Patents

Literature

1100 results about "Construction industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition of fillers with plastics for producing superior building materials

InactiveUS20090062413A1Minimize limitationEasy to assembleCovering/liningsSolid waste managementChemical LinkageBrick

The use of high aspect fillers in the production of simulated stone, masonry and brick textured products such as cladding, siding, panels, or other building and construction materials. High aspect fillers increase the dimensional stability, rigidity, thermal and sound insulation. The high aspect fillers may be included into a matrix polymer with or without chemical bonding. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:CRANE BUILDING PRODS

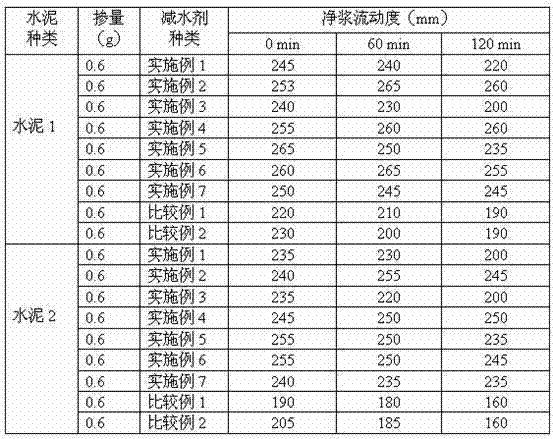

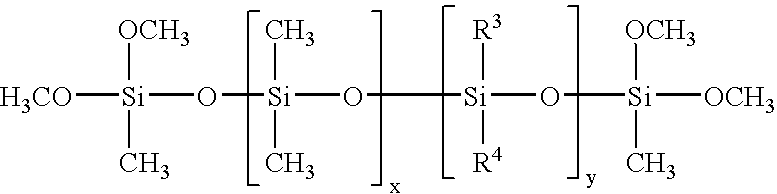

High-performance water reducer of polycarboxylic acid, and preparation method thereof

The invention relates to a high-performance water reducer of polycarboxylic acid, and a preparation method thereof, belonging to the technical field of concrete admixtures in construction industry. The water reducer is prepared by 55-90% of polyoxyethylene ether or ester containing unsaturated double bonds, 8-30% of unsaturated carboxylic acid and derivative thereof, 0-25% of unsaturated sulfonic acid and salt thereof, 0-15% of unsaturated carboxylic esters, and 0.5-5% of redox initiator. The high-performance water reducer of polycarboxylic acid prepared by the invention has the advantages of high water-reducing rate and collapse protectiveness, and has good adaptability for base materials. The water reducer provided by the invention is featured with simple technology, easy material getting, no pollution and low cost, and is industrially produced easily.

Owner:山西科腾环保新材料股份有限公司

Modified silicasol and application thereof in preparing water paint

The invention discloses a modified silica sol and application thereof in preparation of aqueous painting. The inventive modified silica sol is prepared from aqueous silica sol by regulate pH value of raw material to 3-6; charging organosilane with a mass ratio with SiO2 in silica sol of 1:1 - 5:1, water bathing at temperature of 50-80 DEG C., waiting for 0.5-5 hours, vaporizing by-products generated in hydrolysis to obtain transparent sol, which is final product. The modified silica sol has cheap raw material, simple preparation. When used as matrix in preparation of paint, the sol uses only water as solvent, without need of adding any organism such as alcohol. The preparation is simple, economic, environmental protecting. The prepared aqueous paint not only has high decorative, great adhesion and toughness of organic paint, but also has high rigidity, chemical resistance of inorganic paint, which can be used on surface of substrates of metal, glass, wood, plastic and in construction industry.

Owner:DALIAN JIAOTONG UNIVERSITY

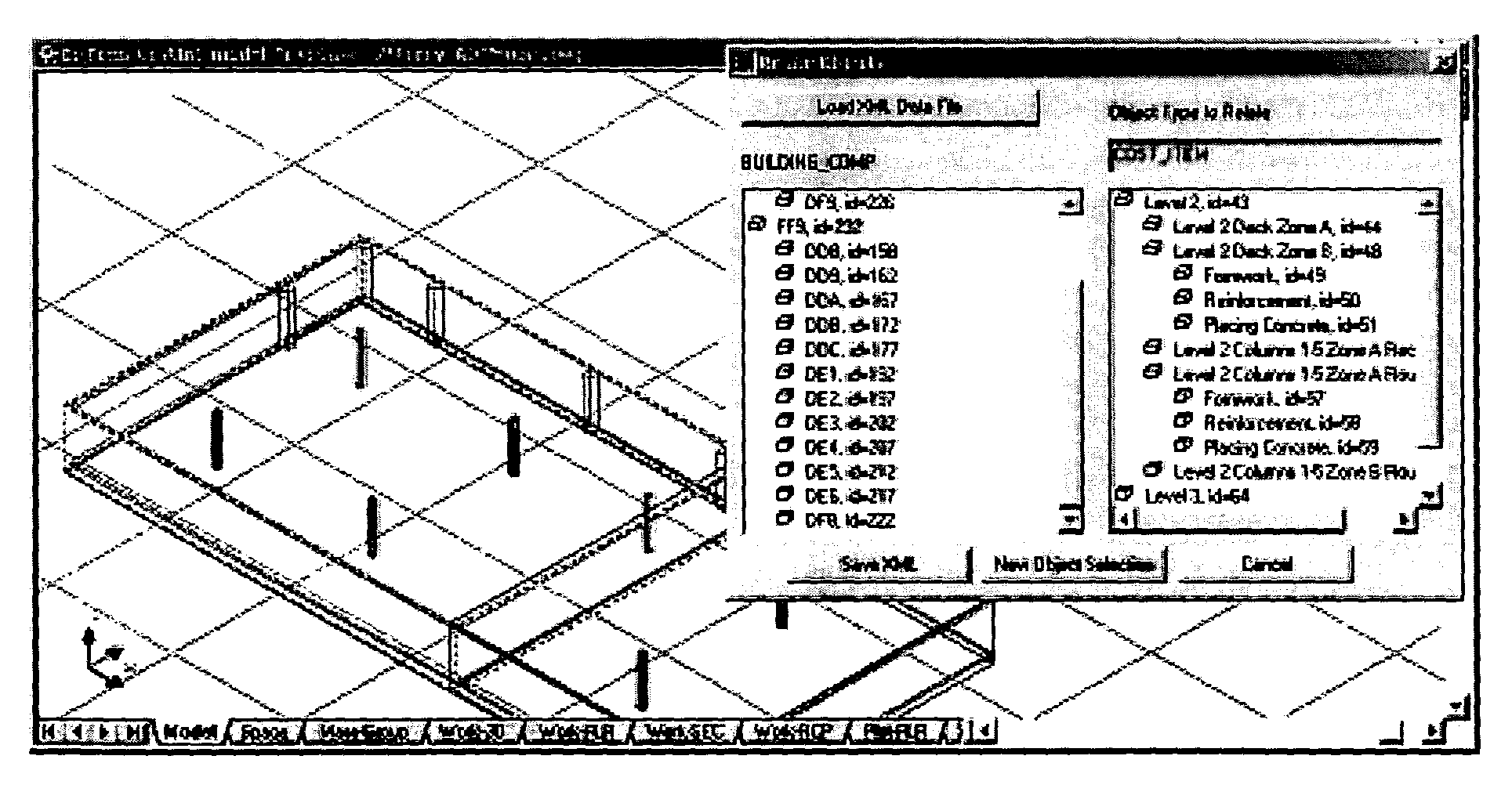

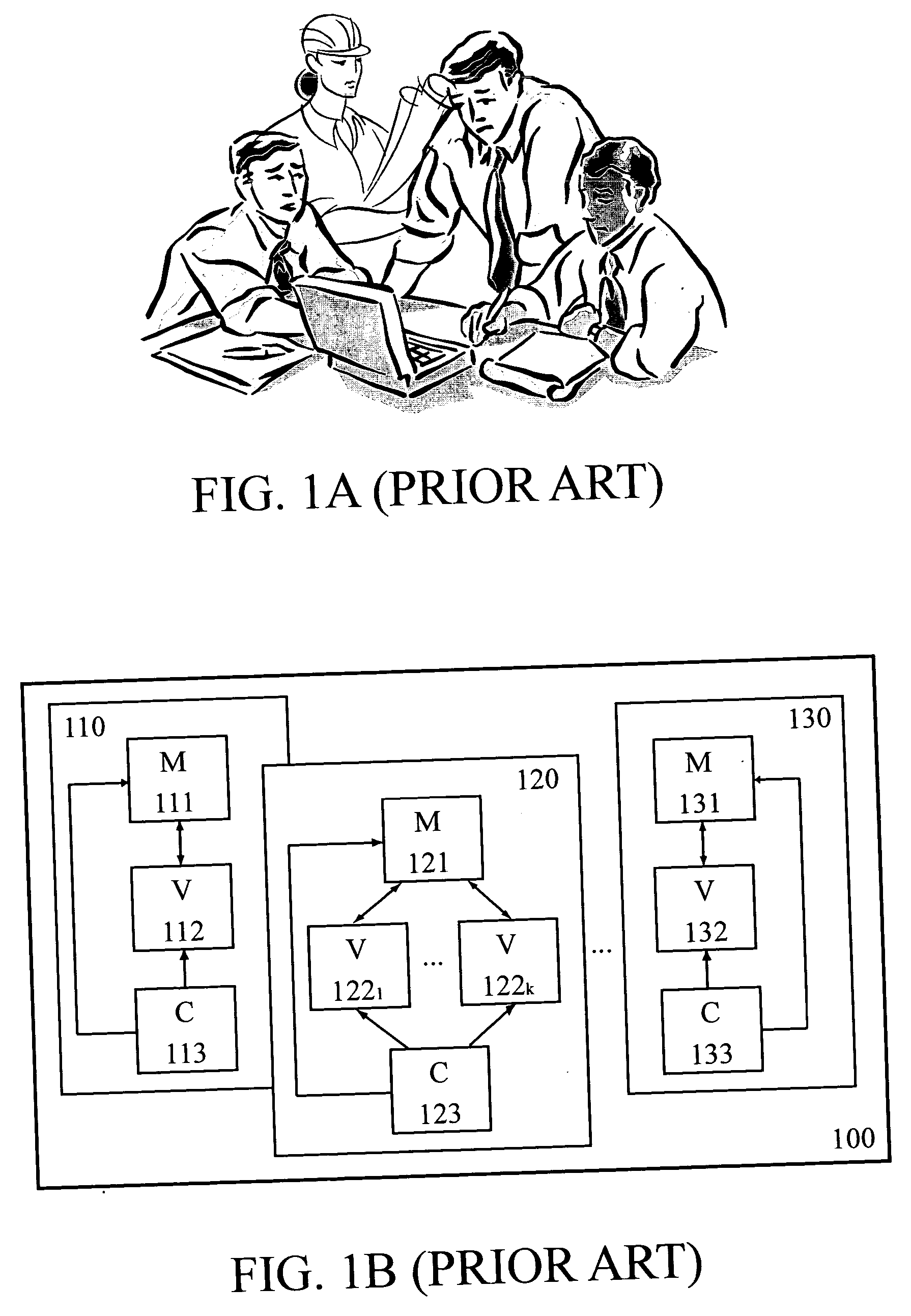

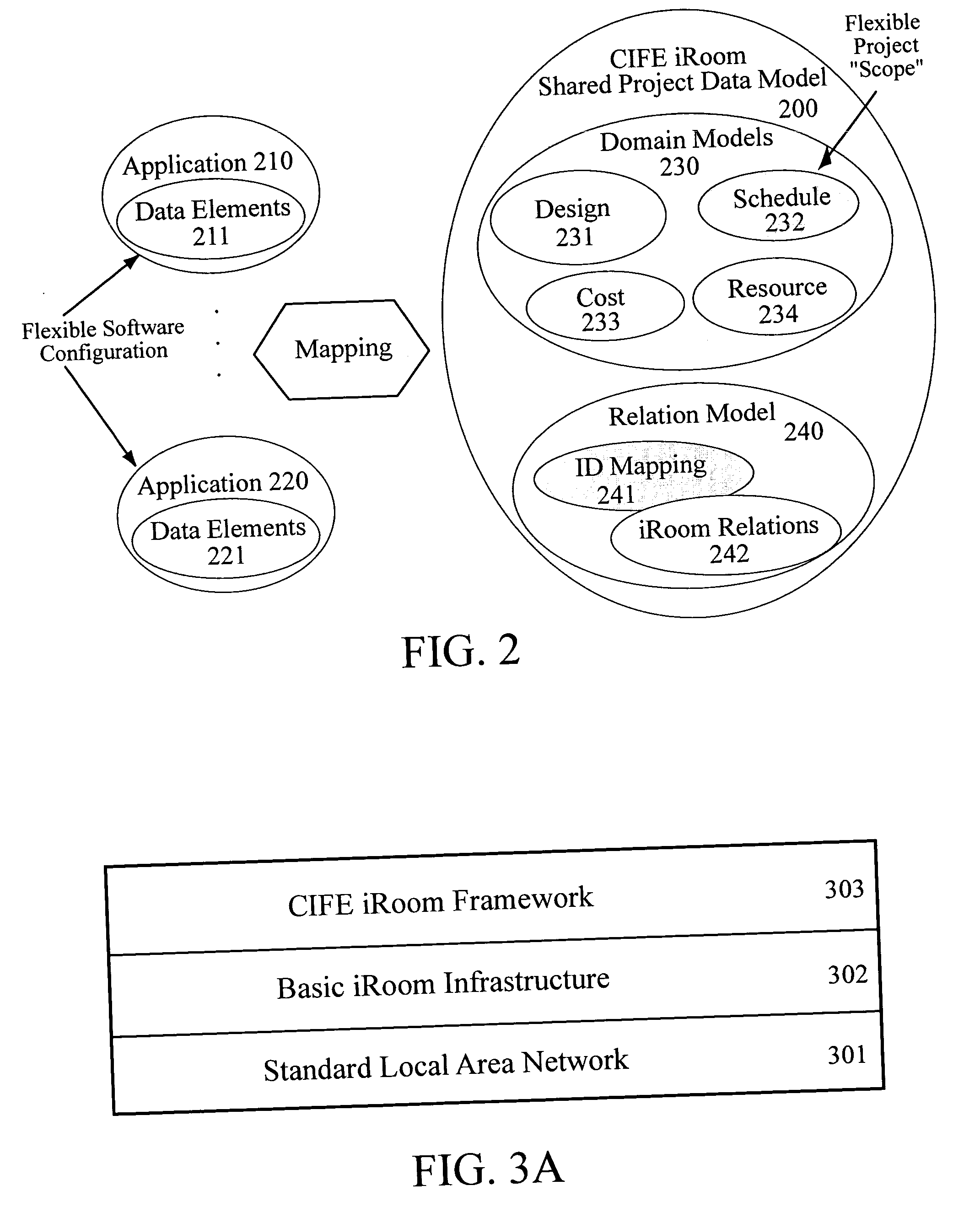

Visualization of commonalities in data from different sources

InactiveUS20050065951A1Improve visualizationData augmentationComputer aided designSpecial data processing applicationsViewpointsDisplay device

In a highly integrated computing environment having a collection of linked software and hardware that allows one or more users to readily structure, display and manipulate various information used to design and implement a large project, two classes of new software tools, viewers and controllers, are disclosed herein to support the construction industry and to enhance the simultaneous visualization of complex information sets on two or more interactive electronic displays. Information Viewers display table, tree, and document views of information representing different viewpoints and approaches of the same project. The Synchronizing Controller links the various, distributed applications to a common date, time, event, and the likes. The Information Viewers are also controllers that extract related data from different applications. The Universal Controller manages and organizes data and applications in the integrated computing environment. A project database containing only data shared among the multiple distributed applications is included.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

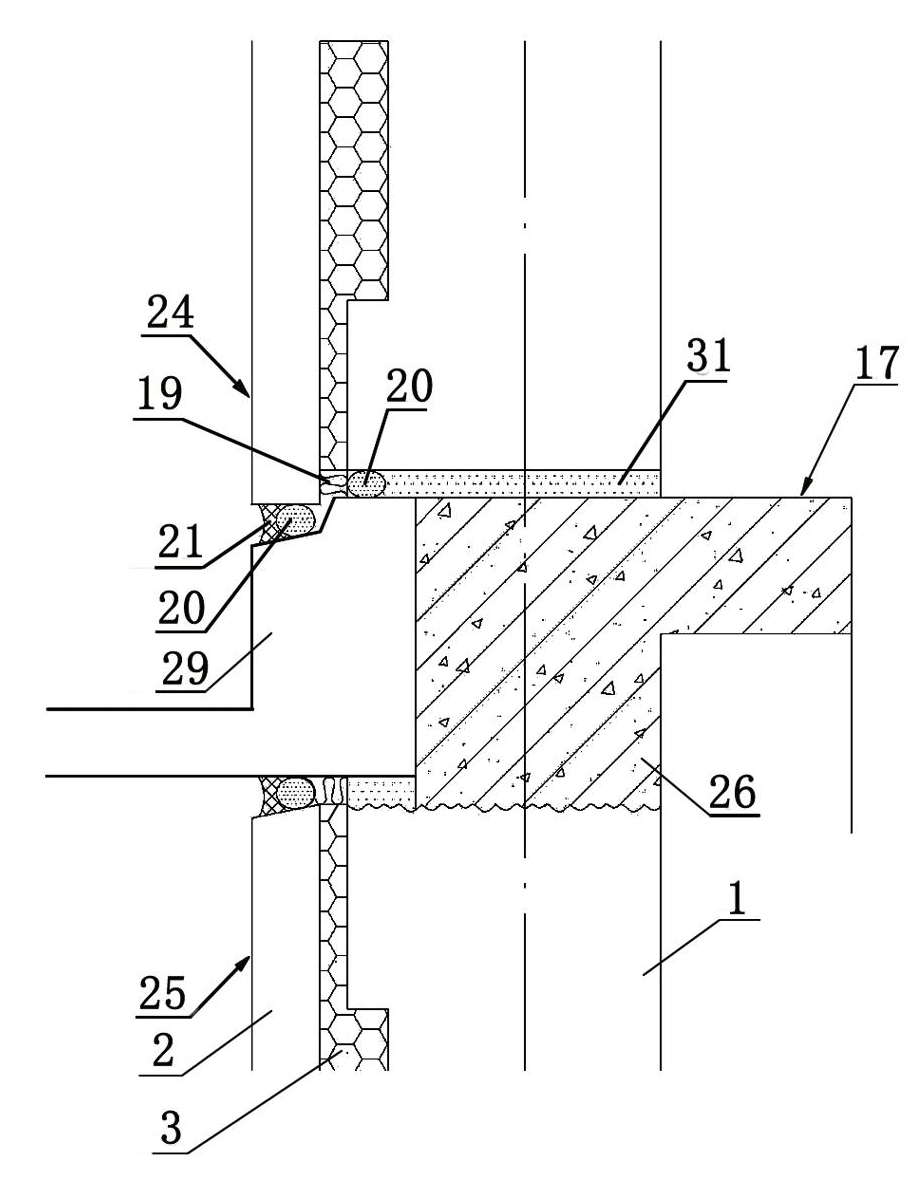

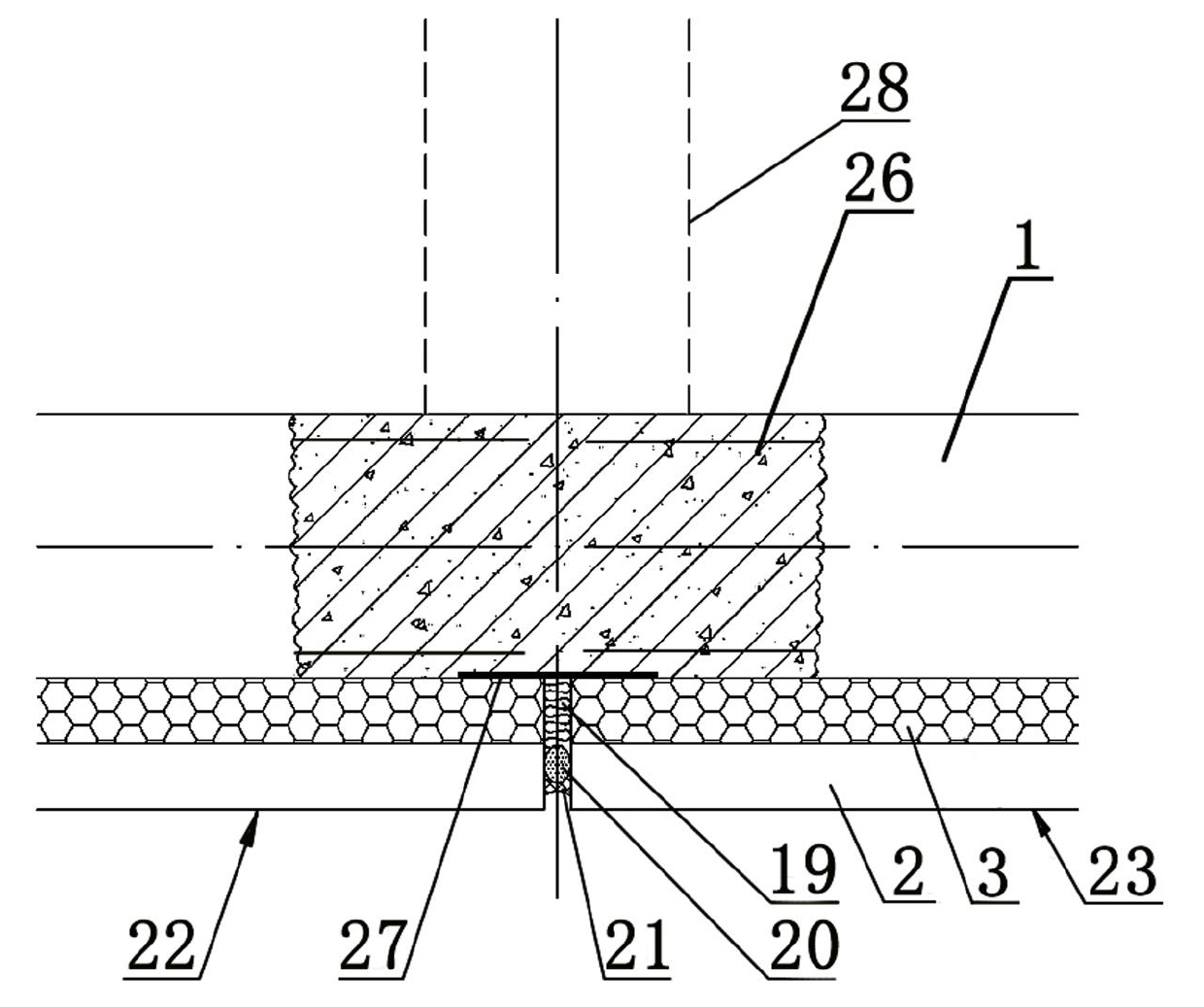

Assembled integral shear wall structure system and construction method thereof

ActiveCN101818527ALow costGuarantee the construction qualityWallsBuilding material handlingReinforced concretePolystyrene

The invention discloses an assembled integral shear wall structure system and a construction method thereof. Prefabricated composite wallboards are hoisted and assembled integrally at a construction site; a board body of the prefabricated composite wallboards comprises a structural layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; the insulating layer is an extruded polystyrene foam plastic board; steel meshes are arranged in the concrete of the protective layer; and anchor bolts in a dotted distribution are connected among the structural layer, the insulating layer and the protective layer. Vertical seams and horizontal seams of prefabricated composite walls adopt structural self-waterproofing, so that common quality problems such as leakage and cracks and the like in a traditional process are solved. The prefabricated composite walls simplify construction processes, speed up the construction, and lower the construction cost. Furthermore, products prefabricated in a factory have uniform specifications and unified quality, so that the construction quality of a building construction can be sufficiently guaranteed; the industrialization, standardization, and generalization of the building walls are realized; and the products can be widely applicable to the construction of reinforced concrete buildings in the construction industry.

