Patents

Literature

537results about How to "High insulation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

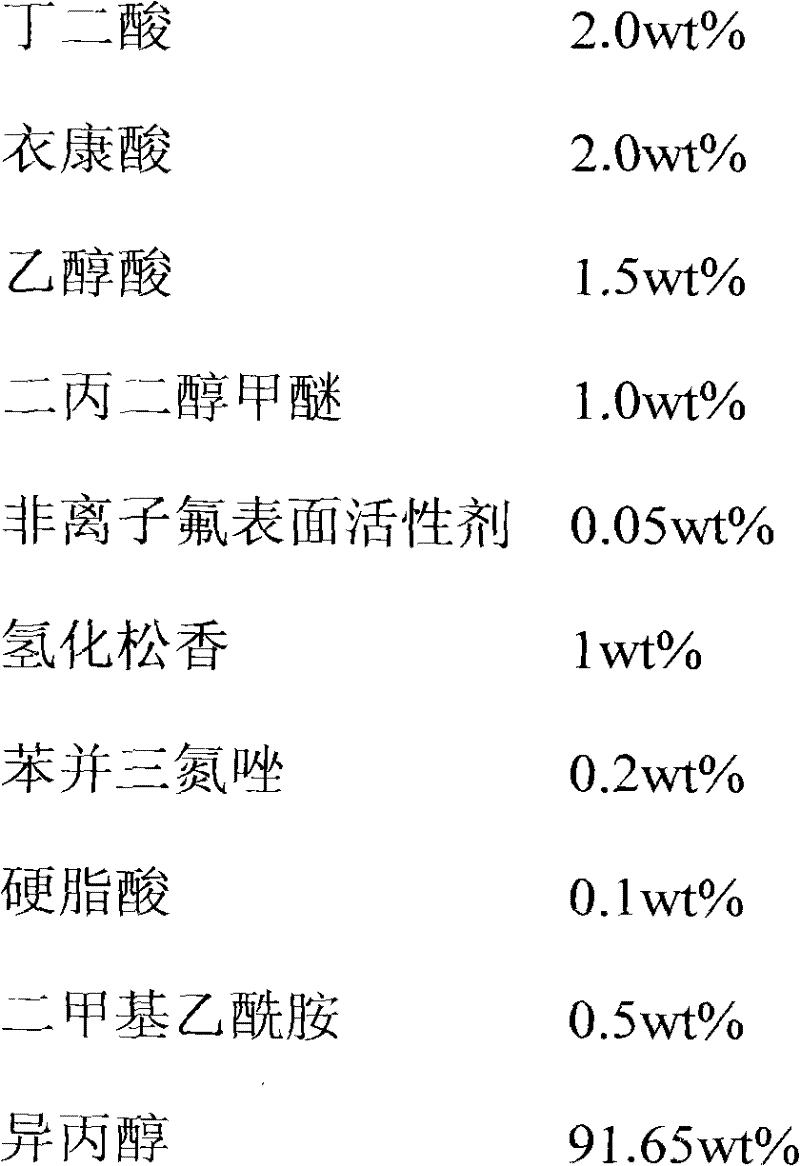

Non-halide cleaning-free welding flux for leadless solder

InactiveCN101062536AImprove solderabilityHigh insulation resistanceWelding/cutting media/materialsSoldering mediaSurface-active agentsAmino acid

The invention relates to a lead free soldering clean free soldering flux with the mass percentage of organic acid activating agent 1. 5-3. 5%, surface active agent 0. 04-0. 6%, organic amine and derivant 2. 0-5. 0%, with the rest being film forming matter. The said organic acid could be one or more of the aliphatic acid mono acid or bi-acid, aromatic acid, or amino acid. The said surface active agent is one or more of the nonion surface active agent, and the said organic amine and the derivant being ethanediamine, tetramethylenediamine, diethyl ethanolamine and so on, with the said film forming material being diethyl ethanolamine or resin. The soldering flux does not have halogen, being environmental protective, good in welding, welding spot being full and luminous, without residue, no corrosion, high in isolation resistance.

Owner:CENT SOUTH UNIV

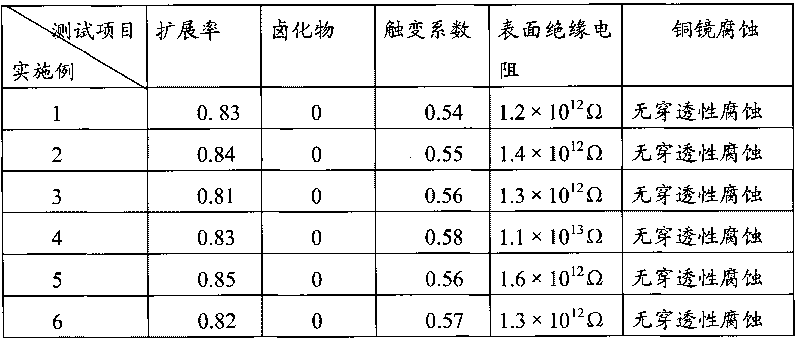

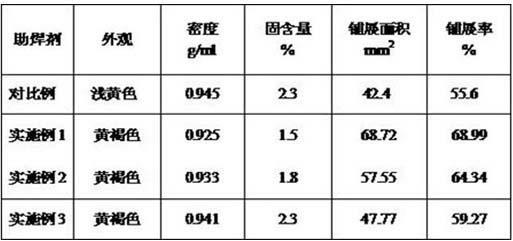

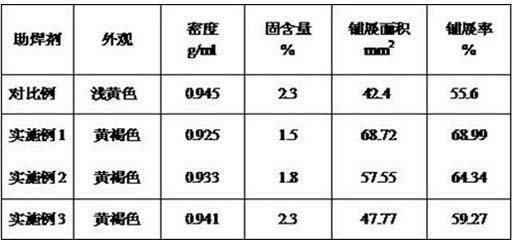

Halogen-free tin-bismuth-copper soldering paste and preparation method thereof

InactiveCN101695794AExtended shelf lifeExtended service lifeWelding/cutting media/materialsSoldering mediaAntioxidantExpansion rate

The invention relates to the technical field of soldering pastes, in particular to a halogen-free tin-bismuth-copper soldering paste and a preparation method thereof. A soldering flux of the halogen-free tin-bismuth-copper soldering paste consists of the following components in percentage by weight: 20 to 40 percent of polymerized rosin, 1 to 6 percent of rosin amine, 4 to 8 percent of thixotropic agent, 5 to 10 percent of organic acid, 5 to 10 percent of organic amine, 1 to 5 percent of antioxidant, 0.5 to 3 percent of surfactant and an organic solvent. The halogen-free tin-bismuth-copper soldering paste is mainly characterized by adopting the organic acid and the organic amine serving as activating agents and comprising no halogens at all, so not only the solderability is not reduced, but also the expansion rate and the insulation resistance value of the soldering paste are improved, and simultaneously the corrosivity of residues after soldering to a base material is reduced and the service life of the soldering paste is prolonged; and particularly, the peak temperature of the soldering paste during soldering is lower in favor of reducing the thermal damages to electronic components.

Owner:东莞市特尔佳电子有限公司

Water-soluble soldering flux dedicated for lead-free solder

InactiveCN1836825AImprove solderabilityImprove performanceWelding/cutting media/materialsSoldering mediaOrganic acidWater soluble

The water soluble soldering flux specially for lead-free soldering material consists of boric acid and organic acid activator 5.0-10.0 wt%, non-ionic surfactant or cationic surfactant 0.1-1.0 wt%, co-solvent 8.0-20.0 wt%, filming agent 0.1-1.0 wt%, corrosion retardant 0.1-0.5 wt%, except deionized water. The compounding process includes the following steps: mixing co-solvent and partial deionized water, adding filming agent under stirring, adding the rest deionized water, activator and surfactant after dissolving, adding corrosion retardant while stirring to dissolve, stilling, and filtering to obtain the filtrate as the soldering flux. The water soluble soldering flux has excellent soldering assisting performance on lead-free soldering material, environment friendship and other advantages.

