Patents

Literature

39results about How to "Improve throughput speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

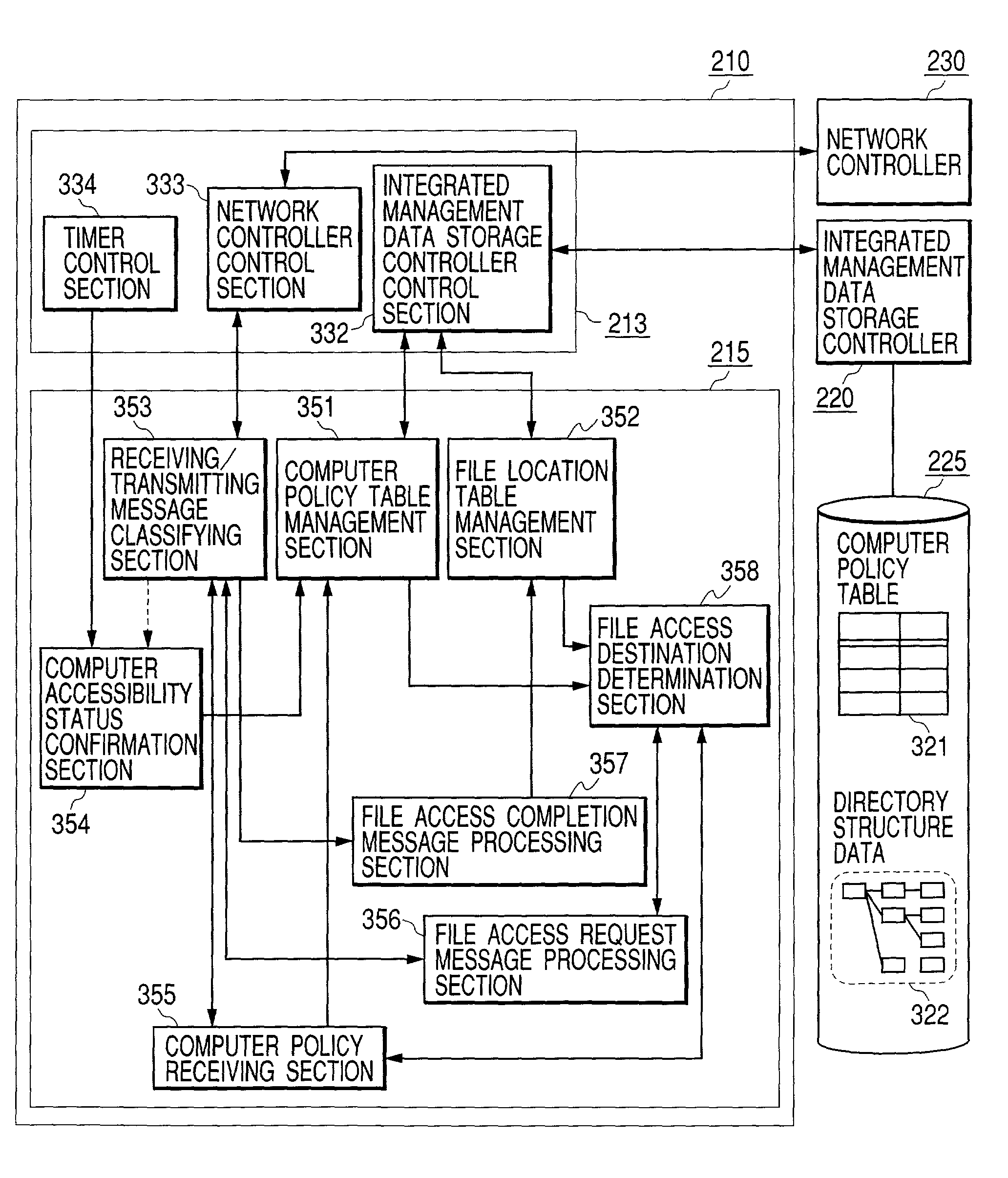

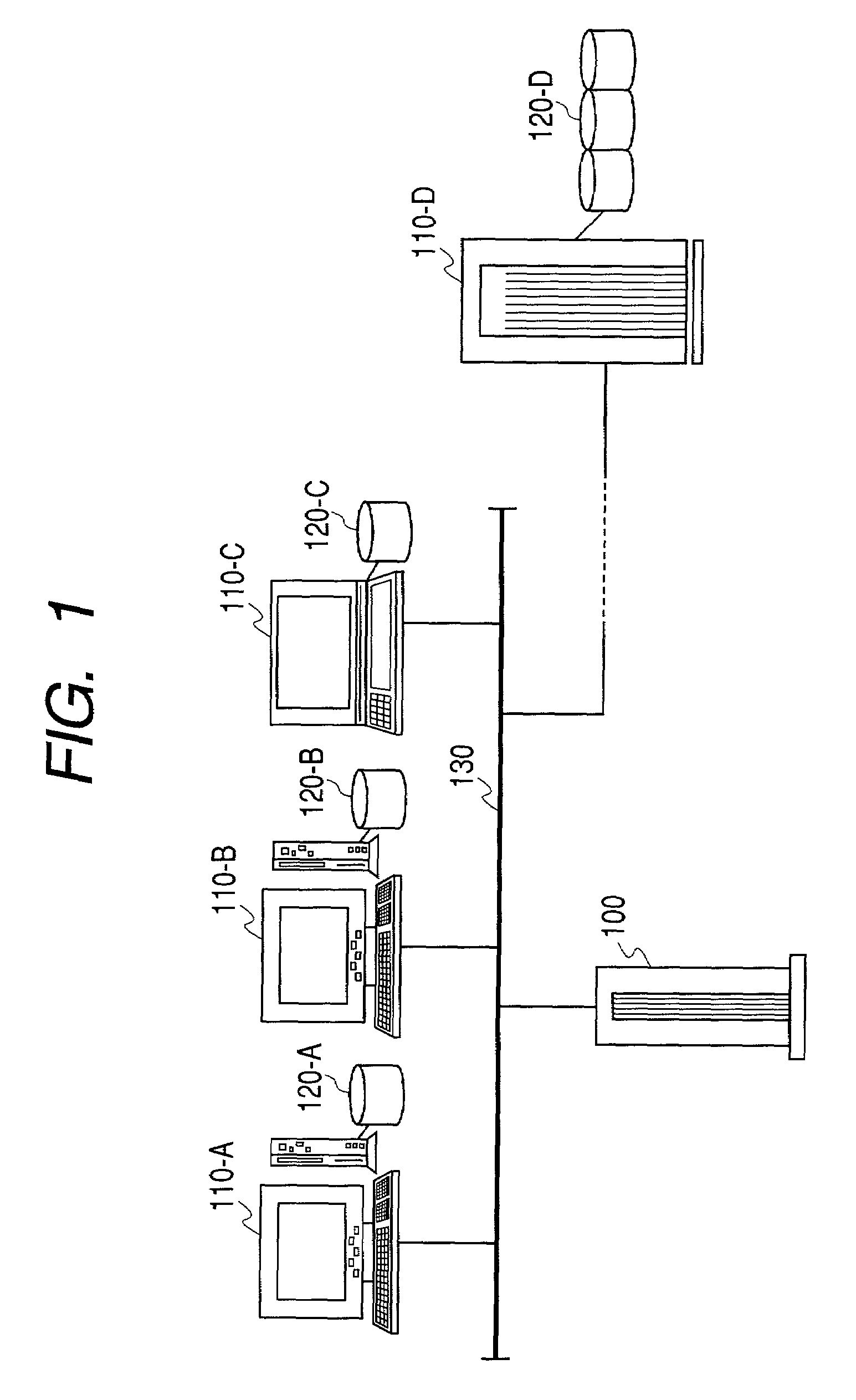

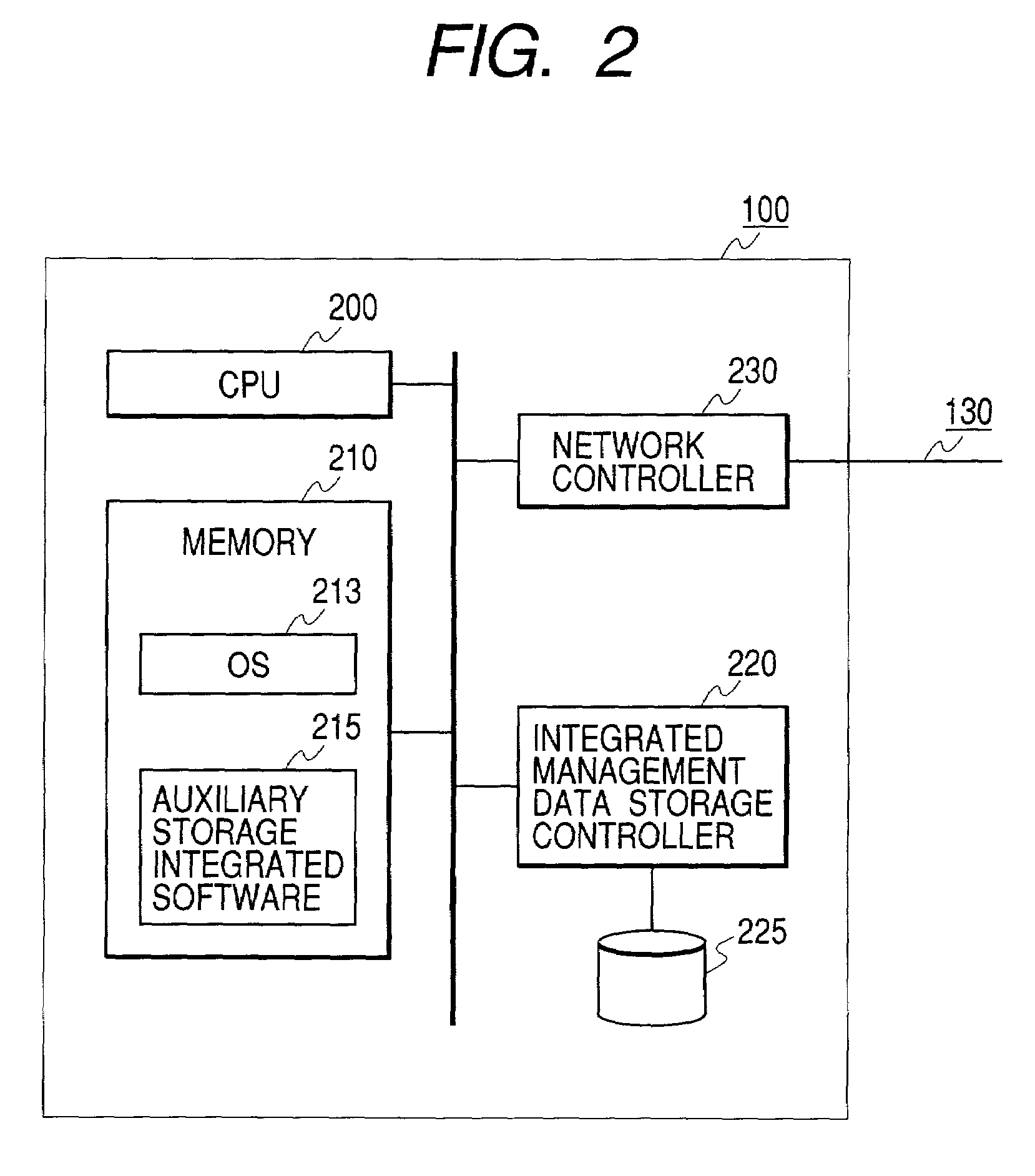

Storage management integrated system and storage control method for storage management integrated system

InactiveUS7120757B2Easy to implementImprove fitInput/output to record carriersDigital computer detailsStorage managementAccessibility

It is intended to achieve an arrangement wherein, when file information of shared disks which are distributed in a plurality of computers connected to a network are used, operating conditions at the time of accessing shared disks can be defined, thus enabling users to easily share files without being bothered by setting-up, or operations of computers located on the other side when they are to perform file sharing.In order to achieve the above-stated arrangement, a storage management integrated server 100 is provided in a network, and respective computers register conditions, an accessibility states and use types pertaining to shared volume to be offered to the server. Thereafter, when a certain computer is to make a file accessing to a shared volume, the computer makes an inquiry to the storage management integrated server for an adequate access destination, determines, on the basis of a response from the server, computers which are suitable to the access source, and makes direct accesses to such computers.

Owner:HITACHI LTD

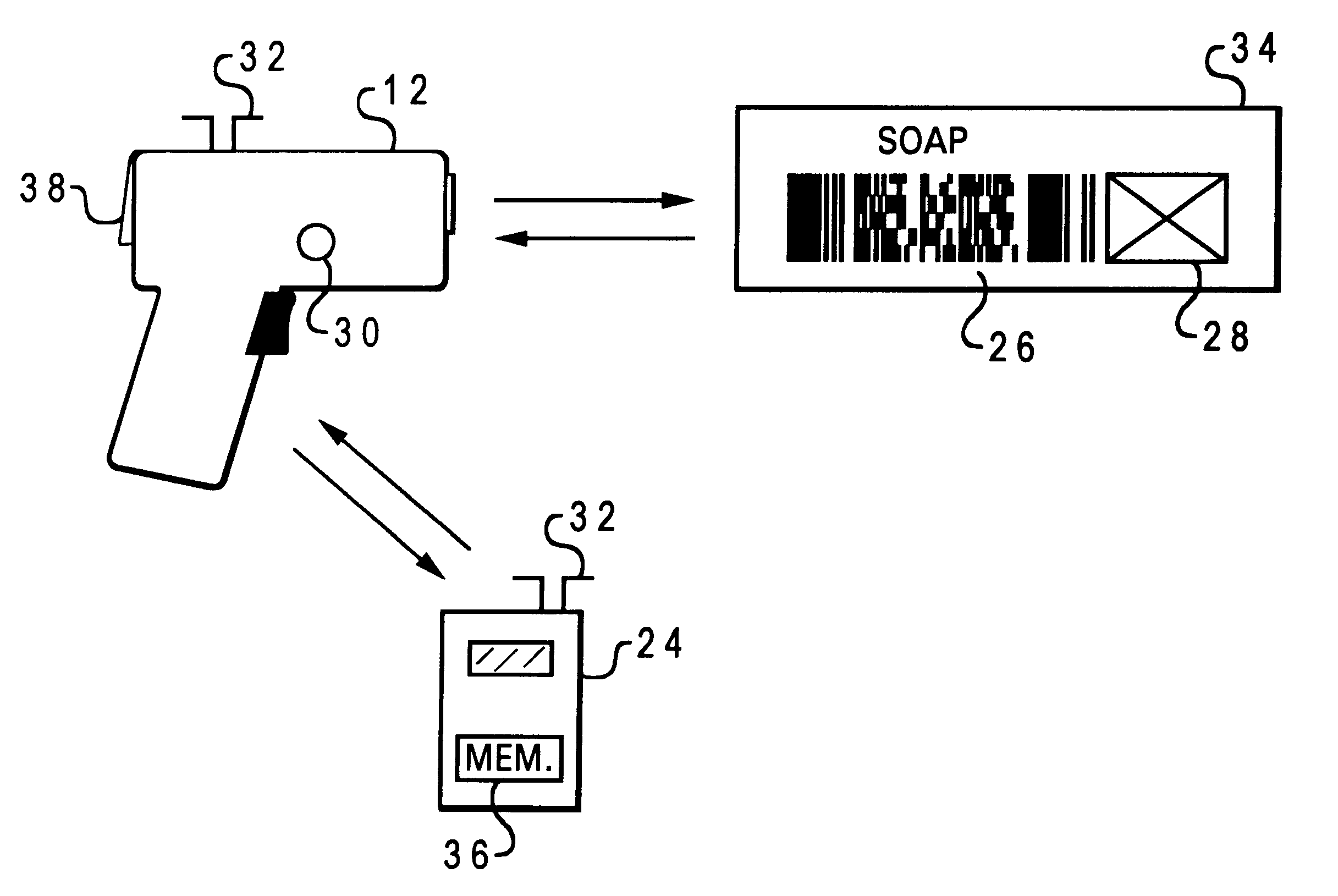

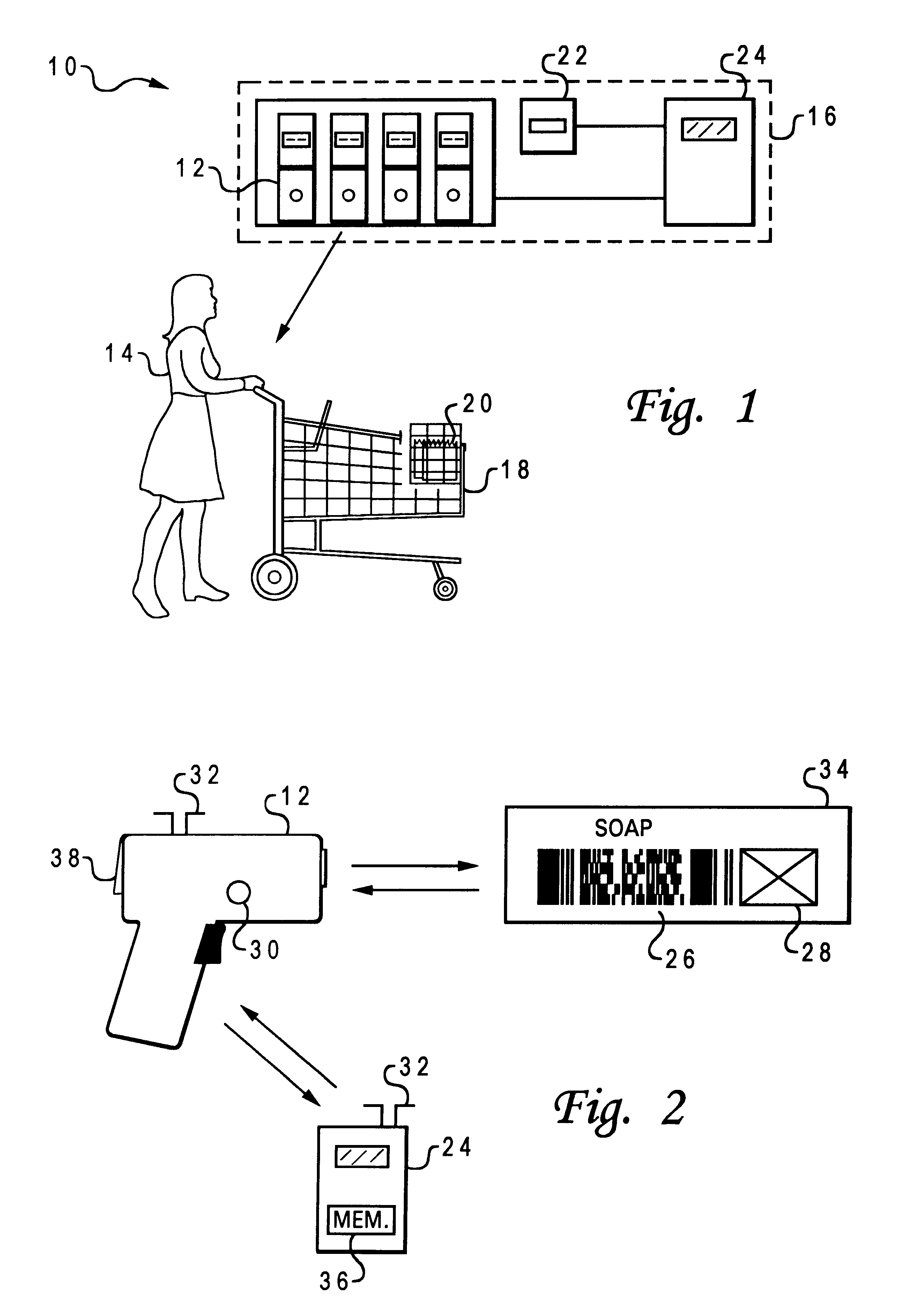

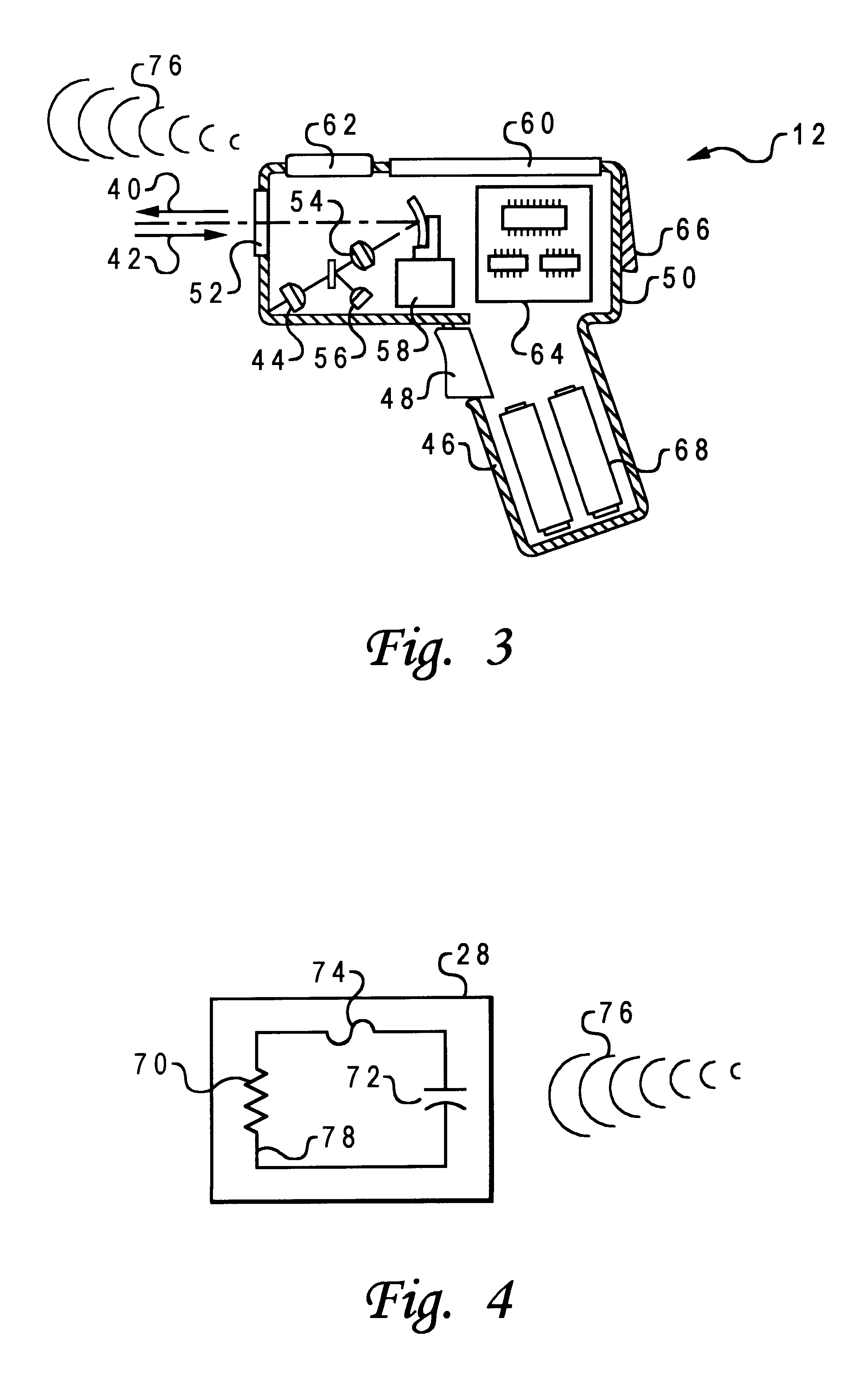

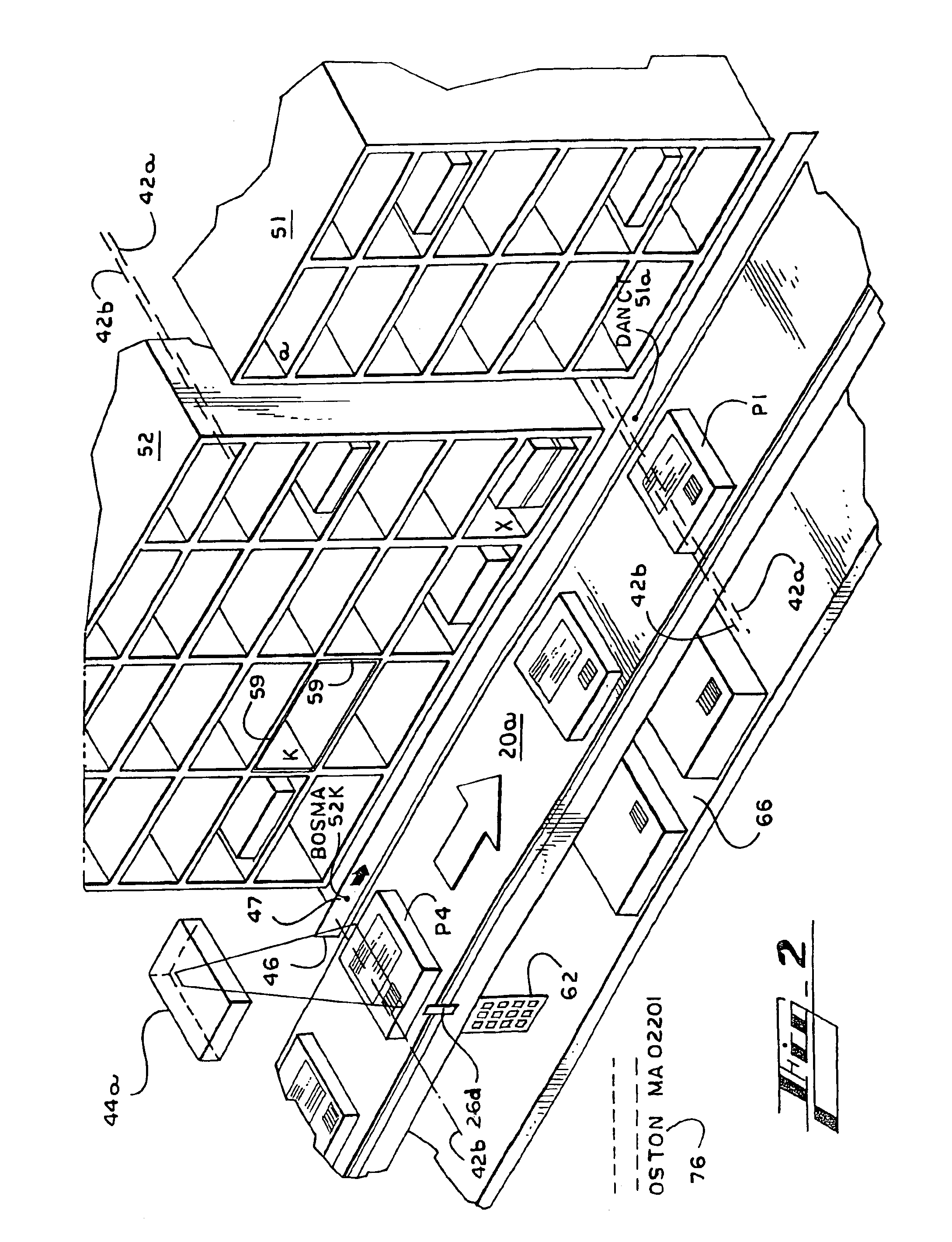

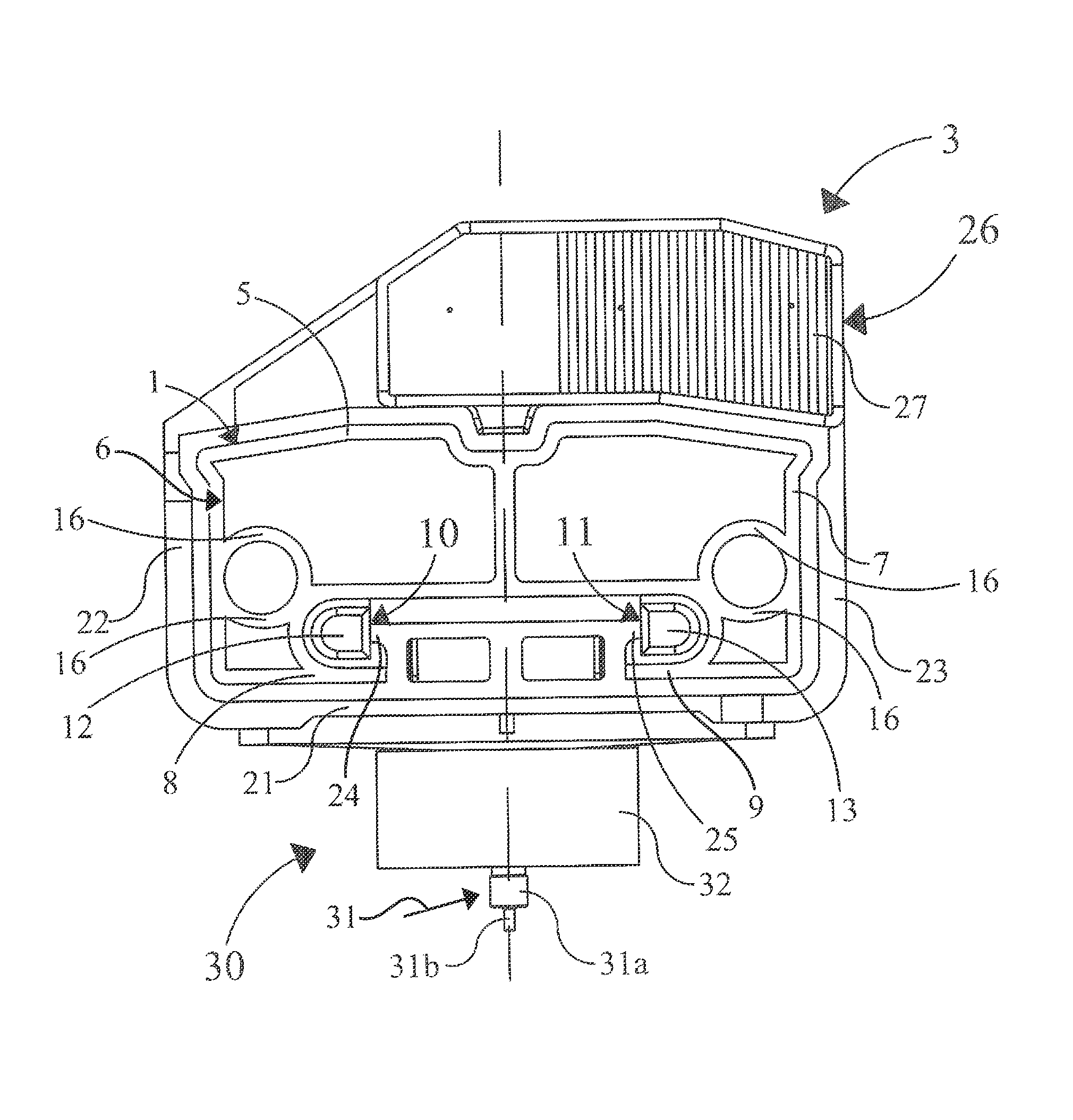

Method and system for a merchandise checkout system

InactiveUS6189789B1Improve throughput speedImprove security levelCredit registering devices actuationCash registersPaymentProduct base

A method and system for a merchandise checkout system utilizes a remote scanning device, a shopping cart and bags for allowing a purchaser to buy merchandise unassisted by store personnel. The remote scanning device reads product identity information from coded levels on products chosen by the purchaser and sends the information to a central processor. The central processor has a memory, which indexes price information and weight for each product based on the product identity information. The central processor sends an accumulated price and weight transaction to the remote scanning device for the purchaser's use. The product identity information on the products further include a security tag device which is deactivated by the remote scanning device. The purchaser upon completion of their purchases takes their shopping cart to a security station for weighing in on a scale wherein an actual combined weight of the shopping cart, bags and products is compared to a predicted weight determined by the central processor and generating a notification signal if a discrepancy occurs. The security station further verifies that the security tag devices have been deactivated and also generates a notification signal. The purchaser next goes to a payment checkout terminal coupled to the central processor, wherein the payment checkout terminal effects financial transactions including acceptance of payment for transactions initiated by the remote scanning device, and the payment checkout terminal is operable by store personnel only.

