Patents

Literature

347results about How to "Improve cut resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

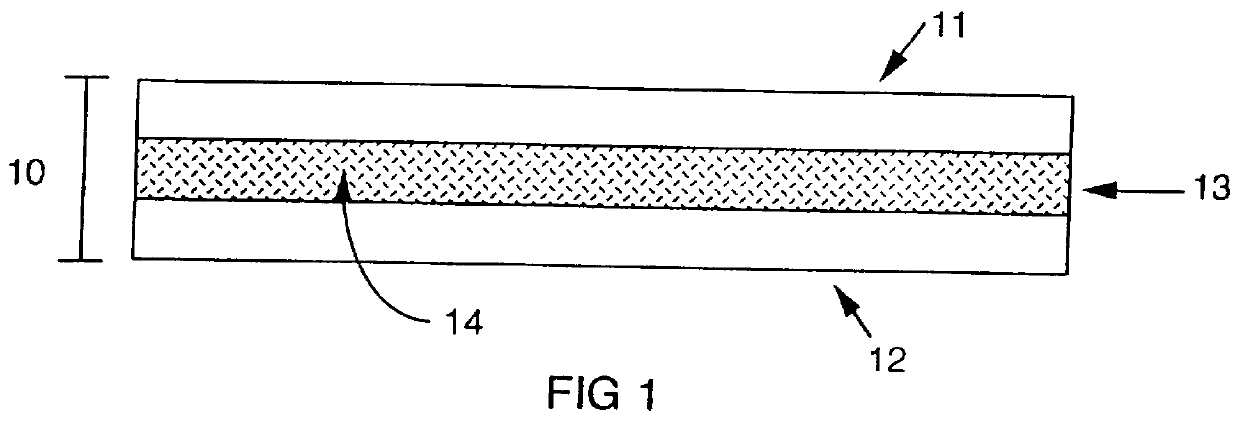

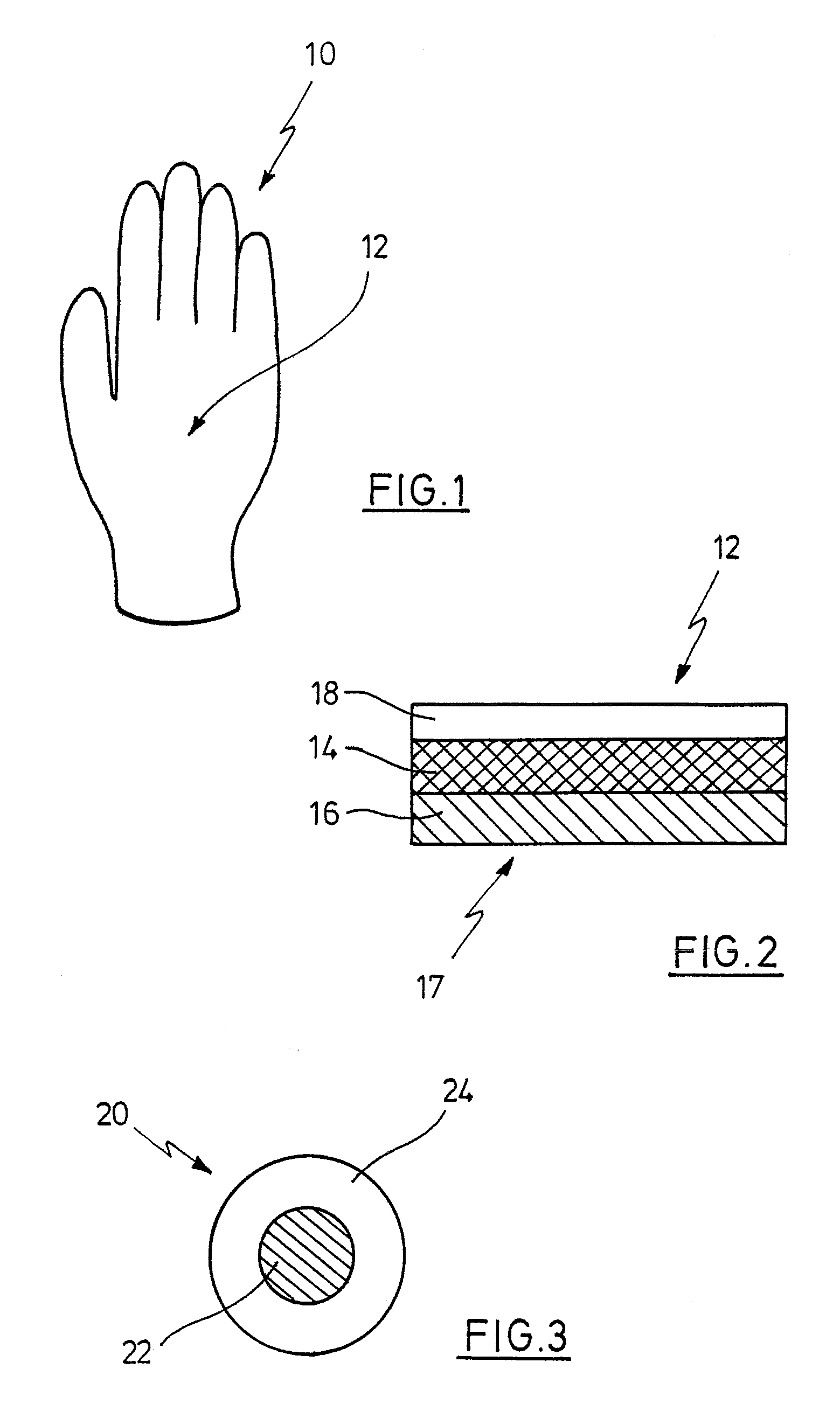

Cut resistant polymeric films

A polymeric film having increased cut resistance comprising a polymeric matrix having dispersed therein a plurality of cut resistance enhancing fibers. These films are preferably made into gloves, for example medical or industrial gloves.

Owner:THE UNIVERSITY OF AKRON

Giant engineering tire tread rubber and giant engineering tyre using the same

InactiveCN101440176ASolve wear resistanceSolve heat resistanceSpecial tyresHeat resistanceTear resistance

The invention discloses tread rubber for a large project tire and the large project tire using the tread rubber. The tread rubber for the large project tire consists of (A) tread cap rubber, (B) tread center rubber and (C) tread base rubber. On one hand, the invention adopts rubber matrixes with three different formulas to well solve the problem that an outer layer is easy to overcure if the tread rubber for the large project tire is thick; and on the other hand, the tread rubber prepared by the three formulas of the rubber matrixes can obtain superior equilibrium between abrasion resistance, heat resistance, tear resistance, low heat generation and curing speed.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

Antimicrobial cut-resistant composite yarn and garments knitted or woven therefrom

Owner:WORLD FIBERS

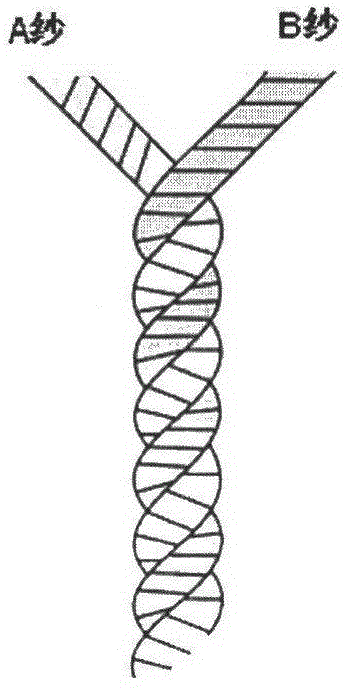

Cut-resistant core-spun yarn and application thereof

The invention discloses a cut-resistant core-spun yarn. The cut-resistant core-spun yarn comprises an outer layer of fiber and a core fiber which is covered through a core-spun technology, wherein the core fiber includes one or a plurality of a glass filament, a basalt filament or a steel wire filament; and the outer layer of fiber is a synthetic fiber which is formed for synthesizing an aramid spun or a polyethylene spun, or the aramid spun and the polyethylene spun according to arbitrary ratio, or is the synthetic fiber which contains the aramid spun and / or the polyethylene spun. The invention further discloses an application of the cut-resistant core-spun yarn to a cut-resistant fabric. The cut-resistant core-spun yarn has excellent quality, the woven fabric is comfortable to wear, a user which uses a production product in a dangerous environment can comfortably and freely work, so the safety and working efficiency are greatly increased.

Owner:CHANGZHOU KEXU TEXTILE CO LTD

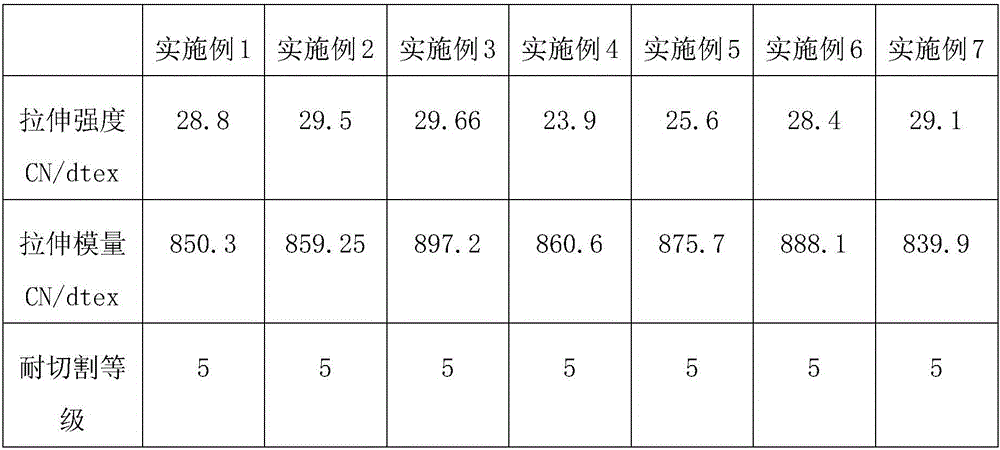

Cut-resistant ultra-high molecular weight polyethylene fibers and preparation technology thereof

ActiveCN106149085AGuaranteed superiorityImprove comfortWet spinning methodsMonocomponent polyolefin artificial filamentFiberPolymer science

The invention discloses cut-resistant ultra-high molecular weight polyethylene fibers. The cut-resistant ultra-high molecular weight polyethylene fibers consist of ultra-high molecular weight polyethylene, expandable organosilicate clay, modified graphene and an antioxidant, wherein the expandable organosilicate clay accounts for 0.1%-10% of the total mass of the composite fibers; and the modified graphene accounts for 0.1%-5% of the total mass of the composite fibers. The invention provides the technical scheme of preparing cut-resistant fibers by using UHMWPE fibers as bodies (cut-resistant level of fiber bodies only can reach 2 levels or so generally at present), the technological process is simple, the cut resistance of the fibers which are not combined to other hard fibers can be good, and therefore, the comfort level of fiber products is improved.

Owner:南通恒尚新材料科技有限公司 +1

High strength polyethylene fibers and their applications

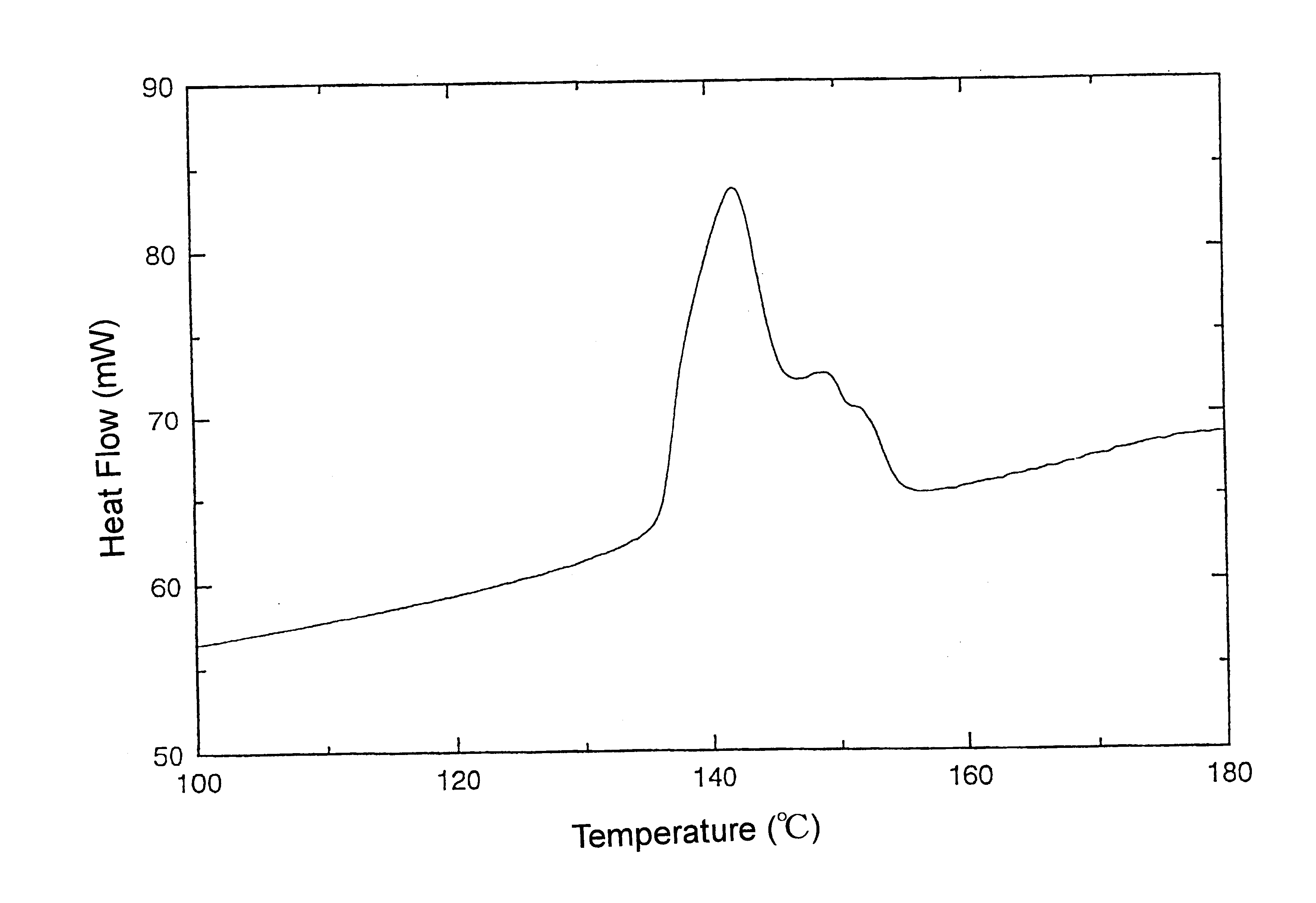

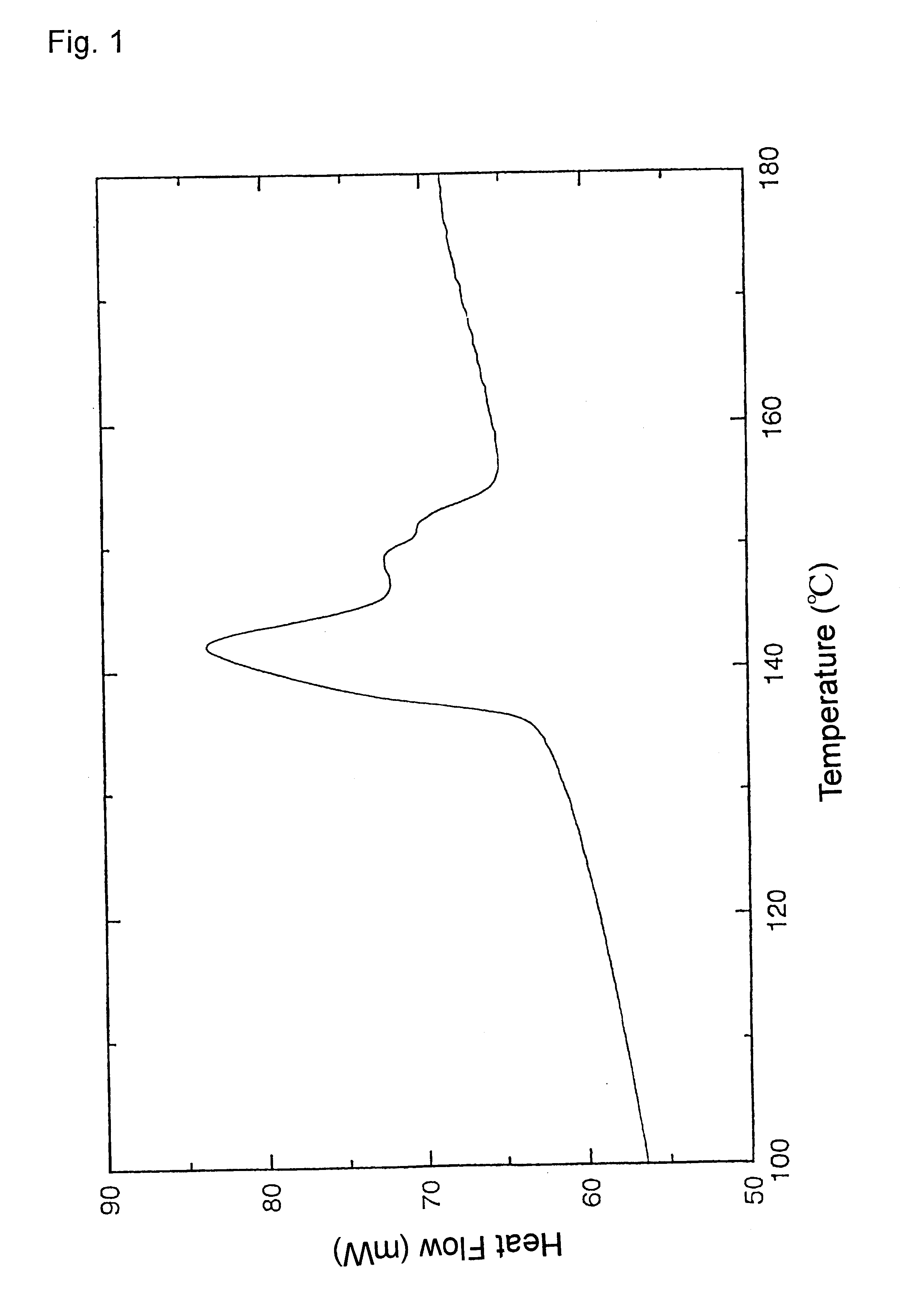

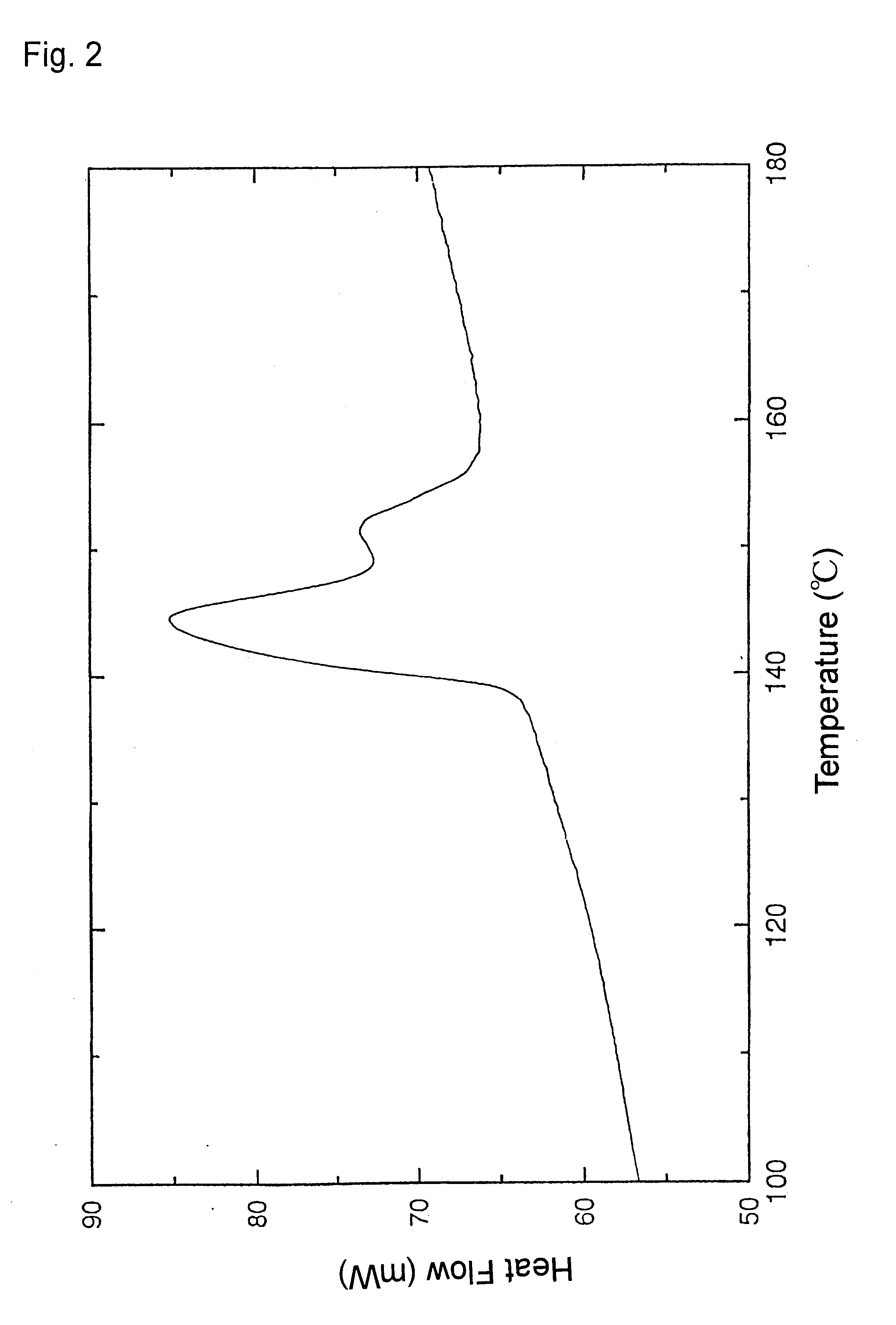

High strength polyethylene fibers and their applications, for example, chopped fibers, ropes, nets, ballistic materials or items, protective gloves, fiber reinforced concrete products, helmets, and other products obtained therefrom, in which the fiber is characterized in that: it contains a high molecular weight polyethylene consisting essentially of a repeating unit of ethylene; it has an intrinsic viscosity number of 5 or larger and an average strength of 22 cN / dtex or higher; and the measurement of the fiber by differential scanning calorimetry (DSC) exhibits a temperature-increasing DCS curve having at least one endothermic peak over a temperature region of 140° C. to 148° C. (on the low temperature side) and at least one endothermic peak over a temperature region of 148° C. or higher (on the high temperature side) or the number of frictions until the fiber is broken in an abrasion test according to method B for measuring abrasion resistance in the Testing Methods for Spun Yarn (JIS L 1095) is 100,000 or larger.