Owner:BEIJING UNIV OF TECH

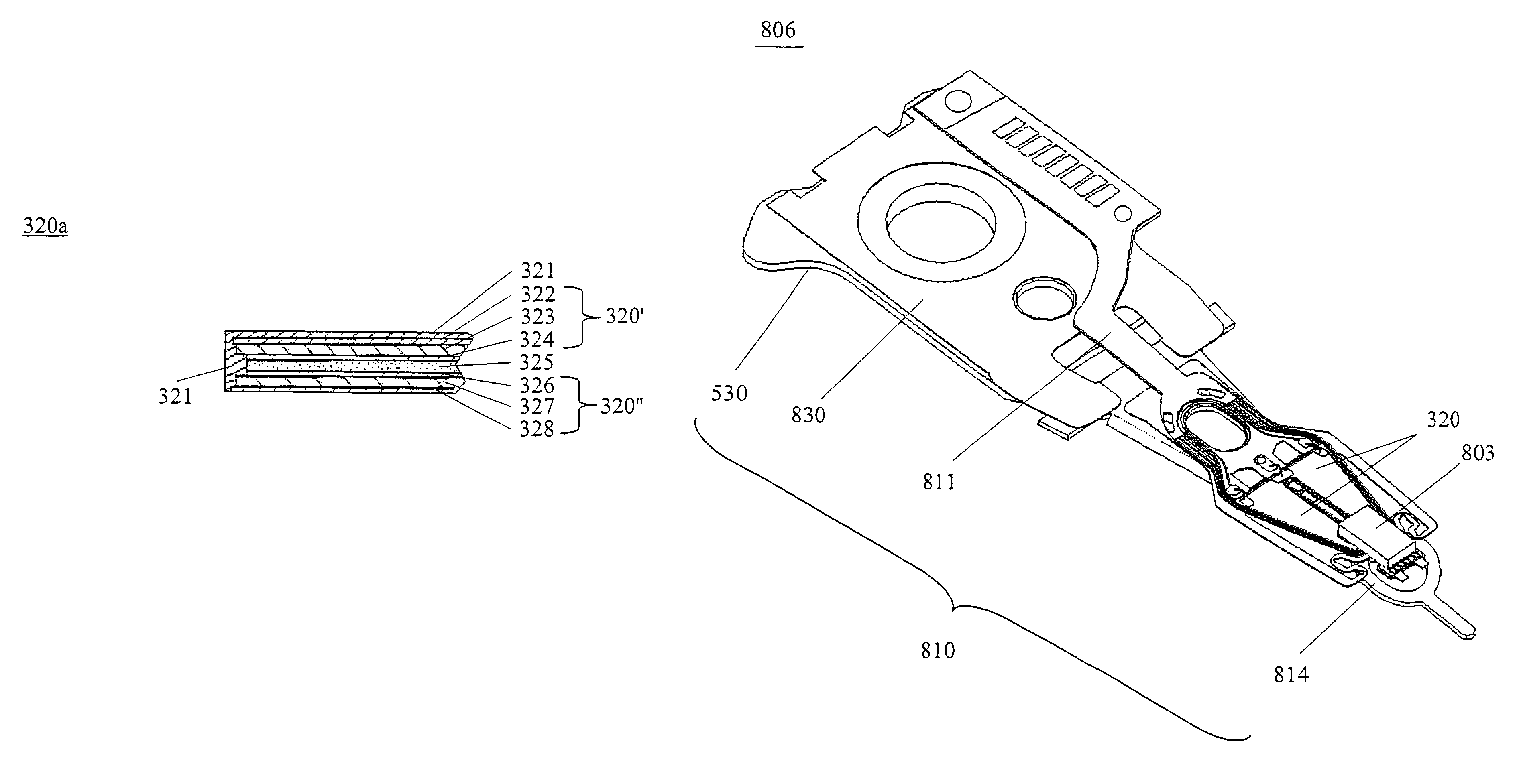

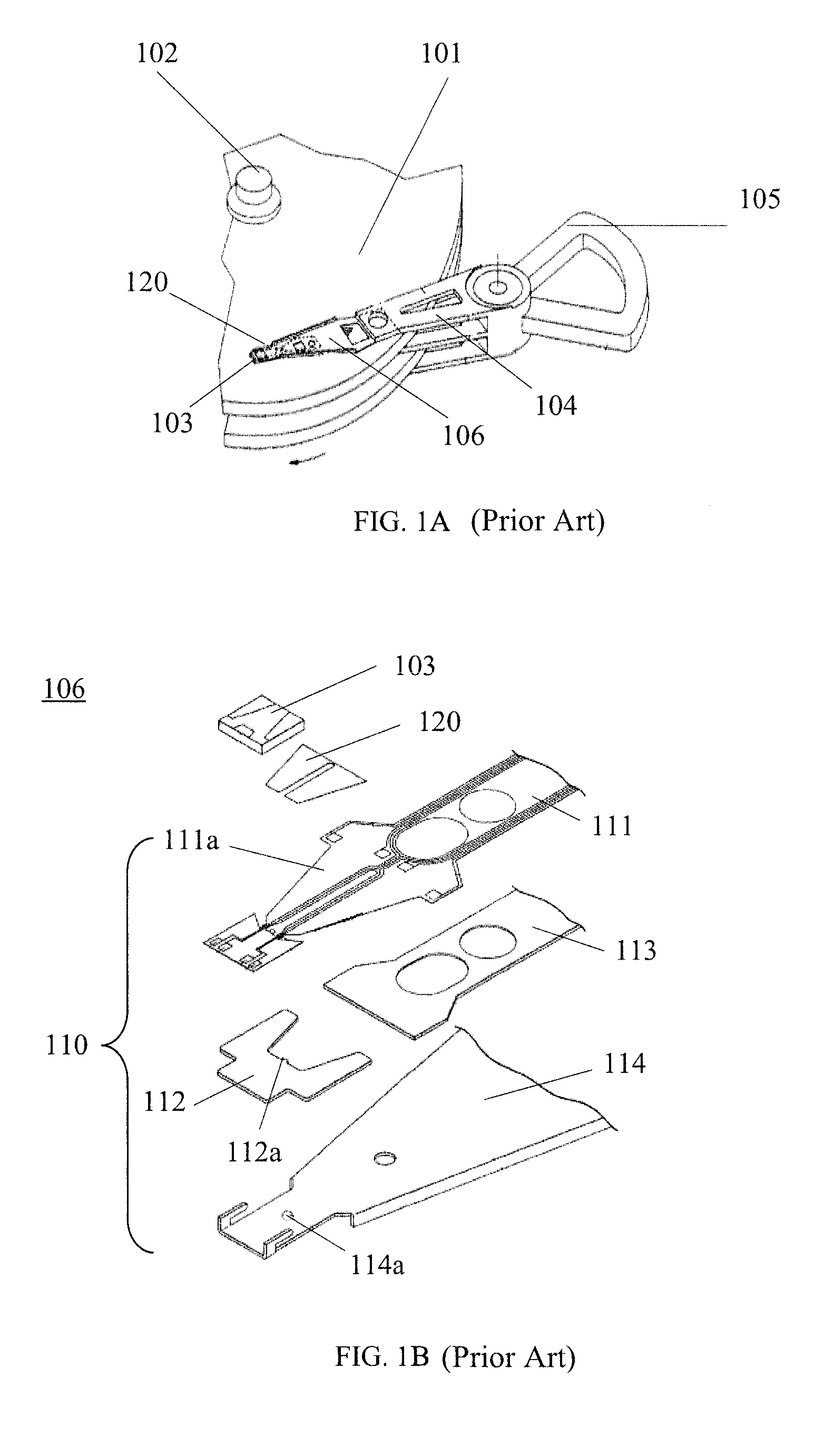

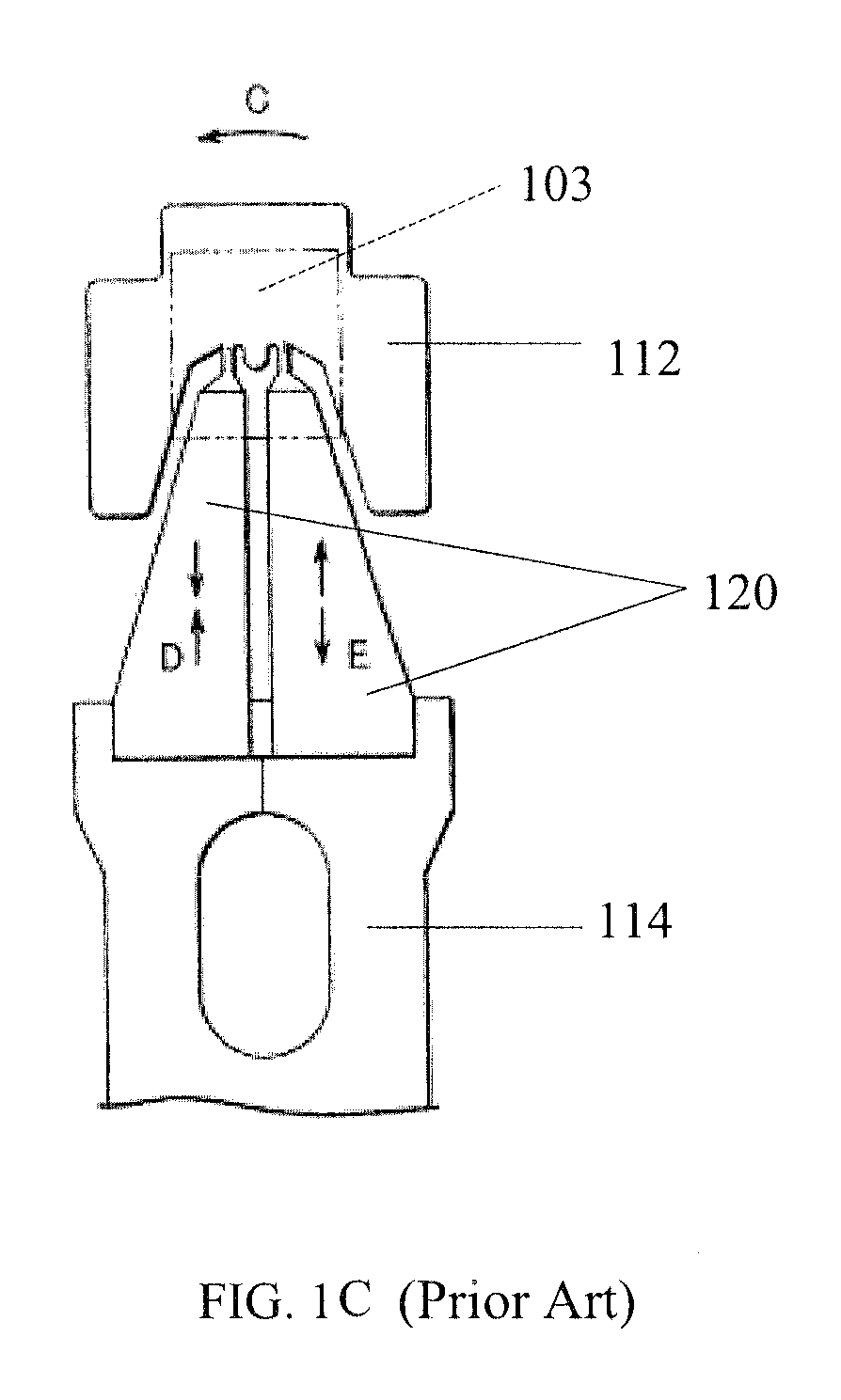

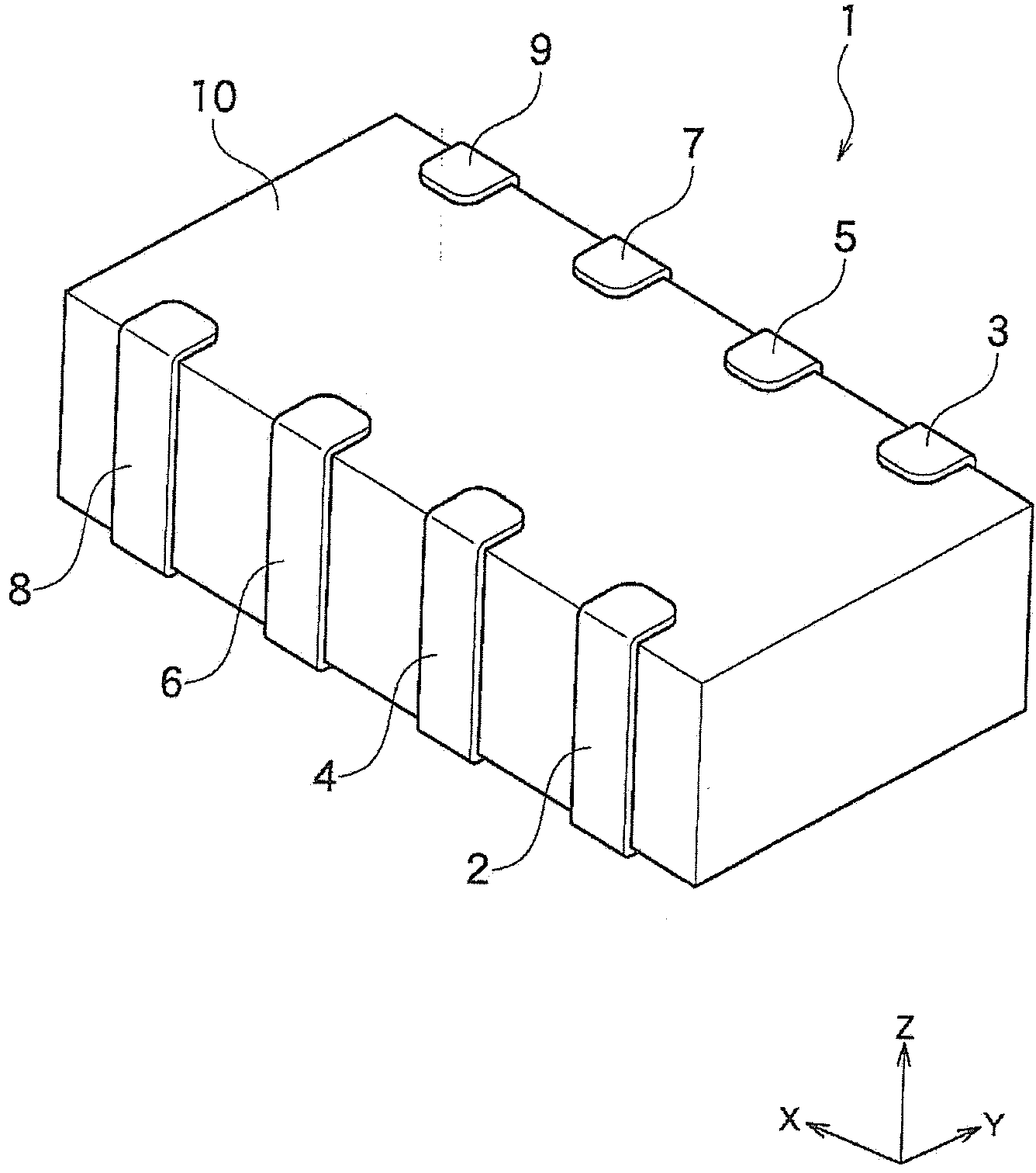

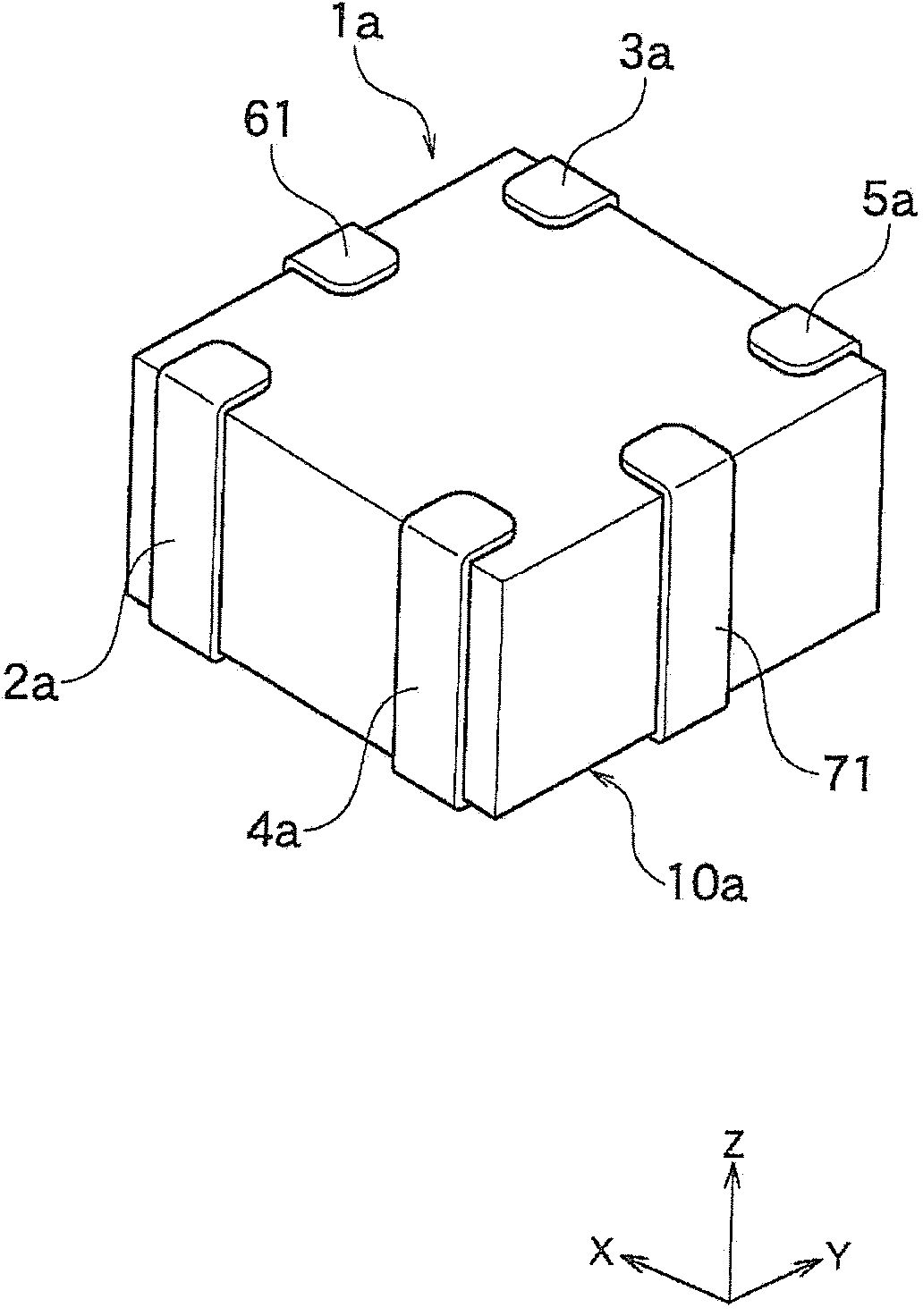

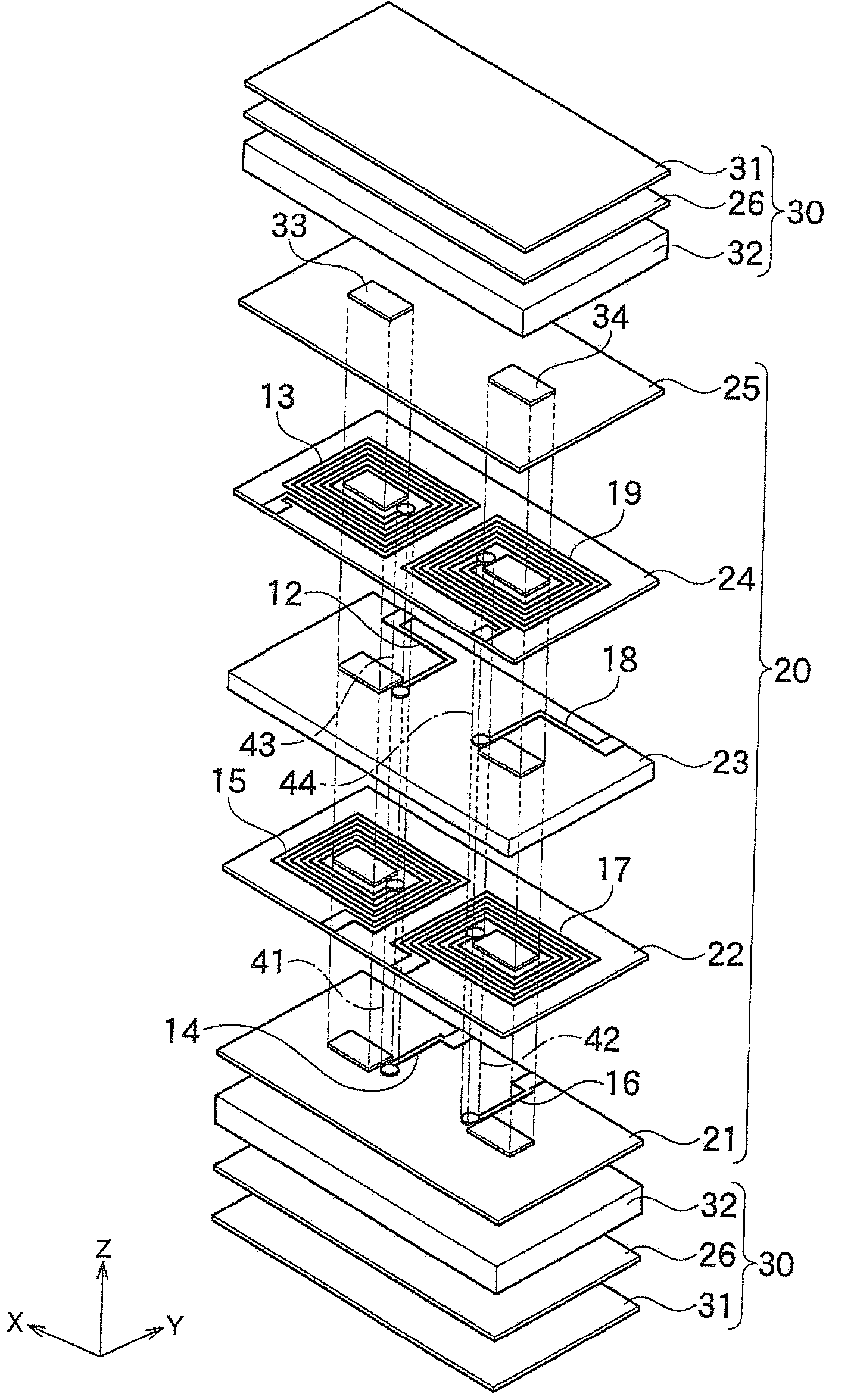

Piezoelectric element having etched portion to form stepped recesses between layers and manufacturing method thereof, head gimbal assembly, and disk drive device with the same

InactiveUS8194359B2High insulation resistanceReduce manufacturing costPiezoelectric/electrostrictive device manufacture/assemblyDisposition/mounting of recording headsElectrical resistance and conductanceStructural engineering

A piezoelectric element comprises a first laminated structure body and a second laminated structure body. Side surfaces of the first and the second laminated structure bodies that are parallel to a laminating direction both have at least a portion etched to form a recess so that a step distance is formed between sides of the two adjacent electrode layers that are parallel to the laminating direction. The design of the step distance increases insulation resistance between the two adjacent electrode layers on the opposite surfaces of the piezoelectric layer, and lowers reject rate. The first and the second laminated structure bodies are symmetrically laminated and bonded together, thus optimizing force balancing performance. The present invention also discloses a method of manufacturing a PZT element, a HGA with the PZT element and a disk drive unit having such HGA.

Owner:SAE MAGNETICS (HK) LTD

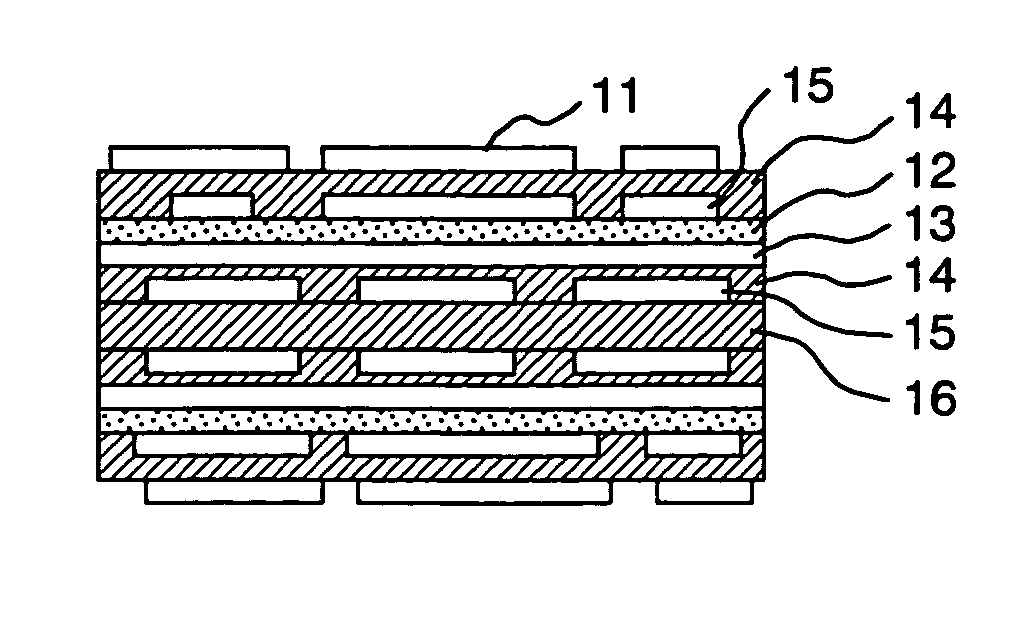

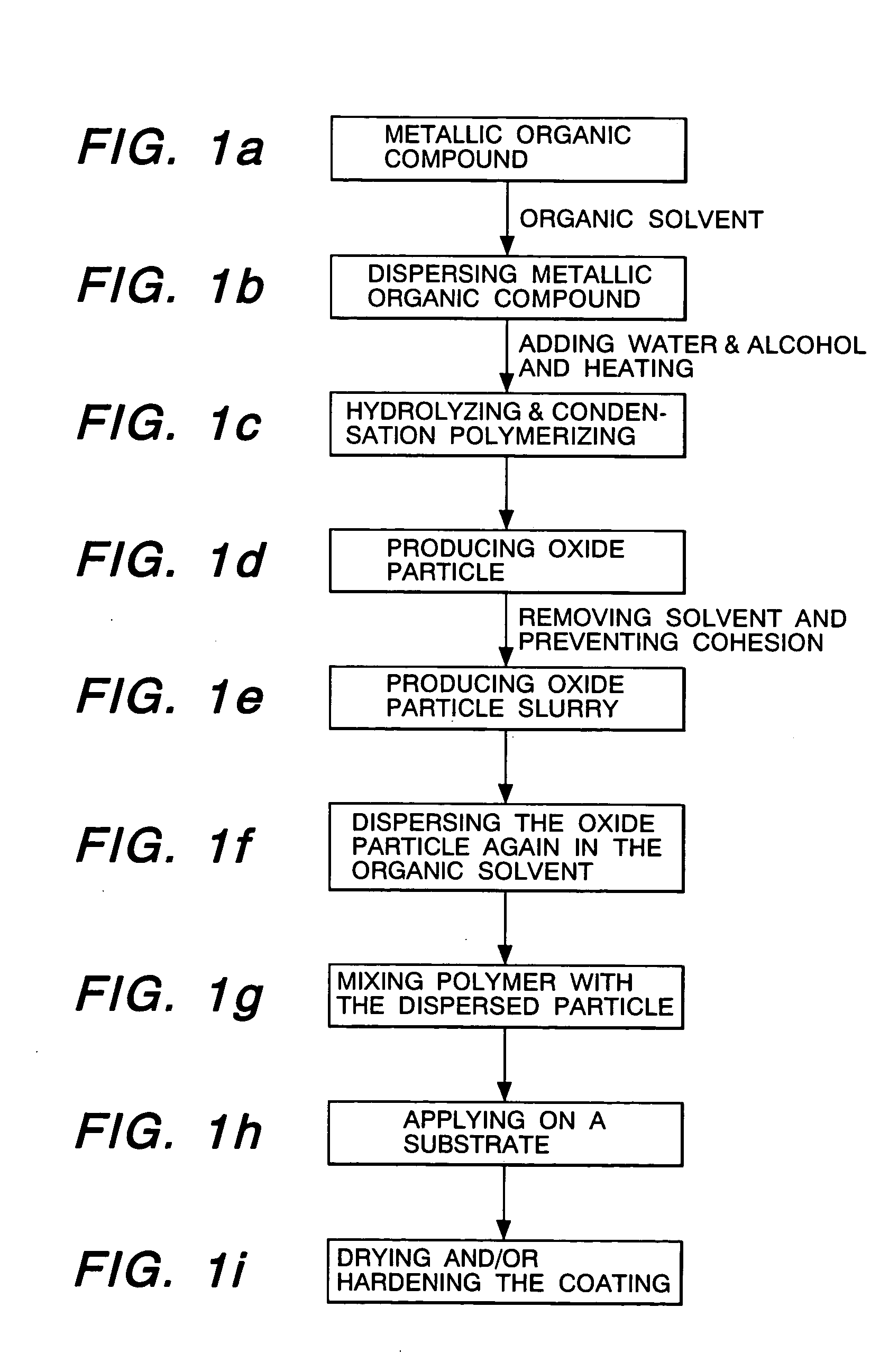

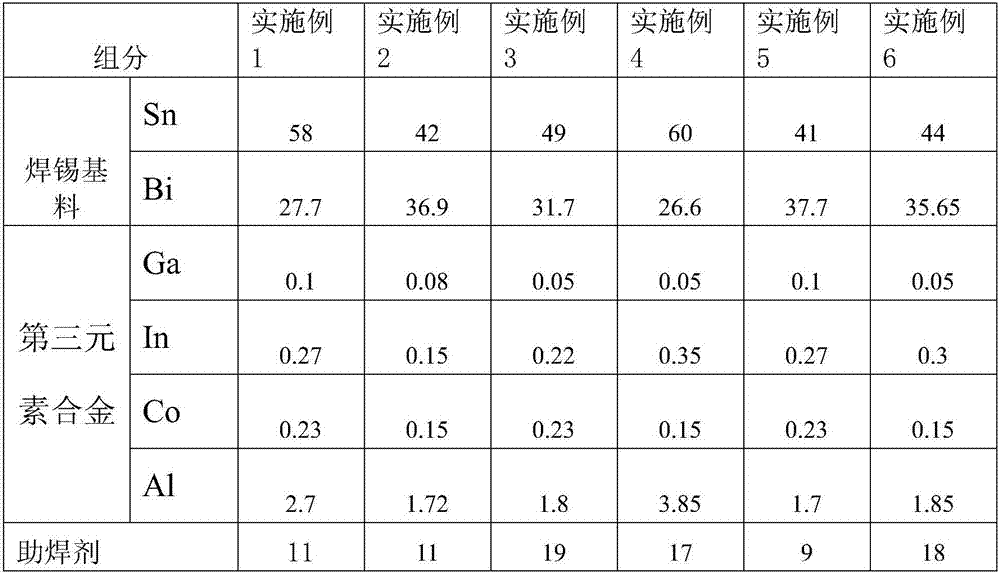

Organic/inorganic oxide mixed film, passive device contained electronic substrate using the film, and method of manufacturing organic/inorganic oxide mixed film

InactiveUS20050029515A1High insulation resistanceLarge capacityThin/thick film capacitorFixed capacitor dielectricCapacitanceCapacitor

An organic / inorganic oxide mixture has high capacitance density so as to realize a capacitor material that can be self-contained in a substrate. The mixture film made of inorganic oxide particle has a mean particle size of less than 90 nm dispersed in organic polymer, of which relative dielectric constant is more than 10 and thickness is less than 900 nm.

Owner:HITACHI LTD

Ethylene propylene rubber cable insulating material for ship and ocean use and manufacturing method thereof

ActiveCN102344612ASmall outer diameterReduce weightPlastic/resin/waxes insulatorsMicrocrystalline waxPolymer science

The invention discloses an ethylene propylene rubber cable insulating material for ship and ocean use and a manufacturing method thereof. The insulating material comprises by weight: 11 parts of ethylene propylene rubber 2470; 9 parts of ethylene propylene rubber 4044; 1.0-1.5 parts of high pressure polyethylene; 0.5-1.0 part of dicumyl peroxide; 0.3-0.4 part of triallyl isocyanurate; 0.5-0.8 part of 2-mercaptobenzimidazole; 1-1.5 parts of titanium dioxide; 1.0-1.5 parts of paraffin oil; 1.0-1.5 parts of zinc oxide; 0.6-1.0 part of microcrystalline wax; 0.2-0.5 part of stearic acid; 1-2 partsof white carbon black; 10-15 parts of superfine talc powder; and 12-16 parts of modified calcined argil. The method consists of the steps of: conducting uniform banbury mixing to ethylene propylene rubber and high pressure polyethylene; then adding titanium dioxide and the like in order for uniform mixing; carrying out triangle bag packaging with an open mill for 7 times, then filtering rubber, and putting the filtered rubber in a banbury mixer and adding an antioxidant for mixing well; finally conducting triangle bag packaging in an open mill for 5 times and extruding rubber sheets. The insulating material has the advantages of low smoke, free of halogen, flame retardation, high mechanical strength and high insulation resistance.

