Patents

Literature

10141results about How to "Reduce coefficient of friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

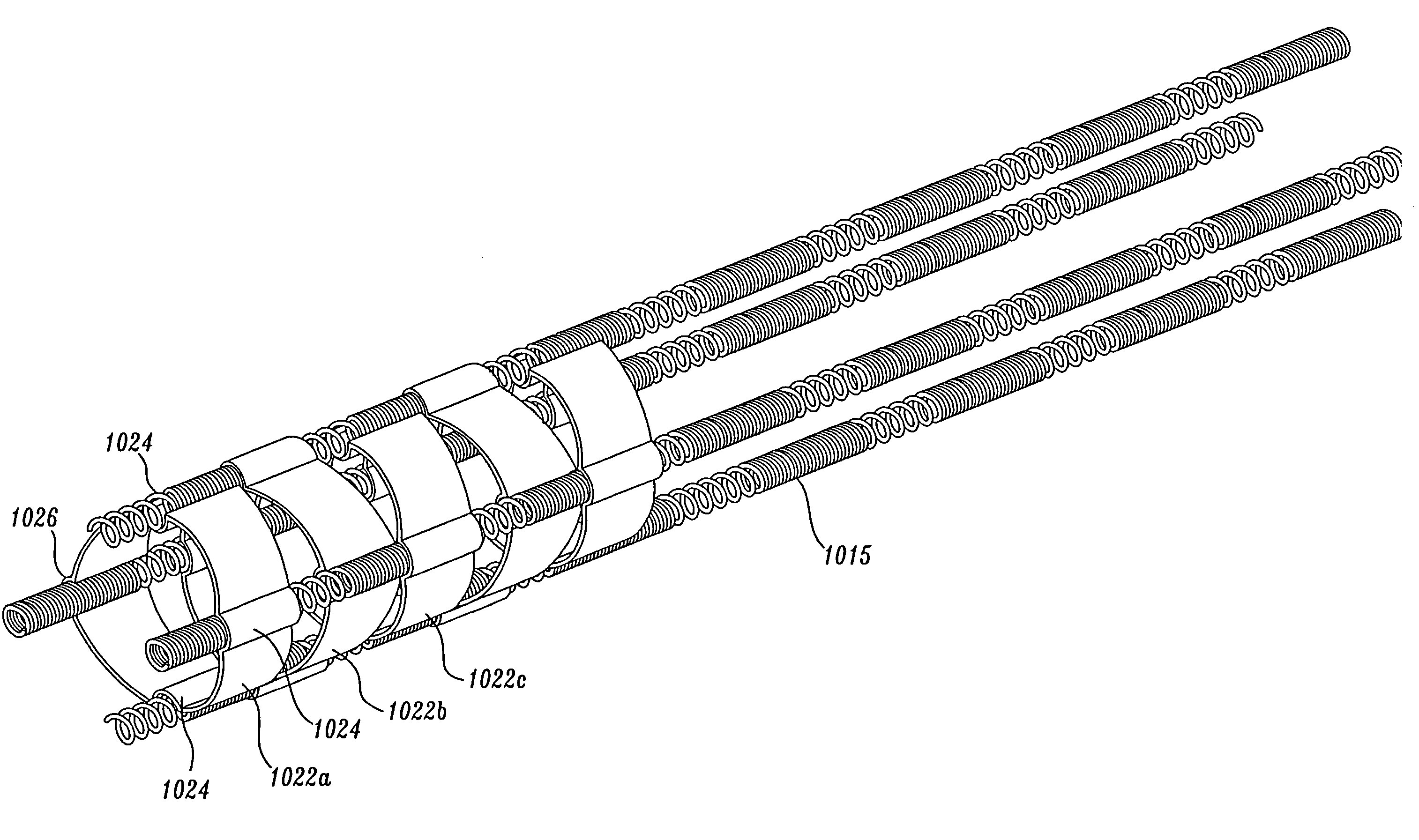

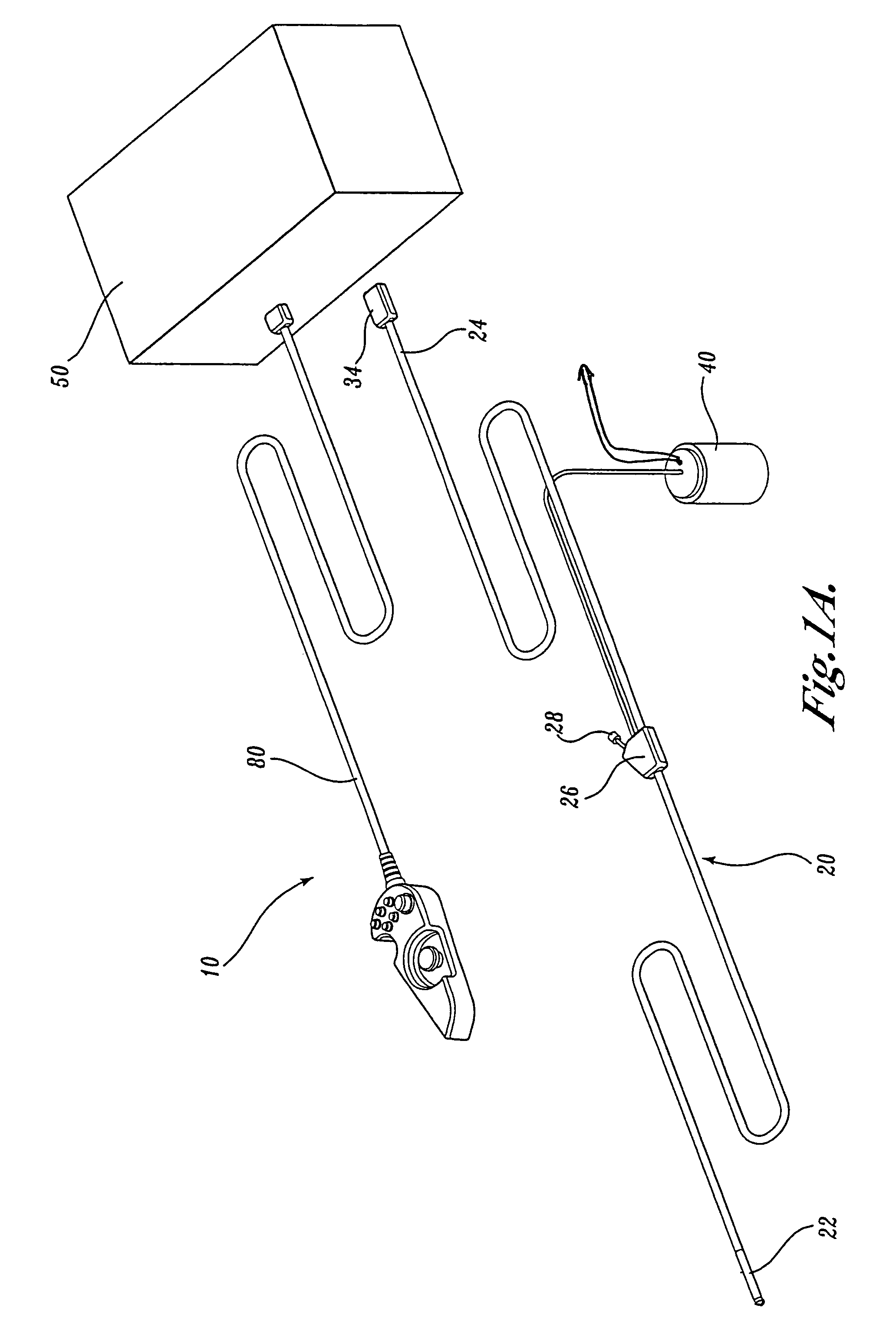

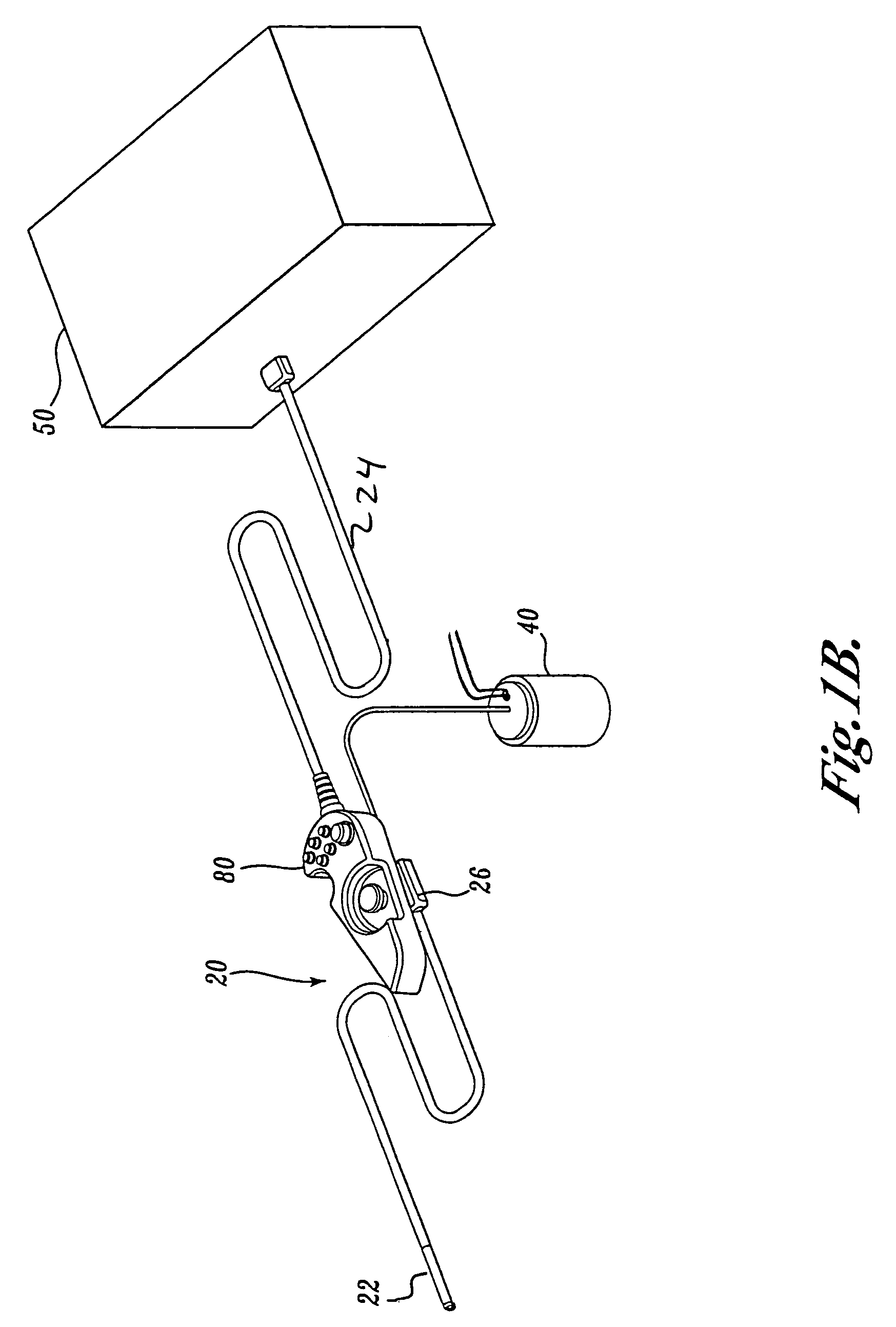

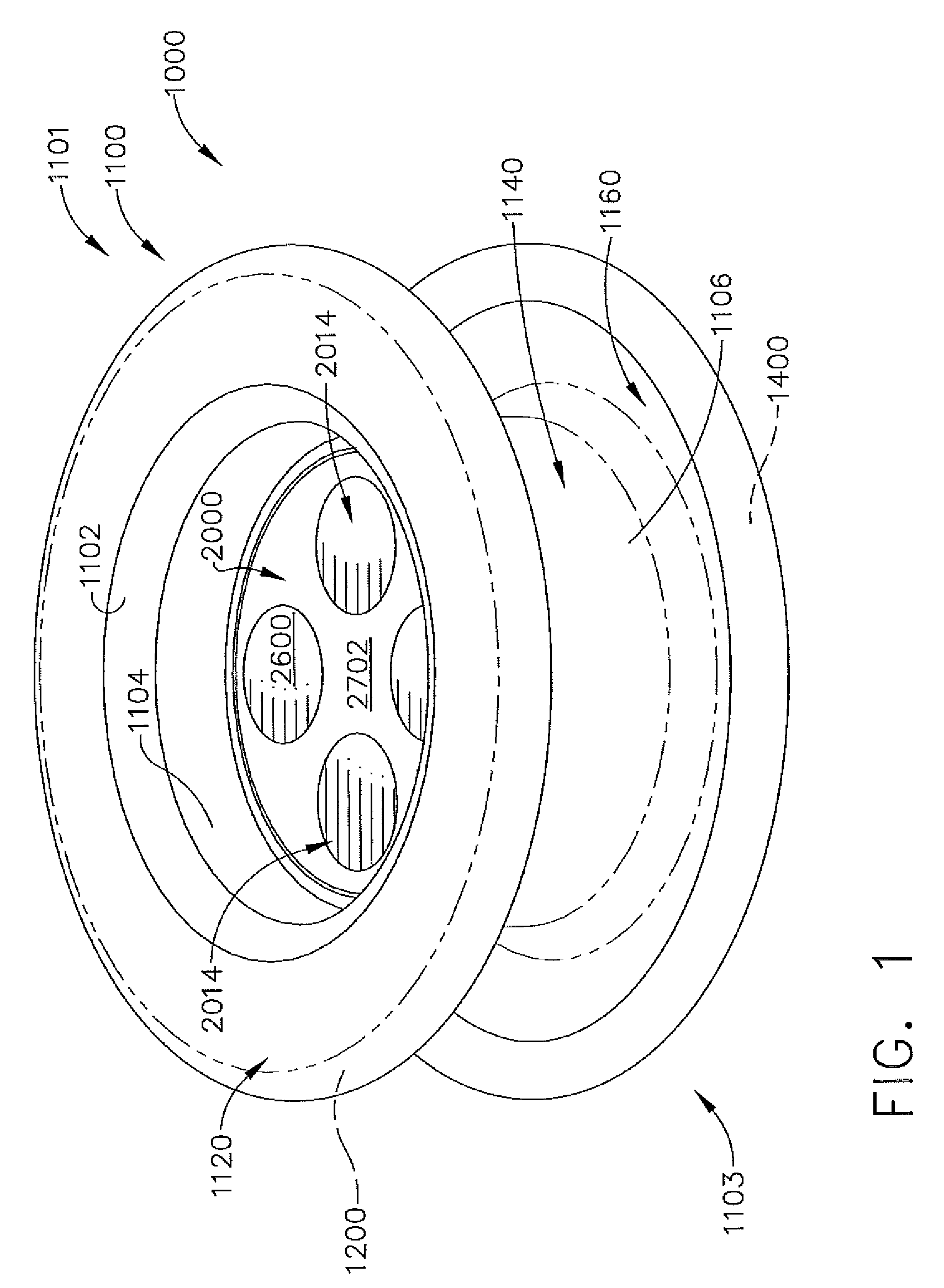

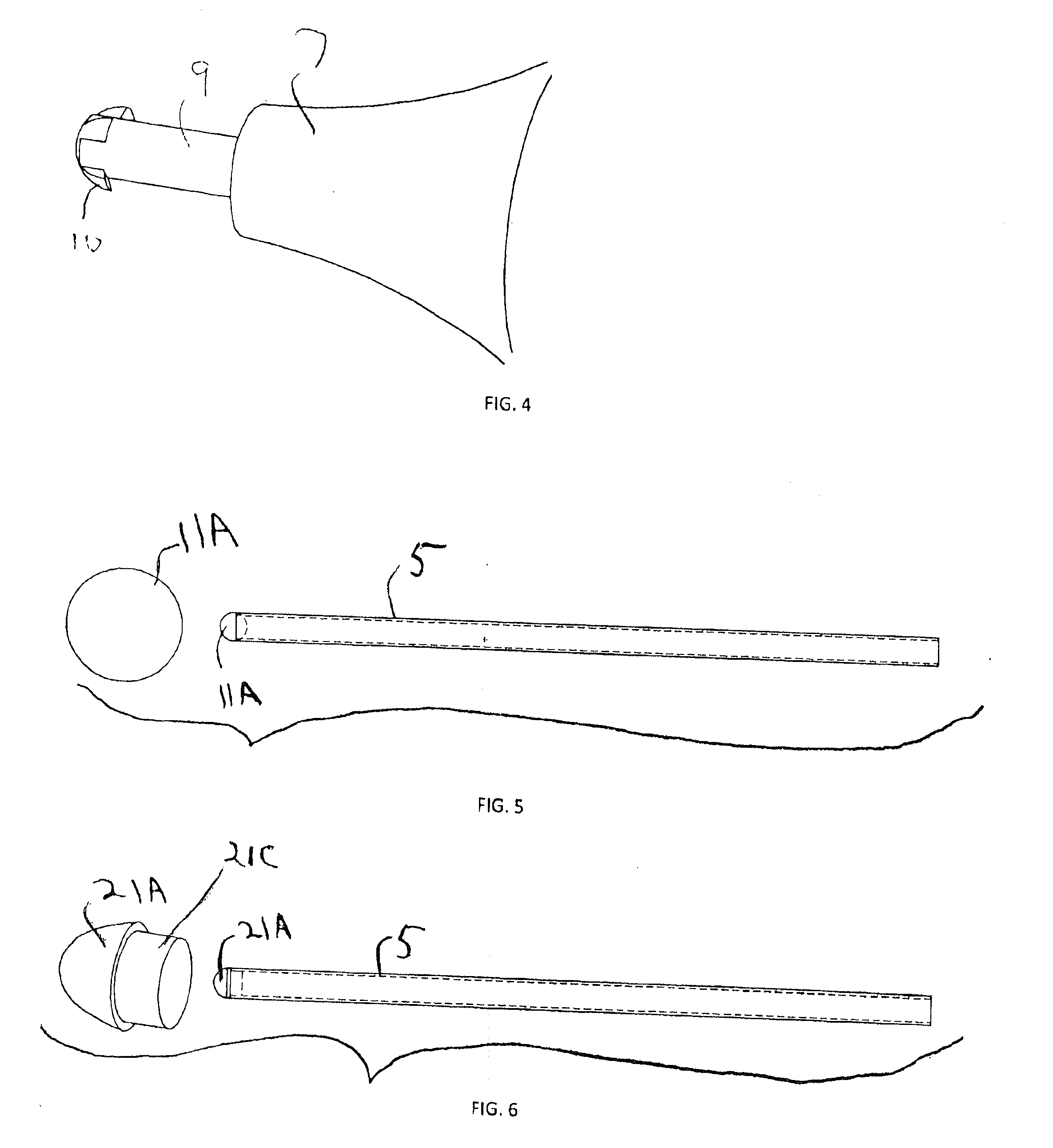

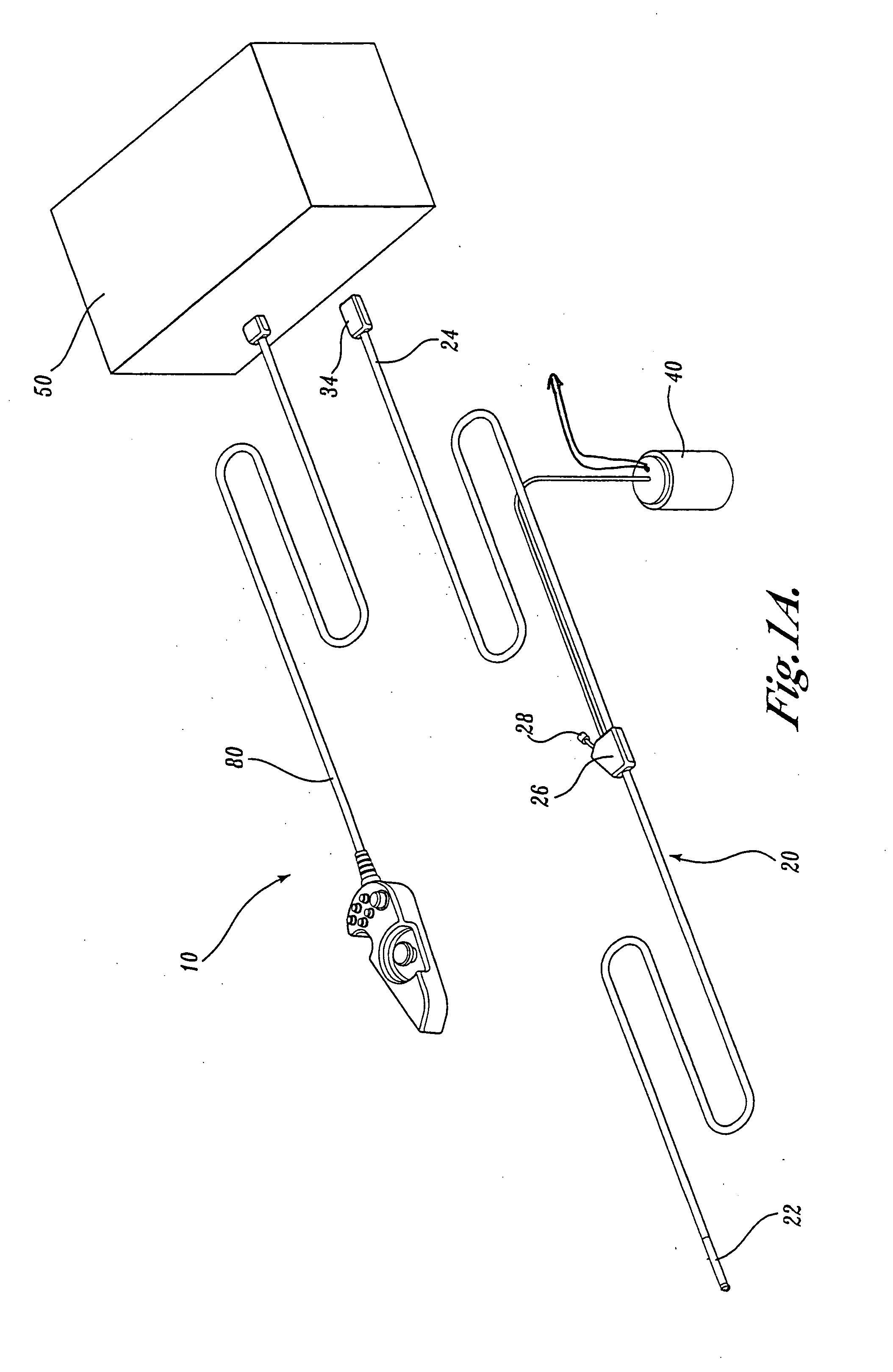

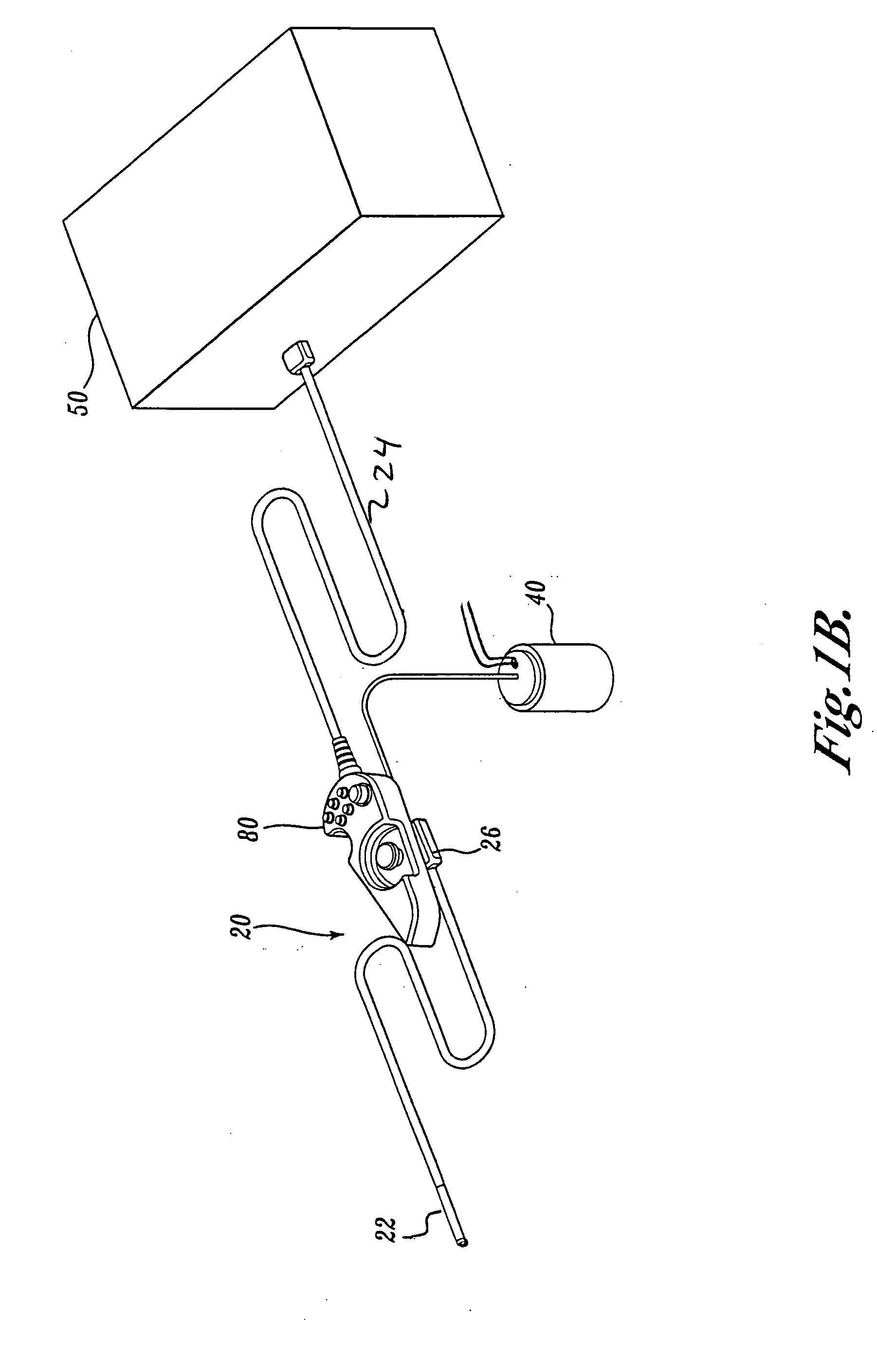

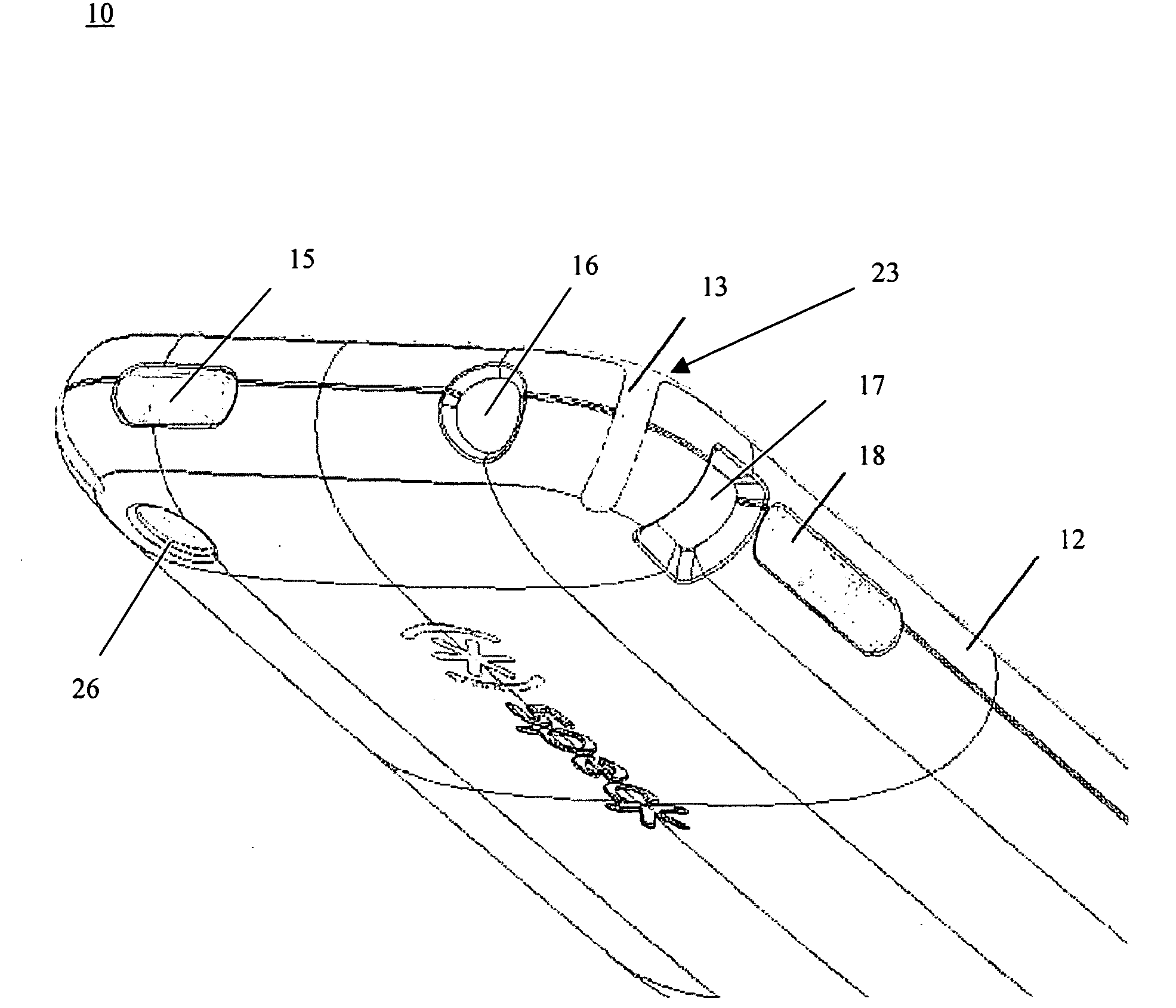

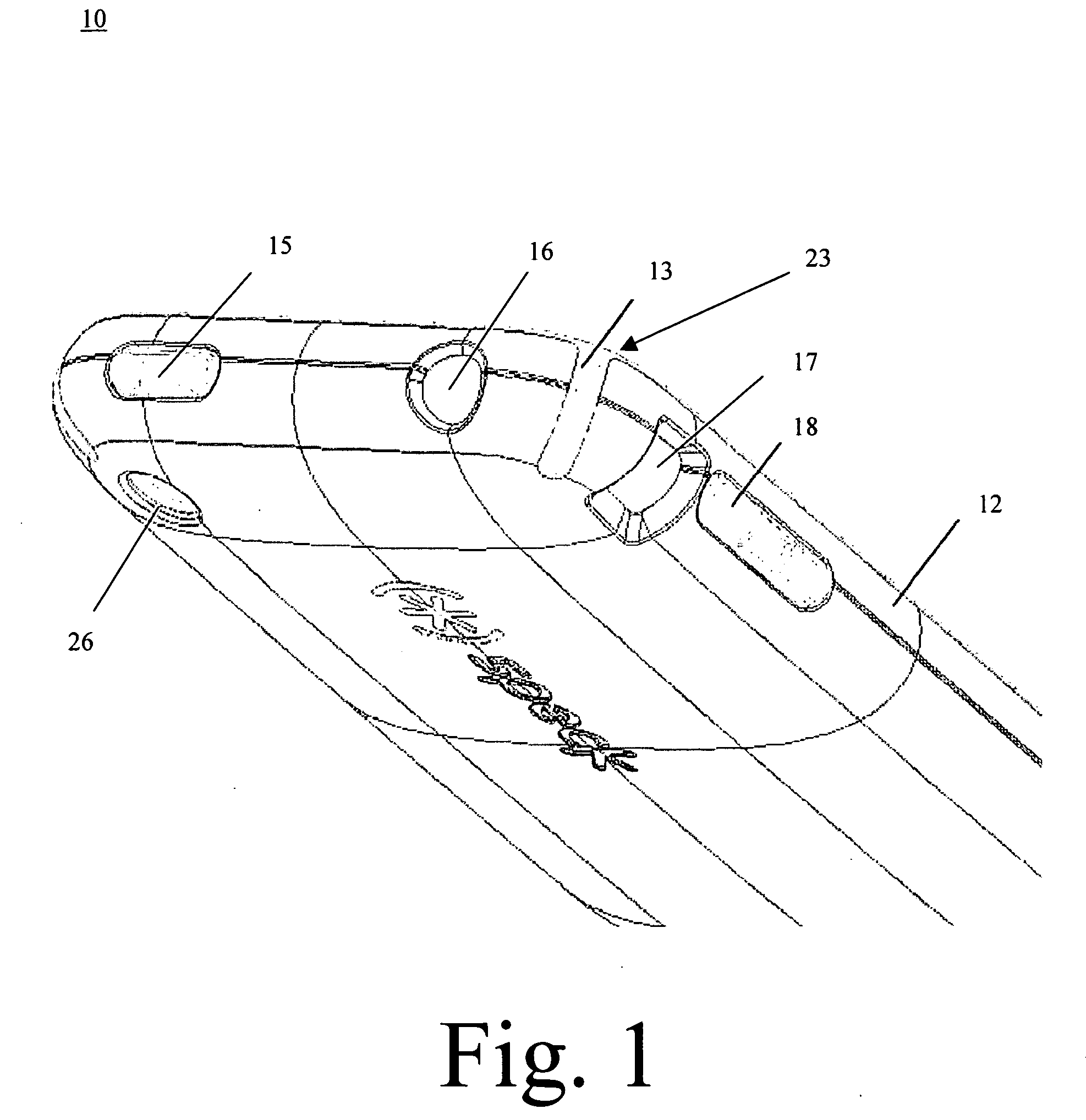

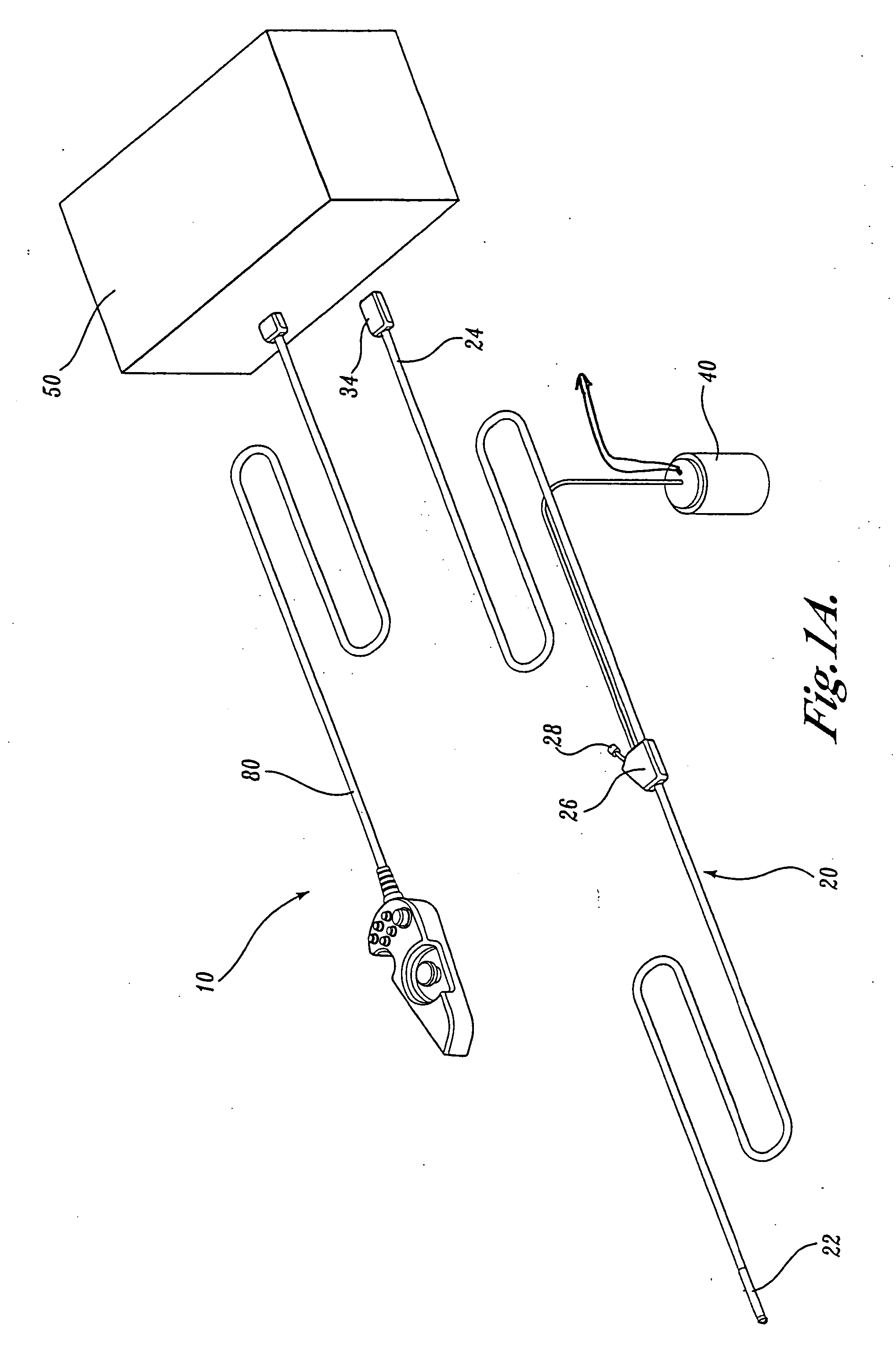

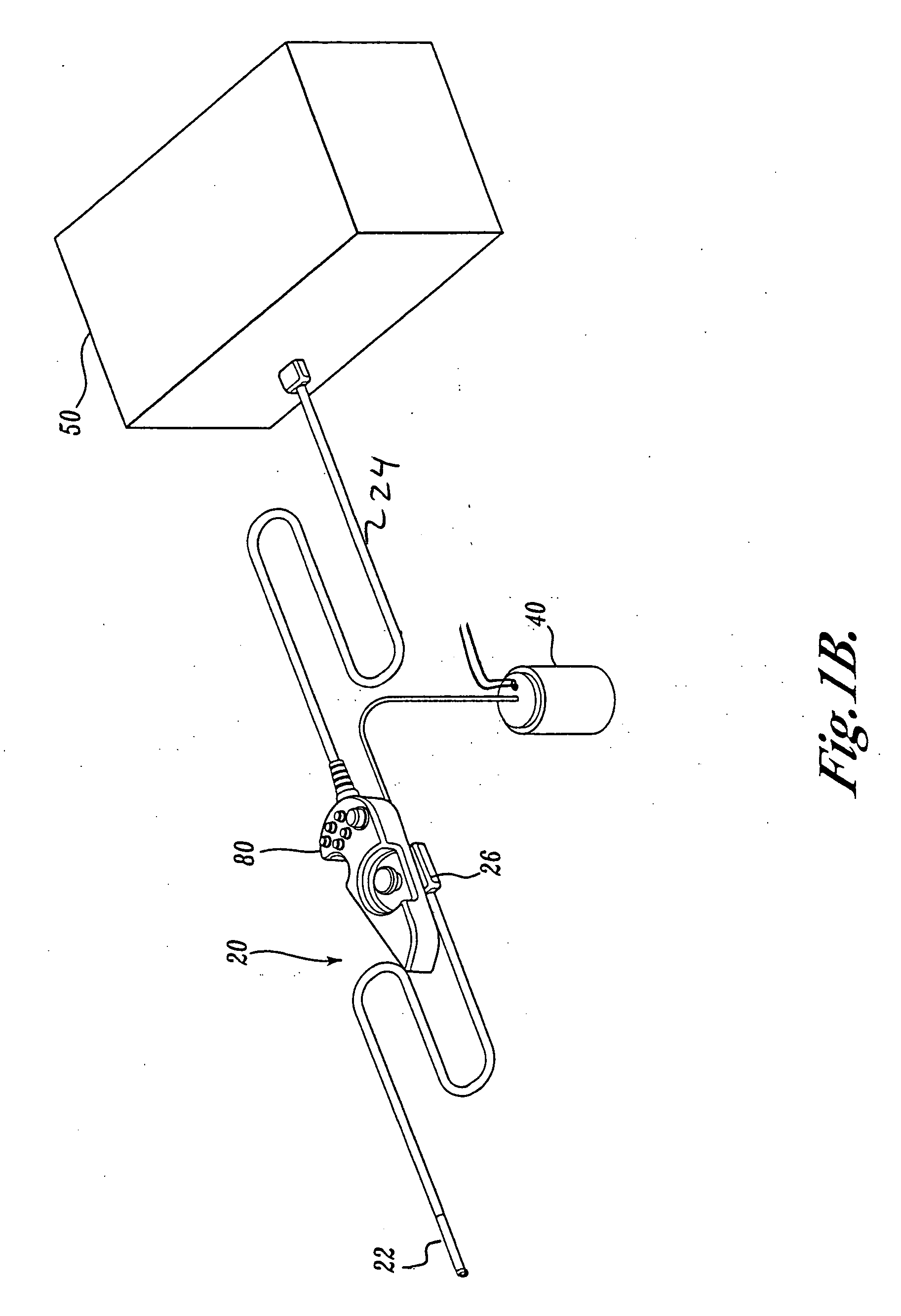

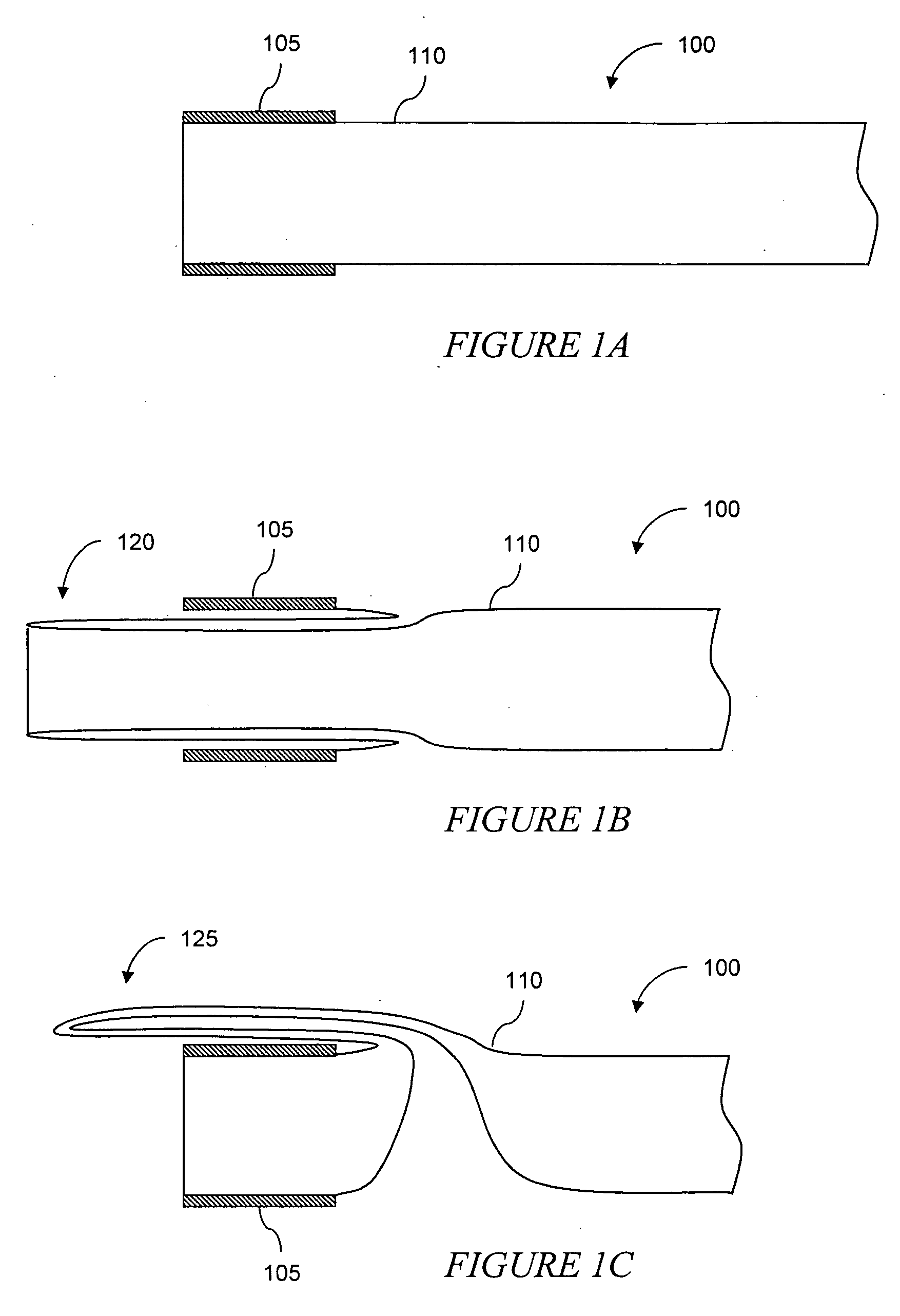

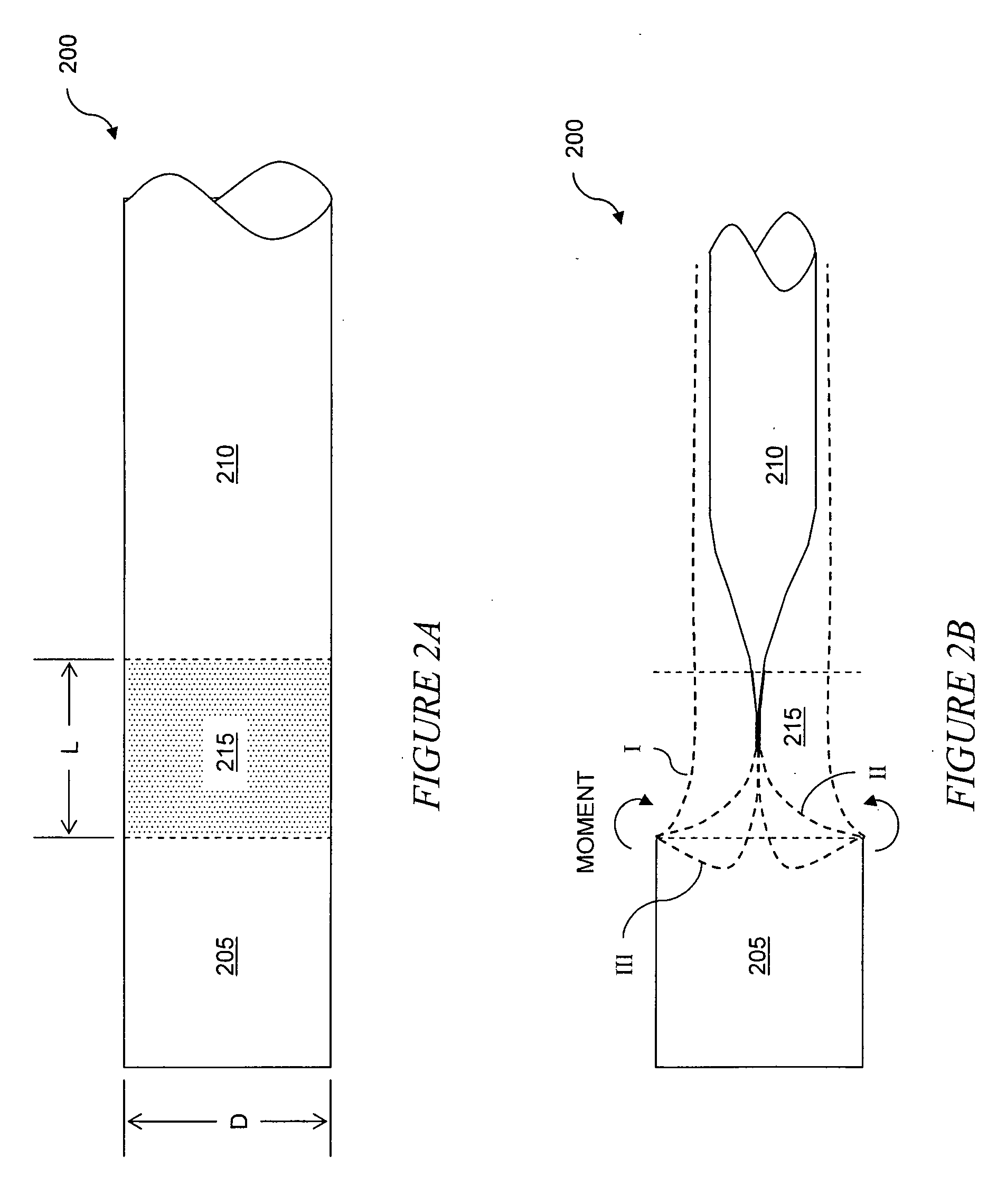

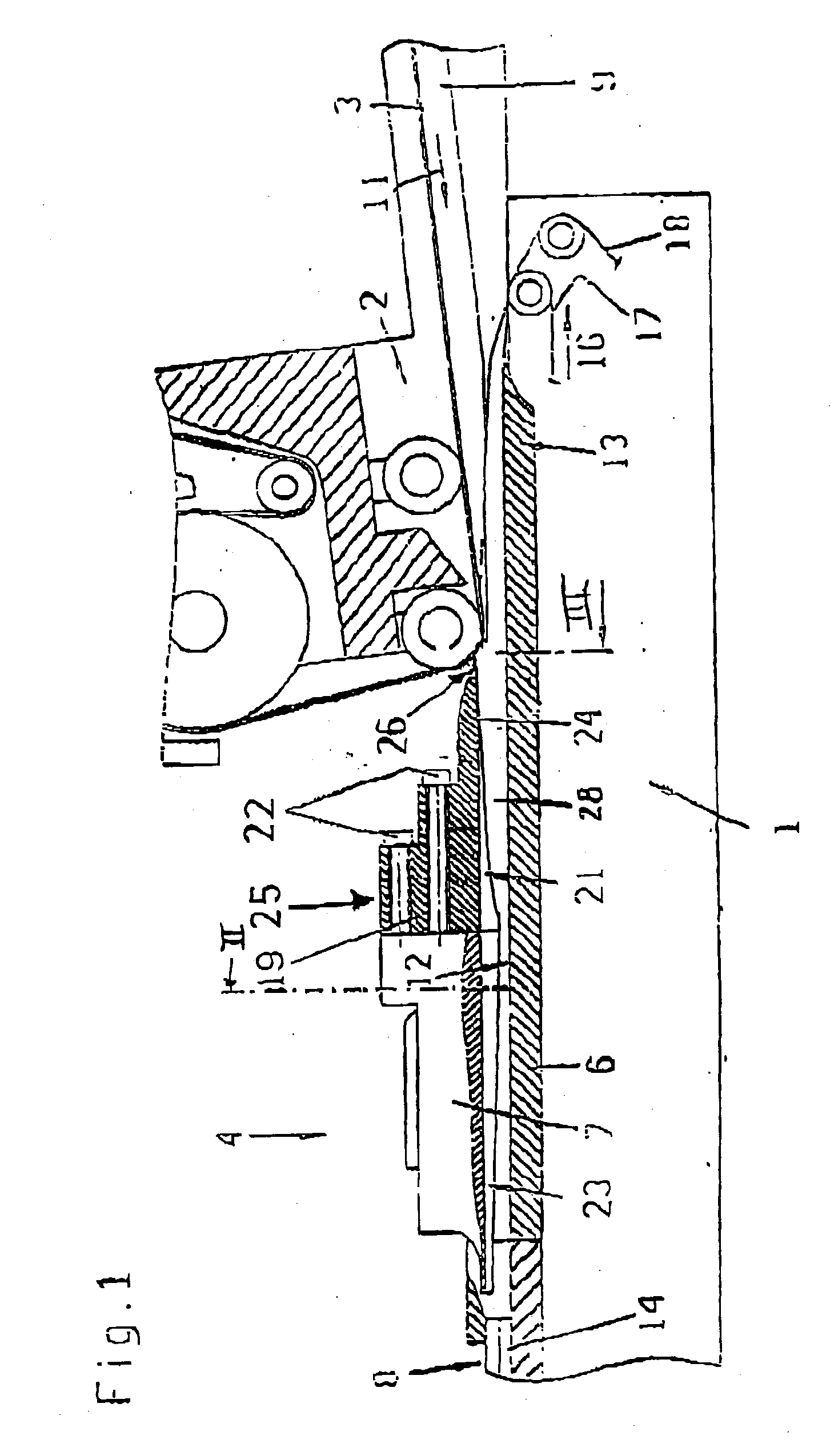

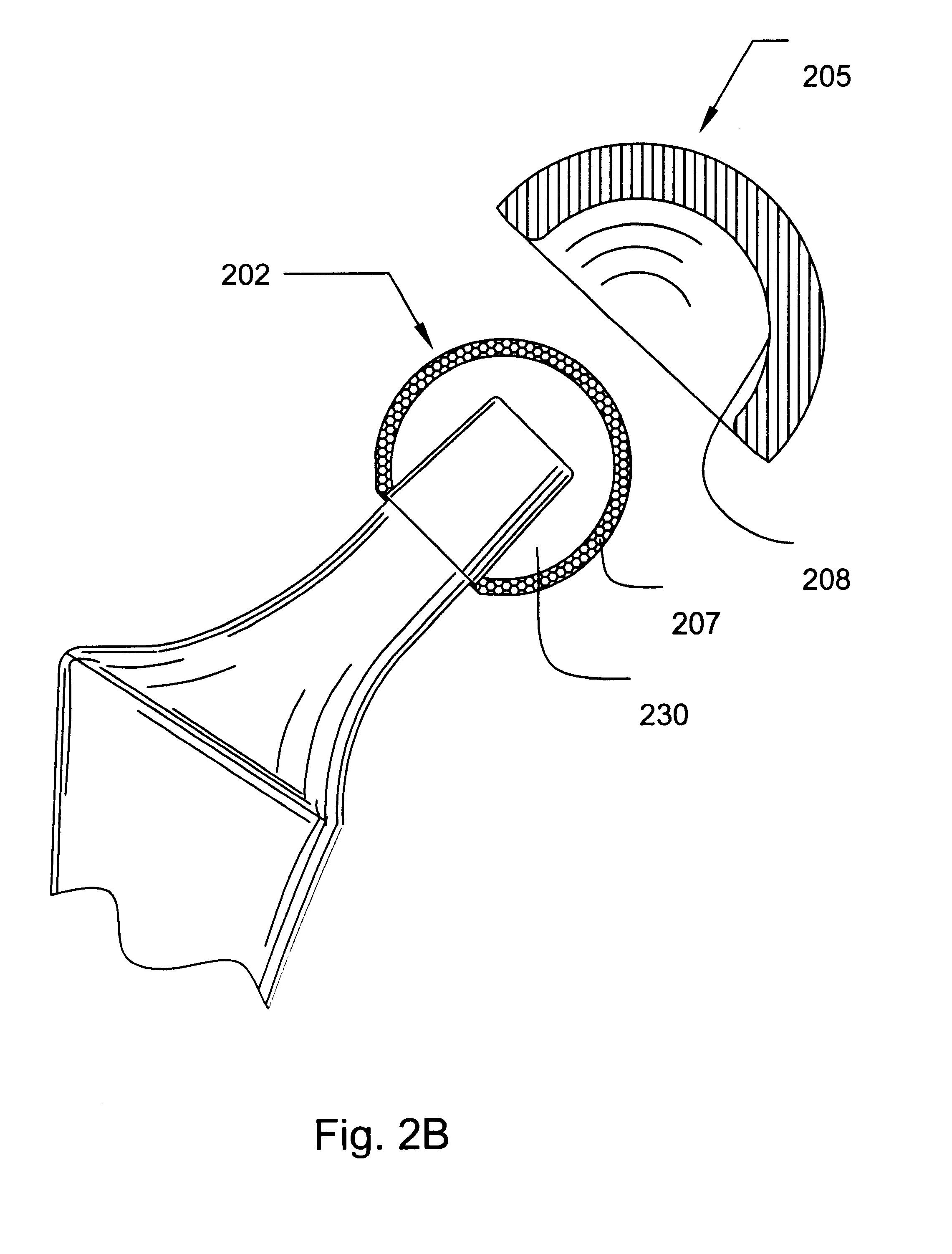

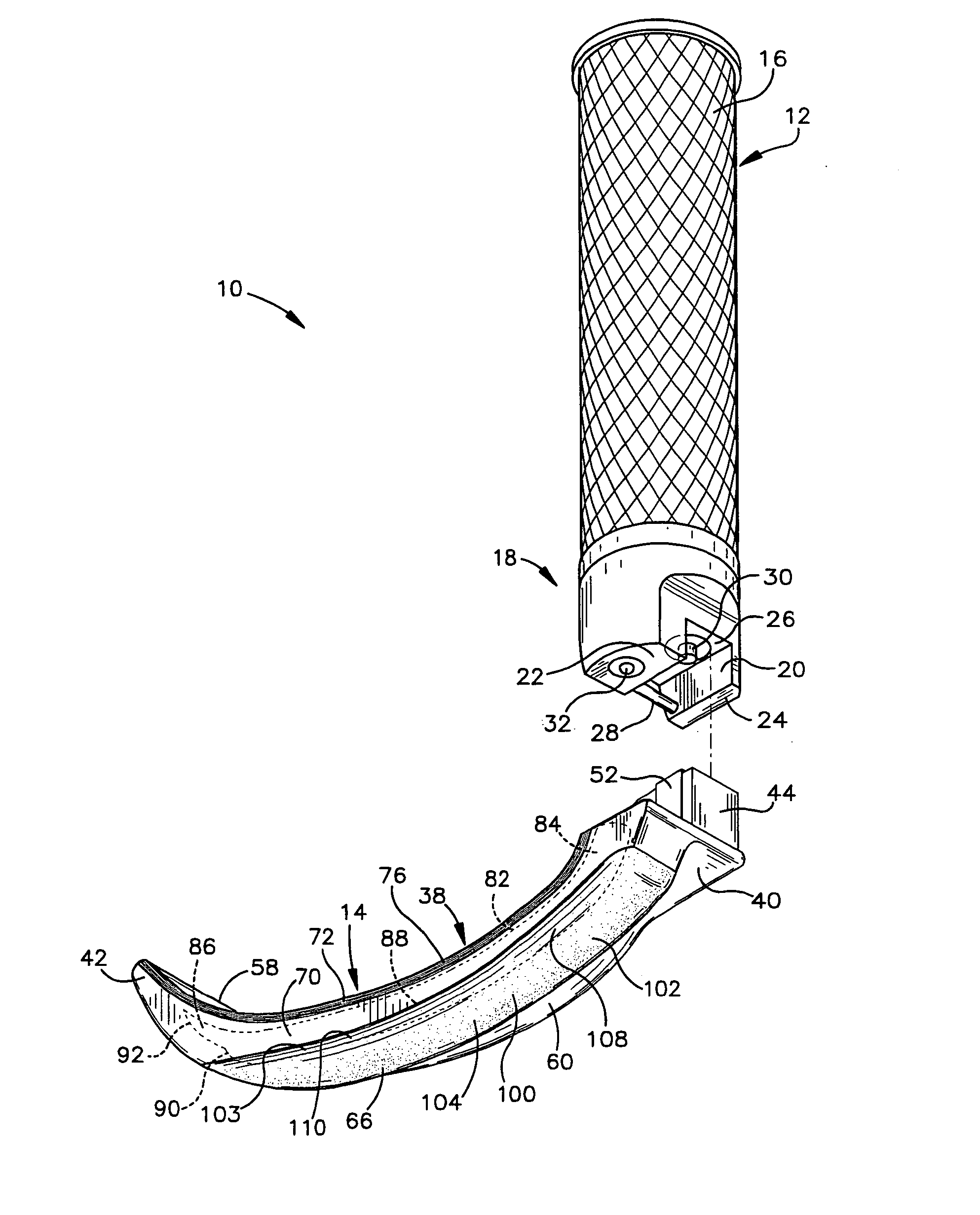

Articulation joint for video endoscope

A video endoscope system includes a reusable control cabinet and an endoscope that is connectable thereto. The endoscope may be used with a single patient and then disposed. The endoscope includes an illumination mechanism, an image sensor, and an elongate shaft having