Patents

Literature

108results about How to "Avoid strength loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement-based composite material suitable for 3D printing rapid-forming process

ActiveCN106830843AControllable clotting time3D printing is goodAdditive manufacturing apparatusPortland cementUltimate tensile strength

The invention relates to a cement-based composite material suitable for making a building structure and components through a 3D printing rapid-forming process. The cement-based composite material is characterized in that an extrudable property is good, a stacking property is good, printing time is controllable, and mechanical properties and durability are excellent. Regarding detailed properties, the material has good thixotropy, controllable condensing and hardening time and good adhesion, hour strength development is rapid, and strength growth is stable at the later stage, requirements for the 3D printing process and rapid construction can be met, and actual application of the 3D printing technology in the building industry is promoted easily. The cement-based composite material includes 100 parts of ordinary Portland cement, 100-300 parts of fine aggregate, 5-20 parts of strength-promoting shrinkage reducing agent, 30-60 parts of mixing water, 0.1-2.0 parts of water reducing agent, 0.5-15 parts of interface reinforcing agent, 0.05-0.2 part of thixotropic agent and 0.5-3.5 parts of liquid coagulating components.

Owner:BEIJING UNIV OF TECH

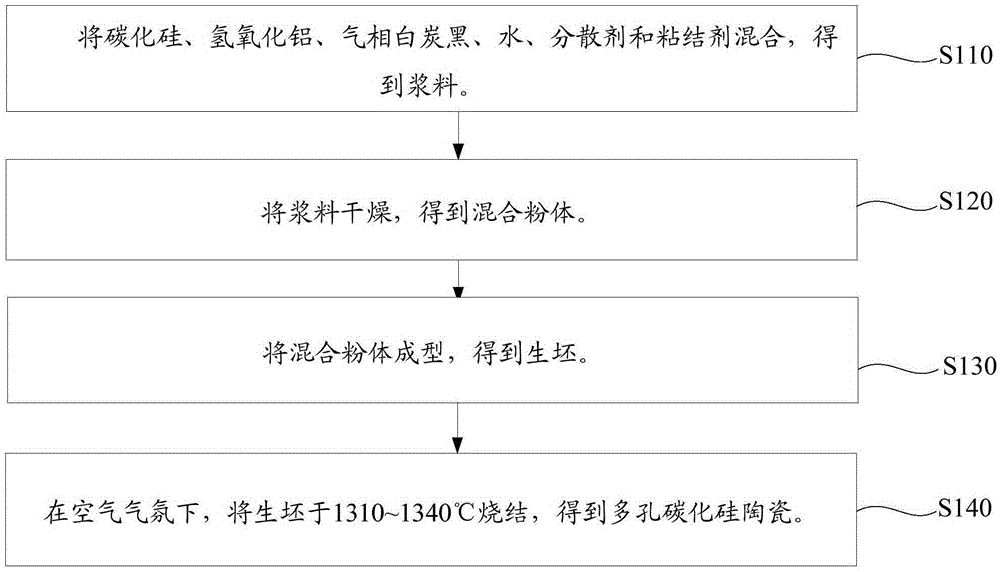

Porous silicon carbide ceramic and preparation method thereof

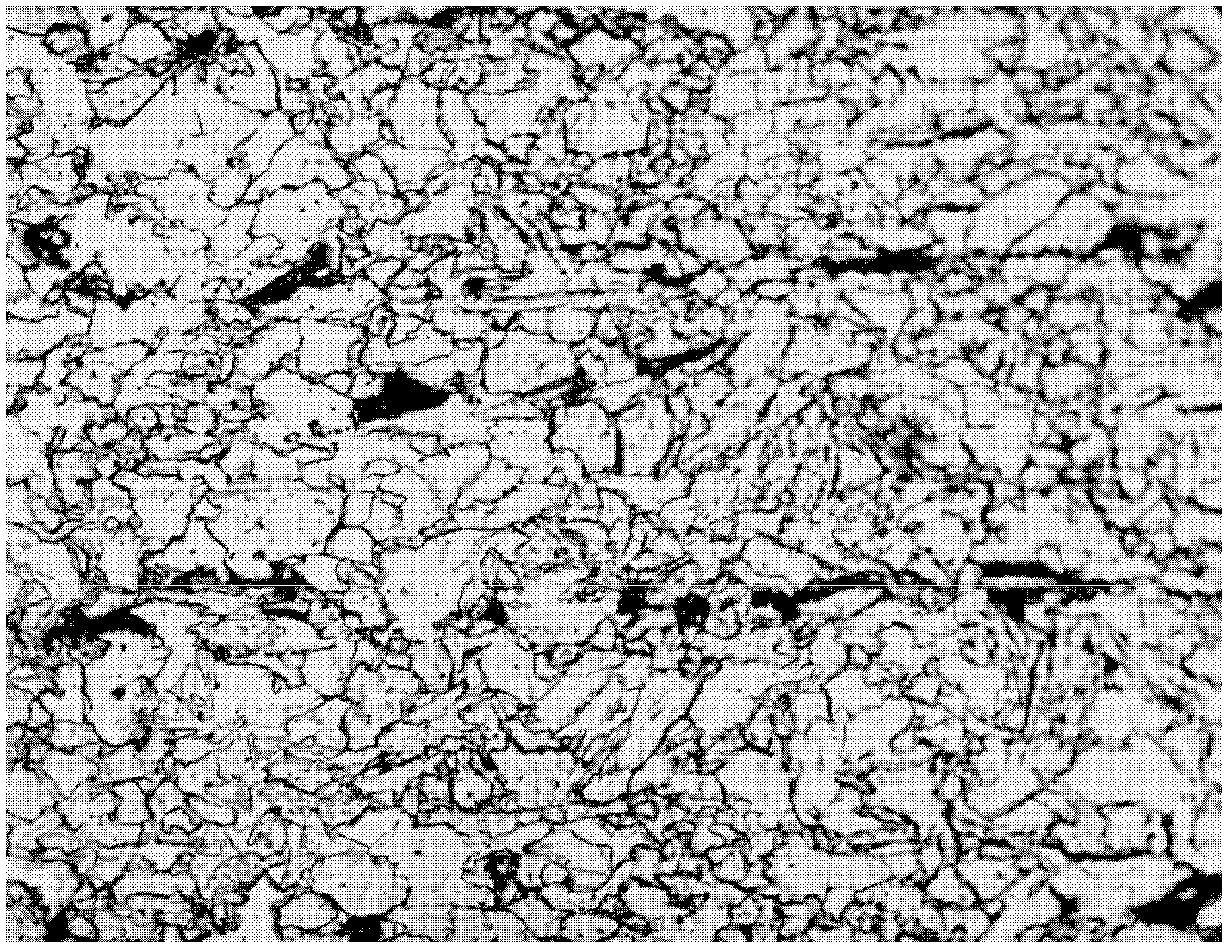

The invention relates to porous silicon carbide ceramic and a preparation method thereof. The preparation method comprises the following steps: mixing silicon carbide, aluminum hydroxide, fumed silica, water, a dispersant and a binder so as to obtain slurry, wherein the sum of the mass of aluminum hydroxide and fumed silica accounts for 5 to 30% of the sum of the mass of silicon carbide, aluminum hydroxide and fumed silica, and a mol ratio of aluminum hydroxide to fumed silica is 2-5: 1; drying the slurry so as to obtain mixed powder; molding the mixed powder to obtain a green body; and sintering the green body in an air atmosphere at 1310 to 1340 DEG C so as to obtain the porous silicon carbide ceramic. The preparation method can prepare the porous silicon carbide ceramic with good bending resistance at a low sintering temperature.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

Moderate-intensity anti-corrosion aluminium alloy material and aluminium alloy rod for cable

The invention discloses a moderate-intensity anti-corrosion aluminium alloy material and an aluminium alloy rod for a cable. The moderate-intensity anti-corrosion aluminium alloy material comprises the components of iron, silicon, magnesium, boron, copper, zinc, rare earth and the balance of aluminium; in a preparation process, an aluminium ingot, aluminum-boron alloy, aluminum-silicon alloy, aluminum-iron alloy, aluminum-rare earth alloy, aluminum-copper alloy, aluminum-zinc alloy and a magnesium alloy ingot are smelted to form alloy liquid, the alloy liquid is refined and stands by thermal insulation, component regulation is performed, then casting is performed to obtain a cast ingot, and homogenization treatment is performed on the cast ingot to obtain a homogenized cast ingot; the homogenized cast ingot is water-cooled, then hot rolling is performed, and the cast ingot is cooled to be below 100 DEG C to obtain hot rolling aluminum alloy; the hot rolling aluminum alloy is heated, kept warm and then cooled to room temperature, and precipitation heat treatment is performed to obtain the moderate-intensity anti-corrosion aluminium alloy material. The moderate-intensity anti-corrosion aluminium alloy material and the aluminium alloy rod for the cable are high in mechanical strength, good in corrosion resistance and excellent in comprehensive performance.

Owner:ANHUI ELECTRIC GRP SHARES

High-strength hard alloy with titanium carbide as main component and preparation method of high-strength hard alloy

The invention discloses a high-strength hard alloy with titanium carbide as a main component and a preparation method of the high-strength hard alloy. The titanium carbide serves as a main material, part of tungsten carbide is added as a hard phase, the titanium carbide and the tungsten carbide are mixed with a cobalt and nickel mixture serving as a binding phase, and the high-strength hard alloy with the titanium carbide as the main component is manufactured. The high-strength hard alloy with the titanium carbide as the main component is prepared from, by weight, 55-70 parts of titanium carbide, 20-45 parts of tungsten carbide, 0-5 parts of cobalt, 8-20 parts of nickel, 0-5 parts of molybdenum and 0.01-0.5 part of vanadium carbide. Firstly, the titanium carbide and the tungsten carbide are mixed into solid solutions, the molybdenum (Mo) is added in the manufacturing process of the solid solutions, the metal molybdenum changes into molybdenum carbide in the manufacturing process of the solid solutions, wettability of the binding phase on the hard phase is improved, the titanium carbide and tungsten carbide solid solutions are mixed with the binding phase and trace element vanadium carbide, and a mixed material is made; and the glue joining of the mixed material, pressing and forming are performed, and finally sintering and forming are performed.

Owner:株洲中工硬质合金工具有限责任公司

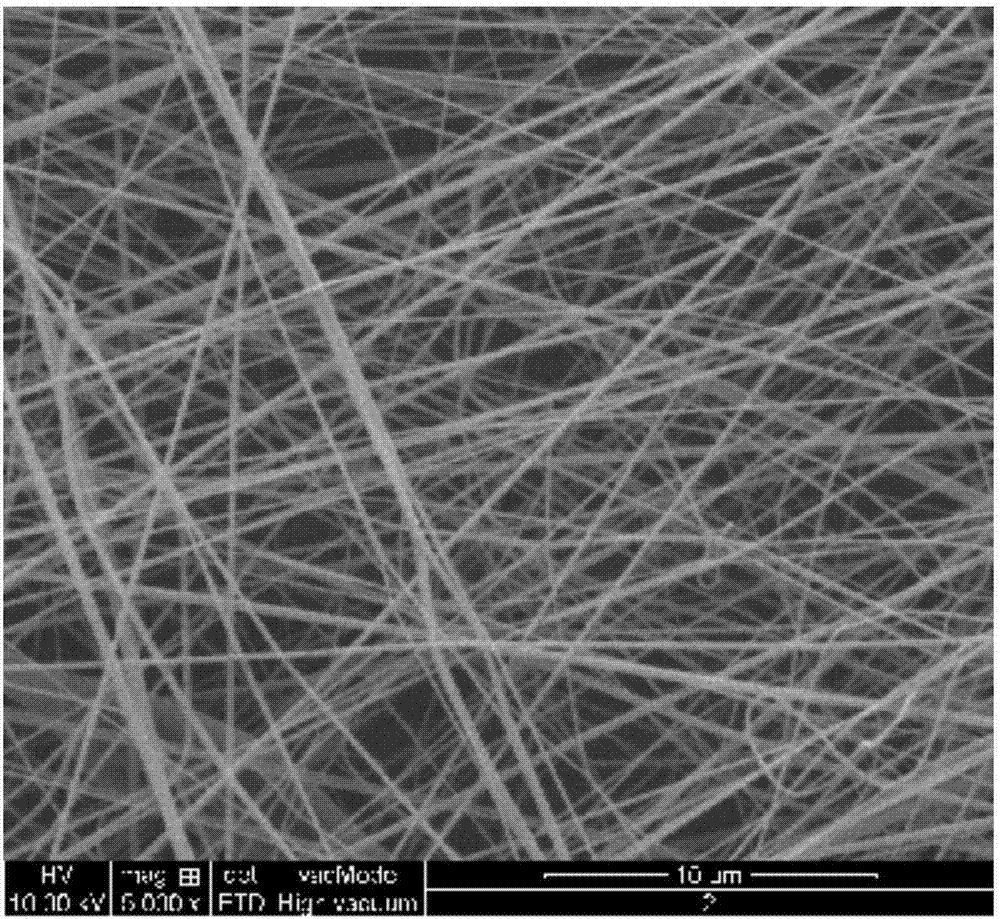

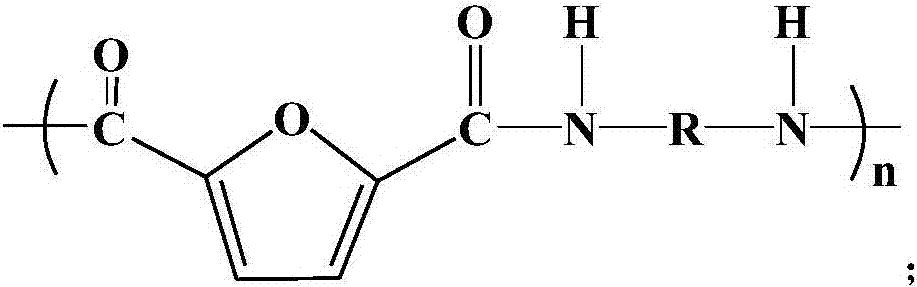

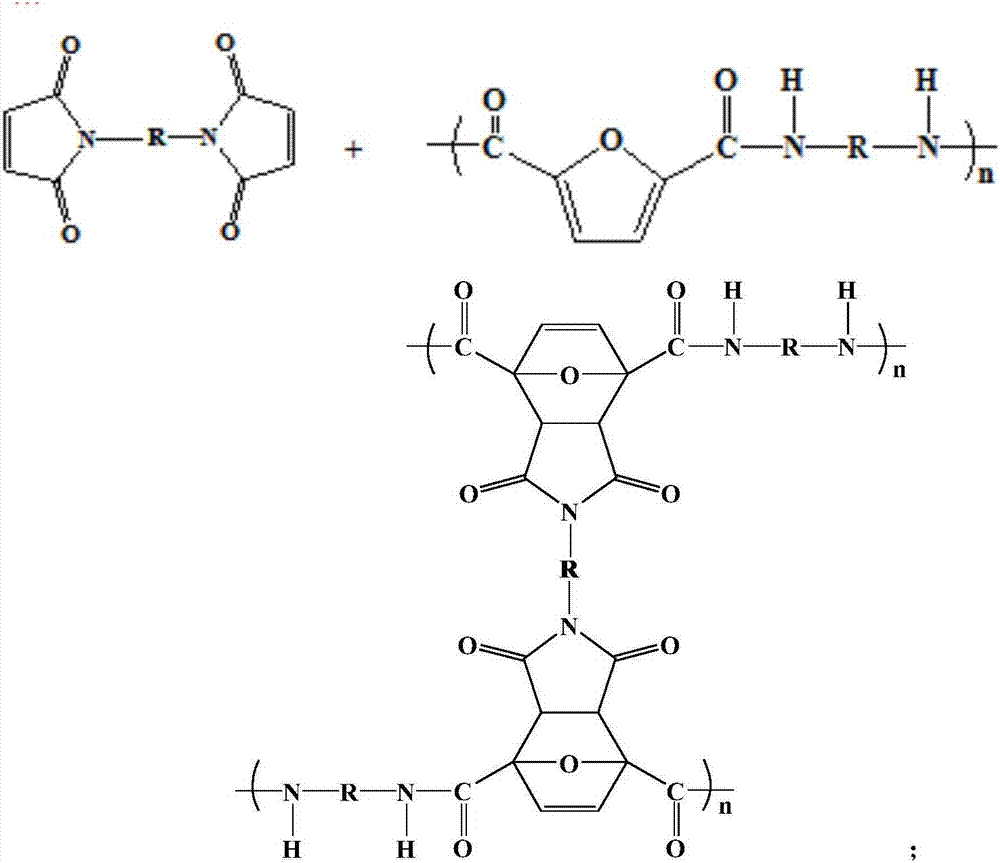

Cross-linked polyimide-based micro/nano fiber membrane and preparation method thereof

ActiveCN107217391AReduce consumptionReduce consumption costArtificial thread manufacturing machinesNon-woven fabricsCross-linkFiber

The invention relates to a cross-linked polyimide-based micro / nano fiber membrane and a preparation method thereof. The preparation method comprises the steps that firstly, a polyimide solution is synthesized in a non-proton polar solvent by using a one-step method, and a polyimide micro / nano fiber membrane is obtained through the solution jet spinning technology; the polyimide micro / nano fiber membrane is immersed a solution containing furan-based aromatic polyamide and a cross-linking agent, micro / nano fiber in the fiber membrane is subjected to chemical crosslinking at the crossed portion through hot pressing, and the cross-linked polyimide-based micro / nano fiber membrane is prepared, wherein the thickness of the cross-linked polyimide-based micro / nano fiber membrane is 16-80 micrometers, the tensile stress of the cross-linked polyimide-based micro / nano is 15-25 MPa, and the aperture is 1.3-1.8 micrometers. The preparation process is simple, the production efficiency is high, the cost is low, and the method is suitable for industrial production; the prepared product is of a cross-linked structure, the mechanical property is greatly improved, the pore structure is adjustable, and the product has good application prospects in fields of diaphragms of lithium ion batteries, catalyst carriers, efficient adsorbents, high-temperature flue gas filter membranes and the like.

