Patents

Literature

229 results about "Lauryl methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sigma-Aldrich offers a number of Lauryl methacrylate products. View information & documentation regarding Lauryl methacrylate, including CAS, MSDS & more.

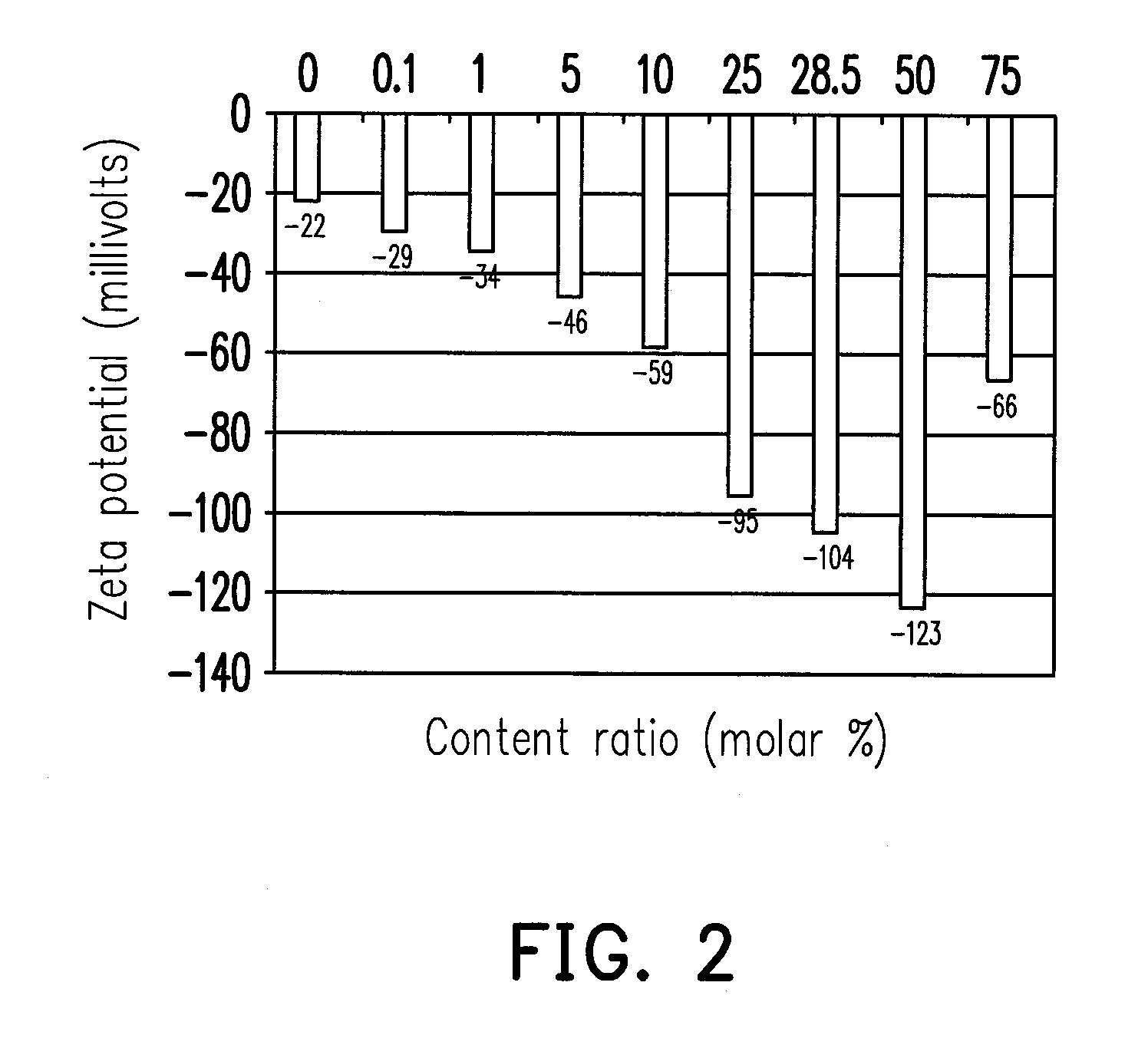

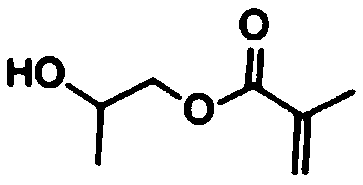

Biocompatible crosslinked coating and crosslinkable coating polymer composition for forming such a coating

