Patents

Literature

177results about How to "Low shear strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

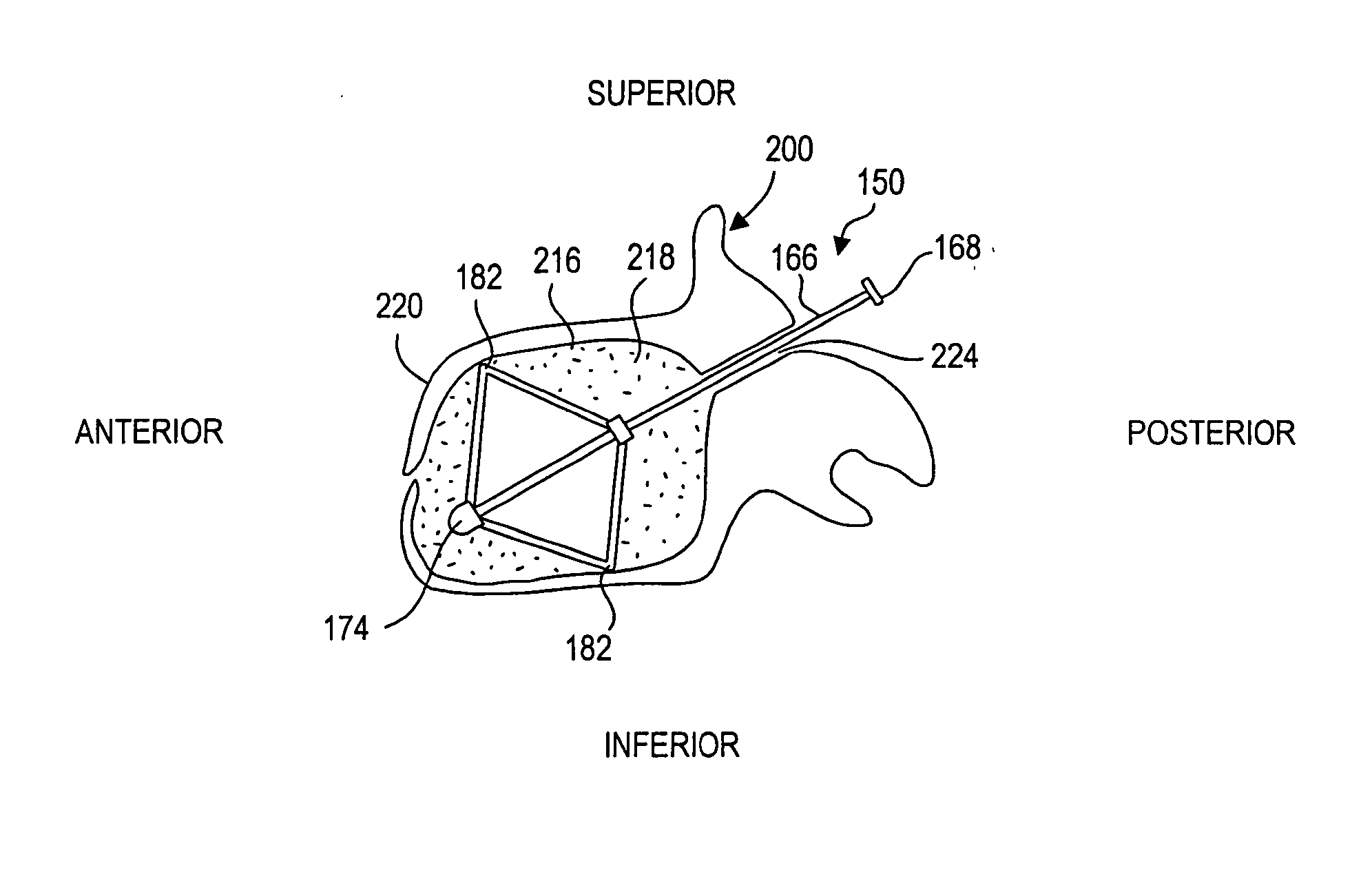

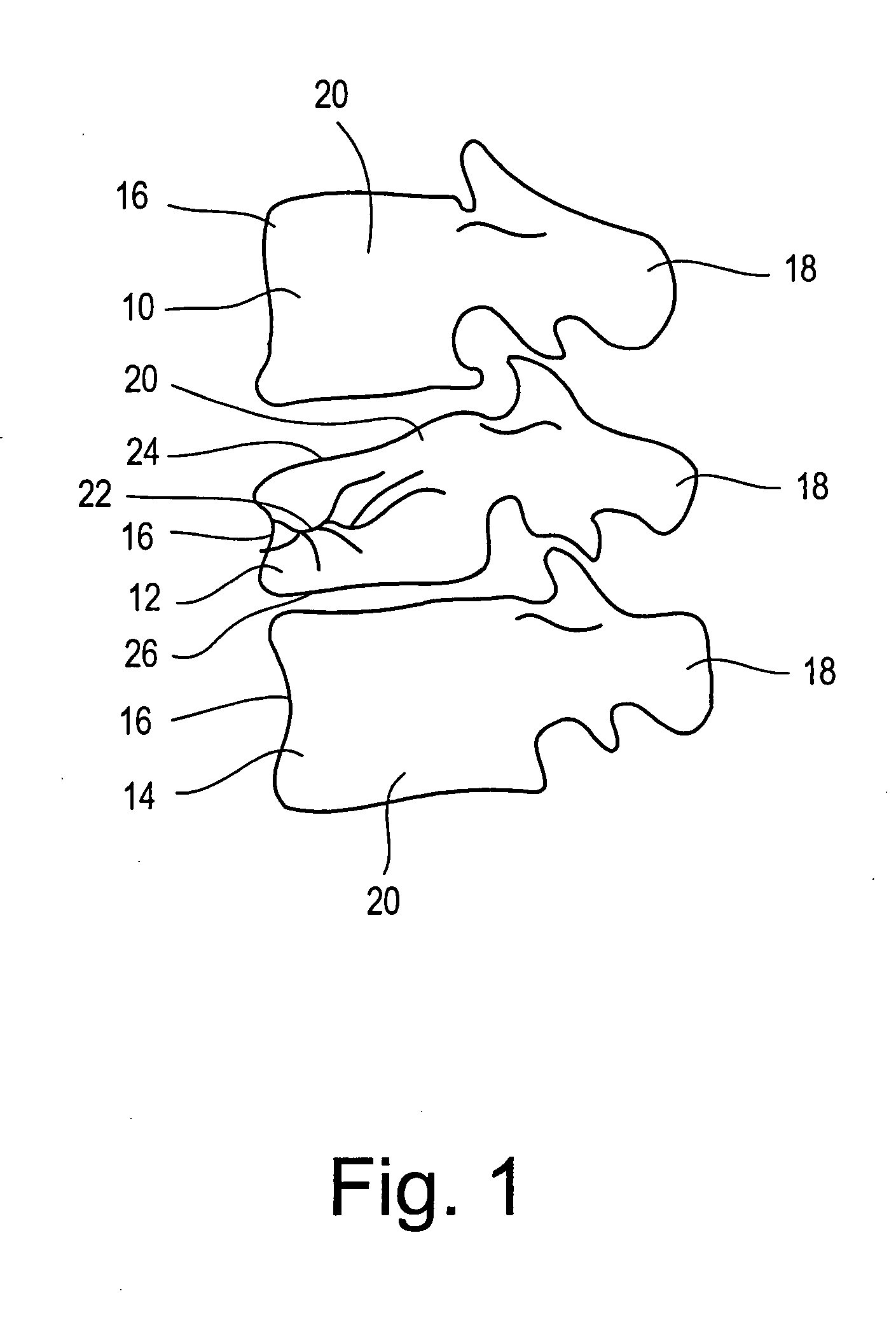

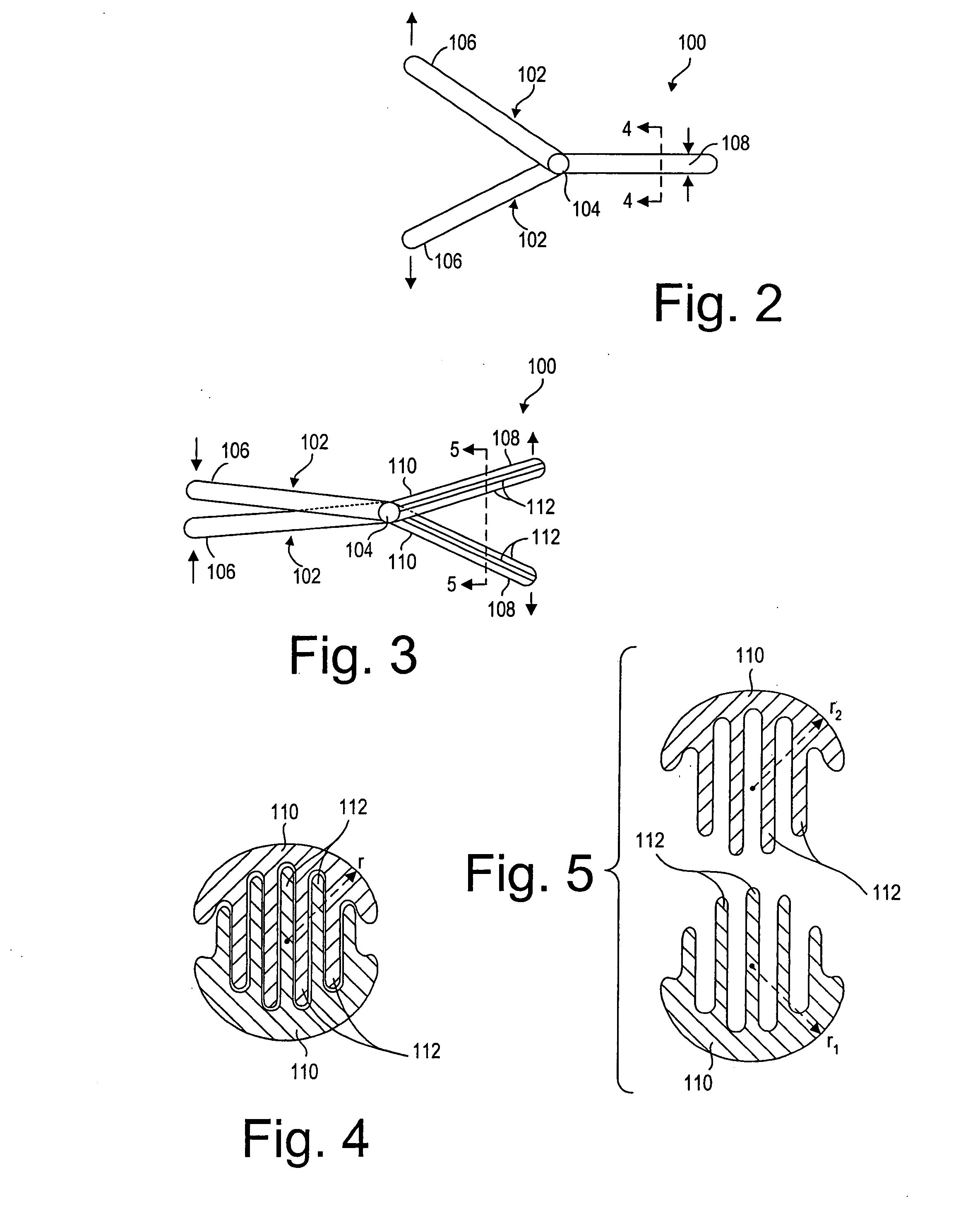

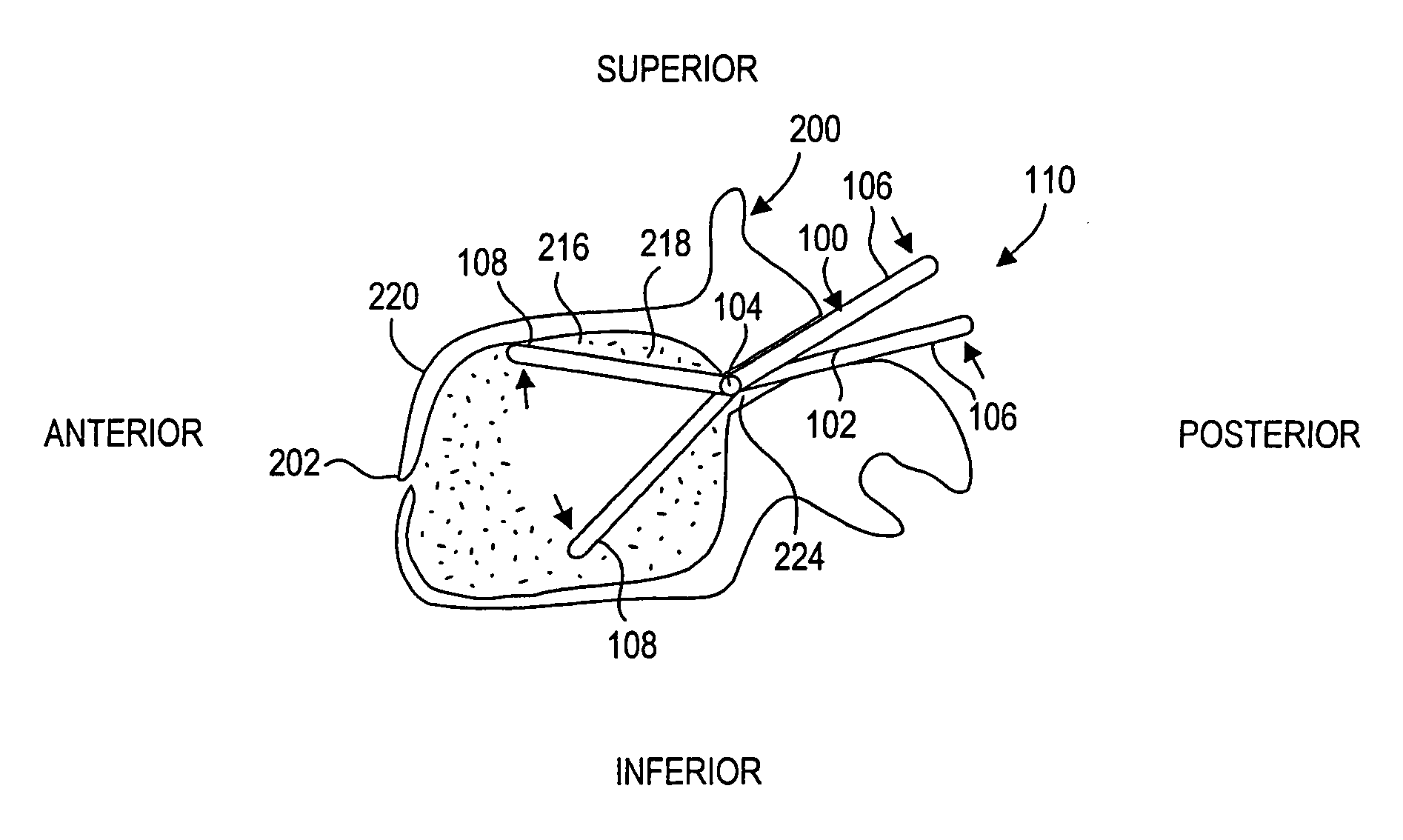

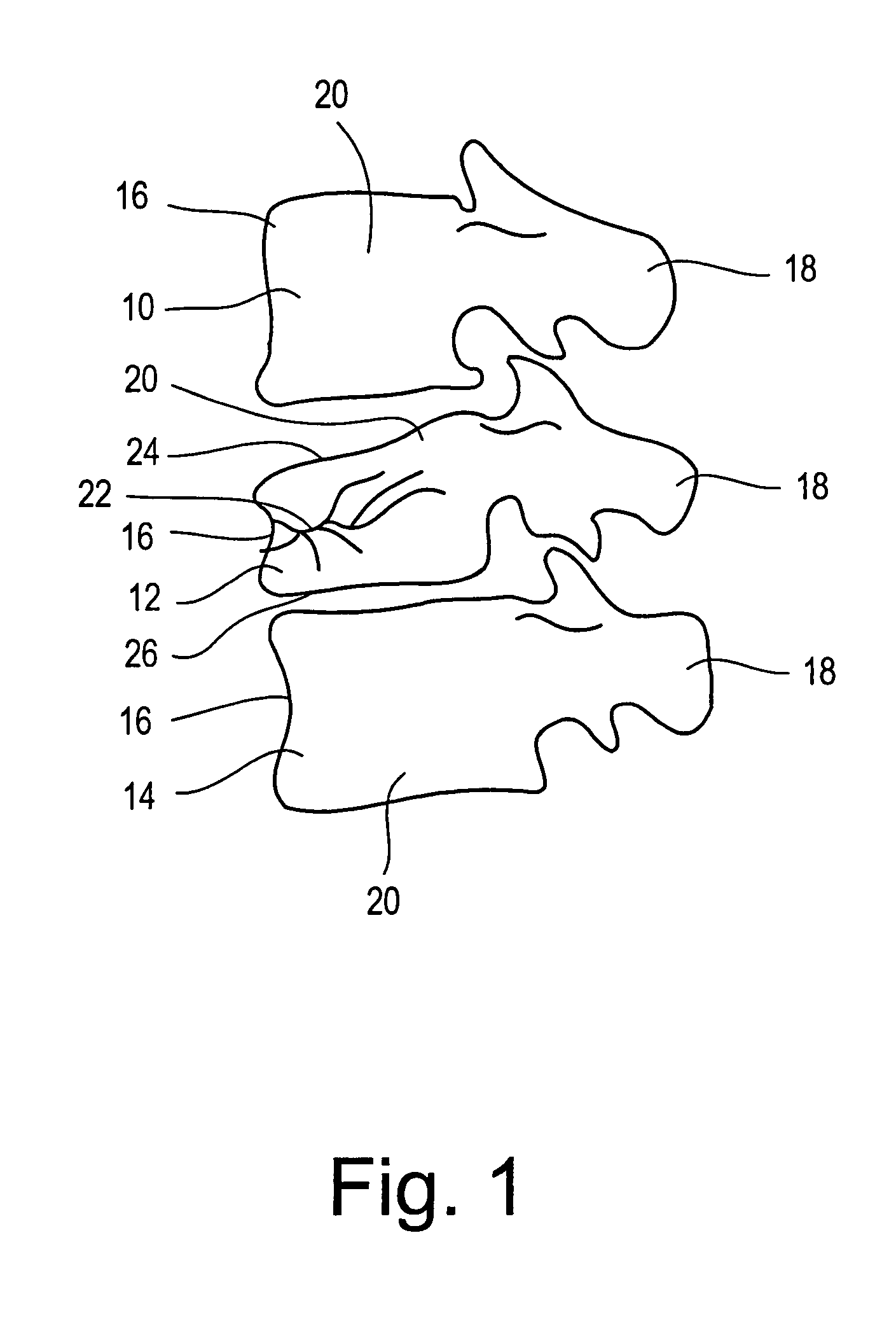

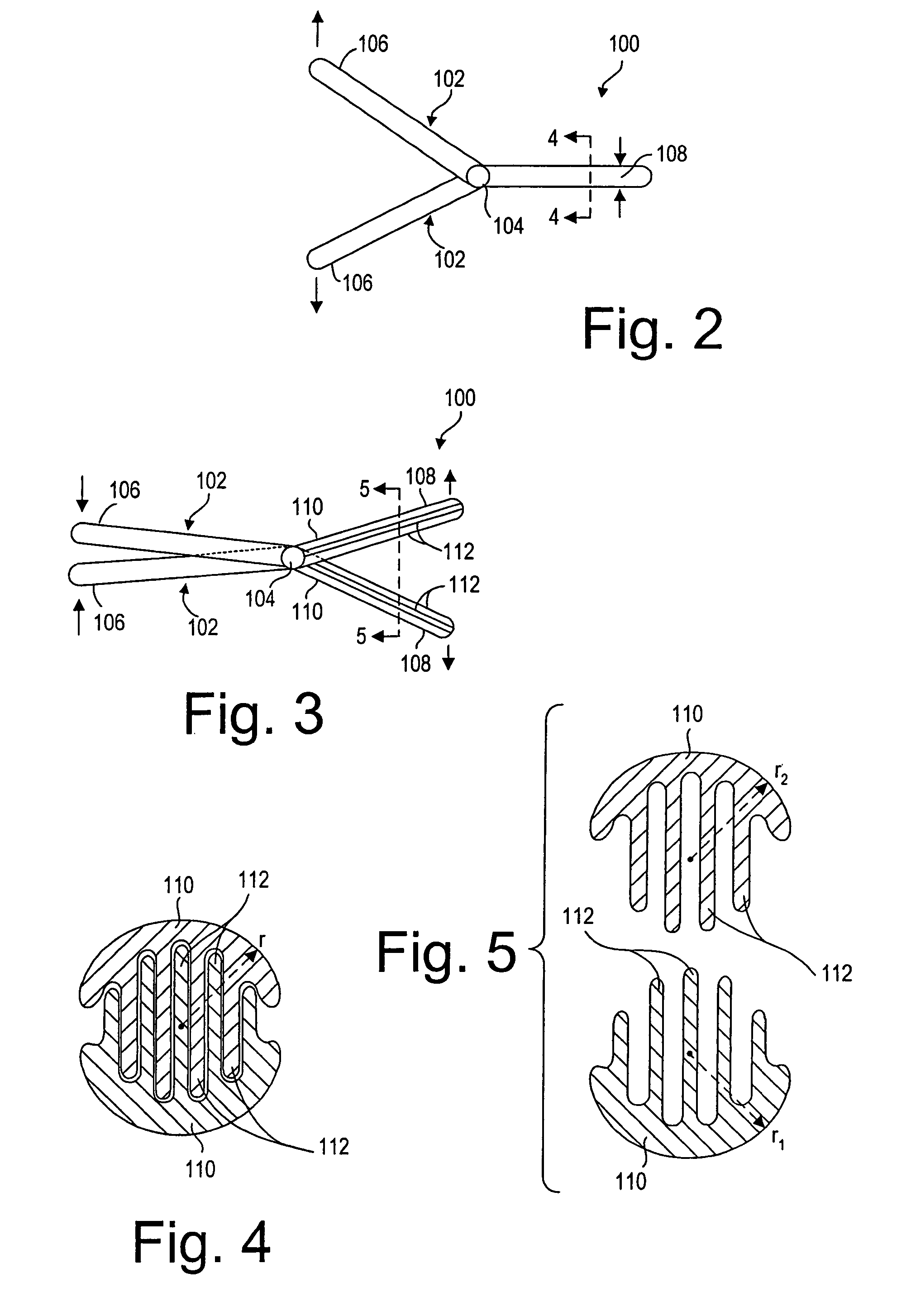

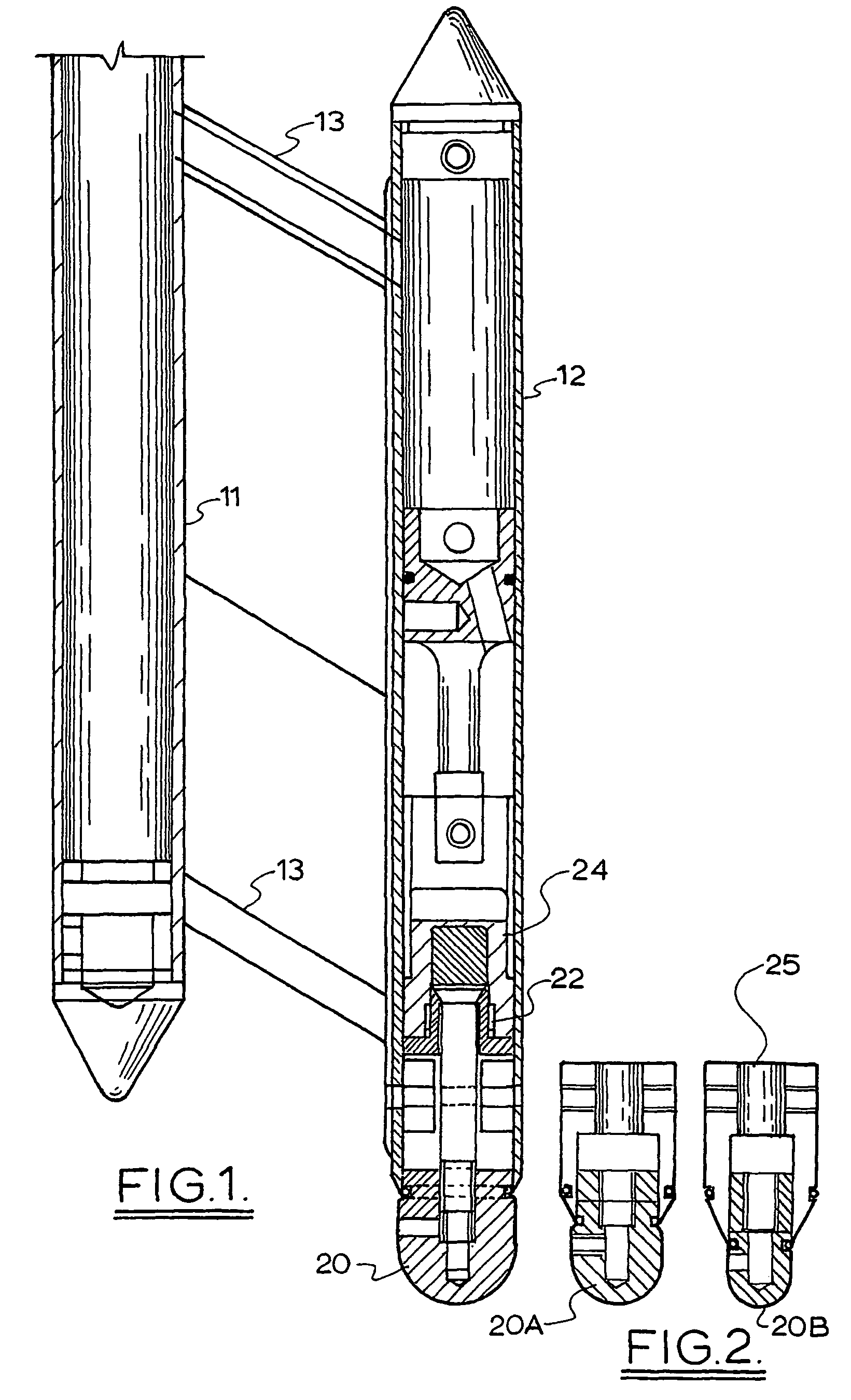

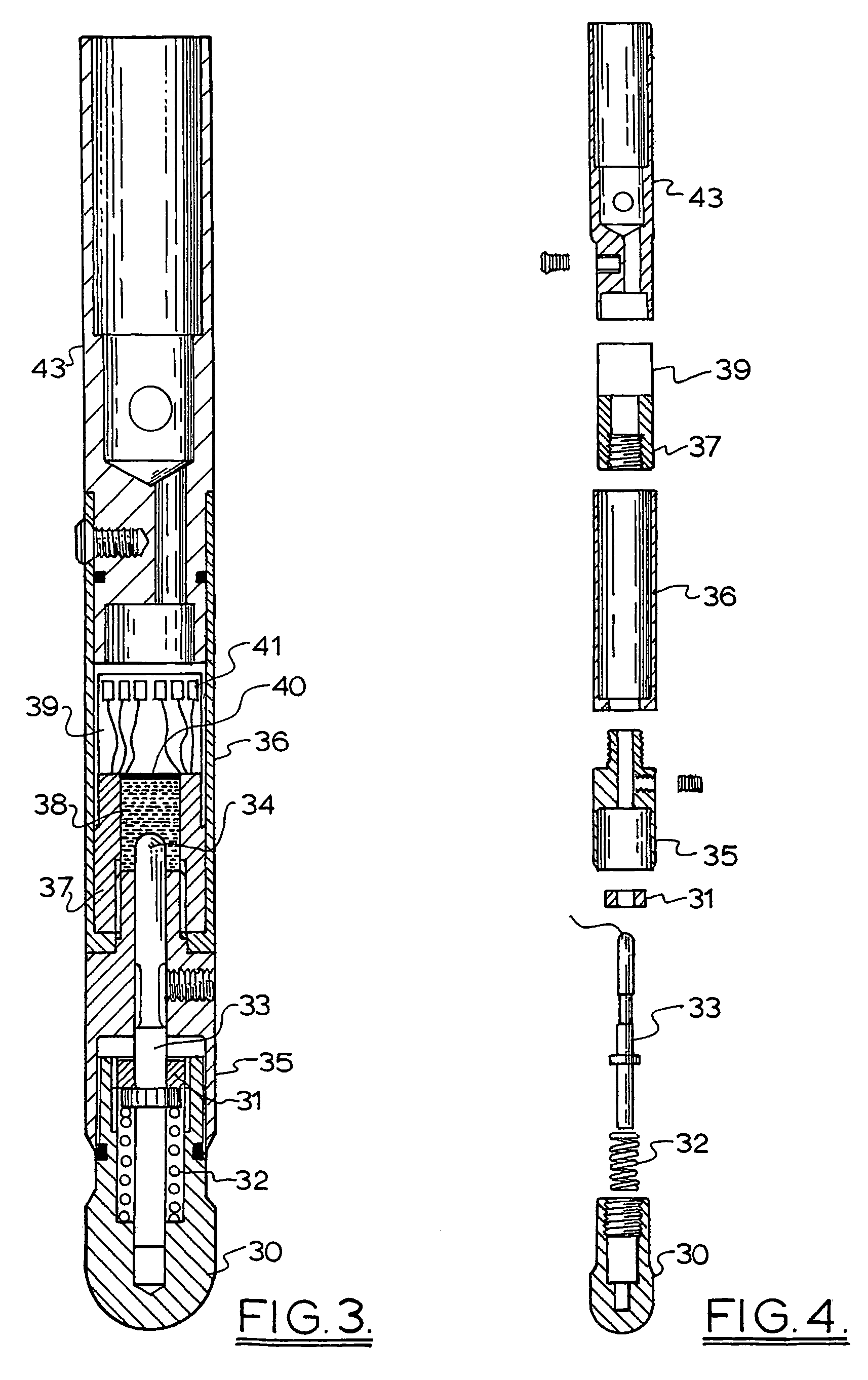

Apparatus and methods for reducing compression bone fractures using high strength ribbed members

InactiveUS20050070911A1Small combined profilePreserving shear strengthInternal osteosythesisDiagnosticsCommon baseBone structure

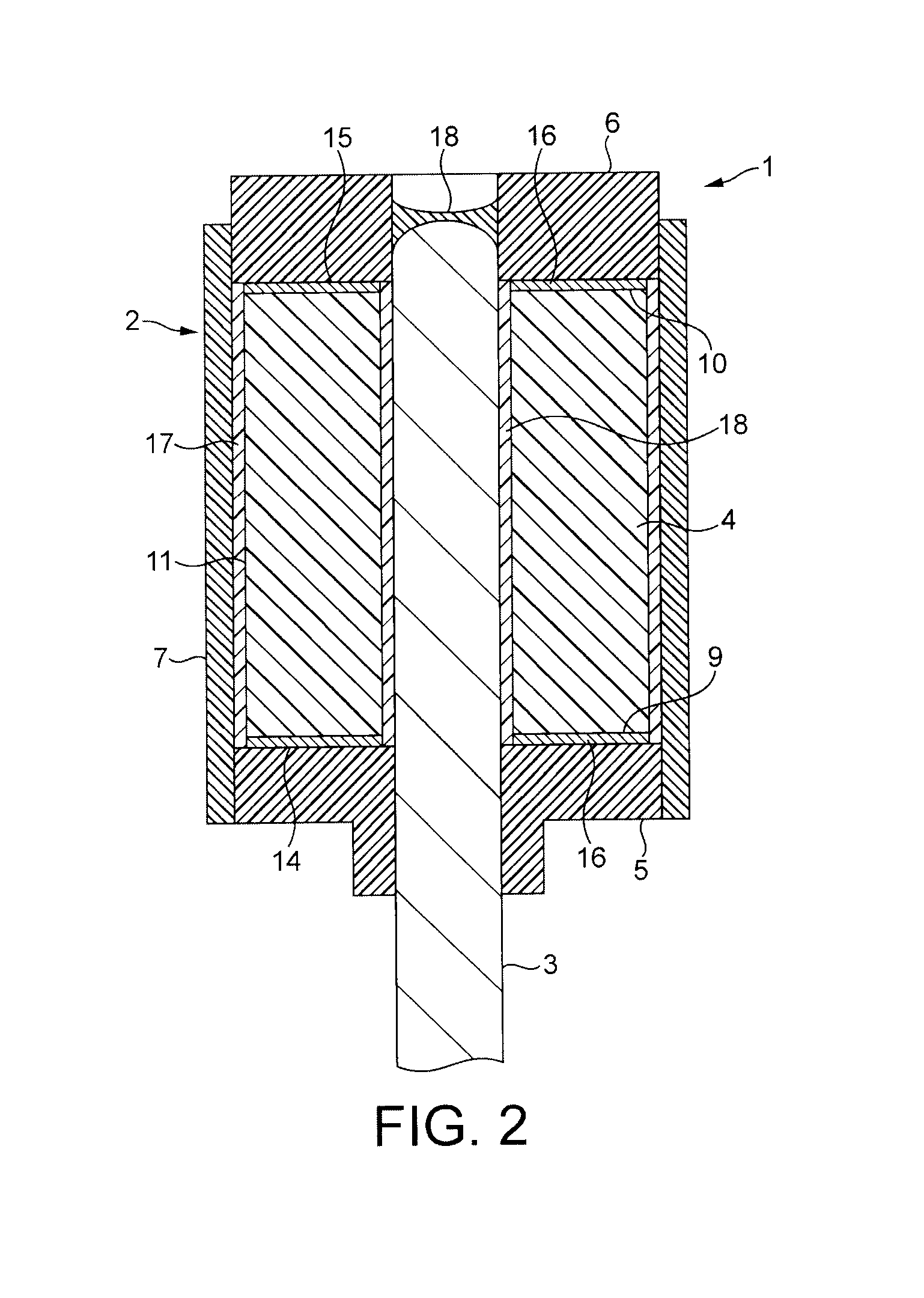

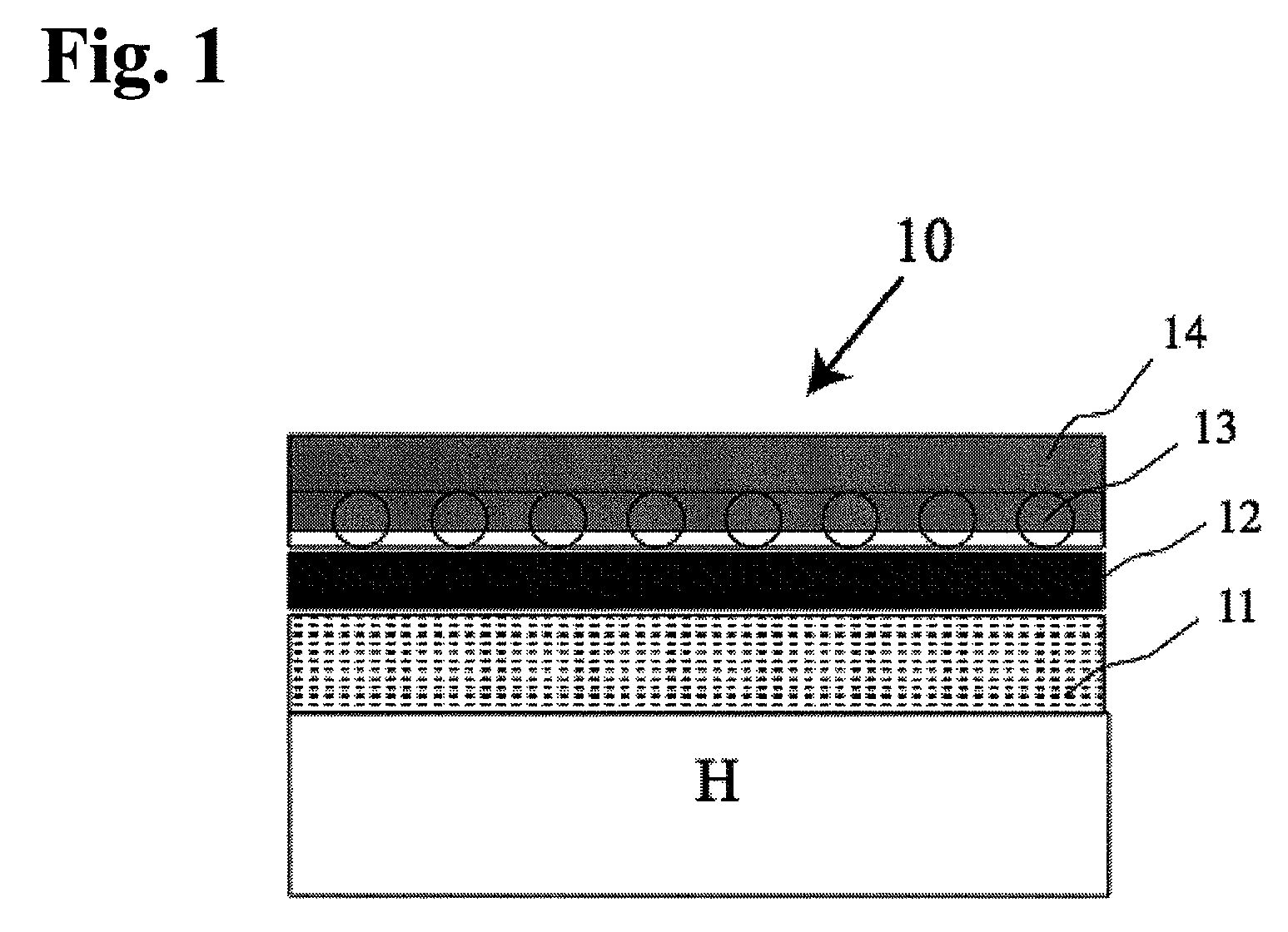

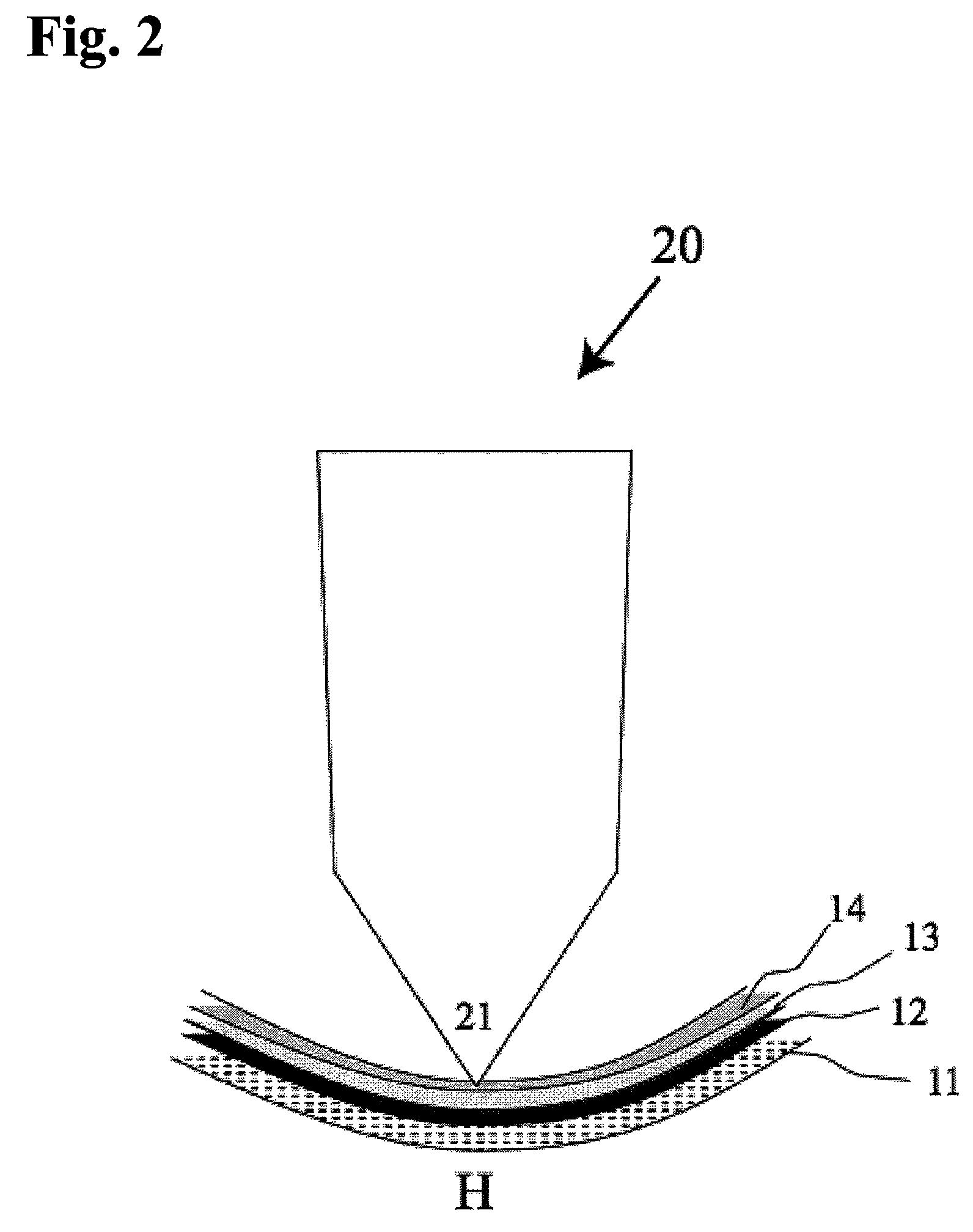

Devices and methods are provided for treating a bone structure (such as, e.g., reducing a bone fracture, e.g., a vertebral compression fracture, or stabilizing adjacent bone structure, e.g., vertebrae) is provided. The device comprises rigid or semi-rigid members, each of which comprises a common base and a plurality of ribs that extent along the a longitudinal portion of the common base. The device is configured to be placed in a collapsed state by engaging the pluralities of ribs of the members in an interposed arrangement, and configured to be placed in a deployed state by disengaging the pluralities of ribs. The ribs can be any shape, e.g., flutes, that allows opposing ribs to intermesh with one another. In this manner, the device has a relatively small profile when placed in the collapsed state, so that it can be introduced through small openings within the bone structure, while preserving the shear strength of the members during deployment of the device.

Owner:BOSTON SCI SCIMED INC

Apparatus and methods for reducing compression bone fractures using high strength ribbed members

InactiveUS7513900B2Low shear strengthSmall profileInternal osteosythesisDiagnosticsCommon baseFracture reduction

Devices and methods are provided for treating a bone structure (such as, e.g., reducing a bone fracture, e.g., a vertebral compression fracture, or stabilizing adjacent bone structure, e.g., vertebrae) is provided. The device comprises rigid or semi-rigid members, each of which comprises a common base and a plurality of ribs that extent along the a longitudinal portion of the common base. The device is configured to be placed in a collapsed state by engaging the pluralities of ribs of the members in an interposed arrangement, and configured to be placed in a deployed state by disengaging the pluralities of ribs. The ribs can be any shape, e.g., flutes, that allows opposing ribs to intermesh with one another. In this manner, the device has a relatively small profile when placed in the collapsed state, so that it can be introduced through small openings within the bone structure, while preserving the shear strength of the members during deployment of the device.

Owner:BOSTON SCI SCIMED INC

Aluminum alloy semisynthesis cutting liquid and preparation method thereof

ActiveCN102925269AResistant to corruption and odorWill not corrodeLubricant compositionActive agentSurface-active agents

