Patents

Literature

1788 results about "Turpentine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Turpentine (also called spirit of turpentine, oil of turpentine, wood turpentine and colloquially turps) is a fluid obtained by the distillation of resin from live trees, mainly pines. It is mainly used as a solvent and as a source of materials for organic synthesis.

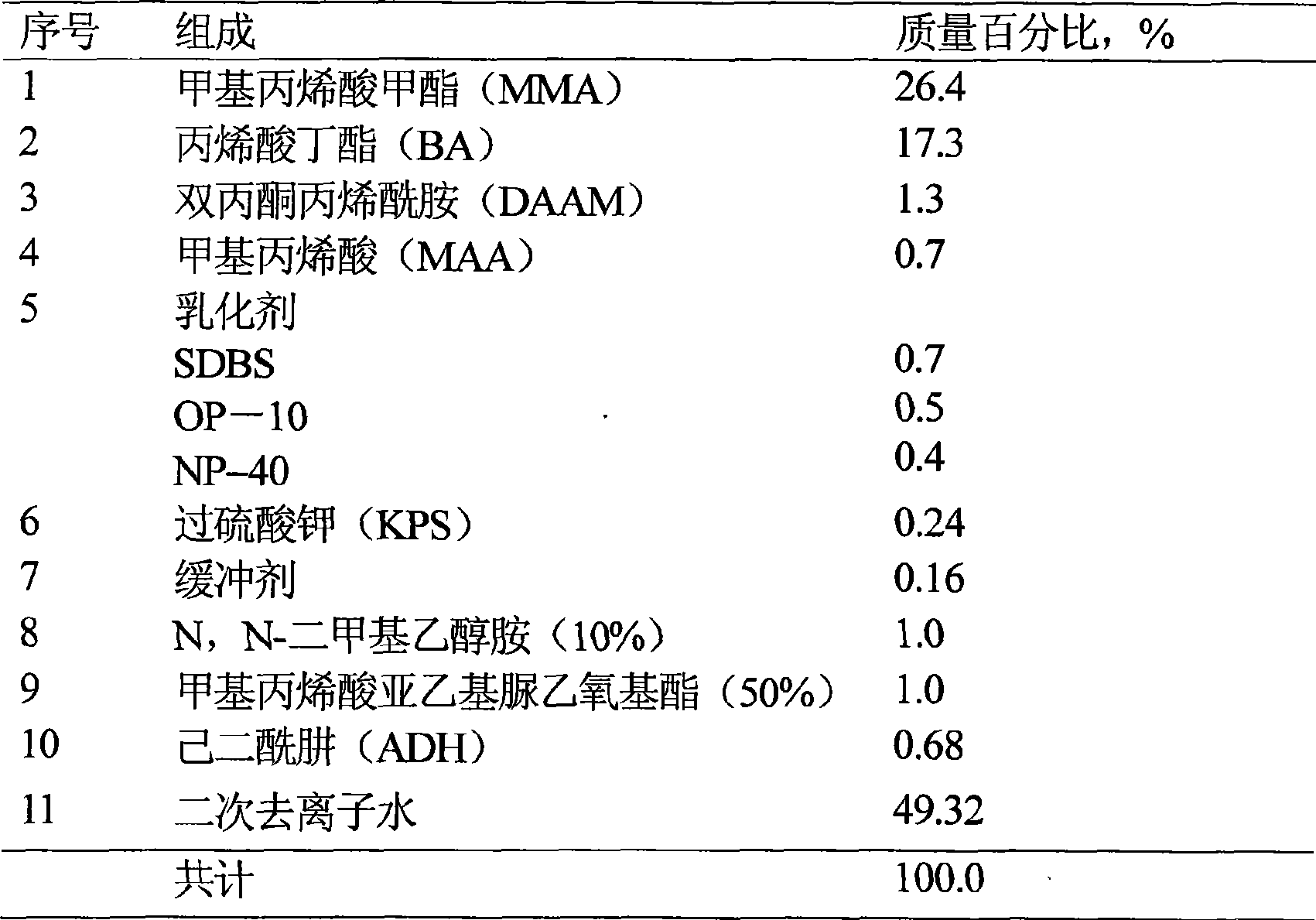

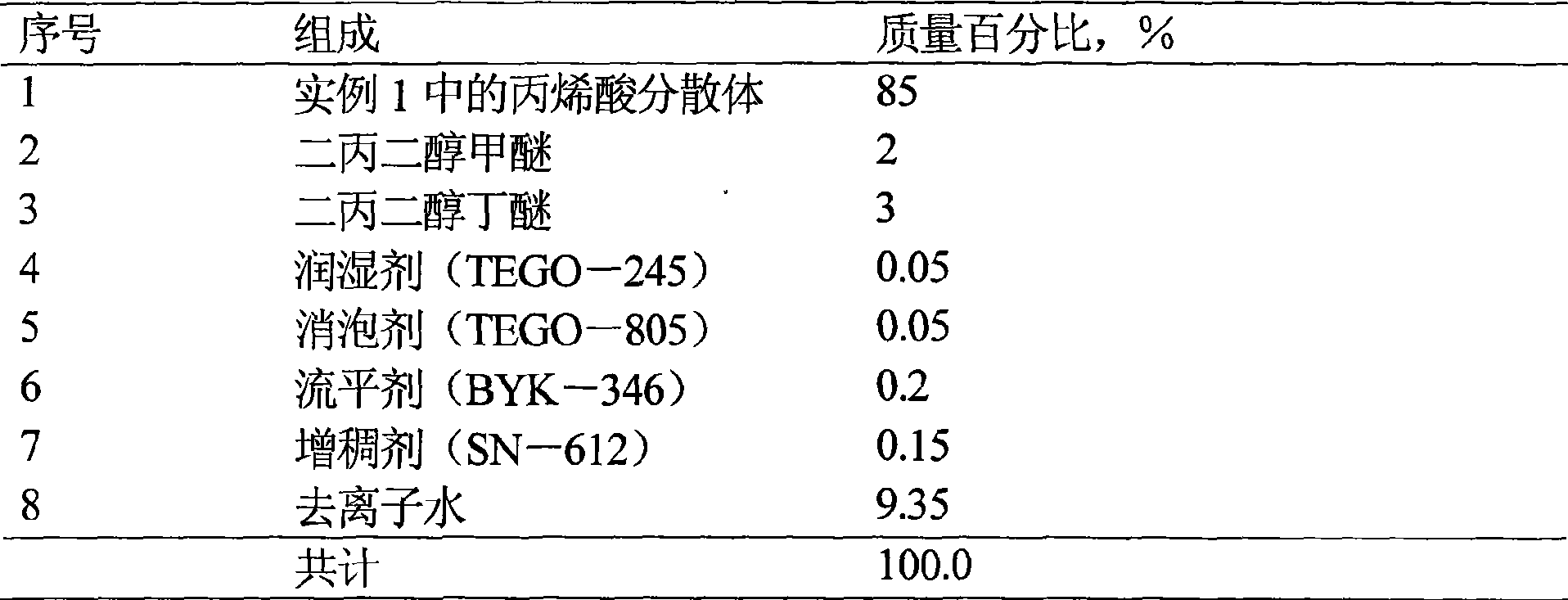

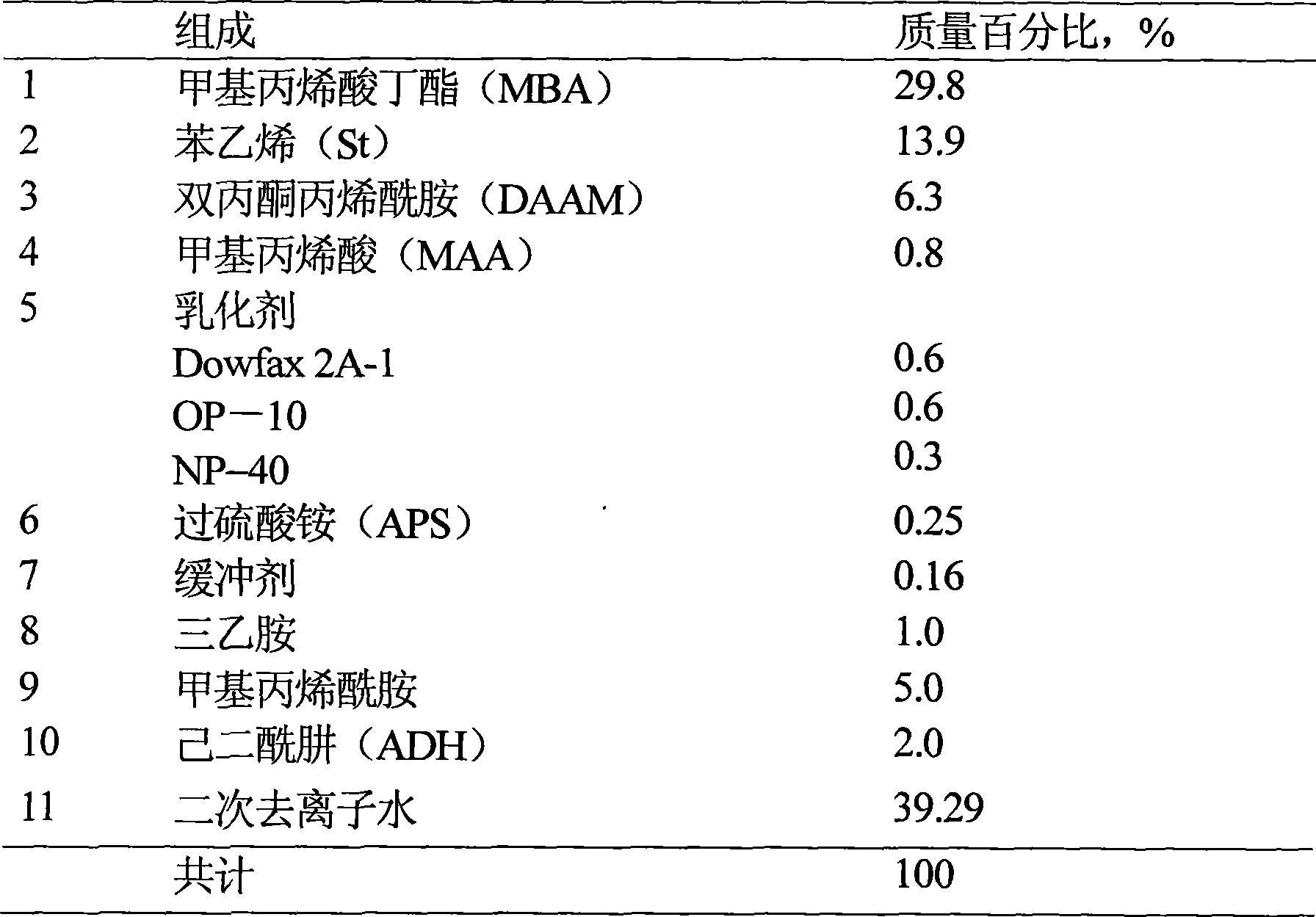

Preparation of high closeness polyacrylacid ester dispersion

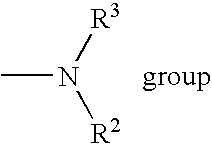

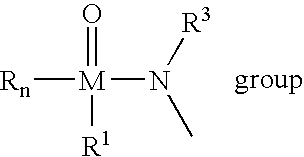

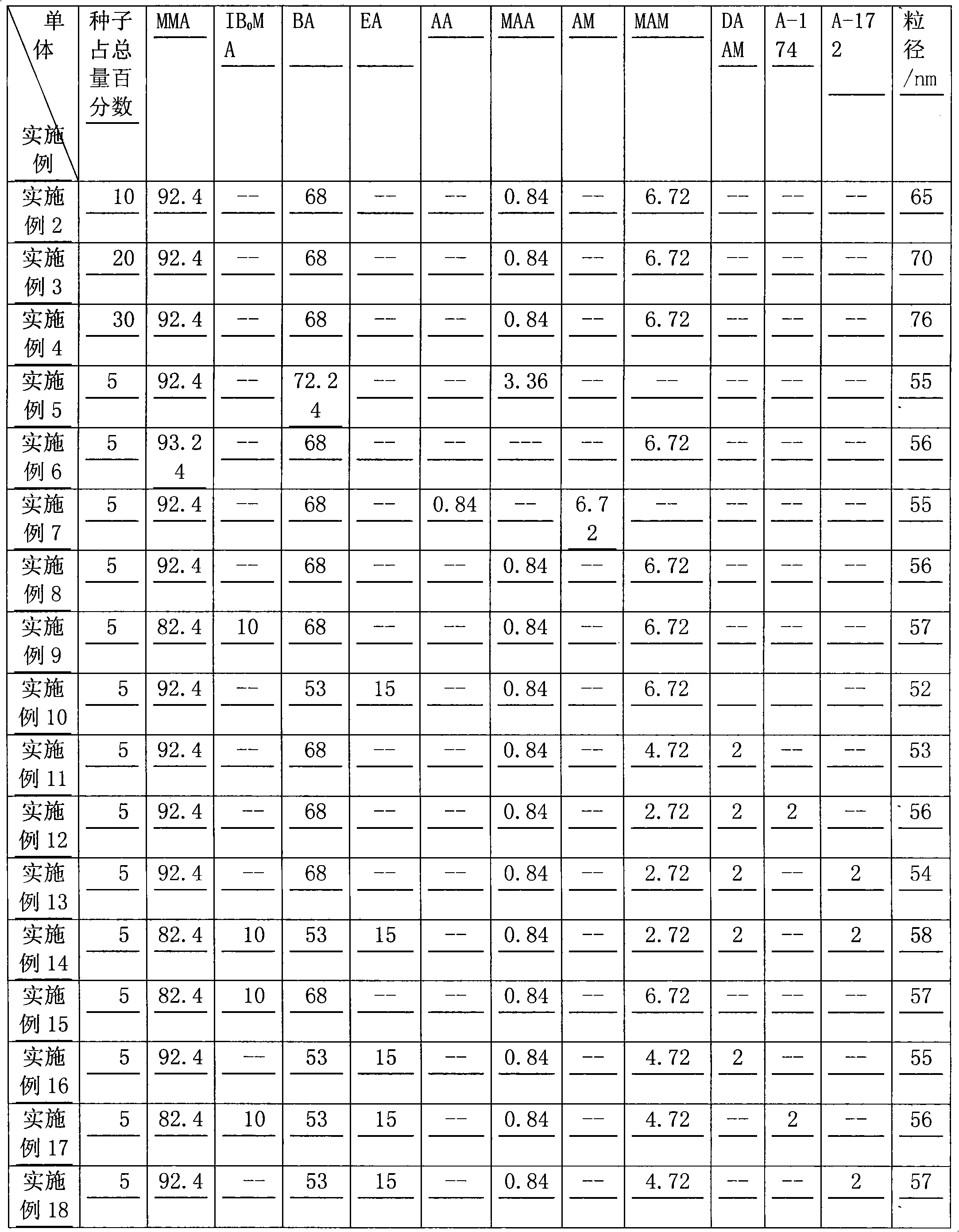

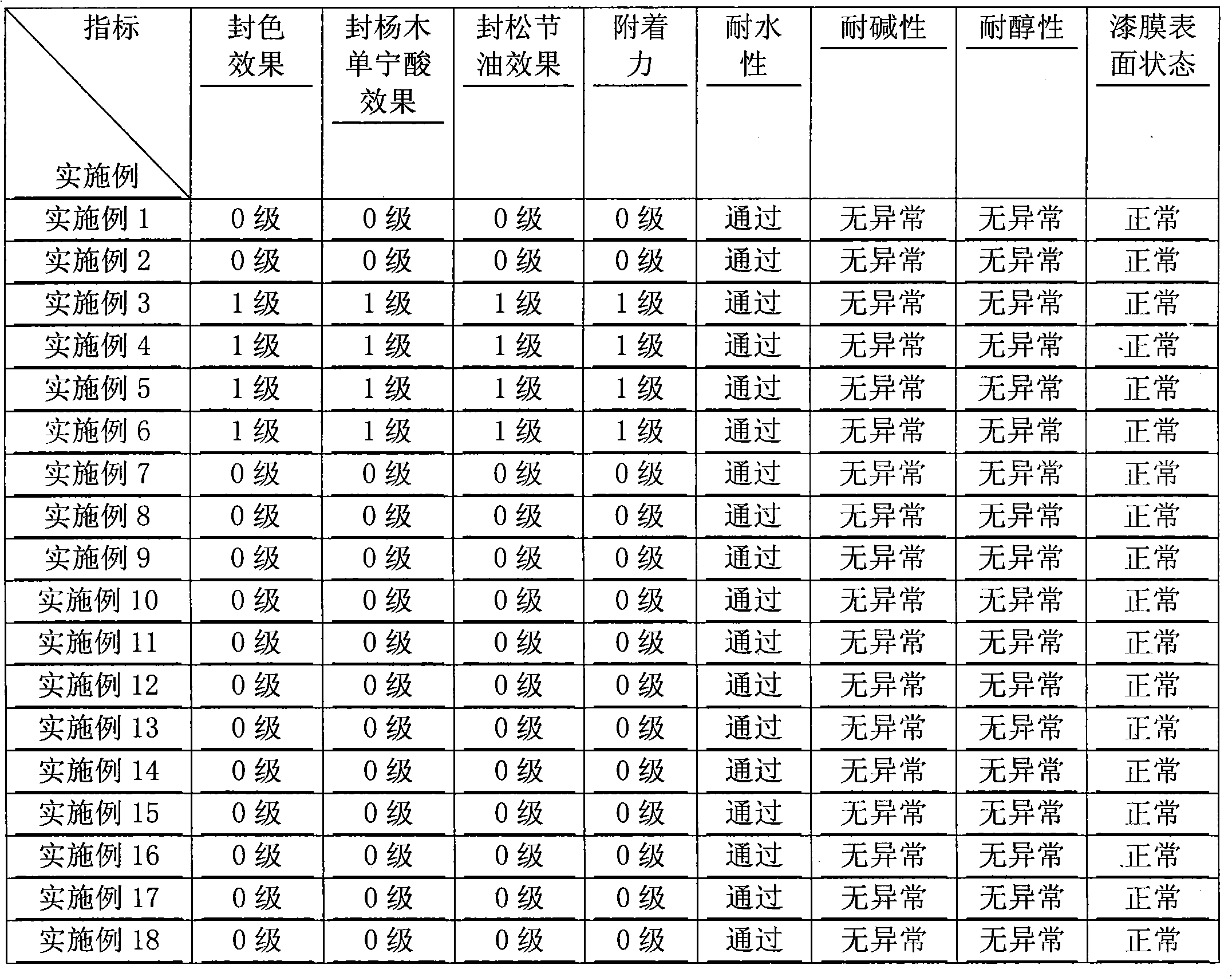

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

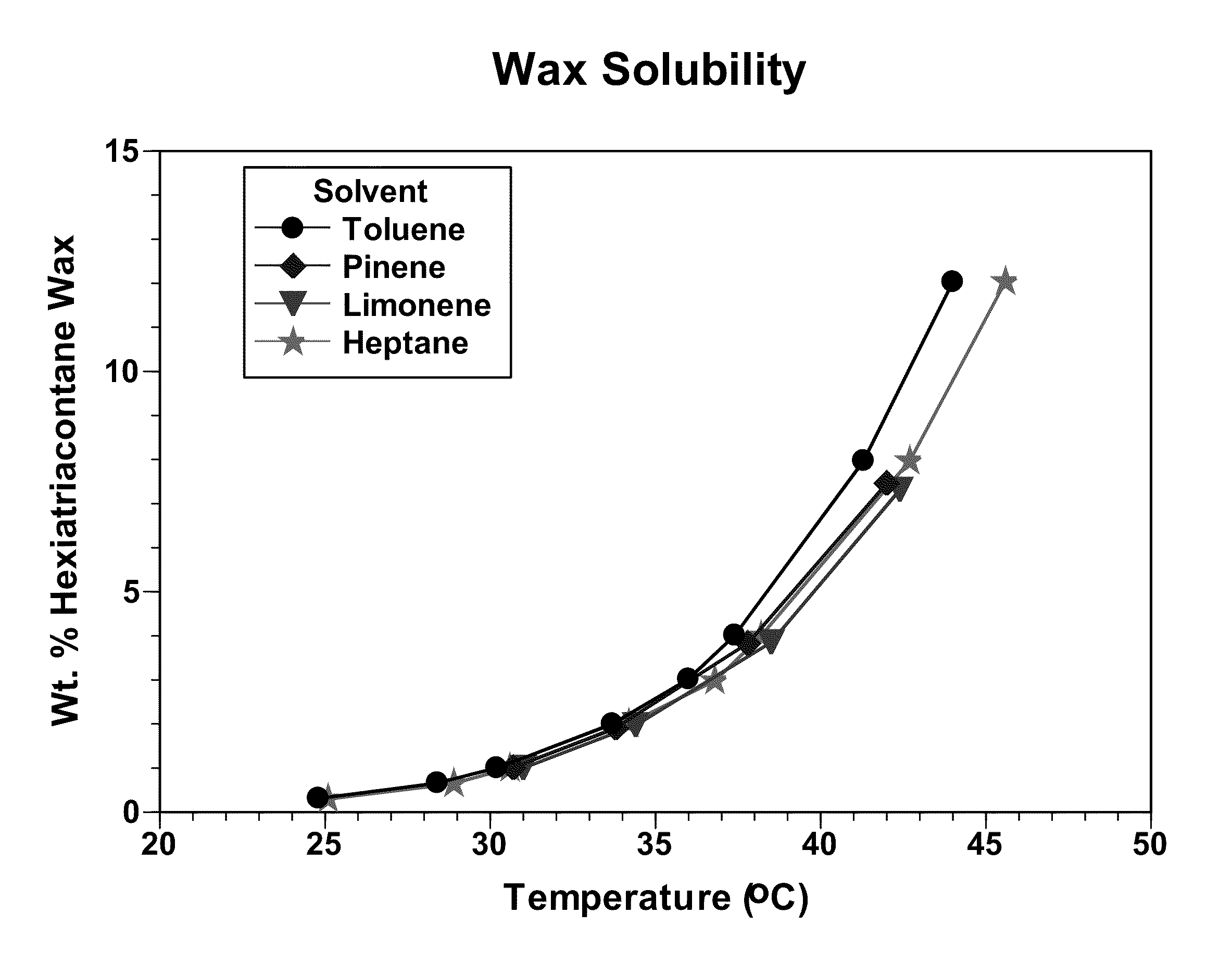

In situ extraction of hydrocarbons from hydrocarbon-containing materials

Hydrocarbon-containing organic matter is extracted from a hydrocarbon-containing material that is a viscous liquid, liquid or gaseous fossil fuel material. A turpentine liquid is contacted with a hydrocarbon-containing material in-situ in an underground formation containing the fossil fuel material to form an extraction mixture so as to extract hydrocarbon-containing organic matter into the turpentine liquid and form an extraction liquid. The extraction liquid is removed from the formation, the extraction liquid including the turpentine liquid containing the extracted hydrocarbon-containing organic matter. The extracted hydrocarbon-containing organic matter is separated from a residual material not extracted.