one or more lumens located therein. An articulation joint at the distal end of the endoscope allows the distal end to be oriented by the actuators in the control cabinet or actuators in a control handle of the endoscope. Fluidics, electrical, navigation, image, display and data entry controls are integrated into the system along with other accessories.

Owner:BOSTON SCI SCIMED INC

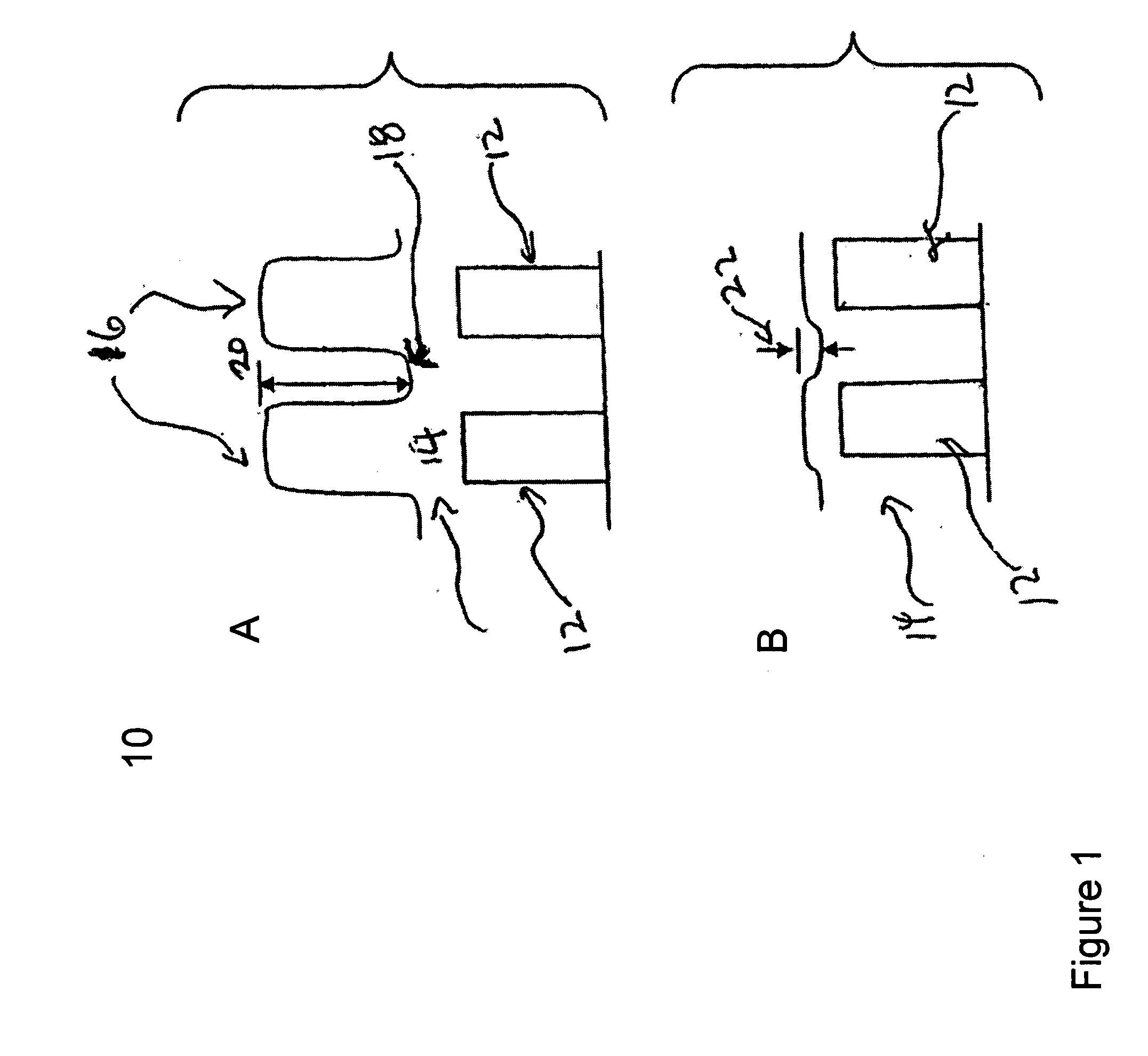

Access device with insert

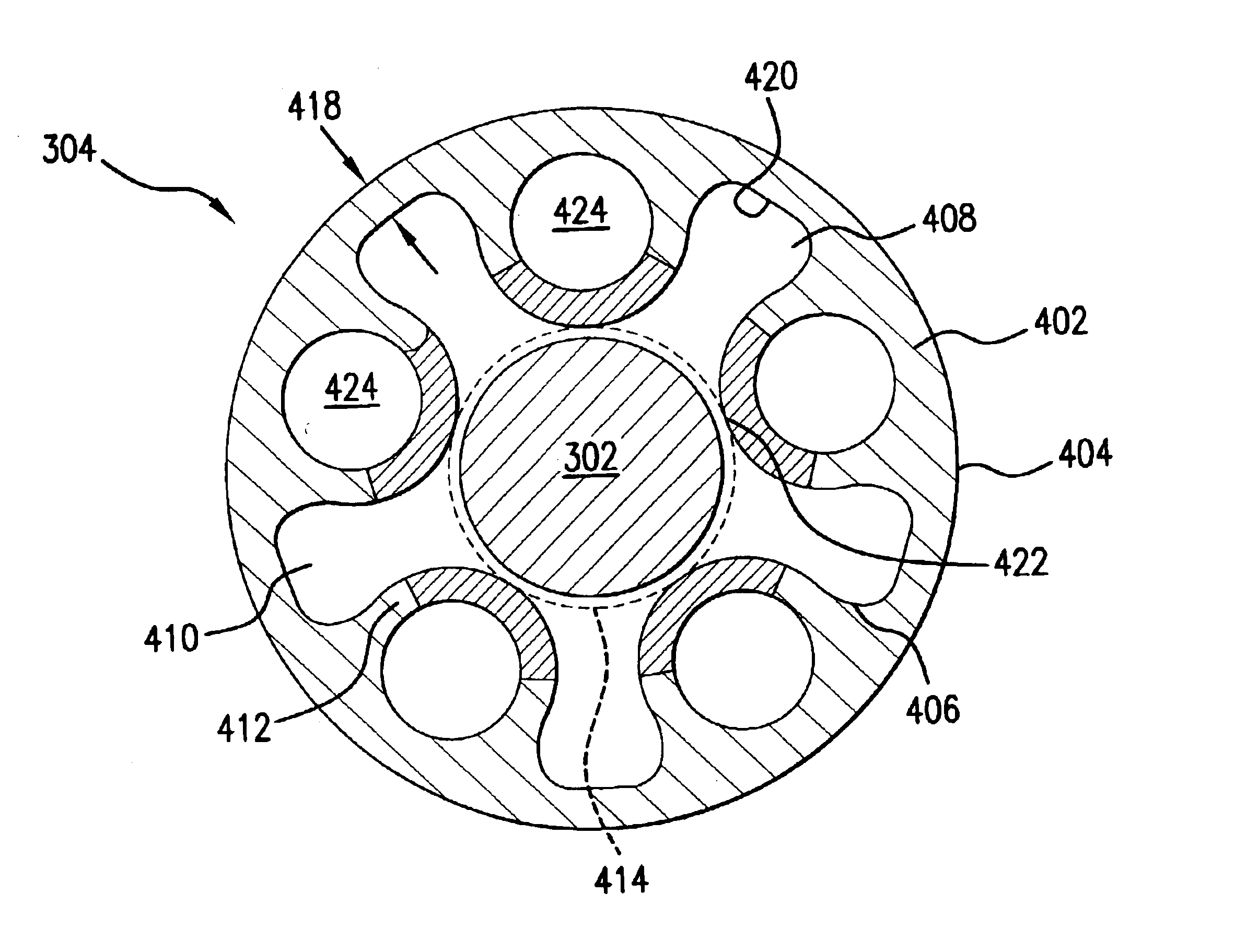

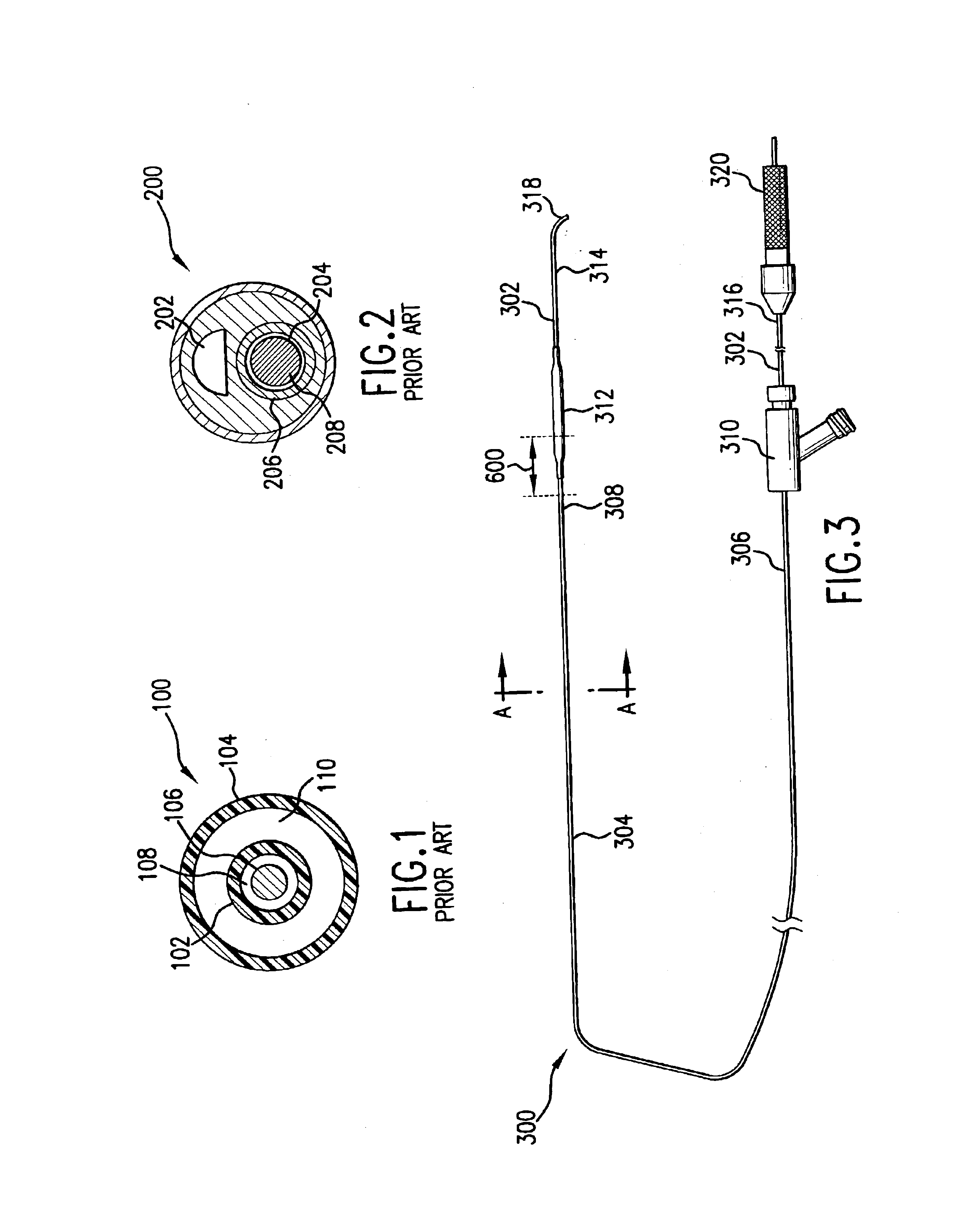

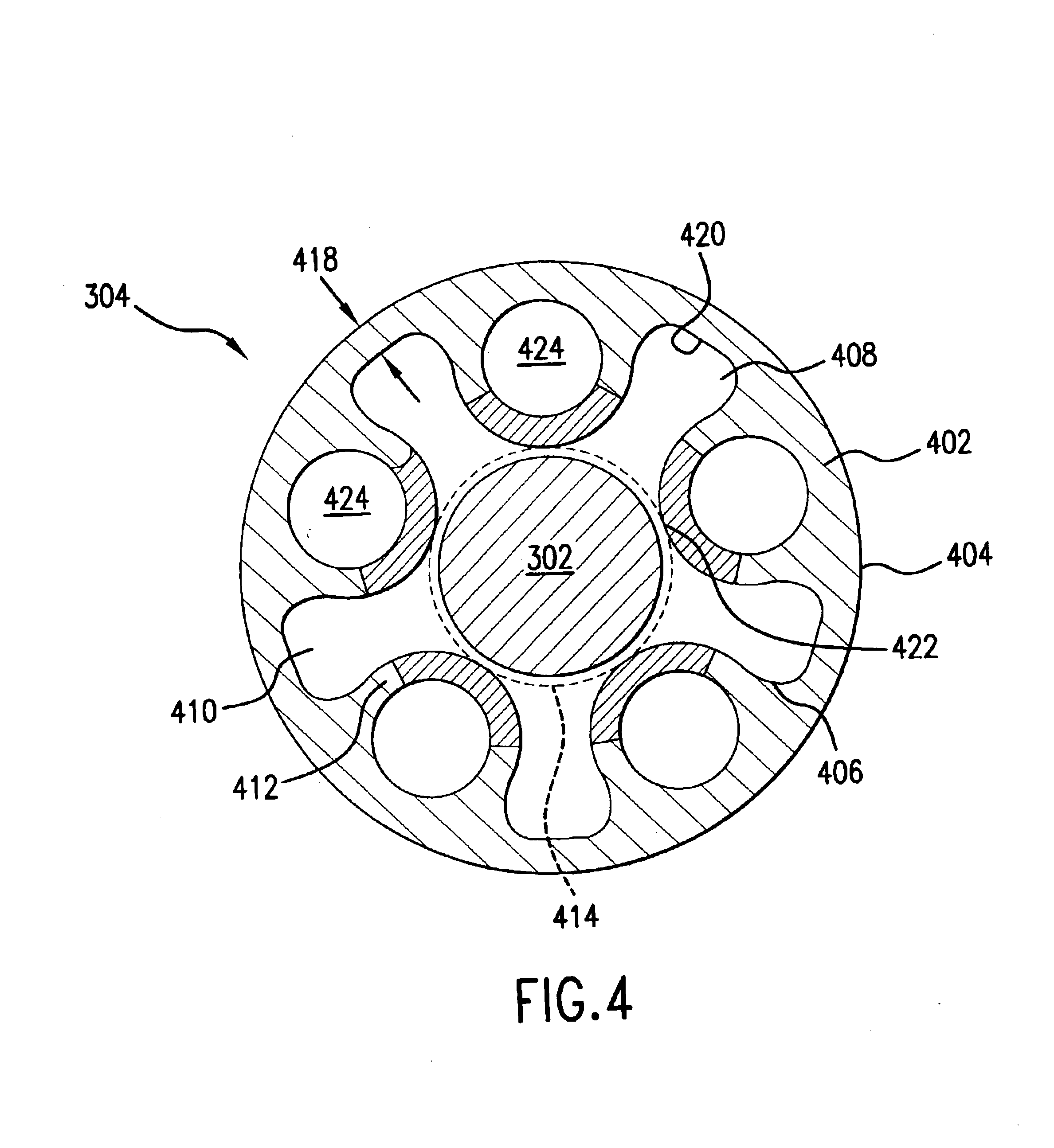

ActiveUS8226553B2Reduce coefficient of frictionImprove puncture resistanceCannulasCatheterMedical deviceBiomedical engineering

Various devices and methods are provided with respect to inserting multiple surgical instruments through a single surgical access device. A medical device including a flexible tissue retractor and a releasable insert having multiple instrument openings is disclosed. The insert can be in the form of an insert assembly including multiple components. A method of using the insert is also described.

