Patents

Literature

42262results about How to "Good compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

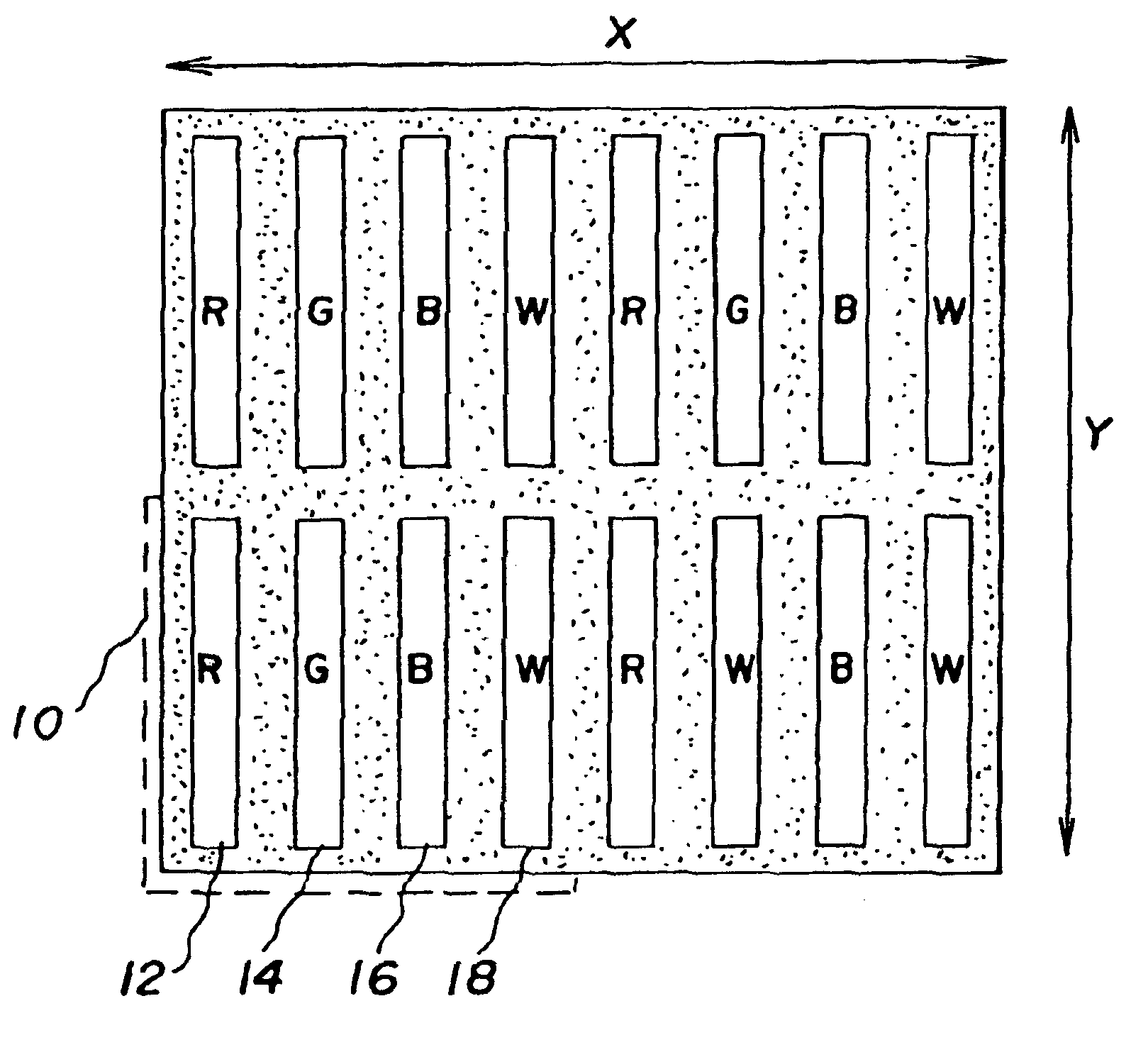

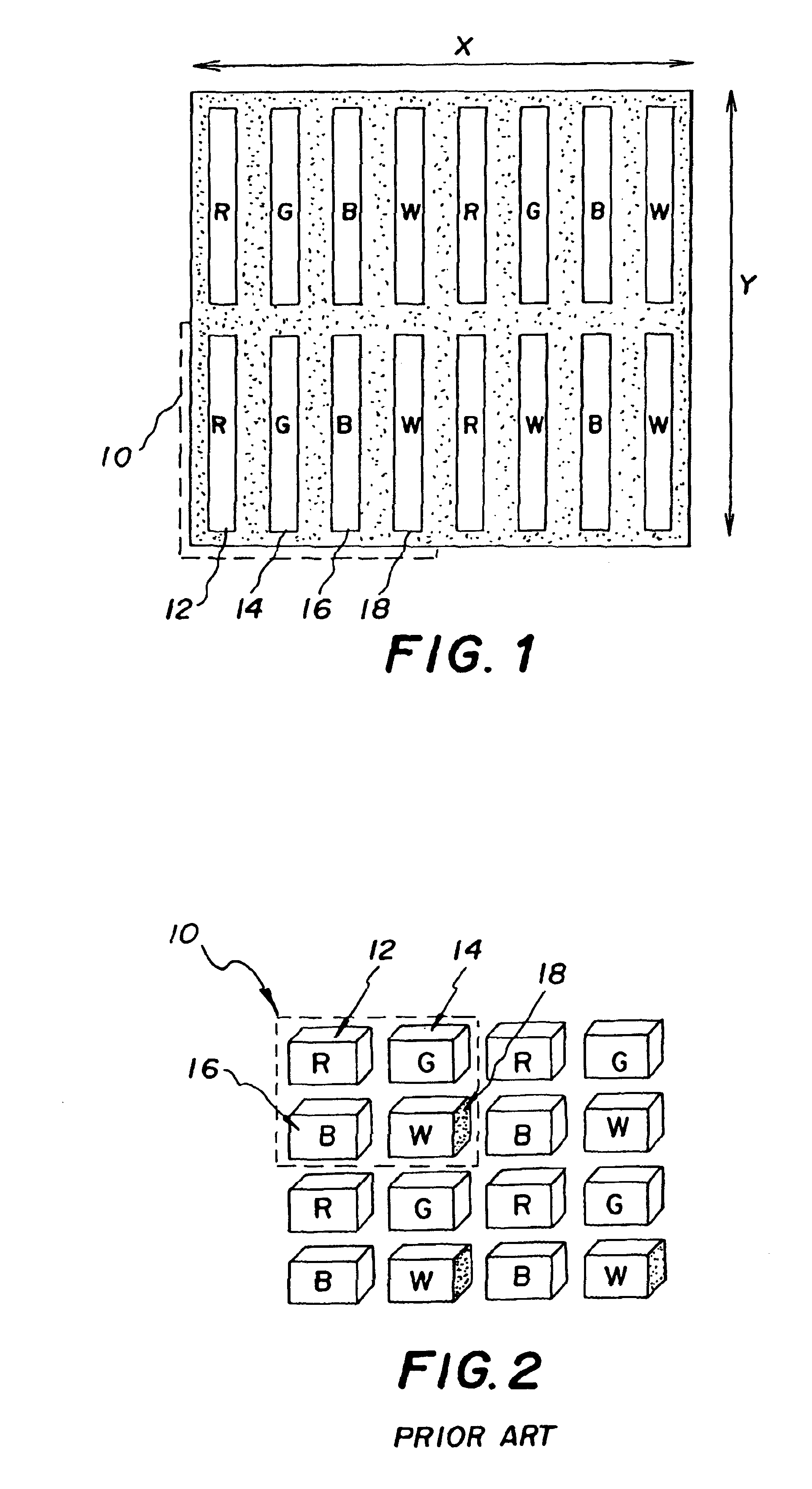

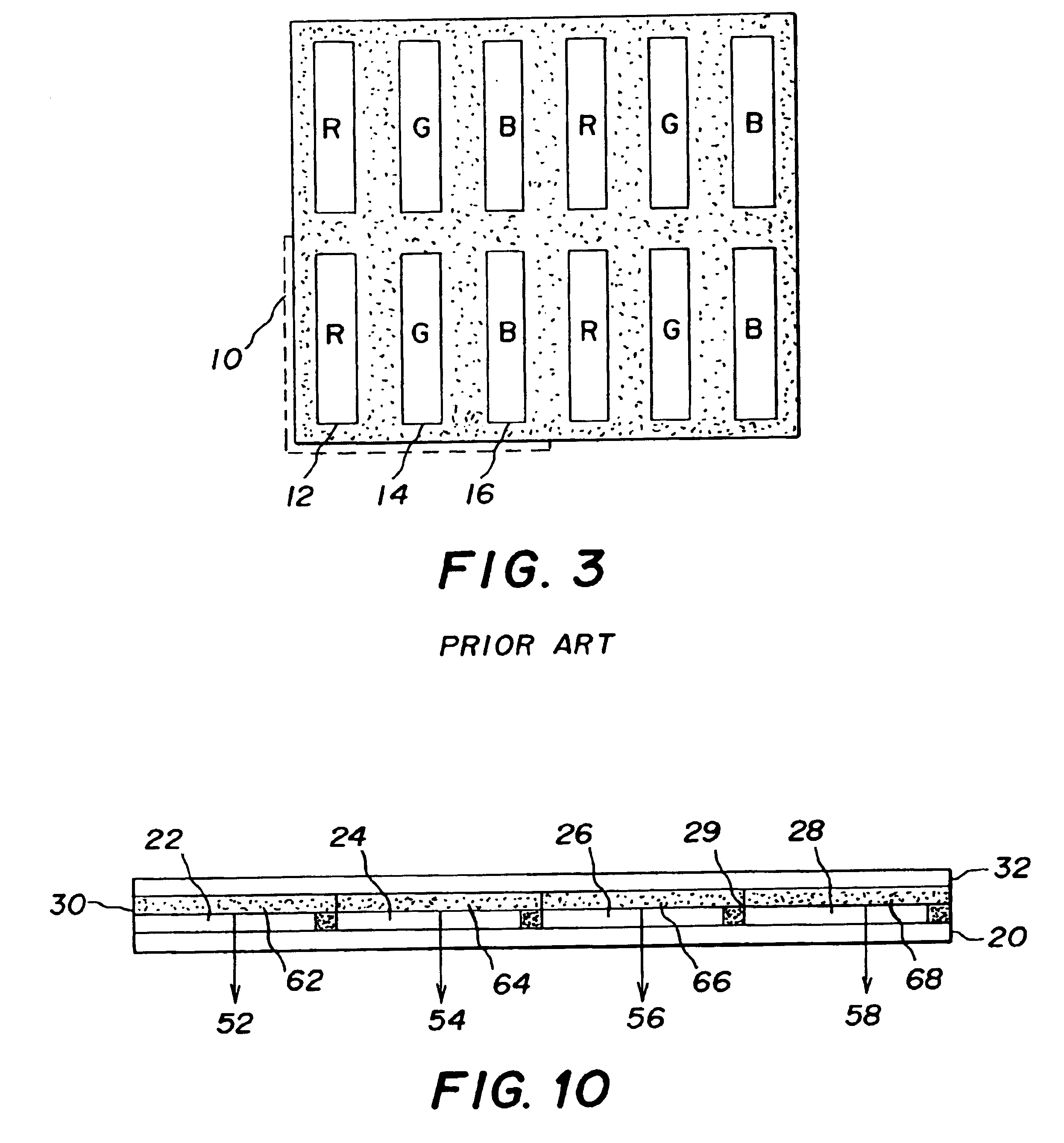

Color OLED display with improved power efficiency

ActiveUS6919681B2Good compatibilityImprove efficiencyDischarge tube luminescnet screensStatic indicating devicesOptoelectronicsDisplay device

A color OLED display includes an array of light emitting OLED pixels, each pixel having three or more gamut elements for emitting different colors of light specifying a gamut and at least one additional element for emitting a color of light within the gamut and wherein the power efficiency of the additional element is higher than the power efficiency of at least one of the three or more gamut elements; wherein all of the gamut elements for each color in the display are arranged in a first direction in a line such that no differently colored gamut element is in the line; wherein the colored gamut elements are arranged in a second direction orthogonal to the first direction in a line such that the colors of the gamut elements alternate in that line; and wherein the additional elements are arranged in lines in both the first and second directions.

