Patents

Literature

31817results about "Lamination ancillary operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

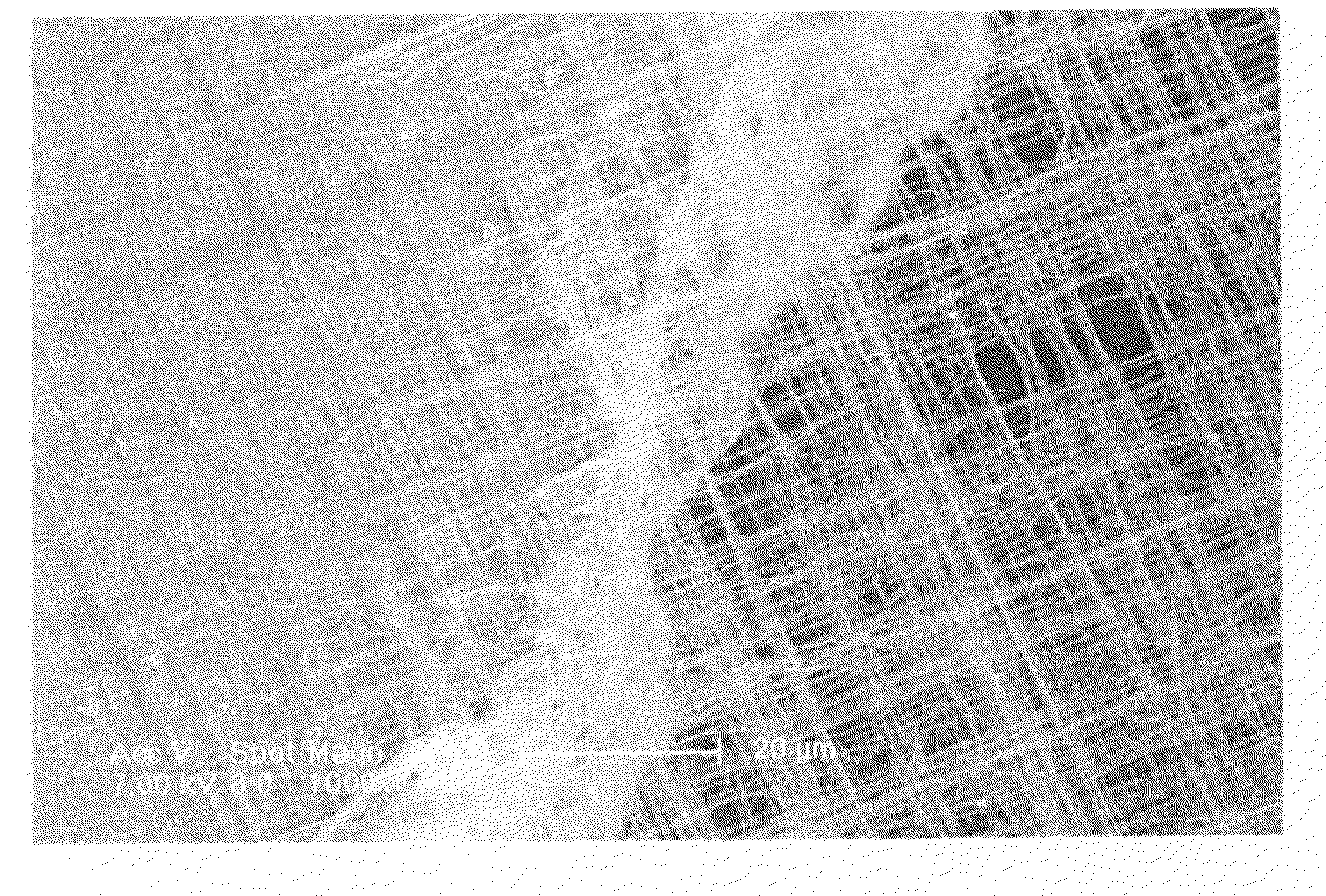

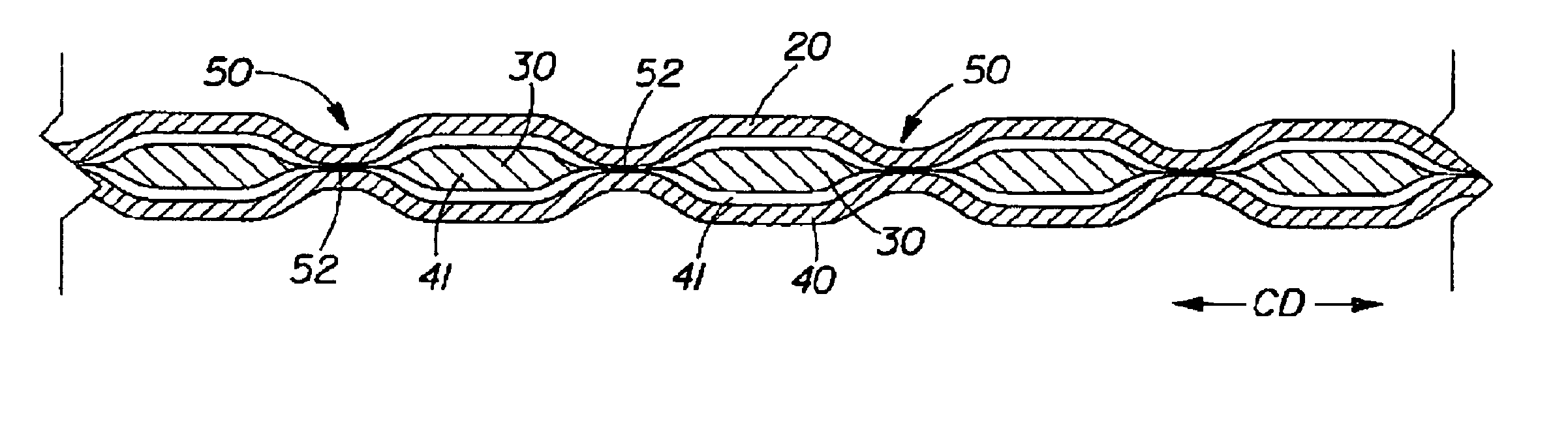

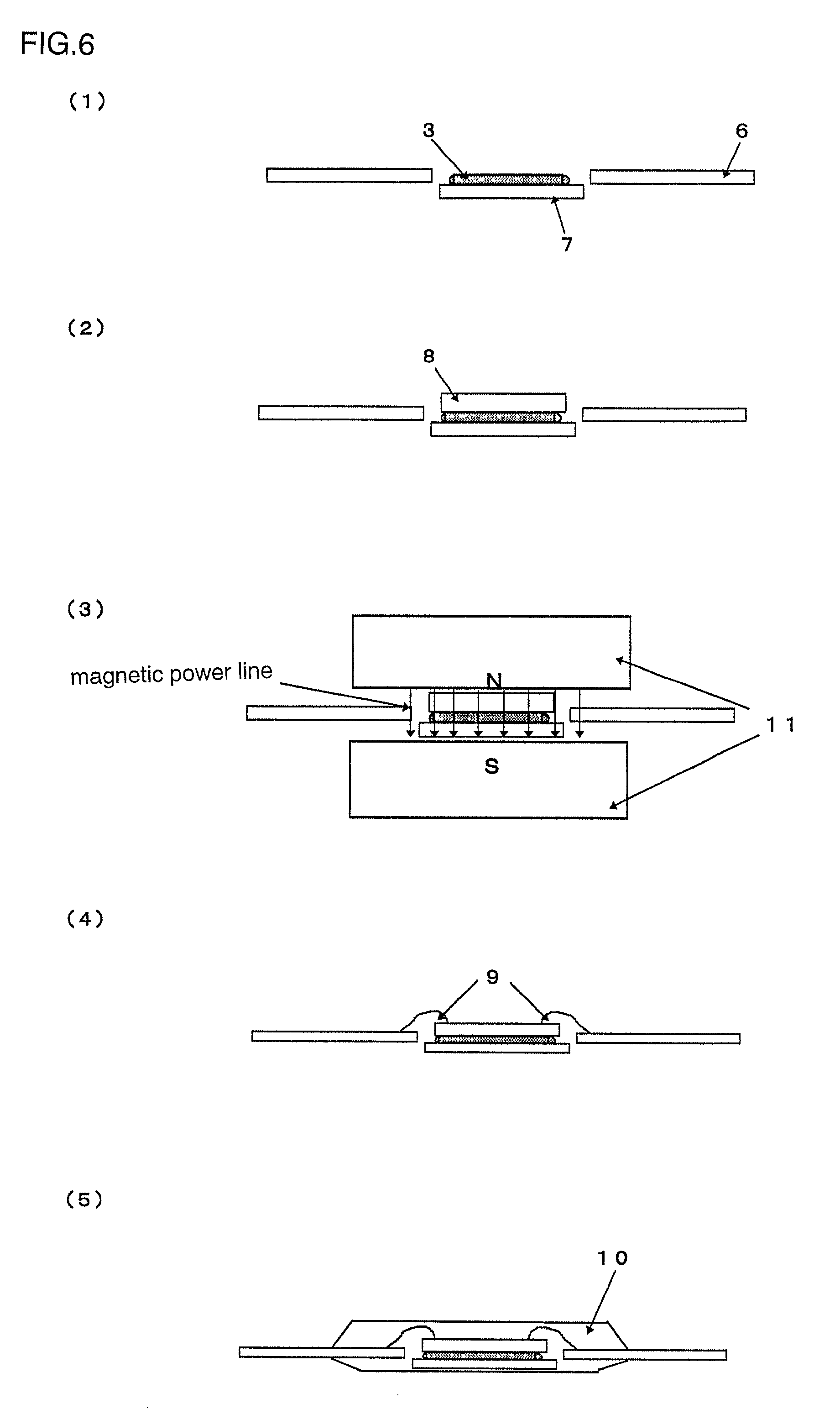

Carbon nano-tube thin film structure and preparation method thereof

ActiveCN101239712ASmall surface to volume ratioNon stickyMaterial nanotechnologyLamination ancillary operationsOrganic solventFixed frame

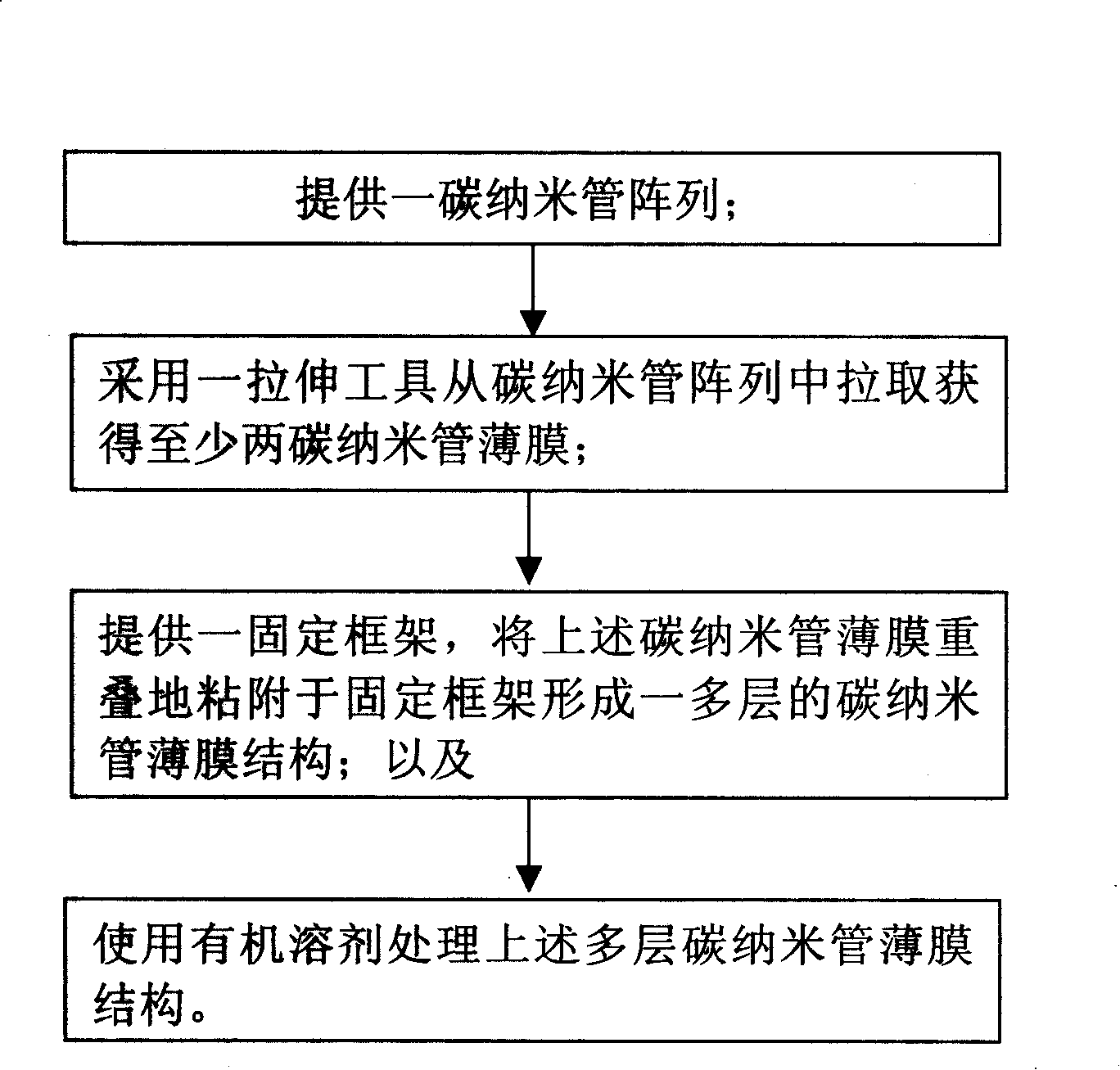

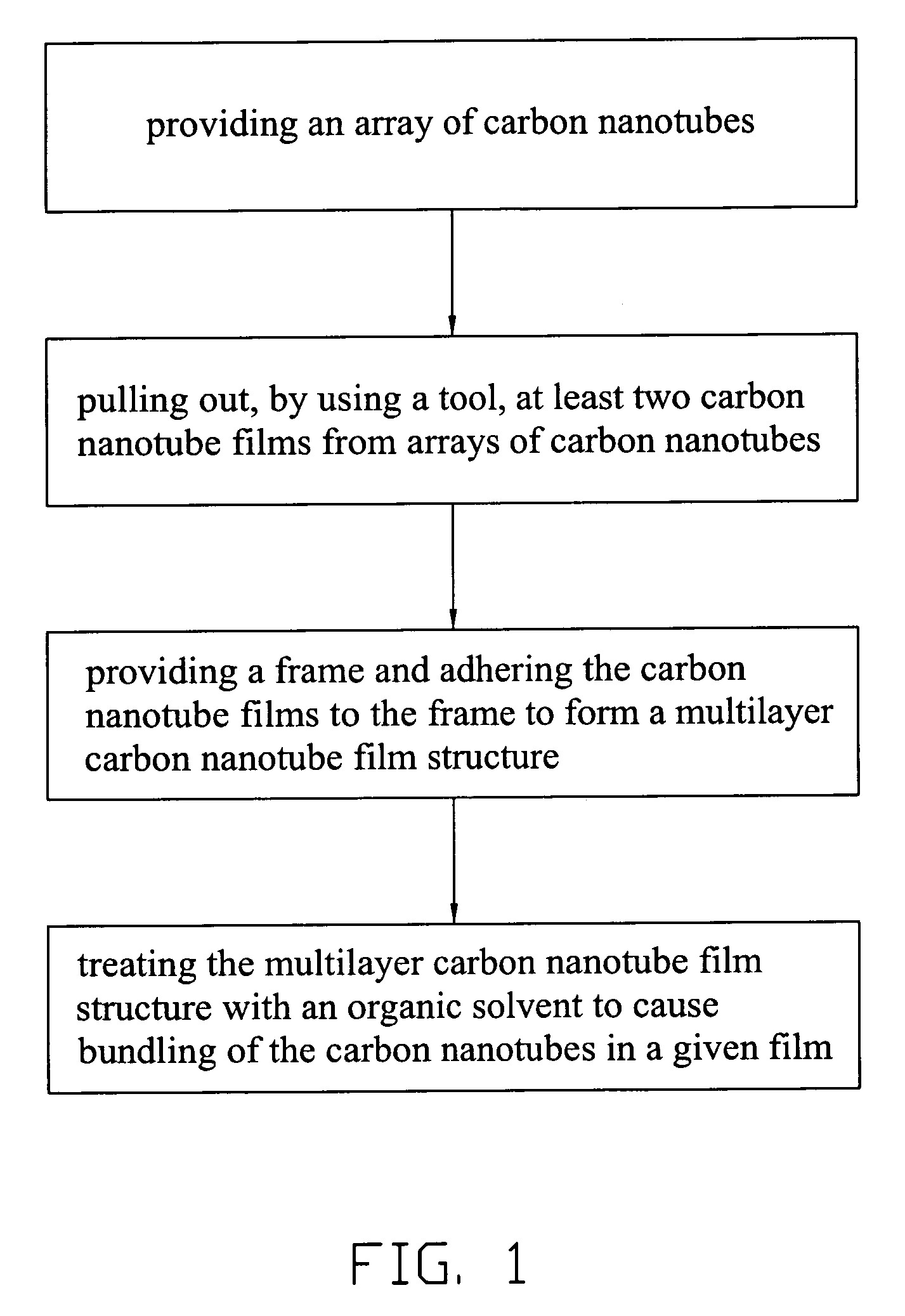

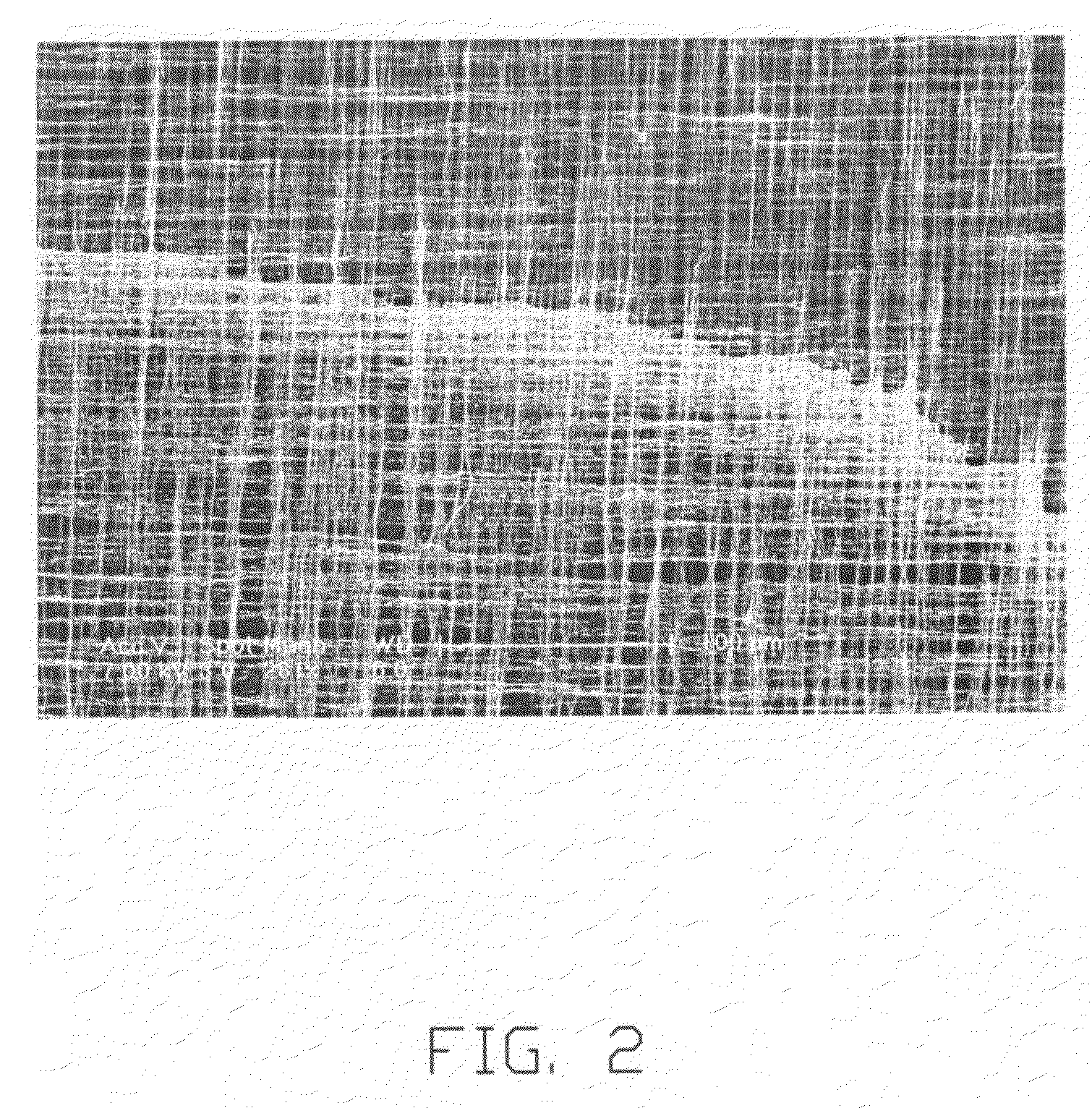

The present invention provides a preparing method of carbon nanotube film structure, including following steps: providing a carbon nanotube array; adopting a pulling tool to acquire at least two carbon nanotube films from the carbon nanotube array; providing a fixed frame, forming a multiple-layer carbon nanotube film structure by overlap adhereing the carbon nanotube film in the fixed frame; and treating the multiple-layer carbon nanotube film by an organic solvent. The carbon nanotube film structure prepared by the method includes at least two layers overlapped and cross-over installed carbon nanotube film, which includes multiple carbon nanotube bundle end to end and arranged in the direction, the multiple-layer carbon nanotube film further includes millipore crosswise formed by multiple carbon nanotube bundles.

Owner:TSINGHUA UNIV +1

Method for hydrophilizing materials using hydrophilic polymeric materials with discrete charges

A method of rendering materials having hard and soft surfaces hydrophilic or more hydrophilic is disclosed. The method involves hydrophilizing such materials by applying a high energy treatment and charged particles and / or one or more hydrophilic polymeric materials with discrete charges to such materials.

Owner:THE PROCTER & GAMBLE COMPANY

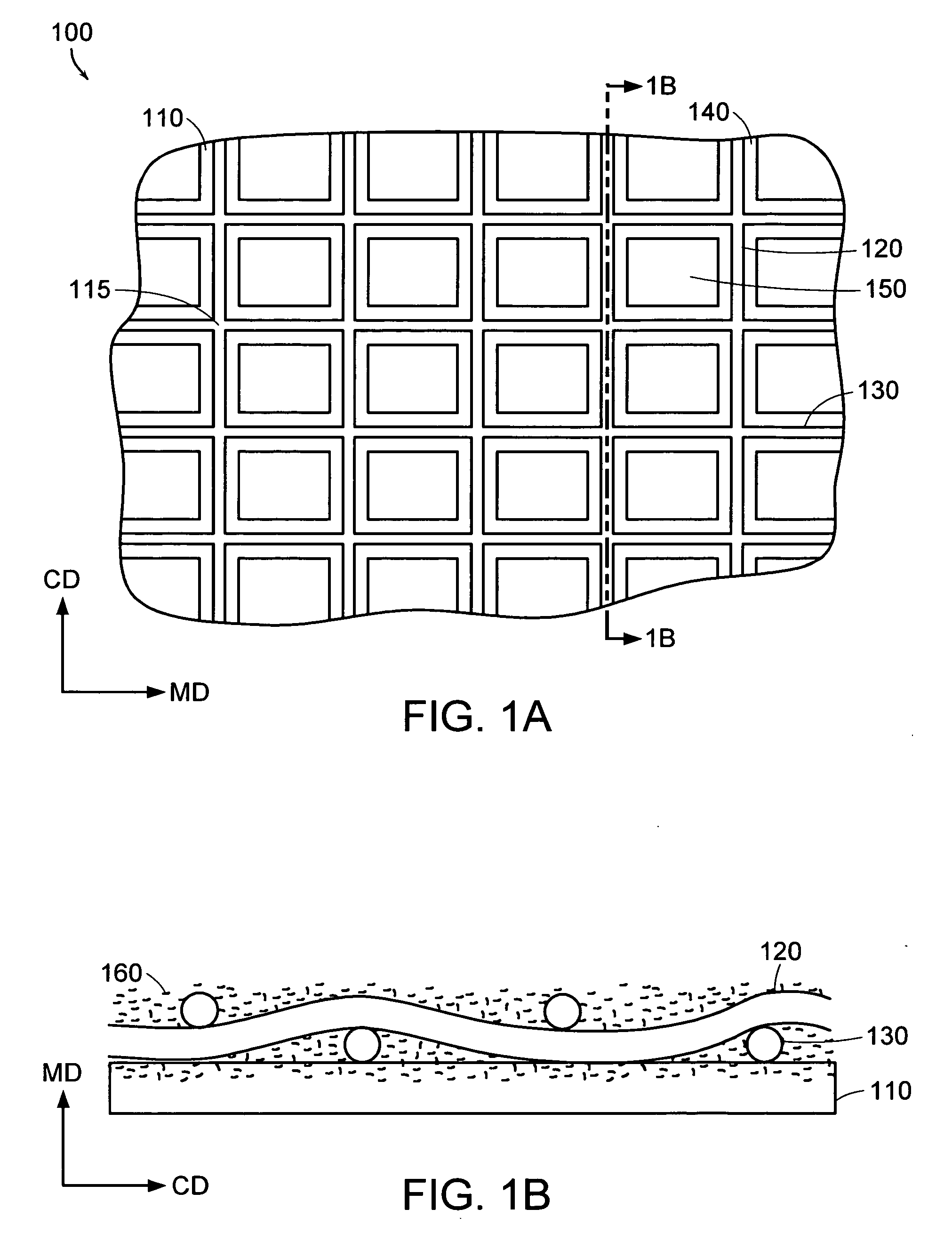

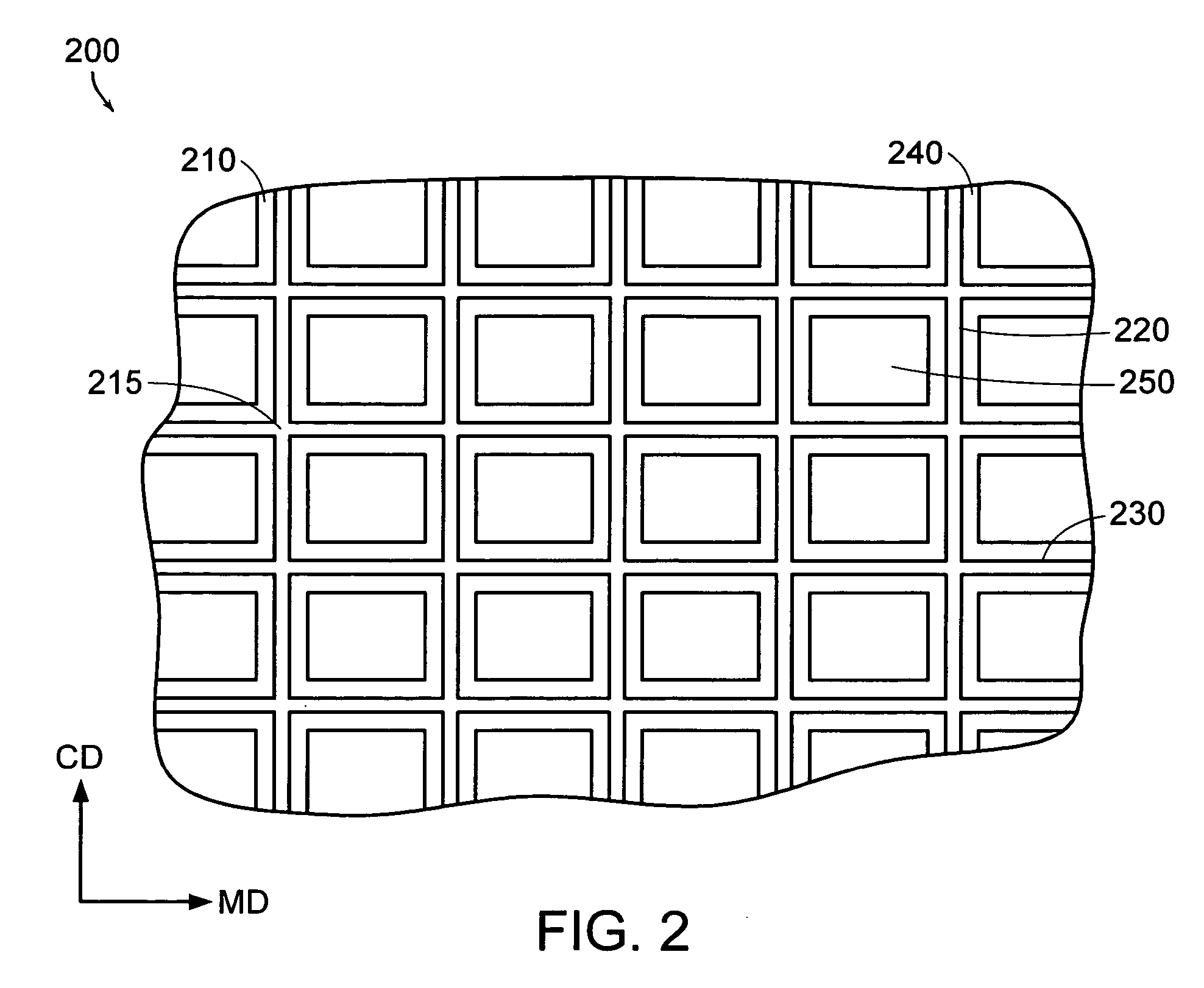

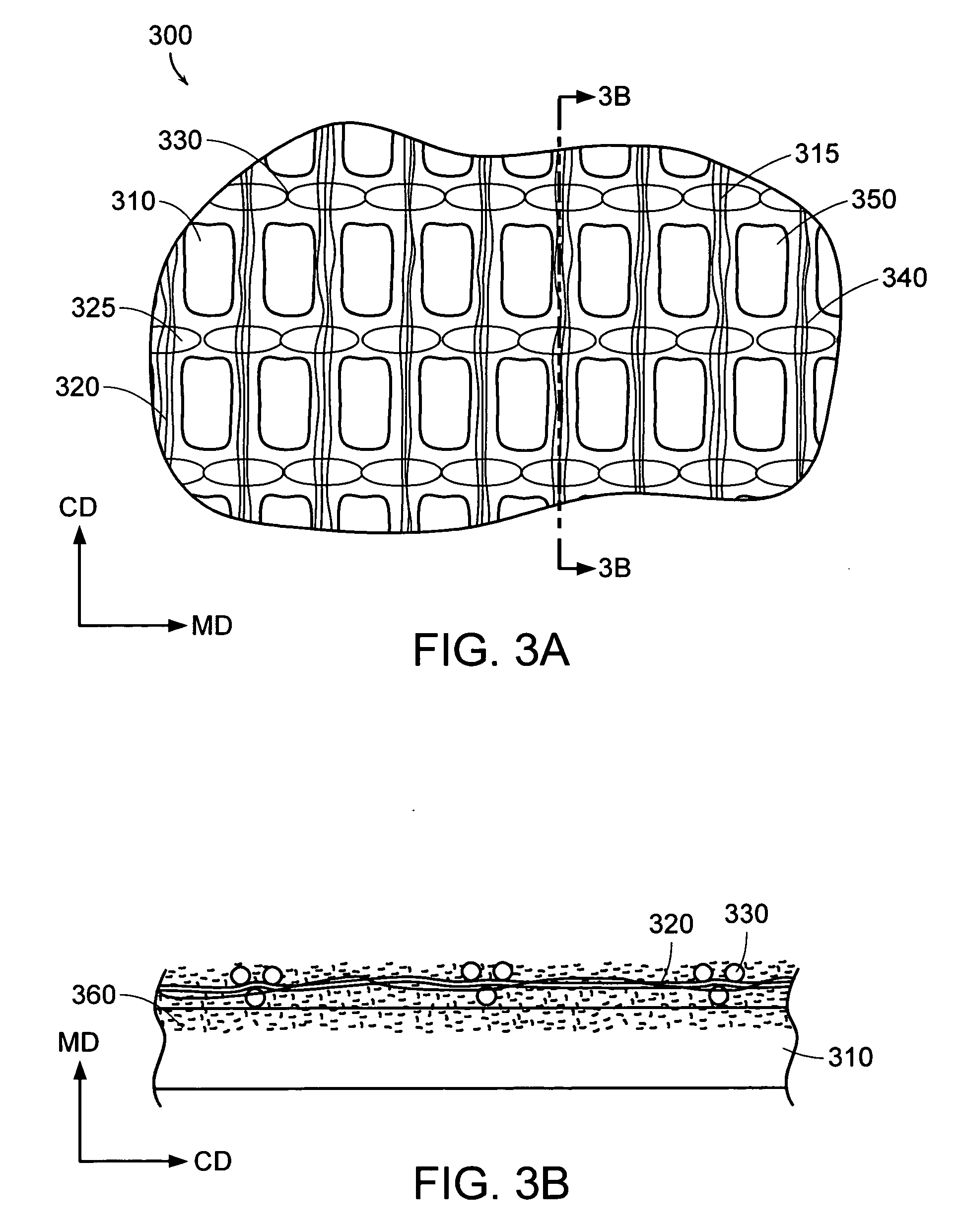

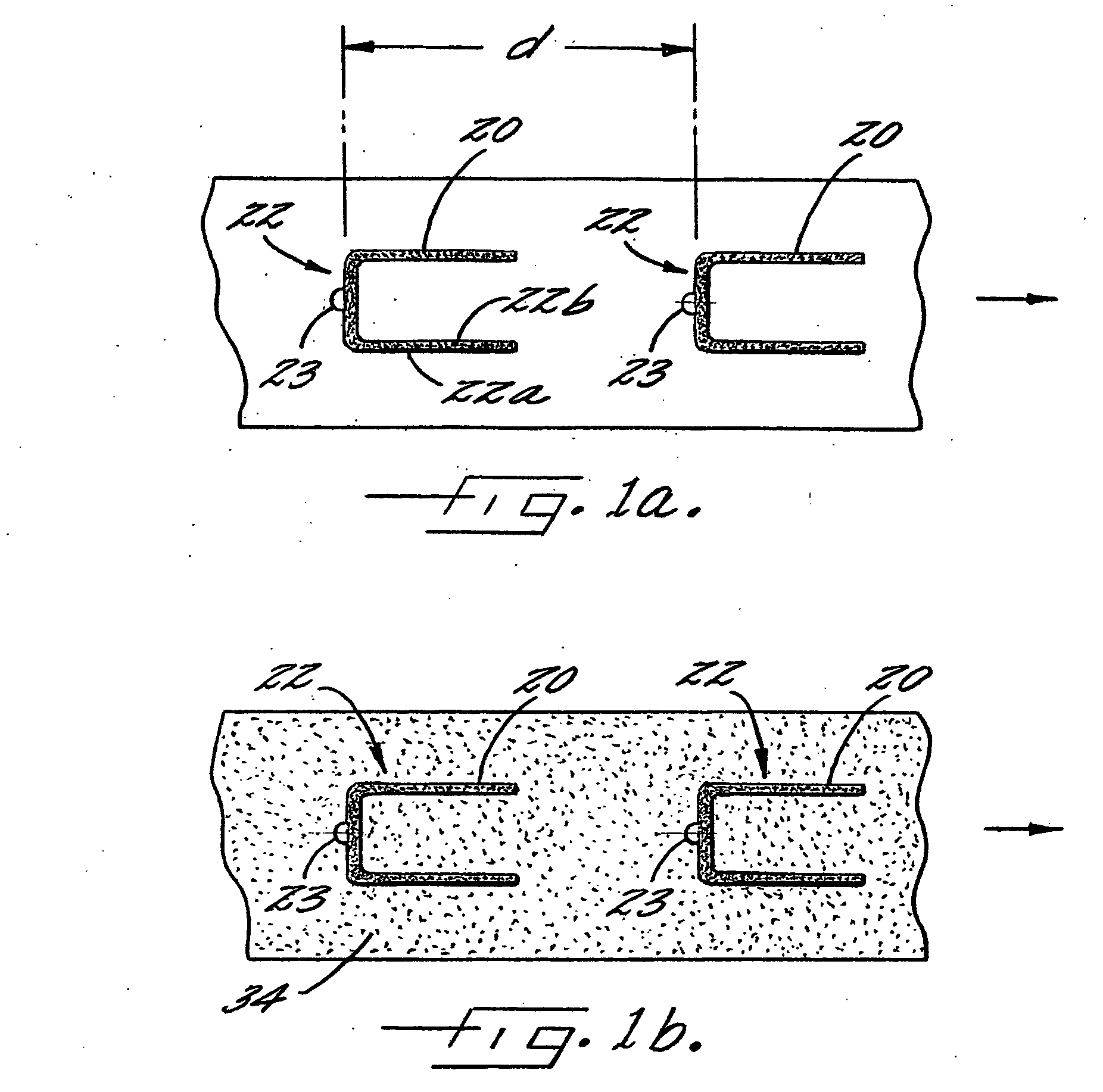

Air permeable pressure-sensitive adhesive tapes

InactiveUS20060154546A1Convenient to to manufactureEasy to useLamination ancillary operationsLayered product treatmentEngineeringPlastic film

A vapor permeable article includes a porous backing substrate and an open fabric applied to one surface of the backing substrate. The open fabric has a greater porosity than that of the backing substrate. The open fabric may be a woven fabric comprising warp (MD) yarns and weft (CD) yarns, and the warp yarns may be of a lower denier than the weft yarns, so as to facilitate hand-tear of the assembled article. The open fabric is coated with an adhesive in such a manner that the open fabric remains porous and vapor permeable. The backing substrate can be a woven, knit or non-woven fabric, or a porous film, such as an apertured plastic film.