Owner:CILAG GMBH INT

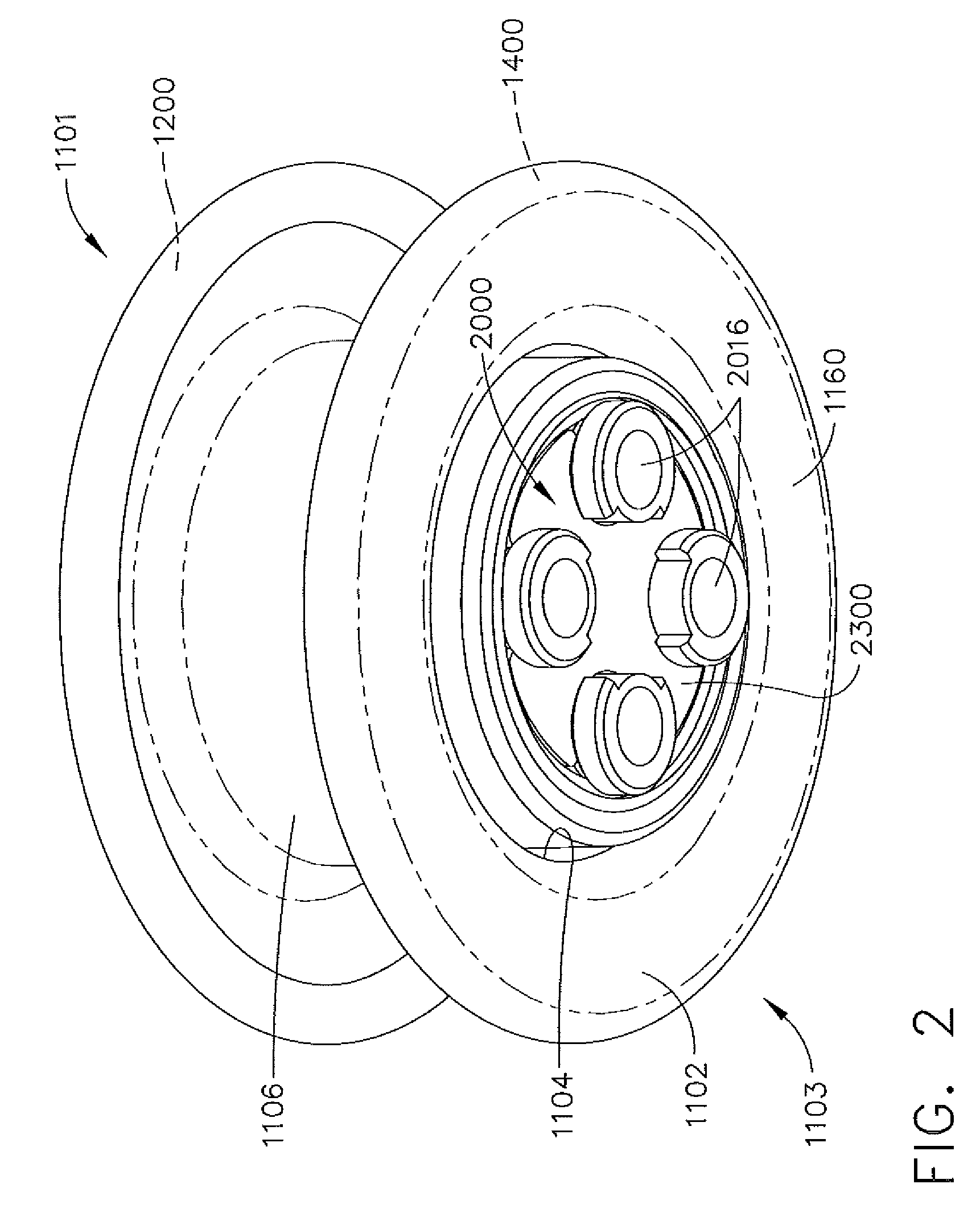

Capacitive touch screen stylus

InactiveUS20110304577A1Reduce coefficient of frictionLower impedanceInput/output processes for data processingCapacitanceFiber

In some embodiments, a stylus for providing input to a capacitive touch screen, having a tip including or consisting of conductive felt, which provides a deformable conductive surface for contacting the touch screen. The tip is produced by felting base fibers (which are typically non-conductive) with conductive fibers. In other embodiments, a capacitive touch stylus having at least a first mode of operation and a second mode of operation, and including at least one conductive tip and switched circuitry (preferably, passive circuitry) including at least one switch biased in a default state indicative of the first mode of operation but switchable into a second state indicative of the second mode of operation in response to movement of the tip (typically, in response to exertion of not less than a threshold force on the tip). In some embodiments, a stylus having a conductive tip (e.g., a conductive, felted tip) and including switched circuitry (preferably, passive circuitry) having a first state which couples a capacitance to the tip, where the capacitance is sufficient to allow a capacitive touch screen device to recognize (as a touch) simple contact of the tip on the screen of the touch screen device, and a second state which decouples the capacitance from the tip, thereby preventing the touch screen device from recognizing (as a touch) simple contact of the tip on the screen.

Owner:RB CONTROLS CO

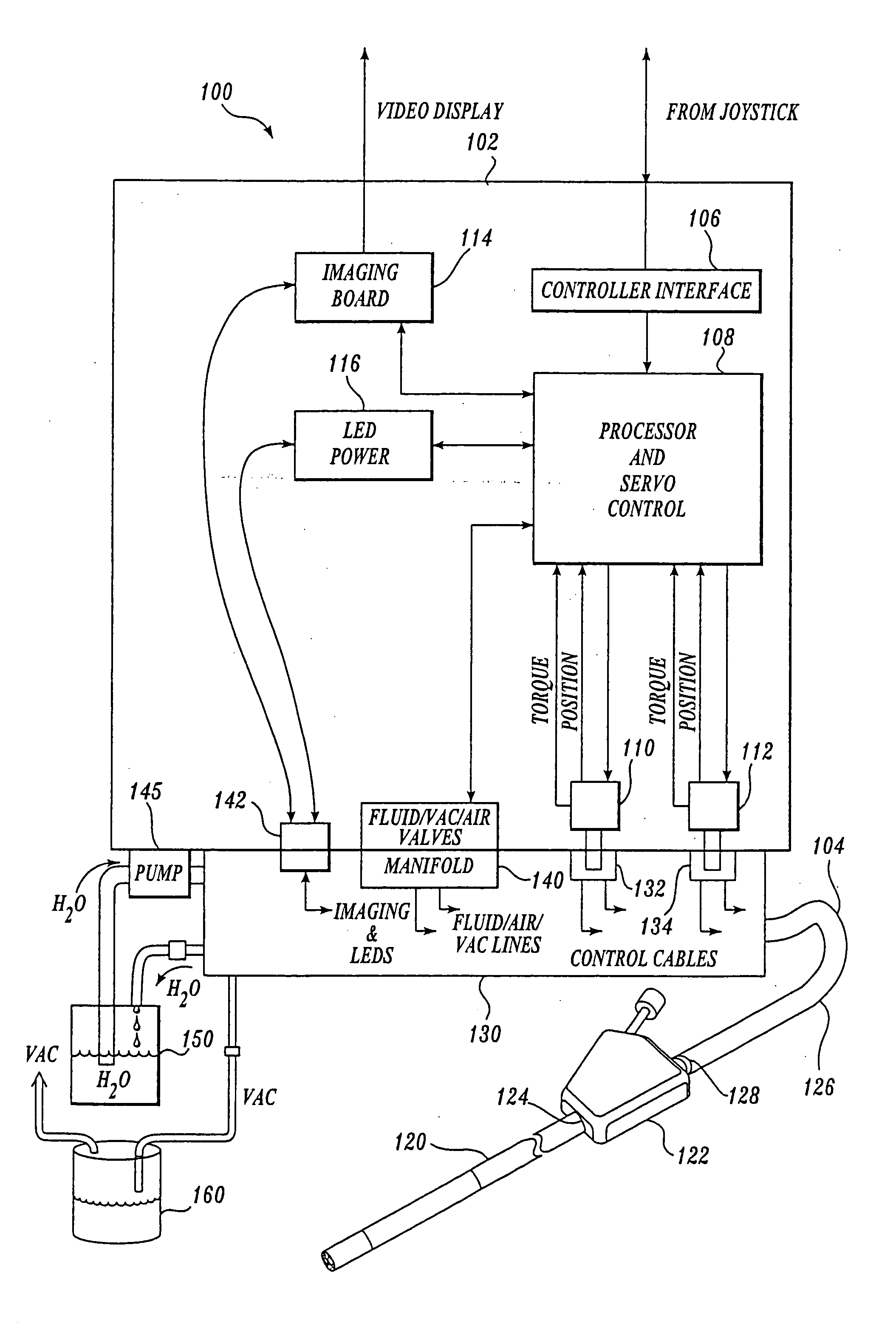

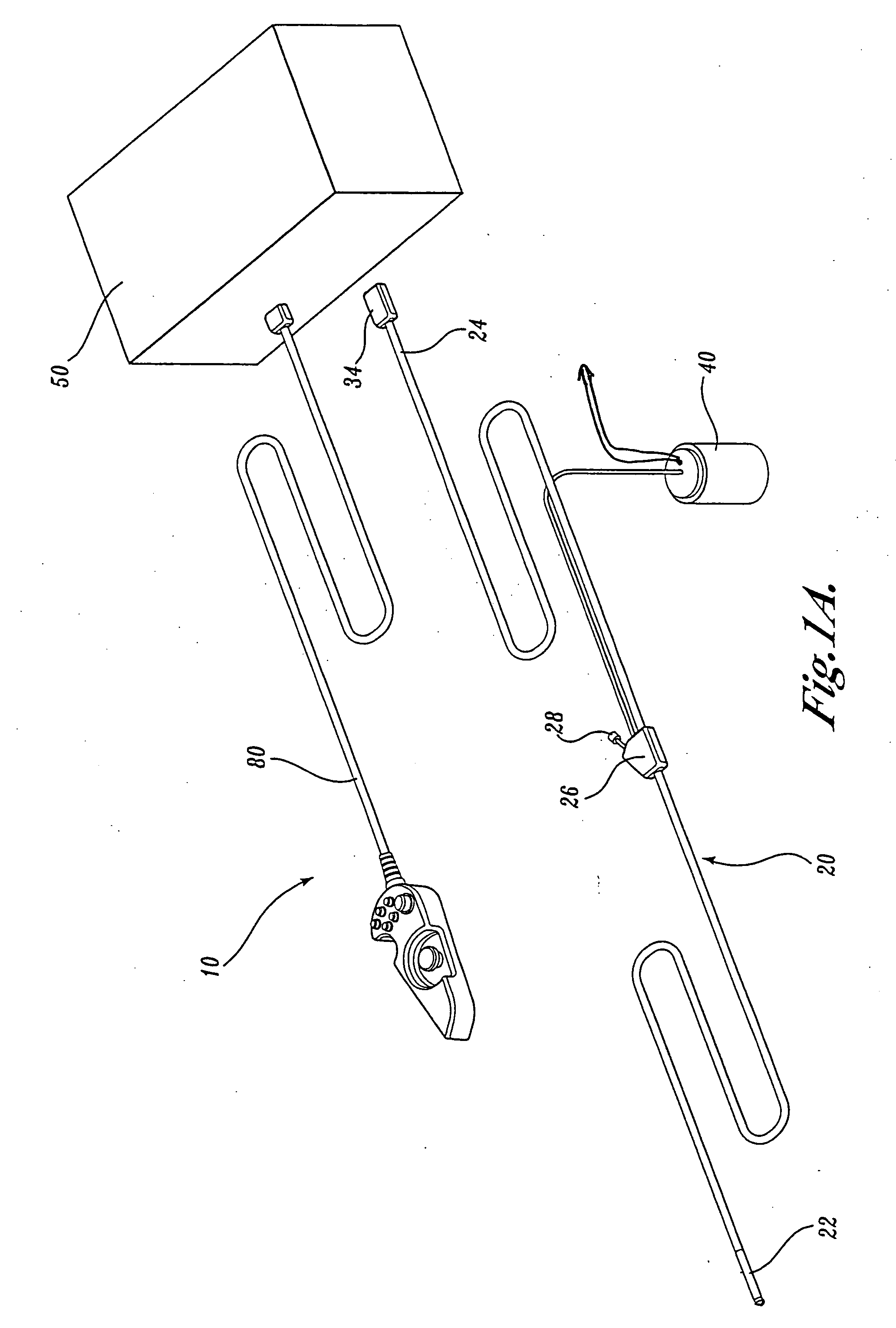

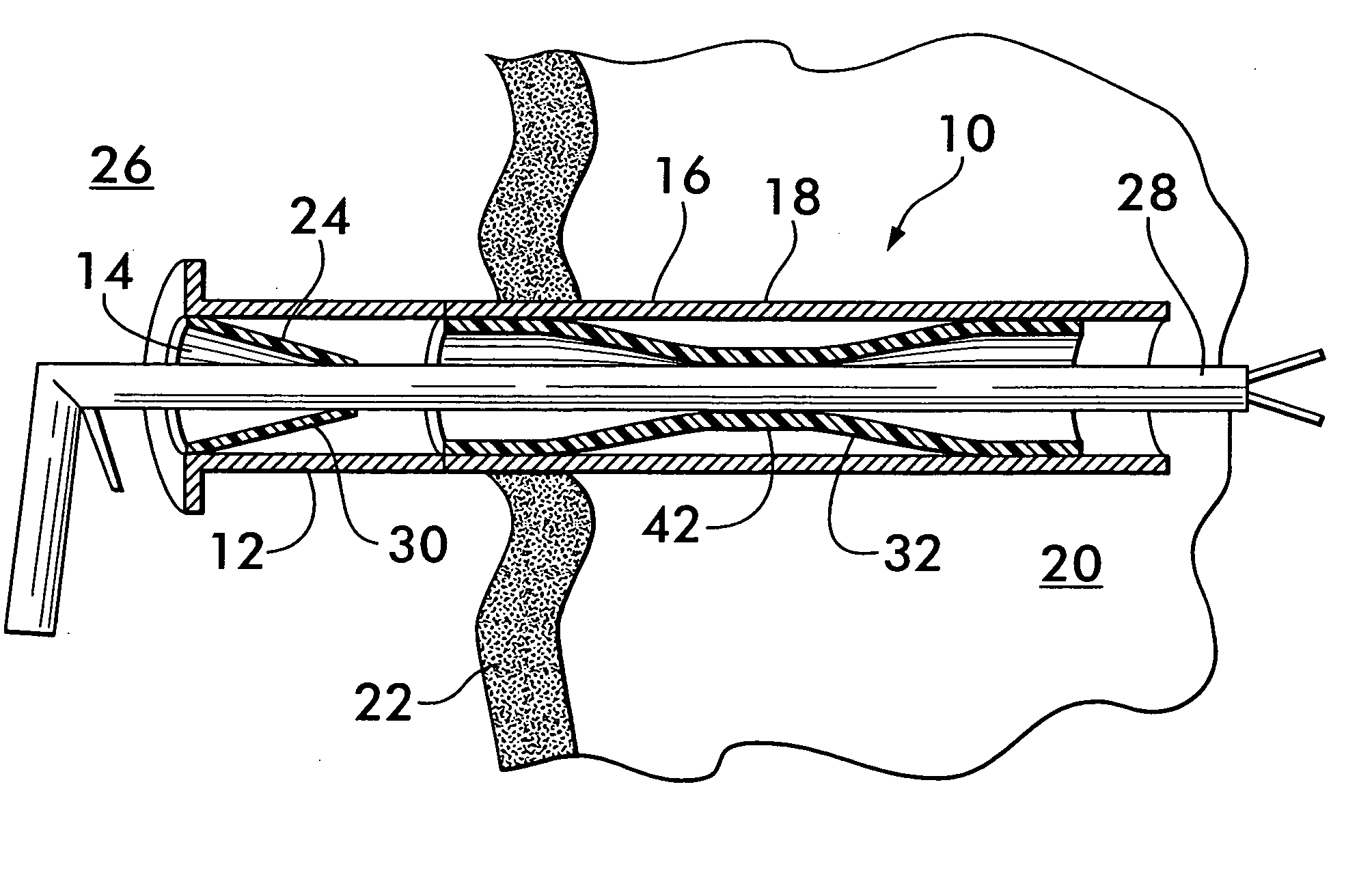

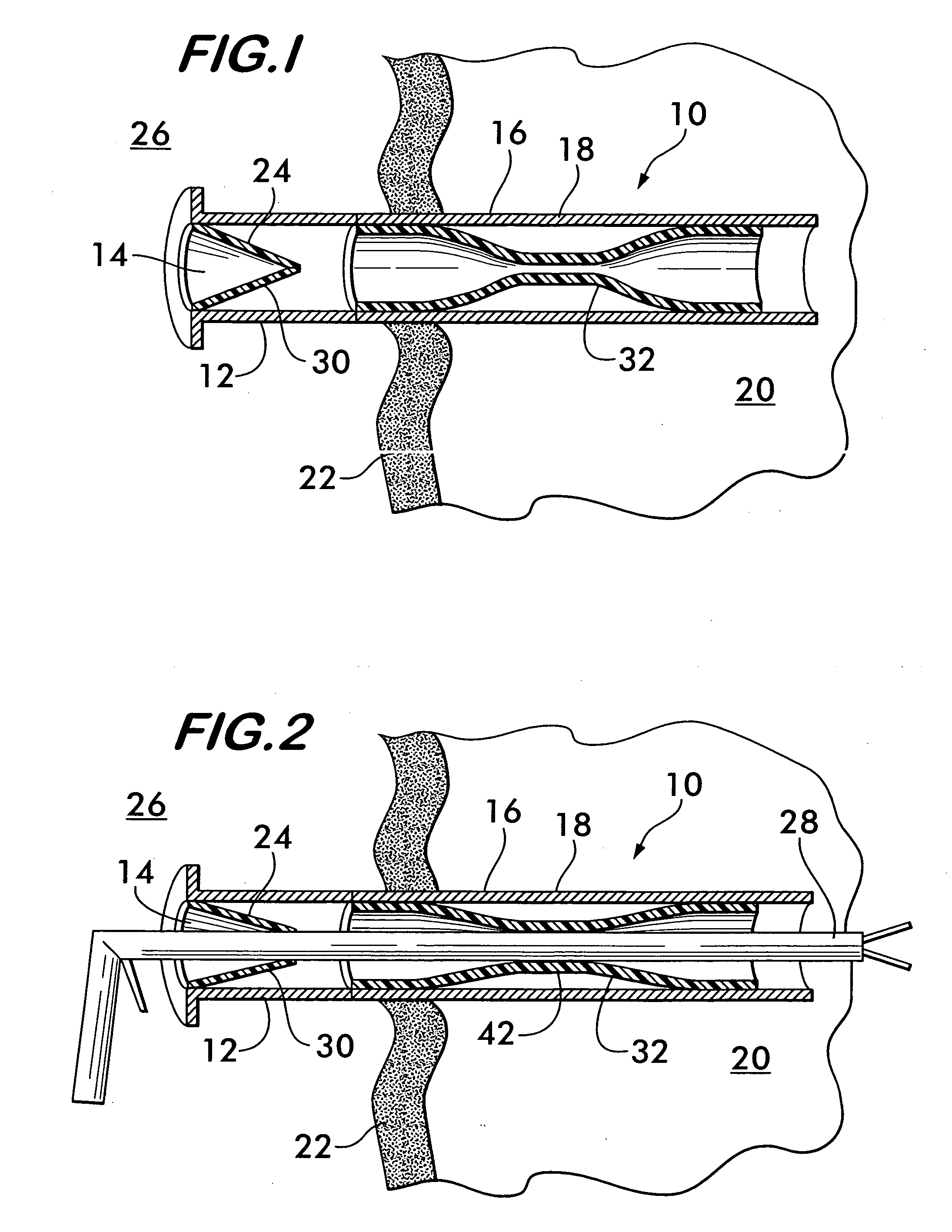

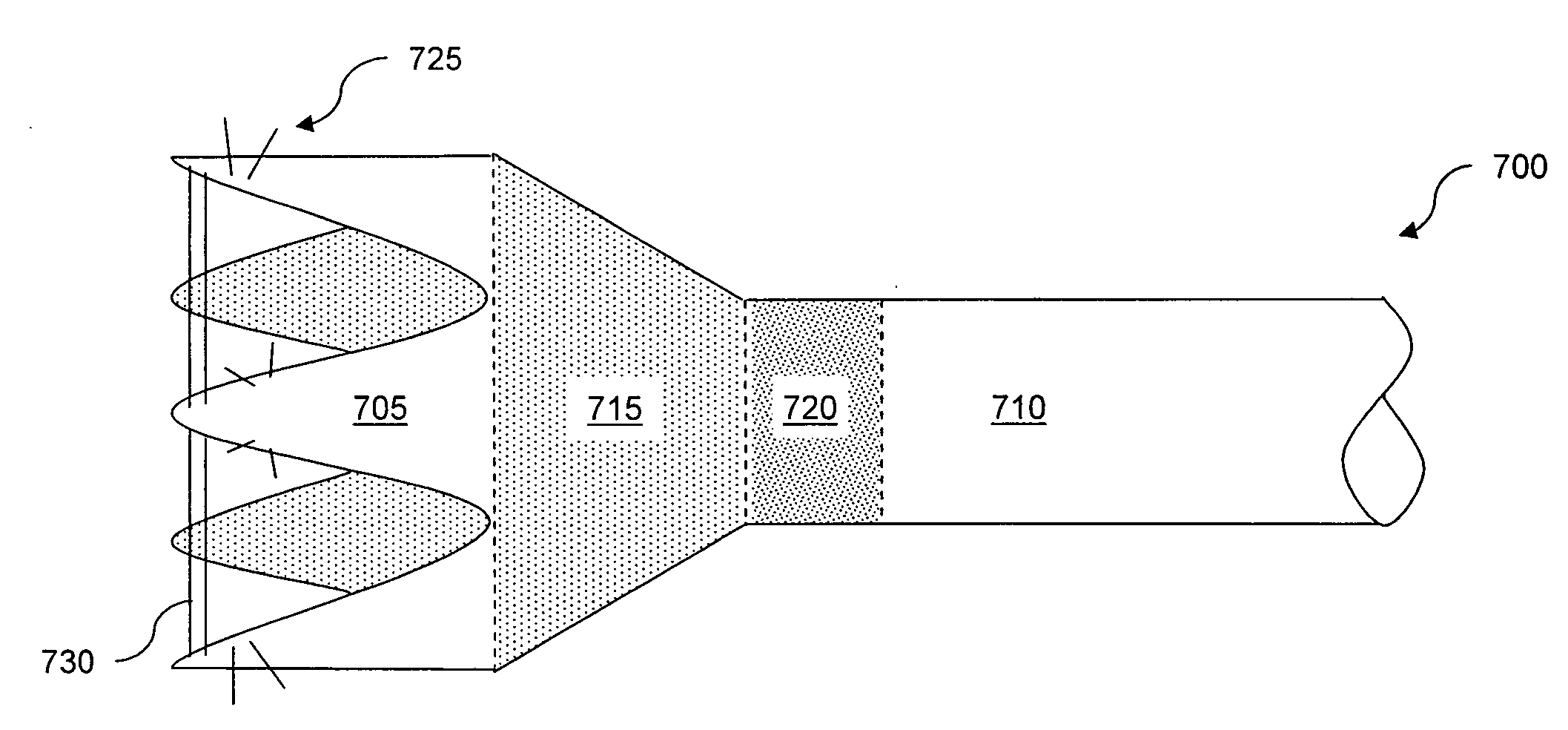

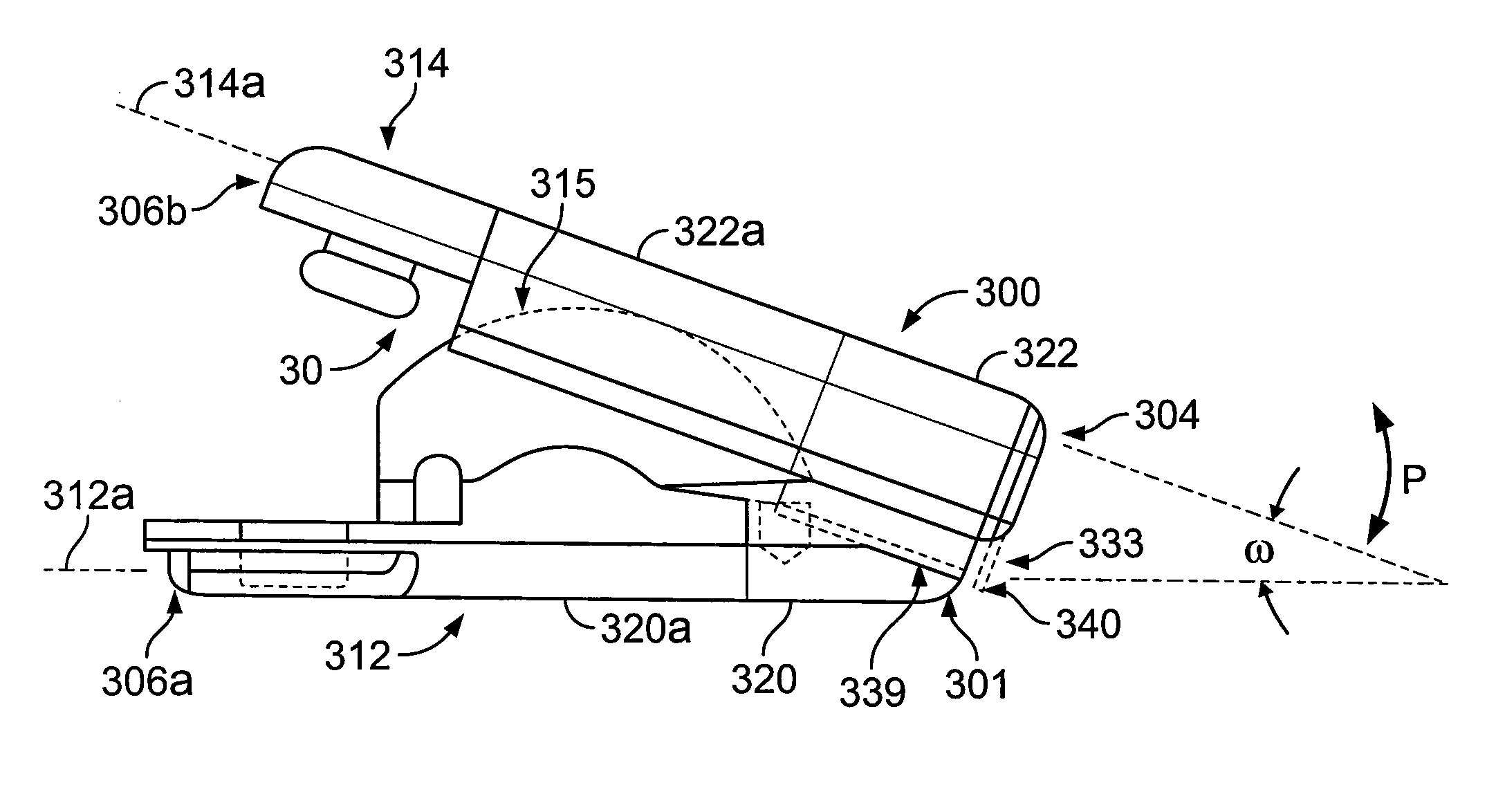

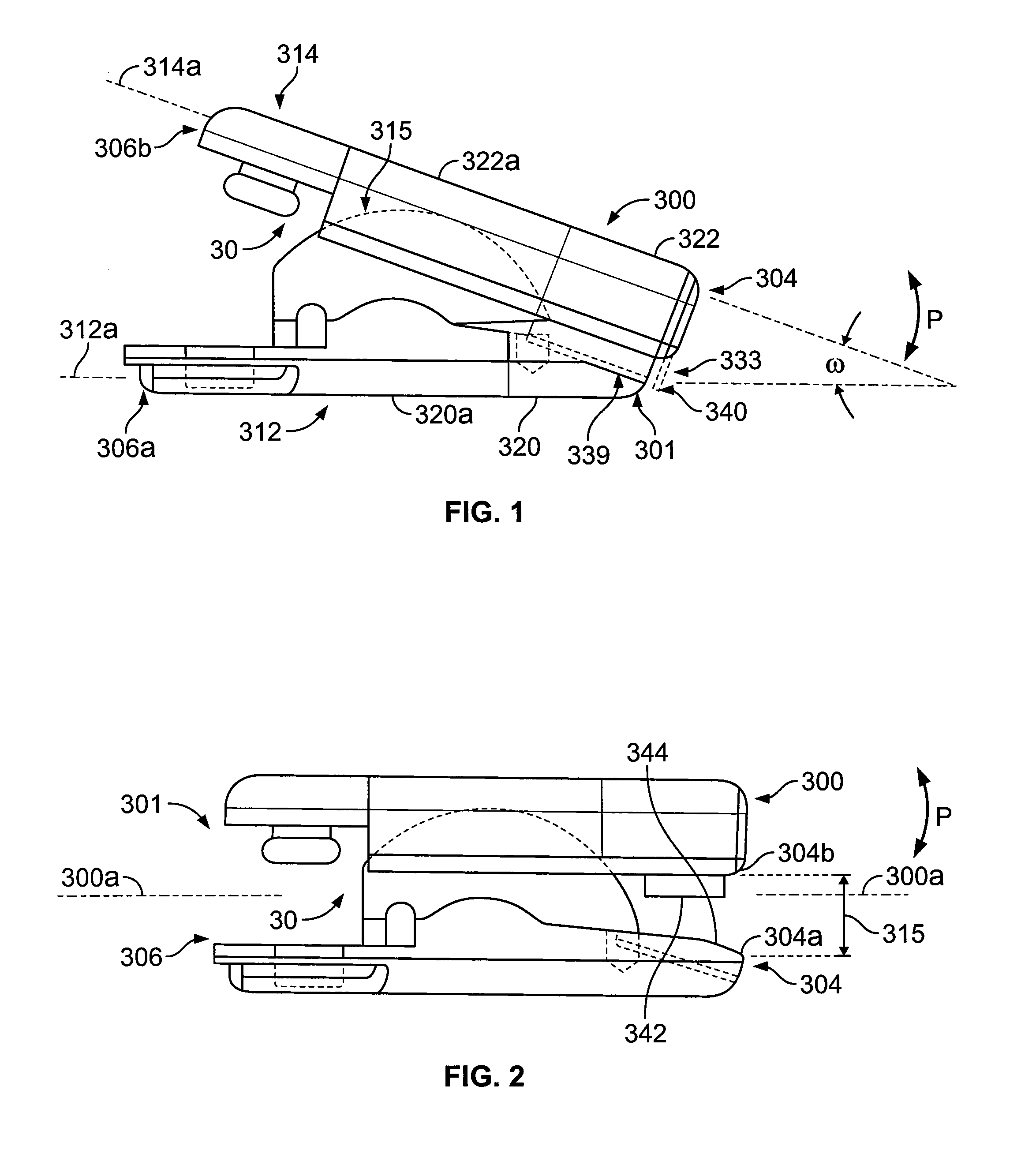

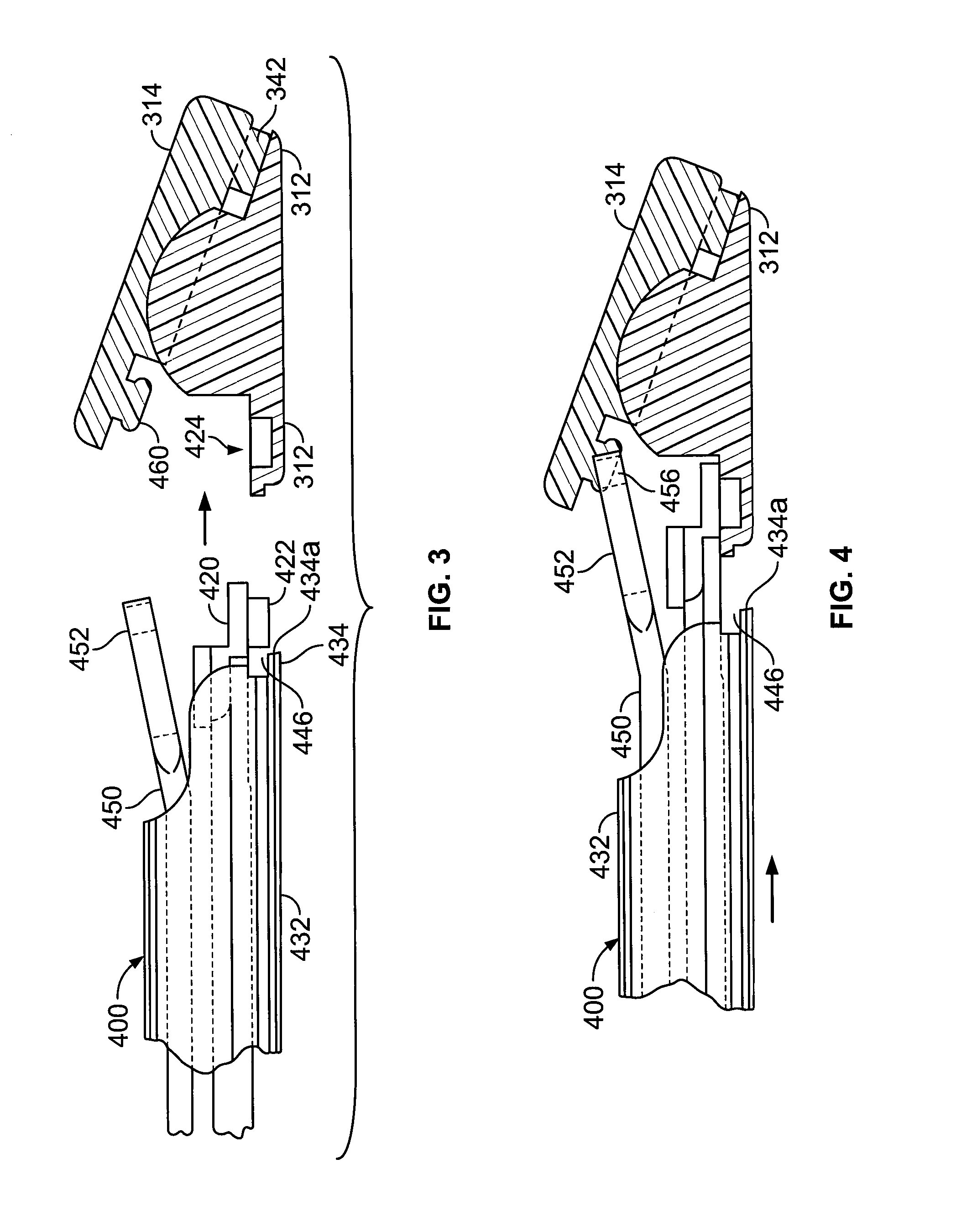

Force feedback control system for video endoscope

ActiveUS20050119527A1Reduce coefficient of frictionImprove device performanceSurgeryEndoscopesFluidicsControl system

A video endoscope system includes a reusable control cabinet and an endoscope that is connectable thereto. The endoscope may be used with a single patient and then disposed. The endoscope includes an illumination mechanism, an image sensor, and an elongate shaft having one or more lumens located therein. An articulation joint at the distal end of the endoscope allows the distal end to be oriented by the actuators in the control cabinet or actuators in a control handle of the endoscope. Fluidics, electrical, navigation, image, display and data entry controls are integrated into the system along with other accessories.

Owner:BOSTON SCI SCIMED INC

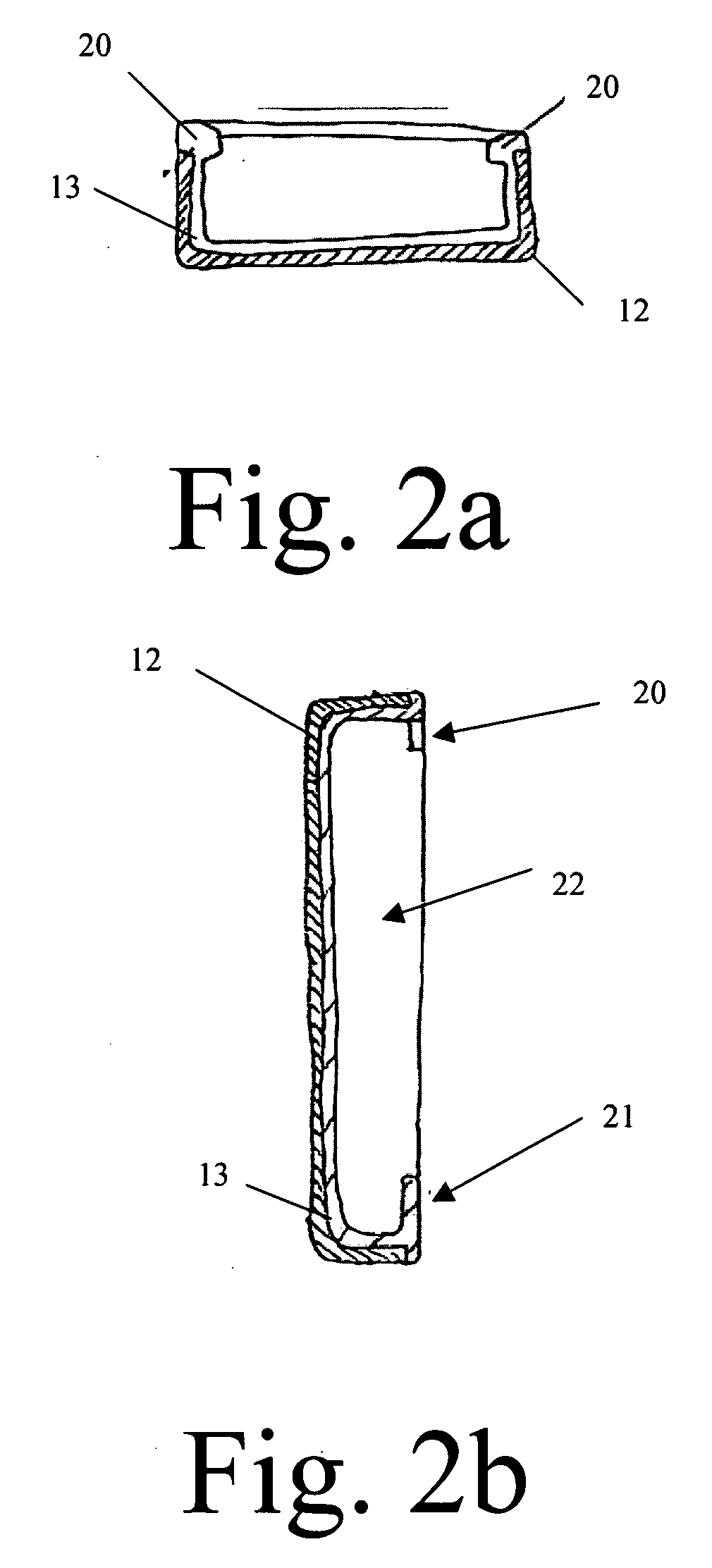

One Piece Co-formed Exterior Hard Shell Case with an Elastomeric Liner for Mobile Electronic Devices

ActiveUS20100203931A1Maximum protectionReduce coefficient of frictionTravelling carriersHoldersElastomerMechanical engineering

A one-piece co-formed exterior hard shell case with an elastomeric liner formed on the interior of the exterior hard shell for mobile electronic devices. This hard protective exterior shell allows the device maximum protection from impacts with sharp objects while the interior elastomeric portion that provides shock protection for the device from impacts. The exterior hard shell part is formed to fit the device closely with a small offset from the devices surface. The exterior hard shell raps around the edges of the device. To allow the shell to be able to be mounted on the device the corners of the hard shell are cut open. This allows each sidewall to flex away when a device is inserted and snap back once it is in place. The elastomeric material fills in the gaps created at the corners of the exterior hard shell to allow flex for mounting.