Owner:GLOBAL OLED TECH

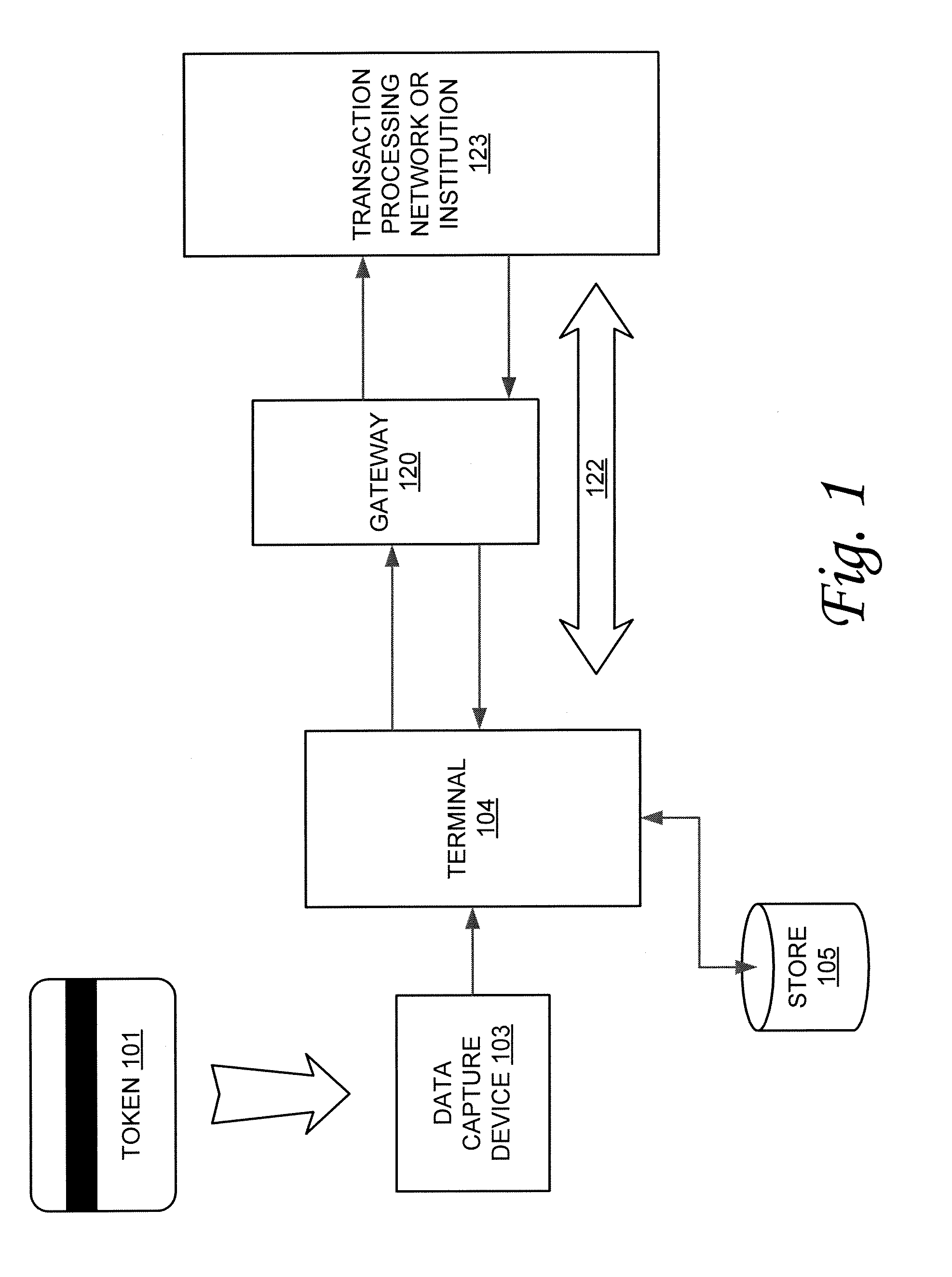

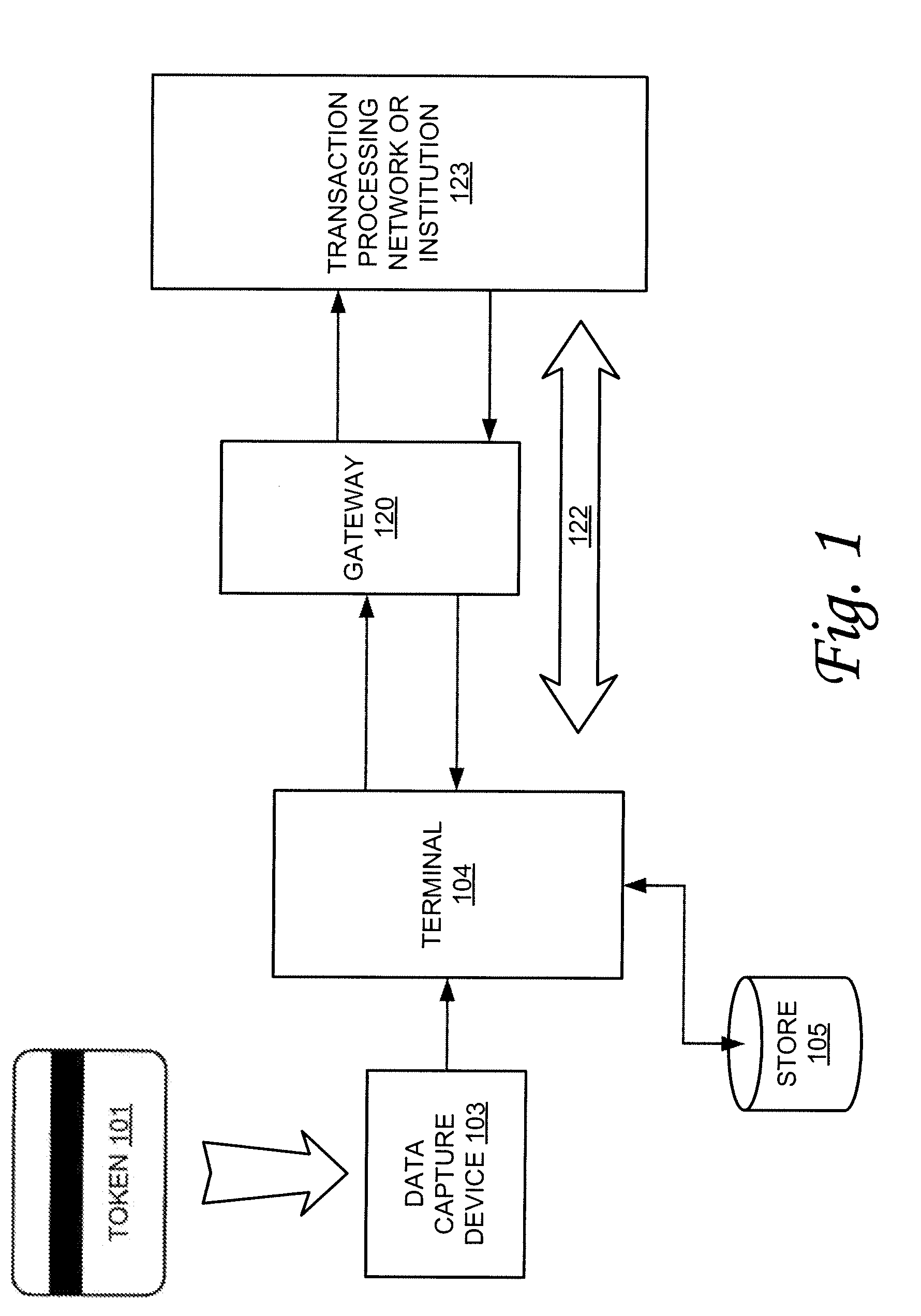

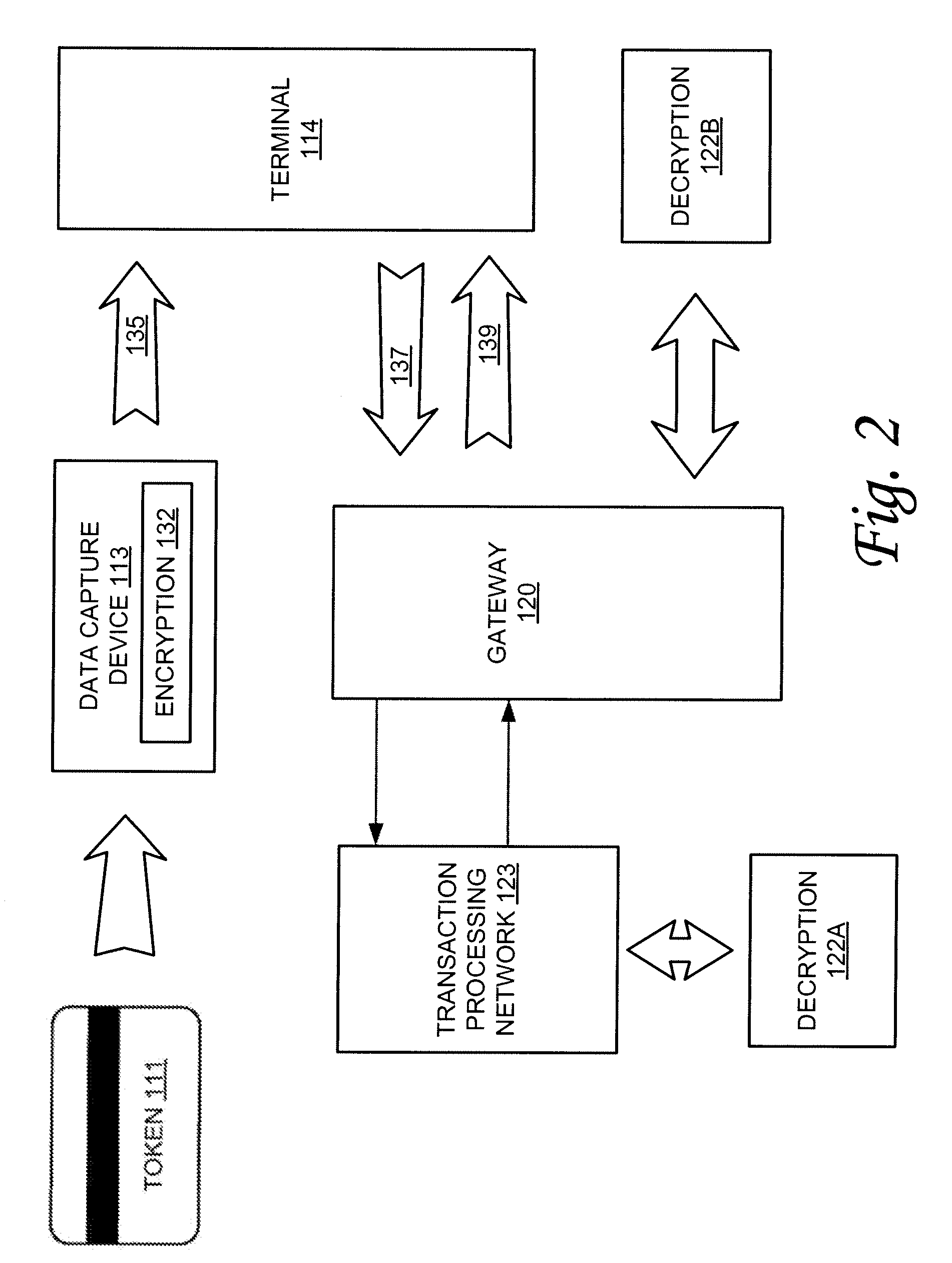

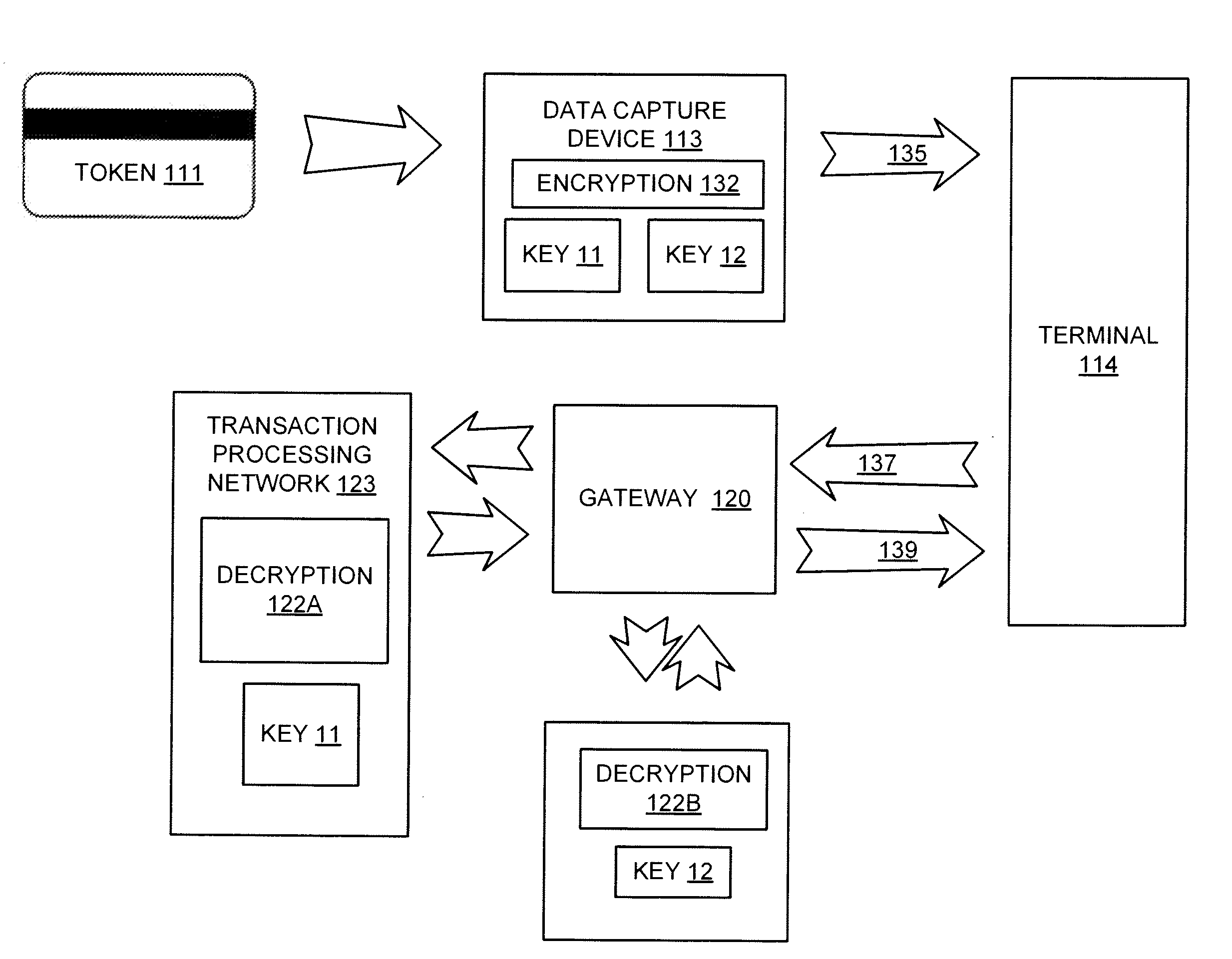

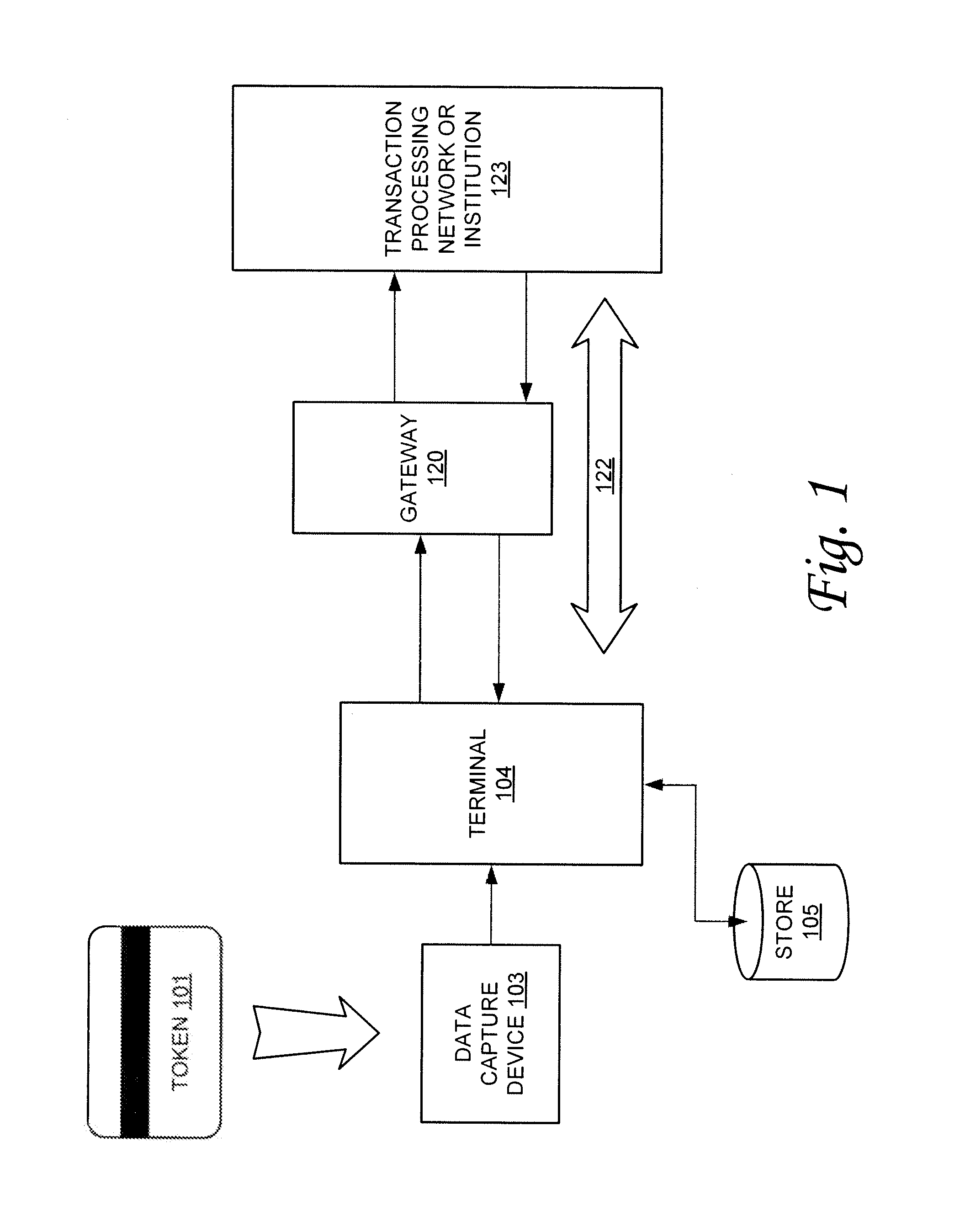

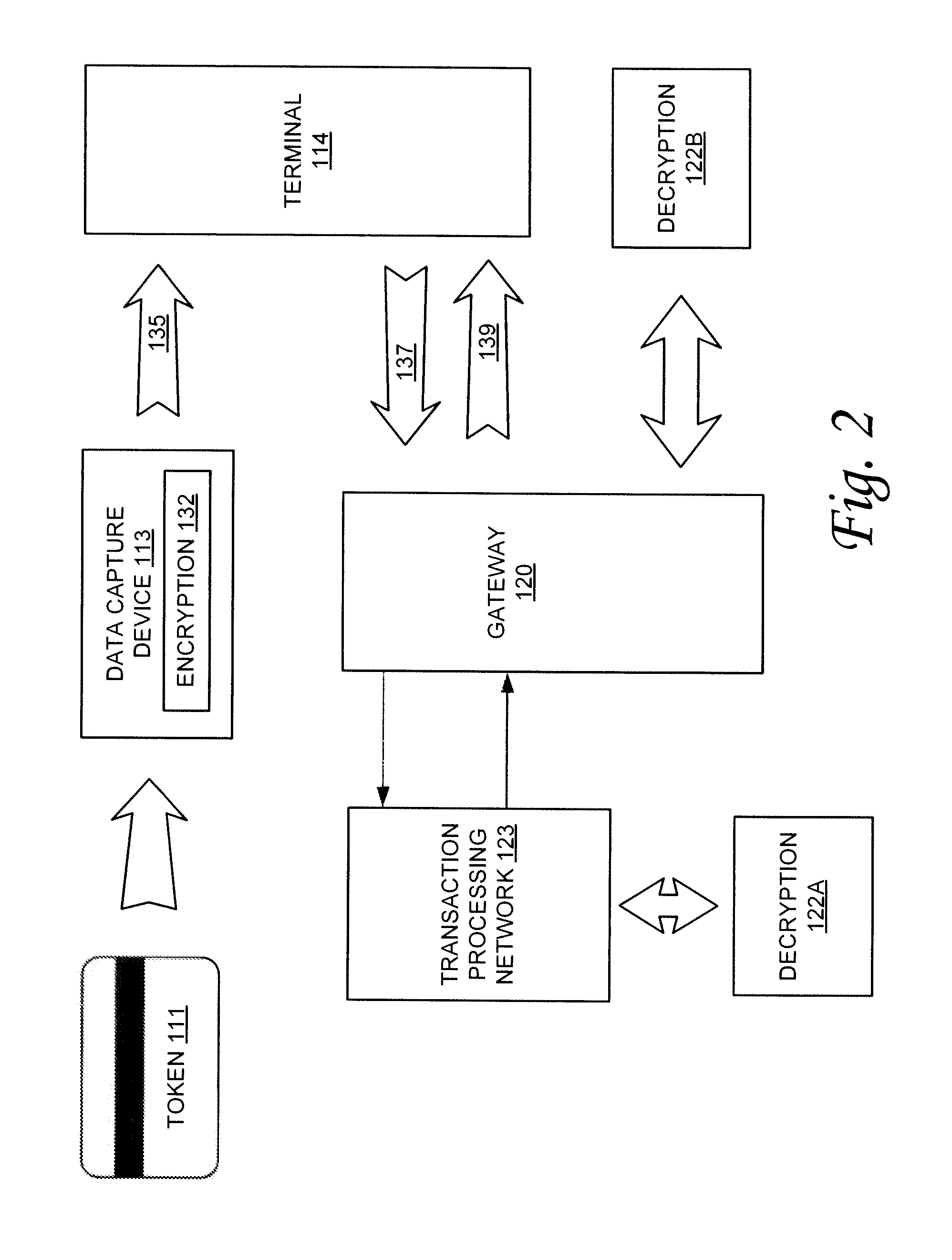

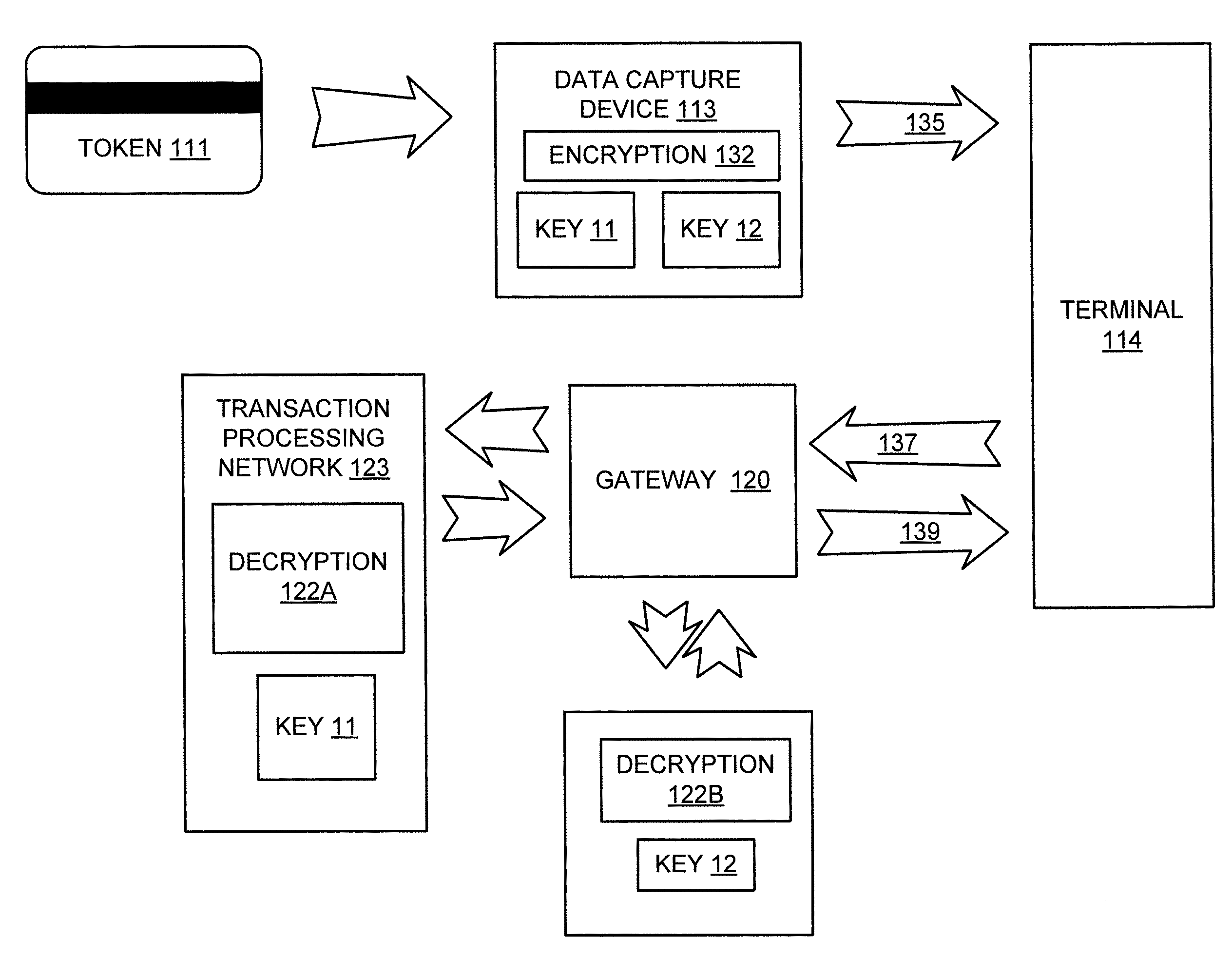

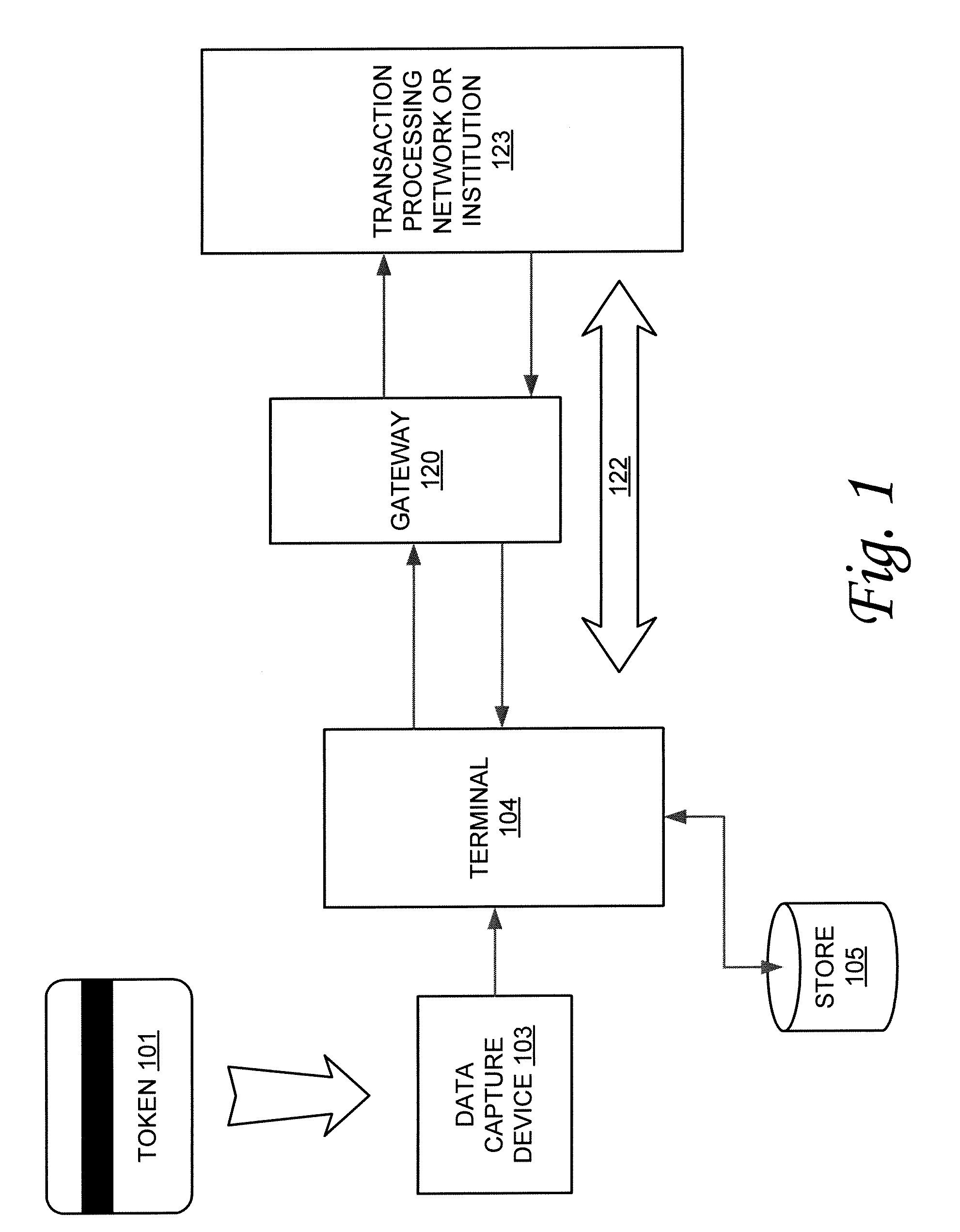

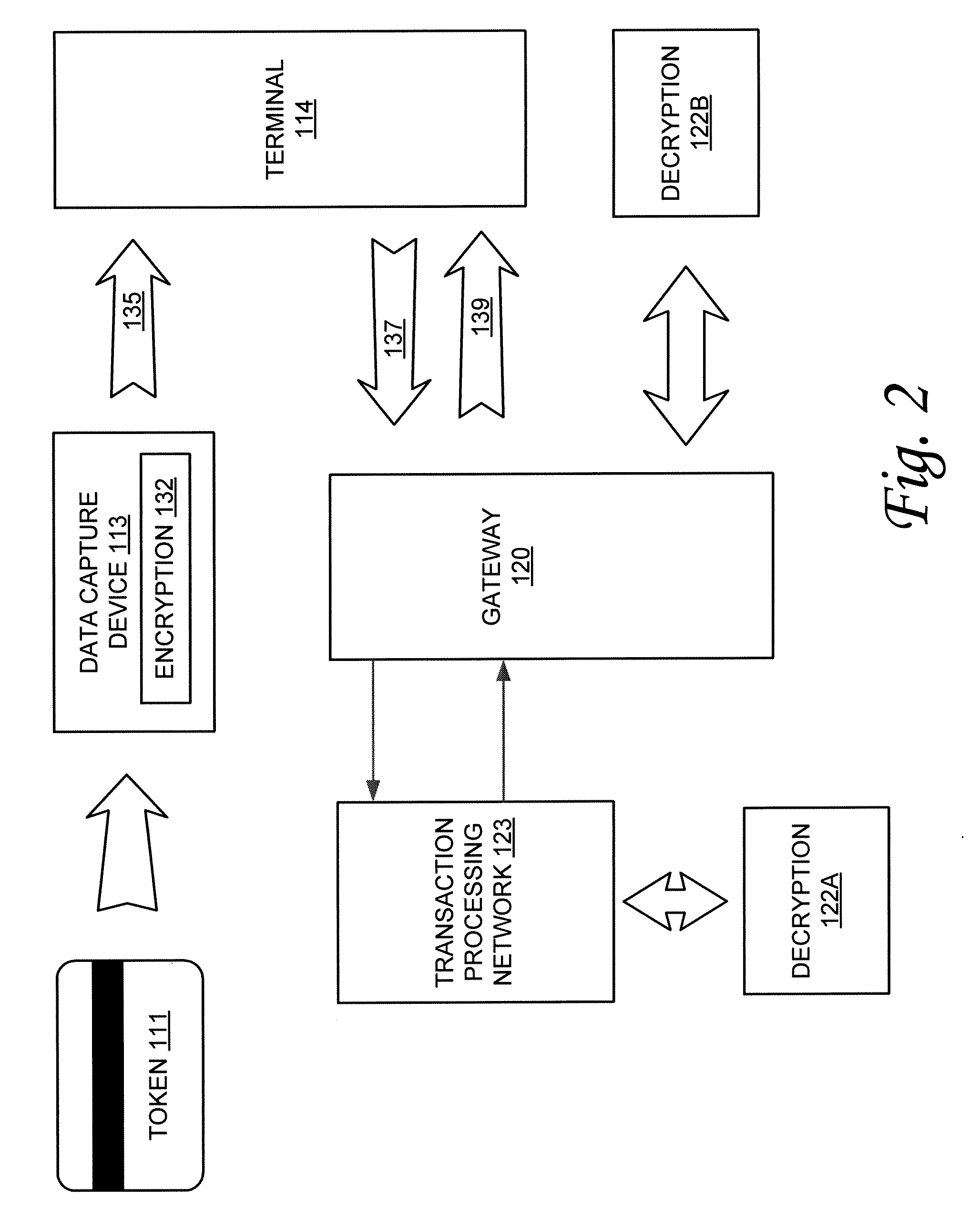

Method and system for secured transactions

InactiveUS20070276765A1Improve securityEasy to upgradeAcutation objectsFinancePlaintextBatch processing

Owner:SEMTEK INNOVATIVE SOLUTIONS

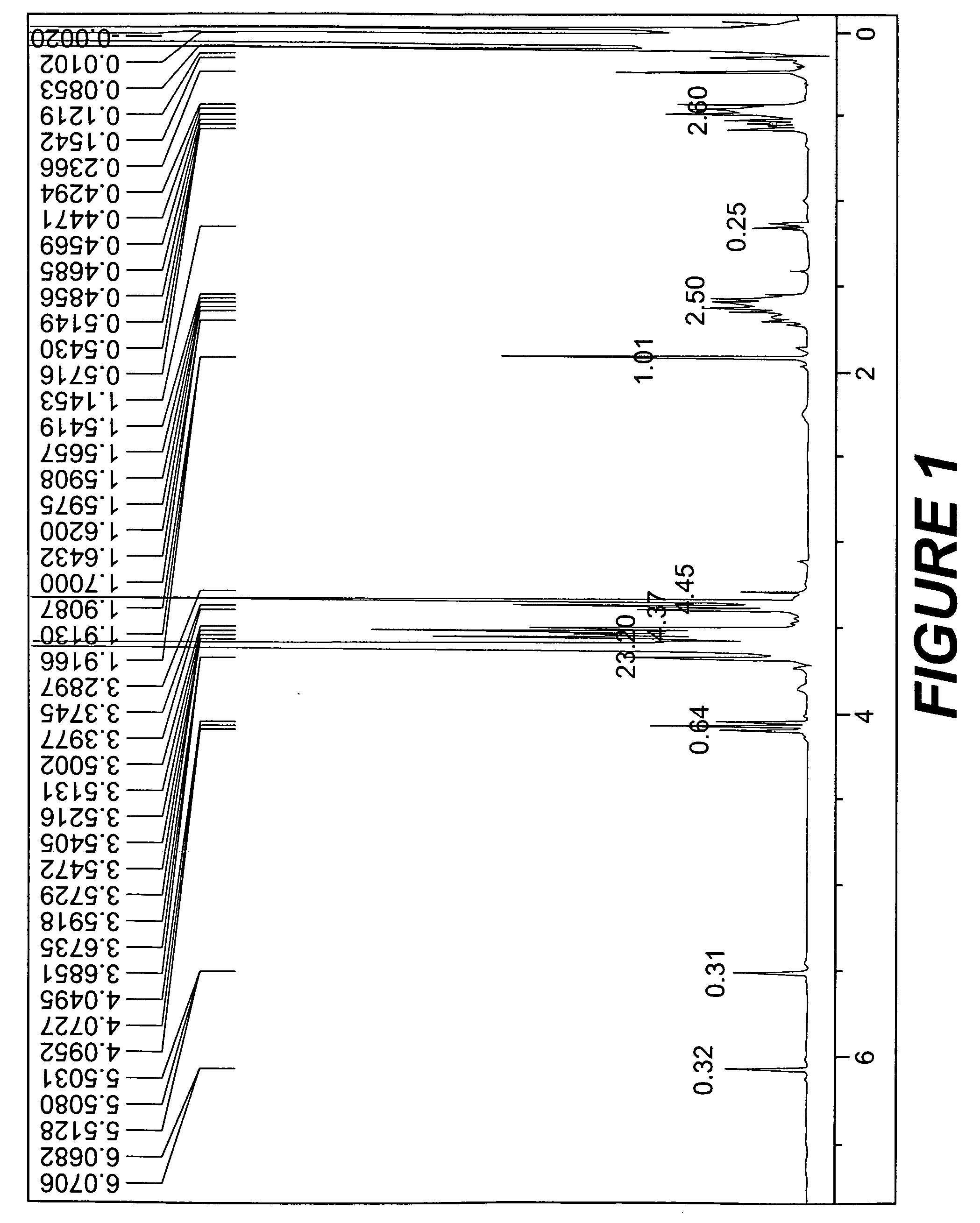

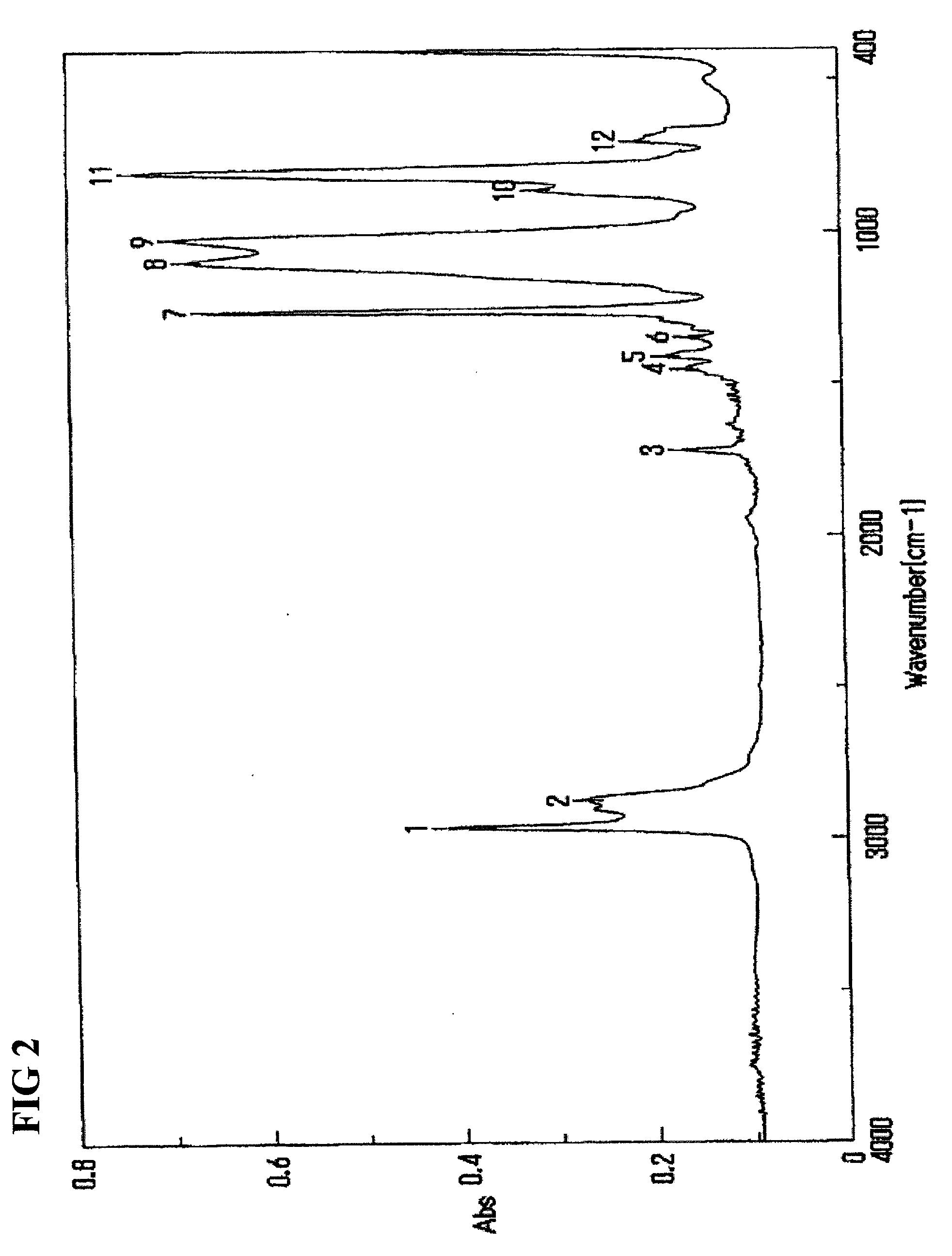

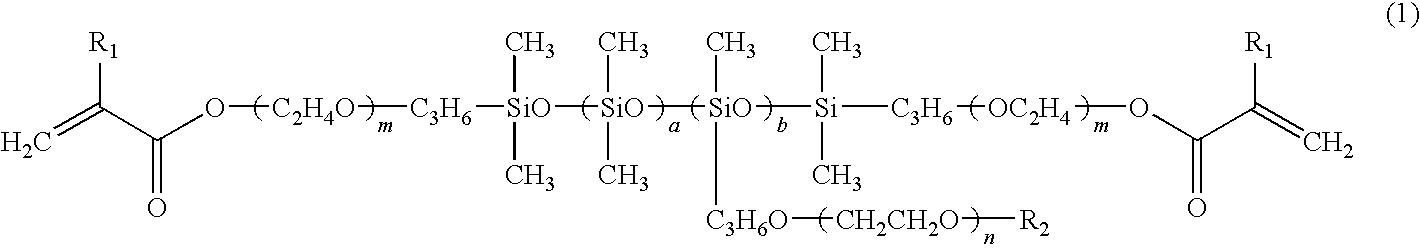

Hydrophilic Polysiloxane Macromonomer, and Production and Use of the same

ActiveUS20090234089A1Improve compatibilityHigh oxygen permeabilitySilicon organic compoundsOptical articlesSide chainHydrophile

Problem to be Solved To provide an ophthalmic lens, which can be more safely worn, that is, to provide a material, which is transparent and has high oxygen permeability and a high hydrophilic property, and to provide a novel monomer to be a raw material thereof.Solution A hydrophilic polysiloxane macromonomer contains polyoxyethylene as a hydrophilic side chains in a polysiloxane main chain, wherein transparency, oxygen permeability, and hydrophilic properties of the material are controlled by regulating the length of the polysiloxane main chain, the length of the hydrophilic polyoxyethylene side chains, and the number of the side chains.

