Patents

Literature

335 results about "Rammed earth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rammed earth, also known as taipa in Portuguese, tapial or tapia in Spanish, pisé (de terre) in French and partly Italian, and hangtu (Chinese: 夯土; pinyin: hāngtǔ), is a technique for constructing foundations, floors, and walls using natural raw materials such as earth, chalk, lime, or gravel.

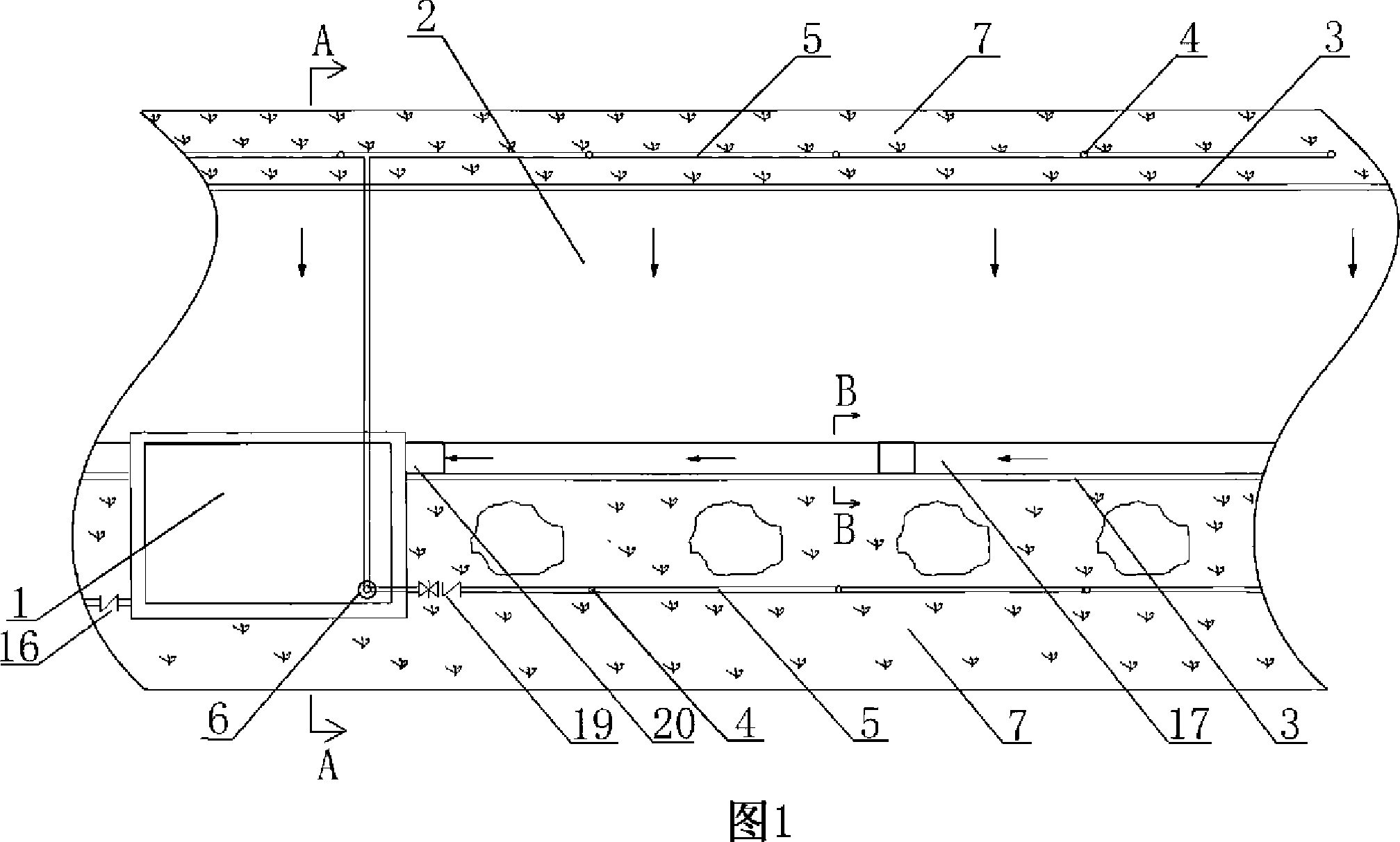

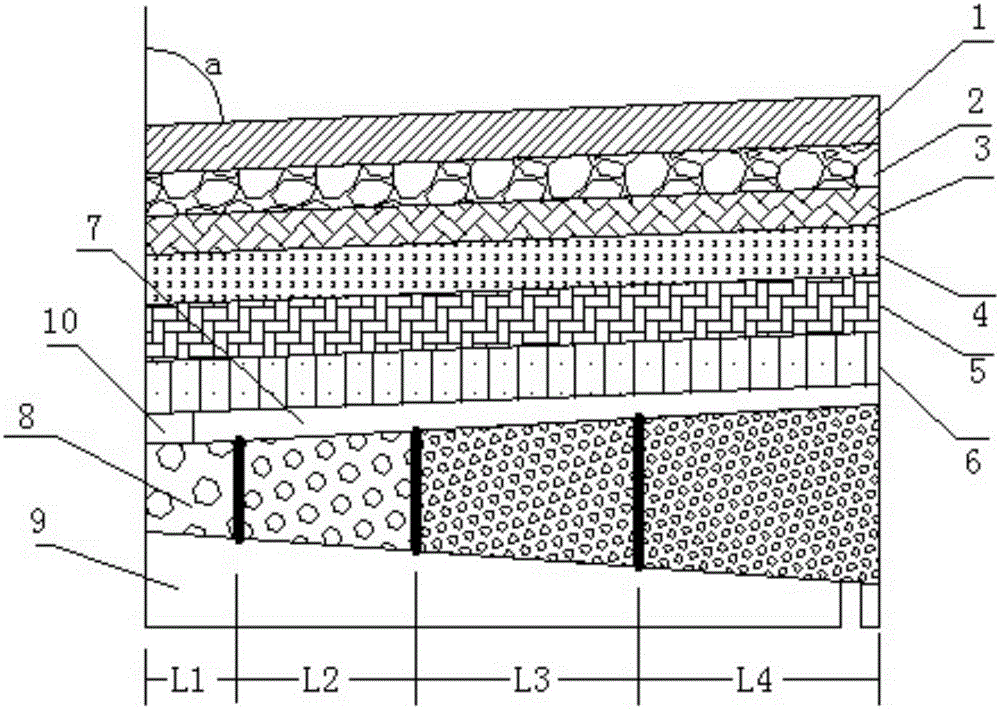

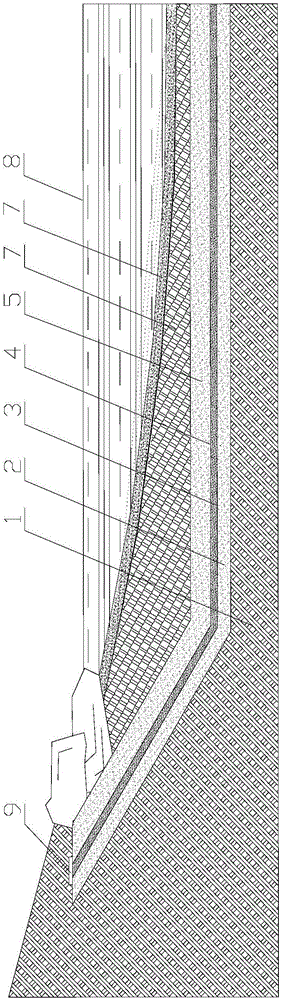

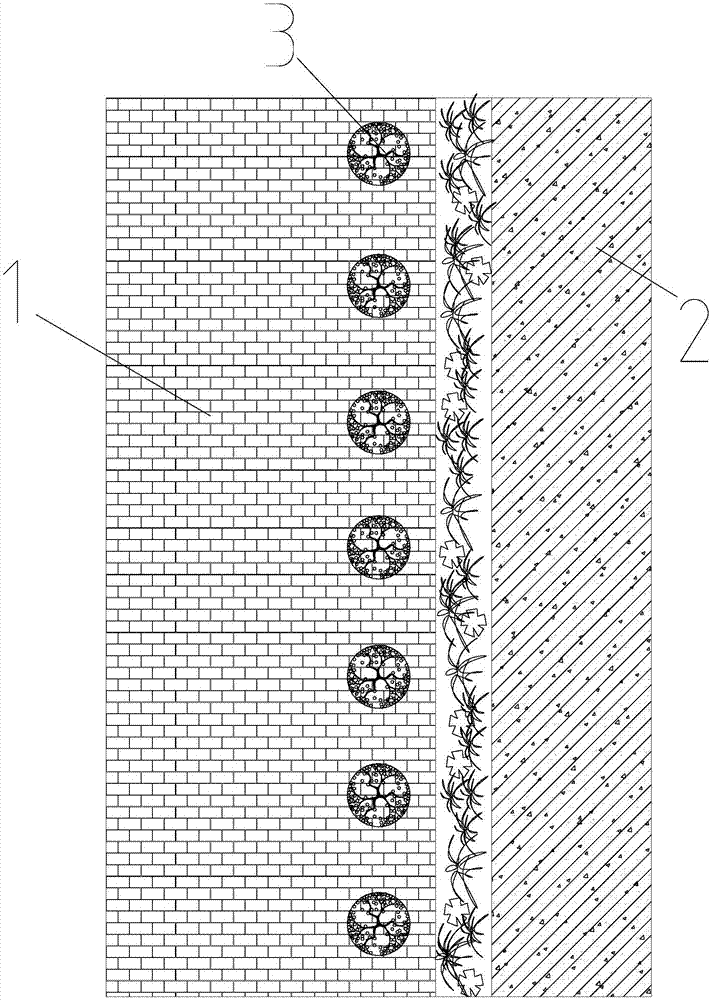

Pervious concrete pavement system capable of collecting rainwater

InactiveCN101003962AReduce negative impactMeet the load-bearing strength requirementsIn situ pavingsSewerage structuresRainwater harvestingRoad surface

The present invention relates to a rainwater-collecting permeable concrete pavement system. It is characterized by that said pavement structure includes rammed earth layer whose thickness is greater than 10mm, general concrete base layer whose thickness is 80-100 mm, permeable concrete structure layer whose thickness is 100-150 mm and permeable concrete face layer whose thickness is 40-60mm from bottom to top. Said pavement system is adjacent to green belt, under the green belt a rainwater-collecting pool is set, and the bottom portion of said rainwater-collecting pool is equipped with a submersible pump. Along the length direction of said pavement structure two sides of said pavement system are respectively equipped with a rainwater-collecting channel, the outlet of said submersible pump is connected with pipe network, and said pipe network is distributed in the green belt.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

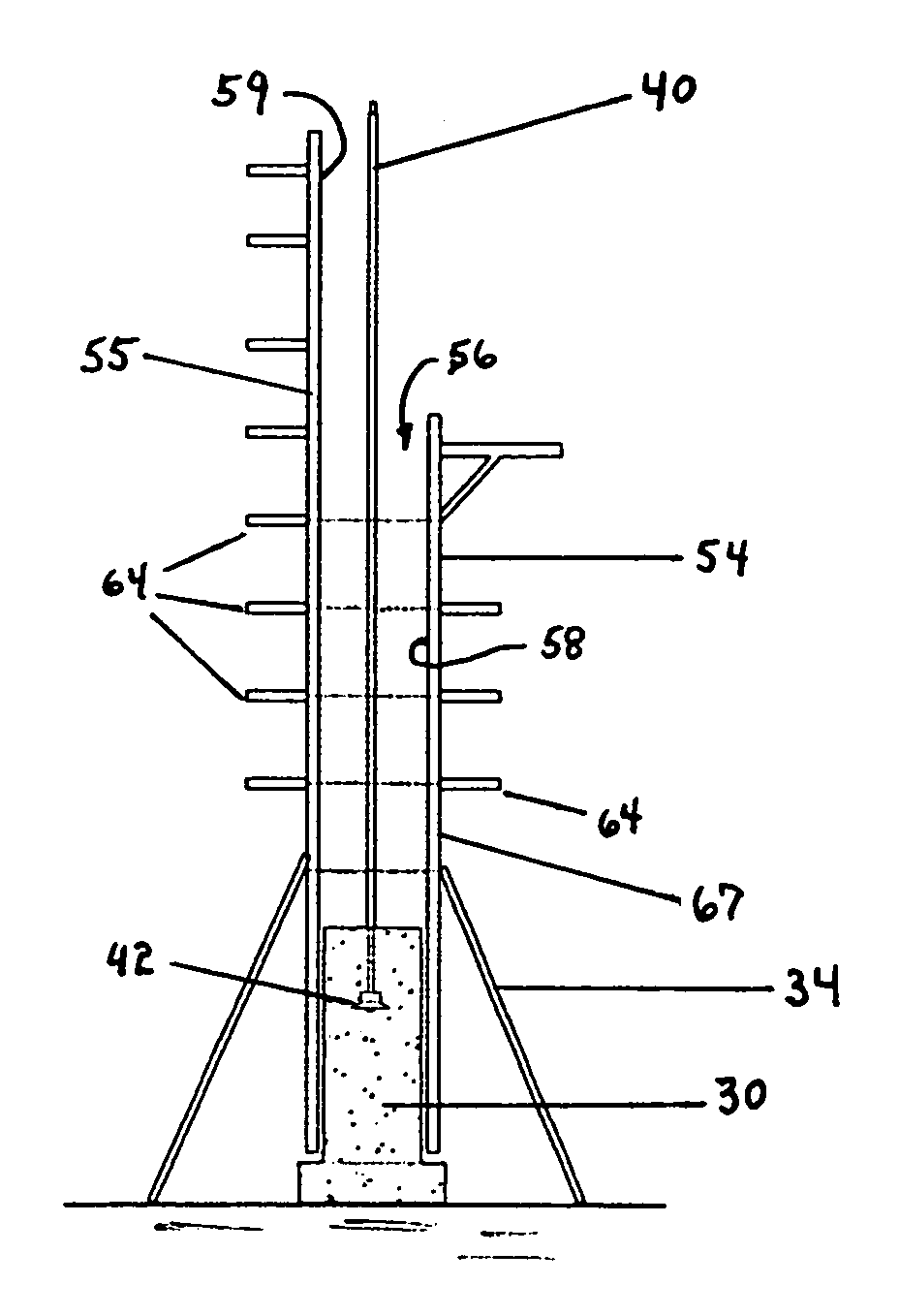

Post-tensioned rammed earth construction

A method for erecting structures composed of rammed-earth. A method of rammed-earth building construction is disclosed wherein walls are post-tensioned to enhance the ability of the wall to receive lateral loading without failing in tension.Post-tensioning rods are anchored to a concrete footing, and temporary forms erected alongside the footing. A protective sleeve is disposed around each post-tensioning rod. An earthen mixture is placed between the forms and around the sleeves, and rammed by compaction in a series of stacked courses. When the rammed-earth wall has obtained the desired height, it is topped with a concrete bond beam through which the post-tensioning rods extend. Using the bond beam as a brace against which a retaining plate may push, retaining plates are disposed upon the bond beam and around the threaded upper ends of each rod. A nut is threaded upon each rod and tightened against the retaining plate to draw the rod into tension. The torque applied to the nut thus loads the wall in compression via the plates and bond beam. Thus compressed, the rammed-earth wall is less susceptible to tension failure.

