Patents

Literature

171results about How to "Cheap to prepare" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic wood material and preparation method thereof

The invention relates to a composite material and particularly relates to a plastic wood material and a method for preparing the material by crop straw and waste plastic. The plastic wood material disclosed by the invention is prepared from the following components by weight: 20-36% of waste plastics, 25-70% of crop straws, 5-44% of fire retardants, 1-10% of bulking agent, and 0.1-3% of lubricating agent, 0.5-3% of plasticizer, 0.01-1% of antioxidant and 0.5-3% of coloring agent. The performance of According to the plastic wood material disclosed by the invention, the performance is more excellent than that of the wood; the crop straw and the waste plastic are utilized for producing the plastic wood material, and the harmless resource utilization of the crop straw and the waste plastic is fully achieved, and the material has the advantages of being environment-friendly, economical and wide in material supply.

Owner:GEM CO LTD

Anti-aging plastic wood composite material and preparation method thereof

The invention relates to a composite material, and particularly relates to an anti-aging plastic wood composite material and a preparation method thereof. The anti-aging plastic wood composite material of the invention is characterized in that the composite material is prepared by the following raw materials by mass: 20%-35% of plastics, 20%-70% of natural wood fibers, 5%-45% of a fire retardant, 1%-10% of a compatibilizer, 0.1%-3% of a lubricant, 0.5%-3% of a plasticizer, 0.1%-2% of a anti-aging filling material, and 0.5%-3% of a coloring agent. According to the invention, the reinforcing anti-aging filling material is added into the plastic wood composite material, which provides the plastic wood profile with both general functions and superpower anti-aging performance, effectively enhances the surface anti-aging performance of the plastic wood profile, and improves the service life of the plastic wood product.

Owner:GEM CO LTD

Method for preparing complete methanation catalyst for hydrothermal chemical process

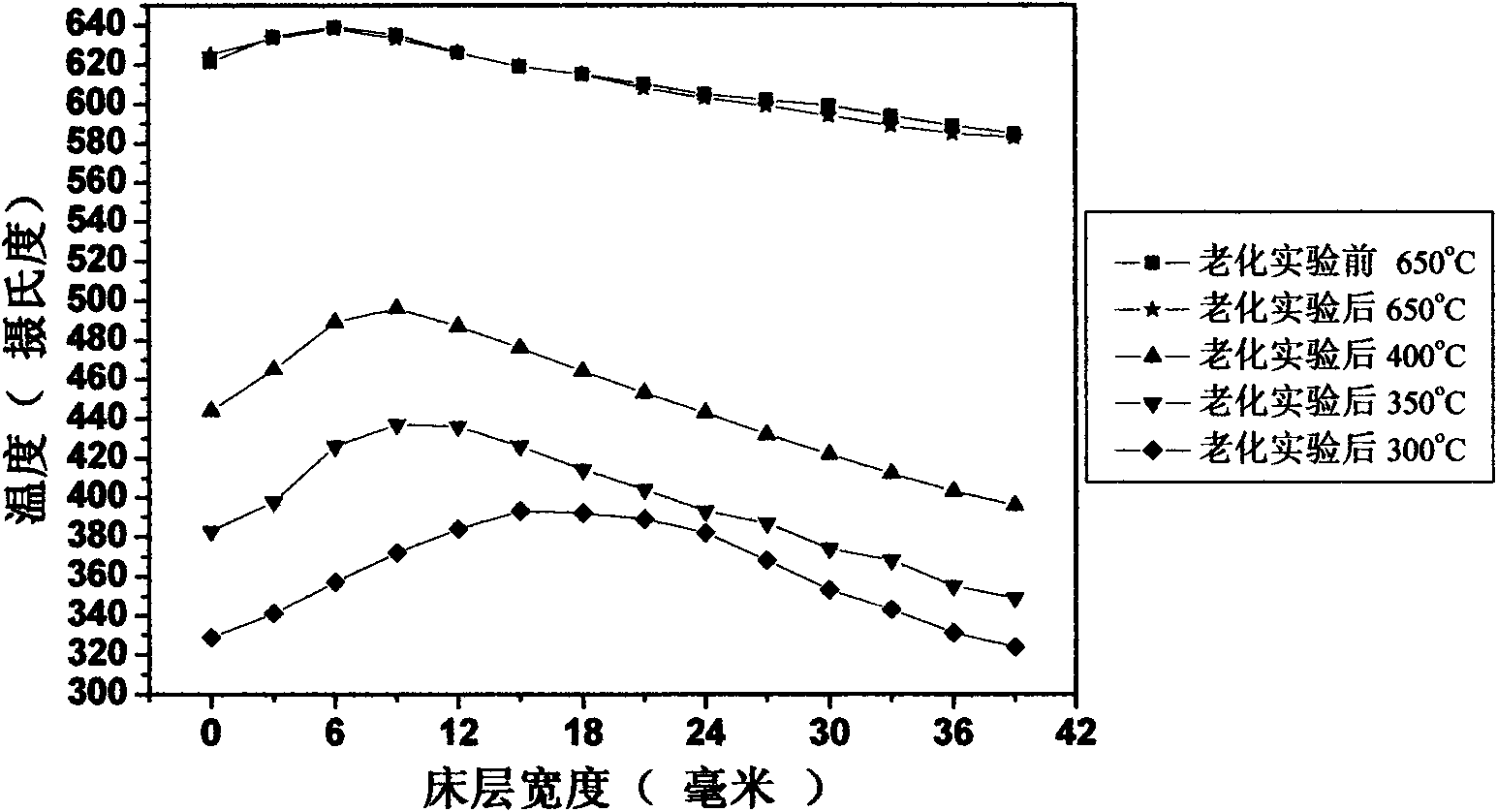

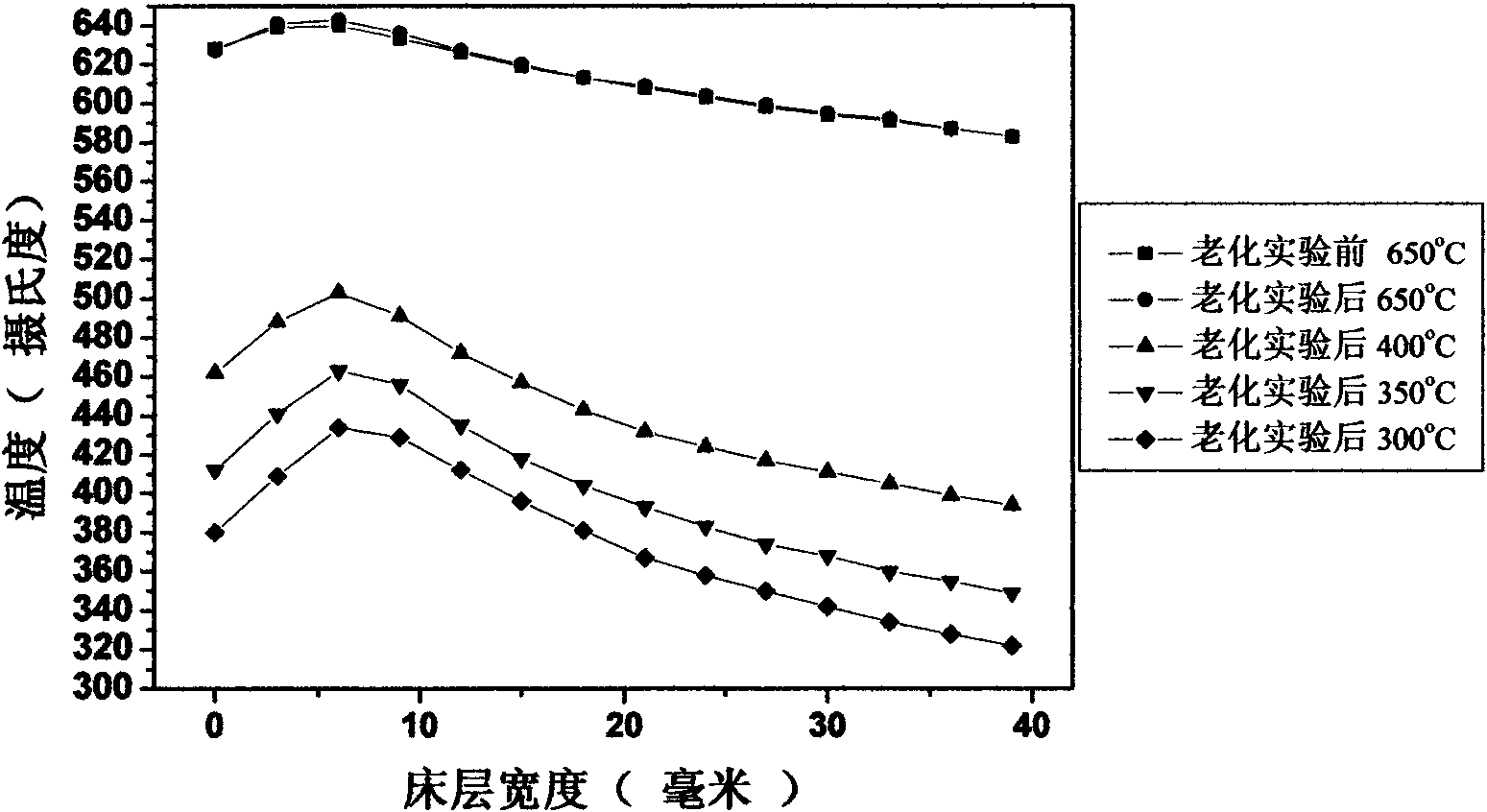

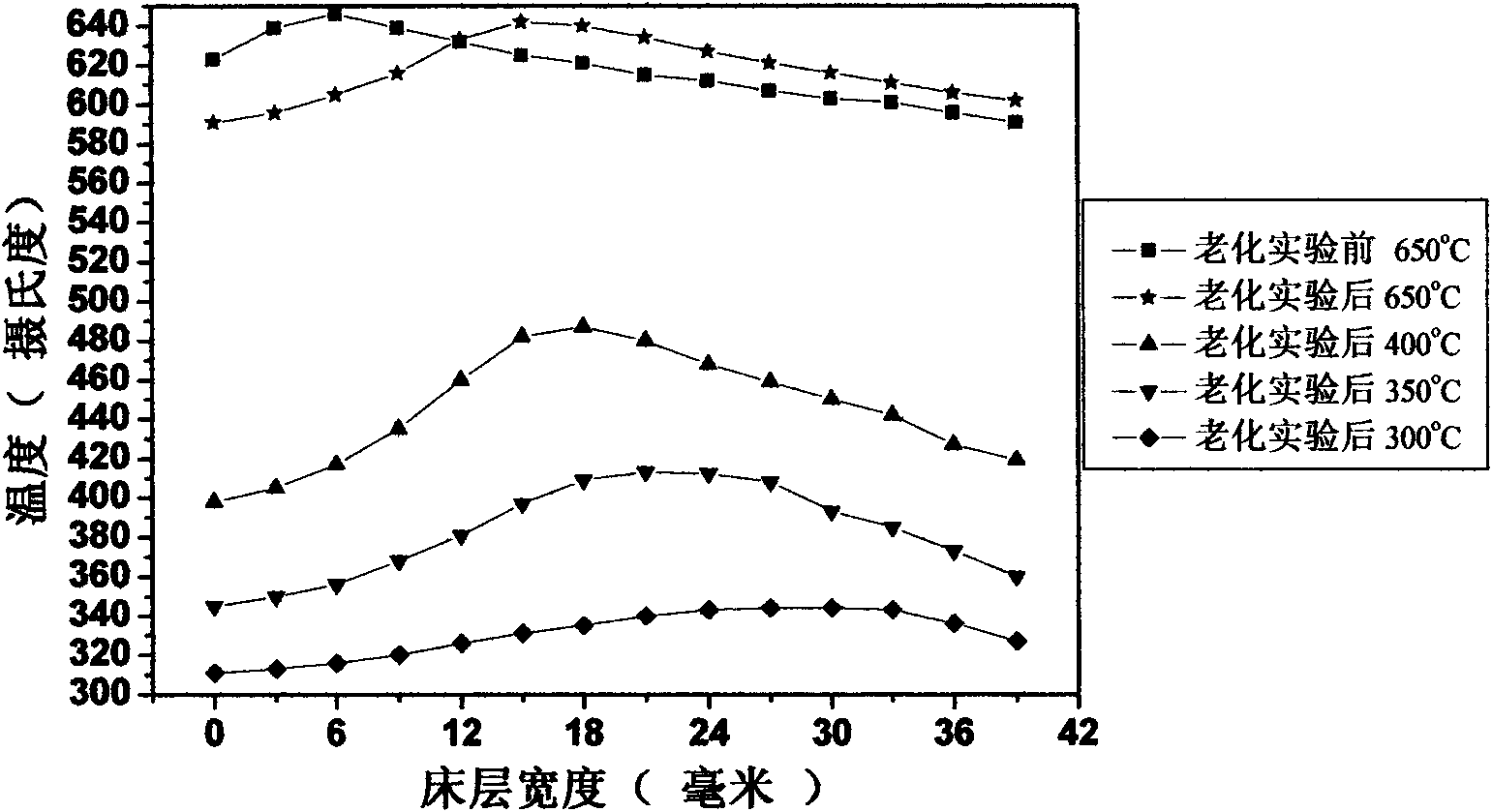

ActiveCN102029161AGood activity and stabilityGood hydrothermal stabilityHydrocarbon from carbon oxidesCatalyst activation/preparationChemical synthesisPtru catalyst

The invention provides a method for preparing a complete methanation catalyst for a hydrothermal chemical process. The catalyst comprises the following components: 10 to 75 percent of active nickel ingredient, 10 to 90 percent of high-temperature resistant carrier and 0.1 to 15 percent of rare-earth auxiliary agent, wherein the content is counted on the basis of metal oxide, and the percentage is weight percentage of the total weight of the active ingredient, the carrier and the auxiliary agent. The preparation method comprises the following steps of: (a) forming a catalyst precursor by using the hydrothermal chemical synthesis process; and (b) preparing the obtained catalyst precursor into the complete methanation catalyst by filtering, washing, drying, roasting, forming, re-roasting and reducing. The method is convenient for crystallization and precipitation of catalyst materials, and has simple process and good repeatability. The method provides guarantee for meeting the current increasing clean energy requirement, and has irreplaceable important effect on the enhancement of energy / resource safety at the same time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

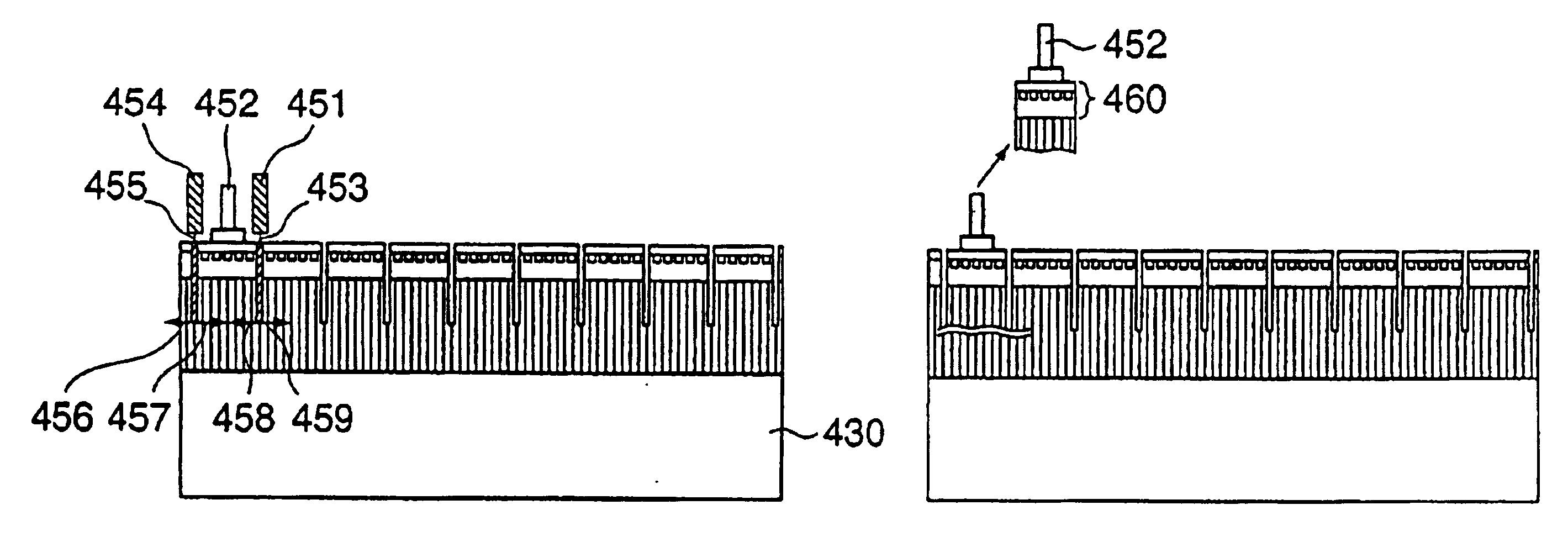

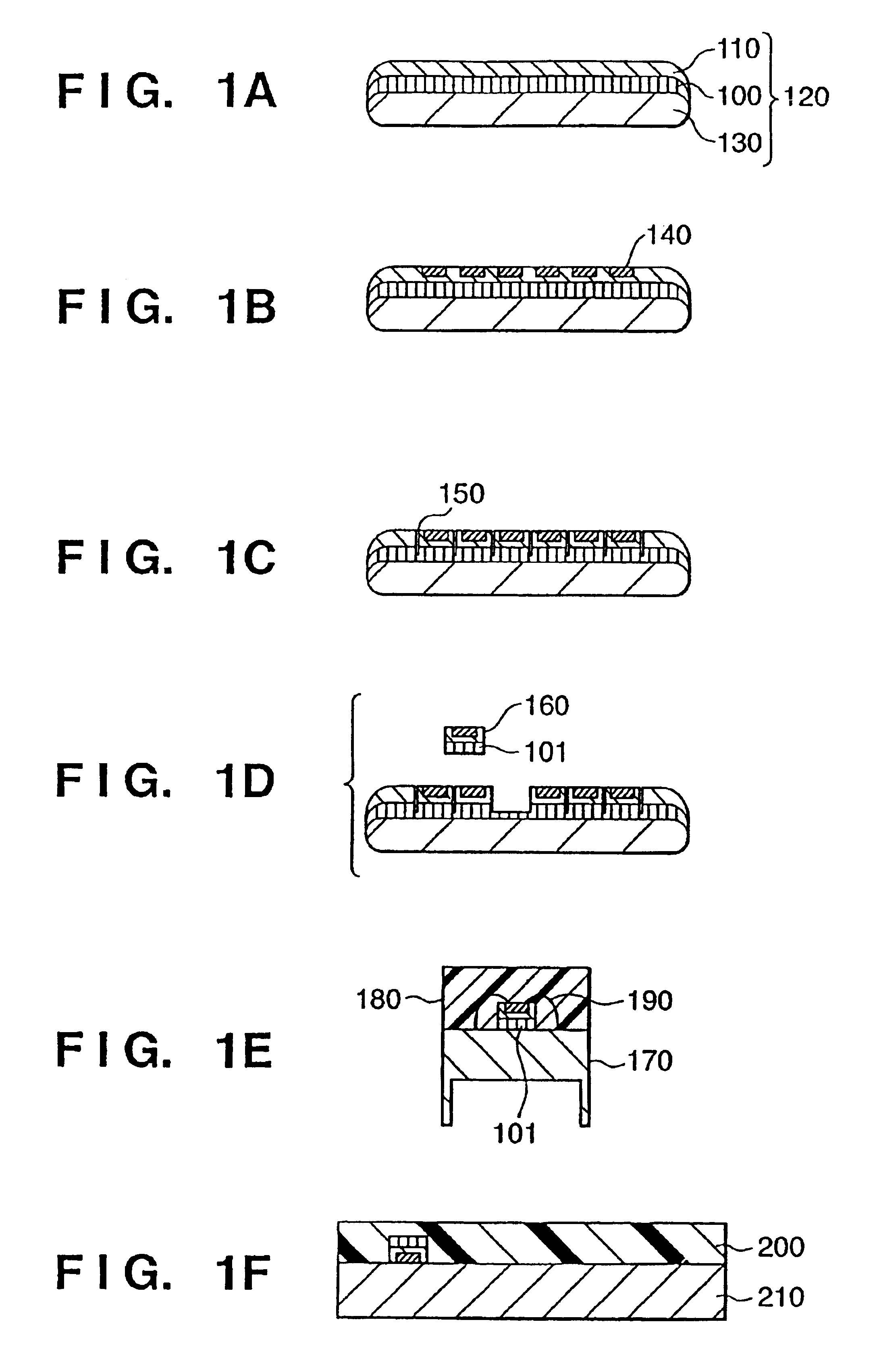

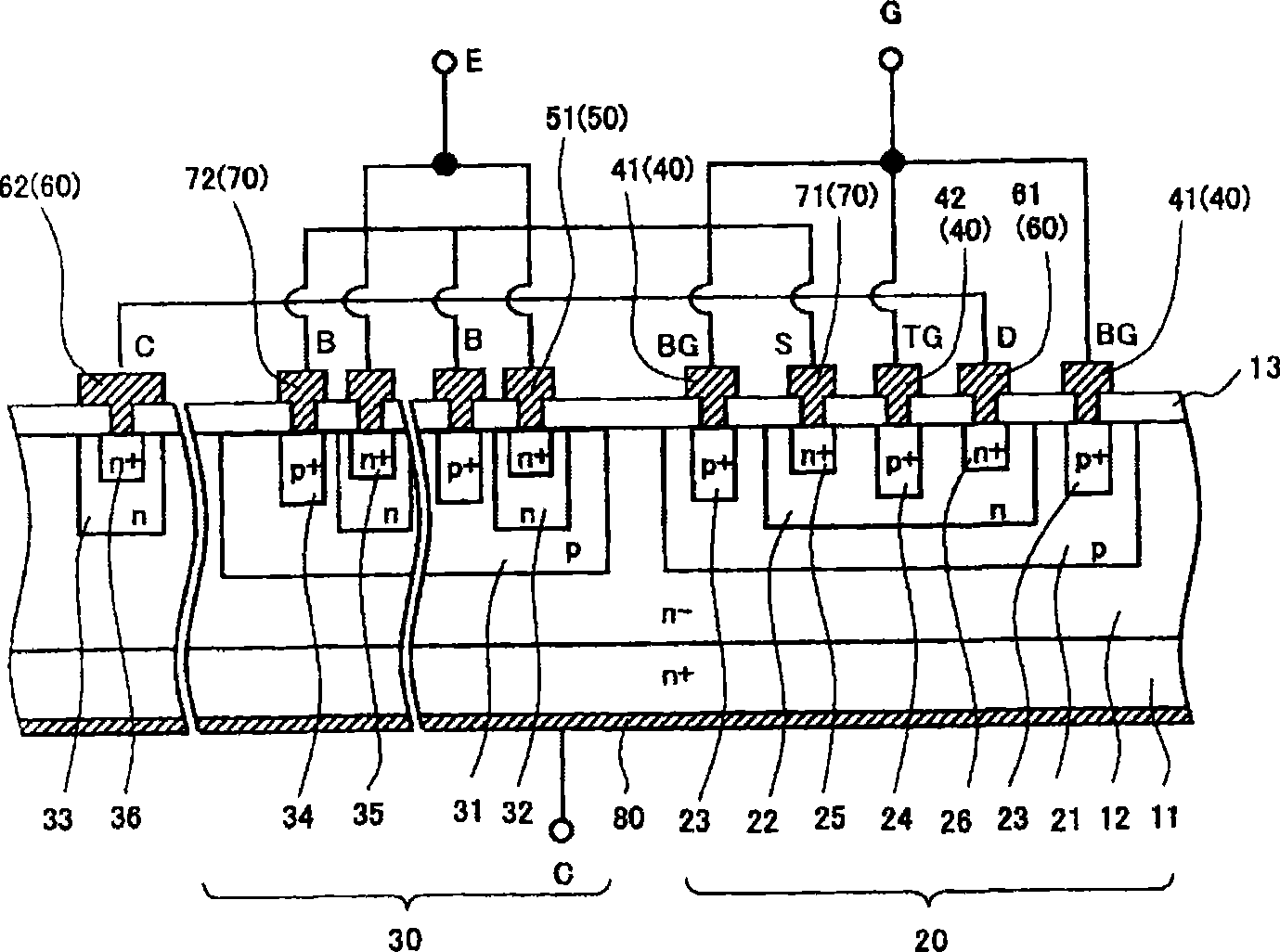

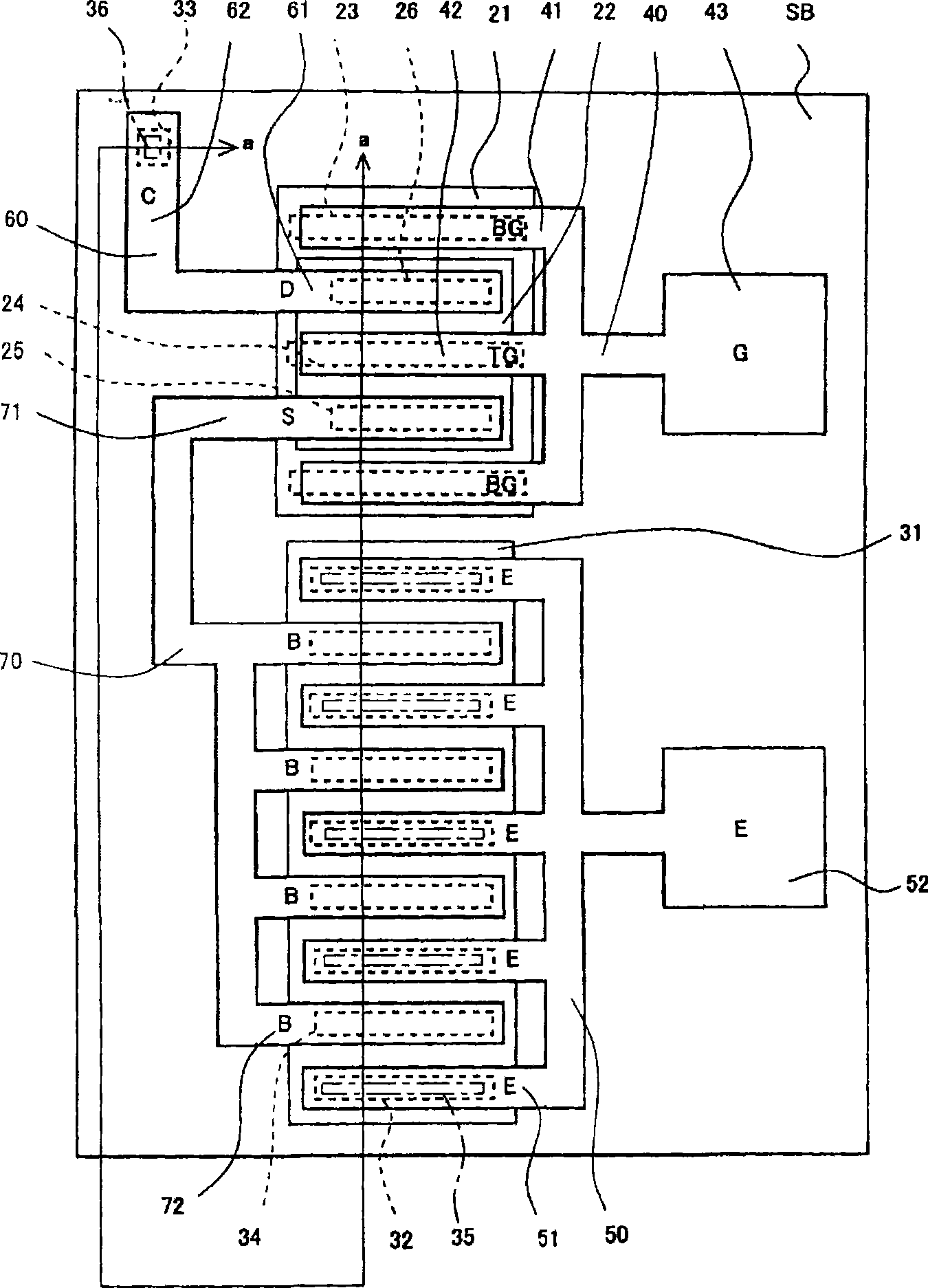

Thin-film semiconductor device and method of manufacturing the same

InactiveUS6972215B2Cheap to prepareImprove efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringPorous semiconductors

A semiconductor device is manufactured using the method including the steps of anodizing a semiconductor substrate to form a porous semiconductor layer on a semiconductor region of the semiconductor substrate; forming a non-porous semiconductor layer on the porous semiconductor layer; forming a semiconductor element and / or semiconductor integrated circuit in the non-porous semiconductor layer; forming kerfs from a surface side of the non-porous semiconductor layer toward the semiconductor region; and applying a pressure of a fluid to the porous semiconductor layer such that the desired region of the semiconductor element and / or semiconductor integrated circuit is separated from the semiconductor substrate.