Owner:COOPERVISION INT LTD

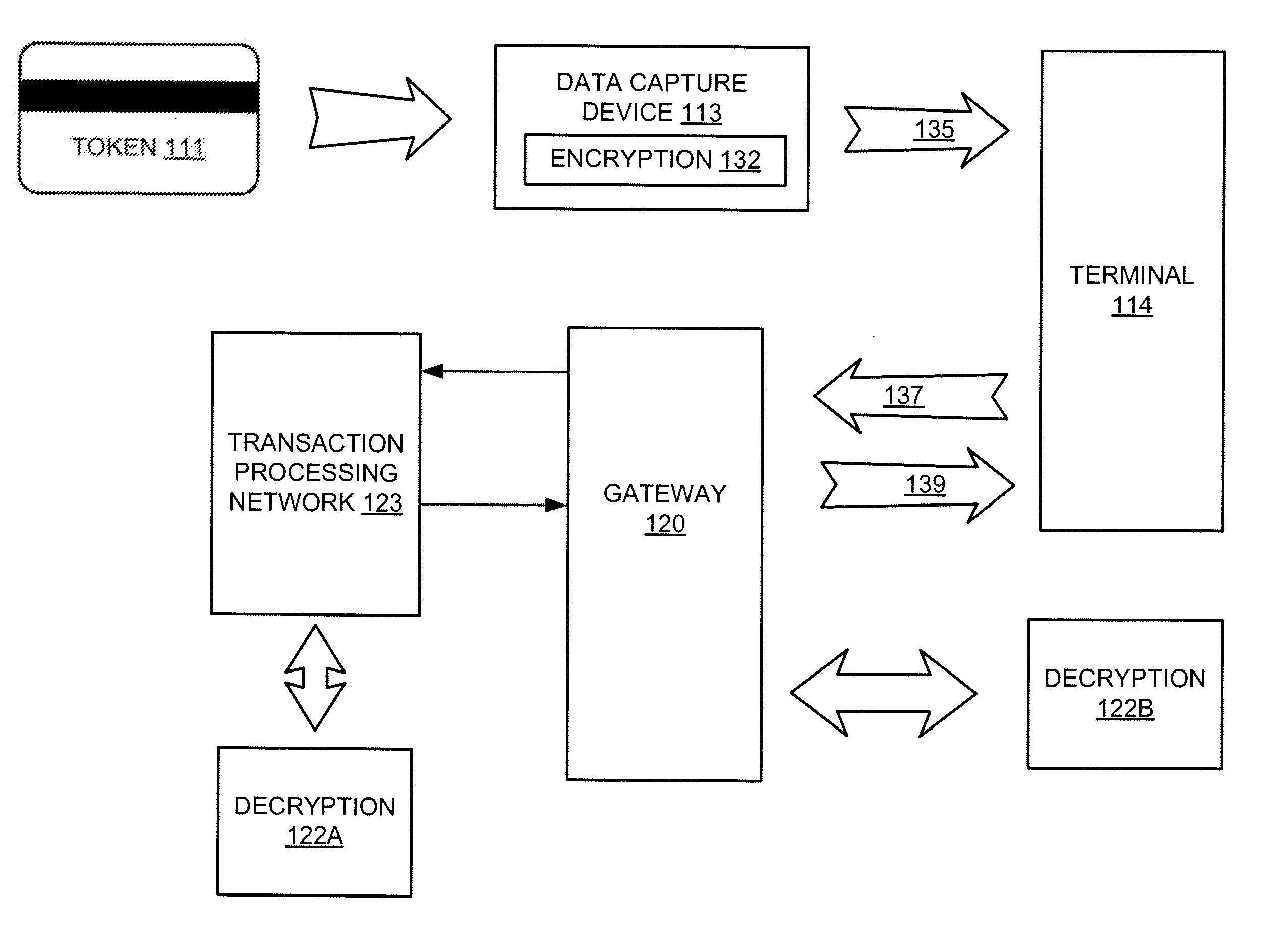

Metrics systems and methods for token transactions

ActiveUS20090048953A1Ensure data securityImprove securityAcutation objectsFinanceOperating systemE infrastructure

Systems and methods for monitoring token access transactions are provided. In one embodiment, the invention provides receiving transaction records for a plurality of bank card transactions, wherein the transaction records include transaction information and infrastructure information; determining whether a reportable event has occurred based on the transaction information with the transaction records; and providing an alert representing the reportable event.

Owner:VERIFONE INC

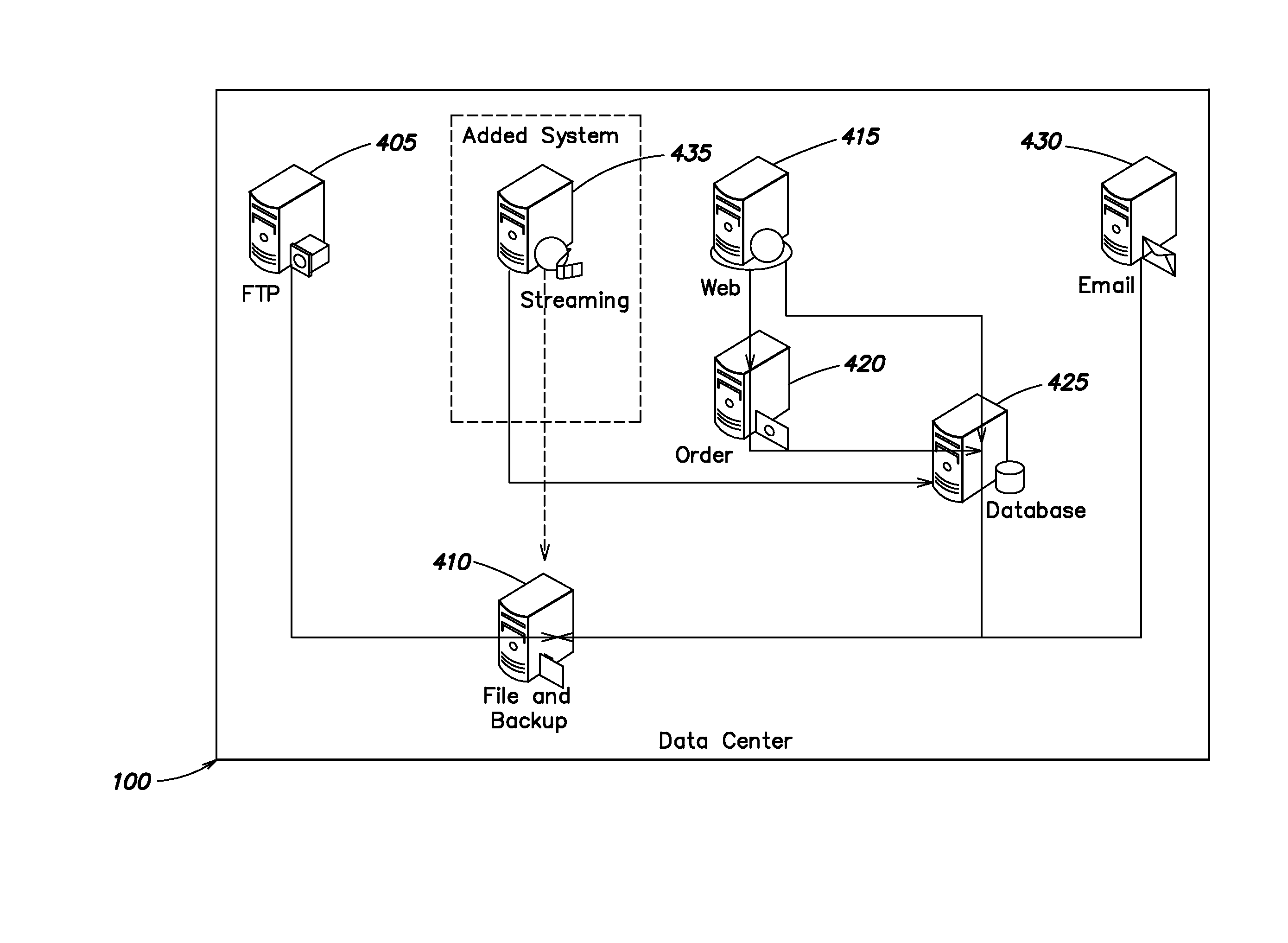

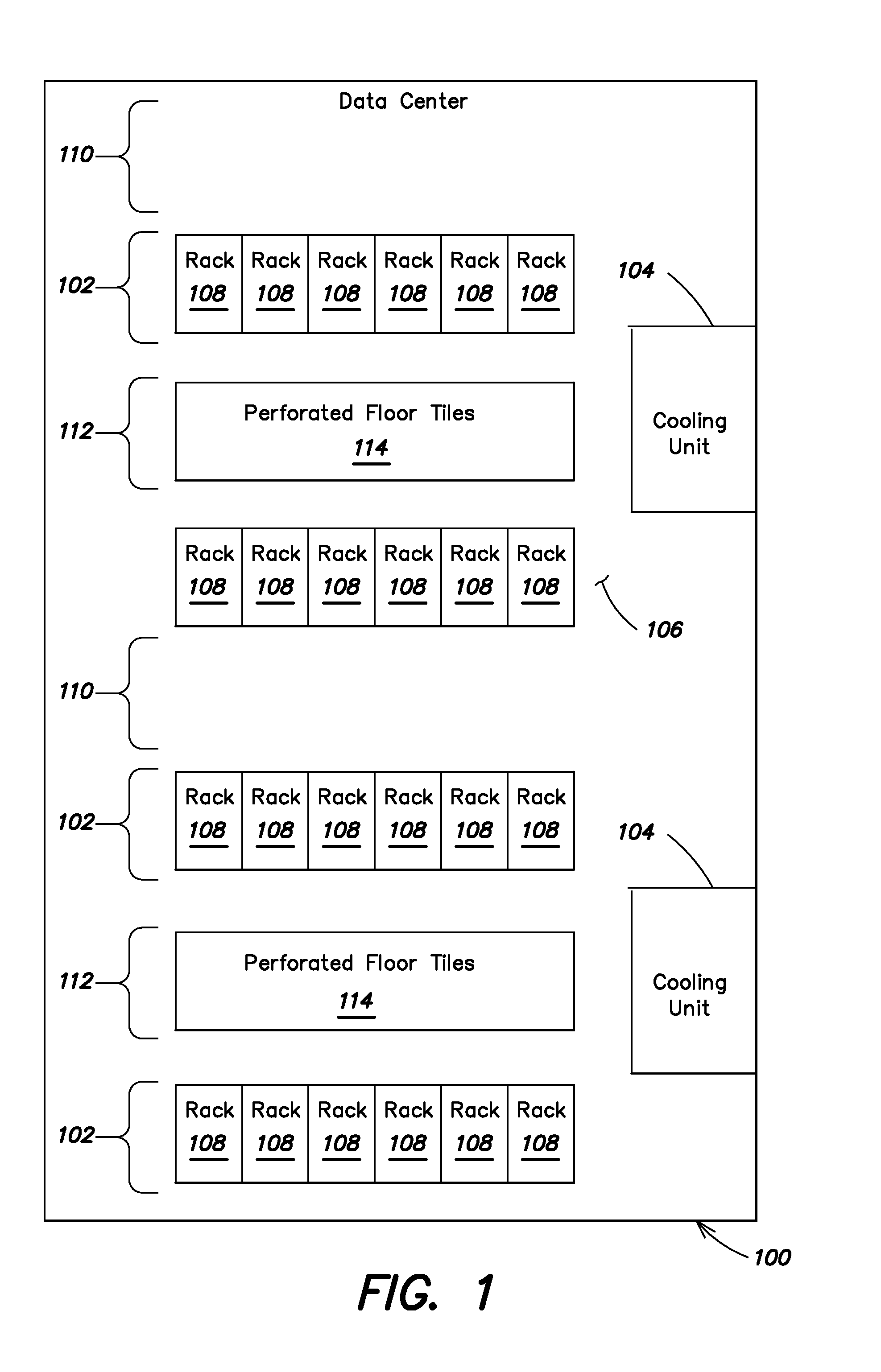

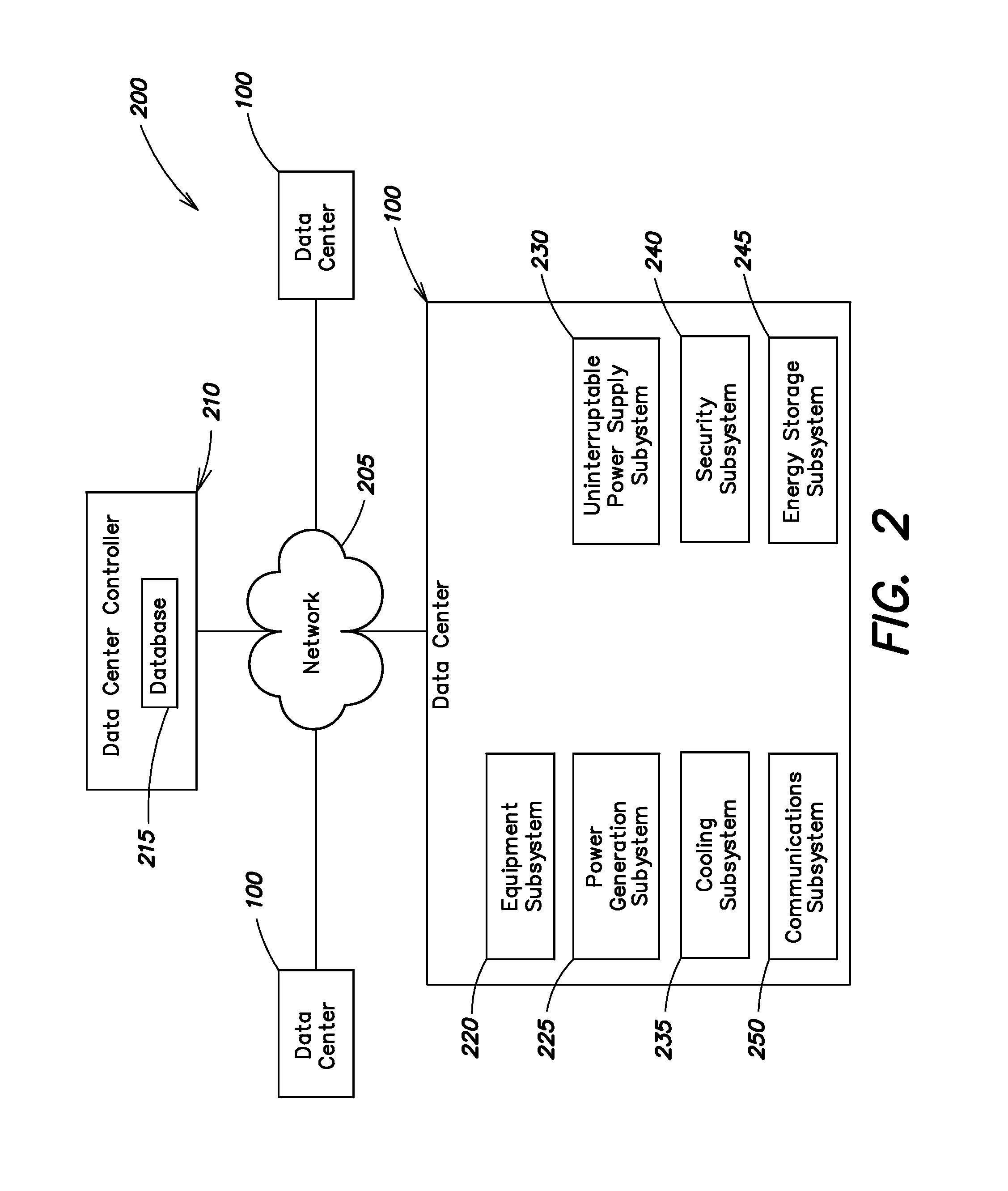

Data center control

ActiveUS20100211669A1Effective controlGood compatibilityResource allocationVolume/mass flow measurementControl systemData center

Systems and methods for data center control are provided that identify parameters of one or more data centers, where each data center includes a plurality of devices. The systems and methods receive a command to execute an application, and identify a selected data center from the one or more data centers as a location to run the application based at least in part on an evaluation of the parameters.

Owner:SCHNEIDER ELECTRIC IT CORP

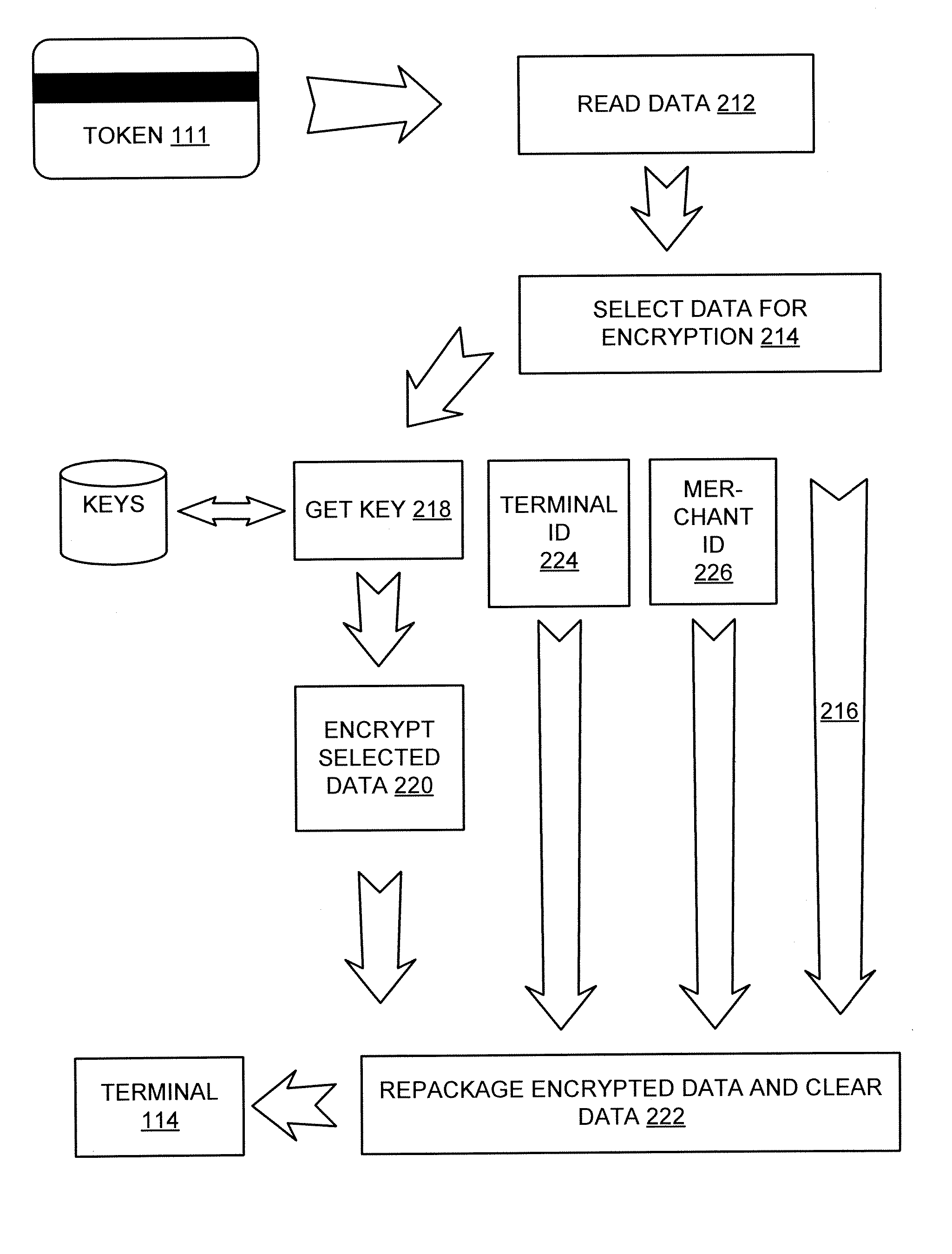

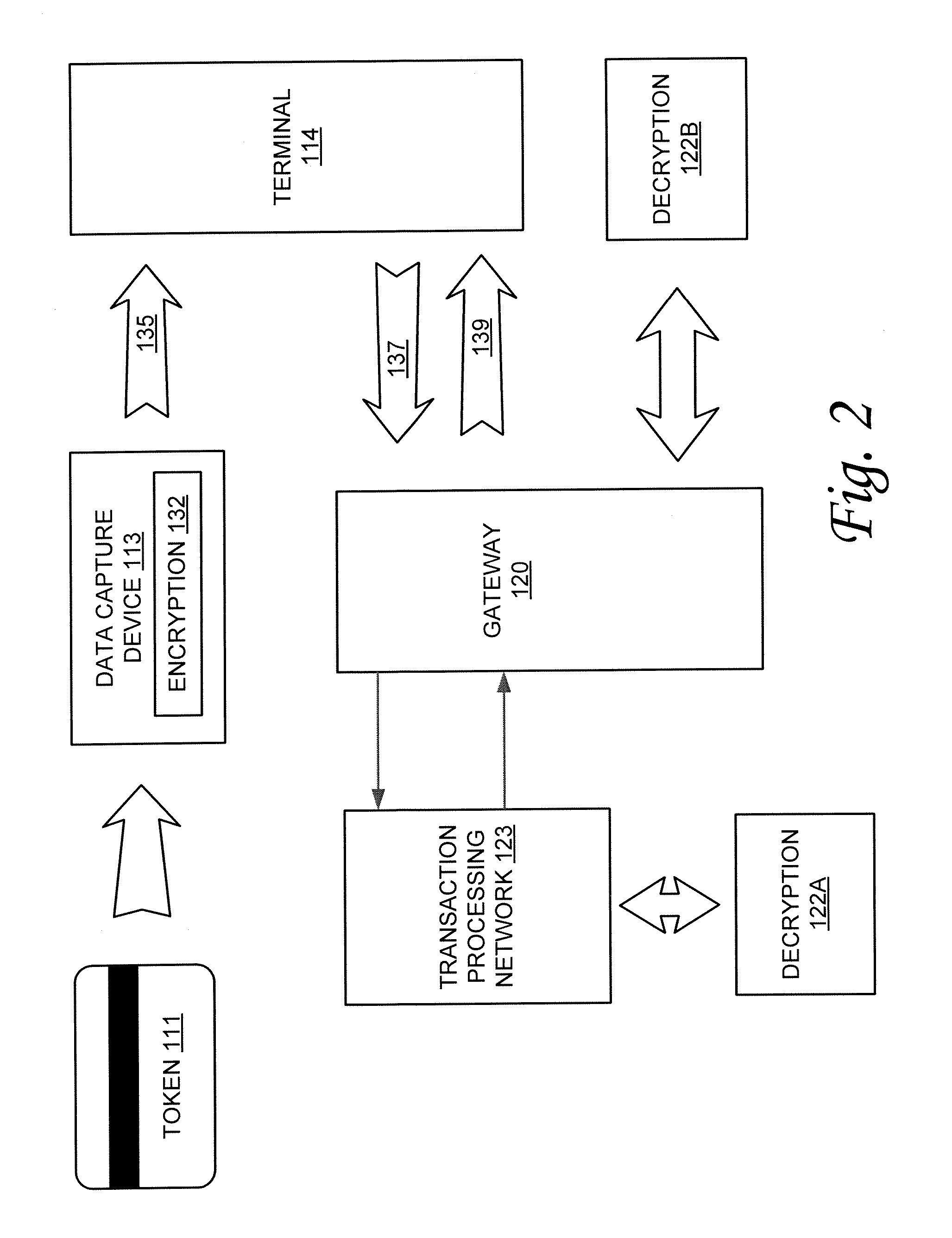

System and method for secure transaction

ActiveUS20090070583A1Improve securityEasy to upgradeFinanceCryptography processingPlaintextAuthentication

Systems and methods for performing a secure transaction provided. In one embodiment, the method includes: reading data on a command token, reading data on a token; encrypting the token data with a key; encrypting an authentication data with a clear text token data; and transmitting the encrypted authentication data with the encrypted token data to a remote device.

Owner:VERIFONE INC

Cast form water borne coating and technique for preparing the same

InactiveCN101497105AGood water dispersibilityGood suspensionFoundry mouldsFoundry coresDefoaming AgentsCorrosion

The invention relates to an auxiliary material for casting a mould, in particular to a casting mould water-based coating formulation for a sand mould or an expendable pattern casting (EPC), and a process for preparing the same. The casting mould water-based coating formulation consists of refractory powder, a suspending agent, a bonding agent, a surfactant, a defoaming agent, a corrosion remover and water. The process comprises the following steps: adding the suspending agent to the water directly, and mixing and dispersing the mixture in a high speed dispersion machine; adding auxiliary agents including the defoaming agent, the surfactant, the corrosion remover, and the like to the water, and mixing the auxiliary agents; adding the refractory powder to the mixture to be mixed; and adding the bonding agent to the mixture to be mixed, and then adding water to adjust the coating until the coating has the thickness in a using state to obtain the finished product. The coating prepared by the process has the effects that the coating ensures that a high-density low-viscosity coating has excellent suspension property and storage stability, a coating layer is not easy to crack after drying, the coating is advantageous to improve the capacity of the coating to resist high temperature metal corrosion, and the like.

