Patents

Literature

85results about How to "Non sticky" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

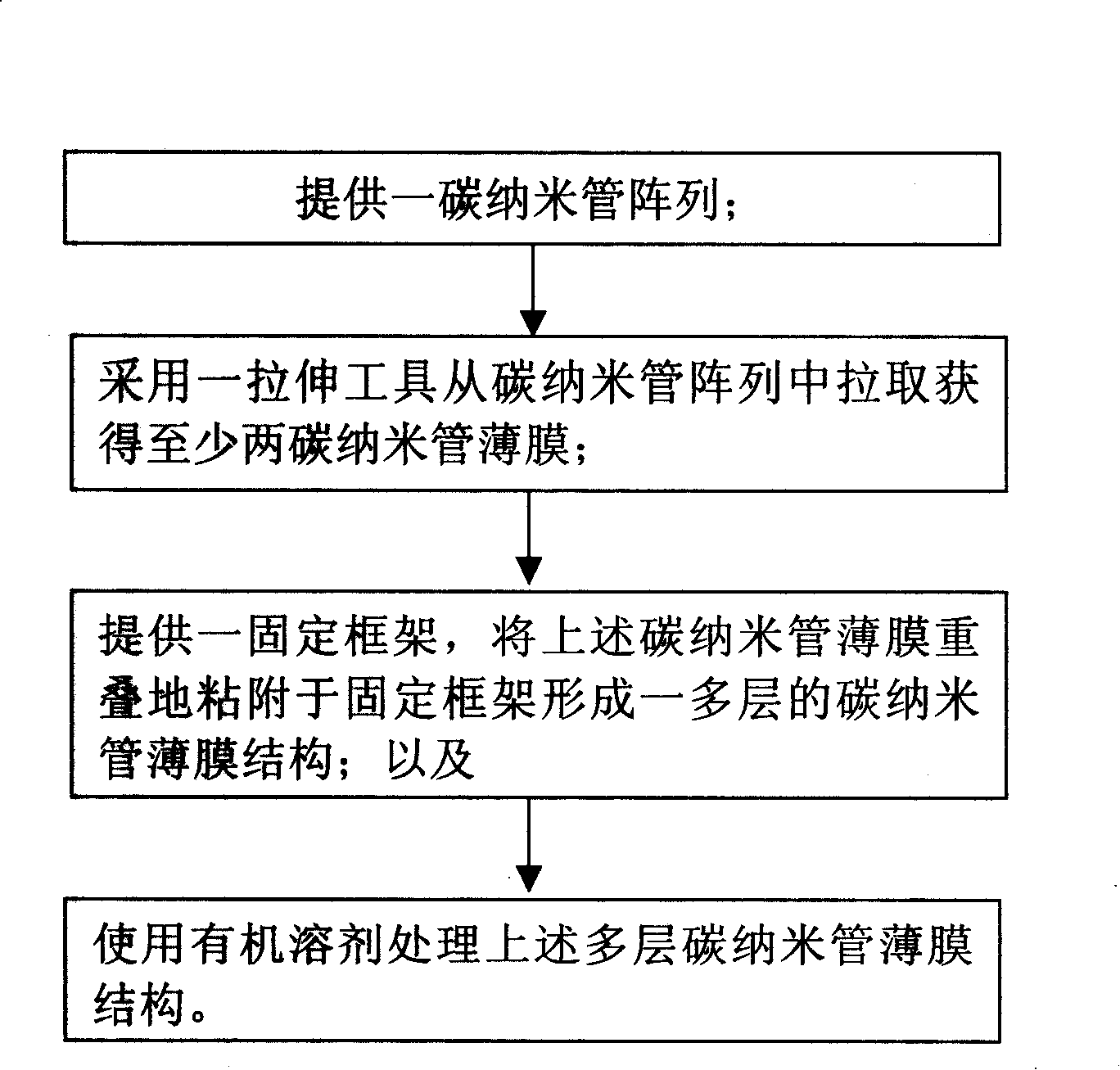

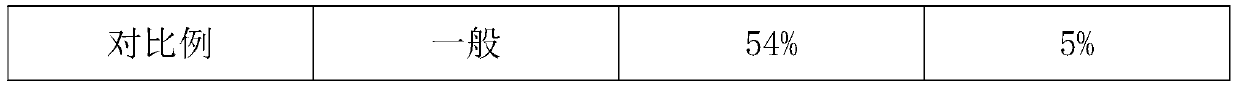

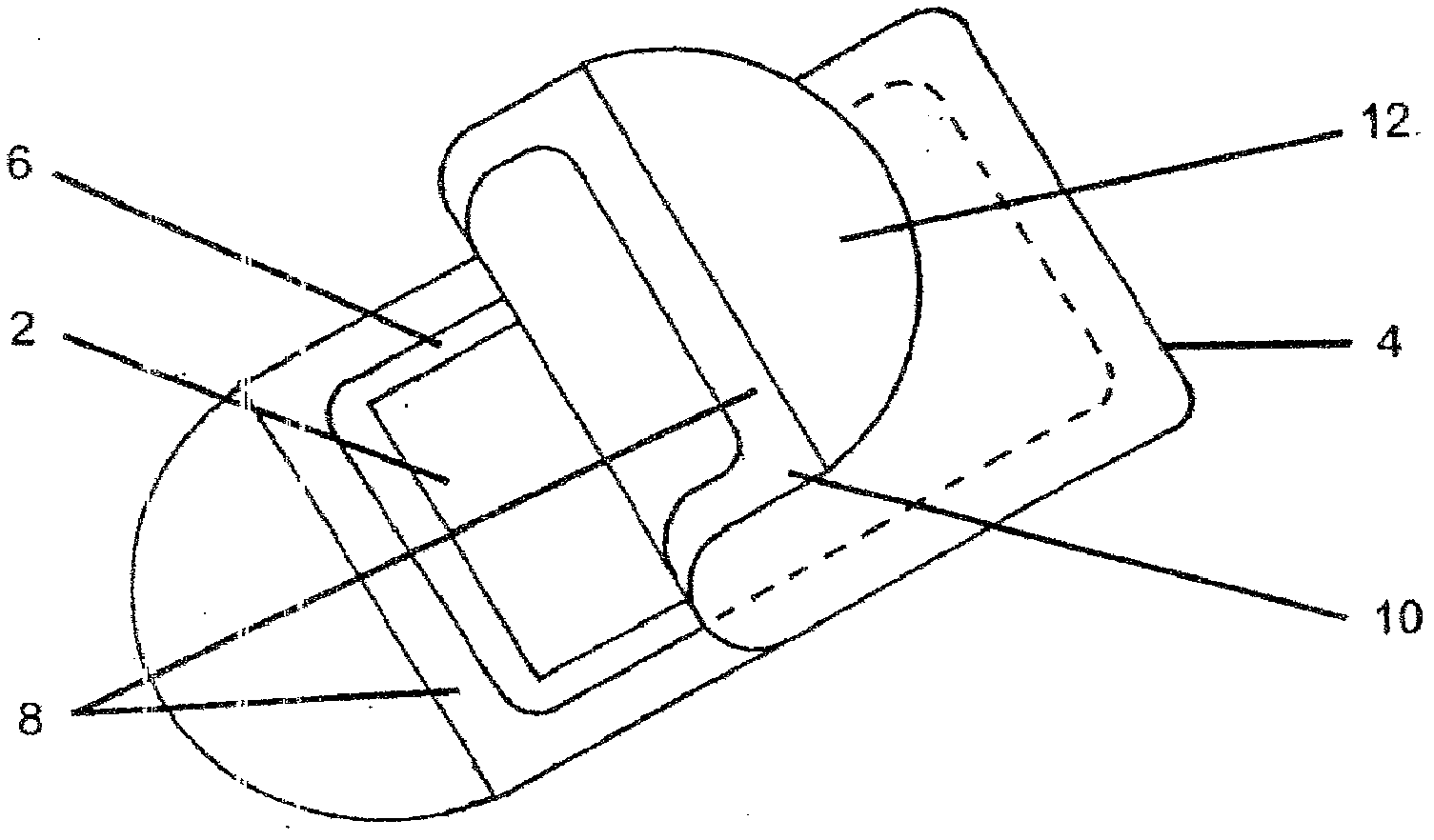

Carbon nano-tube thin film structure and preparation method thereof

ActiveCN101239712ASmall surface to volume ratioNon stickyMaterial nanotechnologyLamination ancillary operationsOrganic solventFixed frame

The present invention provides a preparing method of carbon nanotube film structure, including following steps: providing a carbon nanotube array; adopting a pulling tool to acquire at least two carbon nanotube films from the carbon nanotube array; providing a fixed frame, forming a multiple-layer carbon nanotube film structure by overlap adhereing the carbon nanotube film in the fixed frame; and treating the multiple-layer carbon nanotube film by an organic solvent. The carbon nanotube film structure prepared by the method includes at least two layers overlapped and cross-over installed carbon nanotube film, which includes multiple carbon nanotube bundle end to end and arranged in the direction, the multiple-layer carbon nanotube film further includes millipore crosswise formed by multiple carbon nanotube bundles.