The invention discloses aluminum alloy semisynthesis cutting liquid and a preparation method thereof. The aluminum alloy semisynthesis cutting liquid is composed by weight of 12%-20% of mineral oil, 9%-15% of surfactant, 8%-12% of antirust agent, 1%-2% of aluminum corrosion inhibitor, 3%-7% of lubricant, 8%-12% of extreme pressure agent, 0.5%-1% of defoamer, 0.5%-1% of fungicide and the balance, water. The preparation method includes sequentially adding the surfactant, the antirust agent, the aluminum corrosion inhibitor, the lubricant, the extreme pressure agent, the defoamer, the fungicide and the water into the mineral oil and evenly stirring and mixing the mixture to obtain the aluminum alloy semisynthesis. The aluminum alloy semisynthesis cutting liquid has excellent performance on aluminum corrosion inhibition performance, corrosion resistance, lubricant performance, anti-rust performance, defoaming performance, use period and the like.

Owner:SHANGHAI INST OF TECH

Lead-free solder alloy and in-vehicle electronic circuit

ActiveUS20160056570A1Hinders its propagationExcellent temperature cycle characteristicsRelieving strain on wire connectionSoldered/welded conductive connectionsIn vehicleAttachment site

With the increasing density of in-vehicle electronic circuits, not only conventional cracks at bonding interfaces such as between the substrate and the solder attachment site or a component and the solder attachment site but also novel cracking problems of cracks occurring in the Sn matrix in the interior of the bonded solder have appeared. To solve the above problem, a lead-free solder alloy with 1-4 mass % Ag, 0.6-0.8 mass % Cu, 1-5 mass % Sb, 0.01-0.2 mass % Ni and the remainder being Sn is used. A solder alloy, which not only can withstand harsh temperature cycling characteristics from low temperatures of −40° C. to high temperatures of 125° C. but can also withstand external forces that occur when riding up on a curb or colliding with a vehicle in front for long periods, and an in-vehicle electronic circuit device using the solder alloy can thereby be obtained.

Owner:SENJU METAL IND CO LTD

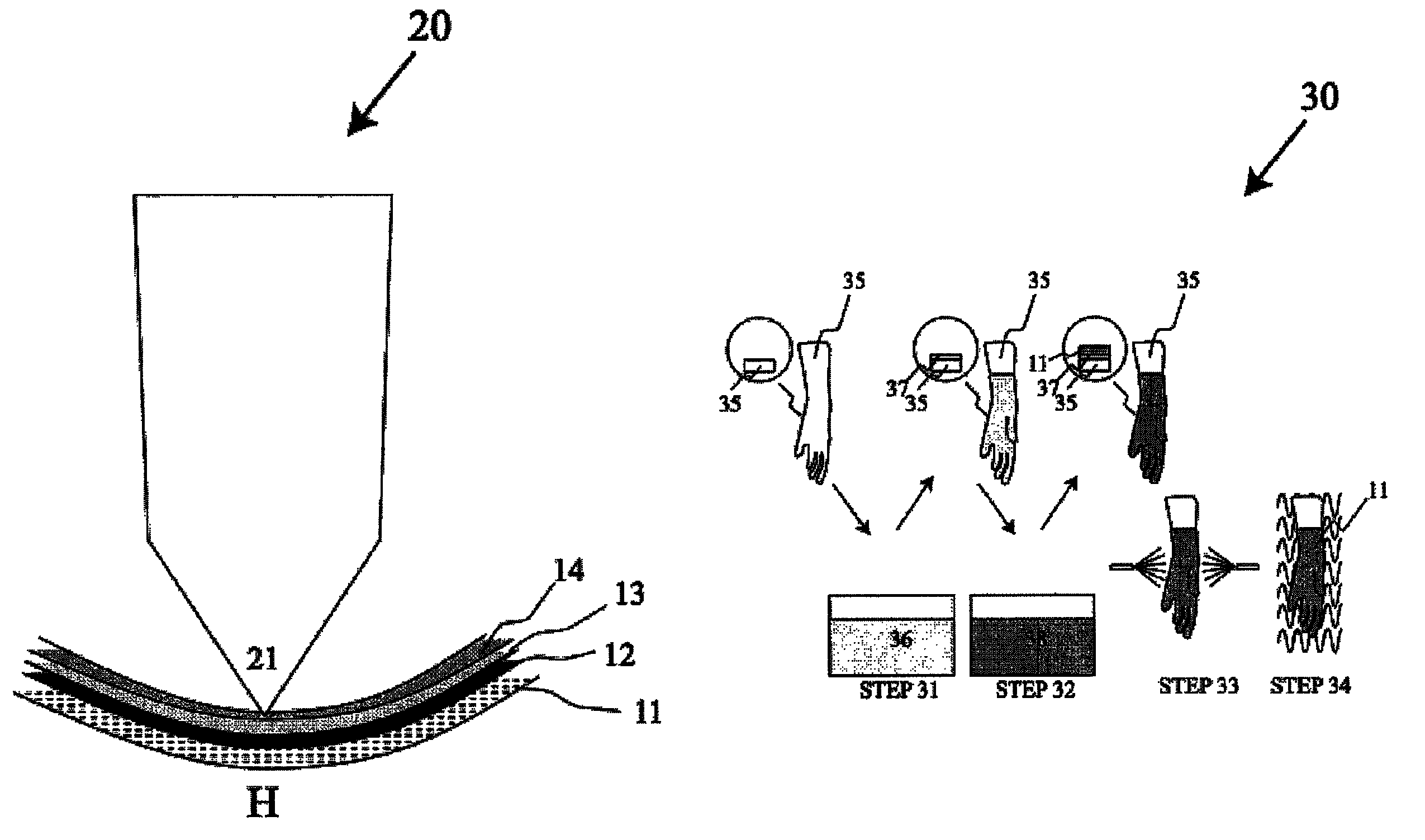

Chemical Resistant Glove Having Cut Resistant Properties

InactiveUS20090077713A1Low shear strengthReduces cut stress intensityGlovesThin material handlingLatex gloveChemical treatment

A cut resistant chemical handling glove that is flexible and lightweight comprises a cured, liquid-impervious polymeric latex shell. A tacky acrylic adhesive with low shear strength can be used. A cut resistant liner is slipped on the tacky adhesive coating and is infiltrated with a polymeric latex coating and cured to integrally attach the cut resistant liner with the cured polymeric coating. When the latex glove is worn on a hand and a cutting edge, such as a knife edge, contacts the glove, a crease is formed due to slip at the tacky adhesive-cut resistant liner interface creating a geometry that reduces cut stress intensity at the knife-edge thereby increasing the cut resistance of the glove. Processes for making and using these gloves are also described.