Owner:ANDOVER HEALTHCARE

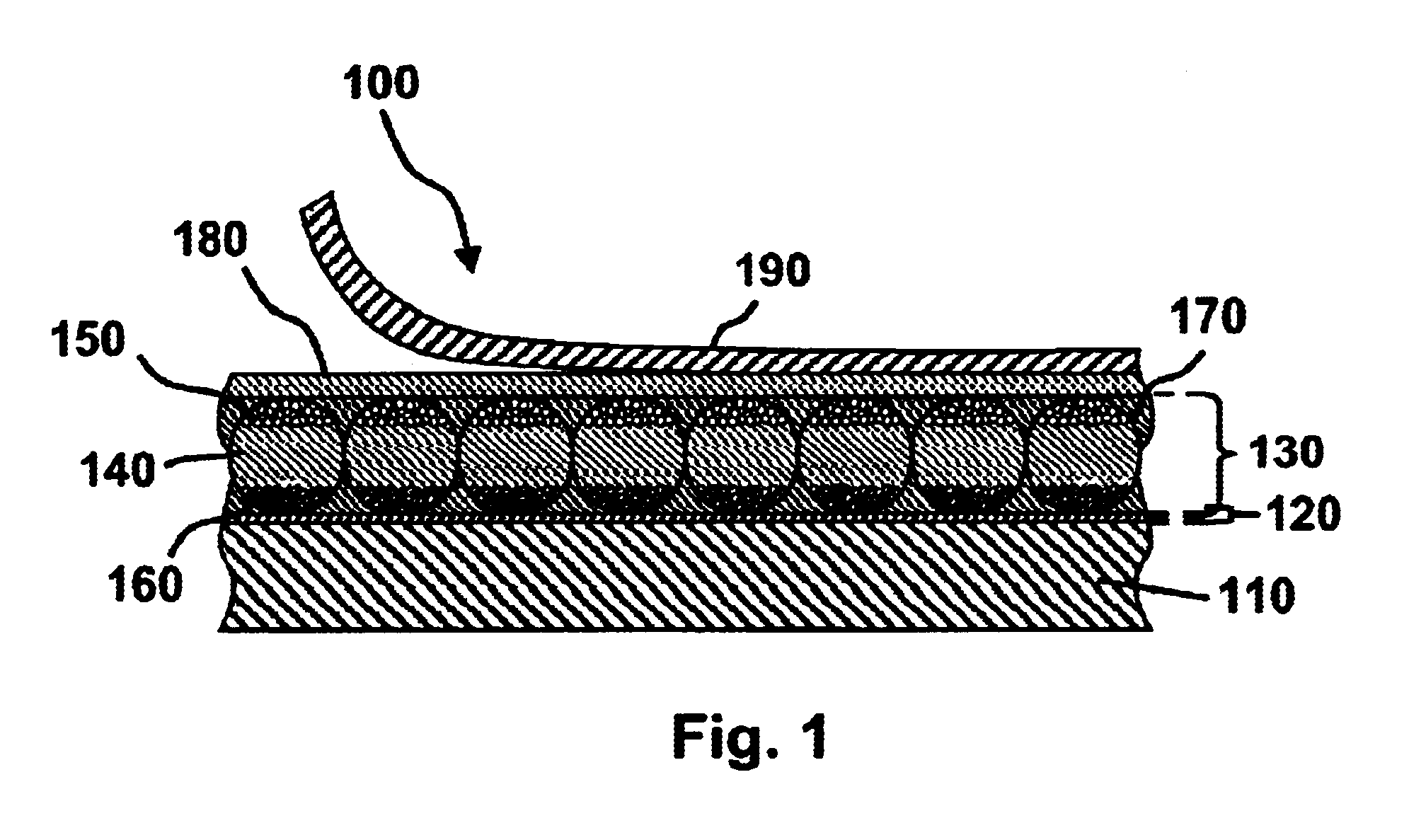

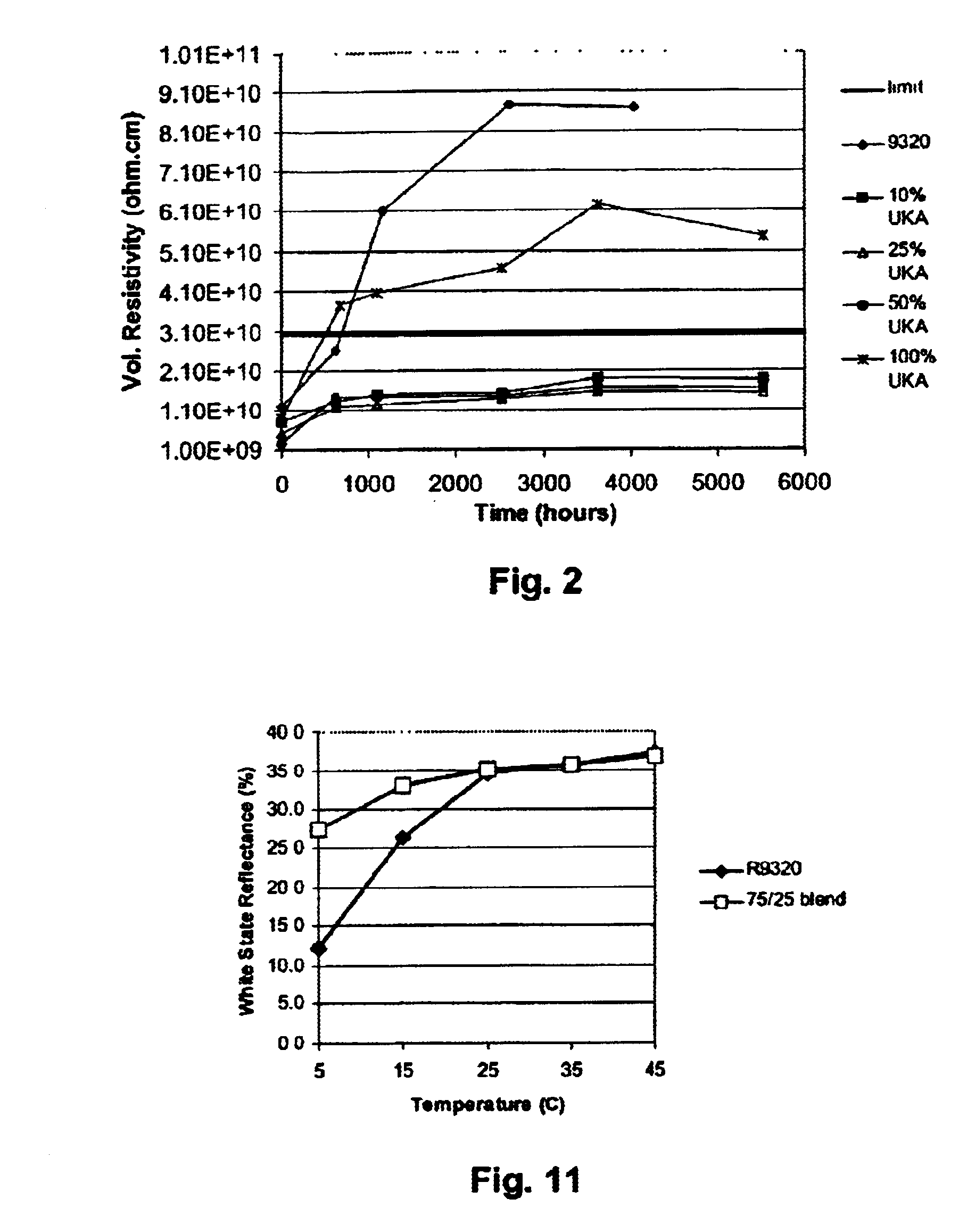

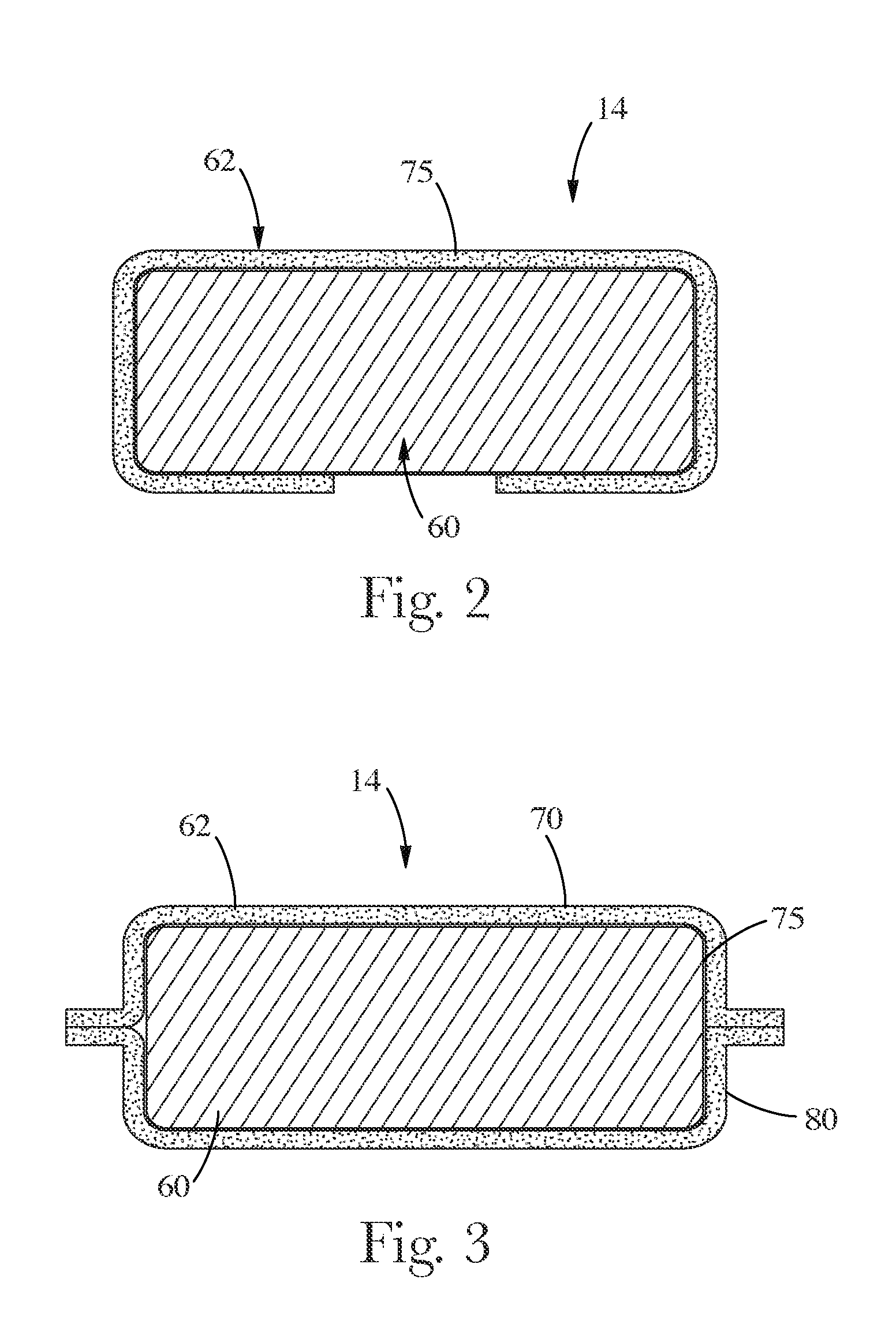

Electro-optic display and lamination adhesive

InactiveUS6831769B2Reduce adverse effectsGood optical performanceLamination ancillary operationsPolyureas/polyurethane adhesivesAdhesiveElectrophoresis

An electro-optic display comprises first and second substrates and a lamination adhesive layer and a layer of a solid electro-optic material disposed between the first and second substrates, the lamination adhesive layer having a volume resistivity, measured at 10° C., which does not change by a factor of more than about 3 after being held at 25° C. and 45 percent relative humidity for 1000 hours. The electro-optic material is preferably an encapsulated electrophoretic material. Other desirable characteristics of lamination adhesives for use in electro-optic displays are also described.

Owner:E INK CORPORATION

Nonwoven Having Durable Hydrophilic Coating

InactiveUS20110268932A1Promote migrationLamination ancillary operationsDecorative surface effectsHydrophilic coatingTrace Amounts

A nonwoven material coated with an amine-polyether silicone. The coating composition may include a wetting agent, an acid, and / or a defoamer. The nonwoven may be incorporated into a disposable absorbent article. The disposable absorbent article may include at least trace amounts of a mineral oil. The coating of the nonwoven may be durable even in the presence of mineral oil.

Owner:THE PROCTER & GAMBLE COMPANY

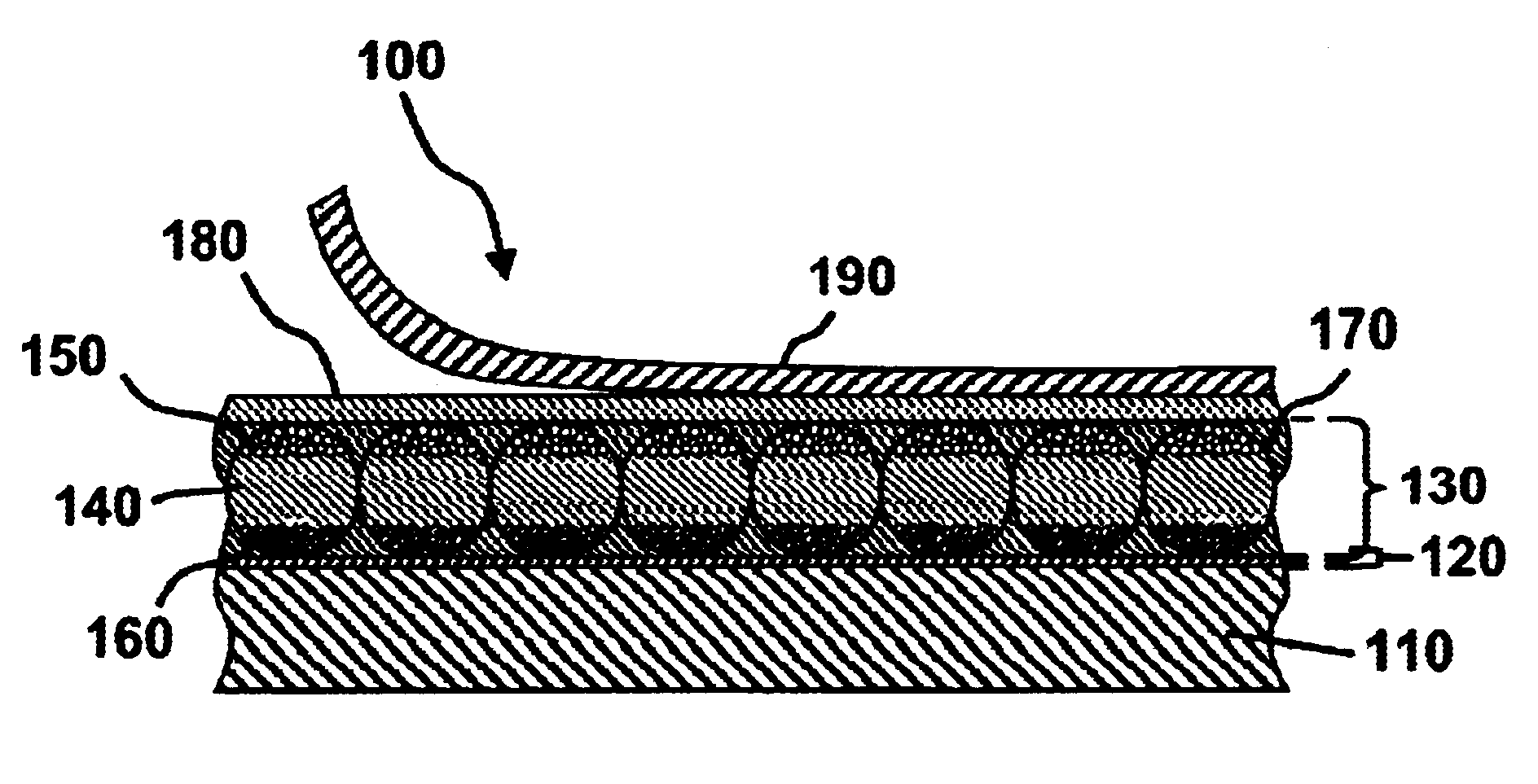

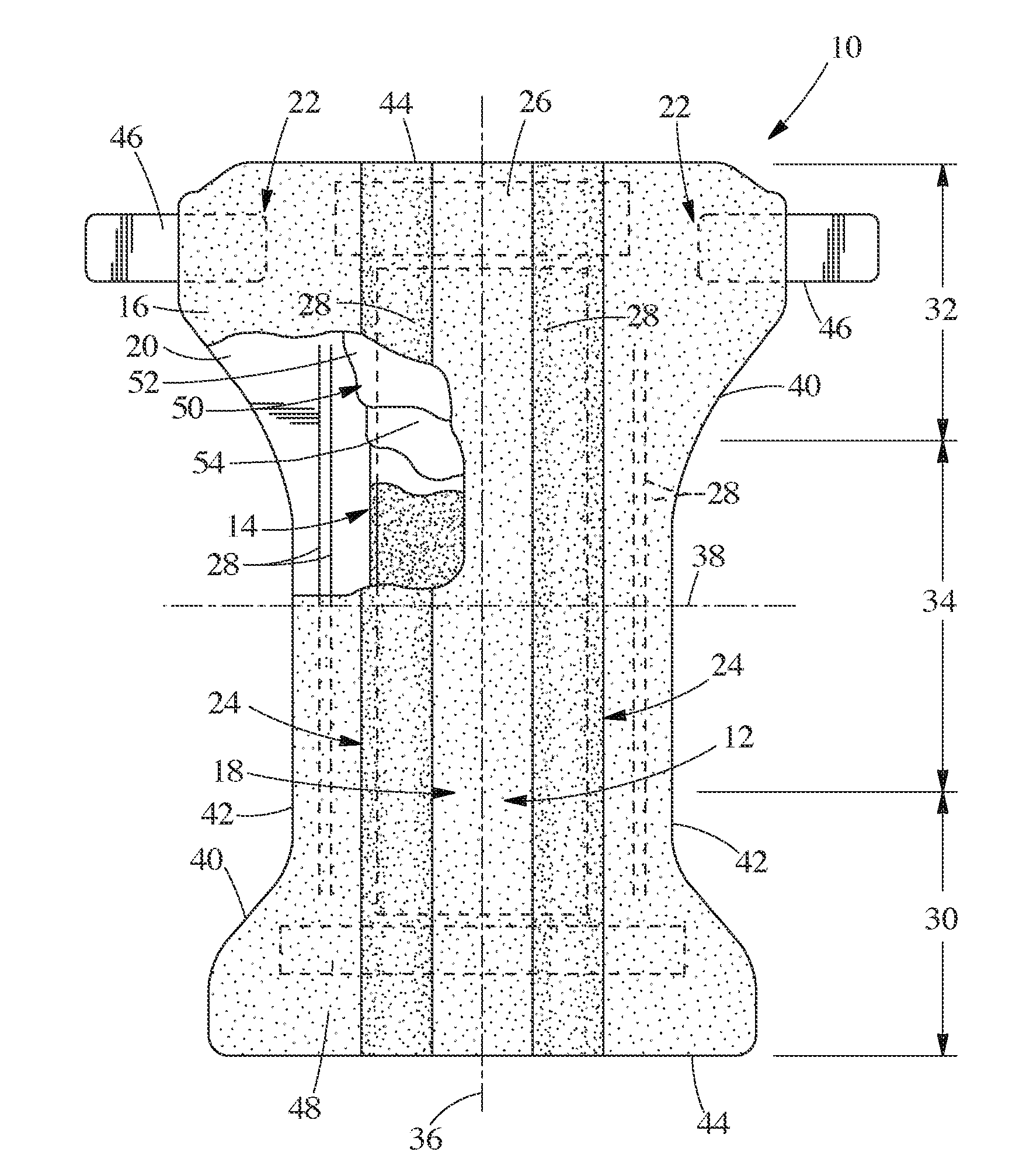

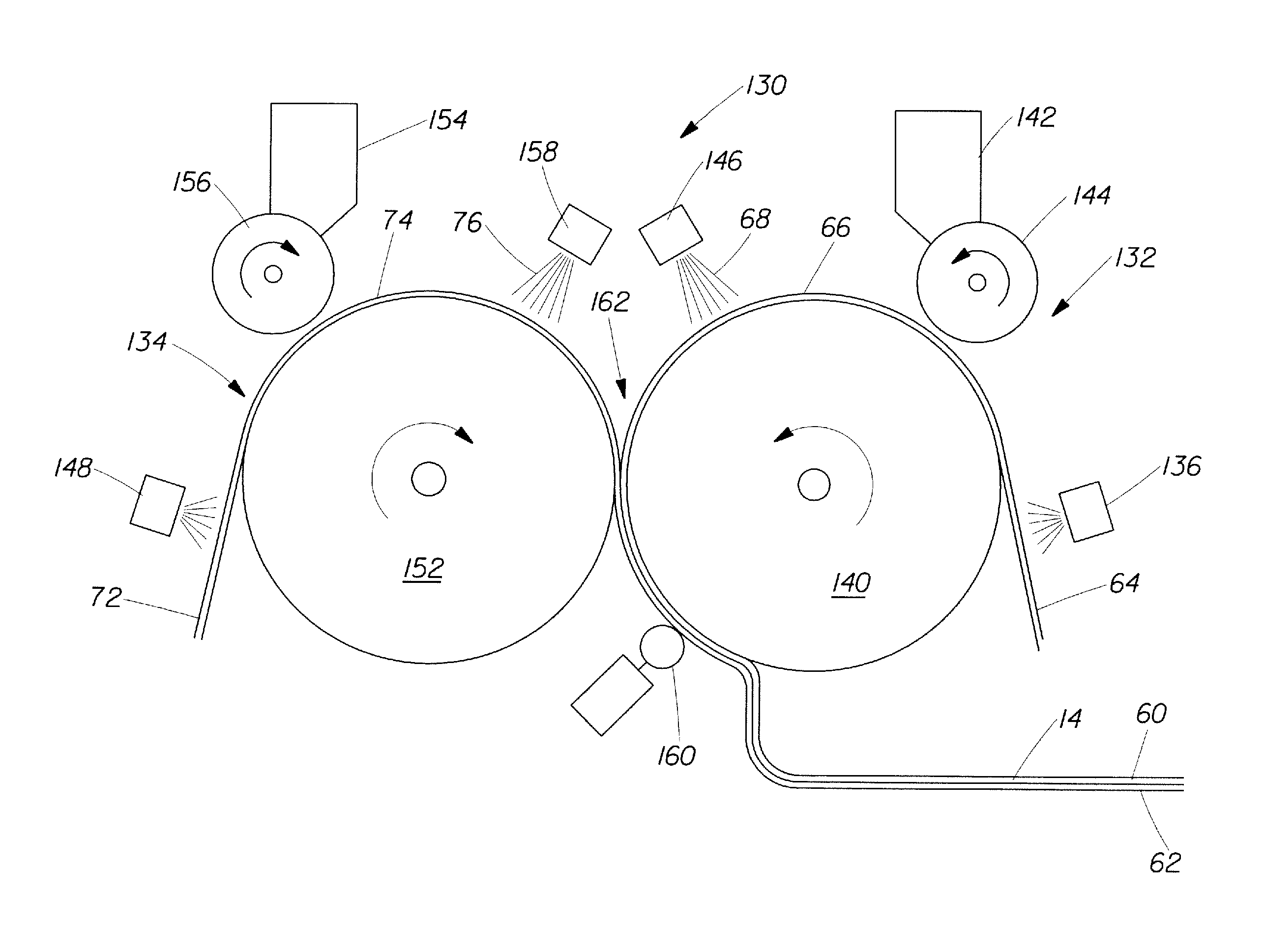

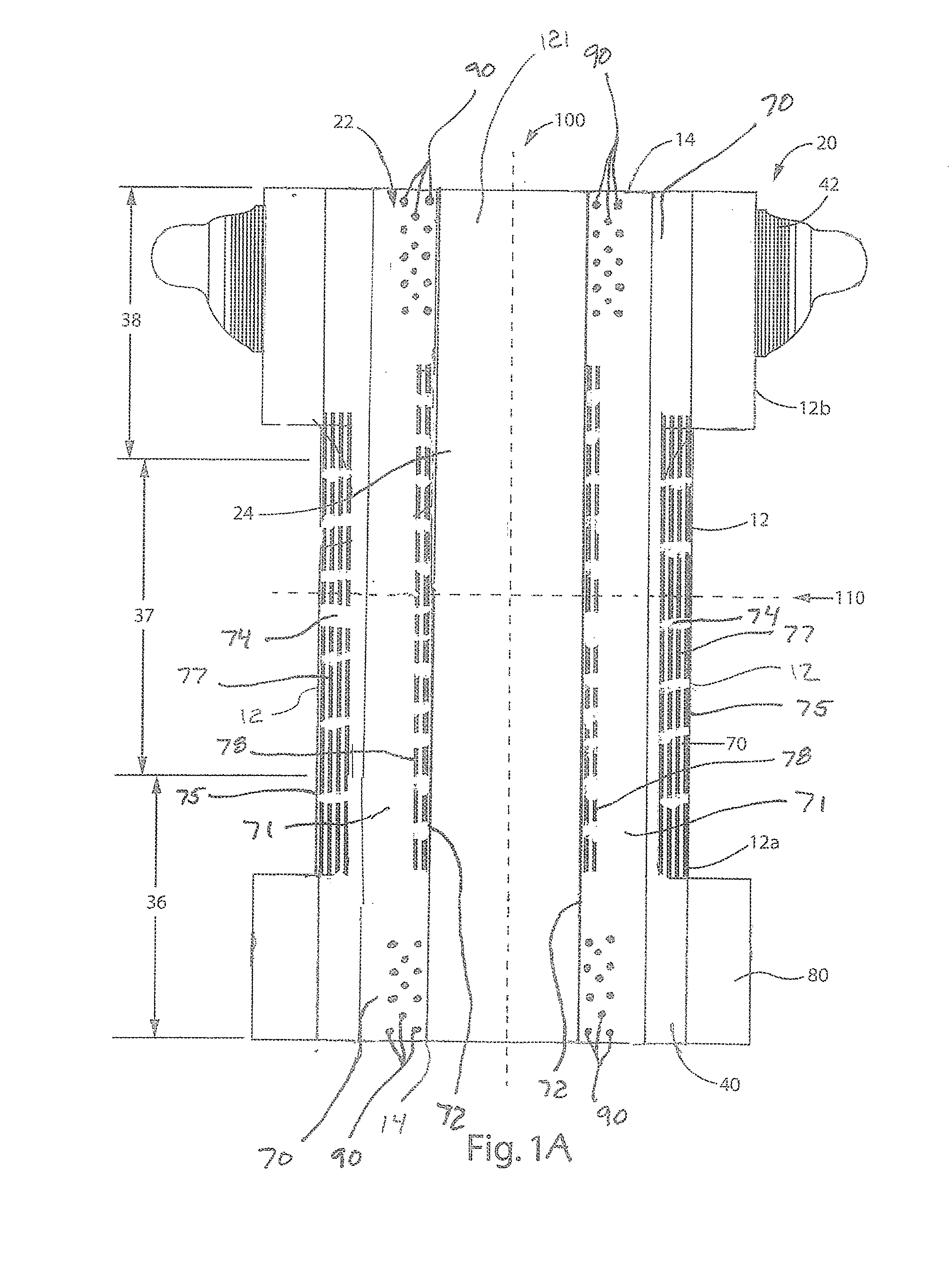

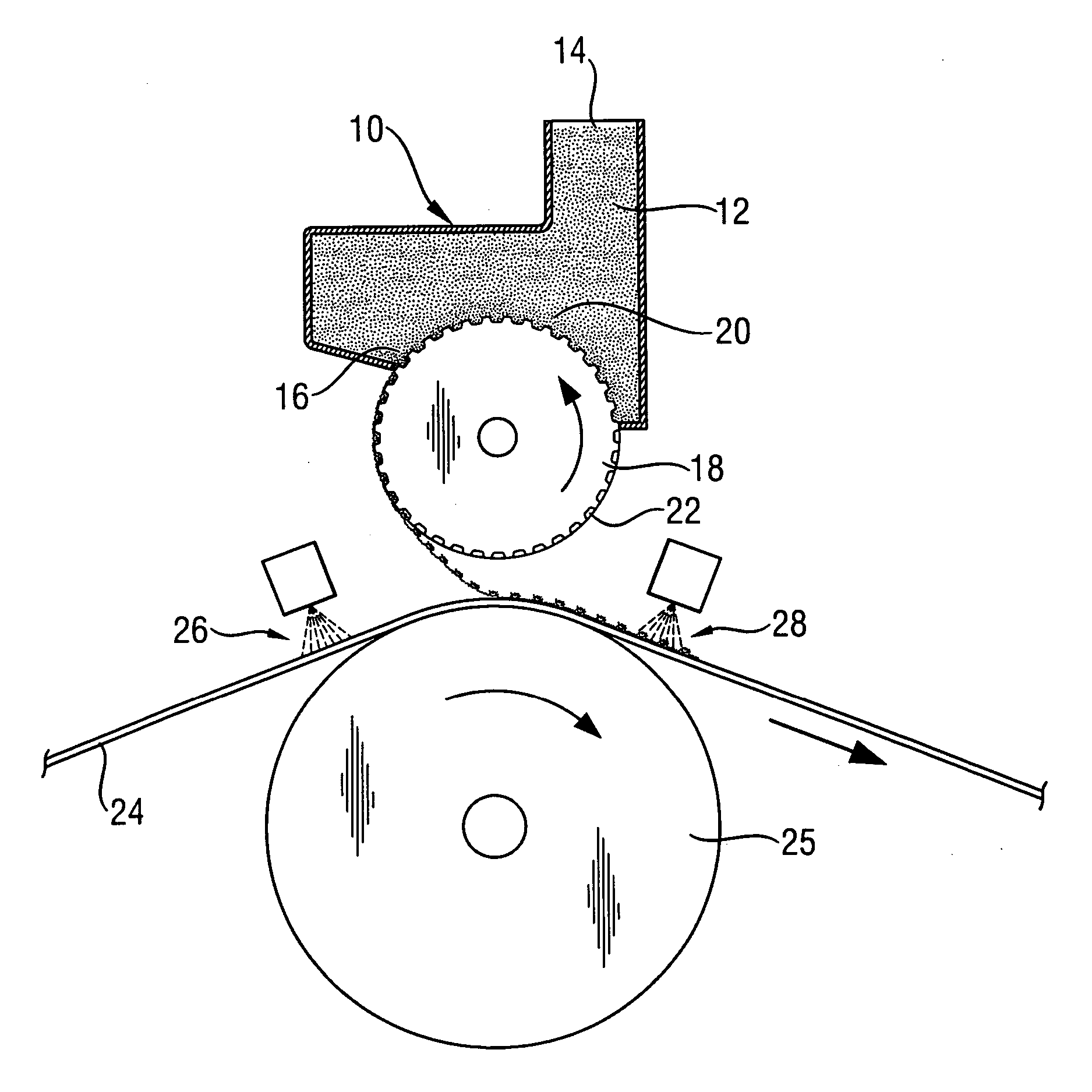

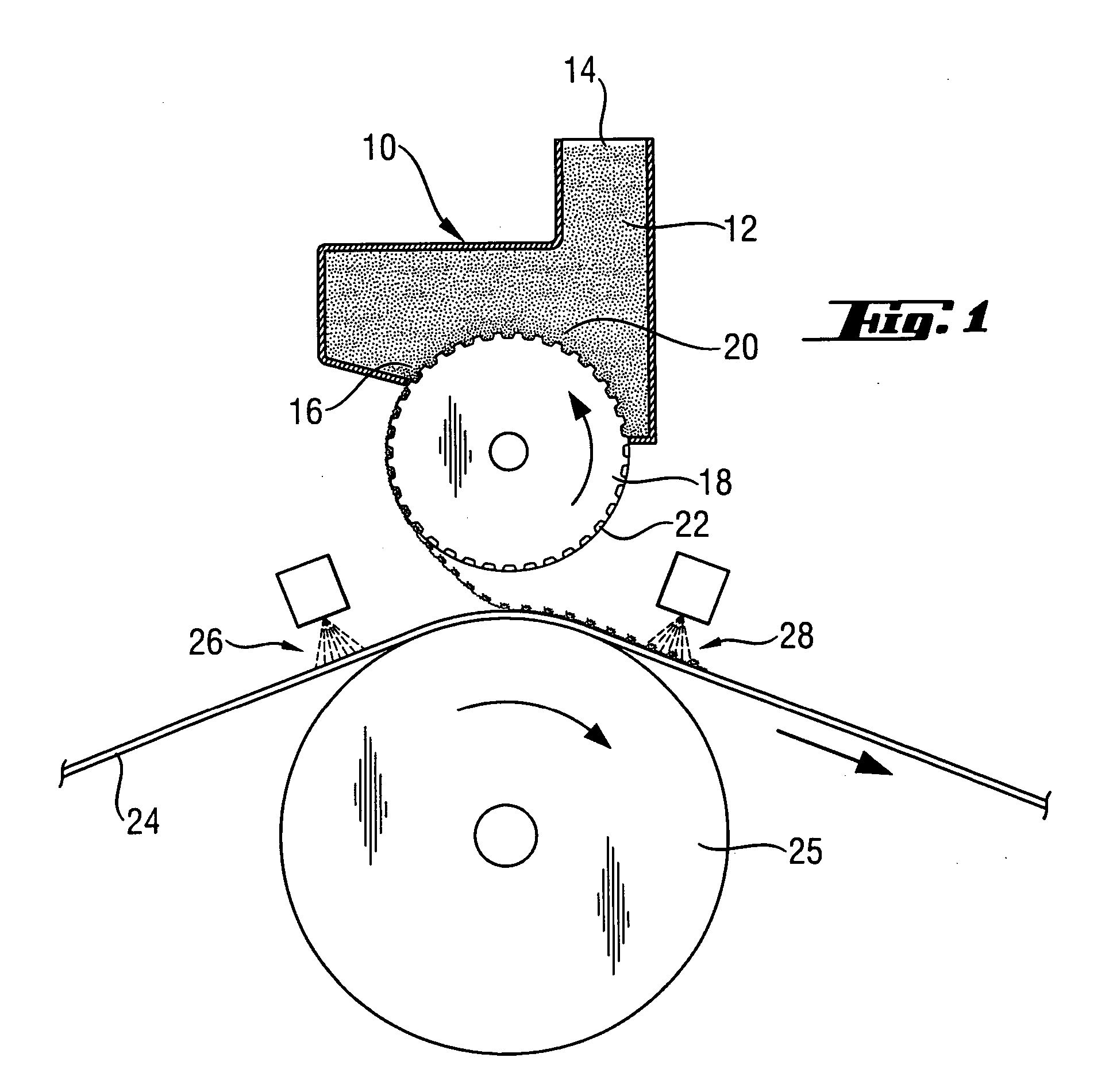

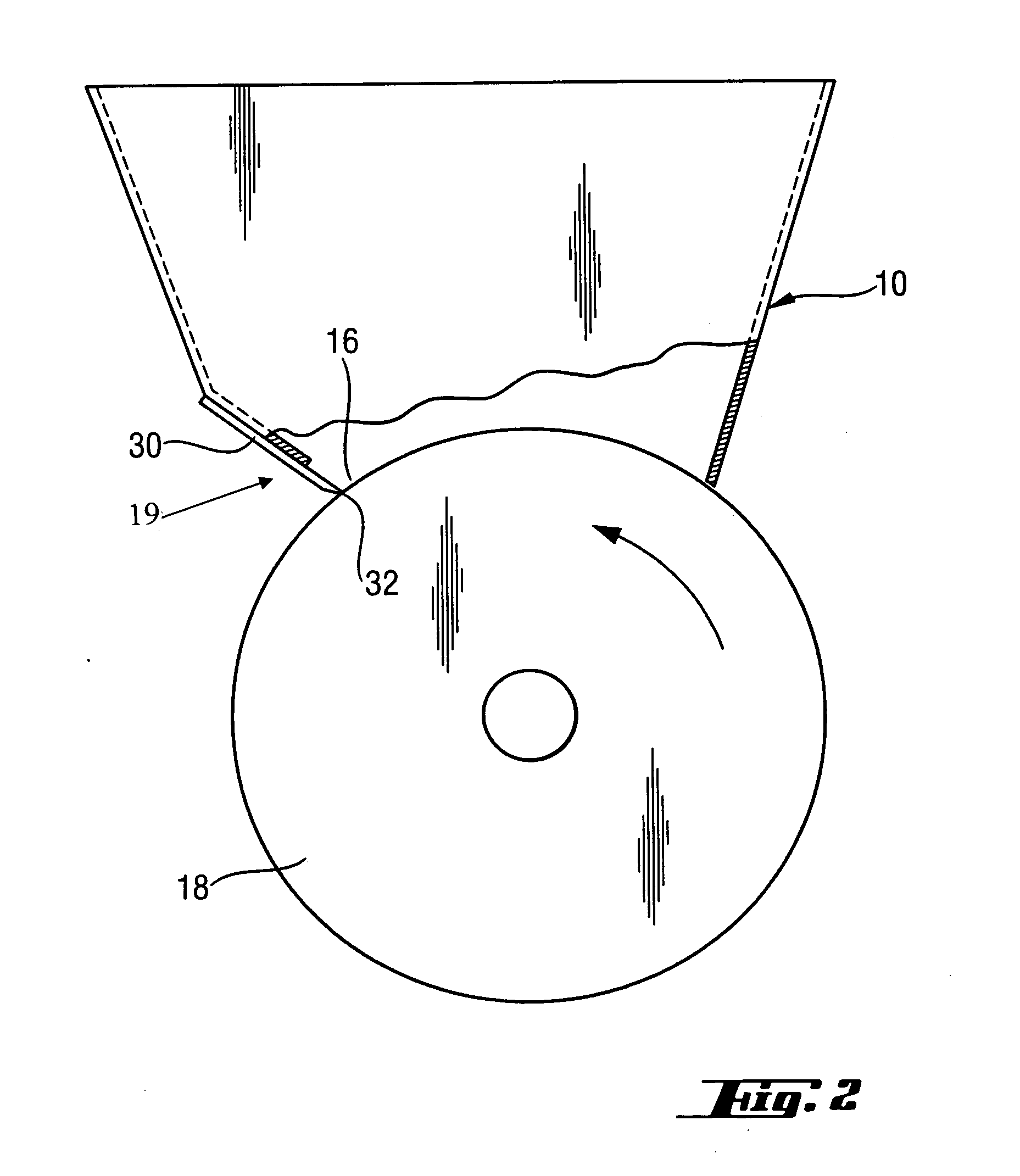

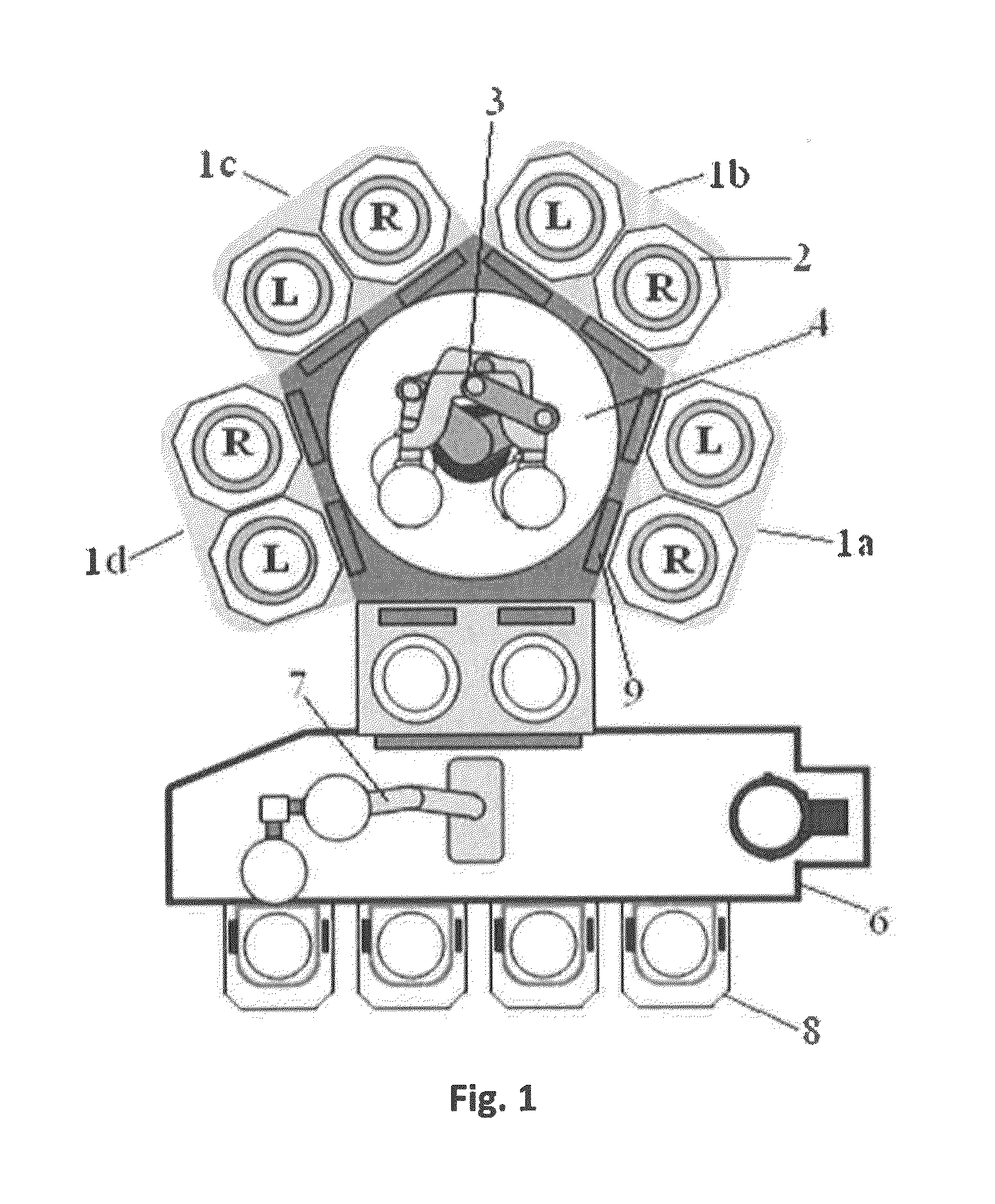

Method And Apparatus For Making Disposable Absorbent Article With Absorbent Particulate Polymer Material And Article Made Therewith

