Patents

Literature

5609results about "Auxillary members of forms/shuttering/falseworks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

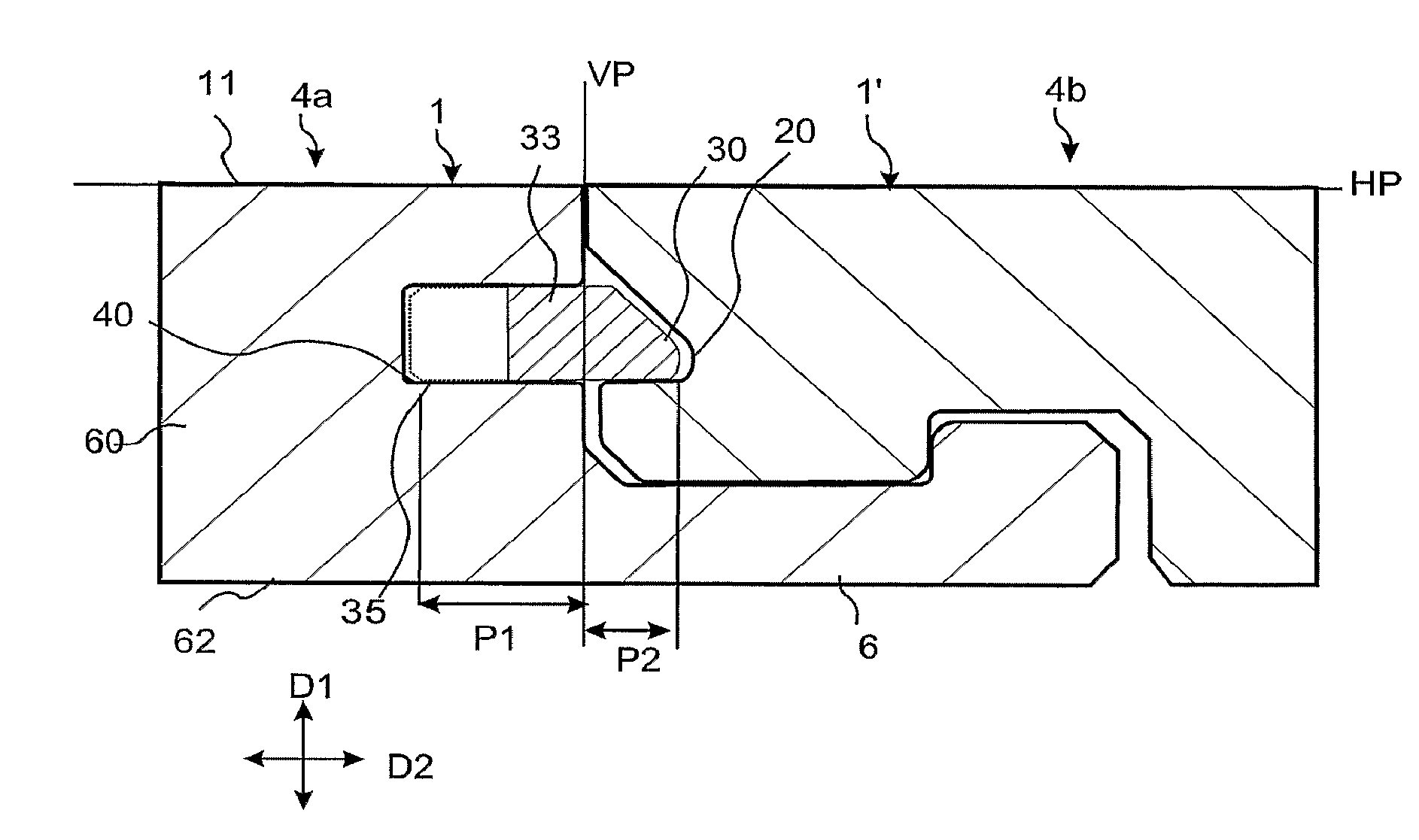

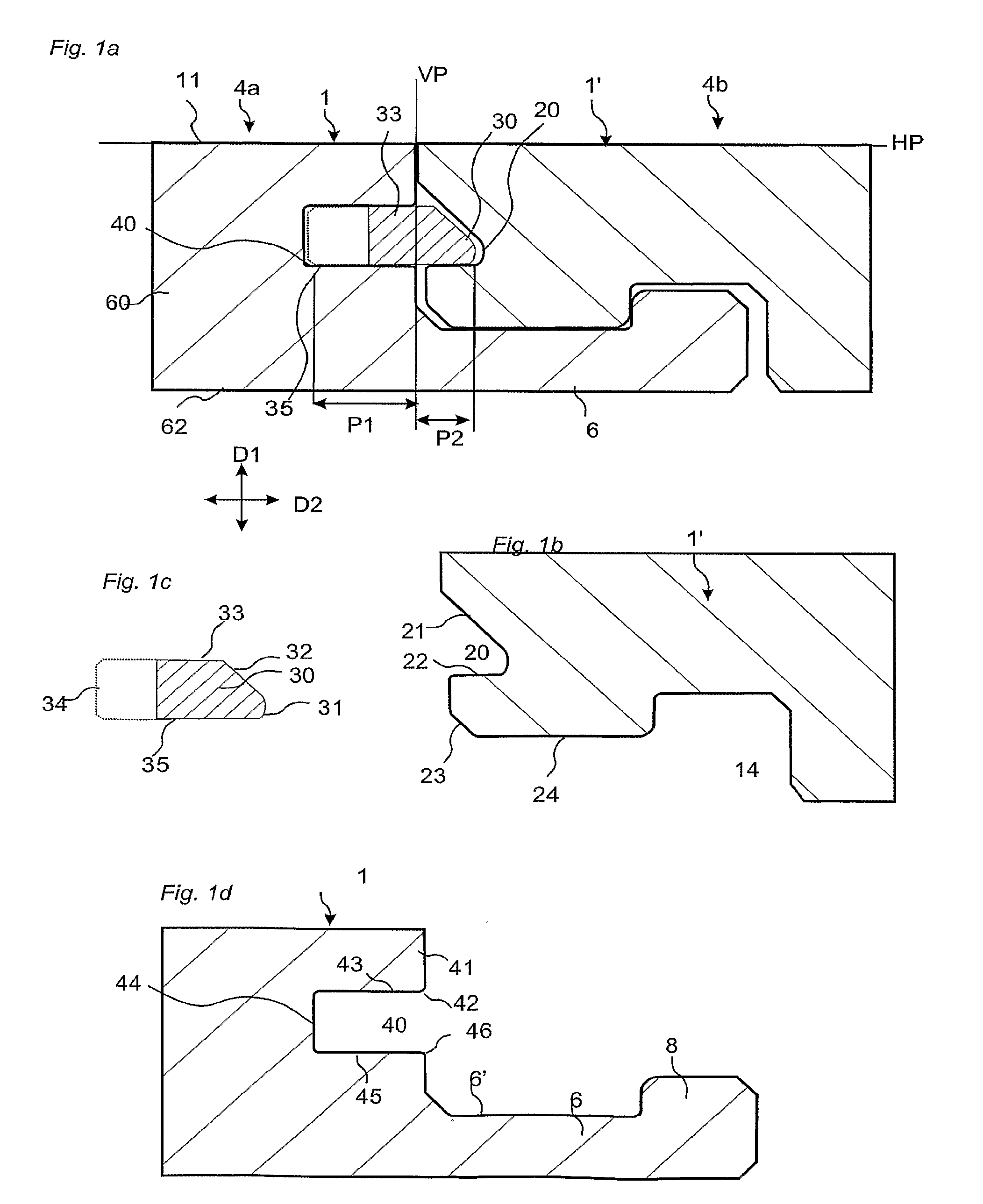

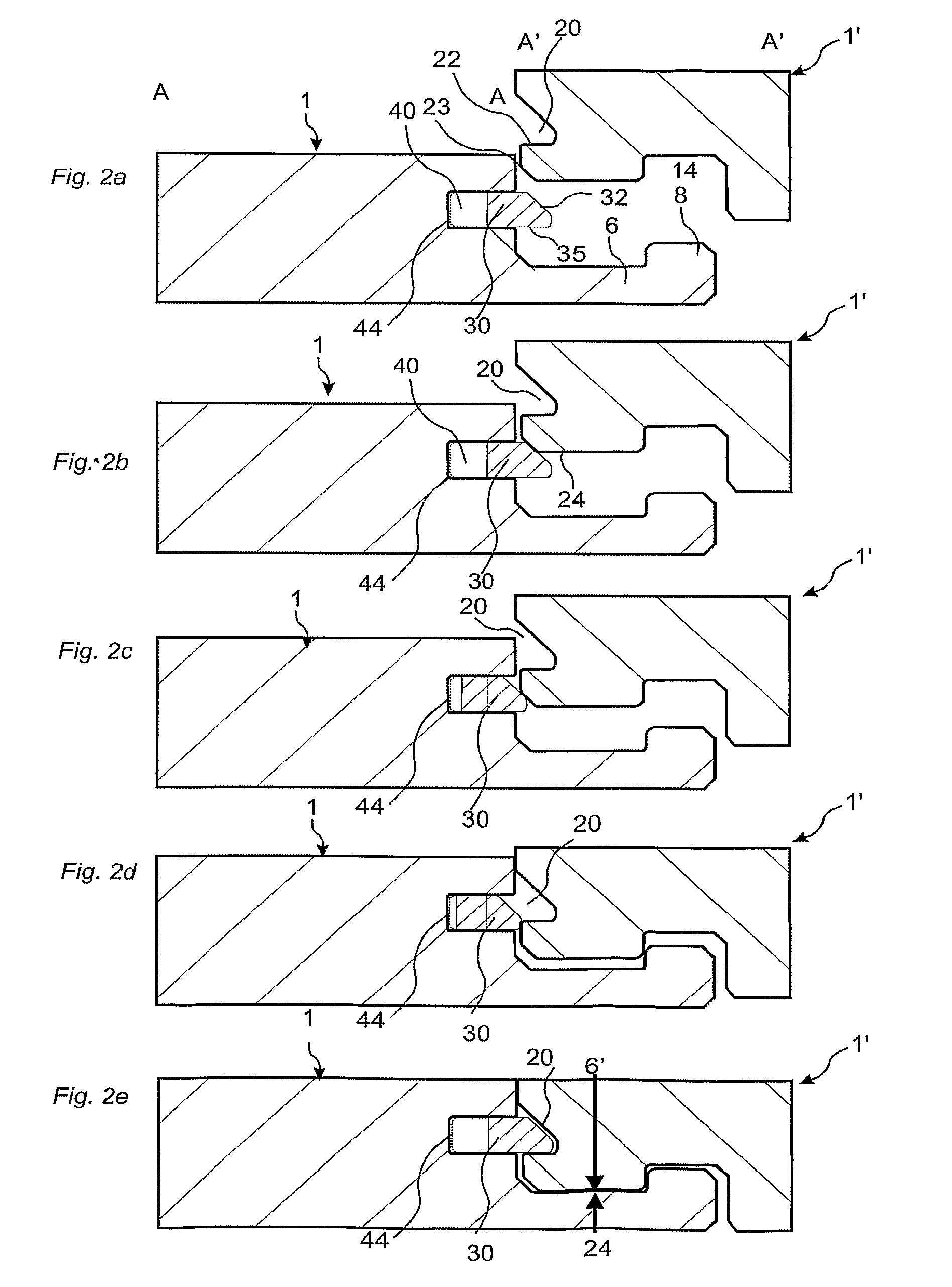

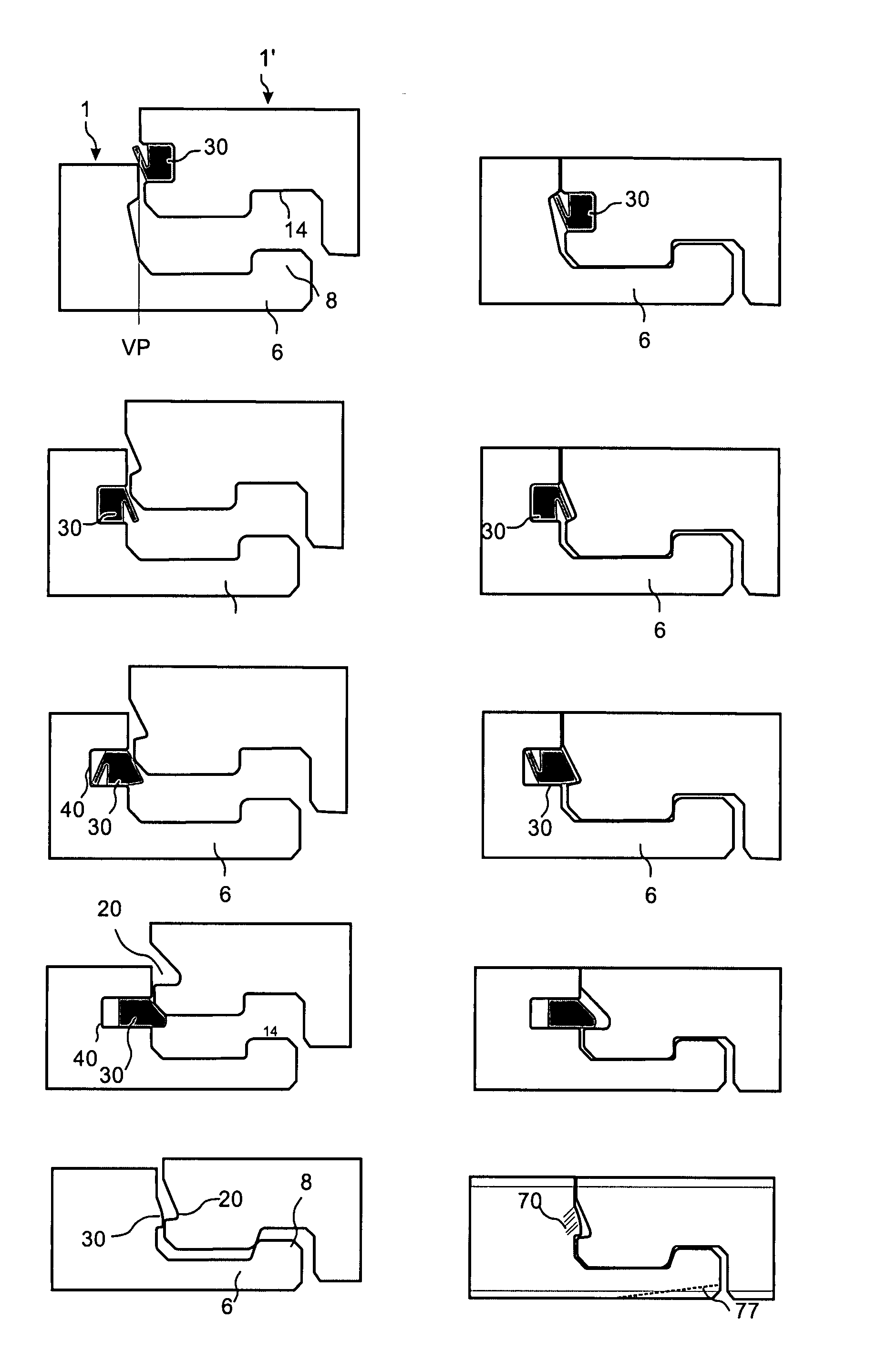

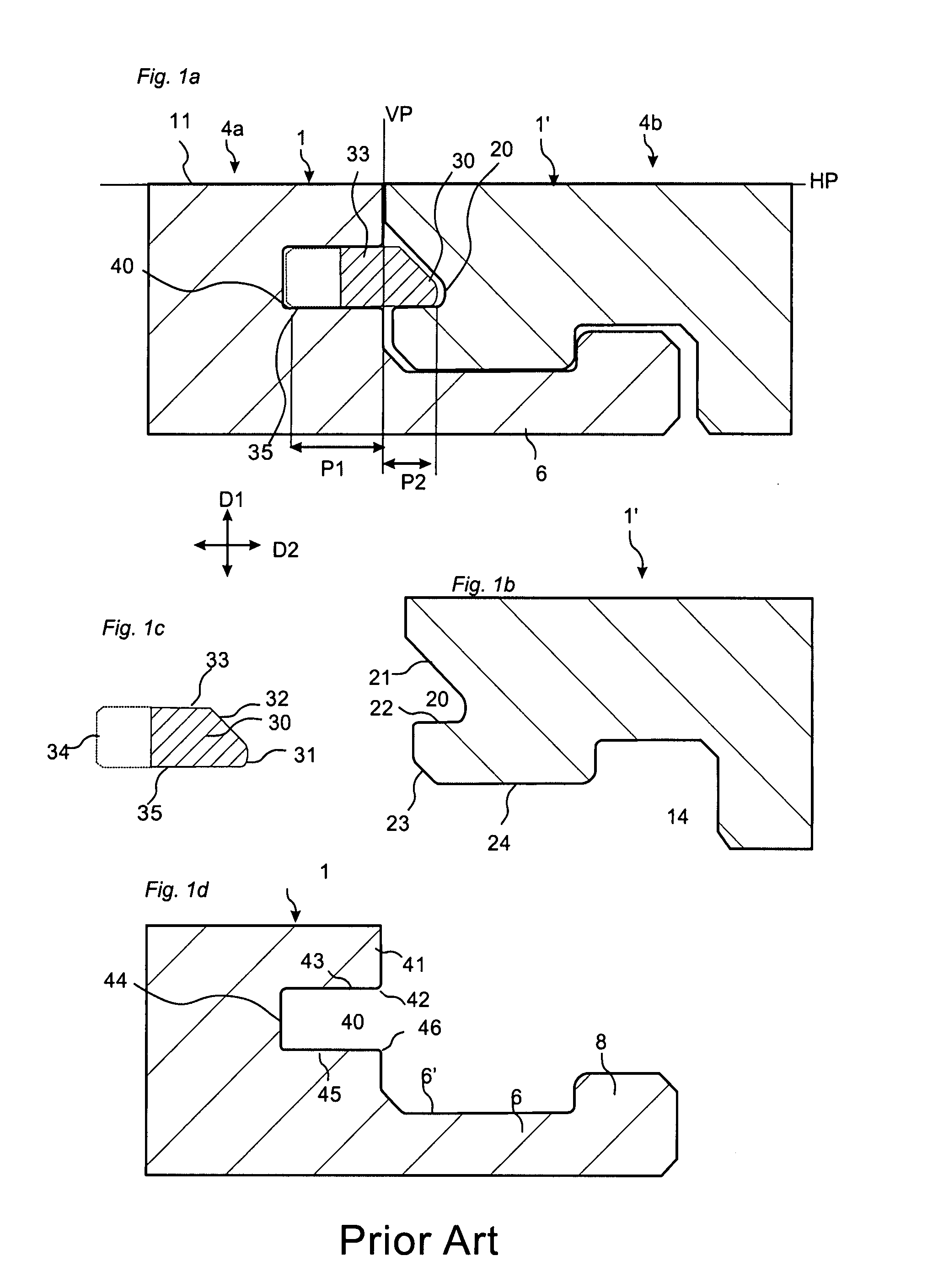

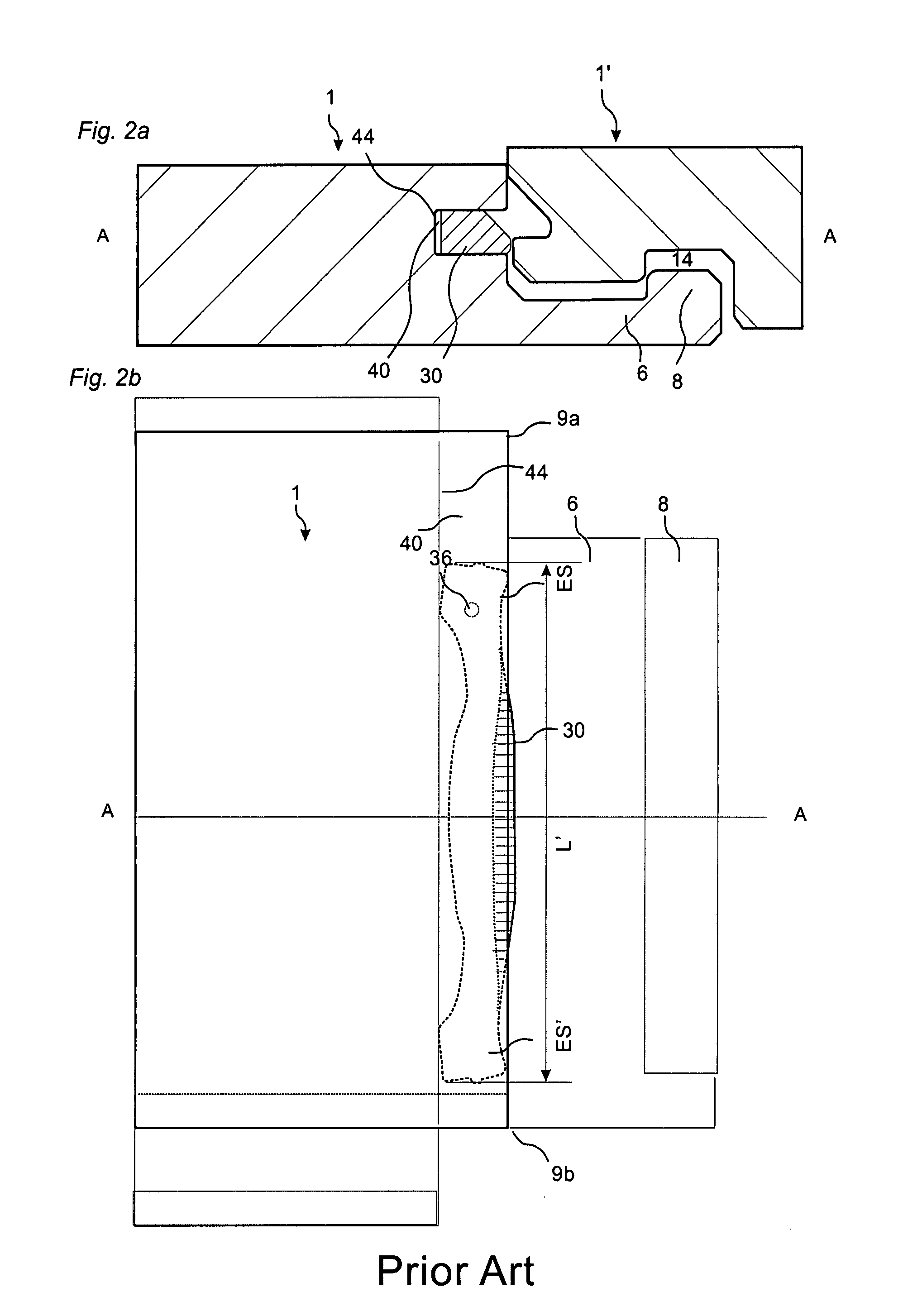

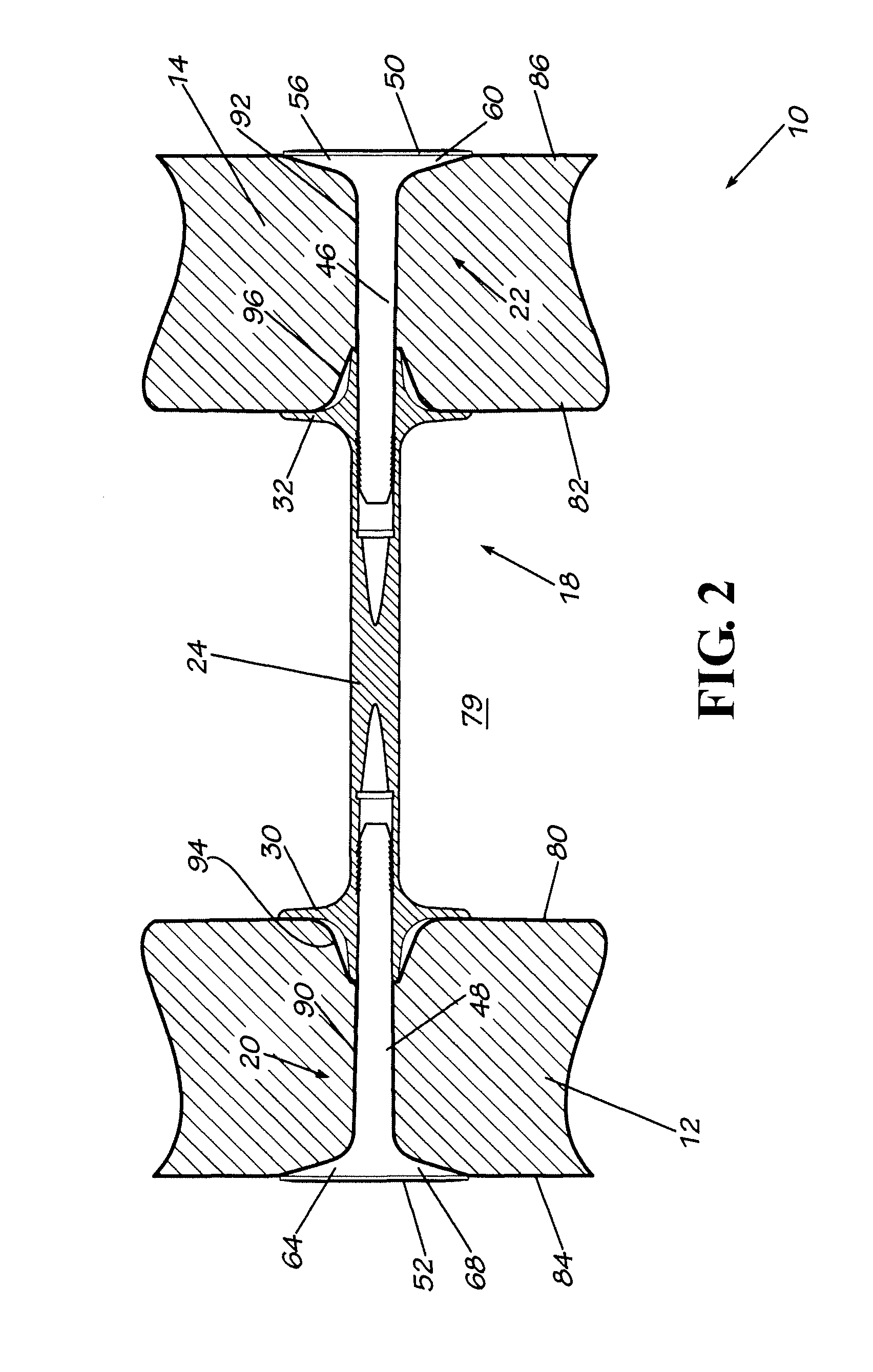

Mechanical Locking of Floor Panels With a Flexible Tongue

Floor panels (1, 1′) are shown, which are provided with a mechanical locking system having a flexible tongue (30) in a displacement groove (40), which during a vertical folding motion is displaced. Moreover, a tongue blank (50), a production method and an installation method are shown.

Owner:VÄLINGE INNOVATION AB

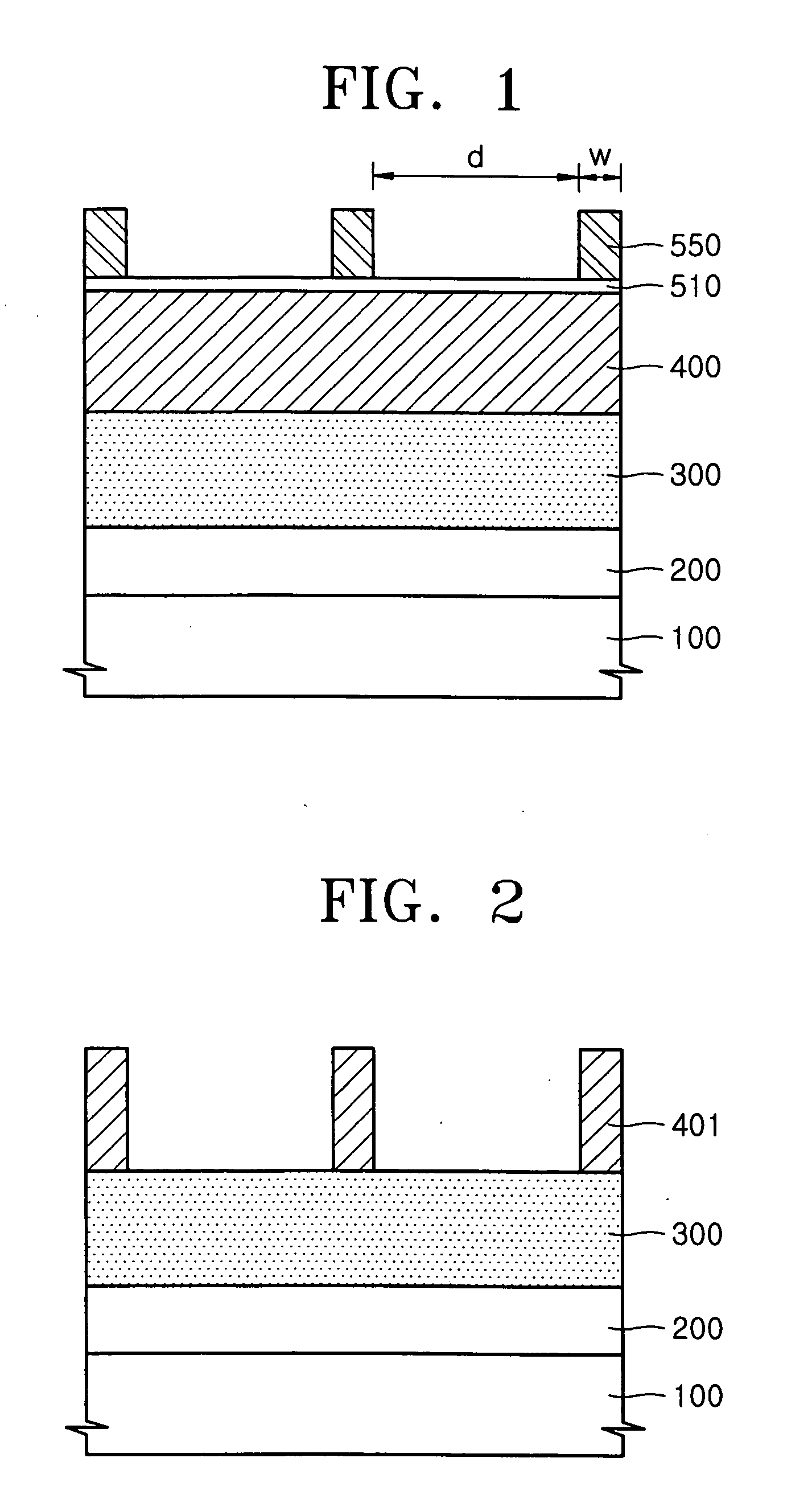

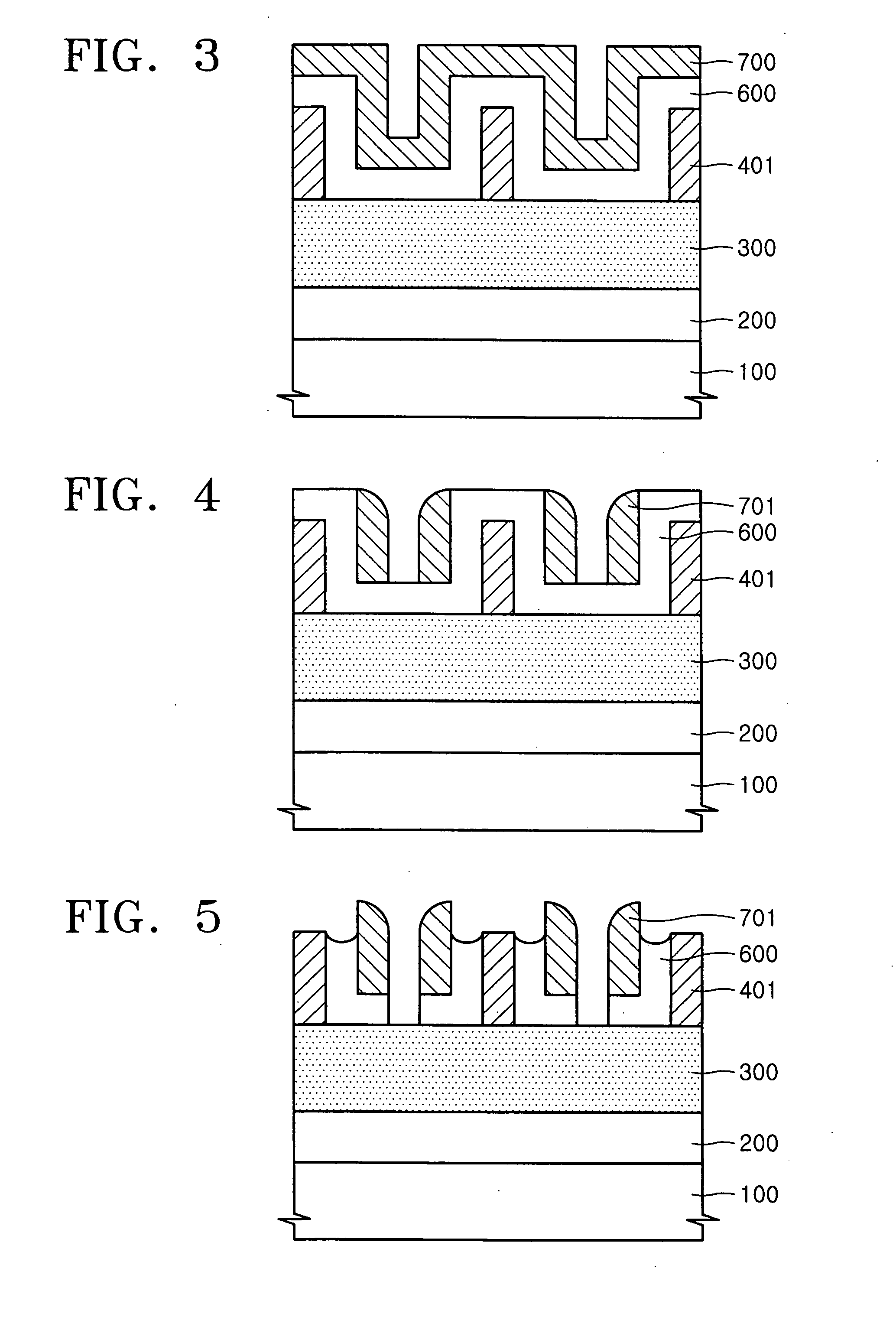

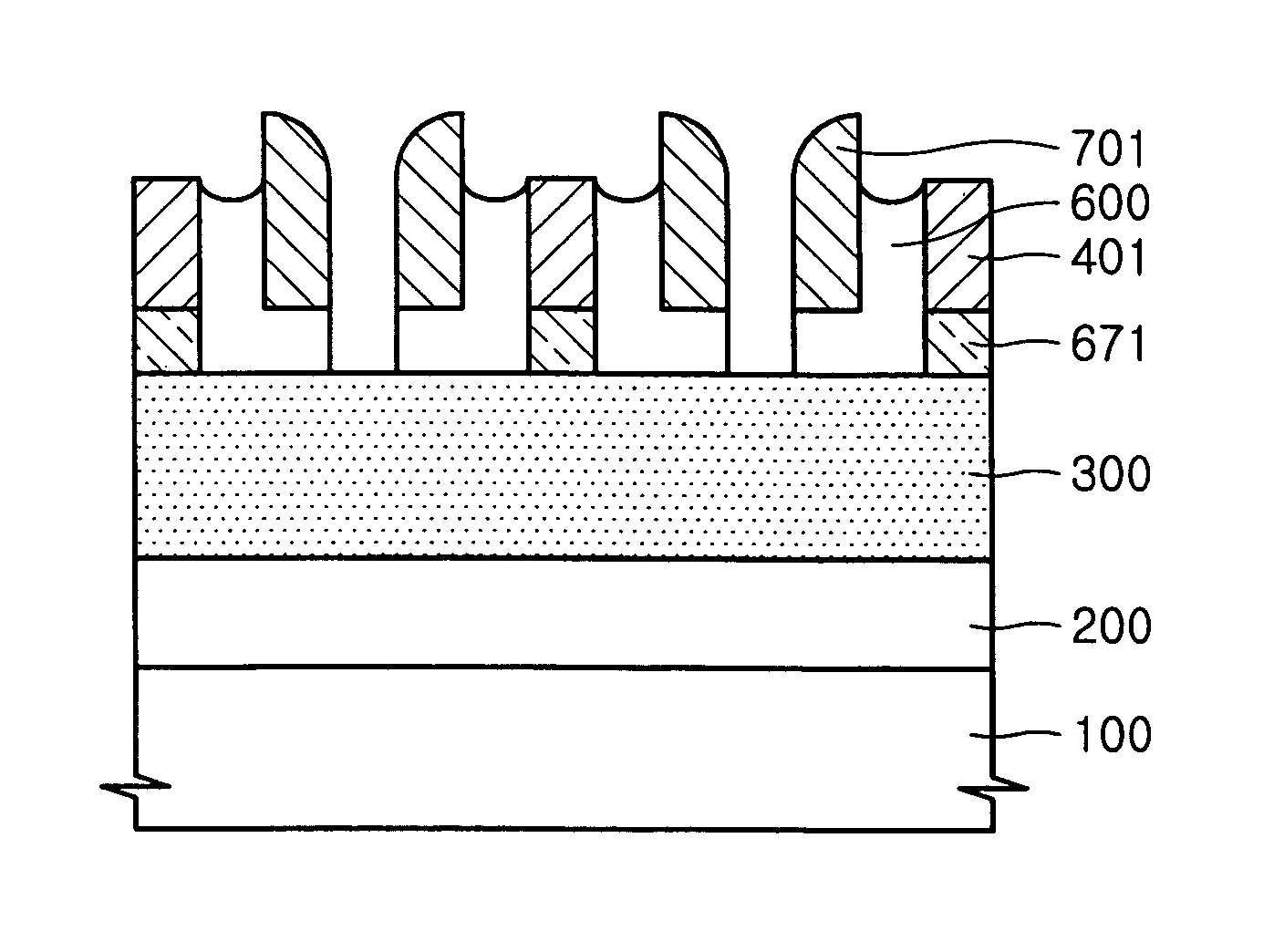

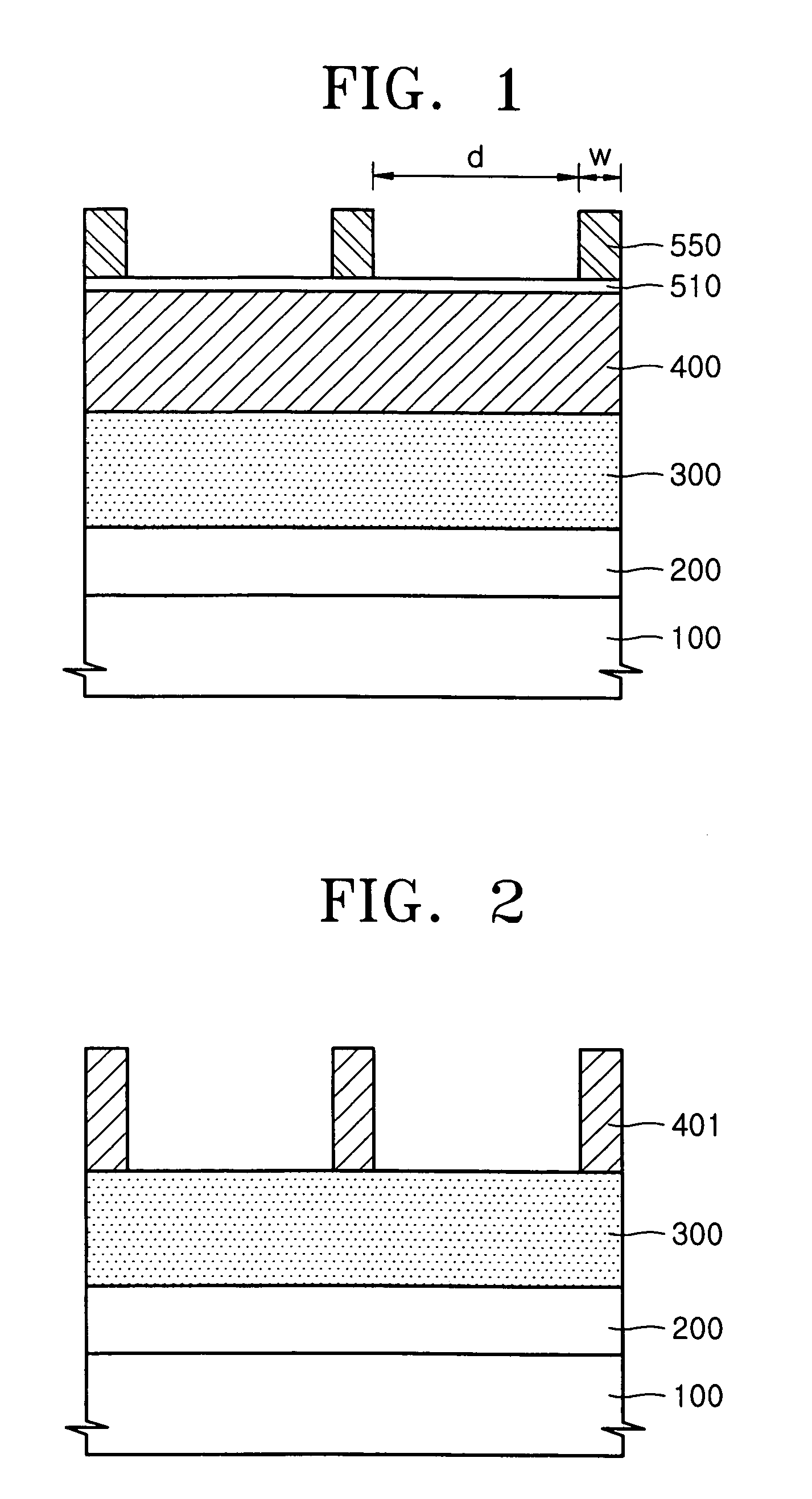

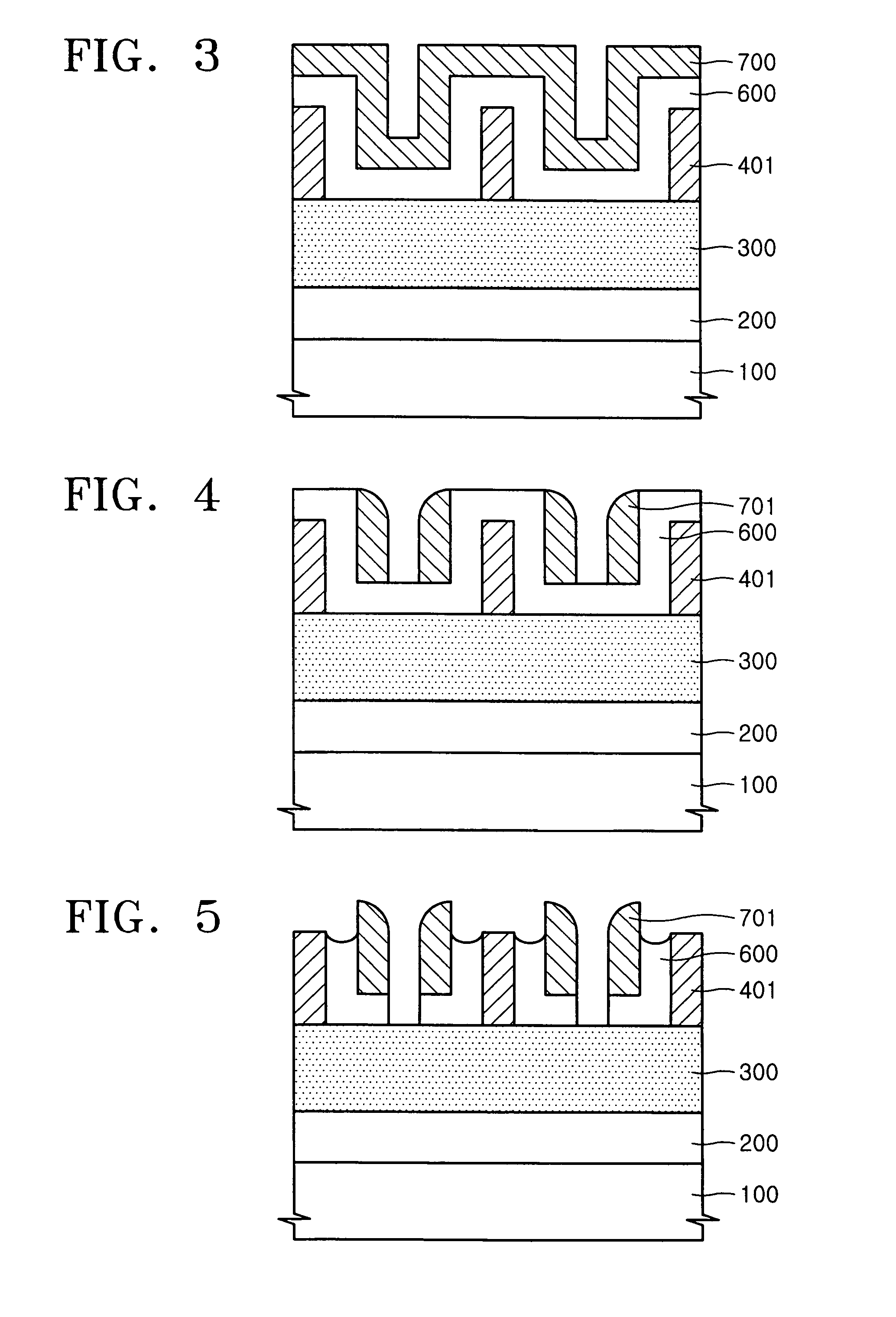

Method of forming small pitch pattern using double spacers

ActiveUS20060240361A1Semiconductor/solid-state device manufacturingAuxillary members of forms/shuttering/falseworksLine widthEngineering