Owner:CANON KK

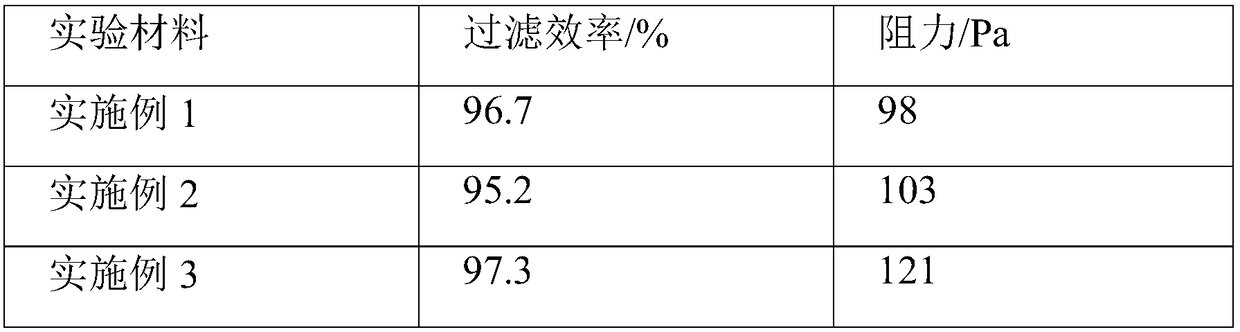

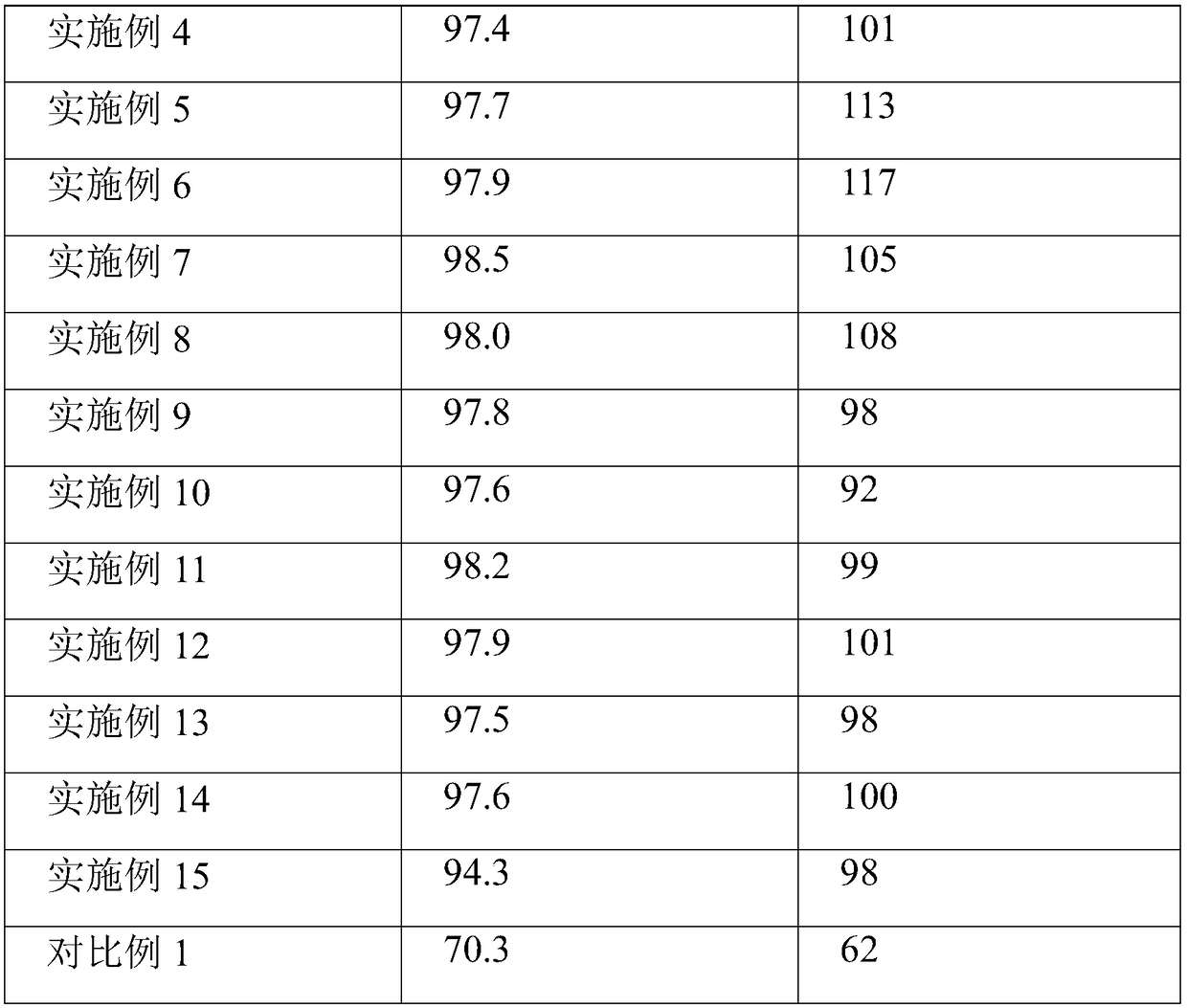

Polypropylene electret master batch material, method for preparing same and application of polypropylene electret master batch material

The invention belongs to the technical field of high-polymer materials, and particularly relates to a polypropylene (PP) electret master batch material, a method for preparing the same and applicationof the polypropylene electret master batch material. The PP electret master batch material is mainly prepared from components including, by weight, 50-100 parts of polypropylene, 8-50 parts of electret agents, 0-3 parts of compatibilizers, 0.05-0.35 part of antioxidants and 0-3 parts of anti-aging agents. The components are molten and granulated to obtain the polypropylene electret master batch material. The polypropylene electret master batch material, the method and the application have the advantages that resin and auxiliaries are uniformly mixed with one another in melt blending modes, accordingly, obvious electret effects can be realized by melt-blow non-woven materials produced from the polypropylene electret master batch material prepared by the aid of the method, the melt-blow non-woven materials are high in filter efficiency and low in filter resistance, and the like.

Owner:联泓(江苏)新材料研究院有限公司

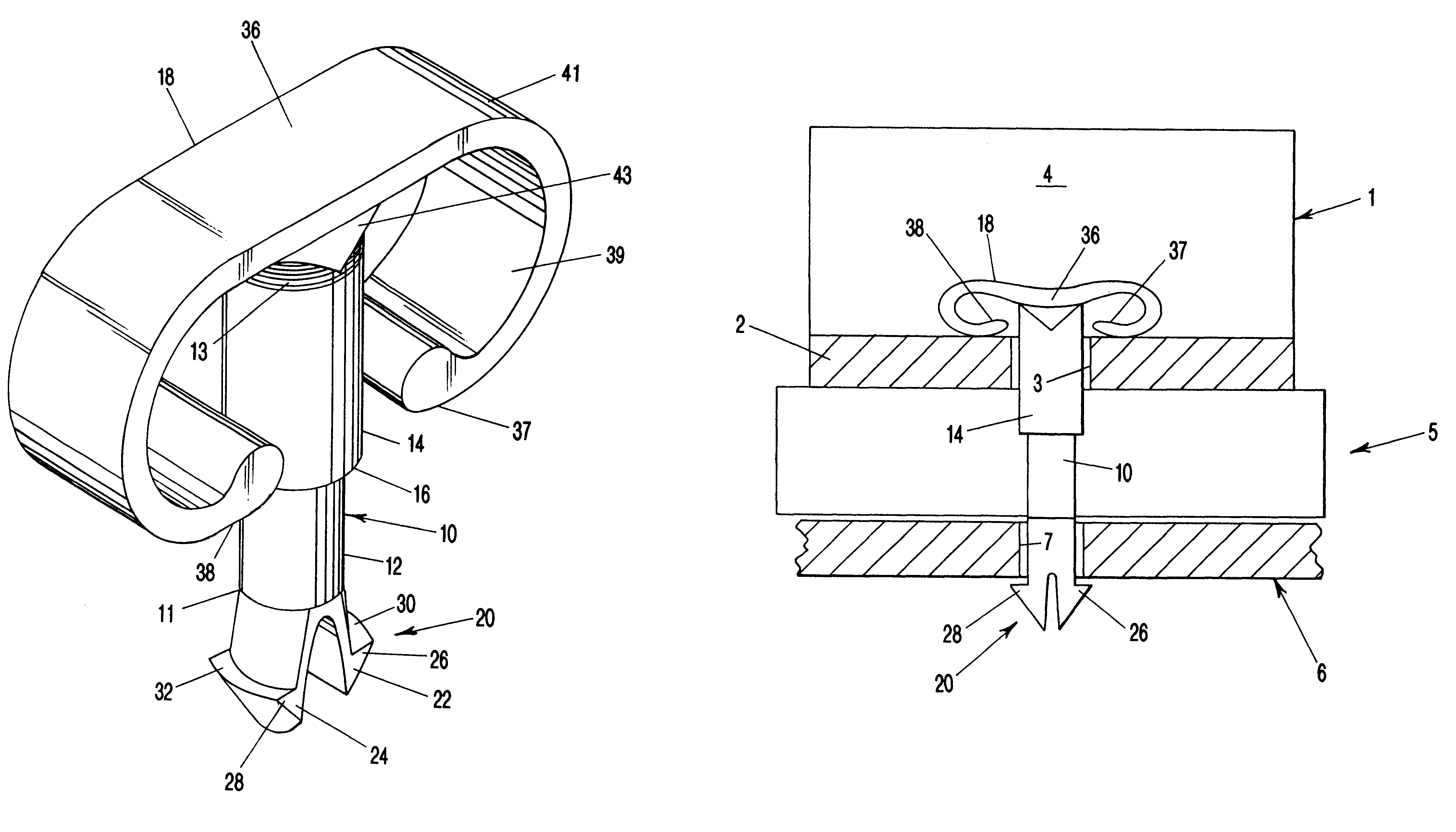

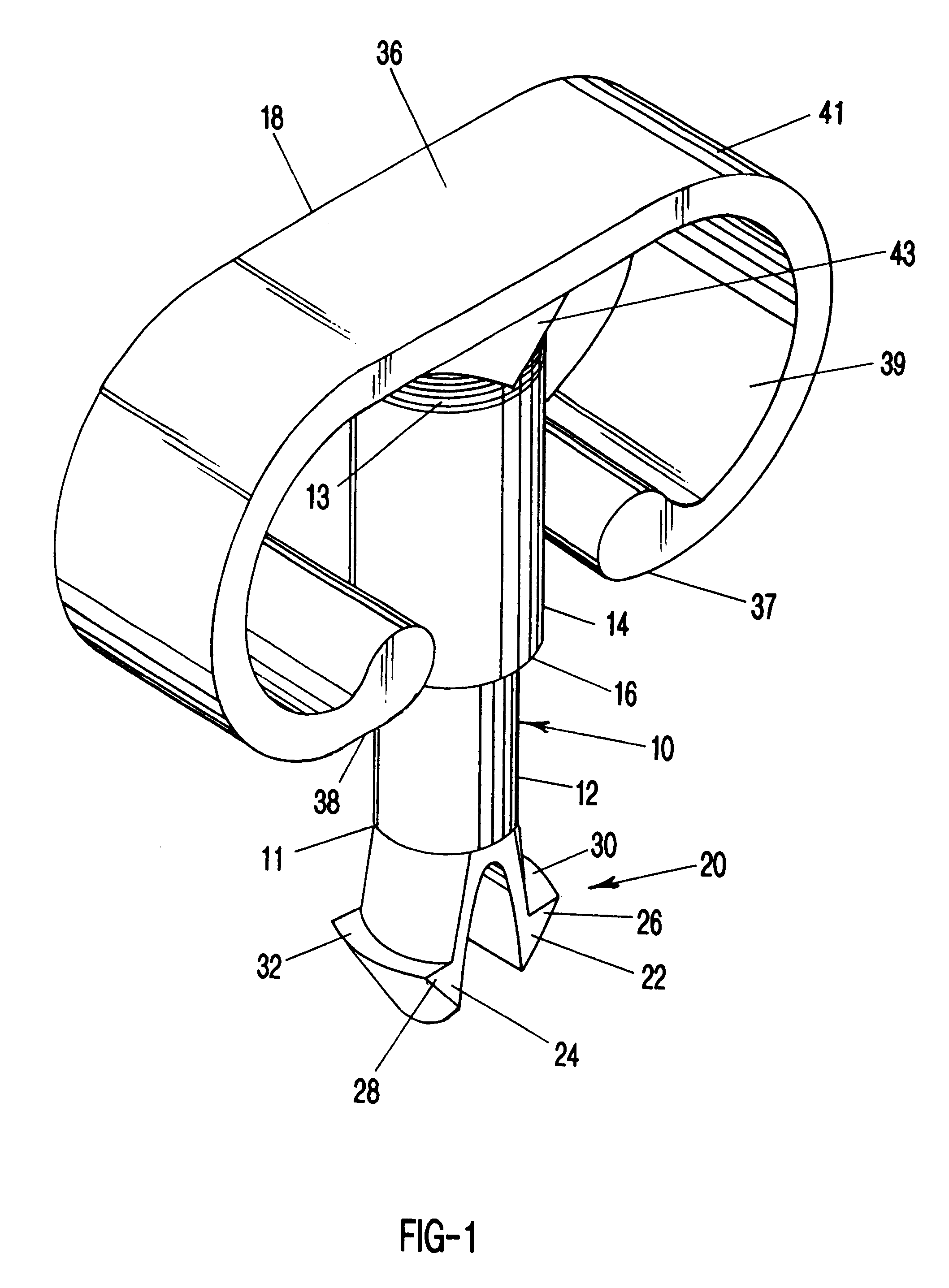

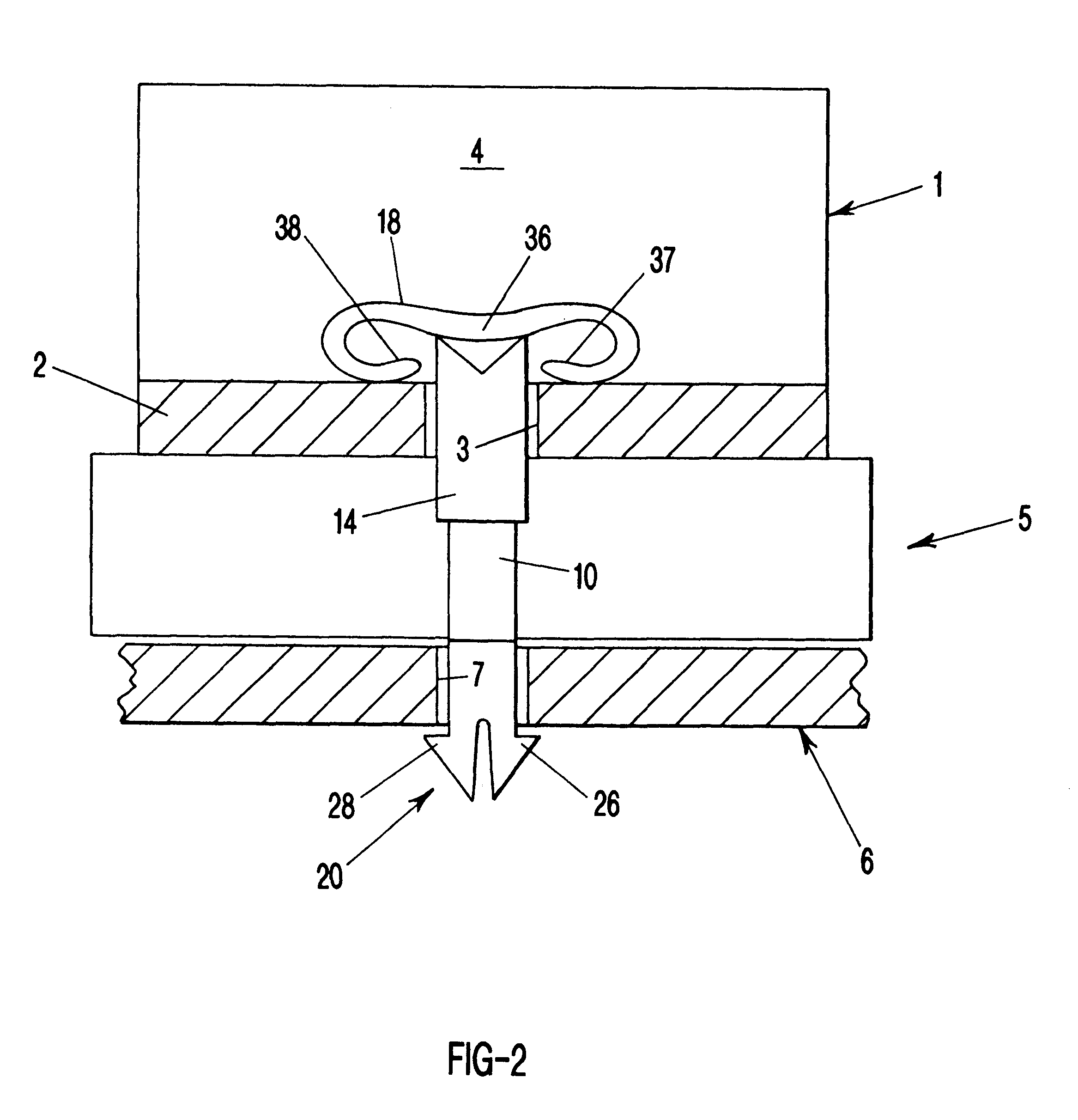

Retainer clip for heat sink for electronic components

InactiveUS6301113B1Easy to insertEasy to releaseSnap-action fastenersSemiconductor/solid-state device detailsBiomedical engineeringHeat spreader

Owner:PSC COMP PRODS

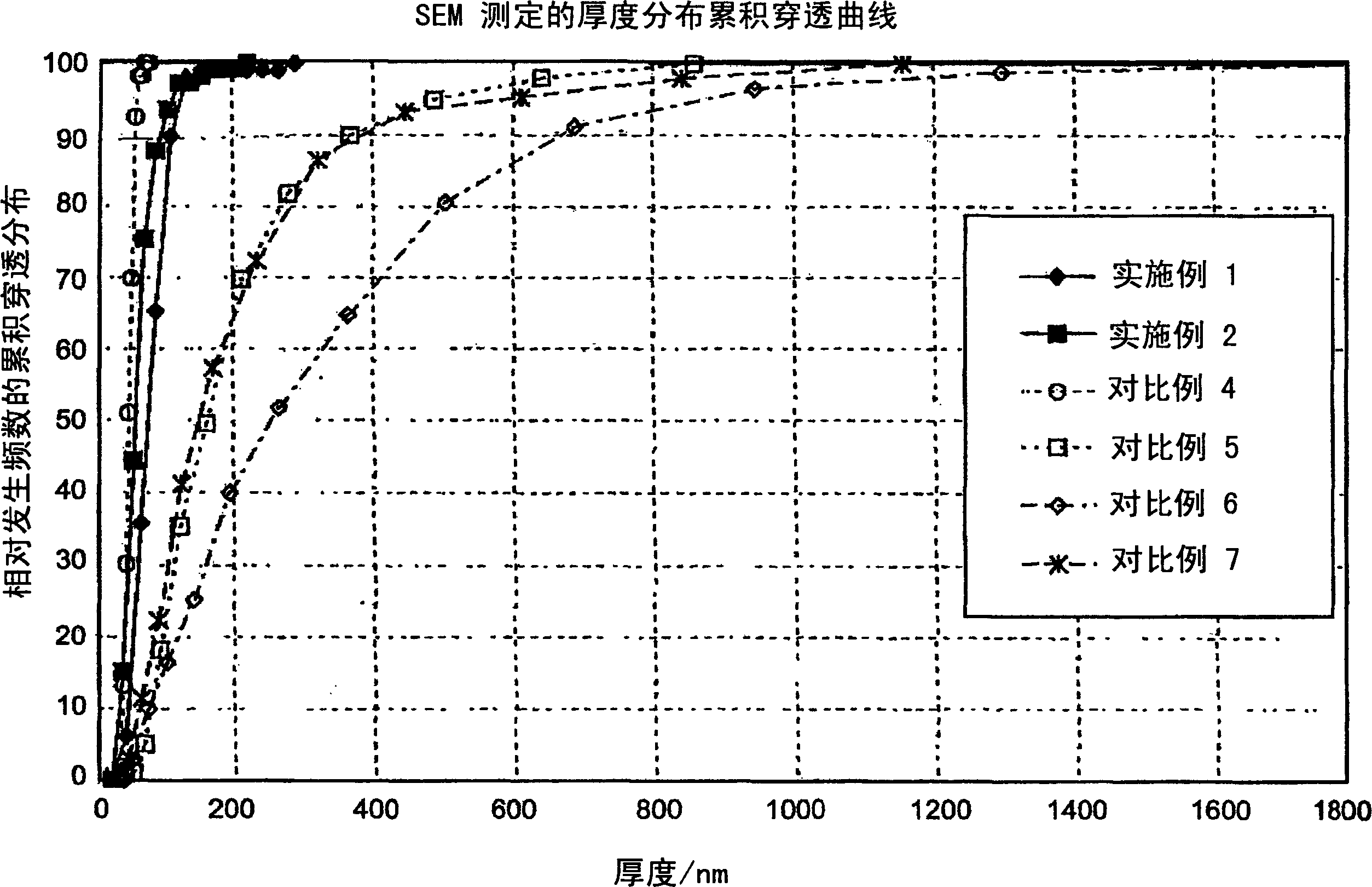

Thin coating aluminum pigments, method for the production thereof, and use of said aluminum pigments

