Patents

Literature

11915results about "Packaging automatic control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

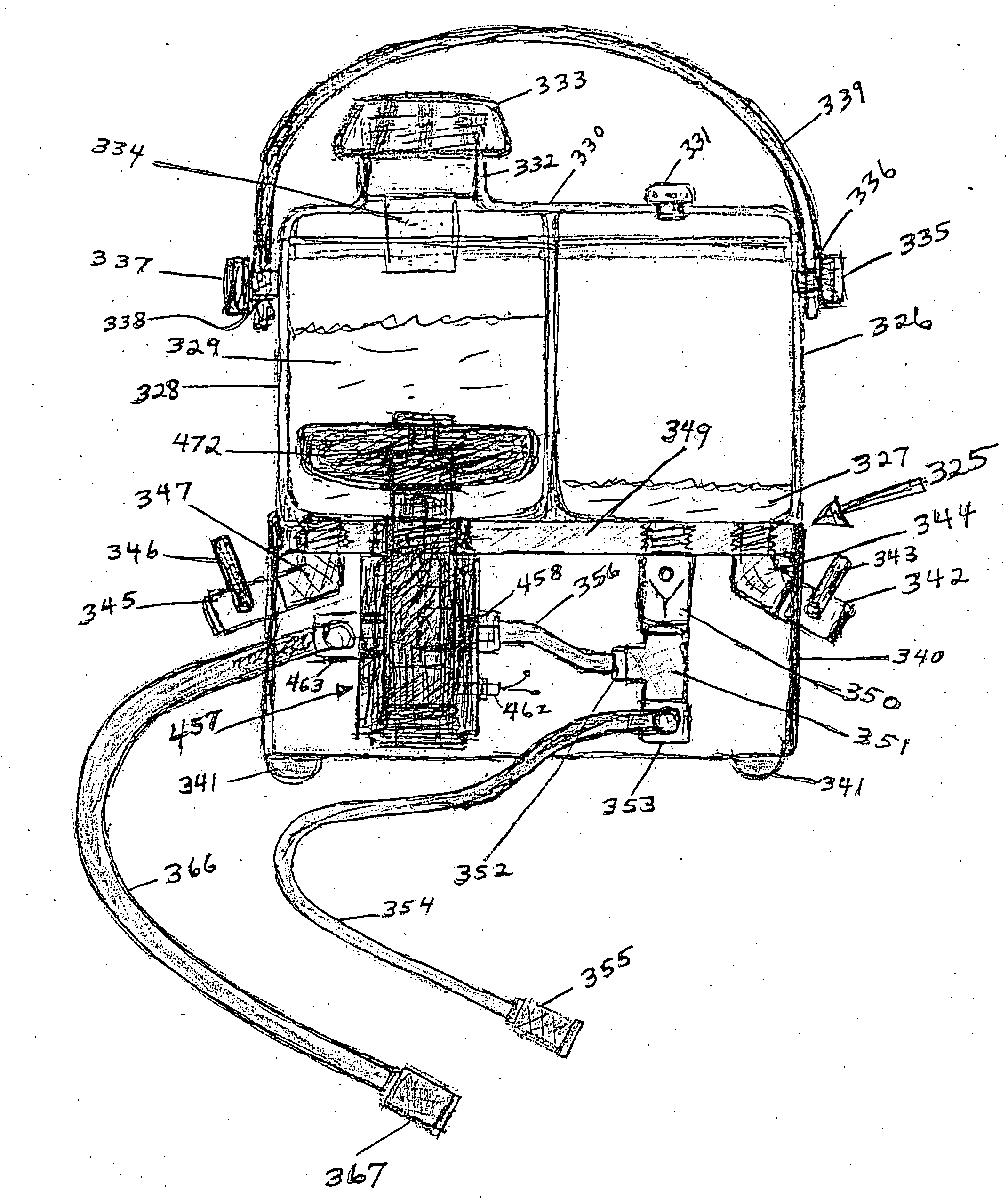

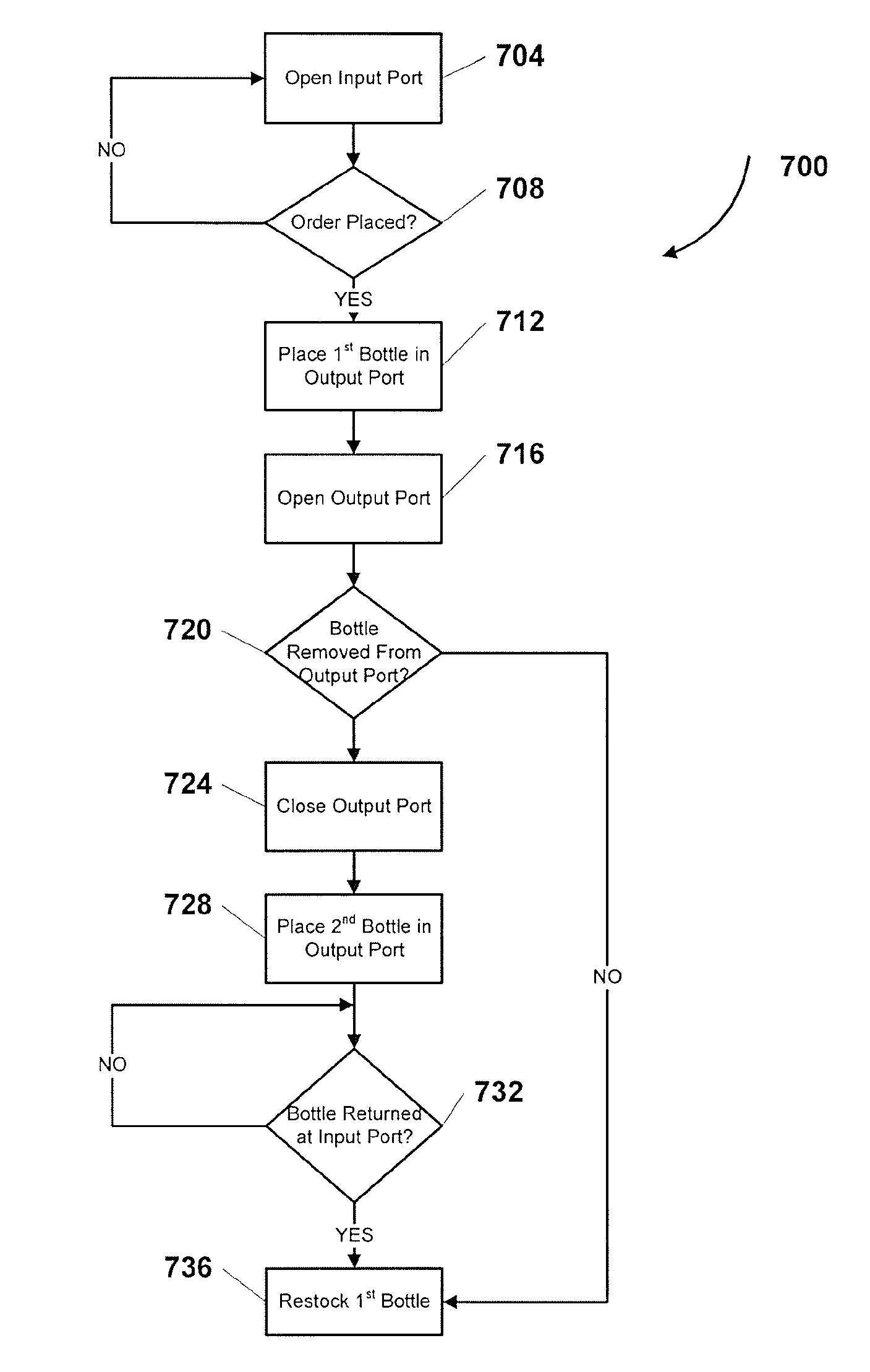

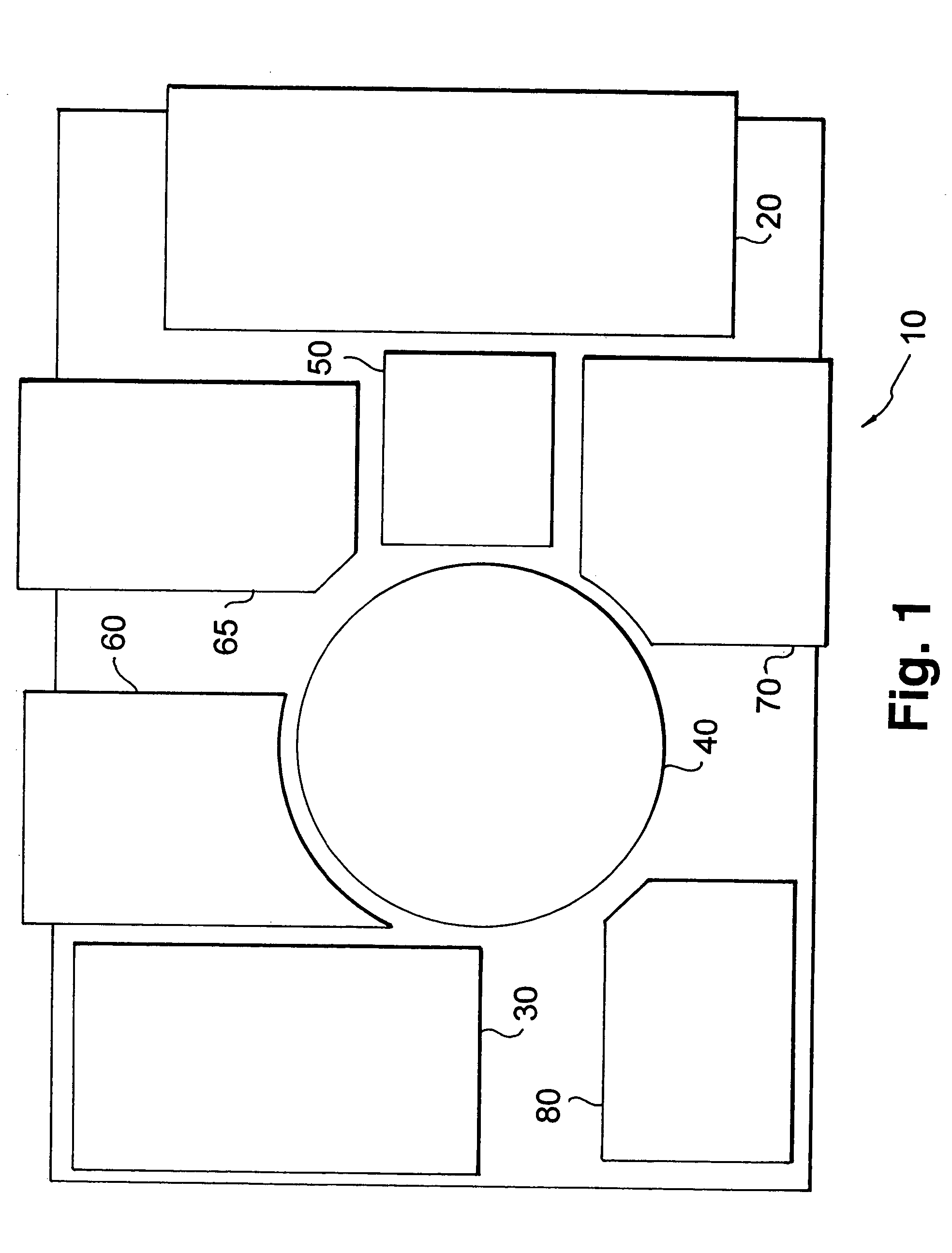

Restocking method for medical item dispensing system

InactiveUS6112502AEfficient restockingImprove securityAcutation objectsDrug and medicationsData terminalData store

A system for monitoring and dispensing medical items which are dispensed for administration to patients includes a data terminal (76, 338, 538) which is connected through a network (82, 328, 536) to at least one computer (84, 324, 532) having a processor and a data store. The system also includes a reading device (348, 538) which is operatively connected to the network. A user of the data terminal or the reading device is enabled to select a patient for whom medical items will be used, and responsive to a request to dispense items the requested items are dispensed from dispensing devices (96, 100, 344, 346, 450, 527, 540) connected to the data terminal. Storage locations in dispensing devices may be restocked using removable liners. The removable liners are stocked with medical items in a stocking location (550) and transported in a secure condition to the storage locations. The storage locations are accessed by an authorized restocking user. The previously installed liners removed and the new liners installed. The previously installed liners are thereafter returned to the stocking location for reuse.

Owner:DIEBOLD NIXDORF

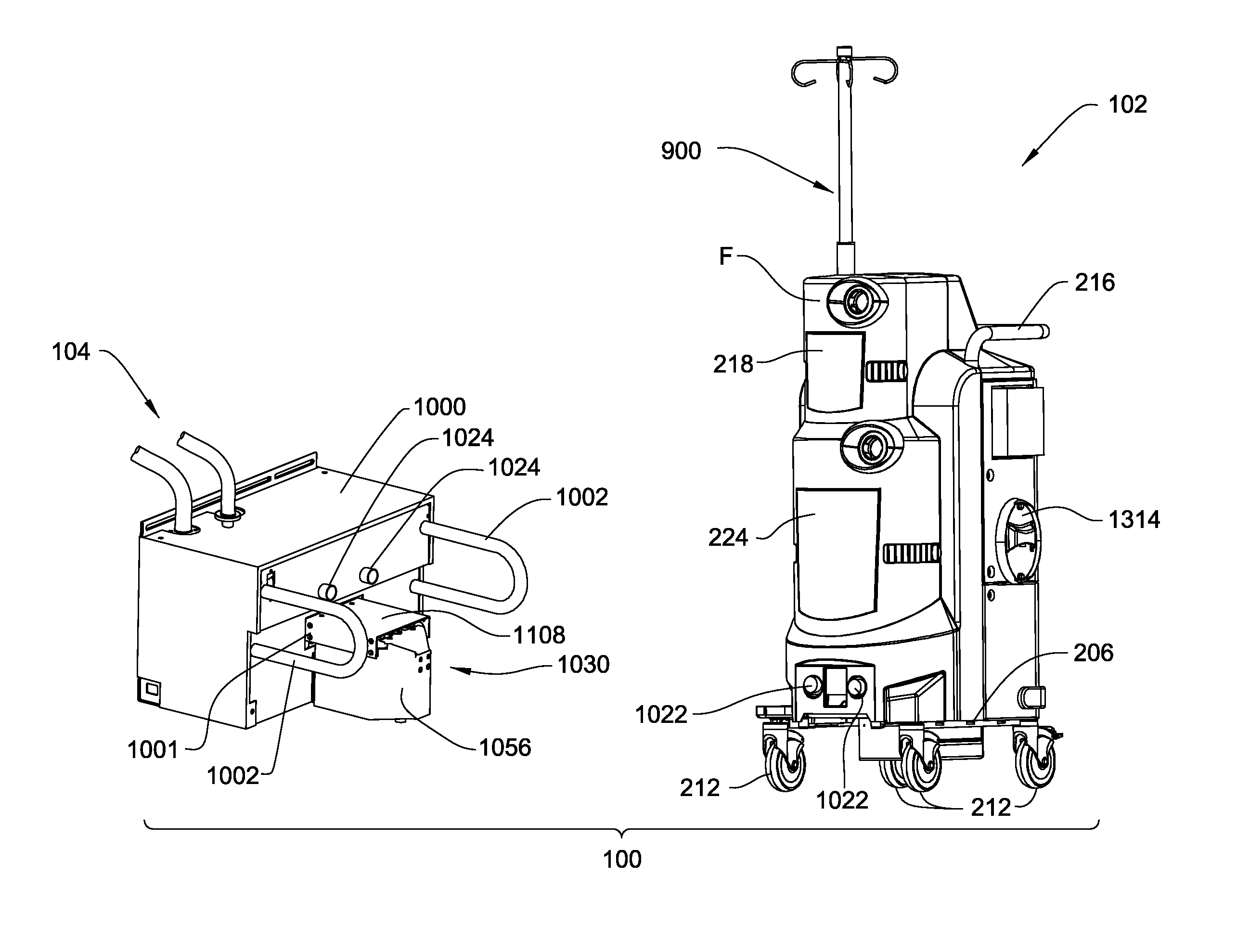

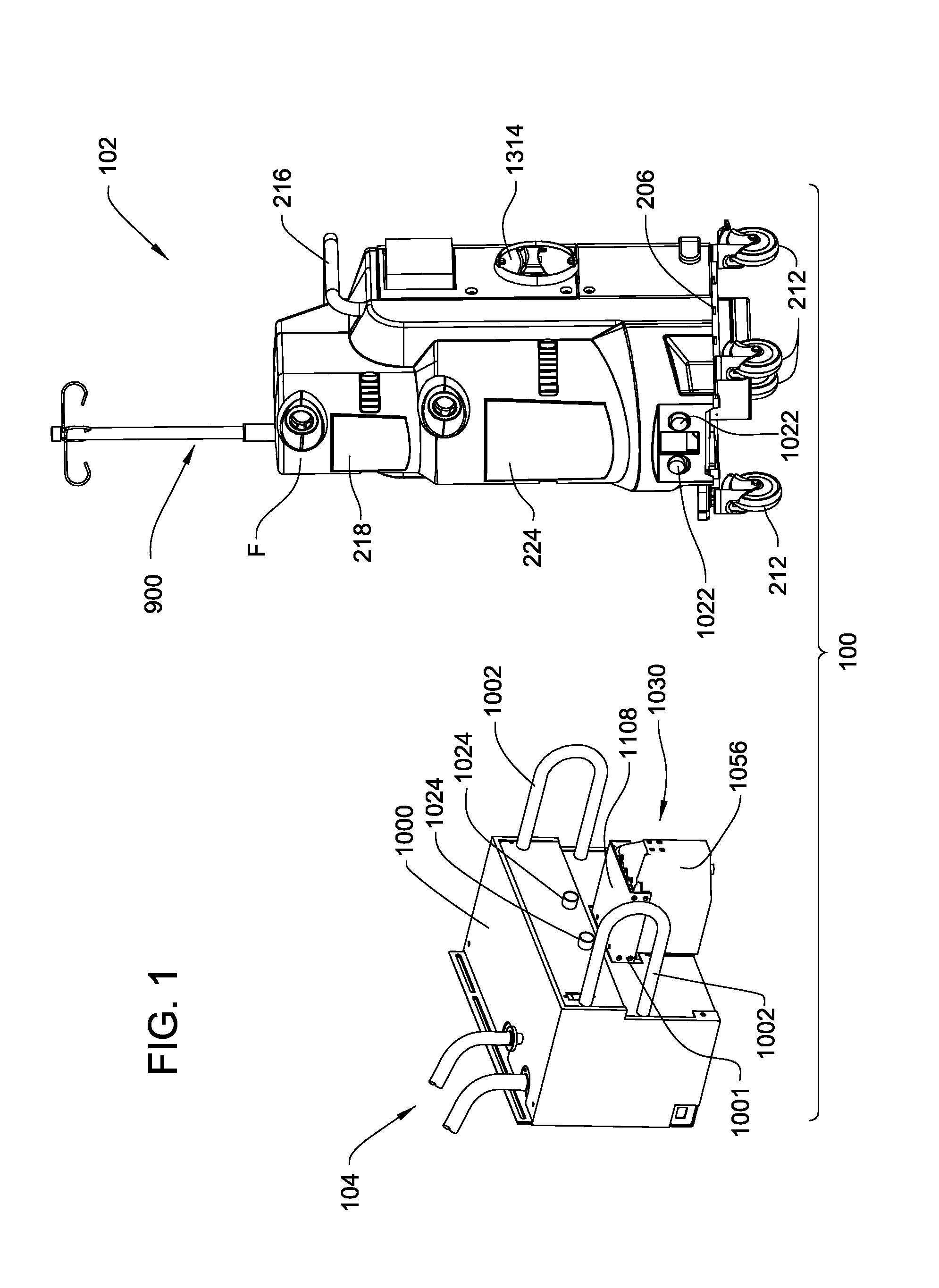

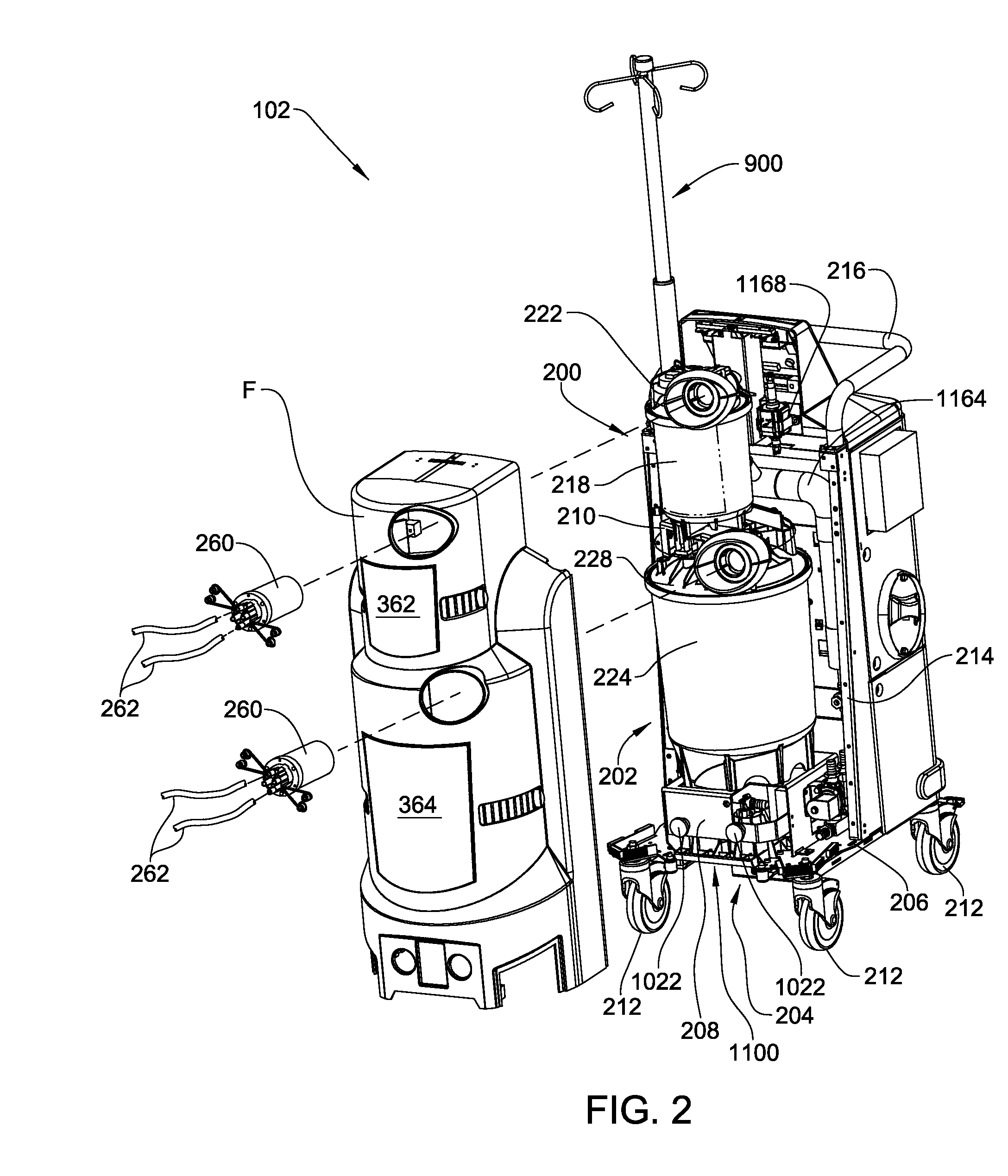

Medical/surgical waste collection unit including waste containers of different storage volumes with inter-container transfer valve and independently controlled vacuum levels

ActiveUS7621898B2Reduce in quantityLarge storage capacityMechanical apparatusDispersed particle filtrationDocking stationVacuum level