A method of forming a small pitch pattern using double spacers is provided. A material layer and first hard masks are used and characterized by a line pattern having a smaller line width than a separation distance between adjacent mask elements. A first spacer layer covering sidewall portions of the first hard mask and a second spacer layer are formed, and spacer-etched, thereby forming a spacer pattern-shaped second hard mask on sidewall portions of the first hard mask. A portion of the second spacer layer between the first hard mask and the second hard mask is selectively removed. The material layer is selectively etched using the first and second hard masks as etch masks, thereby forming the small pitch pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

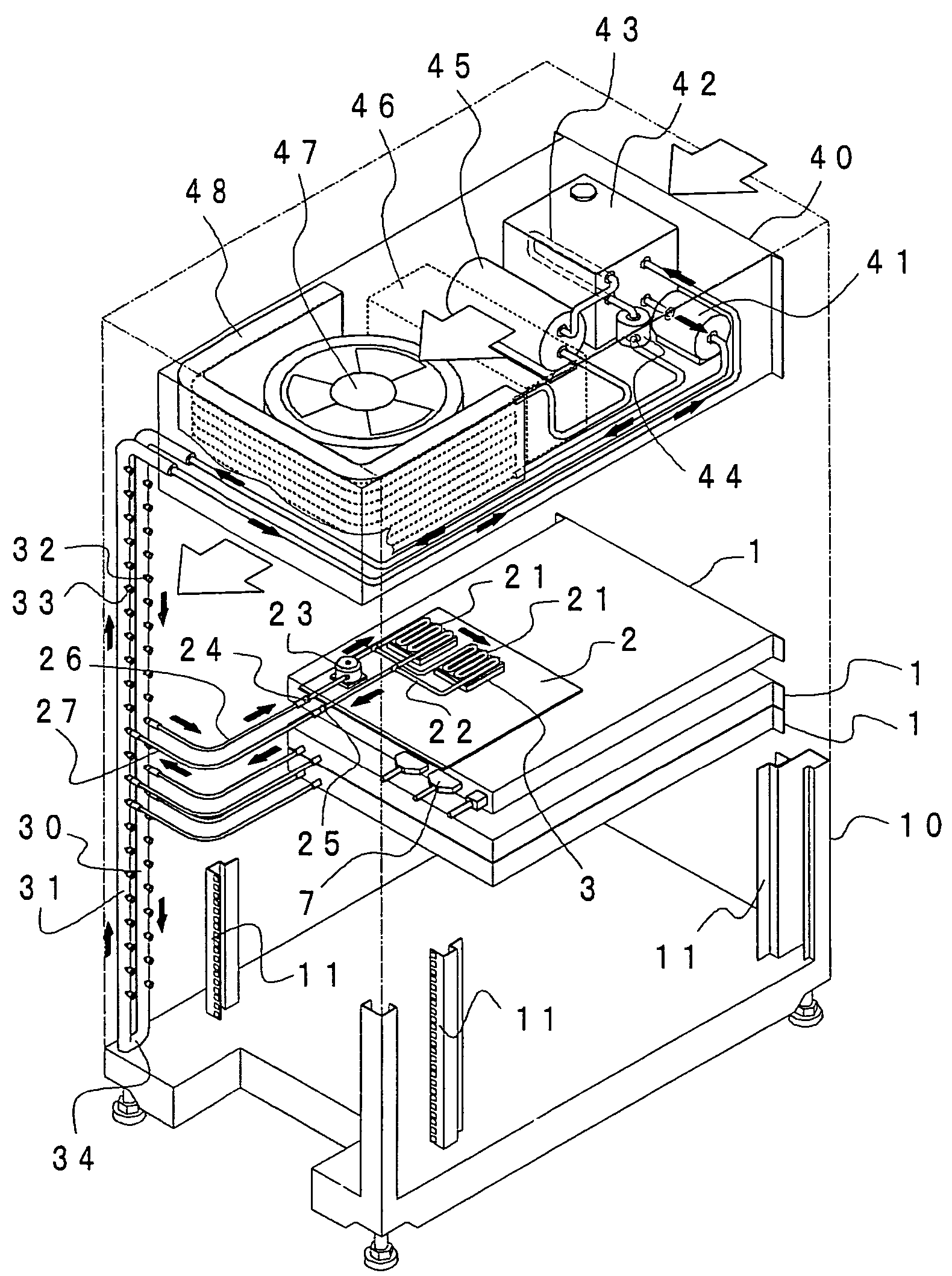

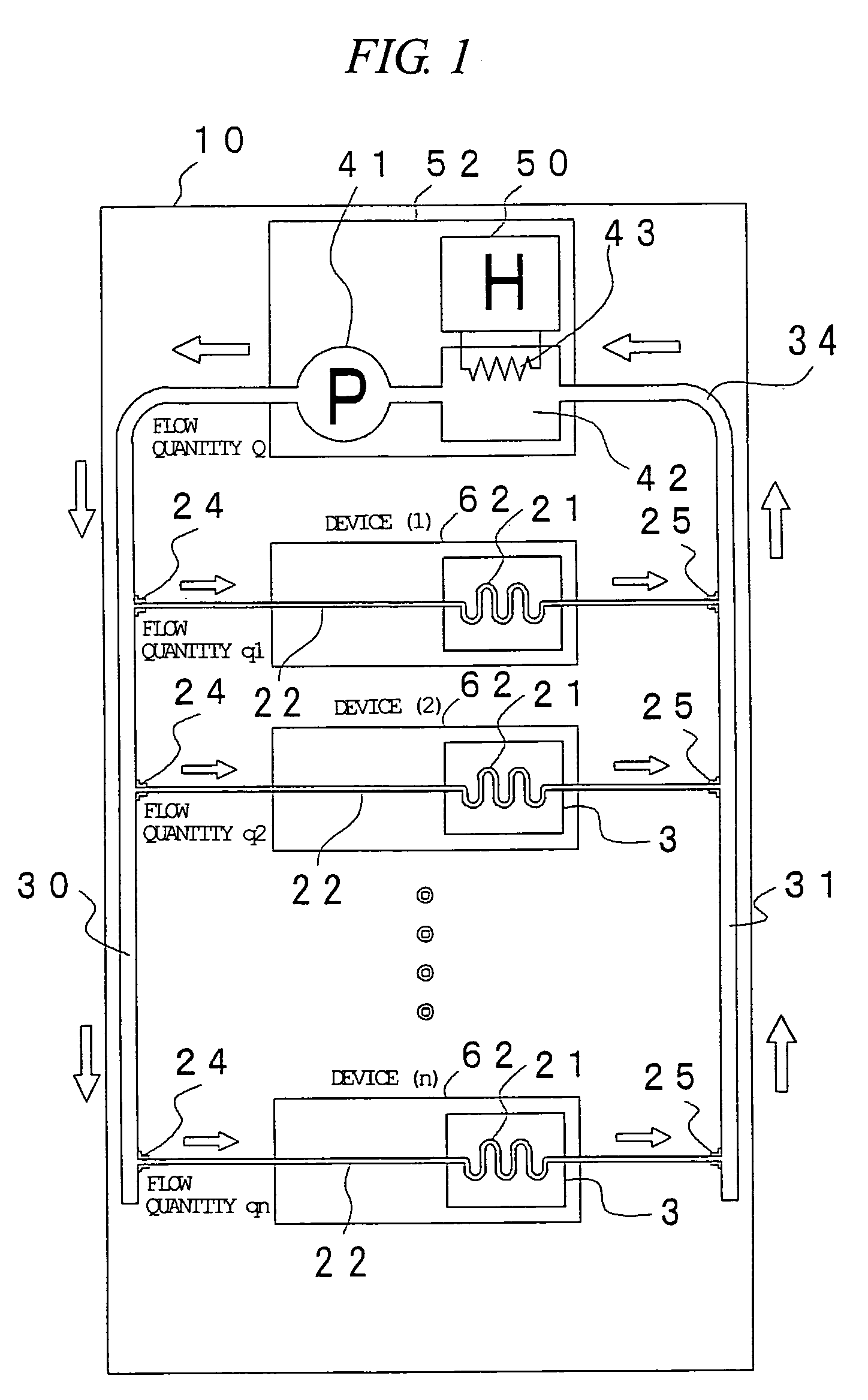

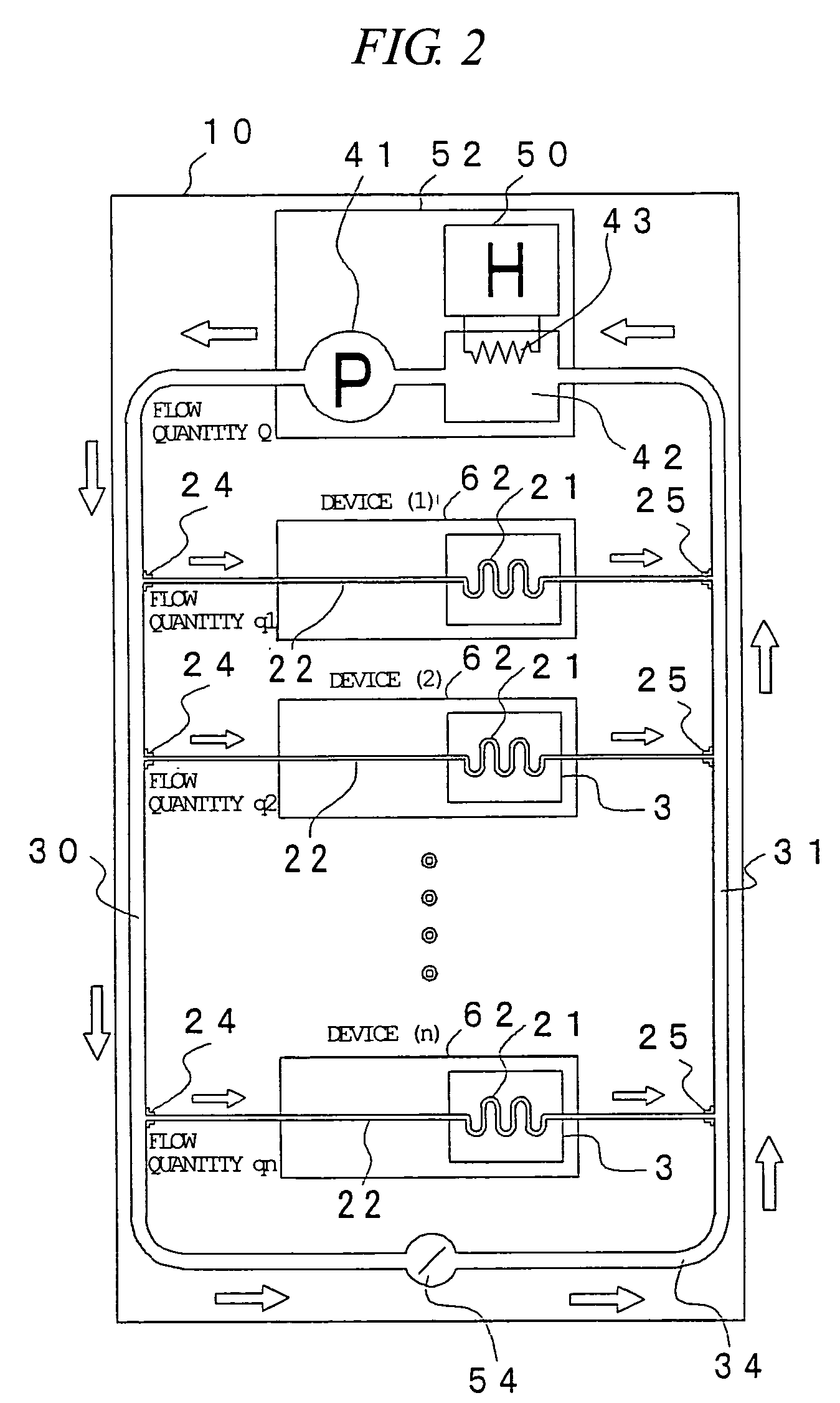

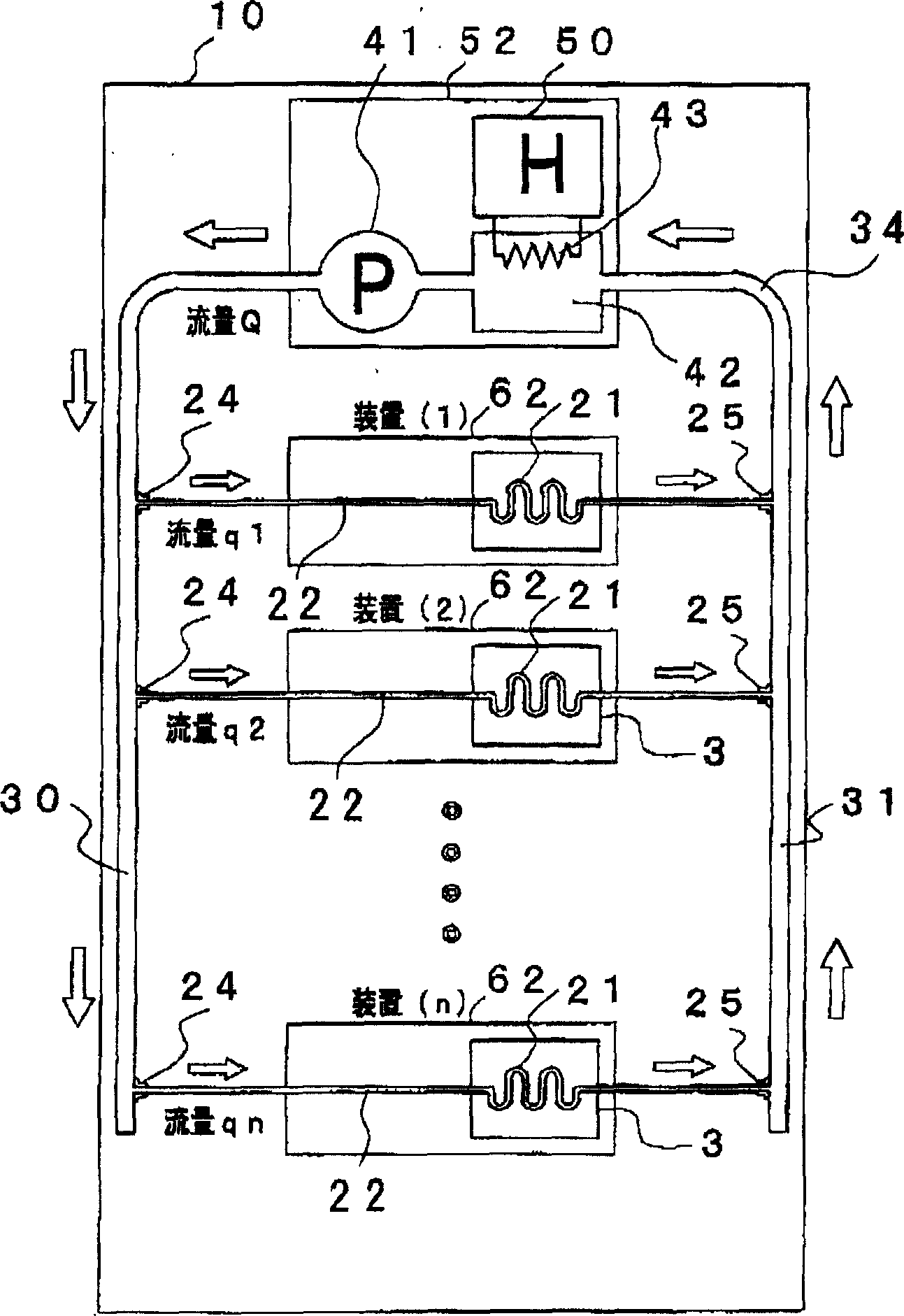

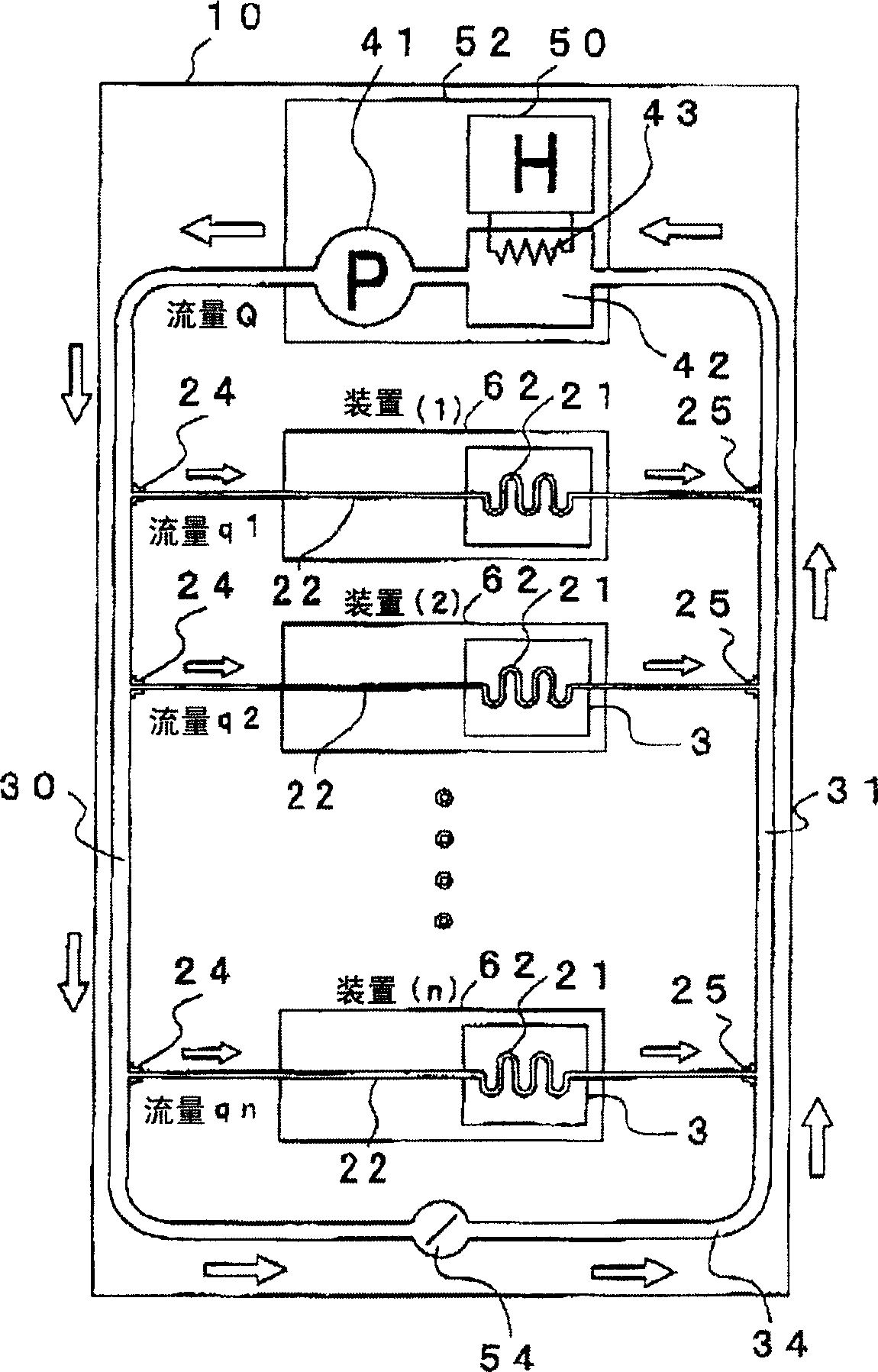

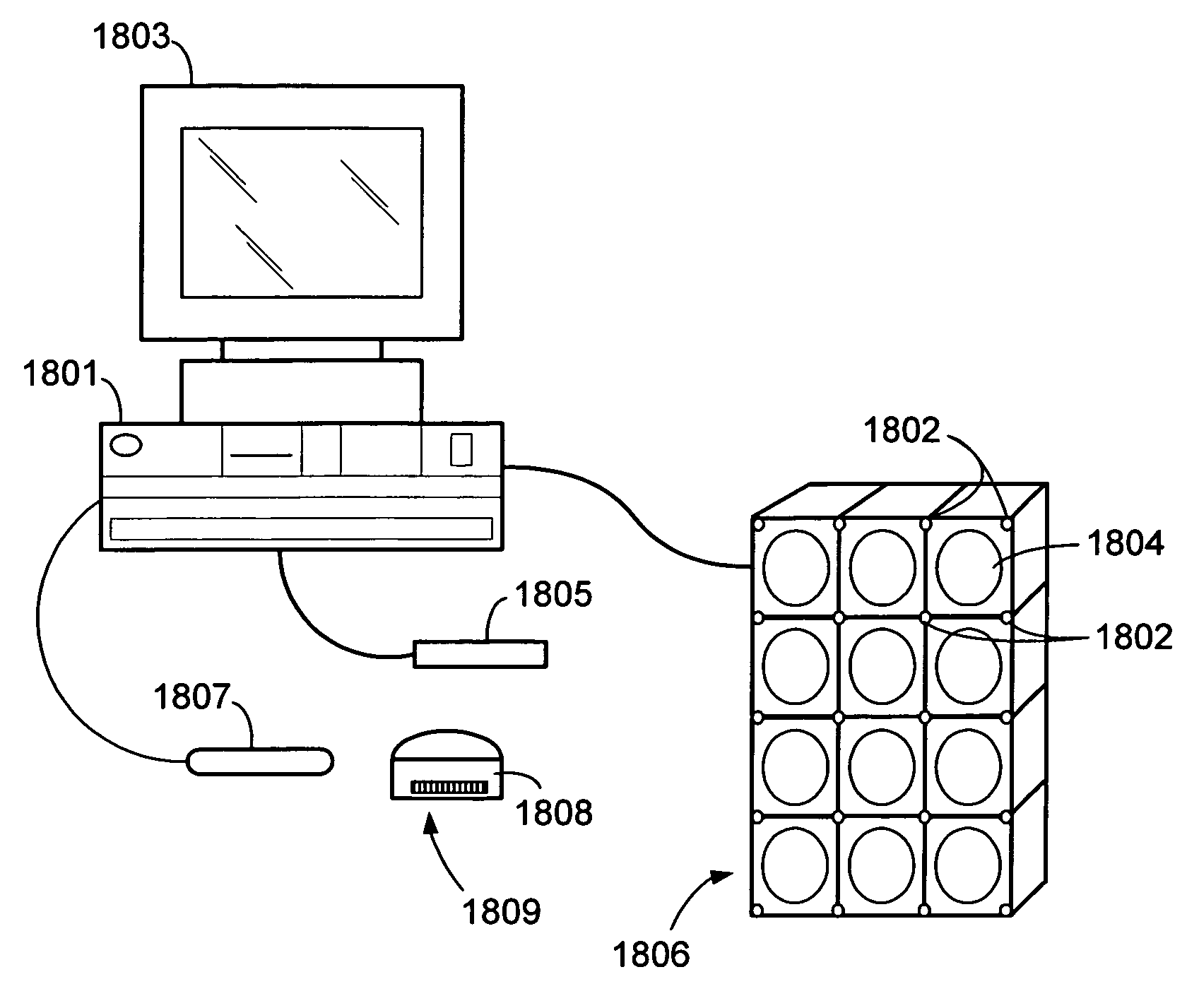

Liquid cooling system for a rack-mount server system

ActiveUS7318322B2Suppress mutationImprove cooling effectDomestic cooling apparatusDigital data processing detailsNuclear engineeringComputer module

A rack-mount server system of a liquid cooling system, in which a heat-generating component such as a CPU is cooled by a coolant has a plurality of server modules with heat-generating components which are cooled by the circulating coolant. The server modules are connected in parallel to a circulation coolant path through which the coolant to cool the server modules is circulated. In the middle of the coolant circulation path is a cooling unit that cools the coolant by radiating its heat to the outside air. Furthermore, a bypass route parallel to the server modules and going around the server modules is provided in the coolant circulation path, and the circulation quantity of the coolant is controlled in the bypass route. Alternatively, the flow quantity of the coolant is controlled in each of the server modules.

Owner:MAXELL HLDG LTD

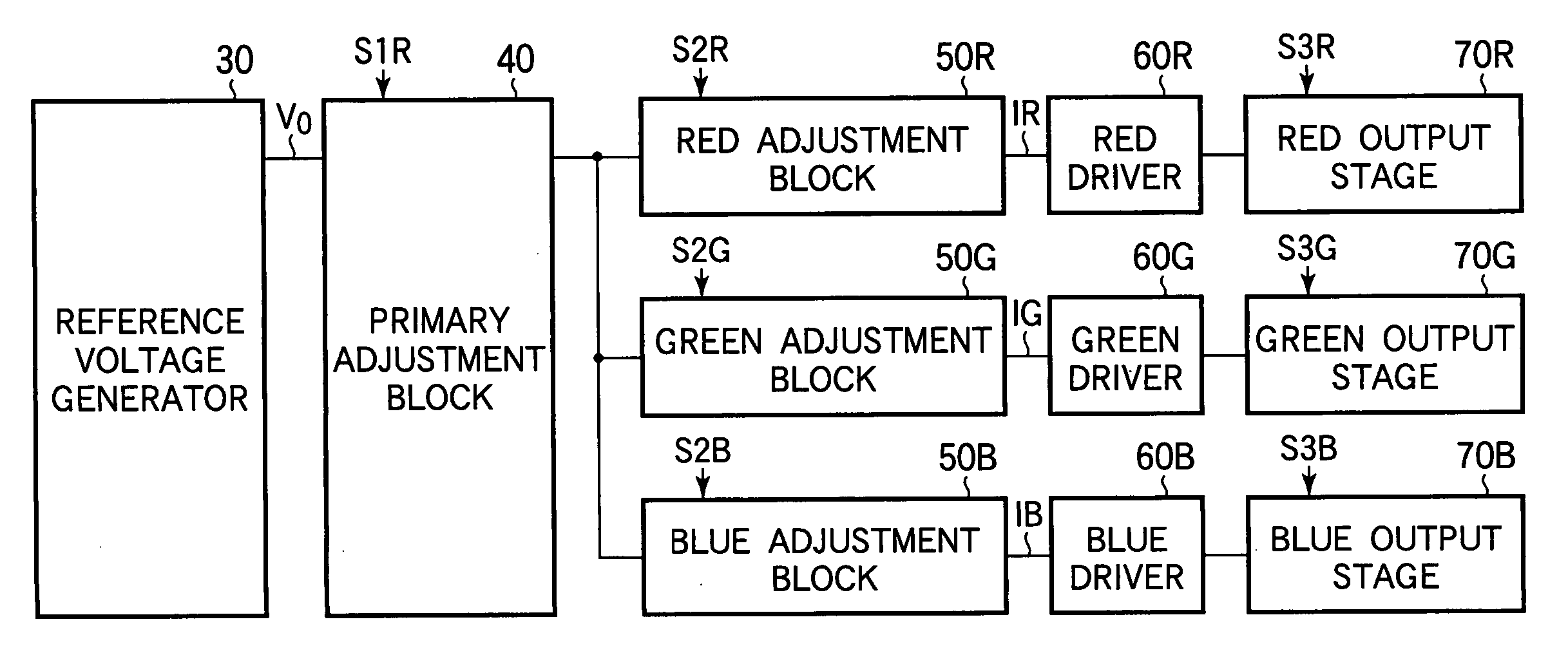

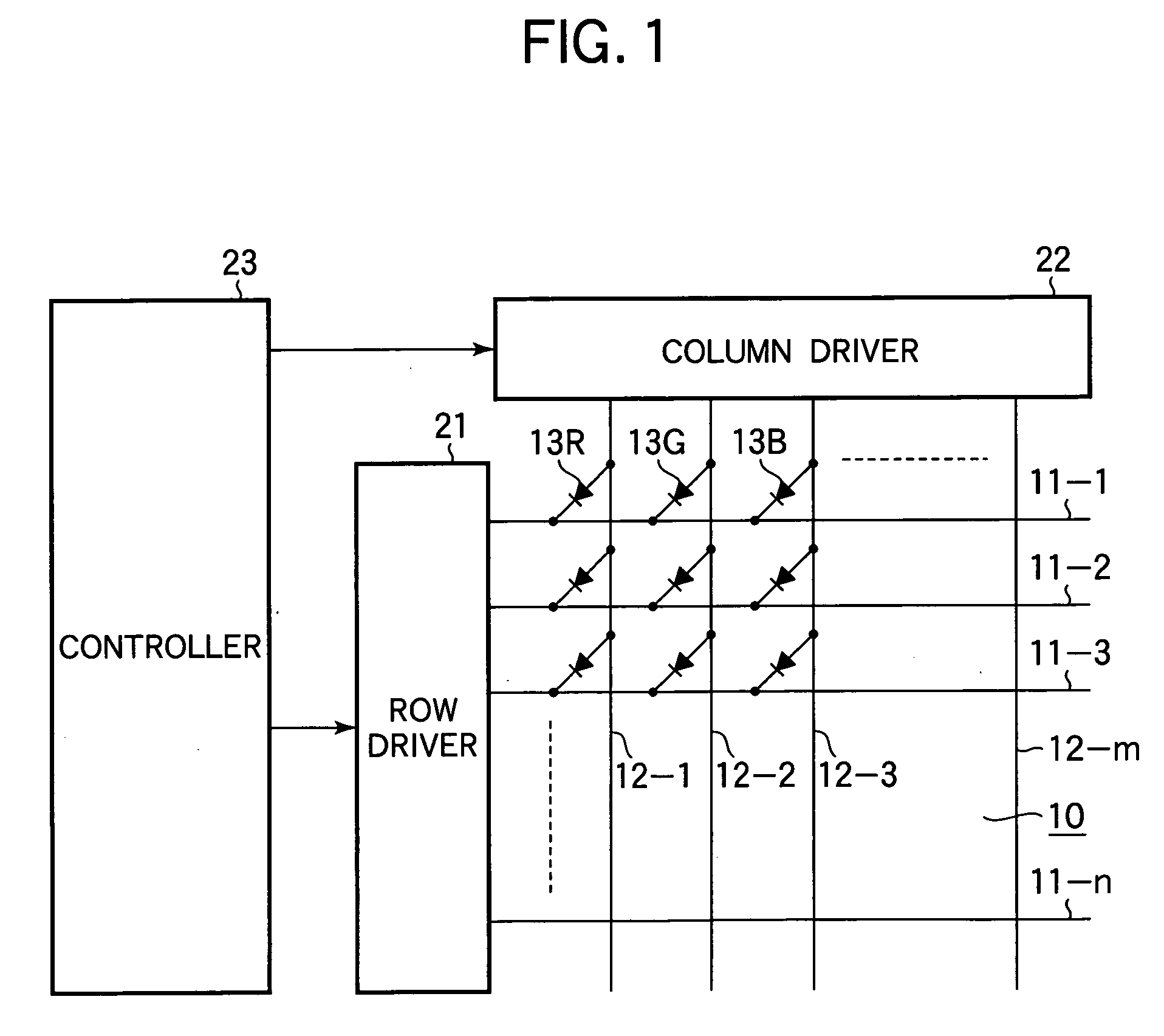

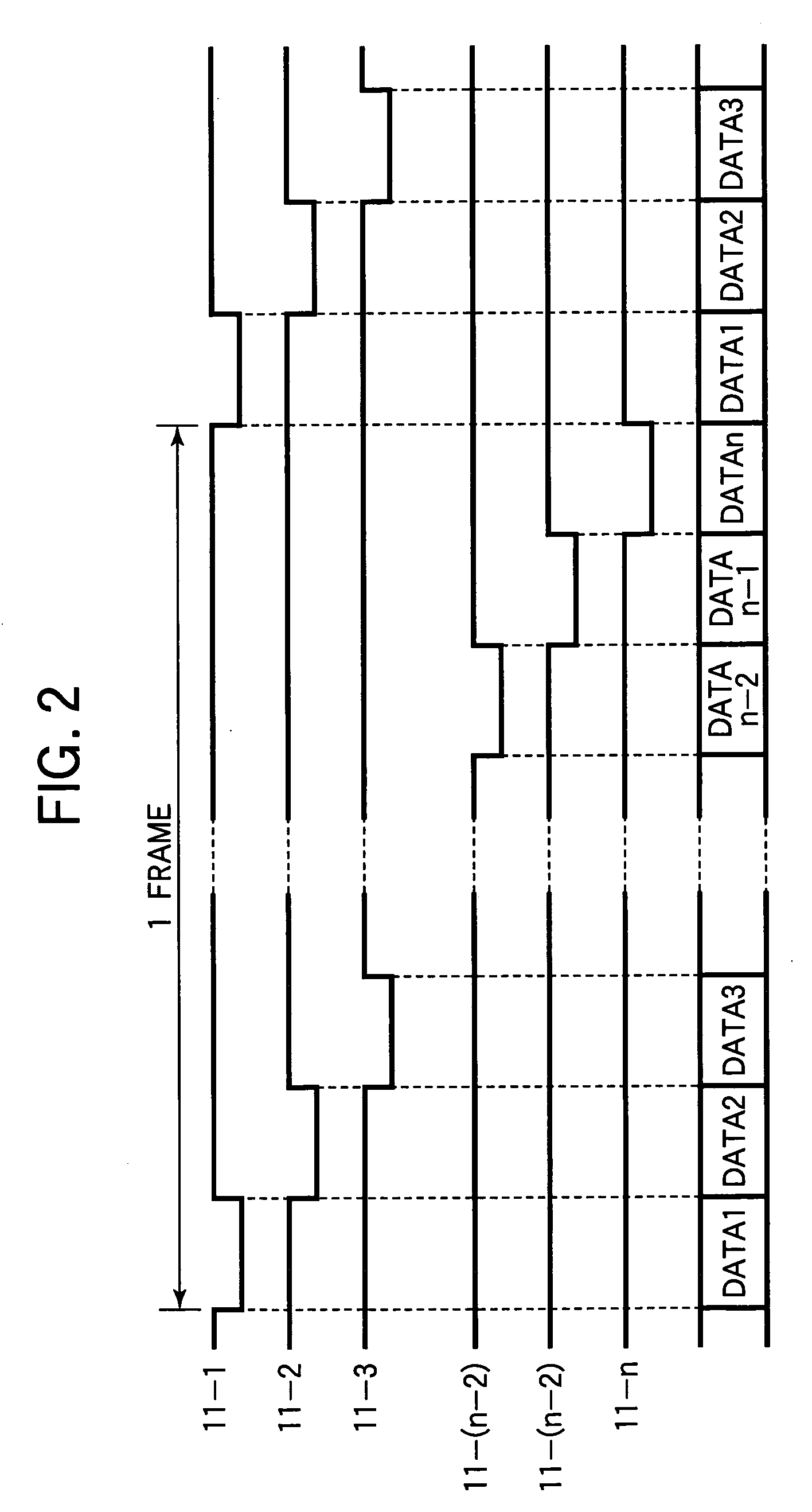

Color balancing circuit for a display panel

InactiveUS20060023002A1Effective balanceSewerage structuresElectrical apparatusDriving currentEngineering

A color balancing circuit for a flat panel display such as an electroluminescent display generates a primary current that can be varied to adjust the overall brightness of the display. Three currents related to the primary current by selectable ratios are generated, by current mirror circuits, for example; the ratios can be individually varied to adjust the color balance. Driving currents are generated from the three adjusted currents, by mirroring the adjusted currents, for example, and are used to drive display elements that emit light in the three primary colors. Image brightness and color balance can accordingly be adjusted separately, even though both are adjusted by adjusting the driving current. Circuit size is reduced in that the same primary current is used for all three primary colors.