Owner:TOYOBO CO LTD

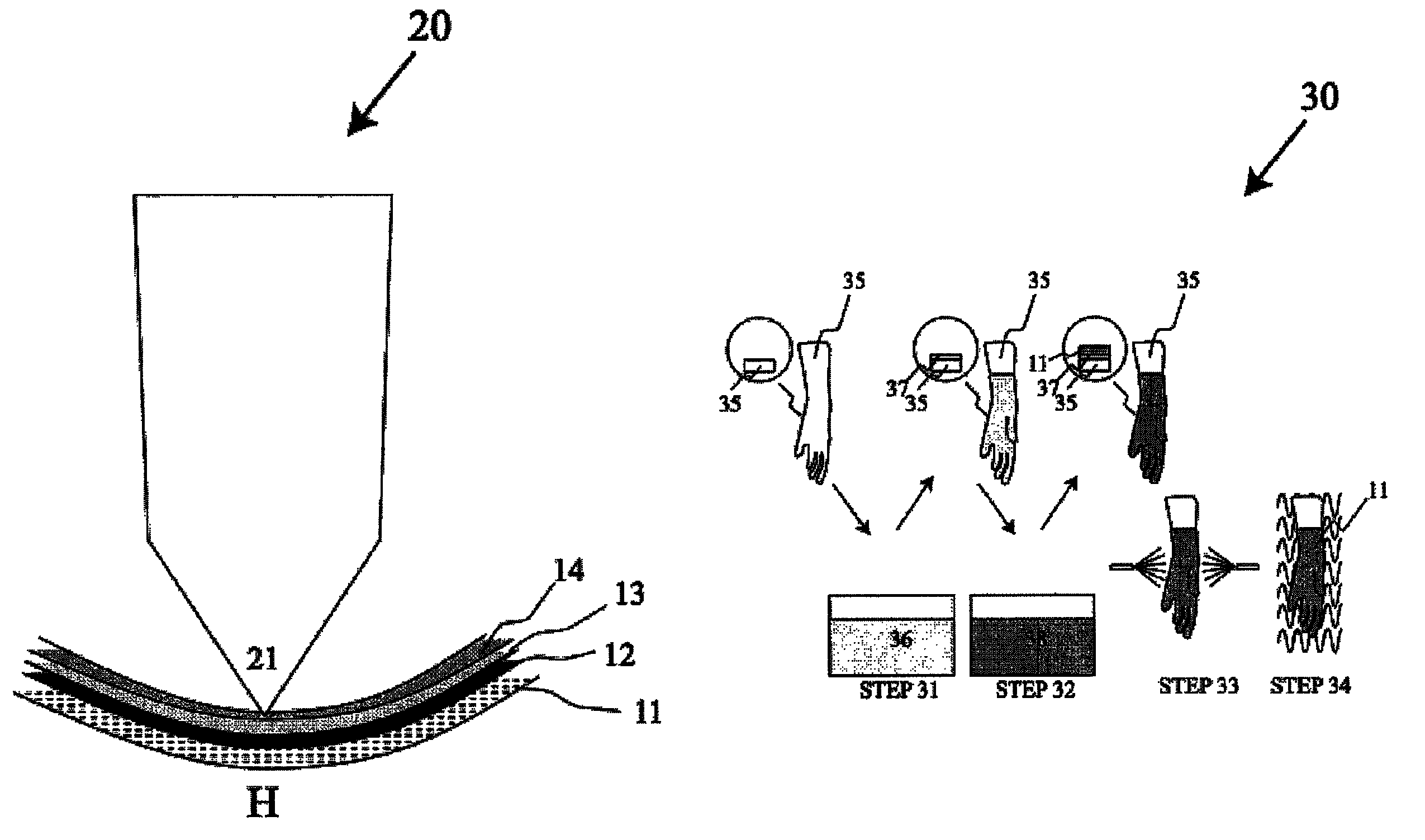

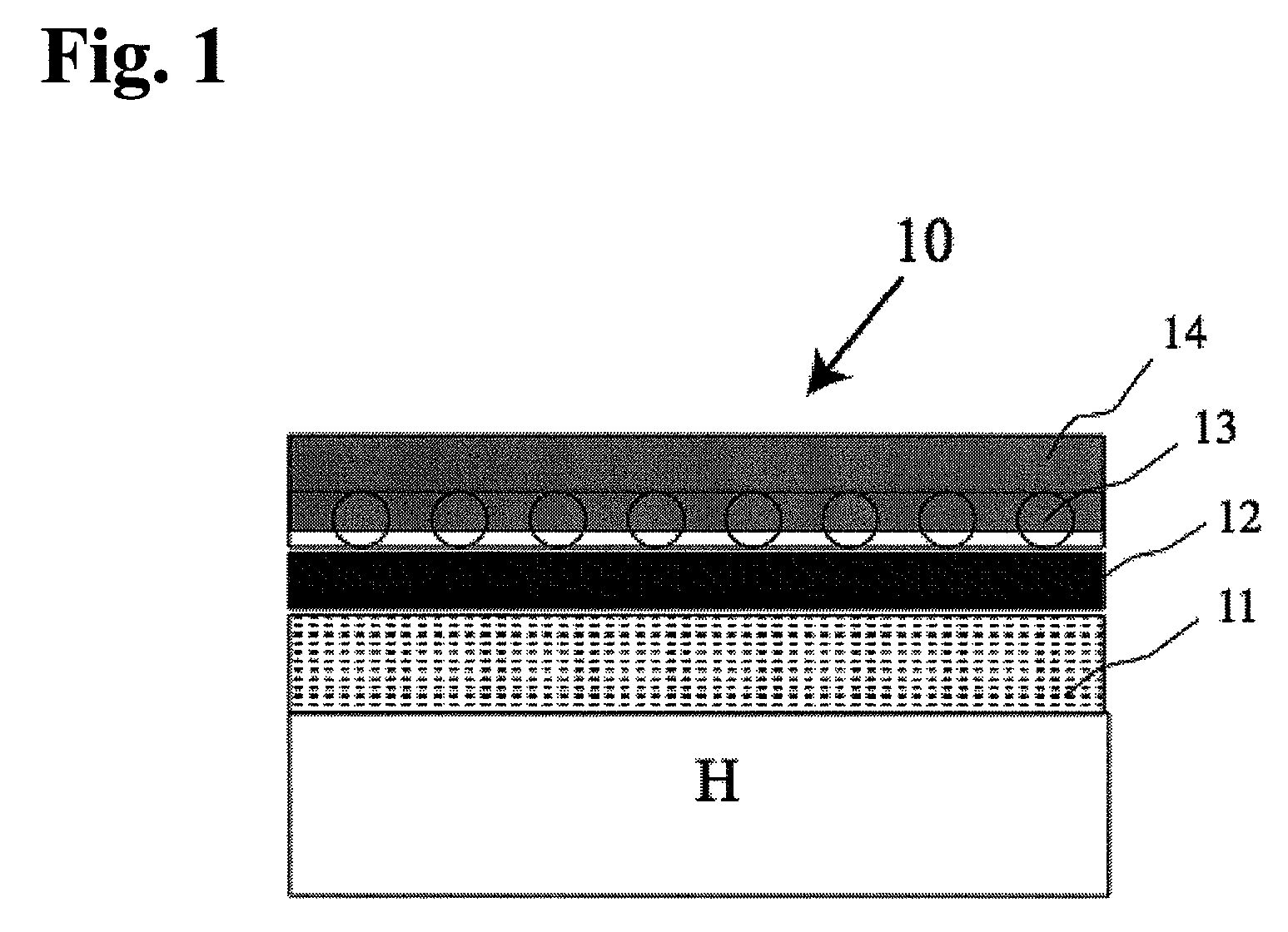

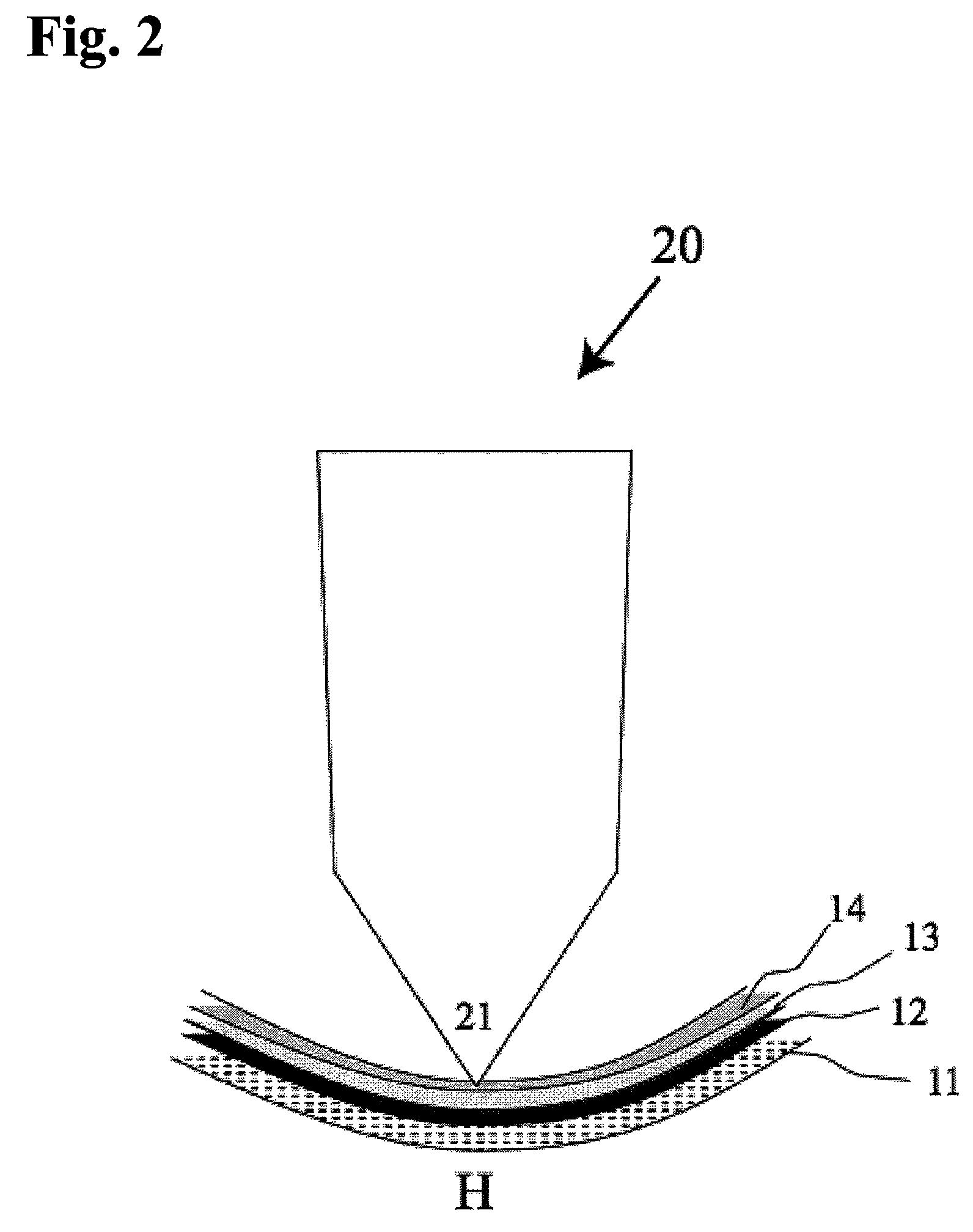

Chemical Resistant Glove Having Cut Resistant Properties

InactiveUS20090077713A1Low shear strengthReduces cut stress intensityGlovesThin material handlingLatex gloveChemical treatment

A cut resistant chemical handling glove that is flexible and lightweight comprises a cured, liquid-impervious polymeric latex shell. A tacky acrylic adhesive with low shear strength can be used. A cut resistant liner is slipped on the tacky adhesive coating and is infiltrated with a polymeric latex coating and cured to integrally attach the cut resistant liner with the cured polymeric coating. When the latex glove is worn on a hand and a cutting edge, such as a knife edge, contacts the glove, a crease is formed due to slip at the tacky adhesive-cut resistant liner interface creating a geometry that reduces cut stress intensity at the knife-edge thereby increasing the cut resistance of the glove. Processes for making and using these gloves are also described.

Owner:ANSELL HEALTHCARE PRODS

Rubber/Short Fiber Master Batch and Production Method Thereof and Pneumatic Tires Using Such Master Batch

A rubber / short fiber master batch obtained by stirring and mixing an aqueous dispersion of short fibers having an average diameter of less than 0.5 μm and a rubber latex, followed by removing the water from the mixture and a practical production method of the same and a pneumatic tire using the master batch.

Owner:YOKOHAMA RUBBER CO LTD

Clay rubber nano-composite material used for cover layer of conveyor belt and preparation method thereof

The invention relates to a clay rubber nano-composite material used for the cover layer of a conveyor belt and a preparation method thereof. The material can be used to support the use of various large carrying capacity and long distance conveyors, and is widely used in metallurgy, mining, ports and other heavy industries. The preparation method of the clay rubber nano-composite material used forthe cover layer of a conveyor belt comprises: taking nano-clay and natural rubber to prepare nano-clay / natural rubber nano-composite masterbatch through an emulsion flocculation method, then adding synthetic rubber for plasticating, and then adding zinc oxide, stearic acid, an age resister, a coupling agent, and a reinforcing agent in order for first mixing, and adding sulphur as well as an accelerator for second mixing so as to obtain the product. The cover rubber of a conveyor belt manufactured with the clay rubber nano-composite material, and can have improved tensile strength, tearing resistance and shearing resistance, so that the service life of the conveyor belt can be prolonged. In the preparation process, the employment of a small amount of nano-clay and a lot of carbon black together to serve as a filling system can have an enhancing effect, and besides, the lamellar structure of the nano-clay can effectively inhibit gas and heat transfer, thus improving the thermo-oxidativeaging resistance, and making the conveyor belt difficult to age when used in an open-air environment for a long time.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