Owner:DONGHUA UNIV

Non-initiating unlocking device and locking and unlocking method thereof

ActiveCN109229431AImprove utilization efficiencyImprove reliabilityCosmonautic vehiclesCosmonautic power supply systemsSpace environmentEngineering

The invention provides a non-initiating unlocking device and a locking and unlocking method thereof, which belongs to the field of unlocking devices. The device comprising a fastening cord, A hot knife assembly and at least two locking release members, the lock release member is used for fixing on the first member and the lock release member is used for fixing on the first member, the fastening cord is for providing a tightening force to the lock release member such that the lock release member locks the second member in a first state, the hot knife assembly comprises a hot knife and a hot knife mounting part, The hot knife mounting part is made of heat insulating material, the hot knife is arranged in the hot knife mounting part, the fastening rope is in close contact with the hot knife,and the hot knife is an electric heating element for generating heat to fuse the fastening rope, so that the locking releasing part returns to the second state and releases the second part. The invention avoids the carbonaceous fragments caused by the radial thrust, and the hot knife and the hot knife mounting part are structured under the space environment, and the performance is stable and the reliability is high.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

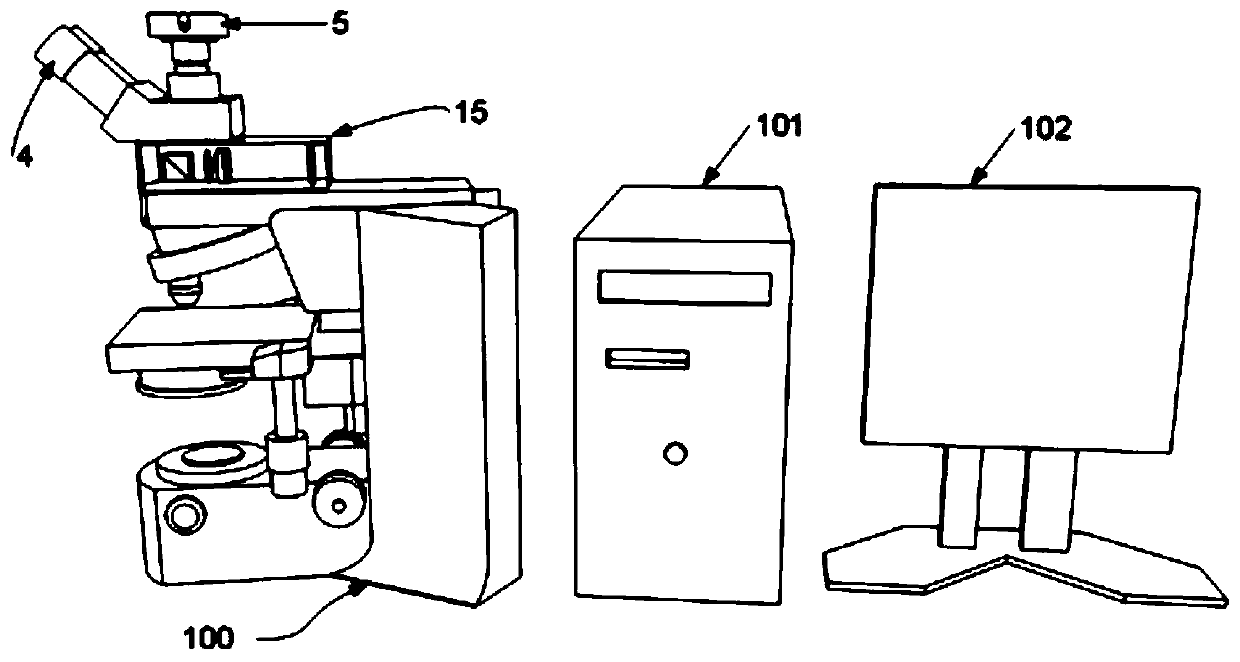

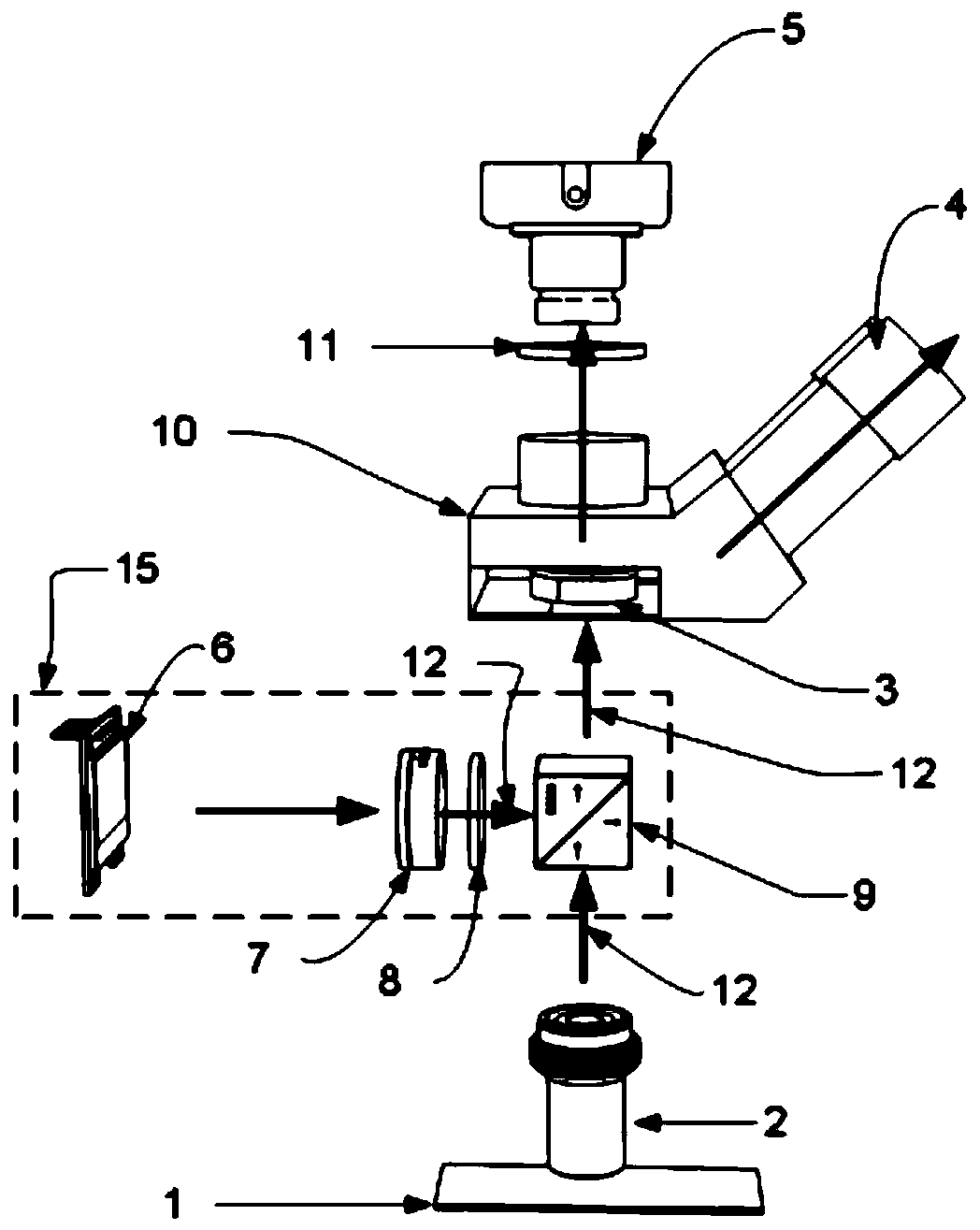

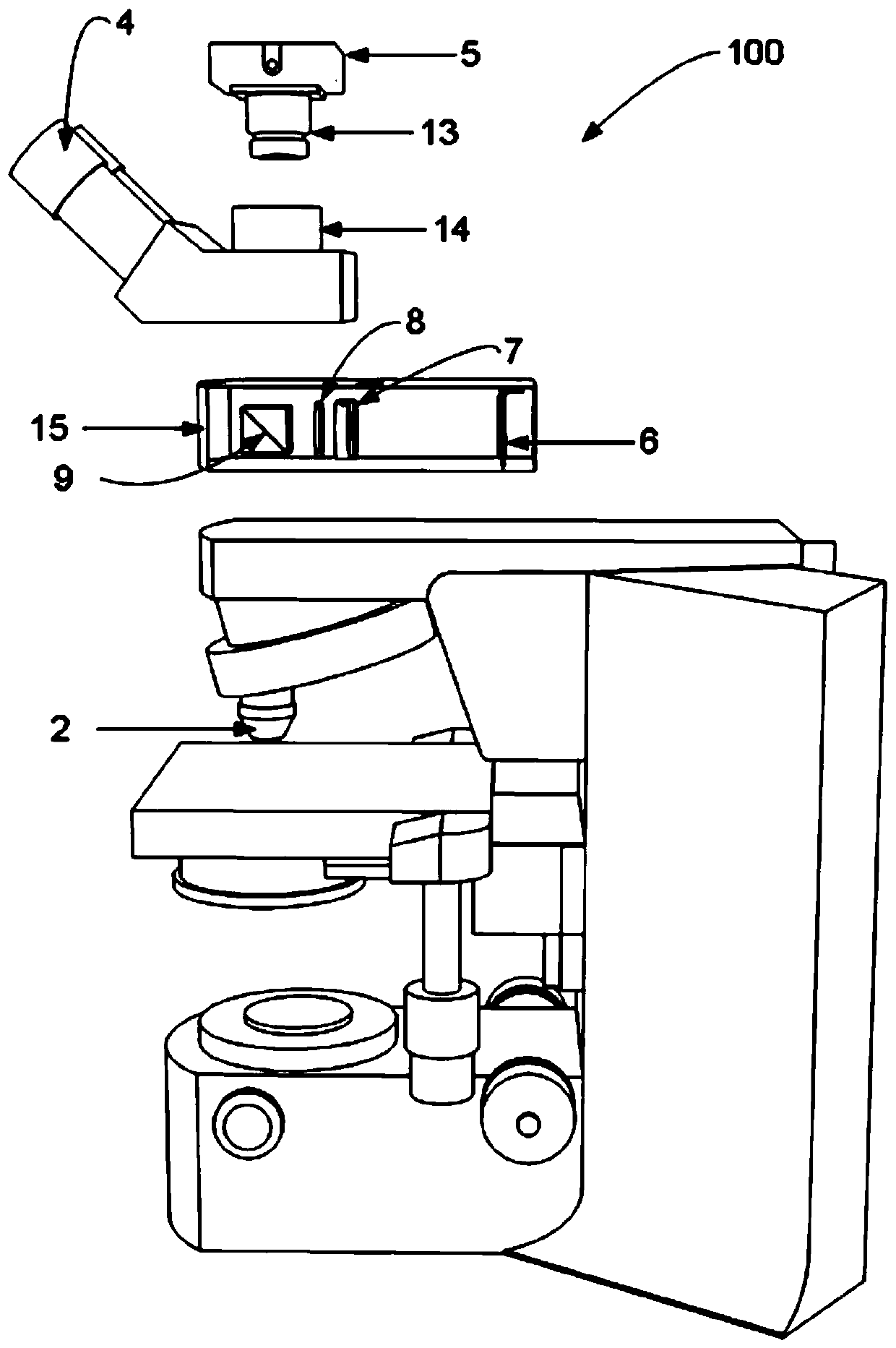

Augmented reality microscope, image projection equipment and image processing system

The invention discloses an augmented reality microscope. The microscope comprises an objective lens, an ocular lens, an N-mesh observation cylinder, an image acquisition module and an image projectionmodule, wherein N is greater than 2, the image acquisition module is physically connected with the N-mesh observation cylinder through a physical interface of the N-mesh observation cylinder, after the light generated by a measured object during observation enters the light path through the objective lens and the light generated by an image projection device in the image projection module entersthe light path through a lens device, the light converges at a light splitting device in the image projection module, then the converged light passes through the N-mesh observation cylinder, one partof the converged light enters the ocular lens, the other part of the converged light enters the image acquisition module, the image acquisition module is used for outputting acquired images to the image processing device, the image processing device processes the images and outputs the processing result to the image projection device, the image acquisition optical path and the image projection optical path are independent of each other, and thereby calibration is facilitated, and image processing precision is improved. The invention further discloses corresponding image projection equipment and an image processing system.

Owner:TENCENT TECH (SHENZHEN) CO LTD

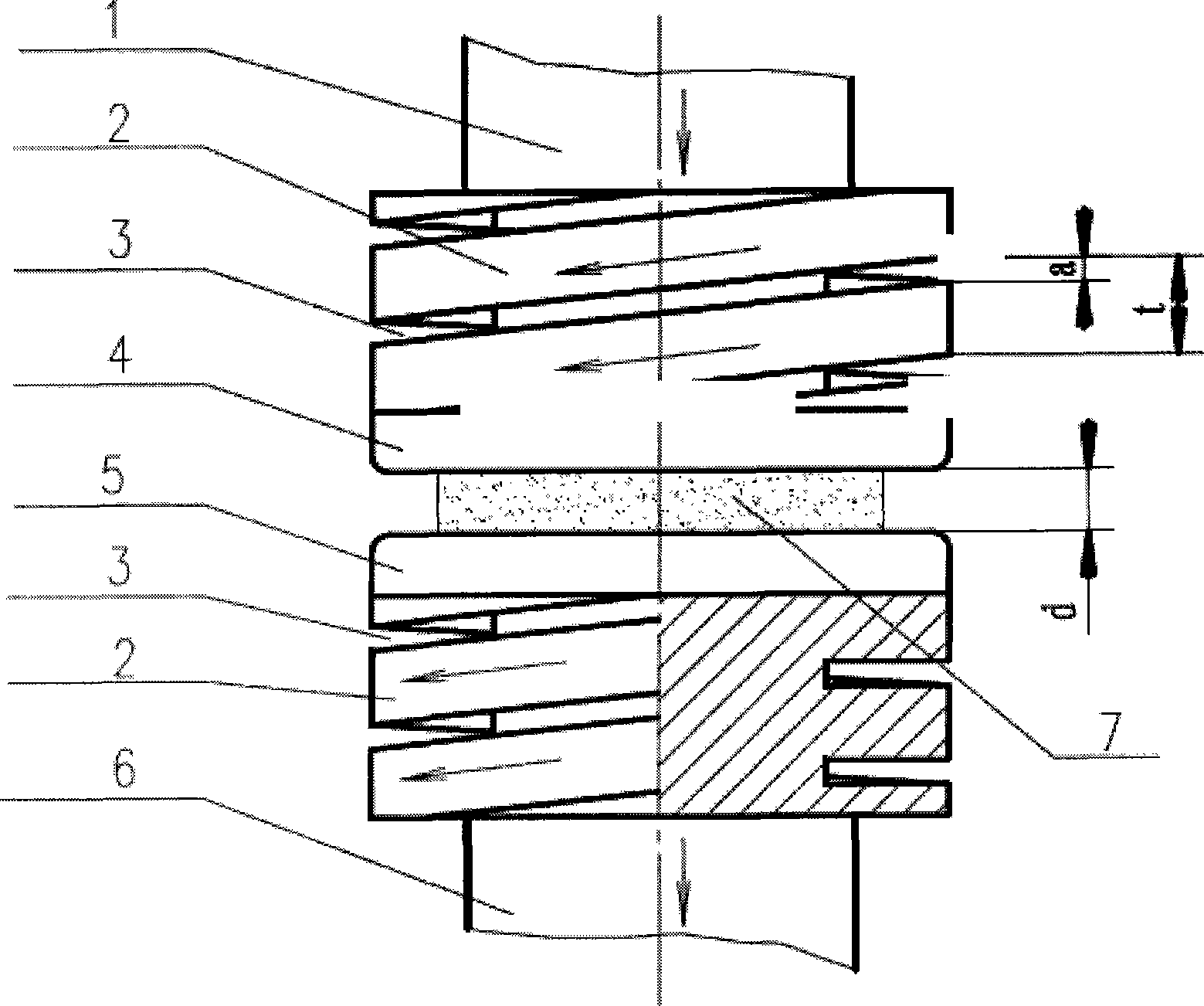

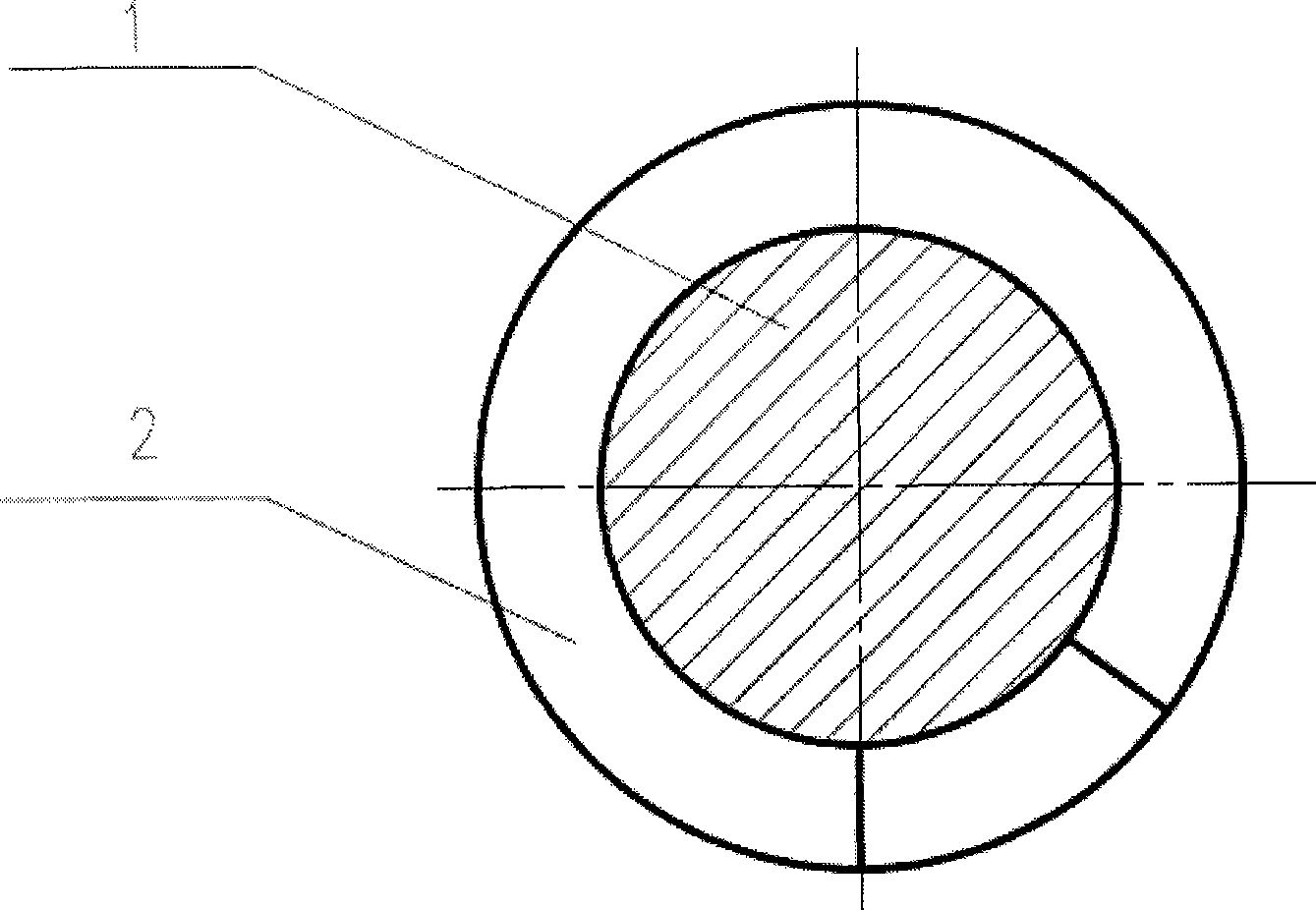

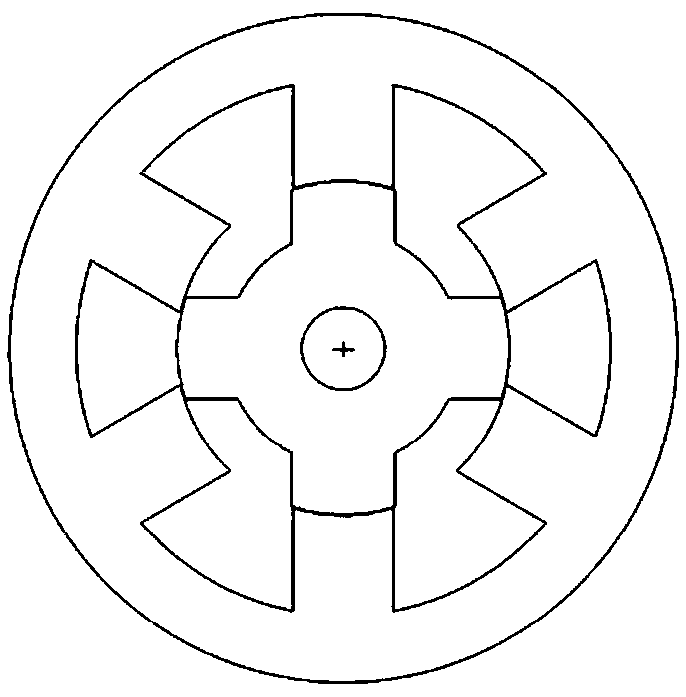

Vacuum switch tube for helical coil longitudinal magnetic field electrode

InactiveCN101425424AObvious superioritySignificant current pathHigh-tension/heavy-dress switchesAir-break switchesEngineeringVacuum switch

The invention provides a thread-coil type longitudinal magnetic field electrode vacuum switching tube which relates to the technical field of vacuum switches. The invention aims at providing a vacuum switching tube which has the arrangement disposal of the thread-coil type longitudinal magnetic field electrode so that the contradiction between the current conduction capacity and the short circuit current on-off capacity can be solved better. The vacuum switching tube comprises a moving conducting rod, a fixed conducting rod, a spiral coil, a spiral groove, a moving contact and a fixed contact which form a conducting loop. A coil of the vacuum switching tube takes the shape of a spiral body, and the turning direction of two thread coils arranged on a moving conductor and a fixed conductor is the same, and the moving contact and the fixed contact connected with the two thread coils are oppositely and longitudinally arranged. In the invention, the produced longitudinal magnetic field causes the vacuum arc produced between the contacts to keep in a non-aggregated state during the live cut-off; and the vacuum arc is extinguished when the current of an external circuit exceeds zero point, thereby the on-off of the circuit is finished.

Owner:湖北汉光科技股份有限公司

Wet strength waste paper repulping process

InactiveCN103898791ACollapsed wet strengthAvoid strength lossPaper recyclingWaste paper working-upFiberAluminum sulphate

The invention relates to a wet strength waste paper repulping process, and belongs to the technical field of papermaking. The repulping process is a novel three-stage composite process,which includes the steps of: 1, a surfactant osmotic hydration stage (adding 0.1-1% surfactant, and soaking for 15 to 30 min); 2, an acidic pulping stage (adding 1.0-3.5% of aluminum sulfate with pH value of 4.5-6.5, pulp concentration of 5-10%); and 3, an alkaline pulping stage (pH of 8-10,and pulp concentration of 5-30%). The process has the advantages of mild conditions, low energy consumption, low cost, good dispersion of fiber and good pulp quality, and is applicable to repulping of a variety of wet strength waste paper.

