Patents

Literature

257 results about "Isobornyl methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isobornyl methacrylate is a minor monomer limited to use only in plastic articles intended for repeated use in contact with food. 21 CFR 177.1010; U.S. National Archives and Records Administration's Electronic Code of Federal Regulations.

Water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and preparation method of matt-leather-membrane aqueous coating adhesive

ActiveCN104831540AAssociative functionCombined with styleFibre treatmentIsooctyl acrylatePolymer science

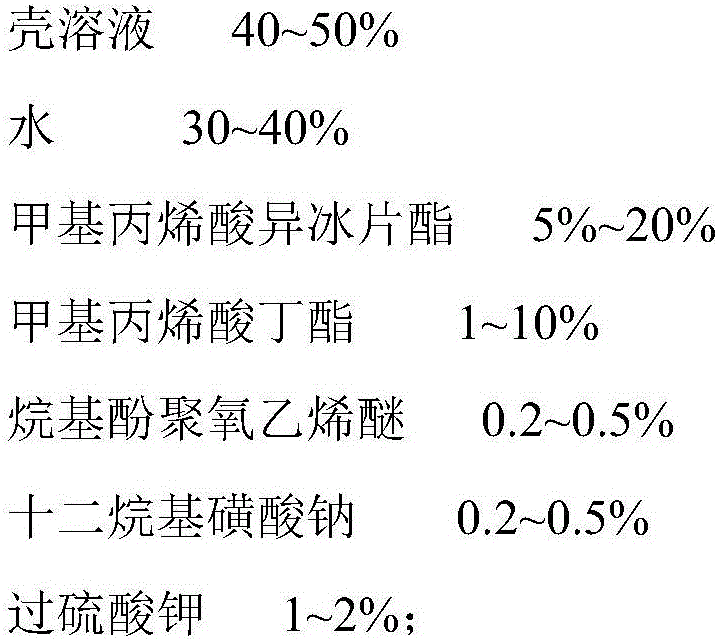

The invention relates to a water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and a preparation method of the matt-leather-membrane aqueous coating adhesive. The preparation method comprises the steps of emulsifying isooctyl acrylate, isobornyl methacrylate, glycidyl methacrylate, trifluoroethyl methacrylate, vinyl trimethoxysilane, hydroxypropyl acrylate, fatty alcohol ethoxylate XL90 and dodecyl benzene sulfonate to trigger polymerization, and compounding a thickening agent, namely an associated polyurethane flatting rheological agent, a cross-linking agent, namely terminated isocyanate, a flatting agent, namely polymethyl urea resin and silicon dioxide with the particle size of 2-7 microns, so as to obtain the matt-leather-membrane aqueous coating adhesive.

Owner:DANDONG UNIK TEXTILE

Binding agents for polyurethane-based paints

InactiveUS6130308ASynthetic resin layered productsPretreated surfacesTERT-BUTYL METHACRYLATEN-Butyl methacrylate

PCT No. PCT / EP97 / 00149 Sec. 371 Date Aug. 20, 1998 Sec. 102(e) Date Aug. 20, 1998 PCT Filed Jan. 15, 1997 PCT Pub. No. WO97 / 29142 PCT Pub. Date Aug. 14, 1997The invention relates to coating compositions for the production of coatings which are resistant to condensed water and comprise binders based on a polyurethane resin PUR which comprises alpha, omega-polymethacrylatediols (A) as structural units. The alpha, omega-polymethacrylatediols (A) preferably consist of the monomer units methyl methacrylate, ethyl methacrylate, propyl methacrylate, n-butyl methacrylate, isobutyl methacrylate, tert-butyl methacrylate, n-pentyl methacrylate, amyl methacrylate, n-hexyl methacrylate, n-octyl methacrylate, 2-ethylhexyl methacrylate, n-decyl methacrylate, cyclopentyl methacrylate, cyclohexyl methacrylate, 4-tert-butylcyclohexyl methacrylate, cyclooctyl methacrylate, phenyl methacrylate or isobornyl methacrylate or mixtures thereof. The present invention additionally relates to processes for the preparation of such coating compositions and to their preferred use as fillers, basecoats and / or topcoats, especially in connection with automotive production-line finishing and / or refinishing.

Owner:BASF COATINGS AG

Aqueous concoction, aqueous polymer emulsion prepared from same and application thereof

The invention provides an aqueous concoction which comprises the following components: (a) isobornyl methacrylate monomer, (b) monomer containing a vinyl unsaturated group, (c) crosslinking monomer, (d) unsaturated organic acid and salt thereof, (e) surface active agent, and (f) aqueous medium. The invention also provides an aqueous polymer emulsion prepared by the polymerization reaction of the aqueous concoction, which can be applied to water paint so as to obtain a paint having high performance and high drying rate. Compared with the traditional solvent-based paint, the water-based paint can reduce the production of organic solvents, thereby better meeting the environment protection requirements.

Owner:ETERNAL CHEM (CHINA) CO LTD

Polyacrylate, pressure-sensitive adhesive and preparation method

ActiveCN109762097AThe polymerization process is simpleHigh temperature resistance and good adhesionEster polymer adhesivesPressure sensitive film/foil adhesivesIsooctyl acrylateGlycidyl methacrylate

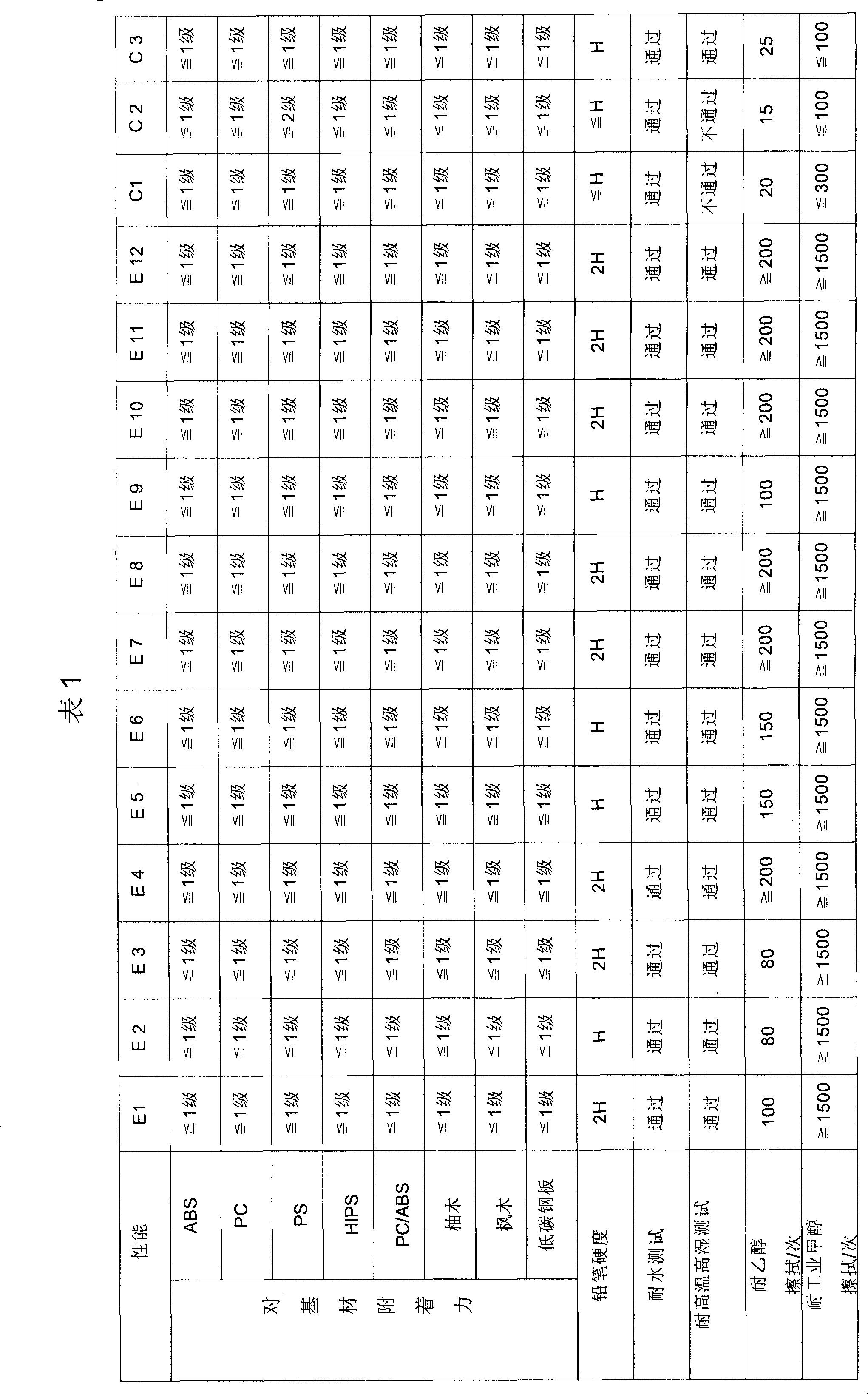

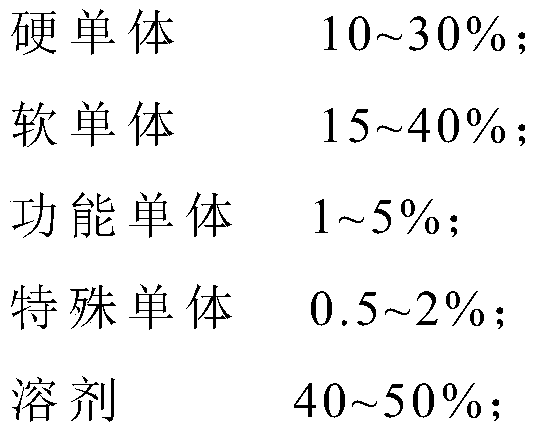

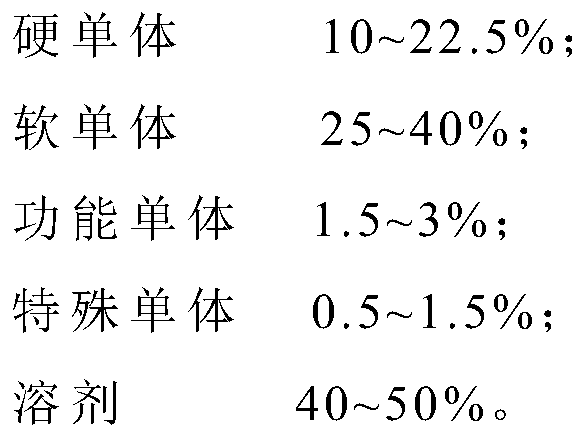

The invention relates to polyacrylate. Polyacrylate is synthesized from raw materials in percentage by mass as follows: 10%-30% of a hard monomer, 15%-40% of a soft monomer, 1%-5% of a functional monomer, 0.5%-2% of a special monomer and 40%-50% of a solvent, wherein the hard monomer comprises one or more of methyl acrylate, methyl methacrylate, vinyl acetate, acrylonitrile and isobornyl methacrylate; the soft monomer comprises one or more of ethyl acrylate, n-butyl acrylate, 2-ethylhexyl acrylate and n-propyl acrylate; the functional monomer comprises one or more of hydroxyethyl acrylate, acrylic acid, methacrylic acid, hydroxypropyl acrylate and 2-hydroxyethyl methacrylate; the special monomer comprises one or more of methacrylamido ethyl ethylene urea, hydroxyethyl methacrylate phosphate and glycidyl methacrylate. A pressure-sensitive adhesive has good high-temperature-resistant adhesive property, does no squeeze out, has no residue, has low cost and can be applied to masking tapesused in capacitor taping in the electronics industry as well as certain high-temperature-resistant adhesive tapes.