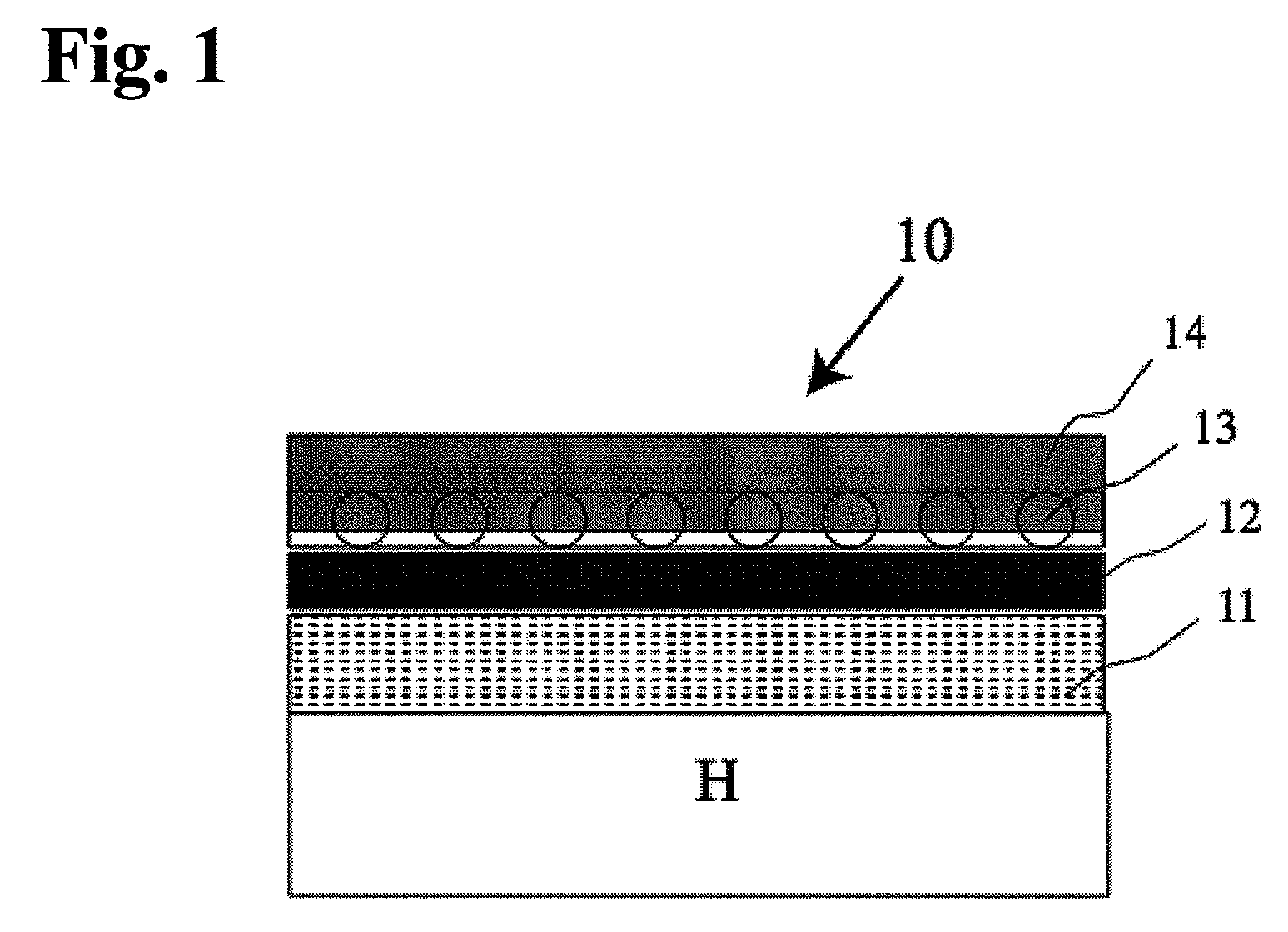

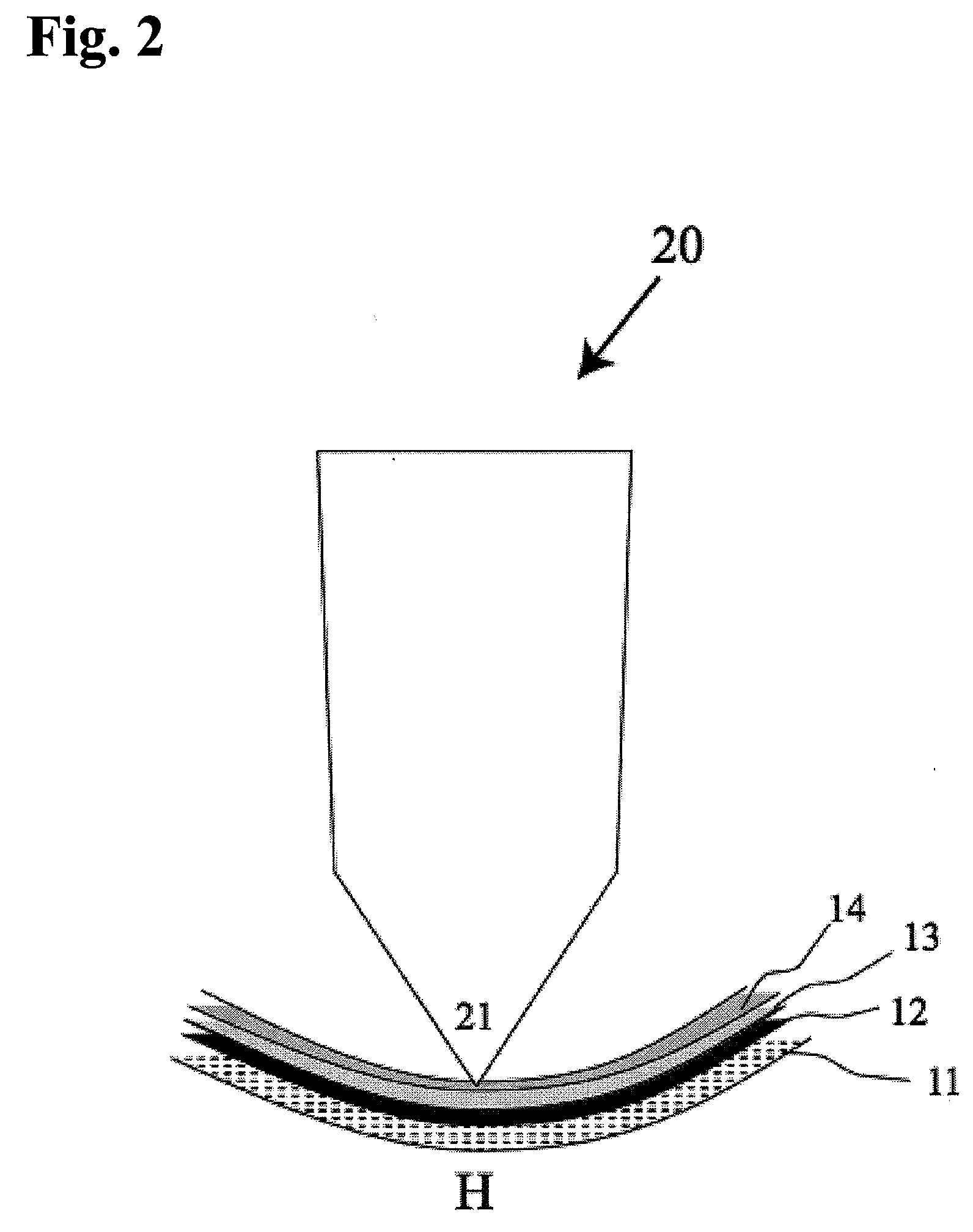

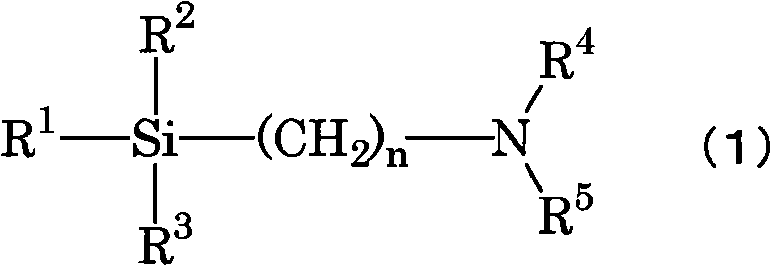

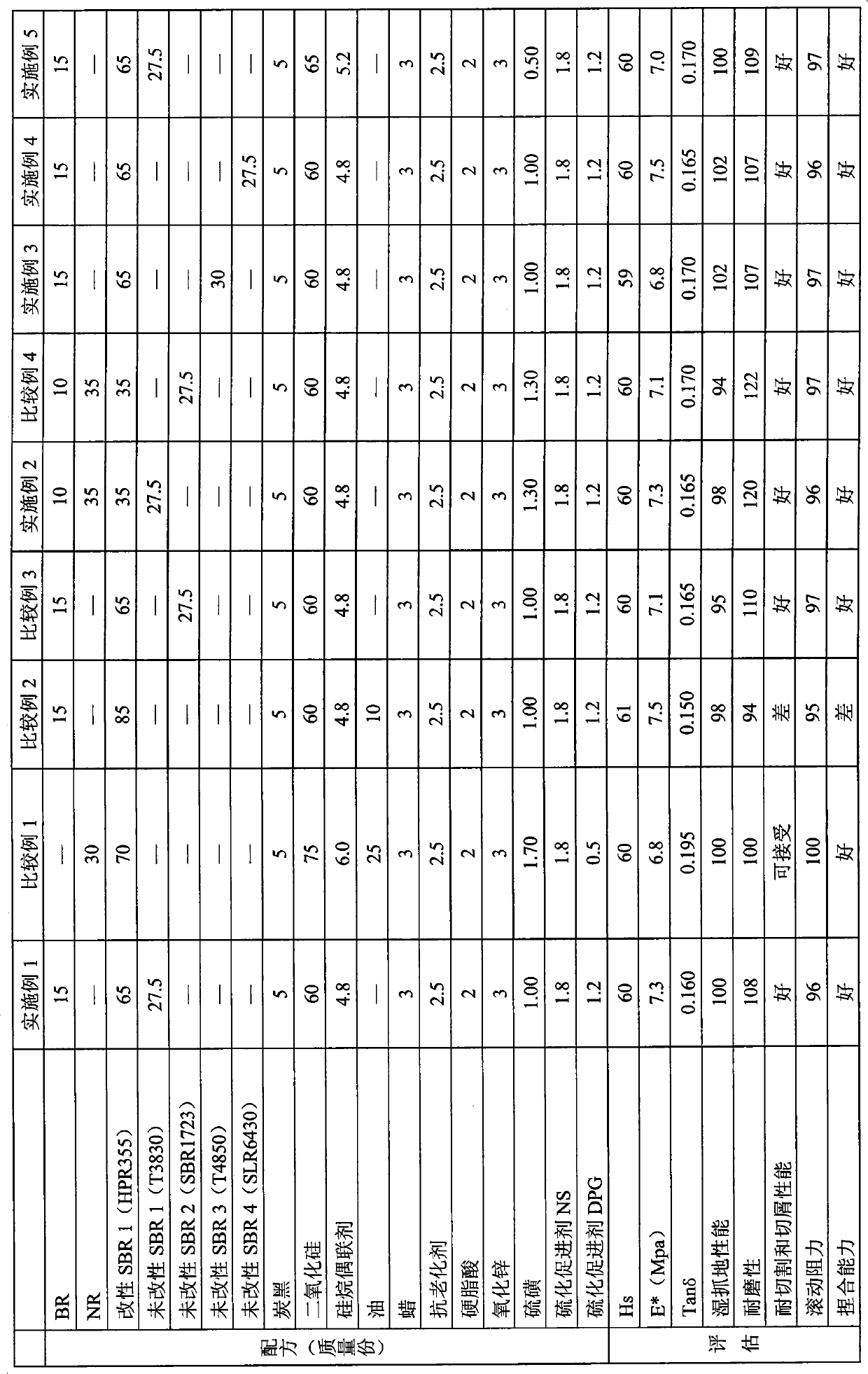

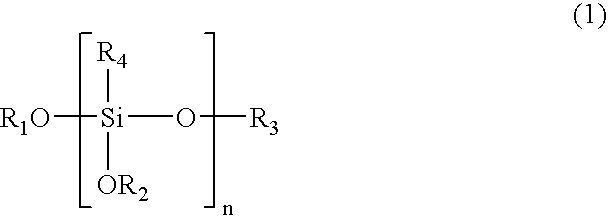

Tire rubber composition and pneumatic tire

ActiveCN102199316AImprove gripGood balance of abrasion resistanceSpecial tyresRolling resistance optimizationRolling resistanceSulfur

The present invention aims to provide a tire rubber composition that achieves a good balance of grip performance (especially, wet grip performance), abrasion resistance, cut and chip resistance, low rolling resistance, and kneadability, and a pneumatic tire using the same. The composition comprise: a rubber component including a styrene-butadiene rubber modified by a compound of formula (1): and a non-modified styrene-butadiene rubber; a filler including silica, the filler being in an amount of 80 parts by mass or less per 100 parts by mass of the rubber component; and sulfur in an amount of 0.5-1.5 parts by mass per 100 parts by mass of the rubber component, the modified styrene-butadiene rubber having a bound styrene content of 20-40% by mass and a vinyl content of 30-65% by mass, and the non-modified styrene-butadiene rubber having a bound styrene content of 25-45% by mass and a vinyl content of 10-50% by mass.

Owner:SUMITOMO RUBBER IND LTD

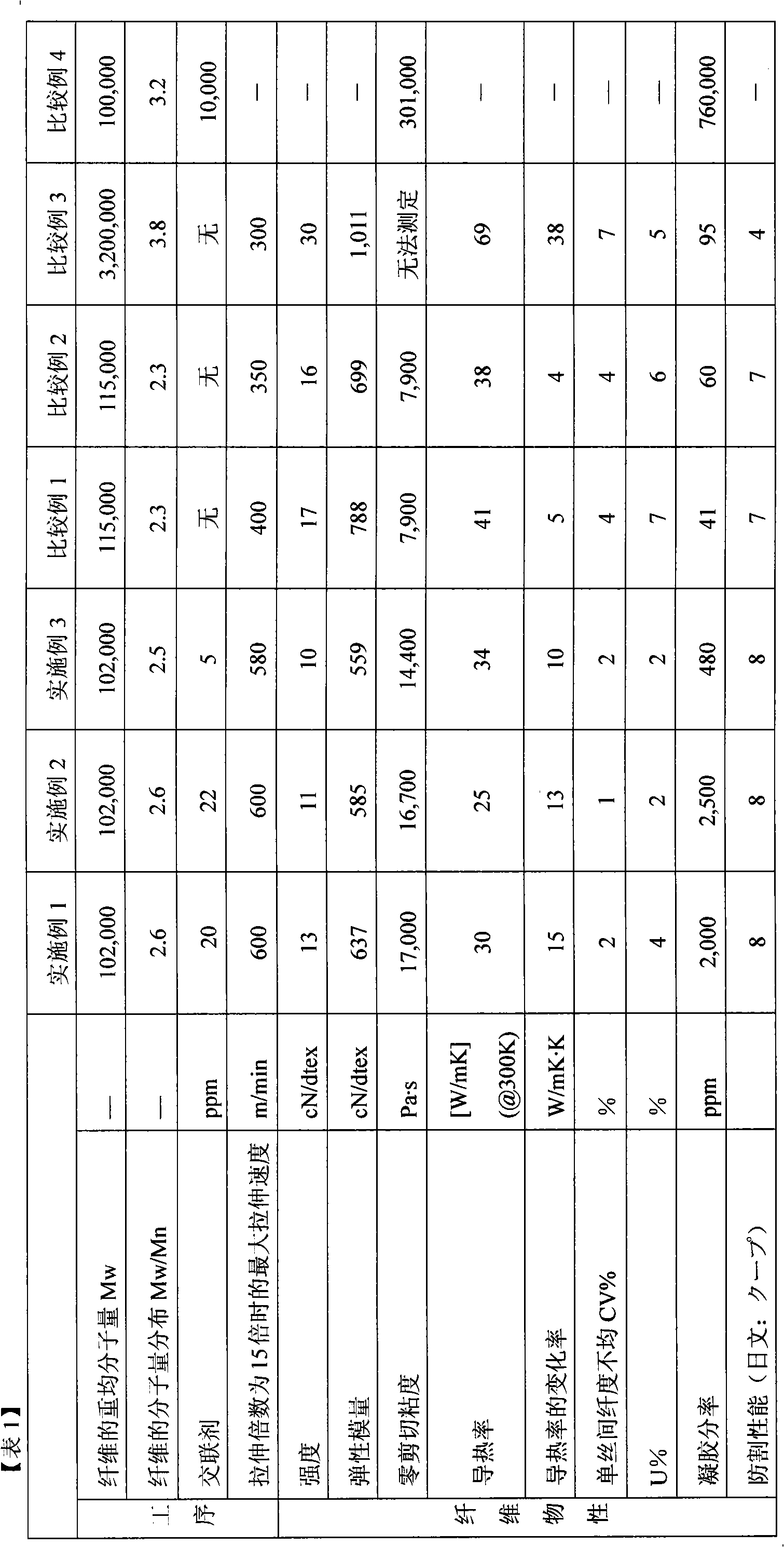

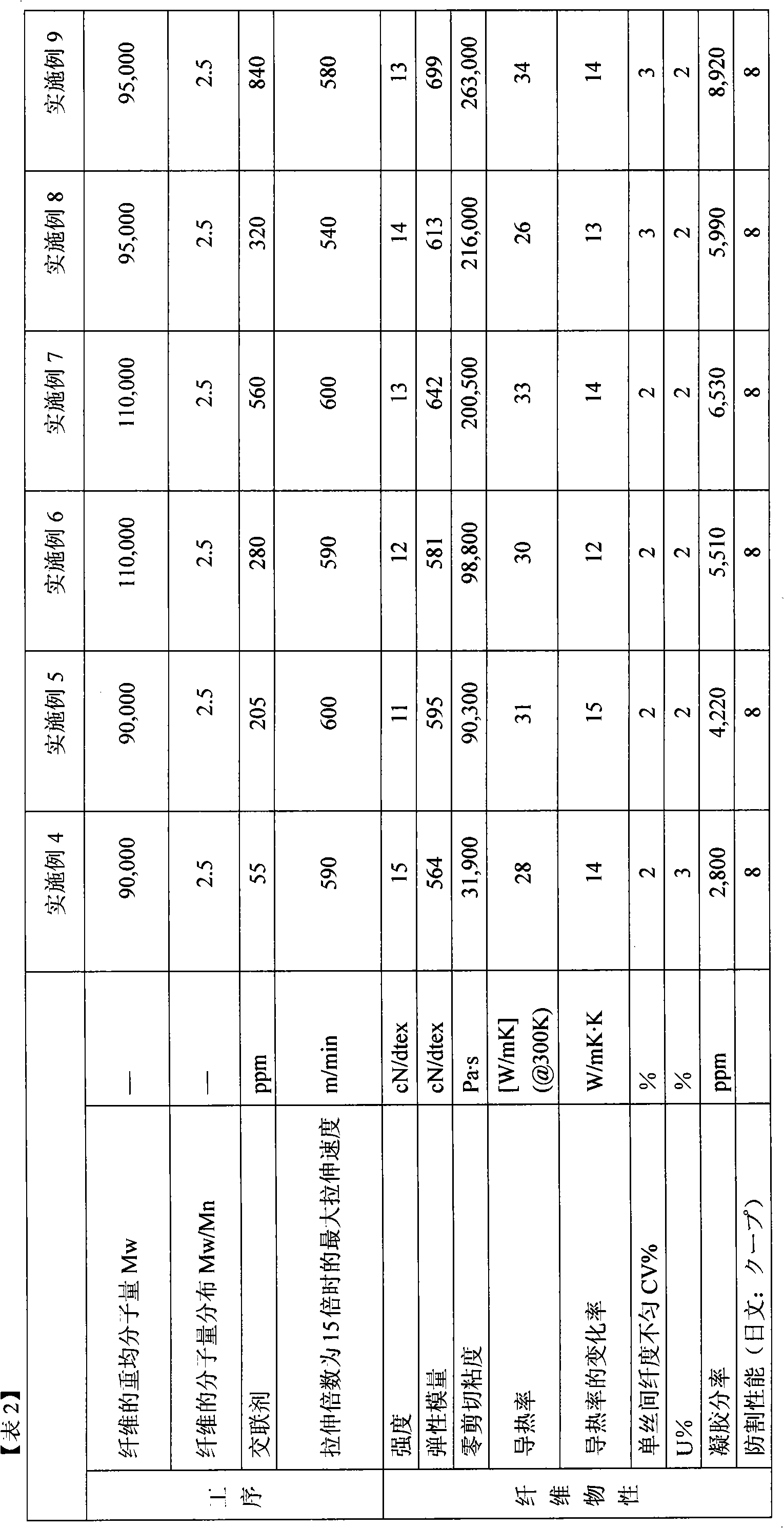

Highly functional polyethylene fiber, woven/knitted fabric comprising same, and glove thereof

ActiveCN102037169AImprove insulation effectImprove cut resistanceGlovesWoven fabricsYarnMolten state

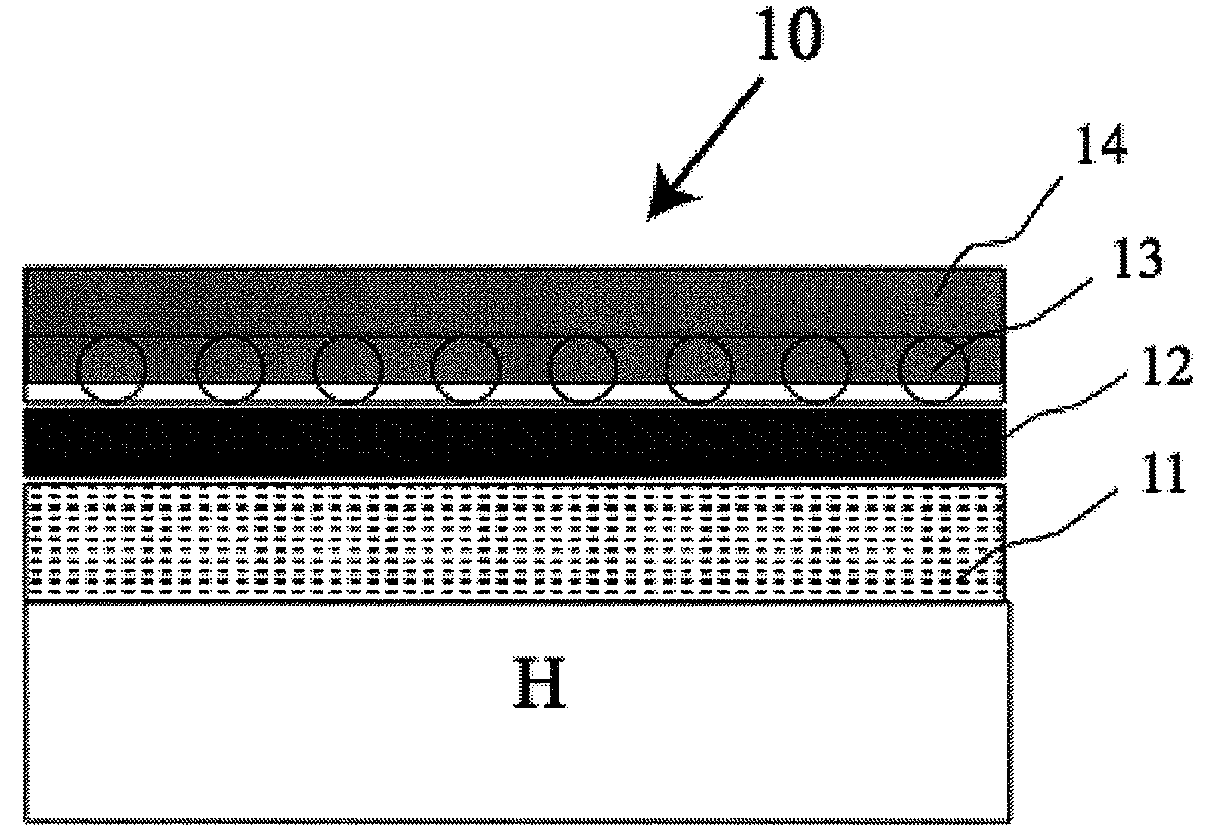

A highly functional polyethylene fiber which combines high heat-insulating properties with cut resistance and is excellent in productivity and suitability for passing through post-processing; and a coated elastic yarn including the fiber, a woven / knitted fabric, and a glove. The polyethylene fiber comprises polyethylene which is constituted of repeating units of substantially ethylene and which, in the fiber state, has a weight-average molecular weight (Mw) of 50,000-300,000 and a ratio of the weight-average molecular weight to the number-average molecular weight (Mn), Mw / Mn, of 4.0 or lower. The polyethylene fiber has a gel content of 100-10,000 ppm or a zero-shear viscosity in a molten state at 190 C of 8,000-300,000 (Pas).

