Seepage-proof water-stop cushion for inspection shaft

A technology for water-stop pads and inspection wells, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve problems affecting the solidity of the foundation around the well wall, easy collapse of the rammed earth layer, and affecting the stability of the inspection well foundation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

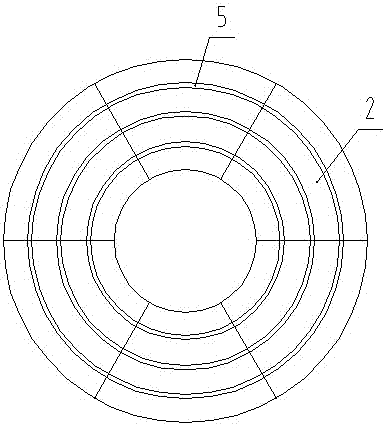

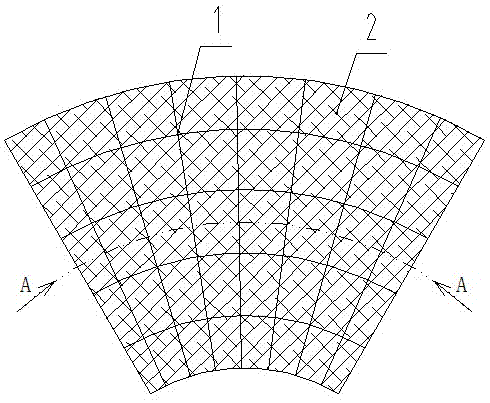

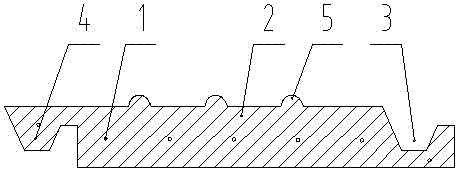

[0014] Embodiment one: if figure 1 , figure 2 and image 3 As shown, the anti-seepage and water-proof pad for inspection well of the present invention includes a backing plate made of elastic flexible material, and the center of the backing plate is provided with a circular through hole 7, and the outer ring of the backing plate has the same shape as the through hole 7. The shape and size of the through hole 7 are identical to the shape and size of the inspection shaft inner wall cross section, the shape and size of the backing plate outer ring is greater than the shape and size of the inspection shaft outer wall cross section, and the backing plate is provided with a pressure rib 1.

[0015] The backing plate is composed of at least two fan-shaped plates 2 of the same size, figure 1 There are six fan-shaped plates 2 in the middle, and the two sides of the same surface of each fan-shaped plate 2 are respectively provided with a card groove 3 and a card bar 4 along the radia...

Embodiment 2

[0019] Embodiment two: if figure 1 , figure 2 and Figure 4 As shown, the difference from the first embodiment is that the surface of each fan-shaped plate 2 is provided with a groove 6 , and the groove 6 is an arc-shaped structure along the circumferential direction of the fan-shaped plate 2 .

Embodiment 3

[0020] Embodiment three: as figure 1 , figure 2 and Figure 5 As shown, the difference from Embodiment 1 is that the surface of each fan-shaped plate 2 is provided with ribs 5 and grooves 6, and the ribs 5 and grooves 6 are arc-shaped structures along the circumferential direction of the fan-shaped plate 2. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com