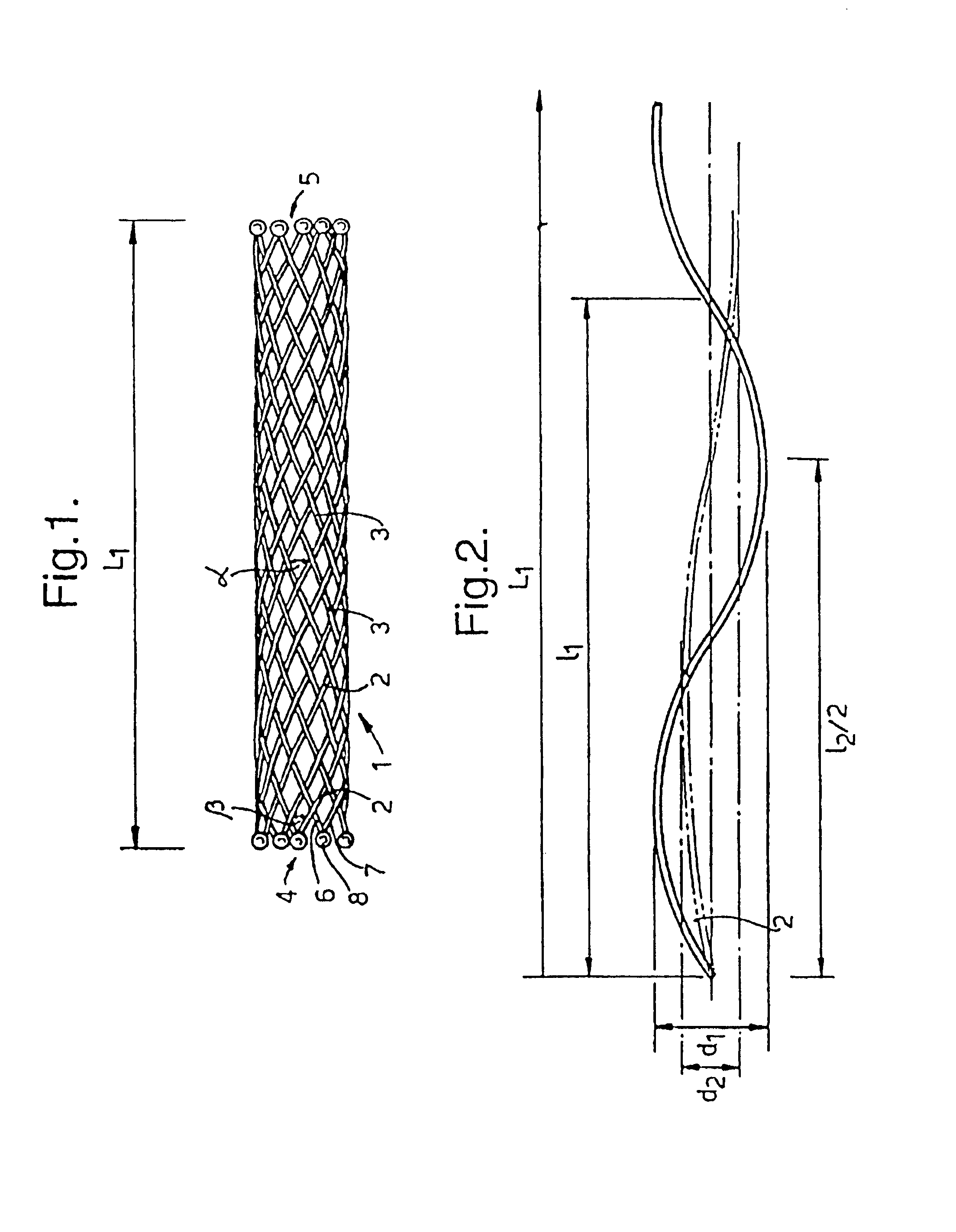

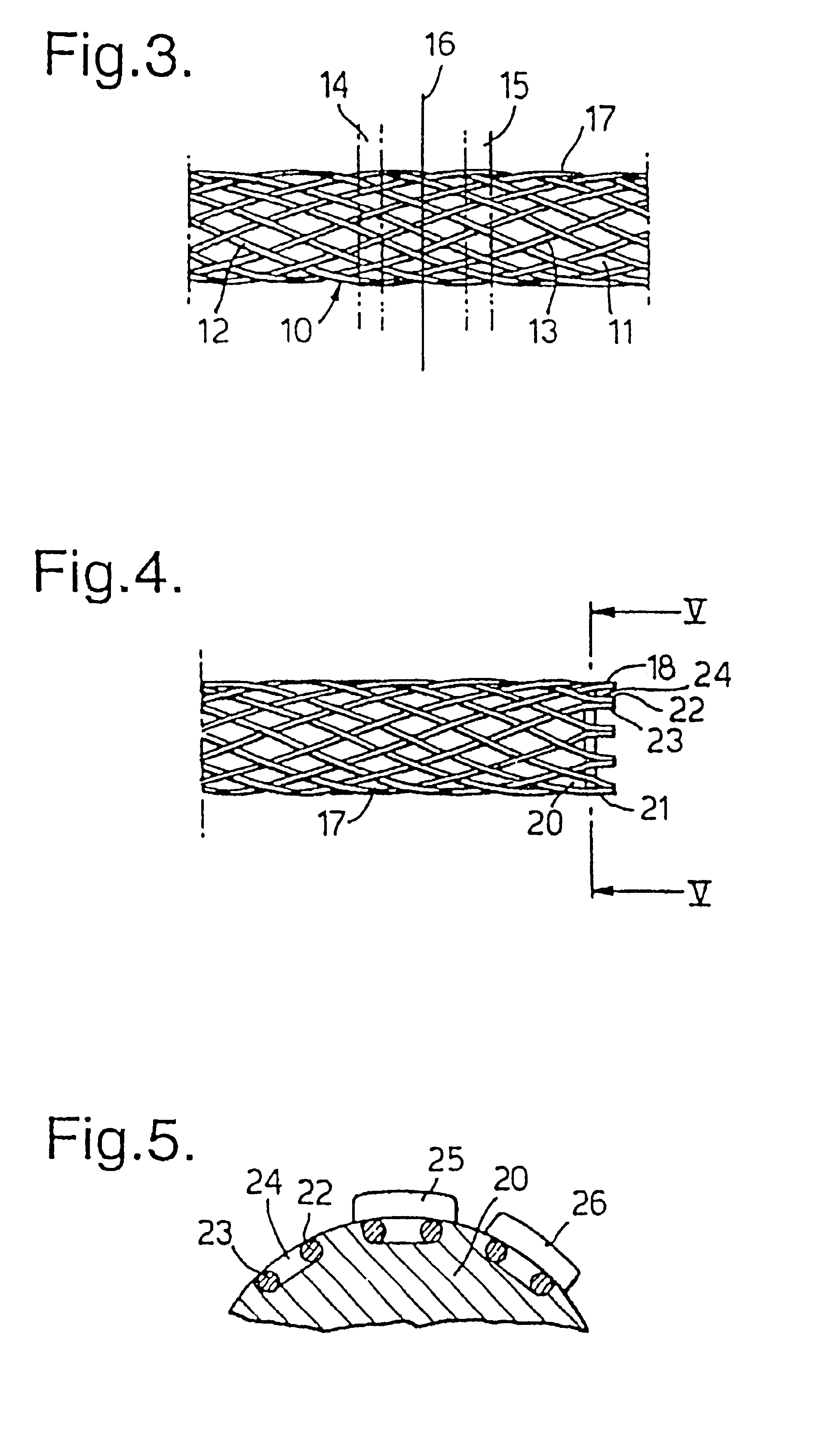

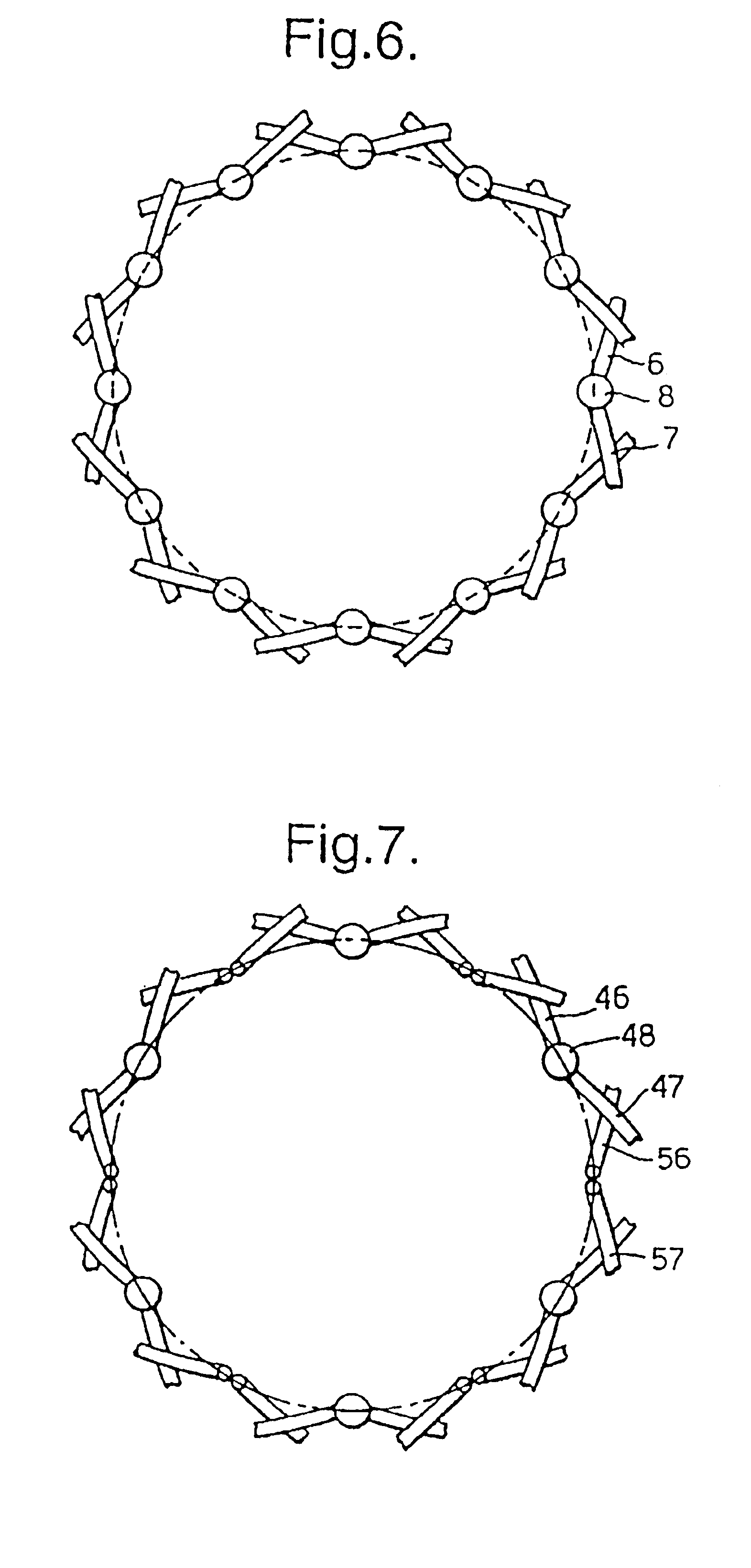

A braided stent (1) for transluminal implantation in body lumens is self-expanding and has a radial expanded configuration in which the angle α between filaments is acute. Some or all of filaments (6,7) are welded together in pairs at each end (4,5) of the stent to provide beads (8), thereby strengthening the stent and assisting its deployment from a delivery device. The stent is preferably completely coated using a biocompatible polymeric coating, said polymer preferably having pendant phosphoryl choline groups. A method of making the stent by braiding and welding is described as well as a delivery device for deploying the device.The present invention provides a biocompatible crosslinked coating and a crosslinkable coating polymer composition for forming such a coating. The biocompatible crosslinked coating may be formed by curing a polymer of 23 mole % (methacryloyloxy ethyl)-2-(trimethylammonium ethyl) phosphate inner salt, 47 mole % lauryl methacrylate, 5 mole % γtrimethoxysilyl propyl methacrylate and 25 mole % of hydroxy propyl methacrylate. The crosslinkable coating polymer may include 23 mole % (methacryloyloxy ethyl)-2-(trimethylammonium ethyl) phosphate inner salt, 47 mole % lauryl methacrylate, 5 mole % γtrimethoxysilyl propyl methacrylate and 25 mole % of hydroxy propyl methacrylate.<?insert-end id="INS-S-00001" ?>

Owner:BIOCOMPATIBLES UK LTD

Preparation method of foamed porous graphene/polypyrrole composite oil absorption material

InactiveCN102617853AEasy to operateMild reaction conditionsOther chemical processesPotassium persulfatePorous graphene

The invention relates to a preparation method of a foamed porous graphene / polypyrrole composite oil absorption material, belonging to the technical fields of environmental protection and composite materials. The method is characterized by comprising the following steps: carrying out KH570 functionalization on graphite oxide prepared from graphite; carrying out ultrasonic treatment on the functionalized graphite oxide product to obtain a graphene oxide aqueous solution with a certain concentration, adding certain amounts of pyrrole, styrene or butyl methacrylate or lauryl methacrylate and an initiator (ammonium persulfate or potassium persulfate); carrying out thermostatic reaction in a hydrothermal reaction kettle for 10 hours, thereby obtaining a black solid; and carrying out freeze-drying on the black solid to obtain the foamed porous graphene / polypyrrole composite oil absorption material in a three-dimensional structure. The graphene / polypyrrole composite oil absorption material ina three-dimensional structure is prepared by a chemical process, so the material has hydrophobicity and large specific area of the graphene, can contain abundant oil molecules, and has high oil adsorbability. The preparation method is simple to operate, and has the advantage of mild reaction conditions.

Owner:DALIAN UNIV OF TECH

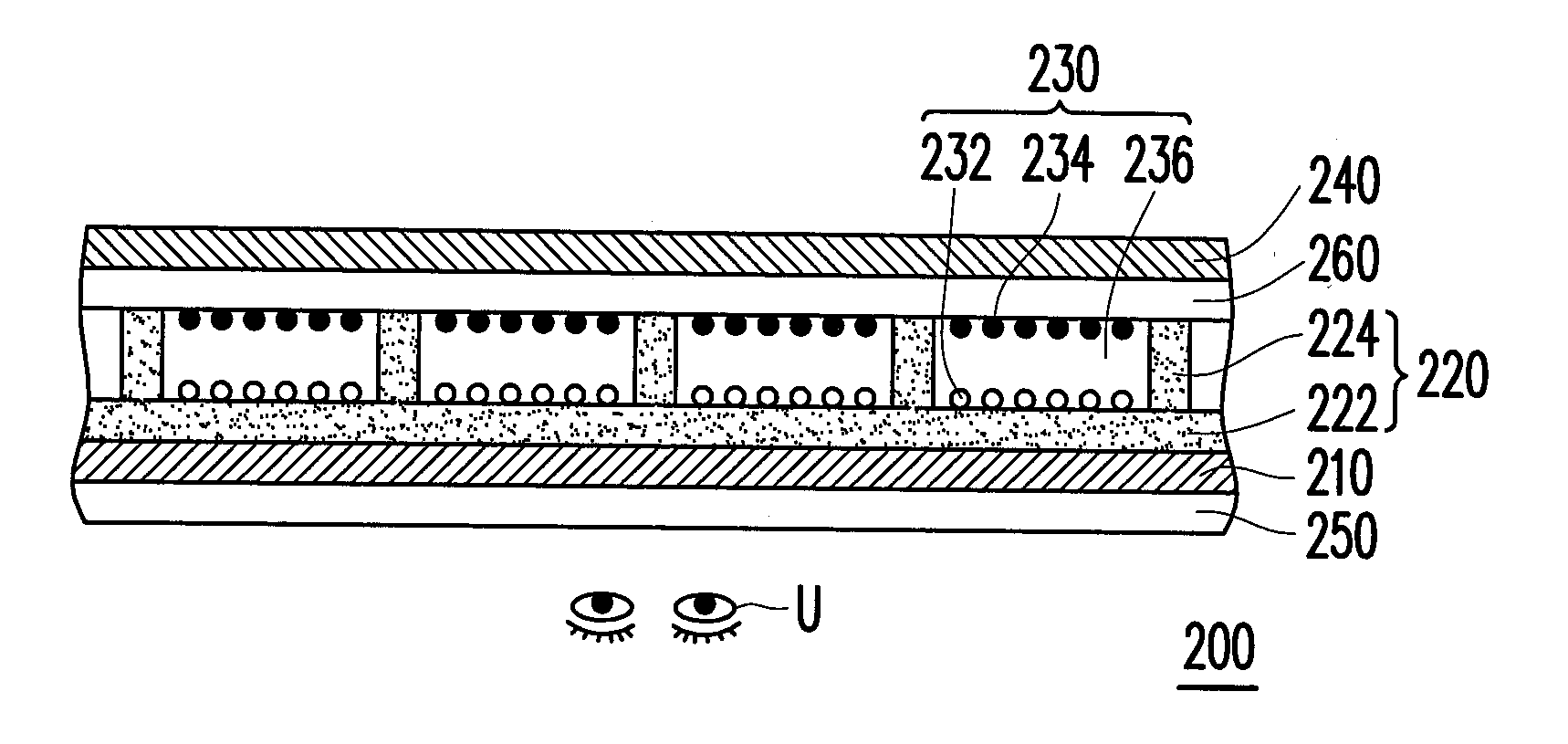

Display medium and manufacturing method thereof and electrophoretic display therewith