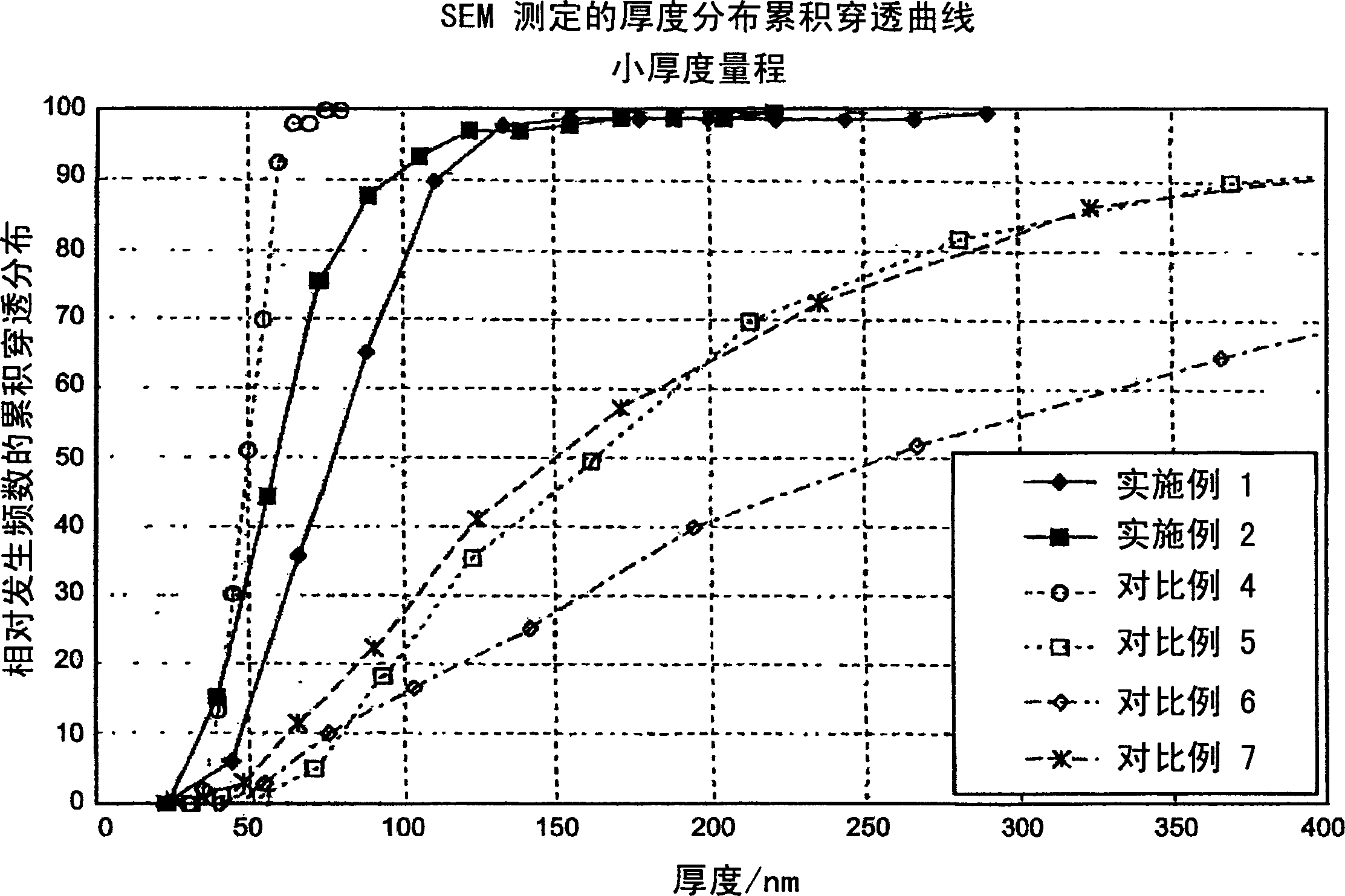

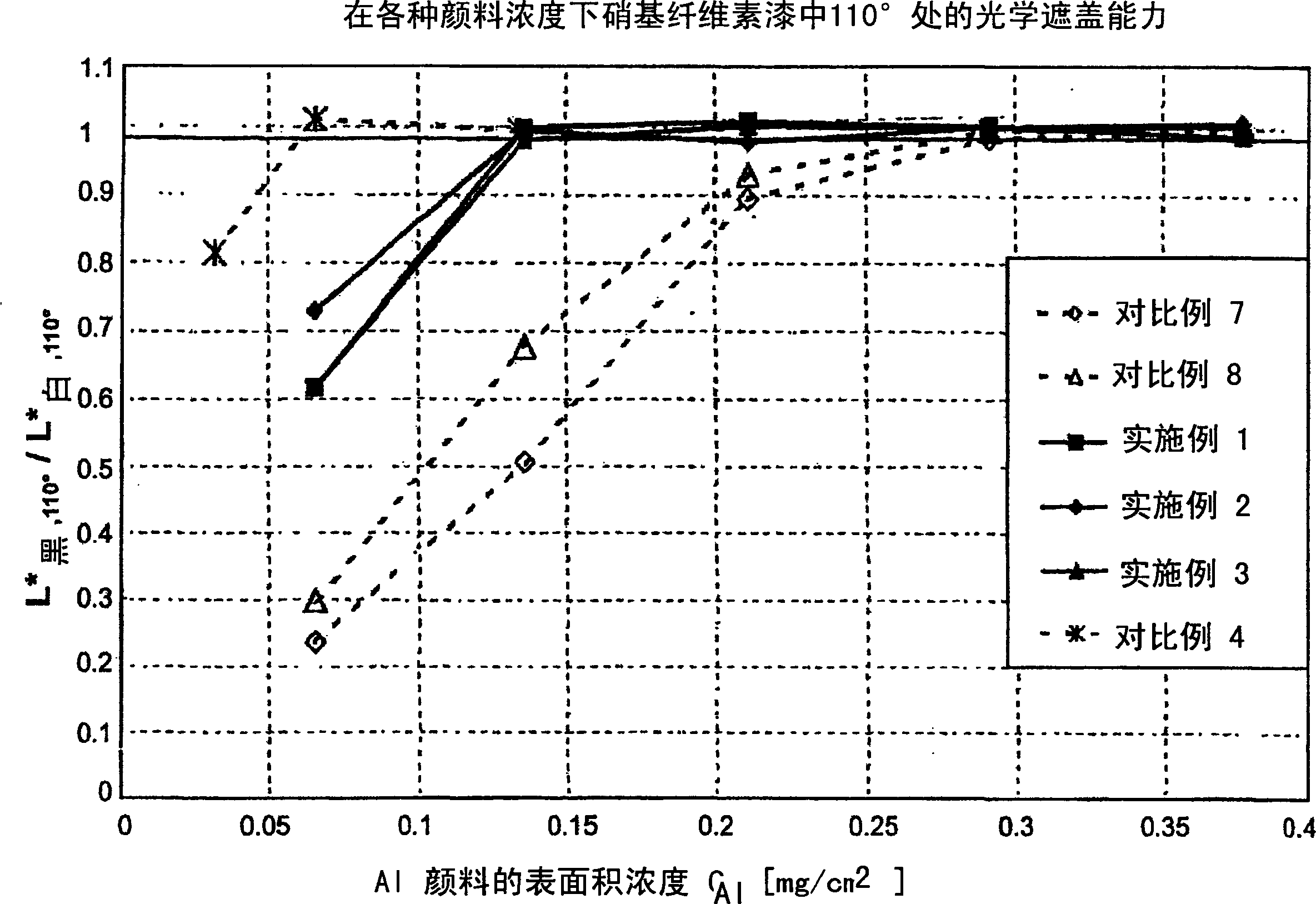

The invention relates to aluminum pigments which are at least partially coated with lubricants, wherein said aluminum pigment have a) a water coverage between 40,000 and 130,000 cm2 / g, b) a mean thickness h of less than 100 to 30 nm, as calculated from the water coverage as well as the h50 value determined from the cumulative breakthrough curve of a scanning electron microscope thickness count, c) as determined by a scanning electron microscope thickness count, a relative width of the distribution of thicknesses Deltah between 70% and 140%, which is calculated on the basis of the corresponding cumulative breakthrough curve of the relative frequencies according to the formula Delta h = 100 x h 90 - h 10 h 50 , , d) an aspect ratio d50 / h of more than 200, e) a roughness value of from 0.30 to 0.9, calculated from the specific surface area, as determined by the BET test method, and the water coverage according to the following formula BET value / 2xwater coverage. The invention also relates to a process for the manufacture of said aluminum pigments and to the use thereof.

Owner:ECKART GMBH & CO KG

Thin-layer composite film based on gas-liquid interface reaction, and preparation method and applications thereof

ActiveCN107158980AIncrease the scope of applicationFacilitates membrane fluxSemi-permeable membranesMembranesChemistryNanofiltration

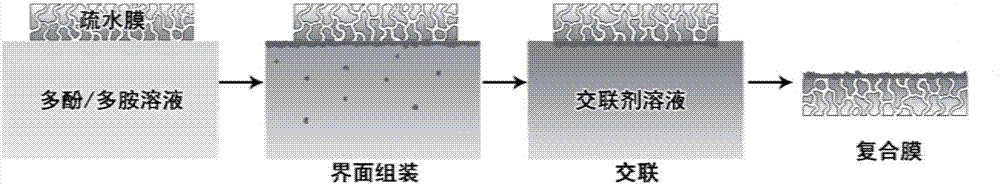

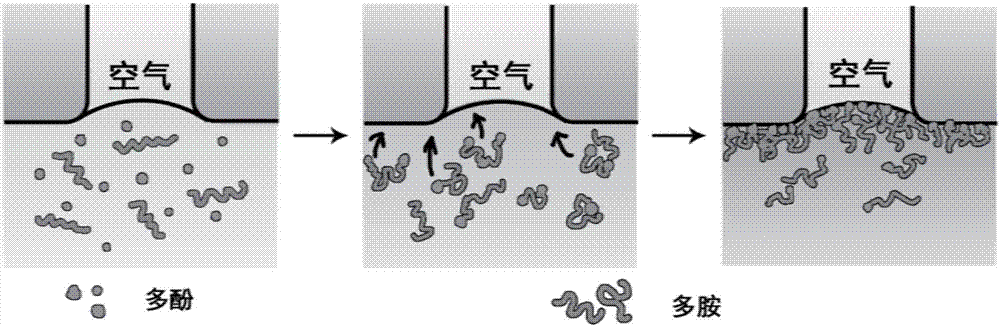

The invention discloses a preparation method of a thin-layer composite film based on gas-liquid interface reaction. The preparation method comprises following steps: 1, floating of a hydrophobic polymer porous base film on the surface of a deposition liquid is carried out, reaction is carried out for 0.1 to 12h at 10 to 90 DEG C so as to form a thin film structure on a polymer porous base film at a gas / liquid interface, wherein the deposition liquid is a solution of a polyphenol monomer and a polyamine monomer, and pH value of the deposition liquid ranges from 6 to 10; and 2, the polymer porous base film obtained in step 1 is delivered into a cross-linking agent solution for cross-linking reaction, so that a selective functional skin layer is formed thin film structure crosslinking of the polymer porous base film, and the thin-layer composite film based on gas-liquid interface reaction is obtained. The preparation method is high in controllability. The thin-layer composite film can be applied in fields such as nanofiltration, reverse osmosis, forward osmosis, or osmosis gasification.

Owner:ZHEJIANG UNIV

Tire rubber powder modified recycled plastic and preparation method thereof

The invention relates to composite materials, in particular to a tire rubber powder modified recycled plastic and a preparation method thereof. The invention aims to solve the existing zero pollution reclamation difficulty and other problems of waste tire rubber, waste plastics, etc. The tire rubber powder modified recycled plastic provided in the invention is prepared from the following raw materials by mass: 20%-70% of waste plastics, 10%-40% of tire rubber powder, 5%-26% of a flame retardant, 1%-10% of a compatibilizer, 0.1%-3% of a lubricant, 0.5%-5% of a plasticizer, and 0.05%-4% of an antioxidant. In the invention, by modifying tire rubber powder to prepare the recycled plastic, the resource utilization rate of waste tire rubber powder is enhanced, a new application technology of rubber powder is developed, the application scope of rubber powder is expanded, and at the same time, the prepared recycled plastic still has good mechanical properties, and the production cost of the recycled plastic is greatly reduced, so that the application fields of recycled plastics can be expected to be further expanded.

Owner:荆门格林循环电子废弃物处置有限公司

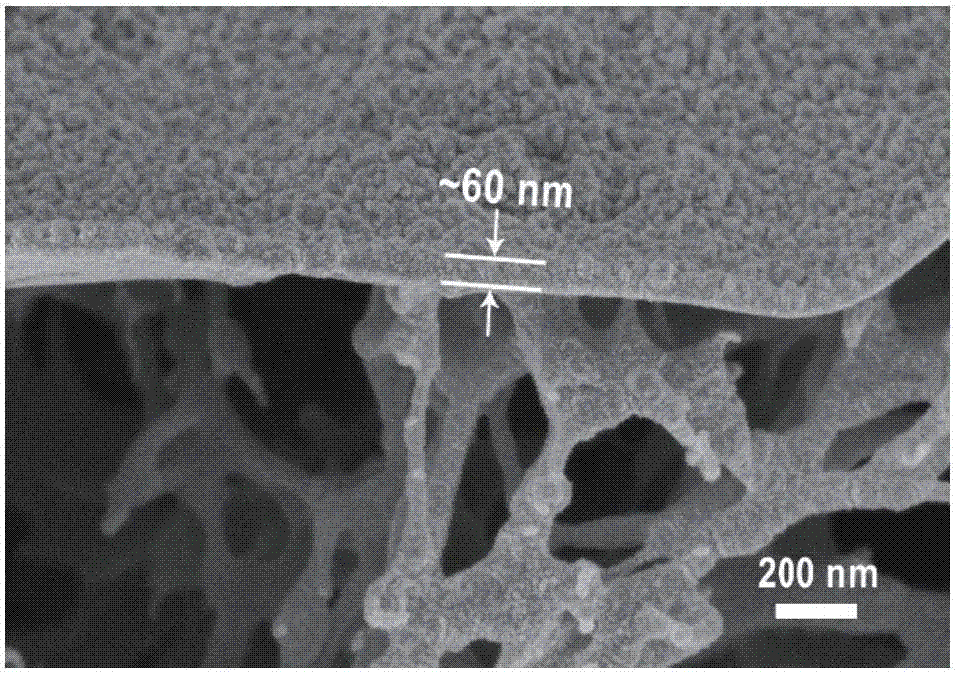

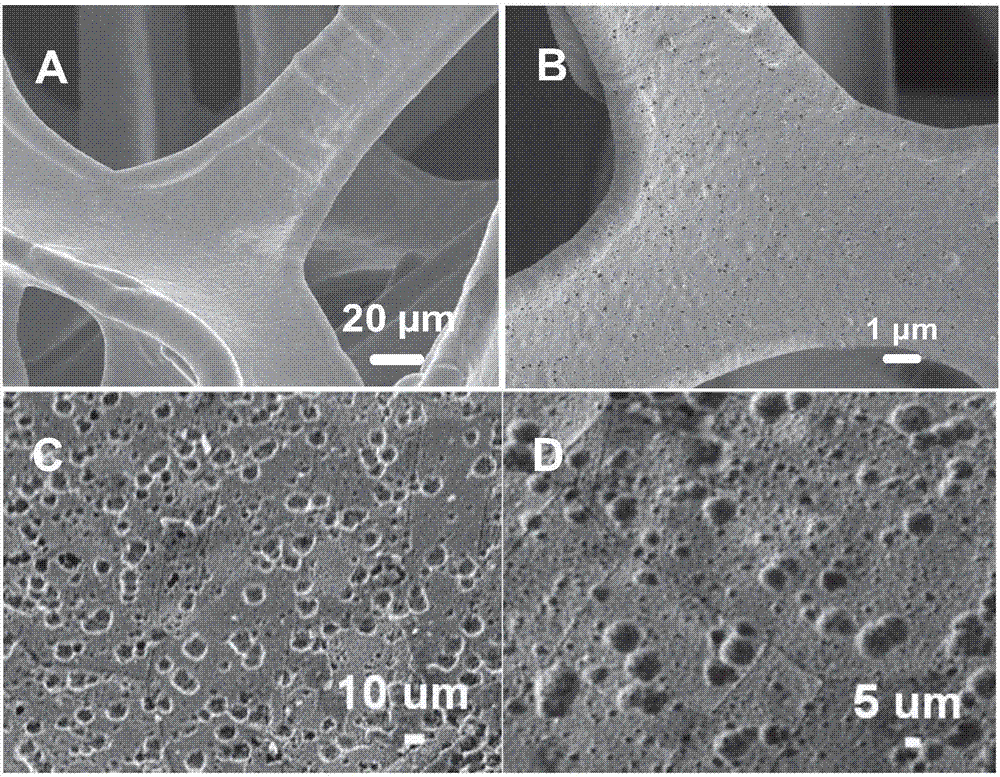

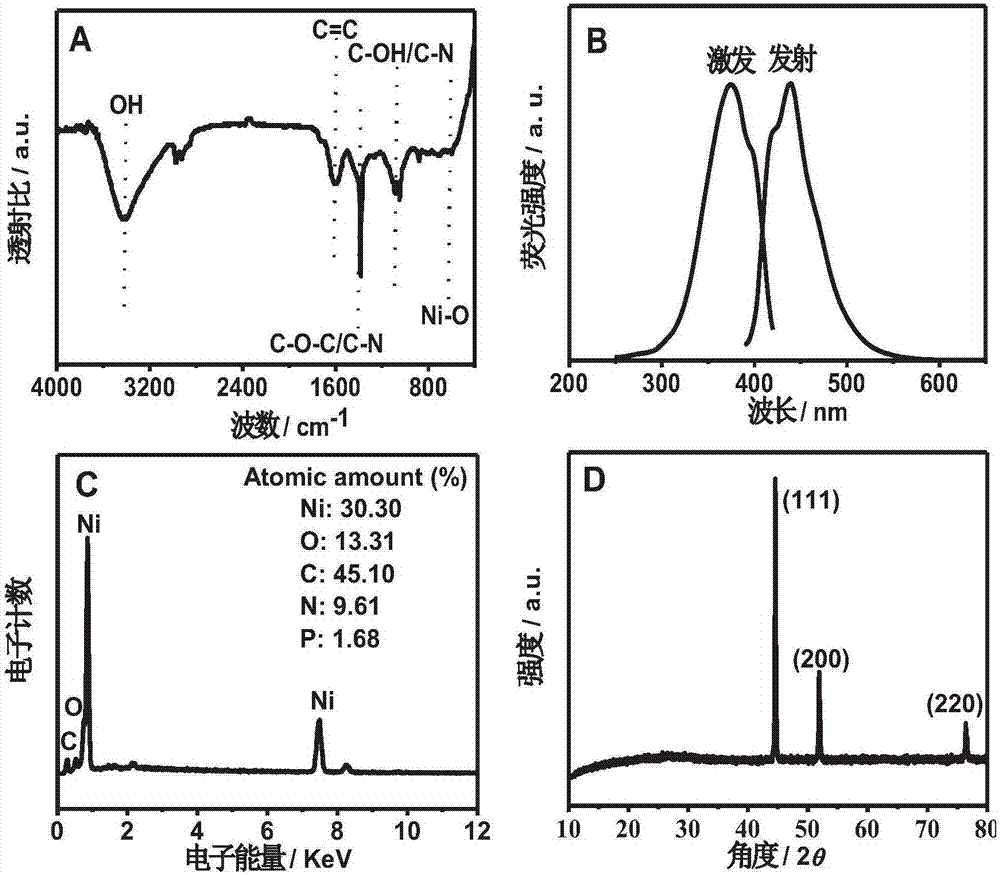

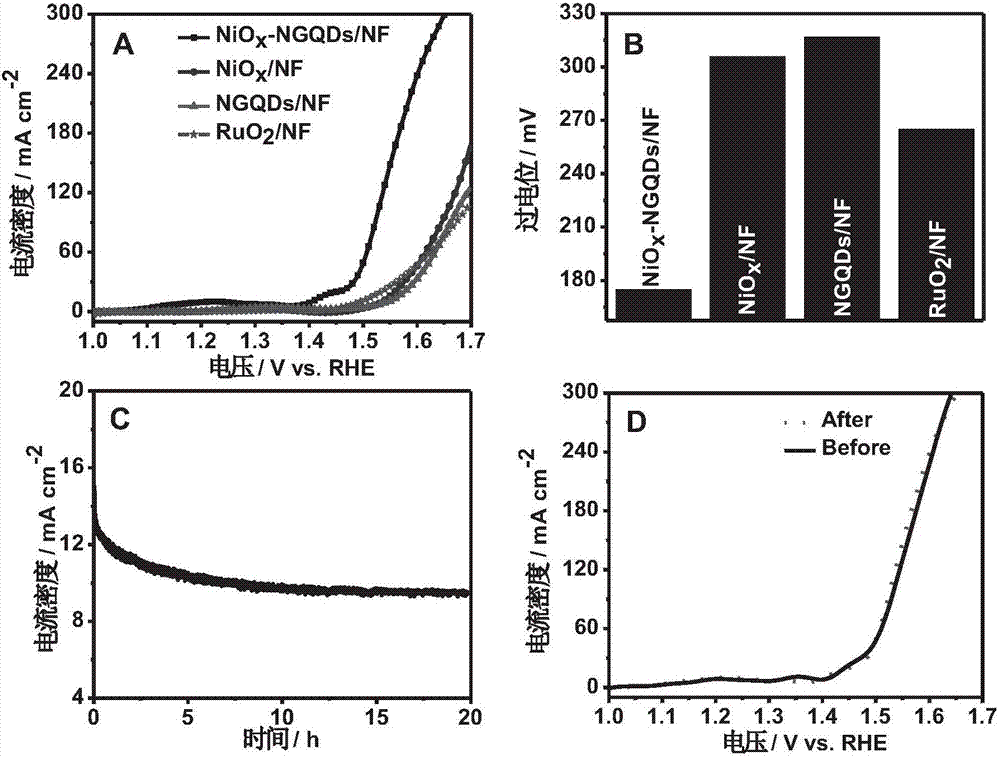

Three-dimensional porous nickel oxide and nitrogen doped graphene quantum dot composition as well as preparation method and application thereof

InactiveCN107321379ALarge specific surface areaHigh catalytic activityPhysical/chemical process catalystsElectrolysis componentsElectrolysisNitrogen

The invention discloses a three-dimensional porous nickel oxide and nitrogen doped graphene quantum dot composition which is prepared from foamed nickel as a matrix, a great number of micron-order pores in the surface of the foamed nickel in an oxidation etching manner, meanwhile a three-dimensional porous structure of the foamed nickel is maintained, and the nickel oxide and nitrogen doped graphene quantum dot composition is formed on the surface of the foamed nickel. The composition has excellent electric catalysis upon oxygen evolution reactions in alkali systems, and overpotential of electrolysis water oxygen evolution reactions can be effectively reduced. The invention further discloses a preparation method of the composition.

Owner:NANJING UNIV

Waste tire rubber powder-filled plastic wood profile and preparation method thereof

The invention relates to a composite material, and particularly relates to a waste tire rubber powder-filled plastic wood profile and a preparation method thereof. The waste tire rubber powder-filled plastic wood profile of the invention is prepared by the following raw materials by mass: 15%-75% of plastics, 10%-70% of wood fibers, 5%-40% of waste tire rubber powder, 5%-45% of a fire retardant, 1%-10% of a compatibilizer, 0.1%-3% of a lubricant, 0.5%-3% of a plasticizer, 0.05%-4% of an anti-oxidant, and 0.05%-2% of a vulcanizing agent. According to the invention, the plastic wood profile is filled with the waste tire rubber powder, which not only improves the resource utilization rate of waste tire rubber powder, develops new application technology of the rubber powder, extends the application scope of the rubber powder, but also provides good mechanical properties for the prepared plastic wood profile, greatly reduces the production cost of the plastic wood profile, and is expected to further extend the application fields of the plastic wood profile.

Owner:GEM CO LTD

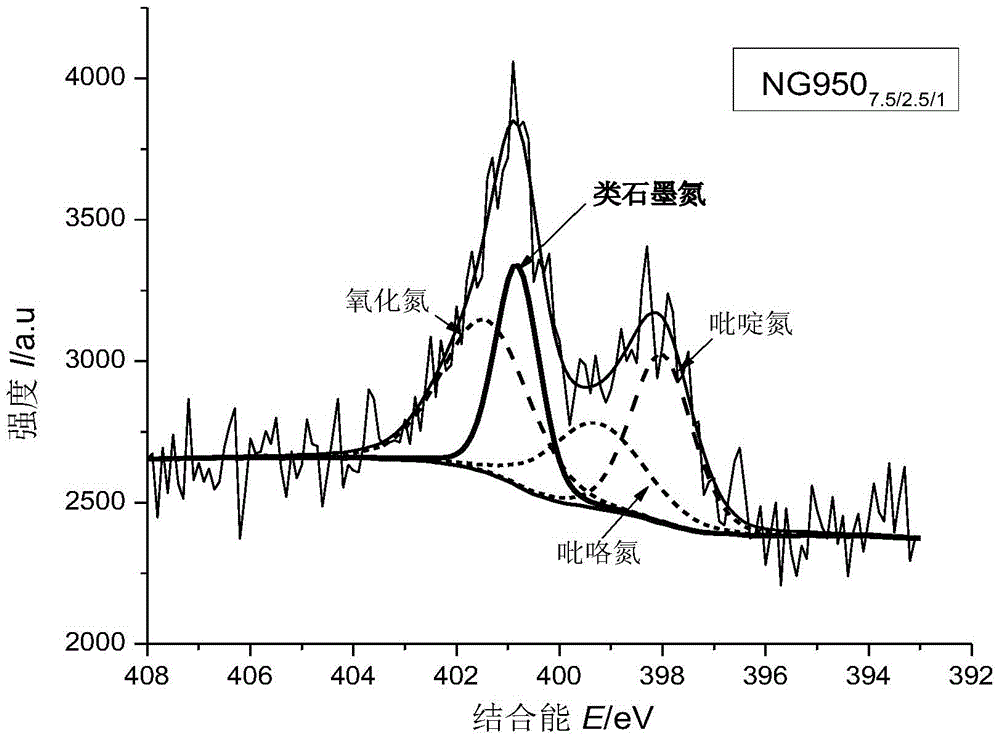

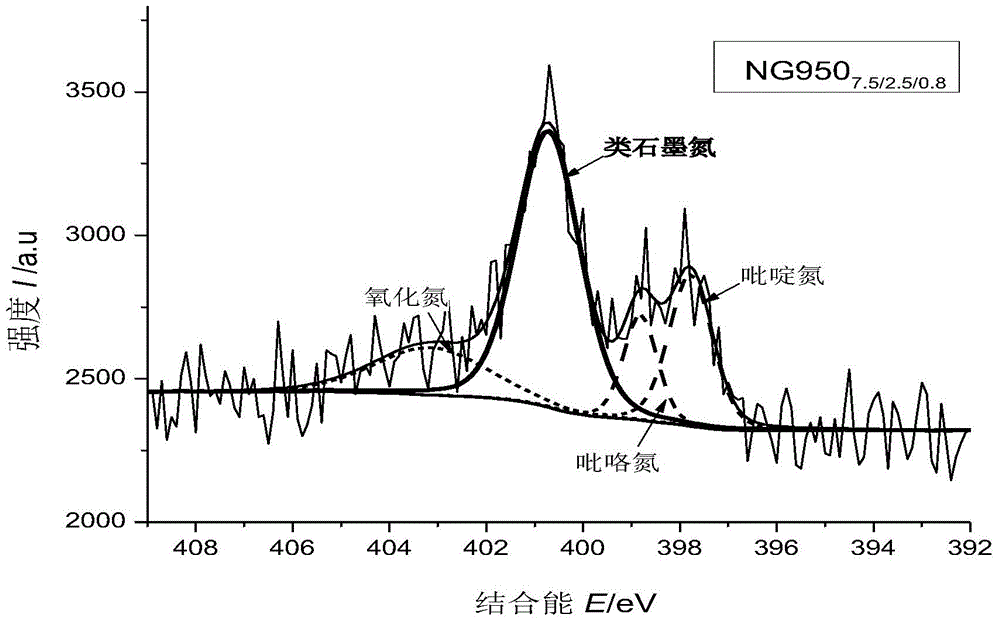

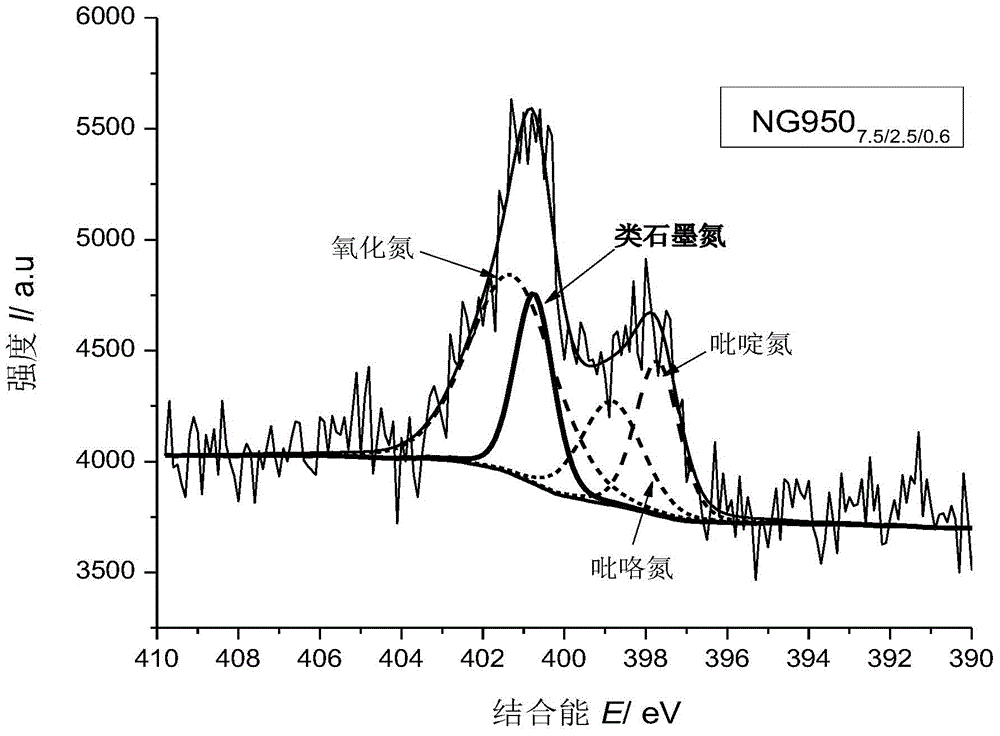

Nitrogen-doped graphene catalyst as well as preparation method and application thereof

InactiveCN104525235AIncrease inertiaImprove hydrophobicityPhysical/chemical process catalystsCell electrodesNitrogen doped grapheneNitrogen gas

The invention discloses a nitrogen-doped graphene catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: drying and dehydrating glucose and urea, and mixing with melamine, wherein the mass ratio of the urea to melamine is 2-4; uniformly grinding the mixture, and calcining the mixture into a muffle furnace at the temperature of 550 DEG C for 3 hours; cooling and grinding uniformly, adding the mixture into a tube furnace, introducing into nitrogen protection, calcining at the temperature of 850-1000 DEG C for an hour, thereby obtaining the nitrogen-doped graphene catalyst. According to the in-situ nitrogen-doped graphene disclosed by the invention, the used raw materials are low in price, the method is simple, the yield is high, and graphite-like nitrogen doped graphene with the highest ratio is obtained by changing the rate of the raw materials and the temperature, so that the catalyst has a good oxidation-reduction effect, and expensive Pt can be replaced to a certain degree.