Owner:华筑(辽宁)建筑工程设计有限公司

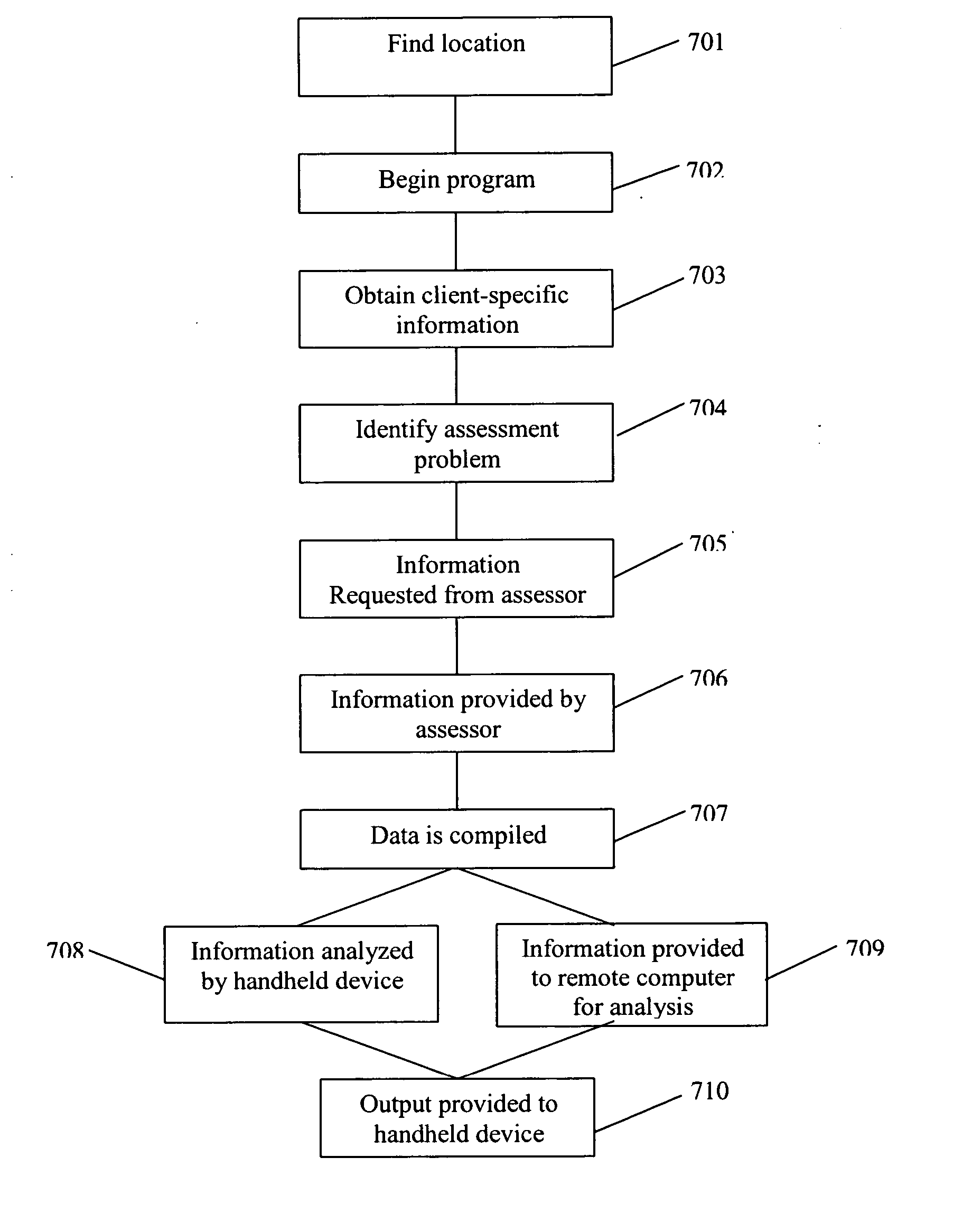

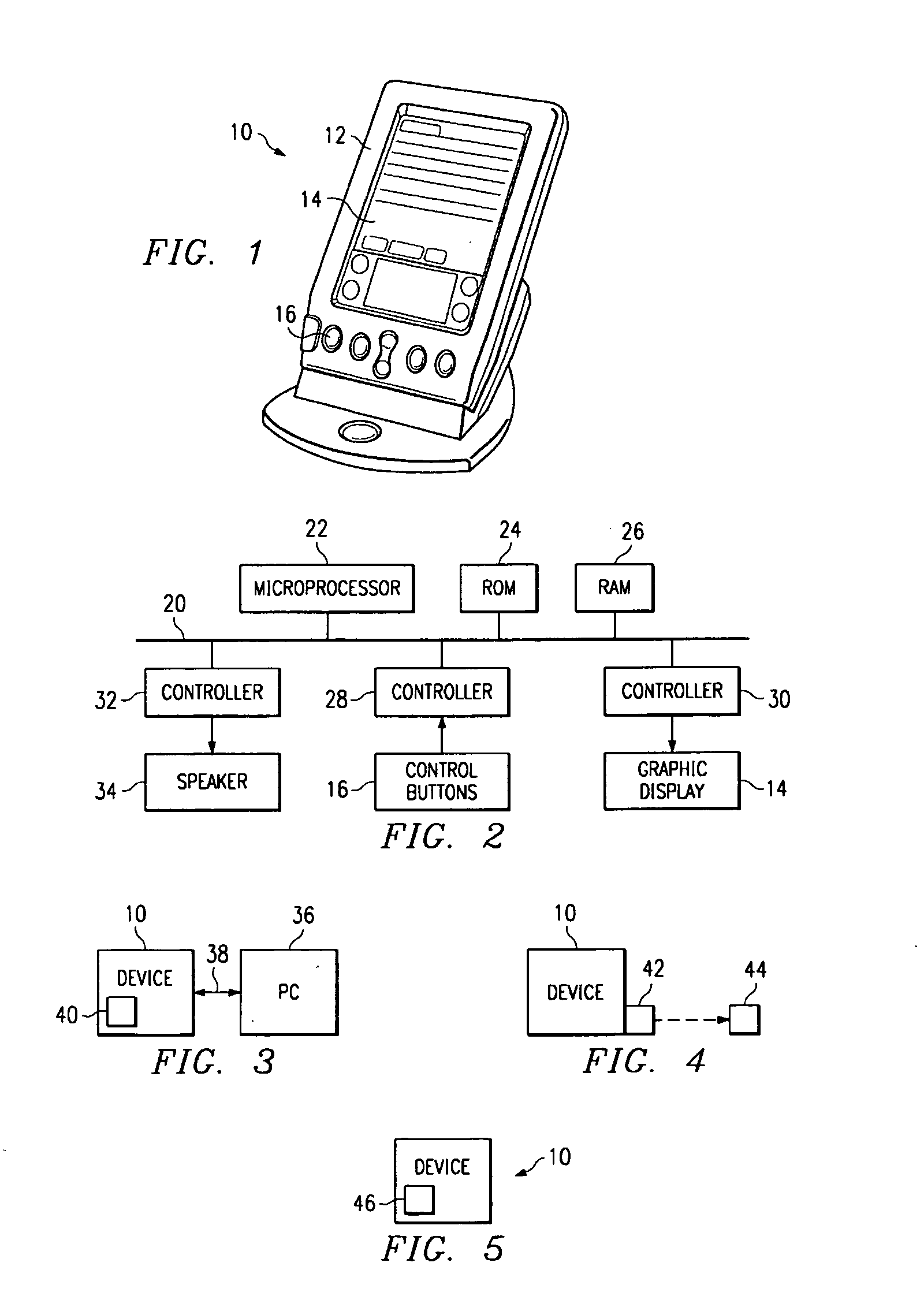

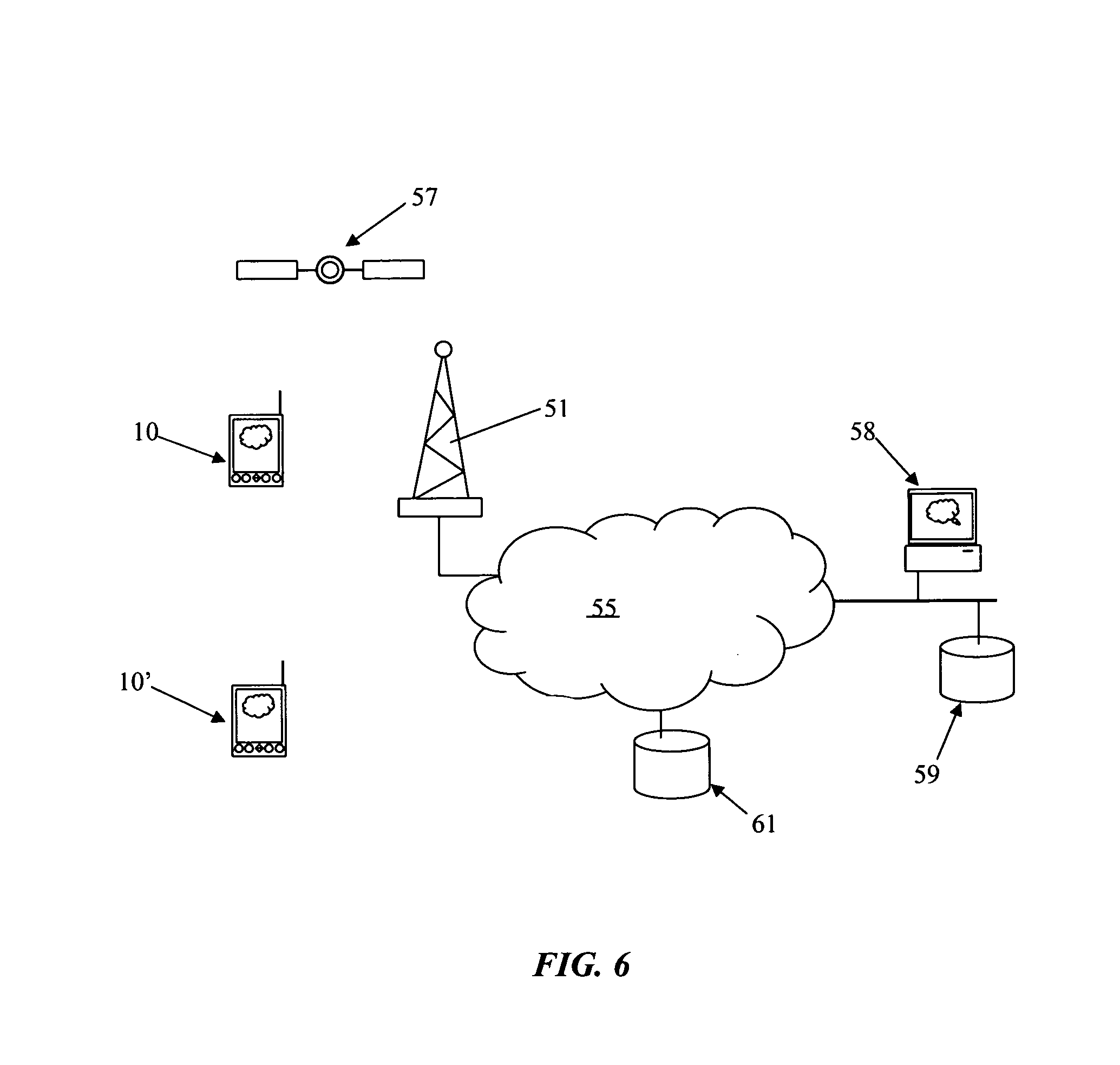

Conducting field operations using handheld data management devices

InactiveUS20070095887A1Facilitate real-time accessElectric/electromagnetic visible signallingSubstation equipmentData synchronizationHand held

Providing users in the field includes portable access to industry-specific programs, instructions and data. Field data synchronization and / or delivery is enabled using wireless capabilities resident in handheld personal computing devices. Data can be synchronized with a server over a network using wireless radio transmission, or directly to a computer workstation using wireless infrared or radio transmission or connected physical connection. Two-way communications is provided between remote computers and handheld data management devices to facilitate real-time access to remote programs, assistance and / or information related to the field assessment being undertaken by using a handheld data management device user. Field data management includes activities for at least one of: construction industry project analysis, HVAC system analysis, project management, equipment readiness inspection, troubleshooting, inventory tracking, inventory ordering, sales (e.g., providing cost estimates to customers), customer invoicing, conducting legal investigations, field data collection, and multi-user remote function coordination.