Owner:朱勇强

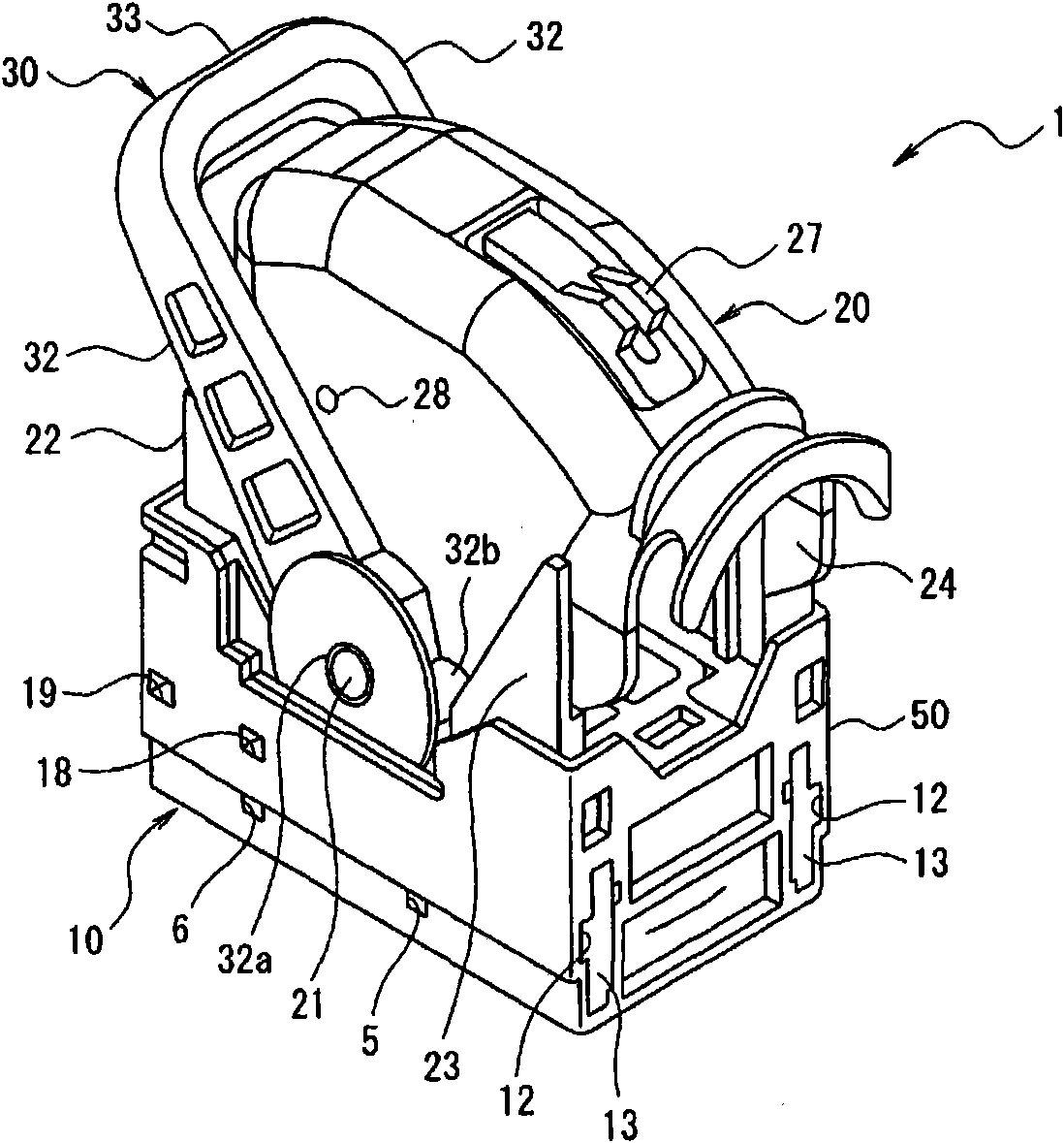

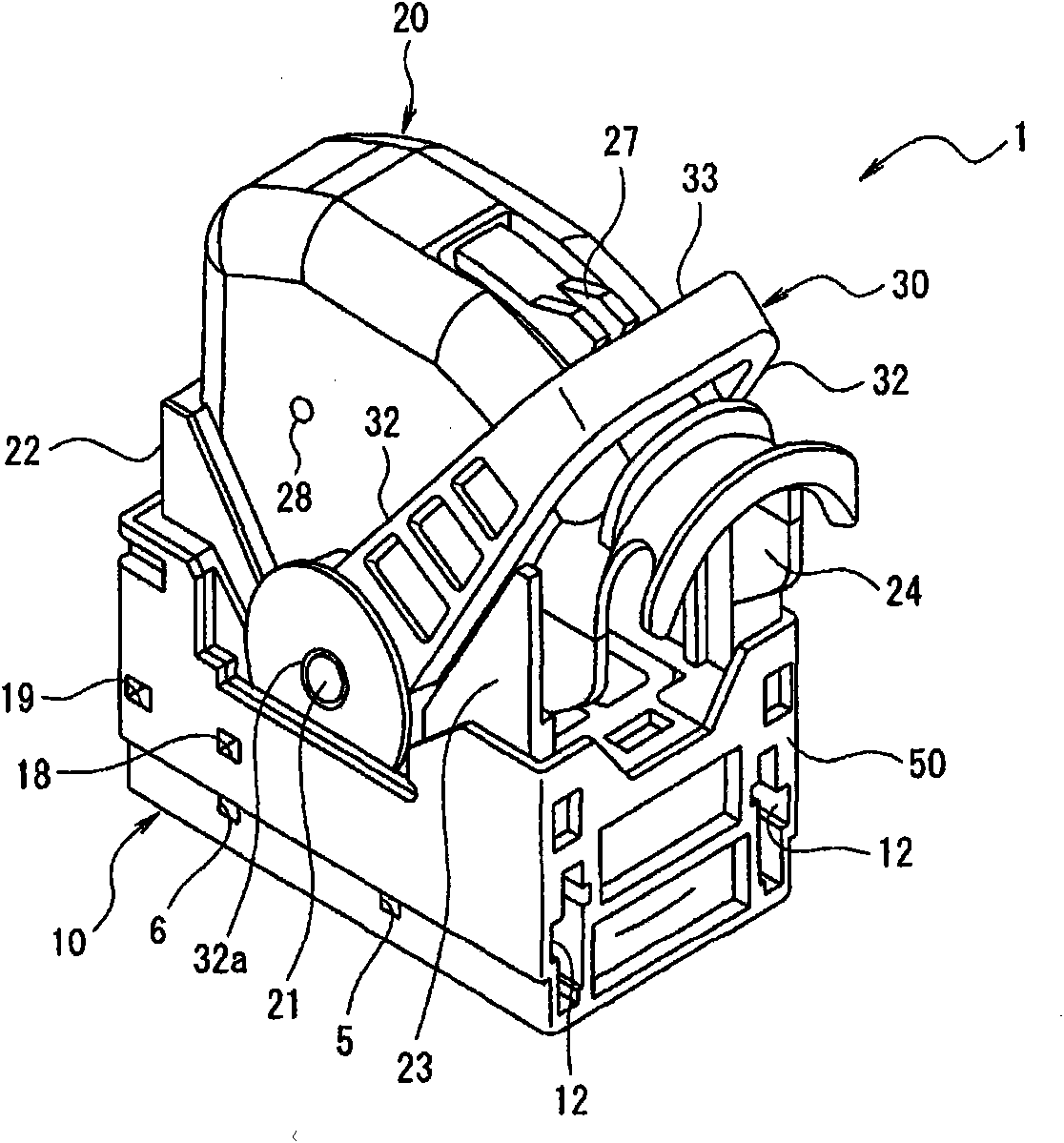

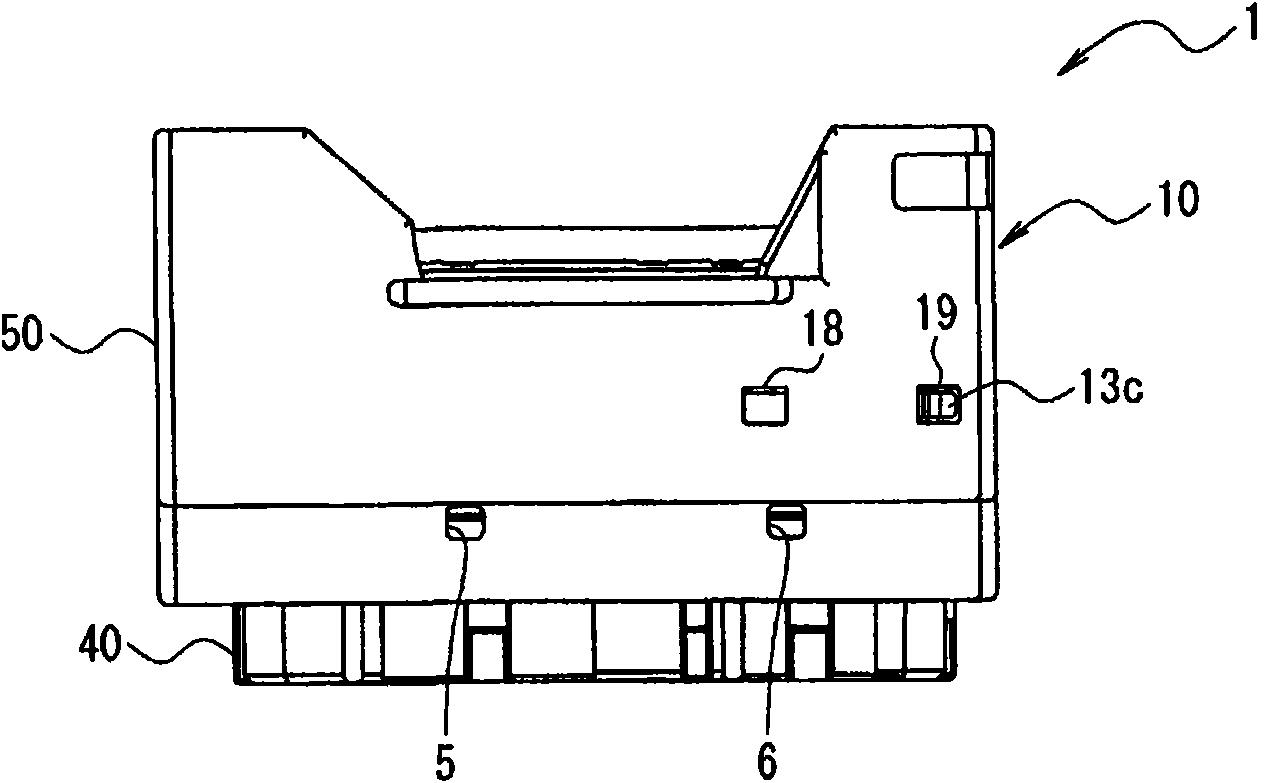

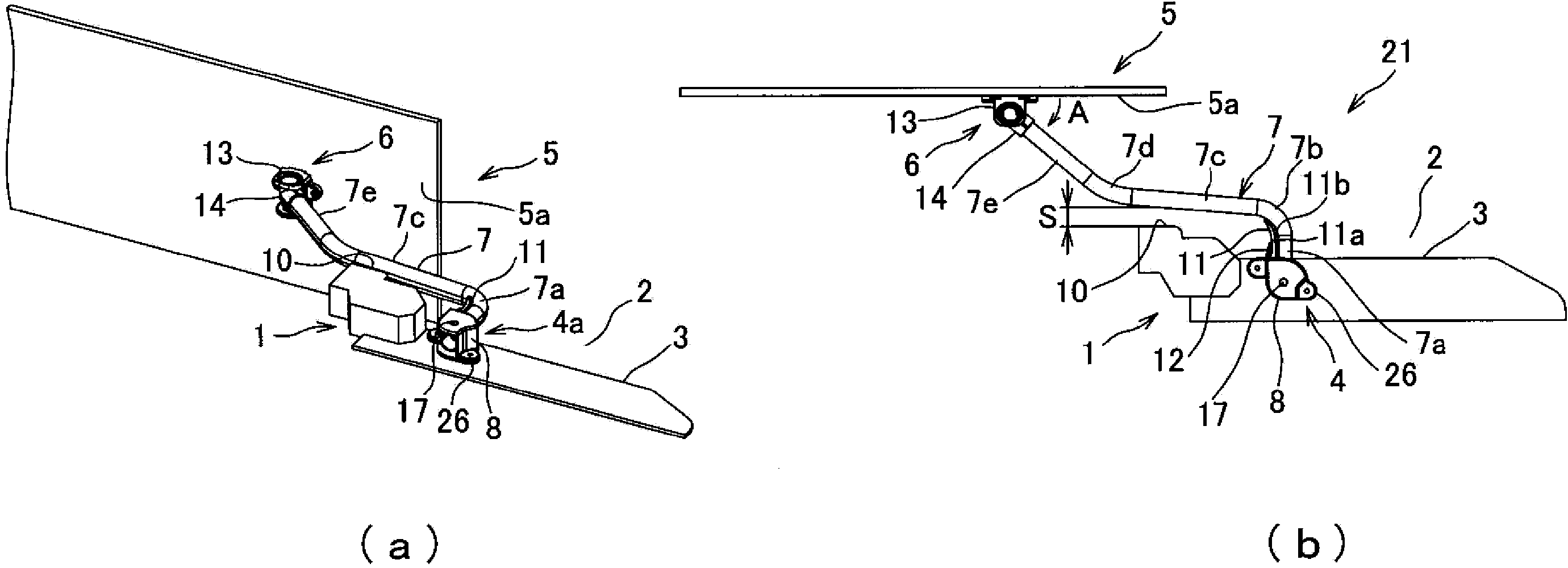

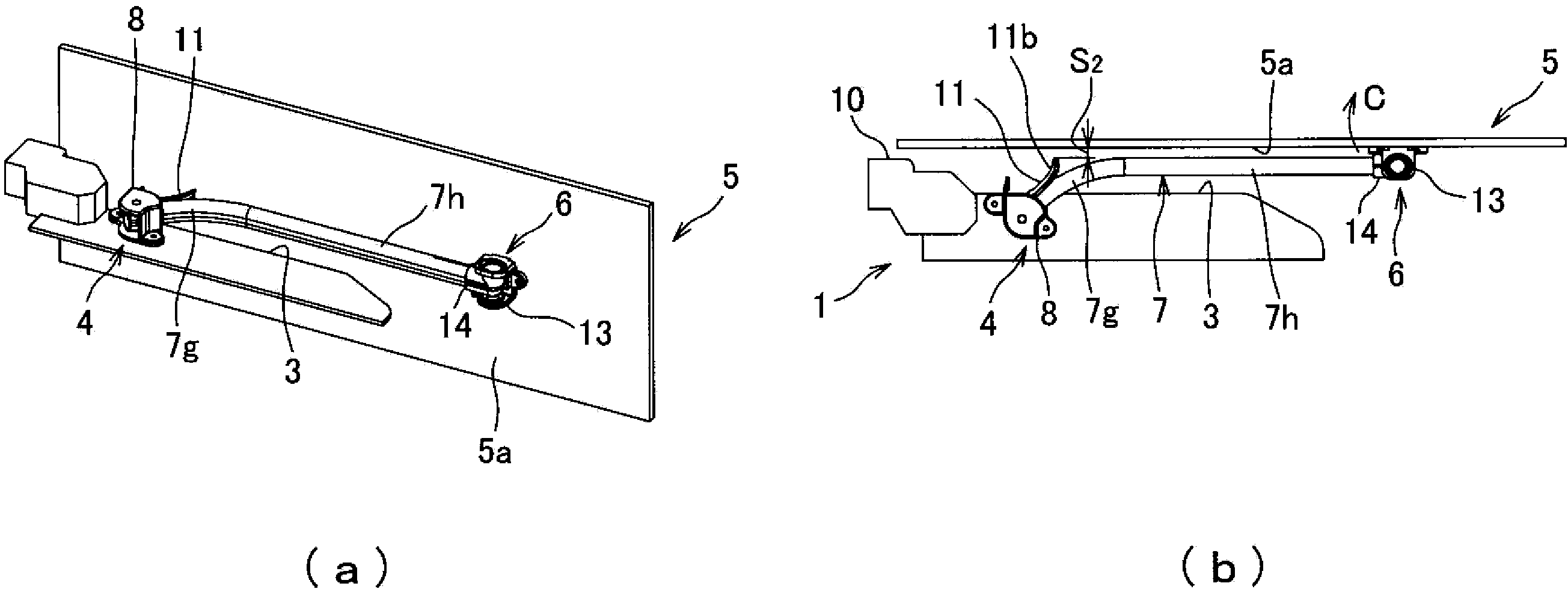

Lever type connector

ActiveCN101983460AAvoid Strength LossReduce intensitySecuring/insulating coupling contact membersEngineeringMechanical engineering

Provided is a lever type connector wherein secondary latching and unlatching of a contact by a retainer can be carried out positively with good work efficiency. The lever type connector (1) comprises a retainer (45) being fitted to an inner housing (40), an outer housing (50) for housing the inner housing (40), and a slider (13) which can be moved between a fitting start position and a fitting completion position. In the lever type connector (1), secondary latching of the contact is effected by arranging the retainer (45) at a regular fitting position. First holes (5, 6) for operating the retainer are provided in the vertical-direction side surface of the outer housing (50) and laterably to the retainer (45), and second holes (3, 4) for operating the retainer are provided in the slider (13). Only when the slider (13) is arranged at the fitting completion position, the first holes (5, 6) for operating the retainer and the second holes (3, 4) for operating the retainer communicate with each other.

Owner:TYCO ELECTRONICS JAPAN GK

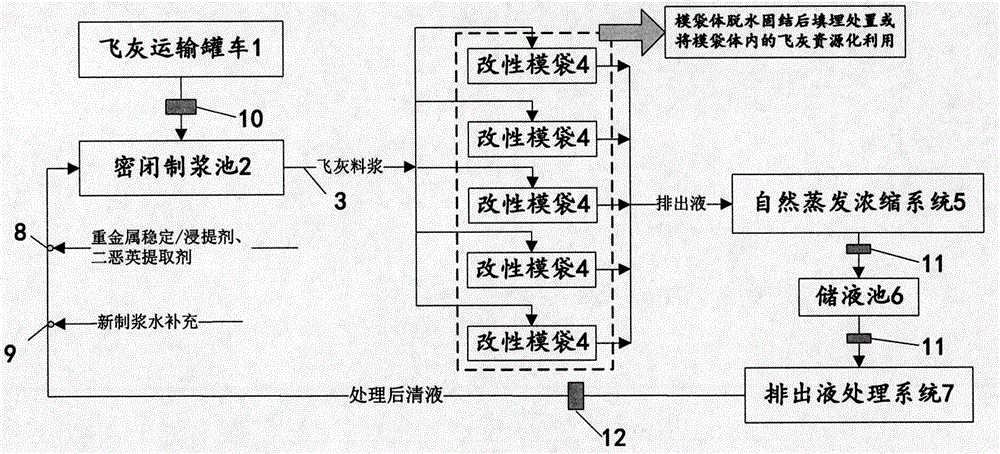

Household garbage incineration fly ash wet-method mold bag treatment method and system

ActiveCN106734045ASimplify processingExpansion of storage capacity utilization factorSolid waste disposalLandfill technologiesHeavy metalsResource utilization

The invention discloses a household garbage incineration fly ash wet-method mold bag treatment method. By means of three links of fly ash slurrying, fly ash slurry conveying and fly ash slurry dewatering / hydrating solidification, fly ash homogenizing, heavy metal and dioxin detoxifying, desalting and spontaneous hydrating solidification forming are achieved sufficiently at the same time; fly ash in mold bags after solidification meets related national standard requirements, solidified mold bag bodies can be subjected to landfill disposal, and fly ash can be taken out of the mold bags to be subjected to resource utilization; and liquid drained out of the mold bags is subjected to natural evaporation and concentration through a landfill space, after heavy metal and dioxin are recycled and impurities are filtered and removed, the liquid is recycled, or after further salt removing is carried out, the liquid is recycled. The invention further discloses a household garbage incineration fly ash wet-method mold bag treatment system. The household garbage incineration fly ash wet-method mold bag treatment method and system can overcome the defects of traditional fly ash dry-method landfill and a water washing pretreatment technology in large-scale industrial application, fly ash homogenizing, detoxifying, desalting, spontaneous hydrating solidification and landfill integrated treatment can be achieved, a basis is laid for follow-up fly ash resource utilization, the treatment cost is low, and the household garbage incineration fly ash wet-method mold bag treatment method and system can be applied to large-scale industrial production.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