Owner:SOUTH CHINA UNIV OF TECH

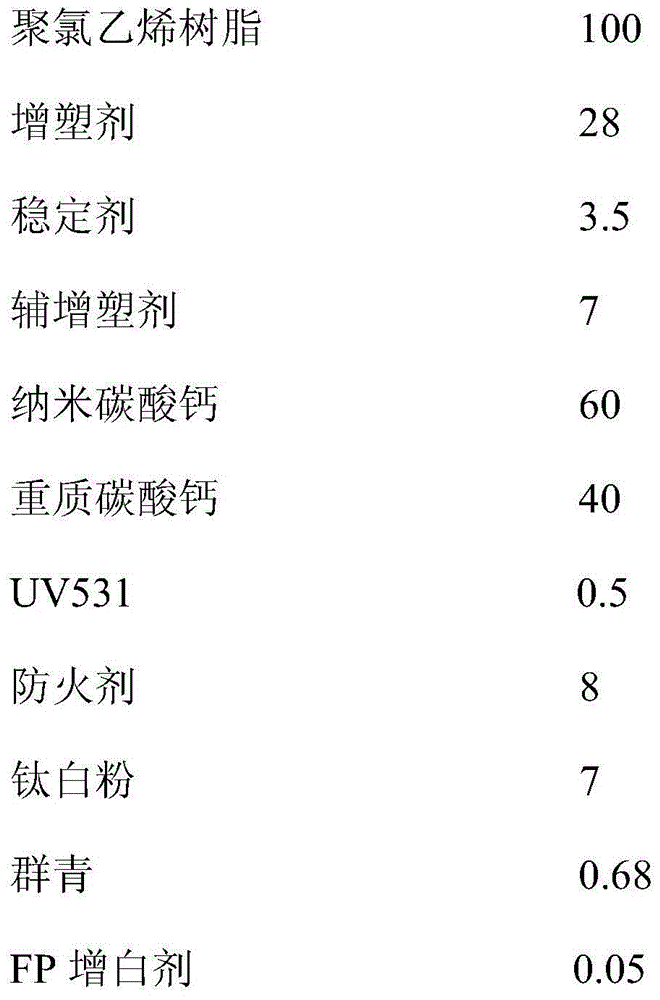

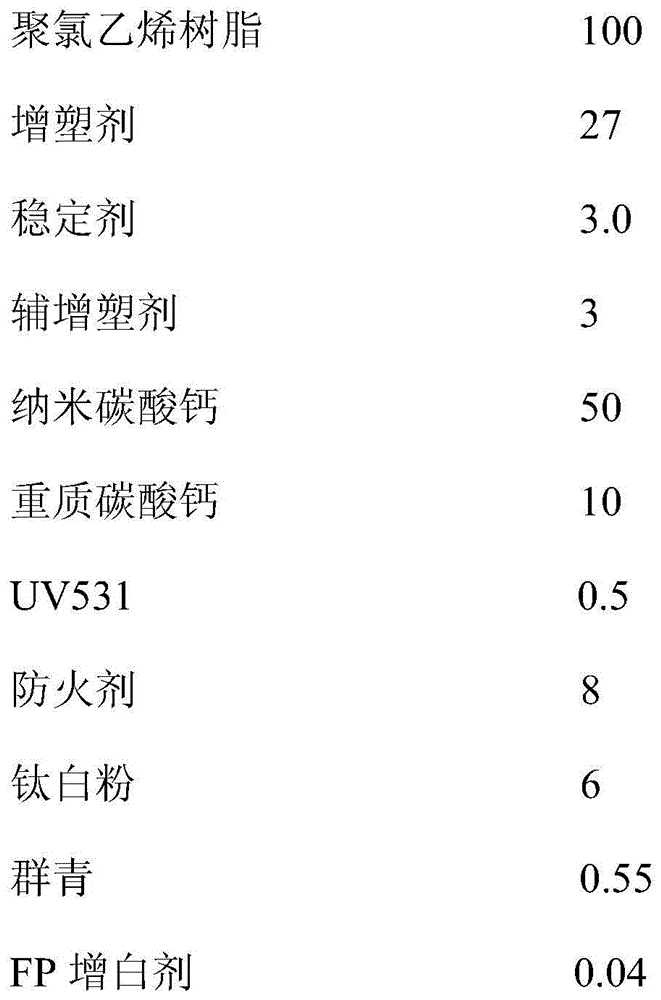

PVC laminated composite cloth comprising films formed through extrusion method and preparation method thereof

InactiveCN104149448ALow costImprove performanceLamination ancillary operationsSynthetic resin layered productsAging resistanceEngineering

The invention relates to a laminated composite material synthesized of warp-knitted and textile materials and PVC and discloses PVC laminated composite cloth comprising films formed through extrusion method. The PVC laminated composite cloth comprises base cloth, a bottom film and a surface film, wherein the bottom film and the surface film are arranged at the two sides of the base cloth and are both PVC thin films The PVC laminated composite cloth has the advantages that the cost is low, the applicability is strong, the performances are good, specifically, the peeling strength, the elasticity, the tensile strength and the tearing strength are obviously improved and the waterproof performance, the flame-retardant performance and the ageing resistance are excellent. The invention also discloses a preparation method of the PVC laminated composite cloth comprising films formed through extrusion method. The preparation method comprises the following steps of: firstly compositing the specific bottom film prepared by extrusion and the base cloth, then compositing with the specific surface films prepared by extrusion. The preparation method disclosed by the invention has the advantages that since no boiler is used and carbon dioxide is not exhausted, air pollution is hardly caused; only cooling circulation water is used, so water pollution cannot be caused; and the process is simple, the energy consumption is low, the popularity rate is high, the cost is low, the profit margin is large and the application prospect is wide.

Owner:胡新佳

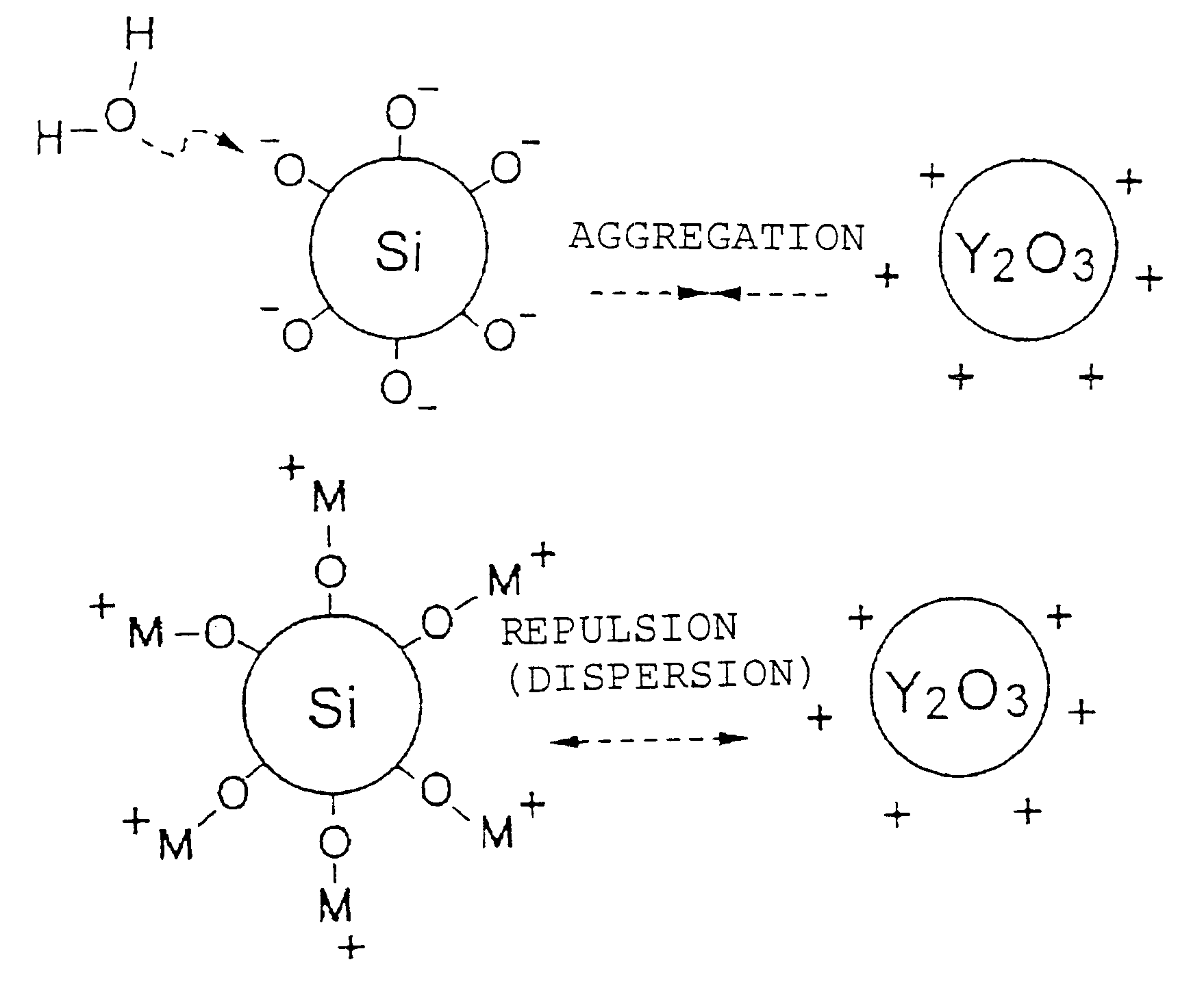

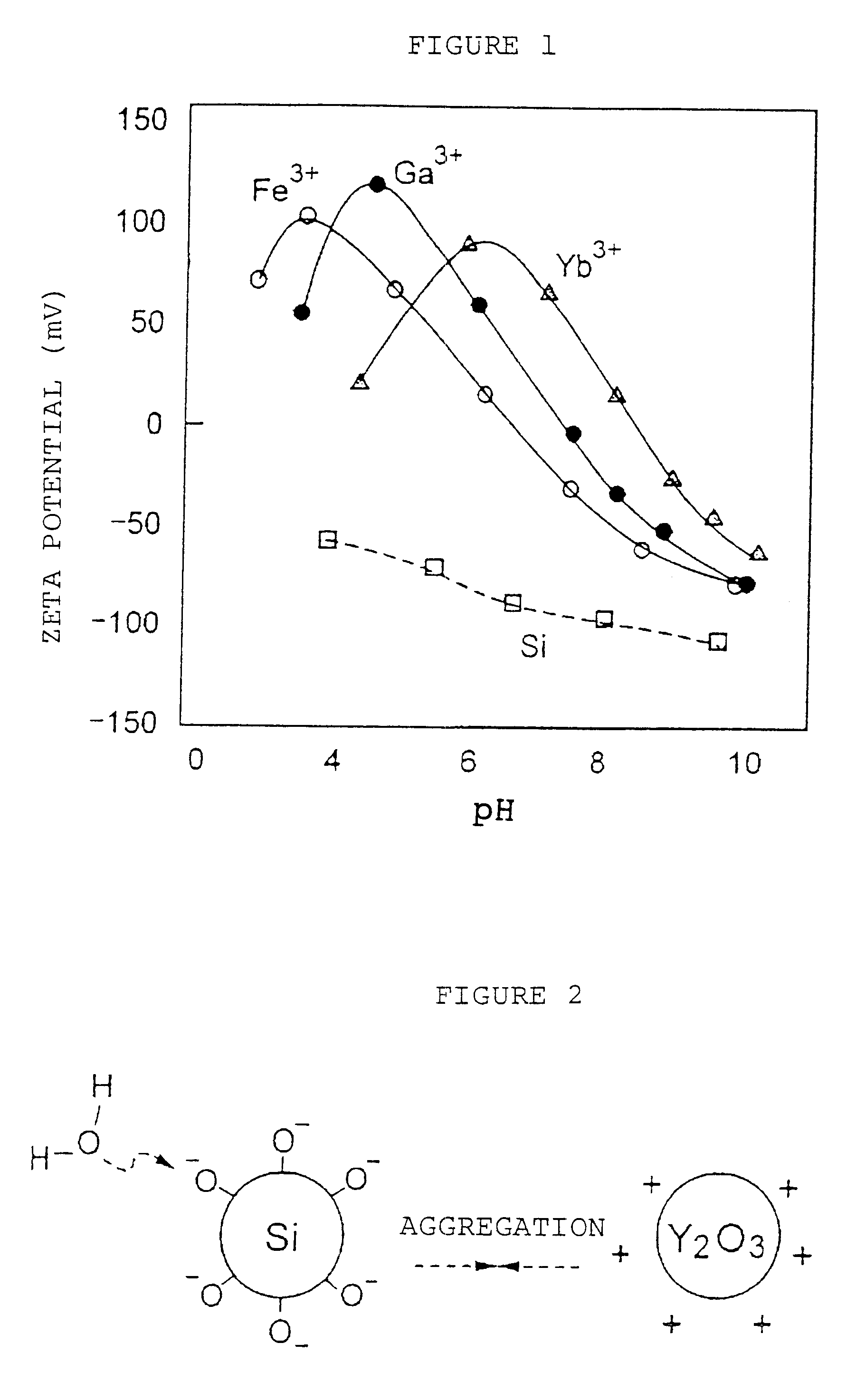

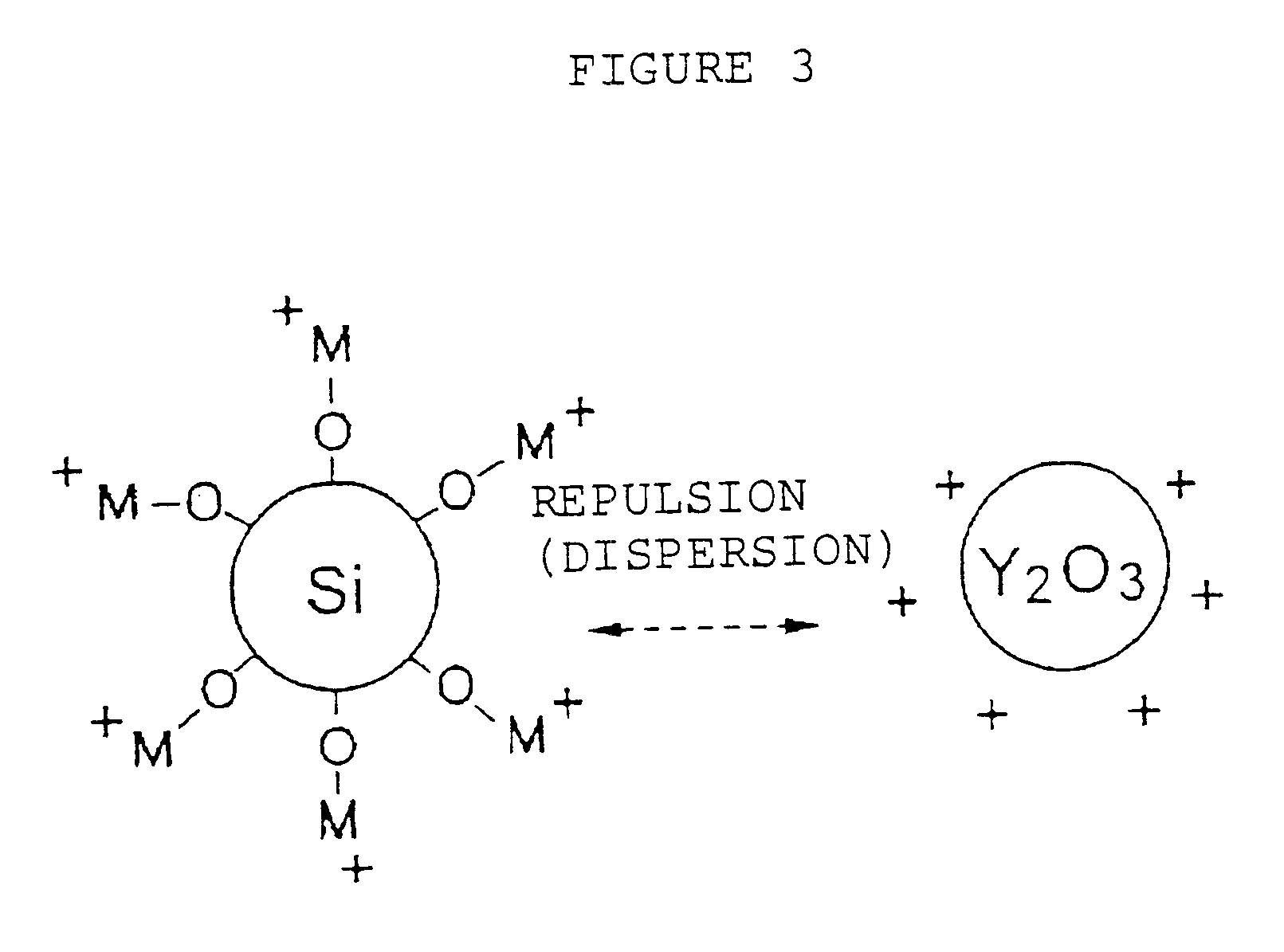

Si3N4 ceramic, Si-base composition for its production, and method for its production

InactiveUS6544917B1Improve oxidation resistanceImprove dispersion propertyMaterial nanotechnologySlurryOxygen

The invention provides a slurry composition suitable for the manufacture of Si.sub.3 N.sub.4 sintered bodies, wherein the dispersion properties and oxidation resistance of Si powder in water are improved, resulting in the homogenous dispersion of a sintering aid powder and a fine Si powder with less oxygen. Si powder, a sintering aid, water in an amount of 50 to 90 wt % relative to the total weight of the composition, and a surface coating agent in an amount of 0.05 to 10 wt % relative to the Si powder are added, the pH is adjusted to between 3 and 8, and the ingredients are milled and mixed. Trivalent metal ions such as Fe or Ga, or a polysiloxane with a BHL of no more than 10 is used as the surface coating agent. The resulting slurry composition can be used to prepare Si.sub.3 N.sub.4 sintered bodies with better electrical, thermal, and mechanical properties.