InactiveUS20140104674A1Improve reliabilityImprove display qualityConductive materialOrganic conductorsPolymer scienceDisplay device

A display medium adapted for an electrophoretic display is provided. The display medium includes at least one particle and a random copolymer bonded with the particle, wherein the random copolymer has a structural unit originated from a first monomer and a second monomer. The first monomer is selected from at least one or a combination of a group of specific compounds consisting of 2-ethylhexyl acrylate, lauryl methacrylate and octadecyl acrylate etc. and the second monomer is selected from at least one kind of a group of specific compounds composed of 2,2,2 trifluoroethyl acrylate, 2,2,3,3 tetrafluoropropyl methacrylate and 1,1,1,3,3,3-hexafluoroisopropyl acrylate. A method of manufacturing the display medium and an electrophoretic display with the display medium are also provided.

Owner:SIPIX TECH INC

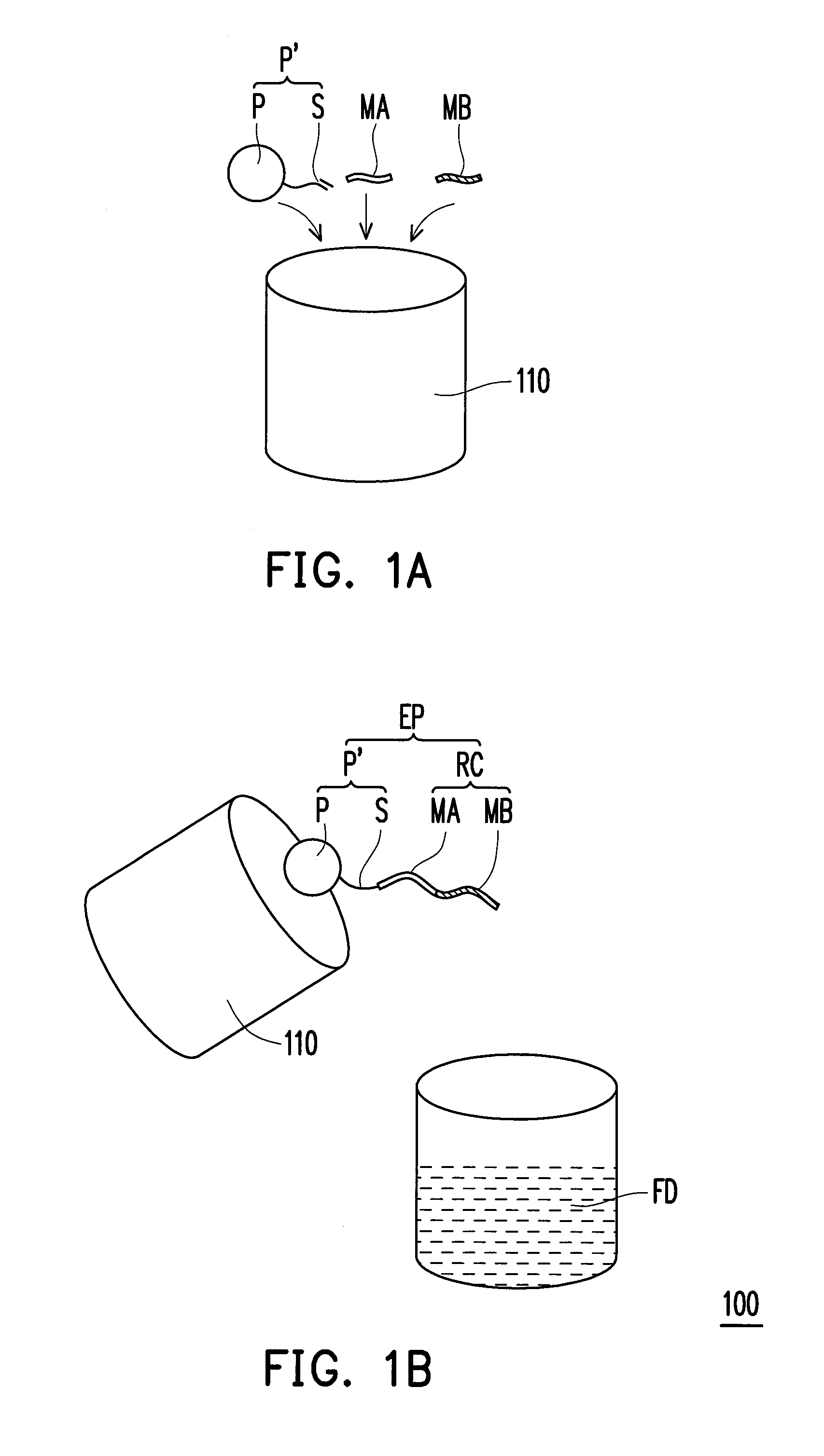

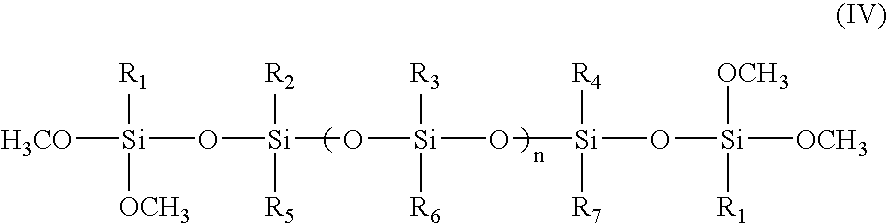

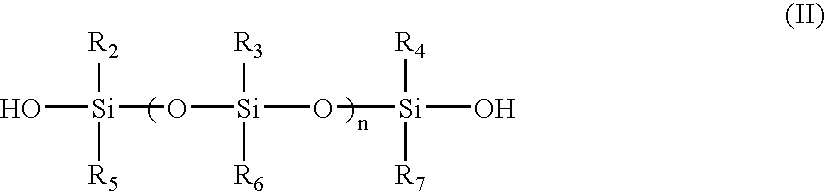

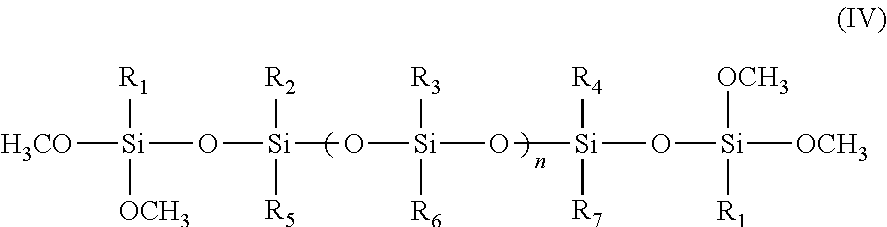

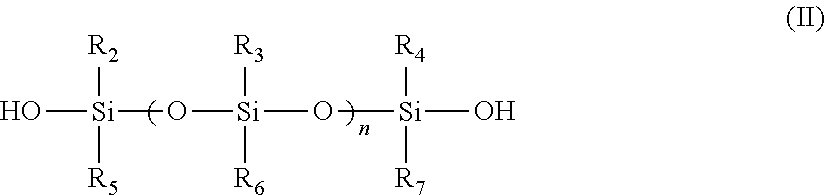

Room temperature-curable polymers

Methods of making room temperature-curable polymers. Reactants include siloxane-terminated polymers and silanols. The reactants are mixed, and the polymerization allowed to proceed in air at room temperature. The polymers are exceptionally useful because they allow for the incorporation into the polymers themselves of one or more therapeutic compounds. Thus, medical devices from which controlled drug release is desirable (for either local or systemic delivery) can be coated with therapeutic compound-containing polymers of the invention. In a preferred embodiment, a polymer of poly(MPCw:LAMx:HPMAy:TSMAz) where w, x, y, and z represent the molar ratios of monomers used in the feed for preparing the polymer; MPC represents the unit 2-methacryoyloxyethylphosphorylcholine, LMA represents the unit lauryl methacrylate, HPMA represents the unit 2-hydroxypropyl methacrylate, and TSMA represents the unit 3-trimethoxysilylpropyl methacrylate is reacted with polydimethylsiloxane. In another preferred embodiment, a therapeutic compound is incorporated into the polymer, such as dexamethasone.

Owner:ABBOTT LAB INC

Room temperature-curable polymers

Owner:ABBOTT LAB INC

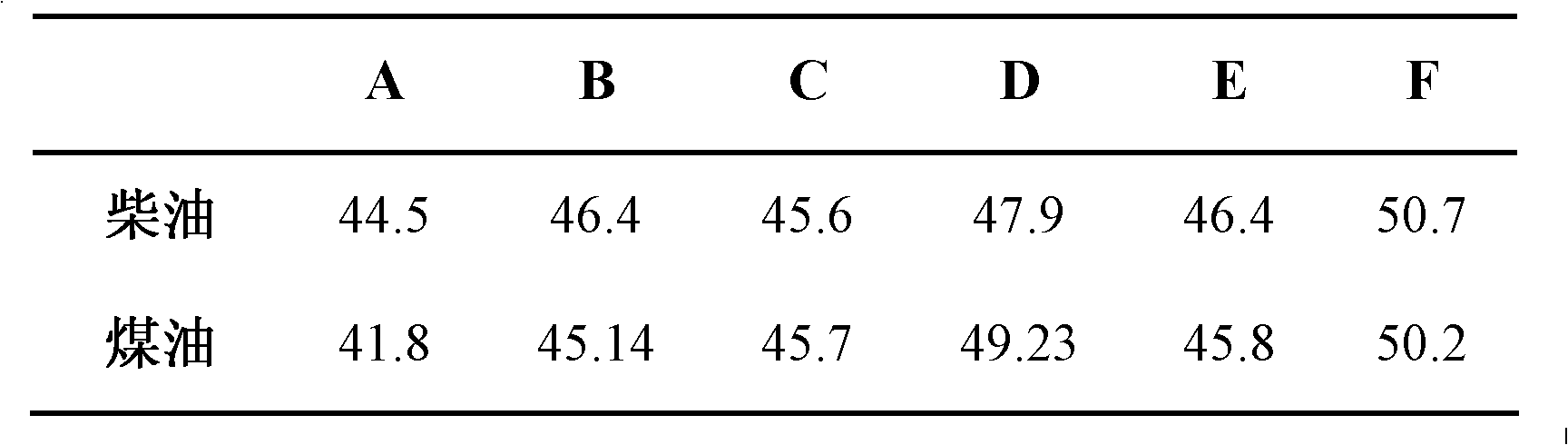

Methanol diesel fuel complex additive and preparation method thereof

ActiveCN101709234AGood compatibility stabilityStable in natureLiquid carbonaceous fuelsCyclohexanoneN-Butylamine