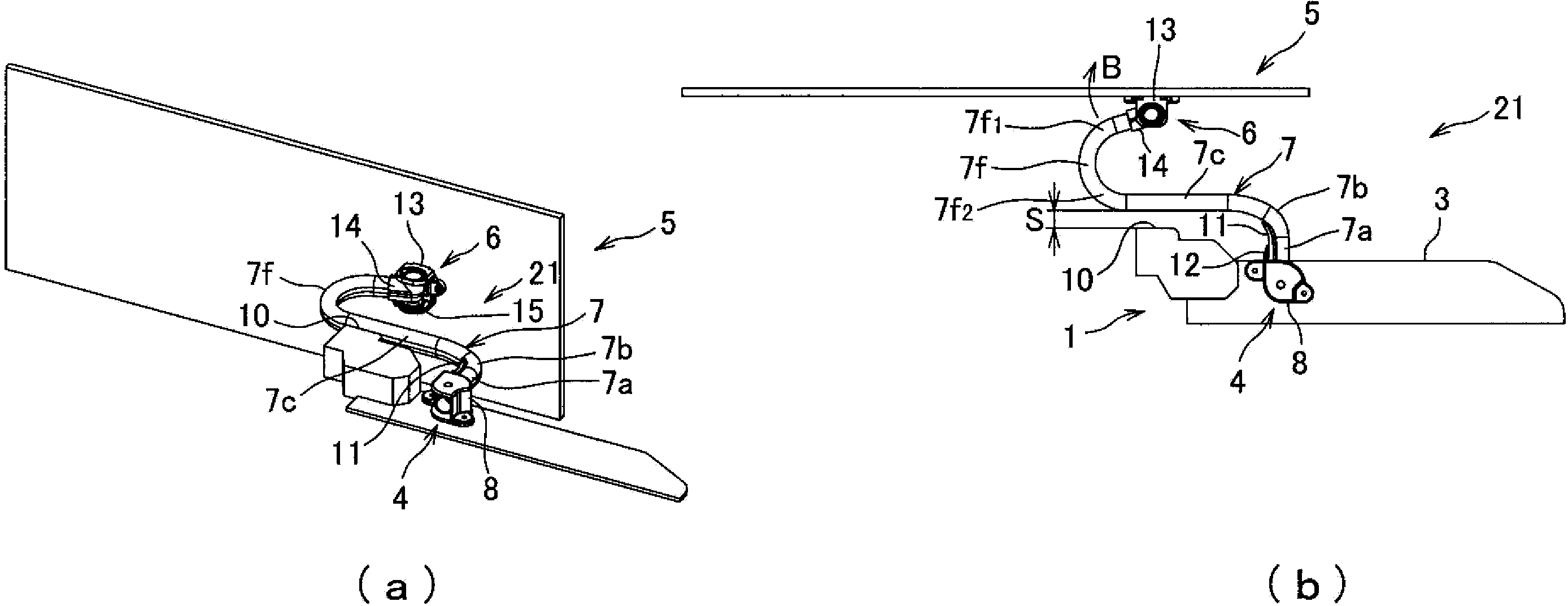

Power feeder device for slide structure

ActiveCN104137368AImprove bending durabilityAvoid interferenceCable arrangements between relatively-moving partsElectric/fluid circuitEngineeringMechanical engineering

