Patents

Literature

213results about How to "The preparation method is simple and feasible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blend of fluorubber and silastic, and preparation thereof

InactiveCN101412835ASmall compression setThe preparation method is simple and feasibleTemperature resistancePolymer blend

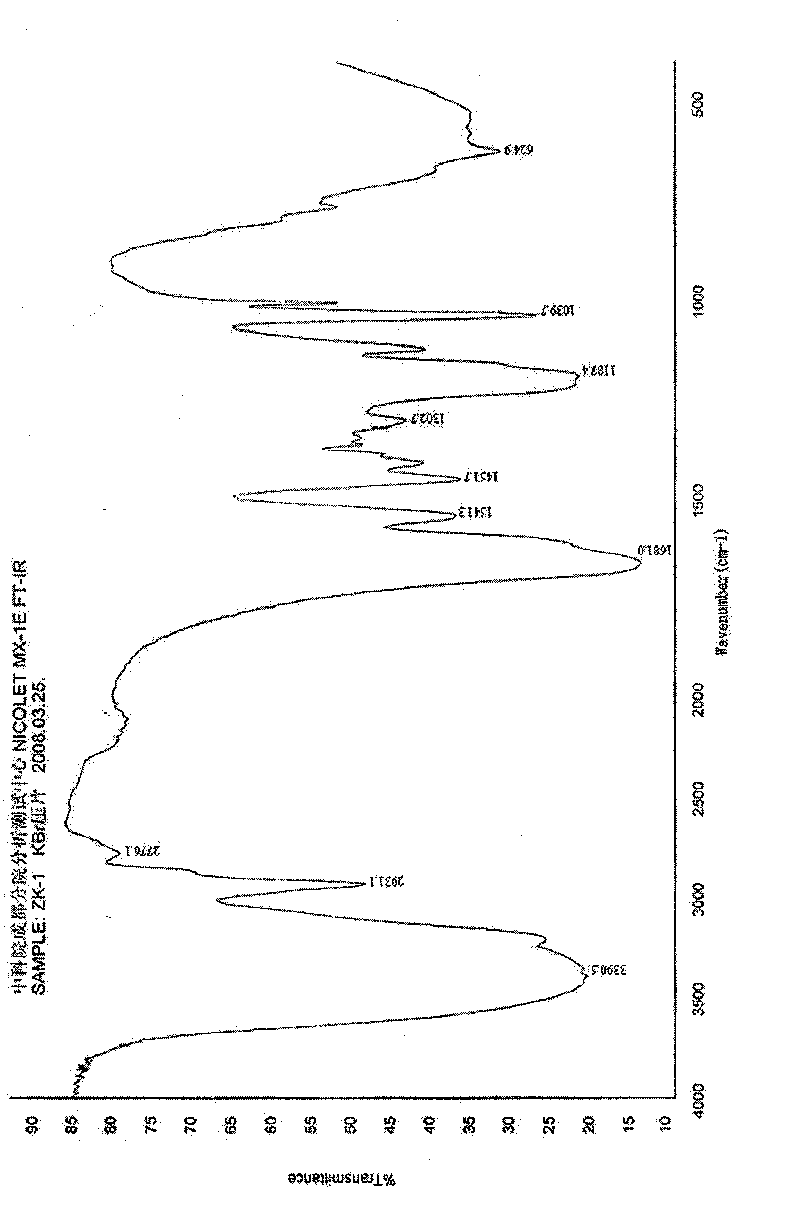

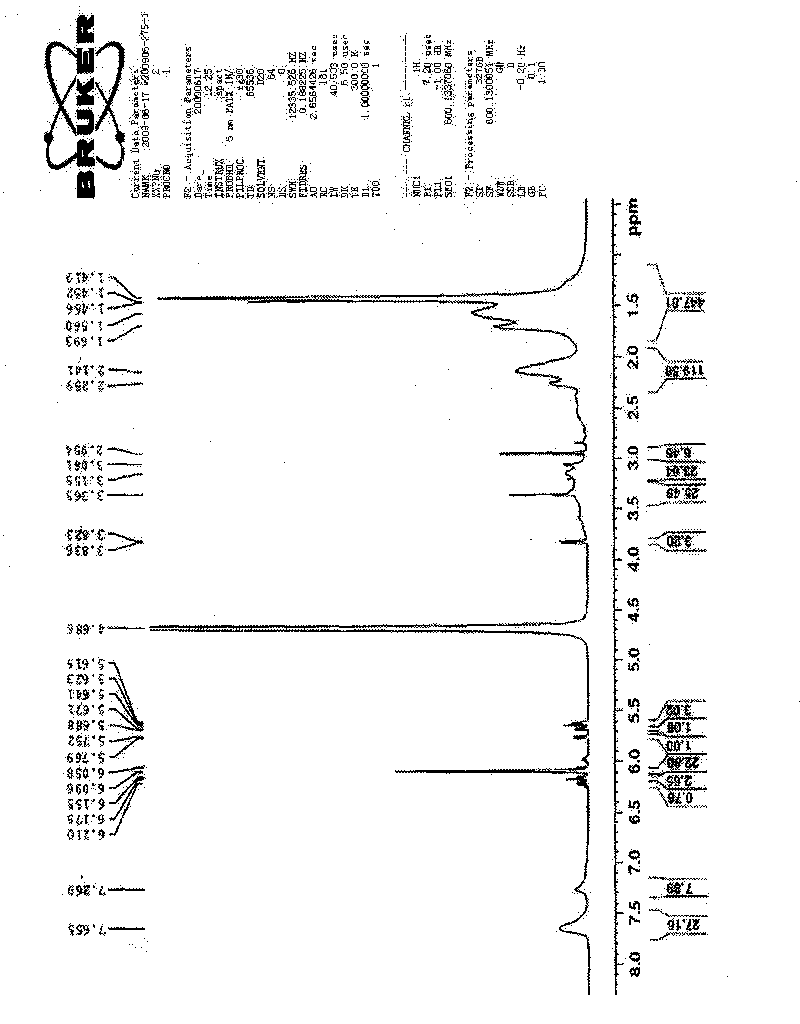

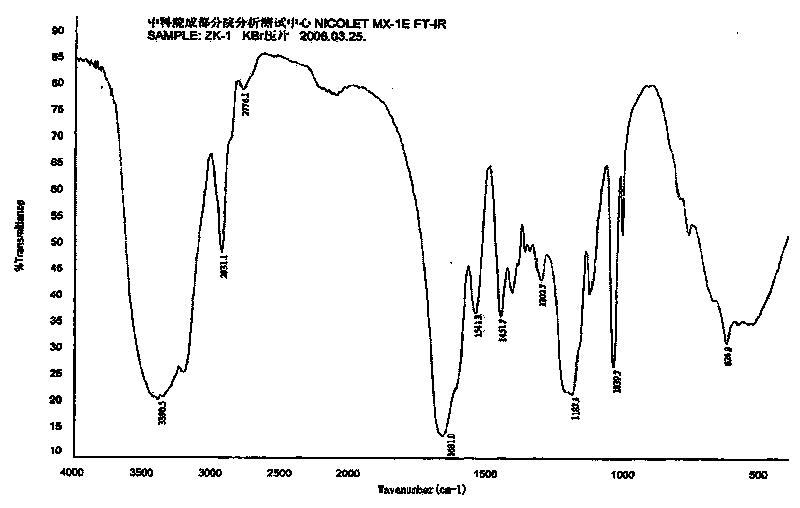

The invention relates to a blend of fluorine rubber and silicone rubber, as well as a preparation method thereof. The composition in weight percentage of the blend of fluorine rubber and silicone rubber is as follows: 12 to 50 percent of fluorine rubber, 12 to 50 percent of silicone rubber, 2.5 to 10 percent of compatibilizer, 2.5 to 10 percent of acid-acceptor, 12 to 35 percent of reinforcing filler, 0.5 to 7 percent of constitution controller, 0.5 to 3 percent of vulcanizing agent and 0.5 to 4 percent of crosslinking additive. The blend of fluorine rubber and silicone rubber is prepared by a mechanical blending method and is vulcanized by use of peroxides. Vulcanized rubber has good mechanical properties, heat resistance, low-temperature resistance, oil resistance and low-compression permanent deformation performance, and can be used for producing and manufacturing high-performance rubber tubes, adhesive tapes, sealing elements, rubber linings and the like needed in automobile, mechanical, chemical, aerospace and other industries.