Owner:STRYKER CORP

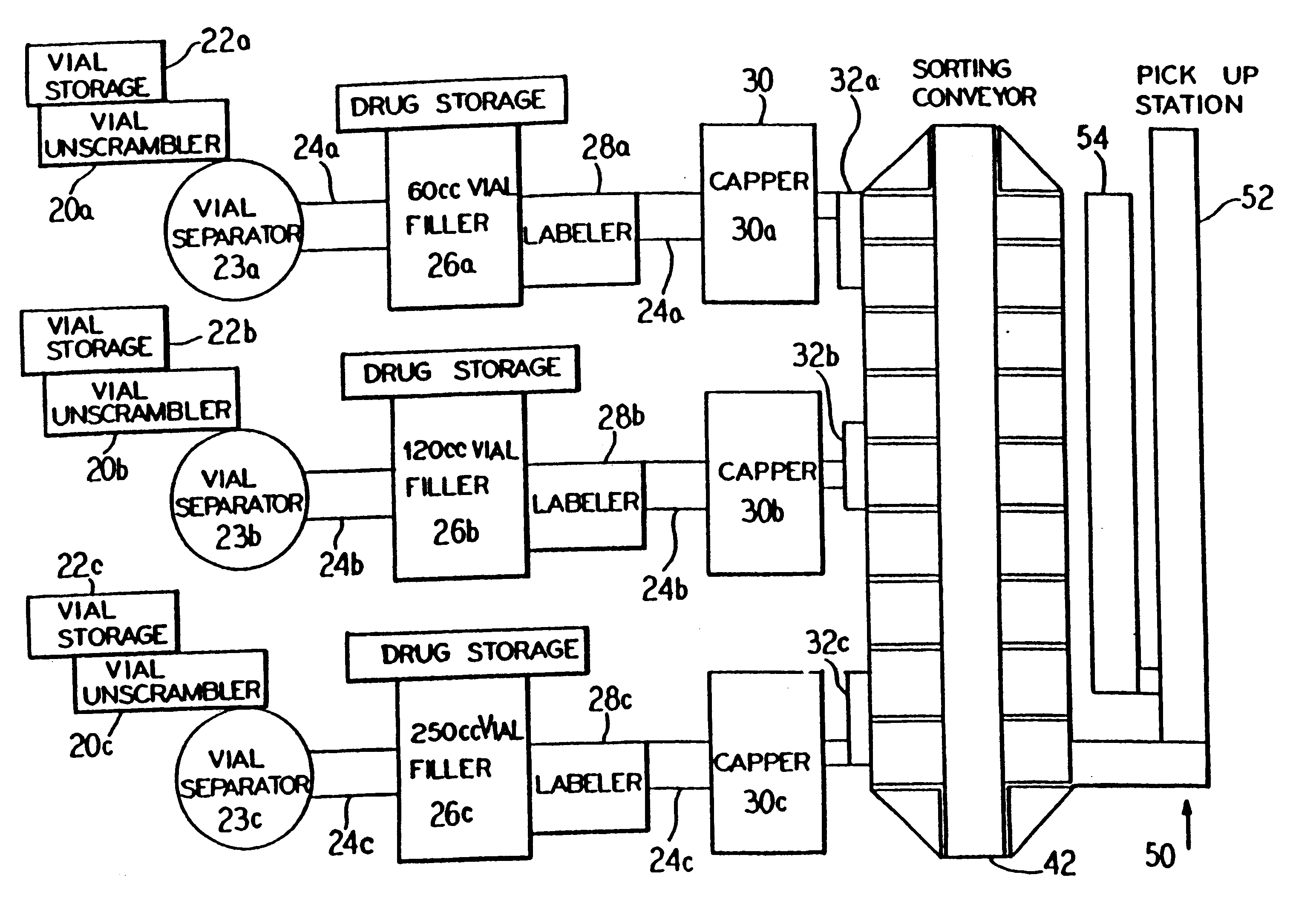

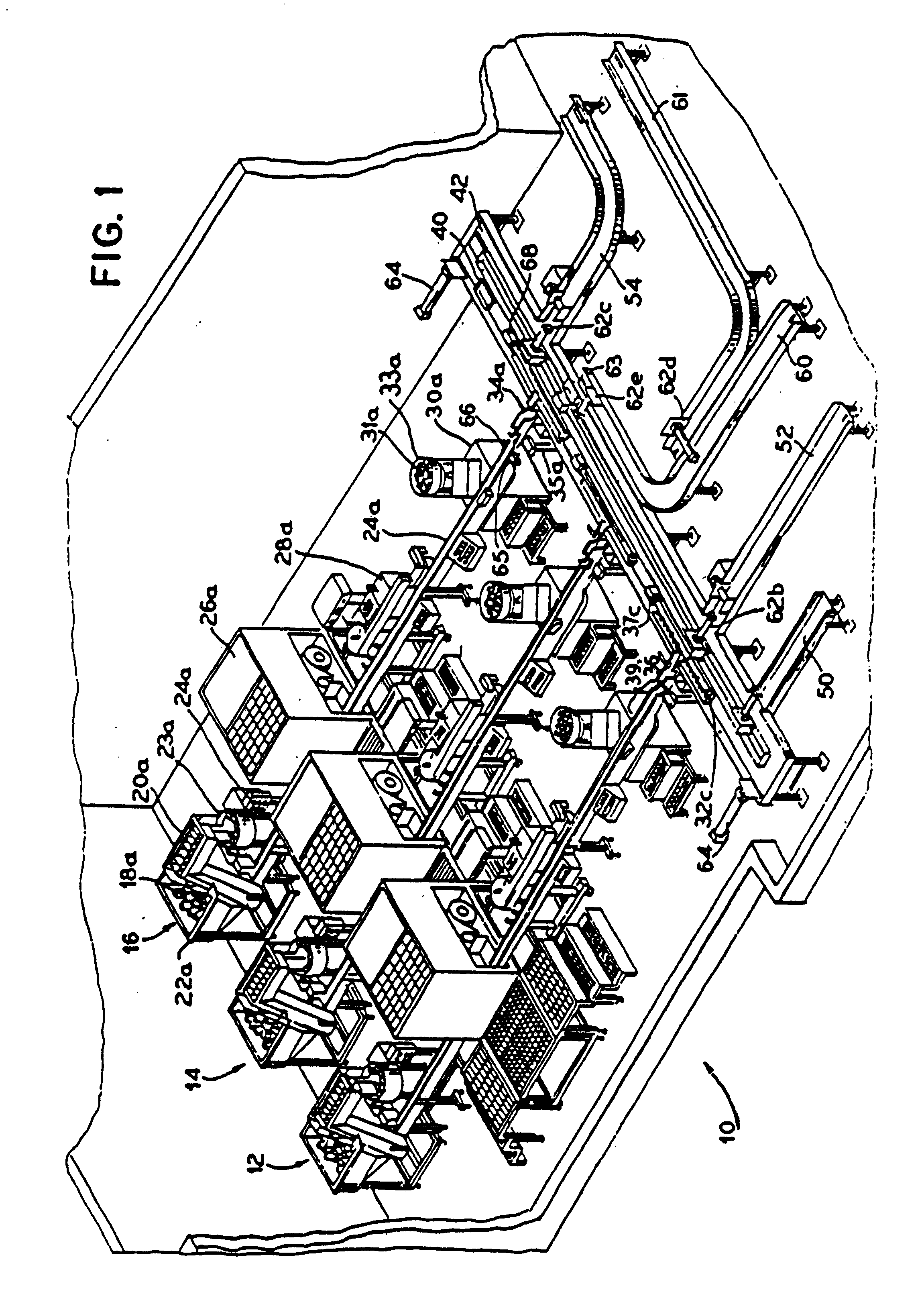

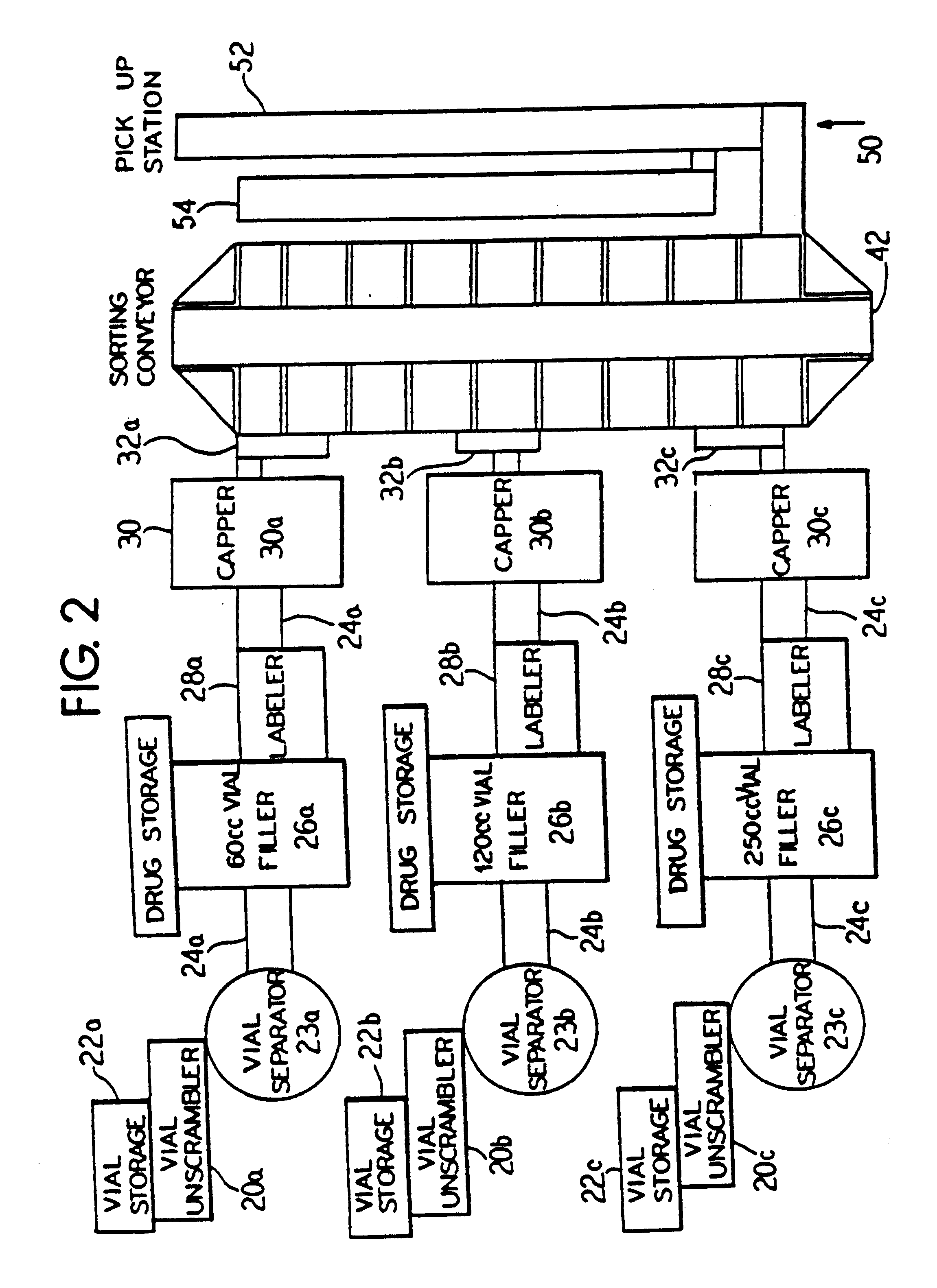

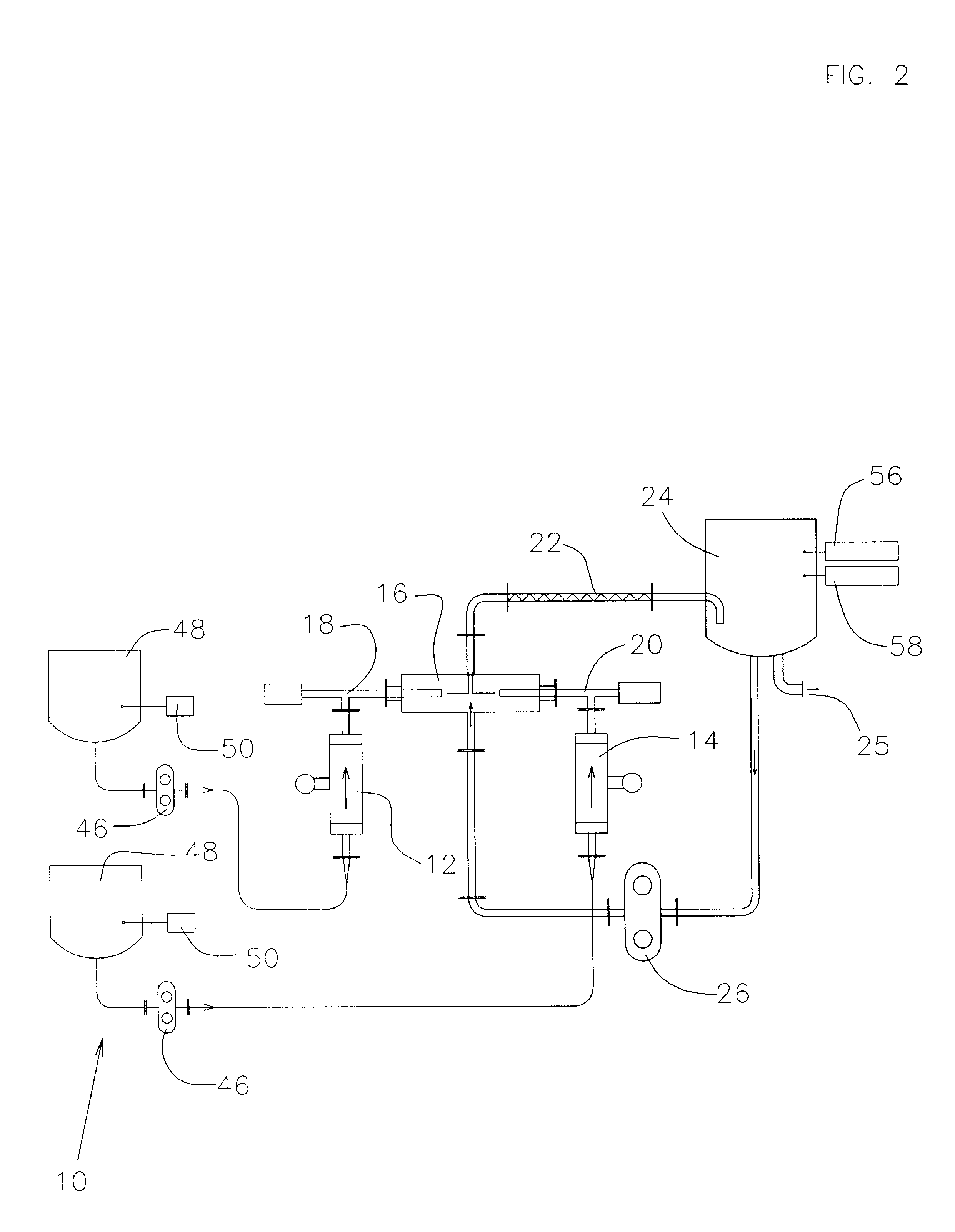

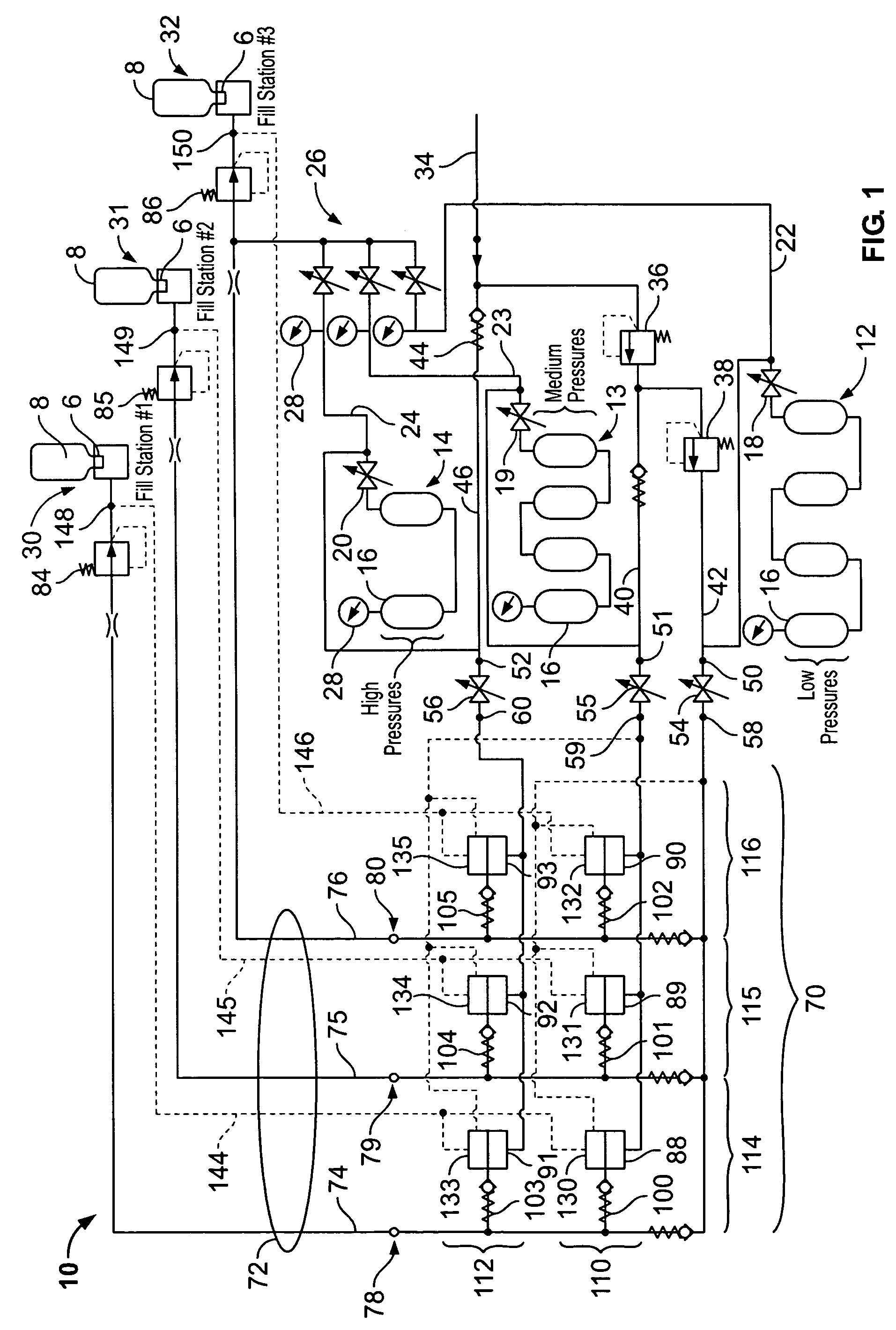

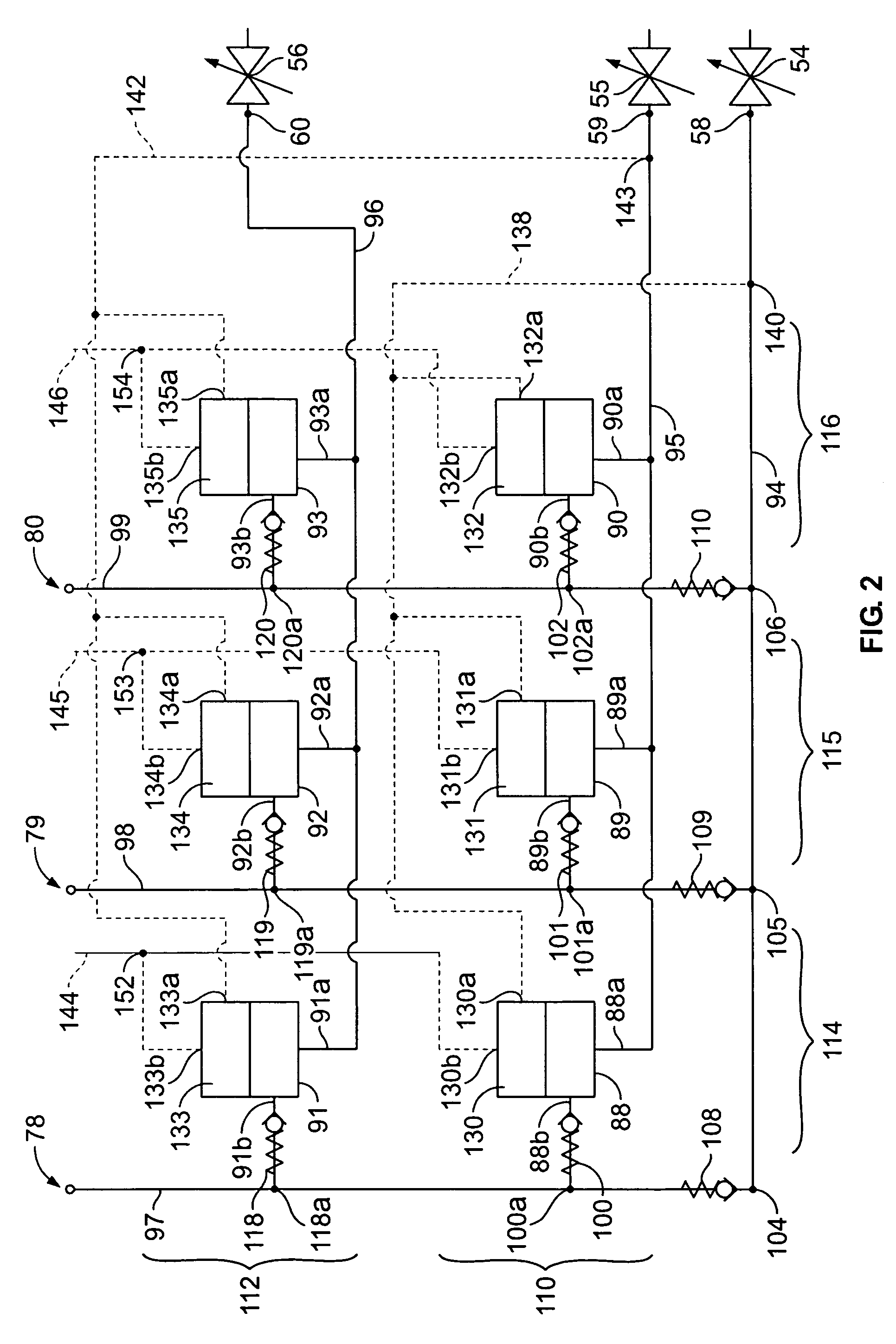

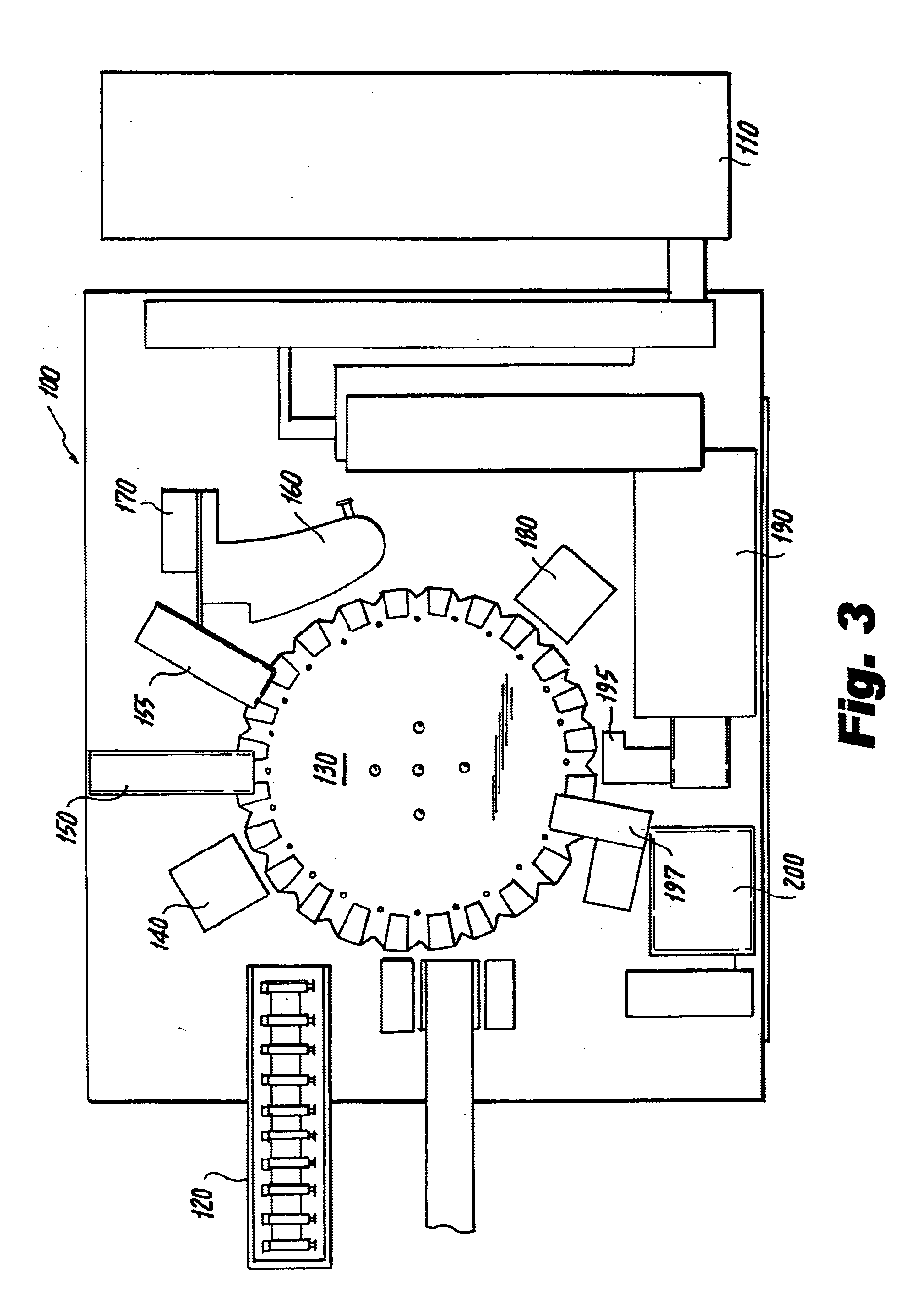

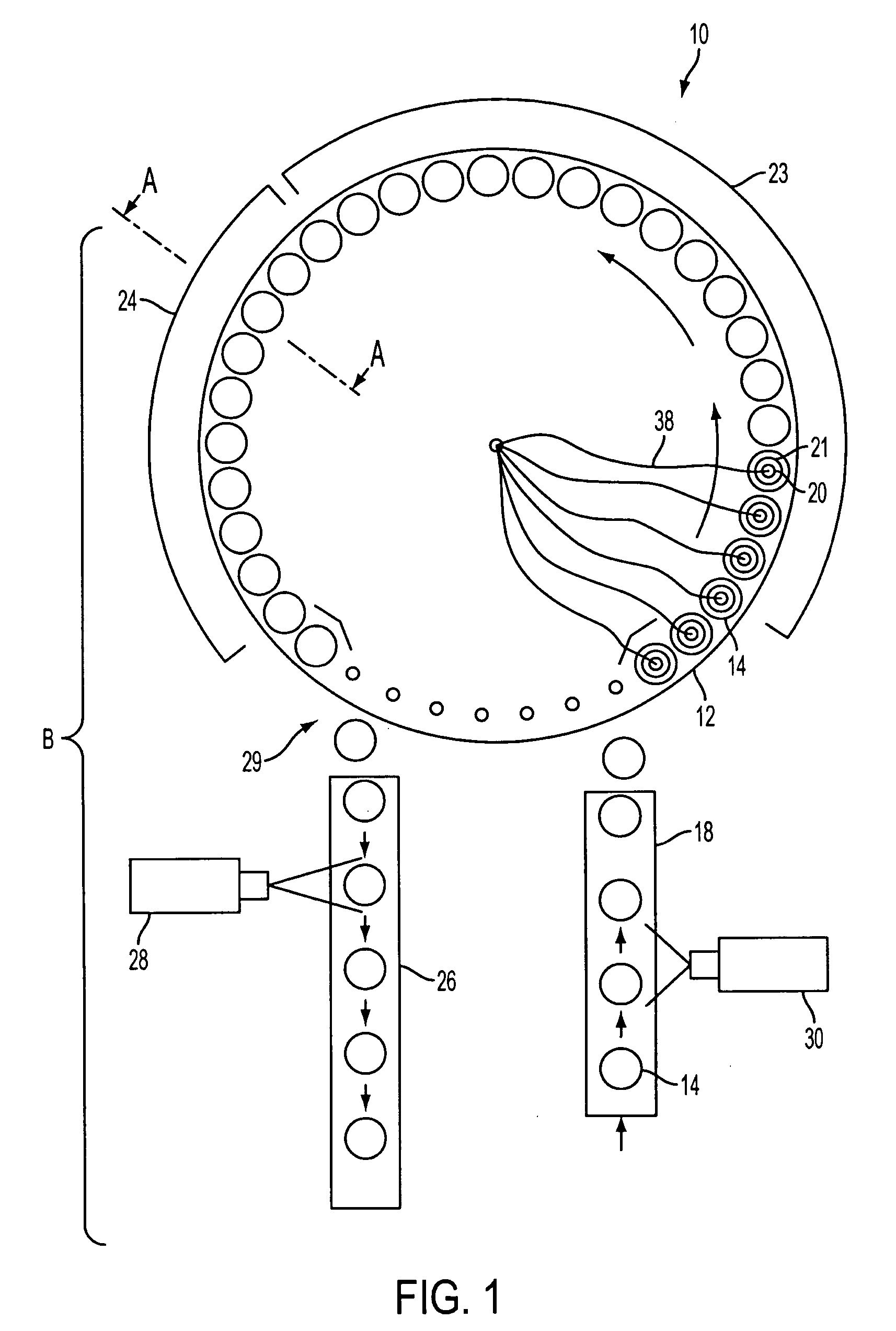

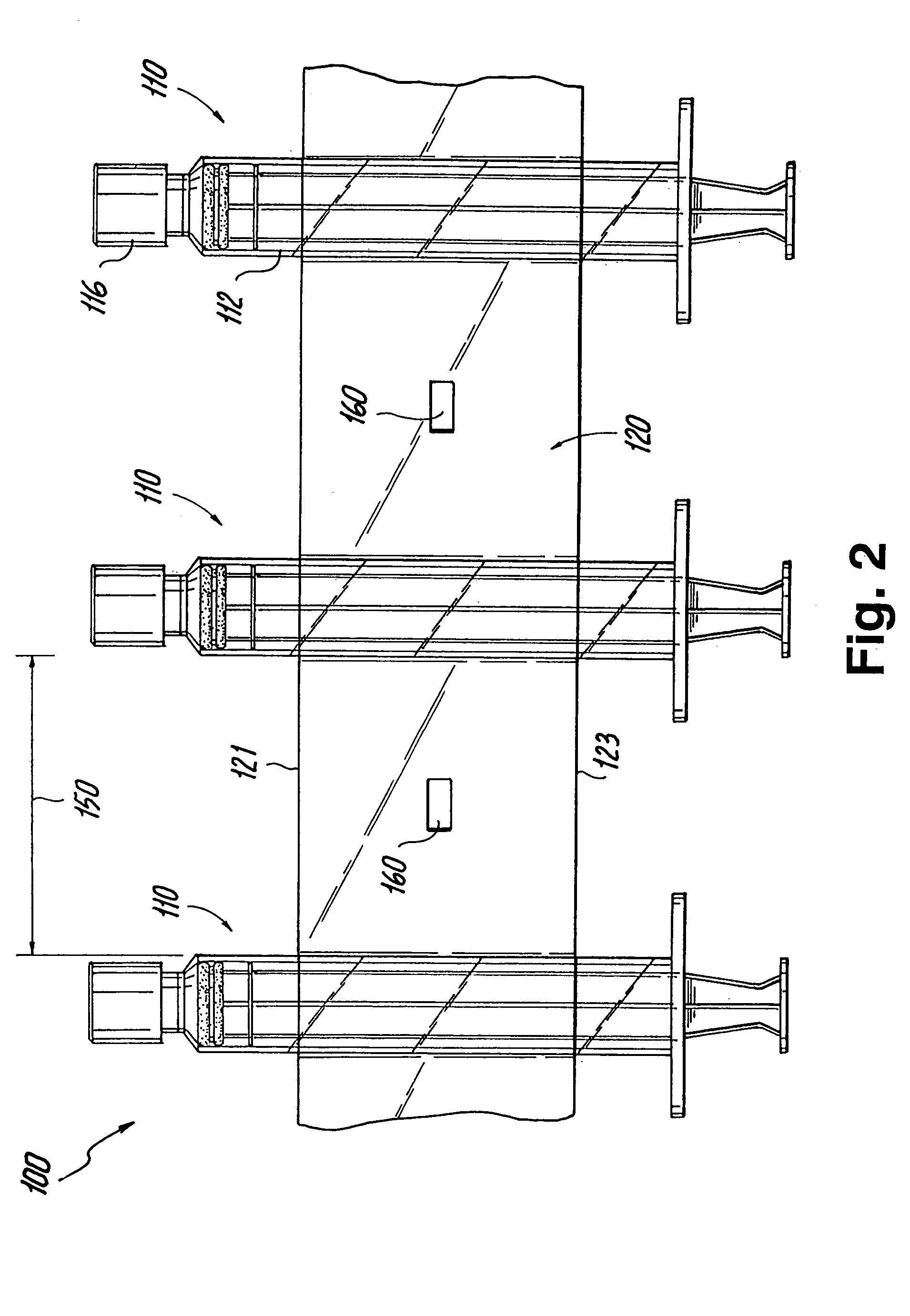

Automated prescription vial filling system

InactiveUSRE37829E1Reduction and inventoryLow costDrug and medicationsDigital data processing detailsMedical prescriptionBiomedical engineering

A method and apparatus for dispensing drugs, wherein a patient's order of one or more prescriptions is automatically filled. Various drugs are stored in three or more filler lines. A vial size is assigned to each line. When a prescription is filled, it is automatically assigned to a line in view of the vial size requirements and processed accordingly. Provisions are made for the inability to fill a prescription or order. Subsequently, all of the patient's prescriptions are collected and made available as a single order.

Owner:AUTOMED TECH

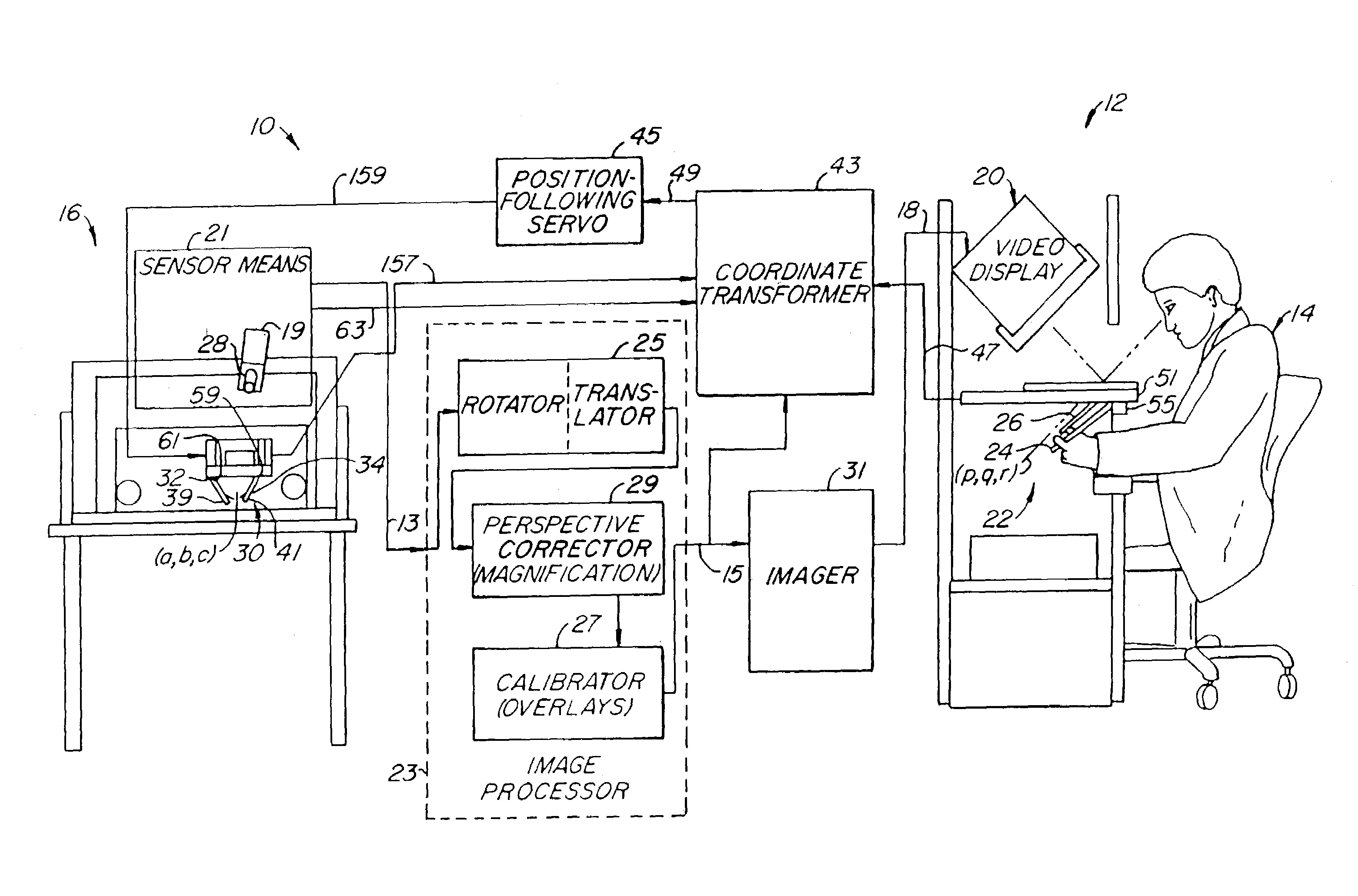

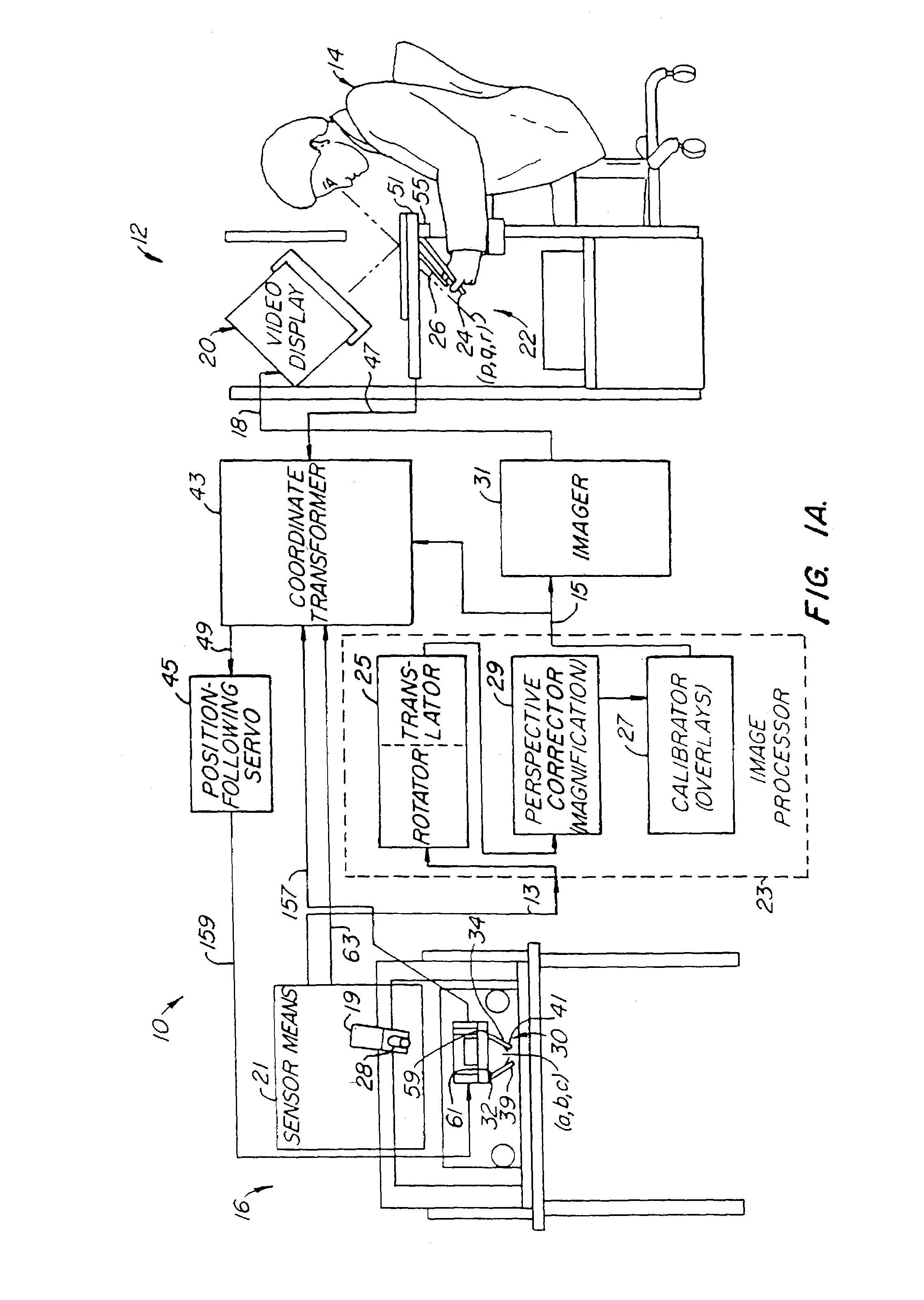

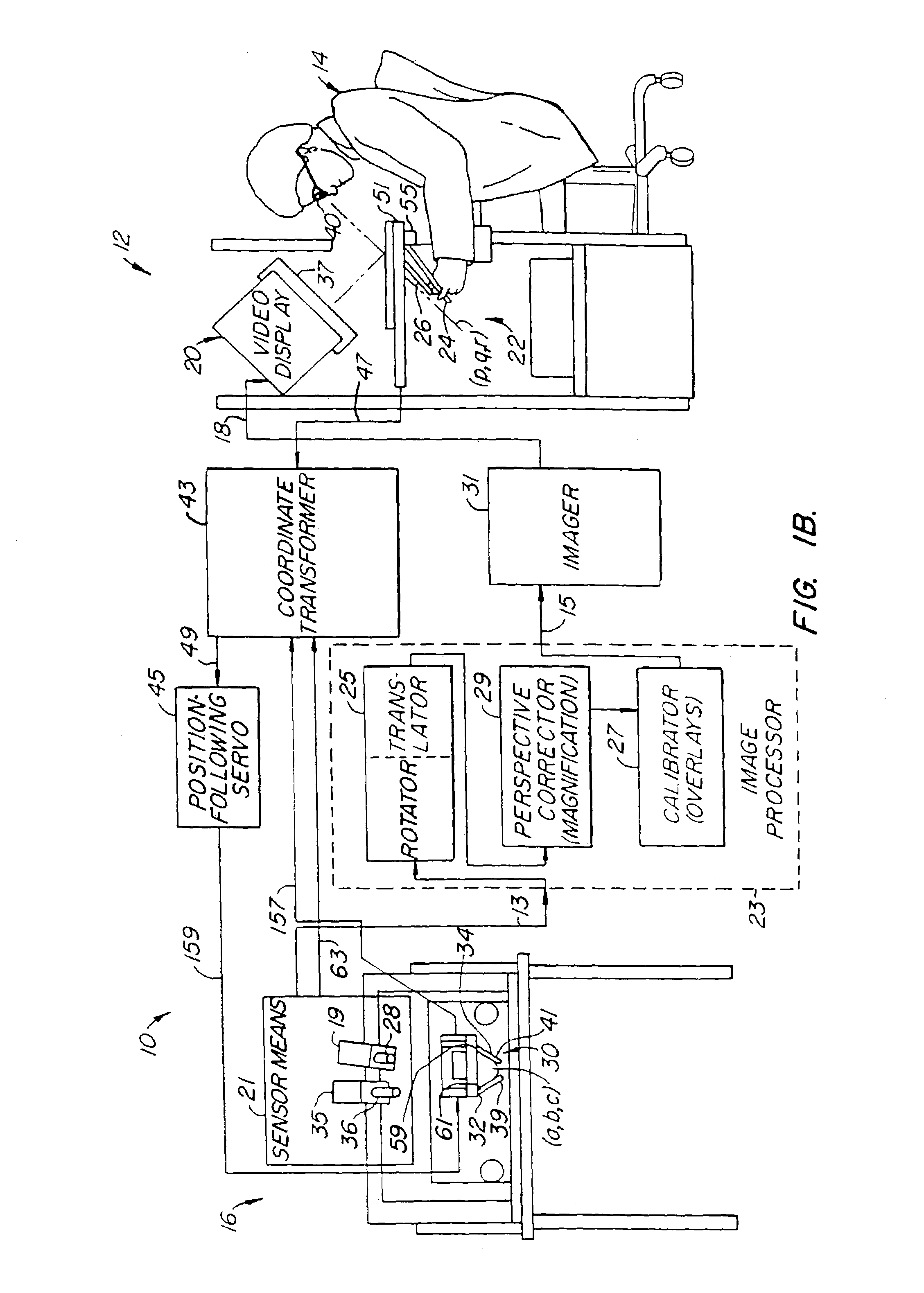

Method and apparatus for transforming coordinate systems in a telemanipulation system

In a telemanipulation system for manipulating objects located in a workspace at a remote worksite by an operator from an operator's station, such as in a remote surgical system, the remote worksite having a manipulator with an end effector for manipulating an object at the workspace, such as a body cavity, a controller including a hand control at the control operator's station for remote control of the manipulator, an image capture device, such as a camera, and image output device for reproducing a viewable real-time image, the improvement wherein a position sensor associated with the image capture device senses position relative to the end effector and a processor transforms the viewable real-time image into a perspective image with correlated manipulation of the end effector by the hand controller such that the operator can manipulate the end effector and the manipulator as if viewing the workspace in true presence. Image transformation according to the invention includes translation, rotation and perspective correction.

Owner:SRI INTERNATIONAL

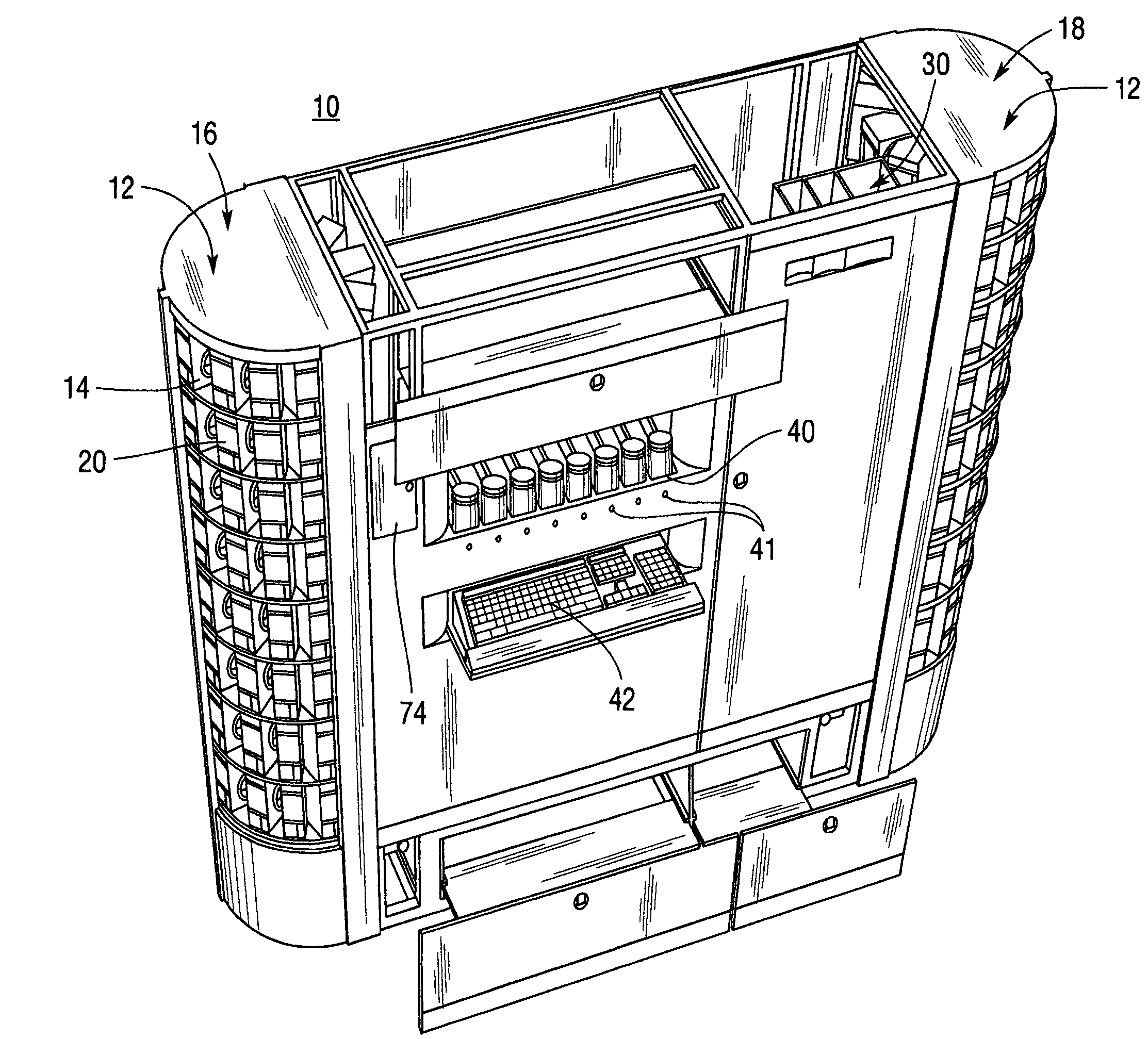

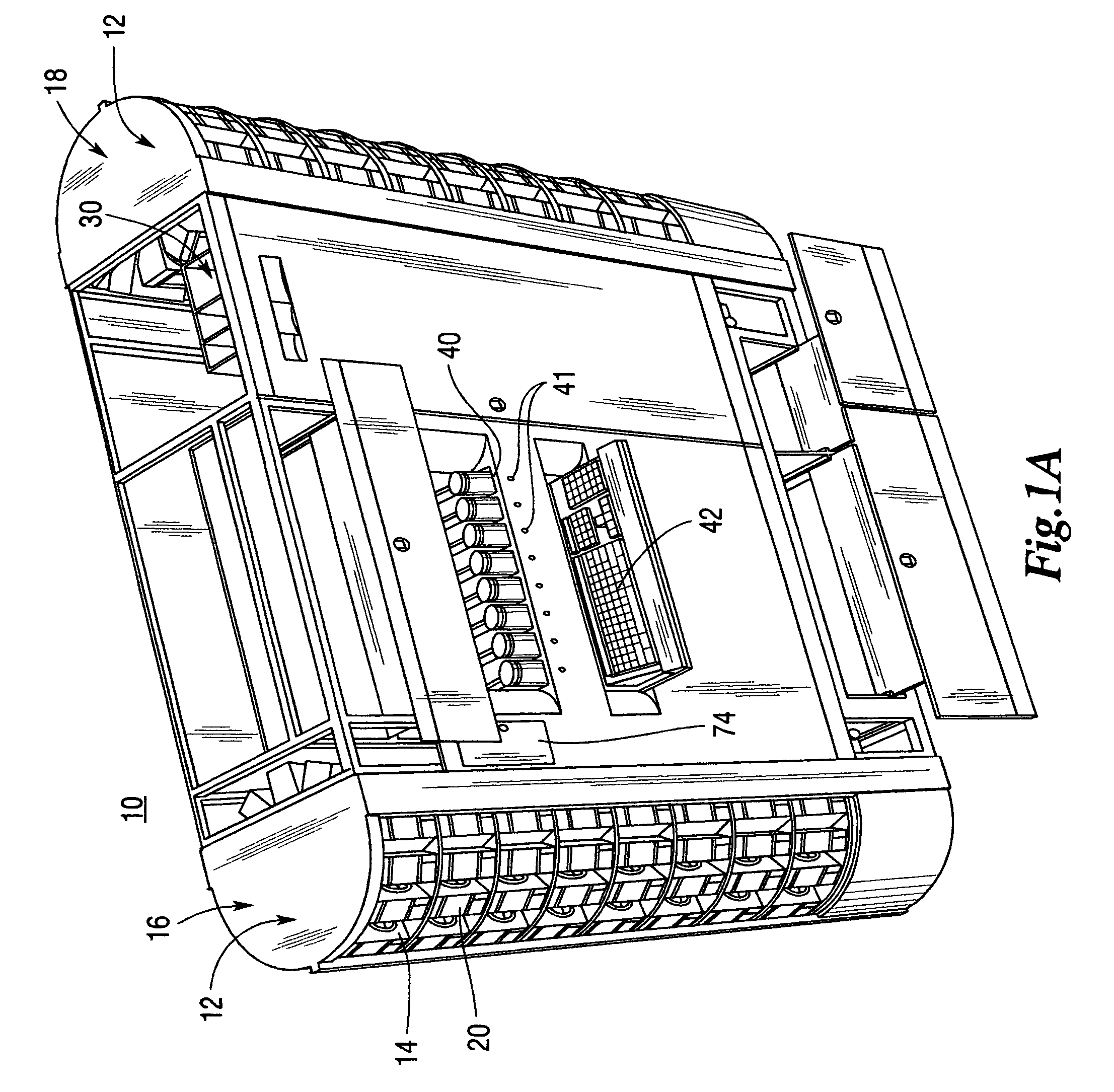

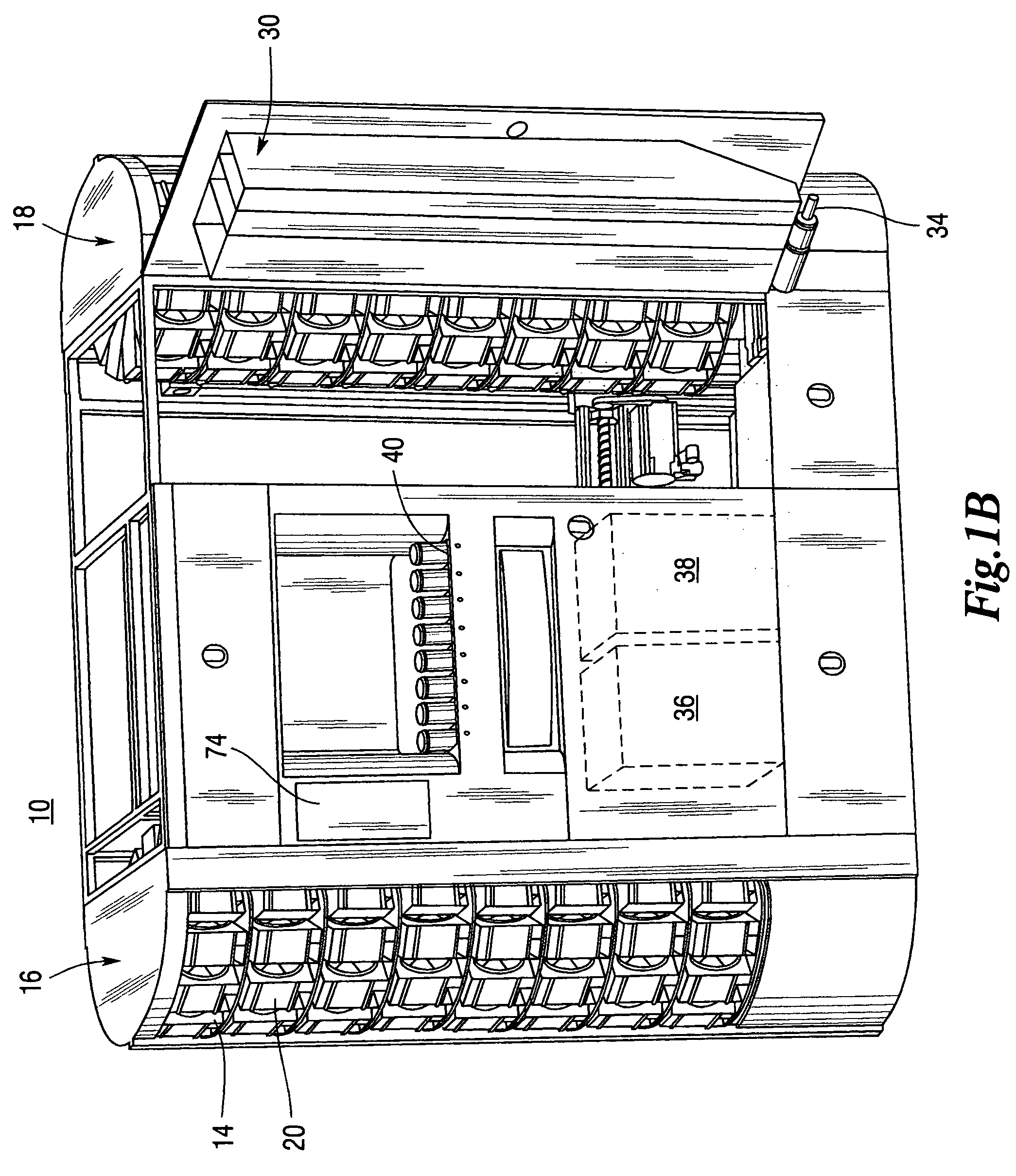

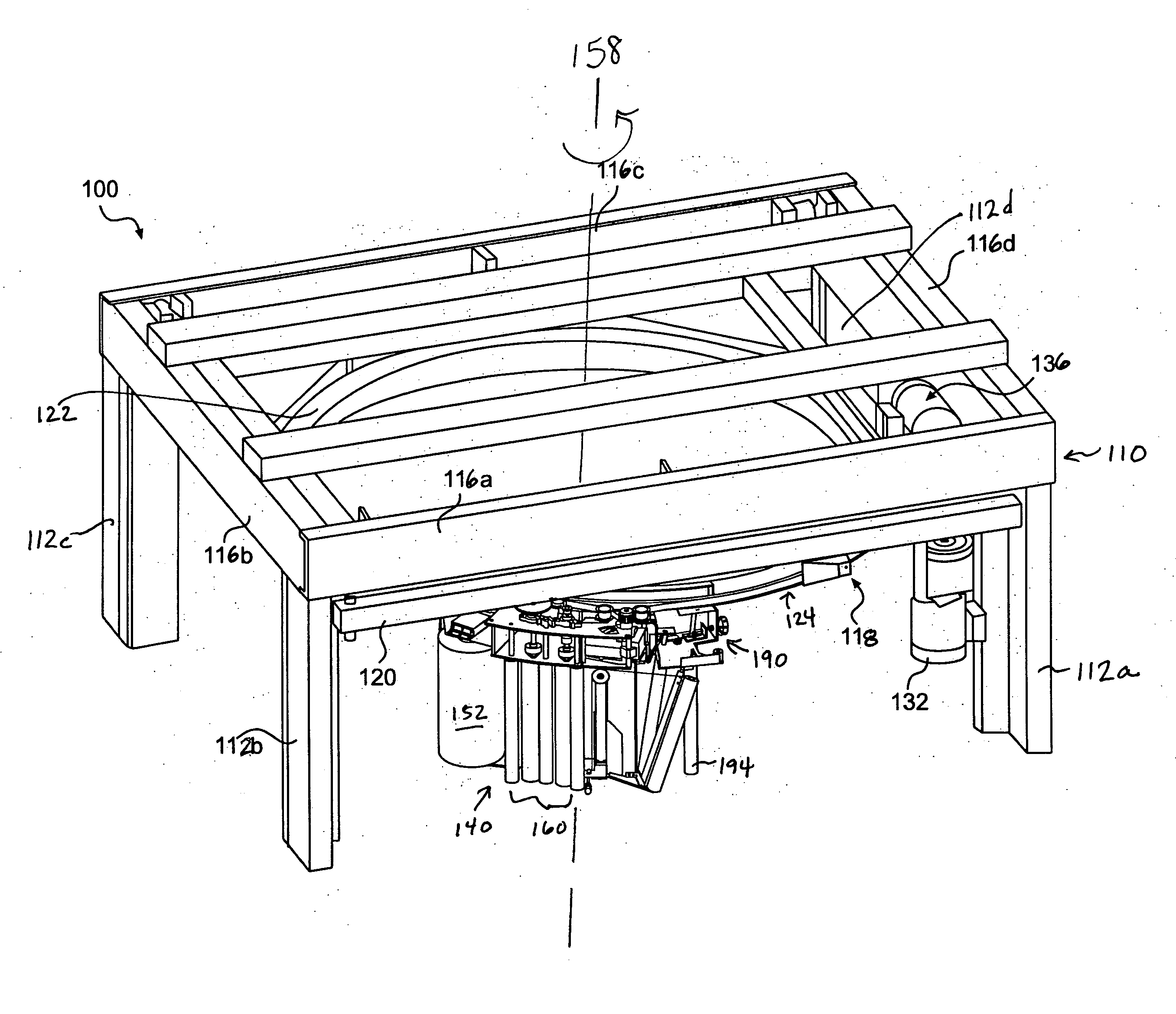

Prescription filling apparatus implementing a pick and place method

ActiveUS7228198B2Easy to scaleSmall footprintDigital data processing detailsSolid materialComputer control systemOutput device

An apparatus for filling vials comprises a shelving unit defining an array of storage locations. The shelving unit may be an array in an XY plane or one or more carousels. A plurality of storage containers are provided, each removably carried by one of the storage locations. A counting and dispensing unit, a source of vials, a label printer and application unit or units, and an output device are also provided. The output device may take a variety of forms such as an output chute, which is preferably used when a capping unit is provided, an output conveyor, a plurality of output lanes, and an output carousel, which may be a dedicated carousel or a portion of the carousel providing the plurality of storage locations. A computer controlled engagement device provides motion in a Z direction. The engagement device may be comprised of a first stage for engaging the storage containers and a second stage for engaging the vials. A computer controlled system carries the engagement device and moves the engagement device in XY directions among the plurality of storage locations, counting and dispensing unit, source of vials, label printer and application unit, and output device. Methods of operating and refilling the vial filling apparatus are also disclosed.