Owner:YAZAKI CORP

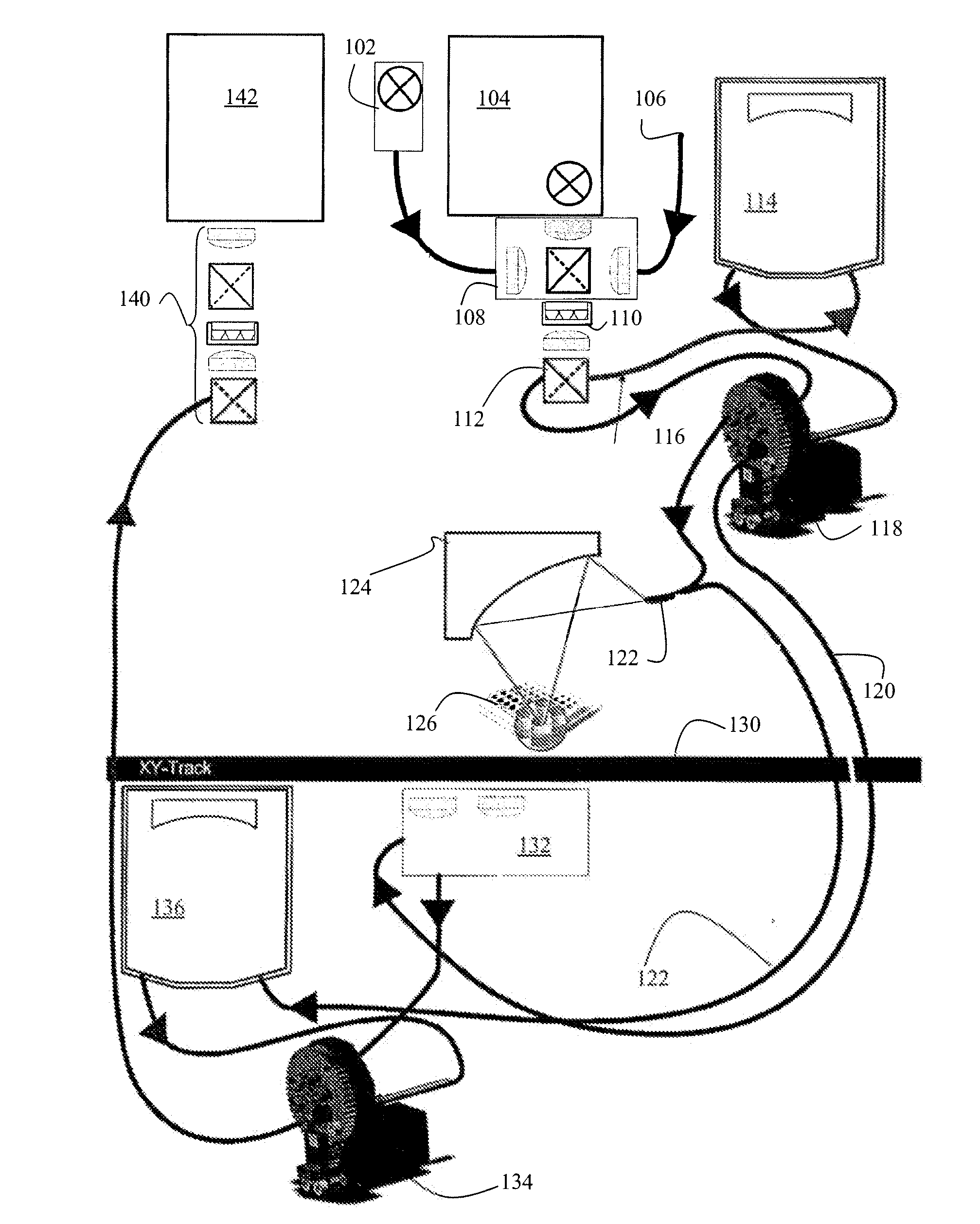

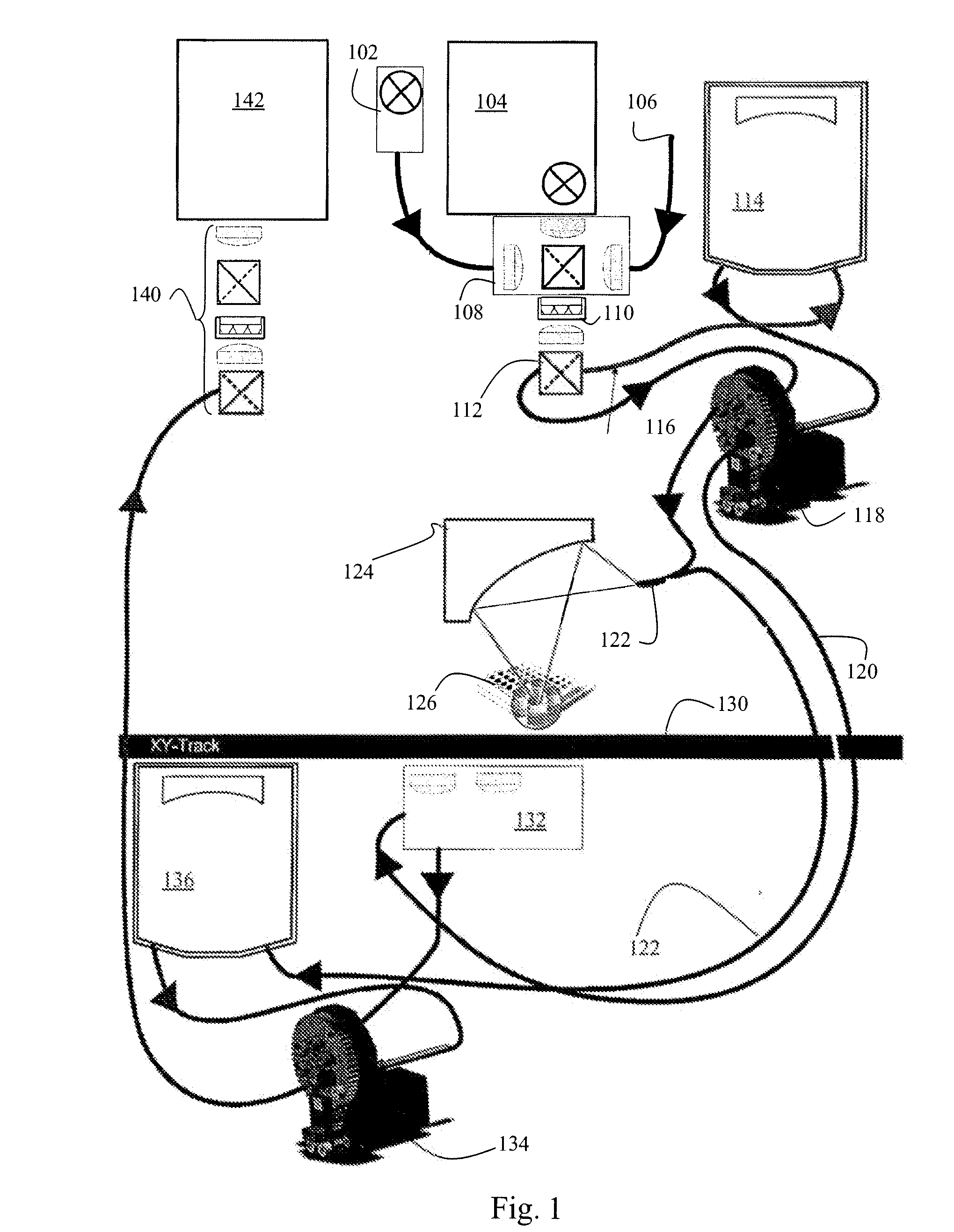

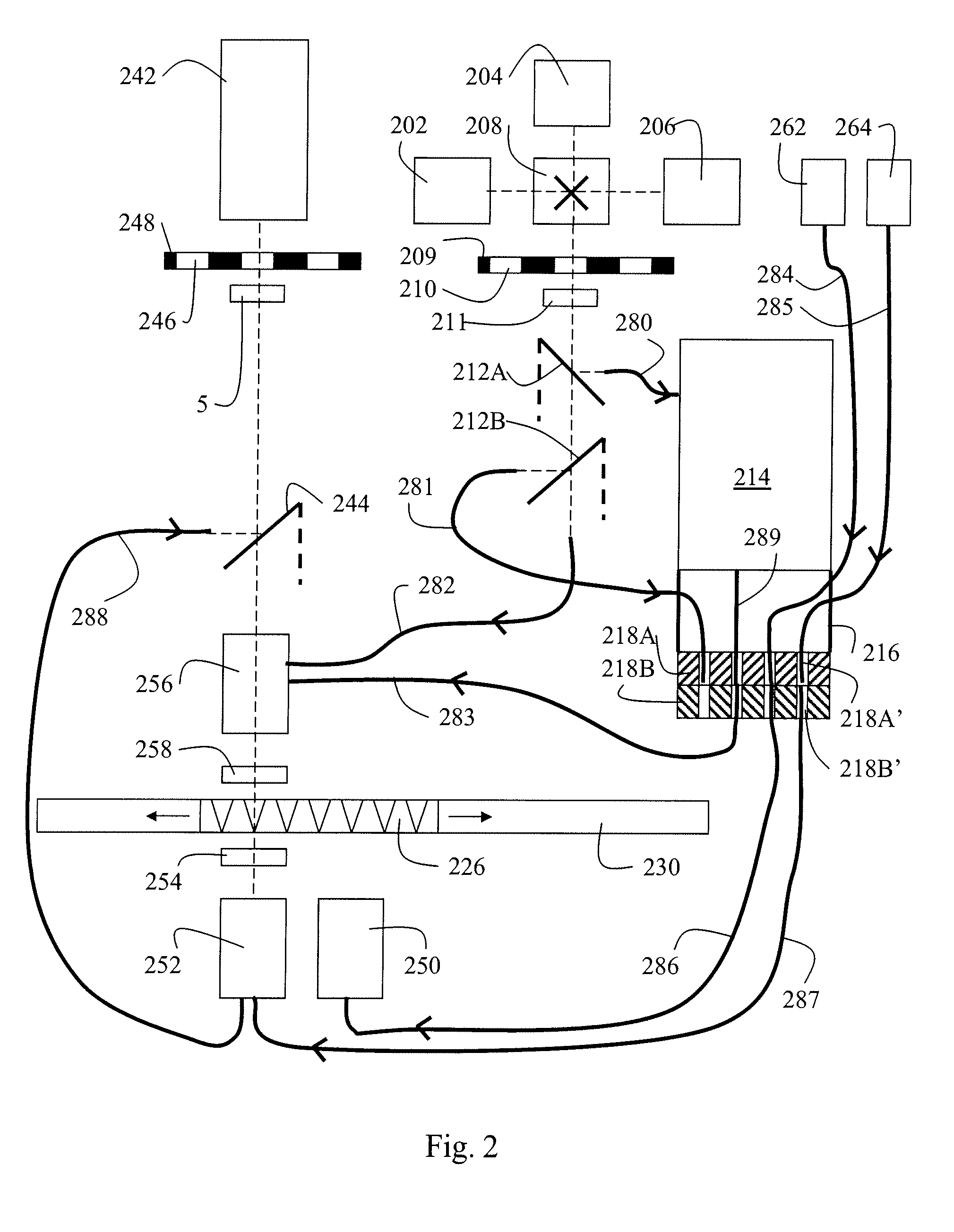

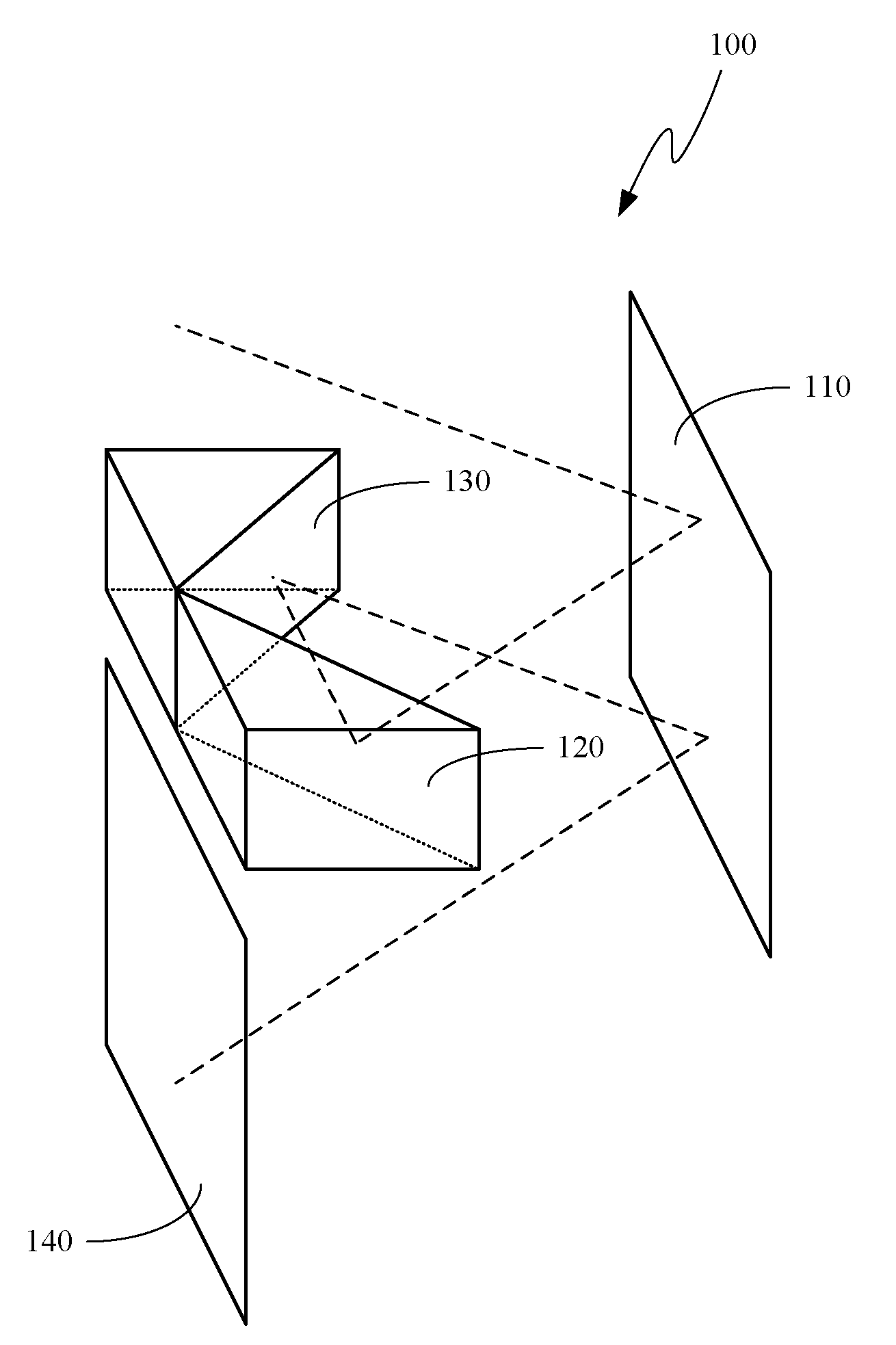

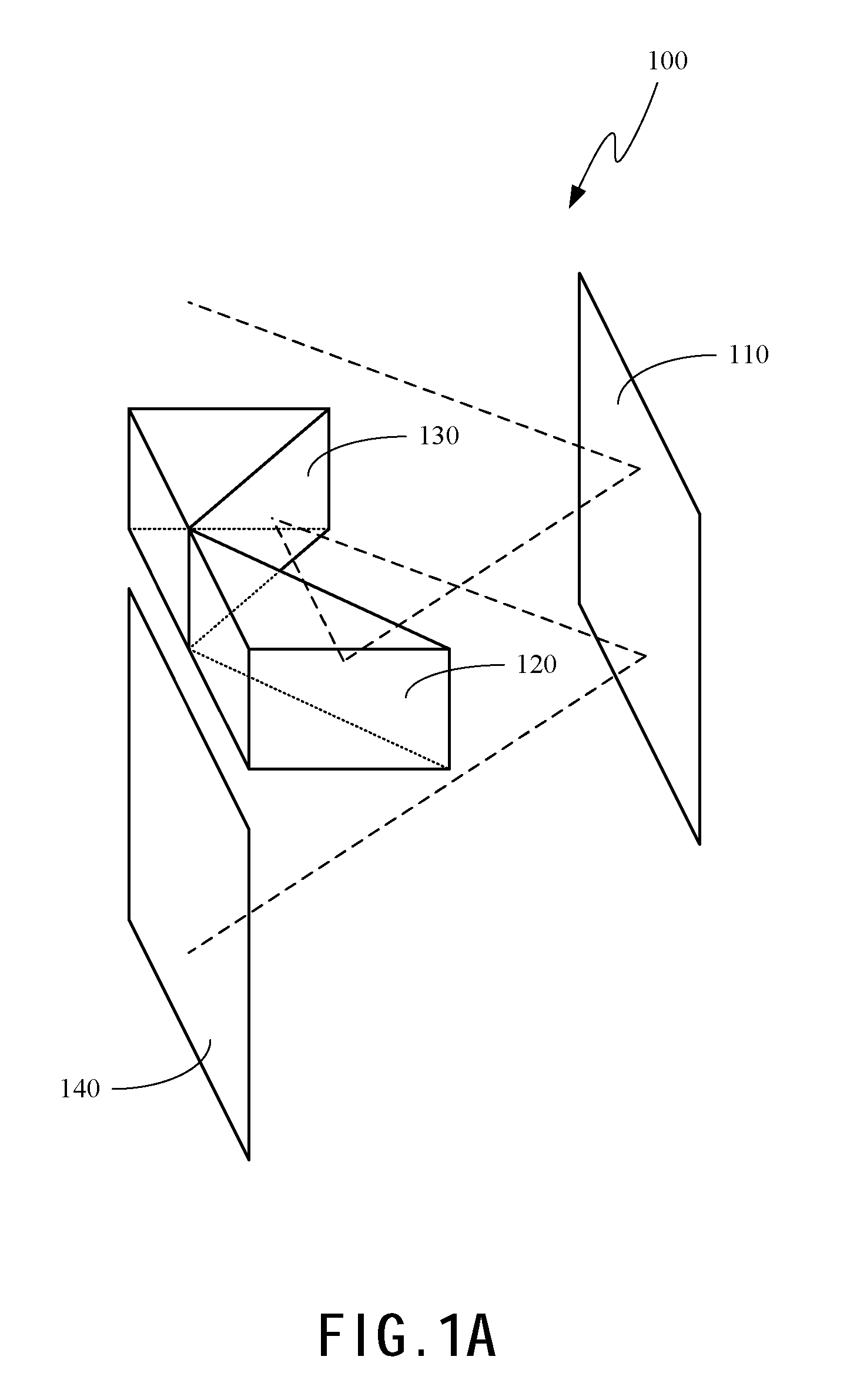

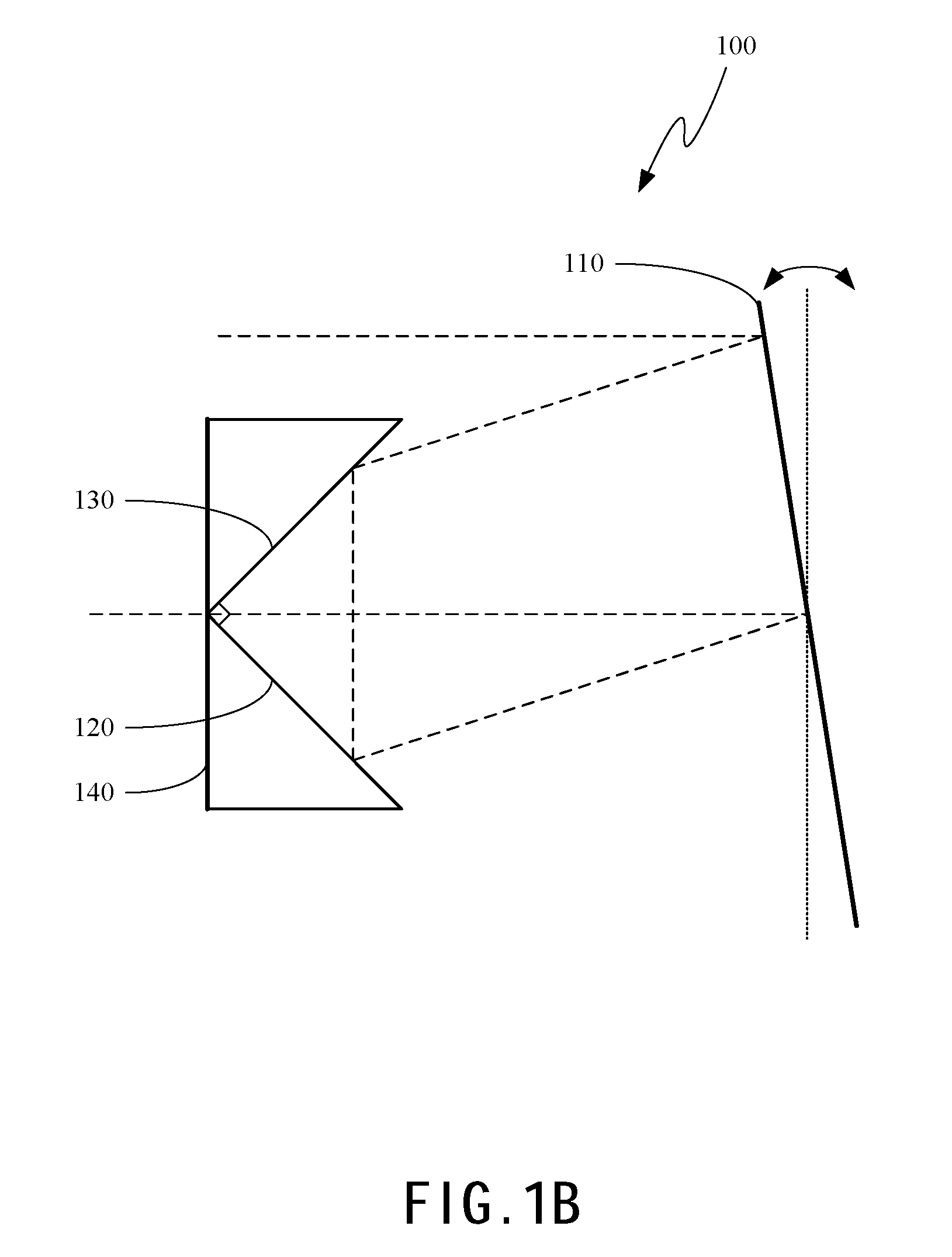

Multi-Purpose Measurement System

ActiveUS20100252748A1Maintaining complexityMaintenance costPhotometryLuminescent dosimetersMonochromatorOptoelectronics

The invention relates to an apparatus for optically analysing samples contained in sample sites of a sample holder, the apparatus comprising a first light source and at least one second light source, a monochromator having an input to which first light source is optically connected or connectable and an output for monochromatized light, light guiding means for guiding light originating from the first and from the at least one second light sources to the sample sites, and a detector for detecting light from the sample sites. According to the invention, the apparatus further comprises a light relay comprising a first input optically connected to the output of the monochromator, at least one second input optically connected or connectable to a second light source such that the light from the second light source by-passes the monochromator, and a first output for guiding light from selected input of the light relay to the sample sites. By means of the invention, a versatile sample analyser can be achieved in a cost-effective manner.

Owner:WALLAC

Method of using landplaster as a wallboard filler

ActiveUS20080160340A1High strengthAvoid strength lossLaminationLamination apparatusSlurryCalcium Sulfate Dihydrate

A gypsum slurry includes calcium sulfate hemihydrate, water and calcium sulfate dihydrate, where the calcium sulfate dihydrate is added downstream of the mixer.In an optional embodiment, the a gypsum slurry includes calcium sulfate hemihydrate, a polycarboxylate dispersant, water and coated calcium sulfate dihydrate. In this case, the hydrophilic, dispersible coating is selected to serve as a modifier to enhance the ability of the dispersant to fluidize the gypsum slurry.

Owner:UNITED STATES GYPSUM CO

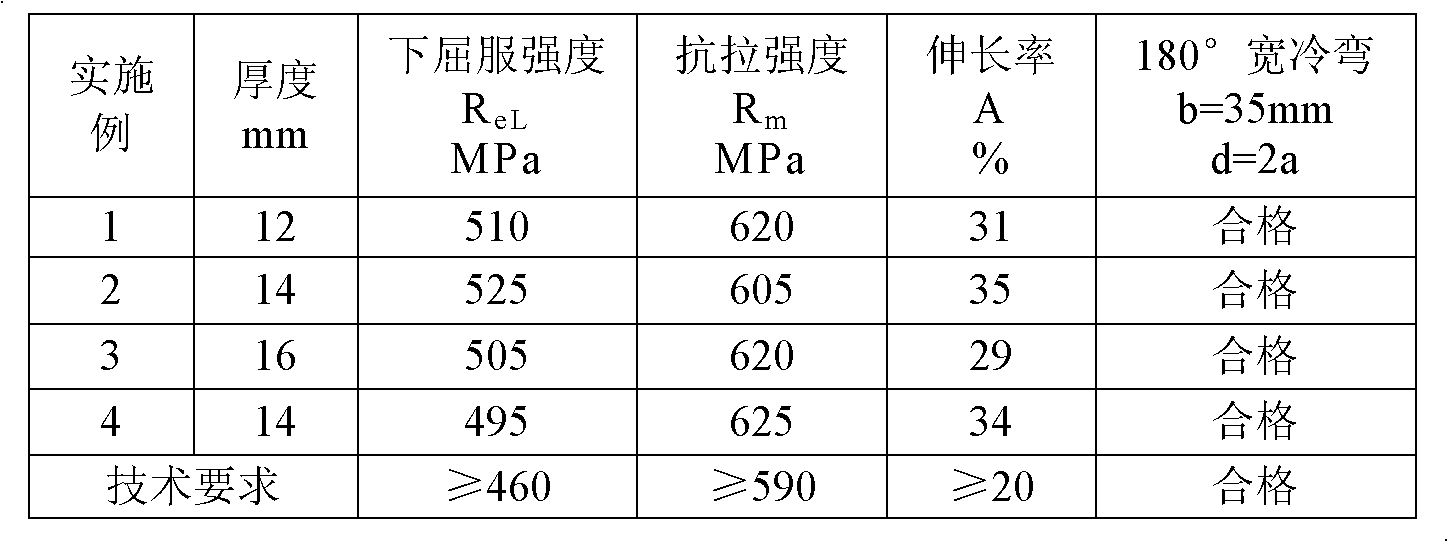

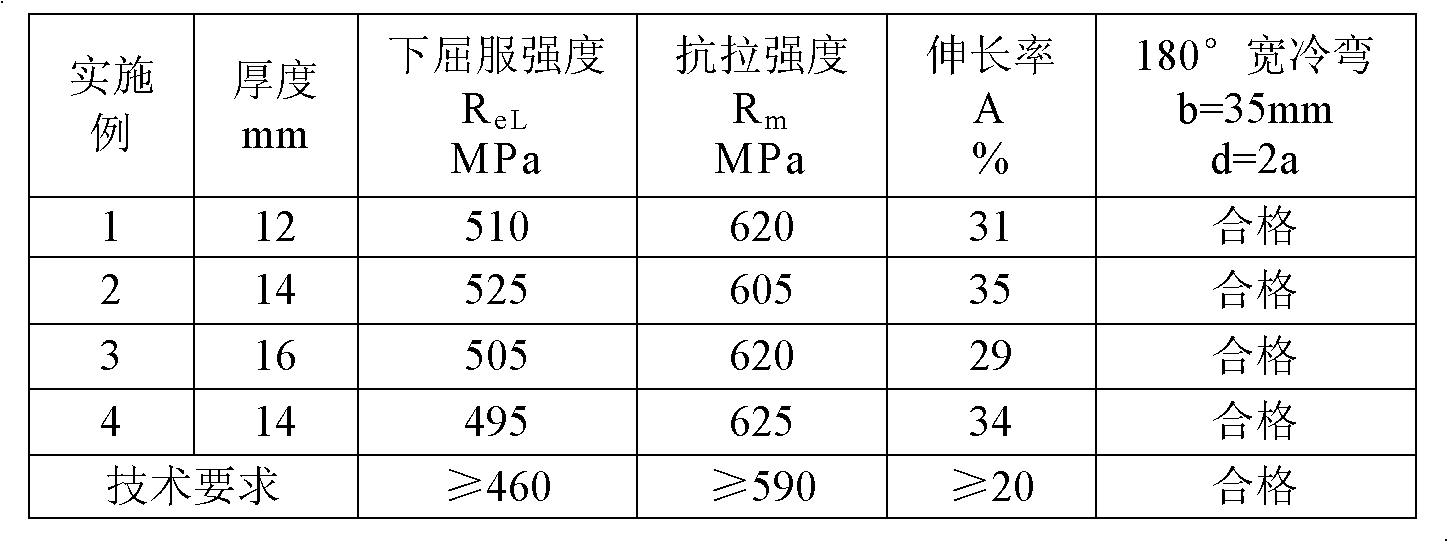

Steel for 12-ton axle shell and production method for steel

The invention relates to steel for a 12-ton axle shell and a production method for the steel. The steel comprises the following chemical components in percentage by weight: 0.004-0.068 percent of C, 0.10-0.60 percent of Si, 1.0-1.29 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.008 percent of S, 0.01-0.06 percent of Al, 0.03-0.048 percent of Nb and the balance of Fe and unavoidable impurities. The production method comprises the following steps of: smelting in a converter; treating in vacuum; performing continuous casting; heating a casting blank; performingrough rolling; performing finish rolling by using a 7 machine frame; performing laminar flow cooling; and coiling. The steel has low carbon content, so that the steel has excellent punching and forming performance and welding performance; the size after the steel is cooled and formed is stable and can fully meet manufacturing and using requirements of the 12-ton axle shell; and through a bench test on the manufactured 12-ton axle shell assembly, the vertical bending fatigue life, the vertical bending rigidity and the vertical bending static strength of the 12-ton axle shell assembly are excellent.

Owner:武汉钢铁有限公司

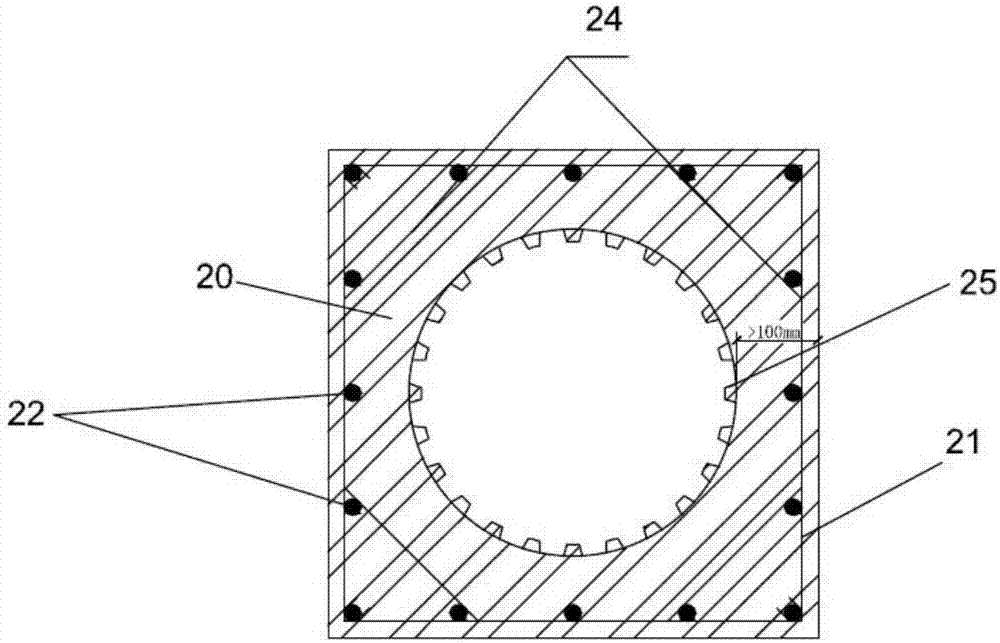

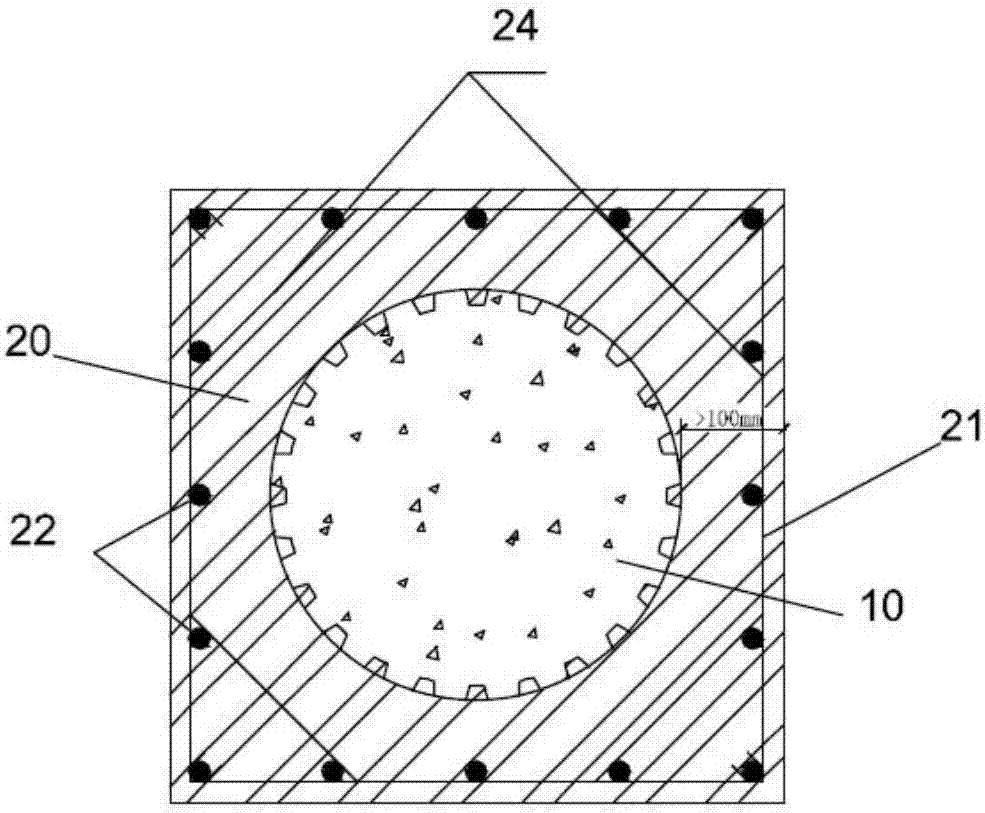

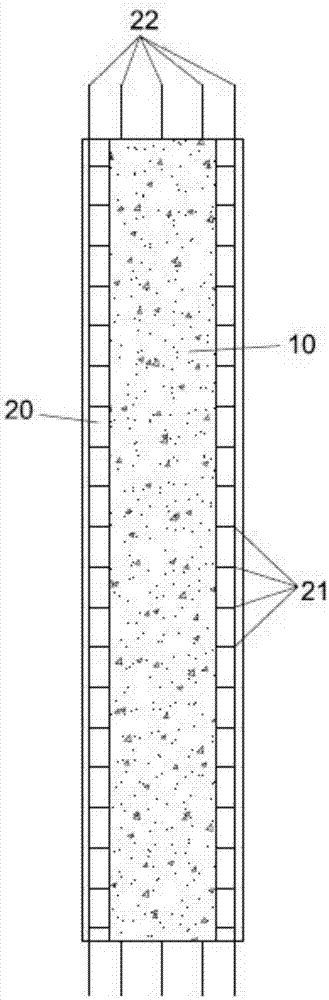

Composite column and fabrication method thereof

InactiveCN107143087AImprove corrosion resistanceReduce tension deformationStrutsBridge structural detailsHigh strength concreteLarge deformation

The invention discloses a composite column and a fabrication method of the composite column. The composite column comprises a high-strength concrete core and a prefabricated steel fiber reinforced concrete pipe, wherein the high-strength concrete core is cast in situ into the steel fiber reinforced concrete pipe; stirrups and longitudinal bearing steel bars are embedded into the steel fiber reinforced concrete pipe; and the surfaces of the longitudinal bearing steel bars are coated with antirust coatings. According to the composite column, the antirust coatings are arranged on the surfaces of the longitudinal bearing steel bars, so that the corrosion resistance of the longitudinal bearing steel bars can be improved by utilizing the antirust coatings; adhesive forces between the longitudinal bearing steel bars and the steel fiber reinforced concrete pipe are small due to action of the antirust coatings, so that deformation of the longitudinal bearing steel bars is relatively independent; when the composite column generates larger deformation due to an earthquake or a large outside acting force, tensile deformation of a concrete part of the steel fiber reinforced concrete pipe is reduced and cracking of concrete is delayed; and the recovery capability of the longitudinal bearing steel bars is significant after the earthquake or deformation reduction due to constraint reduction, so that repair is easy and the resource is saved.

Owner:BEIJING UNIV OF TECH

Steel structure water-based fireproof coating

InactiveCN106928850AAvoid Strength LossBlock deliveryFireproof paintsAntifouling/underwater paintsWater basedCellulose

The invention discloses a steel structure water-based fireproof coating. The steel structure water-based fireproof coating is prepared from the following components in parts by weight: 180 to 220 parts of water, 1.8 to 2.2 parts of HEC cellulose, 1.8 to 2.2 parts of AMP-95 amine neutralizing agent, 1.8 to 2.2 parts of MC preservative, 7 to 9 parts of anti-freezing agent, 1.8 to 2.2 parts of CF-10 wetting agent, 1.8 to 2.2 parts of NXZ defoaming agent, 7.2 to 8.8 parts of 2400 dispersing agent, 13 to 17 parts of film forming aid, 22 to 28 parts of titanium dioxide, 45 to 55 parts of barite powder, 250 to 300 parts of ammonium polyphosphate, 80 to 96 parts of melamine, 80 to 100 parts of pentaerythritol, 200 to 250 parts of BLJ-660 MV emulsion, 1.5 to 2.5 parts of 345 defoaming agents, 2.5 to 3.5 parts of flatting agent and 0.9 to 1.1 parts of thickening agent. The steel structure water-based fireproof coating has the advantages of excellent heat insulation and flame-retardant fire resistance, excellent adhesiveness, good anticorrosion effect, antirust effect and mildew-proof effect, non-toxicity, no smoke, good safety and the like.

Owner:FUJIAN NAN FENG FIREPROOF TECH

Production method of steel for 12-ton axle shell

The invention relates to steel for a 12-ton axle shell and a production method for the steel. The steel comprises the following chemical components in percentage by weight: 0.004-0.068 percent of C, 0.10-0.60 percent of Si, 1.0-1.29 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.008 percent of S, 0.01-0.06 percent of Al, 0.03-0.048 percent of Nb and the balance of Fe and unavoidable impurities. The production method comprises the following steps of: smelting in a converter; treating in vacuum; performing continuous casting; heating a casting blank; performingrough rolling; performing finish rolling by using a 7 machine frame; performing laminar flow cooling; and coiling. The steel has low carbon content, so that the steel has excellent punching and forming performance and welding performance; the size after the steel is cooled and formed is stable and can fully meet manufacturing and using requirements of the 12-ton axle shell; and through a bench test on the manufactured 12-ton axle shell assembly, the vertical bending fatigue life, the vertical bending rigidity and the vertical bending static strength of the 12-ton axle shell assembly are excellent.

