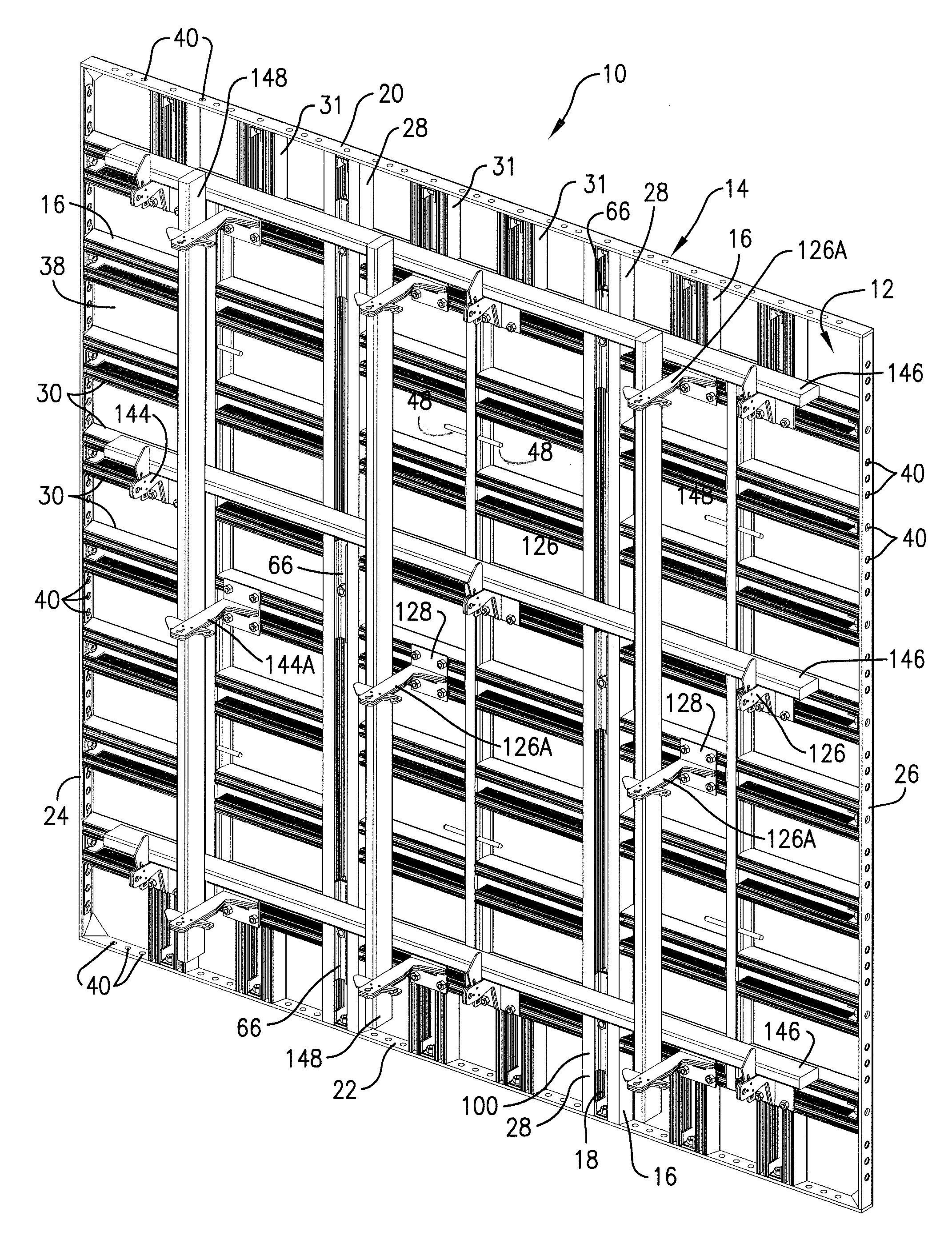

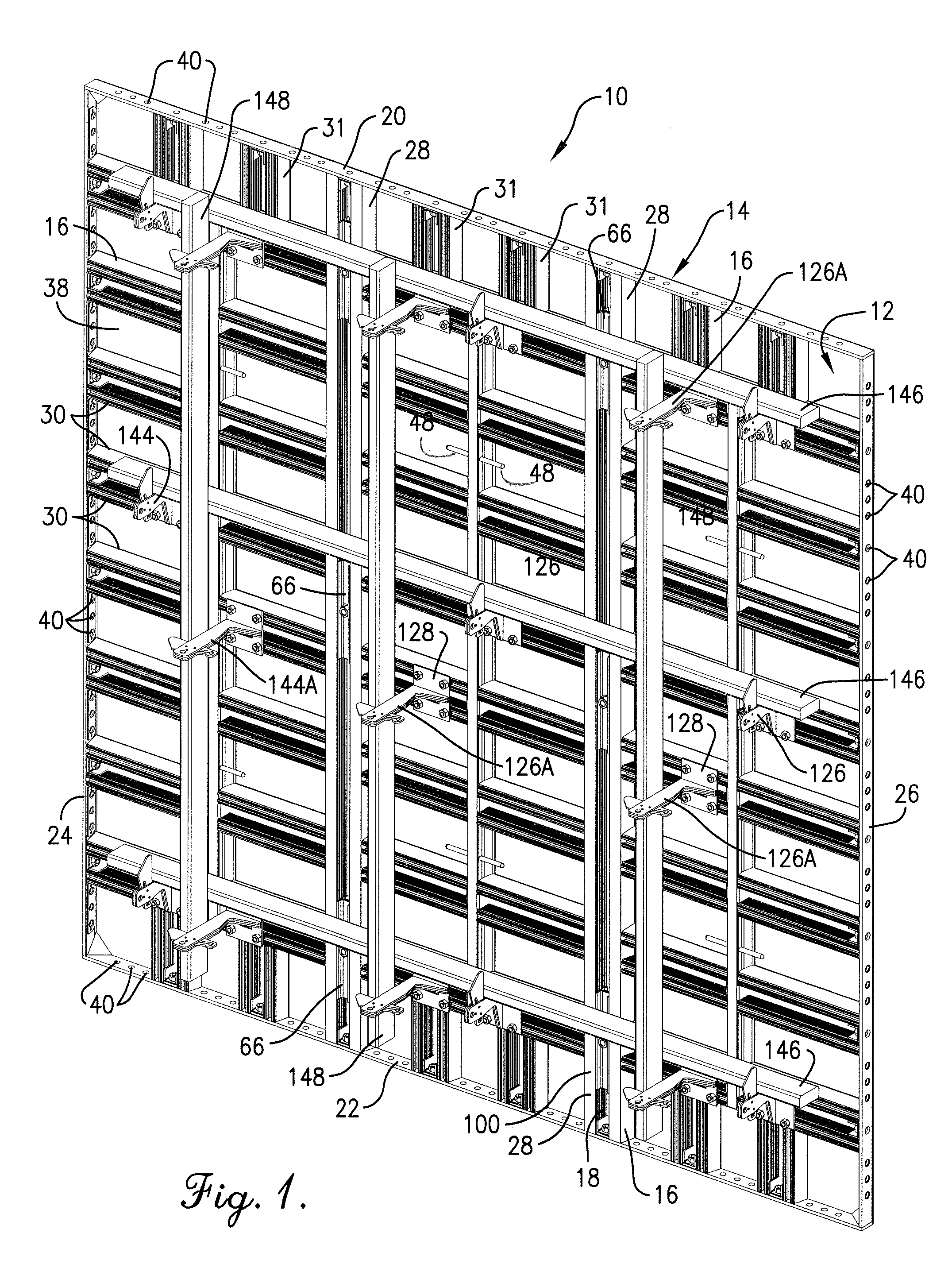

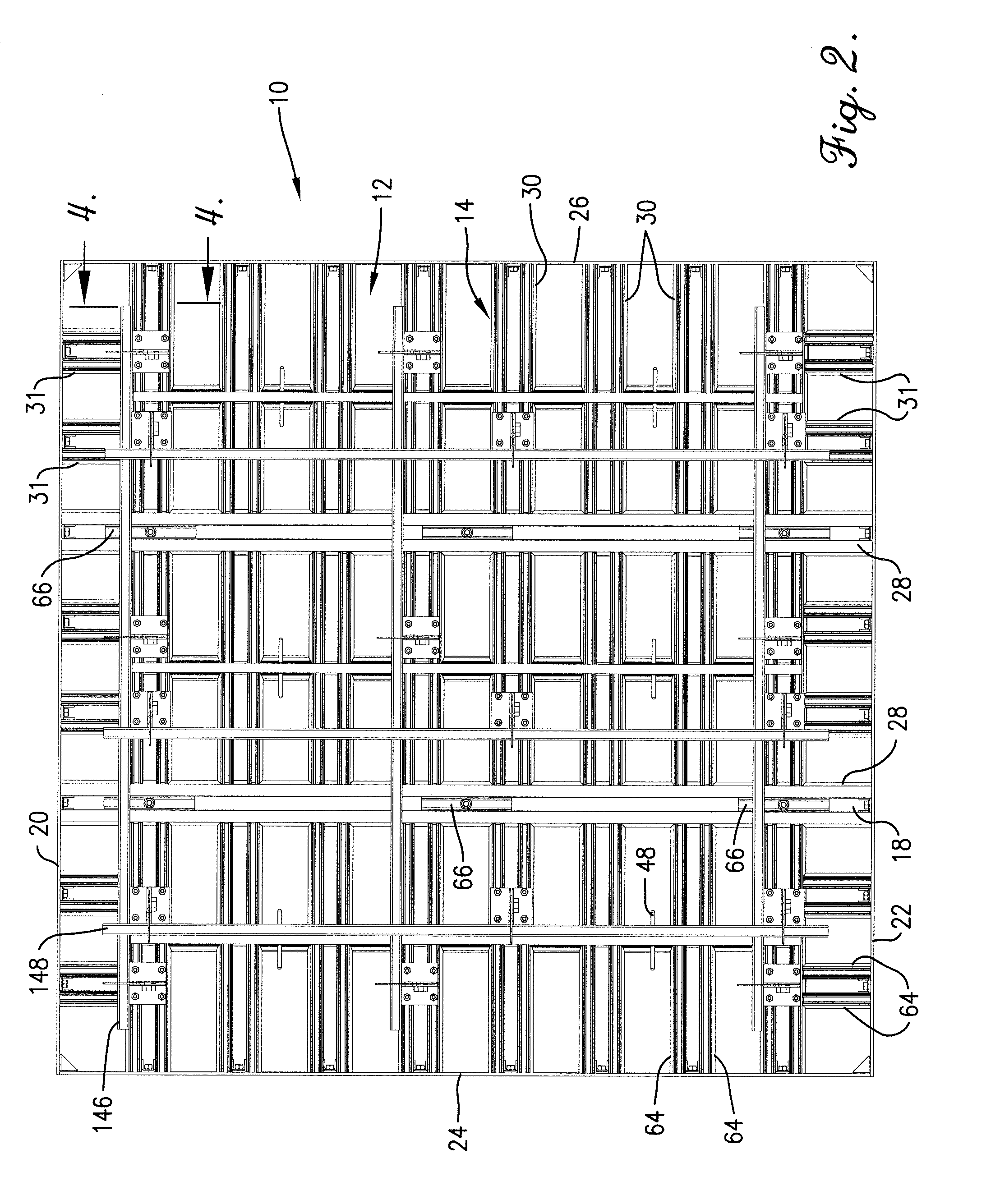

[0008]These and other objects have largely been addressed by the lightweight crane-set forming panel of the present invention. That is to say, the forming panel of the present invention presents significant improvements over prior art in regard to providing a lightweight panel of a size typical of crane-set forming panels, but presents improved capabilities for inhibiting the passage of fine particles of concrete around the frame or through openings in a face plate of the forming panel, and facilitates its use with other conventional panels by the provision of a folding bracket for holding a waler or other structural support. Moreover, while it is common to

mount tie bars to the side rails of a forming panel, the present invention provides a forming panel capable of reuse and which permits the

insertion of a tie rod or tie bar through an opening such as a hole or slot positioned internally of the side rails of the frame.