The invention discloses a methanol diesel fuel complex additive and a preparation method thereof. The complex additive is prepared from the following raw materials in parts by volume: 1-4 parts of diethyl phthalate, 1-8 parts of n-butylamine, 1-9 parts of isooctanol, 1-6 parts of cyclohexanone, 13-42 parts of lauryl methacrylate, 7-30 parts of mixed fatty glyceride, 1-5 parts of phenyl propargyl ether, 1-8 parts of dihexadecyl dimethyl ammonium chloride, 2-12 parts of ethyl formate, 2-14 parts of isooctyl nitrate and 1-6 parts of polyoxyethylene hexadeeylalkyl ether selies. The methanol diesel fuel complex additive can enable methanol diesel fuel to be evenly mixed and to be stably stored for more than 6 months, which effectively improves the fire behaviour of the methanol diesel fuel and inhibits the volatilization when the methanol content is higher; moreover, the production process is simple and the use is convenient, thereby being beneficial to the popularization and application of the methanol diesel fuel.

Owner:临沂星火知识产权服务有限公司

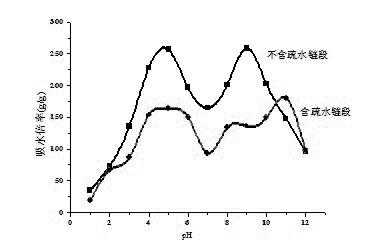

Preparation method of salt-tolerance controlled-release high-water-absorption resin with hydrophobic chain segments

InactiveCN102633944ATo achieve the purpose of sustained releaseTo achieve the purpose of salt toleranceIsooctyl acrylateCellulose

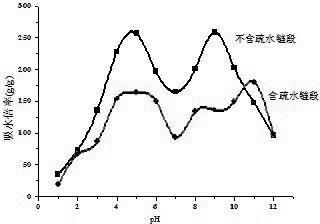

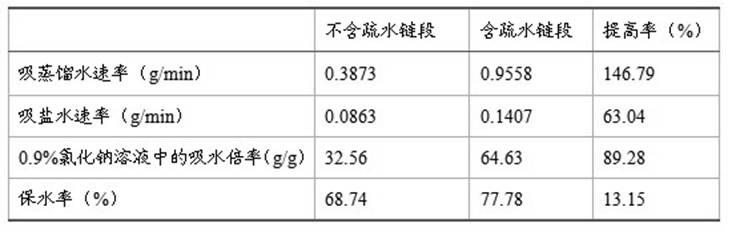

The invention relates to a preparation method of salt-tolerance controlled-release high-water-absorption resin with hydrophobic chain segments. At present, acrylic-acid-series high-water-absorption resin has many defects and particularly has the defects that the salt tolerance is poor and the water absorbing capacity is easy to be weakened remarkably and normally is weakened to dozens of times from hundreds of times under the action of metal ions, therefore, the improvement of the salt tolerance of the high-water-absorption resin has significance. According to the invention, the high-water-absorption resin with a three-dimensional cross-linked network is formed through copolymerization of acrylic-acid hydrophobic monomers such as butyl methacrylate, iso-octyl methacrylate, n-decyl methacrylate, lauryl methacrylate, lauryl methacrylate or octadecyl methacrylate with acrylic acid, acrylic amide and carboxymethy cellulose under the existence of initiator and cross-linking agent. Compared with the high-water-absorption resin without the hydrophobic chain segments, the high-water-absorption resin disclosed by the invention has the advantages that the magnification on absorption of 0.9% sodium chloride solution is improved by 89.28%, and the water retention is improved by 13.15%.

Owner:SHAANXI UNIV OF SCI & TECH

Environment-friendly nontoxic glue

InactiveCN105086847AEasy to makeEasy to useNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveDehydroacetic acidPolyester

The invention discloses environment-friendly nontoxic glue. The environment-friendly nontoxic glue comprises, by weight, 60-160 parts of polyester, 30-40 parts of butylene glycol acrylate, 40-60 parts of trimethylolpropane, 10-30 parts of butanediol, 20-40 parts of metoxyphenol, 8-12 parts of acetone, 9-12 parts of acrylamide, 10-28 parts of styrene, 6-24 parts of ethyl alcohol, 2-6 parts of xylene, 20-30 parts of poly(isobutyl ester), 10-30 parts of aluminum hydroxide, 24-48 parts of phosphotriester, 12-18 parts of antimonous oxide, 100-160 parts of 2-hydroxyethyl methacrylate, 80-100 parts of methyl methacrylate, 20-60 parts of lauryl methacrylate, 12-16 parts of styrene, 150-200 parts of butyl methacrylate, 20-40 parts of methacrylic acid, 8-16 parts of dehydroacetic acid and 20-40 parts of butanol. According to the environment-friendly nontoxic glue, manufacturing is easy, adopted and selected production raw materials are nontoxic, the using effect of the glue is good, environmental friendliness is achieved, a tough coating can be formed, and lasting water repellency and antistatic performance are achieved.

Owner:启东寅昶精密铸造有限公司

Efficient mirror plane flatting agent for powder paint, preparation method and application