Owner:ANSELL HEALTHCARE PRODS

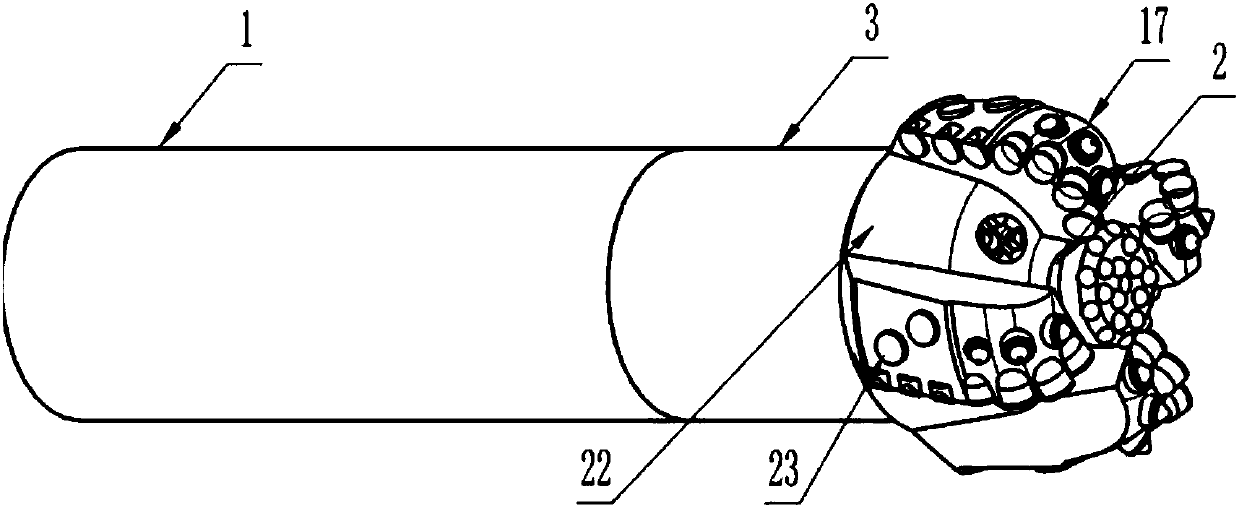

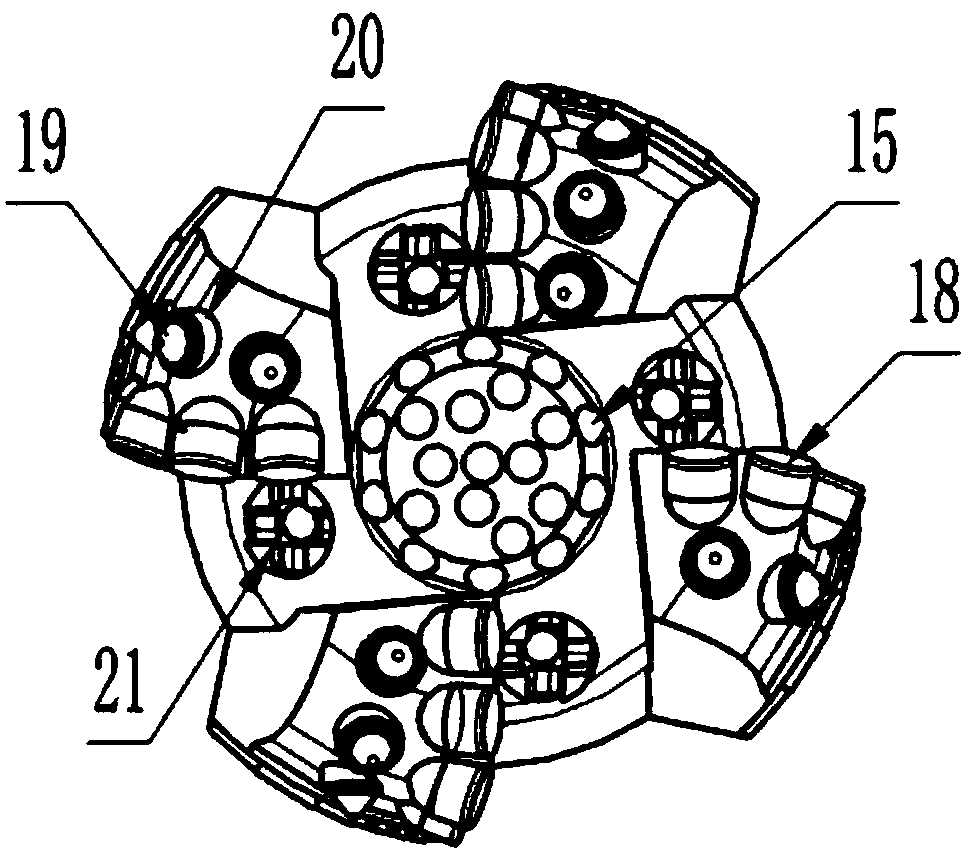

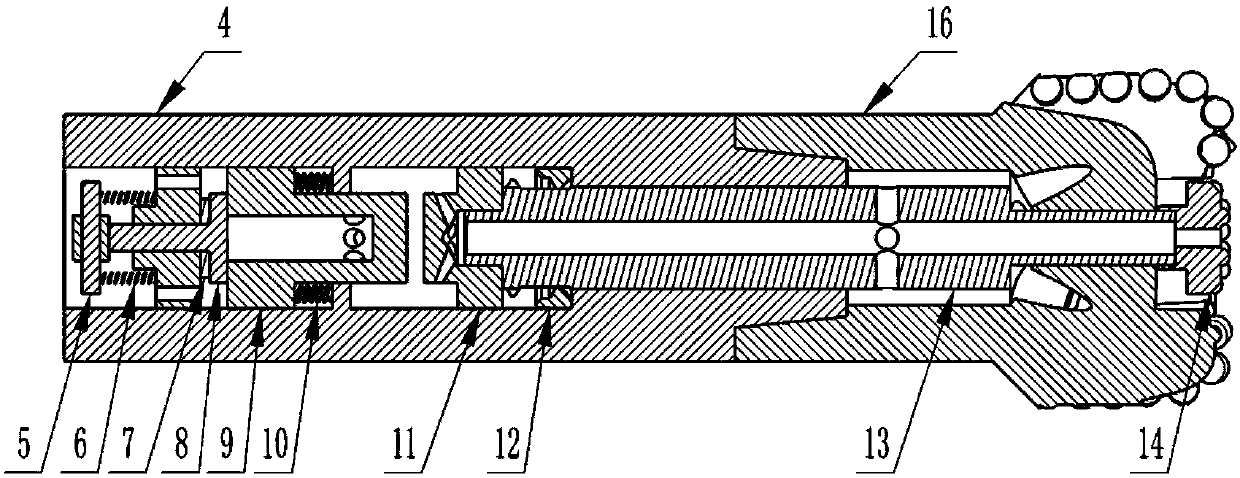

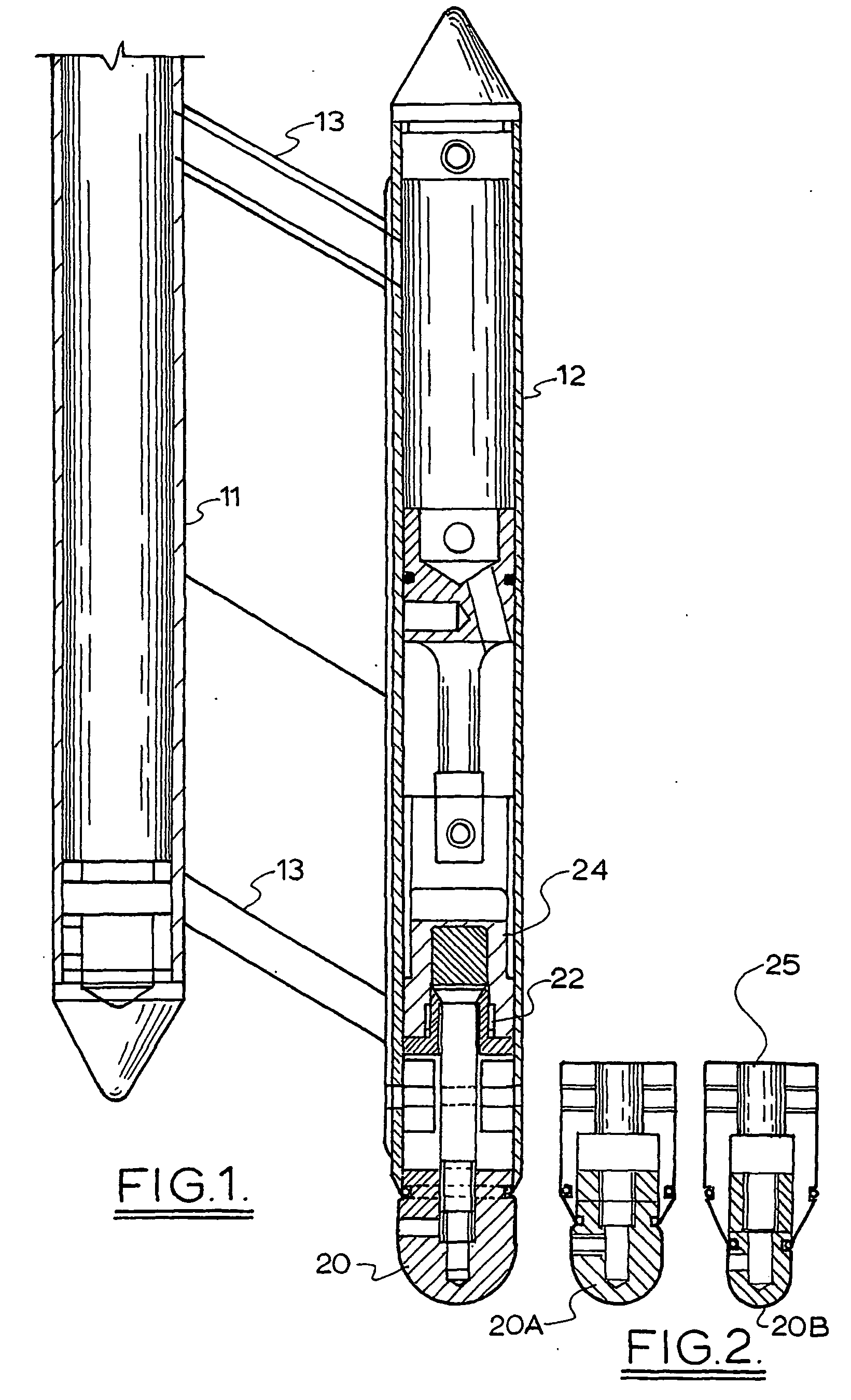

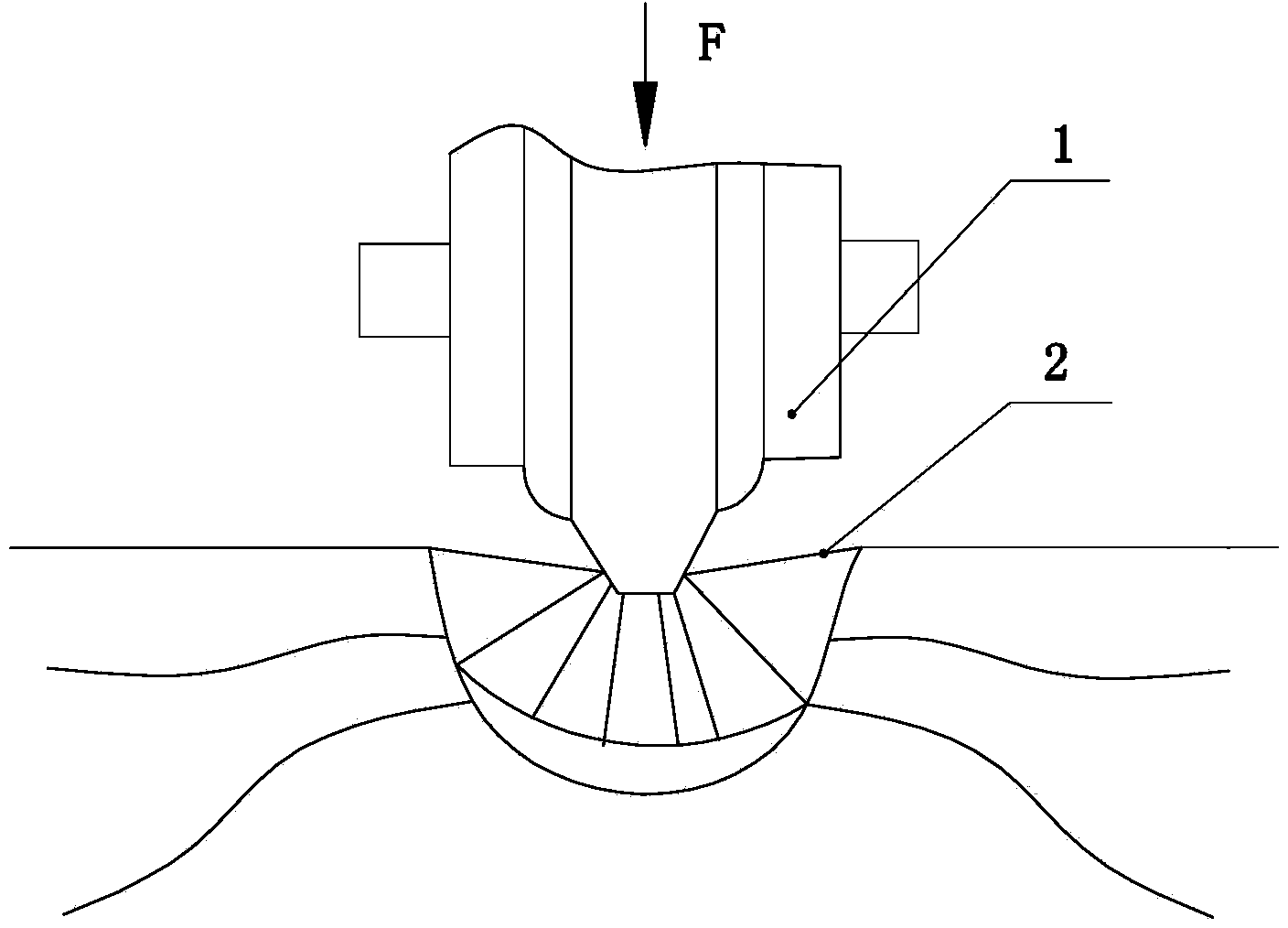

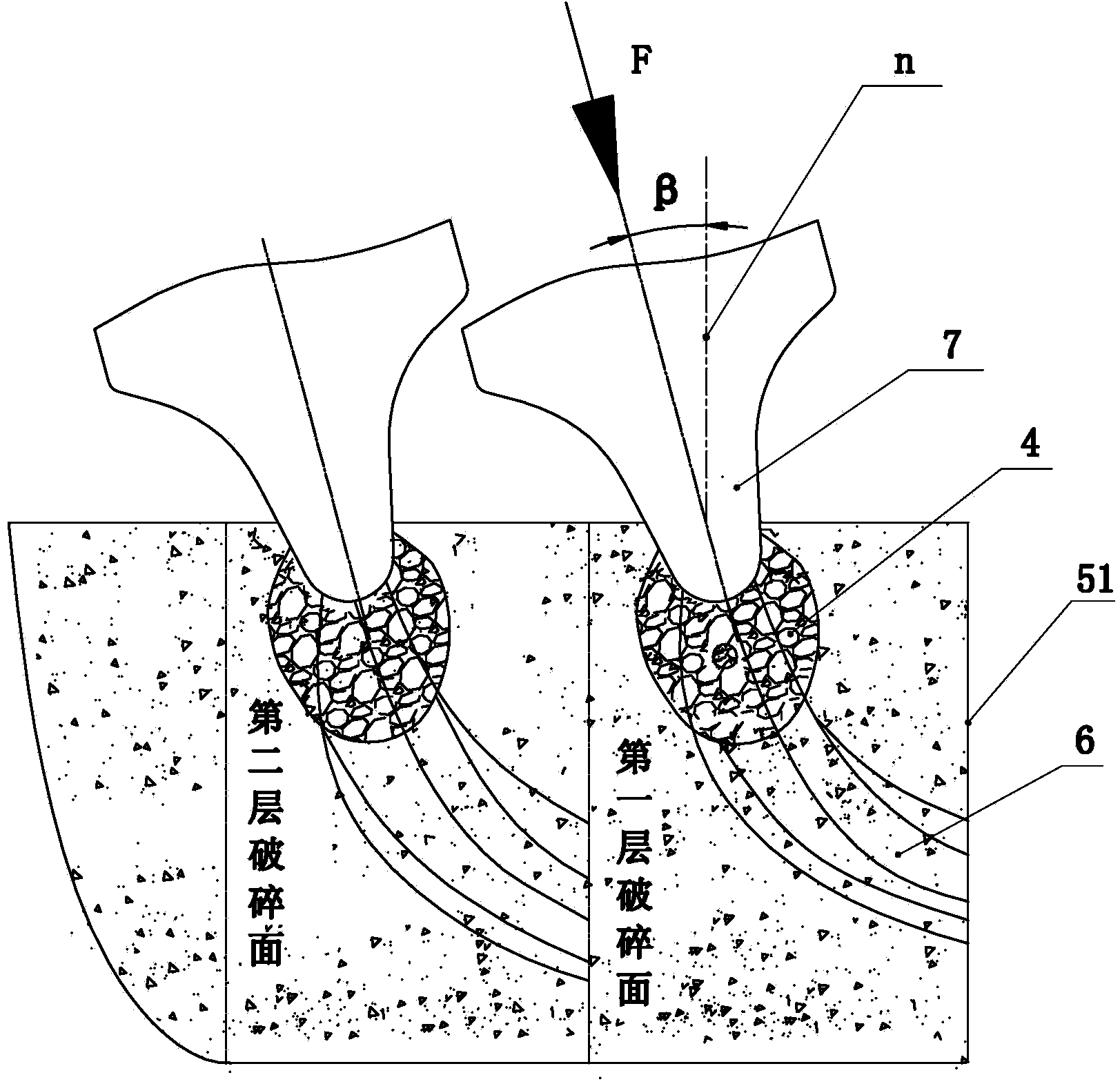

Punching-shear composite drill bit for hard rock drilling

ActiveCN107842317AReduced compressive strengthLow shear strengthDrill bitsTectonic stressPre cracking

The invention discloses a punching-shear composite drill bit for hard rock drilling. The punching-shear composite drill bit comprises three parts of an impactor, an internal punching bore bit and an external cutting drill bit, a lower joint of the impactor can be in threaded connection with the external cutting drill bit, and the upper part of the internal punching bore bit is connected with the impactor in a spline mode; and the lower end face of the internal punching bore bit extends out of the surface of the external cutting drill bit, the central axis of the internal punching bore bit is parallel to or coincident with the central axis of the external cutting drill bit, distributed teeth on the internal punching bore bit and distributed teeth on the external cutting drill bit are combined and can completely cover a downhole, and distributed teeth on the internal punching bore bit and the distributed teeth on the external cutting drill bit are independent of each other. In this way,rock crushing through shearing and rock crushing through impact are creatively combined together, a rock stratum at the hole bottom is pre-cracked first through the internal punching bore bit, the whole tectonic stress of the rock stratum is destroyed, the strength of compression resistance and shearing resistance of rock is reduced so that PDC column teeth and PDC cone teeth can more easily cut / plough-cut the rock, and the rock-breaking efficiency of the super hard rock stratum is greatly improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

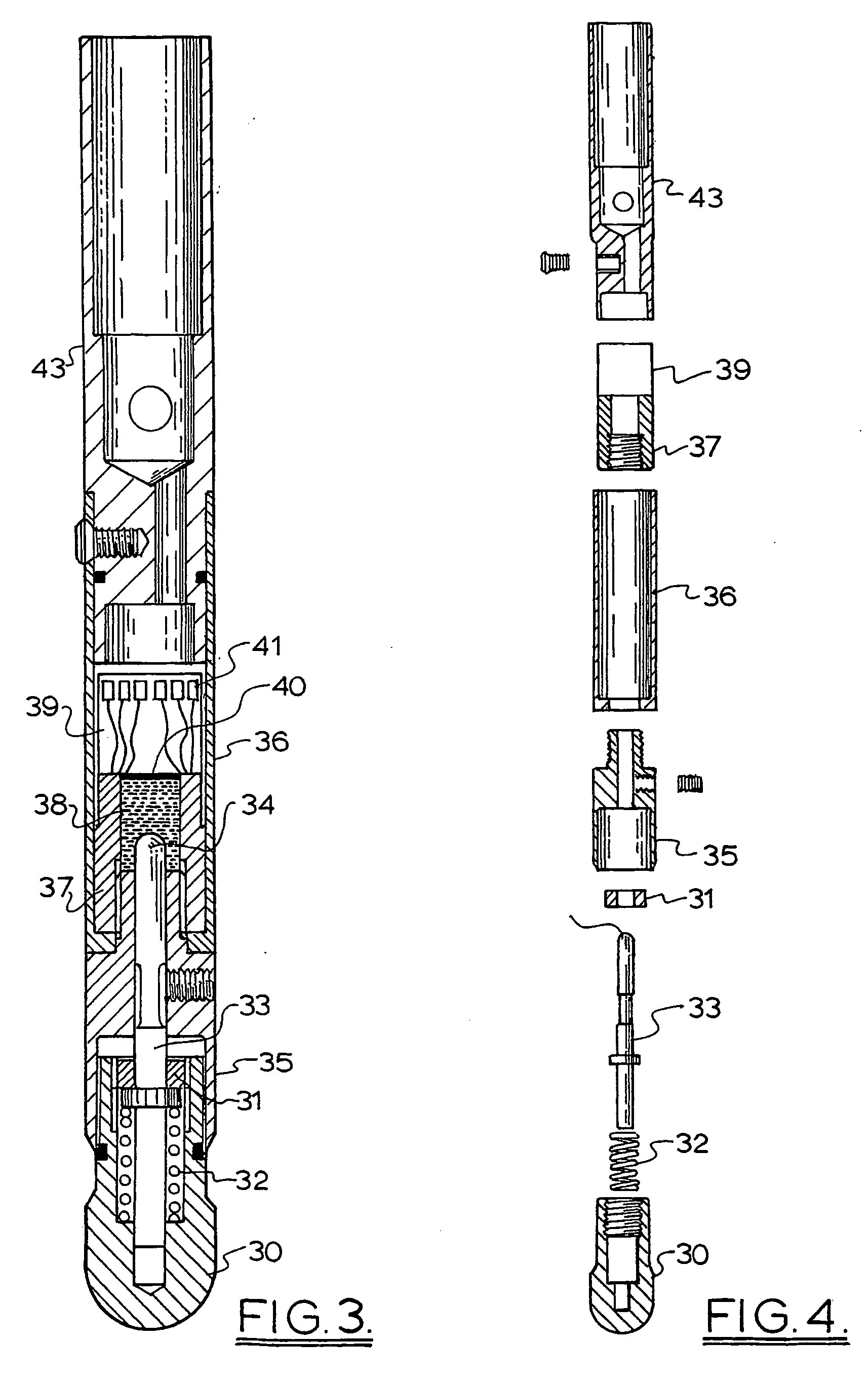

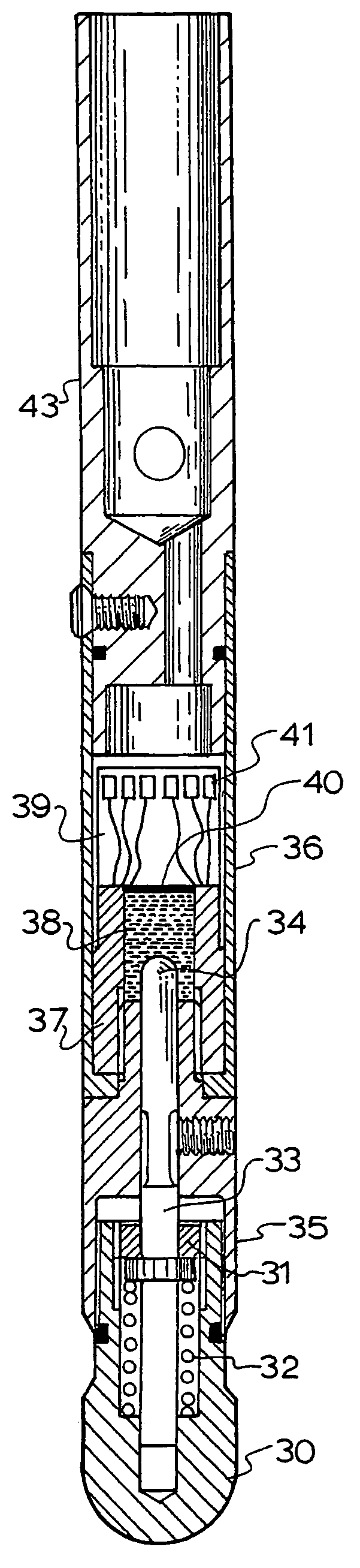

Soil or snow probe

InactiveUS20050076709A1Easy to explainCancel noiseEarth material testingApparatus for force/torque/work measurementAccelerometerEngineering

A soil or snow probe which incorporates a load cell in the probe head and also an accelerometer so that a vertical strength profile of the snow or soil can be established. The device does not need to be driven at a constant speed and can be manually driven into the soil or snow. The resistance to penetration is measured using a load cell which incorporates a low duro polymer selected for its ability to behave like a non compressible fluid. The device is portable and provides data quickly.

Owner:HIMACHAL SAFETY SYST

Magnesium alloy surface treatment method

InactiveCN104805345AReduce heat sensitivityImprove solderabilityMolten spray coatingMetallurgyMaterials science

The invention discloses a magnesium alloy surface treatment method which comprises three stages including a pretreatment stage, a spraying stage and an after-spraying treatment stage. By adoption of a compound spraying method, an anti-corrosion and anti-abrasion coating layer which is high in bonding strength, high in compactness and small in environment pollution is formed on the magnesium alloy surface; the surface treatment method is simple and feasible and is low in cost.