Owner:SOUTH CHINA UNIV OF TECH

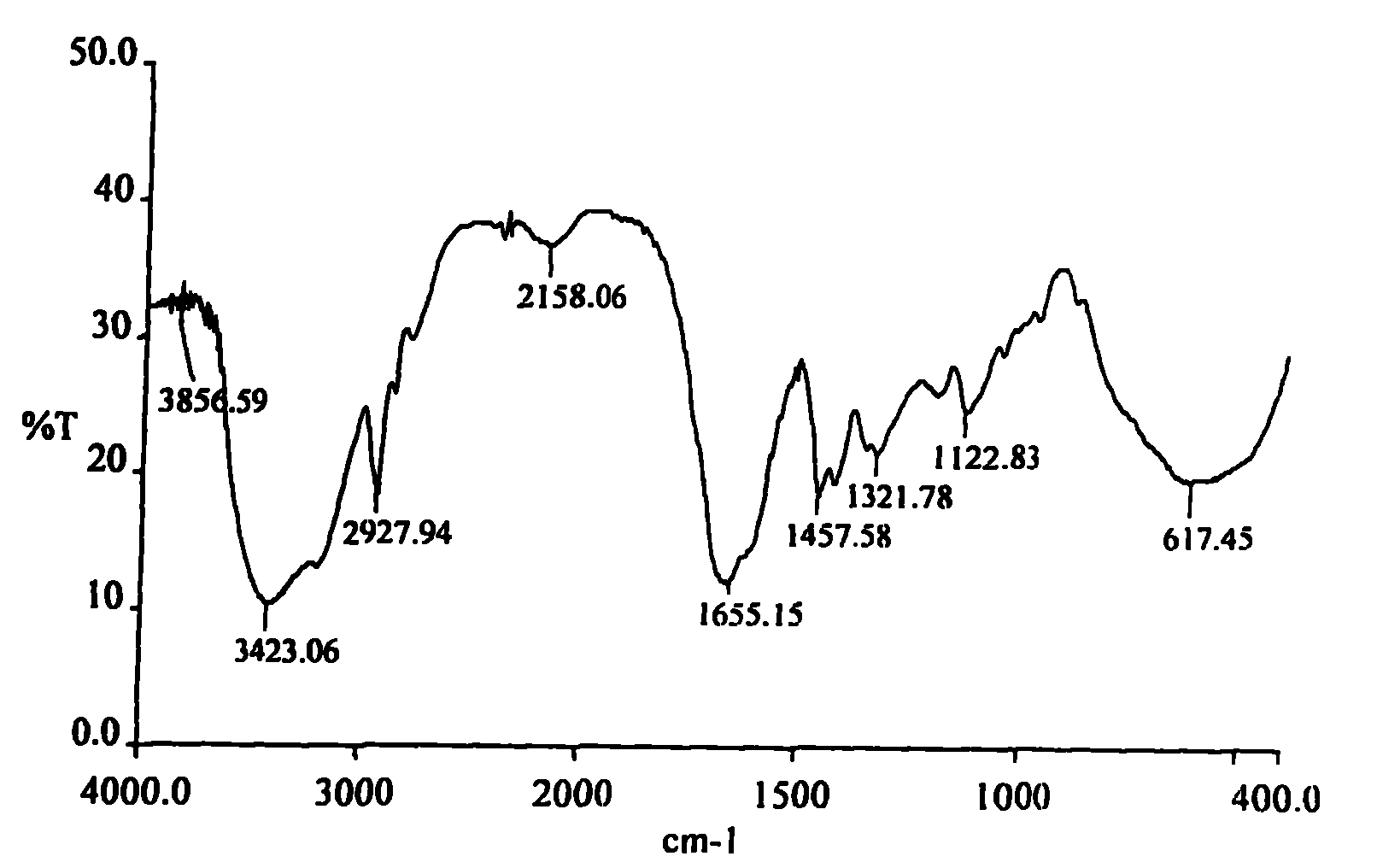

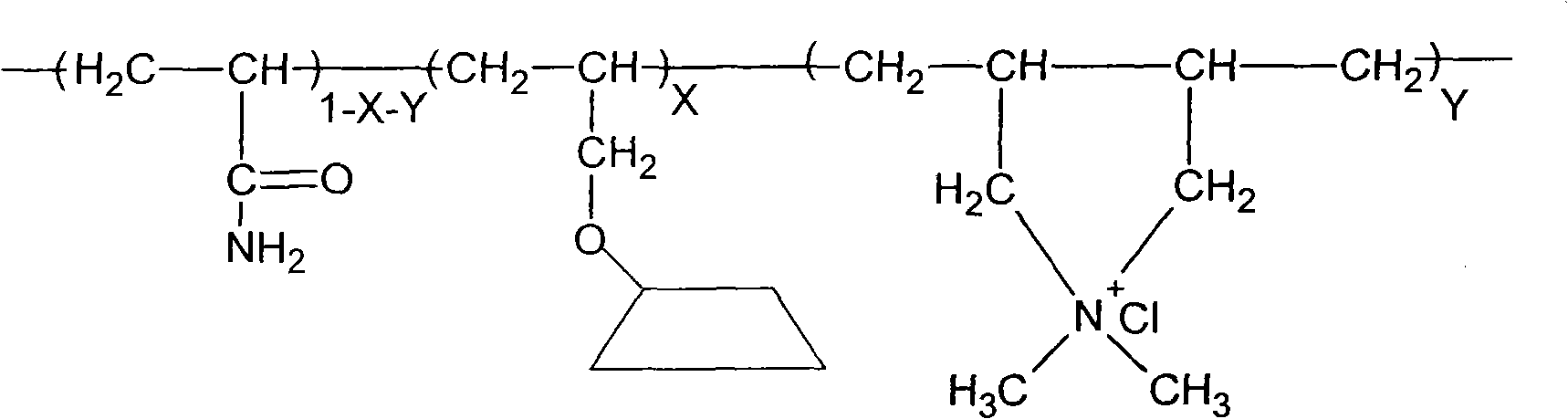

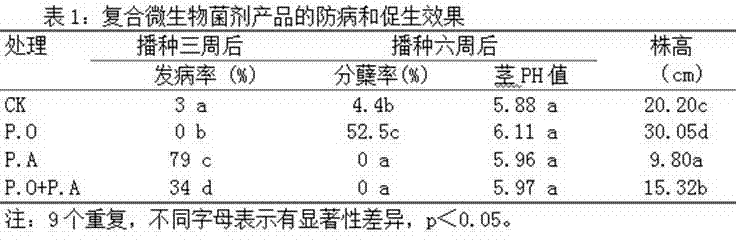

High temperature resistant amphoteric ion polymer fluid loss agent used for drilling fluid and preparation method thereof

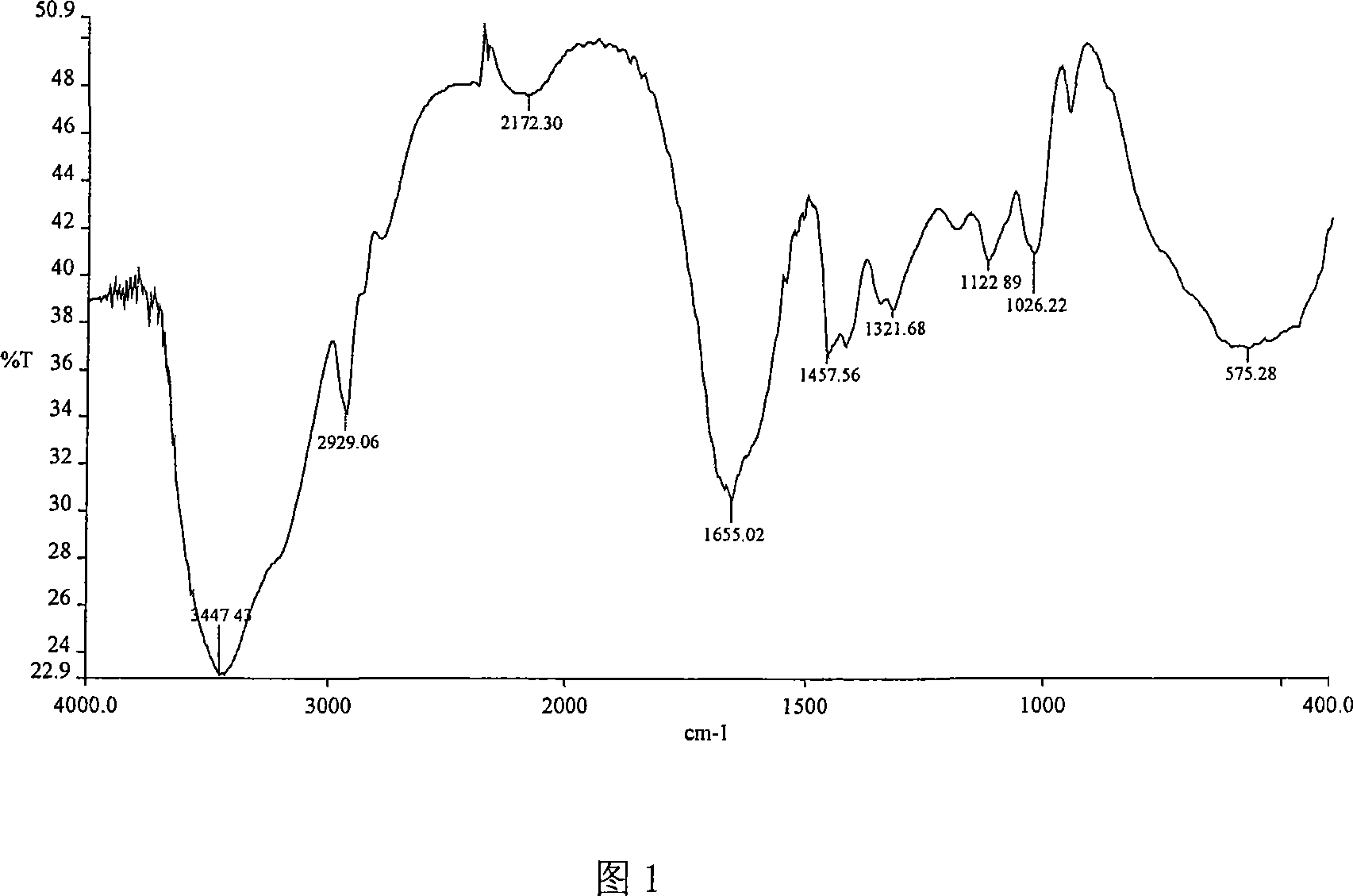

The invention relates to high temperature resistant amphoteric ion polymer fluid loss agent used for drilling fluid of a high temperature and high pressure drilling and a preparation method thereof. Four monomers, namely, acrylamide (AM), 2-acrylamide-2-methyl propane sulfonic acid (AMPS), dimethyl diallylammonium chloride (DMDAAC) and styrenesulfonate (SSS) are used as raw materials, wherein the mole ratio of AM:AMPS:DMDAAC:SSS is (9-11):(3-4):(0.5-1.5):(1.0-1.5); ammoniumpersulfate-sodium bisulfite as an initiator is added and solution is copolymerized through a polymerization method to compose the fluid loss agent. The fluid loss agent provided by the invention has the advantages of ideal high temperature resistant (more than 220 DEG C) reducing filtrate performance, shale inhibition performance and stable fluid rheology performance and simple preparation method, convenient operation and higher yield.

Owner:SOUTHWEST PETROLEUM UNIV

AM/NaAA/allylcyclodextrin polymer with inclusion function and synthetic method thereof