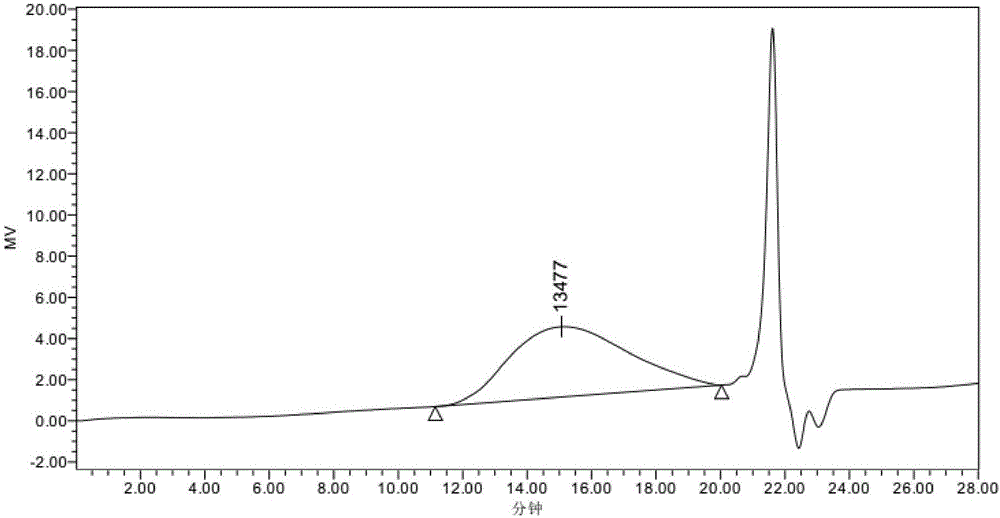

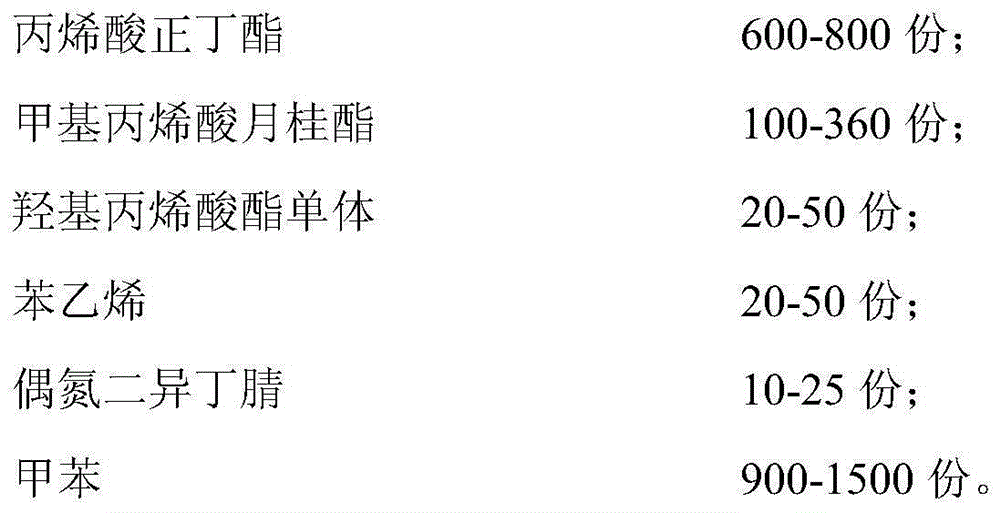

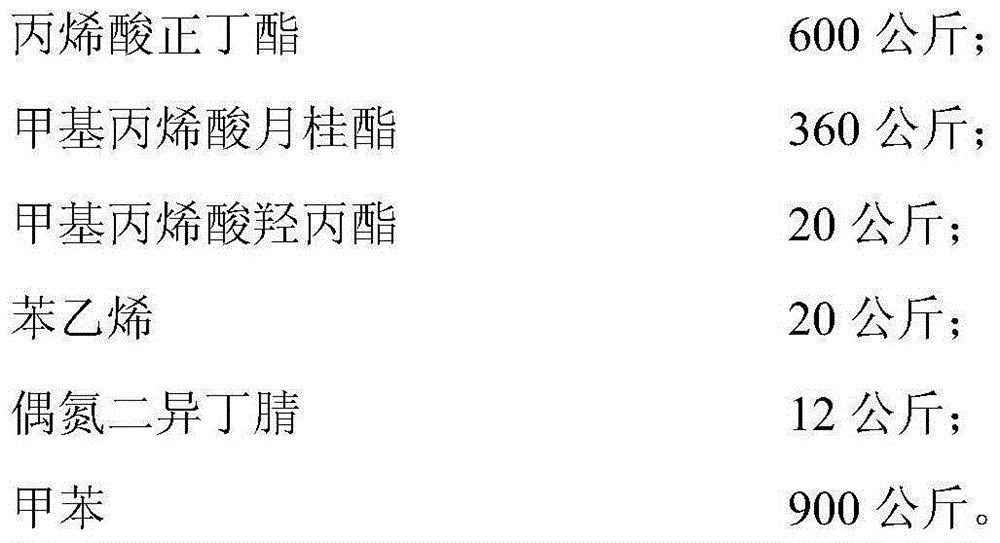

The invention relates to an efficient mirror plane flatting agent for powder paint, an preparation method and an application. The efficient mirror plane flatting agent is prepared from, by mass, 600-800 parts of acrylic acid butyl ester, 100-360 parts of lauryl methacrylate, 20-50 parts of hydroxyl acrylate monomers, 20-50 parts of styrene, 10-25 parts of azodiisobutyronitrile and 900-1500 parts of methylbenzene. The number-average molecular weight Mn of the prepared flatting agent is 6000-7000, the molecular weight distribution PDI is 1.5-2.8, and the flatting agent can be prepared into a solid state through gas-phase silicon oxide adsorption in the later period. The flatting agent is mainly applied to the powder paint, hydroxyl polar groups and benzene rings are introduced in the flatting agent, therefore, the compatibility of the flatting agent and resin in the powder paint and the wettability of the flatting agent for substrates can be effectively facilitated, and then a coating can achieve the excellent flatting, shrinkage cavity resisting and brightening effects; in addition, the Mn of the flatting agent is 6000-7000, the PDI is 1.5-2.8, and therefore the flatting, shrinkage cavity resisting and brightening effects of the coating can be further optimized; furthermore, the polar group hydroxyl is introduced, and therefore the adhesive force of the coating on the metal substrates can be effectively improved.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

High-solid-content finishing oil-based acrylic resin for automobiles and preparation method thereof

The invention discloses a high-solid-content finishing oil-based acrylic resin for automobiles and a preparation method thereof, which belong to the field of automobile paints and solve the problems of low solid content, high viscosity, poor solubility and the like in the existing acrylic resin paint. The resin contains acrylic acid, styrene, butyl acrylate, hydroxyethyl methacrylate, methyl methacrylate, methacrylic acid, butyl methacrylate, 2-ethylhexyl acrylate, n-dodecyl mercaptan, lauryl methacrylate, isoborneol methacrylate, 2-hydroxyethyl acrylate, 2-hydroxypropyl acrylate, 100# solvent oil, di-tert-pentyl peroxide, glycidol tert-carboxylate and a resin reactive diluent. The solid content can reach 90%. The acrylic resin has the advantages of favorable dilution property and low viscosity. The self-made reactive diluent can greatly enhance the water resistance and acid resistance of the paint. The construction solid content of the resin is nearly 70%. The acrylic resin greatly lowers the discharge of VOC (volatile organic compound), and is environment-friendly and practical.

Owner:安徽优科新材料科技有限公司

Finishing water-soluble acrylic resin and preparation method thereof

ActiveCN104403044ASolve pollutionOvercome the shortcomings of water resistance, acid resistance, salt resistance, etc.CoatingsIsooctyl acrylateChemical industry

The invention discloses finishing water-soluble acrylic resin and its preparation method and belongs to the technical field of resin. The resin provided by the invention comprises the following ingredients: acrylic acid, methacrylic acid, styrene, butyl methacrylate, butyl acrylate monomer, hydroxyethyl methylacrylate, 2-ethylhexyl acrylate, N-dodecyl mercaptan, methyl methacrylate, N,N-dimethyl ethanolamine, ethanol, water, lauryl methacrylate, Isobornyl methacrylate, hydroxyethyl acrylate, hydroxy-propyl acrylate and AIBN. The preparation method comprises six steps. By the preparation method, the required finishing water-soluble acrylic resin is finally prepared. The finishing water-soluble acrylic resin prepared by the formula and the preparation method can be used to effectively reduce costs and has an effect of environmental protection, can completely meet requirements of a finishing varnish in the aspect of prepared paint properties and overcomes the defect that water-soluble resin is not resistant to water, acid or salt in the field of traditional chemical industry.

Owner:安徽优科新材料科技有限公司

Fishing net made of modified nylon 6

InactiveCN105778486AEasy to processImprove mechanical propertiesArtifical filament manufactureMonocomponent polyamides artificial filamentAluminium hydroxidePolybutylene terephthalate

The invention discloses a fishing net made of modified nylon 6. The fishing net is prepared from lauryl methacrylate, octadecyl methacrylate, nylon 6, butadiene styrene rubber, polybutylene terephthalate, polycaprolactone, pentaerythritol stearate, nano-aluminium hydroxide, nano titanium dioxide and compound plasticizer. The nylon 6 is subjected to modification and cooperates with the lauryl methacrylate, octadecyl methacrylate, butadiene styrene rubber, polybutylene terephthalate, polycaprolactone, pentaerythritol stearate, nano-aluminium hydroxide and nano titanium dioxide, so that the made fishing net has good processability and mechanical property, is high in strength, good in toughness and abrasion resistance, strong in impact resistance, resistant to oxidation and aging, excellent in anti-ultraviolet property, wide in applicable water area and low in wear.

Owner:巢湖市强力渔业有限责任公司

Chemically prepared toners with size limiting binders

Chemically prepared toner is manufactured by aggregation in which the binder resin is a latex copolymer having a methacrylic acid ester of long chain, saturated alkyl, which may be lauryl methacrylate. This binder resin has a small amount by weight of acrylic acid component and has other nonionic components, which may be styrene and butyl acrylate moieties. Aggregation is carried out in an aqueous medium, which may have organic solvent components. The aggregation is then heated, and because of the selection of the binder resin to have the long chain ester, the heating step has minimal effect on particle size.

Owner:LEXMARK INT INC

Acrylic resin for transfer ink

The invention discloses an acrylic resin for transfer ink. The acrylic resin is prepared by performing copolymerization on soft monomers of which the glass transition temperatures are lower than 25 DEG C and hard monomers of which the glass transition temperatures are higher than 25 DEG C according to a mass ratio of 55 :45-95 :5, wherein the soft monomers are selected from at least one of 2-methylpropenoic acid dinbutyl phthalate, methyl acrylate, ethyl acrylate, butyl acrylate, acrylic di-iso-octyl sebacate, and 2-methylpropenoic acid glycerol trilaurate; the hard monomers are selected from at least one of 2-methylpropenoic acid methyl ester, 2-methylpropenoic acid ethyl ester, 2-methylpropenoic acid butyl acetate and cinnamene. The glass transition temperature of the acrylic resin provided by the invention ranges from 28 to 40 DEG C, the weight-average molar mass is 50,000 to 400,000, and the Tu-4 cup viscosity is 100-200 seconds. The acrylic resin has moderate adhesive force and better tenacity, and the acrylic resin can meet the requirement for the service performance of the transfer ink.

Owner:任婧

Pearlescent slurry concentrate for acrylic sheet

The disclosure provides a highly loaded pearlescent pigment acrylic polymer slurry concentrate for use as a pearlescent pigment additive for an acrylic polymer sheet, comprising: (a) about 35 to about 45 wt. % of a pearlescent pigment based on the weight of the slurry concentrate; (b) about 1.0 to about 5.0 wt. % of a copolymer dispersant comprising a pigment functional component derived from a monomer selected from the group consisting of urethane or urea, epoxy-containing methacrylate esterified with aromatic carboxylic acids, aliphatic carboxylic acids, ammonia and primary, secondary and tertiary aliphatic amines, primary aromatic amines, and alkyl methacrylate; and a solvent functional component derived from a monomer selected from the group consisting of methyl methacrylate, butyl methacrylate, ethyl hexyl methacrylate, lauryl methacrylate, 1,2-propane diol, 6, hydroxyhexanoic acid, and 2-phenoxyethanol; (c) about 15 to about 45 wt. % of a (C1-C22) alkyl ((C1-C10)alk) acrylate; and (d) about 0.1 to about 1.5 wt. % of a thixotropic agent.

Owner:DUPONT ELECTRONICS INC

High-temperature-resistant mirror silver resin and preparation method thereof

The invention discloses a high-temperature-resistant mirror silver resin which is prepared from the following raw materials: first components comprising cellulose acetate butyrate and a solvent; second components comprising methyl methacrylate, butyl methacrylate acetate, hydroxyethyl methacrylate, hydroxypropyl methacrylate, epoxy methylacrylate, vinyl siloxane, isobornyl methacrylate, lauryl methacrylate, acrylic acid and an initiator; and third components comprising an initiator and a solvent. A preparation method of the mirror silver resin comprises the steps of adding cellulose acetate butyrate of the first components into the solvent, dissolving, heating while stirring, heating up to 70-95 DEG C, and introducing nitrogen gas; mixing the second components, dropwise adding into the first components, carrying out heat preservation, and heating up to 85-110 DEG C; and adding the third components, carrying out heat preservation, and finally cooling and filtering. The prepared silver mirror resin has high temperature resistant performance, and has a broad-spectrum adhesive force to a base material; the product has relatively good solvent resistance; and the synthesis process is green and environmentally friendly.

Owner:GUANGZHOU EDL CHEM TECH

Styrene-acrylic emulsion containing carboxylic acid groups as well as styrene-acrylic emulsion interior wall coating and preparation method thereof

ActiveCN101974117AWater-resistant, scrub-resistant, and stain-resistantReduce contentAntifouling/underwater paintsPaints with biocidesSodium bicarbonateSolid component

The invention relates to a styrene-acrylic emulsion containing carboxylic acid groups, which comprises the following raw materials in percentage by weight: 20-25 percent of styrene, 5-8 percent of ethyl acrylate, 7-10 percent of butyl acrylate, 1.5-2.0 percent of triethylene glycol dimethacrylate, 2-3 percent of itaconic acid, 6-8 percent of lauryl methacrylate, 2-4 percent of MS-1 emulsion, 0.2-0.4 percent of potassium persulphate, 0.1-0.2 percent of sodium bicarbonate and the balance of deionized water, wherein the solid component content of the MA-1 emulsion is 30 wt%, the styrene-acrylic emulsion has the glass transition temperature of 2-5 DEG C, the pH value of 4-6 and the viscosity of 250-750mPa.S, the content of a volatile organic compound is not larger than 5g / l, and the solid component content is 48+ / -2 wt%. The invention provides the styrene-acrylic emulsion containing carboxylic acid groups, which has low glass transition temperature Tg and low volatile organic compound content.