Owner:SUZHOU TONGMING MACHINERY

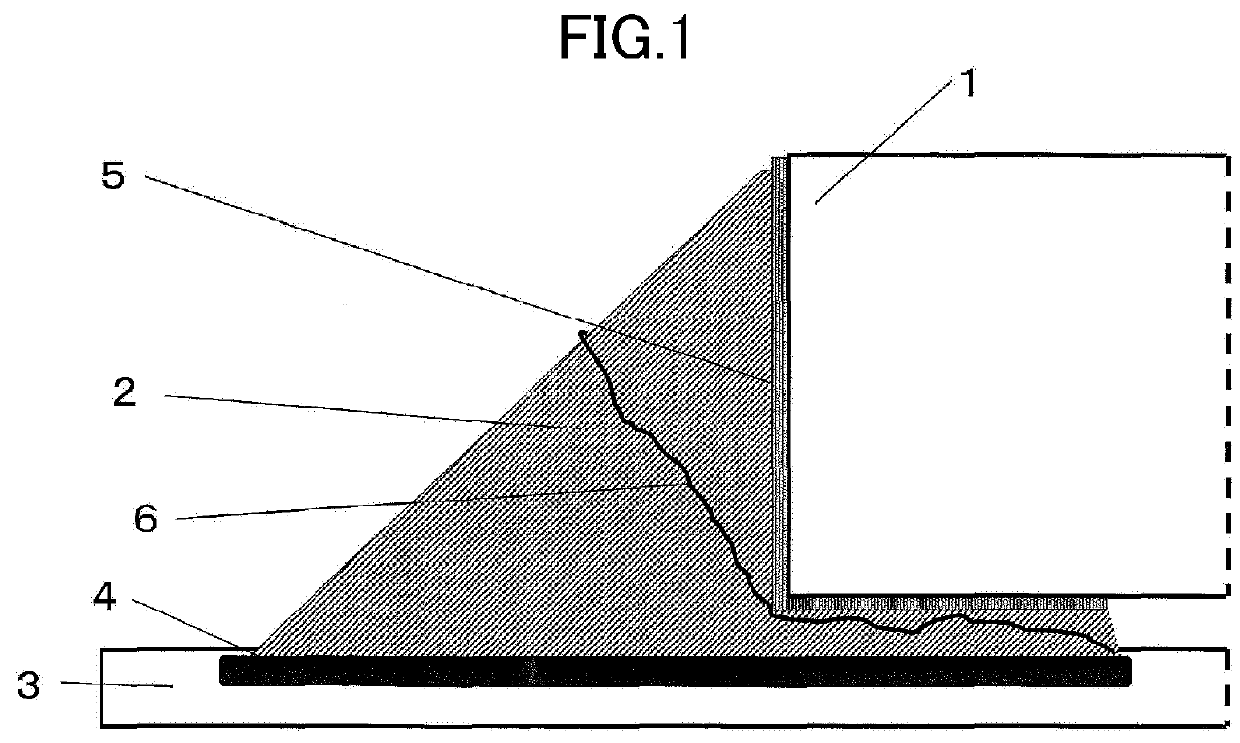

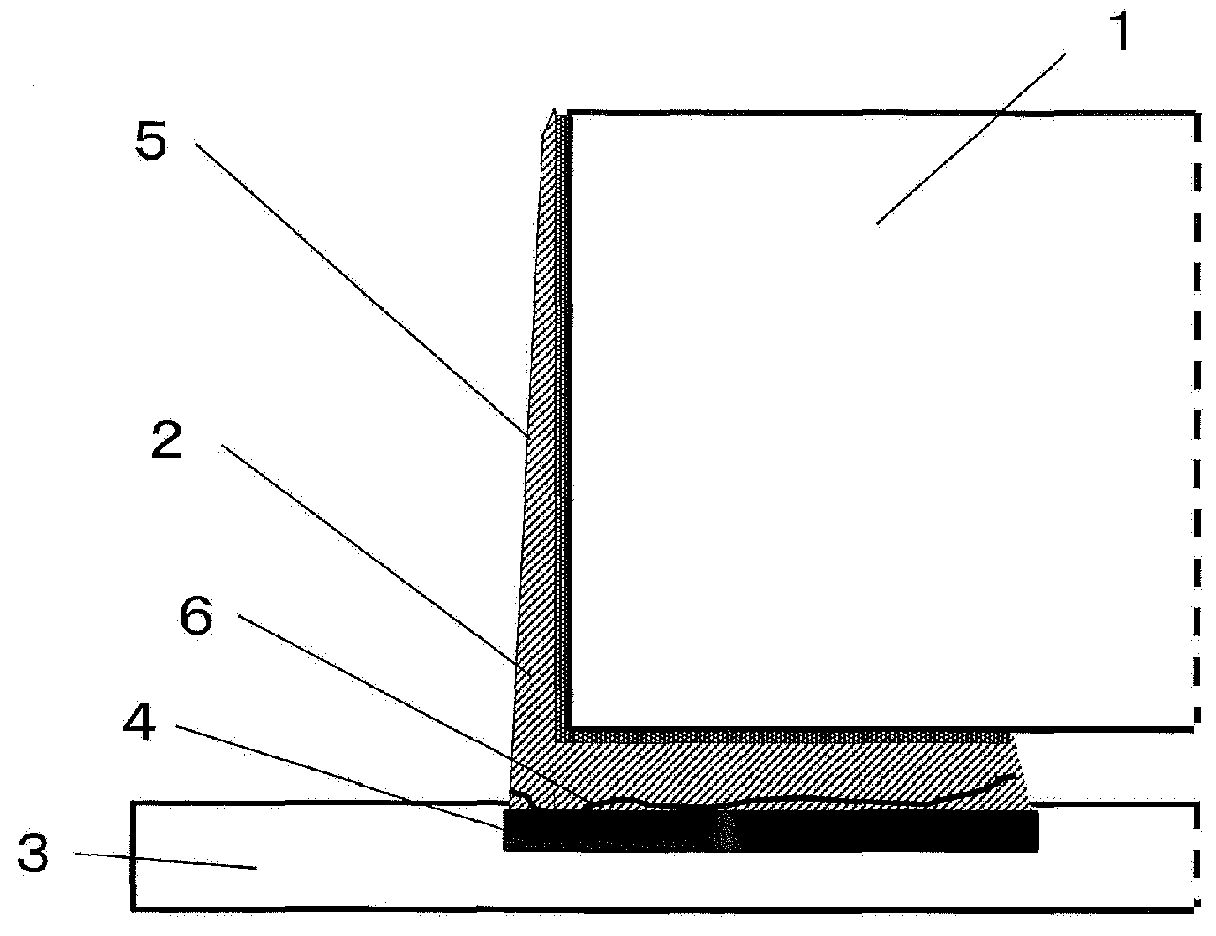

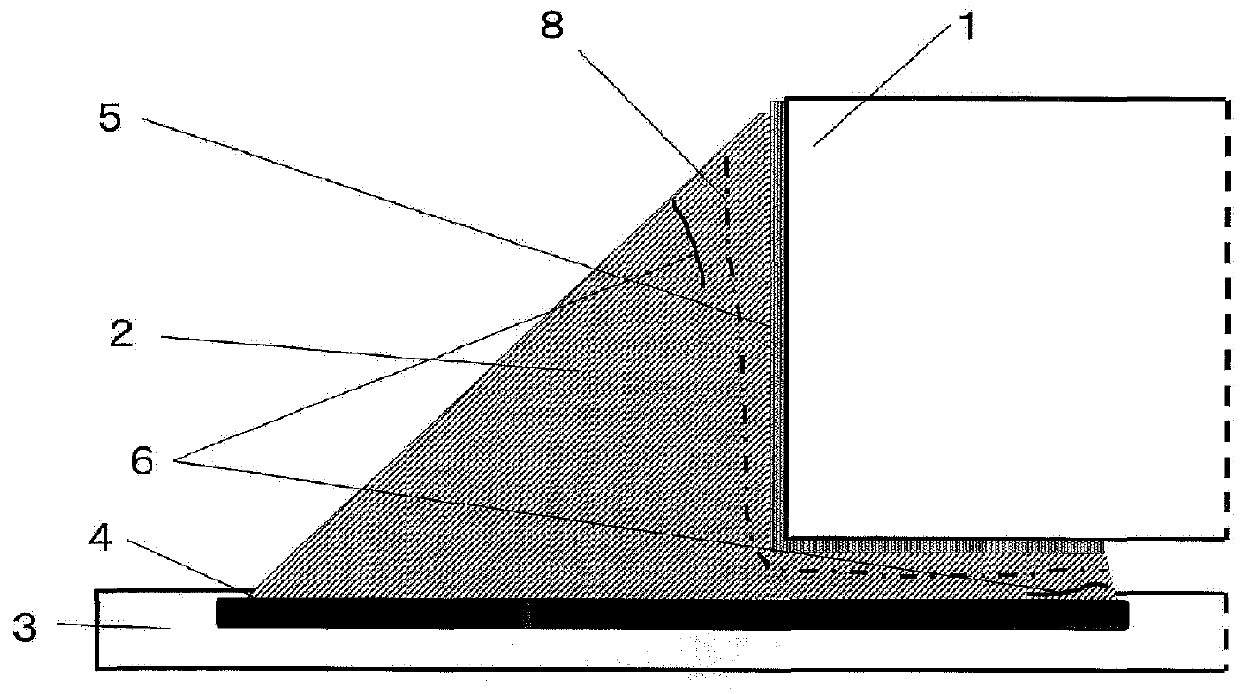

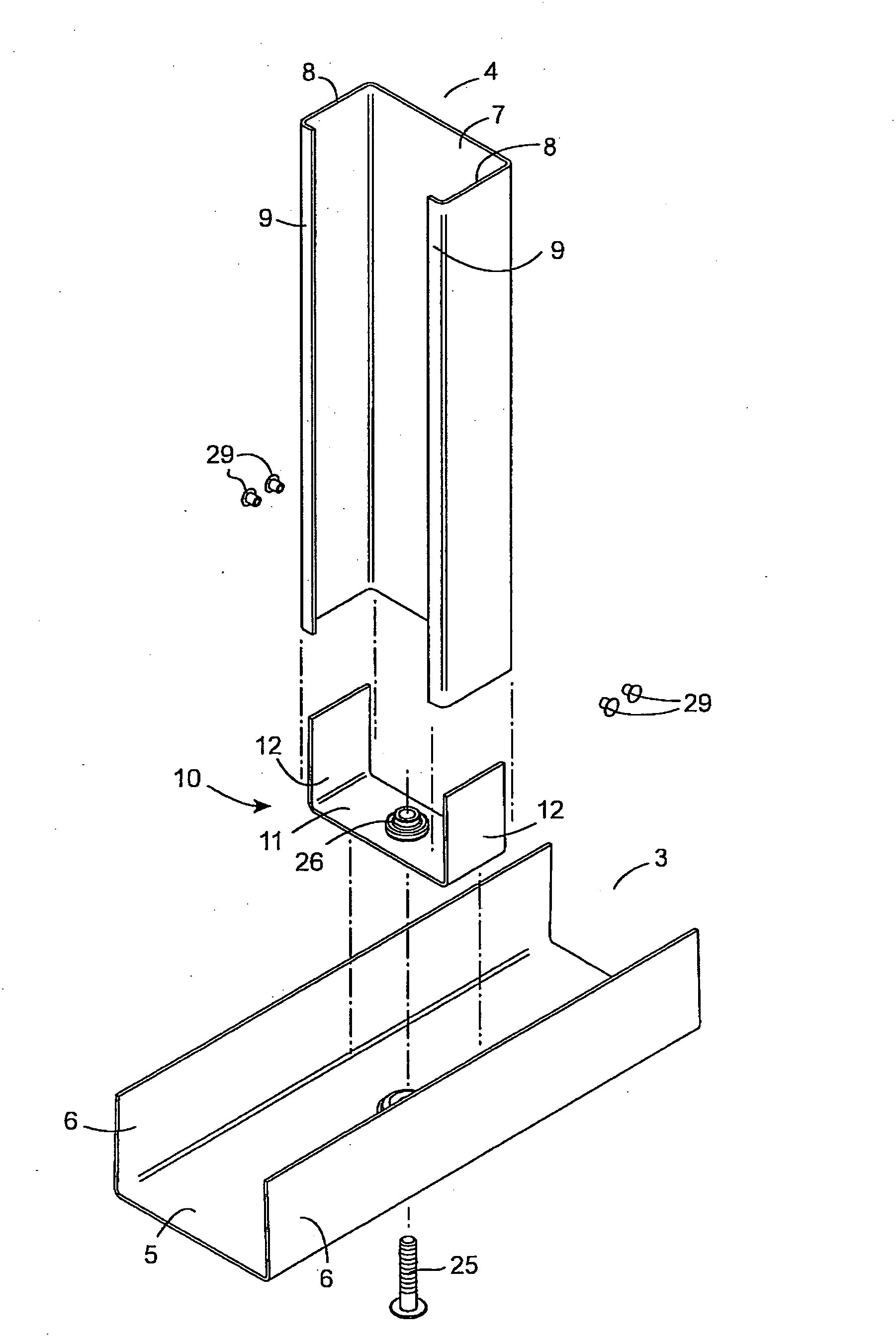

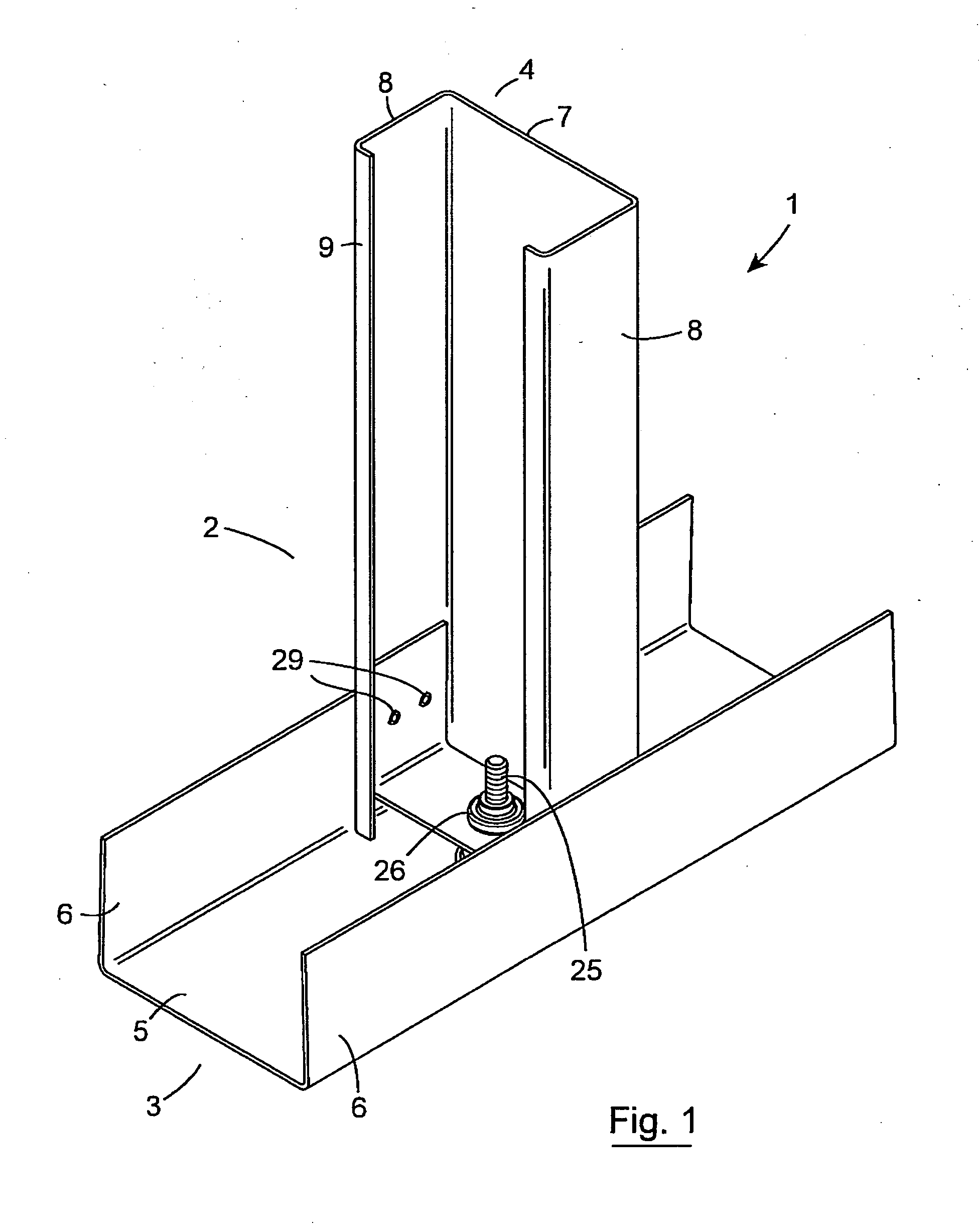

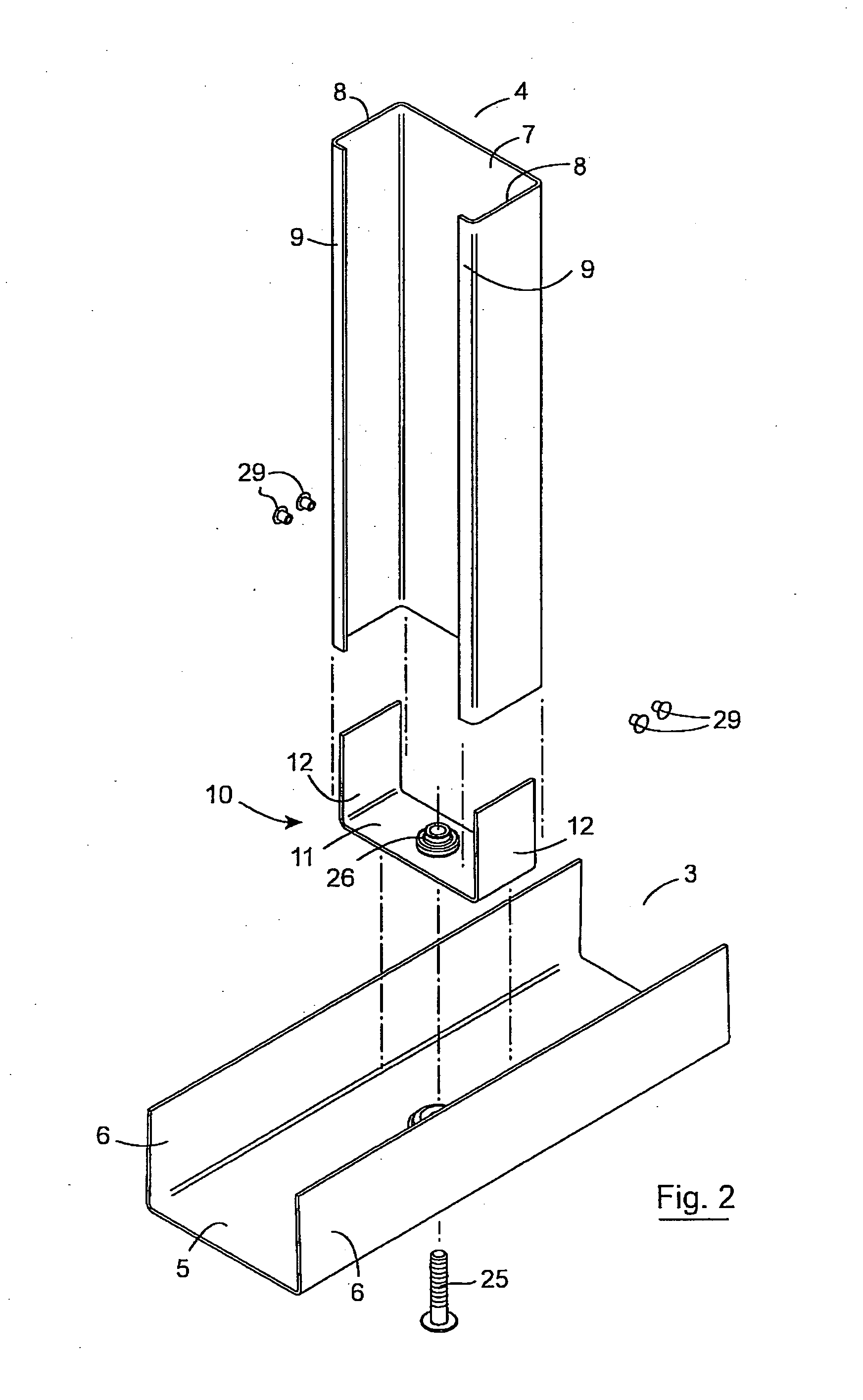

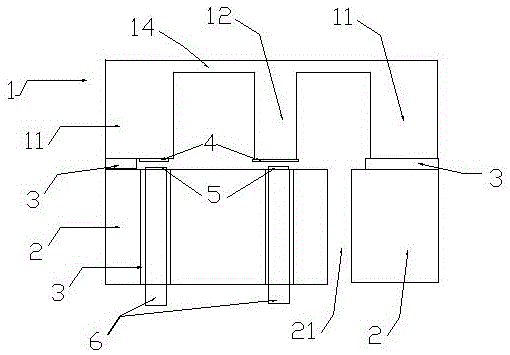

Framing system of studs and rails connected together by adapter members

InactiveUS20100083606A1Low shear strengthHigh complexityWallsBuilding reinforcementsEngineeringFlange

A framing system (1) comprises track frame elements (3) and stud frame elements (4) which are interconnected at joints (2). The framing system comprises connection means for interconnecting the frame elements (3, 4) on assembly. The connection means comprises an adaptor (10) for a frame element and fixing means for fixing the adaptor to the frame elements. The adaptor conforms to at least part of the profile of at least one of the frame elements. In one case the adaptor (10) is of generally channel profile comprising a web (11) and side flanges (12). The side flanges of the adaptor (10) are engagable in the end of the stud frame element (4) such that the flanges (12) of the adaptor engage with the flanges (8) of the stud frame element (4). Rivets (30) are used to fix the stud frame element (4) to the adaptor (10). Track fixing means comprising a fixing bolt (25) extending to engage with a receiver (26) which is captive in the web (11) of the adaptor (10). The cross section of the stud frame element (4) has full bearing with the track frame element (3) for efficient load transfer.