Owner:SPECULATIVE PROD DESIGN

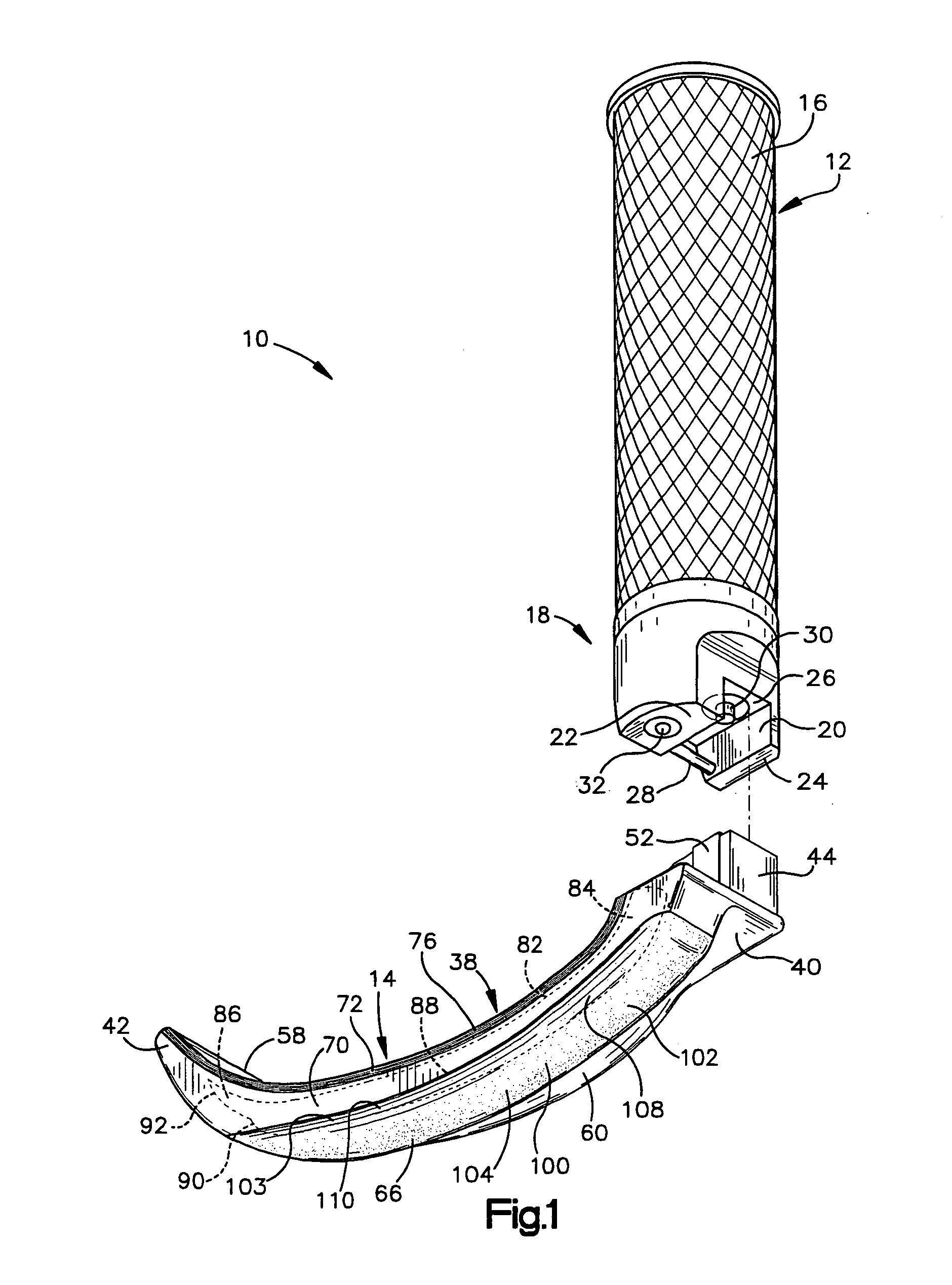

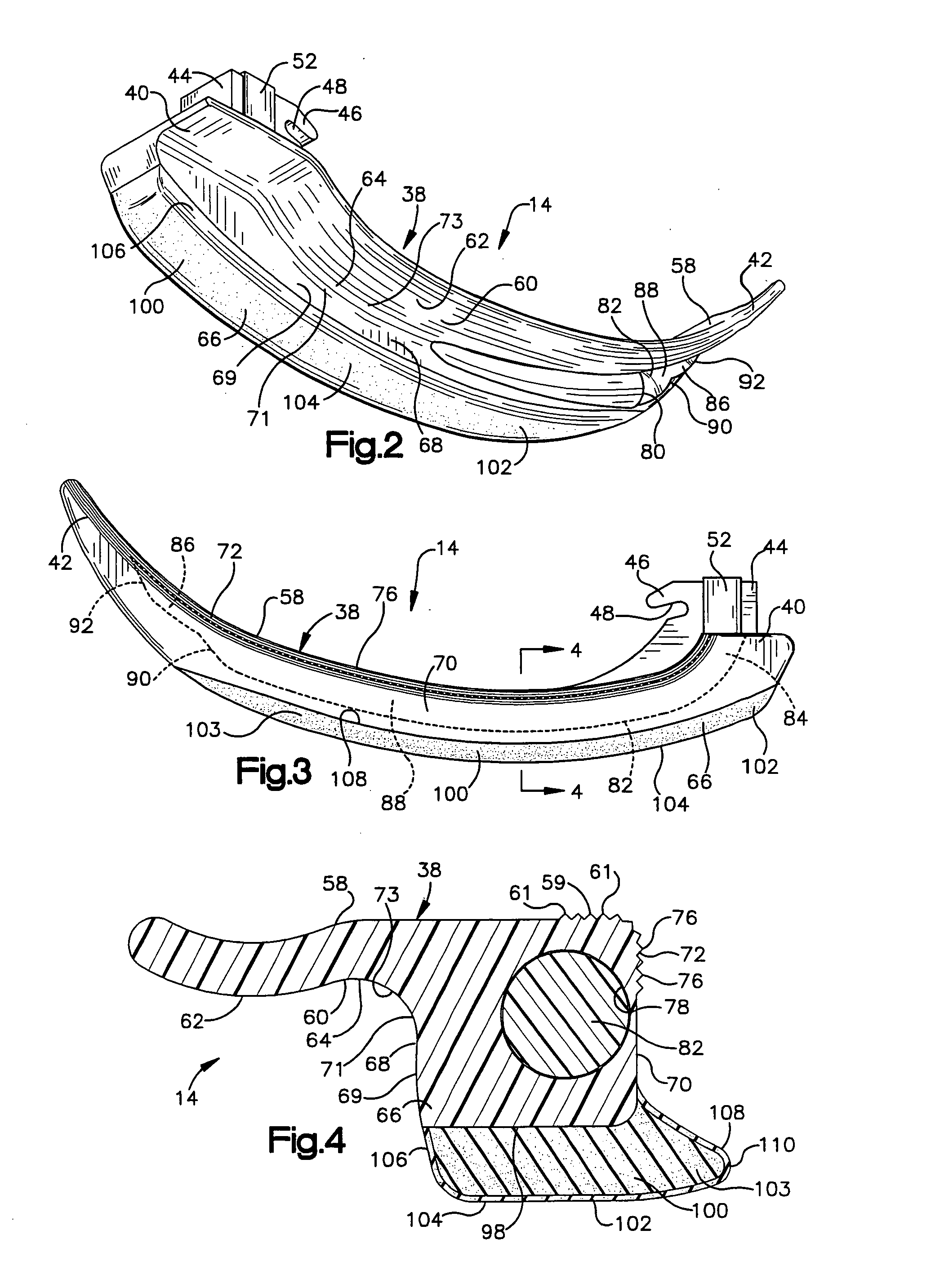

Articulation joint for video endoscope

ActiveUS20050131279A1Reduce coefficient of frictionImprove device performanceSurgeryEndoscopesFluidicsEngineering

A video endoscope system includes a reusable control cabinet and an endoscope that is connectable thereto. The endoscope may be used with a single patient and then disposed. The endoscope includes an illumination mechanism, an image sensor, and an elongate shaft having one or more lumens located therein. An articulation joint at the distal end of the endoscope allows the distal end to be oriented by the actuators in the control cabinet or actuators in a control handle of the endoscope. Fluidics, electrical, navigation, image, display and data entry controls are integrated into the system along with other accessories.