Owner:WARD THOMAS +1

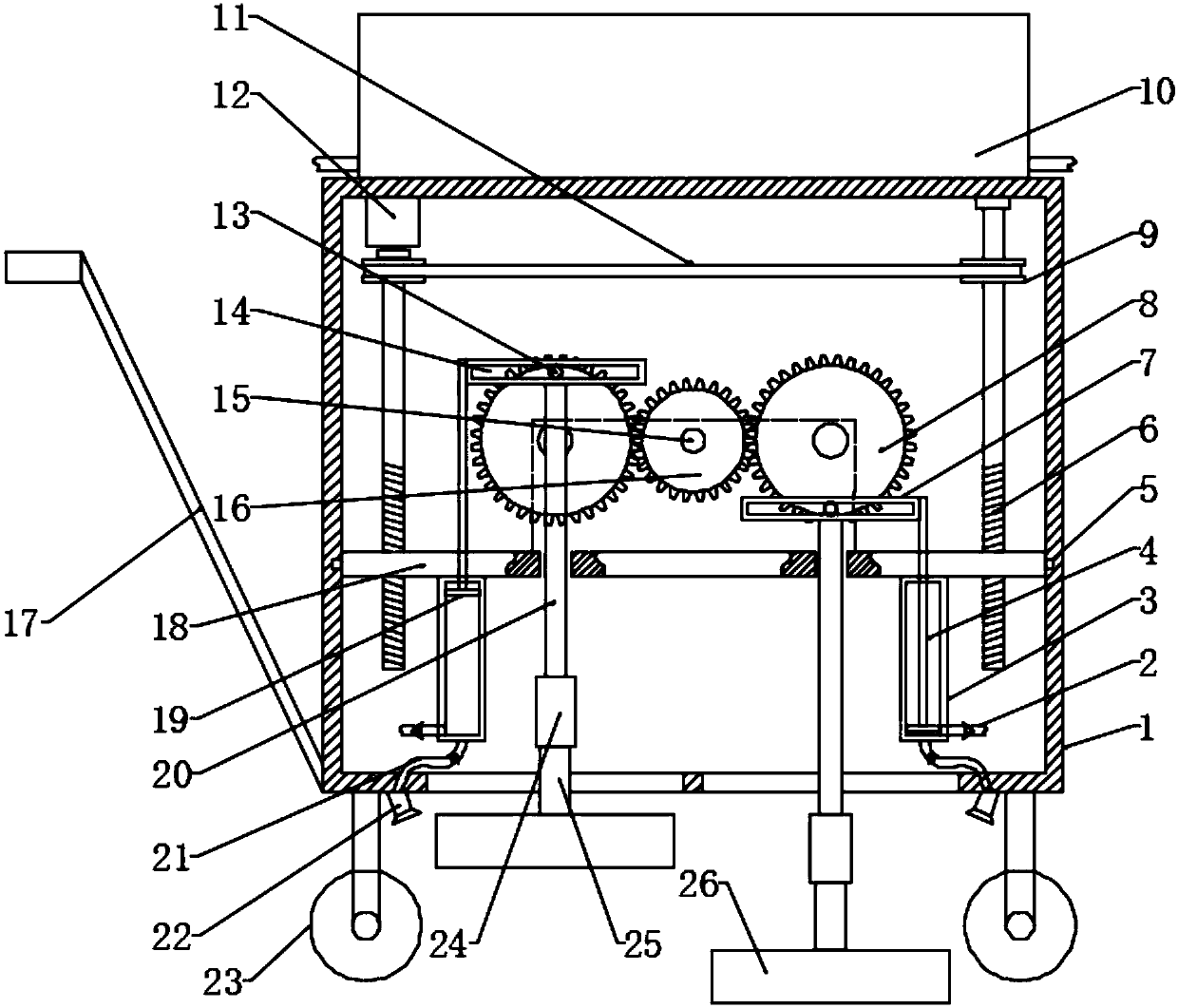

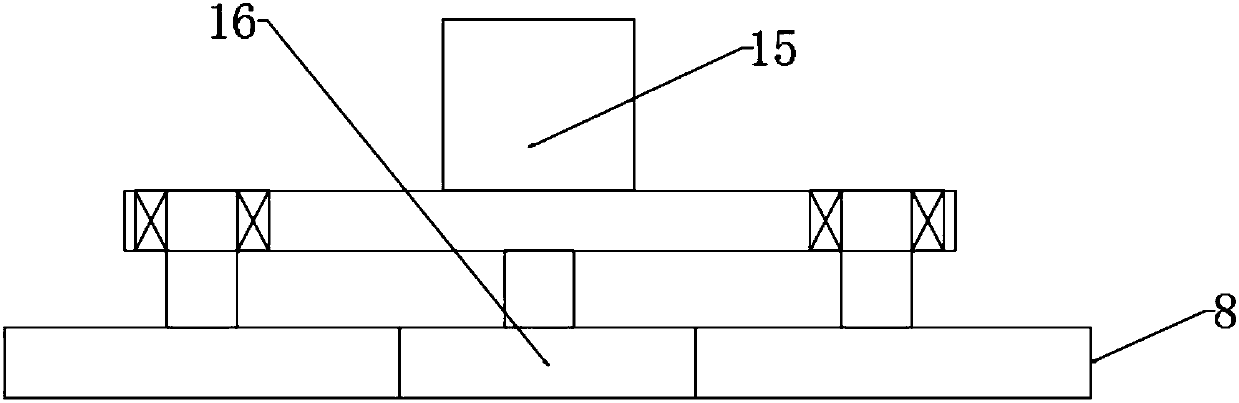

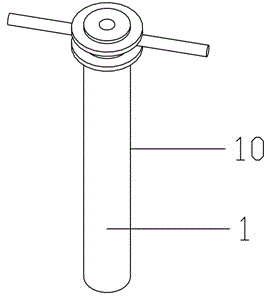

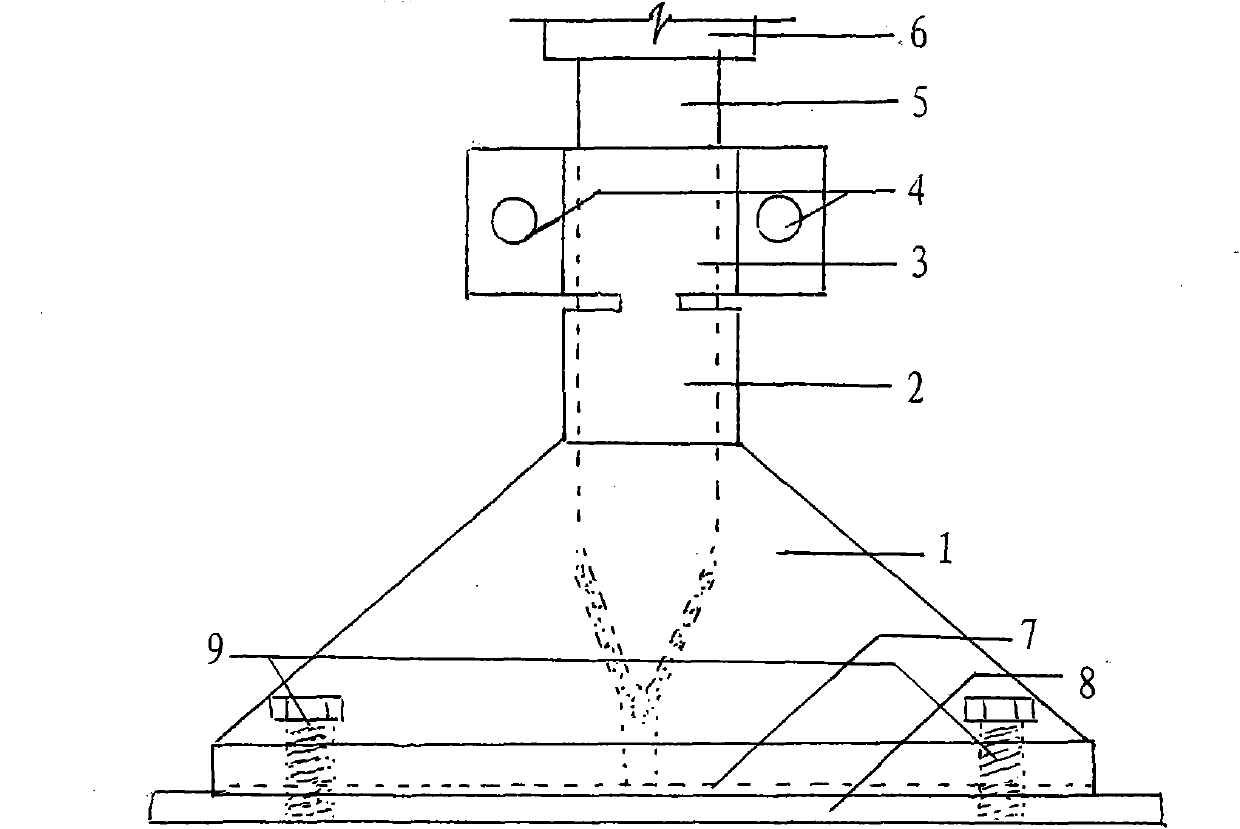

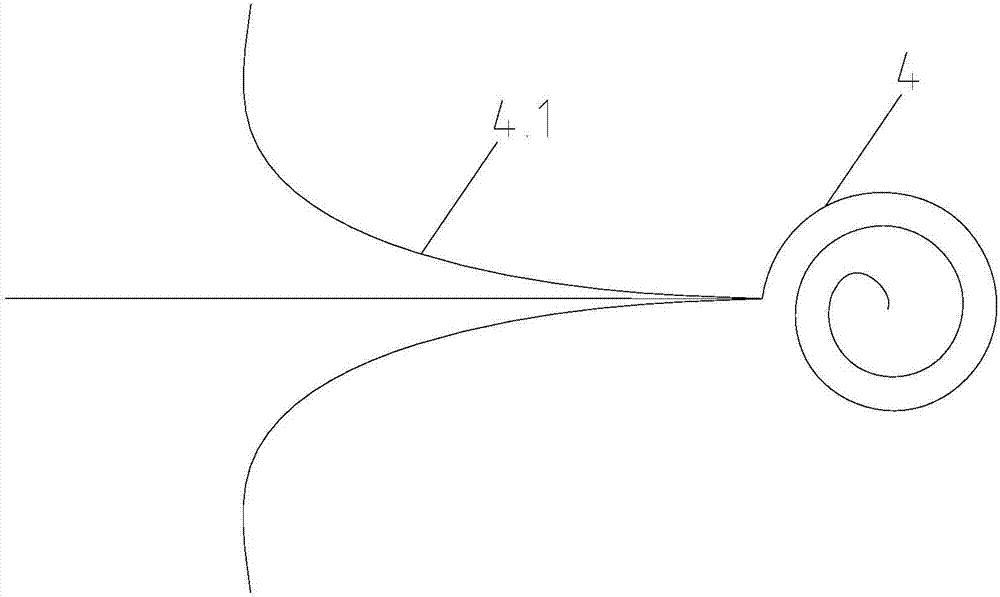

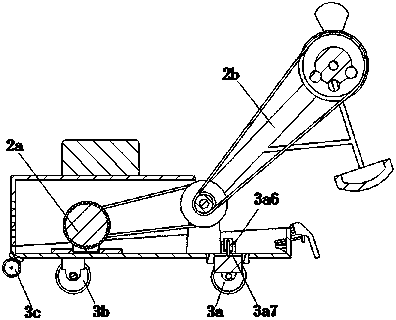

Adjustable continuous earth rammer

InactiveCN107700467AAvoid the impact of vibration and impactReduced service lifeSoil preservationArchitectural engineeringRare earth

The invention discloses an adjustable continuous earth ramming machine, which comprises a box body, a guide plate, a first motor, a driving gear, a driven gear, a movable rod, a first connecting rod, a shock absorbing device, a rammed earth plate, a sprinkler, threaded rod, a second motor, the damping device includes a housing, a first spring, a second spring, a slide plate and a second connecting rod, and the sprinkler device includes a piston rod, a piston, a cylinder, a water tank and a spray nozzle. It is equipped with a first motor, a driving gear, a driven gear, a movable rod, a shock absorbing device and a rammed earth board. Through cooperation, the two rammed earth boards are alternately lowered to carry out continuous rammed earth, which improves the work efficiency and is equipped with a sprinkler. Dust reduction is carried out when ramming the earth to avoid the dust scattered during the ramming and affecting the health of the staff. It is equipped with a second motor and a threaded rod, which can adjust the depth of the rammed earth and the degree of compaction to the ground, and can be adjusted according to different work requirements and ground conditions. Improved work efficiency.