InactiveCN101104665AThe preparation method is simple and feasibleMild reaction conditionsWater/sewage treatmentDrilling compositionSynthesis methodsSolvent

The invention relates to an AM / NaAA / allyl cyclodextrin polymerization with a inclusion function and a synthesis method of the AM / NaAA / allyl cyclodextrin (CD) polymerization, which comprises three structure units of acrylamide, sodium acrylate and allyl cyclodextrin. The synthesis method is as follow: the allyl cyclodextrin is synthesized with DMSO and DMF as solvent, CD as raw material and under the temperature of 0 to 10 DEG C. Then AM is put into the allyl-beta-cyclodextrin water solution, then initiator is added to prepare AM / allyl-beta-cyclodextrin binary copolymer under the conditions that monomer concentration is 10 to 20 percent, initiation system concentration is 40 to 80 mg / l, the temperature is 30 to 50 DEG C, and the time is for 1 to 8 hours. NaOH solution is put into the binary copolymer to hydrolyze, then the AM / NaAA / allyl cyclodextrin polymerization is obtained. The synthesis method of the polymer is processed under the mild condition with simple operation, the product is easy to be purified and separated. The AM / NaAA / allyl cyclodextrin polymerization can be used in the fields such as petroleum exploitation, waste water treatment, chemistry and medicine.