Owner:MCKESSON AUTOMATION SYST

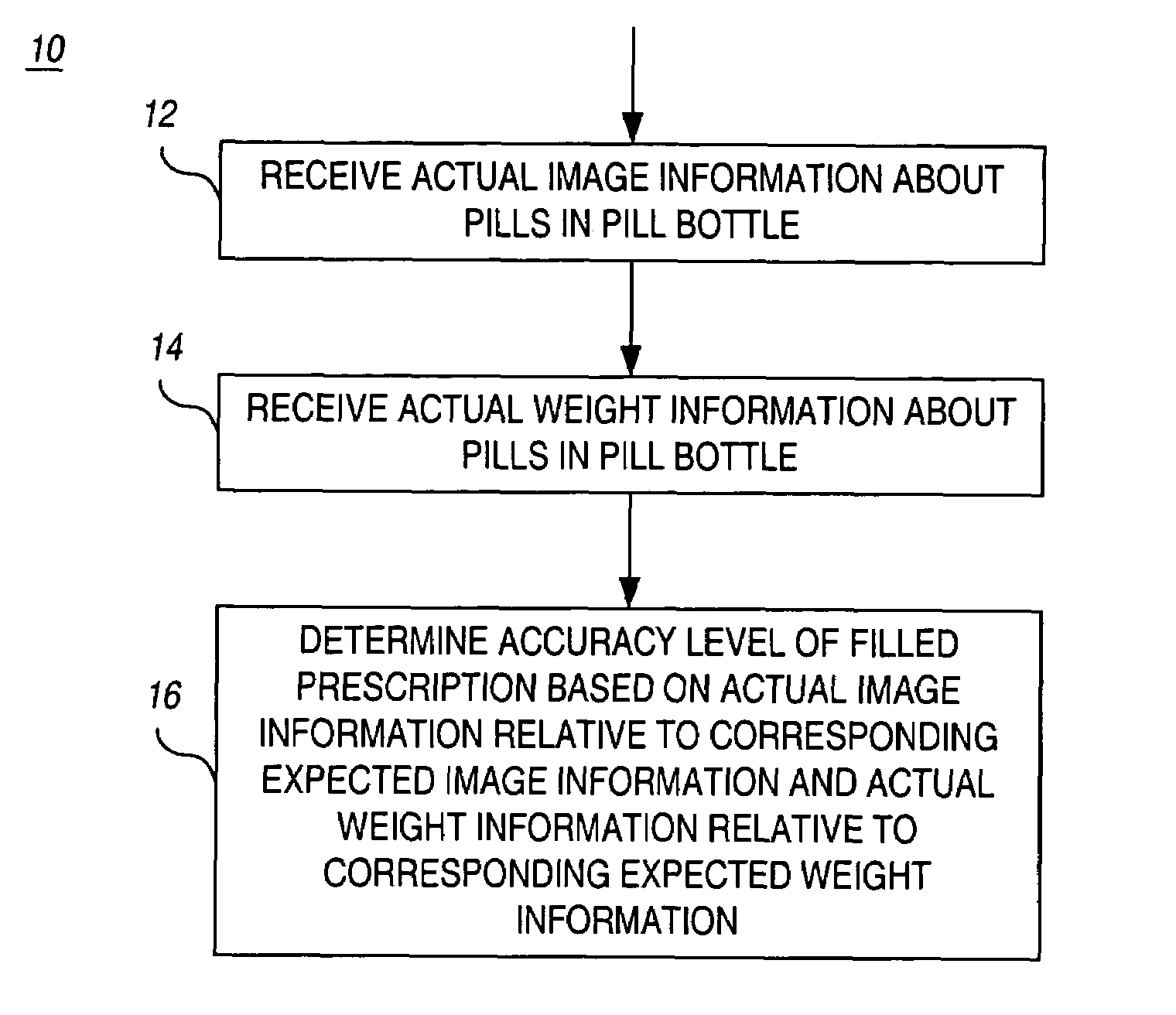

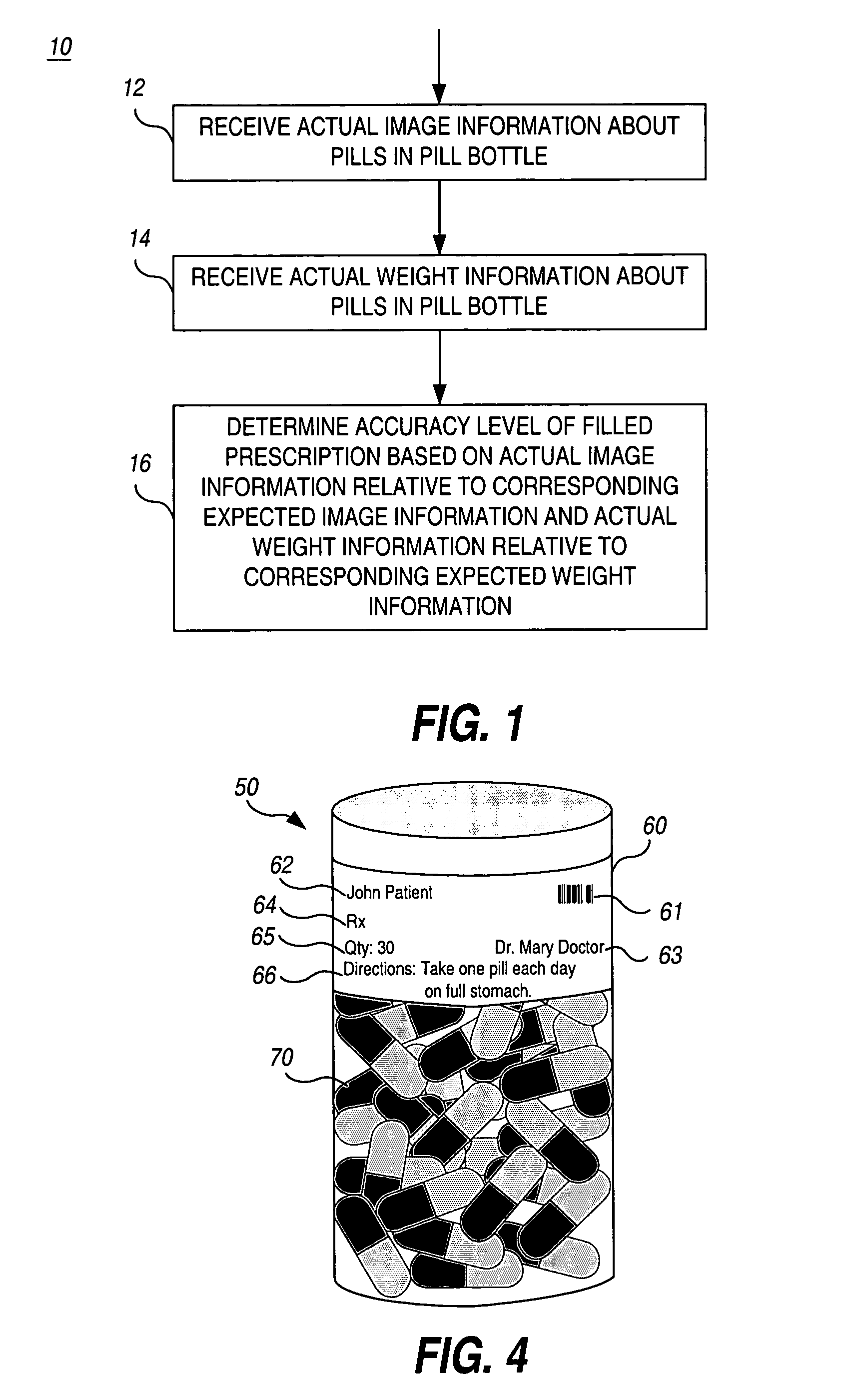

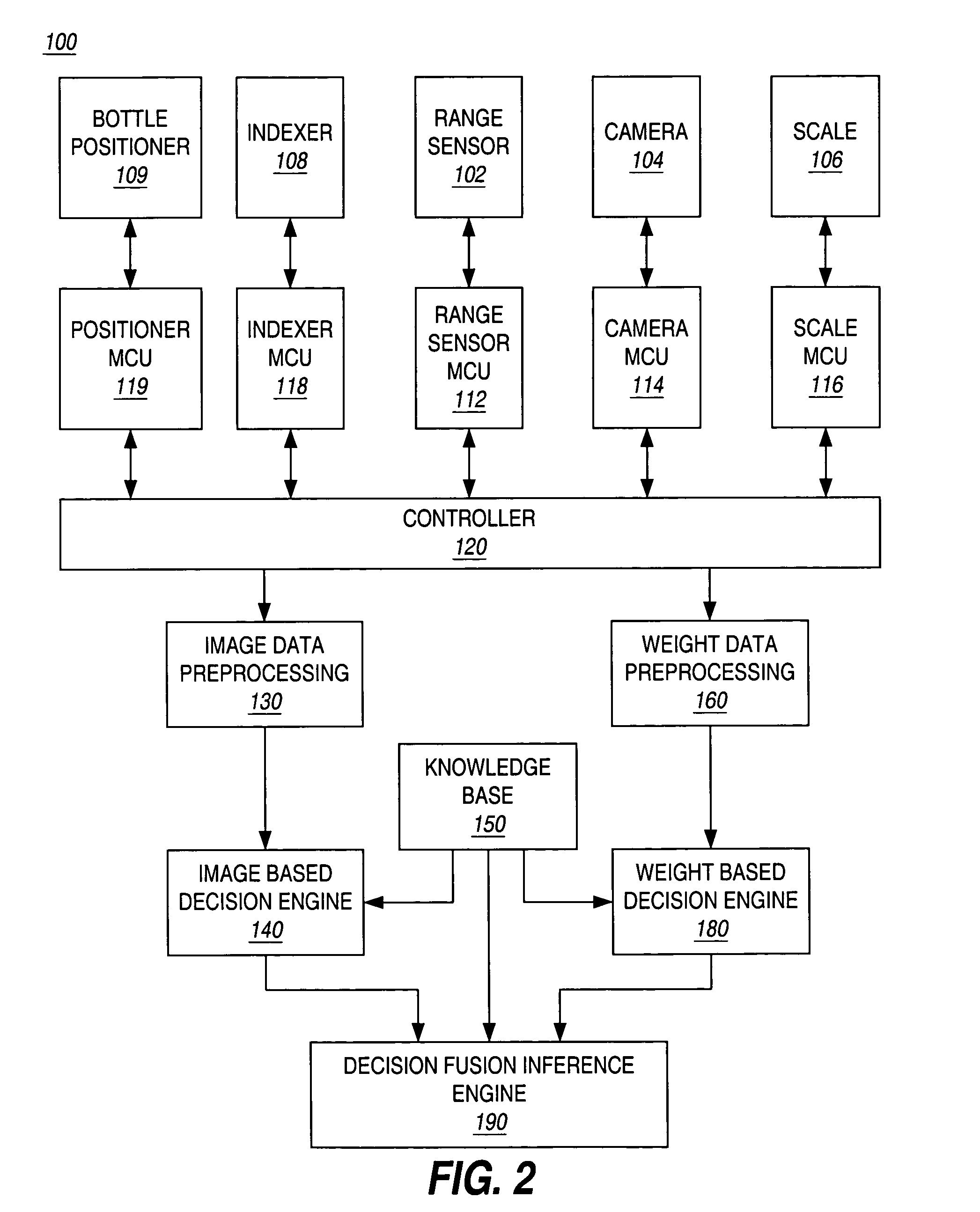

Apparatus and method for automatic prescription verification

InactiveUS7028723B1Eliminate unnecessary idle timeLiquid fillingDrug and medicationsThe InternetOrder form

An apparatus and method are used to perform the verification of a pharmaceutical prescription after it is filled but prior to shipment. Due to the high volume of mail / internet orders, the analysis is to be performed on the whole prescription, not on each individual pill of the prescription. The apparatus automatically gathers information about the pills contained in a pill bottle, including image and weight information, and incorporates a decision-making engine to decide whether the content of the pill bottle matches the prescription order.

Owner:ALOUANI ALI TAHOR +1

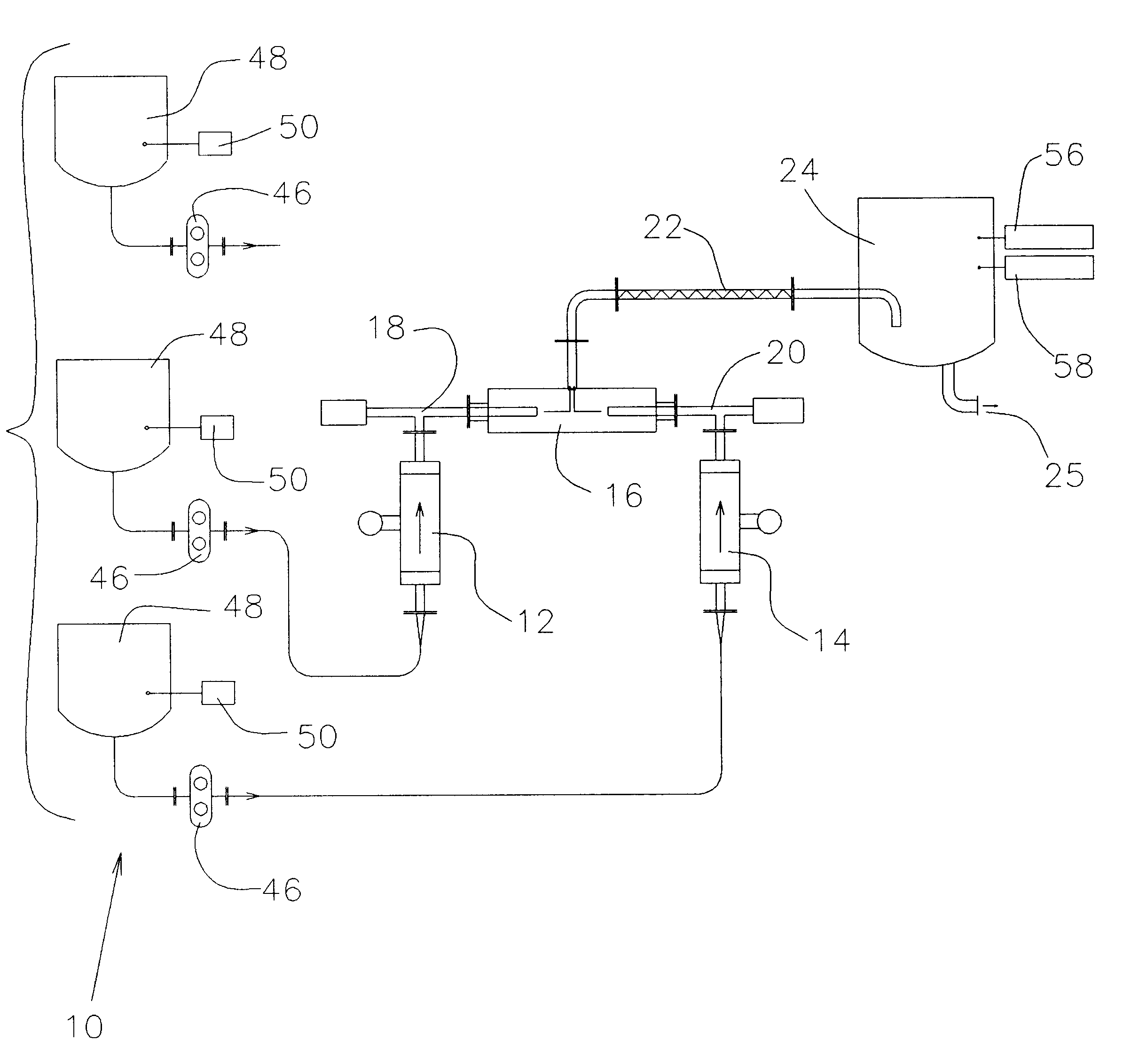

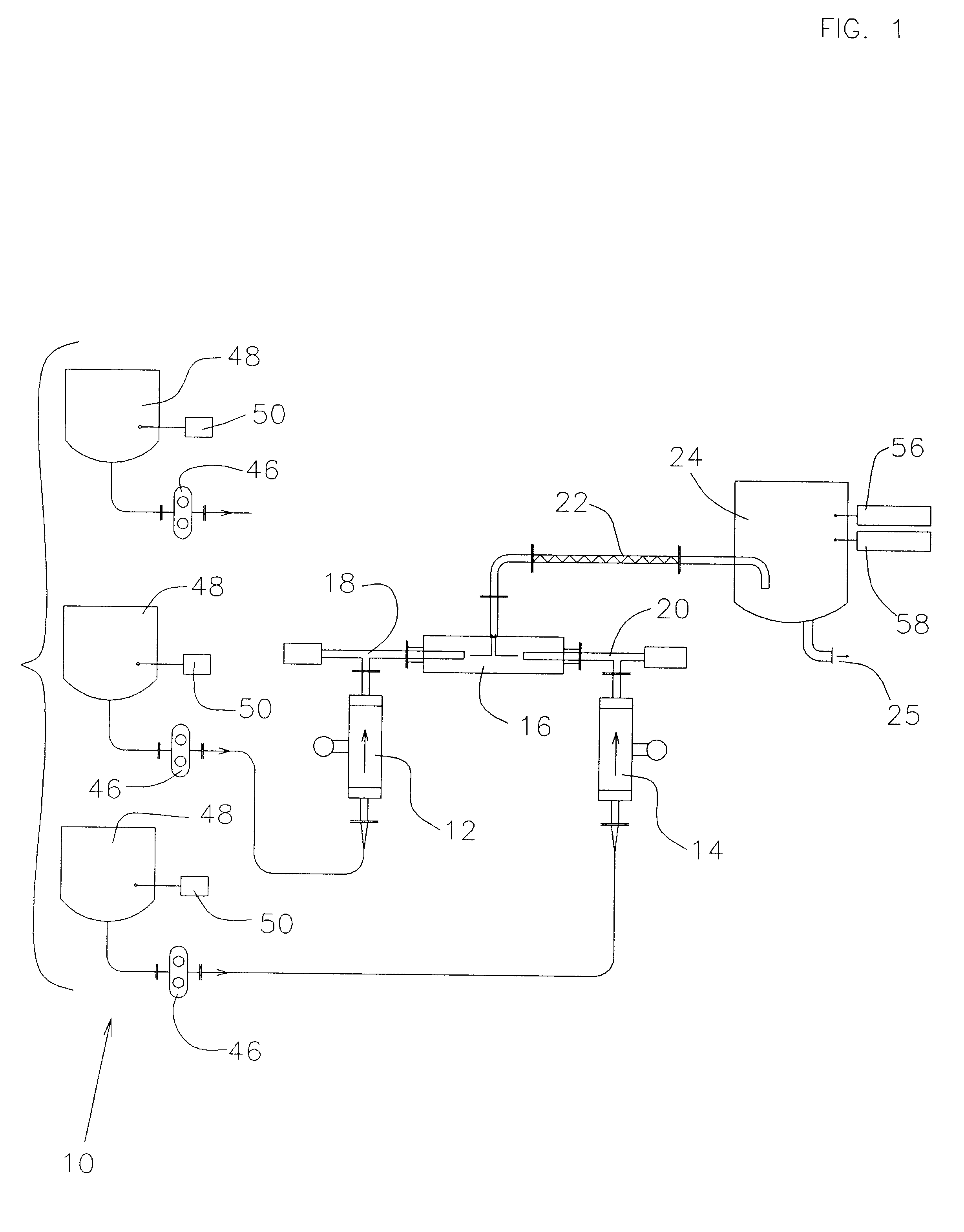

Continuous liquid stream digital blending system

InactiveUS6186193B1More disadvantageSimplifies software and set-up computationLiquid fillingControlling ratio of multiple fluid flowsHybrid systemDigital clock

The present invention consists of a method and apparatus providing for the continuous stream blending, preferably on a mass ratio basis, of two or more liquids. Each individual liquid stream is synchronously dosed in precise mass ratio to a common mixing point. The flow of each stream is on-off or digital. Repeated mass ratio doses of defined and matching flow interval, referred to as synchronous digital flow, interspersed with a defined interval of no flow, constitutes digital flow at a net rate sufficient to meet or exceed some required take-away of the blended liquids. In one preferred embodiment, each dose stream flow is produced and measured by a four element apparatus preferably consisting of a servo motor and controller, a precision positive displacement pump, a Coriolis mass meter and a precision flow stream shut-off device. The servo motor and controller establish and control a periodic and intermittent flow rate necessary to displace a defined mass dose in a precisely defined flow interval. The flow interval is measured against a precision millisecond digital clock. The Coriolis mass meter is used only to totalize mass flow to define the desired mass dose during the defined digital flow interval. The flow stream shut-off device ensures precise delivery of the mass dose to the common mixing point. The flow rate of a stream is automatically adjusted by the control electronics until the required mass dose is delivered in the defined flow interval.

Owner:ODEN MACHINERY

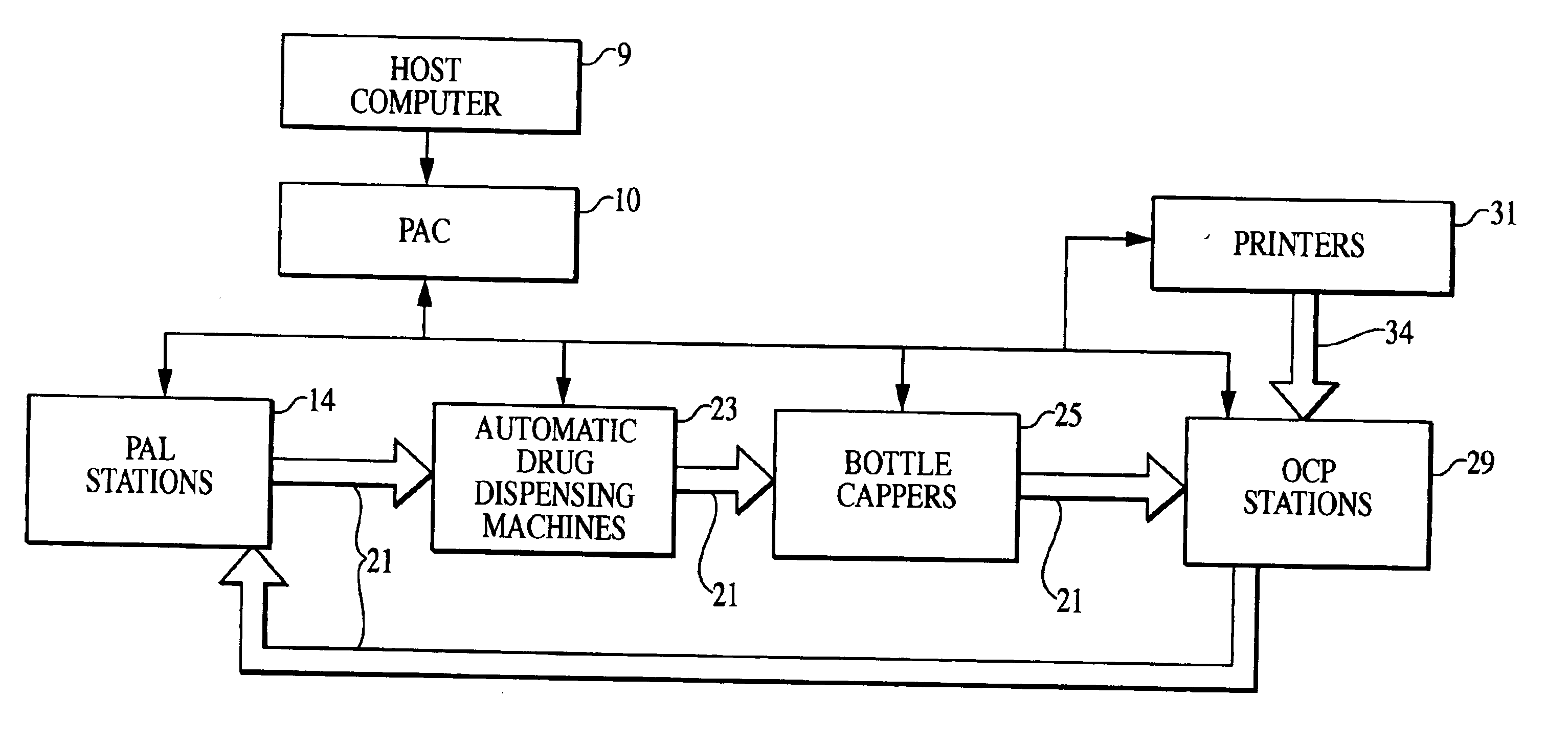

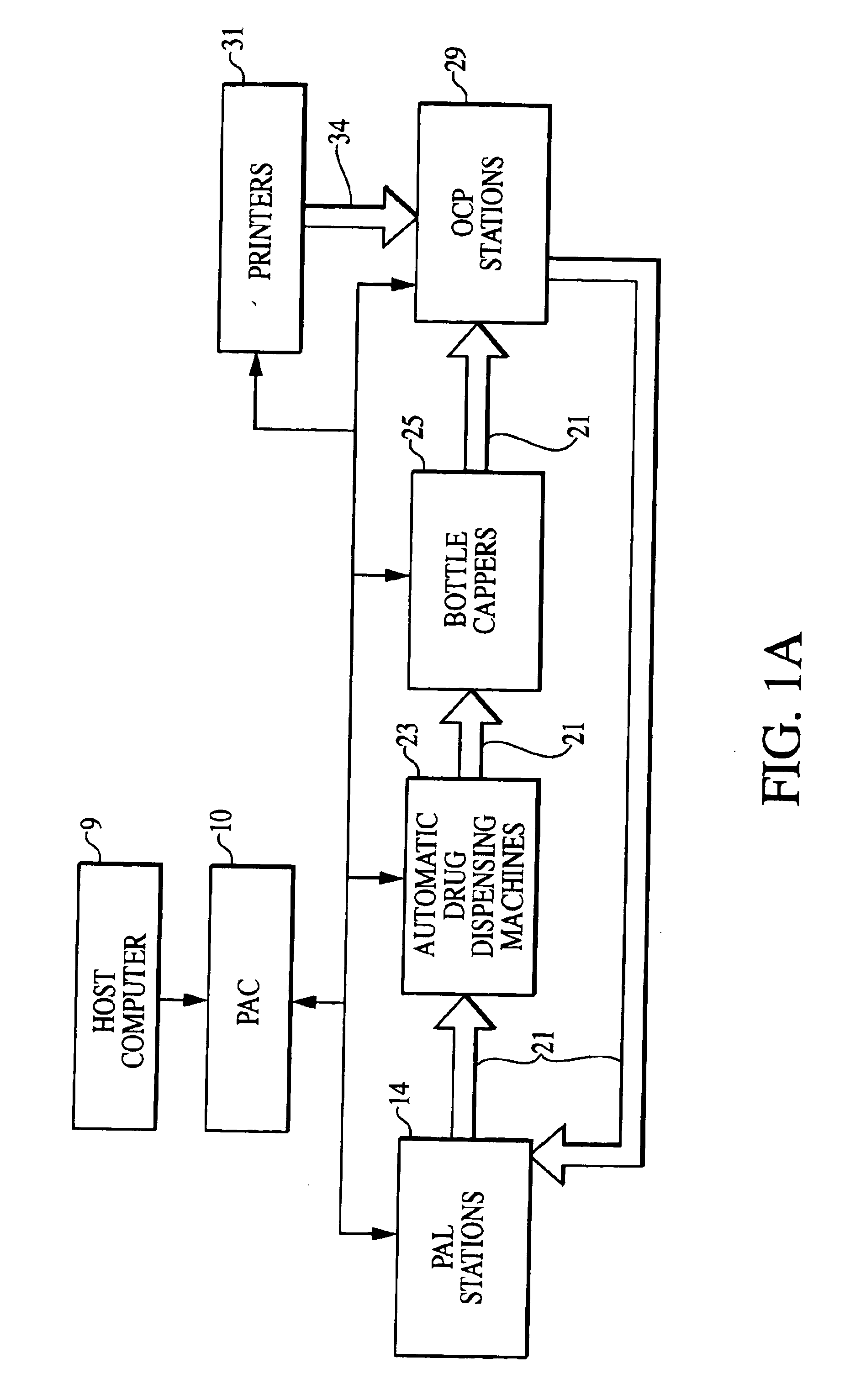

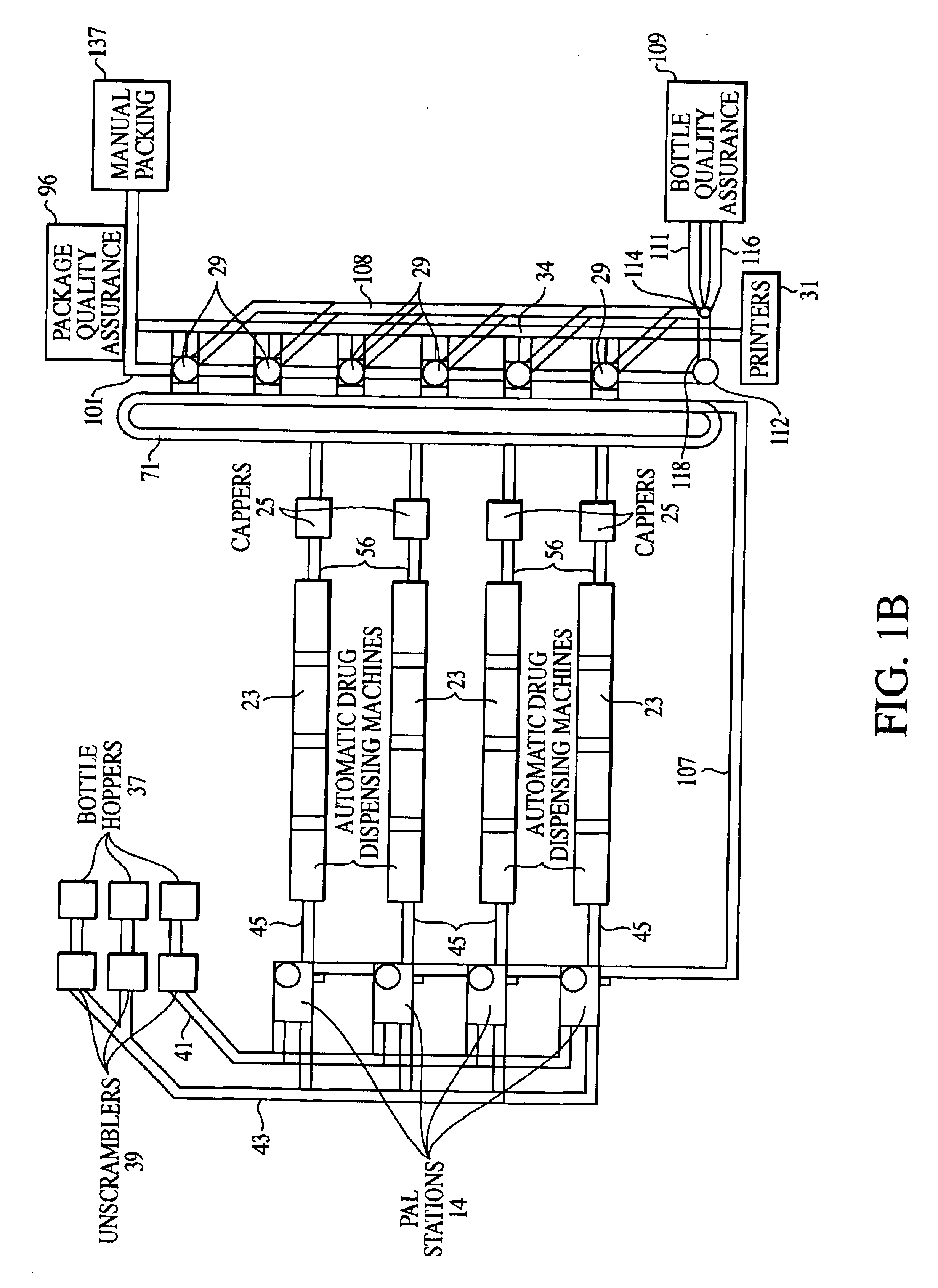

Automated prescription filling system/method with automated labeling and packaging system/method automated order consolidation system/method

Computer assisted systems, methods and mediums for filling one or more orders. One embodiment of the present invention is a system that includes an order consolidation station configured to receive at least one bottle containing pills individually counted and / or at least one package containing pharmaceutical products without having been designated for any of the orders when the package was created and / or at least one literature pack optionally including patient specific information. The order consolidation station is further configured to combine automatically the received bottle and / or package and / or literature pack into a container to be sent to a recipient including, for example, mail order pharmacies, wholesalers and / or central fill dealers for subsequent distribution or sale including retailer distribution or sale. The bottle is specifically designated for the order, and the order generally includes at least one prescription for the package.

Owner:EXPRESS SCRIPTS STRATEGIC DEV INC

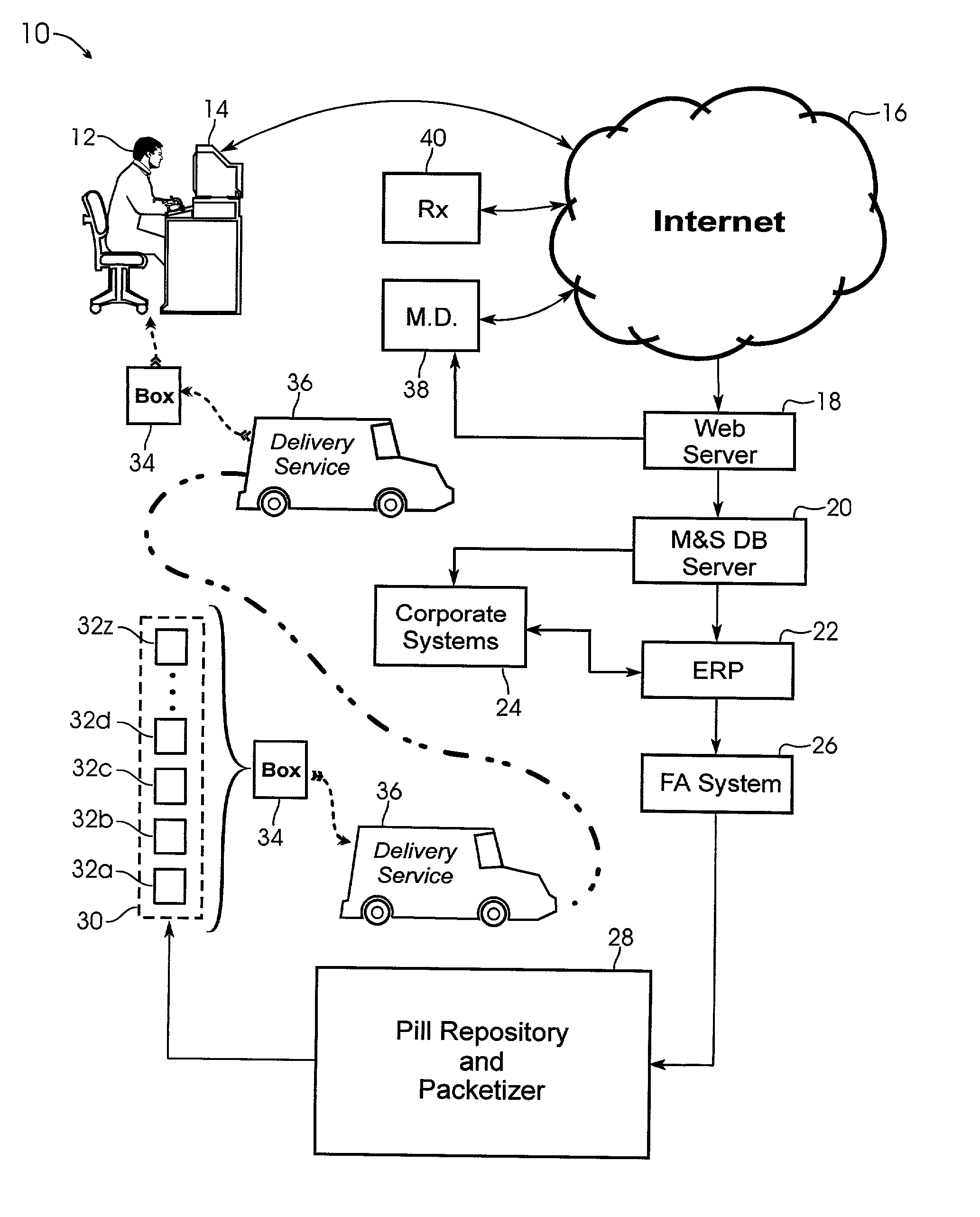

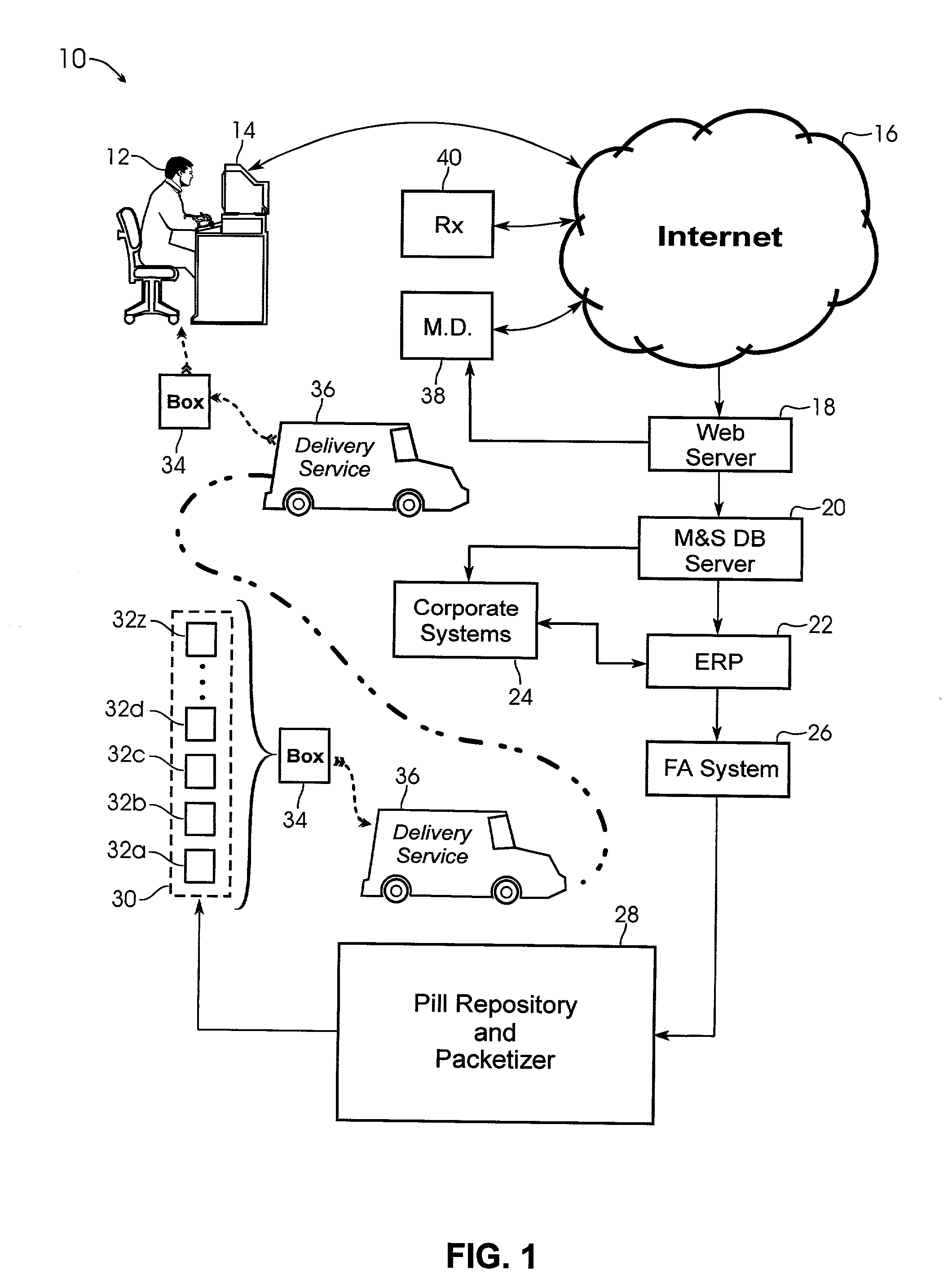

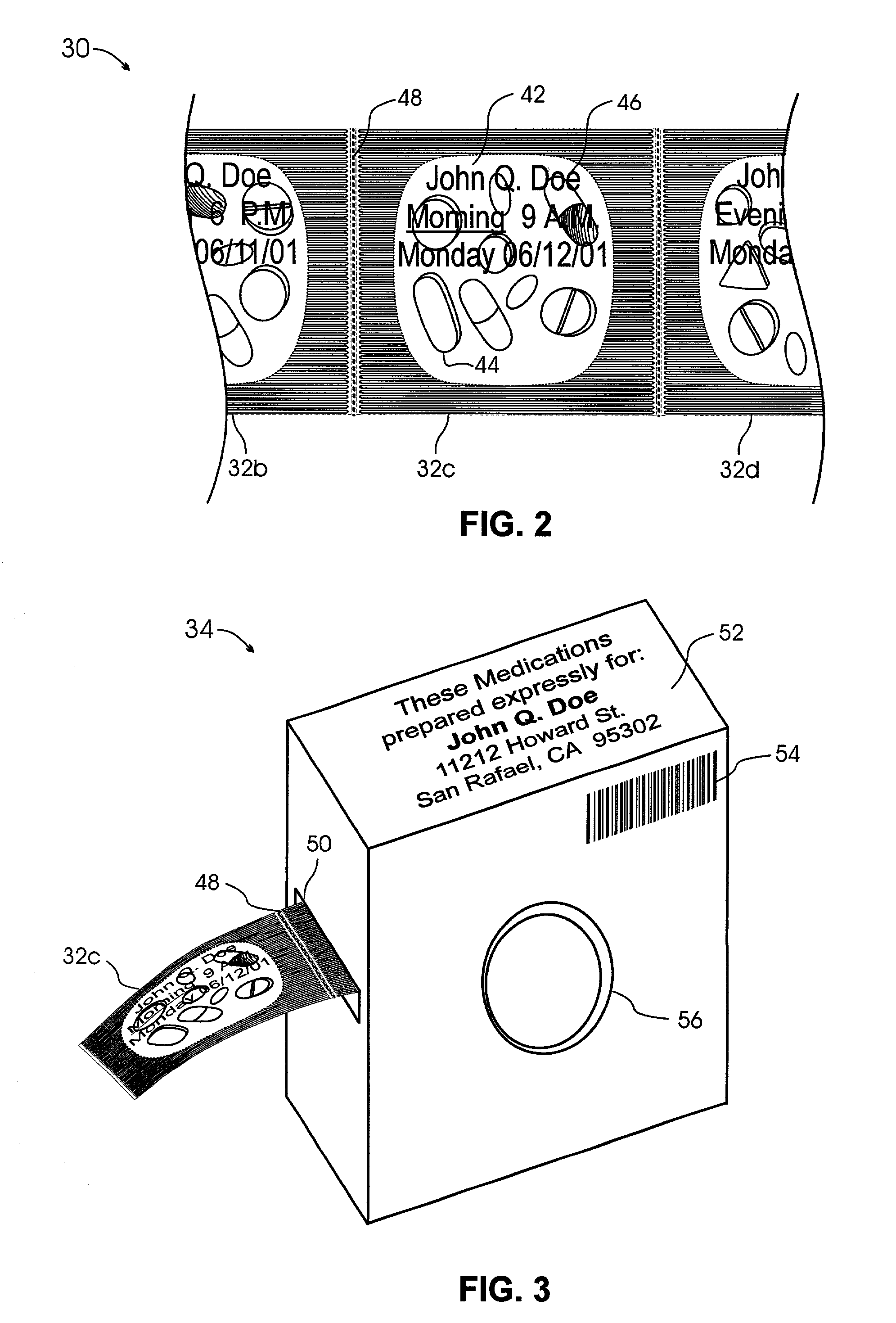

System and method for providing temporal patient dosing

InactiveUS20030200726A1Improve securityImprove reliabilityDrug and medicationsCoin-freed apparatusPersonalizationTime table

A system and method for creating a series of individualized custom doses for a consumer. The individualized doses being delivered in a package or packages, such that each individualized custom dose, comprising a plurality of medications and / or supplements, is individually separable from the remaining doses within the series. By way of example, and not of limitation, a system is described having a web based front-end interface within which the user may establish a dosing schedule, select supplements and / or medications (MS) from an MS database, elect which MS are to be included in each dose, and communicate the order to be processed by a packetizing system. The packetizing system utilizes a conveyance device which interconnects a series of pill dispensing bins. The conveyance device has compartments for collecting a series of doses which are then packetized and shipped for use by the consumer.