Owner:CYBRID TECHNOLOGIES INC

Preparation method of fluorin modified crylic acid resin for helicopter skining paint

the invention discloses a fluorine modified acrylic resin and preparing method for helicopter covering paint, which comprises the following steps: blending composite monomer methacrylic acid borneol ester, n-butyl methacrylate, hydroxyethyl methacrylate, butyl acrylate, methacrylic acid and fluorine monomer in the composite solvent with xylene, propylene glycol methyl ether acetic ester, methyl isobutyl ketone and 100# solvent oil; dripping carbonic glycide ester to polymerize acted by trigger pentaphen peroxide to obtain the product.

Owner:ZHEJIANG UNIV +1

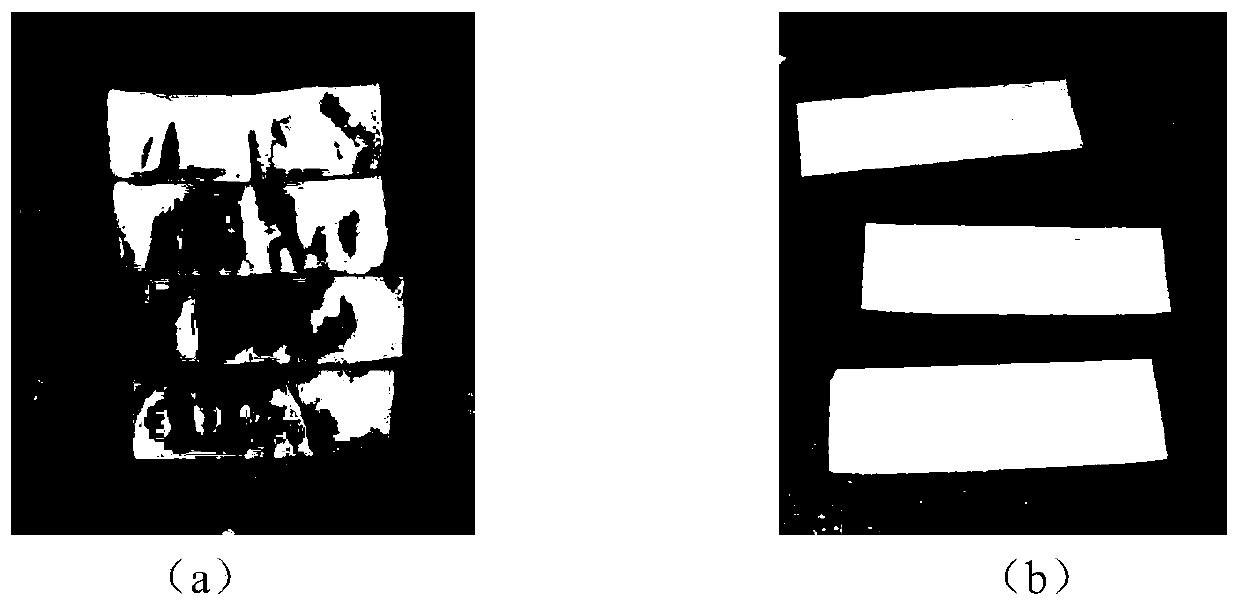

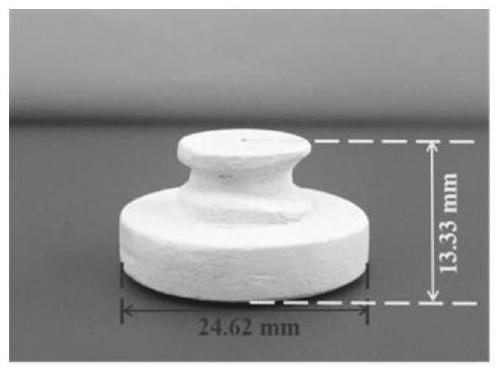

Ceramic pulp for photo-curable 3D printing and preparation method and application of ceramic pulp

ActiveCN110627501AHigh viscosityAdditive manufacturing apparatusCeramic shaping apparatusTripropylene glycolMeth-

The invention discloses ceramic pulp for photo-curable 3D printing and a preparation method and application of the ceramic pulp. The ceramic pulp includes ceramic powder, photo-curable resin, a photoinitiator and a dispersant, wherein the photo-curable resin comprises the components: in percent by mass, 10-60% of bisphenol A epoxy acrylate, 10-60% of trimethylolpropane triacrylate, 10-60% of tripropylene glycol diacrylate and 10-60% of isobornyl methacrylate. The rheological performance of the slurry can be adjusted through selection of reactive diluents with different functionalities and adjustment of the ratio of the diluents, needs of light curing molding can be met by the slurry, and degreasing and sintering are performed on a molded sample so as to obtain a high-density zirconia ceramic product with a relative density of up to 98.8%.

Owner:SHENZHEN RES INST CENT SOUTH UNIV +1

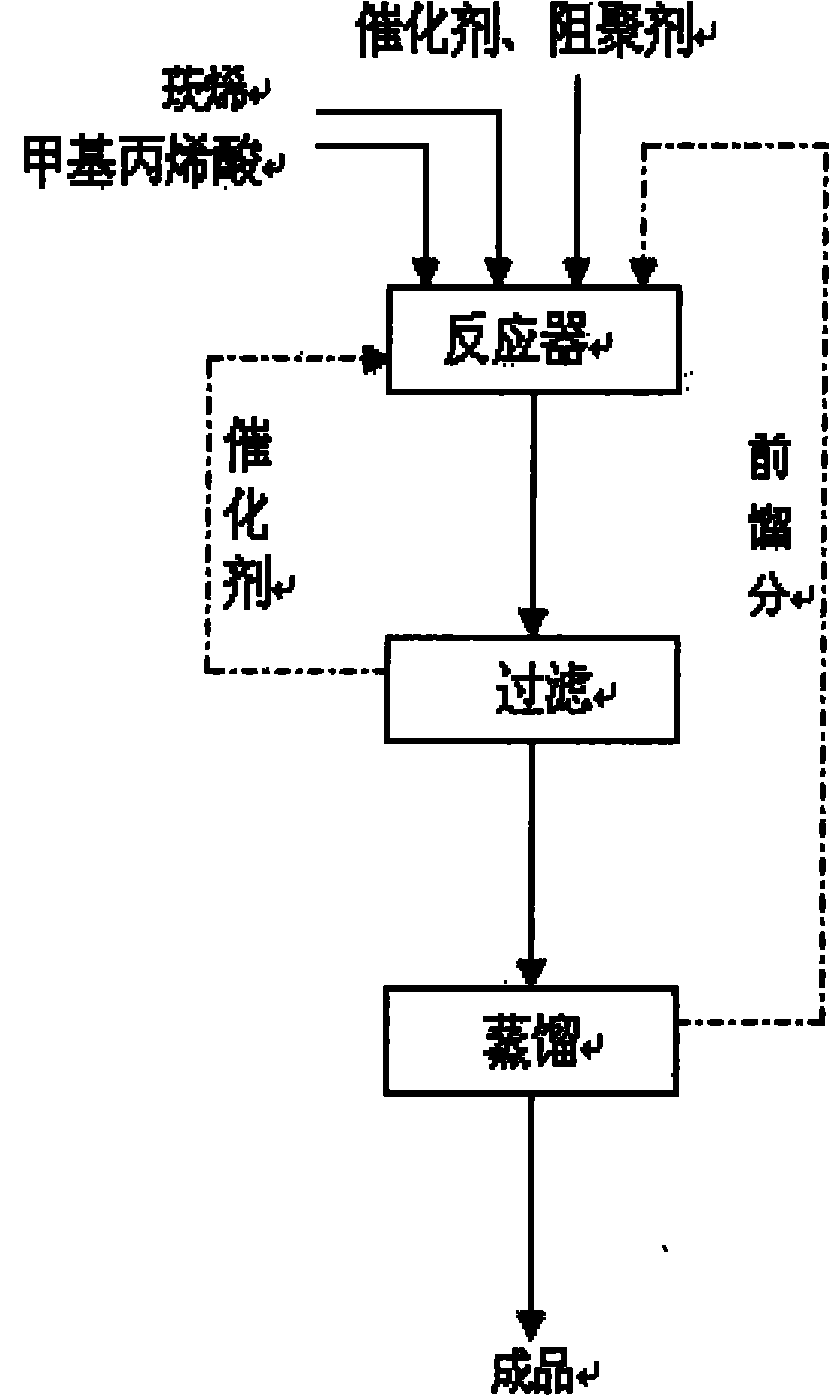

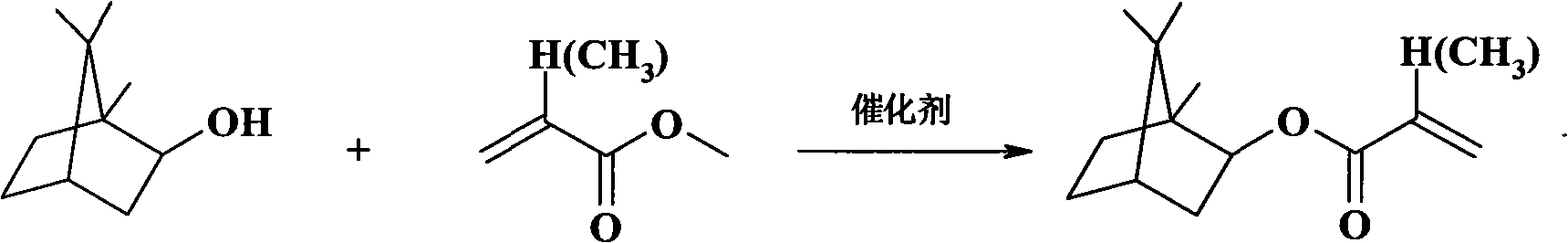

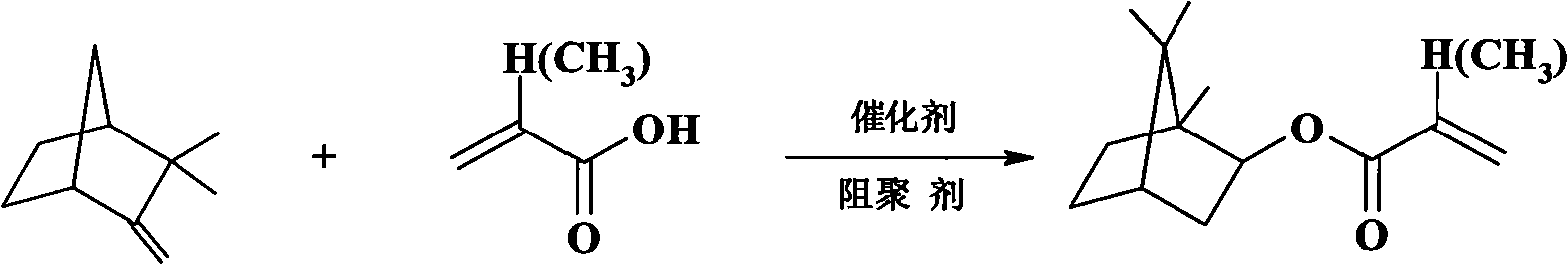

Method for catalytically synthesizing isobornyl methacrylate by activated carbon supported stannic chloride

InactiveCN101863763AEasy to makeLow costPhysical/chemical process catalystsOrganic compound preparationIsomerizationSolvent

The invention provides a method for catalytically synthesizing isobornyl methacrylate by activated carbon supported stannic chloride, which is characterized by using isomerized solution obtained by isomerizing alpha-pinene by metatitanic acid as the raw material and using the activated carbon supported stannic chloride as a catalyst, directly esterifying the isomerize solution, the activated carbon supported stannic chloride and (methyl) acrylic acid without additional solvents, filtering the esterified solution to remove the catalyst and then directly distilling the esterified solution without washing to obtain isobornyl acrylate (methyl). The method has the following advantages: the isomerized solution can be directly esterified without being purified and the esterified solution is directly distilled without being washed to obtain isobornyl acrylate (methyl). The synthetic method has the advantages of low energy consumption, low environmental pollution, good isomerization and esterification reaction selectivity, high yield and the like.