Owner:SOUTHWEST PETROLEUM UNIV

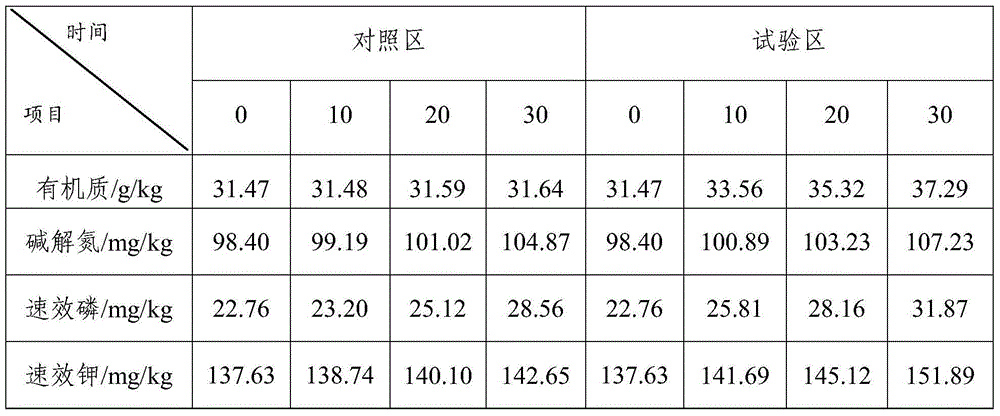

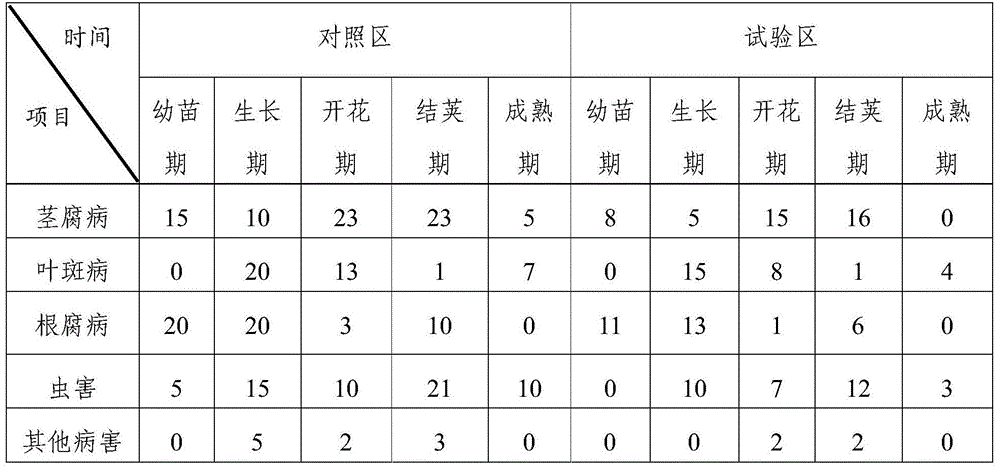

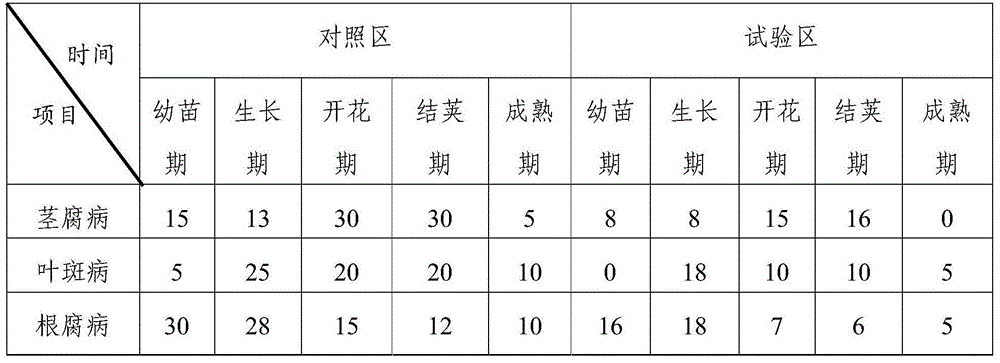

Bacterial manure for peanut planting and preparation method of bacterial manure

ActiveCN103819267AImprove resistance to pests and diseasesIncrease productionFertilising methodsOrganic fertilisersMicrobial agentPaecilomyces lilacinus

The invention provides a special bacterial manure for peanut planting, which comprises the following components in parts by weight: 5-25 parts of a compound microbial agent, 30-65 parts of dreg composite powder, 5-20 parts of starch and 10-25 parts of bentonite, wherein the compound microbial agent is composed of bacillus subtilis agent, a rhodopseudomonas palustris agent, a trichoderma harzianum agent and a paecilomyces lilacinus agent; the mass ratio of the bacillus subtilis agent to the rhodopseudomonas palustris agent to the trichoderma harzianum agent to the paecilomyces lilacinus agent is 5:2:1:2, and the total effective viable count of the compound microbial agent is10 billion cfu / g. The bacterial manure is mainly used as a base fertilizer, and can change the microenvironment around the roots of peanuts to prevent various plant diseases and insect pests while promoting nutrient absorption of the peanuts, so that the yield and quality of the peanuts are improved.

