Aqueous acrylic acid series wooden ware sealing paint and method for preparing special emulsion thereof

A water-based acrylic, acrylic technology, applied in wood processing appliances, coatings, coating impregnation, etc., can solve problems such as construction difficulties and affecting paint film performance, and achieve strong adhesion, small particle size, and excellent sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A: With condensed water, stirring, thermometer, inert gas (N 2 ) protection, add 122 grams of water in the four-necked bottle of the dropping device, 1.26 grams of anionic reactive emulsifier allyl polyethoxysulfonate (dissolved in 3.78 grams of water), 1.26 grams of anionic emulsifier alkyl Sodium oxydiphenylsulfonate (dissolved in 1.54 grams of water), then heated the system to 60°C, added 4.62 grams of methyl methacrylate, 3.4 grams of butyl acrylate, and 0.042 grams of methacrylic acid mixture at one time, and stirred for 30 minutes Finally, add 0.084 grams of ammonium persulfate (dissolved in 5 grams of water), and then add 0.084 grams of sodium bisulfite (dissolved in 5 grams of water) after 5 minutes. Add 87.78 grams of methyl methacrylate, 64.64 grams of butyl acrylate, 0.798 grams of methacrylic acid, 6.72 methacrylamide (dissolved in 70 grams of water) mixture, while adding dropwise 0.084 grams of ammonium persulfate (dissolved in 15 grams of water ) and 0.08...

Embodiment 2-18

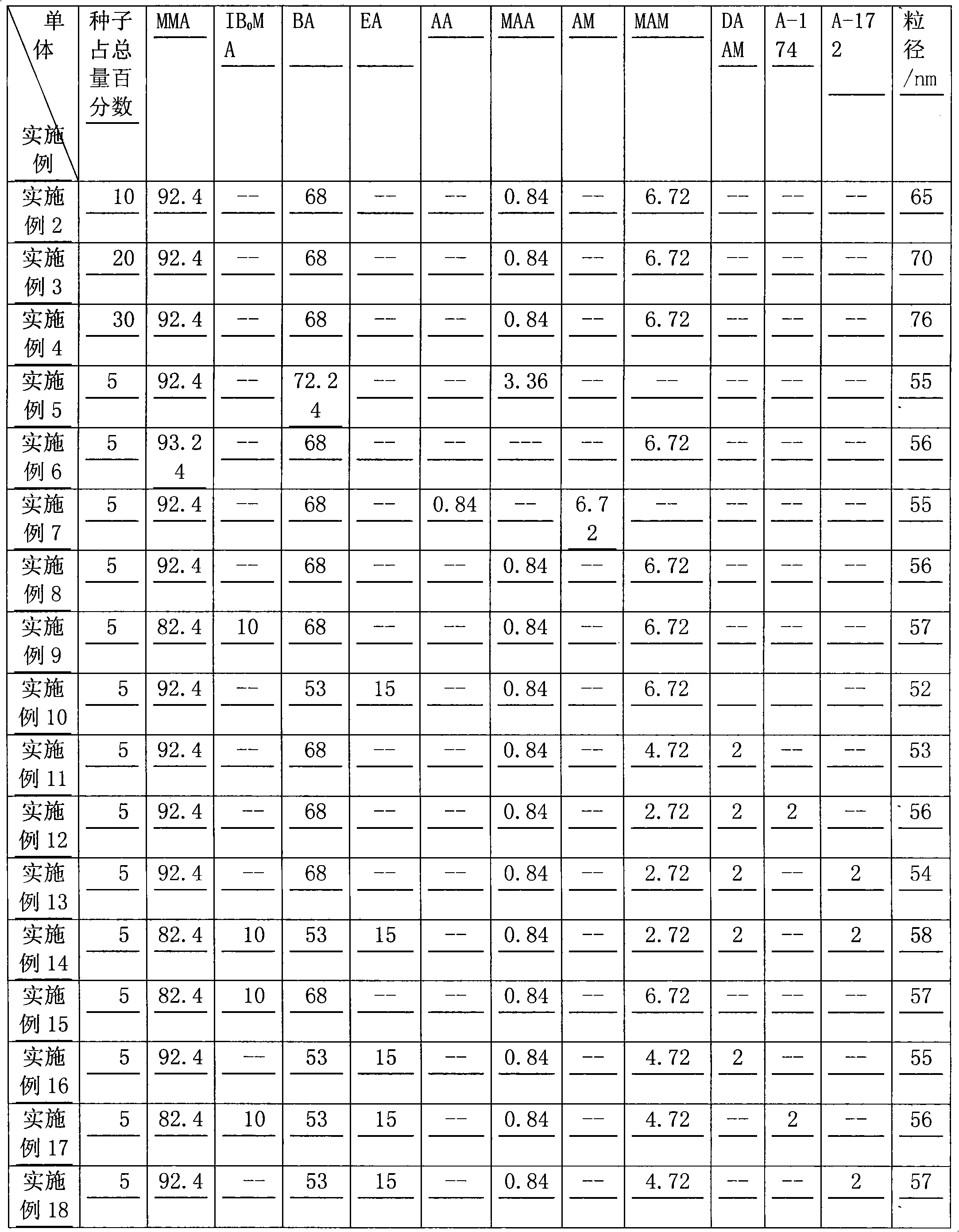

[0032] Embodiment 2-18: The monomers used for synthesizing latex particles and their consumption are shown in Table 1, and other preparation conditions are the same as in Example 1.