Owner:TSINGHUA UNIV +1

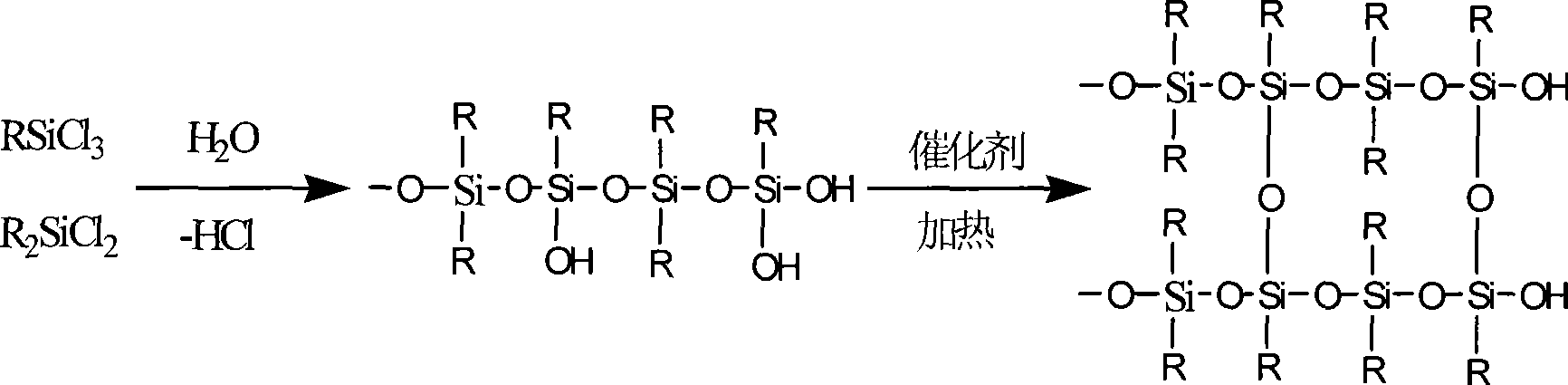

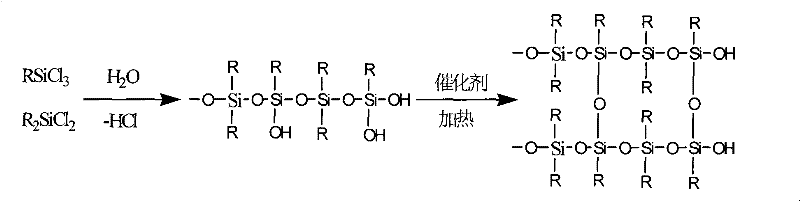

Method of preparing methyl phenyl polysiloxane

ActiveCN101508776AWith high and low temperature resistanceWeather resistantReaction temperatureMethyl phenyl polysiloxane

The invention discloses a method for synthesizing organic silicon, in particular provides a method for preparing methyl phenyl silicone resin which has low curing temperature by self and is not sticky repeatedly. The invention uses the monomers of methyl trichlorosilane, dimethyldichlorosilance, phenyl trichlorosilane, dichloromethylphenylsilane, diphenyl dichlorosilane and the like to obtain a methyl phenyl silicone resin with low curing temperature and a paint film which is not sticky repeatedly after being cured by the processes of adjusting the proportion of raw materials, controlling proper reaction temperature and polymerization time, carrying out hydrolysis reaction and polycondensation reaction, etc. The invention has the advantages that the methyl phenyl silicone resin prepared by the method has the characteristics of low curing temperature, being not sticky repeatedly, being clear and transparent, high and low temperature resistance, weather resistance, being insulating and the like; the methyl phenyl silicone resin is in particular fit for dip varnish higher than grade H; and the methyl phenyl silicone resin is used for confecting insulated paint, weather-resistant paint and heat resistant paint higher than grade H, is used for heat resistant parting agent and also can be used in the fields with rigorous using requirements, such as heat resistant water blocking and sand prevention for oil drilling, etc.

Owner:安徽比特海新材料股份有限公司

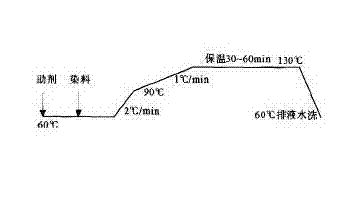

Production process for single-direction rapid moisture guide composite knitted fabric

InactiveCN102733056ASignificant differential effectHas the effect of one-way quick moisture conductionWeft knittingDyeing processFiberAfter treatment

The invention discloses a production process for single-direction rapid moisture guide composite knitted fabric, belonging to the technical field of the single-direction rapid moisture guide fabric. The single-direction rapid moisture guide composite knitted fabric provided by the invention is characterized by using a multilayer composite structure, wherein an outer layer of the fabric is weaved by hydrophilic fibers, and an inner layer is weaved by hydrophobic fibers; the inner layer and the outer layer of the fabric are connected by using hydrophobic moisture guide fibers, so as to form a wicking effect; and meanwhile, the moisture guide property and the comfort sense of the fabric can be further improved through an optimal dying and after-treatment process. With the adoption of the single-direction rapid moisture guide composite knitted fabric, sweat can be rapidly conducted to the outer layer of the fabric from the inner layer of the fabric in a single-direction manner, and rapidly evaporated on the outer layer; the single-direction moisture guide rate is within 30 seconds, so that the warm balance between the inner layer of the fabric and human skin can be kept to improve the thermohumid comfort when the fabric is worn; and furthermore, the fabric provided by the invention is dry, cool and comfortable to wear and is not adhered to a human body when a user sweats.

Owner:ZHEJIANG GANGLONG WEAVING TECH

Water-in-oil emulsion composition and emulsion cosmetic comprising the same

InactiveUS20050118211A1Good touchImprove stabilityCosmetic preparationsToilet preparationsClay mineralsTactile sensation

The present invention is a water-in-oil emulsified composition comprising (a) 0.1-20 wt % organophilic clay mineral, (b) 10-70 wt % oil component, (c) 0.01-10 wt % emulsifier having an HLB value of not more than 7, and (d) 0.1-90 wt % microgel having an average particle size of 0.1-1,000 micrometers obtained by dissolving a hydrophilic compound having a gelation ability in water or an aqueous component, letting it cool down and solidify to form a gel, and pulverizing said gel, as well as an emulsified cosmetic that uses this composition. The present invention provides a water-in-oil emulsified composition that exhibits good emulsified states, does not change over different temperatures and / or time, has superior stability, and gives a non-sticky, fresh, and good tactile sensation during use, as well as an emulsified cosmetic using this composition.

Owner:SHISEIDO CO LTD

Irrigating and lavage compositions

Irrigants to be used with vibratory scaling apparatus and lavage are provided. The irrigants of the invention are characterized in that they contain medicaments for the treatment of conditions in the mouth and have a viscosity and deliquescence adapted to substantially optimize the efficiency of the apparatus. The irrigants are formulated so that they have minimal stickiness on drying, minimal foaming and do not gum-up the apparatus in which they are used. Also provided is a method for treating dental diseases comprising applying the irrigants of the invention through a vibratory scaring apparatus to substantially optimize the efficiency of said apparatus and to substantially optimize destruction and removal of infectious bacteria using said apparatus and the removal or inactivation of endotoxins derived from bacteria or the host.

Owner:DENTSPLY RES DEVMENT

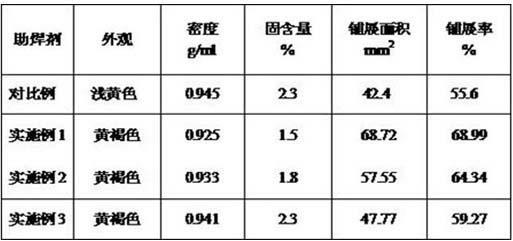

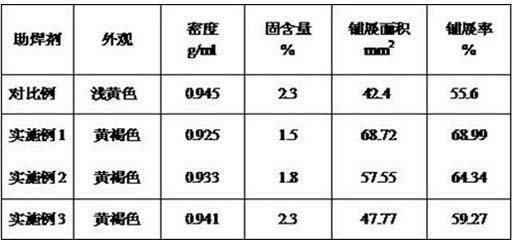

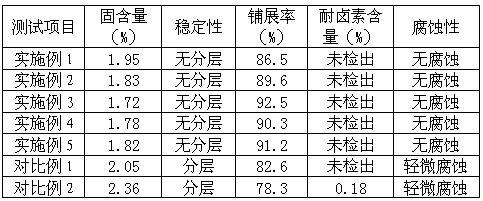

Rosin-based flux for ZnSn-based lead free solder and preparation method thereof

InactiveCN102581522ALow solidsHigh insulation resistanceWelding/cutting media/materialsSoldering mediaRosinSoldering

Rosin-based flux for a ZnSn-based lead free solder comprises rosin, an organic acidity activator, a corrosion inhibitor, a surfactant and an organic solvent. According to the invention, the solder can be additionally provided in injection, spraying or atomization method, the addition amount is easy to accurately control, the disadvantage that the prior soldering flux is hard to brush is overcome, no paste agent, stabilizing agent or thixotropic agent or other substances containing high solid content are included, the solid content of the solder is low, the wetting power to ZnSn-based solder is strong, the residue after welding is little, a metal oxide-film can be effectively removed, the expansion rate is not less than 75%, the effects of film forming and base material protection are possessed, and the preparation method is simple and practicable.

Owner:HENAN UNIV OF SCI & TECH

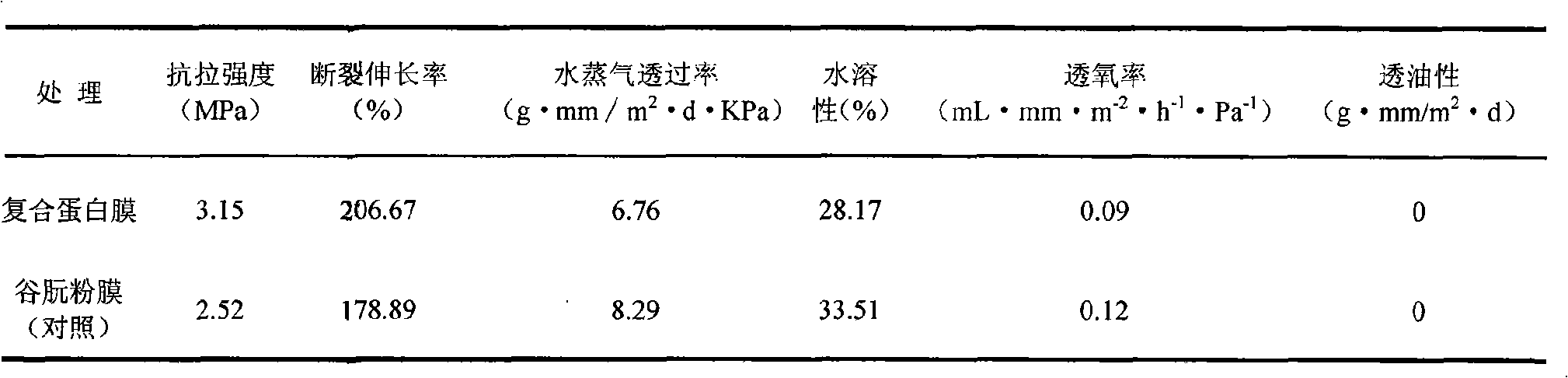

Method for preparing edible composite protein film

InactiveCN101580595AIncrease elasticityImprove toughnessFlexible coversWrappersComposite filmFood packaging

The invention relates to a method for preparing an edible composite protein film. The method adopts wheat gluten and zein as base materials, and adds a plasticizing agent and a reinforcing agent. The method overcomes the defect that the wheat gluten monomer is difficult to be applied in the actual production due to poor film-forming water resistance and mechanical strength. The method has the advantages of wide raw material sources and simple production process, has no environmental pollution, remarkably improves the mechanical strength and the water resistance of the modified wheat gluten-zein composite film, and has wide development prospect in the field of food packaging.

