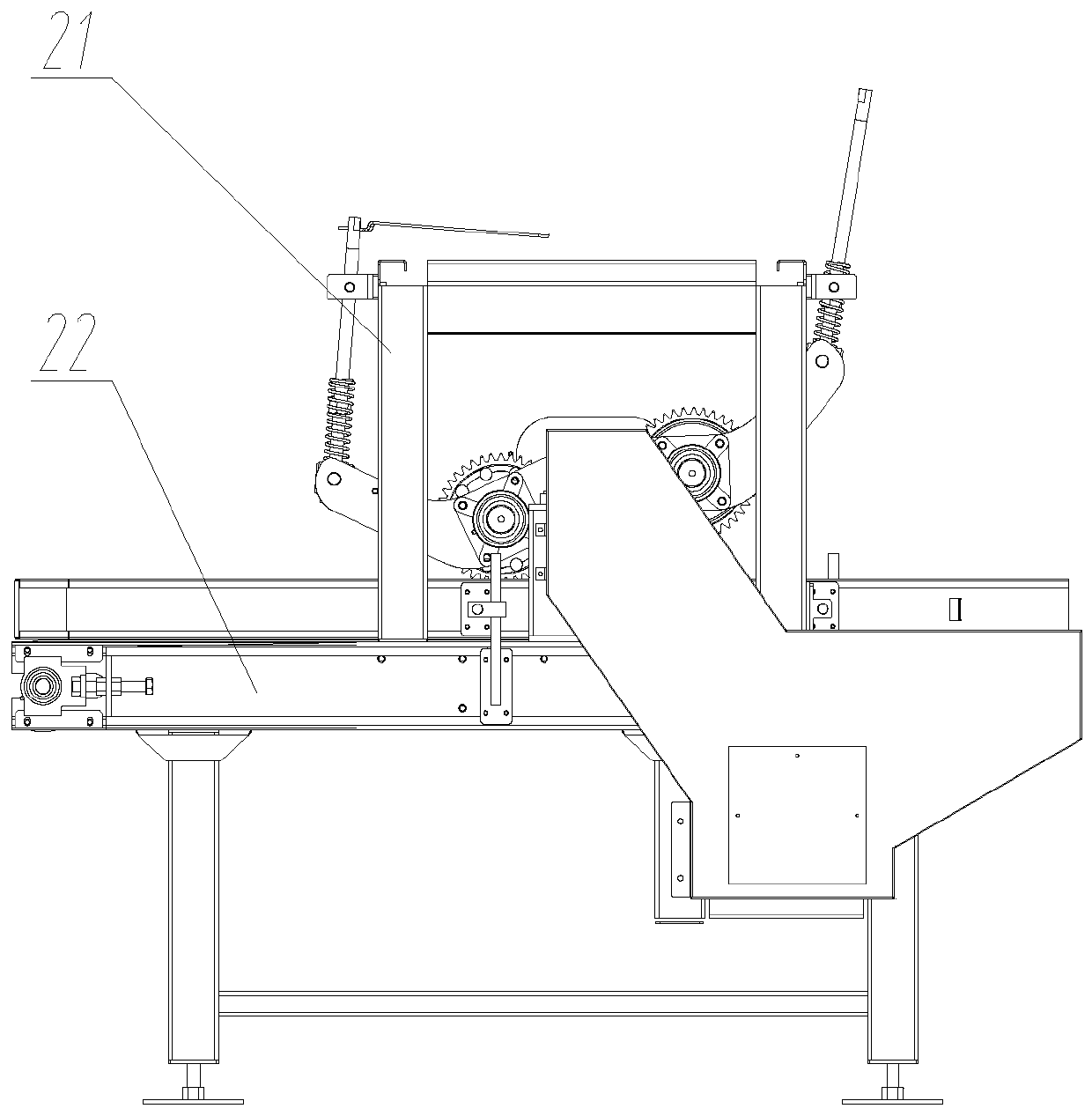

Robot packaging and stacking system and use method

PendingCN110481909ARealize sortingAchieve compactionConveyorsPackaging automatic controlEngineeringRobot