Owner:RAST RODGER H

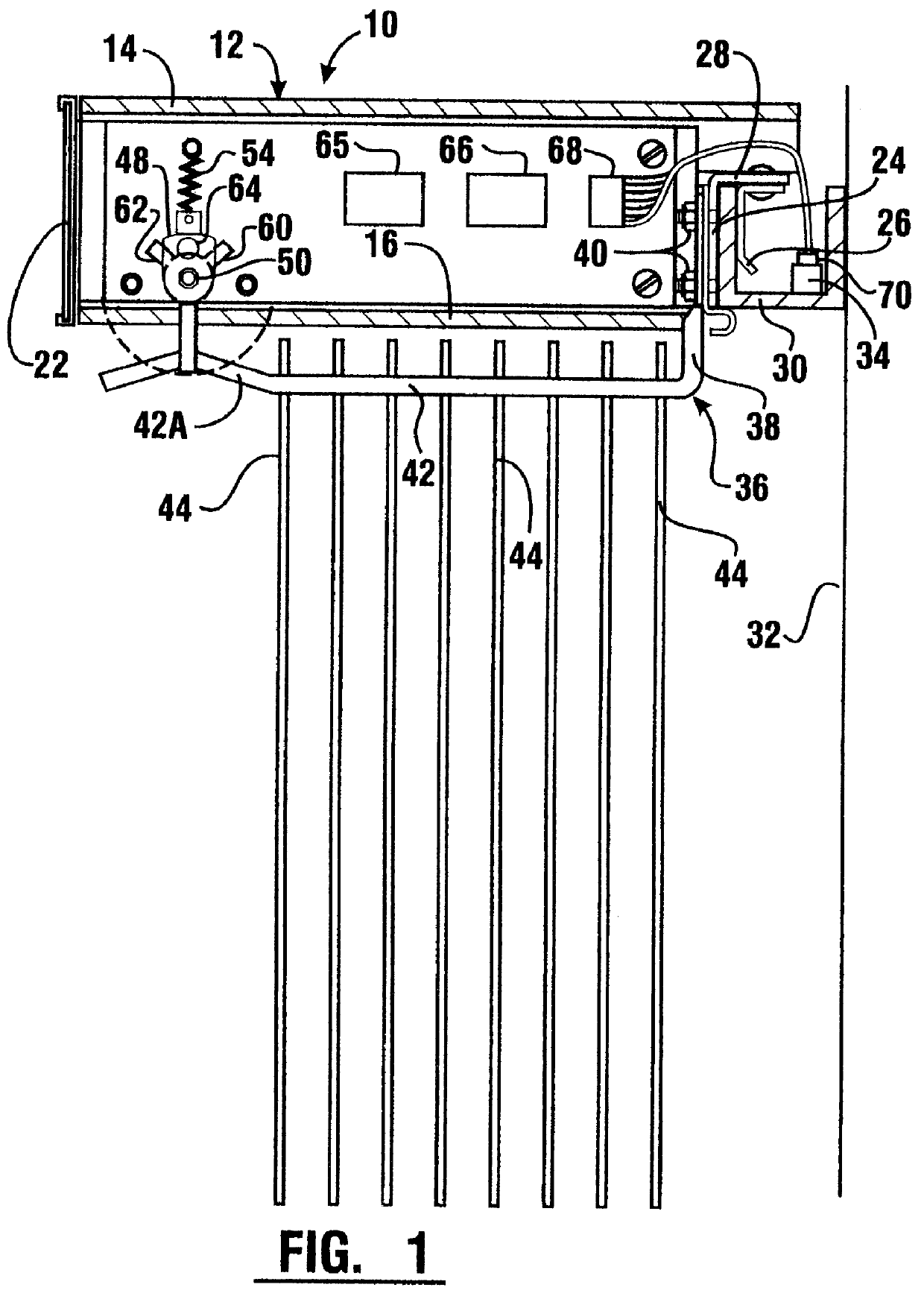

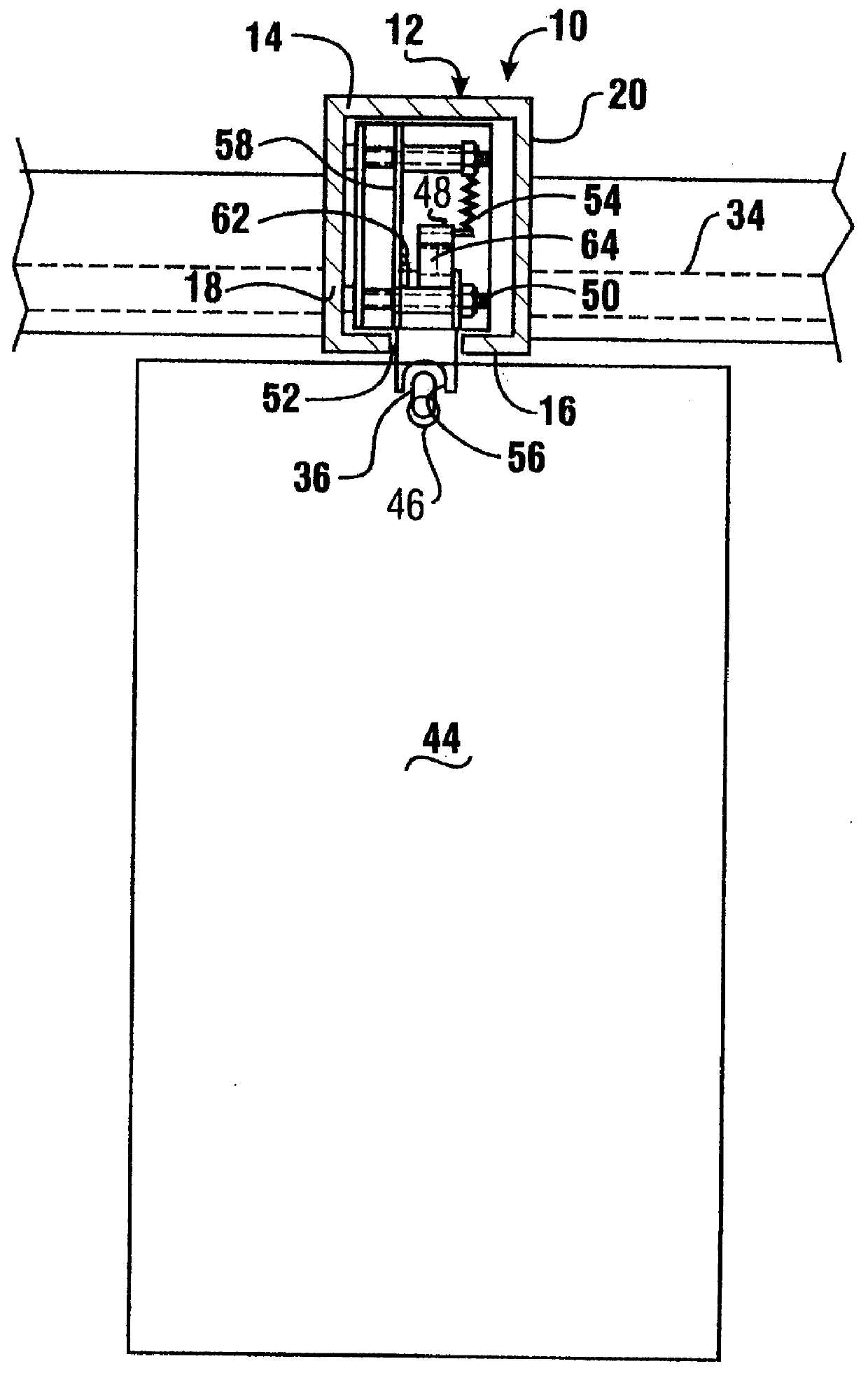

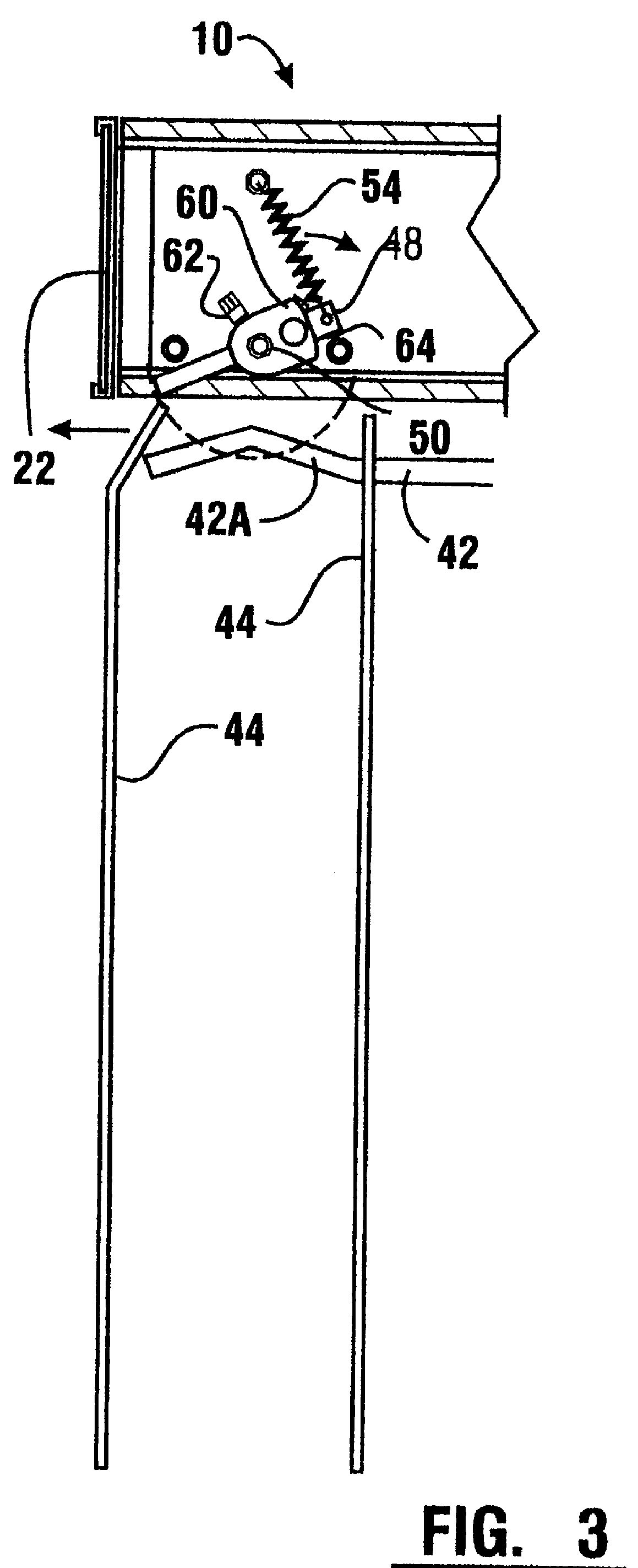

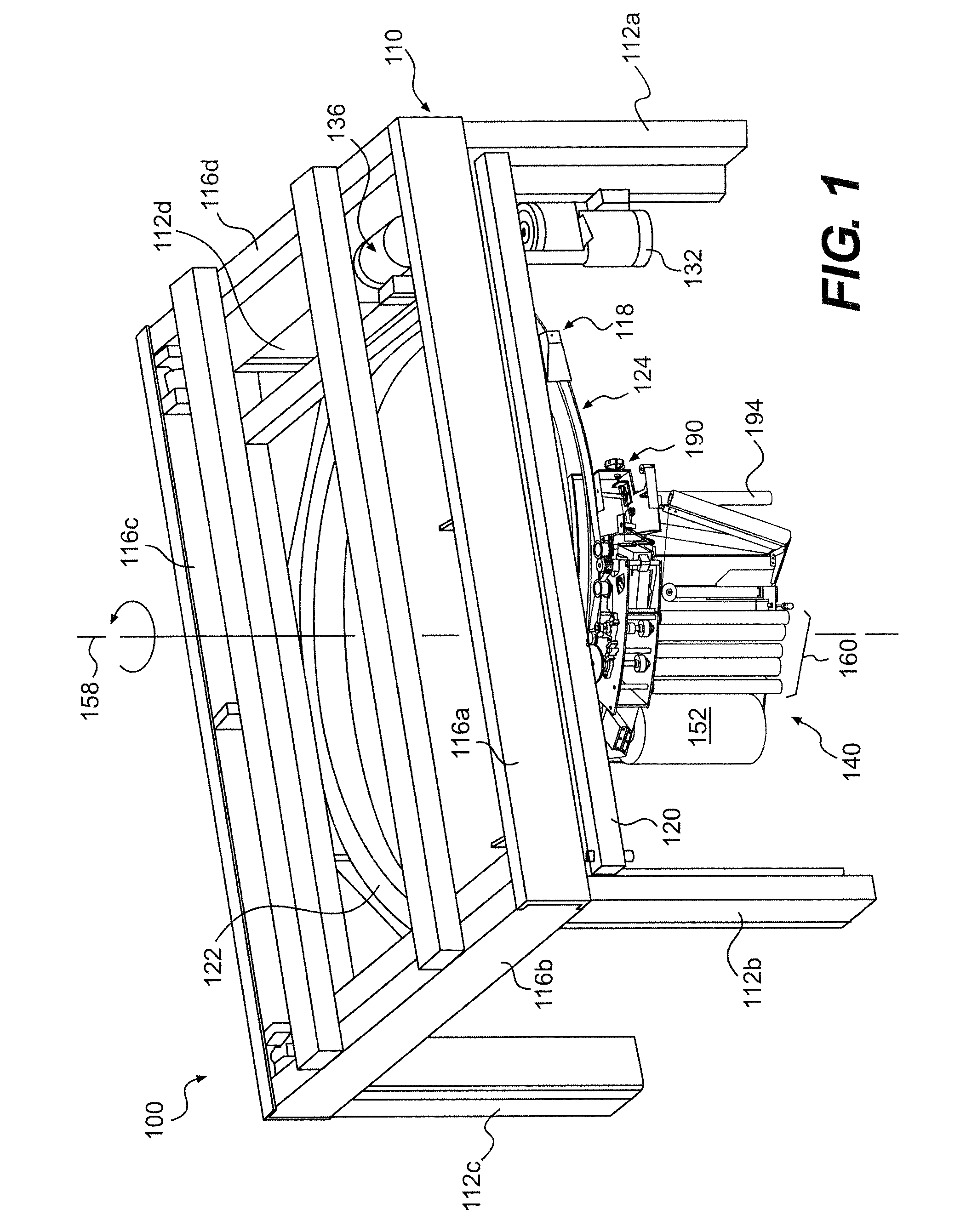

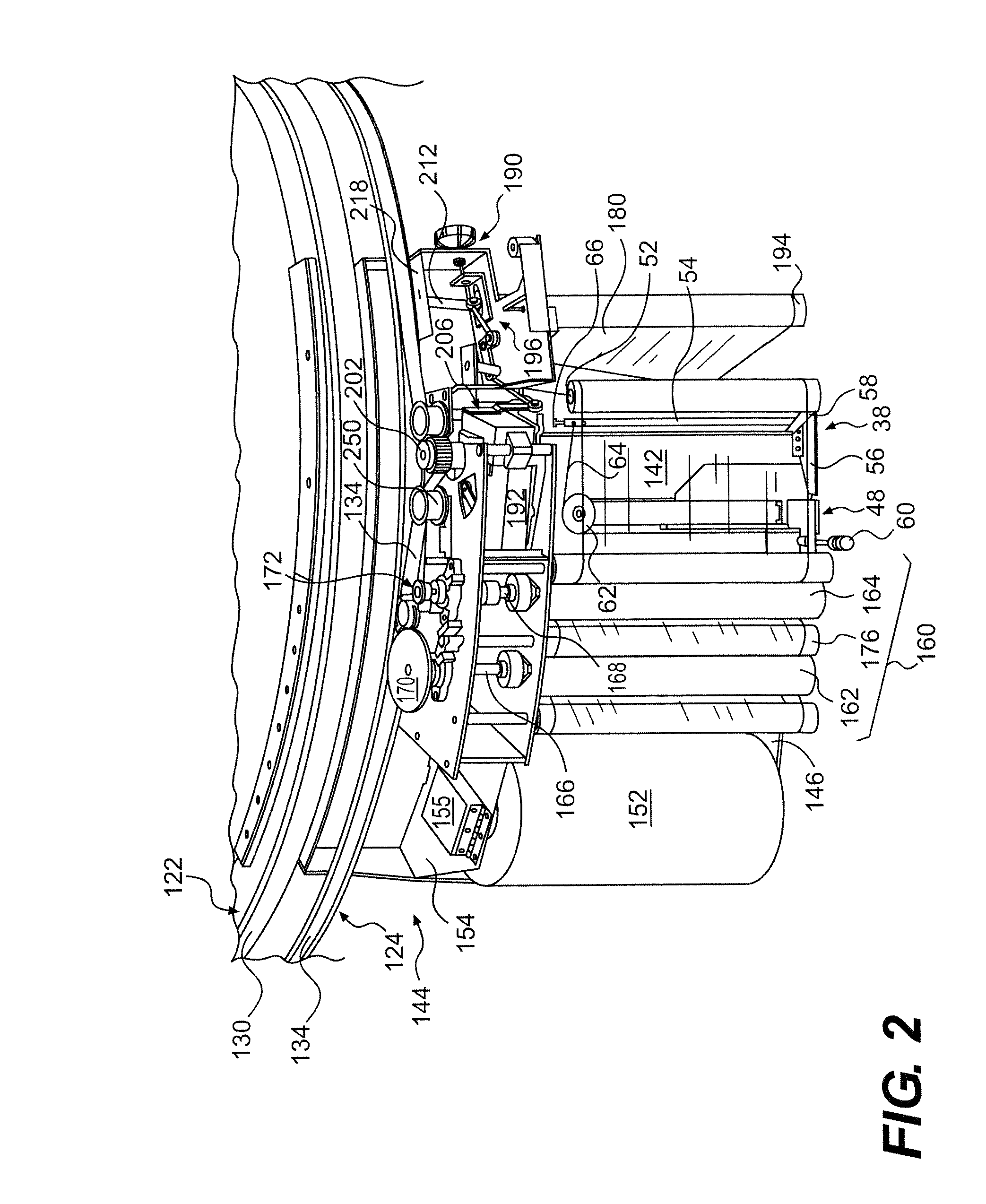

Method and apparatus for metered pre-stretch film delivery

The present invention provides a method and apparatus for dispensing a predetermined substantially constant length of pre-stretched packaging material based upon load girth. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution of relative rotation between a packaging material dispenser and the load is determined. A rotational drive system used to provide the relative rotation is linked to a pre-stretch assembly portion of the packaging material dispenser. The linkage may be mechanical or electrical. The linkage controls a ratio of the rotational speed to the pre-stretch assembly dispensing speed, such that the predetermined substantially constant length of pre-stretched packaging material is dispensed for each revolution of the packaging material dispenser relative to the load regardless of the speed of the rotational drive. In the case of a mechanical linkage, the linkage also connects the rotational drive to the pre-stretch assembly portion such that the rotational drive also drives the pre-stretch assembly portion.

Owner:LANTECH COM

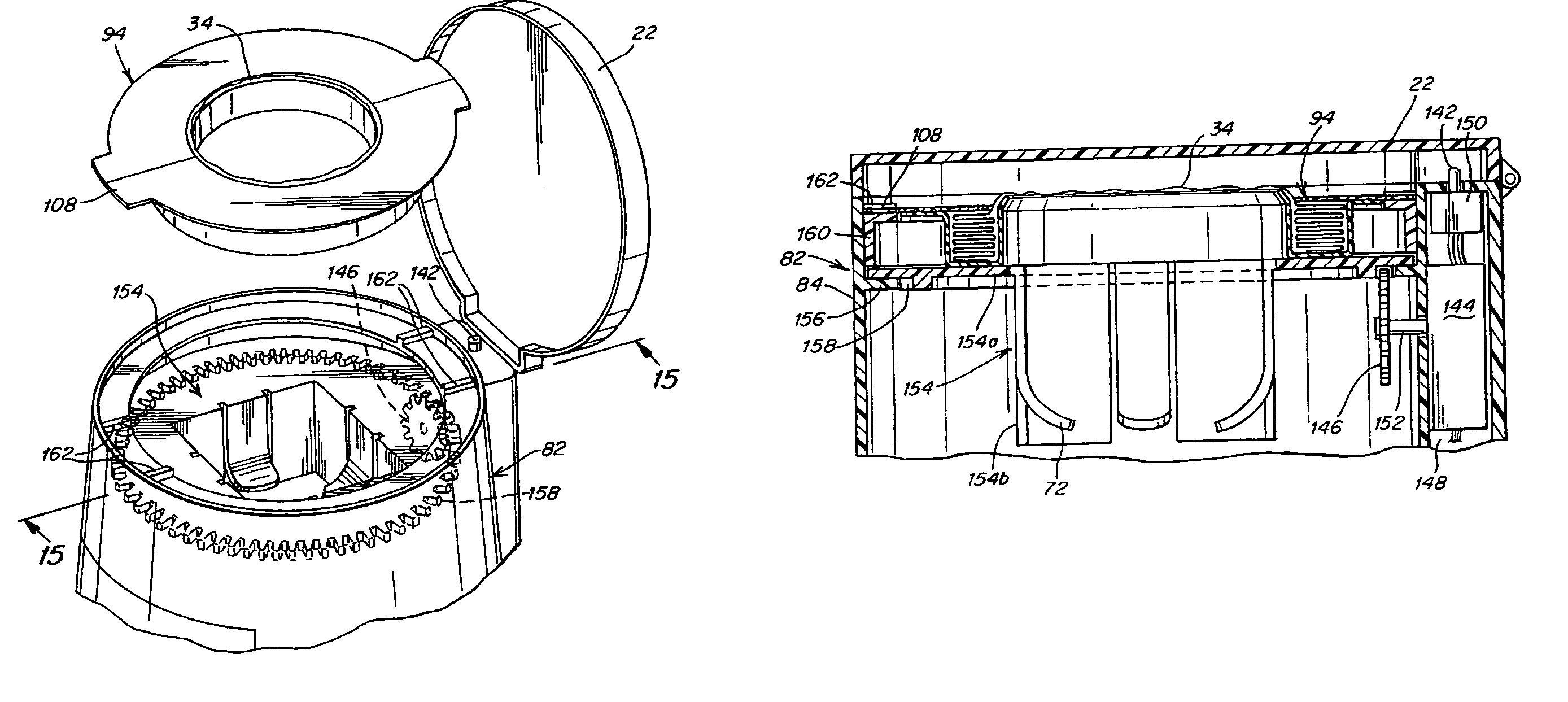

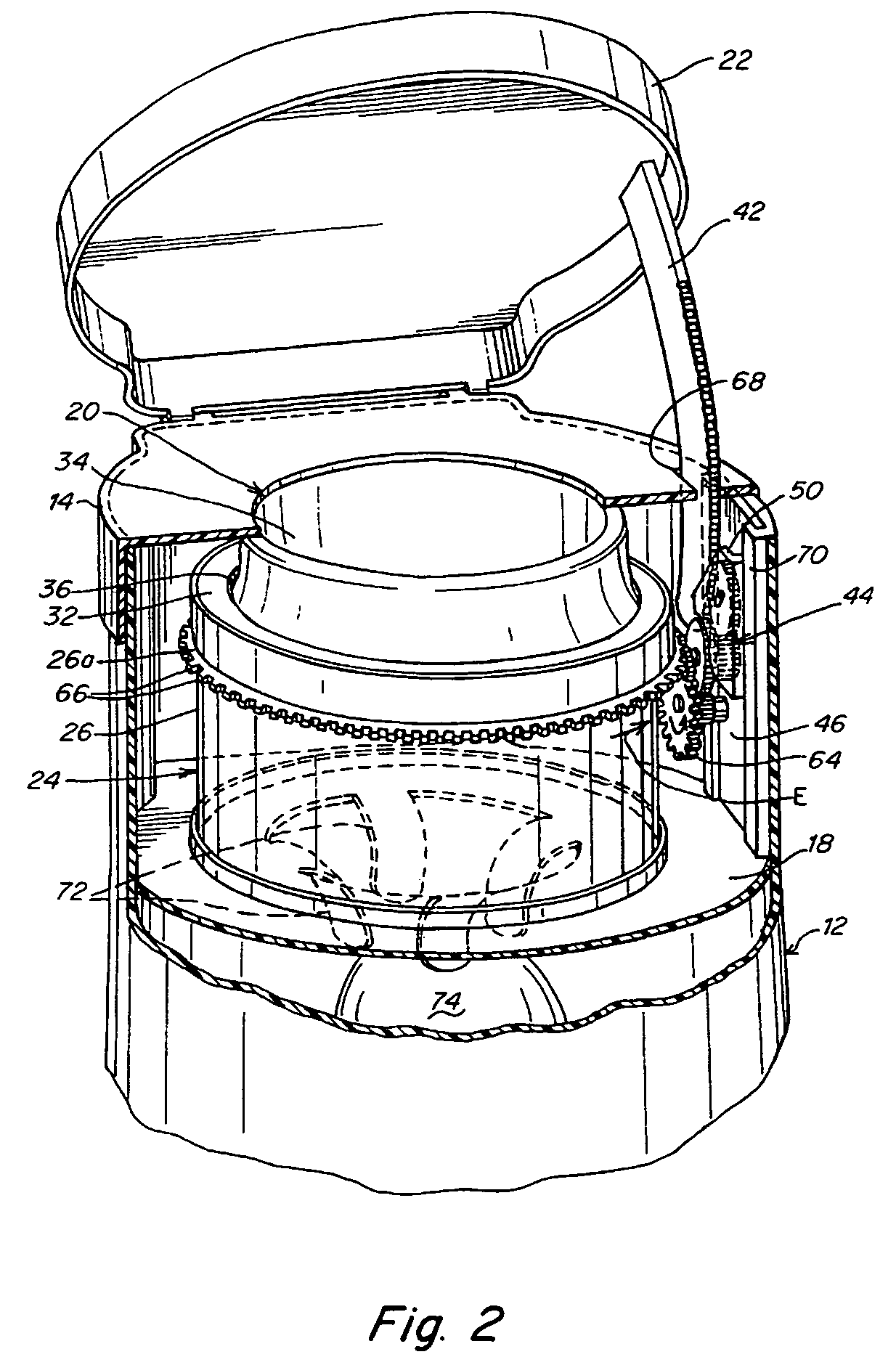

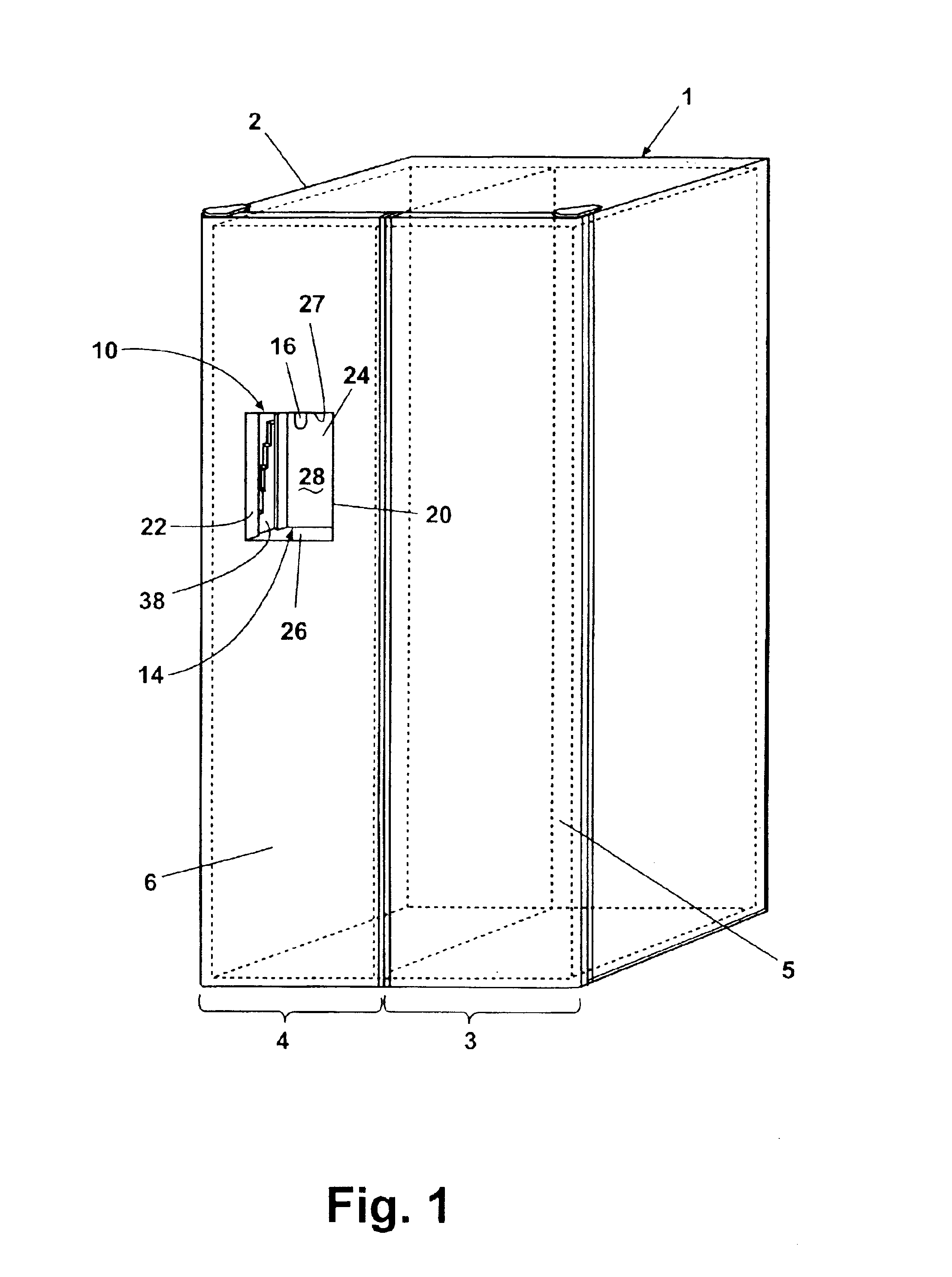

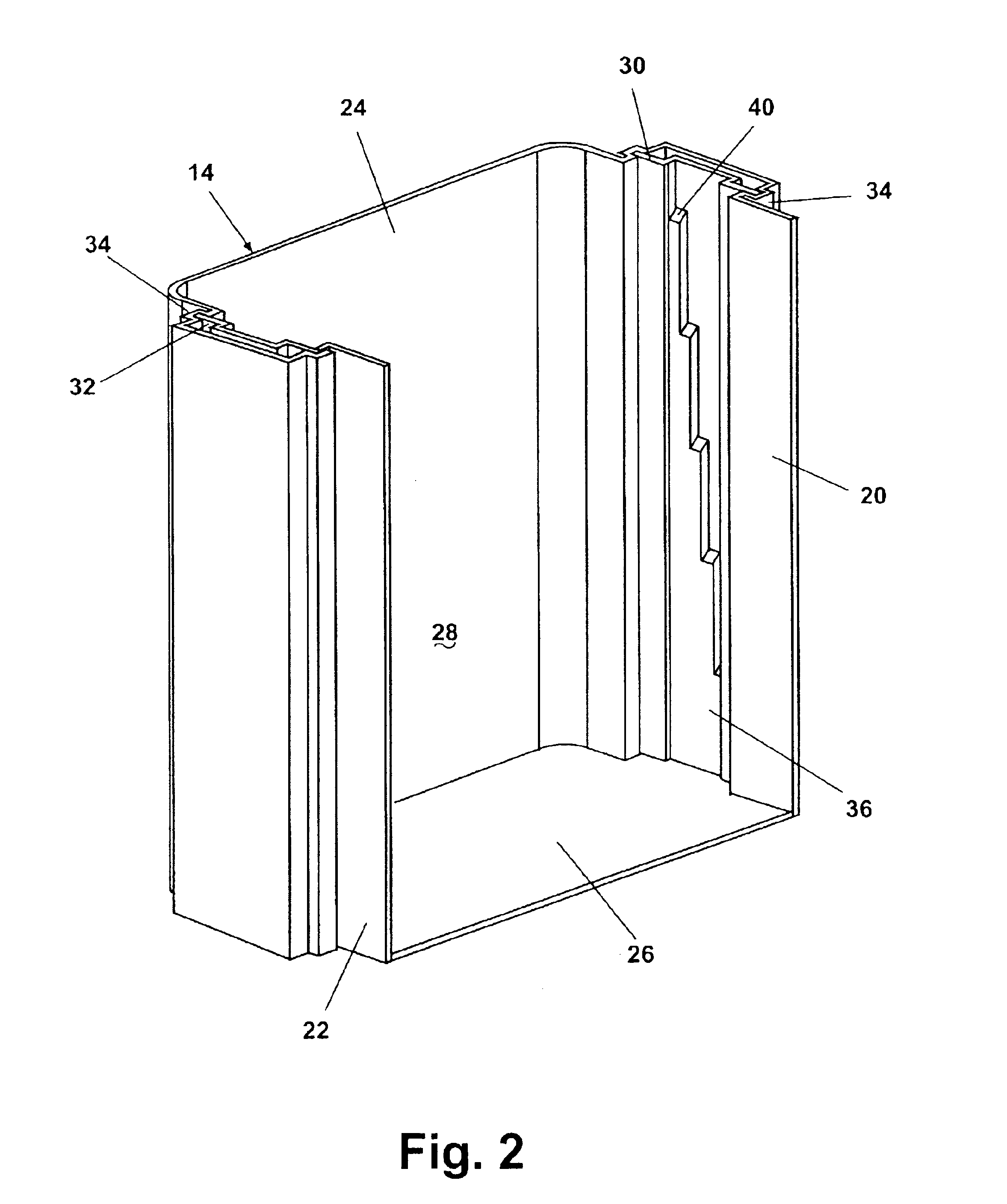

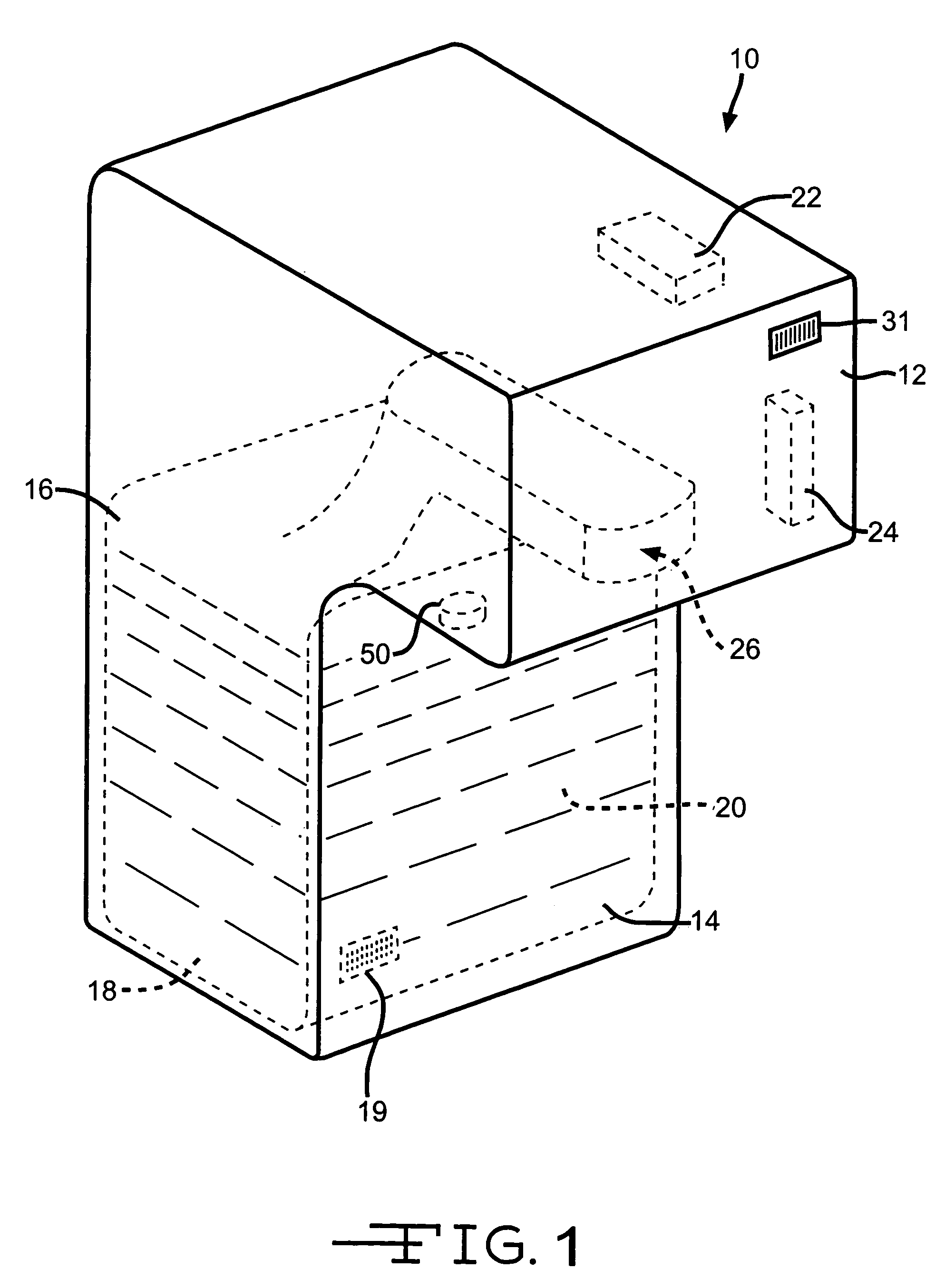

Waste disposal device including a sensing mechanism for delaying the rotation of a cartridge

InactiveUS7712285B2Effectively contains and prevents the release of odors from waste packagesEasy to disassembleContact operating partsLarge containersWaste materialWaste disposal

A waste disposal device including a sensing mechanism for delaying the rotation of a cartridge. The waste disposal device comprises a container defining a waste chamber for receiving encapsulated waste in a flexible tubing. The rotatable cartridge contains the flexible tubing. A lid is coupled to the device and is capable of moving between an open and closed position on the container. A rotation mechanism is operatively configured to engage the rotatable cartridge. A sensing mechanism is arranged to allow for delay in rotation of the cartridge until the lid assumes the closed position so that the waste is encapsulated in the flexible tubing after the closing of the lid, and after the subsequent twisting of the flexible tubing about the waste material caused by the rotation of the cartridge.