Owner:FLEET CONNECT SOLUTIONS LLC

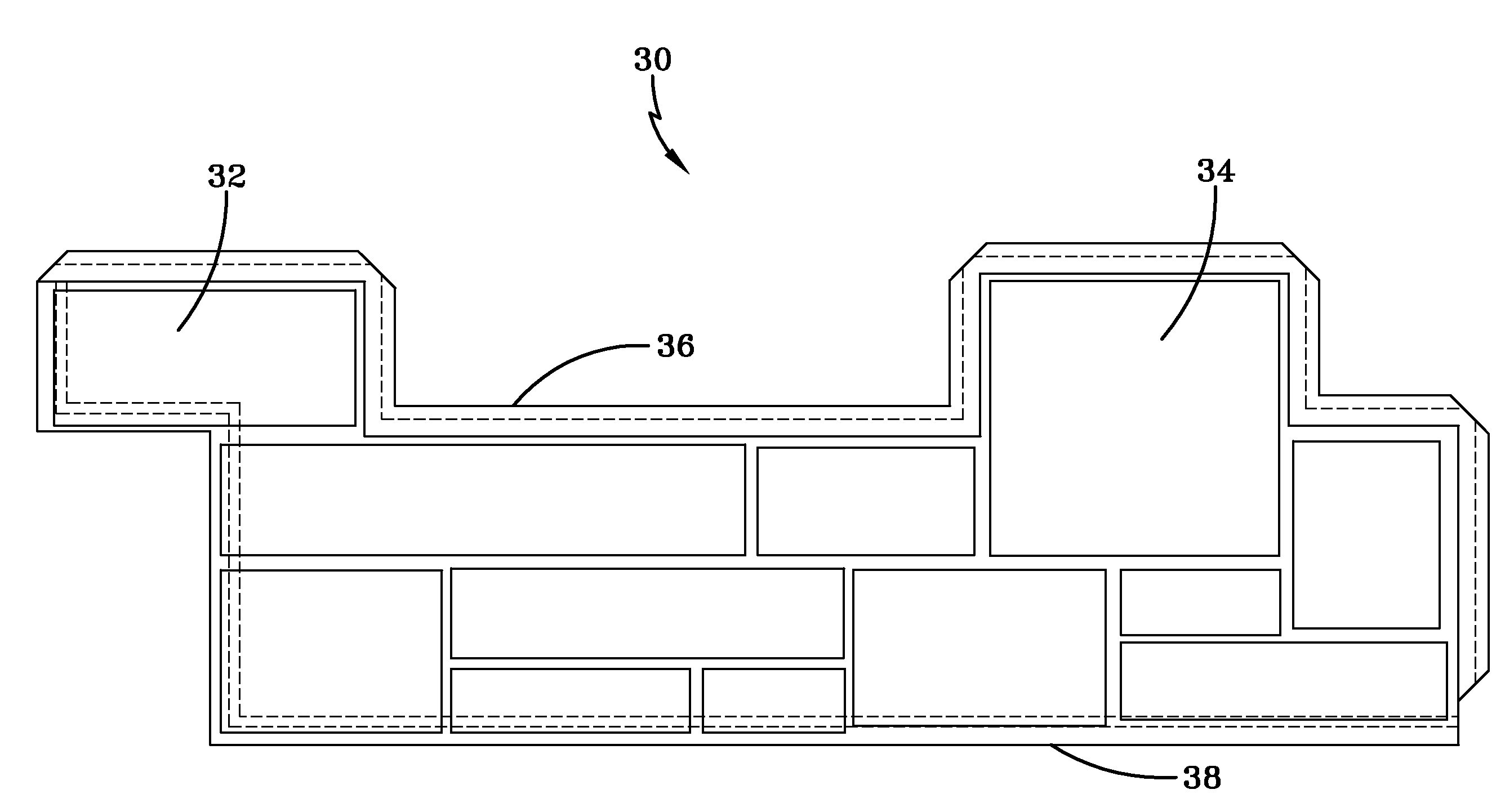

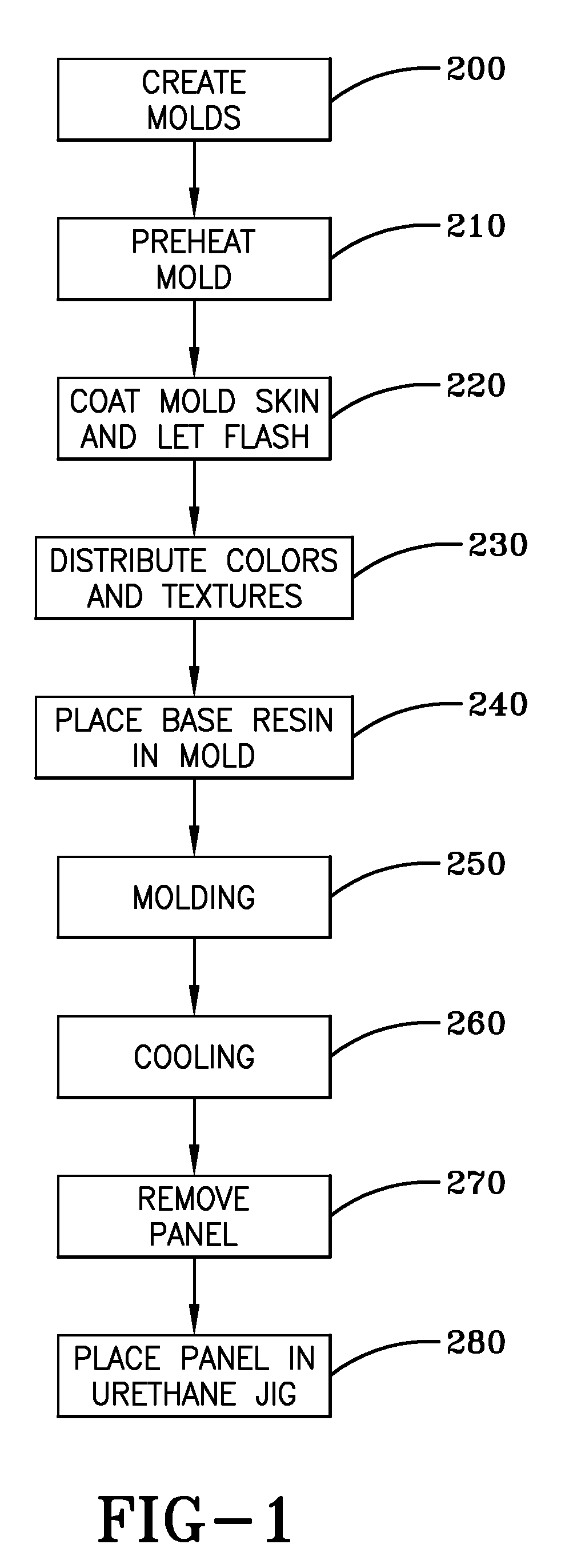

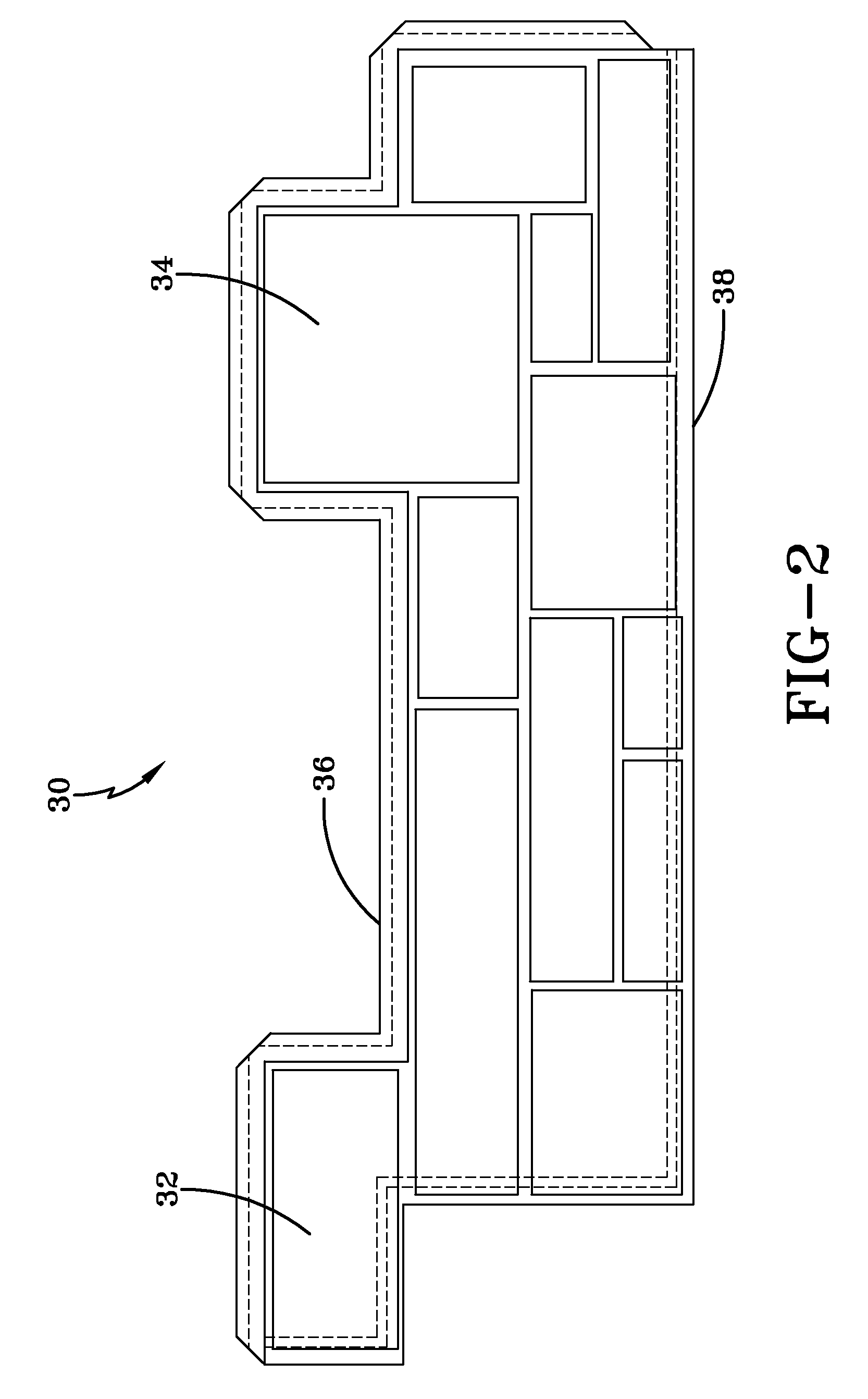

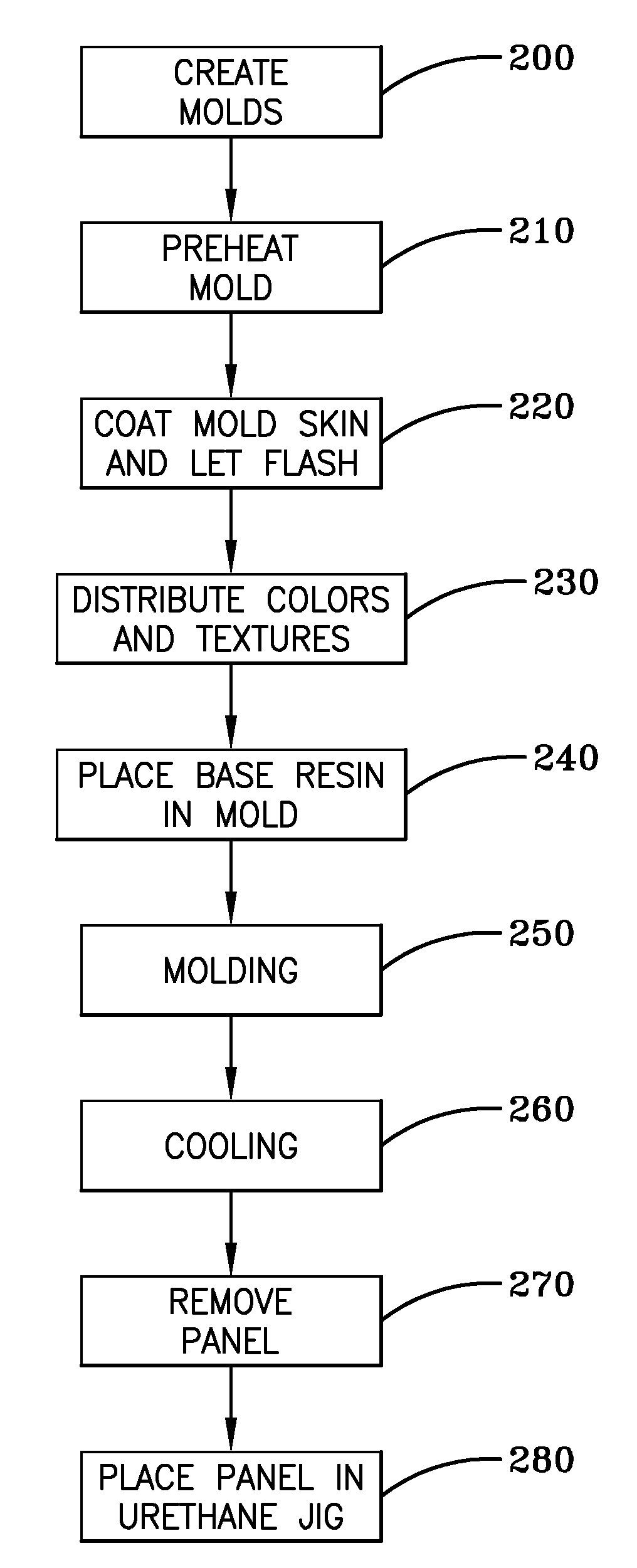

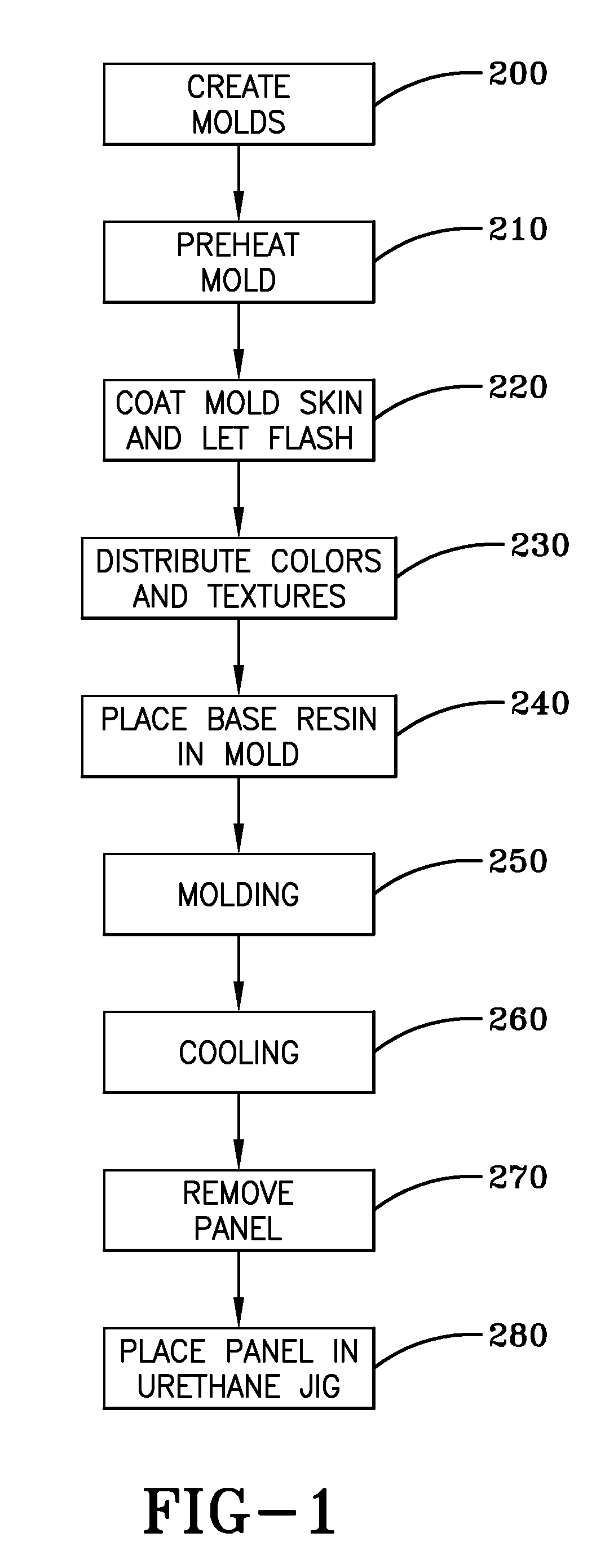

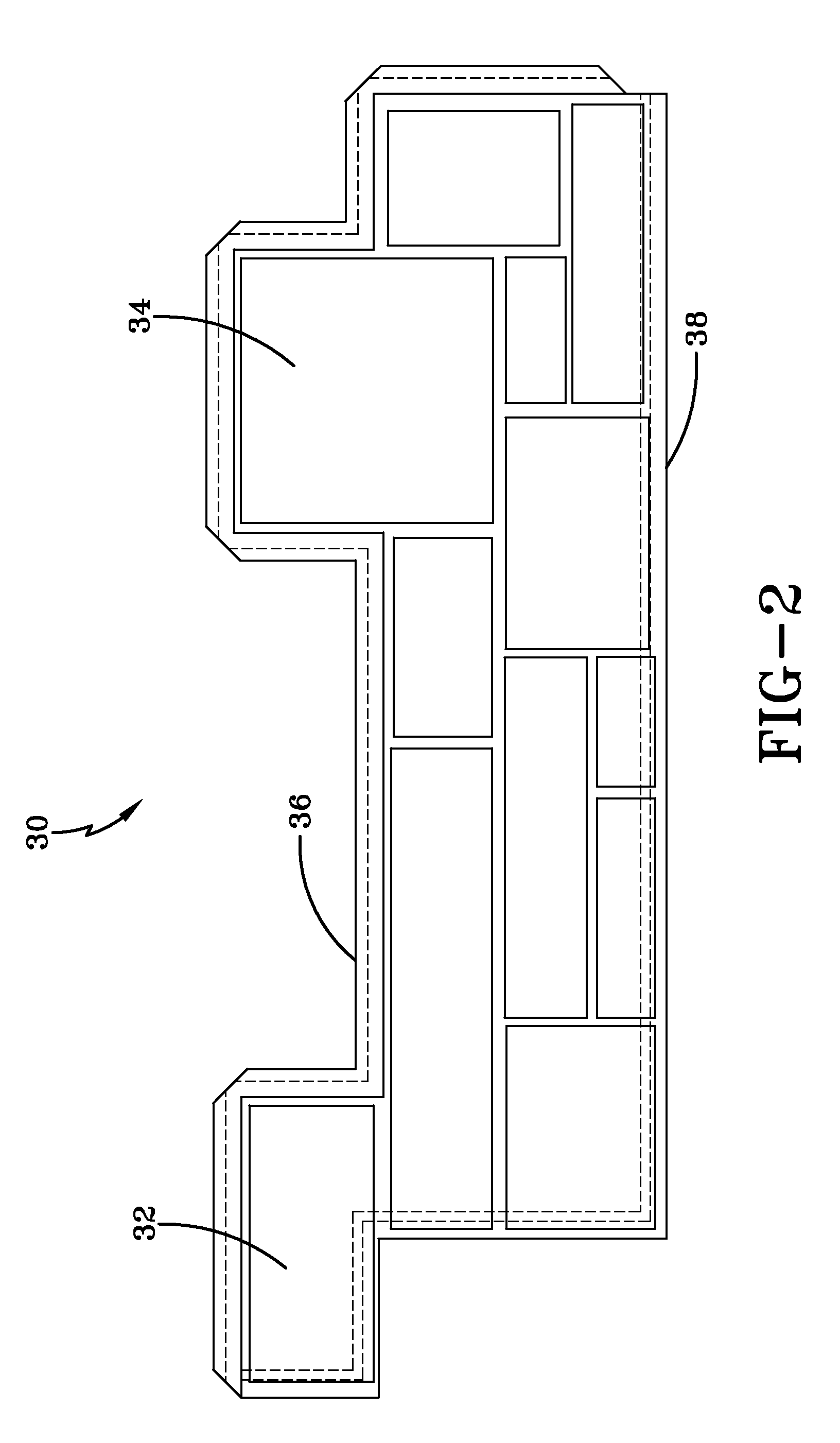

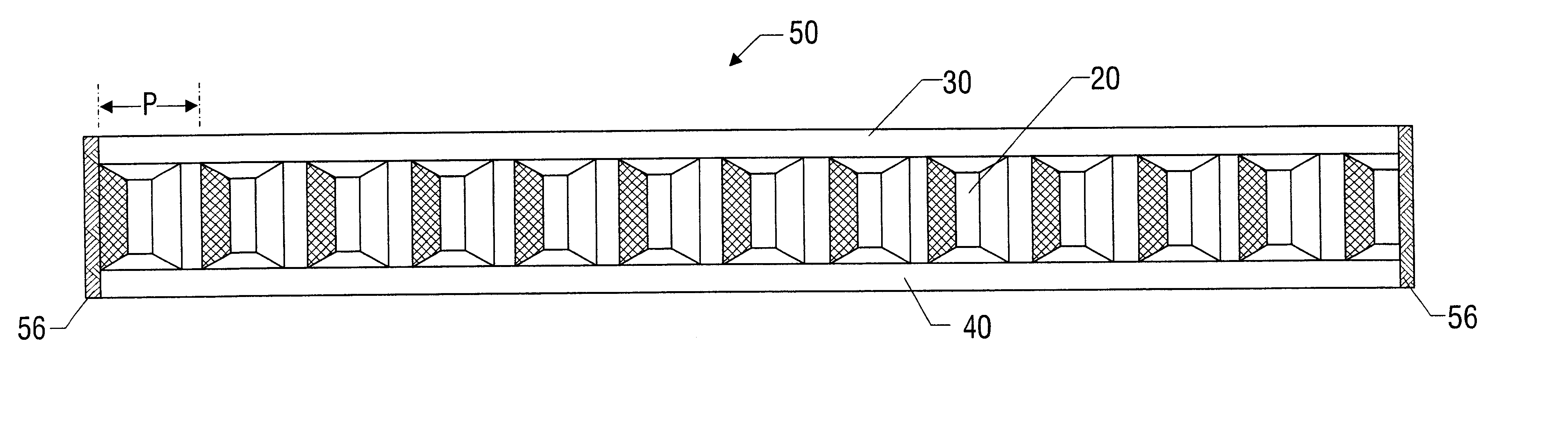

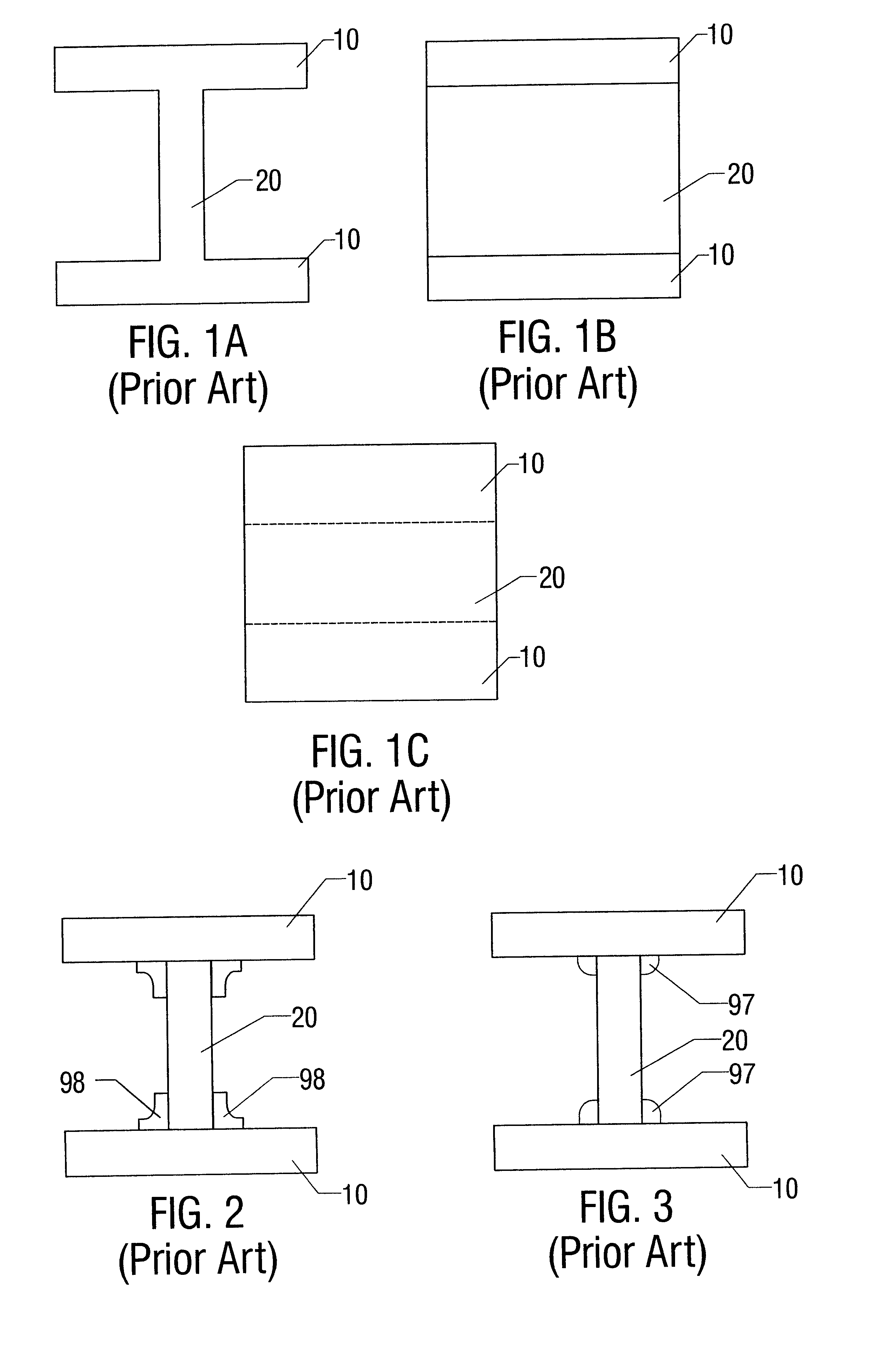

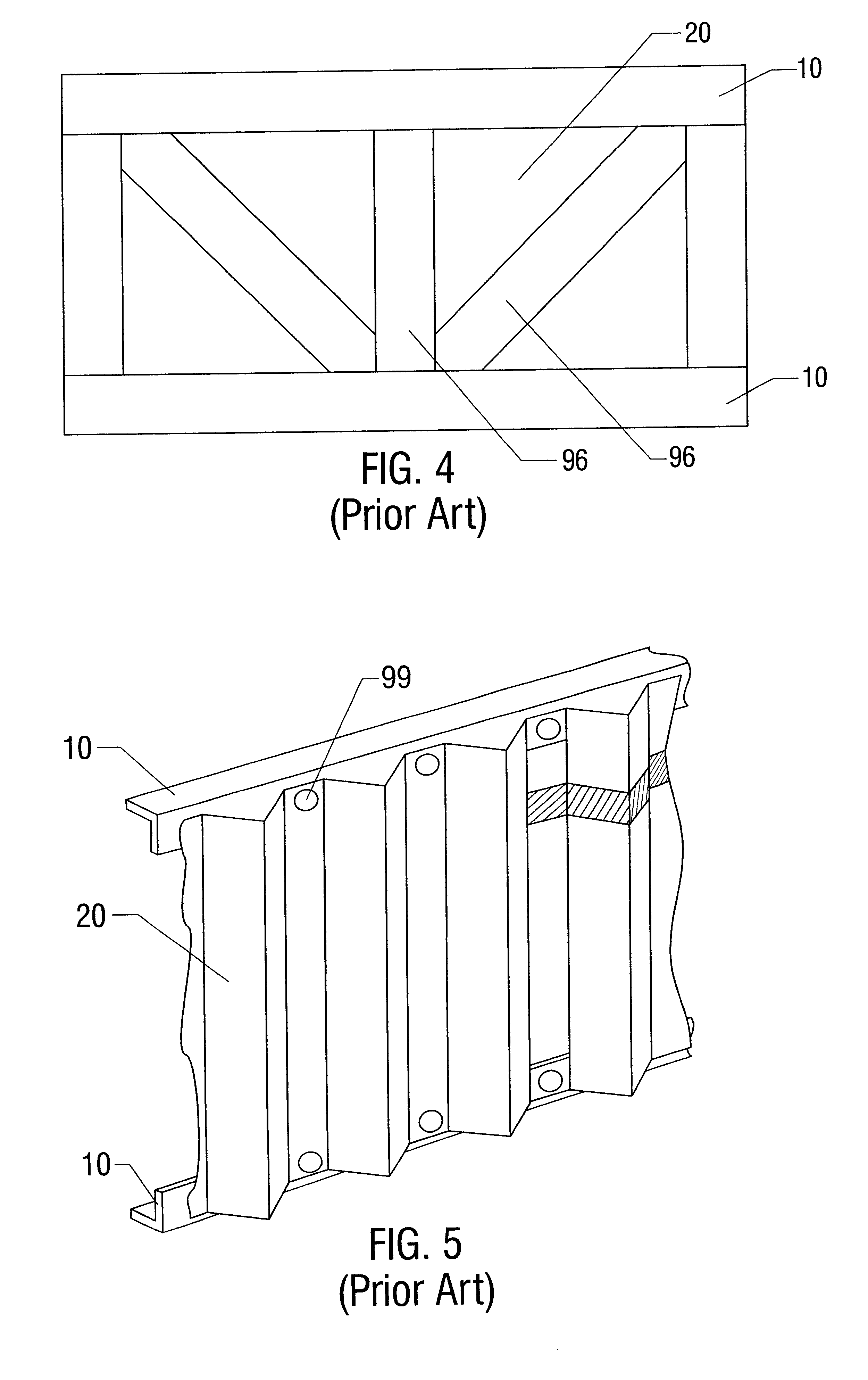

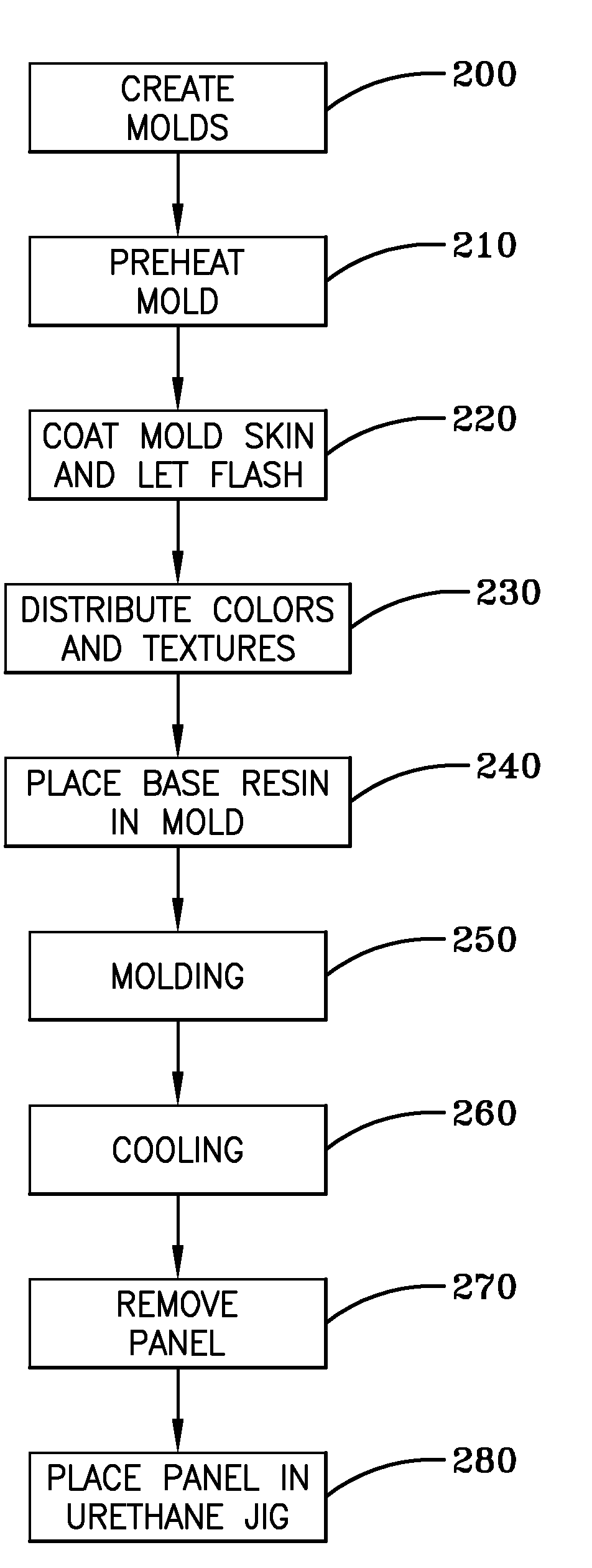

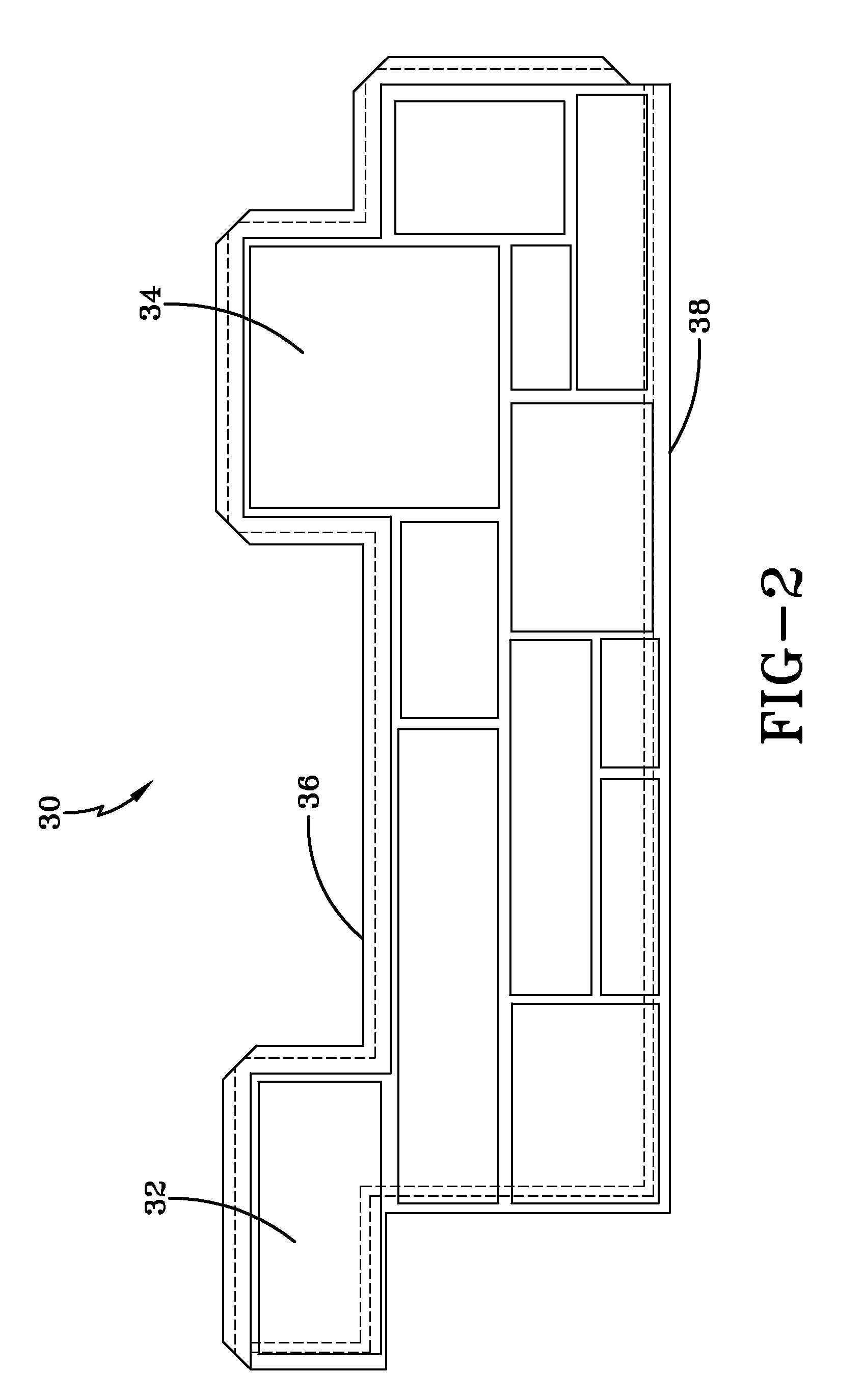

Method of manufacturing simulated stone, brick, and masonry panels and wall structures

InactiveUS20070227087A1Minimize limitationEasy to assembleCovering/liningsNatural patternsBuilding productBrick

Simulated stone, masonry and brick textured products such as siding panels are obtained when specially selected materials are properly admixed and formed via molding techniques. For instance, exemplary methods of manufacturing embodiments of panels, wall structures, and other products that may have contoured and textured surfaces and may simulate the appearances of conventional building or construction materials including, but not limited to, stone, bricks, masonry, concrete, stucco, wood, other conventional building materials, and combinations of any of these materials are disclosed. Such products are manufactured from suitable molds according to a prescribed process methodology using synthetic polymeric materials in addition to other materials such as coloring and texturing materials. Prerequisite surface textures may be produced that effectively simulate actual stone, masonry and brick panels. Methods described herein may enhance the manufacturing, structure, appearance, assembly, or installation of synthetic building or construction products. In particular, exemplary embodiments include panels, wall structures, and other panel assemblies that may have contoured or textured surfaces to simulate the appearances of other building or construction products. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:EXTERIOR PORTFOLIO

