Acrylate-acrylamide type block polymer, synthetic method and application thereof

A technology of block polymer and acrylamide, which is applied in the field of acrylate-acrylamide block polymer and its synthesis, can solve the problem that the use performance cannot fully meet the use requirements, the polymer dispersant is late, and the synthesis method is immature, etc. problem, to achieve the effect of good encapsulation effect, excellent structure, good molecular weight and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

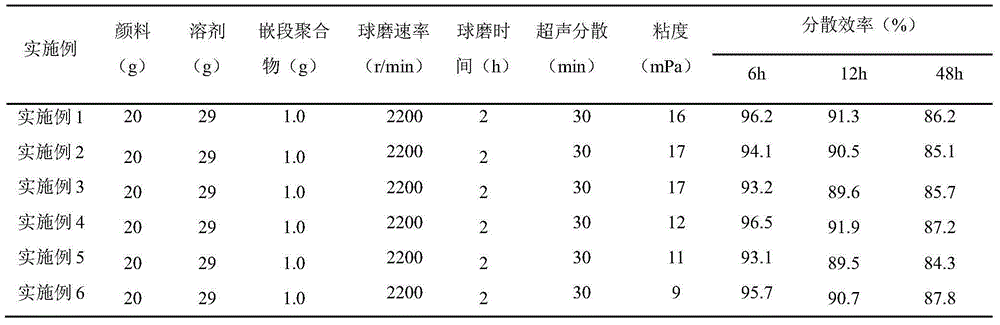

Examples

Embodiment 1

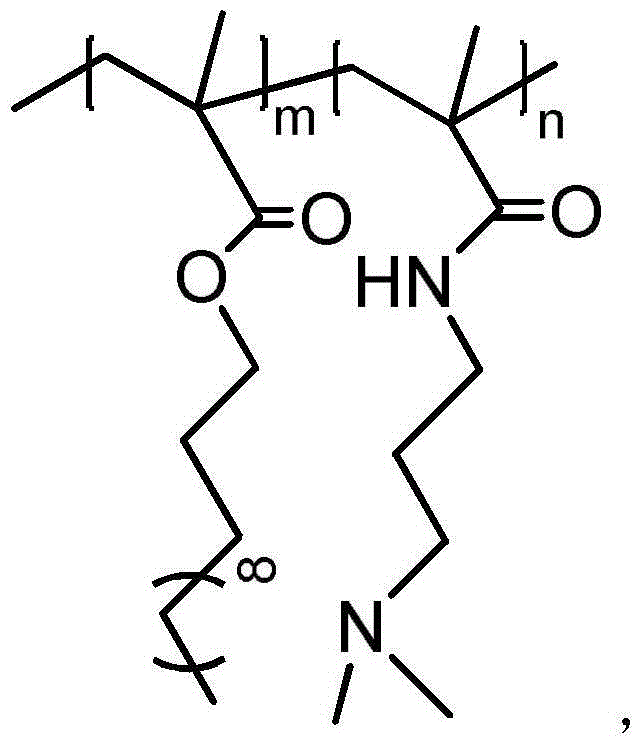

[0059] An acrylate-acrylamide block polymer has the following structure:

[0060] Among them, m is 32, n is 41;

[0061] The synthetic method of described acrylate-acrylamide block polymer comprises the steps:

[0062] (1) 25.44g lauryl methacrylate (LMA) (0.10mol), 0.364g RAFT reagent S-dodecyl-S'-(2-methylpropionic acid) trithiocarbonate (0.001mol) , 0.016g initiator azobisisobutyronitrile (AIBN) (1×10 -4 mol) and 228.96g of toluene were added to the reactor, stirred and mixed; under the condition of ice bath, the reactor was ventilated with nitrogen for 40 minutes to remove the air, and then the temperature was raised to 75°C under the oil bath for reaction, and after 15 hours of reaction, the temperature was rapidly lowered and exposed to In the air, the reaction is stopped, and the product obtained from the reaction is purified to obtain the intermediate product LMA macro-RAFT;

[0063] (2) 10.43g intermediate product LMA macro-RAFT, 17.02g monomer N-(3-dimethylamino...

Embodiment 2

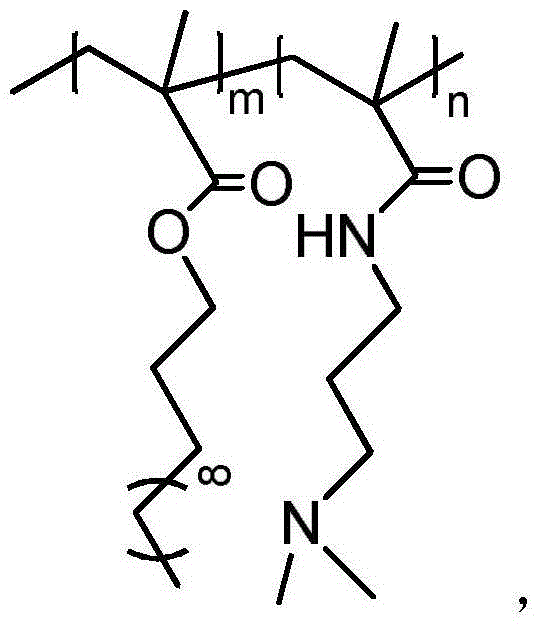

[0065] An acrylate-acrylamide block polymer has the following structure:

[0066] Among them, m is 29, n is 37;

[0067] The synthetic method of described acrylate-acrylamide block polymer comprises the steps:

[0068] (1) 25.44g lauryl methacrylate (LMA) (0.10mol), 0.364g RAFT reagent S-dodecyl-S'-(2-methylpropionic acid) trithiocarbonate (0.001mol) , 0.033g initiator azobisisobutyronitrile (AIBN) (2×10 -4 mol) and 228.96 g of ethyl acetate were added to the reactor, stirred and mixed; under ice-bath conditions, the reactor was ventilated with nitrogen for 40 minutes to remove the air, and then heated to 80 ° C under an oil bath for reaction, and the temperature was rapidly lowered after 20 hours of reaction. Expose to the air, stop the reaction, and purify the reaction product to obtain the intermediate product LMA macro-RAFT;

[0069] (2) 9.41g intermediate product LMA macro-RAFT, 8.51g monomer N-(3-dimethylaminopropyl) methacrylamide (DMAPMA) (0.05mol), 0.033g initiat...

Embodiment 3

[0071] An acrylate-acrylamide block polymer has the following structure:

[0072] Among them, m is 24, n is 32;

[0073] The synthetic method of described acrylate-acrylamide block polymer comprises the steps:

[0074] (1) 25.44g lauryl methacrylate (LMA) (0.10mol), 0.364g RAFT reagent S-dodecyl-S'-(2-methylpropionic acid) trithiocarbonate (0.001mol) , 0.049g initiator azobisisobutyronitrile (AIBN) (3×10 -4 mol) and 228.96g DMF were added to the reactor, stirred and mixed; under the condition of ice bath, the reactor was ventilated with nitrogen for 40min to remove the air, then the temperature was raised to 75°C under the oil bath for reaction, and after 24h of reaction, the temperature was rapidly lowered and exposed to In the air, the reaction is stopped, and the product obtained from the reaction is purified to obtain the intermediate product LMA macro-RAFT;

[0075] (2) 8.14g intermediate product LMA macro-RAFT, 8.51g monomer N-(3-dimethylaminopropyl) methacrylamide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com