Owner:KINGSPAN HLDG (IRL) LTD

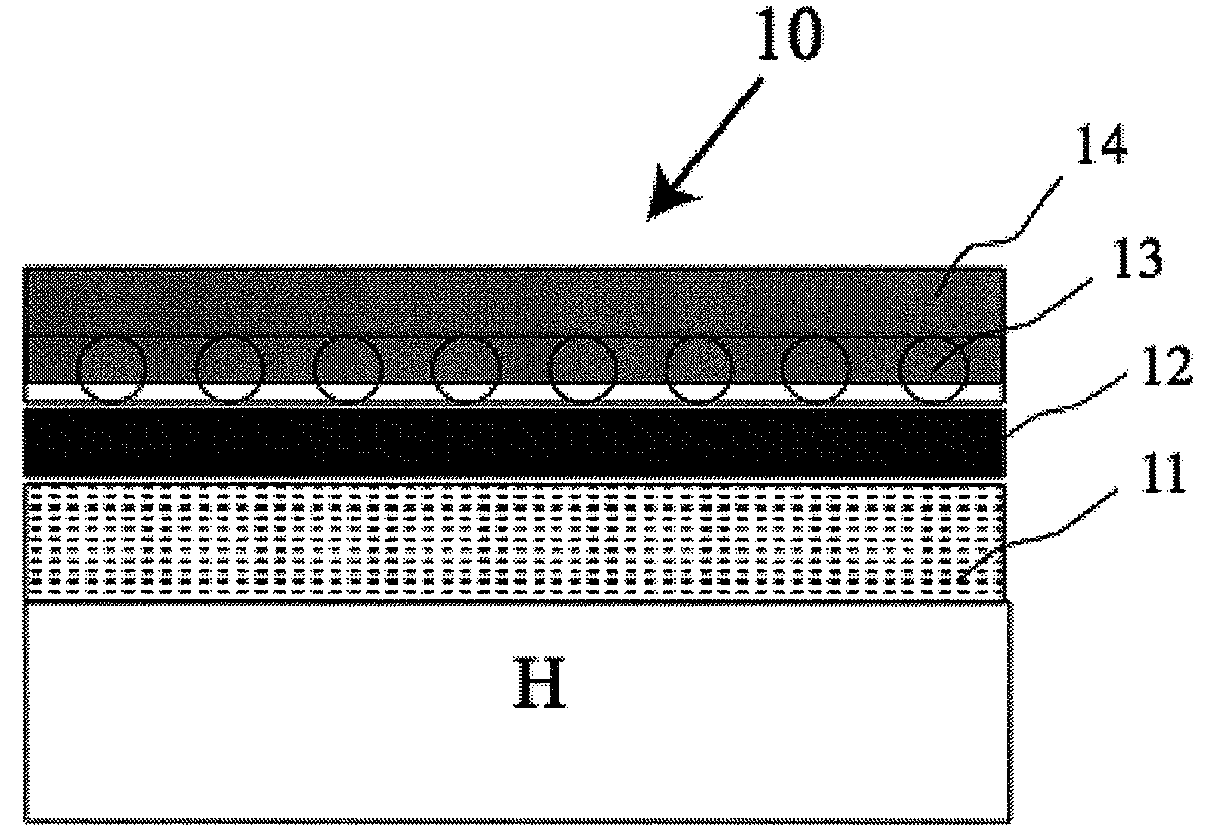

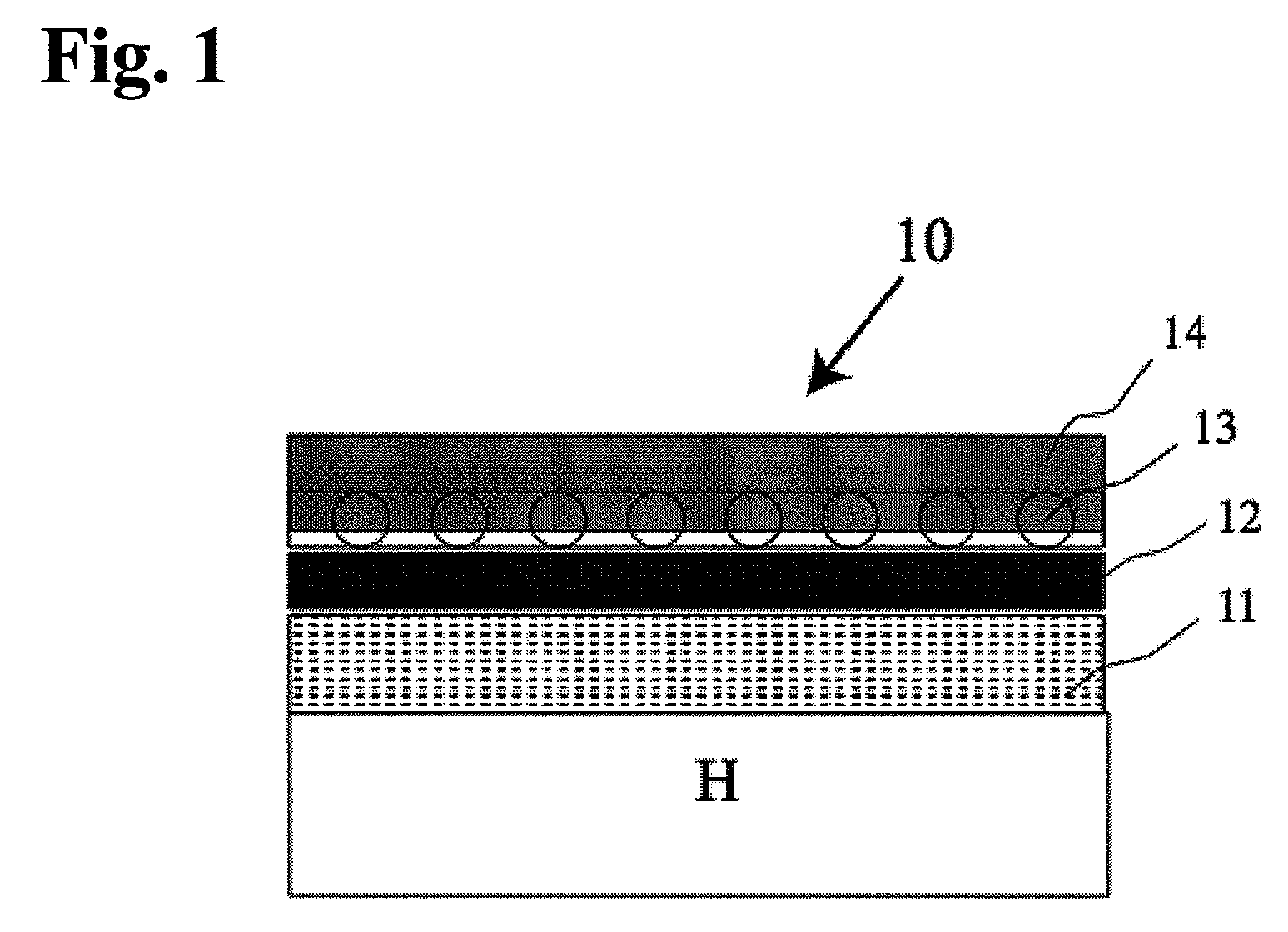

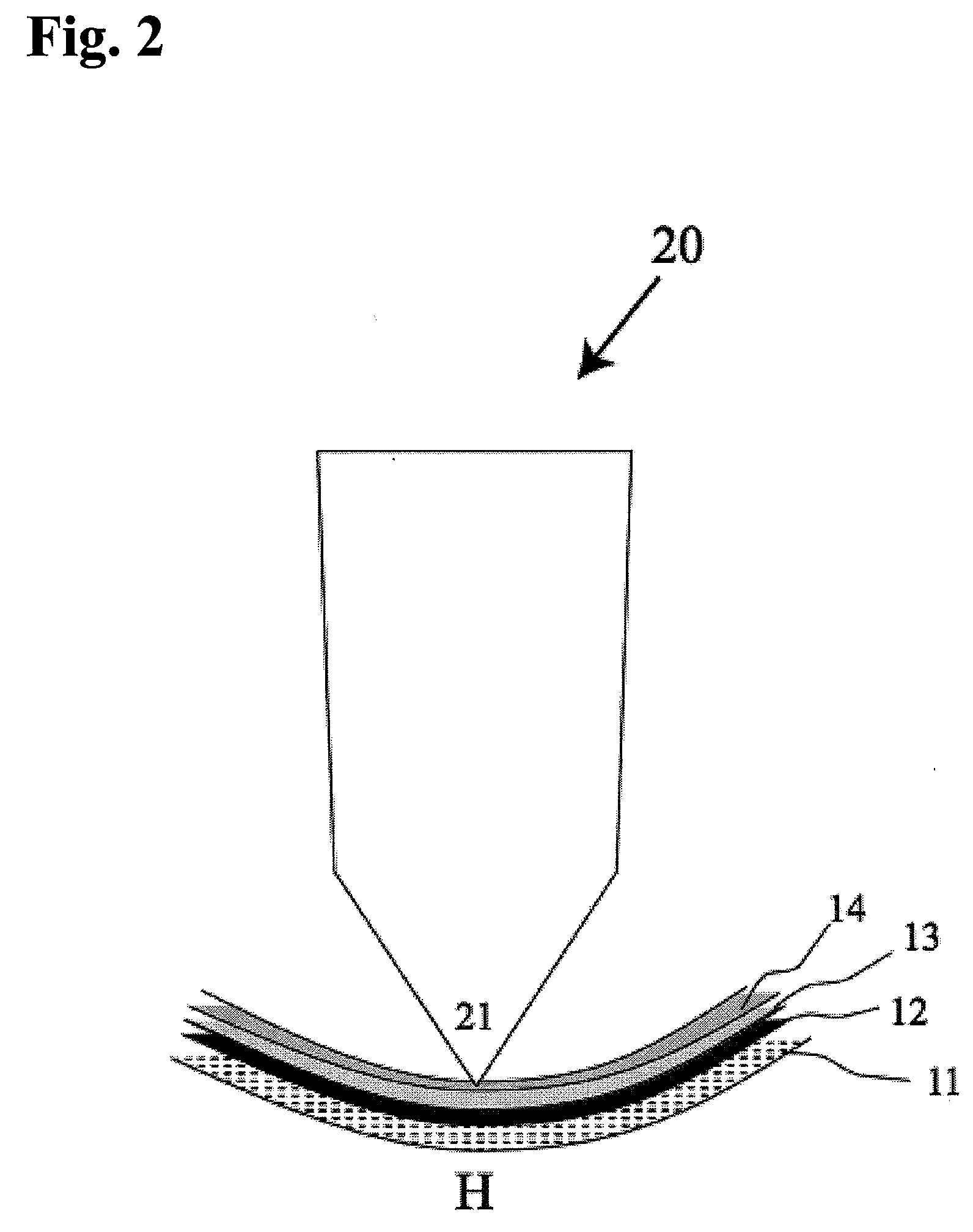

Pressure-sensitive adhesive for wafer grinding and preparation method thereof

InactiveCN103571367AImprove cohesionGood adhesionFilm/foil adhesivesPolyureas/polyurethane adhesivesPlastic materialsCohesive strength

The invention discloses a pressure-sensitive adhesive for wafer grinding and a preparation method thereof. The adhesive comprises a plastic base material, an adhesive layer coated on the base plastic material, and a release film which covers the adhesive layer. The preparation method of the pressure-sensitive adhesive comprises the following steps of: A) preparing a prepolymer; B) preparing an adhesive; C) preparing an adhesive tape. Compared with the prior art, the preparation method has the advantages that the dose and addition way of an initiating agent as well as the polymerizing temperature are controlled to realize the maximum molecular weight as well as high cohesive strength, and the problems of relatively high peeling strength and small shearing strength of the traditional pressure-sensitive adhesive are solved. In addition, a hard monomer added brings the pressure-sensitive adhesive with high shearing strength, and the demand on wafer grinding is met. The pressure-sensitive adhesive for wafer grinding is different from other adhesive tapes for wafer grinding in that a silane coupling agent bringing water resistance is directly polymerized onto a polymer molecular chain, instead of being directly added. Therefore, the migration of micromolecule in storage process is avoided, and the resulting influence to the effect or the resulting residue on a wafer is removed.

Owner:YANTAI DARBOND TECH

Soil or snow probe

InactiveUS7040146B2Easy to explainCancel noiseEarth material testingMaterial strength using single impulsive forceAccelerometerEngineering

A soil or snow probe which incorporates a load cell in the probe head and also an accelerometer so that a vertical strength profile of the snow or soil can be established. The device does not need to be driven at a constant speed and can be manually driven into the soil or snow. The resistance to penetration is measured using a load cell which incorporates a low duro polymer selected for its ability to behave like a non compressible fluid. The device is portable and provides data quickly.

Owner:HIMACHAL SAFETY SYST

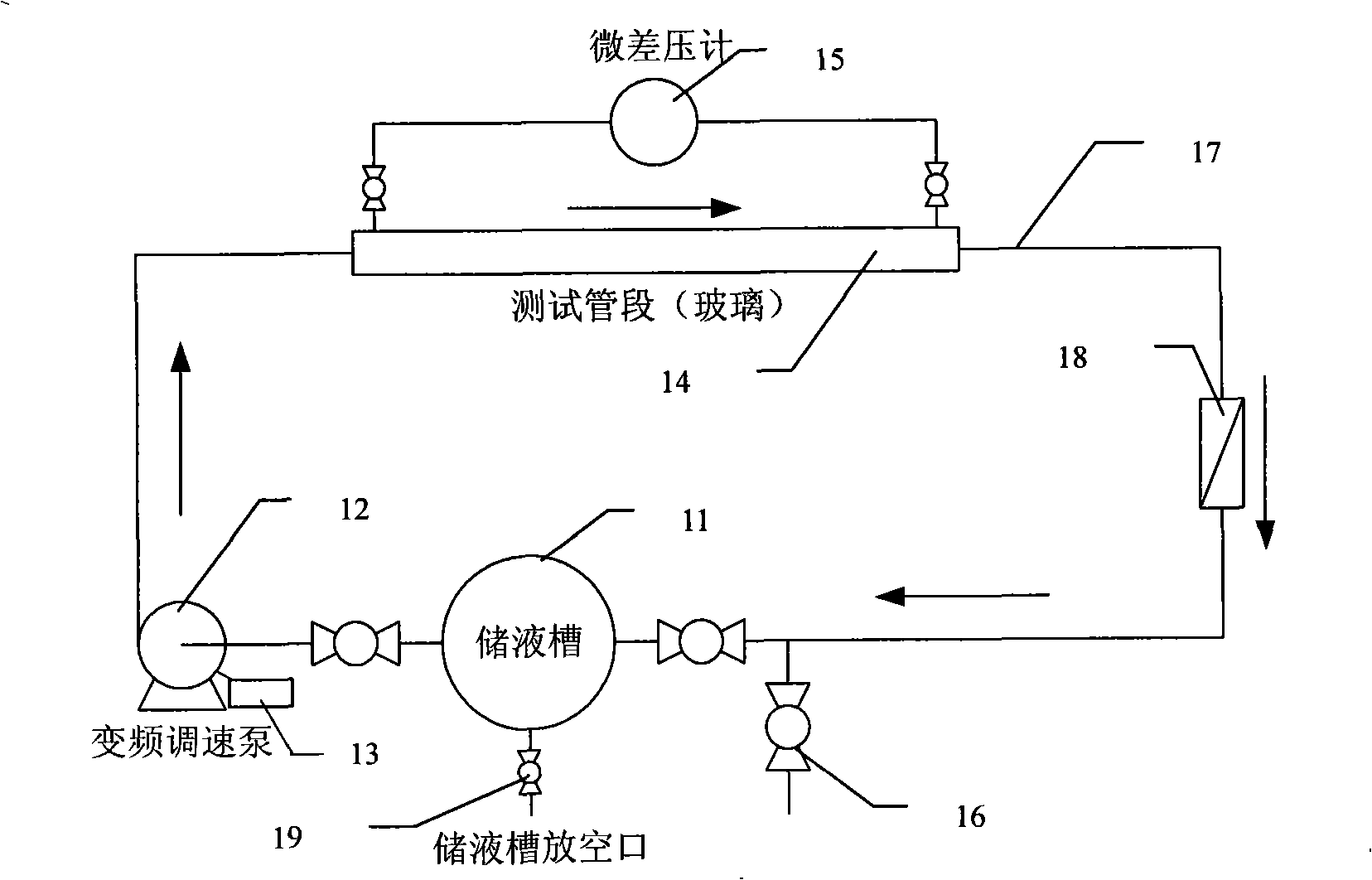

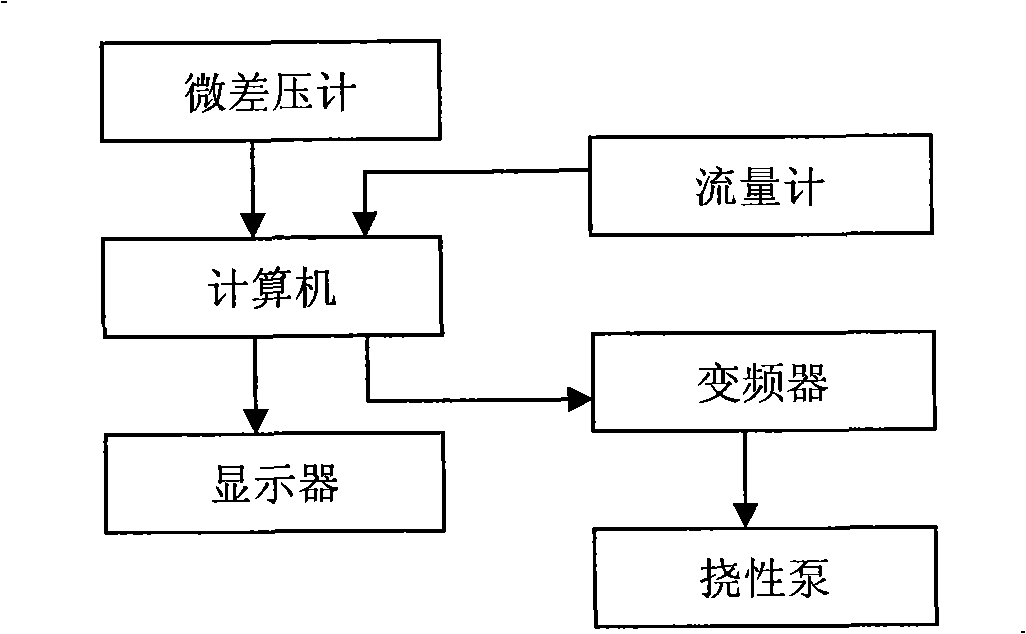

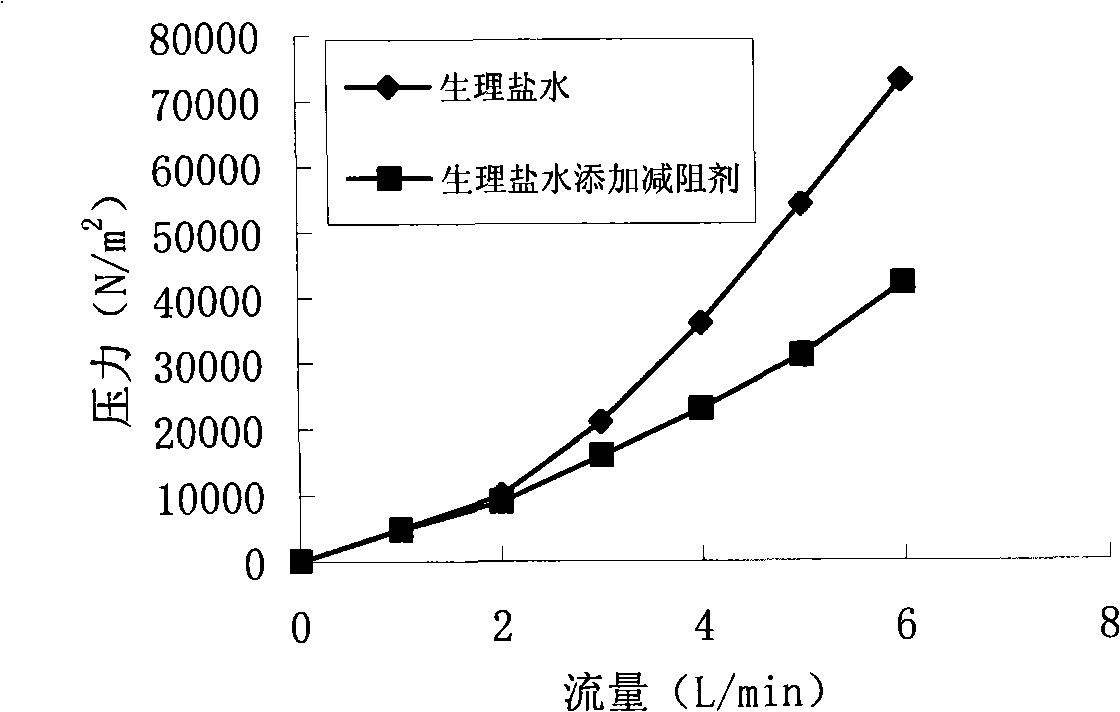

Liquid line flow resistance force detection device and method for detecting drag reduction effect of drag reducer

InactiveCN101329245AIncrease credibilityLow shear strengthVolume/mass flow by differential pressureDirect flow property measurementFrequency changerLiquid storage tank

The invention discloses a liquid pipe resistance detection device which is used for evaluating the drag reduction effect of drag reduction agent. The detection device comprises a set of liquid circulation units and a detection unit; the liquid circulation unit is provided with a liquid storage tank and a circulation pipeline which is formed by a plurality of connecting pipelines and ball valves; the circulation pipeline is provided with a flexible pump and a transducer; furthermore, two ends of a measurement pipe section are respectively provided with a micro-difference pressure meter; the detection unit is electrically connected with the transducer and the micro-difference pressure meter. The liquid pipe resistance detection device adopts the flexible pump which has lower shearing strength than that of a centrifugal pump used in the prior art and is more suitable for evaluating the drag reduction effect; the liquid pipe resistance detection device uses the transducer to control the displacement of the pump, and measures the difference pressure only to simplify the detection device and the operation step, to reduce the measurement links and possible errors and to improve the reliability of results.

