Dielectric paste for metal aluminum substrate thick film circuit and preparation method thereof

A technology of dielectric paste and thick film circuit, which is applied in the direction of circuits, electrical components, electric solid devices, etc. It can solve the problems of reduced thermal conductivity, the working environment temperature of electronic components should not be too high, and the circuit is easy to foam, etc., to achieve insulation resistance High, excellent thixotropy and anti-settling effect, the effect of high breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

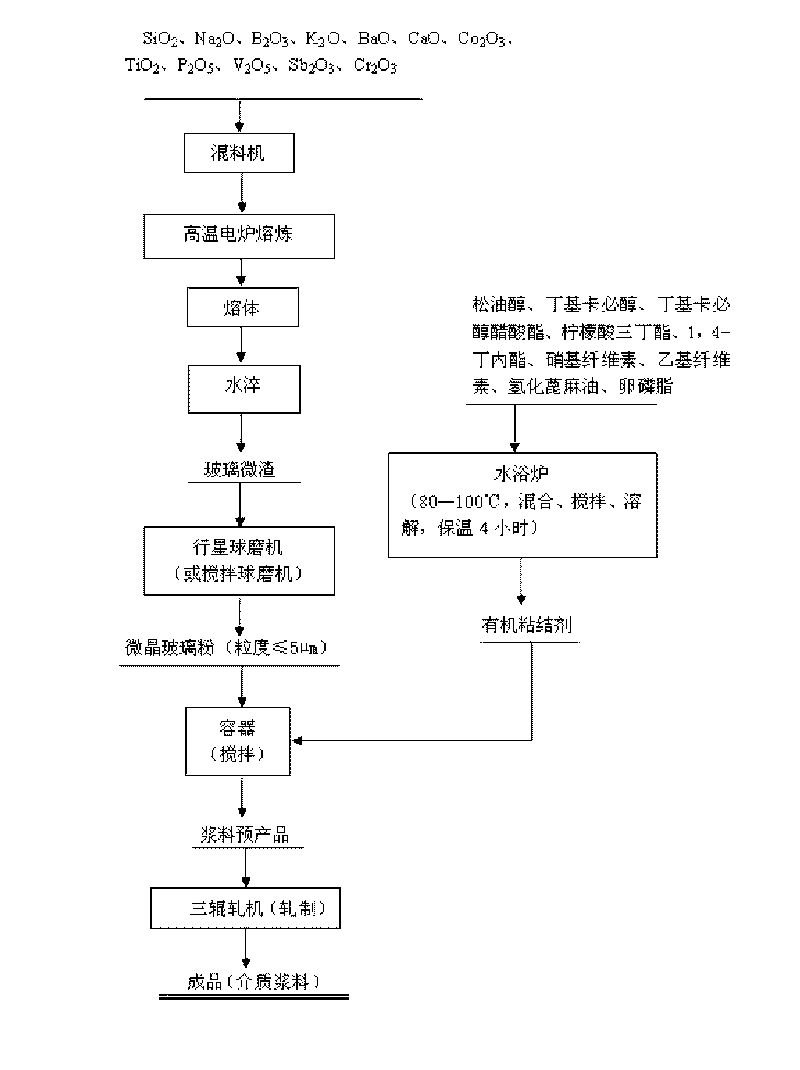

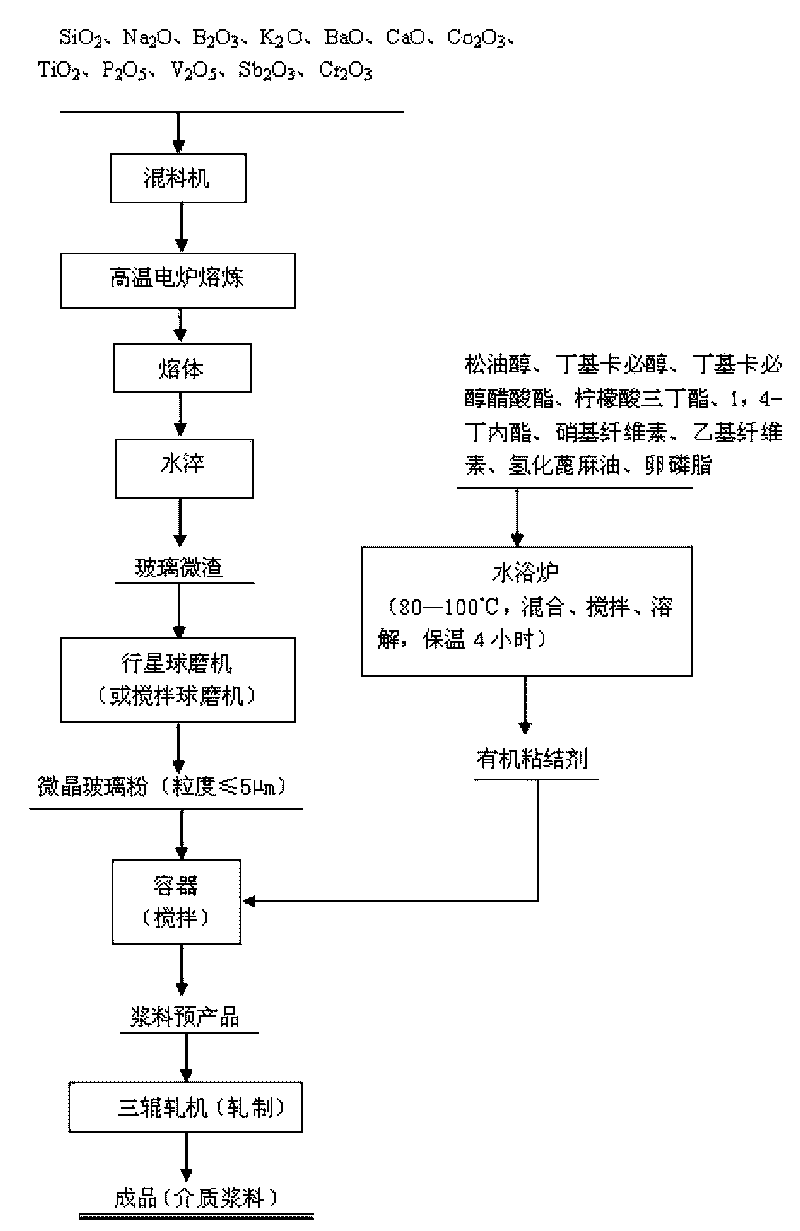

[0020] The preparation method of the dielectric slurry for thick-film circuit of metal aluminum substrate of the present invention is characterized in that the following steps:

[0021] (1) To prepare glass-ceramic powder, mix the components of glass-ceramic powder in the mixer according to the above-mentioned ratio range, and then put them into a high-temperature electric furnace for smelting, quench the melt obtained in water to obtain glass micro-slag, and mix the glass-ceramic powder with water. The fine slag is ground in a ball mill to obtain glass-ceramic powder with an average particle size not greater than 5 microns;

[0022] (2) Prepare an organic binder, mix and dissolve each composition of the organic binder in a water-bath furnace according to the above ratio range to form an organic binder and control its viscosity to be 100-300mPa·s;

[0023] (3) Put the prepared glass-ceramic powder and organic binder in the container according to the above-mentioned ratio range...

example 1