Owner:嘉兴顾翔制冷设备有限公司

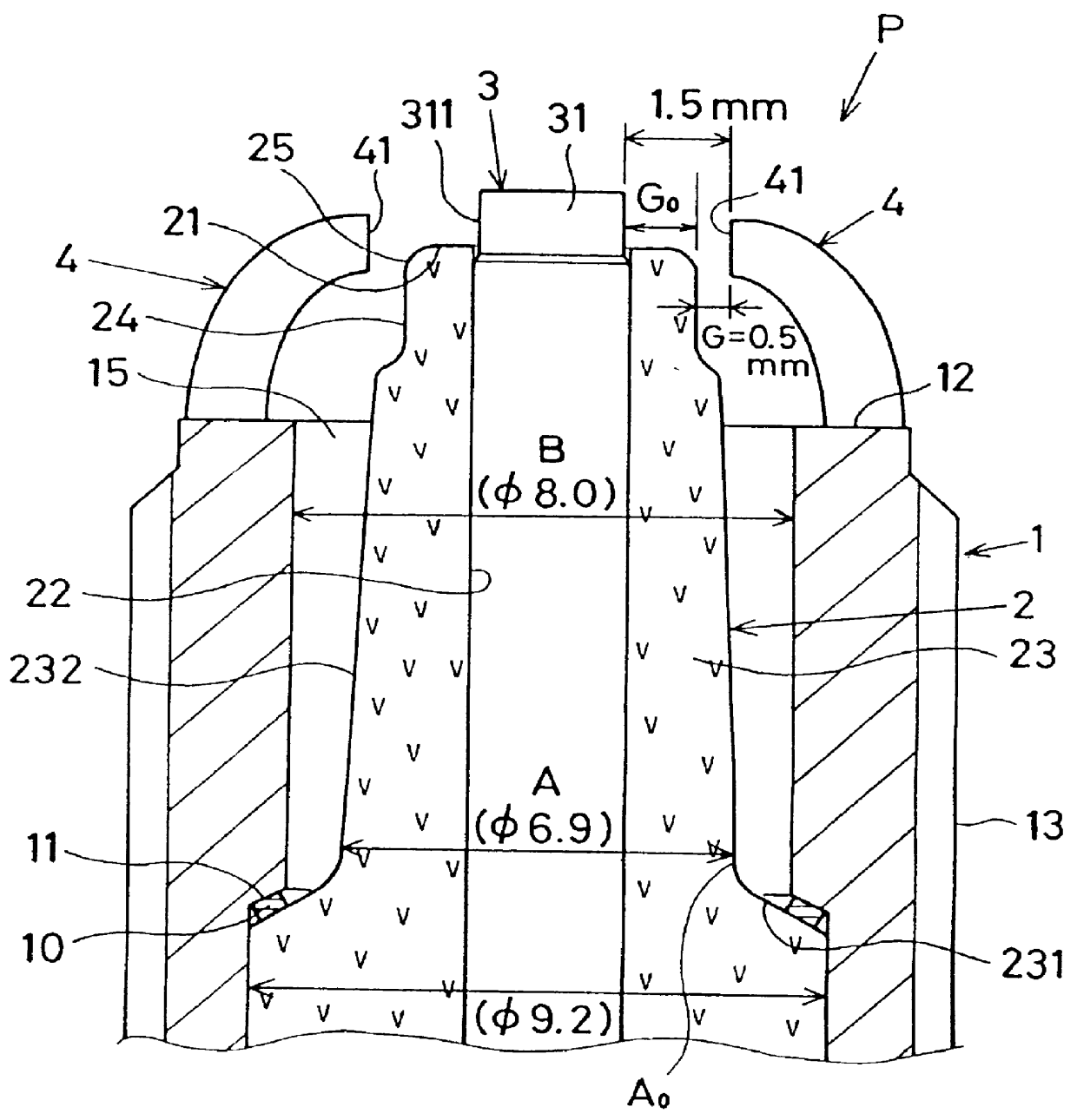

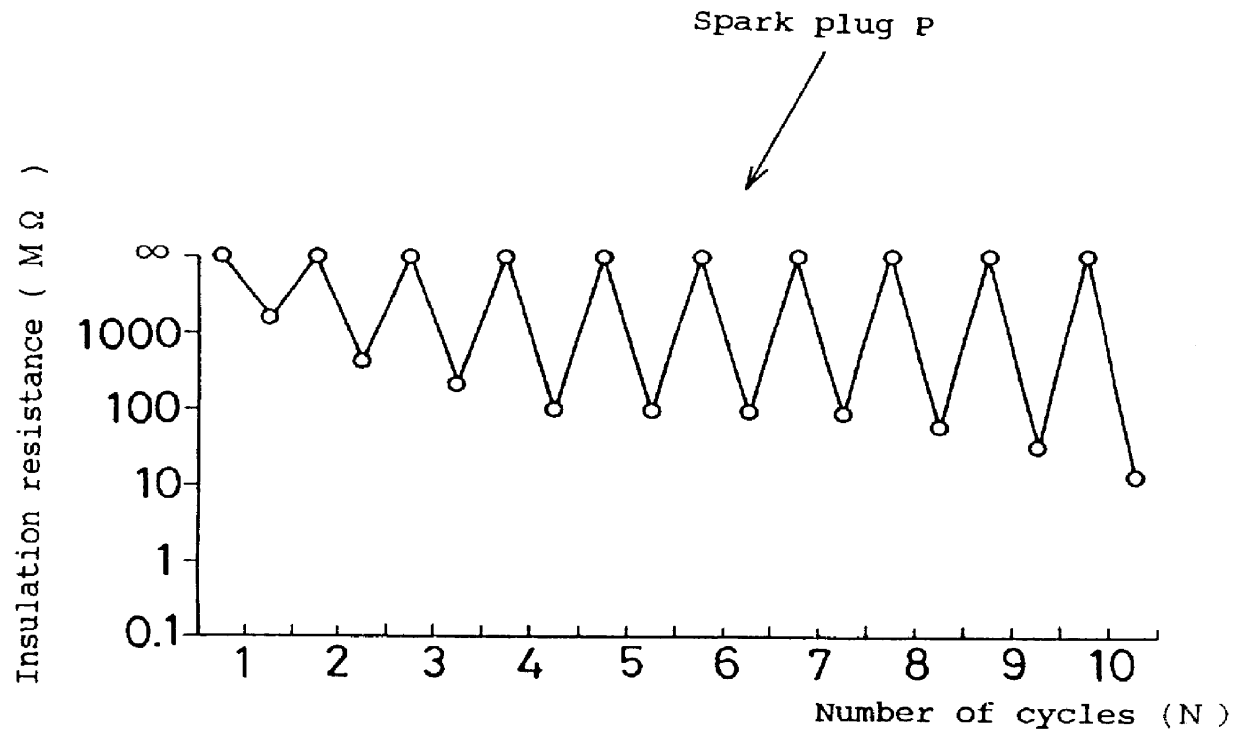

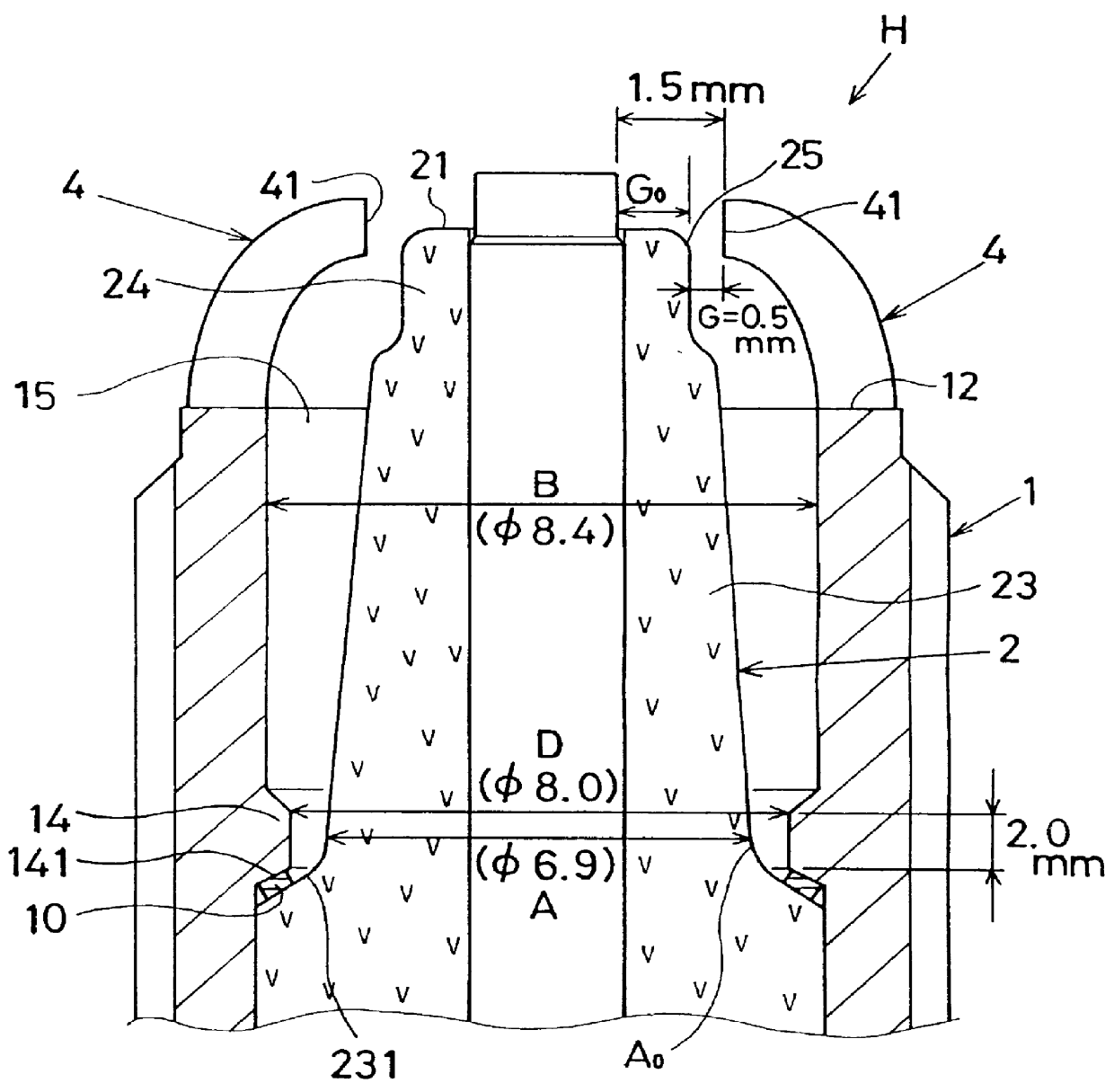

Lateral electrode type spark plug with geometrical relationships with ground electrode

InactiveUS6091185AEffective protectionHigh insulation resistanceSparking plugsFuel injection apparatusNoseEngineering

In a spark plug, a cylindrical metal shell (1) is provided whose inner wall has a rear section and a front section to respectively serve as a diameter-increased section and a diameter-decreased section with a seat portion (1) as a boundary therebetween. An insulator (2) is fixedly placed within the metal shell (1) so that a front end surface (21) of the insulator (2) extends beyond a front end surface (12) of the metal shell (1) with a shoulder portion (231) of an insulator nose (23) engaged against the seat portion (11) of the metal shell (1) by way of a packing (10). A center electrode (3) is fixedly placed within an axial bore (22) of the insulator (2), A ground electrode (4) is connected to the front end surface (12) of the metal shell (1), and bent so that a front end surface (41) of the ground electrode (4) opposes an outer surface (311) of the center electrode (3). The outer surface (311) and a front end surface (31) of the center electrode (3) are provided to respectively serve as a firing portion so as to form a spark discharge gap (Go) with the front end surface (41) of the ground electrode (4), the front end surface (41) of the ground electrode (4) forming an air gap (G) with an outer surface (25) of the insulator (2) so as to release creeping spark discharges along a front end surface (21) of the insulator (2).

Owner:NGK SPARK PLUG CO LTD

Sorbent for processing transformer waste oil and method for producing the same

InactiveCN101406824ANon-flammable and explosiveImprove adsorption capacityTransformers/inductances coolingOther chemical processesHazardous substanceSorbent

The invention relates to an absorbent for treating and reclaiming waste liquid oil, in particular for treating and reclaiming waste transformer oil and a production method thereof. The absorbent is characterized in that the absorbent is prepared from the following raw materials according to the weight ratio: sulphuric acid solution, aluminium sulphate solution, sodium silicate solution and ammonia water are mixed, aged, roasted and dried, cleaned and re-roasted; and the finished product of the absorbent is obtained. The absorbent for treating the waste oil has the characteristics of innocuity, noninflammability, nonexplosiveness and so on, and higher capability of adsorbing substances in the waste oil such as acid, carbon microsphere, metal, water content, gel, and the like. The absorbent is sufficiently contacted with the waste oil so as to remove harmful substances in the oil. The absorbent not only has a simple production process, wide raw material sources, low production cost and no environmental pollution, but also has good effect of waste oil treatment, and high yield. The absorbent can save mass production cost for enterprises and energy for the country.

Owner:STATE GRID CORP OF CHINA

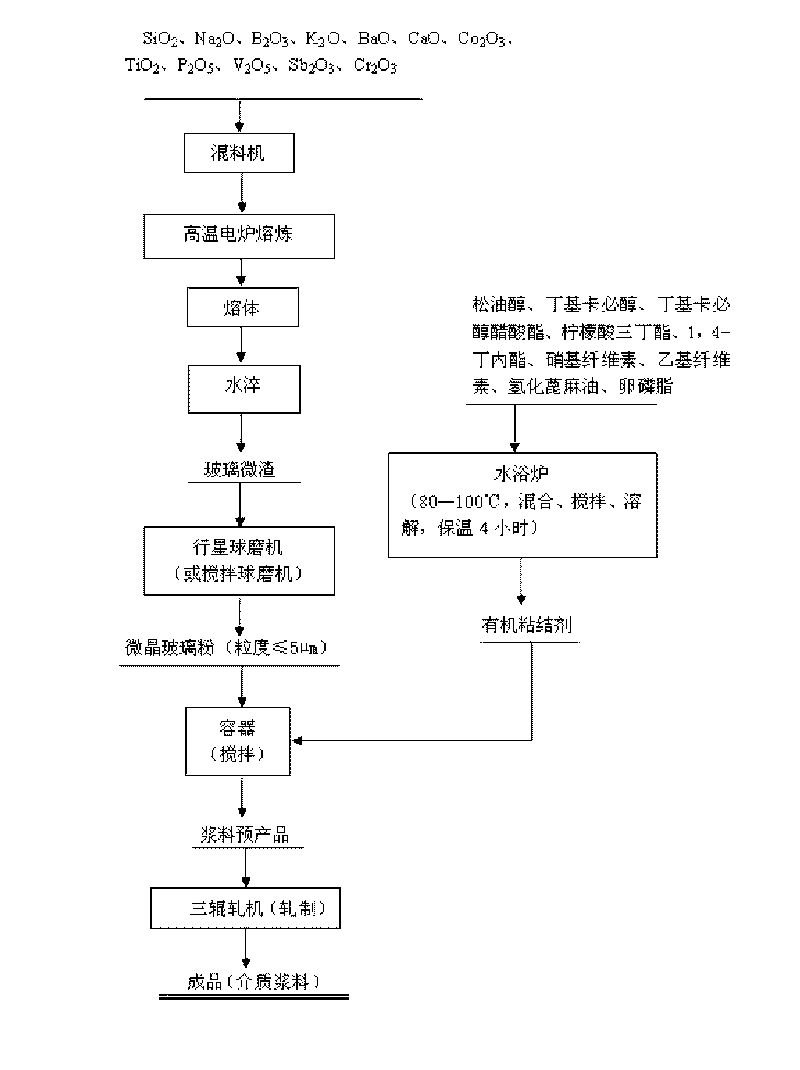

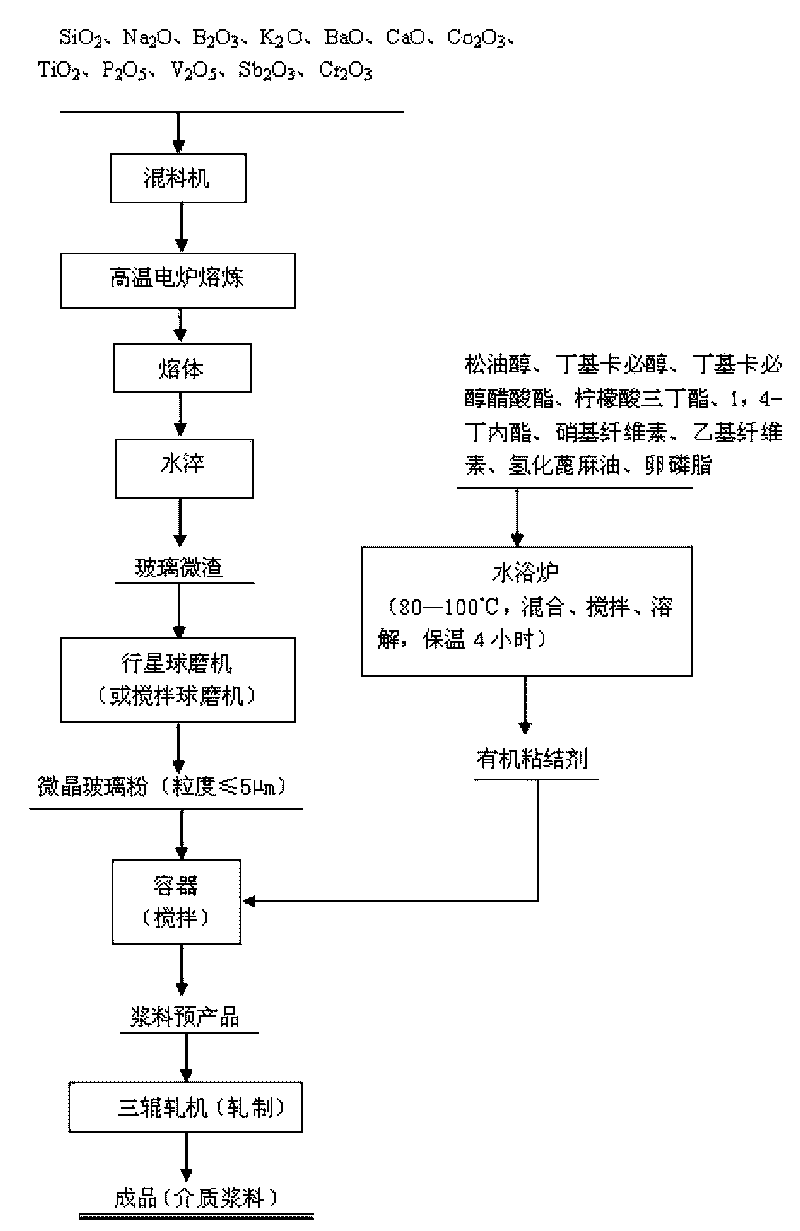

Dielectric paste for metal aluminum substrate thick film circuit and preparation method thereof

InactiveCN101740160AImprove thixotropyGood anti-sinking effectNon-macromolecular adhesive additivesSolid-state devicesDielectricCITRATE ESTER

The invention discloses dielectric paste for a metal aluminum substrate thick film circuit and a preparation method thereof. The invention aims to prepare the dielectric paste matched with a metal aluminum substrate. The dielectric paste is characterized in that SiO2, Na2O, B2O3, K2O, BaO, CaO, Co2O3, TiO2, P2O5, V2O5, Sb2O3 and Cr2O3 are combined to prepare microcrystalline glass powder; and the microcrystalline glass powder and an organic binder which consists of terpinol, butyl carbitol, butyl carbitol acetate, tirbutyl citrate, 1,4-butyrolactone, nitroncellulose, ethyecellulose, hydrogenated castor oil and lecithin are put in a vessel for stirring and rolling by a three-roll roller mill in a weight ratio of the microcrystalline glass powder to the organic binder of 70-90 parts: 30-10 parts so as to prepare the finished product dielectric paste. The dielectric paste is mainly used as the dielectric paste of the thick film circuit formed by being printed on the metal aluminum substrate.

Owner:湖南利德电子浆料股份有限公司

Thermosetting plastic

The invention discloses a thermosetting plastic. The thermosetting plastic is characterized by comprising the following components in parts by weight: 60-95 parts of thermosetting resin, 5-40 parts of low-shrink additive, 150-300 parts of an inorganic mineral filler, 2-4 parts of an initiator, 0.6-1 part of calcium hydroxide micro powder, 2-6 parts of zinc stearate micro powder and 30-60 parts of glass fiber. In comparison with a conventional thermosetting plastic, the thermosetting plastic can be solidified more rapidly, high strength can be maintained within a wide temperature range, and the flame-retardant effect is good.

Owner:宁波华缘复合新材料有限公司

Water-soluble flux for lead-free solder

InactiveCN102233495ADesign scienceReasonable preparationWelding/cutting media/materialsSoldering mediaOrganic acidSolderability

The invention discloses a water-soluble flux for a lead-free solder. The water-soluble flux comprises the following components in percentage by weight: 2 to 5 percent of organic acid activating agent, 0.5 to 1 percent of surfactant, 0.2 to 1 percent of film forming agent, 10 to 15 percent of cosolvent, 0.1 to 0.5 percent of antifoaming agent, 0.05 to 0.35 percent of stabilizing agent, 0.1 to 0.5 percent of corrosion inhibitor and the balance of deionized water. The water-soluble flux special for the lead-free solder can be effectively matched with the lead-free solder and is particularly suitable for a lead-free solder which is used for a low-cost high-performance microelectronic package and consists of the following components in percentage by weight: 0.5 to 1 percent of Ag, 0.3 to 0.7 percent of Cu, 1 to 3 percent of Bi, 0.0002 to 0.0005 percent of P, 0.01 to 1 percent of Ce, 0.01 to 0.15 percent of Ni and the balance of Sn. The flux has high wetting capacity on the lead-free solder, can enhance the solderability of the lead-free solder, can meet the requirement of soldering temperatures of the lead-free solder, has a low corrosion effect on lead-free solder alloy and a small number of residues after soldering, and can be cleanly washed by water; and a dried circuit board has higher insulation resistance.