Owner:SUMITOMO ELECTRIC IND LTD

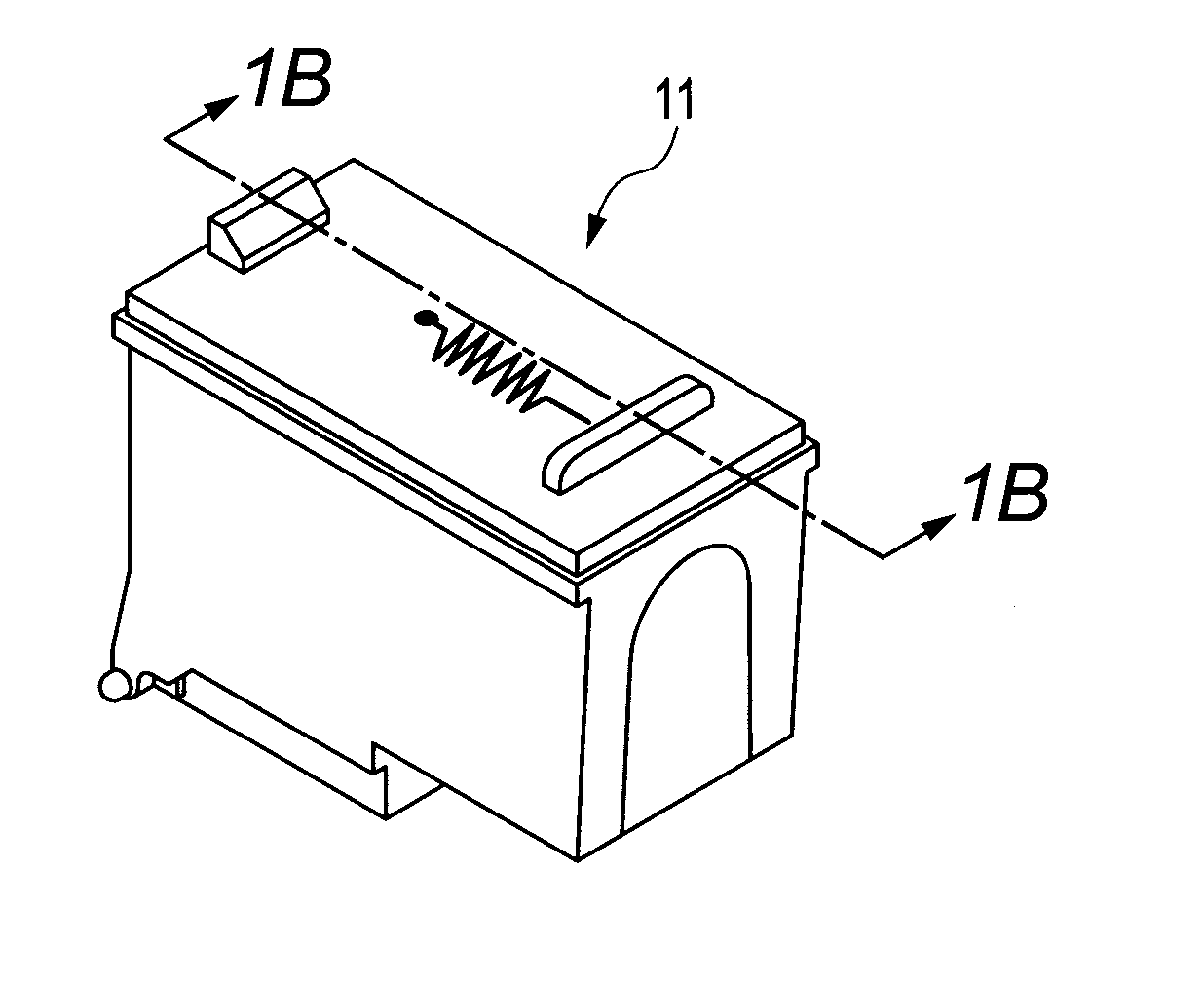

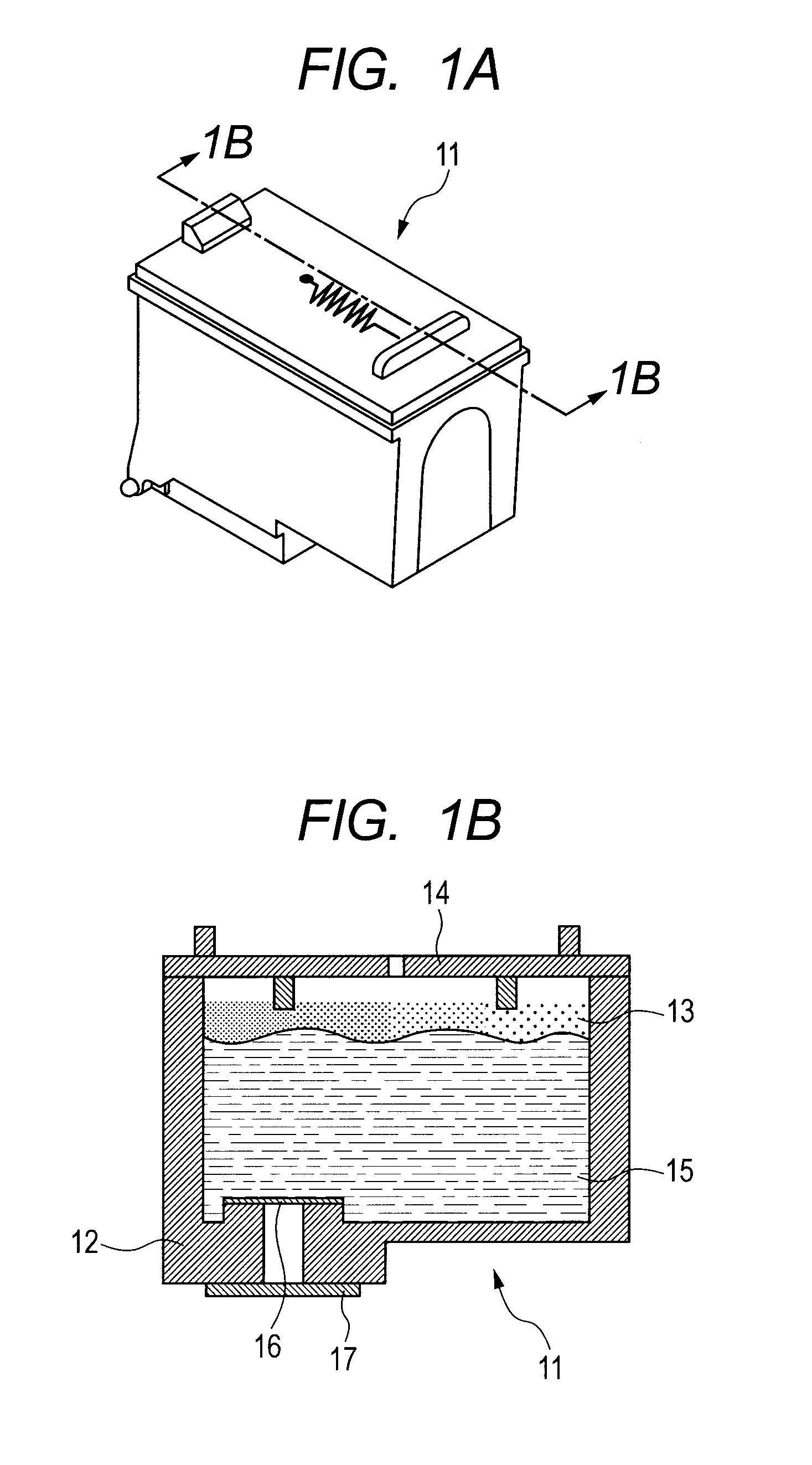

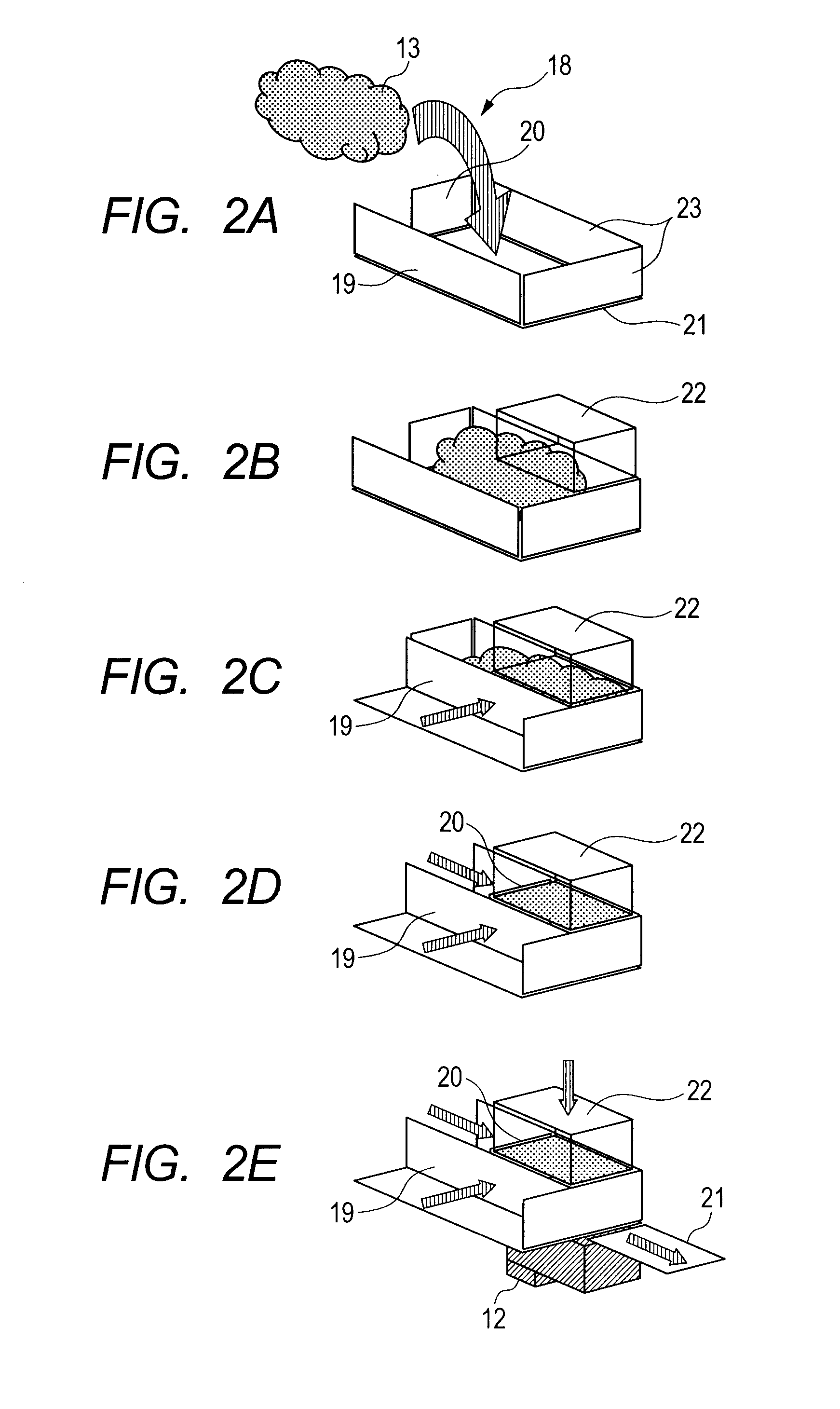

Method for manufacturing ink jet cartridge

InactiveUS20110209335A1Simply and stably formingNo wastePrintingMetal working apparatusFiberMechanical engineering

A predetermined amount of an ink absorber, which is a fiber assembly in which intersections between fibers are not fused together, is charged into a compression and insertion apparatus. A rectangular parallelepiped-shaped insertion block is moved to an upper surface portion of the absorber, and one face of the ink absorber is pushed by a side plate. As such, a part excluding the part of the ink absorber which faces the side plate is compressed and surrounded. In this state, the ink absorber is compressed by the side plate. The ink absorber is inserted into a tank case by making a bottom plate slide, thereby opening the bottom face of the ink absorber and by moving down the insertion block.

Owner:CANON KK

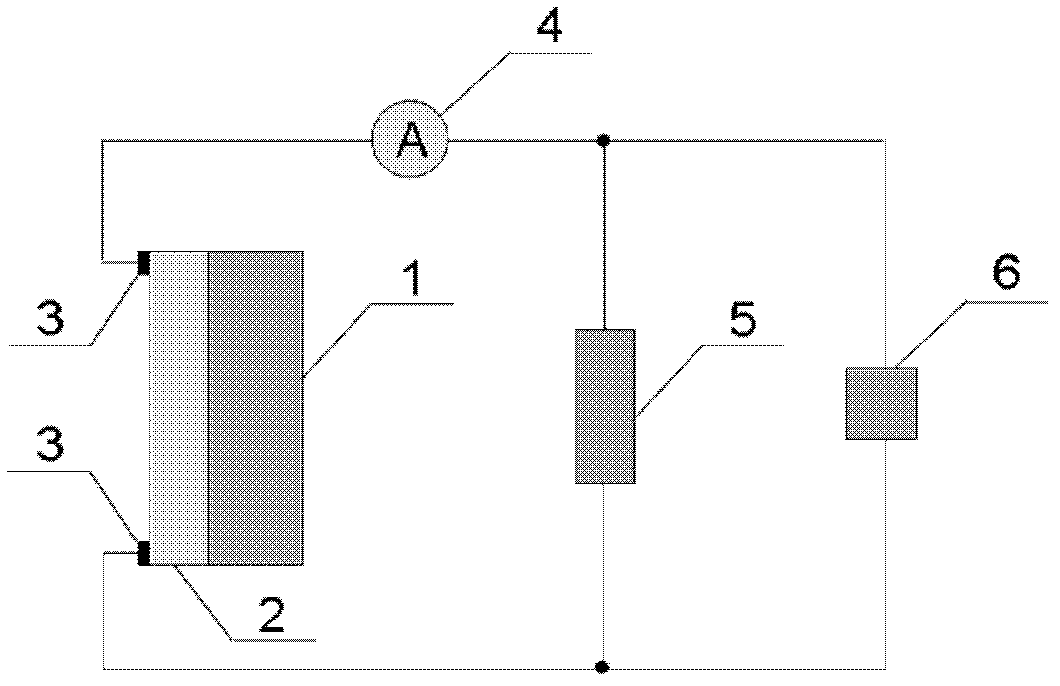

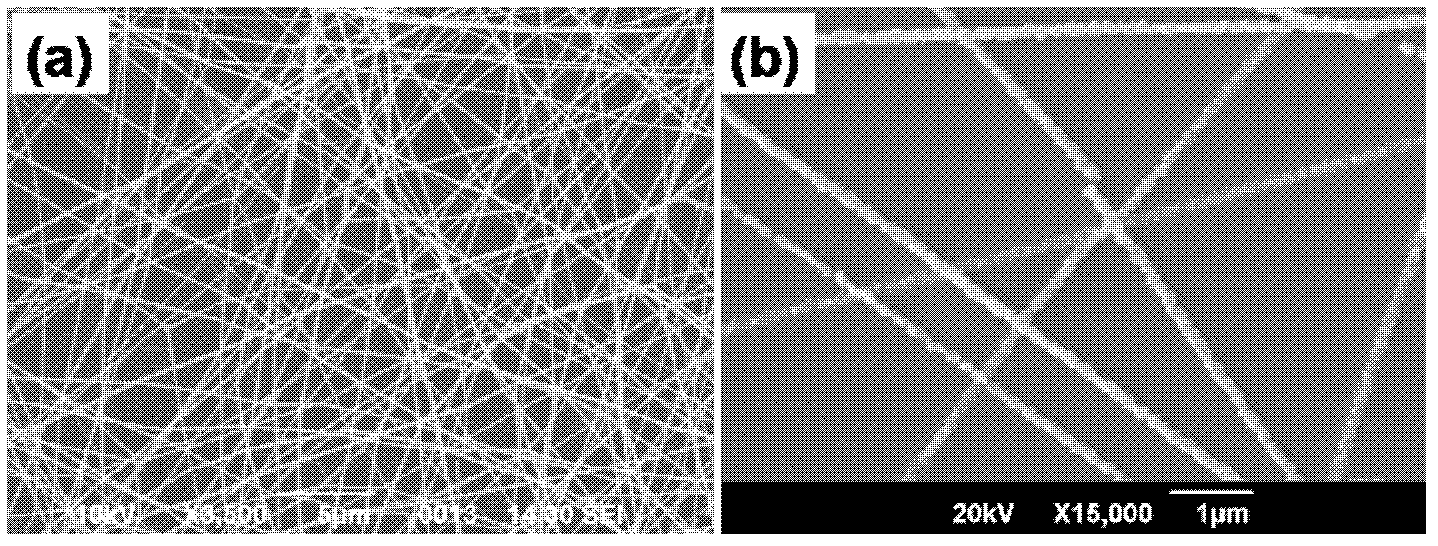

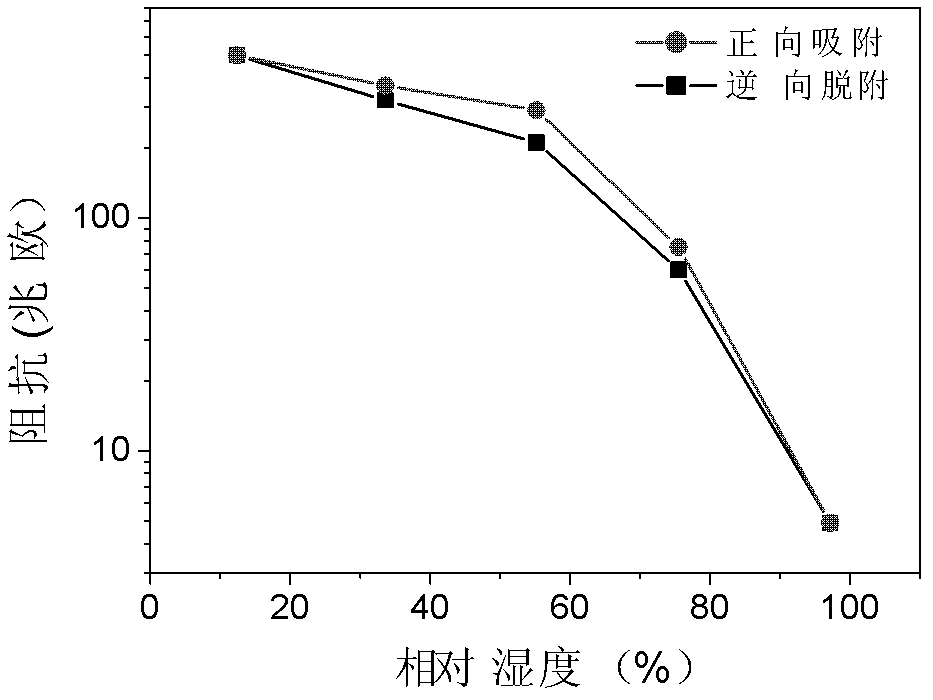

Quick response and recovery type barium titanate nanofiber humidity dependent sensor

The invention belongs to the technical field of sensor manufacture and relates to a quick response and recovery type barium titanate nanofiber humidity dependent sensor. Humidity response layers formed by a collection method on a base plate using a glass, mica or sapphire material as a non-conducting substrate is barium titanate nanofibers prepared by electrostatic spinning; the base plate is encapsulated in a sealed cavity type housing; electrode lead wires are led out through electrodes by using coaxial cables; two electrodes are fixed on the humidity response layers at two ends of the base plate respectively; and one electrode is connected in series with a current meter through a lead wire and then is connected with an end point of a rheostat, which is connected in parallel with a direct current power supply, while the other electrode is connected with the other end point of the rheostat, which is connected in parallel with the direct current power supply, so that the humidity sensor is formed. The quick response and recovery type barium titanate nanofiber humidity dependent sensor is characterized by simple manufacturing method, low cost, high production efficiency, large humidity sensitive width, high sensitivity and quick recovery and can be widely applied in various fields such as forestry and animal husbandry and the like.

Owner:QINGDAO UNIV

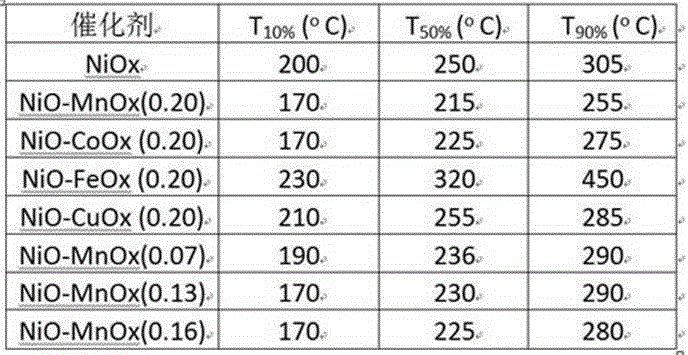

Catalyst for propane catalytic combustion elimination as well as preparation method and application of catalyst

InactiveCN104383925ALow priceEasy to prepareDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSolventHydrogen peroxide

The invention provides a preparation method of a catalyst for propane catalytic combustion elimination. The preparation method comprises the following steps: doping metal species into nickel oxide by adopting a coprecipitation method, dropwise adding a 2mol / L sodium carbonate or potassium carbonate solution into a 0.2mol / L precursor mixed solution to form a precipitate, wherein a solvent of the precursor mixed solution is 10wt% alcohol solution, wherein the volume ratio of the sodium carbonate or potassium carbonate solution to the precursor mixed solution is 2:5; dropwise adding 5-8ml of 30% hydrogen peroxide while dropwise adding a sodium carbonate or potassium carbonate precipitator, wherein the volume ratio of the added hydrogen peroxide to the precursor mixed solution is 1:20; and performing suction filtration on the precipitator, drying at 50-100 DEG C, and roasting at 250-450 DEG C roasting to obtain catalysts doped by different metals for propane catalytic combustion elimination. The catalyst is prepared by adopting the coprecipitation method, and is low in price; the preparation method is simple.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

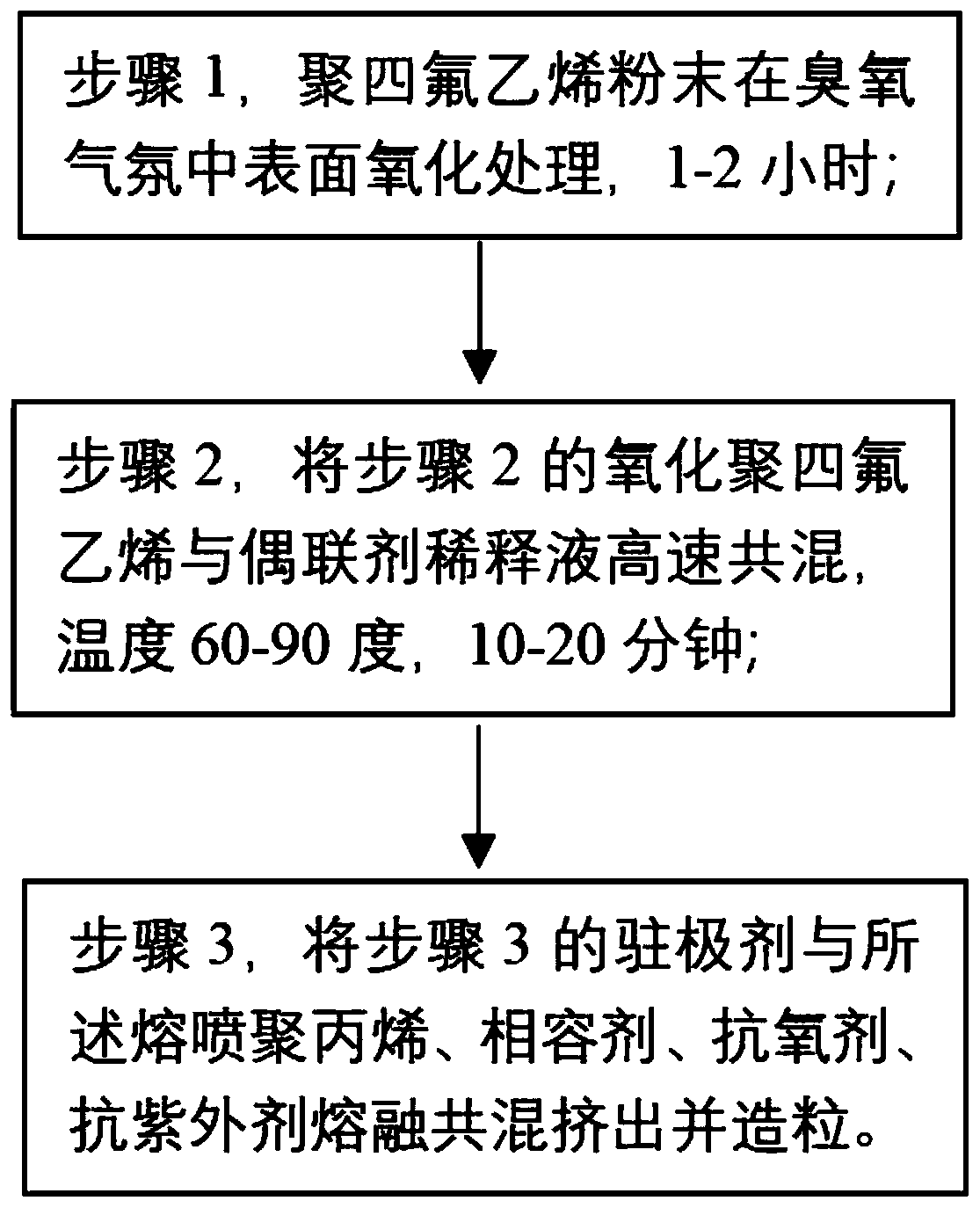

Melt-blown polypropylene electret master batch and preparation method thereof

InactiveCN111303539AElectret effect is goodImprove filtration efficiencyMonocomponent polyolefin artificial filamentArtifical filament manufacturePolymer scienceAntioxidant

The invention discloses a melt-blown polypropylene electret master batch which comprises the following components in parts by weight: 45-100 parts of polypropylene, 5-70 parts of an electret, 1-5 parts of a compatilizer, 0.01-1 part of an antioxidant, and 0.01-5 parts of an anti-ultraviolet agent. The invention also discloses a preparation method of the melt-blown polypropylene master batch material. The master batch has the following beneficial effects: polytetrafluoroethylene subjected to oxidation by ozone and surface modification by a coupling agent is used as an electret, polypropylene resin and corresponding auxiliaries are mixed in a melt blending granulation mode to obtain a melt-blown polypropylene electret master batch material, and a non-woven fabric fiber product produced fromthe master batch and a pure polypropylene raw material has the advantages of being obvious in electret effect, high in filtering efficiency, small in wind resistance and the like. The melt-blown polypropylene electret master batch and the preparation method thereof have the advantages of simplicity, quickness and cheapness, and are suitable for large-scale batch production.