Owner:BOSTON SCI SCIMED INC

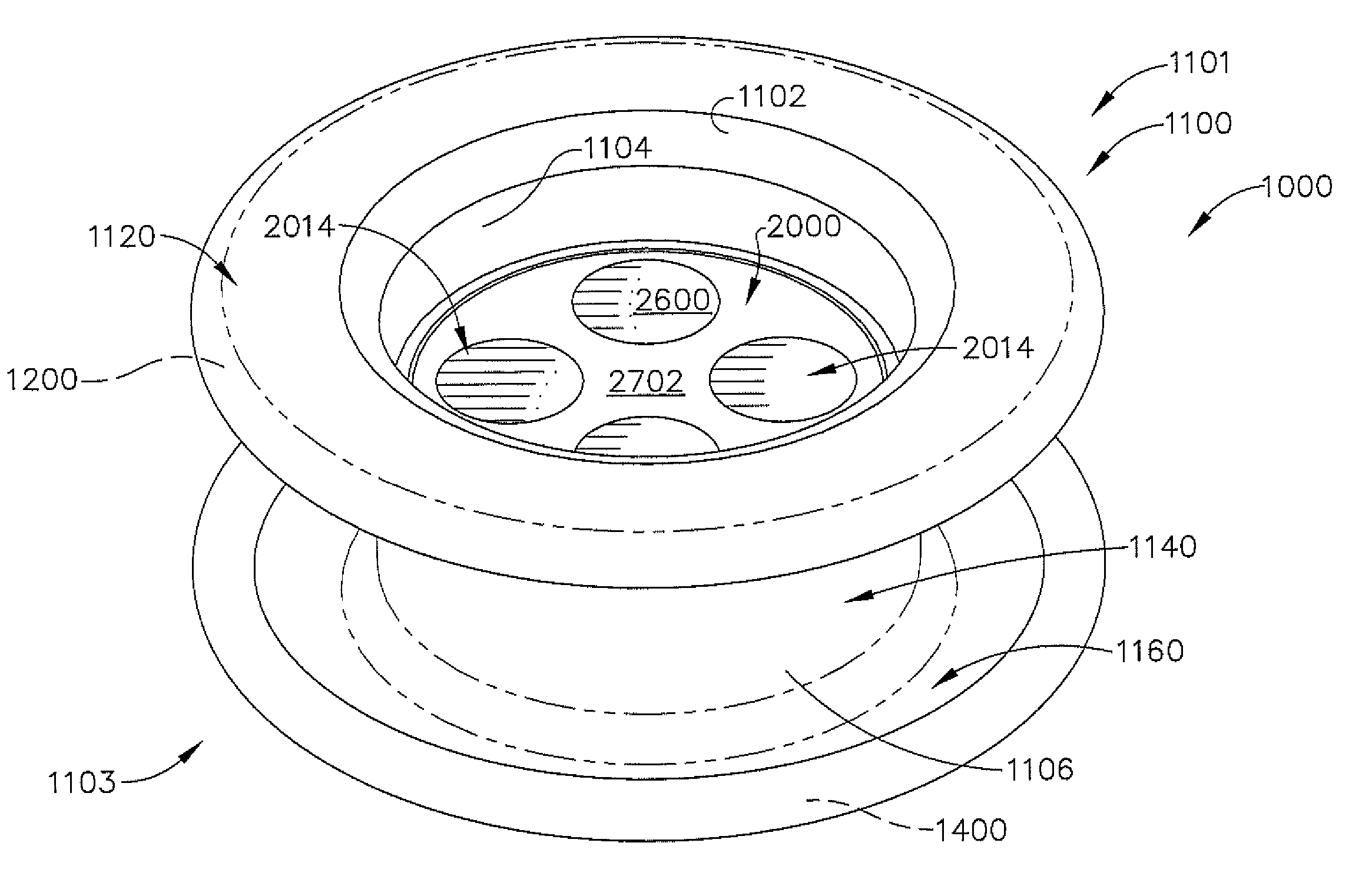

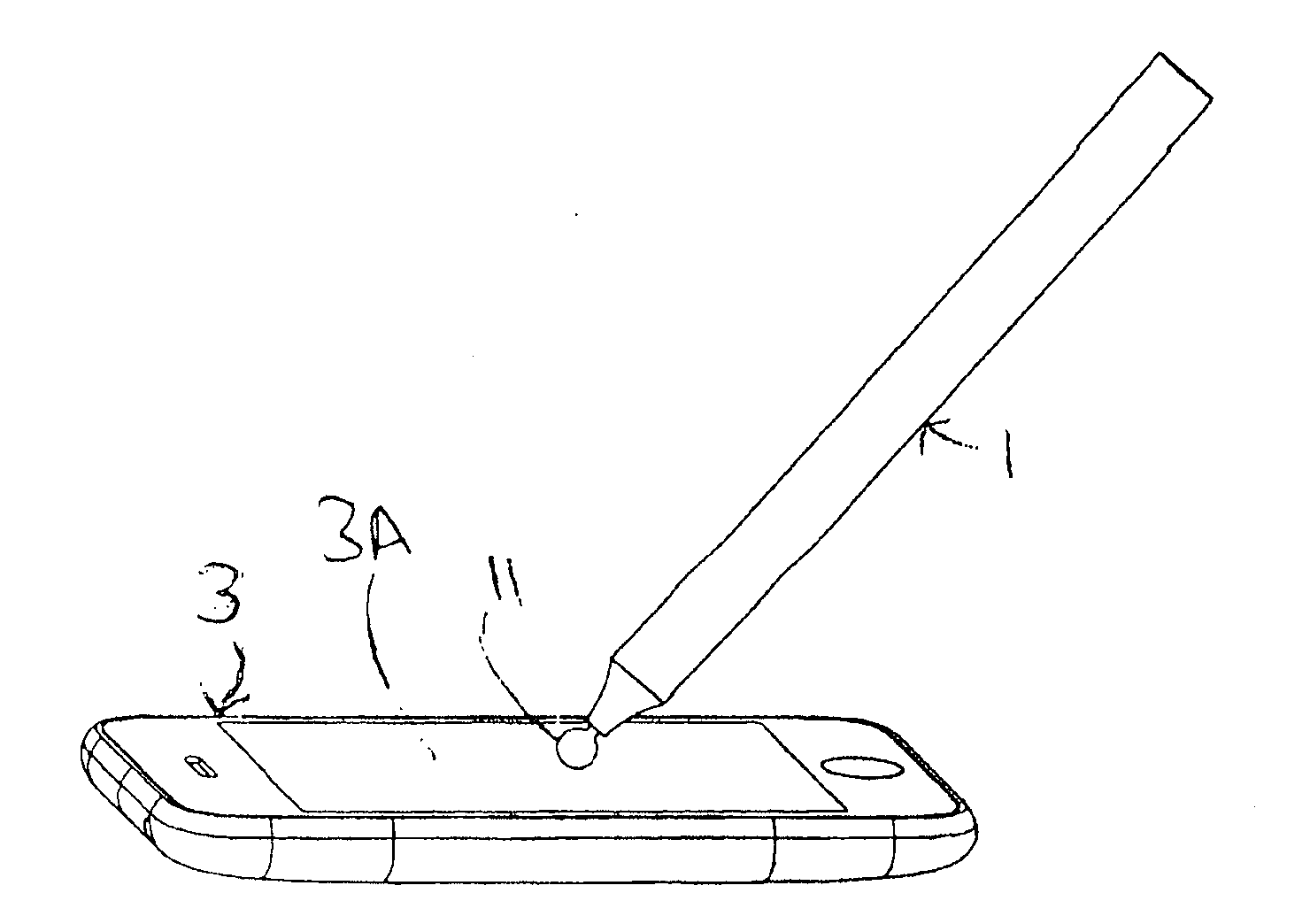

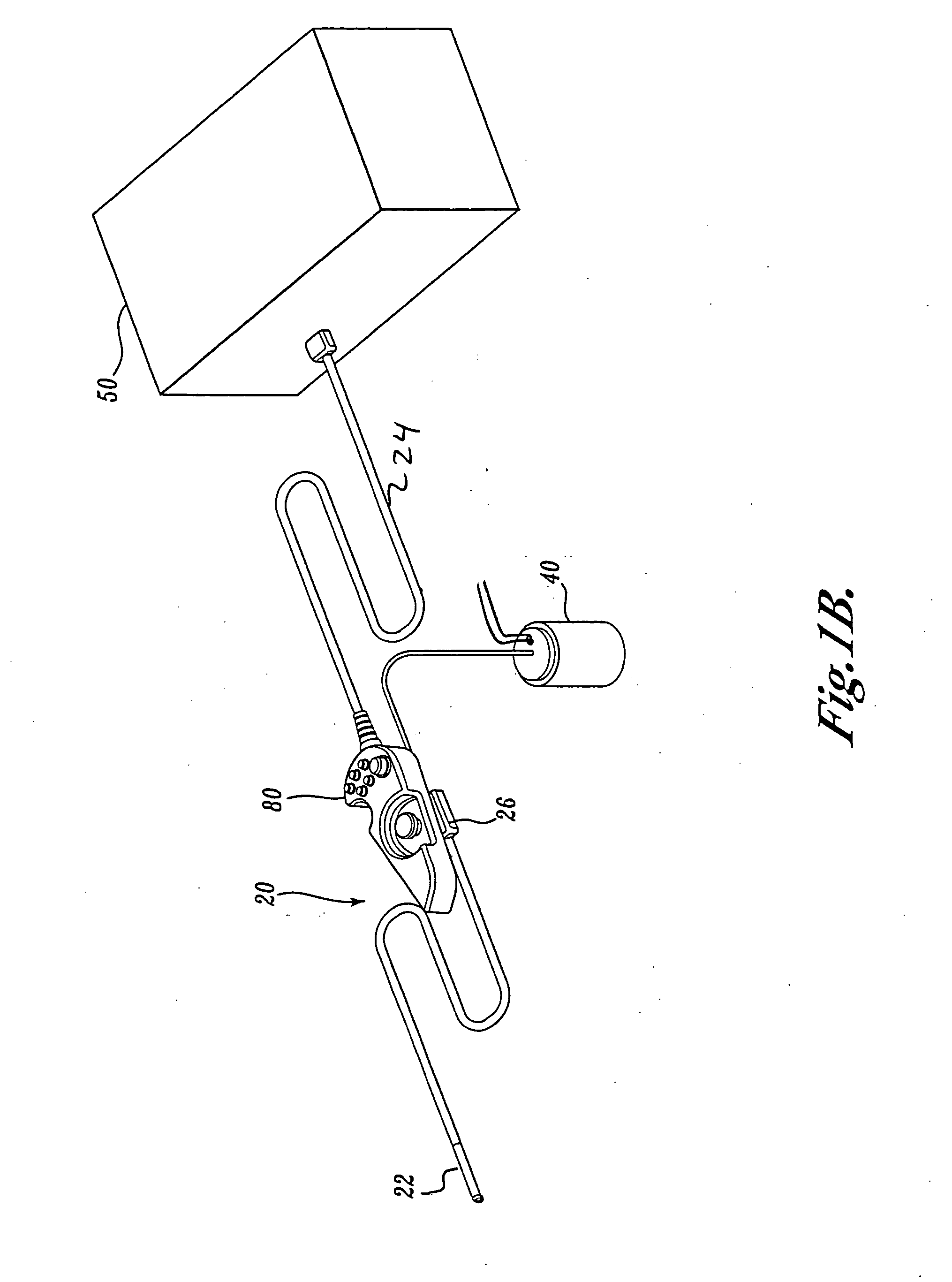

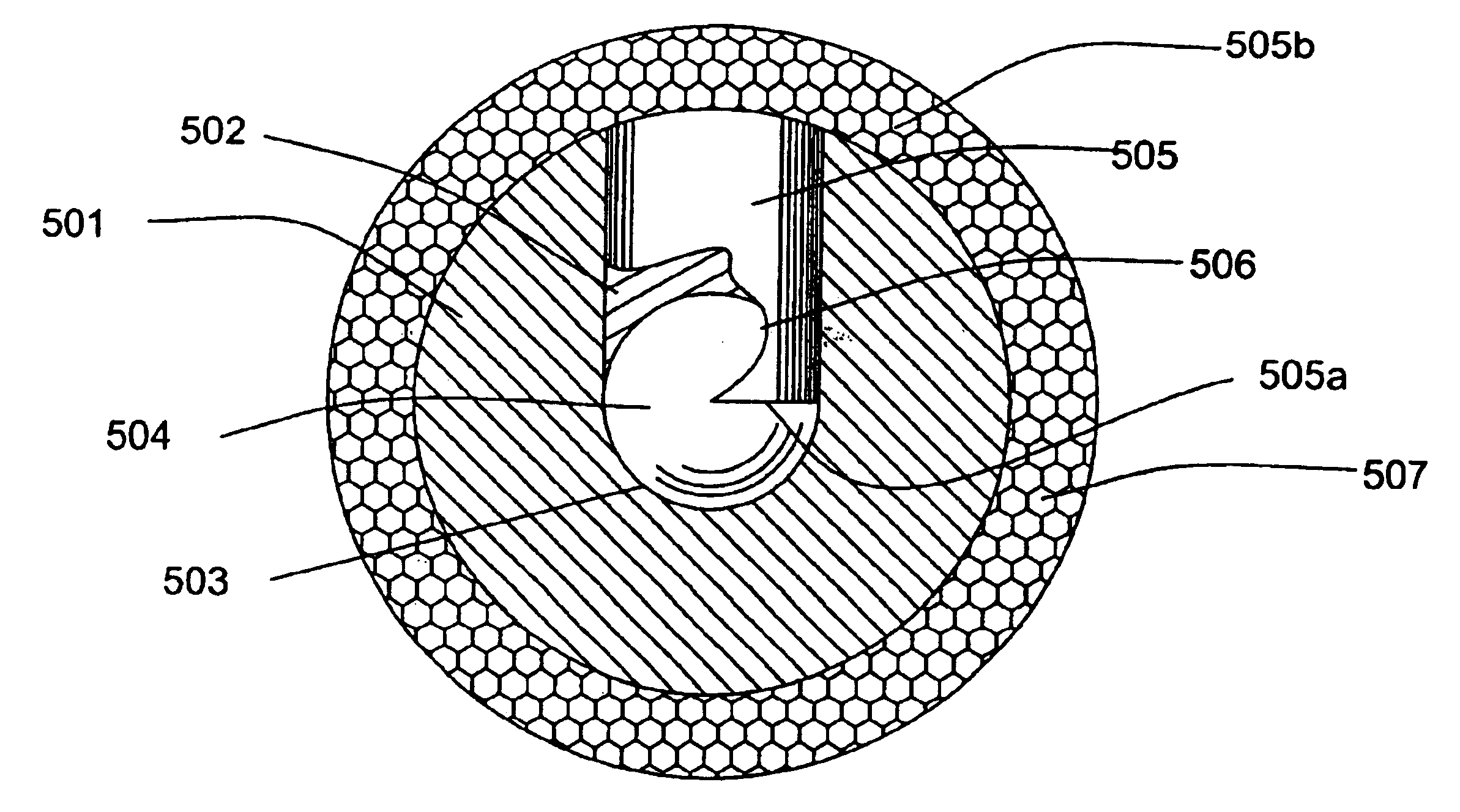

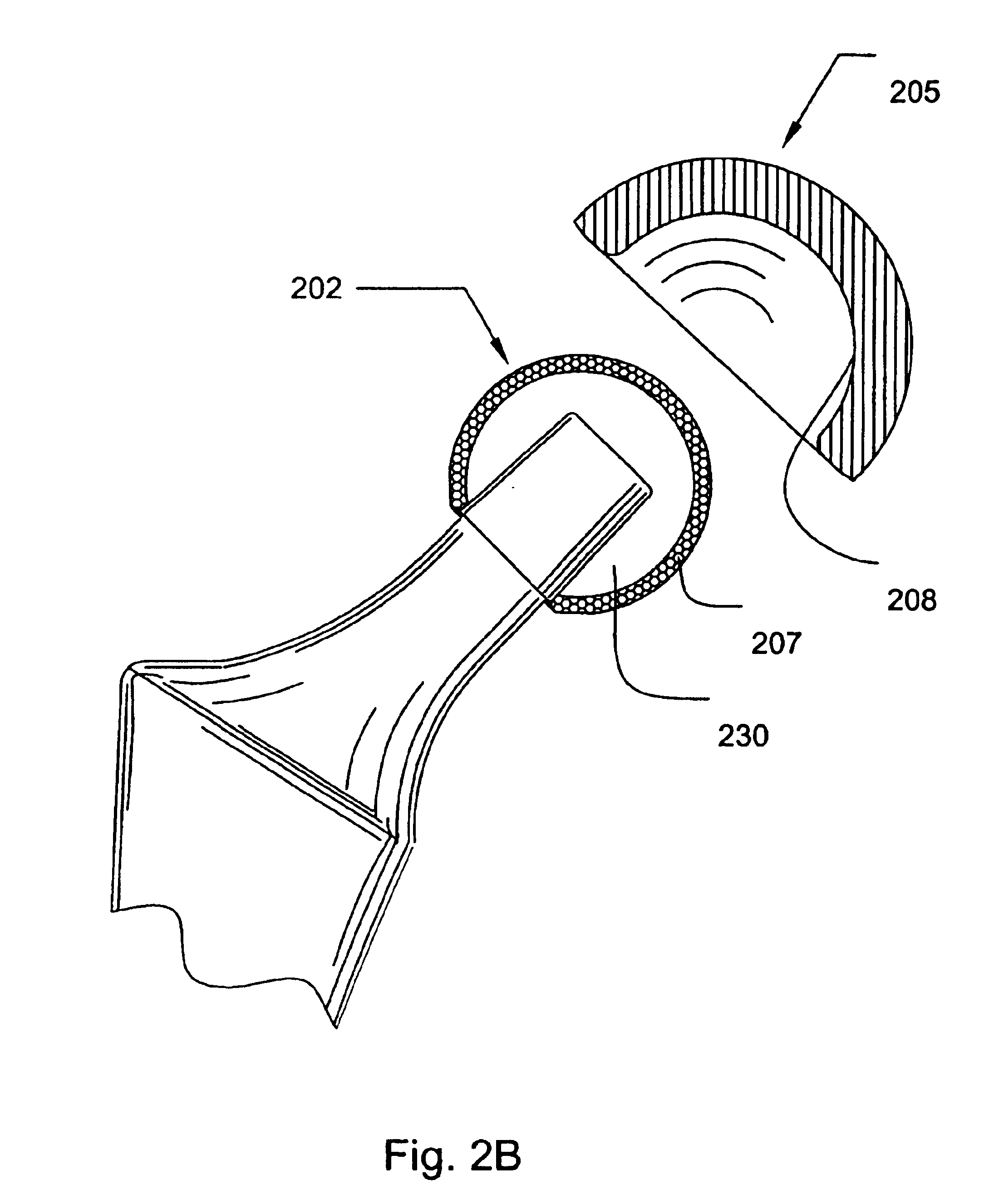

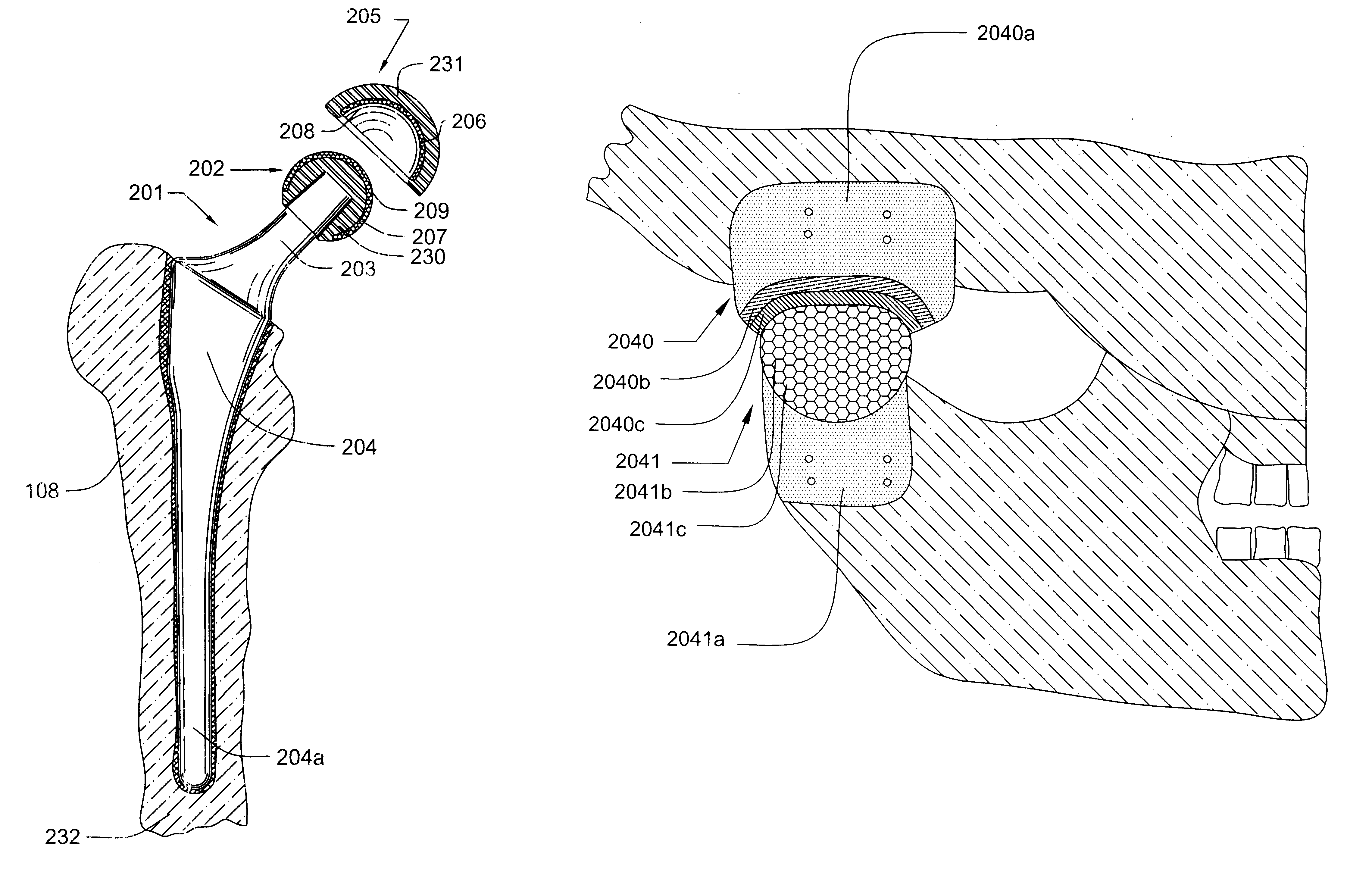

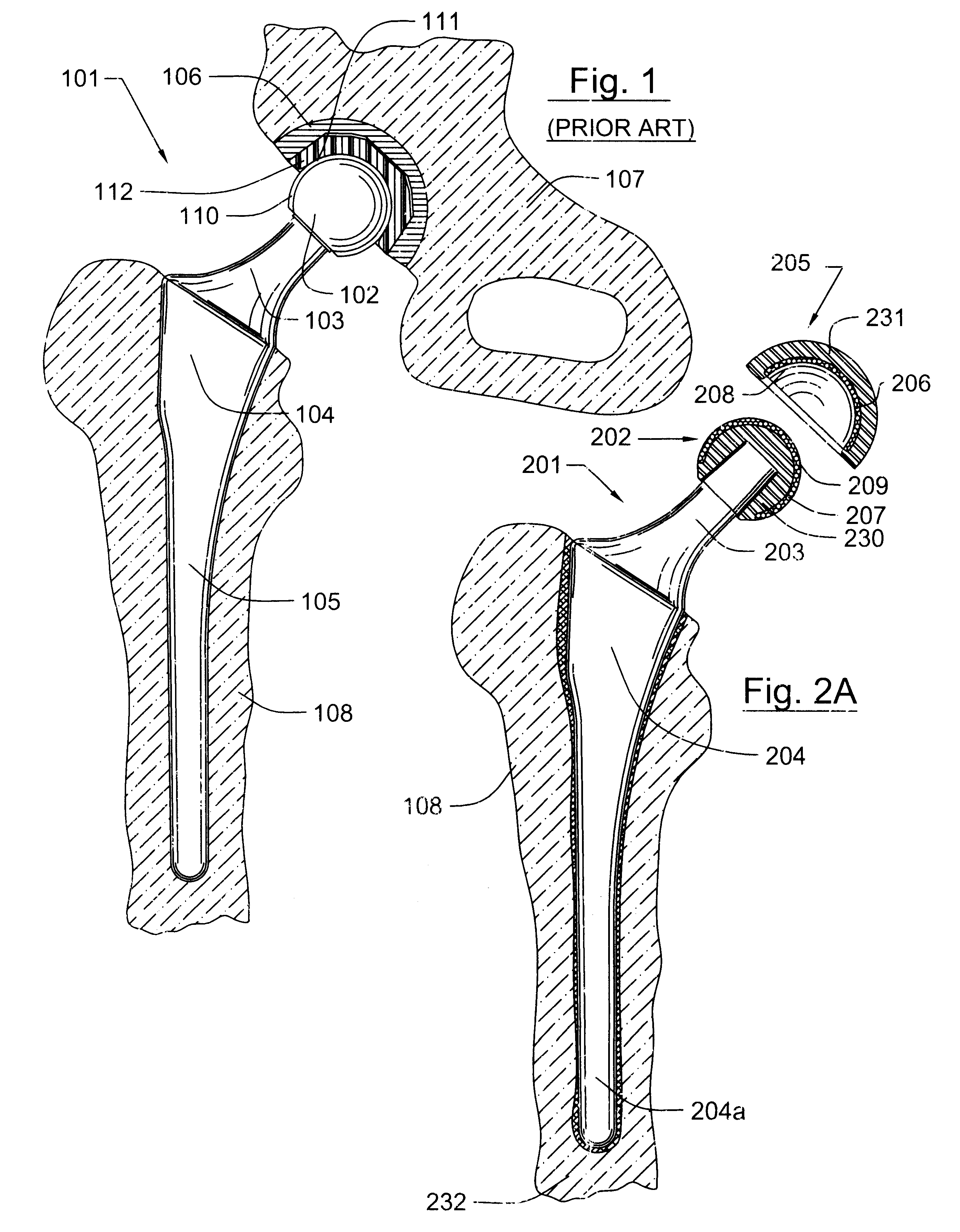

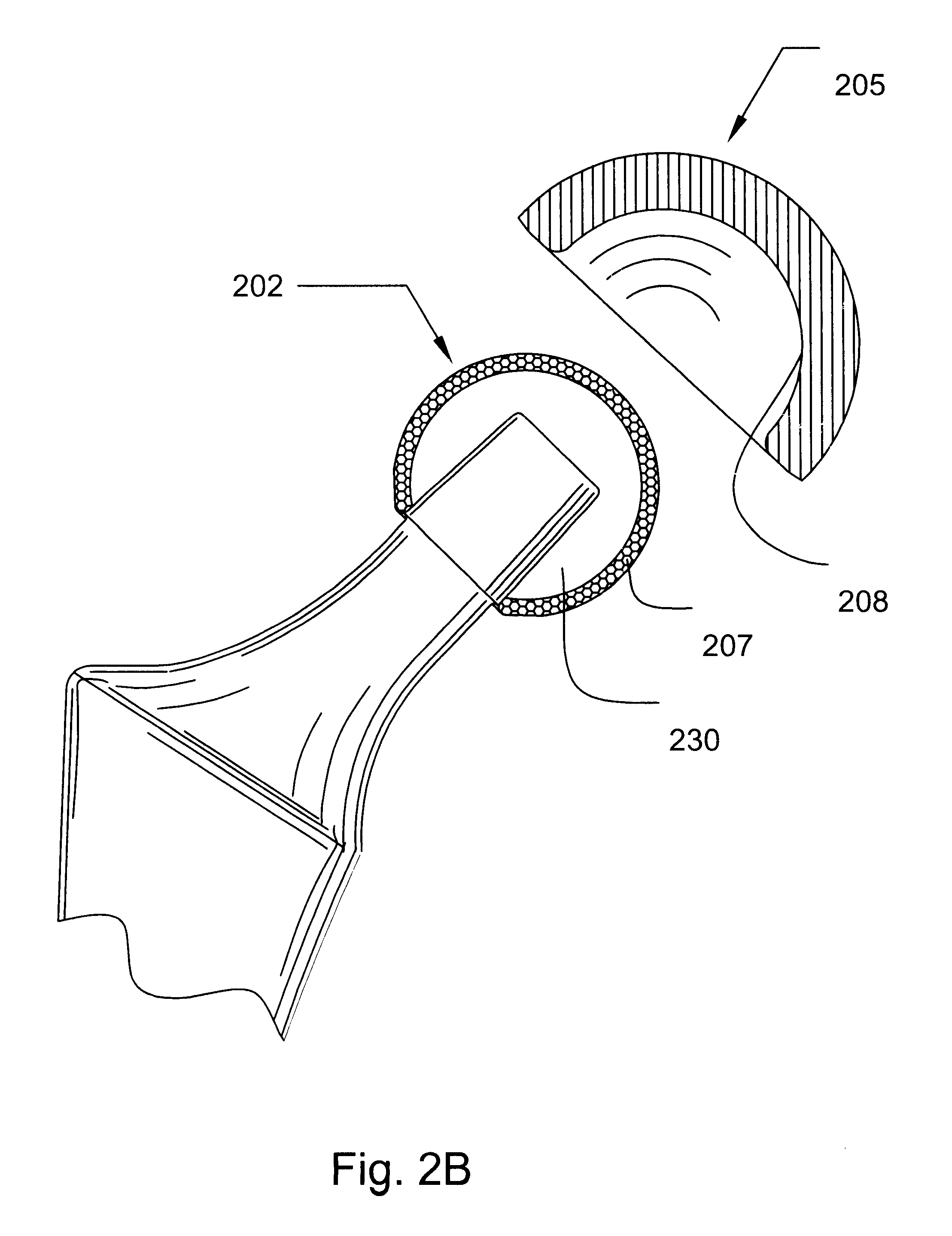

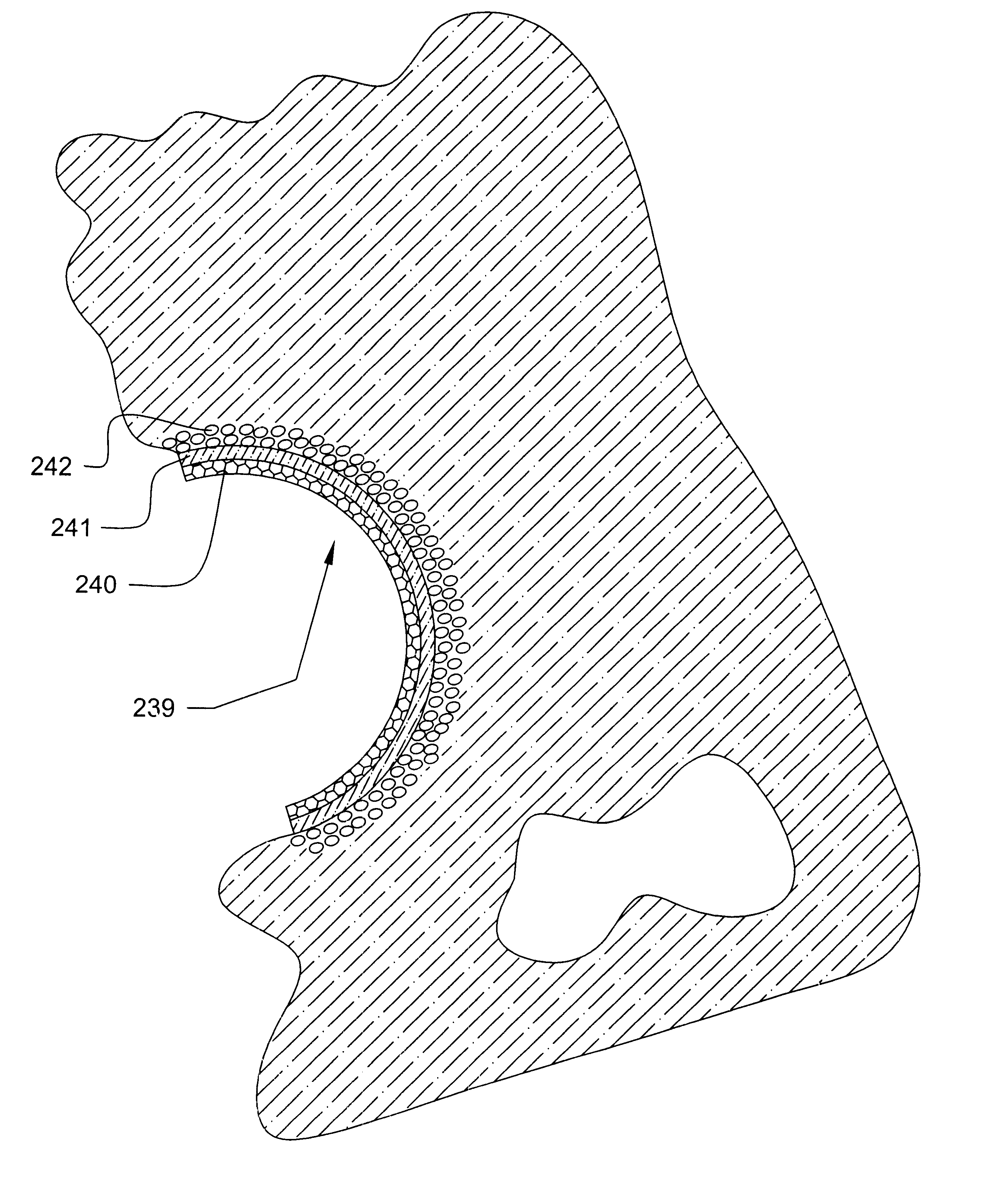

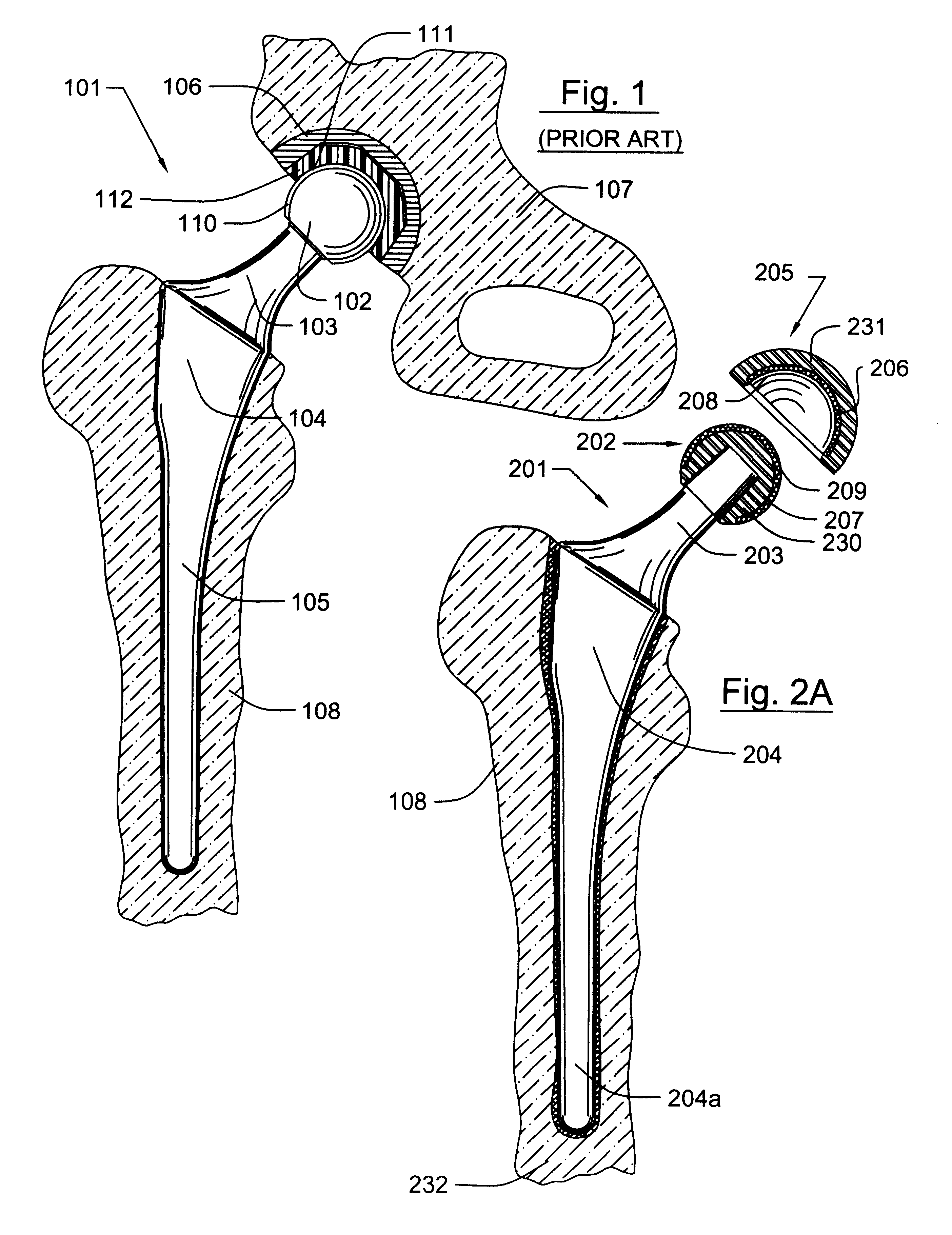

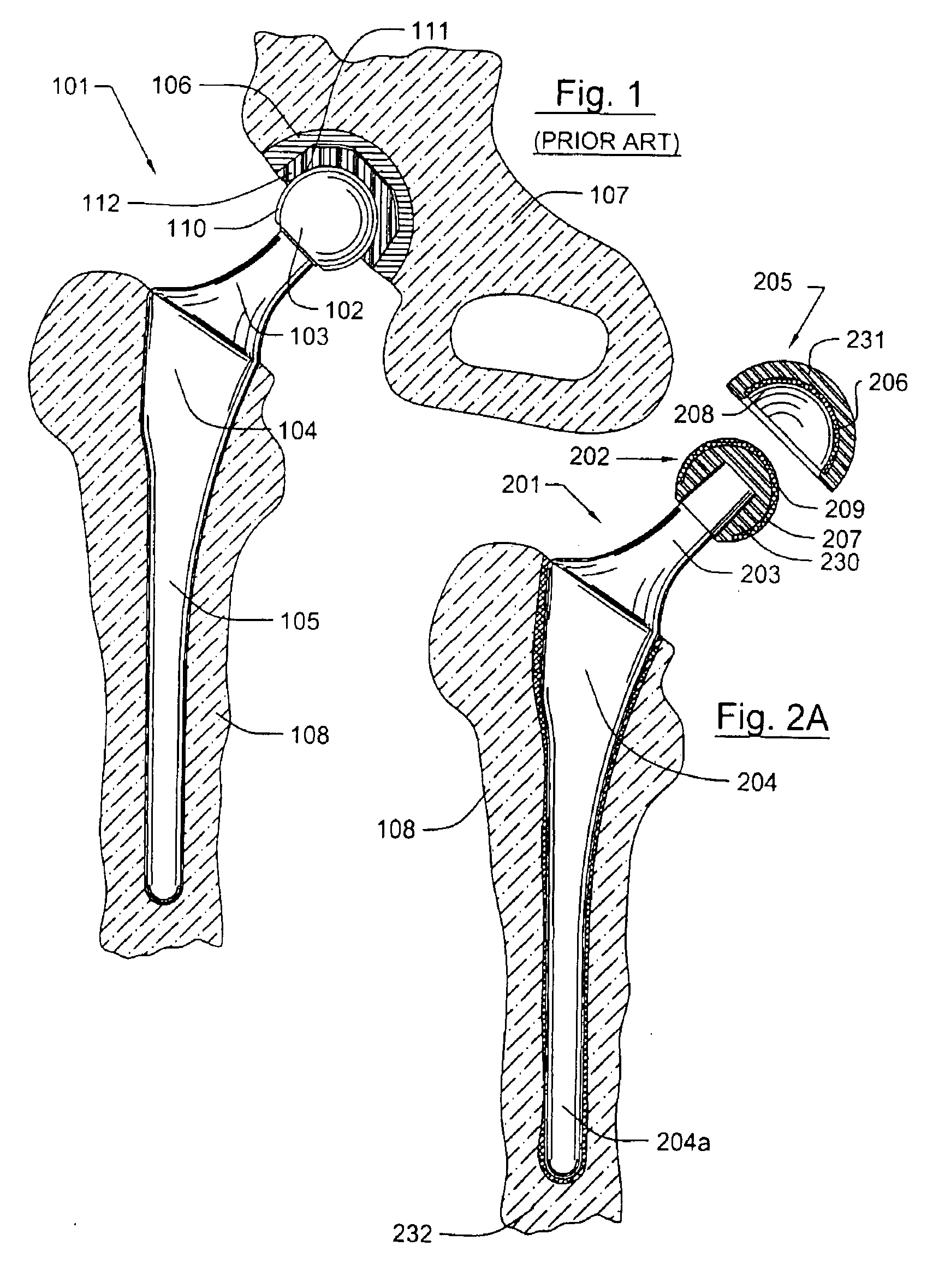

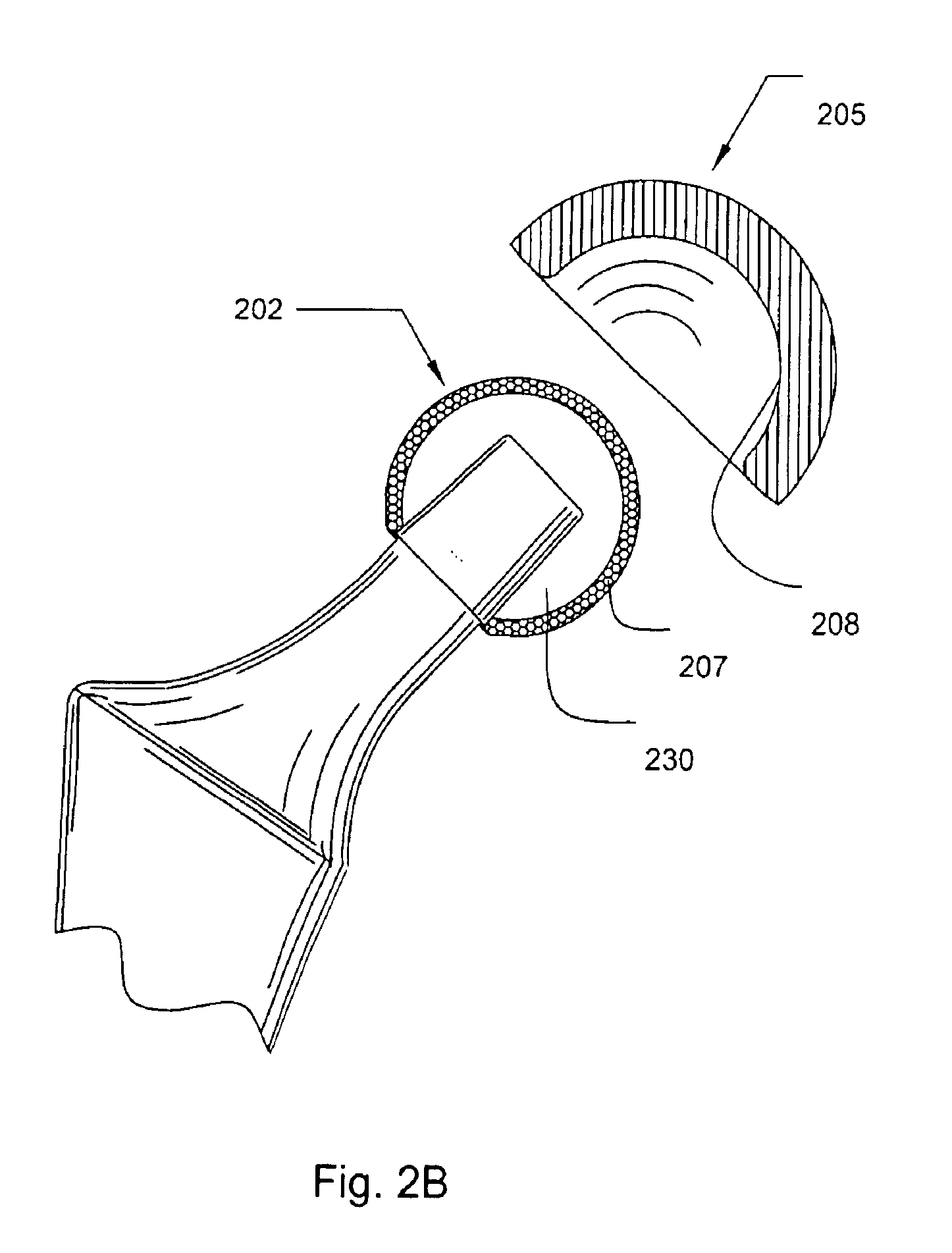

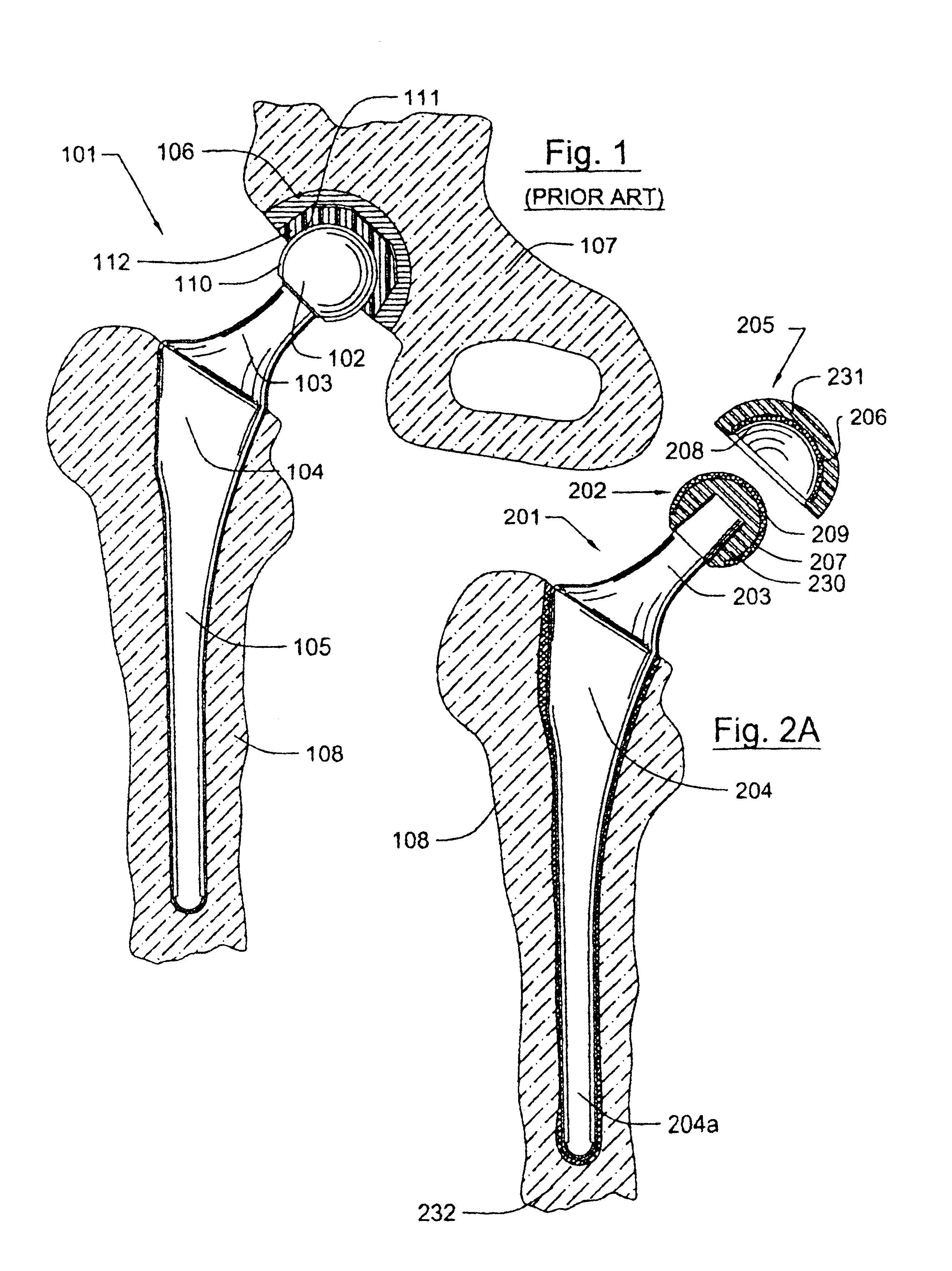

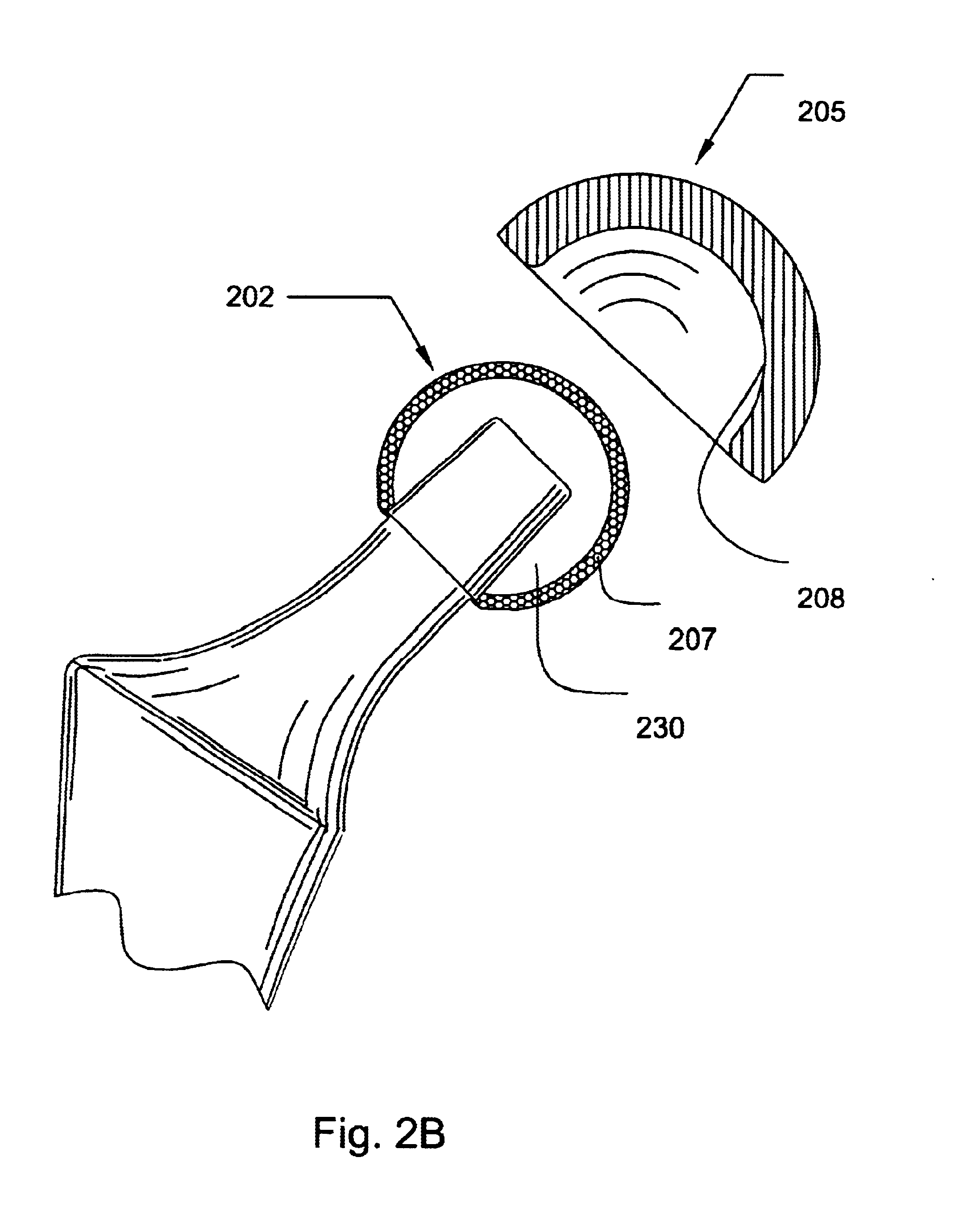

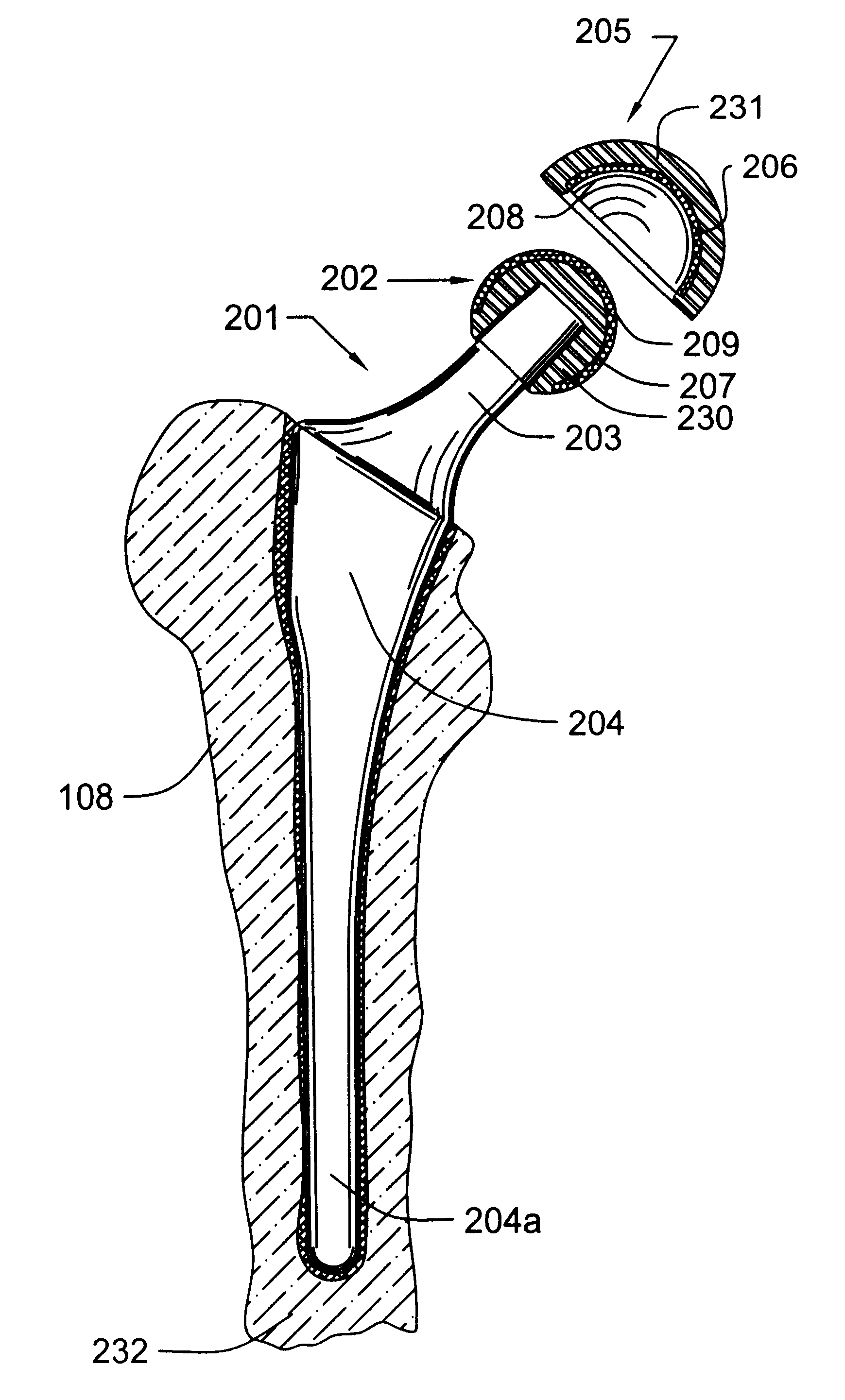

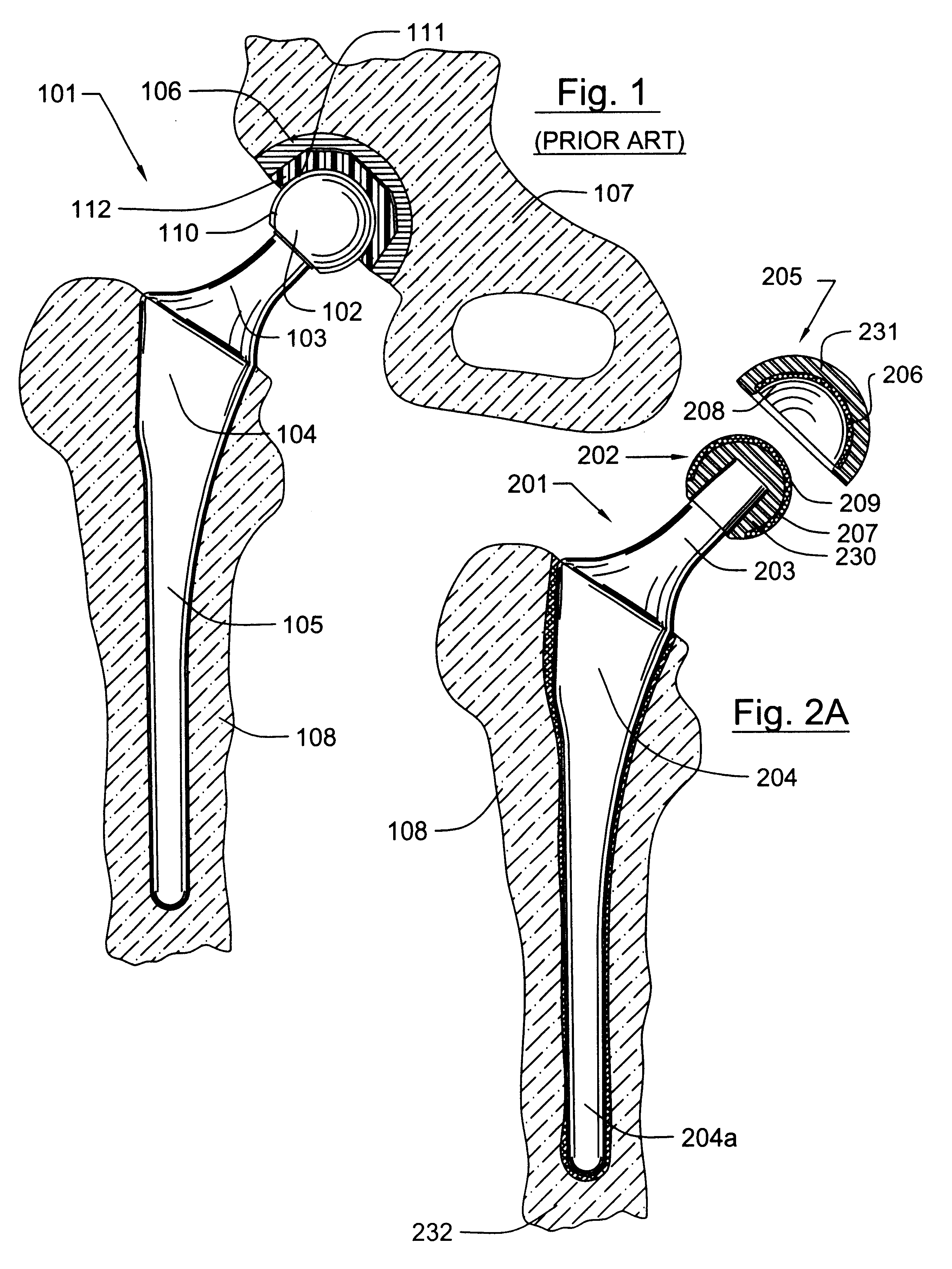

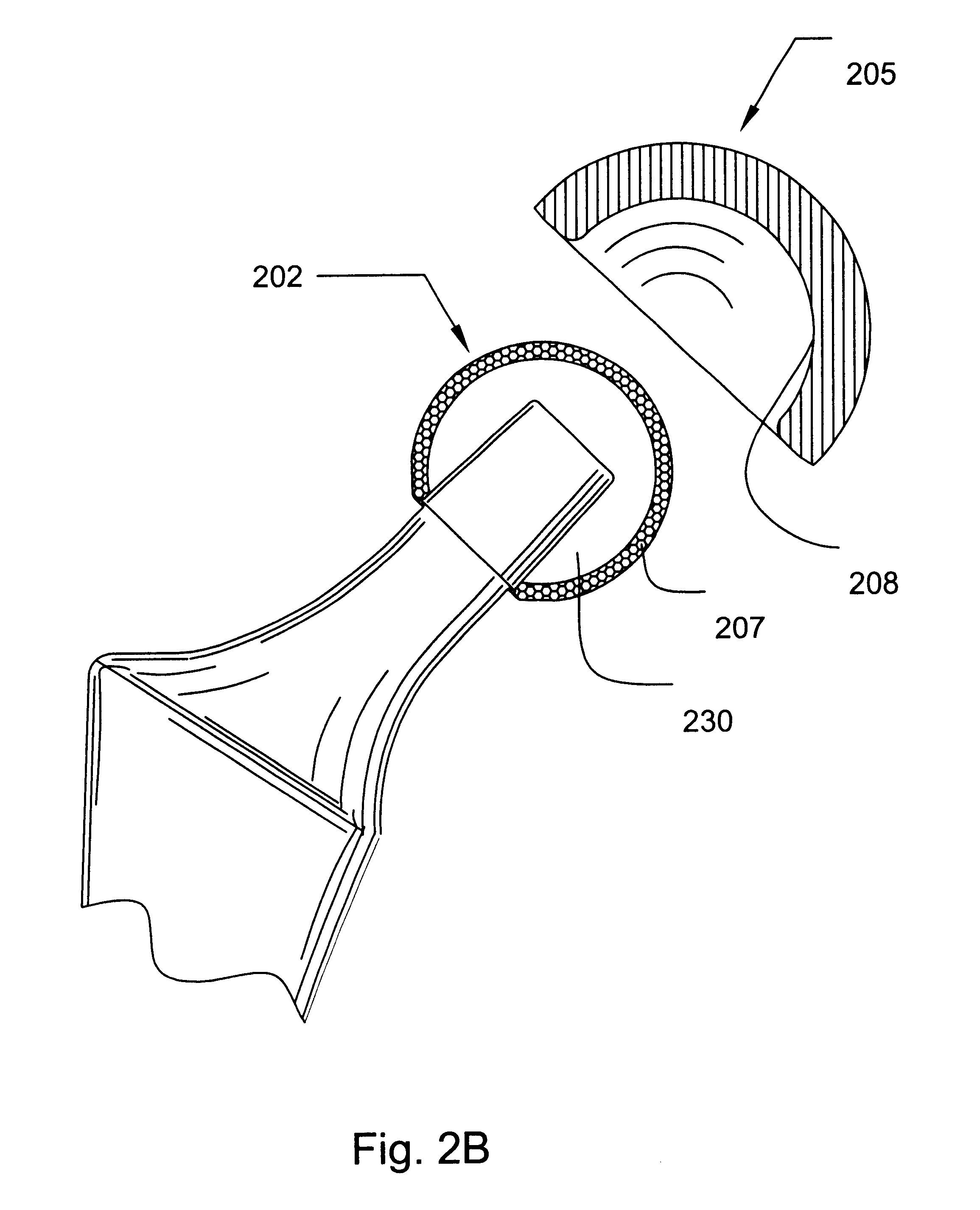

Prosthetic hip joint having a polycrystalline diamond articulation surface and a plurality of substrate layers

InactiveUS6793681B1Less disruptiveLimit stressJoint implantsFemoral headsPolycrystalline diamondProsthesis

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including a prosthetic hip joint having a polycrystalline diamond articulation surface and a plurality of substrate layers.

Owner:DIAMICRON

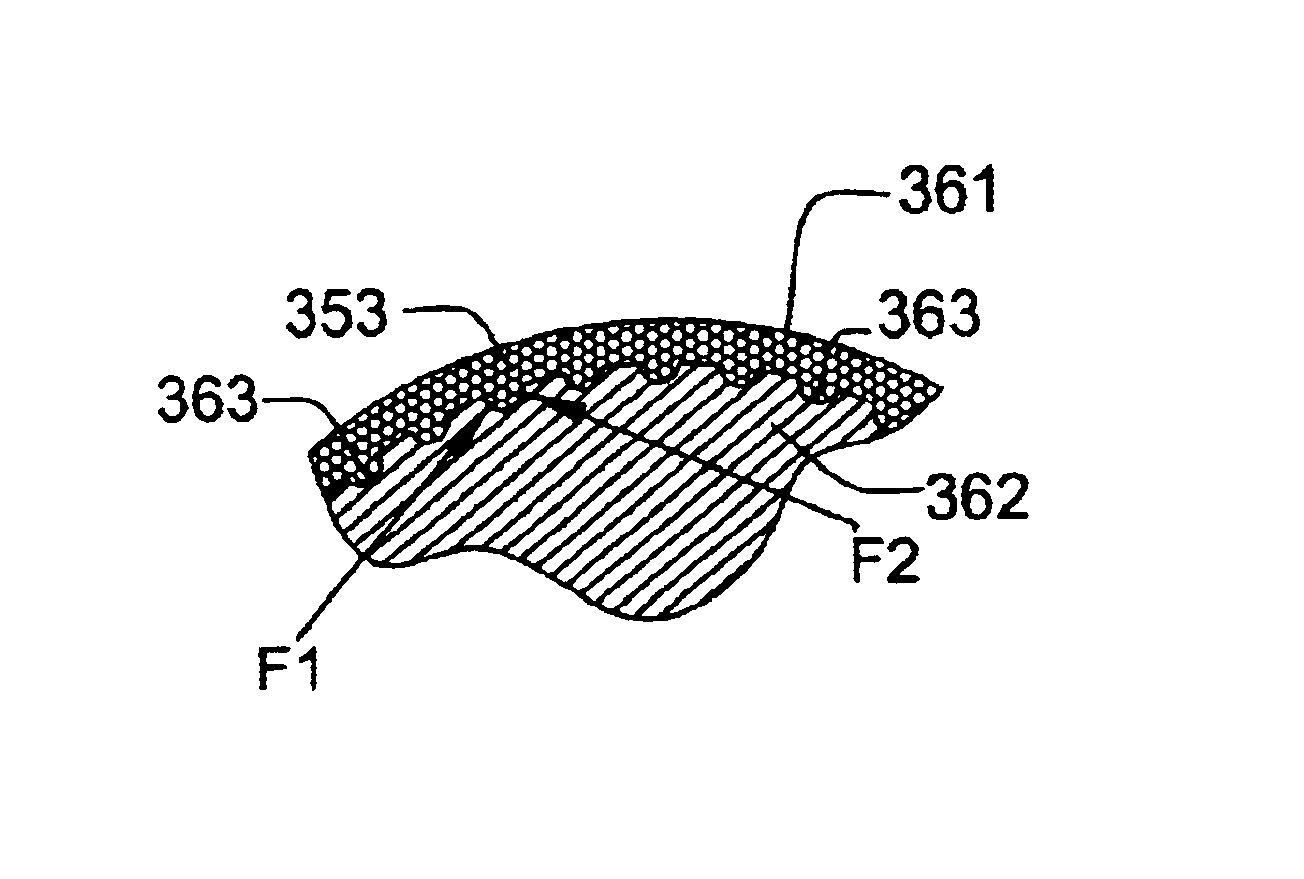

Prosthetic hip joint having sintered polycrystalline diamond compact articulation surfaces

InactiveUS6290726B1Improve wear resistanceReduce coefficient of frictionFinger jointsWrist jointsArticular surfacesProsthesis

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including a prosthetic hip joint having sintered polycrystalline diamond articulation.