Owner:NINGBO ZHUOCHENG SOLDER TECH

Temperature-stable dielectric ceramic composition for multilayer ceramic capacitors with base-metal electrodes

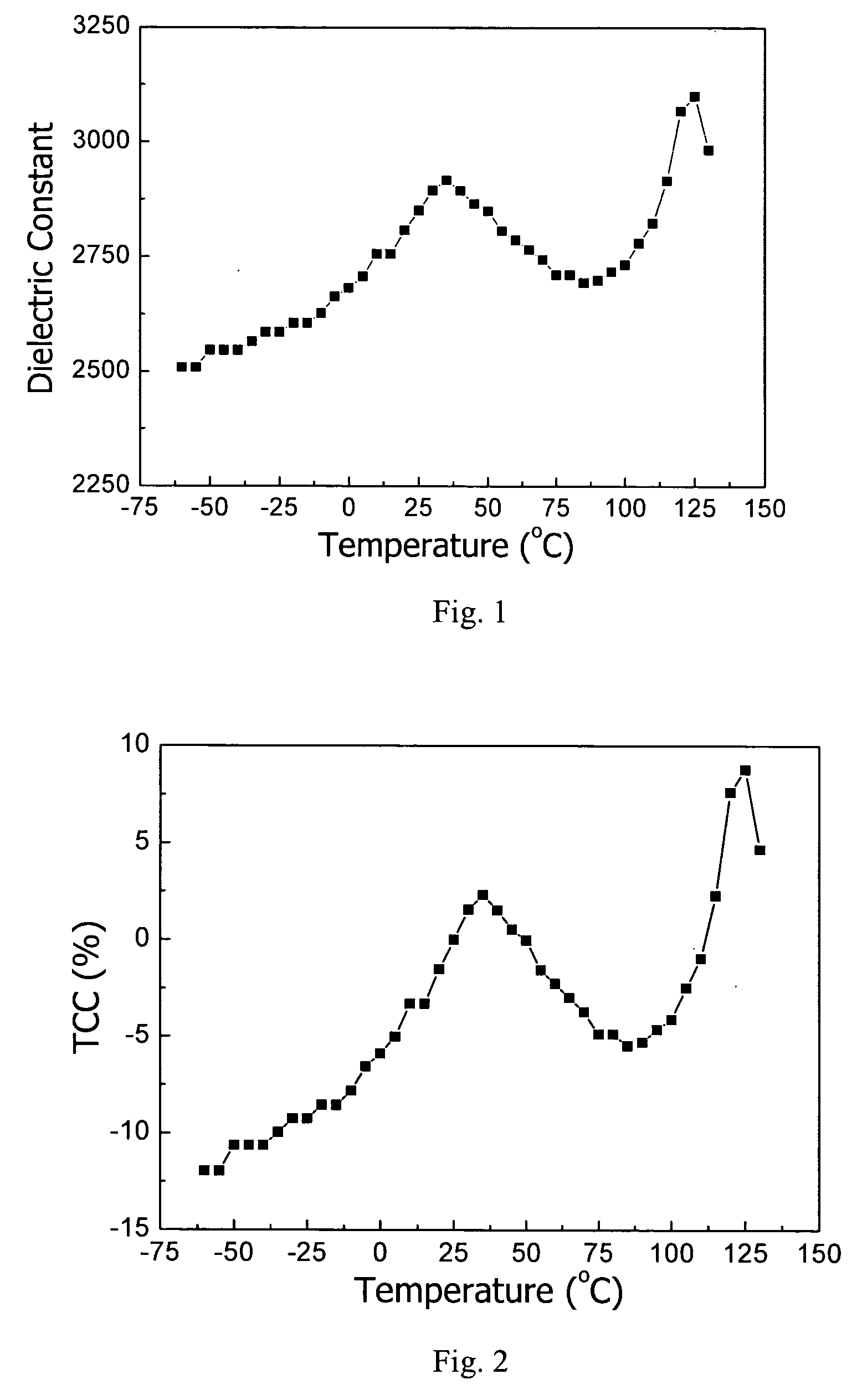

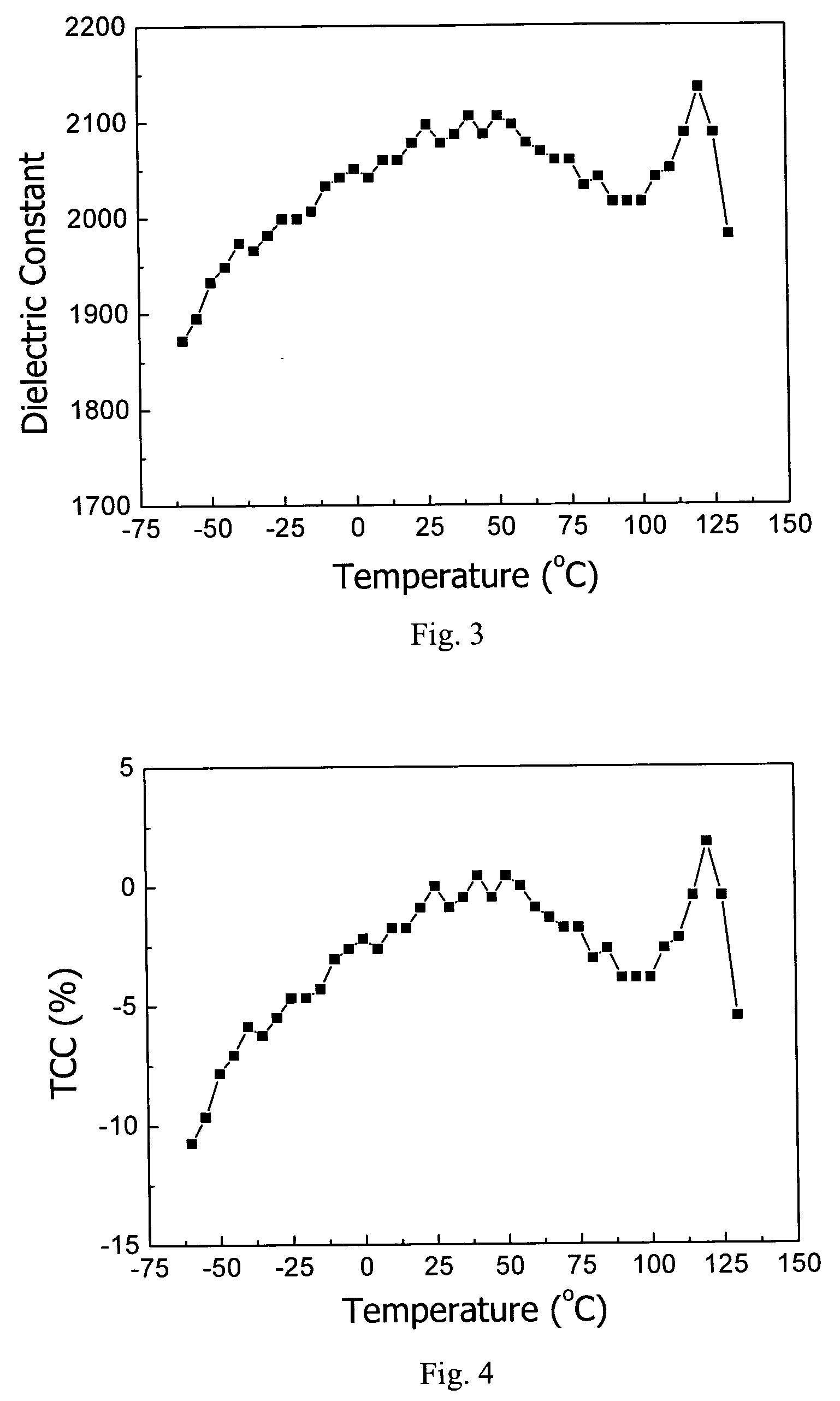

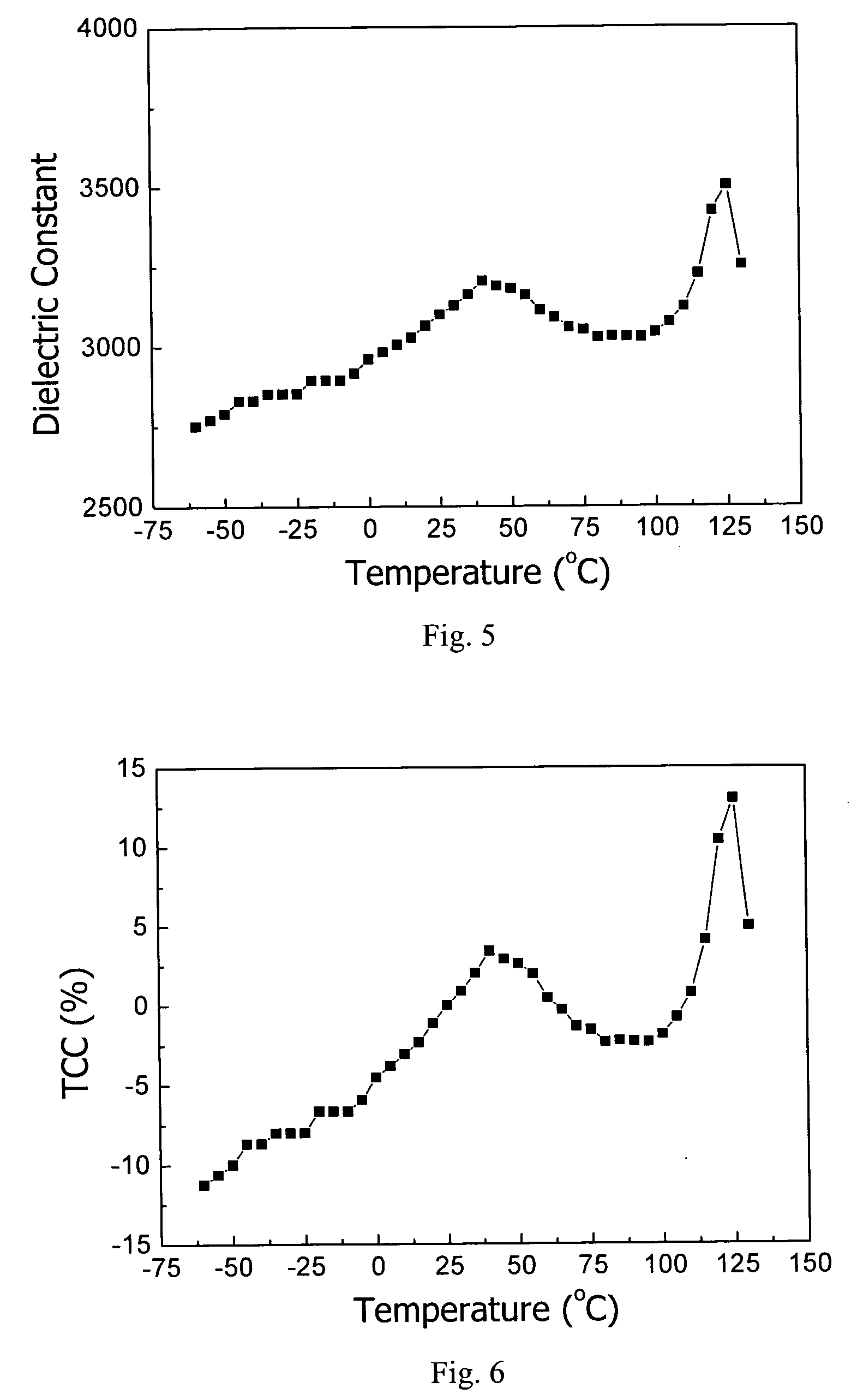

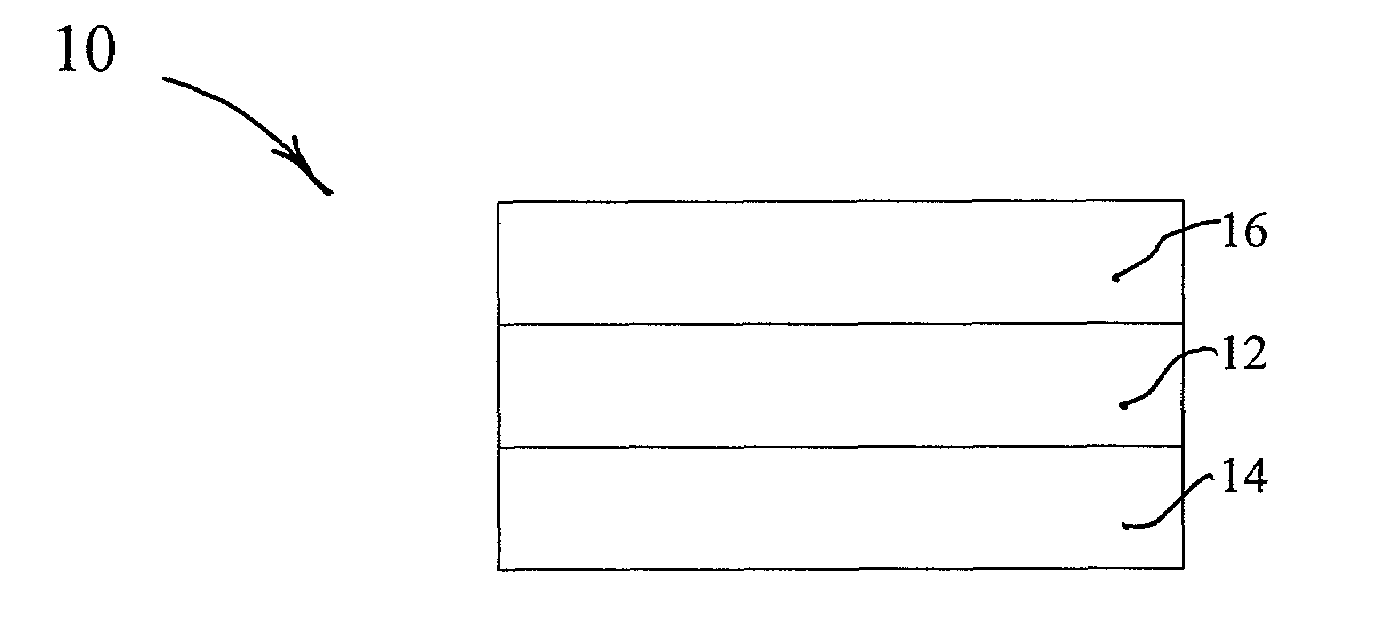

ActiveUS20040138050A1High insulation resistanceFixed capacitor dielectricCeramicsCapacitanceBarium titanate

The present invention relates to a temperature-stable dielectric ceramic composition for multilayer ceramic capacitors. The said dielectric composition comprises barium titanate and additives, wherein the barium titanate ranges from 94 to 99 mol % of the said composition, and the additives range from 1 to 6 mol % of the said composition. The additives comprise oxides of Mg, Ca, Ba, Si and Mn, and oxides of one or more elements selected from the group consisting of Co, Sr, Ti and Fe, and an oxide of Re, or carbonates, hydroxide, oxalates, acetates or nitrates of the above elements. Re represents one or more elements selected from Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Th, Dy, Ho, Er, Tm, Yb and Lu. After being sintered at 1200° C. to 1350° C. under reducing atmosphere, the room-temperature dielectric constant of the composition is 2000 to 3500 and its temperature coefficient of capacitance satisfies X7R characteristic (EIA standards). The composition is useful as material for multilayer ceramic capacitor with ultra-thin dielectric layer (thickness less than 10 mum).

Owner:TSINGHUA UNIV

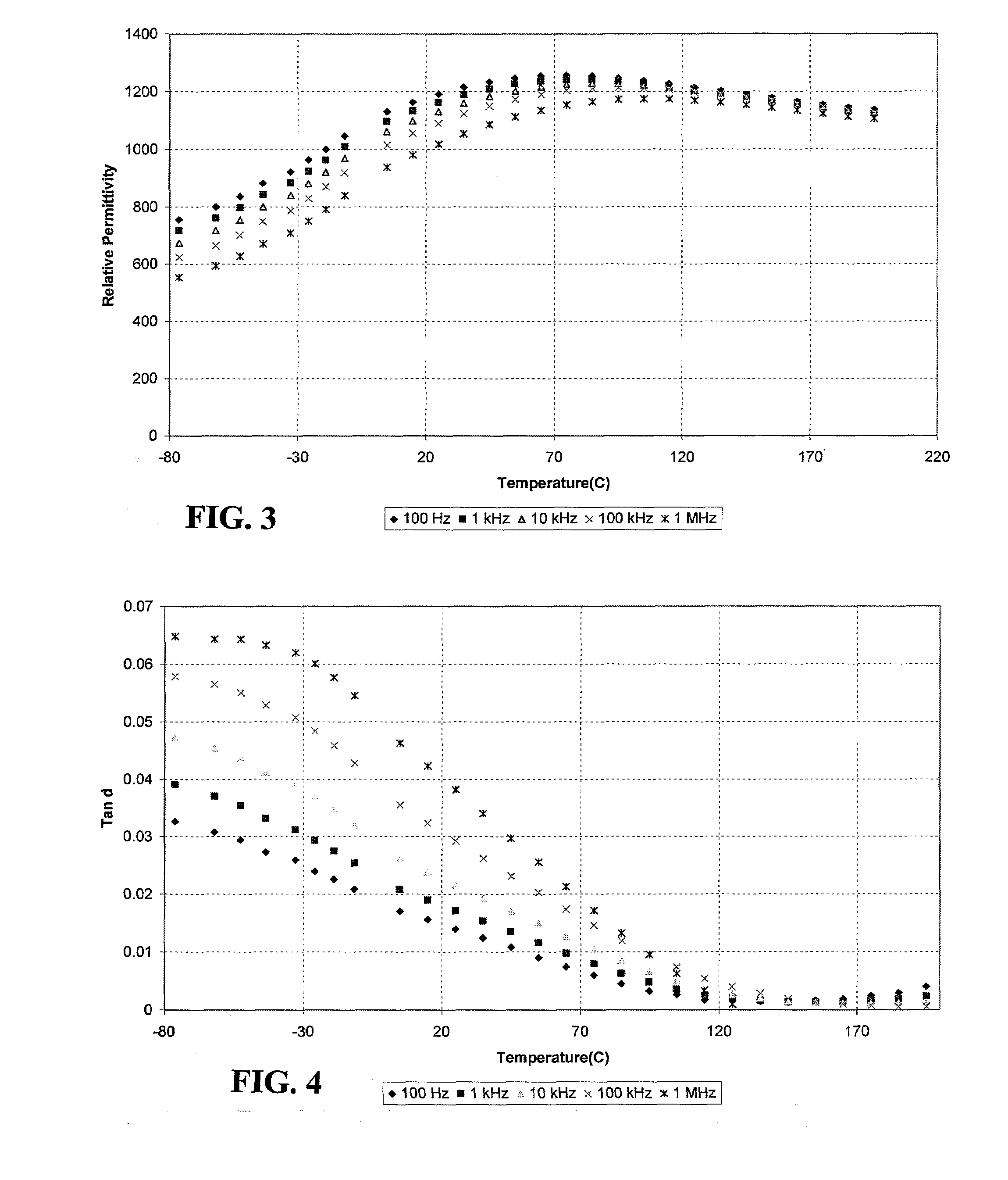

High-Temperature Dielectric Materials and Capacitors Made Therefrom

InactiveUS20080239627A1Reduce lossHigh dielectric constantFixed capacitor dielectricFixed capacitor terminalsCapacitanceLow voltage

A ceramic dielectric composition suitable for preparing capacitors for use in high-temperature service conditions is disclosed. The ceramic material and capacitors made from it exhibit unique and heretofore unrealizable properties including low variation in capacitance with voltage up to high fields, low variation in capacitance with temperature over a broad temperature range, retained high permittivity at temperatures up to 200° C. and beyond, low loss, low field-induced strain and adequate capacitance to retain performance at very low service temperatures. The material is based on sodium bismuth titanate (NBT) with selected additions of substituents and dopants to broaden and flatten its dielectric response, lower loss, lower strain, lower voltage coefficient and increase resistivity.