Owner:CHANGZHOU GUANGHUI CHEM

Acrylic acid microgel emulsion having automatic restoration function and preparation method thereof

ActiveCN106397662AEmission reductionEnvironmental performanceCoatingsCross-link(Hydroxyethyl)methacrylate

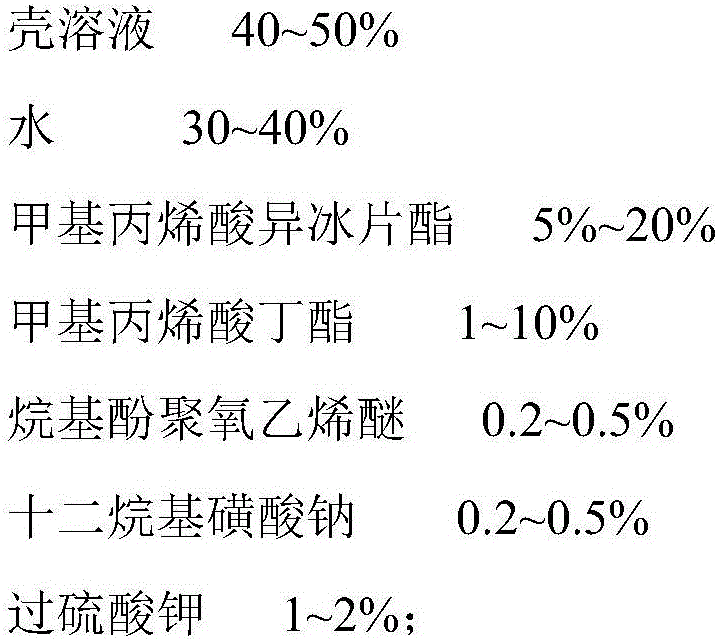

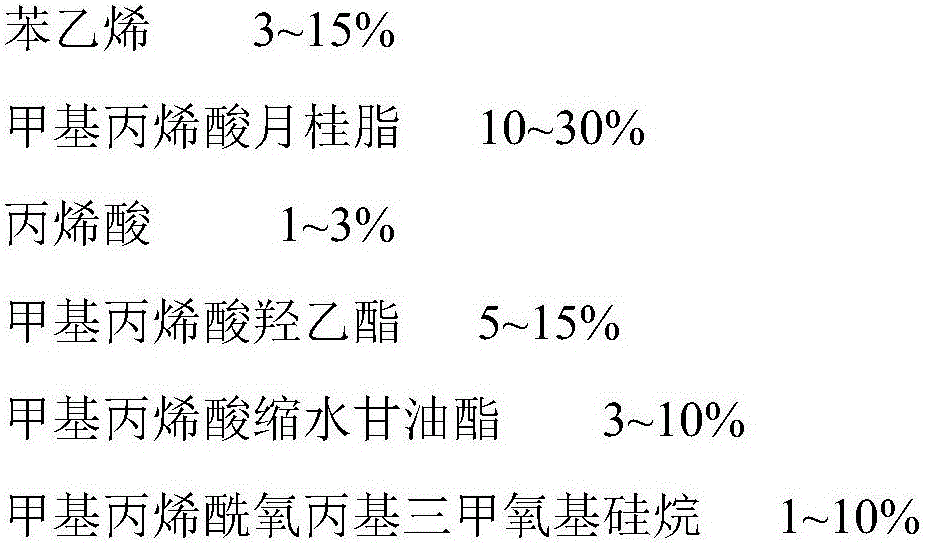

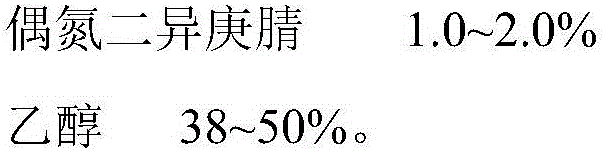

The invention discloses an acrylic acid microgel emulsion having the automatic restoration function and a preparation method thereof, and belongs to the technical field of a modified coating. The acrylic acid microgel emulsion comprises a shell layer and a core, wherein the shell layer includes a shell solution, water, isobornyl methacrylate, butyl methacrylate, alkylphenol polyoxyethylene, sodium dodecanesulphonate and potassium persulphate, and the core includes styrene, lauryl methacrylate, acrylic acid, hydroxyethyl methylacrylate, glycidyl methacrylate, 3-glycidoxypropyltrimethoxysilane, 2,2'-azobis (2,4-dimethyl) valeronitrile and ethanol. The emulsion has the advantages of low VOC discharge capacity and high solid content. The shell layer doesn't crack and the core colloid isn't released when the emulsion is sprayed at the room temperature. When a scratch appears, hot water with the temperature of 80 DEG C is used to wash the scratch, and the shell layer is heated, softened, and collapsed to release the core colloid. The core colloid is heated and softened to gradually fill the scratch, is self-cross-linked, and is hardened, so that the scratch is lightened and disappeared.

Owner:安徽优科新材料科技有限公司

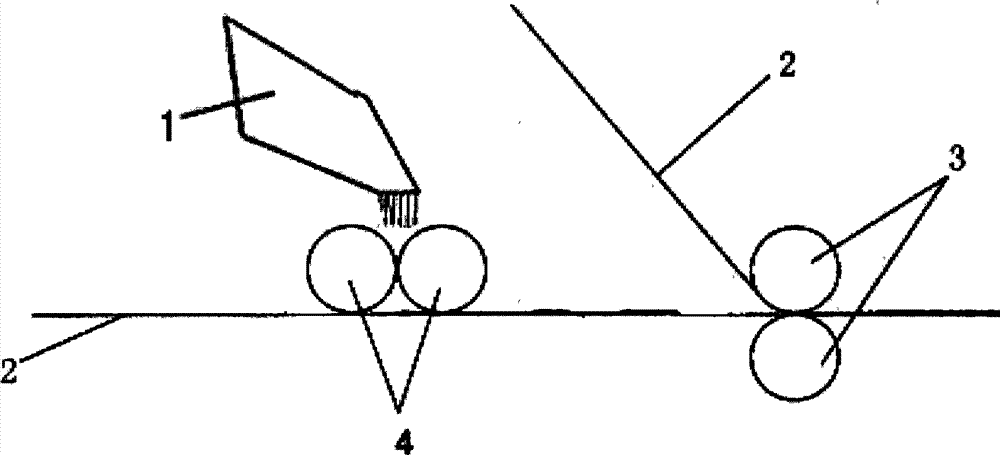

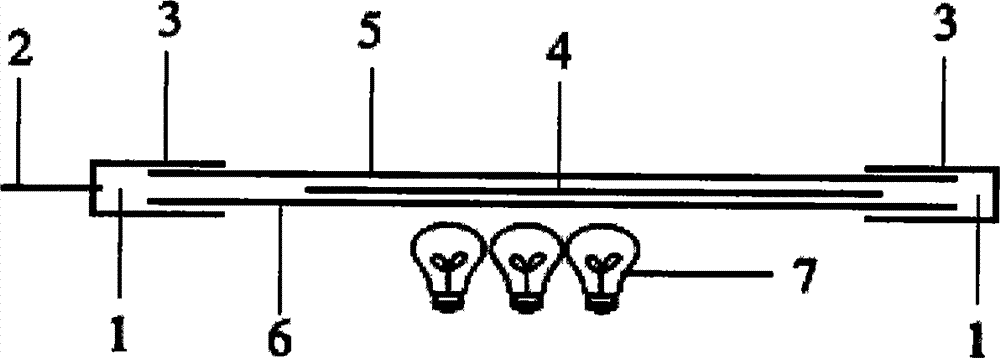

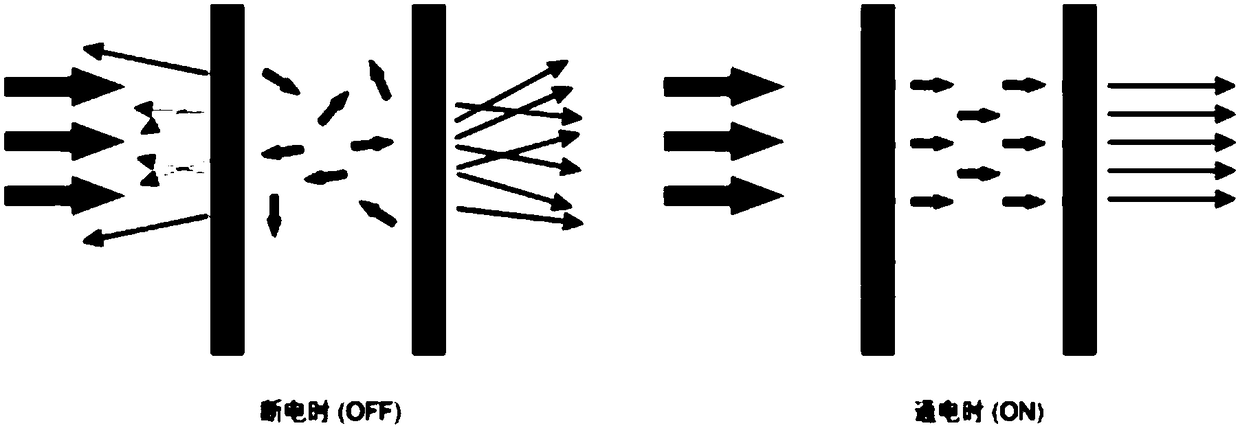

Preparing method of PDLC (polymer dispersed liquid crystal) dimming glass film

InactiveCN104777657AReduce manufacturing costImprove yieldNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveRoom temperatureHydroxypropyl methacrylate

The invention relates to a preparing method of a PDLC (polymer dispersed liquid crystal) dimming glass film. The method particularly comprises the following steps that in a light shading environment, resin, photoinitiators, HPMA (hydroxypropyl methacrylate), OPPEA (ortho-phenyl phenoxyl ethyl acrylate) and LMA (lauryl methacrylate) are proportionally mixed; after the mixing, the materials are uniformly stirred for about 30 minutes at the room temperature being about 25 DEG C; a mixture A is obtained; 35 percent of the mixture A is mixed with 65 percent of liquid crystals, and the mixture is uniformly stored for about 30 minutes at the room temperature about 25 DEG C; a mixture B is obtained; 0.5-percent 20um nanometer materials are added to be mixed with the mixture B, and the mixture is uniformly stirred for about 30 minutes at the room temperature being about 25 DEG C; finally, PDLC raw materials are obtained; coating and pressing are carried out; the curing process is carried out. The method provided by the invention includes the PDLC raw material preparation and a film production method. The production cost of the PDLC film is greatly reduced.