Owner:GREEN SOURCE HLDG LLC

Aqueous acrylic acid series wooden ware sealing paint and method for preparing special emulsion thereof

InactiveCN101817906ASmall particle sizeImprove permeabilityCoating impregnationCoatingsFiberCoating system

The invention relates to aqueous acrylic acid series wooden ware sealing paint and a method for preparing special emulsion thereof. Nano emulsion with small particle diameter and narrow distribution is prepared by using an acrylic acid monomer containing multiple polar groups as a raw material. Multiple aids are added into the emulsion serving as a basic film-forming substance to form the novel aqueous wooden ware sealing paint. The polar functional groups on polymer molecule chains have good wetting property on wood, emulsion particles are easy to permeate into wood fiber conduits and quickly form films in conduit holes, and the paint can effectively prevent the moisture in the aqueous wooden ware paint from permeating into the wood and solves the problem of surface gully caused by the water-swelling wood; and meanwhile, the paint also can effectively seal the substances which are extremely easy to permeate to the outside such as turpentine, tannin and the like acknowledged in the wooden ware industry, and solves common problems for wide application of the aqueous wooden ware paint. The aqueous sealing paint also can be used for a solvent type paint coating system, and effectively prevents a large amount of solvent in the solvent type paint from penetrating into the wood during coating.