Owner:PLAYTEX PROD INC

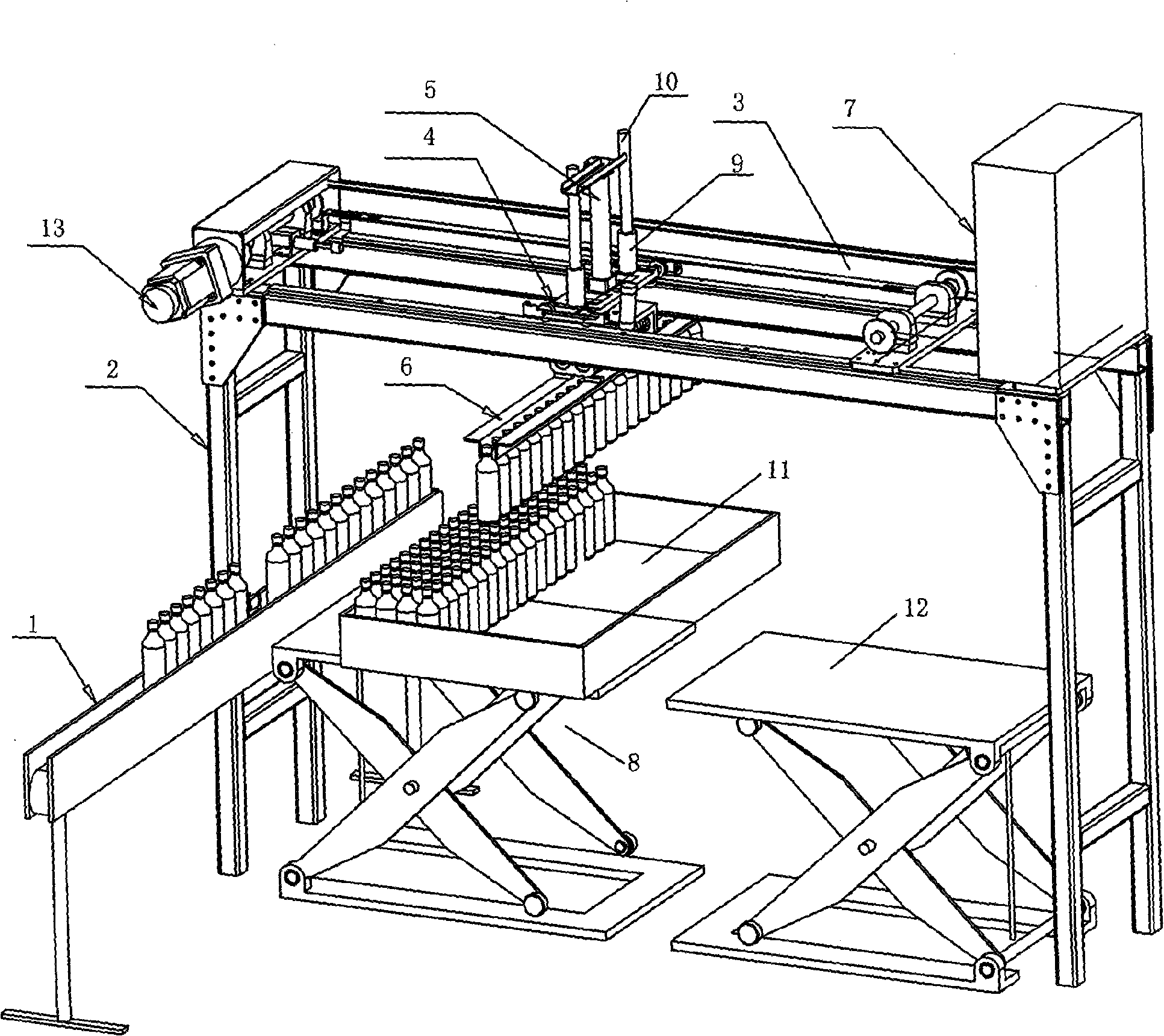

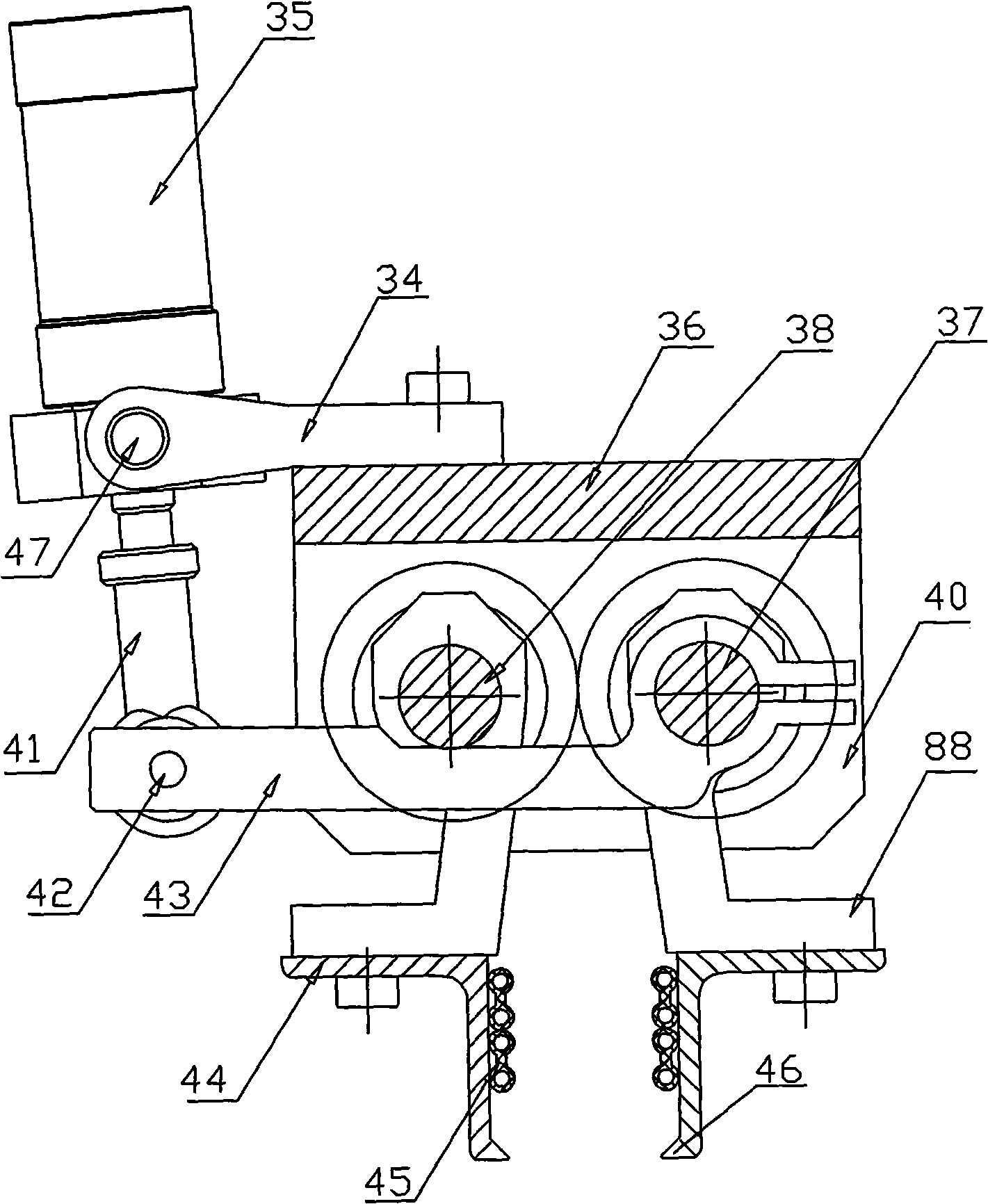

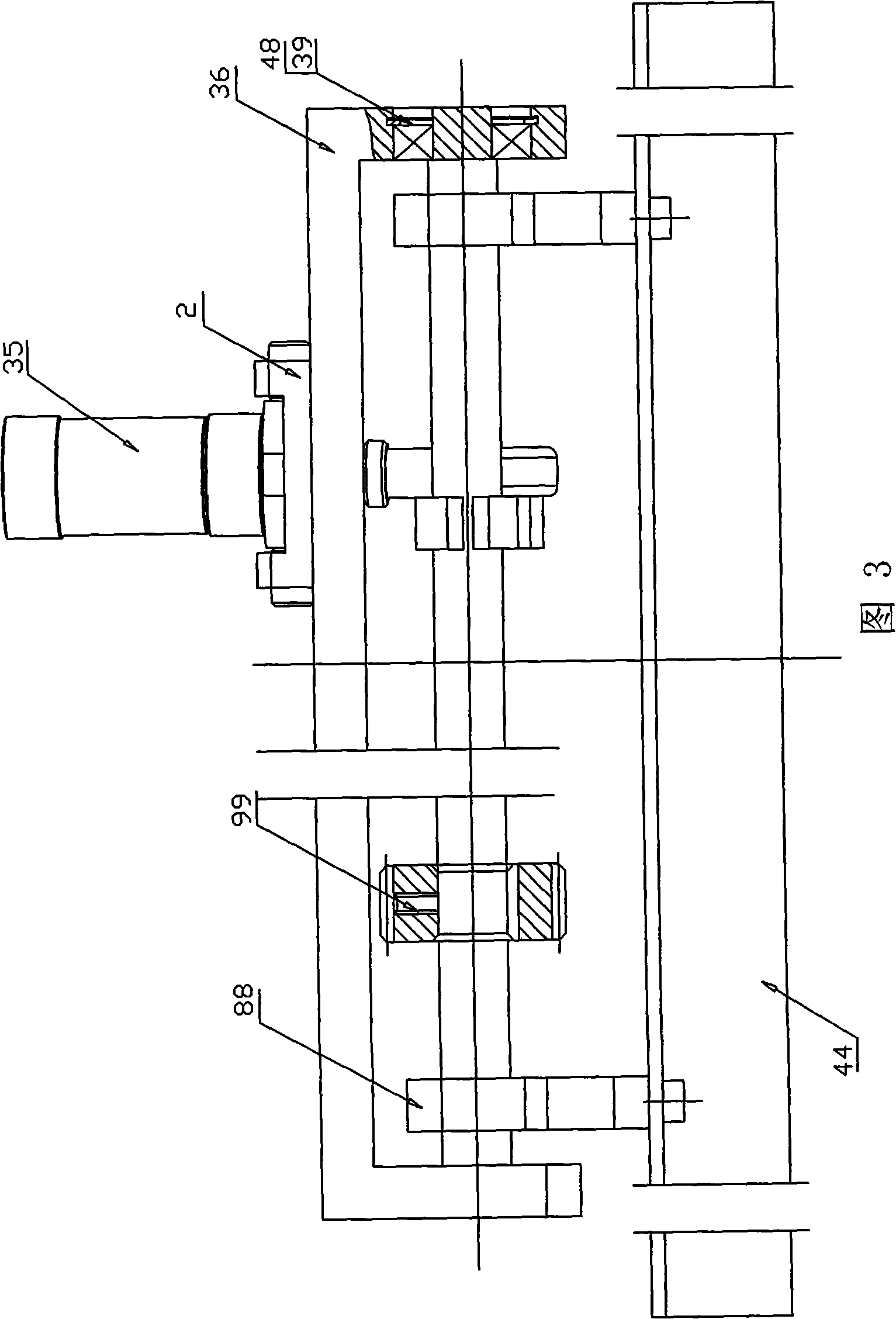

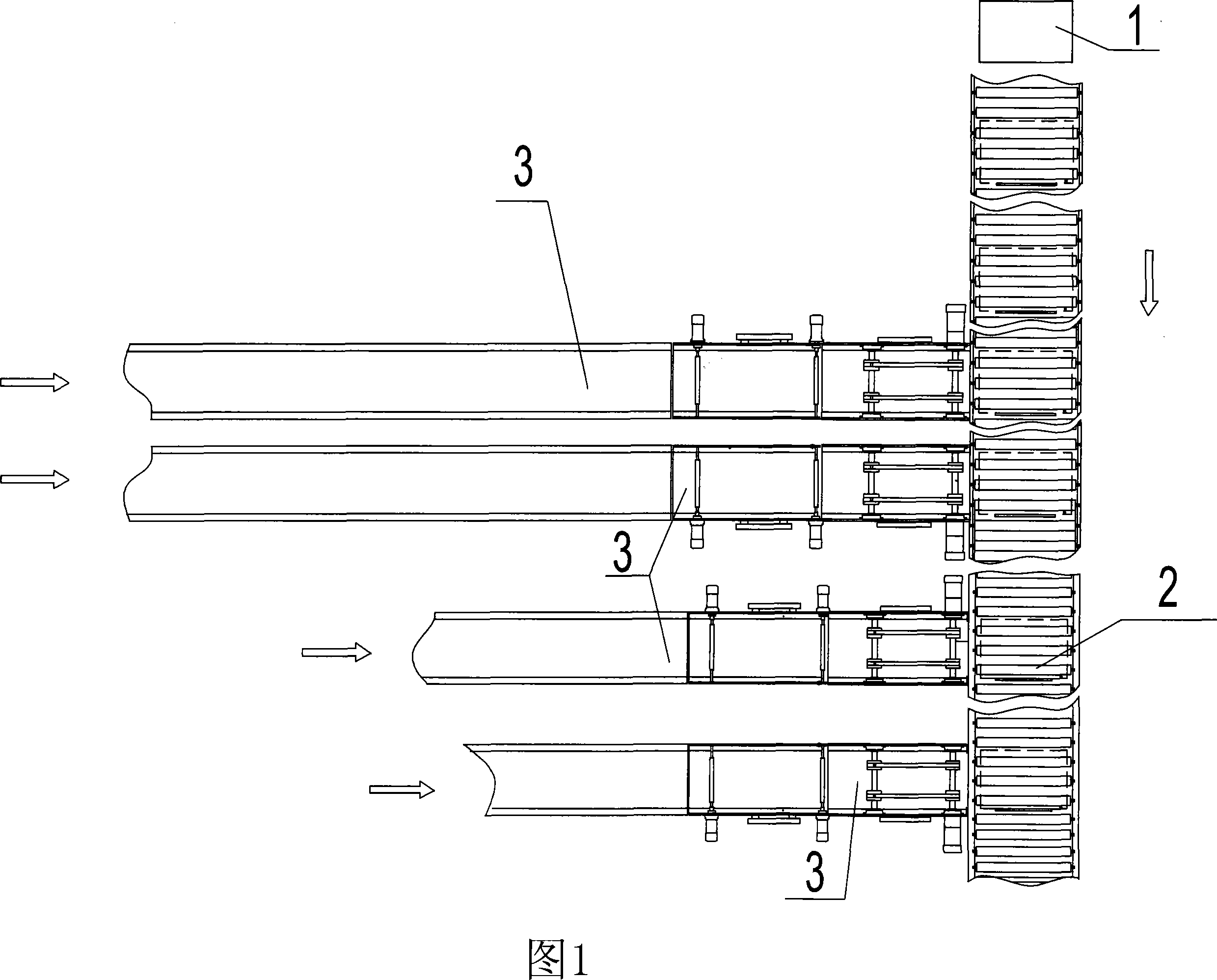

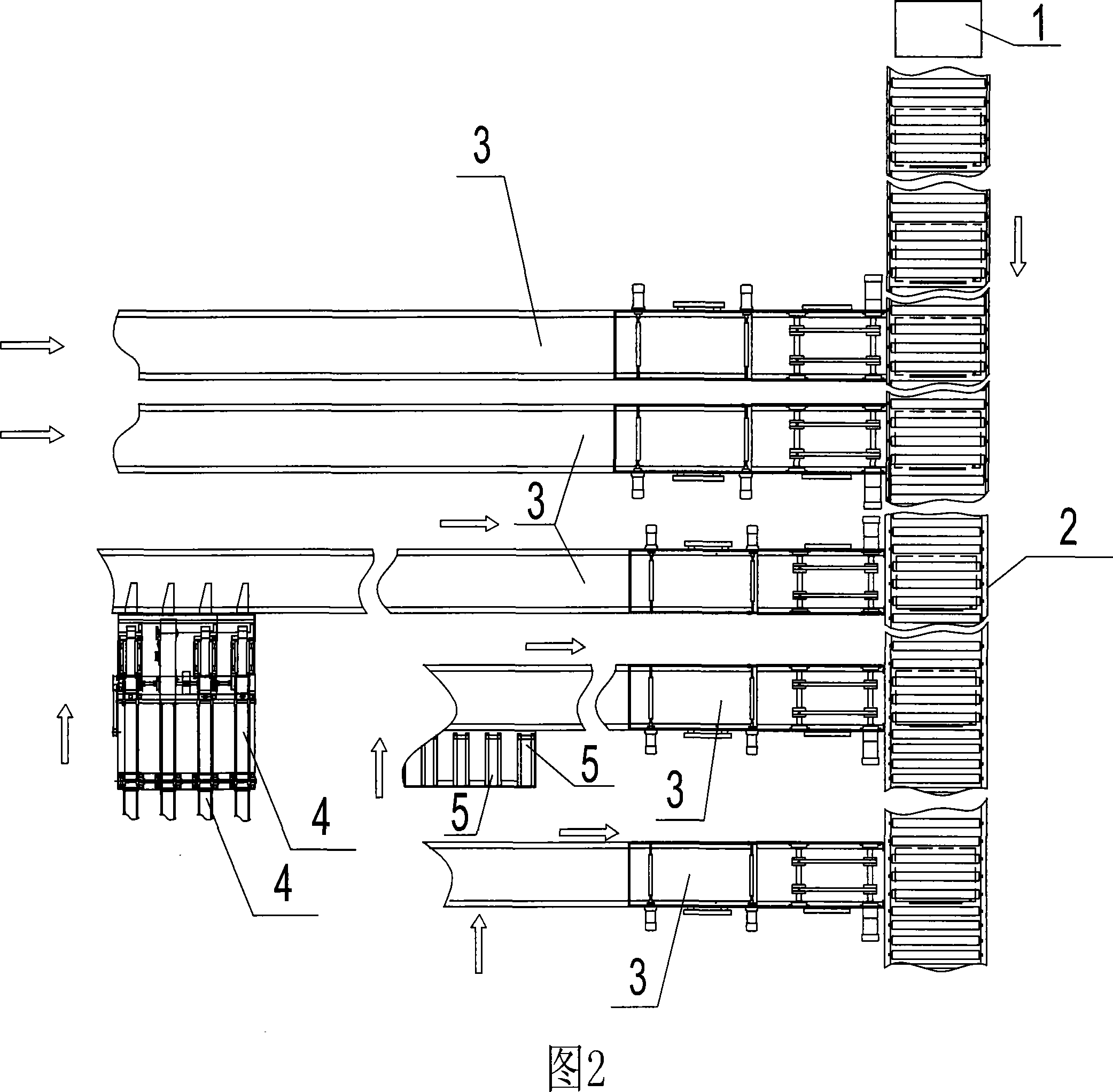

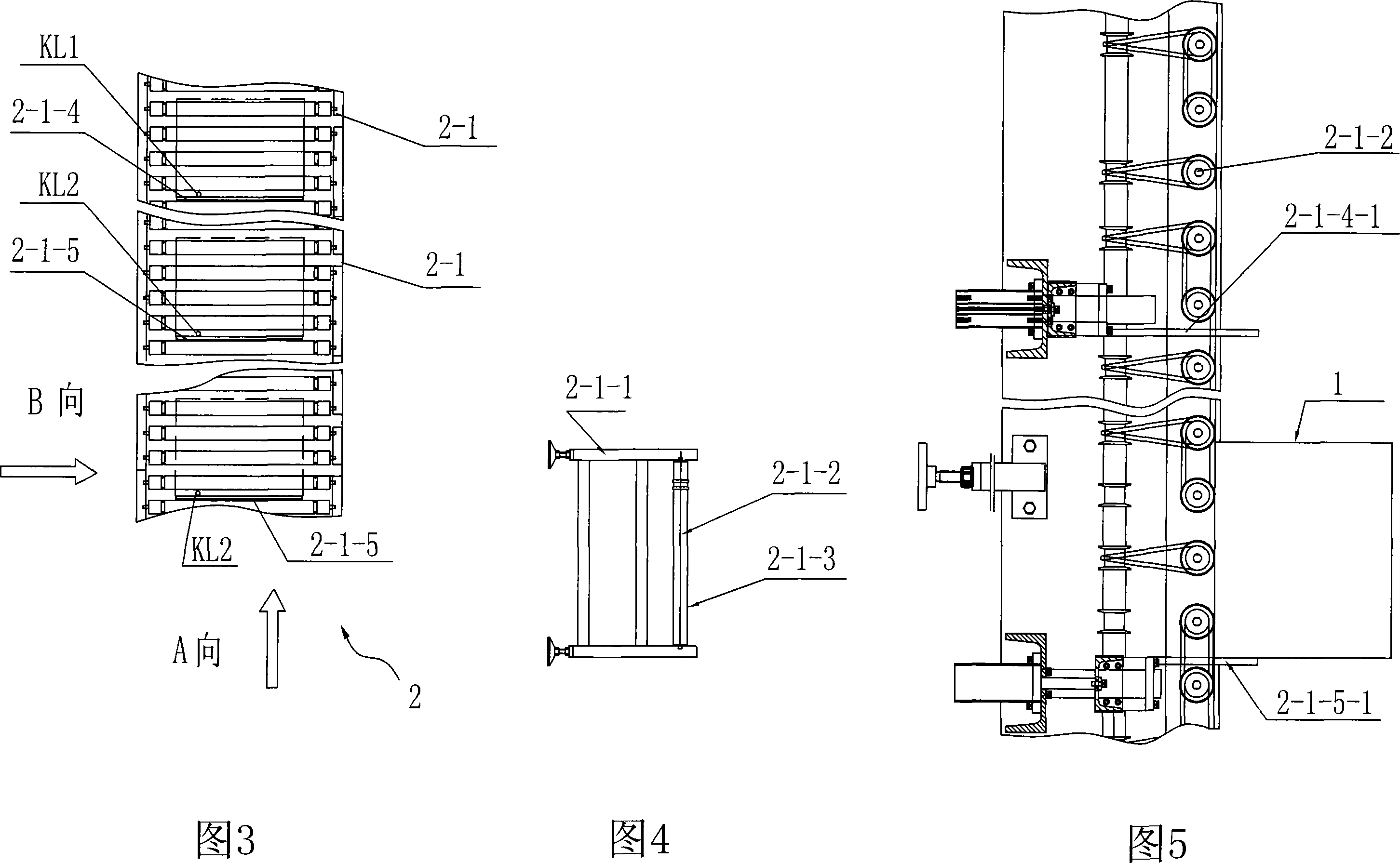

Automatic collecting and arranging machine for plastic soft bottle

ActiveCN101327851AImprove processing progressRealize the collectionProgramme-controlled manipulatorGripping headsAutomatic controlEngineering

The invention discloses an automatic machine for collecting and sorting plastic soft bottles. The device comprises a conveyor for plastic bottles, soft bottles or soft bags, as well as a machine frame, wherein a traction device moving horizontally is arranged above the machine frame; a bottle clamping device connected via a lifting cylinder is arranged on a moving trolley of the traction device; the traction device, the lifting cylinder and the bottle clamping device are connected with an electric control device with electrical automatic control; a product collecting device is arranged below the machine frame beside the conveyor; and the electric control device controls the bottle clamping device to make vertical up-down lifting movement under the drive of the lifting cylinder and to make horizontal translating movement under the drive of the traction device, and controls the bottle clamping device to clamp a product input by the conveyor, to transfer the product to the product collecting device through the lifting cylinder and the traction device and then to unclamp the product. The machine can clamp, lift and translate plastic bottles, soft bottles or soft bags input by the conveyor to a preset distance, drop and put the bottles or bags into the product collecting device.

Owner:SICHUAN KELUN PHARMA CO LTD

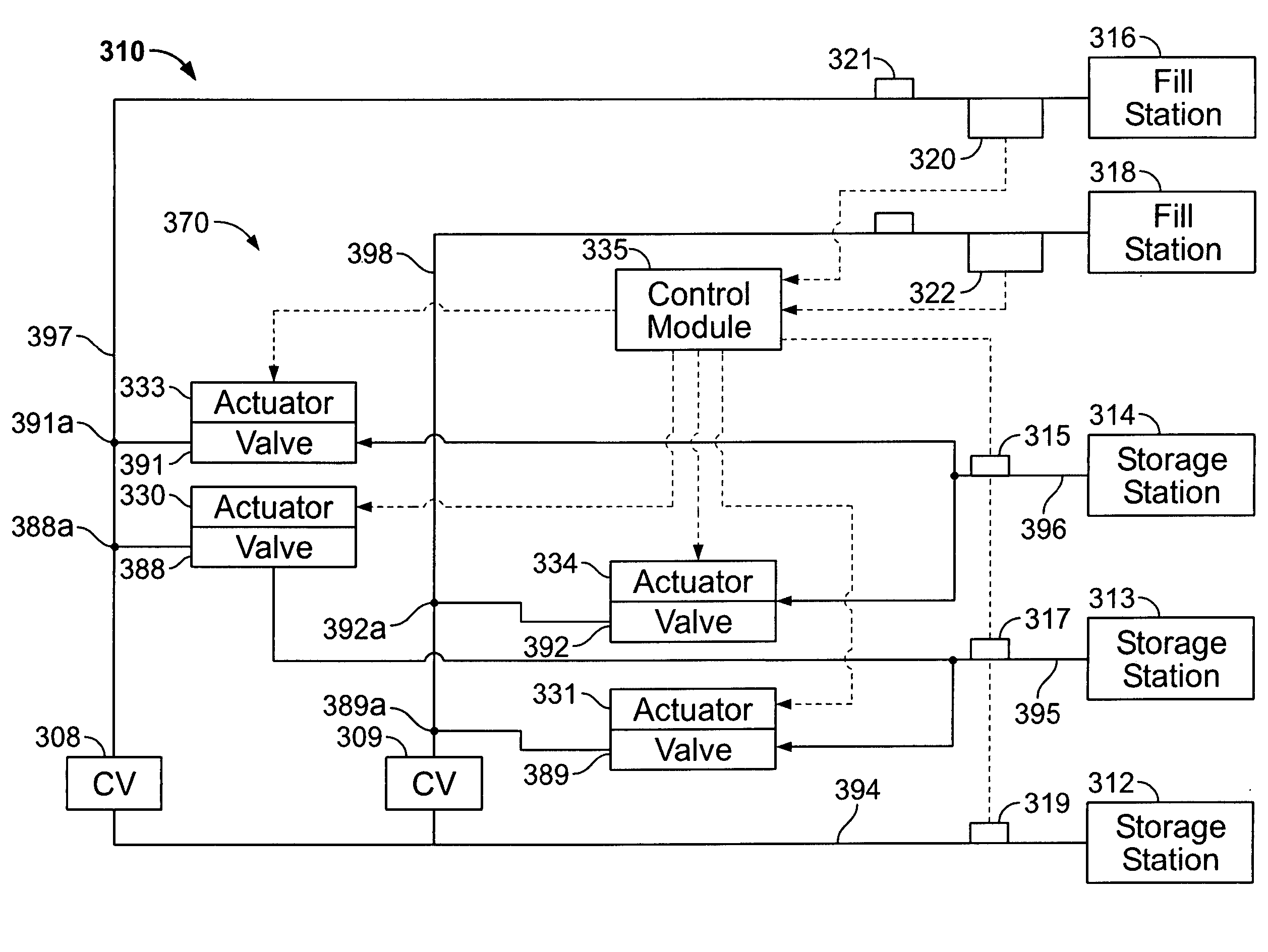

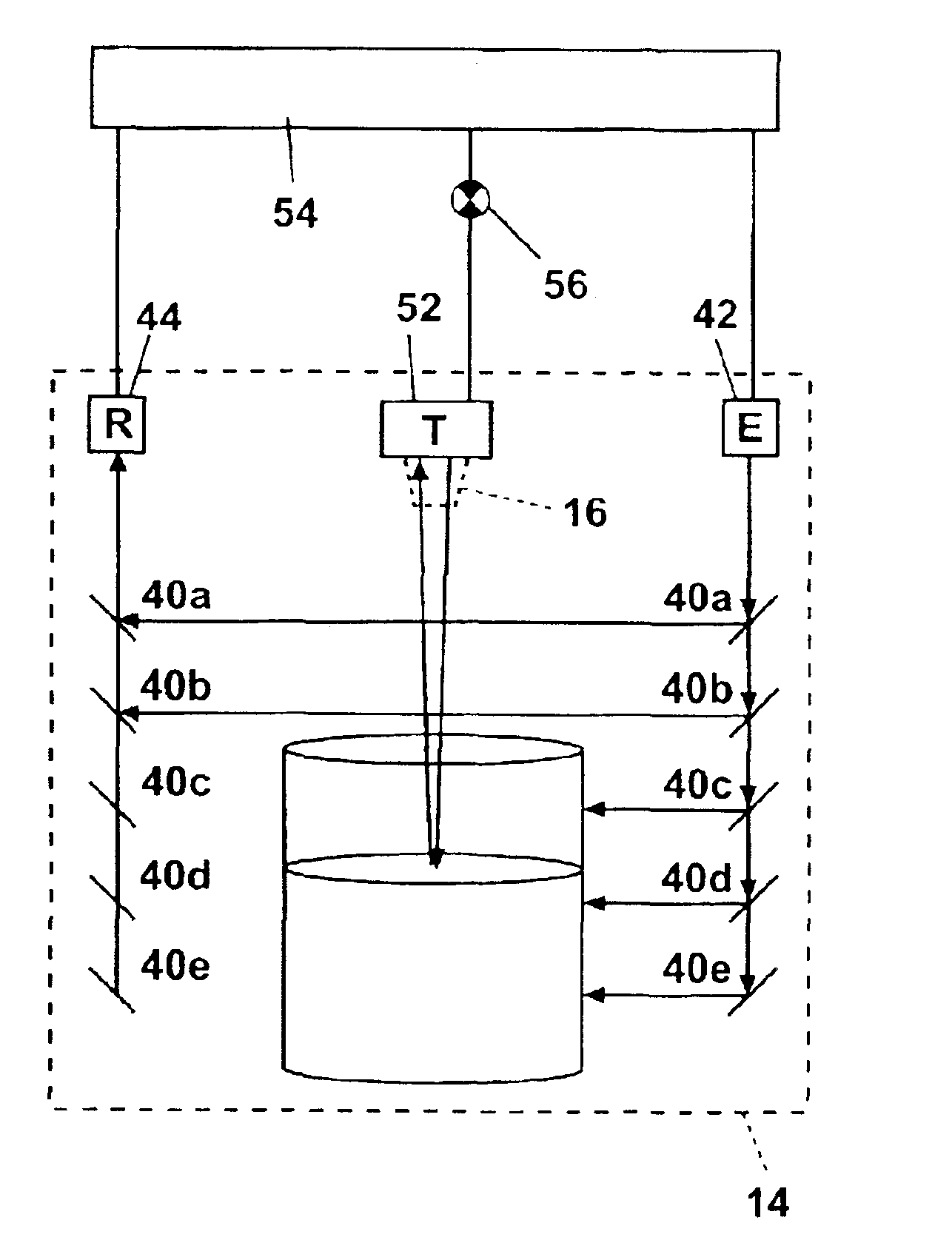

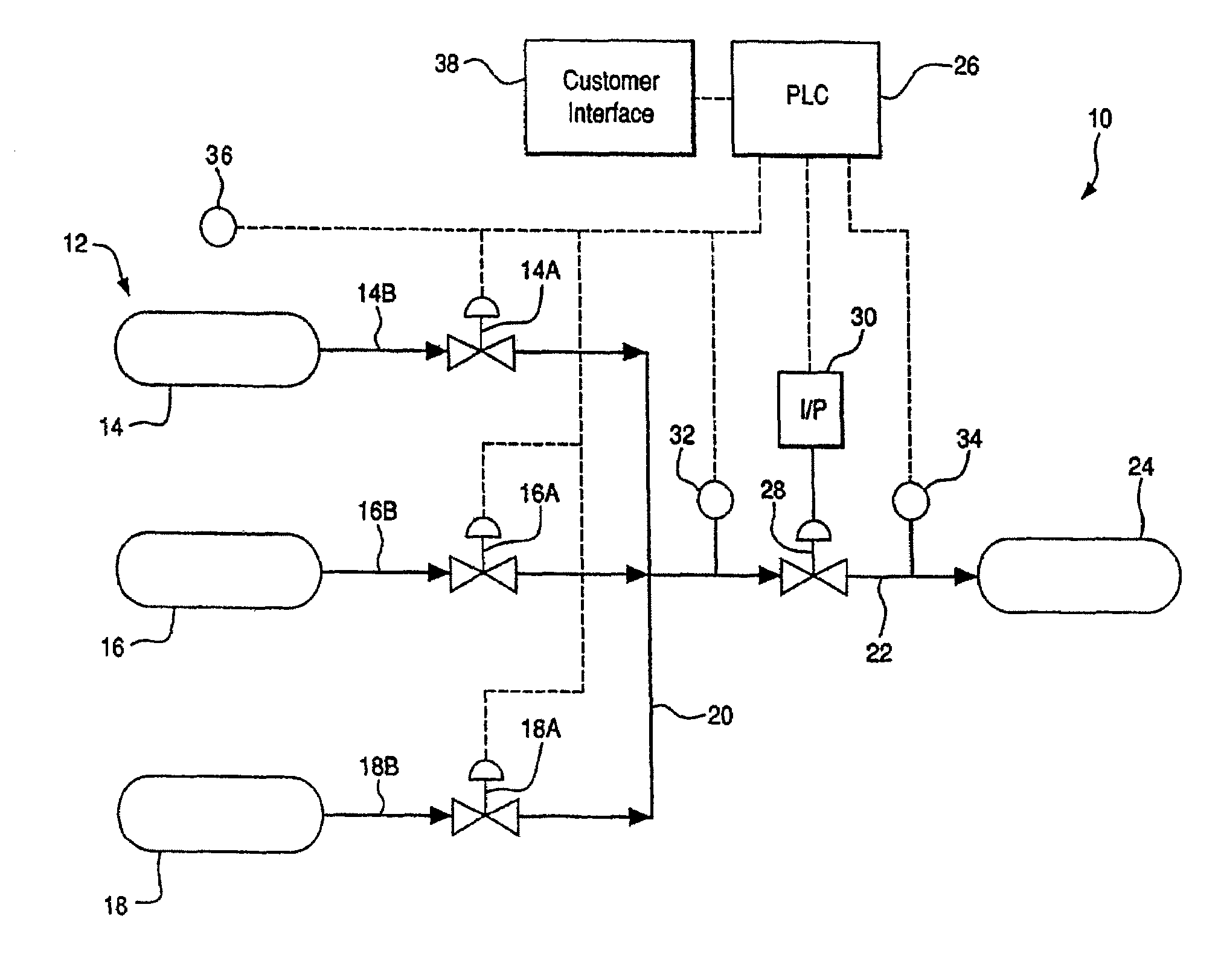

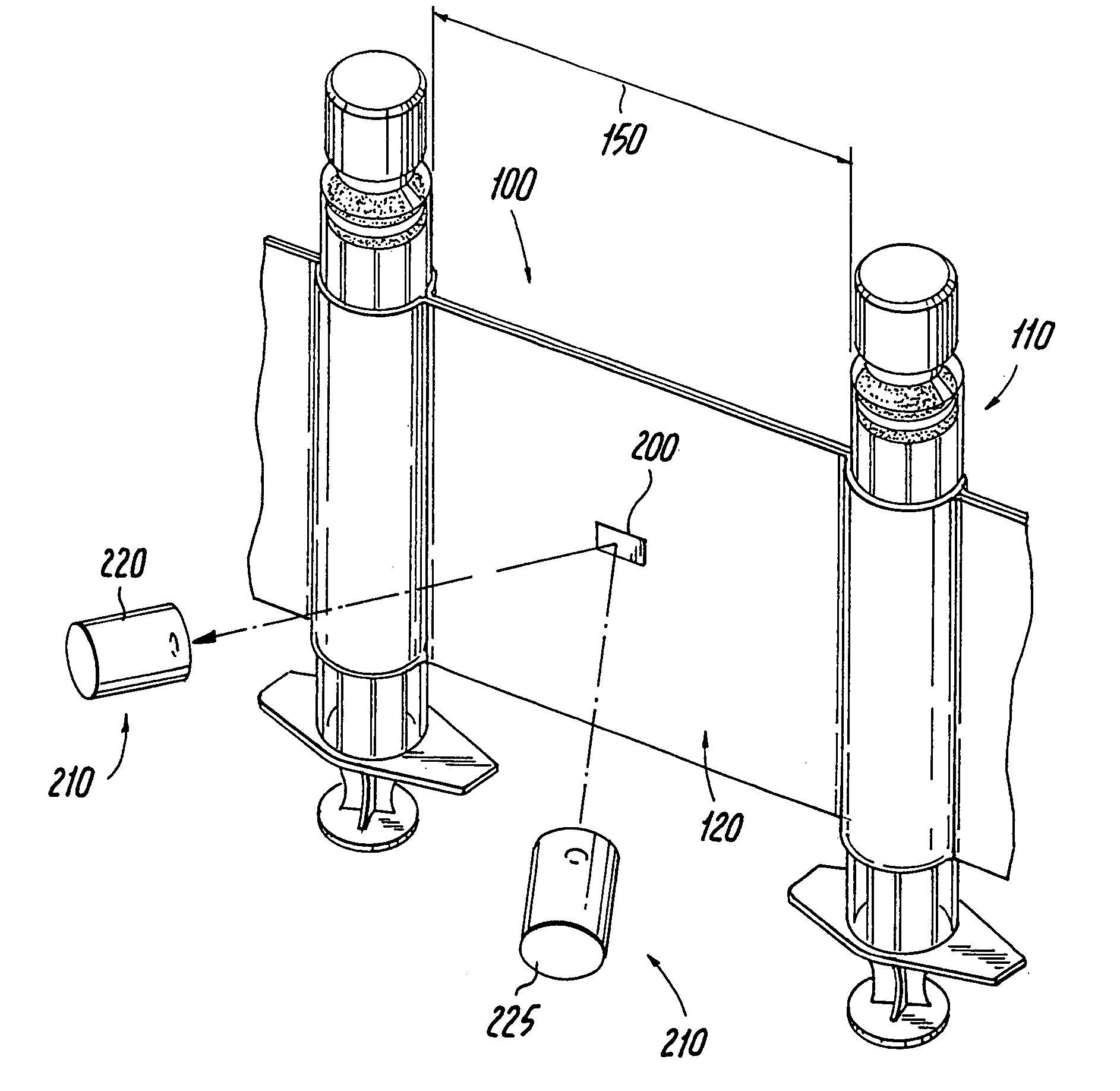

Method and system for independently filling multiple canisters from cascaded storage stations

A canister filling system is provided for independently filling multiple canisters from a common set of storage stations prioritized in a cascaded manner. The system includes first and second fill stations configured to receive and independently fill canisters with pressurized gas. First and second storage stations store gas at corresponding first and second charge pressures, respectively. A supply-chain joins each of the first and second fill stations to both of the first and second storage stations. First and second valve assemblies are provided in the supply-chain to monitor, independent of one another, the canister pressures at the corresponding first and second fill stations. The canister pressures represent the pressure within corresponding canisters. The first and second valve assemblies automatically open and close to permit and prevent discharge of gas from the first and second storage stations, independent of one another, to automatically switch between the first and second storage stations based on the canister pressures. In one embodiment, the valve assembly includes a combination of sequence valves and check valves. Alternatively, the valve assembly may be controlled by electronic sensors and electronic solenoids. The electronic sensors detect the canister pressures and the charge pressures at the storage stations. The electronic solenoids open and close the valves based on the sensed canister pressures.

Owner:SCOTT TECH INC

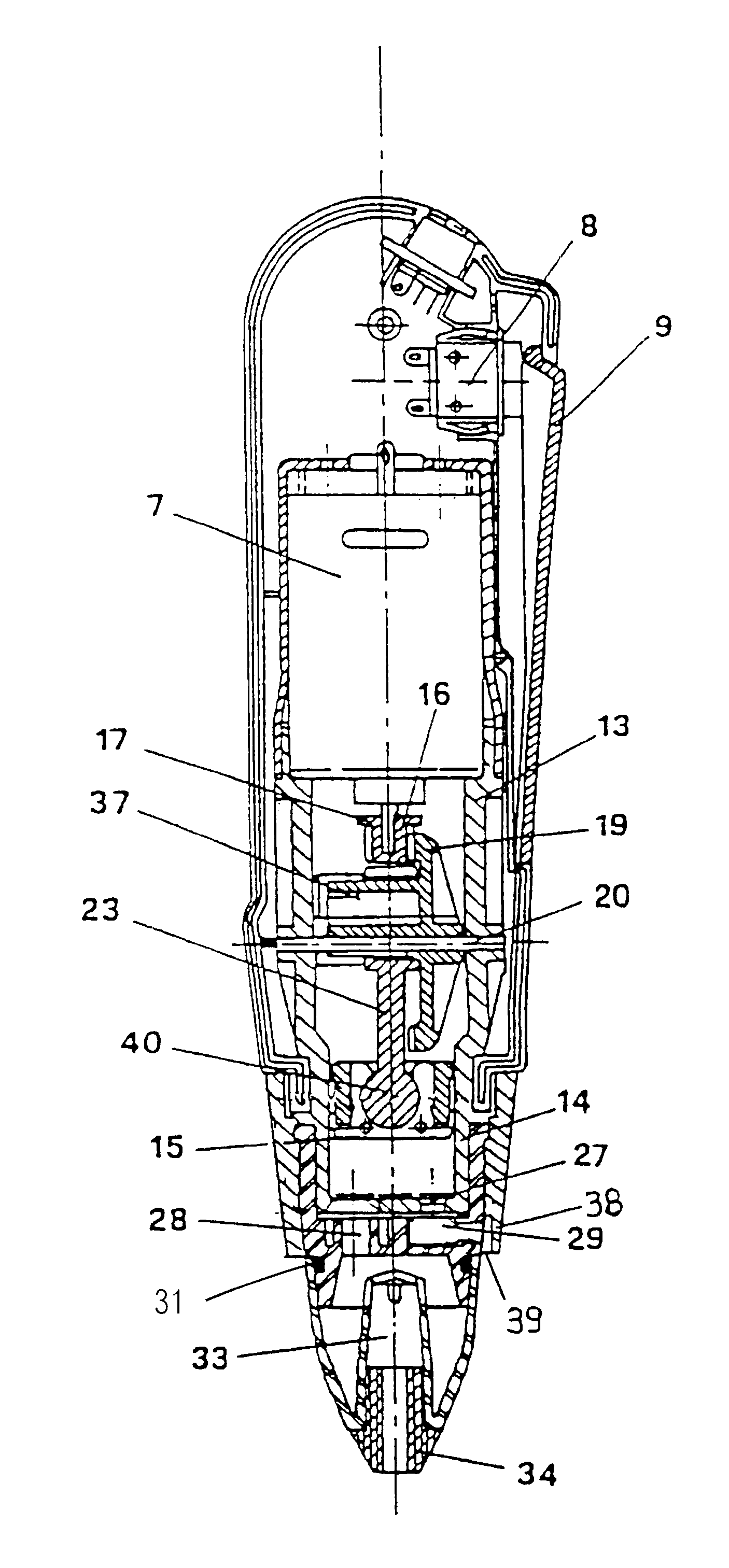

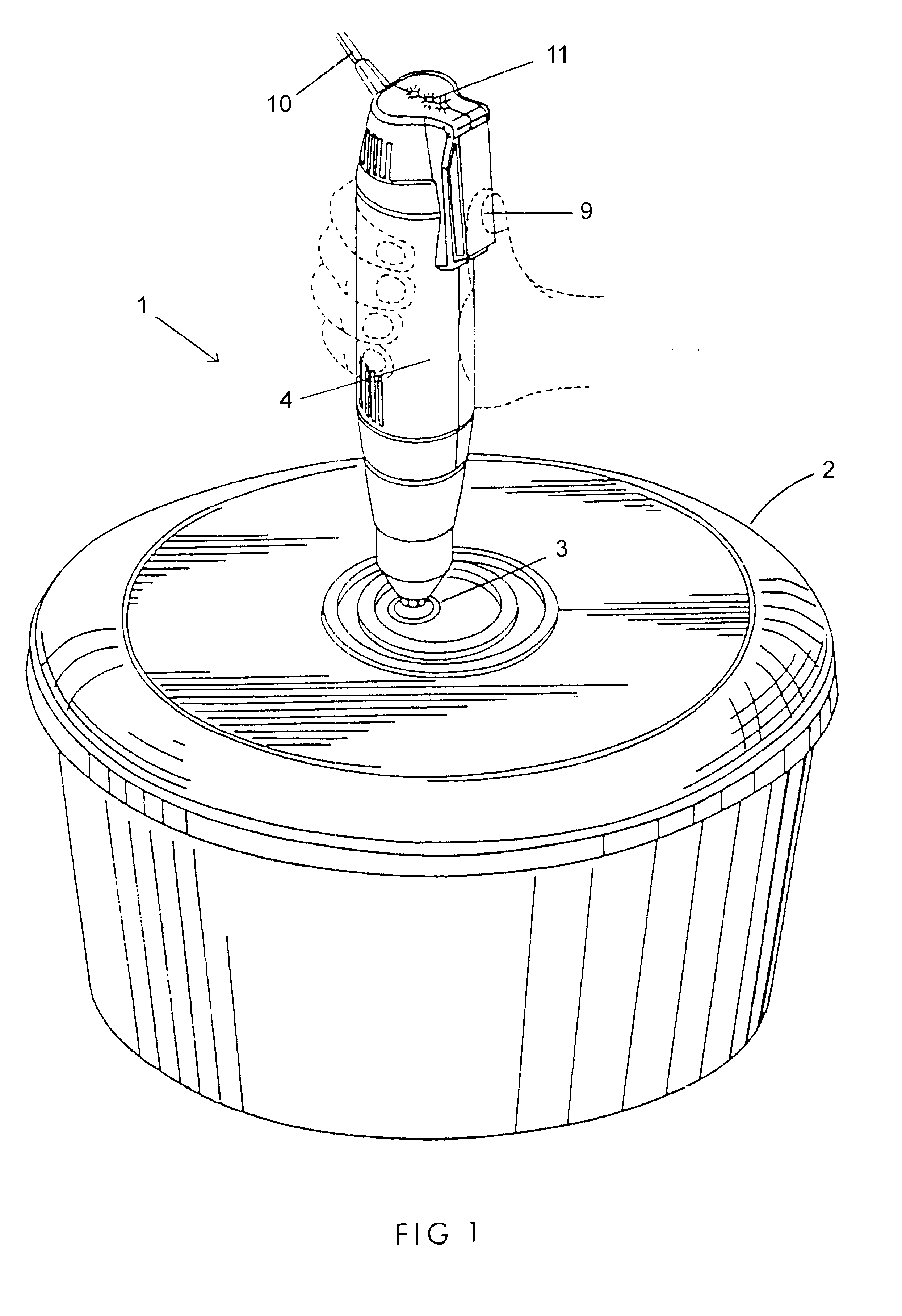

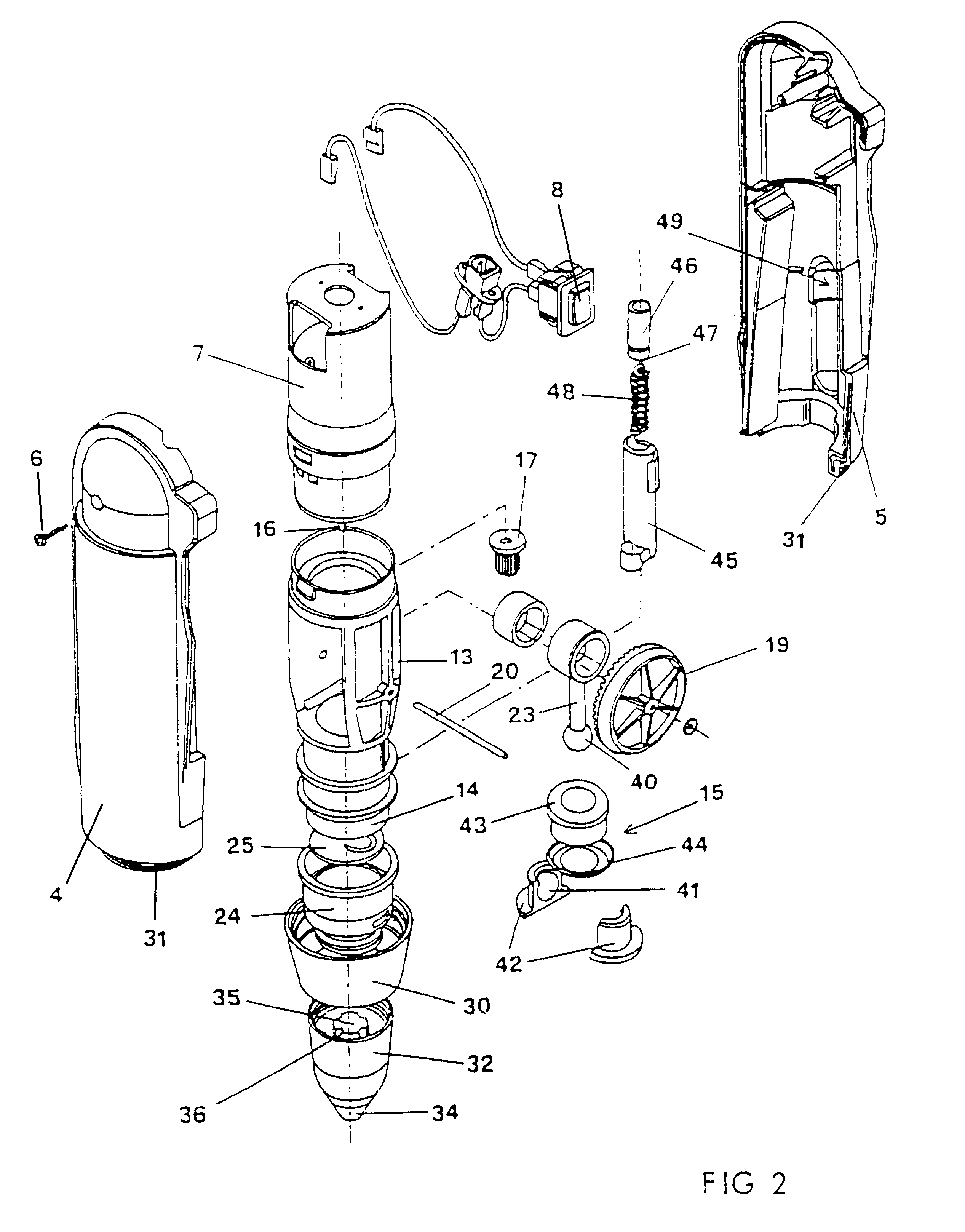

Hand-held suction pump

A hand-held suction pump for creating a vacuum in a container (2) provided with a suction valve (3), comprising an elongated outer casing in which an electric motor (7) and a piston pump (14, 15) driven by the motor (7) are accommodated, wherein the pump chamber (14) of the piston pump is connected by an inlet valve and a suction duct (28) to a hollow tip (34) at the free end of the casing for direct coupling with the suction valve of the container, the pump chamber being further connected by an outlet valve to an exhaust duct (29) having a duct opening on the outer surface of the wall of the outer casing for porting an exhaust flow to the exterior of the outer casing. In order to reduce noise caused by the exhaust flow, the duct opening of the exhaust duct (29) is overlapped by a baffle (38) which is separated by a gapped distance from the outer surface of the wall of the outer casing so as to deflect the exhaust flow exiting the duct opening by a substantial angle.

Owner:ARACARIA

Goods sorting and split charging equipment and method thereof

InactiveCN101234677ASmall footprintReduce the number of employeesControl devices for conveyorsCo-operative working arrangementsElectronic control systemEngineering

The invention discloses an equipment for sorting and packaging goods and a method thereof, wherein, the equipment comprises turning box baskets, a box basket transporting device, a goods-providing device, a radio frequency reader, a wireless radio frequency card, an electronic control system and a system of computer information management, wherein, each box basket box has the wireless radio frequency card; a side on a stopping position of a plurality of box baskets on the box basket transporting device is provided with the goods-providing device; the radio frequency reader is arranged near the stopping positions for the box backsets on the box basket transporting device. The method comprises the following steps: A. configuring devices for the whole line and determining the brands and specifications of goods to be delivered; B. setting the information of device configuration as well as the brands and specifications of the goods; C. setting the allocation proposal; D. preparing and implementing the allocation proposal; E. starting the whole line and pre-allocation; F. inputting empty box baskets; G. applying the box baskets for delivery and allocation; H. unloading the baskets. The equipment for sorting and packaging goods has the advantages of high speed, reliable work, low operation cost, compact structure, and small land occupancy, so the invention is applicable for various goods delivery centers with different delivery requirements and scopes.

Owner:姜广峻

Method for dispensing a predetermined amount of film relative to load girth

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched film based upon load girth. A non-rotating ring carries a belt. A film dispenser is mounted on a rotating ring, and the rotating ring includes a pulley that connects to the belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched film to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum film use is obtained by dispensing a length of pre-stretched film that is between approximately 100% and approximately 130% of load girth. Once the amount of film to be dispensed per revolution is determined, a mechanical ratio of ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / ring rotation) can be set. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of film is dispensed and wrapped around the load.

Owner:LANTECH COM

Demand based wrapping

ActiveUS20110131927A1Prestretching mechanismWeb rotation wrappingControl systemManufacturing engineering

A control system for a wrapping apparatus may include a packaging material dispenser configured to dispense packaging material for wrapping a load. The control system may also include at least one sensor assembly configured to generate a signal based on instantaneous demand for packaging material at the load. The control system may further include a controller configured to control operation of the packaging material dispenser based at least in part on the signal.