Owner:湖南慧谷农业生态研究院有限公司

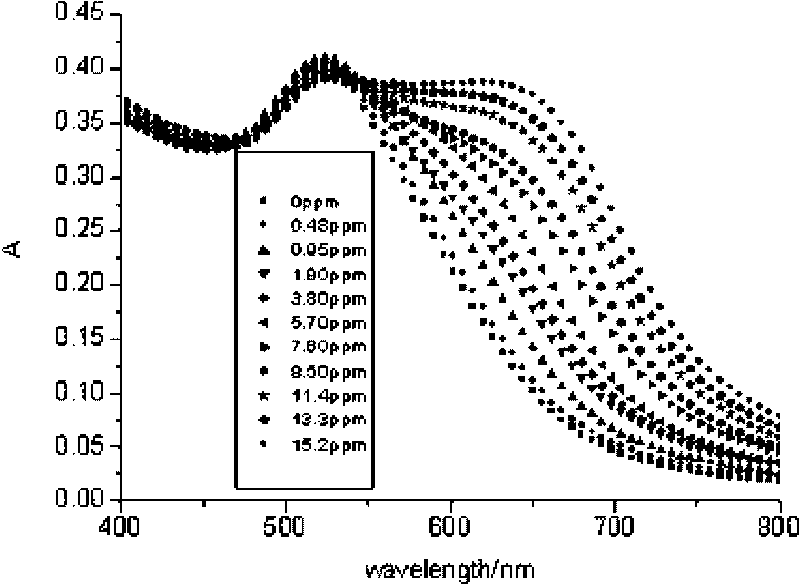

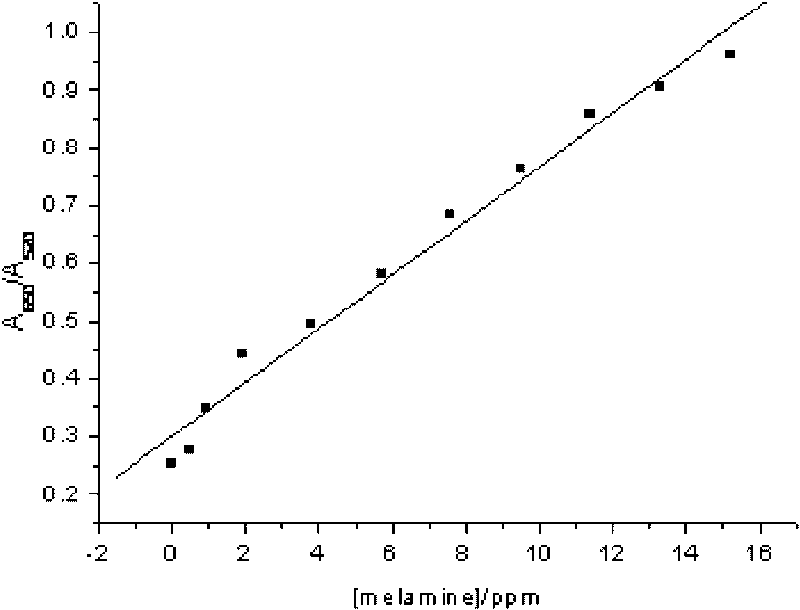

Method for quickly detecting melamine in milk sample based on nanogold

InactiveCN101718708AThe preparation method is simple and feasibleMature technologyMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationMilk sampleNanometre

The invention provides a method for quickly detecting melamine in a milk sample based on nanogold, which aims to solve the problems of the high operation requirement, complex detection process, high cost, long time, incapacity of meeting a lot of food test requirements and the like on the detection of the melamine. The method comprises the following steps: performing pretreatment on the milk sample and adding the pretreated milk sample into a nanogold solution; and adopting visual colorimetry to compare the color of the nanogold added with the sample solution with the color in a color standard series and then qualitatively judging whether the milk contains the melamine or not. The color standard series is prepared through the following steps: adding the pretreated milk samples in an identical volume and containing the melamine of different concentrations into the nanogold solution, wherein the content of the nanogold in each sample is consistent; and after color development reaction, obtaining the color standard series. The method has the advantages of low cost, simple and convenient operation and capacity of visually and quickly detecting the melamine in the milk.