Owner:BEIJING UNIV OF CHEM TECH

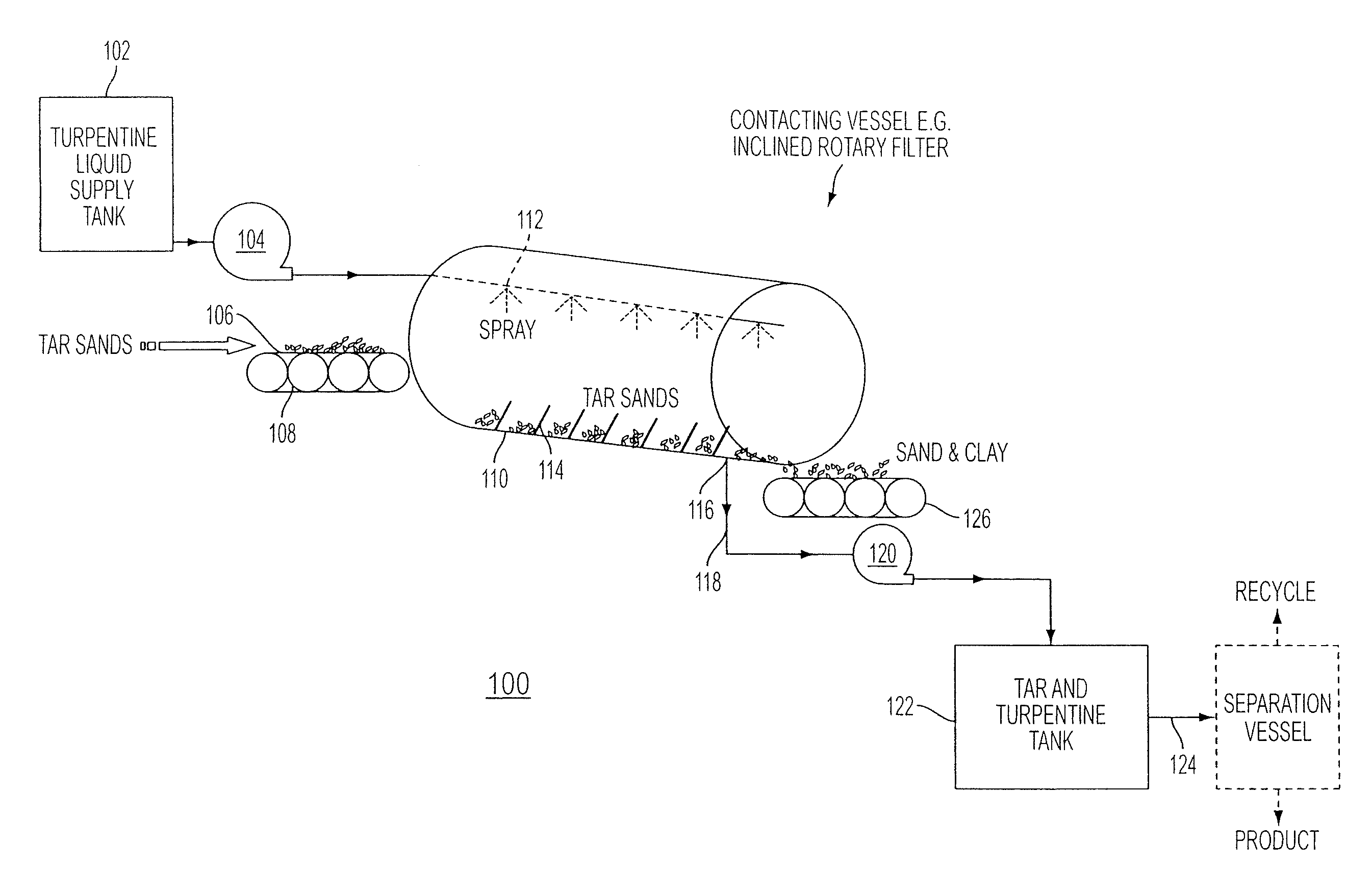

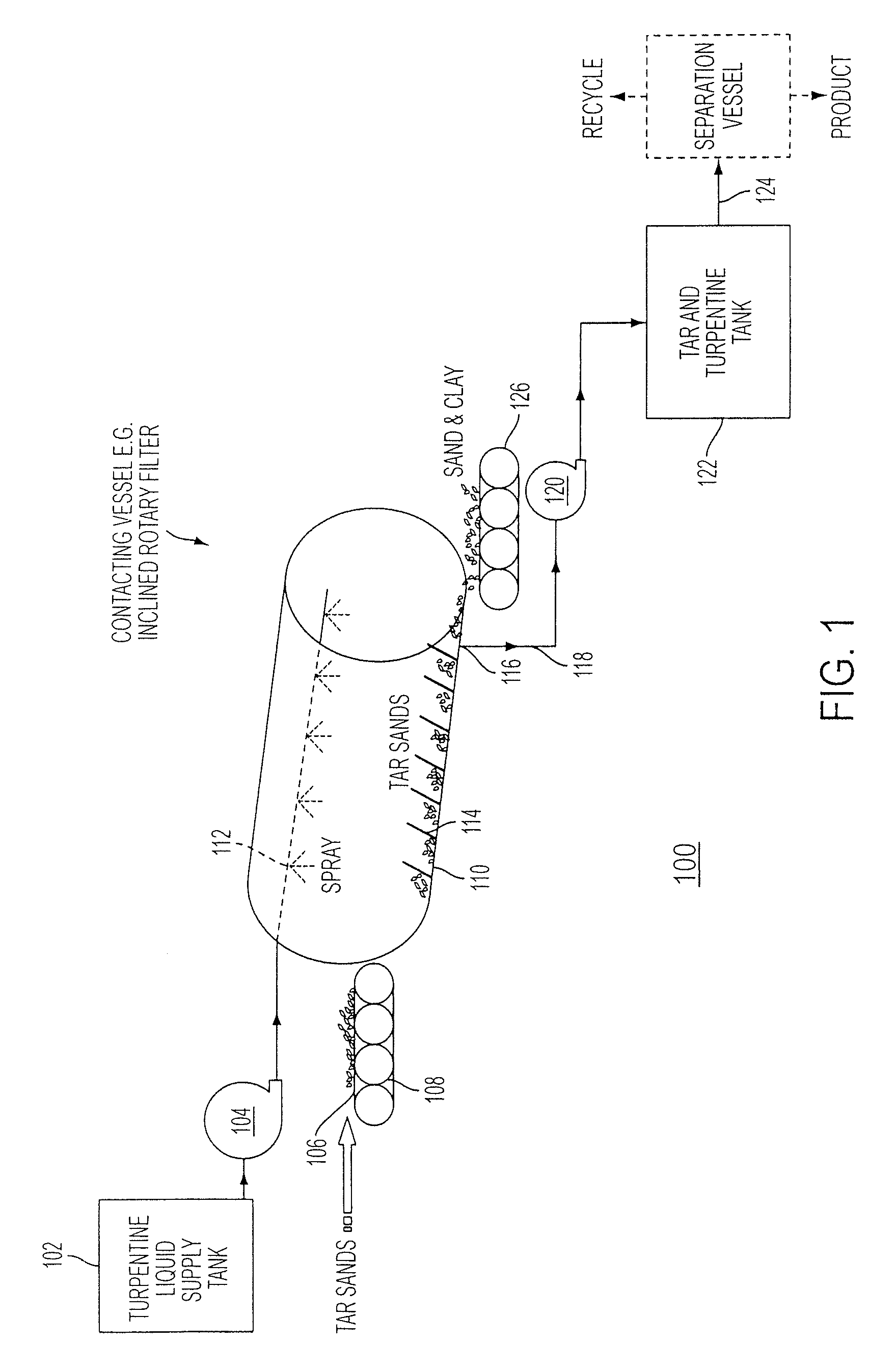

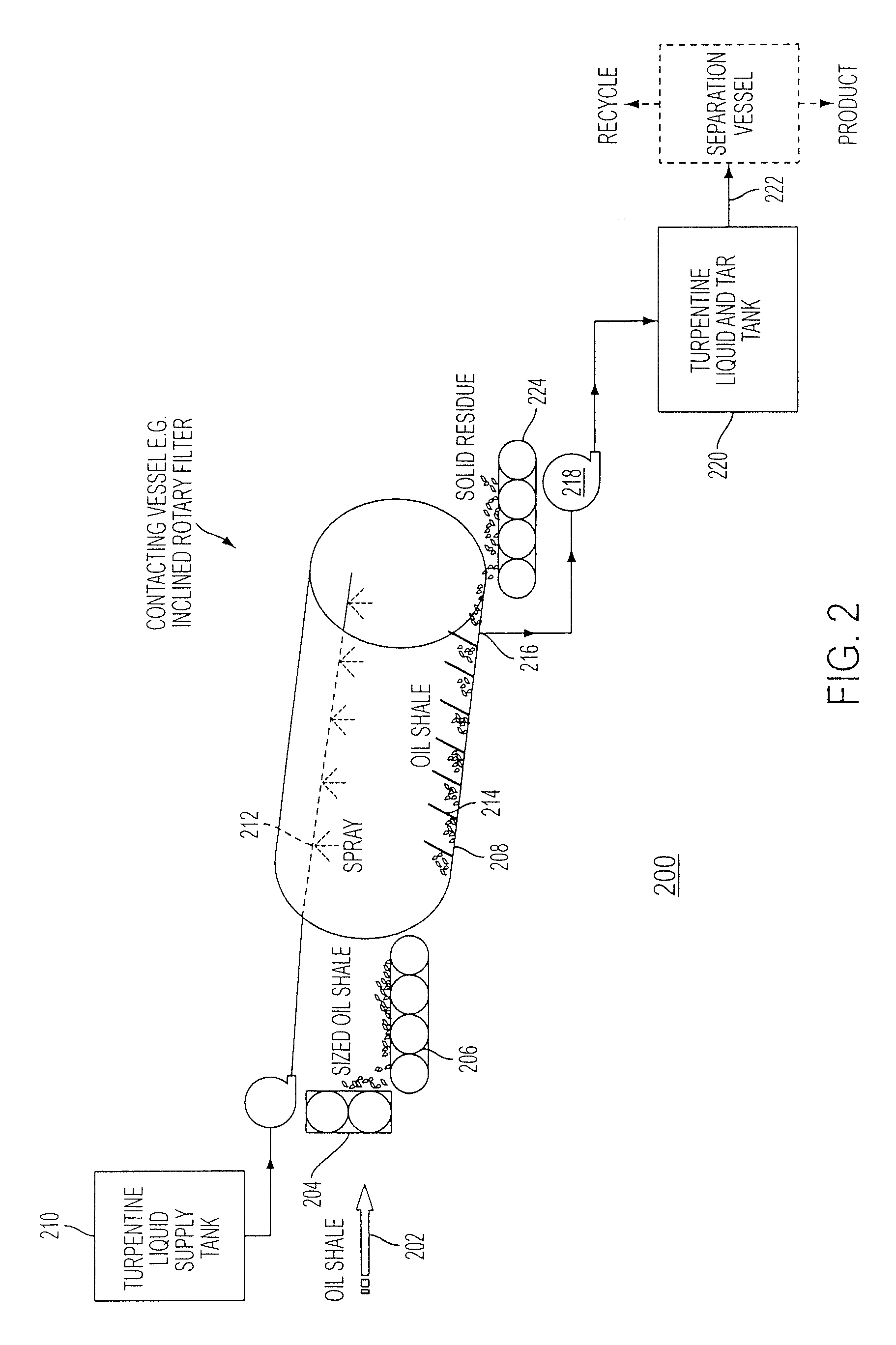

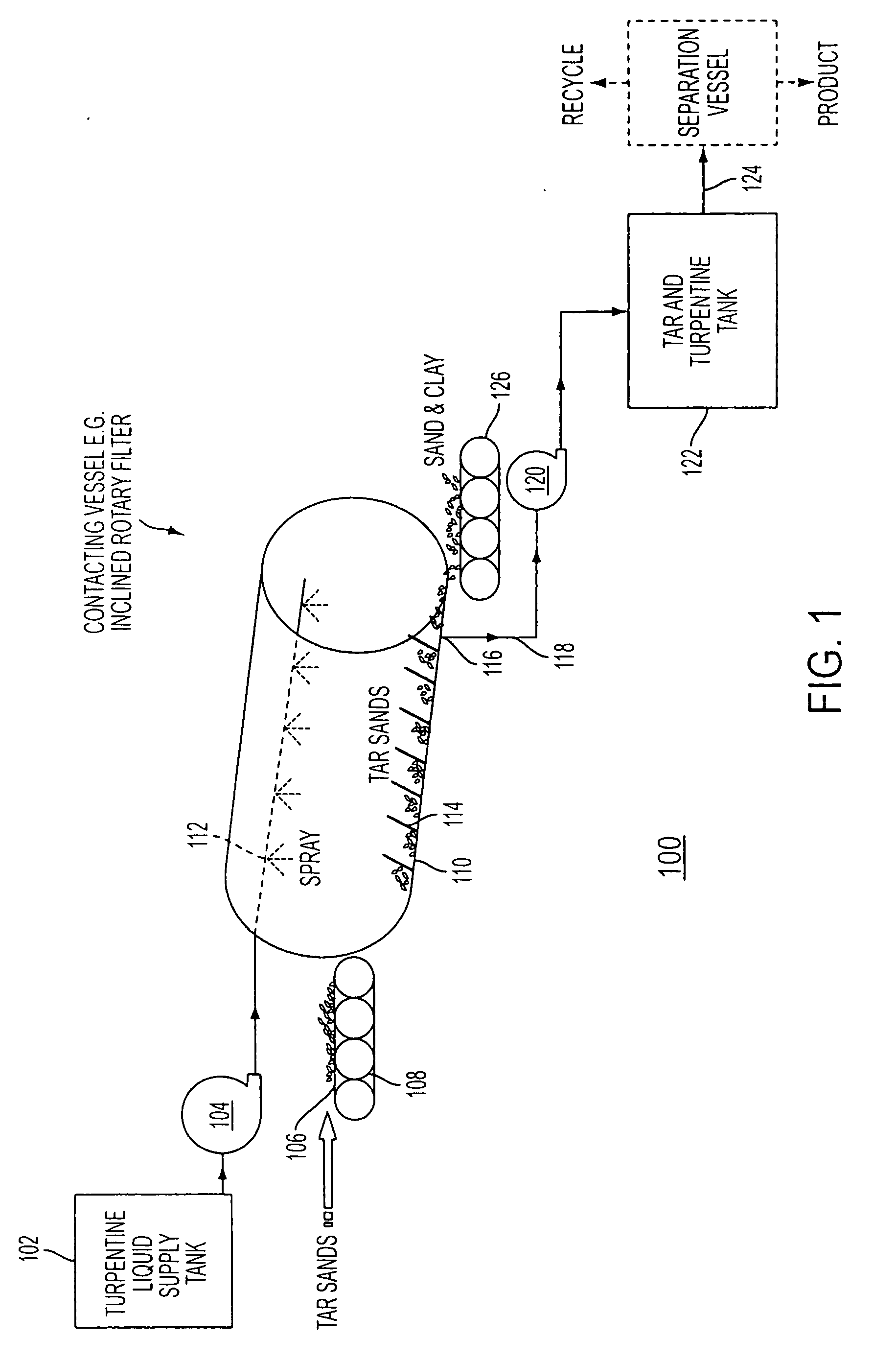

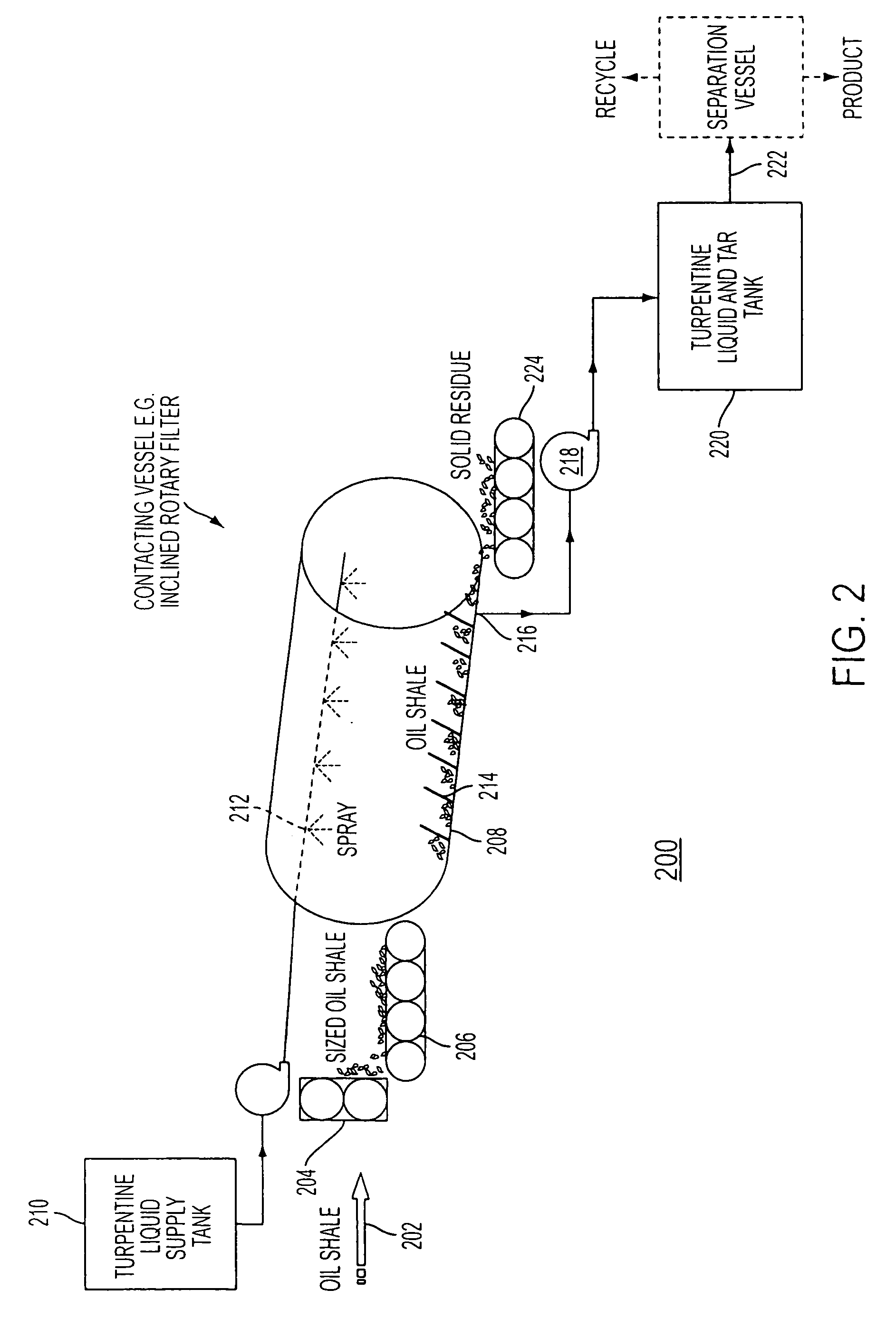

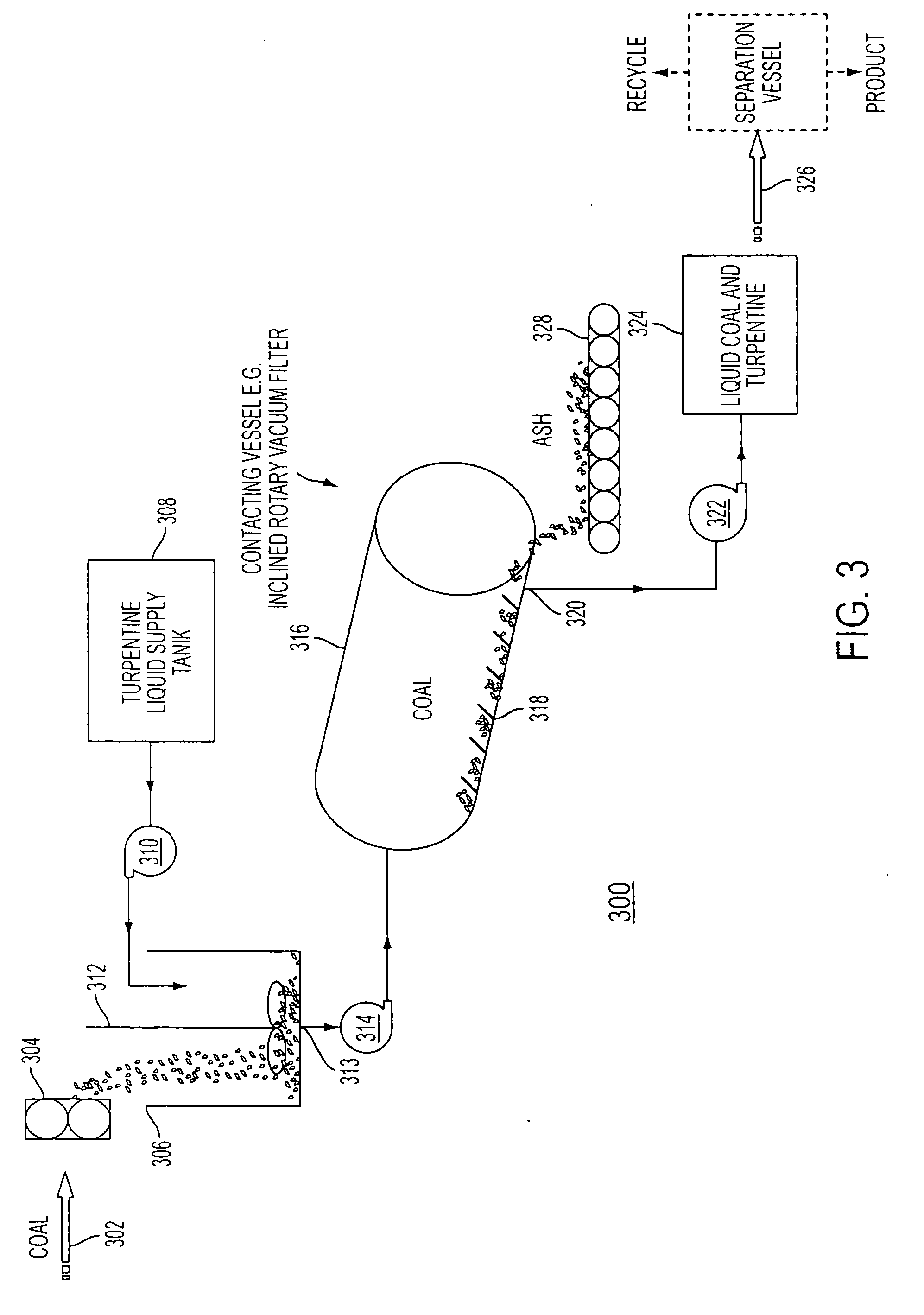

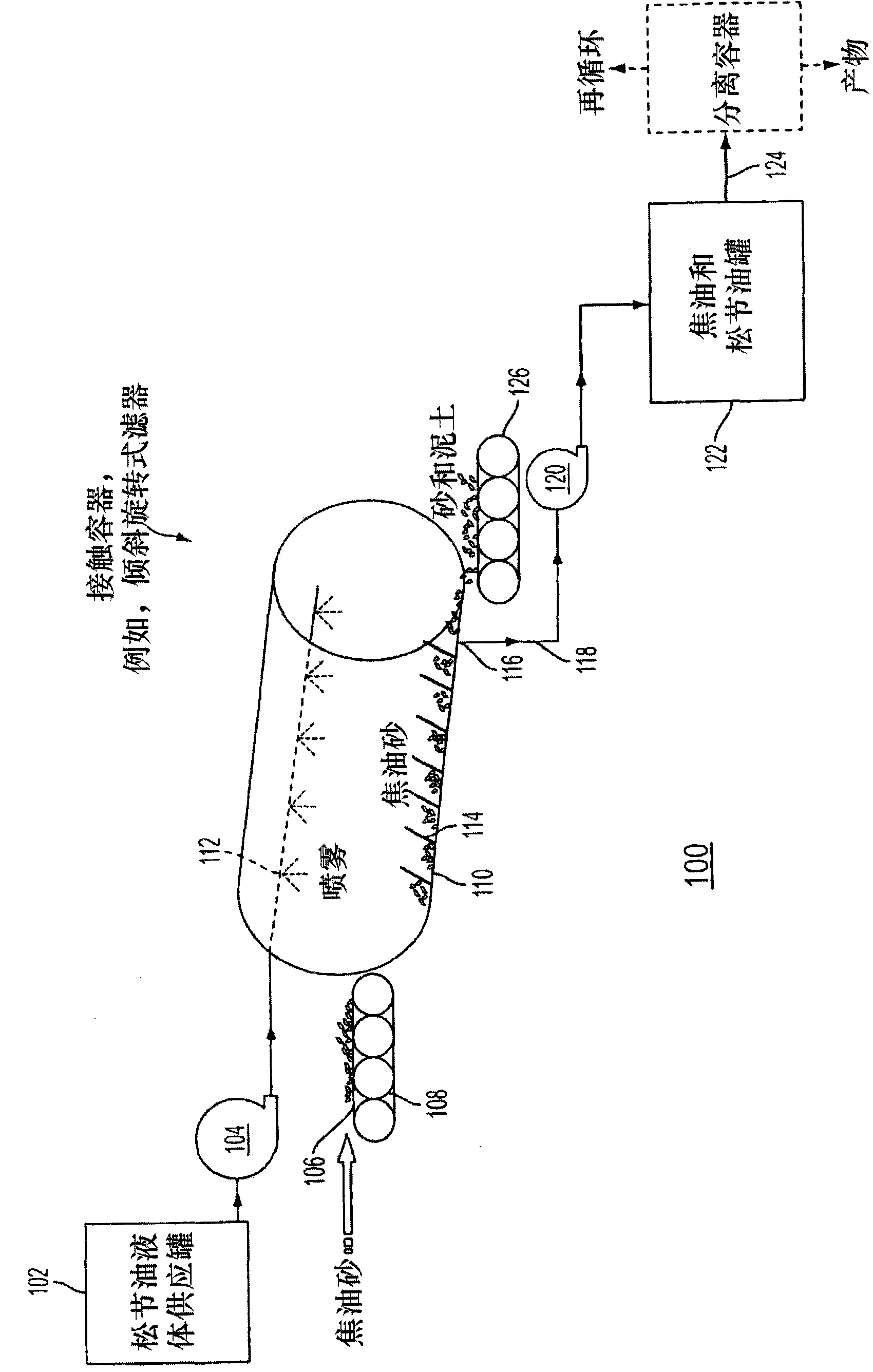

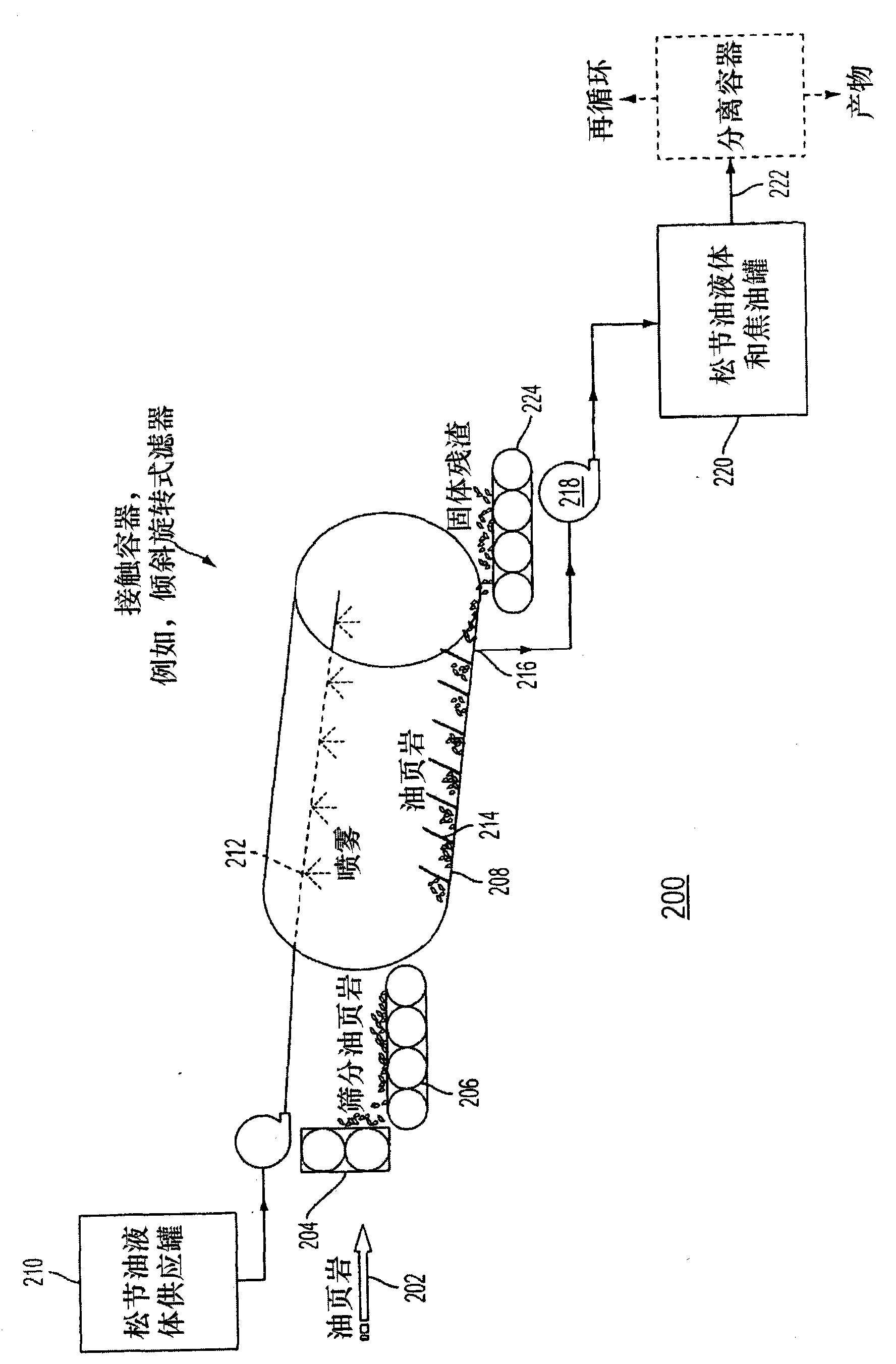

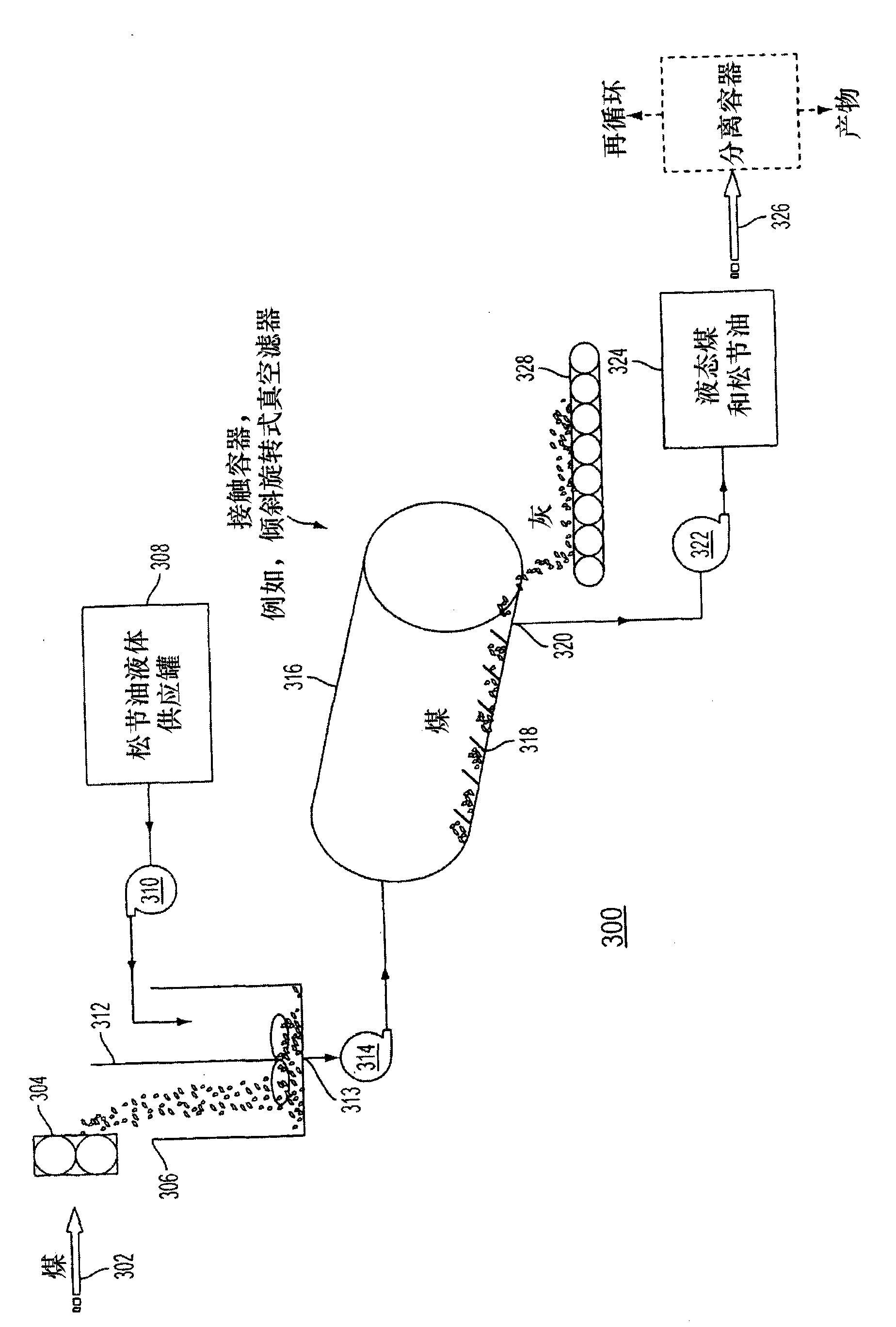

Extraction of Hydrocarbons from Hydrocarbon-Containing Materials and/or Processing of Hydrocarbon-Containing Materials

ActiveUS20090250381A1Low corrosion rateLow costFluid removalLiquid hydrocarbon mixture productionTurpentineOrganic matter

A method of extracting hydrocarbon-containing organic matter from a hydrocarbon-containing material includes the steps of providing a first liquid comprising a turpentine liquid; contacting the hydrocarbon-containing material with the turpentine liquid to form an extraction mixture; extracting the hydrocarbon material into the turpentine liquid; and separating the extracted hydrocarbon material from a residual material not extracted.

Owner:GREEN SOURCE HLDG LLC

In situ extraction of hydrocarbons from hydrocarbon-containing materials

Hydrocarbon-containing organic matter is extracted from a hydrocarbon-containing material that is a viscous liquid, liquid or gaseous fossil fuel material. A turpentine liquid is contacted with a hydrocarbon-containing material in-situ in an underground formation containing the fossil fuel material to form an extraction mixture so as to extract hydrocarbon-containing organic matter into the turpentine liquid and form an extraction liquid. The extraction liquid is removed from the formation, the extraction liquid including the turpentine liquid containing the extracted hydrocarbon-containing organic matter. The extracted hydrocarbon-containing organic matter is separated from a residual material not extracted.