Owner:中山市鸿盛新材料有限公司

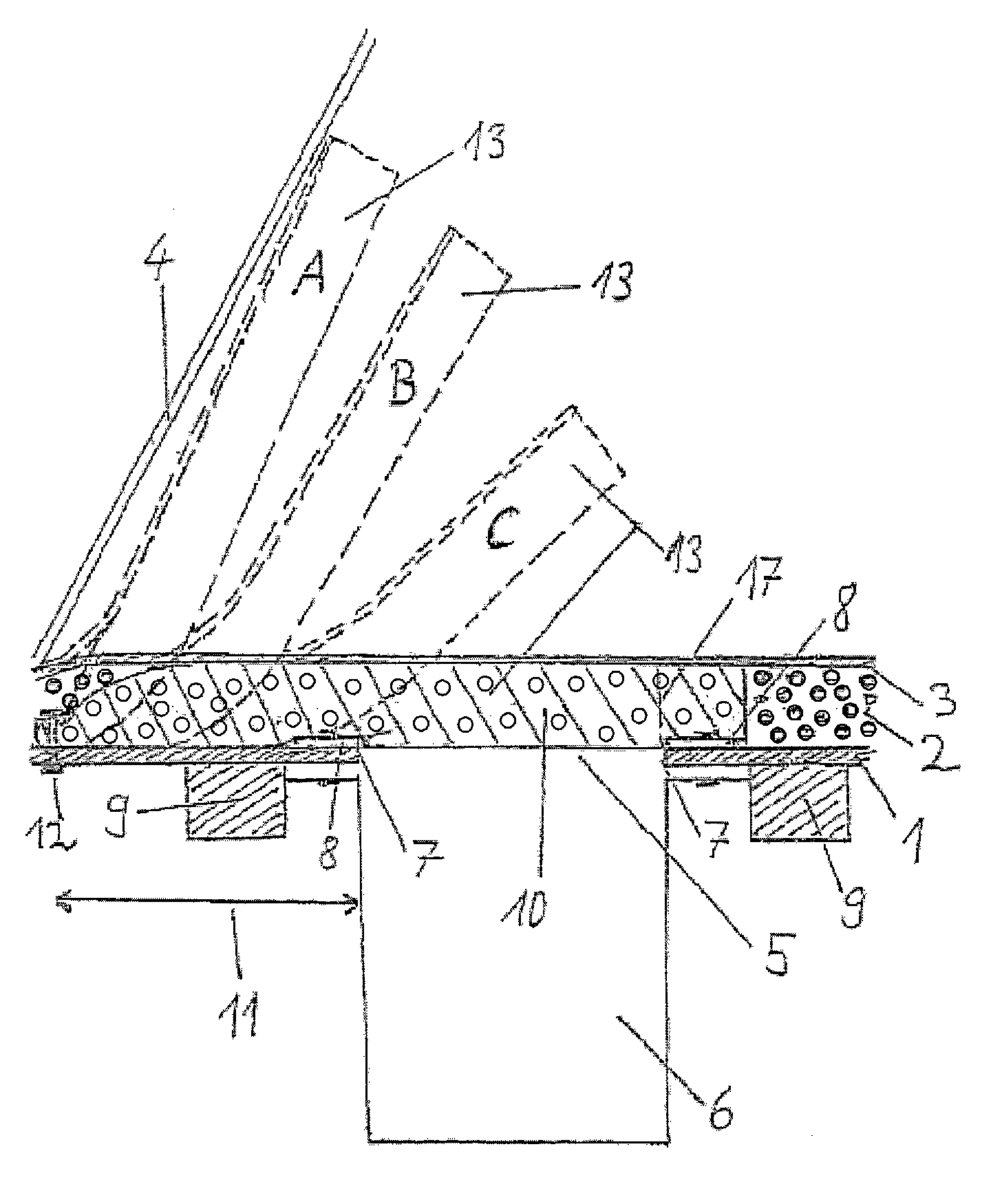

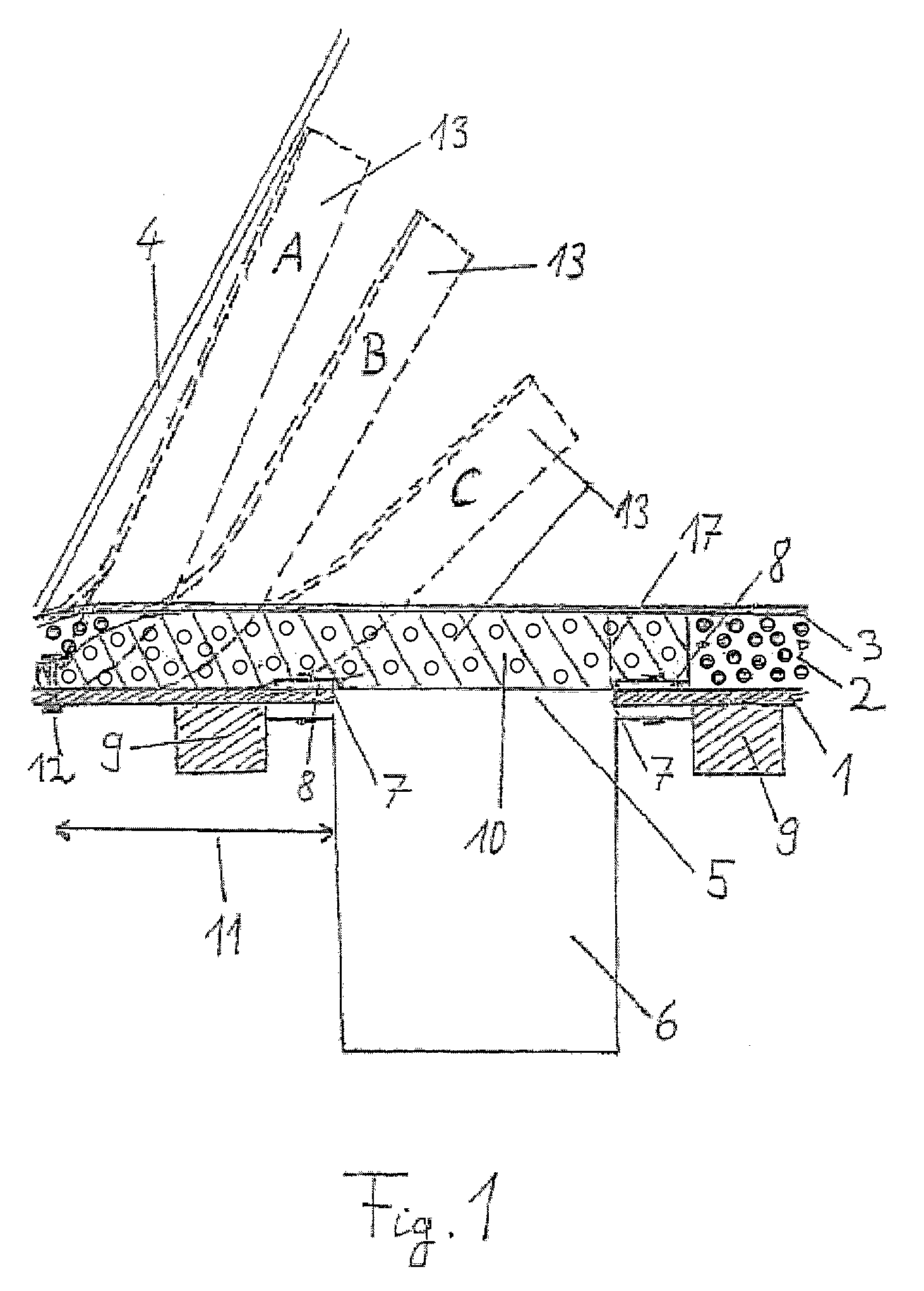

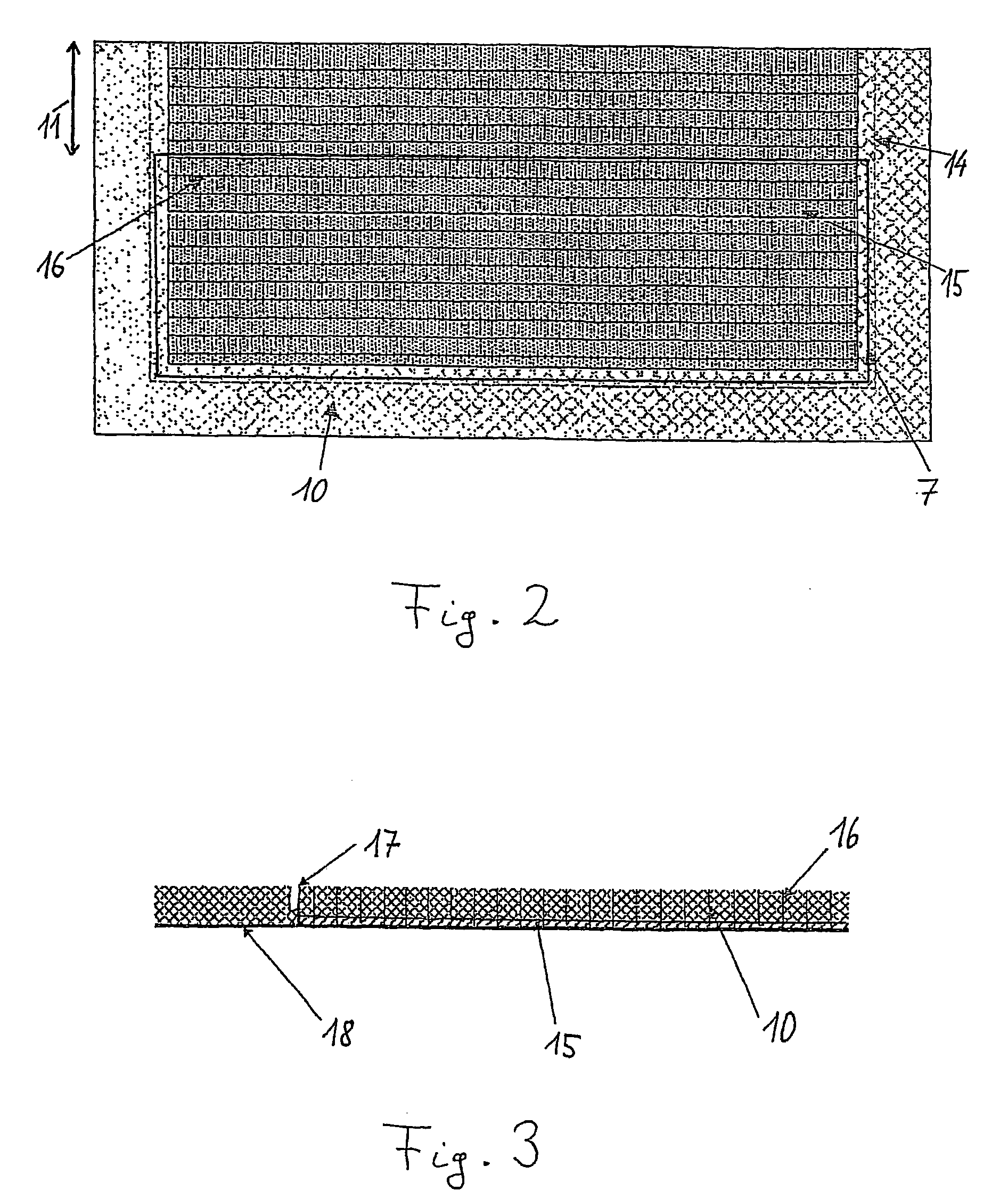

Interior trim part for covering an airbag

ActiveUS7611163B2Simple and inexpensive in constructionPrevent an uncontrolled bursting openPedestrian/occupant safety arrangementSynthetic resin layered productsEngineeringAirbag

Owner:FAURECIA INNENRAUM SYST

Preparation method for ionic liquid hybrid imprinted material

ActiveCN105131181ASolve complexityResolve separabilityOther chemical processesFunctional monomerDouble bond

The invention discloses a preparation method for an ionic liquid hybrid imprinted material. The preparation method comprises the following steps: uniformly mixing a silylating reagent containing an electronegative group at the tail end of an alkyl chain and an imidazole compound in a molar ratio of 1:(1-3) and carrying out a reaction to obtain an ionic liquid; sequentially adding template molecules, functional monomers, a crosslinking agent containing 2-3 double-bond functional groups and an initiator into the ionic liquid, and fully dissolving the components to obtain an organic phase; dissolving a silane crosslinking agent in an organic solvent, and sequentially adding water and ammonia water to dissolve to obtain an inorganic phase; introducing nitrogen, adding the organic phase into the inorganic phase, and carrying out a reaction at 60-80 DEG C for 8-36 hours; washing out the template molecules; and washing the liquid to neutral and drying the liquid to obtain the ionic liquid hybrid imprinted material. The material prepared by the preparation method disclosed by the invention can be used for extracting and separating various and multiple types of targets and the whole preparation process is mild in reaction condition, relatively low in equipment demand, simple in process, convenient to operate, environmental-friendly and suitable for large-scaled production, popularization and application.

Owner:HEBEI UNIVERSITY

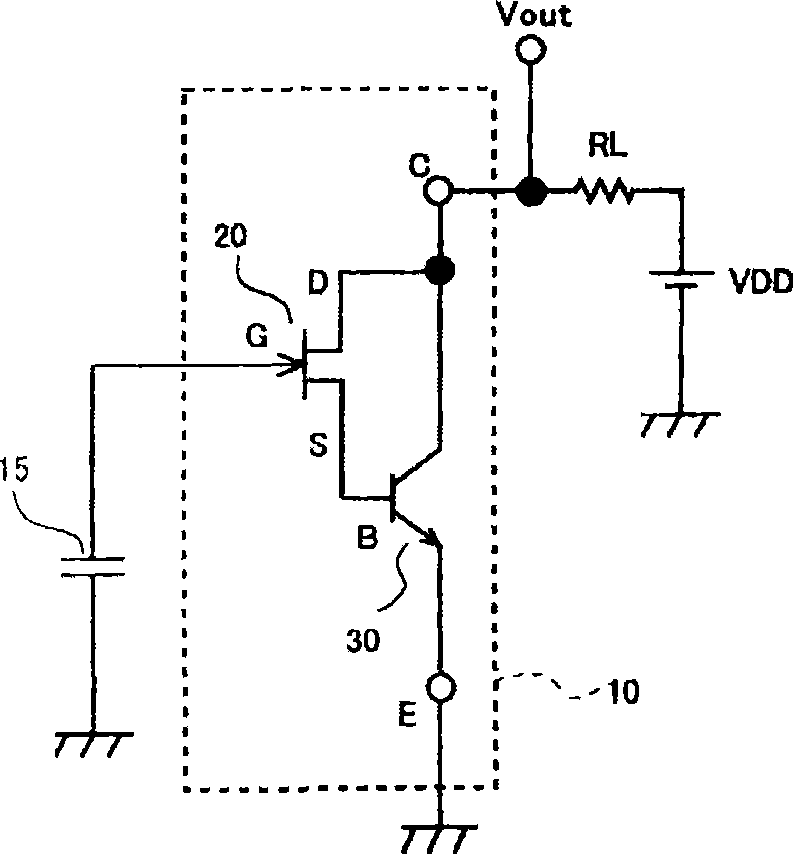

Amplifying element and manufacturing method thereof

ActiveCN101546985AHigh input impedanceEnough outputAmplifier modifications to reduce temperature/voltage variationSolid-state devicesHemt circuitsInput impedance

The present invention provides an amplifying element and manufacturing method thereof. An amplifier integrated circuit element or J-FET is used for impedance conversion and amplification of ECM. The amplifier integrated circuit element has advantages of allowing an appropriate gain to be set by adjusting a circuit constant, and of producing a higher gain than the J-FET; but also has a problem of having a complicated circuit configuration and requiring high costs. On the other hand, using only the J-FET has also problems of outputting a voltage insufficiently amplified and producing a low gain. The invention provides a discrete element in which: a J-FET and a bipolar transistor are integrated on one chip; a source region of the J-FET is connected to a base region of the bipolar transistor; and a drain region of the J-FET is connected to a collector region of the bipolar transistor. Accordingly, an ECM amplifying element with high input impedance and low output impedance can be achieved.

Owner:SANYO ELECTRIC CO LTD +1

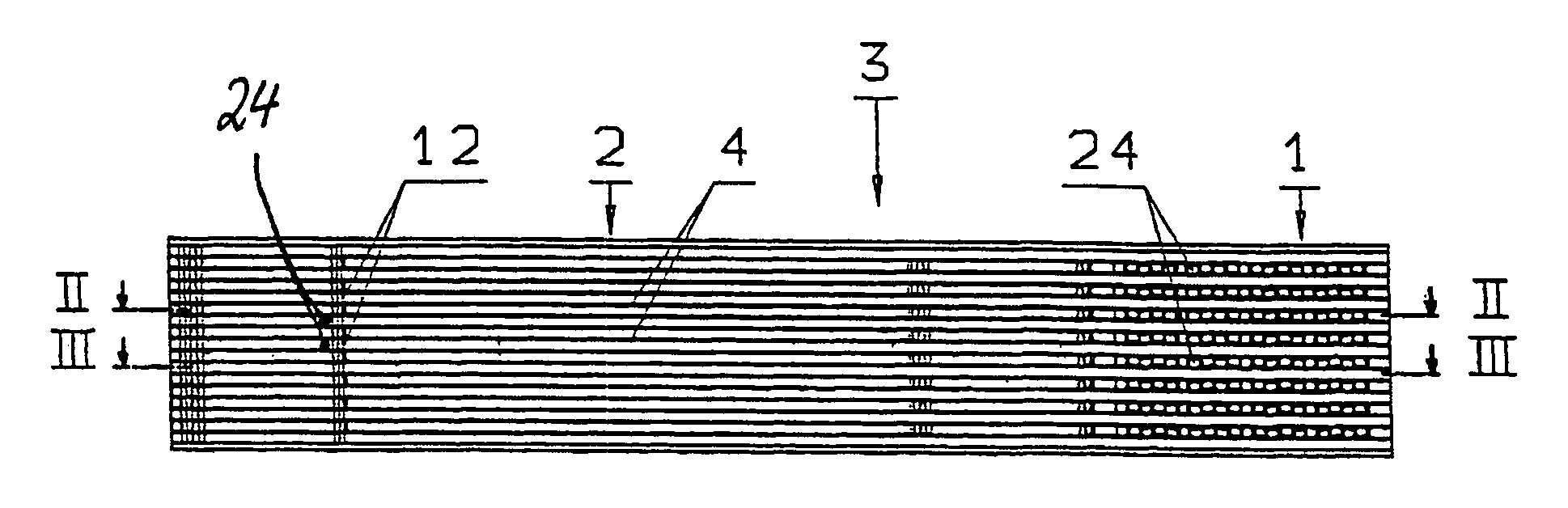

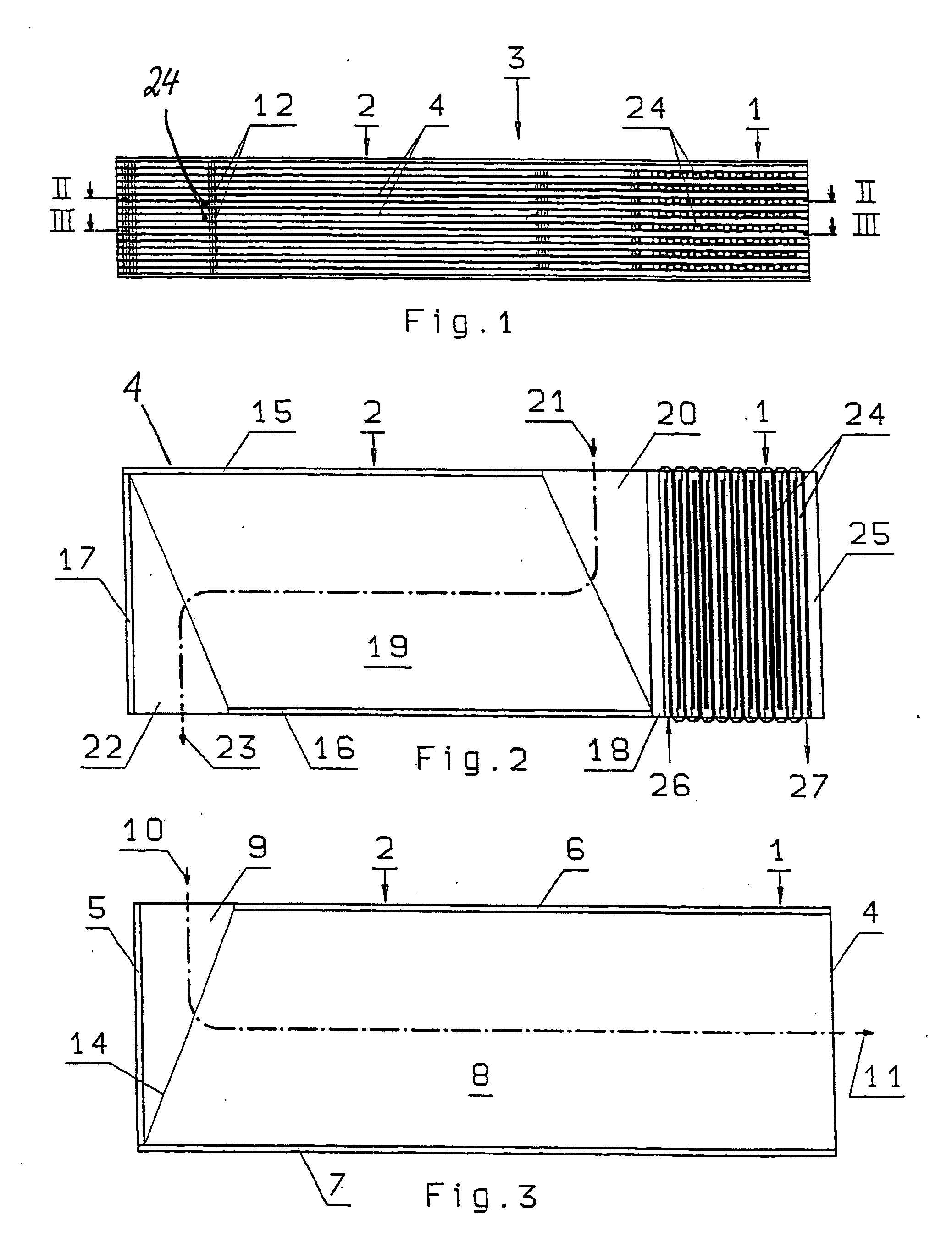

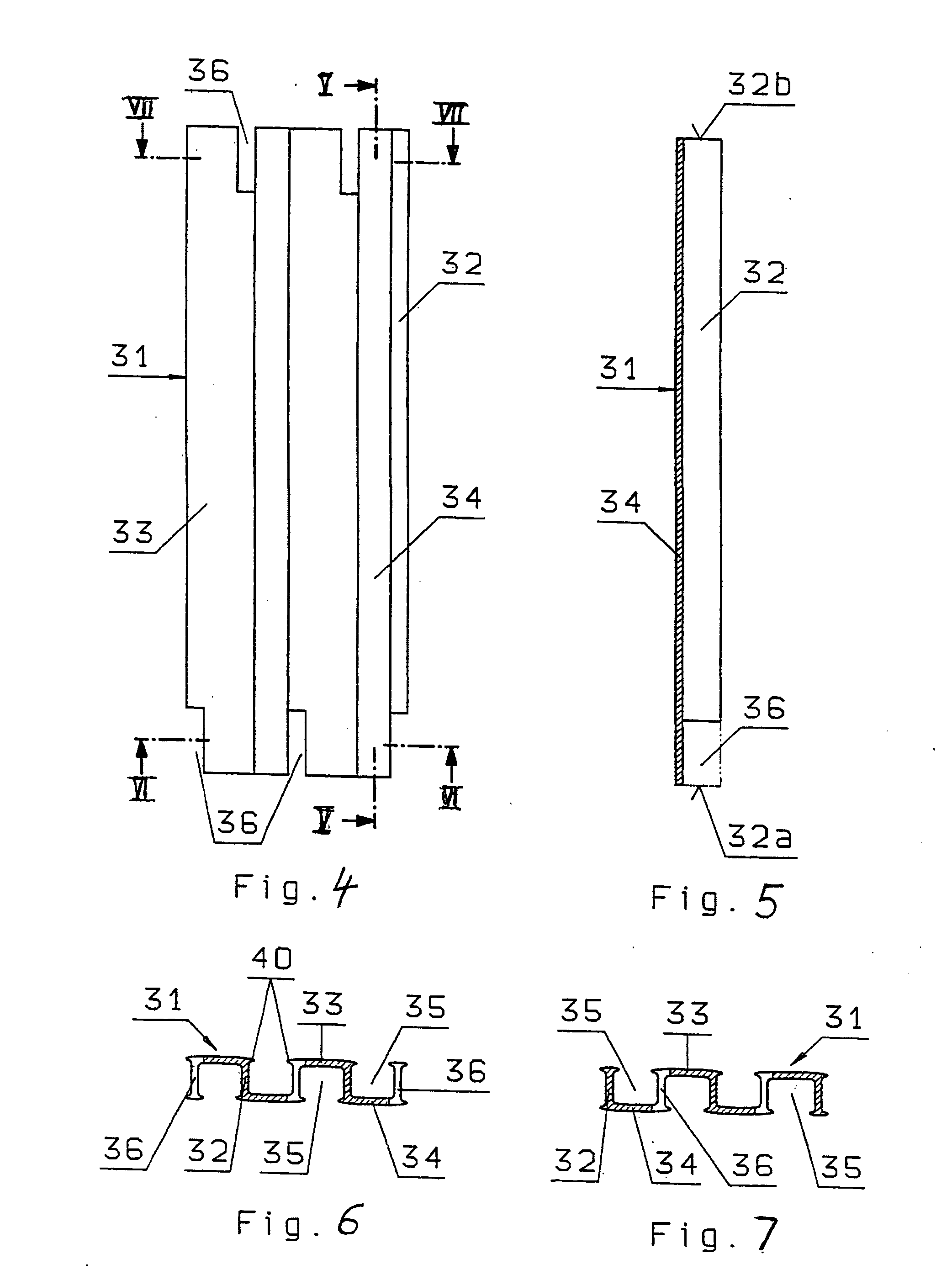

Heat exchanger core and heat exchanger equipped therewith

InactiveUS20070137843A1Produced with required strengthCheap to prepareLaminated elementsStationary plate conduit assembliesEngineeringHeat exchanger

A heat exchanger network has at least one passage for a coolant and a heat exchanger provided with such a core. The coolant passage has a plurality of flow channels which are disposed in parallel and delimited by separating walls and connected to each other in an undulating shape at their ends by deflection zones. The flow channels are formed by at least one lamella which has separating walls and a meandering cross-section. The deflection zones are formed by recesses which are provided at the ends of the separating walls.