Owner:SHENYANG AGRI UNIV

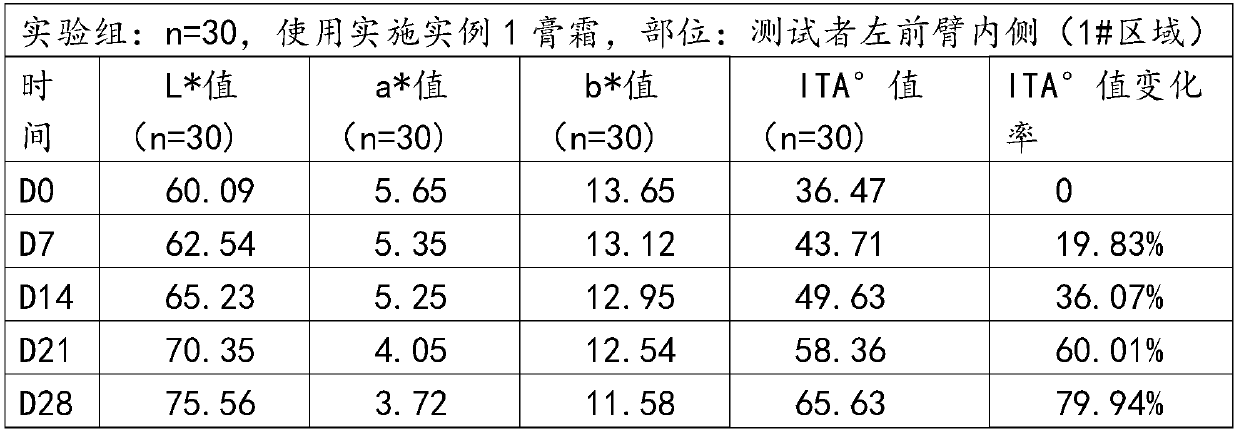

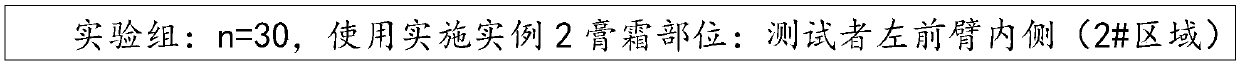

Whitening composition, whitening skin-brightening cream comprising same and preparation method thereof

InactiveCN109528603AAvoid cytotoxicityReduce stimulationCosmetic preparationsToilet preparationsRHODIOLA ROSEA ROOTWhitening Agents

The invention provides a whitening composition, whitening skin-brightening cream comprising the same and a preparation method thereof. The whitening skin-brightening cream is prepared from the following components in percent by mass: 0.1-20% of the whitening composition, 1-25% of a wetting agent, 1-5% of an emulsifier, 1-20% of skin-moistening grease, 0.1-5% of a skin conditioner, 0.05-3% of a permeation aid, 0.01-1% of a chelating agent, 0.1-1% of a thickener, 0-1% of essence, 0.05-2% of a preservative and the balance deionized water. The whitening composition is prepared from eight traditional Chinese medicinal material extraction solutions: ginseng, cortex mori radicis, angelica sinensis, glycyrrhiza, tea leaves, ganoderma atrum, rhodiola rosea and folium ginkgo as well as conventionalwhitening agents nicotinamide and tranexamic acid, and has the functions of whitening synergically and reducing irritation. The whitening skin-brightening cream moistens the skin and is not greasy, iseasy to absorb, and is obvious in whitening and skin-brightening effect.

Owner:上海彤颜实业有限公司

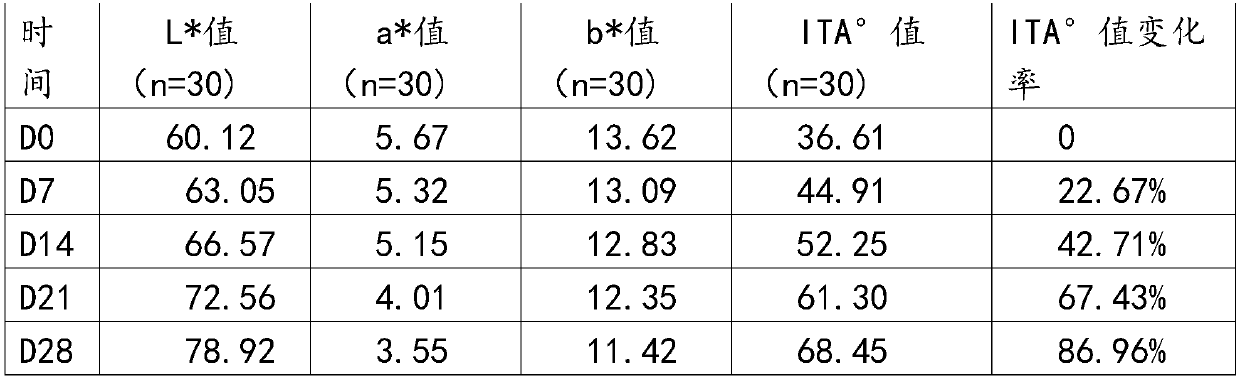

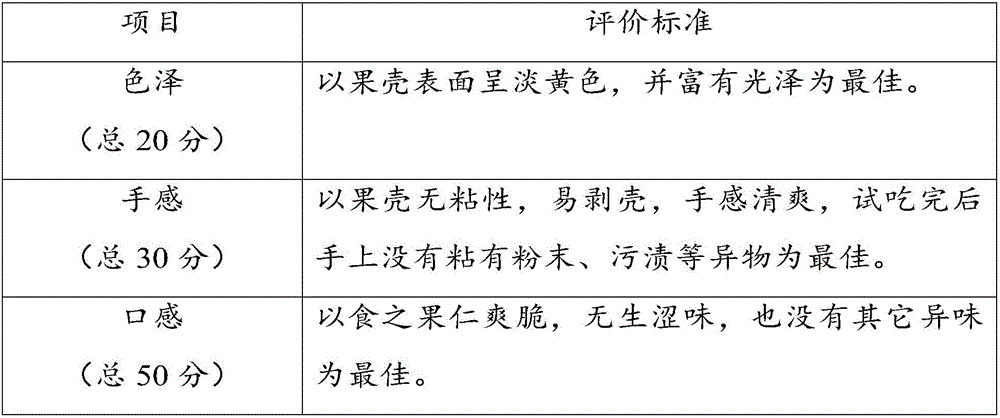

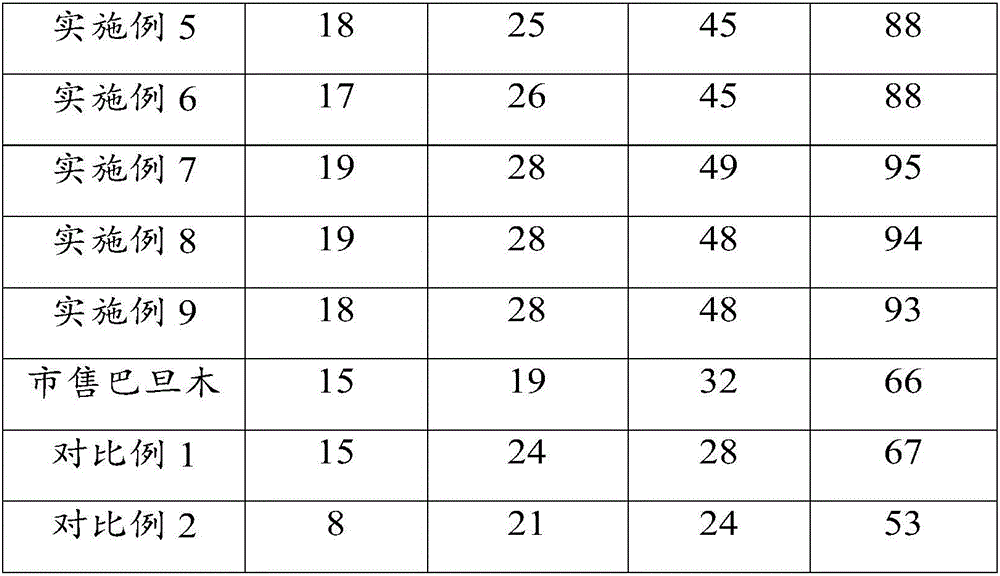

Macadamia and processing method thereof

ActiveCN106579238AImprove quality uniformitySolve the problem of breaking the shellFood scienceEngineeringMacadamia nut

The invention provides macadamia and a processing method thereof, and belongs to the field of food processing. The method comprises the following steps of selecting macadamia; then performing processing to form an opening in the periphery of a macadamia shell in a mechanical cutting manner; then placing the processed macadamia at 75-135 DEG C for fixation treatment for 10-15min; then enabling the macadamia after the fixation treatment to be mixed with feed liquid when the macadamia is hot, and after 2-5min, cleaning the macadamia which is mixed with the feed liquid; and after performing standing treatment for 2-10h, performing drying treatment on the macadamia after standing at 40-100 DEG C for 8-16h. By the processing method disclosed by the invention, the raw and astringent taste of the macadamia can be effectively removed, the mouth feel of the macadamia can be improved, and besides, the problem that macadamia shells are difficult to rind is effectively solved. The macadamia is comfortable and crisp in mouth feel, shell surfaces are reddish-brown and rich in gloss, and besides, the macadamia shells are free from stickness, easy to rind and refreshing in feel.