Owner:LANTECH COM

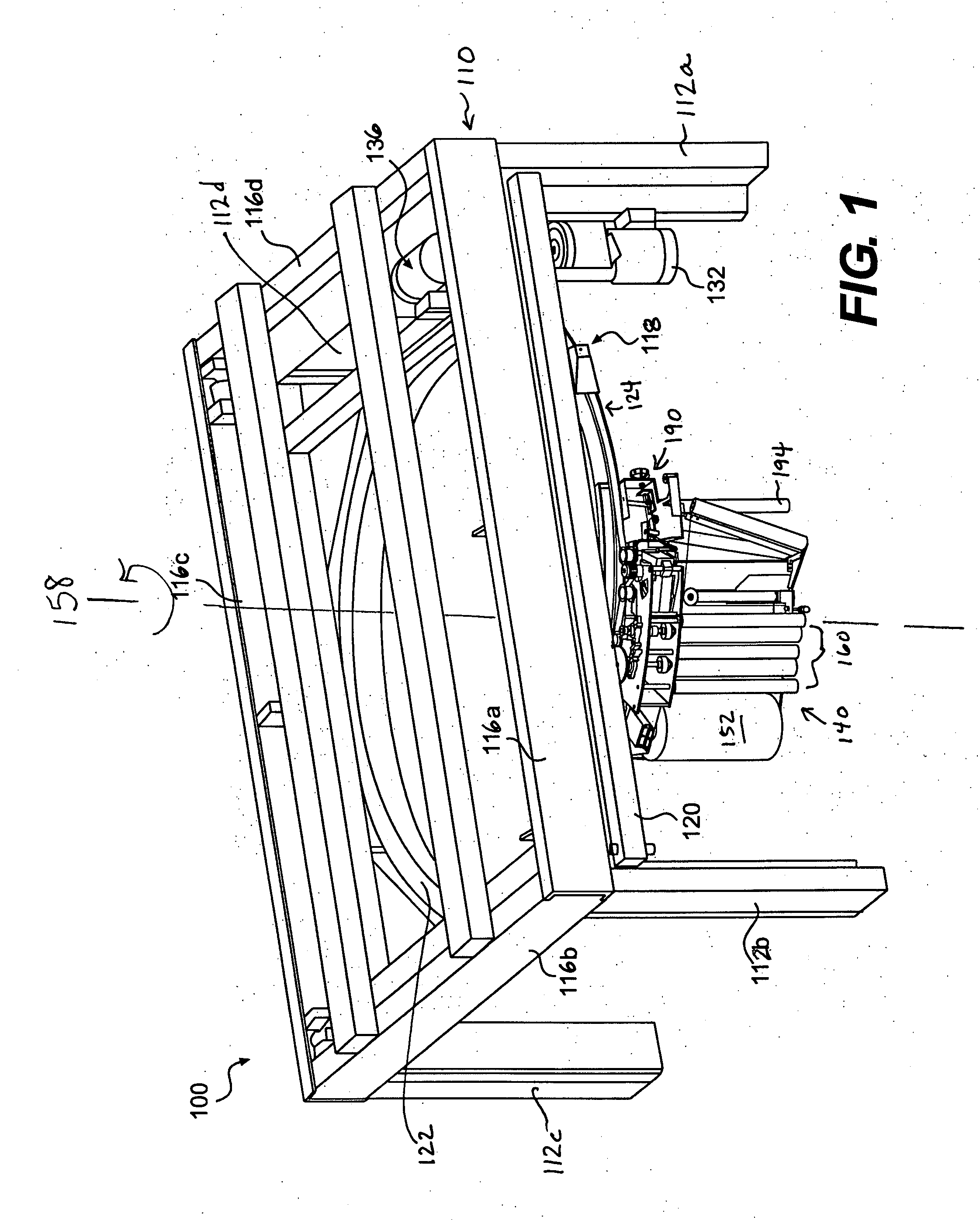

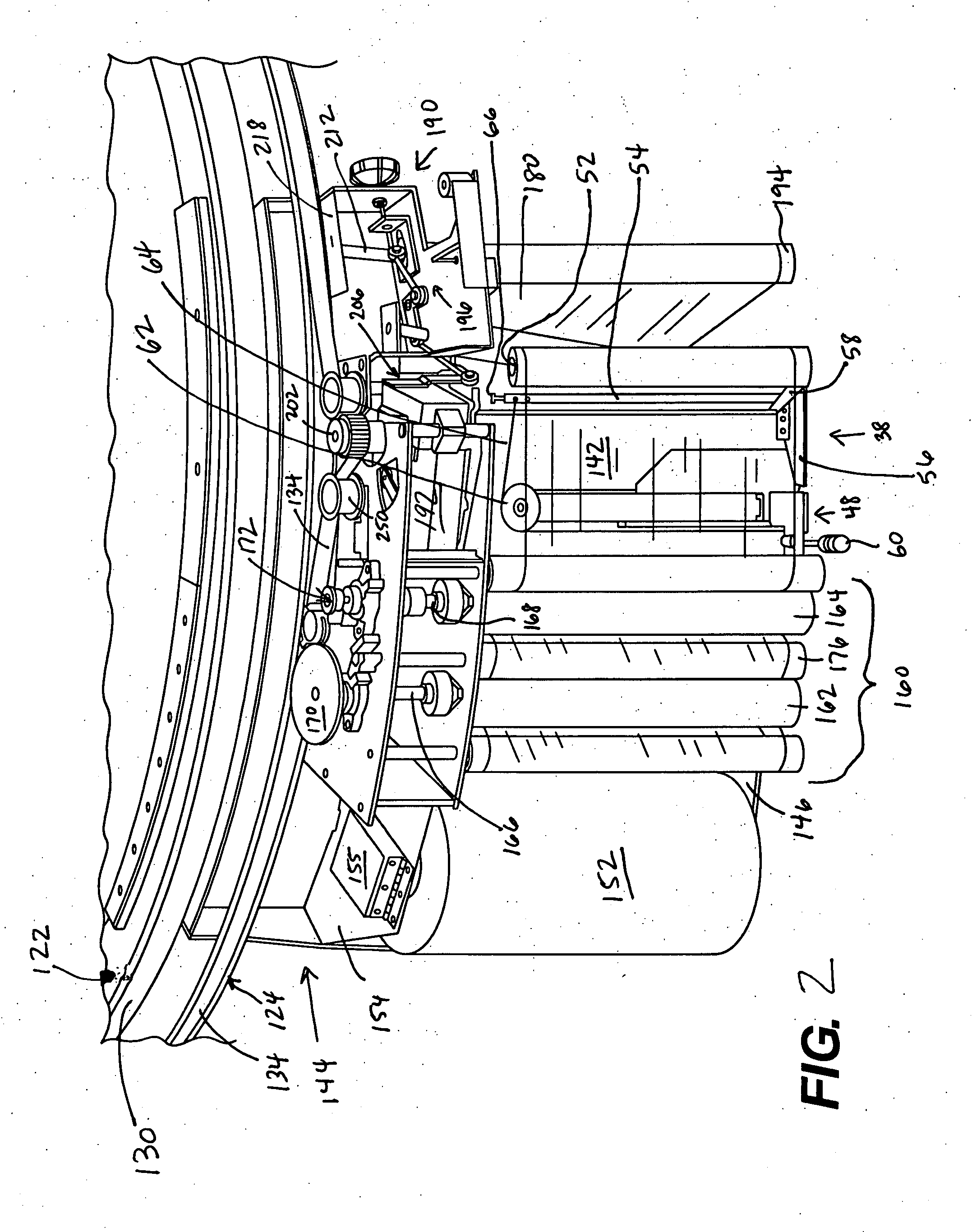

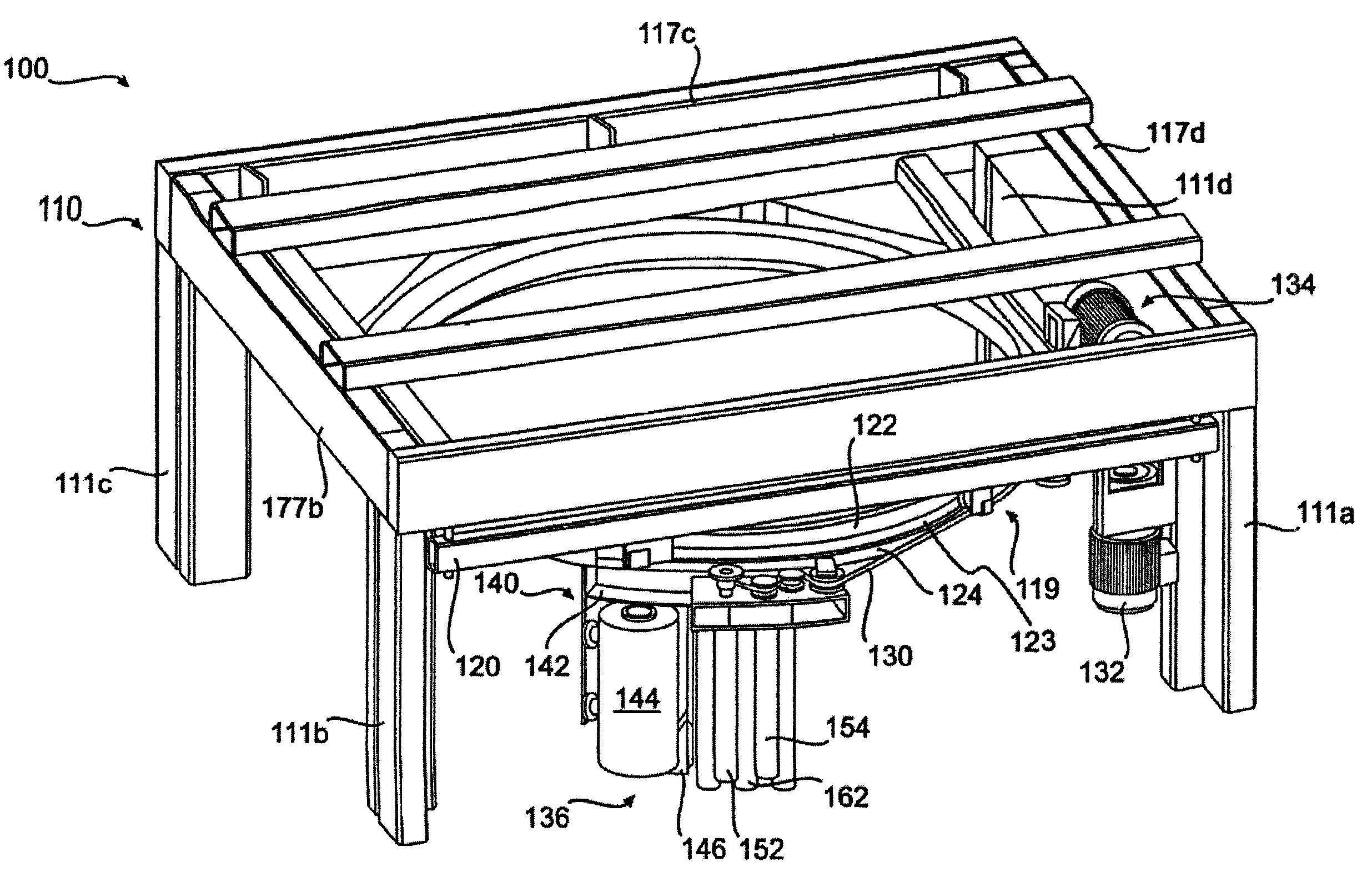

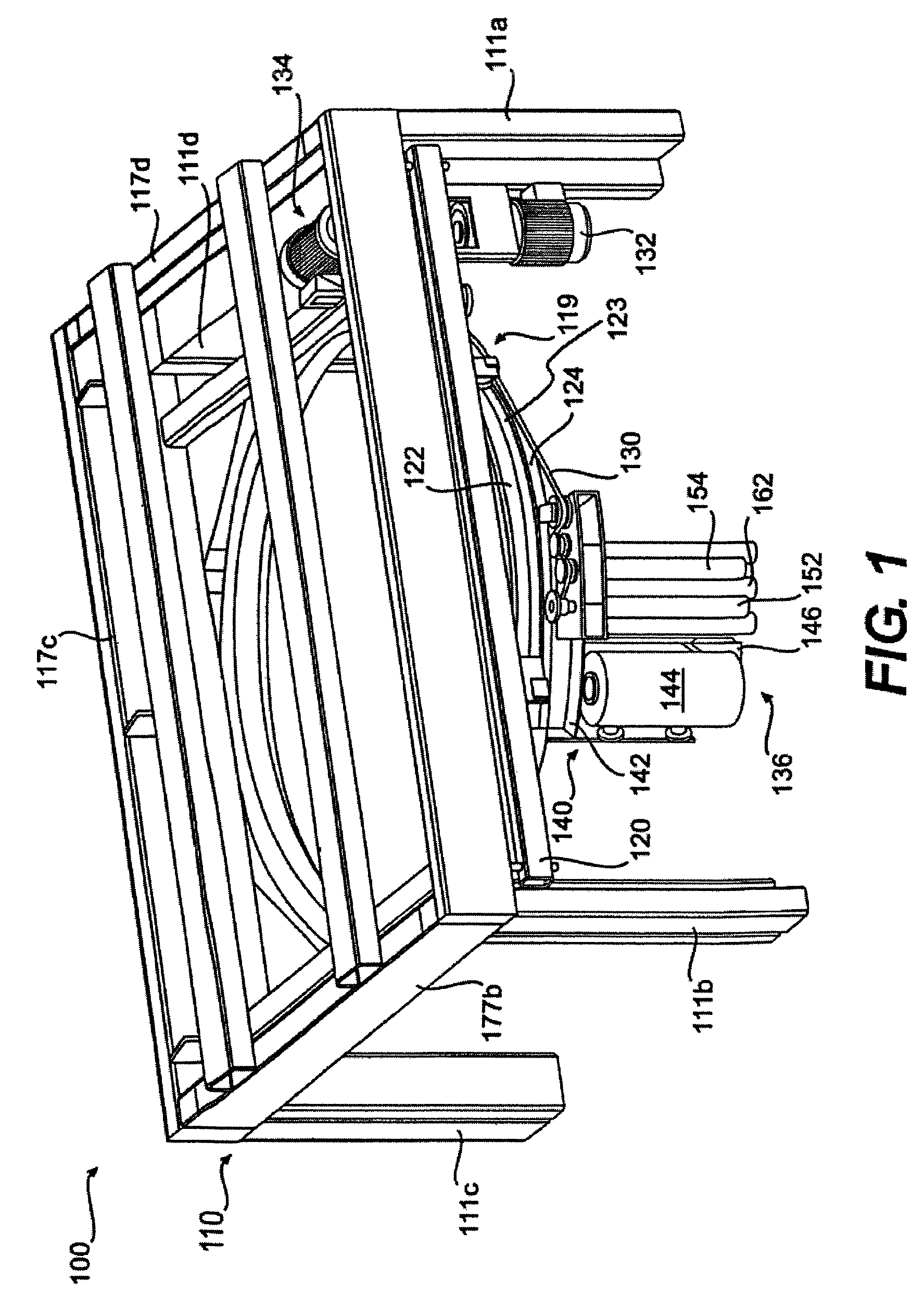

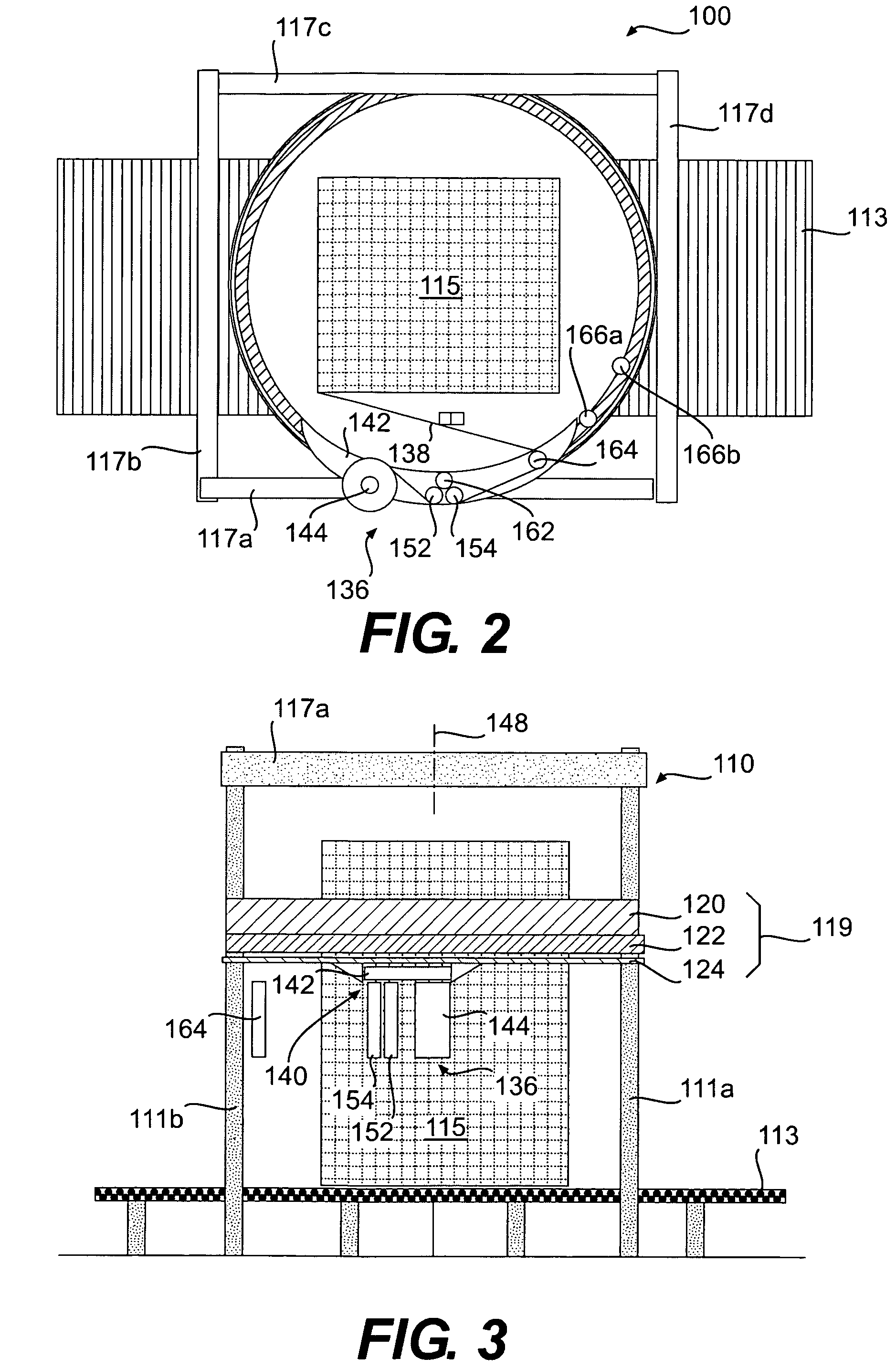

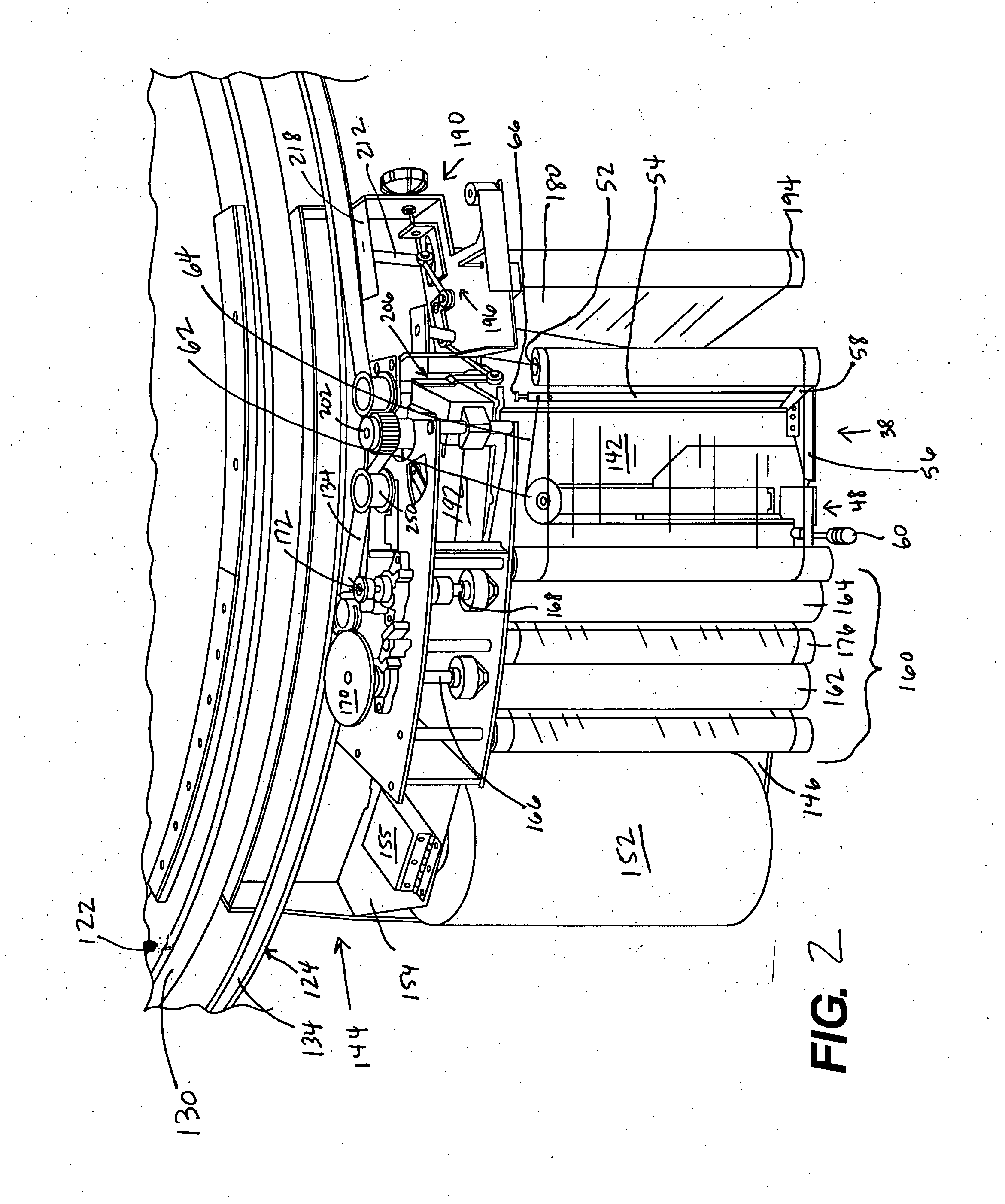

Wrapping apparatus including metered pre-stretch film delivery assembly and method of using

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched packaging material based upon load girth. A non-rotating ring carries a belt driven by a motor. A packaging material dispenser is mounted on a rotating ring, and the rotating ring may include a pulley that connects to the band, such that the rotating ring is driven by the drive belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum packaging material use is obtained by dispensing a length of pre-stretched packaging material that is between approximately 90% and approximately 120% of load girth. Once the amount of packaging material to be dispensed per revolution is determined, a ratio of rotating ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / rotating ring rotation) can be set and mechanically controlled. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of packaging material is dispensed and wrapped around the load. In an alternative embodiment, the ratio is electronically controlled.

Owner:LANTECH COM

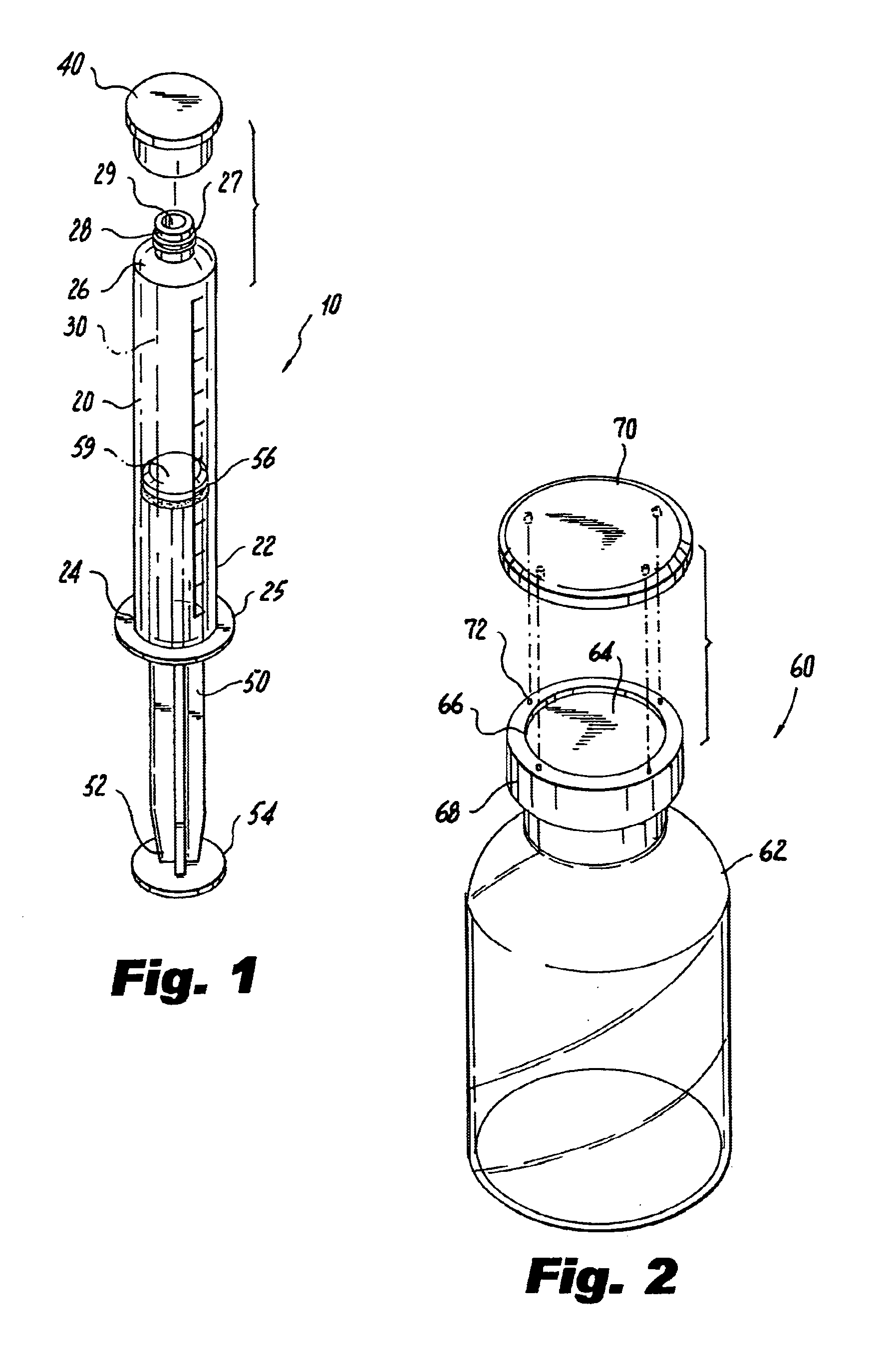

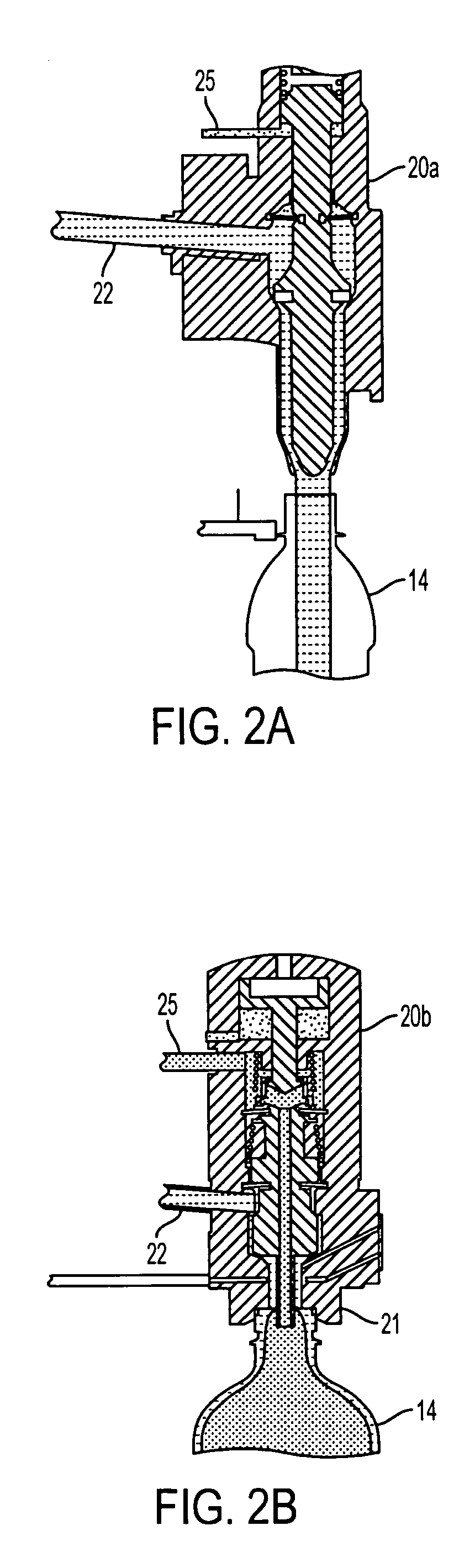

Automated means for withdrawing a syringe plunger

In one exemplary embodiment, an automated means for withdrawing a syringe plunger a method for just-in-time extension of the plunger to permit filling the syringe with a prescribed dose of medication are provided. The method includes the steps of: (1) inputting a desired volume of the prescribed dose of medication; (2) inputting syringe identifying information; (3) calculating a distance that the plunger is to be extended based on the inputted desired volume and syringe identifying information; (4) calculating drive parameters for a controllable drive that causes extension of the plunger when actuated and ensures that the plunger is extended the desired distance; and (5) controlling the drive in view of the calculated drive parameters to cause the plunger to be extended the desired distance.

Owner:BAXTER ENGLEWOOD

Refrigerator and automated liquid dispenser therefor

InactiveUS6789585B1Coin-freed apparatusPhotoelectric discharge tubesEngineeringRefrigerated temperature

Owner:WHIRLPOOL CORP

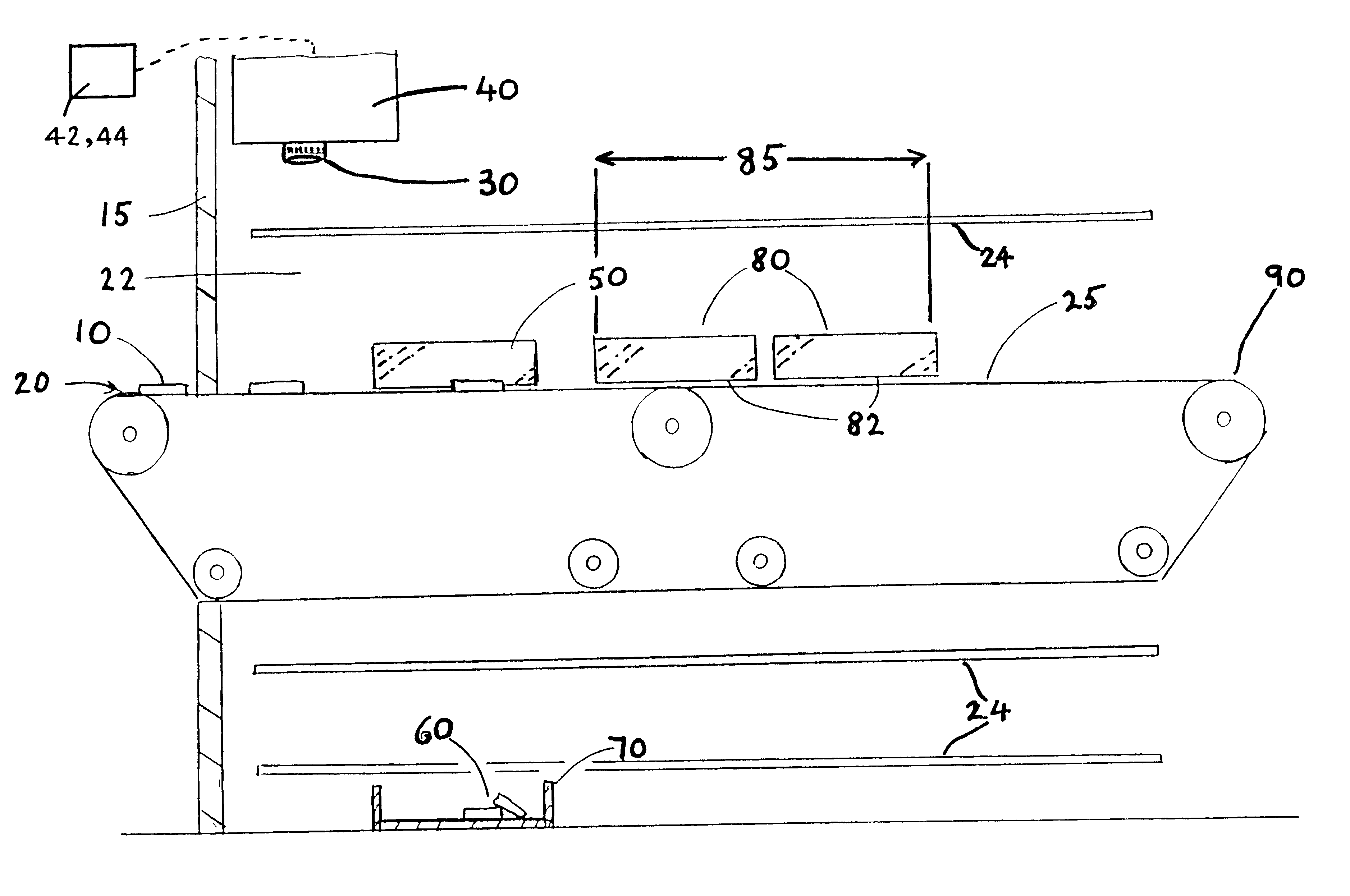

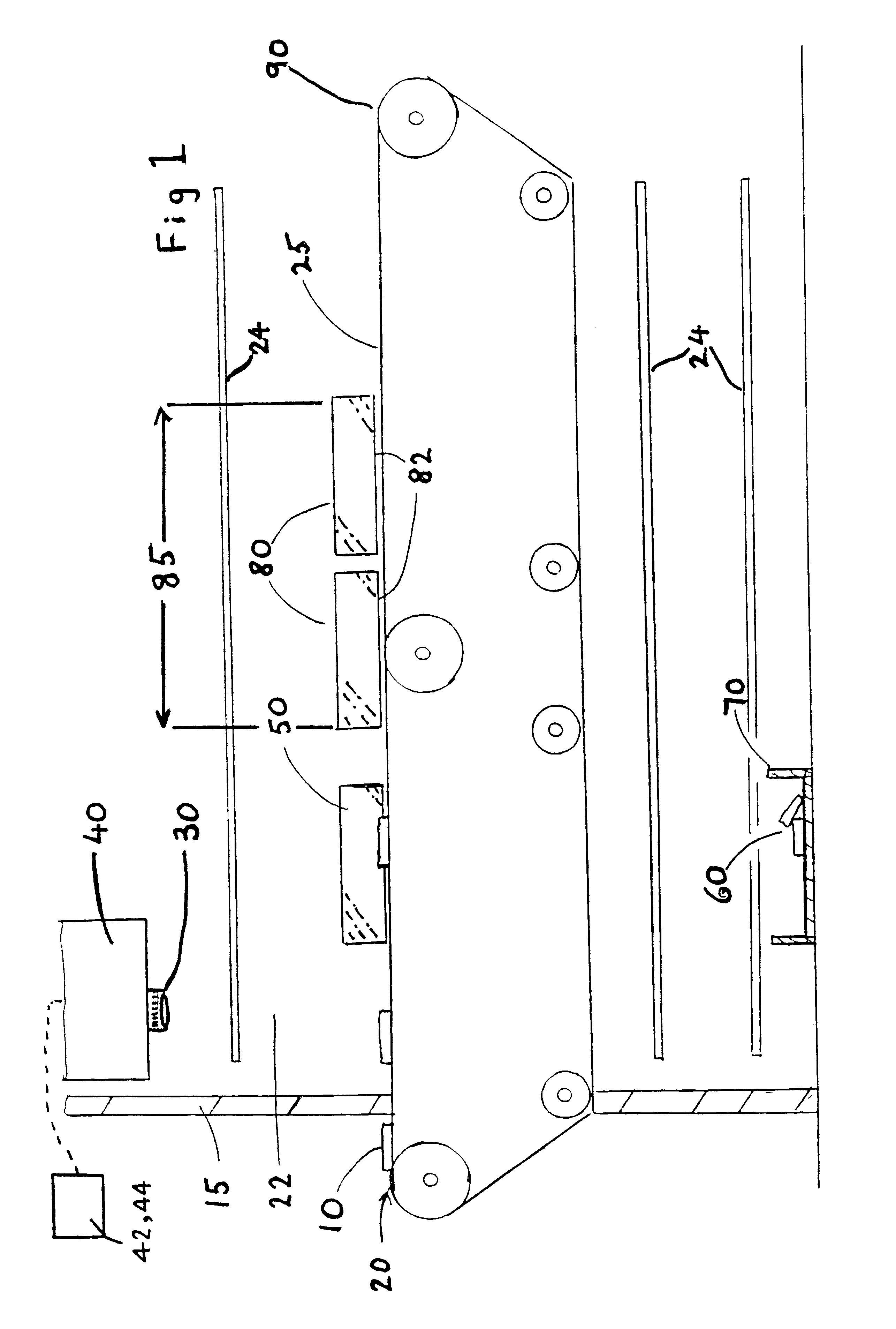

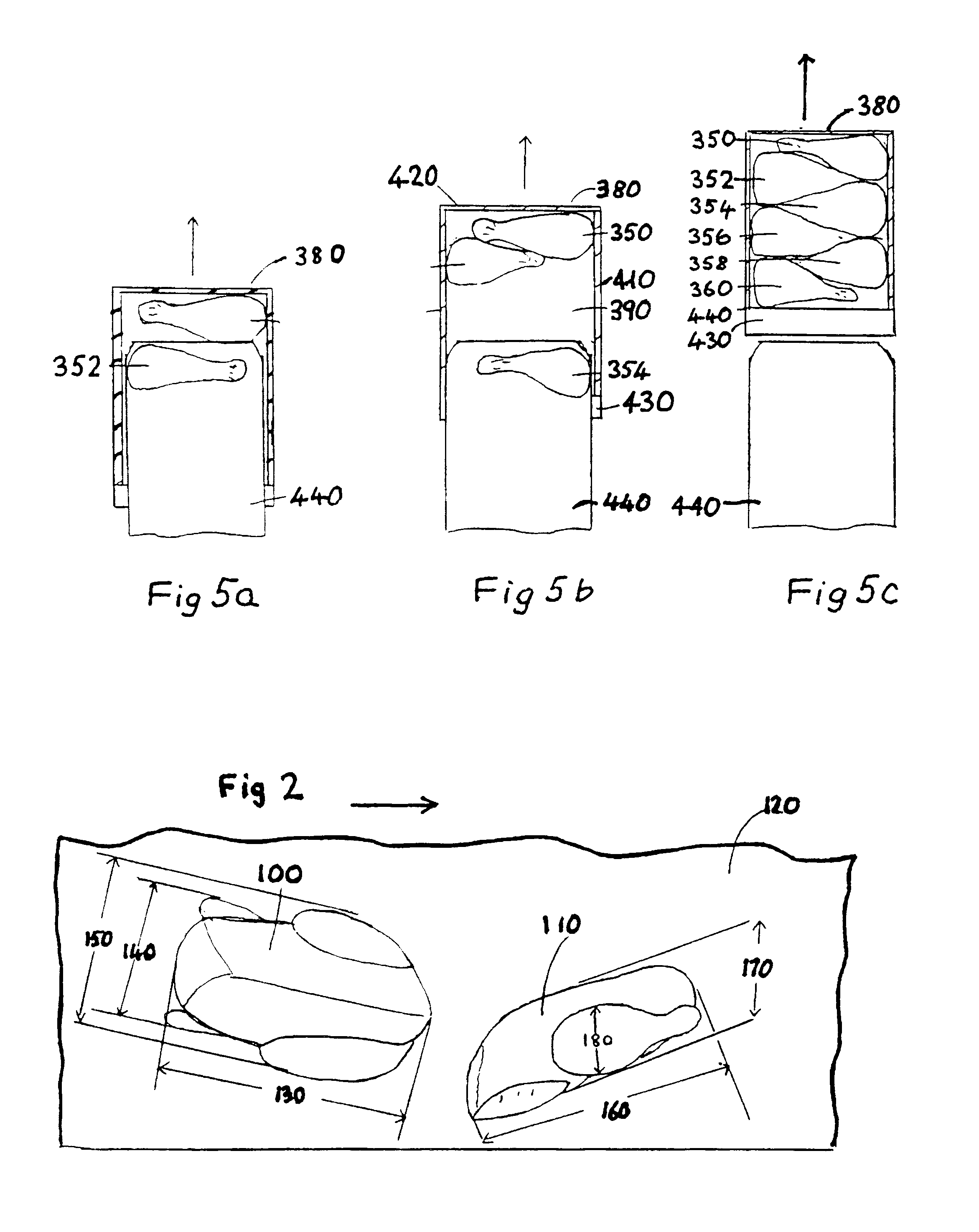

Automated packaging

InactiveUS6349526B1Improve throughput speedIncrease speedPackage sterilisationPackaging automatic controlImaging analysisEngineering

As a substrate (10) is carried on a conveyor (20), an image analysis system (40) detects its presence and derives the various data, at least indicative of the footprint. The footprint data are used in selecting appropriate packaging components. Data may also indicate the transverse location and / or orientation and / or alignment of a substrate, and be used to control position adjustors for adjusting one or more of these. Data may also serve for categorizing the substrate, e.g., in terms of size or color. Such data may be used to control rejection of products, or categorization, e.g., by selection of distinguishable packaging.