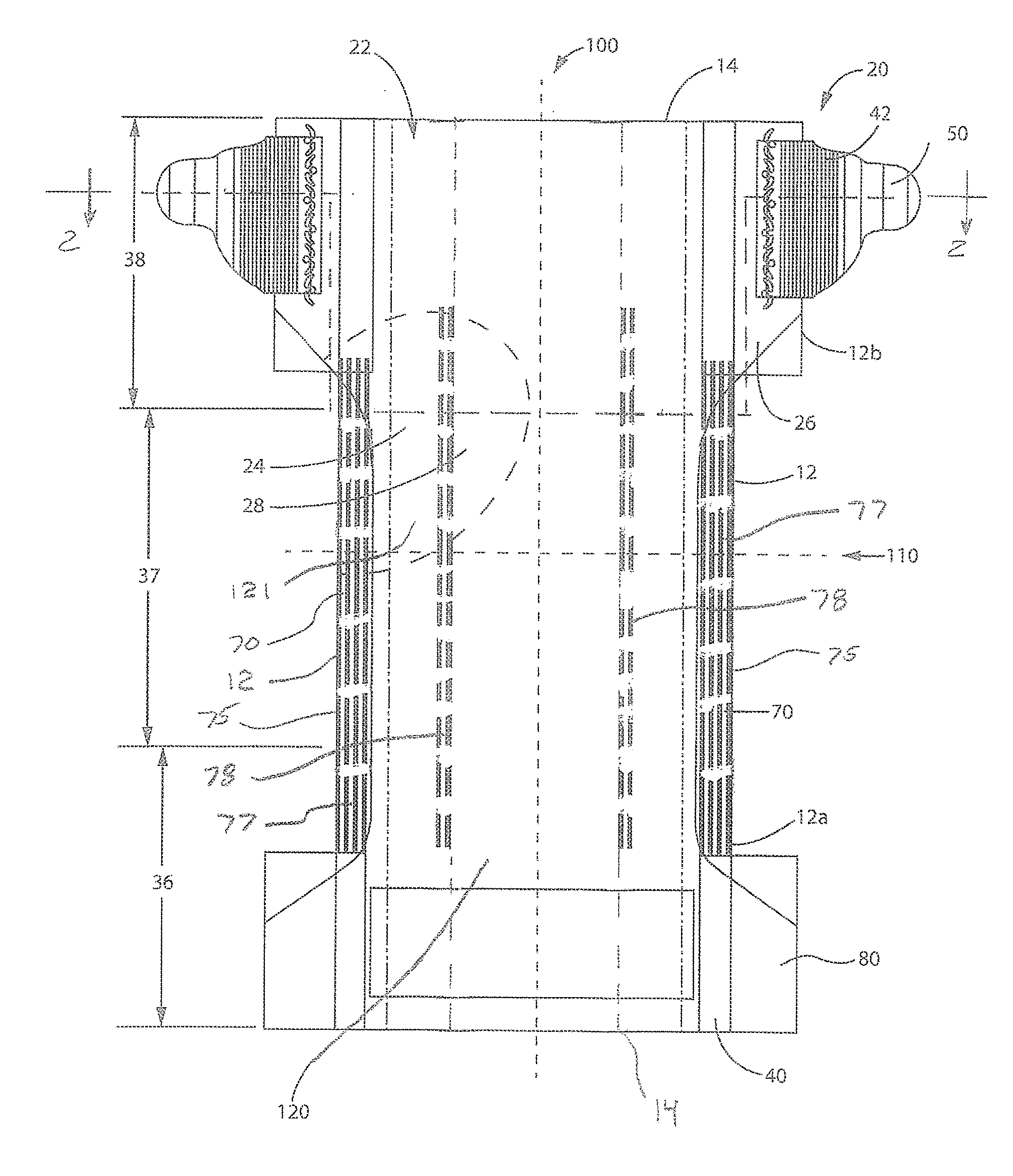

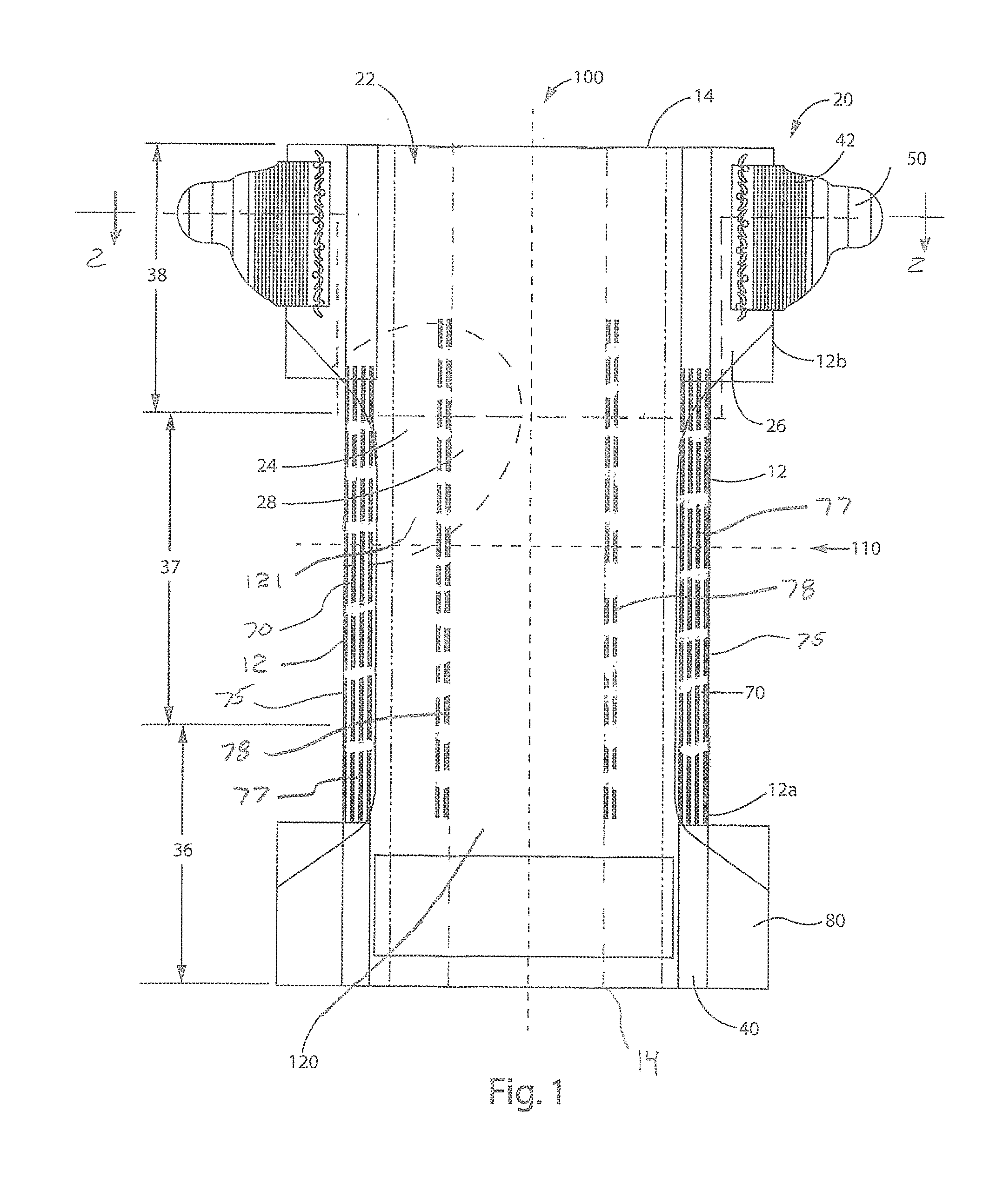

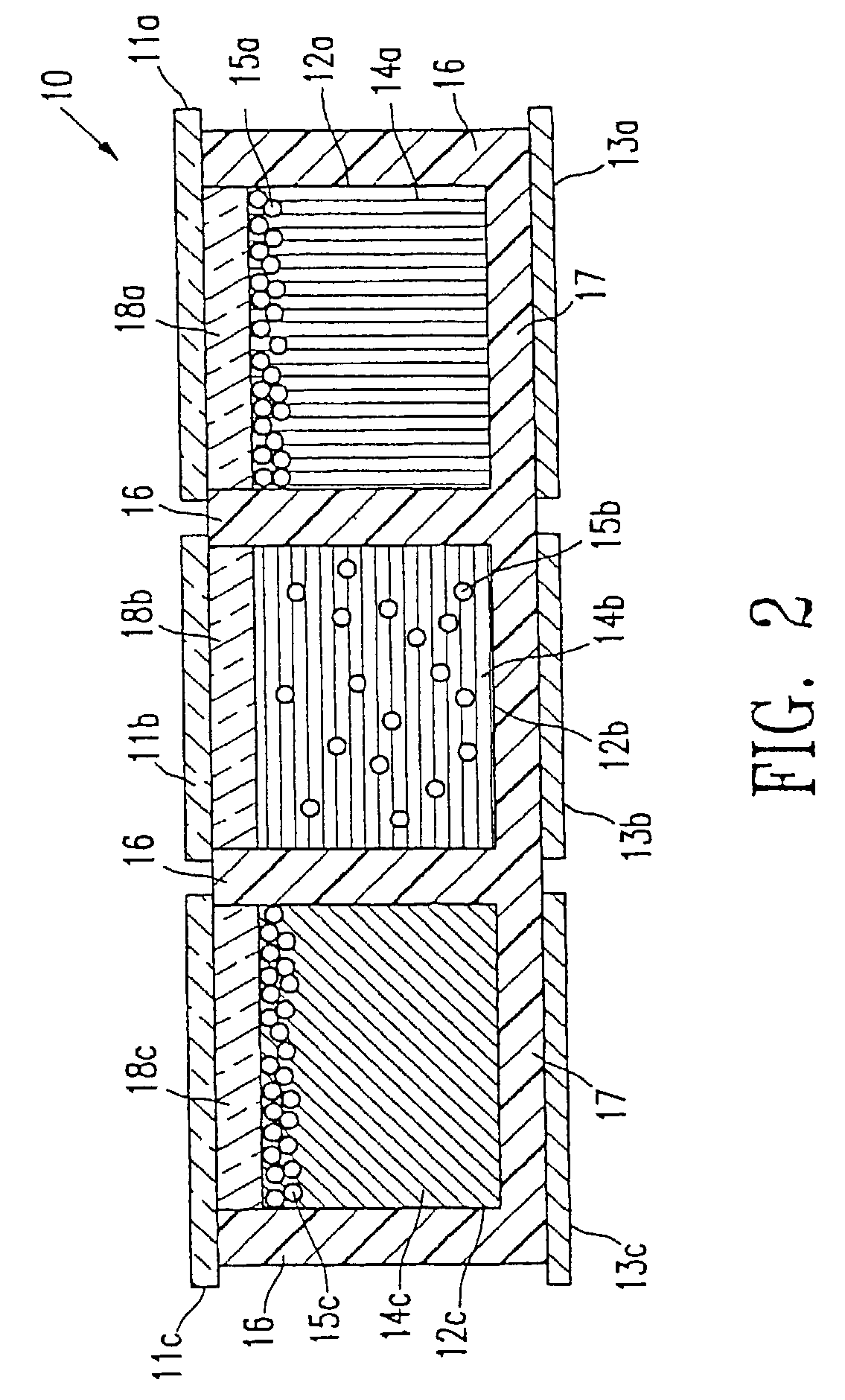

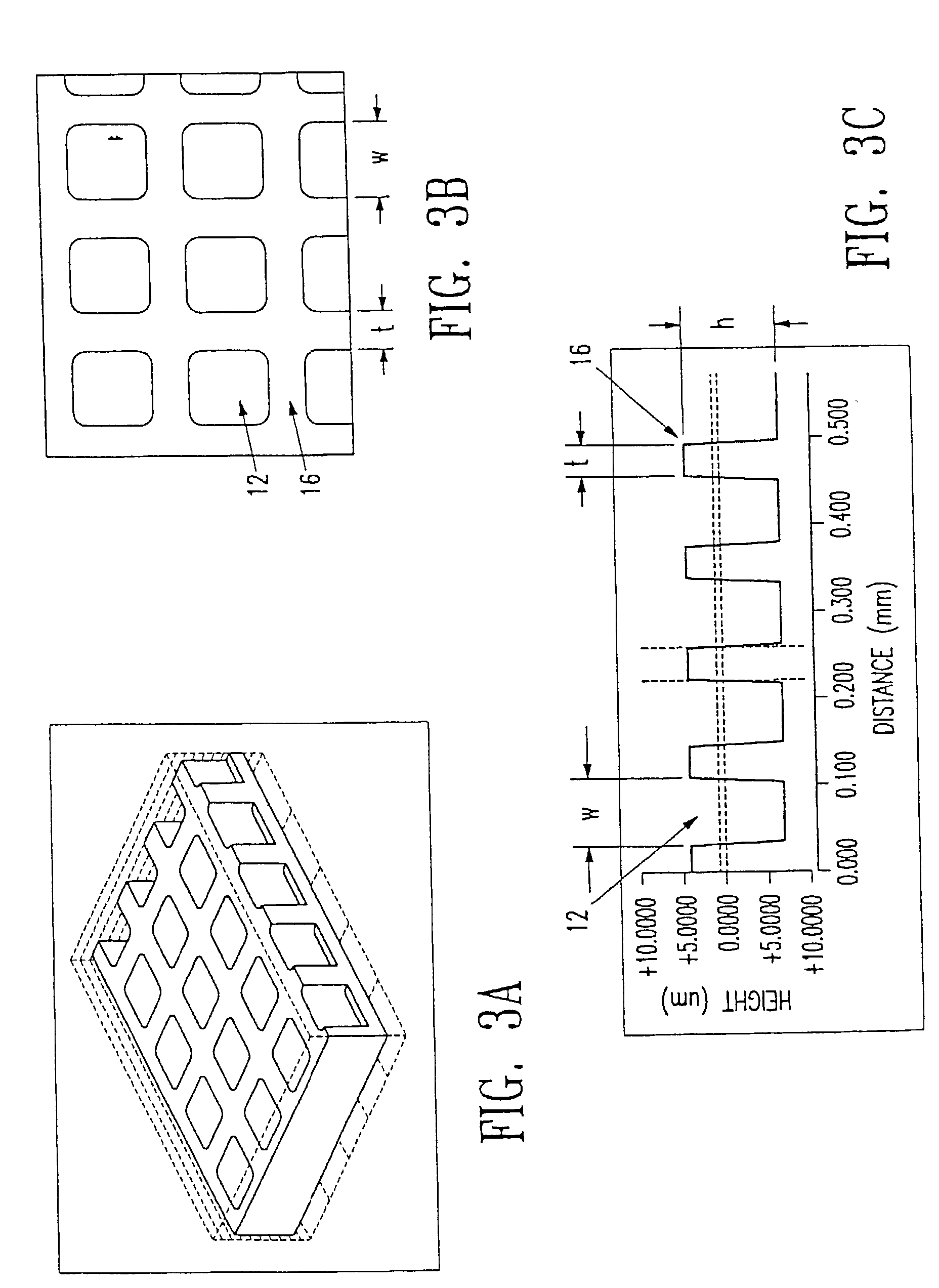

A method for making a disposable absorbent core comprises depositing absorbent particulate polymer material from a plurality of reservoirs in a printing roll onto a substrate disposed on a grid of a support which includes a plurality of cross bars extending substantially parallel to and spaced from one another so as to form channels extending between the plurality of cross bars. The plurality of reservoirs in the first peripheral surface are arranged in an array comprising rows extending substantially parallel to and spaced from one another. The support and printing roll are arranged such that the plurality of cross bars are substantially parallel to the rows of the plurality of reservoirs and the absorbent particulate polymer material is deposited on the substrate in a pattern such that the absorbent particulate polymer material collects in rows on the first substrate formed between the first plurality of cross bars. A thermoplastic adhesive material is deposited on the absorbent particulate polymer material and the substrate to cover the absorbent particulate polymer material on the substrate and form an absorbent layer. A disposable absorbent article and apparatus for making an absorbent article are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

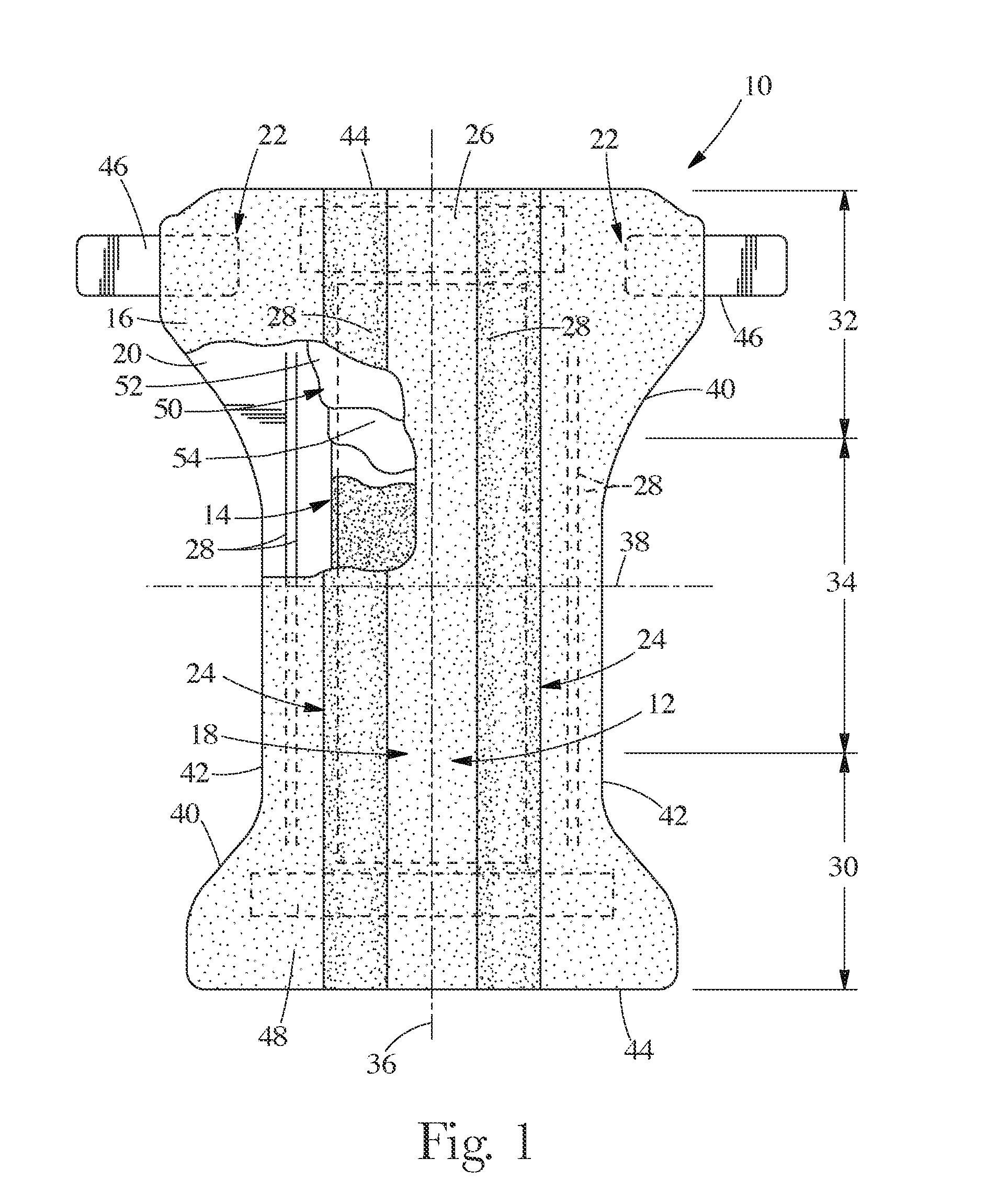

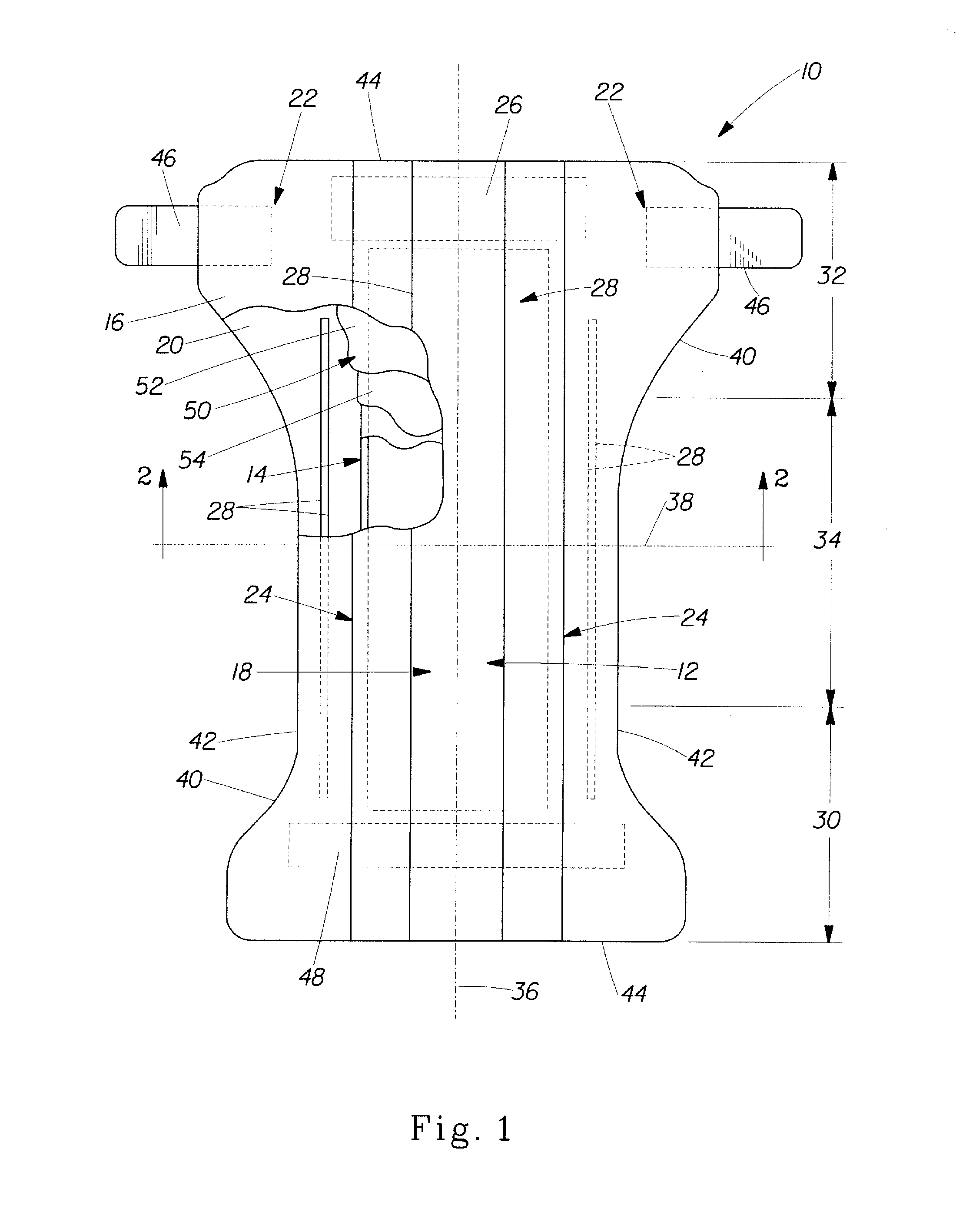

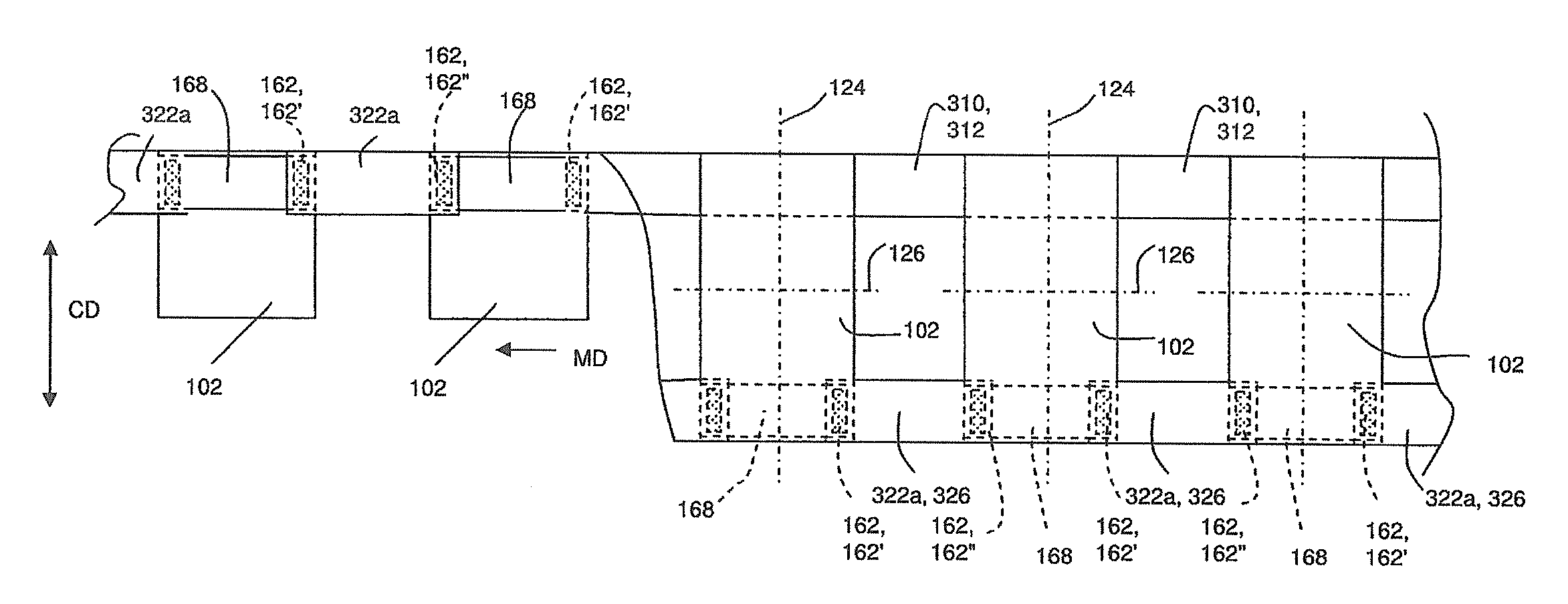

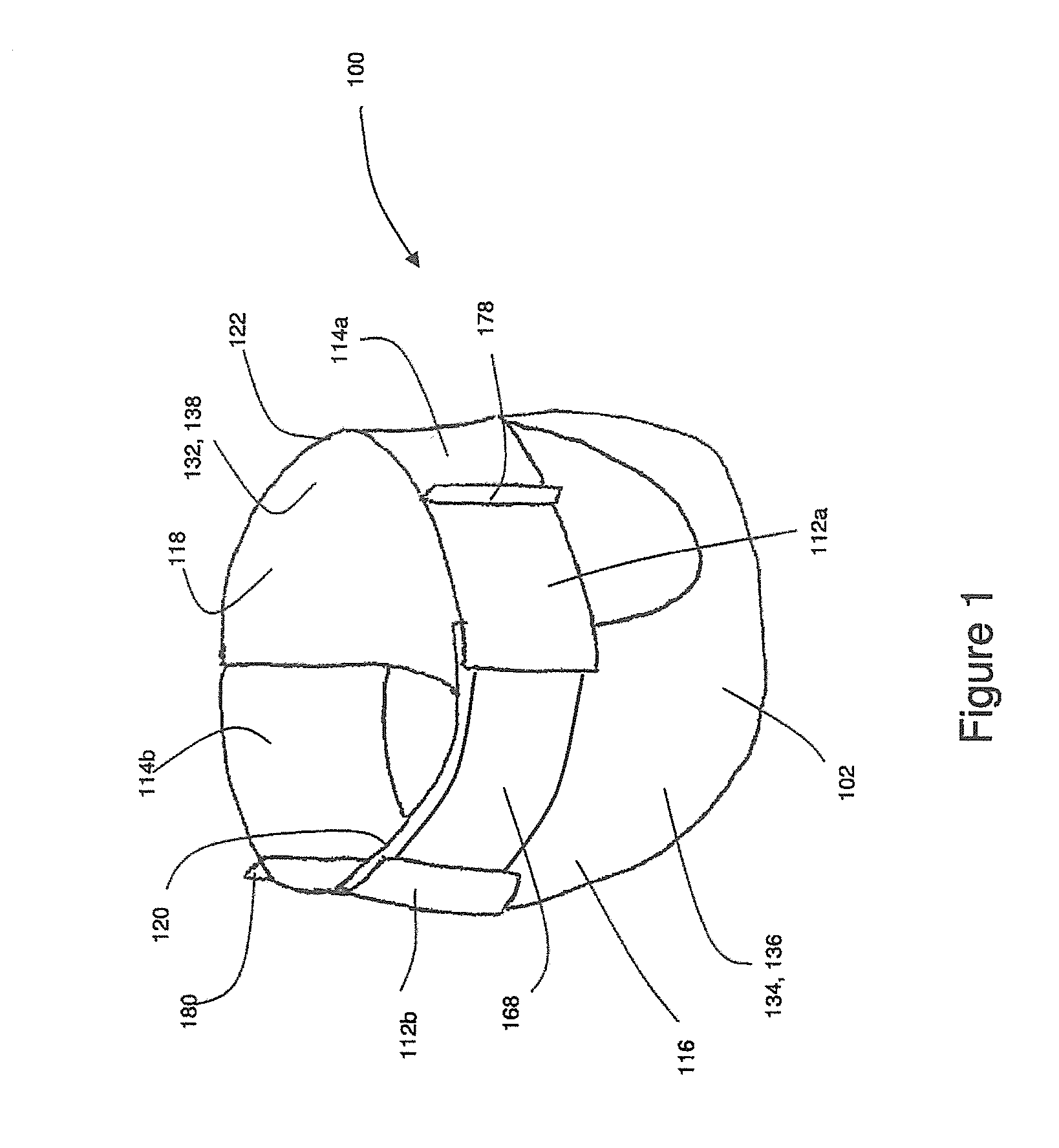

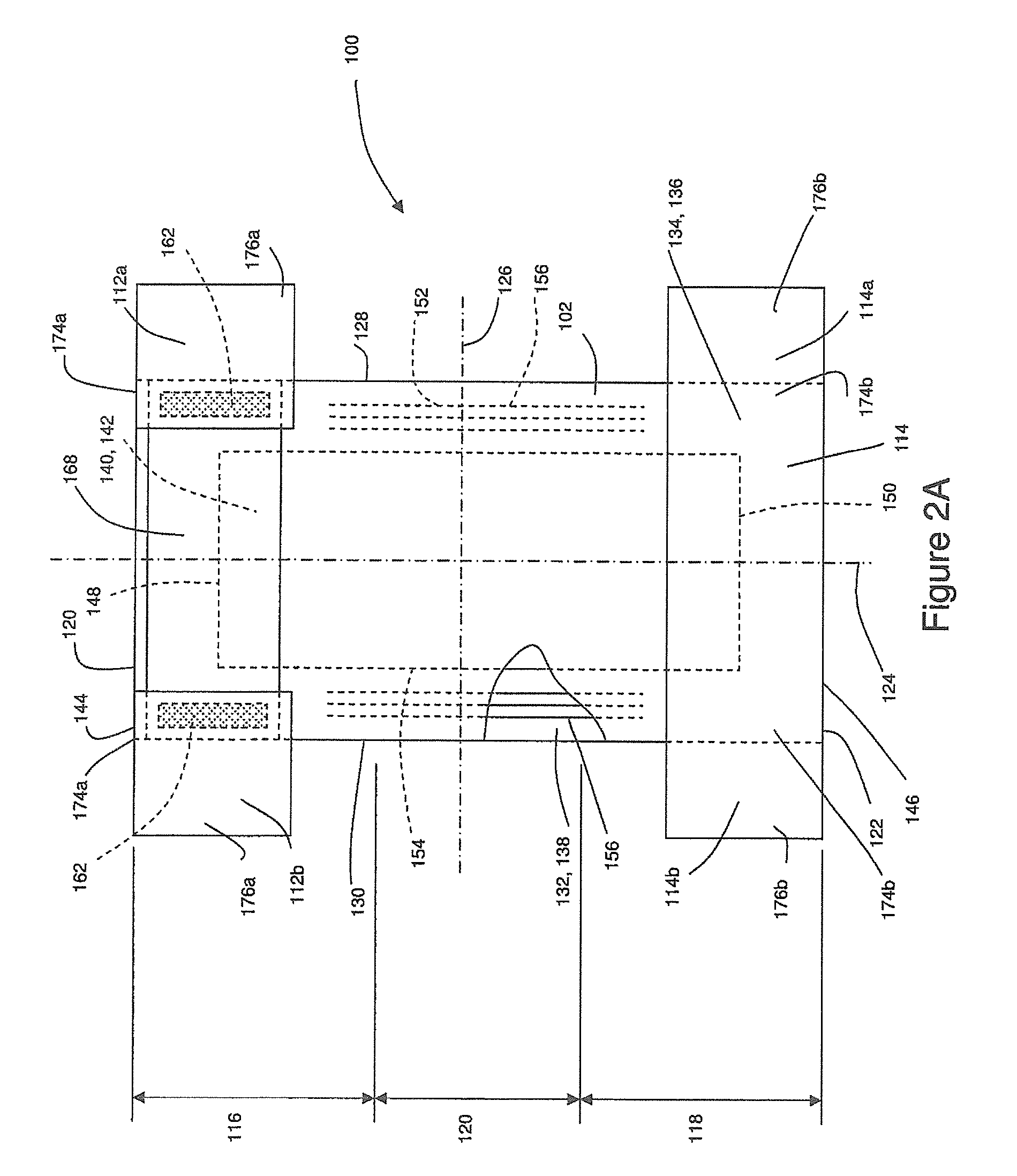

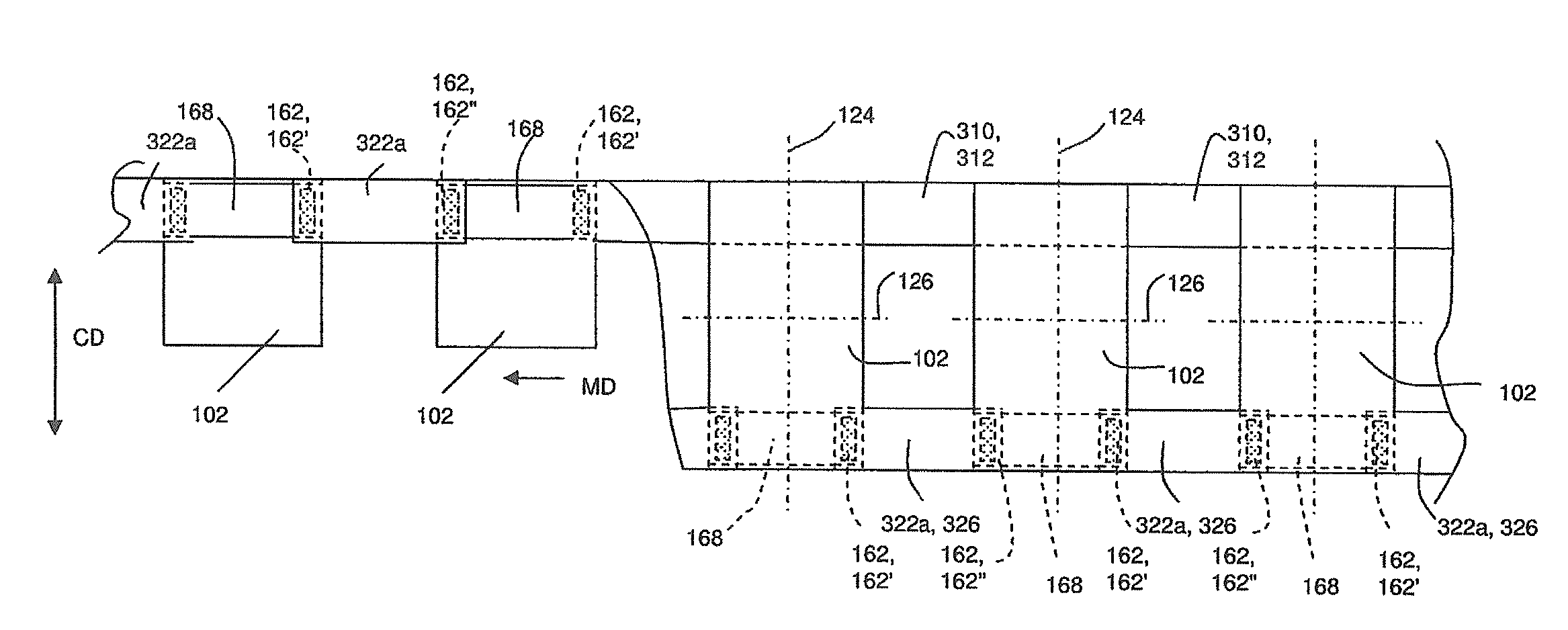

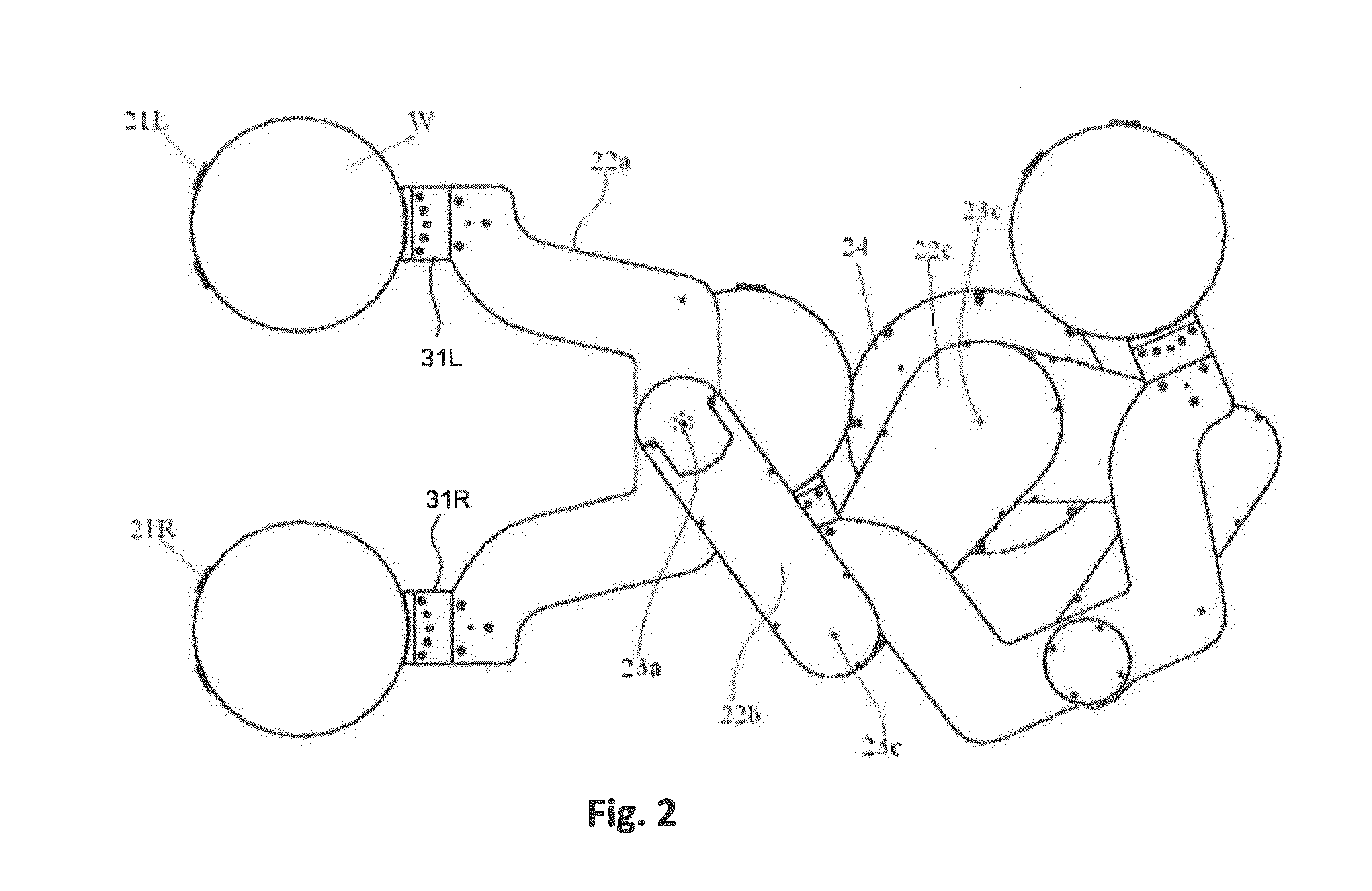

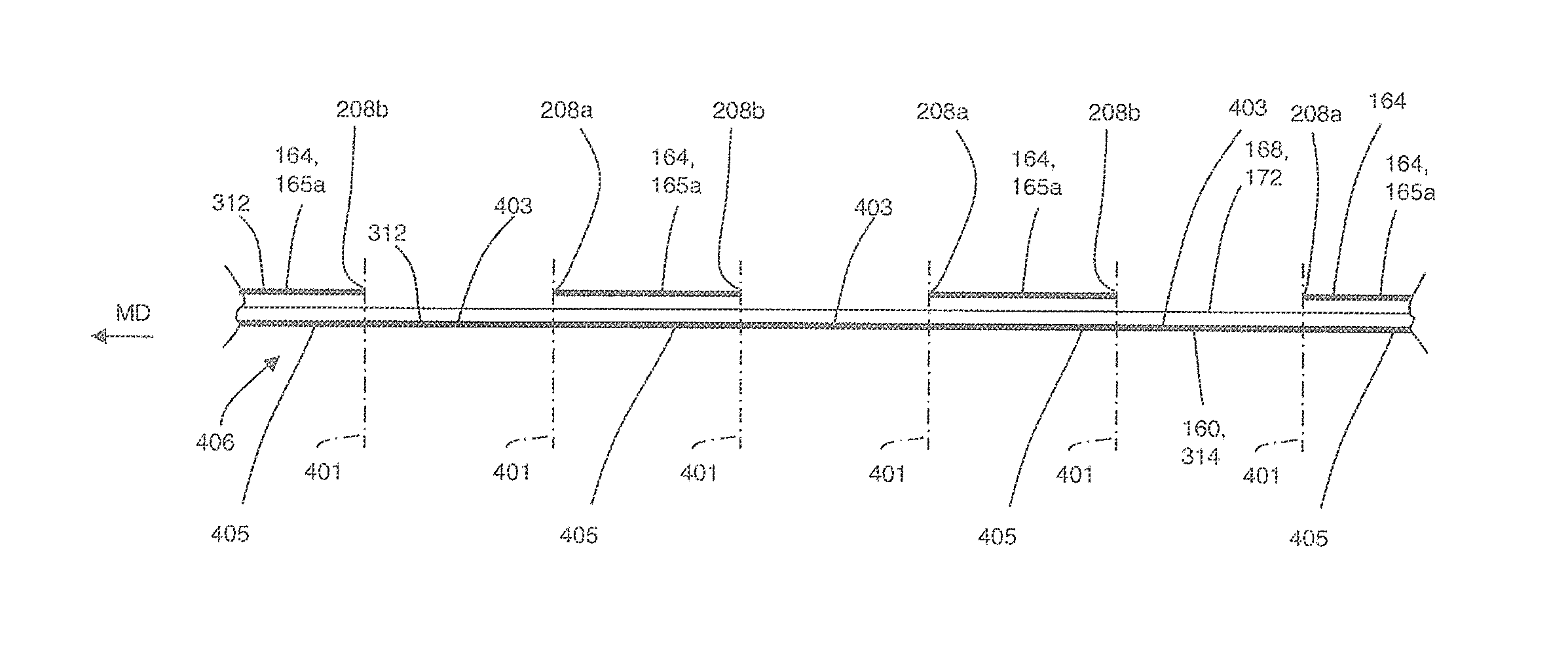

Method of Making Prefastened Refastenable Disposable Absorbent Articles

The present disclosure relates to methods for manufacturing absorbent articles, and in particular, methods for making pre-fastened refastenable pant diapers. Aspects of the methods according to the present disclosure relate to the fabrication of refastenable pant diapers wherein discrete chassis are advanced in a machine direction such that the lateral axis is parallel with the machine direction. First side panels are then refastenably connected with the first waist region, and second side panels are permanently connected the second waist regions of the discrete chassis. The chassis are connected with discrete lengths of side panel material and / or connection zone material. The chassis are then folded, and the first and second side panels are subsequently bonded together. The article is then subjected to knife cut at or adjacent the bonded regions to create discrete, pre-fastened refastenable pant diapers.