[0011]The channel, preferably though not necessarily unitary in construction and extending either fully or partially between the rails of the frame, and a central slot extending therealong is preferably threaded. As used herein in connection with the slot in the channel, the term “threaded” refers to the presence of opposed ridges or flights on the opposing, inward-facing sides of the wall surfaces of the channel forming the slot to permit a threaded member such as a bolt, stud, tie-rod or other externally threaded member to advance into and be withdrawn from the slot when rotated. Because the slot is open at the ends, an encircling opening with internal threads as typically understood by the term “threaded” is not provided, but the ridges on the channel nonetheless permit threadable attachment of such threaded members. Preferably, the channel includes at least a pair of wall surfaces each having a plurality of ribs which cooperatively define a threaded surface in the slot. The channel is preferably formed by

extrusion whereby the threaded slot extends longitudinally along the channel permitting the positioning of a complementary threaded member, such as a bolt,

receiver or plug, to be capable of infinite adjustment along the threaded portion of the channel. The threaded slot further preferably extends substantially the entire length of the channel. Multiple channels may be included in the frame in parallel or transverse orientations. For example, a first set of one or a plurality of channels may be oriented in an upright position when the panel is positioned for use, and another set of channels may be positioned in horizontal relationship. The channels not only serve to provide a grid for multiple attachment locations for accessories to the panel, but also help to reinforce the face panel against deflection. Both the face panel and the frame may be provided of aluminum

alloy or other suitable

metal which is durable and capable of outdoor use. The face plate may also be provided as a composite panel of

layers of material such as

synthetic resin and

metal sheets. The channel may also have external serrations to facilitate gripping of the channel by clamps or other accessories. Beneficially, the preferred embodiment of the invention further includes slot rails accessible from the rear of the form which may be positioned laterally from but extend parallel to the channel. The slot rails may advantageously sized so as to capture and hold a nut or bolt head against turning, thereby greatly facilitating attachment and then tightening to the rear side of the form of form hardware such as the shiftable support bracket described above.

[0013]The forming panel hereof is useful as part of a forming

system wherein a plurality of such panels may be connected by fasteners to provide a forming wall which faces another, opposite one of the forming walls to receive poured cementations material such as concrete therebetween. The threaded slots in the channels and the non-threaded slot rails of the channels greatly facilitate the attachment and securement of tie rods at multiple locations internal to the surrounding edges of the form and the mounting of hardware and accessories such as an expandable wall brace, a horizontal waler, a

scaffold bracket, a lifting bracket with a clevis, and a gang

leveler without the need for small nuts which must be positioned in

narrow channel slots. Rather, the bolts for

coupling such members to the panel may be secured directly to the panel and threaded into the channels while retaining the capability of infinite adjustment along the threaded portion of the panel. Moreover, the forming panel of the present invention may be provided of a reduced rearward depth from the face plate as compared to other crane set forms. This permits the forming panel of the present invention to favorably align along the rear side of the frame, so that the forming panel is complemental in depth and location of holes in the rails to smaller, typically man-set forms. Thus, while retaining the strength required of large, crane-set forms, the forming panel of the present invention can be placed side-by-side with smaller man-set forms and readily coupled thereto using pins and wedges or other fastening members such as the PINLOCK

fastener of Western Forms as shown in U.S. Pat. No. 5,058,855, the entire disclosure of which is incorporated by reference. In addition, a waler or

scaffold placed in spanning relationship across the crane-set form of the present invention may not only provide alignment of the forming panel hereof, but also smaller man-set forms.

Login to View More

Login to View More  Login to View More

Login to View More