Owner:ALFRED UNIVERSITY +1

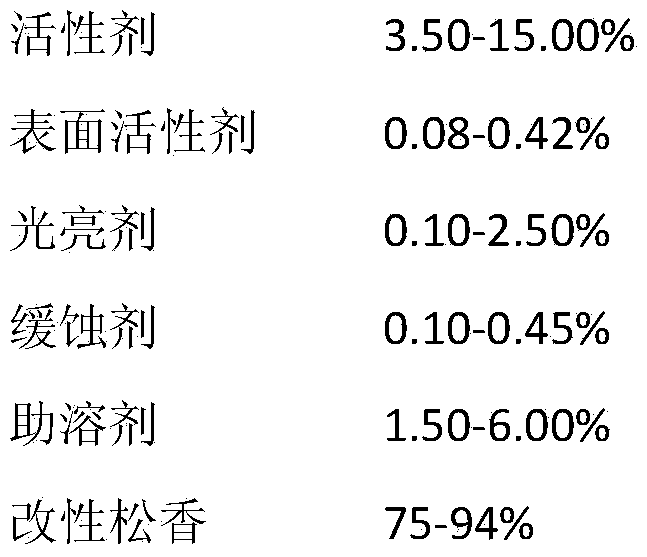

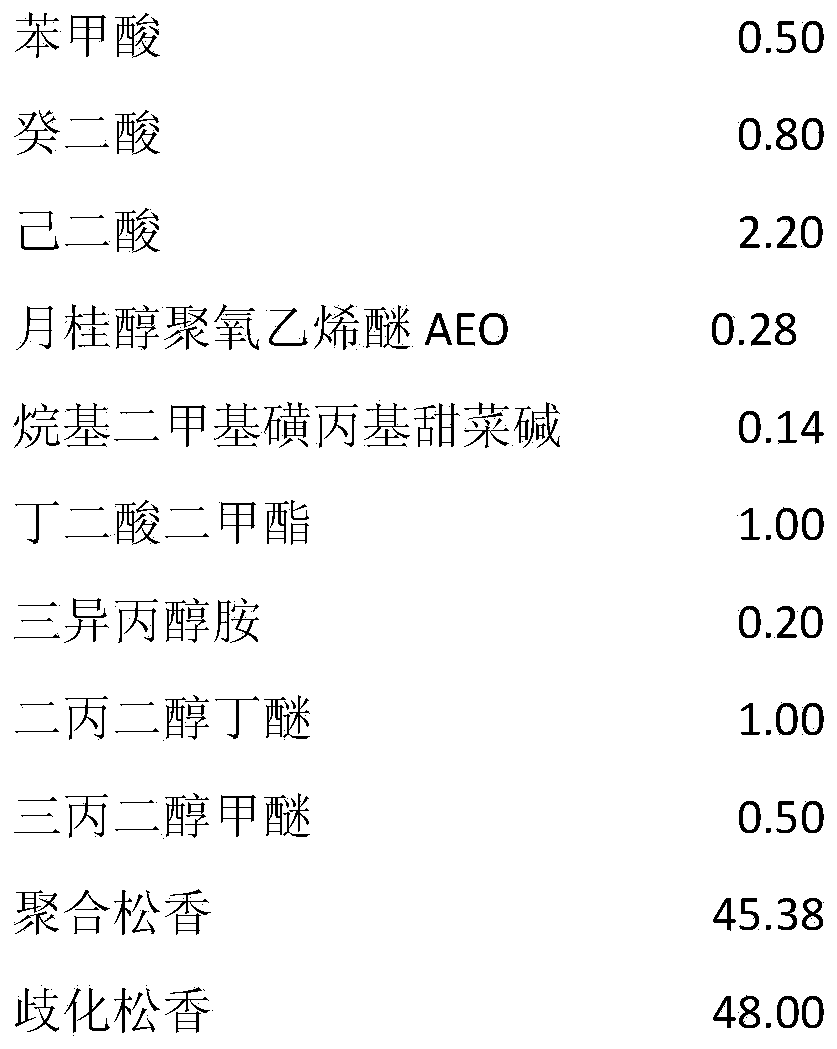

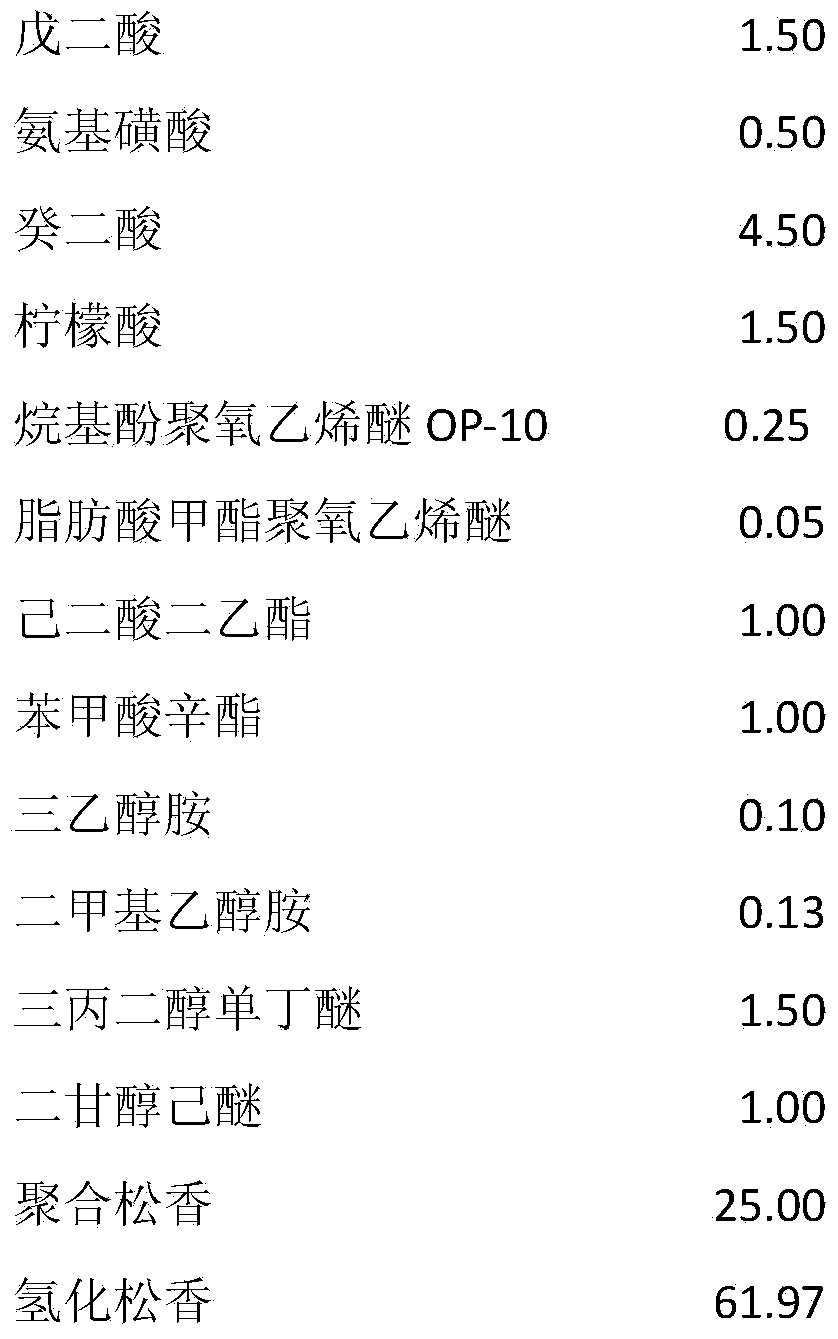

Abietyl-based soldering flux for halogen-free no-clean bright solder wire and preparation method thereof

InactiveCN104070308AIncrease brightnessGood specular reflection abilityWelding/cutting media/materialsSoldering mediaTinningElectricity

The invention discloses an abietyl-based soldering flux for a halogen-free no-clean bright solder wire and a preparation method thereof. The abietyl-based soldering flux comprises, by mass, raw materials including active agent 3.50-15.00%, surface active agent 0.08-0.42%, brightener 0.10-2.50%, corrosion inhibitor 0.10-0.45%, cosolvent 1.50-6.00% and the balance modified rosin. The ingredient proportion in the abietyl-based soldering flux is suitable for manufacture of lead-free solder wires containing the soldering flux in cores, and the soldering flux can be used for automatic welding or manual soldering iron welding. When the solder wire welding is adopted, the process stability is good, tinning speed is high, the splashing amount is small, the defects including continuous tinning, solder skips, insufficient solder, icicles and the like in the welding process can be decreased, welding spots are bright and full after welding, residues are few, the corrosivity is low, cleaning is not needed, and the surface electrical insulation property is excellent after the welded solder wires are placed for a long period of time.

Owner:SOUTH CHINA UNIV OF TECH

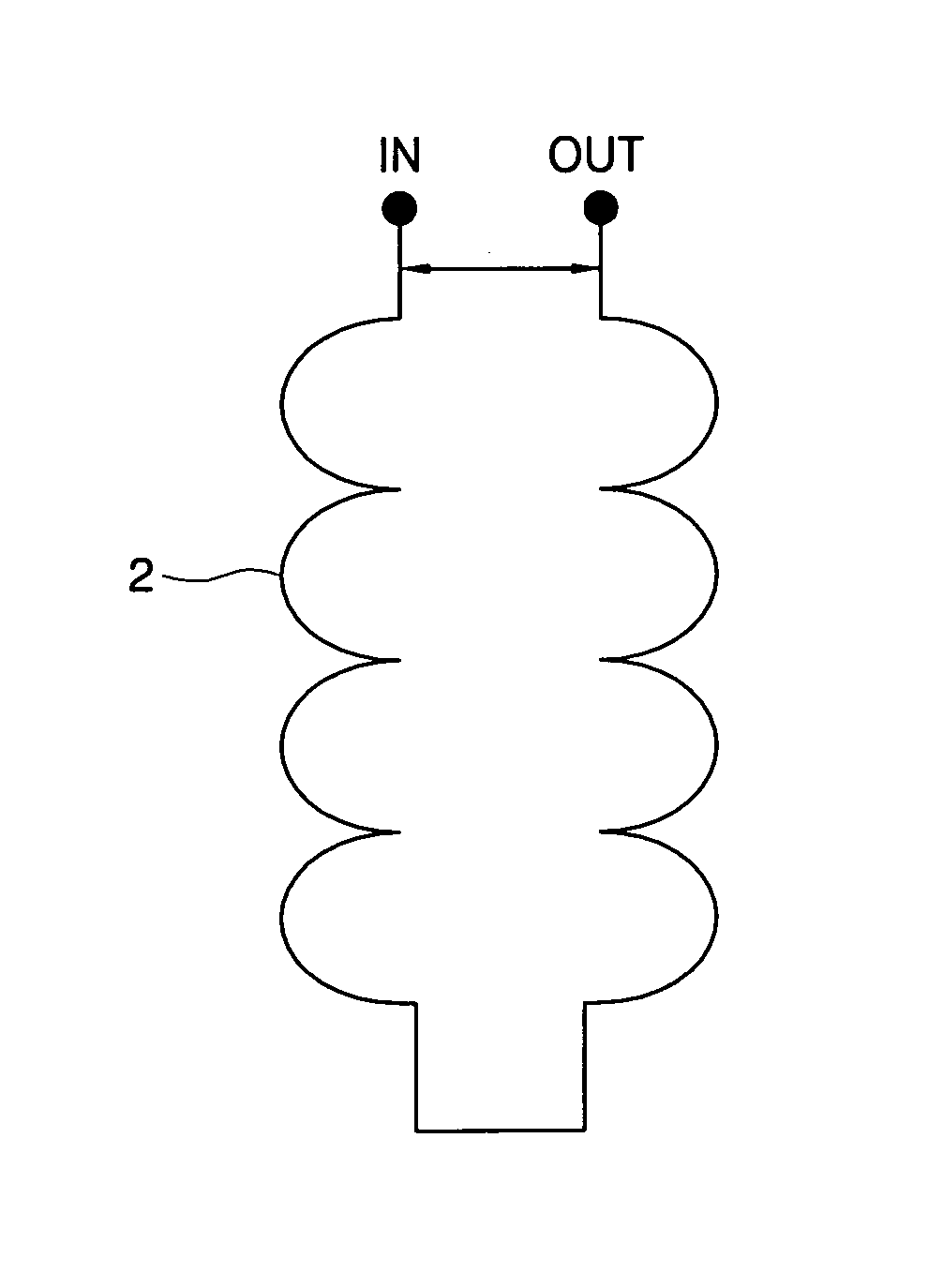

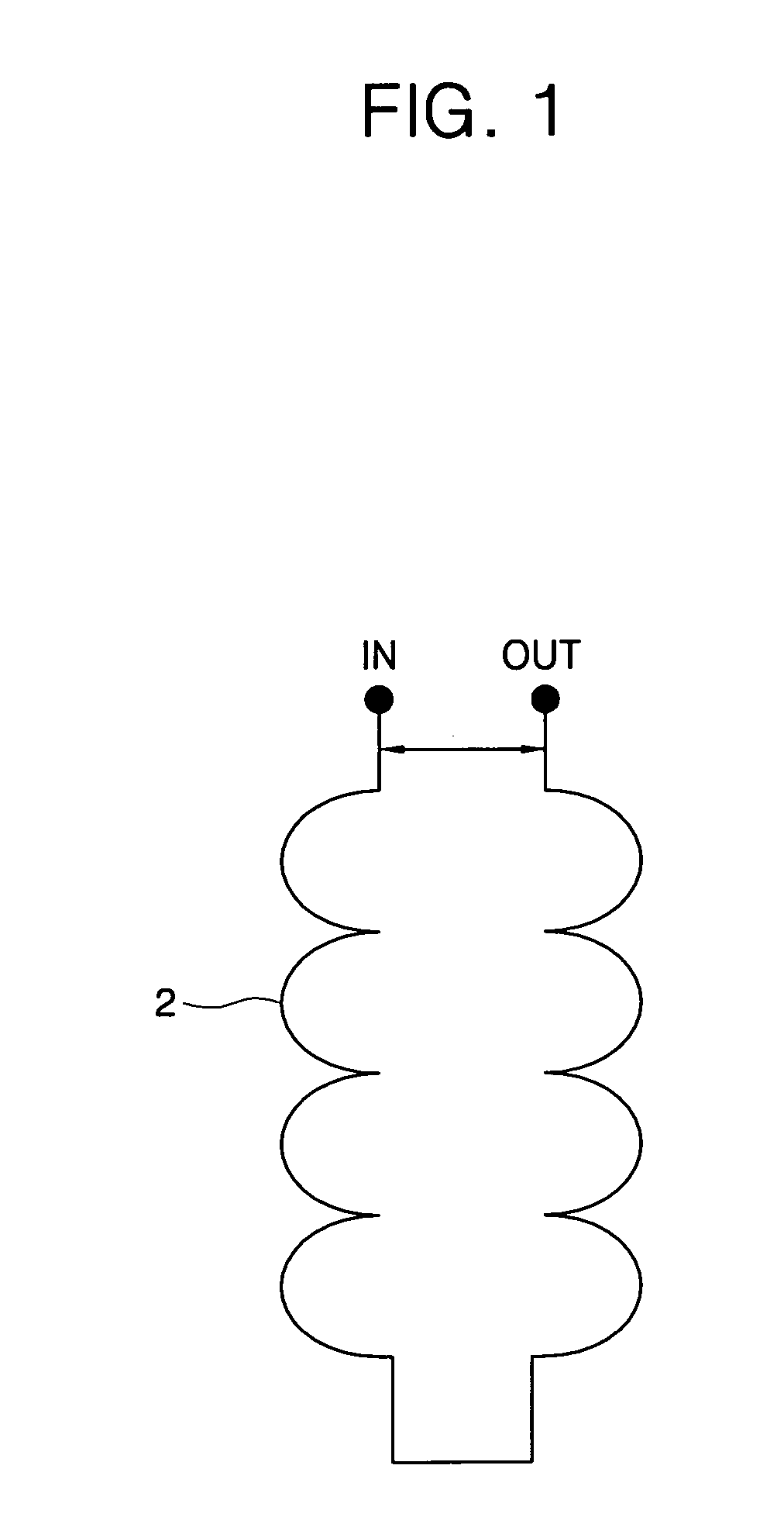

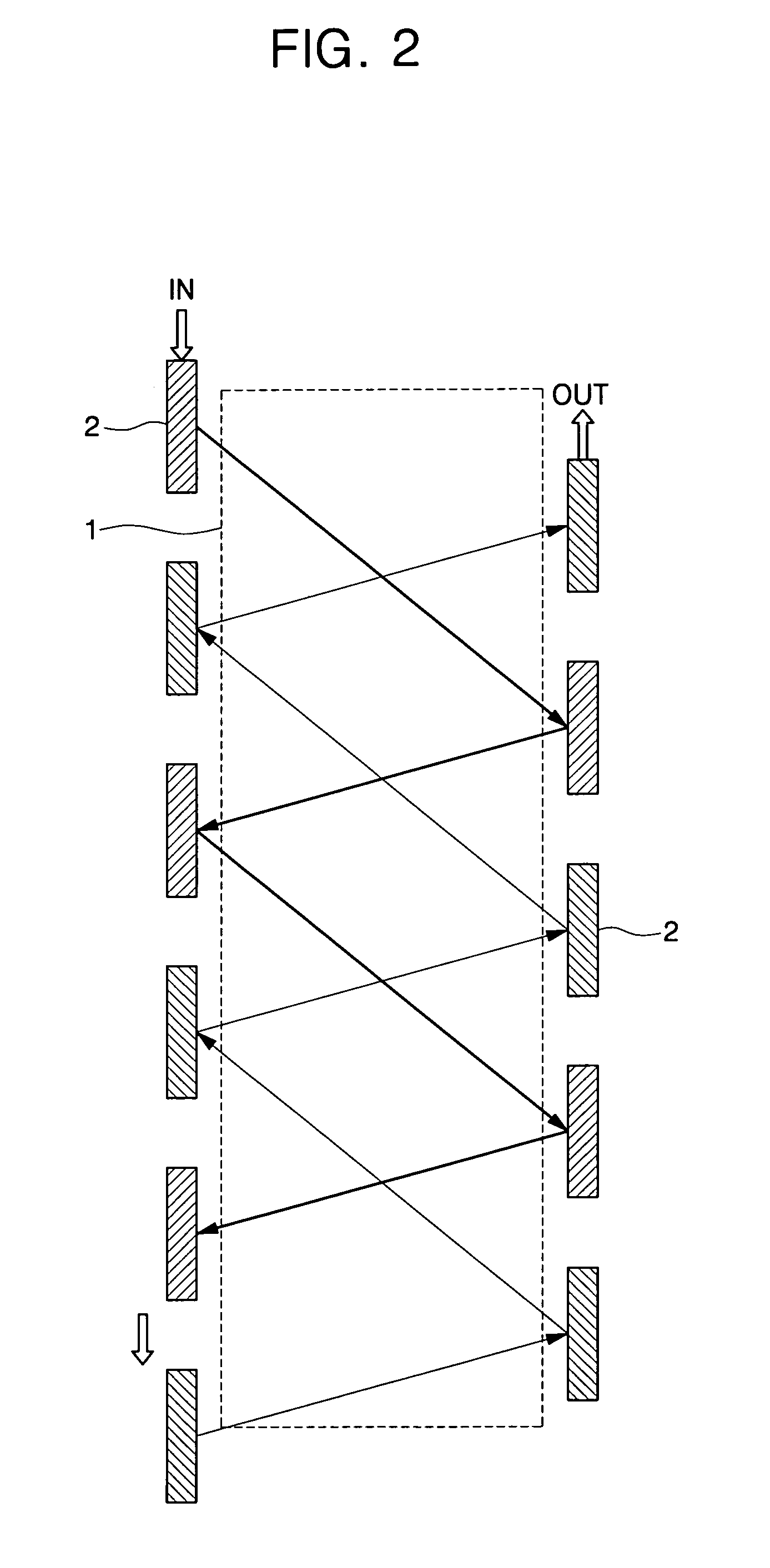

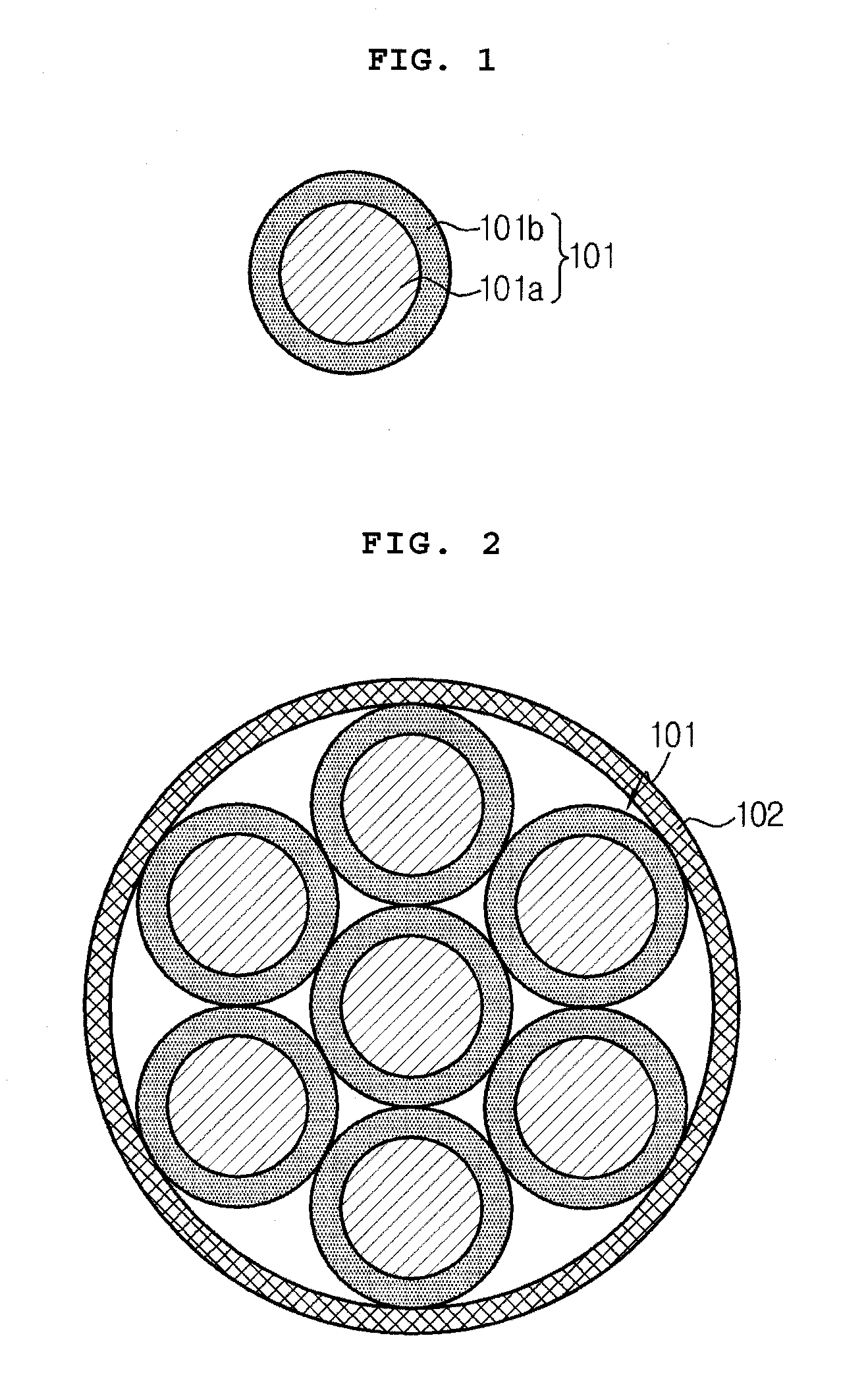

Resistive superconducting fault current limiter

InactiveUS20060268471A1High insulation resistanceIncrease widthUnwanted magnetic/electric effect reduction/preventionSuperconducting magnets/coilsInsulation resistanceElectric generator

Provided is a superconducting fault current limiter capable of reducing a fault current in a power application field, such as a lossless power transmission line, a superconductive magnet for generating a strong or very stable magnetic field, an energy storage, a motor, a generator, and so on, of generating or transporting a large amount of current, and a traffic application field such as a superconducting magnetic levitation train, a superconducting propulsion ship, and so on. In accordance with the present invention, after the inner bobbin is disposed in the outer bobbin, the wires are wound around the inner and outer bobbins to be connected through the current introduction terminal in directions opposite to each other to thereby constitute the superconducting module, and the module is symmetrically formed through the connecting member, thereby completing the current limiter. Therefore, it is possible to obtain a higher insulation resistance by locating an input terminal and an output terminal of the current limiter opposite to each other to stabilize insulation characteristics, though using the same length as a conventional superconducting wire. In addition, it is possible to reduce a temperature increasing width, and rapidly recovering a re-cooling speed of the current limiter.