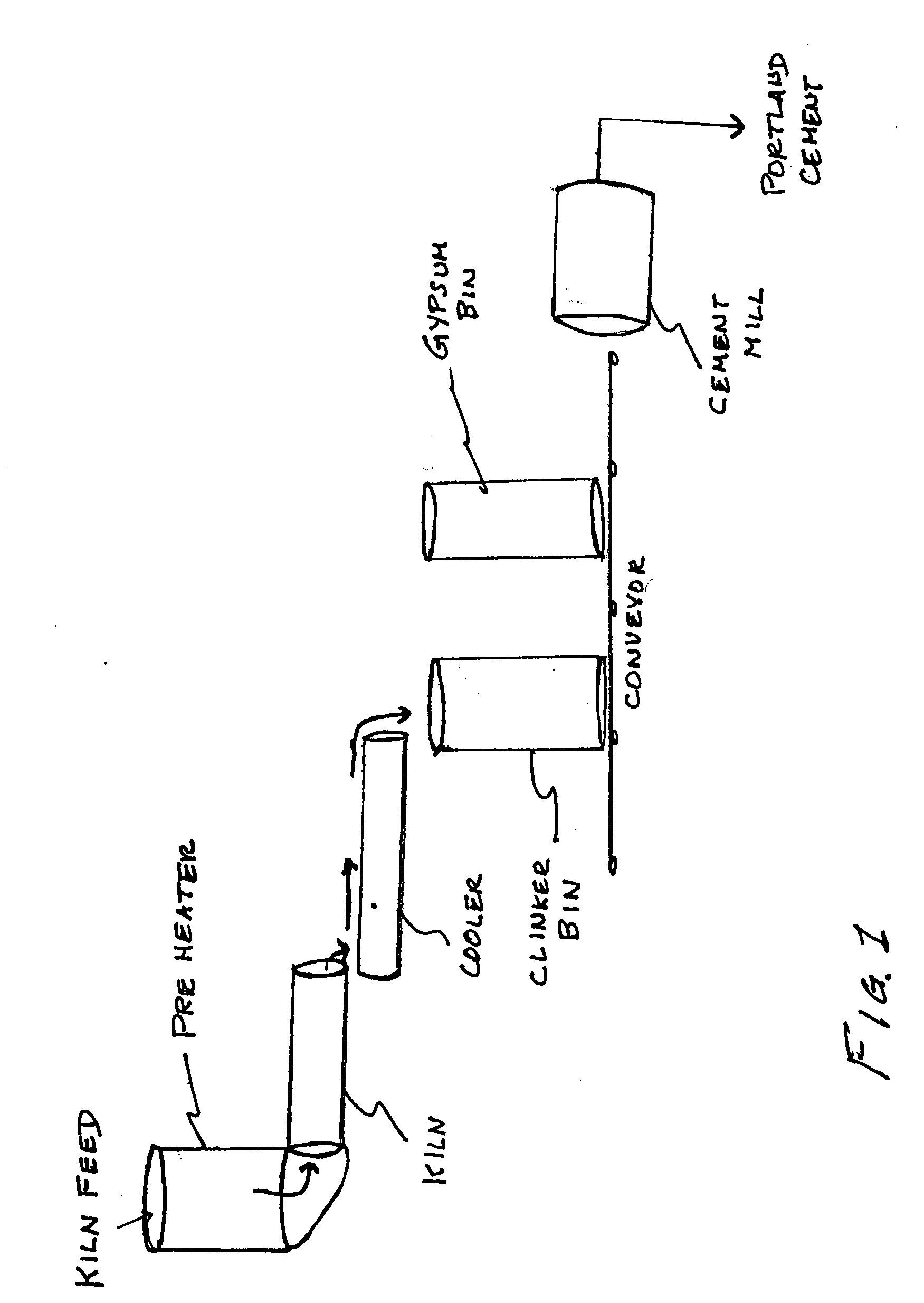

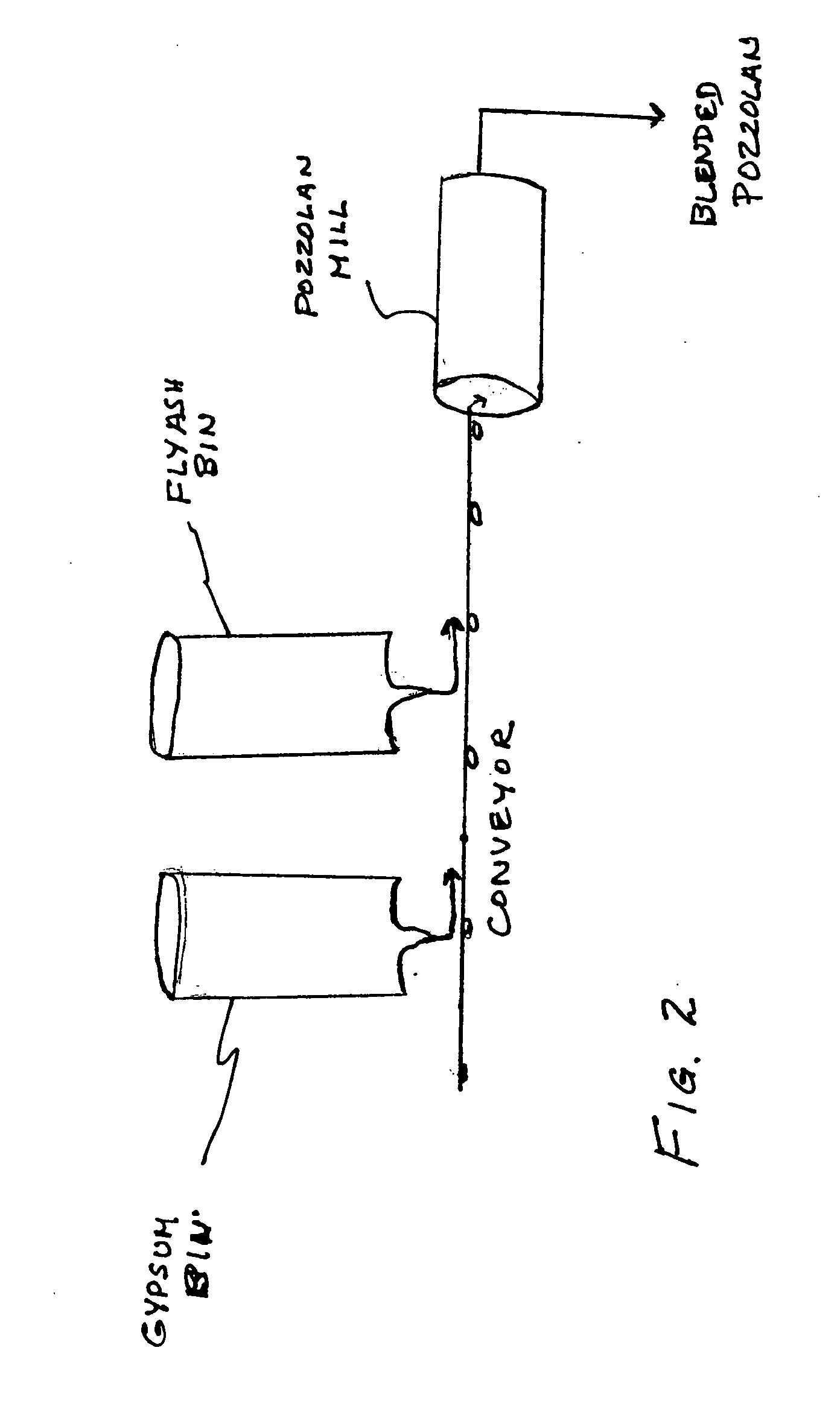

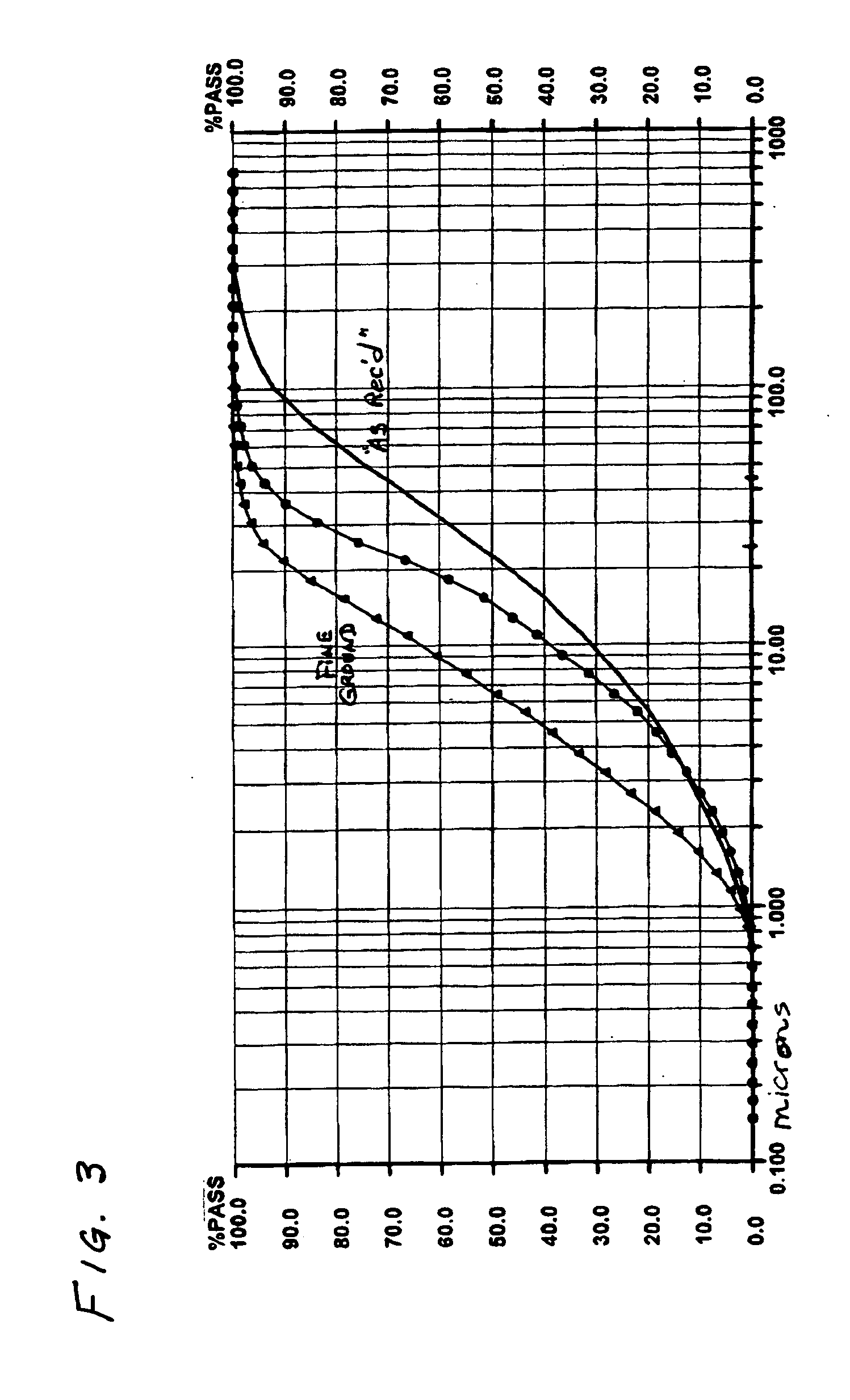

Blended fly ash pozzolans

InactiveUS20060201395A1Improved sulfate resistanceReduce penetrationSolid waste managementVolcanoCoal

Novel premium blended pozzolans for use with hydraulic cement are created by intergrinding an ASTM Class F or Class C coal fly ash and a source of calcium sulfate, such as gypsum, so that the resultant mixture has a fineness of at least 90% passing through a 45 micron sieve. The novel mixture meets the requirements of ASTM C 618. Alternately, a novel concrete composition can be formed using the blended pozzolan with a hydraulic cement, aggregate and water so as to produce a concrete having improved strength, ASR mitigation, improved sulfate resistance and lowered permeability. The novel pozzolans not only reduce production costs by decreasing fuel and raw material consumption per ton of cement, but they also use by-product waste materials from another industry to create a premium product for the construction industry.

Owner:ASH GROVE CEMENT

Lignin-epoxy resin composite material and preparation method thereof

The invention discloses a lignin-epoxy resin composite material and a preparation method thereof, relates to a lignin-polymer composite material and a preparation method thereof, and aims to solve the conventional problem of low effective utilization rate of lignin. The lignin-epoxy resin composite material uses the lignin as a substrate; epoxy resin, a curing agent, a toughening agent, and the like are evenly blended with the lignin; and through the processes of pre-pressing, hot-pressing and curing molding, the lignin-based composite material is obtained. The lignin-epoxy resin composite material disclosed by the invention has the advantages of little water absorption, good mechanical performance, degradability, and the like, is suitable for manufacturing floor boards, wall protection boards, construction formworks, door-window profiles, fences, guardrails, louvers, roof boards, and the like in the construction industry, can be used for manufacturing inner decorative boards of automobile doors, seat backing boards, automobile roof lining, and the like in the automobile industry, and can also be used in the fields of the packaging and transportation industry, the furniture industry, office articles, sports facilities, and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

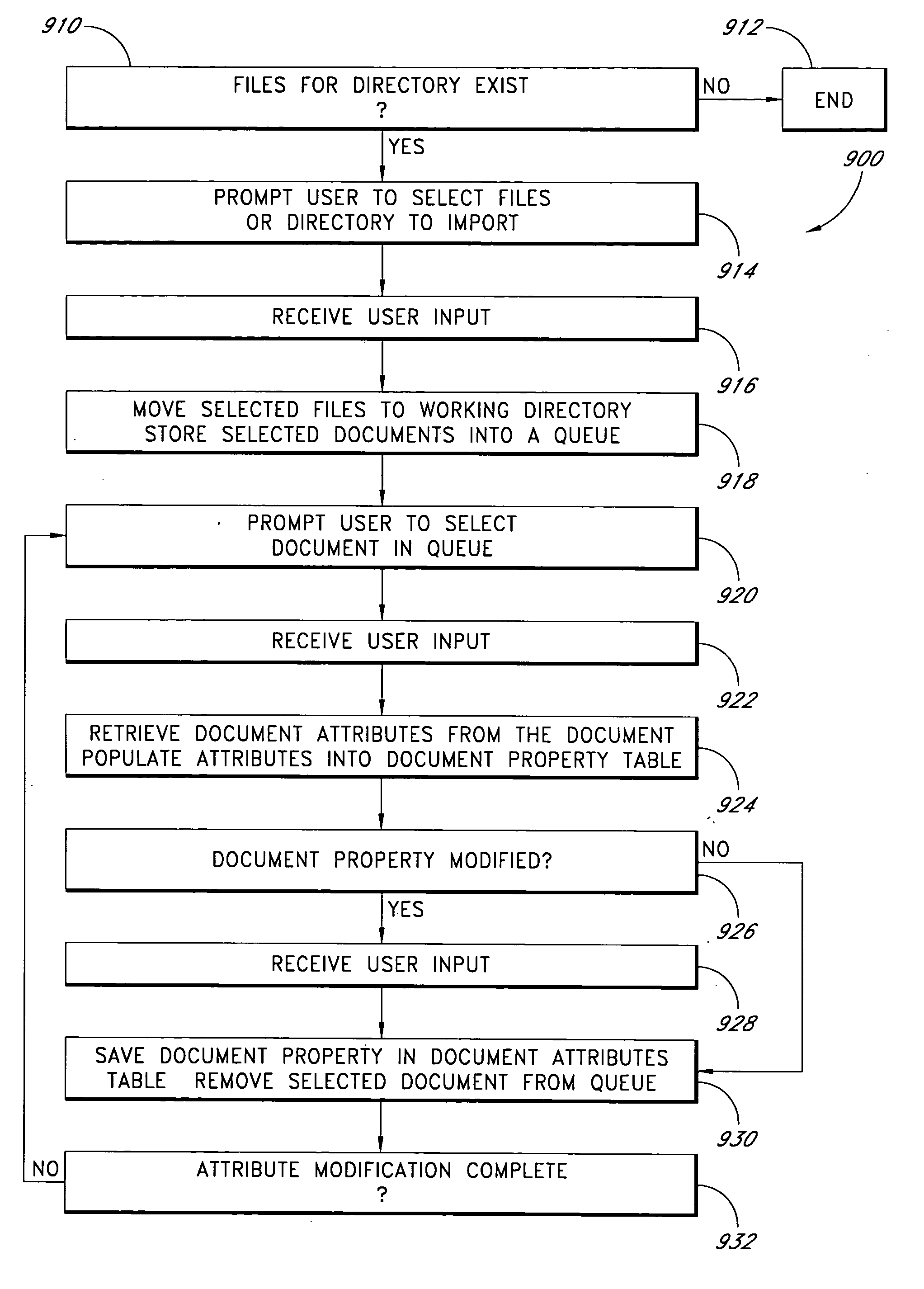

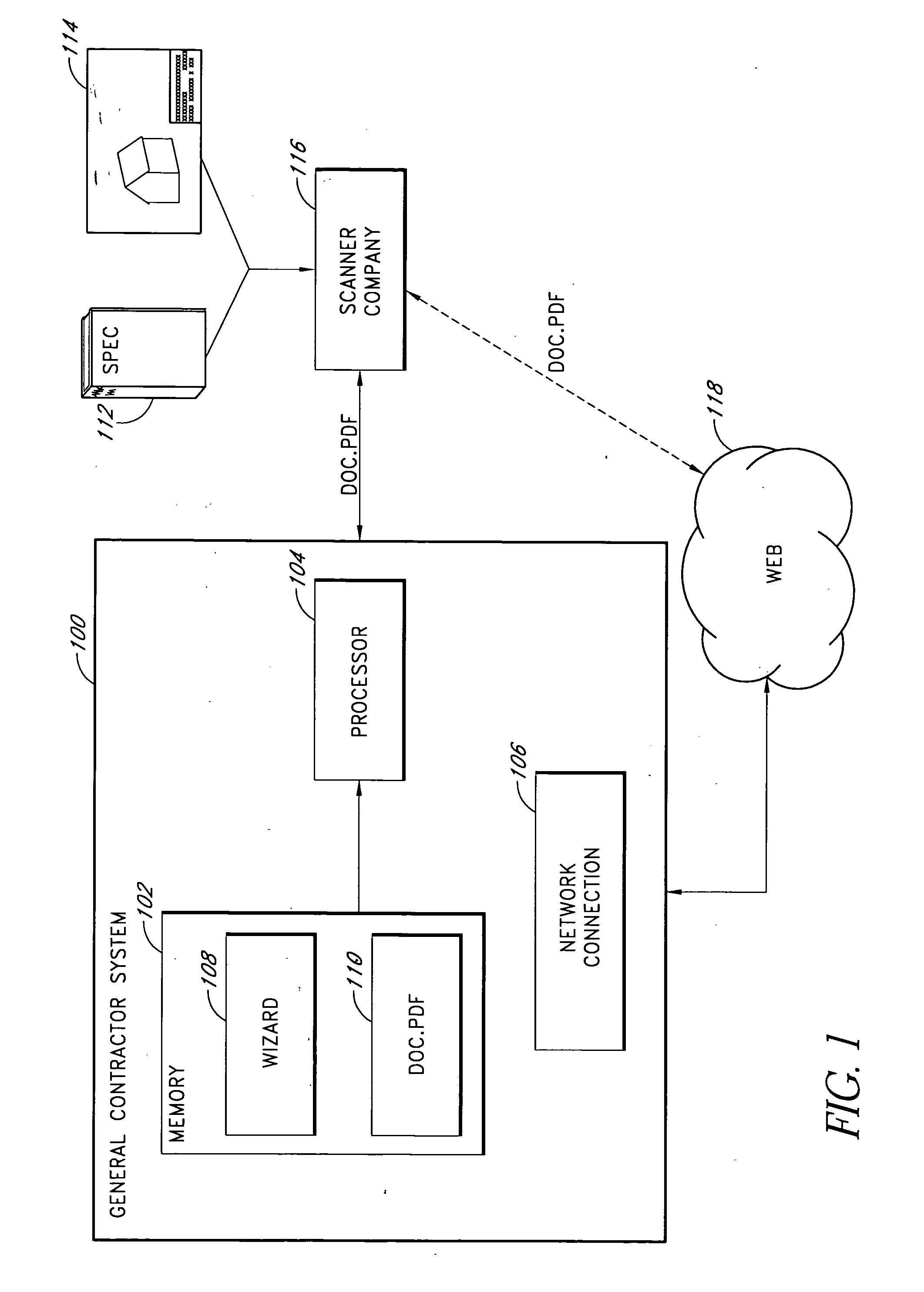

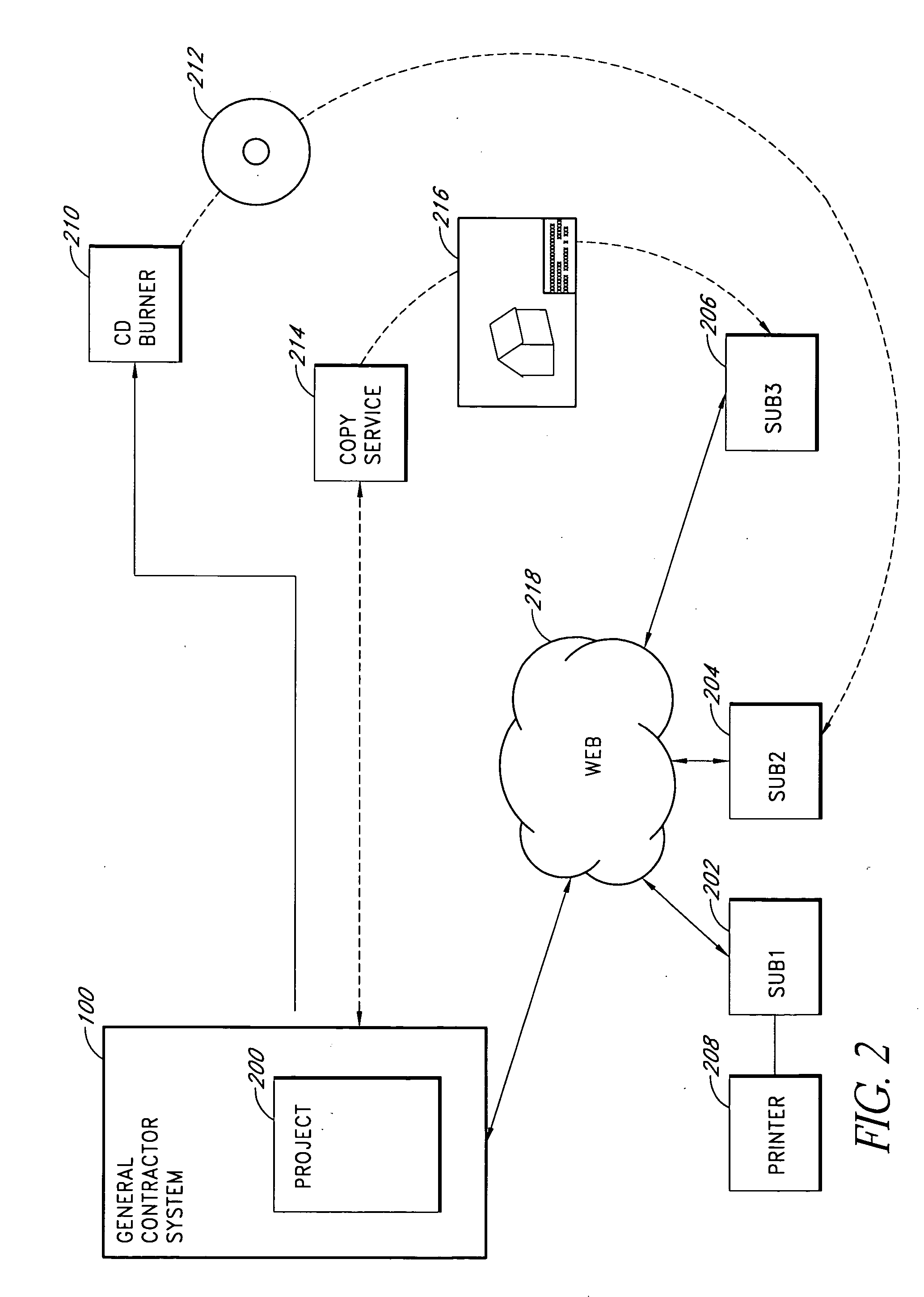

Electronic document management system for the construction industry

InactiveUS20050039115A1Efficient and straightforward creationAvoid dependenceForecastingOffice automationPaper documentDocument preparation

Embodiments of the invention include a document management system for the construction industry that organizes projects into accessible documents in an online computer network, such as the Internet, or computer readable media, such as an optical disk or other media. In one embodiment, the system includes a software utility for generating job-specific websites. Subcontractors, vendors, and the like, accessing the website can gather information useful in the submission of construction bids to the general contractor for all or a portion of the construction.

Owner:GORDON & WILLIAMS

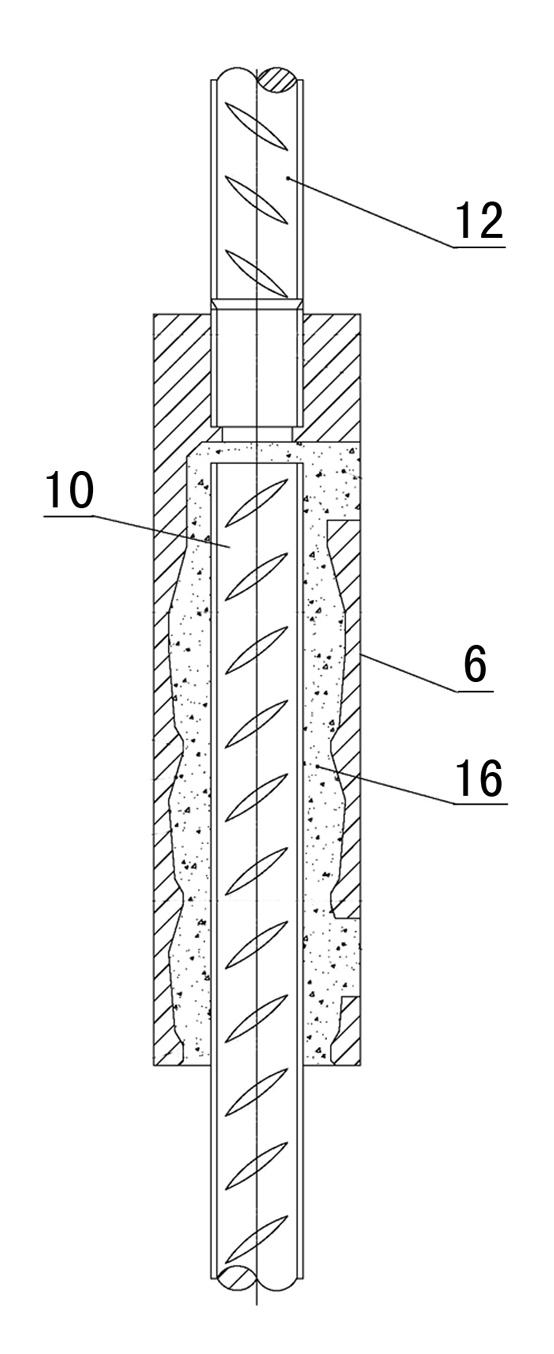

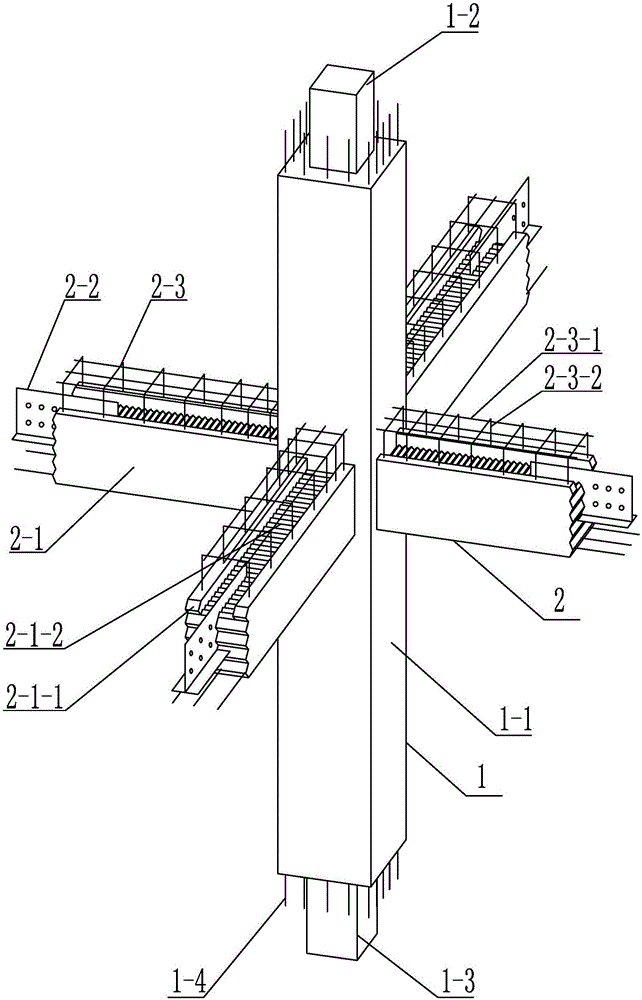

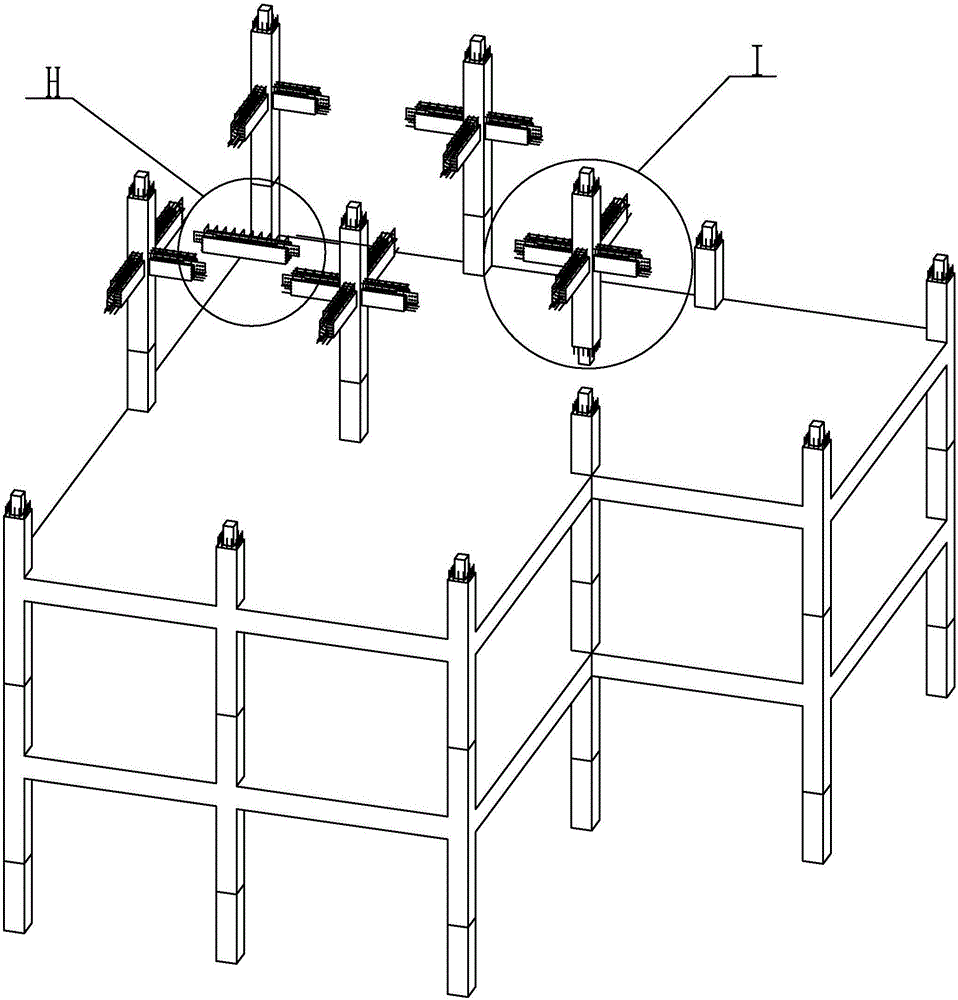

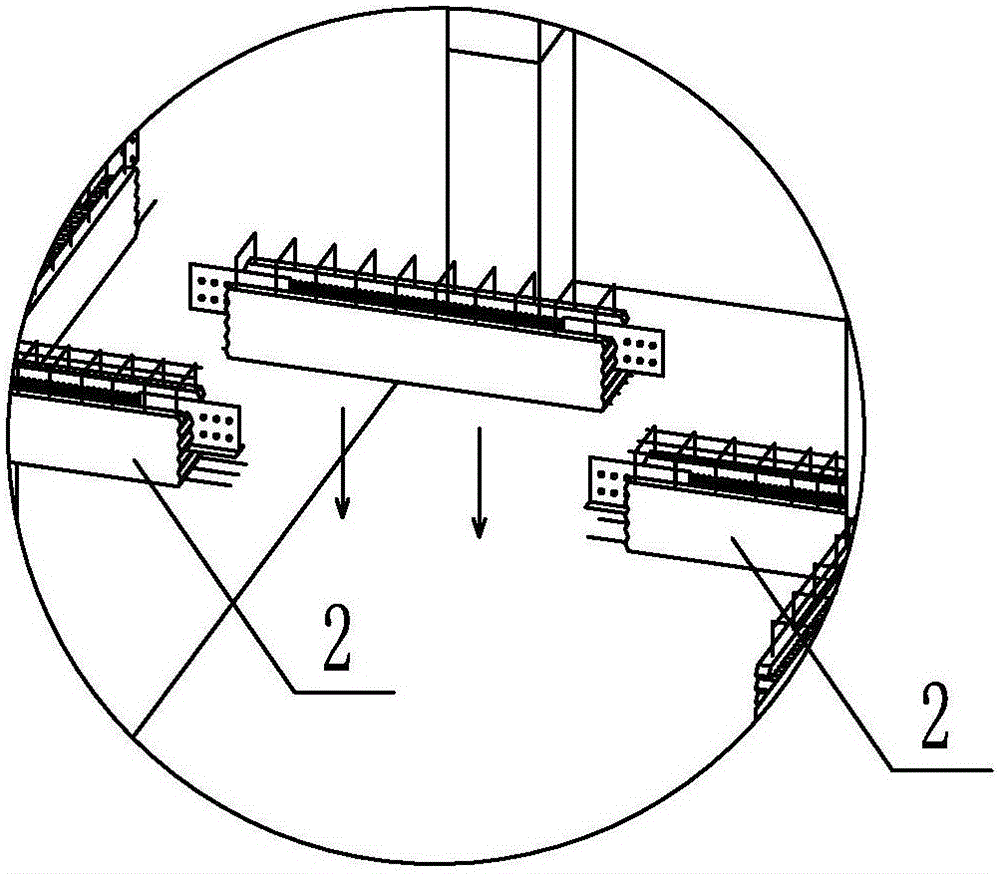

Single-layer prefabricated assembly type reinforced concrete beam-column joint

The invention relates to a prefabricated reinforced concrete beam-column joint, in particular to a single-layer prefabricated assembly type reinforced concrete beam-column joint. In order to solve the problem that the connection integrity of existing prefabricated beams and prefabricated columns is hard to guarantee, the prefabricated joint for one-piece casting manufacturing of a column section and part of beam sections is provided according to the concept of the point of inflection. The single-layer prefabricated assembly type reinforced concrete beam-column joint is formed by overall manufacturing of a vertical column section (1) and joint superposed beam sections (2) in a factory for prefabrication. A manufacturing method comprises the steps of beam-column longitudinal bar and stirrup binding, connector pre-burying, formwork erecting and concrete pouring and curing. The height of the vertical column section (1) of the joint is 1 / 2 of the storey height, and the length of each joint superposed beam section (2) is 1 / 3 of the span of adjacent columns. The vertical column section (1) comprises a pouring section (1-1), a concrete filled steel tube connector (1-2), a steel tube connector (1-3) and column section longitudinal bars (1-4). Each joint superposed beam section (2) comprises a groove-shaped pouring section (2-1), inverted-T-shaped structural steel connectors (2-2) and a reinforcement cage framework (2-3). The single-layer prefabricated assembly type reinforced concrete beam-column joint is applied to the construction industry.