Owner:THE PROCTER & GAMBLE COMPANY

Method of Making Prefastened Refastenable Disposable Absorbent Articles

InactiveUS20120061015A1Lamination ancillary operationsLaminationKnife cutsElectrical and Electronics engineering

Aspects of the methods according to the present disclosure relate to the fabrication of refastenable pant diapers wherein discrete chassis are advanced in a machine direction such that the lateral axis is parallel with the machine direction. First side panels are then refastenably connected with the first waist region, and second side panels are permanently connected the second waist regions of the discrete chassis. The methods disclosed herein connect chassis with discrete lengths of side panel material and / or connection zone material, and forms a continuous web of articles formed by intermittently spaced chassis and intermittently spaced side panels bridging the gap between the intermittently spaced chassis. The chassis are then folded in the cross direction parallel to a lateral centerline and the first and second side panels are subsequently bonded together. The article is then subjected to knife cut adjacent the bonded regions to create discrete, pre-fastened refastenable pant diapers.

Owner:THE PROCTER & GAMBLE COMPANY

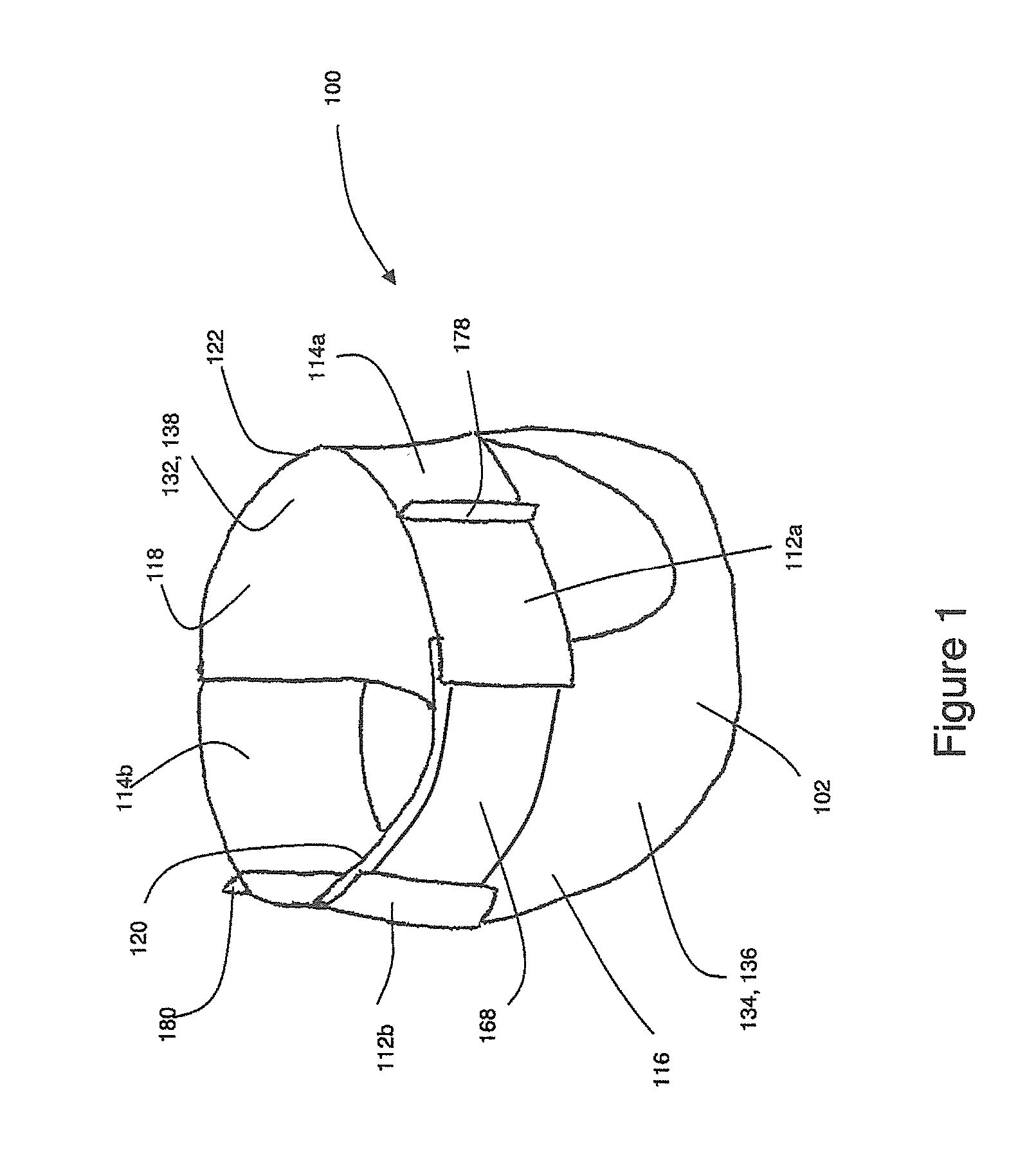

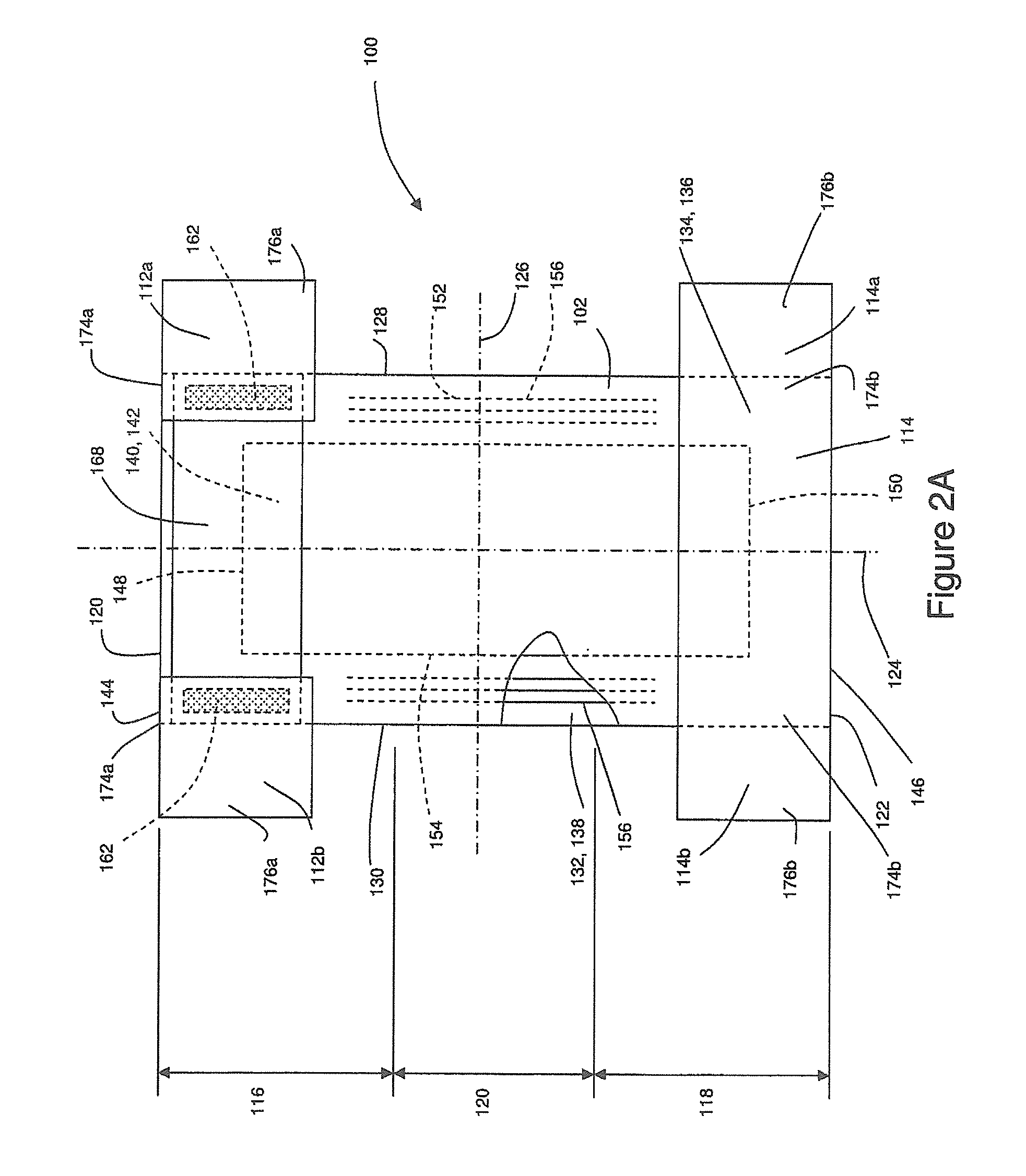

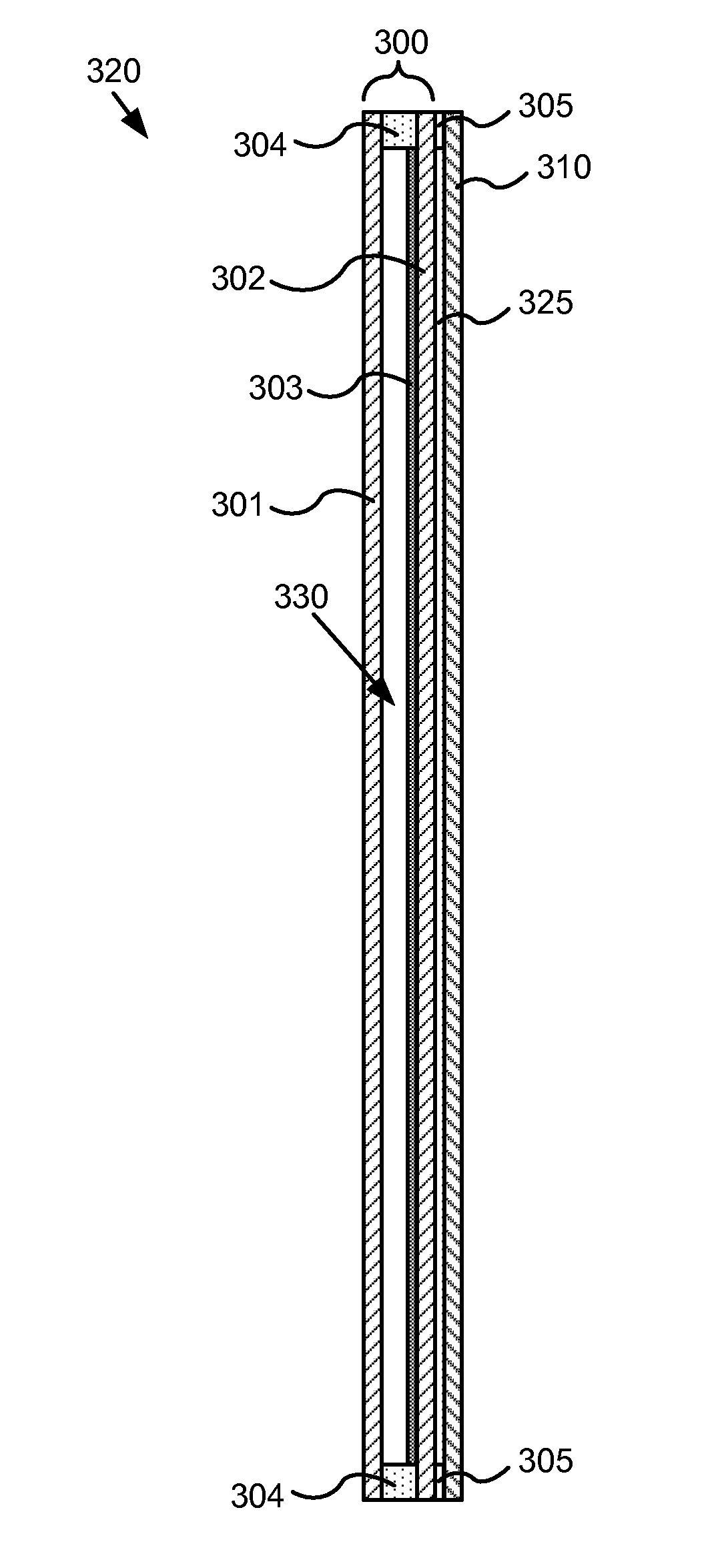

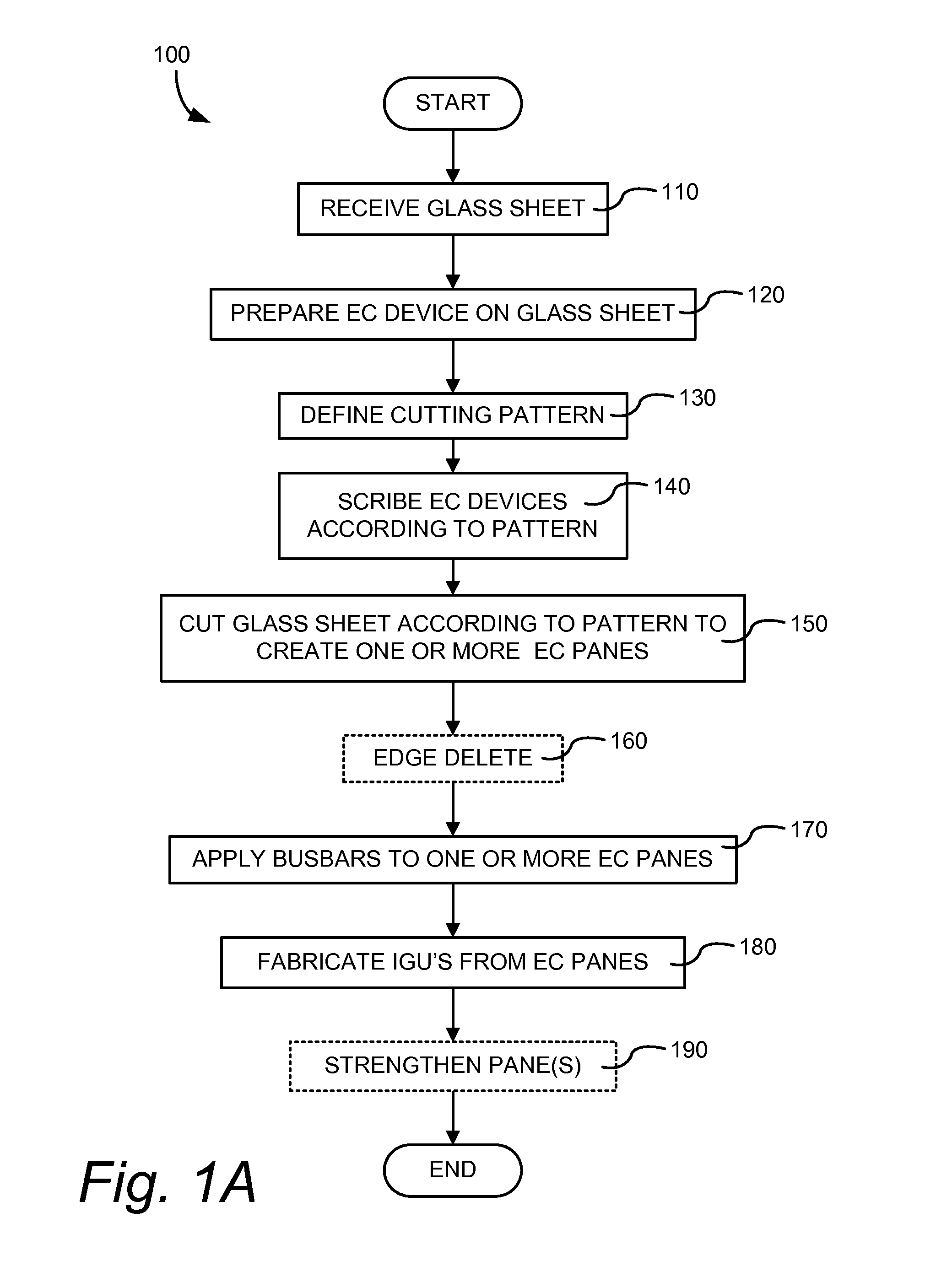

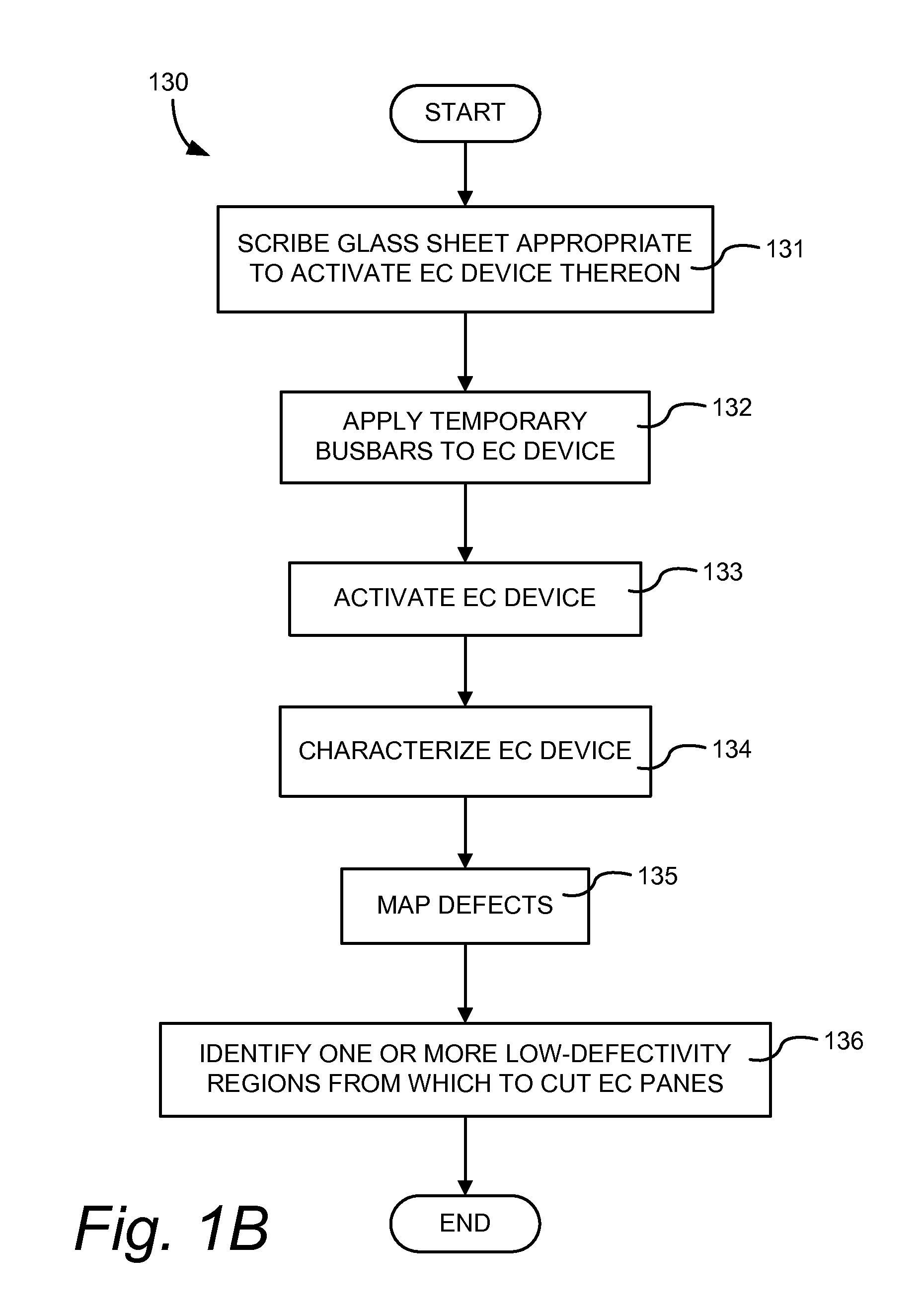

Electrochromic window fabrication methods

ActiveUS20120026573A1Maximize effective useLamination ancillary operationsLaminationEngineeringElectrochromism

Methods of manufacturing electrochromic windows are described. An electrochromic device is fabricated to substantially cover a glass sheet, for example float glass, and a cutting pattern is defined based on one or more low-defectivity areas in the device from which one or more electrochromic panes are cut. Laser scribes and / or bus bars may be added prior to cutting the panes or after. Edge deletion can also be performed prior to or after cutting the electrochromic panes from the glass sheet. Insulated glass units (IGUs) are fabricated from the electrochromic panes and optionally one or more of the panes of the IGU are strengthened.

Owner:VIEW INC

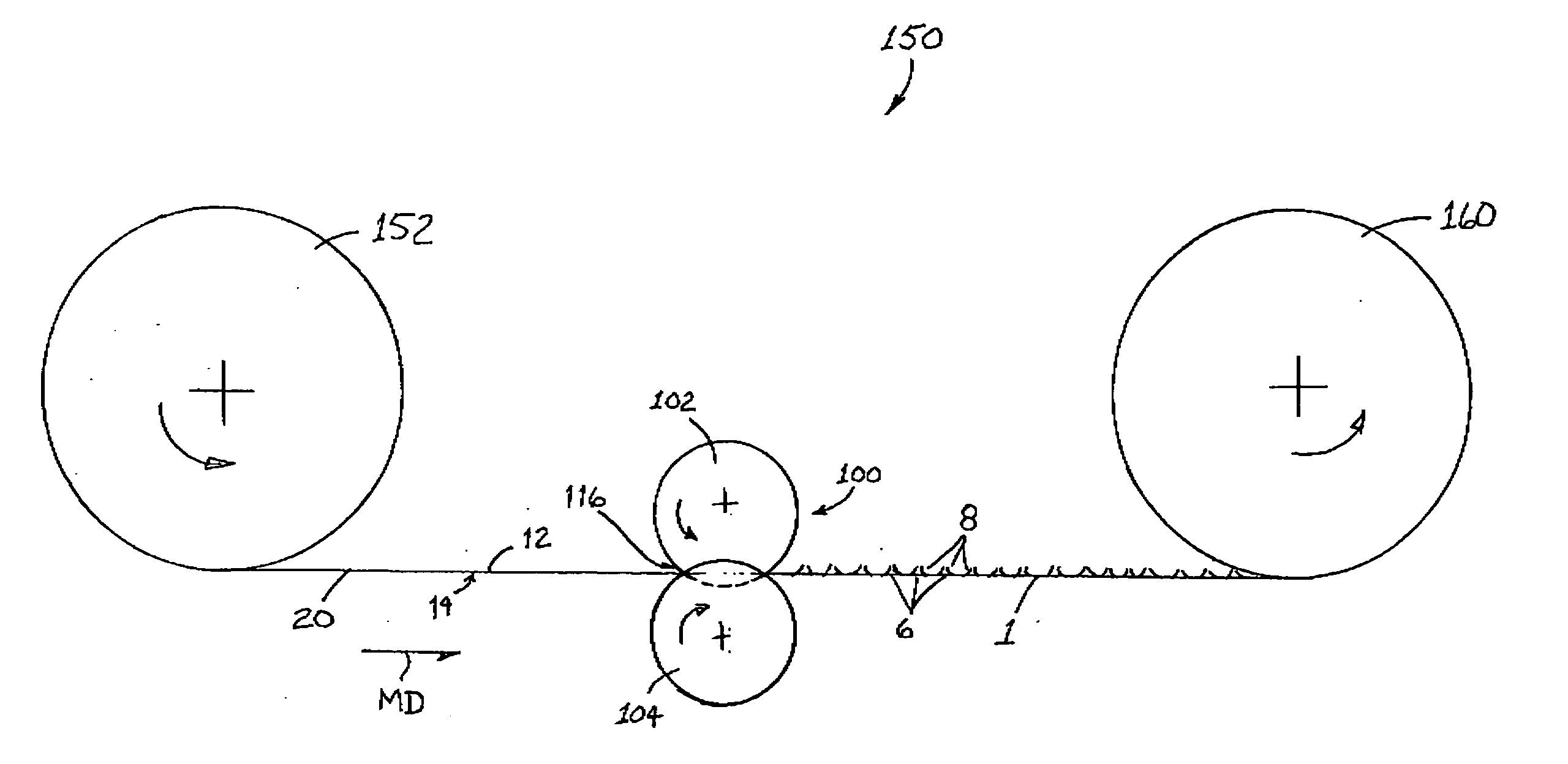

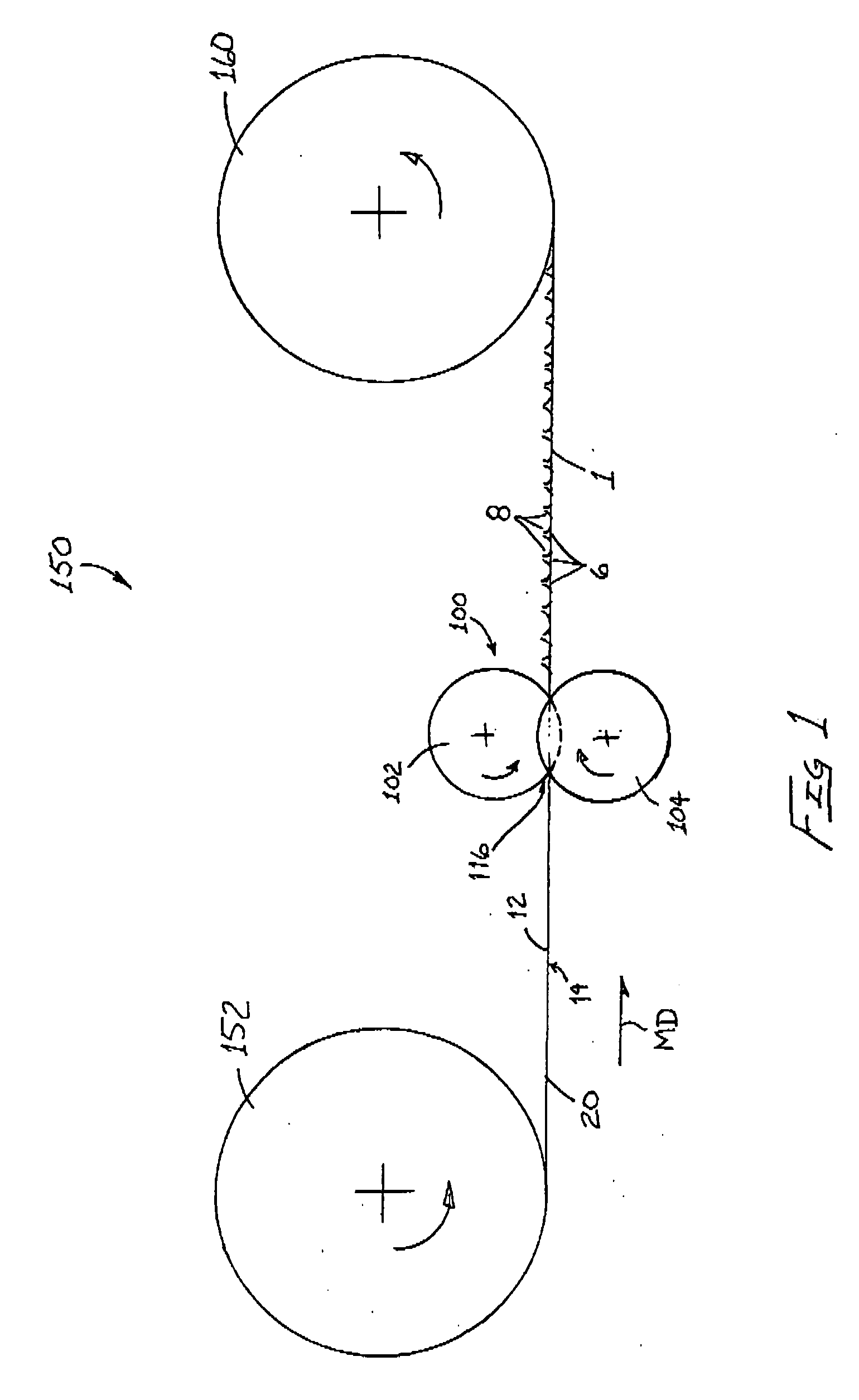

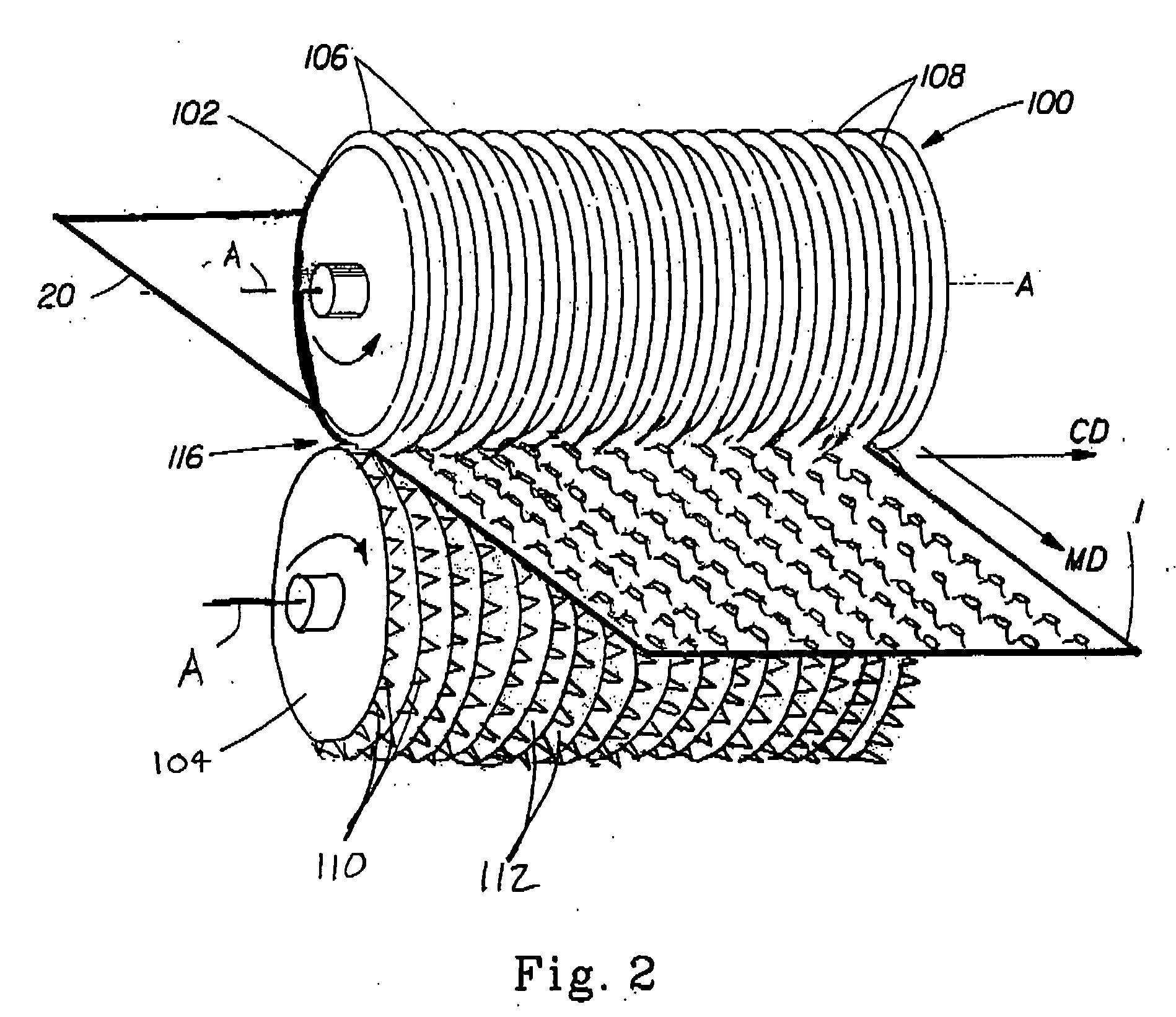

Method and apparatus for making an apertured web

Owner:THE PROCTER & GAMBLE COMPANY

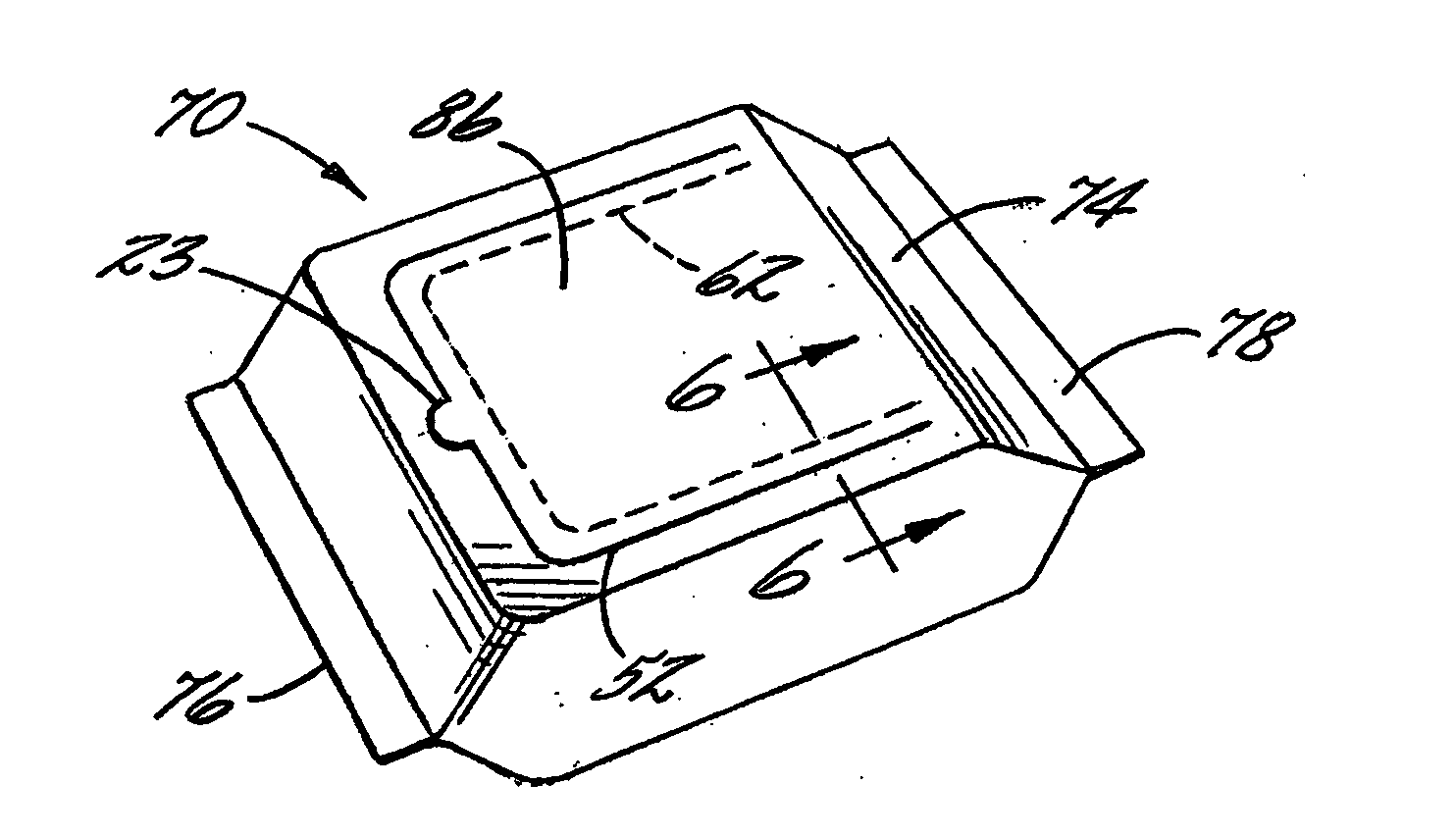

Flexible packaging structure with a built-in opening and reclose feature, and method for making same

ActiveUS20050276525A1Envelopes/bags making machineryWrappersMechanical engineeringPressure sensitive

A flexible packaging laminate is formed to have a built-in opening and reclose feature by forming the laminate as a two-part structure having an outer structure joined in face-to-face relation with an inner structure. Score lines are formed in both structures to enable an opening to be formed through the laminate by lifting an opening portion (e.g., a flap or the like) of the two structures out of the plane of the laminate. The score line through the outer structure defines a larger opening than the score line through the inner structure, such that a marginal region of the outer structure extends beyond the edge of the opening portion of the inner structure. A pressure-sensitive adhesive is used to re-adhere the marginal region to an underlying surface of the inner structure adjacent the opening through the laminate.