Owner:HYUNDAI HEAVY IND CO LTD

Halogen-free soldering flux for lead-free solder paste

ActiveCN102126094AHigh insulation resistanceImprove welding effectWelding/cutting media/materialsSoldering mediaOrganic acidHalogen

The invention discloses a halogen-free soldering flux for lead-free solder paste, which comprises the following raw materials in part by mass: 8 to 12 parts of organic acid activator, 36 to 50 parts of modified rosin, 9.9 to 13.5 parts of thixotropic agent, 1.5 to 8.8 parts of tackifier, 0.5 to 2 parts of antioxidant, 0.5 to 2 parts of pH regulator, 0.2 to 1 part of surfactant, 0.1 to 0.3 part ofchelant and 10.4 to 48.7 parts of organic solvent. The soldering flux does not contain halogen compounds, is environment-friendly, can obviously improve dielectric resistance of residue after soldering, promotes wetting and improves the welding performance of the solder paste; in addition, the solder paste containing the soldering flux ensures that the residue after soldering is light in color and clear.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

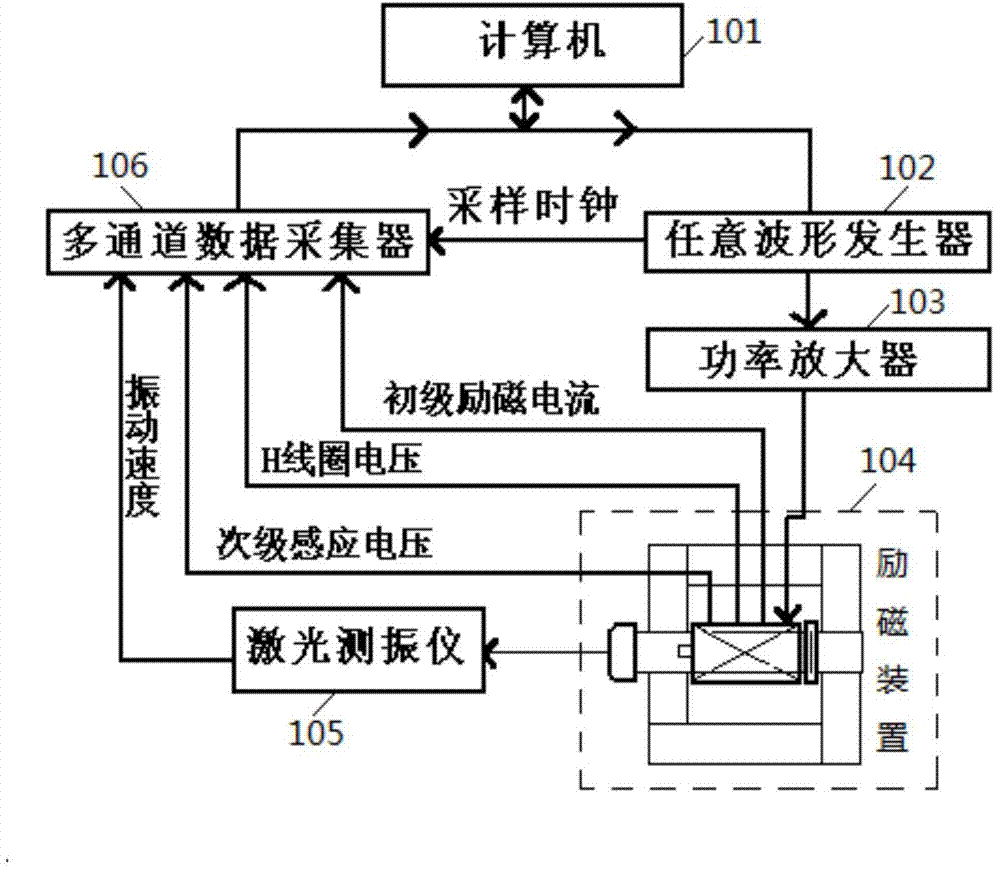

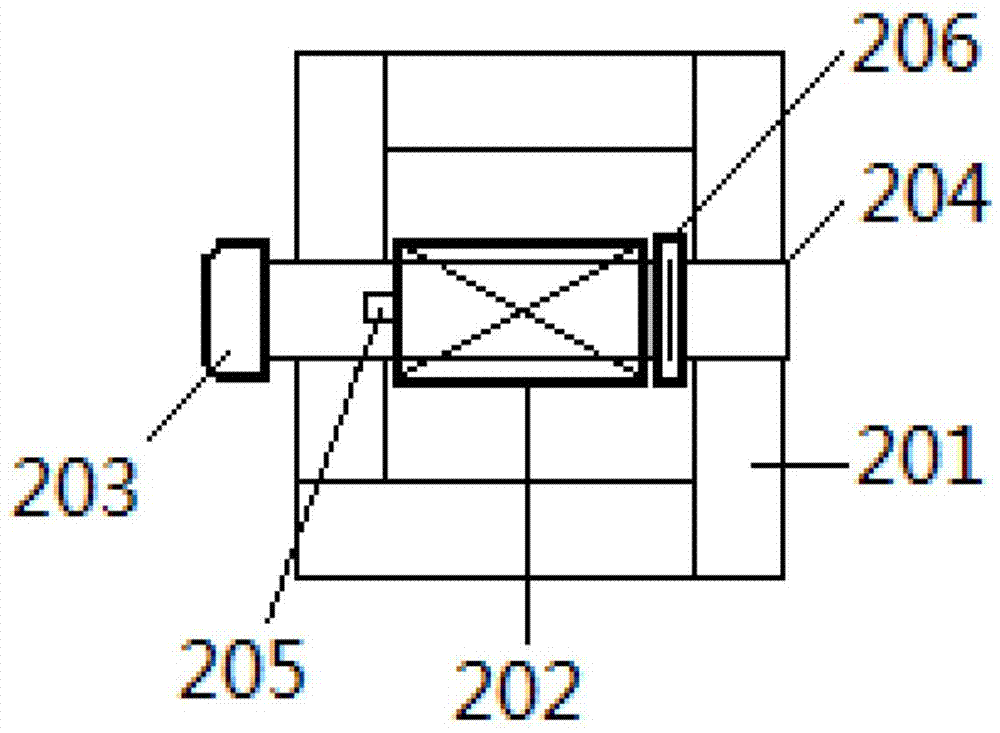

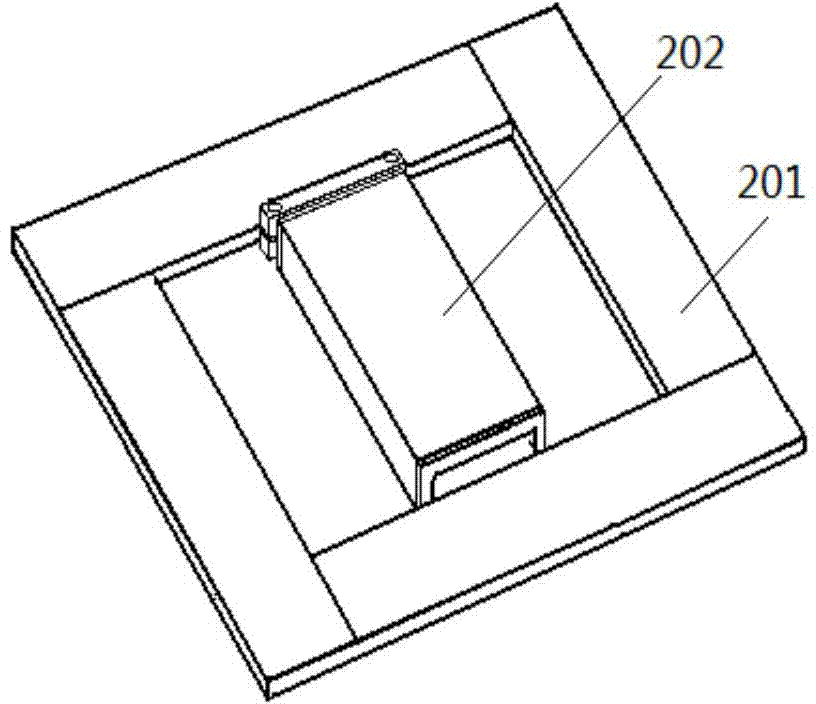

Electrical sheet steel magnetostriction measurement system and method

InactiveCN104122516AImprove measurement accuracyGood repeatabilityMagnetostrictive property measurementsMagnetizationData acquisition

The invention relates to an electrical sheet steel magnetostriction measurement system and method. A computer controls an arbitrary waveform generator to produce waveforms, the arbitrary waveform generator is controlled to change the waveforms according to data uploaded by a multi-channel data acquisition unit, an iterative algorithm is utilized to obtain expected waveforms of magnetic polarization intensity induced voltage, and a magnetostriction loop line of a measured sample is further calculated. A power amplifier performs amplification processing on a received signal, and an excitation device fixes the measured sample to enable the measured sample to work in the closed magnetic circuit condition and exerts stress in the magnetization direction. A laser vibration measurement instrument is used for measuring the vibration speed. The multi-channel data acquisition unit is used for acquiring voltage, current and the vibration speed. The electrical sheet steel magnetostriction measurement system and method achieves measurement of the electrical sheet steel magnetostriction loop line under the conditions of the closed magnetic circuit and the stress, meets a general using environment of an electrical sheet steel, utilizes the iteration method to enable the magnetic polarization intensity induced voltage waveforms to be sine waves, replaces a traditional analog feedback loop and has the advantages of being not prone to oscillation, wide in frequency range and the like.

Owner:NAT INST OF METROLOGY CHINA

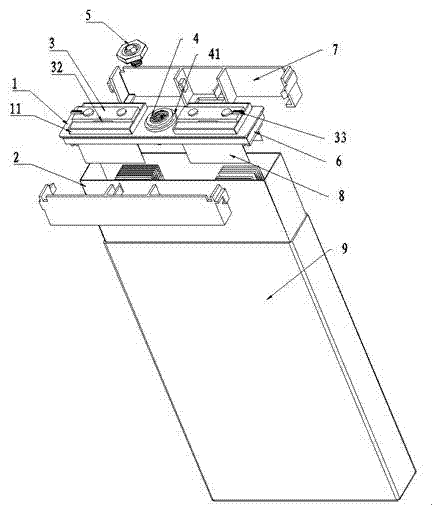

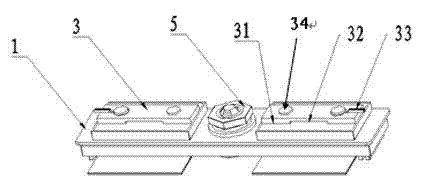

Full-sealed anti-corrosion integrated welded lithium ion battery

InactiveCN102738507AImprove securityHigh insulation resistanceSecondary cellsCell lids/coversEngineeringLithium-ion battery

The invention relates to a full-sealed anti-corrosion integrated welded lithium ion battery, comprising a battery core, a full-sealed cover plate, a full-sealed bush and a shell, wherein the full-sealed cover plate is arranged at the top of the battery core and is connected with the battery core; the full-sealed liner is provided with a top opening; the battery core is sleeved into the full-sealed bush from the top opening, namely, the full-sealed bush completely covers the bottom and the periphery of the battery core; the shell is provided with a top opening; the battery core covered by the full-sealed liner is sleeved into the shell from the top opening of the shell; and the shell is connected with the full-sealed cover plate through welding. According to the full-sealed anti-corrosion integrated welded lithium ion battery, the full sealing of the inner part of the battery is realized, so that electrolyte cannot be contacted with the shell or the cover plate in a liquid injection process; and therefore, the insulation resistance of the shell is enhanced and the safety of the battery is improved.

Owner:SHANGHAI AEROSPACE POWER TECH

High flux environment-friendly tin wire and preparation method thereof

InactiveCN105772979AImprove plasticityImprove insulation performanceWelding/cutting media/materialsSoldering mediaHigh fluxBenzotriazole

The invention discloses a high flux environment-friendly tin wire and a preparation method thereof. The tin wire consists of a solder and a flux, wherein the content of the solder is 94.2-96.7 mass%, and the content of the flux is 3.3-5.8 mass%; the solder comprises the following alloy components in percentage by mass: 95.0-99.2% of tin, 0.1-3.0% of silver, 0.3-2.2% of copper and 0.01-0.1% of nickel; the flux comprises the following components in percentage by mass: 72-85% of rosin, 1.8-4.5% of solvent, 5-10% of synthetic resins, 0.7-1.2% of benzotriazole, 5-10% of activating agents and 1-5% of surface active agents; and the diameter of the tin wire is preferably 0.1-2 mm. The high flux environment-friendly tin wire is uniform and smooth in surface, is excellent in fluidity after melting, is excellent in wettability, is less in splash during welding, is free of corrosion in residues after welding, is green and environment-friendly, and is low in cost.

Owner:SUZHOU YIFEITE ELECTRONICS TECH CO LTD

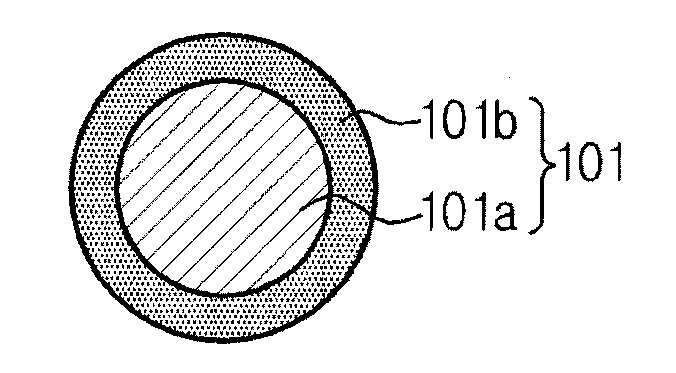

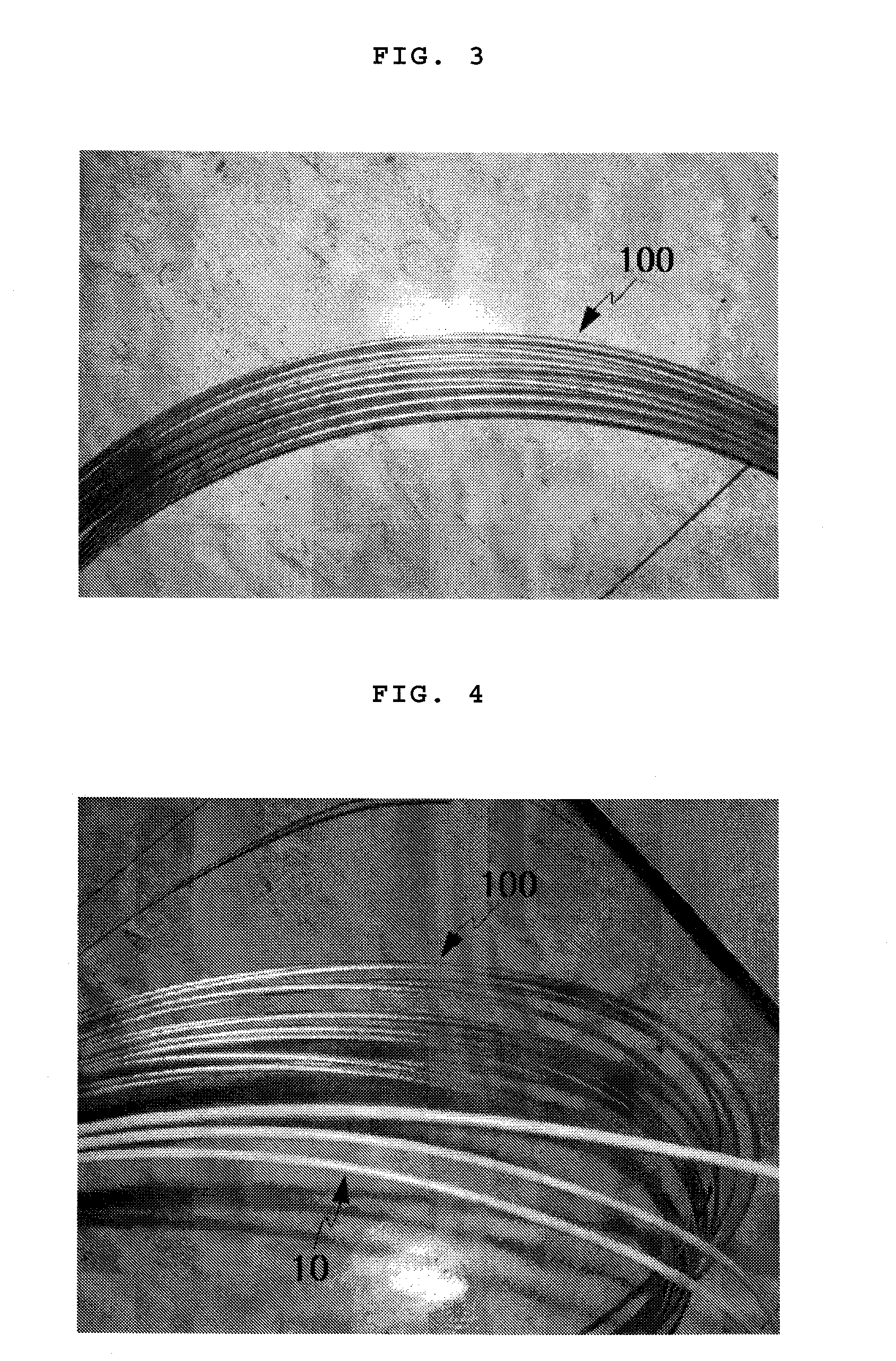

Electric cable for nuclear power plants with improved durability and fabrication method thereof

InactiveUS20110127065A1High tensile strengthHigh elongationPlastic/resin/waxes insulatorsInsulated cablesNuclear powerPolyether ether ketone

Disclosed is a method for fabricating an electric cable for nuclear power plants, comprising: pre-heating a conductor wire; melting a PEEK (poly ether ether ketone) material and extruding the PEEK material in the direction of the conductor wire, to form an insulator such that the insulator coats the surface of the conductor wire; and cooling the insulator quickly.

Owner:LG CABLE LTD (KR)

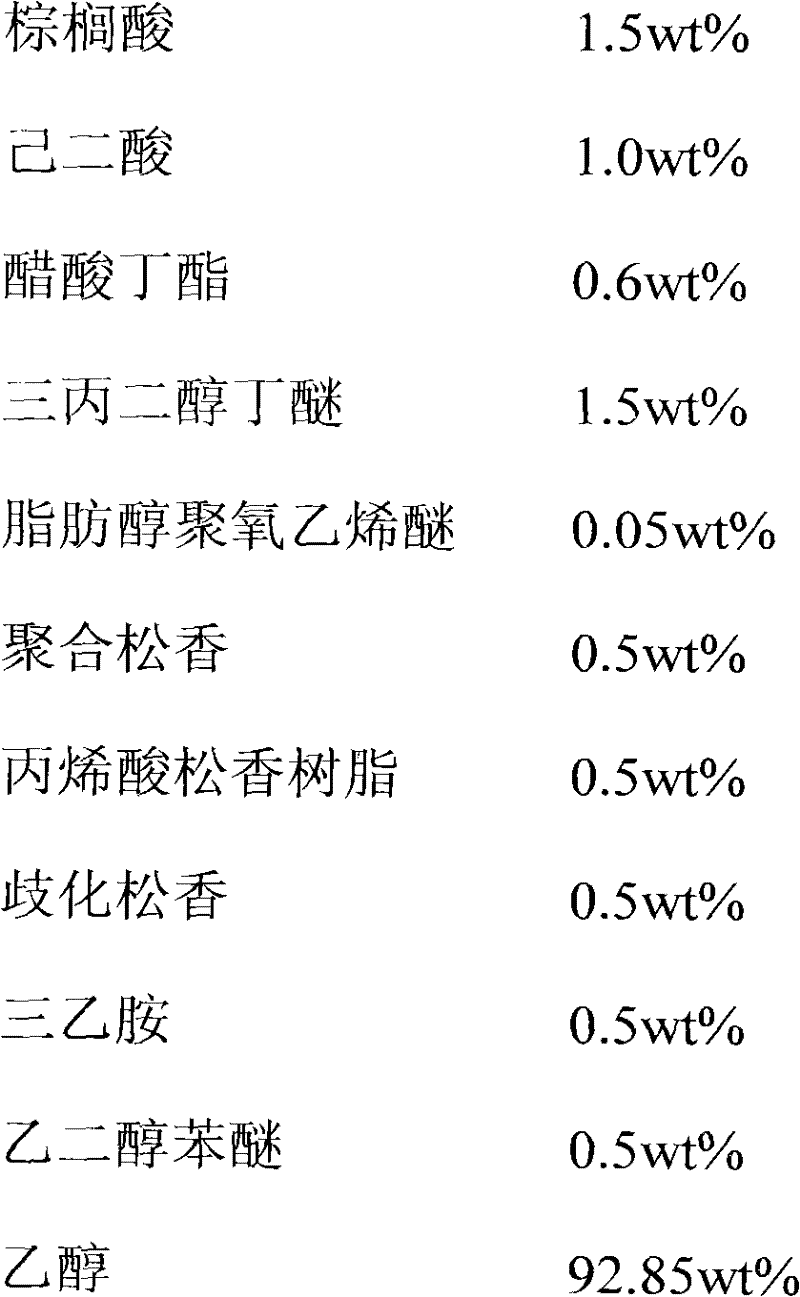

Rosin-based flux for ZnSn-based lead free solder and preparation method thereof

InactiveCN102581522ALow solidsHigh insulation resistanceWelding/cutting media/materialsSoldering mediaRosinSoldering

Rosin-based flux for a ZnSn-based lead free solder comprises rosin, an organic acidity activator, a corrosion inhibitor, a surfactant and an organic solvent. According to the invention, the solder can be additionally provided in injection, spraying or atomization method, the addition amount is easy to accurately control, the disadvantage that the prior soldering flux is hard to brush is overcome, no paste agent, stabilizing agent or thixotropic agent or other substances containing high solid content are included, the solid content of the solder is low, the wetting power to ZnSn-based solder is strong, the residue after welding is little, a metal oxide-film can be effectively removed, the expansion rate is not less than 75%, the effects of film forming and base material protection are possessed, and the preparation method is simple and practicable.