Owner:陆春土

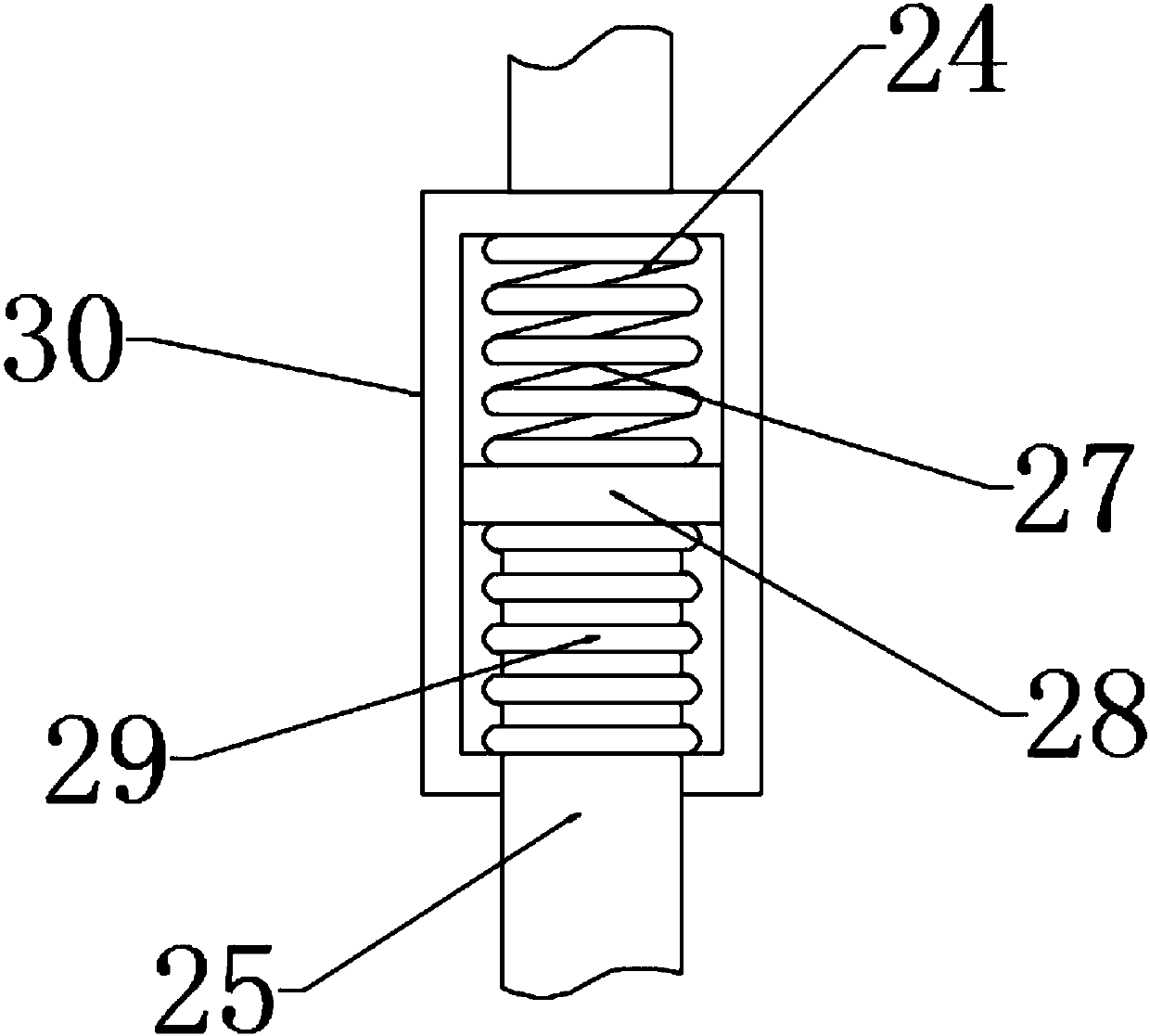

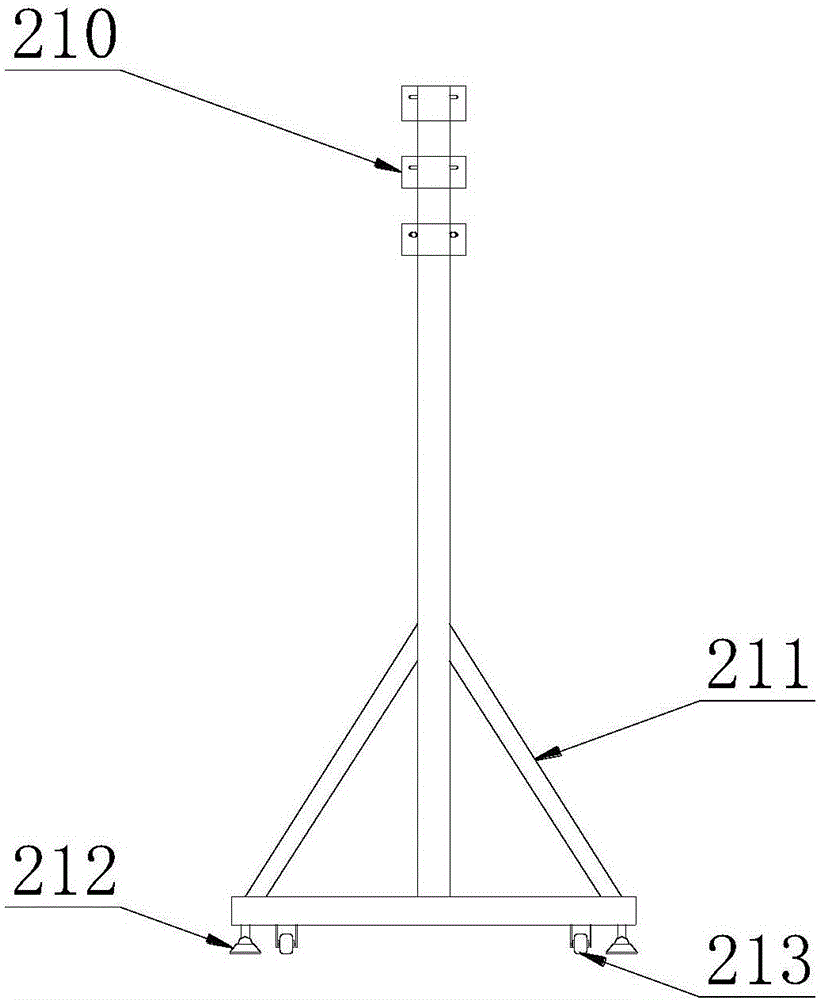

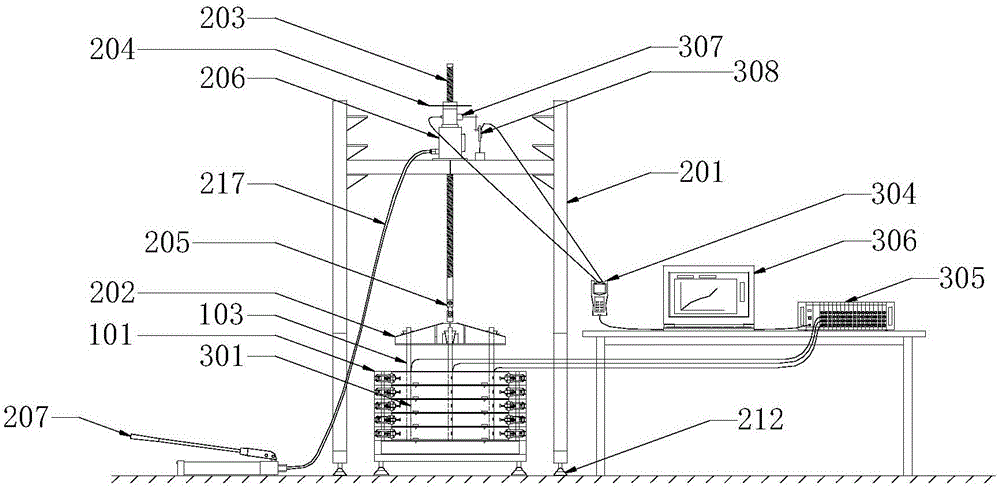

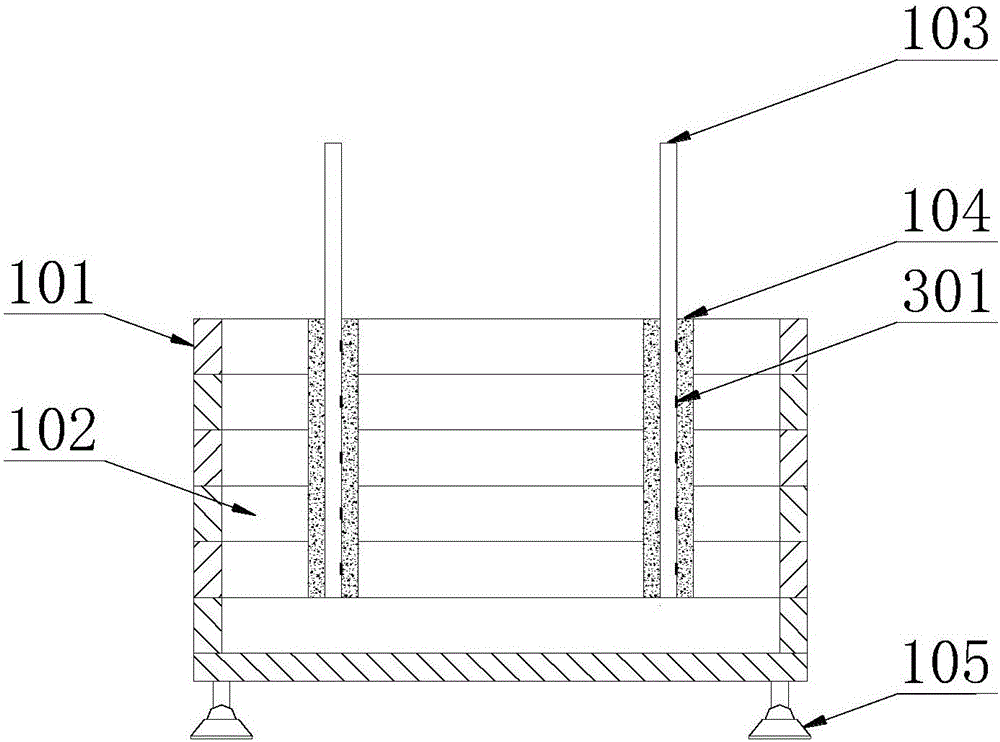

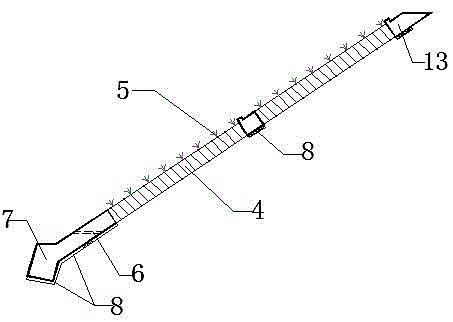

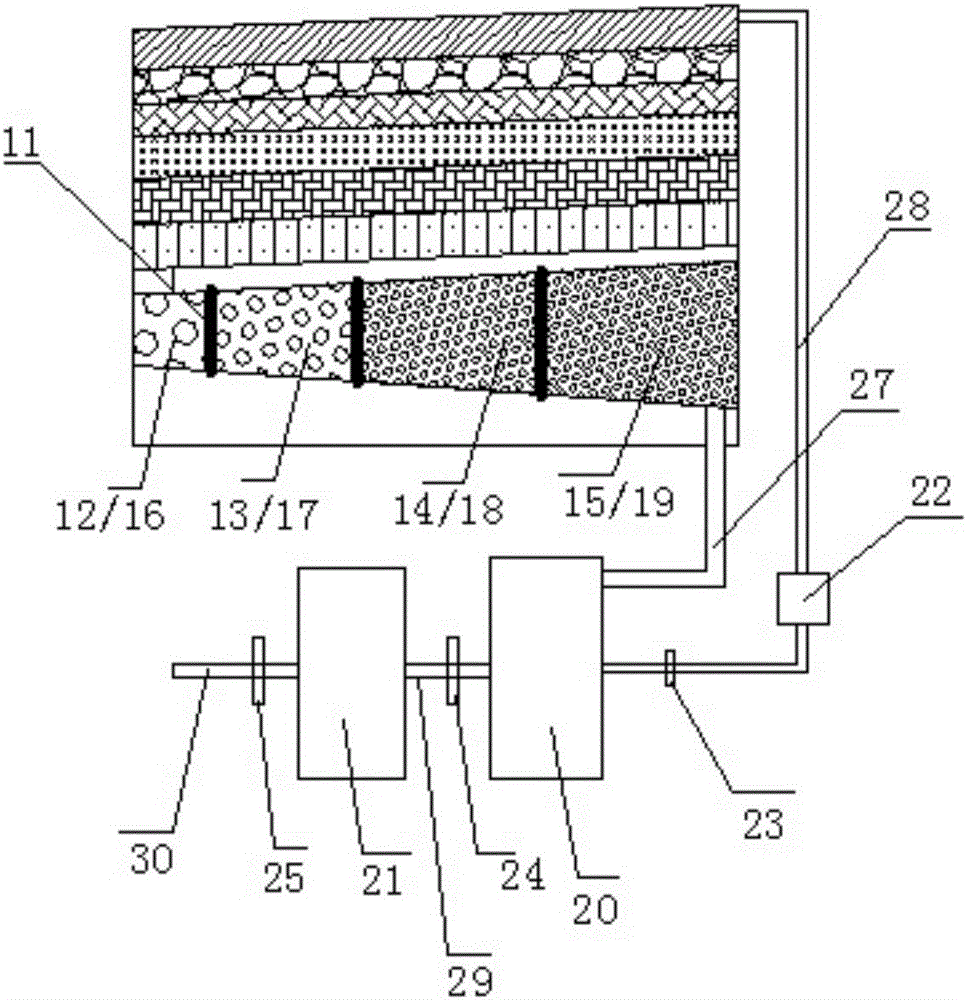

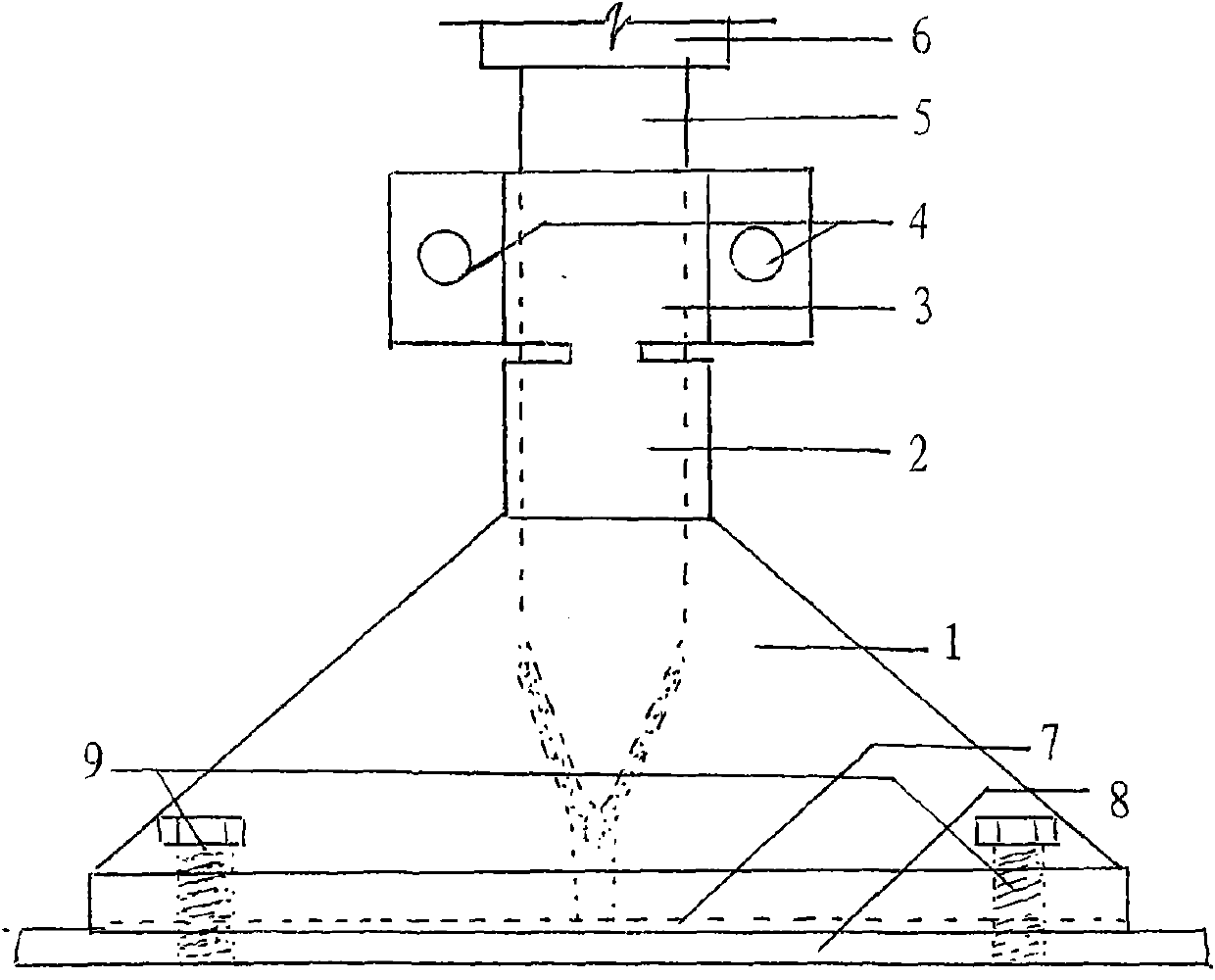

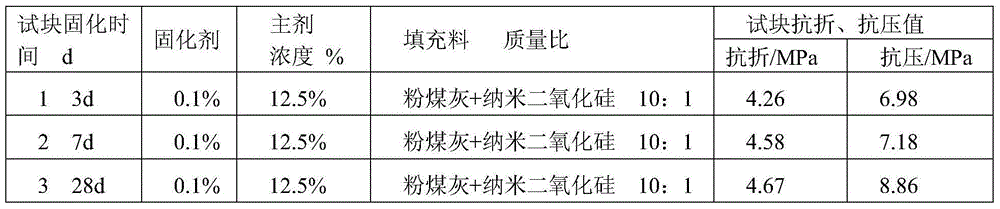

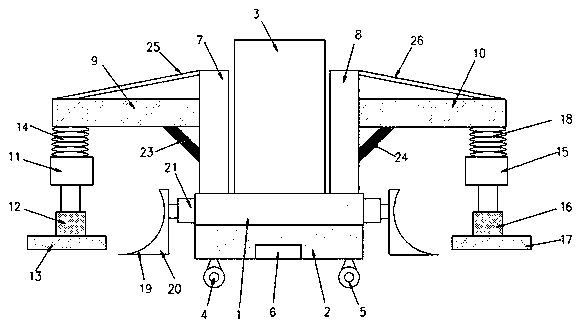

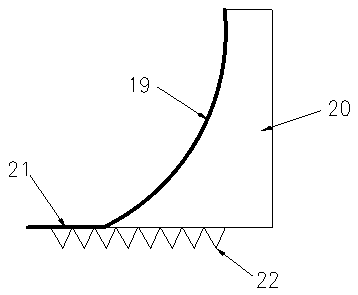

Rammed earth historic site group anchorage pullout test system

InactiveCN106018102AMeet the stiffness requirementsSatisfy the pulling problemMaterial strength using tensile/compressive forcesPull forceData acquisition

The invention discloses a rammed earth historic site group anchorage pullout test system. The rammed earth historic site group anchorage pullout test system comprises a group anchorage anchoring mechanism, a loading mechanism and a data acquisition and processing system; the group anchorage anchoring mechanism comprises a rammed earth box, a rammed earth layer is rammed in the rammed earth box, a plurality of anchoring holes are formed in the rammed earth layer, and the plurality of anchoring holes are uniformly and equidistantly arranged relative to the central axis of the rammed earth layer; an anchoring rod is arranged in each anchoring hole, and anchoring slurry is arranged between the anchoring rod and the anchoring hole; the rammed earth box comprises a box seat and a plurality of box units which are vertically arranged above the box seat, each box unit comprises four channel steels which are arranged in a rectangular shape, and two adjacent channel steels are fixedly connected with each other by virtue of a locking device; and the loading mechanism applies a pulling force to the anchoring rods, and an anchoring force and stress and displacement of the anchoring rods are monitored by virtue of the data acquisition and processing system.

Owner:LANZHOU UNIVERSITY

Construction method for anti-seismic rammed earth wall with reinforced surface skin and core columns

The invention relates to a construction method for an anti-seismic rammed earth wall with a reinforced surface skin and core columns and belongs to the technical field of construction engineering. According to the method, a rammed earth wall formwork is manufactured, and pre-embedded core molds are placed into the rammed earth wall formwork. The effect of the surface skin is reinforced under the tying and connecting action of two kinds dovetail joint type earth materials in the mode that different earth materials are added twice; the anti-seismic performance of the rammed earth wall is enhanced under the action of criss-cross tying and connecting action by prefabricating the pore-forming core columns, earth mass reinforcing columns and steel wire sewn mesh sheets. The method has the advantages that the construction cost of the rammed earth wall is lowered, and the durability and reliability of the rammed earth wall are improved.

Owner:KUNMING UNIV OF SCI & TECH

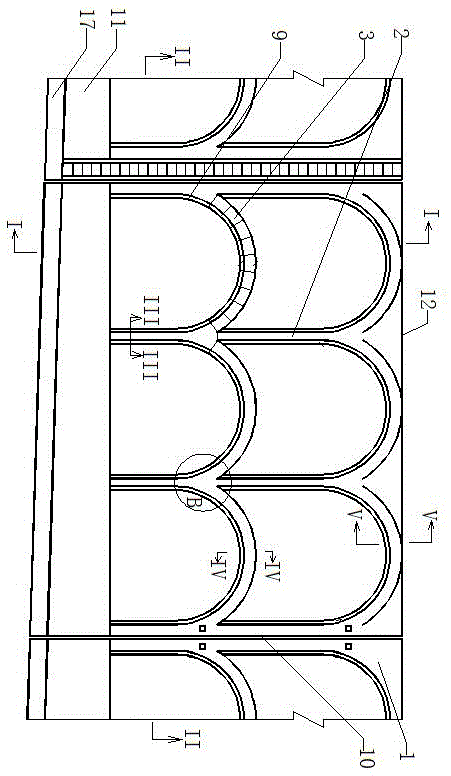

Arch fixing rack for highway/railway tunnel and manufacturing method of arch fixing rack

The invention discloses an arch fixing rack for a highway / railway tunnel and a manufacturing method of the arch fixing rack. A main body comprises rib columns and arch rings; the arch rings are arranged on two sides of the rib columns; the part between the rib columns and the arch rings is filled with rammed earth; shrubs are planted on the rammed earth; the bottom of the main body is of a Z-shaped hollow structure; a drainage groove is formed inside the main body; macadam cushion layers are respectively arranged at the bottoms of the rib columns and the arch rings; the connection parts of the rib columns and the arch rings are of staggered tooth structures; curbing is mounted on two sides of the rib columns and inner sides of the arch rings; the rib columns are of hollow structures; through holes are formed around the centers of the arch rings; reinforcing steel bars are connected in series inside the through holes. The invention further discloses a manufacturing method of the arch fixing rack. The arch fixing rack for the highway / railway tunnel is convenient and rapid to construct, good in pressure resistance, good in water drainage property and long in service life.

Owner:SHANDONG JINGJIN NEW ENERGY CO LTD

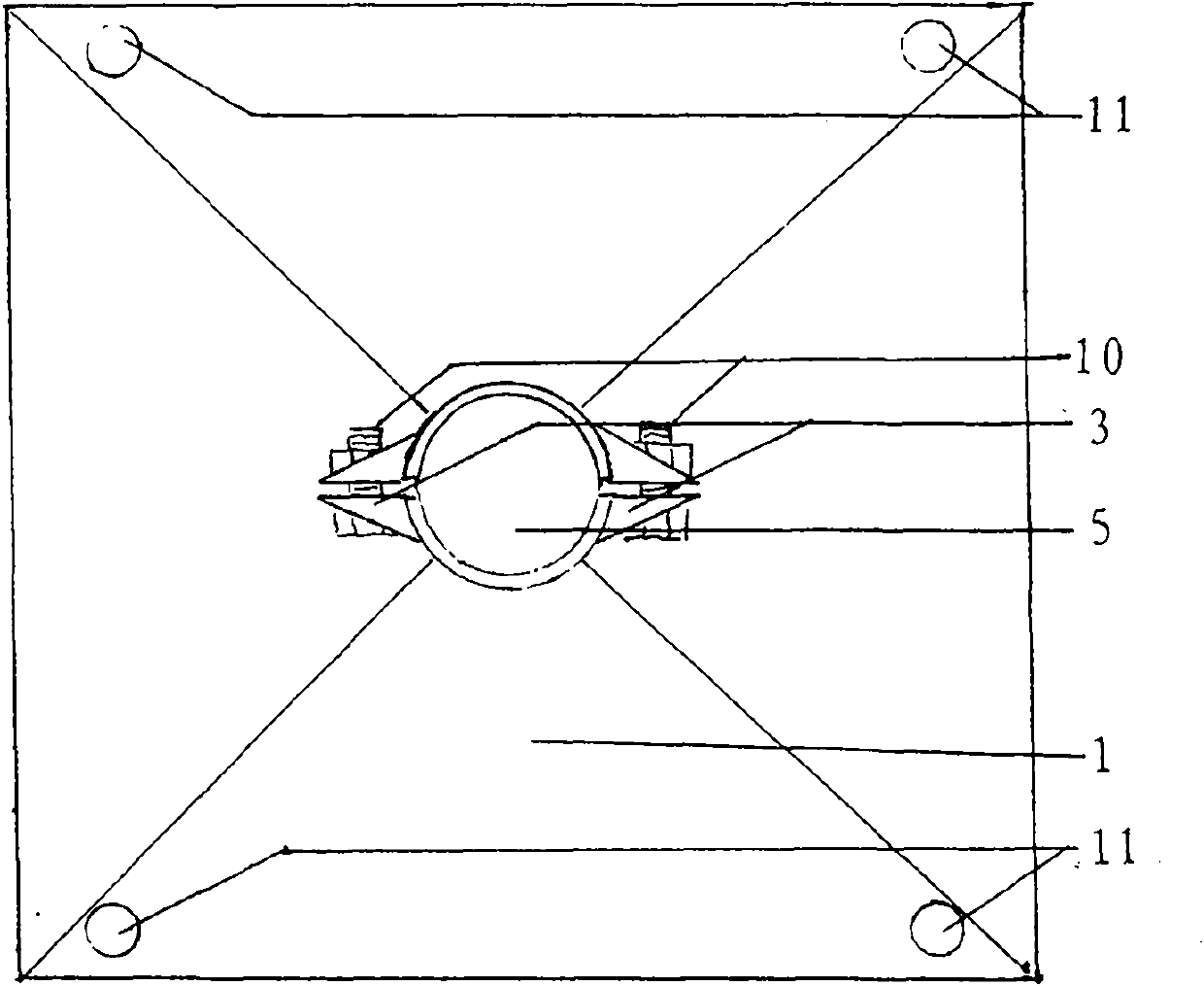

Mold for rammed-earth construction

ActiveCN104100084ASatisfy the working loadIncreased durabilityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringRammed earth

The invention discloses a mold for a rammed-earth construction. The mold comprises a plurality of plastic panels and a plurality of connecting fasteners. The connecting fasteners are combined to fix the plastic panels and enable the same to form a closed type structure. A ramming chamber is formed in the closed type structure. According to the arrangement, compared with the rammed-earth construction wood mold of the prior art, load of various working conditions during the rammed-earth construction is met, and the mold has the advantages such as good durability, long service life and energy conservation and environment protection.

Owner:HUAQIAO UNIVERSITY

Vertical prestress rammed earth wall and construction method thereof

InactiveCN107254925AImprove adhesionIncreased shear capacityWallsBuilding reinforcementsPre stressRebar

Provided are a vertical prestress rammed earth wall and a construction method thereof. The rammed earth wall comprises a wall foundation, a rammed earth body and a vertical prestress applying structure. The vertical prestress applying structure comprises two structure columns, a plurality of sets of prestress components and a capping beam. The two structure columns are fixedly connected with the wall foundation through embedded bolts which are located at the two ends of the wall foundation and used for connecting the two structure columns. The capping beam is arranged at the position, between the two structure columns, of the top of the rammed earth wall and fixedly connected with the structure columns. Each set of prestress component comprises a foundation connecting piece, an outer casing pipe and a prestress steel bar, wherein the foundation connecting piece is fixedly connected with the wall foundation through an embedded bolt which is located on the wall foundation and used for corresponding prestress connection; the lower end of the prestress steel bar is fixedly connected with the corresponding foundation connecting piece, and the upper end of the prestress steel bar penetrates through the capping beam and a steel cushion plate at the upper end of the capping beam to be fixedly connected with the capping beam; and the outer casing pipe is arranged outside the prestress steel bar in a sleeving mode. The rammed earth body is rammed among the structure columns at the two ends, the wall foundation and the capping beam. According to the vertical prestress rammed earth wall and the construction method thereof, the shear-resistant strength between rammed earth layers is enhanced, and the integrality of the wall is improved.

Owner:TIANJIN CHENGJIAN UNIV

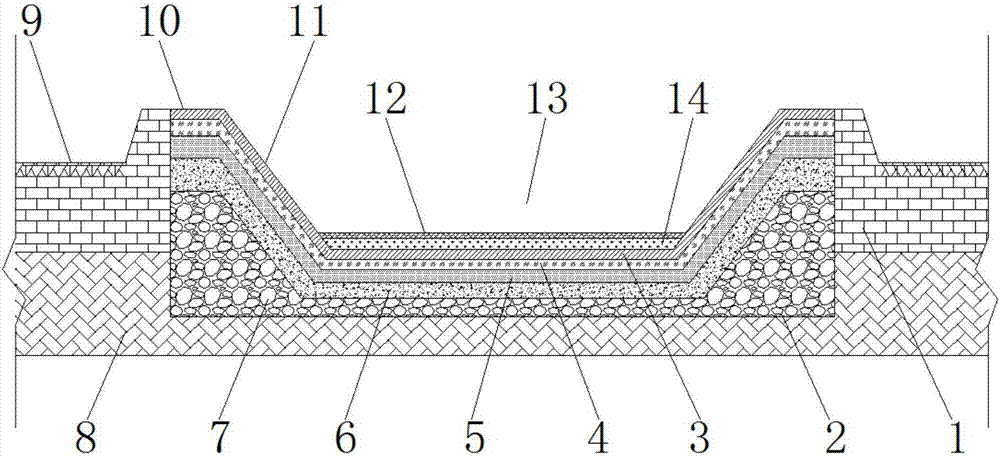

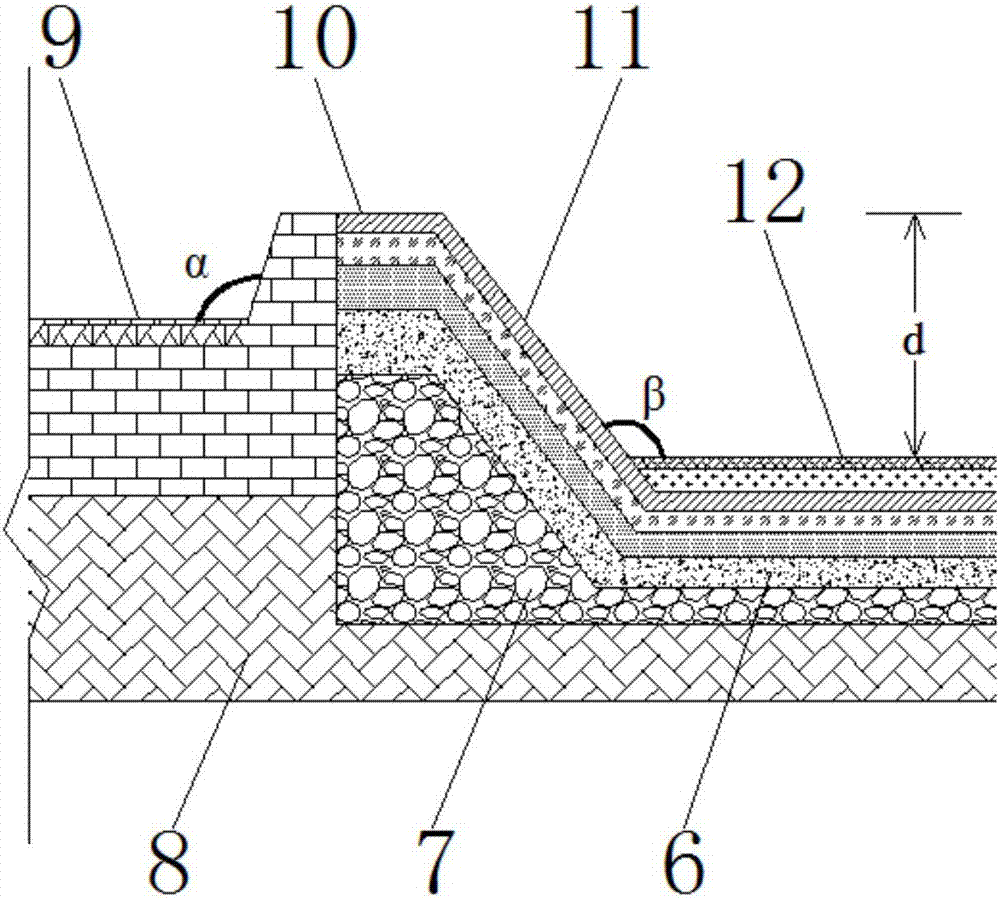

Erosion-resistant channel revetment of water conservancy project

The invention discloses an erosion-resistant channel revetment of a water conservancy project. The erosion-resistant channel revetment comprises a rammed earth layer, a soil foundation layer and a running water channel body and is characterized in that a channel foundation ditch is excavated in the upper portion of the soil foundation layer, stone subbase layer is laid in the channel foundation ditch and is tamped, a sand leveling layer is laid on the upper portion of the stone subbase layer, and an impermeable film is laid on the upper portion of the sand leveling layer; and a concrete base is laid on the upper layer of the impermeable film, and a waterproof bonding layer is laid on the upper layer of the concrete base. The erosion-resistant channel revetment of the water conservancy project is stable in structure, the erosion resisting performance of the running water channel body is improved, and the practicality and safety of the running water channel body are good; growth and reproduction of aquatic plants and animals are facilitated, plant rhizomes and other tissues can absorb and gather nutrition better, and the stability of an ecological system of the running water channel body is guaranteed; and storage of water in the running water channel body is facilitated, the seepage-proofing performance of the running water channel body is improved, water can flow in the running water channel body better, and the amount of water permeating underground is reduced.

Owner:王杰

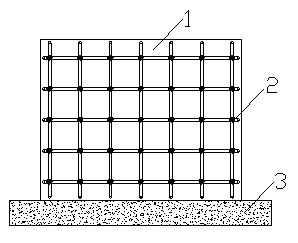

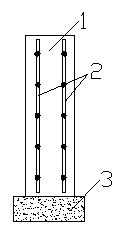

Built-in rope net rammed earth wall body and construction method thereof

InactiveCN102071761ASimple construction processLow costWallsBuilding reinforcementsEarthquake resistanceArchitectural engineering

The invention belongs to the technical field of earth building members of civil engineering, and particularly relates to a built-in rope net rammed earth wall body and a construction method. The wall body comprises a basic rammed earth wall body and a rope net which is positioned in the basic rammed earth wall body, wherein the area of the rope net can be greater than the area of the wall body, so that the side edge of the rope net is connected with other members to form structural integrity; and the construction method of the wall body mainly comprises the following steps that: the rope net is placed according to the requirements on the size and the structure of the wall body; and the wall body is rammed in a layered mode. The rammed earth wall body is easy to construct and is low in manufacturing cost; and compared with the conventional rammed earth wall, the earthquake resistance is obviously improved.