Owner:DIAMICRON

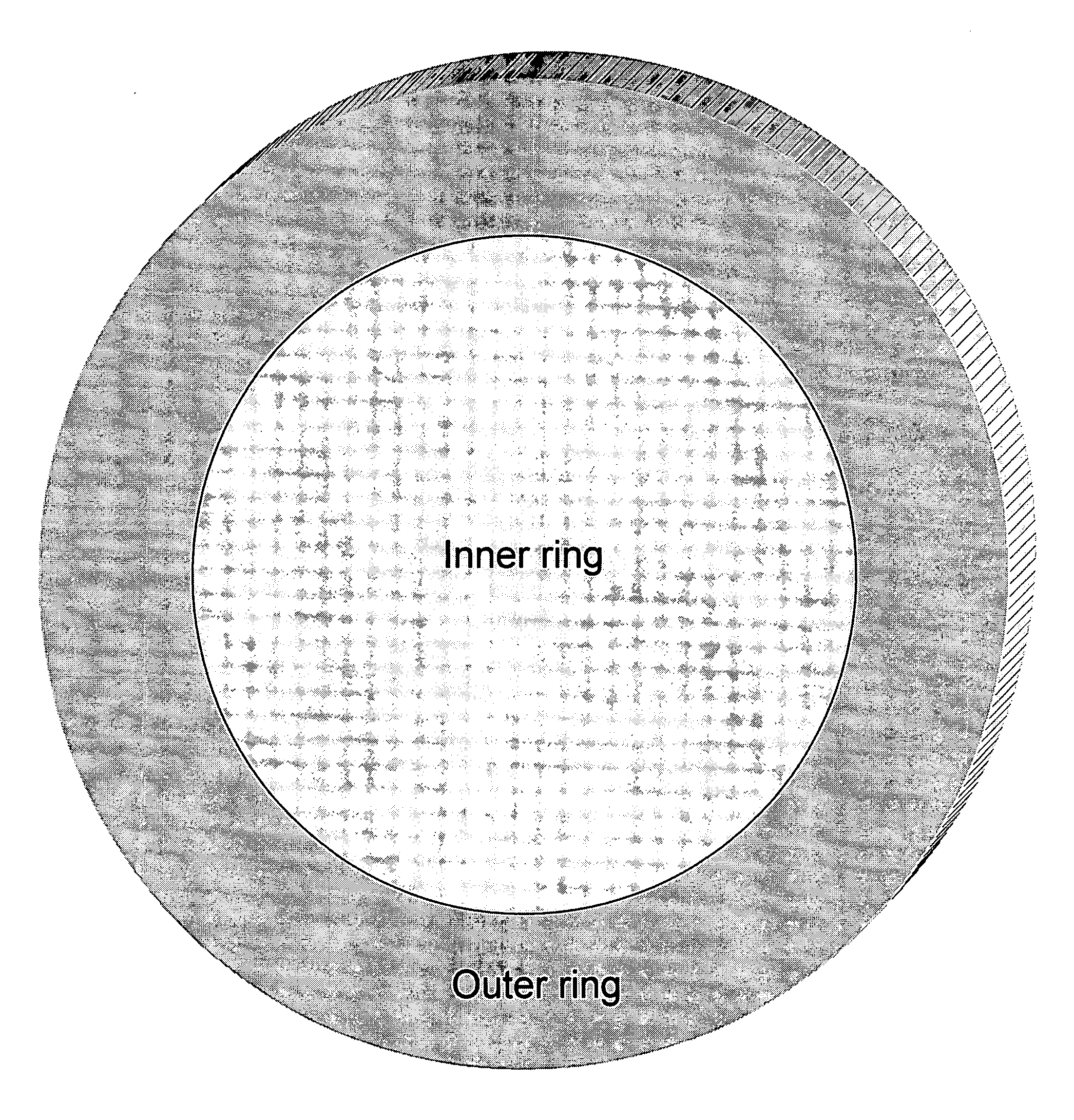

Diamond-surfaced cup for use in a prosthetic joint

InactiveUS6488715B1Improve wear resistanceReduce coefficient of frictionFinger jointsWrist jointsArticular surfacesSacroiliac joint

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including a diamond-surfaced cup for use in a prosthetic joint.

Owner:DIAMICRON

Imaging system for video endoscope

A video endoscope system includes a reusable control cabinet and an endoscope that is connectable thereto. The endoscope may be used with a single patient and then disposed. The endoscope includes an illumination mechanism, an image sensor, and an elongate shaft having one or more lumens located therein. An articulation joint at the distal end of the endoscope allows the distal end to be oriented by the actuators in the control cabinet or actuators in a control handle of the endoscope. Fluidics, electrical, navigation, image, display and data entry controls are integrated into the system along with other accessories.

Owner:BOSTON SCI SCIMED INC

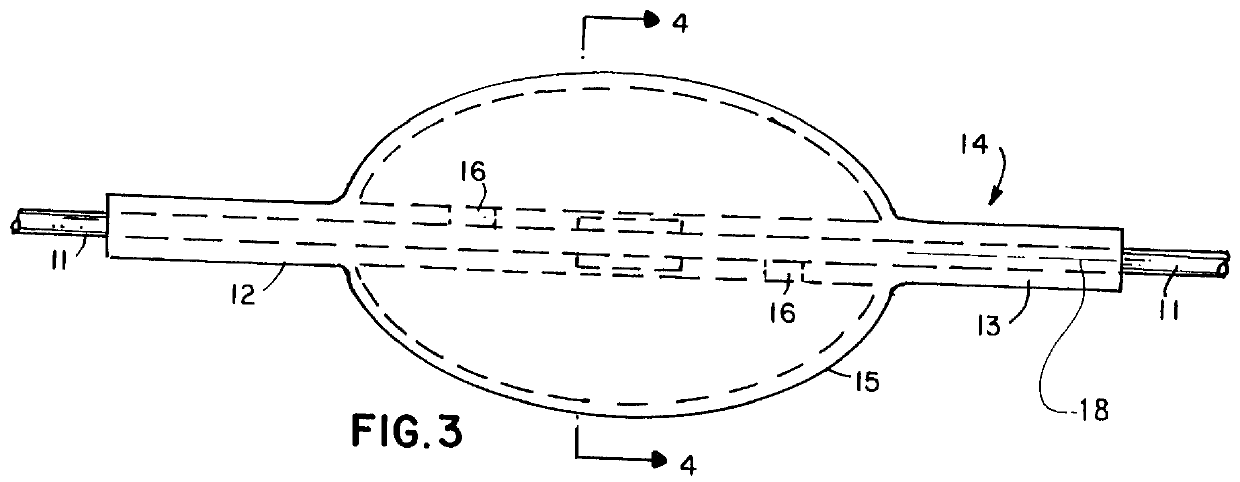

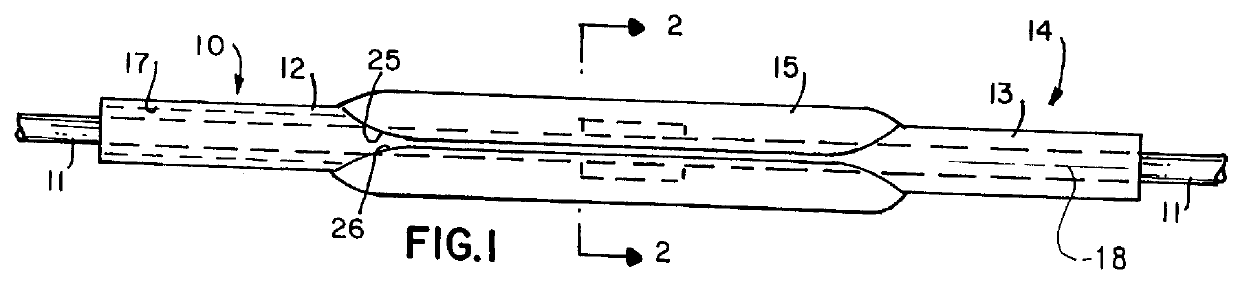

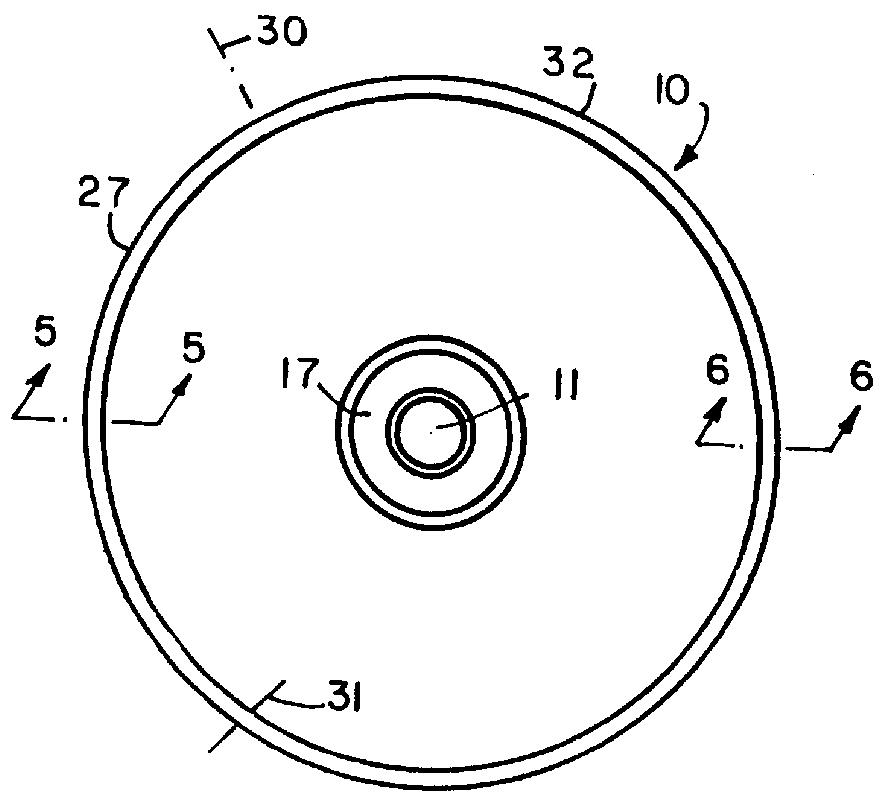

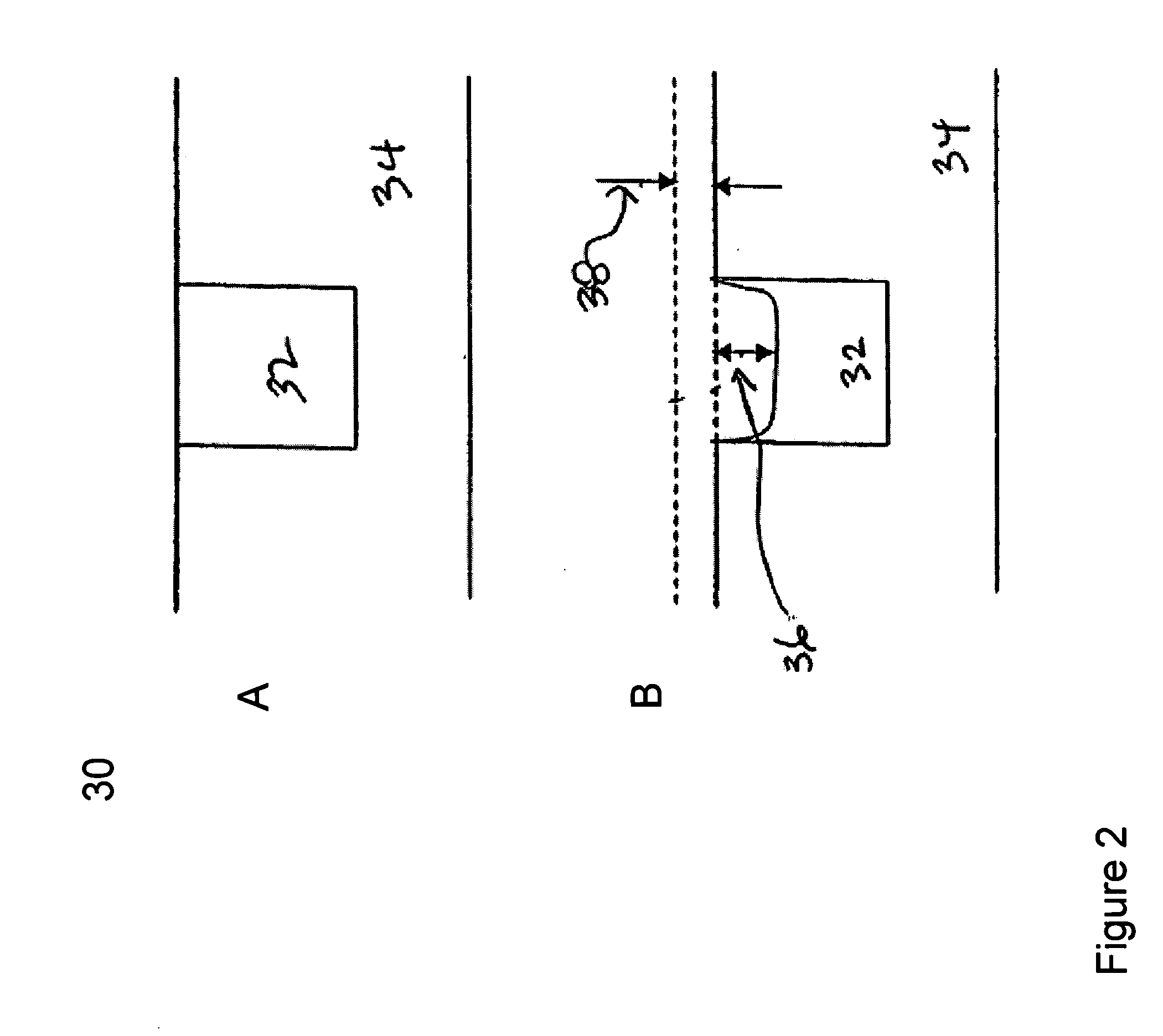

Balloon catheter

InactiveUS6010480AImprovement factorReduce coefficient of frictionStentsBalloon catheterBalloon catheterLesion

An expansible balloon catheter has at least a first exterior surface with a given coefficient of friction and a second exterior surface with a greater coefficient of friction. In a compact form only the first exterior surface is exposed to produce one coefficient of friction during transfer of the collapsed or uninflated balloon to and across a lesion. When inflated, the second surface dominates the first surface and produces a second coefficient of friction.

Owner:BOSTON SCI SCIMED INC

Access port for laparoscopic surgery

InactiveUS20050277946A1Low coefficient of frictionFacilitate insertionEar treatmentCannulasLaparoscopic surgeryEngineering

An access port for use in laparoscopic surgery is disclosed. The port includes a duct having a one-way valve and a tubular seal. The one-way valve has opposed surfaces that co-apt in response to internal pressure within the duct. The tubular seal has an inner layer with a low friction coefficient surrounded by an outer elastic layer that biases the inner layer into sealing engagement with a surgical tool inserted through the duct. The one-way valve seals the duct in the absence of a tool extending through the duct. The low friction coefficient of the inner layer facilitates insertion and removal of the tool through the duct. The port has a distal end insertable into a pressurized cavity, and a proximal end that extends from the cavity and provides access thereto.

Owner:STOUT MEDICAL GROUP

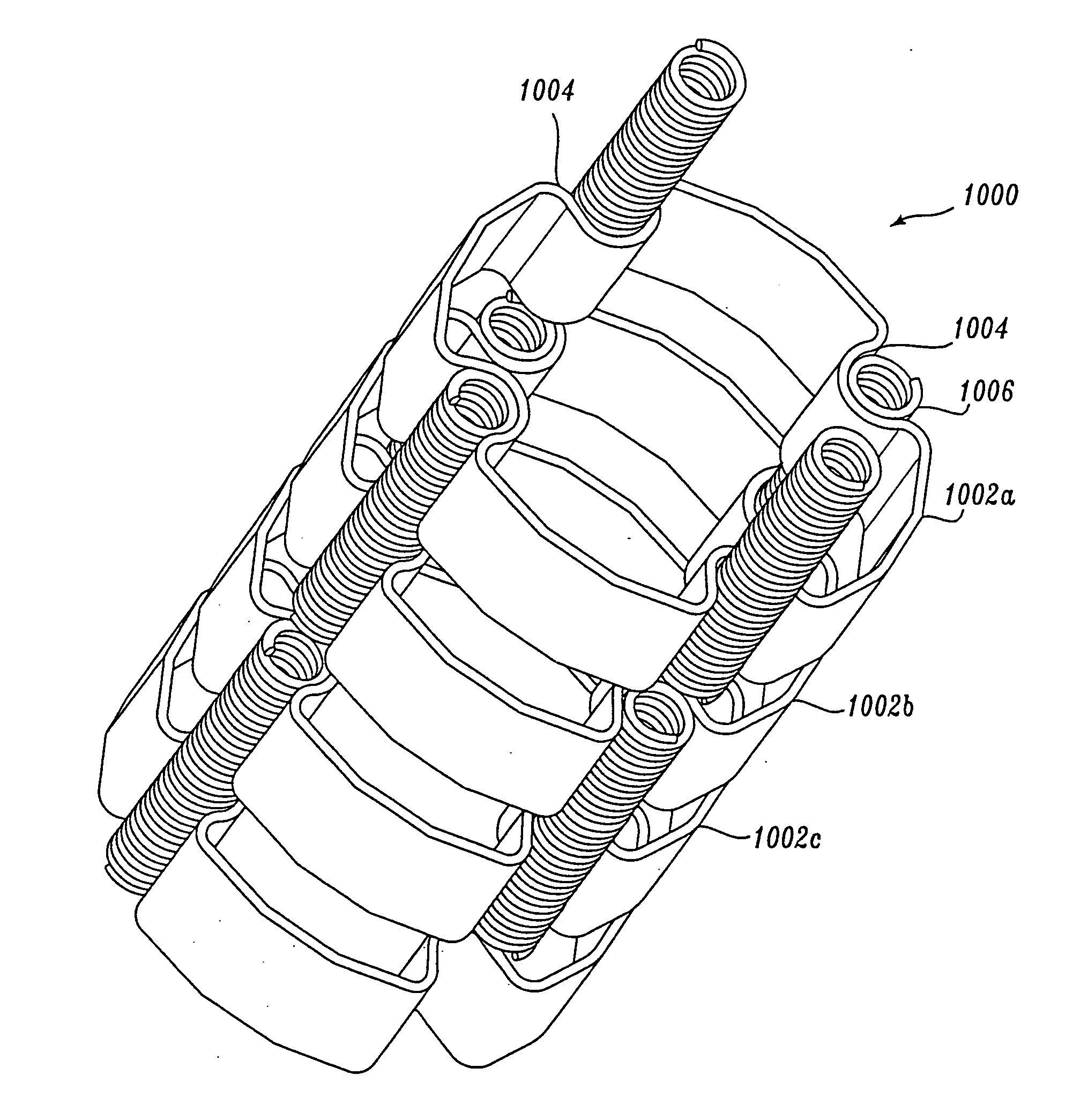

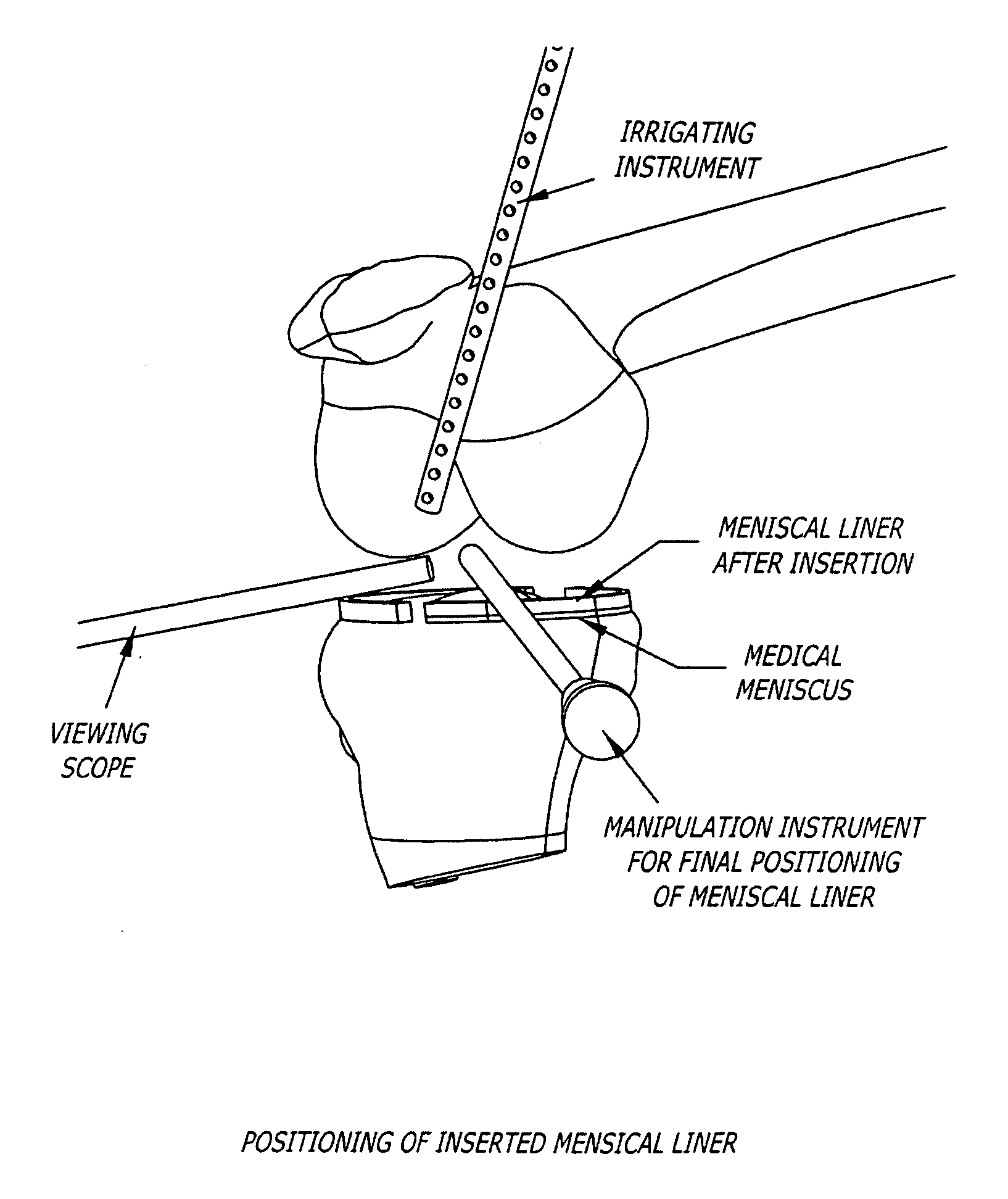

Eversion resistant sleeves

ActiveUS20060161187A1Reduce coefficient of frictionIncrease stiffnessOesophagiIntravenous devicesThin walledDigestive tract

The invention relates to improved means for preventing eversion and subsequent obstruction of thin-walled, floppy gastrointestinal liners implanted in the digestive tract of an animal. The implantable devices include an anchor adapted for attachment within a natural body lumen and a thin-walled, floppy sleeve open at both ends and defining a lumen therebetween. A substantial length of the sleeve has material characteristics that result in the sleeve being prone to eversion in the presence of retrograde pressures. Exemplary eversion-resistant features provide an increased stiffness and / or an increased friction coefficient between the anchor and the proximal end of the sleeve to resist eversion. In some embodiments, the eversion-resistant feature includes an anti-buckling element, such as a wire coupled along the substantial length of the sleeve.

Owner:GI DYNAMICS

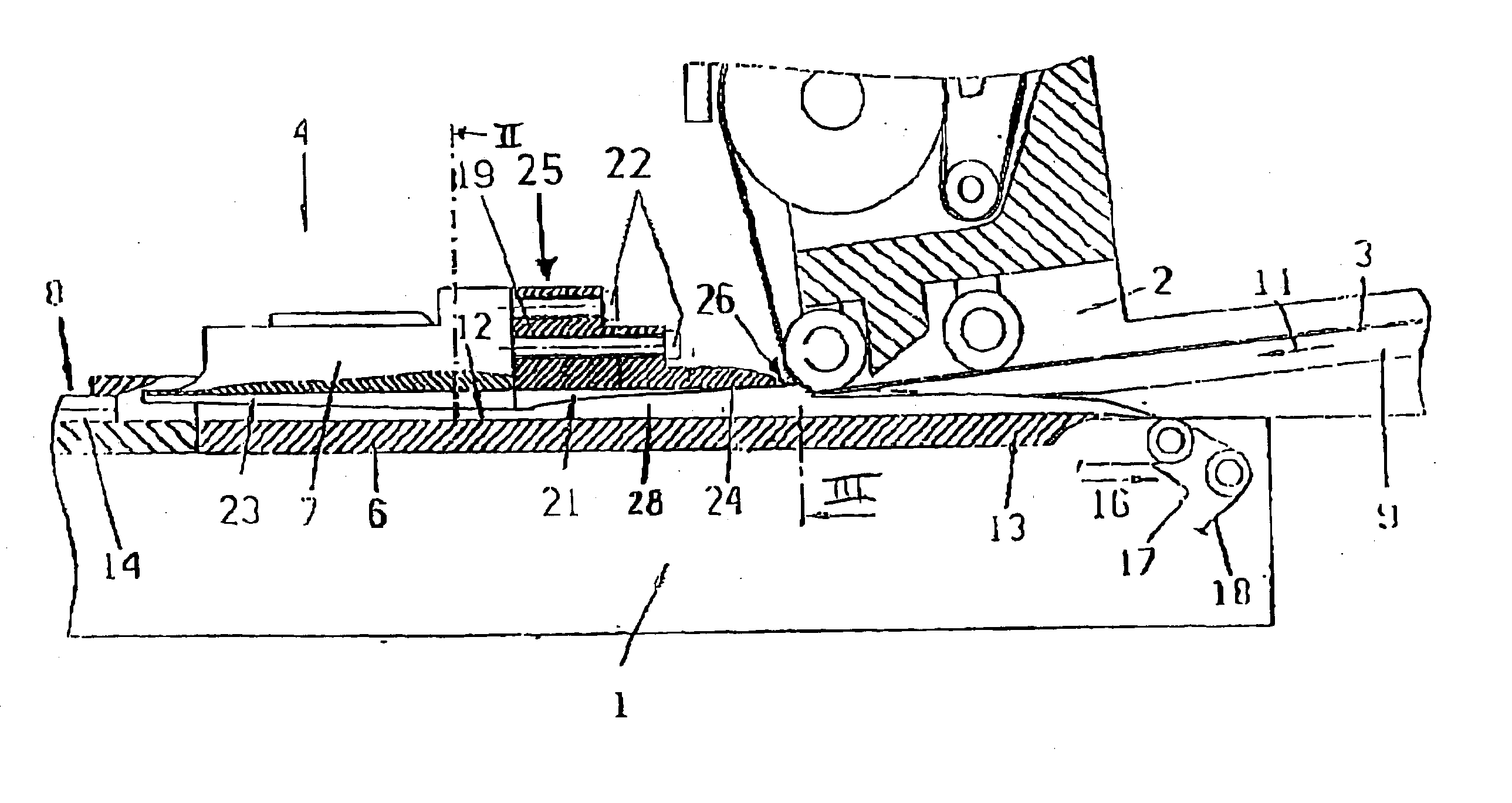

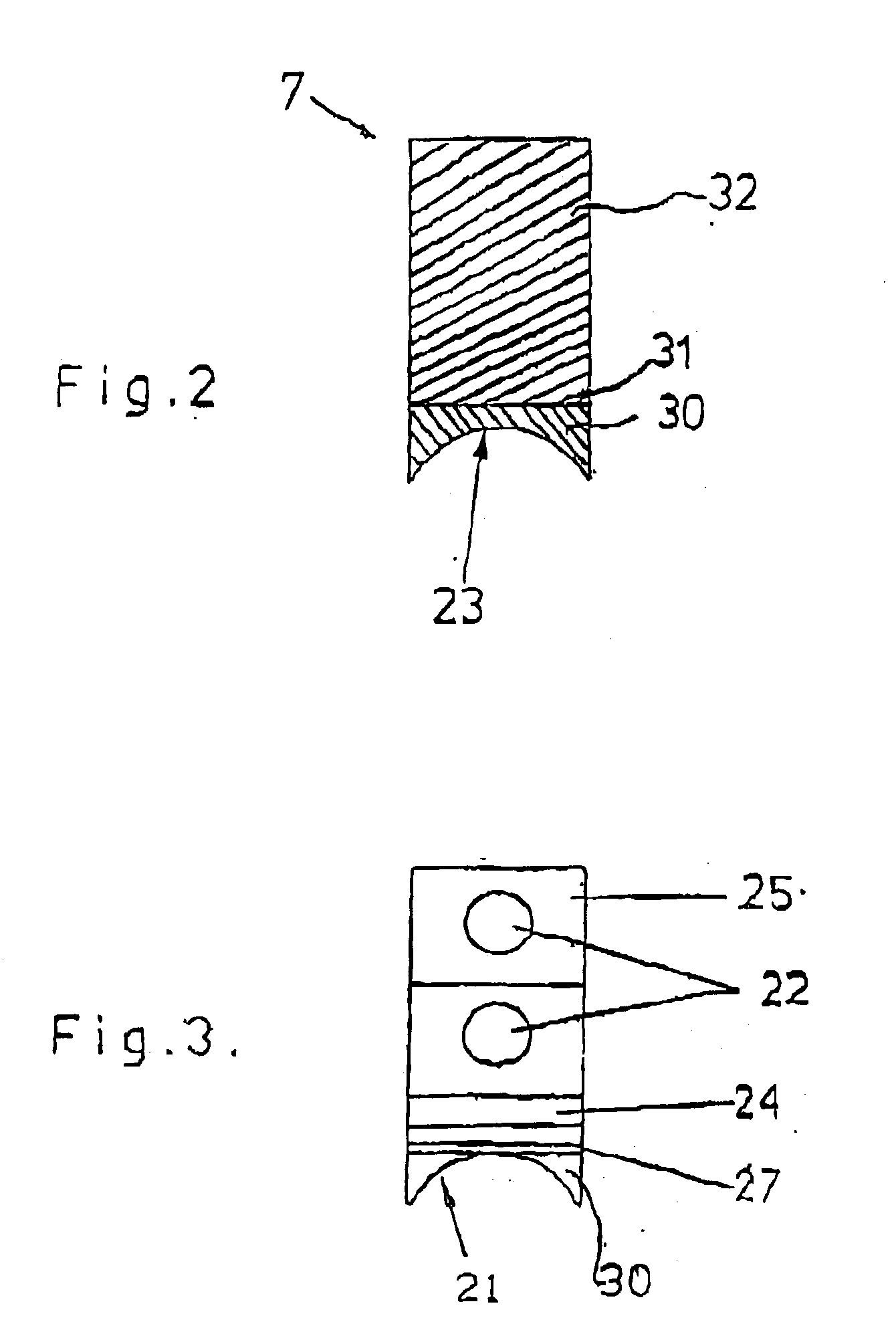

Garniture tongue of a garniture device

InactiveUS20030136419A1Reduce coefficient of frictionEasy to slideCigarette manufactureAlloyTitanium carbide

Garniture tongue of a garniture device of a rod machine arranged for compressing a material. The garniture tongue includes a rod guide surface and the garniture tongue being composed at least in part of a steel alloy with high titanium carbide content. The instant abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:HAUNI MASCHINENBAU AG

Prosthetic joint having at least one superhard articulation surface

InactiveUS6398815B1Less disruptiveImprove overall utilizationFinger jointsWrist jointsArticular surfacesTarsal Joint

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including a prosthetic joint having at least one superhard articulation surface.

Owner:DIAMICRON

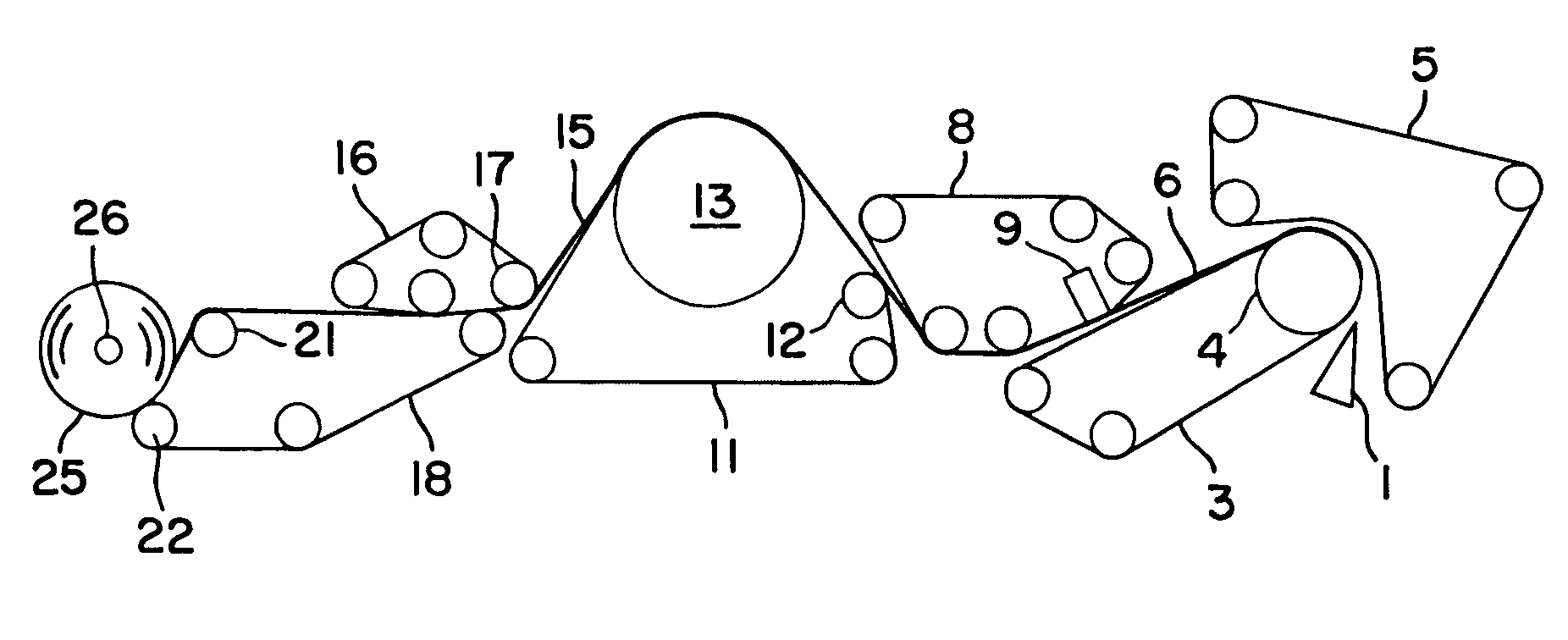

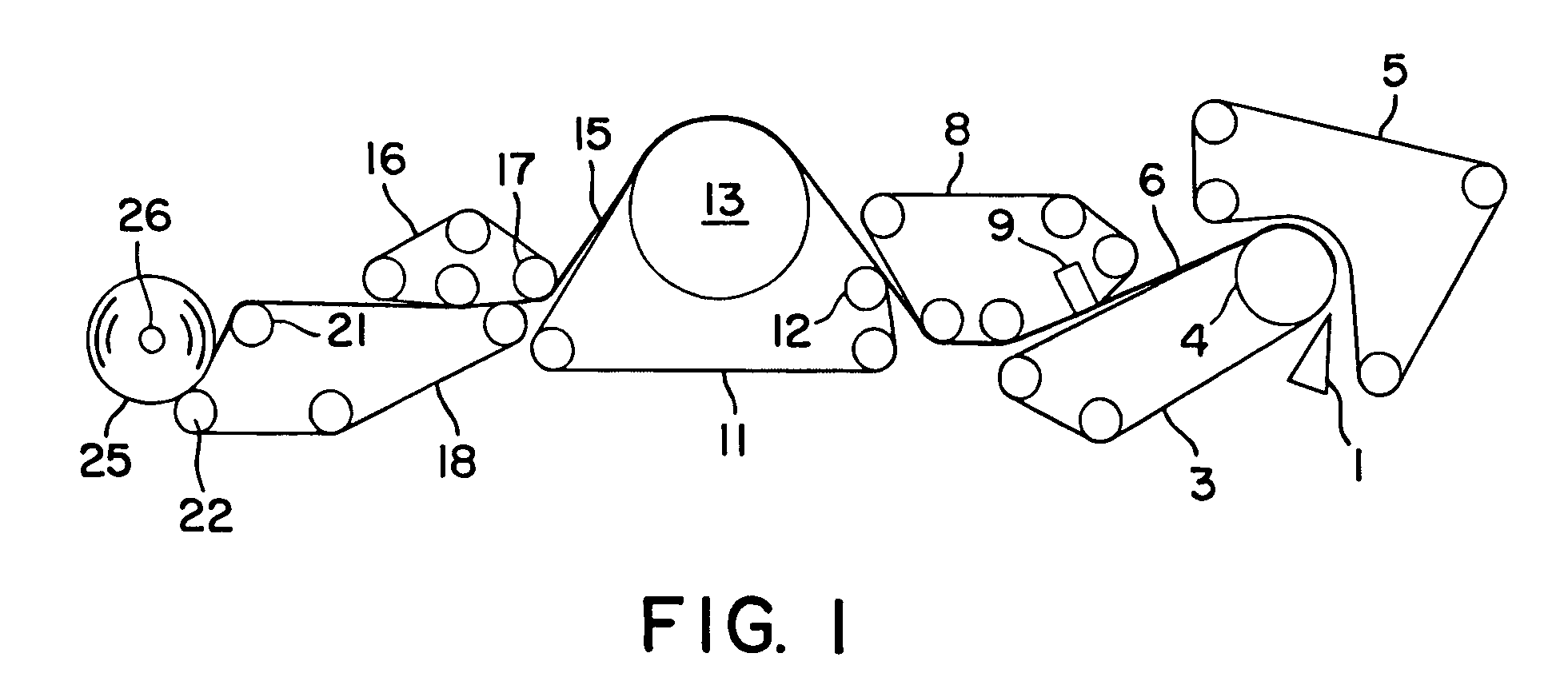

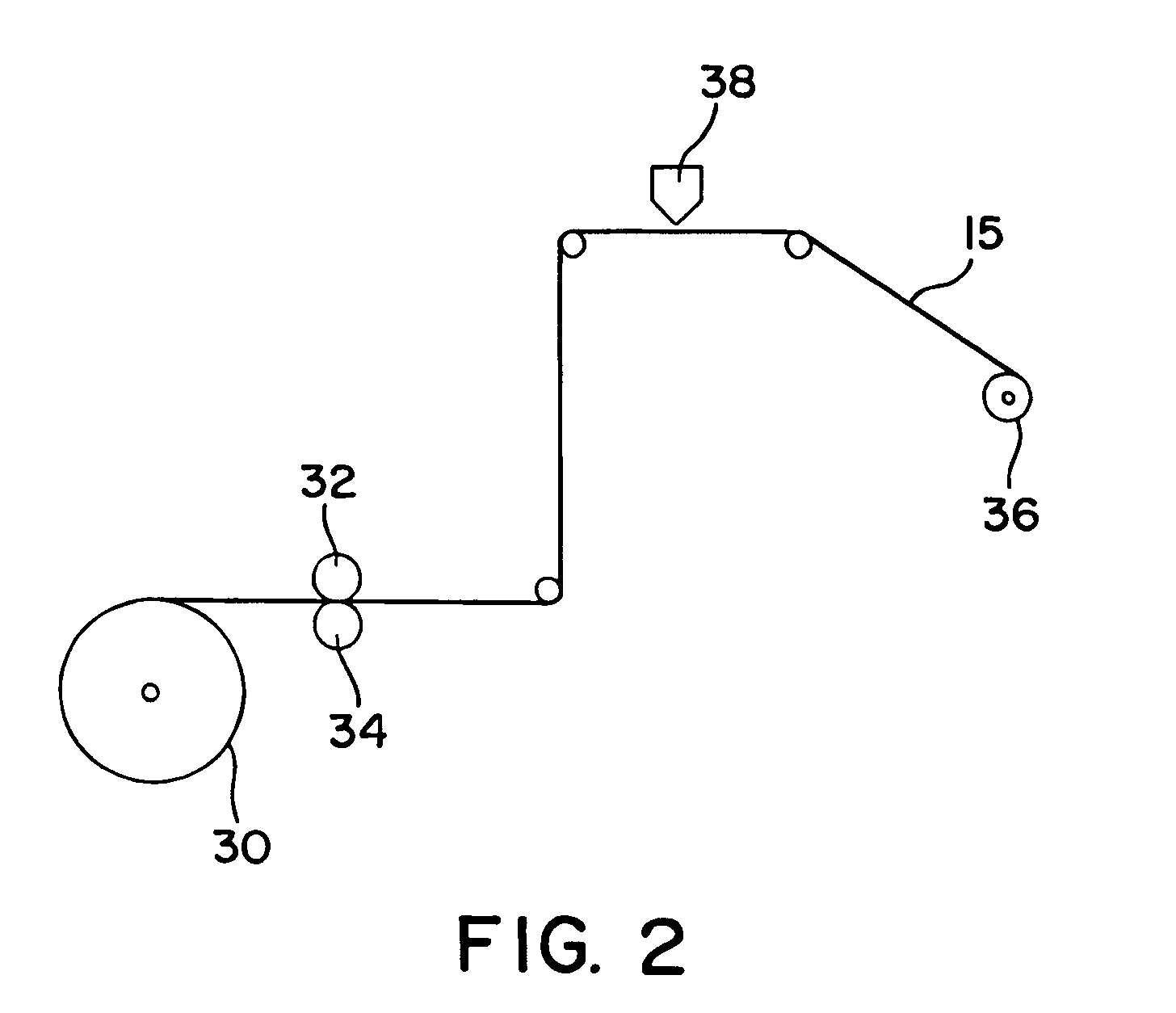

Nonwoven webs having reduced lint and slough

InactiveUS20050148261A1Reduce coefficient of frictionReduce sheddingCosmetic preparationsPersonal careFiberPolymer science