Owner:TOYOBO MC CORP

Plasticizing system for a rubber composition

ActiveUS8324310B2Excellent abrasion resistanceImprove cut resistanceIn situ pavingsSpecial tyresElastomerPolymer science

Plasticizing system which can be used for the plasticizing of a diene rubber composition, wherein it is based on an MES or TDAE oil and on a resin formed of terpene / vinylaromatic copolymer, in particular copolymer of limonene and of stirene. Rubber composition exhibiting an improved abrasion and cut resistance, the composition being based on at least a diene elastomer, a reinforcing filler, a crosslinking system and a plasticizing system comprising between 5 and 35 phr of an MES or TDAE oil and between 5 and 35 phr of such a resin formed of terpene / vinylaromatic copolymer (pce=parts by weight per hundred parts of elastomer). Process for preparing such a composition, use of the composition for the manufacture of a finished article or of a semi-finished product intended for a tire or a tire / motor vehicle connecting system, in particular a tire tread.

Owner:MICHELIN RECH & TECH SA

All-steel truck radical tire tread rubber and tire using it

InactiveCN103254472AVulcanization speed matchingUniform vulcanization rateSpecial tyresVulcanizationTear resistance

The invention relates to an all-steel truck radical tire tread rubber, and also relates to an industrial and mineral all-steel truck radical tire using it. The tread rubber includes 100 parts by weight of a rubber component containing natural rubber or containing natural rubber and styrene-butadiene rubber, a filler containing 15-60 parts by weight of reinforcing carbon black and 8-25 parts by weight of high-dispersibility white carbon black, 1-4 parts by weight of a silane coupling agent, 3-9 parts by weight of an activator, 1-6 parts by weight of an antioxidant, 0.5-2.5 parts by weight of a promoter, 1-2 parts by weight of a processing assistant, 0.5-2.5 parts by weight of common sulfur, 1-6 parts by weight of an anti-tear assistant, and 1-3.5 parts by weight of a phenolic tackifying resin. The industrial and mineral all-steel truck radical tire made through using the tire tread rubber well solves a vulcanization speed coupling problem of the industrial and mineral all-steel truck radical tire tread rubber with the rubber compounds of other parts of the tire, and has the advantages of good wear resistance, good fatigue resistance, good tear resistance and good cutting resistance.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND +1

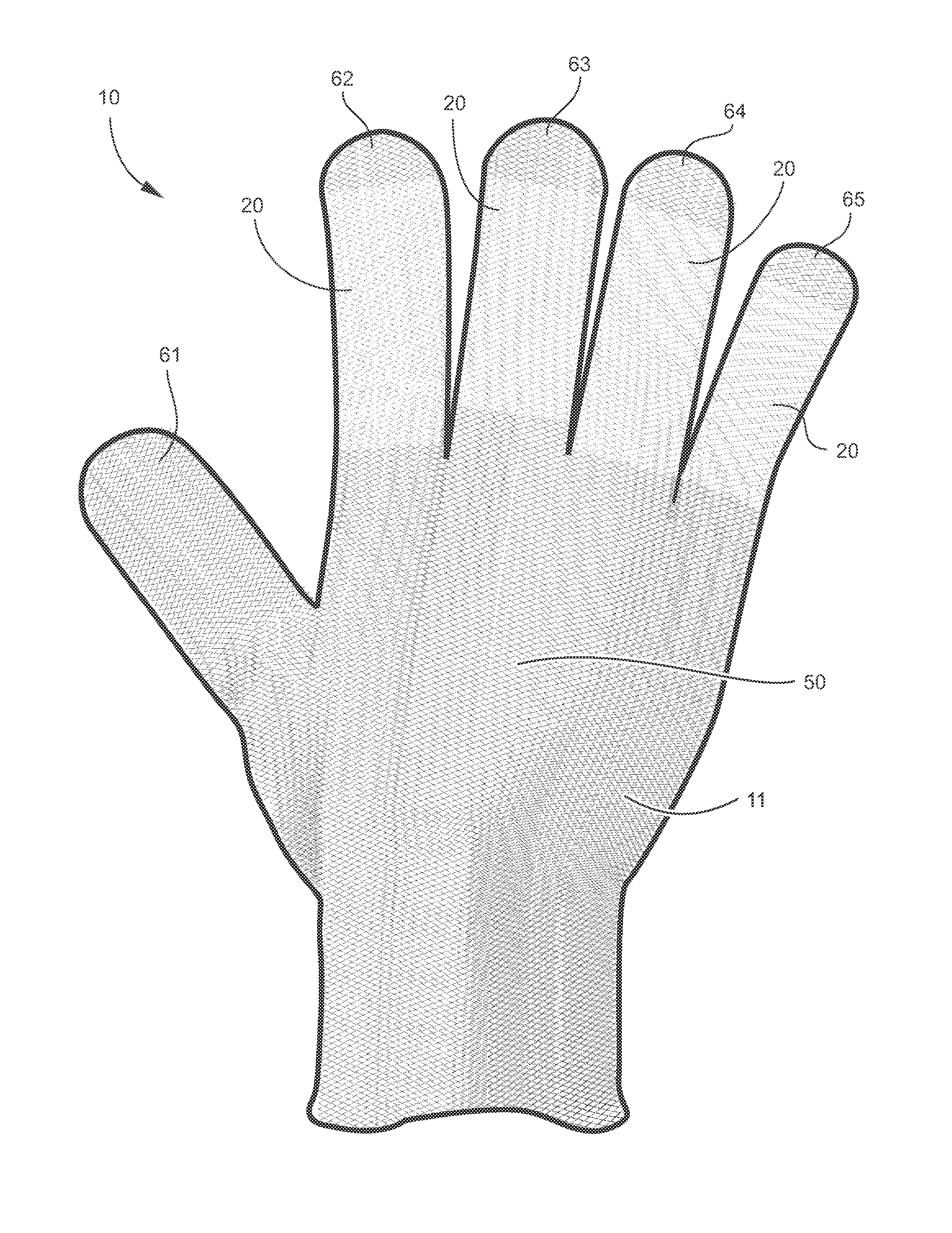

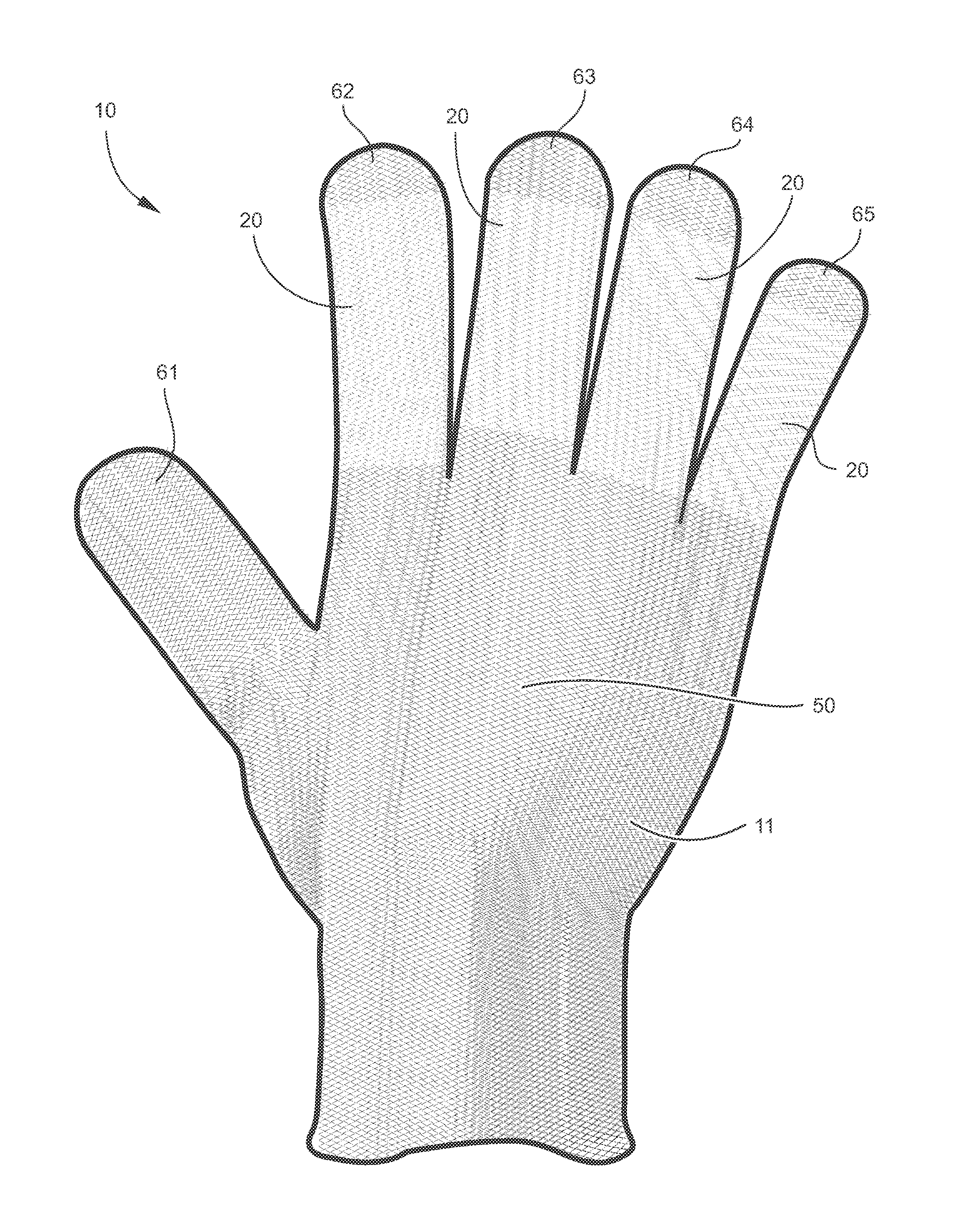

Protective glove with enhanced exterior sections

ActiveUS20140283559A1Improve cut resistanceImprove the immunityOrnamental textile articlesGlovesYarnEngineering

A protective glove includes a primary yarn that forms the palm, thumb and finger sections of the glove. The primary yarn has an interior surface forming the interior surface of the glove, and an exterior surface forming the exterior surface of the glove. A plaiting yarn is plaited to portions of the exterior surface of the primary yarn to form a plurality of enhanced sections on the exterior surface of the glove. The enhanced sections having at least one substantially enhanced physical characteristic in relation to the primary layer, such as increased cut resistance,

Owner:WORLD FIBERS

Preparation method of graphene and ultrahigh-molecular-weight polyethylene composite fiber

ActiveCN108315833AHigh strengthImproves UV resistanceMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberPolymer science

The invention provides a preparation method of a graphene and ultrahigh-molecular-weight polyethylene composite fiber. The preparation method comprises the following steps: S1: dispersing ultrahigh-molecular-weight polyethylene resin and a filler into a solvent by adopting a blending method to form a uniform resin dispersion solution; S2: adding graphene powder into a dispersant, heating the mixture to certain temperature, adding an emulsifier for emulsification, and obtaining a graphene dispersion solution; S3: adding the graphene dispersion solution into the resin dispersion solution, and stirring and heating the mixed solution to obtain a spinning solution; S4: performing spinning, precursor fiber stewing and thermal stretching on the spinning solution, thus obtaining the graphene and ultrahigh-molecular-weight polyethylene composite fiber. According to the preparation method provided by the invention, the intensity of the ultrahigh-molecular-weight polyethylene fiber is enhanced byadding a filling material and graphene into ultrahigh-molecular-weight polyethylene fiber, so that the final intensity is up to 30 to 45 cN / dtex; in addition, the composite fiber further has excellent properties of ultraviolet resistance, cutting resistance and the like.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