Owner:NANJING FORESTRY UNIV +1

Aqueous acrylic resin, and preparation method and application thereof

ActiveCN102516446AGood molding performanceGood physical propertiesThermographyHot stampingInformation layer

The invention discloses an aqueous acrylic resin, and a preparation method and an application thereof. An efficient emulsifier and an improved emulsion polymerization method are used for realizing the preparation of an aqueous emulsion; a novel polymerized monomer, namely, isobornyl methacrylate is added for overcoming the defect of brittleness of high Tg point resin; and a curing agent with certain components is added before the coating operation is performed, so that the temperature tolerance of the resin is obviously increased and the problem of mold-pressing at higher temperature of the resin is solved. The harm to environment and human health caused by an organic solvent during a use process is avoided and certain cost is saved, by using the aqueous acrylic resin. The novel polymerized monomer, namely, isobornyl methacrylate is added for solving the problem of applying acrylic resins to a laser hot-stamping foil information layer, an excellent toughening function is achieved and the mold-pressing implementation of the resin is increased. Under the action of the applied efficient emulsifier and the improved emulsion polymerization method, the prepared resin has excellent physical and chemical properties as well as storage and use stability both reaching the production standard.

Owner:佛山市南海高拓包装材料有限公司

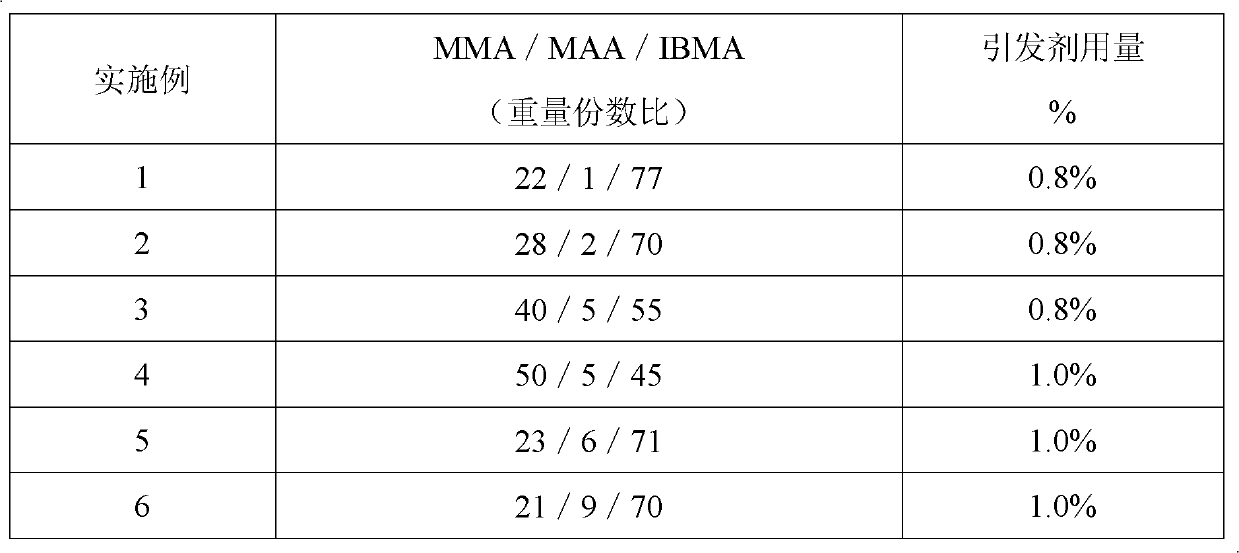

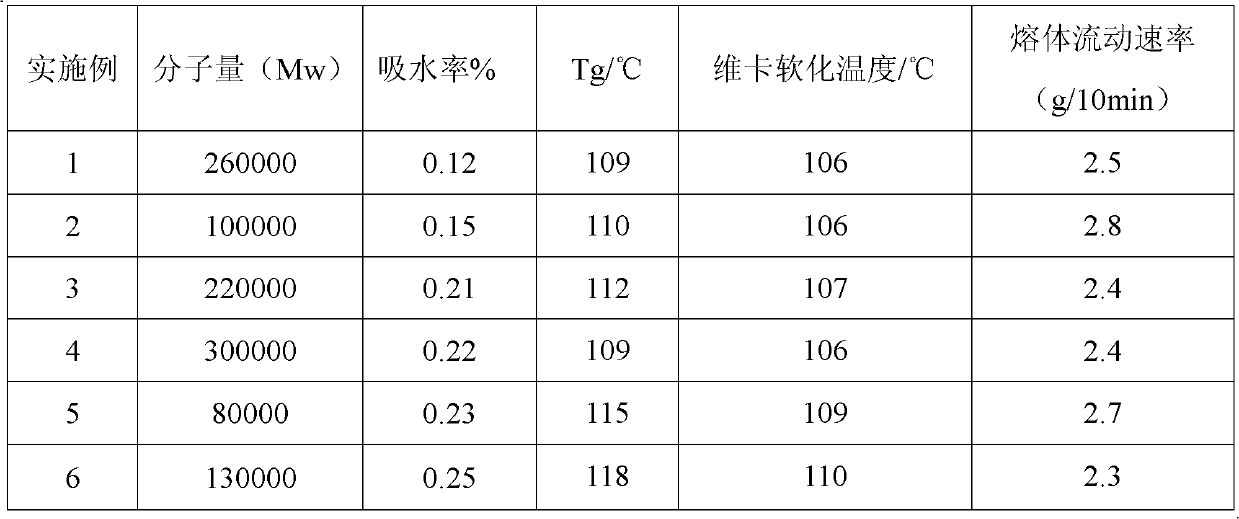

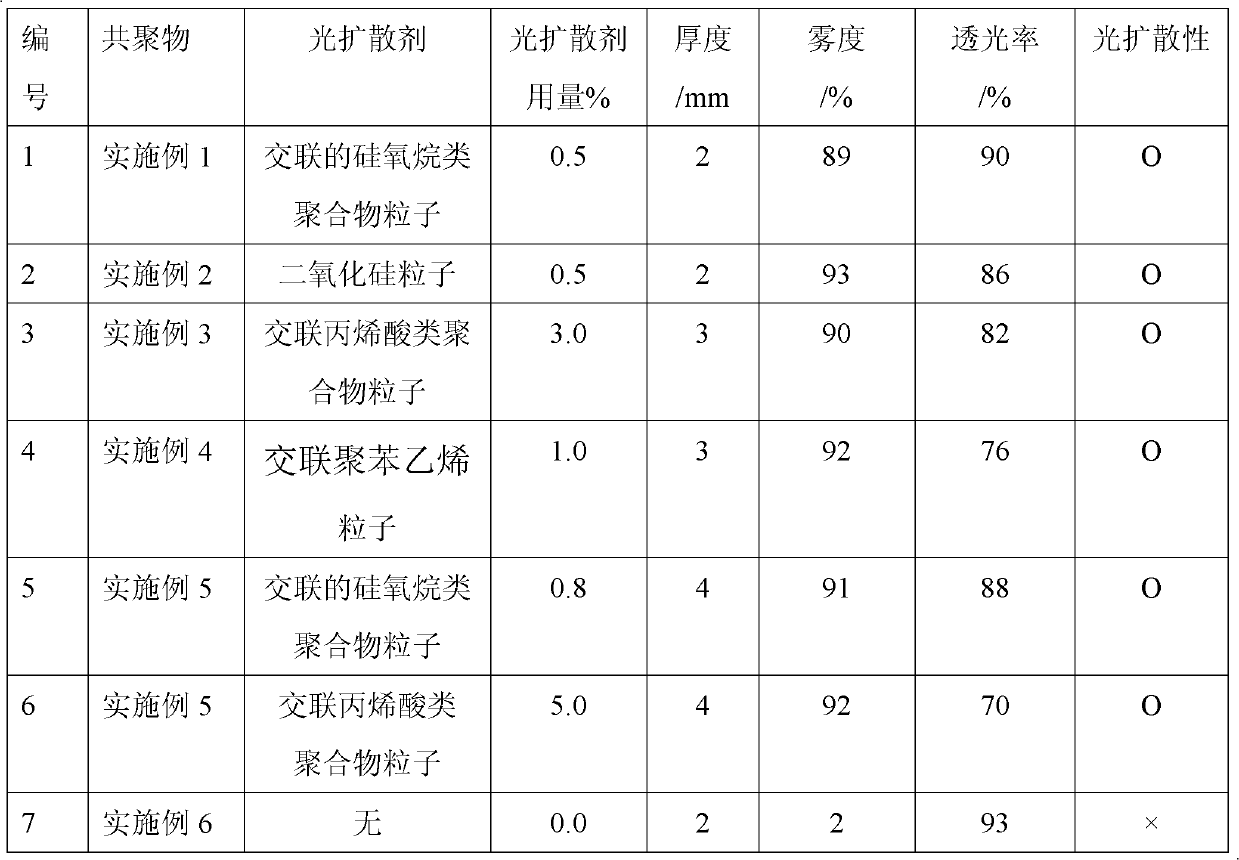

Polymethacrylate copolymer and photodiffusion section bar prepared by adopting same as raw material

ActiveCN102585085ASolve the problem of high hygroscopicityIncrease brightnessDiffusing elementsOptical light guidesPolymer sciencePolystyrene particle

The invention belongs to the field of preparation of optical materials and discloses a polymethacrylate copolymer, a photodiffusion section bar prepared by adopting the same as a raw material, as well as preparation methods and applications of the polymethacrylate copolymer and the photodiffusion section bar. The copolymer comprises the following components in parts by weight: 20-50 parts of methyl methacrylate, 2-15 parts of methacrylic acid and 40-75 parts of isobornyl methacrylate. The copolymer is prepared by carrying out suspension copolymerization or solution polymerization on the components, and the weight-average molecular weight of the product is 60,000-300,000. The photodiffusion section bar is prepared by adopting the method that the copolymer is mixed with a light diffusant of 0.1-5 percent, and then the obtained mixture is molten, granulated and shaped to prepare the photodiffusion section bar with a thickness of 0.5-4mm, wherein the light diffusant comprises crosslinking siloxane polymer particles, crosslinking polystyrene particles, crosslinking acrylic acid polymer particles, titanium dioxide particles or silicon dioxide particles. The section bar has good light diffusivity and light transmittance, can restrain a light source from transmitting and can meet the fabrication requirement of light guide section bars for liquid crystal displays and LED light sources.

