Cut-resistant ultra-high molecular weight polyethylene fibers and preparation technology thereof

A technology of ultra-high molecular weight and preparation process, which is applied in the field of preparation of ultra-high molecular weight polyethylene composite fibers, which can solve the problems of hardening, no comfort, complicated process, etc., and achieve good cutting resistance, good cutting resistance, and process The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

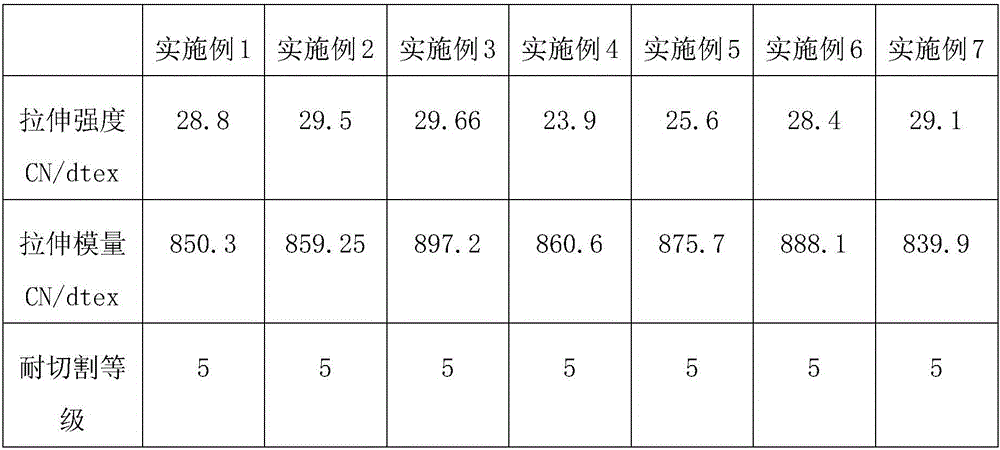

Examples

Embodiment 1

[0045] (1) 2g graphene is added in the mixed solution of 100ml water and ethanol, the volume of water and ethanol is 1:9, 800r / min high-speed stirring is added 0.5h after adding 0.1g aminopropyl-aminoethyltriethoxysilane, 800r / min high-speed stirring for 2h, filtered. After the filter cake was vacuum-dried at 100° C. for 3 hours, it was pulverized by airflow to obtain aminopropyl-aminoethyltriethoxysilane surface-modified graphene powder.

[0046] (2) 5g of expandable organic bentonite is uniformly dispersed in 500g of white oil under the ultrasonic state, and then it is stirred by high-speed shearing by an emulsifier. The speed of high-speed shearing and stirring is 1000r / min, and the stirring time is 1h.

[0047] (3) 1g of surface-modified graphene is added to 500g of white oil, and stirred at a high speed, the speed of the high-speed stirring is 1000r / min, and the stirring time is 1h.

[0048] (4) Add (3) into (2), stir at high speed, the speed of high speed stirring is 10...

Embodiment 2

[0052] (1) Add 4g of graphene to a mixed solution of 200ml of water and ethanol, the volume of water and ethanol is 1:9, stir at 800r / min at high speed for 0.5h, then add 0.2g of dodecyltrichlorosilane, stir at 800r / min at high speed 2h, filter. After the filter cake was vacuum-dried at 100° C. for 3 h, it was air-jet milled.

[0053] (2) 10g of expandable organic bentonite is uniformly dispersed in 1000g of paraffin oil in the ultrasonic state, and then is stirred by high-speed shearing in an emulsifier. The speed of high-speed shearing and stirring is 2000r / min, and the stirring time is 1h.

[0054] (3) 2g of surface-modified graphene is added to 1000g of paraffin oil, and stirred at a high speed, the speed of the high-speed stirring is 2000r / min, and the stirring time is 1h.

[0055] (4) Add (3) into (2), stir at high speed, the speed of high speed stirring is 2000r / min, and the stirring time is 1h.

[0056] (5) Join 985g ultra-high molecular weight polyethylene powder an...

Embodiment 3

[0059] (1) Add 5g of graphene to a mixed solution of 250ml of water and ethanol, the volume of water and ethanol is 1:9, stir at 800r / min for 0.5h, then add 0.25g of dodecyltriethoxysilane, 800r / min Stir at high speed for 2h and filter. After the filter cake was vacuum-dried at 100° C. for 3 h, it was air-jet milled.

[0060] (2) 30g of expandable organic bentonite is uniformly dispersed in 3000g of mineral oil in the ultrasonic state, and then is stirred by high-speed shearing by an emulsifier. The speed of high-speed shearing and stirring is 2000r / min, and the stirring time is 1h.

[0061] (3) Add 3g of surface-modified graphene to 1500g of mineral oil, and stir at a high speed, the speed of high-speed stirring is 2000r / min, and the stirring time is 1h.

[0062] (4) Add (3) into (2), stir at high speed, the speed of high speed stirring is 2000r / min, and the stirring time is 1h.

[0063] (5) 964g of ultra-high molecular weight polyethylene powder and 3g of antioxidant powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com