Owner:深圳市景鼎现代科技有限公司

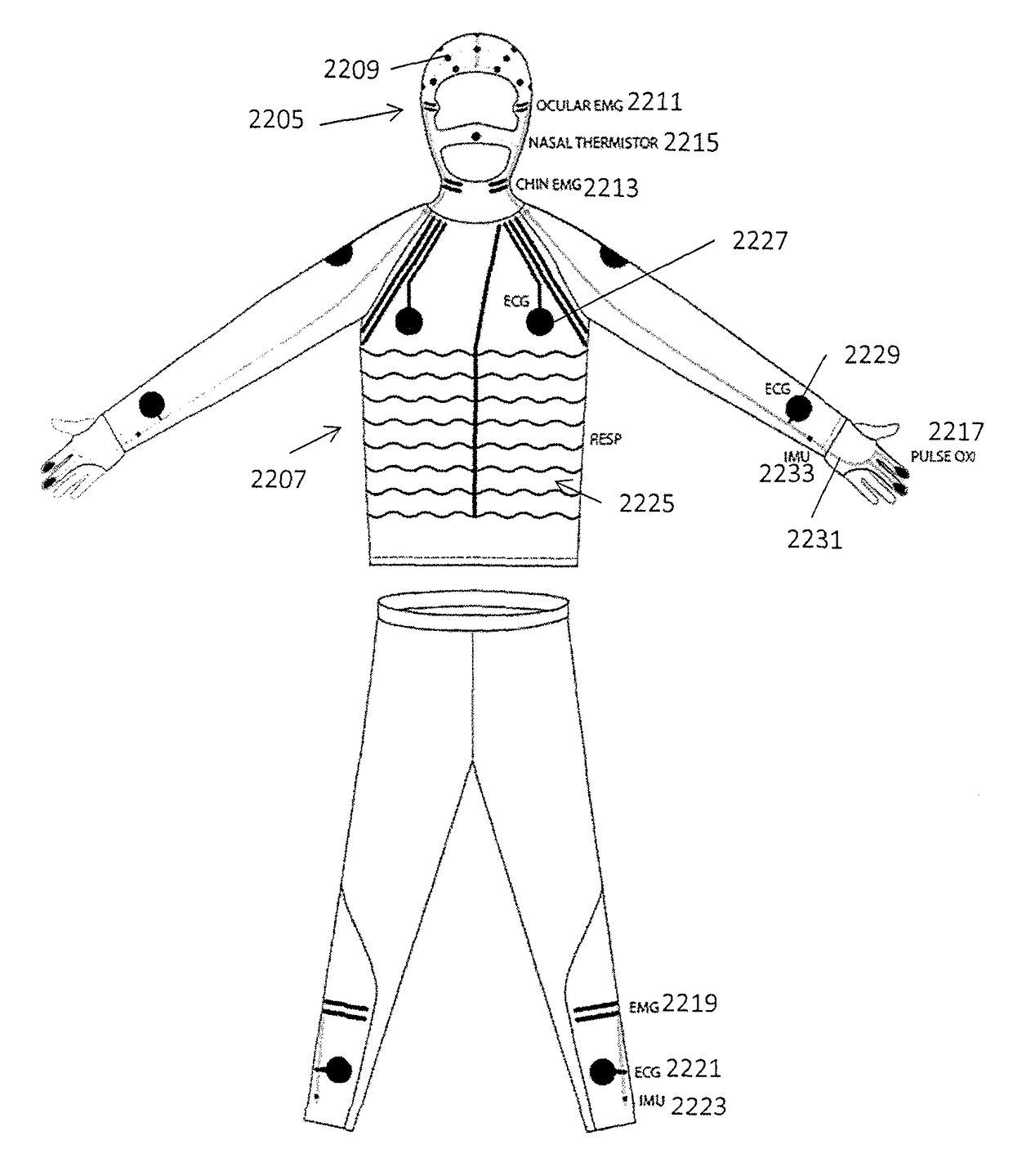

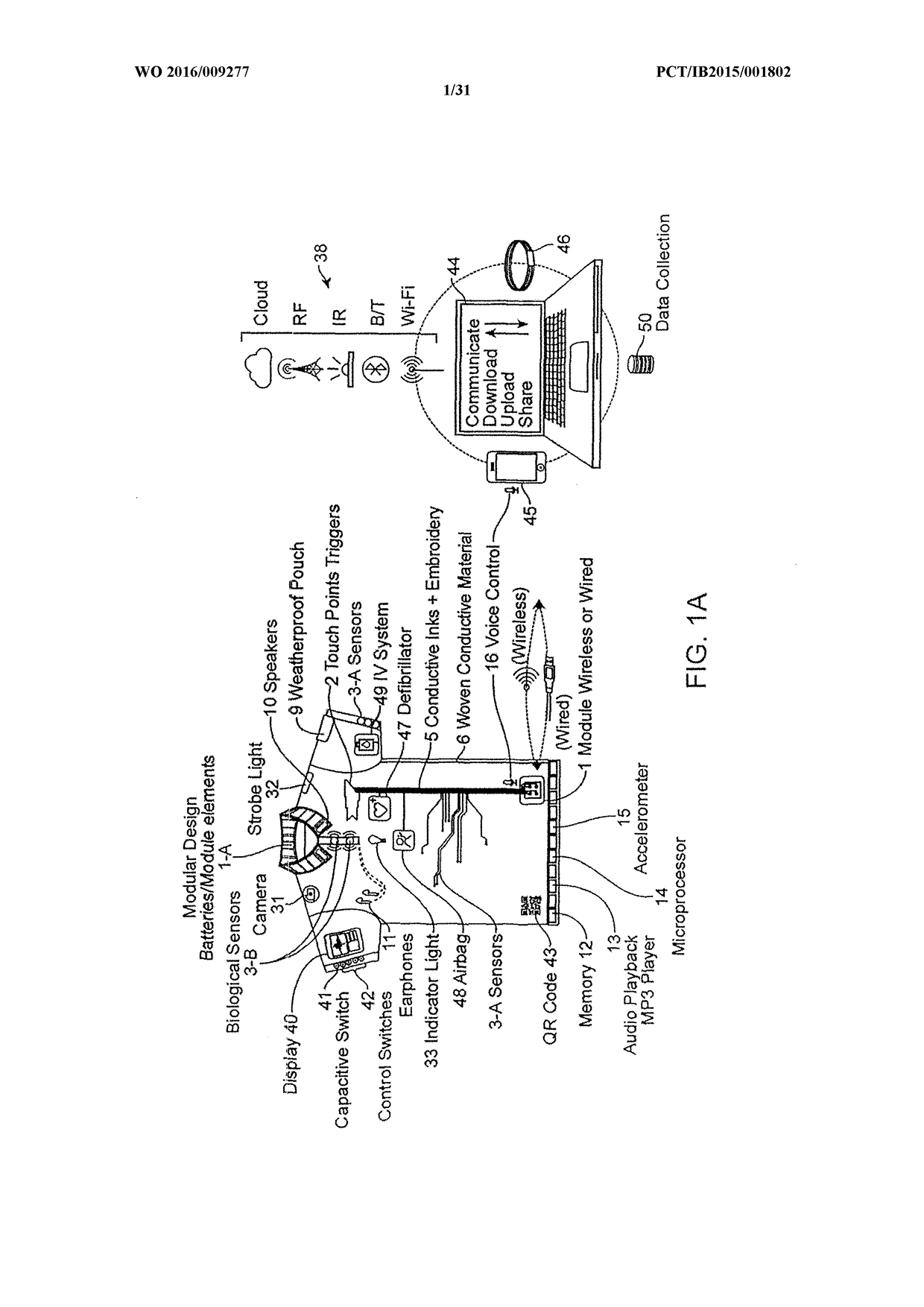

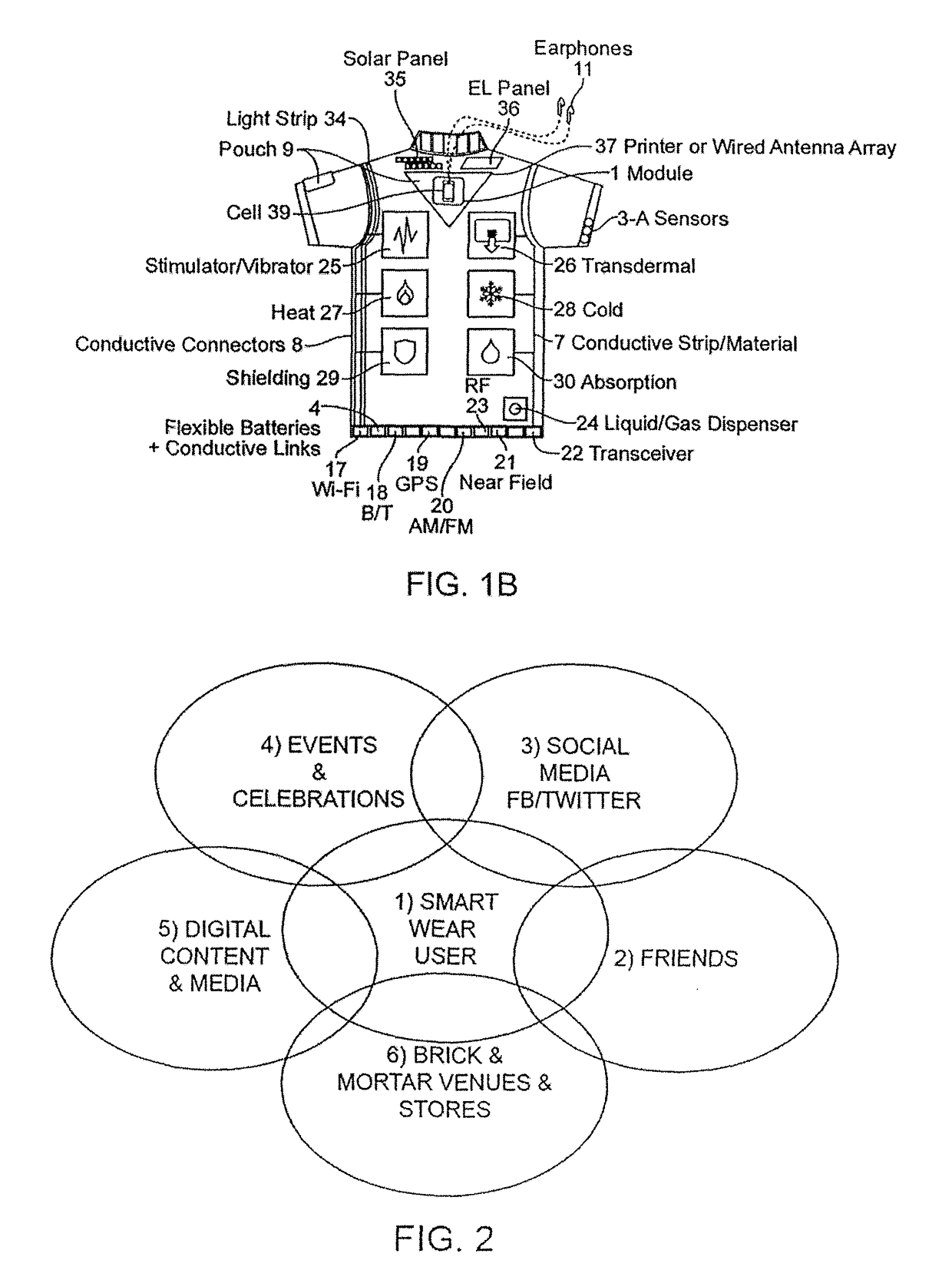

Garments having stretchable and conductive ink

ActiveUS20170196513A1Improve adhesionGood compatibilityPrinted circuit manufactureMeasuring/recording heart/pulse rateAdhesiveEngineering

Methods of forming garments having one or more stretchable conductive ink patterns. Described herein are method of making garments (including compression garments) having one or more highly stretchable conductive ink pattern formed of a composite of an insulative adhesive, a conductive ink, and an intermediate gradient zone between the adhesive and conductive ink. The conductive ink typically includes between about 40-60% conductive particles, between about 30-50% binder; between about 3-7% solvent; and between about 3-7% thickener. The stretchable conductive ink patterns may be stretched more than twice their length without breaking or rupturing.

Owner:L I F E

Elastic blends comprising crystalline polymer and crystallizable polymers of propylene

Improved thermoplastic polymer blend compositions comprising an isotactic polypropylene component and an alpha-olefin and propylene copolymer component, said copolymer comprising crystallizable alpha-olefin sequences. In a preferred embodiment, improved thermoplastic polymer blends are provided comprising from about 35% to about 85% isotactic polypropylene and from about 30% to about 70% of an ethylene and propylene copolymer, wherein said copolymer comprises isotactically crystallizable propylene sequences and is predominately propylene. The resultant blends manifest unexpected compatibility characteristics, increased tensile strength, and improved process characteristics, e.g., a single melting point.

Owner:EXXONMOBIL CHEM PAT INC

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

Batch settlement transactions system and method

InactiveUS20080091944A1Ensure data securityImprove securityCryptography processingUser identity/authority verificationPlaintextBatch processing

Systems and methods for performing settlement of token access transactions are provided. In one embodiment, the invention provides for batch processing bank card transactions, including receiving transaction records for a plurality of bank card transactions, wherein at least some of the transaction records include encrypted token information; determining whether the transaction records contain encrypted token information; decrypting the encrypted token information for a transaction record that is determined to have encrypted token information; and providing clear text token information obtained by decrypting the encrypted token information for a transaction record for transaction settlement.

Owner:VERIFONE INC

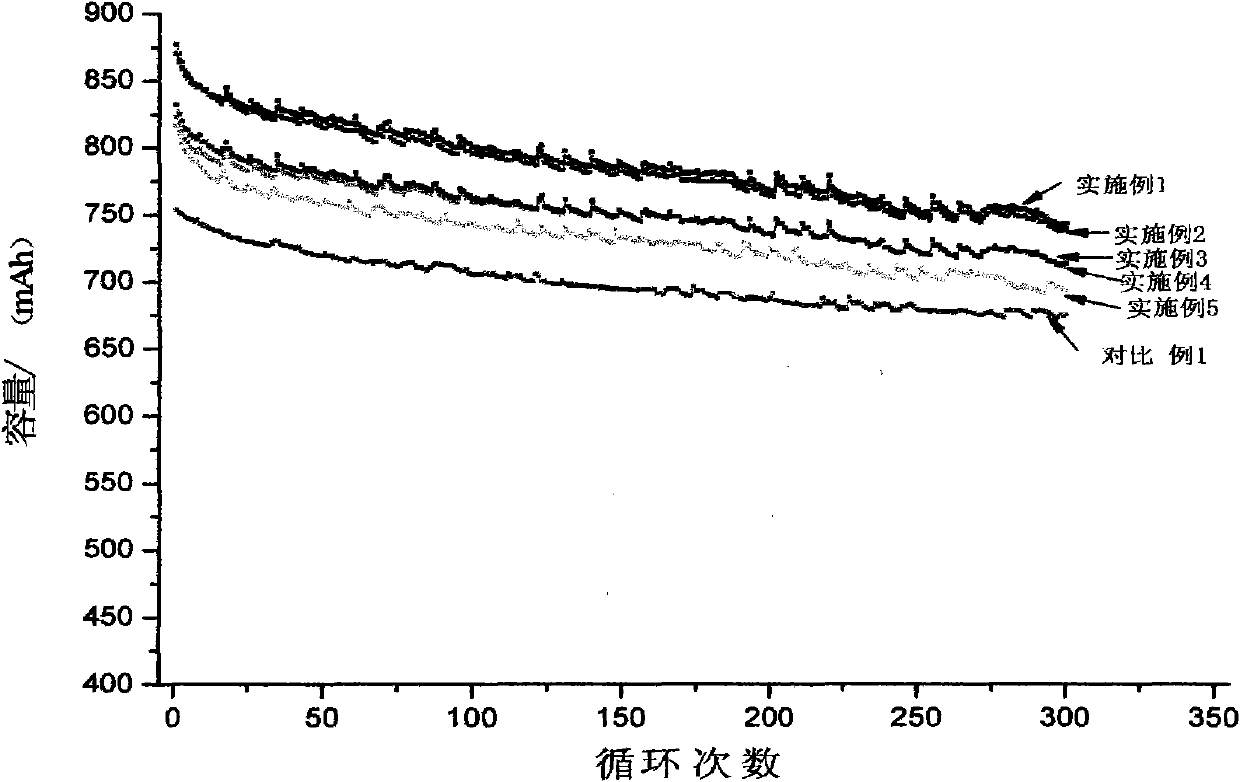

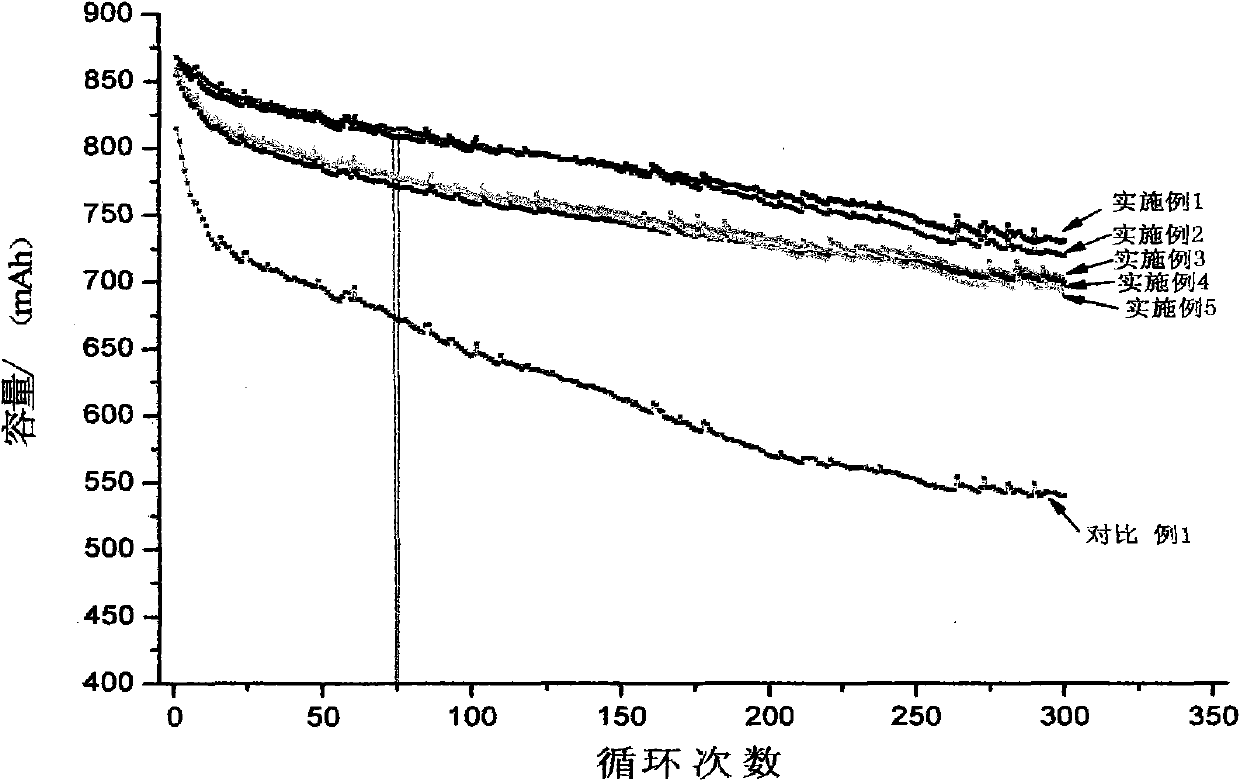

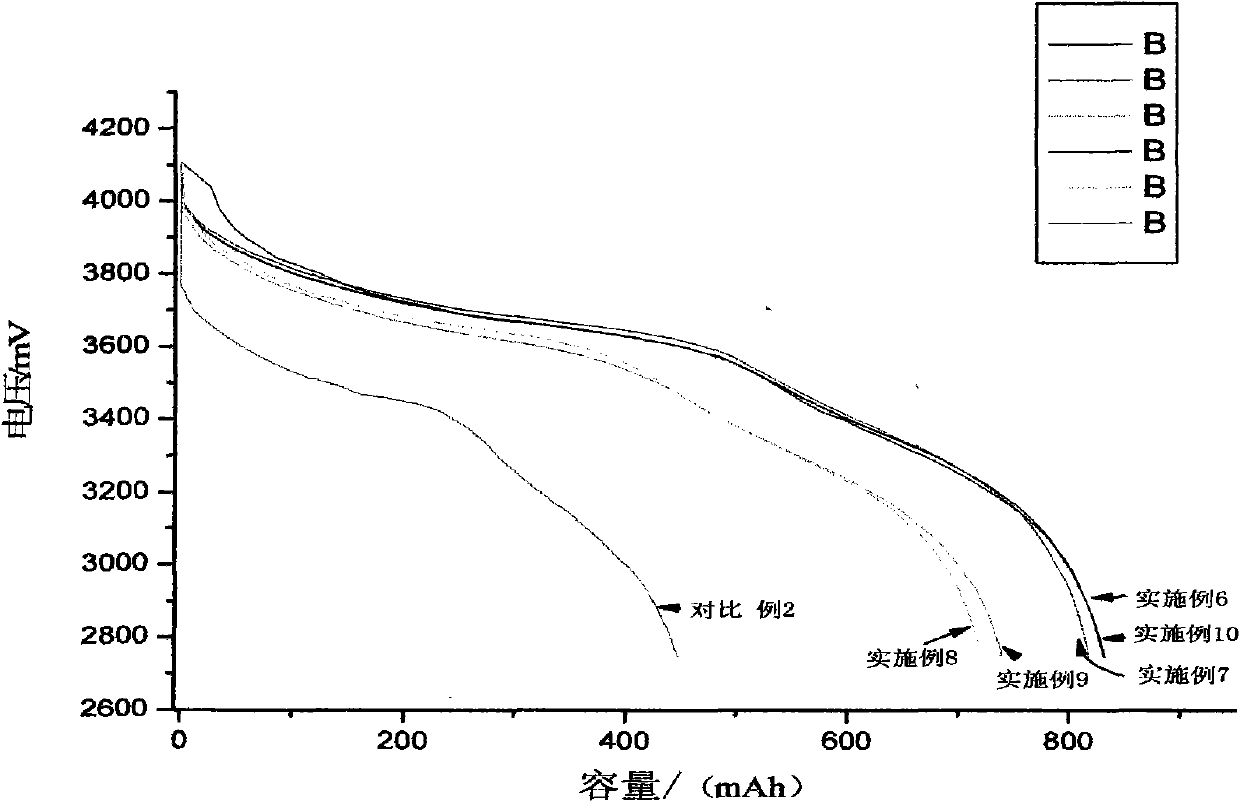

High-capacity lithium-ion electrolyte, battery and preparation method of battery

ActiveCN101771167AIncrease capacityLow costFinal product manufactureCell electrodesElectrolytic agentPhysical chemistry

The invention relates to a high-capacity lithium-ion electrolyte, a battery and a preparation method of a battery, in particular to the high-capacity lithium-ion electrolyte and the battery using the high-capacity lithium-ion electrolyte and the preparation method of the battery. The electrolyte disclosed by the invention comprises lithium salt and non-aqueous organic solvent, and also consists of the following components in weight percent in terms of the total weight of the electrolyte: 0.5-7% of film-forming additive, 0-15% of flame-retardant additive, 2-10% of antiovefill additive, 0.01-2% of stabilizer and 0.01-1% of wetting agent; the electrolyte can enable the anode with high Ni content to work stably, and reduce the battery cost; the high-capacity lithium-ion battery can perform high ratio capacity and excellent safety and high temperature property and cyclic life fully due to the addition and synergetic functions of various functional additives.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

Fluoroligomer surface modifiers for polymers and articles made therefrom

InactiveUS6127507AGood compatibilityImprove stabilitySynthetic resin layered productsPharmaceutical containersPolymer scienceMedical device

A composition comprising in admixture with a polymer, preferably a polyurethane, and a compatible surface-modifying macromolecule having (i) a central portion of a segmented block oligomeric copolymer comprising at least one polar hard segment, and (ii) PROPORTIONAL - omega terminal polyfluoro oligomeric groups, in a surface modifying enhancing amount. The composition is of use in providing articles having improved surface properties, particularly, medical devices having improved resistance to enzyme degradation with acceptable blood compatibility.