Owner:GUANGZHOU KEYUAN INNOVATIVE MATERIALS

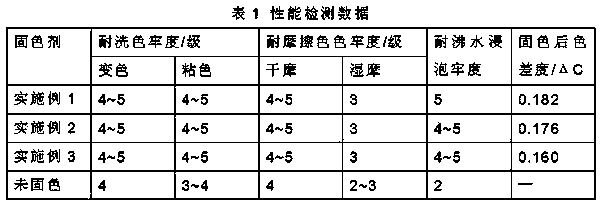

Fabric formaldehyde-free fixing agent and preparation method thereof

ActiveCN103669041AImprove washing fastnessSimple preparation processDyeing processPolymer scienceMeth-

The invention relates to a fabric formaldehyde-free fixing agent, and a preparation method thereof, and belongs to the technical field of textile auxiliary agents. The fixing agent comprises the following components in parts by weight: 15-25 parts of crylic acid butyl ester, 5-9 parts of chitosan hyamine, 6-10 parts of isobornyl acrylate, 7-14 parts of acrylyl oxyethyl acrylate trimethyl ammonium chloride, 8-10 parts of triallylamine, 2-5 parts of organo-siloxane, 3-5 parts of glacial acetic acid, 0.1-1 part of azodiisobutyronitrile and 100-120 parts of deionized water. The fabric formaldehyde-free fixing agent is simple in preparation process, the prepared fixing agent is free of formaldehyde and APEO (Alkylphenol Ethoxylates), static combination of cation groups in fixing agent molecules with anion groups in dye can be achieved, insoluble lake can be formed on the surface of a fabric, and hydrosolvent groups of the dye are sealed up, so that the washing fastness of the colored fabric can be improved.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

Photocureable silicon nitride ceramic paste and preparation method thereof

The invention discloses a photocureable silicon nitride ceramic paste and a preparation method thereof. According to the invention, stearic acid powder and a premixed solution are additionally used asraw materials on the basis of ceramic powder, wherein the premixed solution is composed of a plurality of substances. According to the invention, through addition of the stearic acid powder, the compatibility of the ceramic powder and subsequent resin can be improved, and the solid phase content of silicon nitride ceramic can be easily improved; through optimized selection of all substances in the premixed solution, resin with high refractive index can be introduced into a resin system to reduce the difference of refractive indexes of the ceramic powder and the resin, so the single-layer curing depth of a ceramic paste can be improved; in addition, rigid group containing epoxy resin, isobornyl methacrylate (IBOMA) and the like are added into the resin to reduce shrinkage generated in theprocess of curing; and through optimization of the varieties of all substances, the photocureable ceramic paste provided by the invention has the following advantages: the solid phase content and single-layer curing depth of the isobornyl methacrylate are improved, and the shrinkage amount of the paste photocured into ceramic is reduced.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

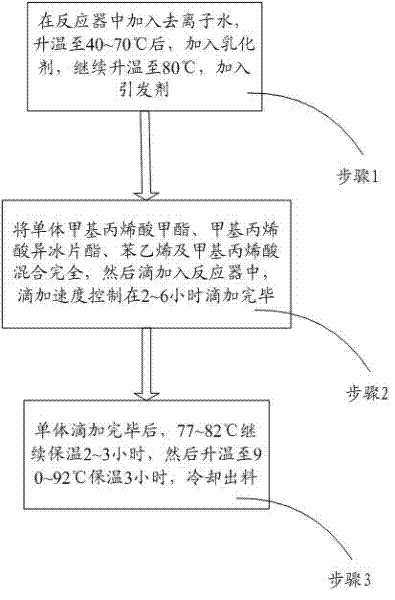

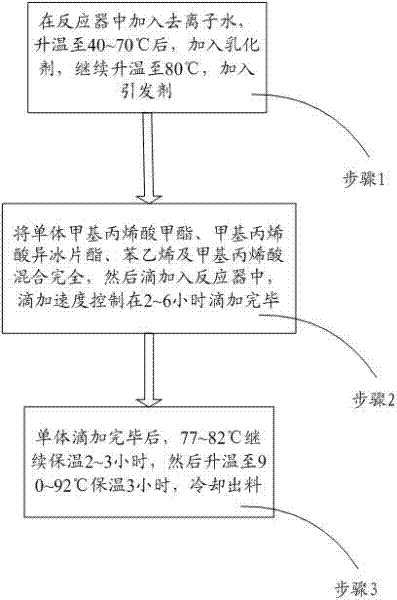

Thermoplastic acrylic resin and preparation method for same

The invention discloses a thermoplastic acrylic resin. The thermoplastic acrylic resin is characterized by comprising the raw materials in parts by weight: 25-40 parts of methyl methacrylate, 20-30 parts of butyl acrylate, 15-30 parts of alkyl-containing acrylic monomer, 2-5 parts of hydroxyethyl acrylate, 1-2 parts of acrylic acid, and 1-2 parts of initiator, wherein the alkyl-containing acrylic monomer is one of isobornyl methacrylate, isobornyl acrylate, cyclohexyl methacrylate, tert-butyl cyclohexyl methacrylate and 3,3,5-trimethyl cyclohexyl methacrylate, or the compound thereof. The invention further provides a preparation method for the thermoplastic acrylic resin. The thermoplastic acrylic resin disclosed by the invention is high in Tg value, low in viscosity, good in application property, levelling property and dryness, full and bright in appearance, not easy to generate indentations, low in VOC (volatile organic compounds) discharge, and environment-friendly.