Owner:HANGZHOU HAOMUSI FOOD

Sn0.3Ag0.7Cu lead-free solder paste and preparation method thereof

InactiveCN104785948AGood adhesionNon stickyWelding/cutting media/materialsSoldering mediaActive agentFilm-forming agent

The invention discloses Sn0.3Ag0.7Cu lead-free solder paste. The Sn0.3Ag0.7Cu lead-free solder paste particularly comprises, by mass, 9-11% of scaling powder and 89-91% of soldering tin powder. The scaling powder comprises, by mass, 20-25% of rosin, 15-20% of film-forming agent, 15-20% of active agent, 5-10% of thixotropic agent, 1-3% of acidity regulator and the balance solvent. The invention further discloses a preparation method of the Sn0.3Ag0.7Cu lead-free solder paste. The method comprises the steps that the solvent and the film-forming agent are stirred at 75 DEG C to be transparent, and the mixture is cooled to be at the temperature of 65 DEG C, added with the film-forming agent, cooled to be at the temperature of 55 DEG C and added with the active agent to be stirred to be transparent; the mixture is cooled to be at 55 DEG C and added with the thixotropic agent to be stirred to be transparent; the mixture is cooled to be at normal temperature and added with the acidity regulator to be stirred for 15 min, and then the mixture and solder powder are mixed and stirred to obtain the Sn0.3Ag0.7Cu lead-free solder paste. The solder paste is good in printing technology and welding performance, residues left after welding evenly cover the surface welding spots, and the effects of electrical insulation, welding spot protection and the like are achieved.

Owner:XIAN UNIV OF TECH

Antibacterial liquid dressing for wounds and preparation method thereof

Belonging to the technical field of antibacterial drugs, the invention in particular relates to an antibacterial liquid dressing product for wounds. By mass percentage, the product comprises: 3-6.5% of a film-forming agent, 0.1-0.3% of an antibacterial substance and the balance a volatile agent. The preferable composition also includes: 0.55-3.2% of an analgesic agent, 0.5-1.5% of a plasticizer and 0.5-2% of a moisturizing agent. The film-forming agent is nitrocellulose. The antibacterial substance is a chitosan oligosaccharide-octenidine hydrochloride embedded substance. The specific preparation process includes: preparation of the antibacterial chitosan oligosaccharide-octenidine hydrochloride embedded substance, preparation of the antibacterial chitosan-octenidine hydrochloride embeddedsubstance and other steps. In general, the antibacterial liquid dressing product for wounds provided by the invention has good long-acting antibacterial effect, can adapt wounds at different parts and of different areas. At the same time, as the relevant preparation method is mature, the antibacterial liquid dressing product for wounds has good practical value and popularization and application significance.

Owner:HENAN HUIBO MEDICAL CO LTD

Washable super-hydrophobic cotton fabric as well as preparation method and applications thereof

ActiveCN103952912ANon-stickyExcellent superhydrophobic propertiesLiquid separationVegetal fibresGlycidyl ethersOil water

The invention discloses a washable super-hydrophobic cotton fabric as well as a preparation method and applications thereof, which belong to the technical field of functional materials. The washable super-hydrophobic cotton fabric is obtained through the steps of washing a cotton fabric, and then sequentially soaking the cotton fabric in an acetone solution of epoxy resin, an aqueous solution of polyethyleneimine, an epoxidized silicon dioxide aqueous solution, and an n-hexane solution of stearic acid for treatment. The preparation method comprises the following detailed steps: 1. washing the cotton fabric; 2. soaking the cotton fabric in an epoxy resin solution; 3. soaking the cotton fabric in a polyethyleneimine solution; 4. soaking the cotton fabric in a modified sub-micro silicon dioxide aqueous solution in which 3-glycidyl ether oxyl propyl trimethoxysilane is dispersed; 5. repeating the steps 3 and 4; 6. soaking the cotton fabric in a stearic acid hydrophobically-modified solution and drying the cotton fabric. The washable super-hydrophobic cotton fabric is used for oil-water separation. The preparation method is simple in technology, low in cost, short in period and low in energy consumption and does not need special complicated equipment; the prepared super-hydrophobic cotton fabric is washable and capable of rapidly separating an oil-water mixture and can be applied to the fields of industrial oil-water separation and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

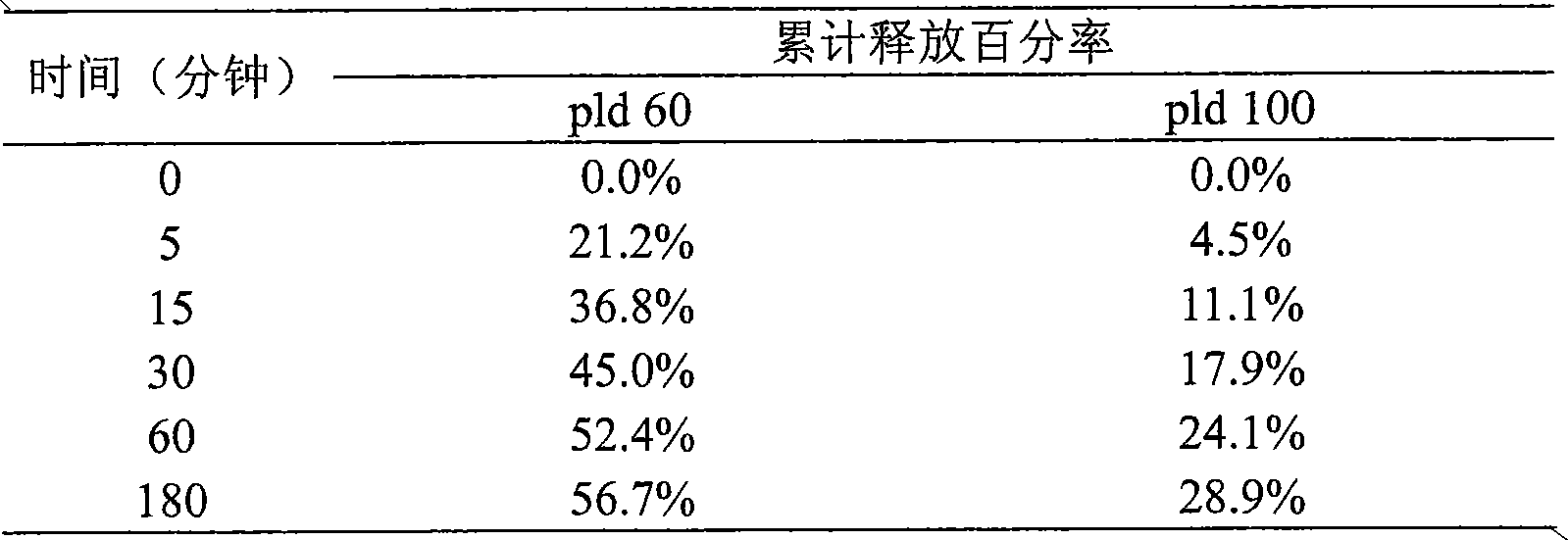

Doxorubicin hydrochloride liposome injection and preparation technology thereof

ActiveCN101897667AImprove solubilityEasy follow-upOrganic active ingredientsSolution deliveryLipid formationCholesterol

The invention discloses a doxorubicin hydrochloride liposome injection and a preparation technology thereof. The injection comprises the following components by weight percent: 0.05-0.5% of doxorubicin hydrochloride, 0.025-3% of hydrogenated soybean phosphatidylcholine, 0.001-1.5% of cholesterol, 0.01-1% of PEG-lipid, 0.0025-2.5% of organic acid or ammonium sulfate, 2.8-20% of sugar, 0.1-10% of buffering agent and the balance water for injection. The preparation technology comprises the following steps: 1) freeze-drying lipid phase; 2) hydrating lipid phase; 3) straightening the granules of lipid phase; 4) forming transmembrane gradient inside and outside phospholipid membrane; 5) loading medicine with liposome; and 6) degerming, subpackaging and storing.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD +1

Organic-inorganic composite electrolyte, preparation method thereof, and application in solid lithium ion secondary battery

ActiveCN109301316ANon stickyIncrease stickinessSolid electrolytesSecondary cellsComposite electrolyteOrganic solvent

An organic-inorganic composite electrolyte is disclosed and is composed of a medium-temperature viscoelastic-transformable polymer, lithium salt, and a fast ion conductor ceramic powder, wherein the medium-temperature viscoelastic-transformable polymer includes a hard monomer, a soft monomer containing ethoxyl group, an initiator, and an organic solvent. The organic and inorganic phases of the composite electrolyte film both have ion-conductivity, thus increasing room-temperature conductivity. The organic-inorganic composite electrolyte film has no viscosity at room temperature, so that the film is easy to reel and be composited with an electrode plate in a multilayer manner. The organic-inorganic composite electrolyte is suitable for industrial production.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