Owner:INTERFACE BIOLOGICS INC

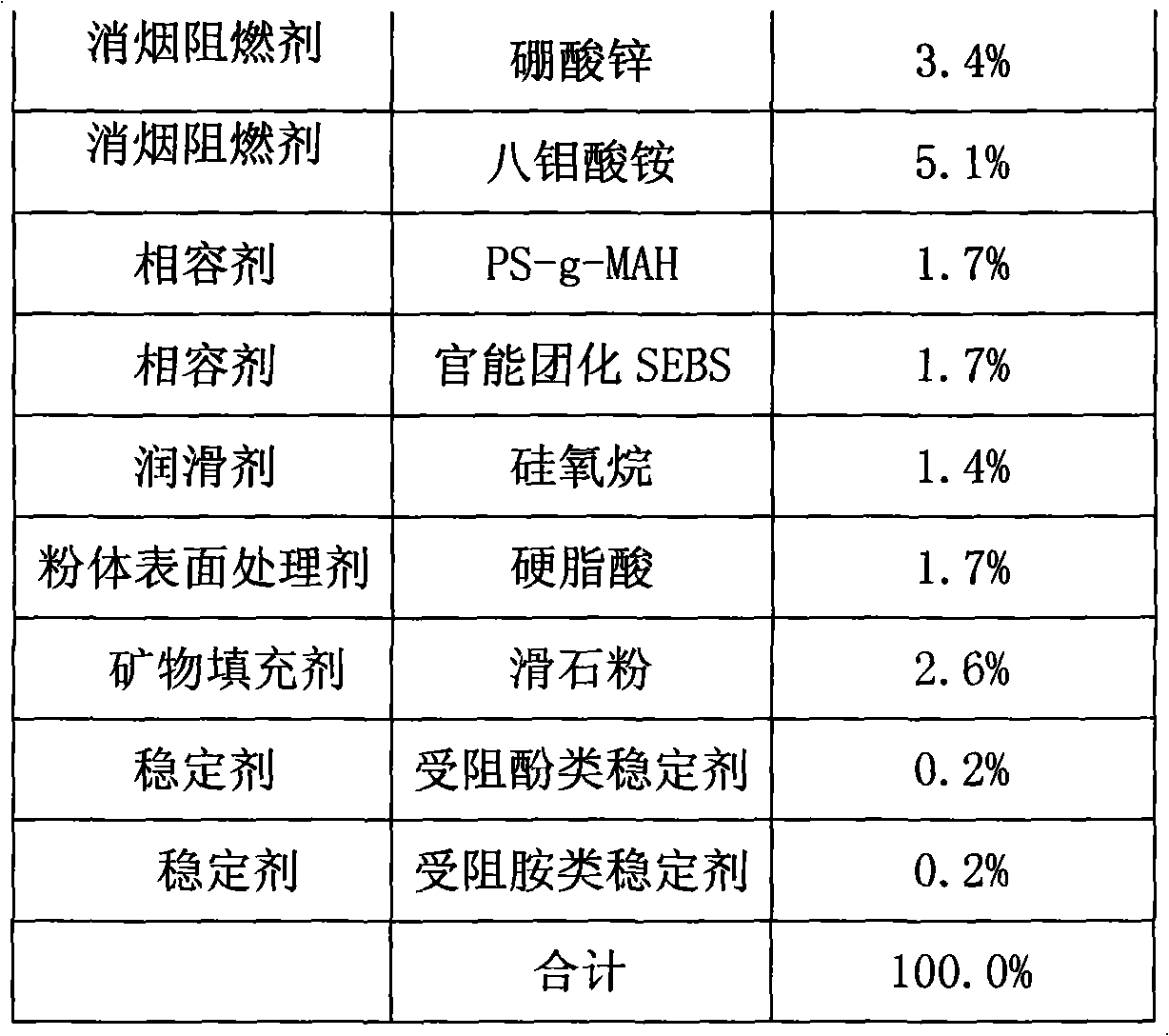

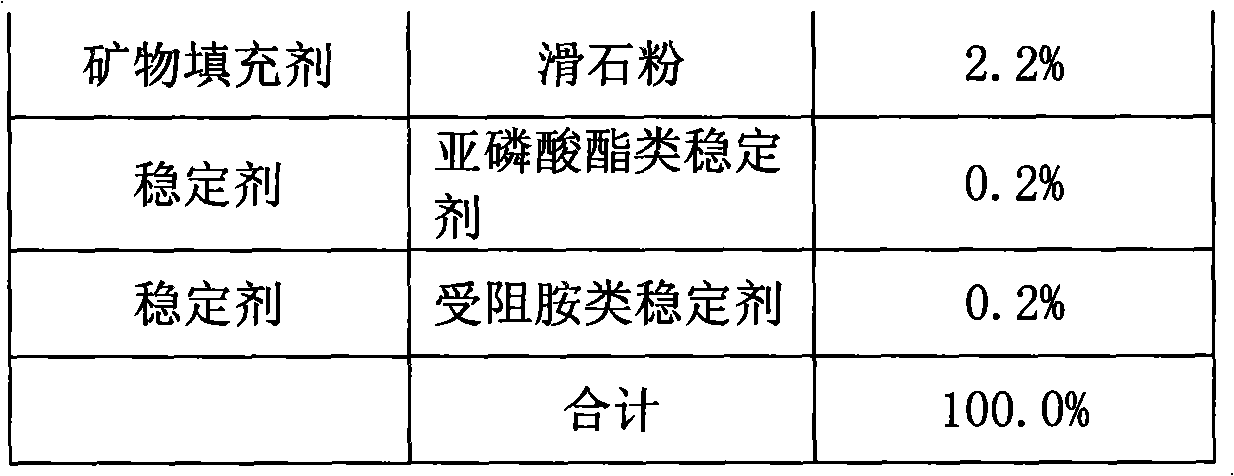

Halogen-free flame-retardant thermoplastic elastomer electrical cable material using polyphenylene ether as base material and preparation method thereof

InactiveCN101358028AGood compatibilityReduce stratificationInsulated cablesInsulated conductorsElastomerPolyphenylene oxide

The invention discloses a halogen-free flame-retardant thermoplastic elastomer cable material with polyphenylether as the base materials and a preparation method thereof. The raw material of the cable material contains the components with the following weight percentage: 10 to 35 percent of matrix resin A; 5 to 15 percent of matrix resin B; 10 to 25 percent of elastomer; 5 to 25 percent of softening plasticizer; 8 to 15 percent of flame-retardant plasticizer; 20 to 40 percent of smoke-suppression flame retardant; 3 to 10 percent of compatilizer; 1 to 5 percent of lubricant; 1 to 5 percent of powder surface conditioner; 0 to 10 percent of mineral filler; 0.1 to 1 percent of stabilizing agent. The invention adds matrix resin, polyphenylether of strong polarity and functional group of styrene-ethylene / butylene-styrene segmented copolymer, which effectively improves the compatibility of non-polar elastomer with polyphenylether; the invention also adds plasticizer, which reduces the hardness of the material and increases the flexibility; and through the optimization and interaction of the softening plasticizer and the flame-retardant plasticizer, the invention reduces the hardness and improves the tactility of the material, and the flame retardant performance is excellent.

Owner:NINGBO SHIP PLASTIC CO LTD

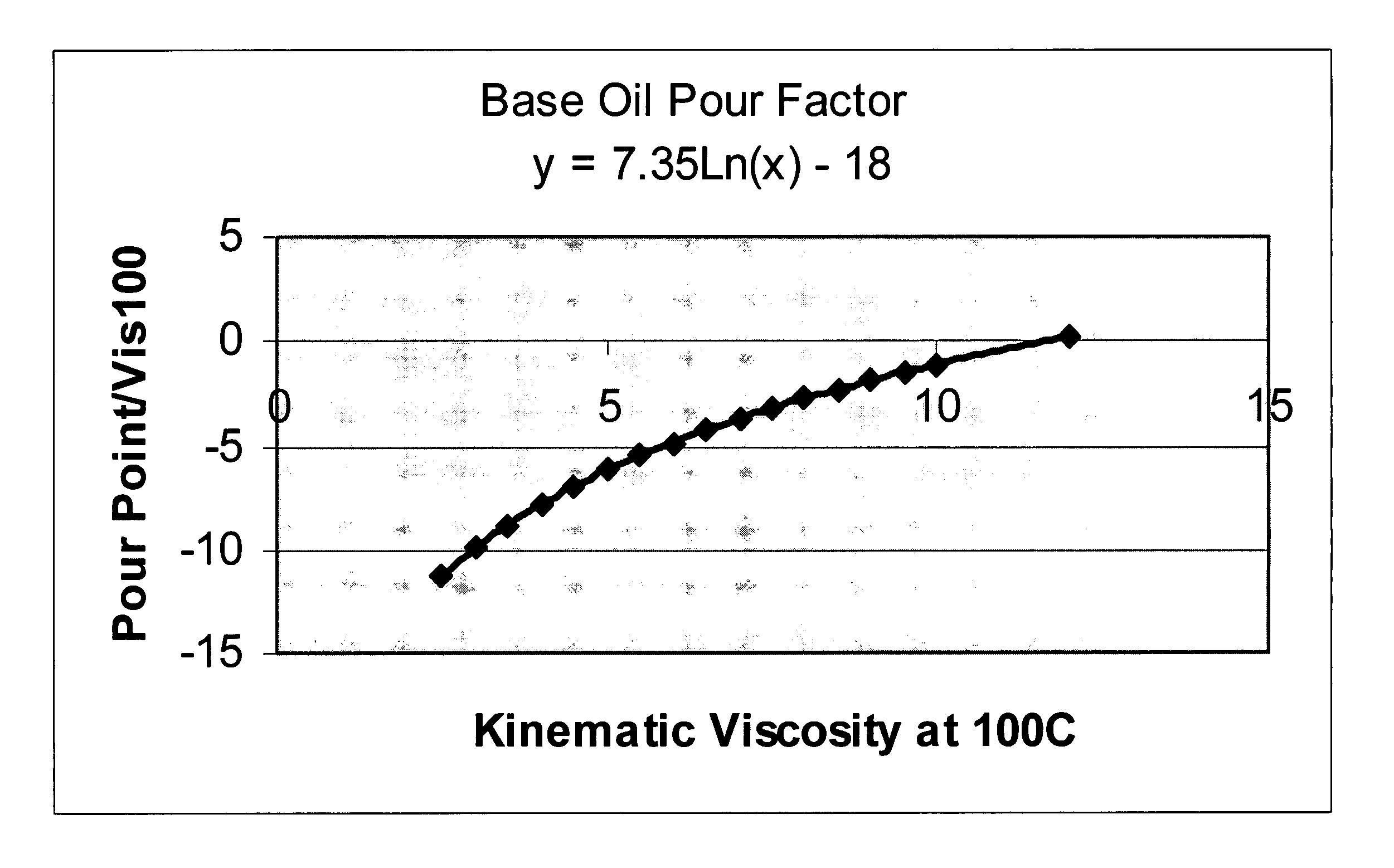

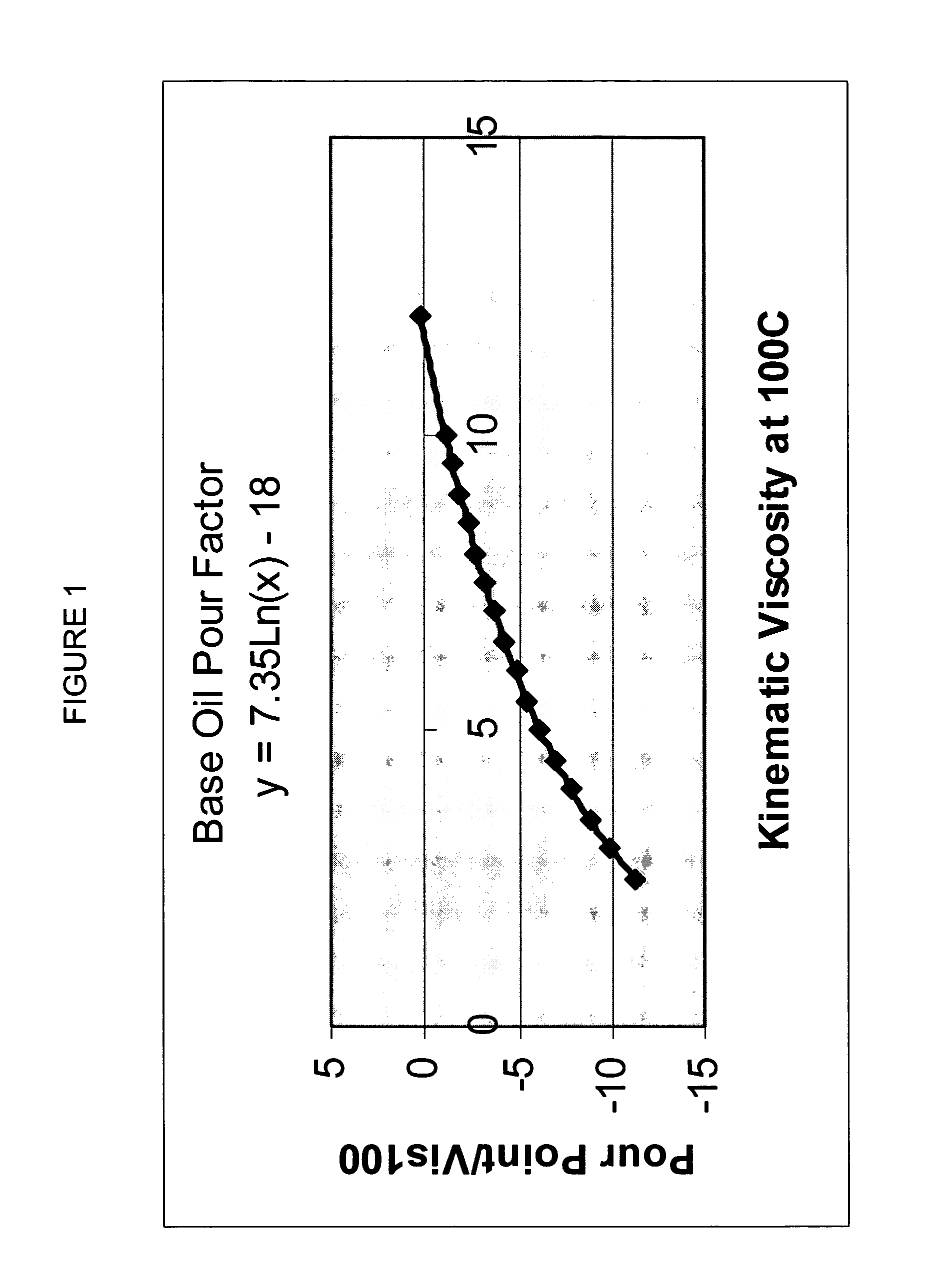

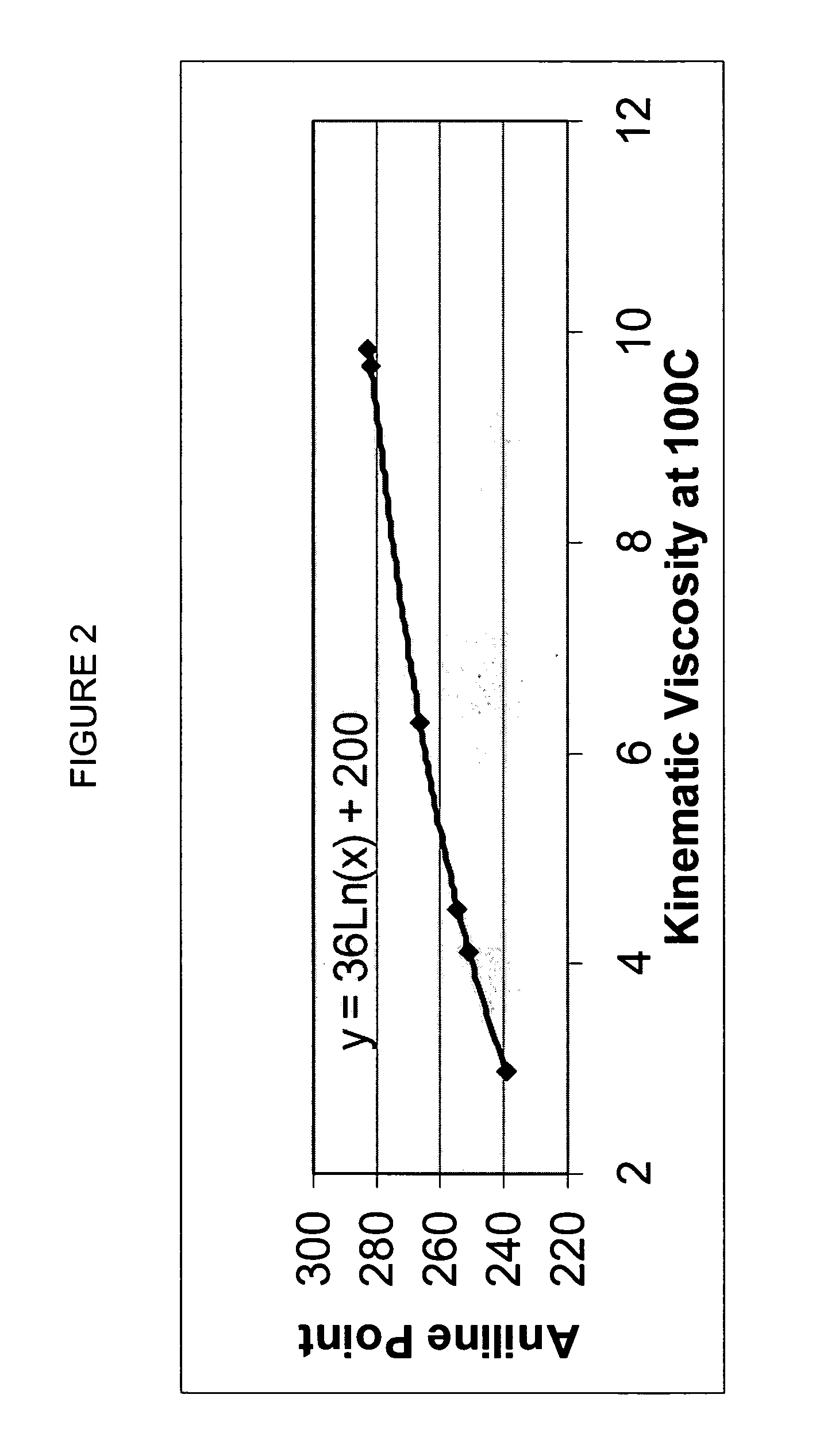

Composition of lubricating base oil with high monocycloparaffins and low multicycloparaffins

ActiveUS7083713B2Improve Oxidation StabilityHigh viscosity indexRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationCycloparaffinsBase oil

A composition of lubricating base oil having a weight percent of all molecules with at least one aromatic function less than 0.30, a weight percent of all molecules with at least one cycloparaffin function greater than 10, and a ratio of weight percent of molecules with monocycloparaffins to weight percent of molecules with multicycloparaffins greater than 15.

Owner:CHEVROU USA INC

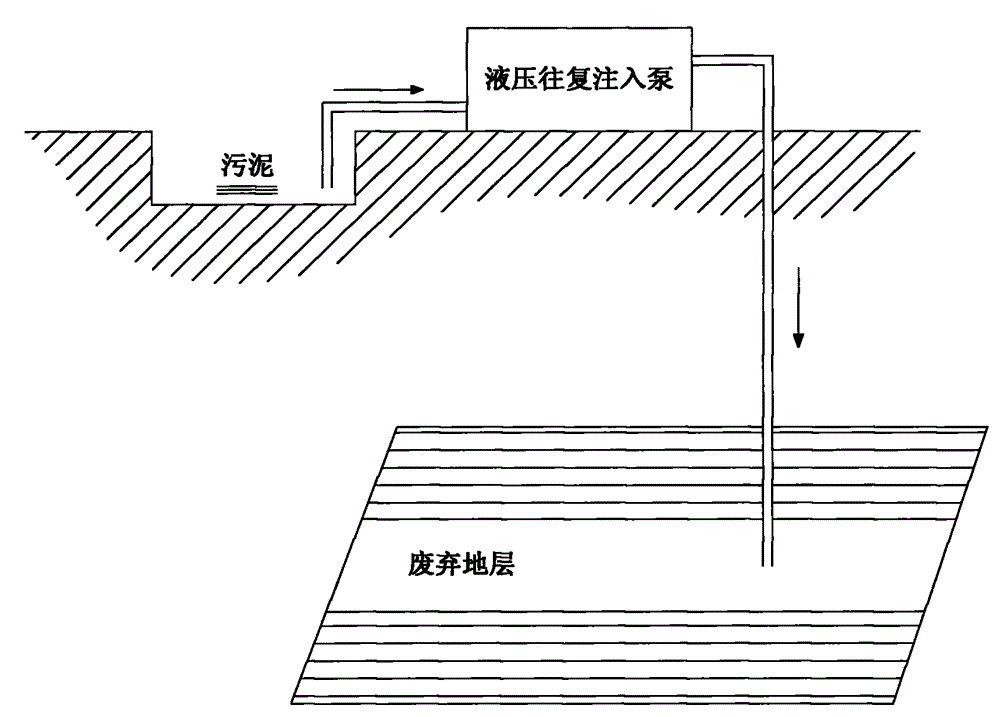

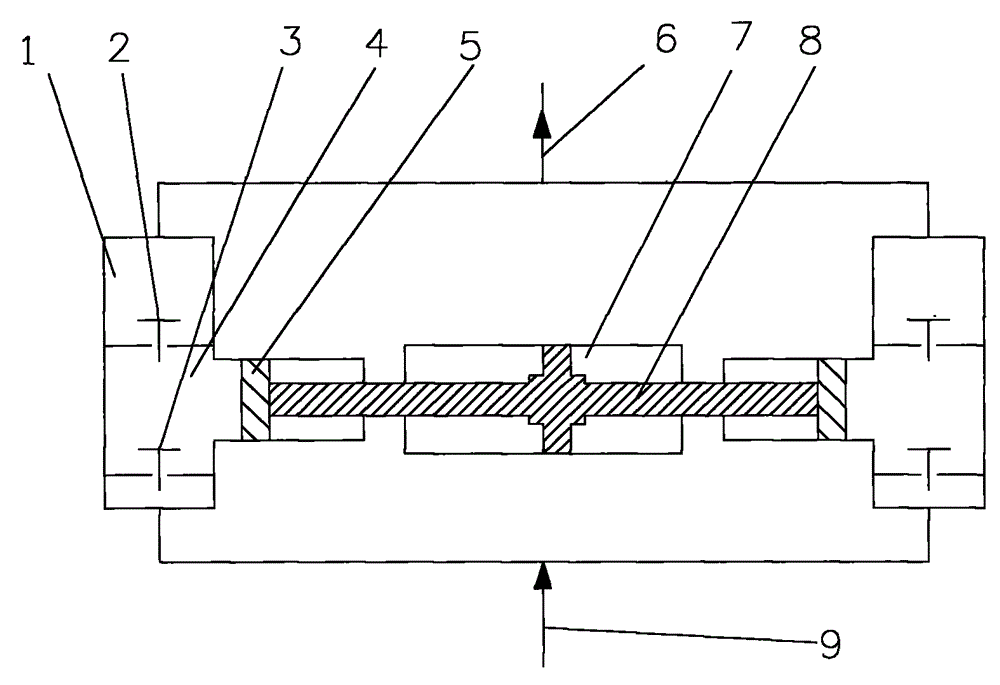

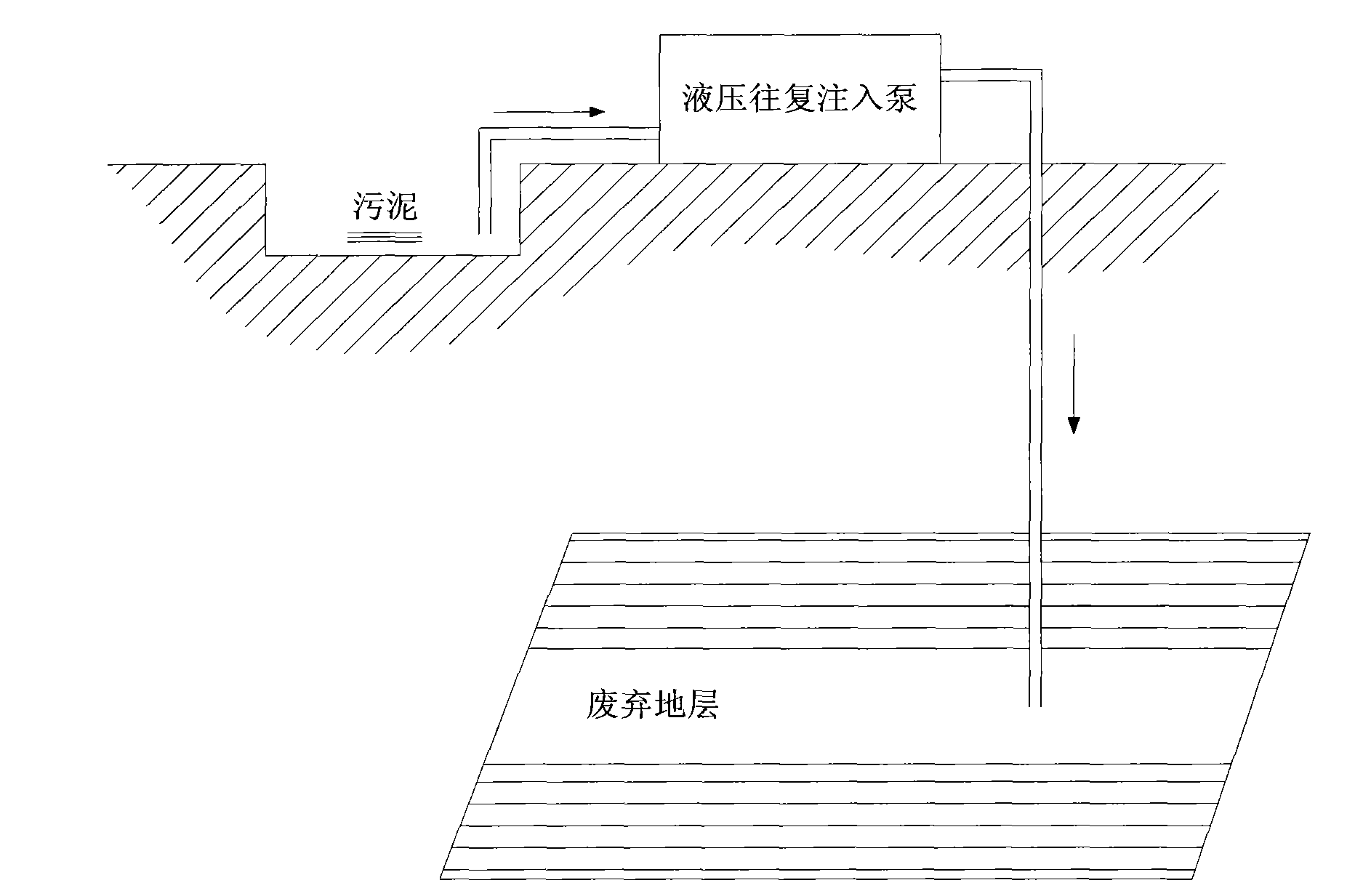

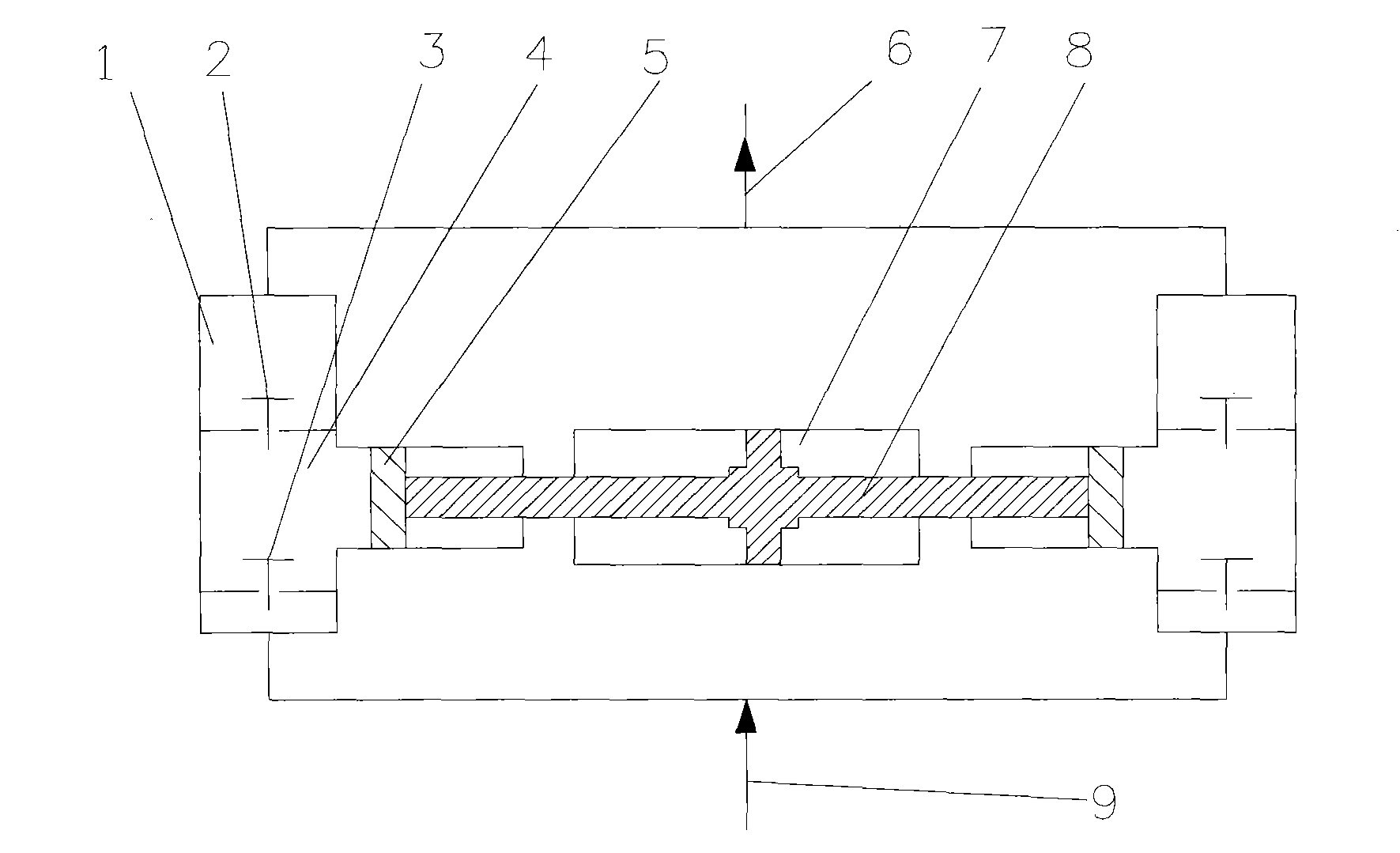

Harmless treatment method for reinjection of oil mining sludge

Relating to the technical field of harmless treatment of petroleum exploitation sludge, the invention provides a harmless reinjection treatment method for petroleum exploitation sludge. By means of a pump station composed of several hydraulic injection pumps in parallel connection, the sludge generated in petroleum exploitation is sent to an abandoned layer of an oil field. The method provided in the invention employs the hydraulic injection pumps with long stroke, low stroke frequency and high pressure to inject the sludge into the abandoned layer of the oil field, therefore, the treatment problem of oilfield exploitation sludge is solved, and simultaneously the sludge is returned to underground, thus realizing recycling of petroleum resources in the sludge, enhancing the petroleum recovery rate of the oil field, and changing the waste petroleum exploitation sludge into things of value.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

Harmless reinjection treatment method for petroleum exploitation sludge

Relating to the technical field of harmless treatment of petroleum exploitation sludge, the invention provides a harmless reinjection treatment method for petroleum exploitation sludge. By means of a pump station composed of several hydraulic injection pumps in parallel connection, the sludge generated in petroleum exploitation is sent to an abandoned layer of an oil field. The method provided in the invention employs the hydraulic injection pumps with long stroke, low stroke frequency and high pressure to inject the sludge into the abandoned layer of the oil field, therefore, the treatment problem of oilfield exploitation sludge is solved, and simultaneously the sludge is returned to underground, thus realizing recycling of petroleum resources in the sludge, enhancing the petroleum recovery rate of the oil field, and changing the waste petroleum exploitation sludge into things of value.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

Blend of fluorubber and silastic, and preparation thereof

InactiveCN101412835ASmall compression setThe preparation method is simple and feasibleTemperature resistancePolymer blend

The invention relates to a blend of fluorine rubber and silicone rubber, as well as a preparation method thereof. The composition in weight percentage of the blend of fluorine rubber and silicone rubber is as follows: 12 to 50 percent of fluorine rubber, 12 to 50 percent of silicone rubber, 2.5 to 10 percent of compatibilizer, 2.5 to 10 percent of acid-acceptor, 12 to 35 percent of reinforcing filler, 0.5 to 7 percent of constitution controller, 0.5 to 3 percent of vulcanizing agent and 0.5 to 4 percent of crosslinking additive. The blend of fluorine rubber and silicone rubber is prepared by a mechanical blending method and is vulcanized by use of peroxides. Vulcanized rubber has good mechanical properties, heat resistance, low-temperature resistance, oil resistance and low-compression permanent deformation performance, and can be used for producing and manufacturing high-performance rubber tubes, adhesive tapes, sealing elements, rubber linings and the like needed in automobile, mechanical, chemical, aerospace and other industries.