Owner:GREEN SOURCE HLDG LLC

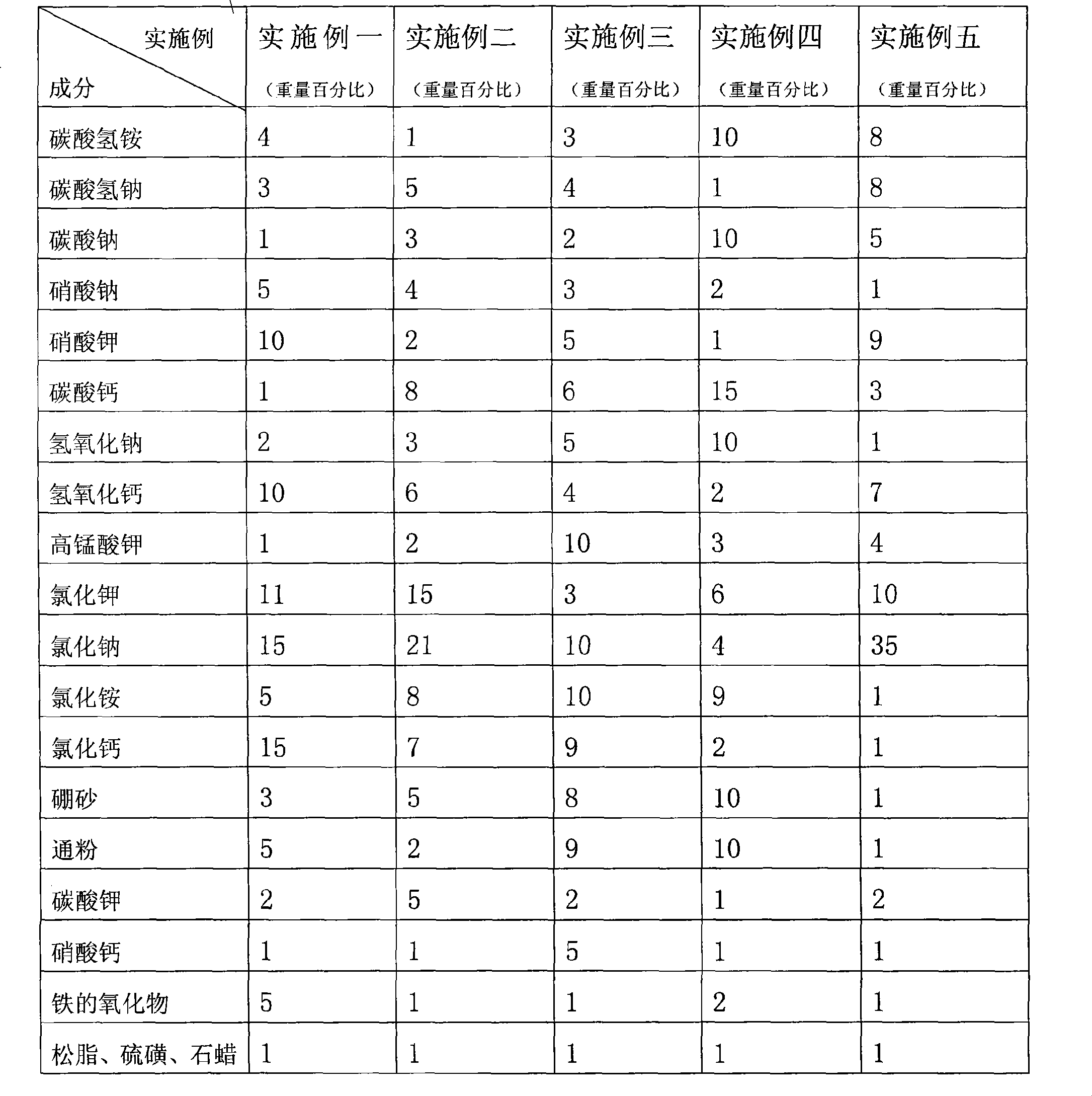

Environment-protecting synergistic agent for fuel coal

InactiveCN101440328AIncreased flammable contentIncreased space gapSolid fuelsFuel additivesSodium bicarbonateFurnace temperature

The invention discloses a bunker coal environment-friendly synergist, which comprises the following components by weight percent: 1 to 10 percent of ammonium bicarbonate, 1 to 8 percent of sodium bicarbonate, 1 to 10 percent of sodium carbonate, 1 to 5 percent of sodium nitrate, 1 to 10 percent of potassium nitrate, 1 to 15 percent of calcium carbonate, 1 to 10 percent of sodium hydroxide, 2 to 10 percent of calcium hydroxide, 1 to 10 percent of potassium permanganate, 3 to 15 percent of potassium chloride, 10 to 35 percent of sodium chloride, 1 to 10 percent of ammonium chloride, 1 to 15 percent of calcium chloride, 1 to 10 percent of borax, 1 to 10 percent of macaroni, 1 to 5 percent of potassium carbonate, 1 to 5 percent of calcium nitrate, 1 to 5 percent of iron oxide, and the balance being micro turpentine, sulfur and paraffin wax. The bunker coal environment-friendly synergist makes flame of combustion be more rampant and denser, the furnace temperature rise to a higher level, the hearth be brighter and cleaner and tail gas be cleaner.

Owner:李政 +1

Devulcanized rubber and methods

ActiveUS20080139678A1Increase contactPlastic recyclingChemical/physical/physico-chemical stationary reactorsPolymer scienceTurpentine

Vulcanized rubber is devulcanized by contacting the vulcanized rubber with a terpentine liquid in a reaction mixture in the absence of an alkali metal.

Owner:AUSTIN RUBBER CO LLC

Method for producing pale disproportionated rosin with high content dehydroabietic acid and P-camphogen simultinuously

InactiveCN1616570APrevent browningPrevent oxidationNatural resin purificationNickel catalystDistillation

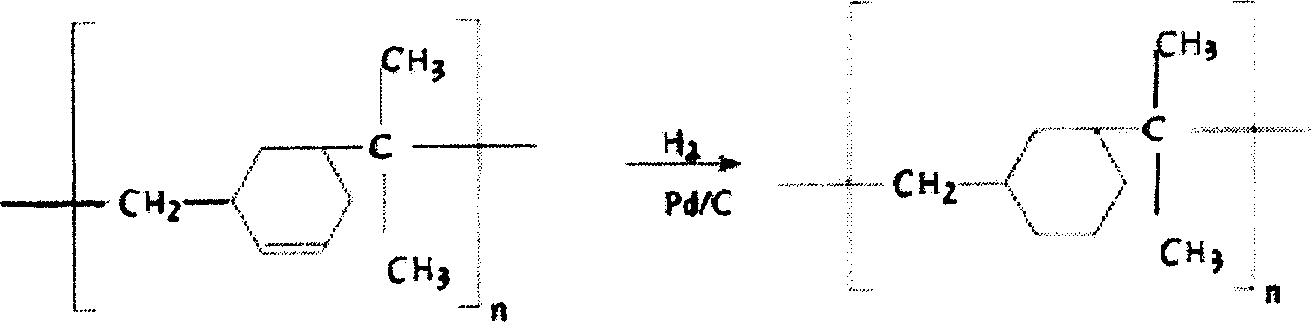

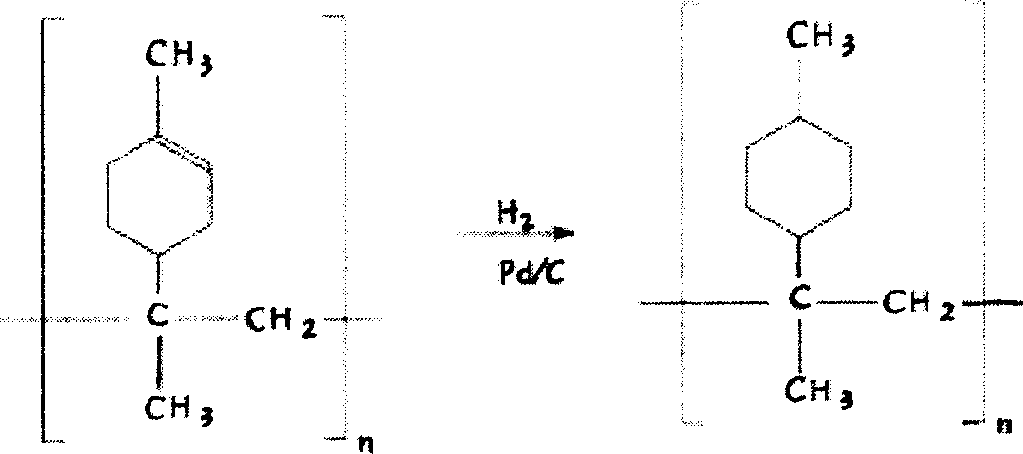

The process of producing pale disproportionated rosin with high dehydroabietic acid content and paracymene simultaneously includes the following steps: rinsing turpentine to eliminate impurity, dissolving turpentine in turpentine oil to form turpentine solution, catalytic disproportionating turpentine in solution in the presence of Pd / C catalyst, filtering and decompression distillation to obtain pale disproportionated rosin with high dehydroabietic acid content and disproportionated turpentine oil containing paracymene in 20-60 %, and distilling disproportionated turpentine oil to obtain paracymene and pinane. Or, the rinsed turpentine as material may be re-crystallized to purify and catalytically disproportionated to prepare pale disproportionated rosin containing high dehydroabietic acid in 72-82 %. The Pd / C catalyst may be replaced with skeletal nickel catalyst.

Owner:GUANGXI UNIV

Extraction of hydrocarbons from hydrocarbon-containing materials

A method of extracting hydrocarbon-containing organic matter from a hydrocarbon-containing material includes the steps of providing a first liquid comprising a turpentine liquid; contacting the hydrocarbon-containing material with the turpentine liquid to form an extraction mixture; extracting the hydrocarbon material into the turpentine liquid; and separating the extracted hydrocarbon material from a residual material not extracted.

Owner:GREEN SOURCE HLDG LLC

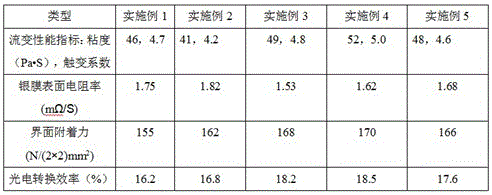

A kind of silver paste for solar cell and preparation method thereof

ActiveCN102290120AImprove screen printing qualityImprove efficiencyNon-conductive material with dispersed conductive materialCable/conductor manufactureTurpentineSilicon oxide

The invention relates to silver paste for a solar cell and a preparation method thereof. The silver paste comprises certain amounts of silver powder, turpentine and glass powder and fumed silica by mass percent, preferably nano methyl modified fumed silica. The silver paste further comprises a nonionic polymer surfactant which is a polyethoxyl / polypropoxy / polyethoxyl triblock copolymer. The silver paste which is prepared by mixing and stirring the above components according to a certain proportion and sequence and is used for the front of the solar cell has good thixotropy, improves the screen printing quality on the silicon wafer, improves the height-width ratio of the sintered screen printing silver wires and reduces the occupied sunlight area, thus improving the efficiency of the solarcell.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Method for production of preserved flower, and processing solution for use in the method

InactiveCN101861092AKeep natural colorReduce processDead plant preservationNatural resinVegetable oil

Disclosed is a method for producing a preserved flower, which enables to keep the original color of a real flower, particularly the subtle gradation in color of the real flower. Also disclosed is a processing solution for use in the method. Specifically disclosed is a method for producing a preserved flower, which comprises immersing a real flower in a processing solution and drying the flower, wherein the processing solution comprises a solution or dispersion containing at least one component selected from a natural oil material oil, a natural resin material, a siloxane, a synthetic resin, a water-addition-reaction-type urethane, a fatty acid ester and a surfactant, wherein the natural oil material is terpin oil, stand oil, whale oil, boiled oil, linseed oil, camellia oil, olive oil, rapeseed oil, a salad oil (a purified plant oil), sesame oil, camphor oil or the like, wherein the natural resin material is rosin, glue, wax, bees wax, rubber, rhus lacquer or the like, and wherein the fatty acid ester is an ester of a saturated or unsaturated fatty acid such as lauric acid, palmitic acid, stearic acid and myristic acid and a lower or polyhydric alcohol.

Owner:坂本好央

Slurry for silicon solar cell

InactiveCN105810284AIncrease contact areaImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureTurpentineCarbon nanotube

The invention belongs to photoelectric cell electrode materials, and discloses a slurry for silicon solar cells. In terms of parts by weight, the slurry raw materials are composed of: 40-60 parts of silver powder, 5-10 parts of copper powder, 10-20 parts of silver-coated aluminum alloy powder, and 1-5 parts of lithium iron phosphate / carbon nanotube composite material , 1-8 parts of glass powder, 0.5-2 parts of silane coupling agent, 8-10 parts of propylene glycol monobutyl ether, 1-5 parts of turpentine, 1-3 parts of lecithin, 0.1-0.5 parts of carbomer, gas phase dioxide Silicon 0.25‑1 part. The invention also discloses a preparation method of the slurry. The slurry obtained in the present invention does not contain lead, fully meets the requirements of environmental protection, is applied to the production of solar cells, can form strong adhesion on the surface of solar cells, and has high photoelectric conversion efficiency of the cells. At the same time, the process of the present invention is simple and the cost is low, so it has broad application potential. application prospects.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

Characteristic kiln change technology of Nixing ceramics

The invention discloses a characteristic kiln change technology of Nixing ceramics, comprising the steps of preparing a blank body, molding the blank body, trimming the blank body, drying the blank body and sintering the blank body. The step of sintering the blank body comprises the following steps: 1) putting the dried blank body in a kiln, heating the temperature up to 450-550 DEG C with a heating speed of 80-120 DEG C / h, then heating the temperature up to 1100-1200 DEG C with a heating speed of 130-180 DEG C / h, and continuously sintering for 0.5-1 h at the temperature of 1100-1200 DEG C; 2) putting materials for kiln change in the kiln from a kiln hole, wherein, the additional quantity of the materials for kiln change is 2-3 kg / m<3>, and the materials for kiln change comprises 1-4 weight portions of pine, 1-3 weight portions of raw leaves, 1-3 weight portions of wood chips, 2-5 weight portions of coal and 2-4 weight portions of turpentine; 3) continuously sintering for 0.5-1 h at the temperature of 1150-1200 DEG C; 4) gradually decreasing the temperature in the kiln; and 5) after cooling, taking out the sintered blank body.

Owner:QINZHOU CITY HUAXIA TAIJIQUAN NINGXING POTTERY

Dry type manufacturing method of animal specimen

InactiveCN1971663AImprove qualityAdequate perfusionDead animal preservationEducational modelsHigh concentrationGlycerol

The invention relates to a dry type making method for animal specimen that includes six steps: collecting material, reshaping antisepsis fix and tube cavity cast, alcohol dewatering fix, glycerol process, turpentine impregnation and air drying, material repairing tinction preservation or seal up for keeping. Thereinto, in step 1, the animal material is bleed and killed via health quarantine, in step 2, potting it with the formalin with colorless glycerin and phenol or alcohol solution, in step 3, controlling the concentration of every step and fixed time, in step 4, marinating it with glycerol moisture absorption soften liquid, and transfer it from low concentration to high concentration of glycerin, and the time is prolonged gradually, in step 5, treating it with turpentine continually, in step 6, printing it. The invention improves the present technique, the quality of specimen is improved greatly, and that can keep the original state of material, the color and the luster. The dried specimen is sanitation without peculiar smell, and good at handle and quality.

Owner:王荣林

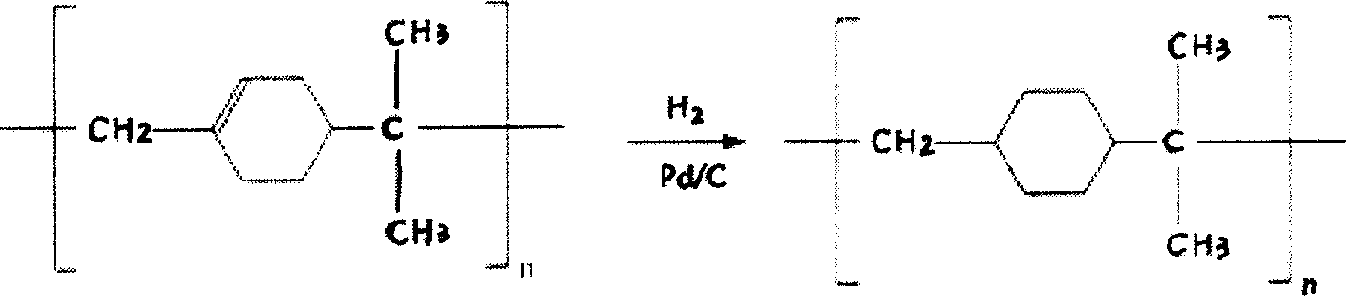

Method for preparing colorless terpene resin

InactiveCN1709927AHighlight substantive featuresSignificant progressTurpentineSolution polymerization

This invention relates to the method of preparing shallow color terpene resin through positive ion polymerization, then preparing colorless terpene resin through catalytic hydrogenation. The preparation process is: makes the ª‡-pinene, beta-pinene or dipentene obtained from fat turpentine or rectified fat turpentine as raw material, and obtain shallow color terpene resin through positive ion polymerization with proper catalyst and temperature, then catalyzation hydrogenate the obtained terpene resin to get colorless terpene resin. The purpose of the invention is to control the polyreaction speed through controlling the activeness of the catalyst in tepene resin preparation by positive polymerization, finally obtain terpene resin of shallow color, high softening point and obtaining rate; use carbon as catalyst, hydrogenate terpene resin under mild condition to get colorless terpene resin.