Owner:FIELD OPERATION BLOOD TRANSFUSION INST OF PLA SCI ACAD OF MILITARY

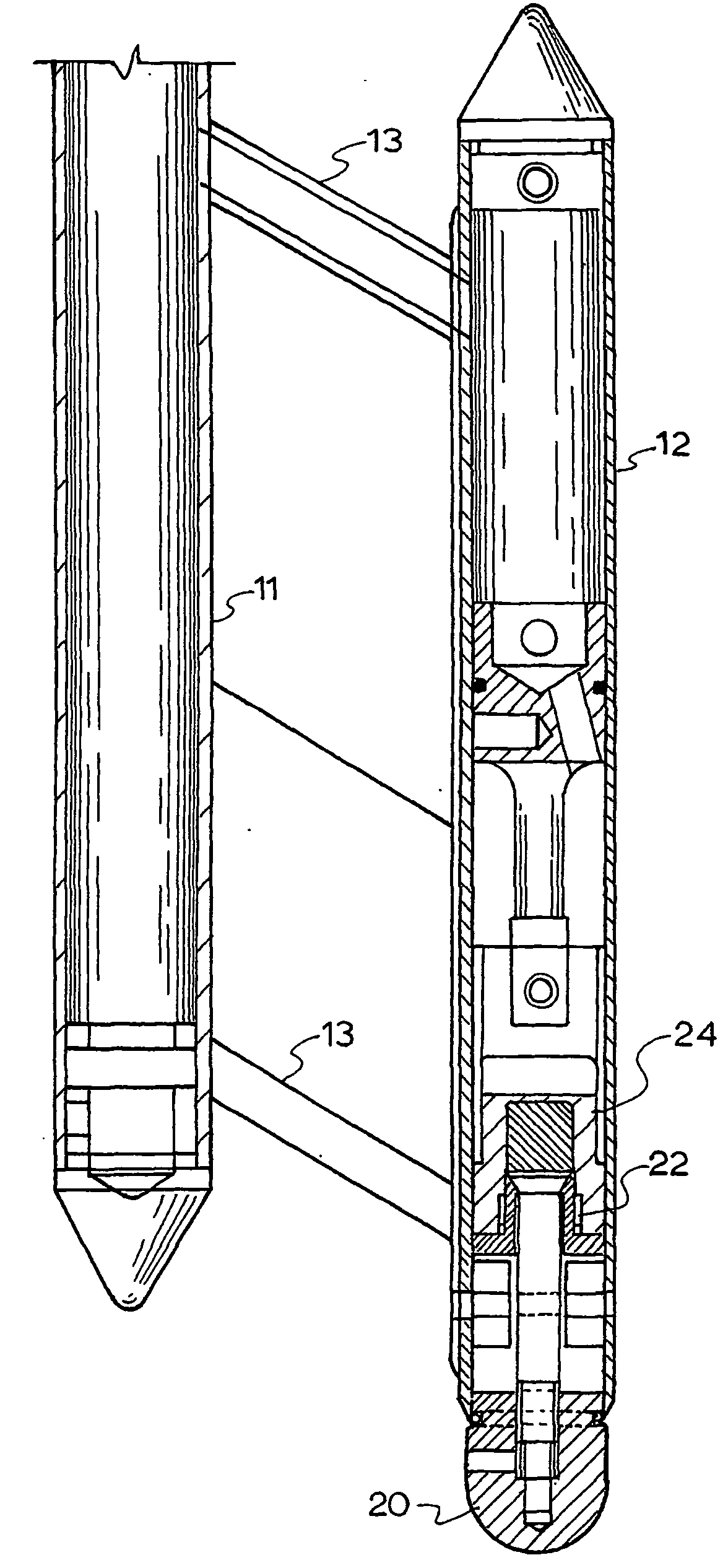

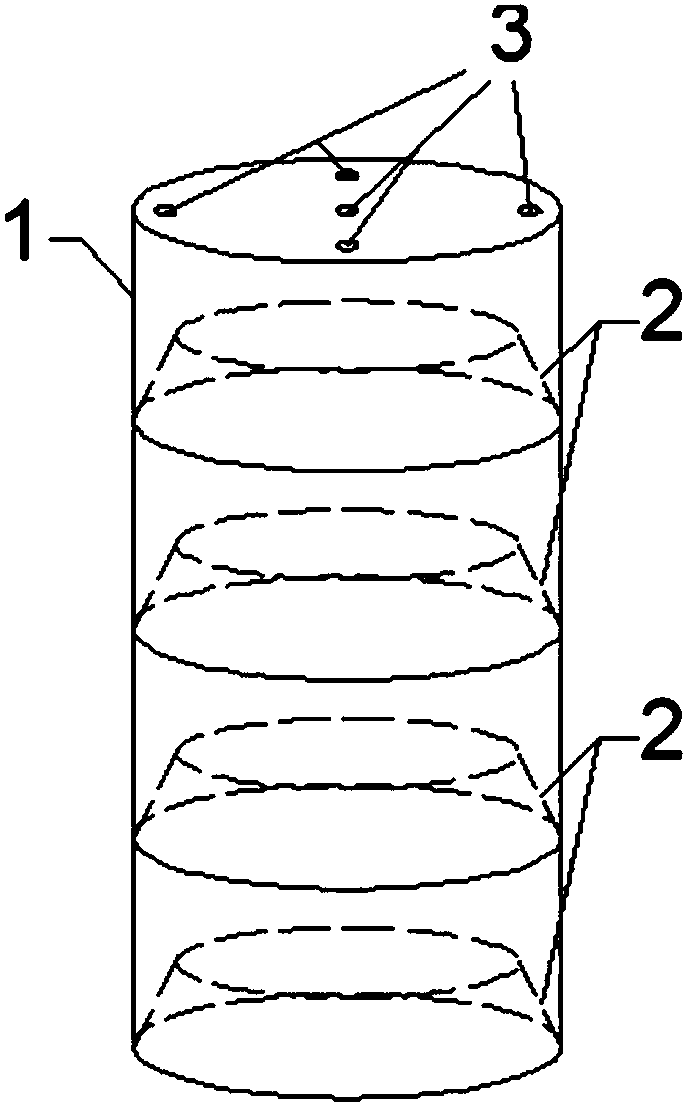

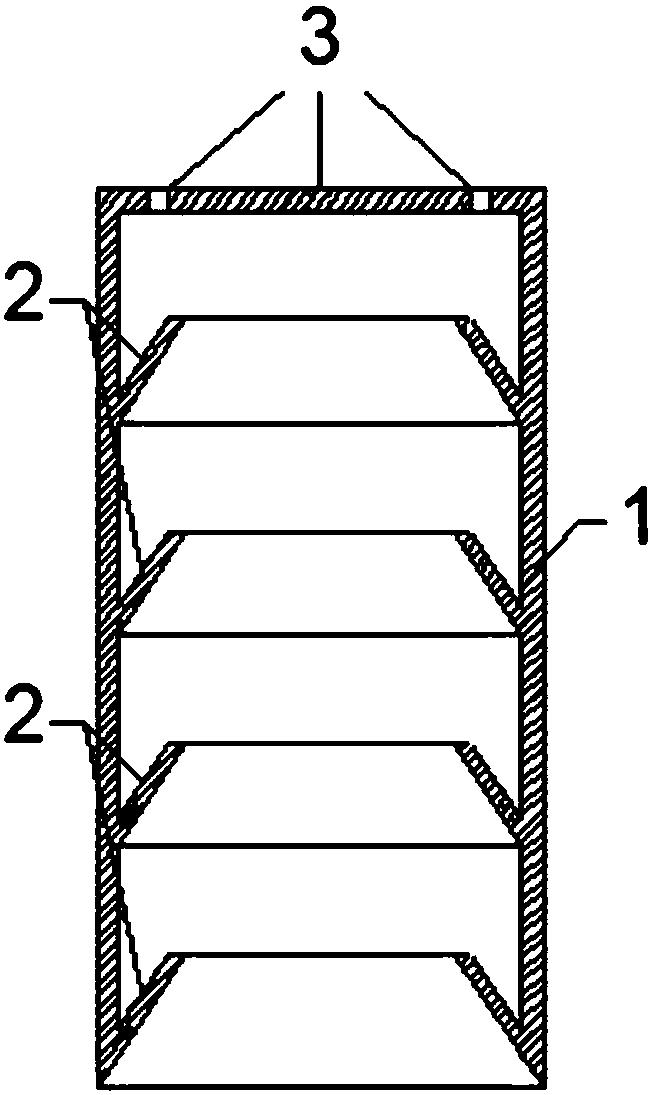

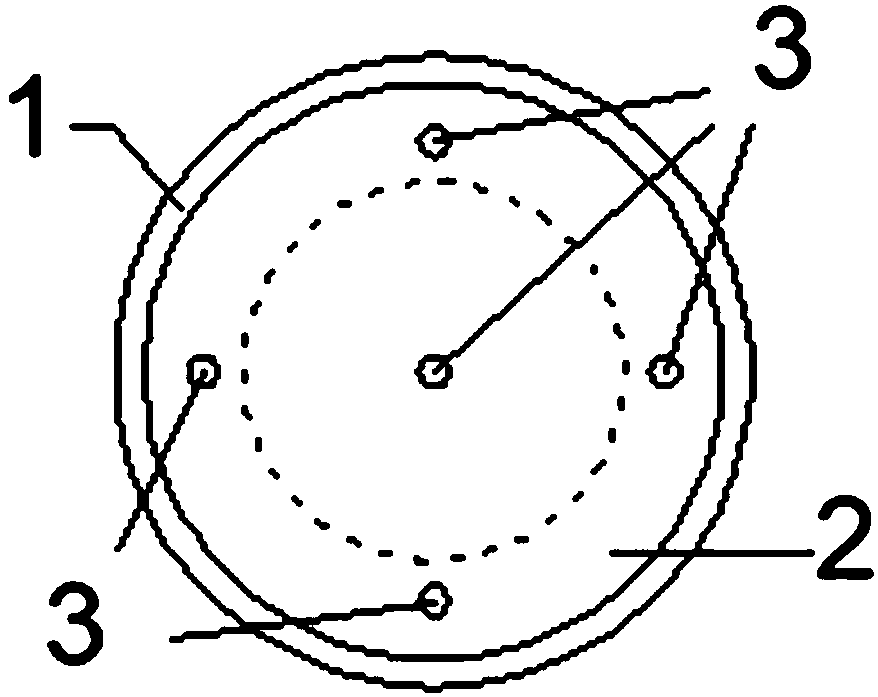

Inner ring type seabed suction anchor for deep sea and installation method thereof

ActiveCN108425379AReduce resistanceReduce construction costsFoundation engineeringSuction stressSea waves

The invention discloses an inner ring type seabed suction anchor for deep sea and an installation method thereof. The suction anchor comprises a suction main barrel, the suction main barrel is of a barrel type structure of which the bottom is opened and the top end is closed, the inner wall of the suction main barrel is provided with a plurality of hollow annular bulges at equal intervals along anaxial direction, the inner wall of the suction main barrel and the side walls of the hollow annular bulges form a barb-shaped structure, and the center and the edges of the top of the suction main barrel are provided with drainage holes. The suction anchor can more smoothly sink and penetrate into the soil, can sink to the preset design depth, reduces the disturbance to the soil outside the barrel to the maximum extent under the effect of increasing side friction resistance, and reduces the erosion of sea waves on existing foundations; the vertical bearing capacity and the ultimate pull-out resistance bearing capacity of the suction anchor can be greatly improved under various working conditions; and under the condition of realizing the functions, the convenience of recycling the suctionanchor can also be ensured.

Owner:ZHEJIANG UNIV

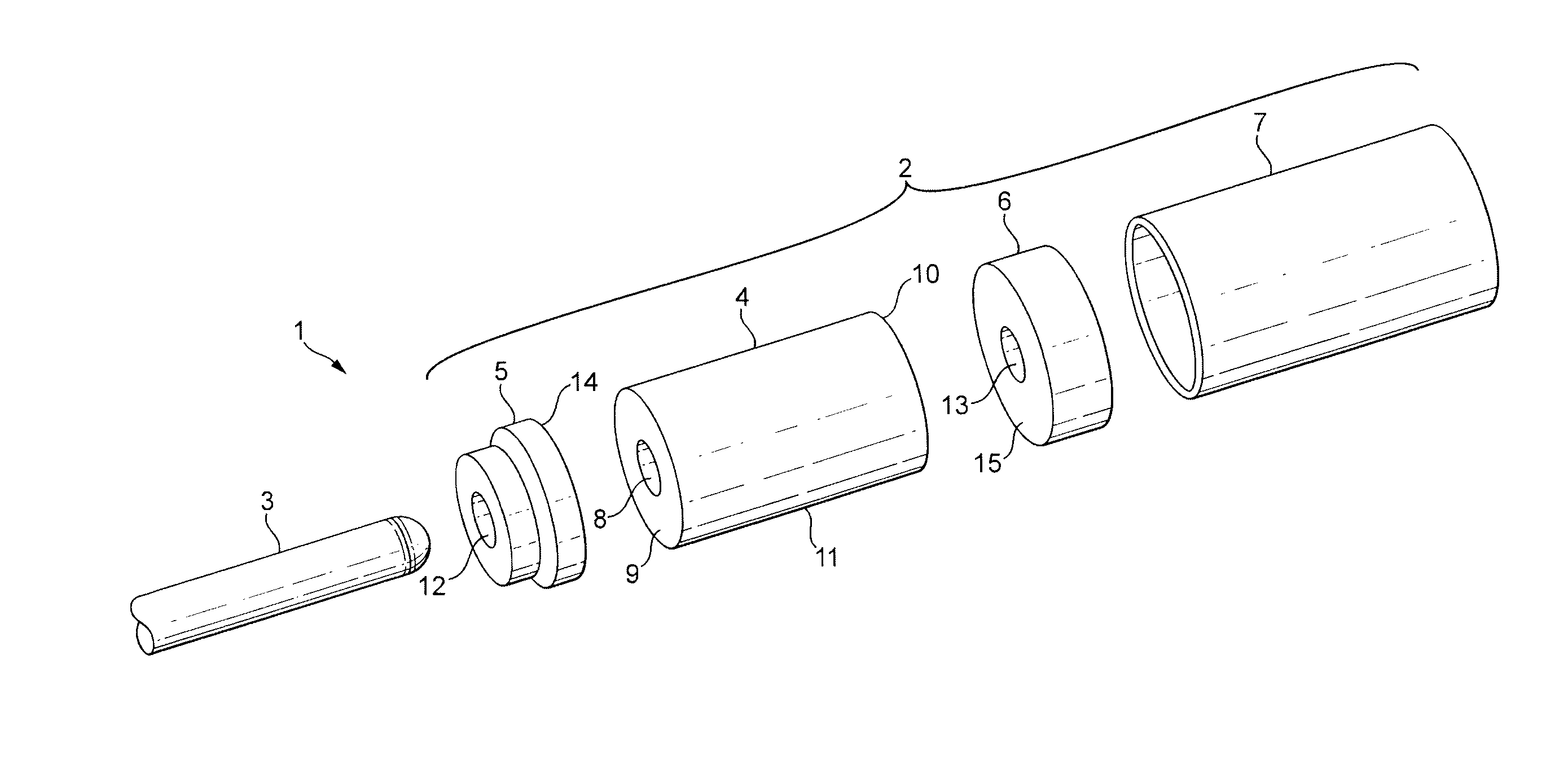

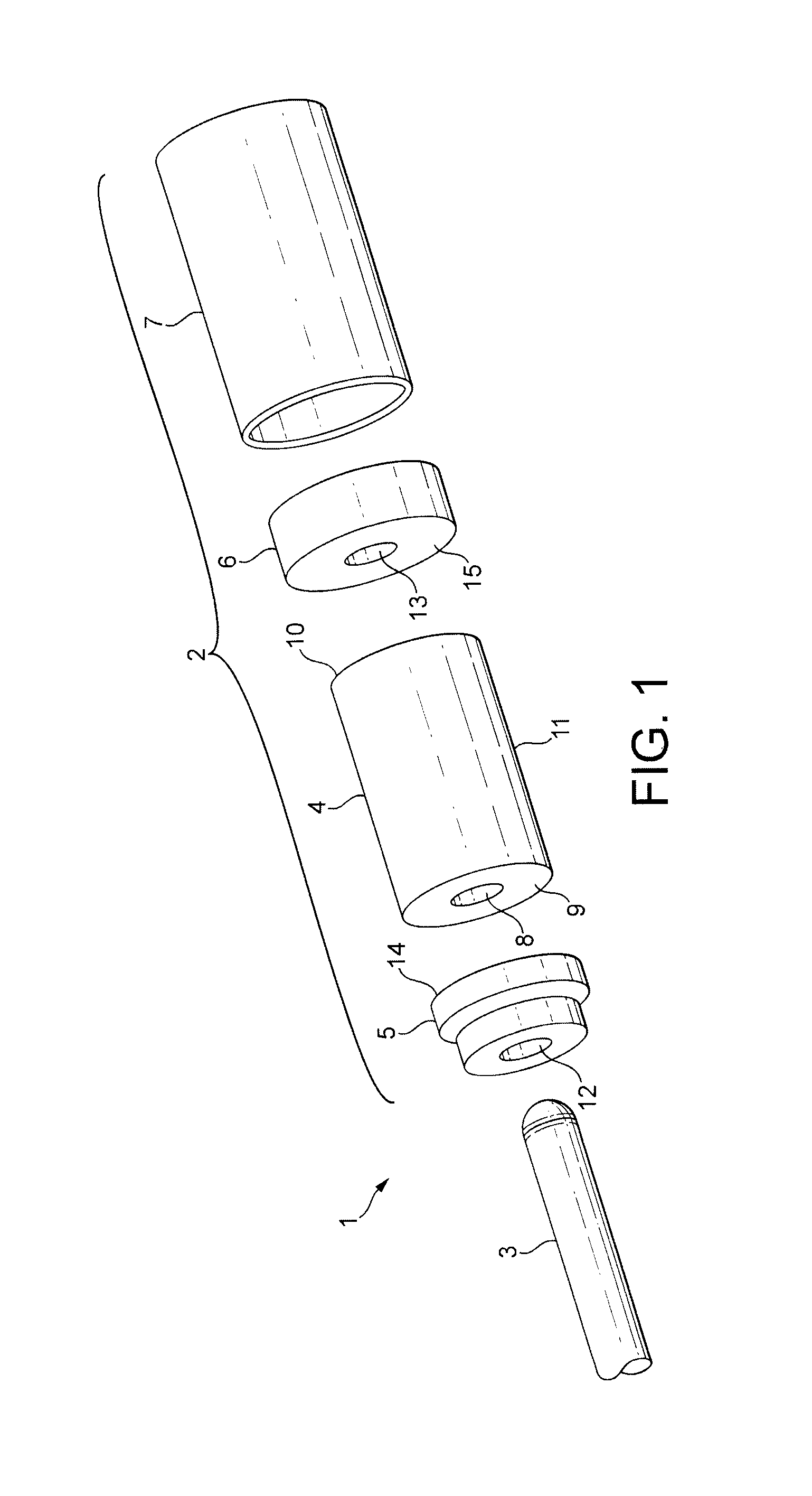

Rotor for an electrical machine

ActiveUS20120049662A1Excessive strainAvoid assemblyMagnetic circuit rotating partsManufacturing dynamo-electric machinesInterference fitElectric machine

A rotor that includes a rotor core assembly secured to a shaft. The rotor core assembly includes a magnet and an end cap secured to an end of the magnet. Each of the magnet and the end cap has a bore into which the shaft extends. The end cap forms an interference fit with the shaft. The magnet forms a clearance fit with the shaft and an adhesive is located in the clearance between the magnet and the shaft. Additionally, a method of manufacturing the rotor. The method includes inserting the shaft into the bore of the end cap. An adhesive is then introduced into the bore of the magnet and the shaft is inserted into the bore of the magnet so as to cause adhesive to be drawn into the clearance defined between the magnet and the shaft.

Owner:DYSON TECH LTD

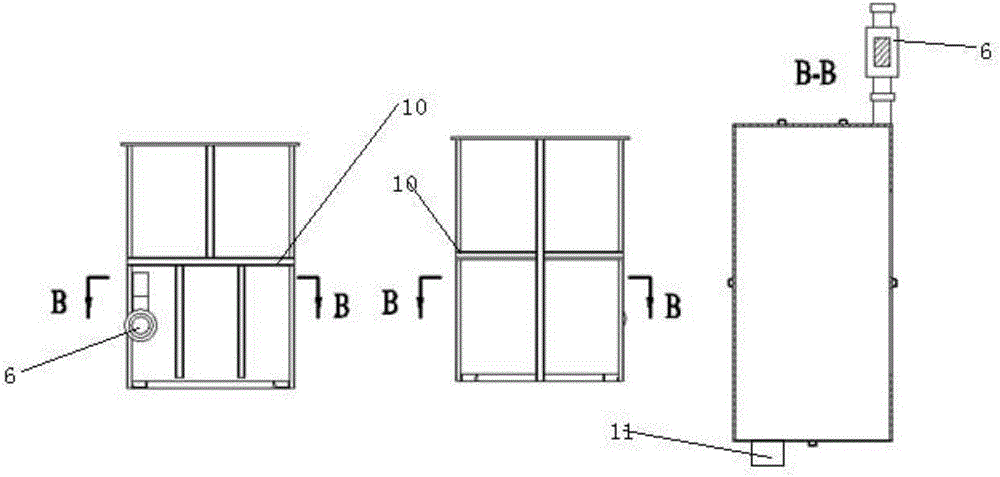

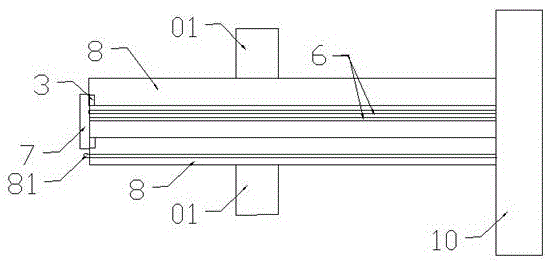

Device and method for depositing film on SiC fiber surface

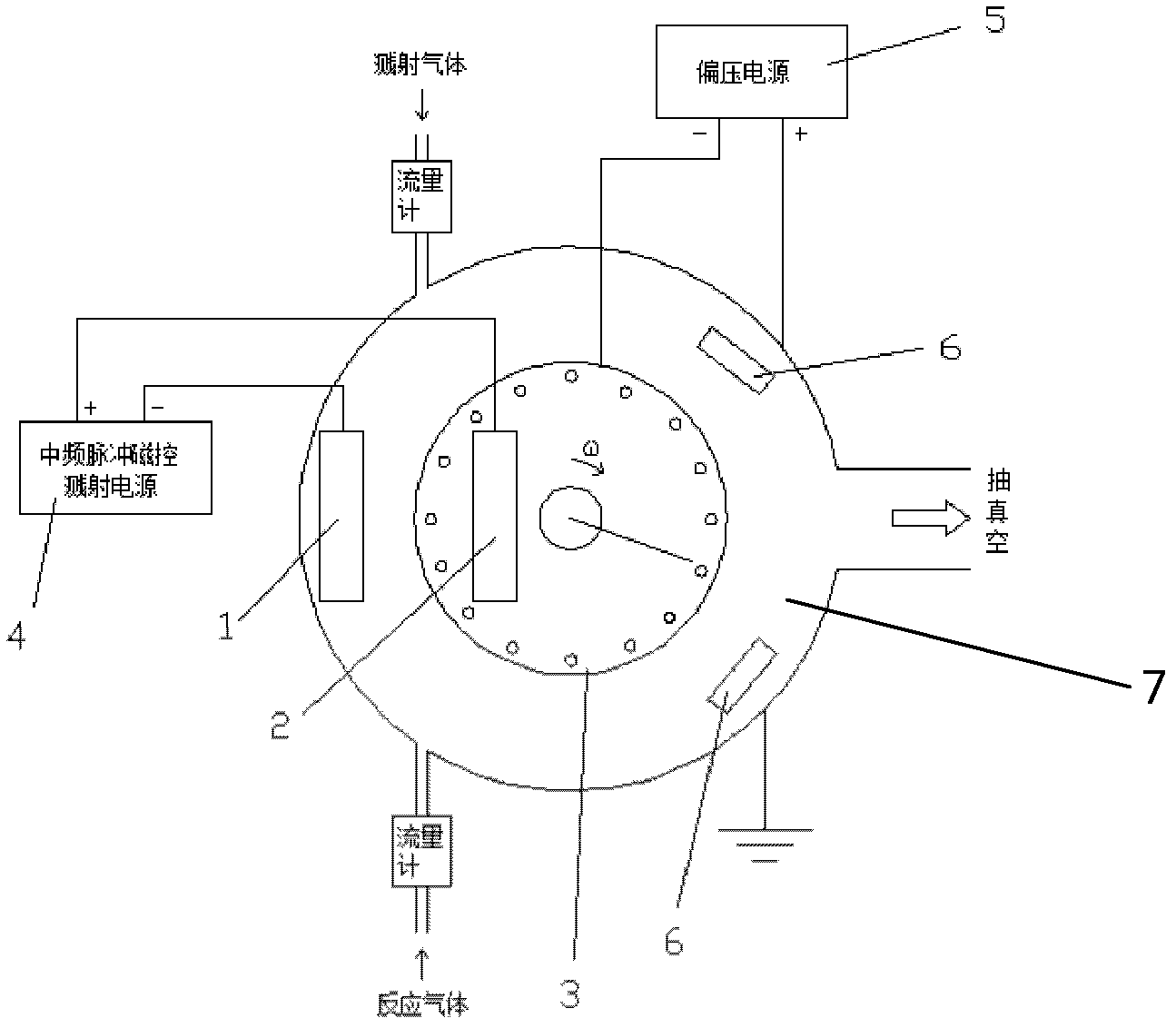

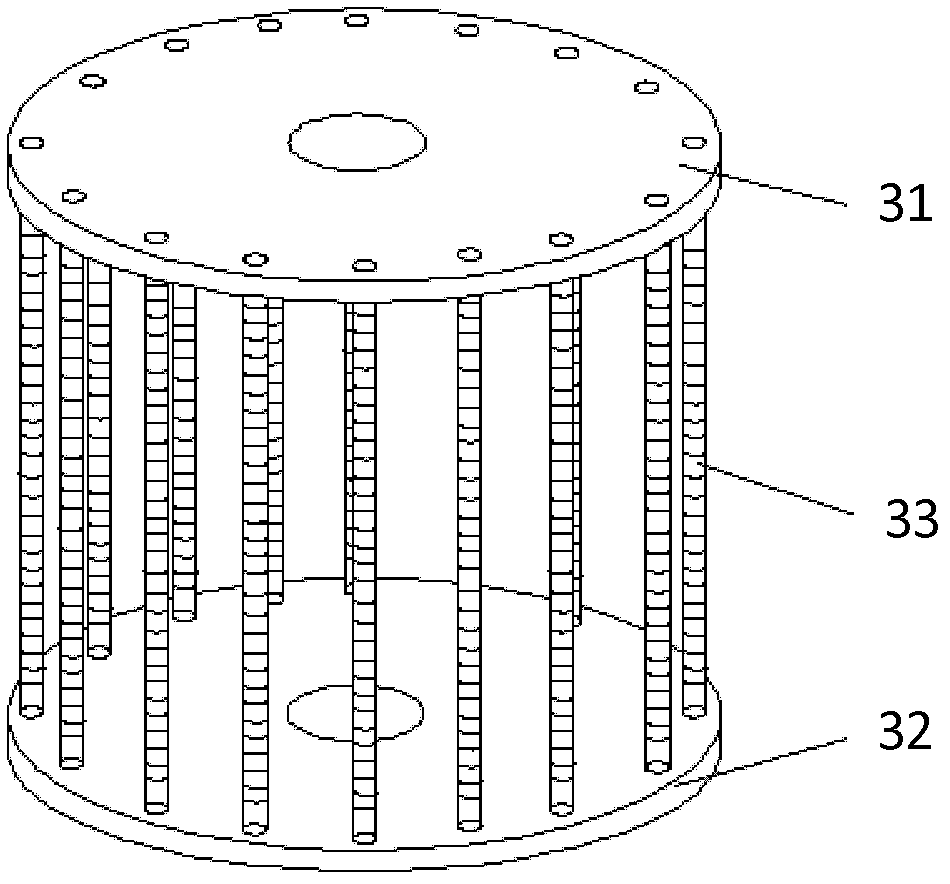

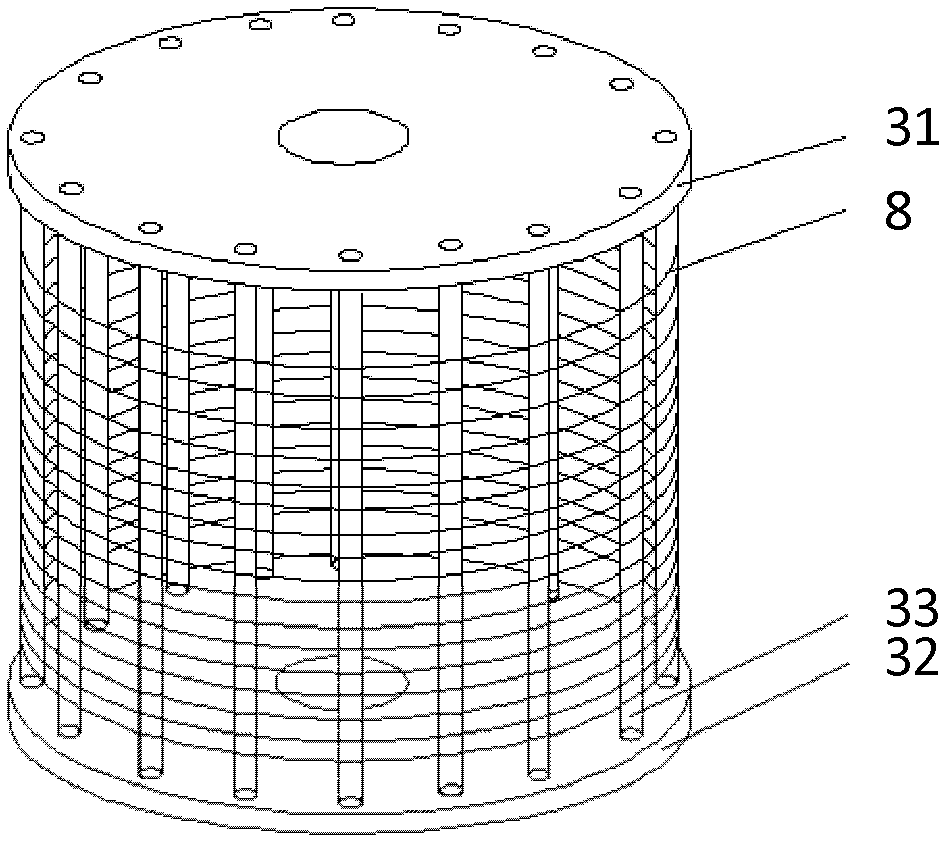

InactiveCN102251224AUniform thicknessPrevent escapeVacuum evaporation coatingSputtering coatingIntermediate frequencySputter deposition

The invention relates to vacuum coating magnetron sputtering deposition technology, and particularly a device and a method for depositing a film on a SiC fiber surface; on one hand, a film with a uniform thickness is deposited on a continuous SiC fiber surface; on the other hand, the problem of target material poisoning of compound film deposition is solved, and the continuity and stability of the deposition process is realized. The device is provided with a target material I, a target material II, a workpiece rotating shelf, an intermediate-frequency pulsed magnetron sputtering power supply, a magnetron sputtering vacuum chamber; the workpiece rotating shelf is disposed in the magnetron sputtering vacuum chamber; the target material I and the target material II are facingly disposed inside and outside the workpiece rotating shelf in the magnetron sputtering vacuum chamber; a cathode of the intermediate-frequency pulsed magnetron sputtering power supply is connected to the target material I; and an anode of the intermediate-frequency pulsed magnetron sputtering power supply is connected to the target material II. According to the invention, the gas flow, the reaction gas types, the sputtering time and the like in the vacuum chamber of the magnetron sputtering device are adjusted so as to realize the deposition of metals or compound films with different types and different thicknesses on a continuous SiC fiber surface, and to realize the surface modification of the SiC fiber.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High speed self-lubricating oily bearing made from powder metallurgical material

InactiveCN101187396AGood physical and mechanical propertiesReduce coefficient of frictionBearing componentsGraphiteBronze

A high-speed self-lubricating oilness bearing is made from powder metallurgy material. The powder metallurgy material is constituted by the following weight percentage of P: 0.5-0.7%, MoS 2: 2-3%, graphite: 0.5-1% and the residual is 663 bronze powders. A process for the preparation of the bearing comprises putting raw powders weighted according to the composition into a ball mill barrel with 2 liters, ball milling raw powders 2h on a roller-type ball mill, pressing into a shape through a steel die with a pressing pressure of five ton / cm 2, sintering in a vacuum furnace with sintering temperature of 800 DEG C, then preserving heat 1h, sizing sintered compacts through a sizing die to increase surface fineness and dimensional precision, vacuum soaking T1# special lubricating oil for the high-speed oilness bearing for 2h to prevent corrosion and finish capillary oil storage. The self-lubricating of material is realized by choosing Cu base powdered material along with solid lubricant and base strengthening elements, and the special surface structure is achieved through the powder metallurgy sintering technology controlling pore space of material, and the oilness effect of material is obtained by utilizing capillary effect.