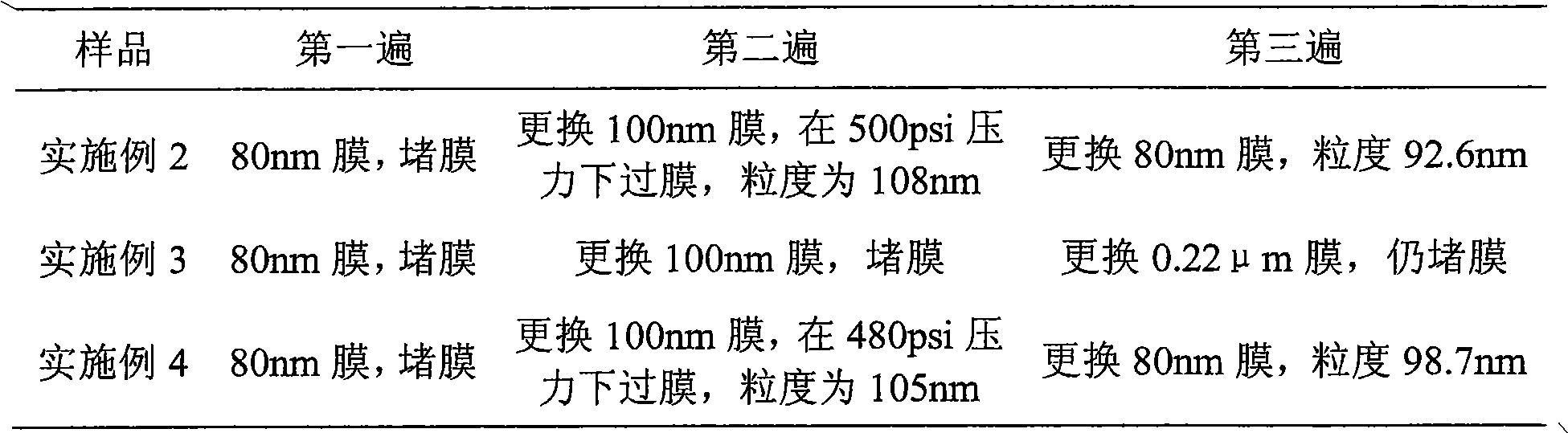

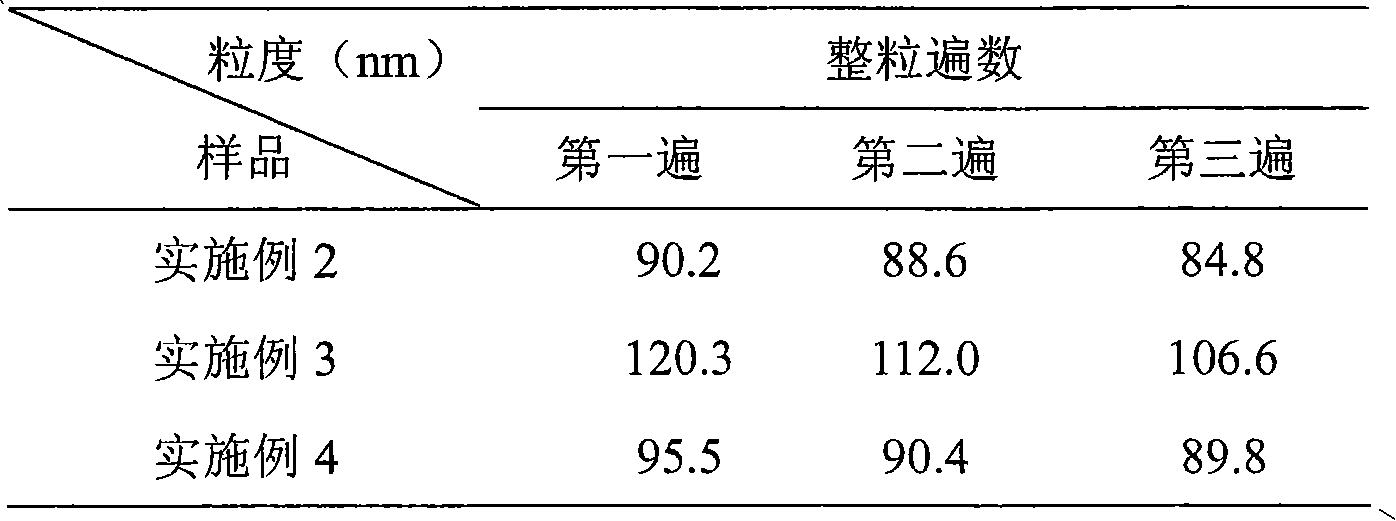

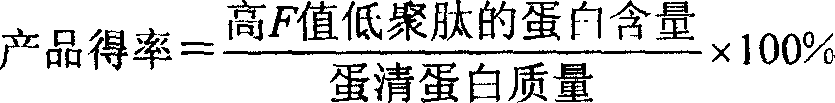

Method for preparation of egg white oligopeptide having high F value

ActiveCN101012472AHas the effect of protecting the liverReduce odorFermentationPre treatmentOligopeptide

The invention discloses a making method of high-F value egg oligopeptide, which comprises the following steps: a. predisposing raw material; b. hydrolyzing protein for two steps; c. adsorbing through active carbon; d. desalting; obtaining the product with molecular weight at 300-1000 and F value more than 20.

Owner:JILIN JINYI FOOD CO LTD

Soybean noodle

InactiveUS20050170065A1Rich in dietary fibreDelicious tasteFood preparationOlder peopleHigh pressure

The present invention is related to a new soybean noodle. This noodle comprises 4 to 10 parts by weight of soybean powder and 2 to 4 parts by weight of wet bean-curd residue with water content of 60%˜80%. Moreover, the noodle may also comprise 0.5 to 2 parts by weight of soybean protein powder. The processing steps are as follows: peeling, defatting and crushing the soybean into powder of 70-120 mesh size; then mixing uniformly the treated powder with wet bean-curd residue and soybean protein powder; and finally extruding and aging the mixture to form finished noodle product using the extruder under the condition of high-temperature and high-pressure. This noodle features rich and balanced in nutrient. Besides rich plant protein, the said noodle comprises dietary fiber with the content up to 3%˜12%. The said noodle tastes delicious without soybean odor. When it is cooked, it is non-sticky and not easy to break. The noodle is suitable for all kinds of consumer groups. Especially, it is a perfect health-care food for adiposis, diabetes, cardiovascular disease and constipation patients and old people.