Nonwoven webs having reduced levels of lint and slough are disclosed. In accordance with the present invention, the nonwoven webs are treated on at least one surface with a small amount of a polymeric component. The polymeric component may be present, for instance, in the form of meltblown fibers. The meltblown fibers are made from a polymer that is compatible with the nonwoven web. By adding relatively small amounts of meltblown fibers to at least one side of the nonwoven material, lint and slough levels have been found to be significantly reduced. The nonwoven web may be any web containing pulp fibers, such as a tissue web or a coform web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

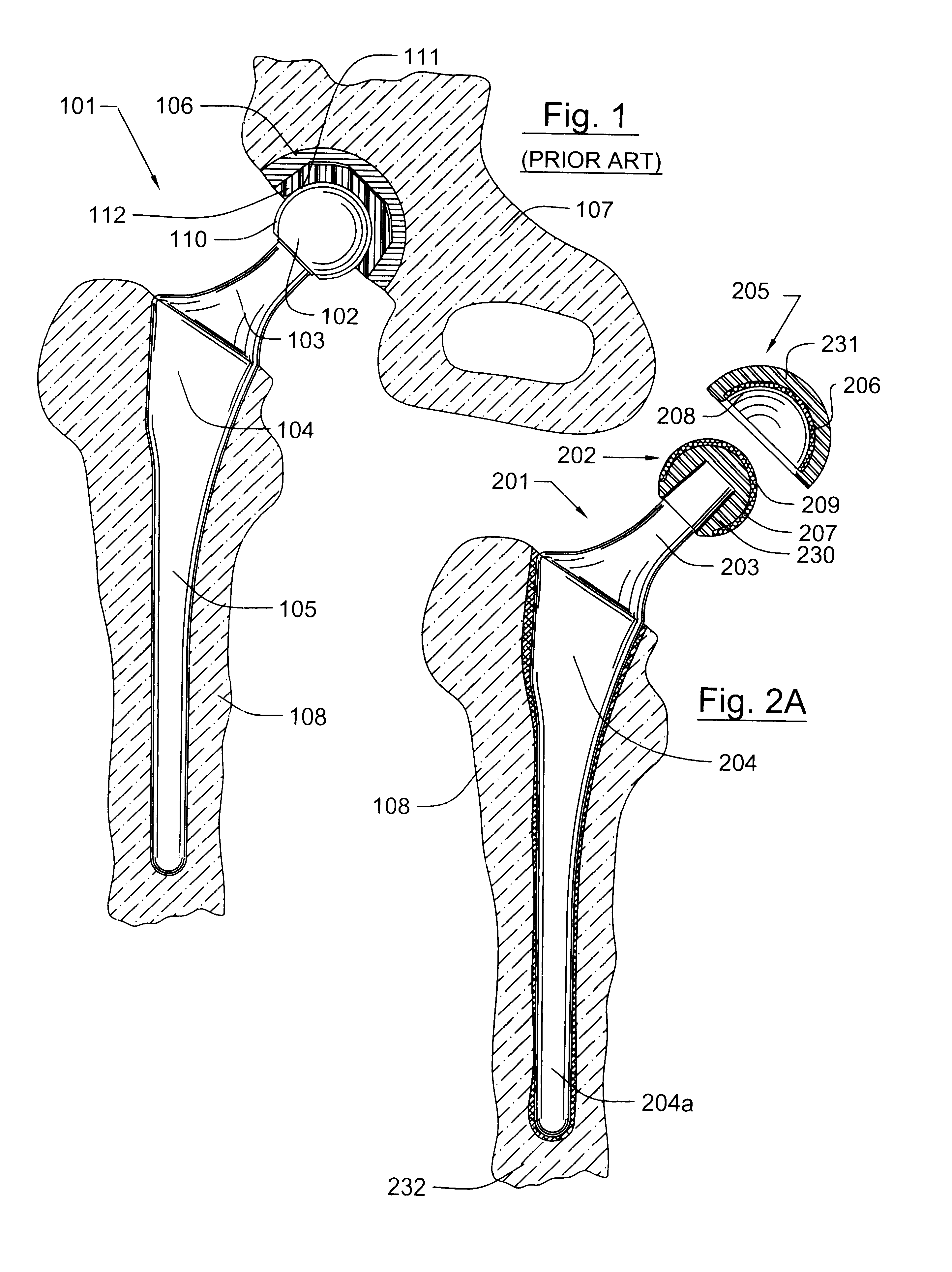

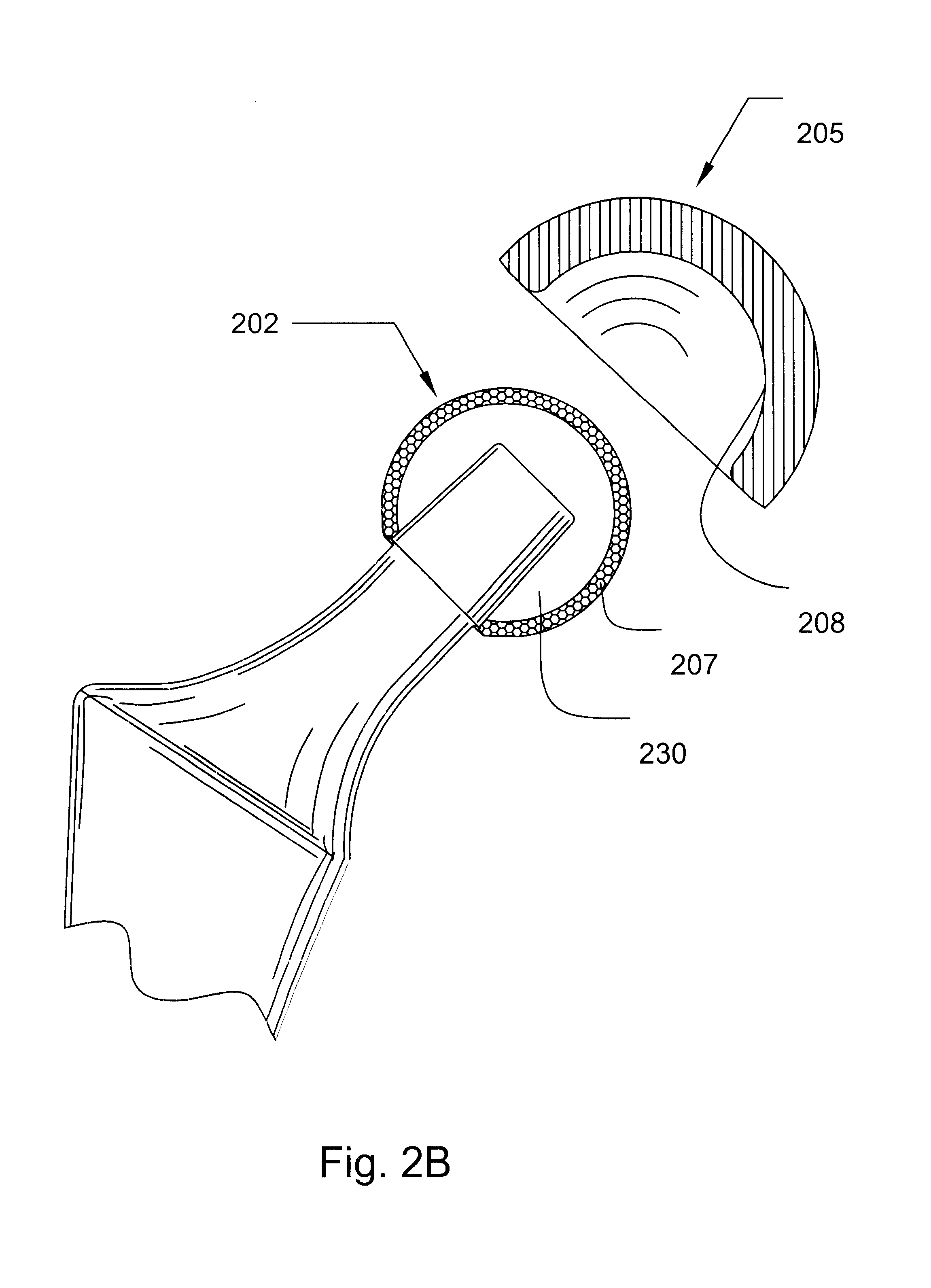

Modular ball and socket joint preferably with a ceramic head ball

InactiveUS6096084AIncrease surgical versatilityImprove proficiencyJoint implantsFemoral headsArticular surfacesArticular surface

Modular ball and socket joint has 1) a cupped ball head, preferably of ceramic, having a support body with an inferior, deep, distally facing, preferably generally planar, surface having a substantially circular outer boundary thereto; a distally opening stem receiving bore preferably centrally located in the support body; a cup wall, extending distally from the support body and having a preferably substantially cylindrical inner surface which extends from said outer boundary of said distally facing surface; and a superficially facing, generally semispherical, smooth external surface, preferably and optimally of a low friction coefficient, encapsulating the support body and cup wall; and 2) an interchangable and modular stem, preferably of metal or metal alloy, having a distally directed spike, and a superior stem cap which is insertable into the bore of the head; optionally with 3) a head-receiving articular cup having an inner articular surface and a mountable back surface, the articular surface of which, when the head-receiving cup is suitably mounted in suitable receiving stock, mates in articulating contact with said smooth external surface of said head when said head and stem are suitably mounted in suitable receiving stock. The head and stem modularity allows for noticeably increased versatility and efficiency in surgical procedures, and the ceramic material is beneficially adapted for employment in the fabrication of femoral resurfacing implants for conservative arthroplasty.

Owner:BIOPRO

Laryngoscope blade

InactiveUS20050240081A1Low coefficient of frictionEasily insertBronchoscopesLaryngoscopesThroatCushion

A laryngoscope blade for detachably connecting to a handle has a rigid skeleton to resist deformation or breakage. The blade includes a first end and a second opposite end. The first end is connectable to the handle. The second end is insertable through a patient's mouth and down the throat and / or hypopharynx to expose the voice box. A light conductor extends through the blade and transmits light from the handle to the second end. The blade has first and second surfaces extending between the first and second ends. The first surface faces and effectively diverts a patient's tongue when the second end is inserted into the patient's mouth and throat. A resilient cushion extends from the second surface. The cushion is supple and deformable to absorb pressure exerted on the cushion by inadvertent contact with the teeth while being inserted in the patient's mouth and throat. The cushion includes an outer skin with a relatively low coefficient of friction. The cushion helps to prevent or minimize accidental damage to the teeth with no restriction on the insertion of the blade.

Owner:THE CLEVELAND CLINIC FOUND

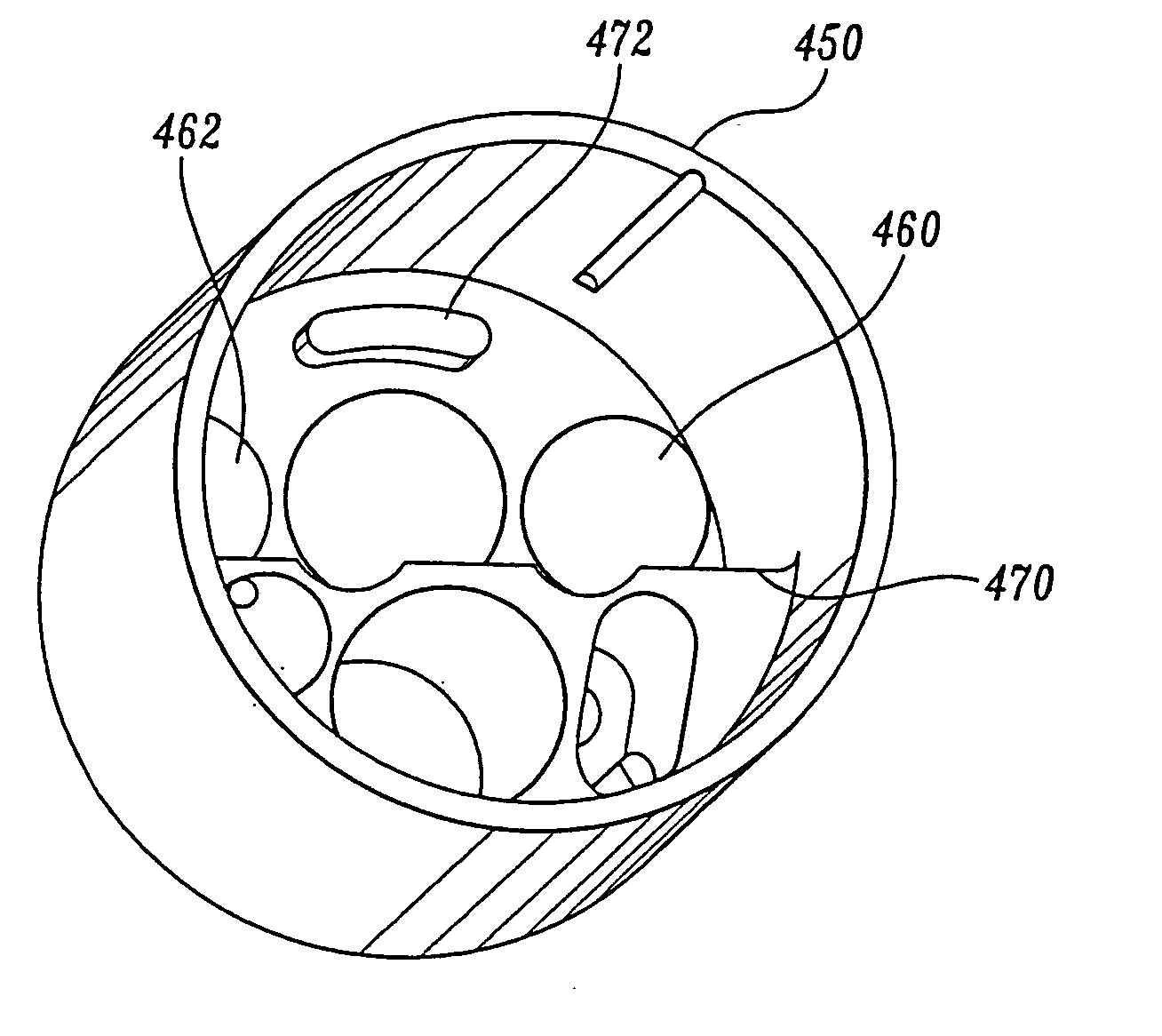

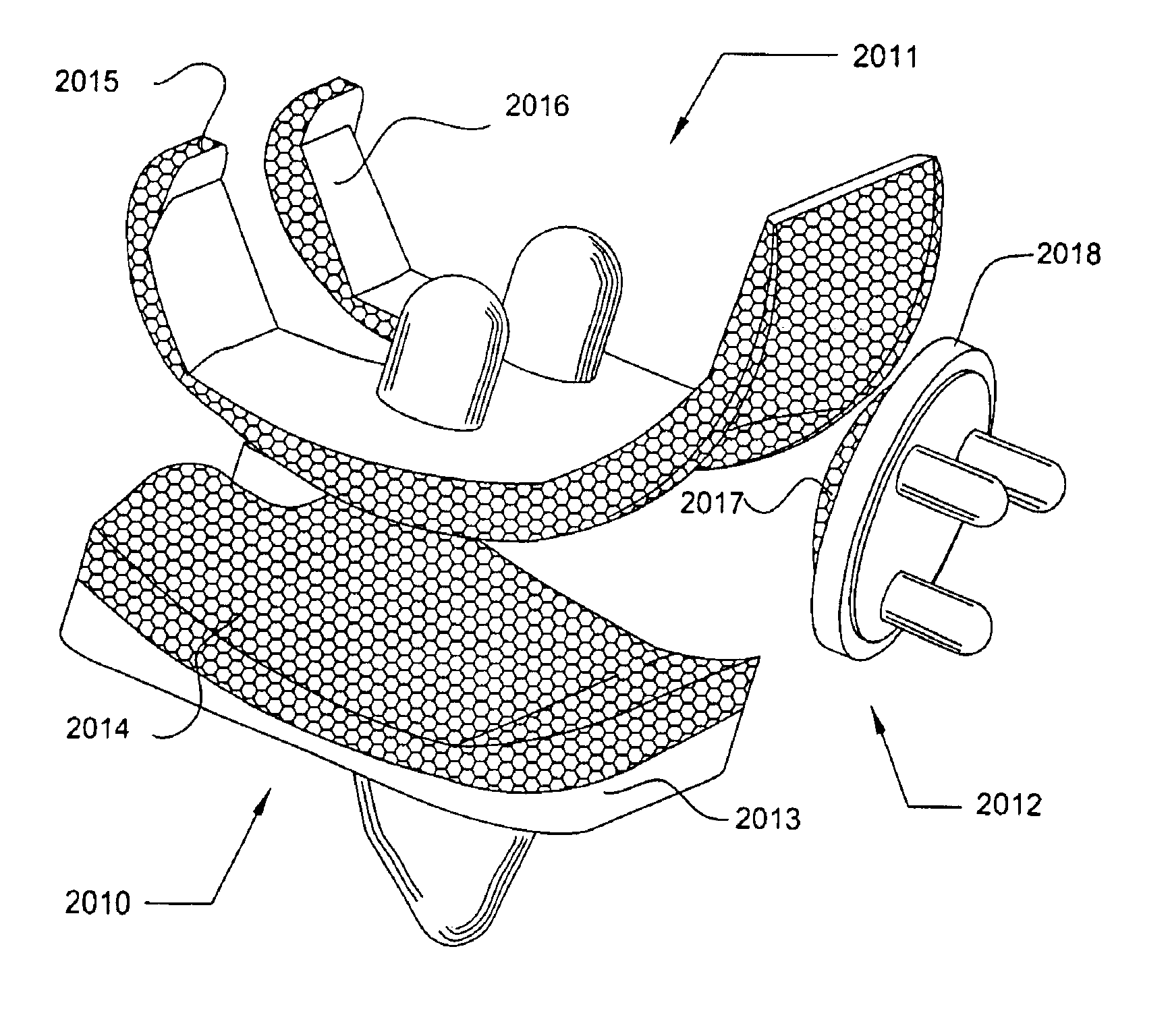

Joint Arthroplasty Devices Having Articulating Members

InactiveUS20080109081A1Improve wear resistanceAvoid Strength LossAnkle jointsJoint implantsJoint arthroplastyPolyether ether ketone

Articulating devices for replacing damaged or degenerated weight bearing joints are provided. The devices may have two or more surfaces that articulate against one another that are coated or fully formed of PEEK or similar materials to provide improved wear capabilities while maintaining sufficient strength to operate in a weight bearing capacity.

Owner:PIONEER SURGICAL TECH INC

Prosthetic knee joint having at least one diamond articulation surface

InactiveUS7077867B1Improve wear resistanceReduce coefficient of frictionFinger jointsWrist jointsArticular surfacesKnee Joint

Owner:DIAMICRON

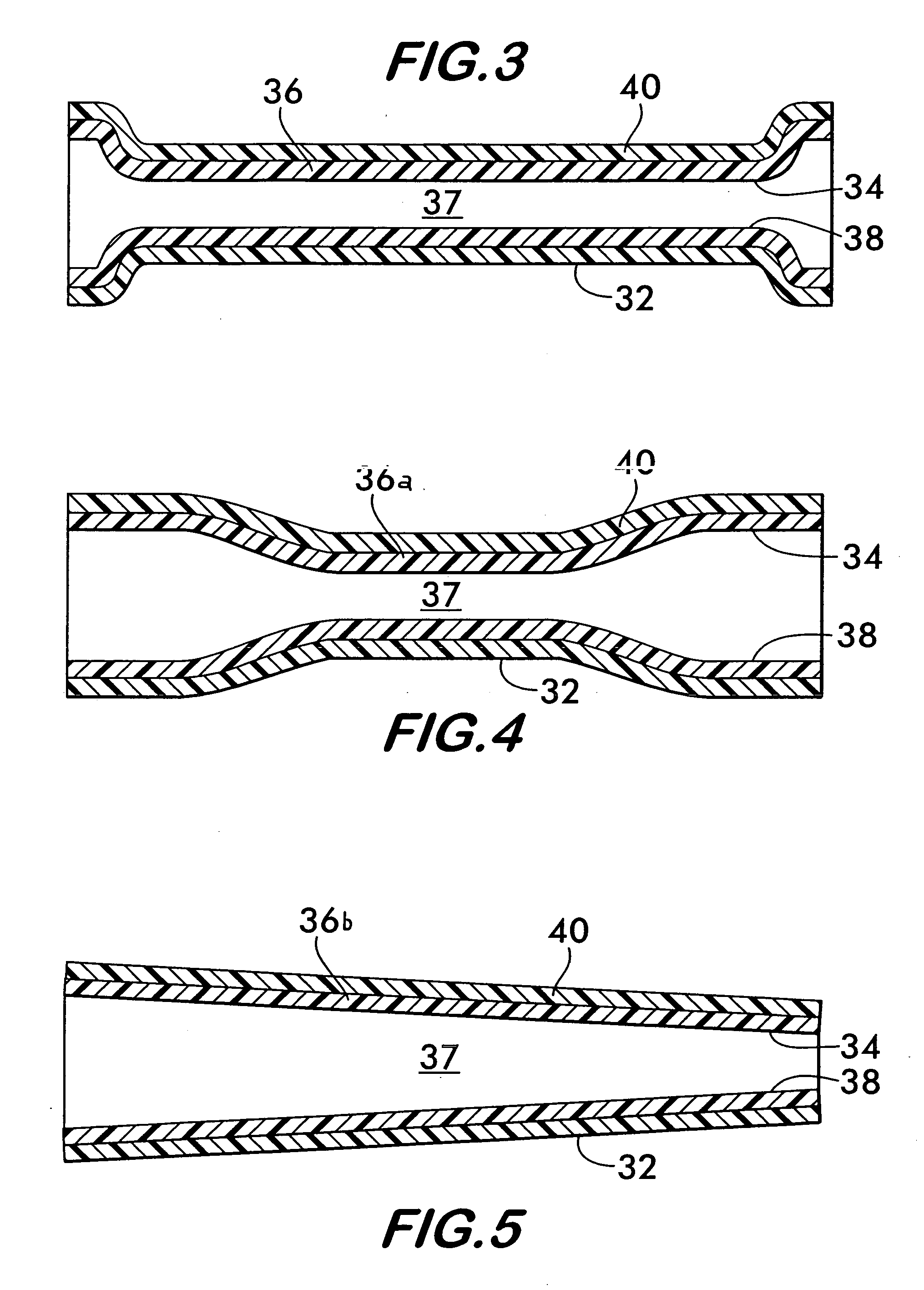

Catheter having a low-friction guidewire lumen and method of manufacture

InactiveUS6849062B2Reduce surface areaIncrease thicknessStentsBalloon catheterLow frictionBalloon catheter

A catheter shaft for a balloon catheter includes a centrally-located guidewire lumen. A body portion of the catheter shaft includes arc-shaped nodes that define a guidewire track within the guidewire lumen. Each node provides a single contact point for a guidewire within the guidewire lumen, thereby limiting frictional contact due to “rolling” friction, rather than “sliding” friction, between the catheter shaft and an inserted guidewire. The nodes include a crown region that includes the contact point. The crown region may be formed of a material having a lower coefficient of friction than the remaining portion of the catheter shaft. At least one node has an inflation lumen extending therethrough. The inflation lumen is in fluid communication with an interior of an inflatable balloon.

Owner:MEDTRONIC VASCULAR INC

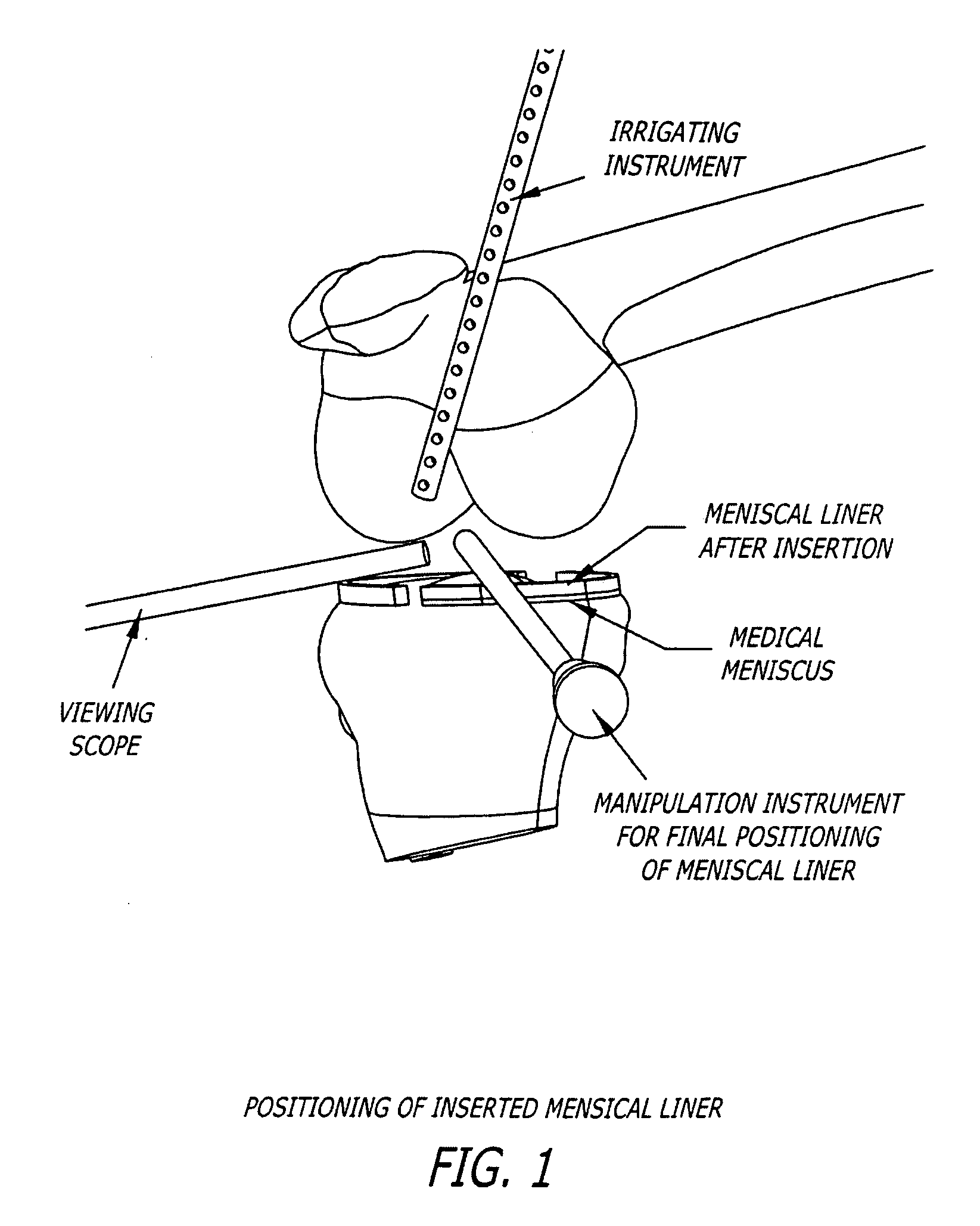

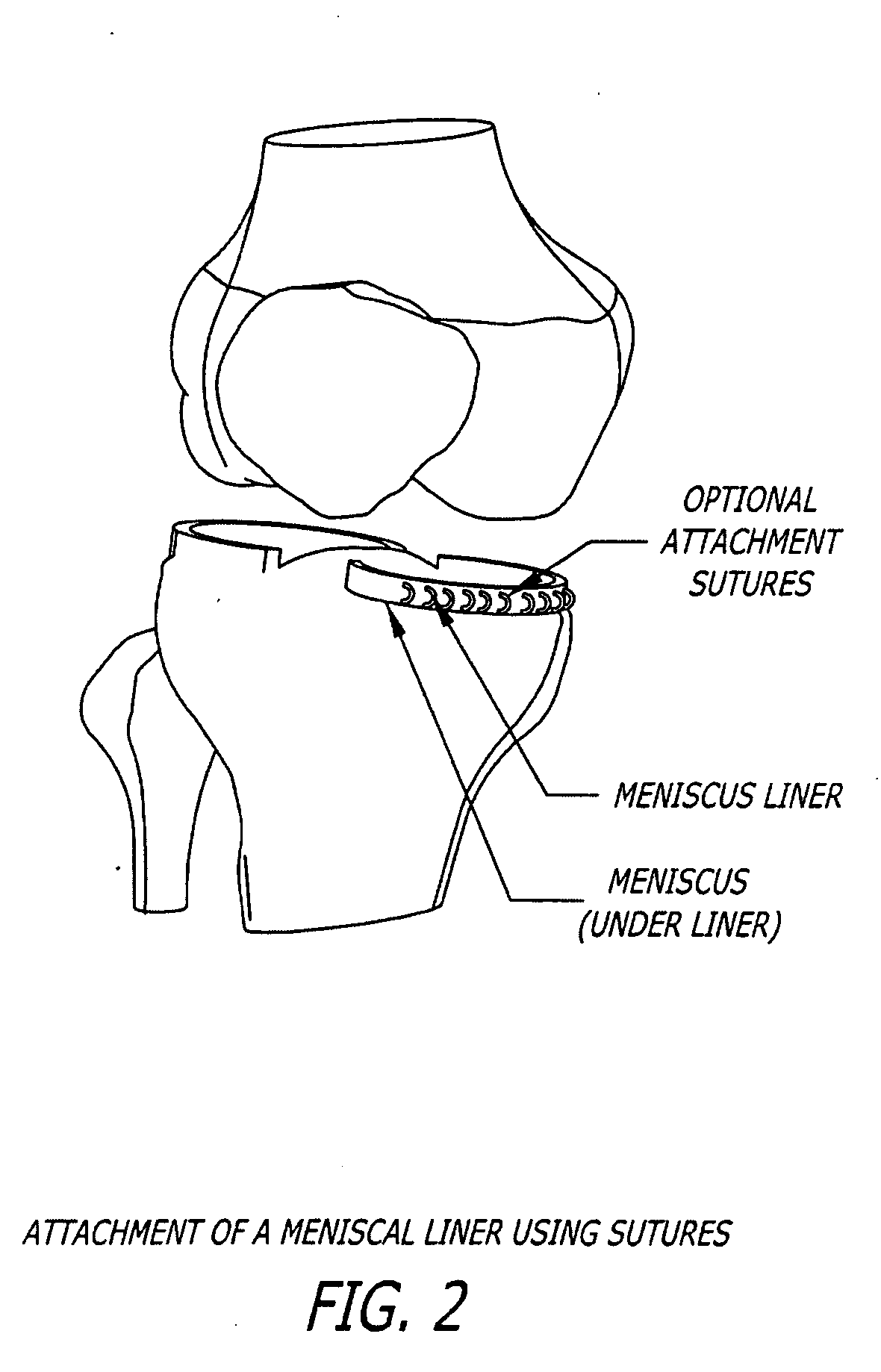

Knee joint prosthesis and hyaluronate compositions for treatment of osteoarthritis

A medical device and methods to relieve joint pain and adapted for knee joint repair, replacement and augmentation. The invention discloses joint lubricant, particularly hyaluronate compositions and methods for treatment of osteoarthritis.