Owner:LUOYANG BEARING SCI & TECH CO LTD

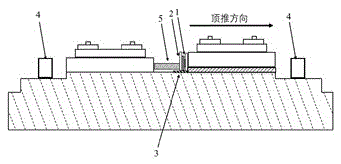

Midline deviation rectifying method for sedimentary offset ballastless track

InactiveCN106702834AReduce constraintsReduce settingsTrack superstructureRailway track constructionFilling materialsHigh pressure

The invention discloses a midline deviation rectifying method for a sedimentary offset ballastless track. The midline deviation rectifying method comprises the following steps that (1) the uplifting quantity and the offset quantity of the sedimentary offset ballastless track line are determined; (2) the track structure characteristics are combined, a grouting uplifting hole is formed in the top surface of the ballastless track structure, and grouting uplifting material is injected into a ballastless track supporting layer or under a base plate through a grouting pipe installed in the grouting hole by adopting high-pressure grouting equipment under a certain grouting pressure according to the determined equipment parameters and the grouting steps, so that an overall ballast bed and the upper structure of the ballastless track are uplifted; (3) a jacking and pushing point is arranged on the side surface of the ballastless track structure, a jacking and pushing device is installed, and the ballastless track line is rectified to the designed position through the jacking and pushing process of grouping loading and jacking and pushing step by step; and (4) after the midline is rectified, the line recovery work is timely conducted, a lower gap of the overall ballast bed of the ballastless track is filled with a filling material, a fastener system is finely adjusted, and the line smoothness is recovered.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

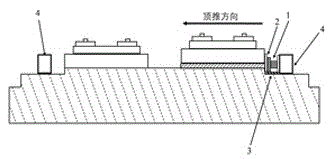

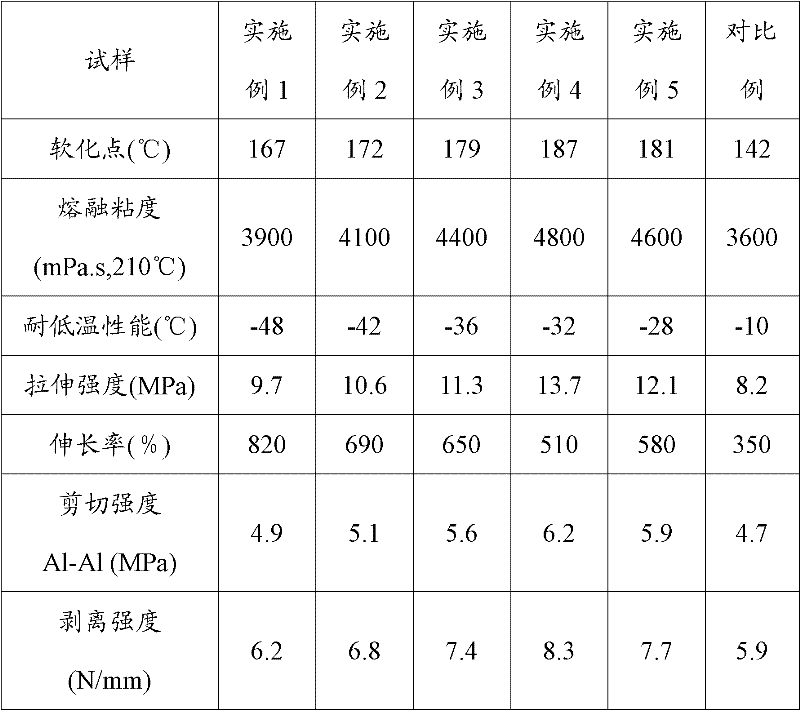

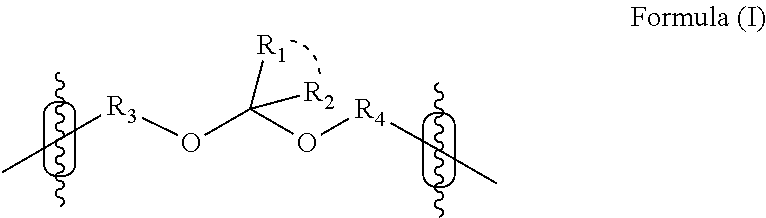

Polyurethane adhesive used for structural bonding of power battery PACK

InactiveCN109609081AImprove heat resistanceLong and smooth molecular chain structureNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolyurethane adhesive

The invention relates to a polyurethane adhesive used for structural bonding of power battery PACK. The polyurethane adhesive comprises an A component and a B component, wherein a volume ratio of theA component to the B component is 1:1; the A component comprises the following materials, in parts by weight: 5-20 parts of an epoxy resin modified polyol, 15-30 parts of a benzene ring-containing polyol, 10-25 parts of a bio-based polyol, 0-3 parts of a crosslinking agent, 0-0.05 part of a catalyst, 20-35 parts of a flame retardant, 3-10 parts of a molecular sieve and 0-5 parts of a thixotropic agent; and the B component comprises the following materials, in parts by weight: 50-70 parts of an isocyanate-terminated polyurethane prepolymer, 0-20 parts of isocyanate, 18-30 parts of a flame retardant, 0.1-0.3 part of an adhesion accelerant, 3-10 parts of a molecular sieve and 0-5 parts of a thixotropic agent. The polyurethane adhesive prepared by the invention has excellent bonding propertieson untreated-surface plastic materials such as PI, PET and PC and metal materials such as aluminum, steel and alloys of the aluminum and the steel, excellent aging resistance and a lower modulus.

Owner:YANTAI DARBOND TECH

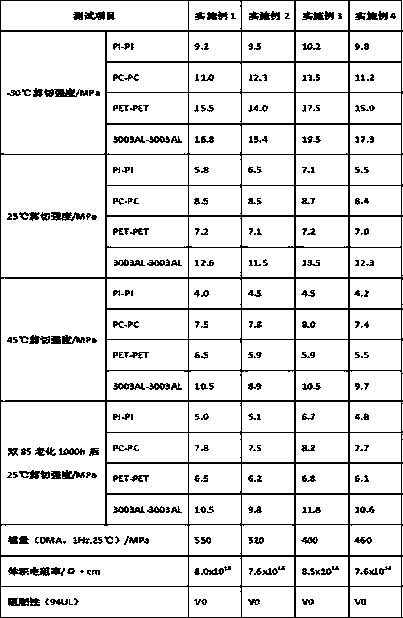

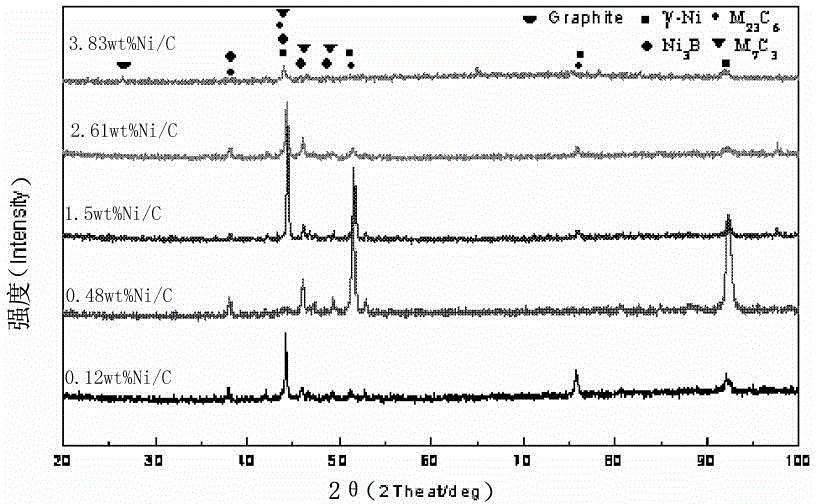

Nickel-coated graphite self-lubricating composite material and application thereof

ActiveCN103060614AGood wear resistanceGood wetting propertiesMetallic material coating processesCarbon steelGrinding

The invention relates to a nickel-coated graphite self-lubricating composite material and an application thereof. An employed technical scheme is that the nickel-coated graphite self-lubricating composite material is composed of, by weight percent: 95.0-99.9 % of self-melting alloy powder and 0.1-5.0 % of nickel-coated graphite. A laser cladding coating process comprises taking the self-melting alloy powder and the nickel-coated graphite, uniformly mixing by a ball milling method or a grinding method, using a preset method or a powder feeding method, and using a continuous CO2 laser device for laser cladding on a substrate. A content of the nickel-coated graphite varies widely. The nickel-coated graphite is uniform and dense in coating structure, excellent in wear resistance and antifriction performances, and good in metallurgy combination with substrates, can meet requirements of carbon steel and alloy steel for friction and wear performance in different working conditions. A coating preparation process is high in scale and automation degree, and thus the nickel-coated graphite self-lubricating composite material can be widely applied in fields of aerospace, machinery, automobile, military industry, etc.

Owner:SHENYANG AIRCRAFT CORP

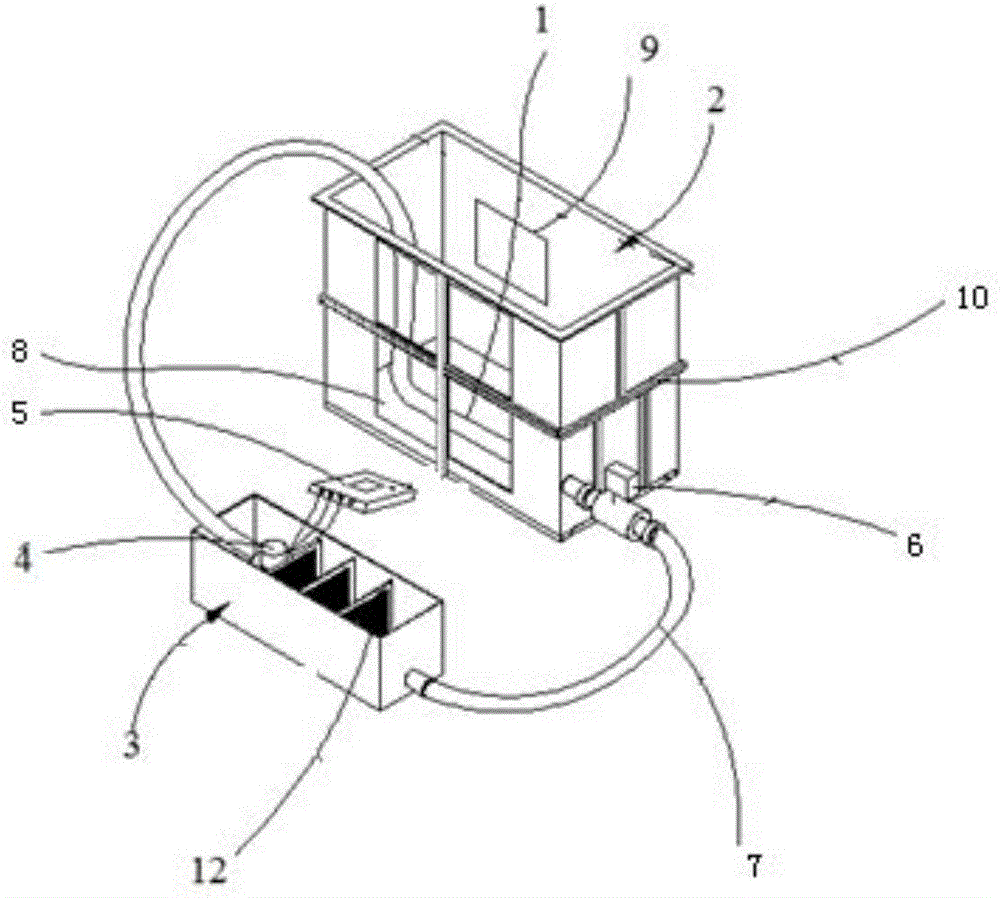

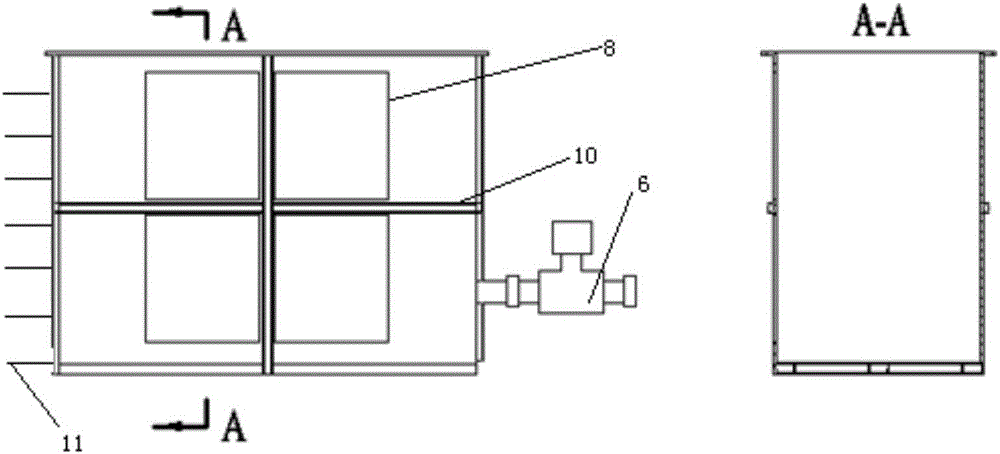

Device for testing surface collapse caused by urban underground pipeline leakage

InactiveCN106018736AGuaranteed buried heightLow shear strengthEarth material testingUnderground pipelineEngineering

The invention provides a device for testing surface collapse caused by urban underground pipeline leakage and belongs to the technical field of surface collapse test devices. The test device comprises soil, an underground pipeline, a surface collapse analog model case, a flow meter and a water box for filtering loss soil particles; the surface collapse analog model case is filled with the soil, and the underground pipeline is buried into the soil in the surface collapse analog model case; the water box for filtering the loss soil particles is divided into four parallel grids by three filtration separation plates, the four parts are communicated, and a submerged pump is arranged in the first grid of the water box for filtering the loss soil particles and connected with a water inlet end of the underground pipeline; an underground pipeline outlet is formed in the position, corresponding to the side surface of the surface collapse analog model case, of a water outlet end of the underground pipeline, and the water outlet end of the underground pipeline passes by the flow meter and is connected with the fourth grid of the water box for filtering loss soil particles by a transparent steel wire pipe; the submerged pump is connected with a frequency converter. The device can be used for testing surface collapse caused by urban underground pipeline leakage.

Owner:BEIJING UNIV OF TECH

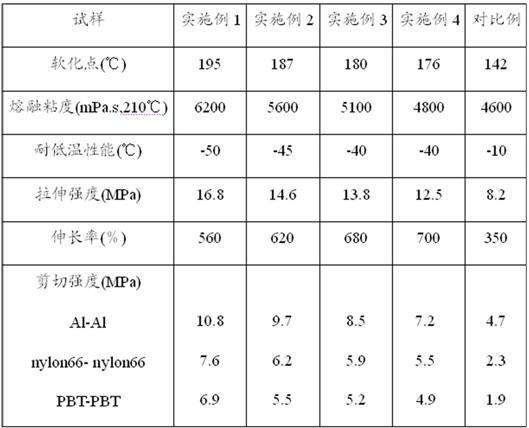

Dimer acid type polyamide hot melt adhesive and preparation method thereof

InactiveCN102220105AHigh elongationImprove low temperature resistanceAdhesivesPolymer scienceLow pressure molding

The invention relates to a dimer acid type polyamide hot melt adhesive and a preparation method thereof. The polyamide hot melt adhesive contains an N alkyl substitution diamine structure and consists of 50 percent of component A and 50 percent of component B according to mole percent, wherein the component A consists of 60-90 percent of unsaturated aliphatic dimer acid and 10-40 percent of aliphatic dicarboxylic acid according to the mole percent; the component B comprises 60-90 percent of N alkyl substituted aliphatic diamine, 10-30 percent of aliphatic diamine and 0-10 percent of heterocyclic diamine according to the mole percent. The dimer acid type polyamide hot melt adhesive has high softening point, good low-temperature resistance, high elongation, low high-temperature melting viscosity, high tensile strength and shearing intensity, and is suitable for low-pressure molding-injection forming process; and the dimer acid type polyamide hot melt adhesive has high bonding reliability and is particularly suitable for bonding of polar high polymer materials.

Owner:YANTAI DARBOND TECH

Chemical resistant glove having cut resistant properties

InactiveUS8656518B2Improve cut resistanceLow shear strengthGlovesSynthetic resin layered productsLatex gloveChemical treatment

Owner:ANSELL HEALTHCARE PRODS

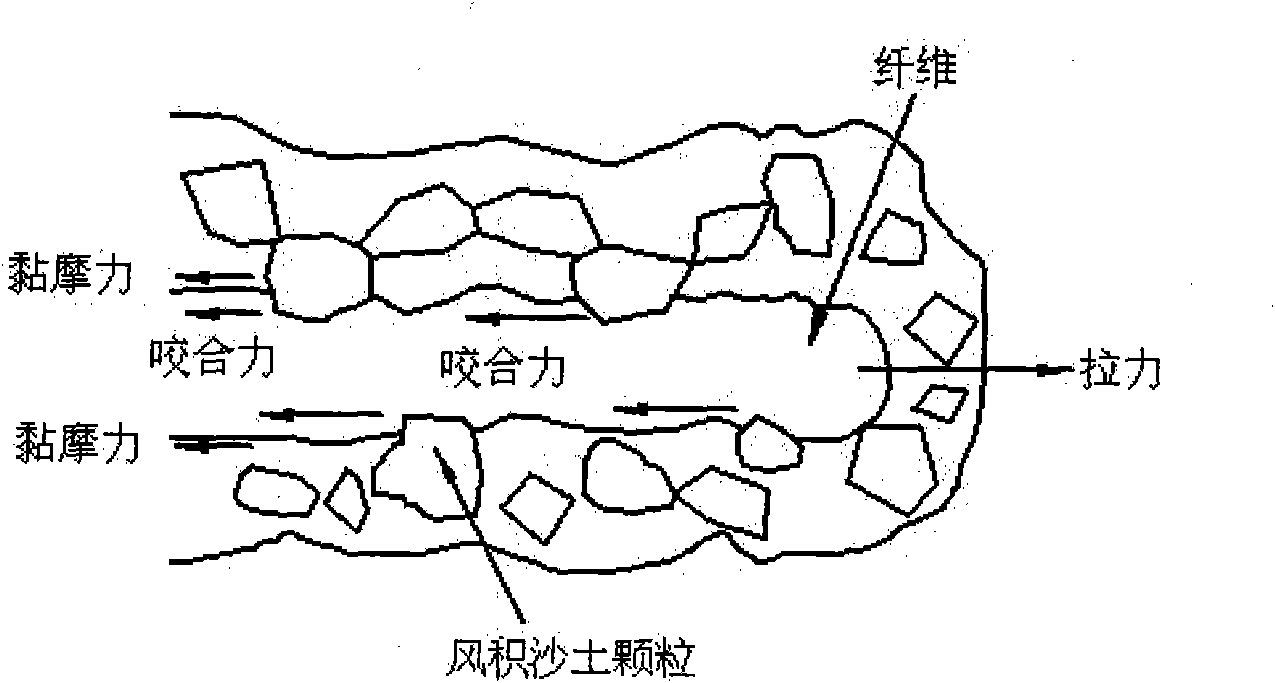

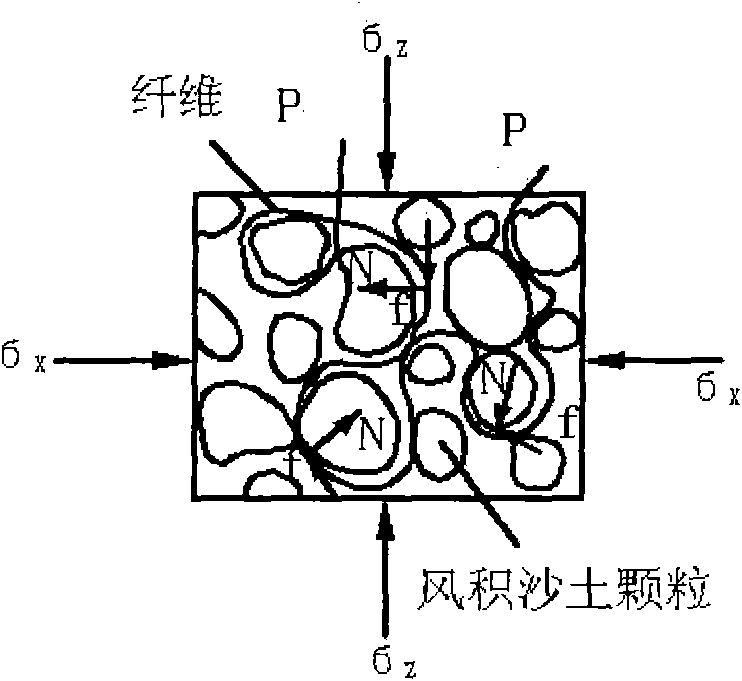

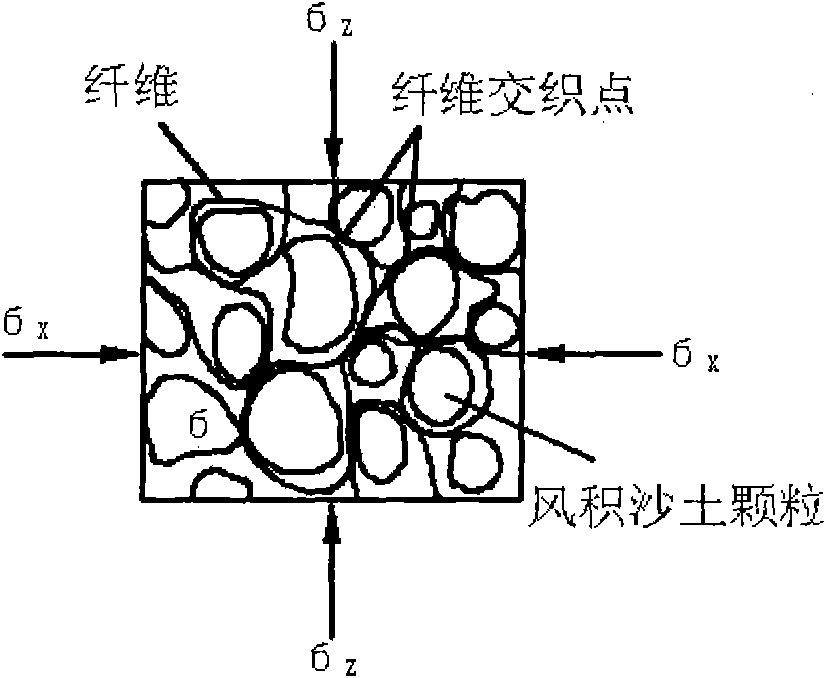

Method for reinforcing aeolian sandy soil by polypropylene fibers

The invention discloses a method for reinforcing aeolian sandy soil by polypropylene fibers. The method comprises the following steps: selecting materials for preparing fiber aeolian sandy soil, wherein the length of the polypropylene fiber is 18mm, the mix ratio of the fiber is 0.3 percent, and the aeolian sandy soil materials are air-dried aeolian sand or aeolian sandy soil (the moisture content accounts for 11.2wt%); according to the proportioning scheme, closely and completely mixing fine TEXSOL with aeolian sandy soil particles by way of spraying, so that a composite three-dimensional spatial structure is formed by the TEXSOL and the aeolian sandy soil; and carrying out mechanical compaction on the composite fiber aeolian sandy soil subjected to spraying, wherein the compaction method and standard of the composite fiber aeolian sandy soil are same as those of common soil, so that the compaction density of the aeolian sandy soil reaches 100 percent of the standard compaction density, and the fiber aeolian sandy soil is compacted closely. By utilizing the method in earth-filled dams, retaining walls and the drainage works of the earth-filled dams, the water stability of the interior of the soil body can be effectively improved, the shearing strength and tensile strength of the soil body can be obviously improved, and the construction process is simple; and because the fiber content of the fiber aeolian sandy soil is very low, the method has the advantages of cheapness and environmental protection.