Owner:武汉钢铁有限公司

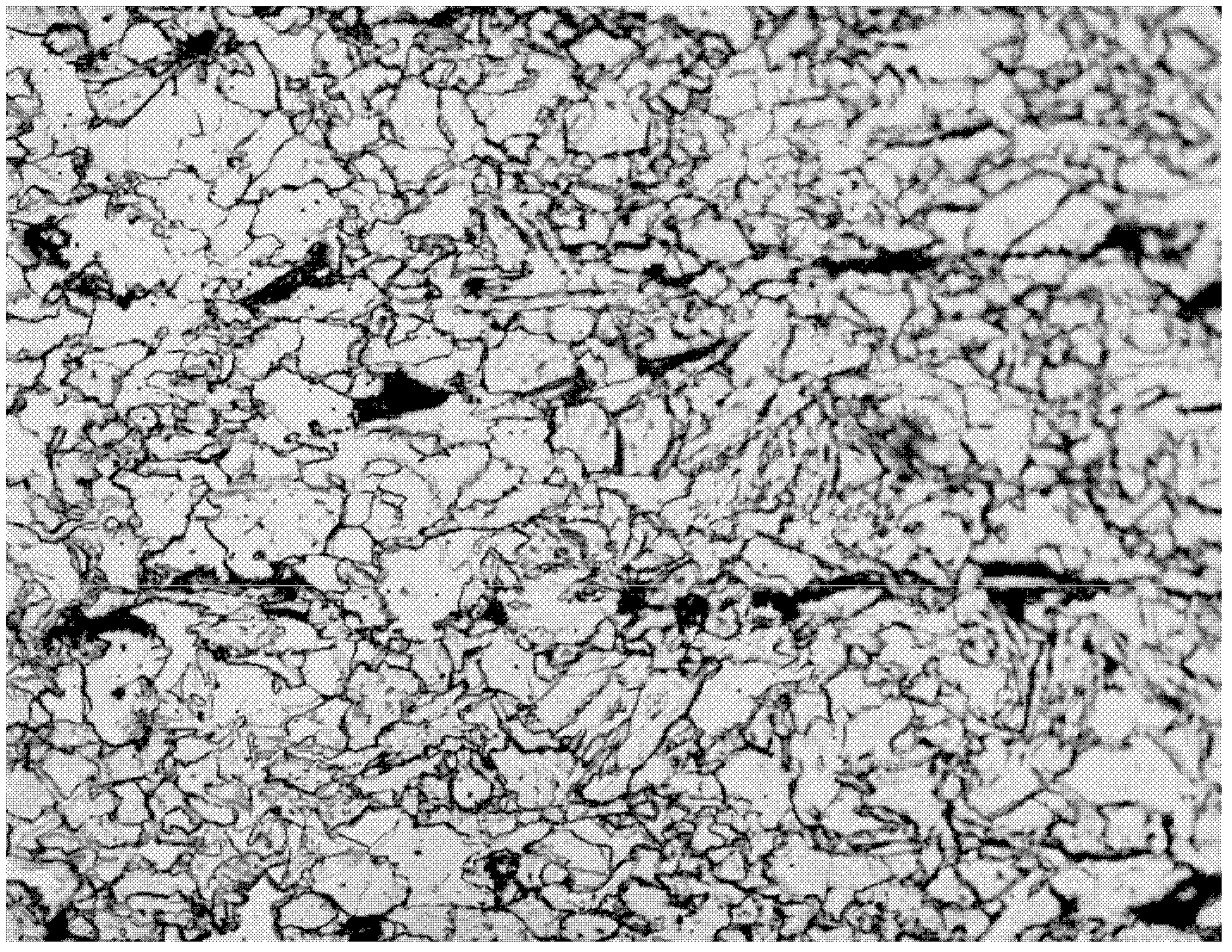

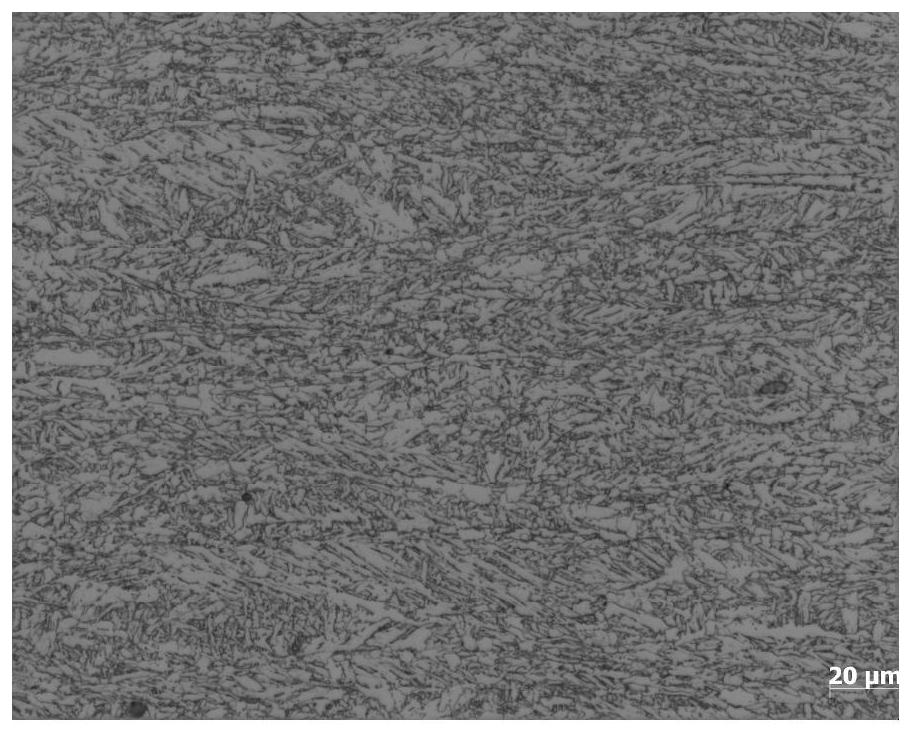

Manufacturing method of thick-wall high-strength ship plate steel for high heat input welding

InactiveCN113249638ARefined grain sizeImprove the stability of welding performanceAustenite grainAlloy

The invention discloses a manufacturing method of thick-wall high-strength ship plate steel for high heat input welding, and relates to the technical field of steel production. A high-cleanliness smelting blank is obtained through a magnesium metallurgy technology by adopting a converter and RH vacuum treatment, a high-reduction rolling deformation technology is carried out below a recrystallization temperature according to a metallurgical principle technology, by means of magnesium metallurgy, growth of austenite grains is effectively controlled in microalloy, the thick-wall high-strength ship plate with fine grains and excellent performance is obtained in cooperation with the after-rolling rapid cooling process, a yield strength ranges from 400 MPa to 600 MPa, and the requirement for high heat input welding is met.

Owner:NANJING IRON & STEEL CO LTD

A cement-based composite material suitable for 3D printing rapid prototyping process

ActiveCN106830843BMeet the requirements of extrusion stackingControllable clotting timeAdditive manufacturing apparatusPortland cementRapid prototyping

The invention relates to a cement-based composite material suitable for making a building structure and components through a 3D printing rapid-forming process. The cement-based composite material is characterized in that an extrudable property is good, a stacking property is good, printing time is controllable, and mechanical properties and durability are excellent. Regarding detailed properties, the material has good thixotropy, controllable condensing and hardening time and good adhesion, hour strength development is rapid, and strength growth is stable at the later stage, requirements for the 3D printing process and rapid construction can be met, and actual application of the 3D printing technology in the building industry is promoted easily. The cement-based composite material includes 100 parts of ordinary Portland cement, 100-300 parts of fine aggregate, 5-20 parts of strength-promoting shrinkage reducing agent, 30-60 parts of mixing water, 0.1-2.0 parts of water reducing agent, 0.5-15 parts of interface reinforcing agent, 0.05-0.2 part of thixotropic agent and 0.5-3.5 parts of liquid coagulating components.

Owner:BEIJING UNIV OF TECH

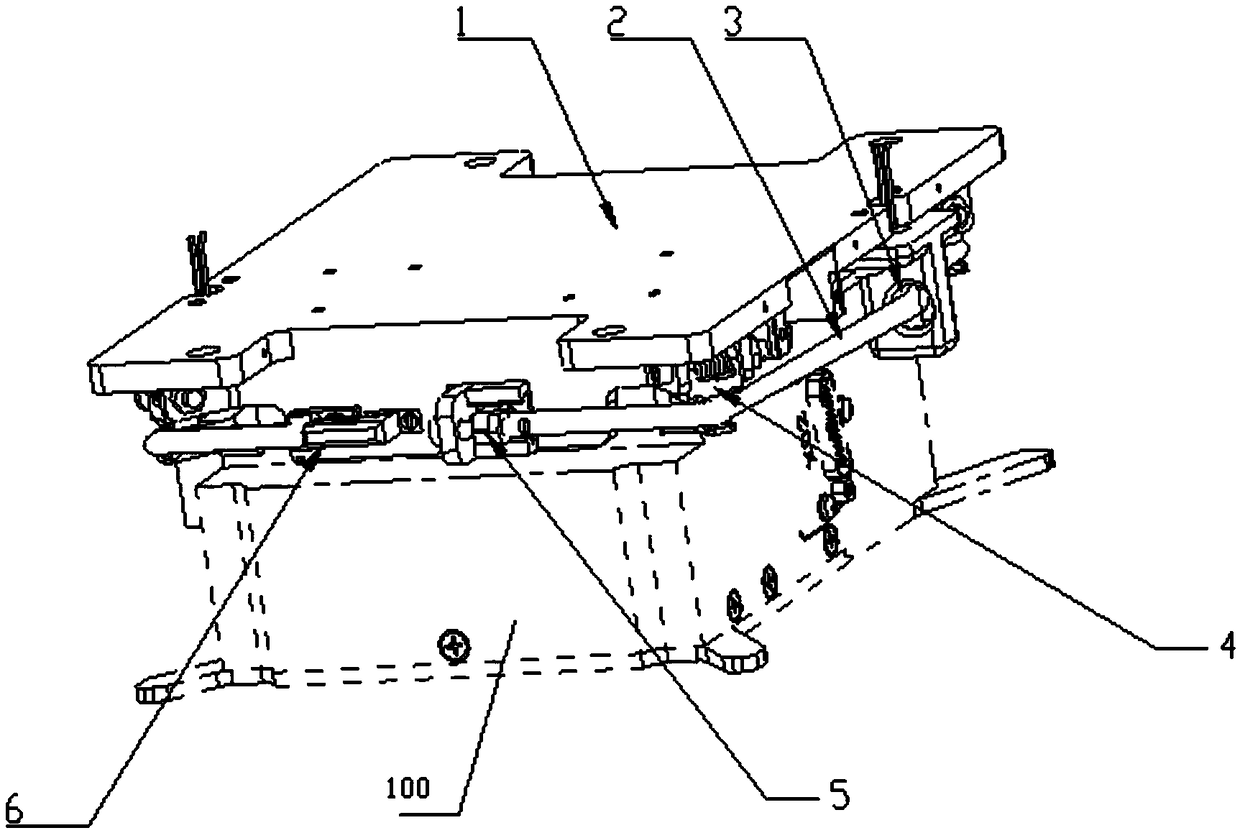

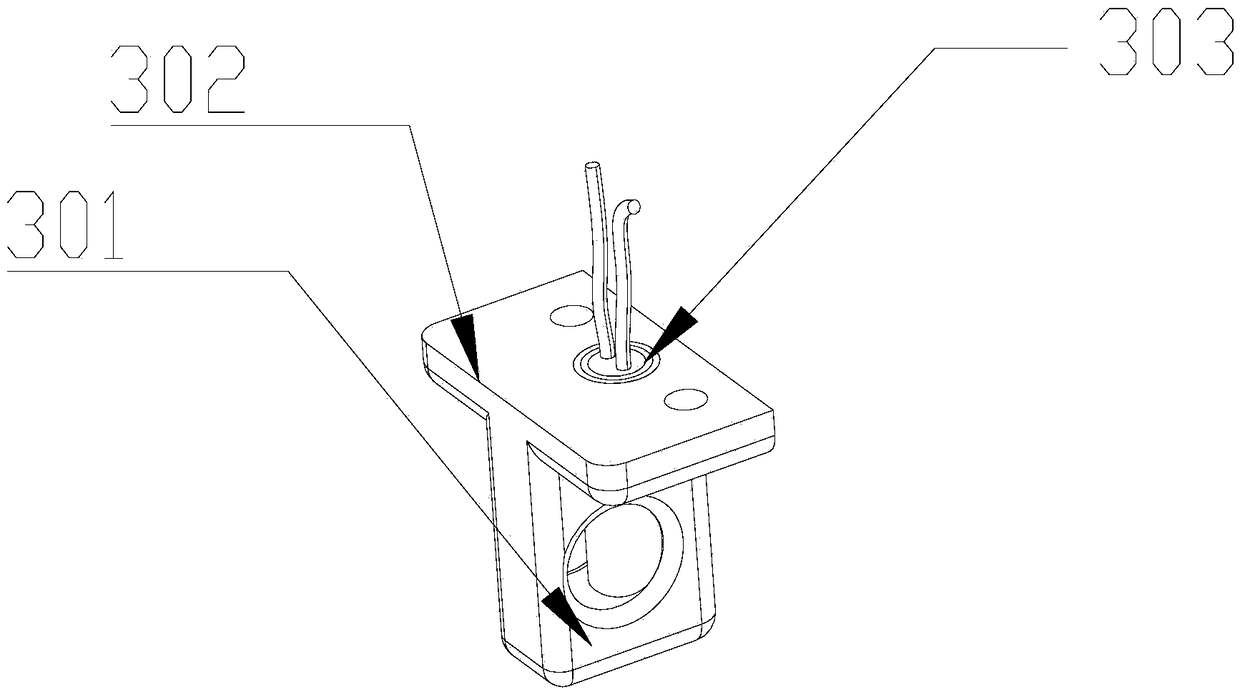

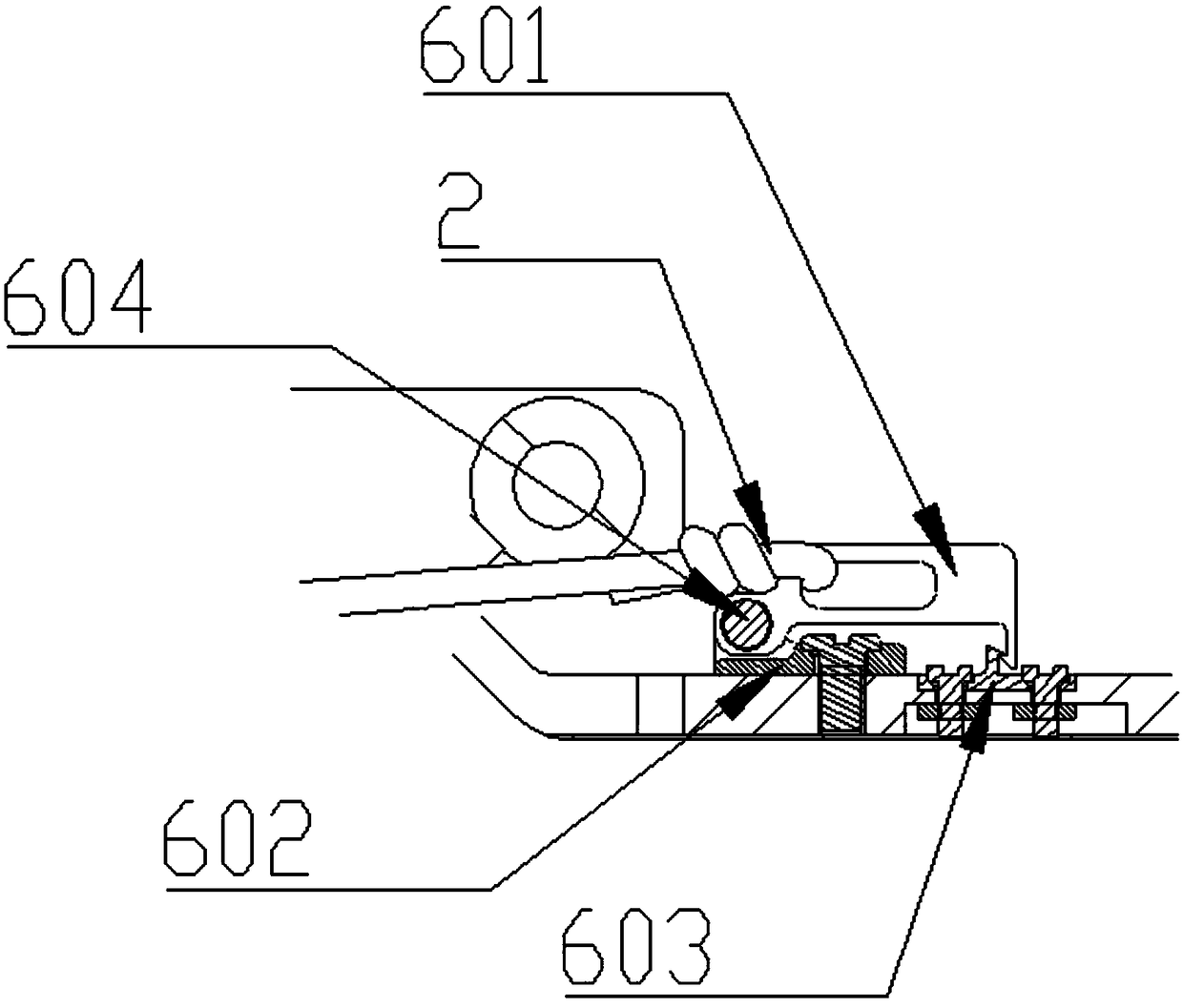

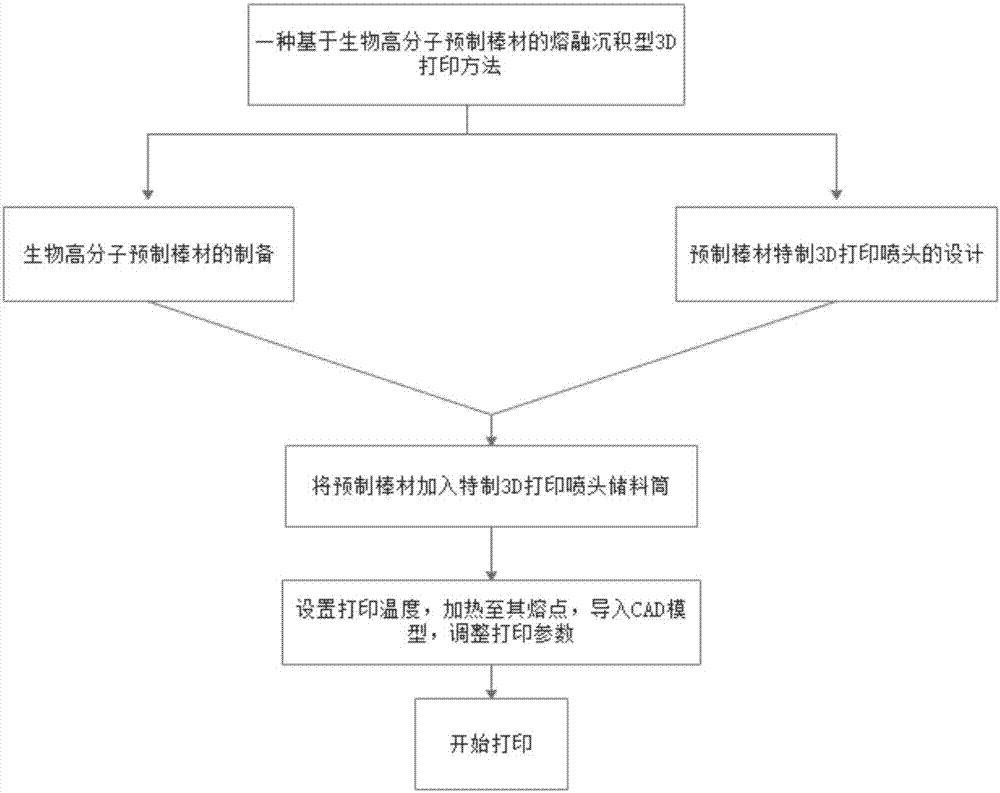

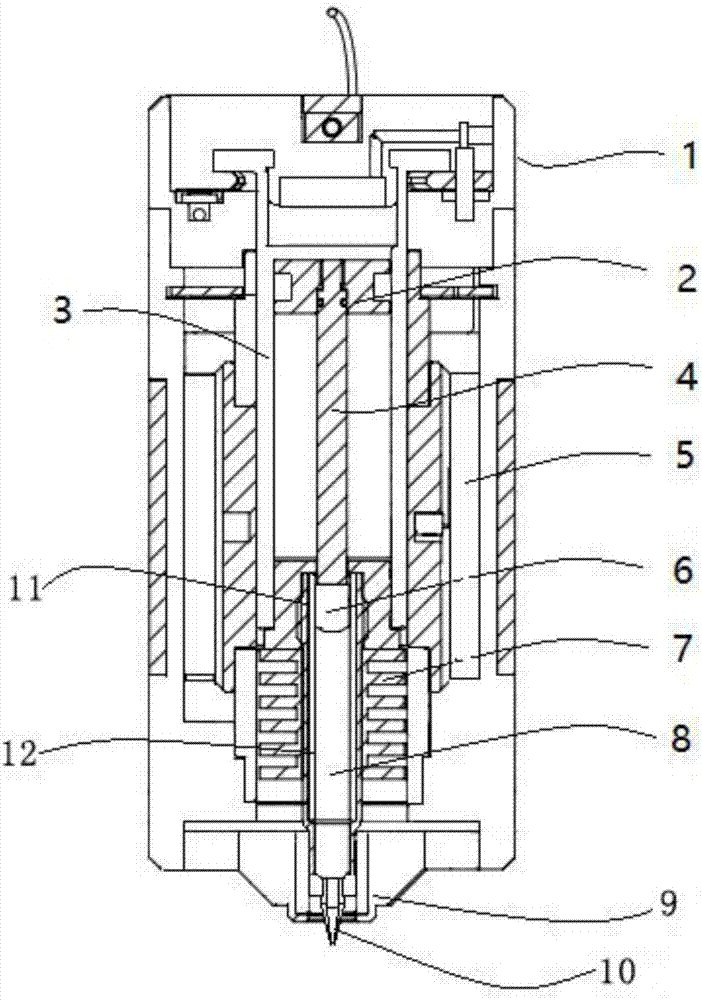

Fused deposition type 3D printing method based on biopolymer prefabricated bar

PendingCN107234806ASimple structure and principleEasy to operate3D object support structuresApplying layer meansPolymer chemistryBiomaterial

The invention discloses a fused deposition type 3D printing method based on a biopolymer prefabricated bar. According to the novel printing method, the biological prefabricated bar and a specially-made printing spray head are effectively combined. The structure principle is simple, operation is convenient, and the customized biological prefabricated bar with the higher degree of freedom can be manufactured. In subsequent application, the excellent performance of organic polymeric materials is maintained while smooth pushing, fusing and extruding of the bar are guaranteed, and pollution and waste of the biomedical polymer materials in the actual printing process are effectively avoided.