Owner:AUTOKUHLER GMBH & CO KG

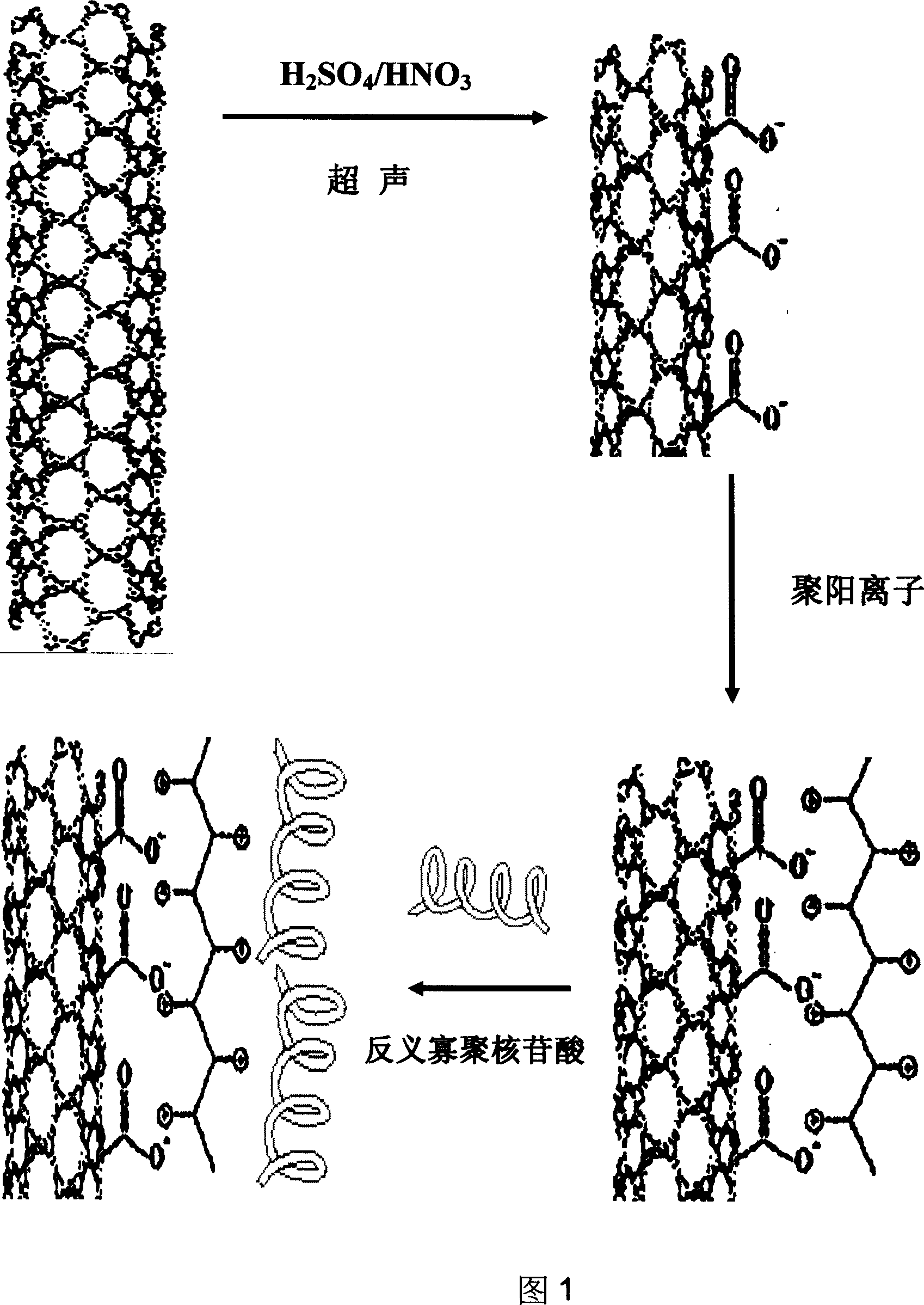

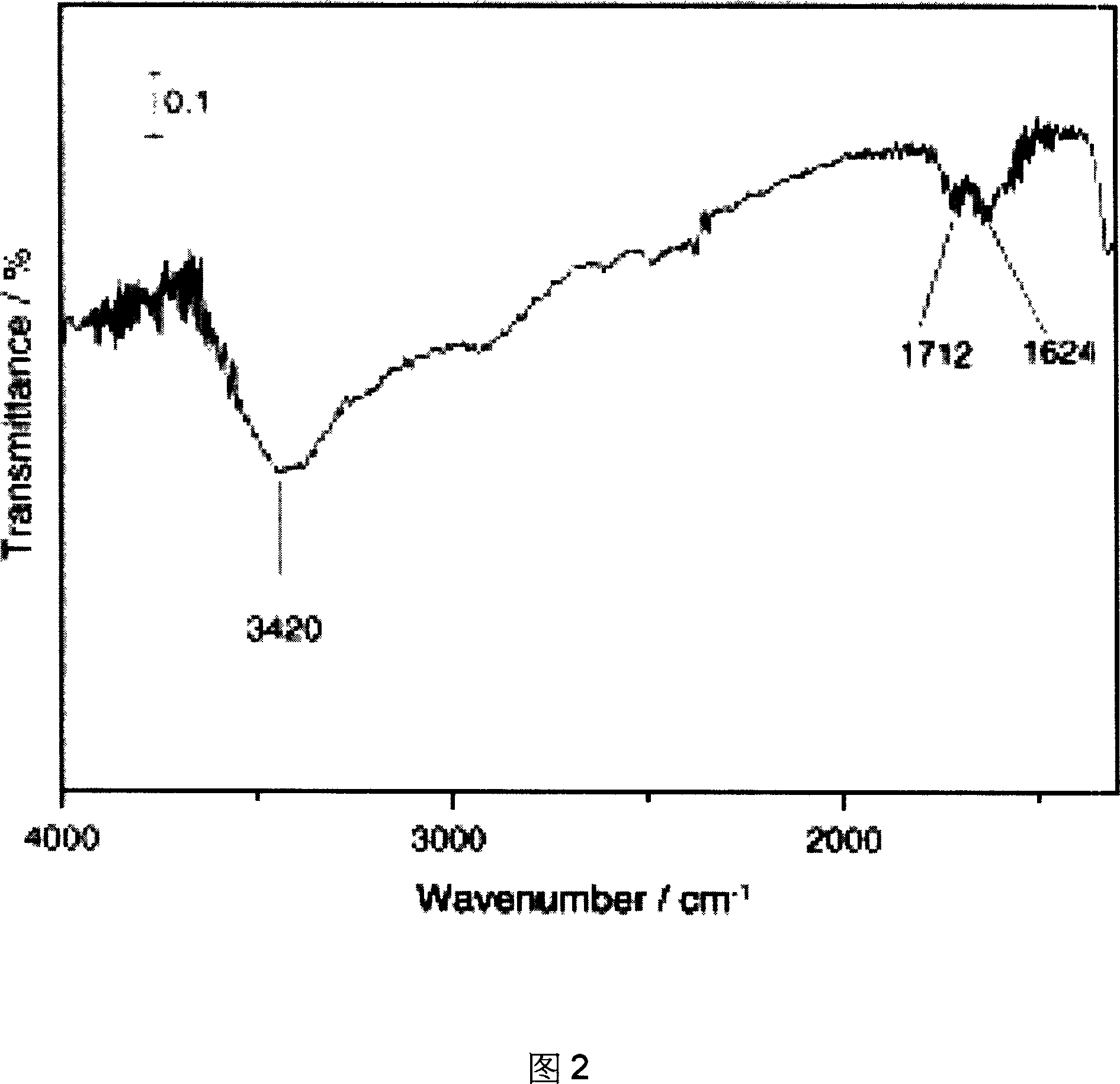

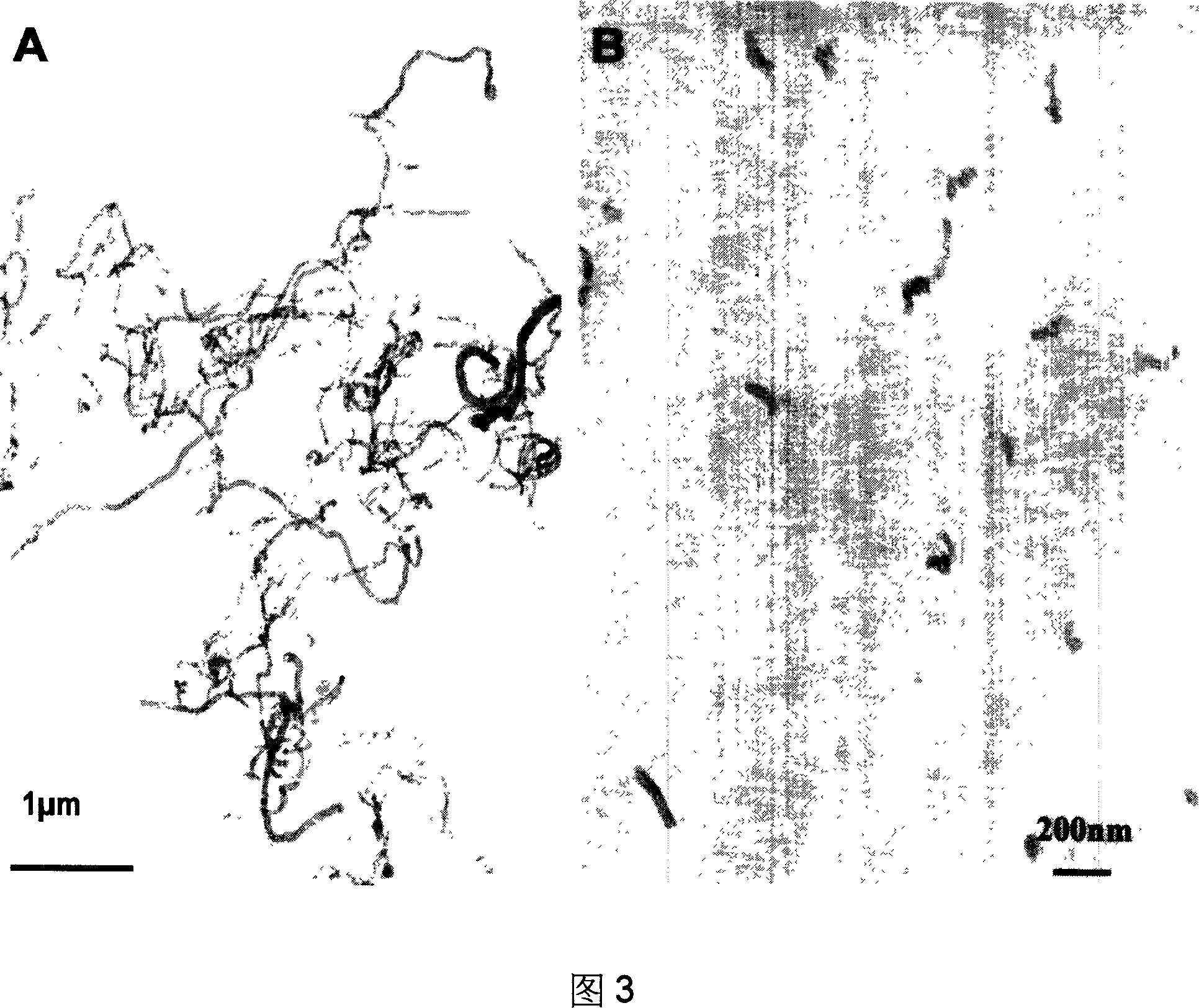

Antisense oligonucleotide-carbon nanotube medicament vector

InactiveCN101015696AHigh transfection rateStrong targetingGenetic material ingredientsPharmaceutical non-active ingredientsCarbon nanotubeStrong acids

This invention relates to an antisense oligonucleotide-carbon nanotubes medicine carrier which comprises carbon nanotube casing and antisense oligonucleotide. The preparation method comprises oxidizing multi-wall carbon nanotube with strong acid to carry carboxyl on the shell of pipe, cutting to 50-200nm with diameter of 10-50nm with ultrasound, adding poly-cationization bichloride to embellish on shell of carbon nanotube, and assembling antisense oligonucleotide to carbon nanotube. The preparation method is simple and rapid. The medicine carrier has high transfection efficiency, high target effect, and good effect in inhibiting tumor cell. Targeted bimolecular or medicine with carbon nanotube as carrier material aim at different biological system can be applied for treating tumor or genetic diseases.

Owner:SHANGHAI NORMAL UNIVERSITY

Preparation method of rosuvastatin intermediate and intermediate compound

InactiveCN104059024AAvoid it happening againReduce difficulty of reactionOrganic chemistryThioureaBenzaldehyde

The invention discloses a preparation method of a rosuvastatin intermediate: 4-(4-fluorobenyl)-6-isopropyl-2-(N-methyl-N-methylsulfonyl amino) pyrimidine-5-formonitrile. The method comprises the following steps: carrying out a reaction on ethyl isobutyrate and acetonitrile to generate isobutyryl acetonitrile; and then carrying out cyclization, methylation, reduction, oxidization and substitution on isobutyryl acetonitrile and p-fluoro benzaldehyde as well as thiourea to prepare the intermediate. The 4-(4-fluorobenyl)-6-isopropyl-2-(N-methyl-N-methylsulfonyl amino) pyrimidine-5-formonitrile prepared by the method is low in cost, simple to react, high in yield and easy to realize industrialized production.

Owner:ZHEJIANG UNIV

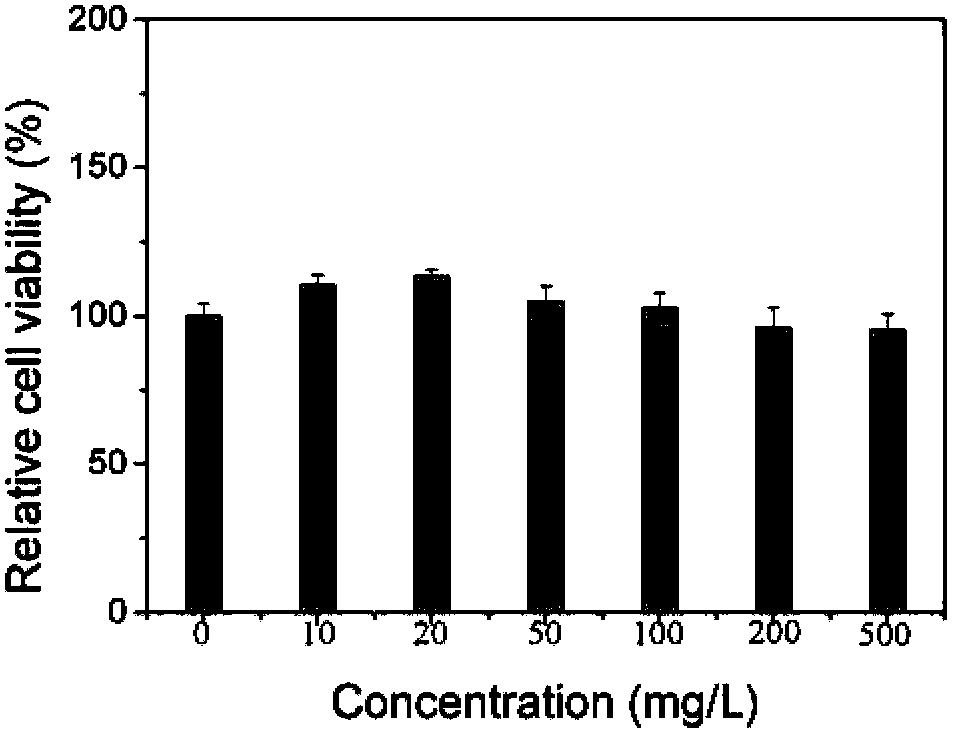

Application of water-soluble carbon nano-grade material

The invention discloses an application of a water-soluble carbon nano-grade material. The invention relates to the application of the water-soluble carbon nano-grade material in preparing a product with mycoplasma infection inhibiting and / or mycoplasma removing functions. In the application, the water-soluble carbon nano-grade material has hydrophilic groups on the surface. The water-soluble carbon nano-grade material is at least one selected from fullerene, graphene quantum dot, carbon quantum dot, carbon nano-tube, carbon nano-fiber, graphene, graphene oxide, and carbon nano-horn aggregate. The carbon nano-grade material has good biocompatibility, and assists in effectively inhibiting and removing mycoplasma, such that cell activity can be protected to a certain extent.

Owner:INST OF CHEM CHINESE ACAD OF SCI

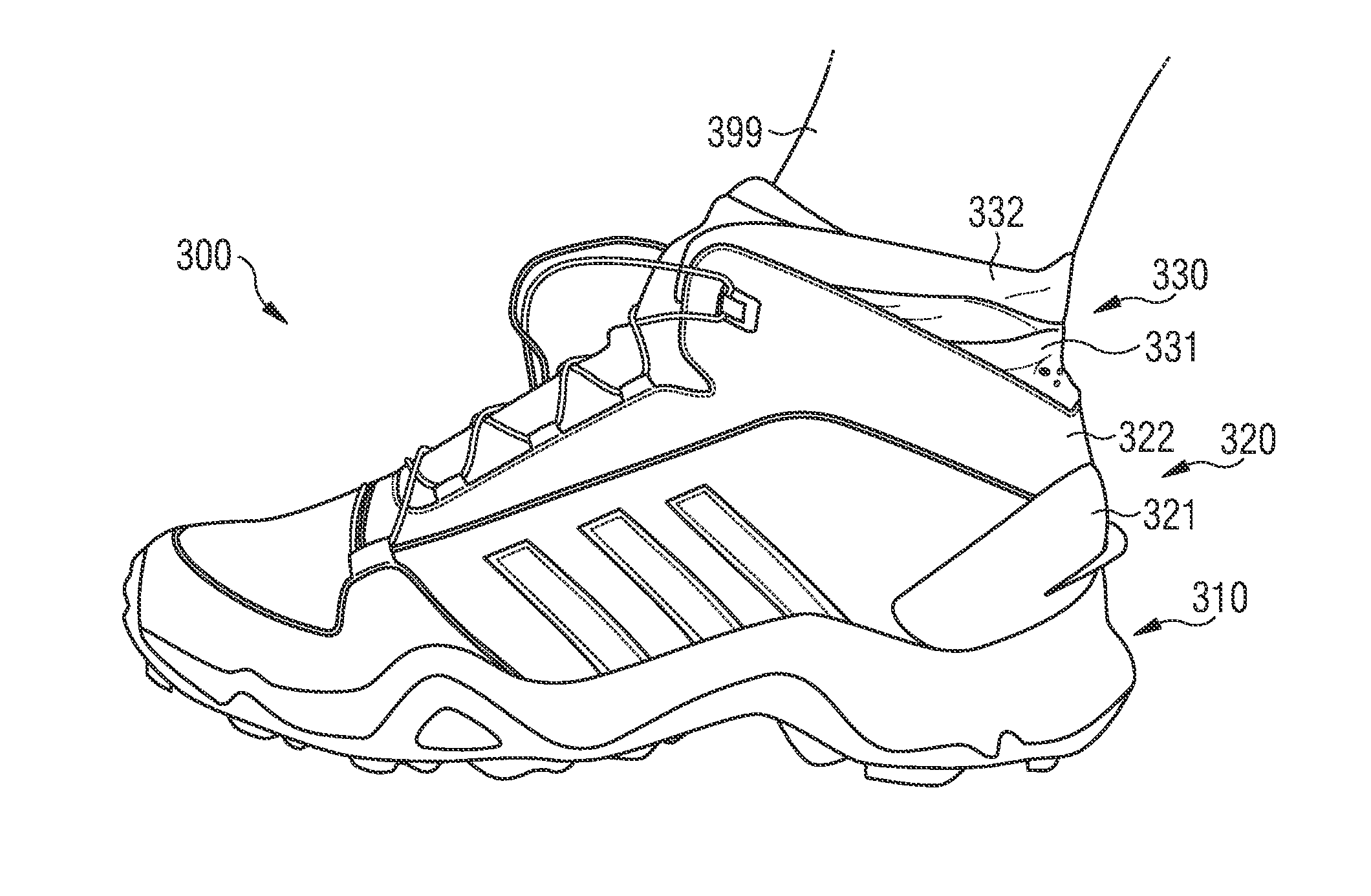

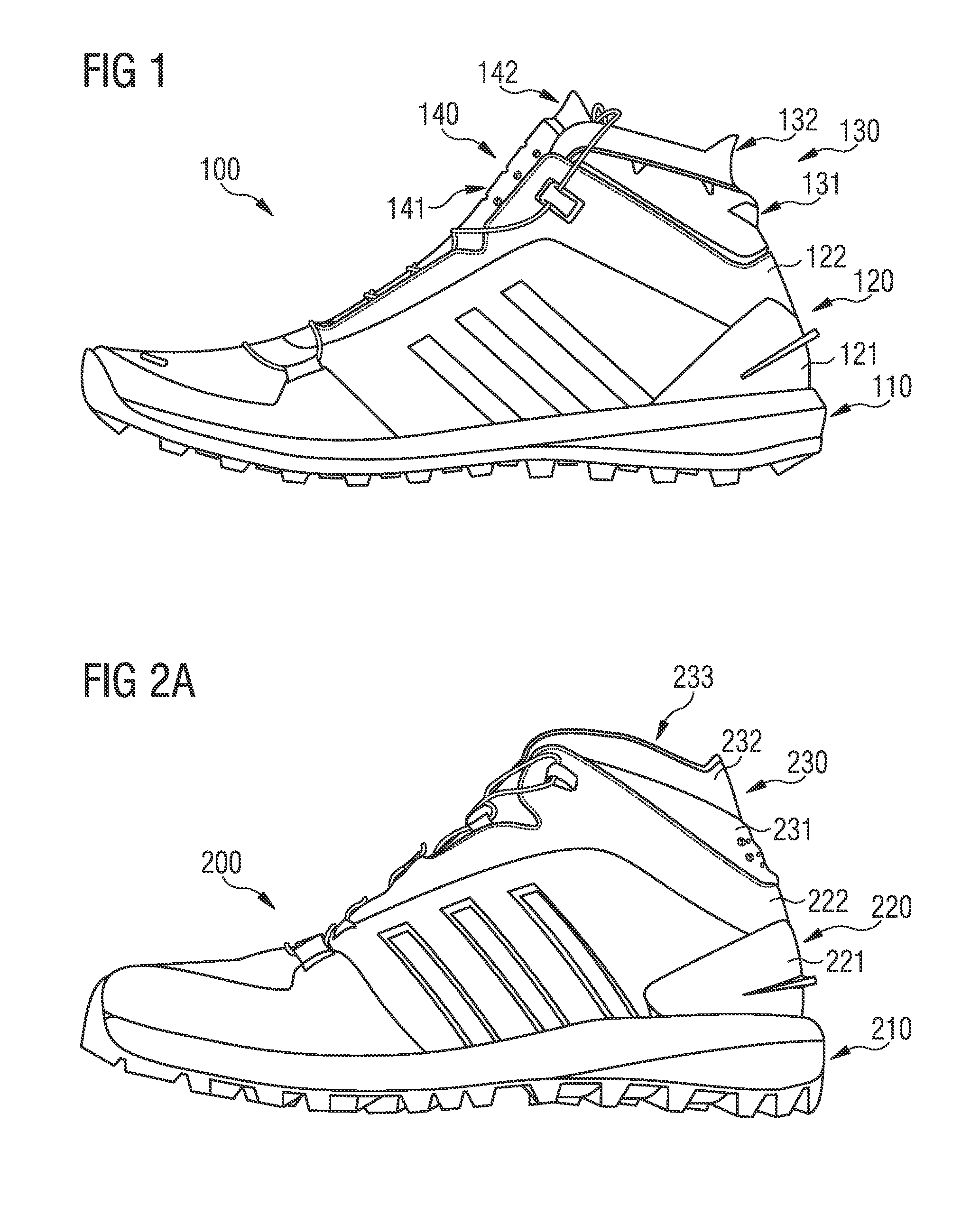

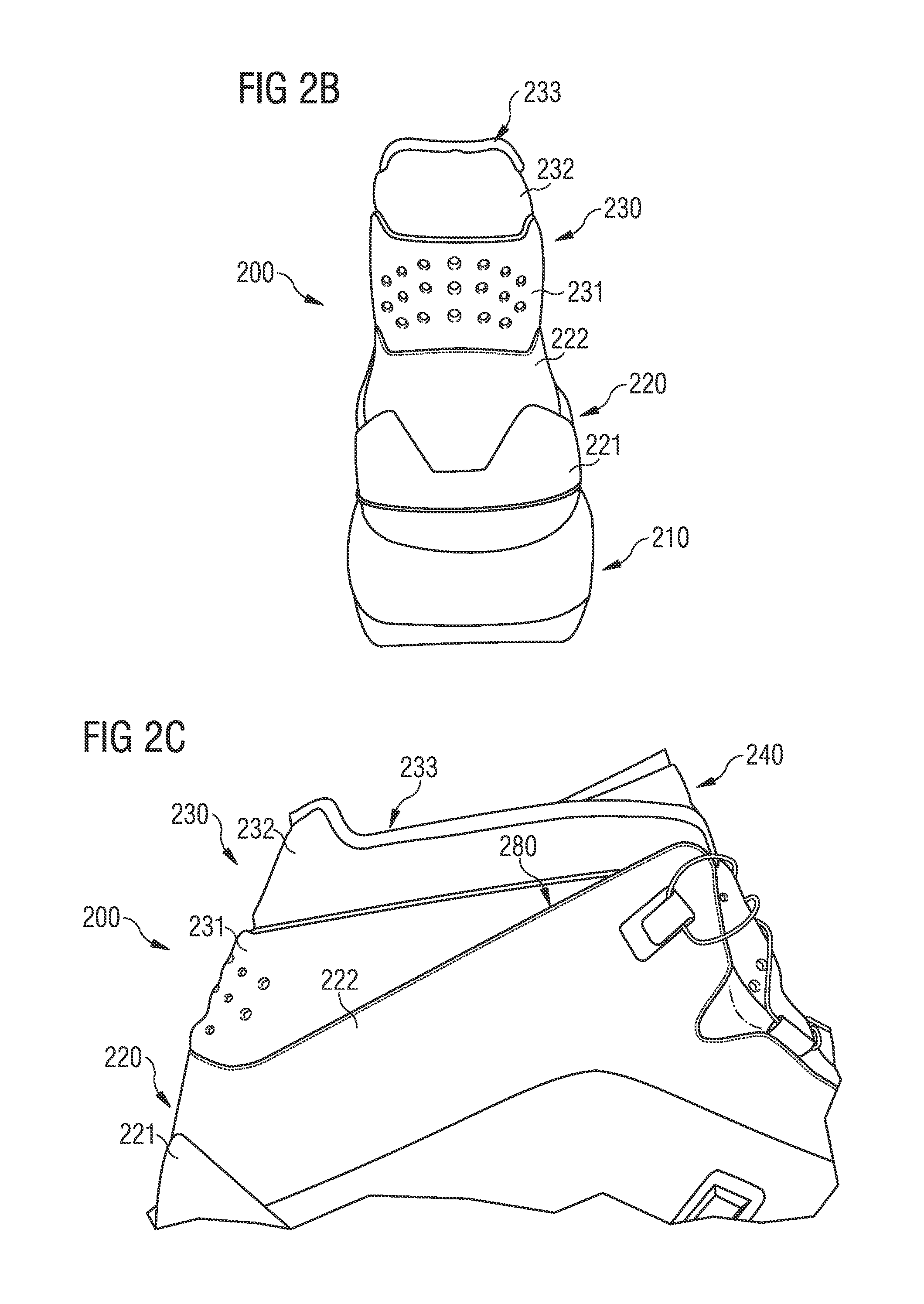

Shoe

Described are shoes with a rigid heel portion, and a collar arranged above the rigid heel portion. The collar includes a first collar portion and a second collar portion, the first collar portion and the second collar portion are configured to partially engage an ankle of a wearer of the shoe on a lateral side, a medial side, and a rear side of the ankle when worn. The first collar portion is more flexible than the rigid heel portion, and the second collar portion is more flexible than the first collar portion.