Owner:CHONGQING BODUO PAINT

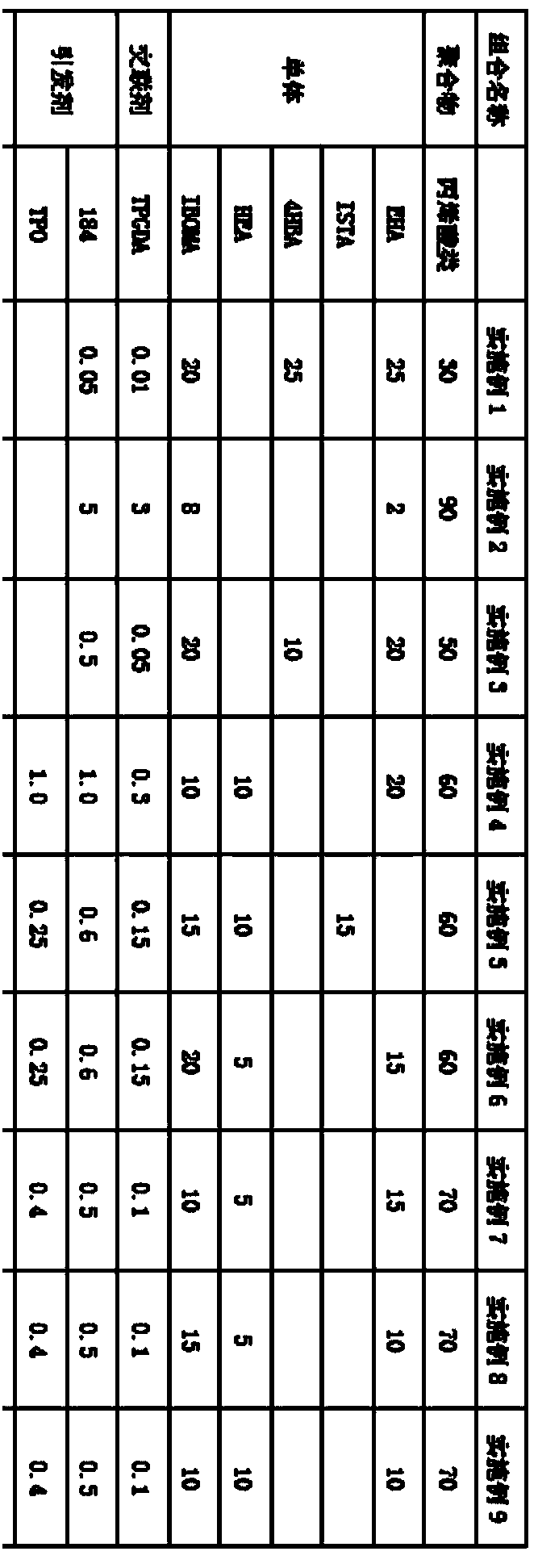

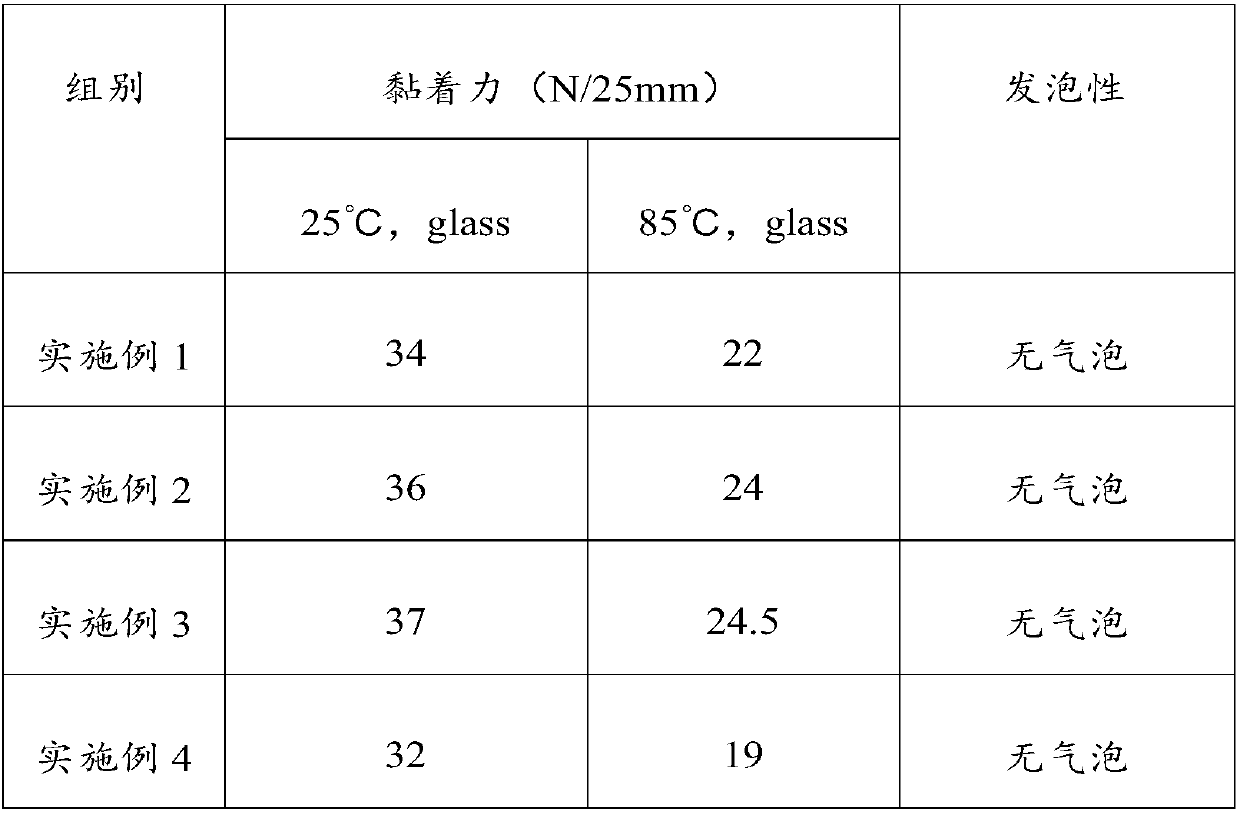

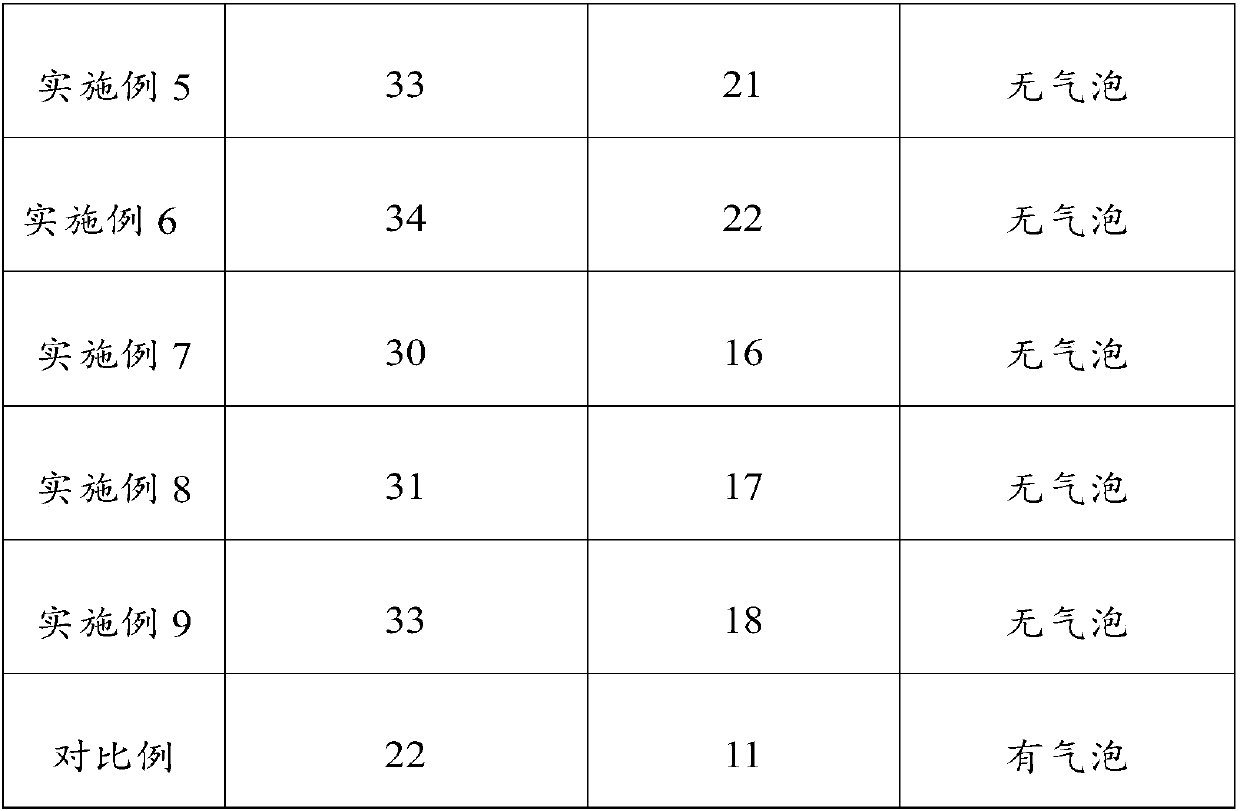

Preparation method of optical adhesive, liquid optical adhesive and curved-screen optical tape

InactiveCN108047965AExcellent adhesionInhibitionOrganic non-macromolecular adhesivePressure sensitive film/foil adhesivesPolymer scienceAdhesive

The invention discloses a preparation method of an optical adhesive, a liquid optical adhesive and curved-screen optical tape and relates to the field of optical display. The optical adhesive comprises acrylic acid derivative polymer, acrylic acid derivative monomer and a photoinitiator, wherein the molecular weight of the acrylic acid derivative polymer is 20w-80w, and the acrylic acid derivativemonomer comprises Isobornyl methacrylate. The optical adhesive is high in adhesive force, high in adhesive force under high temperature, capable of inhibiting the generation of bubbles between the adhesive and a curved screen under high temperature and capable of satisfying high reliability requirements. The preparation method has the advantages that the method is simple and practicable, and theobtained products are applicable to the curved screen and high in high-temperature reliability.

Owner:SUZHOU FINESET MATERIAL TECH CO LTD

Coating composition and method for forming coating film

InactiveUS20110052822A1Excellent finished appearanceModerate curabilityLiquid surface applicatorsPolyurea/polyurethane coatingsMeth-Acrylic resin

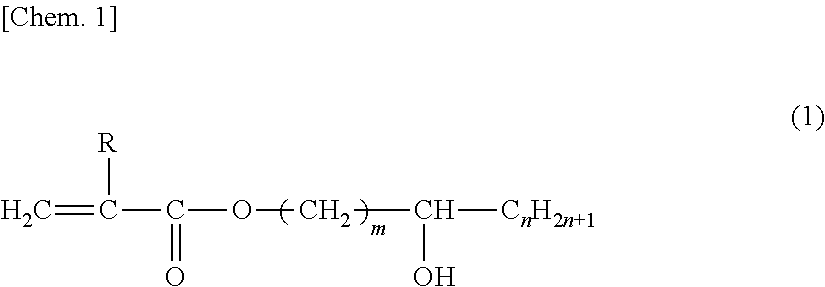

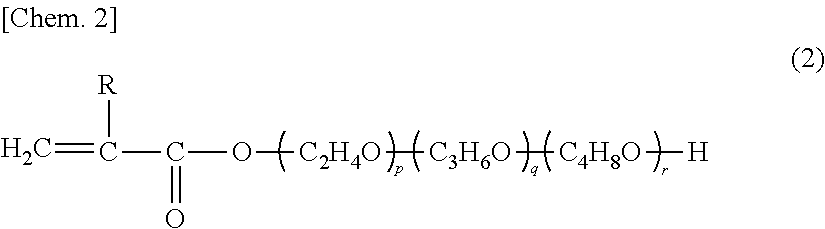

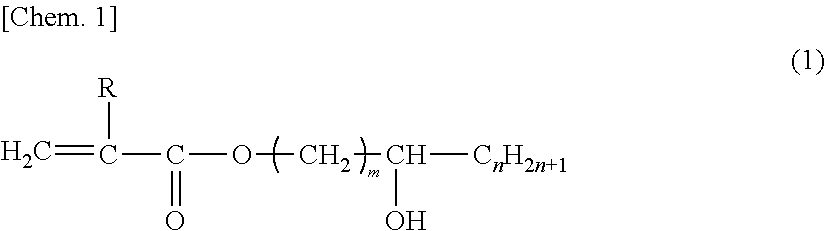

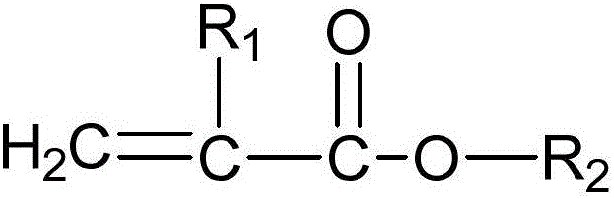

The present invention provides a coating composition that is excellent in application workability, and that can form a cured coating film excellent in coating film performances such as scratch resistance, acid resistance, stain resistance, finished appearance, sagging resistance, etc. Specifically, the present invention provides a coating composition comprising an acrylic resin (A), a polyisocyanate compound (B) and a specific non-aqueous dispersion-type acrylic resin (C), wherein: the acrylic resin (A) is obtainable by copolymerization of a specific secondary hydroxyl group-containing monomer (a-1), a secondary hydroxyl group-containing polyoxyalkylene mono(meth)acrylate monomer (a-2), an isobornyl (meth)acrylate monomer (a-3) and at least one other copolymerizable unsaturated monomer (a-4), the unsaturated monomer (a-1) being used in an amount (mass) greater than that of the monomer (a-2).

Owner:KANSAI PAINT CO LTD

Coloring layer coating suitable for silver alumite hot stamping foils and preparation method thereof

ActiveCN108059858AHigh hardnessStructural solutionFilm/foil adhesive primer layersCoatingsHot stampingSolvent

The invention discloses coloring layer coating suitable for silver alumite hot stamping foils and a preparation method thereof. Paint films of silver alumite hot stamping foils in the prior art are prone to efflorescence; in gold stamping, the defects of gold flying, powder falling and the like are prone to happening; thus, hot stamping quality and a production efficiency are affected. The coloring layer coating disclosed by the invention is prepared from the following raw materials in parts by weight: 15 to 25 parts of thermoplastic methacrylic resin, 1 to 5 parts of chloride-acetate resin, 1to 8 parts of styrene-maleic anhydride copolymer, 1 to 10 parts of cellulose acetate butyrate, 1 to 10 parts of methyl isobornyl acrylate, 1 to 5 parts of impact modifier and 50 to 70 parts of solvent. According to the coloring layer coating disclosed by the invention, the impact modifier is added into the formula ingredients, so that paint film toughness is effectively improved; meanwhile, the coloring layer coating has the characteristics of moderate viscosity, good adhesion with aluminum layers, simple production technology easy to control, stable quality, convenience in long-time storageand the like; a coloring layer paint film of alumite containing the coloring layer coating has the characteristics of high glossiness, large hardness, toughness, wear resistance and the like.

Owner:云南玉溪东魅包装材料有限公司

High-solid-content finishing oil-based acrylic resin for automobiles and preparation method thereof

The invention discloses a high-solid-content finishing oil-based acrylic resin for automobiles and a preparation method thereof, which belong to the field of automobile paints and solve the problems of low solid content, high viscosity, poor solubility and the like in the existing acrylic resin paint. The resin contains acrylic acid, styrene, butyl acrylate, hydroxyethyl methacrylate, methyl methacrylate, methacrylic acid, butyl methacrylate, 2-ethylhexyl acrylate, n-dodecyl mercaptan, lauryl methacrylate, isoborneol methacrylate, 2-hydroxyethyl acrylate, 2-hydroxypropyl acrylate, 100# solvent oil, di-tert-pentyl peroxide, glycidol tert-carboxylate and a resin reactive diluent. The solid content can reach 90%. The acrylic resin has the advantages of favorable dilution property and low viscosity. The self-made reactive diluent can greatly enhance the water resistance and acid resistance of the paint. The construction solid content of the resin is nearly 70%. The acrylic resin greatly lowers the discharge of VOC (volatile organic compound), and is environment-friendly and practical.

Owner:安徽优科新材料科技有限公司

Oil-absorbing resin and preparation method

ActiveCN103333286AImprove hydrophobicityImprove adsorption capacityOther chemical processesPolymer scienceDistilled water

The invention relates to an oil-absorbing resin and a preparation method thereof. The oil-absorbing resin comprises an oil phase: 5-15 parts of glycol dimethacrylate, 15-30 parts of isobornyl methacrylate, 20-40 parts of p-diphenyl sulfone methacrylate, 10-15 parts of triethylene glycol methacrylate, 10-20 parts of divinylbenzene, 20-30 parts of styrene, 50-200 parts of porogen, 0.5-2 parts of AIBN; and a water phase: 500-1000 parts of distilled water, 5-15 parts of PVA, and 20-50 parts of NaCl. According to the preparation method provided by the invention, the isobornyl methacrylate and the p-diphenyl sulfone methacrylate are used as main synthesis materials, and meanwhile, the non-polar crosslinking agents divinylbenzene and glycol dimethacrylate are used as crosslinking agents, and the styrene with higher hydrophobicity is used as a comonomer to synthetically prepare the oil-absorbing resin which can effectively absorb oil.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Water-soluble acrylic resin and preparing method thereof

InactiveCN105859951AGood resistance to salt sprayImprove aging resistanceAcrylic resinDibenzoyl Peroxide

The invention relates to water-soluble acrylic resin and a preparing method thereof, and relates to the technical field of chemical raw materials. The water-soluble acrylic resin is prepared from methyl methacrylate, n-butyl methacrylate, acrylic acid, n-butyl acrylate, 2-ethylhexyl acrylate, methyl isobornyl acrylate, hydroxy-propyl acrylate, dibenzoyl peroxide, water, a neutralizing agent and isobutyl alcohol. The water-soluble acrylic resin is formed by (methyl) methacrylate monomers as a main raw material through chemical polymerization. According to the water-soluble acrylic resin and the preparing method thereof, the water-soluble acrylic resin can be matched with curing agents such as fully etherificated amino resin and closed isocyanate to prepare outdoor environment-friendly paint, and a paint film has excellent salt mist resistance, ageing resistance, self-cleaning performance and weather resistance.