Owner:FUZHOU UNIVERSITY

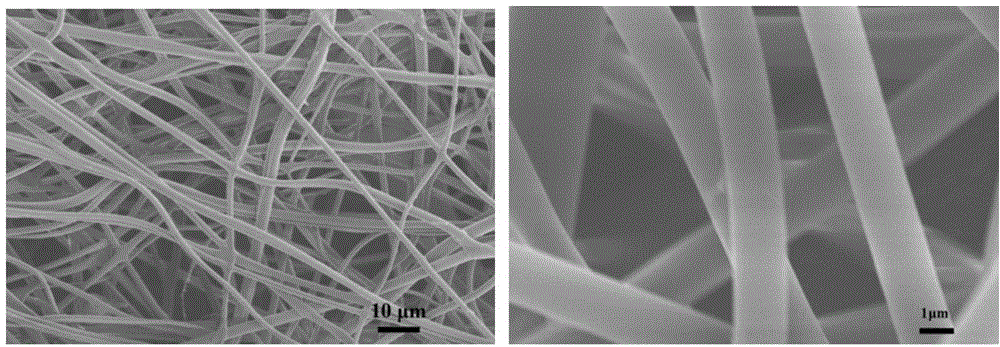

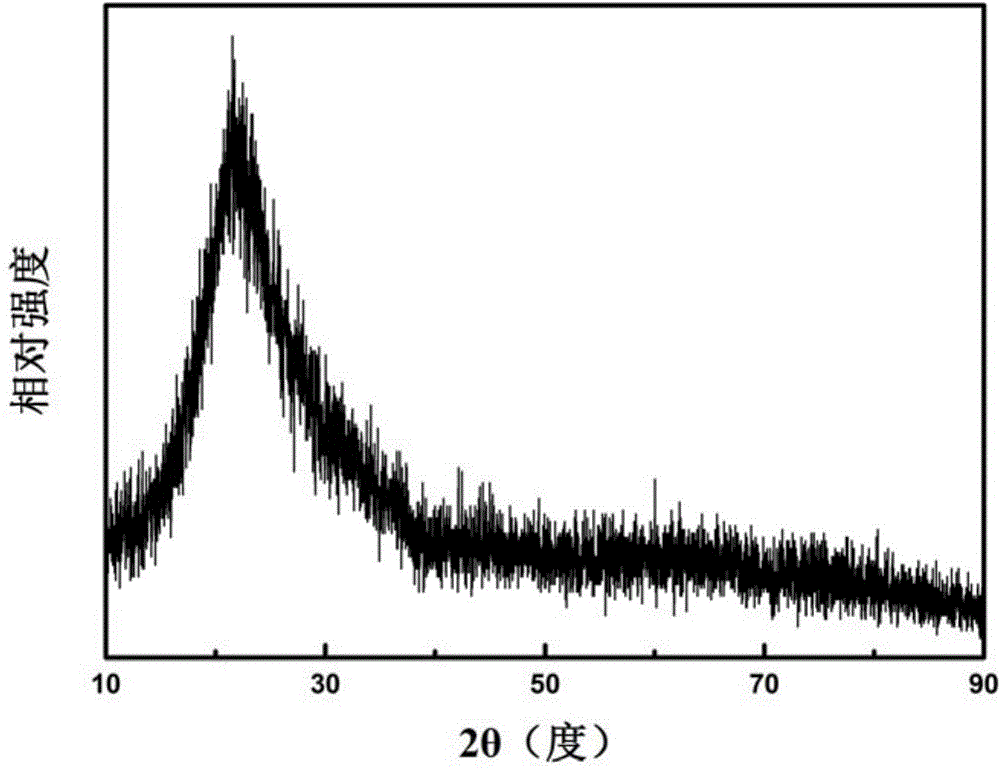

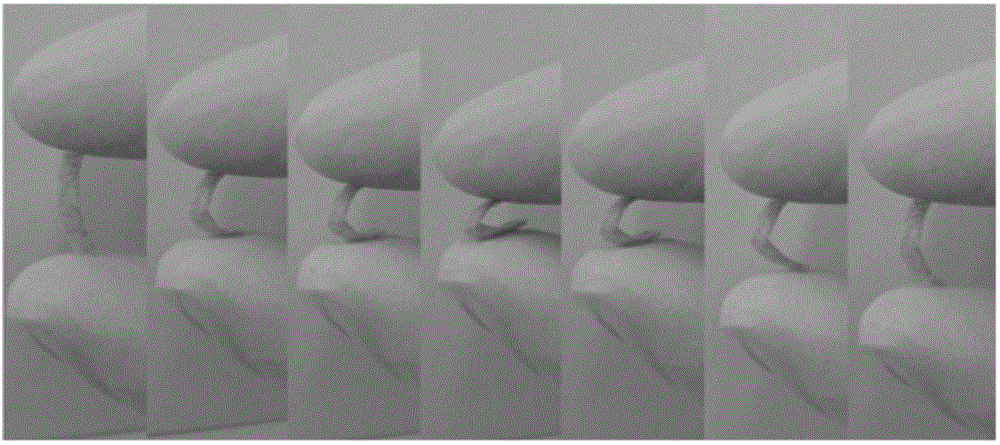

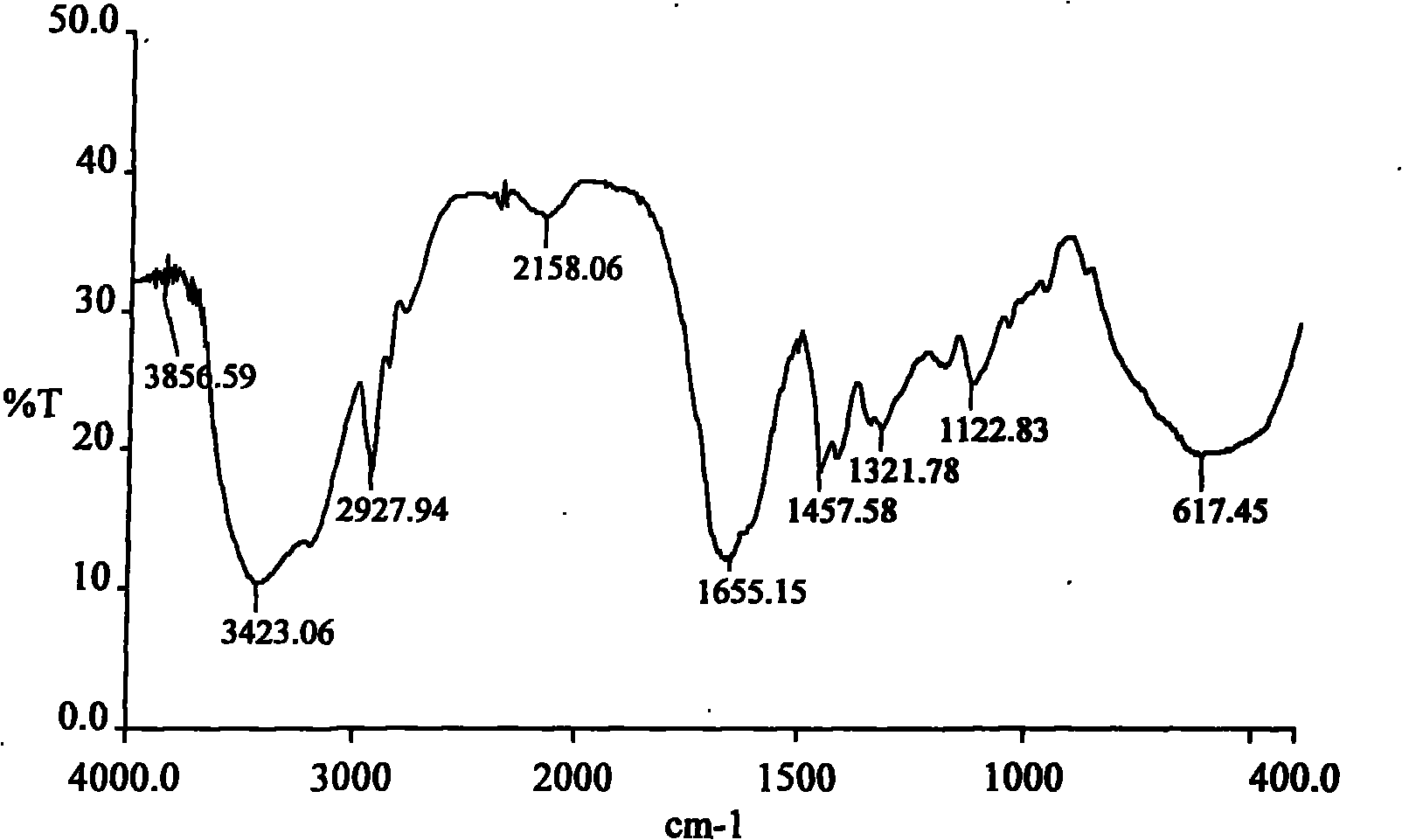

Preparation method of flexible silicon dioxide fiber film

InactiveCN103603136AHigh yieldThe preparation method is simple and feasibleFilament/thread formingFibre chemical featuresFluorescencePhosphoric acid

The invention relates to a preparation method of a flexible silicon dioxide fiber film. The method includes: (1) mixing tetraethyl orthosilicate, ultrapure water and phosphoric acid at room temperature to obtain a transparent and clear silicon source solution; (2) dissolving polyvinyl alcohol in the ultrapure water with stirring at the temperature of 80-90 DEG C for 4-5 hours to obtain a polyvinyl alcohol solution; (3) mixing the silicon source solution with the polyvinyl alcohol solution to obtain a colorless clear spinning solution, standing and ageing prior to electrostatic spinning, and collecting a layer of uniform white fiber film; (4) putting the white fiber film in a muffle furnace, heating to 500 DEG C prior to retaining the temperature for 2-4 hours, then heating to 800 DEG C prior to retaining the temperature for 2-3 hours, and finally naturally cooling to obtain the flexible silicon dioxide fiber film. The preparation method is simple, and the prepared silicon dioxide fiber film is resistant to organic solvents and corrosion, has good flexibility after being subjected to high temperature and has potential application in the fields of catalyst loading and fluorescent films.

Owner:DONGHUA UNIV

AM (Acrylamide)/DMDAAC (Dimethyl Diallyl Ammonium Chloride)/cyclodextrin polymer filtrate reducer and preparation method thereof

InactiveCN101818051AThe preparation method is simple and feasibleMild reaction conditionsDrilling compositionNitrogenReducer

The invention relates to an AM (Acrylamide) / DMDAAC (Dimethyl Diallyl Ammonium Chloride) / cyclodextrin polymer filtrate reducer used in petroleum and gas drilling fluid and a preparation method thereof. The invention can solve the technical problems that a well wall is not stable as water loss increases at the pit bottom under the condition of high temperature, and the like. The AM / DMDAAC / cyclodextrin polymer filtrate reducer is characterized by comprising three monomers of AM, DMDAAC and cyclodextrin; the preparation method comprises the following steps of: firstly adding the AM and the DMDAAC into an allyl cyclodextrin water solution according to the mol ratio among the allyl cyclodextrin water solution, the AM and the DMDAAC of 69.2-84.2:30-15:0.8 in sequence; then adding a chelating agent, an oxidant and a reducing agent in sequence; finally evenly mixing, then injecting nitrogen for 20-40min and deoxidizing, and reacting at 30-50 DEG C for 6-8h to obtain the AM / DMDAAC / cyclodextrin polymer filtrate reducer. The preparation method of the polymer is simple, convenient and available and mild in reaction conditions; and the polymer has good filtrate reduction effect in the drilling fluid, is resistant to temperature up to more than 250 DEG C and used in the petroleum and gas drilling fluid.