Owner:LAPIS SEMICON CO LTD

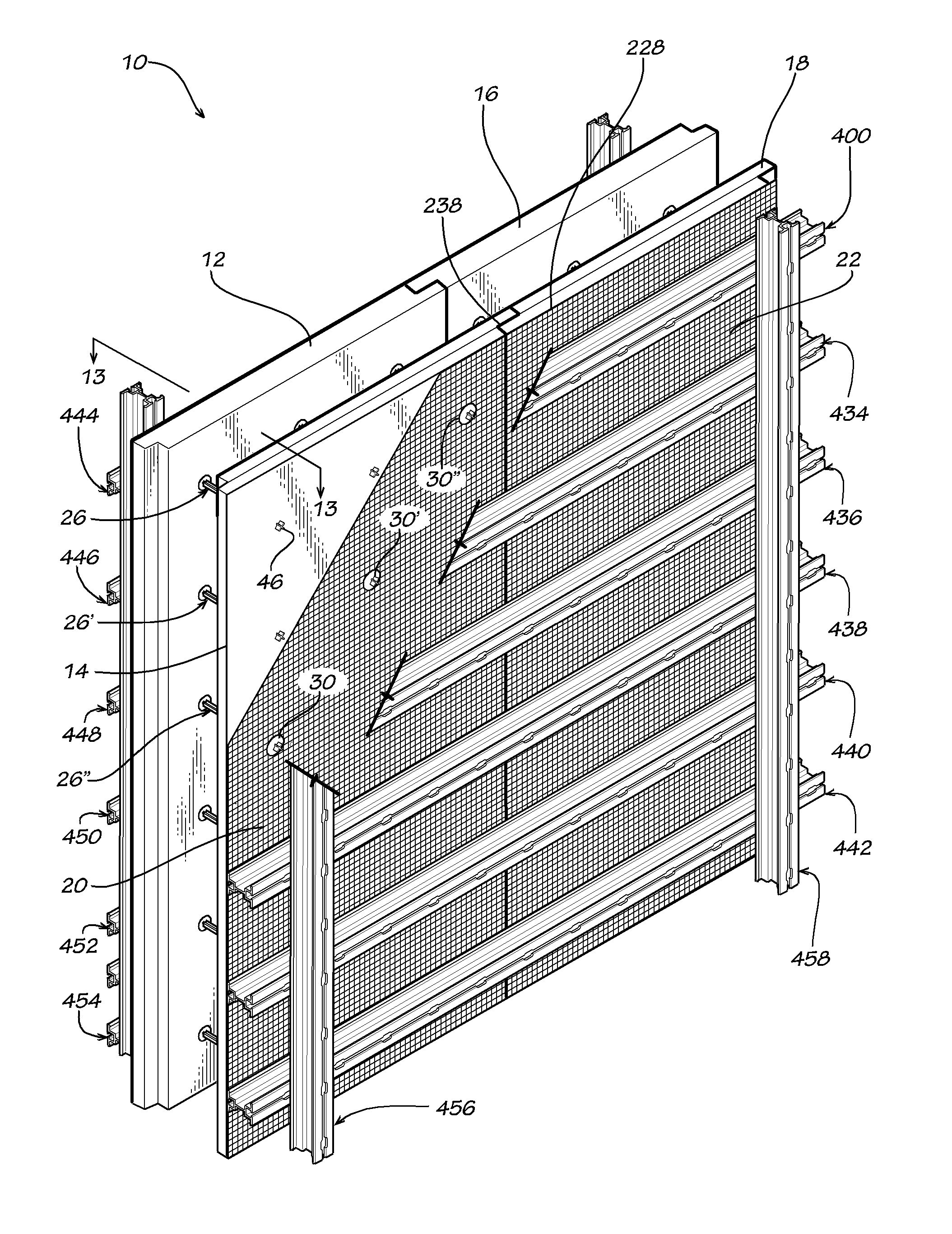

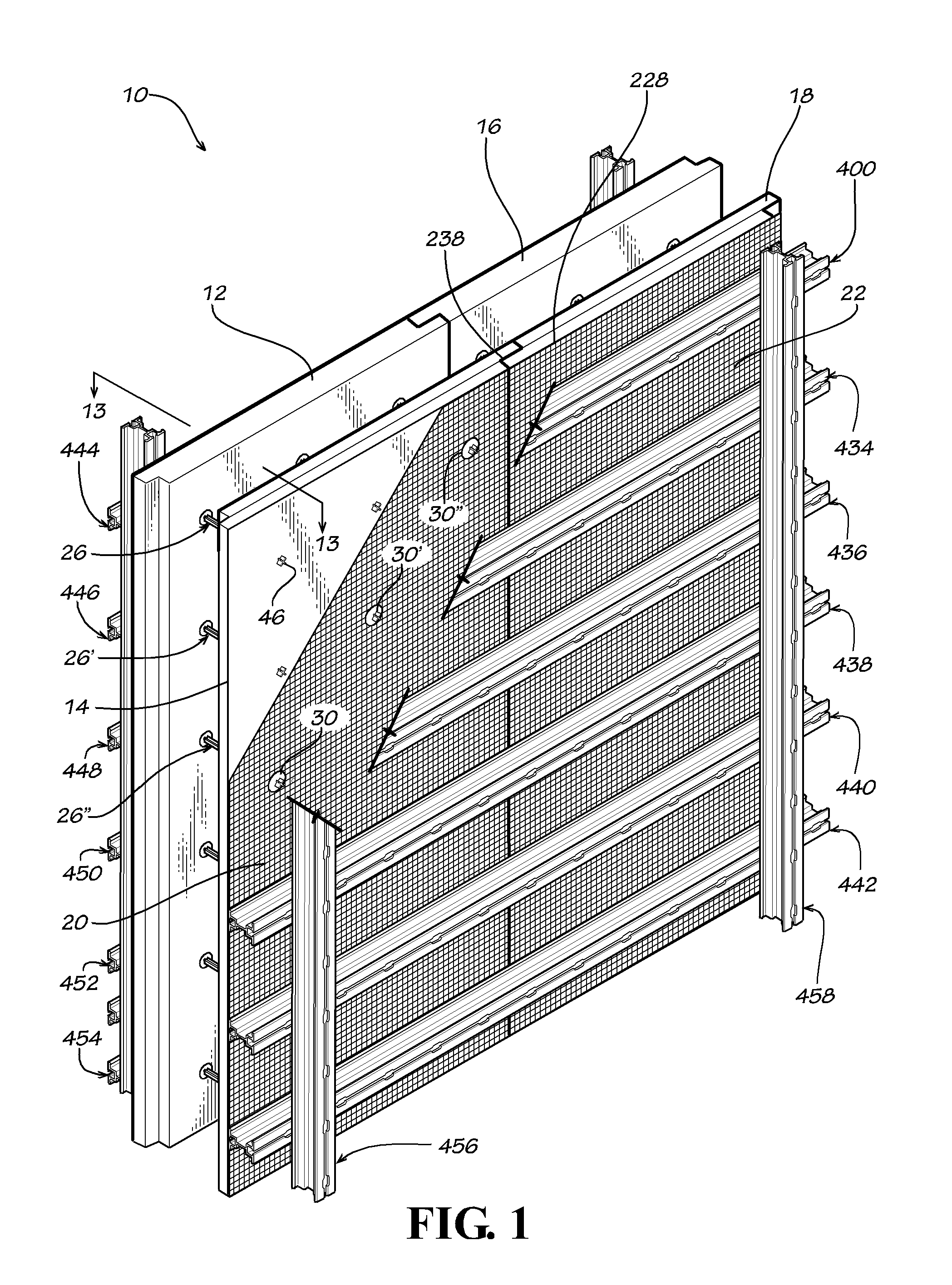

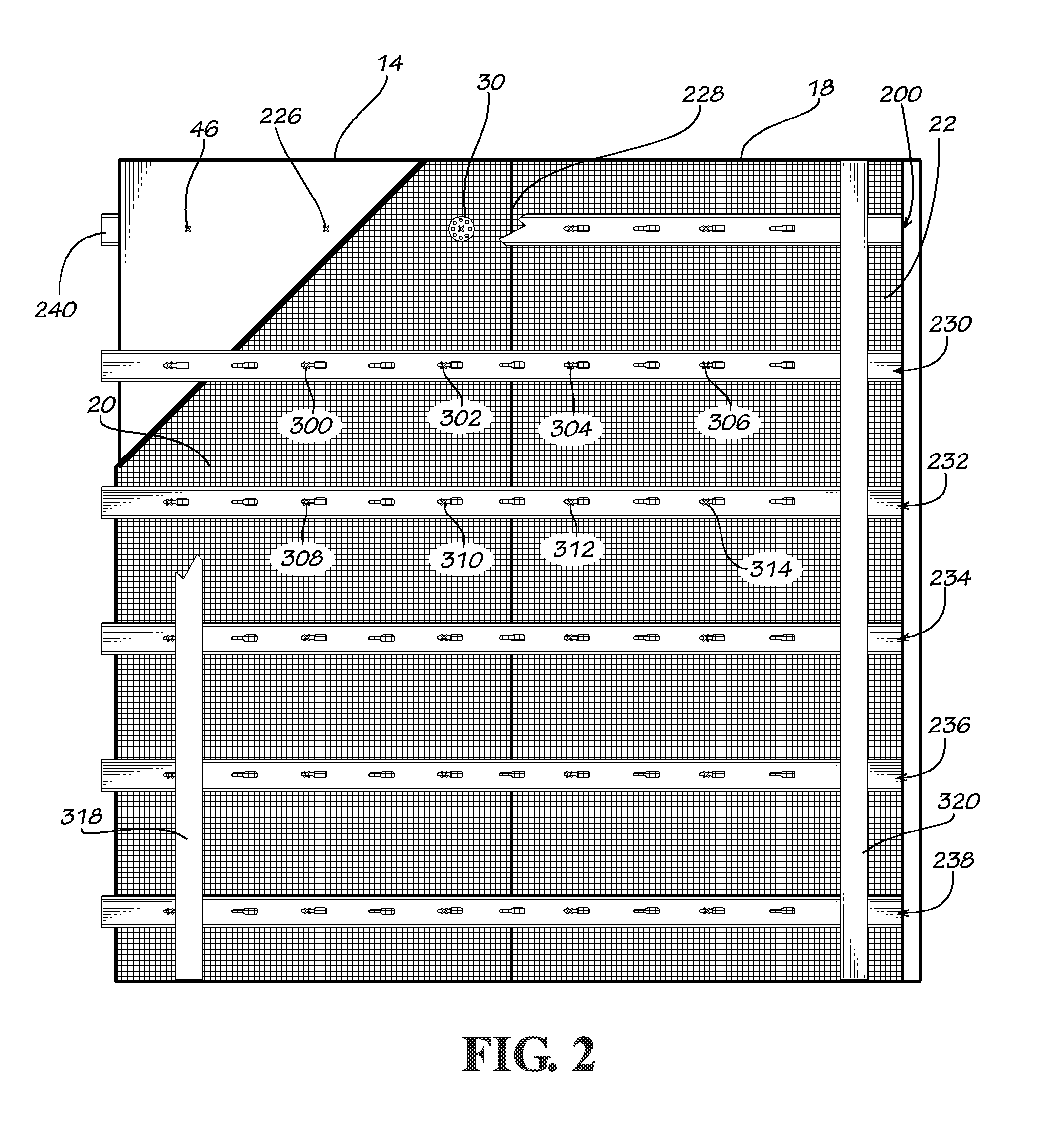

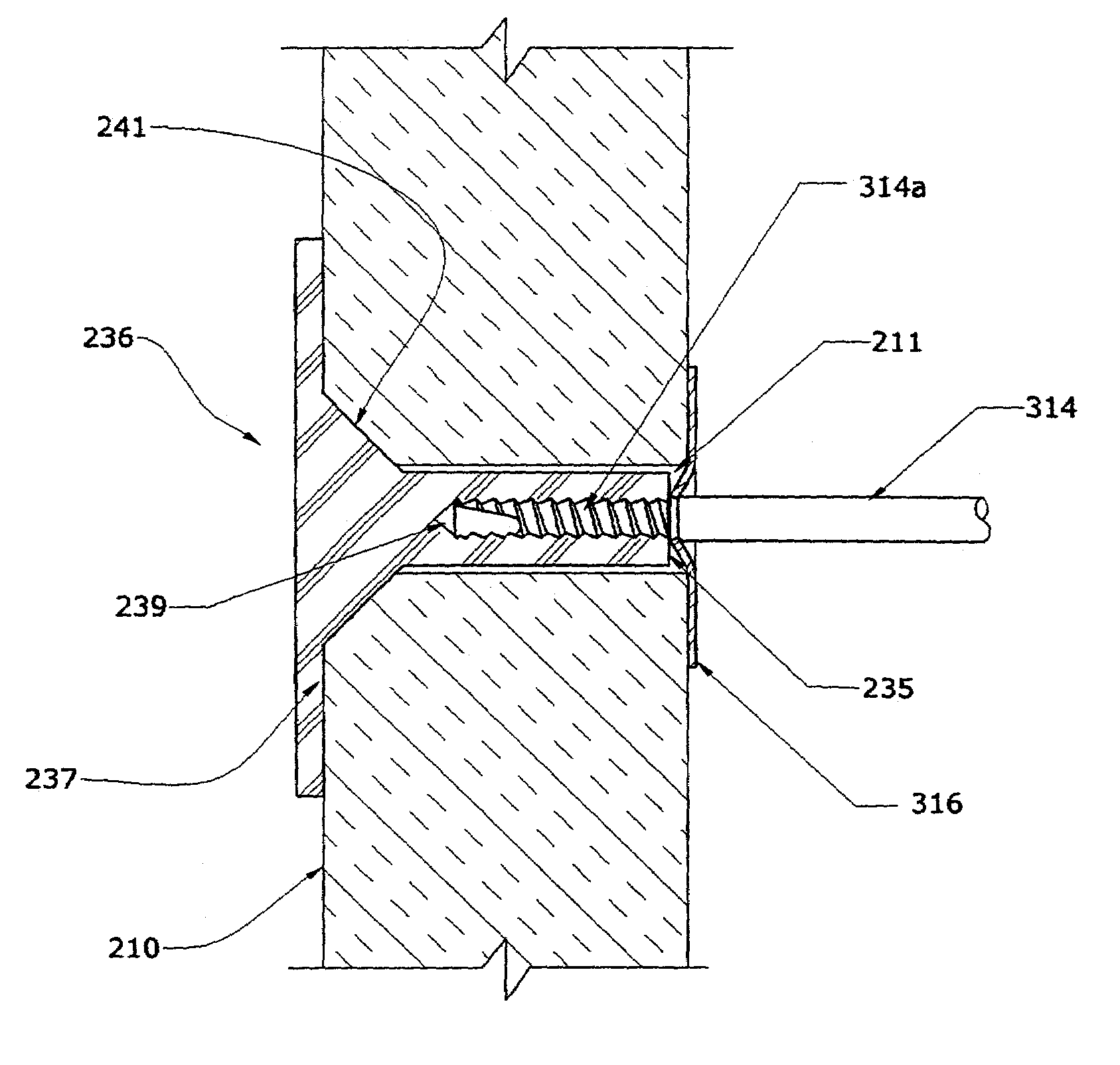

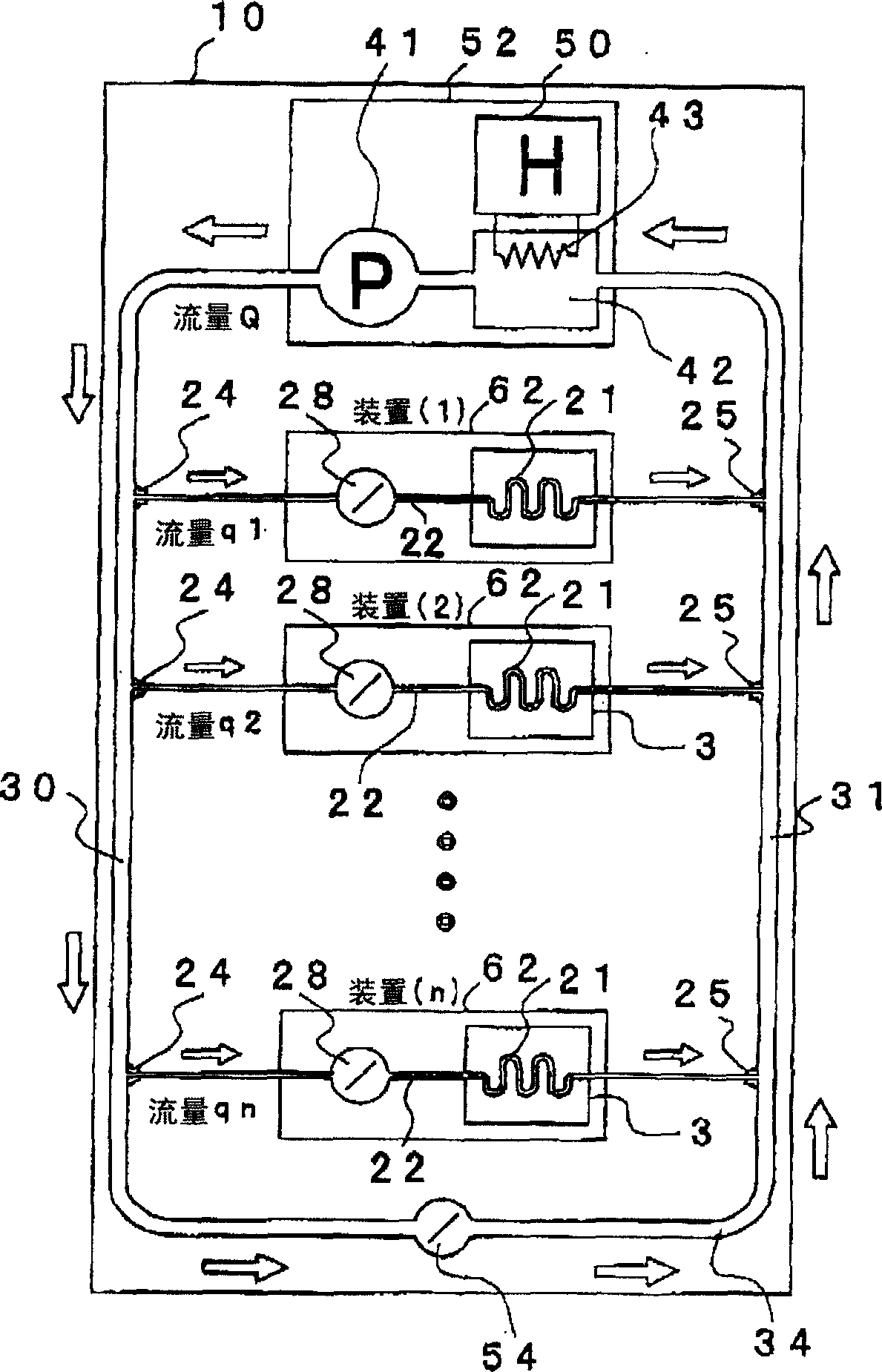

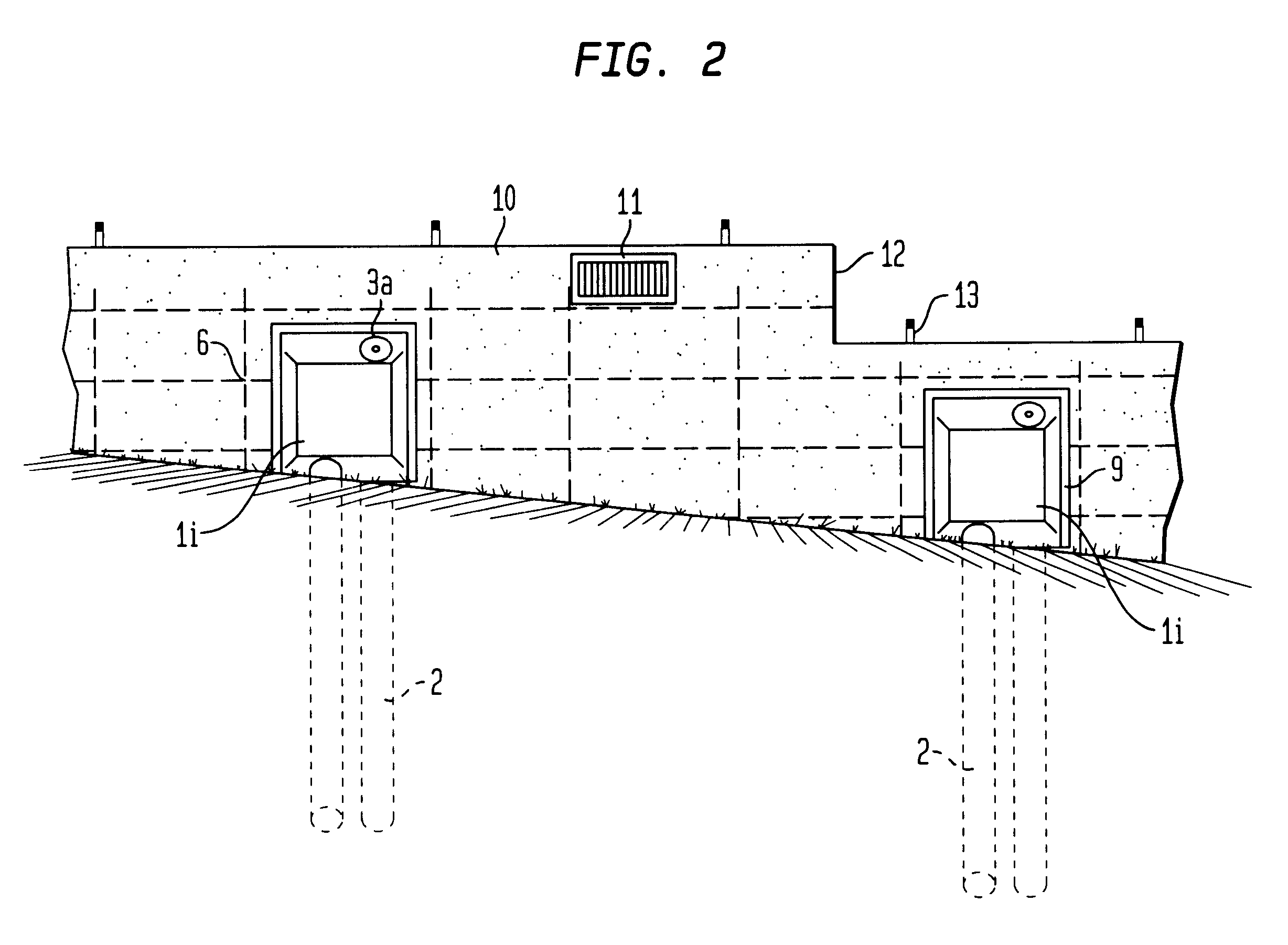

Insulated concrete form and method of using same

InactiveUS20130074432A1Retain heatEasy and inexpensive attachmentCeilingsConstruction materialInsulating concrete formFlange

Owner:CIUPERCA ROMEO ILARIAN

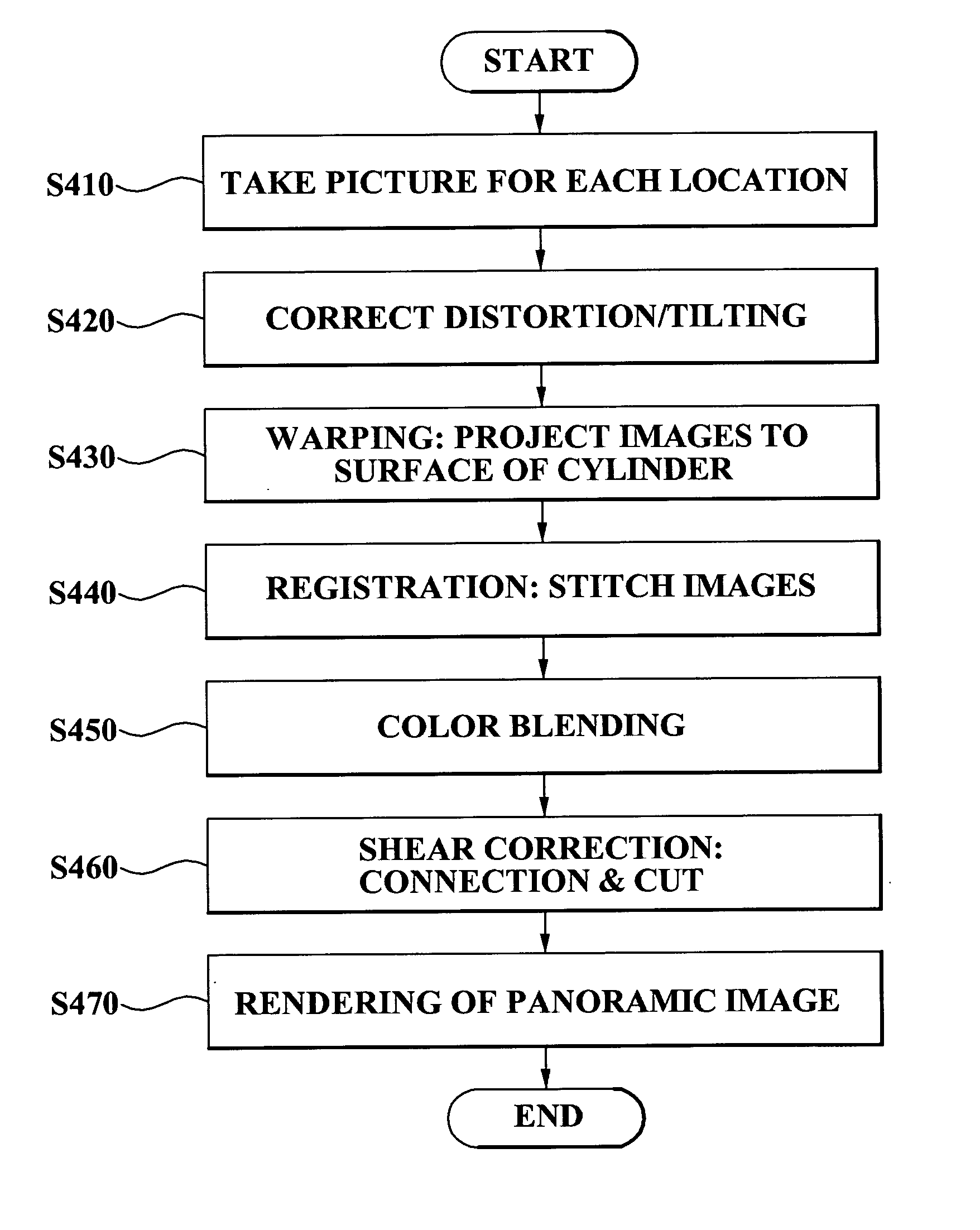

Method and apparatus for providing panoramic view with high speed image matching and mild mixed color blending

ActiveUS20070159524A1Improves speed of colorImprove image stitching speedTelevision system detailsImage analysisSource imageImage matching

An apparatus and method of providing a panoramic image, the method including: preparing images of a plurality of levels, which are made by scaling each of two source images at several rates; computing a Sum of Square Difference (SSD) between two corresponding images in each of the plurality of levels of the two source images to form an image stitched together; and when stitching the two images, the overlapping area is divided into a plurality of parts and each part is assigned a weight which is linearly applied respectively to the divided part of each source image for blending color. The apparatus includes stitching units to stitch source images together at the plurality of levels and blending units to color blend the source images in the overlapped area.

Owner:SAMSUNG ELECTRONICS CO LTD

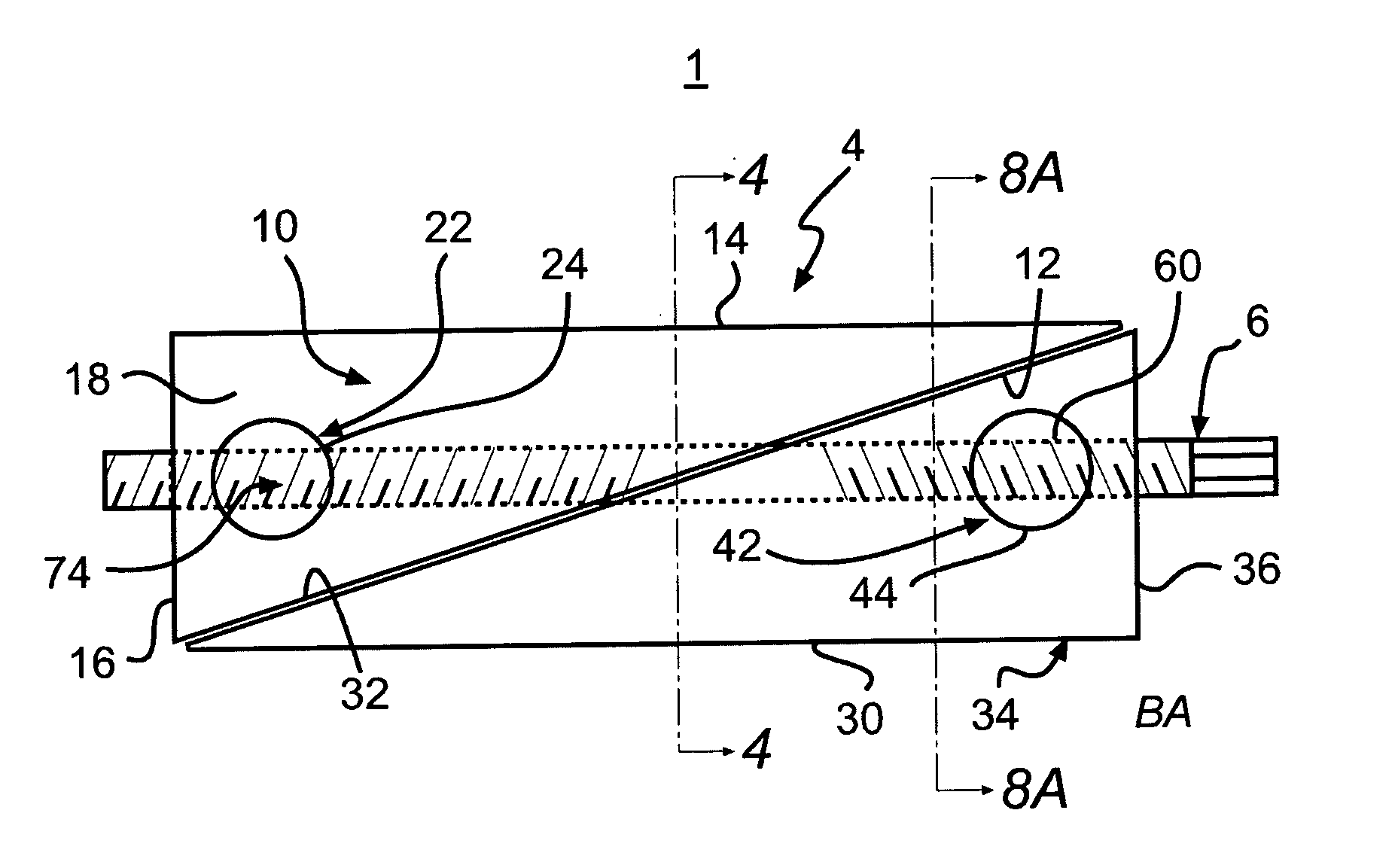

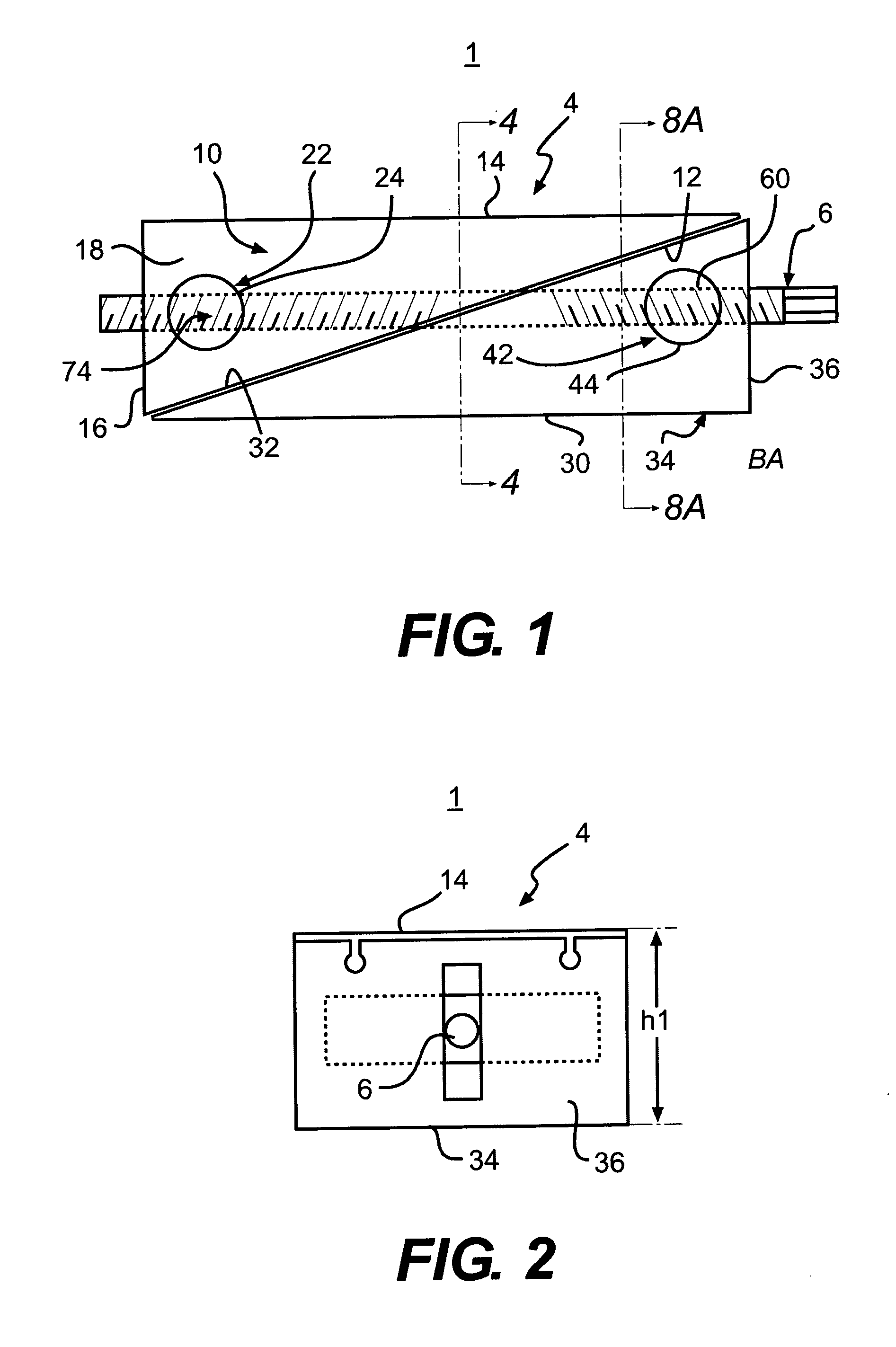

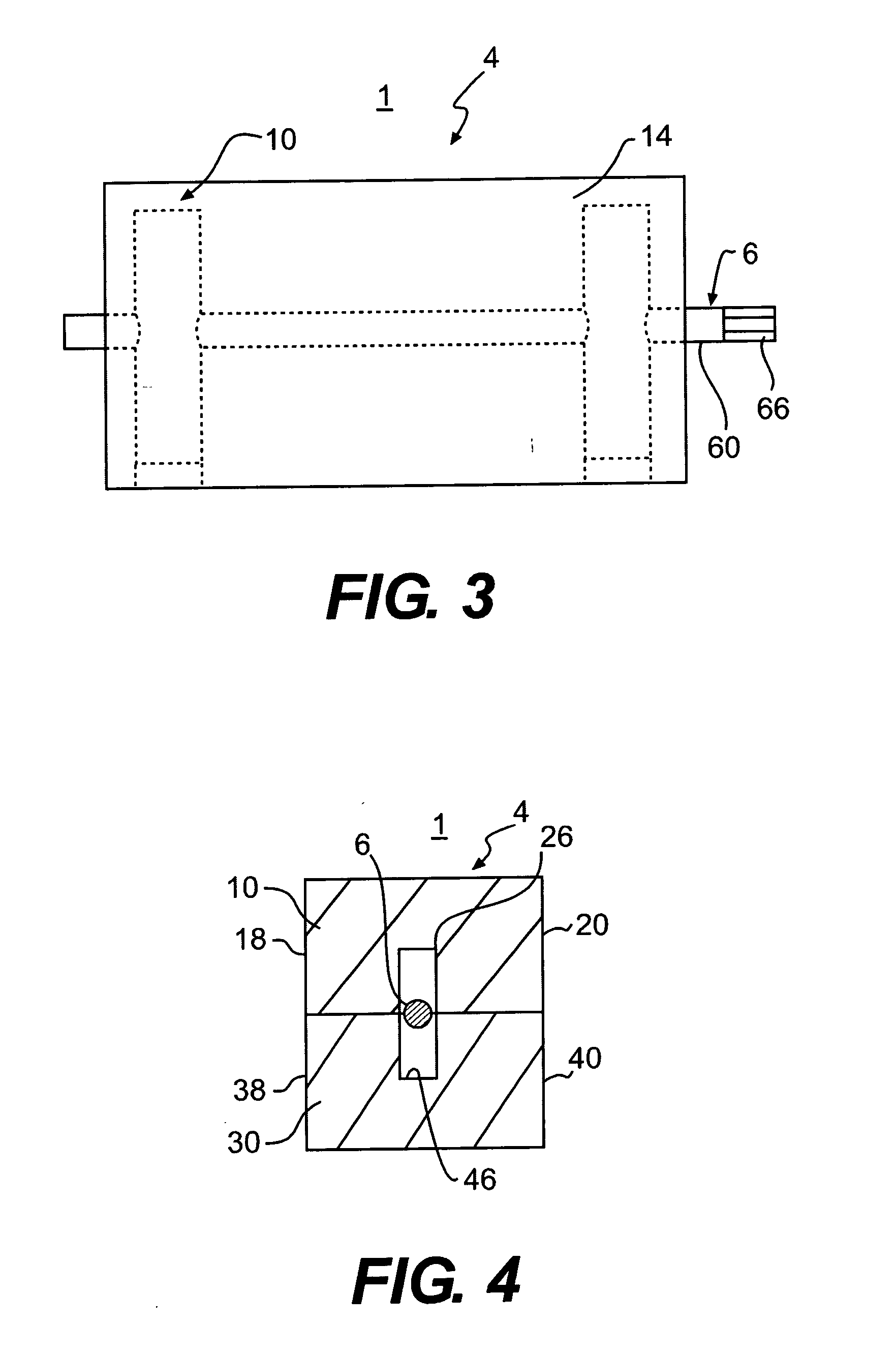

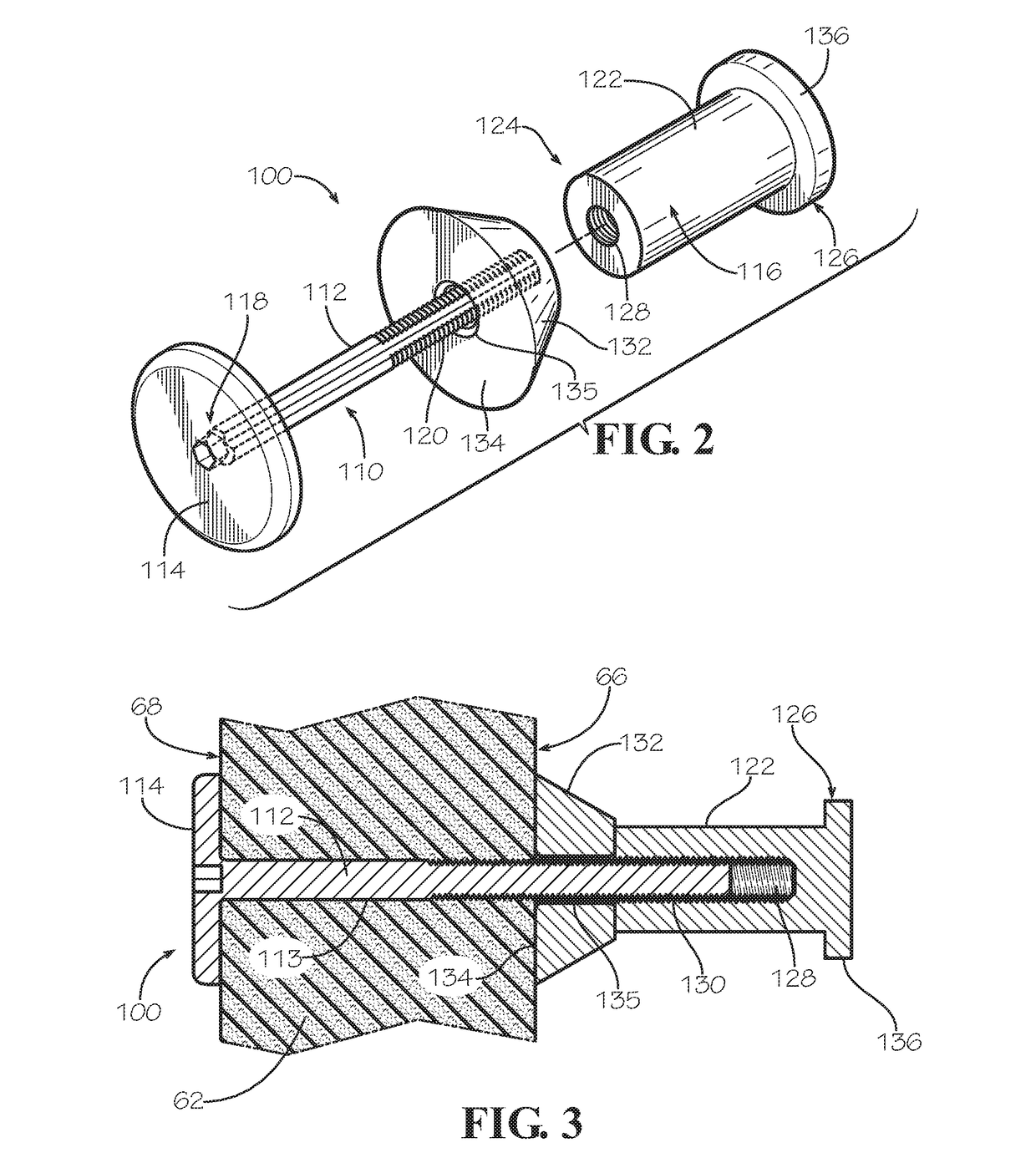

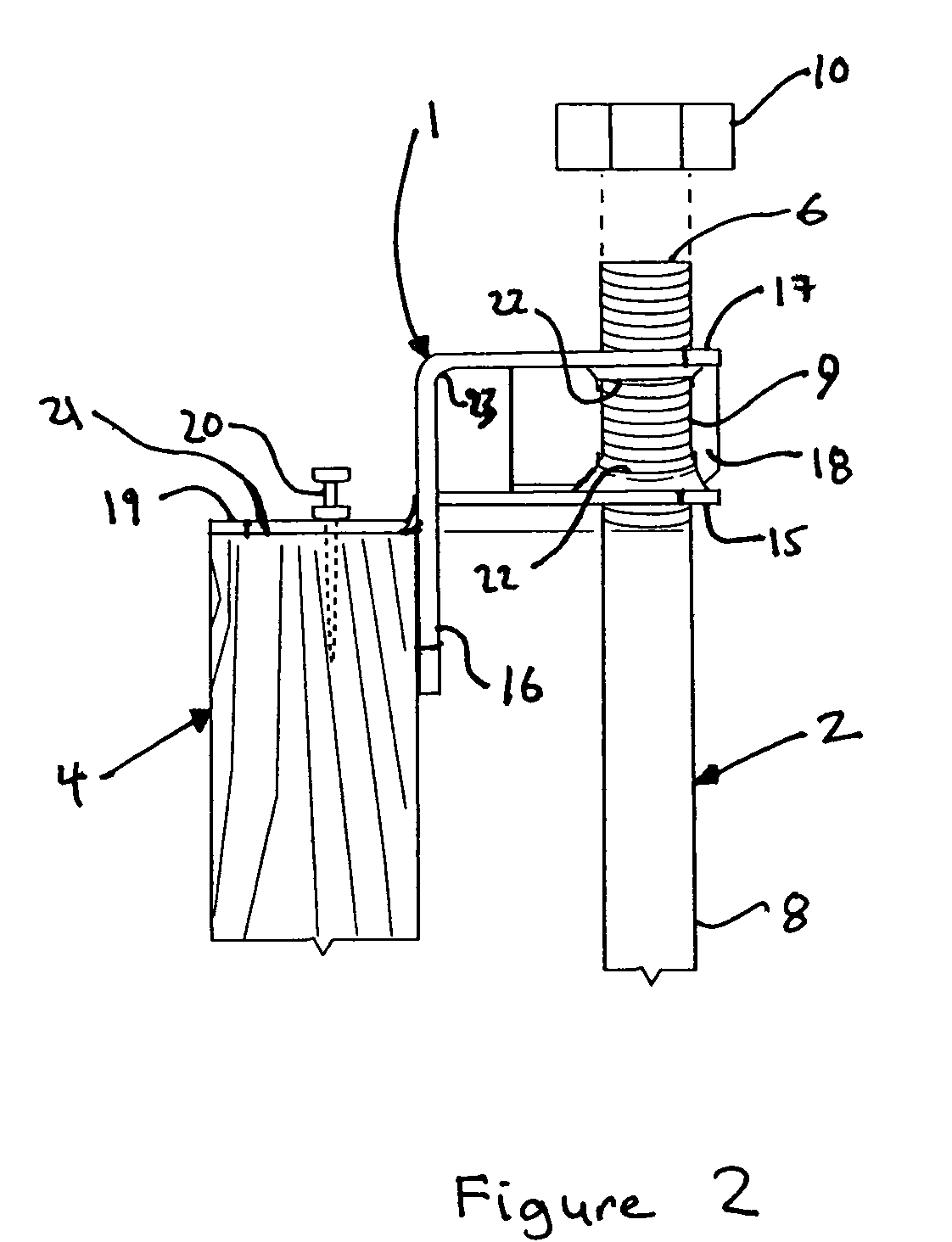

Universal adjustable spacer assembly

In a universal, adjustable spacer assembly, first and second opposed wedges have faces that are inclined with respect to a longitudinal axis. As the wedges translate along the longitudinal axis with respect to one another, vertical distance between an upper face and a lower face of the first and second wedges respectively changes. Longitudinally displaced portions of a rotatable member such as a threaded rod are received in a first and a second collar member pivotally mounted with respect to the first and second wedges respectively. As the rod rotates, longitudinal distance between the collar members changes, and the wedges slide against each other, the collar members rotate within each wedge. In a further form, opposing track members may be fixed to inclined surfaces of the first and second wedges respectively.