Owner:GUANGZHOU NUOBAO TECH DEV CO LTD

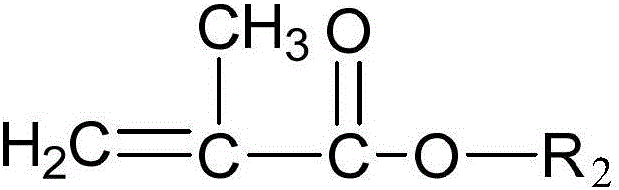

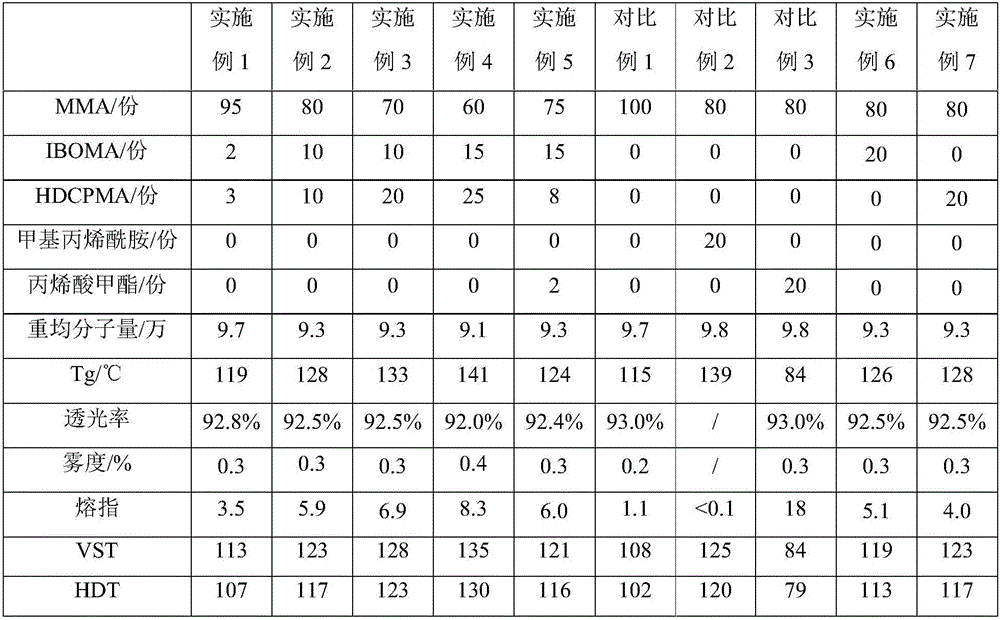

Polymethyl methacrylate and preparation method thereof

The invention relates to polymethyl methacrylate and a preparation method thereof. The polymethyl methacrylate is prepared from the following raw materials: 60-95 parts by mass of methyl methacrylate, 5-40 parts by mass of a cyclic monomer and 0-10 parts by mass of a comonomer, wherein the cyclic monomer is preferably methacrylate having a bicyclic structure and methacrylate having a polycyclic structure, i.e., isobornyl methacrylate and dicyclopentanyl methacrylate. The heat resistance and melt fluidity of the polymethyl methacrylate can be improved at the same time by means of copolymerization of the cyclic monomer and the methyl methacrylate.

Owner:WANHUA CHEM GRP CO LTD

Finishing water-soluble acrylic resin and preparation method thereof

ActiveCN104403044ASolve pollutionOvercome the shortcomings of water resistance, acid resistance, salt resistance, etc.CoatingsIsooctyl acrylateChemical industry

The invention discloses finishing water-soluble acrylic resin and its preparation method and belongs to the technical field of resin. The resin provided by the invention comprises the following ingredients: acrylic acid, methacrylic acid, styrene, butyl methacrylate, butyl acrylate monomer, hydroxyethyl methylacrylate, 2-ethylhexyl acrylate, N-dodecyl mercaptan, methyl methacrylate, N,N-dimethyl ethanolamine, ethanol, water, lauryl methacrylate, Isobornyl methacrylate, hydroxyethyl acrylate, hydroxy-propyl acrylate and AIBN. The preparation method comprises six steps. By the preparation method, the required finishing water-soluble acrylic resin is finally prepared. The finishing water-soluble acrylic resin prepared by the formula and the preparation method can be used to effectively reduce costs and has an effect of environmental protection, can completely meet requirements of a finishing varnish in the aspect of prepared paint properties and overcomes the defect that water-soluble resin is not resistant to water, acid or salt in the field of traditional chemical industry.

Owner:安徽优科新材料科技有限公司

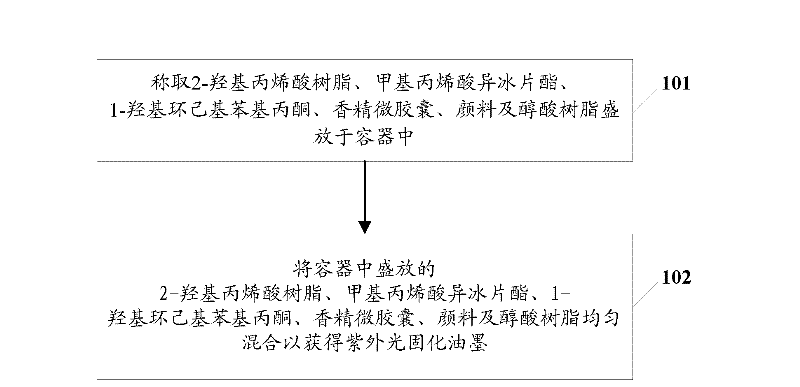

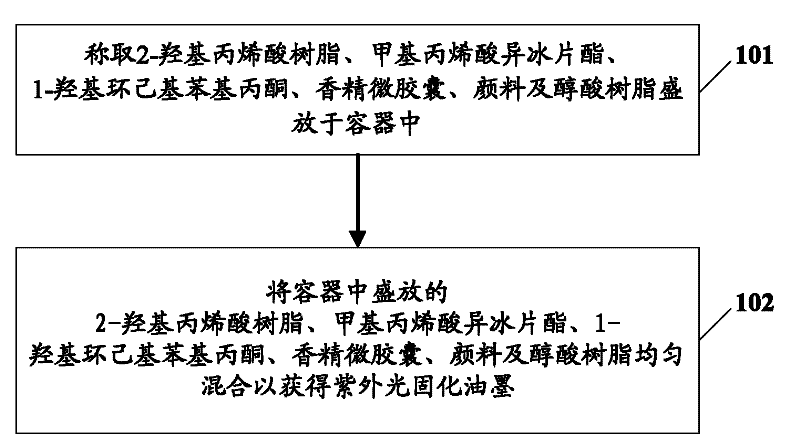

Ultraviolet light curing ink and preparation method thereof

The embodiment of the invention provides ultraviolet light curing ink and a preparation method of the ultraviolet light curing ink, wherein the ultraviolet light curing ink comprises the following ingredients: methacrylic acid isobornyl thiocyanoacetate, 2-hydroxy acrylic resin, 1-hydroxy cyclohexyl phenylacetone, essence microcapsules, pigments and alkyd resin. The ultraviolet light curing ink provided by the embodiment of the invention is favorable for improving the ink toughness, and further, the product quality is improved.

Owner:SHENZHEN BEAUTY STAR

High-temperature-resistant mirror silver resin and preparation method thereof

The invention discloses a high-temperature-resistant mirror silver resin which is prepared from the following raw materials: first components comprising cellulose acetate butyrate and a solvent; second components comprising methyl methacrylate, butyl methacrylate acetate, hydroxyethyl methacrylate, hydroxypropyl methacrylate, epoxy methylacrylate, vinyl siloxane, isobornyl methacrylate, lauryl methacrylate, acrylic acid and an initiator; and third components comprising an initiator and a solvent. A preparation method of the mirror silver resin comprises the steps of adding cellulose acetate butyrate of the first components into the solvent, dissolving, heating while stirring, heating up to 70-95 DEG C, and introducing nitrogen gas; mixing the second components, dropwise adding into the first components, carrying out heat preservation, and heating up to 85-110 DEG C; and adding the third components, carrying out heat preservation, and finally cooling and filtering. The prepared silver mirror resin has high temperature resistant performance, and has a broad-spectrum adhesive force to a base material; the product has relatively good solvent resistance; and the synthesis process is green and environmentally friendly.

Owner:GUANGZHOU EDL CHEM TECH

High-acid-value carboxyl acrylic acid matting resin and epoxy polyester type powder coating containing same

ActiveCN108727530AHigh reactivityLow impact resistancePowdery paintsEpoxy resin coatingsIsooctyl acrylatePolyester

The invention discloses high-acid-value carboxyl acrylic acid matting resin and epoxy polyester type powder coating containing same. The high-acid-value carboxyl acrylic acid matting resin is preparedby co-polymerizing the following various monomers in percentage by weight: 28-35% of an acrylic acid functional monomer, 15-20% of styrene, 0-10% of methyl acrylate, 5-15% of ethyl acrylate, 5-15% ofn-butyl acrylate, 0-5% of ethylhexyl acrylate, 10-15% of any one or combination of alicyclic acrylate, isobornyl acrylate or isobornyl methacrylate, and 10-20% of methyl methacrylate, wherein the acrylic acid functional monomer is one or a mixture of two of acrylic acid or methacrylic acid.

Owner:武汉荣邦华泰科技有限公司

Hollow polymer emulsion and preparation method thereof

InactiveCN102382239AHigh hiding powerHigh elongation at breakPaper coatingCoatingsPolymer scienceWeather resistance

The invention discloses a hollow polymer emulsion and a preparation method thereof. The preparation method adopts the processes of emulsion polymerization, core-shell emulsion polymerization and the like to prepare the hollow polymer emulsion. An emulsion particle is of a structure with a hard shell and a soft shell, and the void fraction of a film formed by the emulsion reaches more than 50 percent. A variety of unsaturated monomers, emulsifier and initiator are adopted to prepare the hollow polymer emulsion, in particular, isobornyl methacrylate and 2,2,3,4,4,4-hexafluorobutyl acrylate are chosen as shell monomers, the contents of isobornyl methacrylate and 2,2,3,4,4,4-hexafluorobutyl acrylate respectively account for 2 to 5 percent and 3 to 6 percent by weight of the total amount of the emulsion, and the mechanical properties, the weather fastness and the dirt resistance of the emulsion film are effectively enhanced. The product has an excellent dry hiding effect, can decrease the density of the film and improve handle, and can be applied in the fields of water-borne coating, paper coating, industrial coating, ink and the like.