Owner:CHANGAN UNIV

Process for producing aluminum titanate-based ceramics fired body, and aluminum titanate-based ceramics fired body

InactiveUS20120034446A1Small coefficientImprove stabilityLayered productsCeramic shaping apparatusPorosityThermal expansion

The invention is to provide a process for producing an aluminum titanate-based ceramics capable of realizing low thermal expansion and high mechanical strength and having little dimensional change in firing, at a low firing temperature of lower than 1500° C. The invention is a process for producing an aluminum titanate-based ceramics fired body comprising a step of shaping a ceramic plastic rammed earth containing a precursor mixture and an organic-based binder into a predetermined shape, wherein the starting material mixture containing a titanium source powder, an aluminum source powder and a silicon source powder, and a step of maintaining the shaped ceramics plastic rammed earth within a temperature range of from 900 to 1350° C. at a temperature change per hour of from −50 to +50° C. / hr for 3 hours or more, followed by heating up to a temperature of 1400° C. or higher and firing at the temperature. And the invention is an aluminum titanate-based ceramics fired body that is obtained by the said invention and having a porosity of from 30 to 60%.

Owner:SUMITOMO CHEM CO LTD

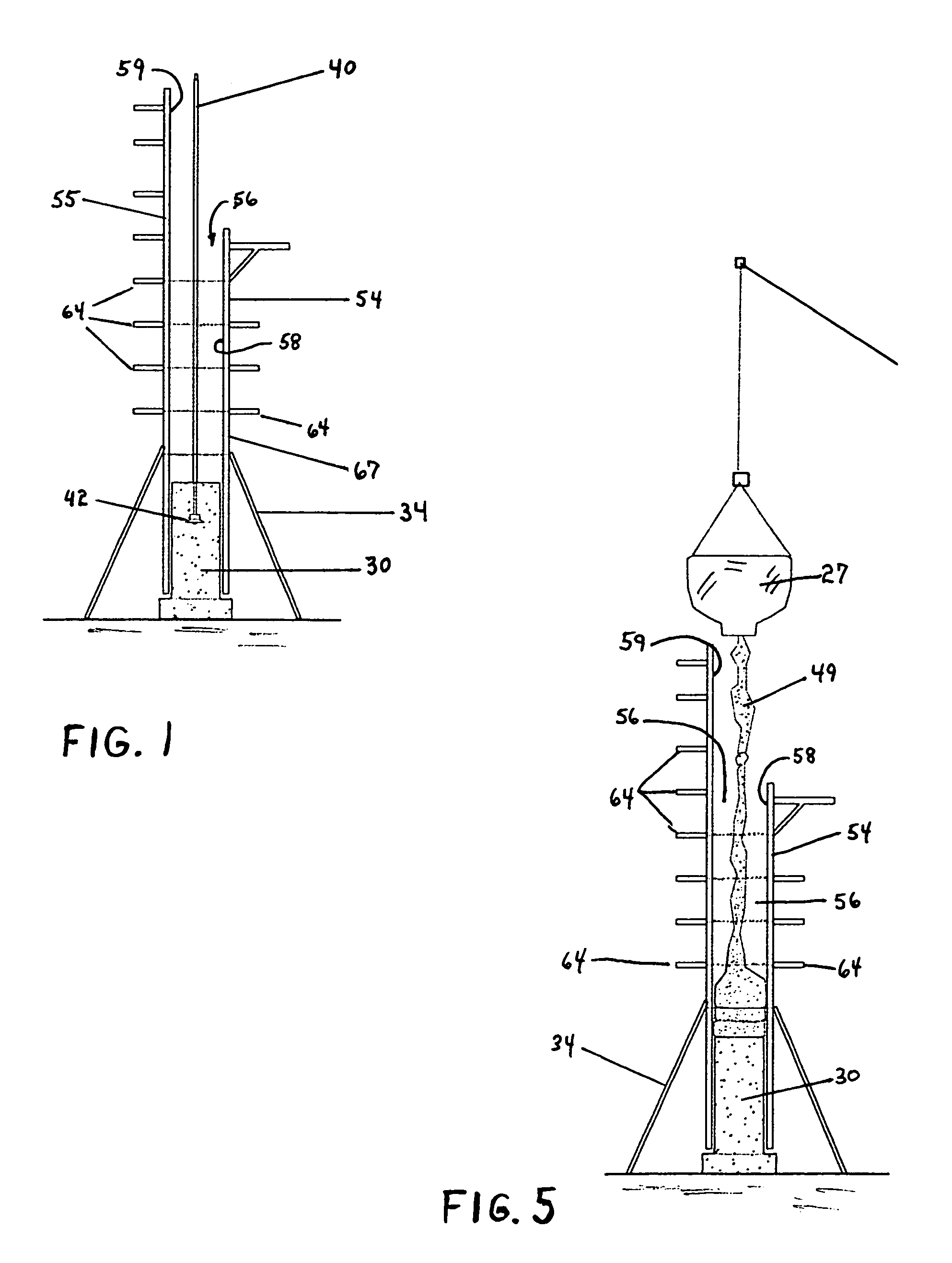

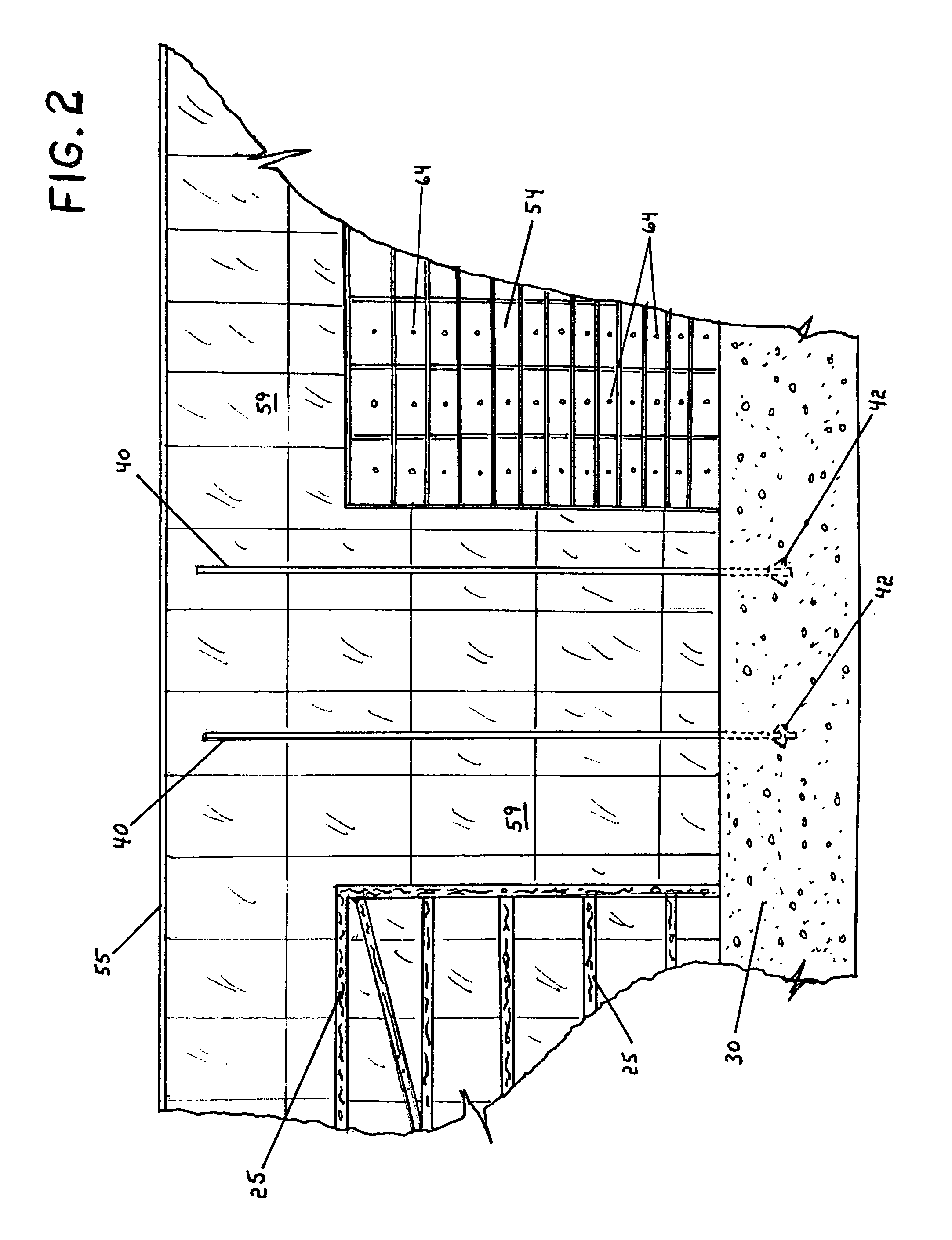

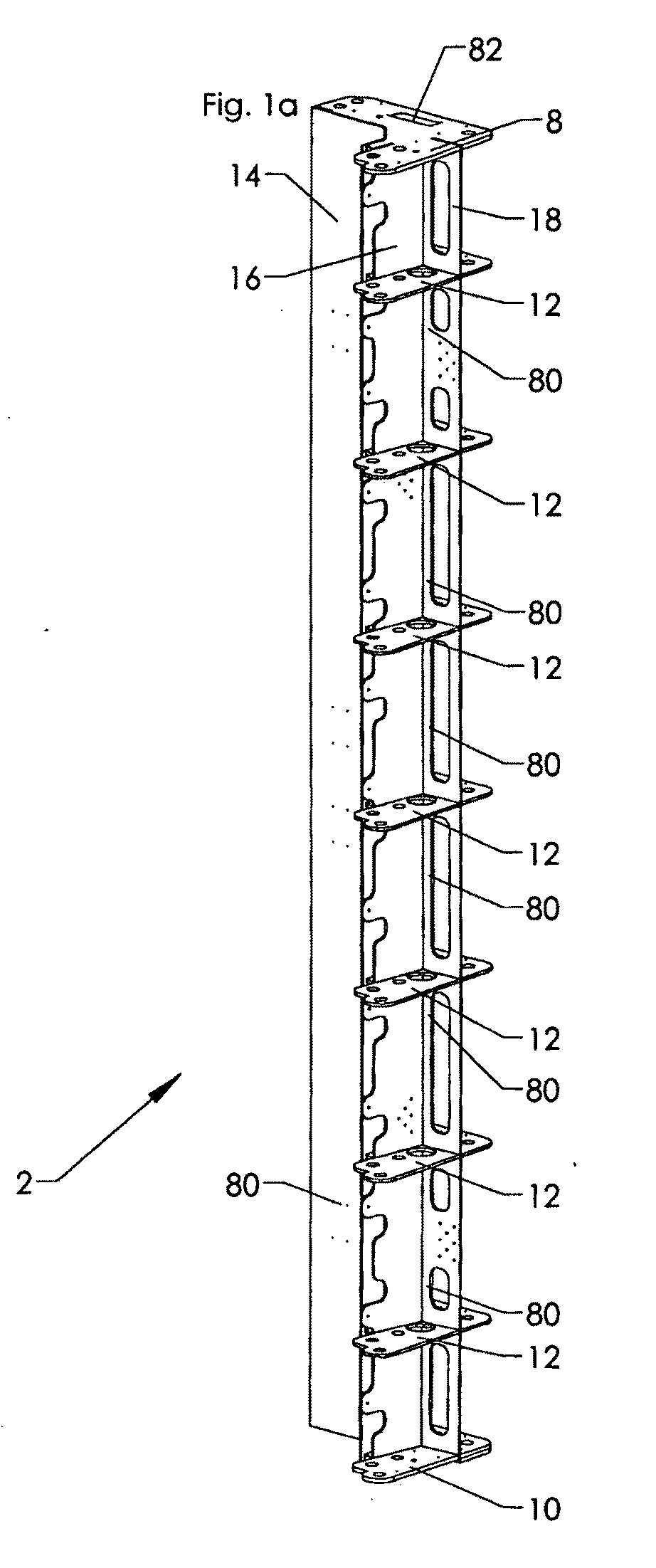

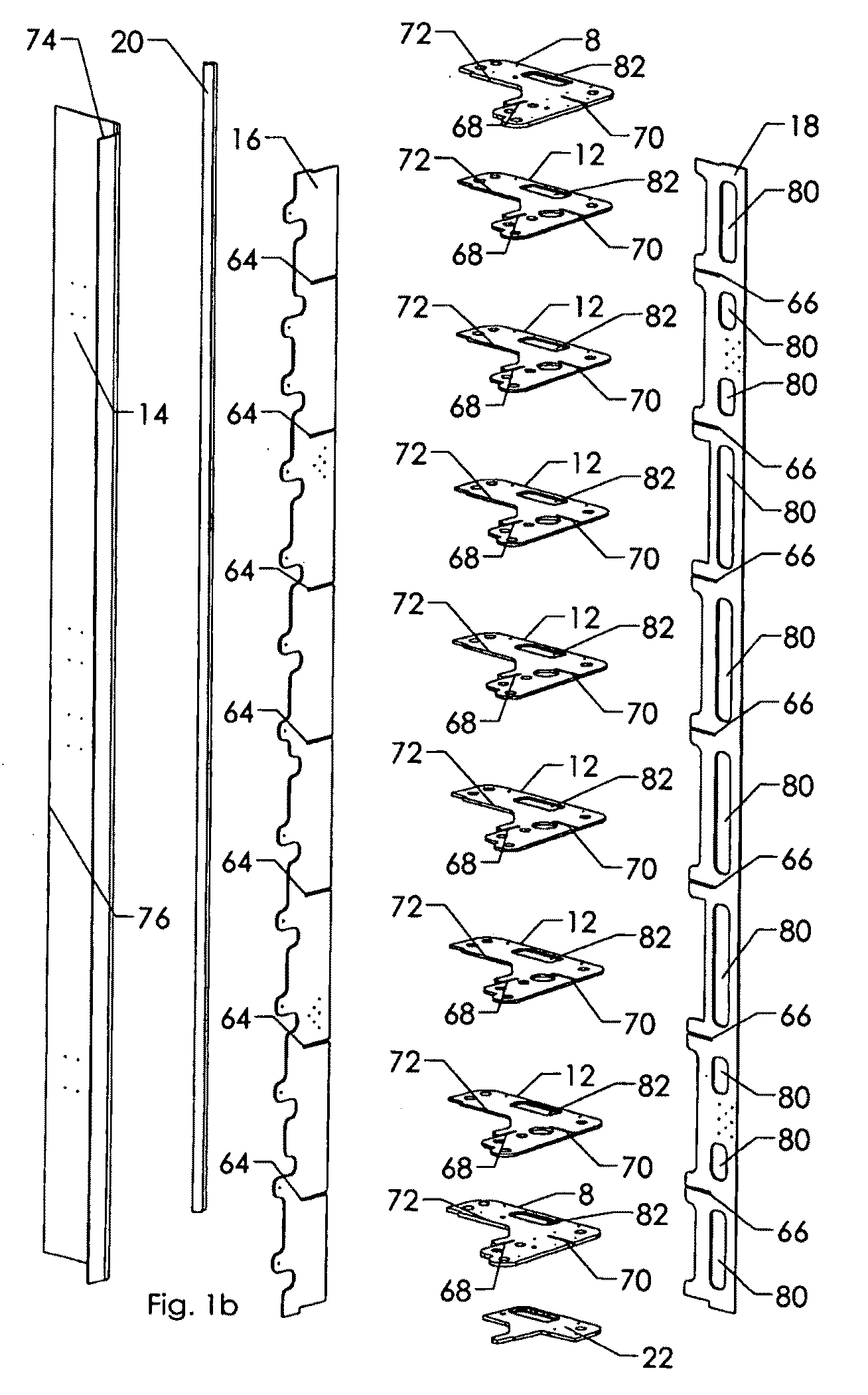

Formwork and method for constructing rammed earth walls

The invention is a formwork system and a method of using the formwork to construct rammed earth walls. The formwork comprises end panels which can be quickly assembled and disassembled to provide end stops to support side panels without the need for through-ties. The end panels comprise integral handholds for access to the full height of the formwork. The end panels are stackable, rotatable and interchangeable, such that one set of formwork may be used to create several different wall configurations. The finished wall contains an internal support structure and insulating core, without through-holes.

Owner:SIREWALL

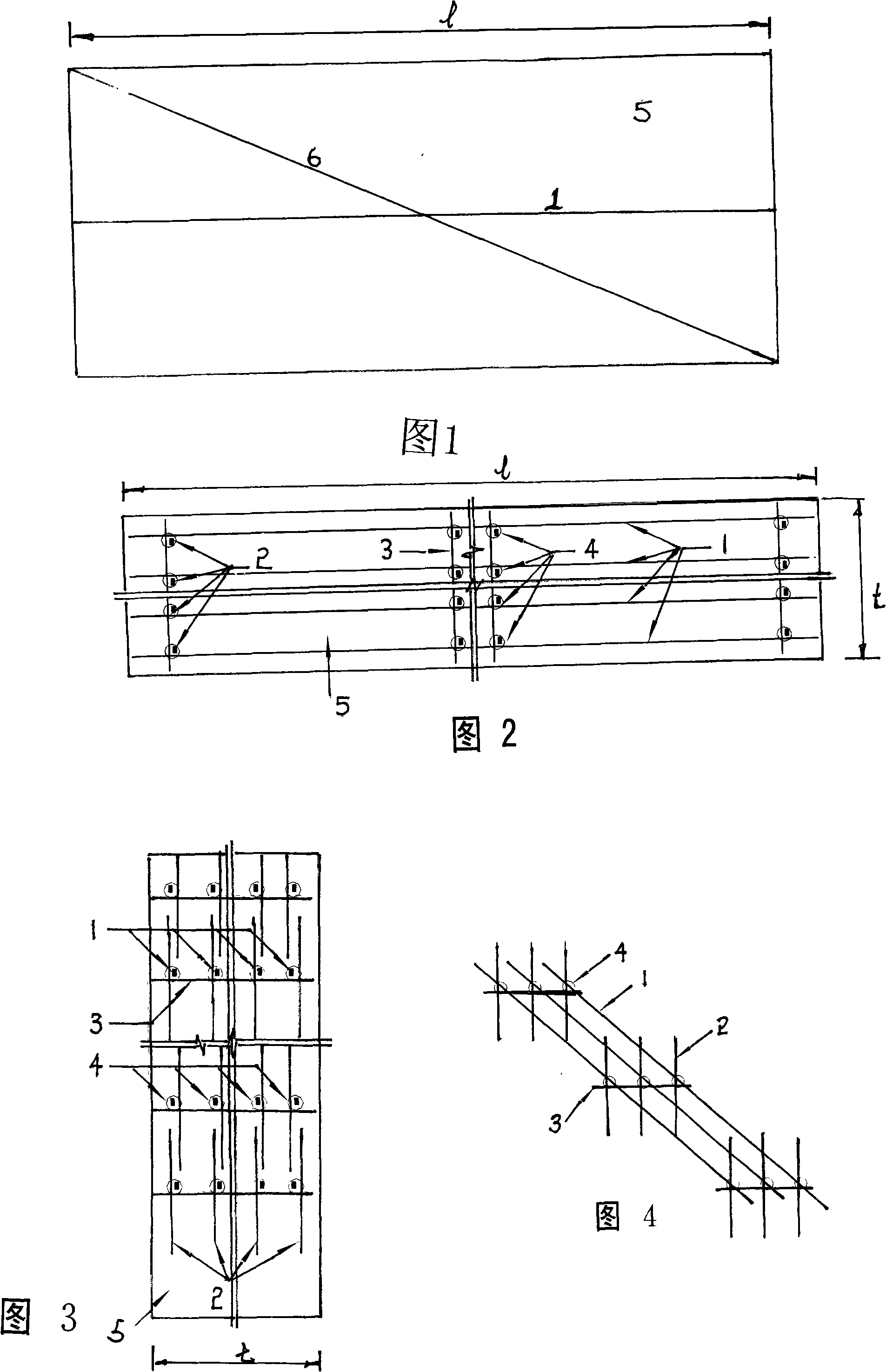

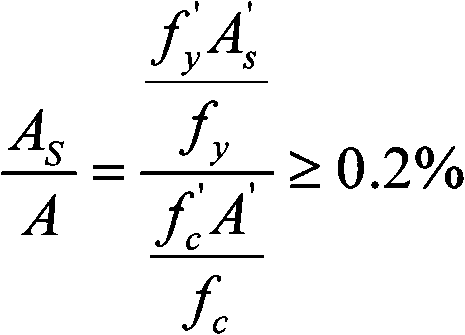

Bamboo reinforcement rammed earth wall building technique

InactiveCN101349078AIncrease horizontal forceImprove seismic performanceWallsBuilding reinforcementsHorizontal stressRural area

The invention relates to a bamboo reinforcement rammed earth wall building technology, belonging to the field of civil engineering, in particular to the technical field of earth building construction. During the prior construction of rammed earth walls, the distribution of bamboo strips are not controlled, so the bamboo reinforcement layer of the wall body becomes a weak link and does not bring into real play the tensile capability of rammed earth wall-inside horizontal stress bamboo reinforcement. The bamboo reinforcement rammed earth wall building technology comprises a rammed earth wall body and bamboo reinforcements, and during the conventional rammed earth building construction, the bamboo reinforcements are arranged on the cross section of the wall body according to proper reinforcement ratio, so that the shock strength of the wall body is obviously improved. The building technology is worth promotion and application for new buildings in rural areas.