Owner:XI CUNKU +2

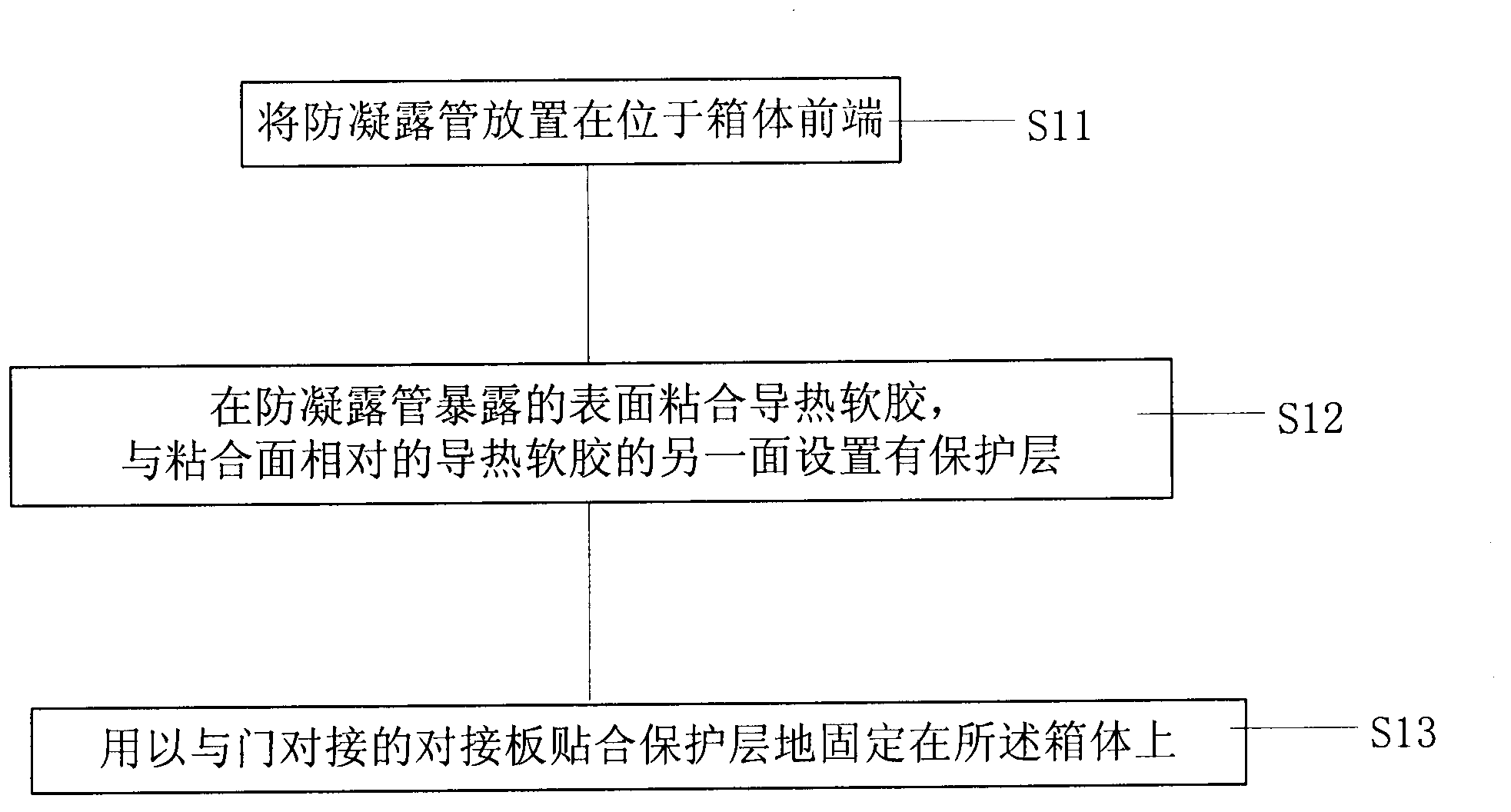

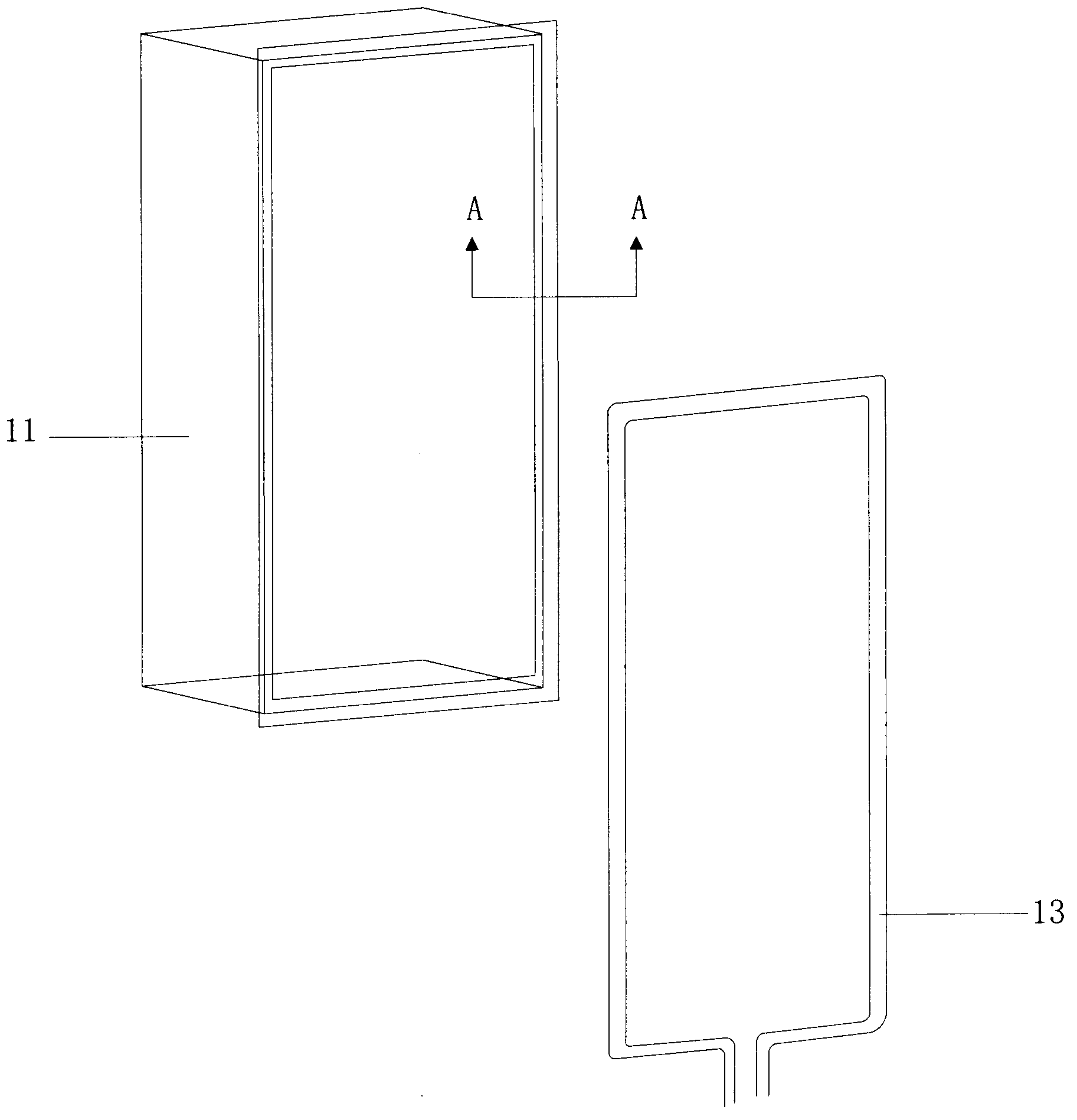

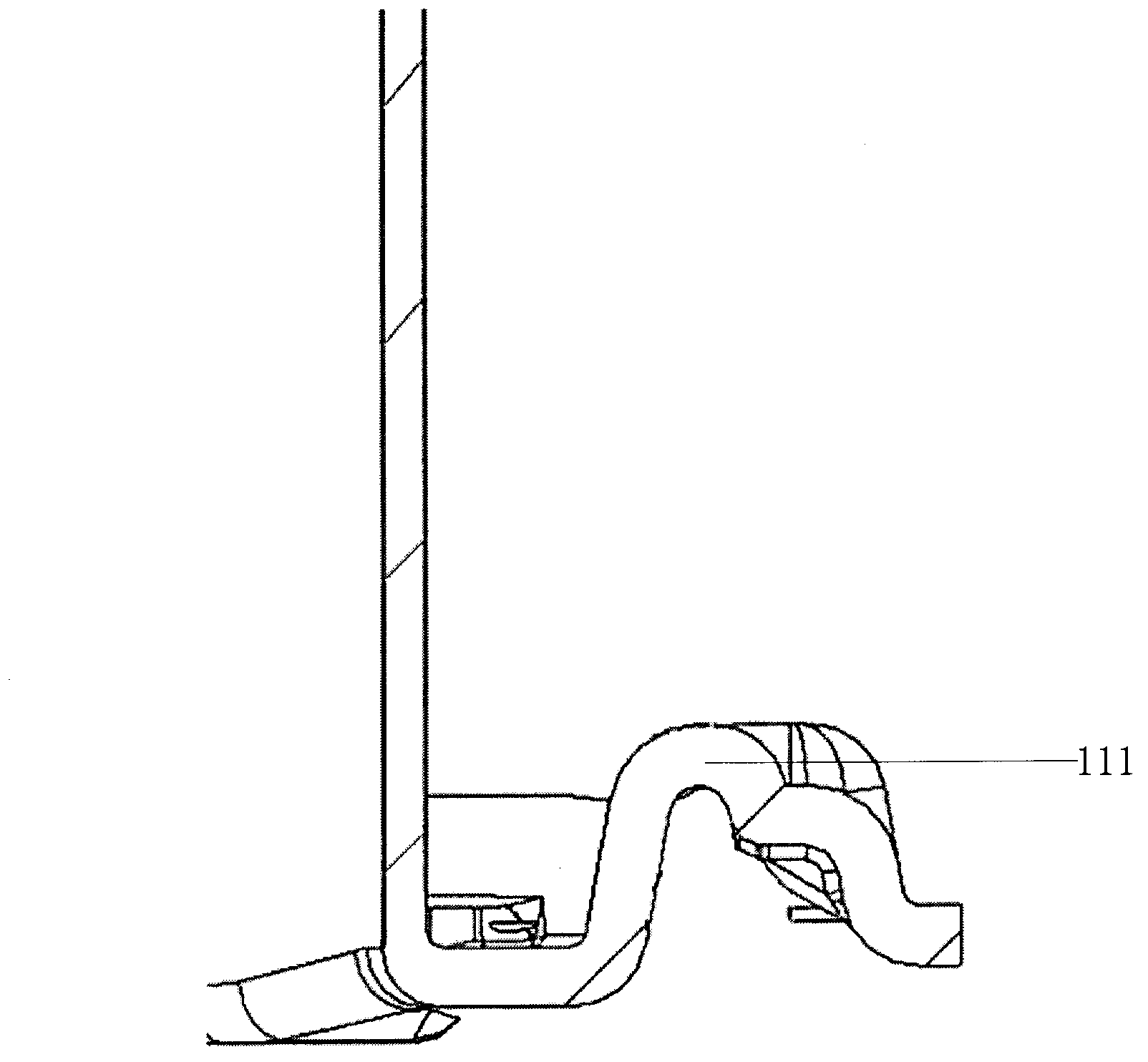

Refrigerating device and manufacturing method thereof

InactiveCN103575028AIncrease profitReduce viscosityLighting and heating apparatusDefrostingHeat conductingEngineering

The invention discloses a refrigerating device, which comprises a box body, at least one door, an anti-condensation pipe and a heat conducting device, wherein the at least one door is connected to the box body, the box body is provided with a butt plate which is used for being butted with the at least one door when the at least one door is closed, the anti-condensation pipe is positioned at the inner side of the butt plate, and the heat conducting device is used for conducting heat of the anti-condensation pipe to the butt plate; the heat conducting device comprises heat conducting soft rubber and a protecting layer positioned between the heat conducting soft rubber and the butt plate. In addition, the invention also provides a manufacturing method of the refrigerating device. After the technical scheme disclosed by the invention is adopted, the anti-condensation effect of the refrigerating device is improved.

Owner:博西华家用电器有限公司

Badam and processing method thereof

The invention provides a badam processing method, and belongs to the field of food processing. The processing method comprises the following steps: picking badam, grinding the badam shells, carrying out enzyme deactivation on grinded badam for 8 to 15 minutes at a temperature of 150 to 190 DEG C, mixing hot badam with a material water solution for 2 to 5 minutes, taking out badam, and cleaning the surface of the badam shells. The processing method can effectively remove the astringent taste of badam, and improve the taste. The shell of processed badam has a light yellow color, is lustrous and non-sticky, and can be easily removed. The hand feeling is fresh. The kernels of processed badam are crispy and fresh and do not have any astringent taste. The processed badam is welcomed by consumers.

Owner:HANGZHOU HAOMUSI FOOD

Method of preparing methyl phenyl polysiloxane

ActiveCN101508776BWith high and low temperature resistanceWeather resistantReaction temperatureMethyl phenyl polysiloxane

The invention discloses a method for synthesizing organic silicon, in particular provides a method for preparing methyl phenyl silicone resin which has low curing temperature by self and is not sticky repeatedly. The invention uses the monomers of methyl trichlorosilane, dimethyldichlorosilance, phenyl trichlorosilane, dichloromethylphenylsilane, diphenyl dichlorosilane and the like to obtain a methyl phenyl silicone resin with low curing temperature and a paint film which is not sticky repeatedly after being cured by the processes of adjusting the proportion of raw materials, controlling proper reaction temperature and polymerization time, carrying out hydrolysis reaction and polycondensation reaction, etc. The invention has the advantages that the methyl phenyl silicone resin prepared by the method has the characteristics of low curing temperature, being not sticky repeatedly, being clear and transparent, high and low temperature resistance, weather resistance, being insulating and the like; the methyl phenyl silicone resin is in particular fit for dip varnish higher than grade H; and the methyl phenyl silicone resin is used for confecting insulated paint, weather-resistant paint and heat resistant paint higher than grade H, is used for heat resistant parting agent and also can be used in the fields with rigorous using requirements, such as heat resistant water blocking and sand prevention for oil drilling, etc.

Owner:安徽比特海新材料股份有限公司

Method for manufacturing calcined type fireproof mica tape

InactiveCN104319029ADoes not fall offDoes not drop powderCable/conductor manufactureProcess engineeringToluene

The invention provides a method for manufacturing calcined type fireproof mica tape. The method includes the steps of preparing tackiness agents, preparing tackiness agent solutions, coating glass fabric with the tackiness agent solutions, gluing mica paper and the glass fabric, and carrying out baking in a dryer. The method is characterized in that baking is carried out within three periods at different temperatures. The mica tape produced with the method is free of falling, powder falling, foam generating and reverse gluing and good in breathability, the mica paper is not separated from the glass fabric after the mica tape is soaked by methylbenzene for seventy-two hours, and the temperature resistant level and the voltage withstand level of the mica tape are higher; in addition, the rate of finished products is quite high, flexibility is excellent, and various properties are more stable.