Owner:李林

Composite material for purifying water

InactiveCN104386776AProduce pollutionRapid sedimentationOther chemical processesWater/sewage treatment by flocculation/precipitationLow-density polyethyleneCellulose

The invention relates to a composite material for purifying water. The composite material is made of the following raw materials in parts by weight: 6-11 parts of anatase titanium dioxide, 8-12 parts of carboxymethyl methylcellulose, 3-9 parts of talcum powder, 6-10 parts of diatomite, 2-5 parts of palm oil, 2-7 parts of lauryl methacrylate, 1-5 parts of atractylodes, 4-9 parts of linear low-density polyethylene, 2-8 parts of potato straw powder, 1-5 parts of iron oxide, 8-14 parts of sodium dihydrogen phosphate, 1-3 parts of attapulgite and 5-11 parts of oyster shell powder. The composite material for purifying water disclosed by the invention plays the role of fast sedimentation, and can adsorb heavy metal ions in water without pollution to the water.

Owner:田琳琳

Epoxy modified electroplated silver resin and preparation method thereof

The invention discloses epoxy modified electroplated silver resin, comprising a first component, a second component, a third component and a fourth component, wherein ingredients of the components and the weight percentage of each ingredient in the epoxy modified electroplated silver resin are as follows: the first component comprises toluene and butyl acetate; the second component comprises methyl methacrylate, tert-butyl methacrylate, lauryl methacrylate, hydroxyethyl methacrylate, glycidyl methacrylate, an AB-4 monomer and tert-butyl peroxybenzoate; the third component comprises butyl acetate and tert-butyl peroxybenzoate; and the fourth component comprises methyl isobutyl ketone. The invention further discloses a preparation method of the epoxy modified electroplated silver resin.

Owner:东莞市比翼新材料科技有限公司

Method for preparing surface hydrophilic modifier for hydrophobic material

The invention relates to the technical field of surface modification, and relates to a method for preparing a surface hydrophilic modifier for a hydrophobic material. The modifier is an amphiphilic block polymer with molecular weight in gradient distribution. The method comprises the following steps: dissolving a polyethylene glycol derivative in a solvent, weighing a free radical polymerization reaction initiator and a lauryl methacrylate monomer, putting the above component into a high-speed mixing machine, stirring at high speed, subsequently dissolving and depositing a product, and drying, thereby obtaining the modifier, wherein the weight part ratio of the polyethylene glycol derivative to the solvent to the free radical polymerization reaction initiator to the lauryl methacrylate monomer is (10-50) to (100-1000) to (0.1-5) to (10-50). The surface hydrophilic modifier synthesized by using the method is used for performing surface modification on resin, not only is the surface hydrophilicity improved, but also the flexibility of substrate resin is improved, and thus the surface hydrophilic modifier can be widely applied to the fields such as polyethylene, polypropylene, polyvinyl chloride, polystyrene, polyvinylidene fluoride and ABS.

Owner:SHANGHAI CHENGYING NEW MATERIALS +2

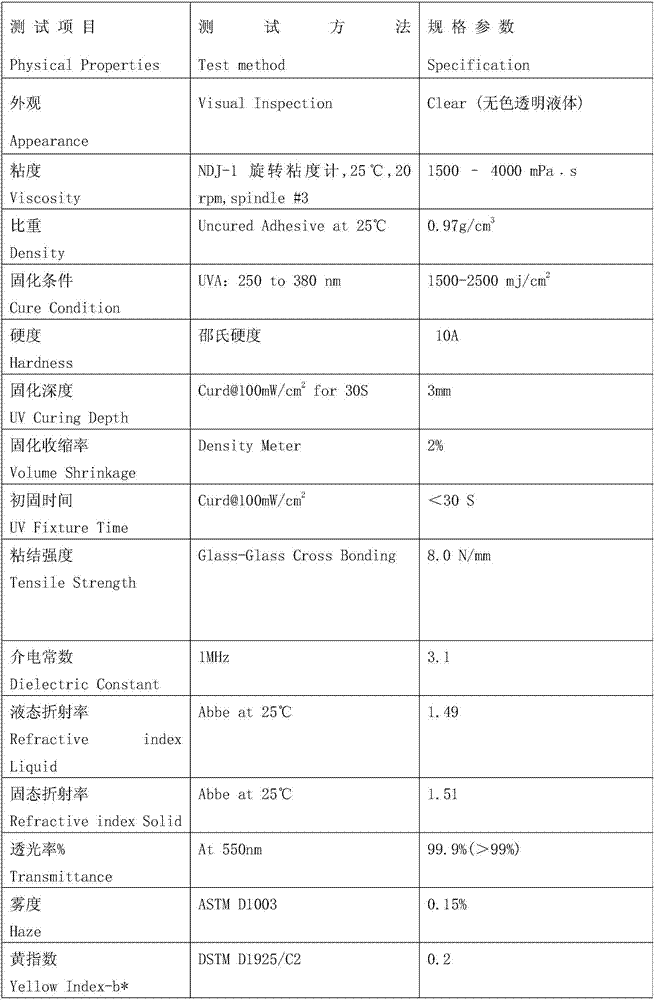

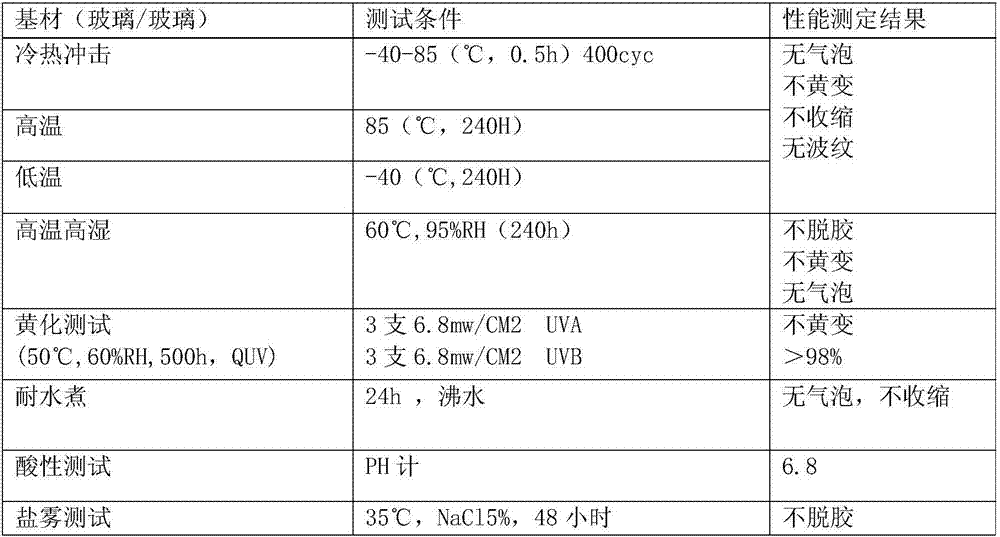

Liquid optical transparent adhesive and preparation method thereof

InactiveCN106928870AReduce hardnessLow shrinkageOrganic non-macromolecular adhesive(Hydroxyethyl)methacrylatePolymer science

The invention discloses a liquid optical transparent adhesive which comprises the following components in parts by weight: 40-70 parts of low polymer, 30-50 parts of acrylate activated monomer, 1-5 parts of photoinitiator and 1-5 parts of assistant, wherein the low polymer is polyisoprene acrylate, polybutadiene acrylate or polyphenyldiene acrylate; the molecular weight of the low polymer is 15000-40000; the functionality degree of the low polymer is 2-3; and the activated monomer is one or two or a combination of more than two of methacrylate, isobornyl acrylate, hydroxyethyl methacrylate, hydroxypropyl methacrylate, ethoxylated nonyl phenol acrylate, lauryl methacrylate, butyl methacrylate, trimethylolpropane diacrylate and trimethylolpropane triacrylate. The adhesive effectively improves yellowing generated in a curing process, therebyimprovingthe quality of a product.

Owner:河源然生新材料有限公司

Polymer dispersed liquid crystal dimming film and preparation method thereof

InactiveCN109407386AQuick responseAchieve instant invisibilityStatic indicating devicesNon-linear opticsEpoxyPolymer science

The invention relates to a polymer dispersed liquid crystal dimming film and a preparation method thereof. The dimming film is prepared from, by weight, 25-30 parts of monomer hydroxypropyl methacrylate, 38-45 parts of epoxy resin, 22-28 parts of o-phenyl phenoxyethyl acrylate, 4-6 parts of lauryl methacrylate, 4-6 parts of a photoinitiator, 4-6 parts of a light stabilizer, 140-180 parts of liquidcrystals and 1.8-2.2 parts of nano particles. The preparation method comprises the steps that monomer hydroxypropyl methacrylate, epoxy resin, o-phenyl phenoxyethyl acrylate and lauryl methacrylate are added to a mixing container to be mixed and stirred, then the liquid crystals are added, then the materials are mixed, then the photoinitiator, the light stabilizer and the nano particles are addedto be stirred, after the raw materials are obtained, coating and pressing fit are carried out, and the polymer dispersed liquid crystal dimming film is obtained after curing is carried out. When theprepared polymer dispersed liquid crystal dimming film is used, the switching response between a scattering state and a transparent state is fast, the driving voltage is low, and safety and reliability are achieved.