Owner:SOUTH CHINA UNIV OF TECH

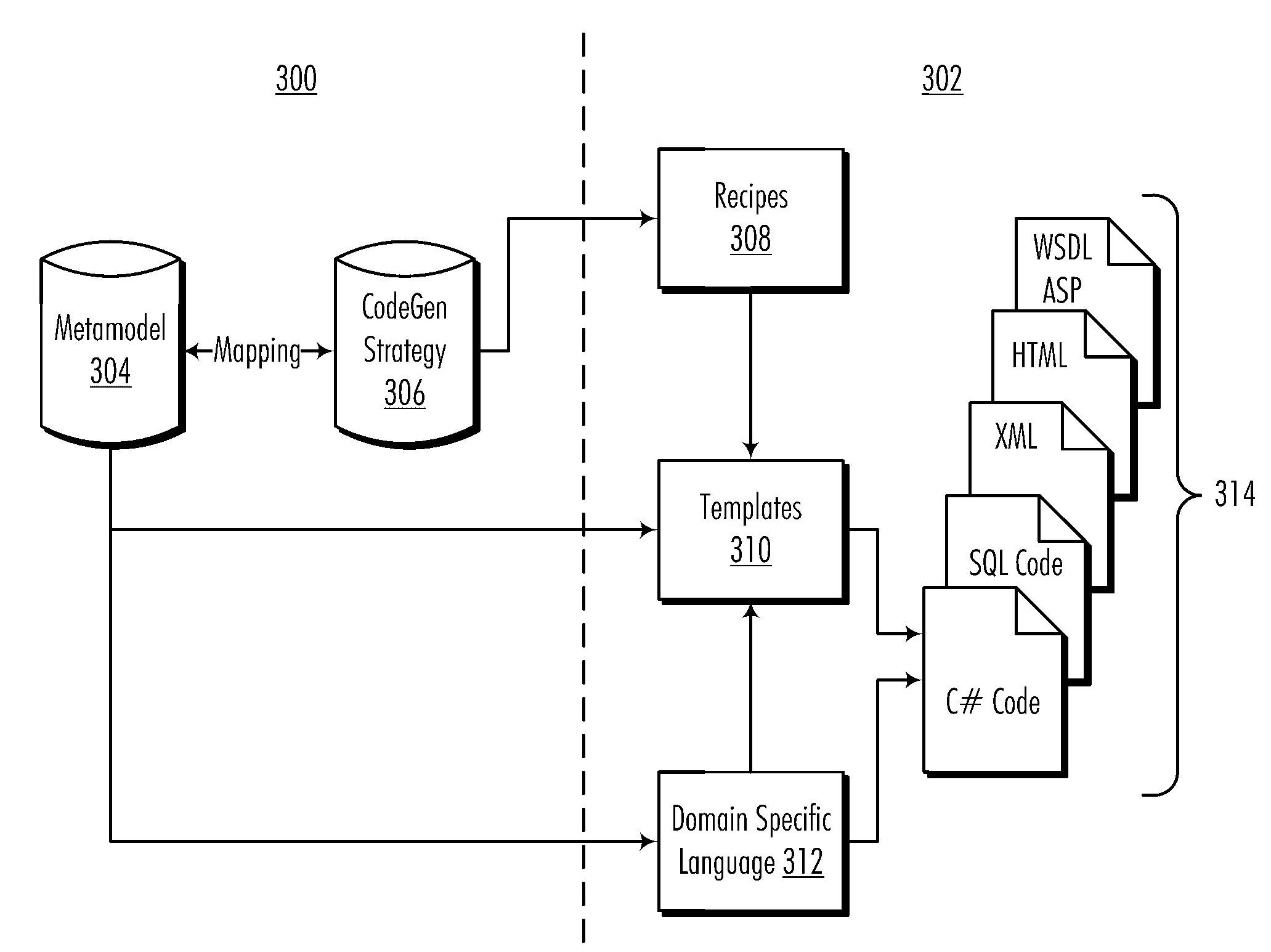

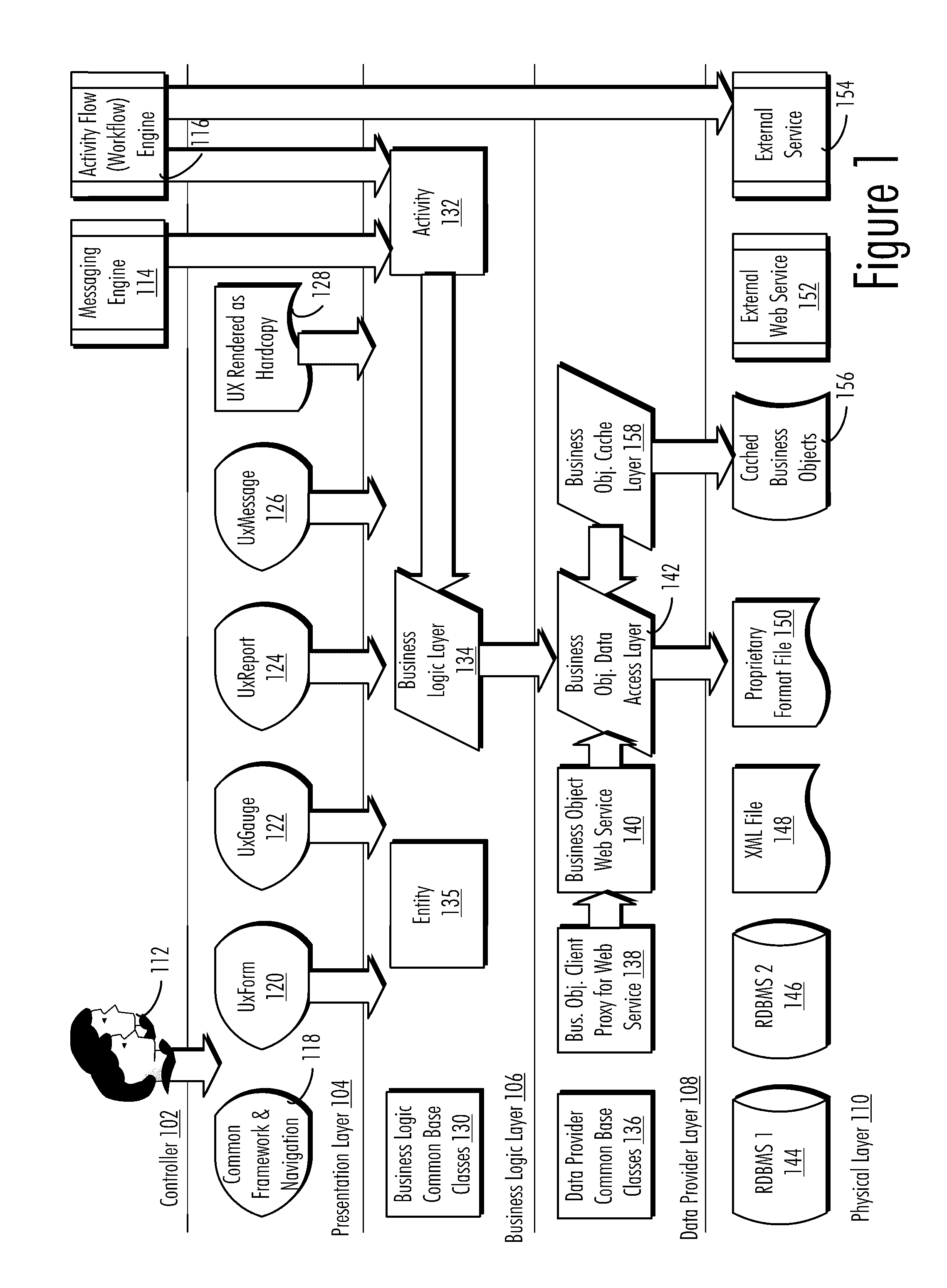

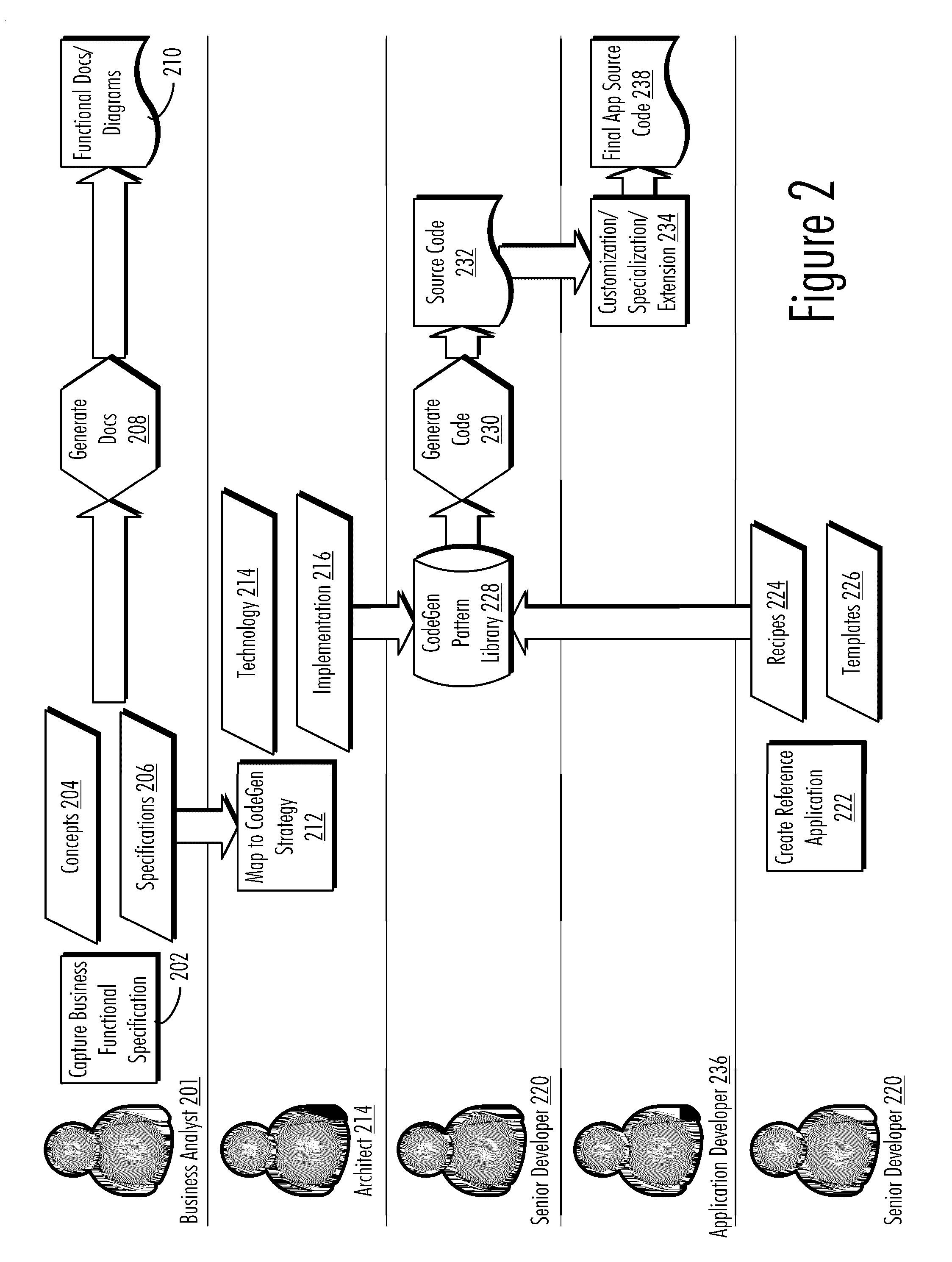

Enterprise-Scale Application Development Framework Utilizing Code Generation

InactiveUS20080127040A1Good compatibilityFacilitate functional comparabilityModel driven codeRequirement analysisData processing systemWeb service

Owner:BARCELLONA JON

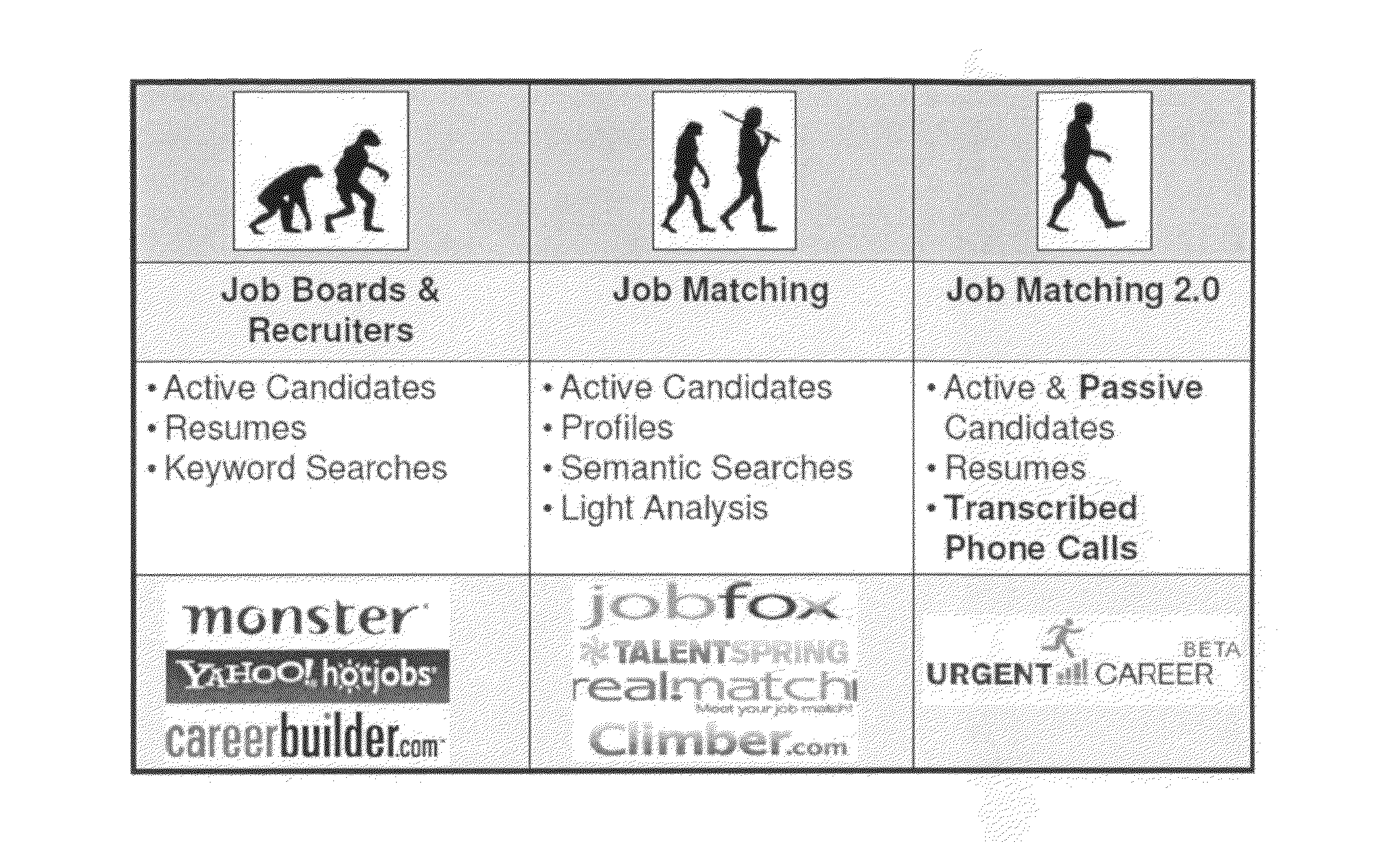

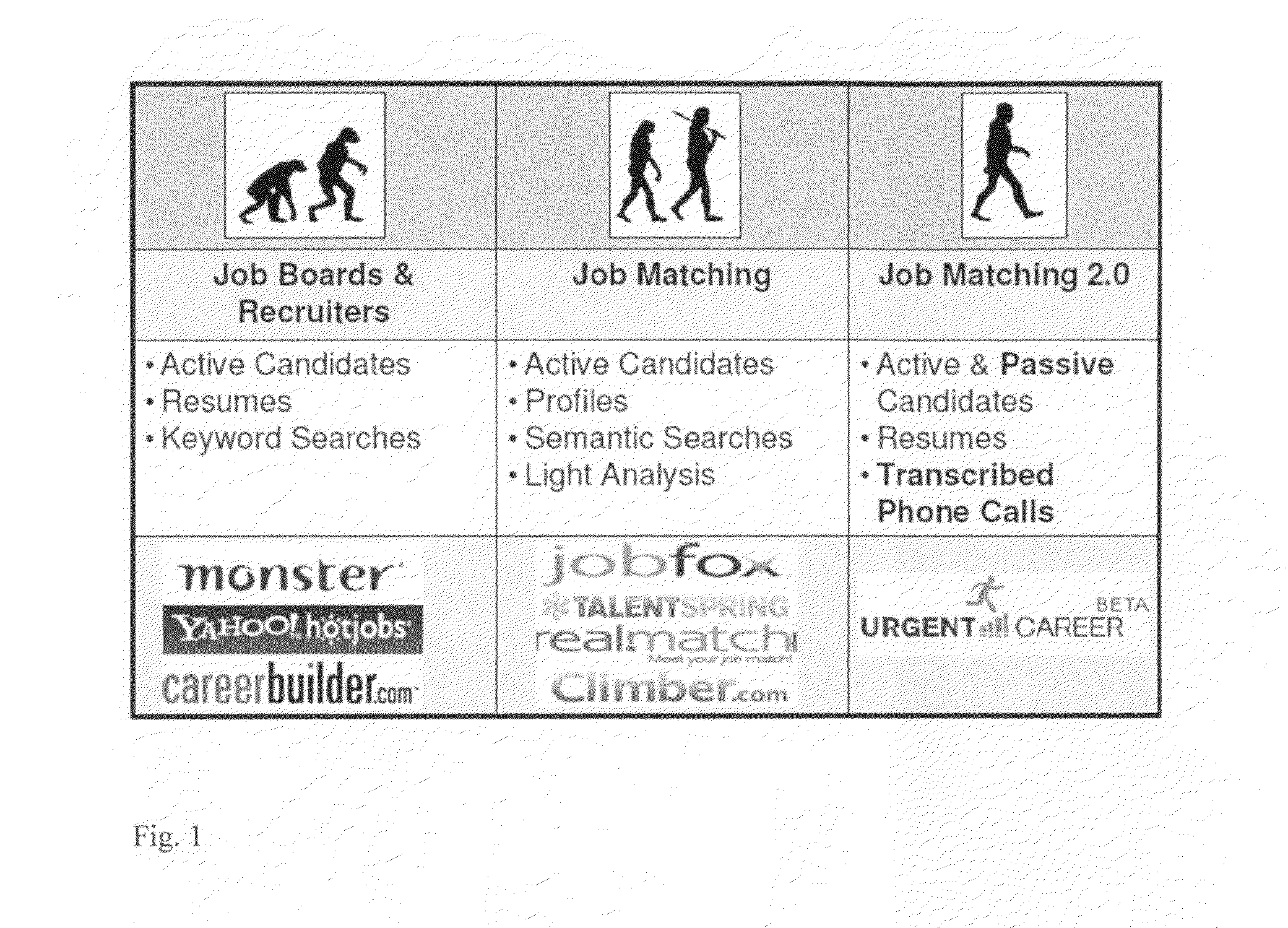

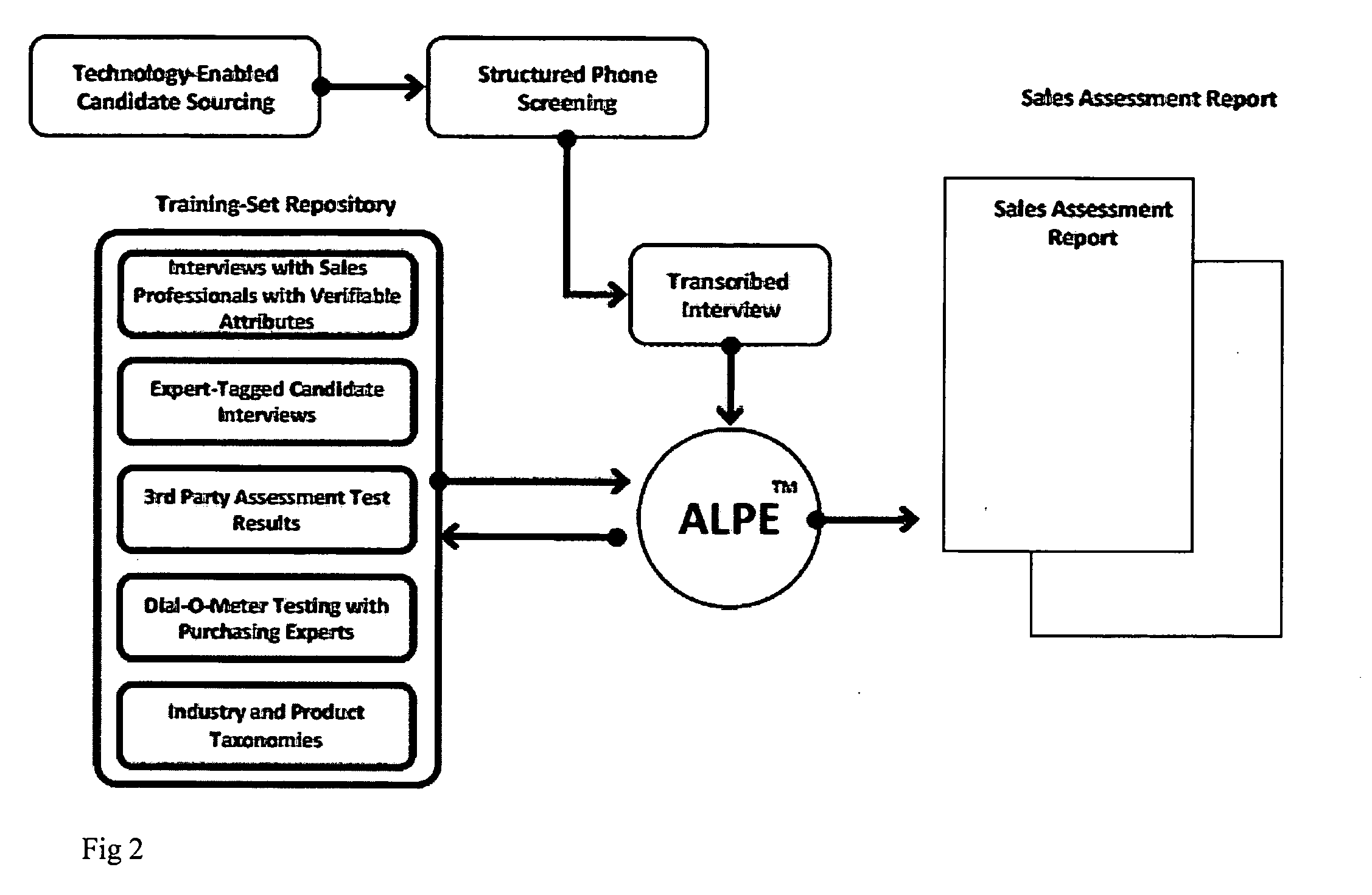

Automated employment information exchange and method for employment compatibility verification

InactiveUS20110055098A1High probability of successHigh probability of satisfactionInstrumentsSystems managementValidation methods

A computer implemented system is provided to manage the exchange of information about people seeking employment with suitable job opportunities through the use of linguistic technologies. The system is particularly useful for job hiring environments which require an exchange between companies looking to hire employees and individuals seeking employment. The system manages a database of job candidates who have been interviewed and answers have been recorded. The system converts the candidate's answers into a personal linguistic profile and then analyzes the linguistic profile to reveal the candidates unique talents and skills to find the most suitable job opportunities.