Owner:TONGCHENG ZHONGTIAN MICA PROD

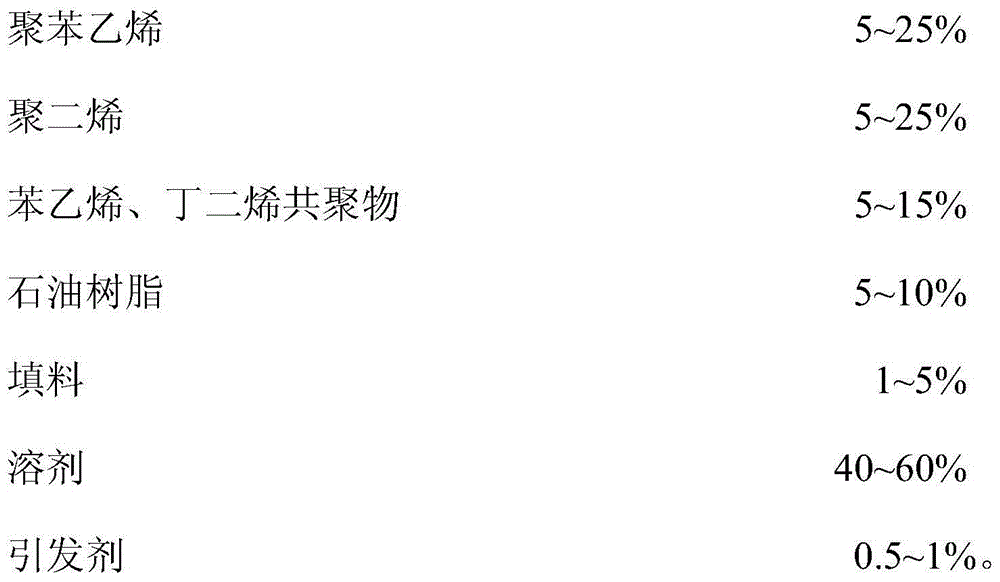

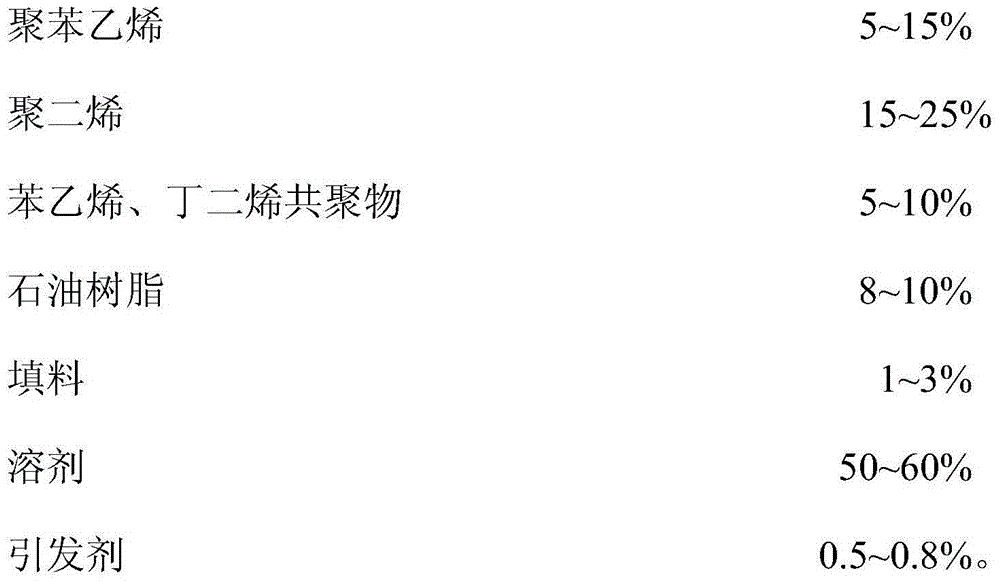

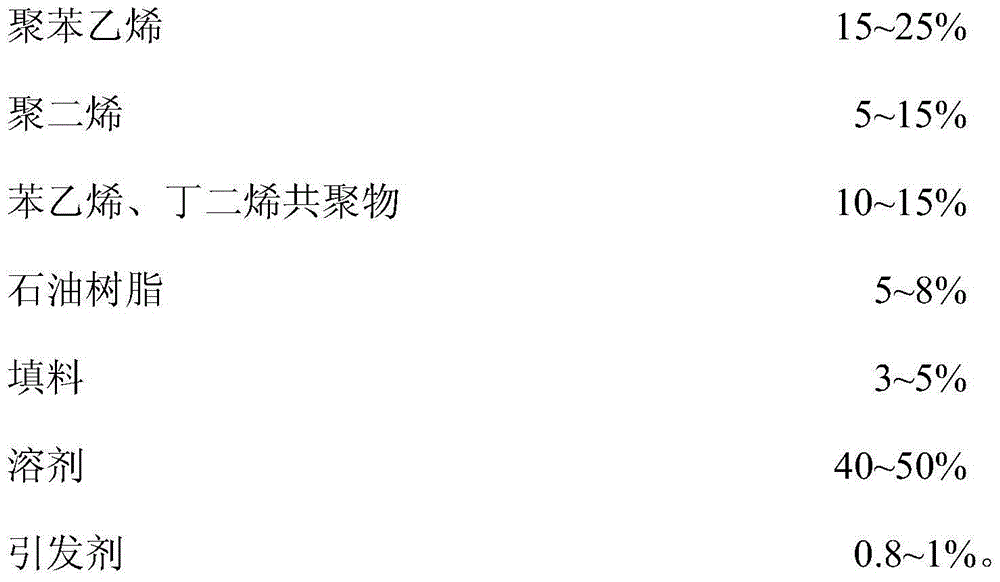

Normal-temperature non-viscous sealing adhesive for lithium battery and preparation method for sealing adhesive

ActiveCN104559846ANon stickyImprove adhesionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAdhesivePolystyrene

The invention relates to a normal-temperature non-viscous sealing adhesive for a lithium battery. The normal-temperature non-viscous sealing adhesive comprises the following raw materials in percentage by mass: 5-25 percent of polystyrene, 5-25 percent of polydiene, 5-15 percent of a styrene and butadiene polymer, 5-10 percent of petroleum resin, 1-5 percent of filler, 40-50 percent of a solvent and 0.5-1 percent of an initiator. Under the normal temperature, the adhesive is non-viscous to polypropylene, generates viscosity to polypropylene under high temperature and high pressure and can resist immersion and corrosion of electrolyte. The preparation method for the adhesive comprises the following processing steps: weighing materials; adding all of the styrene and butadiene polymer, the petroleum resin, 30-50 percent of the solvent and 30-50 percent of the initiator into a first reaction kettle, heating the first reaction kettle to be 95-105 DEG C, and performing constant-temperature reaction for 20-40 minutes; adding all of the polydiene, the residual initiator and the residual solvent into a second reaction kettle to be mixed into a mixed liquid, and dropping the mixed liquid into the first reaction kettle; performing constant-temperature reaction for 1.5-2.5 hours, and adding all the polystyrene and the filler into the first reaction kettle for uniform stirring to obtain a finished product. The method is simple in technology and high in production efficiency.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

Method for treating sludge by utilizing microbial flocculant and microbial wall breaking

PendingCN110885176ALow investment costPromote fermentationSludge treatment by de-watering/drying/thickeningClimate change adaptationMicroorganismHeavy metal chelation

The invention provides a method for treating sludge by utilizing a microbial flocculant and microbial wall breaking. According to the method, residual sludge is subjected to biological modification with a microbial flocculant, the modified sludge is subjected to biological wall breaking with a microbial wall breaking flora and a heavy metal chelating flora, the content of heavy metals is reduced,and sludge is subjected to aerobic fermentation with a sludge fermentation flora and a biomass fermentation flora, such that the sludge is converted into organic humus. No chemical agent is added in the whole process, no energy is input into the sludge in the dehydration process, only a small amount of mechanical power is used during stacking and turning, the sludge is modified, heated and dried by purely utilizing the activity advantage of microorganisms, and finally reduction, harmlessness, stabilization and recycling of the sludge are achieved. According to the invention, a new method for treating and disposing residual sludge and industrial sludge with high organic matter content in municipal sewage plants is opened up, and the method provided by the invention has the advantages of lowequipment investment, simple operation, safety, no pollution, low energy consumption, and good economic and environmental benefits.