Owner:HARBIN INST OF TECH

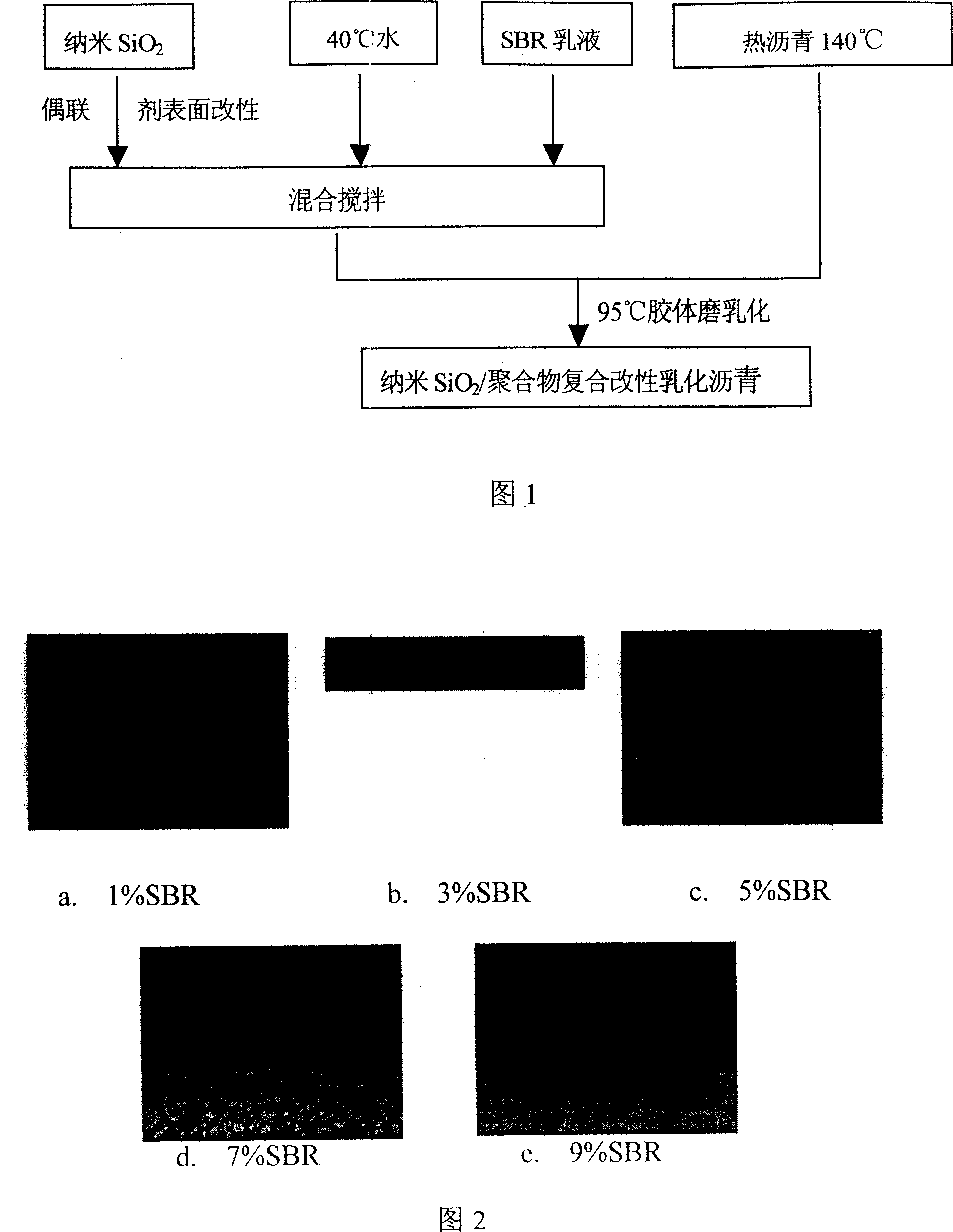

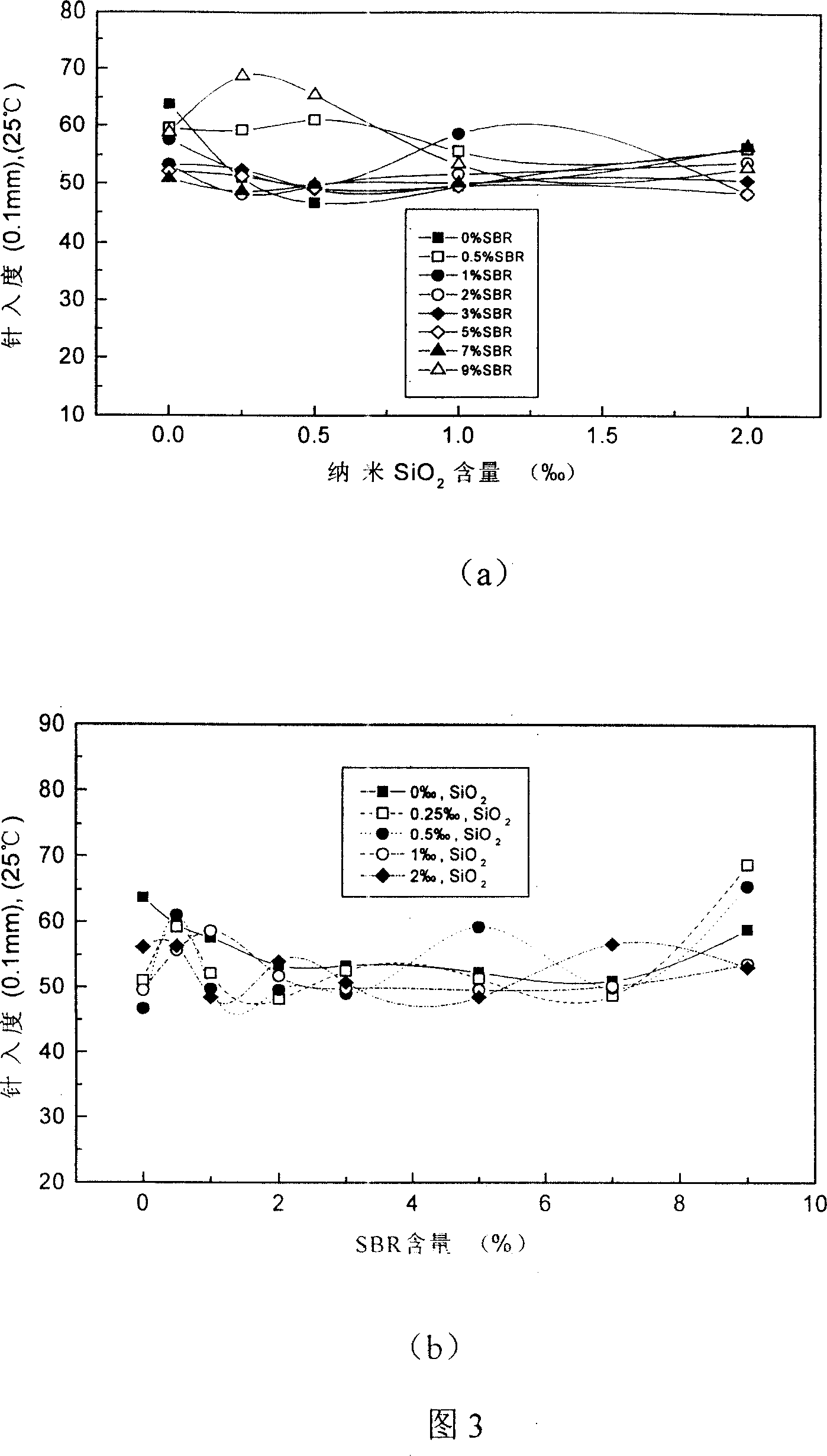

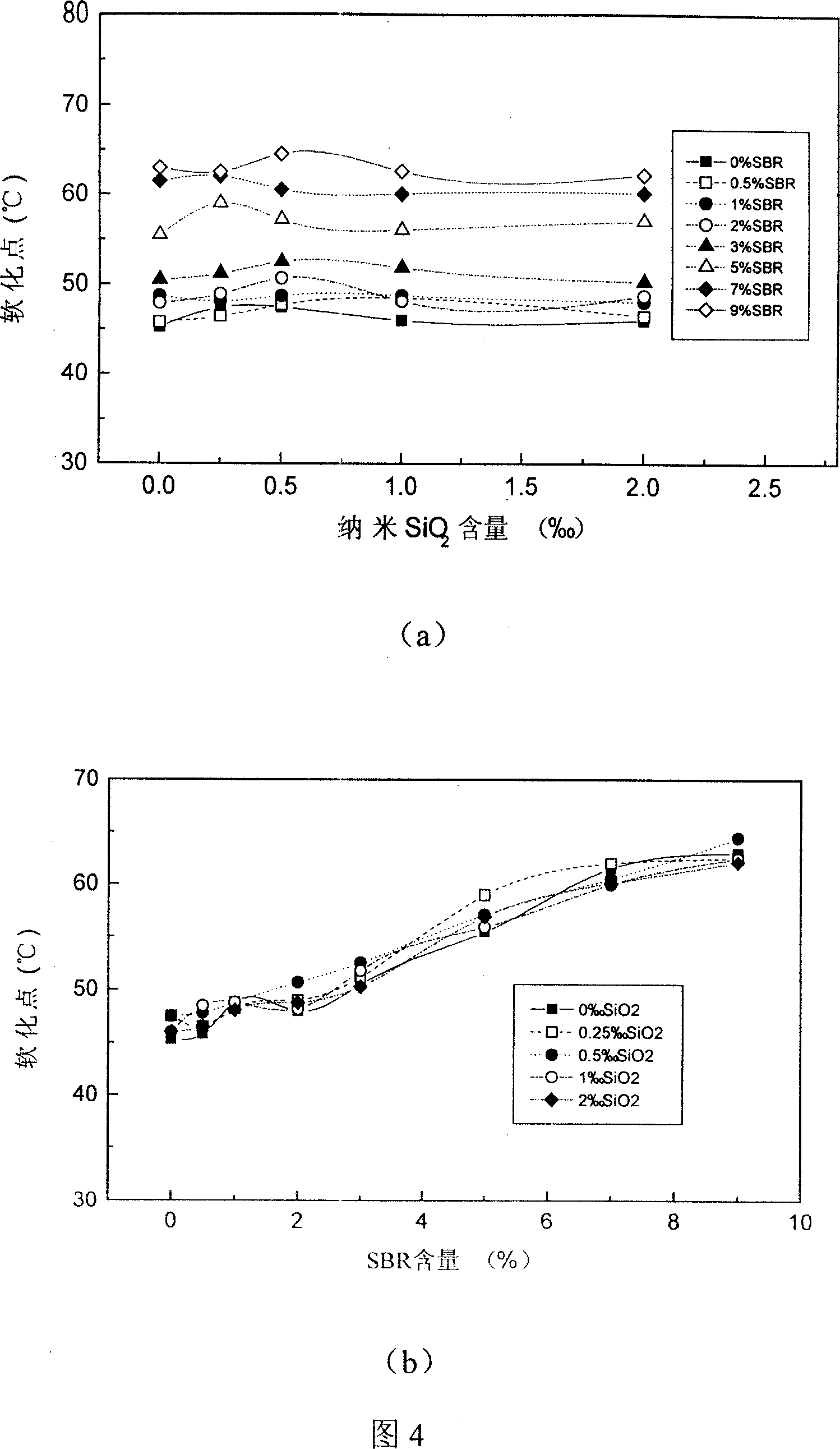

Inorganic nano particle and polymer composite modified emulsified asphalt

InactiveCN101143967AGood resistance to UV agingImprove heat aging performanceBuilding insulationsPolymer scienceButadiene-styrene rubber

A modified emulsion asphalt compounded by inorganic nano-particles and polymer contains 200-700 parts by weight of asphalt, 2-80 parts by weight of modified inorganic nano-particles, 5-50 parts by weight of styrene-butadiene rubber latex, and 170-793 parts by weight of water, wherein the modified inorganic nano-particles is prepared by mixing 95-98 parts by weight of inorganic nano-particles with 2-5 parts by weight of coupling agent, and each components are mixed, followed by normal emulsion treatment to get the emulsion asphalt. The invention utilizes unique surface effect, small size effect and macroscopic quantum tunneling effect etc. of the inorganic nano-particles to give the product comprehensive properties, such as good wear resistance, intensity sum, anti-aging property and fine waterproof effect etc. Using the invention can increase the road maintenance cycle and decrease the cost. Furthermore, the water-proof cost of construction industry is greatly decreased.

Owner:HUNAN UNIV

Dry composition based on mineral binder and intended for the preparation of a hardenable wet formulation for the construction industry

ActiveUS20140371351A1Easy to getEasy to useTransportation and packagingMixing methodsBuilding productFoaming agent

Owner:PAREXGROUP SA

Corrugated web beam connected to a top tube and bottom tube

A structural beam for use in the construction industry is described. The structural beam is comprised of a hollow top section and a hollow bottom section which are connected by one or two webs that may be corrugated. The hollow top and bottom sections may be rectangular. A corrugated web is also described having a trapezoidal shape. Also described is the combination of utilizing rectangular horizontal sections with a corrugated web to produce a structural beam that is light in weight, yet strong and fatigue resistant. Also described is a method of producing a structural beam having a corrugated web, a hollow top section, and a hollow bottom section.

Owner:BEHLEN ACQUISITION CO

Bamboo shoot skin plywood and production process thereof

InactiveCN103538123AReduce manufacturing costHigh strengthLaminationLamination apparatusHair removalPhyllostachys propinqua

Provided are bamboo shoot skin plywood and a production process of the bamboo shoot skin plywood. The bamboo shoot skin plywood adopts bamboo shoot skin of moso bamboo, phyllostachys parvifolia, dendrocalamus latiflorus, phyllostachys propinqua, phyllostachys viridi-glaucescens, overlord bamboo and others as raw materials, uses transparent polyester resin, and is manufactured through a panel material preparation and production process (including the steps of rinsing and hair removal, processing of a solution (70% of clean water, 27% of acetic acid and 3% of ethyl alcohol), water scrubbing, drying, flattening and mould pressing of a spliced picture), a base board production process (including the steps of rinsing and hair removal, drying, flattening, curtain weaving, spreading, gluing and hot pressing), and a third process (including the steps of splicing and spreading of a panel and the spliced picture, gluing, hot pressing of the panel on the surface of a base board, edge sawing, grading detection, and packaging and storage), can be used for the industry, the construction industry, furniture, floor boards, decoration, packaging and the like, and is multipurpose. The bamboo shoot skin plywood and the production process of the bamboo shoot skin plywood sufficiently reflect the concept of recycling waste materials, and solve many problems of existing plywood. The bamboo shoot skin plywood produced through the process is low in cost, high in strength, dampproof, waterproof, good in anti-mold property, not prone to deformation, low in carbon, environmentally friendly, durable, and capable of saving resources, and is a novel substitute product for the development of the plywood industry in our country.

Owner:CHIBI JIAXIANG BAMBOO SHOOT DEV

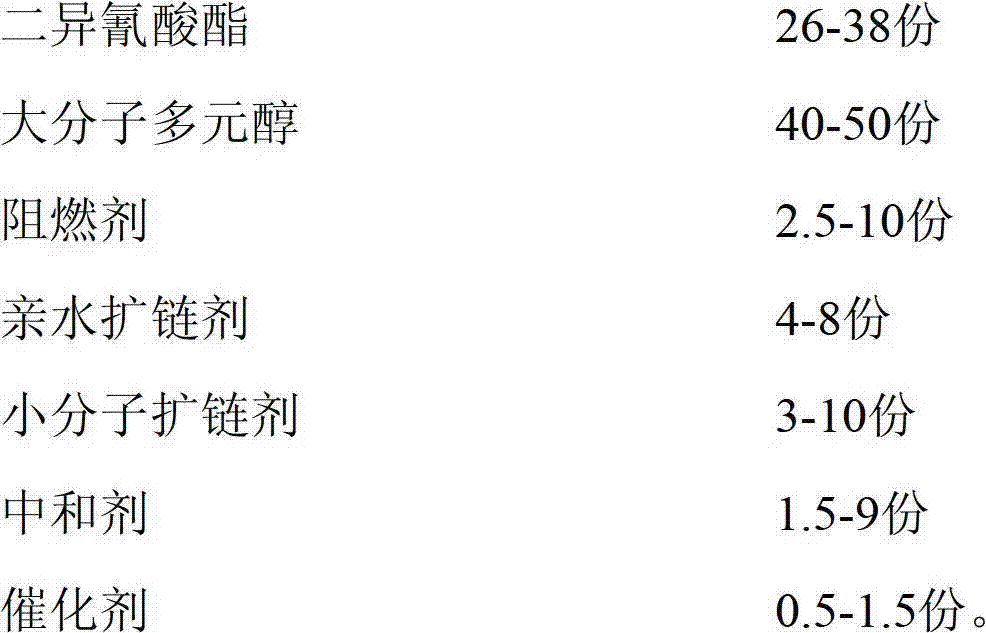

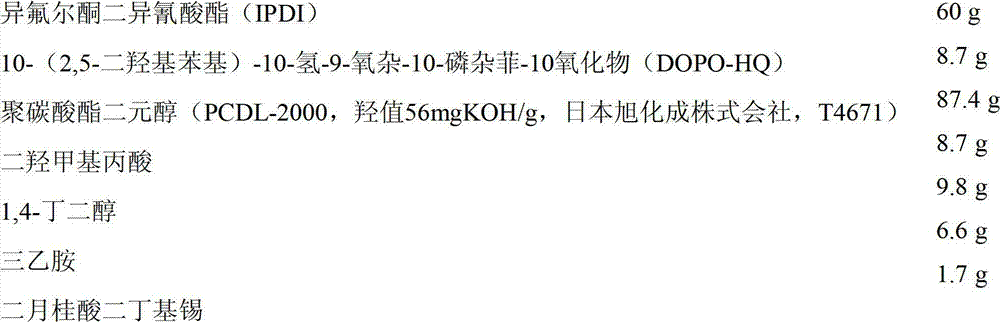

Environment-friendly flame-retardant polyurethane emulsion and preparation method thereof

ActiveCN103030770AGood internal flame retardant effectImprove water resistanceChemical structureEmulsion

The invention discloses an environment-friendly flame-retardant polyurethane emulsion and a preparation method thereof, wherein the environment-friendly flame-retardant polyurethane emulsion is composed of the following raw materials in parts by weight: 26-38 parts of diisocyanate, 40-50 parts of macromolecular polyatomic alcohol, 2.5-10 parts of a flame retardant, 4-8 parts of an hydrophilic chain extender, 3-10 parts of a micromolecular chain extender, 1.5-9 parts of a neutralizer, and 0.5-1.5 parts of a catalyst. According to the invention, a chemical structure with a flame-retardant function is introduced onto a main chain of polyurethane, so aqueous polyurethane has the flame-retardant performance and the application range of the aqueous polyurethane is enlarged; and in addition, gradually increased requirements on the flame-retardant performance in the furniture industry and the construction industry are satisfied.

Owner:HEFEI UNIV OF TECH

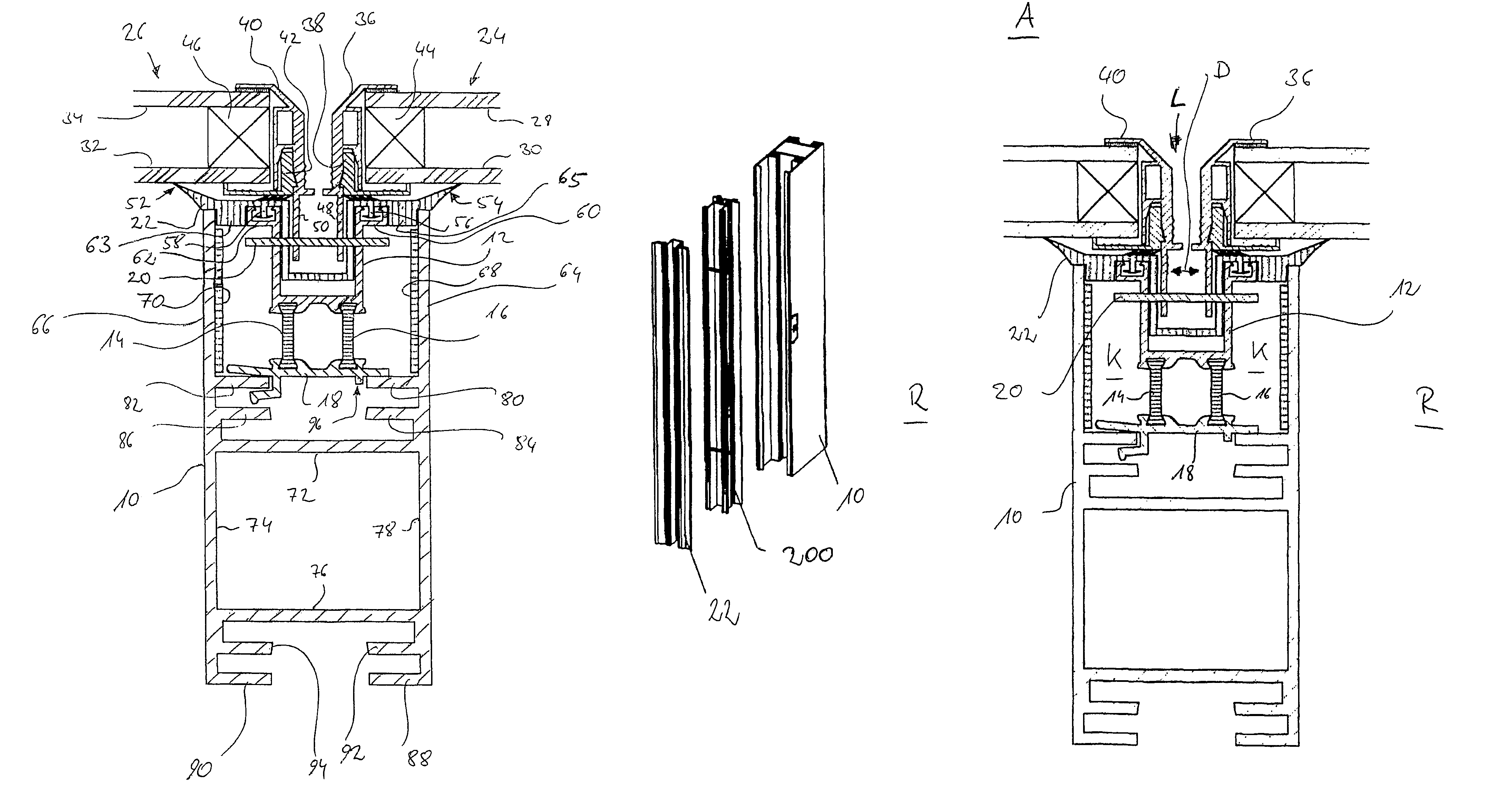

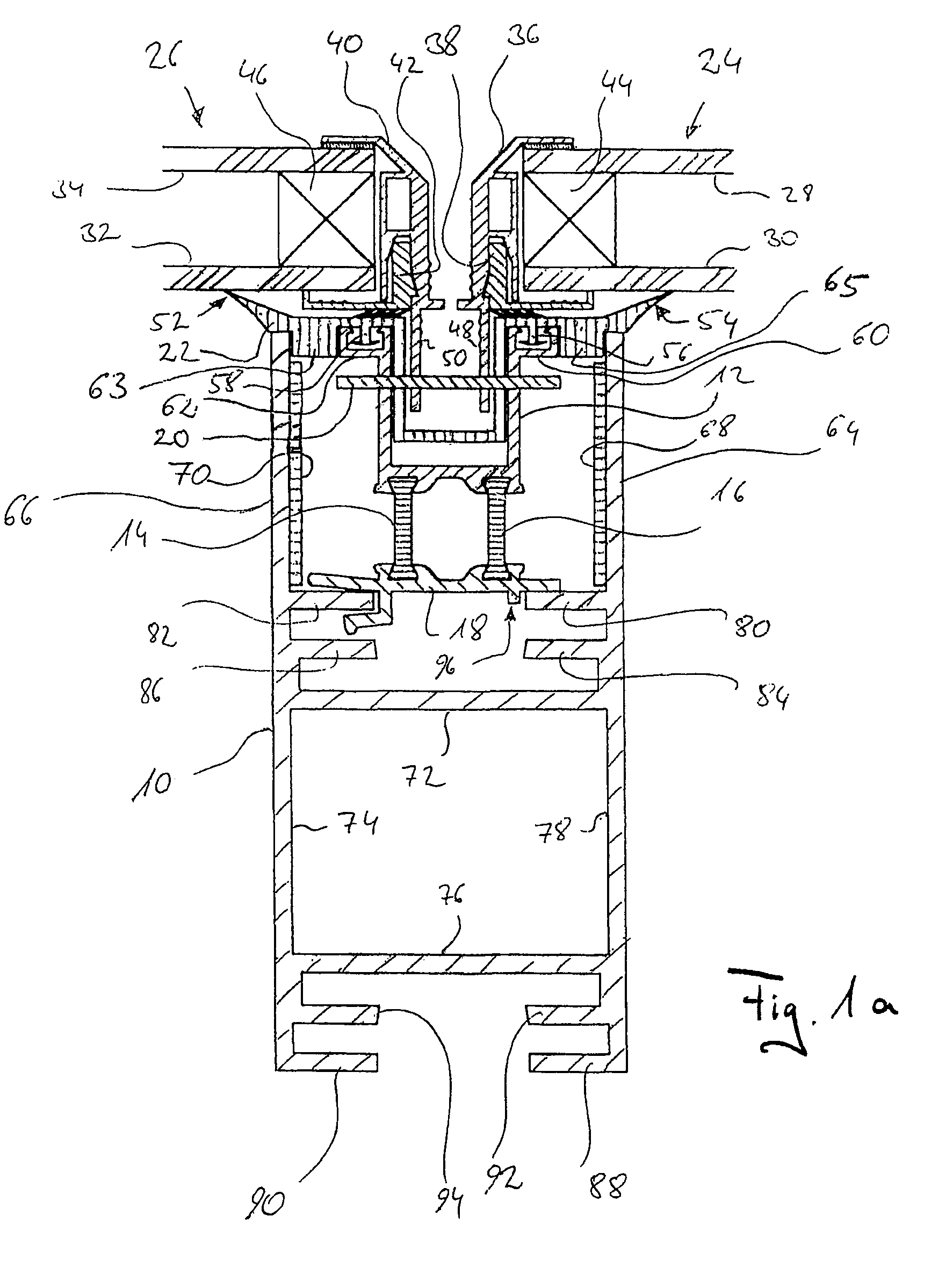

Structural element system and structural elements of such system for curtain facades, facade linings, sun rooms, soundproofing walls, fair buildings and the like