Owner:TOSHIBA GLOBAL COMMERCE SOLUTIONS HLDG

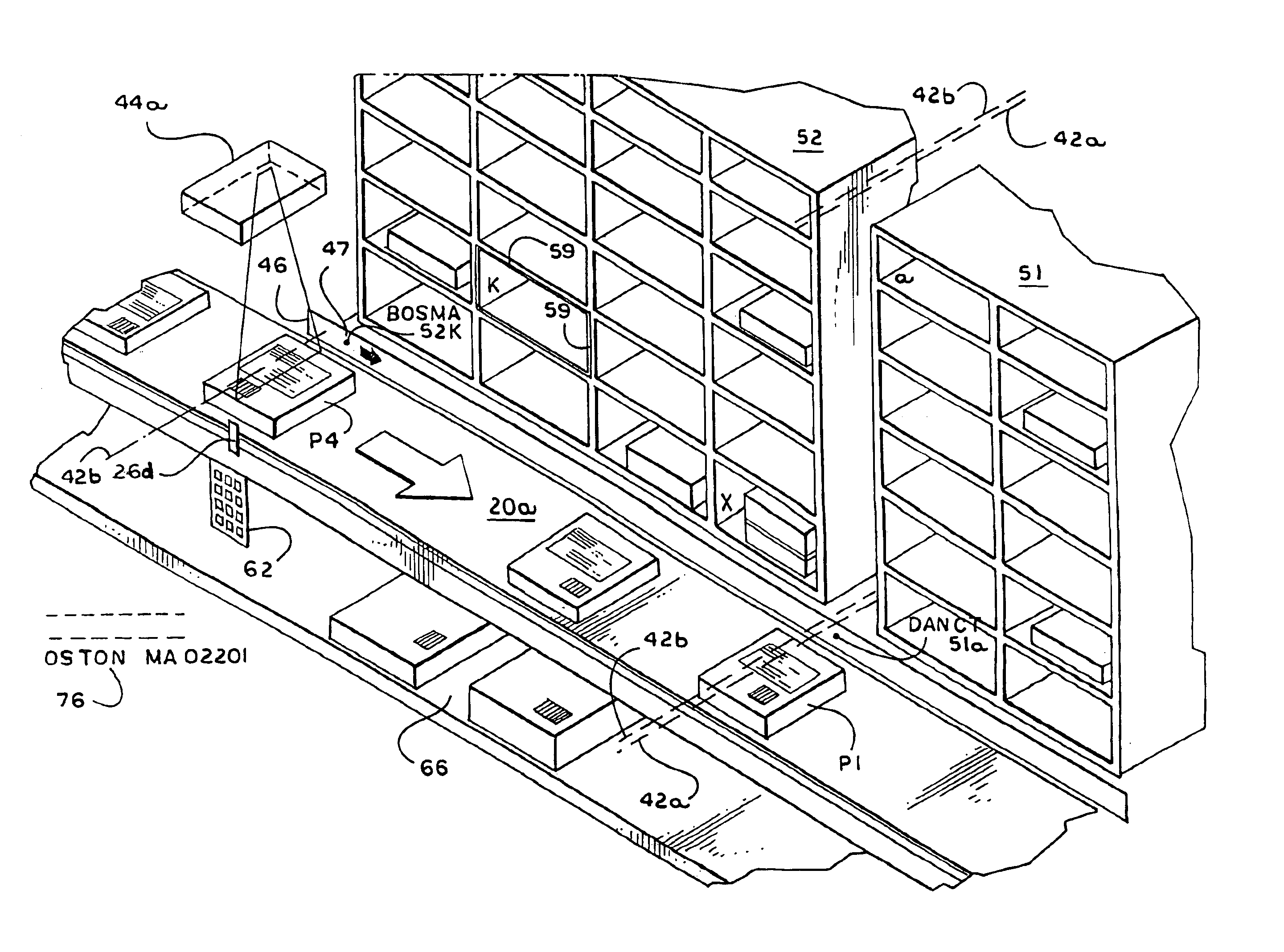

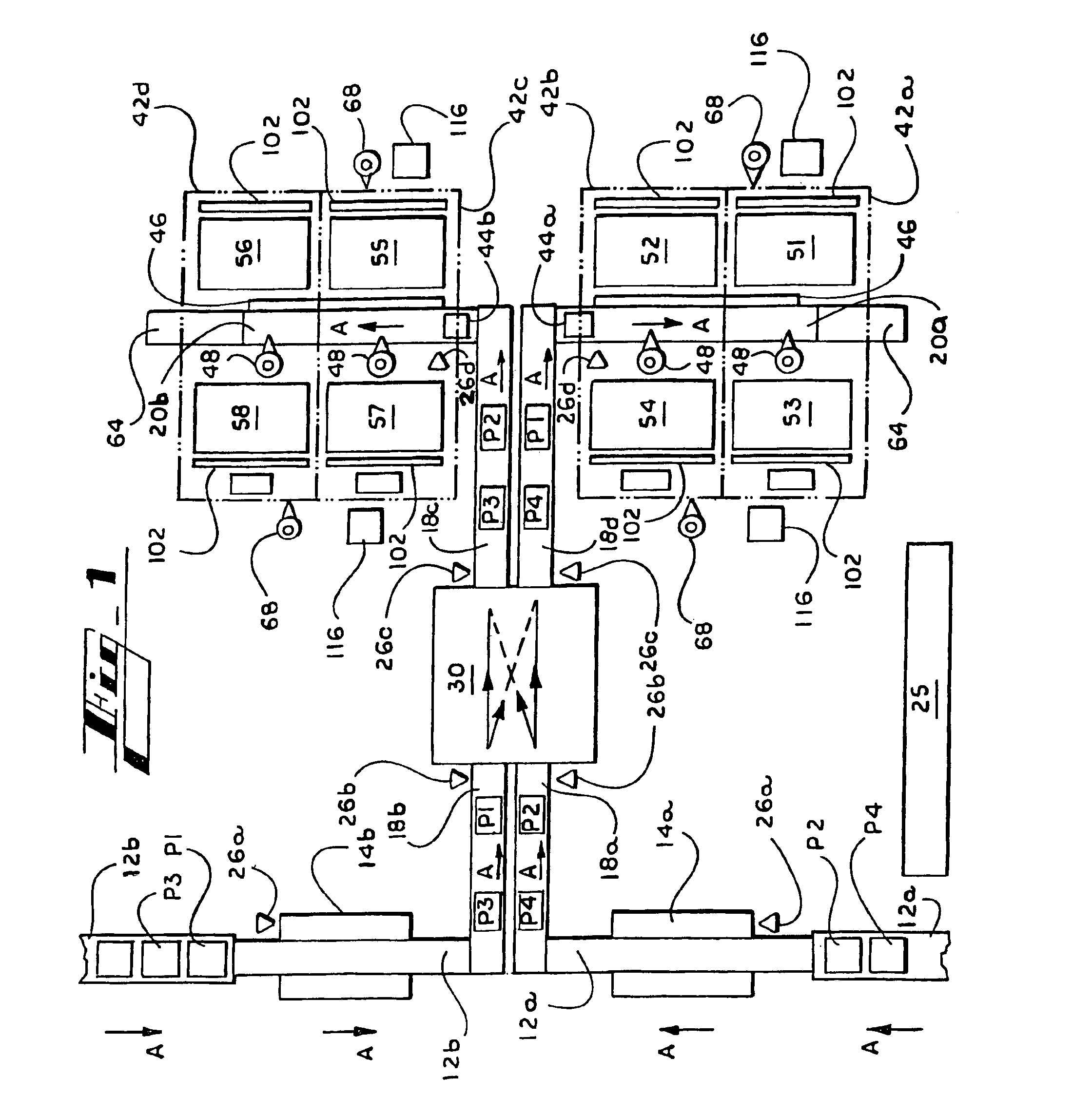

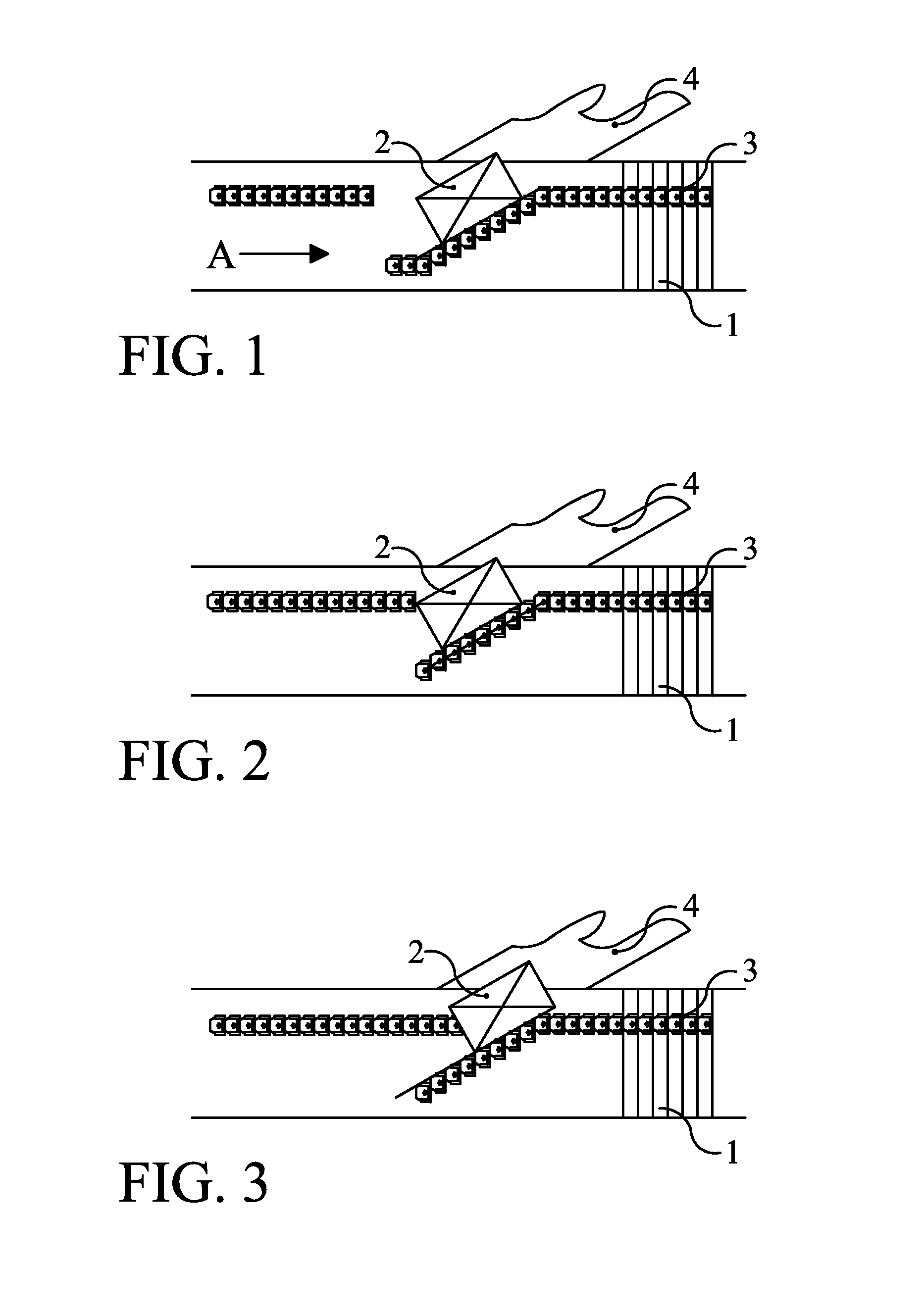

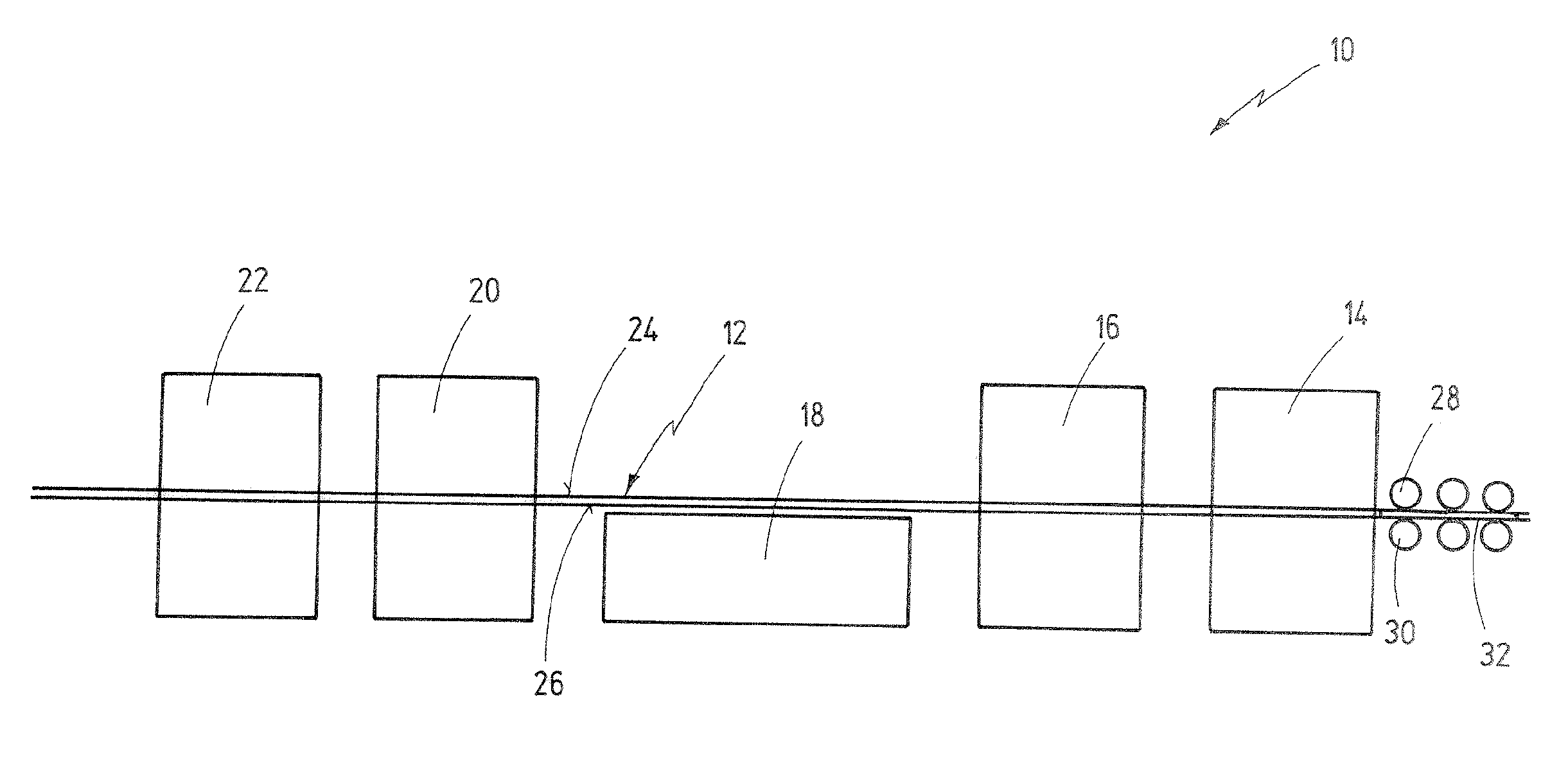

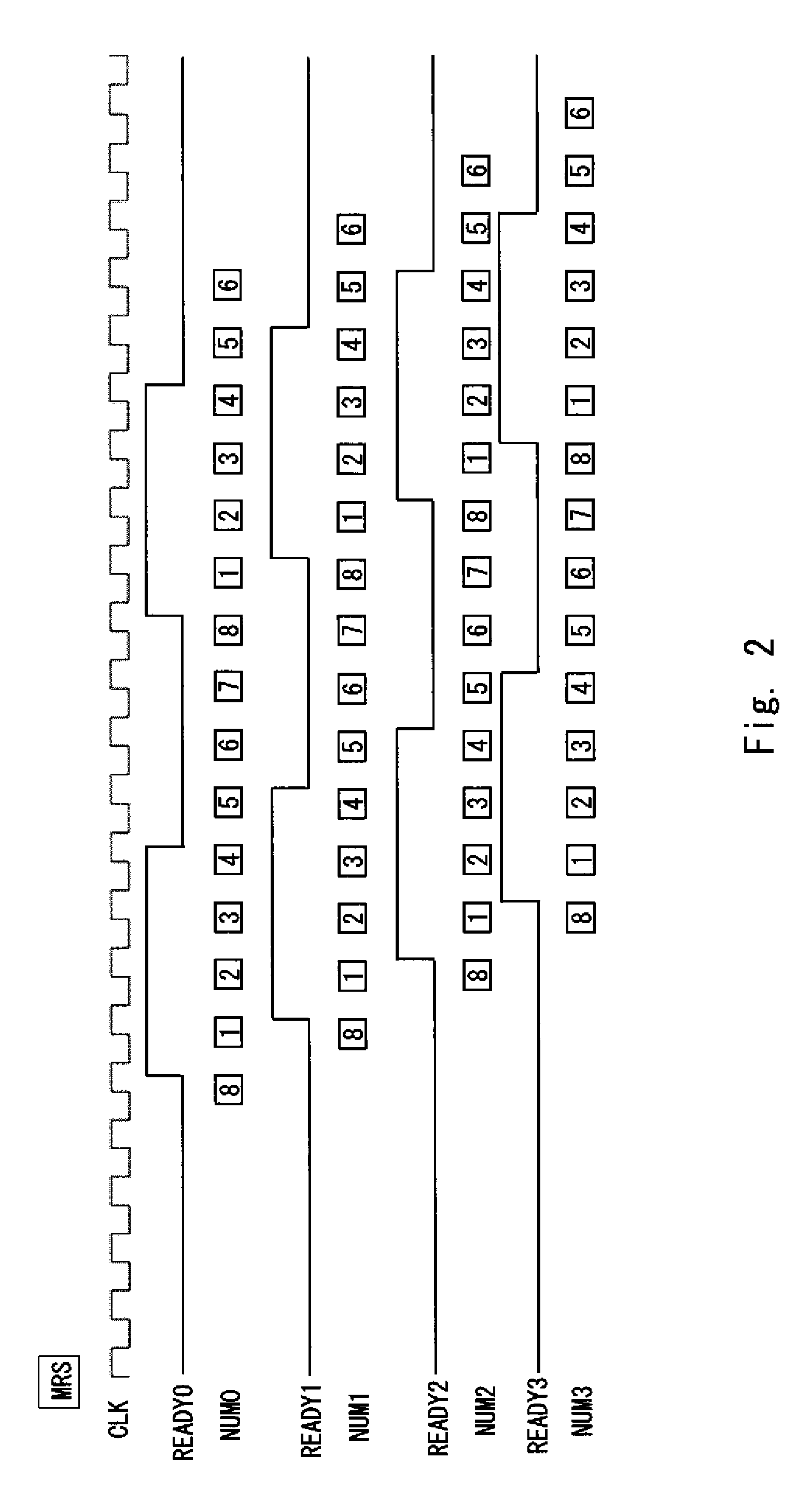

Synchronous semi-automatic parallel sorting

InactiveUS6878896B2Structure can be reduced and expandedReadily apparentDigital data processing detailsCharacter and pattern recognitionParallel sortingSemi automatic

The present invention reveals a sorting system for use in manual sorting, which presents a detached ephemeral display moving in a manner corresponding to the movement of the article, by which an article to be sorted can be quickly and easily identified. To accomplish its purpose, the device comprises: feed conveyors; a switching unit; optical readers positioned to capture destination indicia affixed to each article; a detached moving display which remains close to the article to be sorted and presents information representative of the article's destination location; a destination location which signals when a related article is approaching; and a controller capable of assigning destination locations and controlling display devices.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

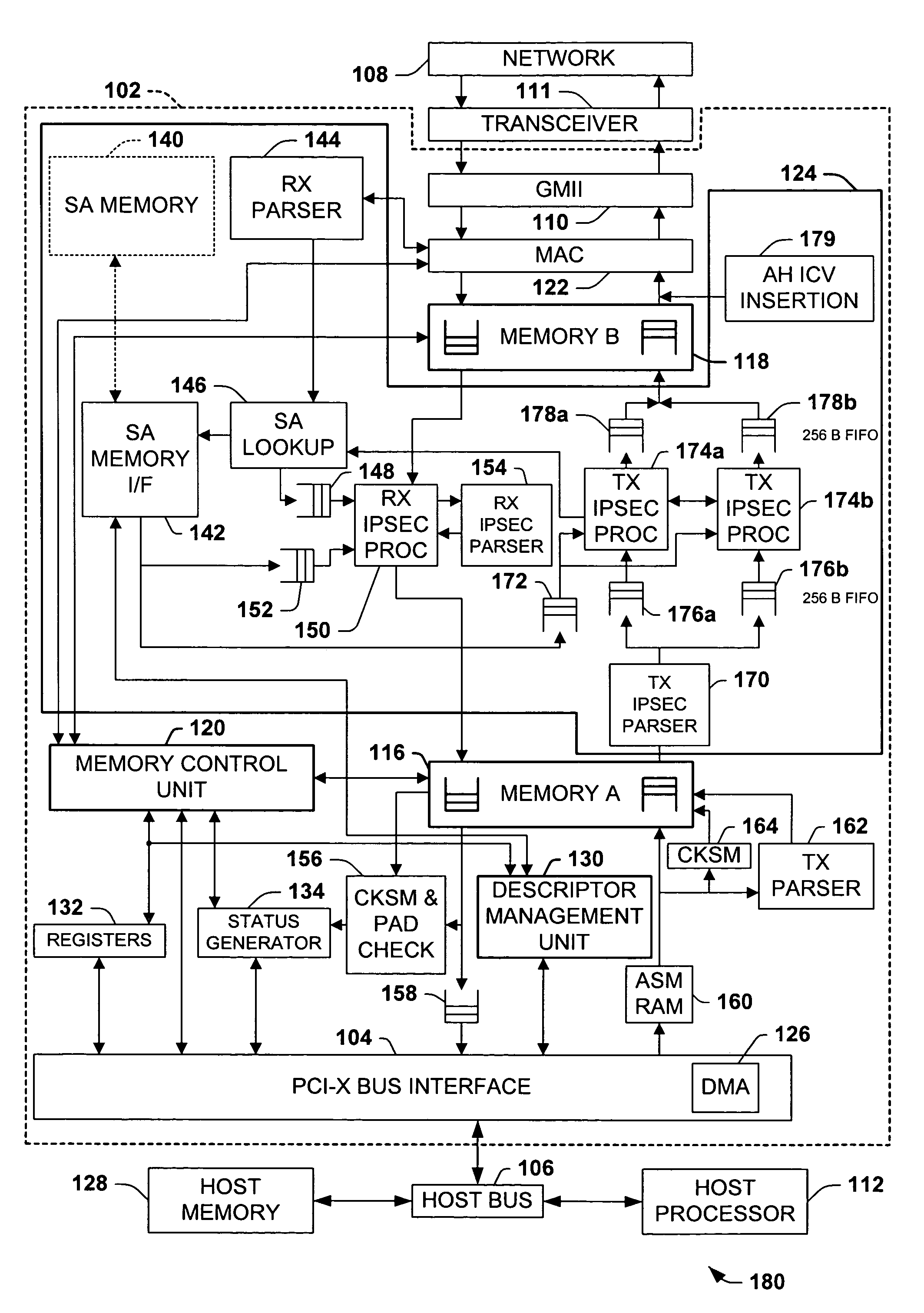

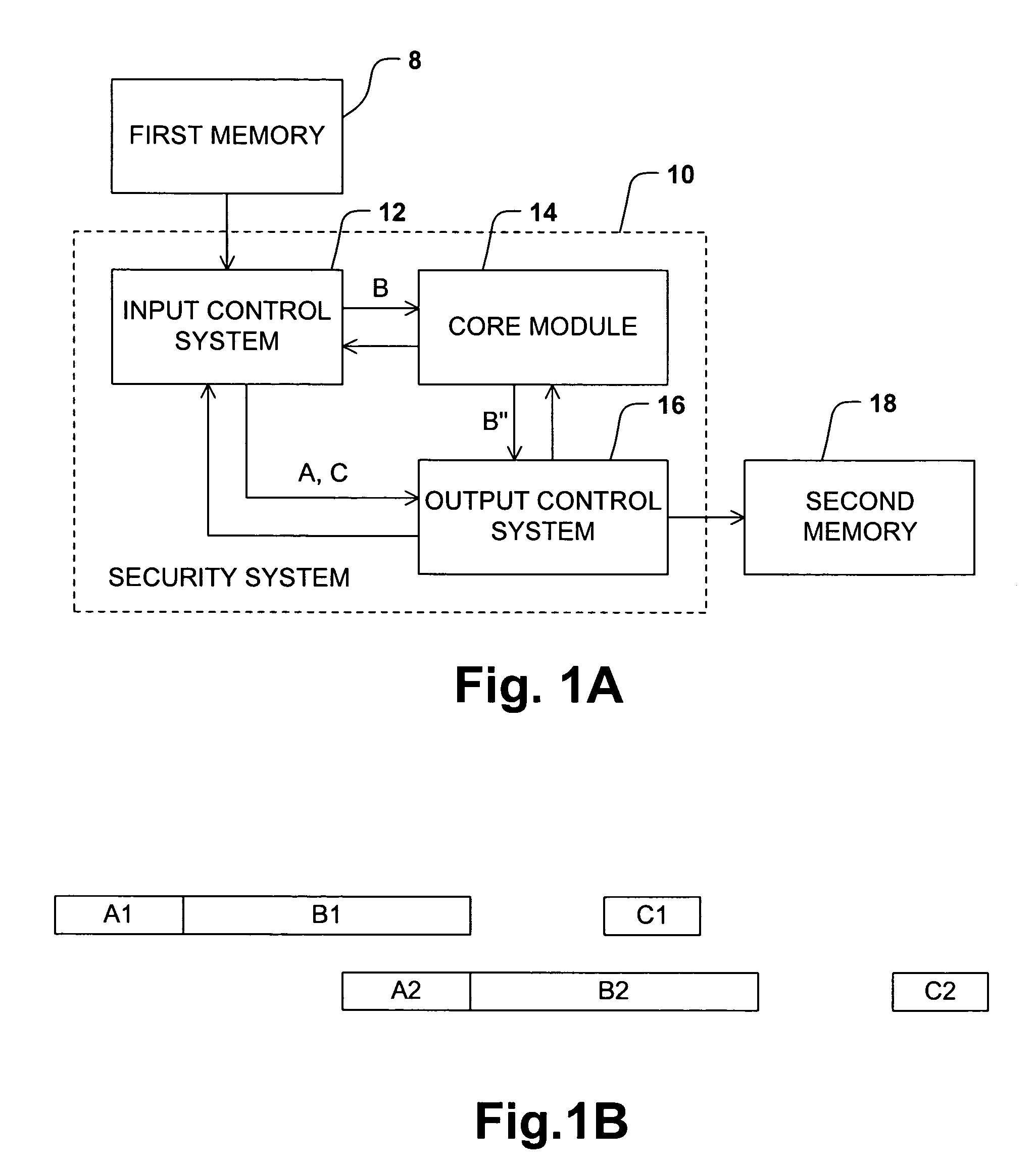

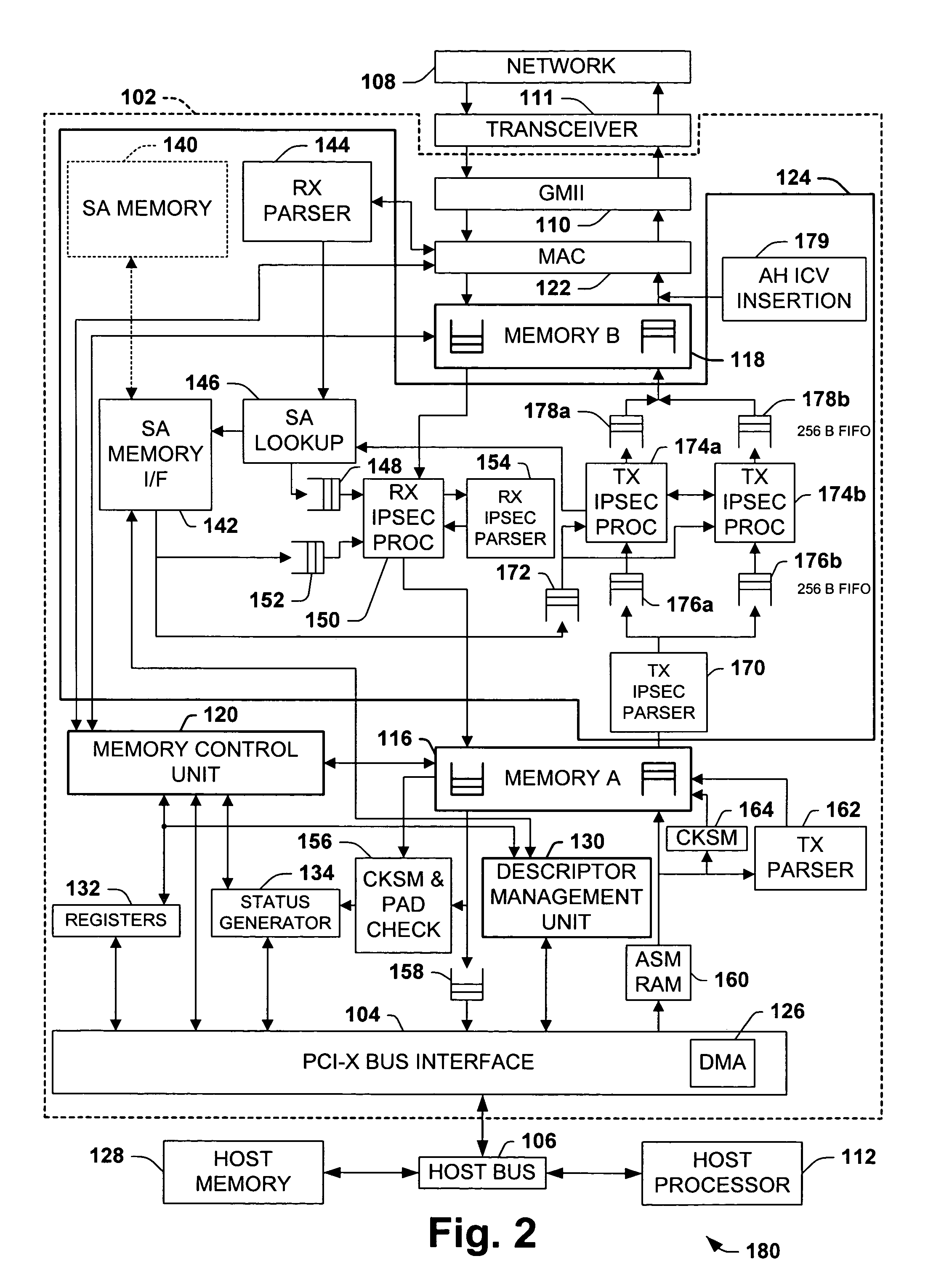

Method and apparatus for out of order writing of status fields for receive IPsec processing

ActiveUS7412726B1Improve throughput speedDigital data processing detailsUser identity/authority verificationIPsecBus interface

Network interface systems are disclosed comprising a bus interface system, a media access control system, a memory system, a security system for selectively encrypting outgoing data and decrypting incoming data, where the network interface system may be fabricated as a single integrated circuit chip. Systems and methods are disclosed wherein out-of-order writing is used to improve throughput for the security system on the receive end.

Owner:ADVANCED MICRO DEVICES INC

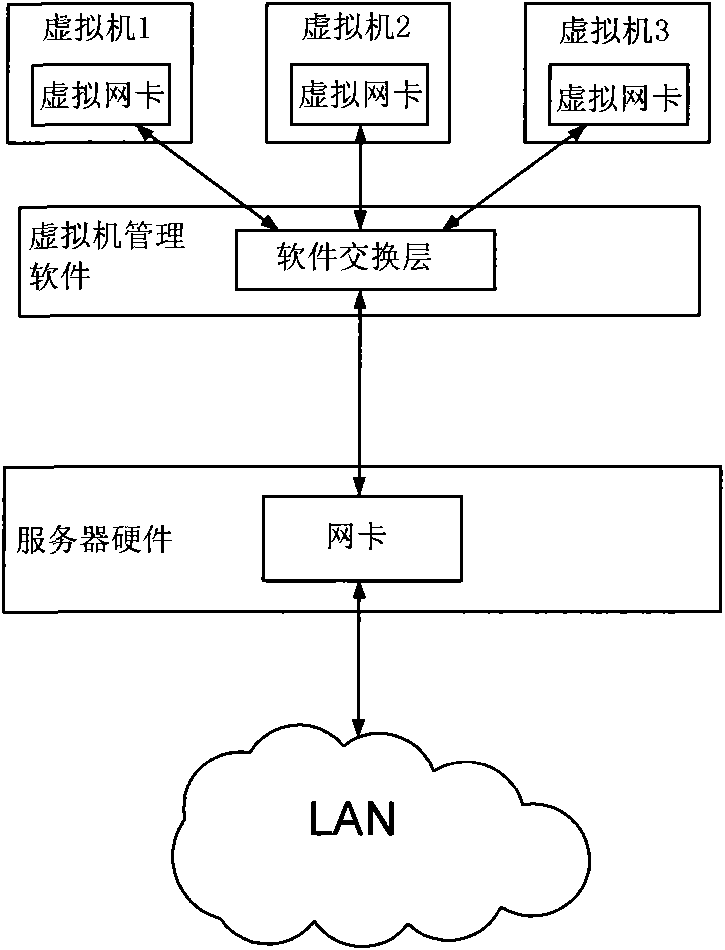

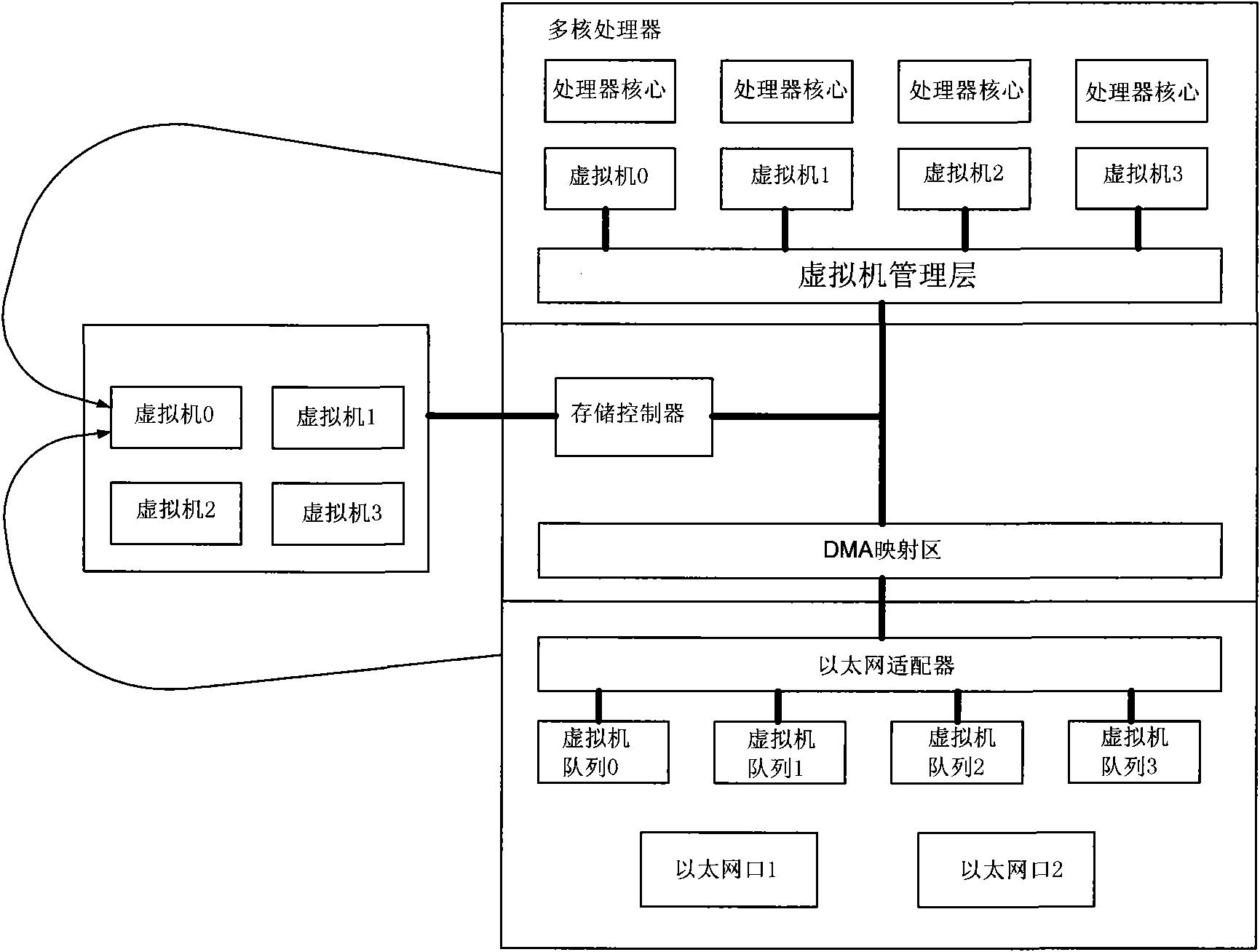

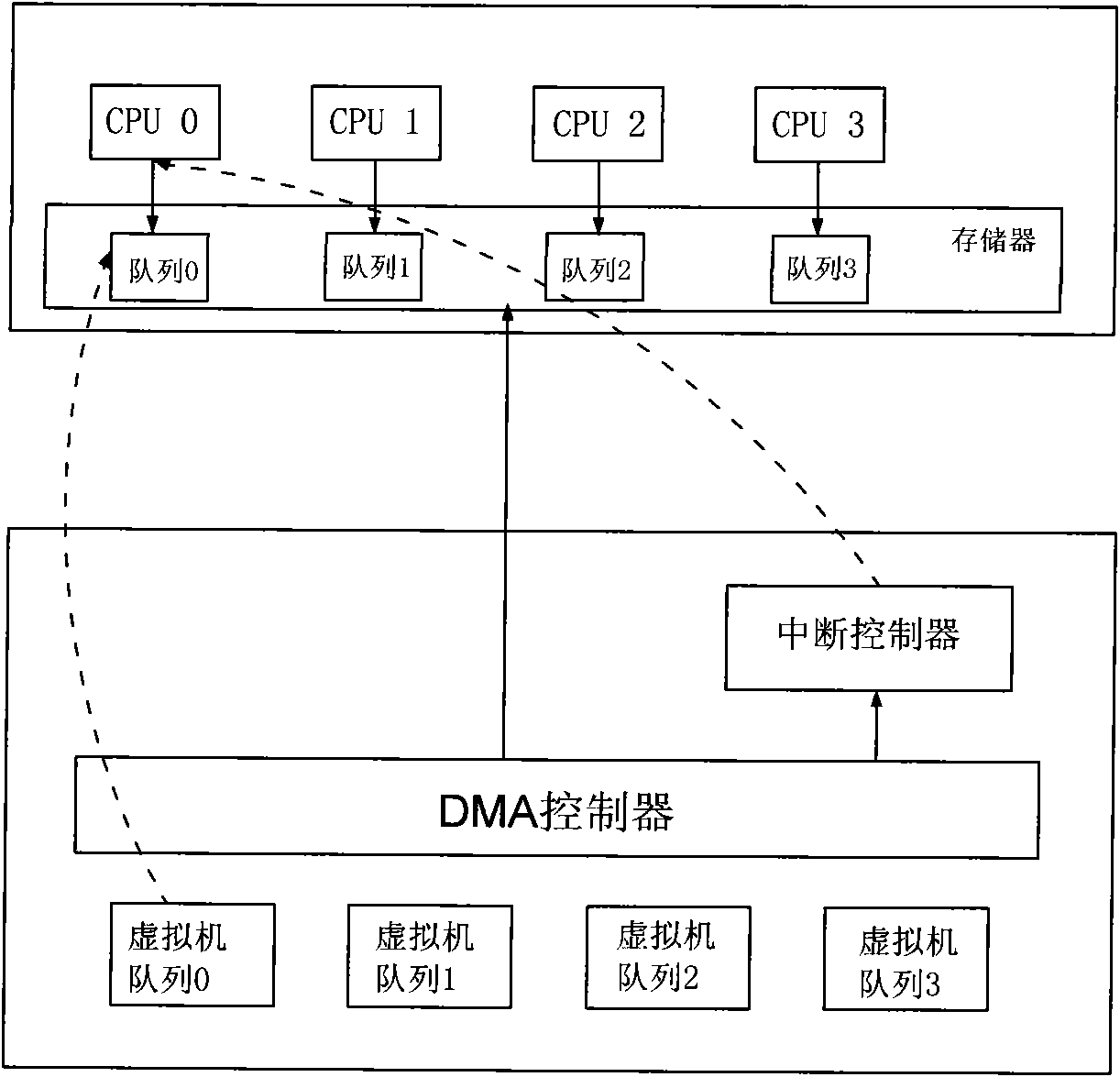

Network card interrupt control method for a plurality of virtual machines

ActiveCN101620551AImplement interrupt handlingImprove throughput speedProgram initiation/switchingVirtualizationNetwork interface controller

The invention relates to a virtual network card interrupt control method for a plurality of virtual machines, which comprises the following steps: reading a descriptor of a data packet firstly to obtain information of a DMA source address, a destination address, length, and the like when a network card receives or transmits the data packet; then, executing DMA operation, back writing the descriptor after the operation is completed; counting by a counter corresponding to a virtual machine queue; transmitting an interrupt request when a numerical value of the counter reaches a preset time threshold value; carrying out the counting operation of the counter when the counter operates; when the numerical value of the counter reaches a preset time threshold value, judging whether the data packetcompletes the operation or not, if completing the operation, transmitting the interrupt request, otherwise, transmitting the interrupt request after the data packet completes the operation, and setting immediate interrupt operation without being restrained by the two threshold values as required. The network card interrupt control method completes the interrupt operation of the original software layer by hardware, completely releases the CPU and reduces the utilization ratio of the CPU, and meanwhile, because the processing speed of the hardware is greatly higher than the processing speed of the software, the data processing speed is greatly increased.