Owner:SONOCO DEV INC

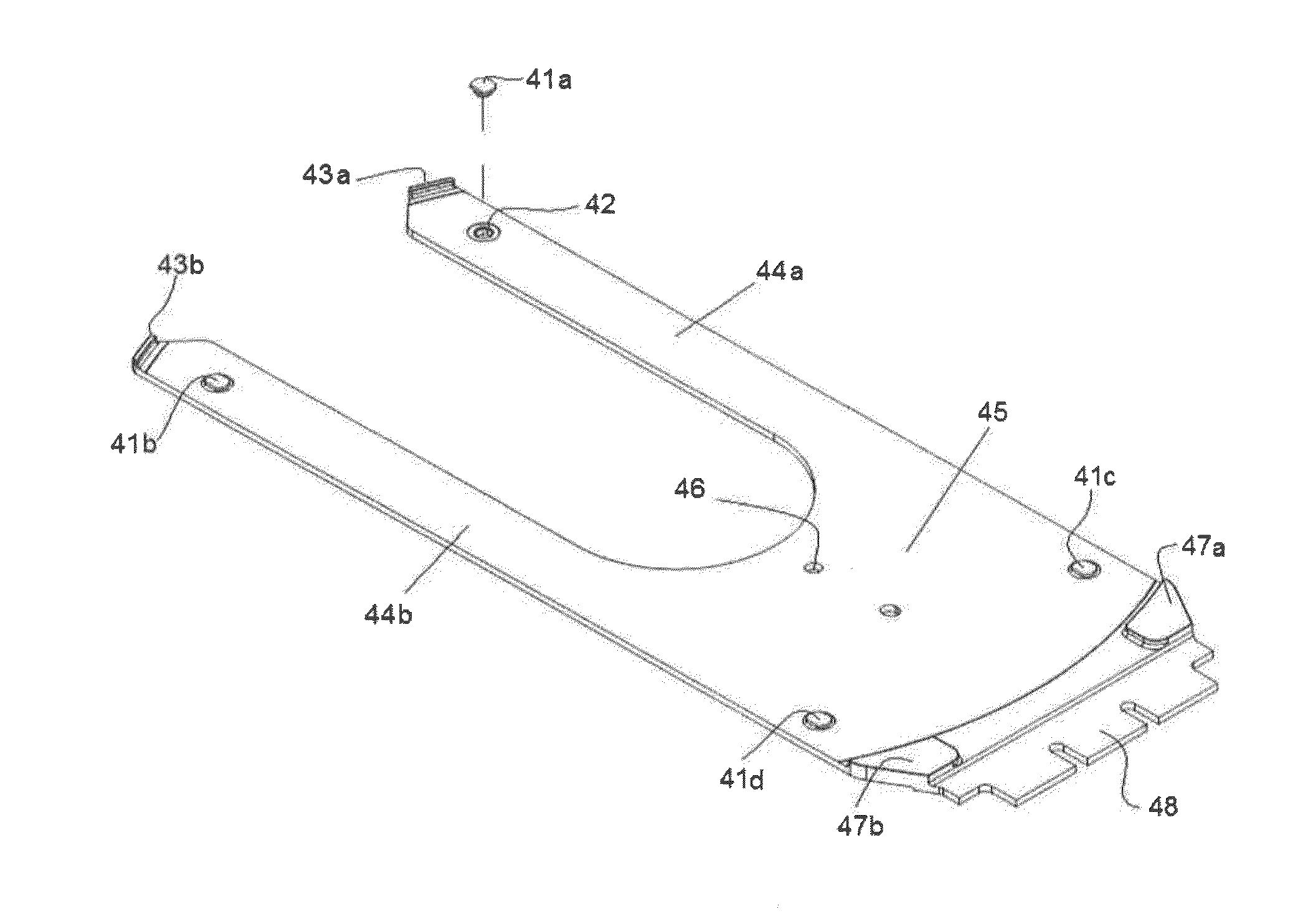

Carbon nanotube film structure and method for fabricating the same

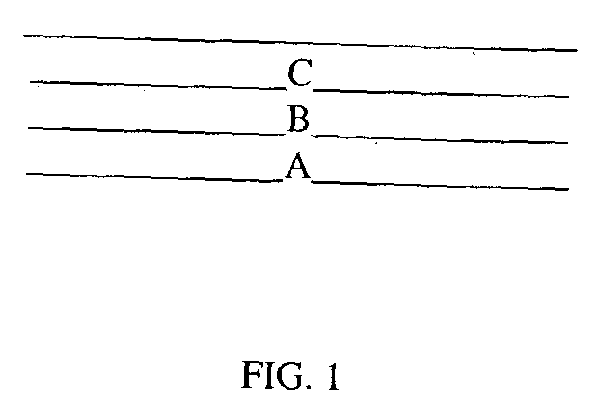

A carbon nanotube film structure includes at least two overlapped carbon nanotube films, with adjoining films being aligned in different directions. Each carbon nanotube film includes a plurality of successive carbon nanotube bundles aligned in the same direction. The carbon nanotube structure further includes a plurality of micropores formed by / between the adjoining carbon nanotube bundles. A method for fabricating the carbon nanotube film structure includes the steps of: (a) providing an array of carbon nanotubes; (b) pulling out, using a tool, one carbon nanotube film from the array of carbon nanotubes; (c) providing a frame and adhering the carbon nanotube film to the frame; (d) repeating steps (b) and (c), depositing each successive film on a preceding film, thereby achieving at least a two-layer carbon nanotube film; and (e) peeling the carbon nanotube film off the frame to achieve the carbon nanotube structure.

Owner:TSINGHUA UNIV +1

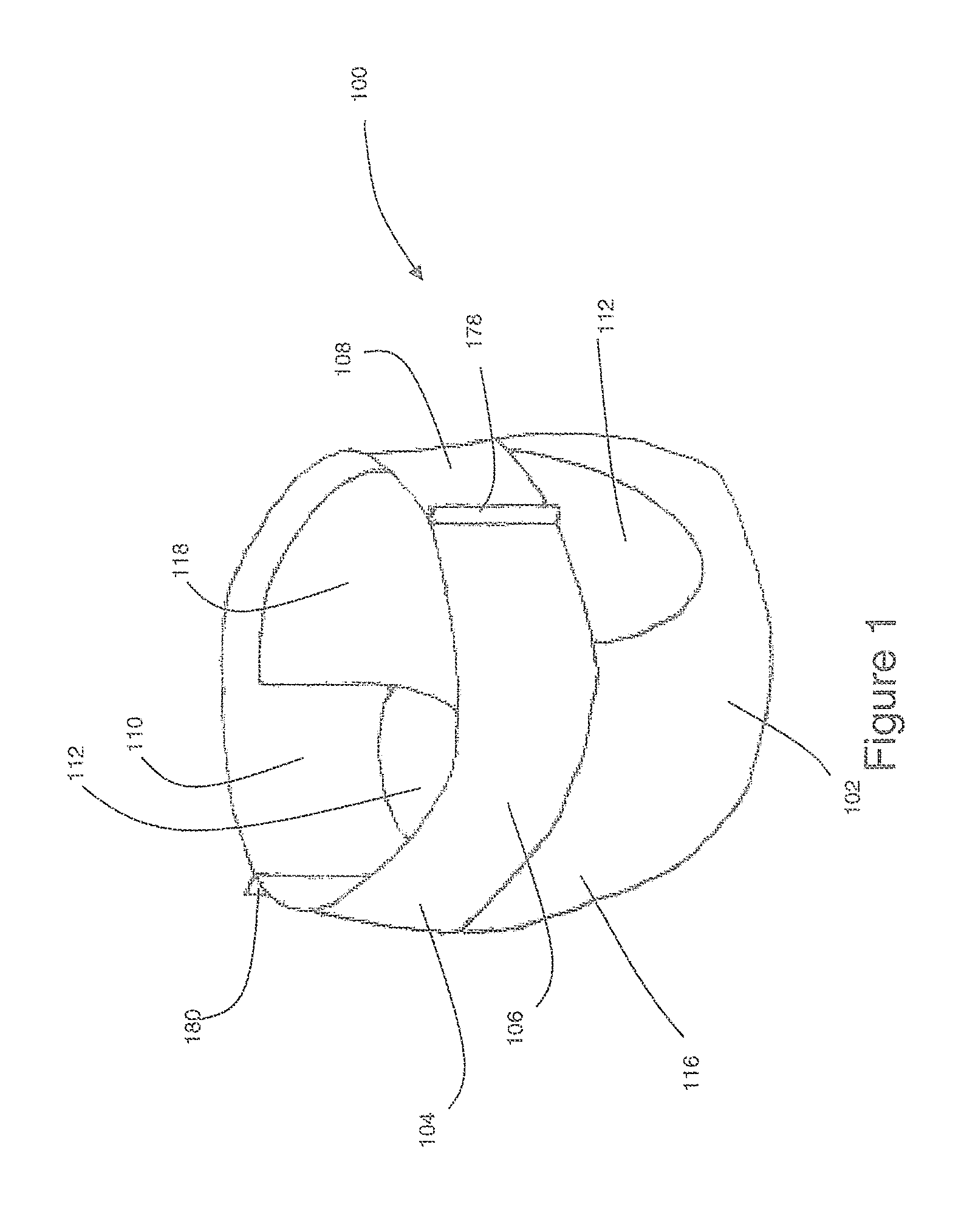

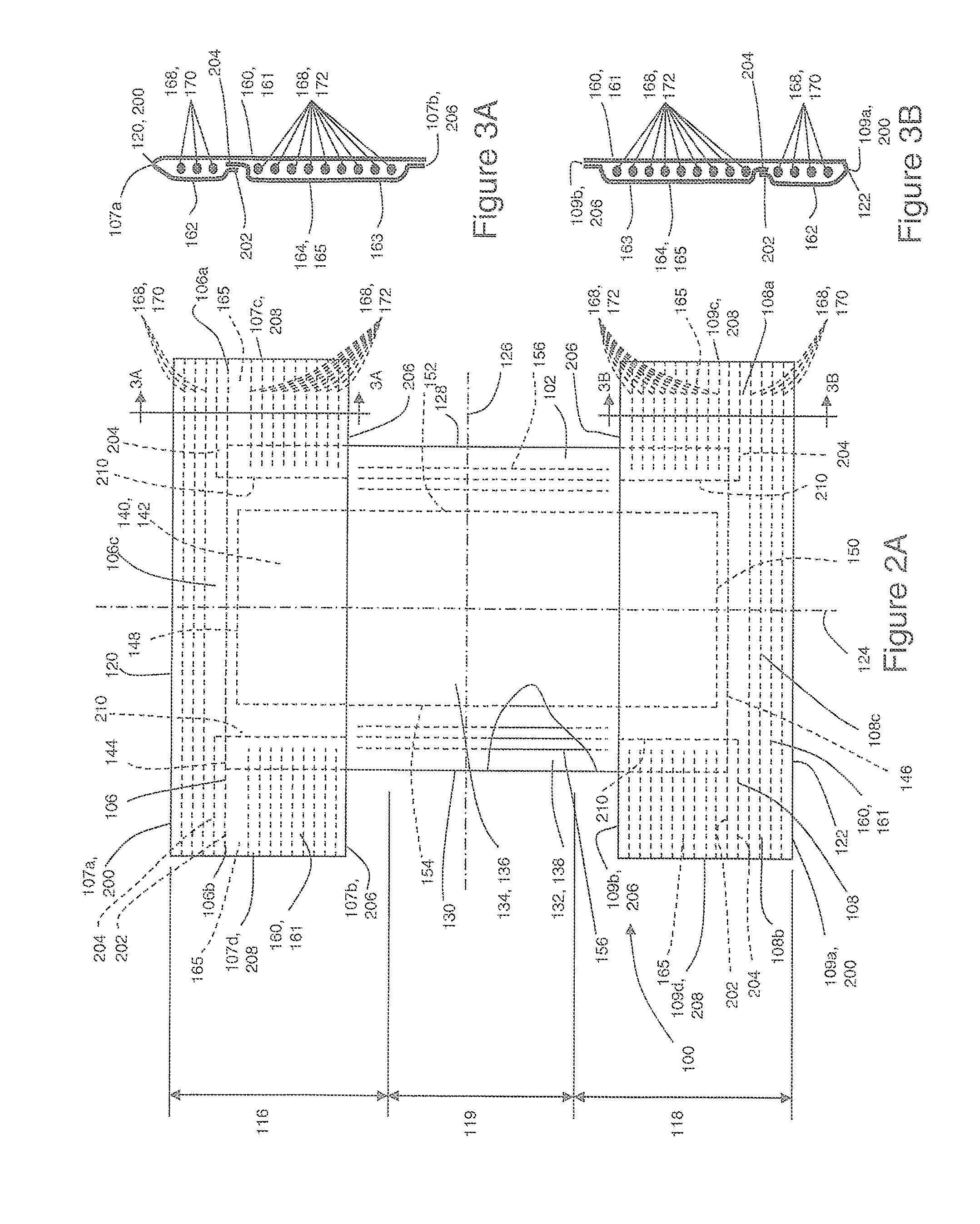

Methods and Apparatuses for Making Leg Cuffs for Absorbent Articles

The present disclosure relates to methods and apparatuses for assembling absorbent articles that include leg cuff gasketing assemblies. As discussed in more detail below, each leg gasketing assembly may be formed from elastic laminates having stretched elastic strands intermittently bonded thereto. As such, the elastic laminate includes bonded regions and non-bonded regions intermittently spaced along the machine direction. The elastic strands are then intermittently deactivated by severing the strands in the non-bonded regions of the continuous elastic laminate to form continuous lengths of leg gasketing assemblies having elastic regions and deactivated regions. The continuous lengths of leg gasketing assemblies may then bonded to a continuous topsheet substrate. In some embodiments, the elastic laminate may be combined with the topsheet substrate before severing the strands in the non-bonded regions.

Owner:THE PROCTER & GAMBLE COMPANY

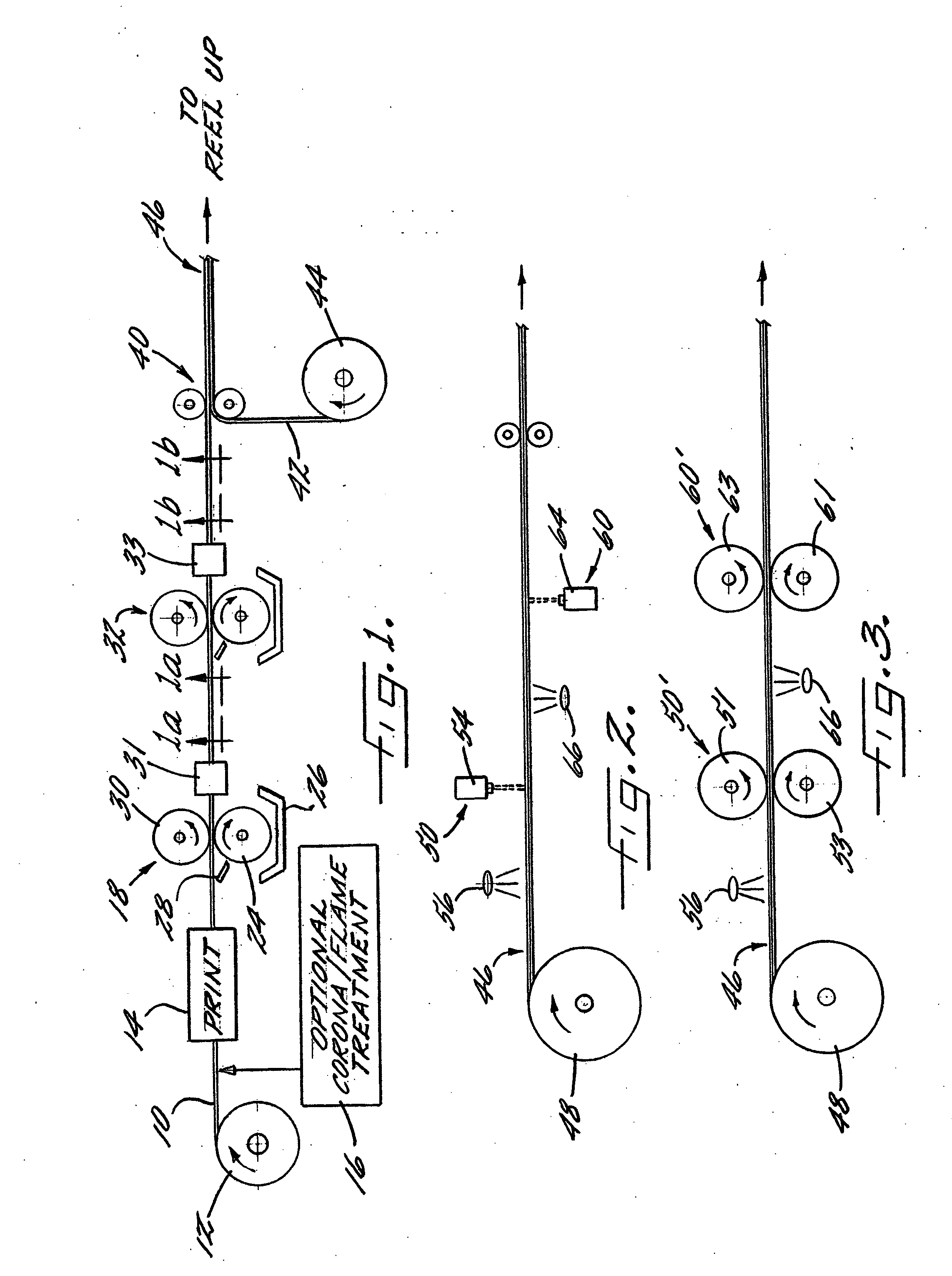

Indirect printing of AGM

ActiveUS20060024433A1High accuracy of distributionHigh accuracy of and patternBaby linensCoatingsEngineeringElectrical and Electronics engineering

The present invention relates to a method of applying absorbent gelling material (AGM) granules by indirect printing onto an carrier layer for use in an absorbent article, particularly diaper for babies or adults, training pants, pull-up diapers (diaper pants), sanitary napkins, panty liners or the like. These articles typically comprise the carrier layer with the AGM particles together with further layers, making up the complete article.

Owner:THE PROCTER & GAMBLE COMPANY

Anti-slip end-effector for transporting workpiece

ActiveUS20150217456A1Lamination ancillary operationsGripping headsStatic friction coefficientActuator