Owner:山东聚东新材料有限责任公司

Acrylic acid microgel emulsion having automatic restoration function and preparation method thereof

ActiveCN106397662AEmission reductionEnvironmental performanceCoatingsCross-link(Hydroxyethyl)methacrylate

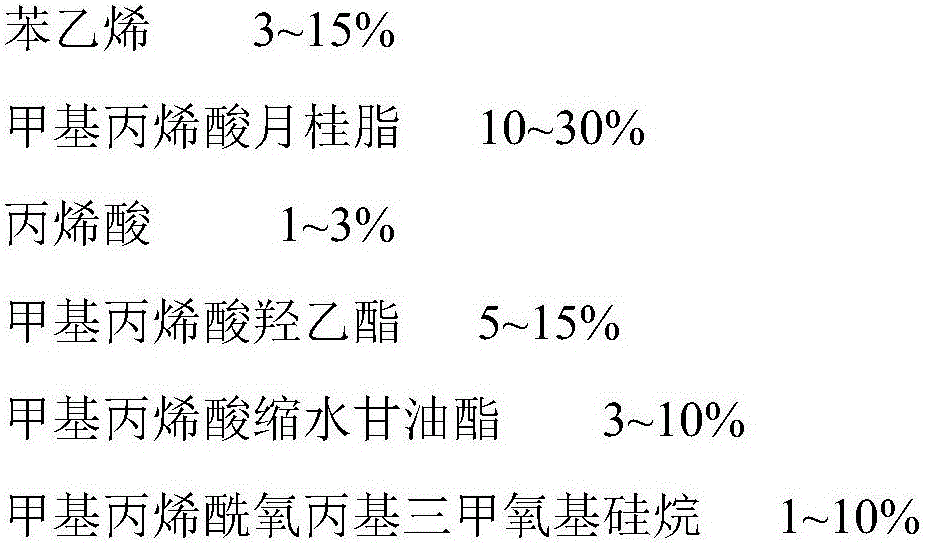

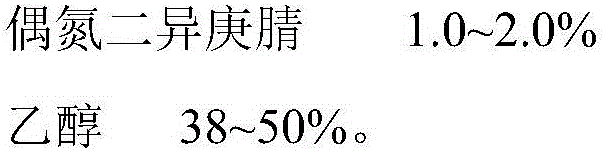

The invention discloses an acrylic acid microgel emulsion having the automatic restoration function and a preparation method thereof, and belongs to the technical field of a modified coating. The acrylic acid microgel emulsion comprises a shell layer and a core, wherein the shell layer includes a shell solution, water, isobornyl methacrylate, butyl methacrylate, alkylphenol polyoxyethylene, sodium dodecanesulphonate and potassium persulphate, and the core includes styrene, lauryl methacrylate, acrylic acid, hydroxyethyl methylacrylate, glycidyl methacrylate, 3-glycidoxypropyltrimethoxysilane, 2,2'-azobis (2,4-dimethyl) valeronitrile and ethanol. The emulsion has the advantages of low VOC discharge capacity and high solid content. The shell layer doesn't crack and the core colloid isn't released when the emulsion is sprayed at the room temperature. When a scratch appears, hot water with the temperature of 80 DEG C is used to wash the scratch, and the shell layer is heated, softened, and collapsed to release the core colloid. The core colloid is heated and softened to gradually fill the scratch, is self-cross-linked, and is hardened, so that the scratch is lightened and disappeared.