Owner:KUNMING UNIV OF SCI & TECH

Rammed earth wall material with high strength, good corrosion resistance and abundant colors and textures

The invention belongs to the technical field of building materials, and concretely discloses a formula of a rammed earth wall material with various color combination and texture effects. The rammed earth wall material is characterized in that the rammed earth wall material comprises a base material and a visual effect adjusting material; the base material comprises, by volume, 35-48% of yellow mud, 12-26% of sands, 20-26% of fine cobblestones, 10-13% of rough cobblestones, and a proper amount of water, wherein the particle size of the fine cobblestones is smaller than 10 mm, the particle size of the rough cobblestones is 10-20 mm, and the content of water makes the rammed earth wall material not become loose after being held in hands; and the visual effect adjusting material is colored cement, and the volume percentage content of the colored cement is 2-16%. The rammed earth wall material has the substantial advantages of abundant colors and textures, good corrosion resistance, high strength, low production cost, and greenness and environmental protection.

Owner:广州昊源闲庭生态创意产业有限公司

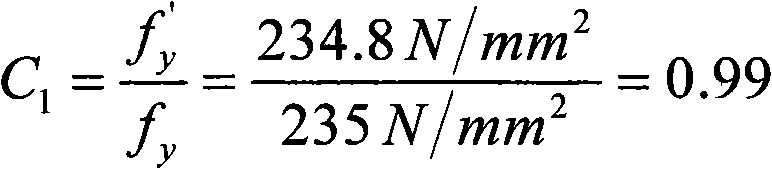

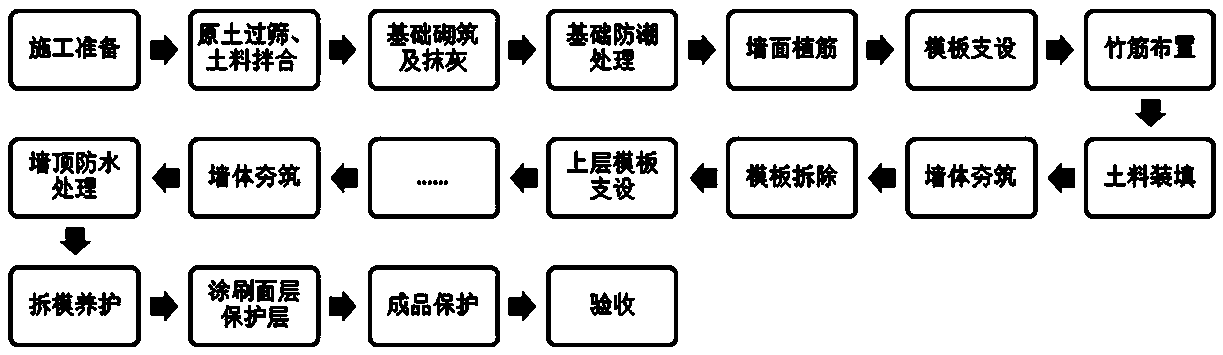

Modern landscape decoration loam wall and construction method thereof

Provided are a modern landscape decoration loam wall and a construction method thereof. Soil in a construction field is adopted as the main raw material, and after the soil is sieved, the soil is stirred with gravel, sand, cement and water according to an earth material mixing proportion, wherein the earth material proportion of the soil to the gravel to the sand to the cement to the water is 6:3:2:(0.55-5):1.2. According to the size of the wall, wooden templates are erected, layered compaction is conducted in the templates, and meanwhile, the combination of steel ribs and bamboo ribs is applied in the wall for pulling and binding, and surface layer treatment is conducted after the templates are dismantled. The innovation content mainly includes the following aspects of the earth materialmixing proportion, a structural reinforcing mode, a wall ramming technology and surface layer nursing, wherein the earth material mixing proportion is the core content of the modern landscape decoration loam wall and serves as the decisive factor on whether or not the decoration wall body can be safe, stable, practical and attractive. Moreover, by means of a structural reinforcing technology, a wall ramming mode and a surface layer nursing measure, it is ensured that use functions of the modern loam wall are achieved, and meanwhile, people's desire for enjoying architectural aesthetics is fully satisfied.

Owner:泛华建设集团有限公司

Novel rammed earth wall and forming method thereof

The invention relates to a novel rammed earth wall. The novel rammed earth wall comprises silt or clay, cement with specification of P.C 32.5, lime, sand and polyester fibers, wherein the content of the components is as follows: 60 to 75 parts of silt or clay; 5 to 20 parts of cement; 10 to 15 parts of sand; 4 to 6 parts of lime, and 0.20 to 0.50 part of polyester fibers. The invention also relates to a forming method of the novel rammed earth wall. The novel rammed earth wall has advantages that by virtue of reasonable proportioning of particles, the density of the rammed earth is maximized, so that the strength of the rammed earth is improved; by doping appropriate aggregates, the skeleton function of the rammed earth is improved, and the strength is improved; by doping active additives, the regrouping of solid substances in the rammed earth is improved, and the strength and durability are improved.

Owner:青海省建筑建材科学研究院有限责任公司

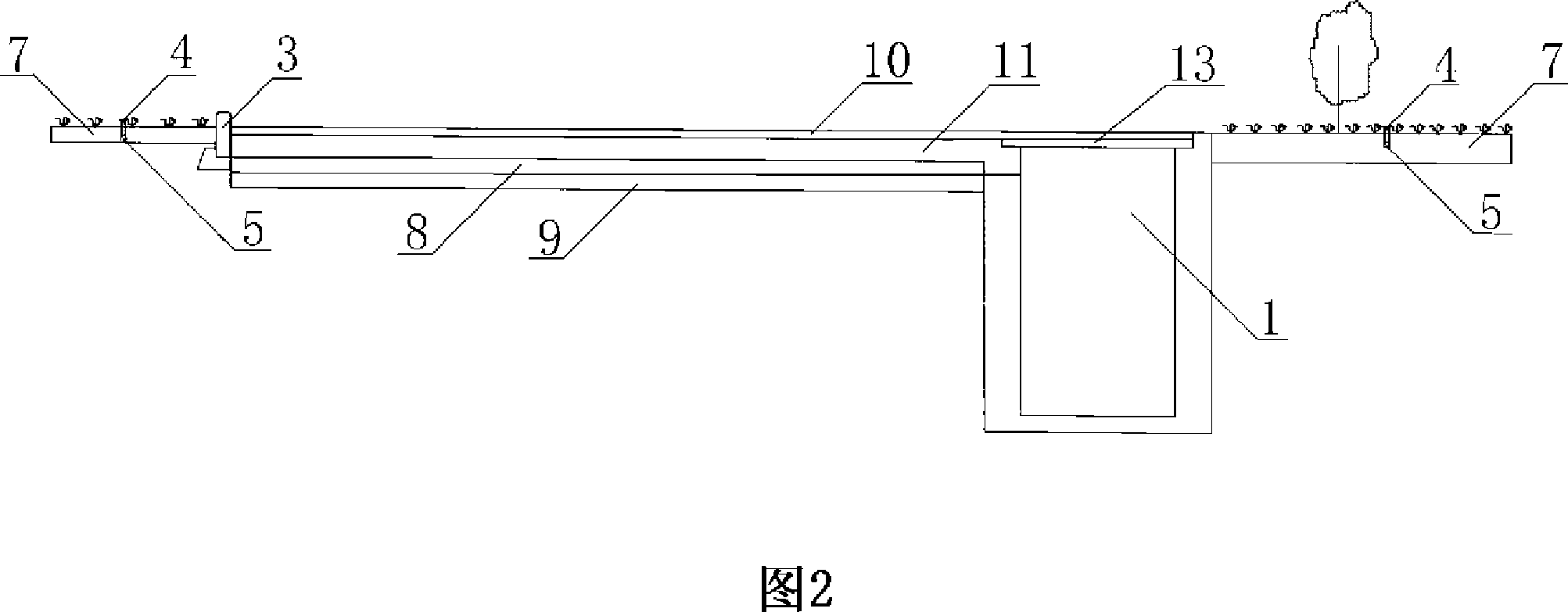

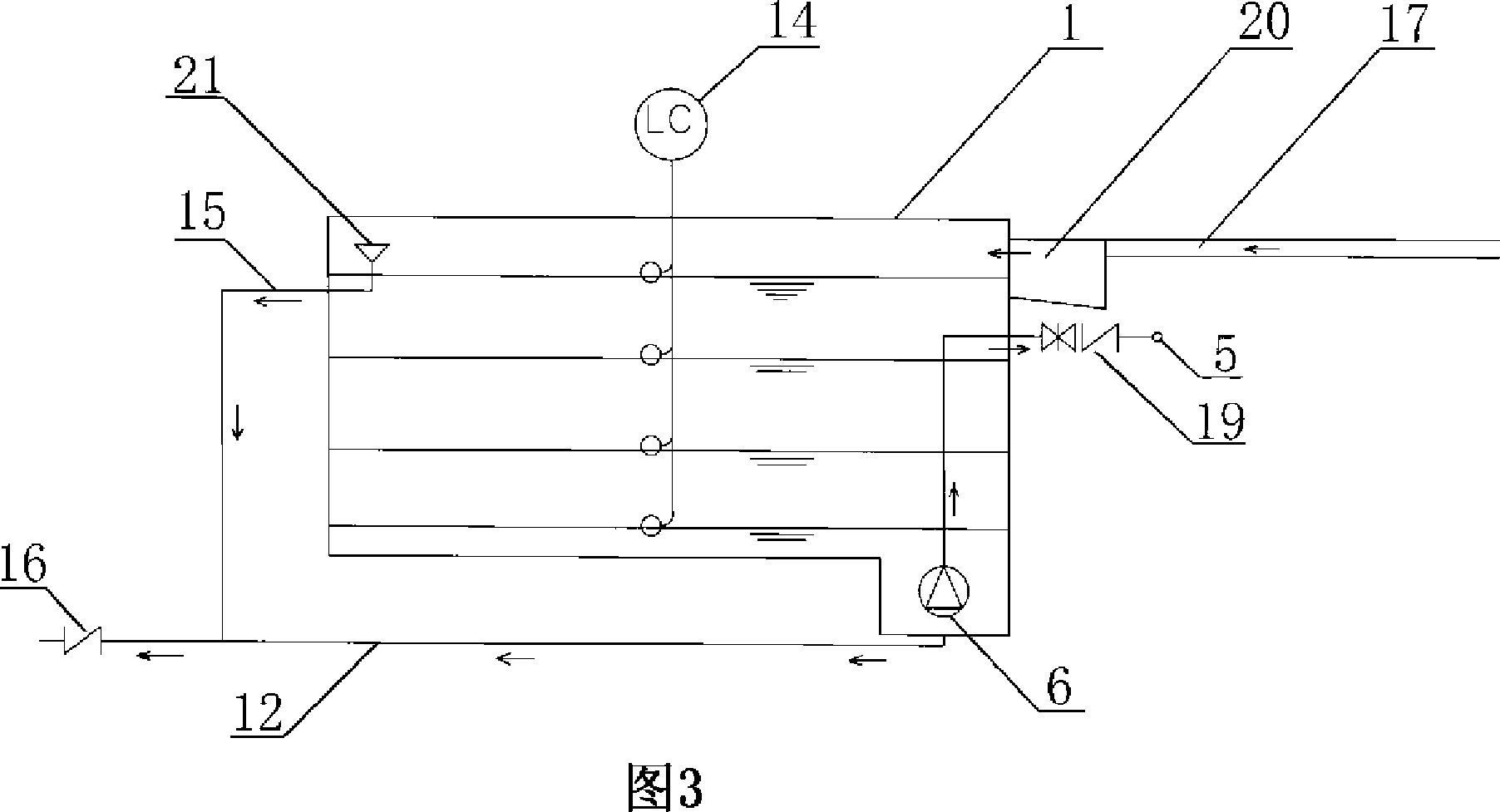

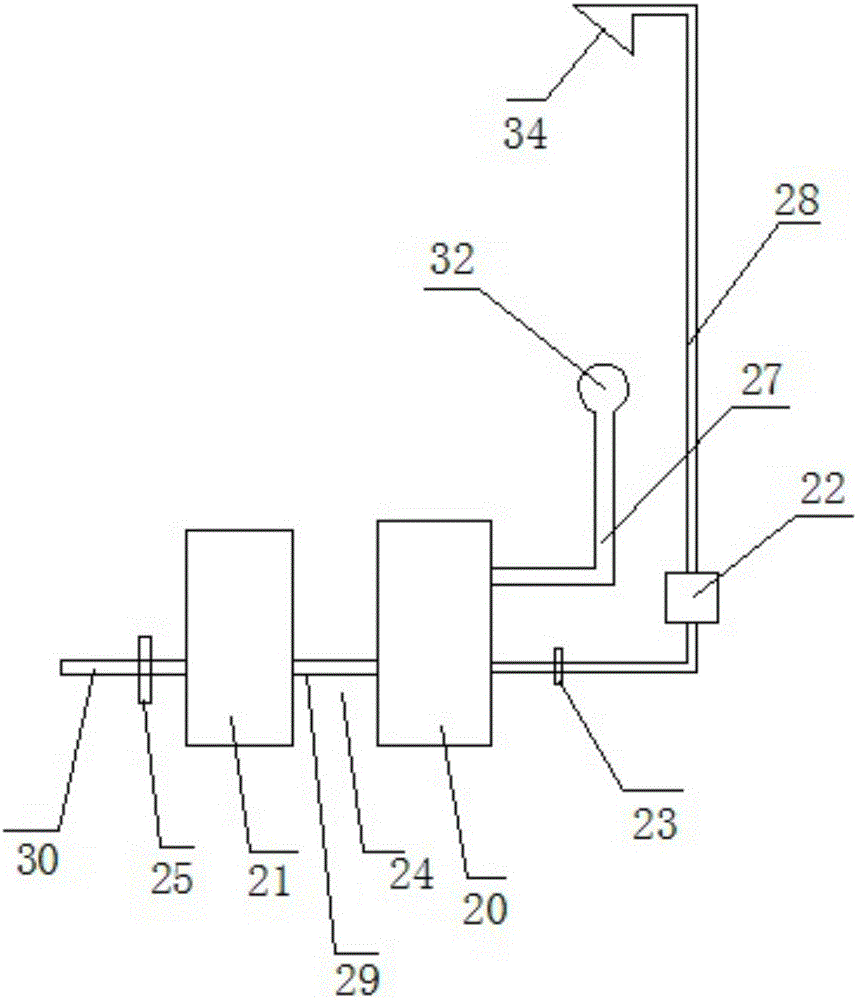

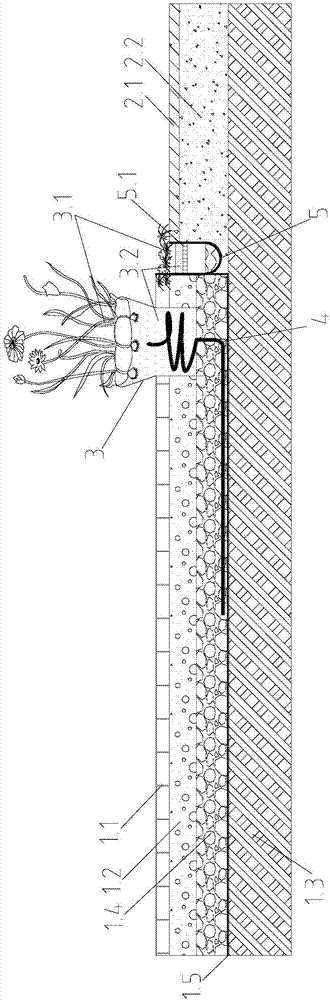

Water-harvesting type roof rainwater garden

ActiveCN106284495AEffective filteringEnsure safetyRoof coveringGeneral water supply conservationVegetationFiltration

The invention relates to a water-harvesting type roof rainwater garden. The water-harvesting type roof rainwater garden comprises an outdoor greening system and a rainwater circulating system, wherein the outdoor greening system comprises a roof vegetation layer, a sandy soil layer, a grit layer, a geotechnical cloth layer, a crushed stone cushion layer, a gravel layer, a barrier layer, a secondary filter layer and a rammed earth layer from top to bottom; the rainwater circulating system comprises a water storage tank, a water purifier, a water pump, a first electromagnetic valve, a second electromagnetic valve, a third electromagnetic valve, a soil humidity sensor, a first pipeline, a second pipeline, a third pipeline, a fourth pipeline and a PLC (programmable logic controller). According to the water-harvesting type roof rainwater garden, the problem about drainage and filtration of rainwater are solved, a graceful landscape environment space is created, and the rainwater is collected, purified and recycled perfectly.

Owner:FLOWER KING ECO ENG CO LTD

Hammerblow tamper of excavator

InactiveCN101906774AIncrease the use of functionsSolve difficult compaction problemsSoil-shifting machines/dredgersSoil preservationArchitectural engineeringExcavator

The invention discloses a hammerblow tamper of an excavator. A ramming mechanism is additionally arranged on a breaking hammer bore bit, and the hammerblow tamper can carry out forced compaction on earthwork or a foundation at an arbitrary difficult construction part by utilizing large hammering power generated by the excavator and a breaking hammer, thereby greatly enhancing the bearing capacity of the earthwork, improving the construction efficiency, and enabling a hydraulic breaking hammer installed on the excavator or a unique function of compacting the earthwork is added on a loader.

Owner:左天德

High-performance rammed earth cube test piece and preparation method thereof

InactiveCN111018475ASolve the main problemsHigh strengthPreparing sample for investigationCompressive strengthRammed earth

The invention discloses a preparation method of a high-performance rammed earth cube test piece. The cube test piece comprises, by weight, 30-60 parts of raw soil, 10-50 parts of sands, 10-50 parts ofstone, 2-10 parts of cement, 2-10 parts of lime, 1-5 parts of a soil stabilizer, 0.1-0.25 part of hemp threads and 1-5 parts of water glass. The preparation method comprises the following steps: 1, weighing and mixing raw materials: weighing the raw materials according to the formula ratio, sequentially putting the raw materials into a stirrer, mixing for 7 min, and controlling the water contentof the obtained mixture to be 8-12%; and 2, ramming the cube test piece. Compared with traditional rammed earth cube test pieces, the rammed earth cube test piece prepared in the invention has the following advantages: the anti-cracking strength and the compressive strength are improved, and the main problems of the traditional rammed earth dwelling are solved to a certain extent.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Construction method for smearing rammed earth facing to show vicissitude texture aesthetics

ActiveCN110761508AHigh strengthGood weather resistanceCovering/liningsFilling pastesWeather resistanceMining engineering

The invention relates to the field of rammed earth facing construction methods, in particular to a construction method for smearing a rammed earth facing to show vicissitude texture aesthetics. The construction method includes the following steps: production of the vicissitude texture of the wall surface is conducted, preliminary treatment of the construction wall surface is conducted, materials and tools are prepared, surface treatment of the construction wall surface is conducted, after two to three hours after painting of an interface agent and anti-alkali primer, 1 to 2 mm thickness of hemp cut mud is scraped in batches, and thus rammed earth wall smearing work can be conducted; and wall surface smearing and production of silica gel texture molds are conducted. According to the construction method for smearing the rammed earth facing to show the vicissitude texture aesthetics, on the basis of ensuring the construction quality and improving the wall strength, weather resistance andwater resistance, the surface effect of the vicissitude texture having historic and cultural connotations and imitation of the traditional rammed earth wall texture can be shown; raw materials, namelyclay and sand are obtained from local sources, the ratio is scientific, the wall strength and hardness are high, the sturdy and durable effects are achieved; the waterproof, anti-penetration, anti-weathering and anti-freeze thawing effects are achieved, and stable and long-lasting performance is achieved; and construction is convenient and quick, the cost is low, the cost performance is high, andin the later period, maintenance and handling are easy.