Owner:SELNESS JERRY N

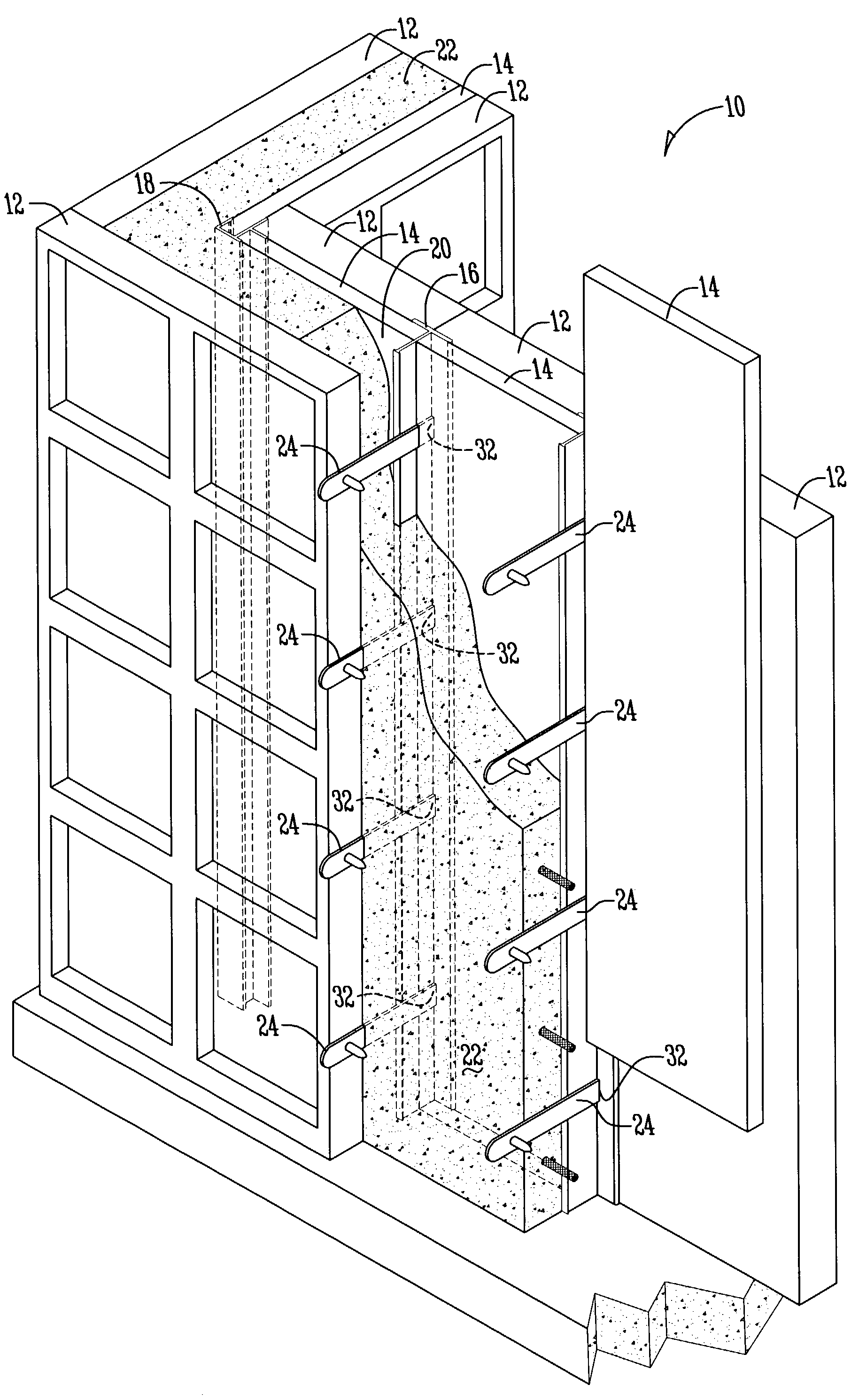

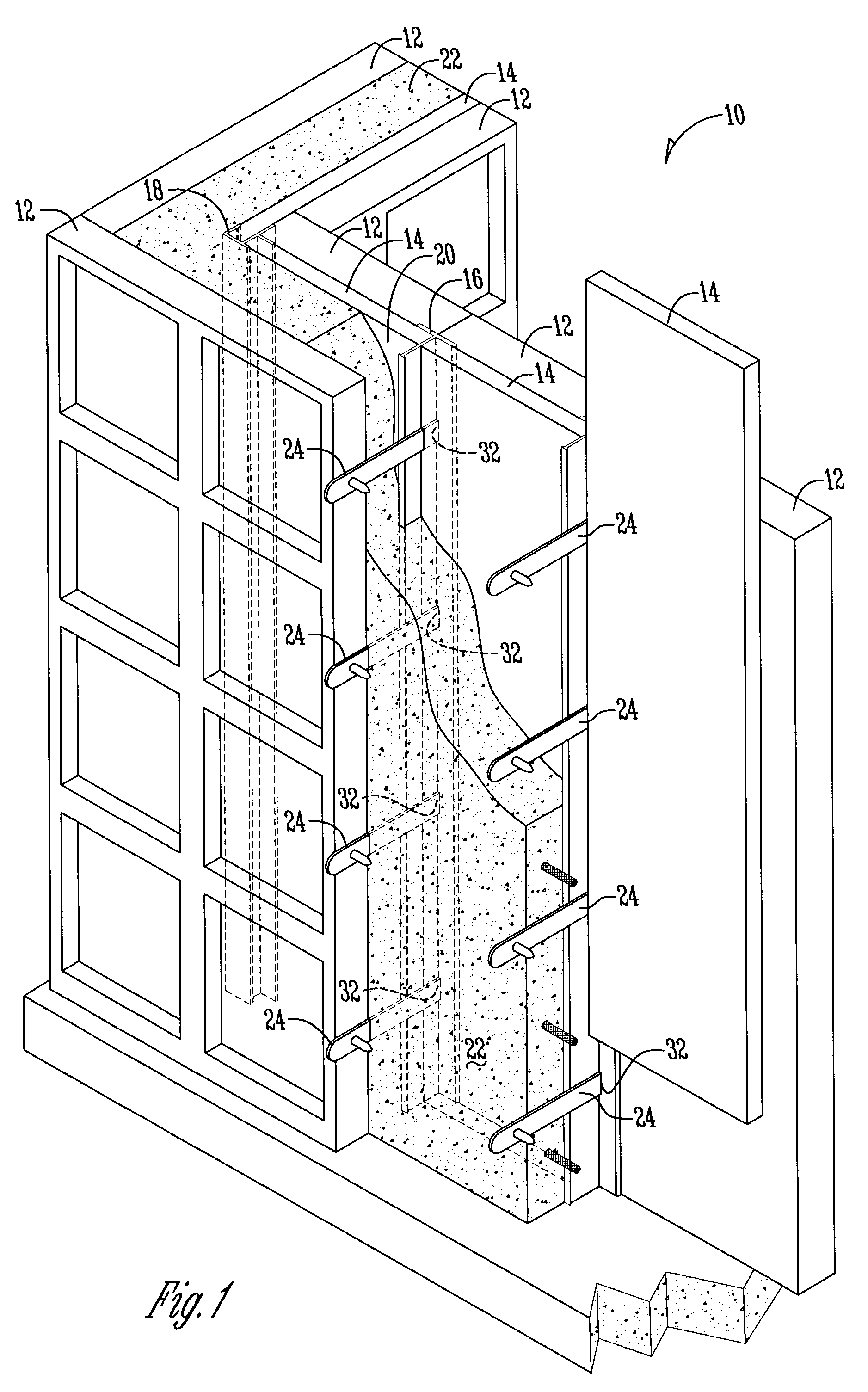

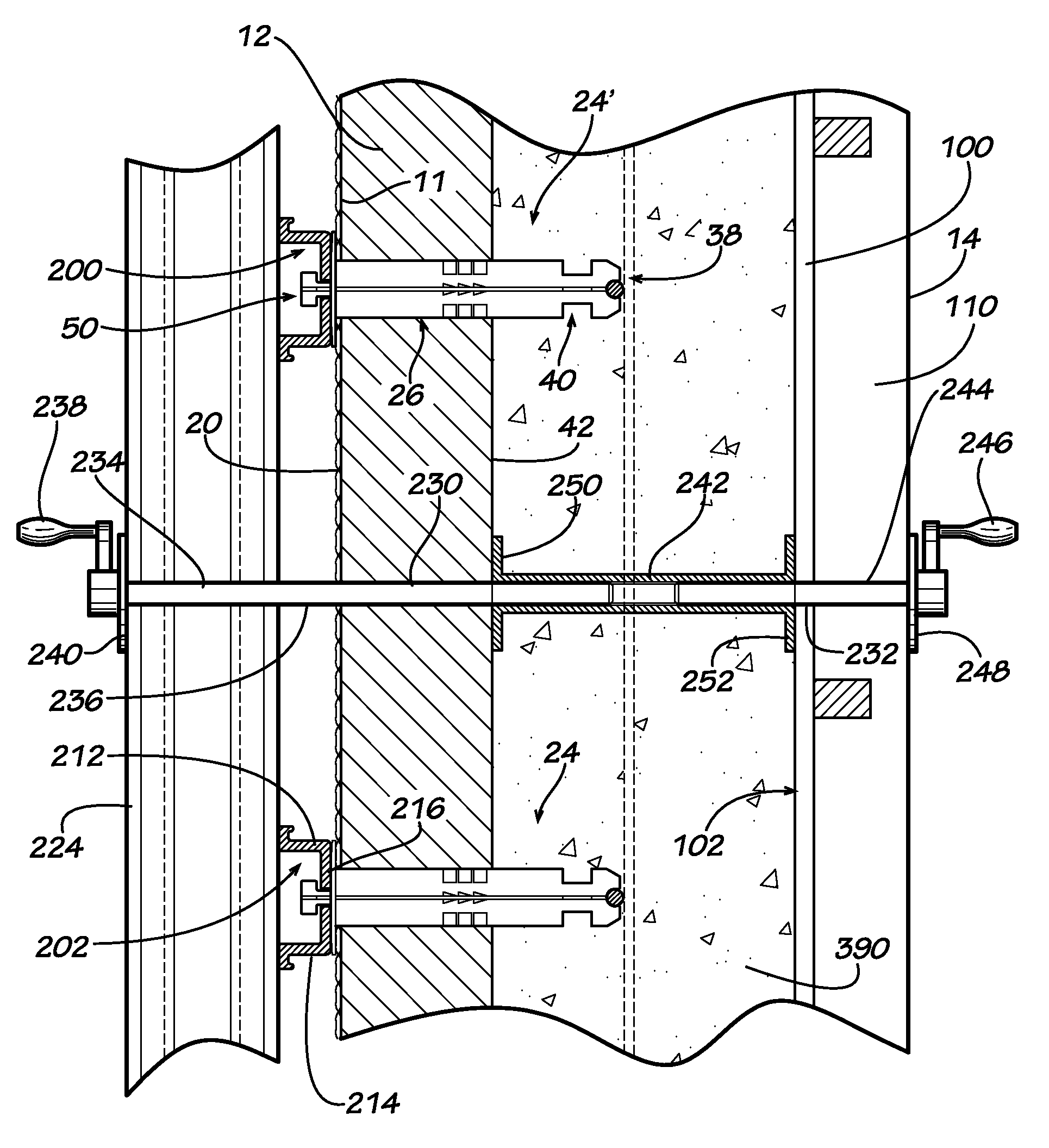

Insulated concrete wall system and method of making same

A method and system for installing an insulated concrete wall includes insulation panels placed in an upright manner. Generally T-shaped wall studs are placed next to the insulation panels such that the front section of the wall stud is on the outside of the insulation panels and an anchoring section of the wall stud extends beyond the insulation panels into the gap into which concrete will later be poured. Concrete pouring forms are placed so as to render the gap into which concrete will be poured a desired thickness. The wall stud may also include slots for receiving cross-ties that secure the concrete pouring forms in proper position and retaining nubs that prevent the insulation panels from floating when concrete is poured. Concrete is then poured into the gap, surrounding the anchoring section the T-shaped wall stud.

Owner:BURGETT FERRALL

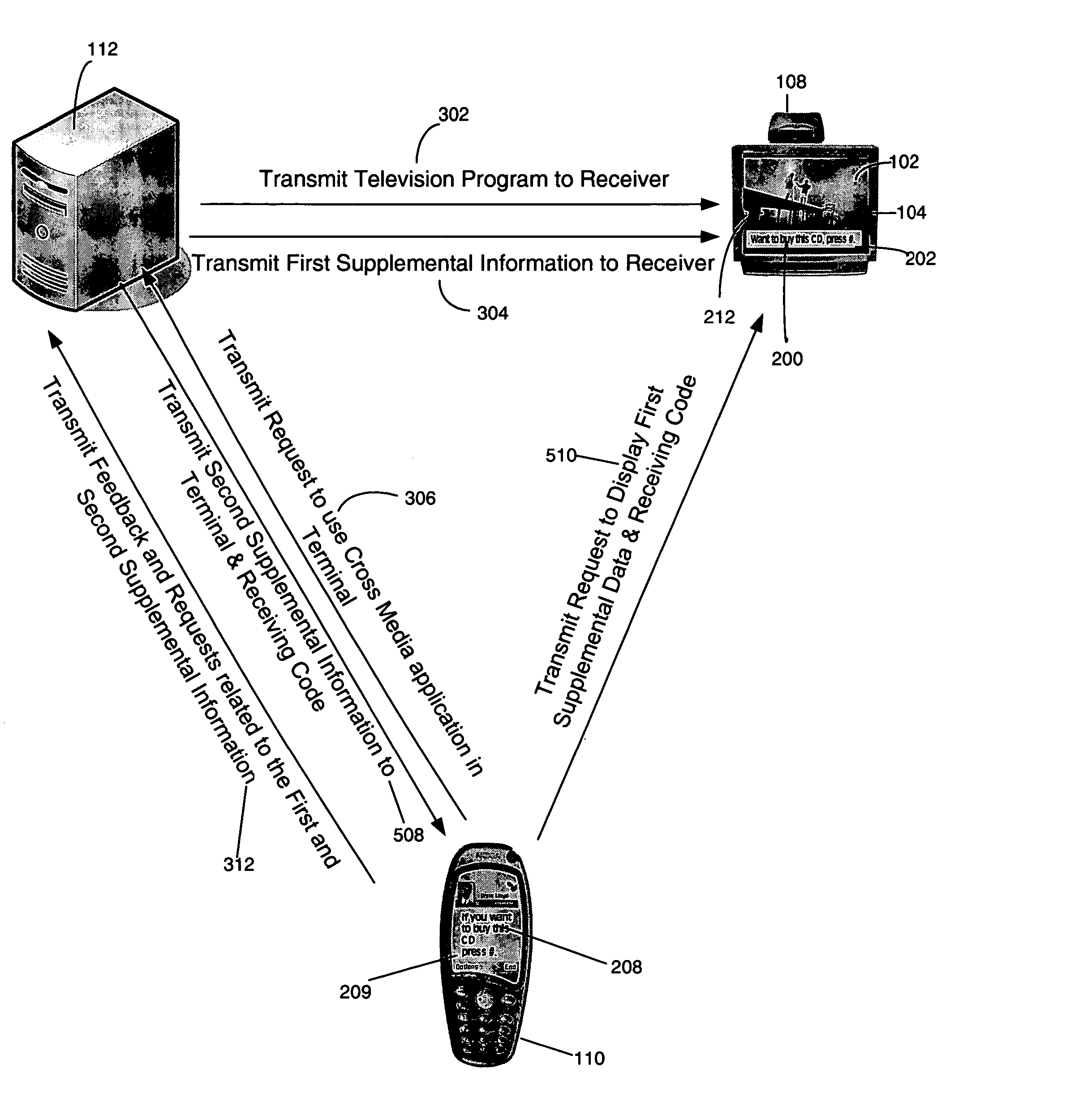

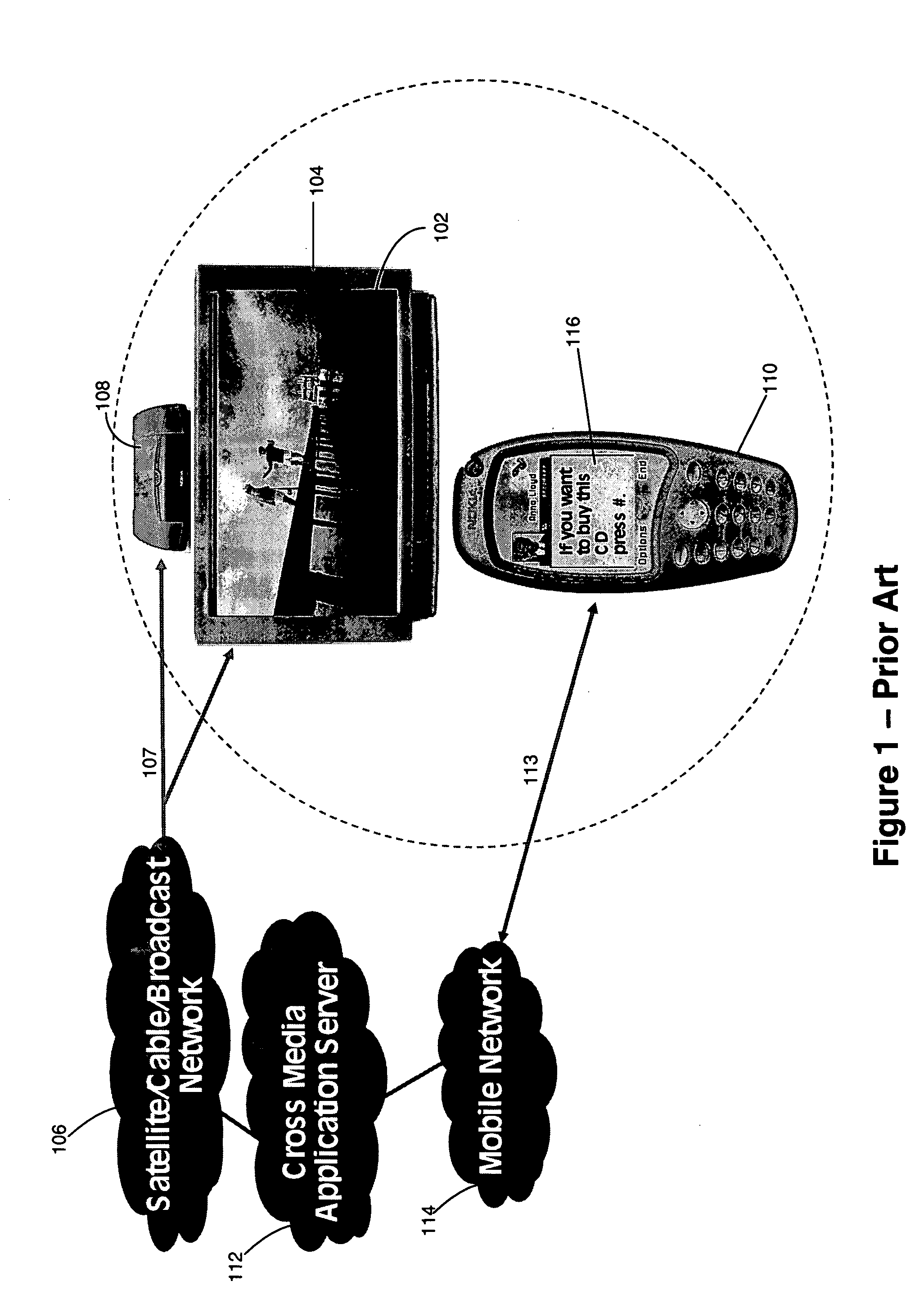

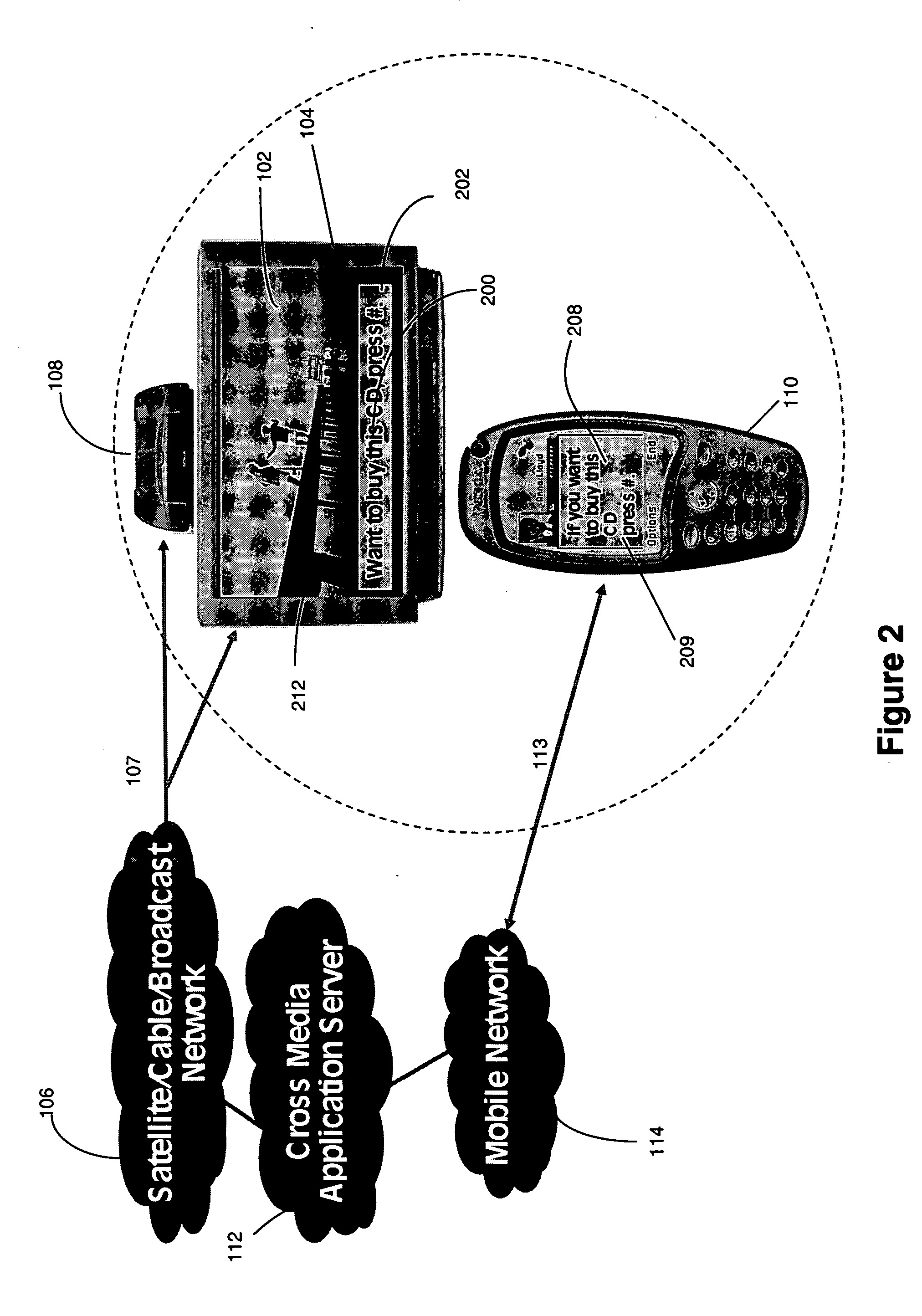

Coordinated cross media service

InactiveUS20050251823A1Improve experienceTelevision system detailsTransmission sytems characterised arrangementsComputer networkCross media

The invention provides coordinated cross media services to users. Supplemental information is provided to multiple cross media devices in order to enhance a user's interaction with a coordinated cross media service.

Owner:NOKIA SOLUTIONS & NETWORKS OY

Reinforced insulated concrete form

Owner:CIUPERCA ROMEO ILARIAN

Insulated concrete form system with variable length wall ties

InactiveUS7818935B2Accelerate buildingFaster and cheap and better buildingWallsAuxillary members of forms/shuttering/falseworksEngineeringPolypropylene

Variable length polypropylene ties are used to form an insulated concrete wall by holding sheet materials in a fixed distance part so concrete can be cast between the two sheet materials.

Owner:VELICKOVIC PJER MISE

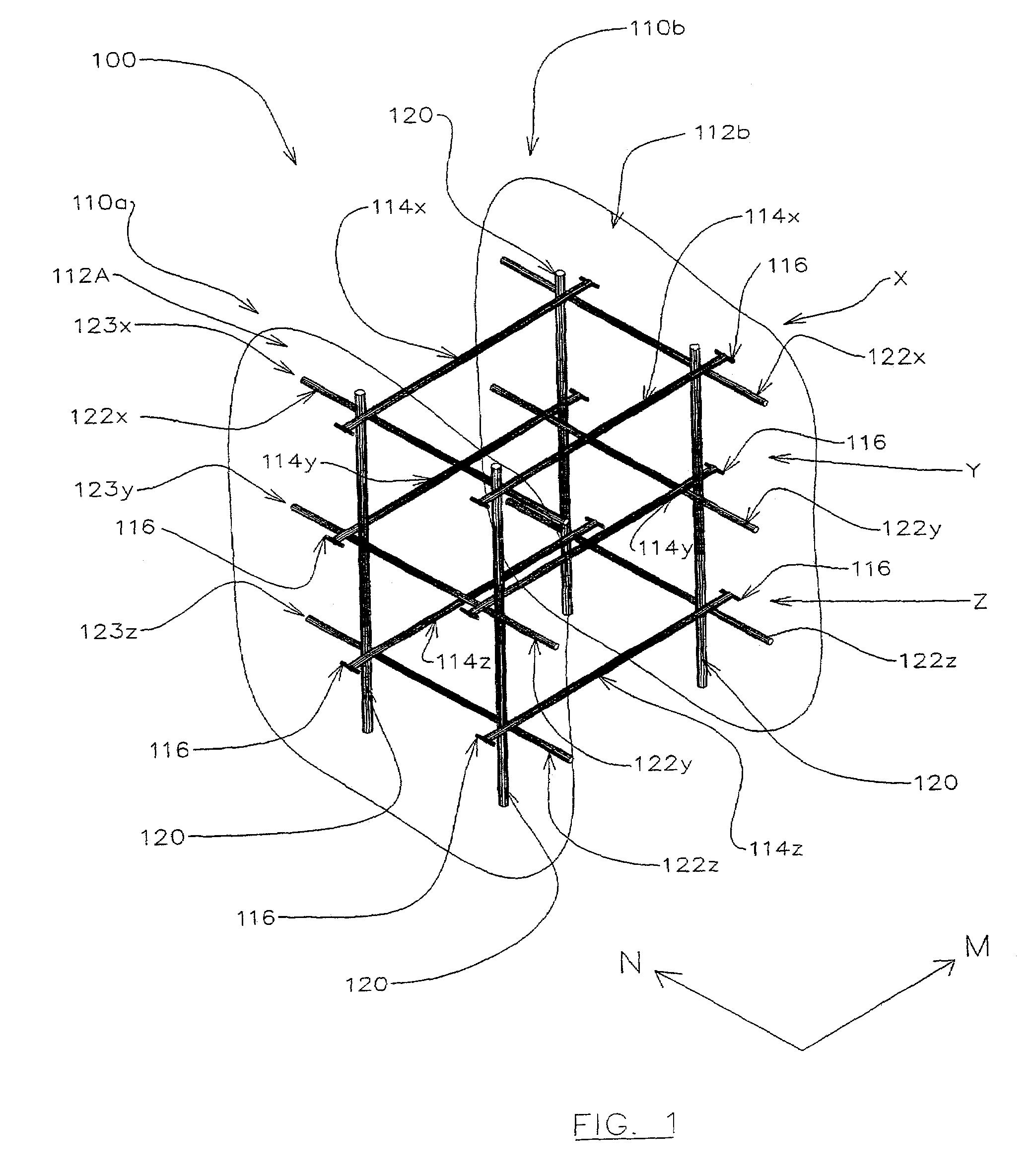

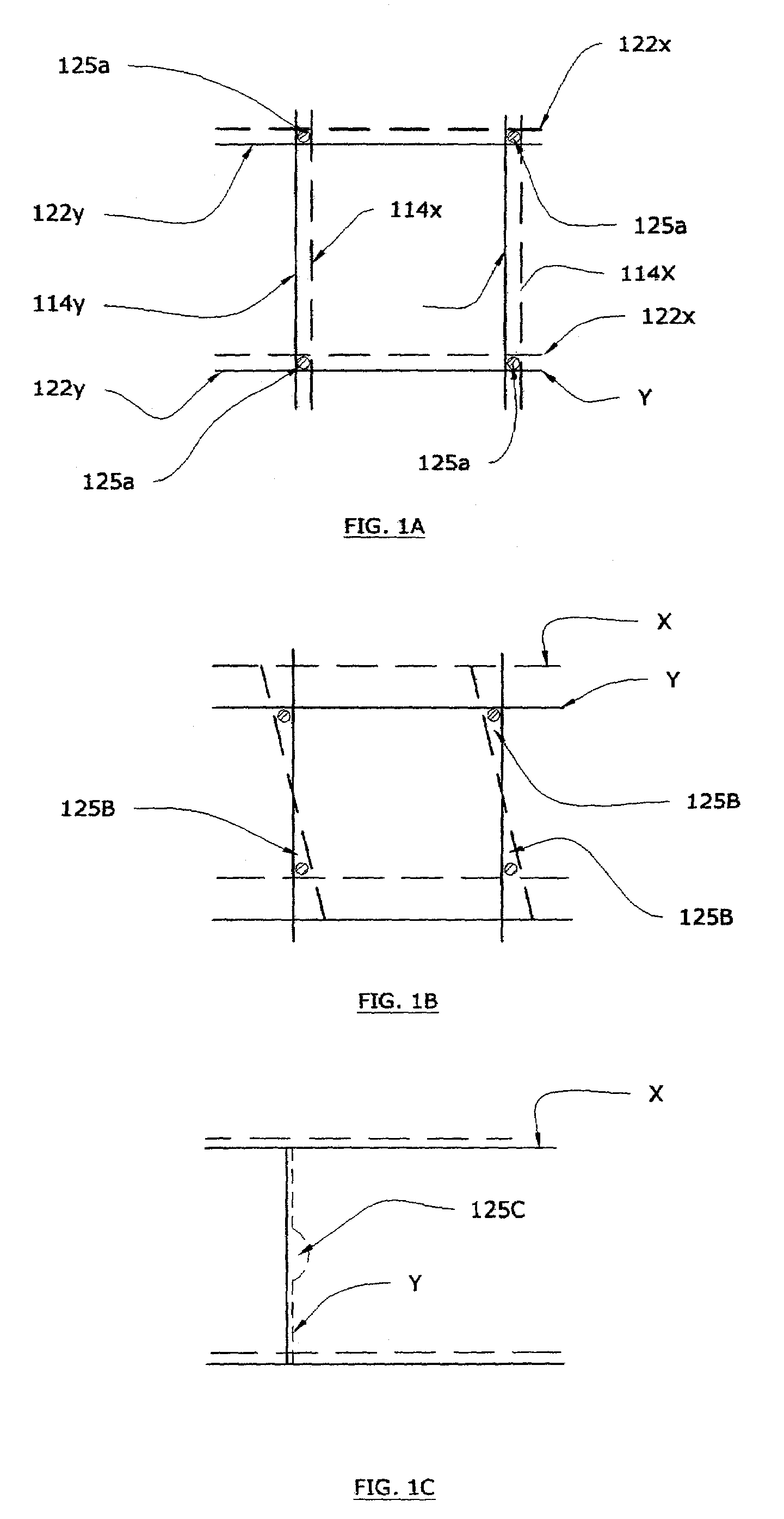

3-D construction modules

A 3D construction module comprising at least one vertically upstanding panel with first and second mesh layers oriented generally transversely and longitudinally. The first and second mesh layers have at least one rod member mounted to said panel and are vertically spaced from each other. The rod members form a first horizontally projected retention cell to restrict translation of a bar held in said retention cell between said first and second mesh layers. A third mesh can also be provided to form a second retention cell between said second and third mesh layers. The first and second retention cells restrict translation movement longitudinally and transversely of a vertical reinforcement member held in said first and second retention cells, and restrict rotation of the vertical reinforcement member about both a longitudinal axis and a transverse axis of the said 3D construction module. Horizontal reinforcement meshes are features of the invention. Other features of the invention include a trough for holding melted panel material, connectors for connecting rods to panels and associated stopper members. Also included are bracers for joining connectors and other devices related to panel connections.

Owner:BRAVINSKI LEONID G

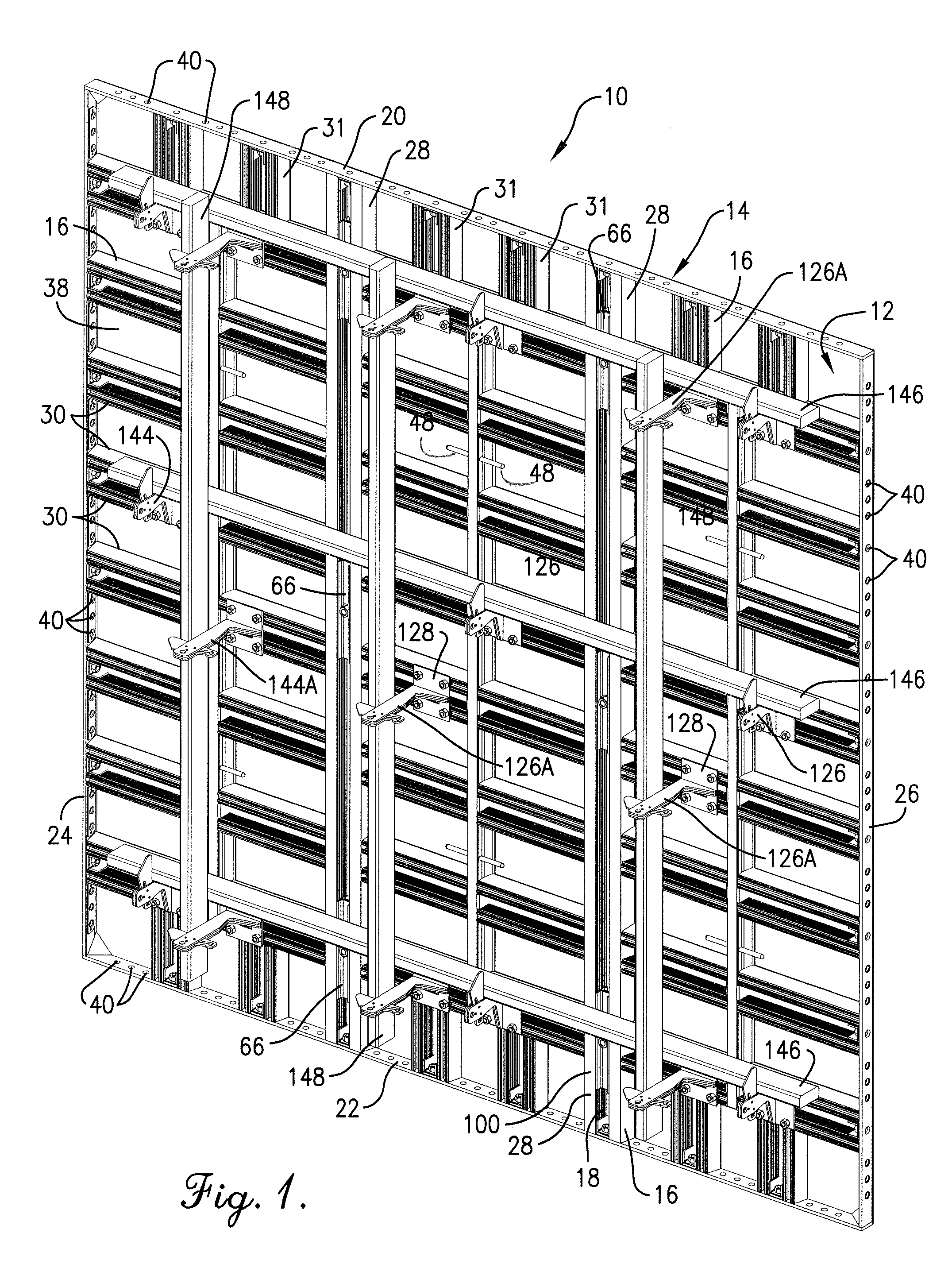

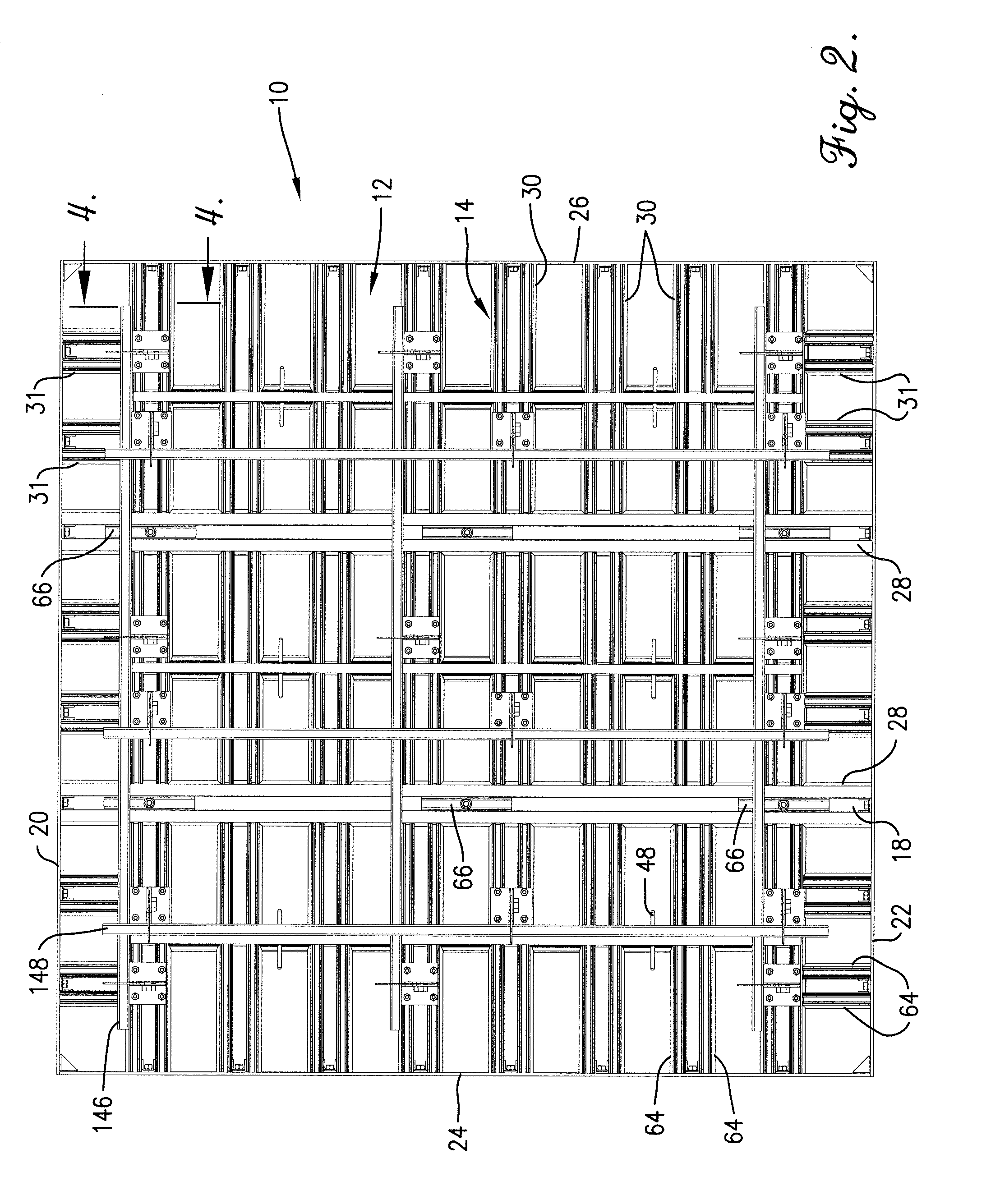

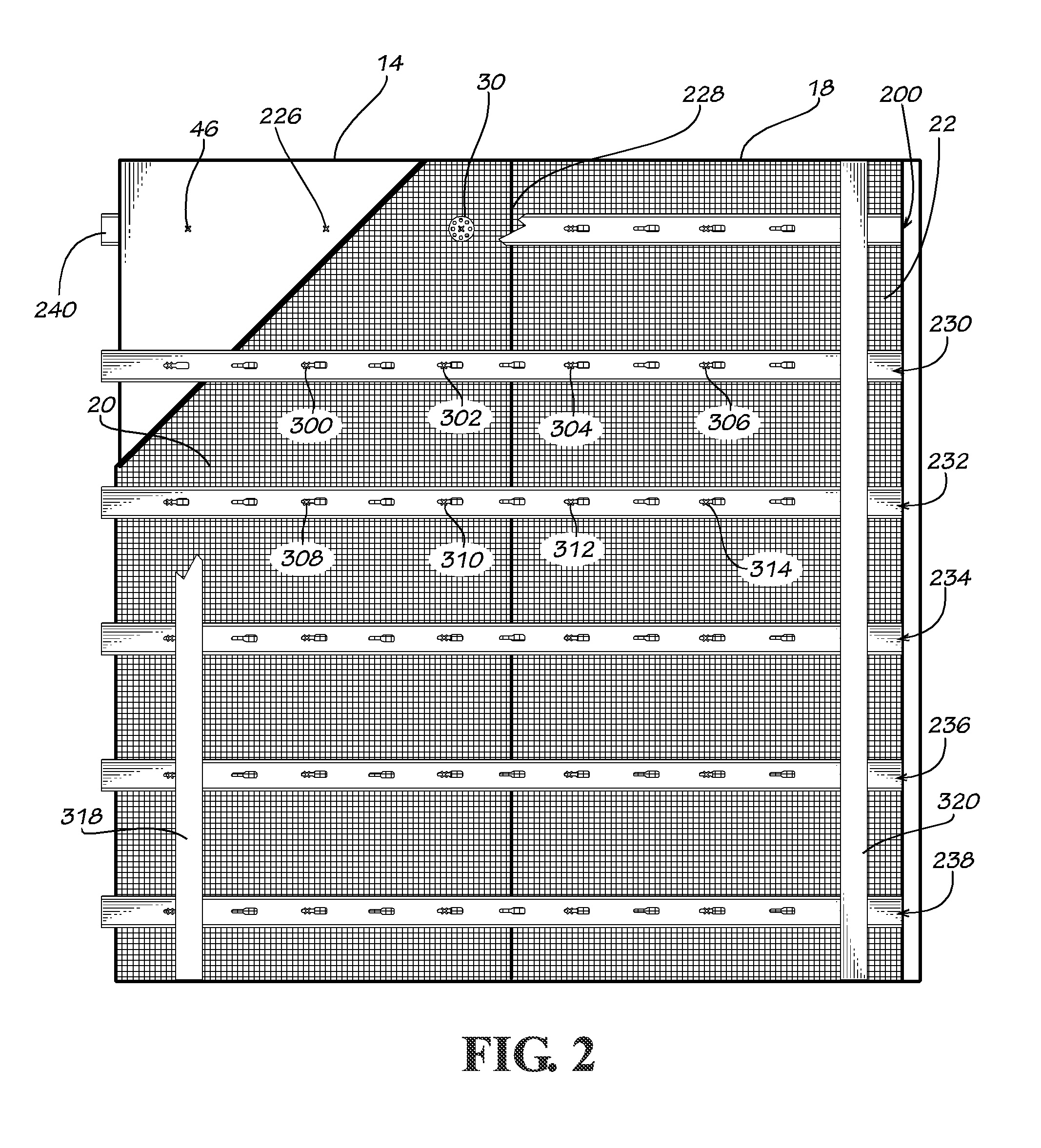

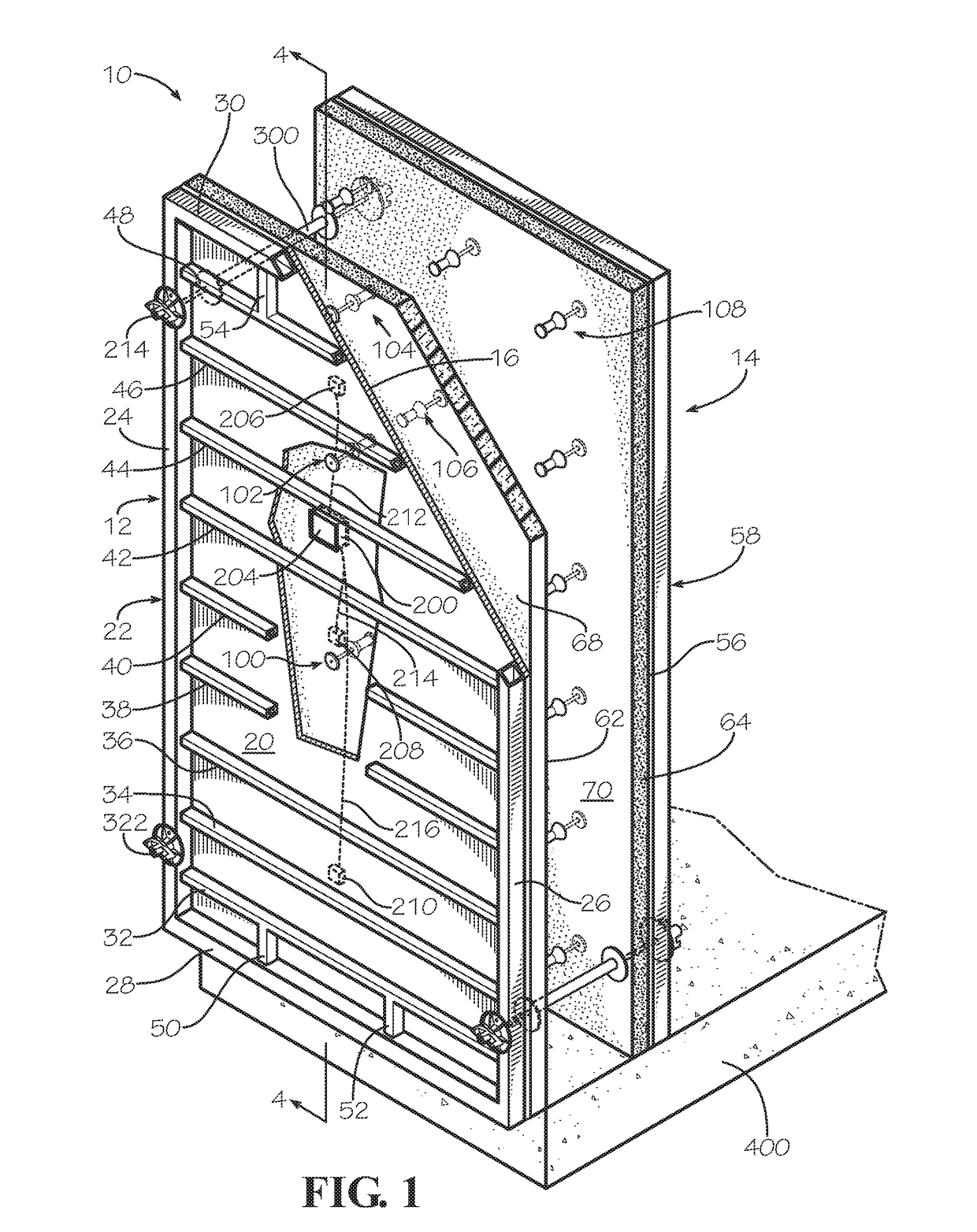

Lightweight Crane-Set Forming Panel

InactiveUS20080173788A1Easy to useReinforce against deflectionCeramic shaping apparatusForms/shuttering/falseworksEngineeringSurface plate

A forming panel is provided which is particularly useful as a large, crane-set forming panel for forming concrete walls. The forming panel includes a face plate and a frame, the frame including channels having a slot extending longitudinally therealong. The slot is adapted to receive a filler insert having a bushing which includes a flexible barrier having a brush-like element with a plurality of filaments extending into a passage configured to receive either a tie bar or a tie rod. The forming panel preferably includes a shiftably mounted bracket for supporting a waler, scaffold or strongback thereon, wherein the bracket includes an arm which may be pivoted to a position substantially parallel to the frame and its mounting plate for transport and / or storage. The face plate may be provided as a multilayered composite panel and the frame may include rails having grooves on the side opposite the face plate which receive flexible barriers for inhibiting the passage of fine particles of concrete therepast.