[0026] Preparation of glass-ceramic powder, composition and weight ratio of glass-ceramic powder: SiO 2 20 parts, Na 2 O 20 parts, K 2 O 15 parts, BaO 1 part, CaO 3 parts, TiO 2 20 copies, P 2 o 5 5 copies, V 2 o 5 10 parts, Sb 2 o 3 5 parts; the above composition is placed in a high-temperature electric furnace, the melting temperature is 1350 ° C, heat preservation for 1 hour, water quenching, to obtain glass slag, and the glass slag is ground in a ball mill to obtain glass ceramics with an average particle size of no more than 5 microns pink;

[0027] Preparation and dissolution process of organic binder, composition and weight ratio of organic binder: 75 parts of terpineol, 10 parts of butyl carbitol acetate, 10 parts of tributyl citrate, 1,4-butyl 1 part of lactone, 3 parts of nitrocellulose, 0.6 part of hydrogenated castor oil, and 0.4 part of lecithin. The dissolution process is to mix, stir and dissolve the above-mentioned composition in a water bath furnace a...

example 2

[0034]Weight ratio of glass-ceramics: SiO 2 40 parts, Na 2 O 10 parts, B 2 o 3 10 copies, K 2 20 parts of O, 5 parts of BaO, Co 2 o 3 5 parts, TiO 2 3 copies, V 2 o 5 1 part, Sb 2 o 3 3 copies;

[0035] Organic binder weight ratio and dissolution process: 40 parts of terpineol, 30 parts of butyl carbitol, 10 parts of butyl carbitol acetate, 10 parts of tributyl citrate, 1,4-butyrolactone 2 parts, 5 parts of ethyl cellulose, 2 parts of hydrogenated castor oil, and 1 part of lecithin. The dissolution process is to mix, stir and dissolve the components of the above-mentioned organic binder in a water bath furnace at a temperature of 90 ° C, and keep it warm. 4 hours.

[0036] The weight ratio of glass-ceramic powder and organic binder in the slurry mixing process is 70 parts: 30 parts, and the solid content of the medium slurry of output is 70%, all the other are the same as example 1

[0037] The performance list of media slurry is as follows:

[0038] col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com