Owner:SOUTHWEST PETROLEUM UNIV

Nutritious energy bar and the method of producing the same

InactiveCN101061868AIncrease energy densityPromote growth and developmentFood preparationFructoseSoybean Lecithin

The invention discloses a nutritious energy rod and its preparing process, wherein the rod is prepared from malt sugar 5-20%, levulose 5-20%, glucose 10-42%, oat powder 3-15%, soybean polypeptide 3-16%, fish protein small peptide 2-12%, fish bone meal 1-5%, cocoa powder 2-10%, onion 3-15%, sea-tangle 2-8%, vitamin 0. 3-3%, microelements 0. 1-2%, amino acid 0. 5-5%, taurine 0. 1-2%, choline 0. 05-1%, soybean lecithin 2-8%, DHA fish oil 3-12% and edible gelatin 1-8%.

Owner:RONGCHENG TAIXIANG FOOD

Method for preparing temperature-resistant anti-salt amphoteric polymer filtrate reducer

The invention relates to a method for preparing a temperature-resistant anti-salt amphoteric polymer filtrate reducer used for drilling fluid. In the filtrate reducer, C6 to C10 paraffin hydrocarbons are used as a continuous phase; Span and Tween are used as a compound non-ionic surface active agent, wherein the mass ratio of the Span to the Tween is 2-4:1-3; three monomers, namely acrylamide(AM), acrylic acid(AA) and styrene sulfonic sodium(SSS), are used as raw materials in a mass ratio of 10:3-6:1-4; and an initiator of ammonium persulphate or redox initiator of ammonium persulphate-sodium bisulphite is added for copolymerization by adopting an opposite micro-emulsion polymerization method to obtain the filtrate reducer. The filtrate reducer provided by the invention has the advantages of higher temperature resistance, salt resistance and filtrate-reducing property, simple preparation method, mild and controllable reaction conditions, high polymerization stability, high reaction speed and high conversion rate.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

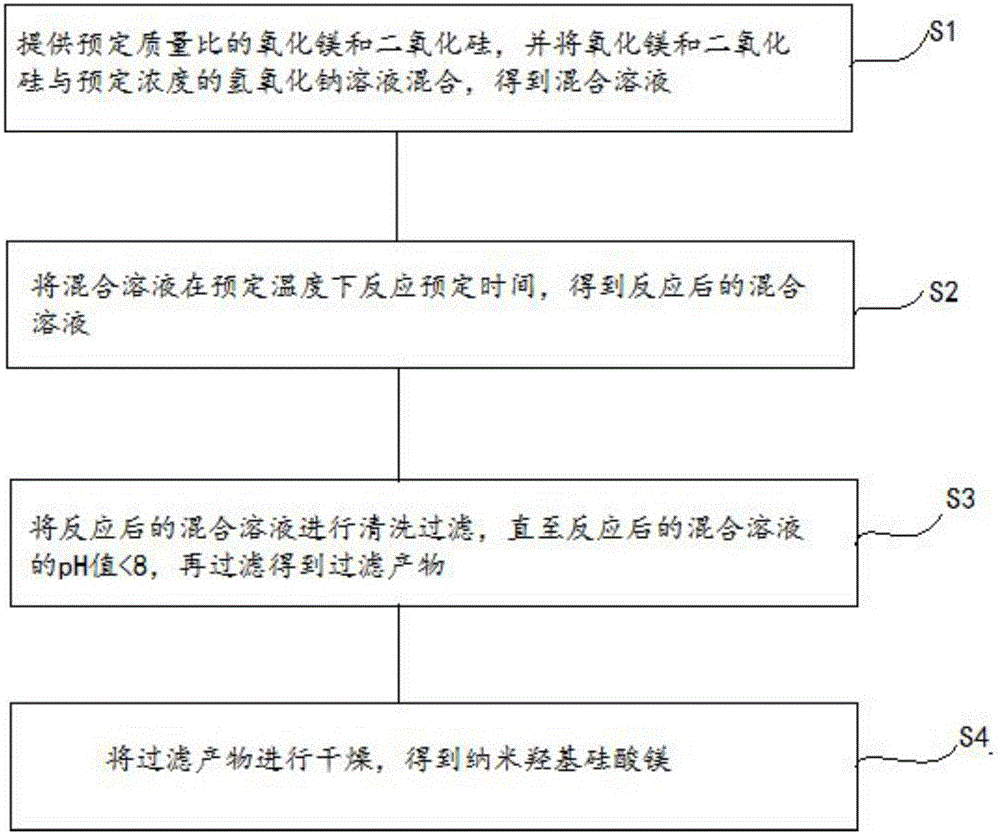

Preparation method of nanometer magnesium silicate hydroxide, and preparation method and application of anti-wear agent

ActiveCN105152178AThe preparation method is simple and feasibleStrong maneuverabilityMagnesium silicatesAdditivesChemistryMagnesium silicate

The invention discloses a preparation method of nanometer magnesium silicate hydroxide, and a preparation method and an application of an anti-wear agent. The preparation method of nanometer magnesium silicate hydroxide comprises the following steps: 1, providing magnesium oxide and silica according to a predetermined mass ratio, and mixing magnesium oxide and silica with a predetermined concentration of a sodium hydroxide solution to obtain a mixed solution; 2, reacting the mixed solution at a predetermined temperature for a predetermined time to obtain a reacted mixed solution; 3, cleaning and filtering the reacted mixed solution until the pH value of the reacted mixed solution is smaller than 8, and filtering to obtain a filtration product; and 4, drying the filtration product to obtain the nanometer magnesium silicate hydroxide. The preparation method of the nanometer magnesium silicate hydroxide disclosed in the embodiment of the invention has the advantages of simplicity, feasibility, strong operability, and realization of the controllable synthesis of magnesium silicate hydroxide nanoparticles through controlling the reaction time.