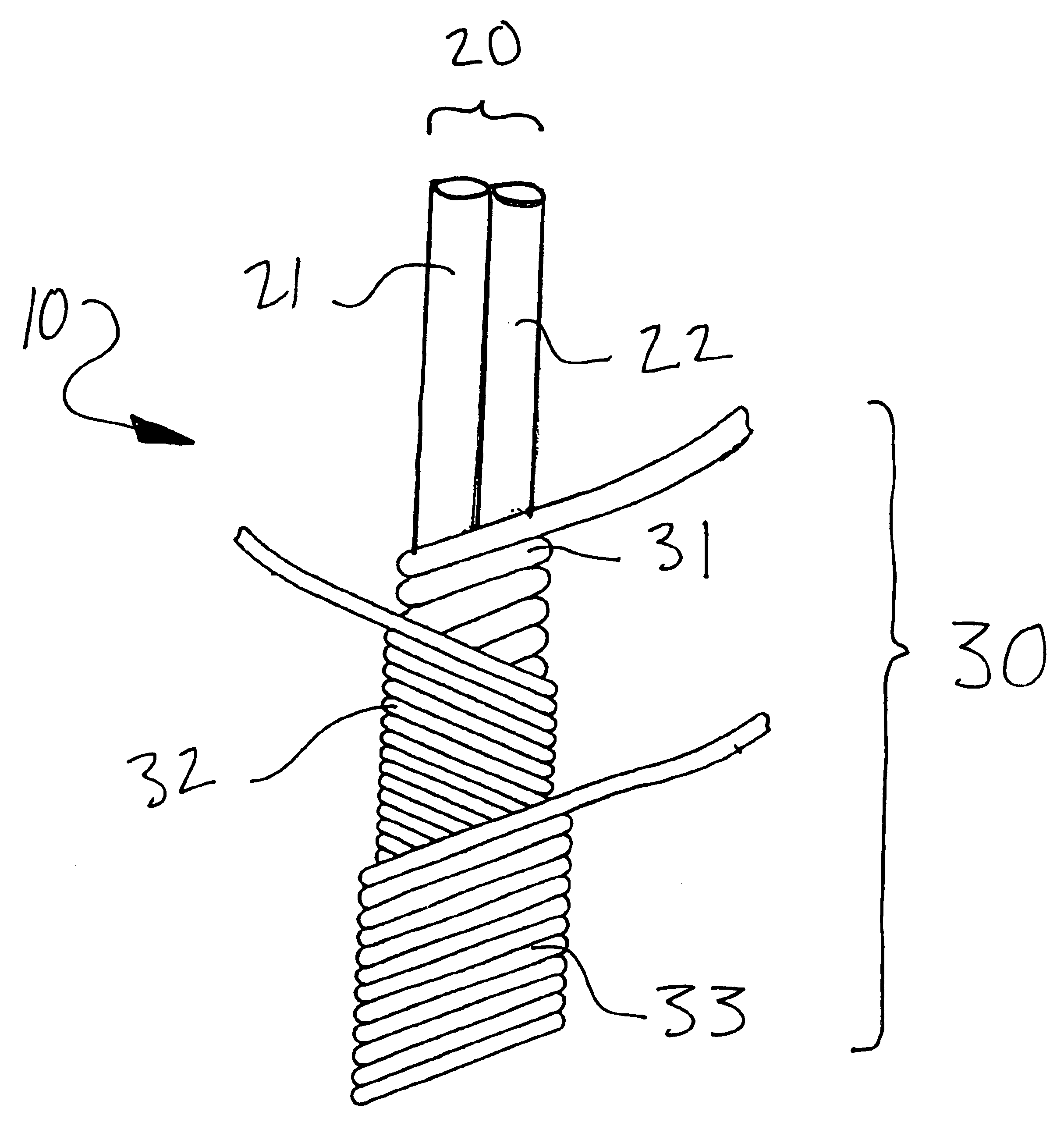

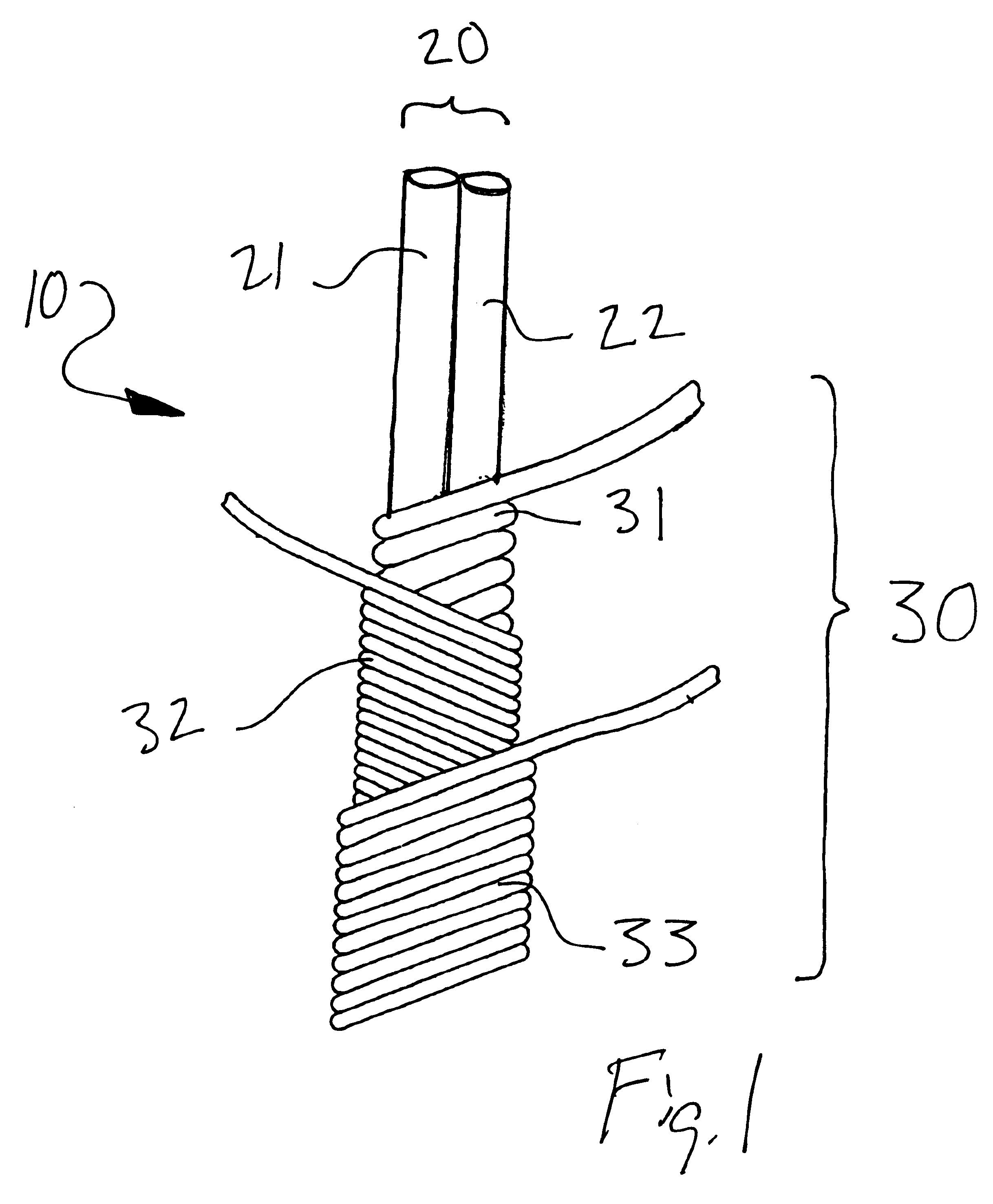

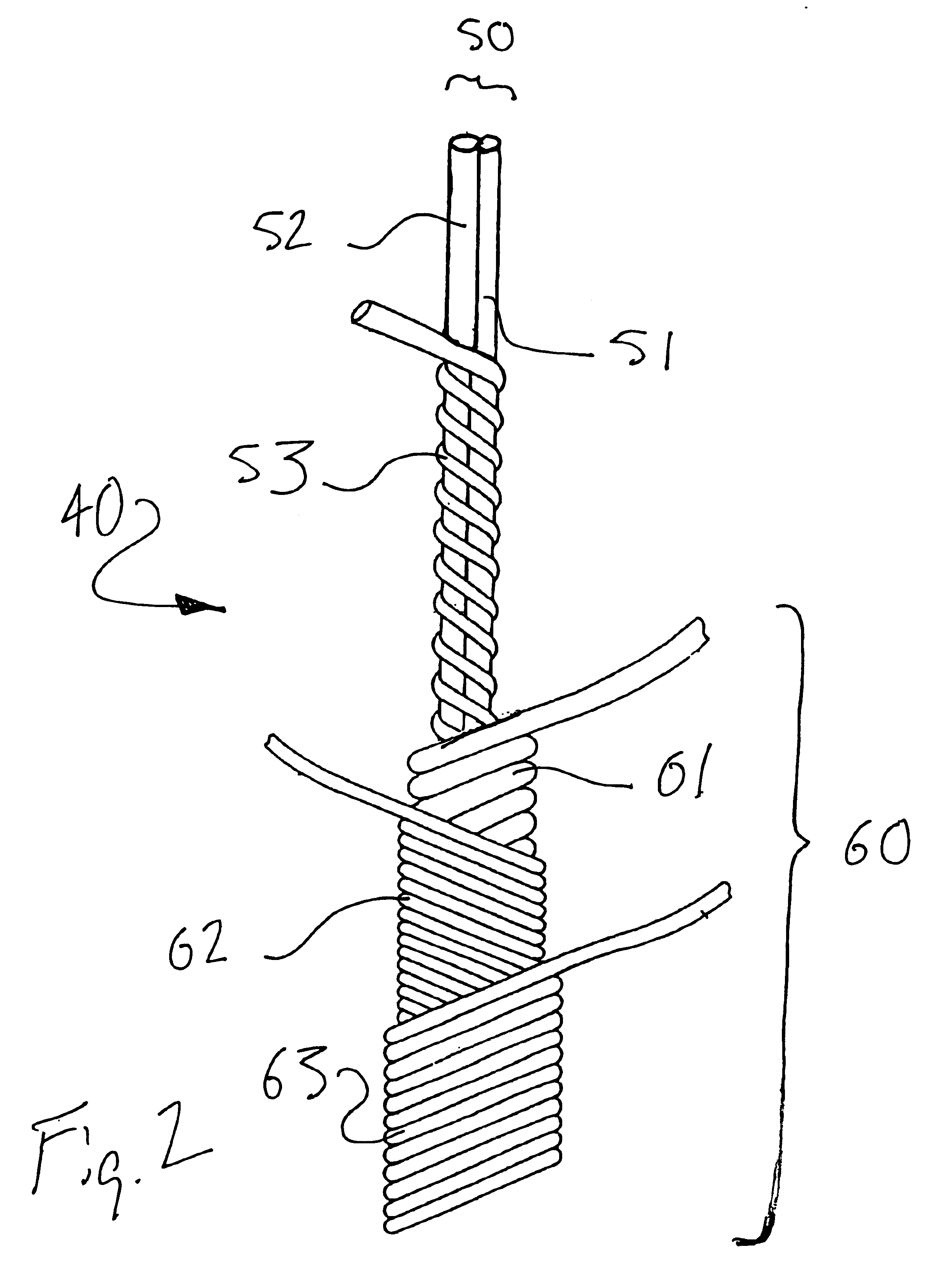

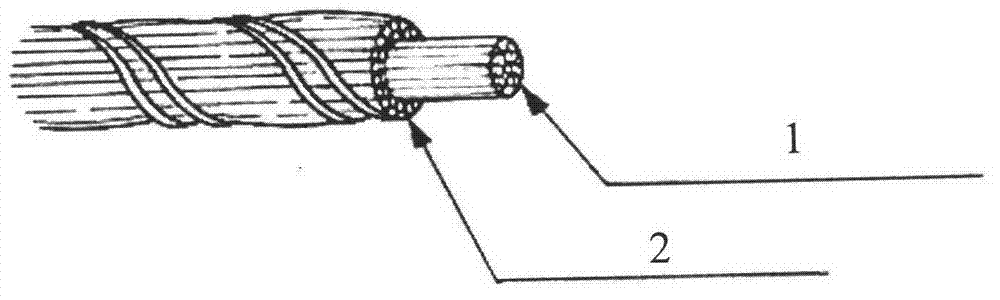

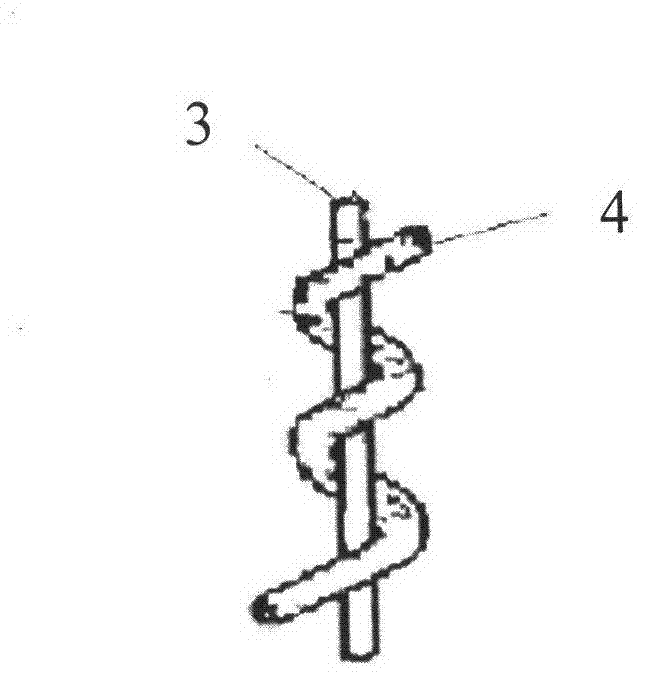

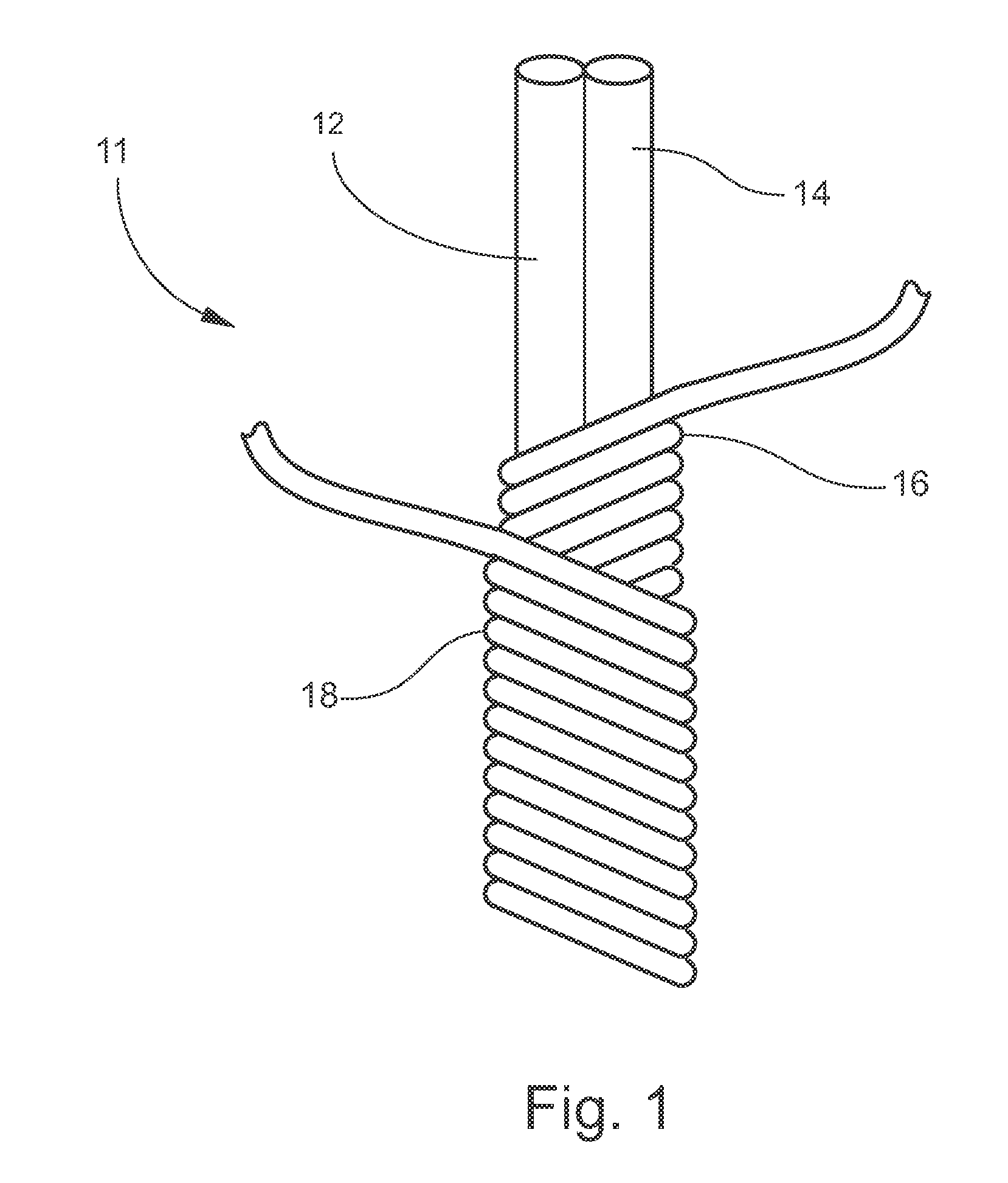

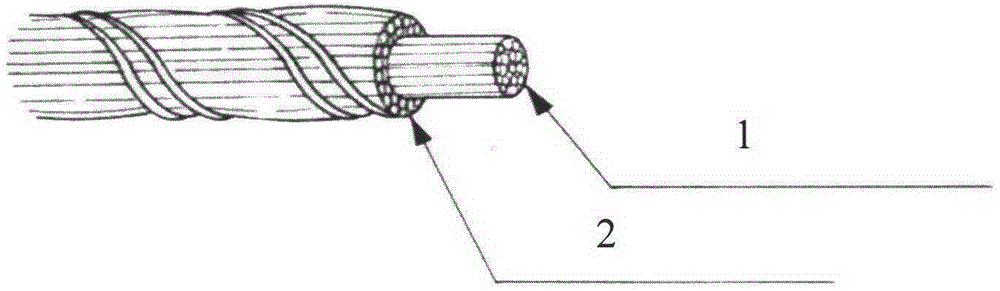

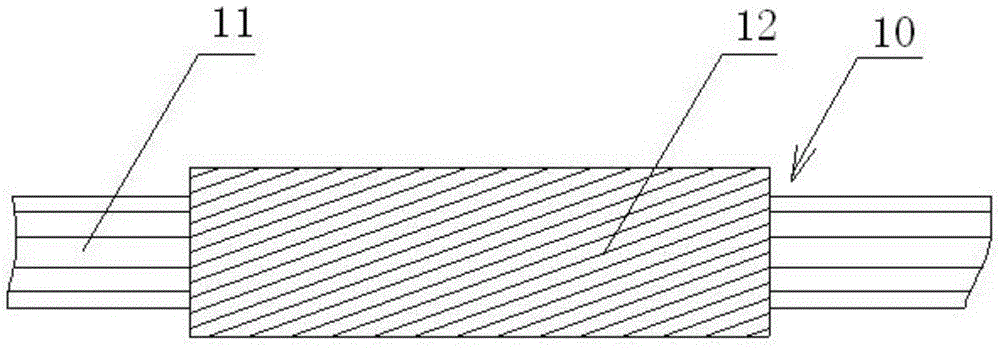

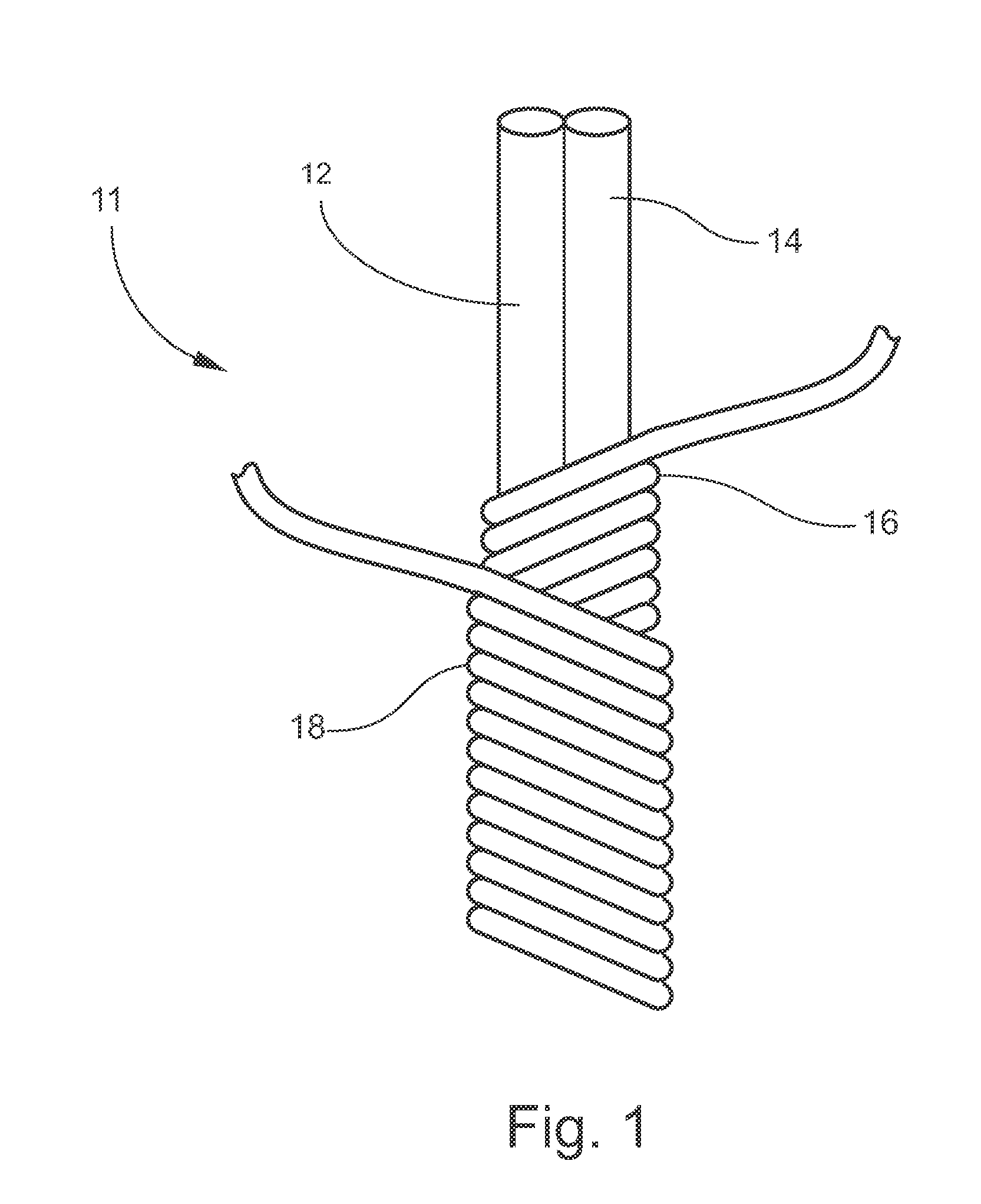

Cutting-resisting yarn

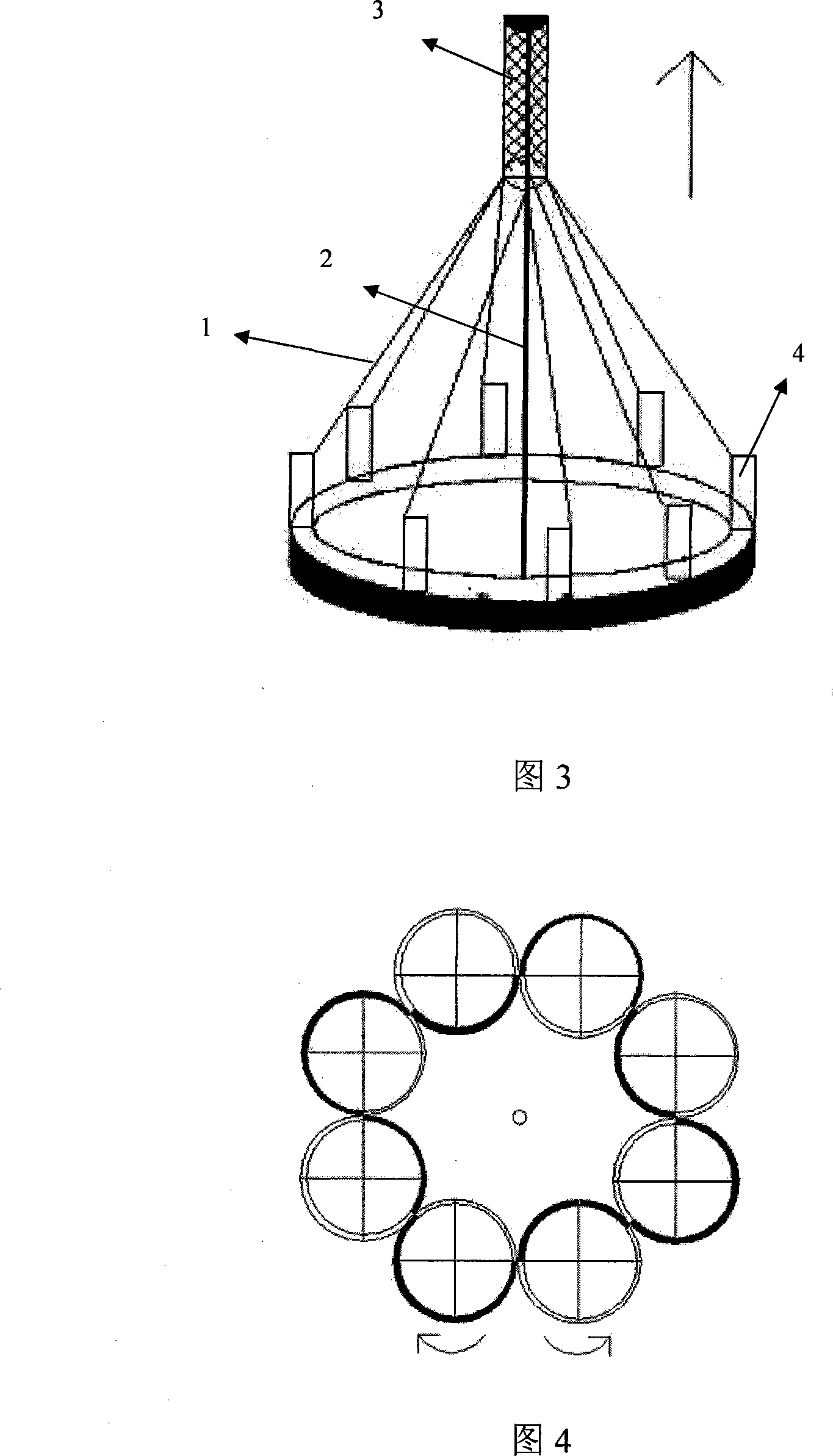

The invention relates to cutting-proof yarn, which is characterized in that the cutting-proof yarn is skin-core composite yarn which is manufacturing through adopting a two-dimensional weaving and molding method, core-spun yarn of the cutting-proof yarn is high strength polyethylene fiber non-twist filament, the fineness is 400-1200 deniers, epiboly yarn of the cutting-proof yarn is aramid fiber filament soft twist yarn, the twisting tension is smaller than or equal to 25twist / 10 centimeter, the fineness is 150-200 deniers, the volume ratio between the core-spun yarn and the epiboly yarn is 0.05-0.5, a two-dimensional weaving and molding method whose braided angle is alpha is adopted to coat the epiboly yarn outside the core-spun yarn evenly, the braided angle alpha is 15-45 degrees, the yarn carriers number of yarn carriers of knitting machine which are used in the two-dimensional weaving and molding method is an even number between 8-16. The cutting-proof yarn of the invention has good cutting resistant property.