Owner:河南朴之原建筑肌理研究院有限公司

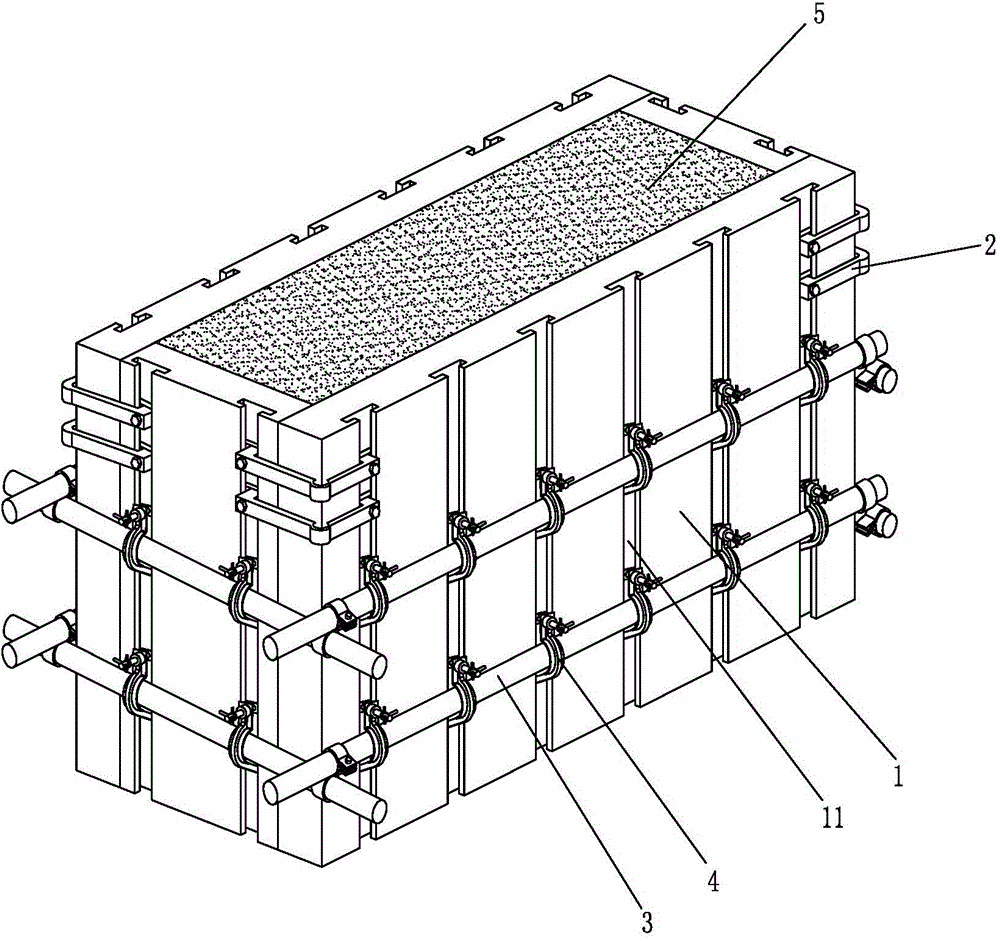

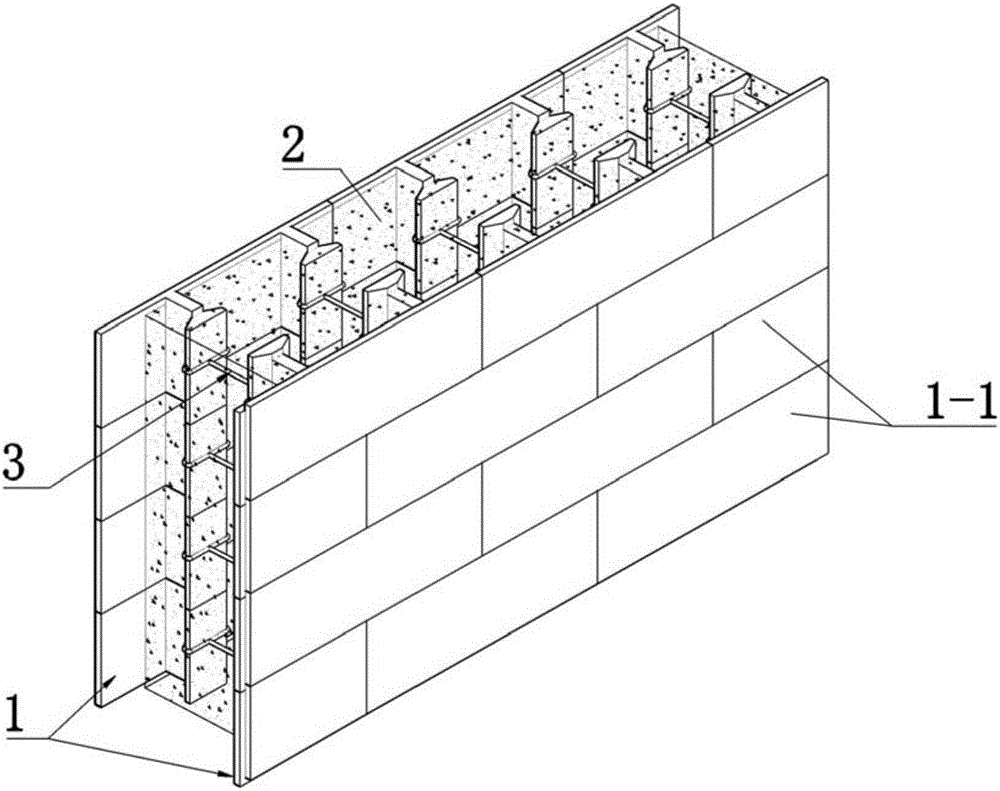

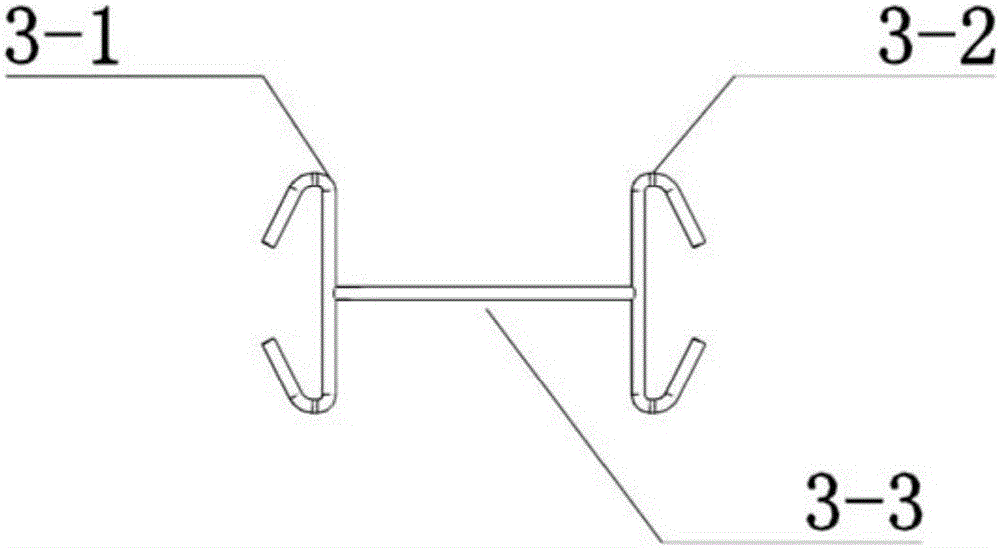

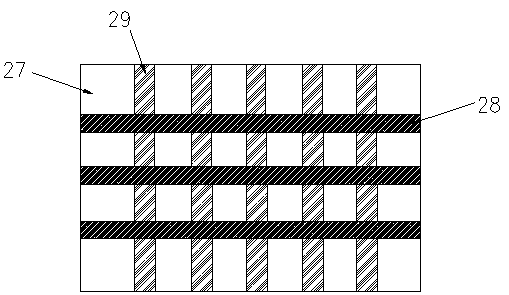

Composite rammed-earth wall, template device adopted in construction thereof and construction method thereof

InactiveCN105804294AHigh strengthPlay a protective effectWallsBuilding material handlingArray data structureWeather resistance

The invention relates to a composite rammed-earth wall, a template device adopted in the construction thereof and a construction method thereof. The wall comprises two wallboards which are arranged in a mirror symmetry manner and a rammed-earth main body filling between the two wallboards, wherein each wallboard is formed by splicing a plurality of unit wallboards according to a way of multiple layers in a vertical direction and multiple wallboards at each layer, each unit wallboard is of a reinforced concrete structure, and a reinforced bar connection part is arranged between every two opposite unit wallboards; a template structure comprises wall templates arranged on two surfaces, side baffle plates arranged at two sides and a plurality of groups of template fixing assemblies, wherein the wall templates on two surfaces form the two wallboards, during the construction process of the wall, the side baffle plates at two sides temporarily limit two sides of filled rammed earth, and the plurality of groups of template fixing assemblies are detachably clamped on the upper end parts of the two wall templates. The construction method comprises: performing construction by adopting the template device, first ramming a first layer of the wall, and then gradually ramming the wall upwards layer by layer until a set height of the wall is achieved. The rammed composite wall is relatively high in strength and relatively good in weather resistance and durability.

Owner:TIANJIN CHENGJIAN UNIV

Waterproof structure for ecological artificial lake

The invention discloses a waterproof structure for an ecological artificial lake, relates to a waterproof technology for underground construction, and specifically relates to a waterproof technology for the bottom of an ecological artificial lake. The waterproof structure for the ecological artificial lake comprises a rammed-earth layer, a silty clay-rolled cushion layer, a silty clay-rolled protection layer and a medium sand water purification layer. The waterproof structure for the ecological artificial lake is characterized in that the constructed layers of the waterproof structure are located at the bottom of the waterproof structure, and sequentially are the rammed-earth layer, the silty clay-rolled cushion layer, a bentonite waterproof layer, a non-woven fabric, the silty clay-rolled protection layer, a silty clay-rolled counter-weight and the medium sand water purification layer from bottom up; the edge of the waterproof structure is more than 200mm higher than the horizontal plane; and a concrete protection belt is laid on the upper part of the edge of the waterproof structure, and the concrete protection belt is located on the upper part of the edge of the bentonite waterproof layer for preventing the bentonite waterproof layer from leakage. The waterproof structure for the ecological artificial lake, which is disclosed by the invention, has the characteristics of being novel in structure, simple and convenient to construct, capable of reducing construction cost, high in waterproofness, capable of achieving a service life of over thousand years, and the like; therefore, a novel waterproof structure for an ecological artificial lake, which integrates economical efficiency with practicability, is achieved.

Owner:何发林

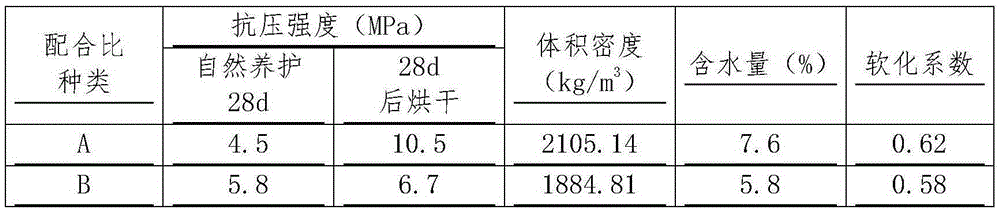

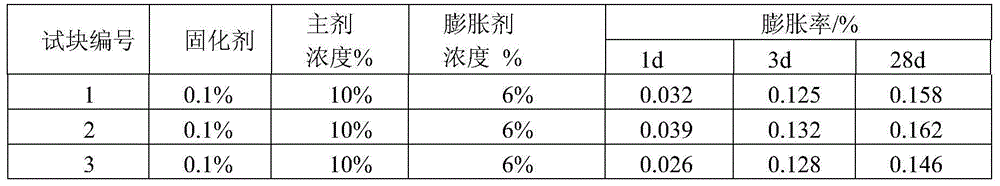

Earthen site grouting material of fiber bakelite rod grouted rock bolt based on water-based fluorine

The invention discloses an earthen site grouting material of a fiber bakelite rod grouted rock bolt based on water-based fluorine. The earthen site grouting material is prepared from the following raw materials at the ratio of (8-10) to (8-10) to (0.5-1.5) to (0.7-1) to (8-10) to (1.5-2.5) to (4-5), wherein the ratio is mass ratio. The earthen site grouting material has consistency with a surrounding soil material in ingredient, physical and chemical property and mechanical property, can be fused into a whole under the action of a curing agent water-based fluorine and inserted bar glue, and has compatibility with a surrounding rammed earth layer; meanwhile, the material contains the water-based fluorine, the inserted bar glue and the like, is close to cotton and bast fiber and phenolic resin in the bakelite rock bolt in property, and has relatively good compatibility; the curing time can be shortened; and filling and anchoring are facilitated.

Owner:SHAANXI NORMAL UNIV

Rammer for construction site

ActiveCN111101500AImprove flatnessNovel structural designSoil-shifting machines/dredgersSoil preservationDrive wheelAgricultural engineering

The invention discloses a rammer for a construction site. The rammer comprises a rotating disc, a base, a cab and soil ramming mechanisms. A front drive wheel and a rear drive wheel are mounted at thebottom of the base. The rotating disc is mounted on the upper end face of the base. The cab is fixed to the rotating disc. A left stand column and a right stand column are vertically mounted on the surfaces of the front end and the rear end of the rotating disc. A left cross beam is fixedly mounted on one side of the left stand column through a bolt, and a right cross beam is fixedly mounted on one side of the right stand column through a bolt. The number of the soil ramming mechanisms is two sets, the soil ramming mechanisms comprises a first soil ramming mechanism and the second soil ramming mechanism, the first soil ramming mechanism is arranged below the left cross beam, and the second soil ramming mechanism is arranged below the right cross beam. The rammer further comprises a firstbulldozing assembly and a second bulldozing assembly. According to the rammer, structural design is novel, redesigning and improving are carried out on the basis of an existing rammer, the functions of rotating, bidirectional bulldozing and bidirectional soil ramming are achieved, the soil ramming efficiency is effectively improved, and flatness of the soil rammed ground can be improved.

Owner:QINGDAO HAIDE ROAD & BRIDGE ENG

Sponge urban ecological sidewalk rain water utilization structure

ActiveCN107142814ARealize collection and storageIncrease profitIn situ pavingsPaving gutters/kerbsSurface layerCrushed stone

The invention discloses a sponge urban ecological sidewalk rain water utilization structure, which is arranged between a sidewalk and a motorway, wherein roadbed filled earth of the sidewalk is successively formed by a water permeable surface layer, a water permeable concrete layer and a rammed earth layer from top to bottom, roadbed filled earth of the motorway is successively formed by a road asphalt layer, a road concrete layer and a rammed earth layer from top to bottom and comprises an ecological isolation pier, the ecological isolation pier is arranged at the water permeable concrete layer, a grading crushed stone layer is also arranged between the water permeable concrete layer and the rammed earth layer, the top of the ecological isolation pier is exposed to the air, the bottom of the ecological isolation pier is communicated with the grading crushed stone layer, planting soil for a plant to grow and a water absorption strip are arranged in the ecological isolation pier, one end of the water absorption strip is arranged in the planting soil, and the other end of the water absorption strip is arranged in the grading crushed stone layer. The sponge urban ecological sidewalk rainy water utilization structure has the advantages that the structural construction is convenient, the energy is saved, the environment is protected, the rain water utilization rate and the urban green coverage rate are increased, the construction price is low, the maintenance is simple, and the like.

Owner:WUHAN YIYE CONSTR ENG

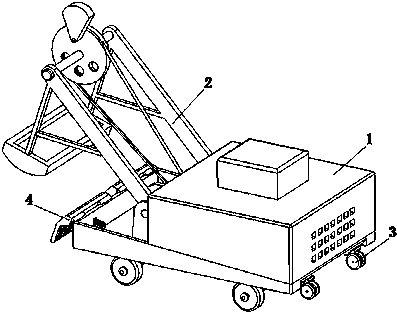

Construction site earth rammer for buildings

PendingCN108560530AImprove efficiencyImprove applicabilitySoil preservationWorking environmentRammed earth

The invention relates to the field of building equipment, and particularly relates to a construction site earth rammer for buildings. The construction site earth rammer comprises a bearing platform, an earth ramming device, a positioning and moving device and a sundries removal device, wherein the bearing platform comprises a storage box and a closing box; the earth hamming device comprises a rammed earth driving part are arranged in the storage box and a rammed earth swinging part; the positioning and moving device comprises a main driving part, a driven part and an auxiliary part; the main driving part and the driven part are respectively arranged at the front end and the rear end of the bottom part of the storage box; the auxiliary part is arranged on the edge of the bottom part of thestorage box; the sundries removal device comprises two removal parts which are symmetrically distributed on a side wall, close to one end of the rammed earth swinging part, of the storage box; the edge of the top part of each of the removal parts is movably connected with a side wall of the storage box. According to the construction site earth rammer for buildings disclosed by the invention, an earth hamming operation of edge corners of wall corners and the like can be realized, the using efficiency of the earth rammer is improved, and the adaptability of the earth hammer is improved; the earth hamming operation of the earth hammer is carried out, so that a safe and clean working environment is provided.

Owner:王红红

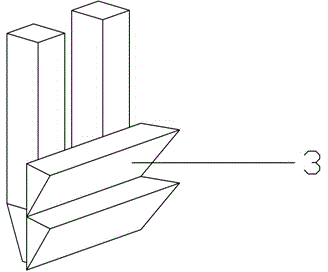

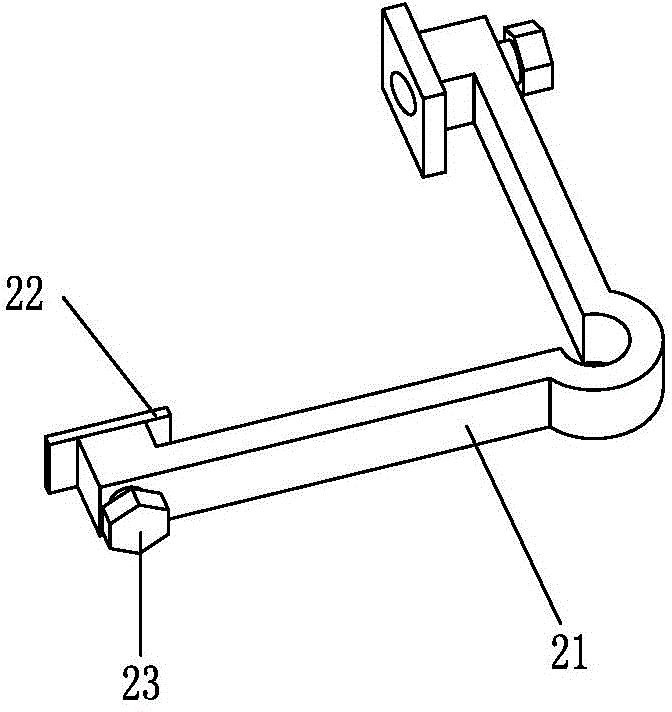

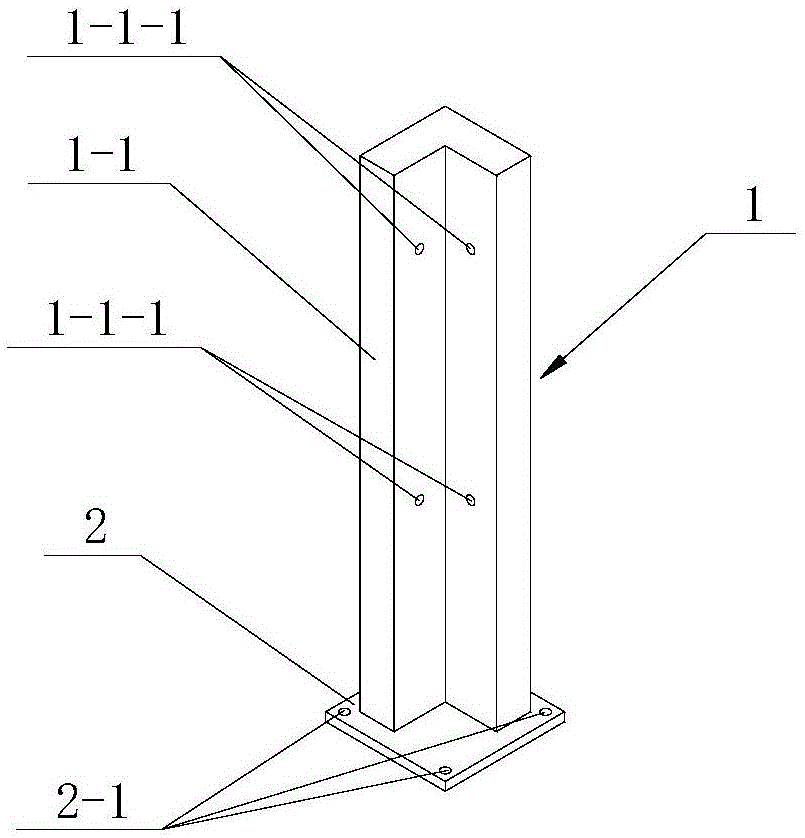

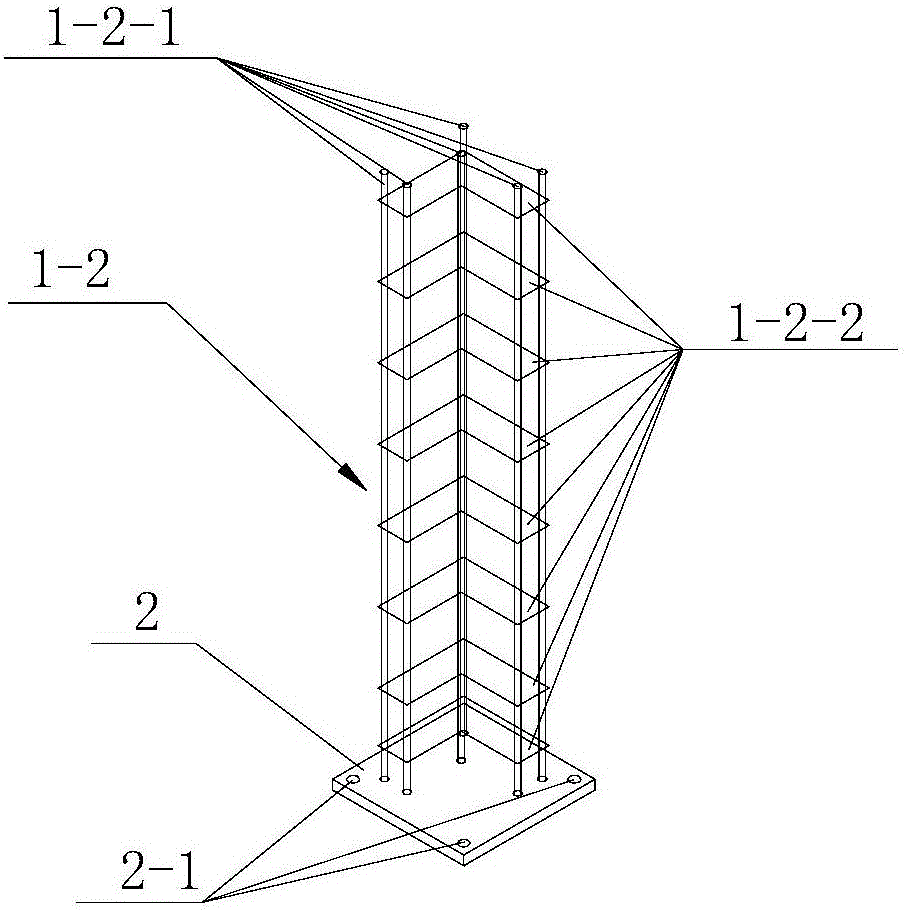

Prefabricated constructional column used at exposed corner of wall and rammed earth wall structure as well as construction method thereof

InactiveCN106545111AAvoid destructionGood anti-collision performanceWallsReinforced concreteEngineering

The invention provides a prefabricated constructional column used at an exposed corner of a wall and a rammed earth wall structure as well as a construction method of the rammed earth wall structure. The prefabricated constructional column is a prefabricated reinforced concrete structure consisting of an L-shaped columnar part and an end plate part, wherein a plurality of tie ring installing holes are formed in two constructional sides of the L-shaped columnar part; the L-shaped columnar part comprises external pouring concrete and a built-in reinforcement cage; the end plate is welded on the lower end of the built-in reinforcement cage; and a plurality of reserved connecting holes are formed in the end plate. The rammed earth wall structure comprises a base ring beam embedded in the ground and the wall arranged above the ground, wherein the wall comprises a rammed earth main body part and the prefabricated constructional column arranged at each exposed corner of the wall; and a plurality of tie bars are connected between the prefabricated constructional columns at the two ends of the same wall. The construction method of the rammed earth wall structure comprises the following steps of: step one. pouring the prefabricated constructional columns in advance; step two. pouring the base ring beam; step three. installing the prefabricated constructional columns on the base ring beam; and step four. ramming the wall. The prefabricated constructional columns have a protecting effect on the exposed corners of the wall. The rammed earth wall structure has relatively good integrality and durability.