Owner:王浪伟

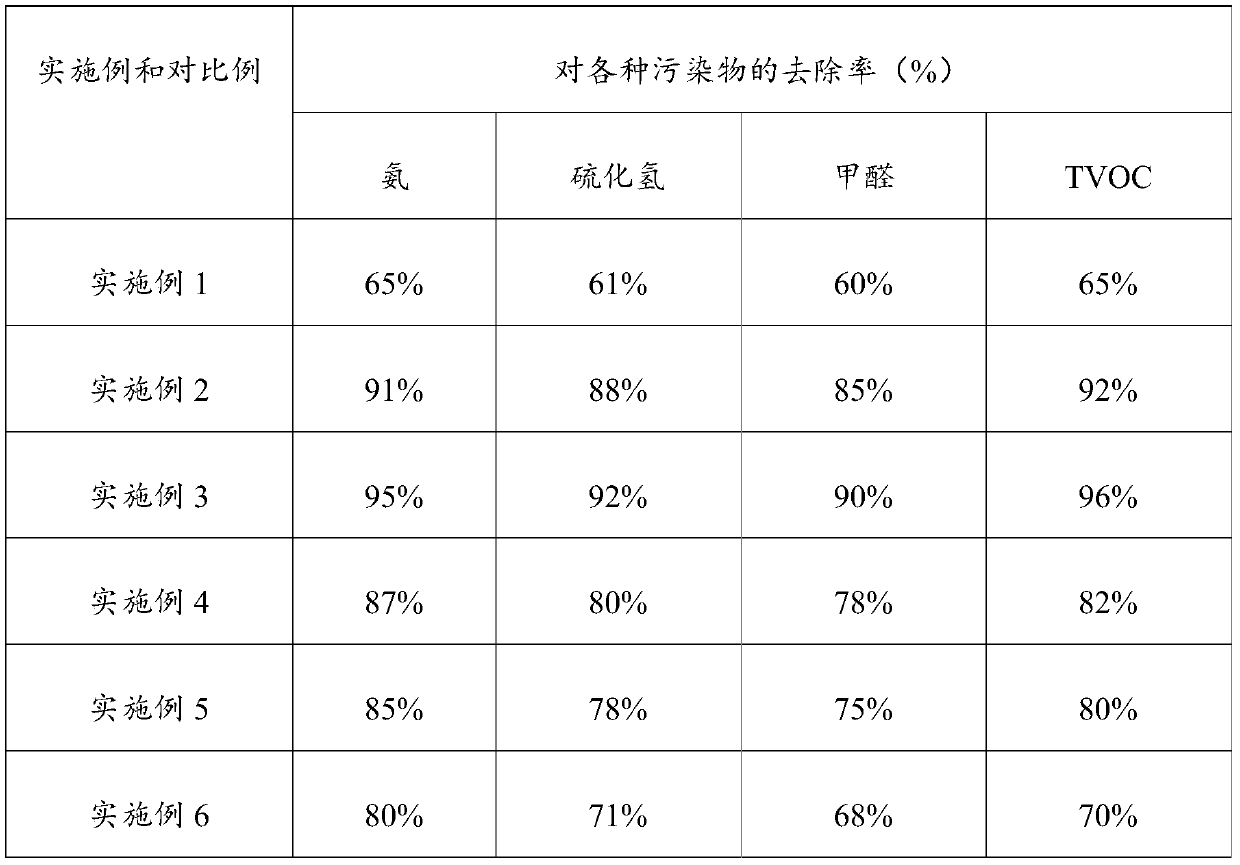

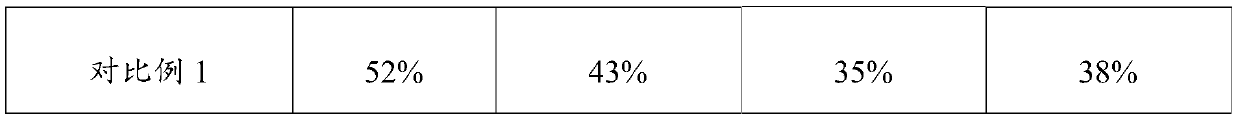

Air purifying agent and preparation method and application thereof

PendingCN110813012AStable in natureEasy to deodorizeGas treatmentDispersed particle separationAir decontaminationEngineering

The invention relates to the technical field of air purification, in particular to an air purifying agent and a preparation method and application thereof. The air purifying agent comprises the following components in parts by weight: 2-15 parts of lauryl methacrylate, 2-5 parts of a plant extracting solution, 1-5 parts of an emulsifier, 5-15 parts of a solubilizer, 5-10 parts of a cosolvent and 50-95 parts of water. According to the preparation method, lauryl methacrylate and the plant extracting solution are compounded, and the air purifying agent which is stable in property and capable of efficiently removing benzene series, formaldehyde, ammonia gas, hydrogen sulfide and other peculiar smell molecules in the air is obtained under the action of the emulsifier, the solubilizer and the cosolvent.

Owner:广东森绿环境科技有限公司

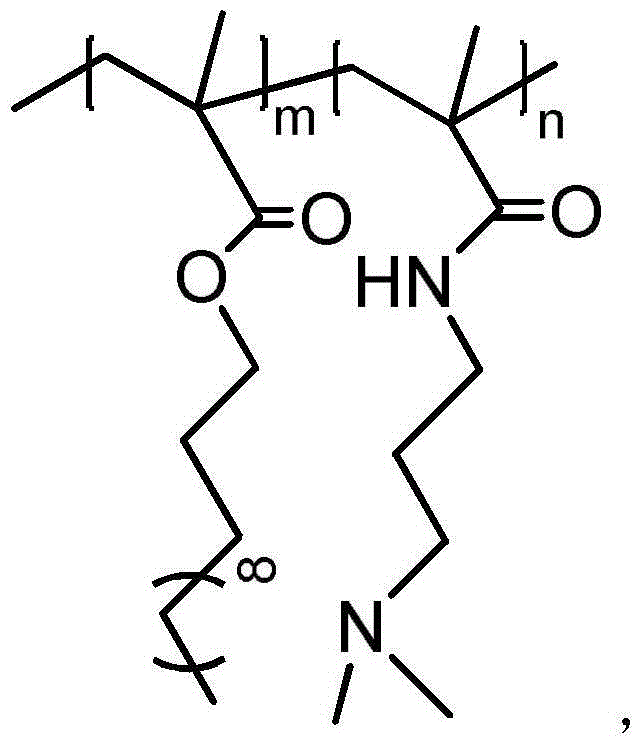

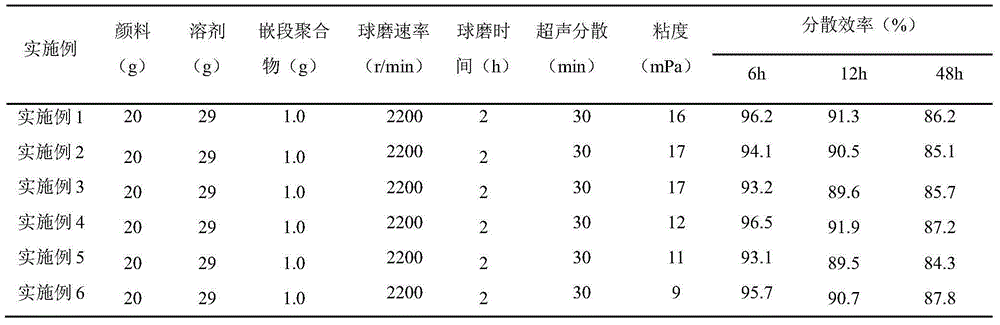

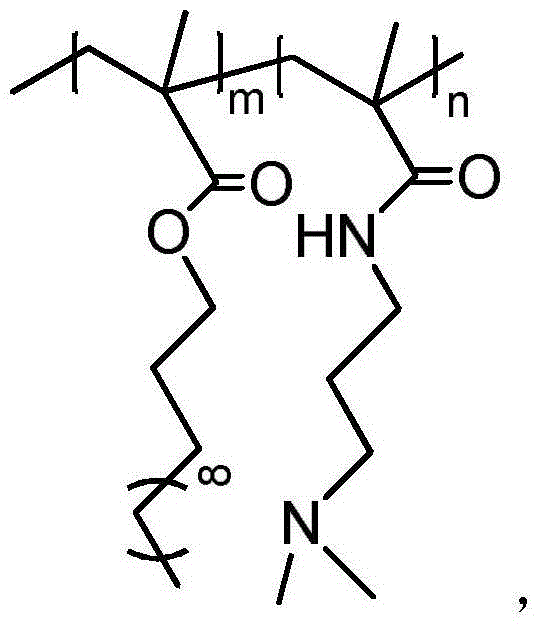

Acrylate-acrylamide type block polymer, synthetic method and application thereof

The invention belongs to the field of high-molecule polymers, and discloses an acrylate-acrylamide type block polymer, a synthetic method and an application thereof. The acrylate-acrylamide type block polymer is prepared from lauryl methacrylate and N-(3-Dimethylaminopropyl)methacrylamide by an RAFT polymerization method. The synthetic method of the acrylate-acrylamide type block polymer comprises the following steps: under an anaerobic condition, preparing RAFT reagent macromolecules from a monomer lauryl methacrylate (or N-(3-dimethylaminopropyl)methacrylamide) under the action of an initiator and an RAFT reagent, reacting the RAFT reagent macromolecules and a monomer N-(3-dimethylaminopropyl)methacrylamide (or lauryl methacrylate) under the induction of the initiator to generate the acrylate-acrylamide type block polymer. The acrylate-acrylamide type block polymer has effects of covering and packaging surfaces of inorganic particles, a dispersion system is stable, and the acrylate-acrylamide type block polymer can be applied to dispersion of ceramic jetting ink.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Preparation method for novel ionic liquid capillary monolithic column

ActiveCN103071314AHigh mechanical strengthStrong ability to resist harsh environmentSolid sorbent liquid separationCross-linkFunctional monomer

The invention relates to a preparation method for a novel ionic liquid capillary monolithic column. Main technical points of the invention are as follows: ionic liquid chlorinated 1-vinyl-3-octylimidazolium and lauryl methacrylate are used as binary functional monomers, ethylene glycol dimethacrylate is used as a cross-linking agent, 1,4-butylene glycol and methanol are used as binary pore forming agents, and the novel capillary monolithic column is prepared by using in situ thermopolymerization technology. The preparation method provided by the invention has the advantages of low cost, a simple synthesis process and easily controllable reaction conditions; the prepared novel capillary monolithic column has high mechanical strength, is applicable to a buffer solution with a wide pH value scope of 2.0 to 12.0 and can be used for fractionation detection of a benzene series, thiourea and analogues thereof and amino acid on capillary electrochromatography.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Modified adsorbing material for phenol wastewater

InactiveCN104043413AImprove poor biocompatibilityExtended service lifeOther chemical processesWater/sewage treatment by sorptionSorbentBiocompatibility Testing

The invention discloses a modified adsorbing material for phenol wastewater. The modified adsorbing material is characterized by comprising the following substances in parts by weight: 6-14 parts of acrylate, 5-9 parts of initiator, 14-26 parts of ethanol, 9-10 parts of ammonia water, 1-2 parts of gallic acid, 25-30 parts of lauryl methacrylate, 12-16 parts of methyl methacrylate, 14-19 parts of fibrous aquatic stone, 6-10 parts of compound adhesive, 25-31 parts of carpesium abrotanoides straw powder, 1-2 parts of maleic anhydride grafted polypropylene, 6-9 parts of polyethylene glycol terephthalate and 9-15 parts of calcium sulfate. The modified adsorbing material has the beneficial effects that the problem of poor biocompatibility of simple resin adsorbents is solved by preparing a porous spongy composite material by taking fiber base materials as carriers to bear polymer materials, and microorganisms can be loaded on the composite material to complete degradation of phenol.

Owner:QINGDAO QIANXIANG ENVIRONMENTAL PROTECTION TECH

Fiber mat and process for making same

ActiveUS7268091B2High strengthImproved dry mat tensile strengthsCellulosic pulp after-treatmentSynthetic resin layered productsFiberEngineering

A fiber mat of improved wet web strength and a process of making same is disclosed. The fiber mat comprises fibers; a resinous fiber binder; and a vinylpyrrolidone / acrylic acid / lauryl methacrylate terpolymer.

Owner:BMIC LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com