Owner:WESTERN FORMS

Insulated concrete form and method of using same

InactiveUS8756890B2Improve sound insulationImproved curing environmentCeilingsConstruction materialEngineeringInsulating concrete form

Owner:CIUPERCA ROMEO ILARIAN

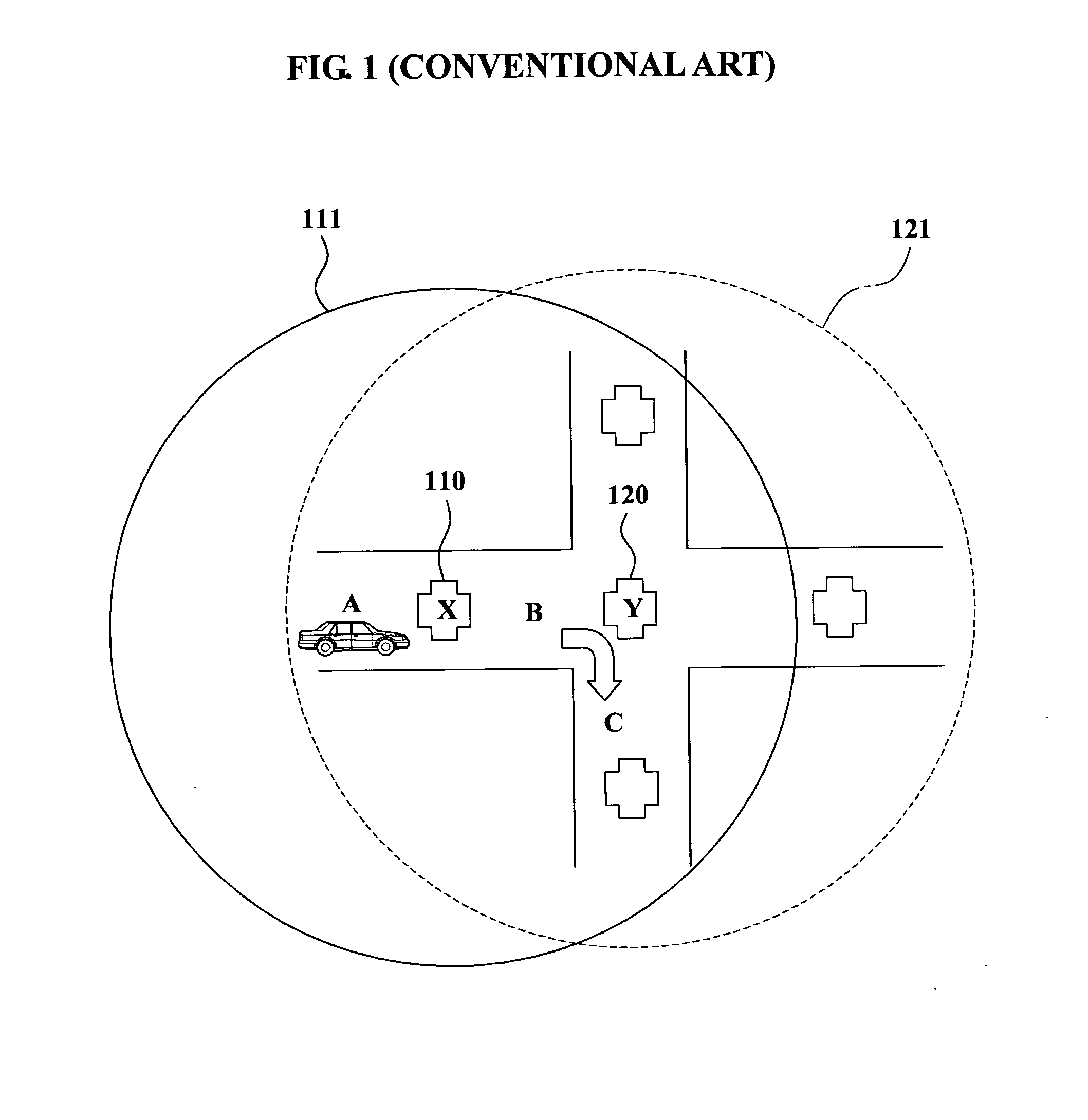

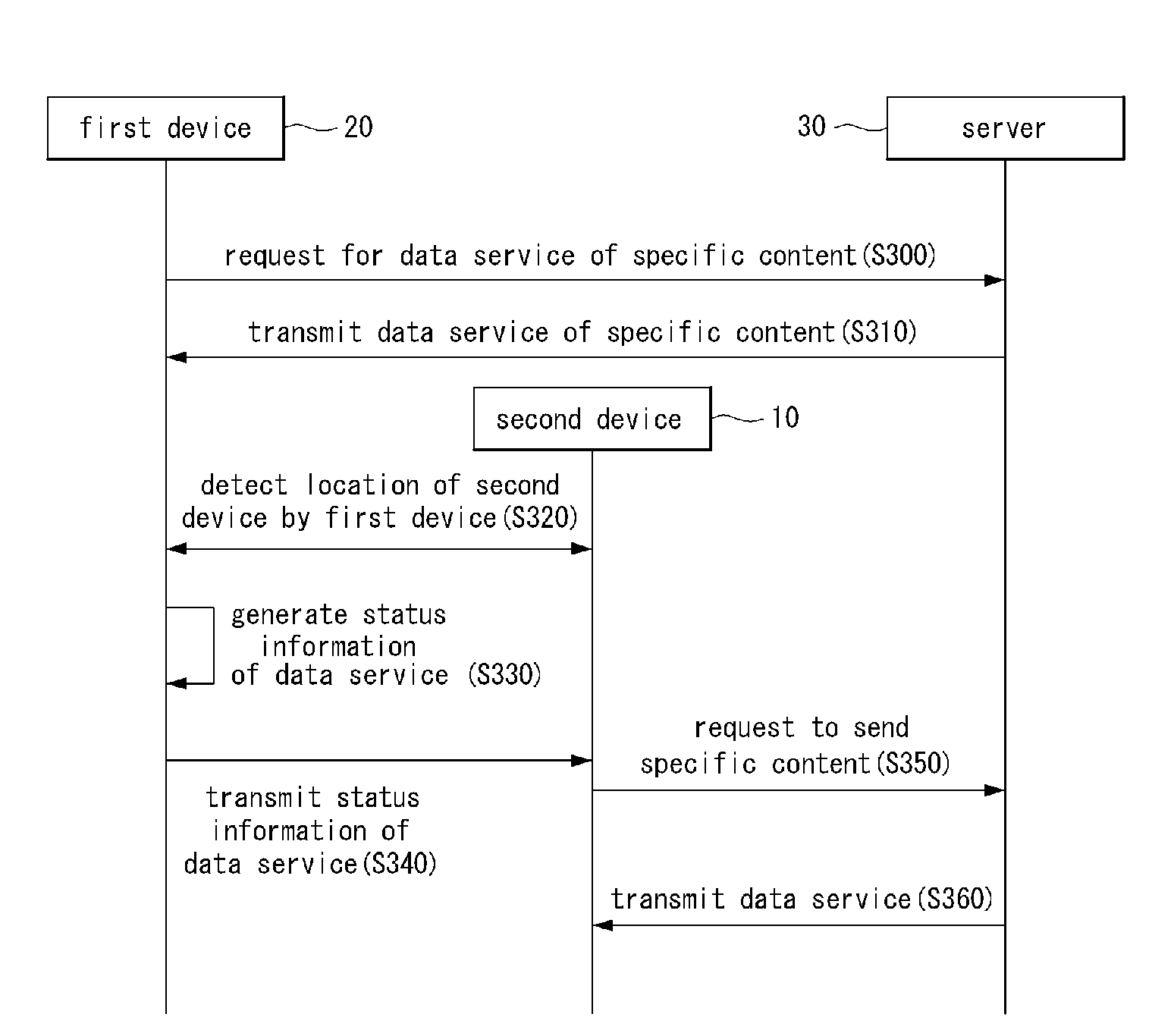

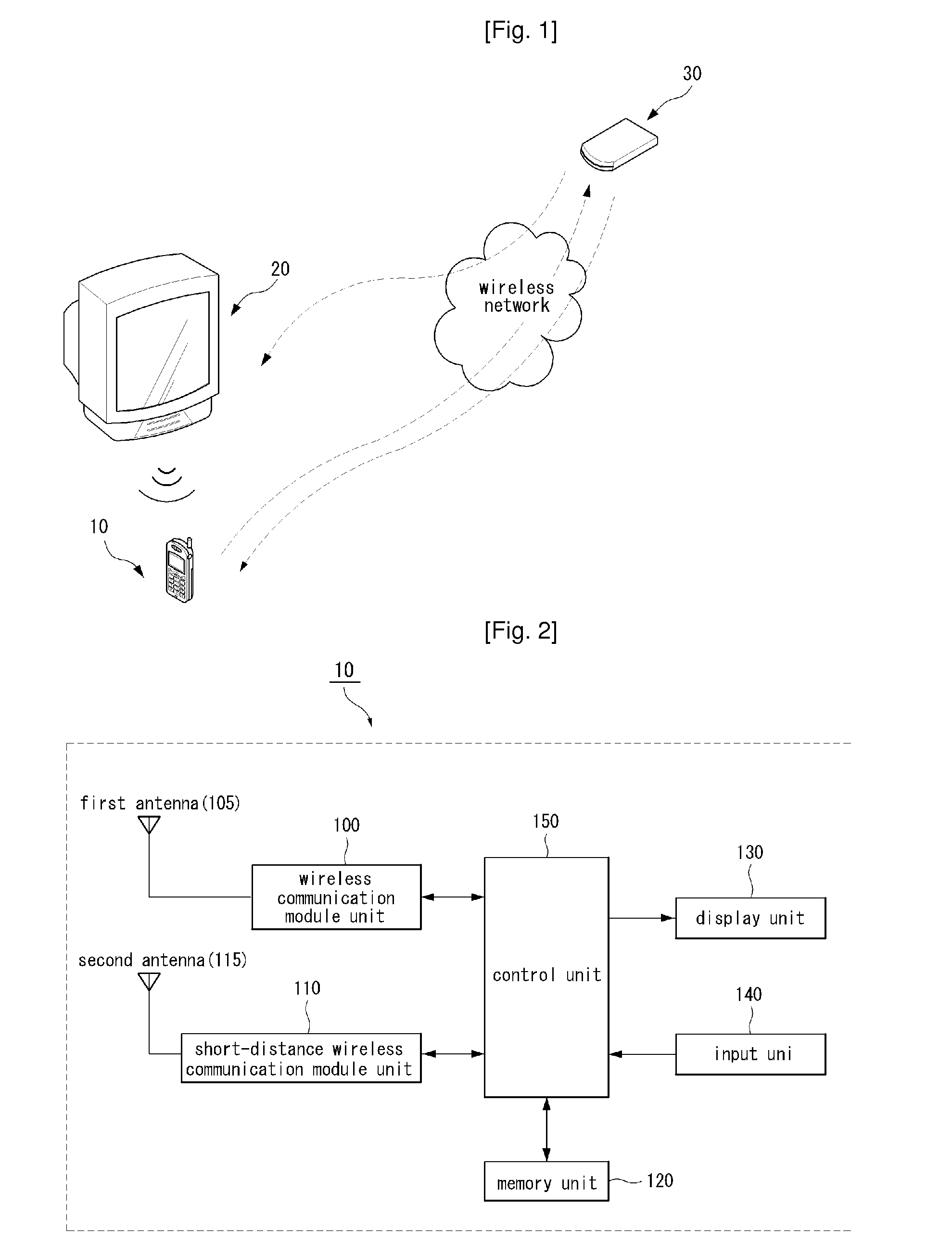

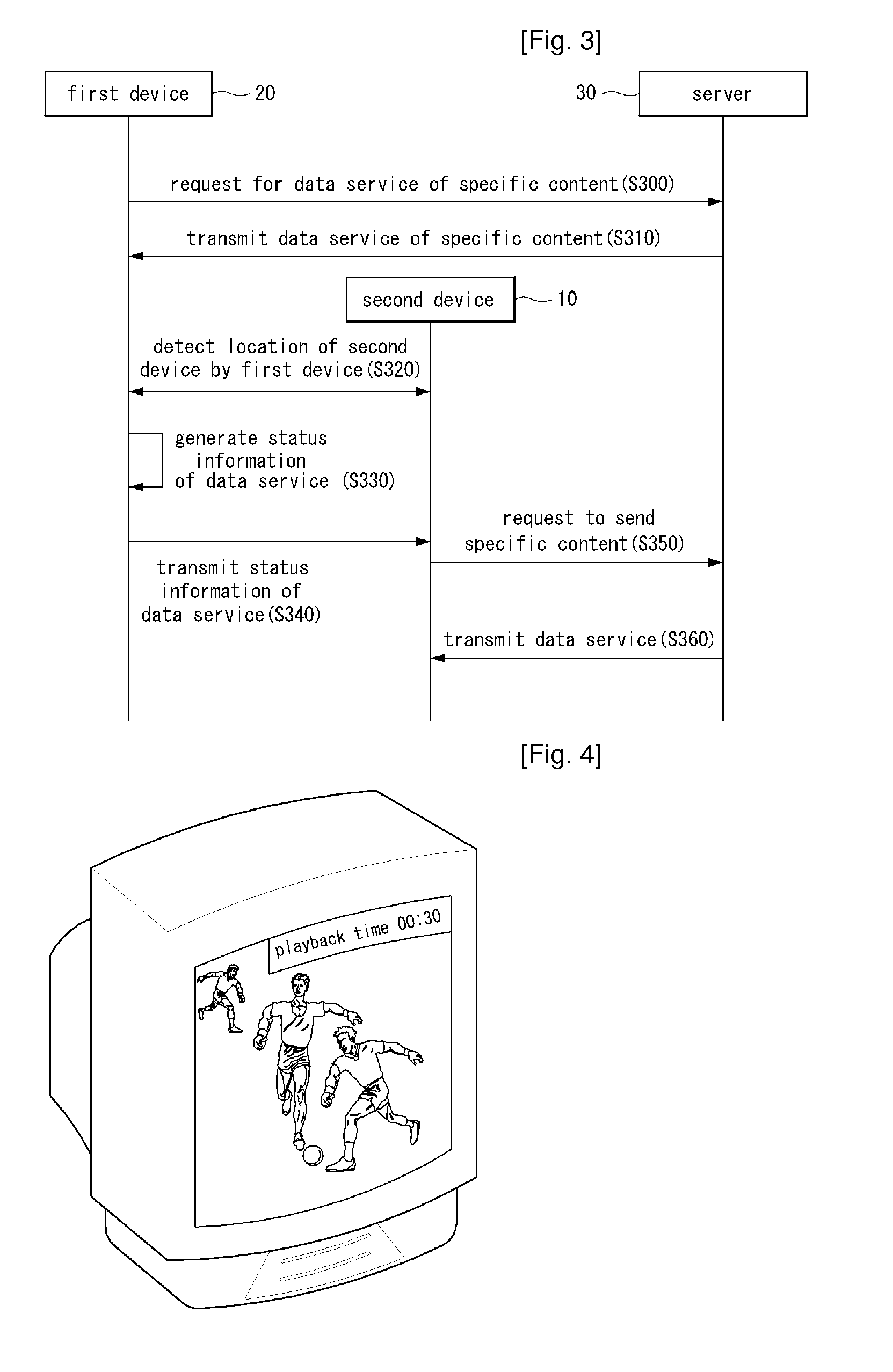

Method for receiving data service

InactiveUS20100099359A1Transmission control/equalisingConnection managementComputer networkShortest distance

A method for receiving a data service is disclosed. A method for handoff in content transmission comprises the steps of: receiving status information of a data service via short-distance wireless communication from a first device receiving a data service of a specific content through a server; transmitting the status information of the data service to the server; and continuing the reception of the data service being transmitted to the first device from the server. Accordingly, there is an effect of convenience because another apparatus continuously services a corresponding data service during the reception of a specific data service using a specific device.