Owner:TIANJIN POLYTECHNIC UNIV

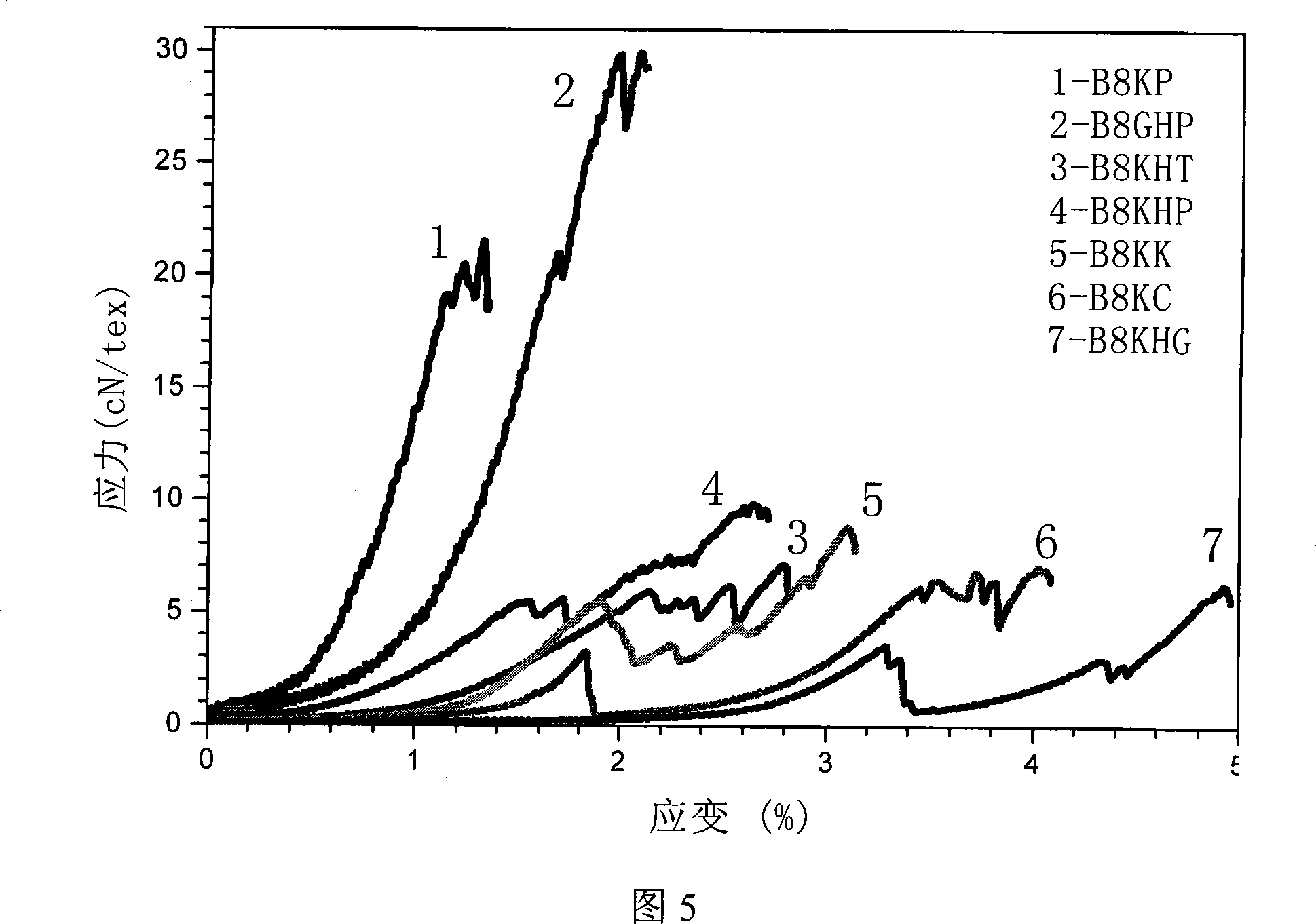

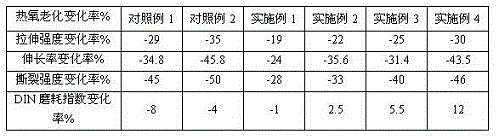

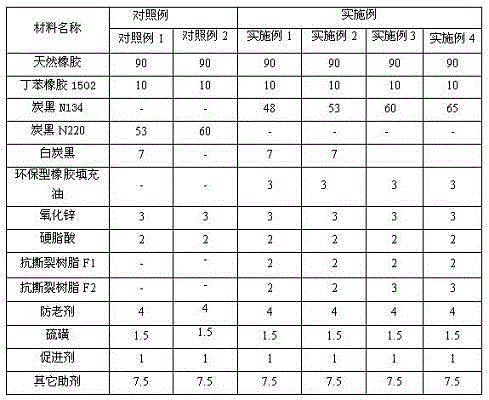

Articulated truck tire tread rubber composition and preparation method thereof

InactiveCN104356442AImprove wear resistanceImprove cut resistanceSpecial tyresSulfenamideStearic acid

The invention relates to an articulated truck tire tread rubber composition and a preparation method thereof, belonging to the field of tire production. The articulated truck tire tread rubber composition is composed of the following components in parts by weight: 75-100 parts of natural rubber, 0-25 parts of styrene-butadiene rubber, 50-70 parts of small-particle-size highly-structure-reinforced carbon black, 0-15 parts of silica white, 0-10 parts of tear-resistant resin, 0-3 parts of protective wax, 0-4 parts of N-(1,3-dimethyl butyl)-N'-phenyl-p-phenylenediamine, 0-1 part of acetone-diphenylamine high-temperature condensate, 0-3 parts of stearic acid, 0-10 parts of environment-friendly oil, 0-5 parts of phenol formaldehyde resin tackifier, 0-5 parts of zinc oxide, 0-1 part of anti-reversion agent WK-901, 0-5 parts of dispersing agent, 0-2.5 parts of sulfur and 0.5-2.5 parts of N-cyclohexyl-2-benzothiazole sulfenamide. The articulated truck tire tread rubber composition has the advantages of excellent wear resistance, excellent cutting resistance and excellent thermo-oxidative aging resistance, and can adapt to the operating requirements of high wear resistance, high cutting resistance and excellent thermo-oxidative aging resistance for the articulated truck tire tread rubber.

Owner:TRIANGLE TIRE

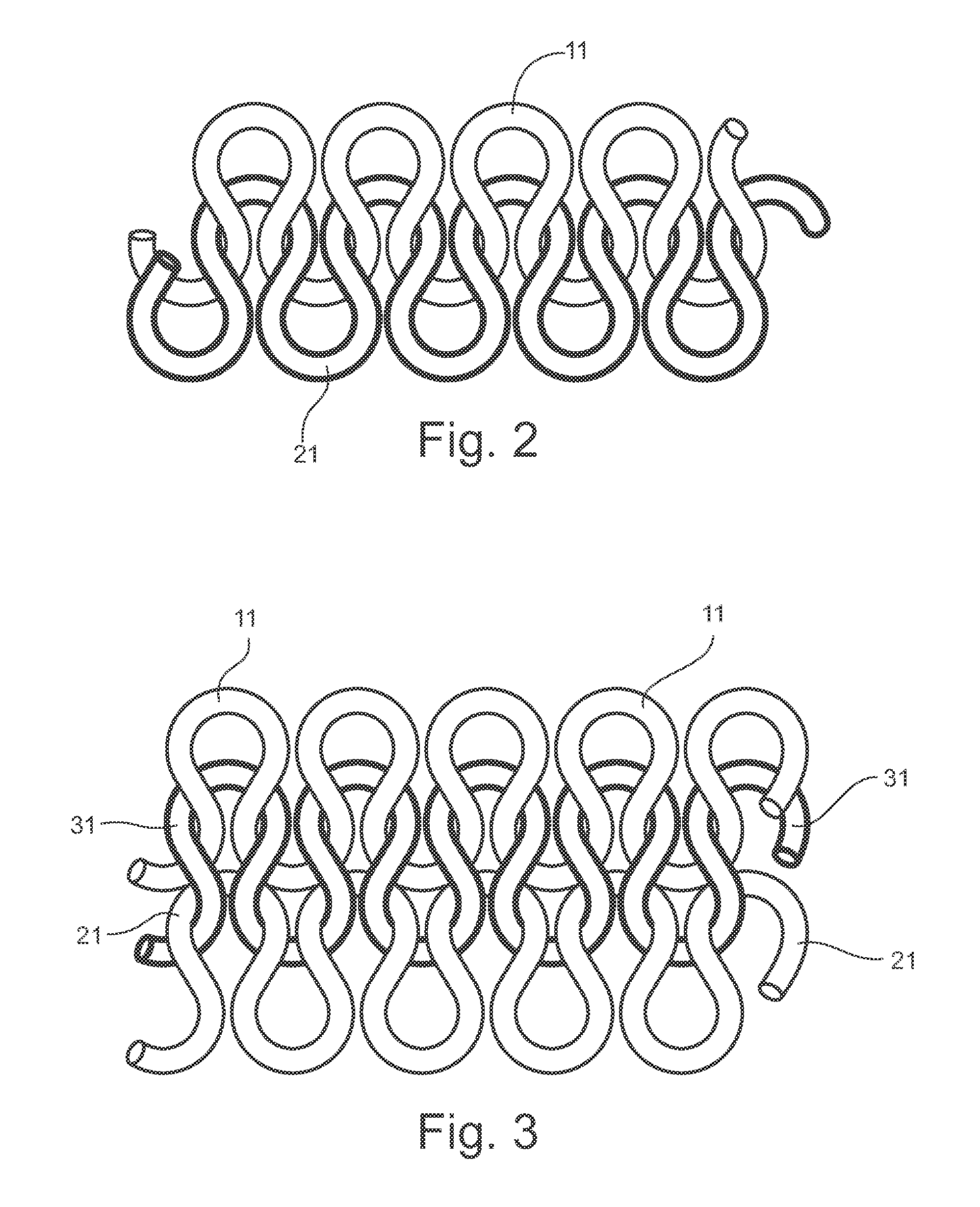

High-performance core spun yarn and application thereof

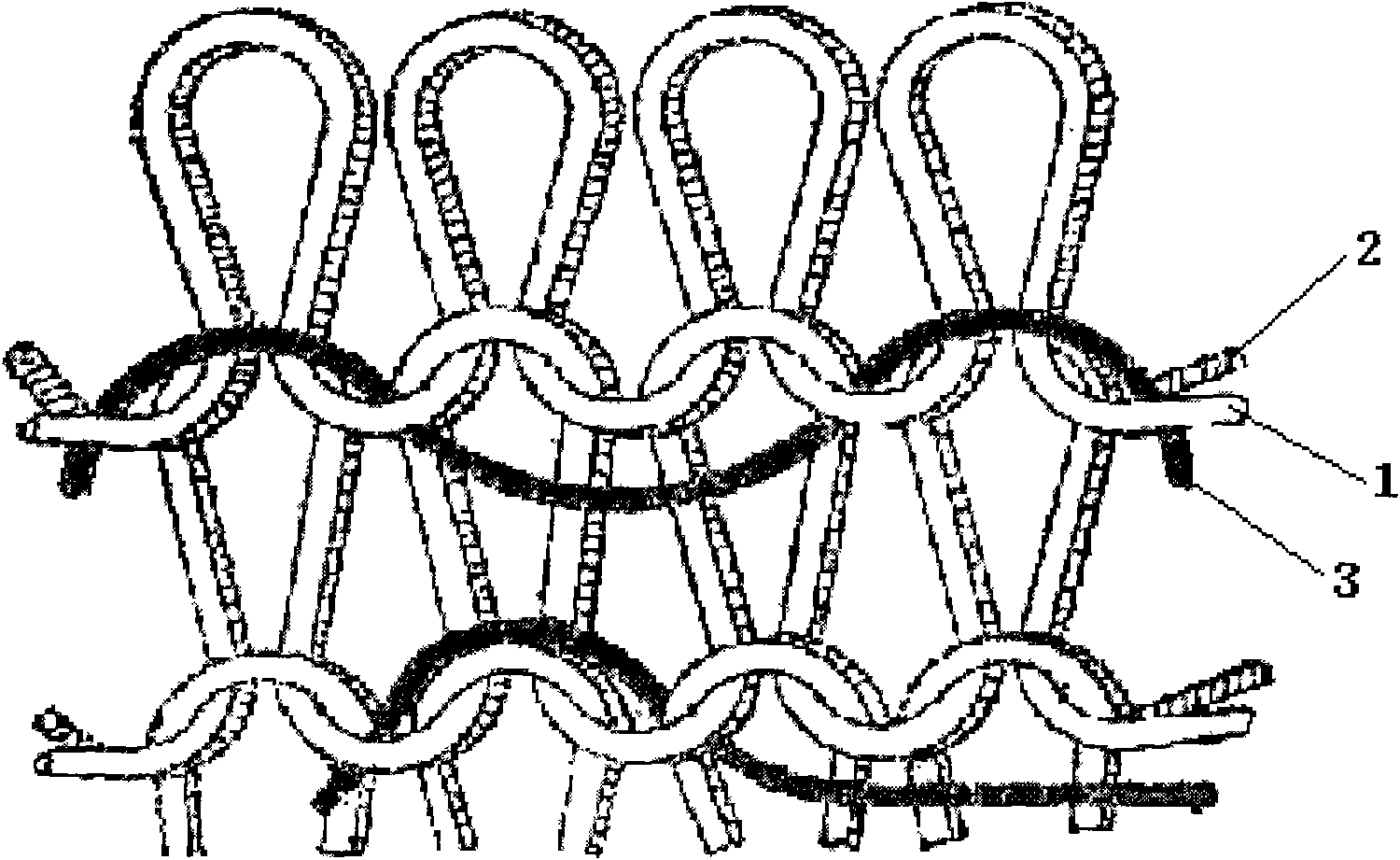

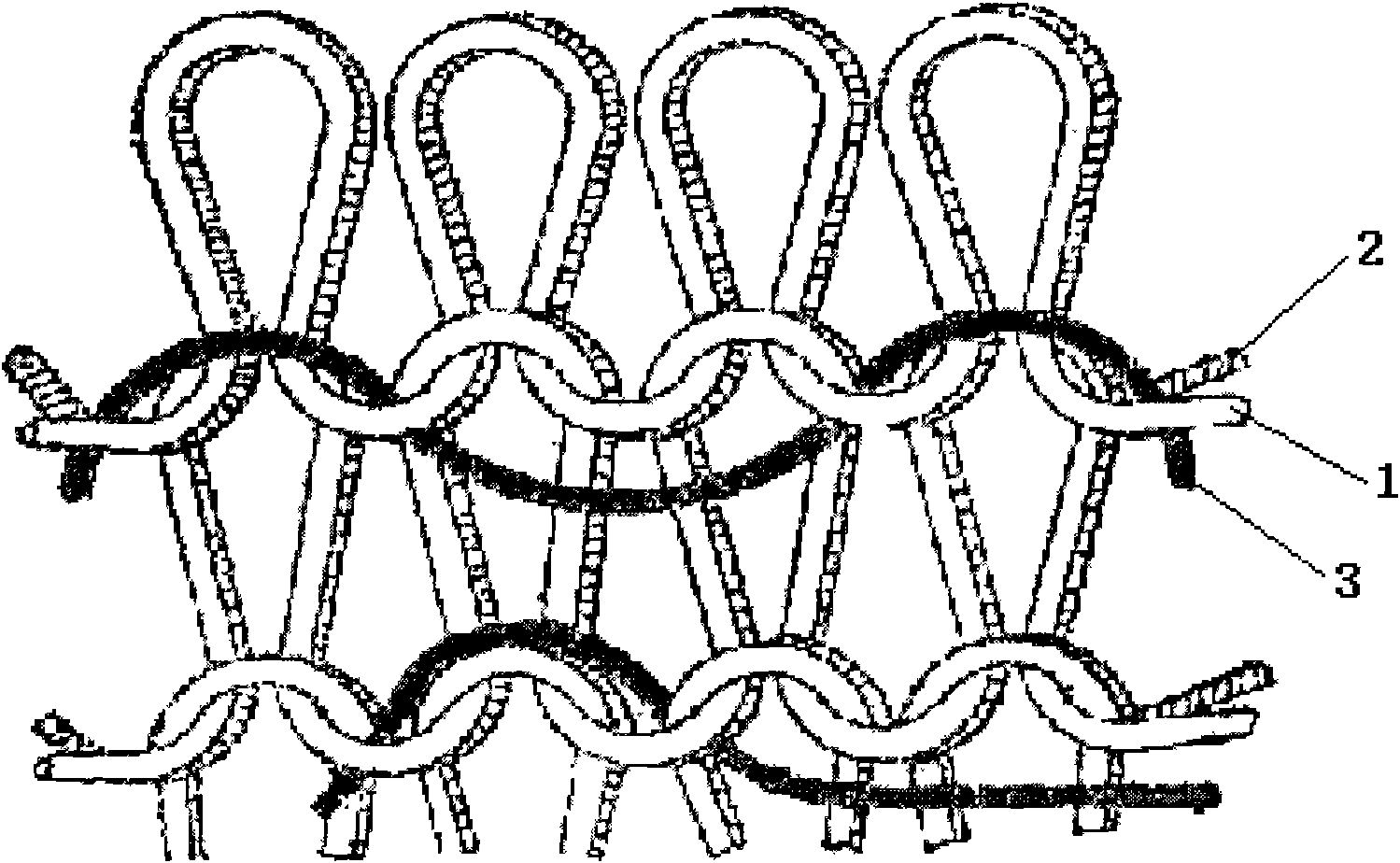

InactiveCN104452007AImprove cut resistanceExtended service lifeWeft knittingWoven fabricsEngineeringMetal

The invention discloses a high-performance core spun yarn. The high-performance core spun yarn comprises an outer layer fiber and a core fiber wrapped by the core spinning technology. The core fiber includes one or more of a filament yarn, a staple fiber yarn or a wrap yarn made of a glass, basalt or metal material. The outer layer fiber refers to a single or mixed short fiber. The invention further discloses application of the high-performance core spun yarn to cutting-resisting fabric and an additional function, namely visually displaying of service life, of the core spun yarn. The high-performance core spun yarn has the advantages that cutting resistance is excellent, woven fabric is comfortable to wear, protection product users in danger environments can work comfortably and freely, and product service life is prolonged obviously; meanwhile, the product service life can be more visual and visible, so that safety and working efficiency of the users are improved greatly.

Owner:CHANGZHOU KEXU TEXTILE CO LTD

Cutting-resistant ultra high molecular weight polyethylene fiber, preparation method and application thereof

ActiveCN106350882AImprove cut resistanceExcellent processabilitySpinnerette packsWet spinning methodsFiberMohs scale of mineral hardness

The invention relates to cutting-resistant ultra high molecular weight polyethylene fiber, a preparation method and application thereof. The cutting-resistant ultra high molecular weight polyethylene fiber is endless tow or / and short fiber in morphology; the matrix of the polyethylene fiber comprises rodlike particles; the Moh's hardness of each rodlike particle is of grade 3 and above (one with high hardness is preferred); the length-diameter ratio of each rodlike particle is greater than or equal to 2 micrometers; the diameter of each rodlike particle is smaller than 30 micrometers. By adopting the cutting-resistant ultra high molecular weight polyethylene fiber, the cutting resistance of high molecular weight polyethylene fiber and a fabric of the high molecular weight polyethylene fiber can be improved, the fiber has post processing properties prior to those of conventional cutting-resistant fiber of a same grade and fabrics of the conventional cutting-resistant fiber, and the cost can be lowered.