Owner:HENAN UNIV OF SCI & TECH

Dielectric ceramic composition, electronic element and composite electric element

A dielectric ceramic composition includes a main ingredient containing 40-65% by weight of SiO2-K2O-B2O3-based glass, 35-50% by weight of quartz, and the balance being amorphous silica; and a subsidiary ingredient containing 1.5-4% by weight of alumina and 5-20% by weight of K2O-MO-SiO2-B2O3-based glass ("MO" is at least one selected from a group consisting of CaO and SrO), relative to the main ingredient of 100 weight %.

Owner:TDK CORPARATION

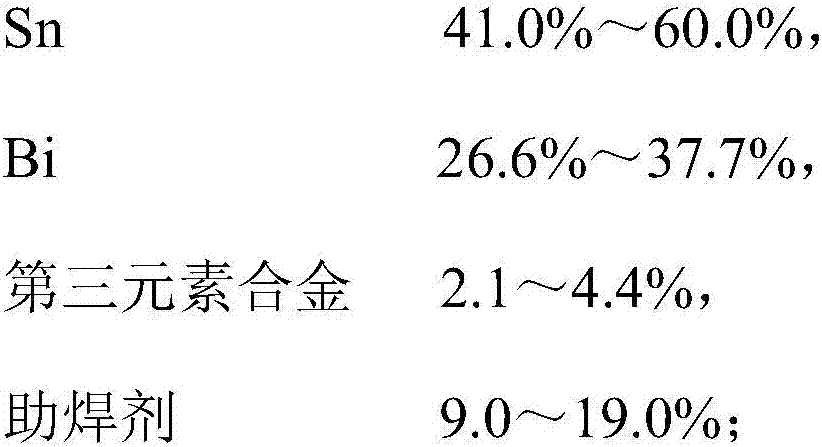

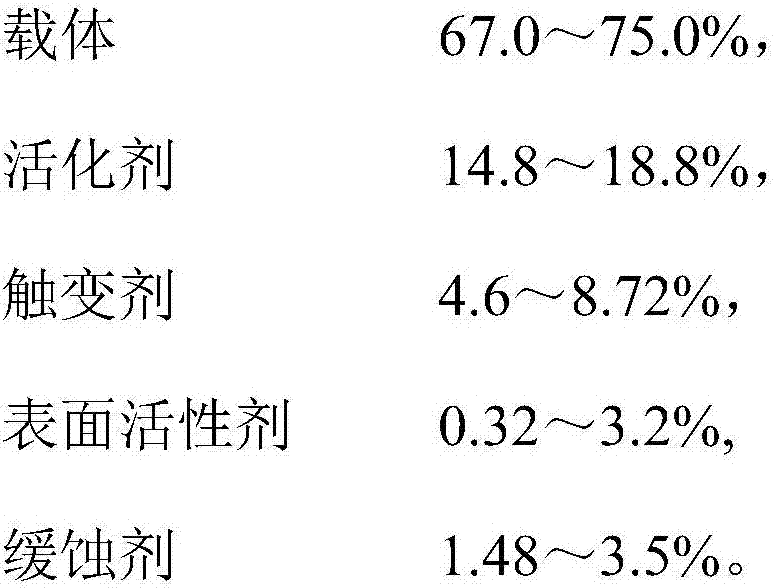

Environment-friendly and low-temperature residue-free solder paste and preparing method thereof

ActiveCN107088716AMeet welding needsHigh insulation resistanceWelding/cutting media/materialsSoldering mediaAlloySolid solution

The invention relates to environment-friendly and low-temperature residue-free solder paste and a preparing method thereof. According to the technical scheme, the environment-friendly and low-temperature residue-free solder paste is characterized in that the solder paste comprises, by weight, 41.0%-60.0% of Sn, 26.6%-37.7% of Bi, 2.1%-4.4% of a third element alloy and 9.0%-19.0% of scaling powder; and the scaling powder comprises, by weight, 67.0%-75.0% of a carrier, 14.8%-18.8% of an activating agent, 4.6%-8.72% of a thixotropic agent, 0.32%-3.2% of a surface active agent and 1.48%-3.5% of corrosion inhibitor. The environment-friendly and low-temperature residue-free solder paste is provided, halogen-free components are adopted in a formula, volatile components are avoided in the tin paste, and smells are avoided during using. After welding, residues are colorless and transparent, and the effect of replacing Pb containing tin paste or halogen-containing tin paste is achieved. Under the low-temperature welding condition, nano aluminum powder is added, a high-temperature solid solution is formed during welding to serve as an auxiliary part for supplementary welding, poor welding of a Sn-Bi alloy is effectively improved, and the welding requirement for aluminum components on the surface of an electronic component can be met; and meanwhile, the storage period of the tin paste is prolonged, and better wettability is brought.

Owner:中山翰华锡业有限公司

Silane halogen-free flame retardant cross-linking polyolefine cable and manufacturing method thereof

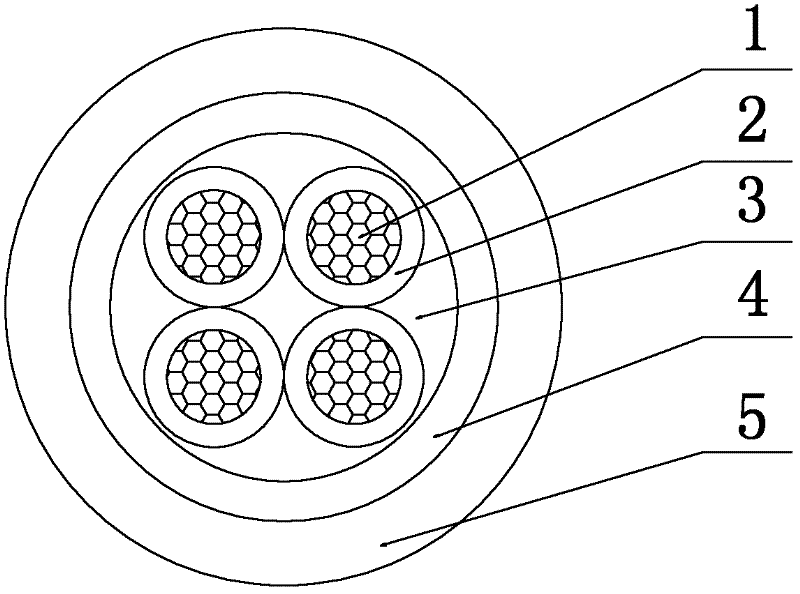

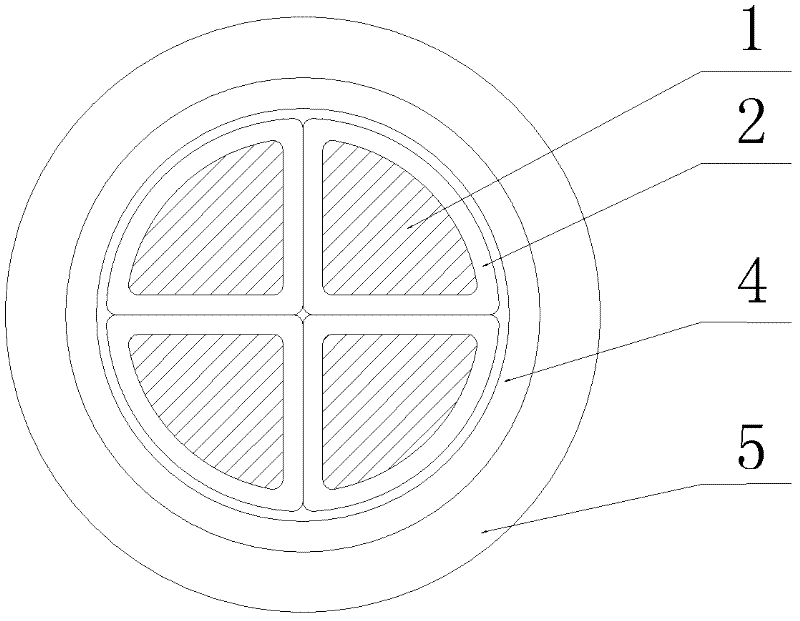

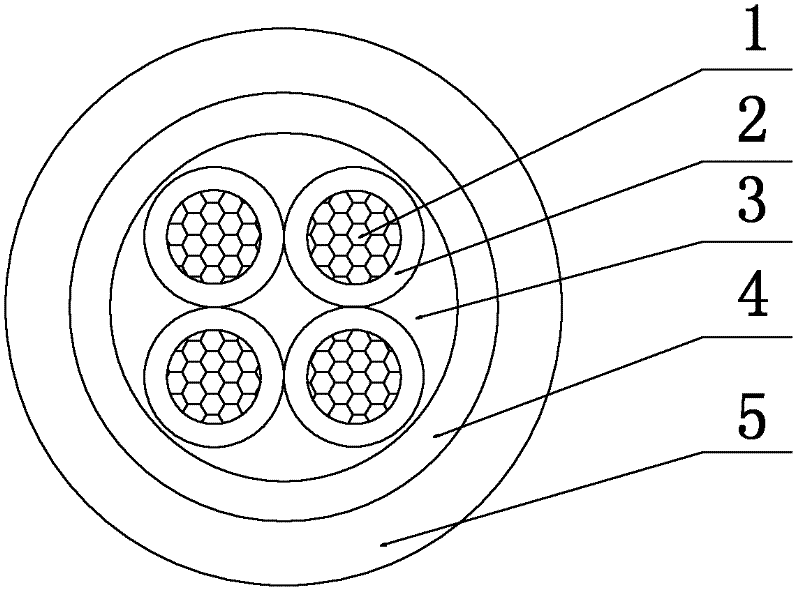

InactiveCN102509577AMeet performance requirementsGuaranteed temperature resistanceNon-insulated conductorsInsulated cablesCross-linkElectrical conductor

The invention relates to a silane halogen-free flame retardant cross-linking polyolefine cable. The cable is successively composed of a conductor, an insulating layer, a packing layer, a flame retardant oxygen barrier layer and an outer protective layer, and is characterized in that the insulating layer adopts a low-fume halogen-free flame retardant silane cross-linking polyolefine material, a halogen-free high flame retardant bag belt is wrapped outside a cable core so as to form the oxygen barrier layer, and the outer protective layer adopts a thermoplastic low-fume halogen-free flame retardant silane cross-linking polyolefine material; low-fume halogen-free flame retardant silane cross-linking polyolefine is prepared by a two-step method, namely adding a grafted silane copolymer into a catalysis master batch at the mass ratio of 95:5 and then extruding out by virtue of a common extruding machine with the phi of 90 / 25; and cross linkage is realized through any of the following methods: a, immerging in hot water at 90-90DEG C, and performing cross linkage for 2-4 hours; and b, exposing to low pressure steam humidity at 0.15bar, and performing cross linkage for 3-5 hours. The cable provided by the invention has the advantages of greatly improving the insulating property, and meeting the requirements of an environmentally-friendly cable.

Owner:南洋电缆集团有限公司

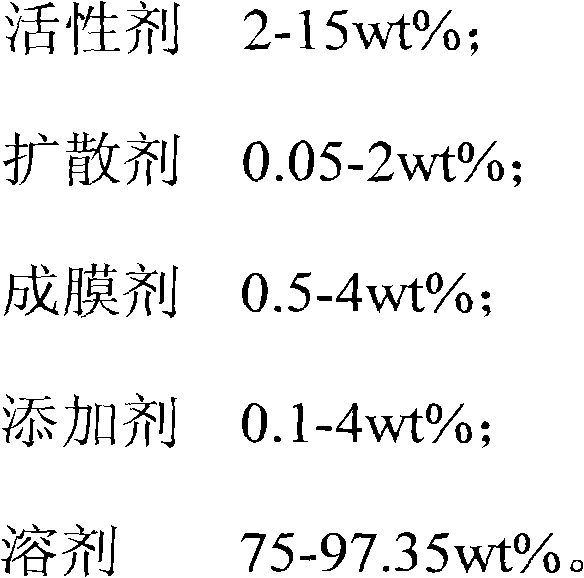

Flux

InactiveCN102513733AHigh insulation resistanceModerate weldabilityWelding/cutting media/materialsSoldering mediaSolventMaterials science

The invention belongs to the field of welding materials, and particularly relates to a halogen-free, low-residue, high-impedance and cleaning-free flux, which comprises the following components: 2-15wt% of activator, 0.05-2wt% of dispersing agent, 0.5-4wt% of film-forming agent, 0.1-4wt% of additive and 75-97.35wt% of solvent. Compared with the prior art, the flux has the advantages that the expansion ratio of the flux is higher than 80% of the standard, the flux is moderate in weldability and halogen-free, ionic contamination is at the highest I grade, the flux is applicable to high-reliability electronic products, the surface insulation resistance of the flux is at a 1010 grade after a copper mirror corrosion test, and the flux has the advantages that the flux is high in insulation impedance, high in insulation resistance, low in electric leakage risk, low in solid content, environment-friendly, clean and cleaning-free, residue is less, a post-weld board is tack-free and the like.