Owner:DAWNING INFORMATION IND BEIJING +1

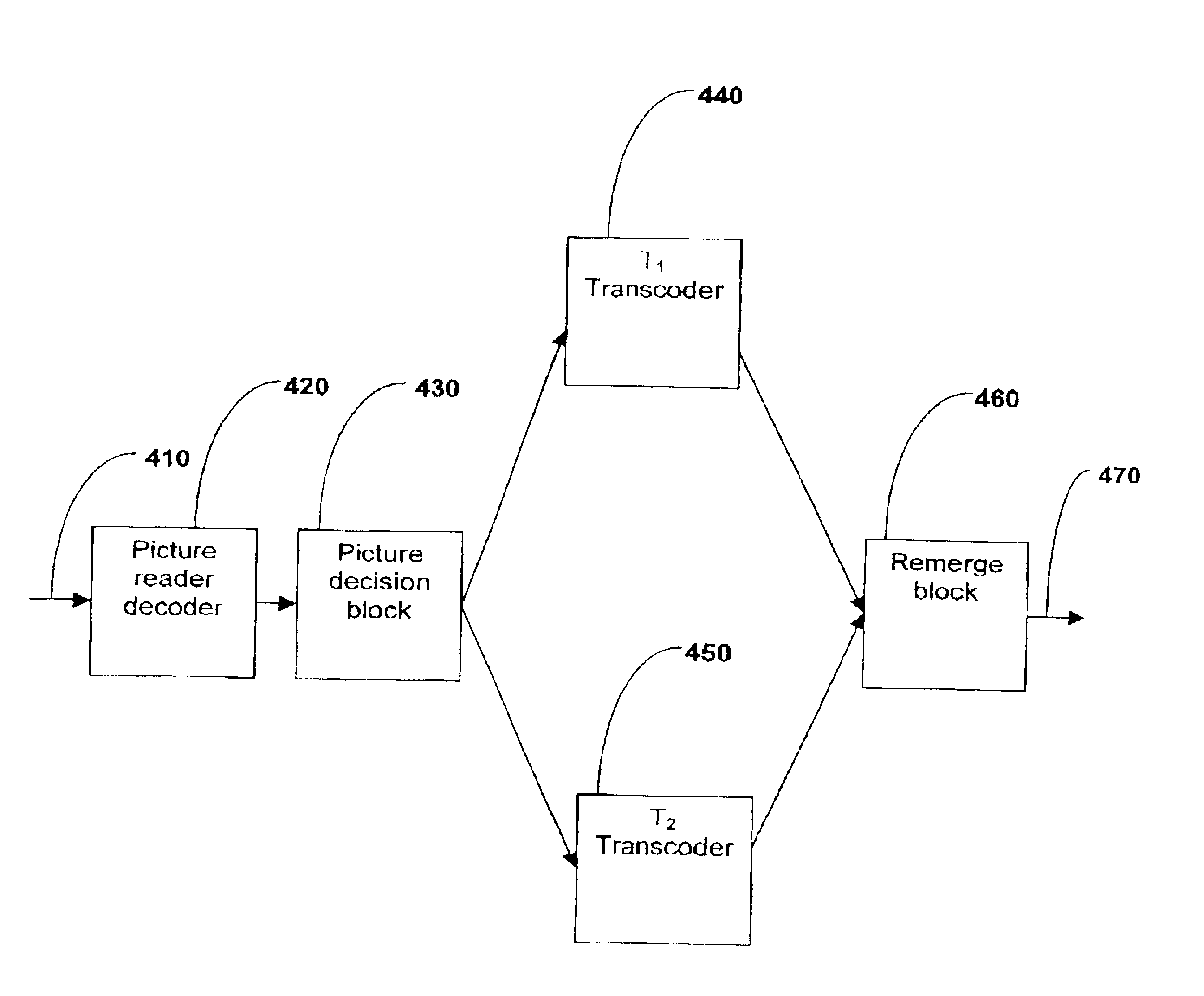

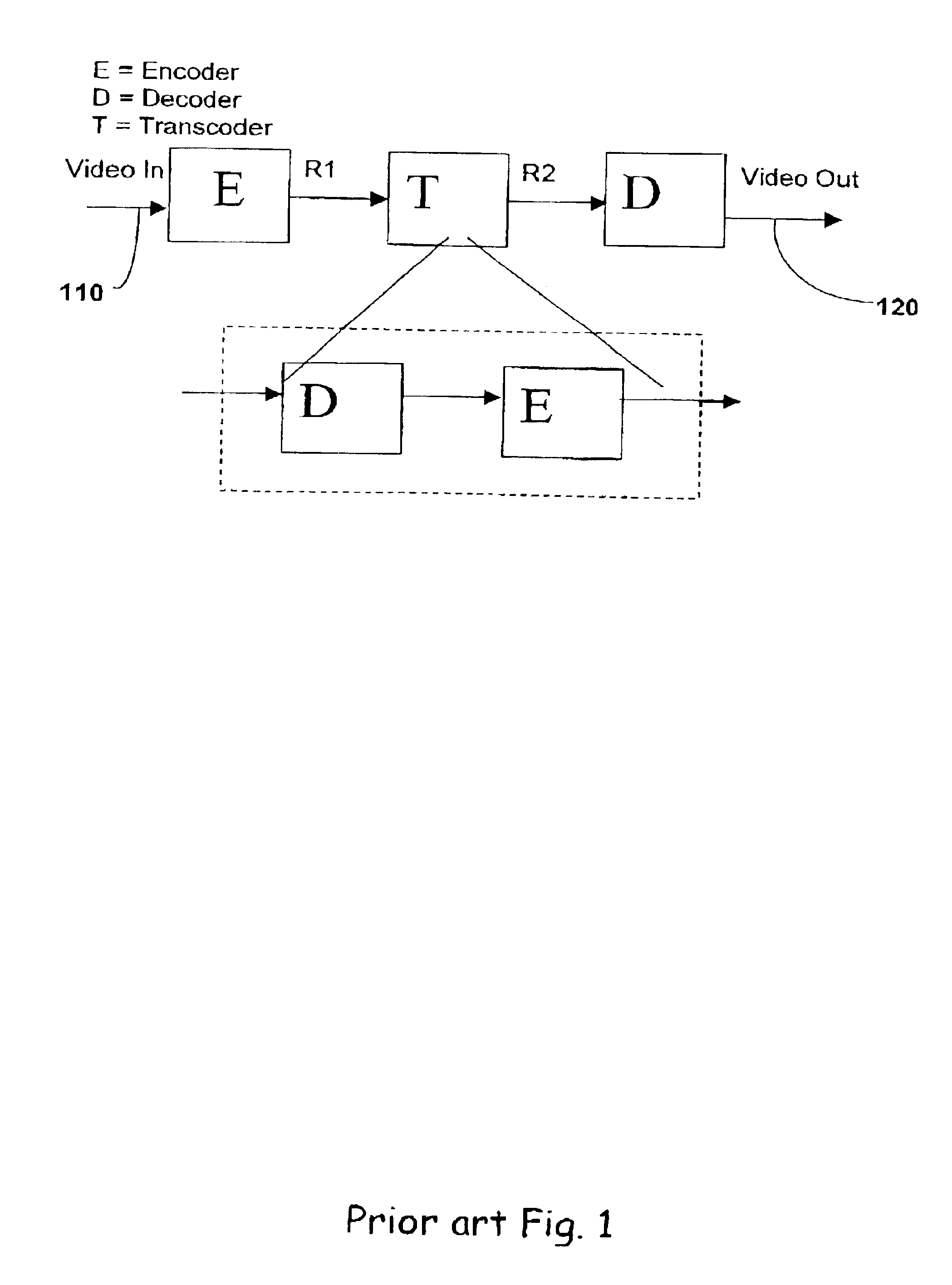

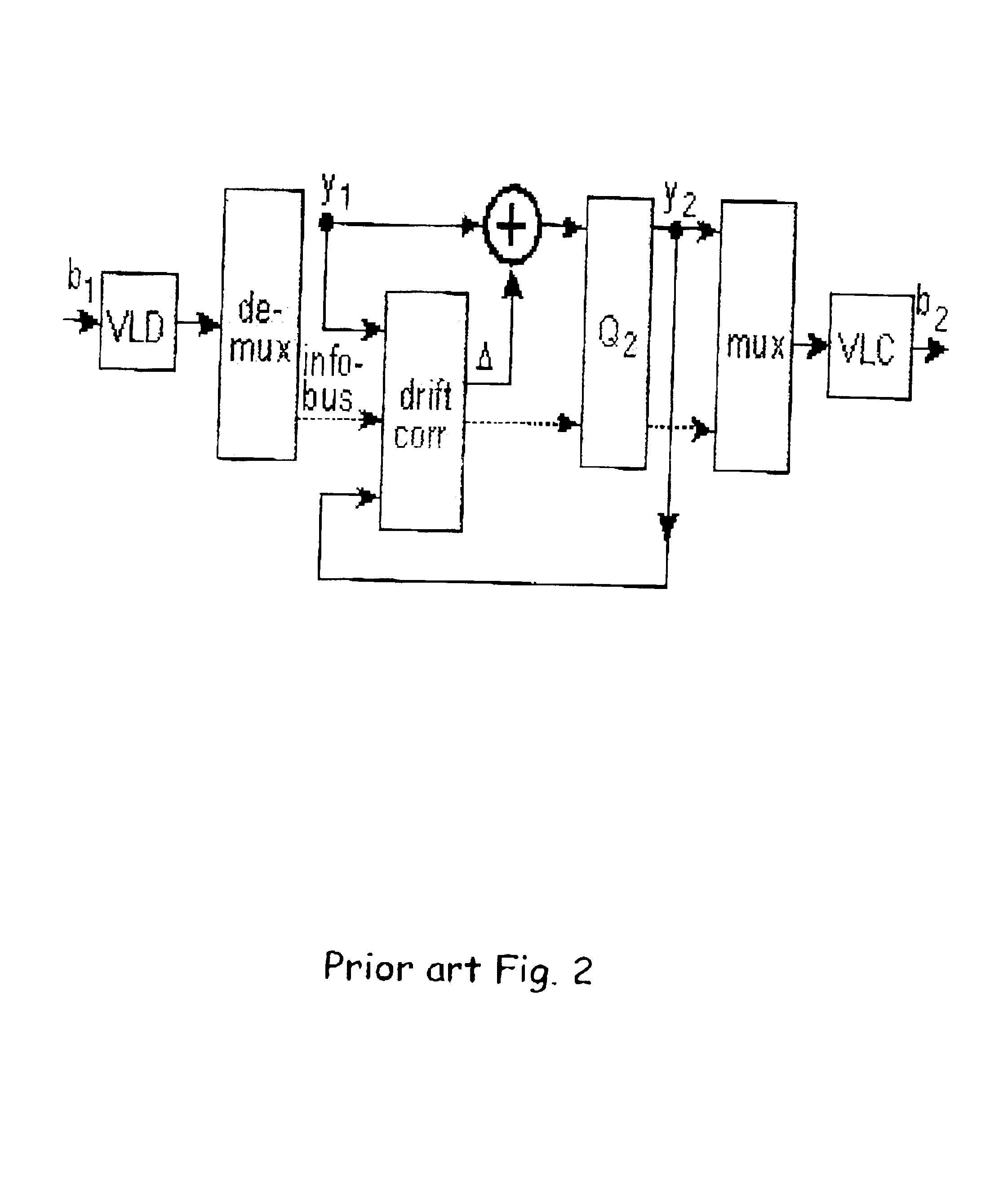

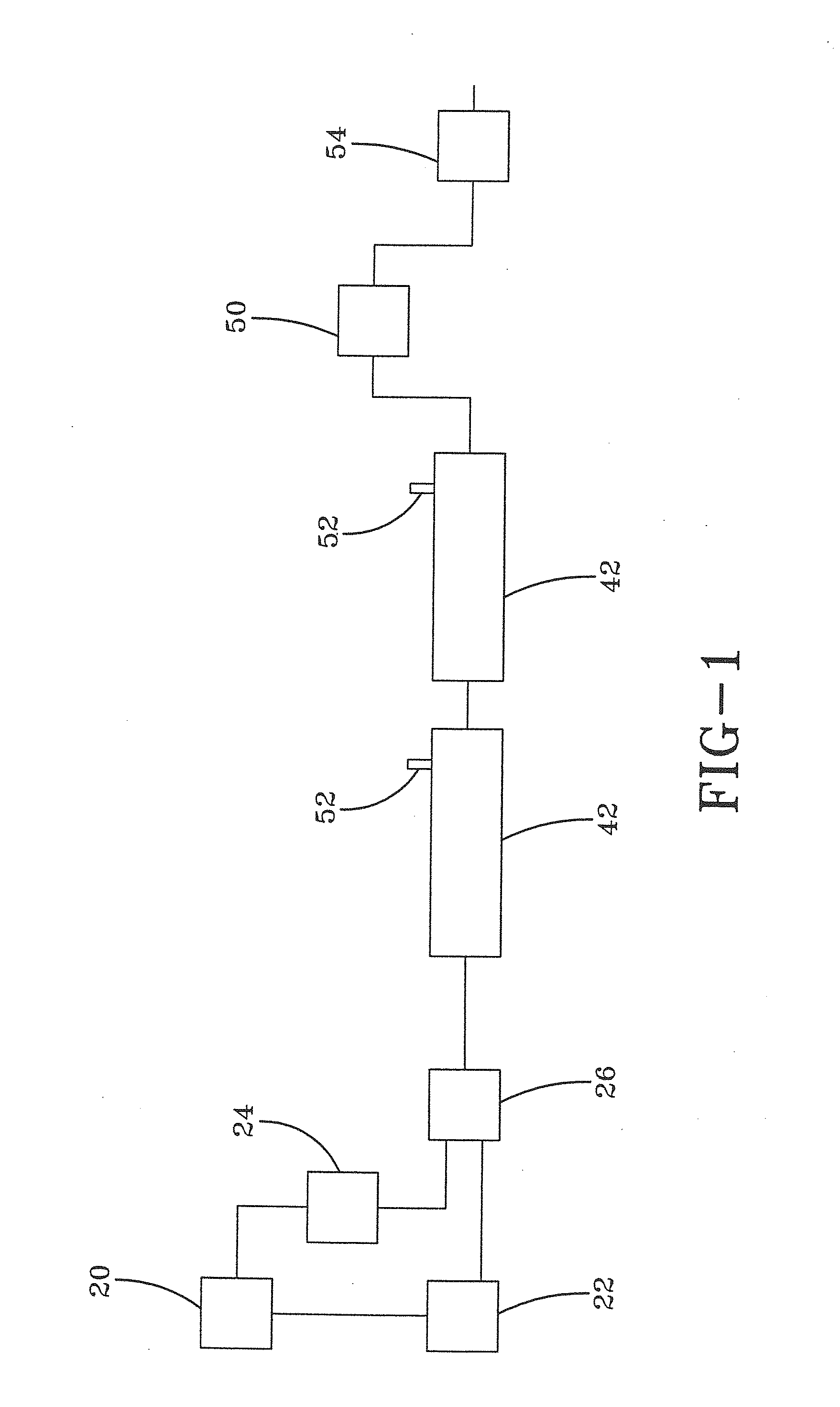

Transcoder system for compressed digital video bitstreams

InactiveUS6961377B2Efficient compressionOvercome limitationsColor television with pulse code modulationColor television with bandwidth reductionDigital videoVideo bitstream

A transcoder system for compressed digital video bitstreams comprising three frame types: I-frames, P-frames and B-frames. The system includes a picture reader decoder to ascertain the type of each frame prior to transcoding. The system also includes a T2 transcoder for processing I-frames and P-frames, possibly excepting the last P-frame of a group-of-frames (GOP), a T1 transcoder for processing B-frames and (optionally) the last P-frame of a GOP and a picture decision block for separating all frames into I-frames and P-frames, possibly excepting the last P-frame of a GOP for processing by the T2 transcoder and B-frames and (optionally) the last P-frame of a GOP for processing by said T1 transcoder. Another component is a remerge block for recombining the output of all frames from said T1 transcoder and the T2 transcoder into a reconstituted output bitstream, such that most of the frames are processed by the much faster T1 transcoder, thereby achieving substantial improvement in the transcoding throughput speed while retaining a low error rate.

Owner:HARMONIC VIDEO NETWORKS +1

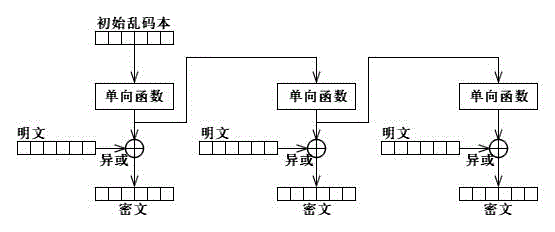

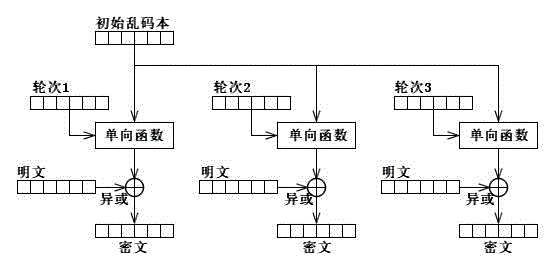

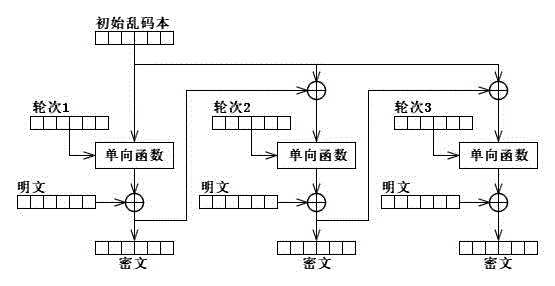

Limited gibberish text one-way conversion method and encryption/decryption application thereof

ActiveCN104579646AImprove the speed of encryption and decryptionEnsure safetyKey distribution for secure communicationEncryption apparatus with shift registers/memoriesExclusive orEncryption decryption

The invention discloses a limited gibberish text one-way conversion method and an encryption / decryption application thereof. The limited gibberish text one-way conversion method includes subjecting an initial gibberish text to one-way conversion with limited times and exclusive OR with message. The limited gibberish text one-way conversion method is actually an encryption / decryption method spending fewer bandwidths to accelerate the encryption / decryption speed. Compared with the traditional standard encryption / decryption method, the limited gibberish text one-way conversion method has the advantages that with fewer bandwidth spent, the encryption / decryption speed is improved by 10-100 times at the premise that the data safety is guaranteed; method is simple and widely applicable to large-scale data storage and transmission.

Owner:NANJING FAWEIKE INFORMATION TECH CO LTD

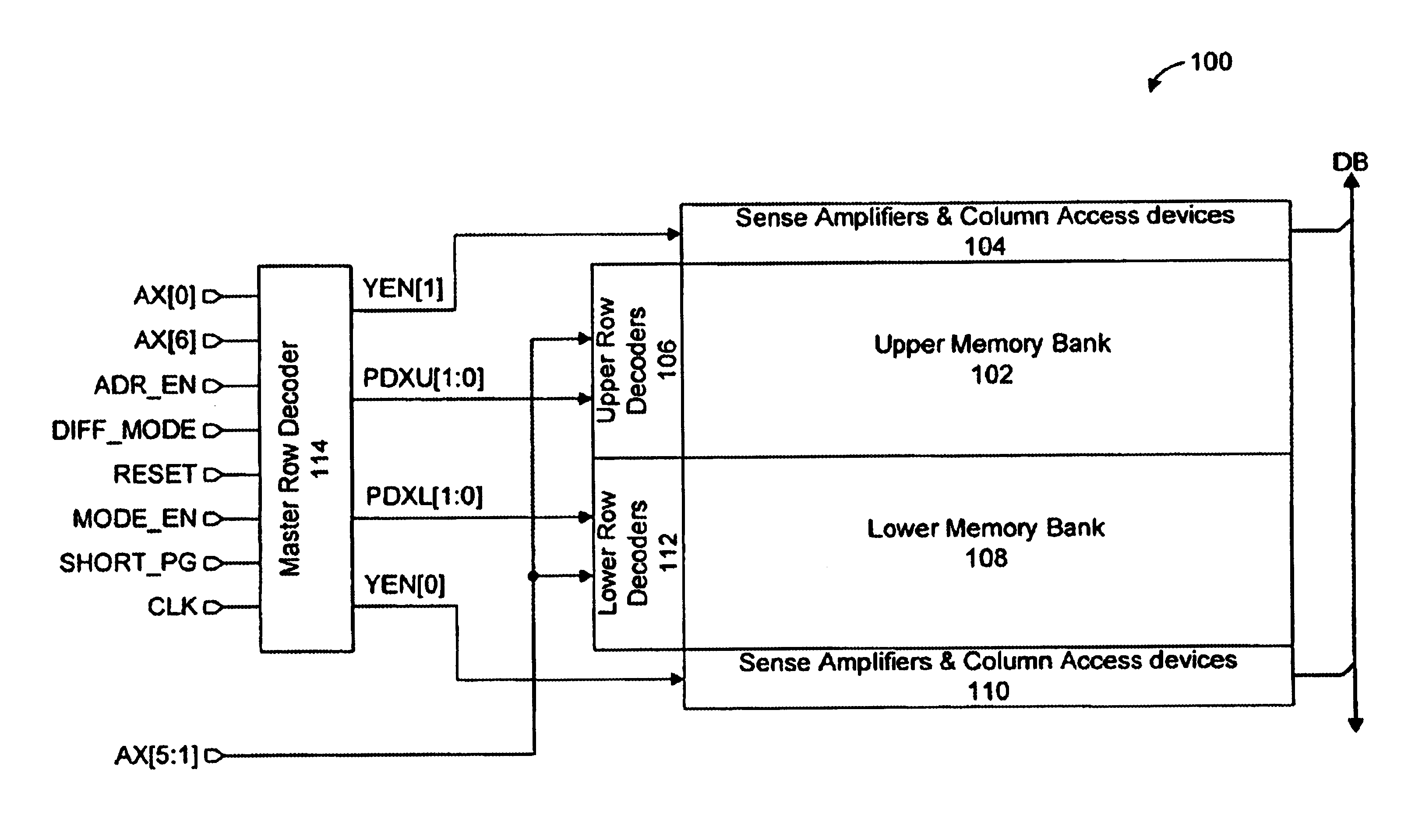

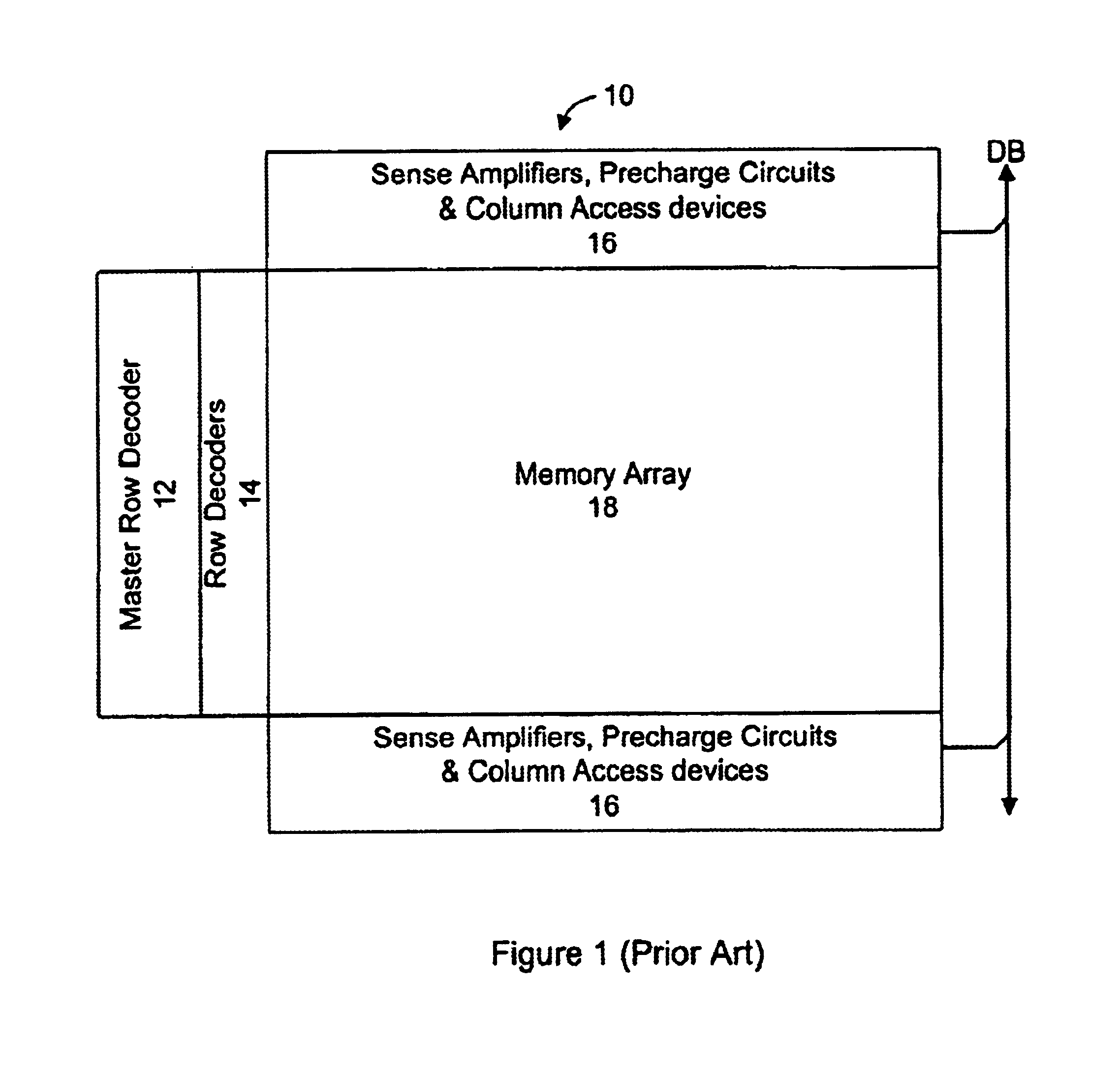

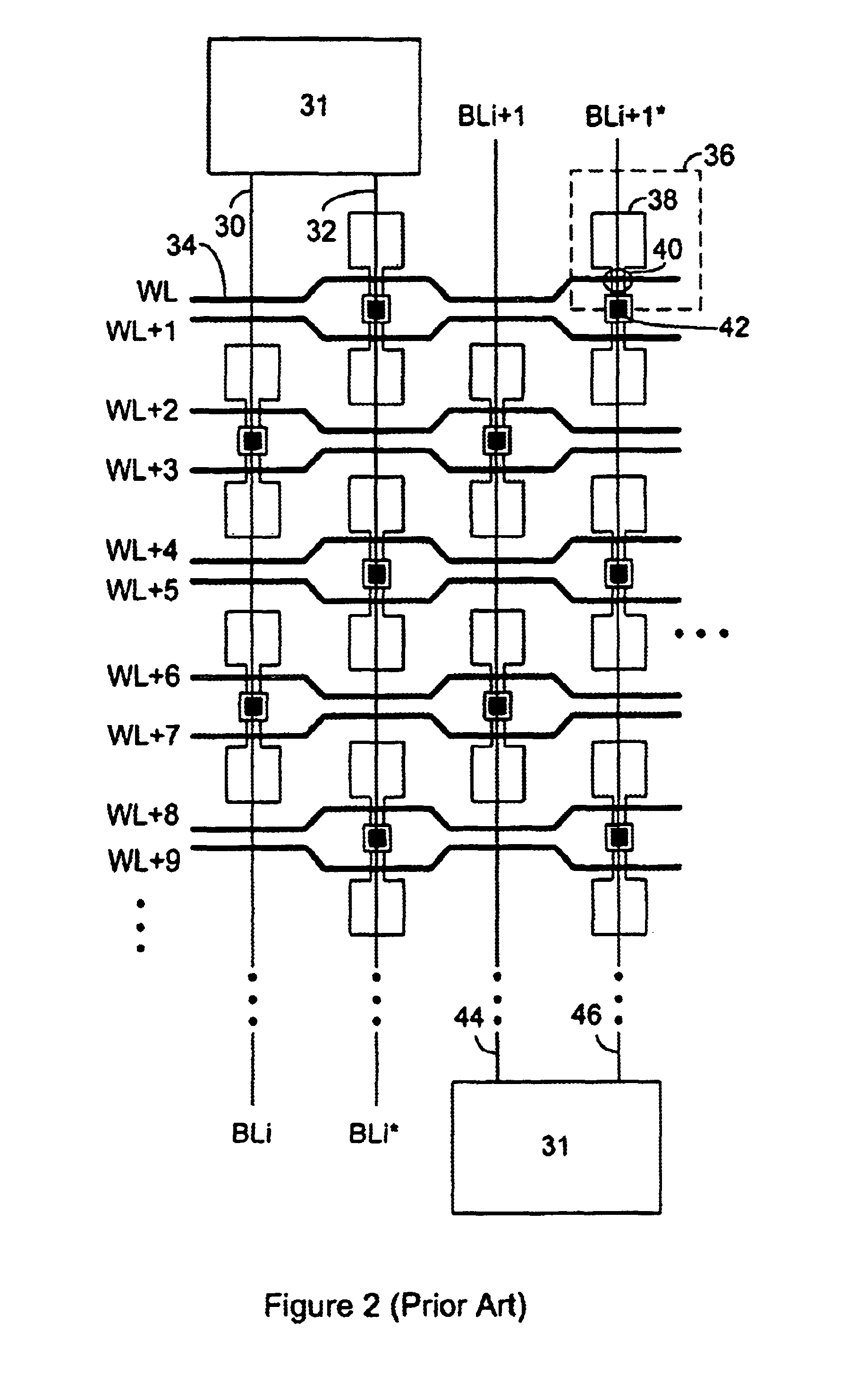

RAM having dynamically switchable access modes

InactiveUS6894941B2Increase data access throughput speedReduce refresh power consumptionDigital storageBit lineMemory bank

A row addressing circuit for DRAM memory is disclosed. Additional address or mode bits are used to dynamically select between long page and short page access modes, and to dynamically select between single cell per bit and dual, or two cell per bit modes in each memory bank within a memory block. In the short page access mode, only one wordline in a memory block is activated. In the long page access mode, two wordlines in the memory block are activated for accessing twice the number of bits as in short page access mode. In the single cell per bit mode, one bit of data is stored in one DRAM cell. In the two cell per bit mode, the row addressing circuit simultaneously activates two wordlines in a bank of the memory block to access one DRAM cell connected to each bitline of a pair of complementary bitlines for writing and reading complementary data. The row addressing circuit can combine the different access modes for system design flexibility.

Owner:INVENSAS CORP

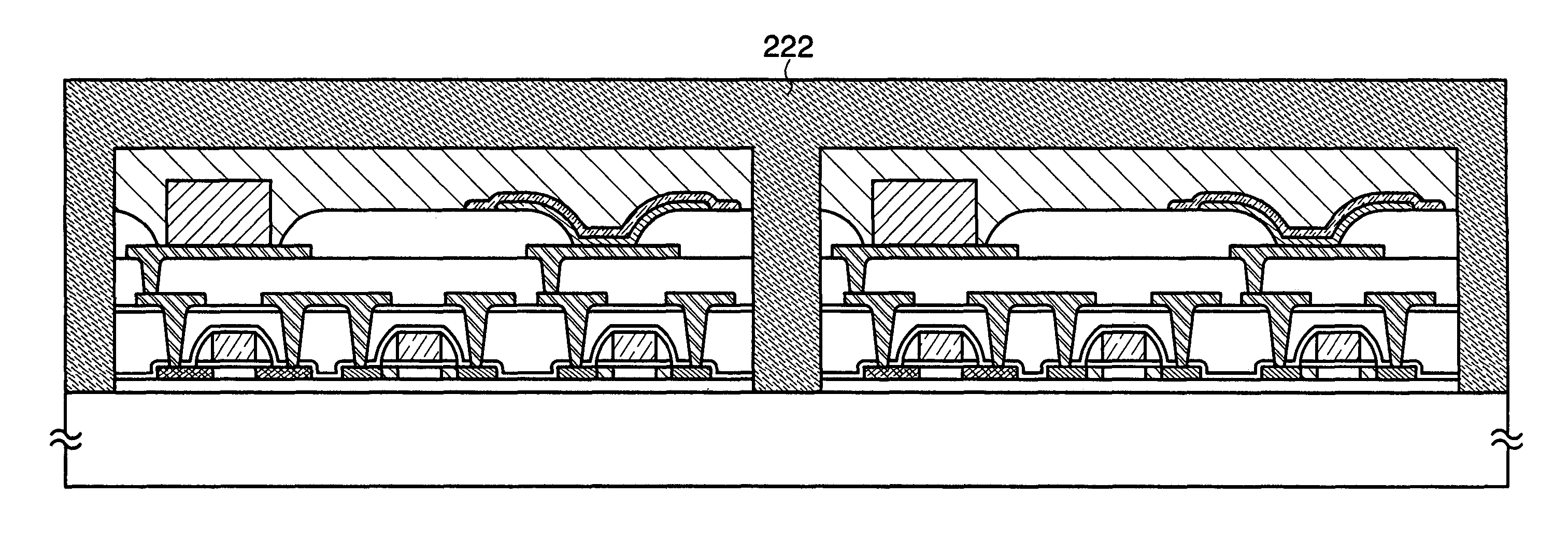

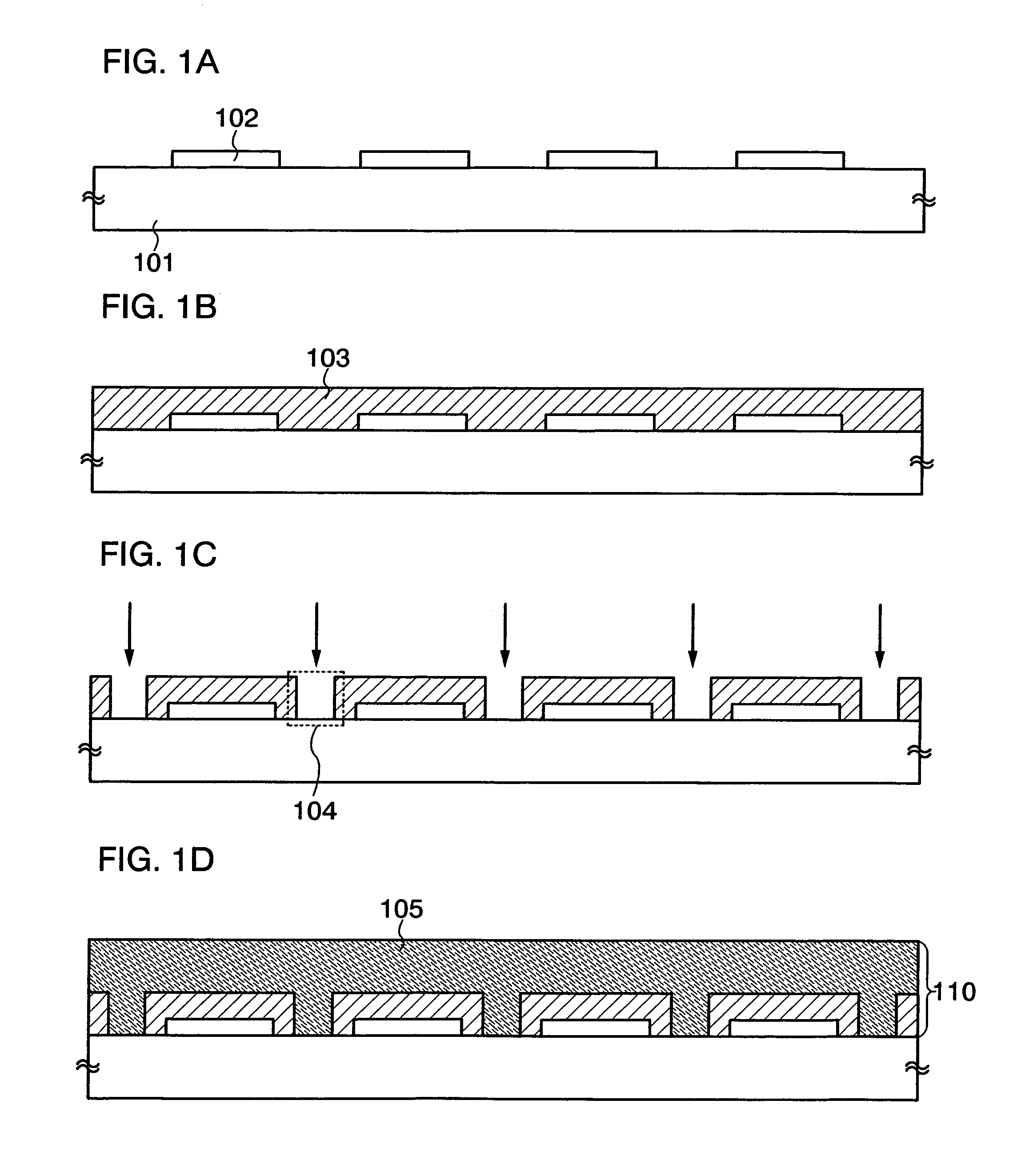

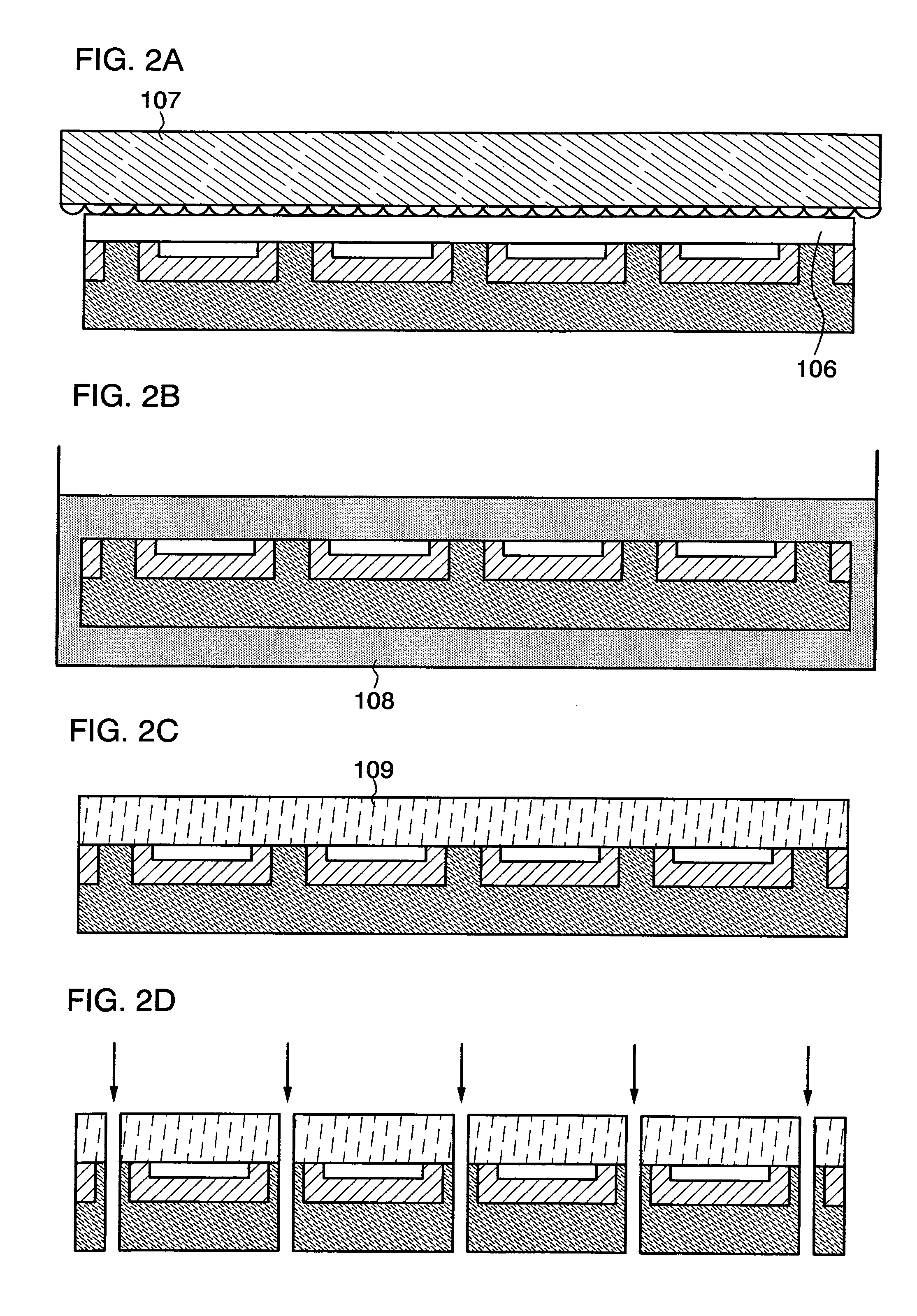

Manufacturing method of semiconductor device

InactiveUS7928510B2Improve throughput speedAvoid damageTransistorSemiconductor/solid-state device detailsEngineeringSemiconductor device

It is an object of the present invention to provide a manufacturing method of a semiconductor device where a semiconductor element is prevented from being damaged and throughput speed thereof is improved, even in a case of thinning or removing a supporting substrate after forming the semiconductor element over the supporting substrate. According to one feature of the present invention, a method for manufacturing a semiconductor device includes the steps of forming a plurality of element groups over an upper surface of a substrate; forming an insulating film so as to cover the plurality of element groups; selectively forming an opening to the insulating film which is located in a region between neighboring two element groups in the plurality of element groups to expose the substrate; forming a first film so as to cover the insulating film and the opening; exposing the element groups by removing the substrate; forming a second film so as to cover the surface of the exposed element groups; and cutting off between the plurality of element groups so as not to expose the insulating film.