Owner:ADIDAS

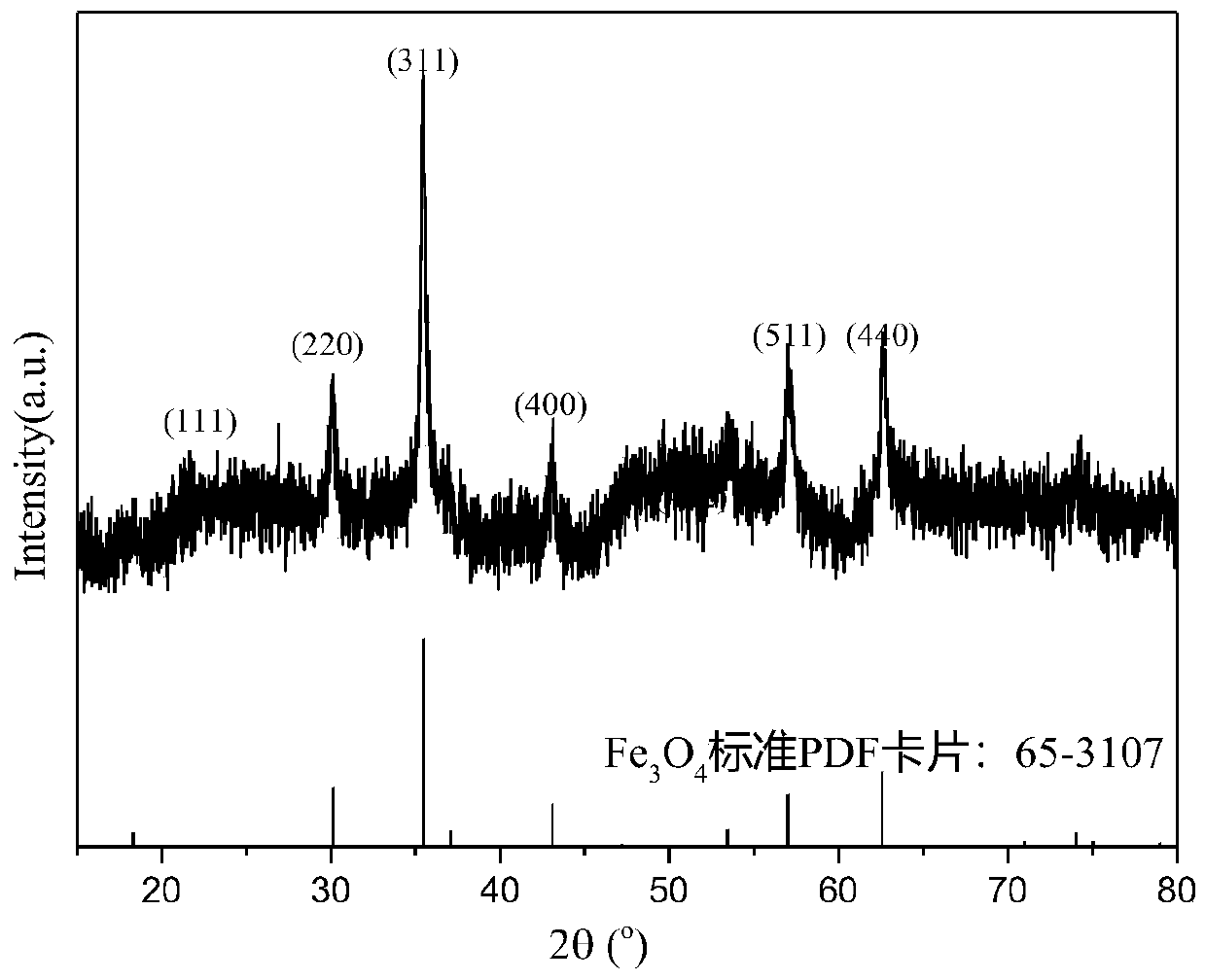

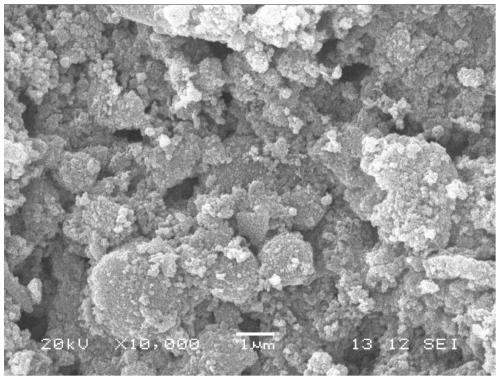

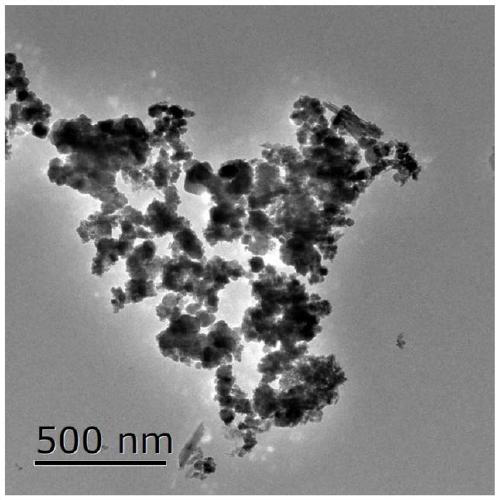

Titanium modified Fe3O4 magnetic nano-particle, preparation method and application thereof

InactiveCN110075846ARapid hydrolysisGreen environmental protection equipment requirementsWater treatment compoundsWater contaminantsMagnetite NanoparticlesSolvent

The invention provides a titanium modified Fe3O4 magnetic nano-particle, a preparation method and the application thereof. The preparation method specifically comprises the following steps: in a eutecticevaporate solvent of choline chloride and urea, taking ferrite as an iron source, tetrabutyl titanate as a titanium source and air as an oxidizing agent, and using a precipitation oxidization process to synthesize the titanium modified Fe3O4 magnetic nano-particle in one step. According to the preparation method provided by the invention, the obtained material has excellent catalytic degradation capacity (for example, under the conditions of room temperature and neutral pH, the color removal rate for a 0.01 mmol / L methylene blue solution within 2h reaching 93.8%, and the removal rate for a20 mg / L Ciprofloxacin solution reaching 96.5%) for organic waste water, is easy for magnetic separation recycle and stable in reuse performance, and is a novel magnetic environmentally-friendly material with low cost, quick and convenient operation, obvious effect and wide application prospect.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Non-acidizing method for producing high-efficiency phosphorus fertilizer

ActiveCN101429071APrevent compactionImprove fertilityBio-organic fraction processingOrganic fertiliser preparationPhosphateSoil fertility

The invention relates to a method for preparing high-efficiency phosphorus fertilizer without acidification. In the method, the material is ground by a vibration milling wet method to prepare super fine activated phosphate rock powder which has high specific surface area, the particle size is 90 percent and can passes through a 400-mesh sieve, the super fine activated phosphate rock powder is mixed with biological organic fertilizer according to the weight ratio of between 1 to 4 and 1 to 1, and pseudomonas fluorescens is added for mixing stockpile manure and fermenting so as to prepare the non-acidification high-efficiency phosphorus fertilizer. The method has the advantages of preparing the high-efficiency phosphorus fertilizer by physical and biological methods, reducing the environmental pollution, solving the problems of environmental pollution, high cost and the like existing in the prior phosphorus fertilizer preparation method and lowering cost of producing the phosphorus fertilizer, along with simple technique; moreover, in long-term usage, the phosphorus fertilizer can prevent the sealing of soil, improve the soil and enhance the soil fertility.

Owner:山东清大生态科技有限公司 +1

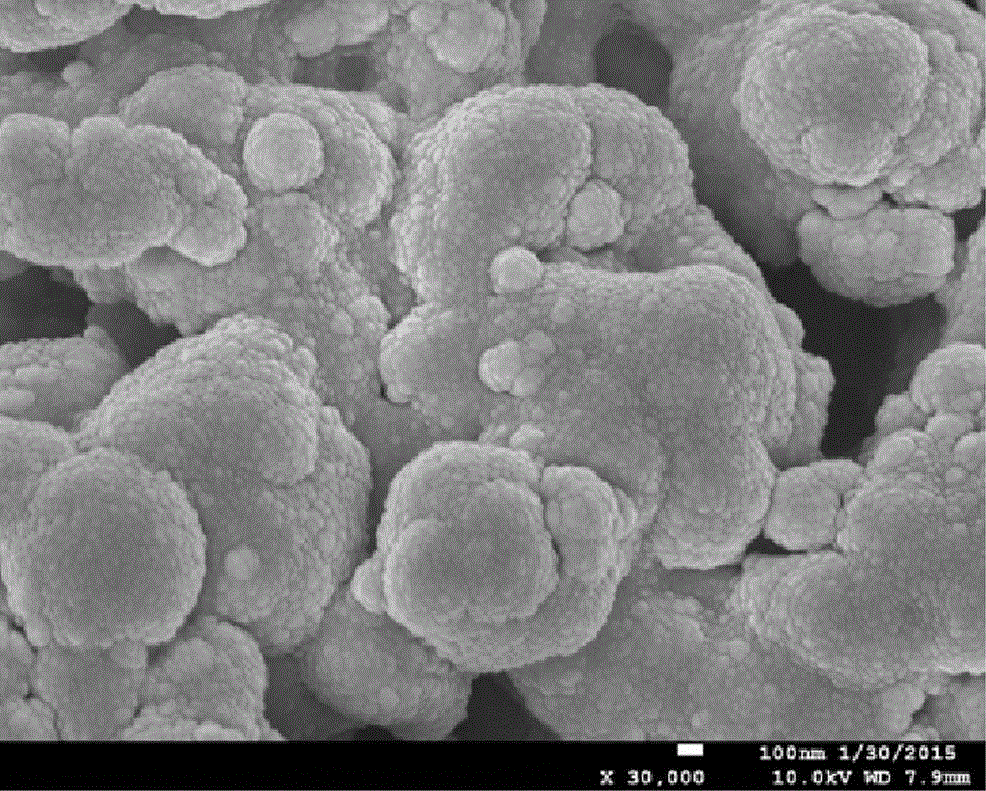

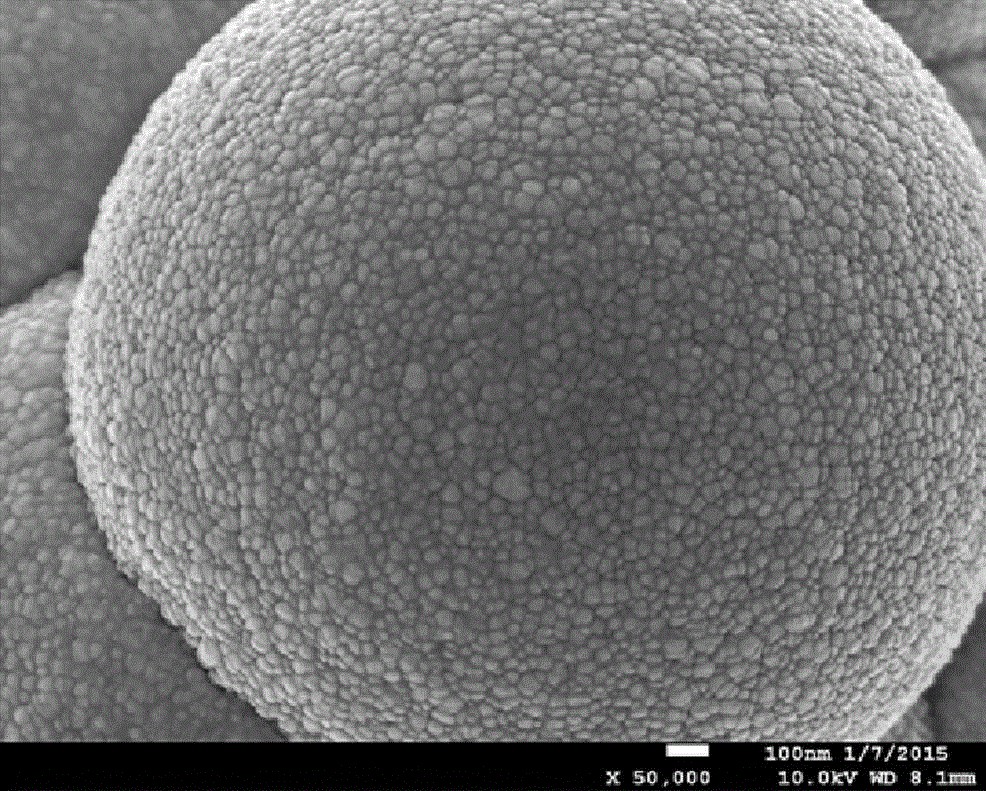

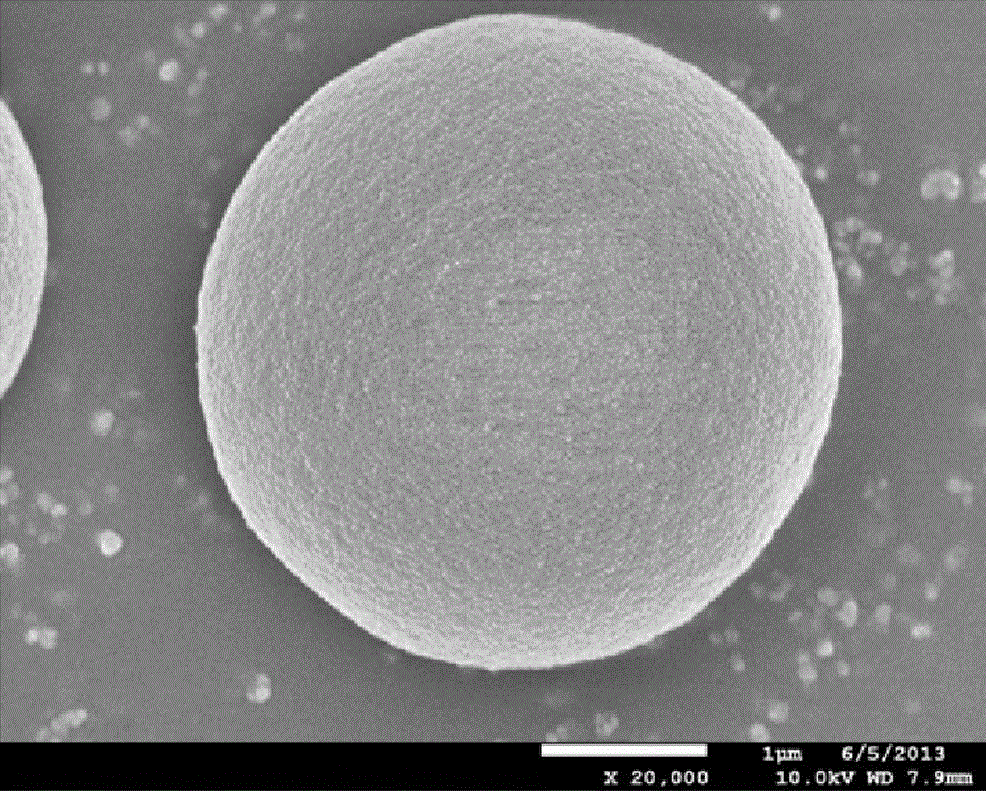

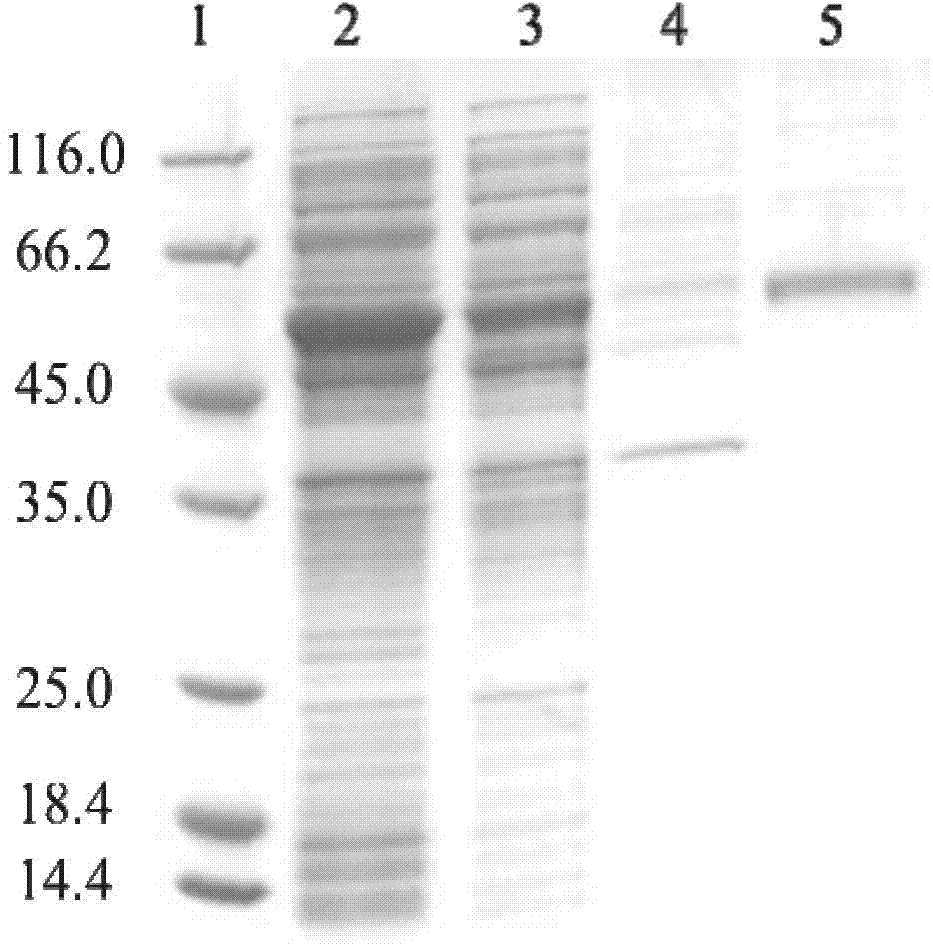

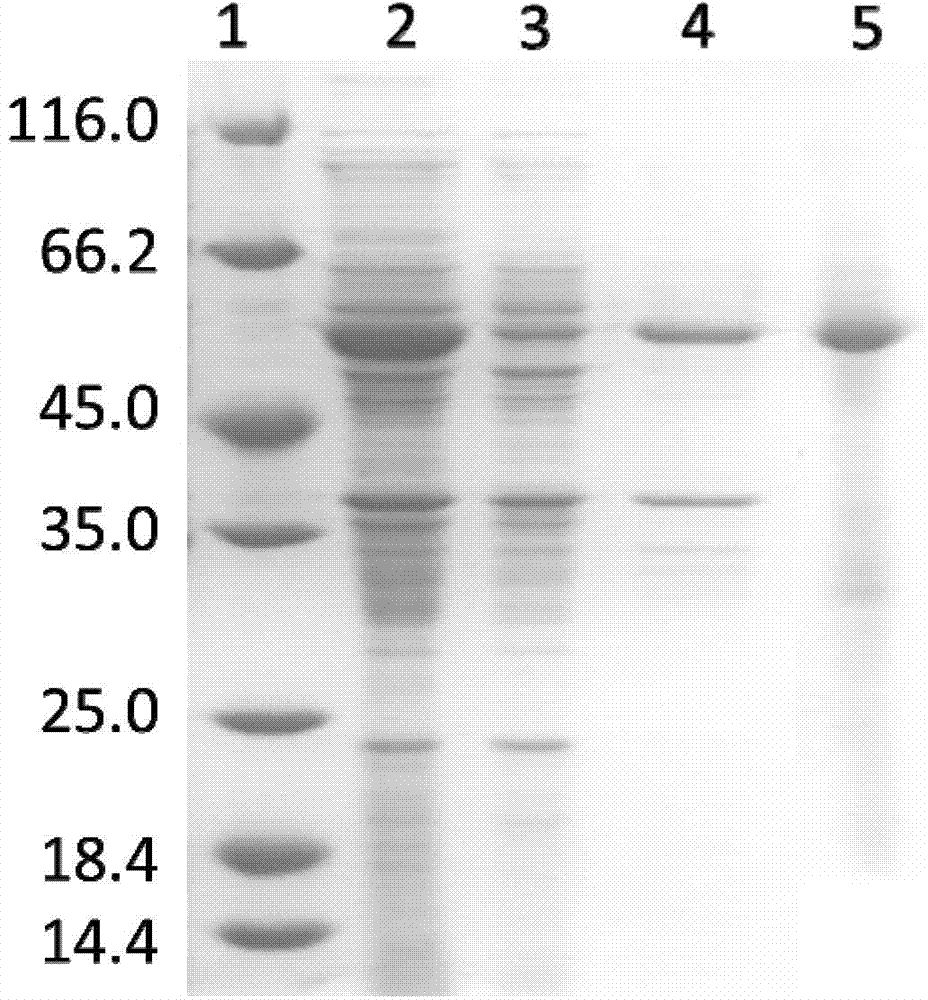

Magnetic affinitive nanomaterial for separating and purifying GST (glutathione S-transferase) tag fusion protein as well as preparation method and application thereof

InactiveCN103877956AEasy to prepareCheap to prepareIon-exchange process apparatusOther chemical processesChemistryOxide

The invention provides a magnetic affinitive nanomaterial for separating and purifying GST (glutathione S-transferase) tag fusion protein as well as a preparation method and application thereof. The magnetic affinitive nanomaterial comprises ferroferric oxide nanoparticles and a polydopamine coating which wraps the ferroferric oxide nanoparticles, wherein reduced glutathione is fixed on the surface of the polydopamine coating. According to the magnetic affinitive nanomaterial provided by the invention, the specific surface area is relatively large, the rate and quantity of bonding between the nanomaterial and protein molecules are increased, the superparamagnetic property of the nanoparticles simplifies the operation strength of a separation process, the preparation method is simple and low in cost, and the process for separating and purifying the GST fusion protein is simple, convenient, quick and effective. The nanomaterial has wide application prospect and practical value in the field of biotechnology.

Owner:EAST CHINA UNIV OF SCI & TECH

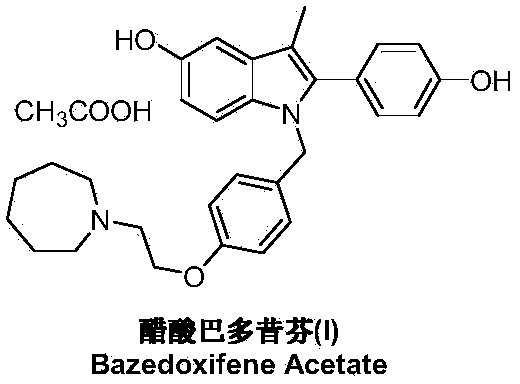

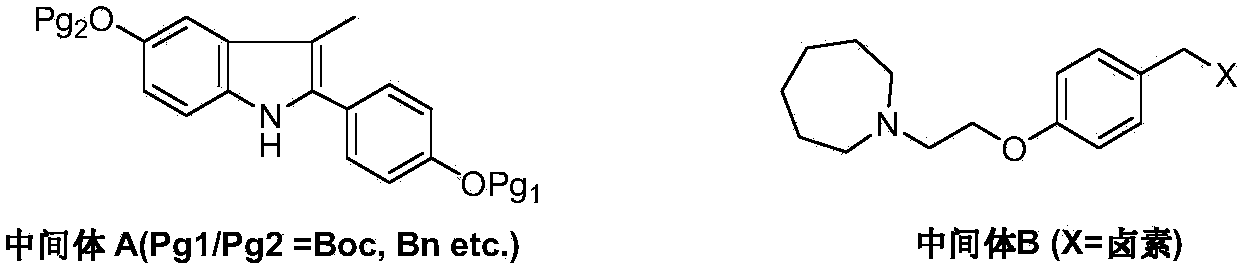

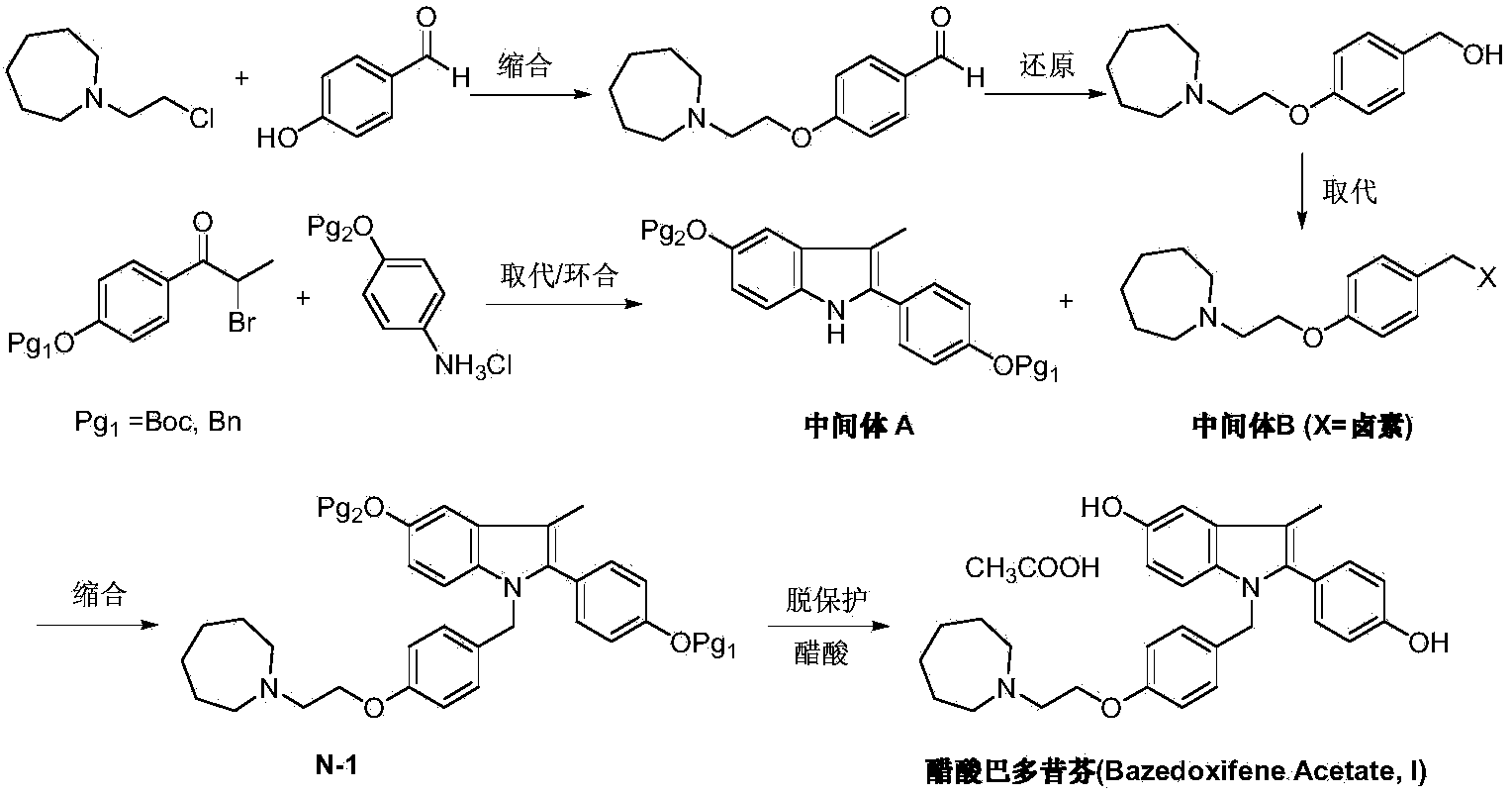

Preparation method of bazedoxifene acetate

ActiveCN103864665AEase of industrial productionPromote the development of economy and technologyOrganic chemistryAcetic acidAlcohol

The invention discloses a preparation method of bazedoxifene acetate. The method comprises the following steps: carrying out a condensation cyclization reaction on 1-(4-Pg1 oxygroup phenyl) propyl alcohol (II) and N-{4-(2-azacycloheptane-1-yl-ethyoxyl-benzyl)}N-{4-(Pg2 oxygroup phenyl)} hydrazine (III) so as to obtain 1-{4-(2-azacycloheptane-1-yl-ethyoxyl-benzyl)}-2-(4-Pg1 oxygroup-phenyl)-3-methyl-5-(Pg2 oxygroup)-1H-benzpyrole (IV); and carrying out deprotection on the intermediate (IV) and salifying the intermediate (IV) with acetic acid so as to obtain the bazedoxifene acetate (I). The preparation method is concise in process, high in yield, economical and environment-friendly, thereby providing a novel preparation way for the industrial production of the bazedoxifene acetate.

Owner:苏州特瑞药业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com