Owner:INTERSECT PARTNERS

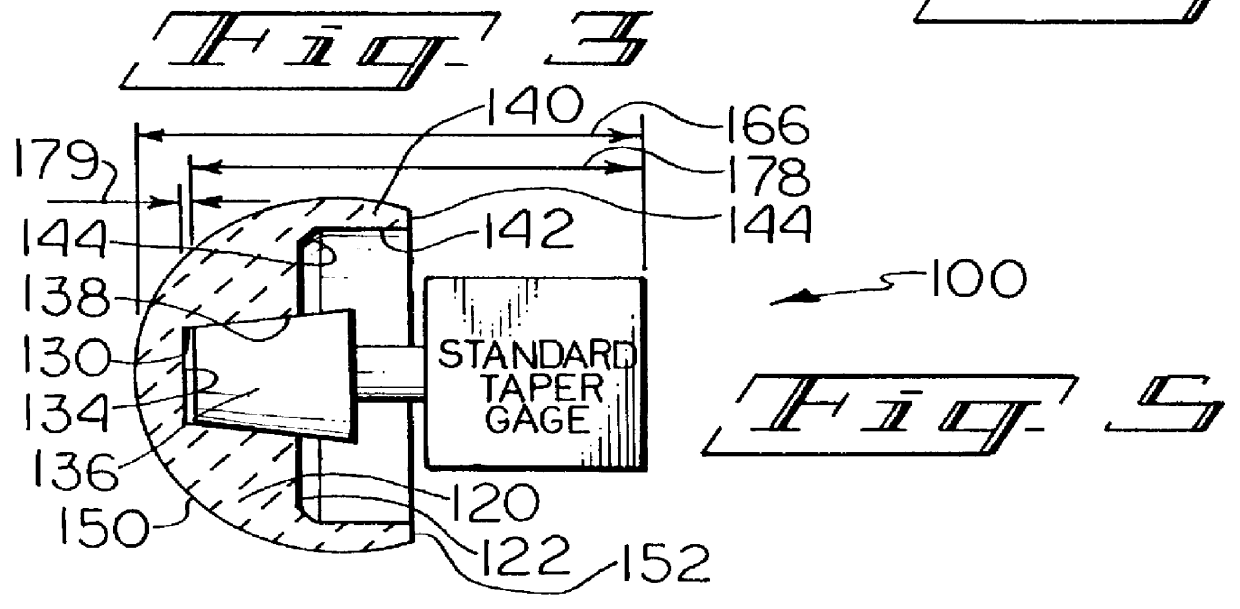

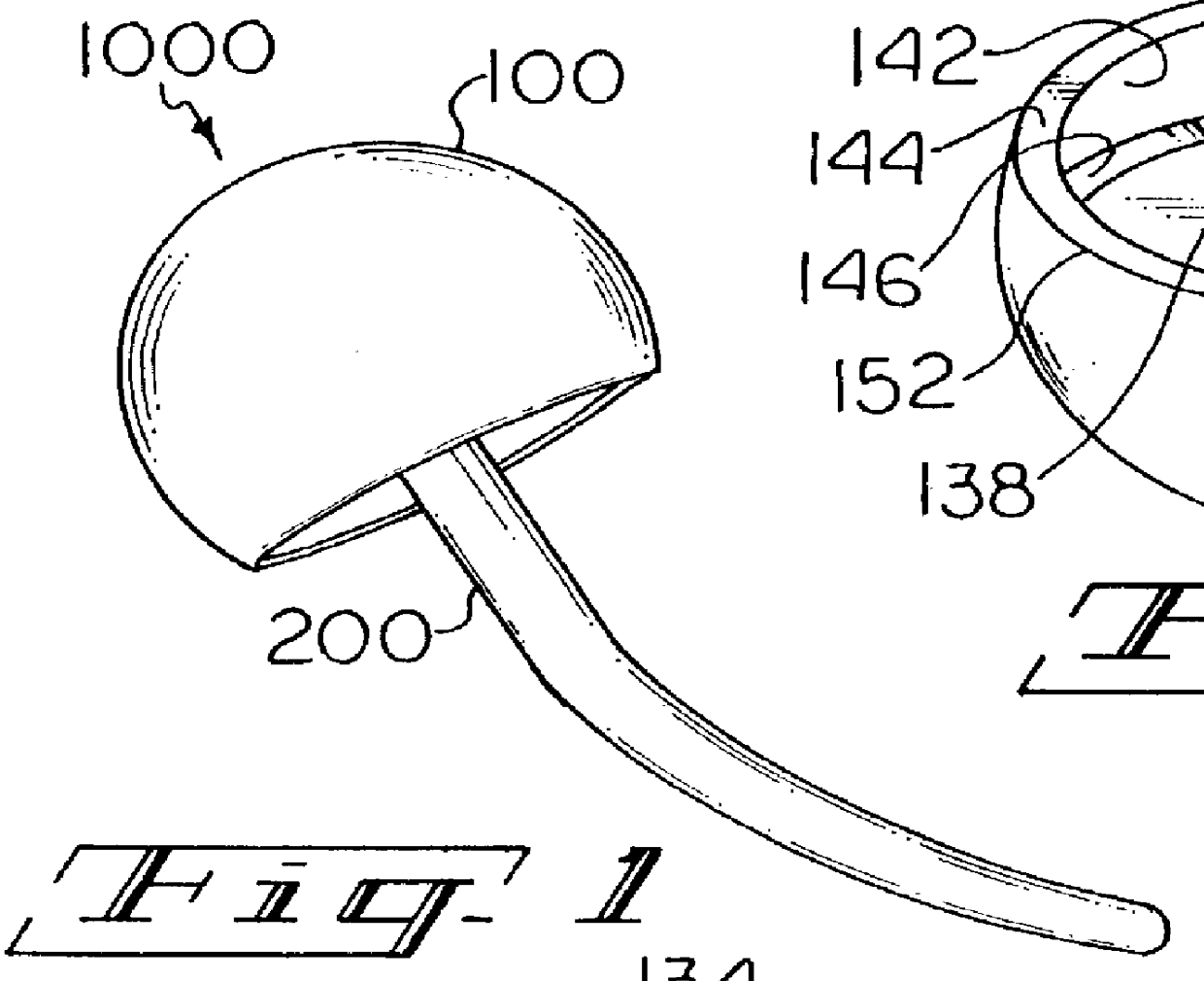

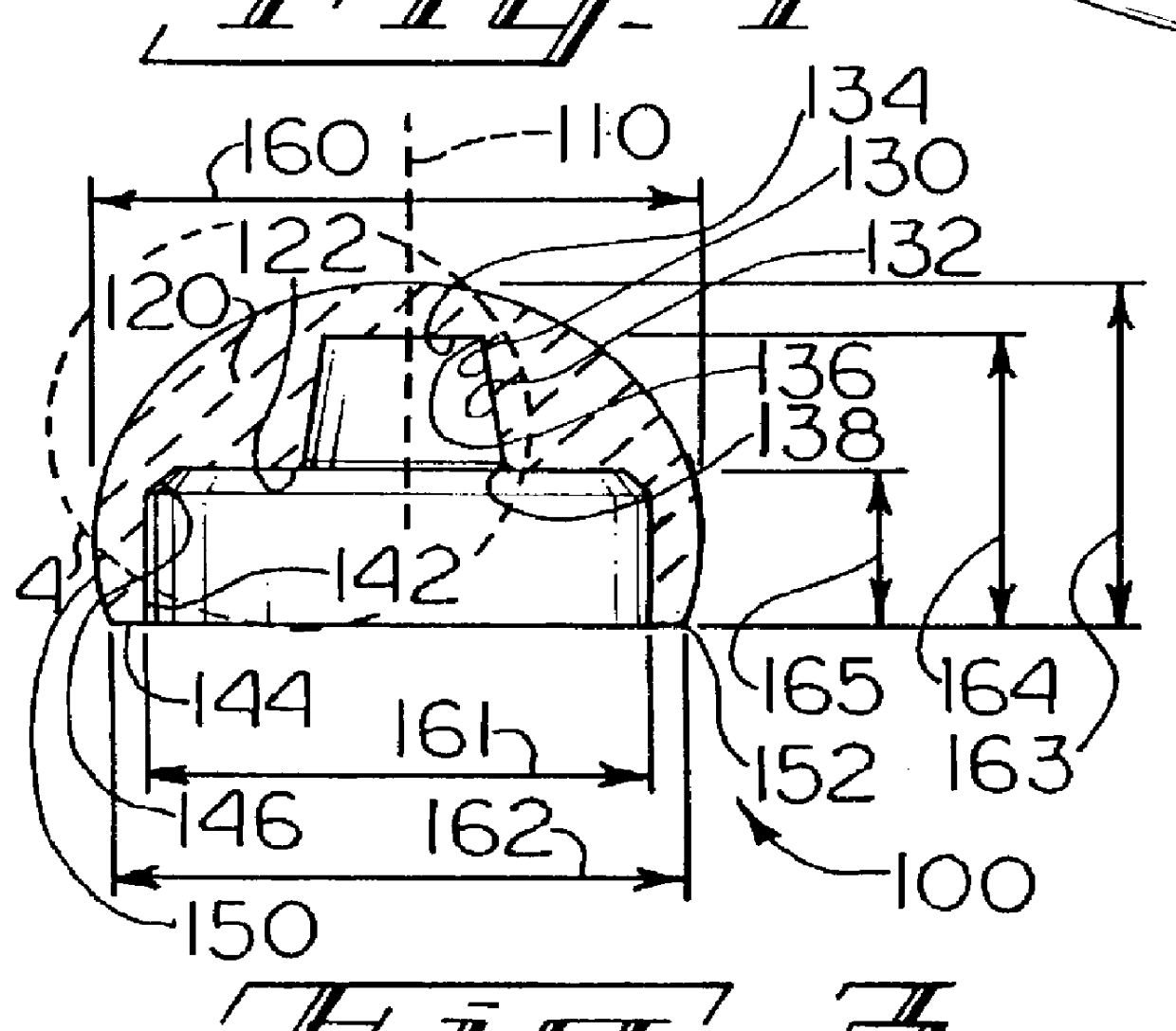

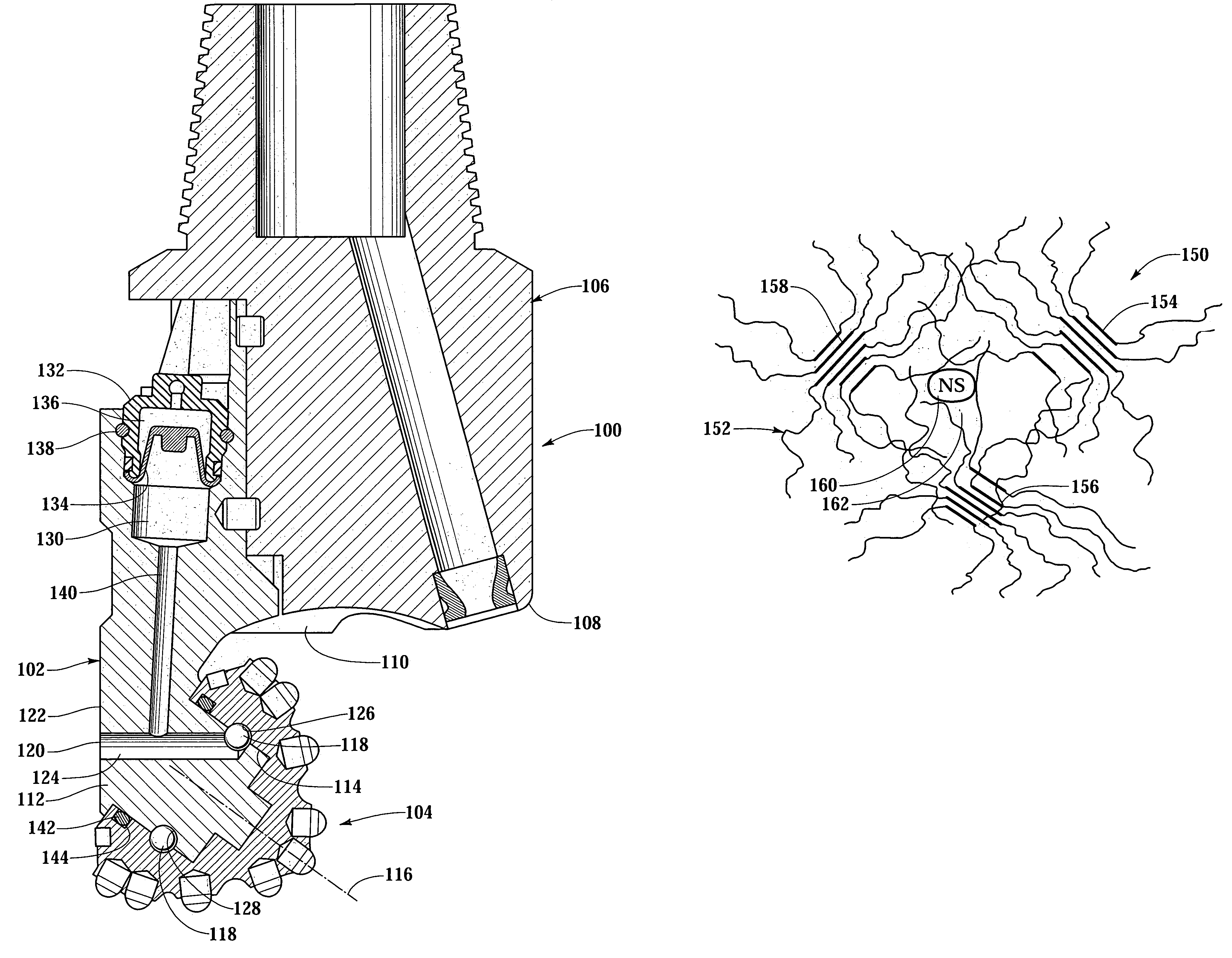

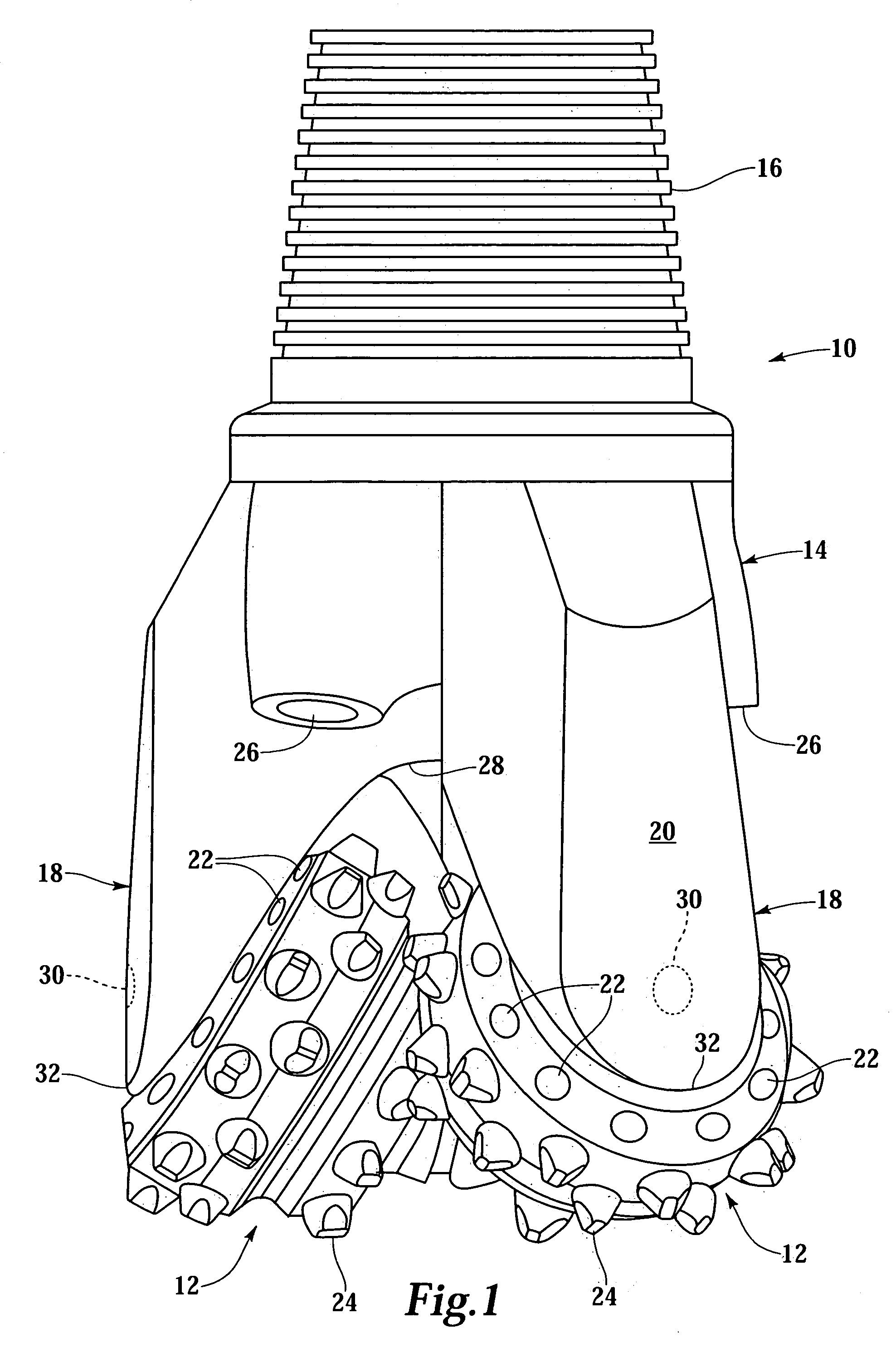

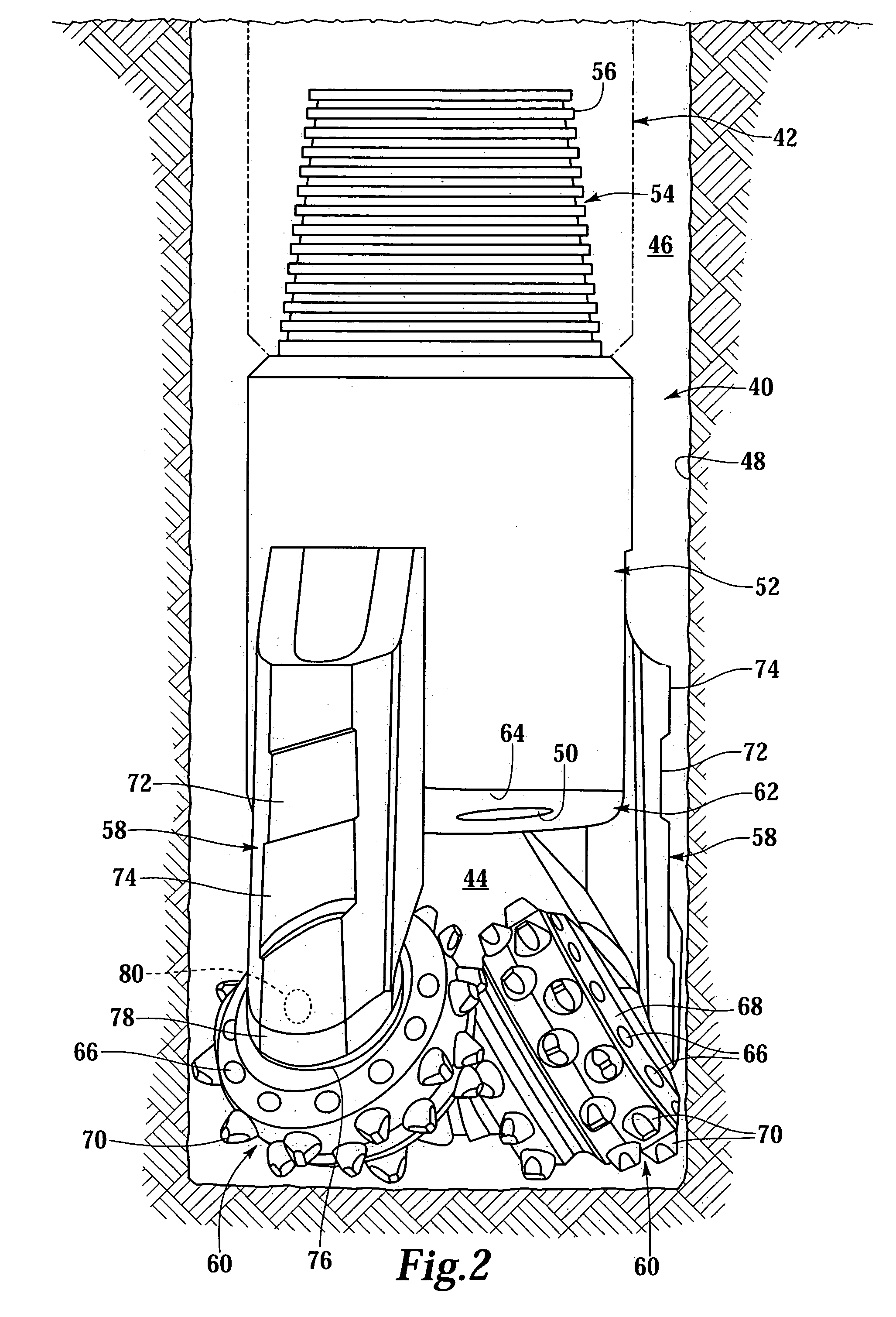

Drill bit having an improved seal and lubrication method using same

InactiveUS7013998B2Improve sealingIncrease resistanceDrill bitsConstructionsHost materialNanostructure

A drill bit (100) for drilling a wellbore that traverses subterranean formations includes a drill bit body (106) having a plurality of journal pins (112), each having a bearing surface (128), and a rotary cutter (104) rotatably mounted on each journal pin (112), each rotary cutter (104) including a bearing surface (126). A pressure-compensated reservoir (130) is in fluid communication with the bearing surfaces (126, 128) and has a lubricant therein. A seal element (144) is positioned between each journal pin (112) and rotary cutter (104) and retains the lubricant in the bearing surfaces (126, 128). The seal element (144) is formed from a nanocomposite material including a polymer host material and a plurality of nanostructures.

Owner:HALLIBURTON ENERGY SERVICES INC

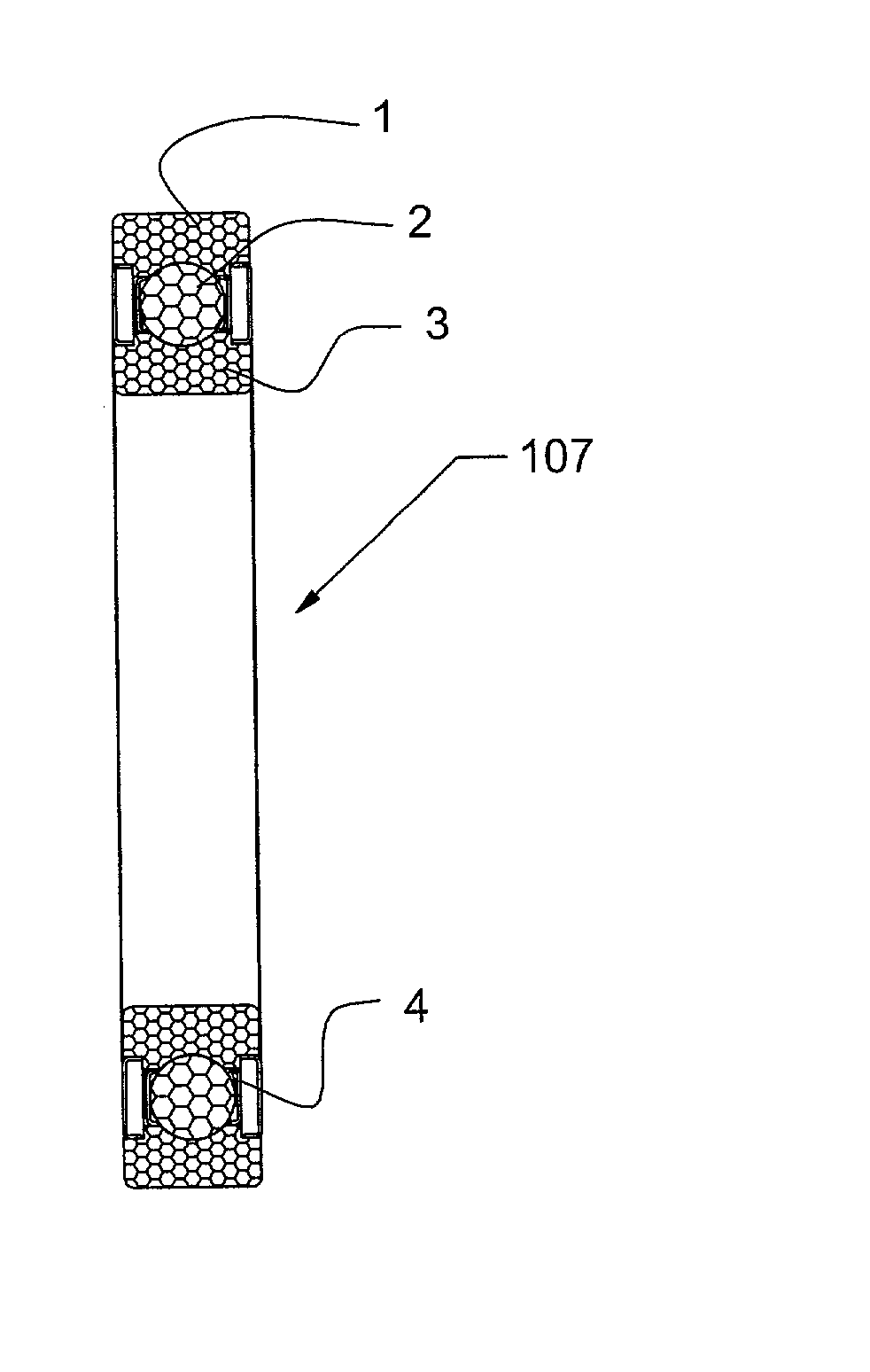

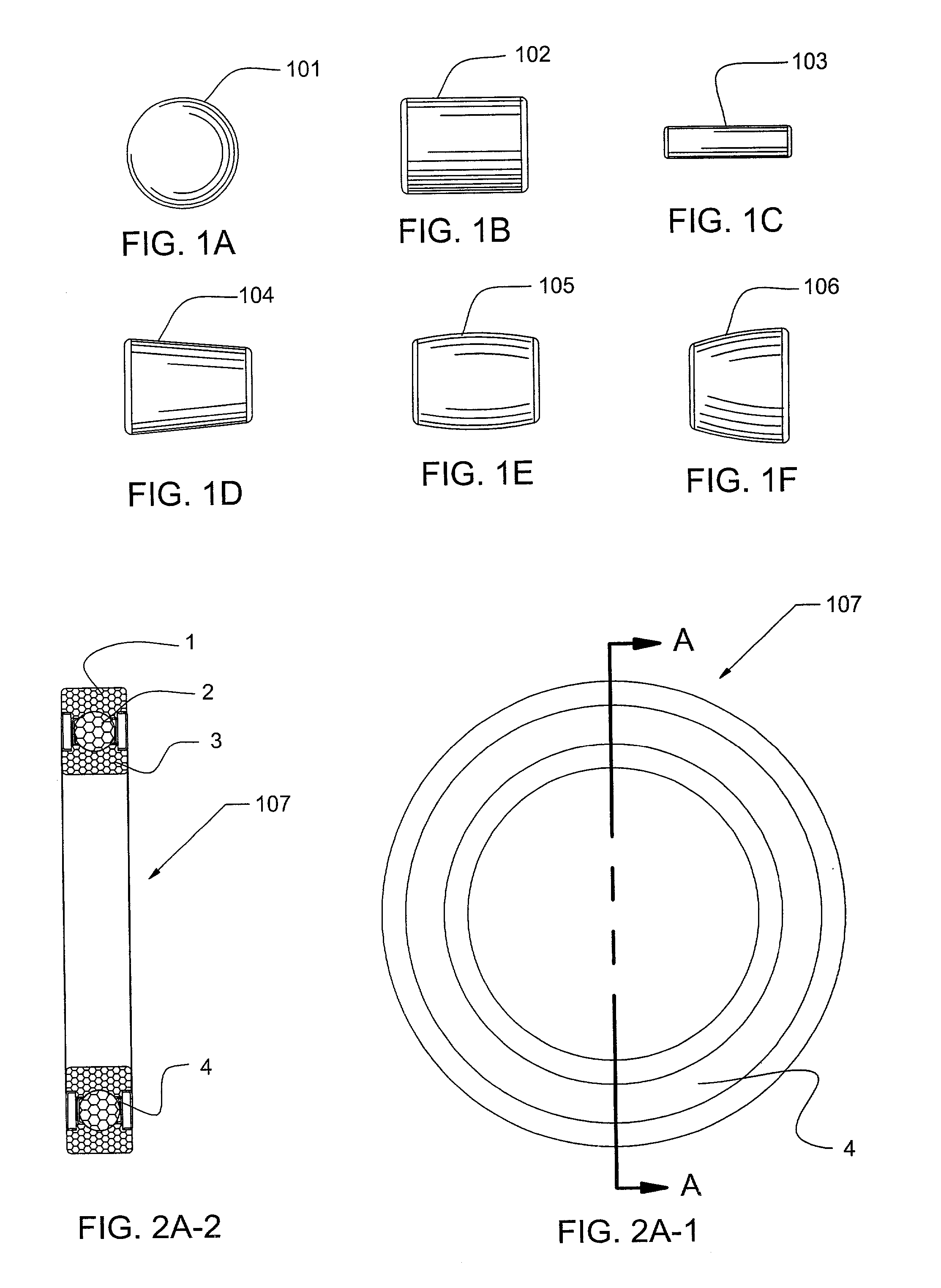

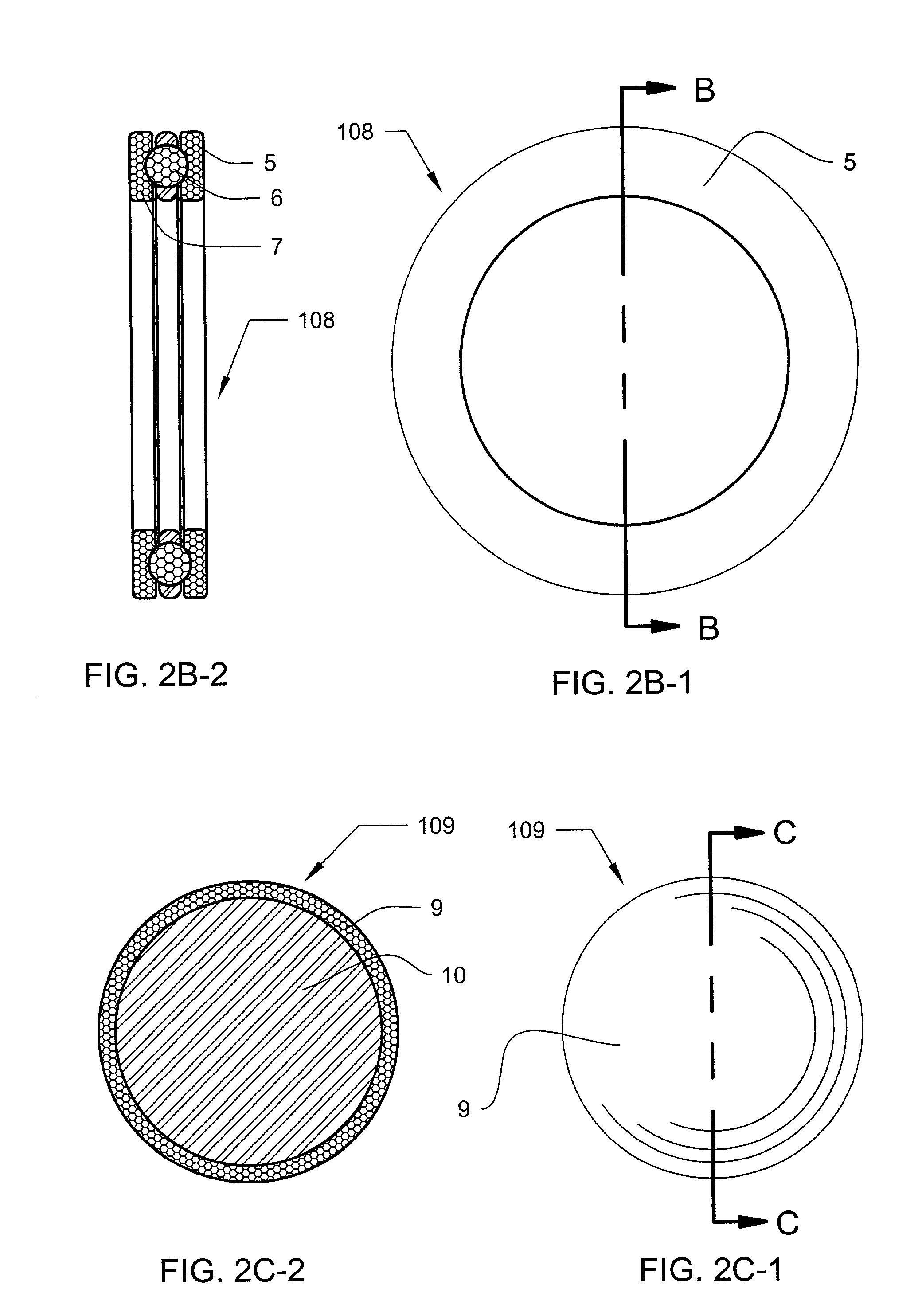

Methods for making bearings, races and components thereof having diamond and other superhard surfaces

InactiveUS20030019106A1Easy to polishReduce coefficient of frictionShaftsMetal-working apparatusPolycrystalline diamondHigh pressure

Method for making diamond bearings and diamond bearing components. Some methods include sintering diamond feedstock and a substrate under high pressure and high temperature to create a sintered polycrystalline diamond compact with a non-planar bearing and articulation surface. Various machining, grinding and polishing methods for finishing the compact are provided.

Owner:DIAMICRON

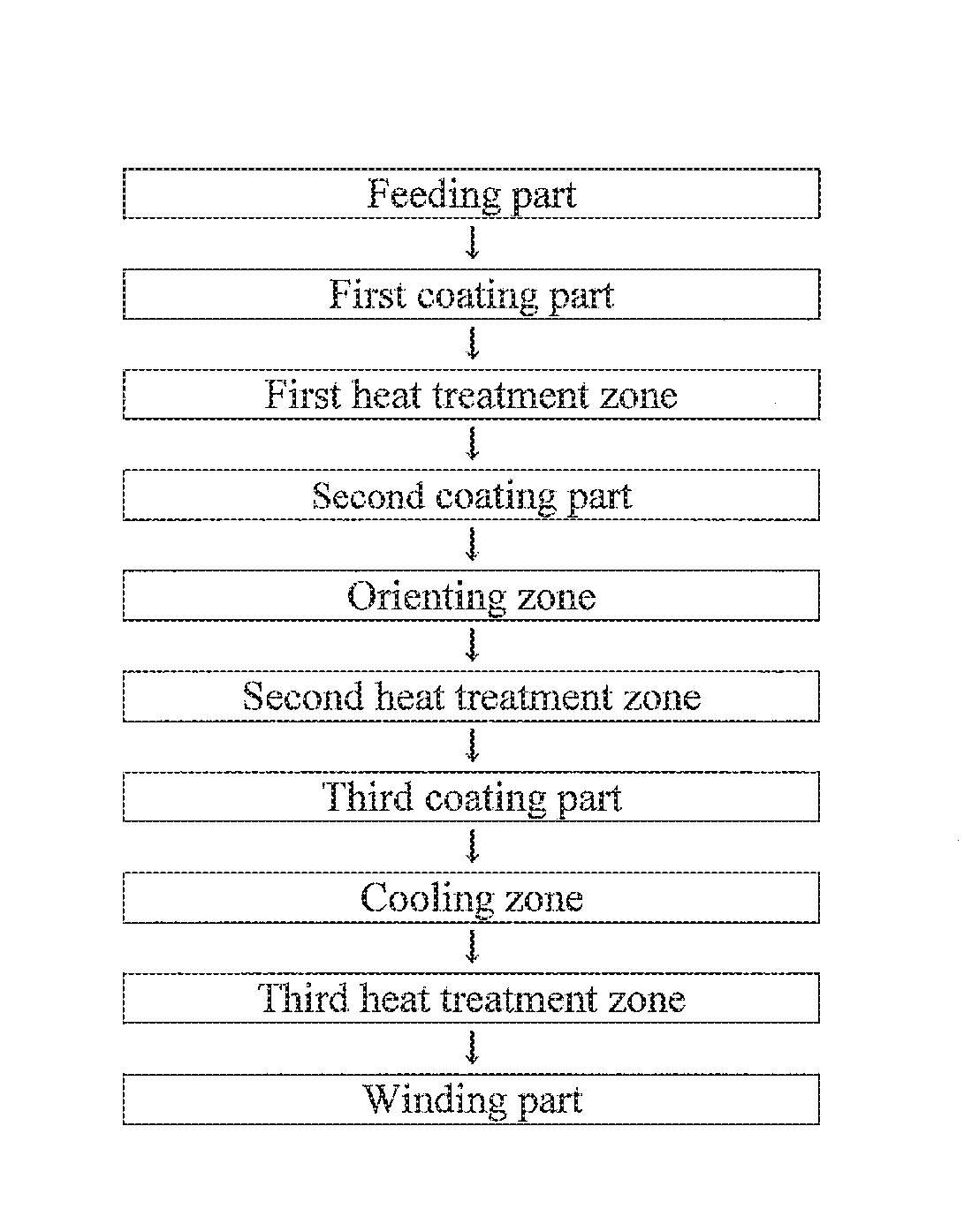

Magnetic recording medium

InactiveUS20130084470A1Good running durabilityGood dispersionMagnetic materials for record carriersRecord information storageInorganic particleNon magnetic

An aspect of the present invention relates to a magnetic recording medium comprising a magnetic layer containing a ferromagnetic powder and a binder on a nonmagnetic support, wherein the ferromagnetic powder has a hexagonal ferrite structure, the magnetic layer comprises a coefficient of friction-lowering component in the form of nonmagnetic inorganic particles, and a compound in which a substituent selected from the group consisting of a hydroxyl group and a carboxyl group is directly substituted on an aromatic ring.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS10026430B2Improve noiseDeterioration of characteristicRecord information storageMagnetic recordingMagnetic tapeNon magnetic

The magnetic tape comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder, nonmagnetic powder, and binder, wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm, and a coefficient of friction as measured on a base portion of a surface of the magnetic layer is less than or equal to 0.35.

Owner:FUJIFILM CORP

Prosthetic joint component having at least one sintered polycrystalline diamond compact articulation surface and substrate surface topographical features in said polycrystalline diamond compact

InactiveUS6676704B1Less disruptiveImprove overall utilizationFinger jointsWrist jointsArticular surfacesPolycrystalline diamond

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including a prosthetic joint component having at least one sintered polycrystalline diamond compact articulation surface and substrate surface topographical features in said polycrystalline diamond compact.

Owner:DIAMICRON

Magnetic tape and method of manufacturing the same

ActiveUS9704527B2Increase coefficient of frictionReduced stabilityRecord information storageMetals or alloysMagnetic tapeNon magnetic

Owner:FUJIFILM CORP

Methods for manufacturing a diamond prosthetic joint component

InactiveUS6596225B1Improve wear resistanceReduce coefficient of frictionCoatingsProsthesisArticular surfacesProsthetic joint component

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including methods for manufacturing a diamond prosthetic joint component.

Owner:DIAMICRON

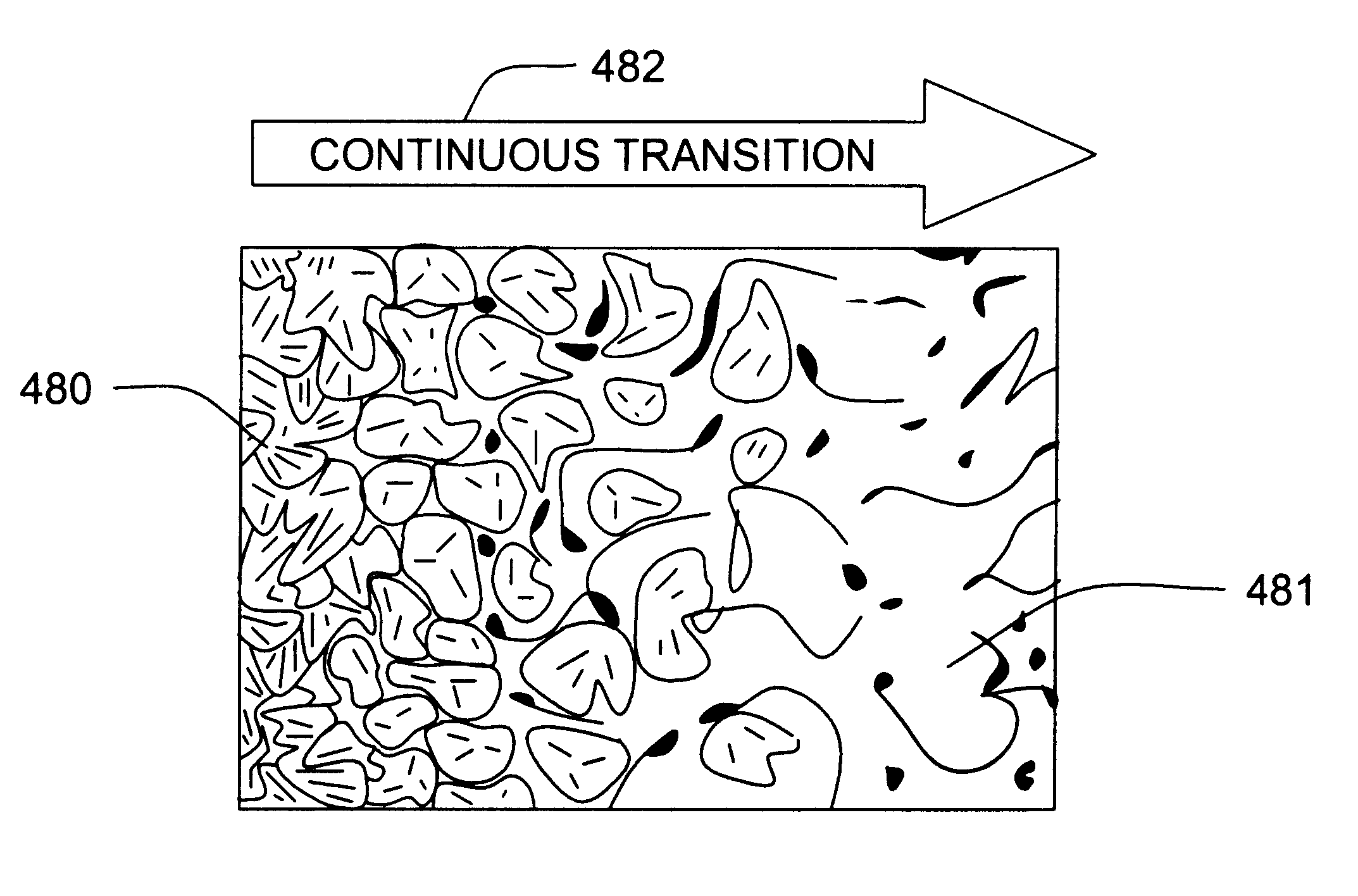

Customized polishing pads for CMP and methods of fabrication and use thereof

ActiveUS20060276109A1Easy to controlImpact on polishing propertyAdditive manufacturing apparatusLapping machinesPorositySurface engineering

The present application relates to polishing pads for chemical mechanical planarization (CMP) of substrates, and methods of fabrication and use thereof. The pads described in this invention are customized to polishing specifications where specifications include (but not limited to) to the material being polished, chip design and architecture, chip density and pattern density, equipment platform and type of slurry used. These pads can be designed with a specialized polymeric nano-structure with a long or short range order which allows for molecular level tuning achieving superior themo-mechanical characteristics. More particularly, the pads can be designed and fabricated so that there is both uniform and nonuniform spatial distribution of chemical and physical properties within the pads. In addition, these pads can be designed to tune the coefficient of friction by surface engineering, through the addition of solid lubricants, and creating low shear integral pads having multiple layers of polymeric material which form an interface parallel to the polishing surface. The pads can also have controlled porosity, embedded abrasive, novel grooves on the polishing surface, for slurry transport, which are produced in situ, and a transparent region for endpoint detection.

Owner:CMC MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com