Owner:CHANGSHU SUPERFIBER

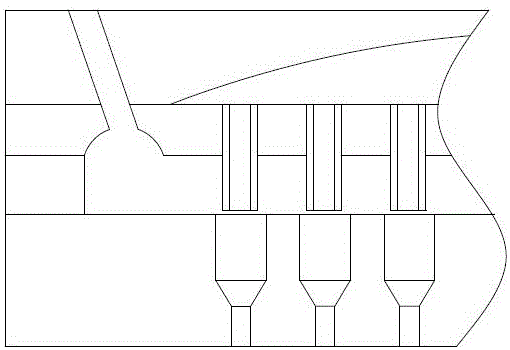

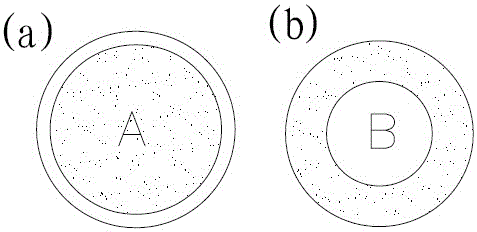

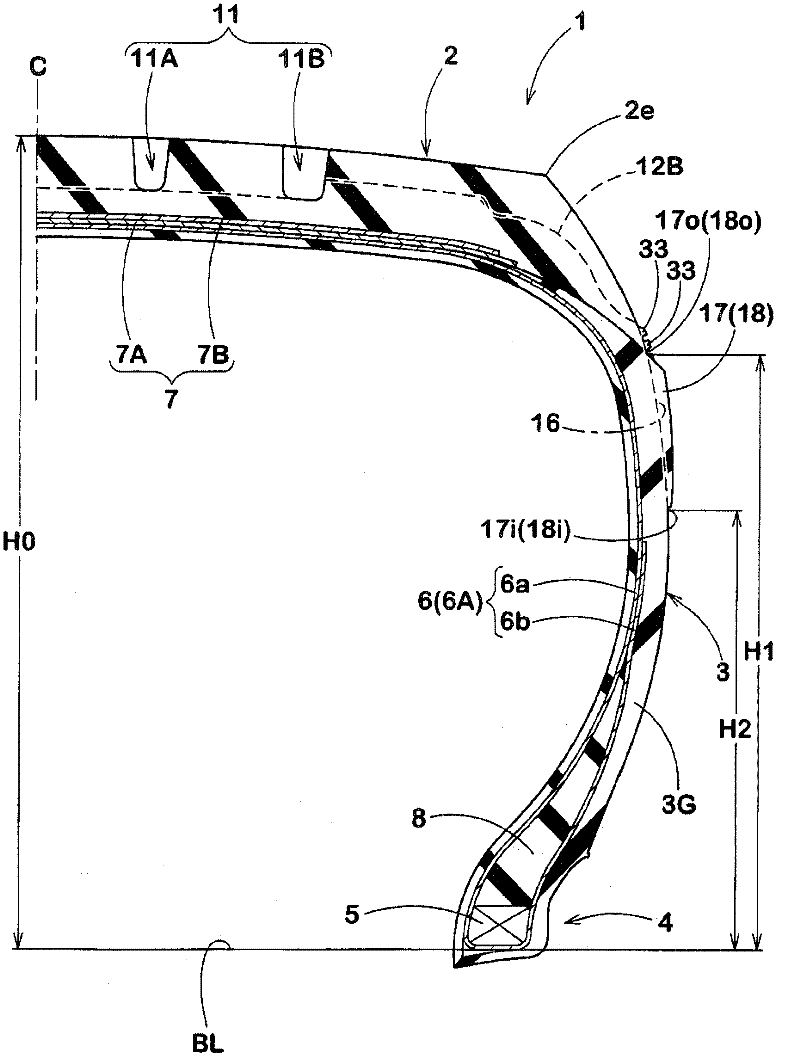

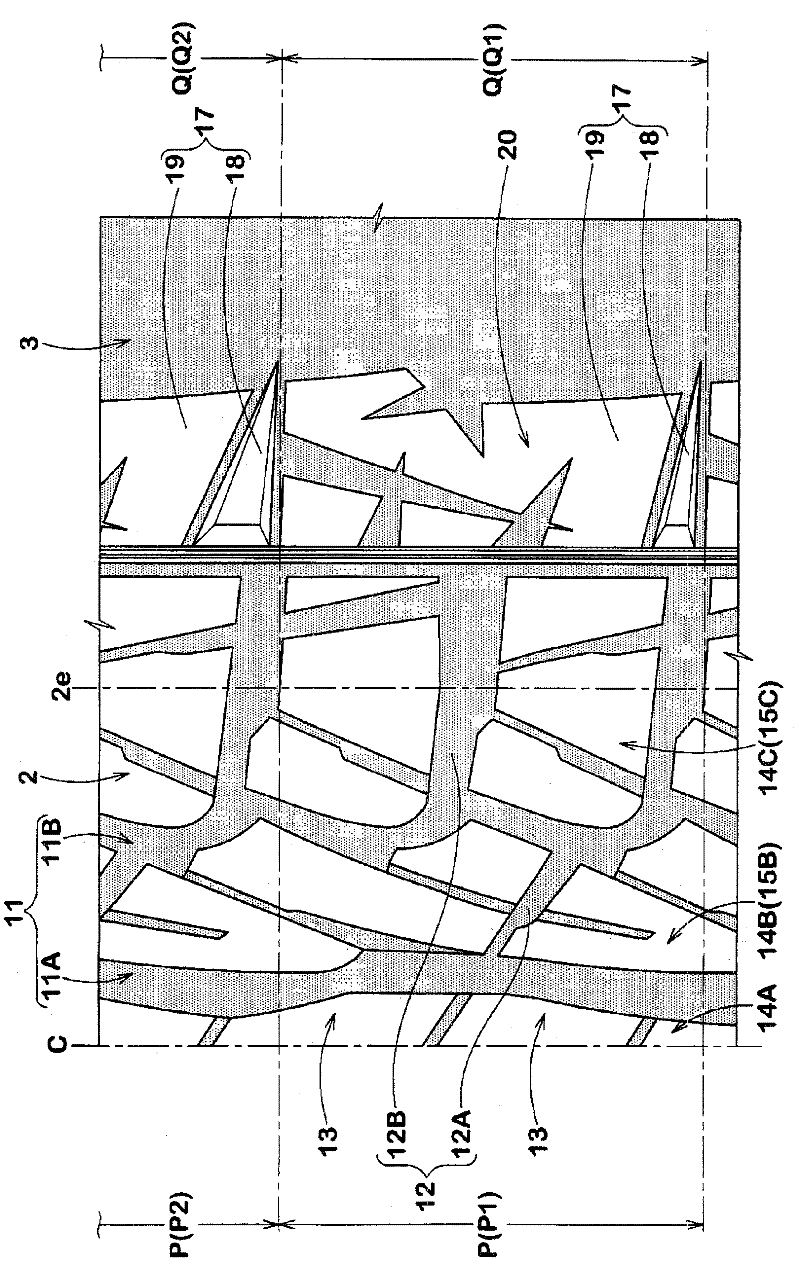

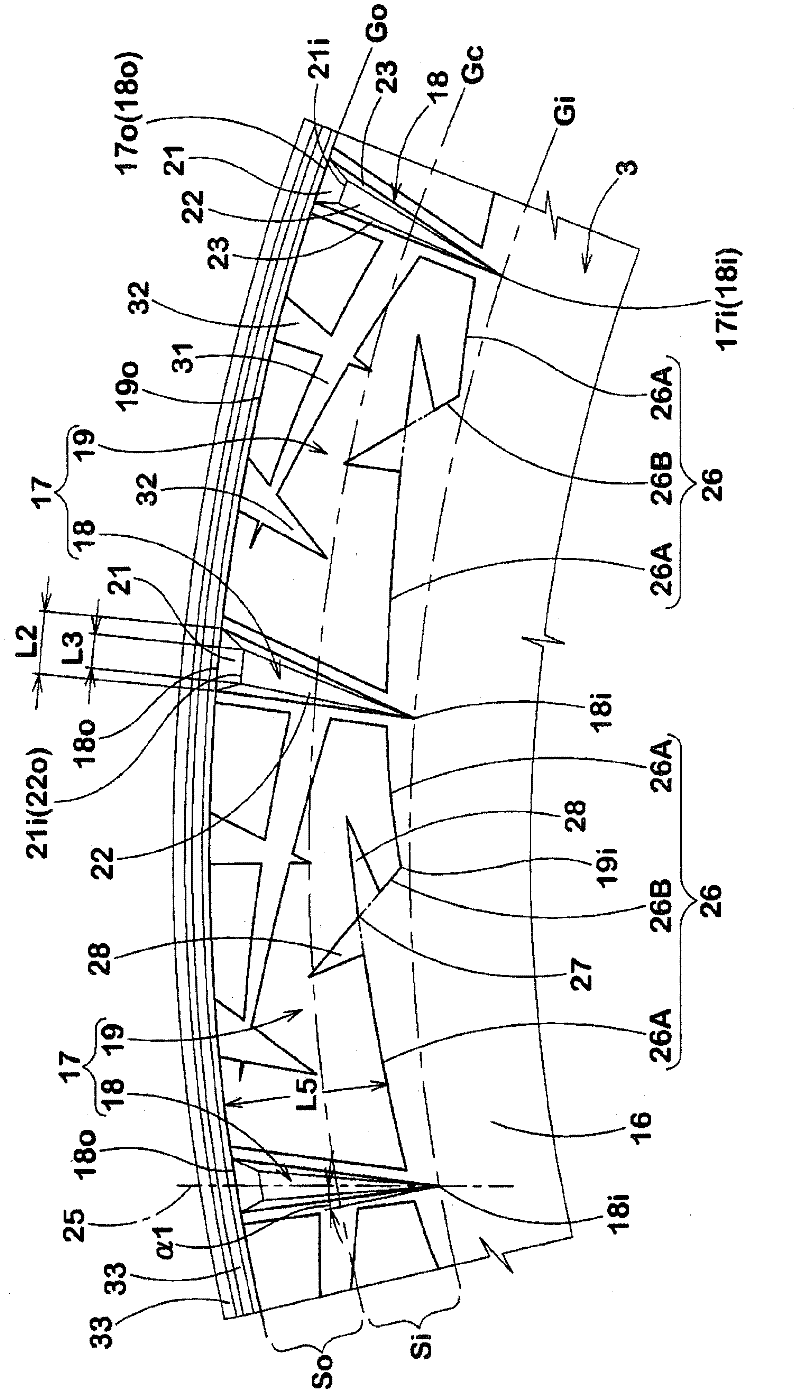

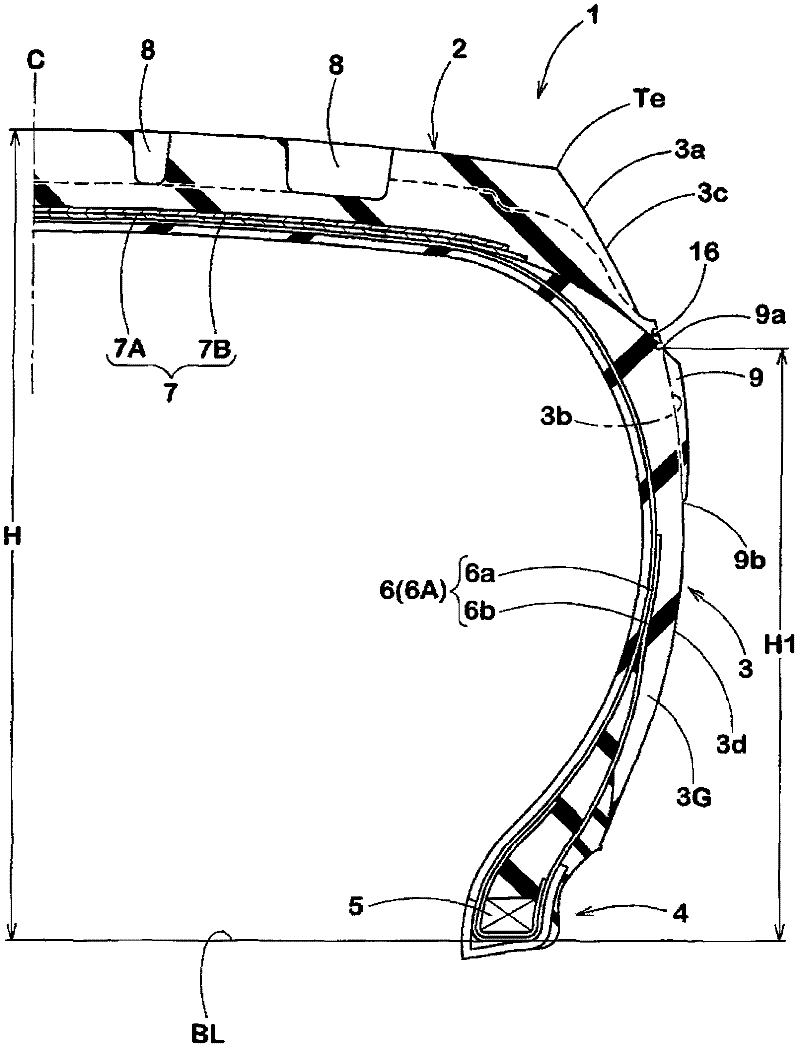

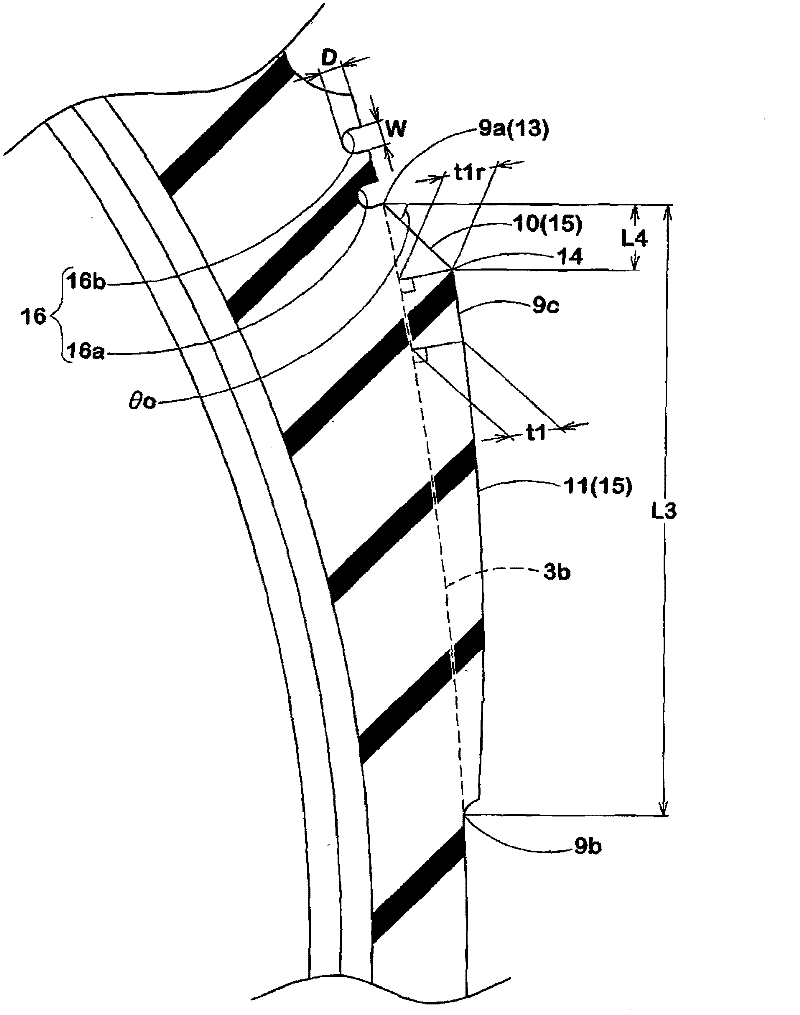

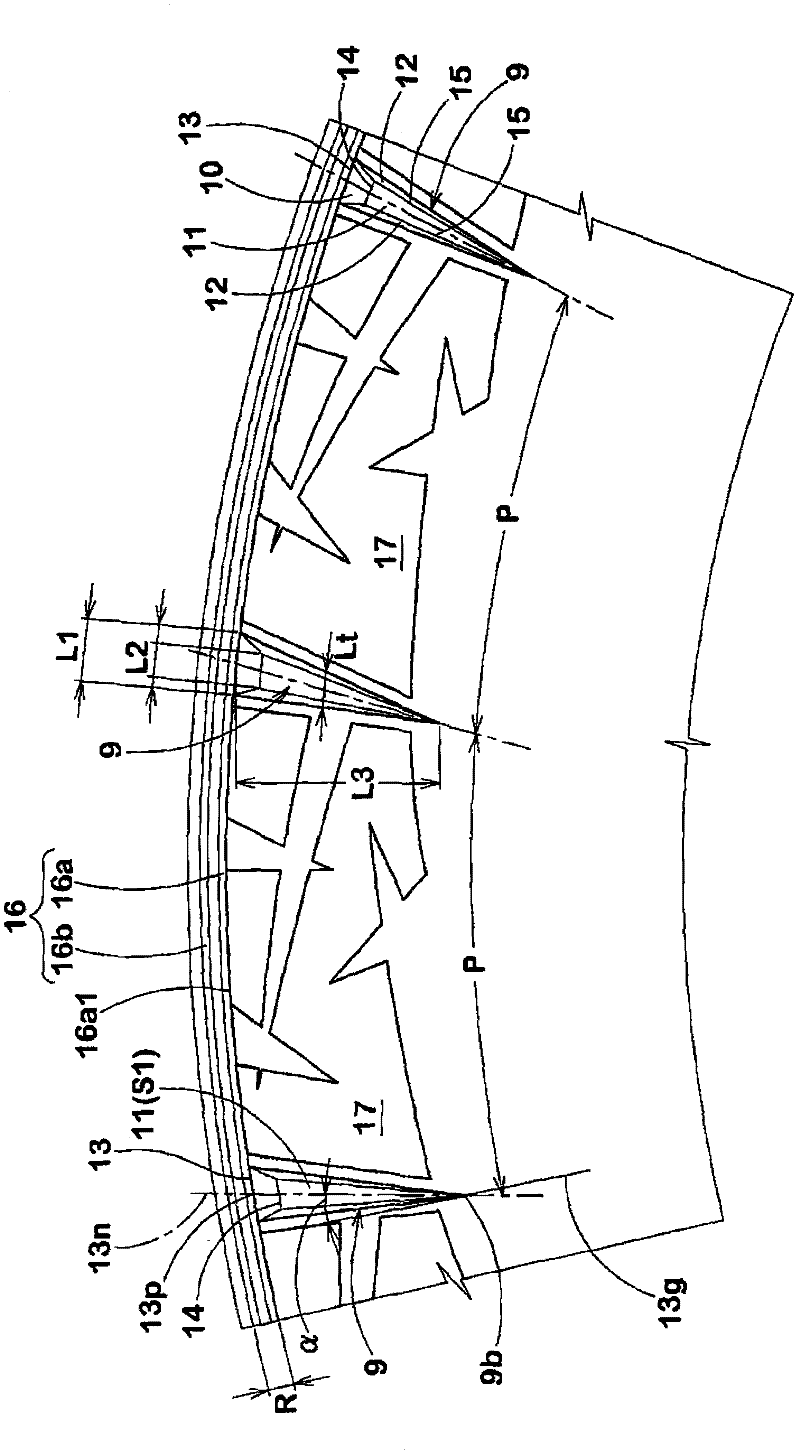

Pneumatic tire

ActiveCN102649390AImprove rigidityIncreased rubber volumeTyre tread bands/patternsTyre sidewallsMechanical engineeringTread

The invention provides a pneumatic tire which can maintain high cutting resistance and operation stability and restrain increase of tire weights. The pneumatic tire (1) includes a tread portion (2), sidewall portions (3) and bead portions (4).A protrusion (17) protruding on a tire side reference outside surface (16) is formed on at least one of the sidewall portions (3). The protrusion (17) includes a plurality of longitudinal ribs (18) and a low height part (19). Each rib has a protruding height of 0.5 to 7.0 mm from the normal outer surface of the sidewall. Each low height part has a protruding height from the normal outer surface of the sidewall that is lower than that of the longitudinal ribs. The sidewall portion with the protrusion has a ratio between a total area (A1) of the protrusion projected onto the normal outer surface of the sidewall portion and an area between an outer circumferential line (Go) on the sidewall portion passing through a radially outmost point (17o) of the protrusion (17) and an inner circumferential line (Gi) on the sidewall portion passing through a radially innermost point (17i) of the protrusion in a range of from 50 to 80%.

Owner:SUMITOMO RUBBER IND LTD

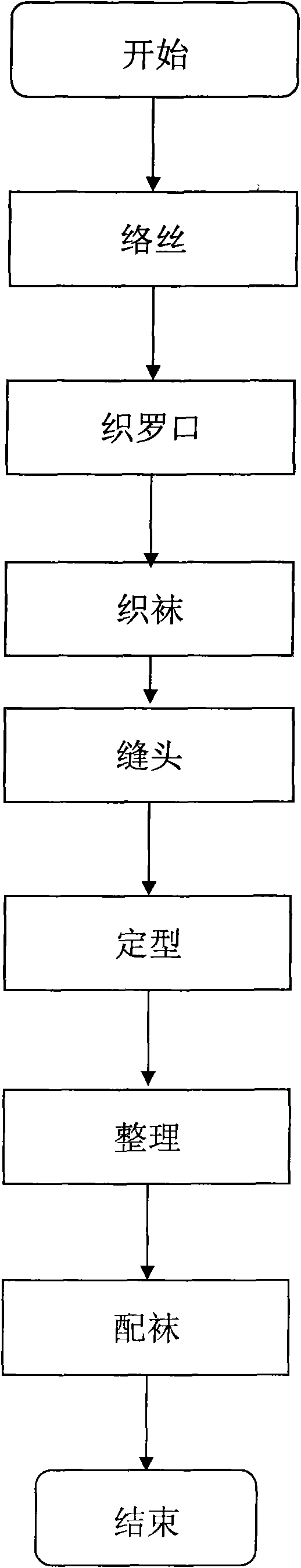

Method for producing ultra-high molecular weight polyethylene cotton-type anti-cutting gloves

ActiveCN104814549ASimple processImprove cut resistanceProtective garmentSpecial outerwear garmentsUltra-high-molecular-weight polyethyleneFilament yarn

The invention discloses a method for producing ultra-high molecular weight polyethylene cotton-type anti-cutting gloves. The gloves are formed by mixing and weaving of yarns such as ultra-high molecular weight polyethylene / polyester staple fiber blended yarns, polyester spandex wrap yarns, polyvinyl chloride (PVC) coated glass fiber spandex filament yarns and elastic yarns, cuffs of woven gloves are closed up by knitted rib cuffs, hot melting edge wrapping and one-time forming are achieved through a hot melting machine at the temperature from 120 DEG C to 180 DEG C, and surface chemical processing is performed through water-proof finishing agents so that finished products can be obtained. According to the method for producing the ultra-high molecular weight polyethylene cotton-type anti-cutting gloves, the process is simple, large-scale automatic production can be achieved, the anti-cutting performance of the gloves is high, the elasticity is good, a user can conveniently and comfortably wear the gloves, and the operation is flexible. Besides, the dust-proof effect is good, and harm to products due to falling of fibers of the gloves can be avoided. The gloves can be widely applied to people in special industries such as automobile assembly industry, glass industry, metal rolling sheet industry, cutting industry, recovery processing industry, police and the like.

