PVC laminated composite cloth comprising films formed through extrusion method and preparation method thereof

An extrusion method and composite cloth technology, which is applied in the field of laminated composite materials, can solve the problems of complex production process, low yield rate, and high energy consumption, and achieve the effects of low cost, high yield rate, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Extrusion film-forming PVC laminated composite cloth, including base fabric, base film and mask, the base film and mask are arranged on both sides of the base fabric; base film and mask are both PVC films.

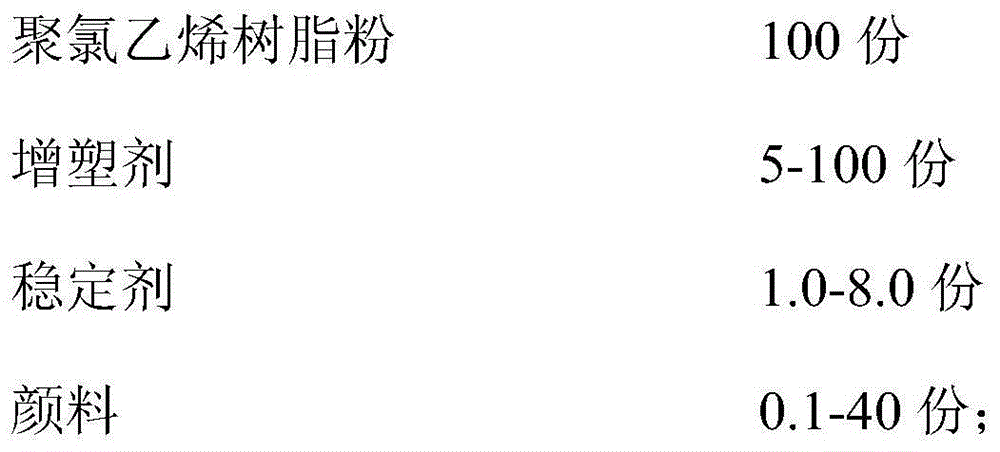

[0046] The composition of bottom film is in parts by weight, and each component and content are:

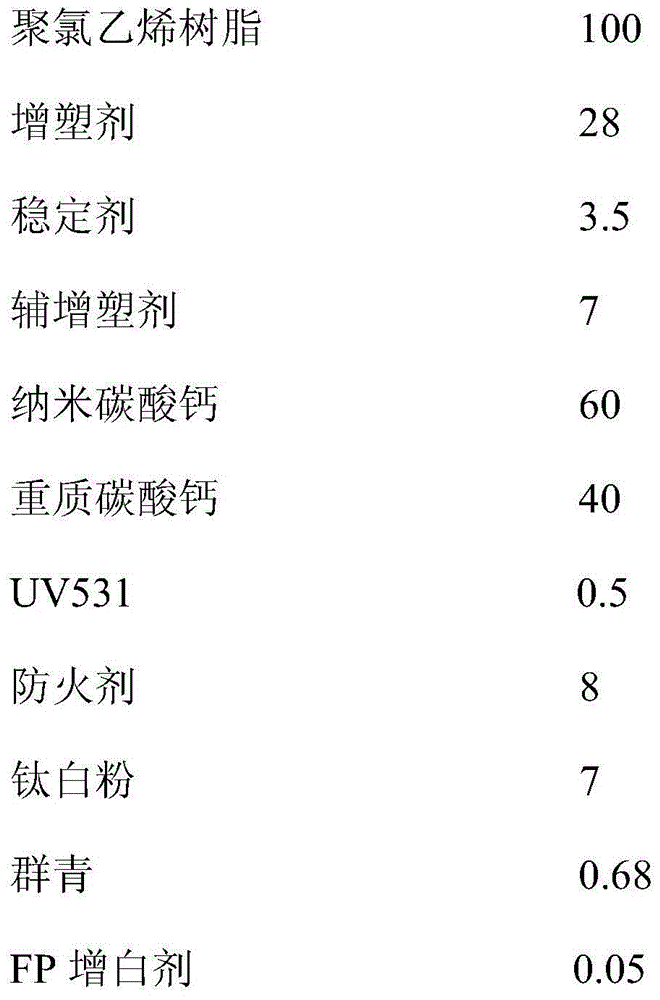

[0047]

[0048] Wherein the polyvinyl chloride resin is calcium carbide method resin method polyvinyl chloride resin powder, plasticizer is dioctyl phthalate, stabilizer is barium cadmium zinc composite stabilizer, auxiliary plasticizer is epoxy soybean oil, auxiliary filler Nano-calcium carbonate and heavy calcium carbonate are selected, specifically nano-scale light calcium and 2500-mesh heavy calcium. The ultraviolet absorber is UV-531, and the fire retardant is antimony trioxide. The pigment is prepared from anatase titanium dioxide, ultramarine blue and FP brightener.