The invention discloses a robot packaging and stacking system and a use method. The robot packaging and stacking system comprises a packaging machine, a bag pressing machine, a weighing and conveyingdevice, a stacking robot and a compacting machine. The weighing and conveying device is located on the right side of the bag pressing machine, and the stacking robot is arranged on the right side of the weighing and conveying device. The compacting machine is arranged behind the stacking robot, and a conveying device is arranged on the lower side. The bag pressing machine comprises a supporting frame, a bag pressing assembly and a vibration conveying device. The supporting frame is erected on the vibration conveying device, and a transmission assembly in the bag pressing assembly drives a pressing assembly to carry out rotary bag pressing. The compacting machine comprises a lifting device, a plate drawing device and a push-on device. A lifting platform in the lifting device is arranged onthe lifting frame in a vertical sliding manner through the lifting assembly. A driving assembly controls a supporting plate to relatively move on the lifting platform left and right. According to therobot packaging and stacking system and the use method, the layout is compact, packaging bag material arrangement and compaction are achieved, materials are prevented from being accumulated in packaging bags, the packaging bags are more compact, and weighing is more precise.

Owner:HEFEI EAGLE AUTOMATION ENG TECH +1

Method for preparing cement clinker by using oil shale waste residues

ActiveCN102491701BAvoid bulk accumulationReduce manufacturing costClinker (waste)Process engineering

The invention discloses a method for preparing cement clinker by using oil shale waste residues. The method comprises the following steps of: 1, mixing the following components according to the following proportions: 81 to 84 percent of limestone, 12 to 15 percent of shale waste residues, 1 to 2 percent of iron tailings sand and 2 to 4 percent of moulding sand; and 2, grinding the mixture obtained in the step 1 to obtain raw materials which is screened by a 80um square-hole sieve of which the screen residue is less than 5 percent, calcining the raw materials at temperature of between 1,350 and 1,450 DEG C for 15 to 20 minutes, and cooling to obtain the cement clinker. The method is used for preparing the cement clinker by using the oil shale waste residues replacing clay, so that a large quantity of clay resources are saved, and the production cost of the cement is reduced; furthermore, the doped quantity of the oil shale waste residues is large and up to 13 percent, so that the oil shale waste residues are used fully; therefore, the economic benefit is increased, wastes are turned into treasures, a large quantity of stacked residues are avoided, the land occupied amount is reduced, and the environment pollution is reduced.

Owner:FUSHUN MINING IND GROUP

Multifunctional draining well cover

ActiveCN104695534AAvoid odor emissionAvoid bulk accumulationSewerage structuresEngineeringWater leak

The invention discloses a multifunctional draining well cover. The multifunctional draining well cover is used for solving the problem that the existing draining well cover cannot drain according to water yield. The multifunctional draining well cover comprises a supporting frame and a garbage baffle, wherein a water leaking hole is arranged on the garbage baffle, the installing end of the garbage baffle is hinged on a short side of the supporting frame, a free end of the garbage baffle is lapped at the other one short side of the supporting frame; a swaying plate is hinged on the short side of the supporting frame, and a spring is arranged between the free end of the swaying plate and a corresponding short side of the supporting frame; under the function of the spring, the upper surface of the swaying plate is contacted and fit with the bottom part of the supporting frame. The free end of the garbage baffle is glidingly equipped with a gliding plate, and a rope is arranged between the free end of the swaying plate and the fee end of the gliding plate, a notch and a baffle corresponding to the water leaking hole are arranged on the gliding plate. The draining well cover can prevent garbage from entering a sewer, and realize drainage of rainwater according to rainwater amount.