Owner:JIANGSU HANVO SAFETY PROD CO LTD

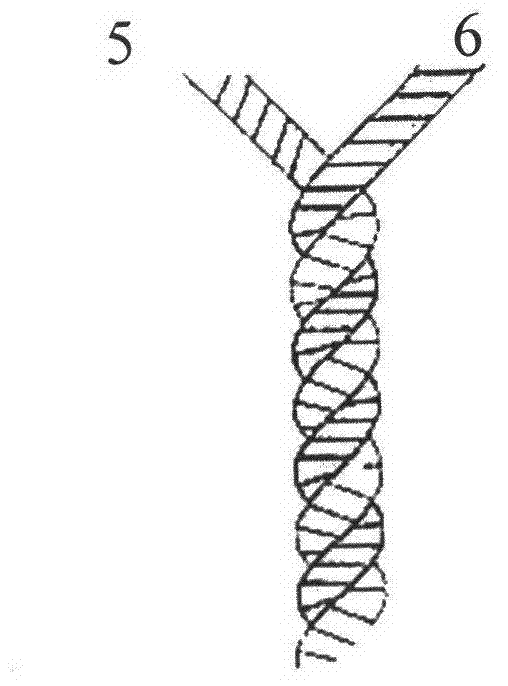

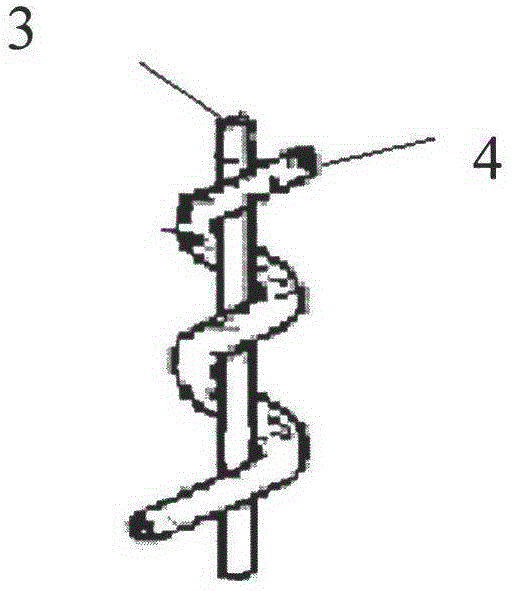

Composite yarn for high-cutting-resisting-degree fabric

The invention discloses composite yarn for high-cutting-resisting-degree fabric. The composite yarn comprises a core material filament and a covering layer. The yarn is characterized in that a dust cage spinning technology is used, so that short fibers in the covering layer cover the outer face of the core material filament in the vertical direction. According to the composite yarn for the high-cutting-resisting-degree fabric, the dust cage spinning technology is used, high-content inorganic fiber filament core materials are spun, an outer high-intensity short fiber shell layer covers the core materials by 100% to form core spun yarn, the core spun yarn can be subjected to independent knitting or composite double-layer knitting with spandex covering yarn to form the high-cutting-resisting-degree fabric, and the fabric can reach the cutting-resisting fifth level by the American standard. According to the structure of the composite core spun yarn, the inner portion is tight, the outer portion is loose, and fabric handfeel is soft and comfortable. The fabric can be widely used for products which need to provide high-level cutting protection, for example, various products of space flight and aviation seat linings, gloves and linings thereof, aprons, oversleeves and the like.

Owner:SHANGHAI LABON TECHNICAL FIBER CO LTD

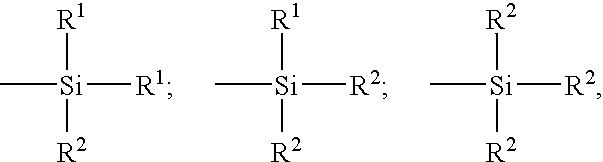

Composite comprising heat-resistant fiber and siloxane polymer

InactiveUS20050165154A1Improve heat resistanceImprove toughnessEngine sealsSynthetic resin layered productsPolymer scienceHeat resistance

The present invention provides a fiber-reinforced glass having excellent heat resistance and toughness, or a composite comprising a heat-resistant fiber and a siloxane polymer, which has a modified surface structure and is useful as a heat-resistant fiber.

Owner:IWAMIYA YOKO

Pneumatic tire

ActiveCN102416830ALight in massIncreased longitudinal rigidityHeavy duty tyresHeavy duty vehicleNormal loadEngineering

Owner:SUMITOMO RUBBER IND LTD

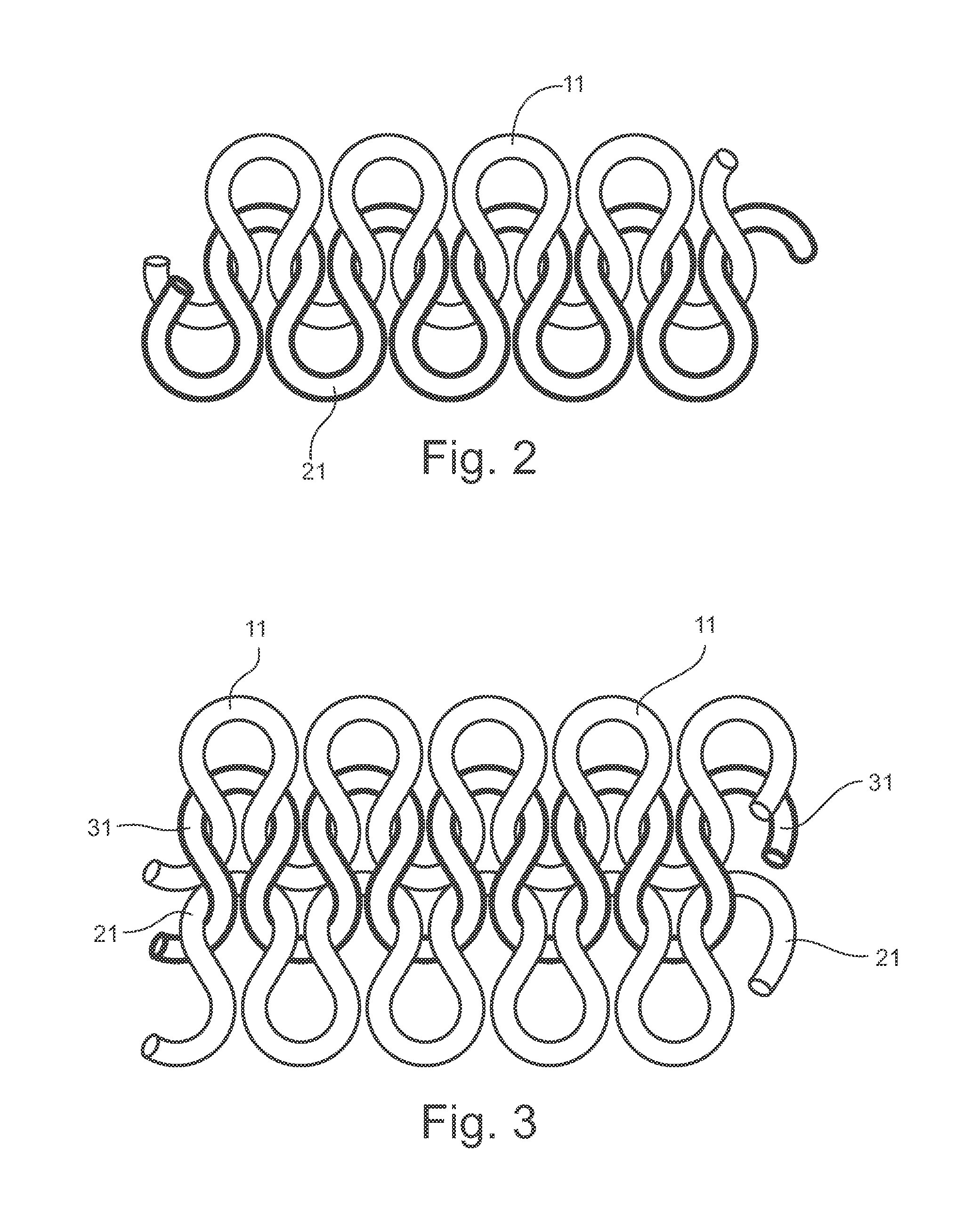

Protective glove with enhanced exterior sections

InactiveUS20150181956A1Improve cut resistanceImprove the immunityGarment special featuresWeft knittingYarnEngineering

A protective glove includes a primary yarn that forms the palm, thumb and finger sections of the glove. The primary yarn has an interior surface forming the interior surface of the glove, and an exterior surface forming the exterior surface of the glove. A plaiting yarn is plaited to portions of the exterior surface of the primary yarn to form a plurality of enhanced sections on the exterior surface of the glove. The enhanced sections having at least one substantially enhanced physical characteristic in relation to the primary layer, such as increased cut resistance,

Owner:WORLD FIBERS

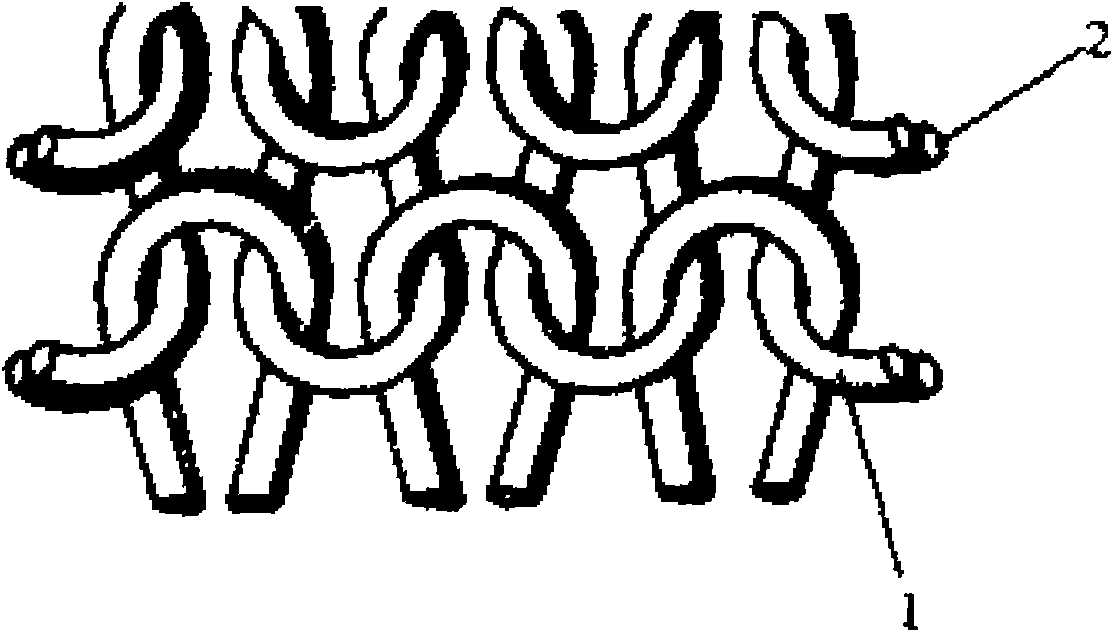

High-strength and high-modulus polyethylene fiber/spandex coated wire and high-performance protective socks using same

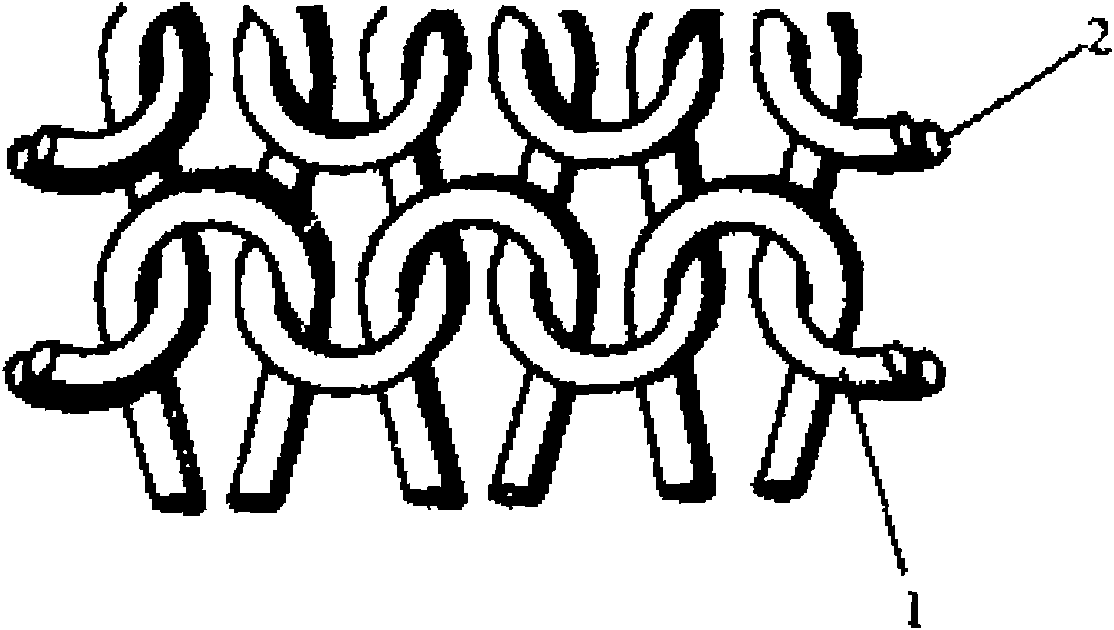

InactiveCN101597824AImprove cut resistanceImprove wear resistanceWeft knittingWarp knittingYarnCombing

The invention discloses a high-strength and high-modulus polyethylene fiber / spandex coated wire and high-performance protective socks using the same, and the coated wire comprises coated wire and combed cotton yarn which take plating stitch structures, the coated wire uses spandex wire as core wire and high-strength and high-modulus polyethylene fiber as outer coated wire. In the invention, the coated wire using spandex wire as the core wire and high-strength and high-modulus polyethylene fiber as the outer coated wire is adopted, and is used to weave socks with combed cotton yarn by plating stitches, therefore, the high-strength and high-modulus polyethylene fiber / spandex coated wire has the good performances of anti-cutting, fire retarding, wear resistance, health care, comfortable wear, and the like. When fabric is compacted in a high speed, impact absorption energy is about as twice as para-aramid, friction coefficient is lower than other high-strength fibers, wear resistance is good, and repeated fatigue resistance is good. The high-strength and high-modulus polyethylene fiber / spandex coated wire can be widely applied to special industrial workers such as loggers, mining machine operators, firefighters, armed polices, soldiers and the like.

Owner:ZHEJIANG QINGYI SOCKS IND

Aramid 1414 fiber/spandex coated wire and multifunctional protective socks using same

InactiveCN101597823AExcellent flame retardantImprove cut resistanceWeft knittingWarp knittingYarnCombing

The invention discloses an aramid 1414 fiber / spandex coated wire and multifunctional protective socks using same. The aramid 1414 fiber / spandex coated wire comprises coated wire and yarn which take plating stitch structures, the coated wire uses spandex wire as core wire and aramid 1414 fiber as outer coated wire, and the yarn uses combed cotton yarn or aramid 1313 / flame retardant viscose blended yarn. In the invention, the coated wire using spandex wire as the core wire and aramid 1414 fiber as the outer coated wire is adopted, and is used to weave socks with combed cotton yarn or aramid 1313 / flame retardant viscose blended yarn by plating stitches, therefore, the aramid 1414 fiber / spandex coated wire has the good performances of anti-cutting, fire retarding, wear resistance, health care, comfortable wear, and the like, and can be widely applied to special industrial workers such as loggers, mining machine operators, firefighters, armed polices, soldiers and the like.

Owner:ZHEJIANG QINGYI SOCKS IND

Chemical resistant glove having cut resistant properties

InactiveUS8656518B2Improve cut resistanceLow shear strengthGlovesSynthetic resin layered productsLatex gloveChemical treatment

Owner:ANSELL HEALTHCARE PRODS

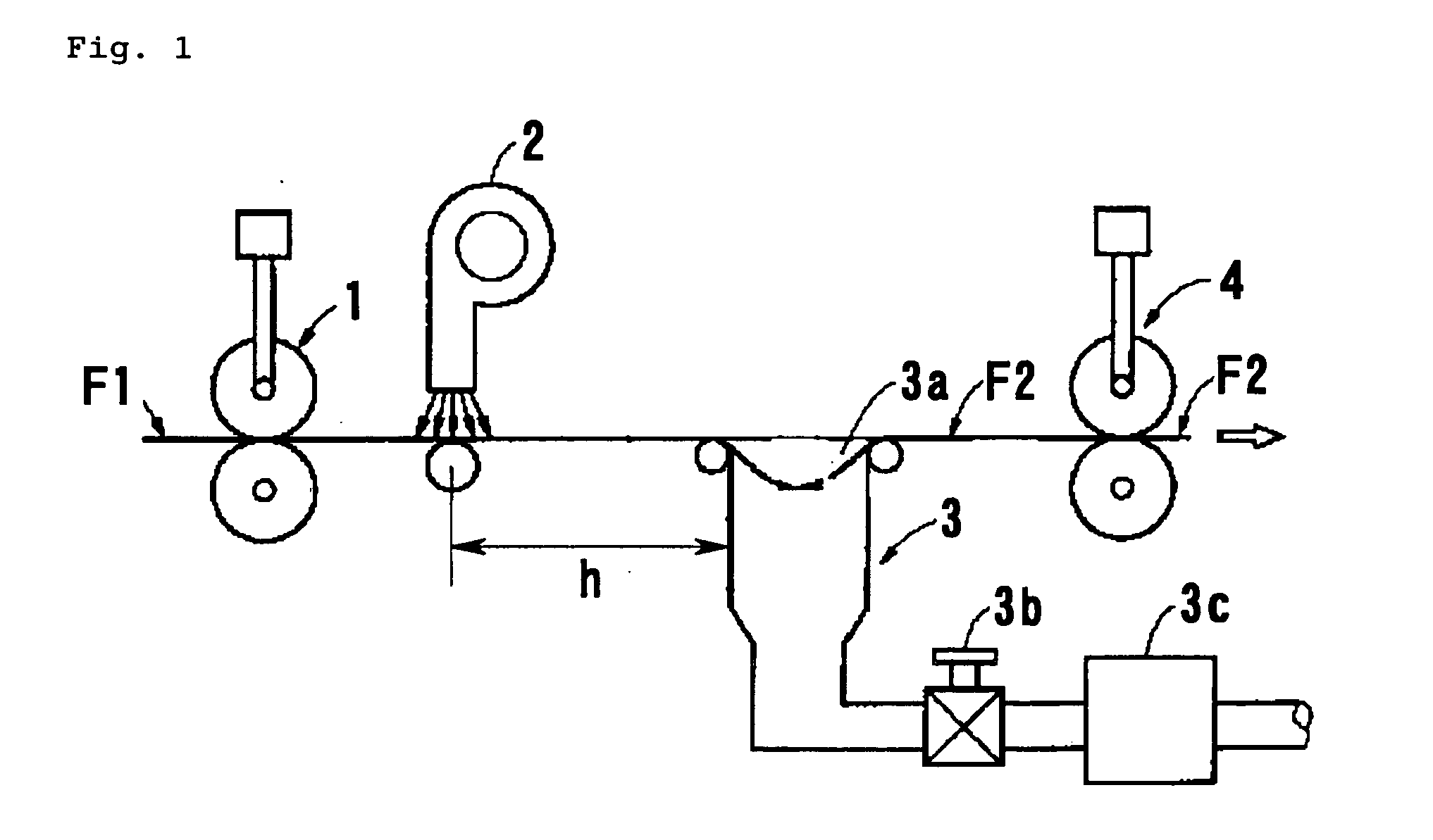

Resin composition for optical fibre paint, coated optical fibre and optical fibre unit utilizing it

InactiveCN1456622ASatisfactory toughnessImprove cut resistanceCladded optical fibrePolyurea/polyurethane coatingsOligomerEthyl ester

A resin composition for a coating for an optical fiber which comprises a radical polymerizable oligomer (A) and a radical polymerizable monomer (B), wherein (A) comprises a radical polymerizable oligomer (A1) with Mn of 600 to 1600 formed by reacting compounds (1) to (3) below: (1) an aliphatic polyol compound with Mn of 50 to 600, (2) a polyisocyanate compound with a ring structure, and (3) a compound with a hydroxyl group and a radical polymerizable unsaturated group; and a radical polymerizable oligomer (A2) formed by reacting compounds (4) to (6) below: (4) an aliphatic polyol compound with Mn of 800 to 10,000, (5) a polyisocyanate compound, and (6) a compound with a hydroxyl group and a radical polymerizable unsaturated group; a mass ratio (A1) / (A2) is 20 / 80 to 80 / 20, and a concentration of urethane linkages within the resin composition is 1.85 to 3.00 mol / kg.

Owner:DAINIPPON INK & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com