Owner:安徽优科新材料科技有限公司

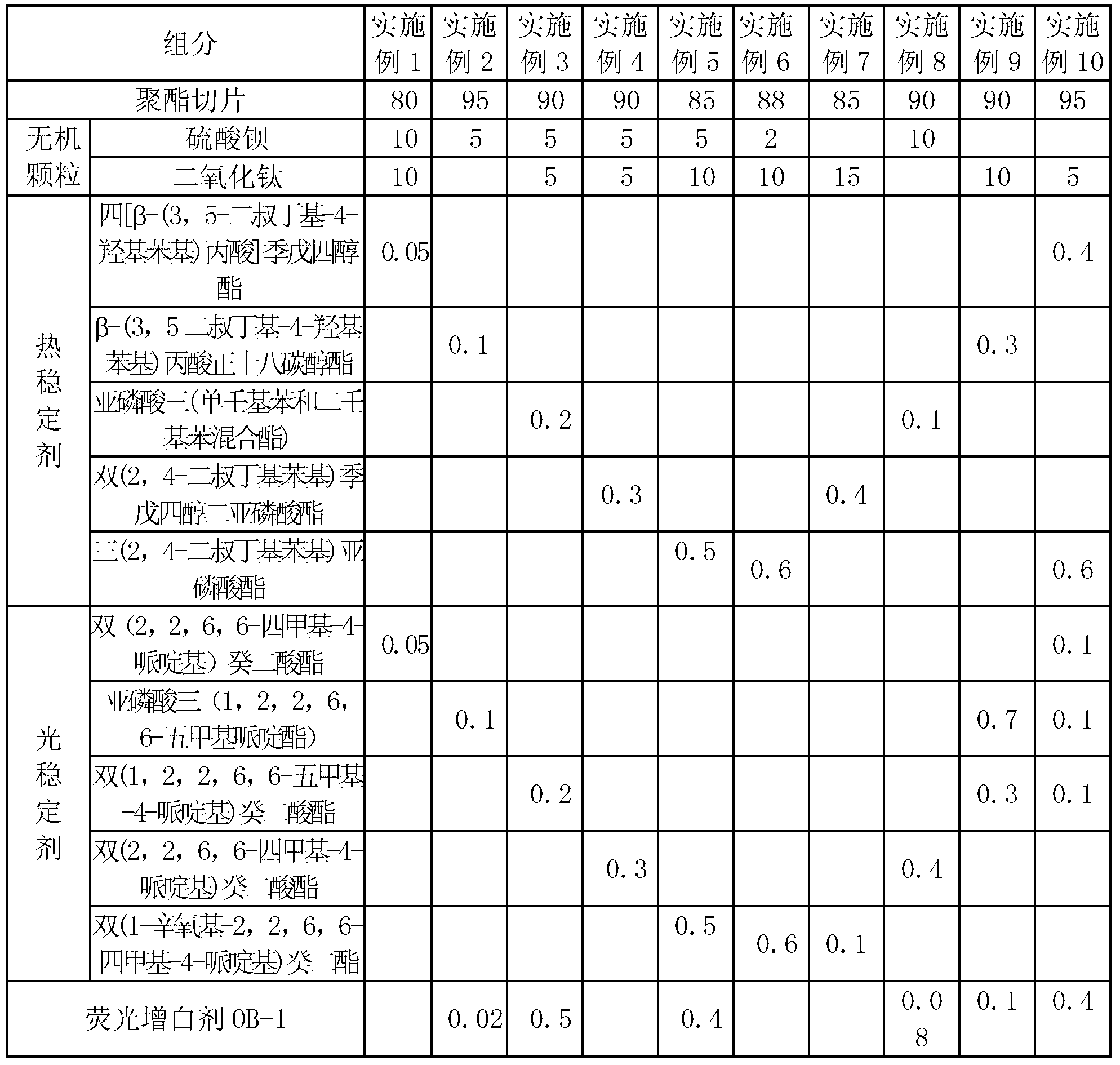

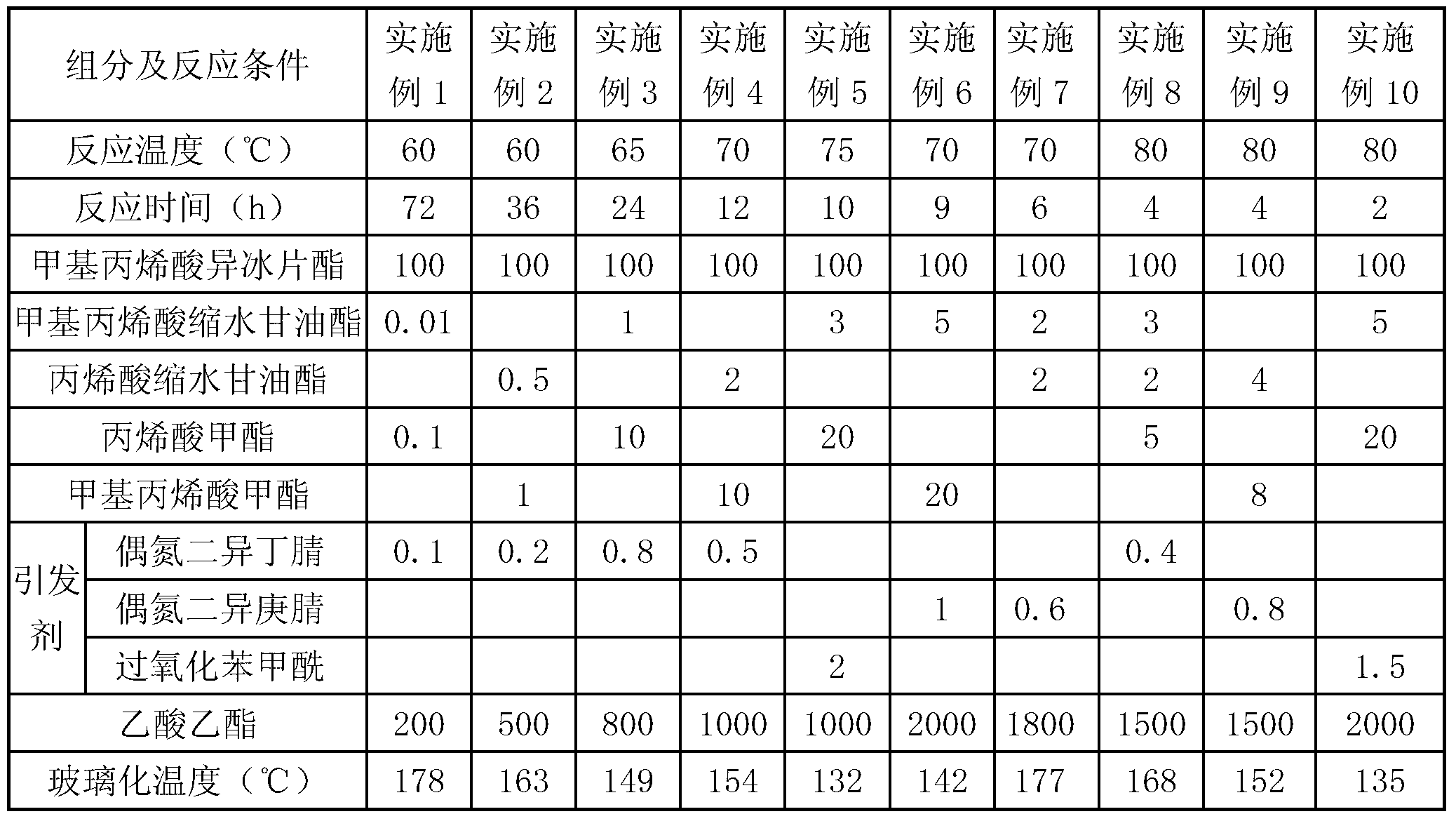

Polyester reflecting film and preparation method thereof

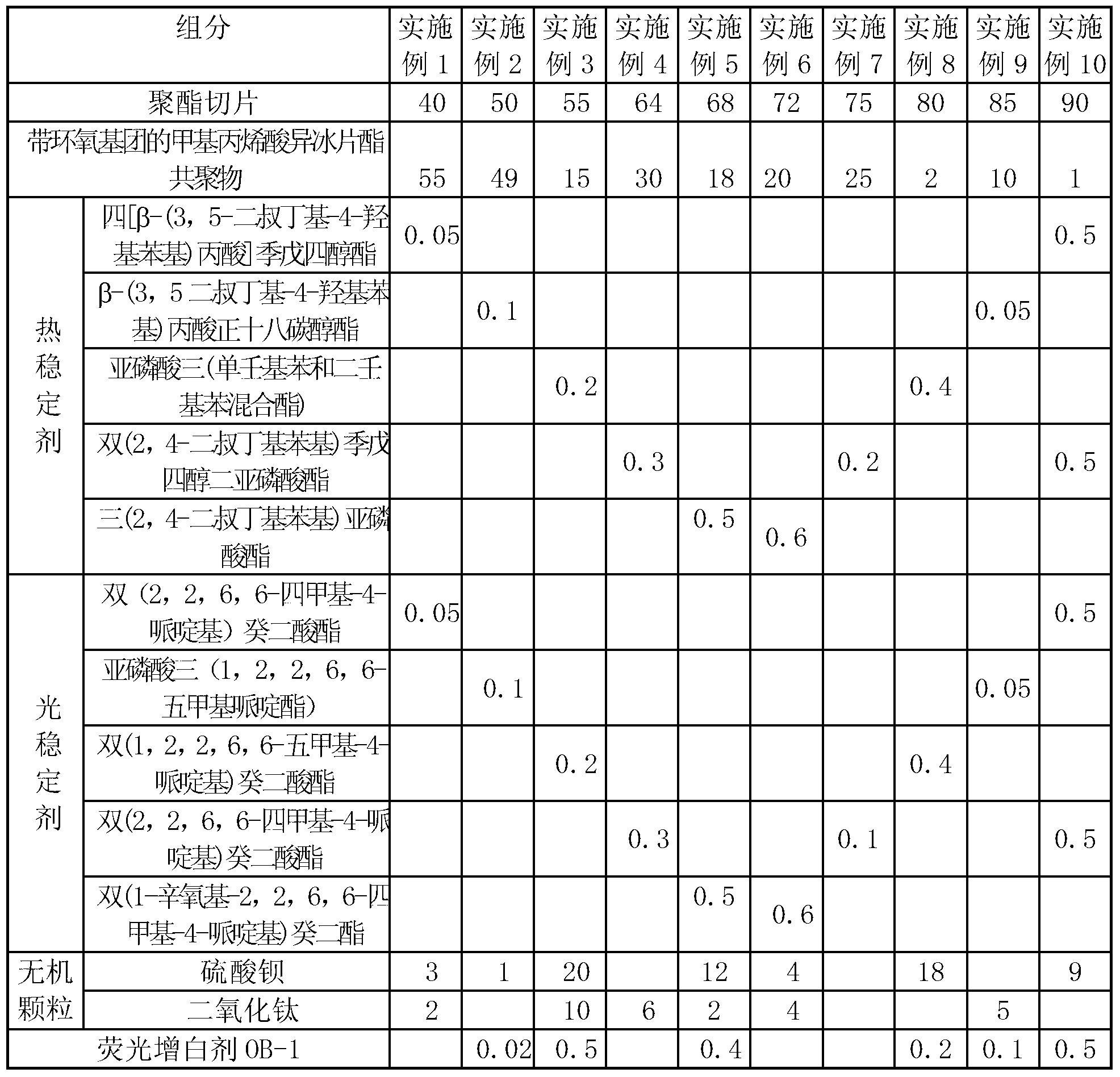

ActiveCN103217729AAvoid degradationImprove mechanical propertiesDiffusing elementsSynthetic resin layered productsVitrificationInorganic particle

The invention relates to a polyester reflecting film and a preparation method thereof. The polyester reflecting film comprises one or more surface layers and a middle porous core layer; the core layer comprises the following components in parts by weight: 40-90 parts of polyester slices, 1-55 parts of methyl isobornyl acrylate copolymers with epoxy groups, 0.05-1 part of a heat stabilizer and 0.05-1 part of a light stabilizer; and the surface layers comprise the following components: 80-95 parts of polyester slices, 5-20 parts of inorganic particles, 0.05-1 part of heat stabilizer and 0.05-1 part of light stabilizer, wherein the methyl isobornyl acrylate copolymers with epoxy groups have a glass transition temperature higher than 130 DEG C; and the grain size of the dispersing phase of the copolymer in the polyester matrix is 0.05 micron to 2.0 microns. According to the polyester reflecting film and the preparation method thereof, the methyl isobornyl acrylate copolymers with epoxy groups are used as pore-forming agent, so that the polyester reflecting film has the characteristics of being simple in formula, low in manufacturing cost, low in hot-shrinkage rate and good in mechanical performances.

Owner:JIANGSU YUXING FILM TECH

Water-base metallic coating for automotive interior materials and coated article

InactiveUS20070129485A1Excellent in adhesion to substrateGood alkali resistancePaints with free metalsWater basedHigh concentration

An object of the present invention is to provide a water-base metallic coating for automotive interior materials being single-coat metallic finished which is excellent in adhesion to a substrate and fats and oils resistance and is further provided with so high alkali resistance as to be free from being whitened or discolored even by an aqueous high-concentration alkali solution. As a means of achieving this object, the water-base metallic coating for automotive interior materials according to the present invention comprises a metallic pigment and a vehicle, and is characterized in that the vehicle includes: a first water-based hydro-dispersion resin (A) obtained by hydro-dispersing, without using a surfactant, an acrylic resin which indispensably contains isobomyl methacrylate as a monomer component and no styrene and has a theoretical Tg in a range from 80 to 140° C., an acid value in a range from 10 to 25 mgKOH / g, and an SP value in a range from 9.5 to 10.0; and a second water-based hydro-dispersion resin (B) obtained by hydro-dispersing, without using a surfactant, an acid-modified chlorinated polyolefin resin having an acid modification quantity in a range from 1.6 to 2.5% by mass, a chlorine content in a range from 18 to 25%, and a weight average molecular weight in a range from 50,000 to 80,000.

Owner:HONDA MOTOR CO LTD +1

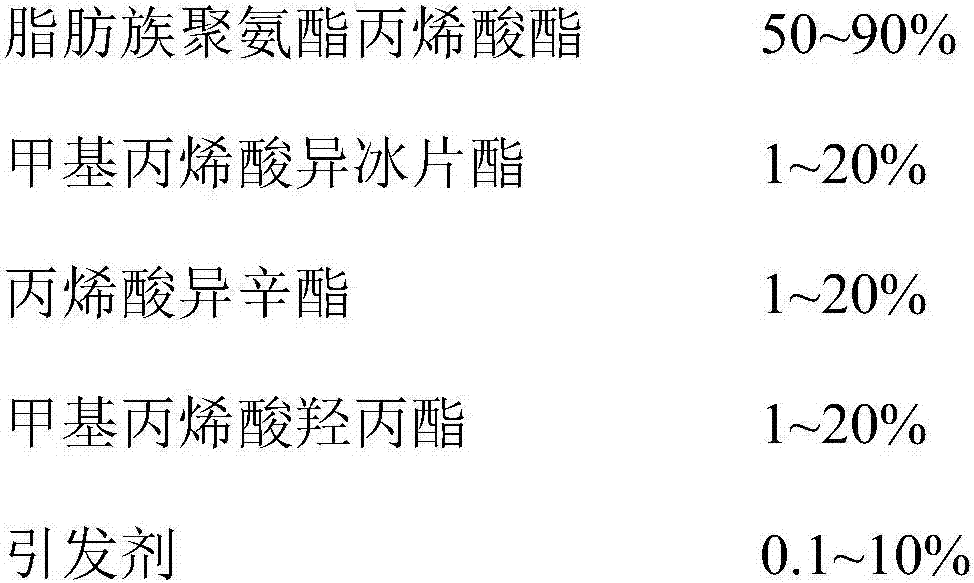

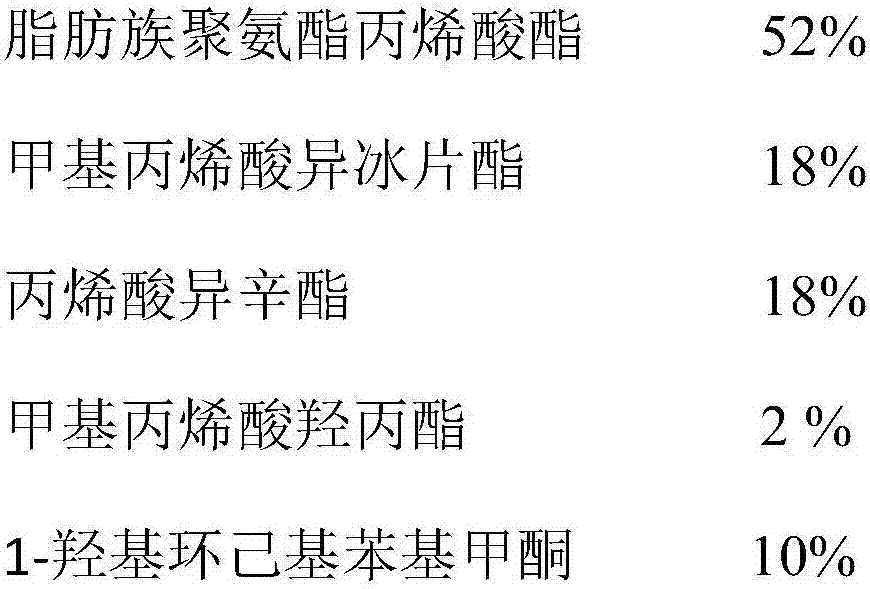

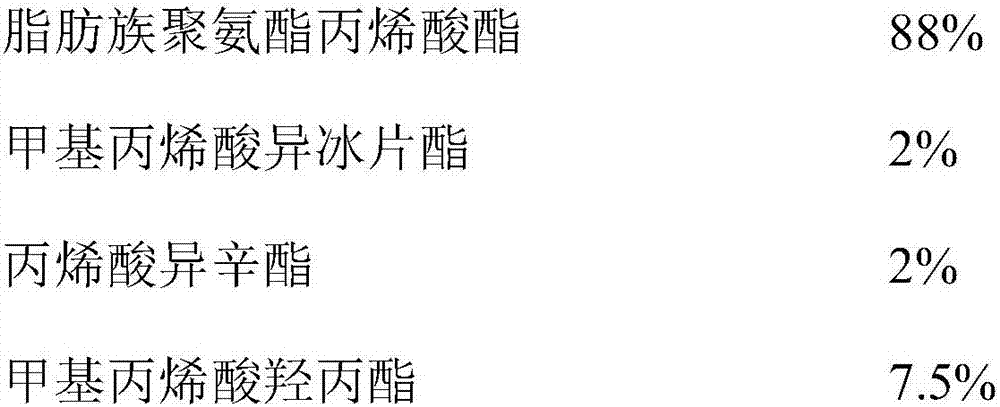

OCA optical cement for mobile phone glass screen protector

InactiveCN106883796AEasy to produceHigh light transmittanceFilm/foil adhesivesGraft polymer adhesivesTransmittanceIsobornyl methacrylate

The invention provides an OCA optical cement for a mobile phone glass screen protector. The OCA optical cement is prepared by reaction between the following substances by mass percent: 50-90% of aliphatic polyurethane acrylate, 1-20% of isobornyl methacrylate, 1-20% of 2-ethylhexyl acrylate, 1-20% of hydroxypropyl methacrylate and 0.1-10% of an initiator. The components are sequentially added into a stirred tank by mass percent, uniform mixing and stirring are performed under a dark condition, the mixture is naturally left to stand for defoaming to prepare a glue, after that, a PET release film is coated with the glue by use of a scraper or a coater, and UV curing is performed after attachment of the PET release film. The OCA optical cement has the beneficial effects that the light transmittance is high, the adhesive property, the water resistance and the anti-aging performance are excellent, the stripping performance is favorable, coating production is easy, the 100% curing environmental protection effect is good and the price is low.

Owner:广东鼎立森新材料有限公司

Anticorrosion and anti-rust waterborne acrylic coating and preparation method thereof

InactiveCN107573795AImprove hydrophobicityInhibit entryAnti-corrosive paintsChemical industryAcrylic resin

The invention relates to the technical field of chemical industry and in particular relates to anticorrosion and anti-rust waterborne acrylic coating. Aiming at solving the technical problems, the invention provides the waterborne acrylic coating with excellent anticorrosion performance, good anti-rust effect and good stable performance. By adopting the technical scheme, the anticorrosion and anti-rust waterborne acrylic coating is characterized in that acrylic resin is prepared from the following raw materials in percentage by weight: 1 percent to 10 percent of acrylic acid, 5 percent to 20 percent of n-butyl acrylate, 1 percent to 10 percent of methyl methacrylate, 5 percent to 20 percent of hydroxyethyl acrylate, 1 percent to 10 percent of 2-ethylhexyl acrylate, 40 percent to 60 percentof isobornyl methacrylate, 5 percent to 50 percent of vinyl versatate Veova10, 10 percent to 50 percent of alicyclic acrylate, 0.1 percent to 20 percent of a chain extender, 0.5 percent to 5 percentof an initiator and 30 percent to 50 percent of water; the raw materials are prepared into waterborne acrylic resin with the Tg of -10 DEG C to 80 DEG C.

Owner:LINFEN TIE HUAN PAINT IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com