Owner:SEMICON ENERGY LAB CO LTD

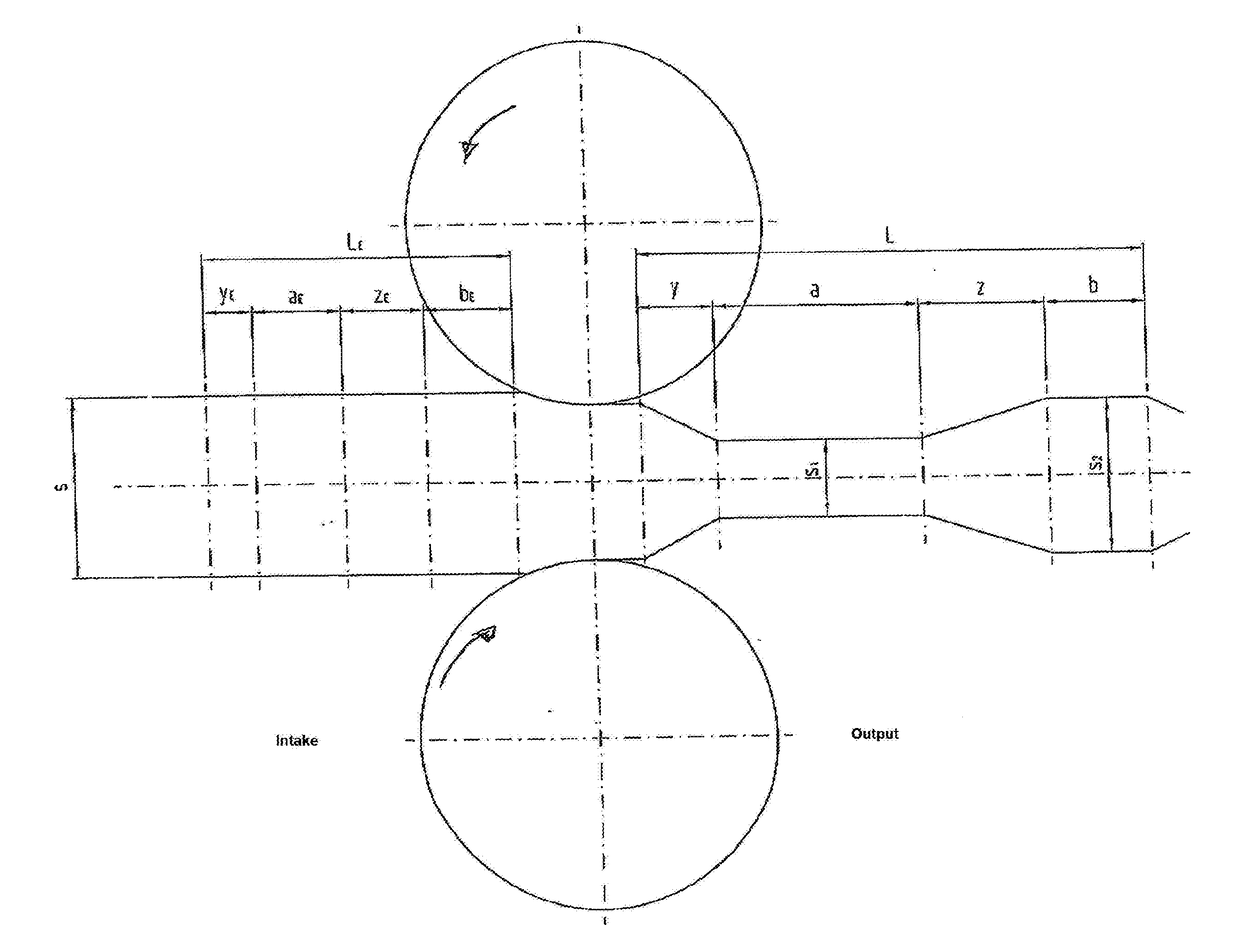

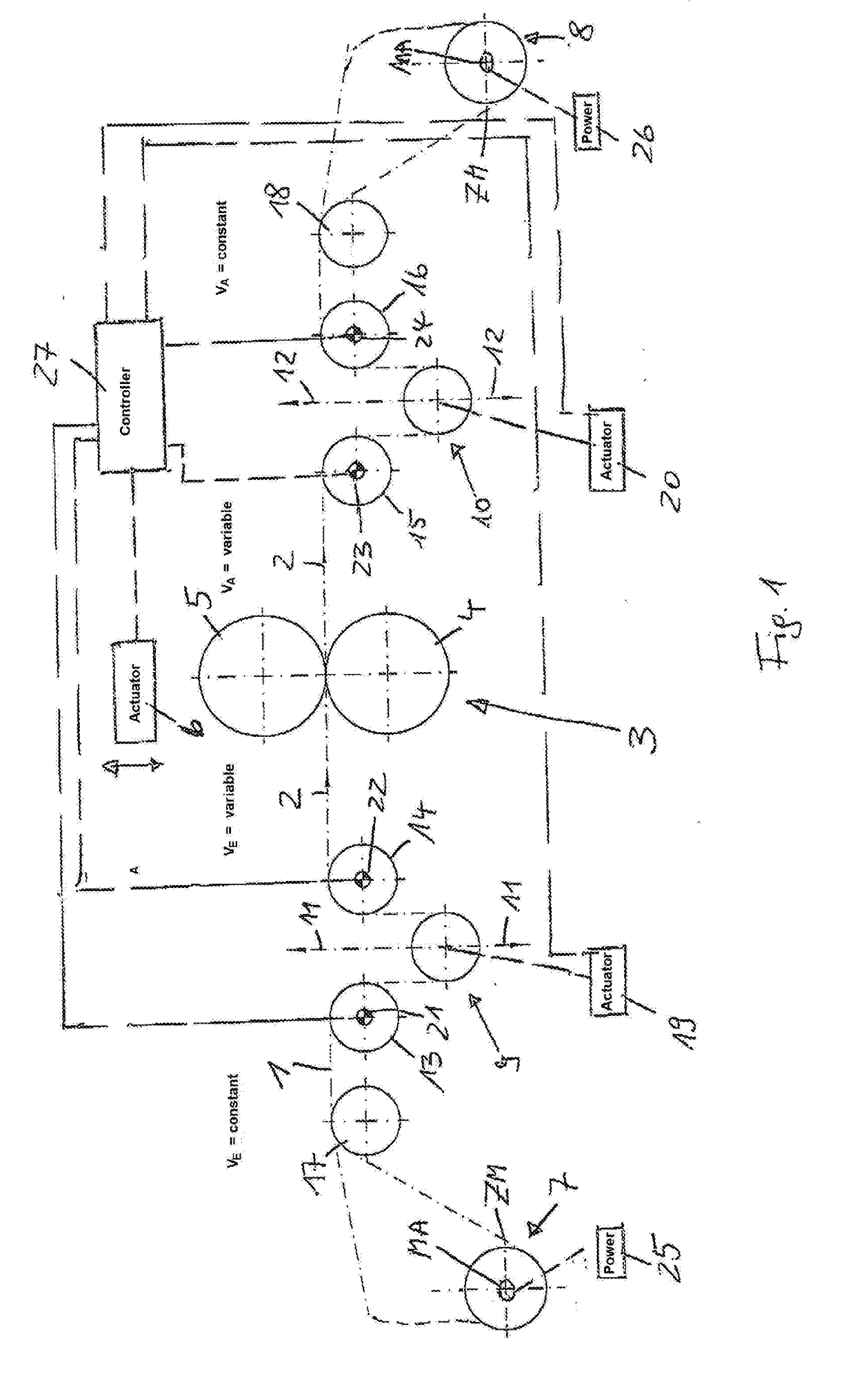

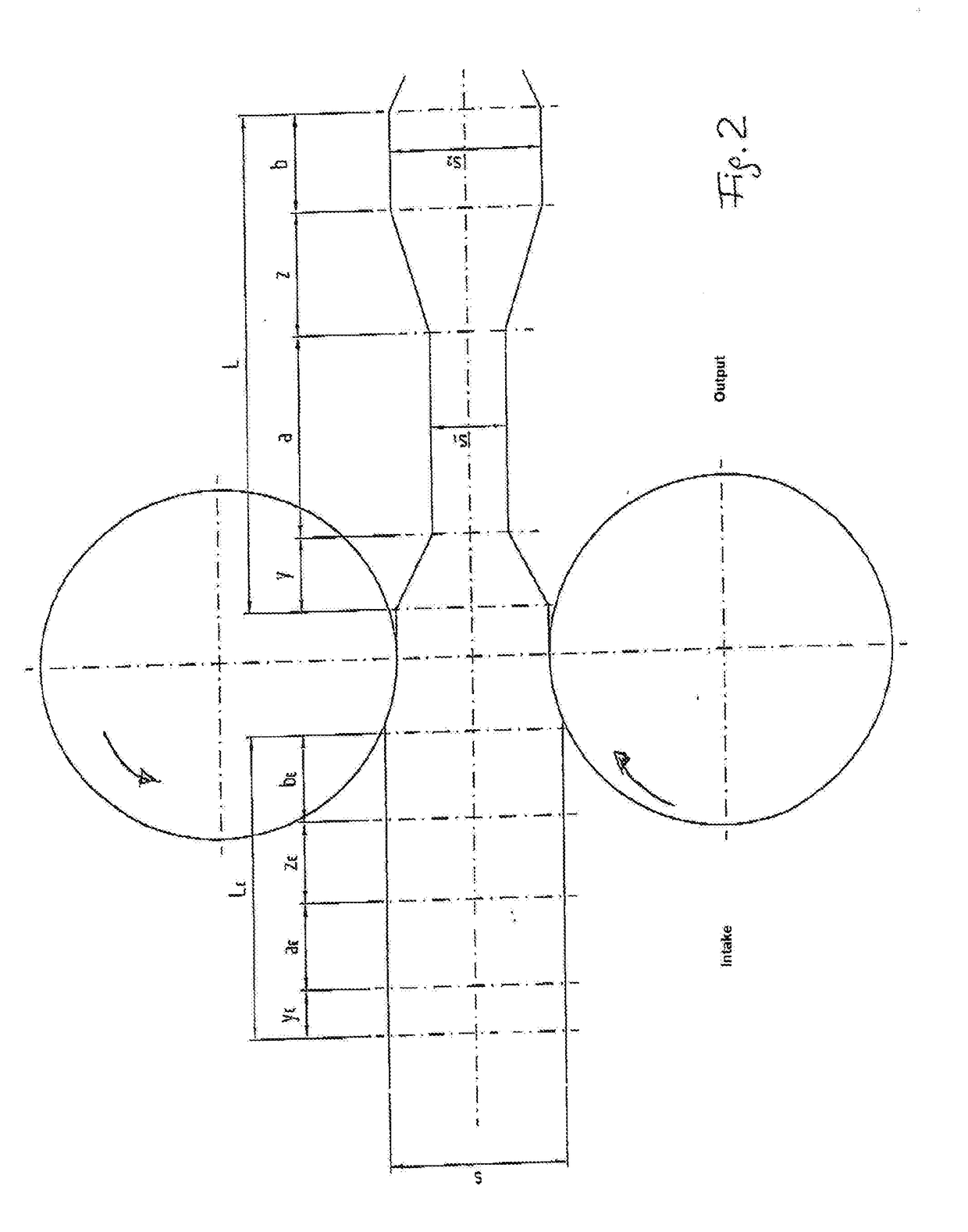

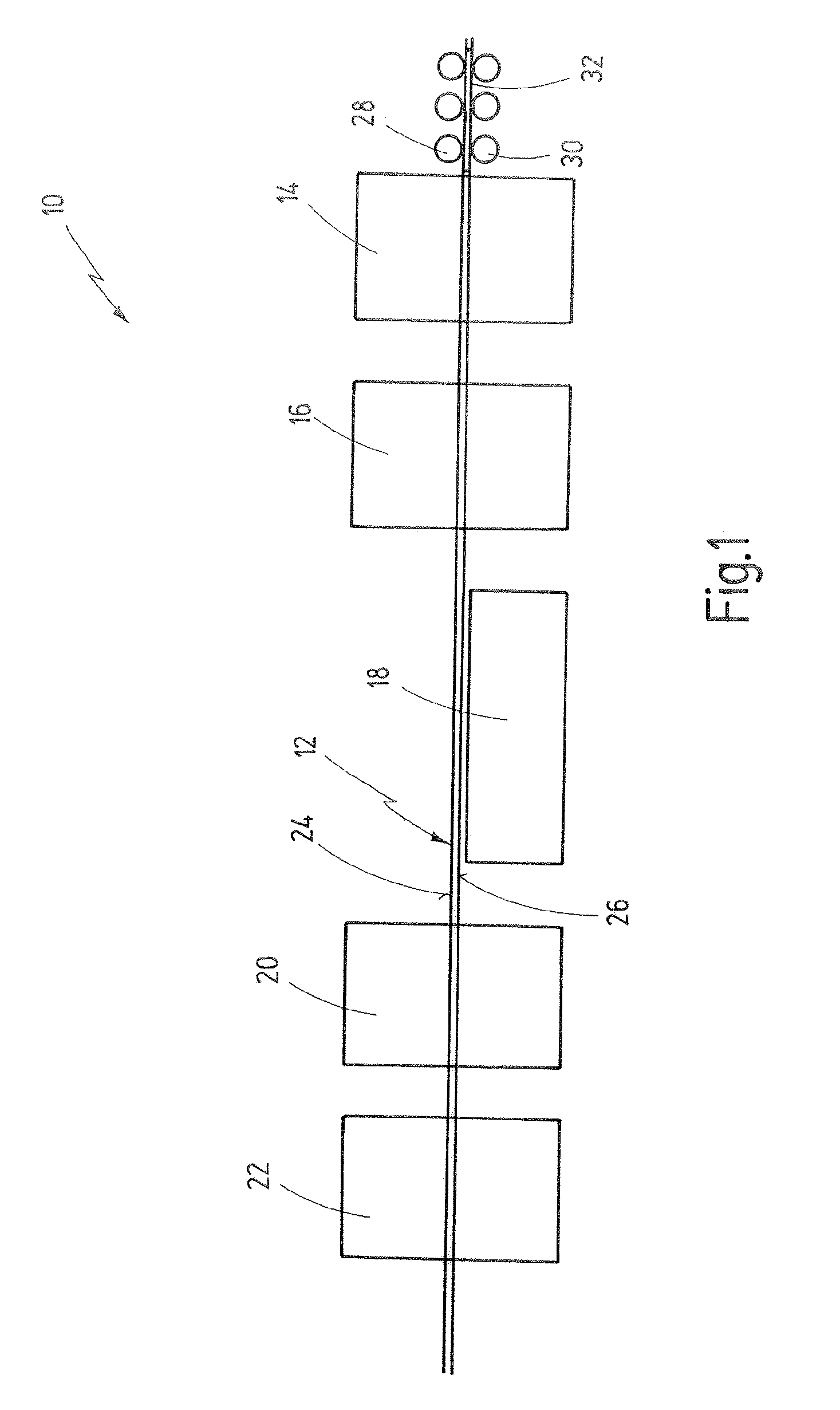

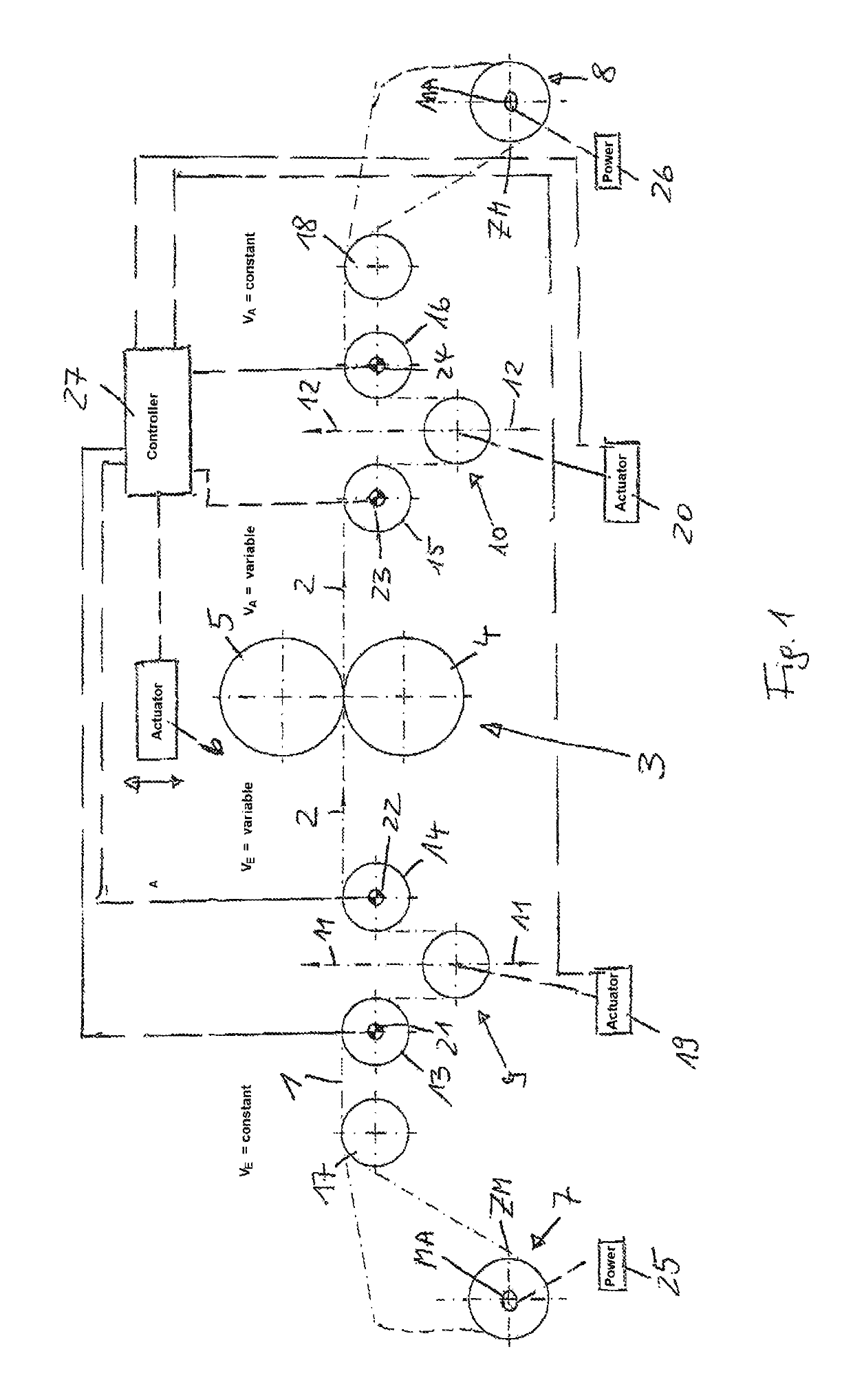

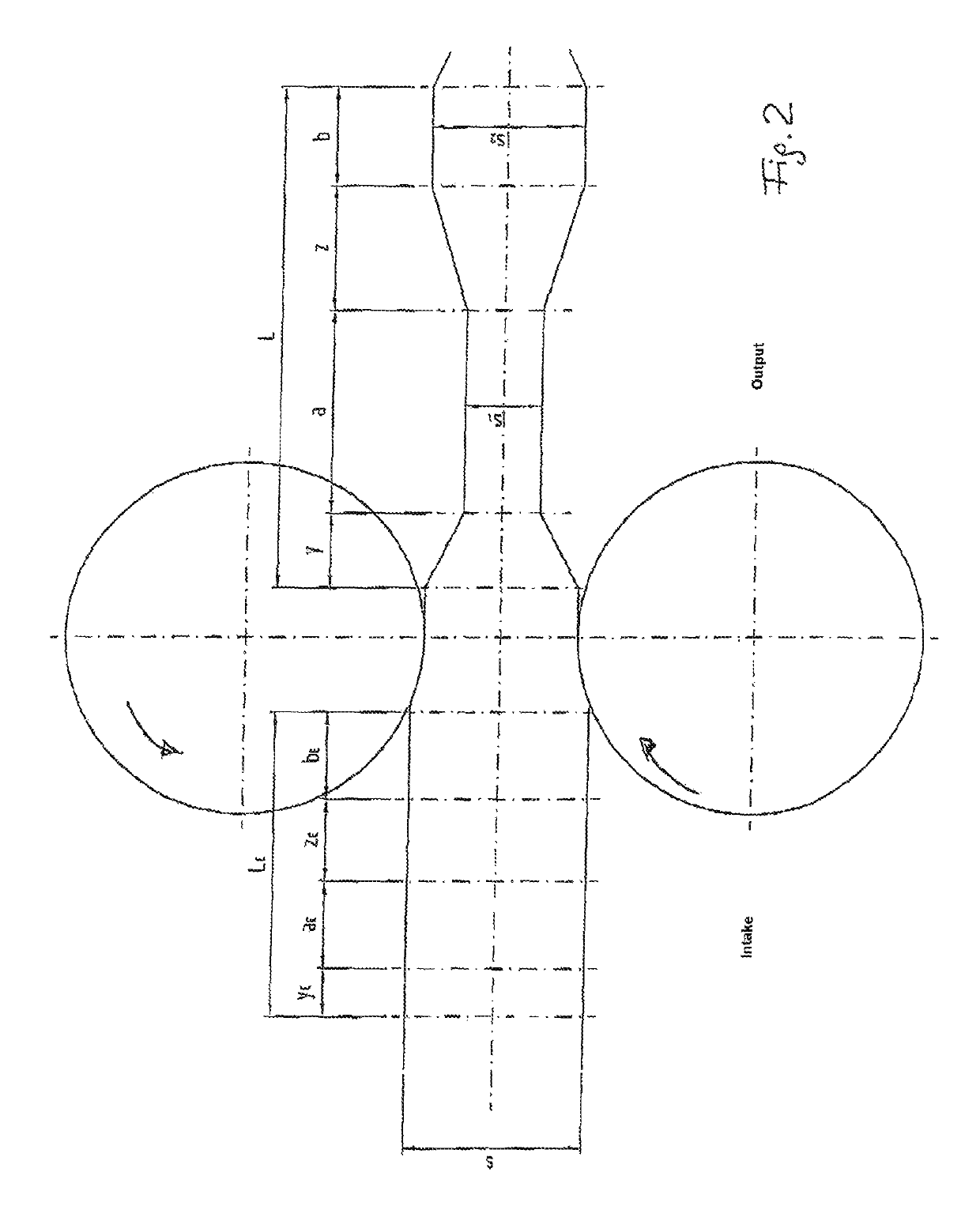

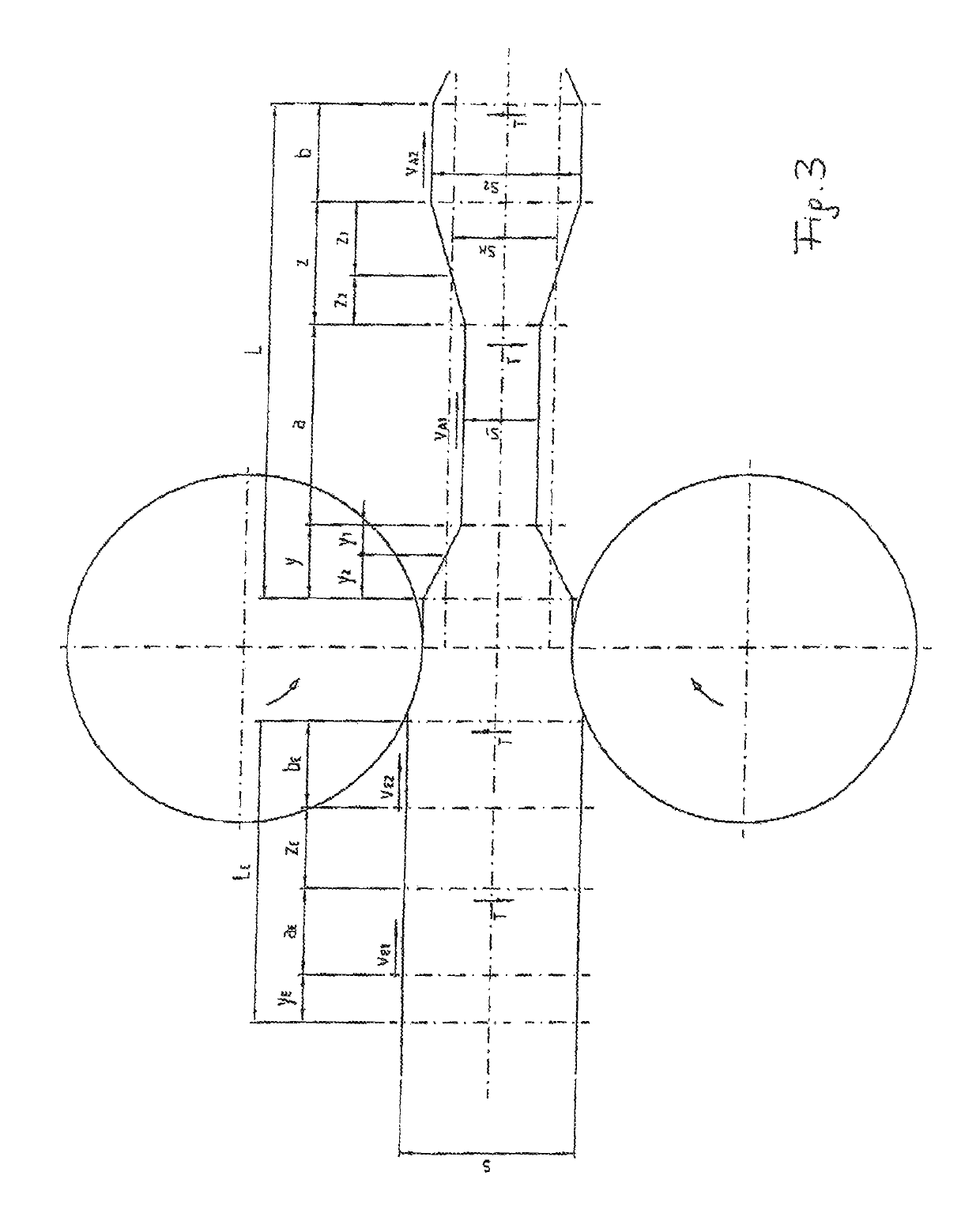

Method of and apparatus for rolling strip of fluctuating thickness

ActiveUS20170239700A1Simple methodQuality improvementMeasuring devicesTension/compression control deviceEngineeringActuator

An apparatus for rolling strip having a periodically fluctuating strip thickness has a roll stand with a set of rollers defining a gap, an adjustment actuator for adjusting the gap of the set of rollers, unwinder for feeding the strip with an initial thickness to an intake side of the roller gap, winder for receiving the strip with a desired final thickness from an output side of the gap, respective upstream and roller assemblies each having an immersion roller provided upstream of the roll stand between the unwinder and the roll stand and downstream of the roll stand between the roll stand and the winder. The strip is guided around the immersion rollers. A controller sets positions of the immersion rollers while operating the rollers of the roll stand at a constant roller speed, for determining the roller gap in dependence on the setting of the rollers.

Owner:BILSTEIN

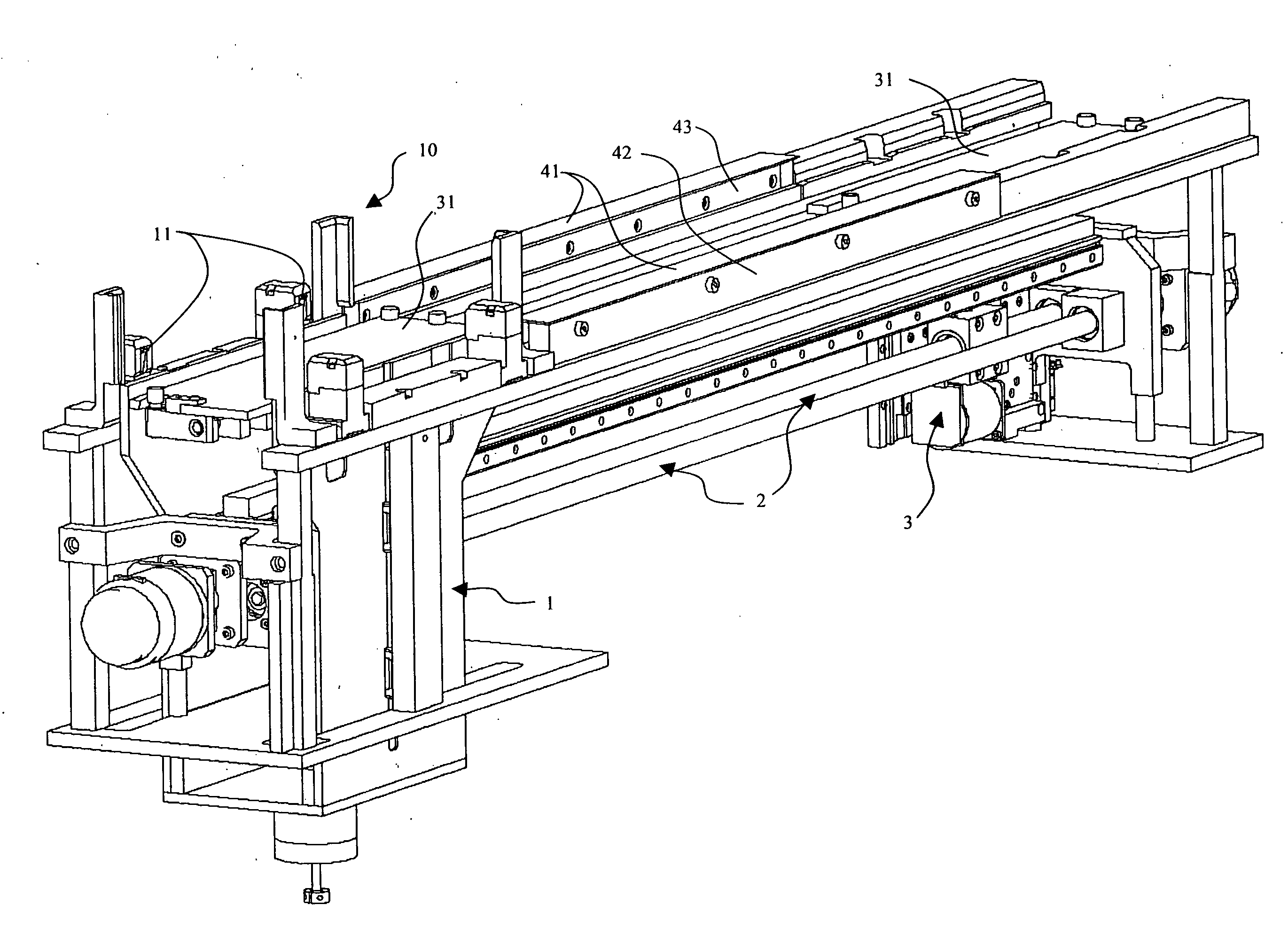

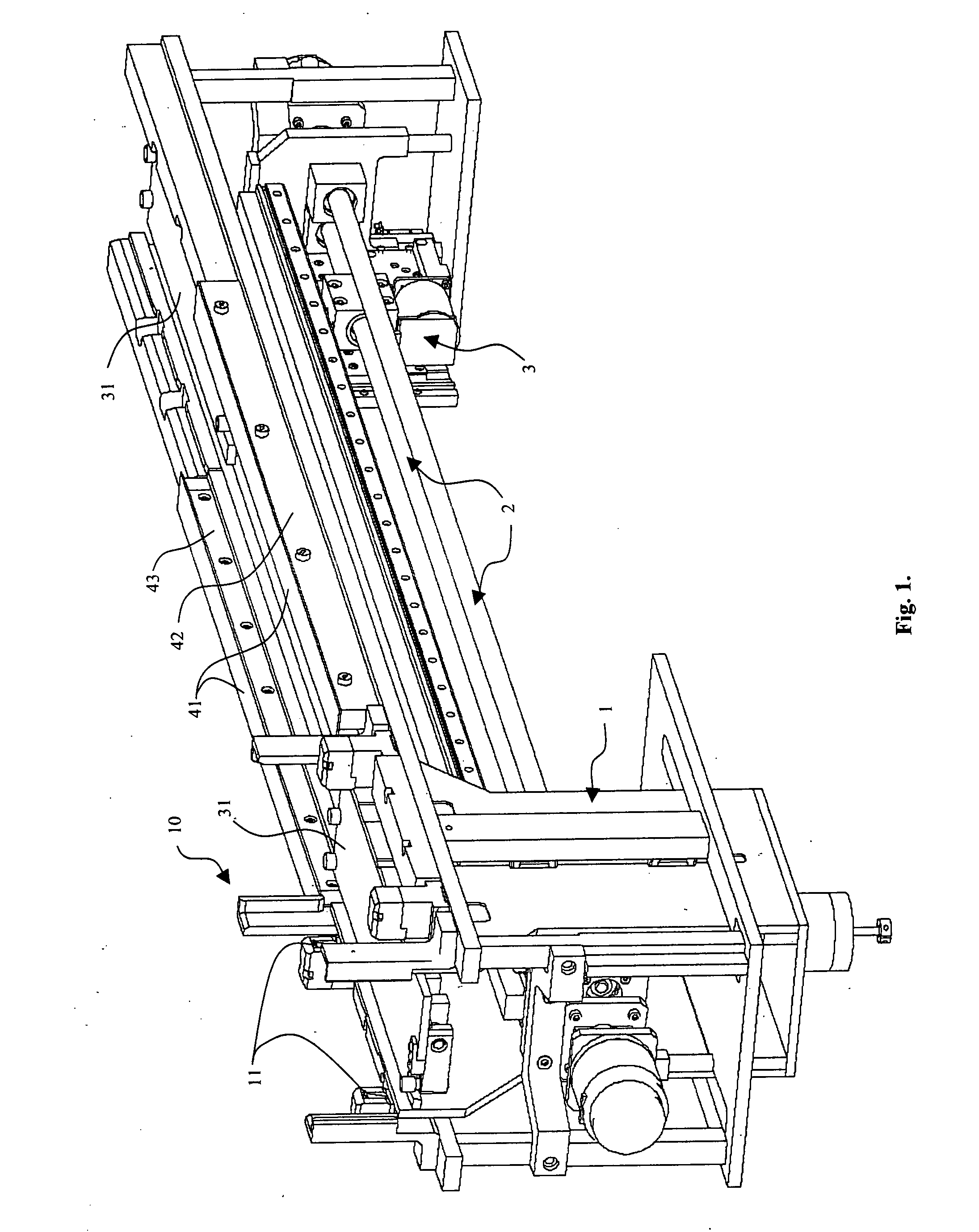

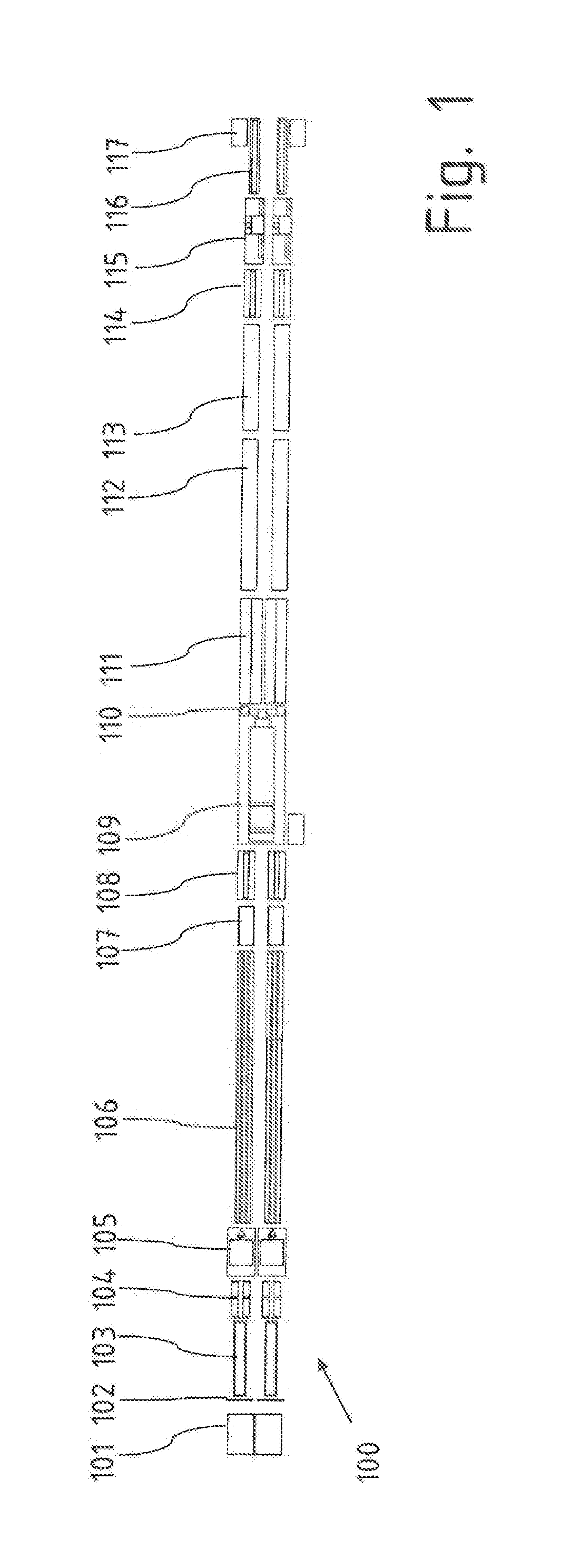

High speed tray transfer system

InactiveUS20080003084A1Improve throughput speedAccurately and repeatably positionSemiconductor/solid-state device manufacturingStorage devicesTransfer systemSemiconductor

A high-speed tray transfer system for trays of semiconductor devices for increasing the rate at which trays are delivered to, and advanced through, a pick and place that moves orthogonal to the tray movement, so as to increase the overall throughput speed of a semiconductor handling machine. The invention utilizes two or more platens that carry trays. The platens can pass over, under or otherwise around each other so that while one platen is under and servicing the pick and place, another platen is cycling around and preparing another tray of electronic devices for the pick and place.