[0049] The composition of facial mask is measured in parts by weight, and each component a...

Embodiment 2

[0054] Extrusion film-forming PVC laminated composite cloth, including base fabric, base film and mask, the base film and mask are arranged on both sides of the base fabric; base film and mask are both PVC films.

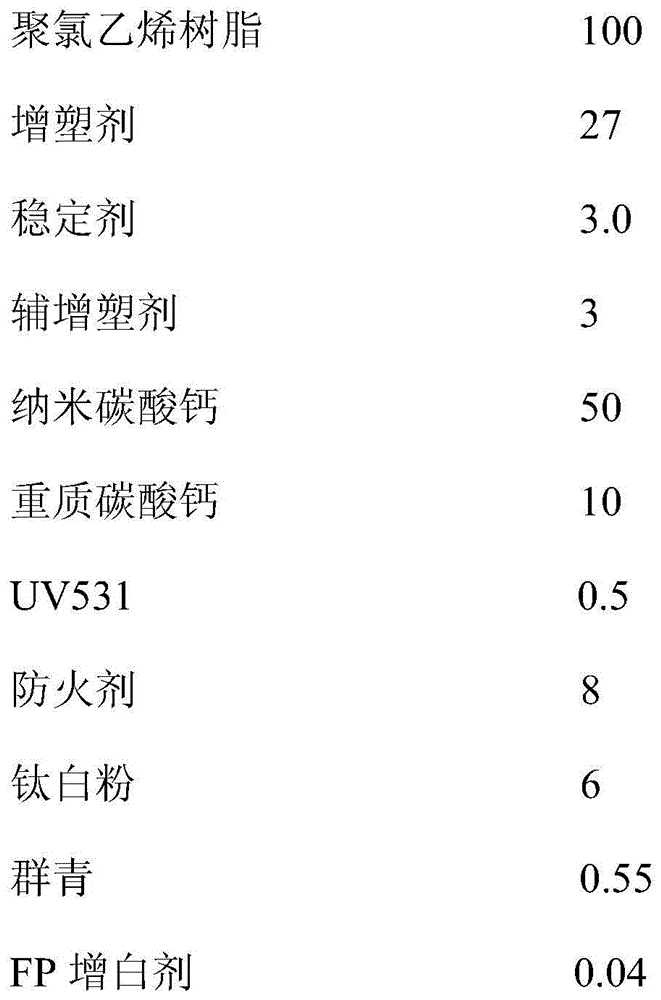

[0055] The composition of bottom film is in parts by weight, and each component and content are:

[0056]

[0057]

[0058] Wherein the polyvinyl chloride resin is calcium carbide method resin method polyvinyl chloride resin powder, plasticizer is dioctyl phthalate, stabilizer is barium cadmium zinc composite stabilizer, auxiliary plasticizer is epoxy soybean oil, auxiliary filler Nano-calcium carbonate and heavy calcium carbonate are selected, specifically nano-scale light calcium and 2500-mesh heavy calcium. The ultraviolet absorber is UV-531, and the fire retardant is antimony trioxide. The pigment is prepared from anatase titanium dioxide, ultramarine blue and FP brightener.

[0059] The composition of facial mask is measured in parts by weight, and each c...

Embodiment 3

[0065] Extrusion film-forming PVC laminated composite cloth, including base fabric, base film and mask, the base film and mask are arranged on both sides of the base fabric; base film and mask are both PVC films.

[0066] The composition of bottom film is in parts by weight, and each component and content are:

[0067]

[0068] Among them, the polyvinyl chloride resin is ethylene-based polyvinyl chloride resin powder, the plasticizer is dioctyl phthalate, the stabilizer is barium cadmium zinc composite stabilizer, the auxiliary plasticizer is epoxy soybean oil, and the auxiliary filler is carbonic acid calcium. The ultraviolet absorber is UV-531, and the fire retardant is antimony trioxide. The pigment is prepared from anatase titanium dioxide, phthalocyanine blue and permanent violet.

[0069] The composition of facial mask is measured in parts by weight, and each component and content are:

[0070]

[0071] Among them, the polyvinyl chloride resin is ethylene-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com