Owner:GUANGXI UNIV

Green making technology of animal tissue paraffin section

A green making technology of animal tissue paraffin section disclosed in the invention aims at providing a technique of making a paraffin section of animal tissue applied to the agricultural university medicine and other majors, characterized by that the type of chemical reagents that are used is limited, the chemical reagents have no toxicity, and dehydrate the tissue thoroughly, accelerate making sections but not lead to excessive contraction and increasement of hardness of the tissue, and substitute dimethyl benzene used in the traditional making technology of the paraffin section which isharmful to human body, so as to eliminate the occupational diseases and environmental pollution caused by dimethyl benzene. The making technology comprises the following steps: carrying out fixation with a fixative solution (100ml of the fixative solution comprises 91 ml 85% alcohol, 4 ml methanol and 5 ml glacial acetic acid ), dehydrating the tissue with graded ethanol, then putting the fixative and dehydrated tissue in a mixed transparent reagent (comprising 14wt% of analytically pour n-butanol, 29wt% of acetone and 57wt% of absolute alcohol ) for standing for 3 hours, then carrying out normal waxing and embedding, using analytically pour turpentine (60 DEG C) for section staining, carrying out dewaxing twice, carrying out hydration under normal temperature, using haematoxylin for staining nuclei, decoloration and bluing, and using eosin for staining, dehydrating until get absolute alcohol, then carrying out air drying, and directly using the gum diluted by turpentine to sealing the section.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

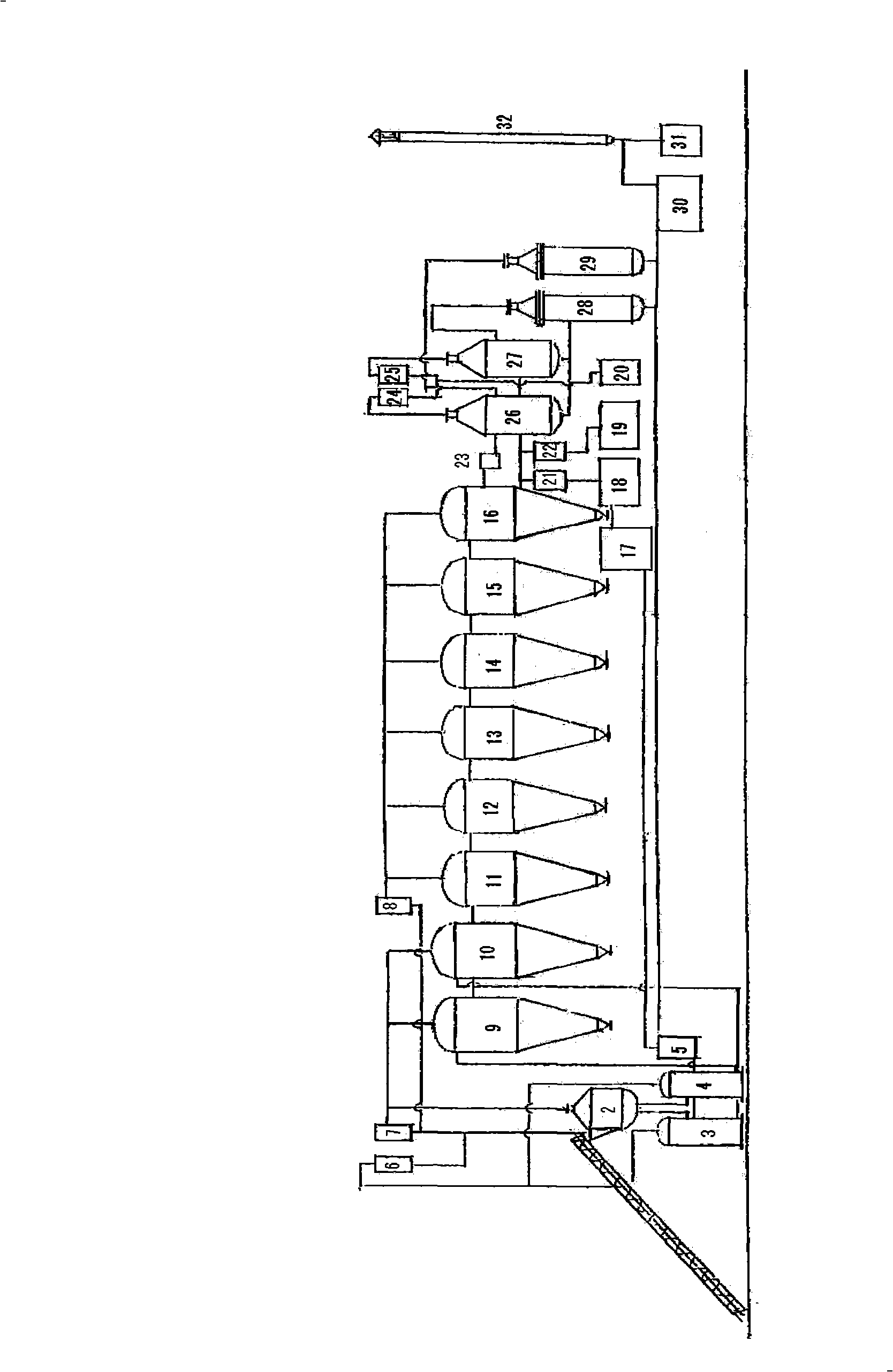

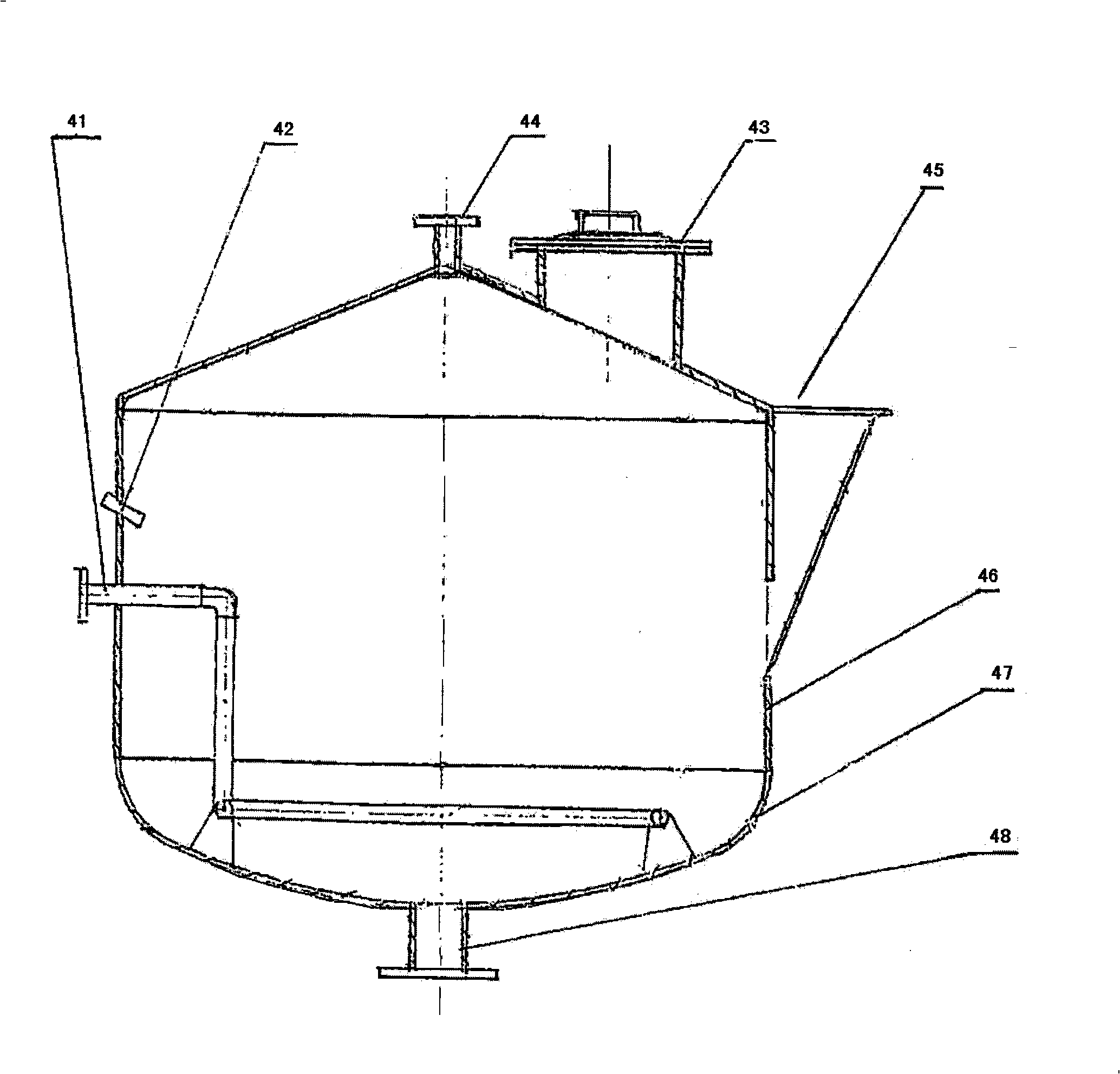

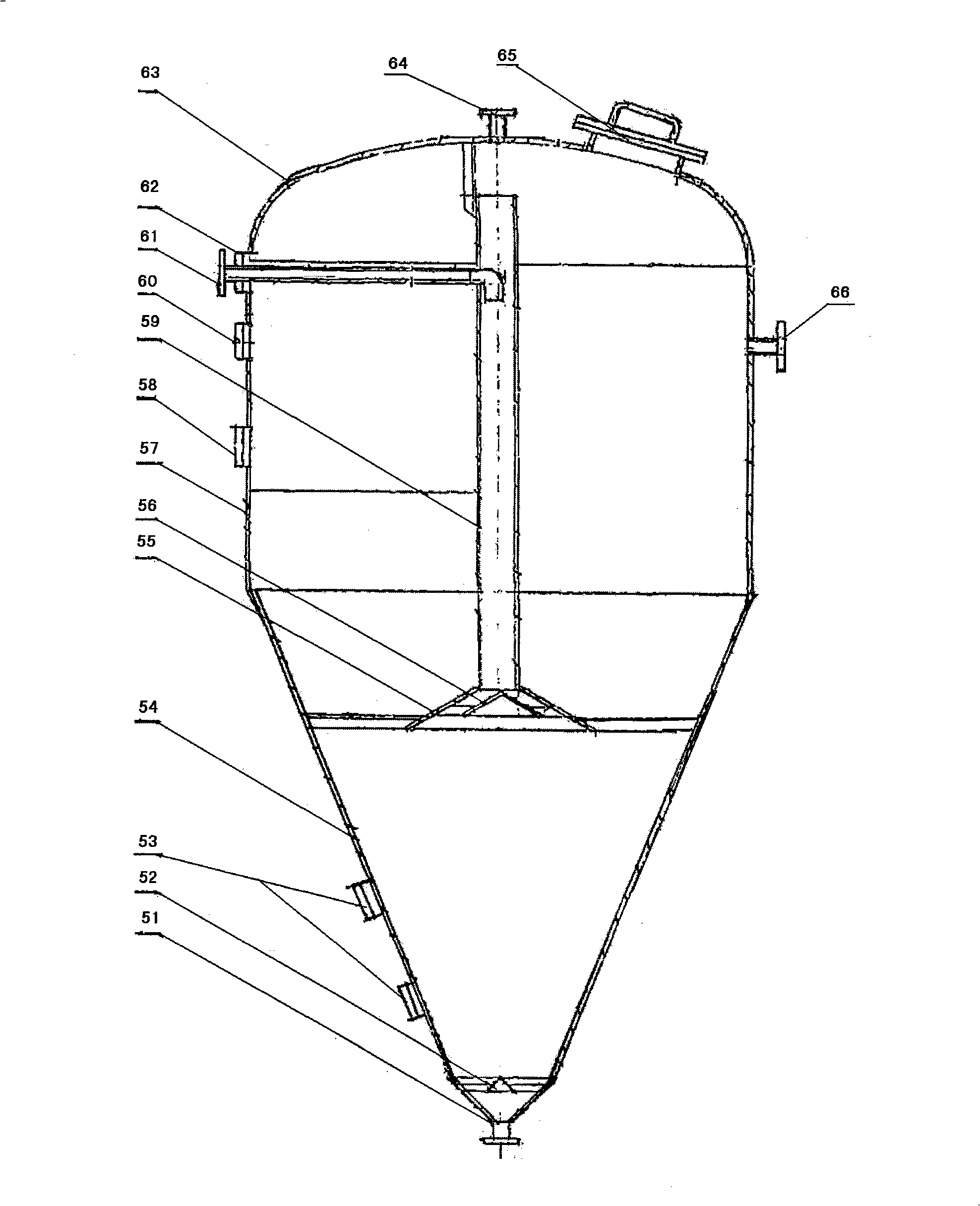

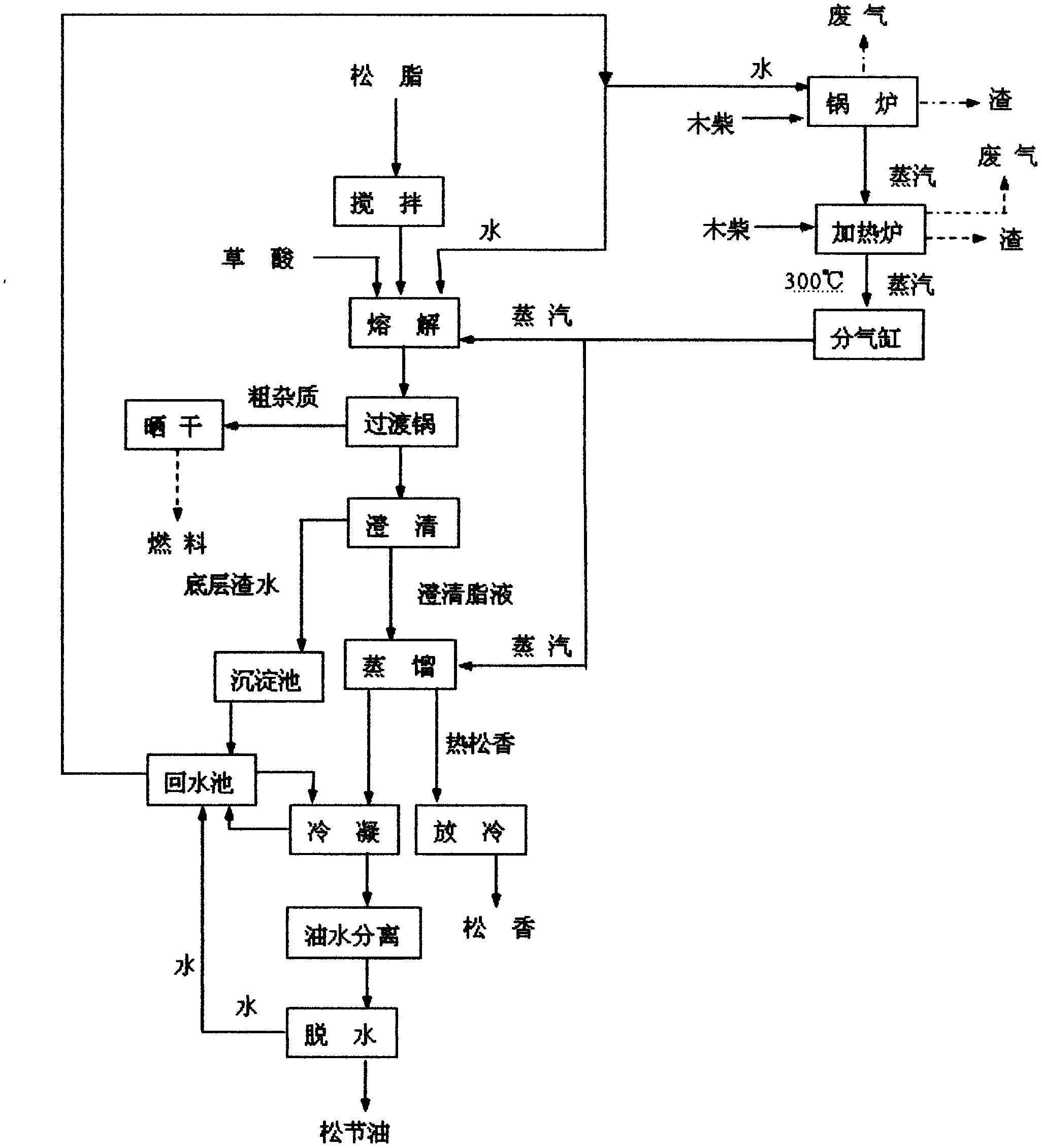

Pine gum processing method and equipment

InactiveCN101343509AIncrease productionRosin quality improvementNatural resin purificationTurpentineRosin

The invention discloses a processing technology of turpentine by a steaming process and the device. The invention adopts the technology that the turpentine is previously preheated and then dissolved, the dissolved turpentine enters into the clearing procedure after adopting the transitional clearing step, the turpentine liquid is preheated after being filtered, then oil gas and colophony are distilled out, turpentine oil is obtained through the condensation of the oil gas, and the distilled high-temperature tail gas and oil gas are recovered to preheat the turpentine and the turpentine liquid; the device adopts that a turpentine preheating pot is arranged in front of a liquating pot; a transitional clarifying kettle is arranged before a clarifying kettle; a distilling and preheating pot is arranged between a turpentine liquid filter and a distillatory kettle. Compared with the prior discontinuous process technology, the processing technology can greatly increase the production, the quality of the colophony is greatly improved, more than 98 percent of the colophony can reach the special grade and the first-grade, the distilling degree of the top grade turpentine reaches 97 percent, half of the standard coal consumed by one ton of colophony is approximately saved, half of the steam and the cooling water are also reduced, and the energy saving and consumption reducing effects are remarkable.