Owner:NEWMAN PAUL BERNARD

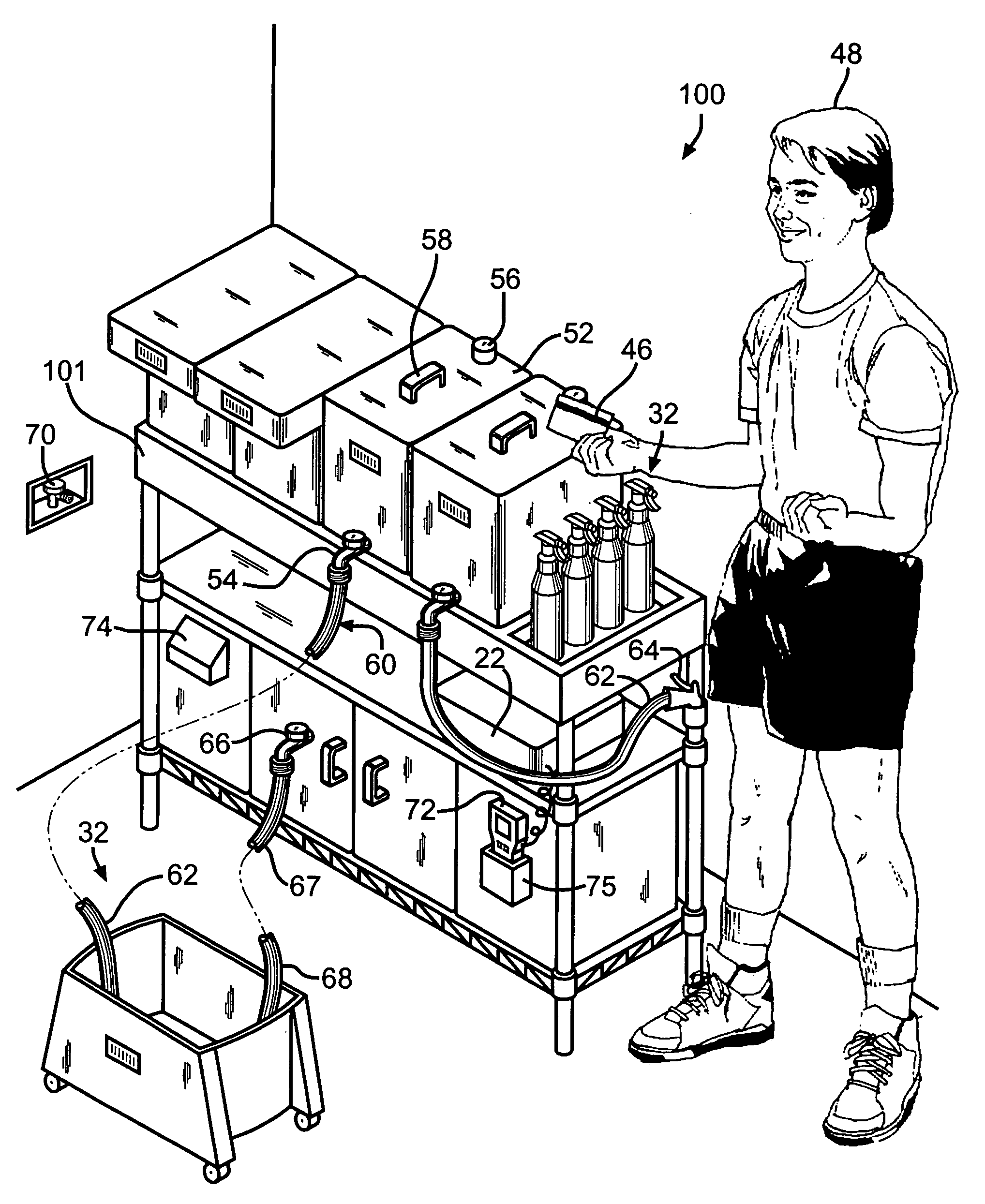

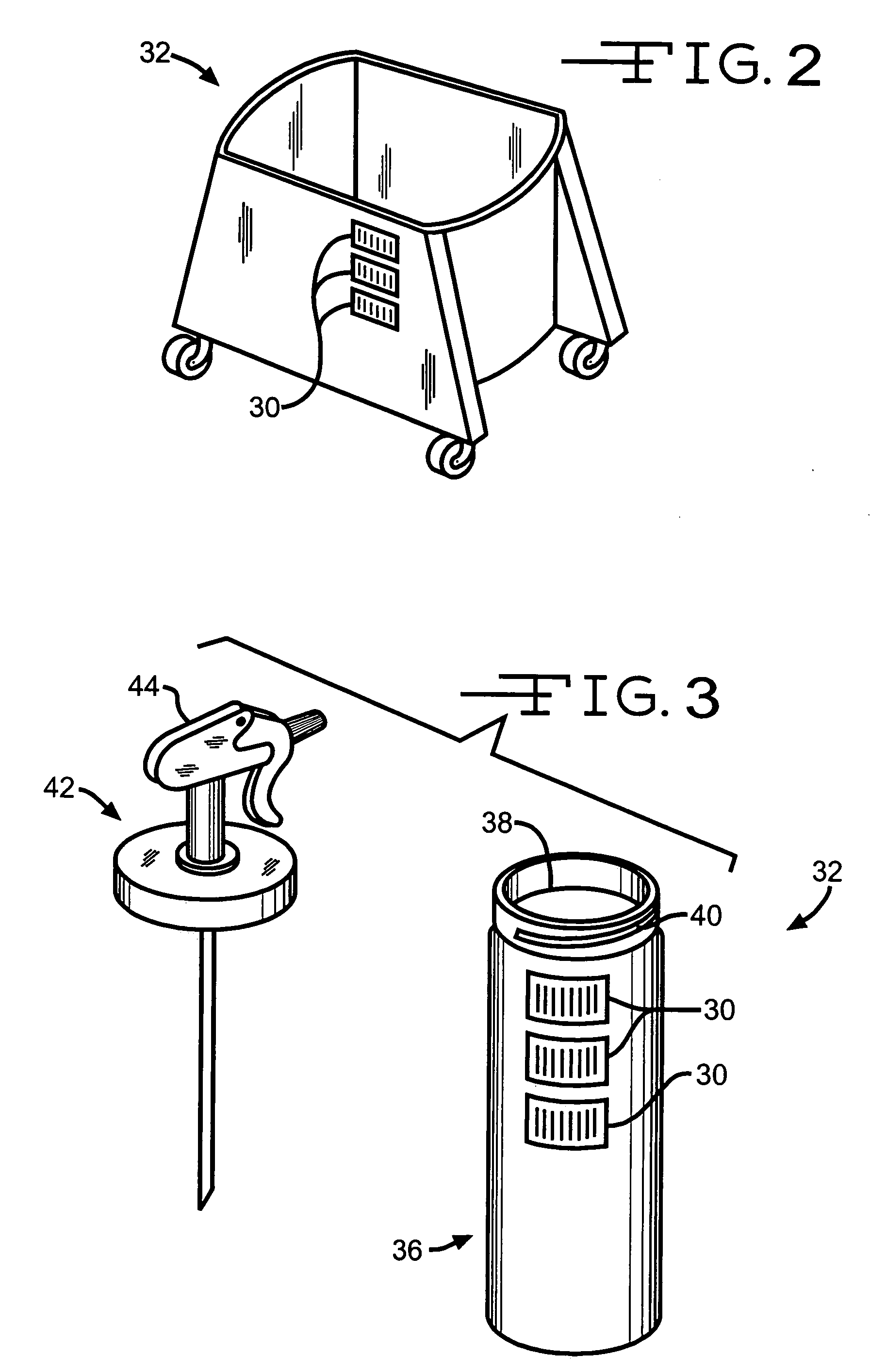

Apparatus for dispensing a substance

InactiveUS6968876B2Liquid fillingLiquid flow controllersData storingElectrical and Electronics engineering

A container filling apparatus includes at least one source container that contains a substance and a reading mechanism capable of reading data from a data indicator on a receiving container wherein the data indicator identifies data about the receiving container. The apparatus also includes a controller that is connected to the reading mechanism. The controller is programmed to determine when a dispensing condition is satisfied. The apparatus also has a dispenser for discharging the substance into the receiving container in response to a signal from the controller. The dispensing condition can be a match between data from the data indicator and the data stored for access by the controller. The source container can also have a data indicator. The dispensing condition is then satisfied when the data from the source container data indicator matches the data from the receiving container data indicator.

Owner:IDISPENSE

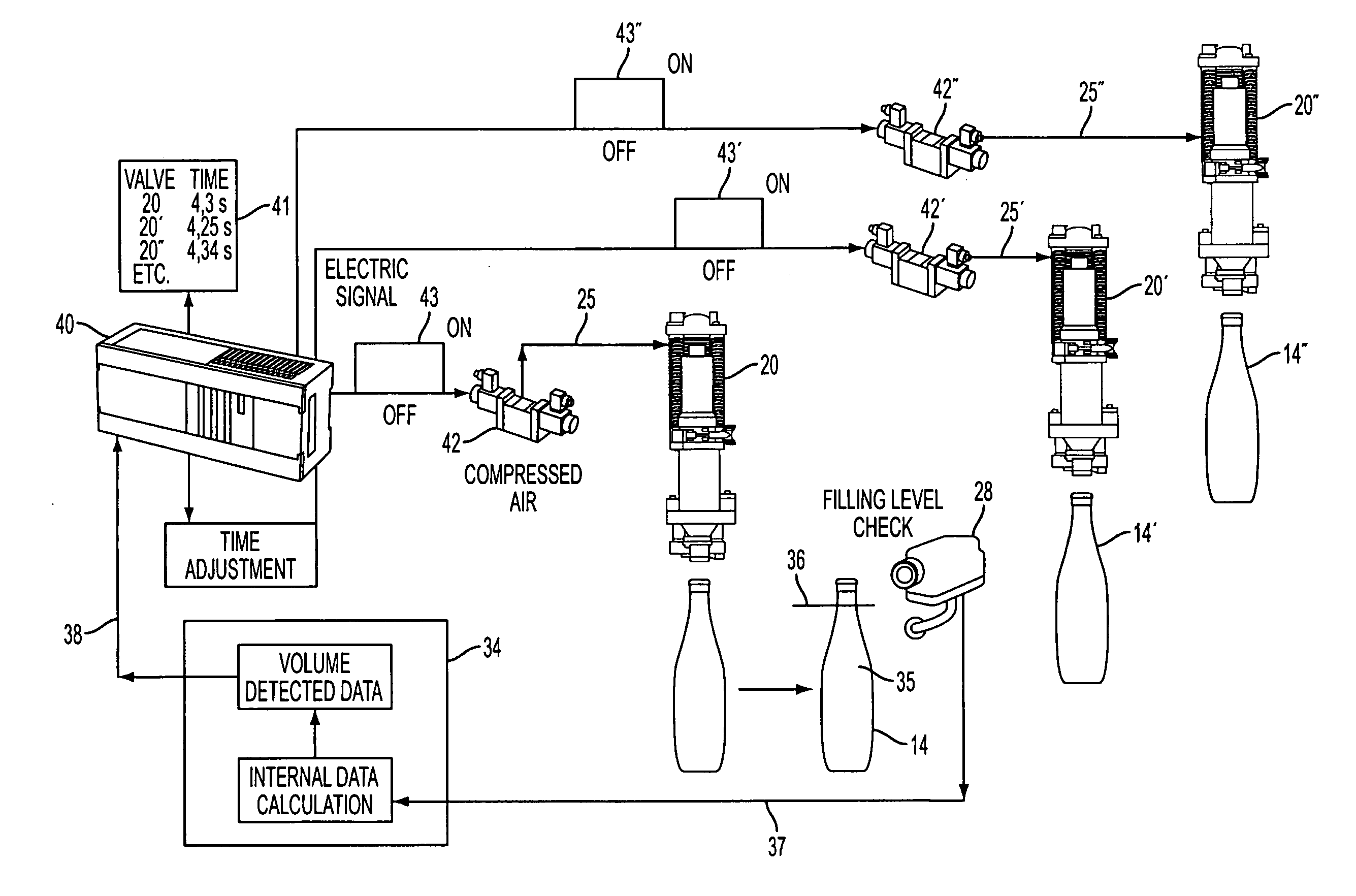

Bottle filling machine with sensor and method thereof

InactiveUS20070107801A1Reduce generationImprove trustVolume measurement and fluid deliverySafety device in filling machineryEngineeringBottle

A filling apparatus and method including a carrier for transporting containers and having a plurality of valves, each of the valves being opened for an individual, specific period of time to control a flow of liquid into the respective containers, while the containers are transported by the carrier. An exit feed path transports the containers after the containers have been filled, and a sensor, such as a camera, detects a level of liquid in the respective containers, while the containers are on the exit feed path. The sensor produces a signal that is stored as data representing the level of liquid for the individual containers. The data is then tracked and used for valve optimization. A period of time that each individual valve is opened for subsequent fillings is adjusted based on the signal and the historical performance of each valve.

Owner:SIDEL PARTICIPATIONS SAS +1

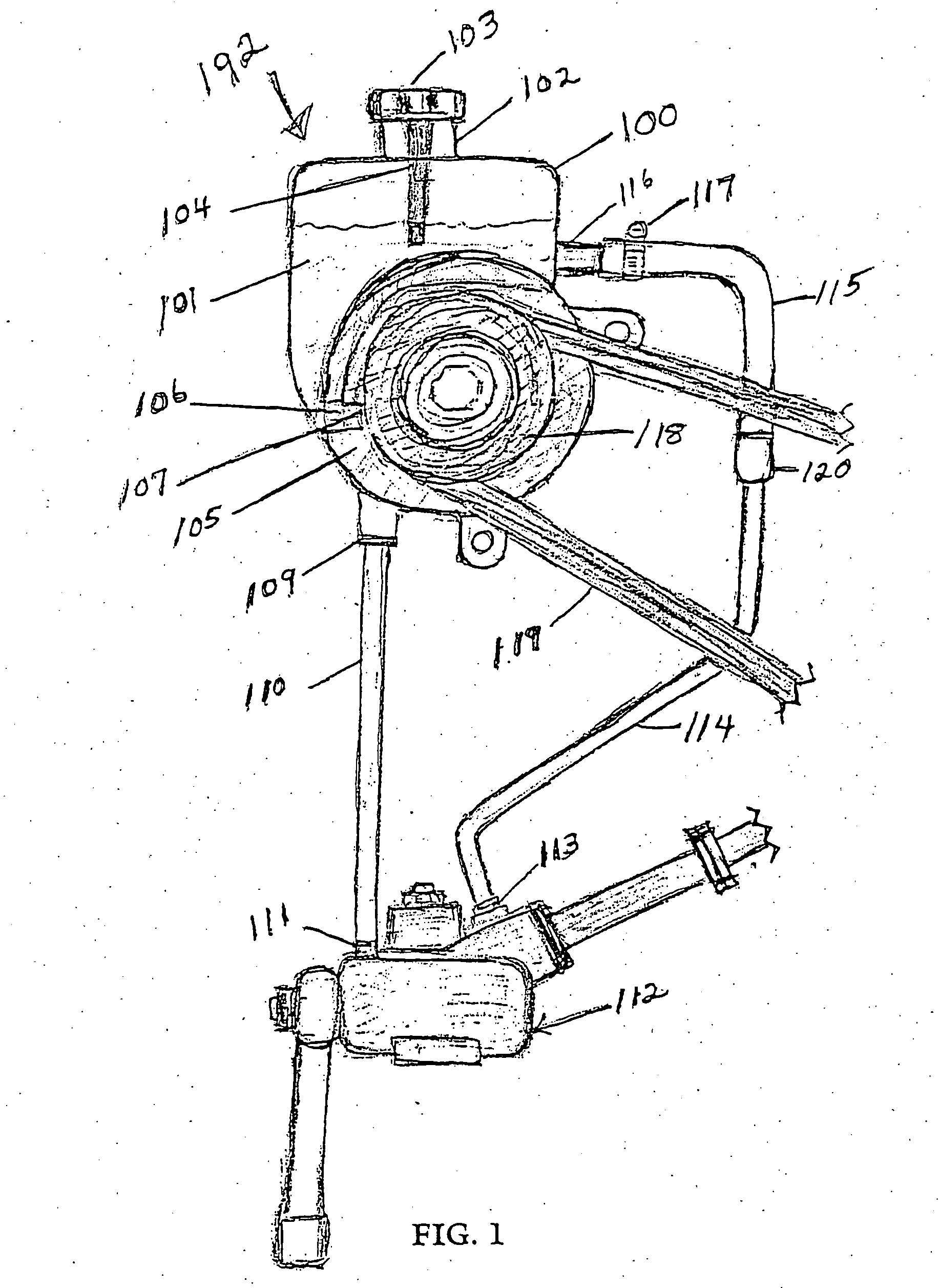

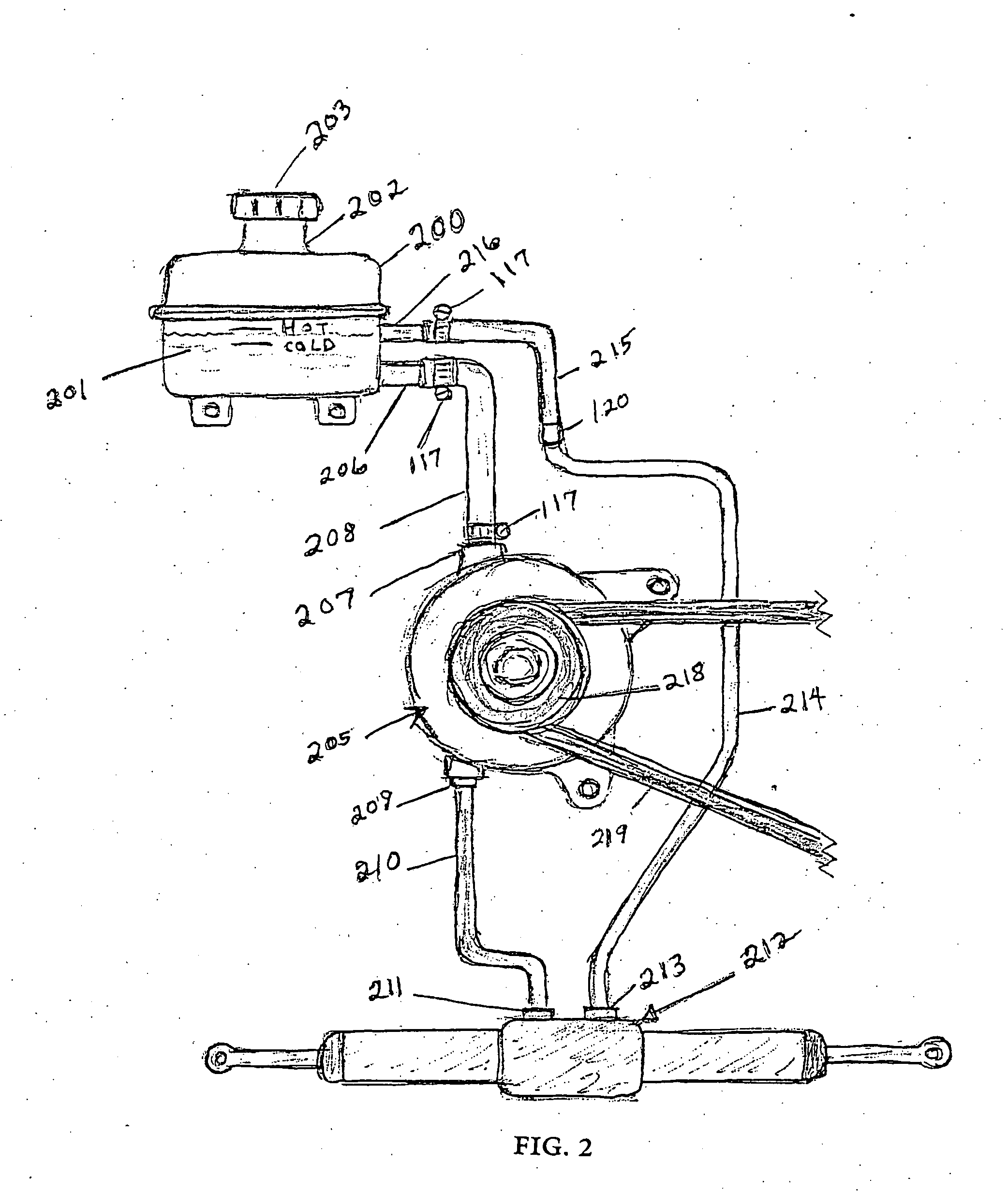

Automatic fluid exchanger

InactiveUS20050166993A1Preventing air infusionEffective blockingLiquid fillingPackaging by pressurising/gasifyingFluid controlPositive pressure

A fluid exchanger for servicing the fluid circuits of vehicular power steering systems and other fluid circulating or hydraulic circuits. The fluid exchanger uses a float operated fluid control valve to harness fluid pressure provided by a pump of an accessed hydraulic circuit. The fluid control valve uses both negative and positive pressure of the circuit's pump to control fluid flow patterns. The float and fluid control valve are matched to be either mechanical / hydraulic or electrical / hydraulic in design. If the exchanger is provided with a mechanically operated fluid control valve, a mechanical float is provided in the exchanger's fresh fluid reservoir and is directly connected to the valve slide of the fluid control valve. If the exchanger is provided with an electric solenoid operated fluid control valve, a float operated electrical switch is provided in the exchanger's fresh fluid reservoir and is wired to control the solenoid of the valve.

Owner:VIKEN JAMES P +1

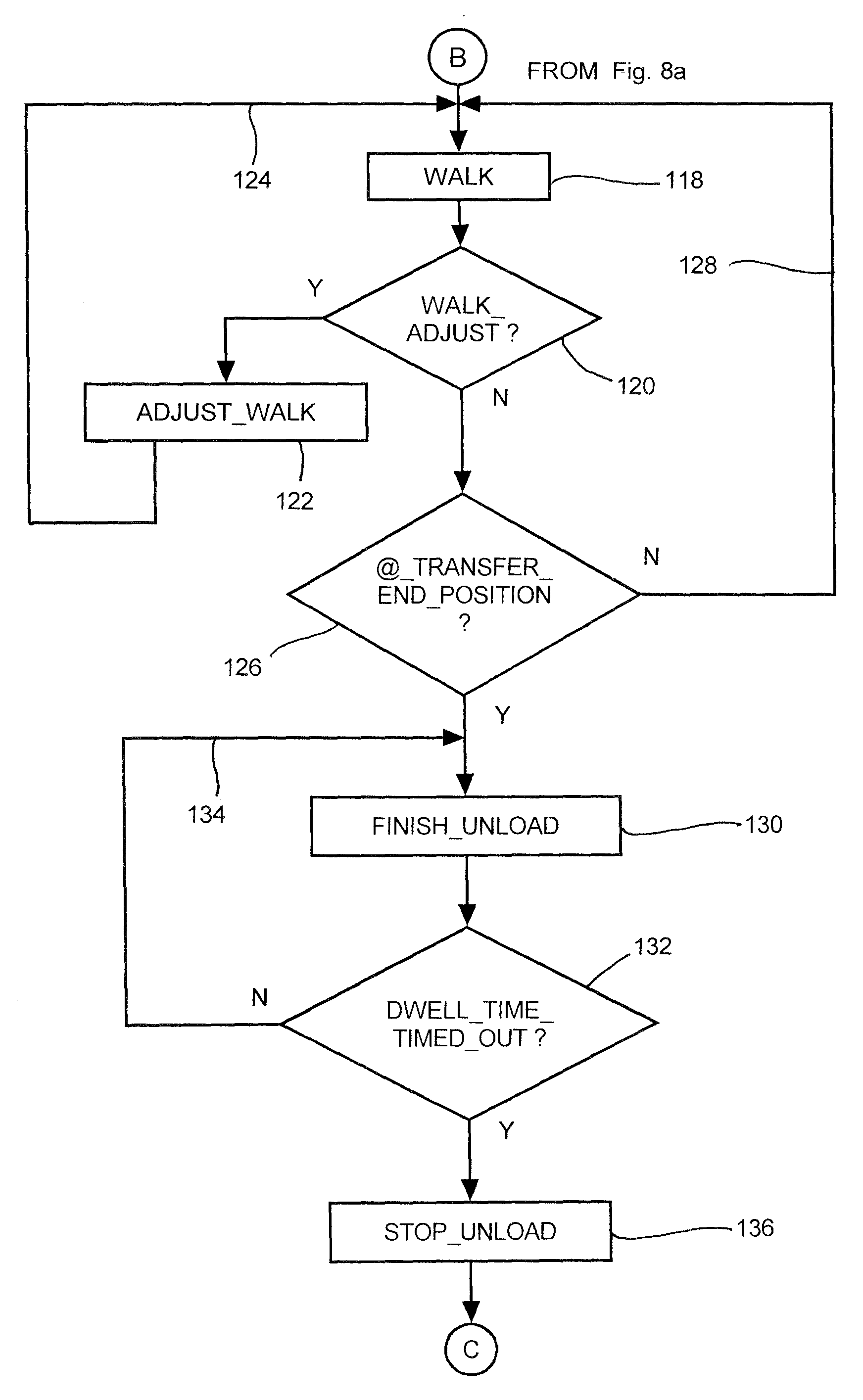

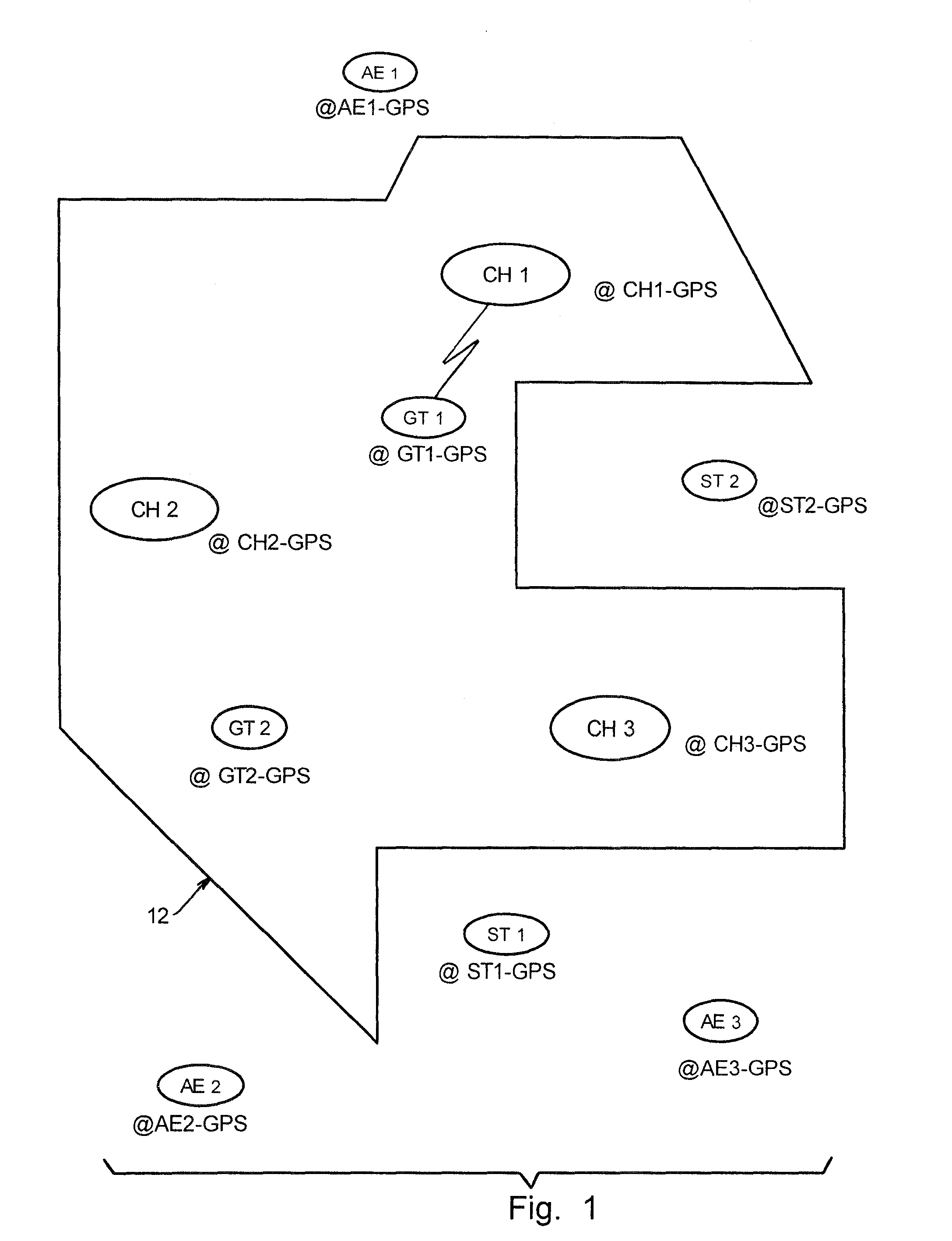

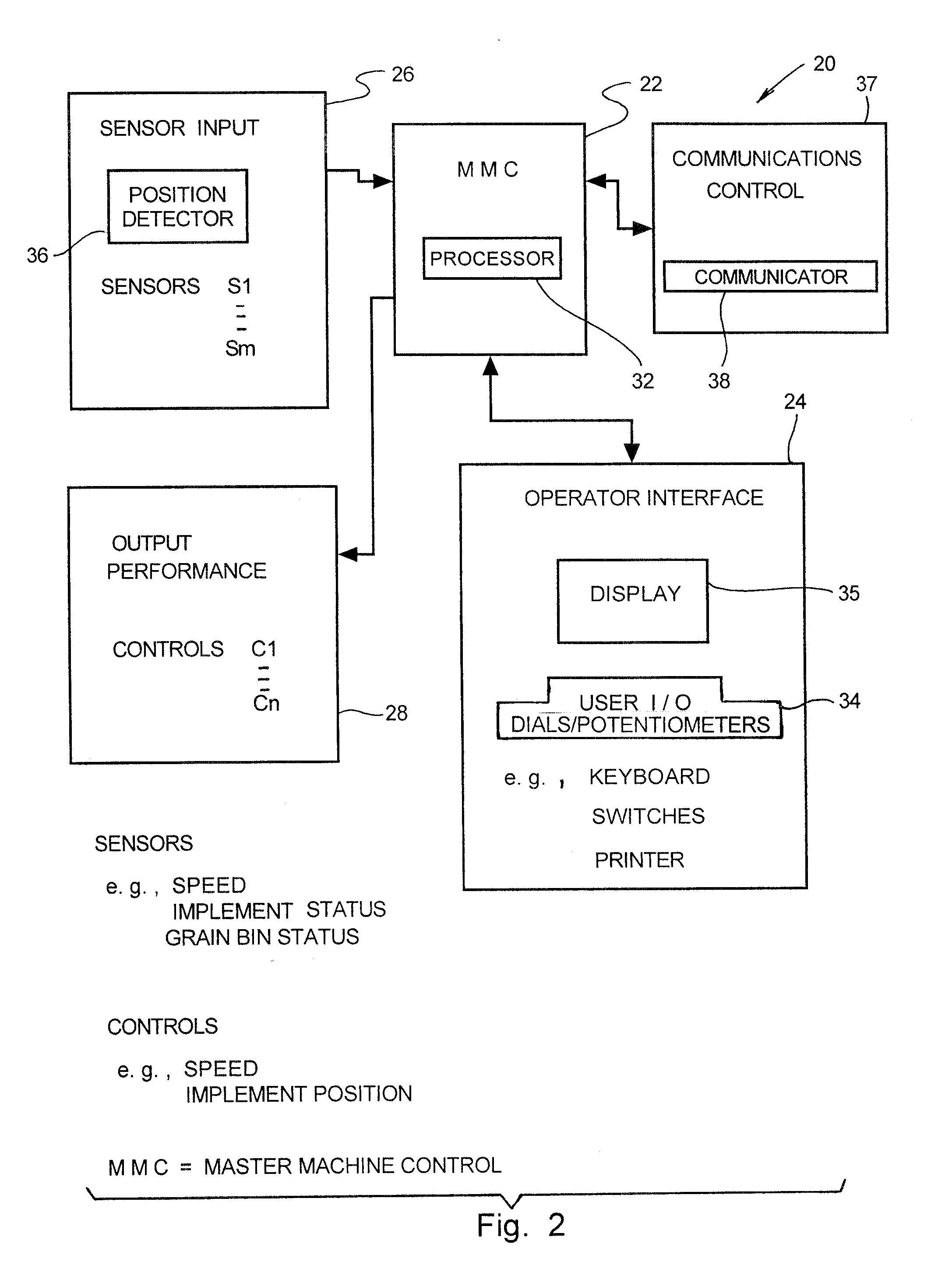

Grain transfer control system and method

ActiveUS20100274452A1Evenly filledDigital data processing detailsRoad vehicles traffic controlAutomatic controlControl system

A grain transfer control system, and method of use thereof, for automatedly controlling the transfer of grain from a mobile transferor-type vehicle, such as a combine harvester, to a mobile transferee-type vehicle, such as a crop transport, by varying the position and speed of the transferor-type and transferee-type vehicles relative to one another during the transfer operation, especially by varying the position and rate of walk of the discharge spout along at least a portion of the length of a grain holding receptacle of the transferee-type vehicle, to effect a generally even fill of the grain holding receptacle of the transferee-type vehicle along the length of the grain holding receptacle.

Owner:BLUE LEAF I P INC

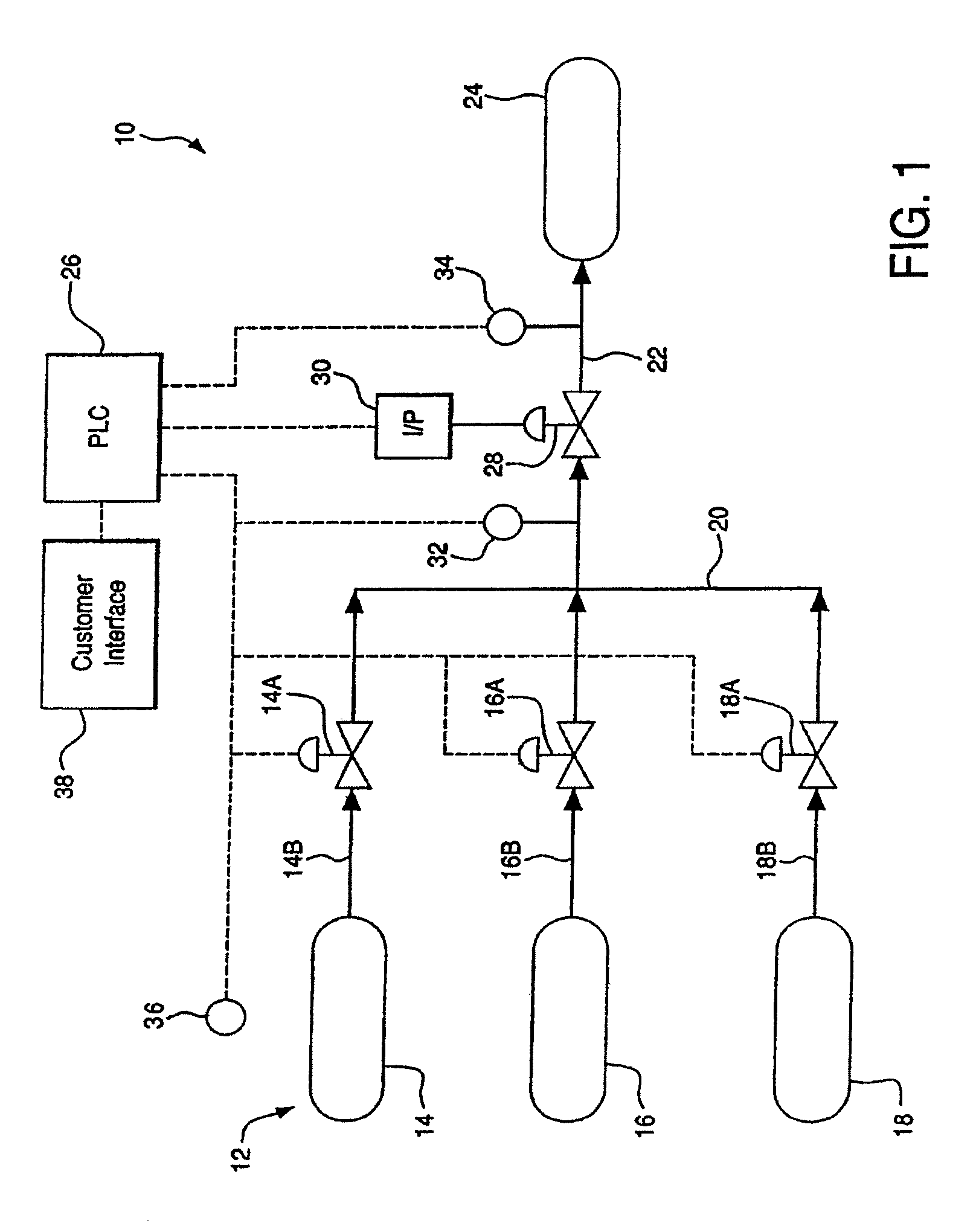

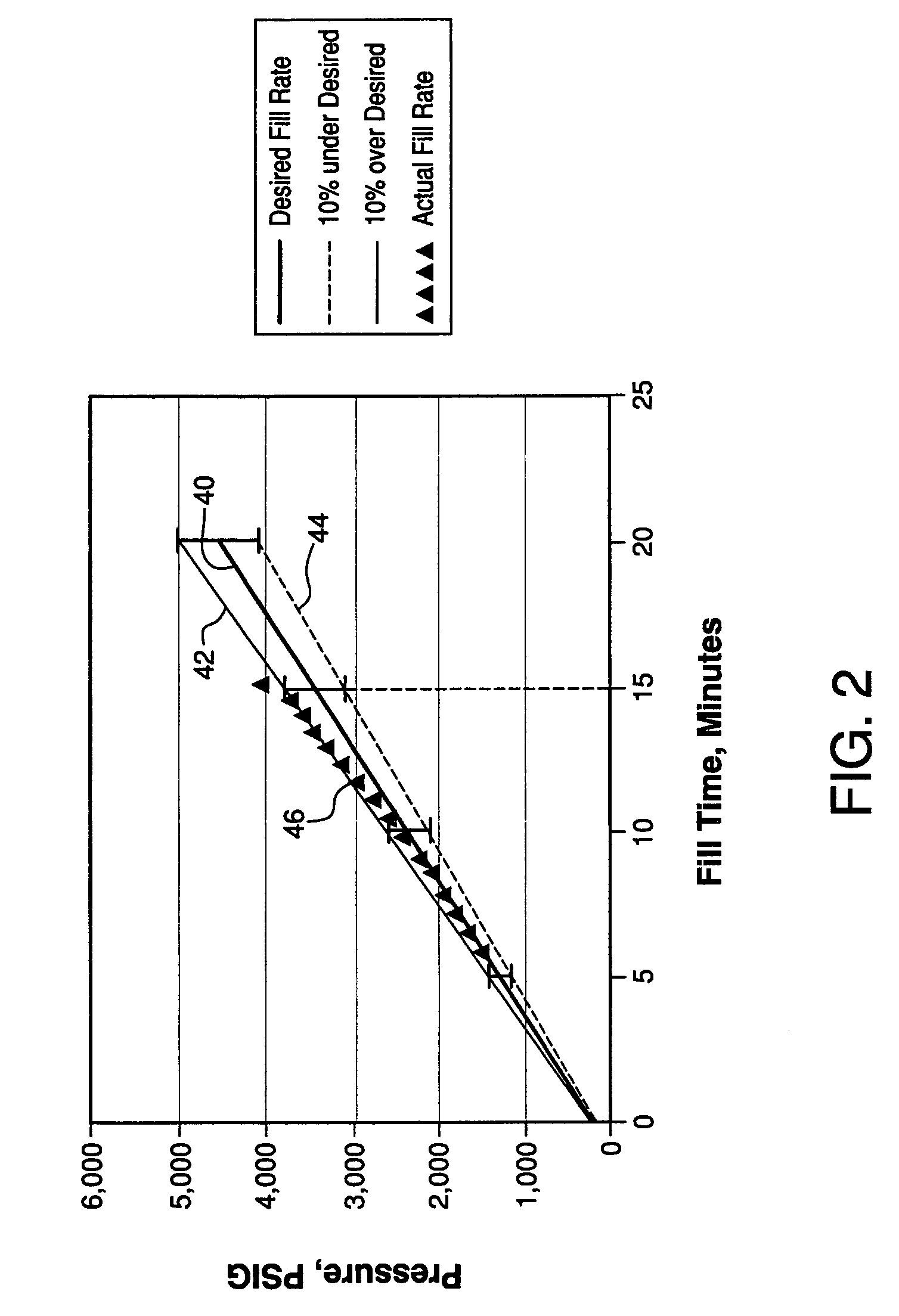

Diagnostic method and apparatus for a pressurized gas supply system

ActiveUS7568507B2Prevent excessive pressure risePreventing a potentially dangerous overheating problemLiquid fillingGas handling applicationsLine tubingEngineering

A diagnostic method for a gas supply system includes: determining a desired ramp rate for filling a vessel from a supply of compressed gas; monitoring the actual pressure of gas entering the vessel; and discontinuing the flow of gas into the vessel when the actual pressure deviates from the intended pressure at the desired ramp rate by an undesired amount. A system for carrying out the method includes a flow controller for controlling operation of the supply system to deliver compressed gas from a source to a vessel through a supply line at a desired ramp rate. The system employs a pressure monitor downstream of a control valve for measuring the pressure of gas directed into the vessel and transmitting pressure-related data to the flow controller, which closes the control valve to discontinue filling of the vessel if the actual pressure exceeds a permissible deviation from the intended pressure.