Owner:REGENOVO BIOTECH

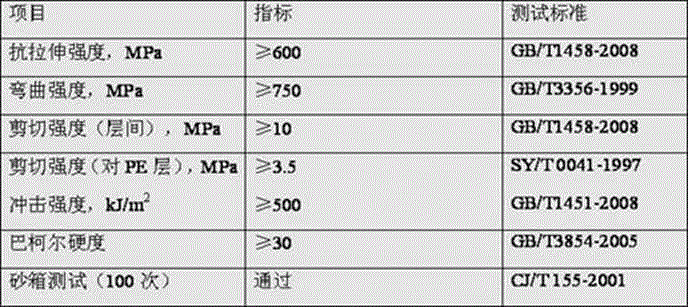

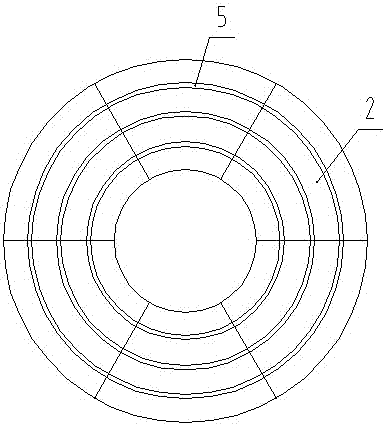

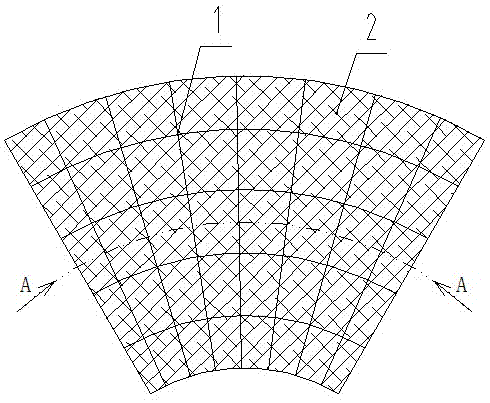

Anticorrosion layer protective structure of pipeline of directional drilling crossing section and method for manufacturing anticorrosion layer protective structure

ActiveCN104565677AImprove operational safetyImprove reliabilityPipe protection against damage/wearYarnViscose

The invention provides an anticorrosion layer protective structure of a pipeline of a directional drilling crossing section and a method for manufacturing the anticorrosion layer protective structure. The anticorrosion layer protective structure comprises a steel pipe and an anticorrosion layer. The anticorrosion layer covers the outer surface of the steel pipe, and a composite protective layer further covers the outer surface of the anticorrosion layer. The method for manufacturing the anticorrosion layer protective structure includes steps of (1), pretreating the anticorrosion layer of the pipeline; (2), distributing resin adhesive; (3), discharging yarns and dipping the yarns in the adhesive; (4), winding and forming the yarns; (5), trimming the yarns. The anticorrosion layer protective structure and the method have the advantages that the anticorrosion layer protective structure of the pipeline is excellent in abrasion-resistant and scratch-resistant performance, high-temperature resistance and corrosion resistance; the method for manufacturing the anticorrosion layer protective structure is high in mechanization and automation degree, the defect of easiness in generating bubbles due to the fact that glass fiber cloth is adhered on the surfaces of existing anticorrosion layers layer by layer and the shortcoming of degradation of the strength of products due to stress concentration at interlacing points of cloth marks and the tail ends of short glass fibers can be overcome, and the shear strength of the protective layer can be greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

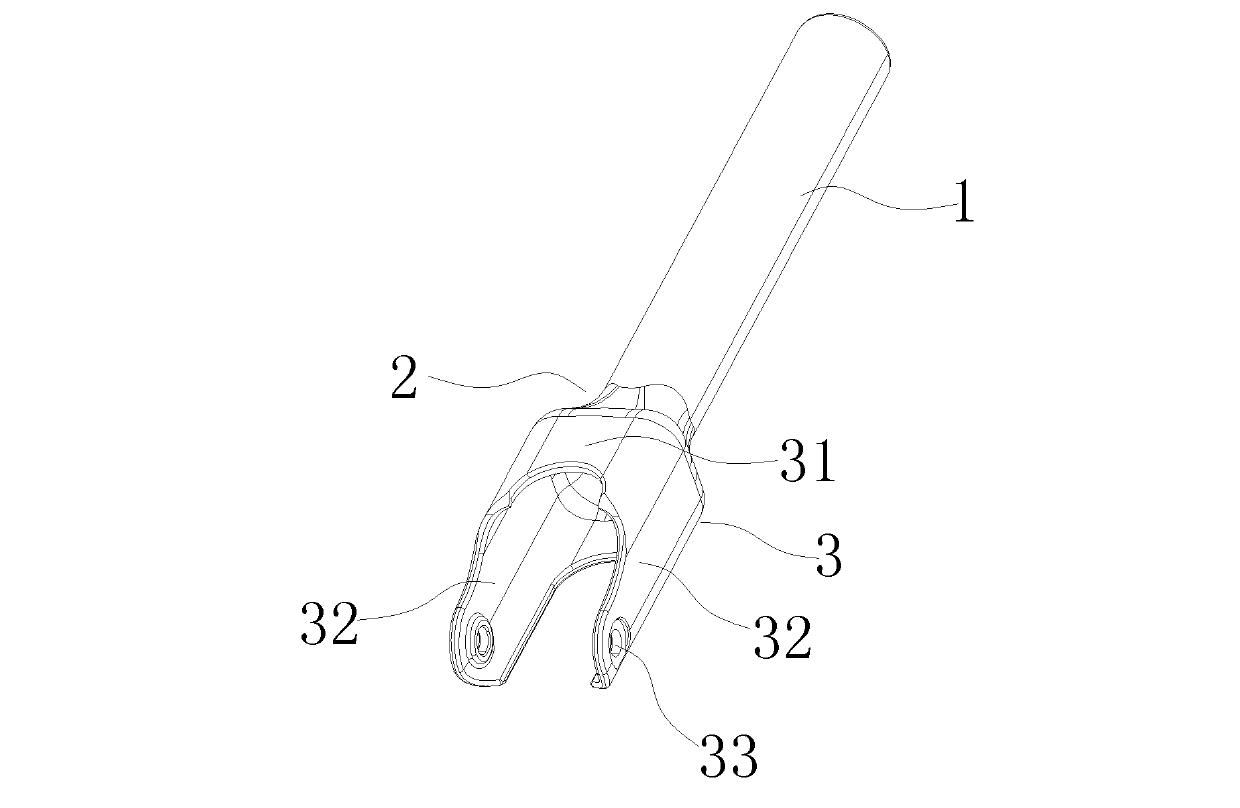

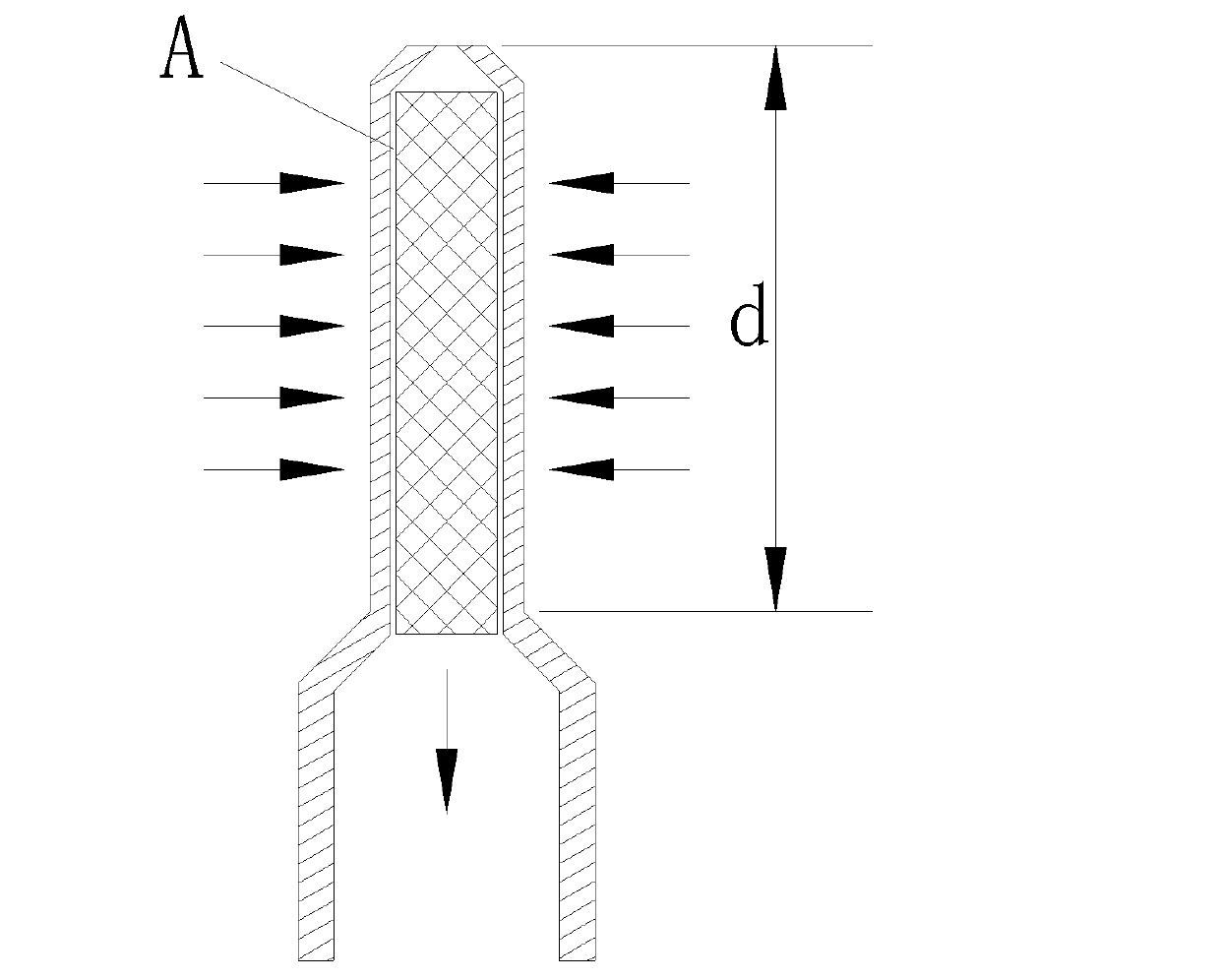

Integrally-formed front fork and manufacturing method thereof

InactiveCN102602489AHigh strengthEasy to manufactureSteering deviceUltimate tensile strengthStrength loss

The invention discloses an integrally-formed front fork and a manufacturing method. The integrally-formed front fork comprises a cylindrical turning pipe, a connecting portion and a front fork piece, and the turning pipe and the front fork piece are integrally formed at the upper end and the lower end of the connecting portion respectively. The manufacturing method of the integrally-formed front fork mainly includes steps of pipe reducing and molding and the like to process the front fork. Compared with the prior art, the integrally-formed front fork has higher strength, capability of meeting service requirements and bearing larger axial and turning impact during extreme motions. Meanwhile, the welding step is omitted in the manufacturing method, the manufacturing process of the front fork is simplified, assembling and material cost of the front fork is reduced and strength loss caused by welding can be avoided.

Owner:SHENZHEN KEMEITE MACHINERY EQUIP

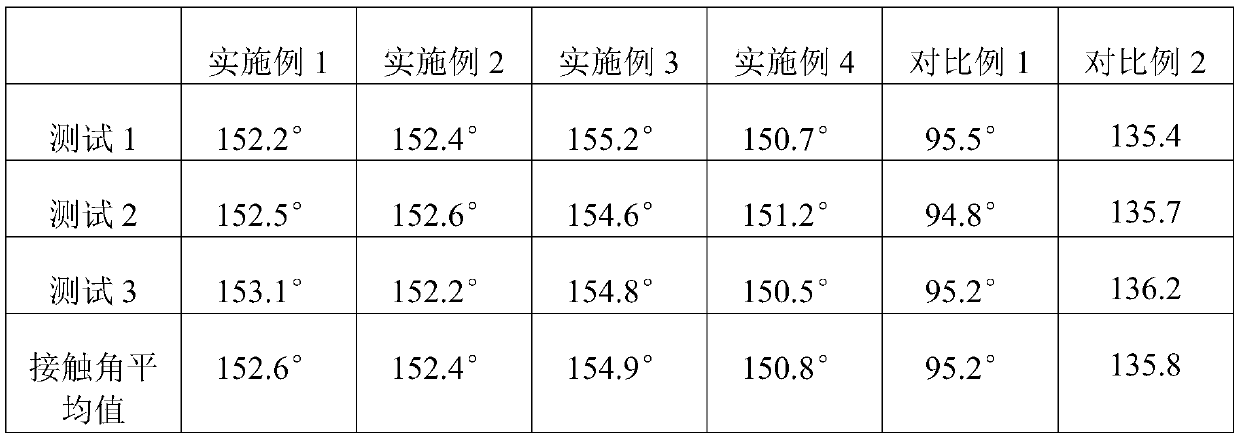

Inking process of automobile glass

Relating to the technical field of glass, the invention discloses an inking process of automobile glass. The method includes the steps of: 1) preparation of varnish; 2) preparation of low-melting-point glass powder; 3) preparation of glass ink; 4) pretreatment of an automobile glass substrate: wiping the automobile glass substrate with acetone and then performing drying; 5) primary sintering: printing glass ink on the plane at the peripheral edge of the pretreated automobile glass substrate in a silk-screen printing mode to form an ink layer, and performing primary sintering; and 6) secondarysintering: spraying nitrogen with silicon carbide composite particles to the surface of the ink layer, performing secondary sintering, then taking out the product, and conducting cooling. The siliconcarbide layer with corrosion resistance is prepared on the surface of the automobile glass ink layer to increase the roughness of the automobile glass ink surface, thus endowing the surface of the automobile glass ink layer with super-hydrophobicity, preventing acid rainwater from contacting the surface of the ink layer, and prolonging the service life of the glass ink layer.

Owner:陈圆圆

System and Method of the Optical Delay Line

InactiveUS20080304125A1Easy to manufactureAvoid strength lossPrismsMirrorsLight beamOptical delay line

This invention provides a system and a method of the optical delay line, wherein the system comprises a source and an array of mirrors, wherein the array of mirrors comprises a first reflective mirror, a second reflective mirror, a third reflective mirror, and a fourth reflective mirror. Beams from the source could be delayed because the beams are multi-reflected by the reflective mirrors.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

Seepage-proof water-stop cushion for inspection shaft

InactiveCN103205984AInconvenient transportationImprove stabilityArtificial islandsUnderwater structuresEngineeringRoad surface

The invention discloses a seepage-proof water-stop cushion for an inspection shaft. The seepage-proof water-stop cushion comprises a cushion plate made of elastic flexible materials, wherein a round, fan-shaped or rectangular through hole is formed in the center of the cushion plate; the outer ring of the cushion plate has the same shape as the through hole; the size of the through hole is same as that of the cross section of the inner wall of the inspection shaft; and the size of the outer ring of the cushion plate is greater than that of the cross section of the outer wall of the inspection shaft. According to the technical scheme, the cushion plate is laid between the upper surface of a walling crib of the inspection shaft and the lower surface of a well lid base, the edge of the inner ring of the cushion plate is consistent with the inner ring of the inspection shaft wall, and the outer edge of the cushion plate is laid between a roadbase and a pavement, so that the elastic sealing function of the cushion plate can effectively prevent rainwater on the pavement from seeping along the crack and gap between the outer side of the inspection shaft wall and the pavement, a rammed earth layer around the inspection shaft is prevented from losing strength after long-term immersion by rainwater, the roadbase can maintain favorable consistency and bearing capacity all along, the smoothness of a road can be maintained, the inspection shaft can be protected, and the service life of the inspection shaft can be prolonged.

Owner:詹春生

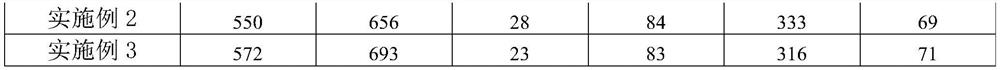

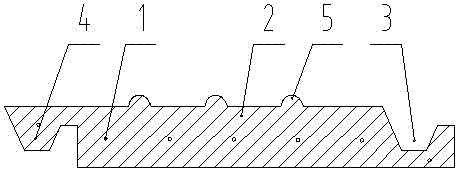

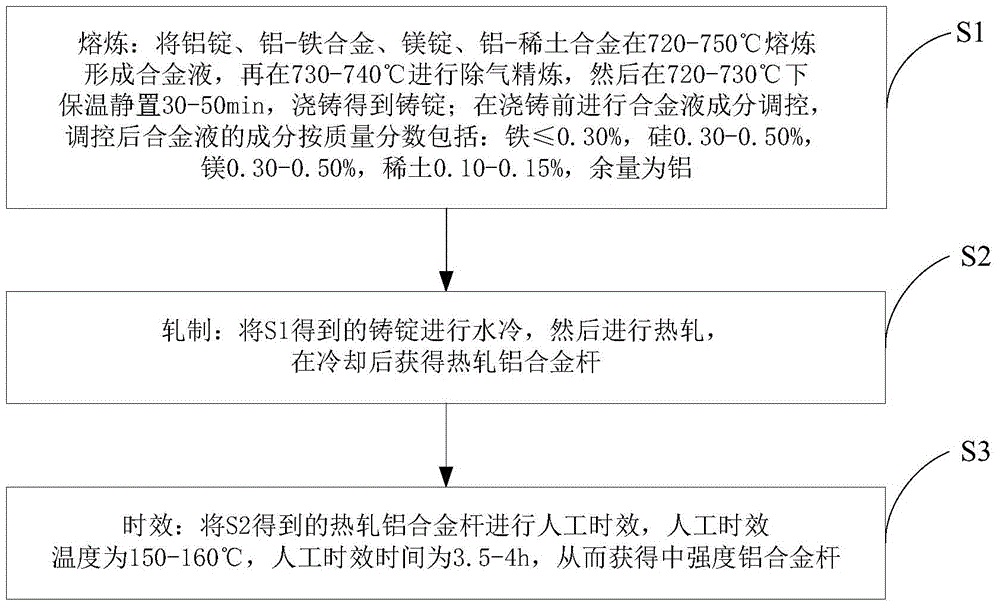

Intermediate-strength aluminium alloy rod and preparation method thereof

The invention discloses a preparation method for an intermediate-strength aluminium alloy rod. The preparation method comprises the following steps: smelting an aluminium ingot, aluminium-silicon alloy, aluminium-iron alloy, a magnesium ingot and aluminium-tombarthite alloy at 720-750 DEG C to form an alloy liquid, then degassing and refining at 730-740 DEG C, then standing at 720-730 DEG C for 30-50 min, and casting to obtain an ingot; adjusting and controlling alloy liquid components before casting, wherein the adjusted and controlled alloy liquid comprises the following components in percentage by weight: smaller than or equal to 0.30% of alloy, 0.30-0.50% of silicon, 0.30-0.50% of magnesium, 0.10-0.15% of tombarthite and the balance of aluminium; performing water cooling on the obtained ingot, then conducting hot rolling, and cooling so as to obtain a hot rolled aluminium alloy rod; conducting artificial aging on the obtained hot rolled aluminium alloy rod, wherein the artificial aging temperature is 150-160 DEG C, and the artificial aging time is 3.5-4 h, so as to obtain the intermediate-strength aluminium alloy rod. The invention further discloses the intermediate-strength aluminium alloy rod obtained by adopting the preparation method for the intermediate-strength aluminium alloy rod.