Owner:广东中实金属有限公司

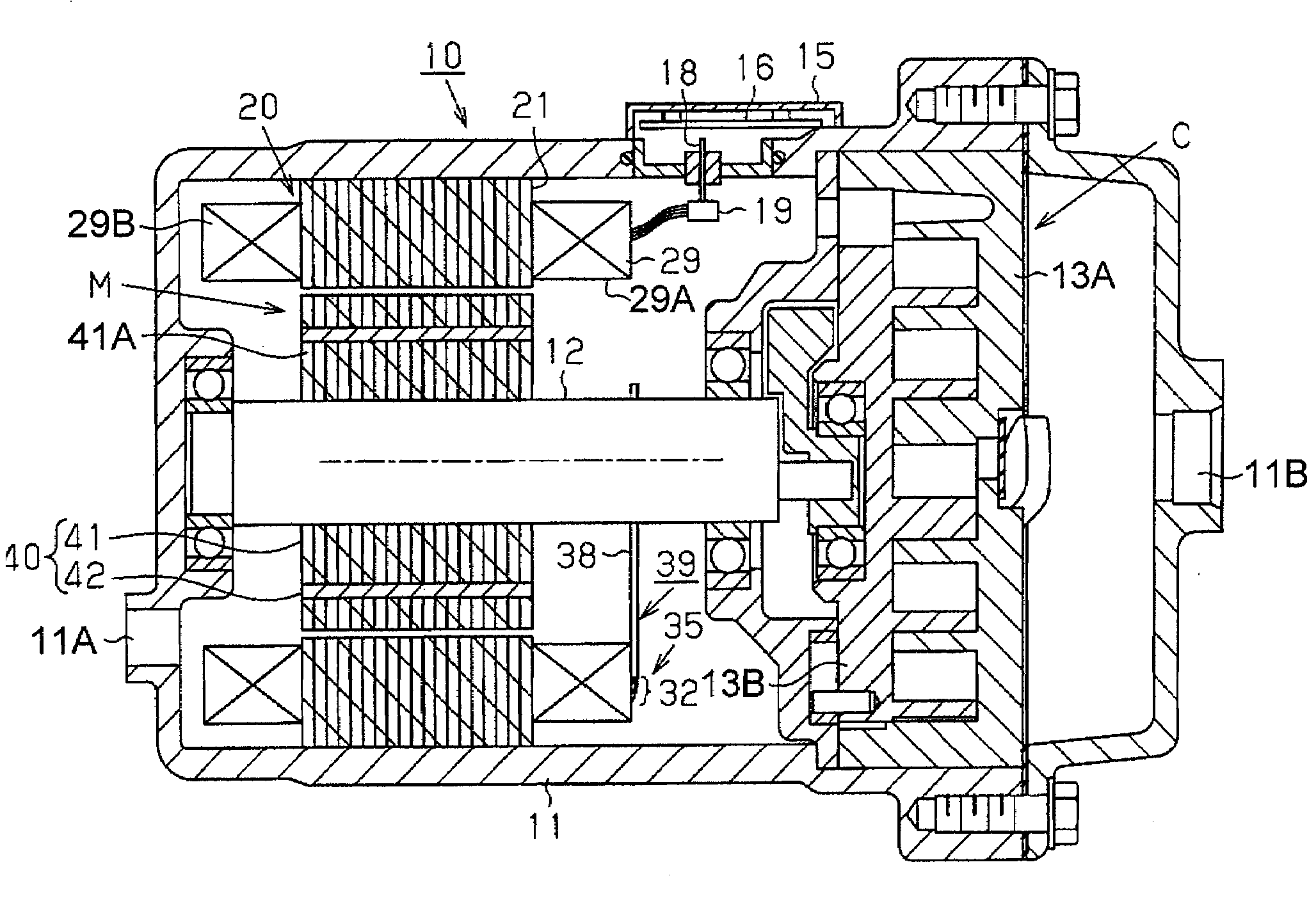

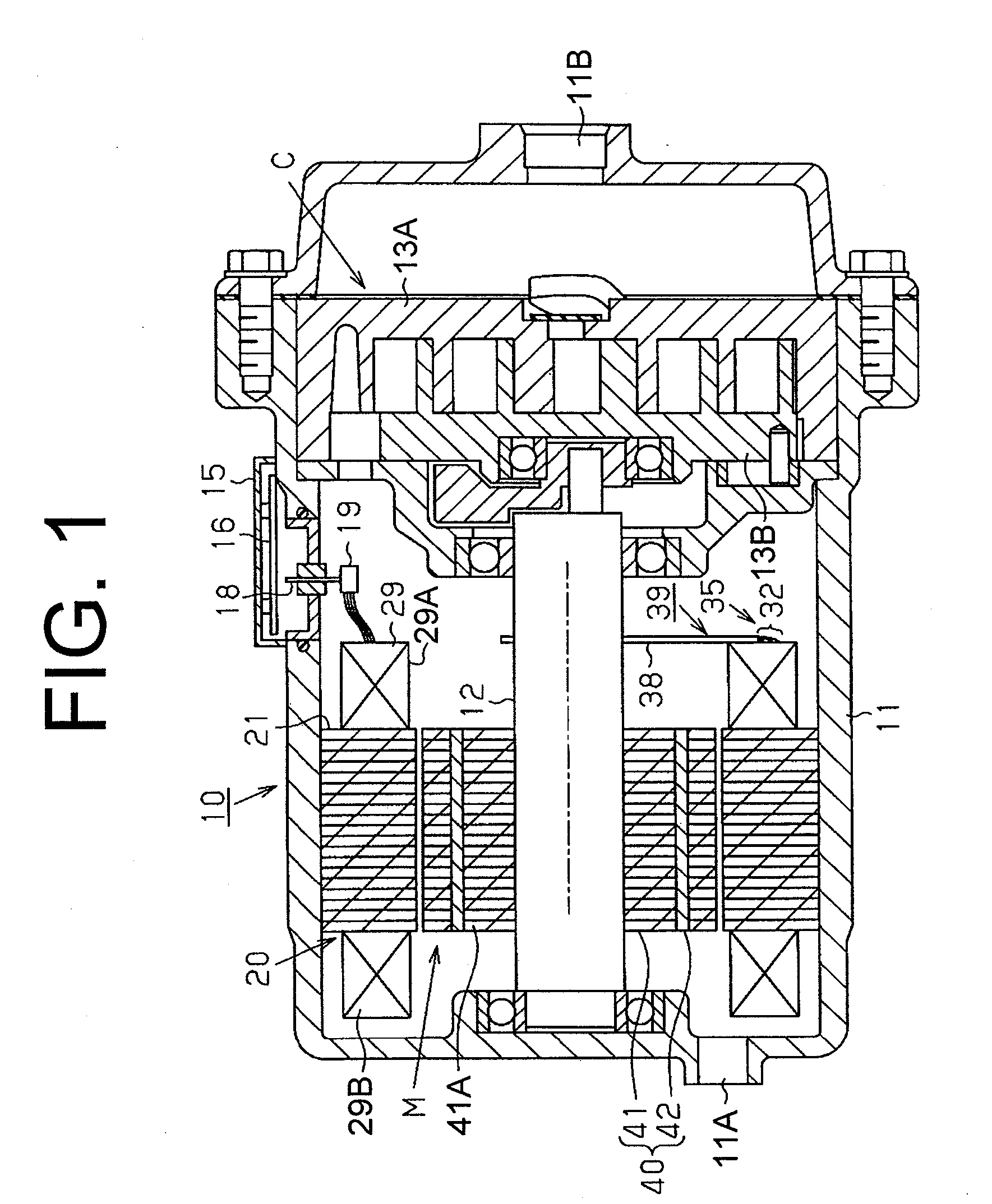

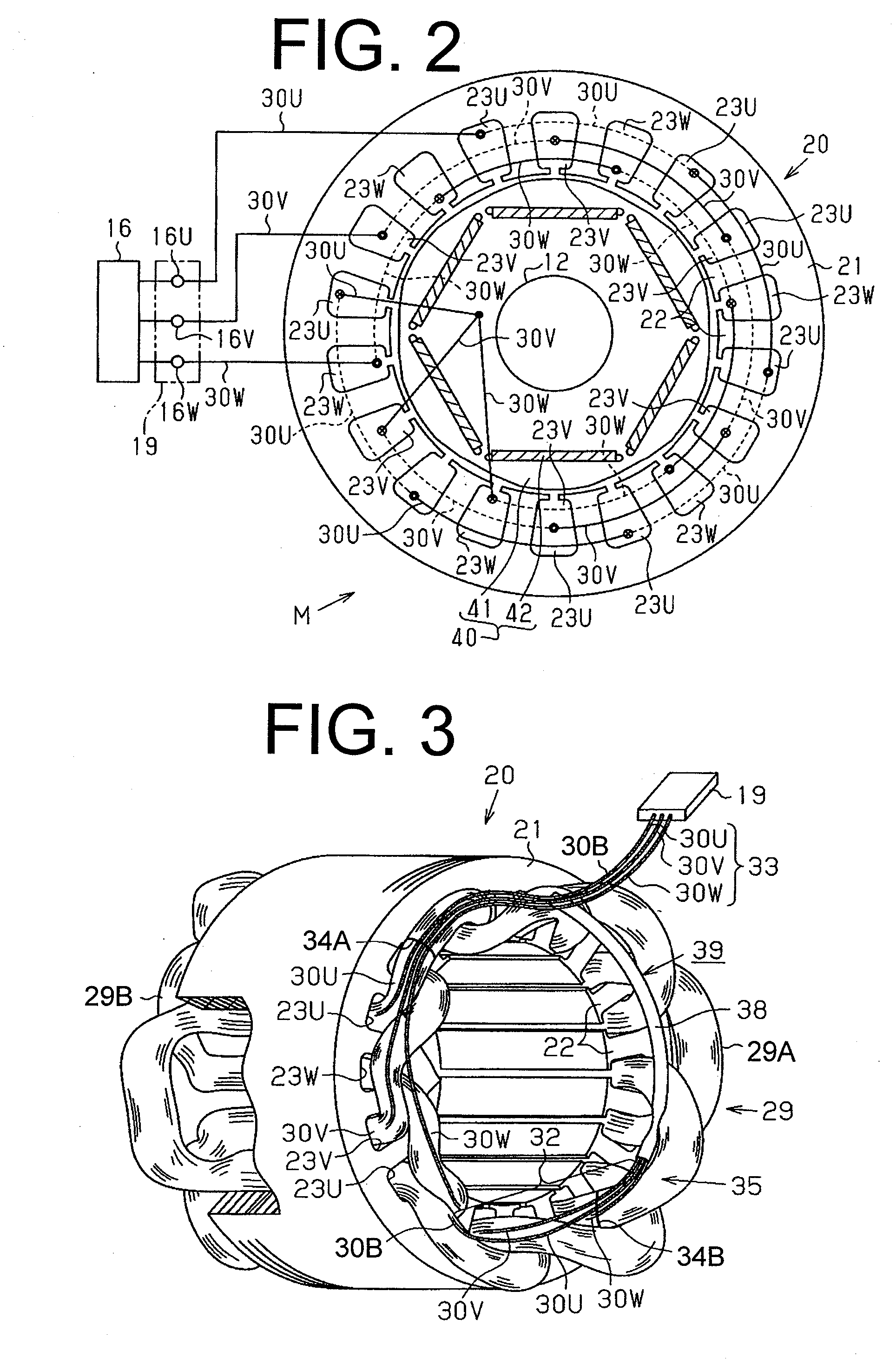

Motor-driven compressor

InactiveUS20090269222A1High insulation resistanceIncrease creepage distanceRotary/oscillating piston combinations for elastic fluidsWindingsElectrical resistance and conductanceMotor drive

An electric motor includes a cylindrical stator that is formed with a plurality of slots. The cylindrical stator has polyphase coils that are formed by winding a plurality of conductive wires in the slots to have polyphase, a wire bundle and an insulating tube covering the wire bundle. Each conductive wire includes a core wire and an insulator that covering the core wire. The wire bundle has a drawing portion, a connecting portion and an elongated portion that is elongated between the drawing portion and the connecting portion for increasing creepage distance between the connecting portion and the housing thereby to increase insulation resistance. The connecting portion of the wire bundle provides a neutral point of the electric motor. The elongated portion and the connecting portion of the wire bundle are covered with the insulating tube.

Owner:TOYOTA IND CORP

Fire extinguishing aerosol composition suitable for use for precise electric equipment

InactiveCN101088578AHigh insulation resistanceGuaranteed fire extinguishing performanceFire rescueFire extinguisherAdhesivePotassium

The present invention relates to one kind of fire extinguishing aerosol composition suitable for use for precise electric equipment. The fire extinguishing aerosol composition includes oxidant mixture comprising potassium salt in 5-15 wt% and strontium salt in 52-60 wt%; flammable of guanidines, azoles and / or their salt; additive of metal powder, metal oxide powder, carbon powder, inorganic salt, organic acid and / or organic salt; and adhesive of resin, cellulose, ester and / or polymer; with all the components having size below 50 micron. It is used in extinguishing fire of precise electric equipment, and can ensure the insulating resistance not lower than 100 megaohms. The present invention is environment friendly.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

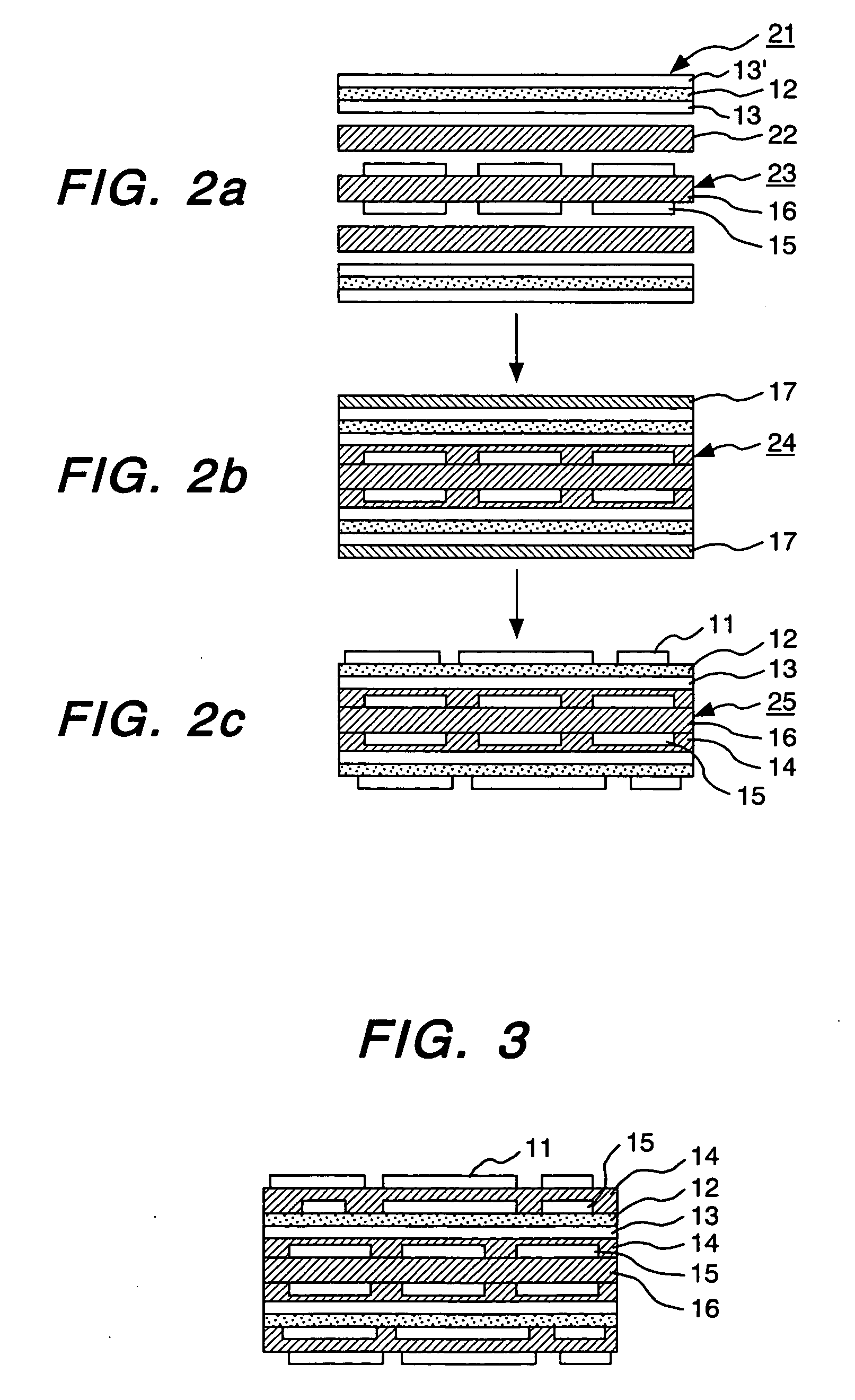

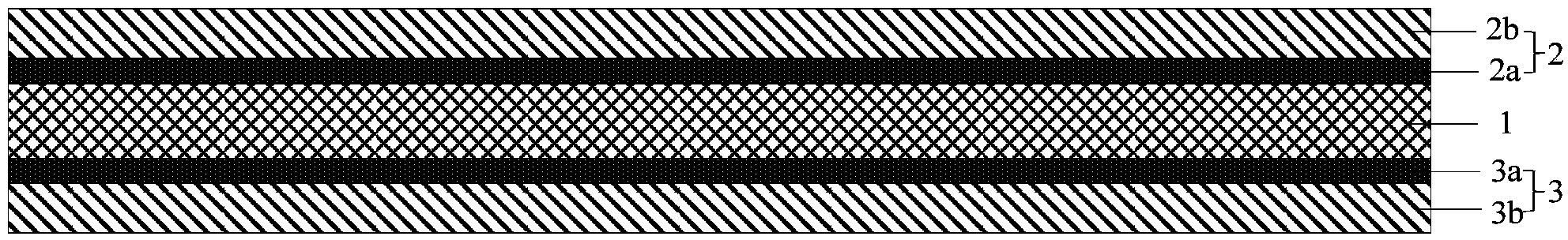

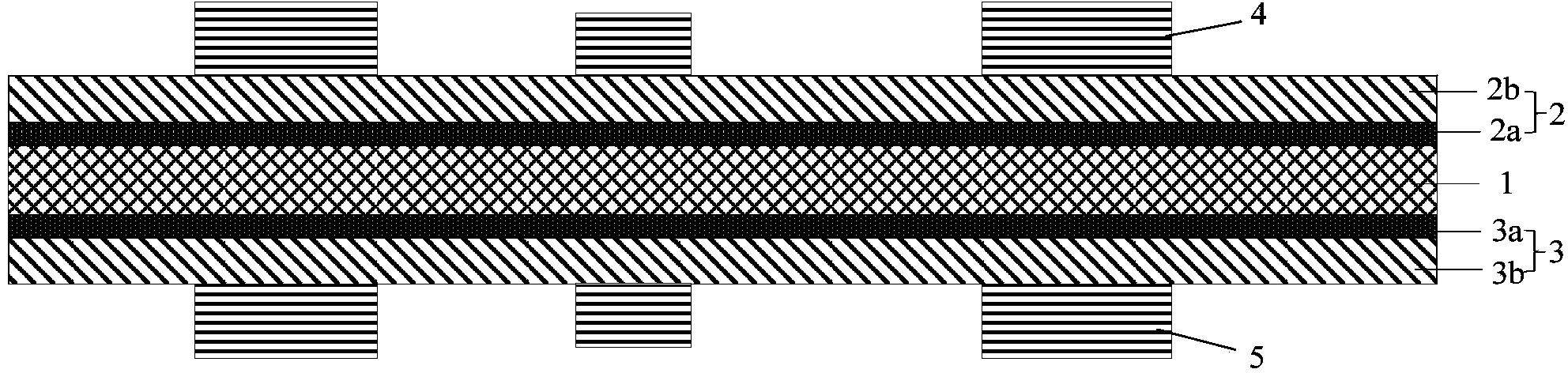

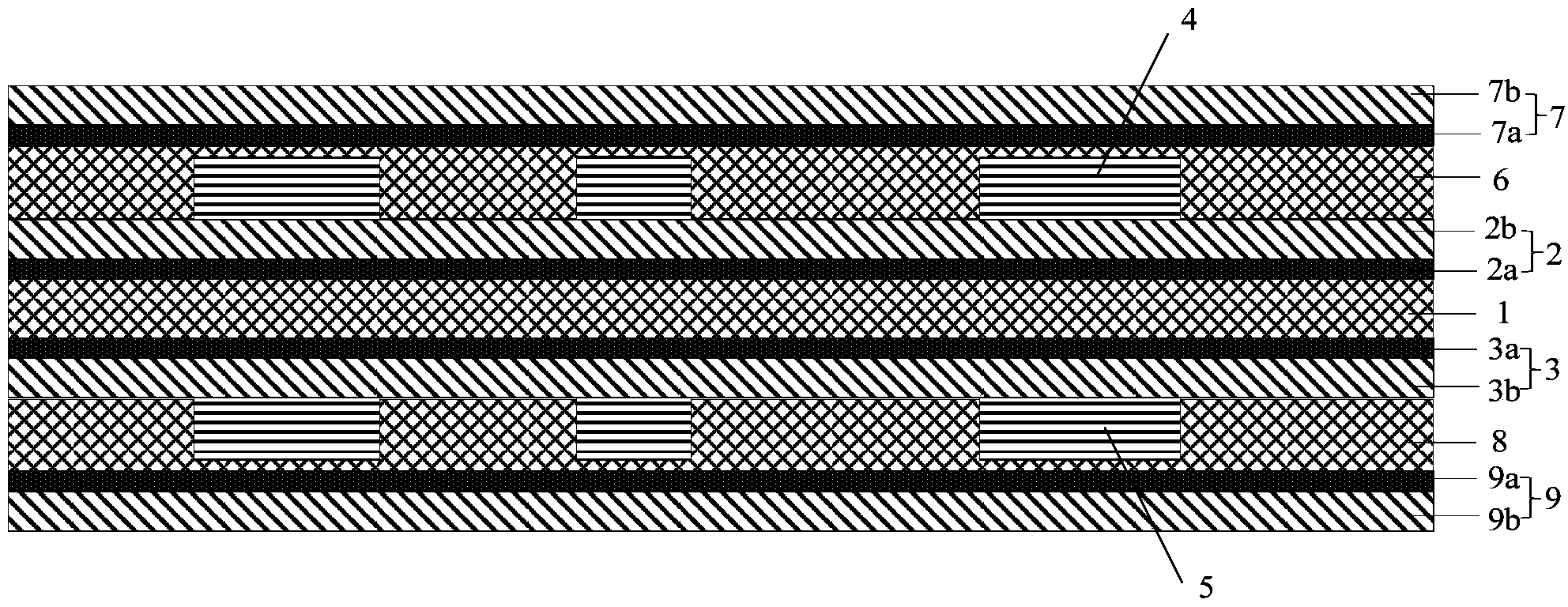

Method for manufacturing coreless substrates of symmetrical structure

ActiveCN104244597AImprove rigidityImprove flatnessPrinted circuit manufactureInter layerElectrical performance

The invention provides a method for manufacturing coreless substrates of a symmetrical structure. Compared with the prior art, the rigidity of the whole coreless substrates is greatly improved, and mechanical stress problems such as warping can be solved better. Two identical coreless substrates are obtained after double-face machining is performed on one core plate and final stripping is performed. Due to the machining technology for the symmetrical structure, the number of machining times is reduced, the machining cost for production can be reduced, the reliability of the coreless substrates can be improved, and the coreless substrates can achieve good electrical performance. The method for manufacturing the coreless substrates of the symmetrical structure mainly includes the steps of the first time of double-face pressing fit, manufacturing of inner layer circuit patterns, the second time of double-face pressing fit, manufacturing of blind holes, manufacturing of outer layer circuit patterns, etching of outer layer base copper foil, separation, single-face etching, resistance welding preventing processing and the like. According to the method, both faces of each integrated substrate are pressed and not prone to warping, and inter layer carrier copper foil on the front side and the back side is kept before separation. Therefore, both the rigidity and the flatness of the substrates are kept good in the manufacturing process, the coreless substrates can be manufactured at a time, and cost is reduced.

Owner:NAT CENT FOR ADVANCED PACKAGING

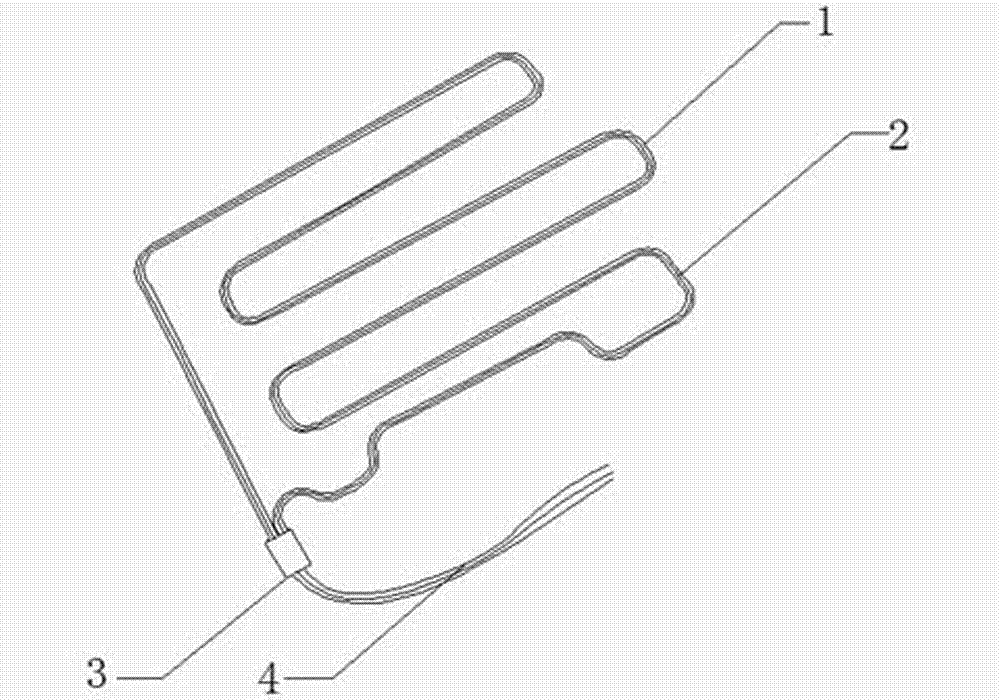

Heating pipe for defrosting

InactiveCN102740518AImprove adaptabilityHigh insulation resistanceHeating element shapesHigh humidityEngineering

The invention discloses a heating pipe for defrosting, which comprises a pipe body, wherein an electric heating wire is arranged in the pipe body, both ends of the pipe body are fixedly connected with an insulating layer, the insulating layer is connected with conducting wires, the material of the pipe body is an aluminum foil, a clearance in the pipe of the pipe body is filled with compacted magnesia sand, the material of the electric heating wire is ferrochromium, the pipe body is designed into an E shape, and the number of the conducting wires is 3. The structure is simple. The aluminum foil pipe body has very good adaptability under the conditions of low temperature and high humidity, and the insulation resistance of the low-temperature state of a pipe-shaped electric heating element is enhanced by filling the compacted magnesia sand. Meanwhile, leakage current at a low-temperature state is lowered, and the E-shaped pipe body which is exclusively arranged can be inlaid on the fins of an air cooler and a condenser and at a chassis of a water accumulating disk more conveniently for defrosting.

Owner:ANHUI HAOLAIXI TECH

Halogen-free no-clean flux for tin wire core

InactiveCN102284809AImprove solderabilityNo splashWelding/cutting media/materialsSoldering mediaSolventElectron

The invention relates to a no-halogen cleaning-free soldering flux for a tin wire core, which comprises the following components by mass percentage: 0.5-5 percent of tin oxalate, 0.5-25 percent of organic acid type activator and 0-3 percent of cosolvent, with the rest adopting rosin. Since the tin oxalate is used as an activator along with the organic acid type activators and no halogen is adopted, the soldering flux has good welding performance, no spattering and little smoke and odor can be caused during welding, the quantity of residues can be greatly decreased after welding, a plate surface is free from corrosion, welding points are full and bright, and the insulation resistance is high. The soldering flux is suitable for electronic precision welding with high reliability and solderability requirements.

Owner:宁波喜汉锡焊料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com