Owner:AIR PROD & CHEM INC

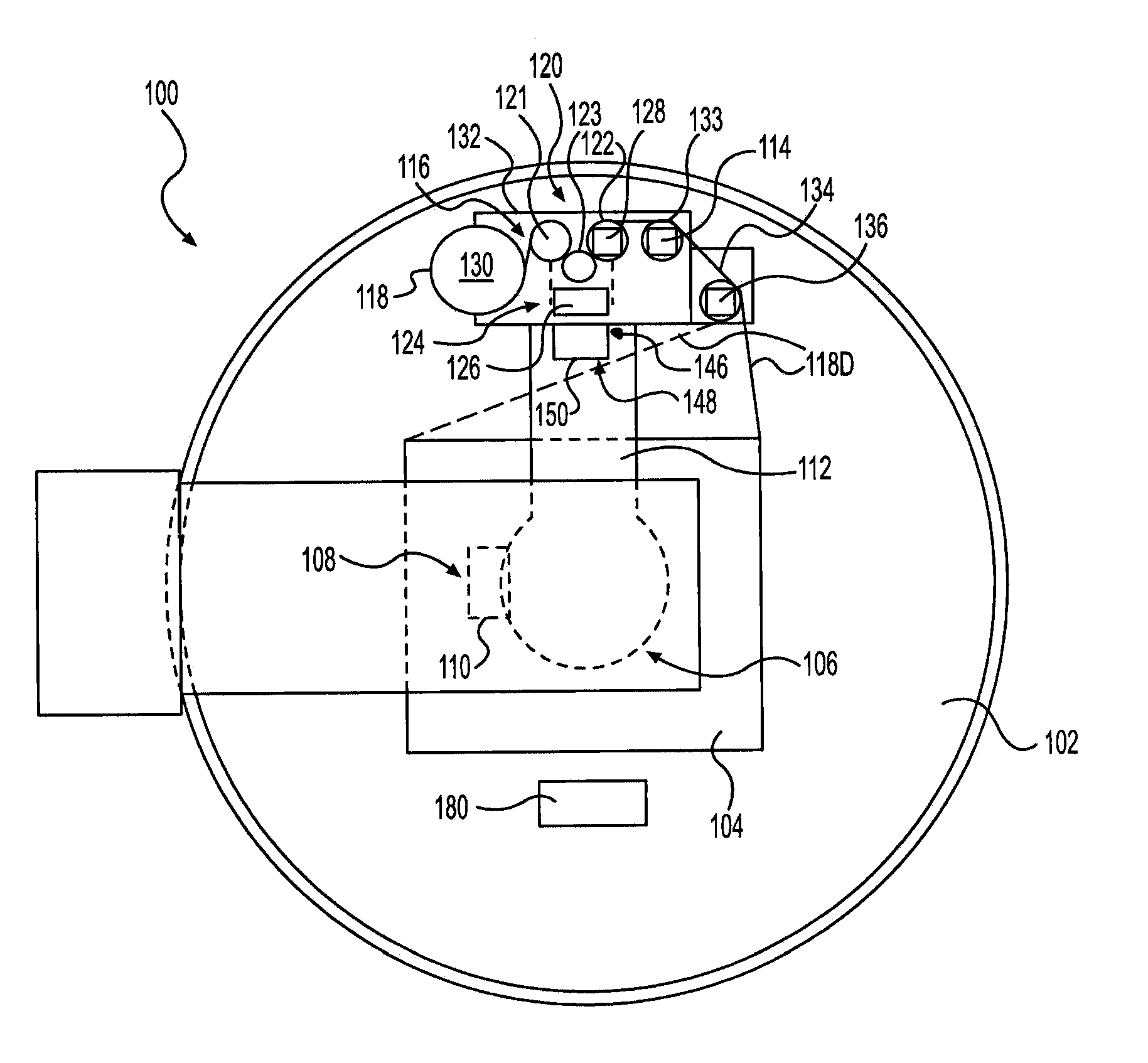

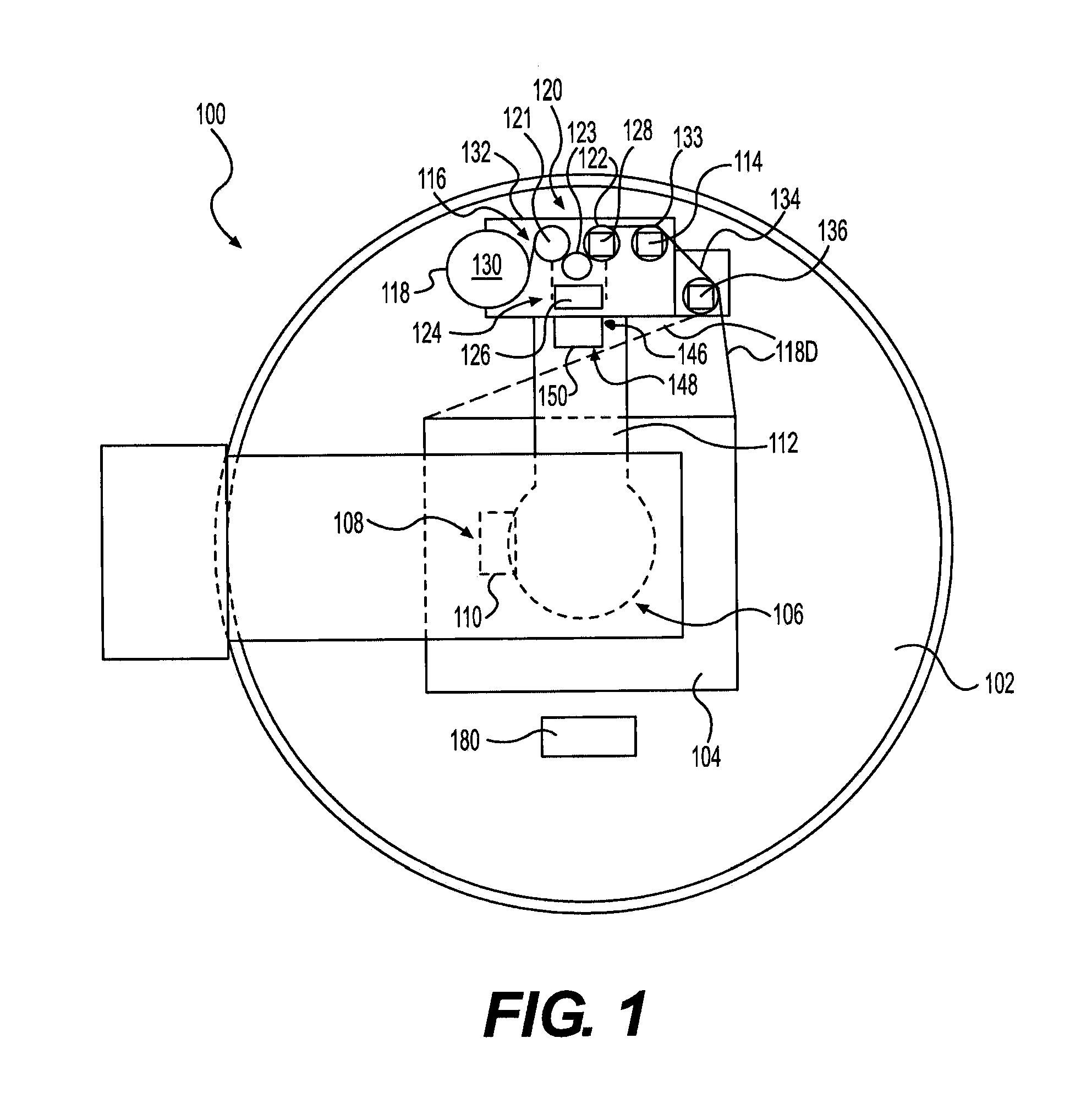

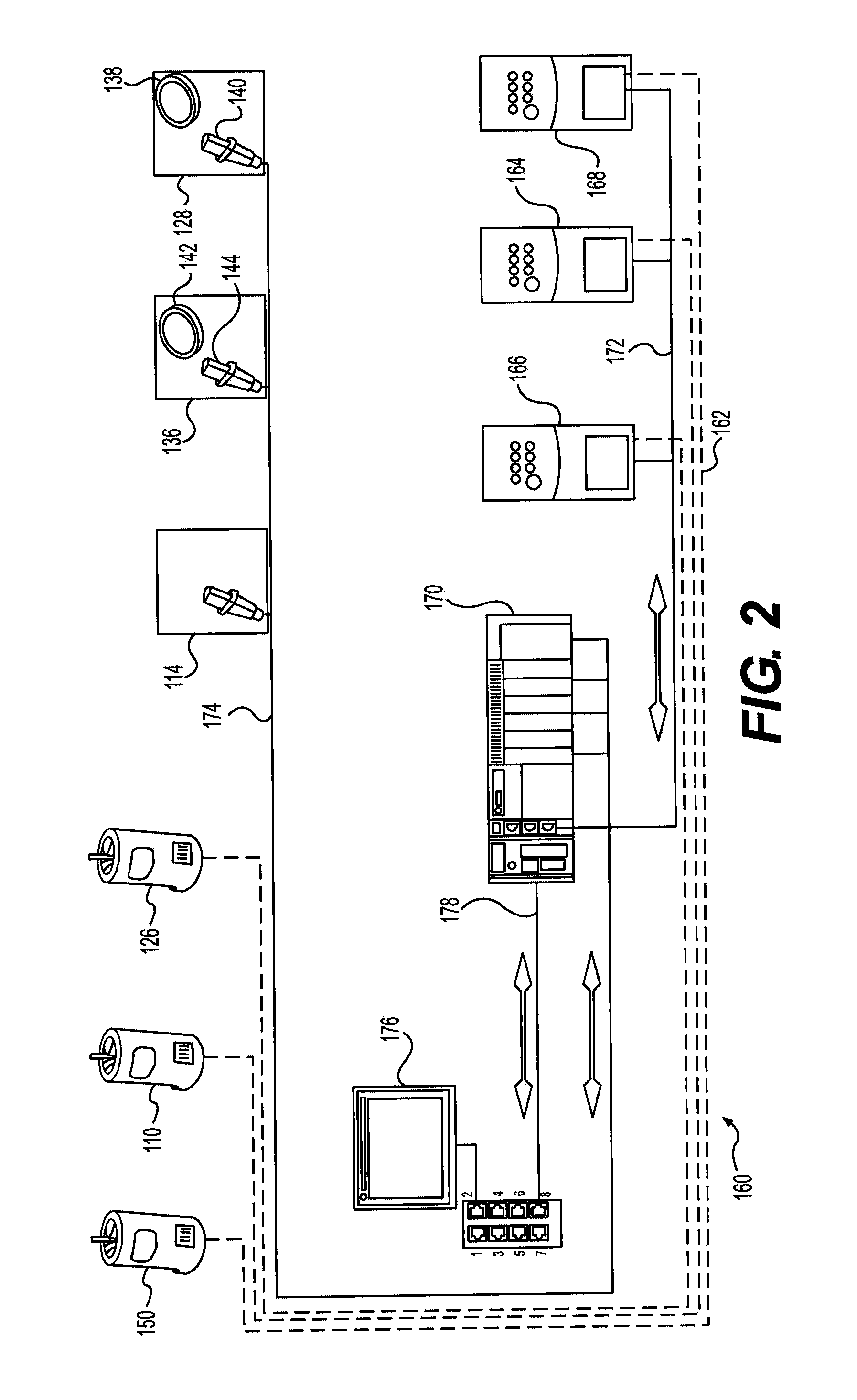

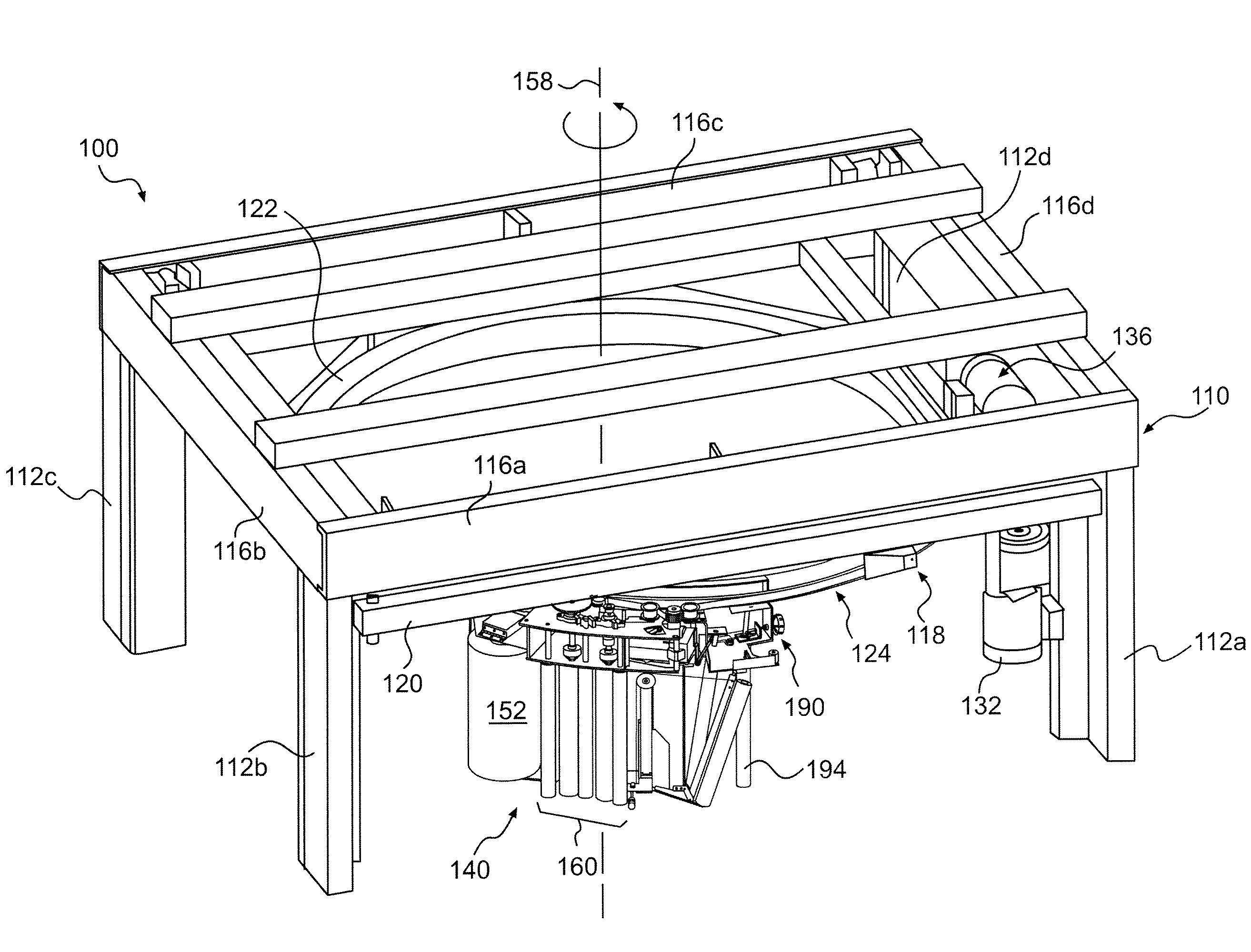

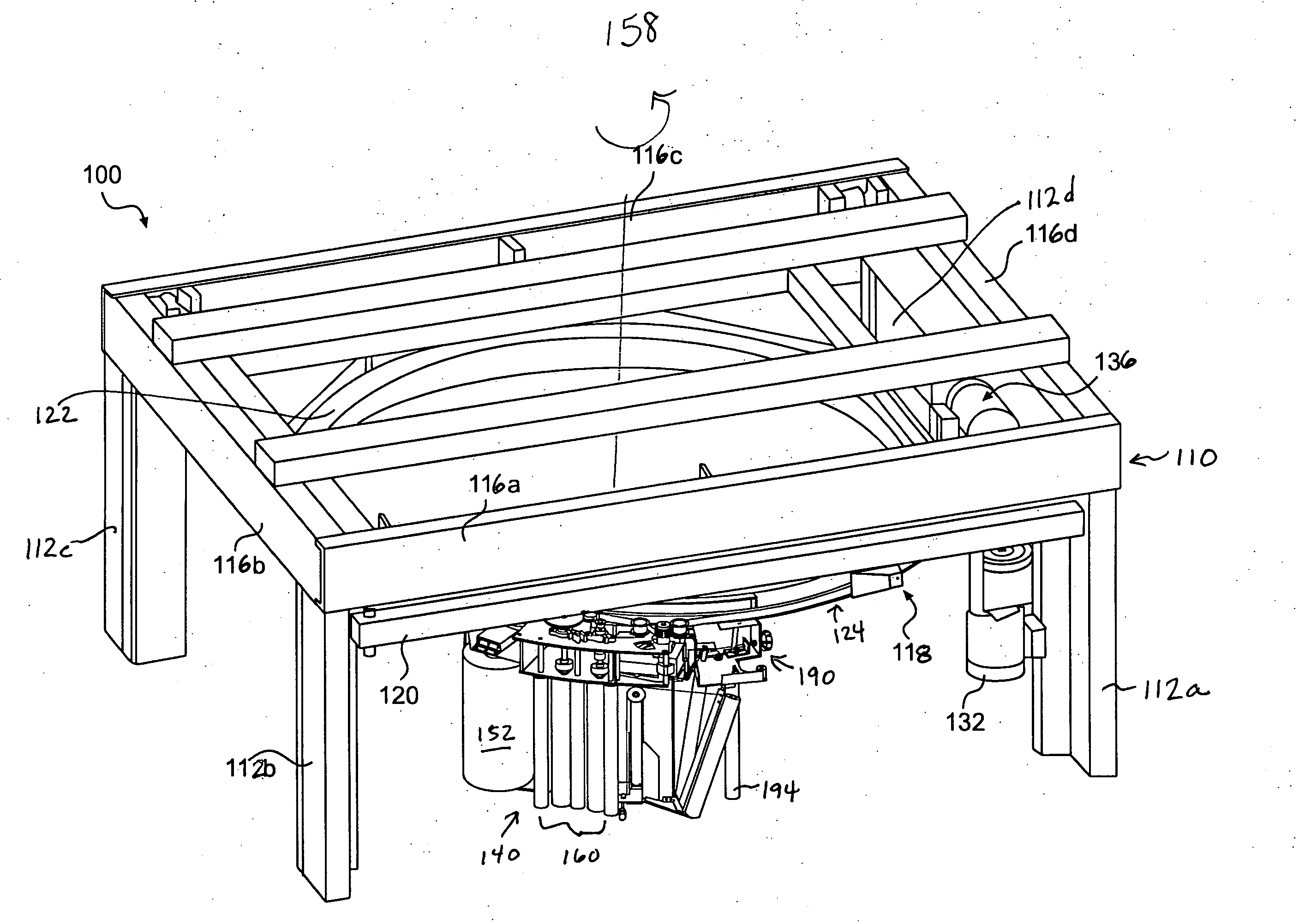

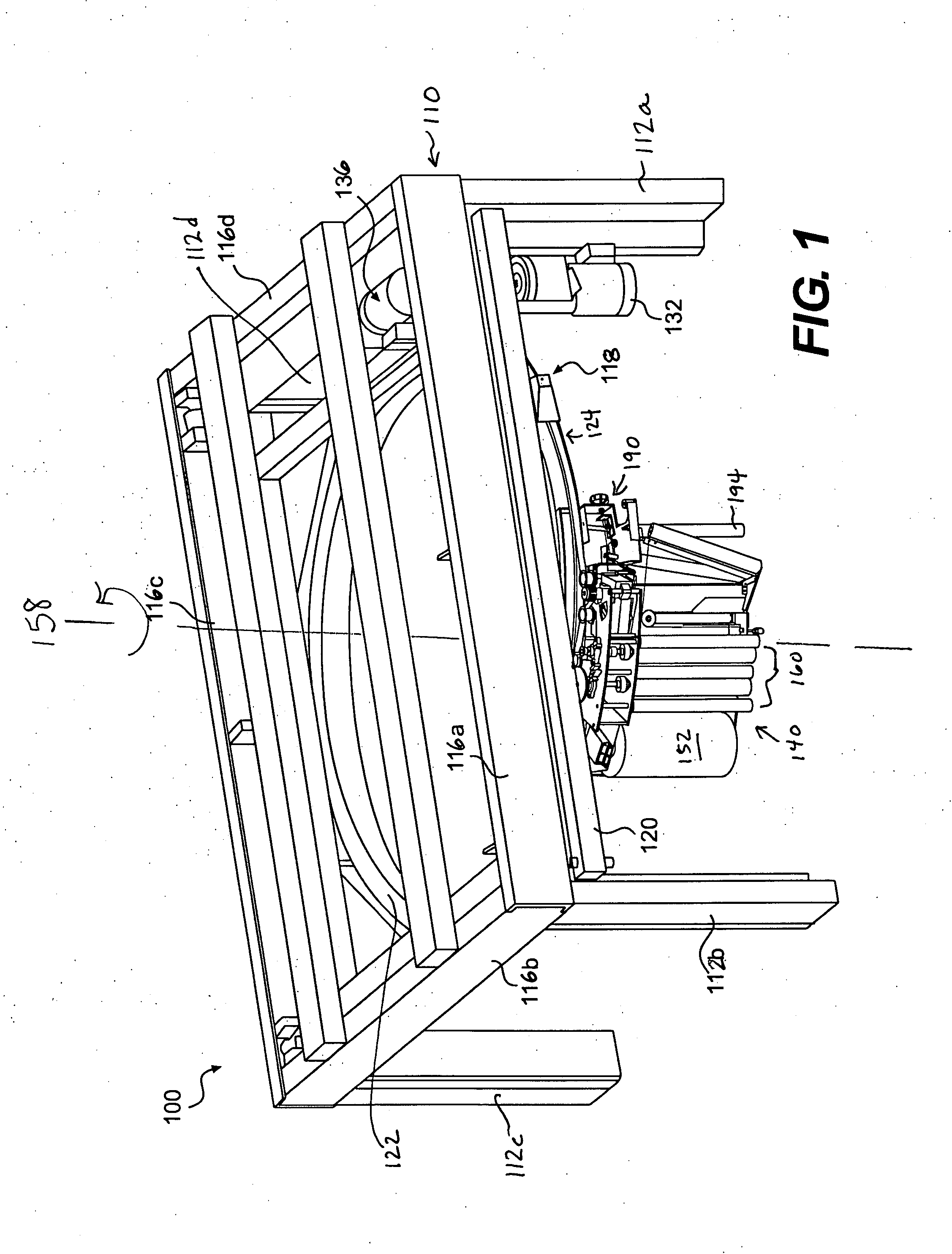

Ring wrapping apparatus including metered pre-stretch film delivery assembly

The present invention provides a method and apparatus for dispensing a predetermined fixed amount of pre-stretched packaging material based upon load girth. A non-rotating ring carries a belt driven by a motor. A packaging material dispenser is mounted on a rotating ring, and the rotating ring may include a pulley that connects to the band, such that the rotating ring is driven by the drive belt. Based upon the girth of the load to be wrapped, an amount of pre-stretched packaging material to be dispensed for each revolution made by the rotating ring is determined. Good wrapping performance in terms of load containment (wrap force) and optimum packaging material use is obtained by dispensing a length of pre-stretched packaging material that is between approximately 90% and approximately 120% of load girth. Once the amount of packaging material to be dispensed per revolution is determined, a ratio of rotating ring drive to final pre-stretch surface speed (i.e., number of pre-stretch roller revolution / rotating ring rotation) can be set and mechanically controlled. Thus, for each revolution of the rotating ring and dispenser, a predetermined fixed amount of packaging material is dispensed and wrapped around the load. In an alternative embodiment, the ratio is electronically controlled.

Owner:LANTECH COM

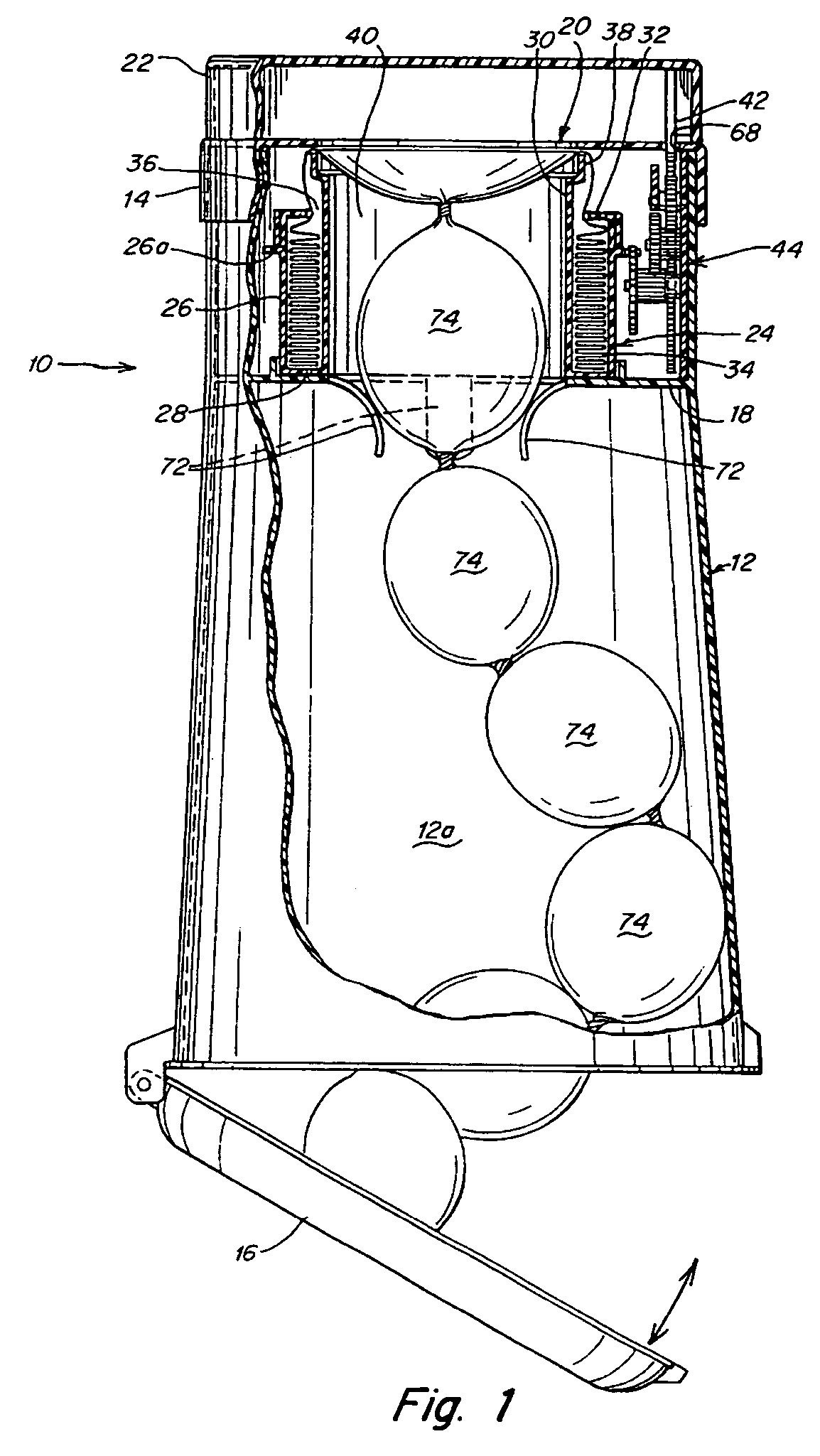

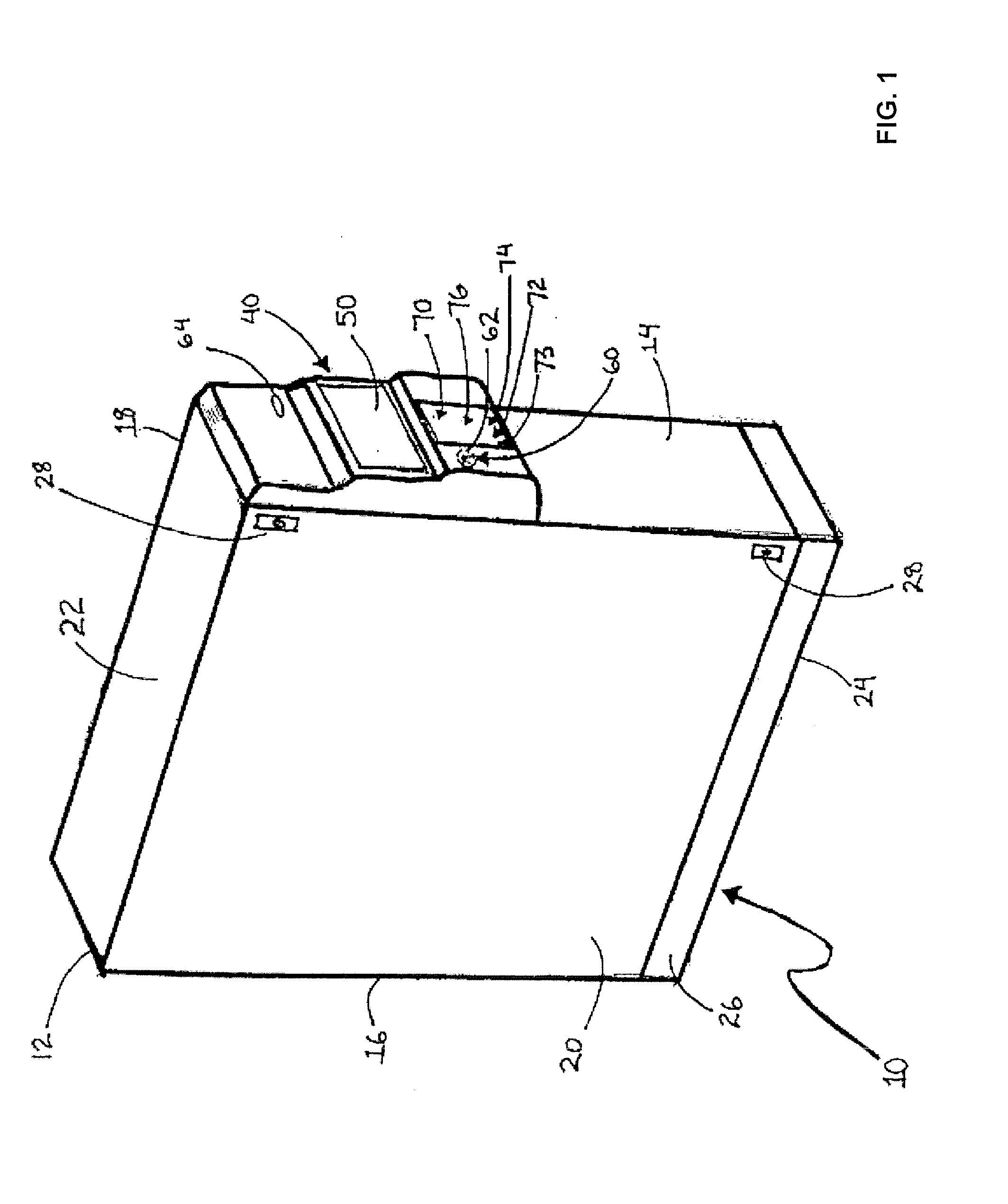

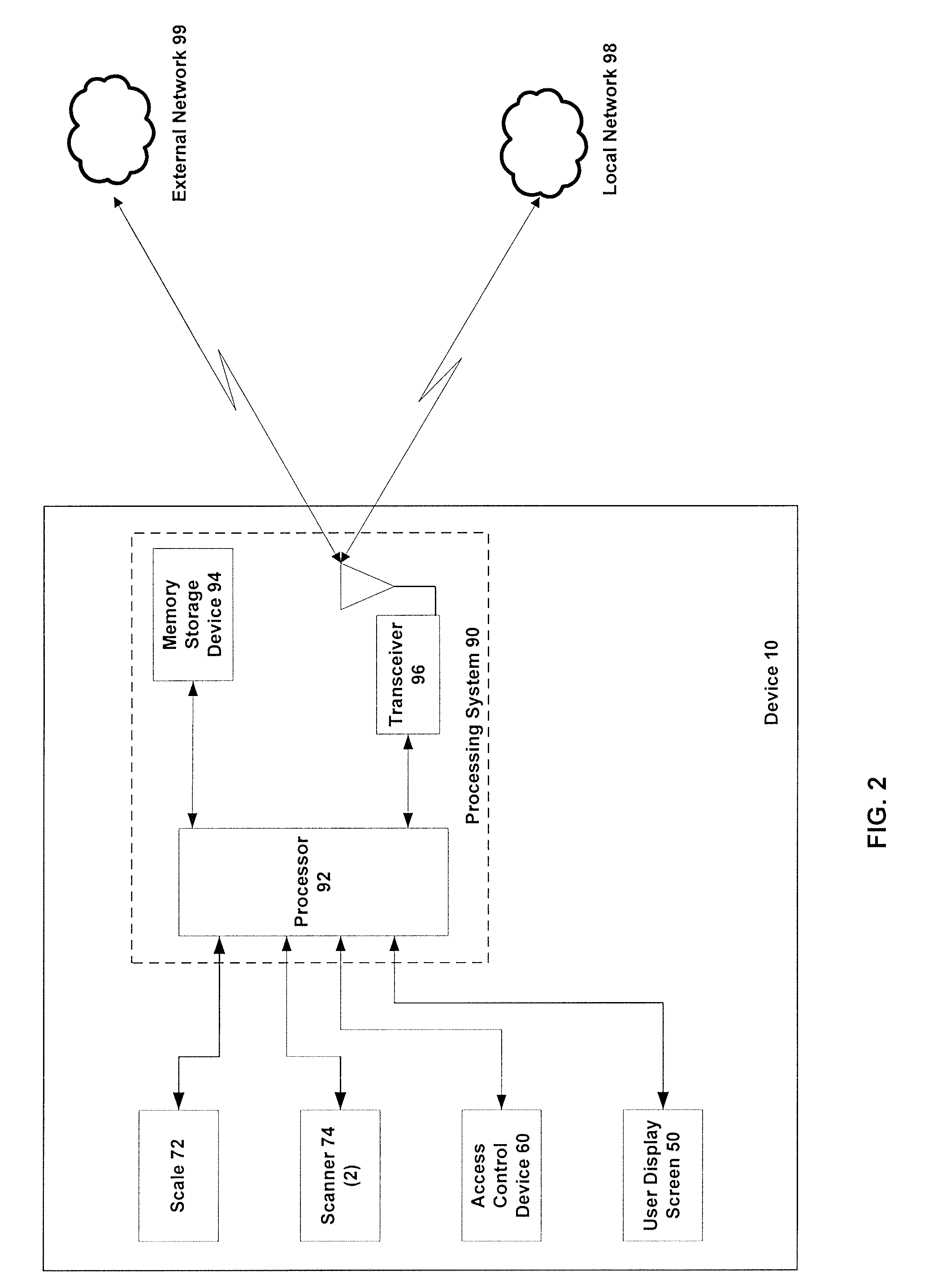

Pharmaceutical storage and retrieval system and methods of storing and retrieving pharmaceuticals

ActiveUS20110184751A1Improve consistency and efficiency and cost reductionData processing applicationsDrug and medicationsPharmacySoftware system

A pharmaceutical storage and retrieval device and a method of accessing and loading the device. The device include a housing, at least one port with controlled access to inventory stored within the device, a robotic transfer mechanism for moving inventory items to and from the controlled port, software for tracking the inventory and users of the device, and an interface with the pharmacy software system to track and monitor which inventory is authorized for access by each user and which inventory is needed to fill a prescription.

Owner:RXSAFE

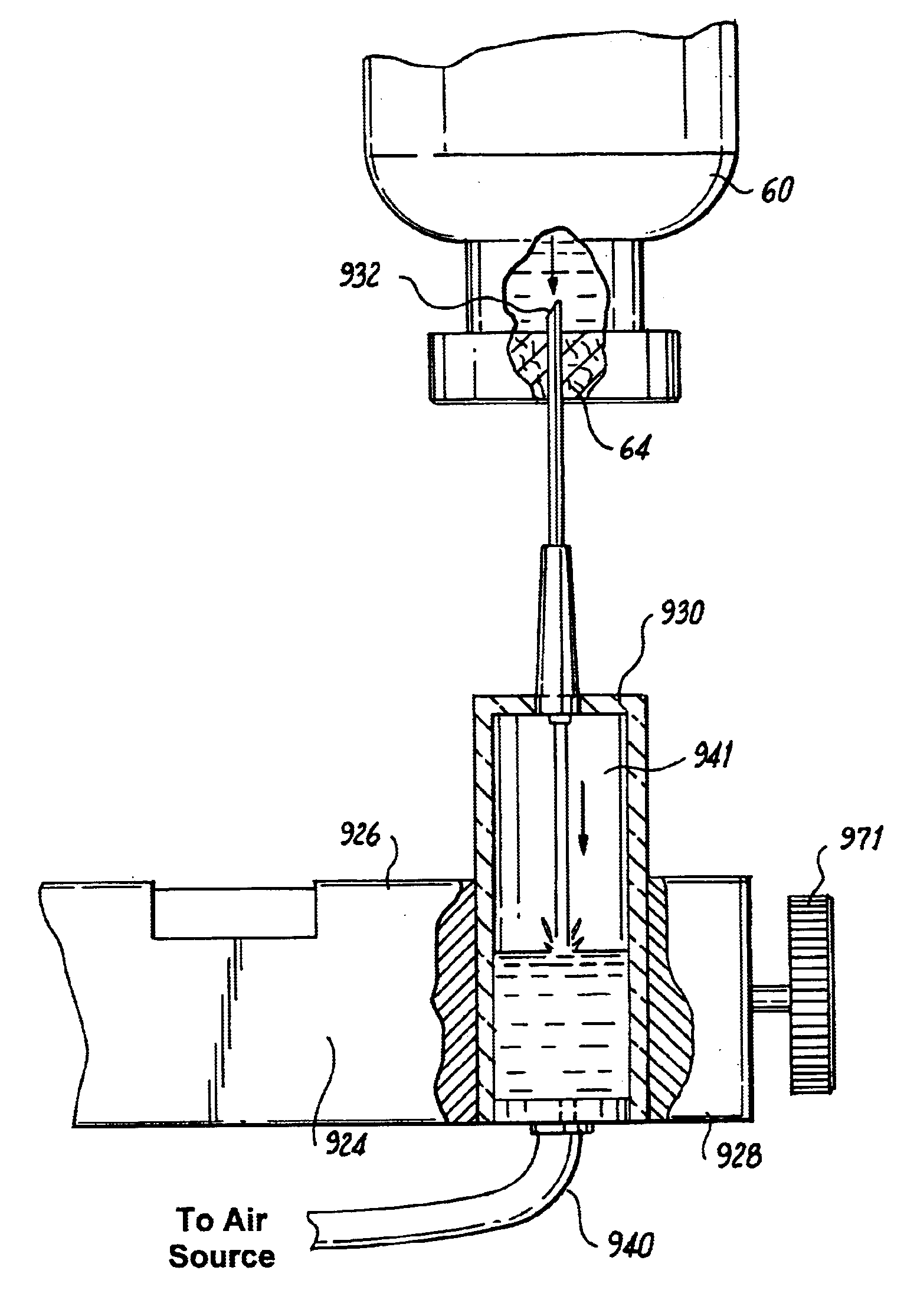

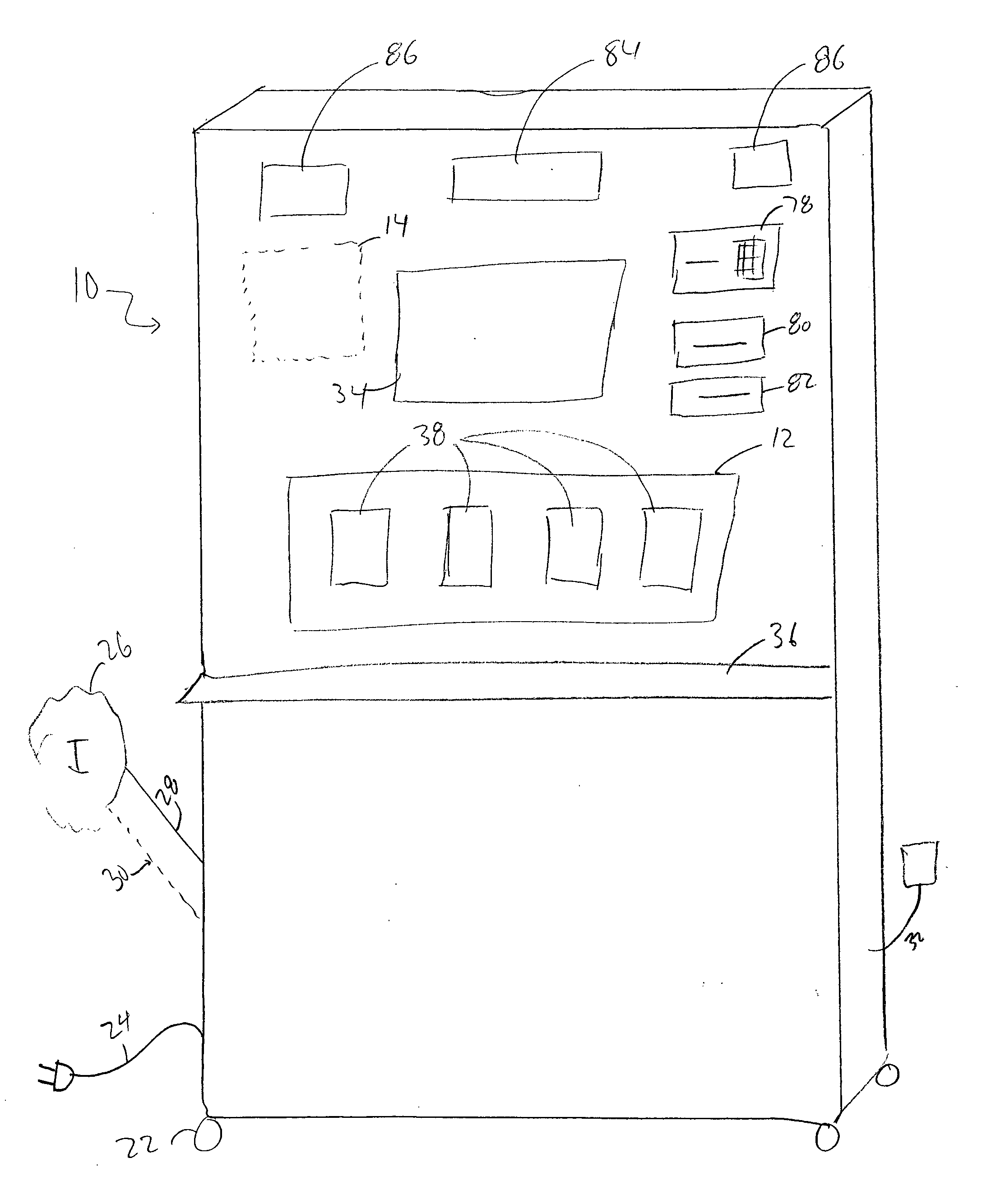

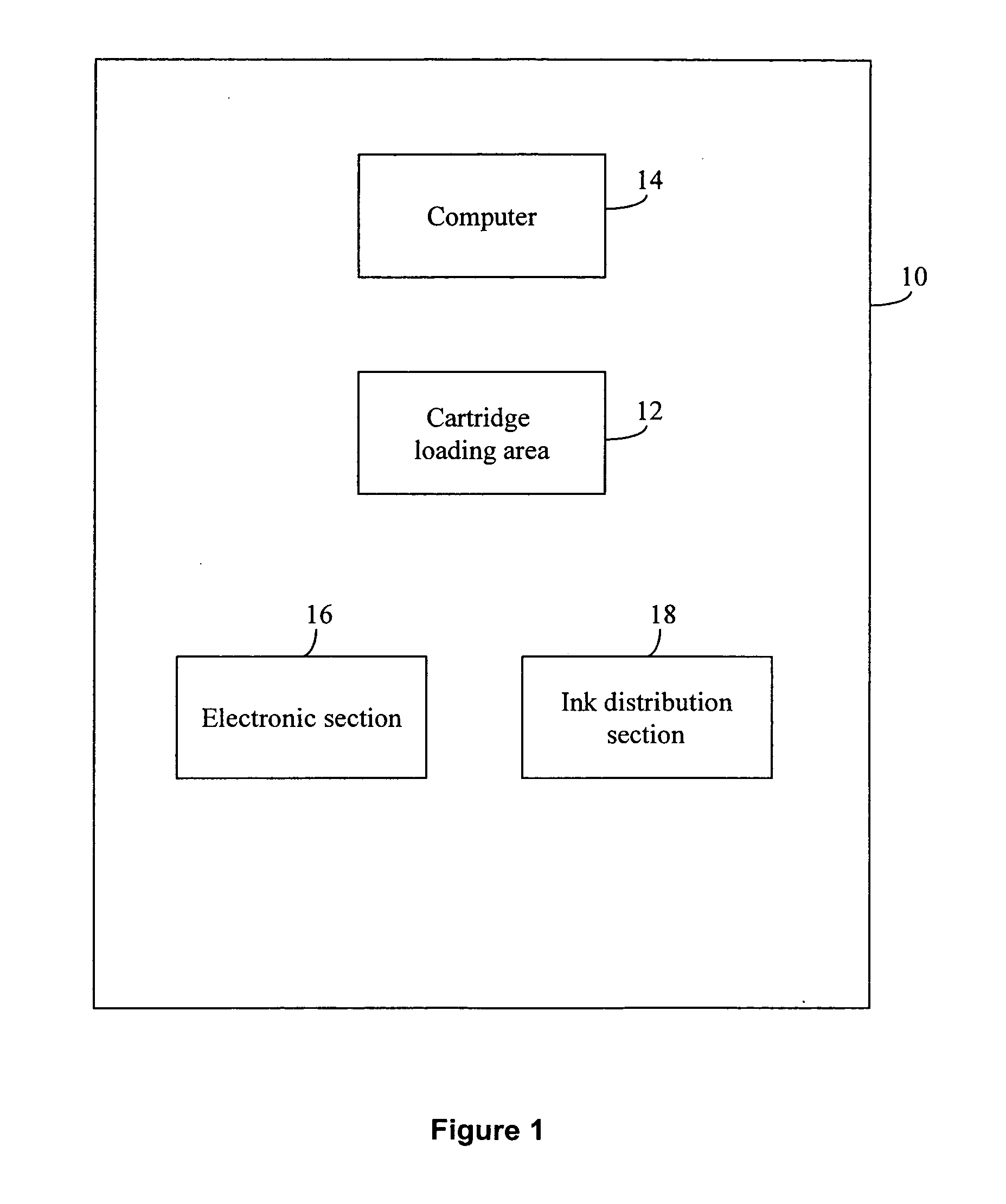

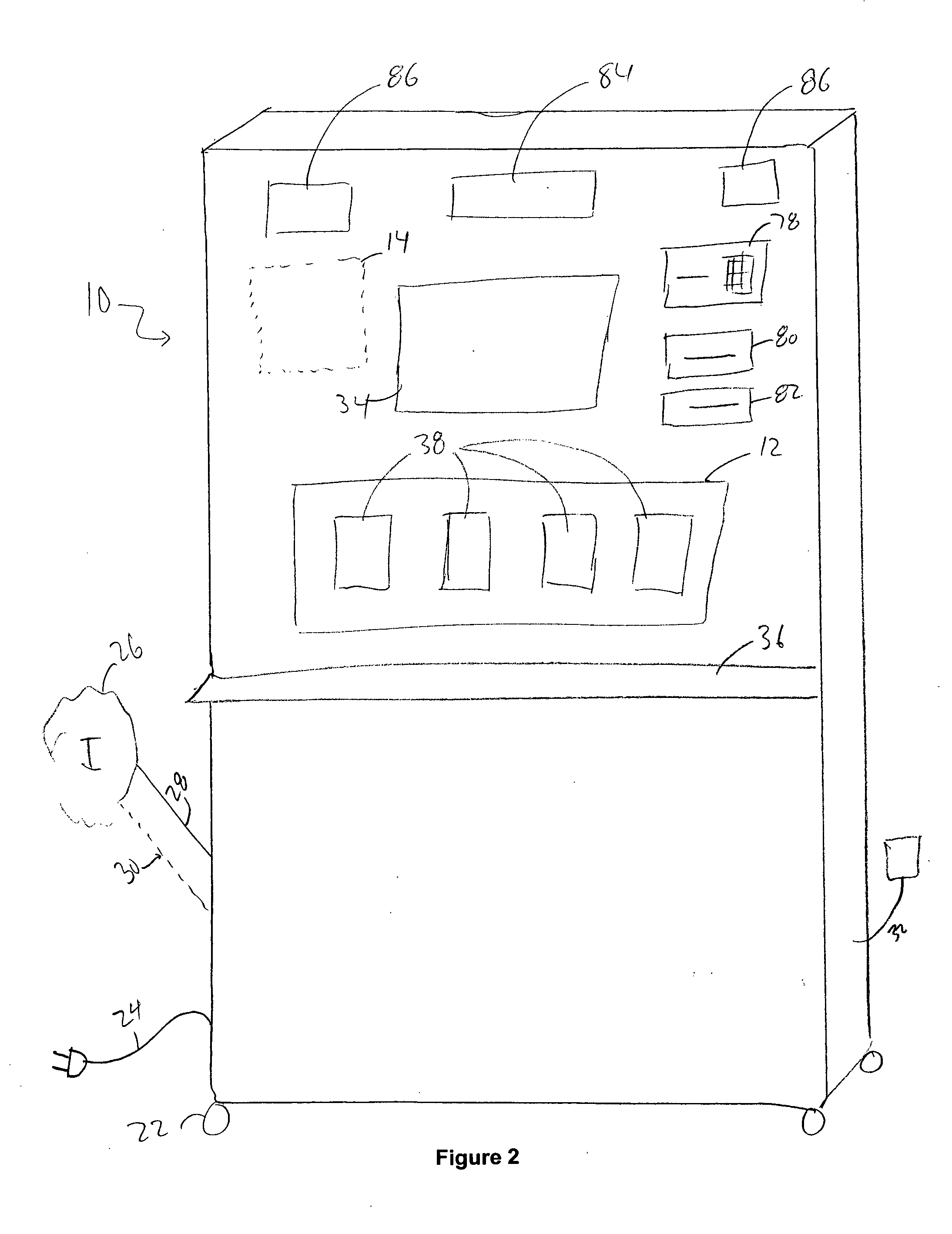

Apparatus for refilling inkjet cartridges and methods thereof

An integrated inkjet-cartridge refilling system that is comprised of an arrangement of mechanical, electrical, electronic, pneumatic, and software elements, which is used by an operator in a retail environment to automatically connect one of many types of inkjet cartridges that are used in printing devices and refill the cartridge.

Owner:TONERHEAD

Syringe bandoleer with control feature

A bandolier of syringes for use in an automated syringe handling system is provided. The automated syringe handling system generally receives syringes and fills the syringe with a substance, such as a medicament. In one exemplary embodiment, the syringe handling system is a system that disperses one or more medicaments into the syringes in an automated manner. The bandolier includes a web, e.g., a strip of transparent material partially encapsulating bodies of syringes that are bound to the web at a prescribed interval. The bandolier includes a feature disposed within the prescribed interval and between the syringes with the feature being different from the surrounding web.

Owner:BAXTER ENGLEWOOD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com