Owner:李国鸿

Heat Generation Process for Treating Oilfield Deposits

ActiveUS20110114323A1Increase temperatureIncreased deposit solvencyCleaning apparatusHollow article cleaningOil processingFuran

Generating heat within a combination solvent / acid system removes undesirable deposits from petroleum reservoir formations (especially the near well-bore region), oilfield equipment, and petroleum processing equipment. An exothermic reaction occurs between the solvent and the acid and the heat evolved helps remove organic solid deposits. The acids may include organic acid compounds, such as sulfonic acids, sulfuric acid and nitric acid. The solvents may include terpene- and terpene-derivative-containing solvents, including, but not necessarily limited to, limonene, pinene, dipentene, myrcene, turpentines and compounds having at least one double bond, such as methyl furan, dienes, styrene, vinyl acetate and the like. The exothermic reaction produces a great amount of heat, and together with using certain acids and solvents already known as effective to remove paraffin and asphaltene deposition, removing such deposits is improved.

Owner:BAKER HUGHES INC

Eugenol biological pesticide and preparation method thereof

The invention discloses a eugenol biological pesticide which comprises the following ingredients in percentage by weight: 0.1% to 70% of eugenol, 6% to 20% of surfactant, 0.01% to 0.5% of plant immunity regulator, 10% to 50% of synergist, and raw materials of alcohol and turpentine for the rest part. With the advantage of reasonable formula, the eugenol biological pesticide is characterized in that the active volatility of the active ingredient eugenol is improved, the pesticide effect of the eugenol is enhanced, pesticide doses are reduced, and the pesticide cost for farmers is reduced; pureplant solvents are used in the eugenol biological pesticide which belongs to low-carbon and environment-friendly pesticide, so pollution and harm to the environment are reduced, and the eugenol biological pesticide is safe and environment friendly for use. The eugenol biological pesticide is used for preventing and treating powdery mildew, botrytis and downy mildew and regulating plant immunity, and has the effects of synergy, simultaneous treatment, resistance prevention, resistance delay, etc.

Owner:山东亿嘉农化有限公司

Environment-friendly and durable wax oil and preparation method thereof

The invention relates to the field of wood coatings, and particularly relates to environment-friendly and durable wax oil and a preparation method thereof. The environment-friendly and durable wax oil is prepared from the following raw materials in parts by weight: 50-80 parts of vegetable oil, 5-20 parts of biological wax, 5-10 parts of gum dammar, 5-10 parts of isopropanol, 5-10 parts of ethyl ester, 3-5 parts of nanosilicon dioxide, 3-5 parts of sodium silicate, 3-5 parts of calcium sulfate, 2-5 parts of silicone emulsion, 2-5 parts of polyvinyl butyral, 0.5-1 part of a dryer, 0.1-0.3 part of an anti-skinning agent, 0.1-0.3 part of an ultraviolet light absorber, and 0.1-0.3 part of a mould inhibitor. The vegetable oil is a mixture of 15-30 parts of tung oil and 40-60 parts of turpentine. The product is good in durability, low-temperature resistant, fire-proof, less in peeling possibility, good in abrasive resistance, and good in glossiness, and can be widely applied to coating protection of woodwork. Guarantee is provided for the product by the preparation method.

Owner:HANGZHOU EABY ENVIRONMENTAL PROTECTION TECHCO

Degradable agricultural natural insect-repelling mulching film and preparation method thereof

The invention discloses a degradable agricultural natural insect-repelling mulching film and a preparation method thereof, wherein the degradable agricultural natural insect-repelling mulch is made of a degradable plant fiber film, and a natural repellent is applied to the degradable plant fiber film. The preparation method comprises the following steps: mixing one, two or more plant extracts of cinnamomum camphora, houttuynia cordata, turpentine, eucalyptus, wormwood and pyrethrum with capsalcin or / and garlicin to prepare the natural repellant with insect repelling effect; and soaking the degradable plant fiber film into the natural repellant or spraying the natural insect repellant to the degradable plant fiber film. The degradable agricultural natural insect repelling mulching film disclosed by the invention has good insect repelling effect when spread on the ground or suspended on a crop, so that use of pesticide can be greatly reduced, pesticide residues on the crops can be reduced, the crops can grow in an environmentally-friendly environment, and food safety is ensured from the source.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

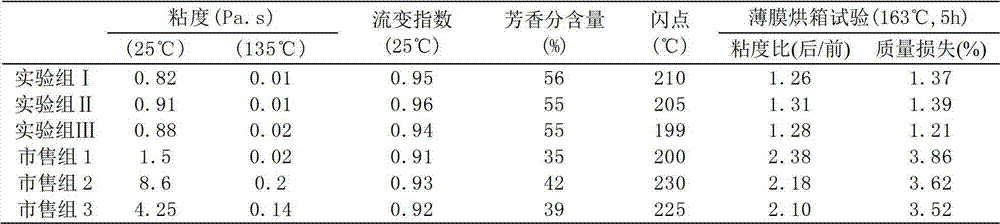

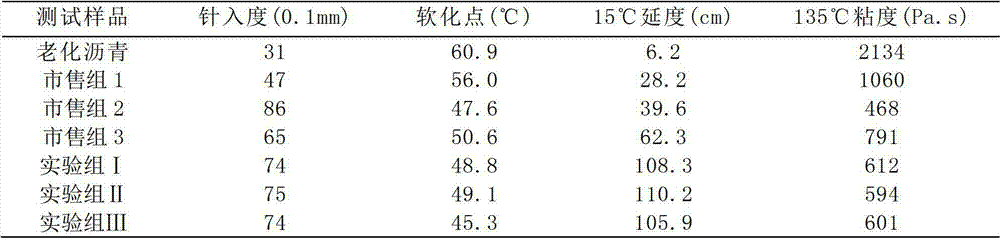

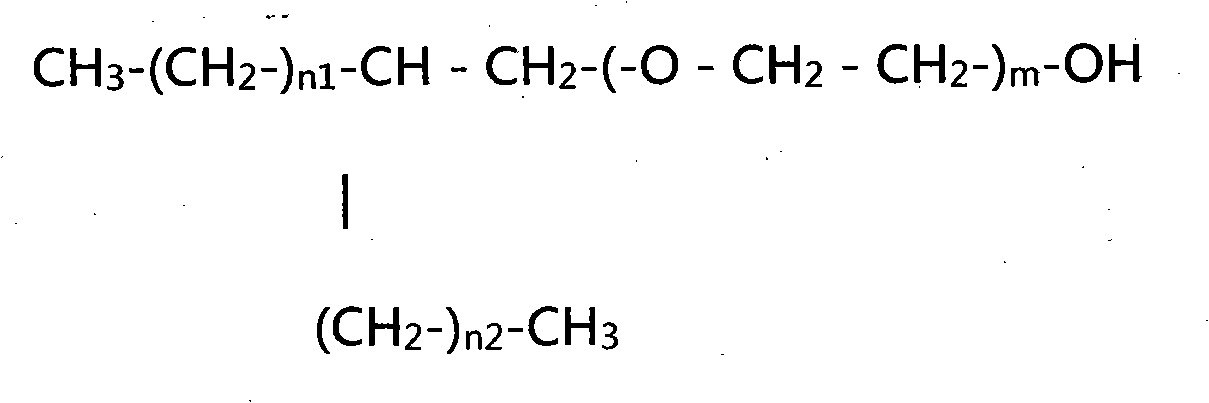

Waste and old asphalt thermal circulation recycling regenerating agent and preparation method thereof

ActiveCN102786806AImprove the safety of useReduce volatilityBuilding insulationsPetroleum resinPlasticizer

The invention provides a waste and old asphalt thermal circulation recycling regenerating agent which has a prescription comprising extract oil from fourth side line of a vacuum tower, epoxidized soybean oil, turpentine and petroleum resin, wherein the epoxidized soybean oil serves as a plasticizer and softener. The waste and old asphalt thermal circulation recycling regenerating agent has various physicochemical indexes obviously higher than those of commercially available waste and old asphalt regenerating agent, and meets the national recommended standard; more important, the epoxidized soybean oil is adopted as the plasticizer and the softener instead of dibutyl phthalate DBP and dioctyl phthalate DOP, so that the quantity of violated harmful substance is lower, and the safety of the regenerating agent in use is improved.

Owner:CHONGQING ZONJO RENEWABLE RESOURCES DEV CO LTD

High efficiency low-foaming blue leather degreaser

InactiveCN101831362ASuitable for a wide temperature rangeFacilitates cleaning removalNon-ionic surface-active compoundsDetergent compounding agentsWater basedKerosene

The invention relates to a degreaser used for degreasing blue leather. The degreaser is a washing composite mainly using surfactant as base material and is clear and transparent microemulsion. The formula of the degreaser comprises the following components by weight percent: 20-60% of surfactant (one or two of non-ionic surfactants such as fatty alcohol polyoxyethylene ether, fatty alcohol polyoxypropylene ether and alkanolamide, 10-40% of solvent (one or two of toluene, xylene, turpentine, C8-C12 of solvent oil, trichloroethylene, tetrachloroethylene and solvent kerosene), 0-5% of cosolvent ( one or two of ethanol, n-propanol, isopropanol and ethylene glycol monobutyl ether, 0-10% of acidic lipase, 0-2% of defoaming agent and 40-60% of water. The application temperature of the microemulsion degreaser is wide, and can be stored for long time without layering and have stable state; and the degreaser has the advantages of solvent degreasing and emulsion degreasing, the fat dissolving and cleaning functions of organic solvents and the cleaning characteristics of water-based surfactants. Therefore, the natural fat in blue leather can be reduced to less than 1%.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Method for producing colophony by using natural turpentine and residue and waste liquor from colophony production factory

InactiveCN1837309AIncrease sedimentationBeneficial to ChengdianNatural resin processLiquid wasteManufacturing technology

The invention discloses an abietyl producing method through natual colophony and abietyl factory waste liquid, which is comprises the following steps: dissolving; filtering roughly; stewing; clearing; filtering distilled waste; distilling the filtrate; packaging the product. The invention increases the usage of dissolved oil (abies) greatly based on common abietyl manufacturing technology, which quickens the impurity separation goal.

Owner:古远亮

Plant source compound formaldehyde clear spray, and preparation method and application thereof

ActiveCN102698580AGood formaldehyde removal effectNo pollution in the processDispersed particle separationDistillationAloe reitzii

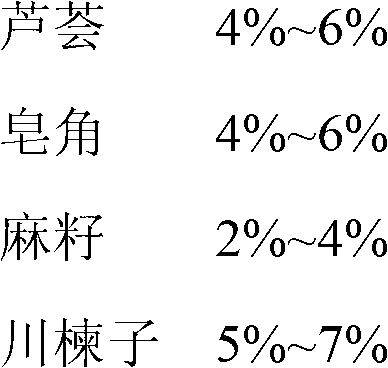

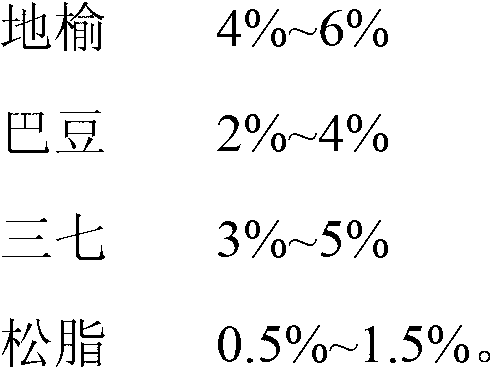

The invention discloses plant source compound formaldehyde clear spray, a preparation method of the formaldehyde clear spray and an application of the formaldehyde clear spray. The plant source compound formaldehyde clear spray comprises the following components by weight percent: 4-6% of aloe, 4-6% of Chinese honeylocust fruit, 2-4% of hemp seed, 5-7% of szechwan Chinaberry fruit, 4-6% of garden burnet, 2-4% of croton, 3-5% of pseudo-ginseng and 0.5-1.5 % of turpentine. The method comprises the steps of: A) mixing and soaking the raw materials; B) distilling and collecting distillation parts; C) diluting by adding water and mixing; and D) diluting again by adding water, and carrying out spontaneous fermentation. The plant source compound formaldehyde clear spray adopts a plant source extractive compounding technology, is friendly to human bodies and environments, is free from pollution, has a relatively good formaldehyde clearing effect and can be used for formaldehyde in air.

Owner:上海复振科技有限公司

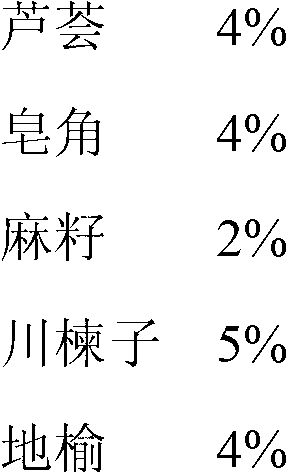

Plant-based antibacterial and production method thereof

The invention belongs to an antibacterial, in particular to a plant-based antibacterial and a production method thereof. The antibacterial is prepared by physically crushing and mixing 20 to 63 weight percent of rheum officinale, 5 to 10 weight percent of turpentine, 5 to 10 weight percent of aloe, 17 to 40 weight percent of golden cypress bark, 5 to 10 weight percent of saponin and 5 to 10 weight percent of root of melia azedarach linn; immersing the mixture in ethanol; and concentrating. When used, the plant-based antibacterial is very stable and forms bacteriostatic thin films on thesurface of plants after being sprayed and contacted with the target plants so as to effectively kill germs and control the spread of the disease. In the invention, the raw materials are rich, the production method is simple, the plant-based antibacterial is cheap, convenient, environmentally-friendly, free from arousing medicine resistance and safe to human beings and livestocks, can be used for preventing and controlling various diseases such as powdery mildew, downy mildew and anthracnose in crops such as vegetables, fruits, flowers and plants.