Owner:ASM IP HLDG BV

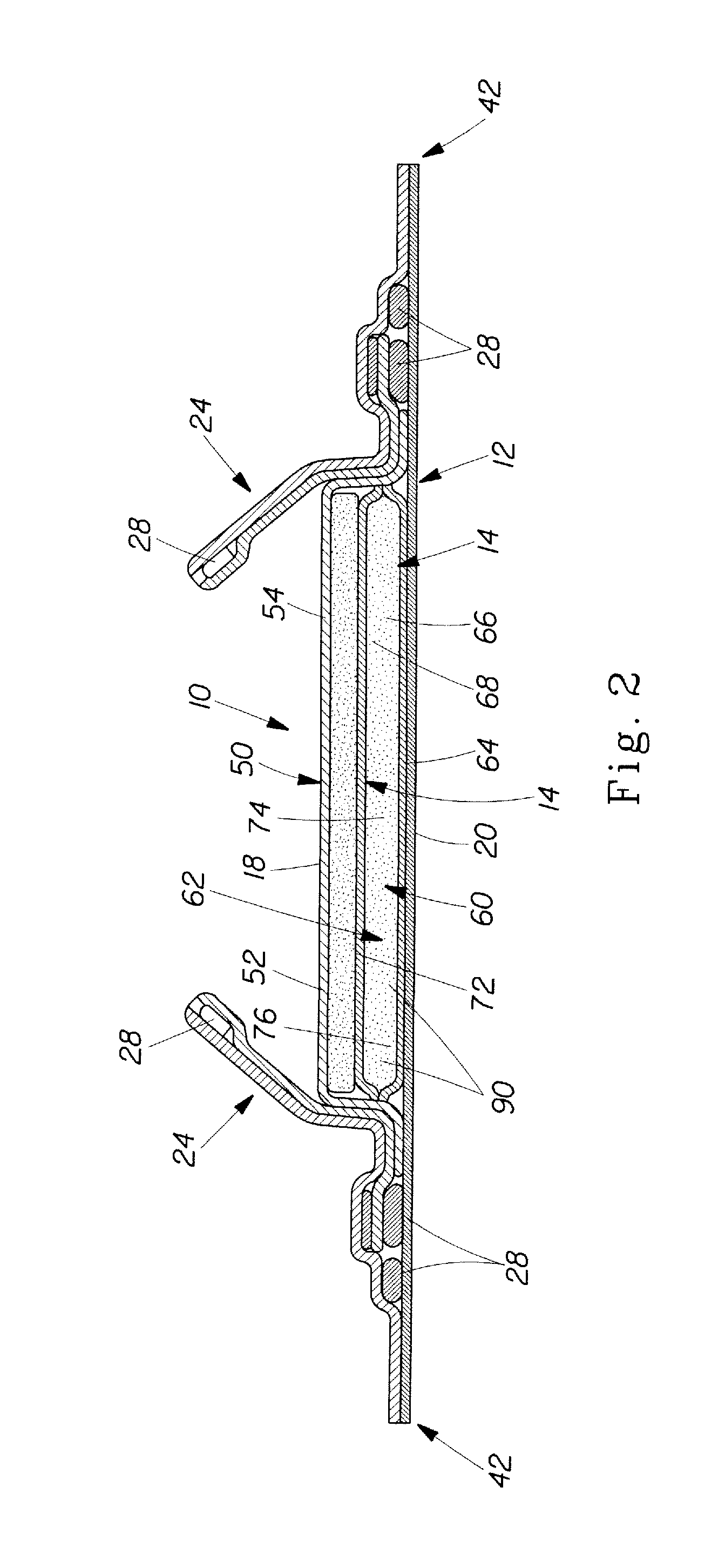

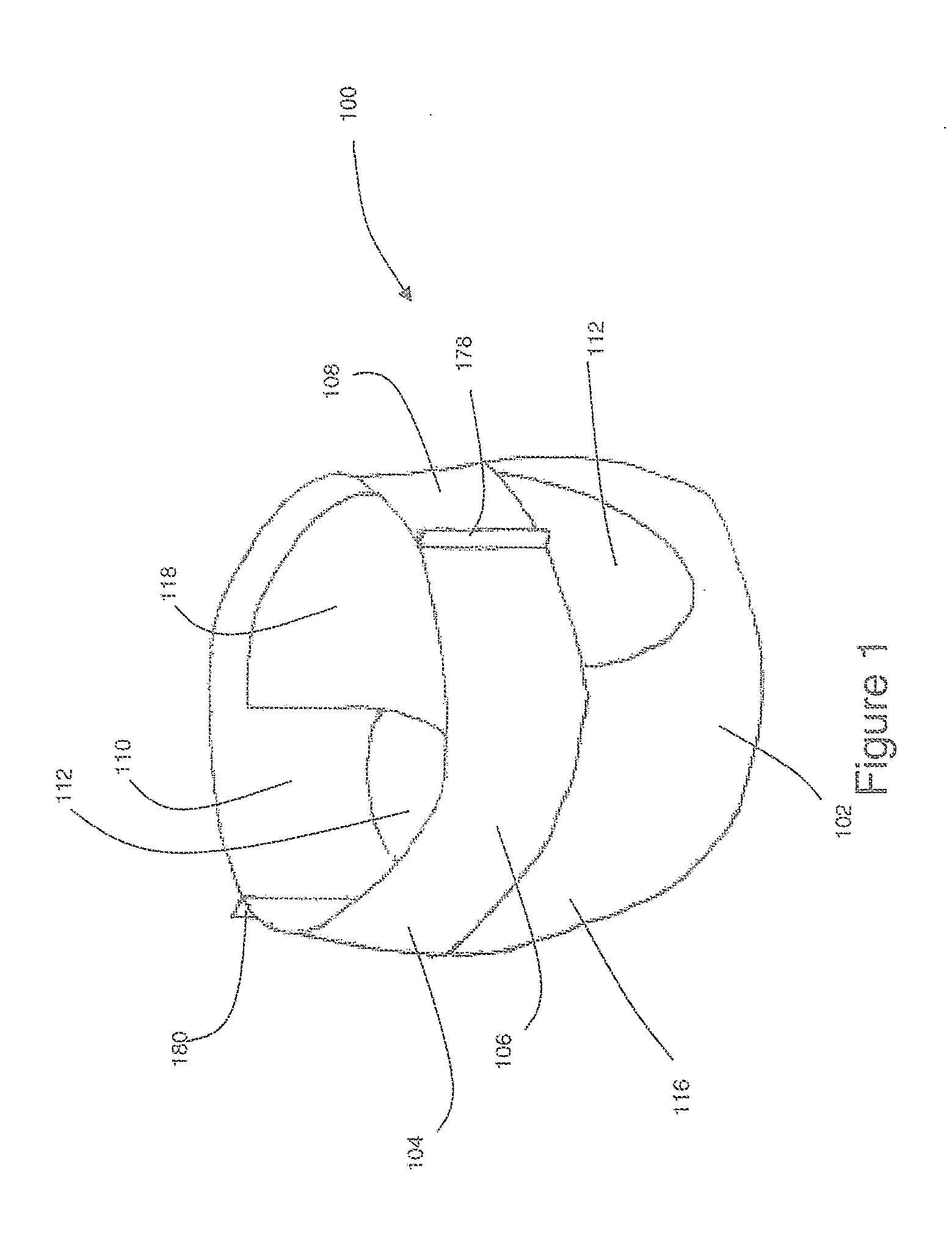

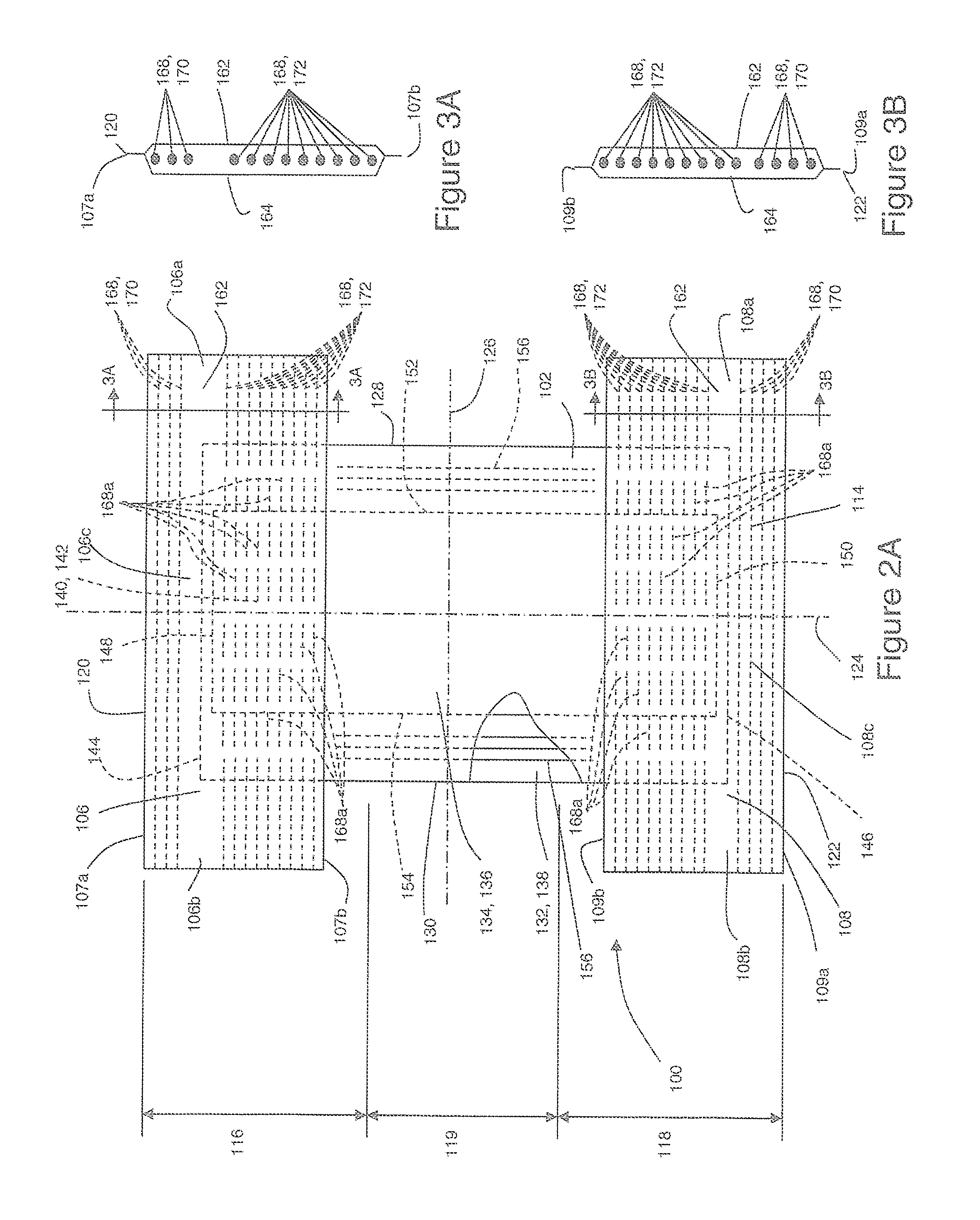

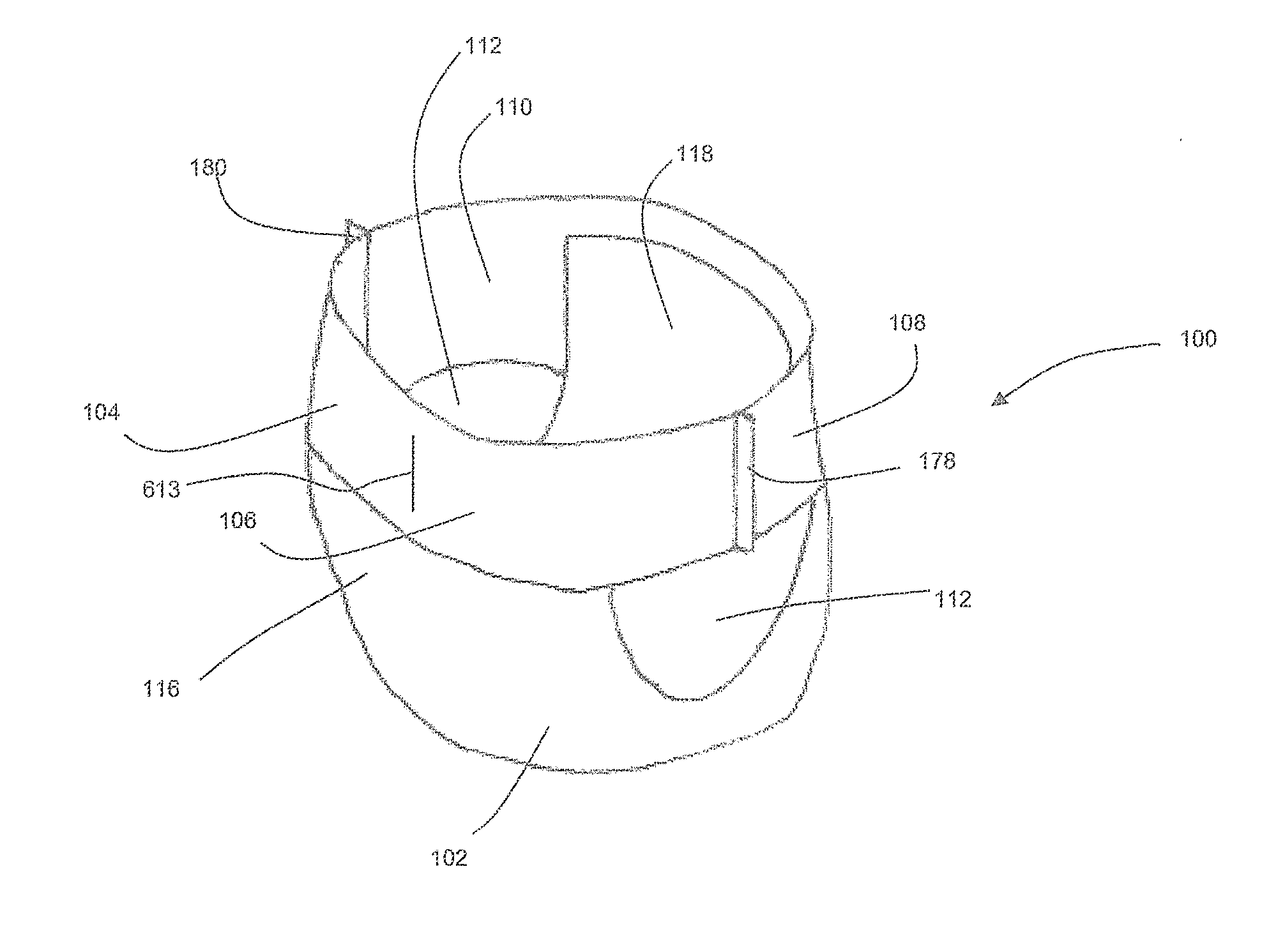

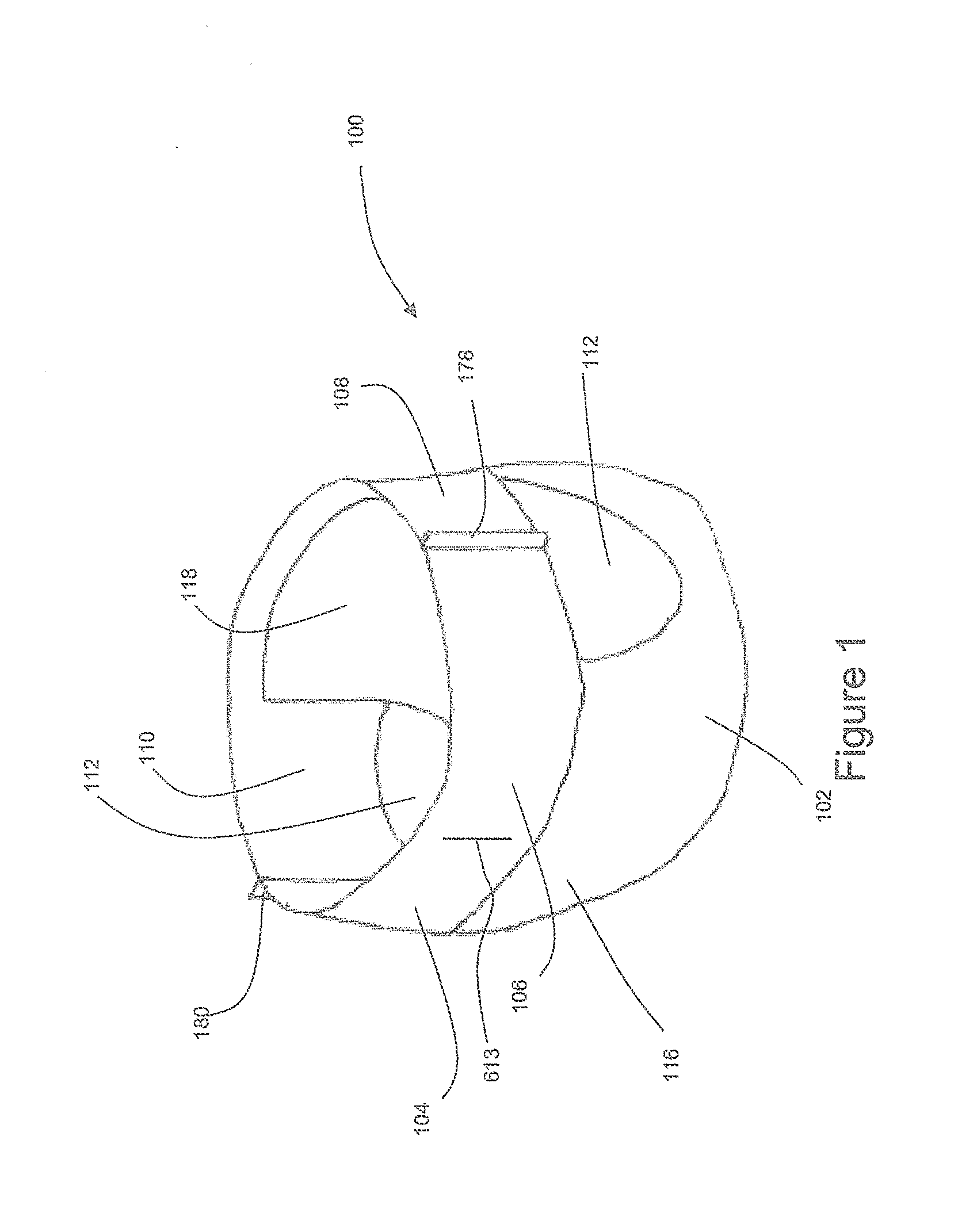

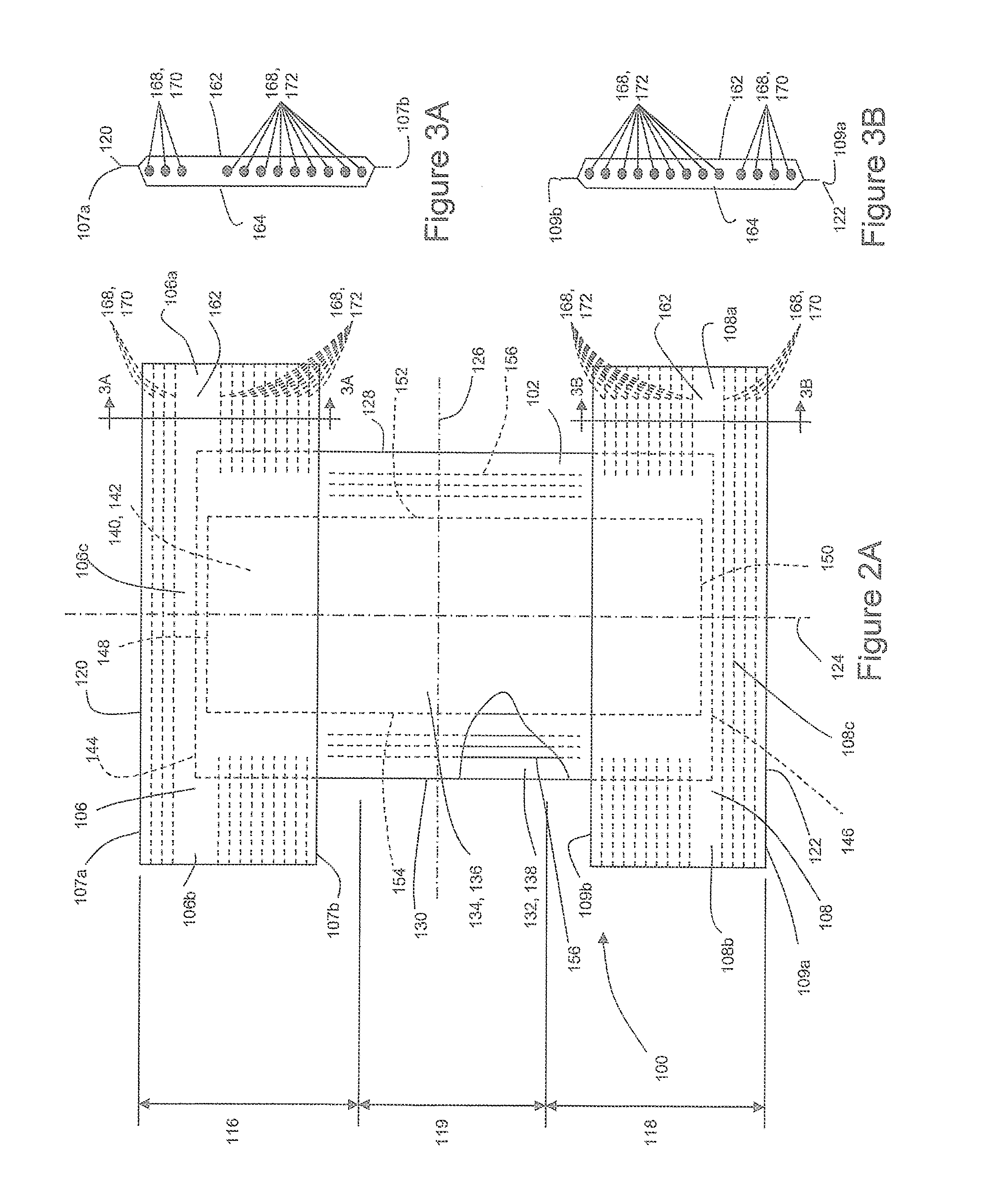

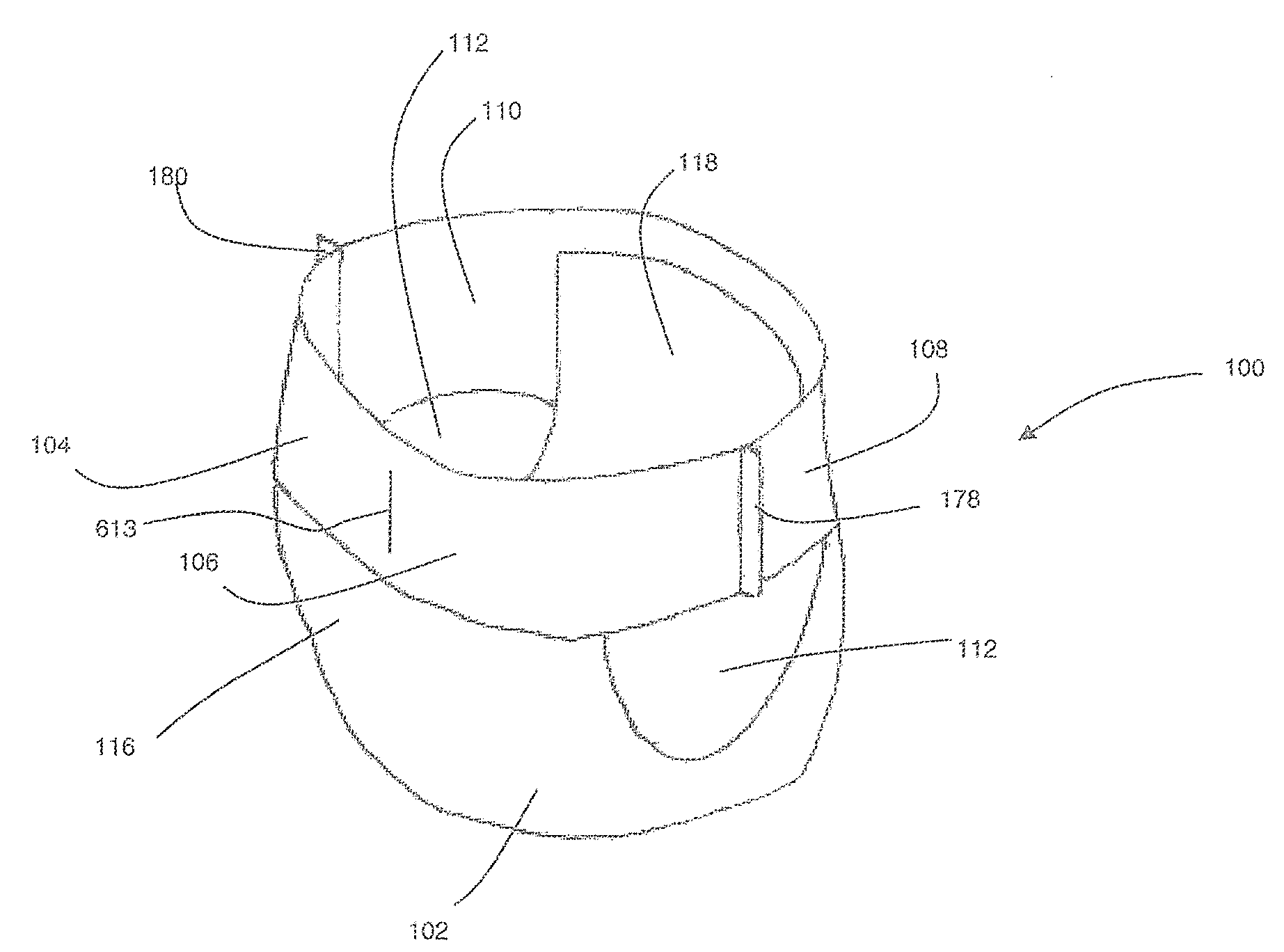

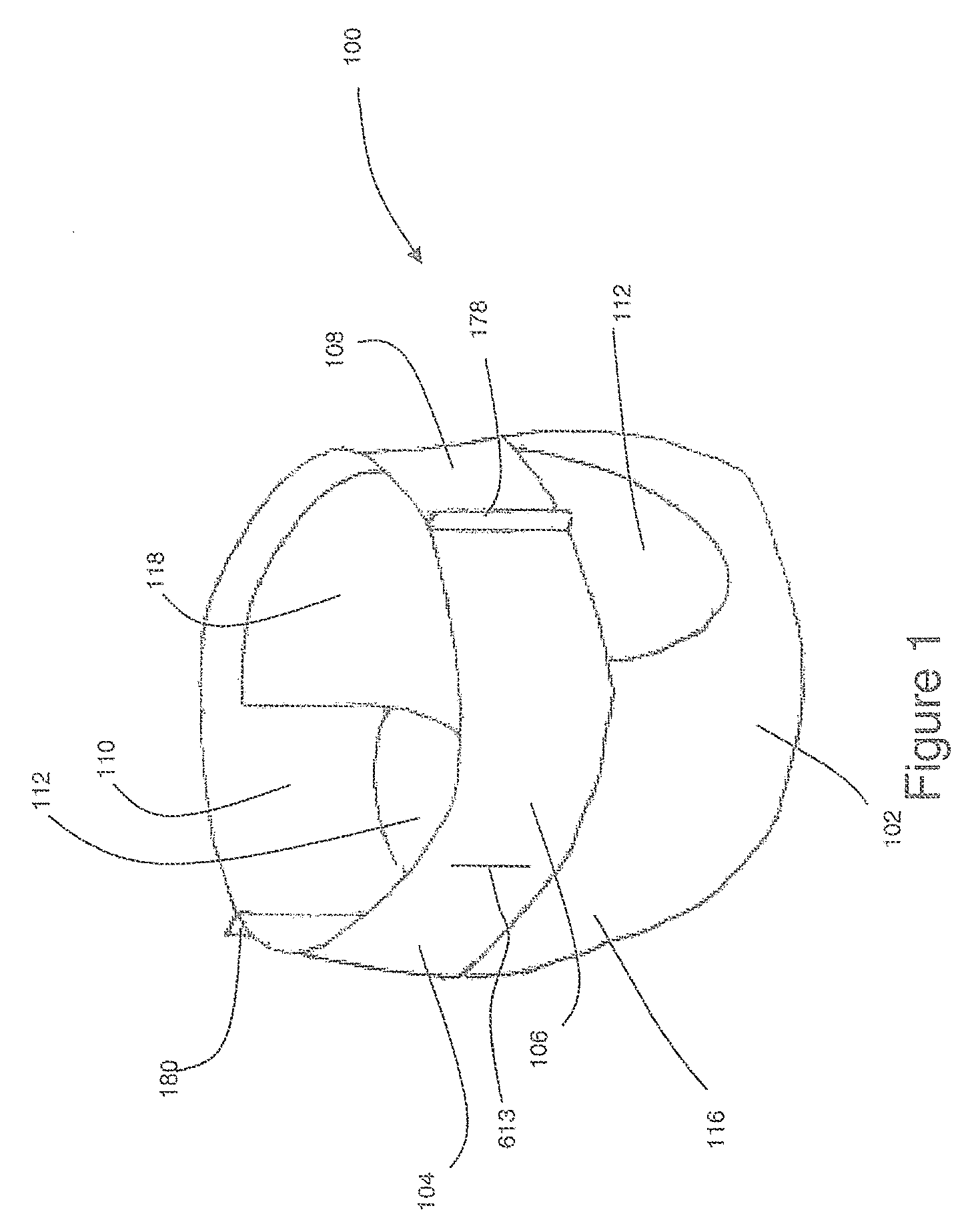

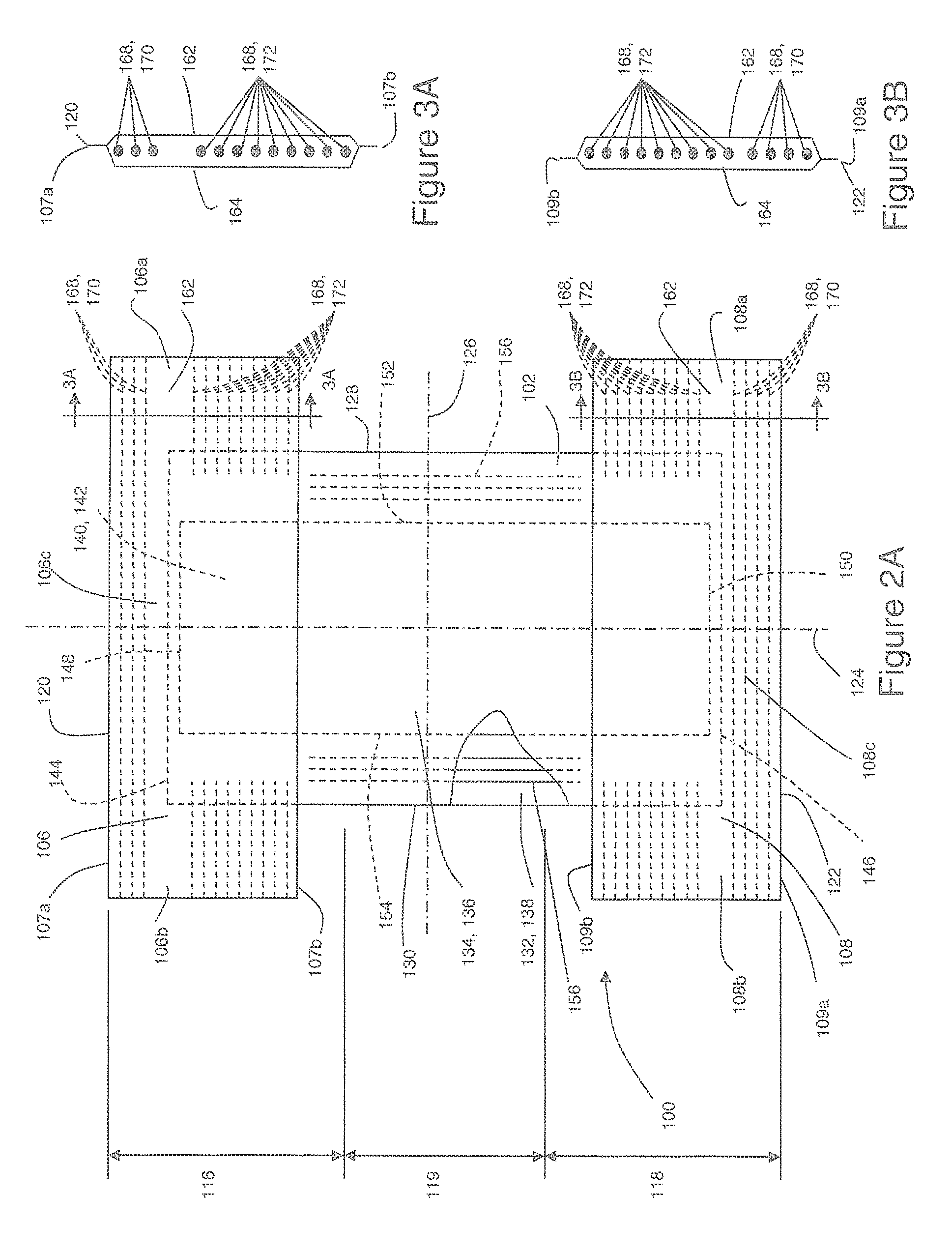

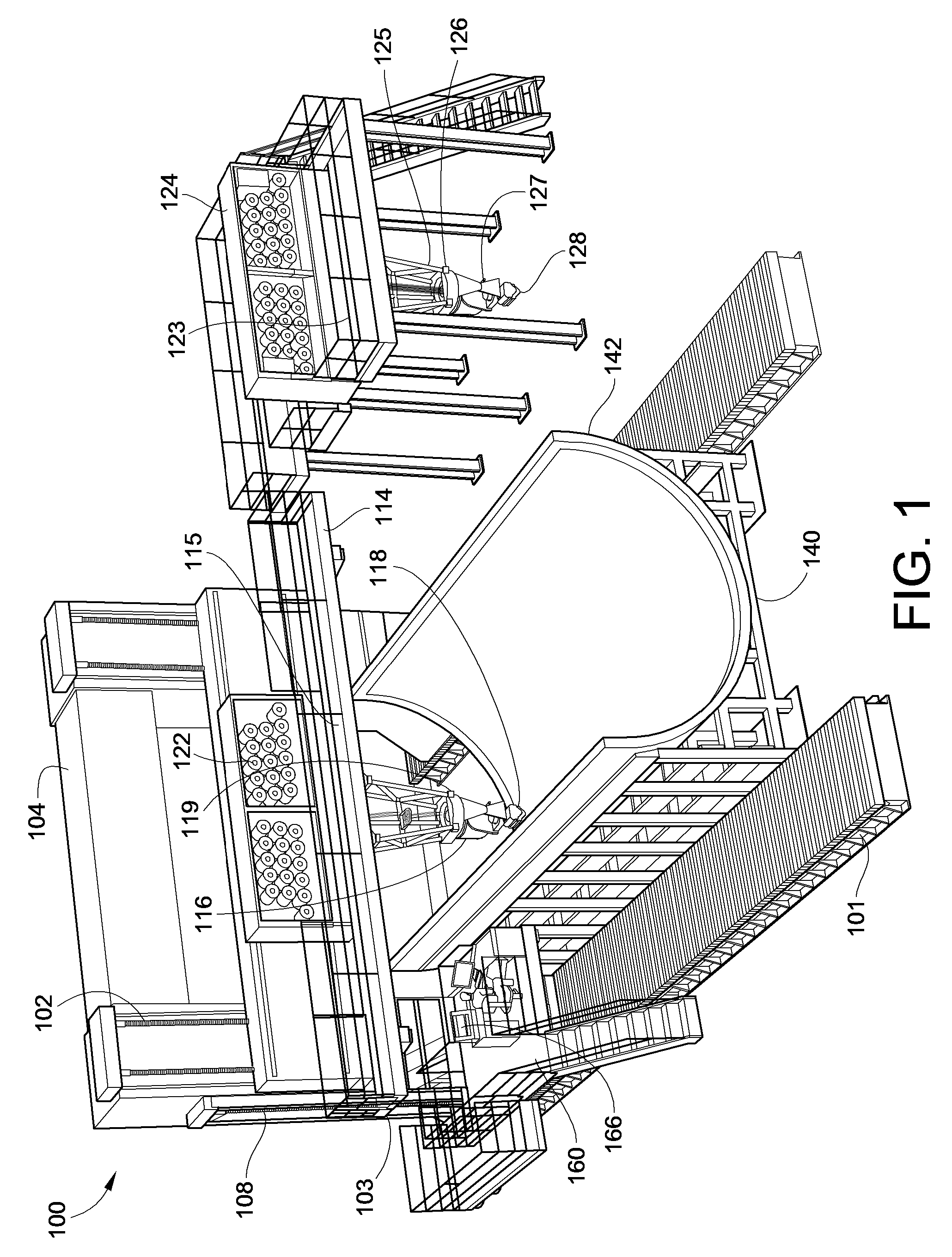

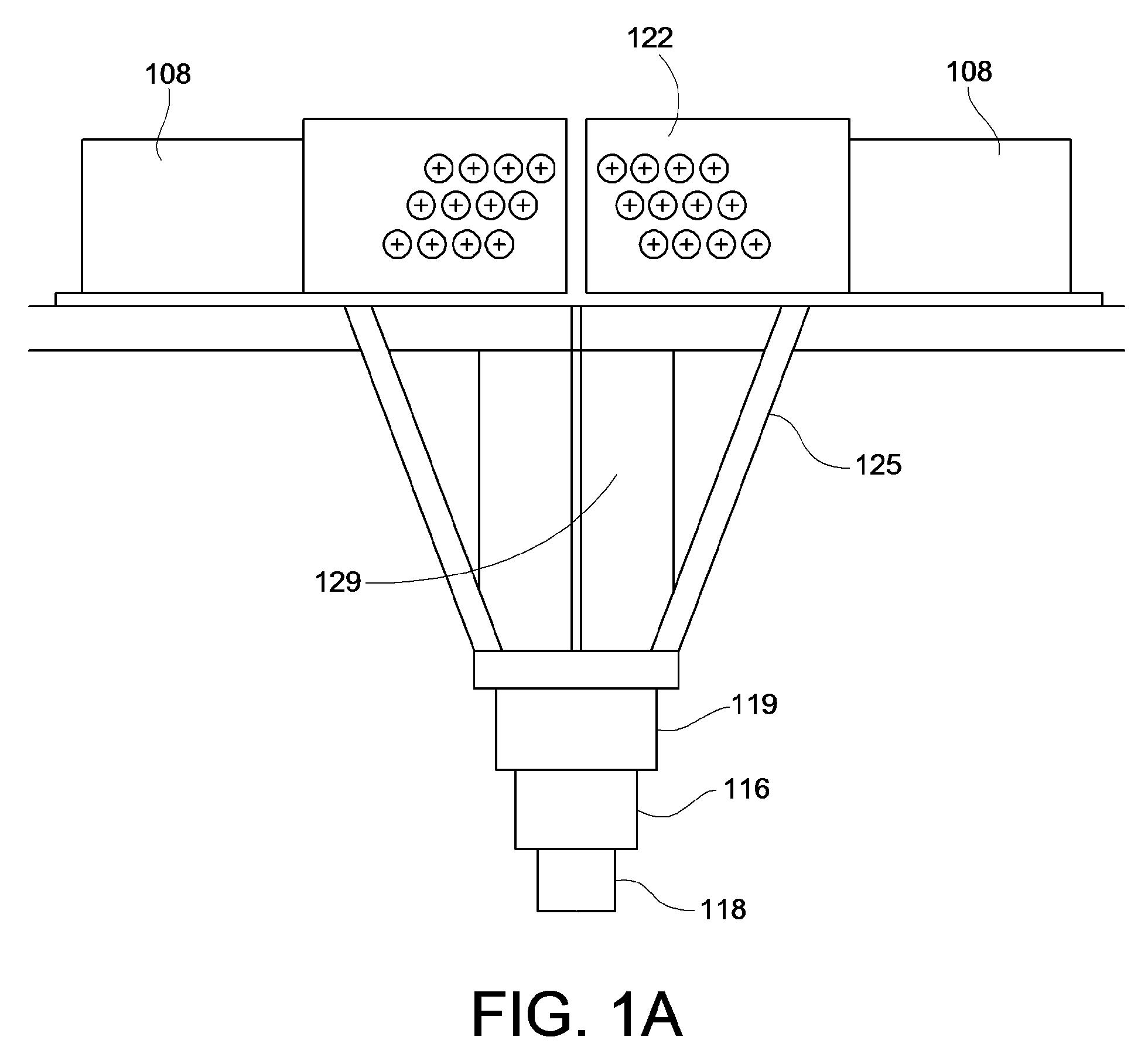

Apparatuses and Methods for Making Absorbent Articles

The present disclosure relates to methods and apparatuses for assembling diapers, each including a chassis connected with front and back elastic belts. As discussed in more detail below, opposing end regions of the chassis are connected with regions of the elastic belts where the elasticity of the elastic belts has been removed or deactivated. An elastic laminate may be formed by continuously bonding elastic strands between a first continuous substrate layer and a second continuous substrate layer such that the elastic strands are bonded to both the first substrate layer and the second substrate layer in heavy-bond regions. And the elastic strands are bonded to the first substrate layer and / or the second substrate layer with in light-bond regions. The elastic strands are then intermittently deactivated by cutting the strands into one or more discrete pieces in the light-bond regions. The discrete pieces retract and remain in the light-bond regions.

Owner:THE PROCTER & GAMBLE COMPANY

Apparatuses and Methods for Making Absorbent Articles

The present disclosure relates to methods and apparatuses for assembling absorbent articles, and more particularly, diapers, each including a chassis connected with front and back elastic belts. Opposing end regions of the chassis are connected with regions of the elastic belts where the elasticity of the elastic belts has been removed or deactivated. As discussed in more detail below, an elastic laminate is formed by intermittently bonding elastic strands between a first continuous substrate layer and a second continuous substrate layer. The elastic strands are then intermittently deactivated by severing the strands in the non-bonded regions to form deactivated regions of the elastic laminate. A plurality of chassis may then be bonded with the elastic laminate, wherein the first or second end regions of each chassis may be bonded with deactivated regions of the continuous elastic laminate.

Owner:THE PROCTER & GAMBLE COMPANY

Apparatuses and Methods for Making Absorbent Articles

ActiveUS20130255864A1Slow and controlled rateLamination ancillary operationsLaminationChassisLight Bond

The present disclosure relates to methods and apparatuses for assembling absorbent articles, and more particularly, diaper pants, each including a chassis connected with front and back elastic belts. As discussed in more detail below, opposing end regions of the chassis are connected with regions of the elastic belts where the elasticity of the elastic belts has been removed or deactivated. As discussed in more detail below, an elastic laminate may be formed by continuously bonding elastic strands between a first continuous substrate layer and a second continuous substrate layer. The elastic strands are then intermittently severed in light-bond regions of the elastic laminate. Adhesive on the laminate causes the severed elastic ends to retract or snap back from the light-bond regions at a relatively slower and / or controlled rate.

Owner:THE PROCTER & GAMBLE COMPANY

Apparatuses and Methods for Making Absorbent Articles

The present disclosure relates to methods and apparatuses for assembling diaper pants, each including a chassis connected with front and back elastic belts. Opposing end regions of the chassis may be connected with regions of the elastic belts where the elasticity of the elastic belts has been removed or deactivated. An elastic laminate may be formed by intermittently bonding elastic strands with a first continuous substrate, defining bonded regions and non-bonded regions intermittently spaced along the machine direction. A second continuous substrate may be cut into discrete lengths or patches intermittently spaced along the machine direction. The discrete lengths of the second substrate may then be bonded with the first continuous substrate and elastic strands in the bonded regions. The elastic strands are then intermittently deactivated by severing the strands in the non-bonded regions. And plurality of chassis may then be bonded with non-bonded regions of the elastic laminate.

Owner:THE PROCTER & GAMBLE COMPANY

Composition and process for the sealing of microcups in roll-to-roll display manufacturing

InactiveUS7144942B2Improve adhesionQuality improvementLamination ancillary operationsLaminationCrystallographyElectrophoresis

Owner:E INK CALIFORNIA

Dimensionally stable, breathable, stretch-thinned, elastic films

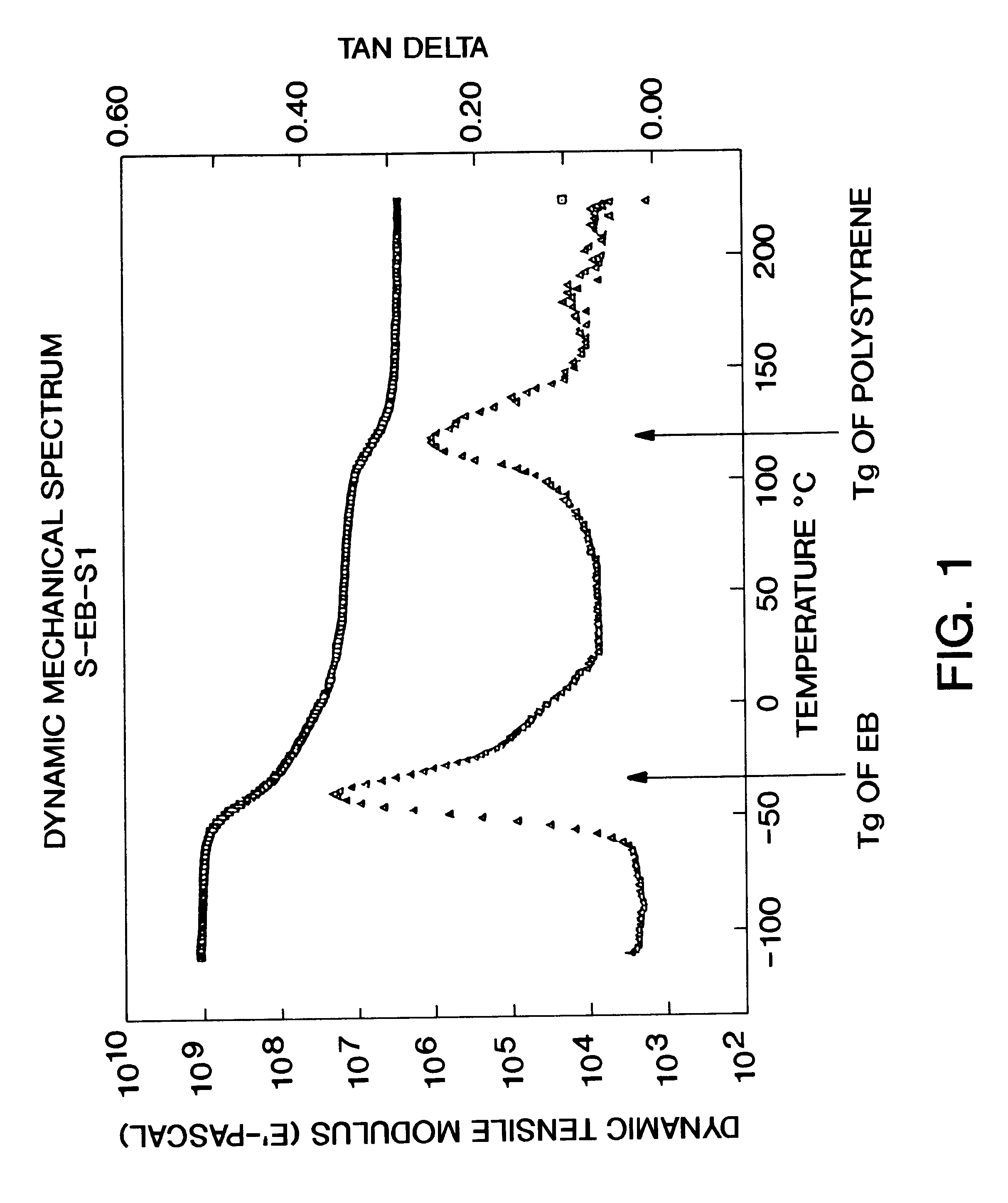

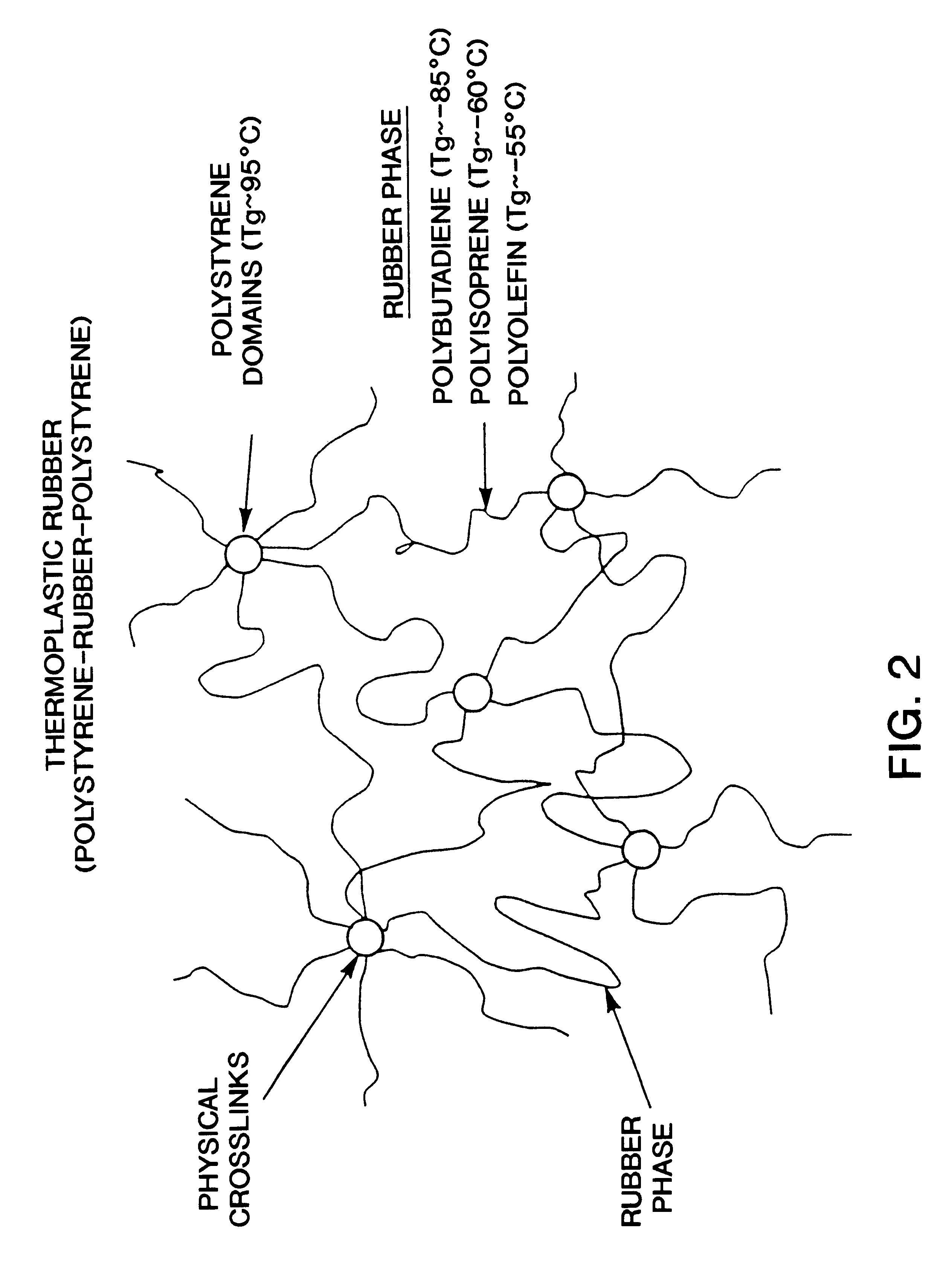

A method for producing a stretch-thinned elastic article having dimensional stability over time and at elevated temperatures in which a thermoplastic block copolymer is melt-processed into a stretchable article such as a film or fiber. The article is then conditioned at an elevated temperature greater than or equal to a glass transition temperature (Tg) of a hard phase of the thermoplastic block copolymer. The article is stretch-thinned at the elevated temperature to a desired percentage stretch, forming a stretch-thinned article, after which it is cooled to a temperature below the glass transition temperature of the hard phase of the thermoplastic block copolymer. Films produced by this method are suitable for use in durable and disposable articles including personal care articles such as diapers, incontinence wear, training pants, and feminine care articles, as well as wound dressings, wipes, towels, napkins, and protective apparel.

Owner:KIMBERLY-CLARK WORLDWIDE INC

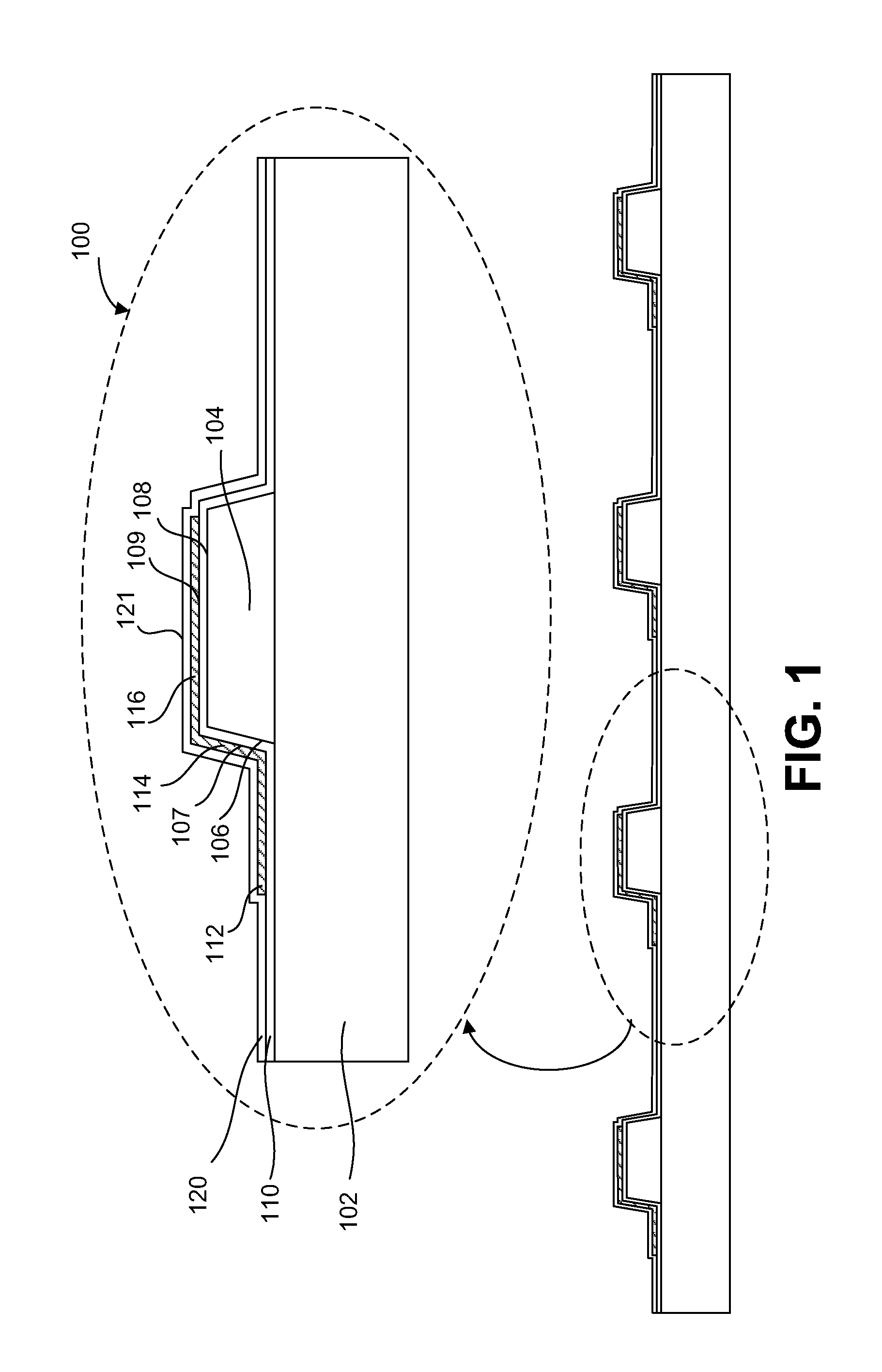

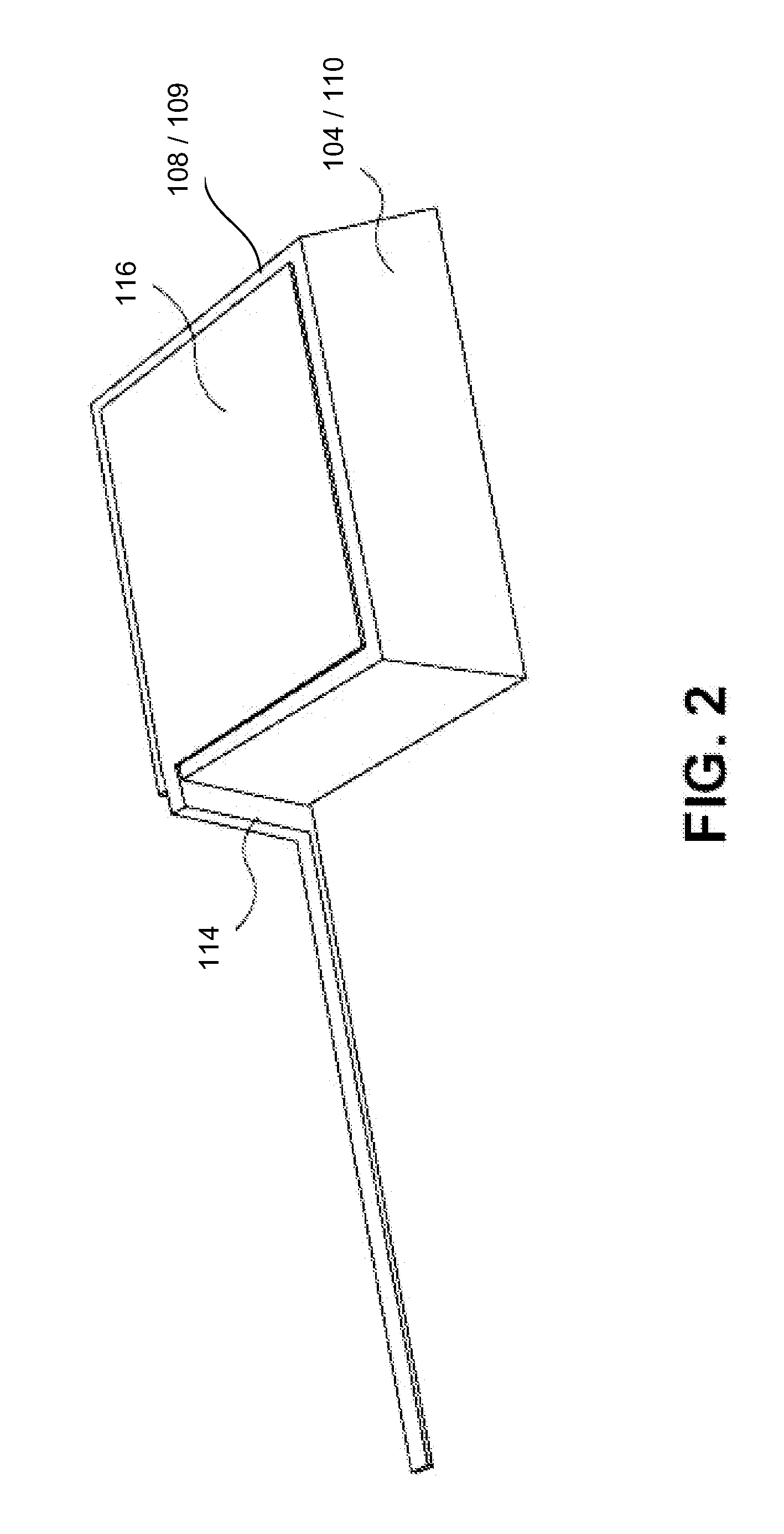

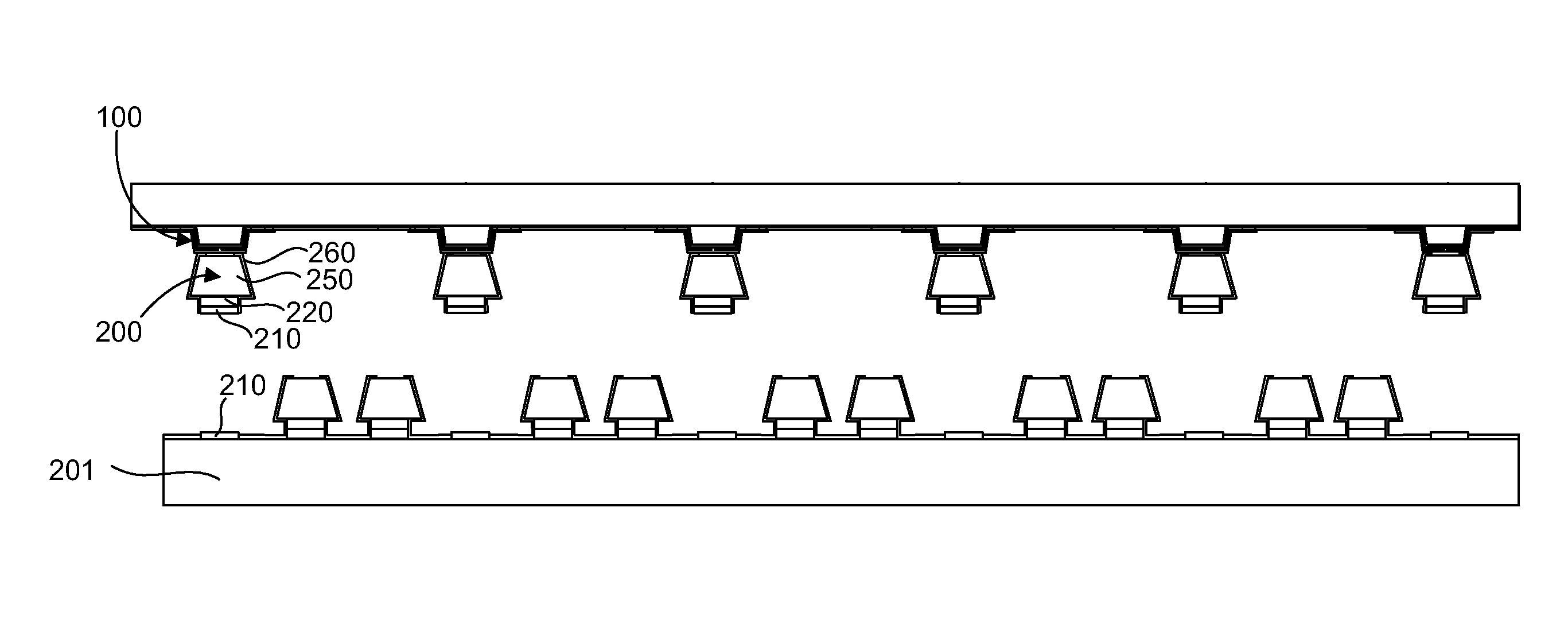

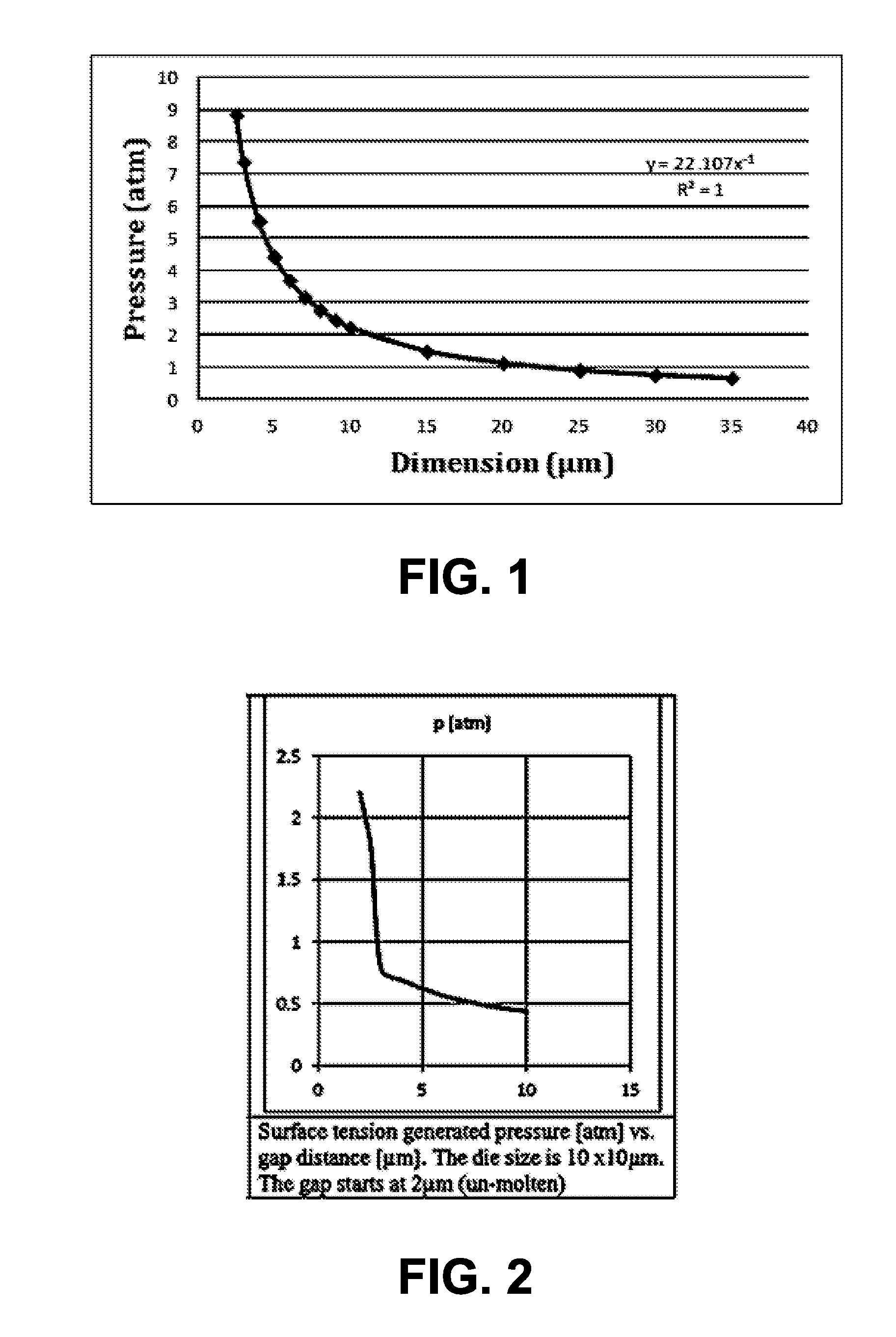

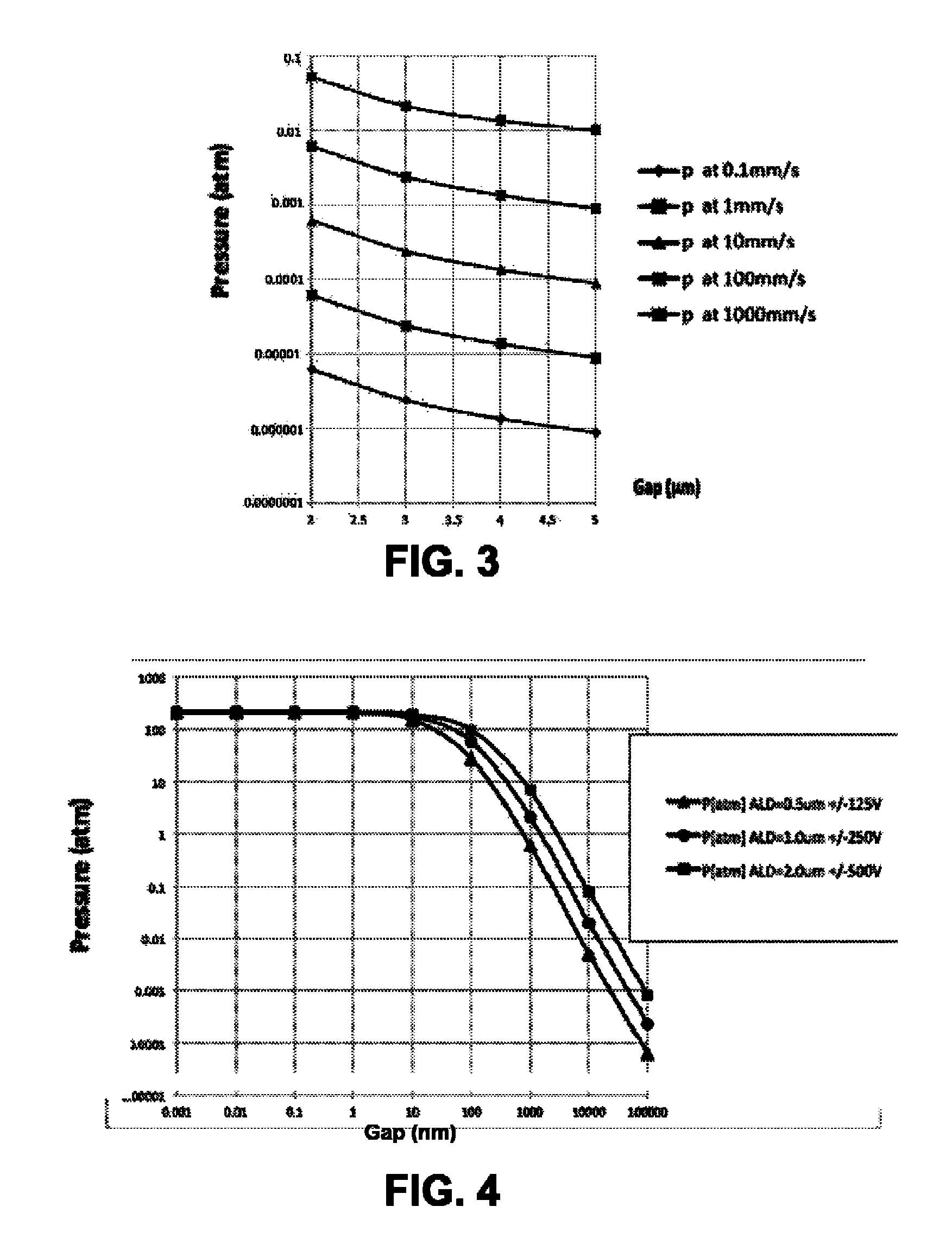

Method of transferring a micro device

A micro device transfer head and head array are disclosed. In an embodiment, the micro device transfer head includes a base substrate, a mesa structure with sidewalls, an electrode formed over the mesa structure, and a dielectric layer covering the electrode. A voltage can be applied to the micro device transfer head and head array to pick up a micro device from a carrier substrate and release the micro device onto a receiving substrate.