Owner:HARBIN INST OF TECH

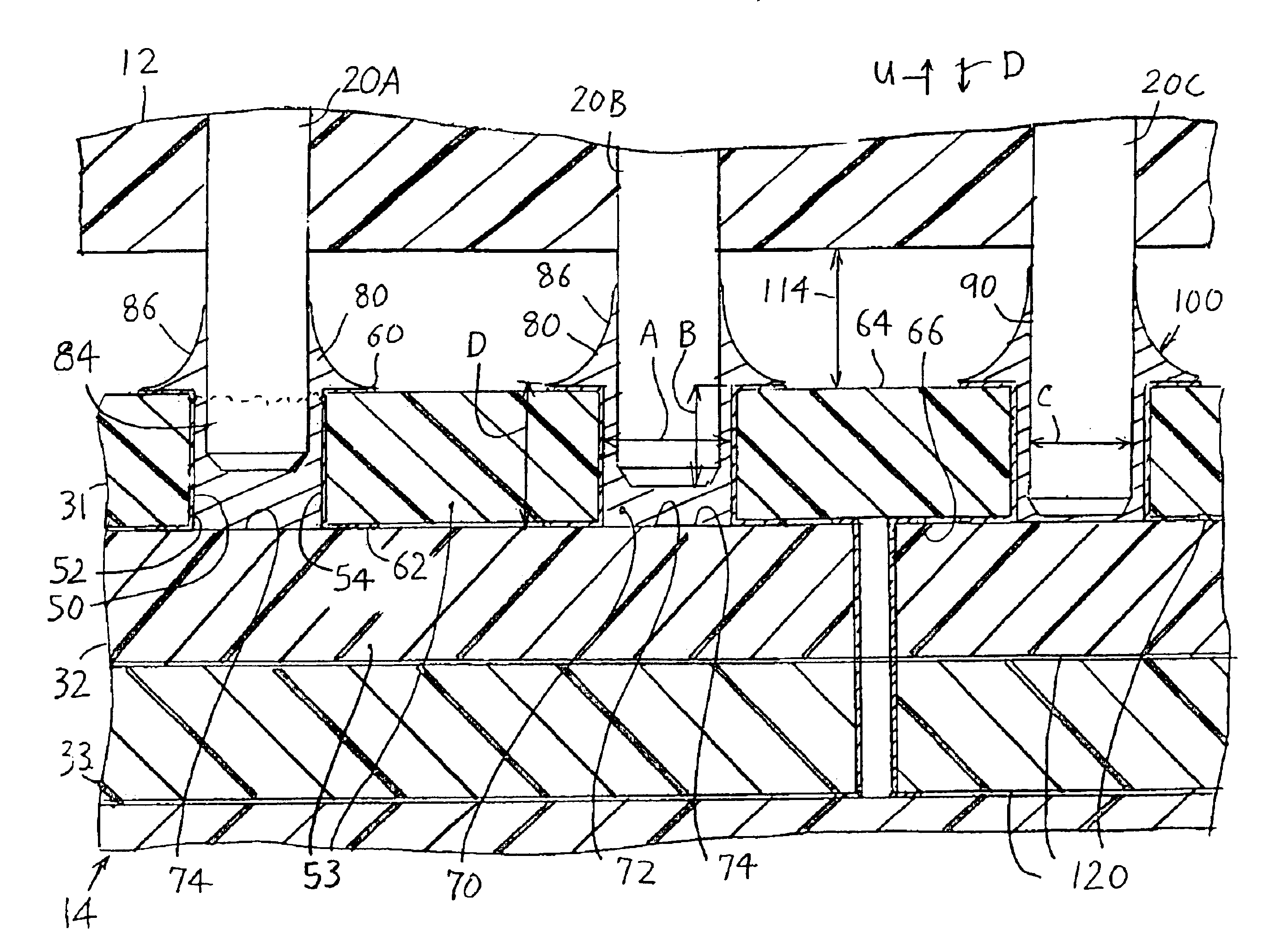

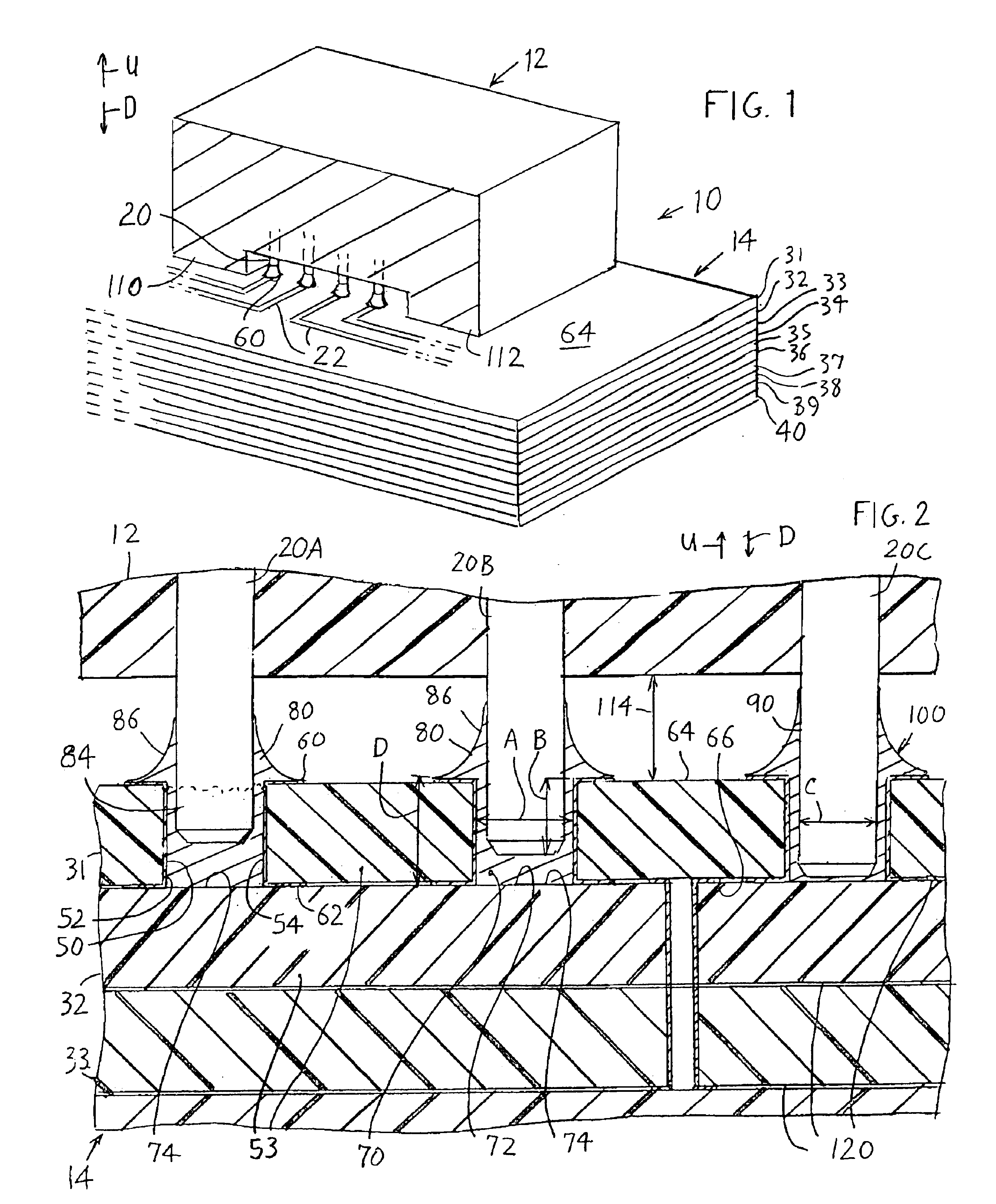

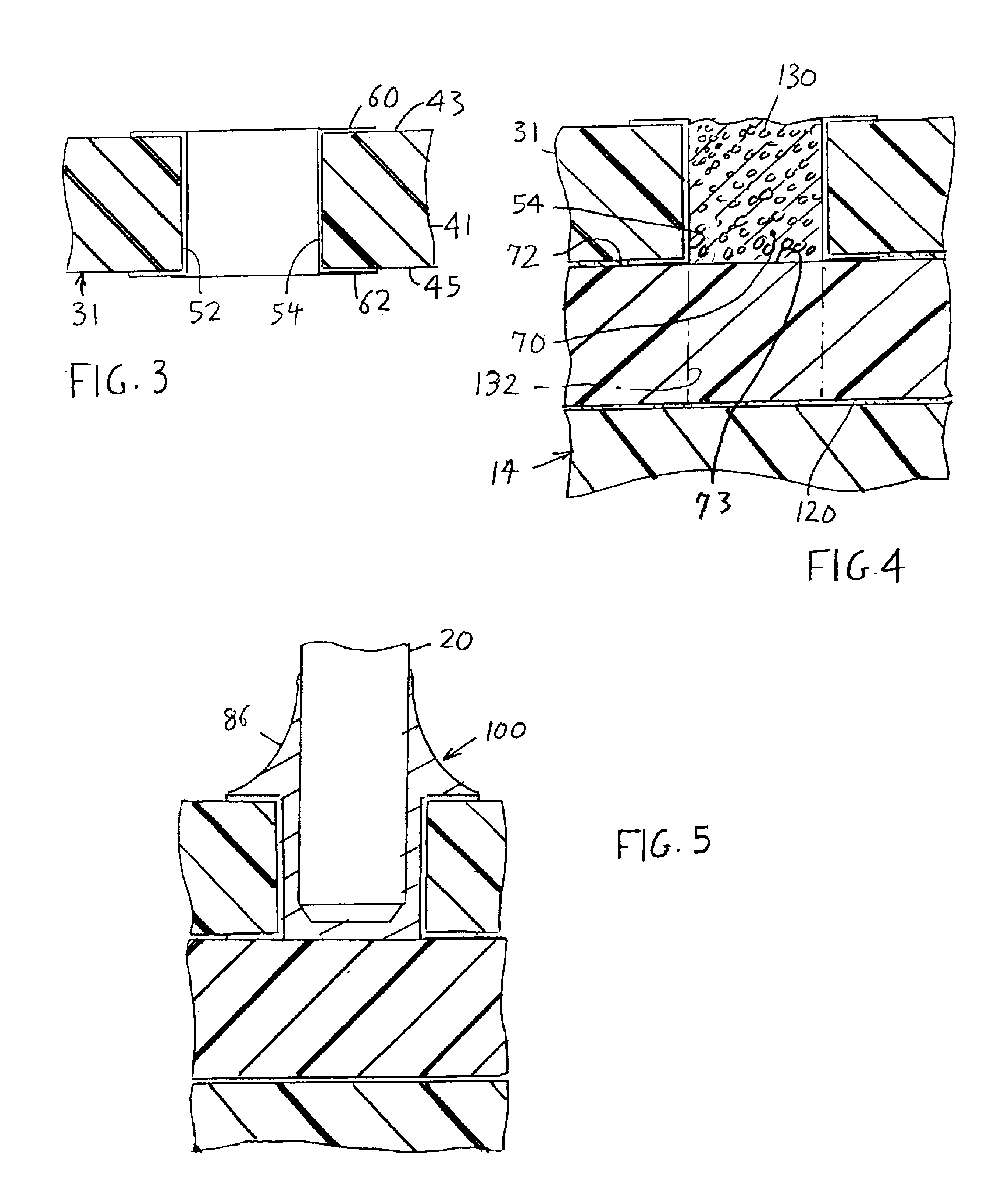

Blind hole termination of pin to pcb

InactiveUS6963494B2High capacitance loadingLow shear strengthPrinted circuit assemblingPrinted electric component incorporationSurface mountingEngineering

Tails (20) projecting from an electrical component (12) that lies on a circuit board surface, are terminated to traces on a multi-layer circuit board (14) in a manner that minimizes the disadvantages of long through hole soldering and of surface mount techniques. A blind hole is drilled and plated in a first layer (31) that will become the topmost layer of the stack, to form a shallow well (70). The well is filled with a soldering composition (130). A tail (20) is projected downward into the soldering composition, and the soldering composition is heated to solder the tail to the hole plating.

Owner:ITT MFG ENTERPRISES LLC

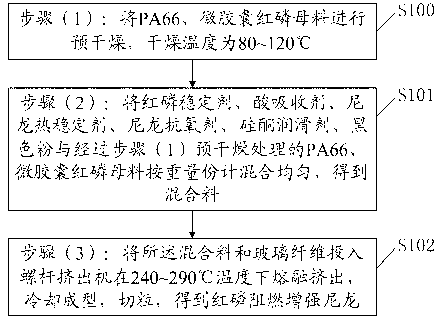

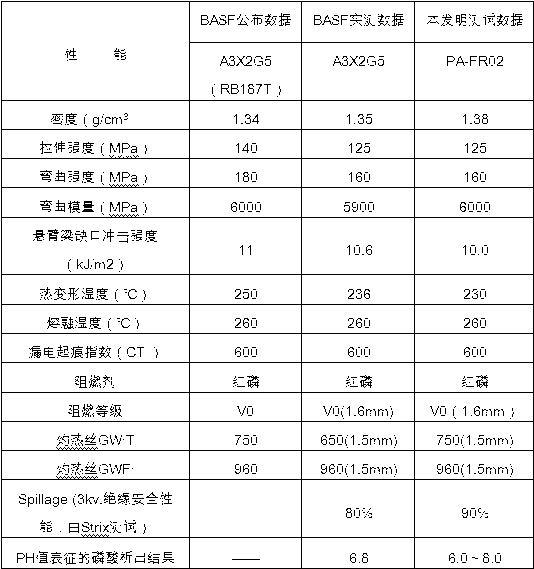

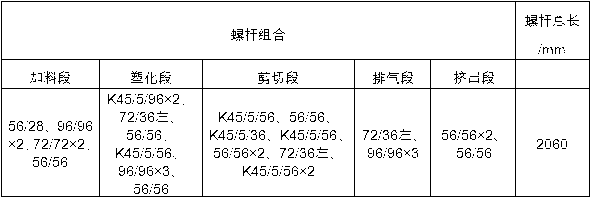

Acid-corrosion-free and high electric insulation red phosphorus flame retarded reinforced nylon and production method thereof

InactiveCN103304997AImprove electrical insulation safety performanceLow shear strengthTO-18Electricity

The invention discloses acid-corrosion-free and high electric insulation red phosphorus flame retarded reinforced nylon. The acid-corrosion-free and high electric insulation red phosphorus flame retarded reinforced nylon comprises, by weight percent, 50 to 60 parts of PA 66, 10 to 18 parts of microencapsulated red phosphorus master batch, 1 to 4 parts of red phosphorus stabilizer, 2 to 5 parts of acid absorbent, 0.5 to 1 part of nylon thermal stabilizer, 0.2 to 0.5 part of nylon antioxygen, 0.5 to 1 part of silicone lubricant, 0.5 to 2 parts of black powers and 20 to 30 parts of glass fibers. The embodiment of the invention also discloses a production method of the acid-corrosion-free and high electric insulation red phosphorus flame retarded reinforced nylon. According to the acid-corrosion-free and high electric insulation red phosphorus flame retarded reinforced nylon and the production method thereof, production formulas and production technologies are improved, general performances such as a good mechanical performance, a thermal performance, a flame retardant performance and a CTI (Comparative Tracking Index) are maintained, the phosphoric acid precipitation and corrosion problem of the PA66 of the red phosphorus flame retarded reinforced nylon is solved, and the electric insulation safety performance of the materials is improved.

Owner:广东泰昊新材料科技有限公司

Aqueous Self-Adhesive Coating for Electrical Steel and its Uses

ActiveUS20070231463A1Friendly and safe to environmentLong shelf lifeNon-fibrous pulp additionCoatings with pigmentsEpoxyElectrical steel

The present invention relates to a self-adhesive coating for electrical steel and its uses. The coating comprises 81-99.9 weight parts of aqueous epoxy resin emulsion, 0.07-17 weight parts of curing agent, and optionally 0.3 weight parts of accelerant. If required, said coating can optionally contain additives selected from diluent, filler, toughener, colorant, fire retardant, antirusting agent, antisettling agent, thixotropic agent or antifoamer, thickener, pigment dispersant, preservative, and the like. The coating can be used as electrical steel coating. The present coating is capable of making electrical steel with a self-adhesive coating in a way of heat by naked-flame, and also there are no poisonous organic solvents to volatilize during the entire process. Furthermore, the coating permits to omit apparatus for burning organic solvents, and the cost is thereby reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Polyamide hot melt adhesive for adhering nonpolar materials and preparation method thereof

InactiveCN102382614ASoftening is higherImprove low temperature resistanceAdhesivesPolymer sciencePolyamide

The invention relates to a polyamide hot melt adhesive for adhering nonpolar materials and a preparation method thereof. The hot melt adhesive is formed by components A and B respectively in a mole ratio of 1:1. The component A comprises, in a mole ratio, 40% to 80% of unsaturated aliphatic dimeric acid and 20% to 60% of aliphatic dicarboxylic acid. The component B comprises, in a mole ratio, 20% to 80% of aliphatic diamine, 0% to 20% of heterocyclic diamine and 20% to 60% of dihydric alcohol. The polyamide hot melt adhesive is high in softening point, good in low temperature resistance, long in sizing opening time, low in high-temperature melting viscosity, high in T- peel strength and shearing strength, suitable for a low pressure injection molding process, high in adhering reliability and particularly suitable for adhesion of nonpolar high polymer materials.

Owner:YANTAI DARBOND TECH

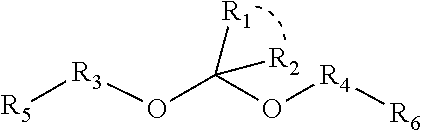

Degradable and Recyclable Epoxy Conductive Adhesive as well as Preparing, Degrading and Recycling Methods therefor

ActiveUS20170342301A1Low shear strengthIncreased shear strengthOxygen/ozone/oxide/hydroxideNon-macromolecular adhesive additivesChemistryAdhesive

The present invention provides a degradable and recyclable epoxy conductive adhesive, which comprises the following raw materials in percentage by weight: 15% to 30% of epoxy resin, 1% to 10% of a curing agent, 0.1% to 2% of a reaction diluent and 15% to 85% of a conductive filler, wherein the curing agent comprises a breakable molecular structure. According to the epoxy conductive adhesive of the present invention, after the epoxy resin in the conductive adhesive is cured by using the recyclable and degradable epoxy resin curing agent of a specific molecular structure, the conductive adhesive can be degraded in normal pressure, mild and specific conditions, the process is simple and the operation is convenient, no contamination is brought to the environment, the recycling cost is largely reduced, and the recycling of the conductive adhesive has enormous economic and environmental advantages. By using the recyclable and degradable epoxy resin curing agent of a specific molecular structure, the shear strength of the conductive adhesive is greatly increased, and the reliability and the service life of the conductive adhesive are largely improved.

Owner:JANSSEN PHARMA NV +1

High-temperature pressure sensor and manufacturing method thereof

InactiveCN105067184ALow shear strengthReduce intensityFluid pressure measurement using ohmic-resistance variationSignal processing circuitsRocket

The invention discloses a high-temperature pressure sensor, which comprises a pressure sensitive core body, a high-temperature sintering layer and a connecting rod, wherein the pressure sensitive core body is connected with the connecting rod through the high-temperature sintering layer, the head part of the connecting rod is provided with a platinum-rhodium platinum thermocouple for measuring temperature and compensating thermal sensitivity drift and thermal zero drift, the middle part of the connecting rod is connected with a high-temperature alloy steel fixing member in clamping and sleeving manner, the high-temperature alloy steel fixing member is connected with a measured structure, the tail part of the connecting rod is provided with a signal processing circuit, a sapphire optical fiber is installed in the interior of the connecting rod, and the pressure sensitive core body is connected with the signal processing circuit through the sapphire optical fiber. The purpose of the invention is to provide the high-temperature pressure sensor which can measure gas pressure at 1200 DEG C ambient temperature, directly measure intensity of pressure of the high-temperature gas ejected by a jet engine of an aircraft or a rocket without using a pressure guiding pipe, and measures the thrust of the jet engine in real time.

Owner:昆山泰莱宏成传感技术有限公司

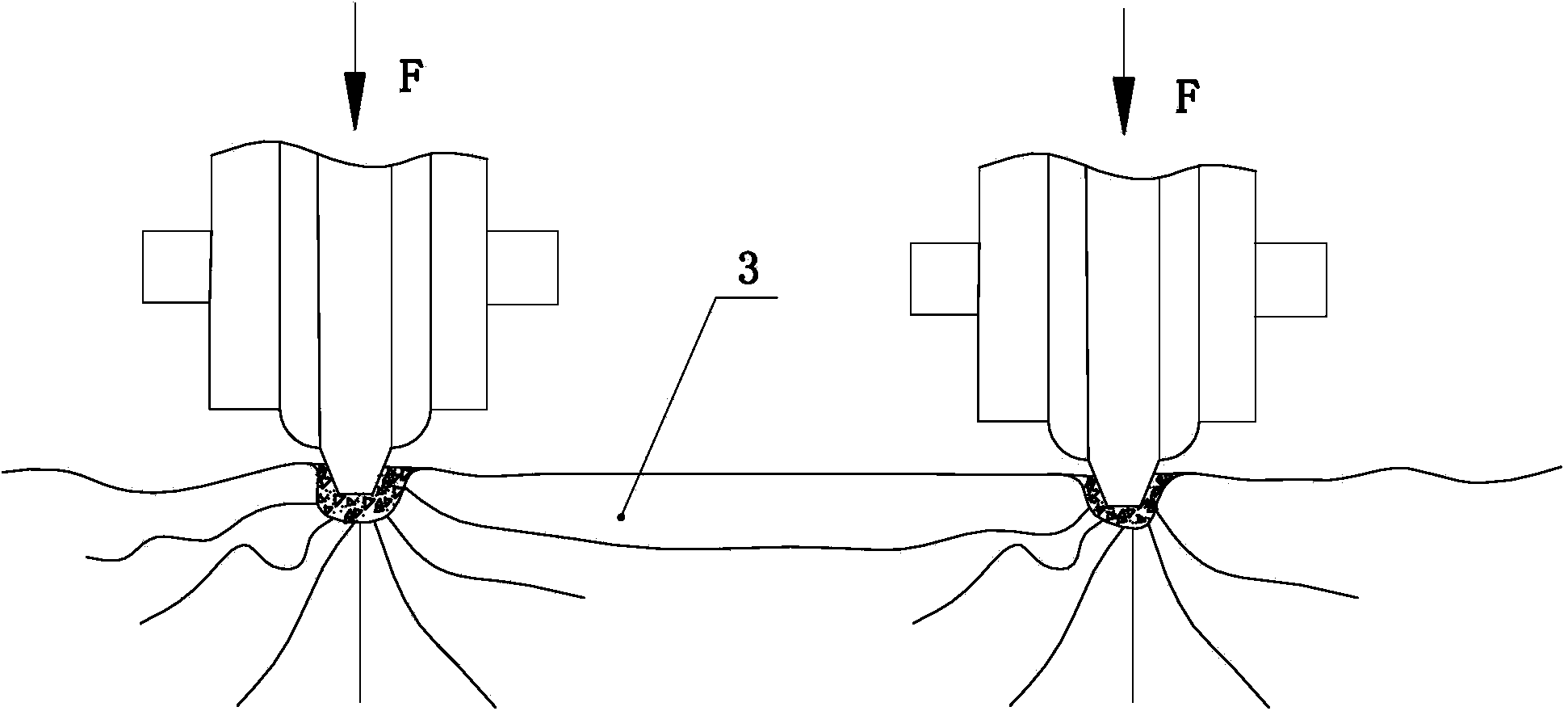

Novel rock breaking method and rock breaking hob

InactiveCN103953357AExtended service lifeShear strength to overcomeTunnelsCompressive strengthUltimate tensile strength

The invention discloses a novel rock breaking method and a rock breaking hob and relates to the technical field of tunnel boring. The novel rock breaking method and the rock breaking hob are applied to the rock breaking operation of tunnels; the problems that a hob is seriously worn and is short in service life in the existing rock breaking method are solved. According to the chipping rock breaking method, an included angle beta is formed between a hob blade and a normal of a tunnel face; after the pressure is applied to the disc-shaped hob, the blade penetrates into rock and a dense kernel is generated at the front end of the blade; the dense kernel continuously expands to tear off surrounding rock and forms a breaking area; rocks on a dangling face are chipped by expanding the breaking area; the blade of the disc-shaped hob is mainly used for bearing a shear force; the strength of the shear force is 6-9 percent of the compressive strength of the rock. The chipping rock breaking method has the advantages that firstly, the hob blade is mainly used for overcoming the shear resisting strength of the rocks, the compressive strength of a hob single spindle is greatly reduced, the blade of a hob ring is slow in wear and the hob is long in service life; secondly, the chipping rock breaking method is high in rock breaking and high in tunneling efficiency and is particularly suitable for excavating and tunneling of full-section hard-rock geology; thirdly, consumed power of tunneling equipment is lower.

Owner:邵祥顺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com