Owner:TIANJIN CHENGJIAN UNIV

Rammed earth wall formula and preparation method thereof

Owner:FUZHOU UNIV

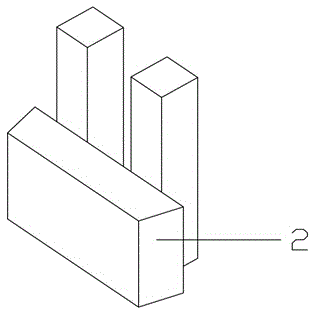

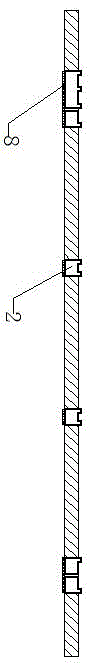

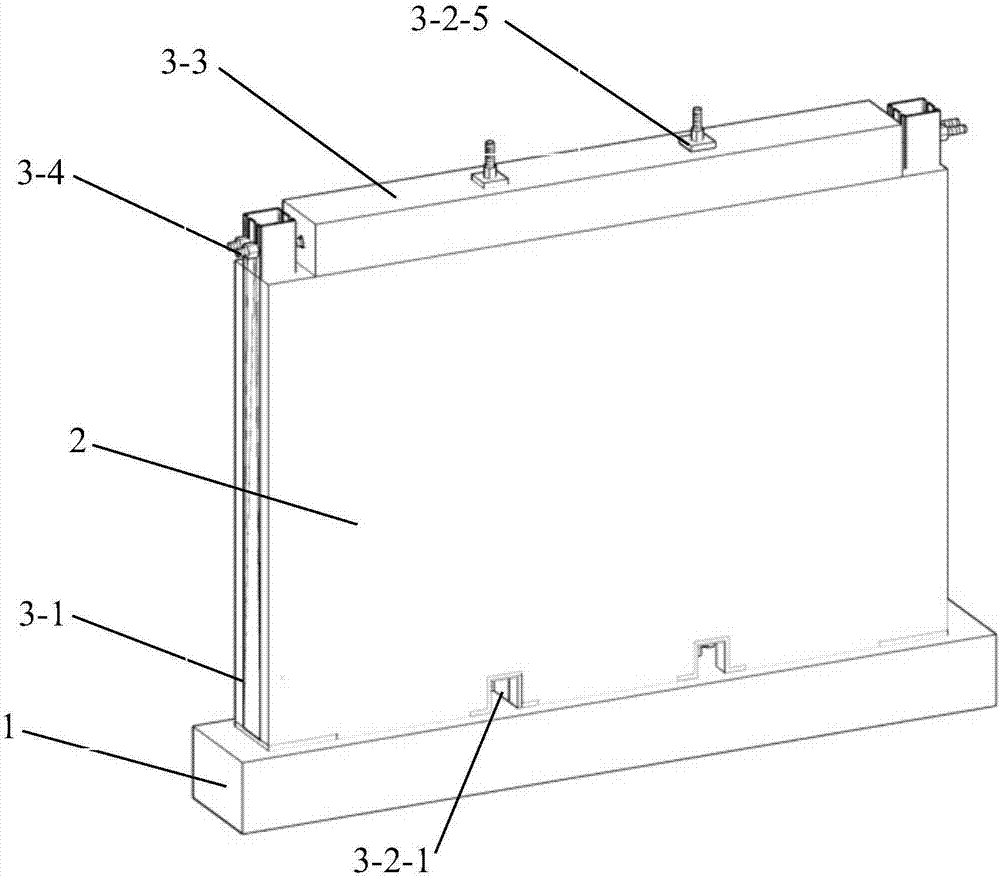

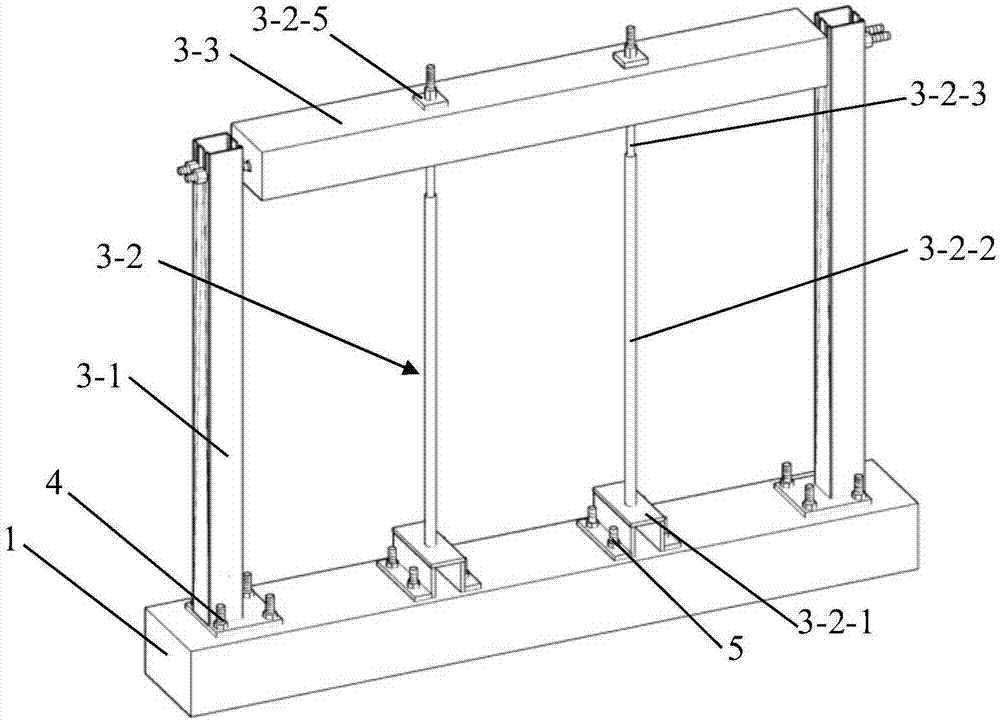

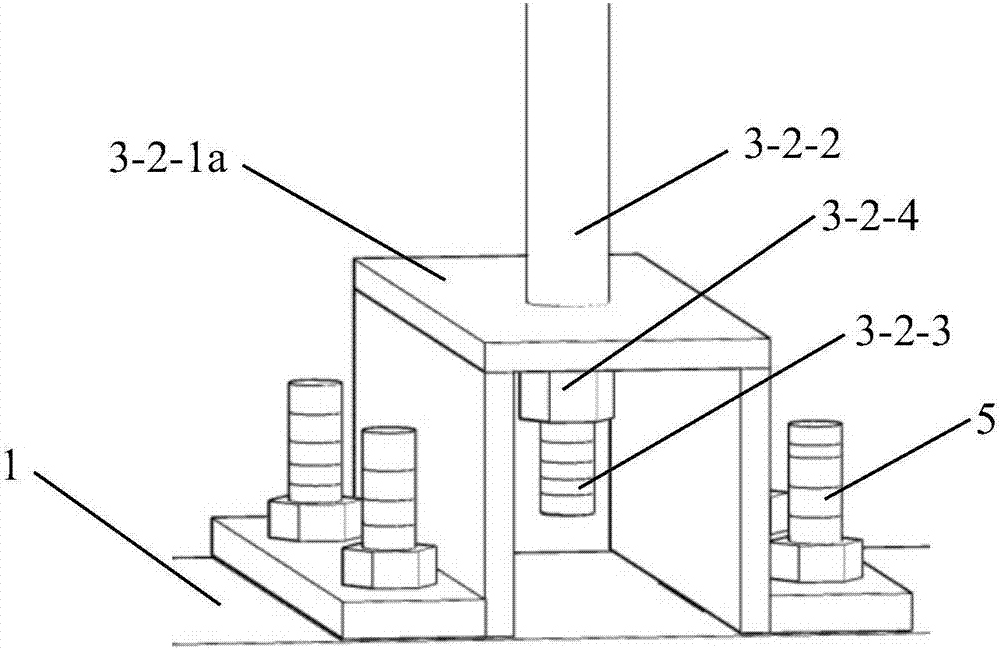

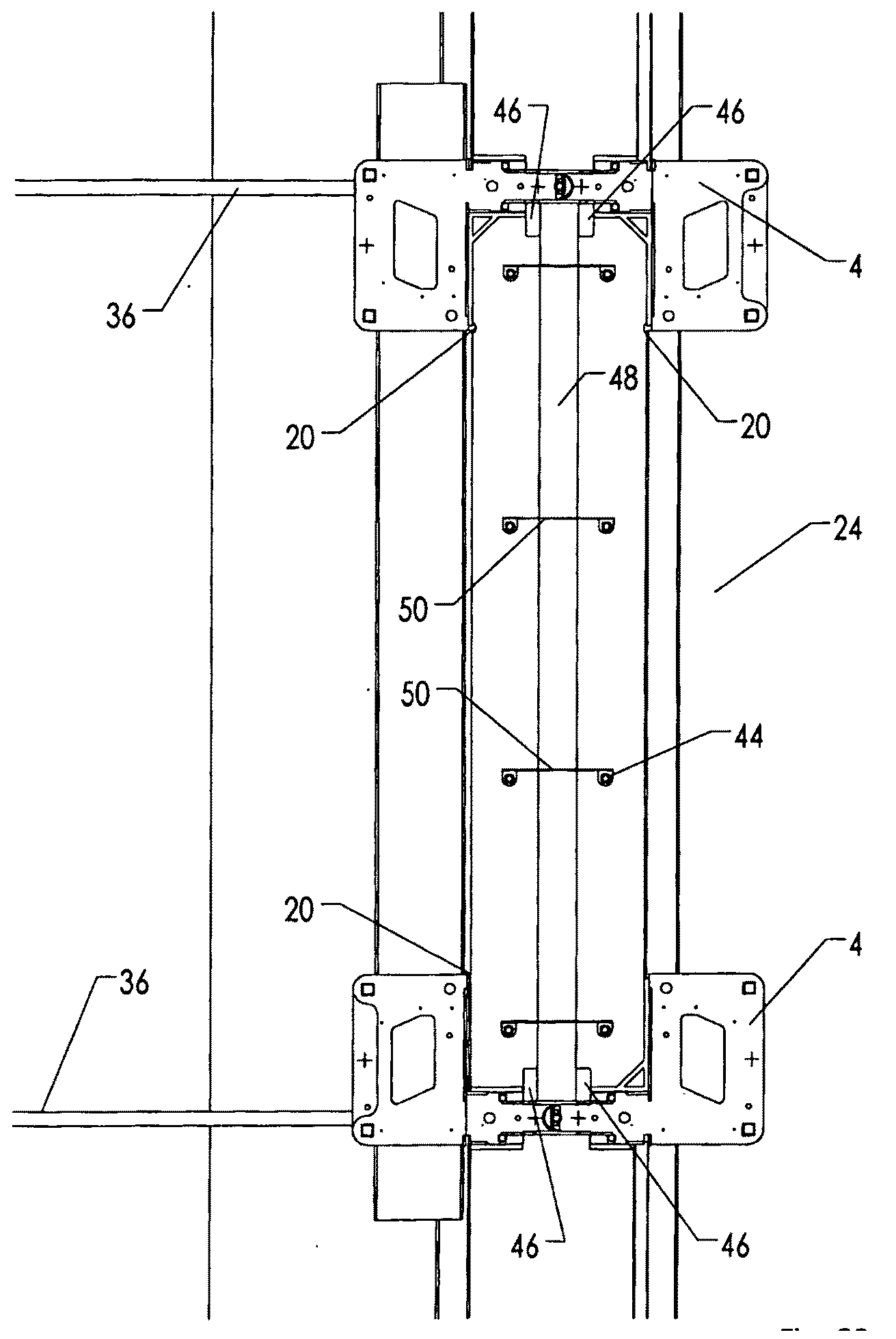

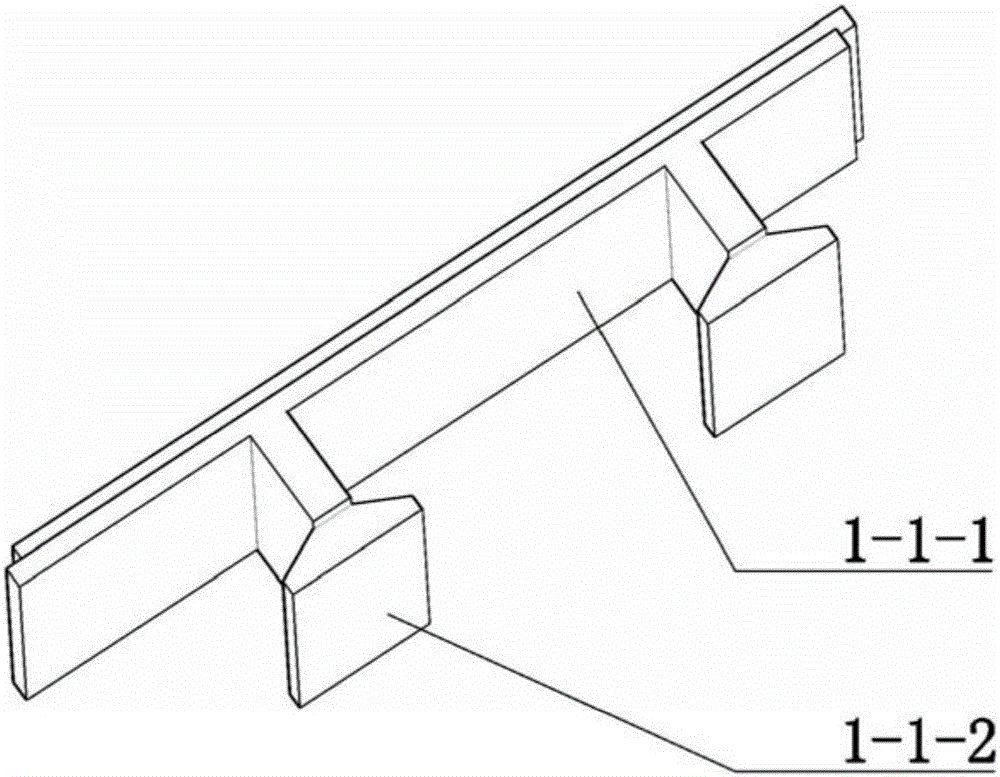

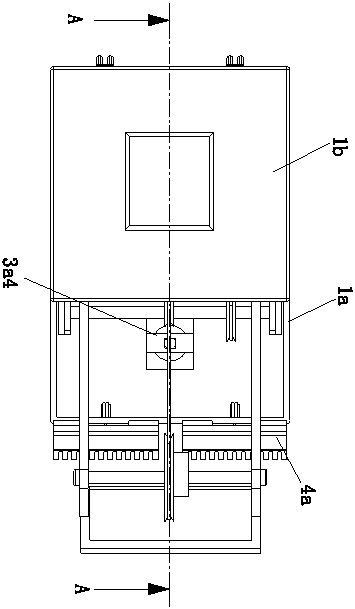

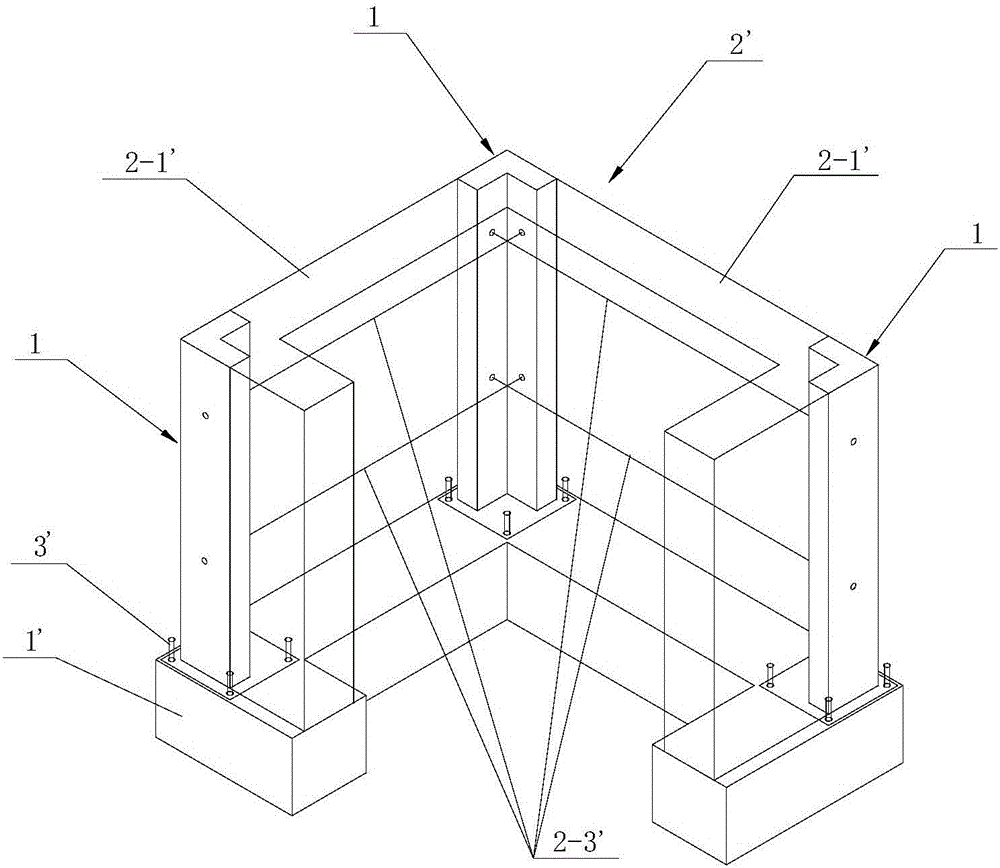

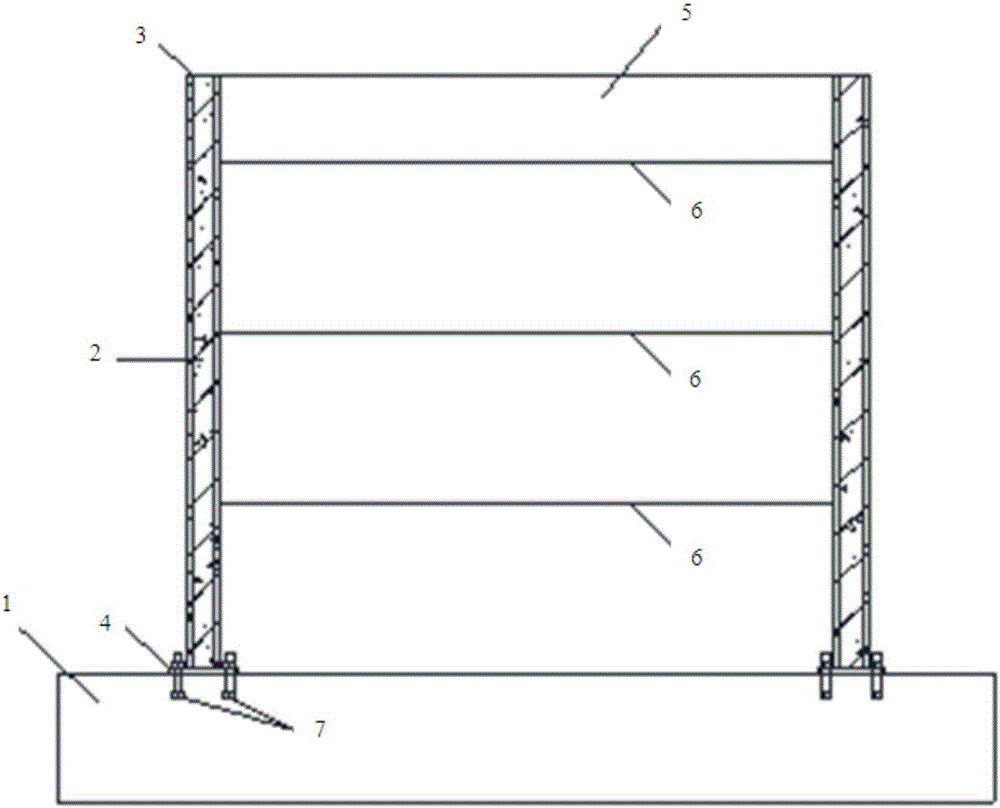

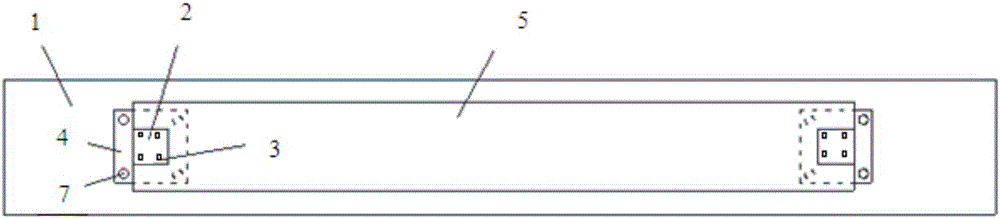

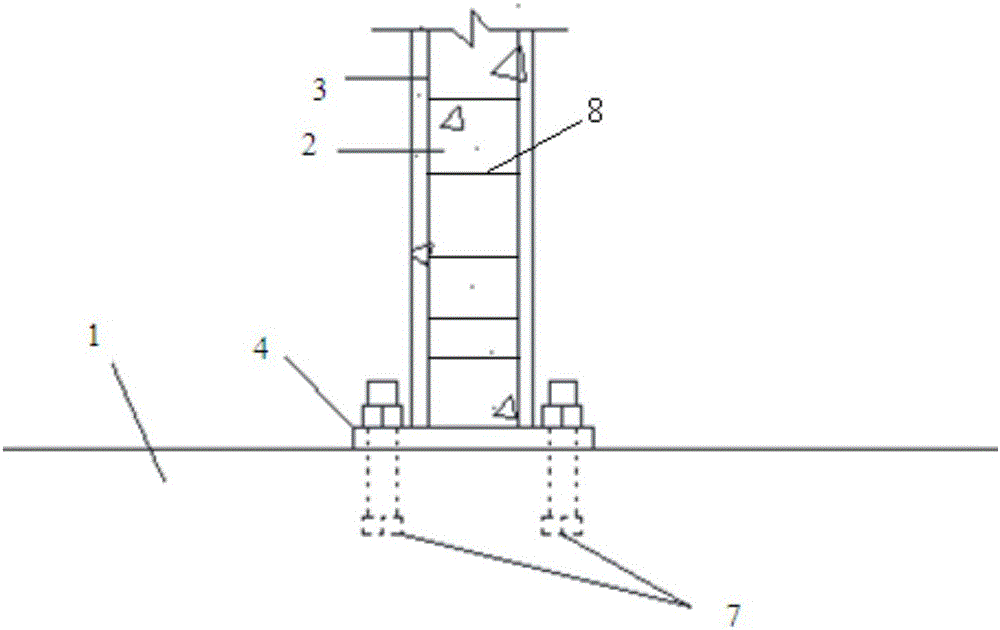

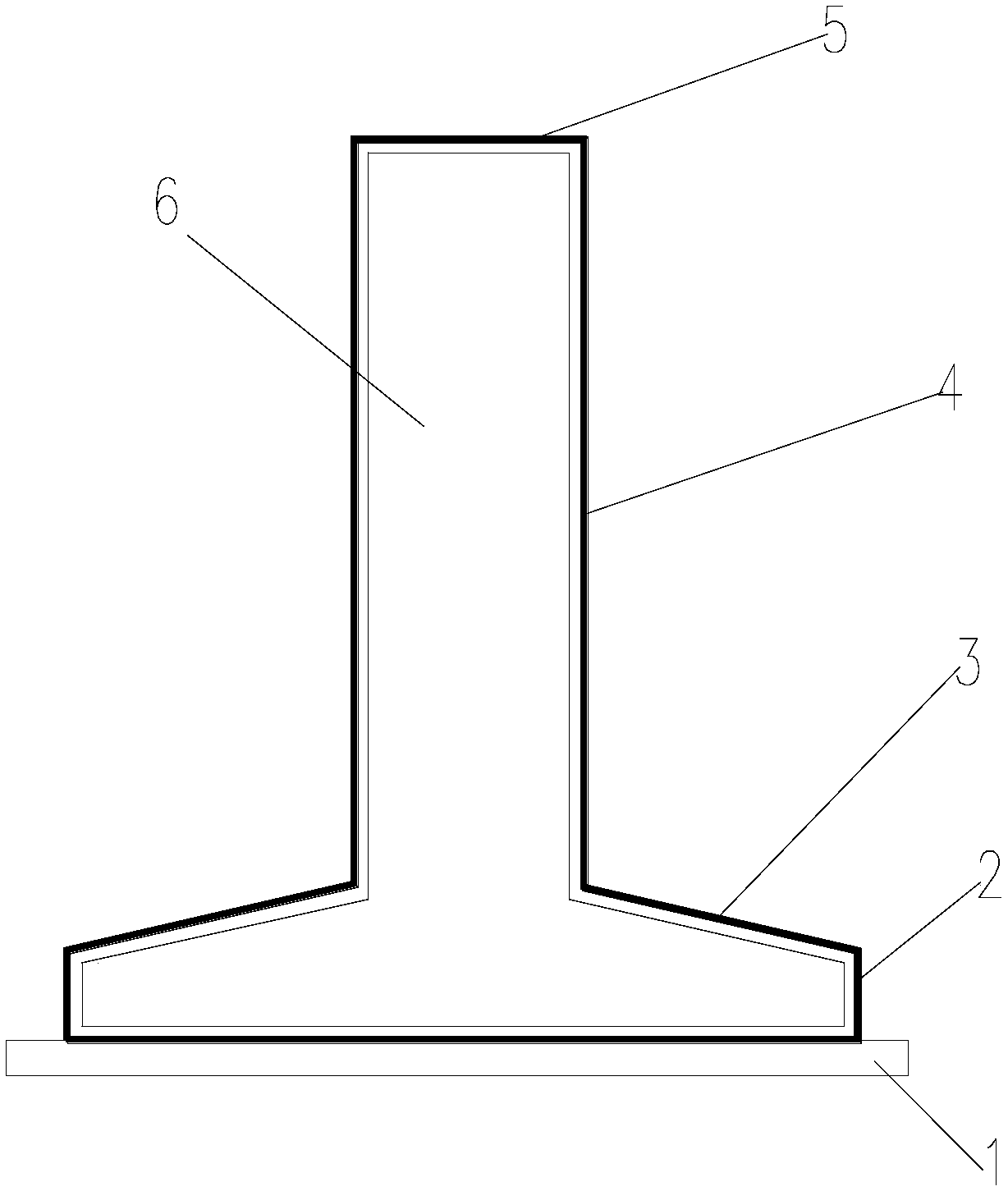

Rammed earth wall with precast concrete constructional columns

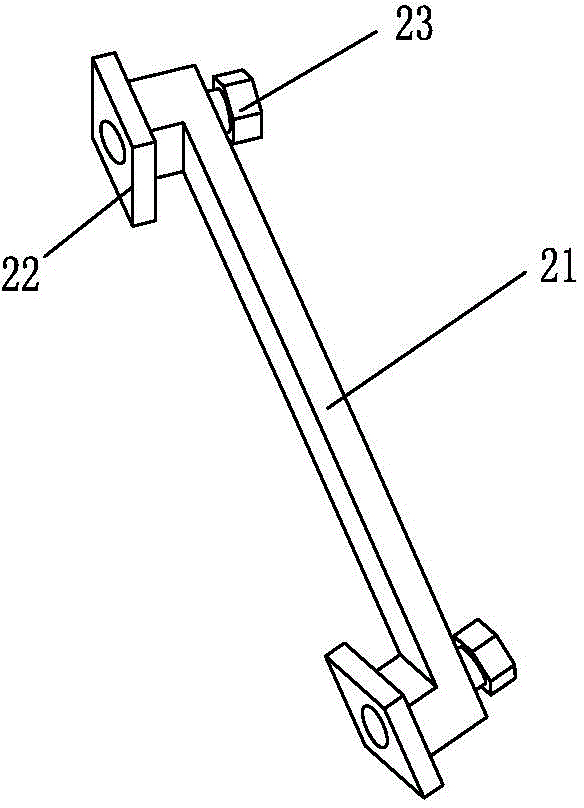

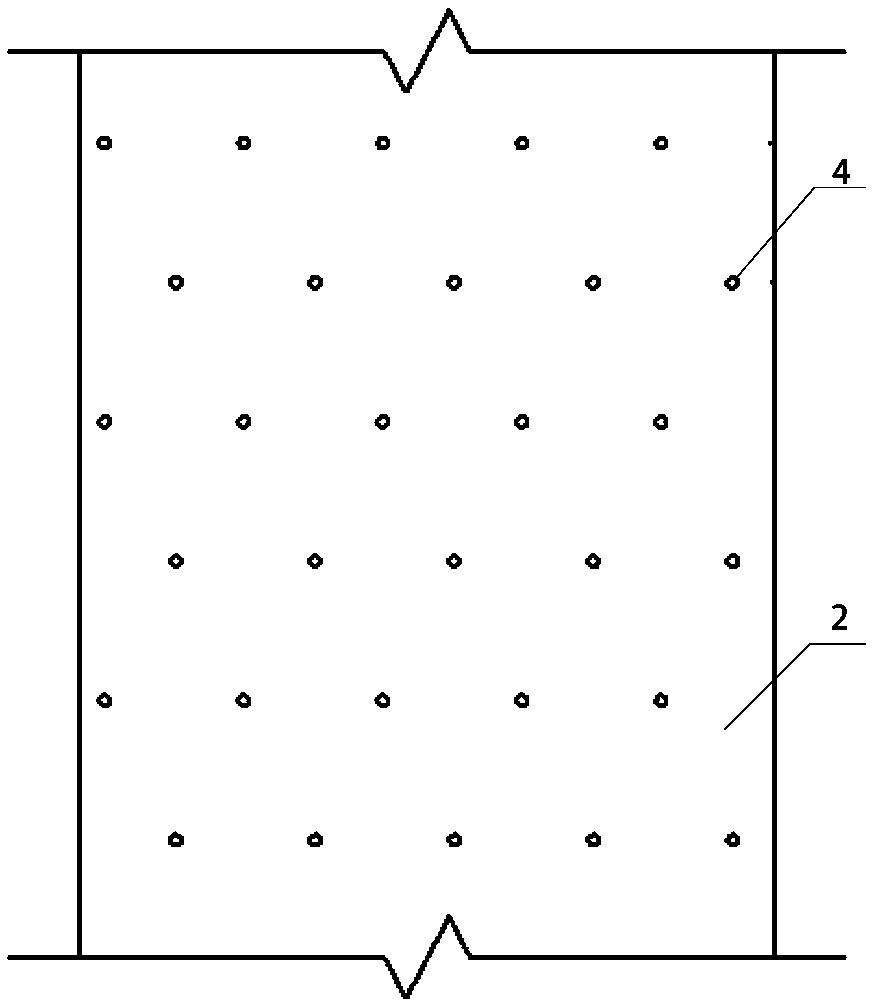

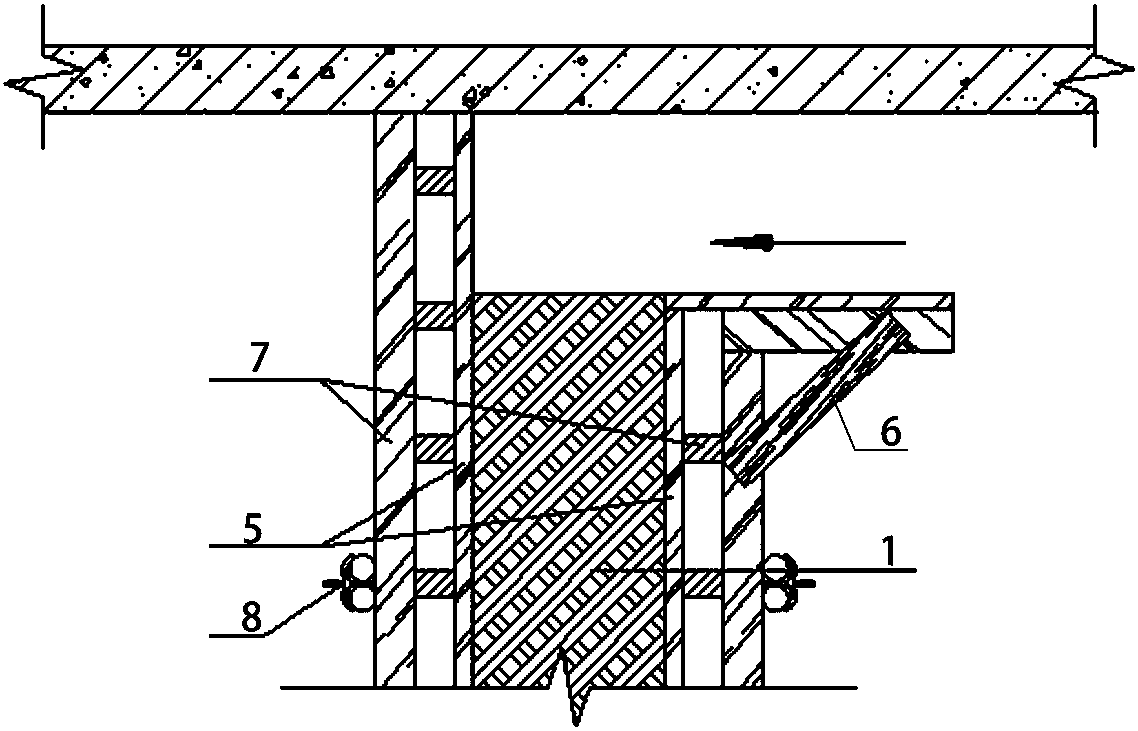

The invention discloses a prefabricated concrete structural column rammed earth wall, which is characterized in that it comprises a foundation ring beam (1), a prefabricated concrete structural column (2), a fixing plate (4), a rammed earth wall (5), and tie materials ( 6), pre-embedded bolts (7); said precast concrete construction column (2) is provided with four precast concrete construction column longitudinal bars (3), and said precast concrete construction column (2) is equipped with stirrups (8 ), the bottom of the precast concrete construction column (2) is provided with a fixing plate (4), and the precast concrete construction column (2) is fixedly connected with the foundation ring beam (1) with embedded bolts (7), the The fixed plate (4) is