Owner:APPLE INC

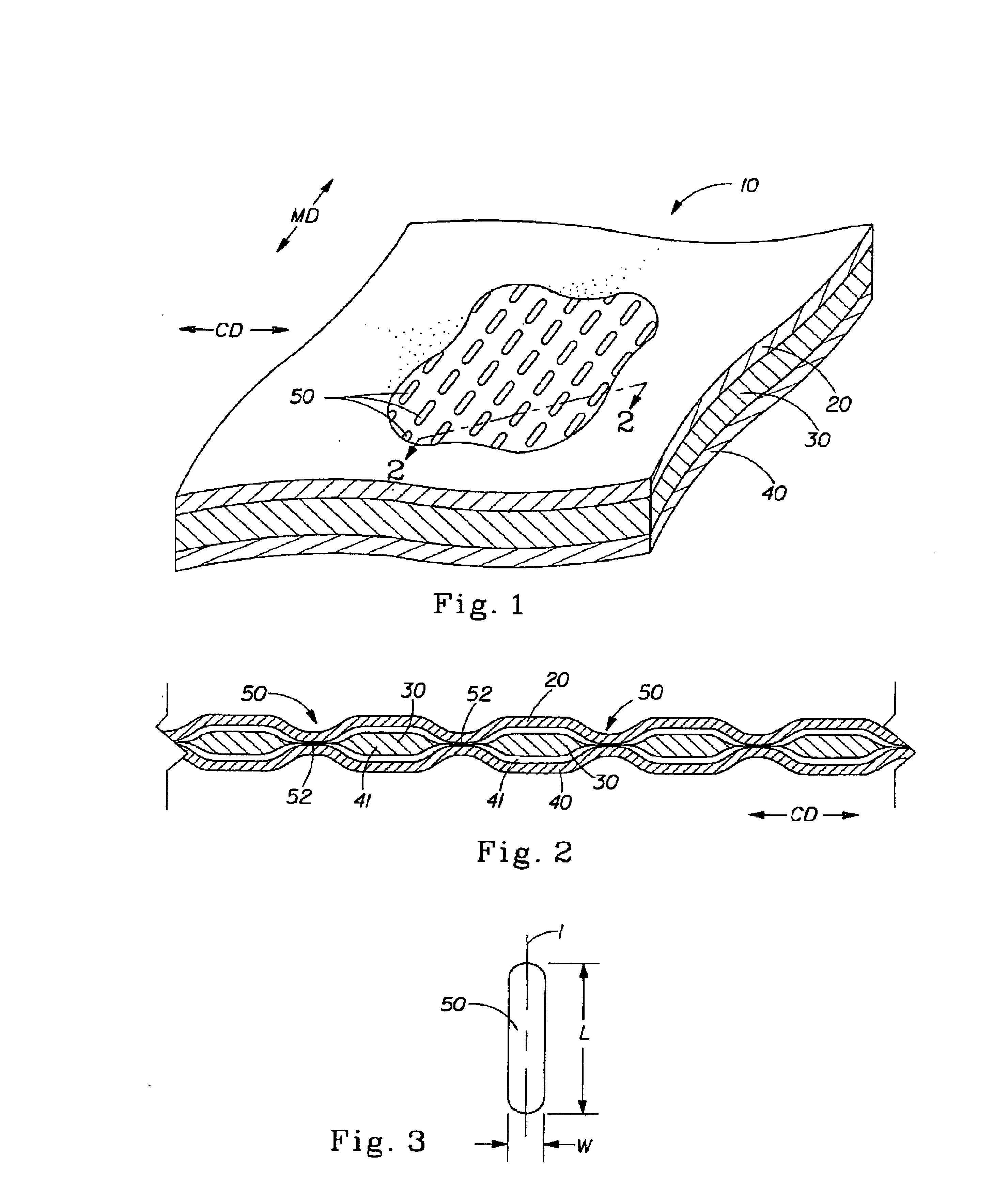

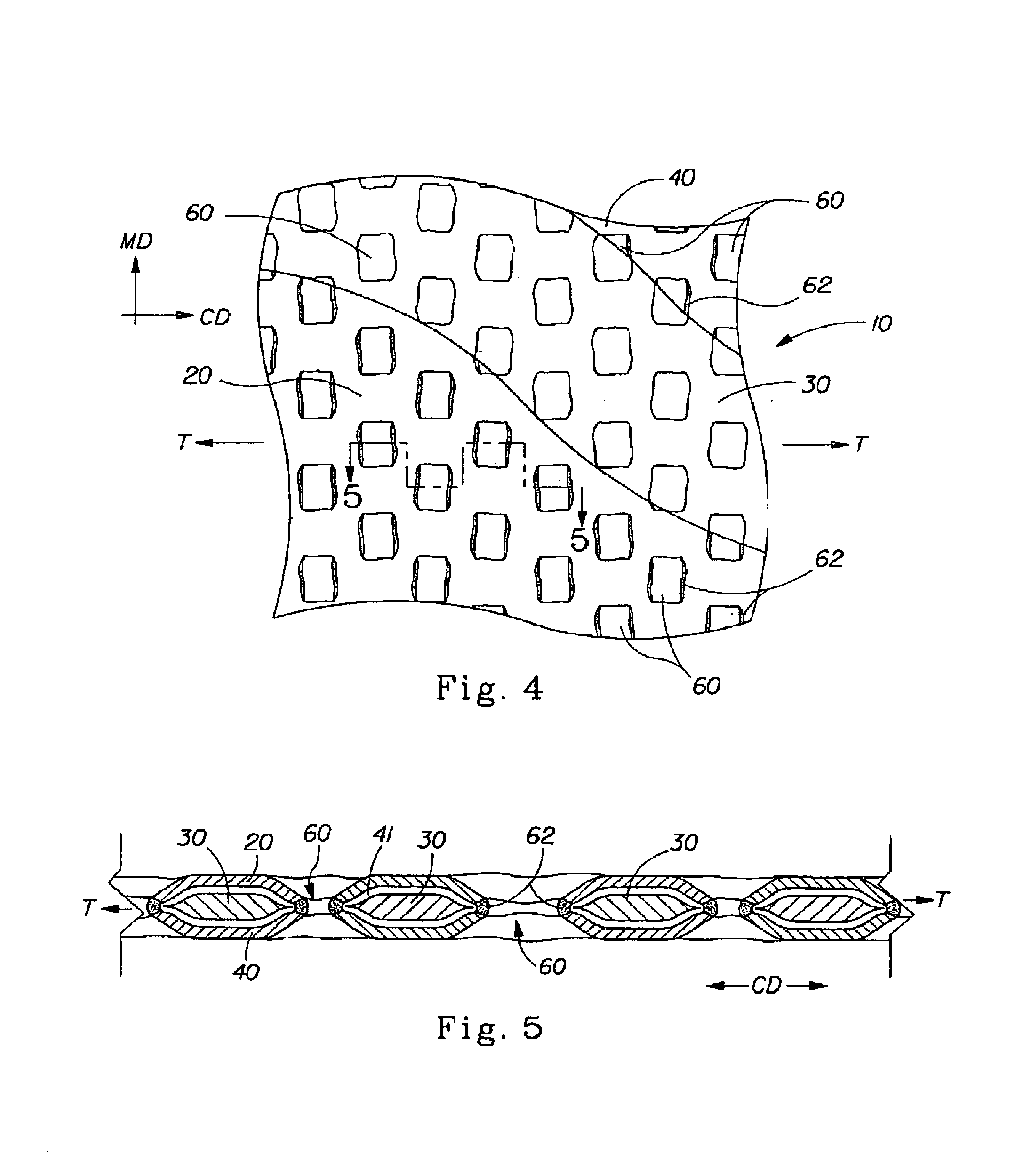

Laminate web

A laminate web is disclose, the laminate web comprising a first web, a second web joined to the first web at a plurality of discrete bond sites; and a third material disposed between at least a portion of the first and second nonwovens. The third material is apertured in regions adjacent the bond sites, such that the first and second nonwoven webs are joined through the apertures. In one embodiment an apertured laminate web is disclosed, having a first extensible web having a first elongation to break, and a second extensible web joined to the first extensible web at a plurality of bond sites, the second extensible web having a second elongation to break A third web material is disposed between the first and second nonwovens, the third web material having a third elongation to break which is less than both of the first or second elongations to break. In a further embodiment, an apertured laminate web is disclose, having first and second extensible webs being joined at a plurality of discrete bond sites and a third material disposed between the first and second nonwoven webs. The first and second nonwoven webs are in fluid communication via the apertures and have distinct regions being differentiated by at least one property selected from the group consisting of basis weight, fiber orientation, thickness, and density.

Owner:THE PROCTER & GAMBLE COMPANY

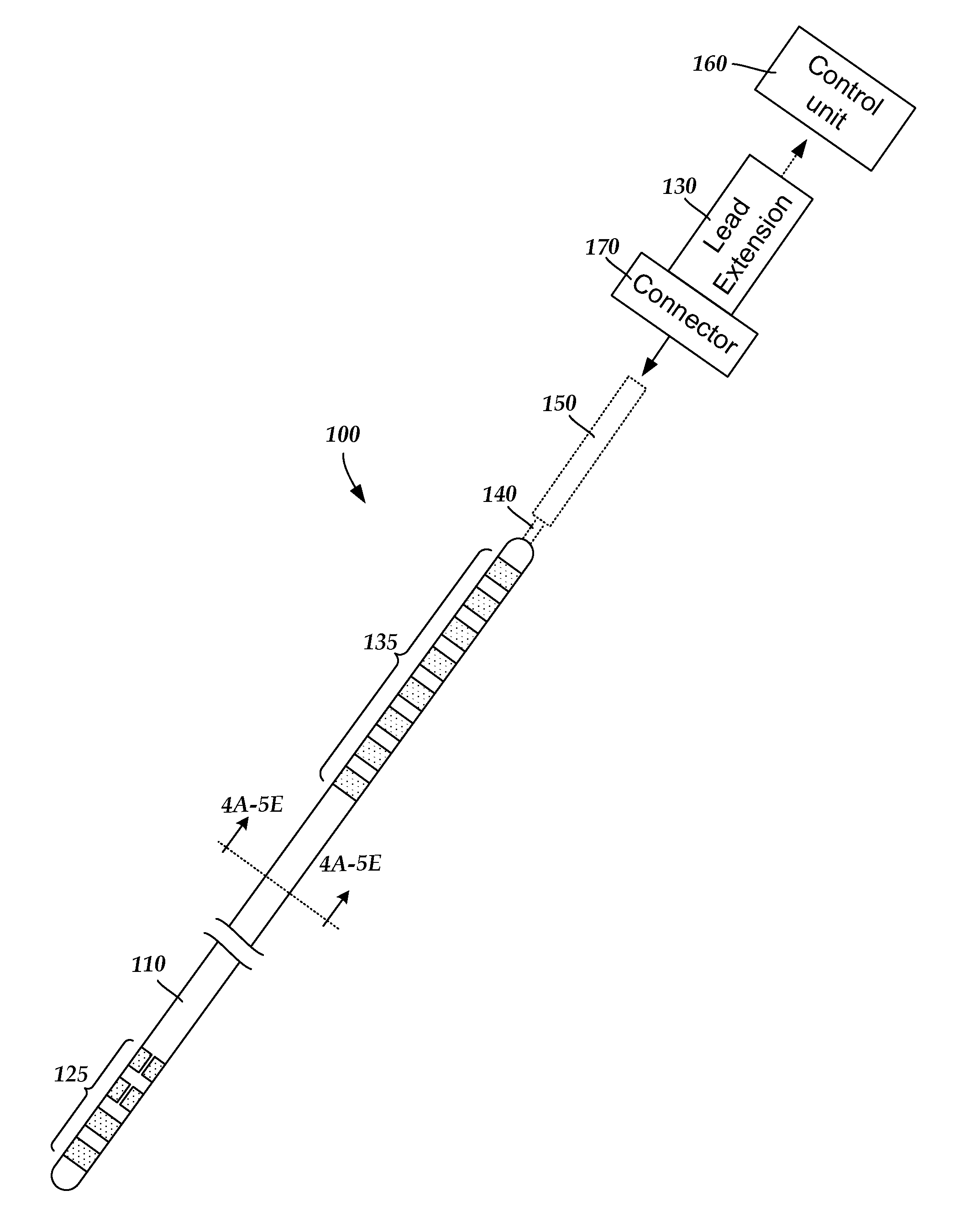

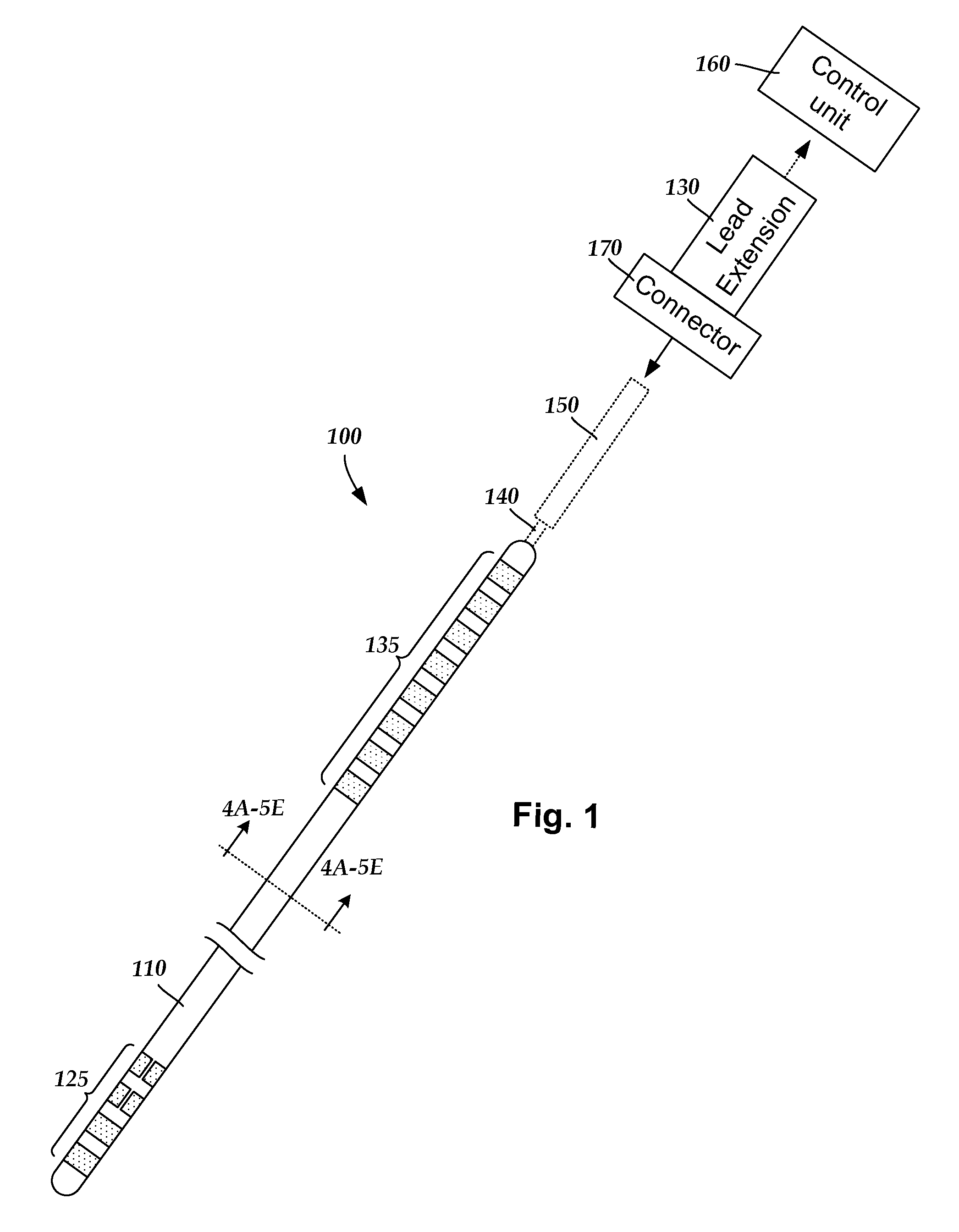

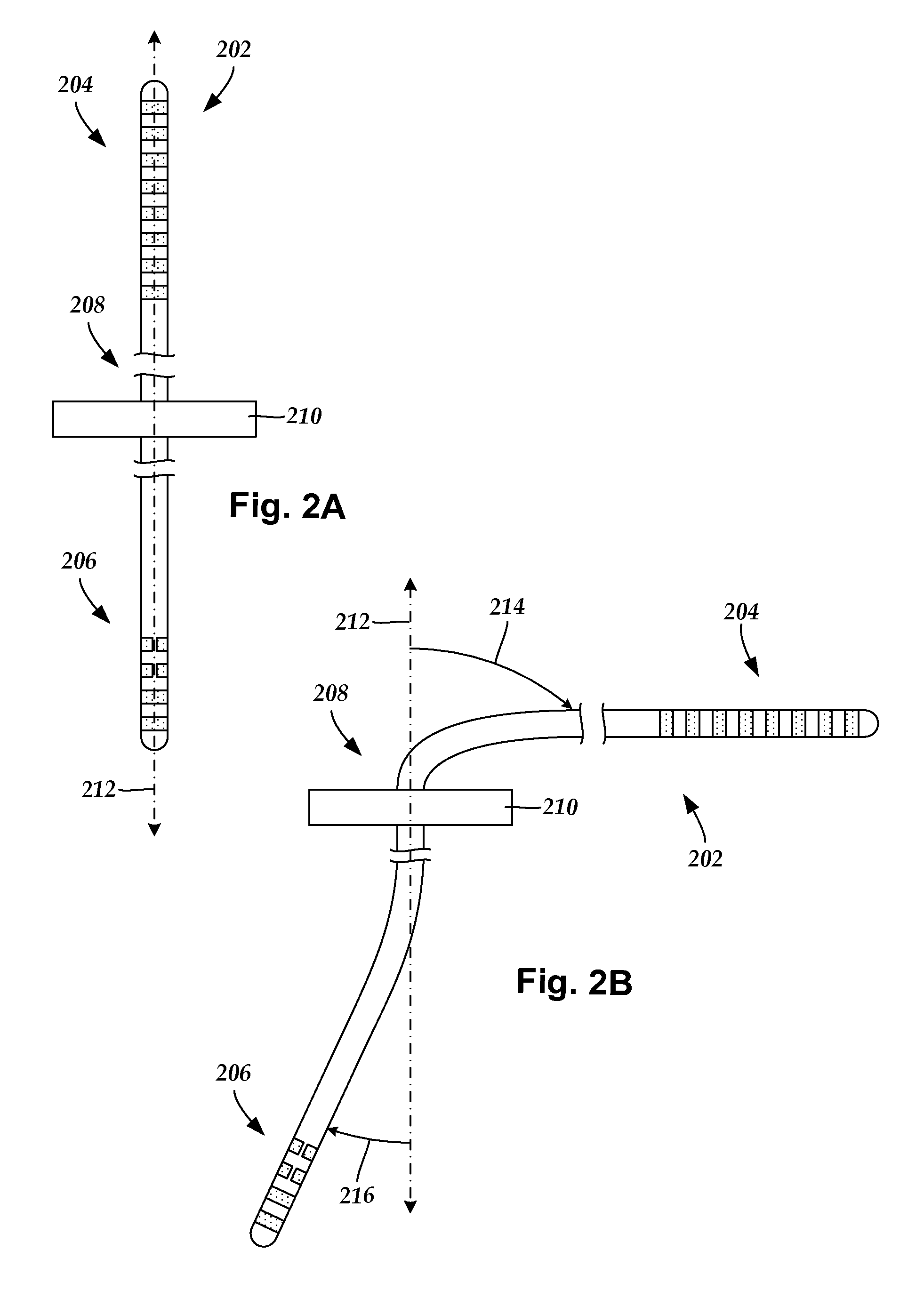

Systems and methods for making and using improved leads for electrical stimulation systems

ActiveUS20130105071A1Reduce gapLine/current collector detailsHead electrodesElectricityElectrical conductor

A method for manufacturing a lead includes pre-forming at least one relief section along a length of an elongated conductor having a first end and an opposing second end. The conductor with the pre-formed relief section is inserted into a conductor lumen defined along a length of an elongated lead body. The lead body has a first end and an opposing second end. An electrode is disposed at the first end of the lead body. The first end of the conductor is electrically coupled to the electrode. A terminal is disposed at the second end of the lead body. The second end of the conductor is electrically coupled to the terminal.

Owner:BOSTON SCI NEUROMODULATION CORP

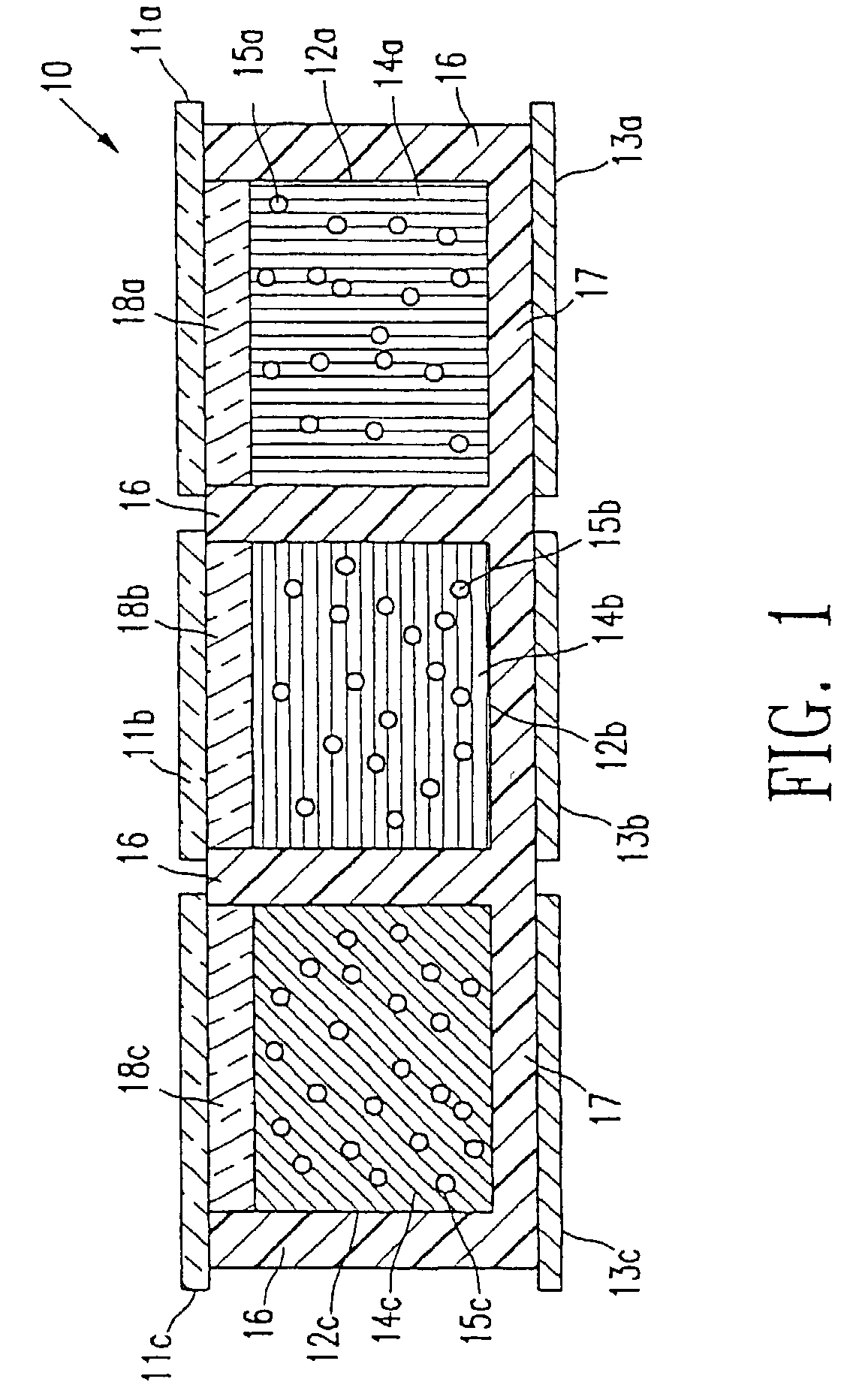

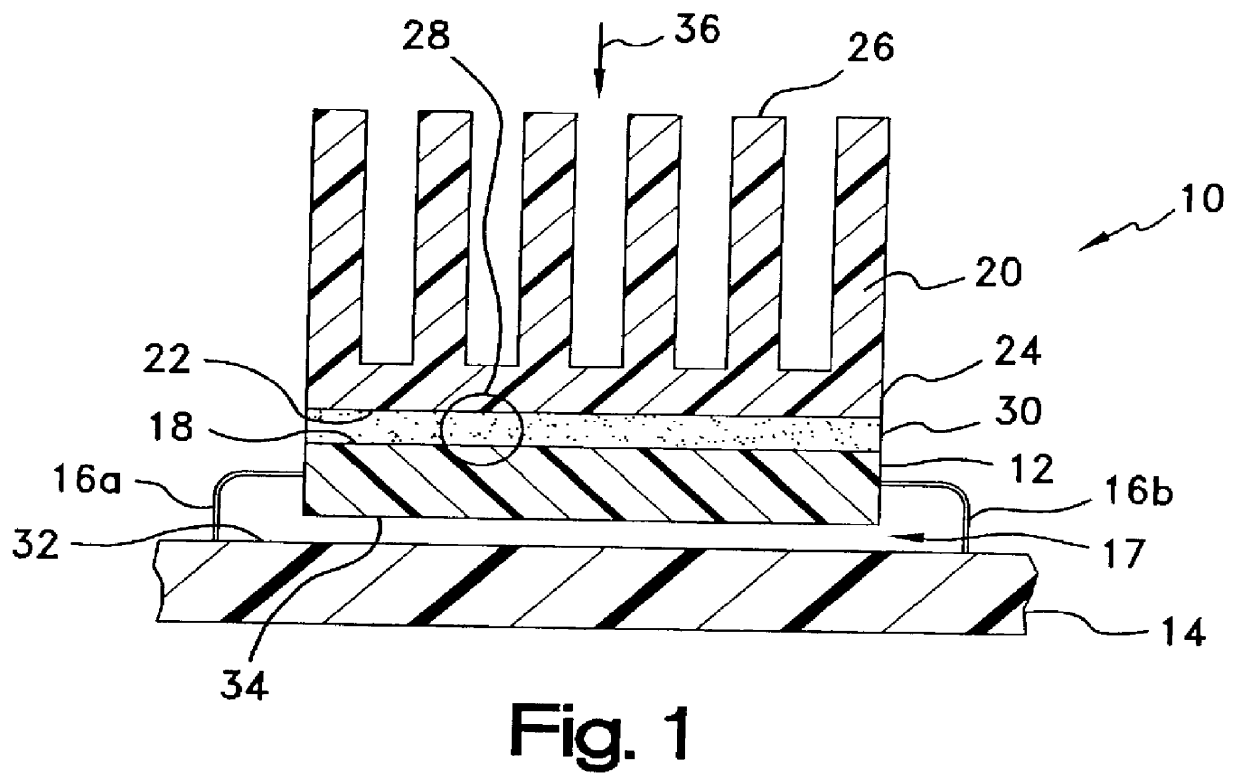

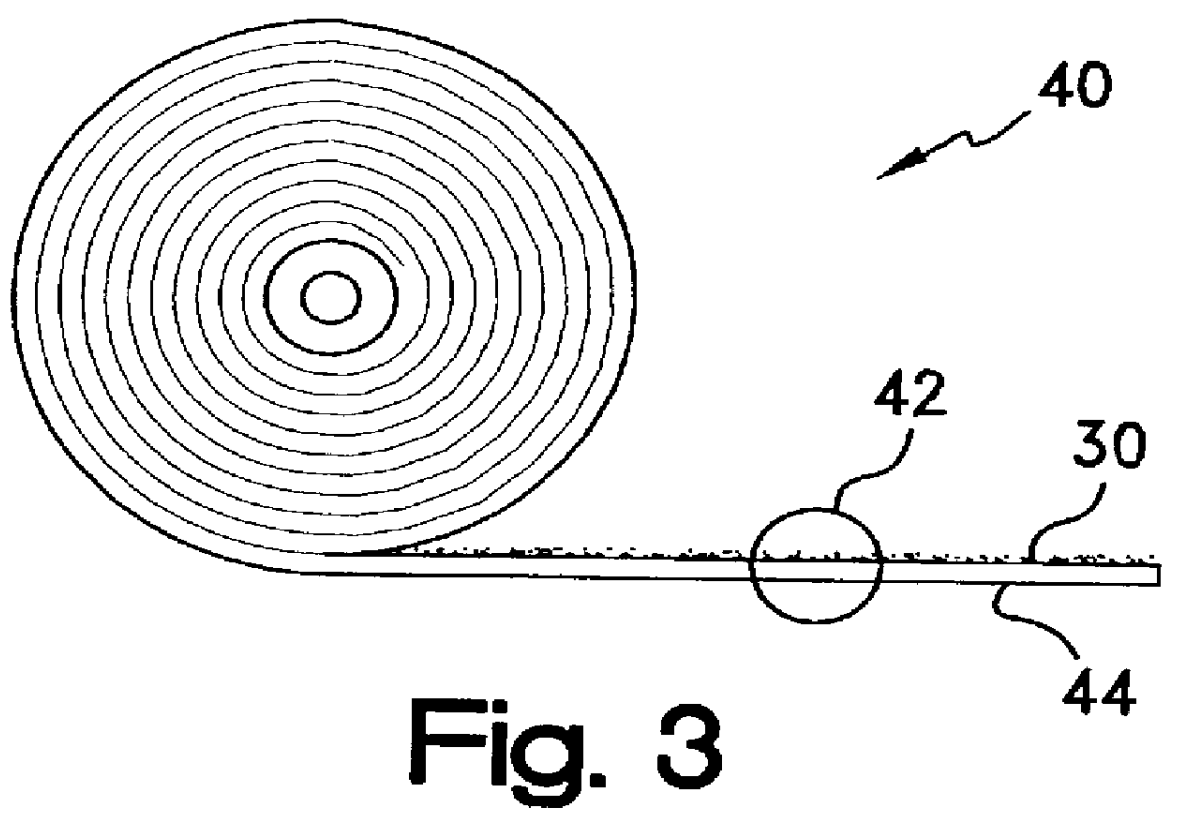

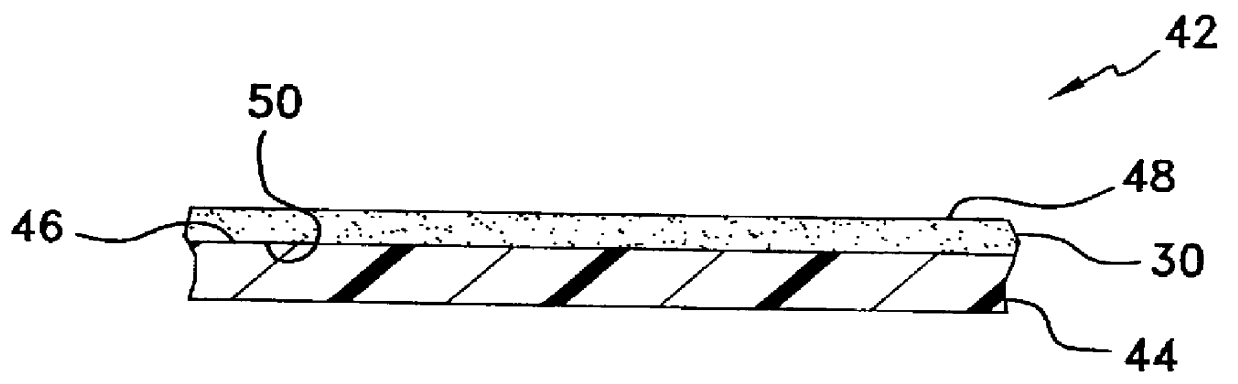

Conformal thermal interface material for electronic components

InactiveUS6054198AOptimize allocationReadily apparentSemiconductor/solid-state device detailsSolid-state devicesRoom temperatureConductive materials

A thermally-conductive interface for conductively cooling a heat-generating electronic component having an associated thermal dissipation member such as a heat sink. The interface is formed as a self-supporting layer of a thermally-conductive material which is form-stable at normal room temperature in a first phase and substantially conformable in a second phase to the interface surfaces of the electronic component and thermal dissipation member. The material has a transition temperature from the first phase to the second phase which is within the operating temperature range of the electronic component.