[0033] Table 1: The monomers and consumptions used in the synthetic latex particles of embodiment 2-18

[0034] Unit: grams

[0035]

[0036] Note: in embodiment 1, seed monomer accounts for 5% of total monomer content

[0037] In the table, MMA is methyl methacrylate, IBOMA is isobornyl methacrylate, BA is butyl acrylate, EA is ethyl acrylate, AA is acrylic acid, MAA is methacrylic acid, AM is acrylamide, and MAM is methacrylic acid Amide, DAAM is diacetone acrylamide, A-174 is 3-(methacryloyloxy)propyltrimethoxysilane, A-172 vinyltris(β-methoxyethoxy)silane;

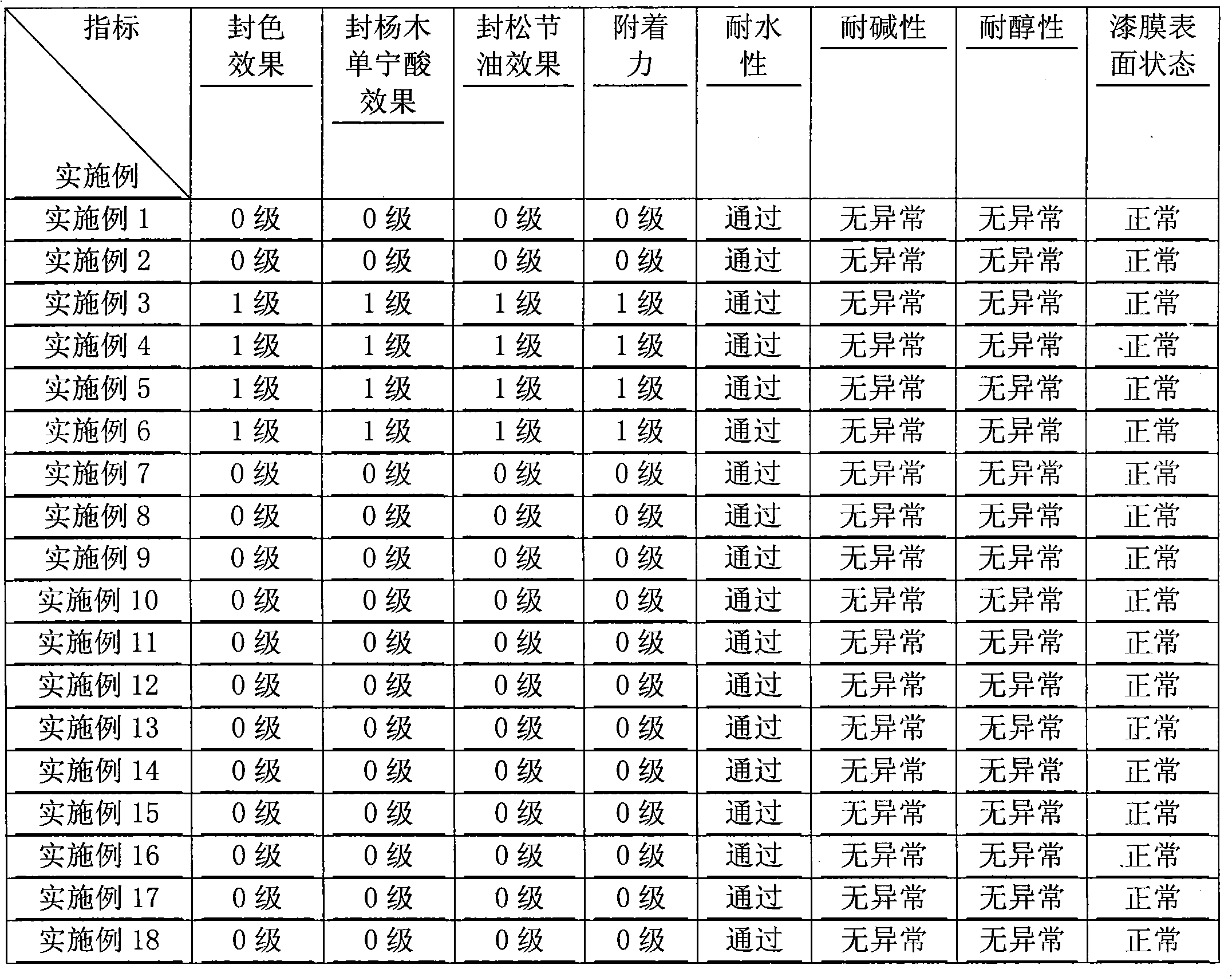

[0038] Table 2: Test results of various performance indicators of the water-based wood sealing coatings of Examples 1-18

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com