Owner:LG ELECTRONICS INC

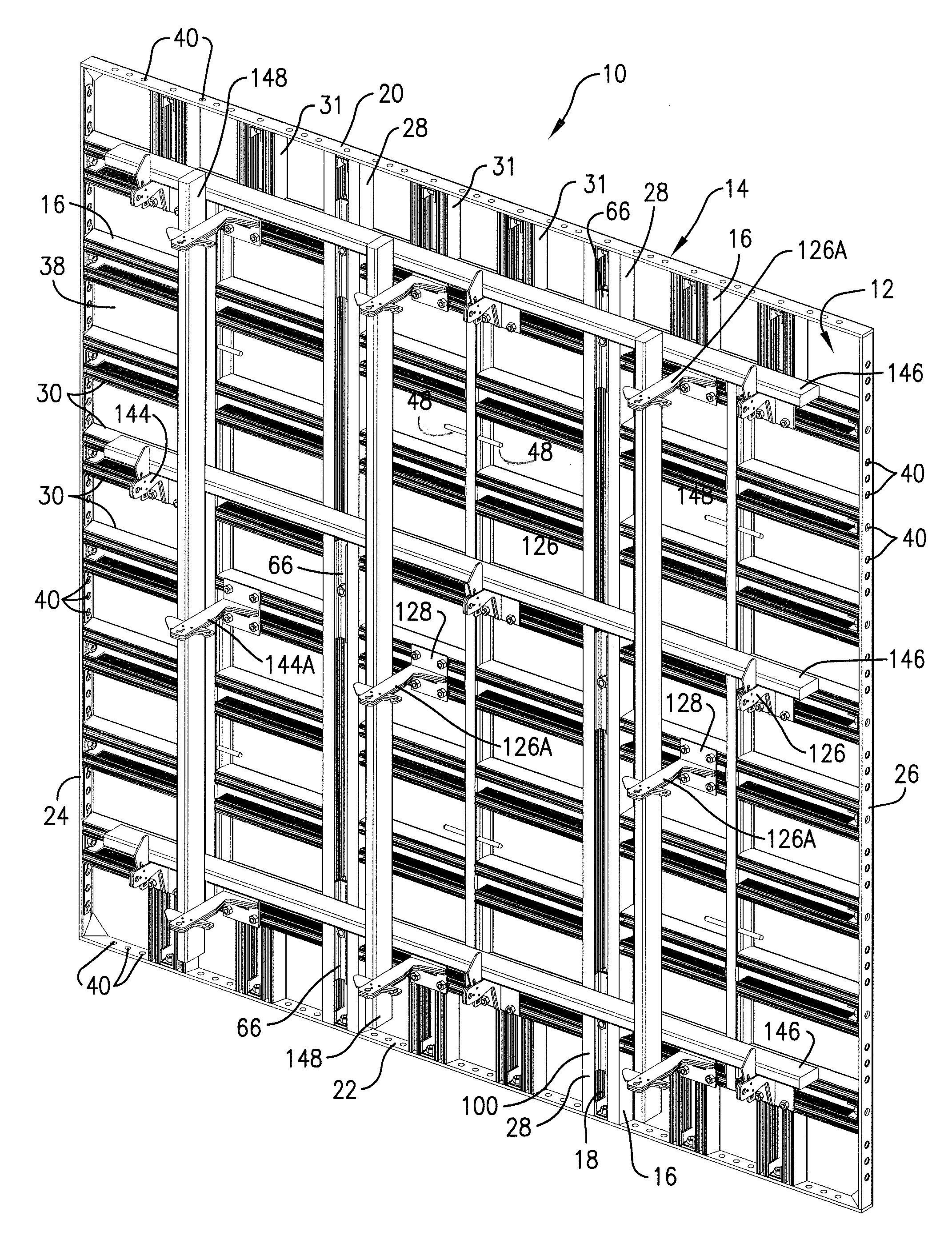

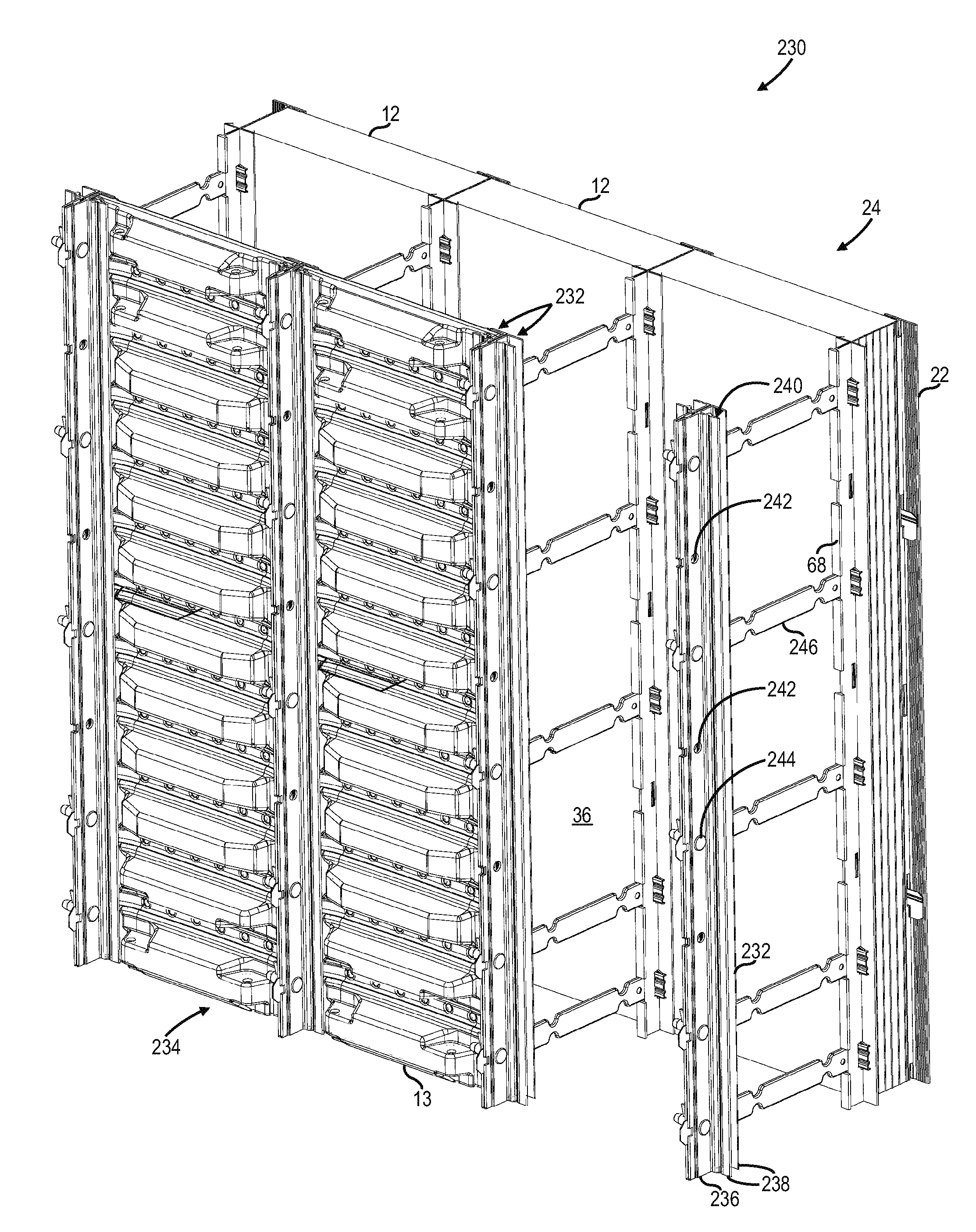

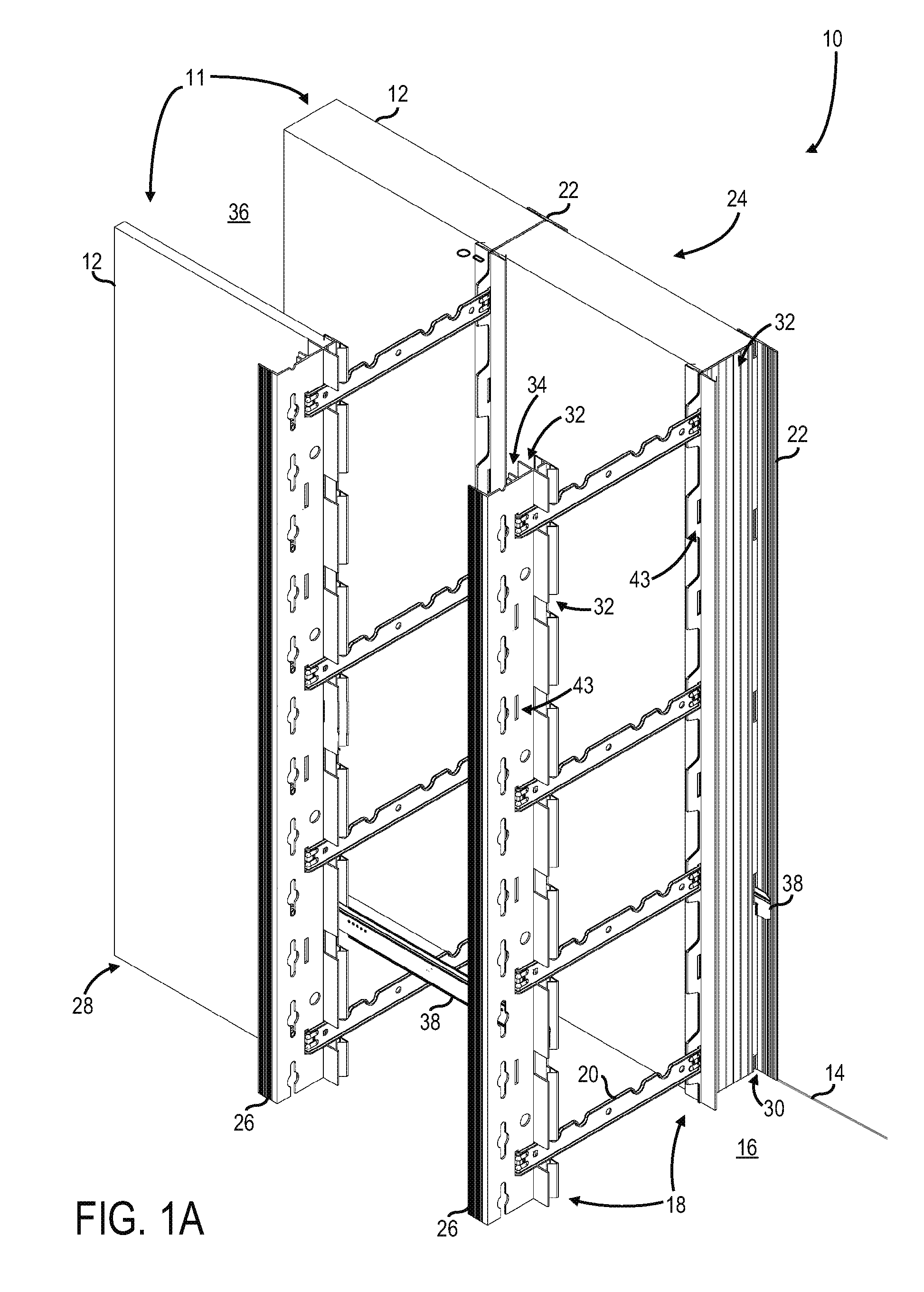

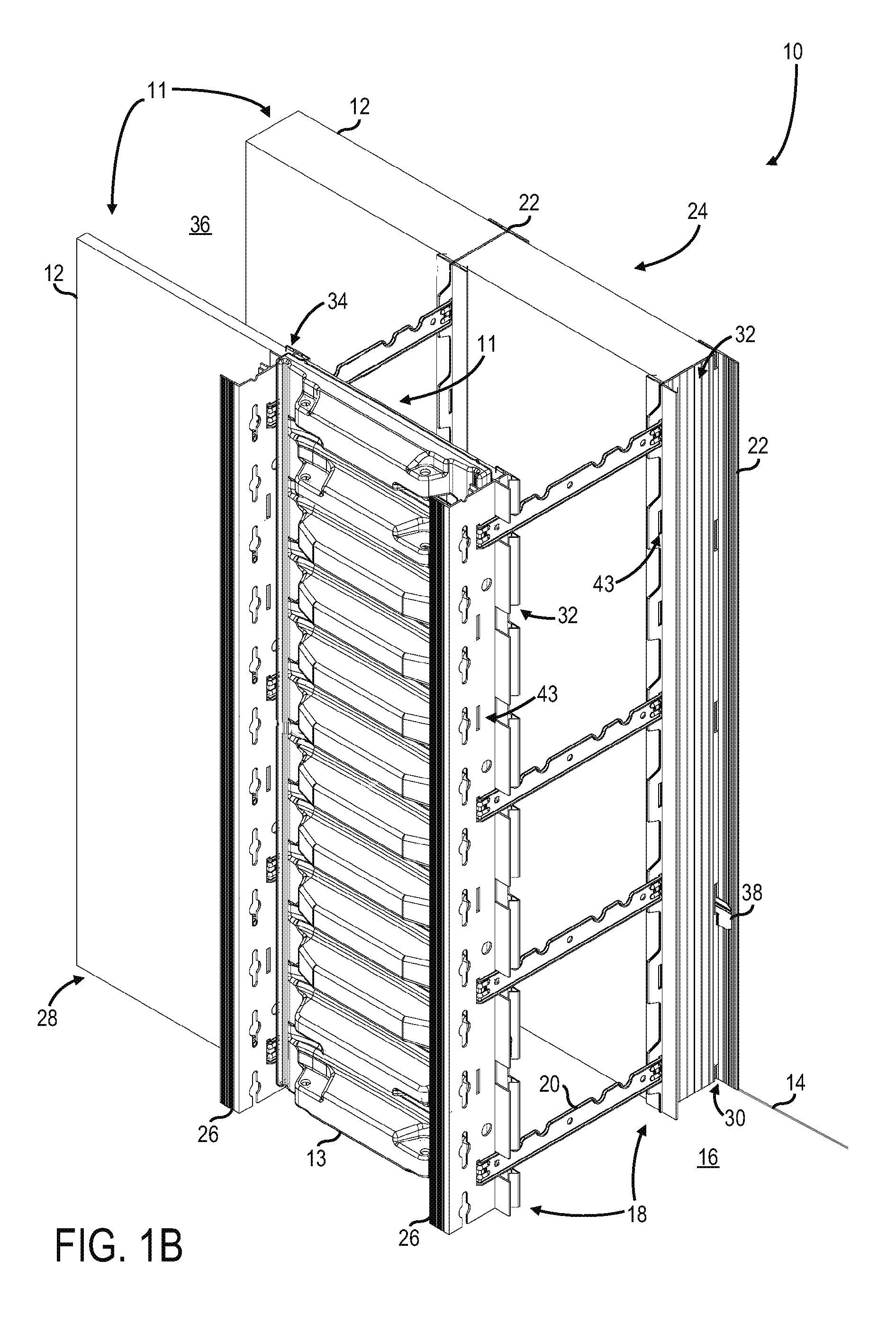

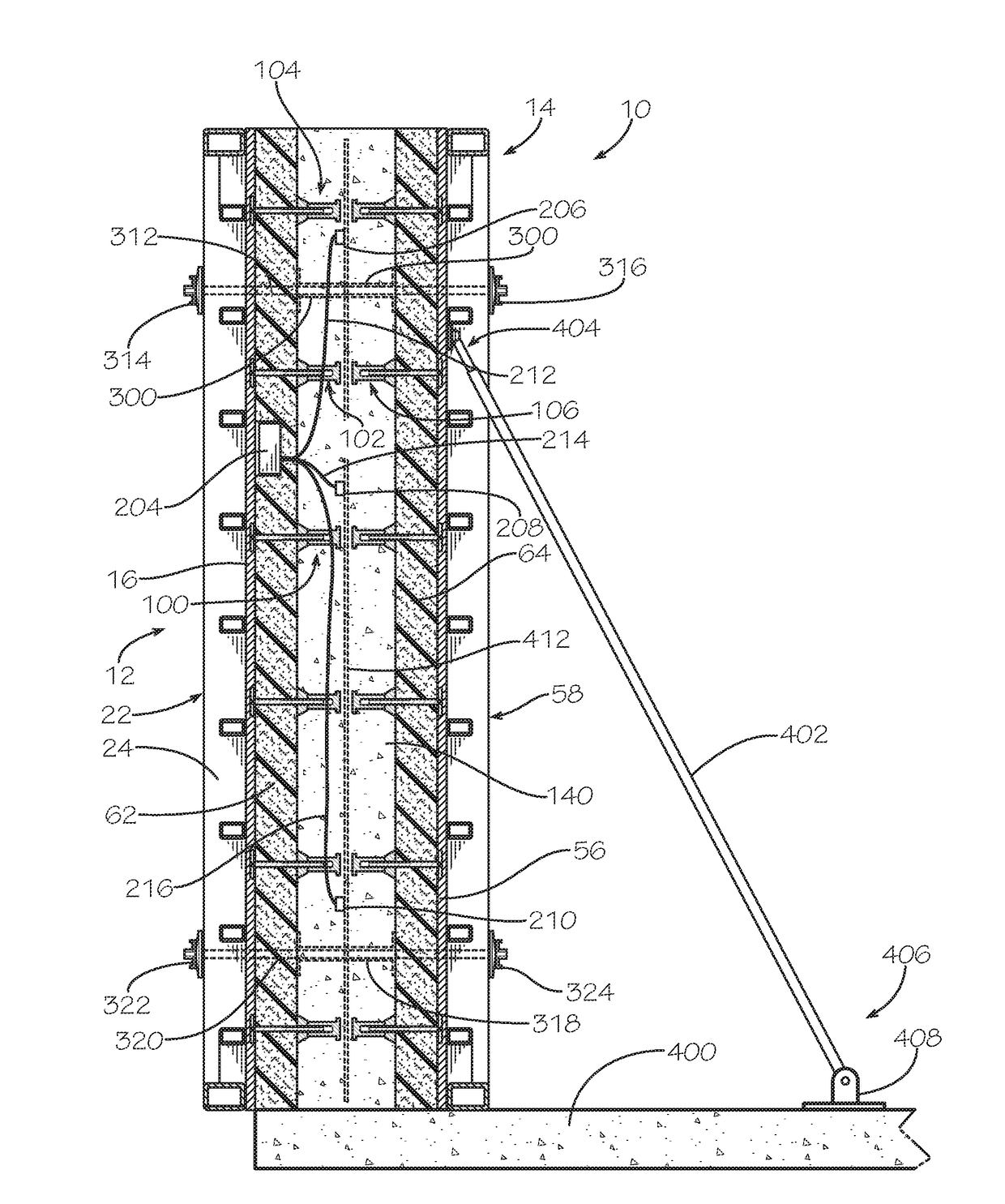

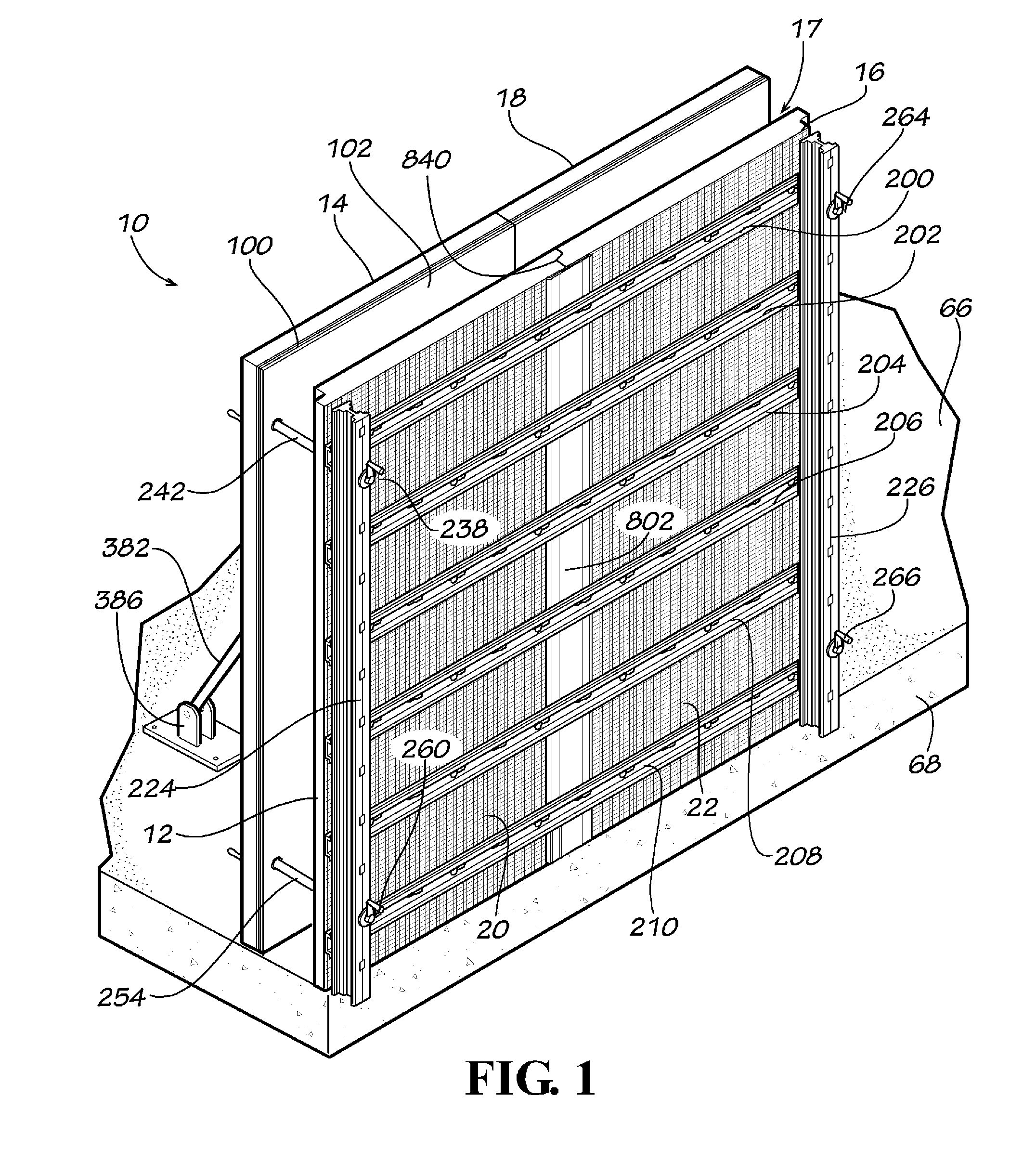

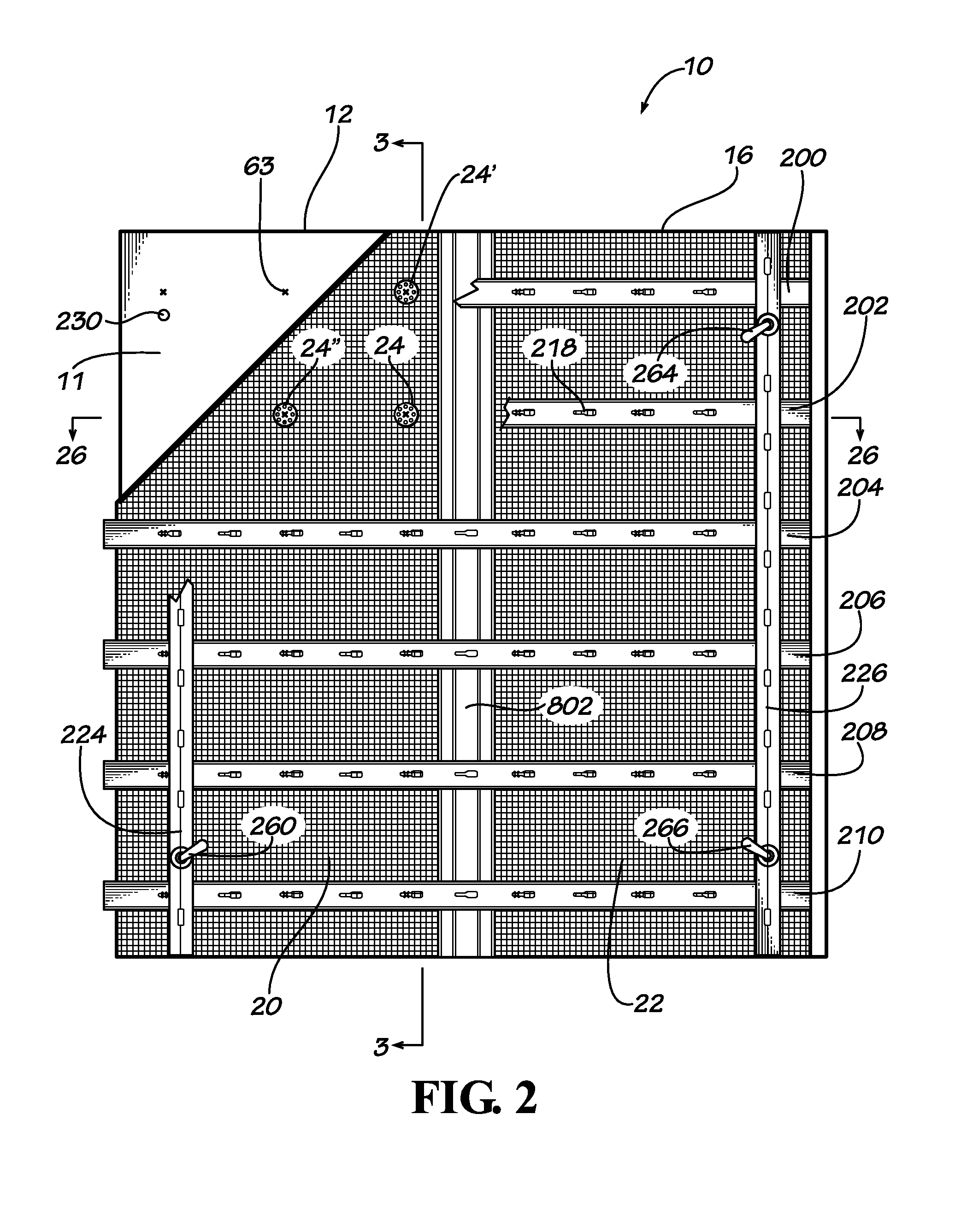

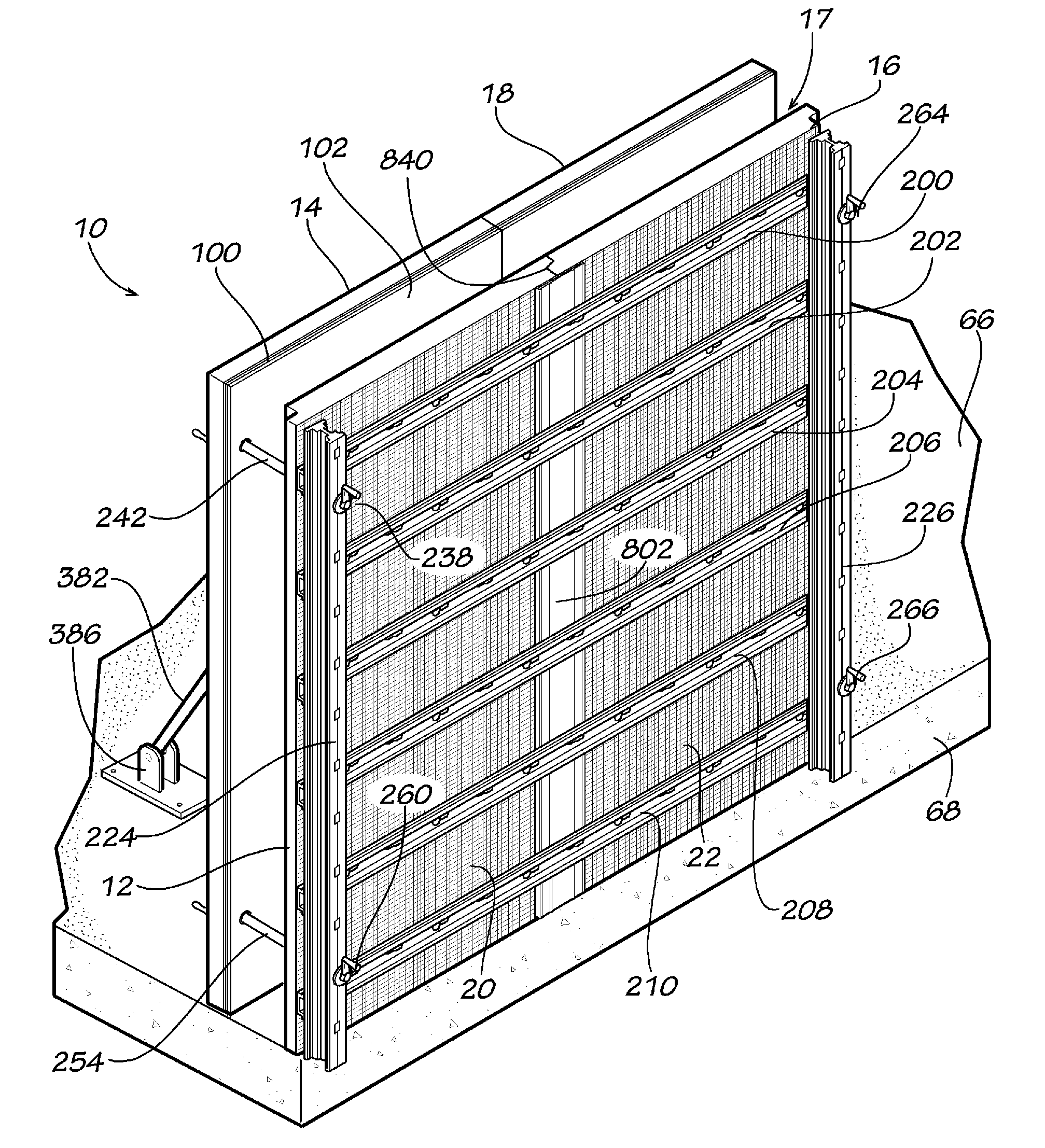

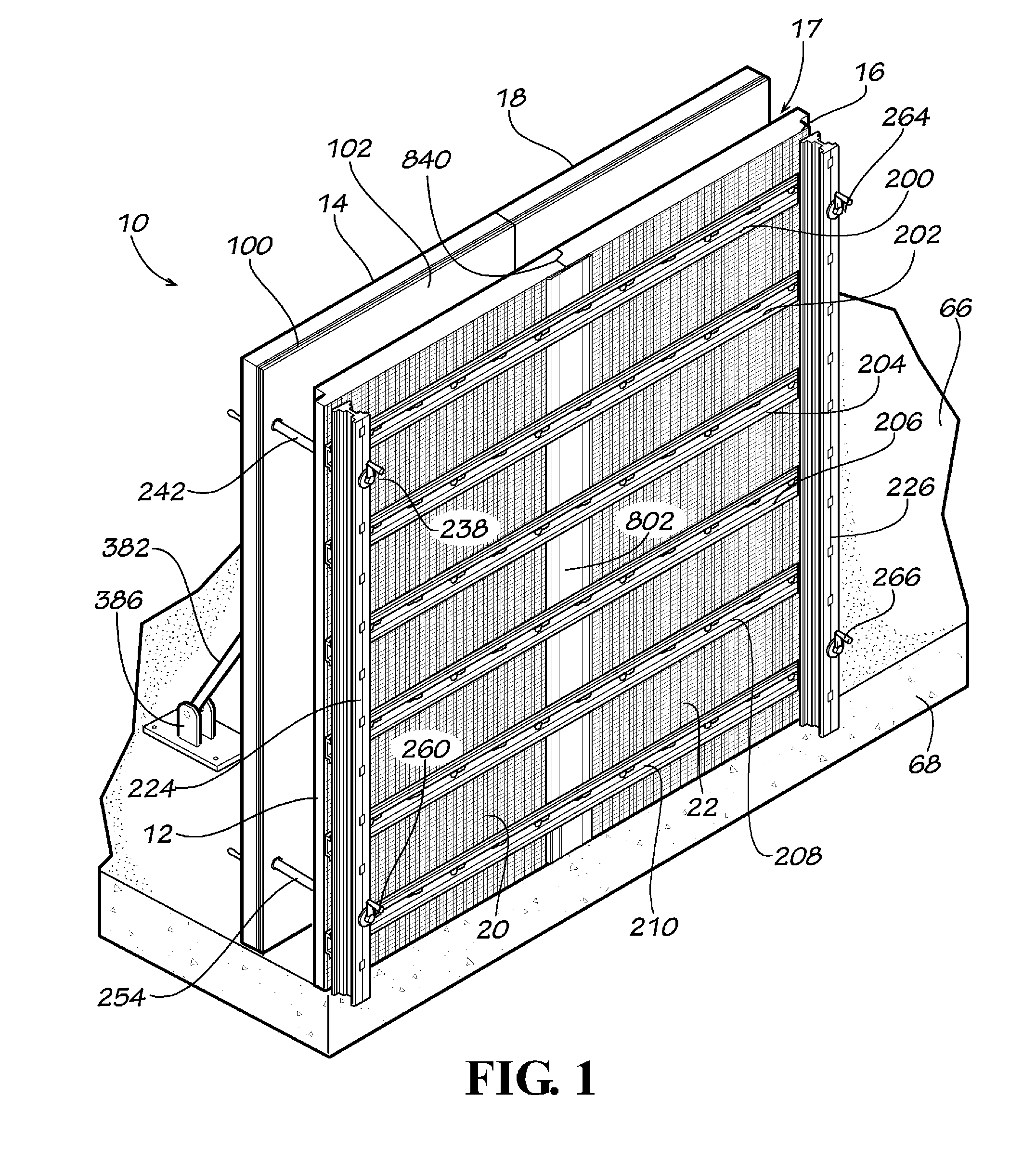

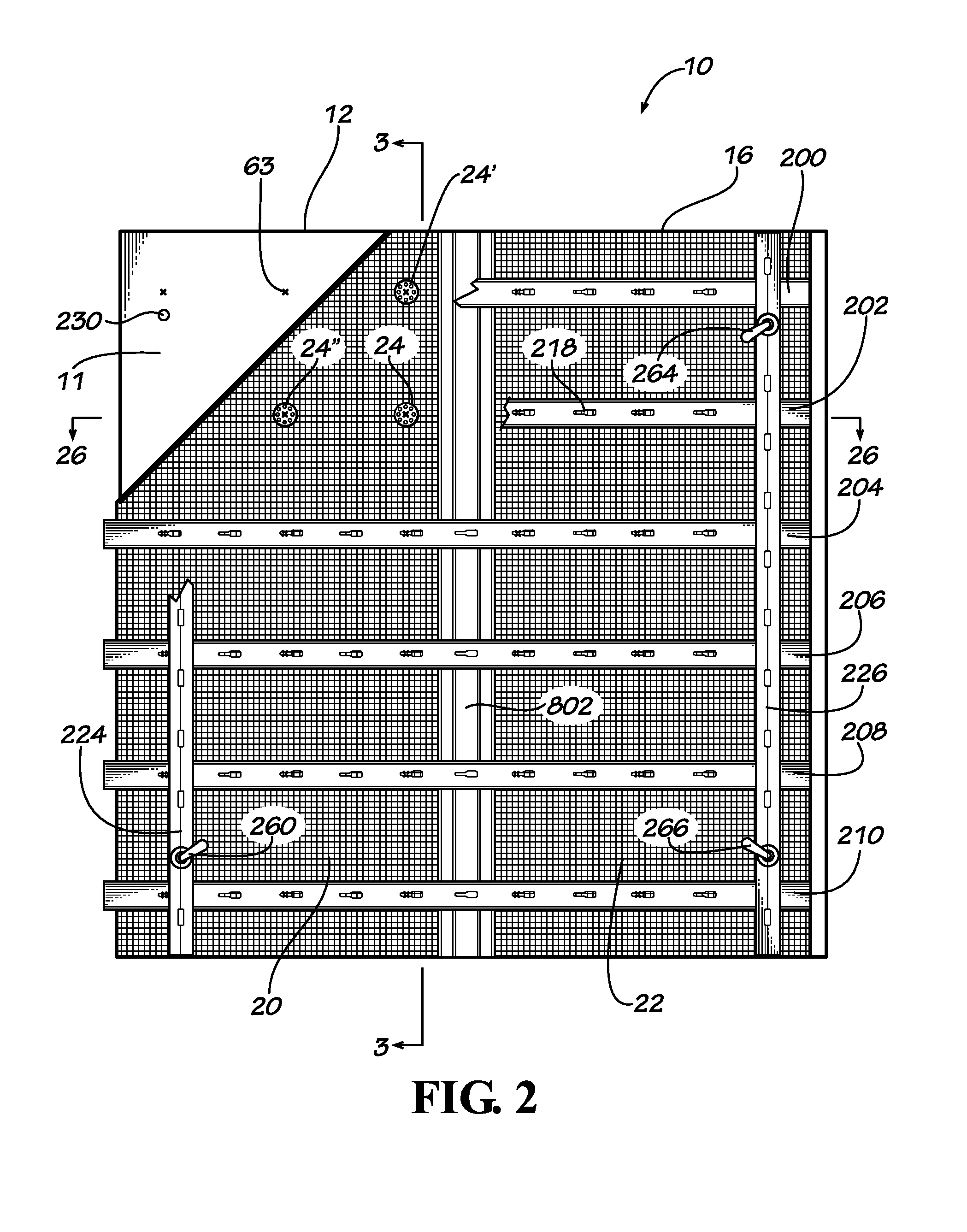

High strength adjustable vertical concrete form

A construction form system for forming concrete walls for use as above grade walls, foundations, frost walls, exterior envelopes, and the like, is disclosed. The system includes a plurality of pairs of opposing vertical forming panels spaced from each other to define a forming cavity disposed to receive a hardenable material. Each pair of opposing forming panels comprises an inner panel forming part of an inner wall and an outer panel forming part of an outer wall. The system also includes an outer rail positioned between each adjacent pair of outer forming panels and an inner rail positioned between each adjacent pair of inner forming panels. The inner forming panels comprise support panels configured to be selectively addable and removable from between each adjacent pair of inner rails prior to and subsequent to a pouring of the hardenable material into the cavity.

Owner:TF FORMING SYST

Rack-mount server system, its cooling system, rack cabinet and server assembly

ActiveCN1521591AImprove performanceFacilitate thinningDigital data processing detailsRack/frame constructionNuclear engineeringLiquid cooling system

A rack-mount server system of a liquid cooling system, in which a heat-generating component such as CPU is cooled by a coolant, is composed of: a plurality of server modules with heat-generating components which are cooled by the circulating coolant; a coolant circulation path to which the server modules are connected in parallel and through which the coolant to cool the server modules is circulated; and a cooling unit connected in the middle of the coolant circulation path, the cooling unit circulating the coolant and cooling the coolant by radiating its heat to the outside air. Furthermore, a bypass route parallel to the server modules and going around the server modules is provided in the coolant circulation path, and the circulation quantity of the coolant is controlled in the bypass route. Alternatively, the flow quantity of the coolant is controlled in each of the server modules. In this manner, the cooling enough to ensure the reliability of a plurality of server modules mounted in the rack cabinet can be achieved.

Owner:MAXELL HLDG LTD

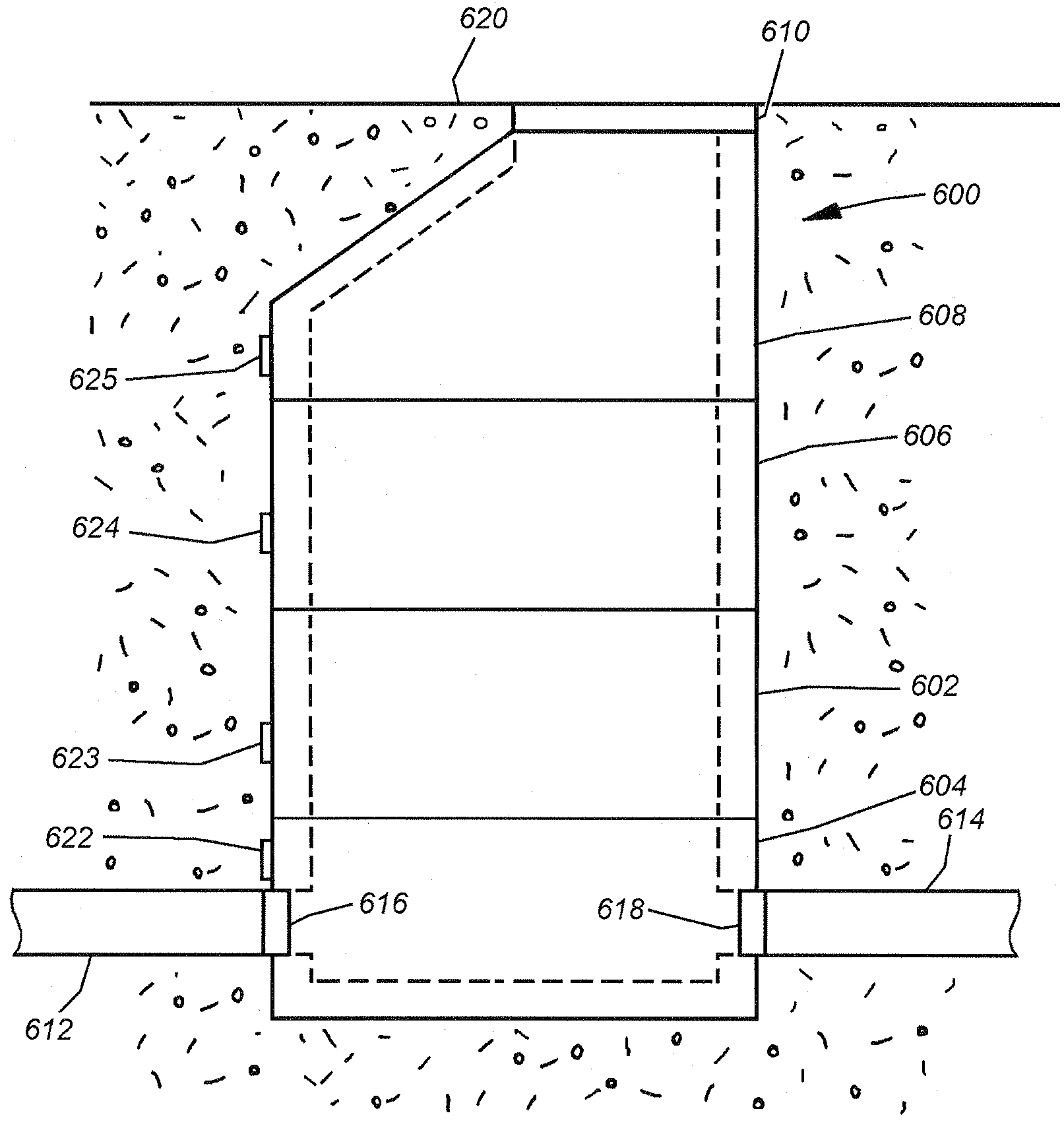

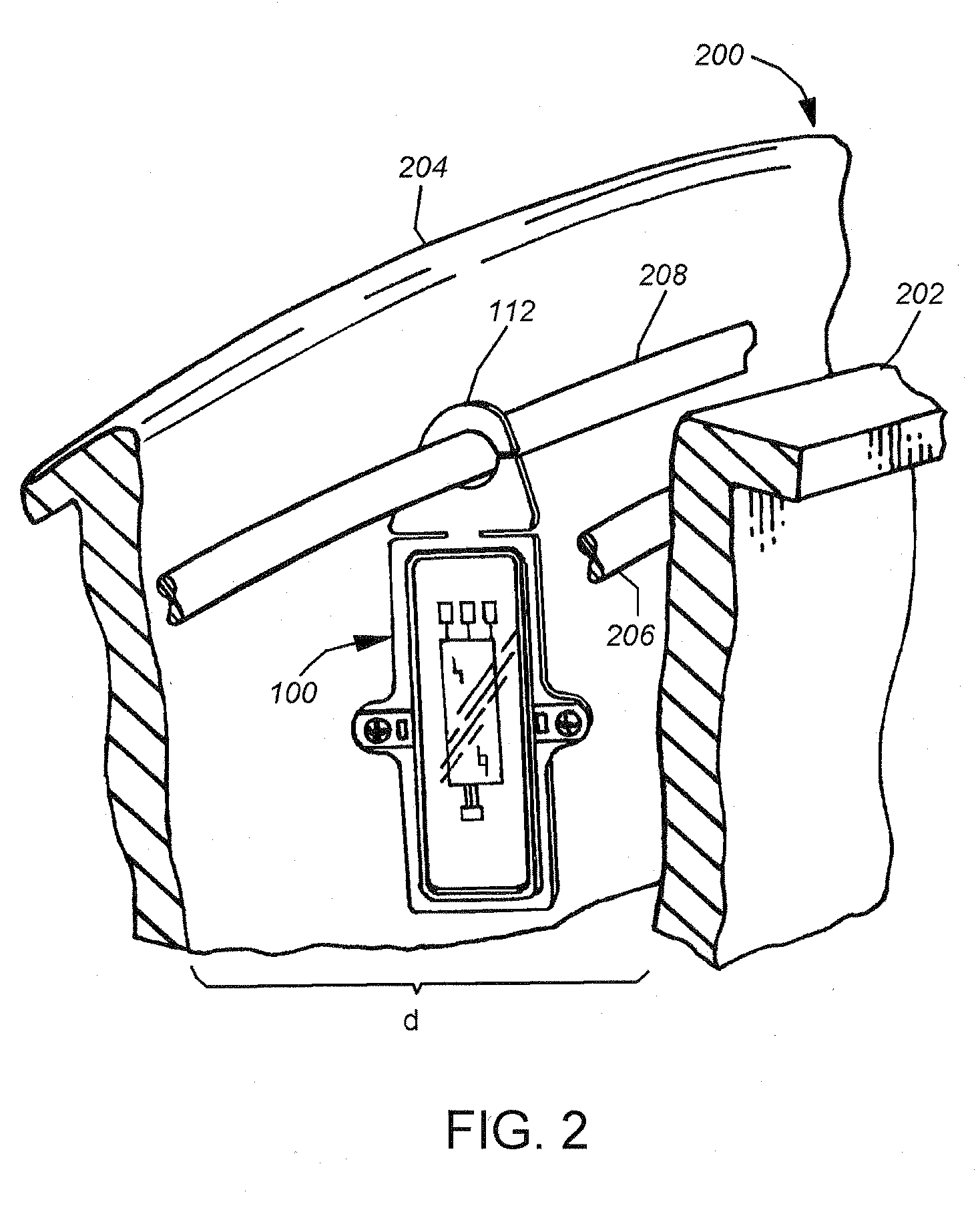

Radio frequency identification system and method for use in cast concrete components

ActiveUS20090072978A1Facilitate of permanent bondAccurate settingArtificial islandsCeramic shaping apparatusRadio frequencyBackplane

A radio frequency identification (RFID) assembly is configured for use with cast concrete components. The RFID assembly has a planar back plate having a plurality of break-away, registration posts extending perpendicular to the nominal plane of the back plate, and a plurality of gripping surfaces extending opposite the registration posts. The RFID assembly further includes a RFID transponder encapsulated between the back plate and a cover. The RFID transponder is programmed with information concerning the cast concrete component to which the RFID tag is affixed.

Owner:IDENCIA INC

Self-annealing concrete, self-annealing concrete forms, temperature monitoring system for self-annealing concrete forms and method of making and using same

ActiveUS20170218614A1Improved curing environmentAvoid insufficient heatingConstruction materialWallsForming faceTemperature monitoring

The invention comprises a product. The product comprises a first removable concrete form having a concrete forming face and a first insulating panel insert having a first primary surface and an opposite second primary surface, wherein the second primary surface of the first insulating panel insert contacts the concrete forming face of the first removable concrete form. The product also comprises an elongate anchor member having an enlarged portion and an elongate portion, the elongate portion having a first end and an opposite second end, wherein the enlarged portion is disposed adjacent the first end and contacts the second primary surface of the first insulating panel insert and wherein the elongate portion extends through the first insulating panel insert and extends outwardly from the first primary surface of the first insulating panel insert. A method of using a removable insulated concrete form system is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

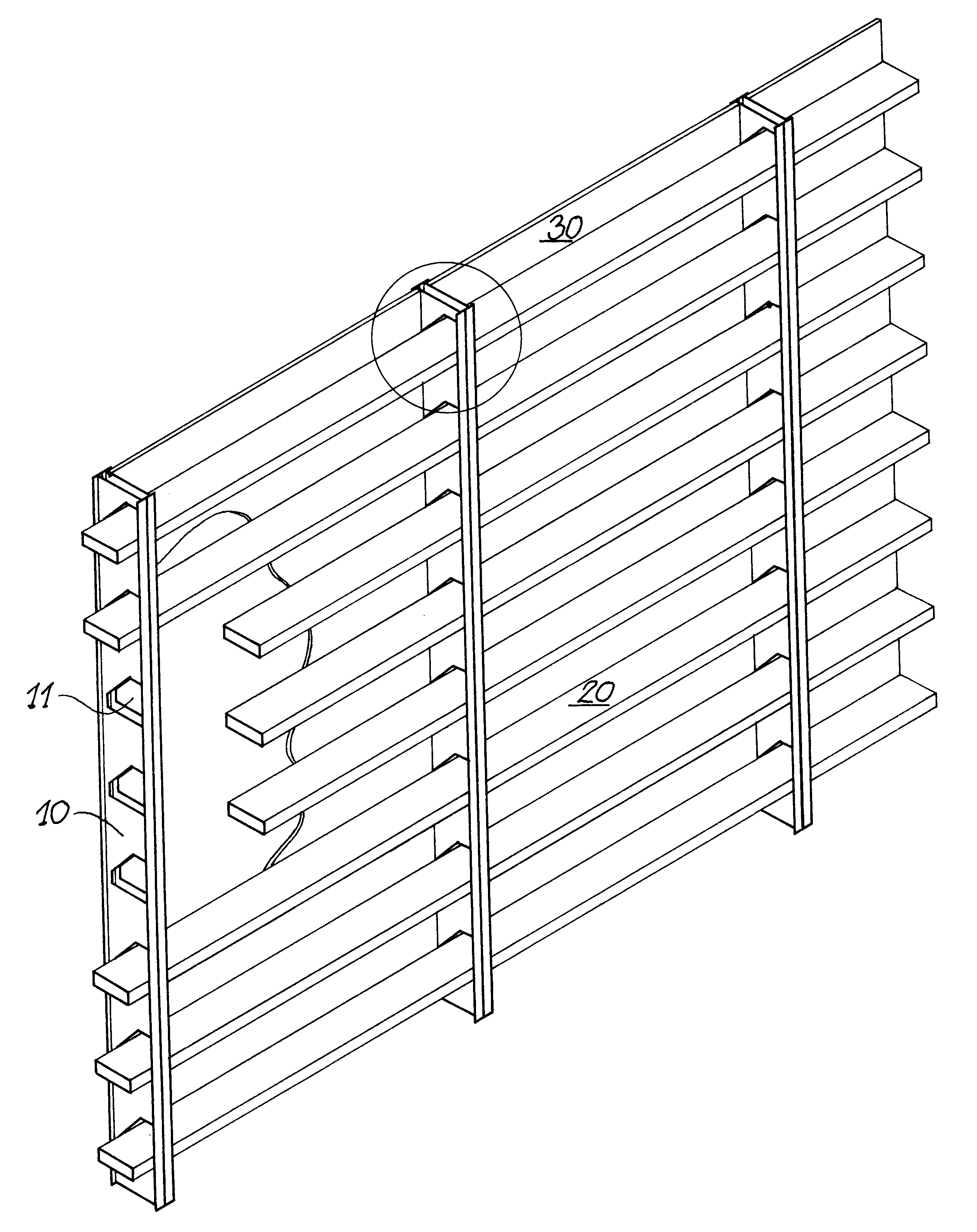

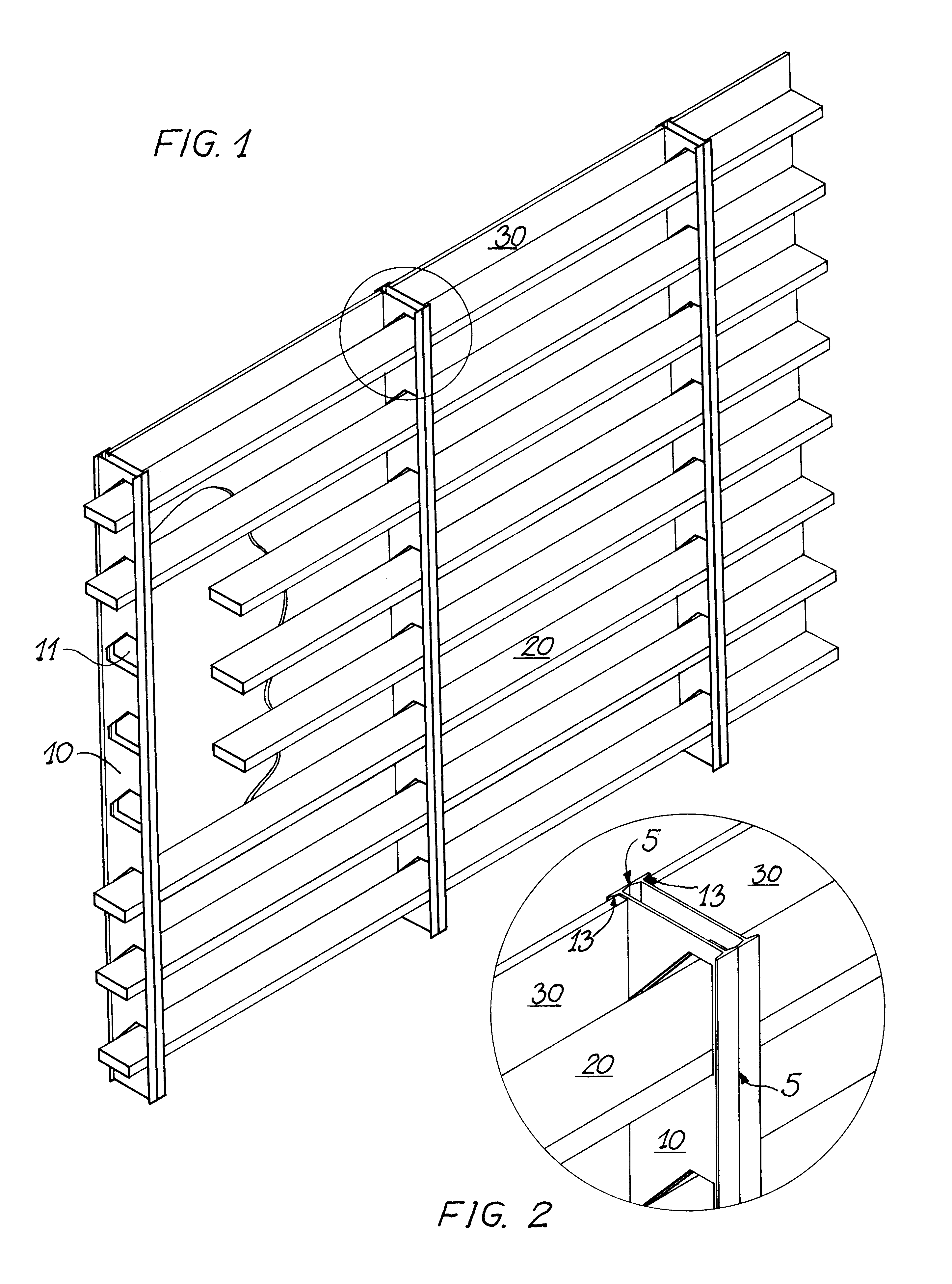

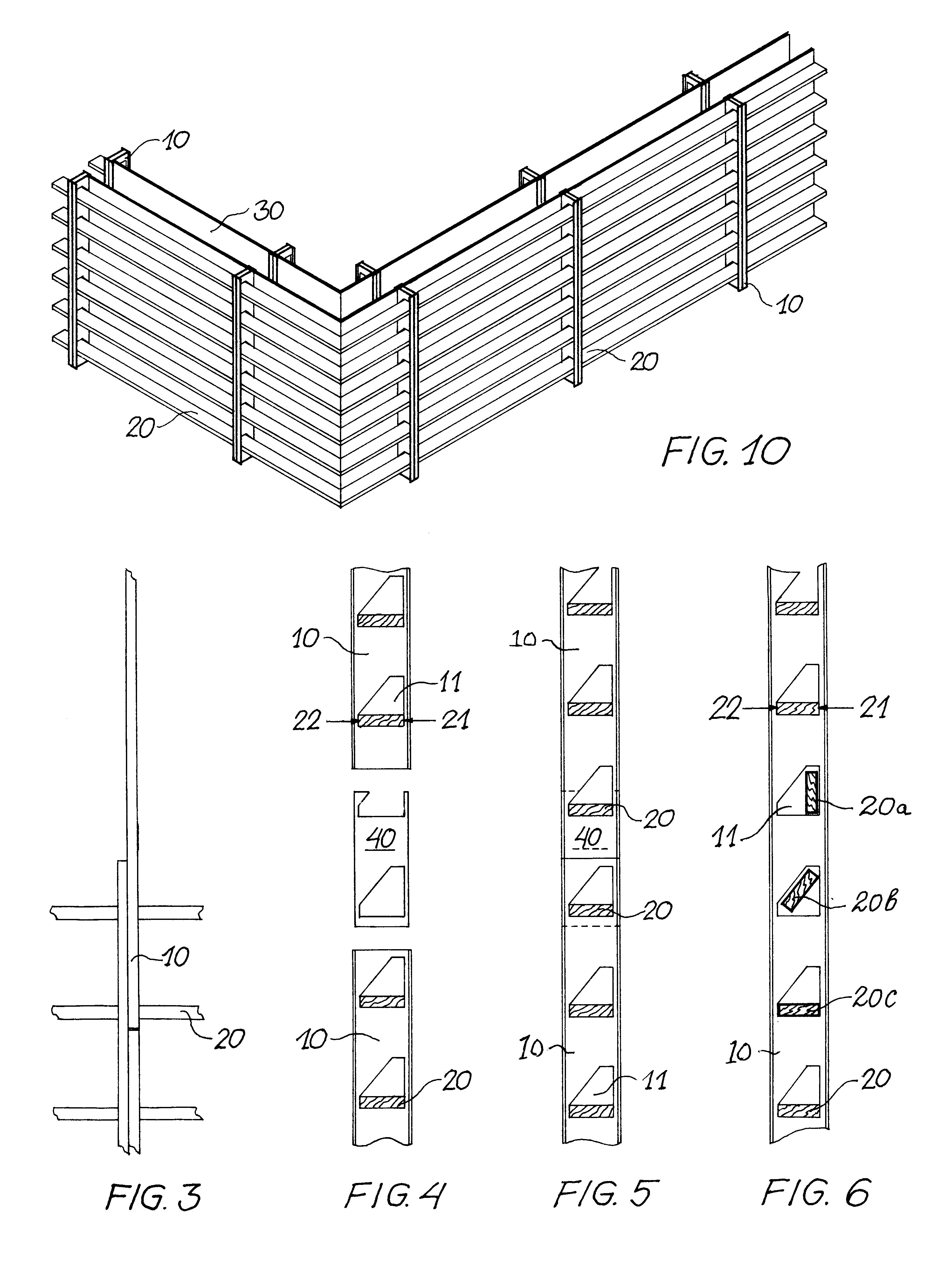

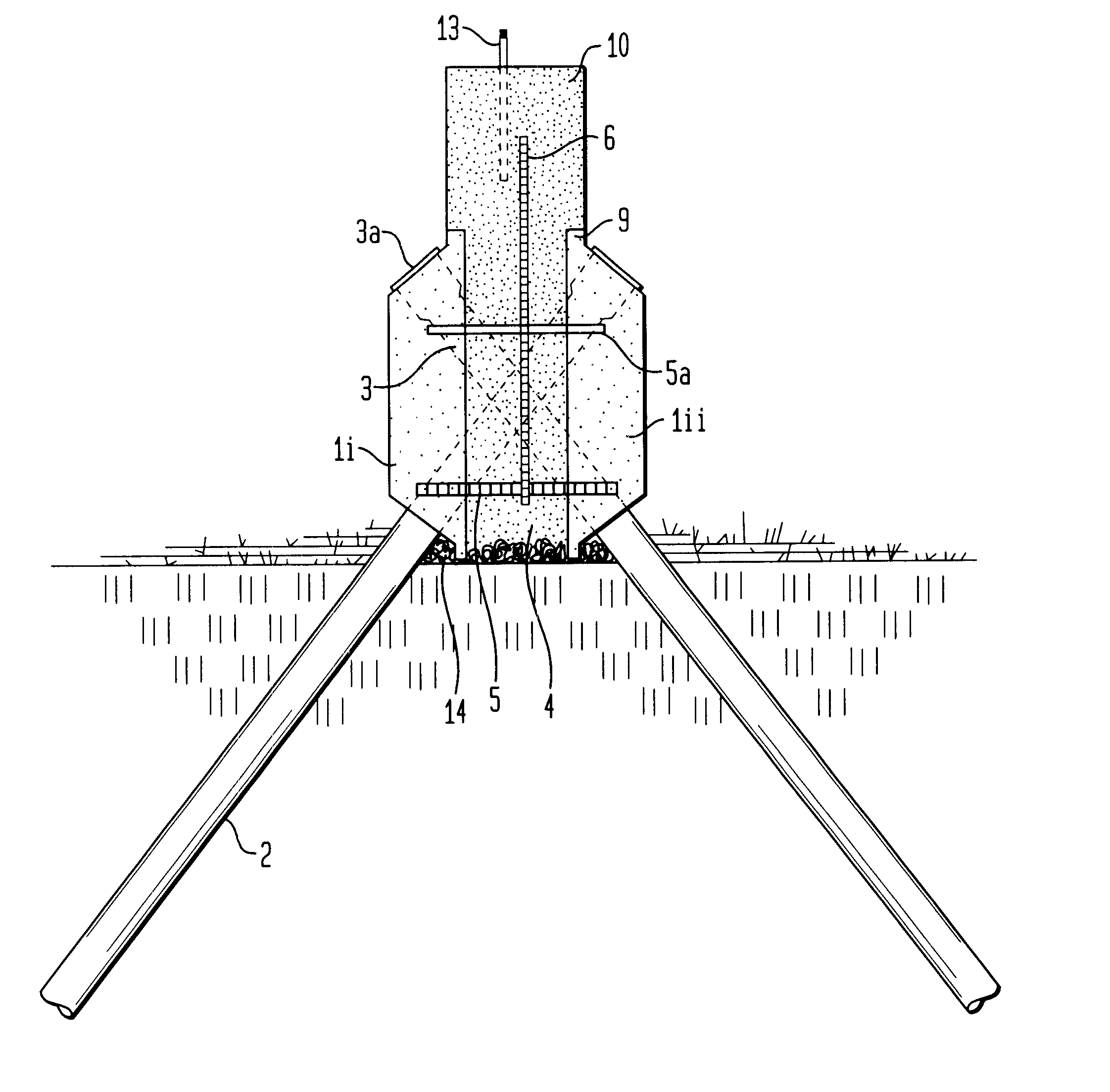

Sub-rigid fast-form barrier system

The invention disclosed herein is remarkable in its simplicity and promises wide commercial application as the labor costs for construction become increasingly prohibitive. The extraordinary absence of nails, screws, bolts, welds or any other fastening device allows these barriers to compete with many conventional barrier systems, such as those employed for fencing, vehicular trailer beds, removable stages, and scale models or toys of all fabrications mentioned plus many more. In this age time is money and the erection speed this barrier system offers may well revolutionize conventional "post and beam" framing. The invention is specifically aimed at eccentric beam loading where barriers must be economically fabricated to withstand hurricane force winds, earthquake reactions, or liquid concrete pressure in a sub-rigid manner. The Fast-Form System will offer insurers building products that will protect their interests for any and all applications. When the barriers disclosed herein are utilized for concrete formwork, contractors will have a new option that embraces standard building products, with barrier fabrication accomplished in half the time of the systems that precede it.