InactiveUS7162842B2Heat transport via the sections isMinimal heat conductivityWallsPublic buildingsThermal insulationEngineering

Owner:RIBIC WALTER

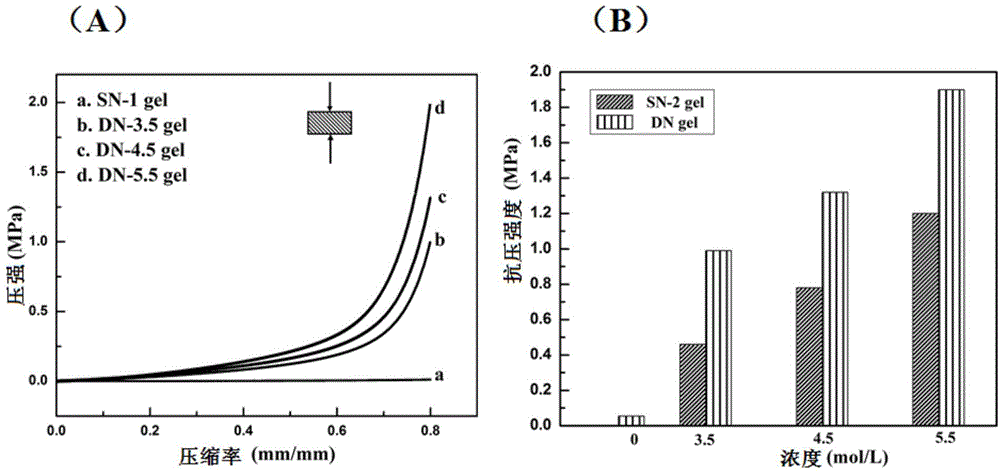

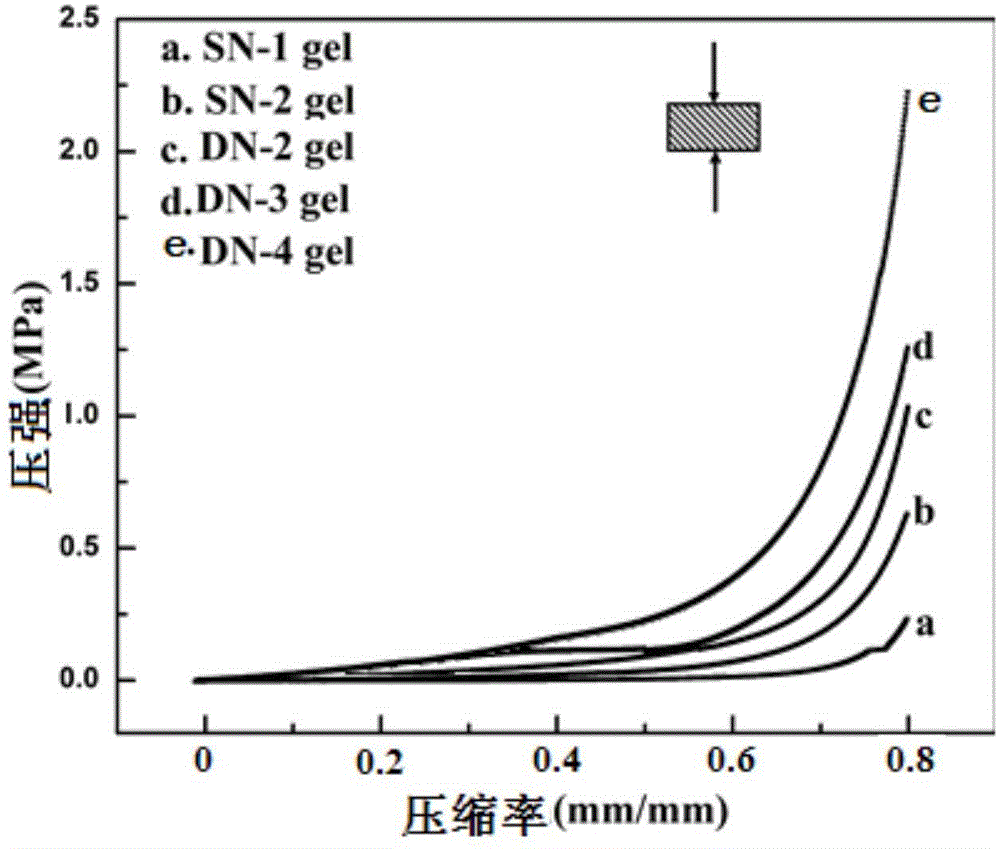

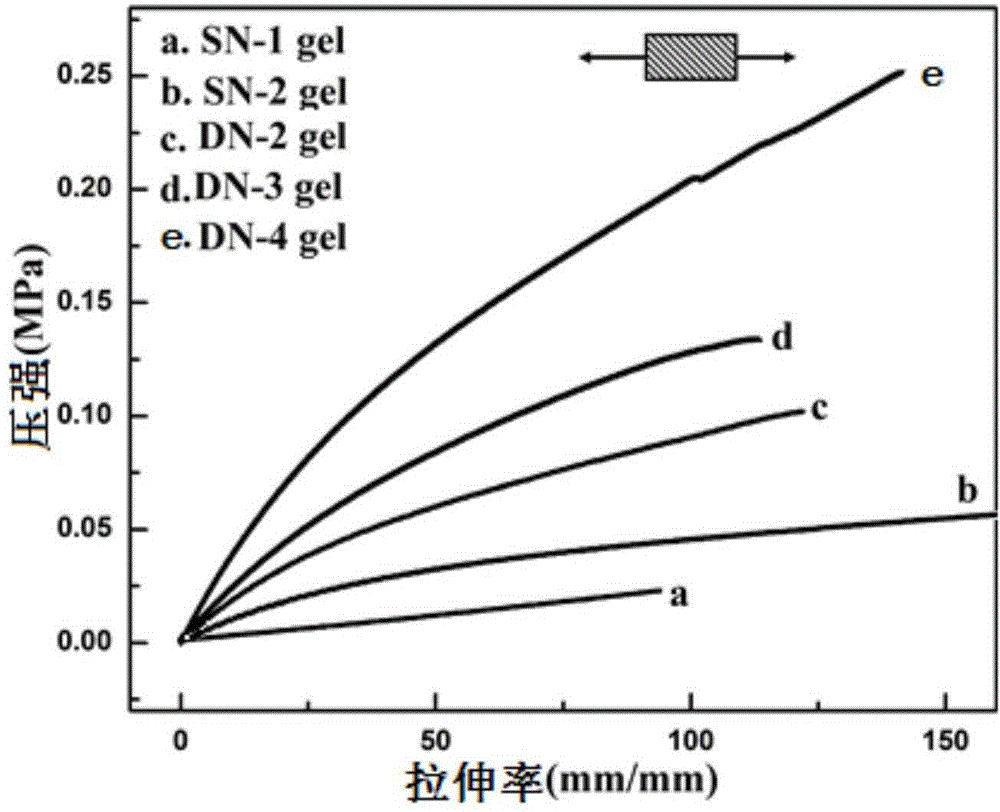

Chitosan-based double-network hydrogel and preparation method thereof

The invention provides chitosan-based double-network hydrogel. The hydrogel is of a double-network structure. A first network is chitosan graft hydrogel, and the chitosan graft hydrogel is formed by chitosan liquid, an initiator, a first single body and a cross-linking agent through grafting reaction. A second network is inserted inside the first network, and the second network is hydrogel which is formed by polymerization of a second single body, a cross-linking agent and a photo-initiator under the radiation of ultraviolet light and has high compression strength and tensile strength. Due to the introduction of chitosan, the biocompatibility of the hydrogel is improved. Thus, application of the double-network hydrogel in the fields such as biological medicine, the construction industry, the chemical industry and the mining industry is improved. The invention further provides a preparation method for preparing the chitosan-based double-network hydrogel. The method is simple in technology and enables industrialization to be easy.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