Owner:SYSTATION SEMICON

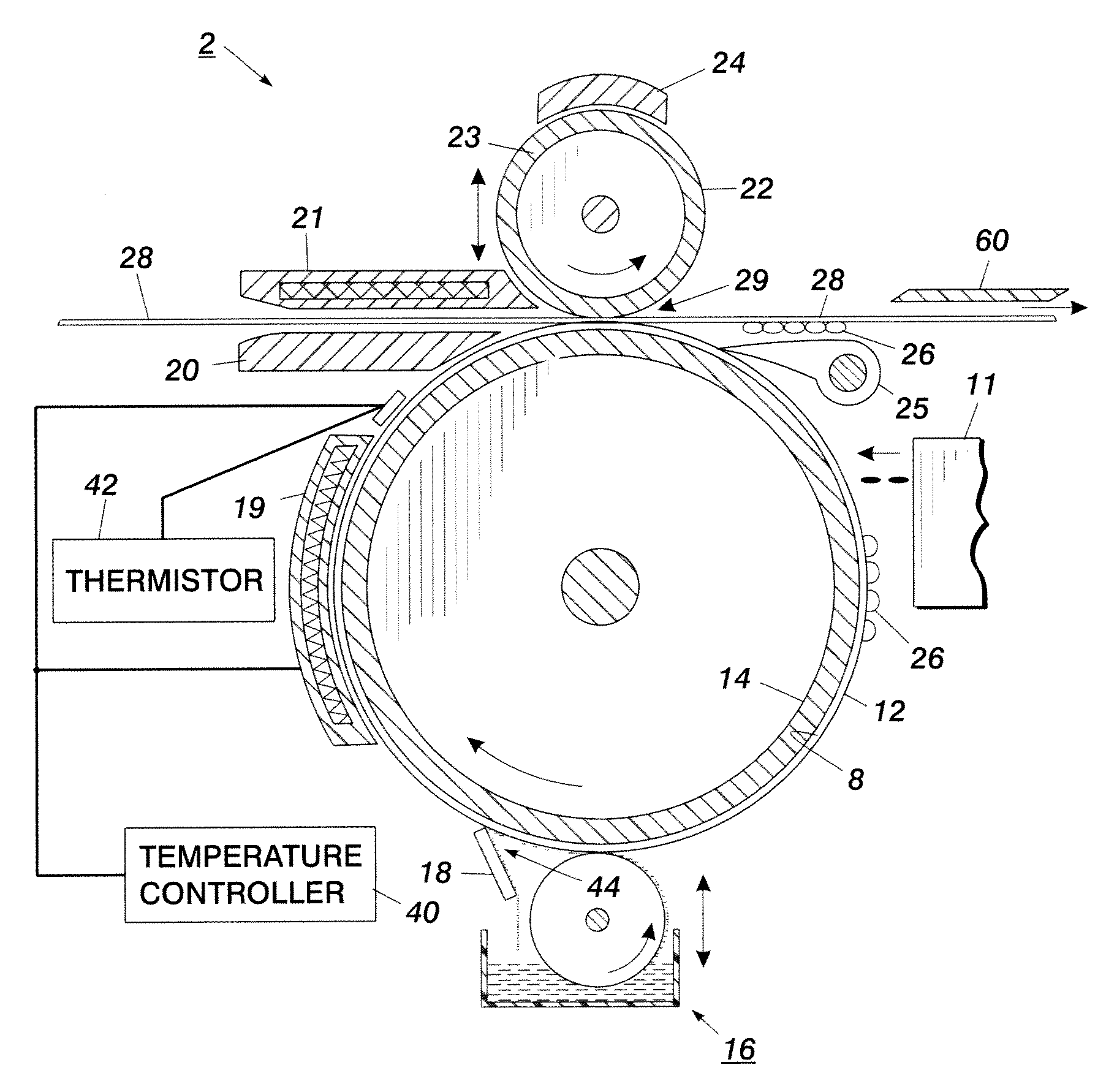

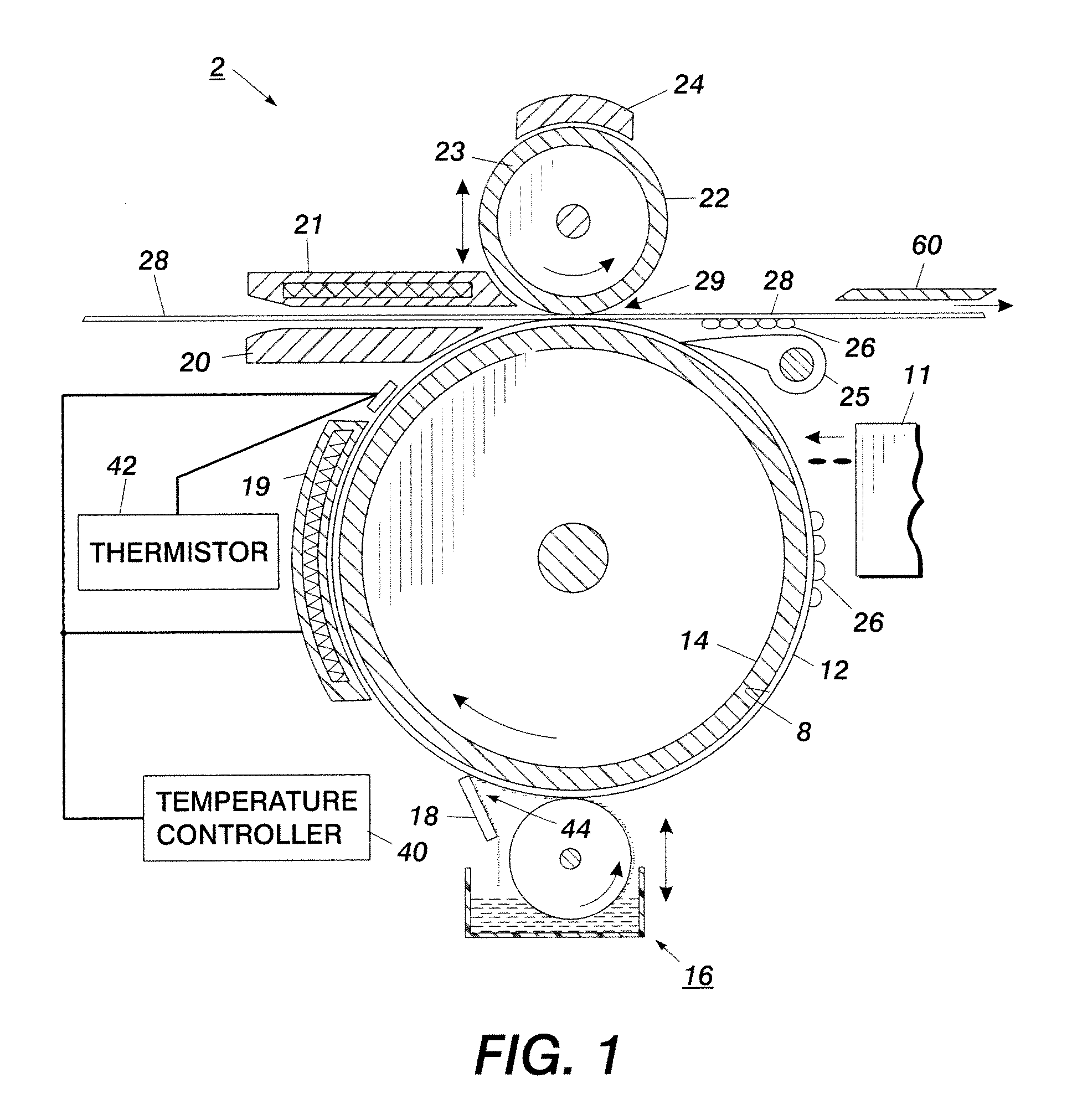

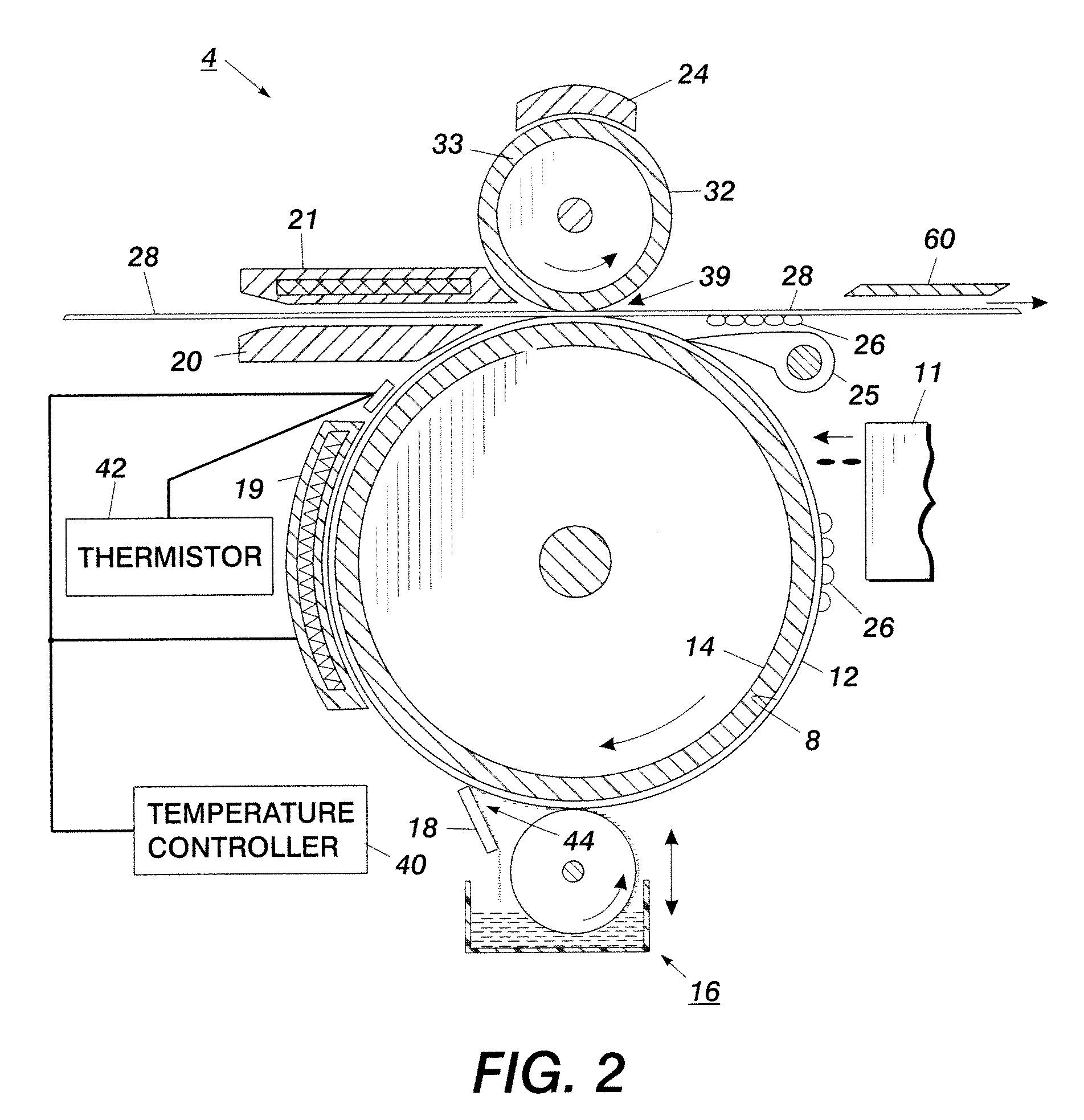

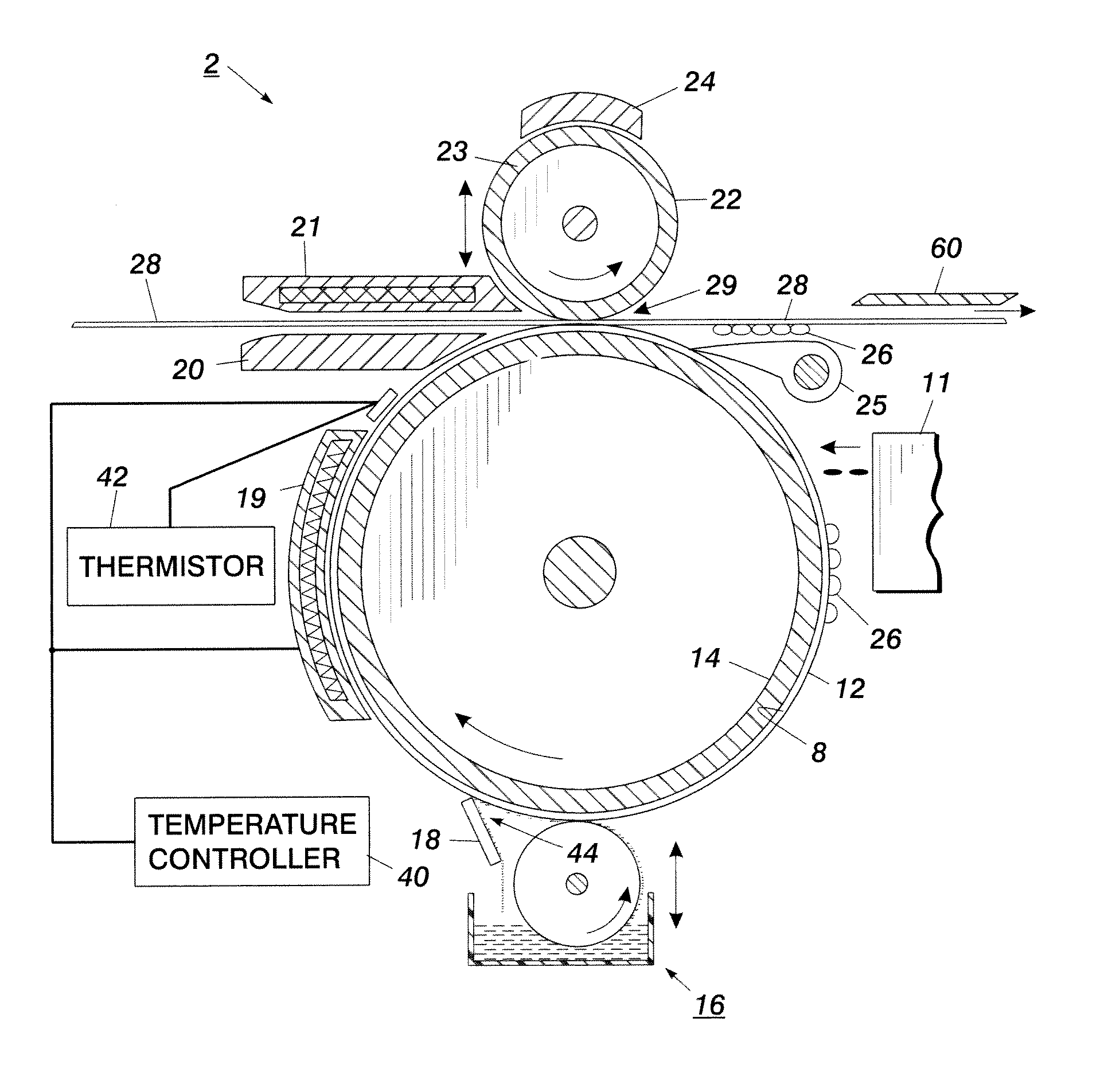

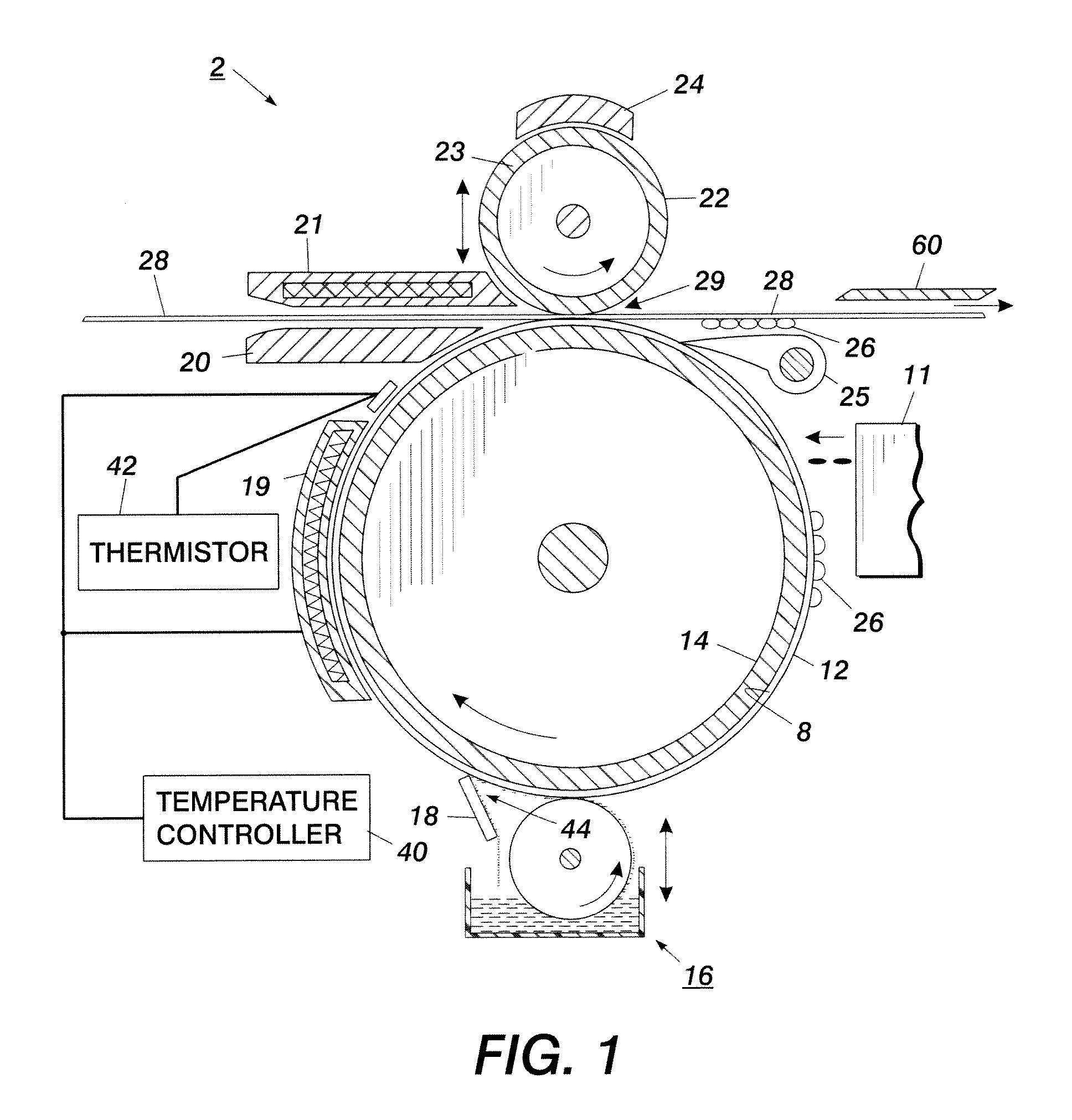

Duplex printing with integrated image marking engines

InactiveUS20100020119A1Quality improvementImprove throughput speedTypewritersElectrographic process apparatusEngineeringElectrical and Electronics engineering

The present disclosure provides a method for controlling printing in a solid ink jet printing system. The method comprises forming a first ink image and a second ink image on a transfer surface; passing a receiving substrate through a first nip simplex path of a first ink jet printer at a first print speed; exerting a first pressure on the receiving substrate in the first nip to transfer the first ink image from the transfer surface to a first side of the receiving substrate; moving the receiving substrate through an inverter path; passing the receiving substrate through a second nip simplex path of a second ink jet printer at a second print speed; and, exerting a second pressure on the receiving substrate in the second nip to transfer the second ink image from the transfer surface to a second side of the receiving substrate.

Owner:XEROX CORP

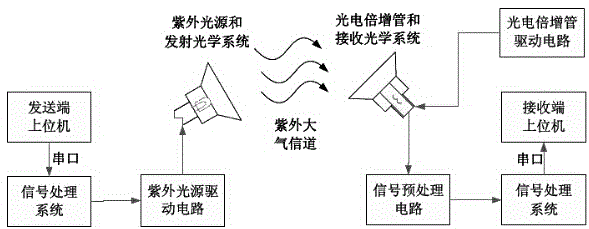

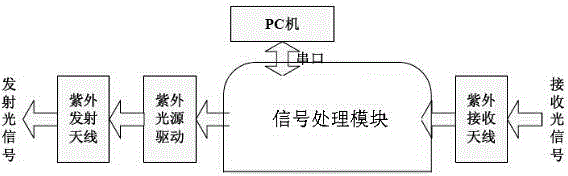

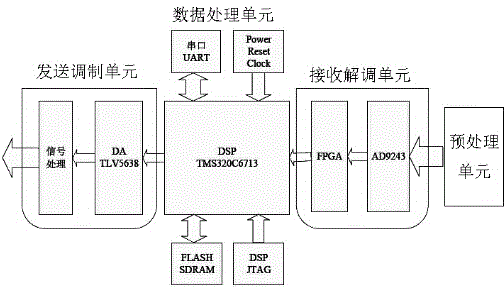

Ultraviolet light communication system based on SR digital signal processing technology

InactiveCN104917565AImprove response rateFast responseClose-range type systemsDigital signal processingControl signal

The invention discloses an ultraviolet light communication system based on a SR digital signal processing technology. A signal processing module is developed, wherein a high speed floating point type DSP chip is taken as a core and a FPGA is a coprocessor. A DSP main processor mainly carries out modulation and demodulation on a signal. The FPGA coprocessor is responsible for digital filtering and data buffering after the data is collected. The system comprises an ultraviolet light transmitting antenna, an ultraviolet light source driving module, a signal processing module, an upper computer and an ultraviolet receiving antenna. The signal processing module is communicated with the upper computer through a serial port. The ultraviolet receiving antenna receives an ultraviolet light signal. The module converts the light signal into a voltage signal and transmits to the signal processing module. The ultraviolet light source driving module receives a control signal of a signal processing unit and drives the ultraviolet receiving antenna to emit an ultraviolet signal. The design in the invention satisfies requirements of industrialization, a practical ability and miniaturization. High-efficient transmission of a long distance and a large amount of data can be realized.

Owner:徐云鹏

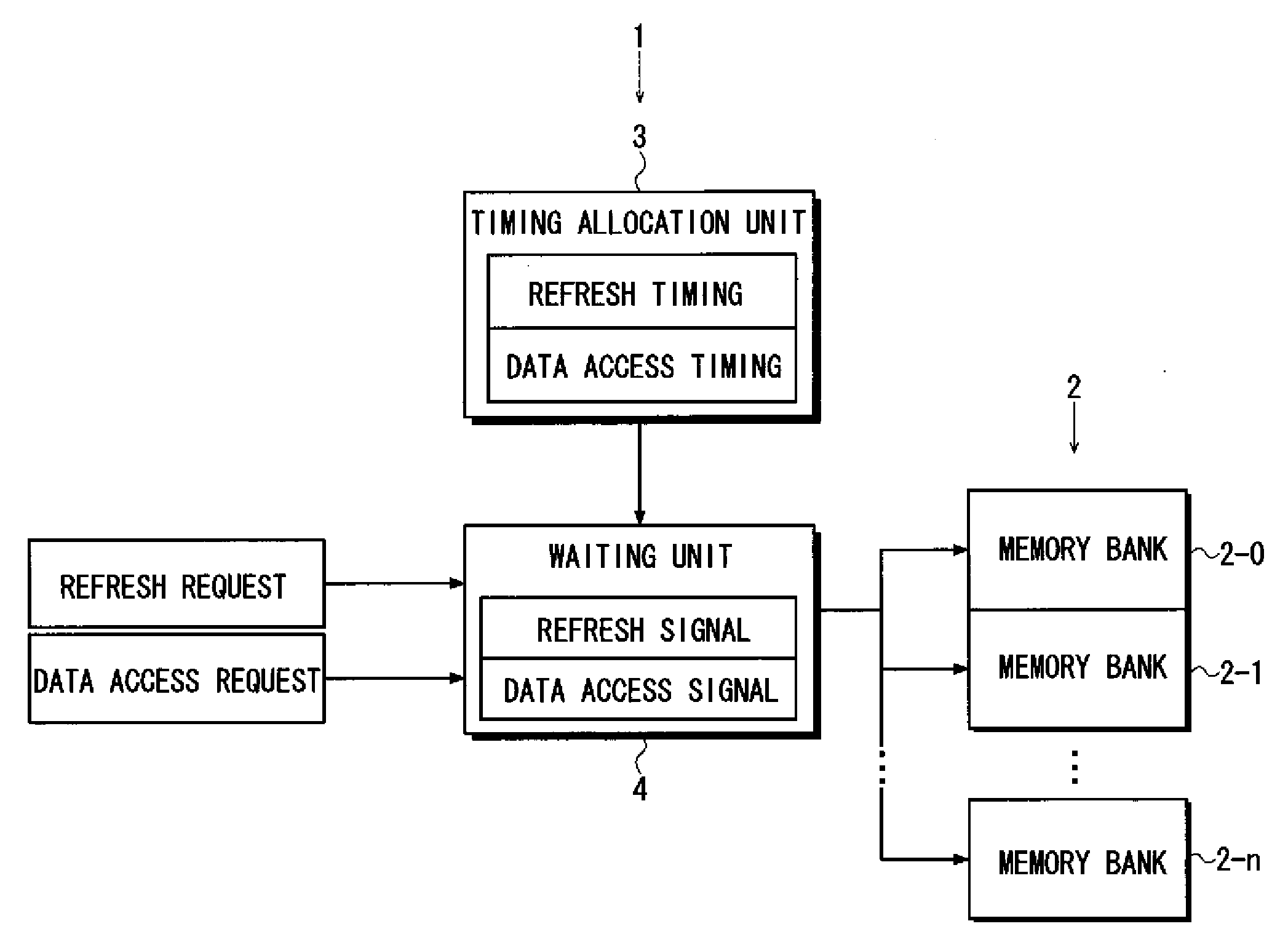

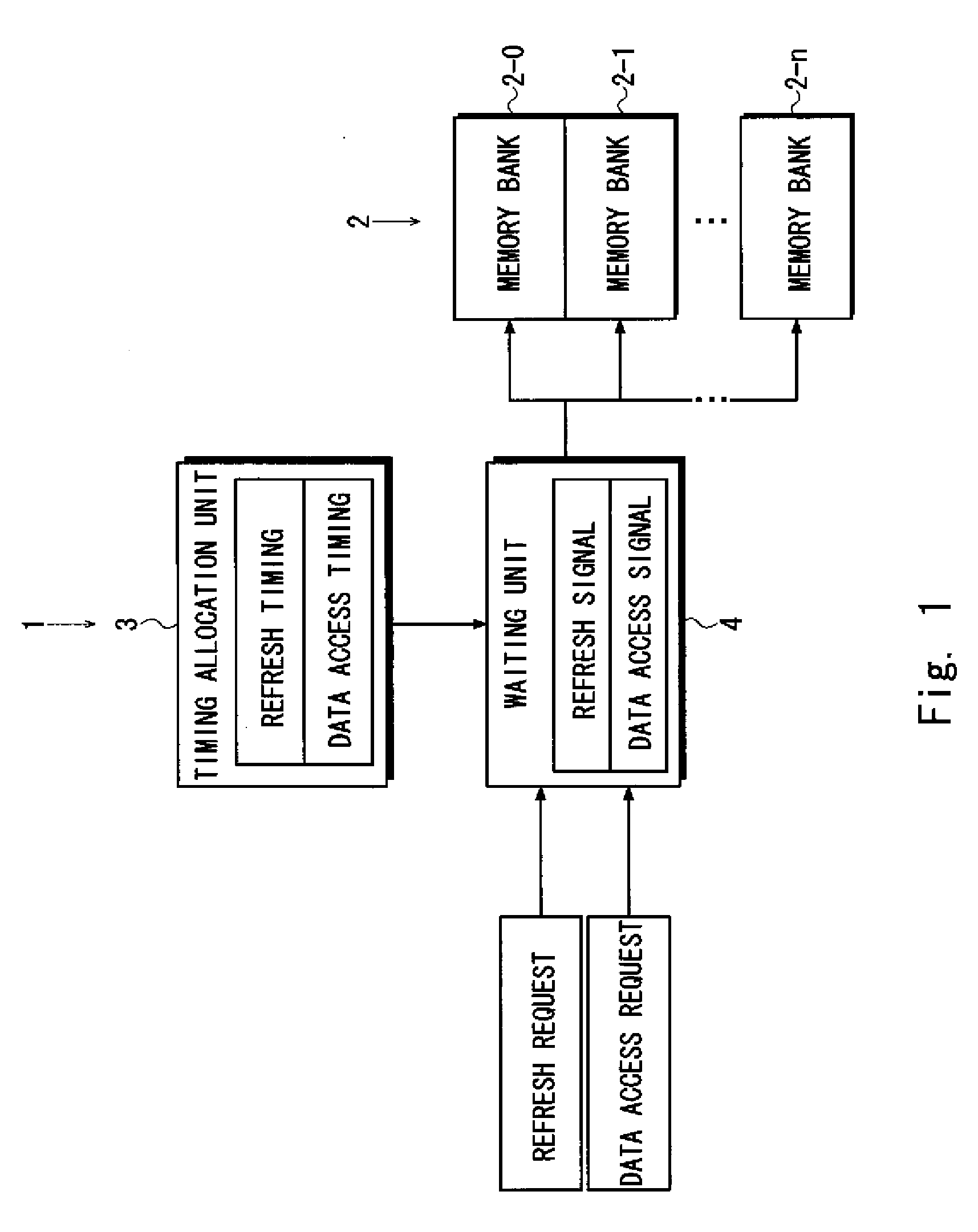

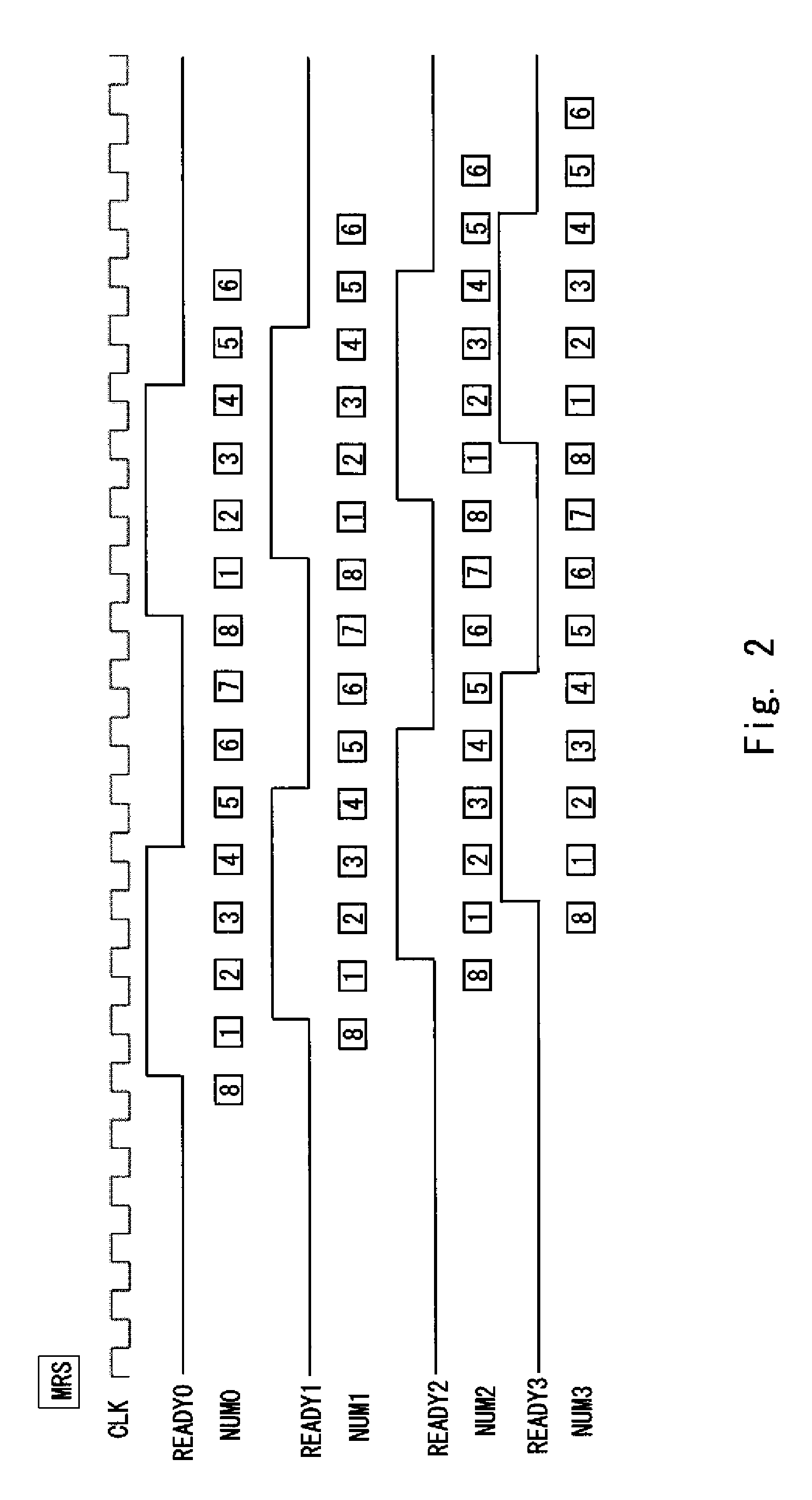

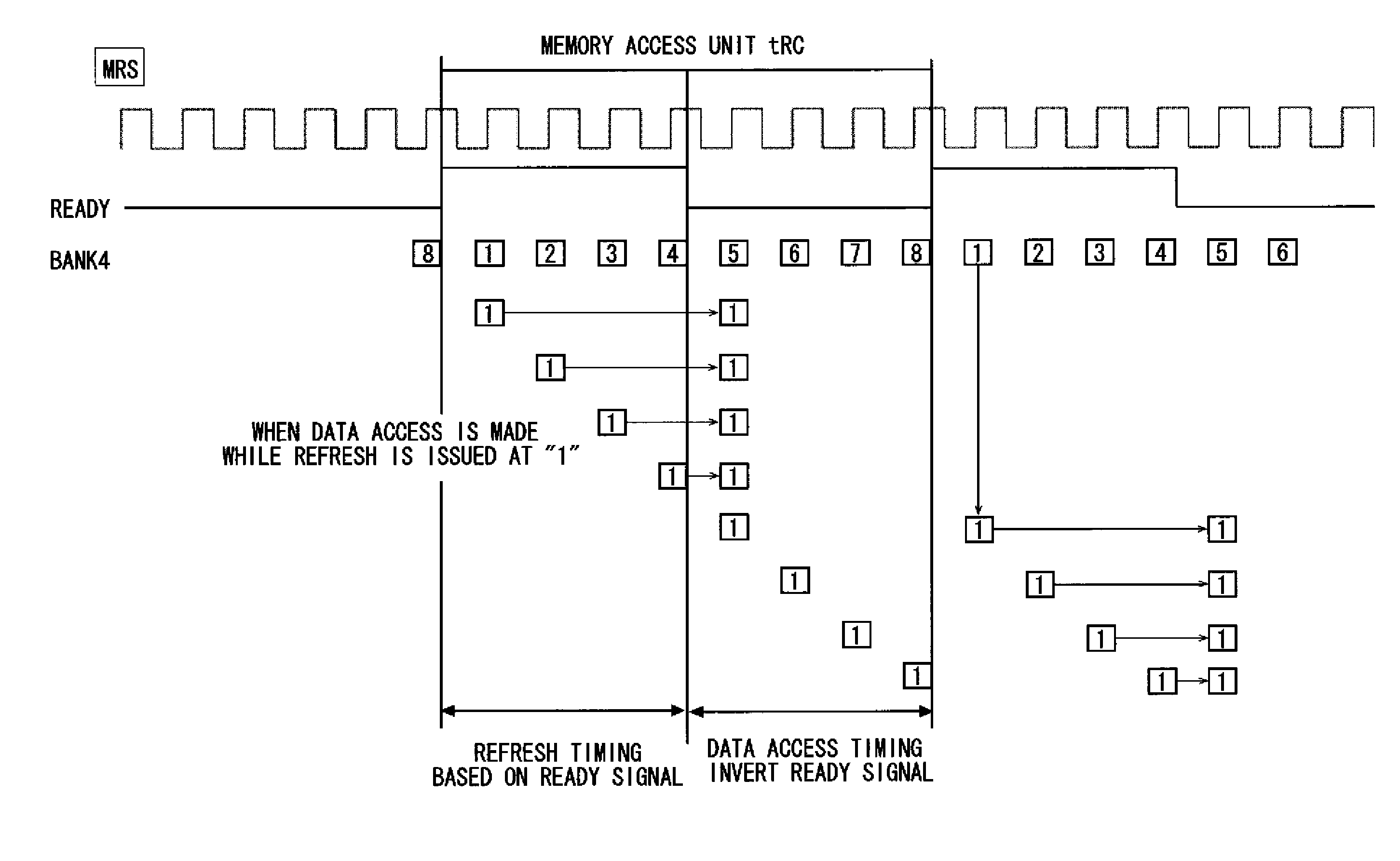

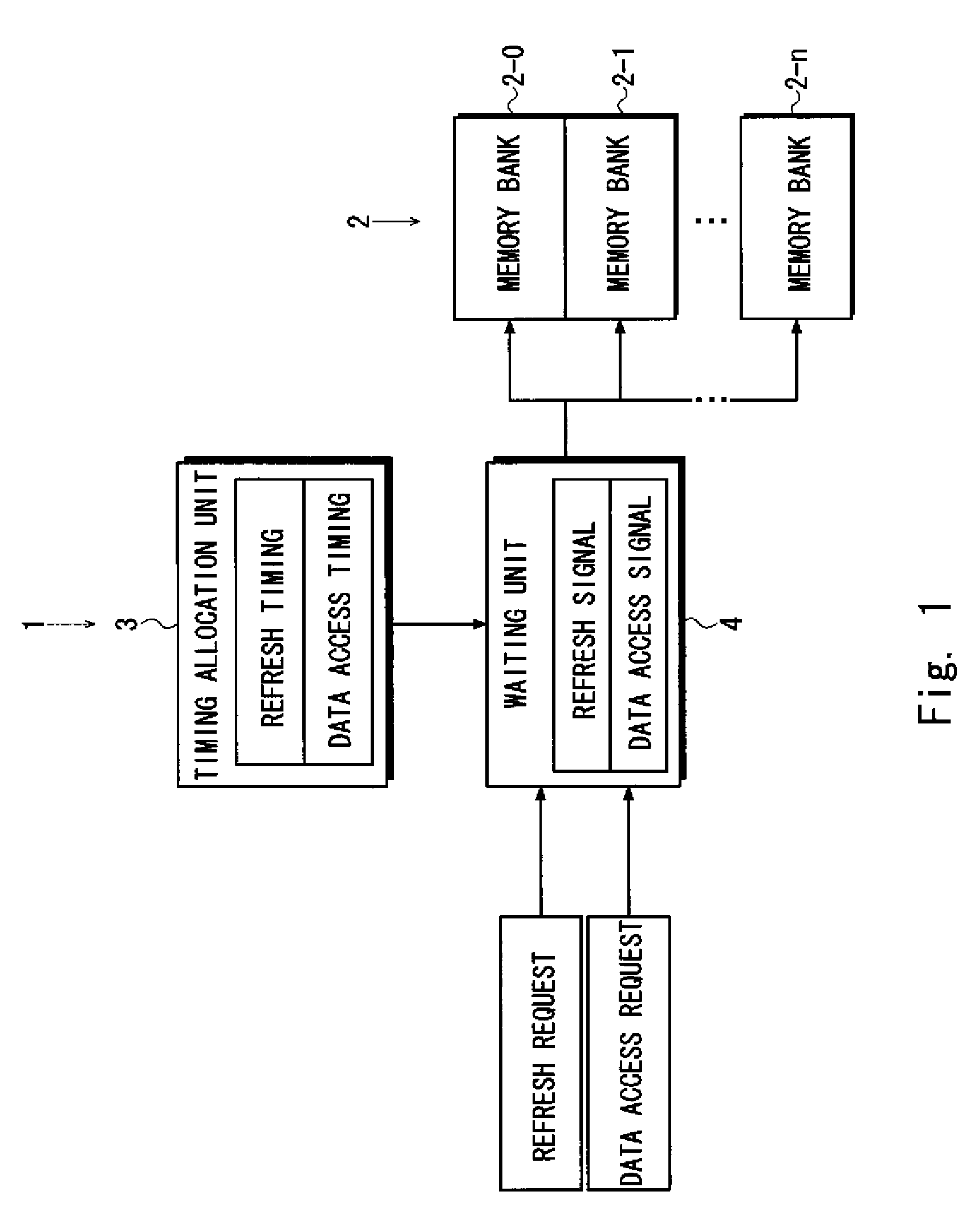

Semiconductor storage device and control method of the same

A semiconductor storage device includes a timing allocation unit that sets refresh timing to preferentially perform a refresh operation for maintaining data and data access timing to preferentially perform a data access operation for reading or writing the data in accordance with a clock signal with respect to each memory bank including a plurality of memory cells, and a waiting unit that waits start of the data access operation until the data access timing is started in a case where a request for the data access operation is made during the refresh timing and waits start of the refresh operation until the refresh timing is started in a case where a request for the refresh operation is made during the data access timing.