Owner:PARKER INTANGIBLES LLC

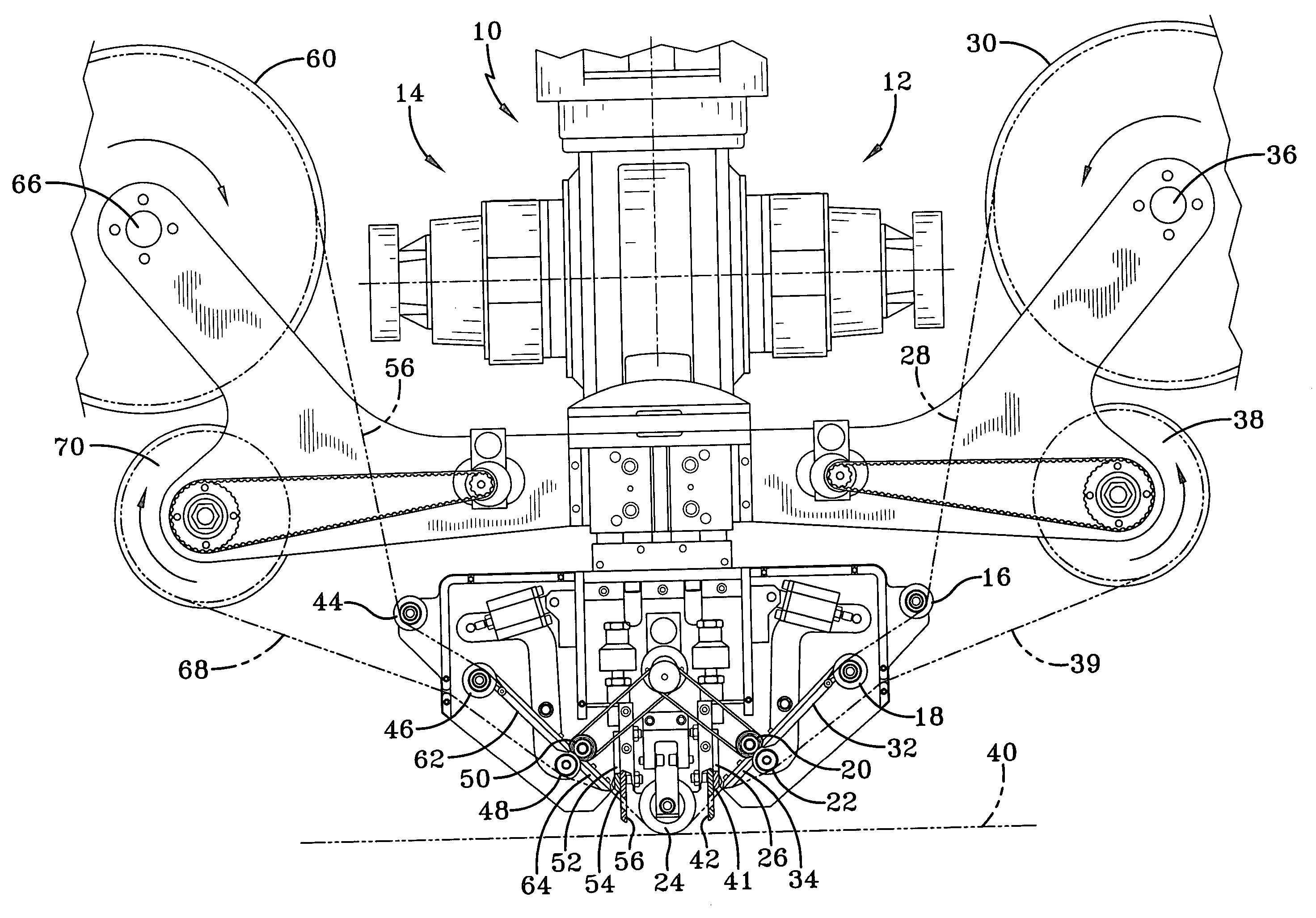

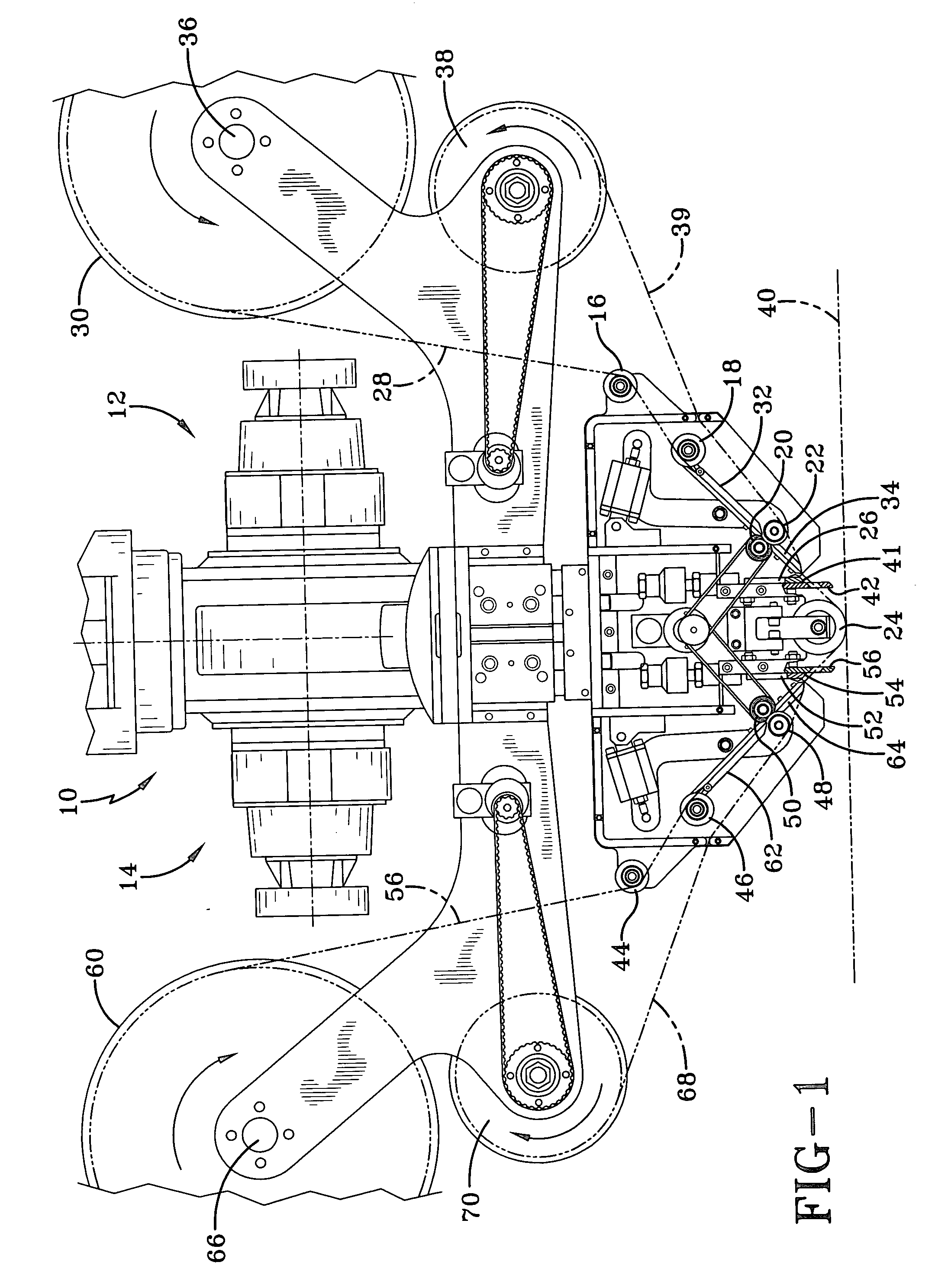

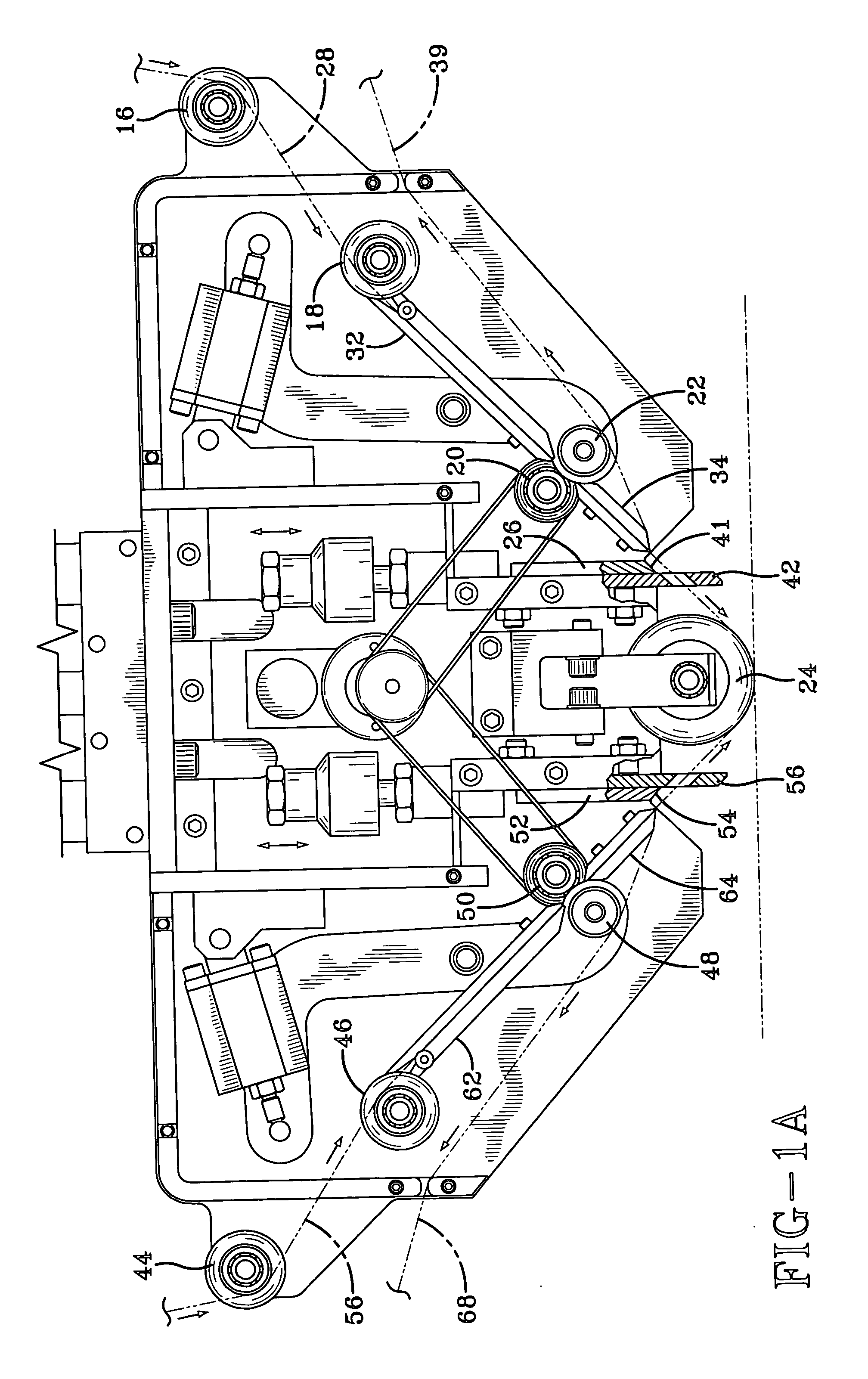

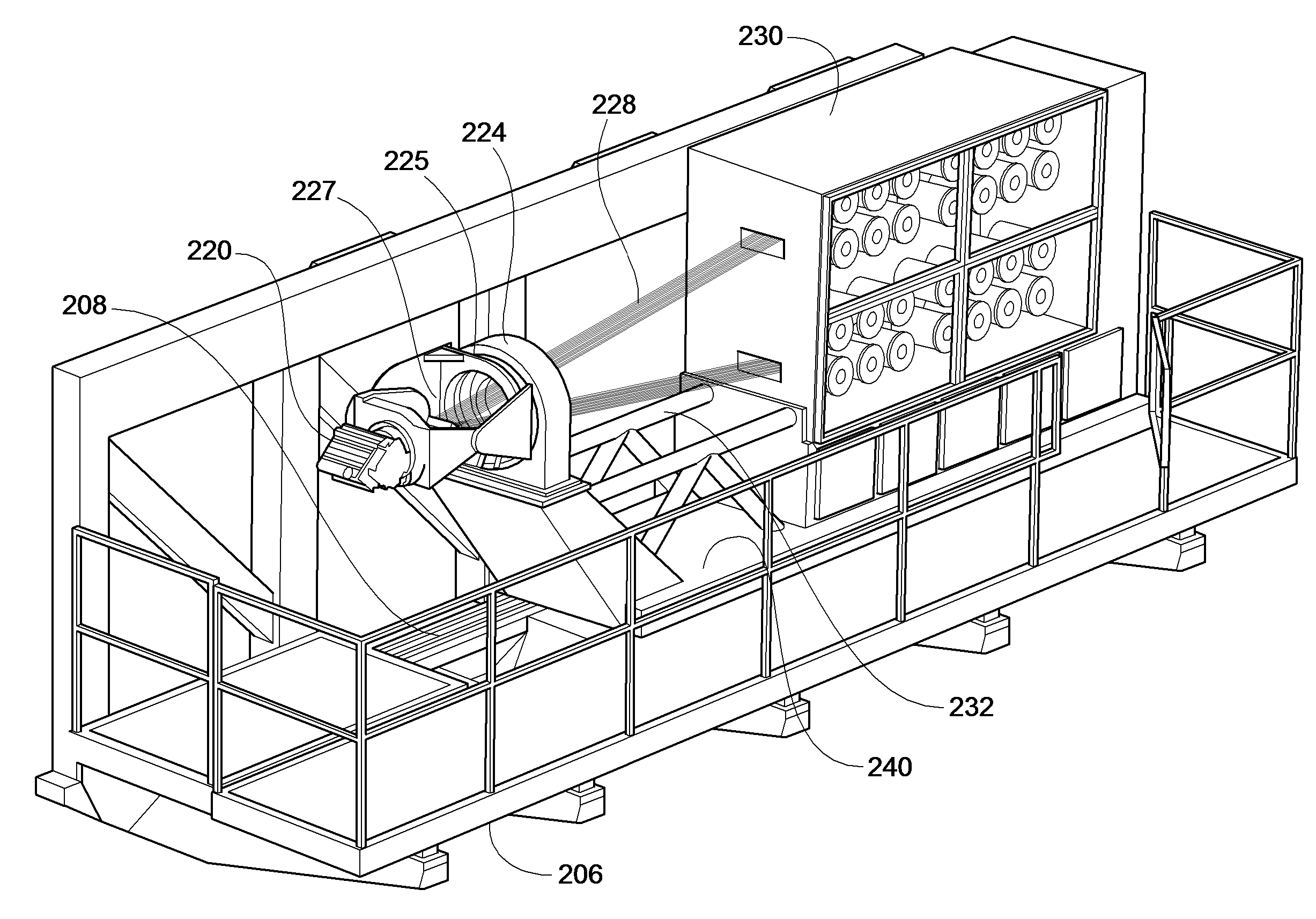

Multiple tape laying apparatus and method

ActiveUS20050061422A1Satisfactory depositionAvoid stickingLamination ancillary operationsPaper/cardboard articlesFiberMultiple layer

A fully automated method and apparatus is disclosed to laminate various structural articles with multiple layers of a resin impregnated fiber tape. The fiber tape is deposited with a tape laying member moving alternately in different travel directions. The tape laying member removes all backing layers from the tape being employed, then deposits the unbacked tape on the surface of the structural article and finally severs the end of the tape being deposited. An automated cut and restart procedure is employed in the present apparatus to increase throughput.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

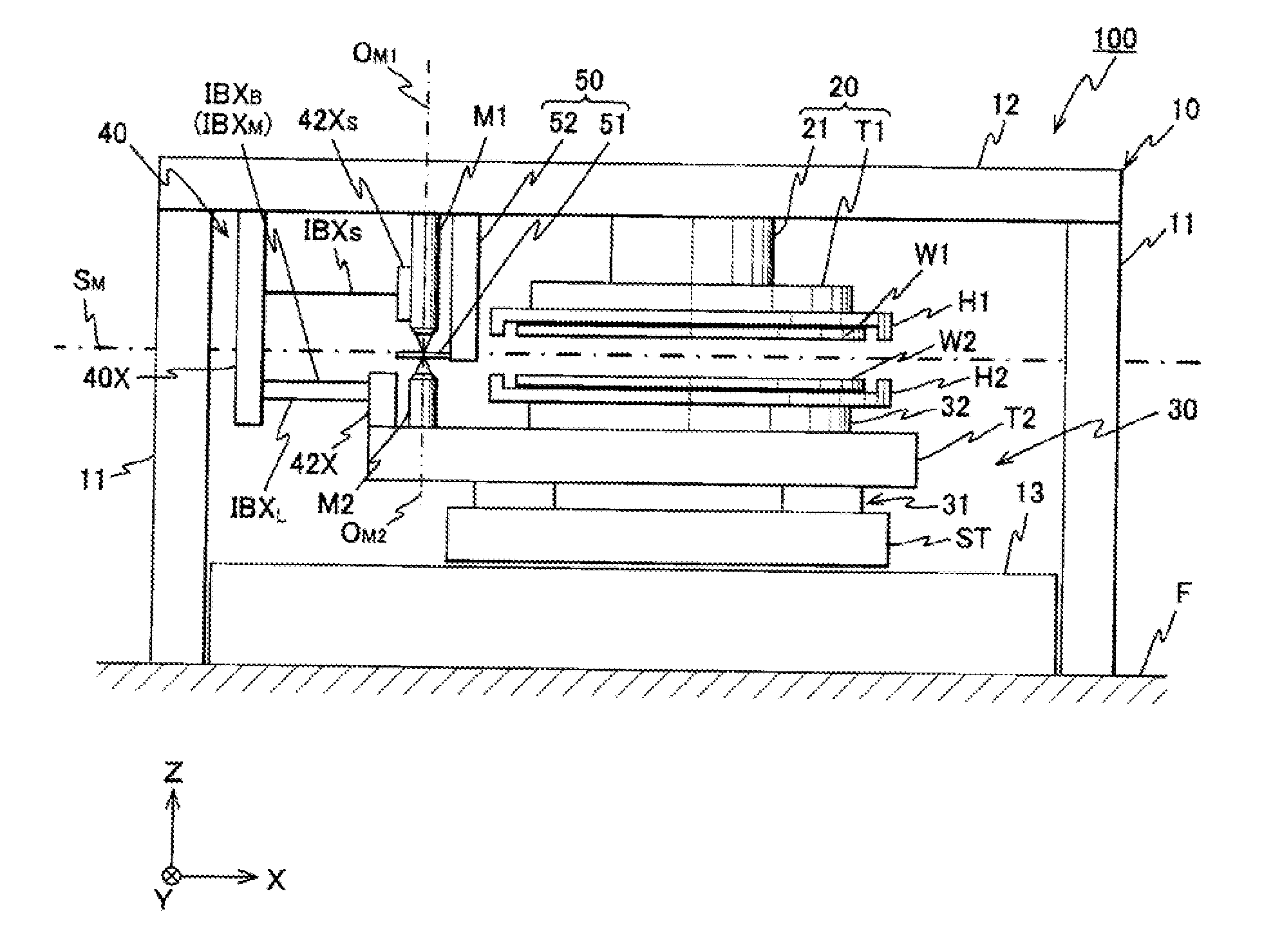

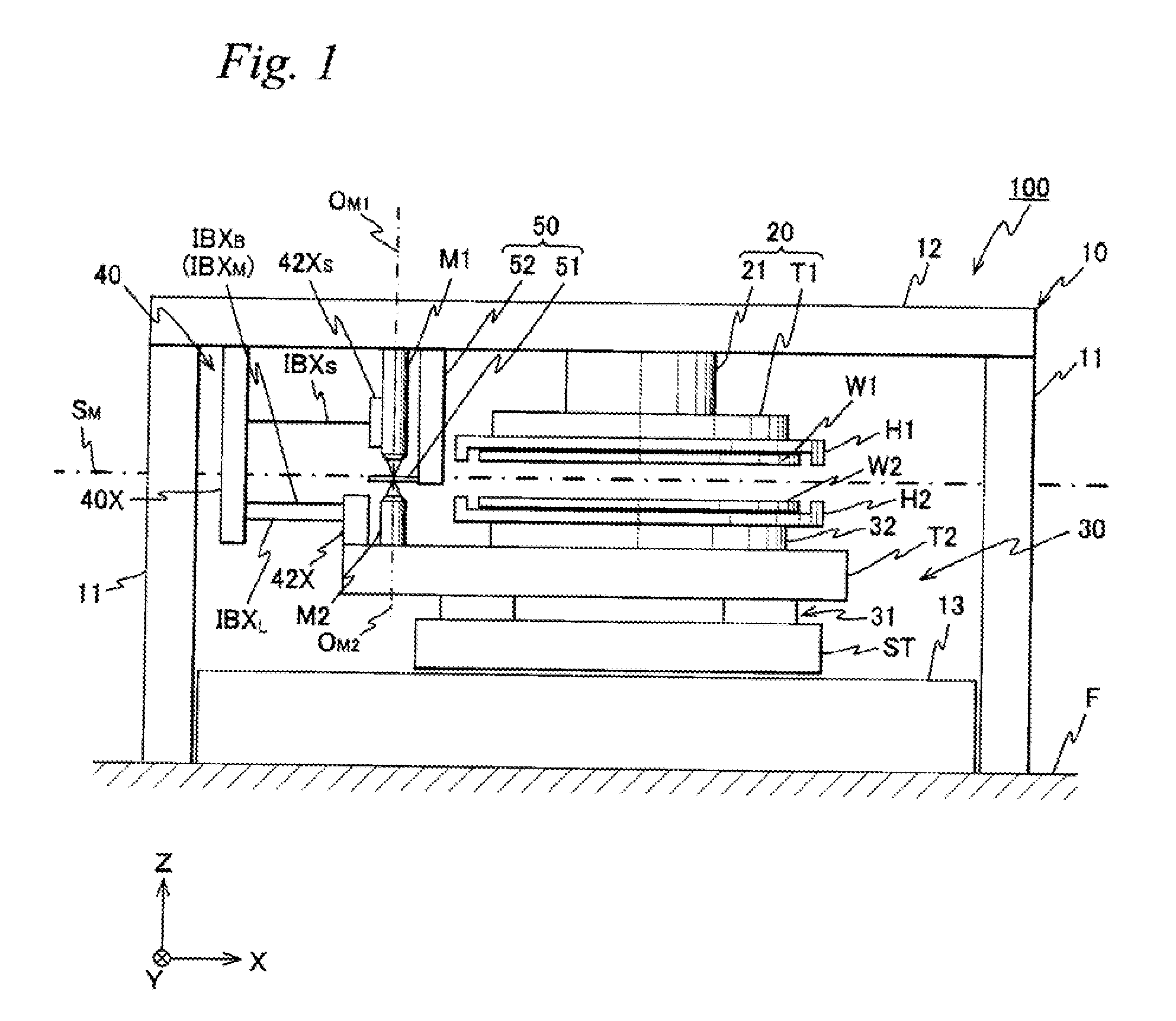

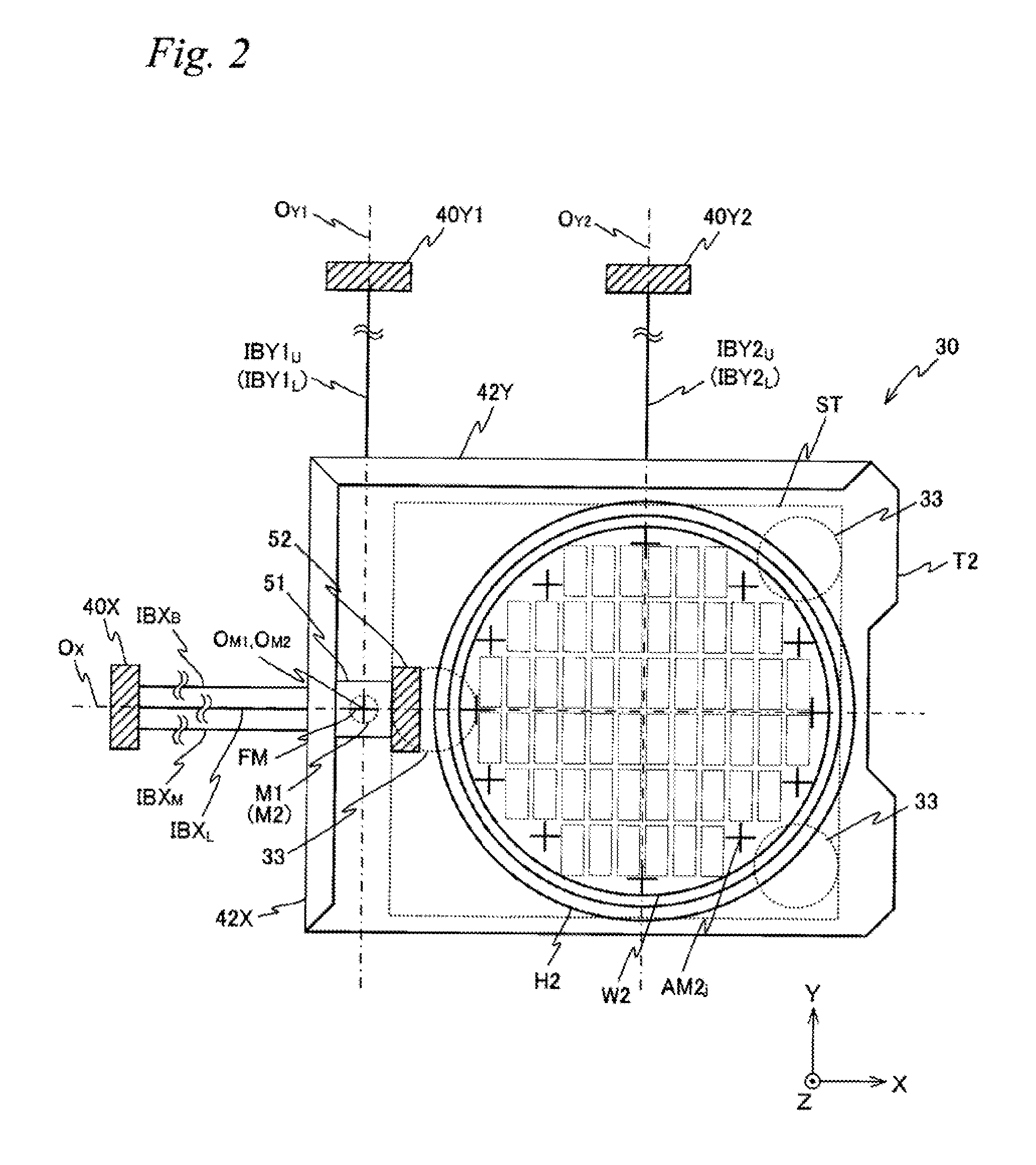

Substrate Bonding Apparatus and Substrate Bonding Method

ActiveUS20100139836A1Improve accuracyPrecise alignmentLamination ancillary operationsSemiconductor/solid-state device testing/measurementEngineering

A substrate bonding apparatus is equipped with a first table that holds one wafer of two wafers, a stage device that holds the other wafer in an orientation capable of opposing to the one wafer and that is movable at least within an XY plane, an interferometer system that measures positional information of the stage device within the XY plane, a first mark detection system that can detect subject marks including alignment marks on the other wafer held by the stage device, and a second mark detection system fixed to a part (the second table) of the stage device that can detect subject marks including alignment marks on the one wafer held by the first table.

Owner:NIKON CORP

Adhesion method and electronic component

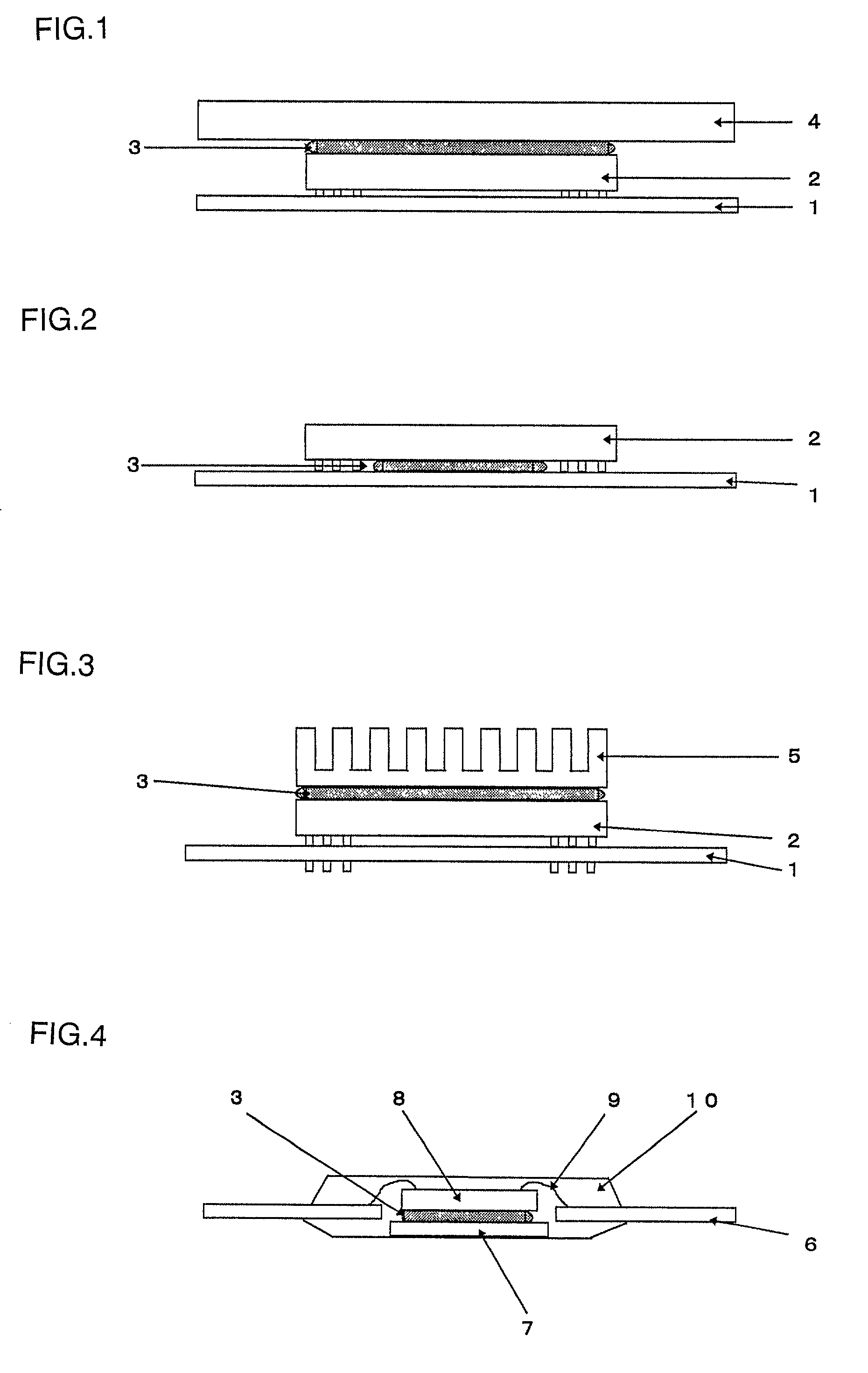

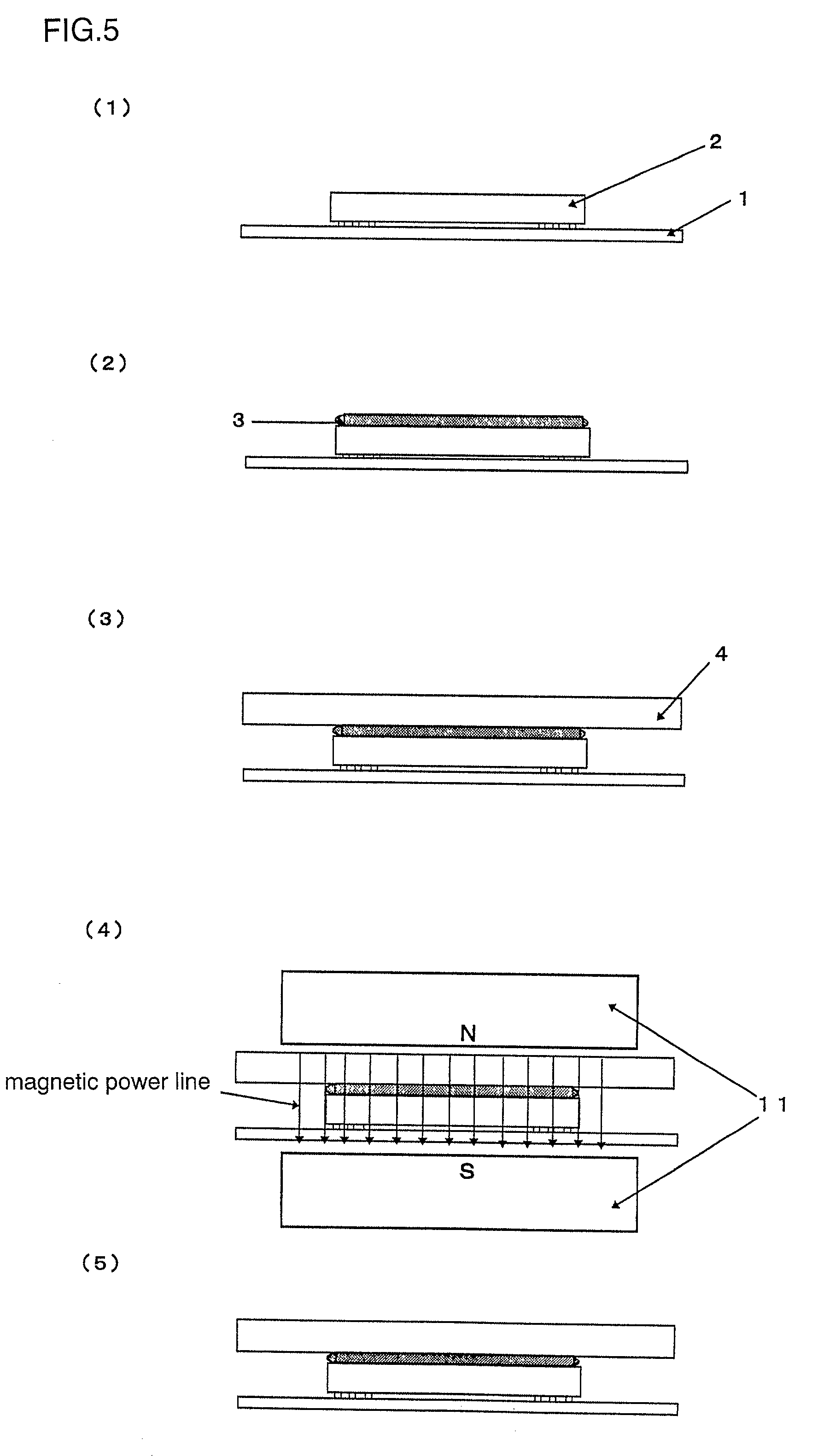

InactiveUS20010004131A1Efficiently dissipatedEnhanced radiationAdhesive processesLamination ancillary operationsAdhesiveBoron nitride

The present invention provides an adhesion method of improving the heat conduction in a fixed direction by using a heat conductive adhesive made by blending boron nitride powder and adhesive polymer and adhering by orienting boron nitride powder in the heat conductive adhesive to the fixed direction under the magnetic atmosphere and an electronic component for effectively dissipating heat generated from semiconductor device 2, power source 4, light source or other components used for the electric products, and an electronic component excellent in radiation.

Owner:POLYMATECH CO LTD

Fiber Placement Machine Platform System Having Interchangeable Head and Creel Assemblies

Owner:INGERSOLL MACHINE TOOLS

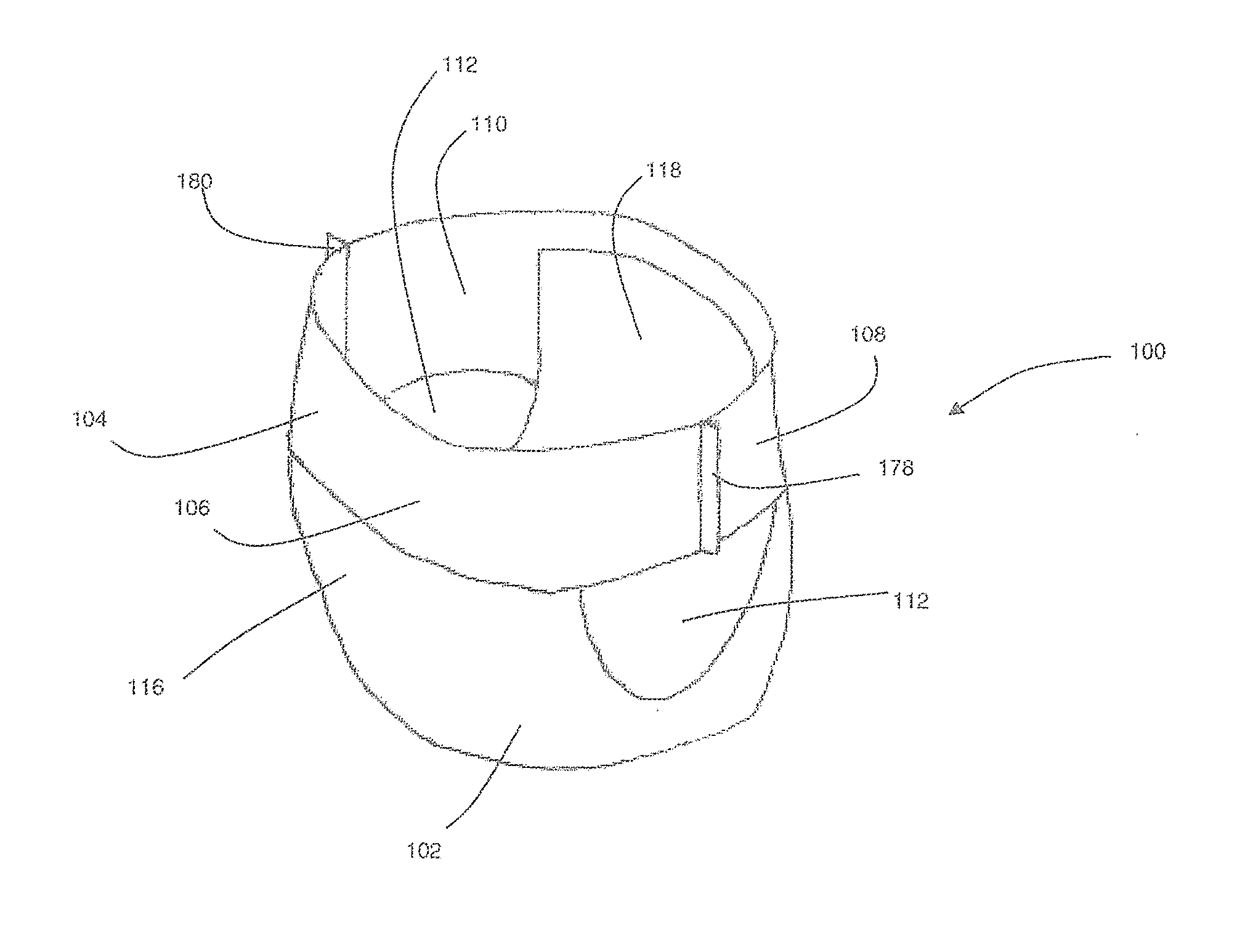

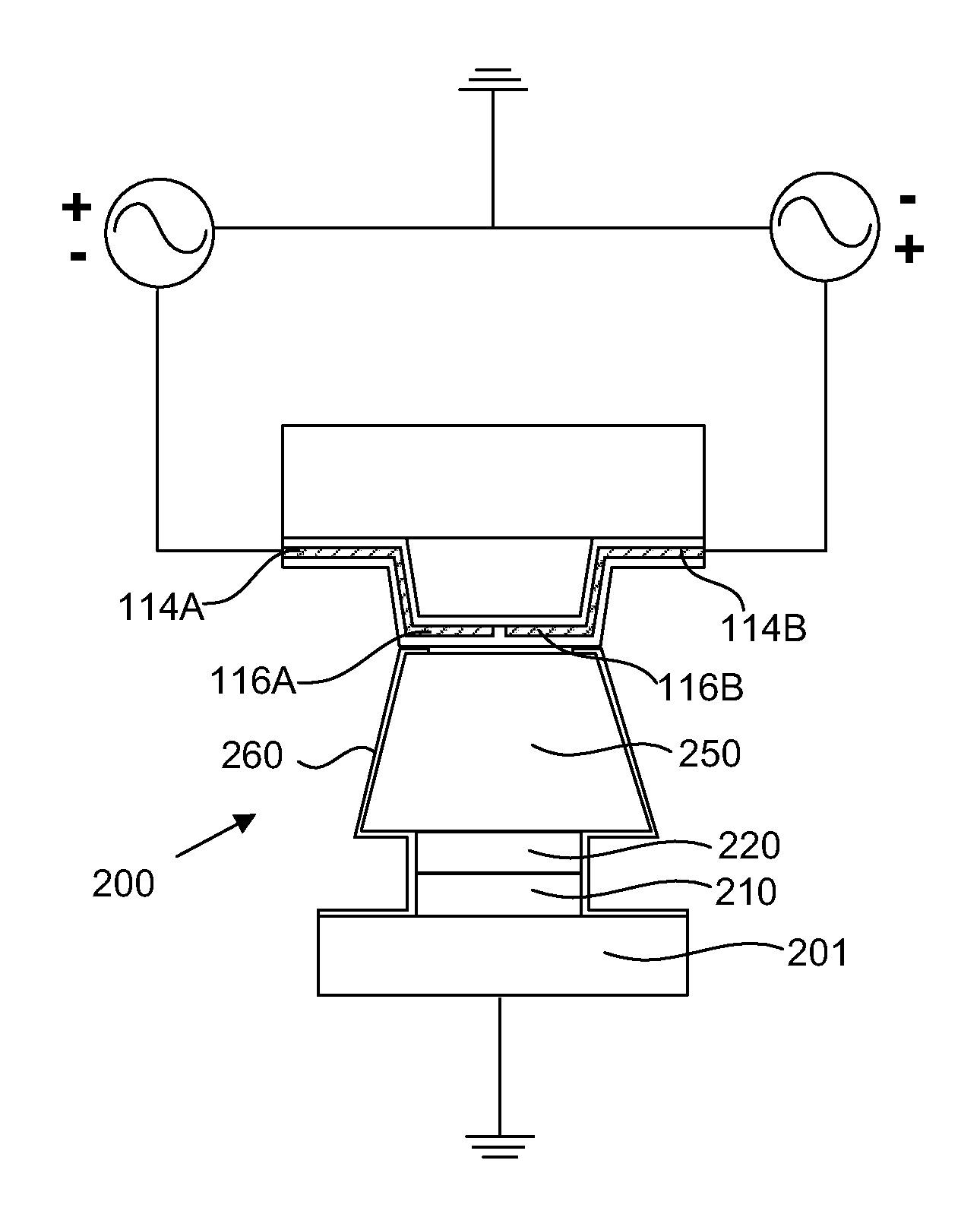

Micro device transfer head heater assembly and method of transferring a micro device

A method of transferring a micro device and an array of micro devices are disclosed. A carrier substrate carrying a micro device connected to a bonding layer is heated to a temperature below a liquidus temperature of the bonding layer, and a transfer head is heated to a temperature above the liquidus temperature of the bonding layer. Upon contacting the micro device with the transfer head, the heat from the transfer head transfers into the bonding layer to at least partially melt the bonding layer. A voltage applied to the transfer head creates a grip force which picks up the micro device from the carrier substrate.

Owner:APPLE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com