Owner:NELSON THOMAS PAGE

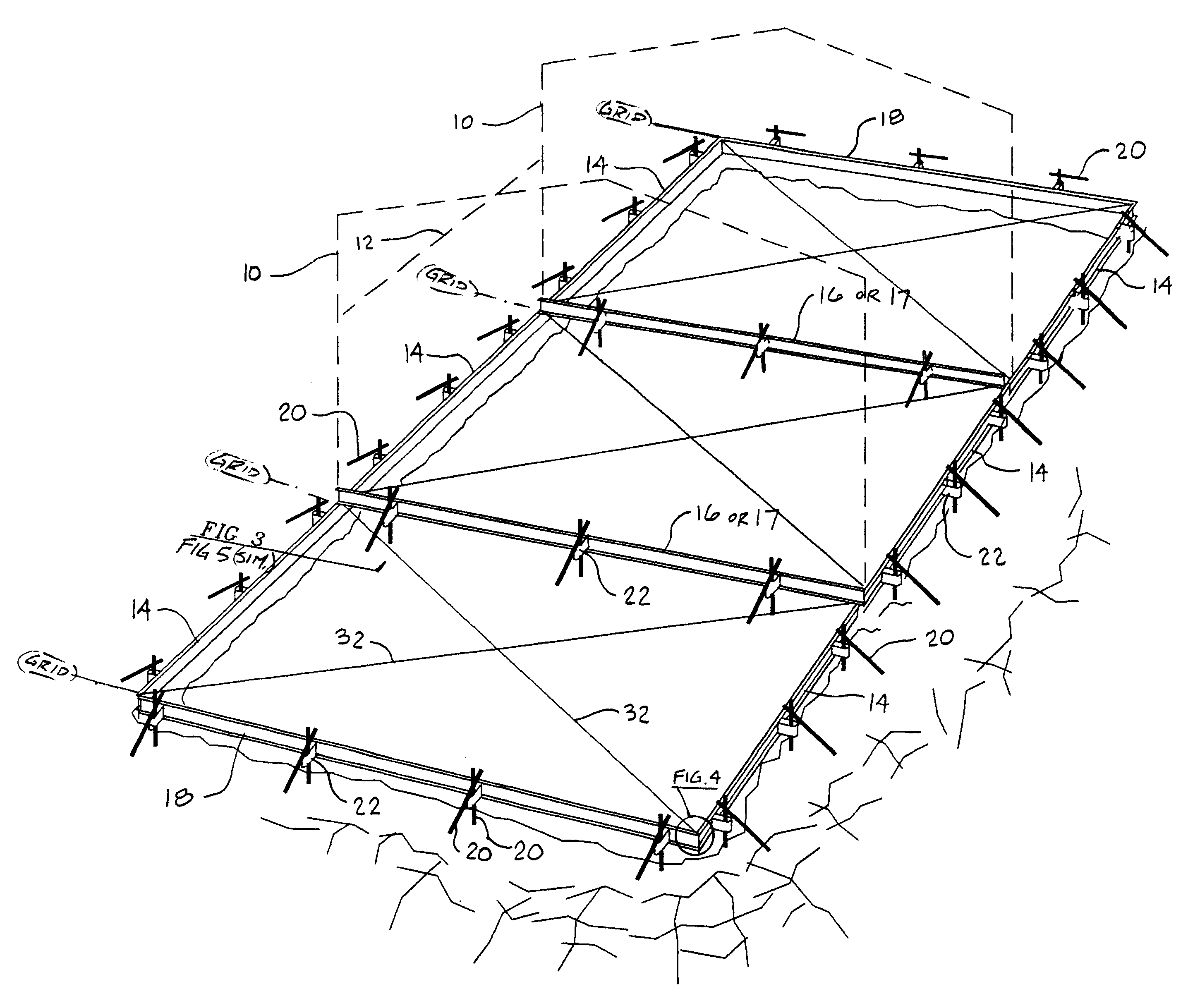

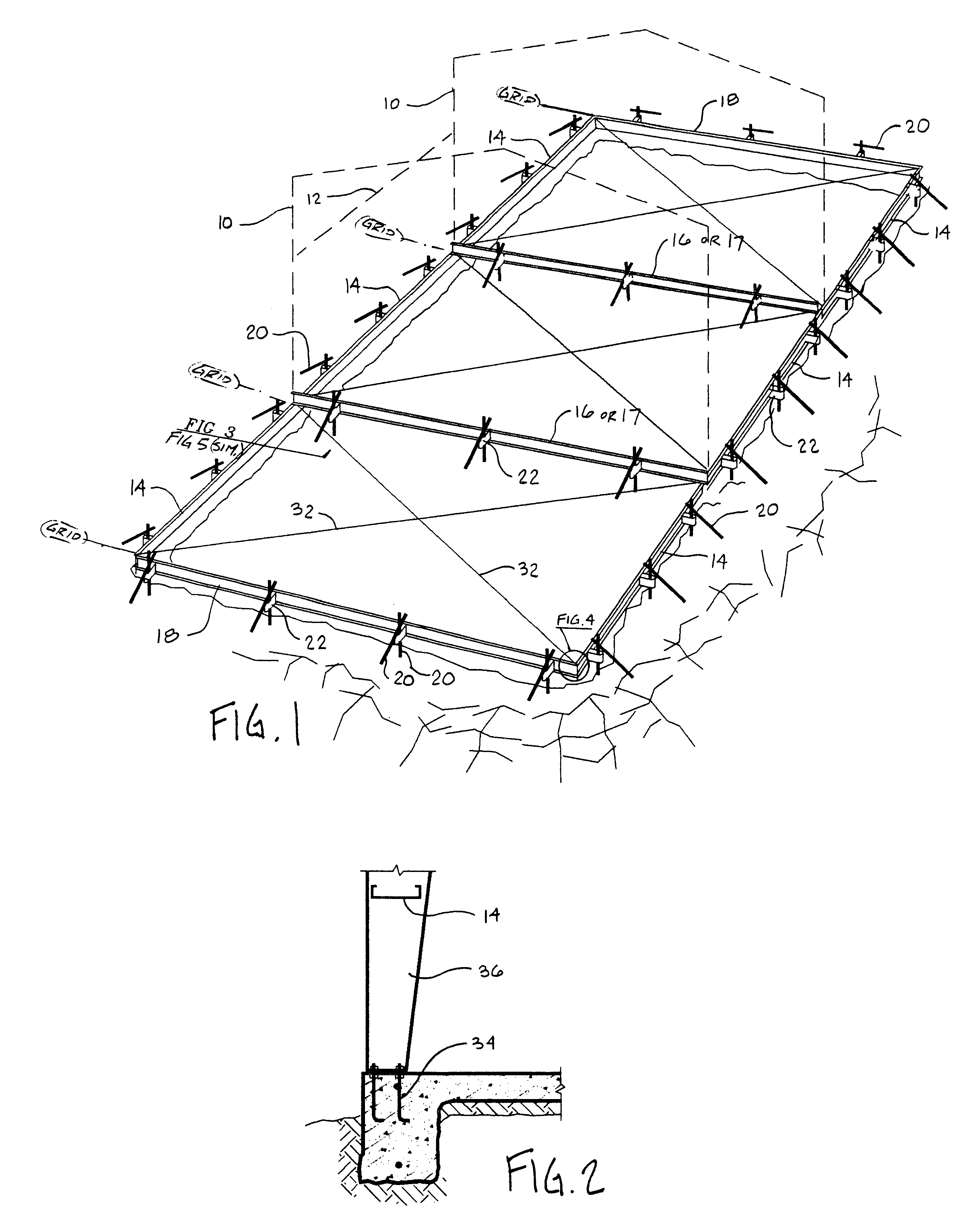

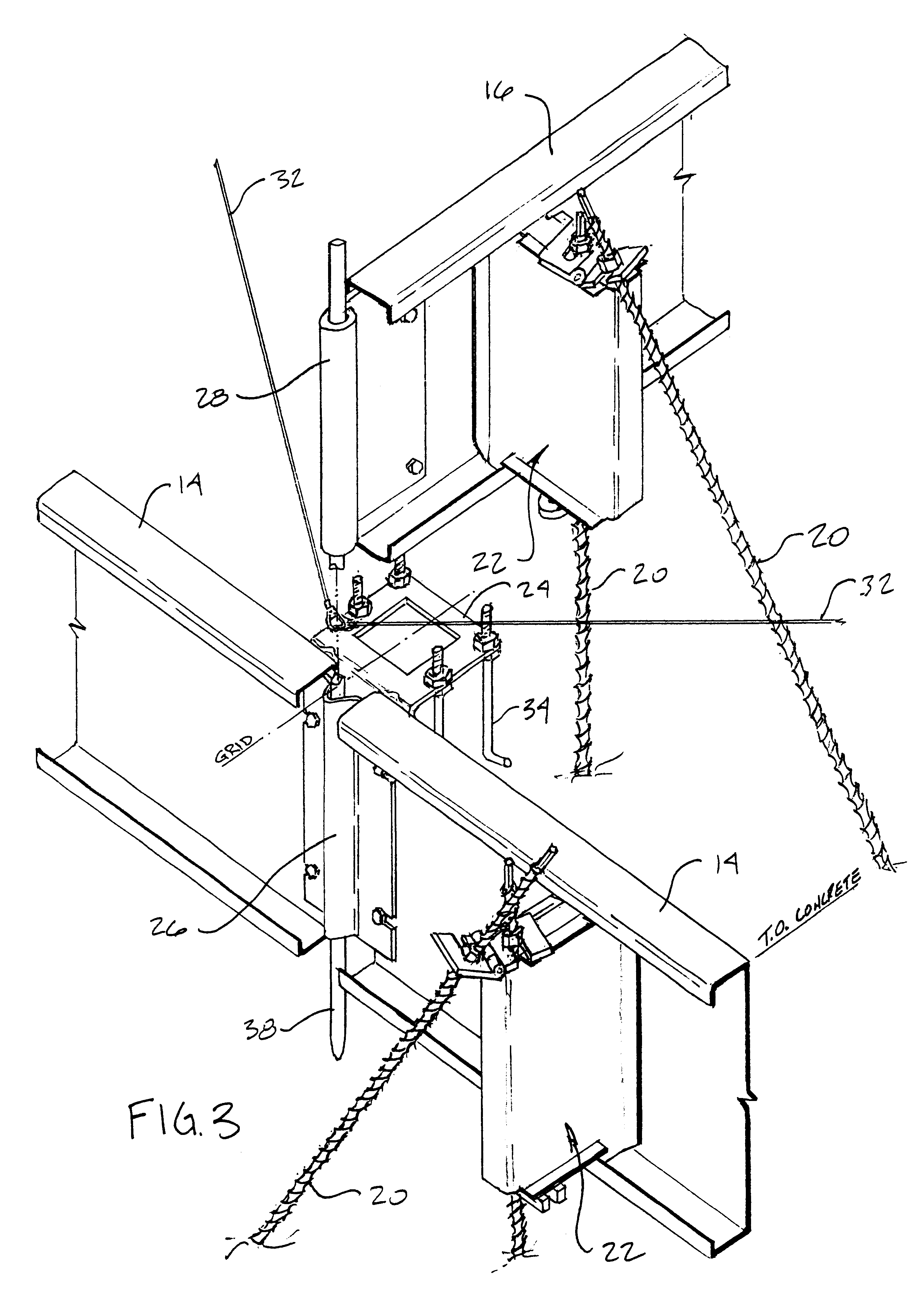

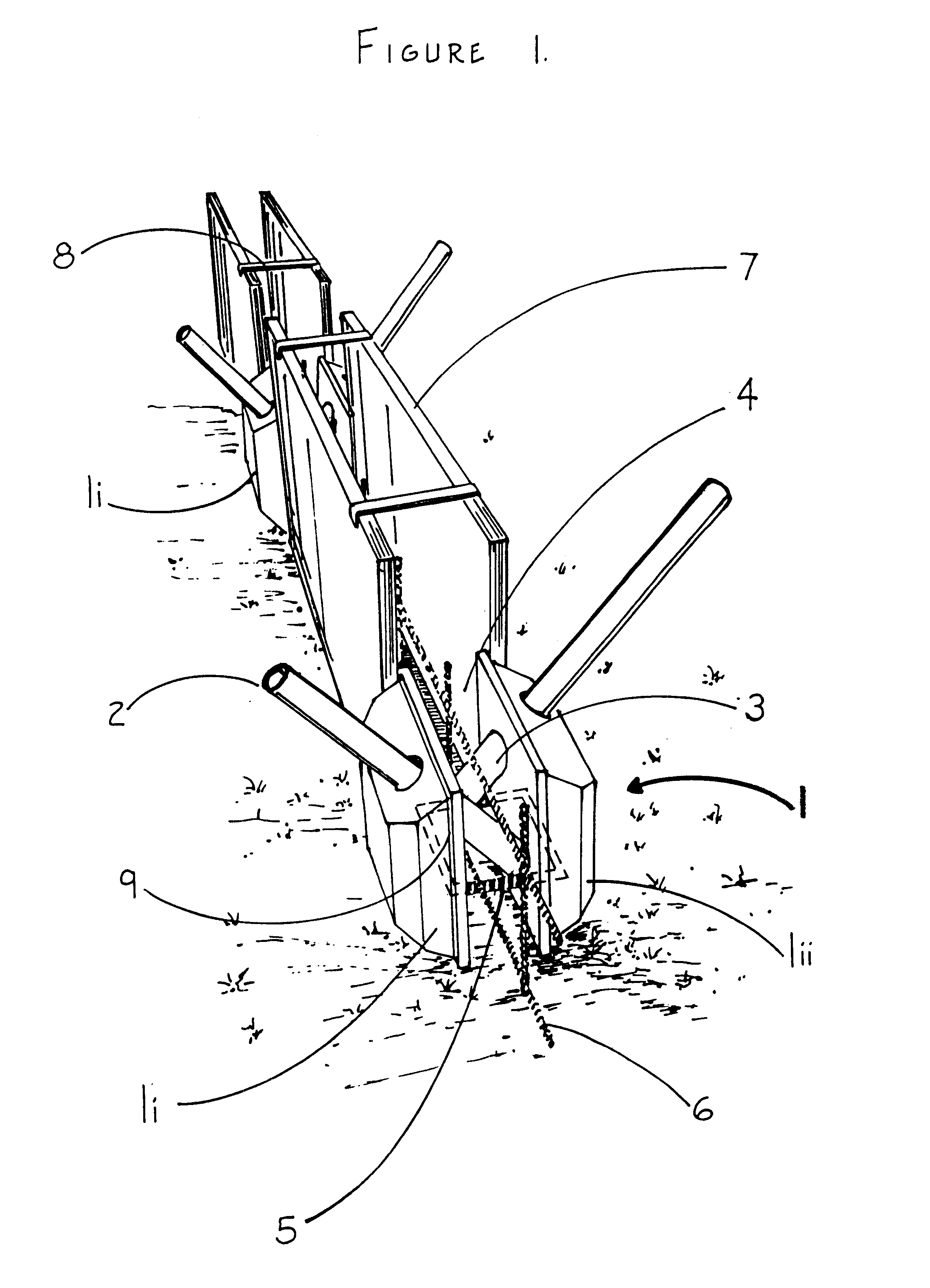

Slab foundation construction fixture, particularly as adapts standard girts for pre-use as foundation forms

InactiveUS6550213B1Easy to adjustLess laborFloorsBuilding repairsSteel moment frameCold-formed steel

A system for forming concrete slabs has been developed for commercial buildings having a steel moment-frame structure. This system utilizes the cold-formed-steel framing members, such as the wall girts shipped with a particular building package, to be first utilized as slab foundation forming elements before being framed into the building. The system defines foundation geometry upon simple assembly of the forming elements, and efficiently provides for placement of anchoring hardware which corresponds exactly to the connections of the structural frames.

Owner:BUTLER MICHAEL G

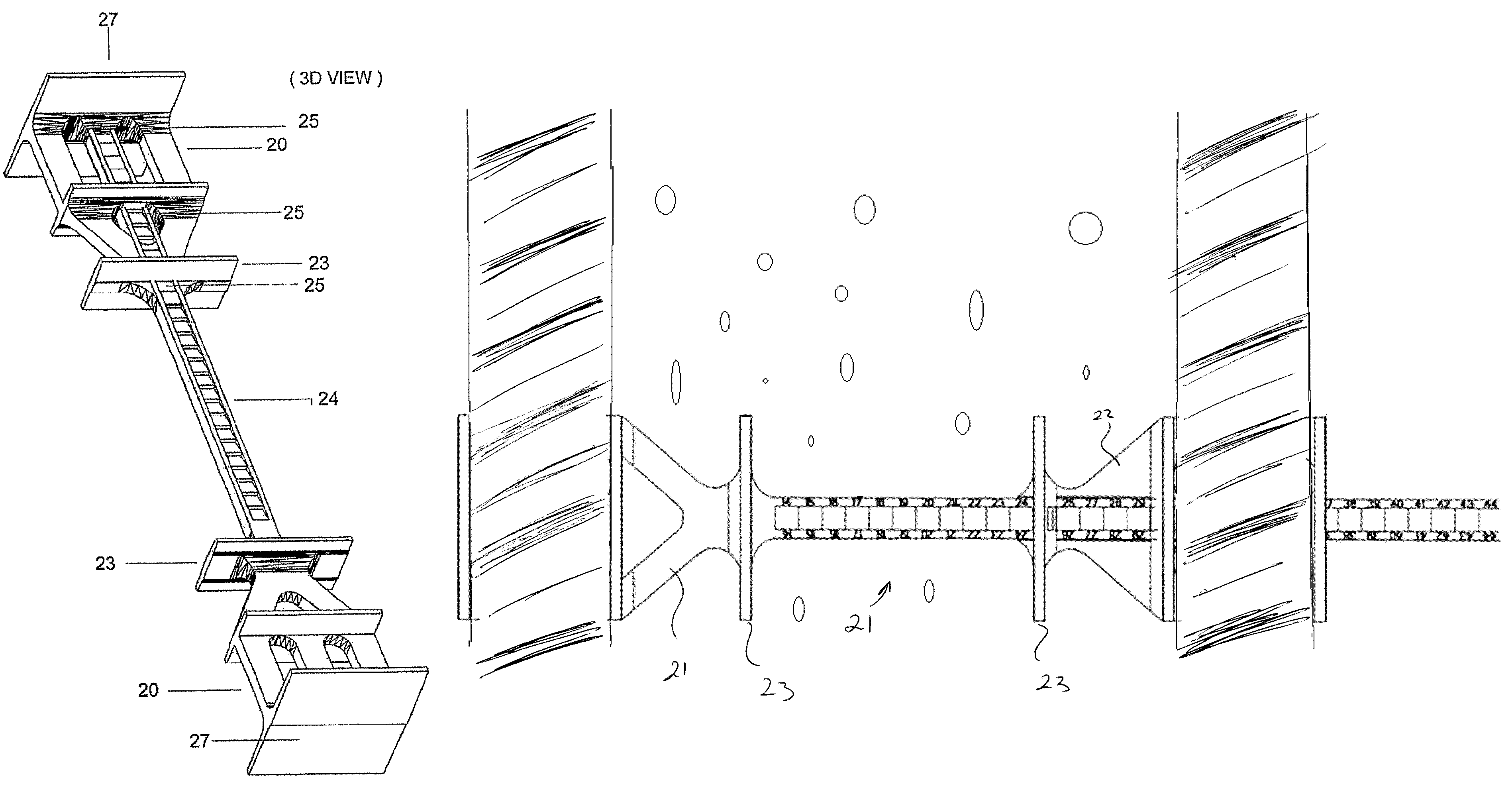

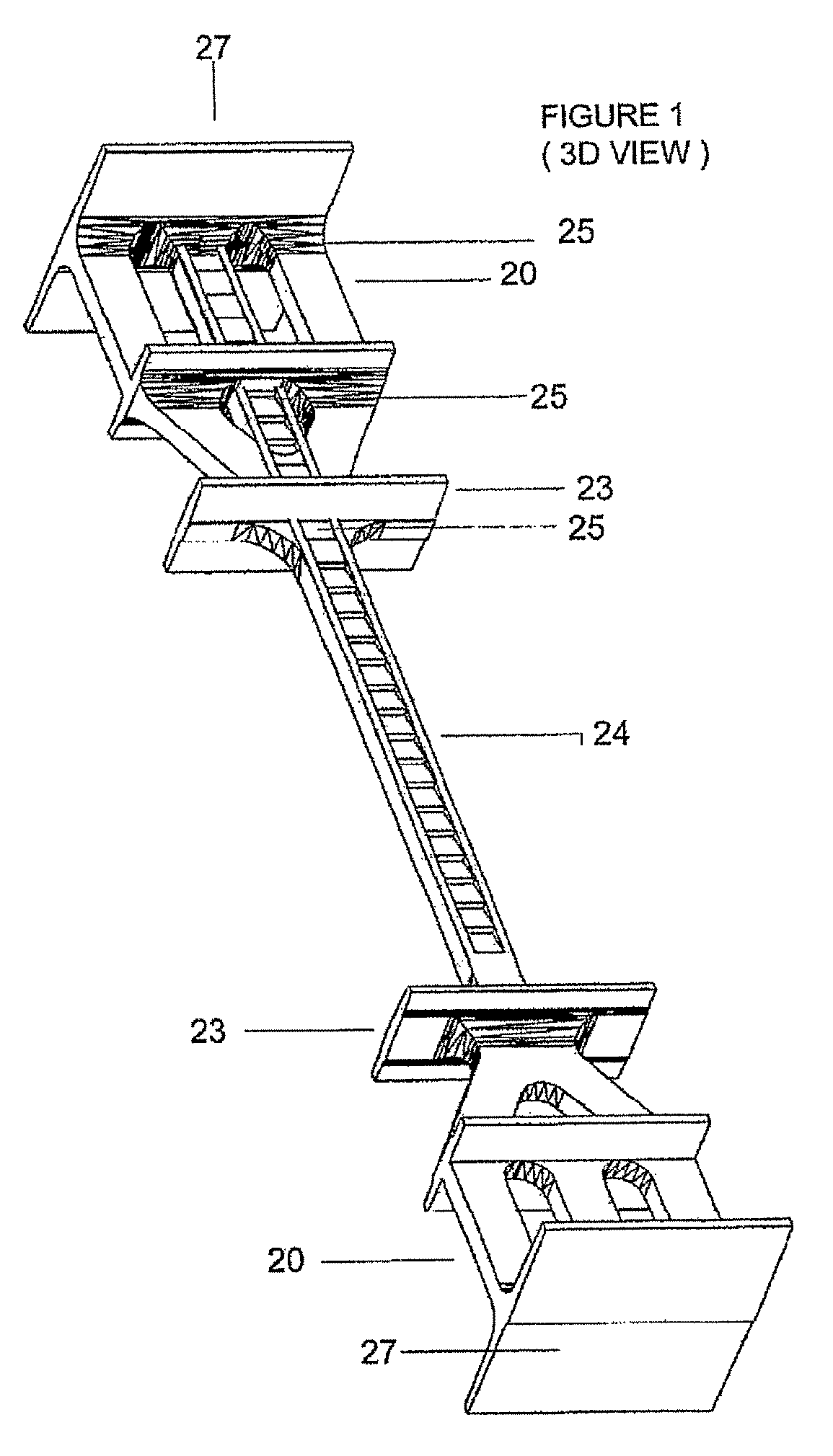

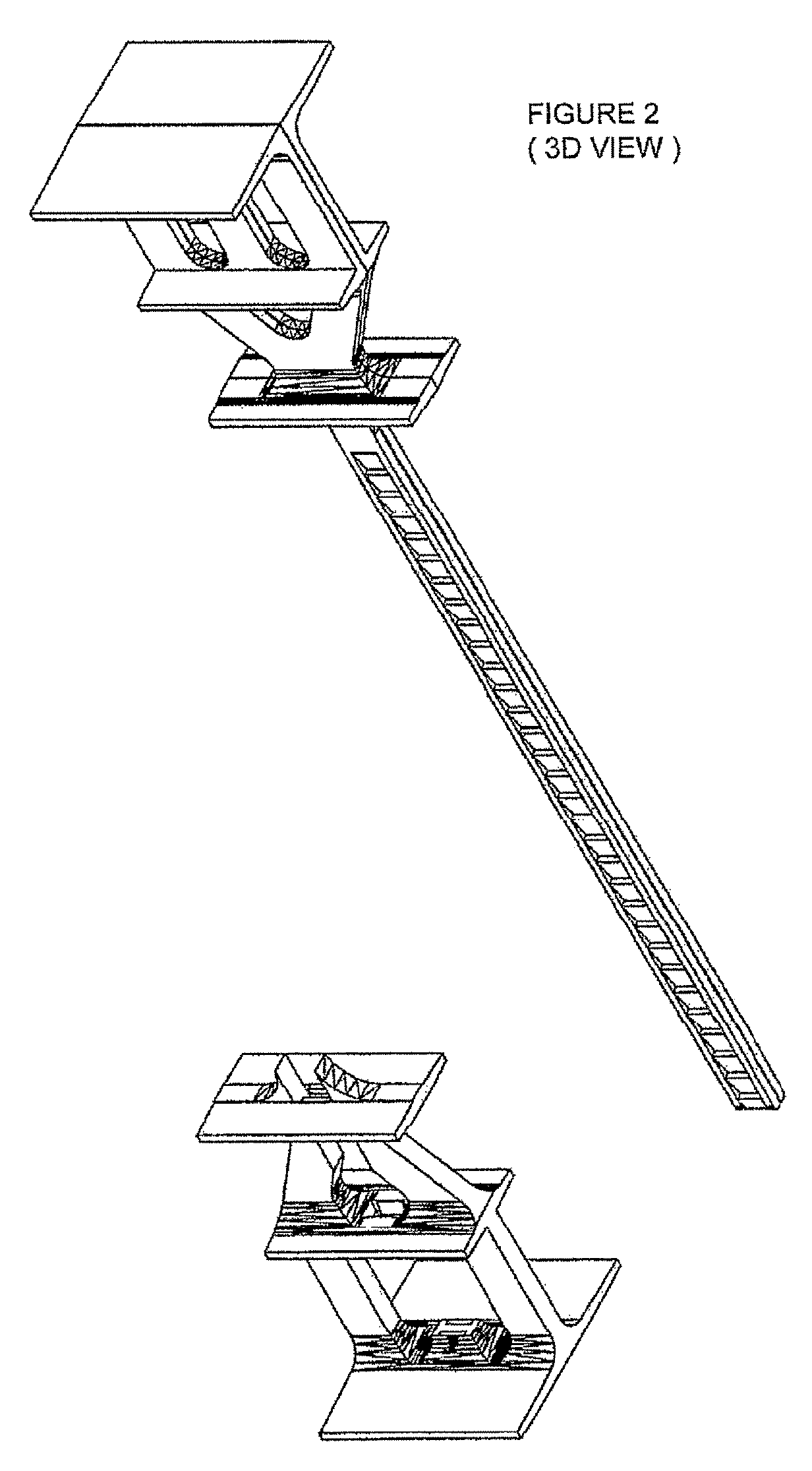

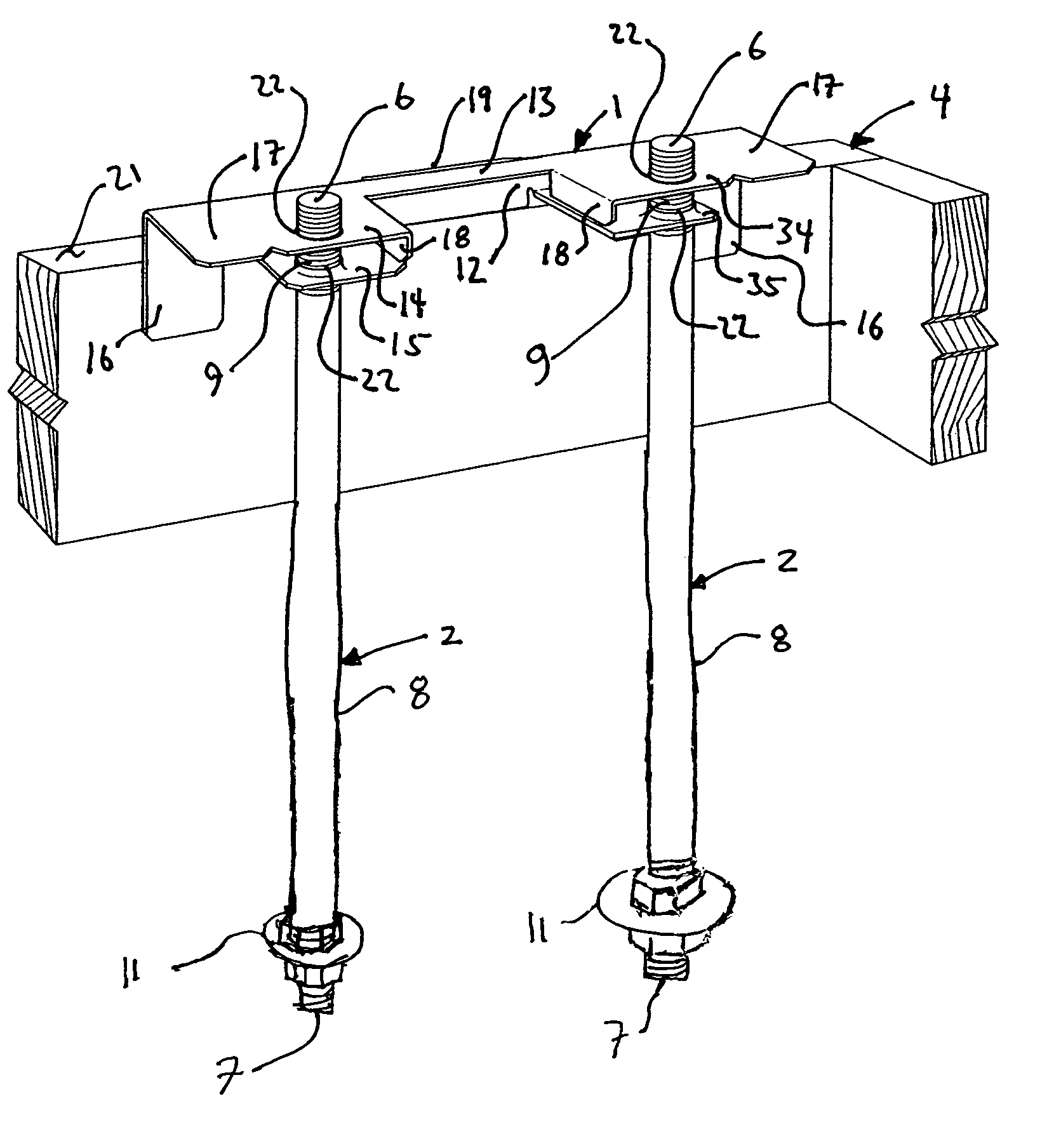

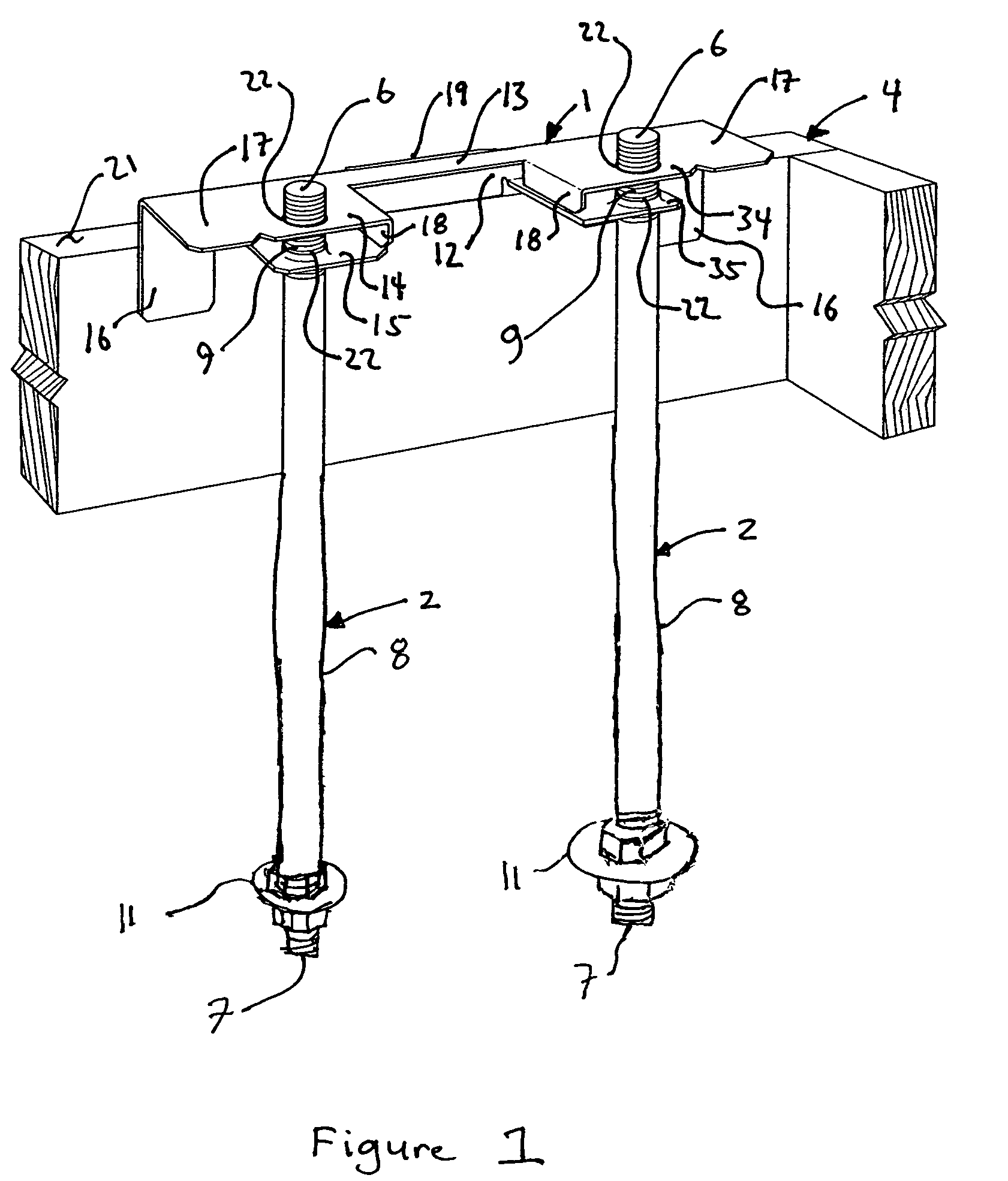

Shear wall template

ActiveUS7445192B2Precise positioningPig casting plantsAuxillary members of forms/shuttering/falseworksEngineeringFastener

A connection is provided between a holder and a plurality of anchor bolts by means of a template. The holder is typically a form board for a cementious member such as a foundation. The template is releasably attached to the form board. The template is formed with a central elongated support, and a plurality of pairs of primary and secondary anchor bolt receiving platforms connected to the central elongated support. The pairs of primary and second anchor bolt receiving platforms are spaced along the central elongated support from each other. Each of the primary and secondary anchor bolt receiving platforms has an opening therein for receiving one of the anchor bolts there through, the openings in each pair of primary and secondary anchor bolt receiving platforms being in alignment so as to receive the same one of the anchor bolts. A plurality of fasteners are releasably connected to the plurality of anchor bolts and are supported by the template to releasably attach the anchor bolts to the template, suspending them in the form where wet cement can surround and envelope the lower portions of the anchor bolts.

Owner:SIMSON STRONG TIE COMPANY

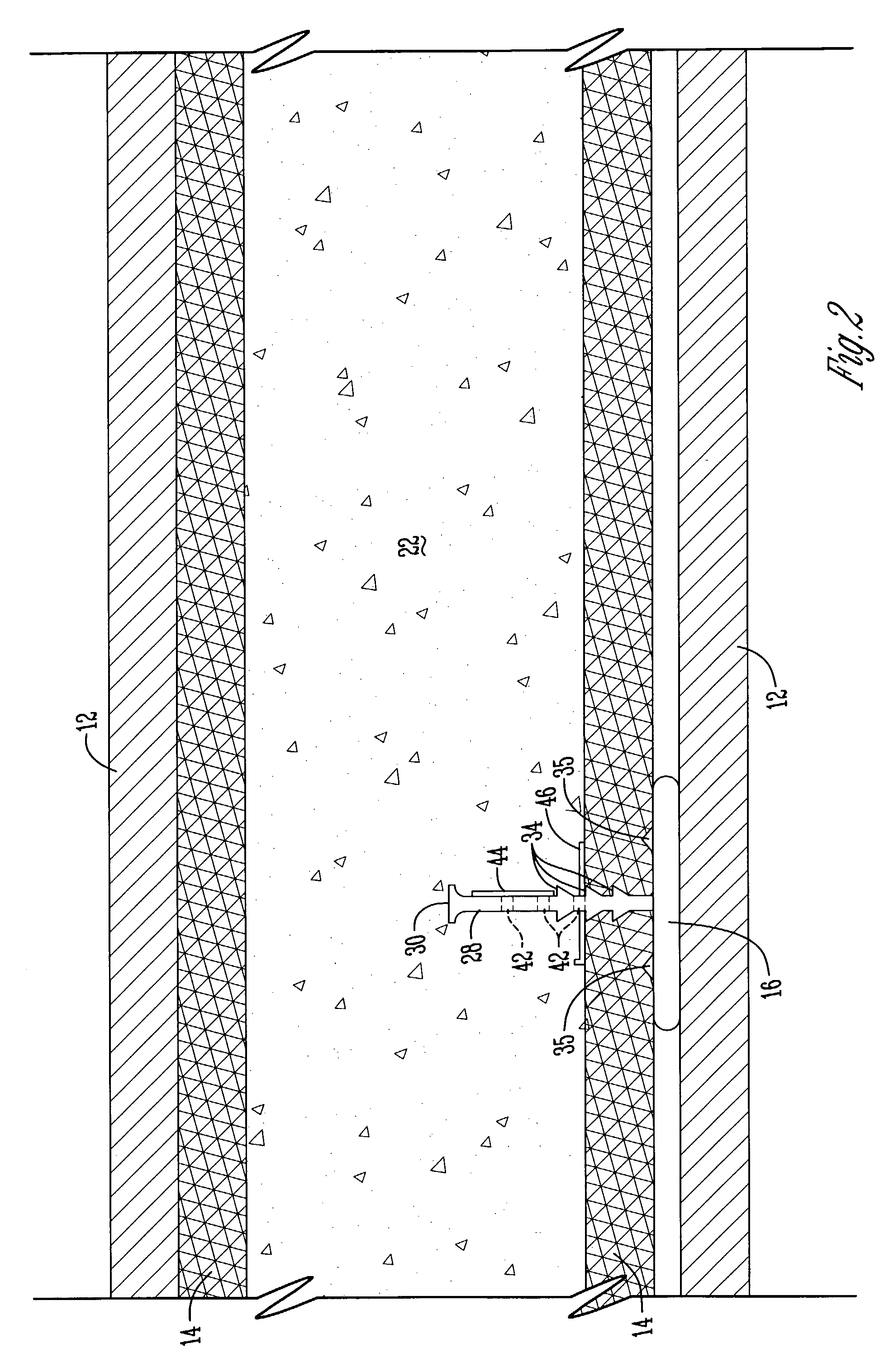

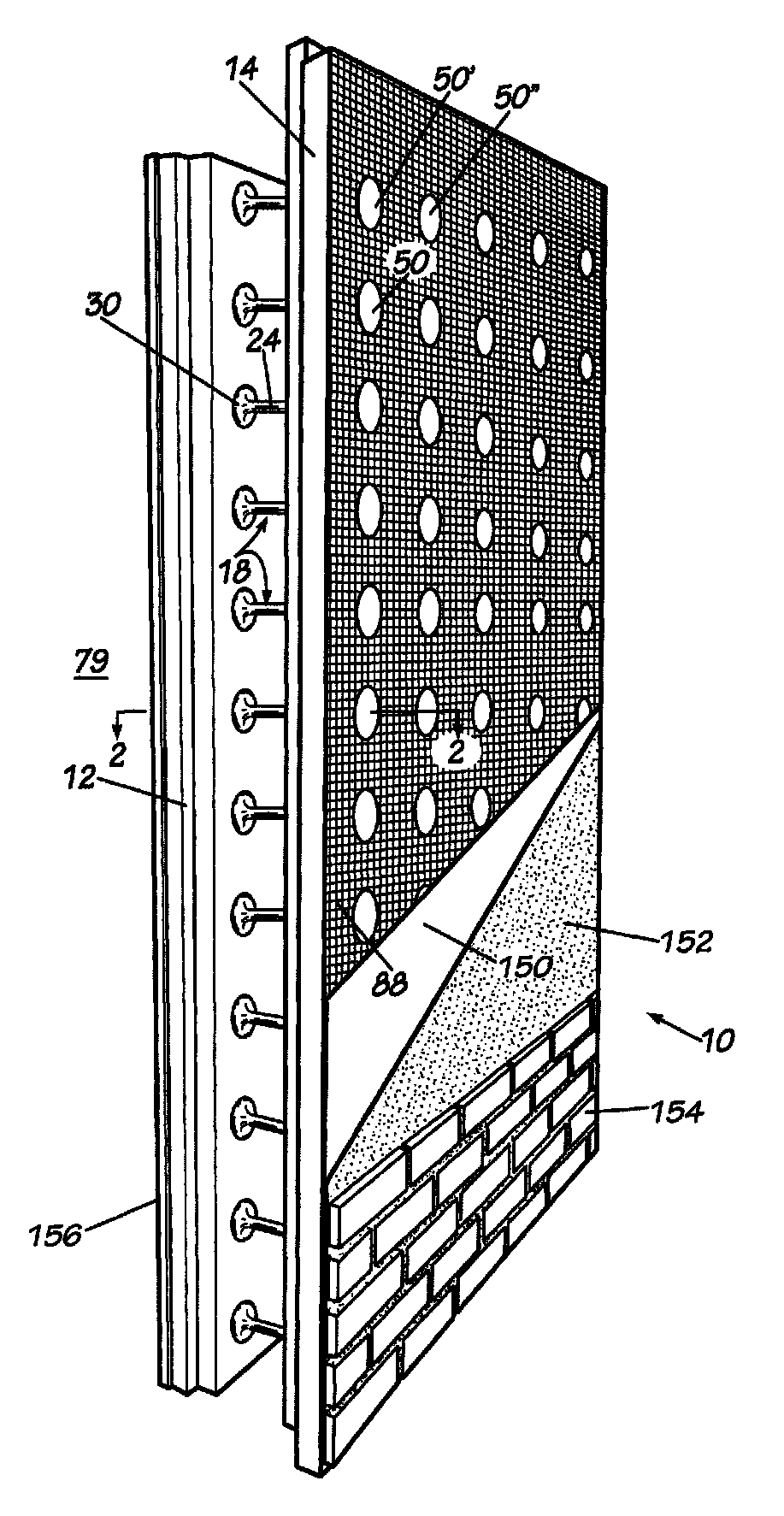

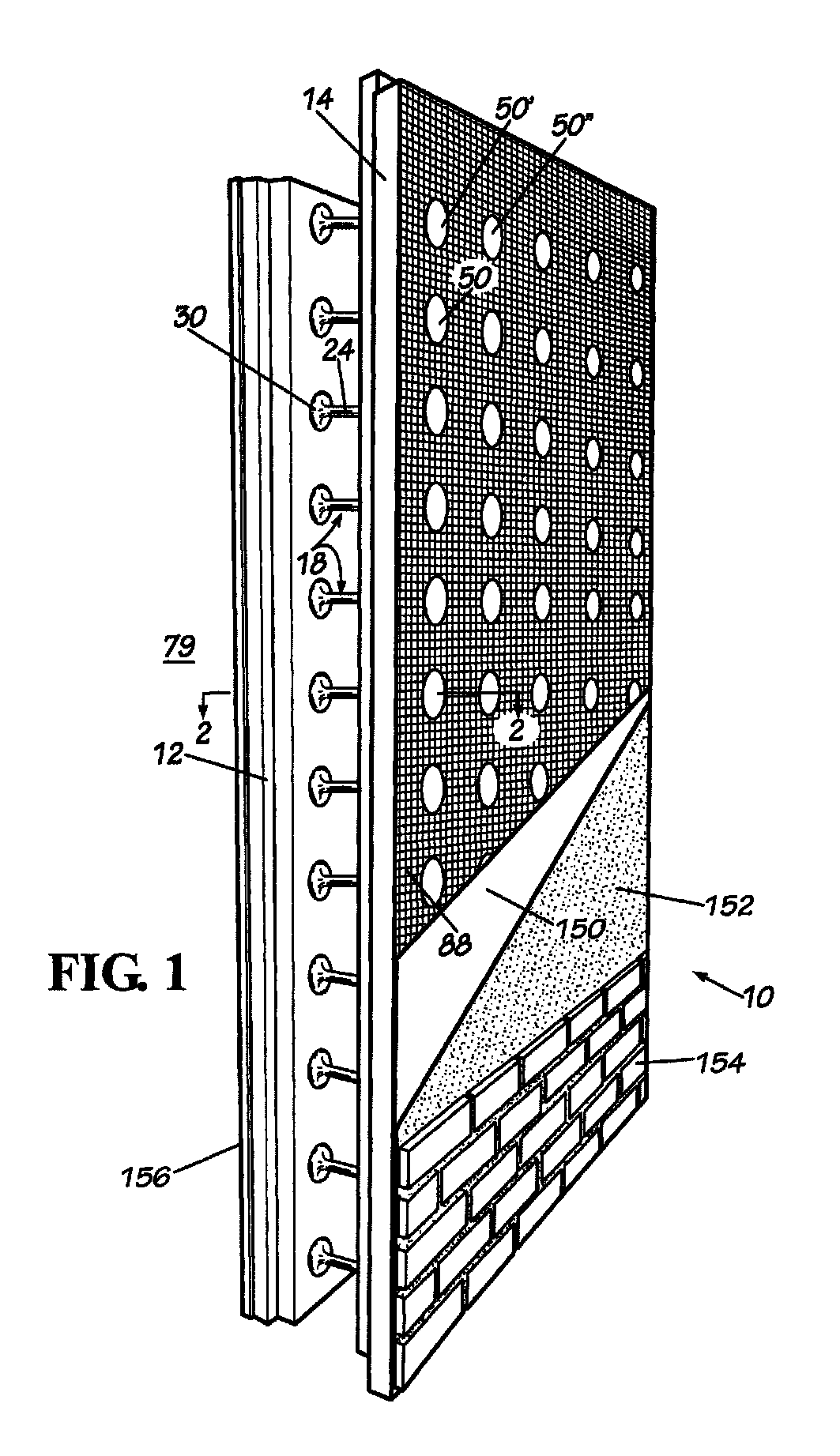

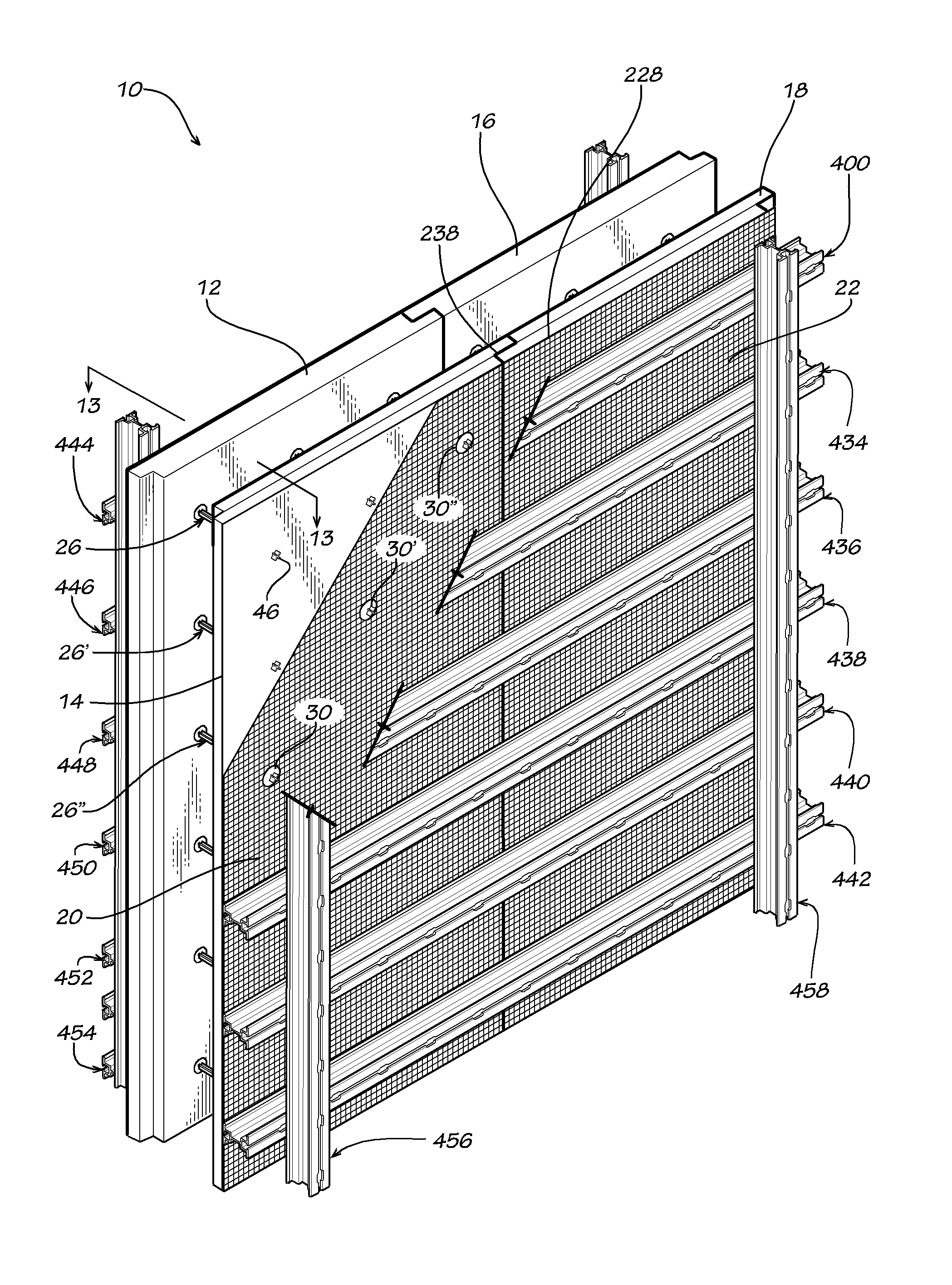

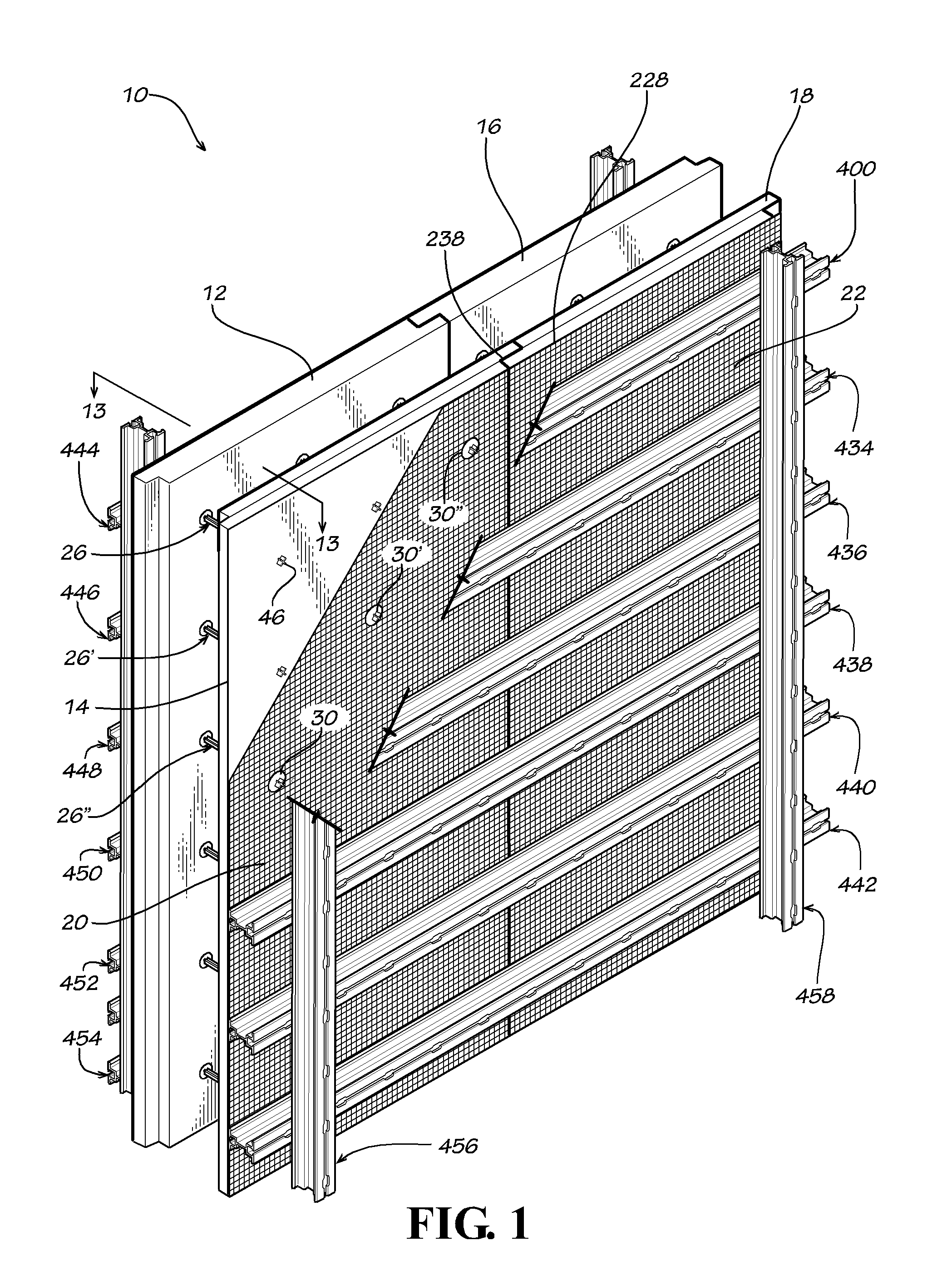

Hybrid insulated concrete form and method of making and using same

The invention comprises a product. The product comprises a foam insulating panel having a first primary surface and an opposite second primary surface. A removable concrete form is spaced from the foam insulating panel and a concrete receiving space is defined between the second primary surface of the foam insulating panel and the removable concrete form. A method of using a hybrid insulated concrete form is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