Owner:UNIV OF JINAN

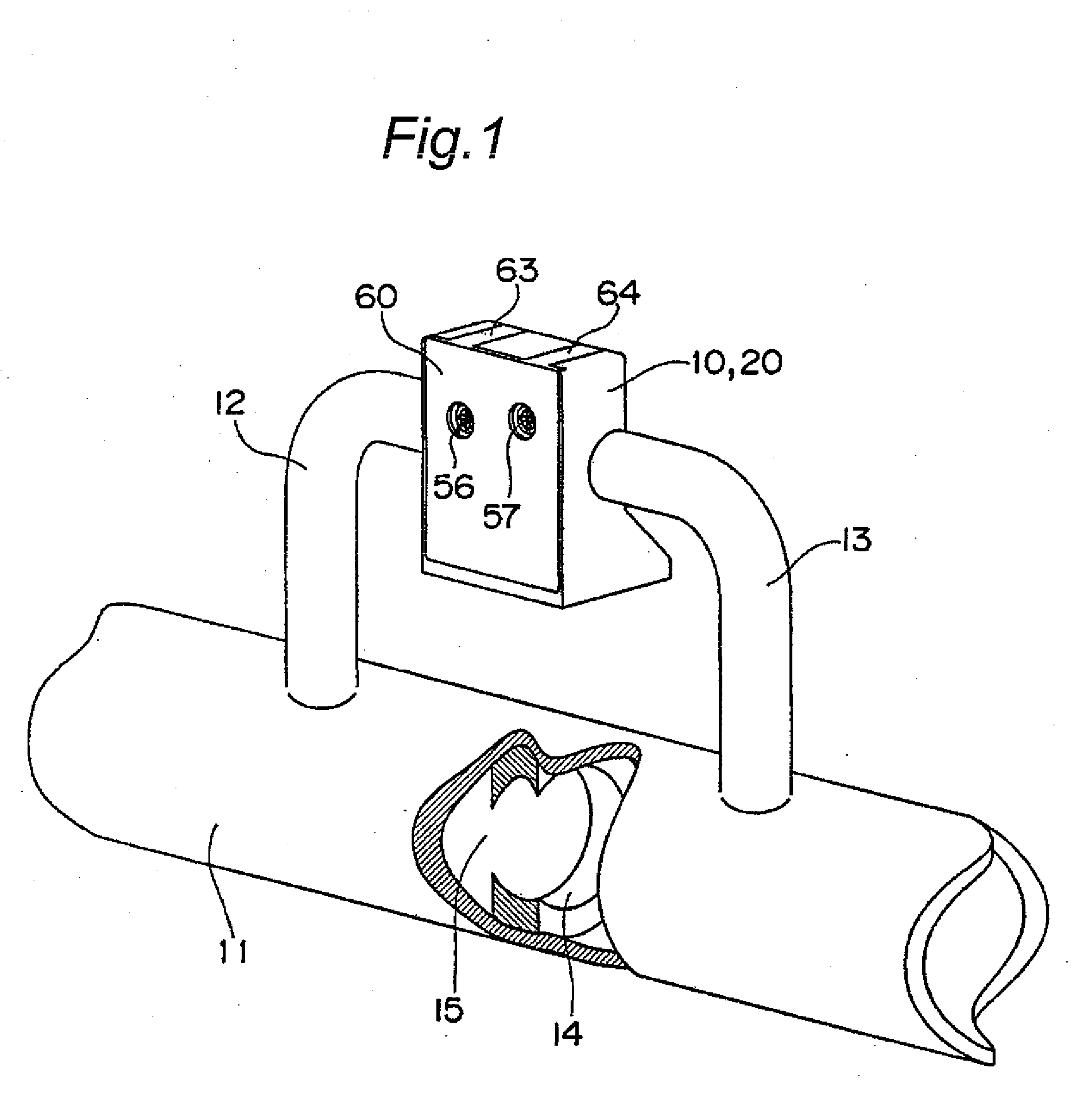

Flow Rate Measuring Device

ActiveUS20080314140A1Inhibit deteriorationEasy maintenanceVolume flow proportion measurementVolume indication and recording devicesEngineering

Owner:ORMON CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com