Owner:STEWART JEFFREY A

Graphene and carbon fiber composite material, and preparation thereof

The invention relates to a Graphene and carbon fiber-based composite material and a preparation method thereof. The composite material is prepared by taking the Graphene and the carbon fiber as raw materials, and coating a Graphene coating layer on the surface of the carbon fiber by a coating method, and the thickness of the coating layer is 1nm-5mum. The Graphene is taken as a surface coating material of the carbon fiber, and the Graphene and the carbon fiber are carbon materials and have high compatibility, thus Graphene solution coated on the surface of the carbon fiber can form the high-performance composite material and further improve the mechanical property, conductivity and heat resistance of the carbon fiber. The composite material has low cost, simple operation and strong applicability.

Owner:NANKAI UNIV

High nutrient compound selenium fertilizer and preparation method thereof

InactiveCN102320879AGood compatibilityPromote degradationFertilizer mixturesTrace element compositionInorganic materials

The invention discloses a high nutrient compound selenium fertilizer comprising selenium, nuisanceless organic material-inorganic material and medium and trace elements, and a preparation method thereof. The high nutrient compound selenium fertilizer comprises 45-60 wt% of organic material, 55-35 wt% of inorganic material, 1-6 wt% of medium and trace elements, and 0.011-0.025 wt% of purified selenium. The fertilizer disclosed in the invention can increase yield efficiently, and allow the applied plant to contain selenium element which has health care effect to human body. The fertilizer adopts a plurality of internal adsorptions to protect selenium to let the selenium in the selenium fertilizer be effective, has good intermiscibility and degradability, keeps selenium from fix, and obviously improves the biological absorption utilization rate of selenium of plants (including tea).

Owner:李子先 +1

Nano porous high-temperature-insulating material taking thixotropic colloid as template agent and preparation method for high-temperature-insulating material

InactiveCN105314999AAvoid reunion and scatter problemsSimple preparation processCeramicwareThermal conductivityAerospace

The invention relates to a high-temperature-insulating material and a preparation method therefor and particularly relates to the high-temperature-insulating material, which has a nano porous structure, prepared through forming an aqueous-phase uniform three-dimensional-network nano porous structure by taking thixotropic colloid as a template agent and adding a binding agent, aggregates, powder materials, an opacifier and admixtures. The preparation method for the high-temperature-insulating material, disclosed by the invention, is simple and easy in operation, low in production cost and environment-friendly and safe in process, does not need high-pressure special equipment, is free of combustible and explosive or other harmful substances and is beneficial to mass production. The high-temperature-insulating material disclosed by the invention has the characteristics of light weight, high strength and low coefficient of thermal conductivity, can be used for preparing high-temperature-insulating bricks, heat-insulating plates, special-shaped pieces and coating materials and can be applied to the heat insulating protection of equipment such as high-temperature furnace hearths, pipelines and valves in the fields of aerospace and military industries, metallurgical forging, petroleum refining, electric power and the like, so that the safety of use and the level of energy saving and consumption lowering are improved.

Owner:浙江圣润纳米科技有限公司

High-Strength Film Laminates Having Layers Of Plasticizer-Containing Polyvinyl (N)Acetal and Plasticizer-Containing Polyvinyl (Iso)Acetal

ActiveUS20130022824A1Improve mechanical propertiesHigh plasticizer compatibilitySynthetic resin layered productsGlass/slag layered productsArchitectural glassGlass composites

The invention relates to film laminates, formed from at least three layers A, B and C, each layer containing at least one plasticizer and at least one polyvinyl acetal, wherein, at least one of the layers A, B or C contains at least one polyvinyl (iso)acetal having a mean degree of polymerisation of less than 3000, 10 to 25% by weight of polyvinyl alcohol groups and a proportion 50 to 80% by weight of polyvinyl (iso)acetal groups, and wherein layer B has a plasticizer content of less than 32% by weight. The film laminates can be used for the production of glass / film laminate / glass composites for motor vehicles, aircraft, ships, architectural glazings, façade components, or for the production of photovoltaic modules.

Owner:KURARAY EURO GMBH

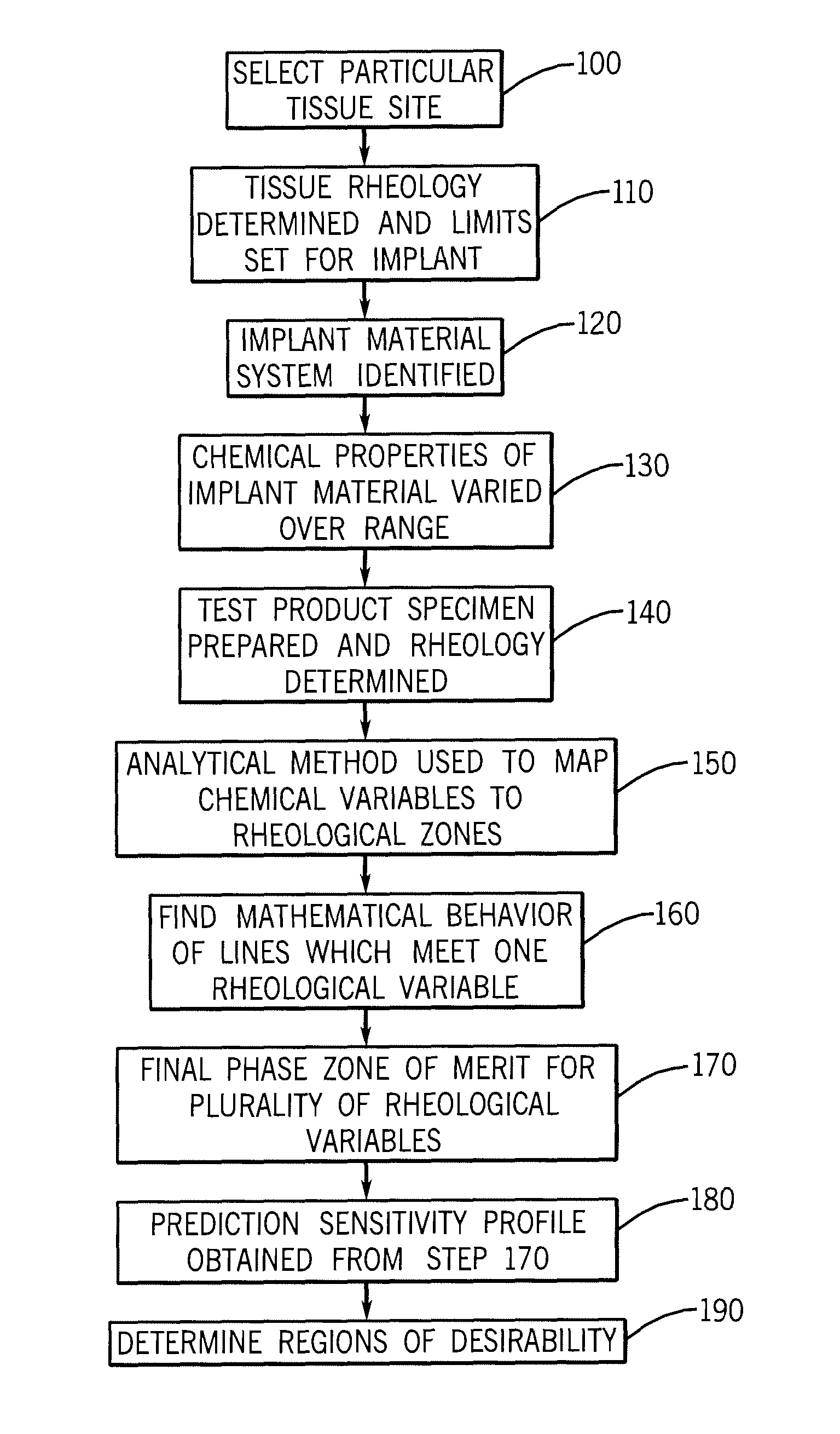

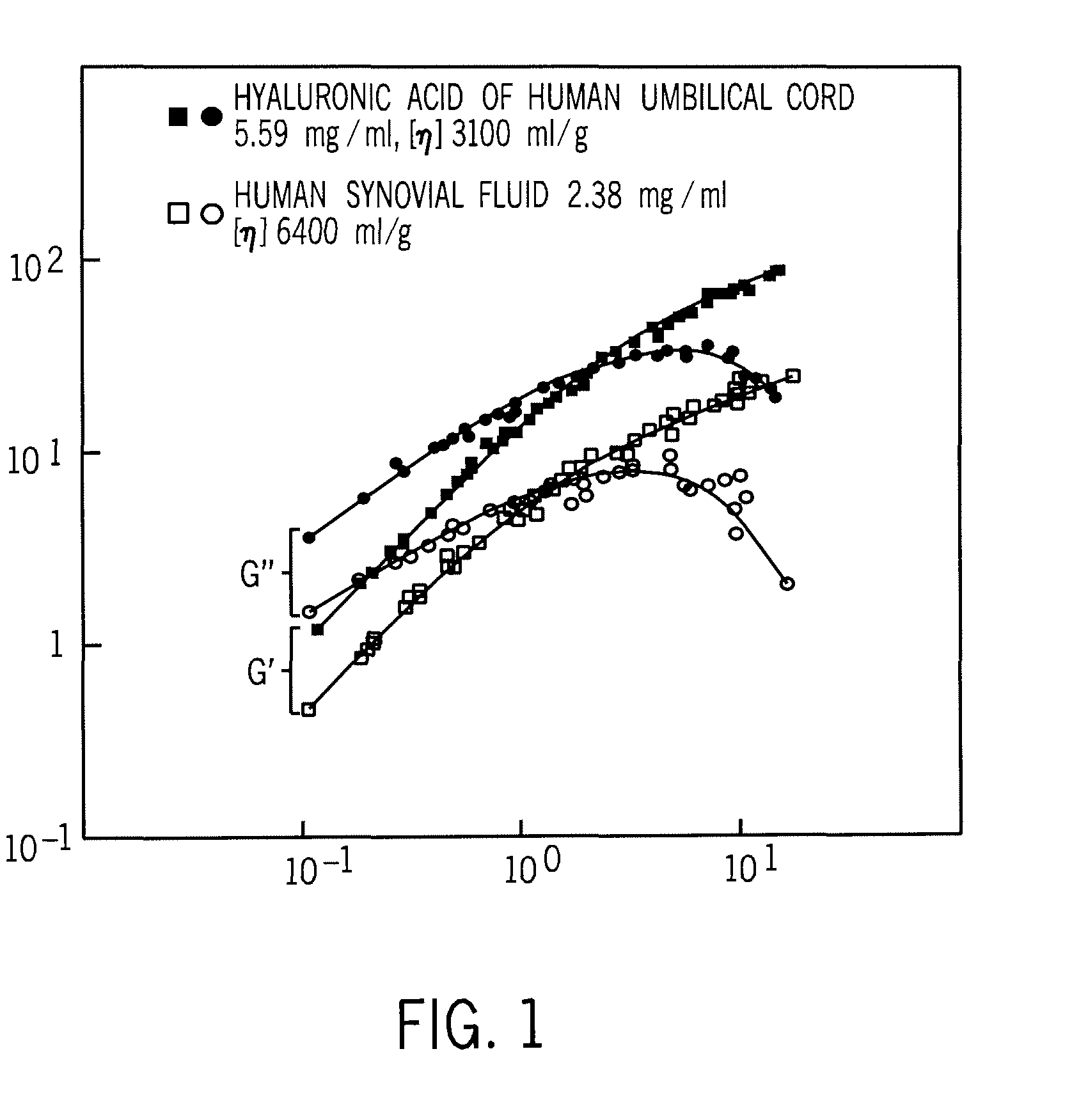

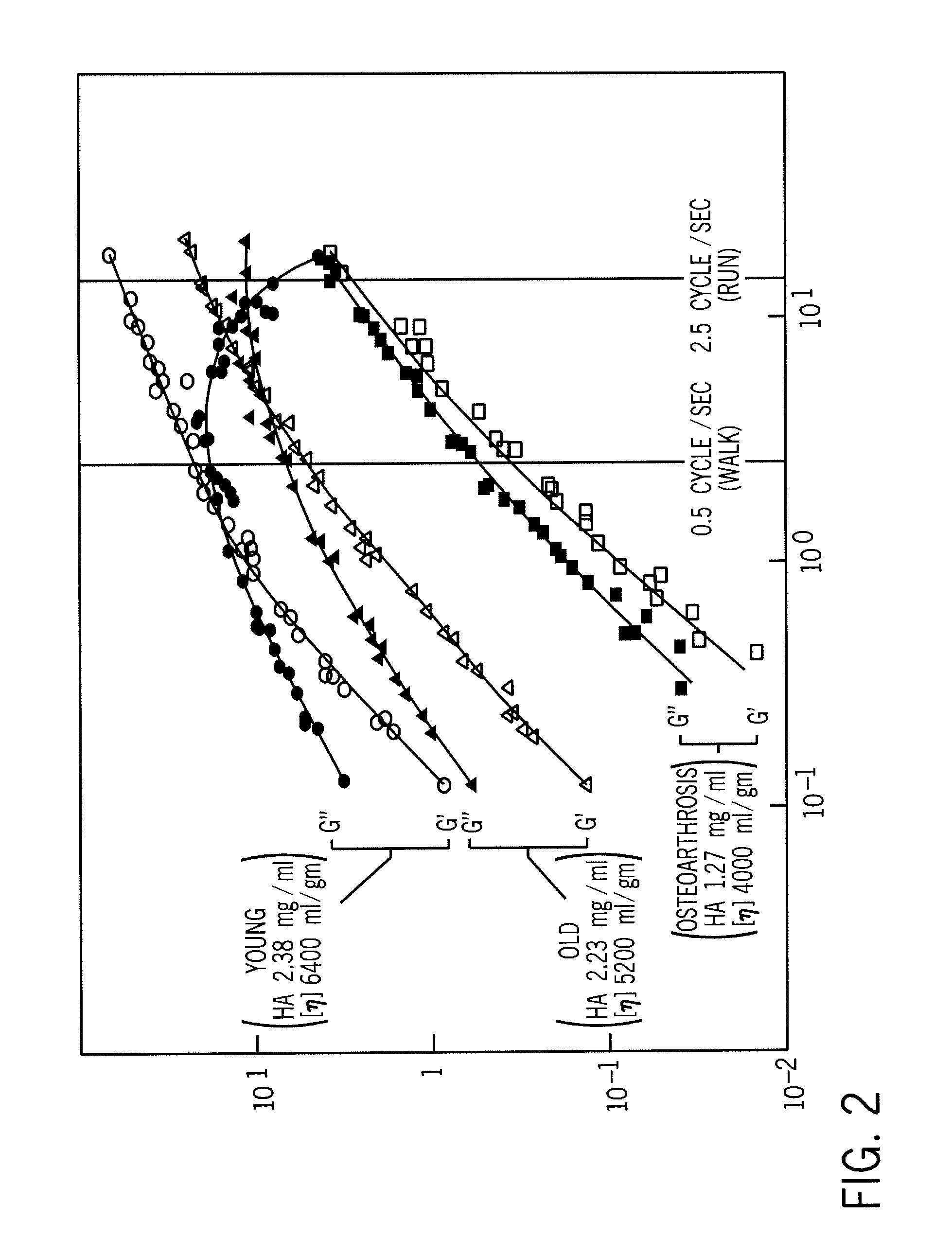

Implantation Compositions for Use in Tissue Augmentation

InactiveUS20100041788A1Good compatibilityMinimized immuno-histo tissue responseOrganic active ingredientsSurgical adhesivesPolymer solutionPolysaccharide

A composition of matter and method for preparation of a tissue augmentation material. A polysaccharide gel composition is prepared with rheological properties selected for a particular selected application. The method includes preparing a polymeric polysaccharide in a buffer to create a polymer solution or gel suspending properties in the gel and selecting a rheology profile for the desired tissue region.

Owner:MERZ AESTHETICS

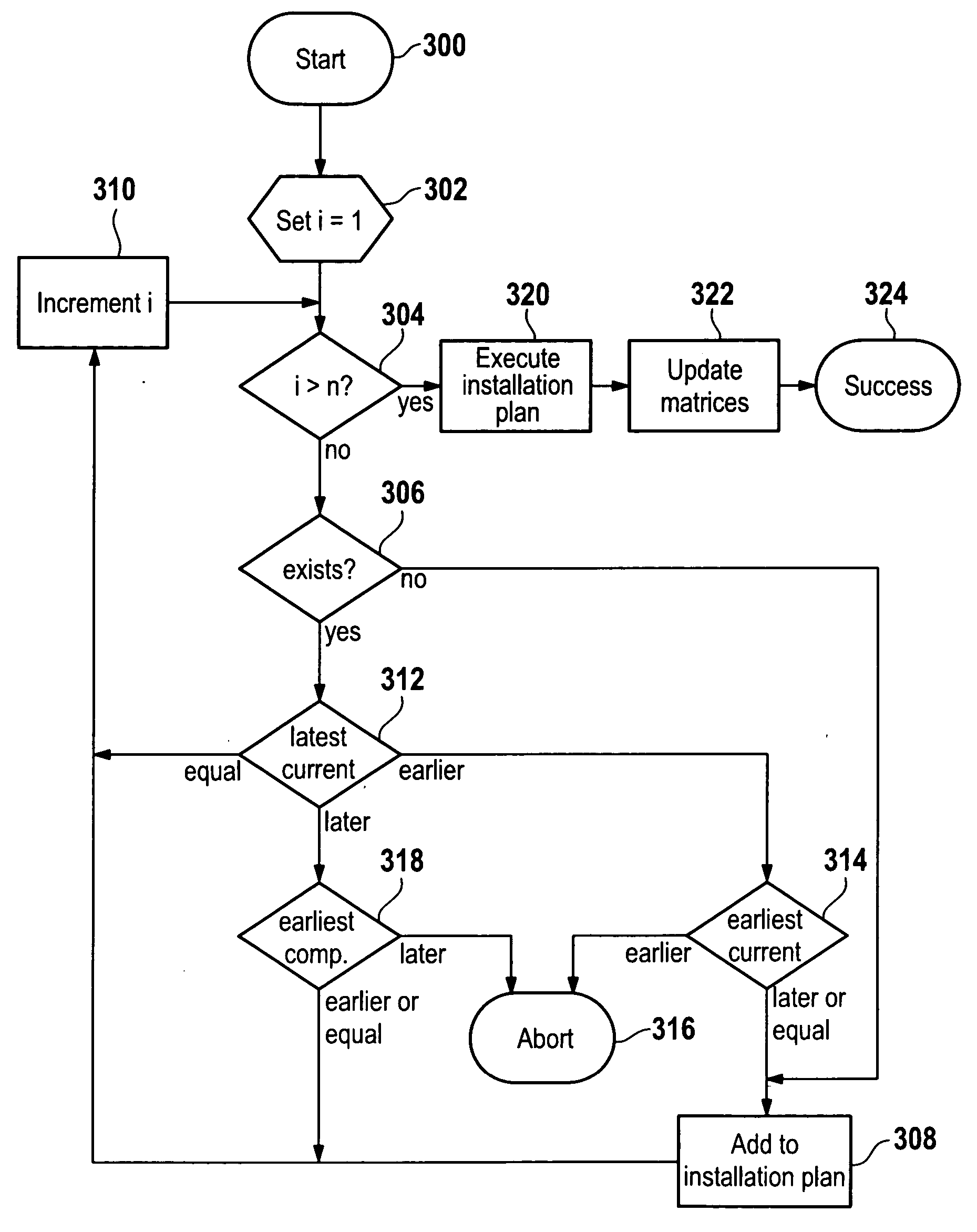

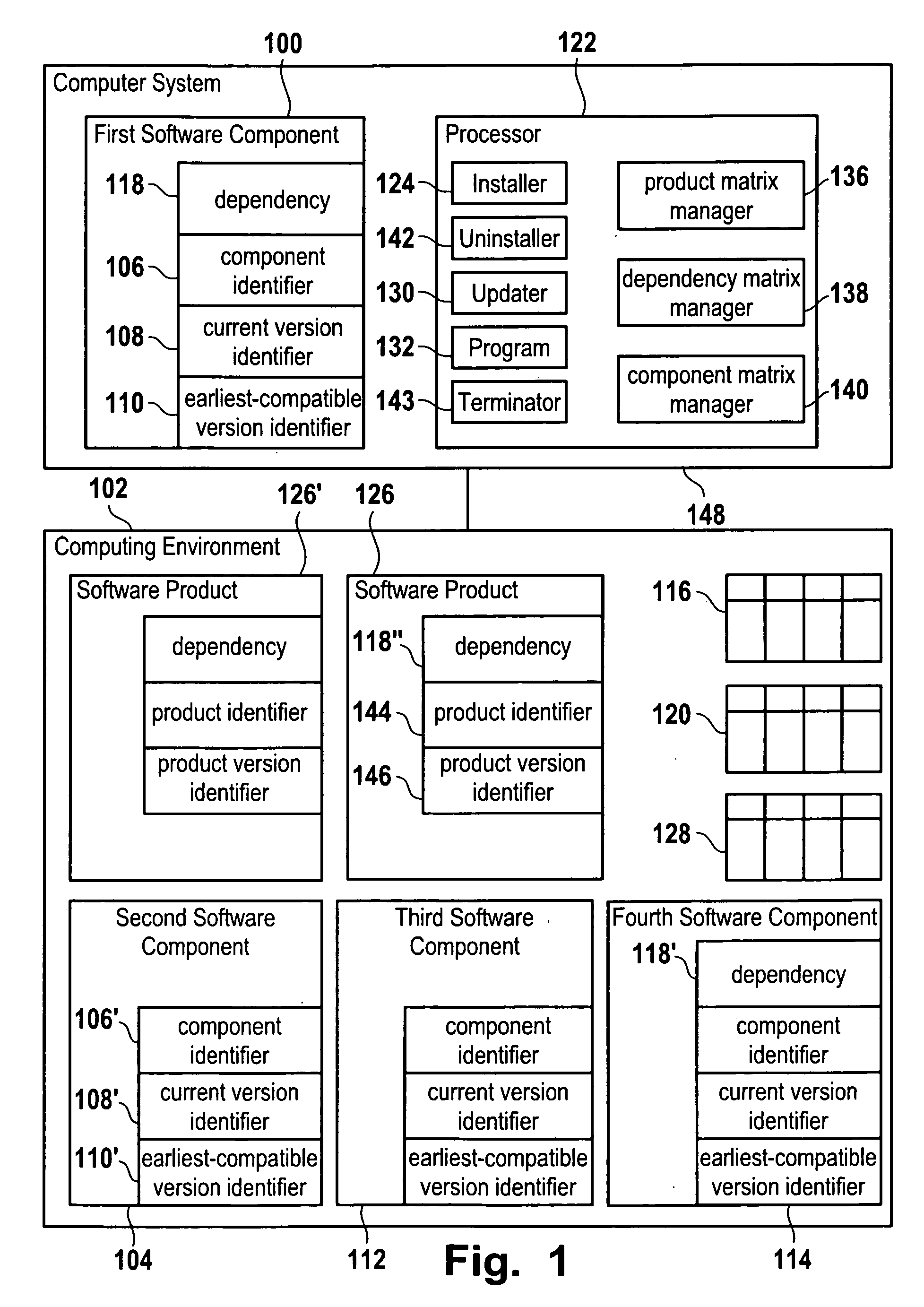

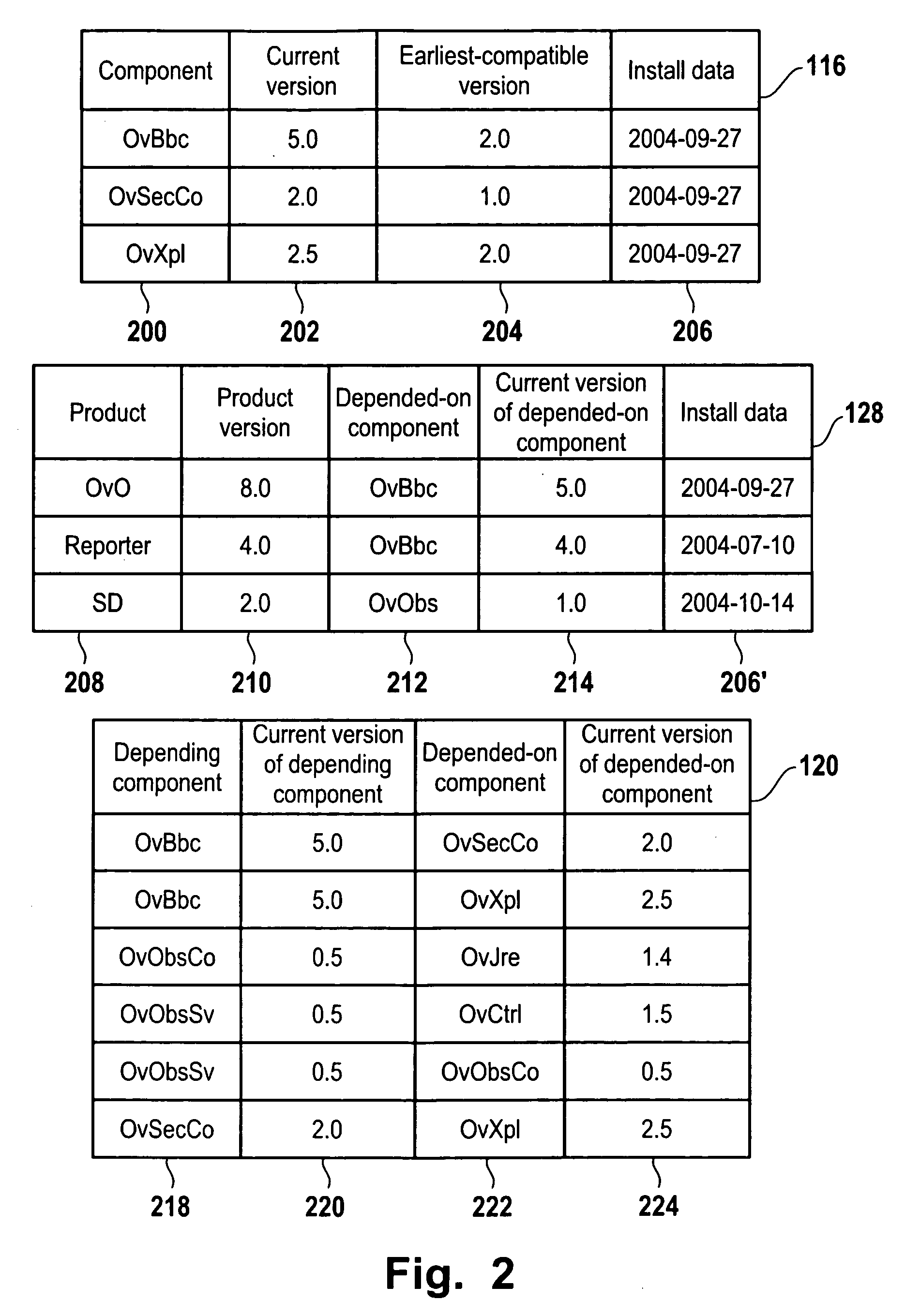

Software installation method and computer system

InactiveUS20070006222A1Installation processGood compatibilityProgram loading/initiatingMemory systemsVersion identifierSoftware

A method and a computer system are provided for installing a first software component into a computing environment, the computing environment comprising an already installed second software component. The method involves aborting the installation if the first and second software components have matching component identifiers and a current-version identifier of the first software component signifies an earlier version than an earliest-compatible-version identifier of the second software component.