welded to the longitudinal reinforcement (3) of the precast concrete construction column, and the two sides of the rammed earth wall (5) are provided with tie materials (6) at intervals of a certain height, and the tie materials (6) The rammed earth wall (5) and the prefabricated concrete structural column (2) are formed as a whole.

Owner:TIANJIN CHENGJIAN UNIV

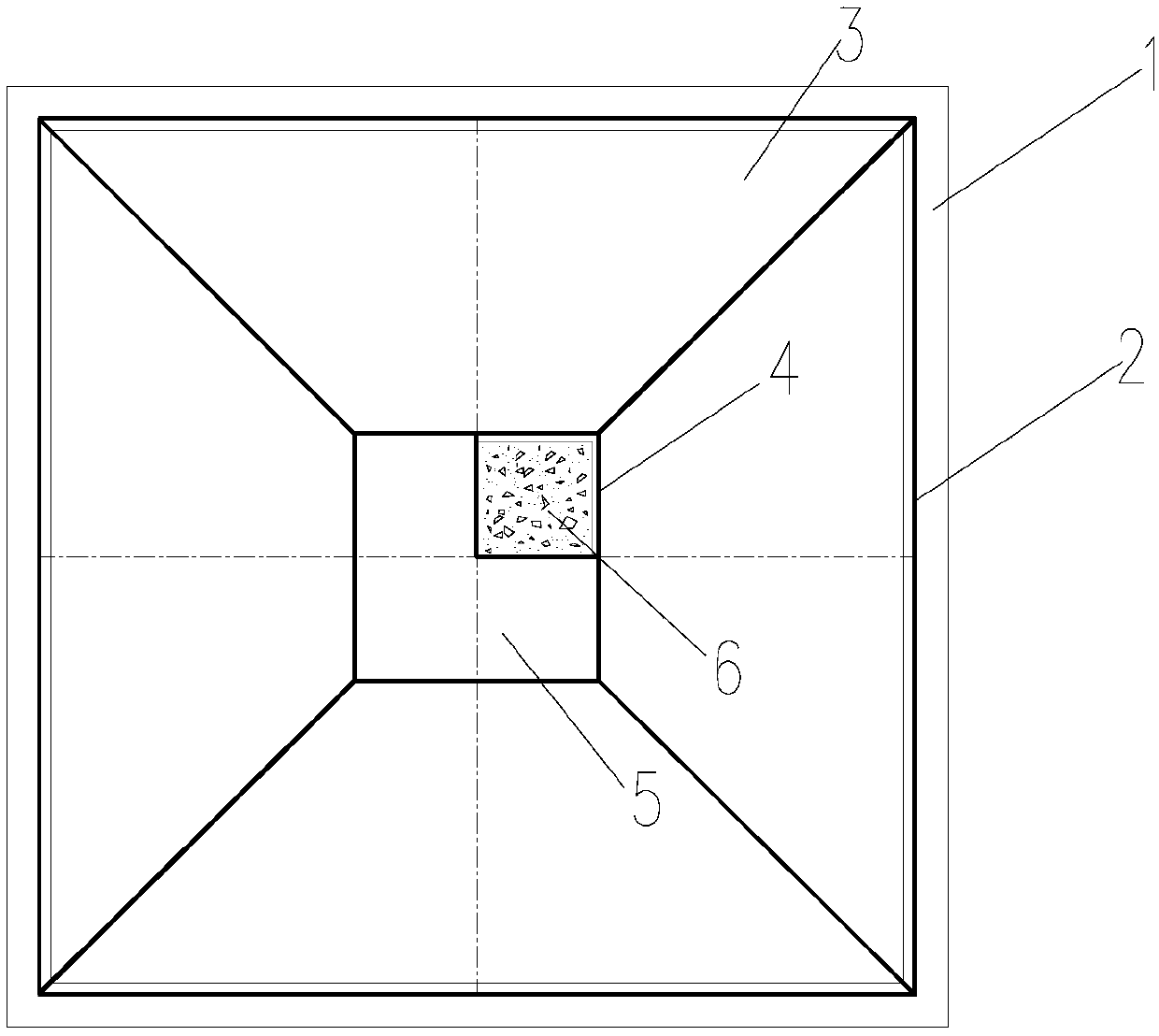

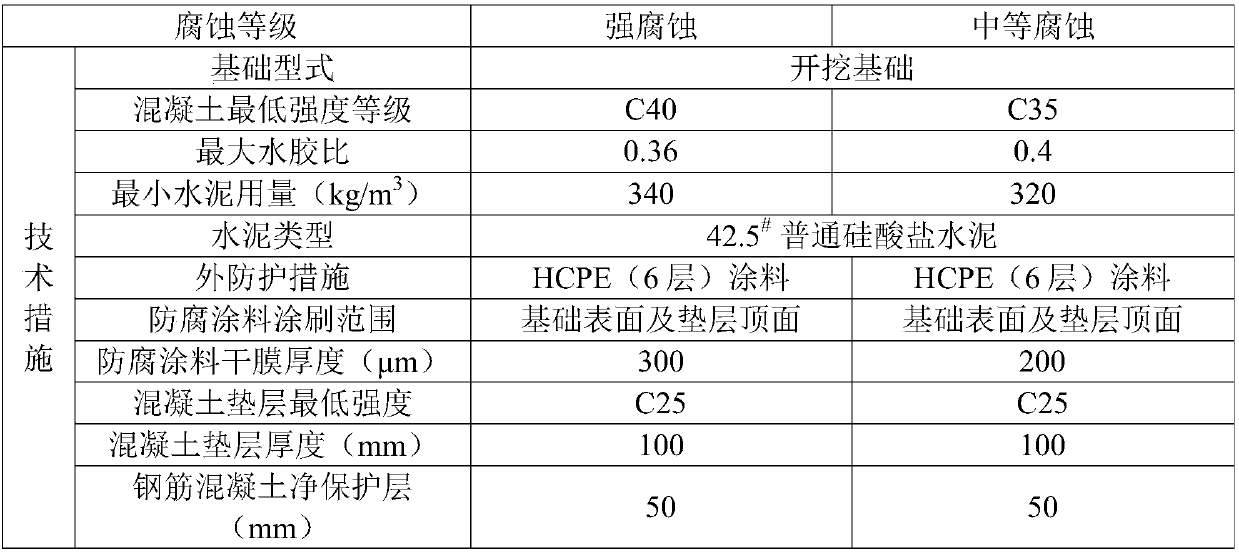

Large excavation anticorrosion foundation of transmission line tower, and construction method

The invention discloses a construction method of a large excavation anticorrosion foundation of a transmission line tower. The construction method comprises the steps of firstly excavating a foundation pit largely, preparing a concrete cushion in the foundation pit, and installing a glass fiber reinforced plastic (GRP) template bottom shell above the concrete cushion; binding foundation main bodysteel bars and column steel bars in the GRP template bottom shell, and meanwhile installing GRP template columns on the outer sides of the column steel bars; then, pouring concrete, and meanwhile installing a GRP template top shell and a FRP template top plate; and sealing the seams of GRP templates by plying epoxy resin matched with fiberglass fabric; and backfilling rammed earth after initial set of concrete. The foundation stated by the invention is high in durability and corrosion resistance, and applicable for construction of the transmission line tower at moderate and strong corrosion regions.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com