Owner:ANHUI ELECTRIC GRP SHARES

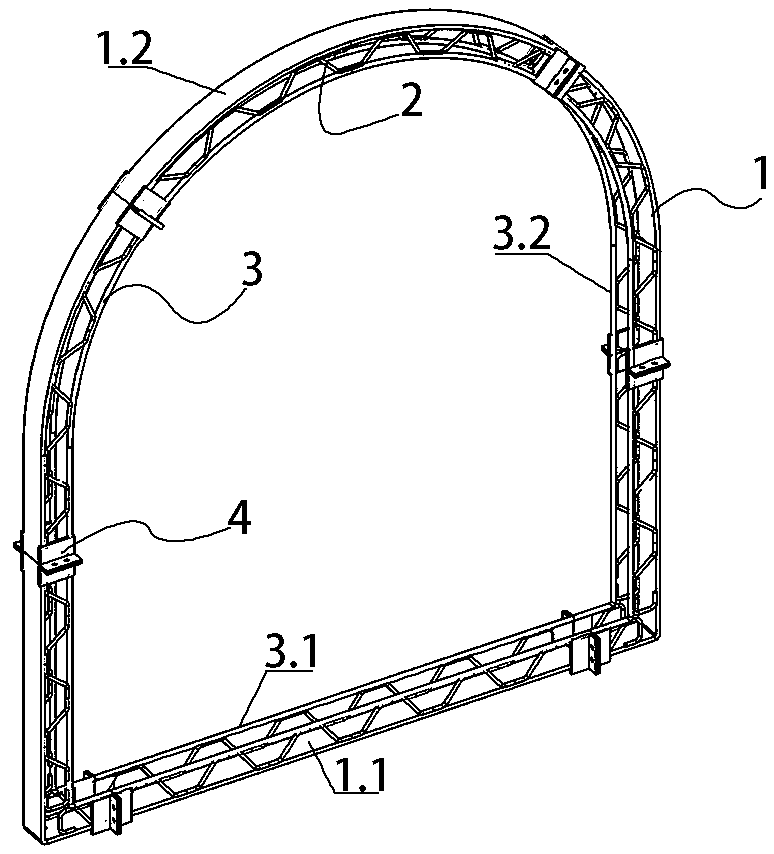

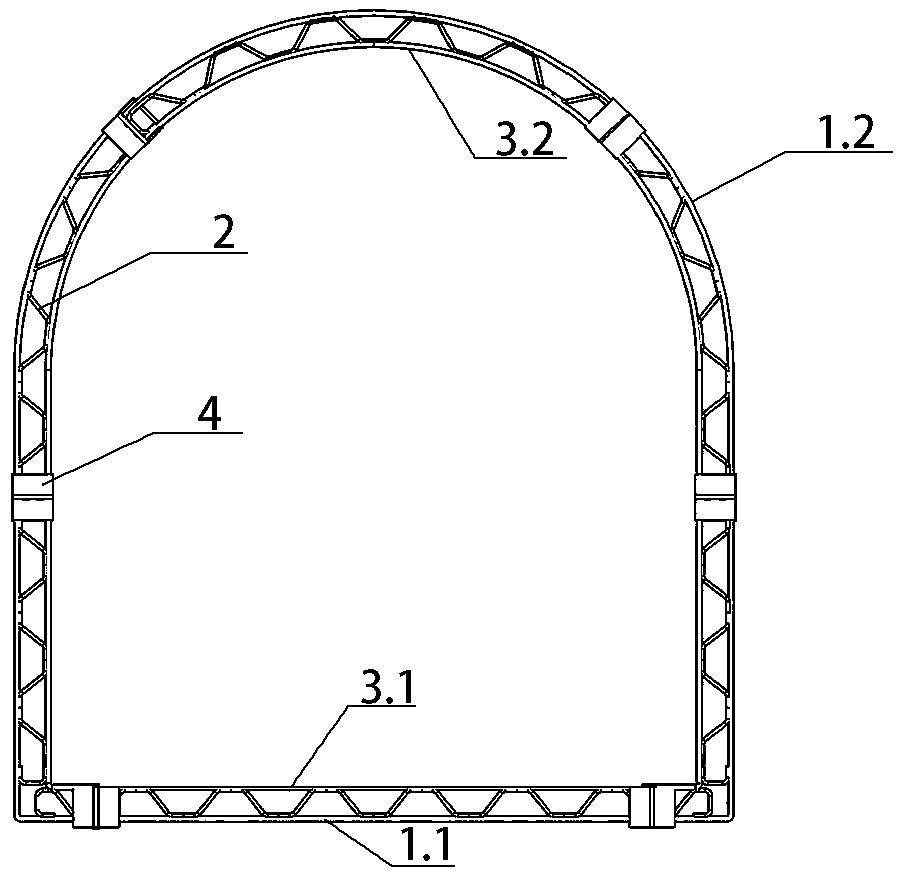

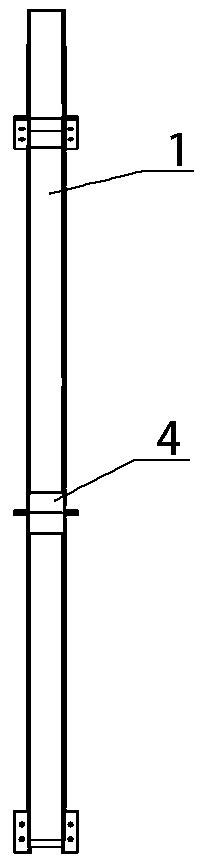

3D printed steel fiber reinforced concrete tunnel preliminary support grating arch frame and construction method thereof

PendingCN110159299AReduce processing stepsAvoid precisionAdditive manufacturing apparatusUnderground chambersSteel frame3d printer

The invention provides a 3D printed steel fiber reinforced concrete tunnel preliminary support grating arch frame and a construction method thereof. The arch frame is divided into a plurality of unitjoints in the extending direction of the arch frame. Each unit joint is formed in an integral printed manner through 3D printing equipment. Each unit joint comprises a 3D printed outer support plate,a 3D printed reinforcing support, a 3D printed inner side support and 3D printed bolt connecting plates. The 3D printed bolt connecting plates are arranged at the head end and the tail end of each unit joint. Transverse plates of two L-shaped plates on the same side of two adjacent unit joints are mutually connected to form the overall arch frame. According to the arch frame, the steel fiber reinforced concrete outer support plates are large in stress area, can bear surrounding rock pressure more effectively than grating steel frame main reinforcement, and can effectively ensure stress performance of preliminary support components. The arch frame is integrally manufactured by adopting the printing form of a 3D printer, the weight of the arch frame is low compared with grating steel arch frame preliminary support components, hoisting and installing are facilitated, and the hoisting cost can be reduced effectively. Meanwhile, the situation that traditionally, grating steel frame is welded and machined manually on preliminary support site is avoided, the labor cost is reduced, and the construction period is shortened.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

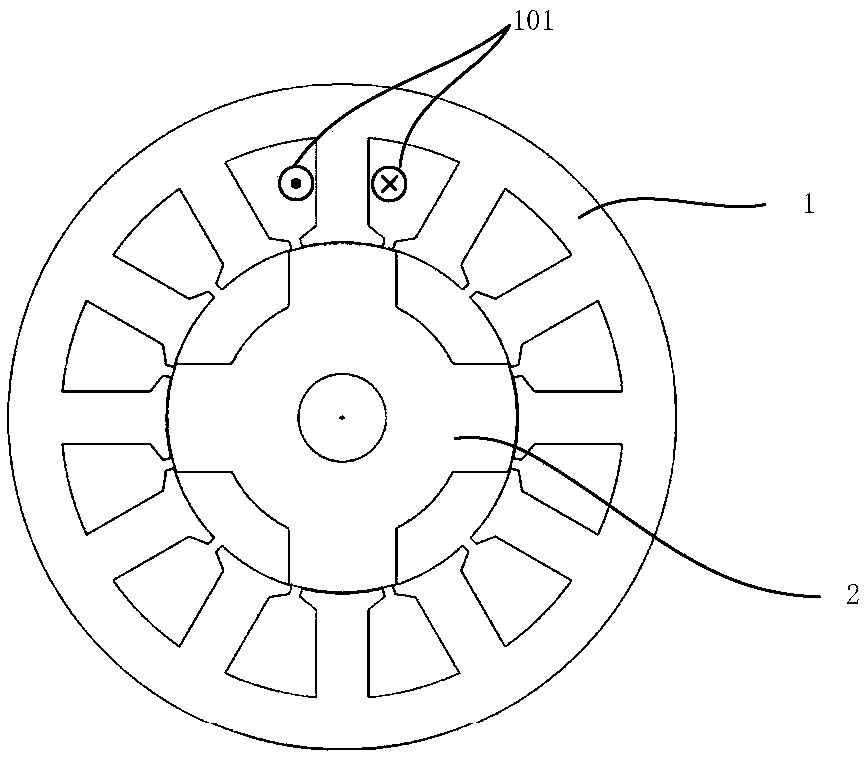

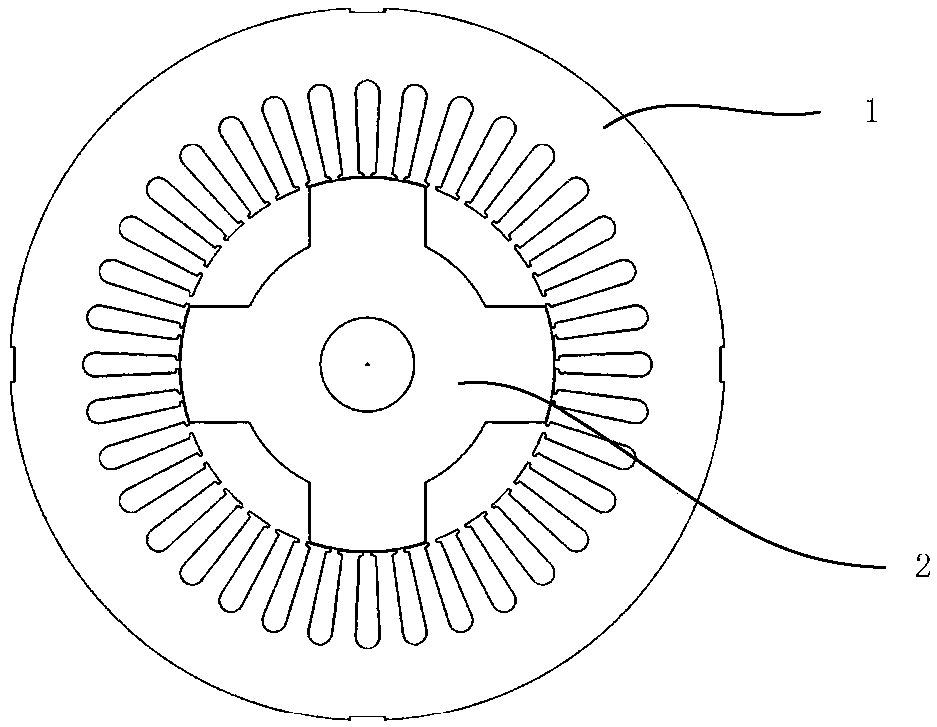

Synchronous switched reluctance motor

PendingCN108712045ASimple structureSmall current rippleMagnetic circuit rotating partsSynchronous motorsLow noiseSynchronous reluctance motor

The invention provides a synchronous switched reluctance motor, mainly comprising a three-phase stator, a salient pole rotor, a rotor position sensor, a casing, a motor controller and a shaft, whereinthe three-phase stator adopts a three-phase concentrated winding or a three-phase distributed winding and generates a synchronous rotating magnetic field under the driving control of the motor controller, and the strength and rotating speed of the synchronous rotating magnetic field can be controlled by the motor controller through the three-phase stator; the salient pole rotor does not include apermanent magnet or a squirrel cage structure, does not need to open a reluctance groove, is formed by laminating only silicon steel sheets and has an even number of salient poles; the three-phase stator is mounted inside the casing, the salient pole rotor is mounted on the shaft and mounted on the casing through the shaft, and the rotor position sensor is mounted at one end of the shaft; and thethree-phase stator and the salient pole rotor constitute a radial magnetic circuit. The novel synchronous switched reluctance motor not only retains the advantages of simple structure of a switched reluctance motor and the advantages of small torque ripple and low noise of a synchronous reluctance motor, but also overcomes the large torque ripple of the switched reluctance motor and the complicated structure of the synchronous reluctance motor.

Owner:北京动力京工科技有限公司

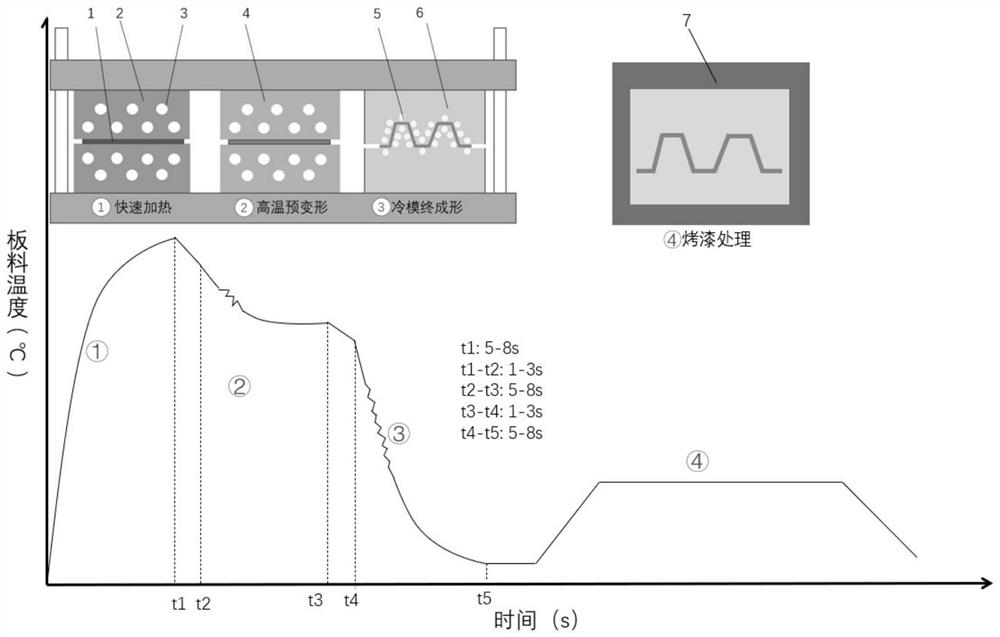

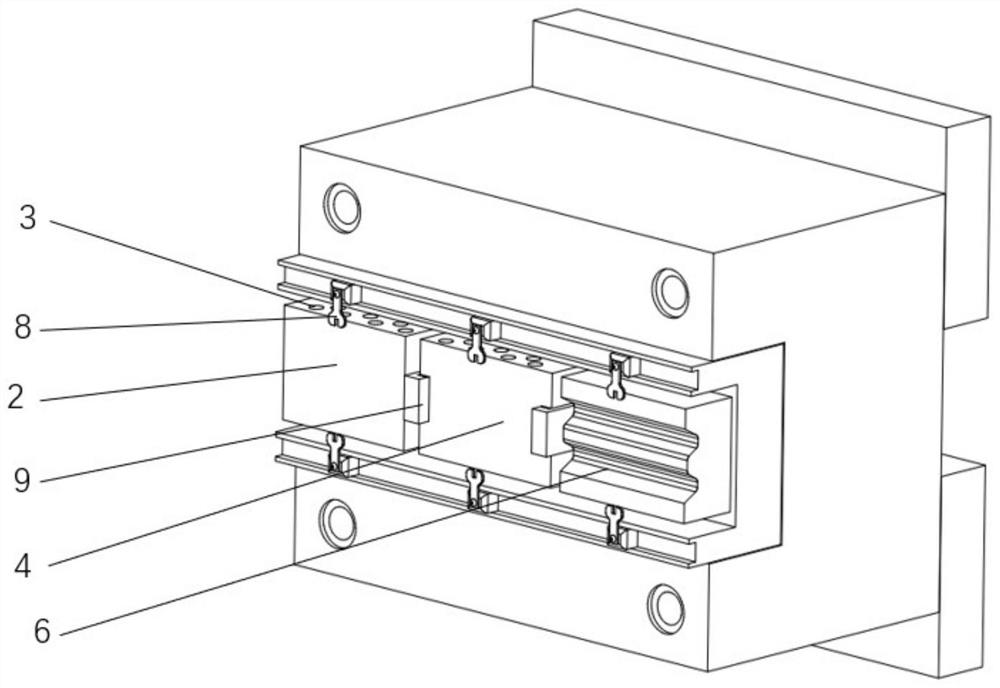

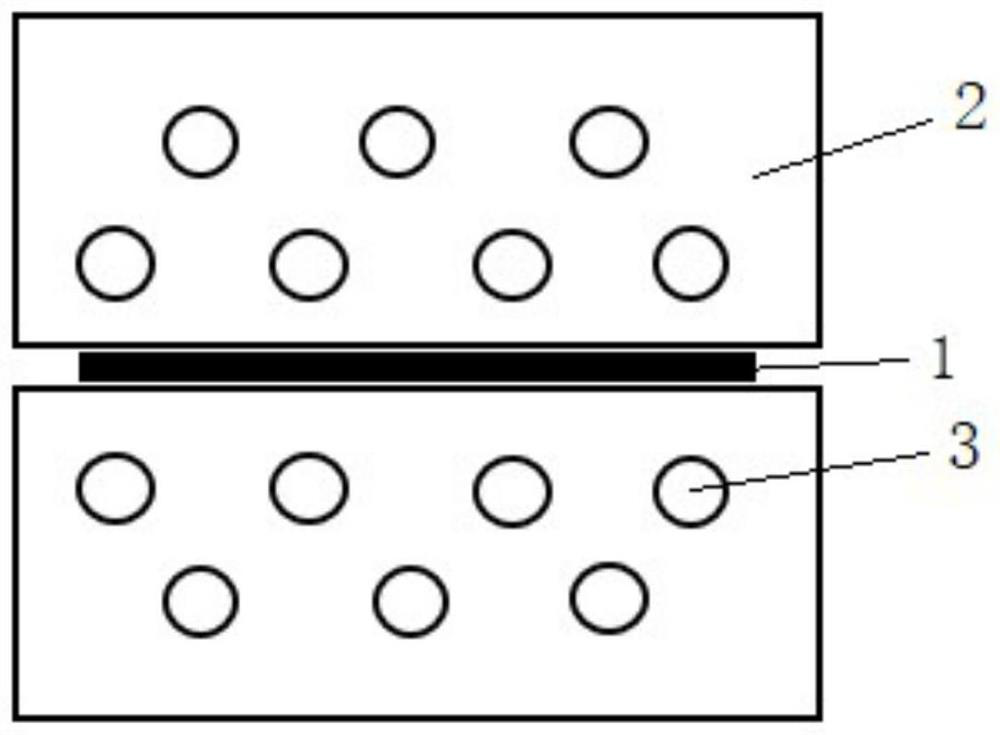

Aluminum alloy thin-wall component as well as efficient hot stamping forming method and application thereof

ActiveCN112775310AStable and controllable tempoImprove processing efficiencyShaping toolsVehicle componentsHot stampingAluminium alloy

The invention provides an aluminum alloy thin-wall component as well as an efficient hot stamping forming method and application thereof. According to the aluminum alloy thin-wall component as well as the efficient hot stamping forming method and application thereof, by means of the characteristics of high efficiency, fast rhythm and high integration degree of a progressive die, the process steps of rapid heating-precooling and predeformation-final forming of a cold die are integrated into one progressive die, and paint baking treatment is carried out, namely, aging-state high-strength aluminum alloy is adopted, carries out rapid heat exchange by making contact with a heating flat plate die, and a forming temperature interval can be reached by controlling a contact pressure and maintaining the pressure for a short time; uniform accumulative dislocation of strain is generated through the precooling and predeformation, meanwhile, a high-temperature softening phenomenon of the aluminum alloy material in a high-temperature deformation stage is avoided, and the purpose of deformation is achieved; and finally, stamping is carried out in a room-temperature final forming die to obtain a required part, and the paint baking treatment is carried out. According to the method, the production cycle for an aluminum alloy hot-formed part is greatly shortened, the method is suitable for a fast-rhythm continuous industrial production mode, and high in process step integration degree, the equipment cost and the time cost are saved, and meanwhile the mechanical property of the formed part is guaranteed.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com