Owner:RENESAS ELECTRONICS CORP

Transport device

ActiveUS8069969B2Improve throughput speedShorten the switching timeBuilding roofsRoof covering using slabs/sheetsEngineeringMechanical engineering

A transport device for objects comprises a frame with a series of carriers that run mutually parallel and are pivotally coupled to an endless drivable moving track so as to enable displacement in a direction of displacement. At least some of the carriers comprise pusher shoes with guiding construction that are shiftable along the relevant carriers transversely of the direction of displacement using guide means arranged on the frame. The guiding construction comprises a guide pin with a guide body arranged thereon, wherein the guide pin comprises at least two portions of differing diameter, that the guide means comprise a guide channel in which the guide pin can engage, and that the depth of the guide channel progresses such that, at first engagement, the portion of the guide pin with the largest diameter engages in the guide channel, and with further engagement a portion with a smaller diameter.

Owner:VAN RIET EQUIP

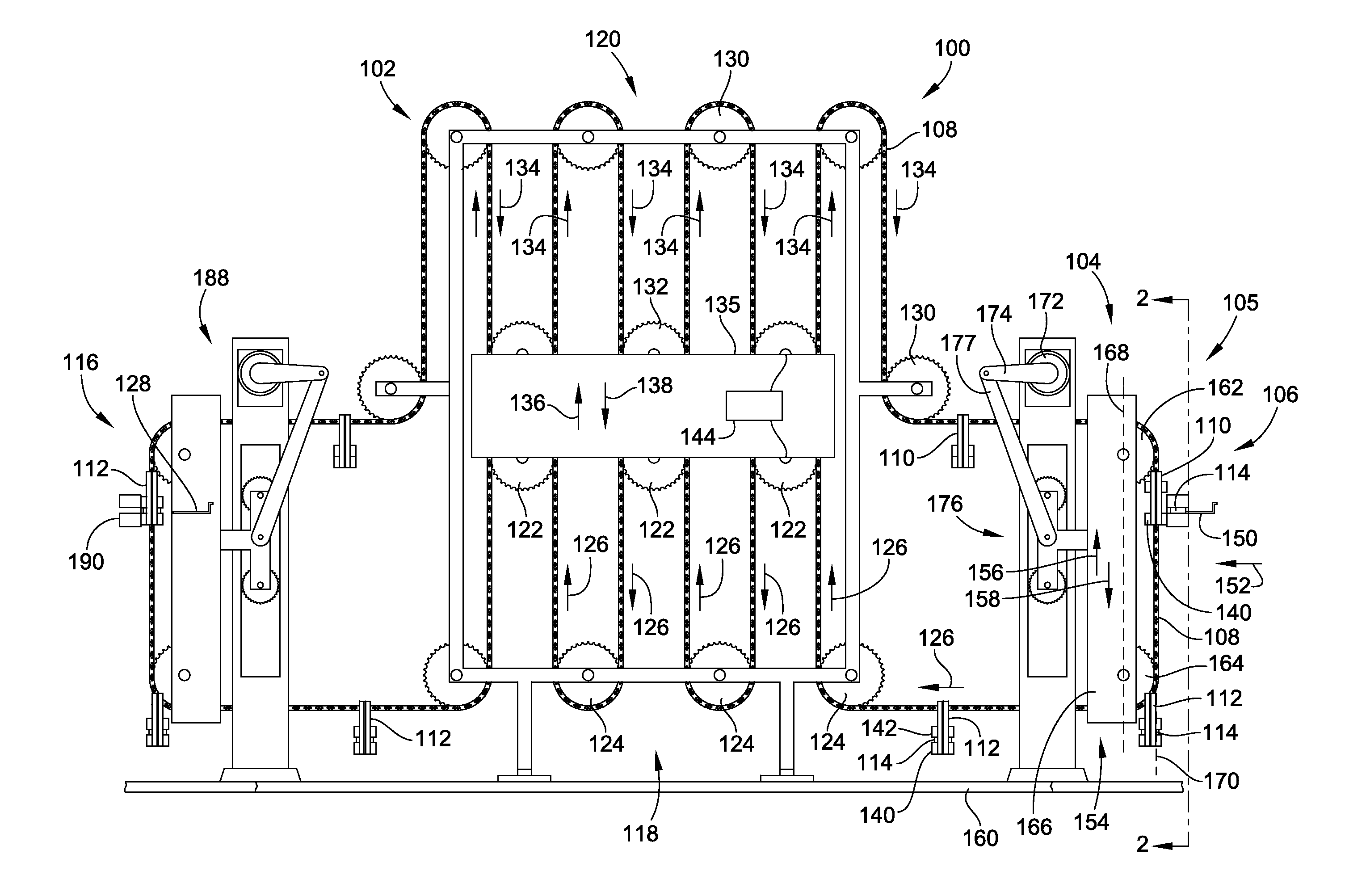

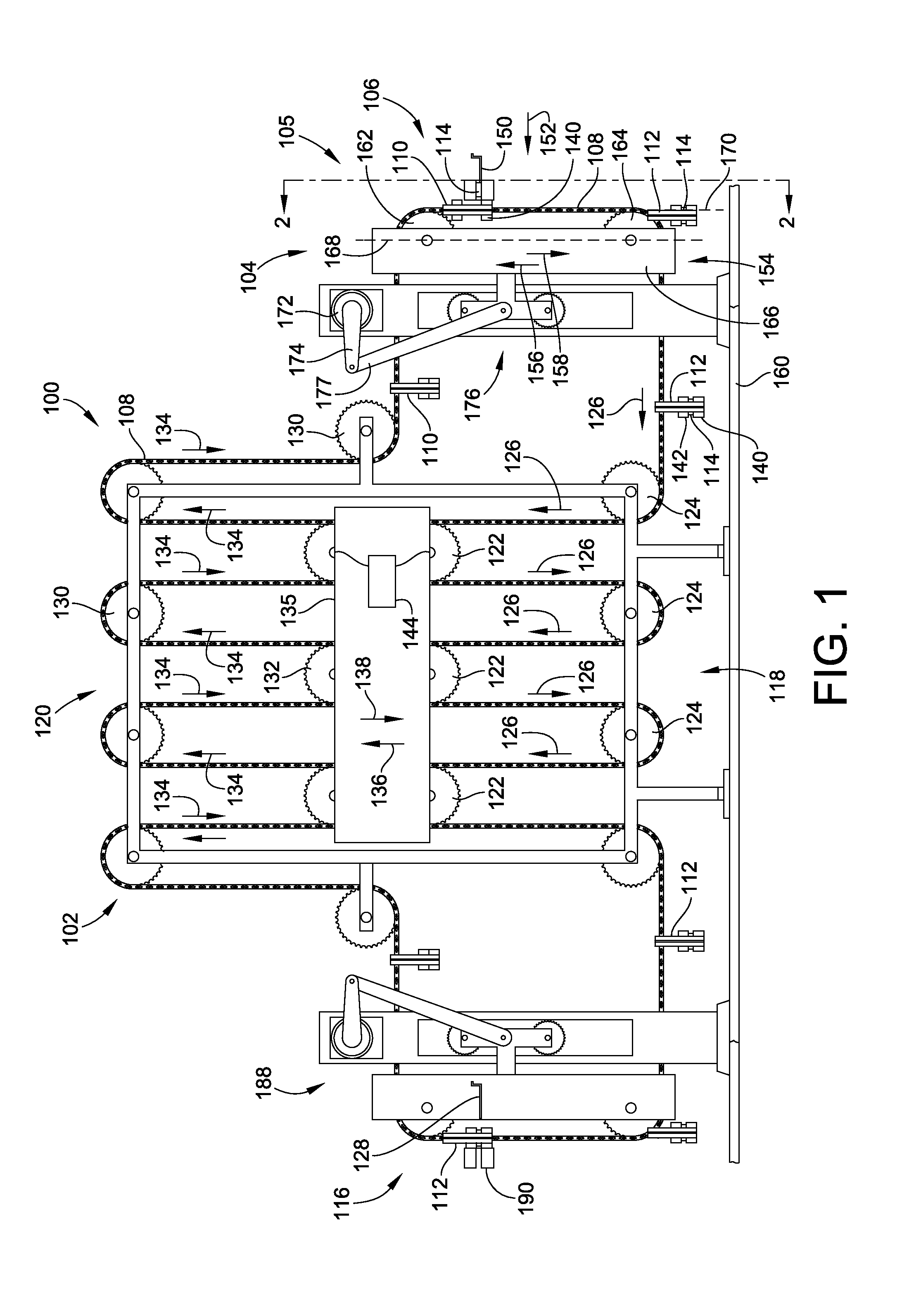

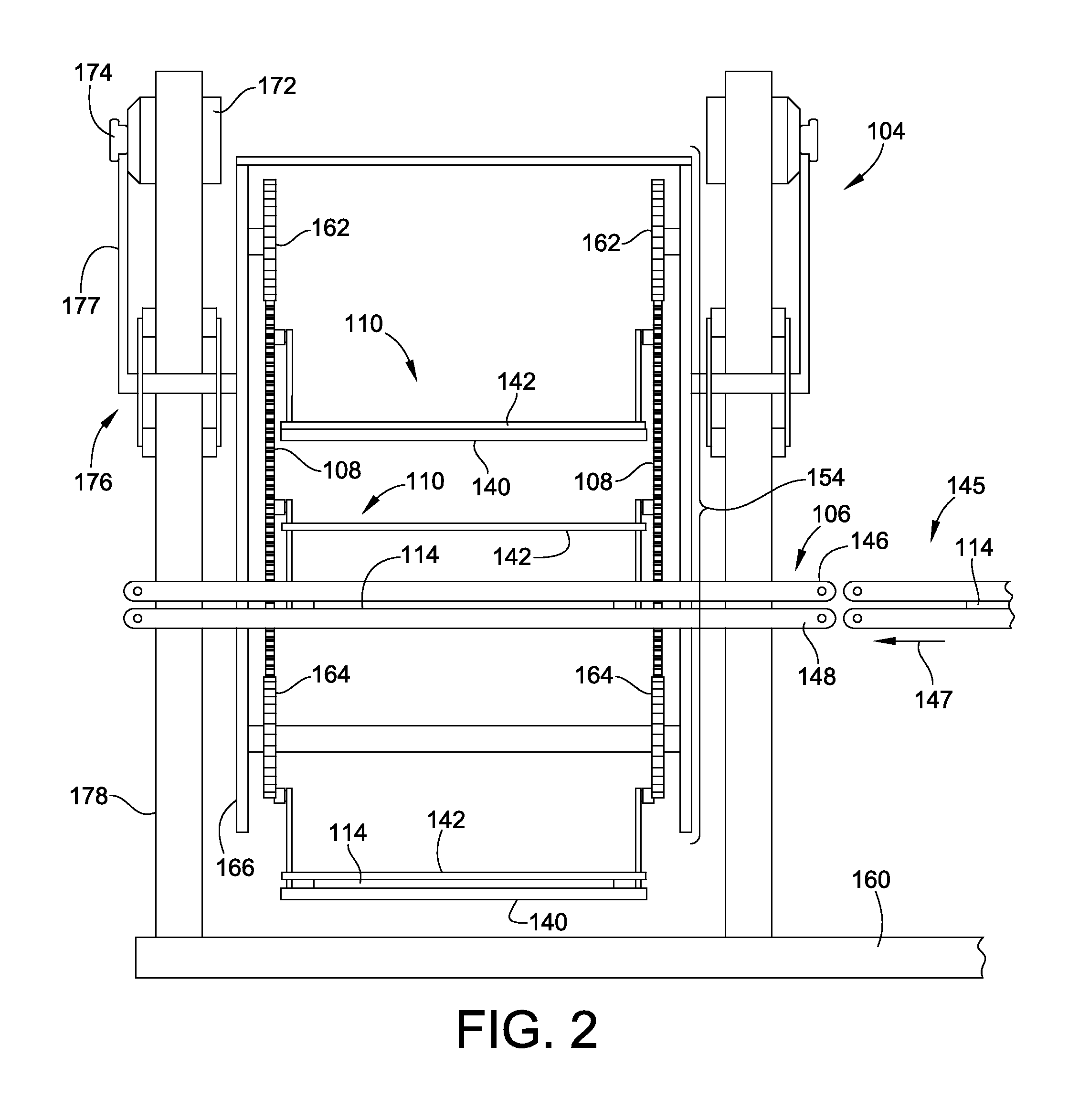

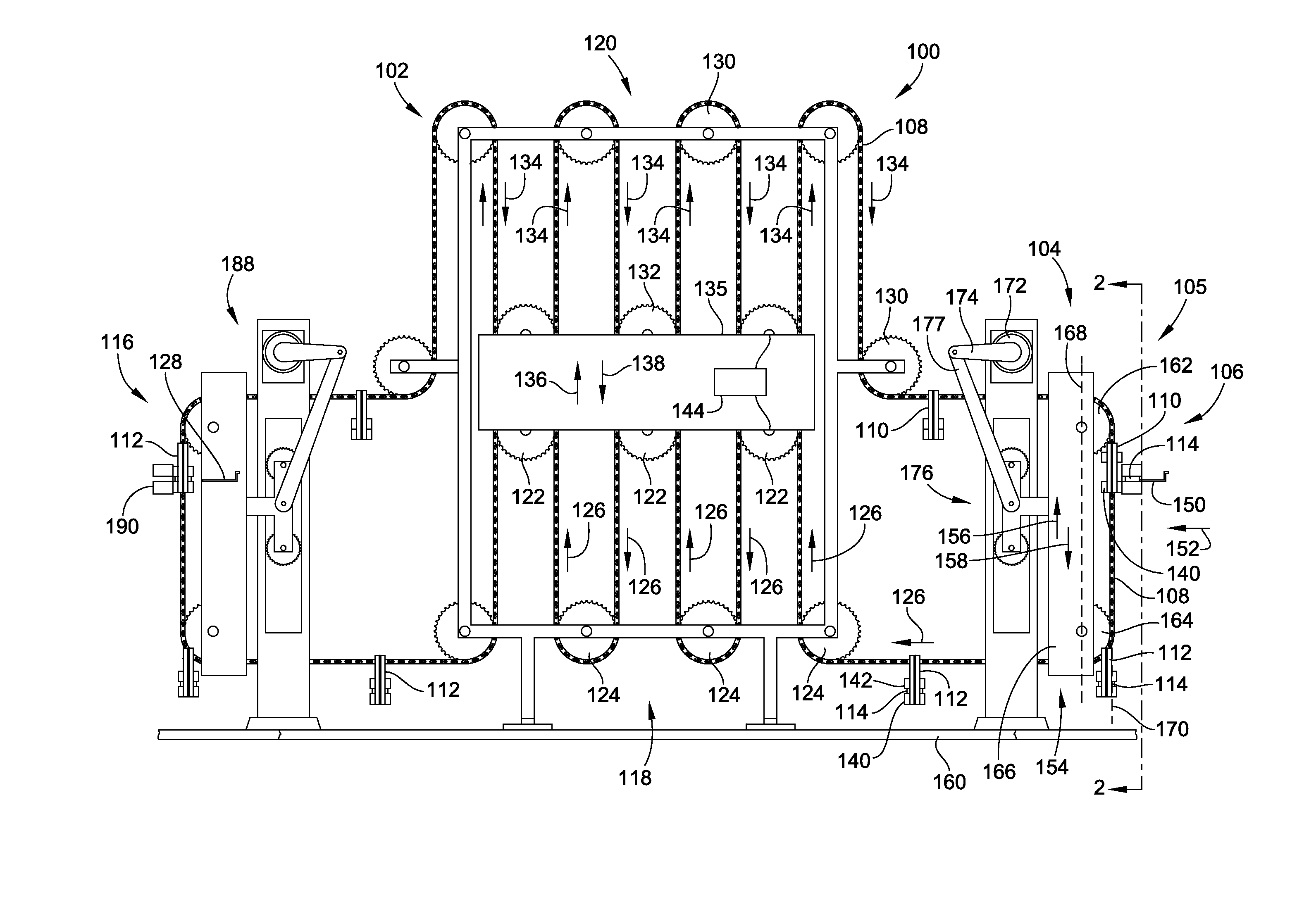

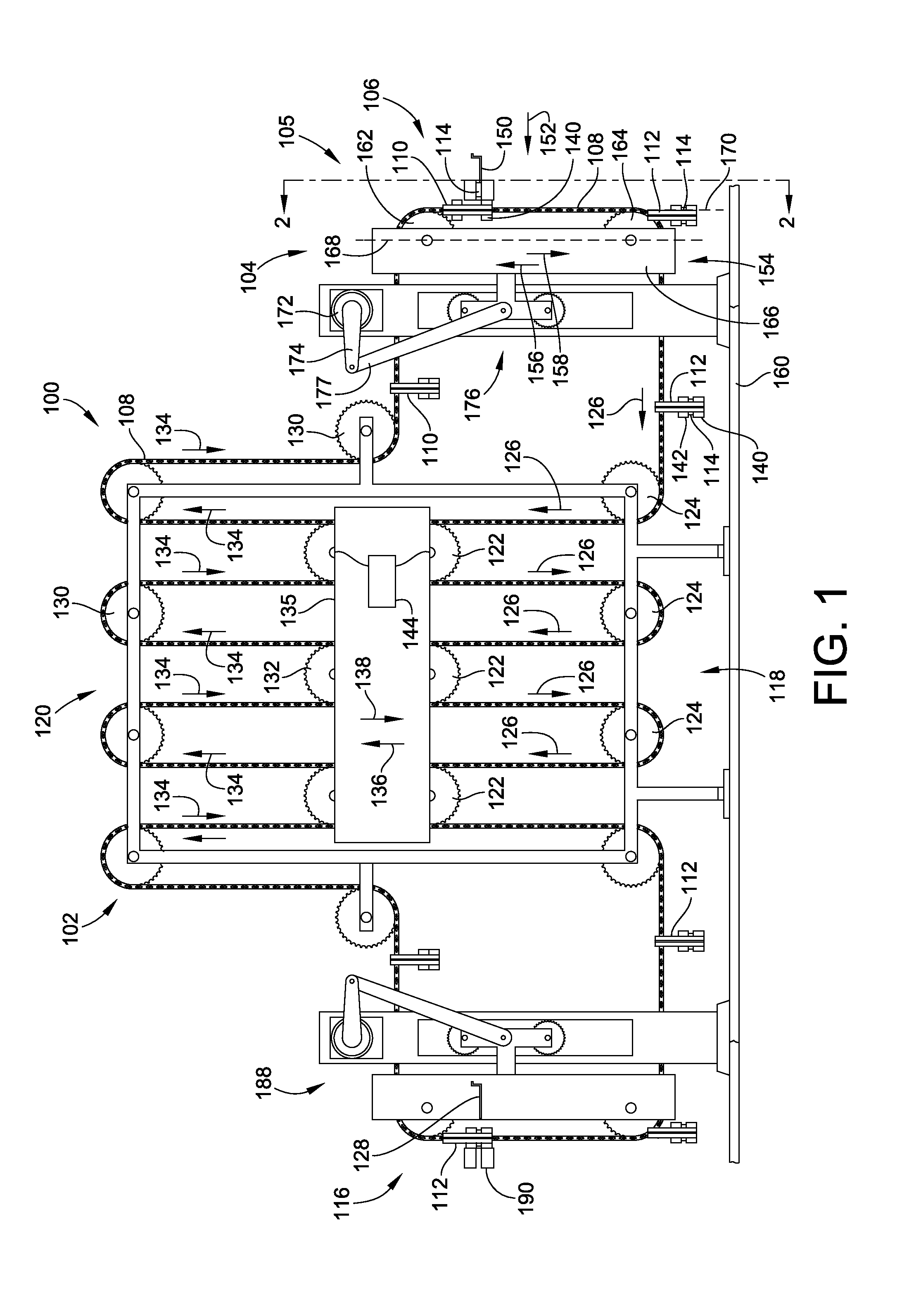

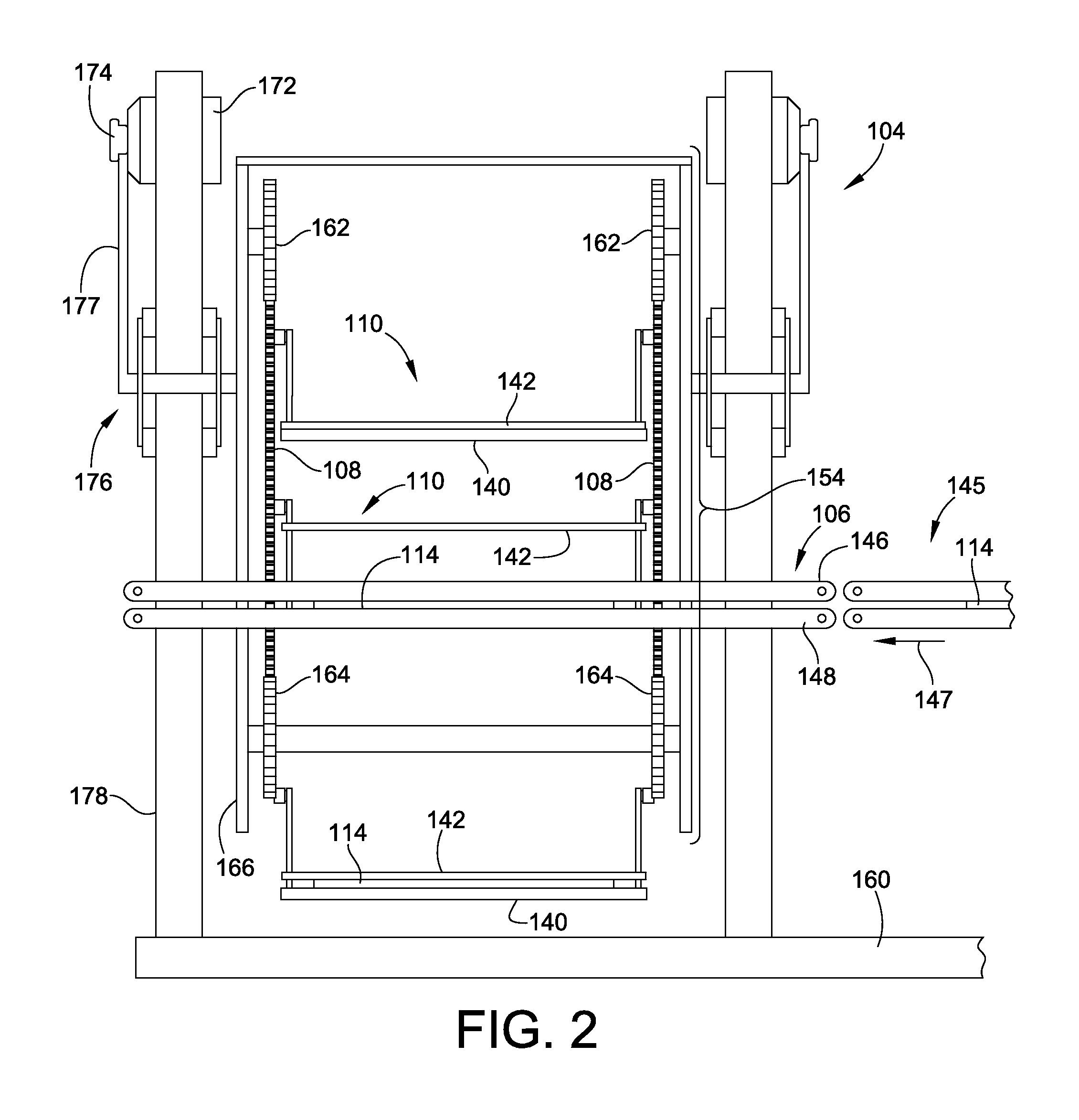

High speed interfolded log accumulator

ActiveUS20120163944A1Improve throughput speedAvoid swingingSemiconductor/solid-state device manufacturingStorage devicesTransport systemEngineering

A log accumulator comprising a plurality of buckets, a feed arrangement and a transport system and methods are provided. The feed arrangement loads logs onto the buckets. The transport system transports the buckets past the feed arrangement for loading of the buckets. The transport system and the feed arrangement are configured to maintain the feed arrangement in a fixed relative position with one of the buckets for an extended period of time while the feed arrangement loads the one of the buckets. The accumulator may include an unload arrangement that operates to unload logs in substantially the same manner as the feed arrangement.

Owner:C G BRETTING MFG

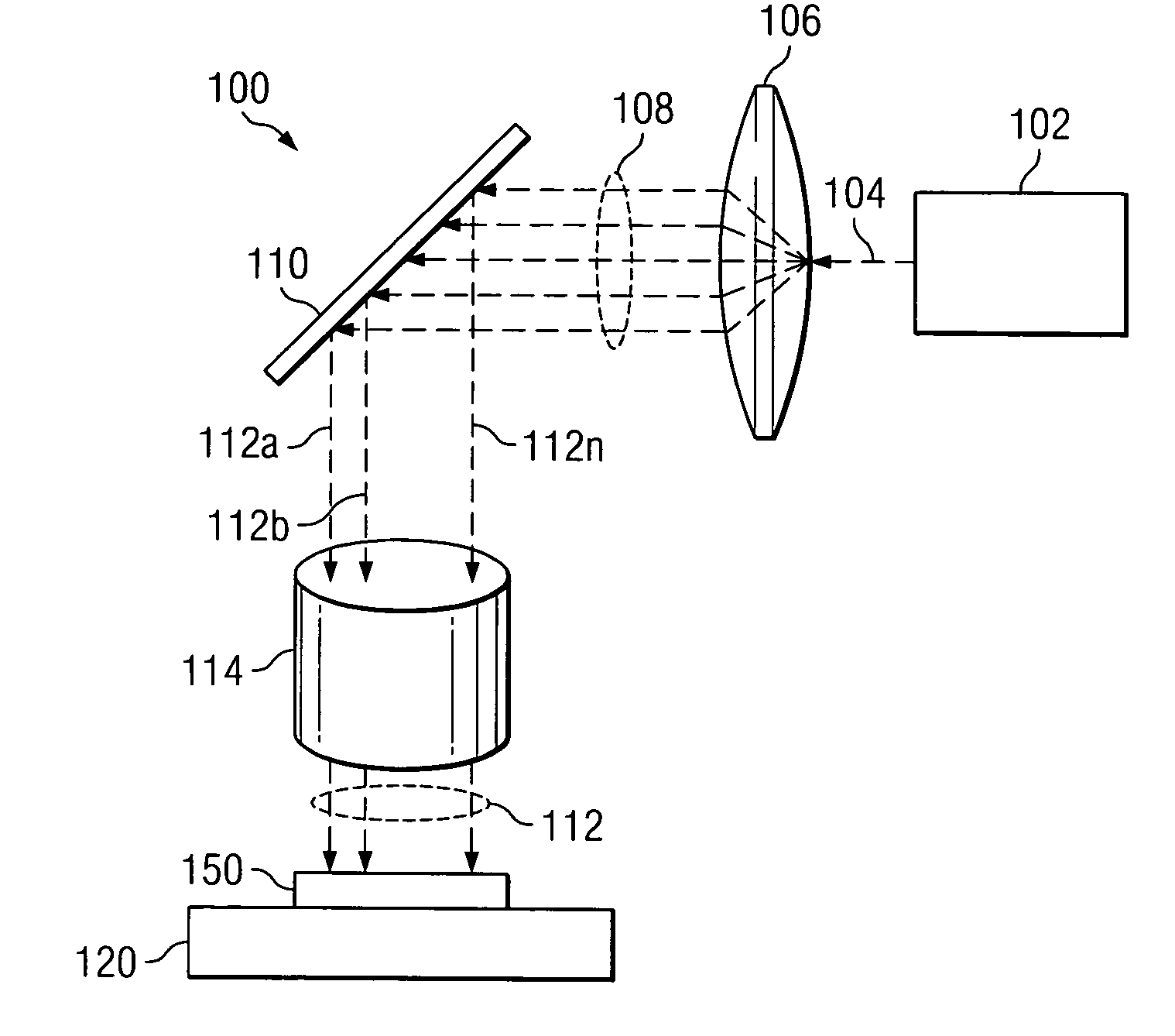

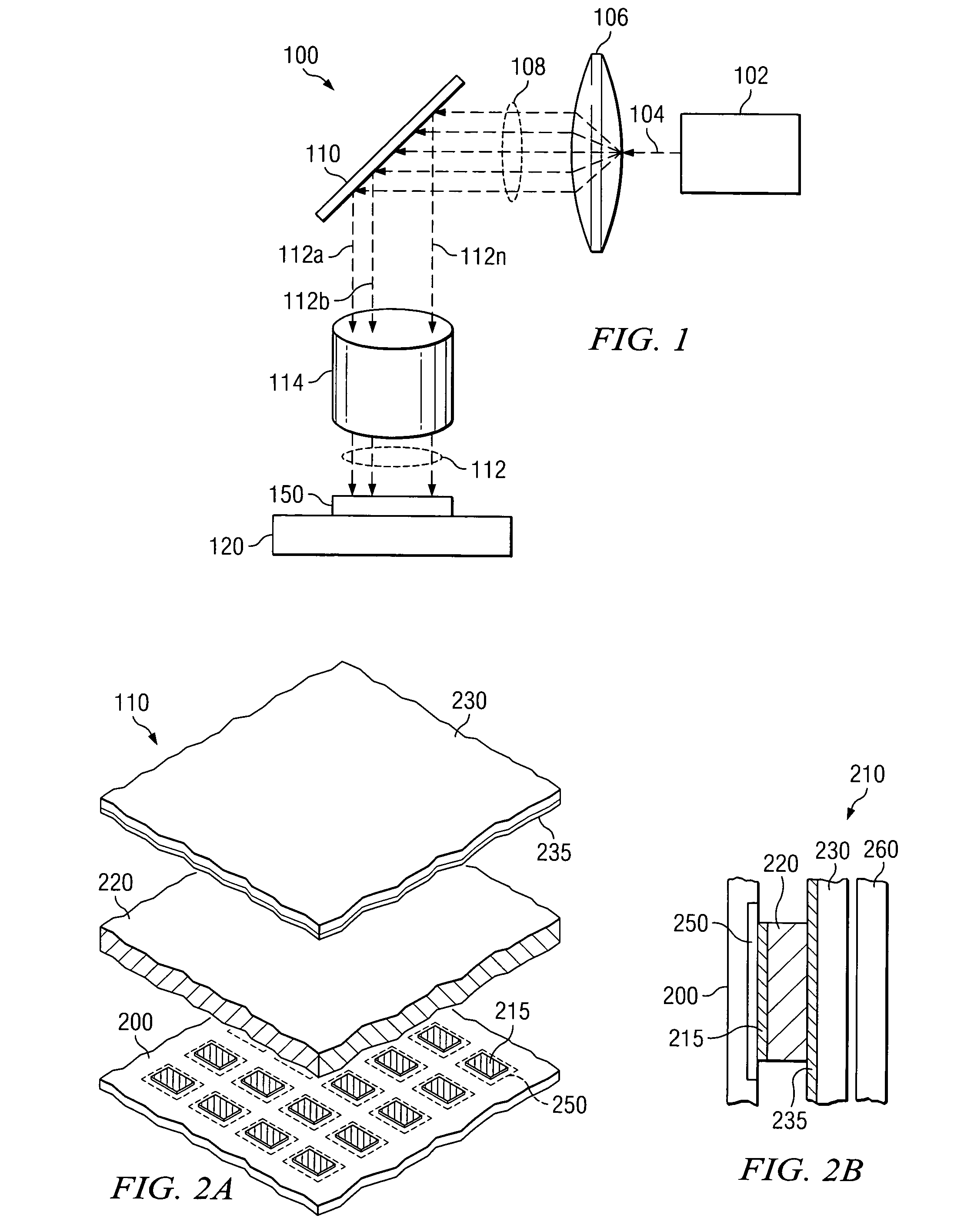

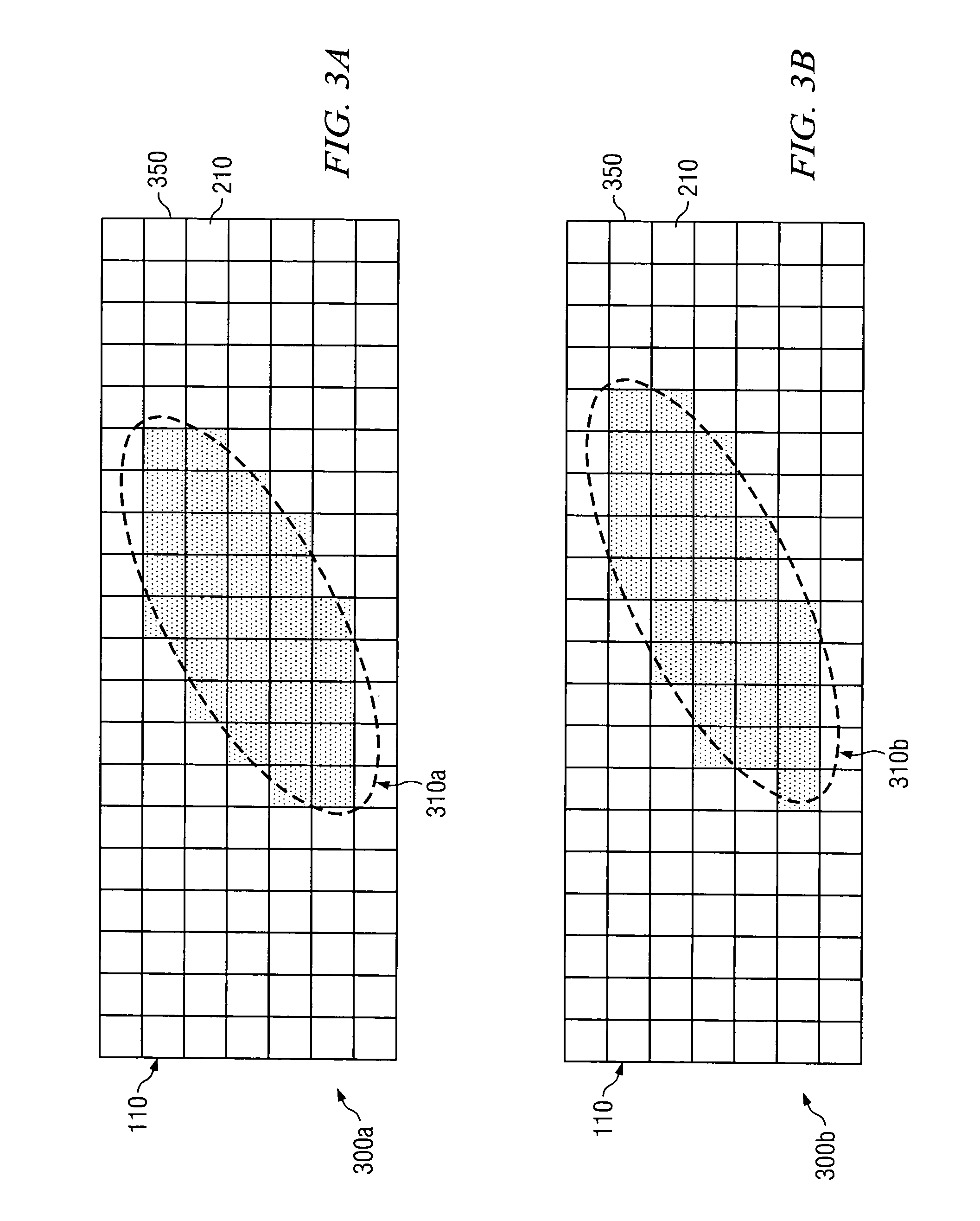

Real time image resizing for dynamic digital photolithography

InactiveUS7006196B2Low costImprove throughput speedCathode-ray tube indicatorsPhotomechanical exposure apparatusSpatial light modulatorComputer graphics (images)

A dynamic photolithography system resizes a pattern in real time and photolithographically transfers an image of the resized pattern onto a surface to compensate for distortions in the surface and / or optics. The system uses two or more pre-stored spatially offset renderings of the pattern. Each spatially offset rendering includes pixel data identifying light modulation elements within a spatial light modulator representing the pattern. The pattern is spatially offset between the renderings. Portions of the two or more spatially offset renderings are selected as a function of the distortion to resize the pattern and photolithographically transfer the image of the resized pattern onto the surface.