Hybrid insulated concrete form and method of making and using same

ActiveUS20140263942A1Retain heatEasy and inexpensive attachmentMoulding surfacesWallsInsulating concrete form

The invention comprises a product. The product comprises a foam insulating panel having a first primary surface and an opposite second primary surface. A removable concrete form is spaced from the foam insulating panel and a concrete receiving space is defined between the second primary surface of the foam insulating panel and the removable concrete form. A method of using a hybrid insulated concrete form is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

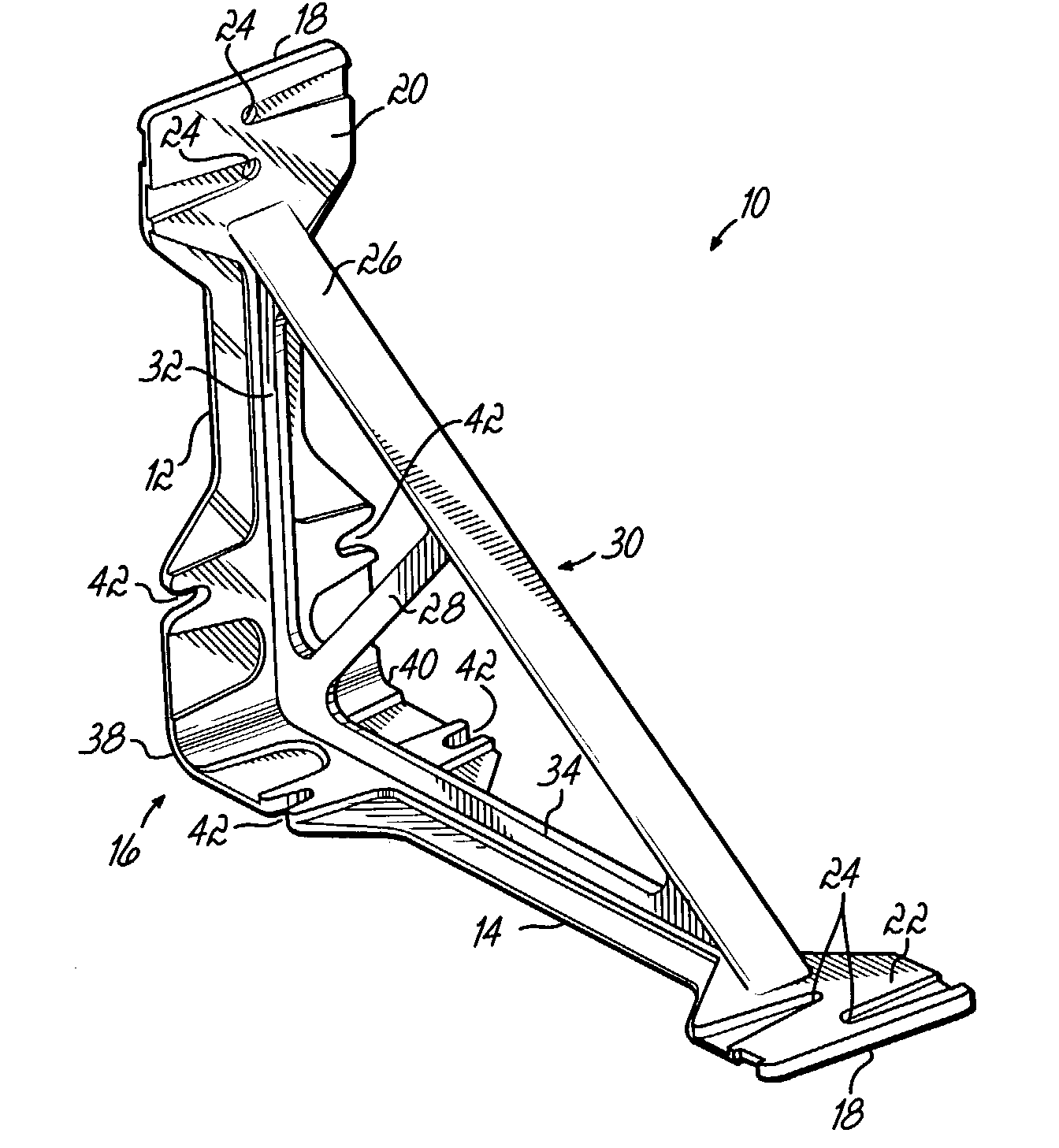

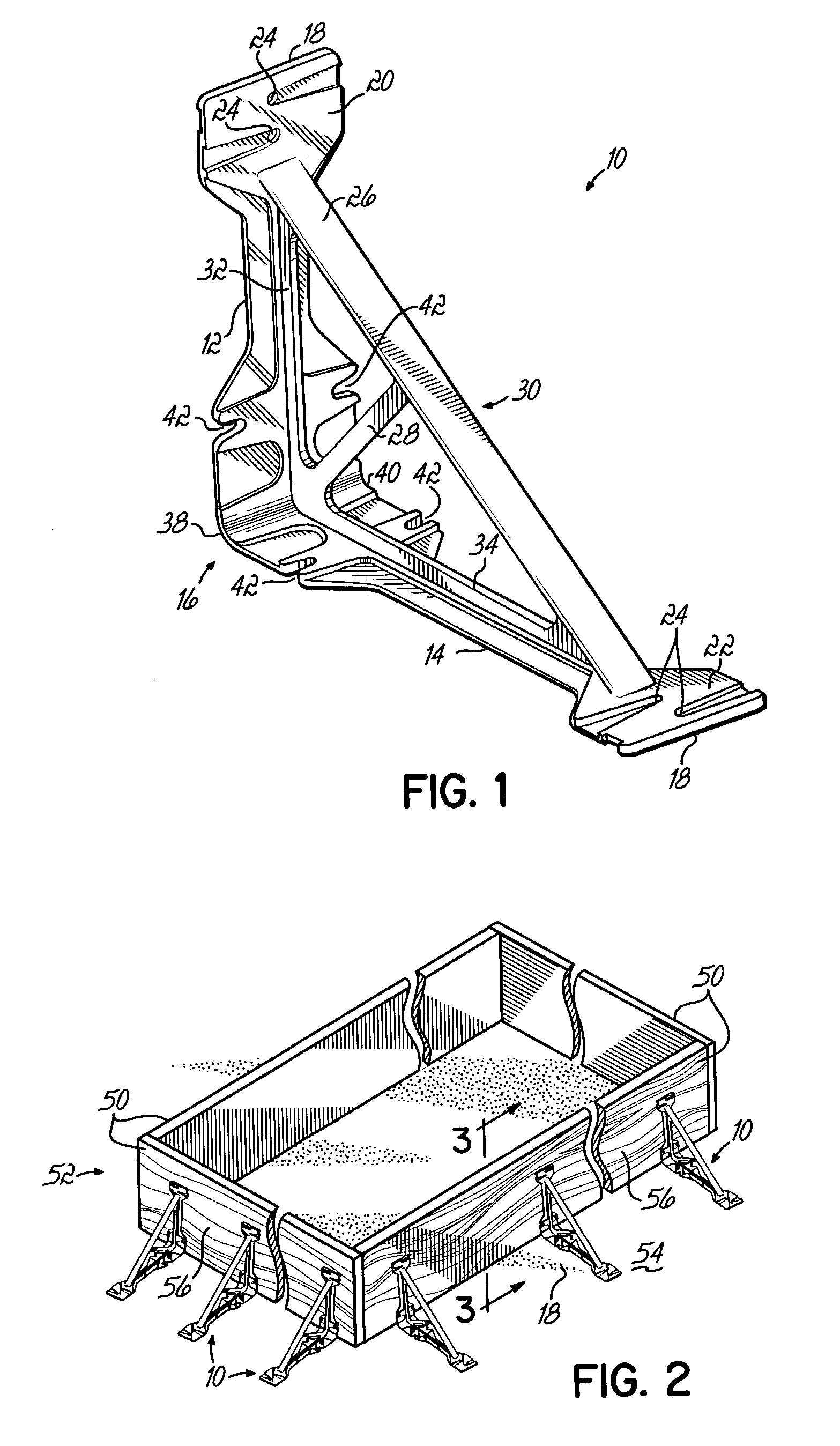

Brace for concrete forms

InactiveUS7051988B2Lend strengthLend durabilityIn situ pavingsStands/trestlesMechanical engineeringEngineering

A brace for securing concrete form members to a casting surface. First and second leg members are spaced to form an angle. A bridging member extends between opposing ends of the leg members and a strut extends between the joined ends of the leg members and the bridging member. The bridging member and strut form a truss, together with raised ribs along the legs and bridging member. The brace may be molded from plastic as a one-piece structure.

Owner:DAYTON SUPERIOR CORP

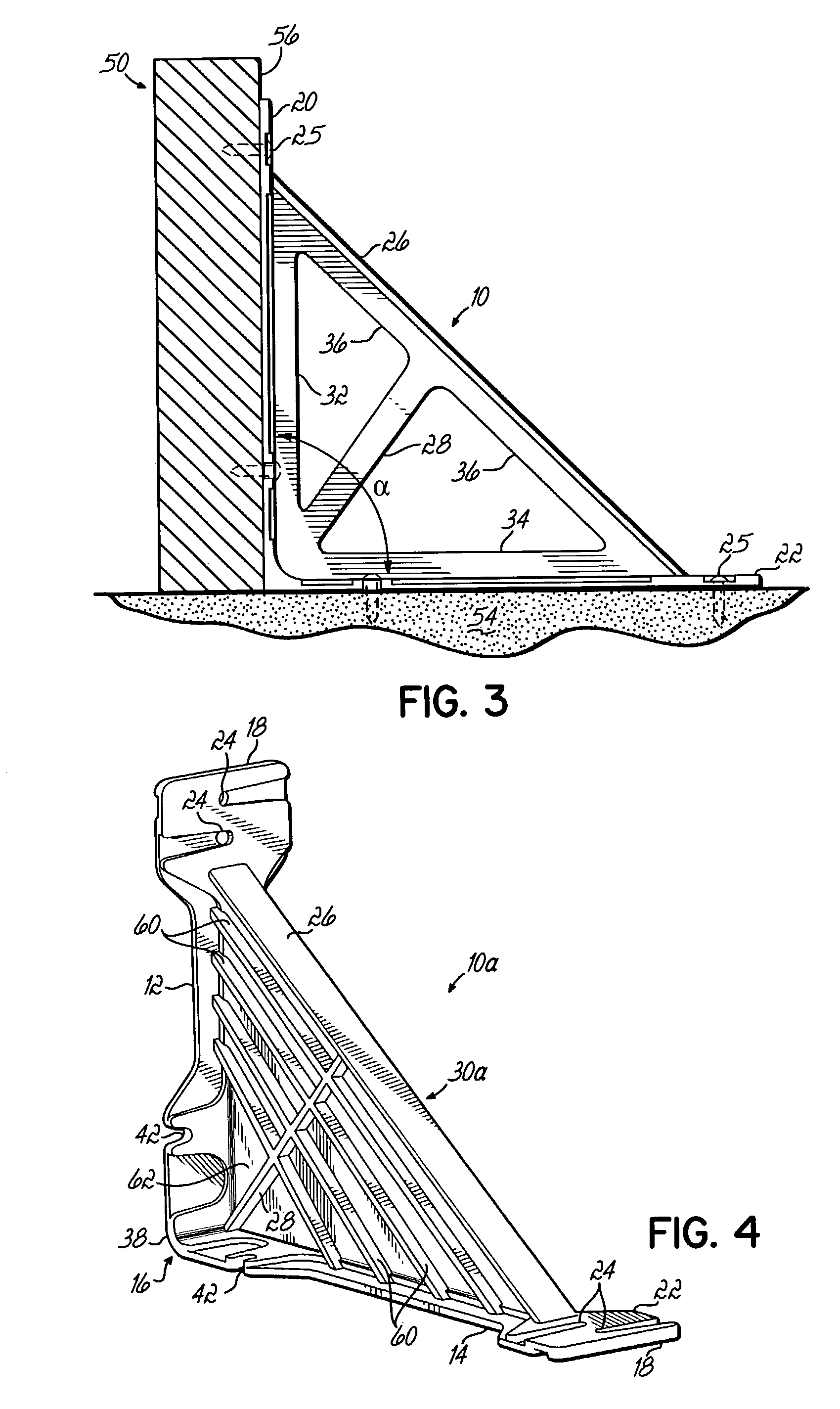

Integrated precast footings

InactiveUS6578333B1Improve quality controlSmooth interfaceWallsForms/shuttering/falseworksEngineering

A low impact foundation system requiring little or no excavation, and allowing for the preservation of the soil and drainage characteristics of the site upon which it is erected. The system utilizes small obliquely driven piles in combination with a pre-cast component designed to engage a standard foundation wall.

Owner:GAGLIANO RICHARD J

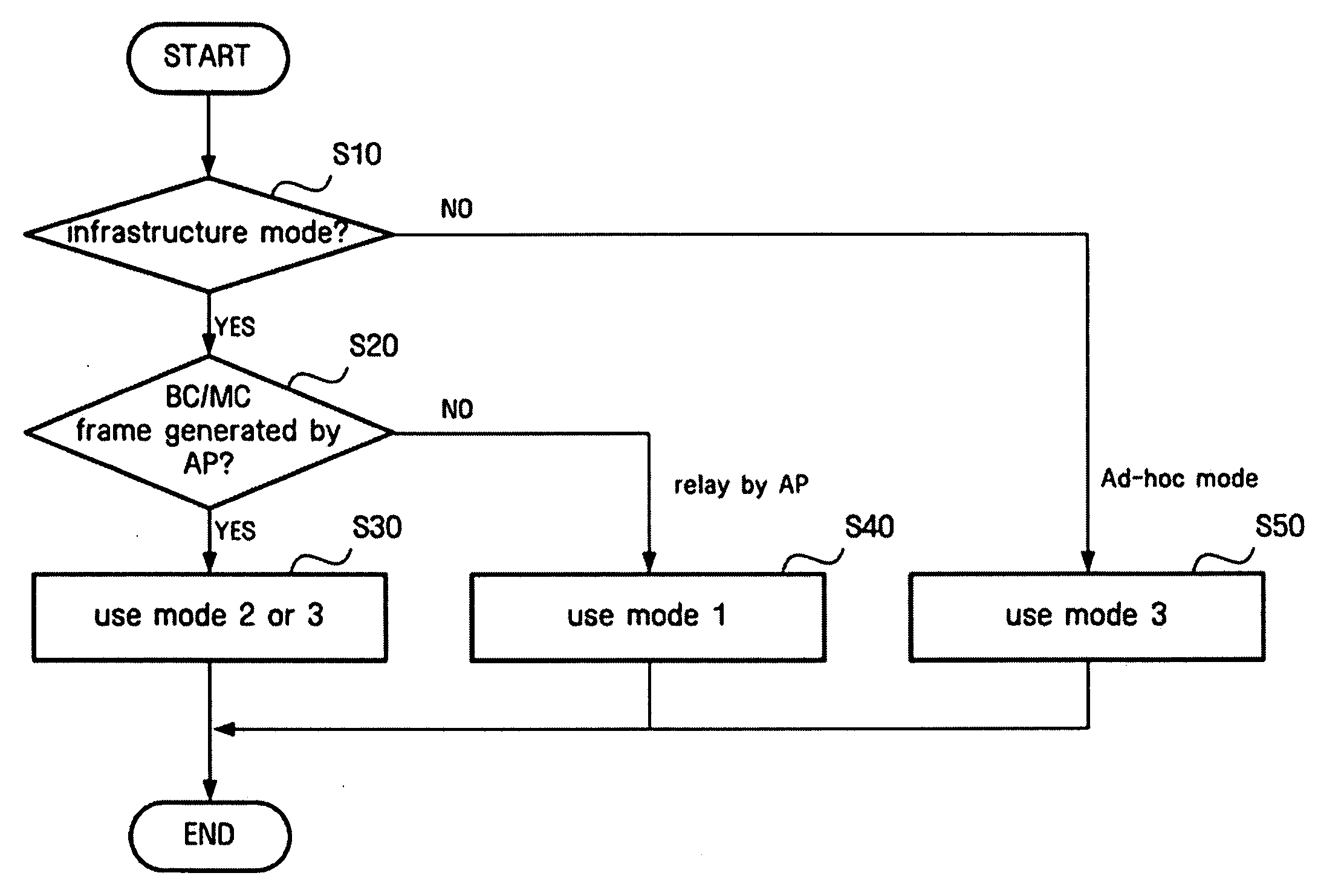

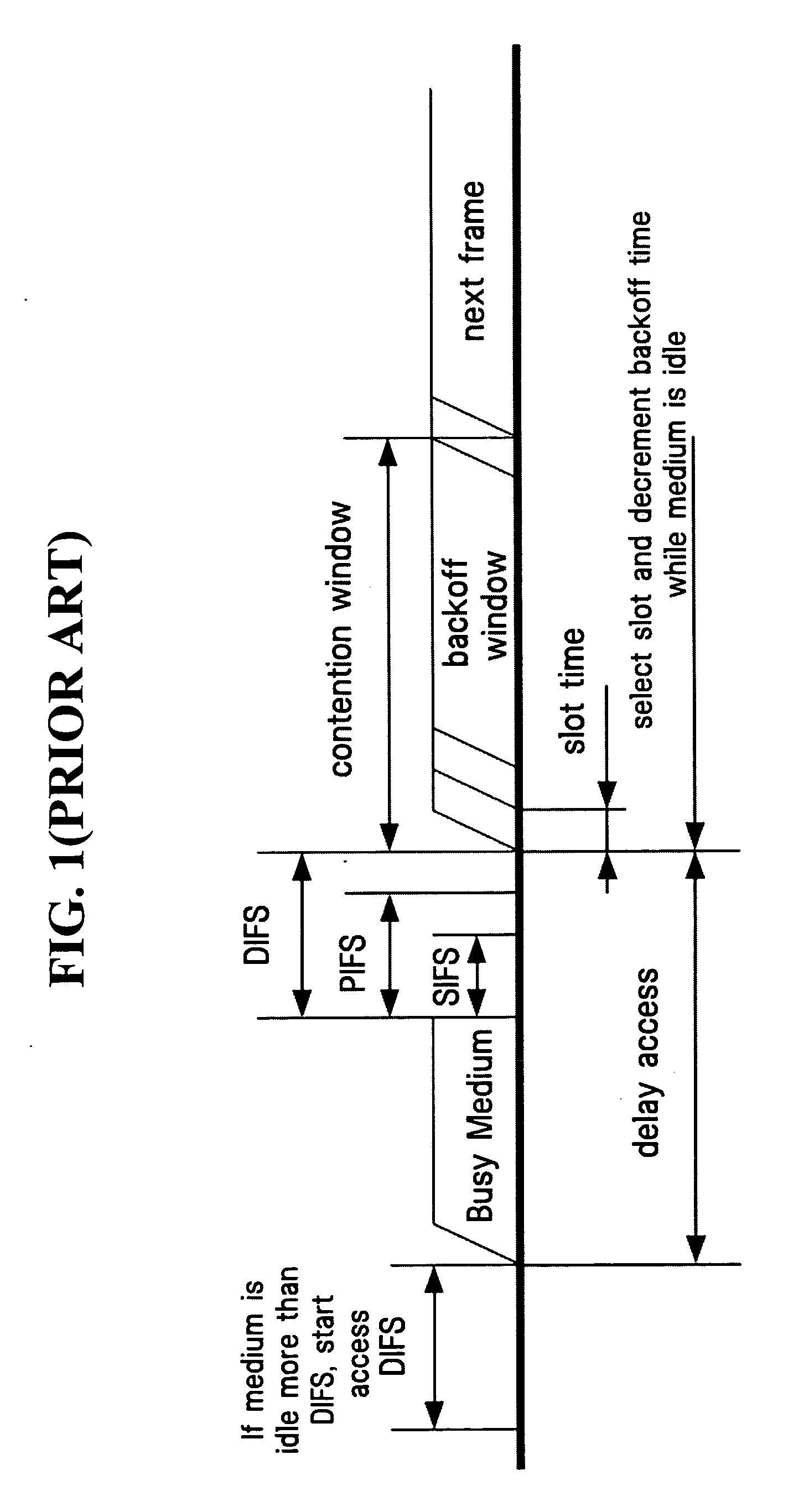

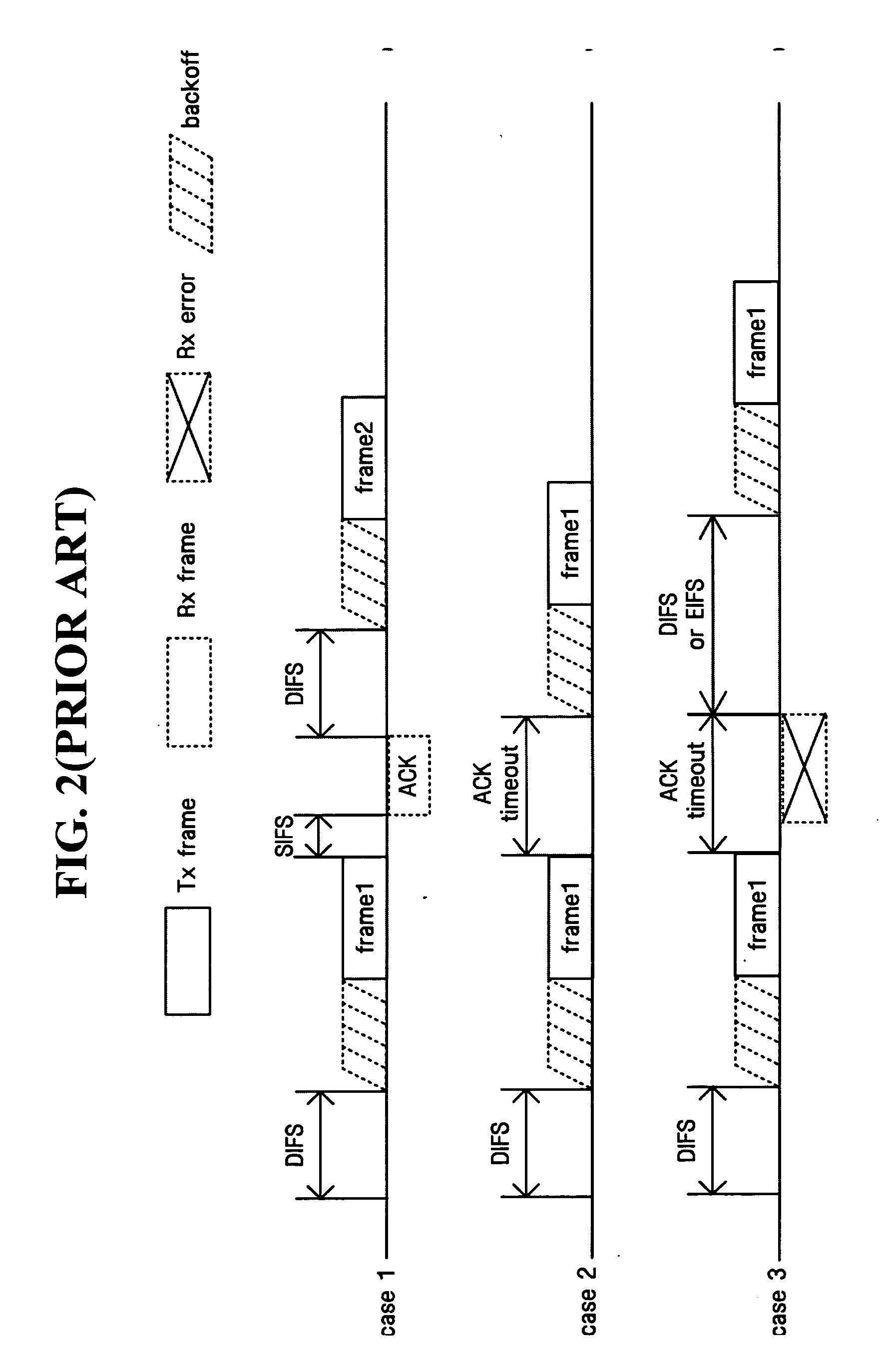

Wireless communication method following DCF rule

ActiveUS20050157747A1Improve reliabilityNetwork topologiesTime-division multiplexDistributed coordination functionTelecommunications

Provided are a method and apparatus which can reduce the possibility of collision with other frames when transmitting a broadcast / multicast frame in a wireless local area network (LAN) following a Distributed Coordination Function (DCF) rule, thereby ensuring reliable transmission. The wireless communication method for sending or receiving a predetermined frame through contention between an access point and one or more stations according to DCF is characterized in that the access point uses the shortest of interframe space (IFS) intervals for access to a wireless medium. Therefore, when wireless LAN STAs operate in a DCF mode, the possibility of collision during broadcast or multicast frame transmission can be reduced while adopting conventional CSMA / CA mechanism, thereby improving reliability in successful frame transmission.

Owner:SAMSUNG ELECTRONICS CO LTD

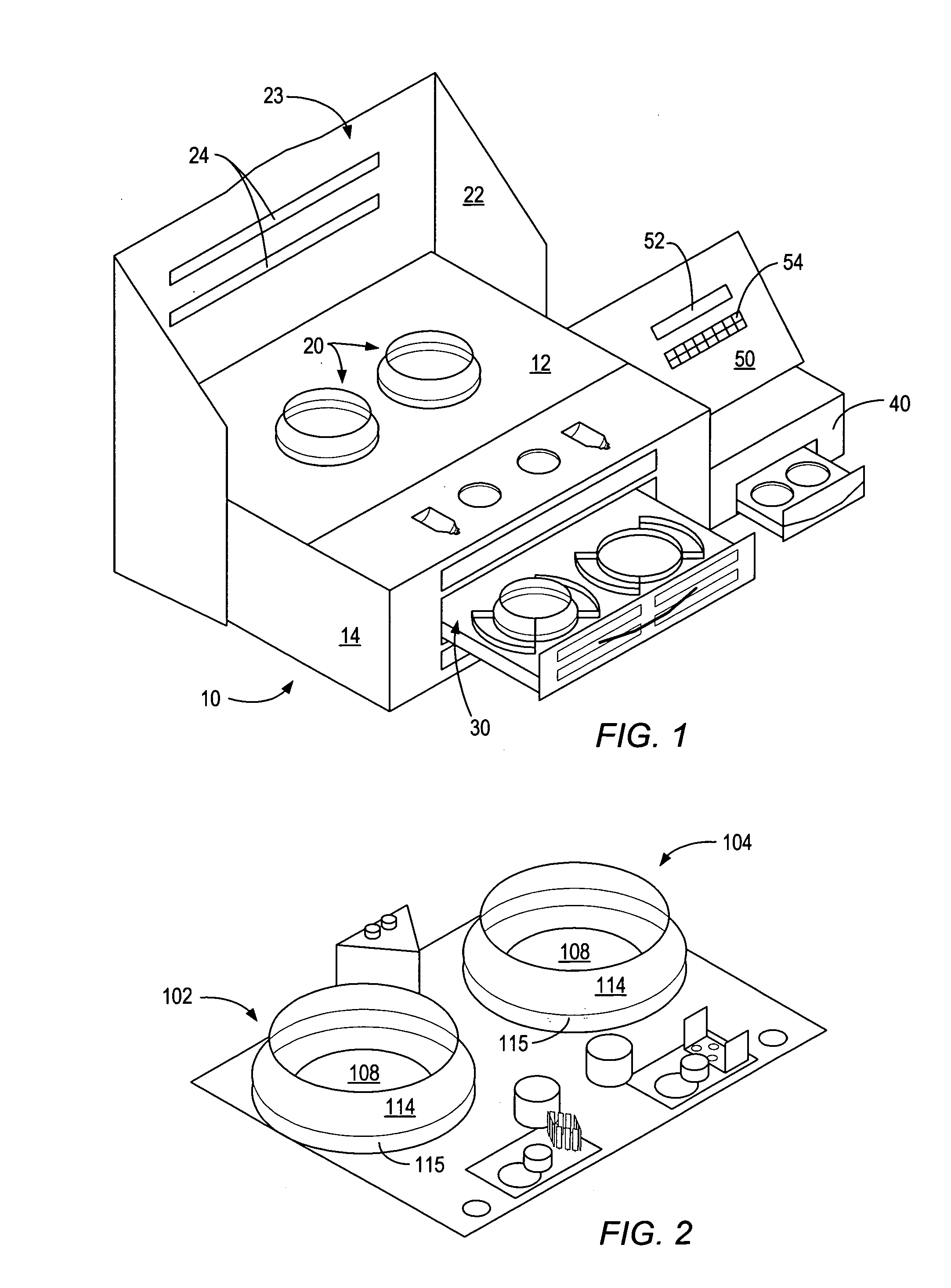

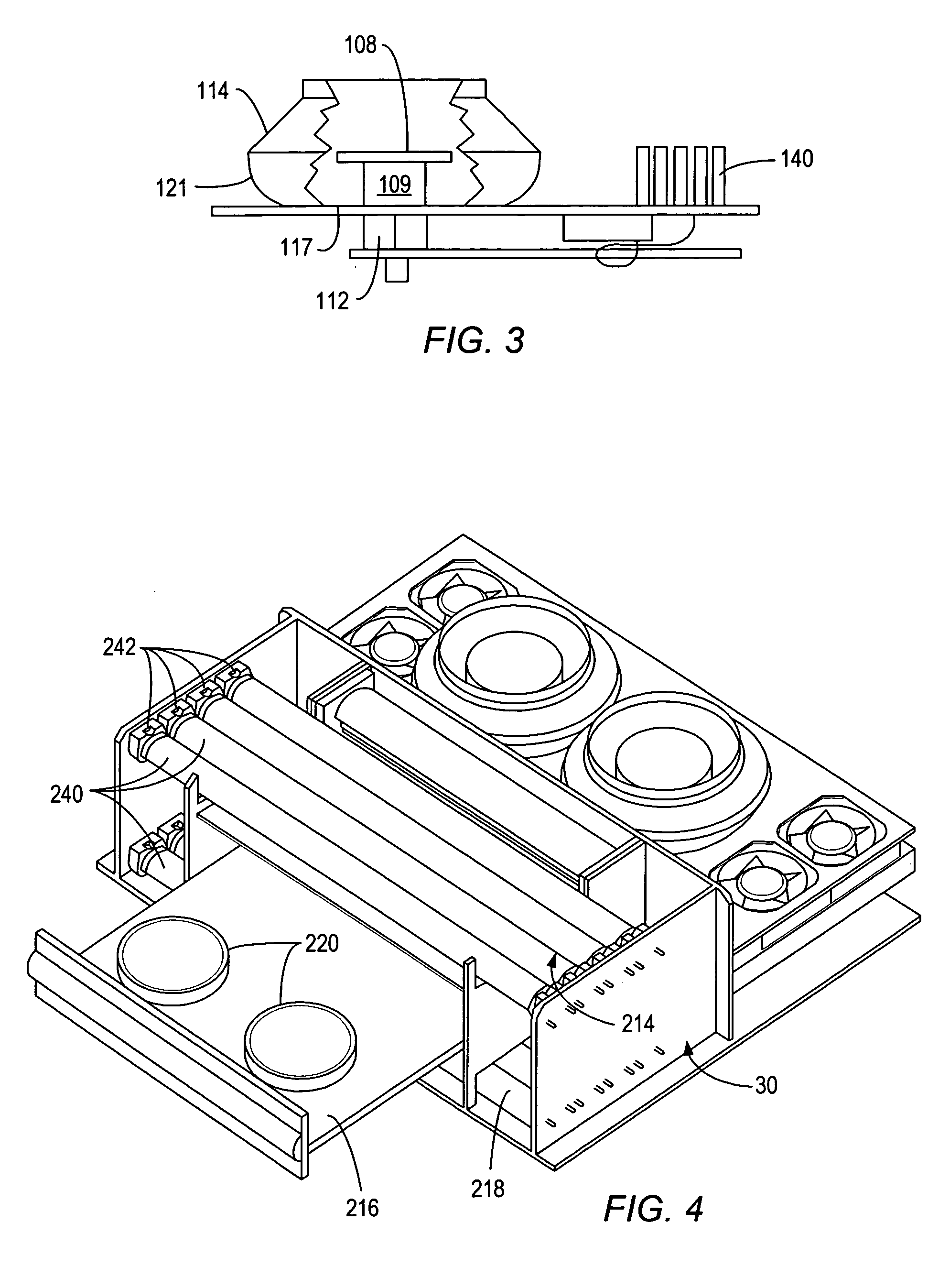

Methods and systems for coating eyeglass lens molds

Systems and methods for storing, locating, identifying and coating eyeglass lens mold members for use in the production of eyeglass lenses are disclosed. An embodiment includes storing eyeglass lens mold members in a storage array. A plurality of indicators may be coupled to the storage array and associated with storage locations. A controller may be configured to select mold members, and to identify the locations of the mold members. A user may input mold member identifying information. The controller may activate indicators associated with determined storage location. A mold reader may be used to input the mold member identifying information. The mold reader may detect a light pattern formed by illumination of the identifying information and determine the identity of the mold member based on the light pattern. Additional embodiments relate to separating a cast lens from a lens mold. Such embodiments may include a clamping mechanism for elastically deforming the lens mold. The lens mold and lens may then be separated by applying a separating force.

Owner:Q2100

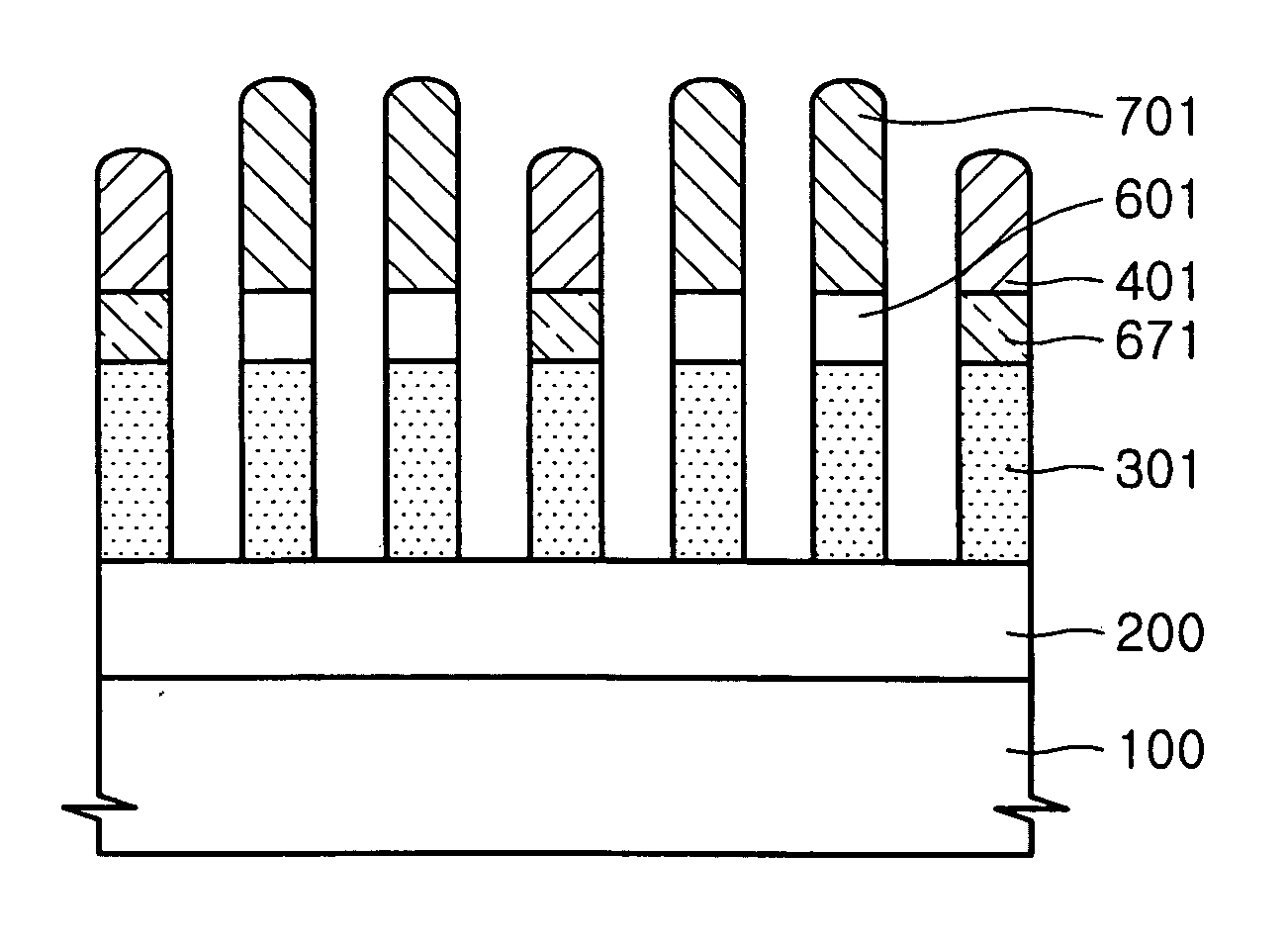

Method of forming small pitch pattern using double spacers

ActiveUS7842601B2Photomechanical apparatusSemiconductor/solid-state device manufacturingLine widthEngineering

A method of forming a small pitch pattern using double spacers is provided. A material layer and first hard masks are used and characterized by a line pattern having a smaller line width than a separation distance between adjacent mask elements. A first spacer layer covering sidewall portions of the first hard mask and a second spacer layer are formed, and spacer-etched, thereby forming a spacer pattern-shaped second hard mask on sidewall portions of the first hard mask. A portion of the first spacer layer between the first hard mask and the second hard mask is selectively removed. The material layer is selectively etched using the first and second hard masks as etch masks, thereby forming the small pitch pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com