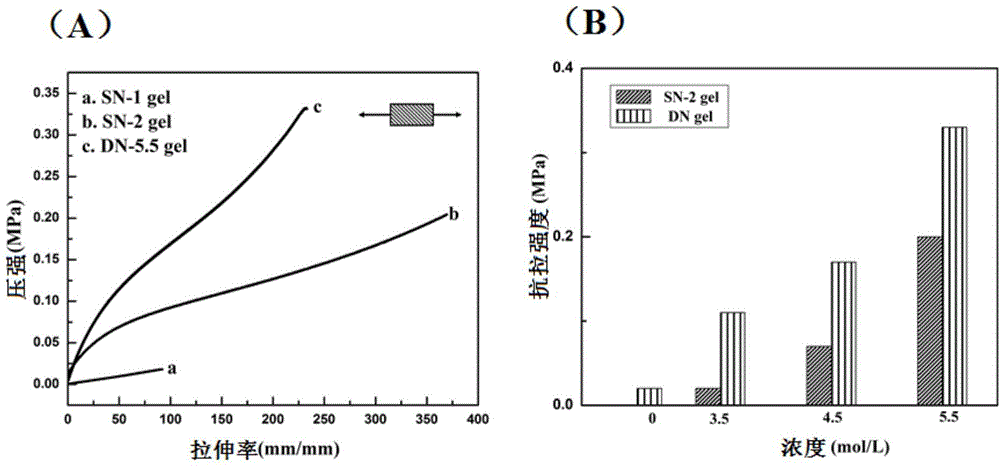

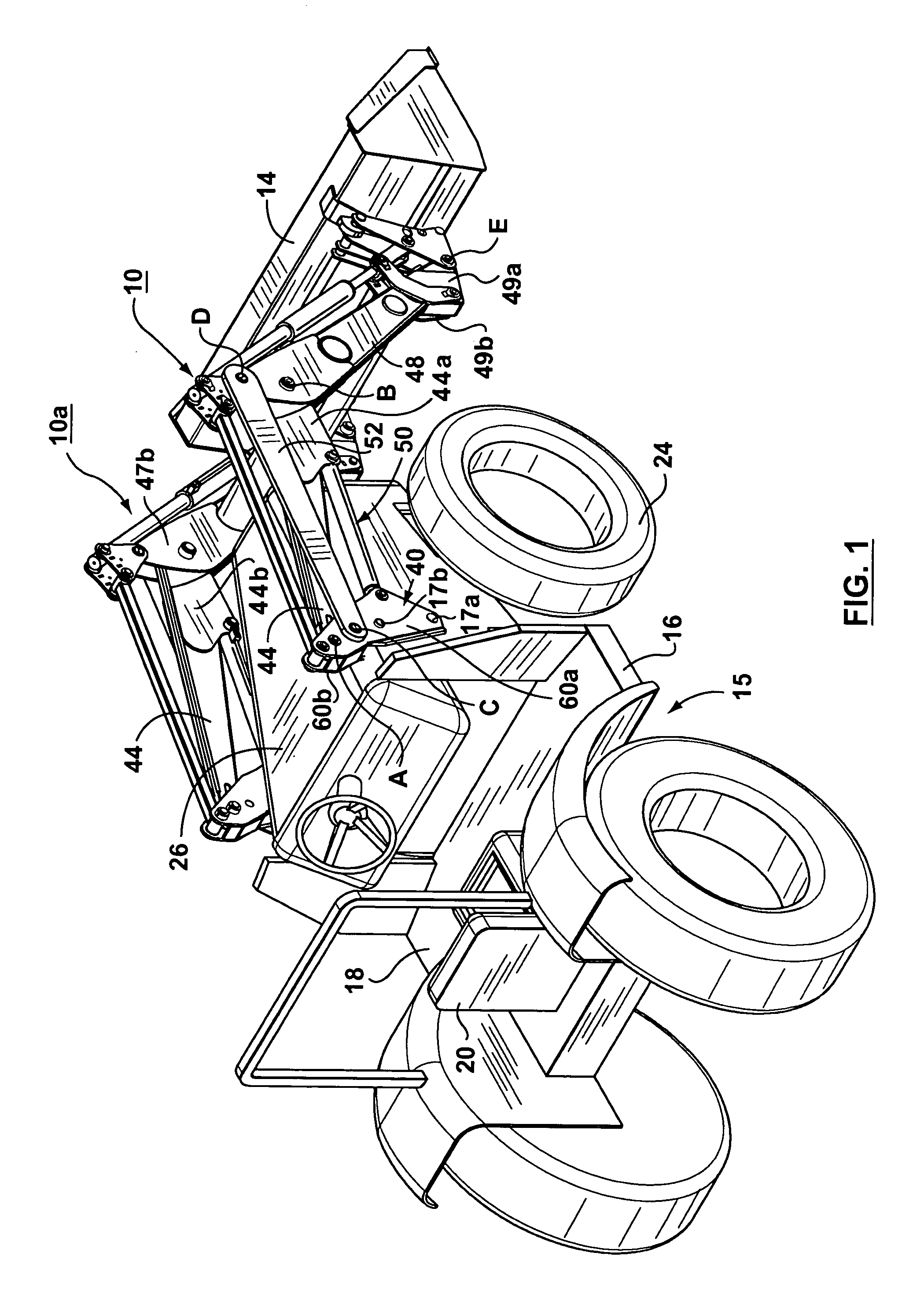

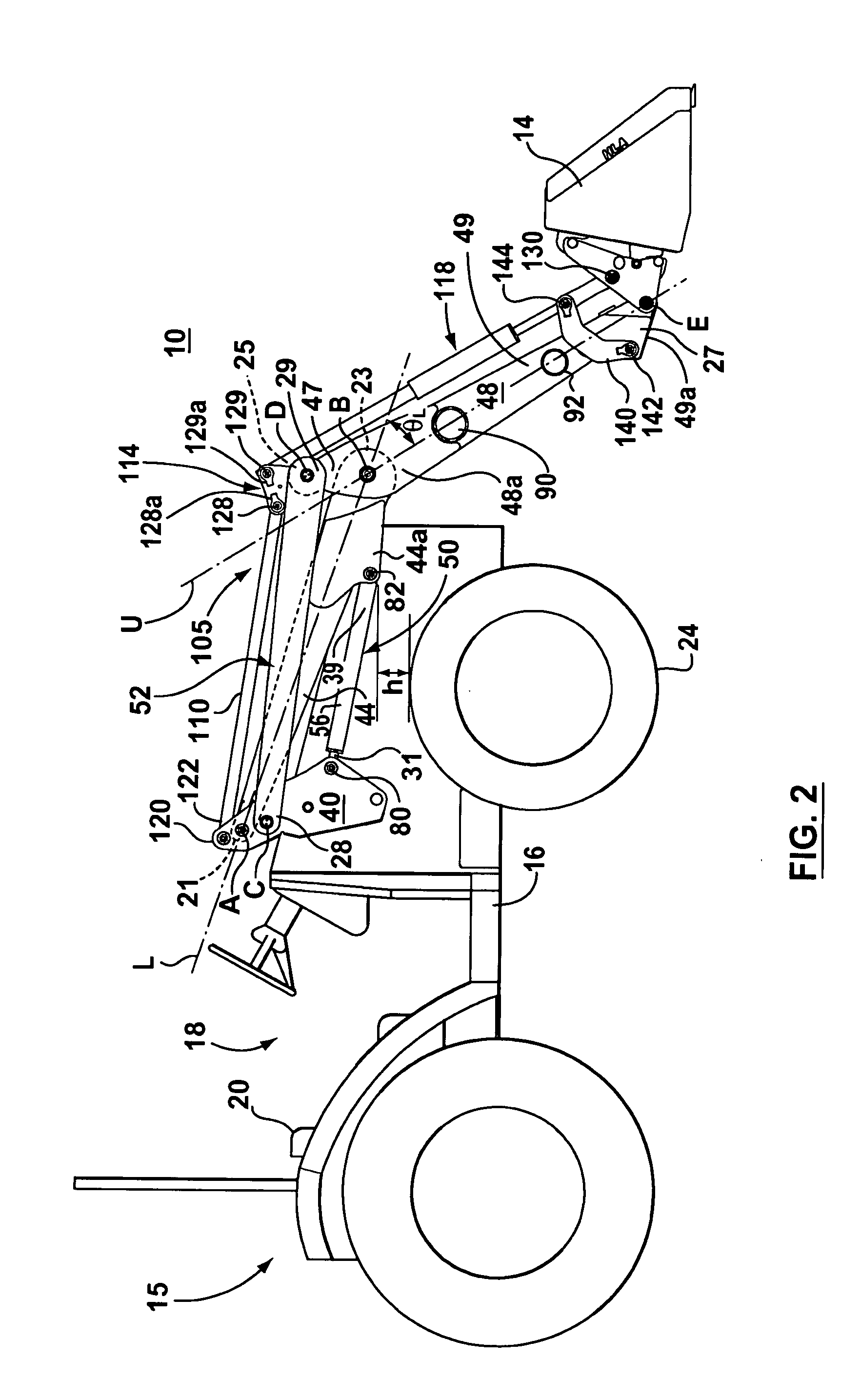

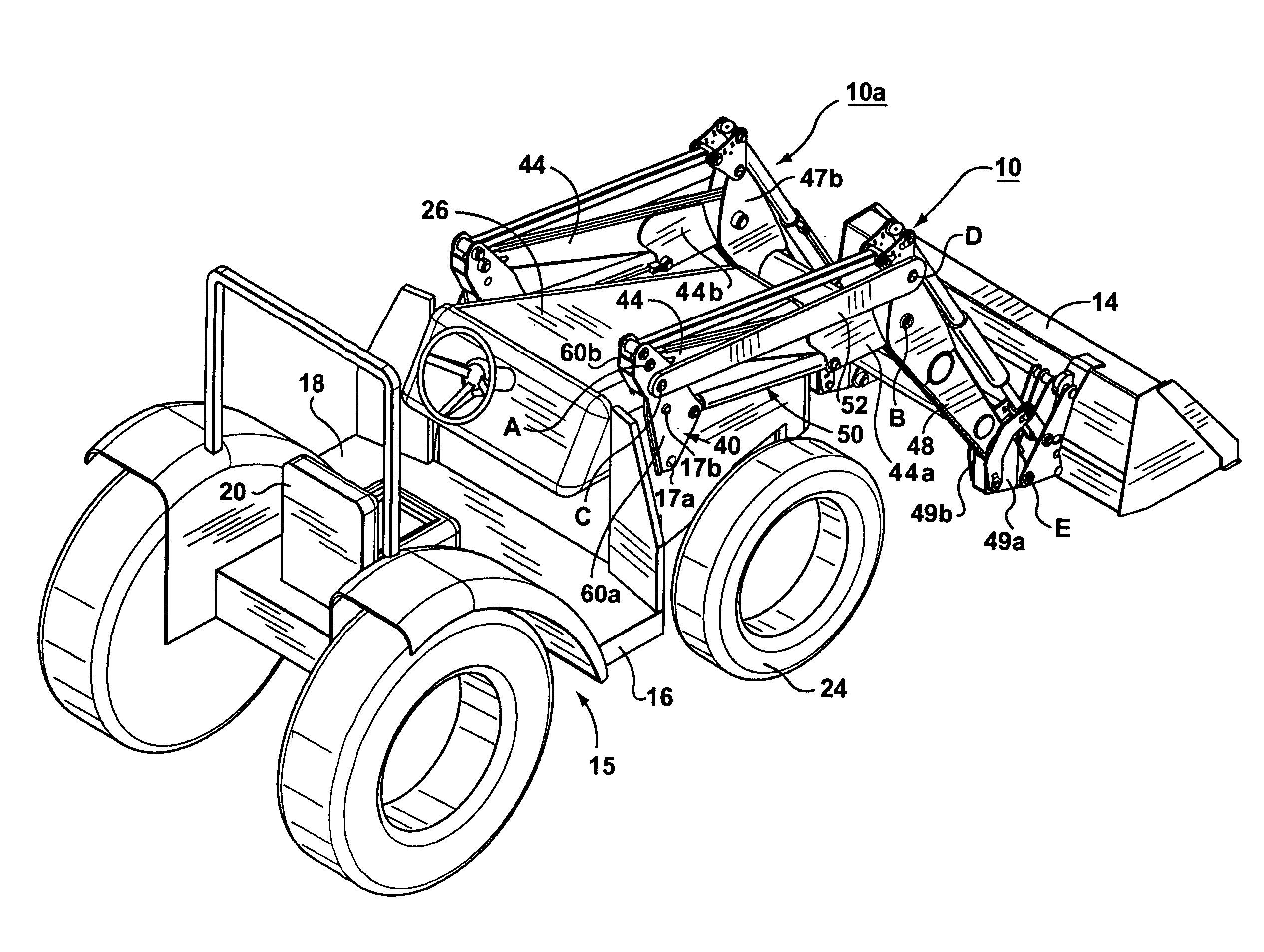

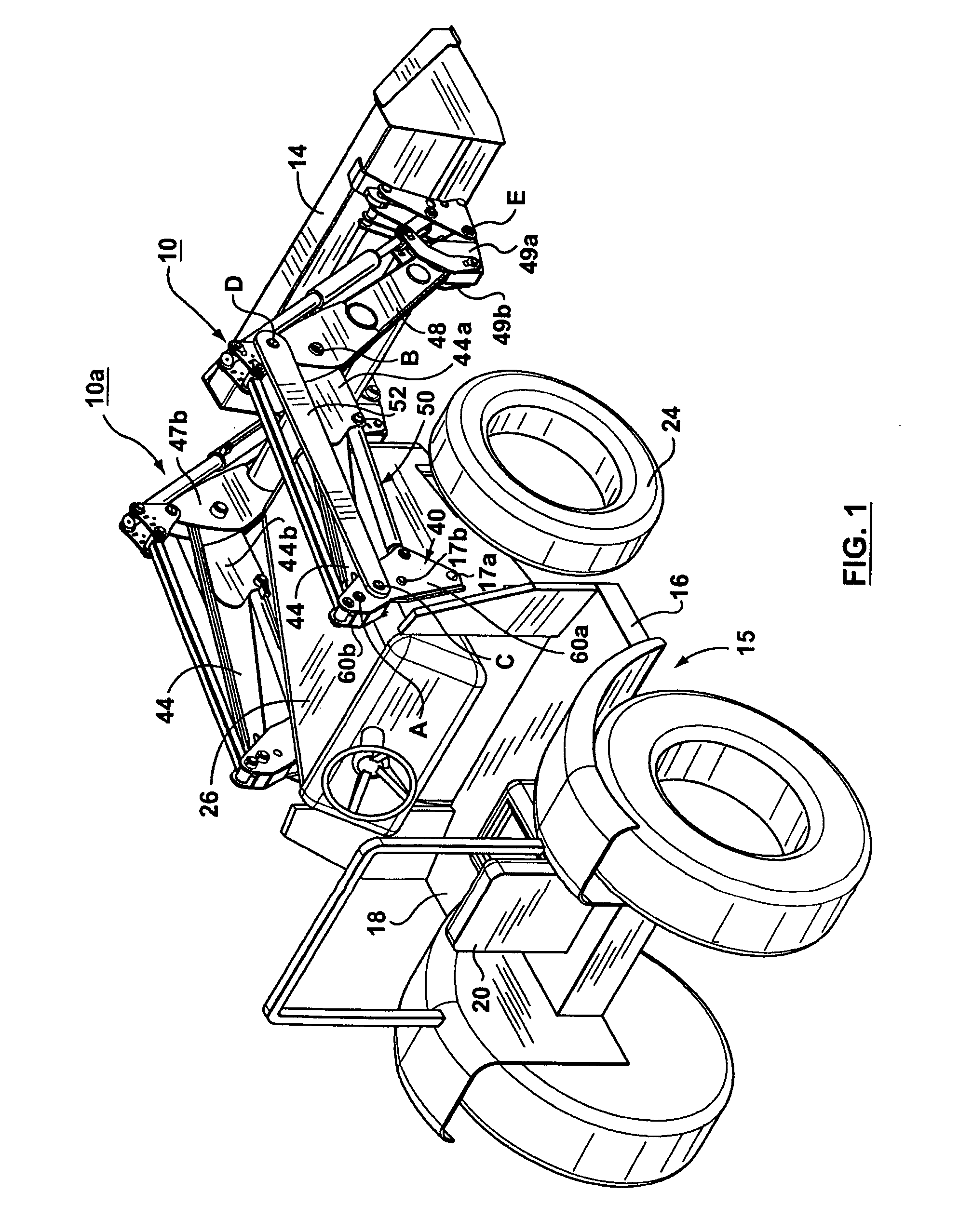

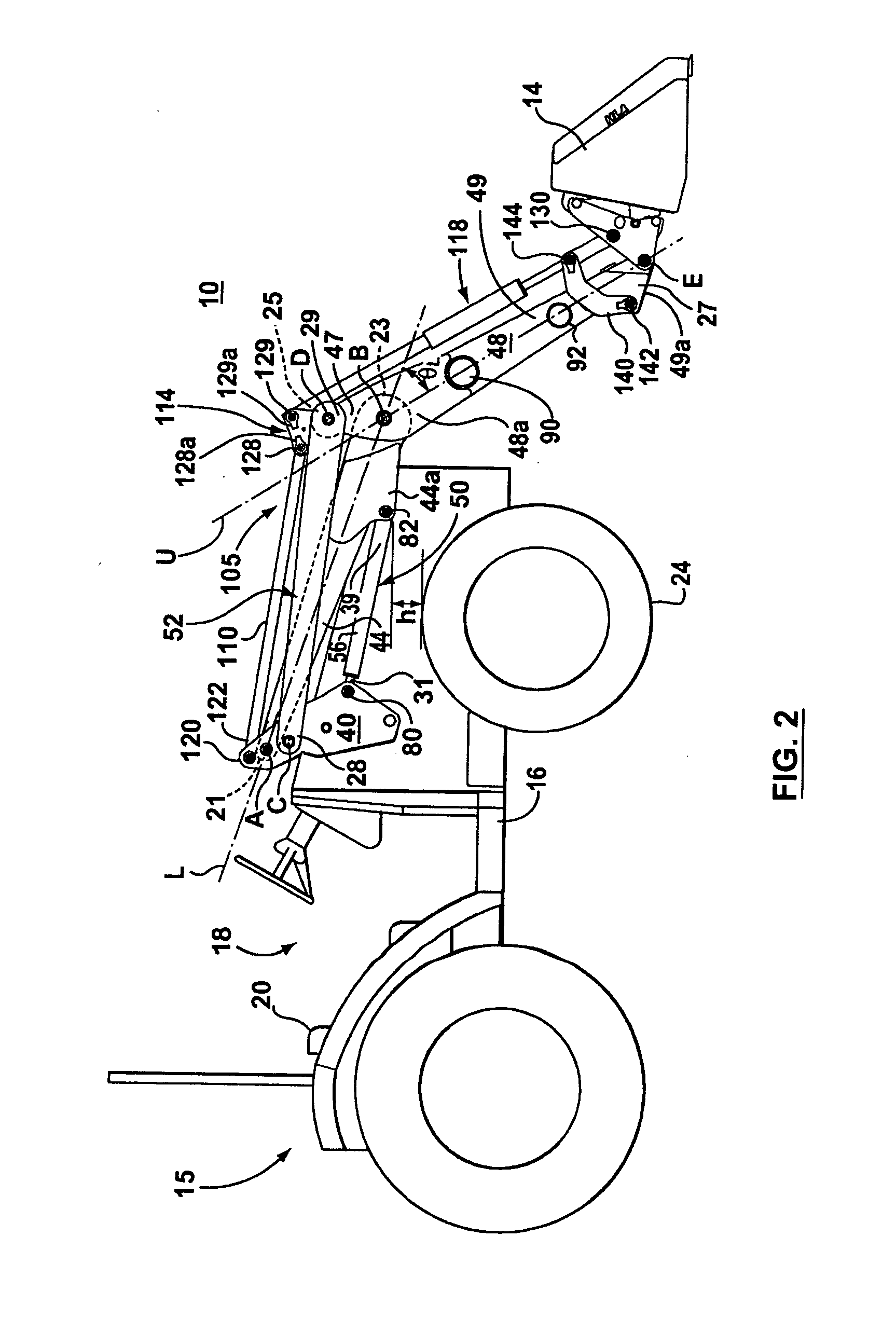

Loader boom arm

A loader boom arm for a material handling vehicle used in the agricultural or construction industries includes a post attachable to the vehicle, a lower arm pivotally connected to the post, an upper arm pivotally connected to the lower arm, a pivoting mechanism coupled to the post and the lower arm, and a link arm pivotally connected to the post and to the upper arm. The boom arm is raised and lowered in an angular direction of rotation by pivoting the lower arm about the post using the pivoting mechanism. As the lower arm is pivoted, the link arm causes the upper arm to pivot relative to the lower arm such that the upper arm pivots further in the direction of angular rotation than the lower arm, thus changing the angle between the lower arm and upper arm. The subject loader boom arm allows an operator to move material in a bucket attached to the boom arm to locations of higher elevation and further reach than typically available with conventional boom arms.

Owner:TUBE LINE MFG

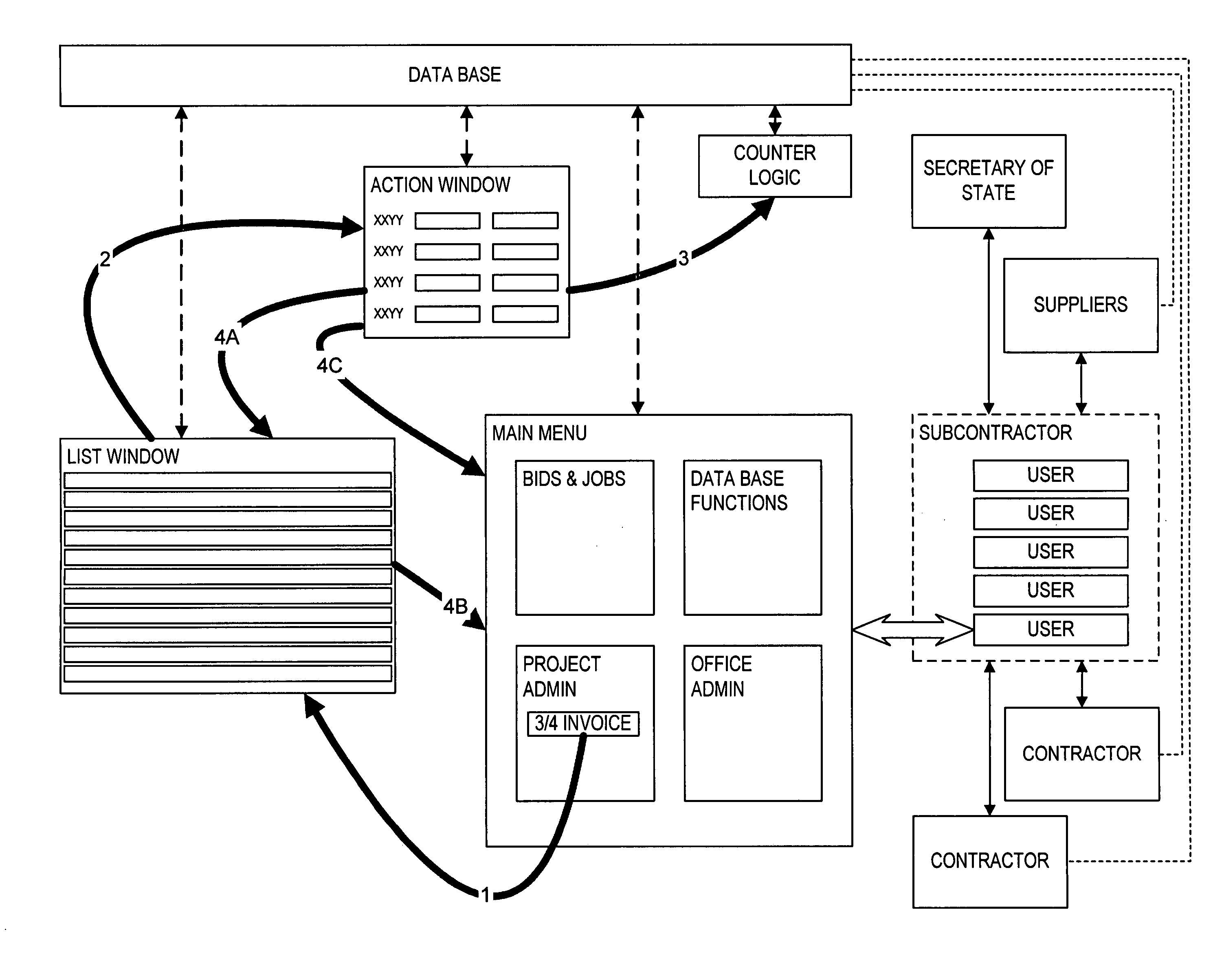

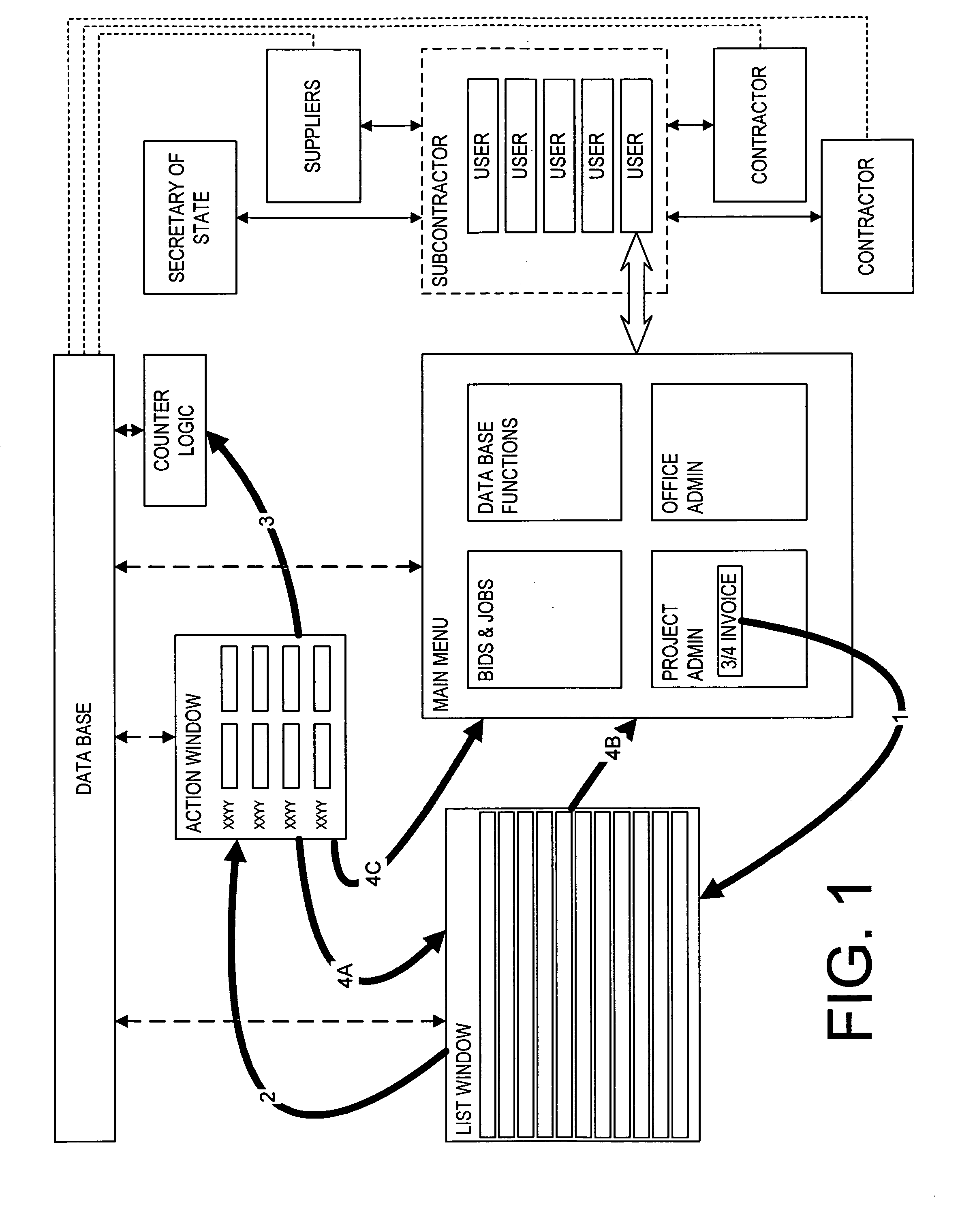

Management of tasks required of trade subcontractors in the construction industry

The management of tasks required of trade subcontractors in the construction industry data base is performed comprehensively, quickly, and with little opportunity for error or omission by the use of a novel method, preferably implemented by computer. A method, user interface, computer program, and system are described that makes as much project information available as quickly as possible to those working within a subcontractor's office, and that provides a flexible workflow process to allow for the seemingly endless possibilities and variations of demands placed on a subcontractor.

Owner:PHEIL DONALD STANLEY +1

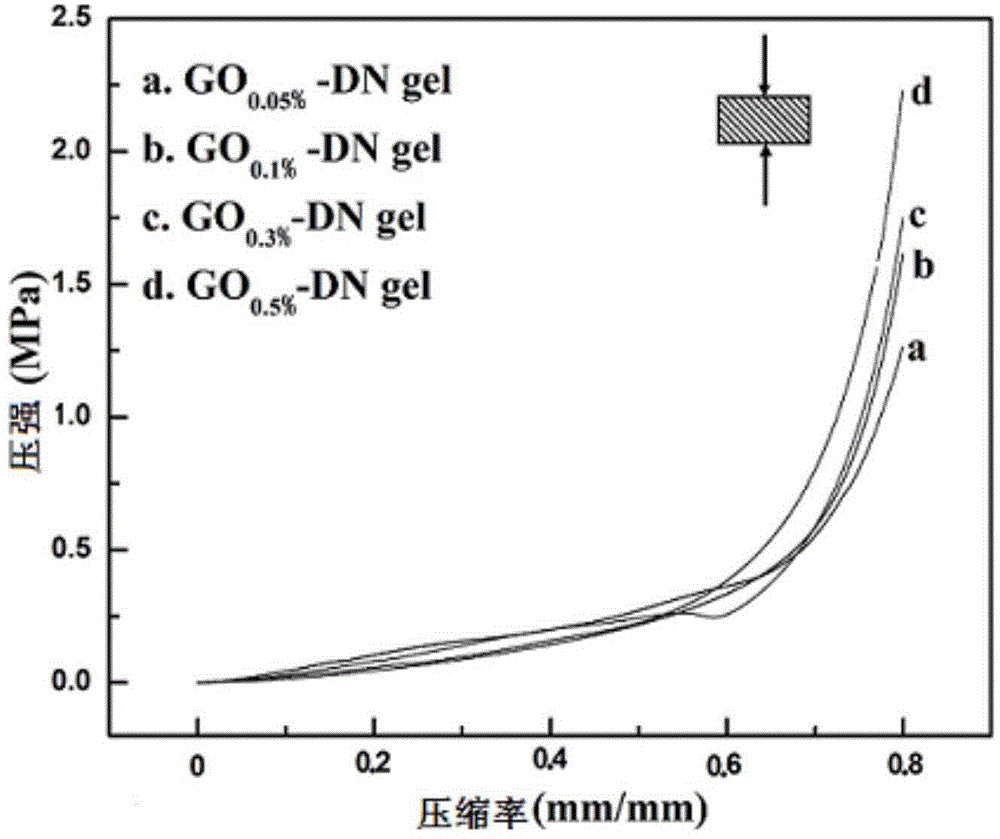

Graphene oxide/chitosan grafted type double-network hydrogel and preparation method thereof

The invention provides graphene oxide / chitosan grafted type double-network hydrogel. The graphene oxide / chitosan grafted type double-network hydrogel is of a double-network structure, wherein the first network is graphene oxide / chitosan grafted hydrogel which is formed by a graphene oxide solution, a chitosan solution, an initiator, a first monomer and a cross-linking agent through grafting reaction, the second network is inserted in the first network in a penetrating mode, and the second network is hydrogel which is formed by a second monomer, a cross-linking agent and a photo-initiator through polymerization under ultraviolet irradiation. The graphene oxide / chitosan grafted type double-network hydrogel has high compression strength and tensile strength. Due to the fact that the chitosan is introduced, biocompatibility of the hydrogel is improved, and then the double-network hydrogel can be better applied to the fields of biological medicine, construction industry, chemical industry, mining industry and the like. The invention further provides a preparation method for preparing the graphene oxide / chitosan grafted type double-network hydrogel. The method is simple in process, and industrialization can be easily achieved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

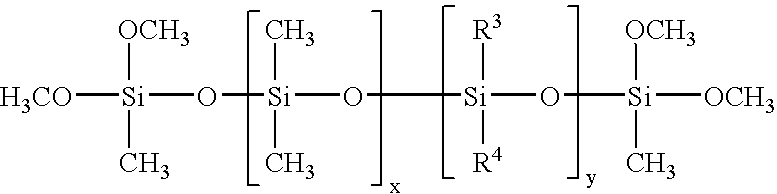

Composition of matter

ActiveUS20090062431A1Heavy and cumbersome to handleMinimize limitationCovering/liningsNatural patternsBrickMaterials science

Composition of matter for the production of simulated stone, masonry, and brick textured products. Exemplary embodiments of panels, wall structures, and other products may have contoured and textured surfaces and may simulate the appearances of conventional building or construction materials including, but not limited to, stone, bricks, masonry, concrete, stucco, wood, or other conventional building materials, and combinations of any of these materials are disclosed. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:WESTLAKE ROYAL BUILDING PROD (USA) INC

Low smoke density poly(arylene ether) compositions, methods, and articles

Thermoplastic compositions and methods of making the compositions are disclosed. The thermoplastic compositions include poly(arylene ether), a poly(alkenyl aromatic), an organophosphate ester flame retardant, a functionalized polysiloxane, and an organic acid. The thermoplastic compositions produce surprisingly low smoke density when burned, and they are useful for the fabrication of articles for the transportation and building and construction industries.

Owner:SHPP GLOBAL TECH BV

Method for preparing jade type microcrystalline glass with high-temperature furnace slag

The invention discloses a method for preparing jade type microcrystalline glass with high-temperature furnace slag, which comprises the steps of: taking molten furnace slag as main materials; adding auxiliary materials such as fluxing clarifying agent and additive, and the like; further melting and clarifying in a high-temperature furnace to form glass liquid; pouring or calendaring the glass liquid to form basic glass; heat processing the basic glass by means of crystallization to obtain the rough product of the jade type microcrystalline glass; and finish machining to obtain the finished product of the jade type microcrystalline glass. The method not only effectively utilizes the molten high-temperature furnace slag, but also sufficiently utilizes heat energy stored in the high-temperature furnace slag, and prevents the high-temperature furnace slag from generating huge amounts of corrosive hot steam in the process of discharging. The jade type microcrystalline glass prepared by the method is in the status of semitransparent wax, exactly looks like natural jade, has good cutting performance, high intensity and good tenacity, can be used for replacing natural stones in construction industry, and can be used for replacing natural rare jades in machining artware.

Owner:TSINGHUA UNIV

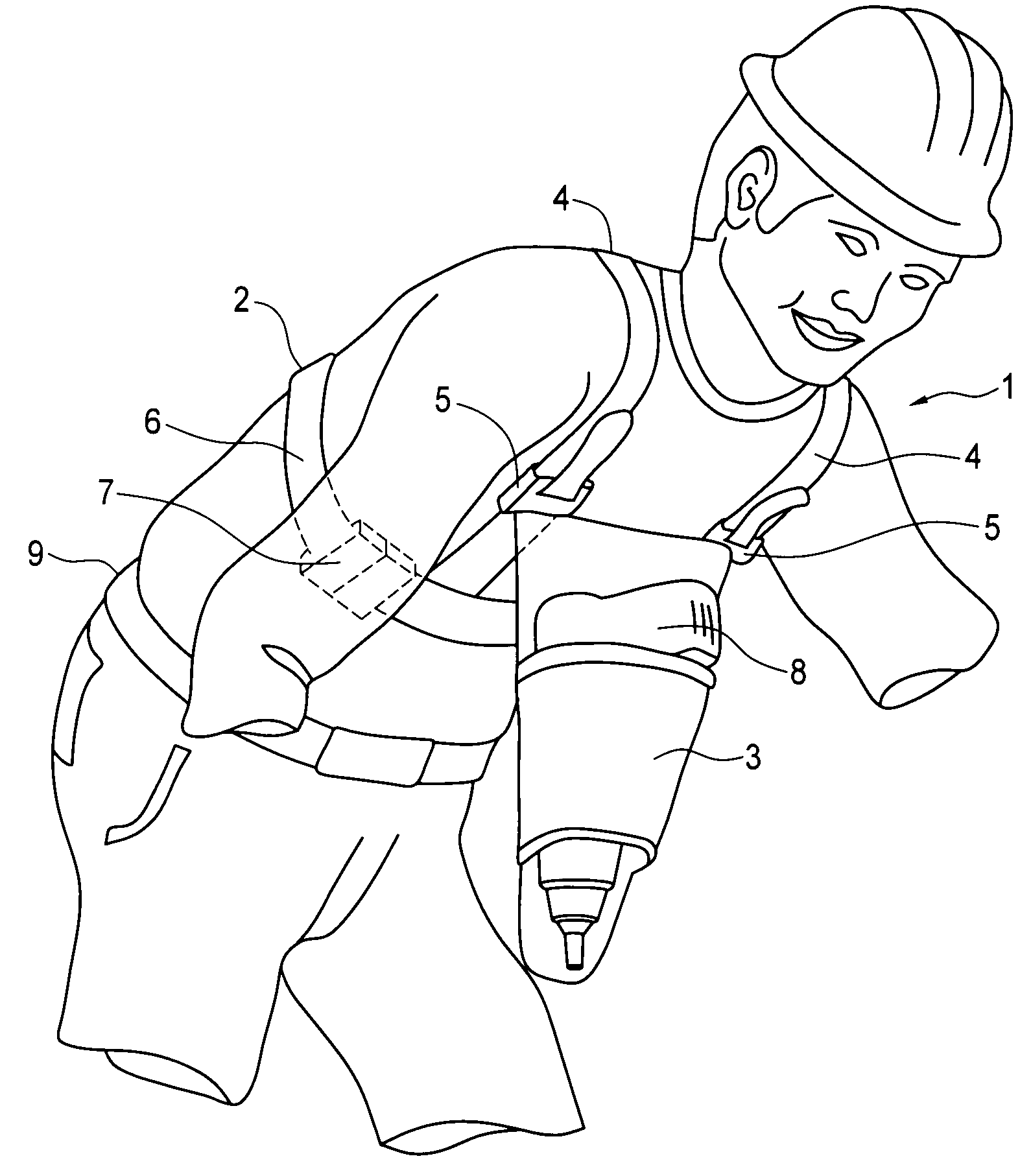

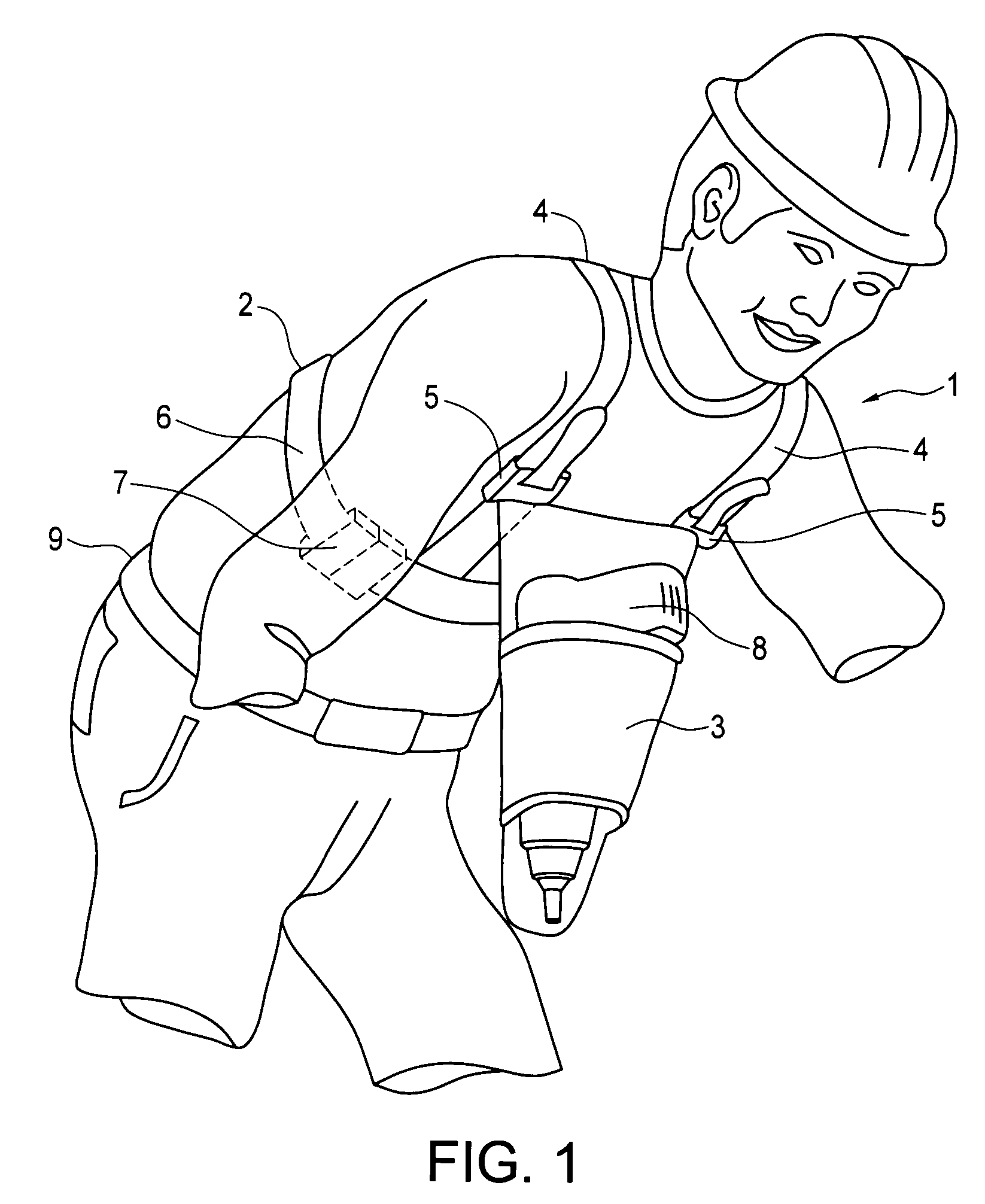

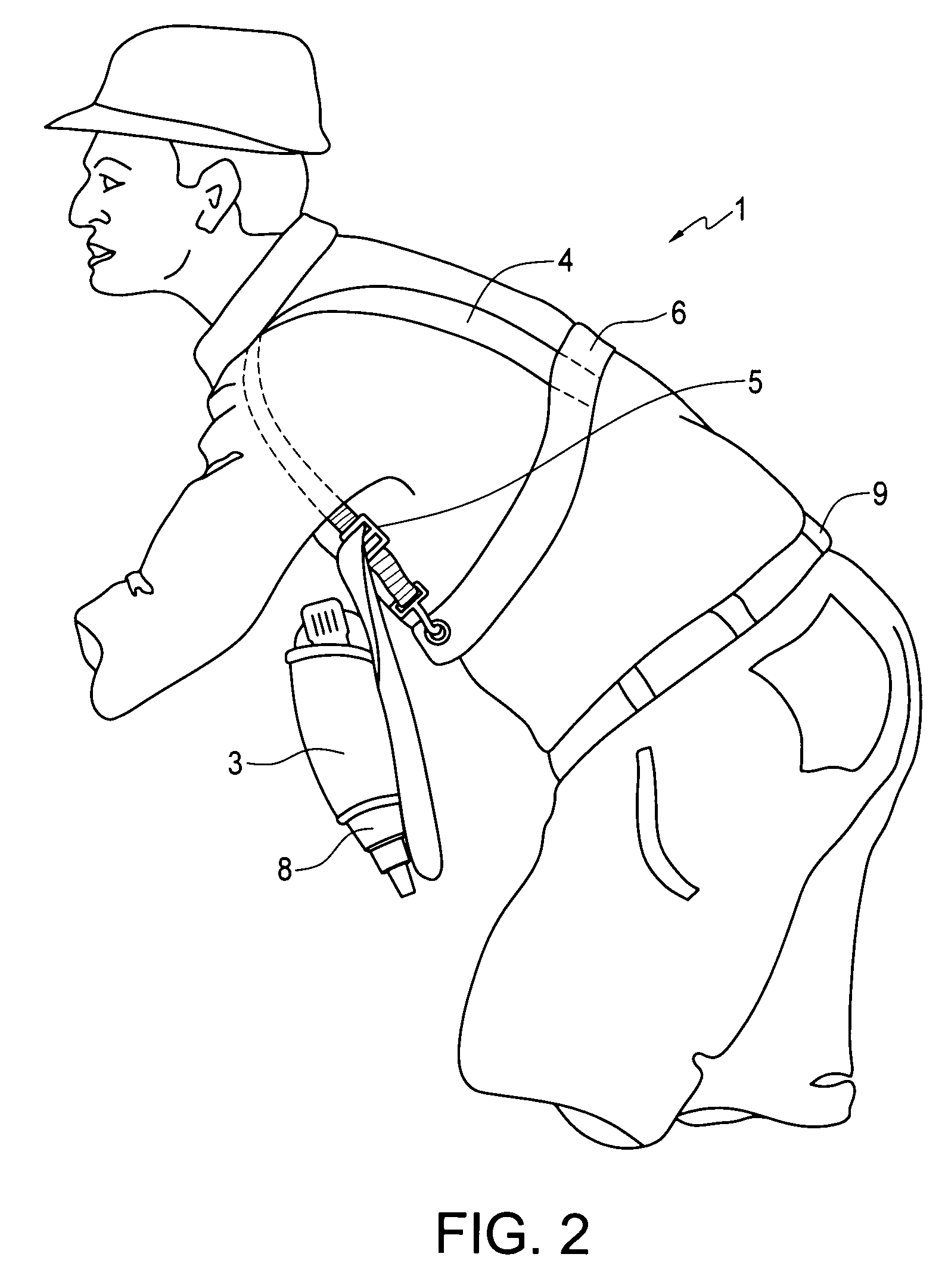

Portable hand tool carrier harness

This invention relates to a novel design of portable hand drill carrier harness for use by workers in the construction industry. More specifically, the invention pertains to a cord powered or cordless drill carrier harness which combines a quick-draw drill carrying holster with a harness which fits about the torso of a cordless drill user. A drill carrier apparatus comprising: (a) a harness for fitting about the torso and over the shoulders of a person; (b) a portable tool carrier connected to the chest area of the harness; and (c) a mechanism which enables the elevation of the tool carrier to be adjusted relative to the elevation of the harness.