Owner:AGILENT TECH INC

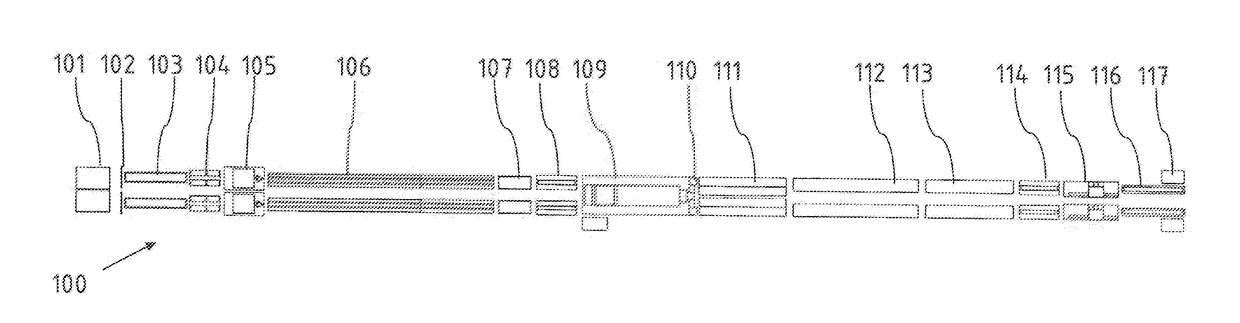

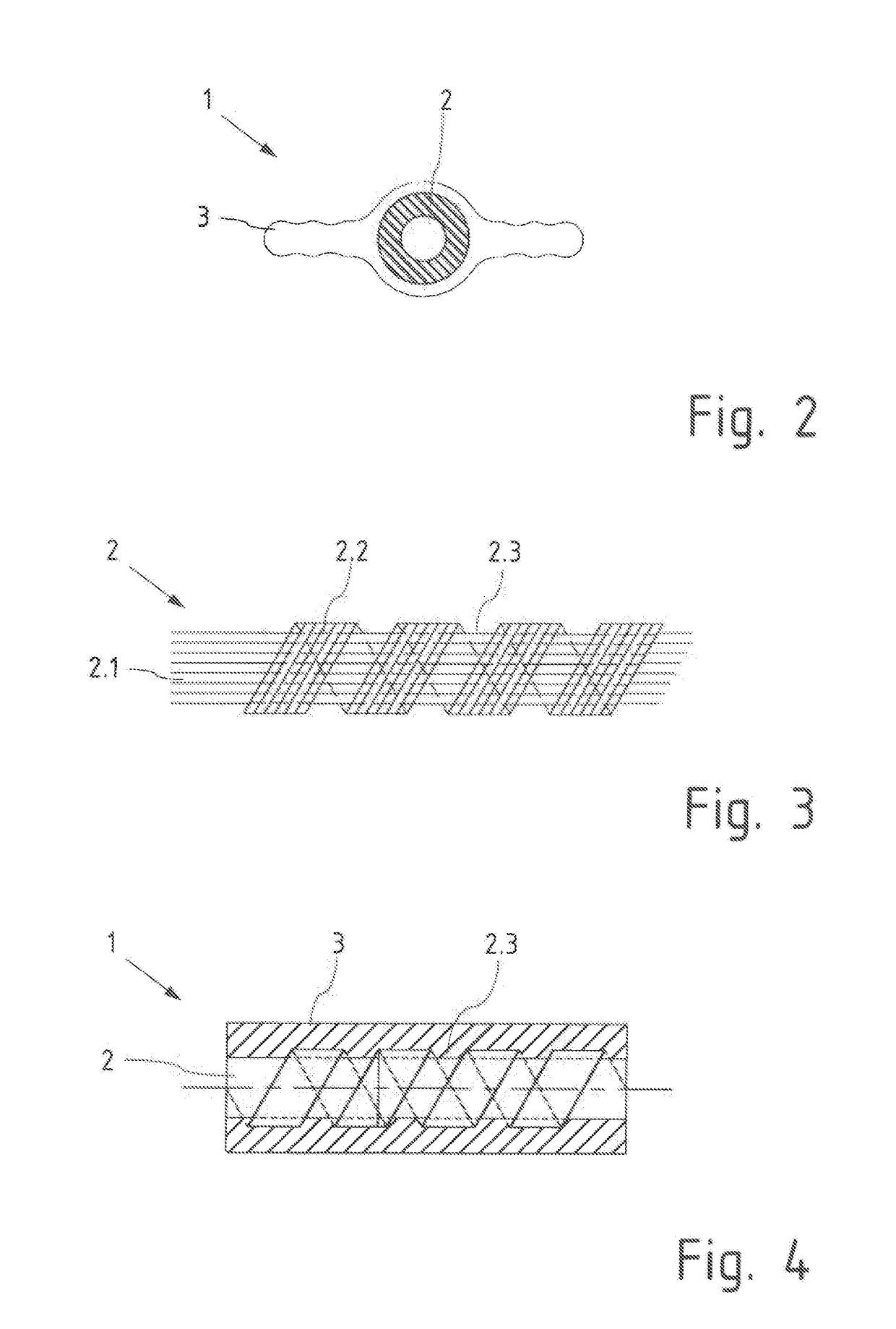

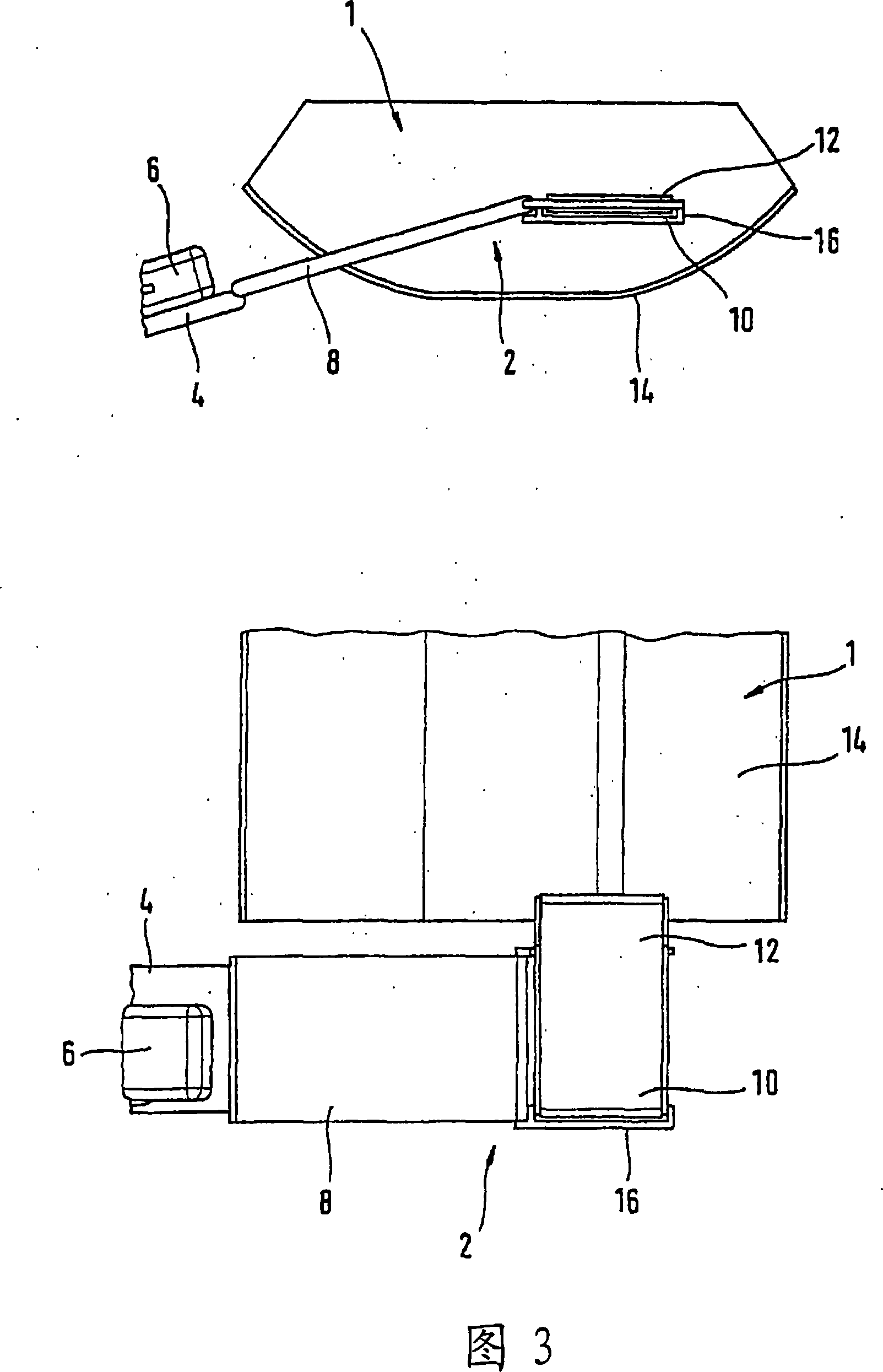

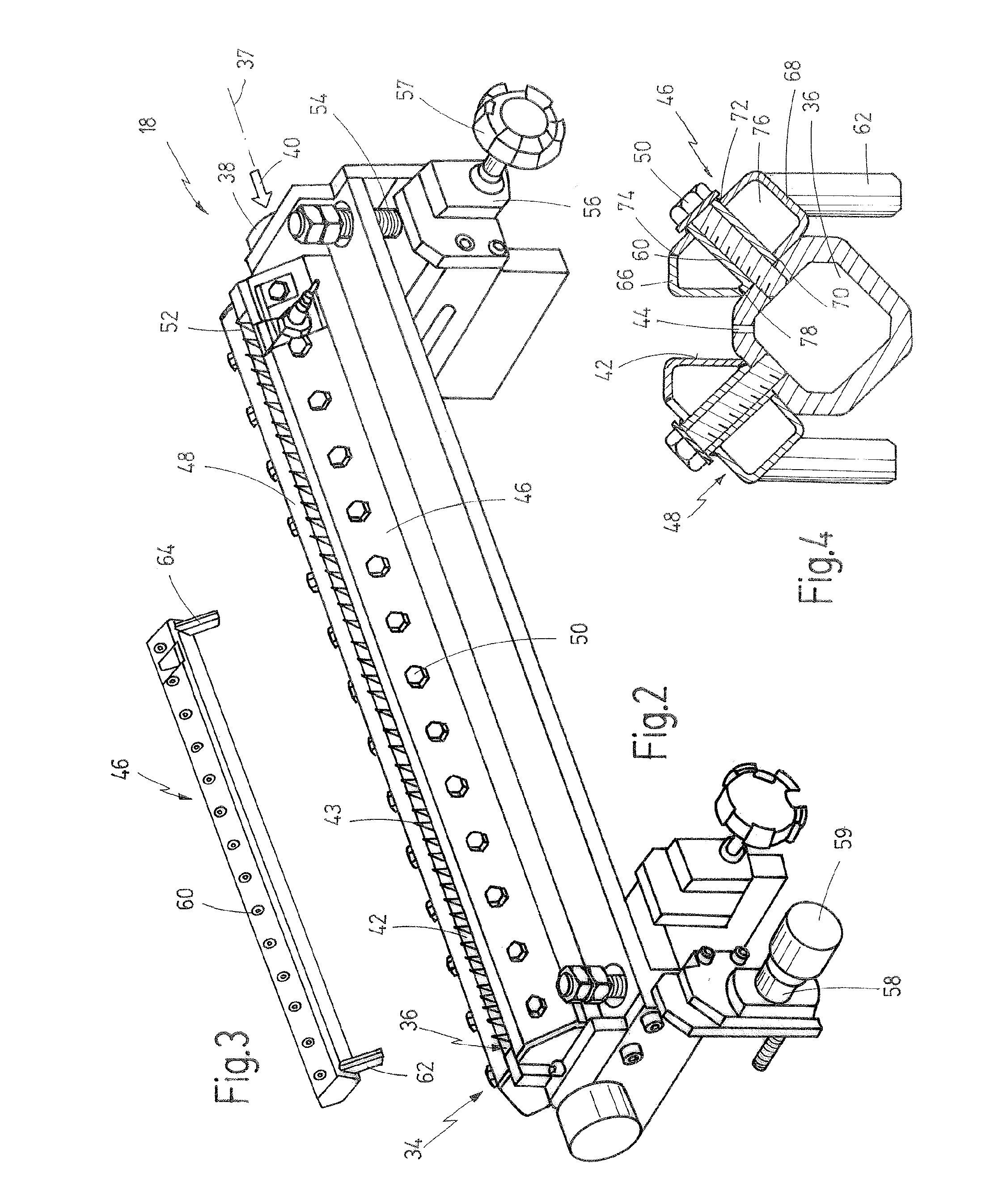

Inline method for producing a spring strip profile for a slatted frame

ActiveUS20180289173A1Improve throughput speedCheap to prepareSpring mattressesCoatingsWinding machineFiber bundle

An inline method for producing a spring strip profile (1) for a slatted frame that comprises at least one core strand (2) formed by a fiber-reinforced plastic and at least one thermoplastic cover layer (3) surrounding the core strand (2), comprises at least the following steps: joining multiple fibers, threads and / or filaments to form a fiber bundle (2.1); impregnating the fiber bundle (2.1) with a thermally activatable reaction resin; molding the outer contour of the fiber bundle (2.1) impregnated with the reaction resin; thermally activating the reaction resin (2.1) to form a cured core strand; introducing the core strand (2) into an extruder head (110); applying thermoplastic melt in the extruder head (110) to form the cover layer (3) on the spring strip profile (1); and cooling and calibrating the spring strip profile (1) in a cooling and calibrating device (111, 112, 113). The outer contour of the fiber bundle (2.1) is wrapped around, in a winding machine (105), by at least one thread or filament (2.2) supplied laterally in relation to the fiber bundle in at least one position and orientation, and, in a heating section (106), before the core strand (2) is introduced into the extruder head (110), at least a partial curing of the reaction resin is achieved, at least in the wrapped outer layer of the fiber bundle (2.1).

Owner:OKE GROUP

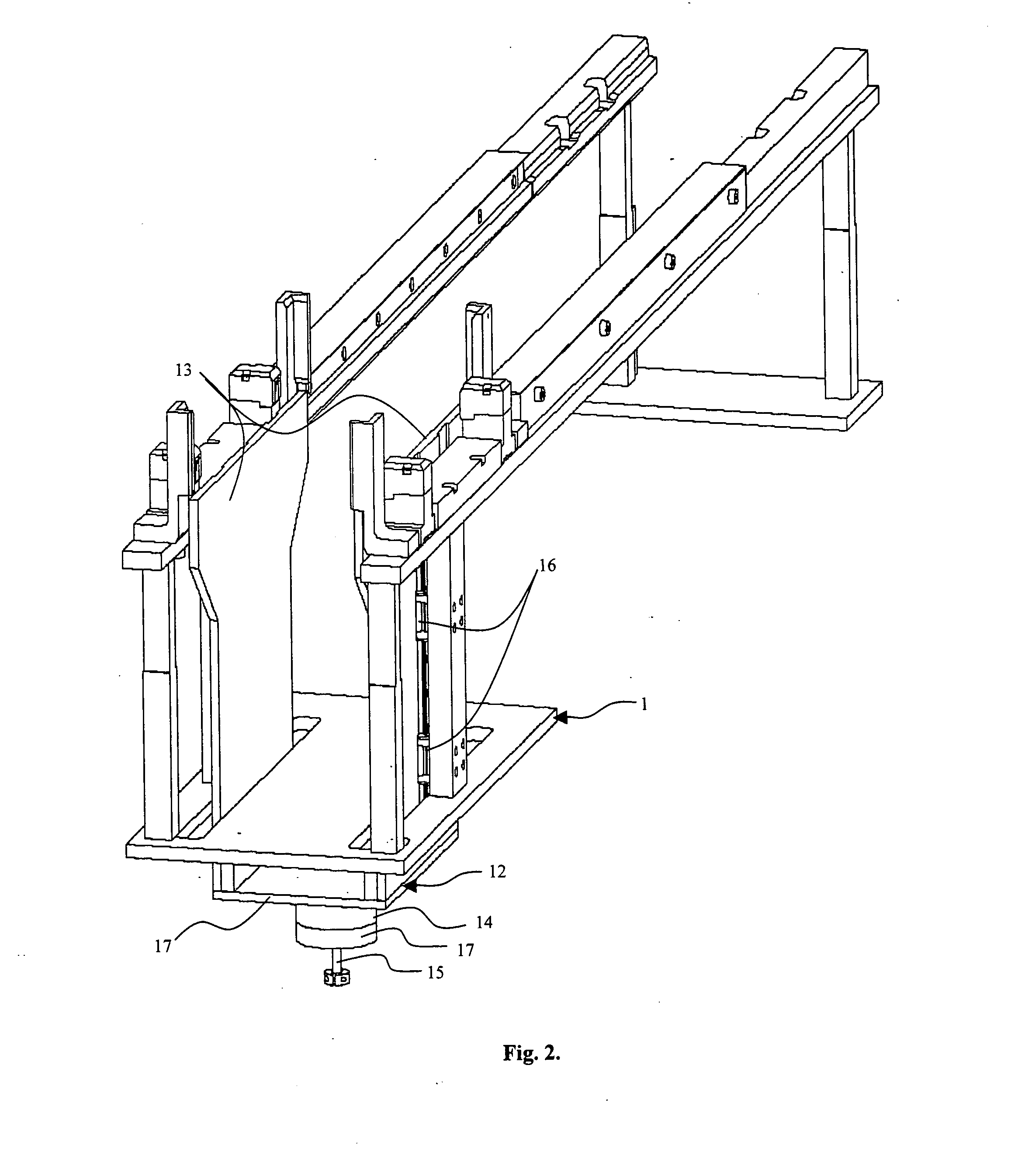

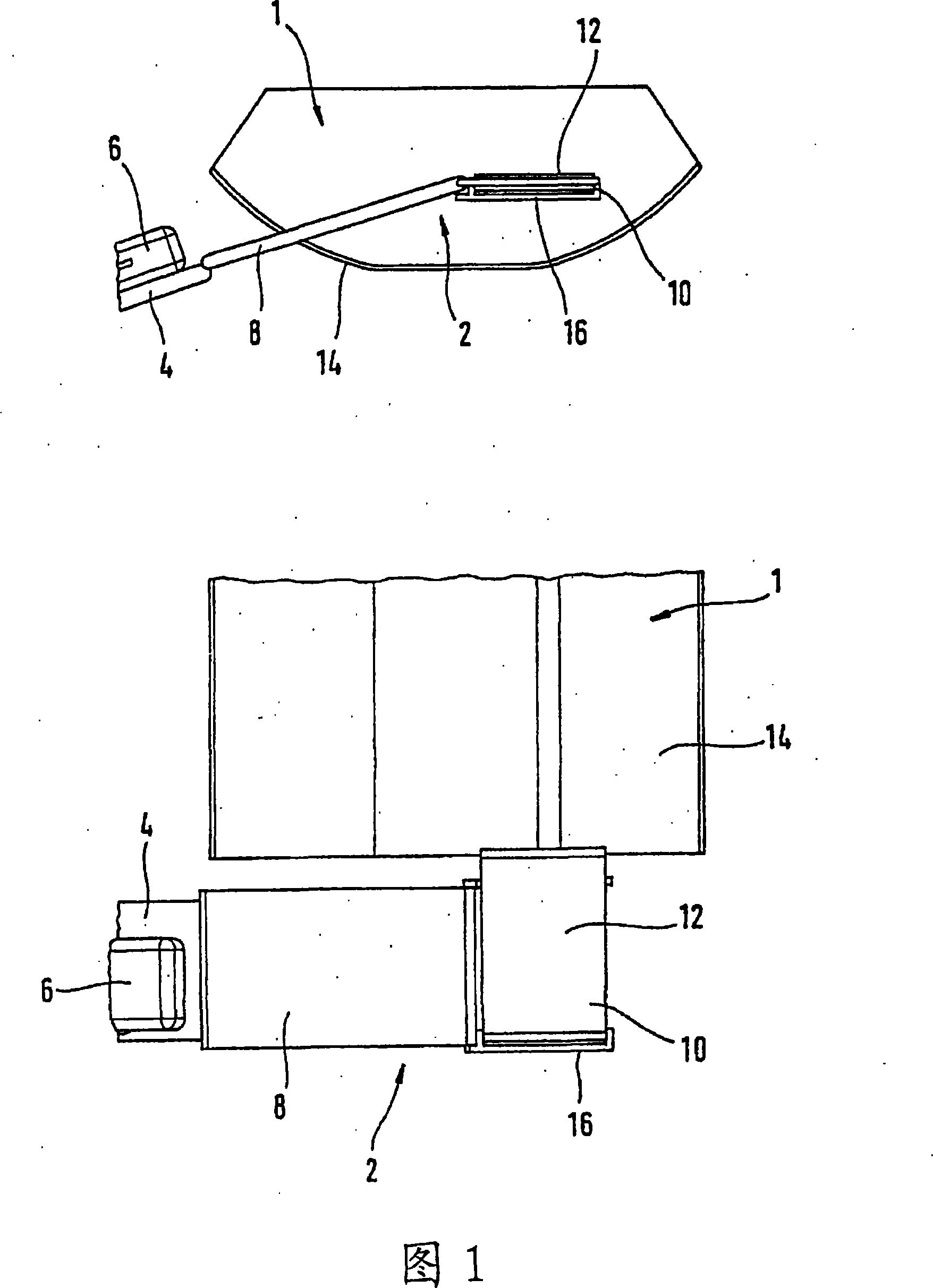

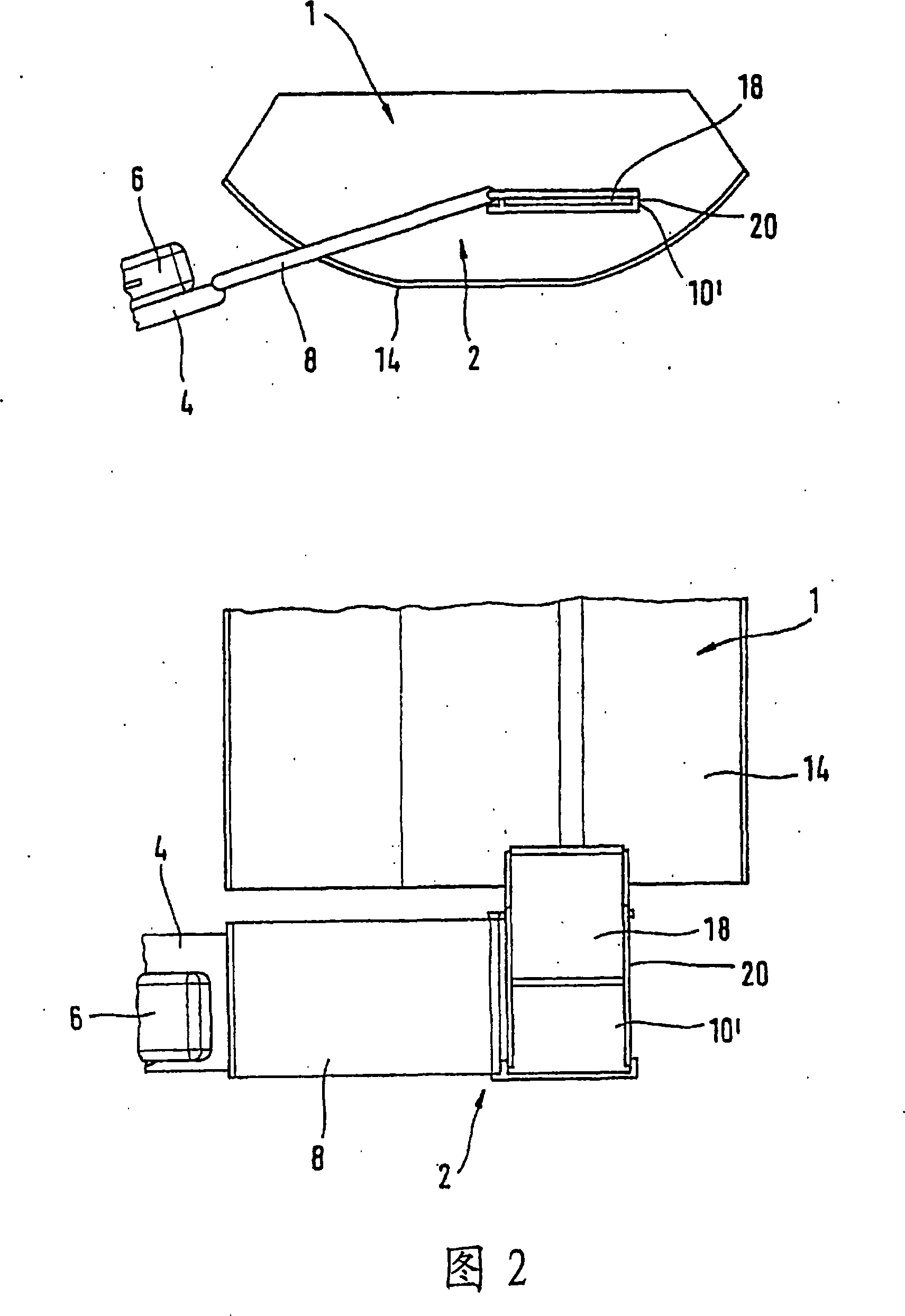

System for loading and unloading unpakced cargo and intermediate transport device or unit

InactiveCN101239658AEliminate dangerImprove throughput speedWeight reductionFreight handling installationsFuselageAirplane

The system for loading and unloading piece goods (6) in the cargo hold (1) of an aircraft has a transporting device (14) covering the floor of the cargo hold and a conveyor device (4) outside the vehicle and adjacent to the cargo hold opening. An intermediate conveyor unit (2) is provided between the aircraft side end of the outside conveyor device and the forward end of the transporting device in the cargo hold, and by which the cargo when loading is first conveyed in the transverse direction deeper into the fuselage of the aircraft and then in the longitudinal direction and is laid upon the forward end of the transporting unit in the cargo hold.

Owner:TELAIR INTERNATIONAL GMBH

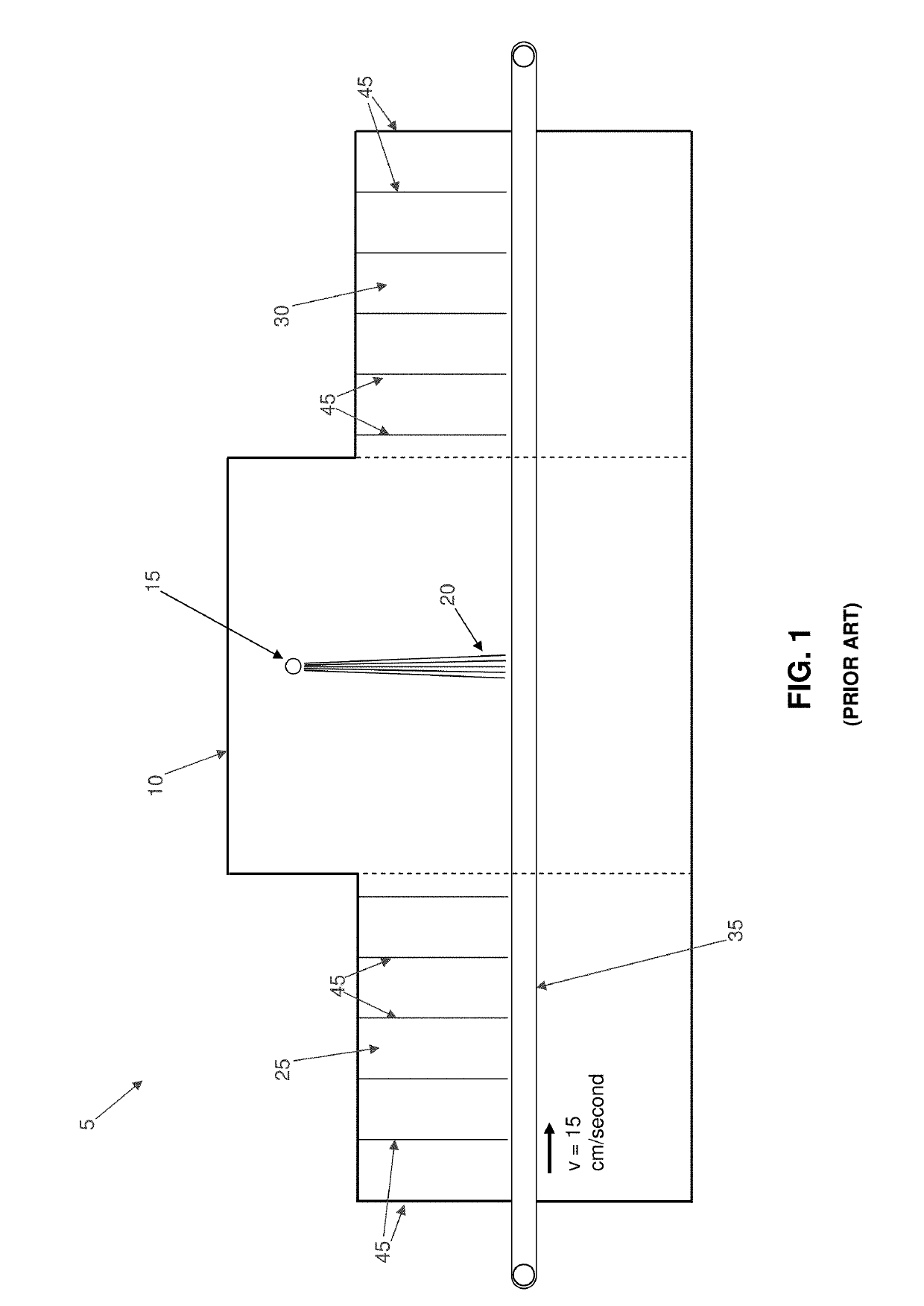

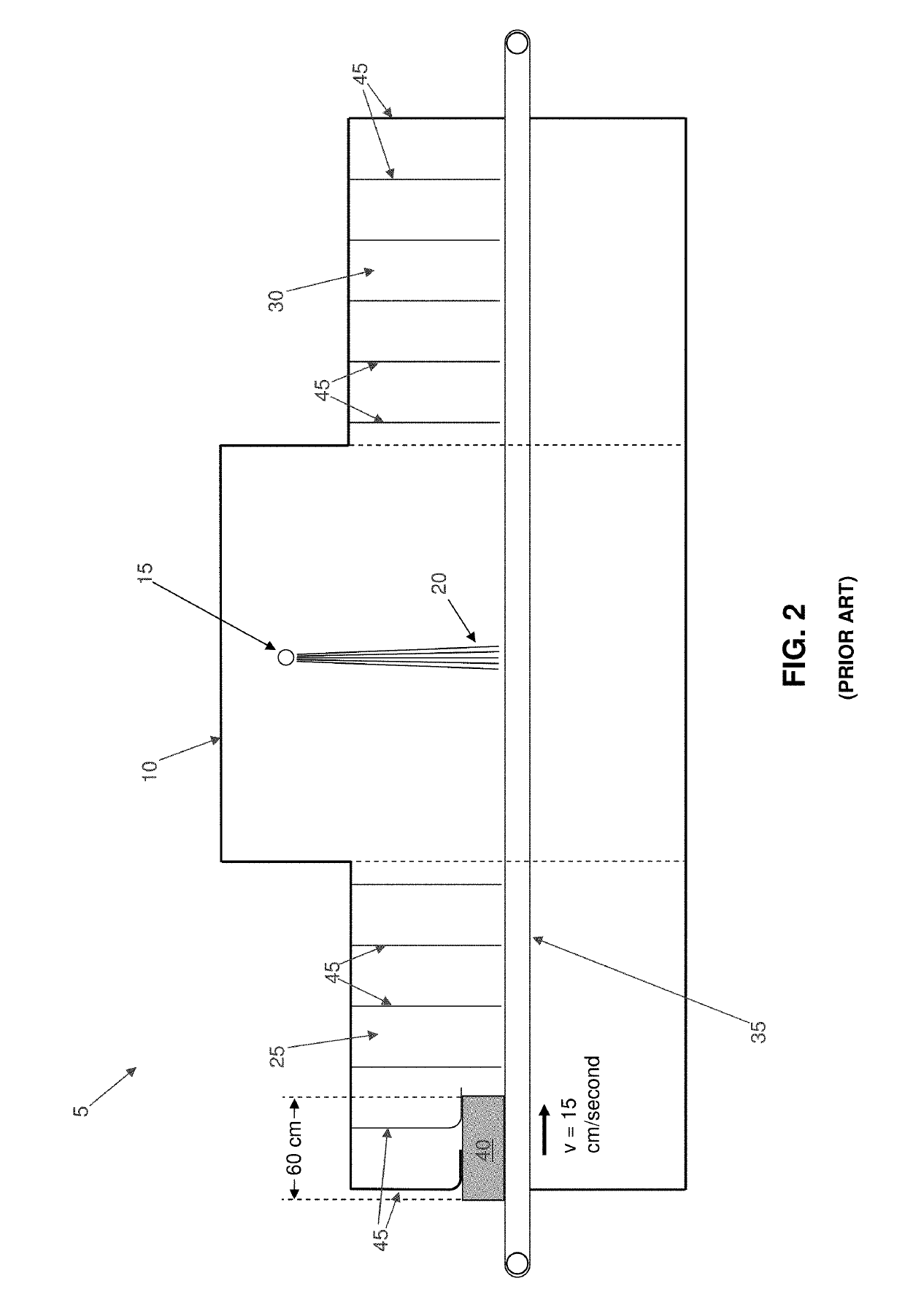

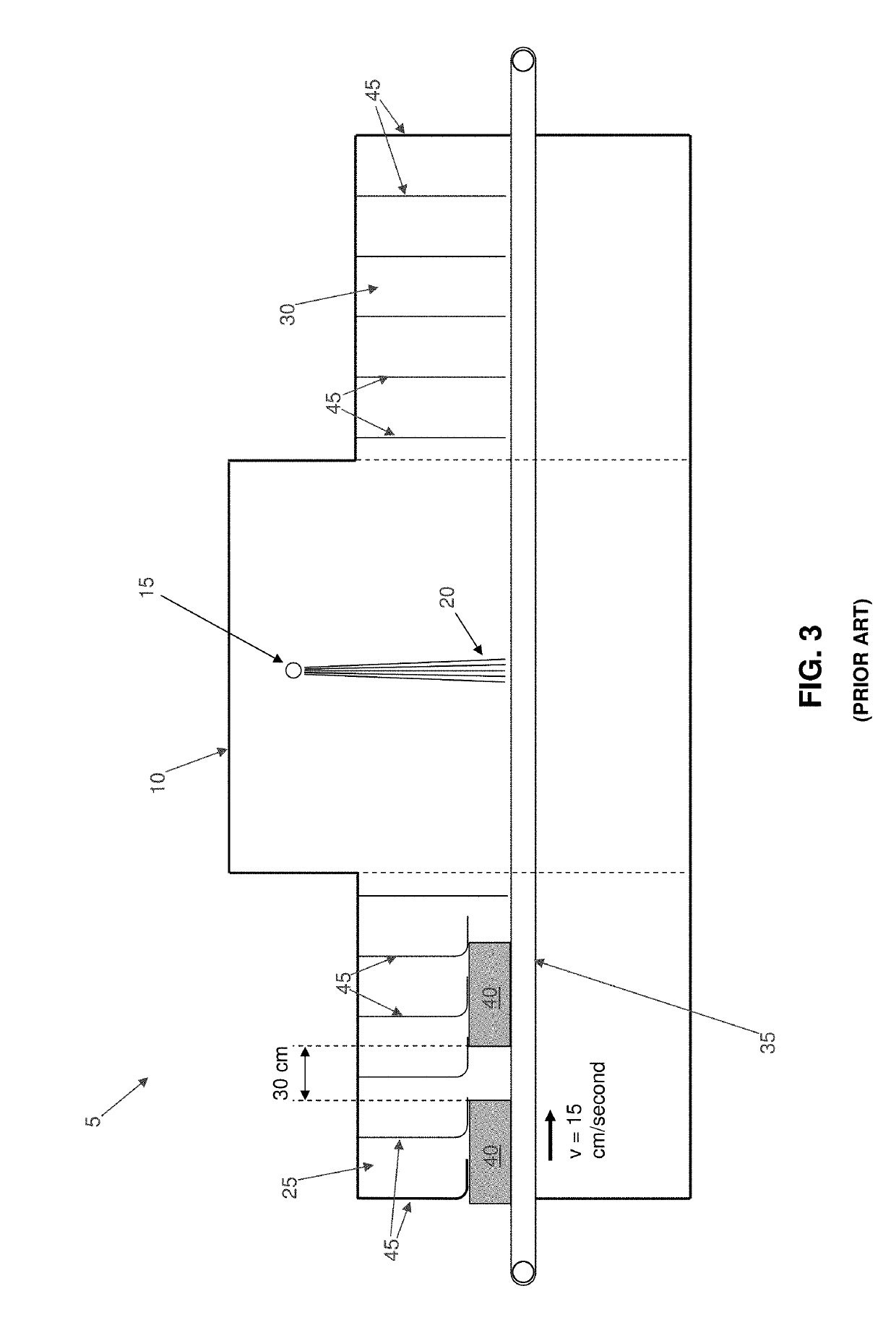

Computed tomography (CT) security inspection system with enhanced x-ray shielding

ActiveUS20190154869A1Improve throughput speedIncrease costMaterial analysis using wave/particle radiationShieldingSoft x rayComputed tomography

A method for scanning an object in an X-ray security inspection system, wherein the X-ray security inspection system comprises an ingoing tunnel equipped with radiation-shielding curtains, an X-ray section and an outgoing tunnel equipped with radiation-shielding curtains, the method comprising: passing the object through the ingoing tunnel at a first rate of speed and with a first extent of separation between successive objects; passing the object through the X-ray section at a second rate of speed and with a second extent of separation between successive objects; and passing the object through the outgoing tunnel at a third rate of speed and with a third extent of separation between successive objects; wherein the second rate of speed is less than the first rate of speed and the third rate of speed, and wherein the second extent of separation between successive objects is less than the first extent of separation between successive objects and the third extent of separation between successive objects.