Owner:韶关市高信塑胶制品有限公司

Extraction of hydrocarbons from hydrocarbon-containing materials

A method of extracting hydrocarbon-containing organic matter from a hydrocarbon-containing material includes the steps of providing a first liquid comprising a turpentine liquid; contacting the hydrocarbon-containing material with the turpentine liquid to form an extraction mixture; extracting the hydrocarbon material into the turpentine liquid; and separating the extracted hydrocarbon material from a residual material not extracted.

Owner:ENERGREEN CO LTD

Rosin production technology process

InactiveCN104342034AImprove melting abilityThere will be no meltingChemical industryTurpentine spiritsSteam pressureTurpentine

The invention discloses a rosin production technology process. The process comprises the following steps: conveying turpentine to a melting boiler, adding water, turpentine oil, and oxalic acid, wherein the weight ratio of turpentine to water to turpentine oil is 2-4:1-2:1, and the oxalic acid accounts for 0.1 to 0.3% of the turpentine weight; heating the boiler to melt the mixture in the boiler; transferring the melt mixture to a transition boiler; introducing the melt mixture into a clarifying boiler after precipitation in the transition boiler, then transferring the liquid to a steaming boiler to carry out steaming, wherein during the steaming process, water and turpentine oil are continuously steamed out from the liquid. The provided rosin production technology process has the following advantages: the turpentine is fully stirred before melting so as to grind the turpentine, thus the turpentine melting effect is improved, at the same time the phenomenon that some turpentine is not melted during the melting process is avoided, and thus the yield is increased; moreover, the metling is reduced, the energy consumption is reduced, and the rosin color will not turn darker; the condensed hot water can be directly applied to the boiler so as to reduce the temperature difference between the inlet water and outlet water, the boiler efficiency is improved, the steam pressure is more stable, and more energy is saved.

Owner:琼中森富松香加工厂有限公司

Environment-friendly orange peel extract limonene degumming and decontaminating agent and preparation method thereof

InactiveCN101962601AQuick removalEfficient removalOrganic non-surface-active detergent compositionsTurpentineLimonene

The invention relates to an environment-friendly orange peel extract limonene degumming and decontaminating agent and a preparation method thereof, and belongs to the technical field of articles for daily use, such as a cleaning agent and the like. The degumming and decontaminating agent is characterized by consisting of 5 to 30 mass parts of turpentine, 70 to 100 mass parts of orange peel extract limonene comprising 60 to 95 mass percent of limonene, and 0.5 to 10 mass parts of medical-grade ethanol with concentration of greater than or equal to 95 percent, wherein the materials are placed in a clean container and uniformly mixed at the normal temperature so as to obtain the orange peel extract limonene degumming and decontaminating agent; and the orange peel extract limonene degumming and decontaminating agent is bottled. All the raw materials used in the invention are natural and nontoxic raw materials with superior volatility; a mark does not remain on the surface after dirt is cleaned by using the degumming and decontaminating agent, and the degumming and decontaminating agent has fresh air of mandarin orange and rosin smell, does not have harm to environment and belongs to the environment-friendly products; and the degumming and decontaminating agent is wiped with cloth in use so as to ensure convenience.

Owner:无锡龙腾画材有限公司

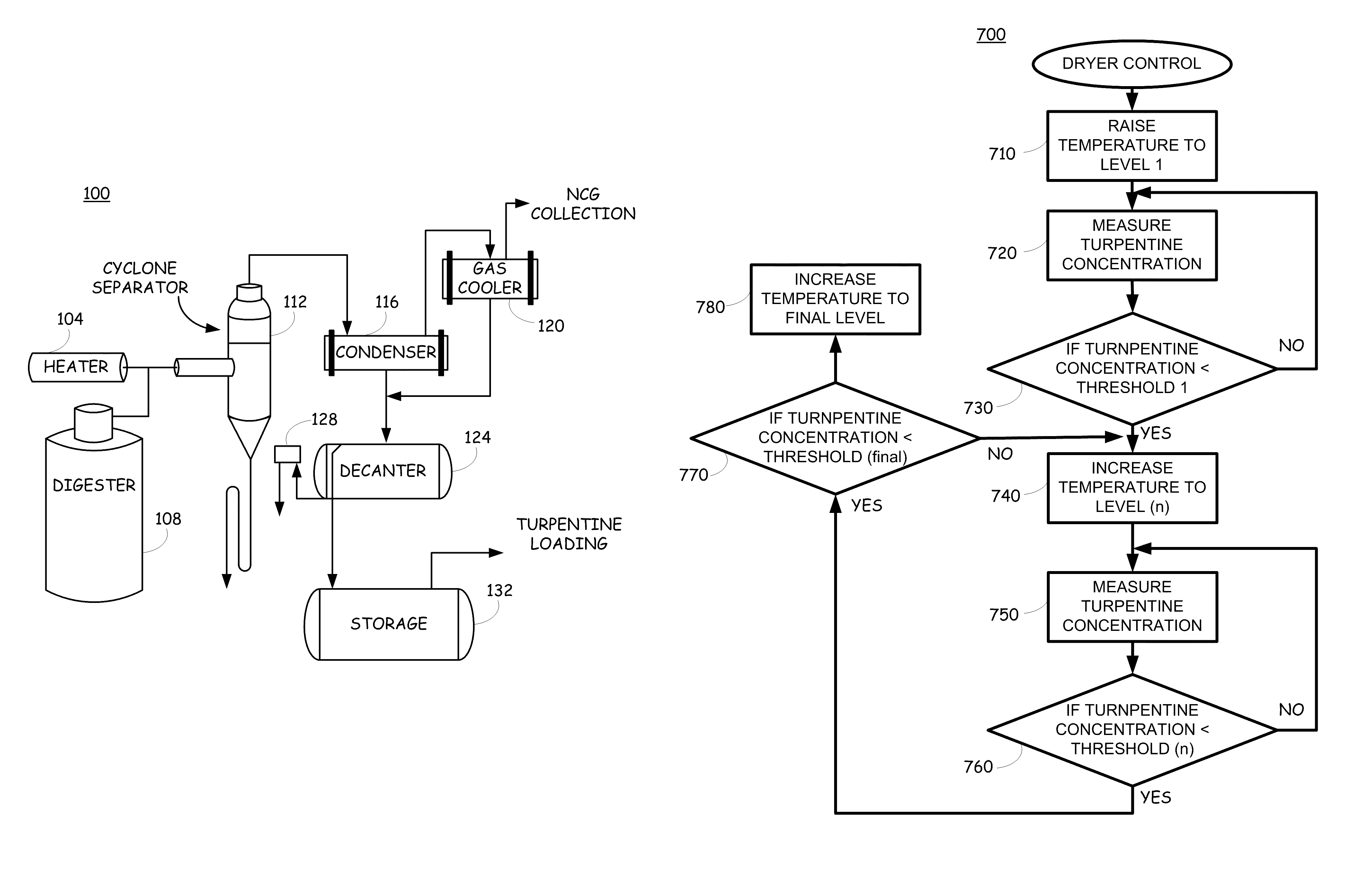

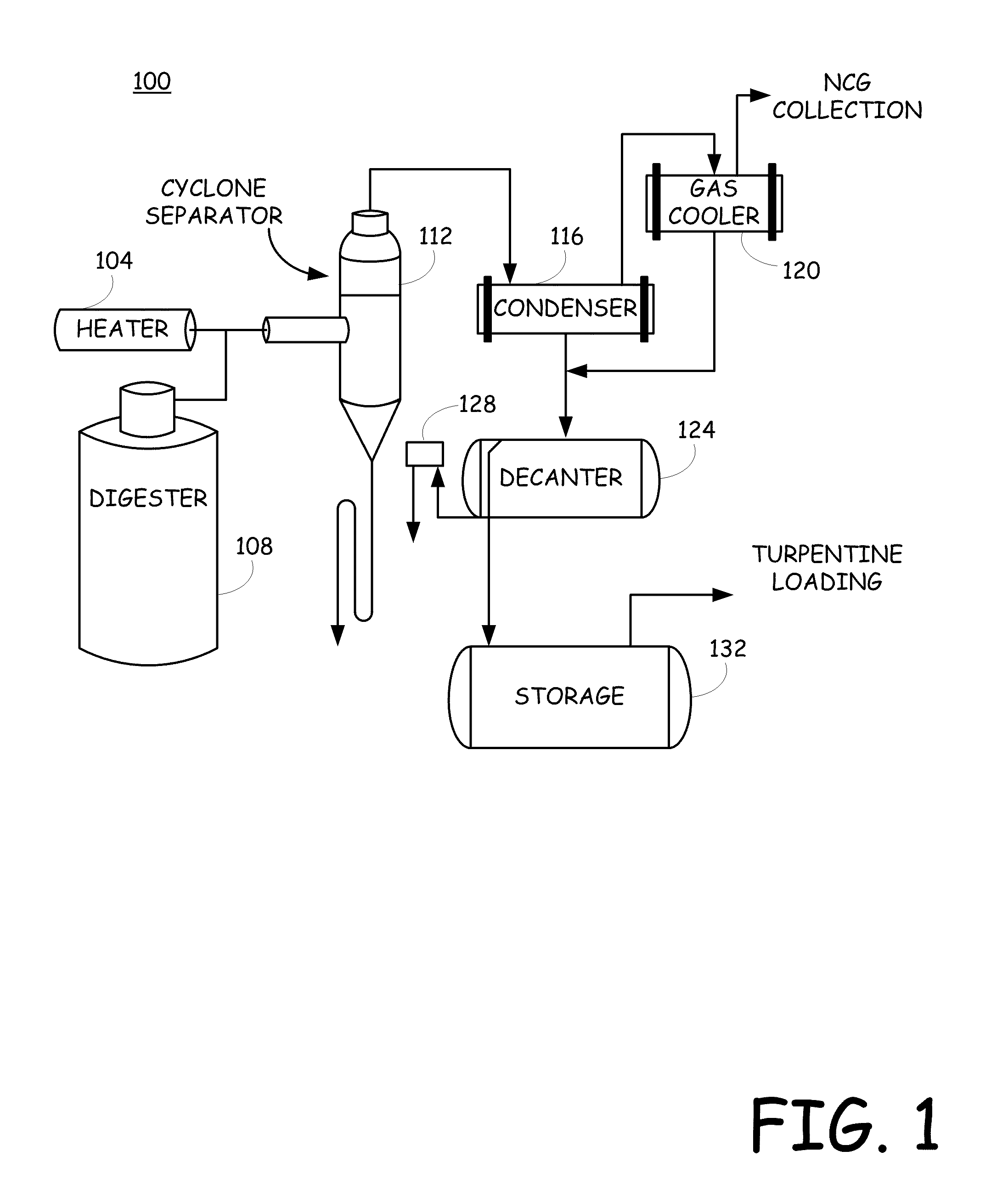

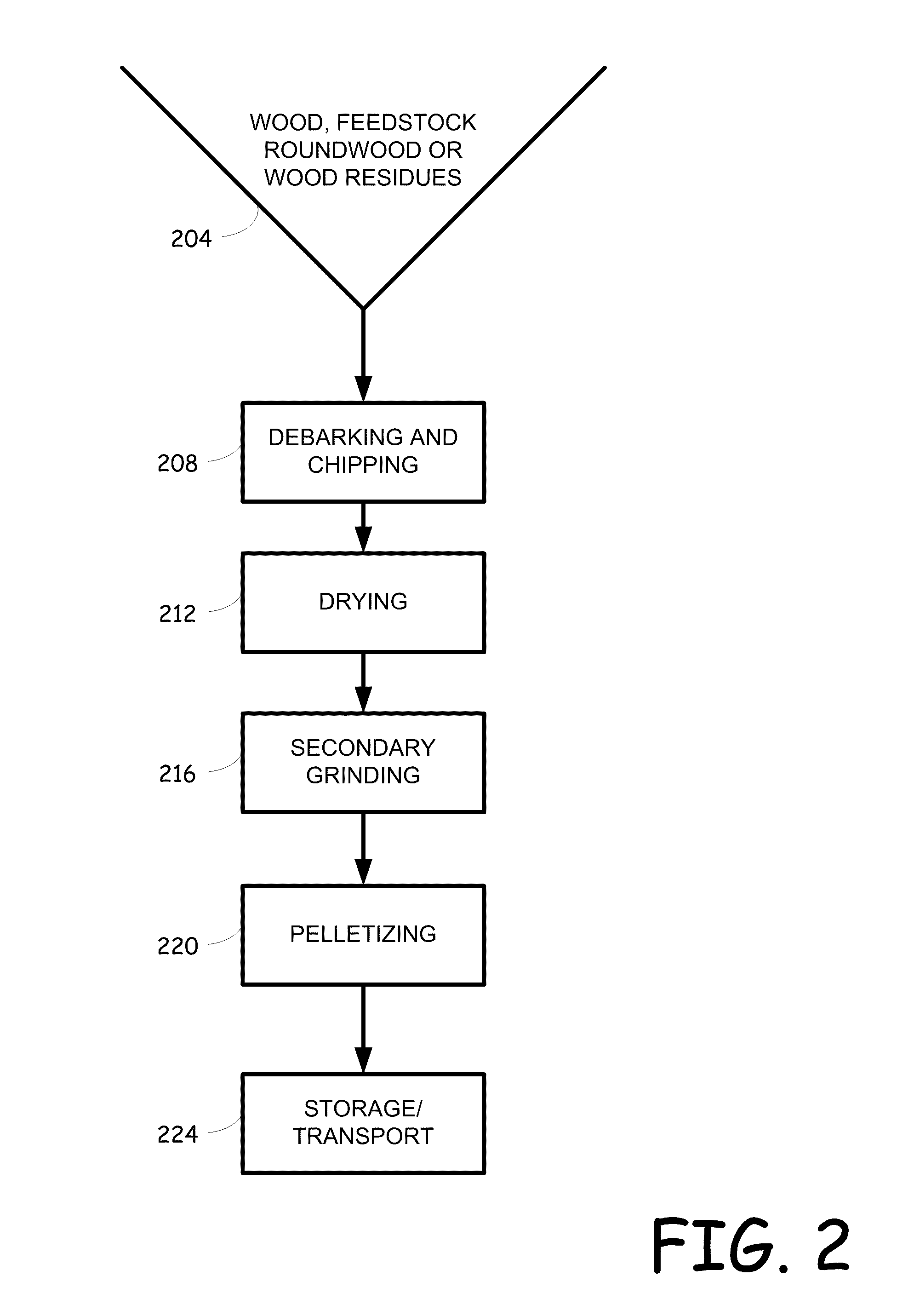

System and method for recovering turpentine during wood material processing

InactiveUS8832964B2Reduction in capital and operation costDrying using combination processesDrying solid materials with heatTurpentinePulp and paper industry

A system, method and configuration for recovering turpentine during the manufacturing of wood chips, wood pellets or other substances that may include turpentine. In general, a turpentine recovery system is used to capture turpentine from exhaust of a dryer as wood chips are being dried. Advantageously, application of the various techniques disclosed herein can result in the recovery of turpentine that can then be sold to generate revenue and, may contribute to a reduction in the capital and operation costs for emission controls for the dryer exhaust.

Owner:FOXEN ROBERT J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com