Owner:DORMAAR BRENT RONALD

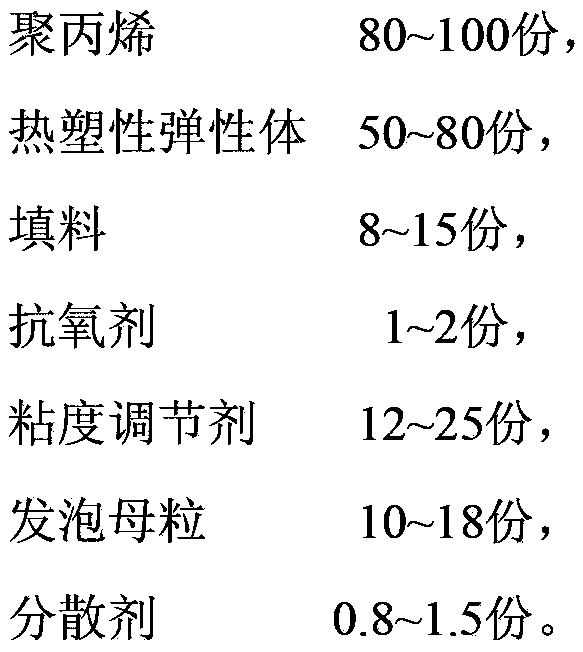

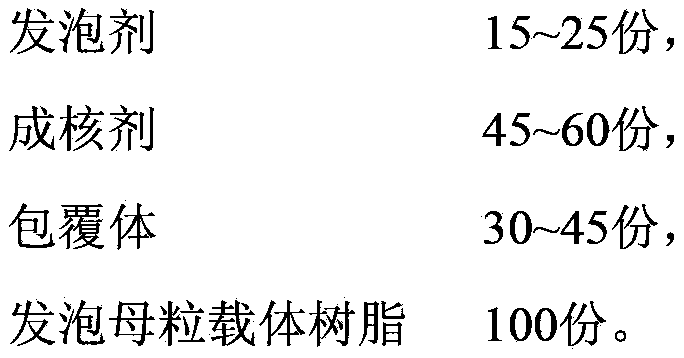

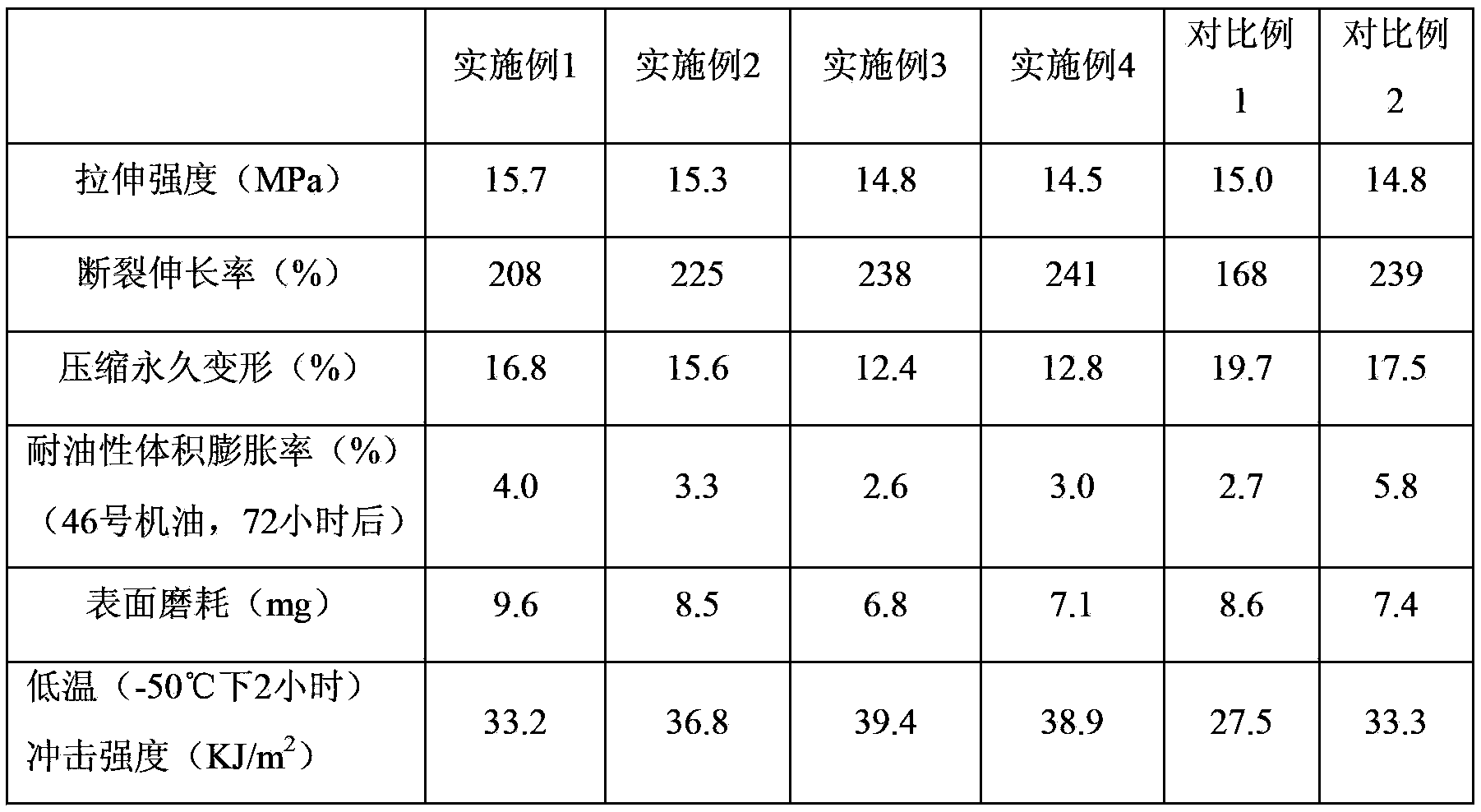

Thermoplastic micro-foaming damping material and preparation method thereof

The invention belongs to the technical field of polymer material processing, and relates to a thermoplastic micro-foaming damping material and a preparation method thereof. The damping material is composed of the following components in parts by weight: 80 to 100 parts of polypropylene, 50 to 80 parts of thermoplastic elastomer, 8 to 15 parts of filling materials, 1 to 2 parts of antioxidant, 12 to 25 parts of viscosity adjusting agent, 10 to 18 parts of foaming master batch, and 0.8 to 1.5 parts of dispersant. Polypropylene is co-modified by the thermoplastic elastomer and a viscosity adjusting agent to prepare the thermoplastic micro-foaming damping material so as to achieve the goals of toughening and strengthening; and at the same time, foaming master batch is added for injection foaming, so the foaming is uniform and the product appearance is beautiful. The preparation method has the advantages of simple formula, easily available raw materials, low cost, simple operation, controllable technology conditions, low operation cost, high production efficiency, and good product performance. The thermoplastic micro-foaming damping material is widely used in industries such as package industry, construction industry, automobile industry, aerospace industry, and sports equipment industry.

Owner:南京清研新材料研究院有限公司

Loader boom arm

A loader boom arm for a material handling vehicle used in the agricultural or construction industries includes a post attachable to the vehicle, a lower arm pivotally connected to the post, an upper arm pivotally connected to the lower arm, a pivoting mechanism coupled to the post and the lower arm, and a link arm pivotally connected to the post and to the upper arm. The boom arm is raised and lowered in an angular direction of rotation by pivoting the lower arm about the post using the pivoting mechanism. As the lower arm is pivoted, the link arm causes the upper arm to pivot relative to the lower arm such that the upper arm pivots further in the direction of angular rotation than the lower arm, thus changing the angle between the lower arm and upper arm. The boom arm also preferably includes a low profile self leveling linkage assembly for maintaining the levelness of a bucket during raising and lowering of the boom arm, having a control arm pivotally connected to the lower arm, a rotator link pivotally connected to the upper arm at a leveling fulcrum, and an output arm pivotally connected to the rotator link and pivotally connectable to a work implement. The subject loader boom arm allows an operator to move material in a bucket attached to the boom arm to locations of higher elevation and further reach than typically available with conventional boom arms.

Owner:TUBE LINE MFG

Disinfecting, antimicrobial sealing compositions and methods of using the same

The present invention relates to novel compositions for disinfecting and sealing a substrate, while also providing the surface with long-term fungicidal protection. Due to this unique and advantageous combination of capabilities, the composition finds particular utility in the construction industry, where it may advantageously be employed to treat a wide variety of construction articles.

Owner:SPECIALTY CONSTR BRANDS

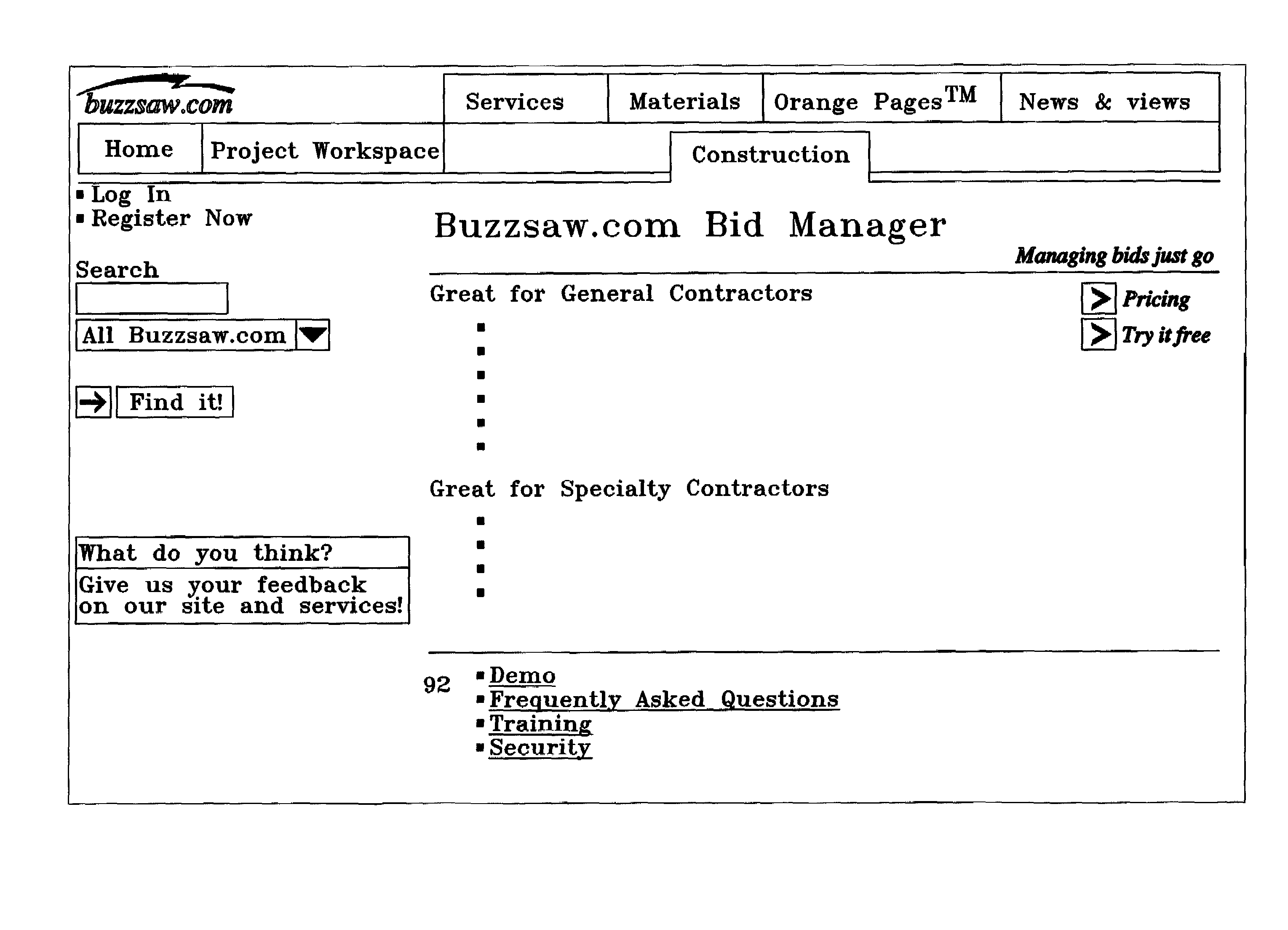

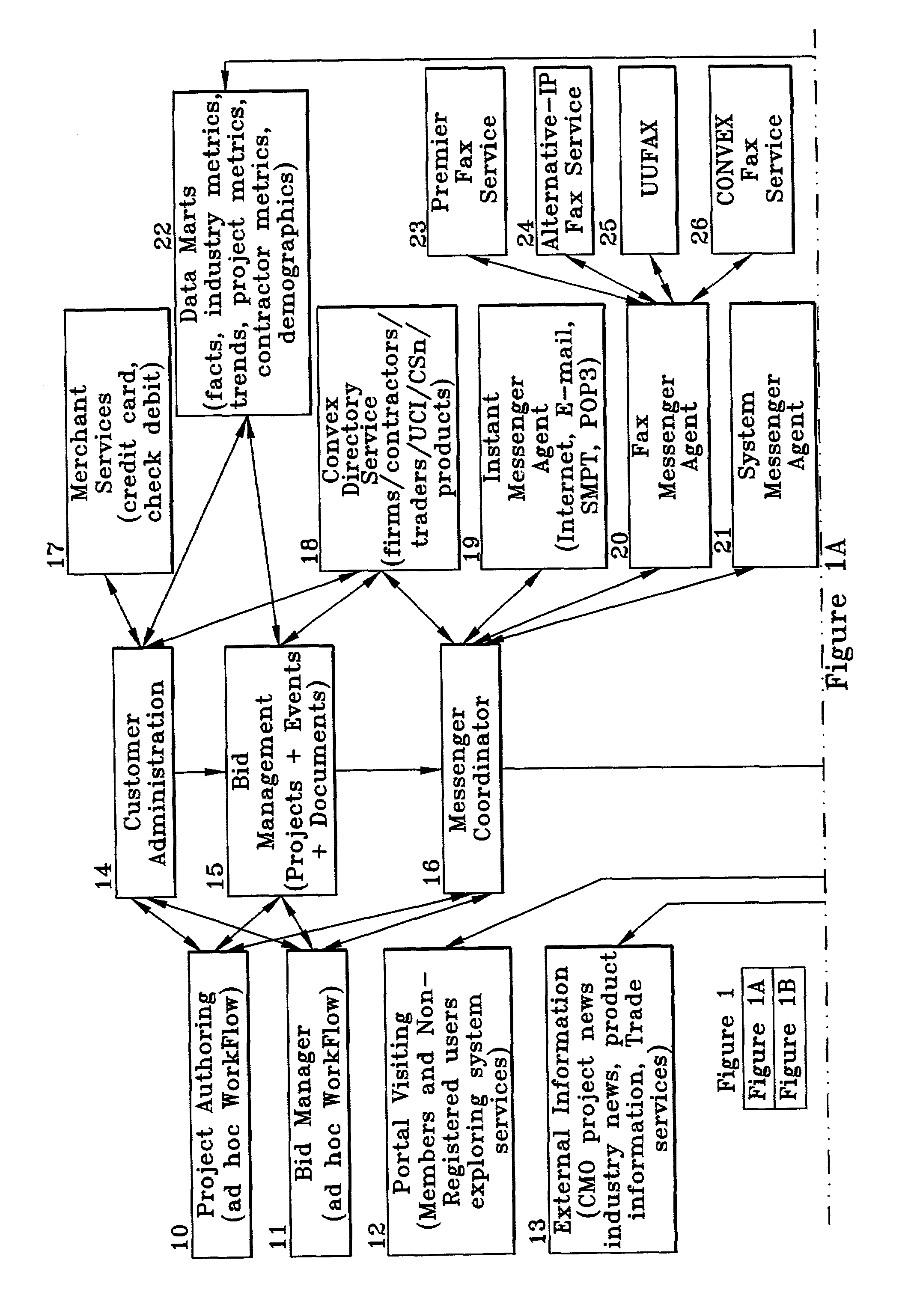

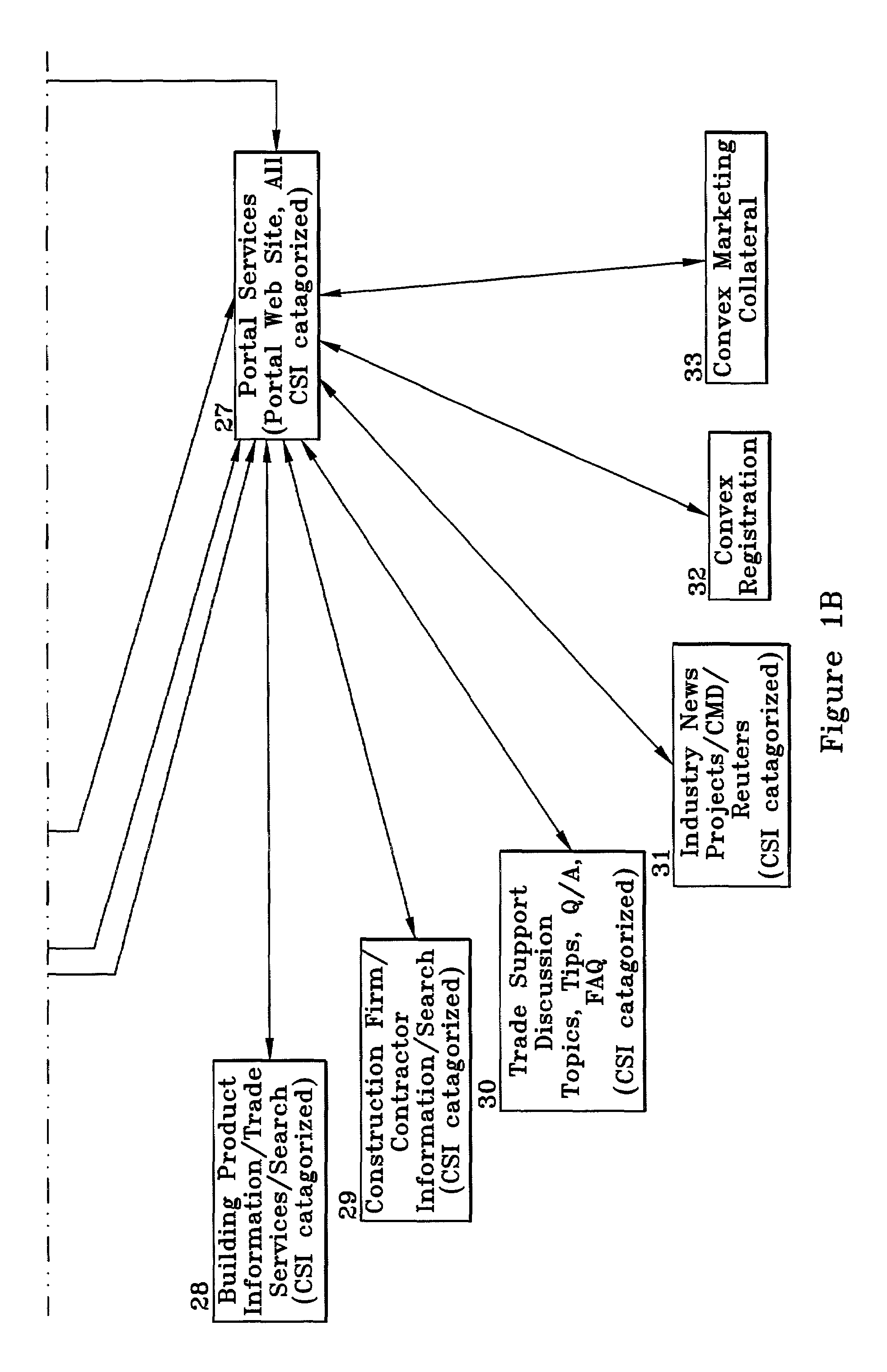

E-commerce bid and project management system and method for the construction industry

ActiveUS7330821B2Cost efficientImprove performanceFinanceResourcesPerformance enhancementGlobal system

An integrated electronic commerce (e-commerce) based construction industry bidding and project management system and methods, including document distribution, supply chain automation and on-line auctioning. In a pre-construction setting, the e-commerce based bidding and project management system and method provides for a user the means for participating and competing in the bidding and construction project management tasks using on-line computerized telecommunications technologies. The on-line system and methodologies help the participants to achieve cost efficiencies and performance enhancements that traditional prior art manual bidding and construction management systems and methods have not achieved. In a global system setting the present invention facilitates management of real estate, development, building and construction industries, including architecture, engineering and construction (AEC) project phases, including design, specification, research, bidding, financing, procurement, construction, and maintenance.

Owner:AUTODESK INC

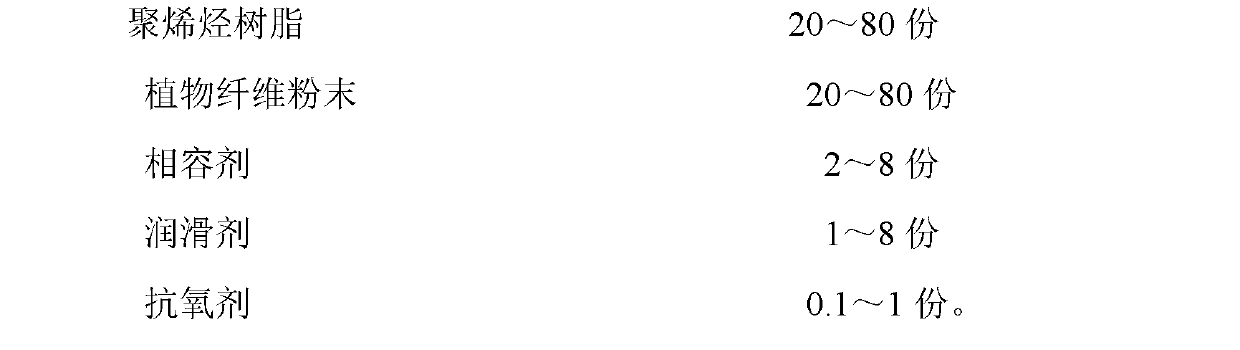

Polyolefin wood-plastic composite material and preparation method thereof

The invention discloses a polyolefin wood-plastic composite material. The polyolefin wood-plastic composite material is prepared by blending and extruding the following components in parts by weight: 20 to 80 parts of polyolefin resin, 20 to 80 parts of plant fiber powder, 2 to 8 parts of compatilizer, 1 to 8 parts of lubricant, and 0.1 to 1 part of antioxygen, wherein the lubricant includes pentaerythritol tetra-benzoate. The composite material has the balance torque of 3.2 to 8.4N.M, bending strength of 30.1 to 66.3MPa, and bending modulus of (0.80-22.6)*10<4>MPa. The invention also discloses a preparation method of the polyolefin wood-plastic composite material. The ester bond of the pentaerythritol tetra-benzoate contained in the wood-plastic composite material and the hydroxyl of the plant fibers can produce high hydrogen bond effect, so that the plant fibers can be promoted to be uniformly dispersed, the filling amount can be increased, the product cost is reduced, the defect on the appearance of the product is avoided, the melting and extruding efficiency is improved, and the bending performance and water absorbing performance of the material are improved; and the polyolefin wood-plastic composite material can be used as the high-level polyolefin wood-plastic composite material to be widely applied in the fields such as indoor and outdoor decoration and construction industry.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com