Owner:PHOTO DIAGNOSTIC SYST INC

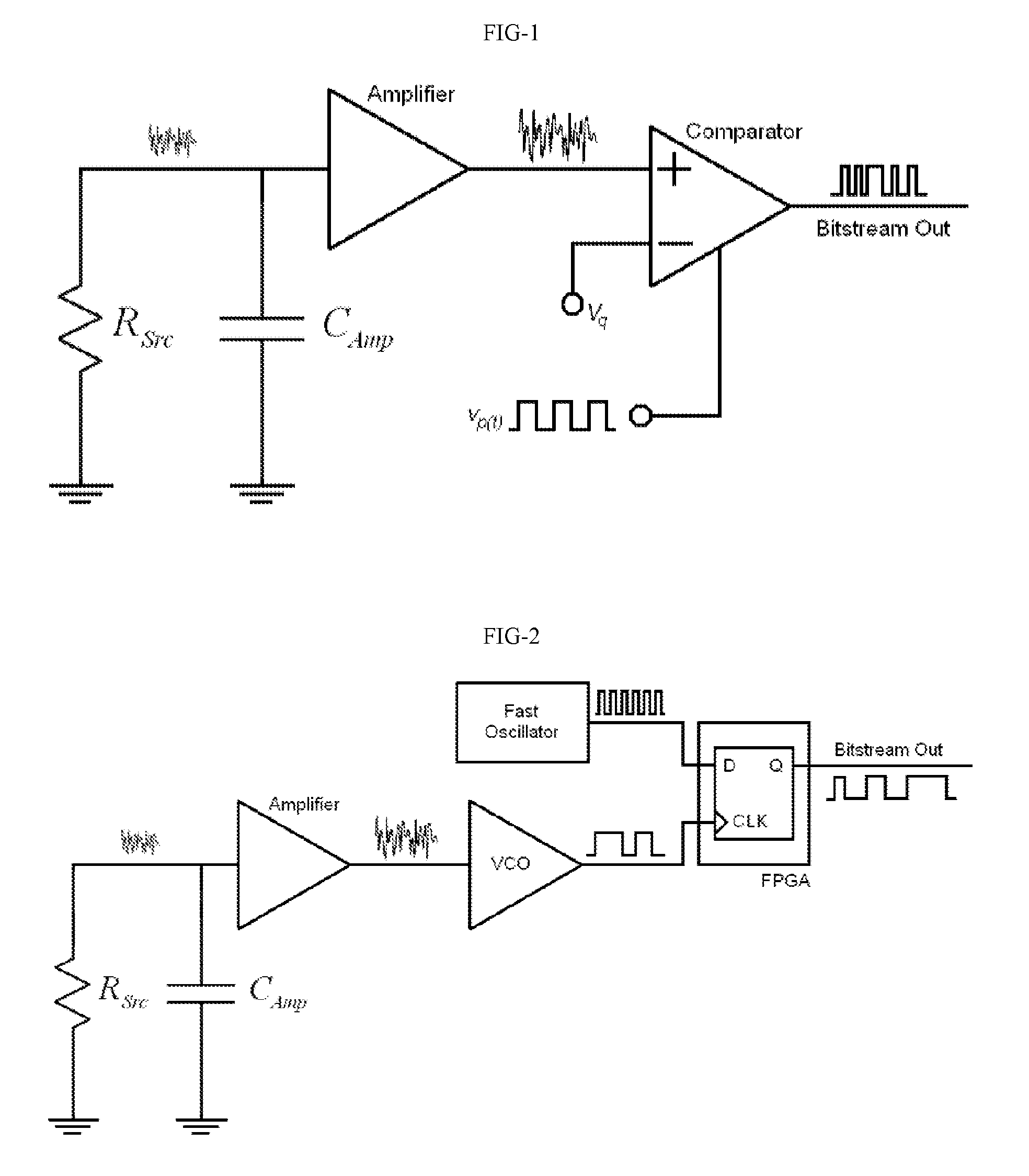

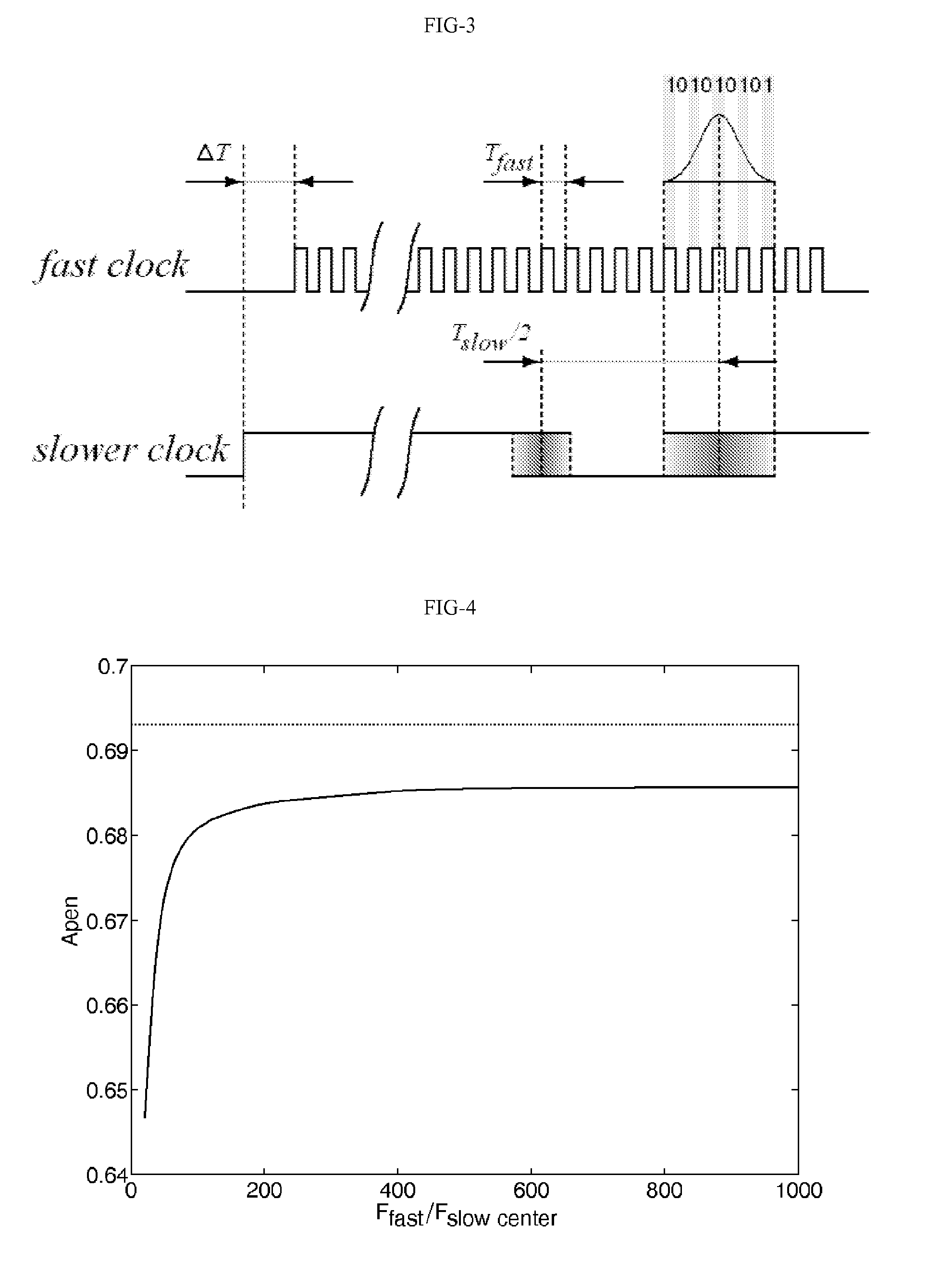

Method and hardware for generating random numbers using dual oscillator architecture and continuous-time chaos

ActiveUS8612501B2Improve throughput speedQuality improvementRandom number generatorsSecuring communication by chaotic signalsStatistical qualityNumber generator

Novel random number generation methods and novel random number generators based on continuous-time chaotic oscillators with dual oscillator architecture are presented. Numerical and experimental results not only verify the feasibility of the proposed circuits, but also encourage their use as a high-performance IC TRNG. In comparison with RNG's based on discrete-time chaotic maps, amplification of a noise source and jittered oscillator sampling, which are advantageous in the sense that true random behavior can be mathematically proven thanks to an analytical model that has been developed, it is seen that RNG's based on continuous-time' chaotic oscillators can offer much higher and constant data rated without post-processing. The proposed innovation increases the throughput, maximizes the statistical quality of the output sequence and is robust against external interference, parameter variations and attacks aimed to force throughout. The proposed circuits can be integrated on today process at GHz range.

Owner:TUBITAK

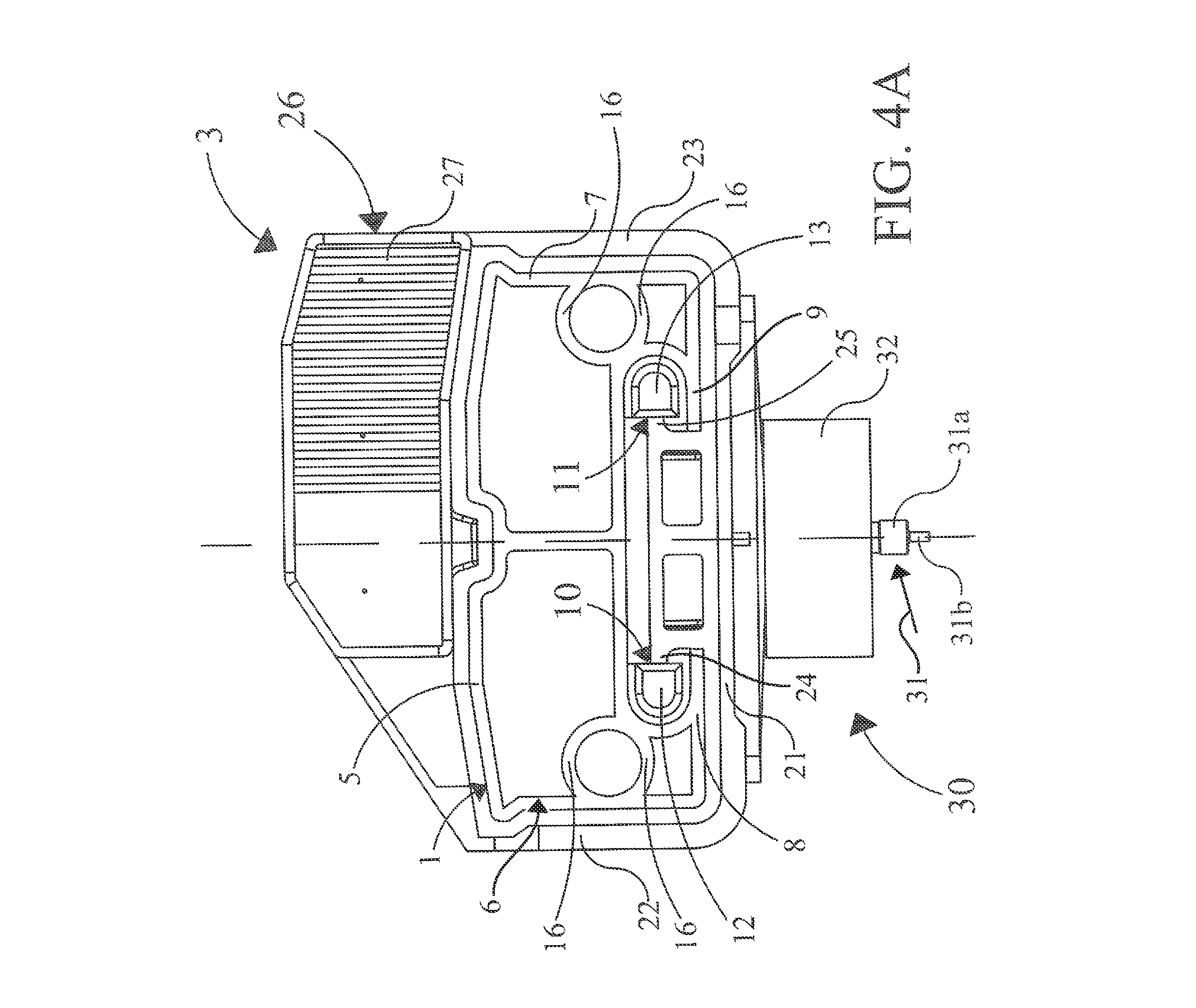

Device for folding and bolding plastic-laminated pre-cut blanks

InactiveUS20080085824A1High speedImprove throughput speedMechanical working/deformationBoxes/cartons making machineryCardboardCombustor

The invention discloses a device for folding and bonding plastic-laminated pre-cut blanks, in particular PE-laminated cardboard packages for beverages, comprising a peeling station for selectively peeling off a plastic lamination of a pre-cut blank; a creasing station for production of a folding line in a blank; a heating station for selectively heating up a plastic lamination on a blank that is to be bonded; a folding station for folding a blank about a folding line; a pressing station for pressing and bonding a folded blank; and conveying means for conveying blanks through the stations. The heating station comprises a burner having an oblong burner chamber which is provided on its top with a series of flame openings arranged one behind the other in the axial direction, for permitting flames to exit the chamber, and a liquid cooling system.

Owner:FORTUNA SPEZIALMASCHEN +1

Semiconductor storage device and control method of the same

A semiconductor storage device includes a timing allocation unit that sets refresh timing to preferentially perform a refresh operation for maintaining data and data access timing to preferentially perform a data access operation for reading or writing the data in accordance with a clock signal with respect to each memory bank including a plurality of memory cells, and a waiting unit that waits start of the data access operation until the data access timing is started in a case where a request for the data access operation is made during the refresh timing and waits start of the refresh operation until the refresh timing is started in a case where a request for the refresh operation is made during the data access timing.

Owner:RENESAS ELECTRONICS CORP

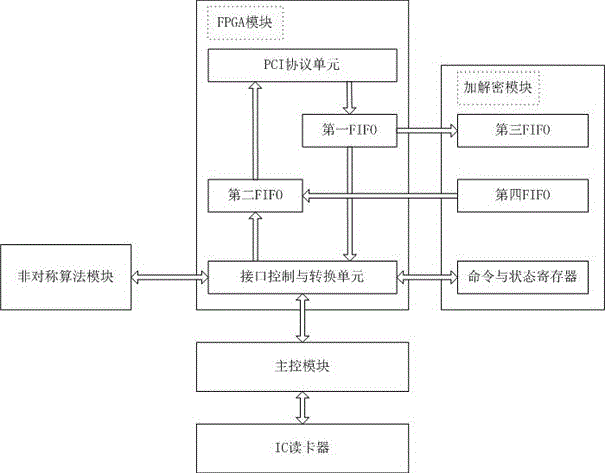

Micro stock market data processing system using FPGA encryption card

InactiveCN106529314AEncryption and decryption high speedImprove throughput speedDigital data protectionData processing systemComputer module

The invention discloses a micro stock market data processing system using an FPGA encryption card. The micro stock market data processing system comprises an FPGA module, an encryption and decryption module, an asymmetric algorithm module and a main control module; the encryption and decryption module, the asymmetric algorithm module and the main control module are separately connected with the FPGA module; the main control module and the asymmetric algorithm module are separately connected with an interface control and conversion unit; the FPGA module comprises a PCI protocol unit, a first storage module, a second storage module and the interface control and conversion unit; the PCI protocol unit transmits data to the interface control and conversion unit through the first storage module; the interface control and conversion unit transmits the data to the PCI protocol unit through the second storage module; and the encryption and decryption module comprises a third storage module, a fourth storage module and a command and state register. According to the micro stock market data processing system disclosed by the invention, the encryption and decryption module is arranged, so that high-speed encryption and decryption of SM1 can be realized; operation results grouped before can be output while the data is input; therefore, pipeline operation can be supported; and the data throughput speed is increased.

Owner:成都力雅信息技术有限公司

Wall base and formulation for making the same

InactiveUS20120302666A1Sufficiently flexibleSufficiently softSynthetic resin layered productsConstructions elementsEngineeringRenewable materials

A composition for manufacturing flooring accessories, such as a wall base, and process for manufacturing the composition. The composition includes a first formulation and a second formulation that are cured together by a partial cure. The composition incorporates rapidly renewable materials, natural filler materials and has a low weight per linear foot.

Owner:TARKETT USA

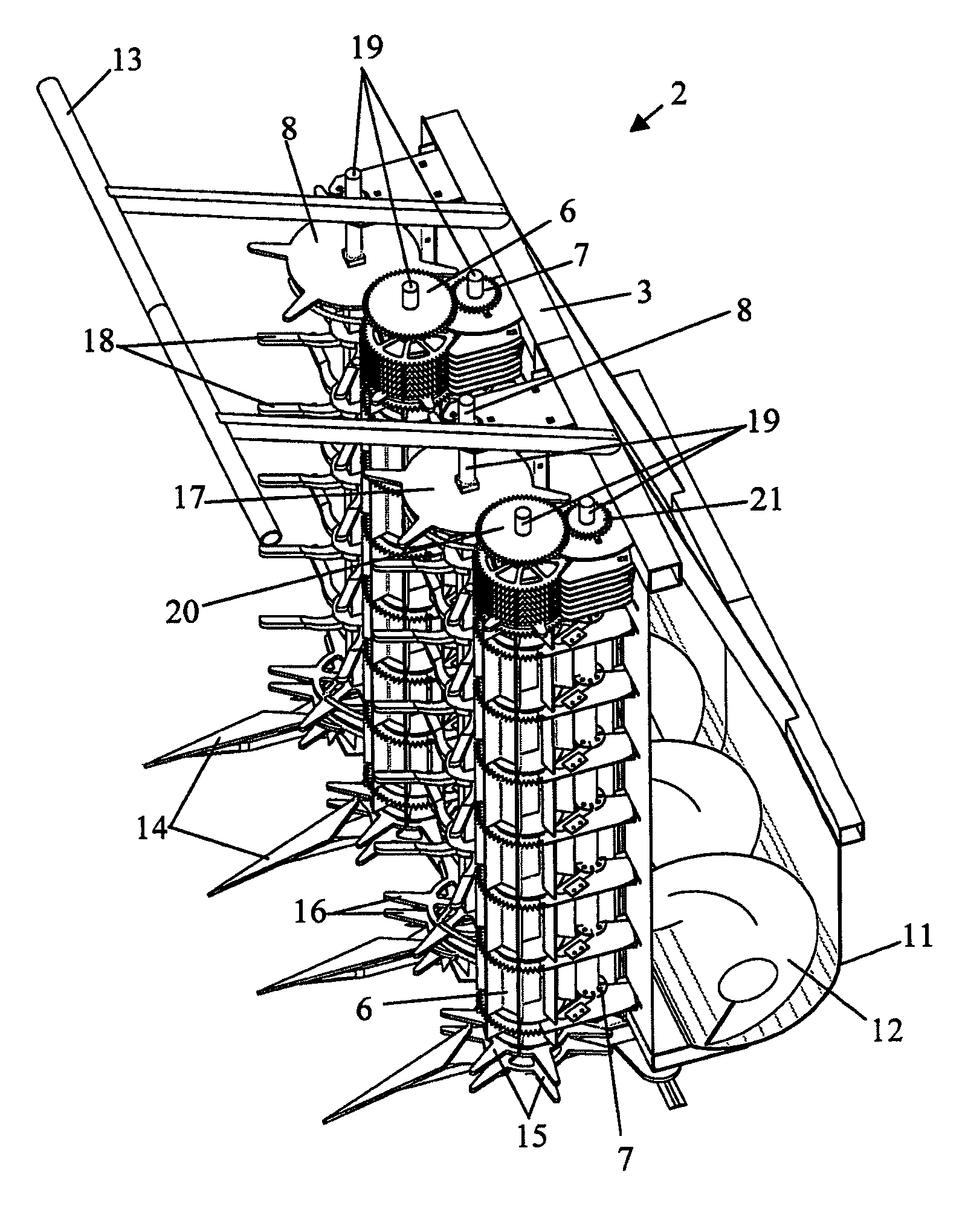

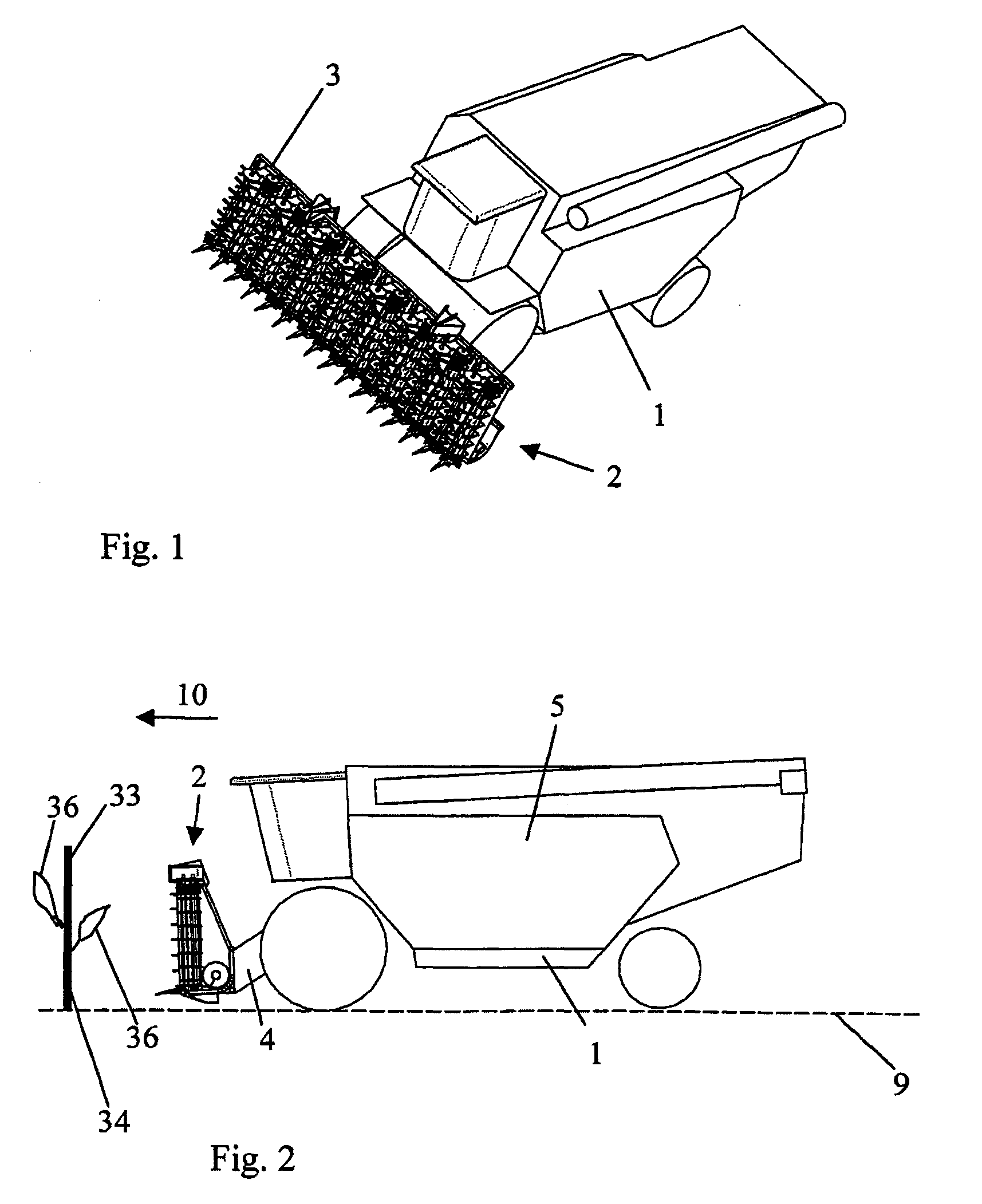

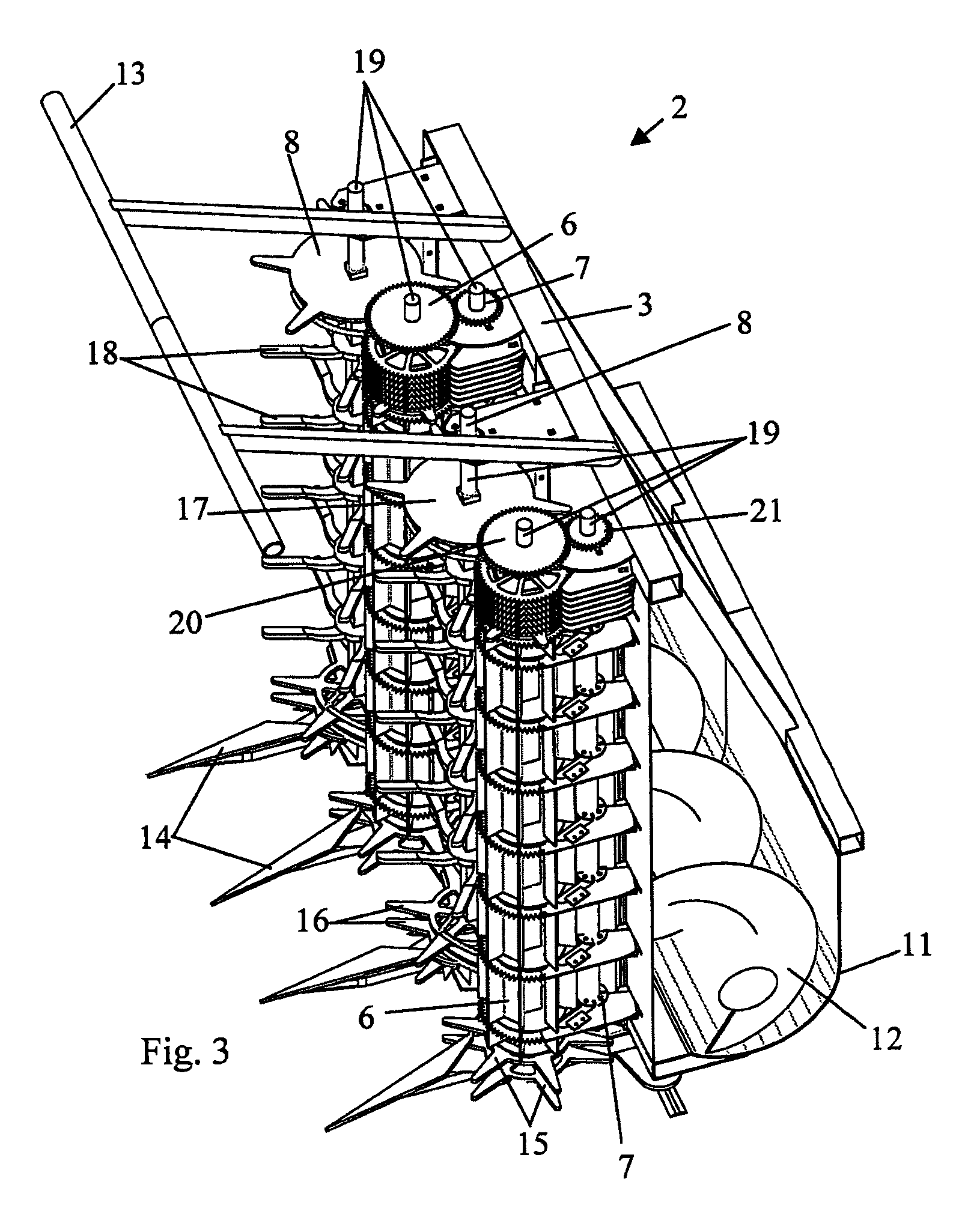

Picking arrangement for picking fruit on an elongate stem

InactiveUS8028507B2Improve throughput speedReduce harvesting lossesMowersEngineeringMechanical engineering

Picking arrangement for picking at least one fruit (36) located on an elongate stem (33) of a plant (34), has a holder (3), that can be moved along the ground (9), and having an elongate picking gap (30), which is provided on the holder (3), bounded by lateral edges (31) and through which the stem (33) can be guided. The fruit (36) is separated off along the edges (31) in the process, wherein the picking gap (30) is oriented such that the step (33) can be fed to the picking gap (30) with its longitudinal axis oriented parallel, or essentially parallel, to the longitudinal axis of the picking gap (30).

Owner:CARL GERINGHOFF GMBH & CO KG

Method of and apparatus for rolling strip of fluctuating thickness

ActiveUS10413949B2Simple methodQuality improvementMeasuring devicesTension/compression control deviceEngineeringActuator

An apparatus for rolling strip having a periodically fluctuating strip thickness has a roll stand with a set of rollers defining a gap, an adjustment actuator for adjusting the gap of the set of rollers, unwinder for feeding the strip with an initial thickness to an intake side of the roller gap, winder for receiving the strip with a desired final thickness from an output side of the gap, respective upstream and roller assemblies each having an immersion roller provided upstream of the roll stand between the unwinder and the roll stand and downstream of the roll stand between the roll stand and the winder. The strip is guided around the immersion rollers. A controller sets positions of the immersion rollers while operating the rollers of the roll stand at a constant roller speed, for determining the roller gap in dependence on the setting of the rollers.

Owner:BILSTEIN

High speed interfolded log accumulator

ActiveUS8490772B2Improve throughput speedAvoid swingingSemiconductor/solid-state device manufacturingLoading/unloadingTransport systemEngineering

A log accumulator comprising a plurality of buckets, a feed arrangement and a transport system and methods are provided. The feed arrangement loads logs onto the buckets. The transport system transports the buckets past the feed arrangement for loading of the buckets. The transport system and the feed arrangement are configured to maintain the feed arrangement in a fixed relative position with one of the buckets for an extended period of time while the feed arrangement loads the one of the buckets. The accumulator may include an unload arrangement that operates to unload logs in substantially the same manner as the feed arrangement.

Owner:C G BRETTING MFG

Duplex printing with integrated image marking engines

InactiveUS8096650B2Quality improvementImprove throughput speedTypewritersElectrographic process apparatusElectrical and Electronics engineeringInkjet printing

Owner:XEROX CORP

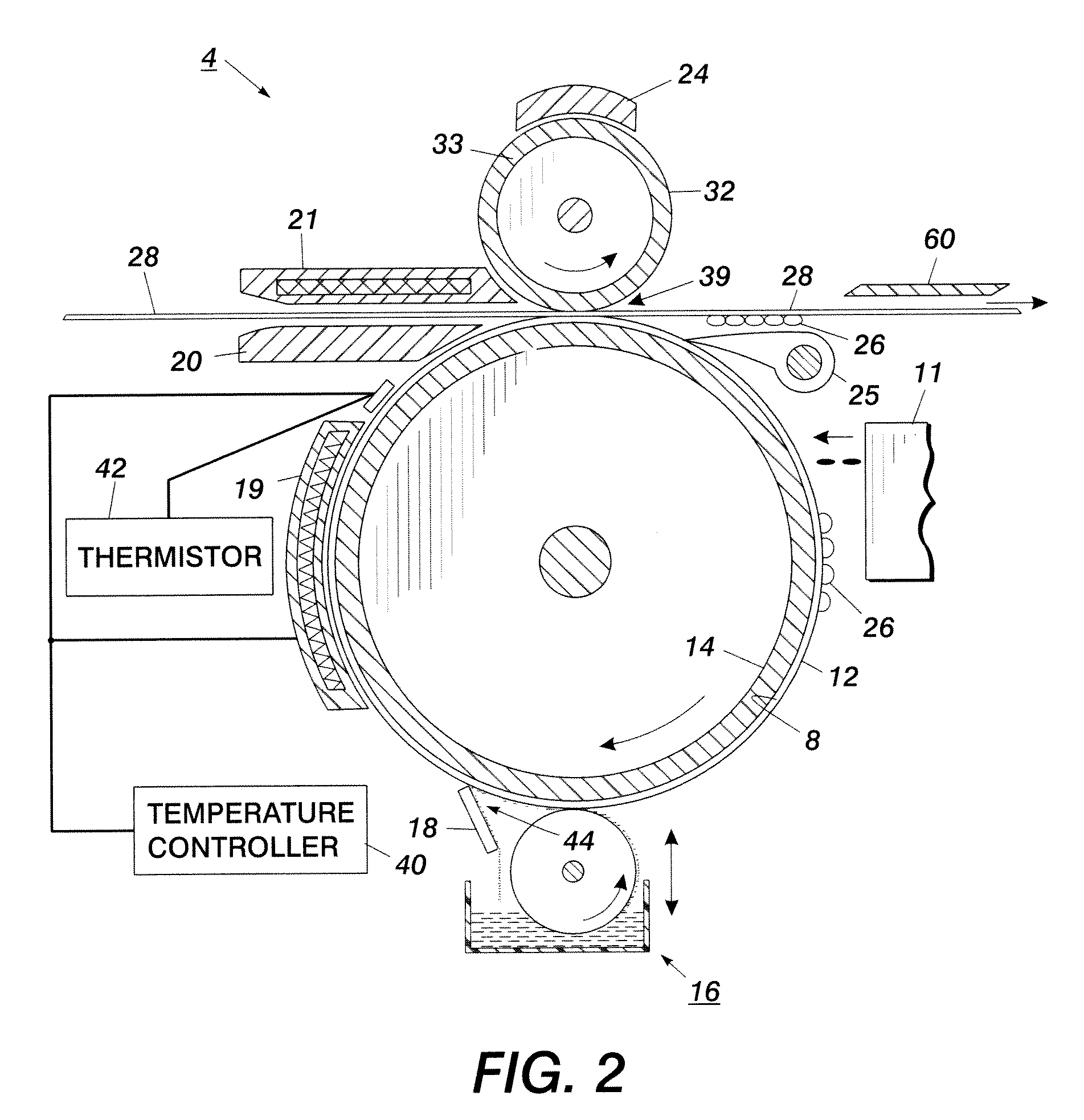

Log pre-writing method and system based on RocksDB

PendingCN114138200AIncrease storage capacityTake advantage ofDatabase updatingInput/output to record carriersFile systemParallel computing

The invention particularly relates to a log pre-writing method and system based on RocksDB. According to the log pre-writing method and system based on the RocksDB, a fixed number of threads bound with cores are started to accept, manage, execute and return a writing request of NVMe SSD equipment; partitioning, managing and optimizing the hybrid storage device by using a self-made file system; reading data of the high-speed NVMe SSD equipment by using the SPDK to realize pre-write log recovery; a synchronization mechanism of the pre-write file system is realized by using a sliding window algorithm and / or a bitmap algorithm and a busy waiting technology. According to the log pre-writing method and system based on the RocksDB, the high storage performance of the NVMe SSD can be fully played, the throughput speed of a database is greatly increased, it can be guaranteed that all hardware devices can be fully utilized, the problem of the writing speed of the database caused by the slow disk writing speed is avoided, the recovery speed of the database is increased, and the recovery efficiency of the database is improved. And the reading and writing performance of the database is greatly improved.

Owner:上海沄熹科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com