Owner:HEWLETT PACKARD DEV CO LP

Preparation method of silica aerogel aqueous heat-insulating coating

InactiveCN102719129ADoes not require surface hydrophobic modificationWon't collapseCoatingsSilicon compoundsMicrosphereAlkoxy group

The invention discloses a preparation method of a silica aerogel aqueous heat-insulating coating, and is characterized in that: prepared SiO2 microspheres are hydrophobic inside and hydrophilic outside; and the aerogel microspheres can be added into an aqueous coating carrier to prepare a good heat-insulating material. The main preparation method comprises the following steps of: before drying the prepared wet gel microspheres, performing surface modification by using an organic silane or an organic chlorosilane, so that the prepared wet gel microspheres are hydrophobic by grafting a large number of alkoxy groups or alkyl groups on the surfaces thereof, or directly preparing the hydrophobic wet gel microspheres; performing surface modification on the microspheres by using a hydrophilic silane coupling agent, and drying to obtain the SiO2 microspheres which are hydrophobic inside and hydrophilic outside; and adding the prepared microspheres into an aqueous coating for preparing the aqueous heat-insulating coating.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

High-strength activated polyester industry yarn and preparation method thereof

ActiveCN104499080AGood flexibilityGood compatibilityNew-spun product collectionMelt spinning methodsPolyesterChemistry

The invention relates to a high-strength activated polyester industry yarn and a preparation method thereof. The high-strength activated polyester industry yarn is a modified polyester industry yarn of which the surface is coated with an activating agent and the high-strength activated polyester industry yarn is prepared from modified polyesters through spinning; the modified polyester is composed of polyester and aminoadipic acid gylcol ester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume of the fiber is increased when the high-strength activated polyester industry yarn is at 70-80 DEG C, a part of activating agent molecules are dispersed into fiber gaps, more -OHs and -NHs with strong activity are introduced into the polyester molecules, a firm resinoid coating is formed on the surface of a polyester cord thread and the reactivity of the polyester fiber is improved; and the high-strength activated polyester industry yarn can be applied to triangular belt cords, radial tire cord fabrics and the like.

Owner:JIANGSU HENGLI CHEM FIBER

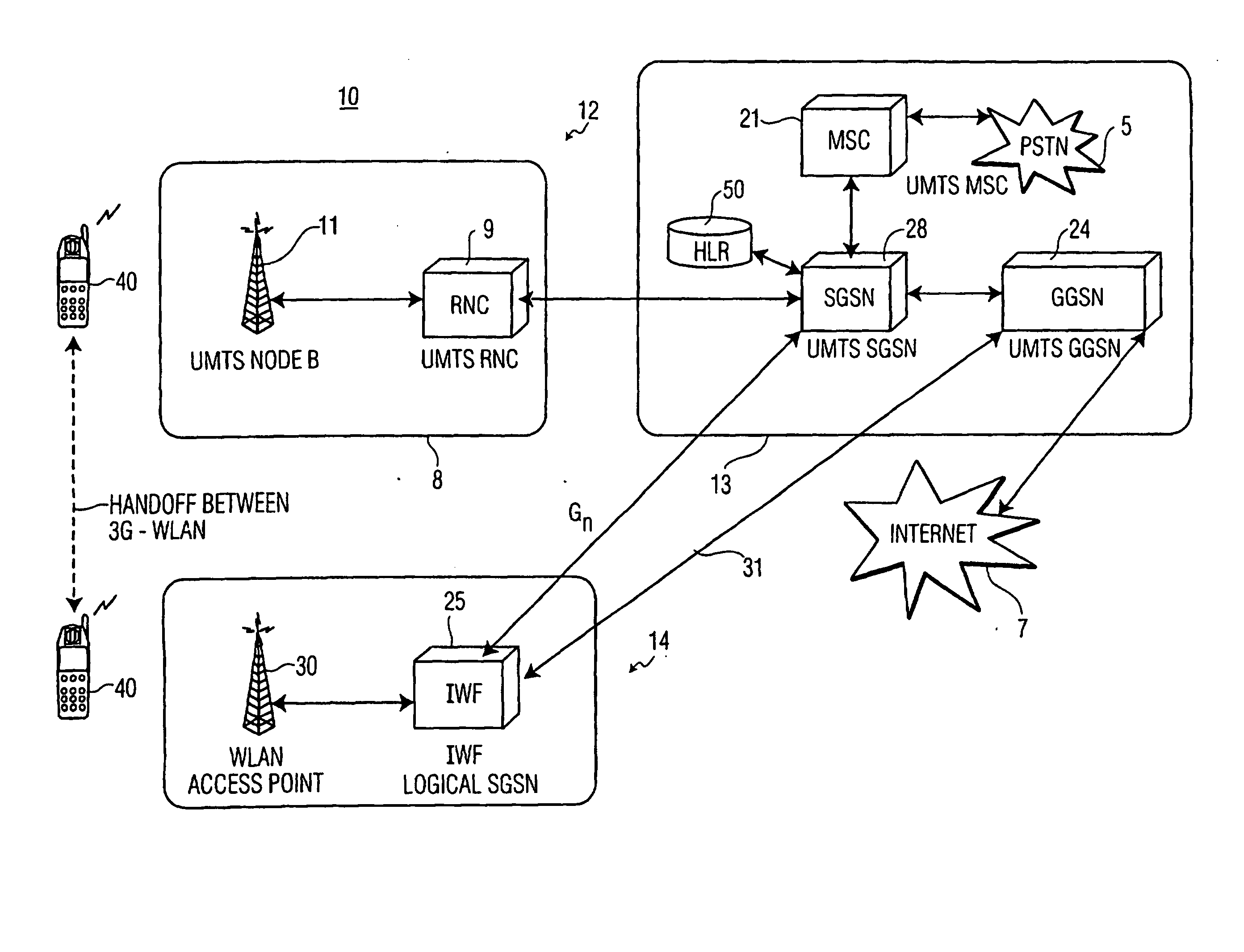

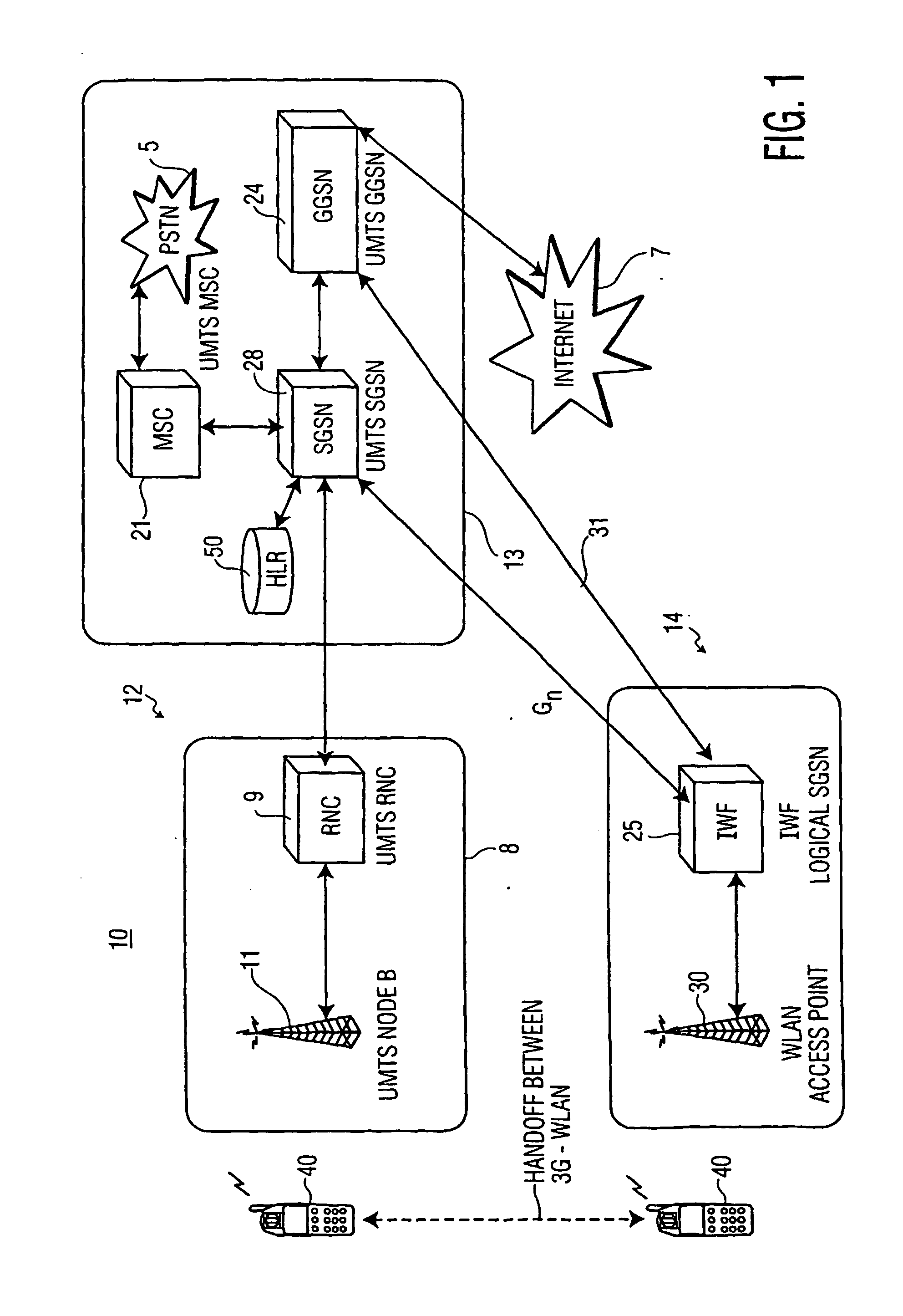

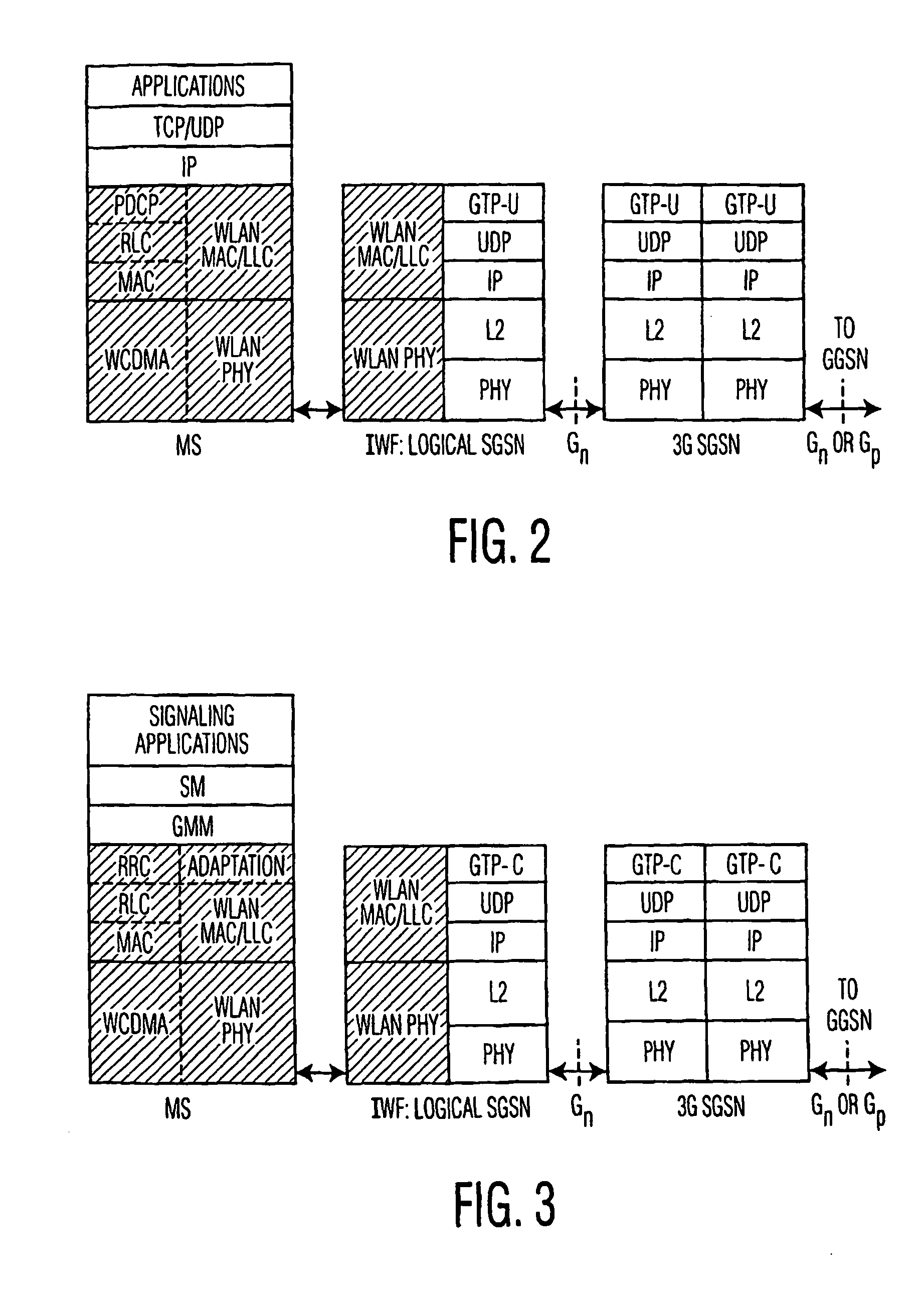

Interfacing a wlan with a mobile communications system

ActiveUS20050157673A1Increase in available service bandwidthMore efficientNetwork topologiesTime-division multiplexLocal area networkProtocol stack

An interface for connecting networks includes an interworking function provided between a wireless local area network (WLAN) and a public mobile land network (PLMN) to provide communication interactions between the PLMN and the WLAN. The interworking function includes a dual-protocol stack, which interfaces the WLAN protocols and PLMN protocols to provide seamless communications between the WLAN and the PLMN such that an increase in available service bandwidth provided for users of the PLMN is maintained.

Owner:THOMSON LICENSING SA

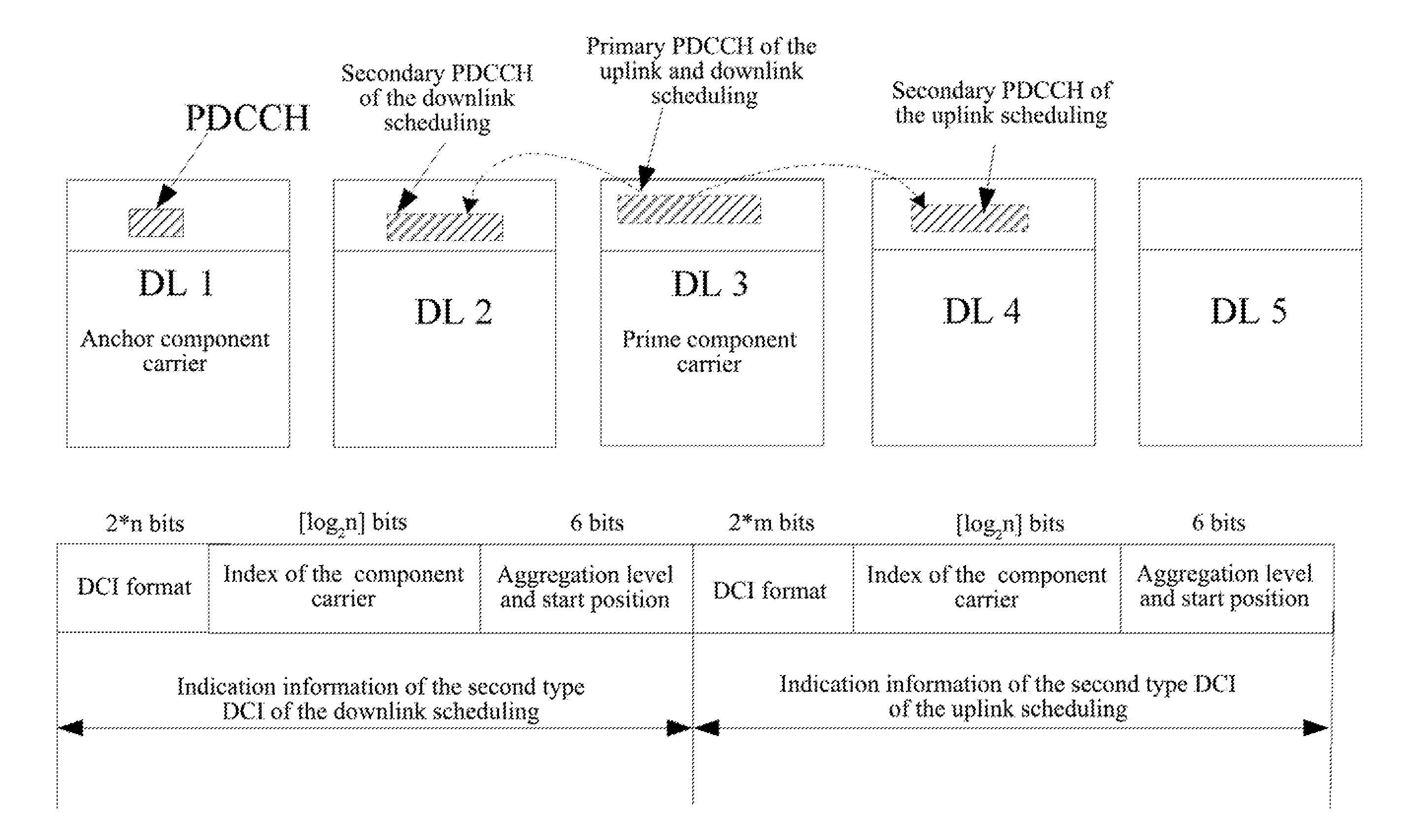

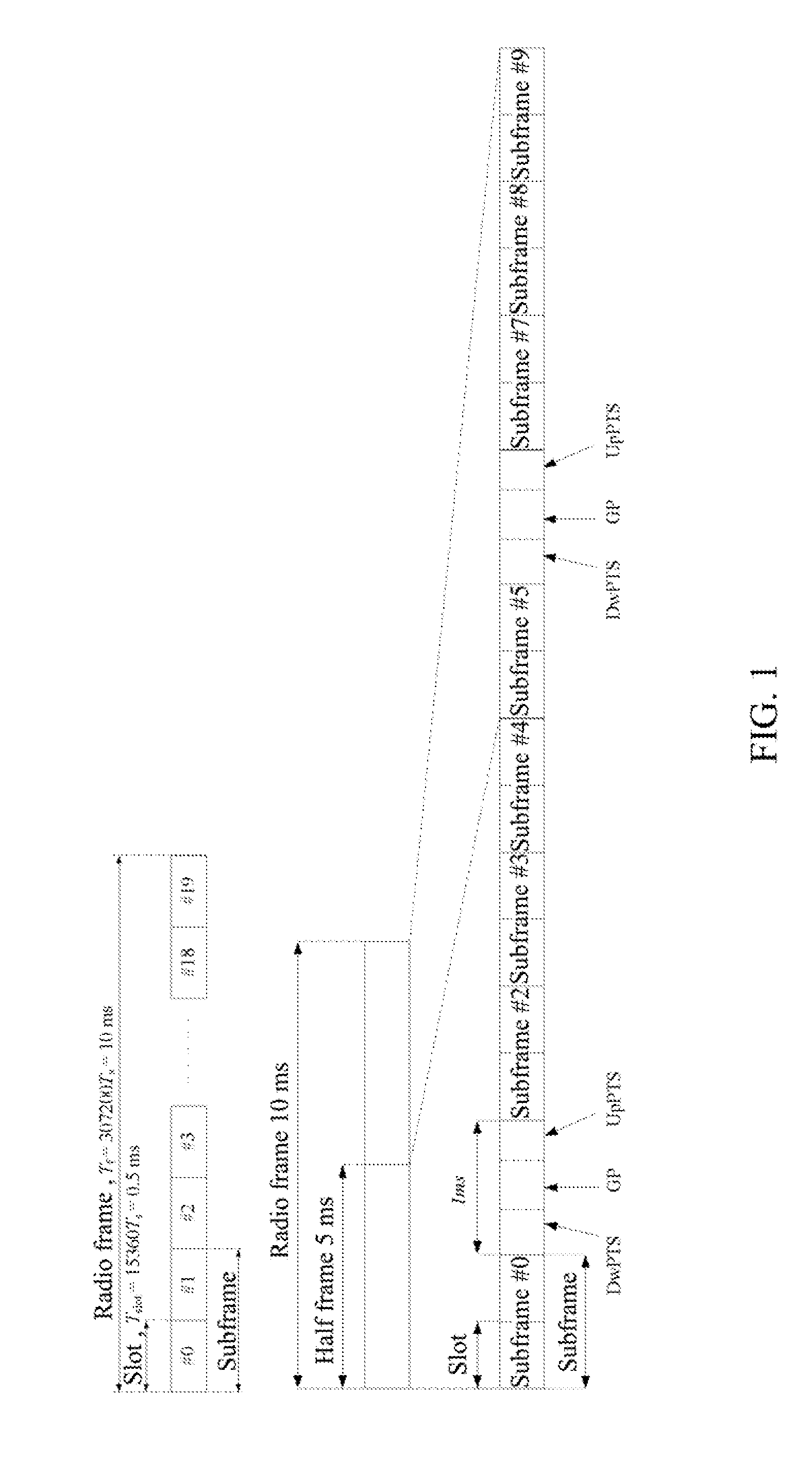

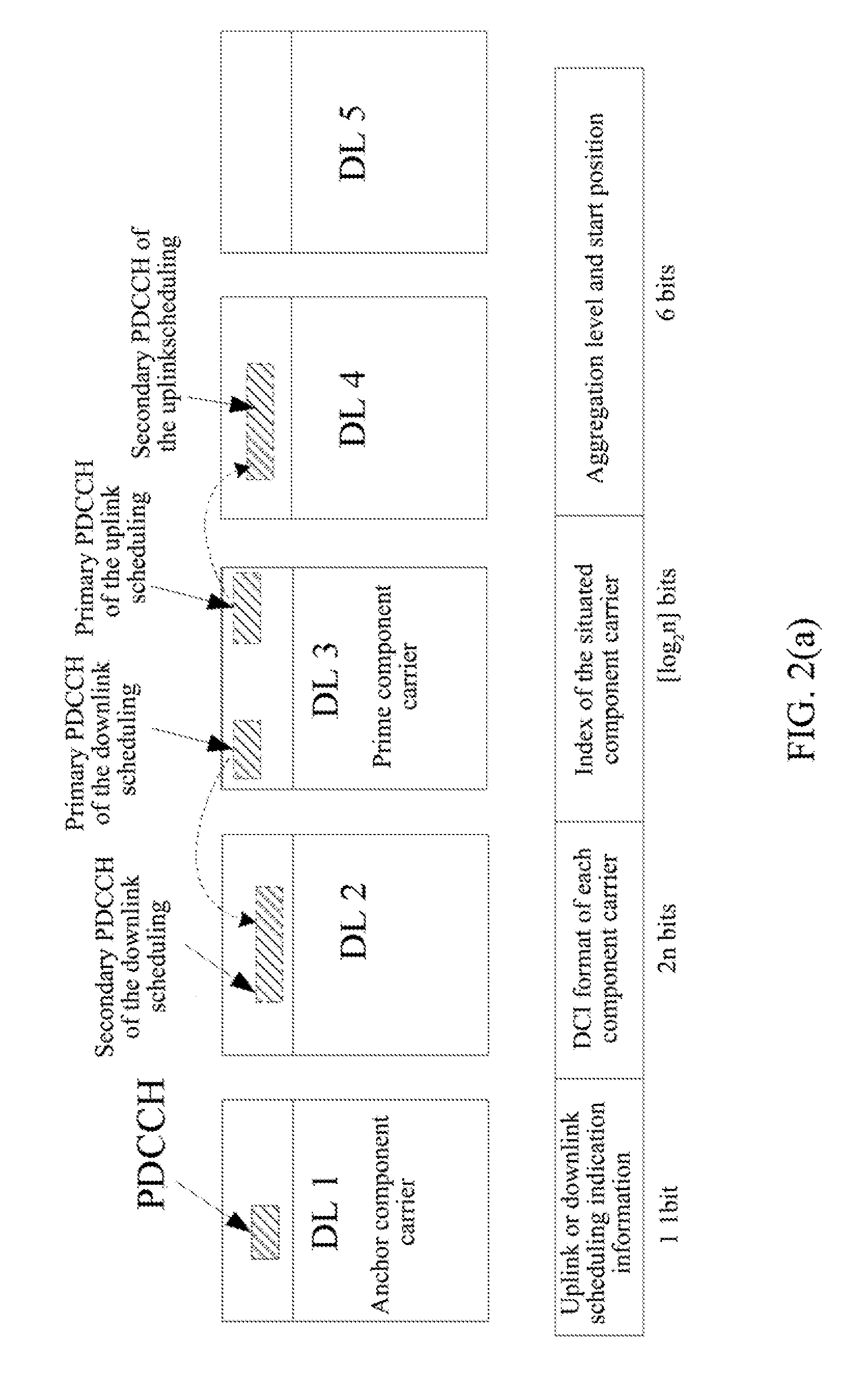

Method for Sending and Detecting Downlink Control Information

InactiveUS20120033627A1Low total numberLess signal overheadTransmission path divisionSignal allocationCarrier signalPower control

A method for sending and detecting downlink control information is provided. A base station carries the downlink control information in a physical downlink control channel, and sends said physical downlink control channel through component carriers. Said base station bears first type downlink control information on an anchor component carrier, and bears third type downlink control information on a prime component carrier, wherein said first type downlink control information bears one or more types of uplink scheduling information, downlink scheduling information and uplink power control information of its component carrier, said third type downlink control information bears indication information of the second type downlink control information which bears the uplink scheduling information and / or the downlink scheduling information of one or more component carriers. A terminal detects the first type downlink control information on the anchor component carries and detects the third type downlink control information on the prime component carrier.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com