Owner:河南莫大生物科技有限公司

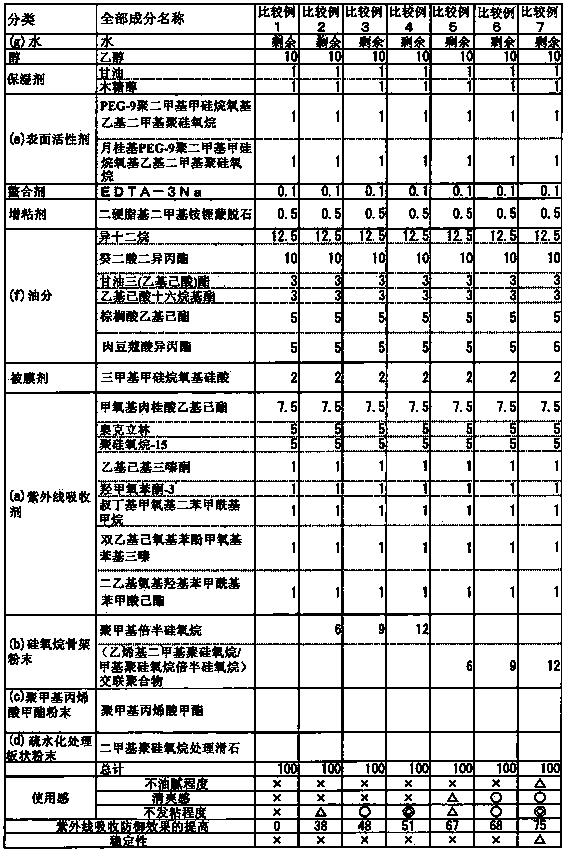

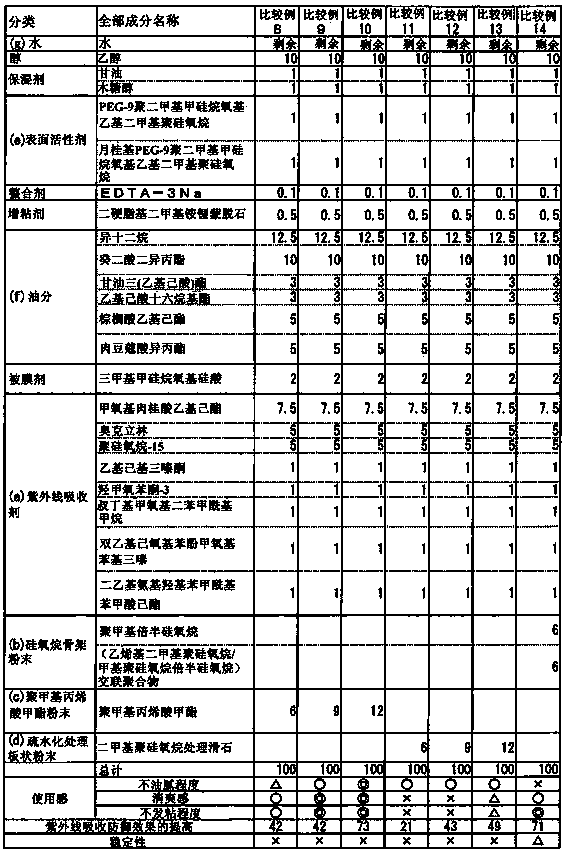

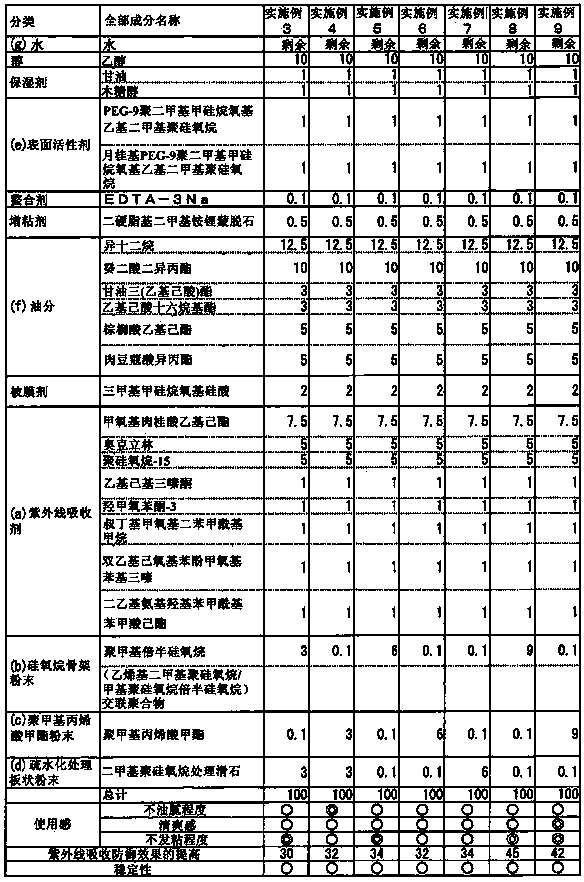

Water-in-oil emulsion sunscreen cosmetic

InactiveCN103501759ARefreshingNon-stickyCosmetic preparationsToilet preparationsWater in oil emulsionUltraviolet protection

The present invention provides a water-in-oil emulsified sunscreen cosmetic characteristically comprising the following (a) through (g) : (a) Ultraviolet absorbent (b) Silicone backbone powder (c) Methyl polymethacrylate powder (d) Hydrophobicized platelike powder (e) Surfactant (f) Oil component (g) Water The object of the present invention is to provide a water-in-oil emulsified sunscreen cosmetic that manifests a superior texture during use, a high ultraviolet protection effect, and superior stability.

Owner:SHISEIDO CO LTD

Mixed knitting fabric of far infrared magnetic fiber and kendyr mixed spinning fiber

A fabric for increasing the blood flow in human body, and improving human microcirculation, metabolism and immunity is prepared from far-infrared magnetic fibers (30-70 Wt%) and the mixture of kendir fibers and cotton (or hemp) fibers (30-70 Wt%).

Owner:马建华

High-temperature-resistant anti-radiation mortar and preparation method thereof

The invention discloses high-temperature-resistant anti-radiation mortar and a preparation method thereof, and belongs to the technical field of anti-radiation mortar. The high-temperature-resistant anti-radiation mortar consists of the following components in parts by weight: 5 to 15 parts of cement, 6 to 10 parts of mineral powder, 3 to 5 parts of dispersed emulsion powder, 30 to 50 parts of vitrified micro-beads, 2 to 4 parts of glass fibres, 2 to 4 parts of aluminium oxide, 3 to 5 parts of perlite powder, 5 to 7 parts of nano-lead particles, and 2 to 4 parts of rubber powder. The invention aims to provide the high-temperature-resistant anti-radiation mortar and the preparation method thereof. The inherent characteristics of the aluminium oxide and the nano-lead particles are utilized and are combined with the interactions of other components, so that the high-temperature-resistant anti-radiation mortar has good rigid-flexible characteristics, does not layer, segregate and sag, has high structural stability under a high temperature, and meanwhile, has the characteristics of corrosion resistance, wear resistance and the like, and has high anti-radiation performance; the safety level of the anti-radiation mortar is improved.

Owner:YIYANG JINYU BUILDING MATERIAL TECH CO LTD

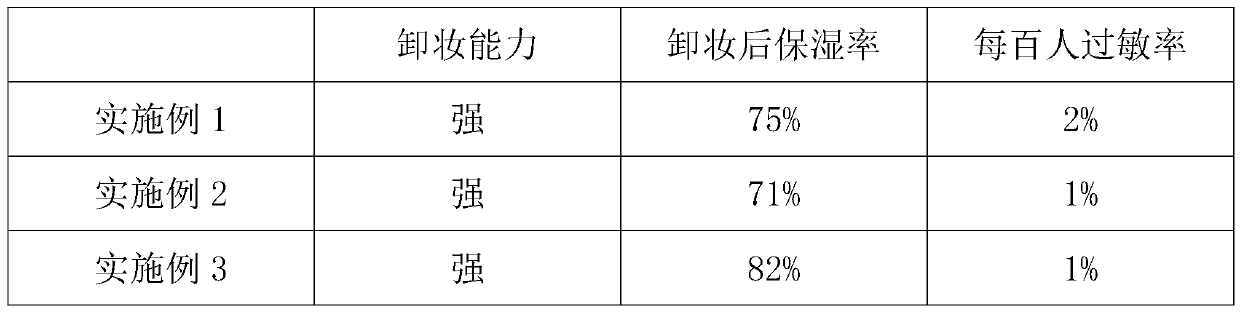

Makeup removal dry wipes

PendingCN110215426ANon-irritatingWill not cause sensitivityCosmetic preparationsToilet preparationsBetaineAdditive ingredient

The invention relates to the technical field of cosmetics, and particularly discloses makeup removal dry wipes. The makeup removal dry wipes are prepared from, by weight, 30-50 parts of purified water, 20-30 parts of potassium cocoyl glycinate, 20-30 parts of cocoalkanoylamido propyl betaine, 20-30 parts of glycerinum, 5-10 parts of propylene glycol, 15-20 parts of lotus embryo extracts and 5-10 parts of butanediol. According to the makeup removal dry wipes, the cocoalkanoylamido propyl betaine and the potassium cocoyl glycinate are adopted to neutralize raw material ingredients, and the compatibility of the cocoalkanoylamido propyl betaine and the potassium cocoyl glycinate with various surface active agents is high so that various effective ingredients in the raw materials can be effectively released; in use, it is not required that a lot of water is used for washing, the makeup removal dry wipes are convenient to carry and high in makeup removal capacity, and cosmetic residues on the face can be cleared away without repeated rubbing with wet wipes. In the process of long-time use, sensitive skin cannot be caused, and the dry wipes contain black carbon powder fiber membrane clothand has an extremely powerful function of cleaning and adsorption. While excessive facial grease is taken away, facial dirt and the cosmetic residues can be more deeply adsorbed, and the clean and smooth skin is recovered.

Owner:上海仙集新材料有限公司

Nicotine dissolving film with or without menthol

InactiveCN102625698AThe right amountEasy to controlOrganic active ingredientsNervous disorderMentholMoisture

Owner:INFINITE FINANCIAL SOLUTIONS

Low-solid no-clean soldering flux and preparation method thereof

InactiveCN108788520AReduce corrosionLow solid contentWelding/cutting media/materialsSoldering mediaSalicylic acidFilm-forming agent

The invention discloses a low-solid no-clean soldering flux and a preparation method thereof. The low-solid no-clean soldering flux is prepared from the following raw materials in parts by weight: 25to 35 parts of resin, 5 to 10 parts of resin emulsifying agents, 3 to 8 parts of o-hydroxybenzoic acid, 2 to 4 parts of fluoboric acid, 3 to 6 parts of salicylic acid, 3 to 6 parts of tripolyvinylimide, 2 to 5 parts of N,N-dimethylethanolamine, 0.3 to 0.6 part of film forming agents, 0.8 to 1.4 parts of surfactant, 1.2 to 1.6 parts of corrosion inhibitors and 20 to 35 parts of cosolvent. The low-solid no-clean soldering flux has the advantages of less residual after soldering, less corrosion and high stability, and the environmental requirements are satisfied.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

Culture medium

InactiveUS20050044782A1Easy to optimizeGrowth inhibitionGrowth substratesCulture mediaParticulatesPumice dust

The invention aims at providing a pumice-based culture medium which shows outstanding characteristics as a culture medium to be used in protected horticulture. To this end, the invention provides a culture medium comprising particulate pumice having a saturated water permeability of 0.3-0.8 cm / sec and an air permeability of 15-40 cm / sec in both a dry sample and a wet sample. In another embodiment, the invention provides a culture medium having charcoal added to a culture medium comprising the particulate pumice having the above-described physical properties.

Owner:EBARA CORP

Technique for jet printing long term anti-corrosive paint on cable bridge rack

InactiveCN101097036AExtended service lifeSave human effortCorrosion preventionPipe protection against corrosion/incrustationFluorocarbonLife length

The invention discloses a method to spray long period anticorrosion paint for cable crane span structure, which is characterized by the following: basing on original cable crane span structure spraying paint craft; spraying fluorocarbon resin substratum, mesosphere and surface course. This invention possesses the advantages of high brightness, high strength and long durability.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com