Owner:BEIJING JIAOTONG UNIV

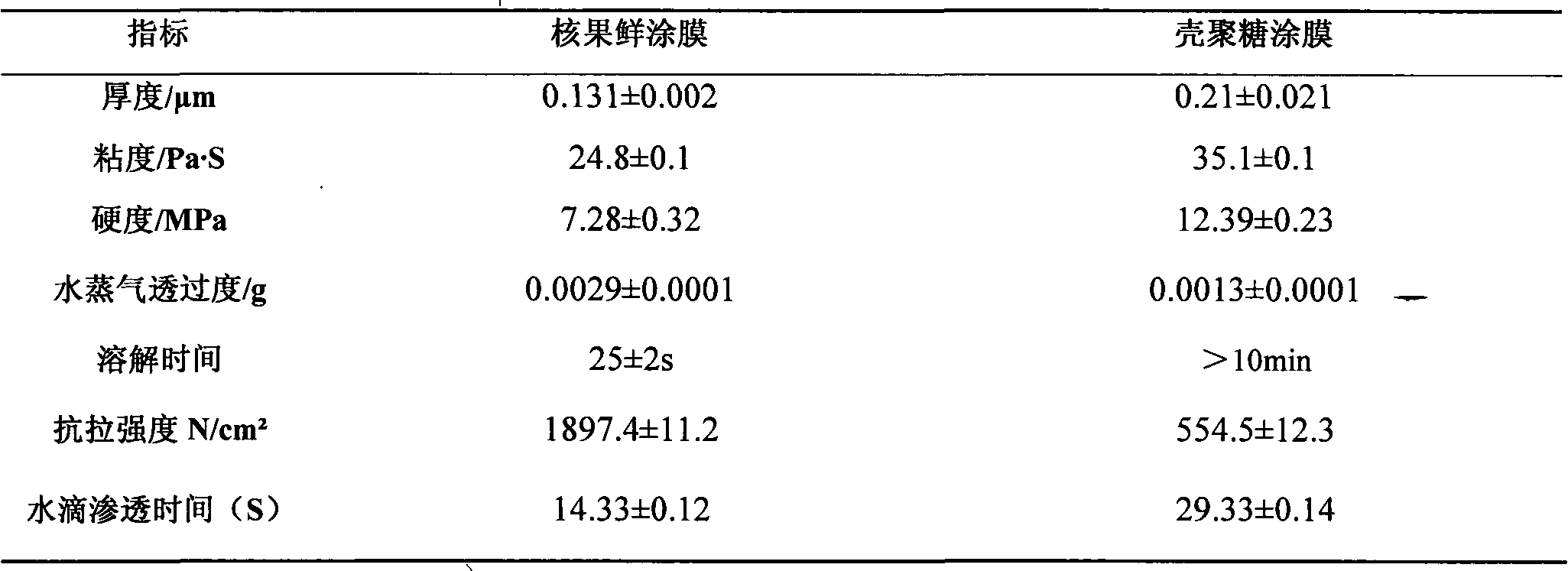

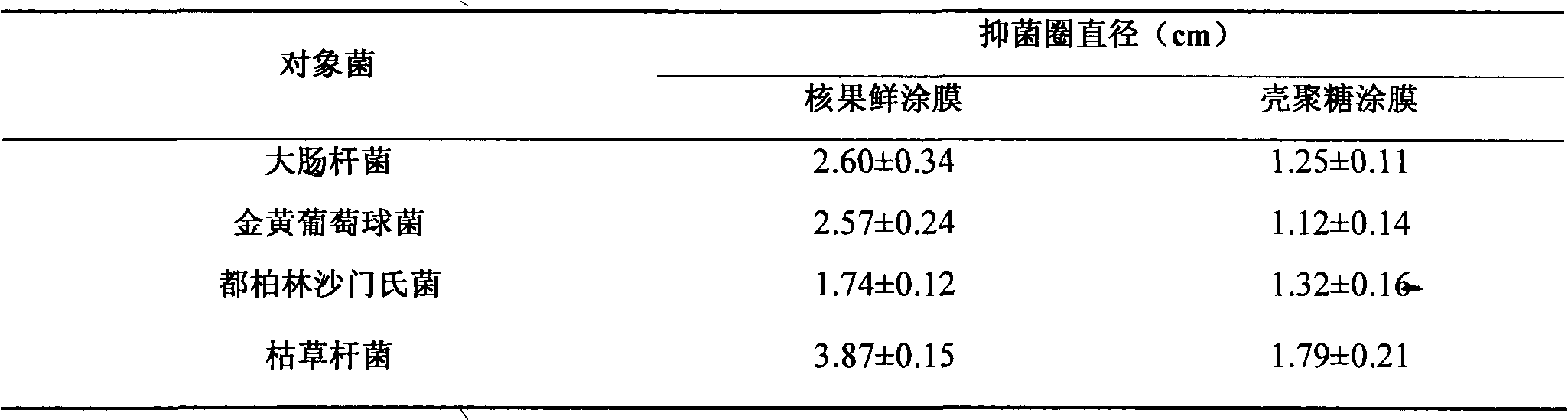

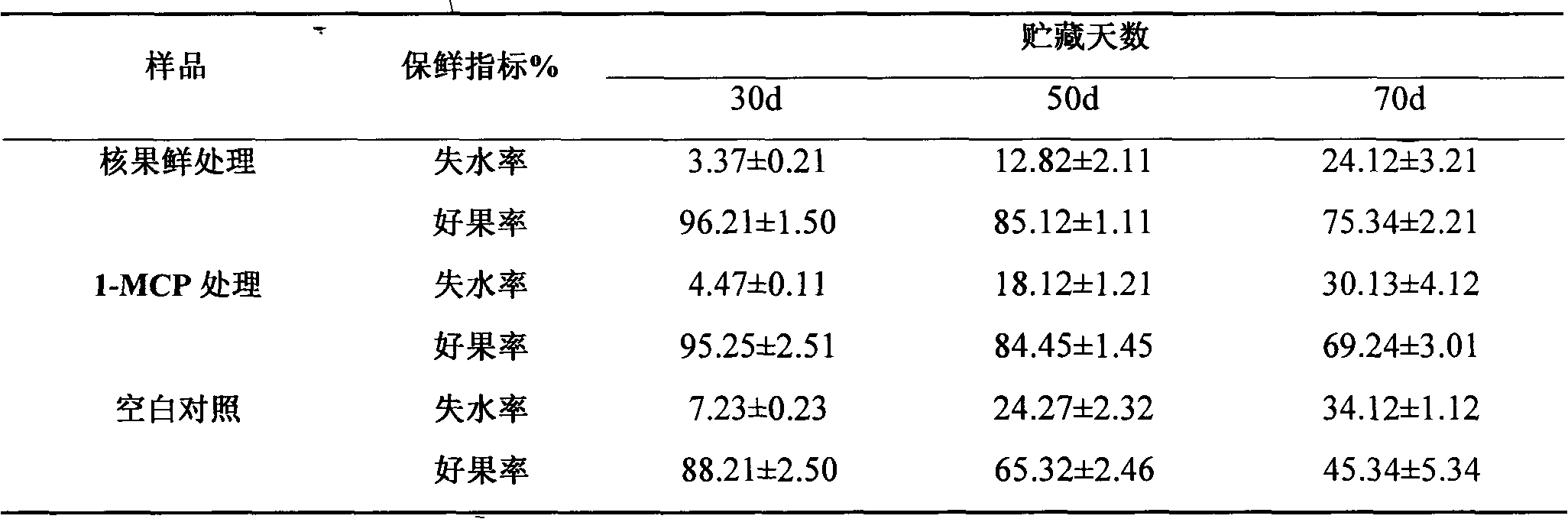

Edible compound coating antistaling agent for drupes

InactiveCN102057983AReduce water transpirationRespiratory suppressionFruits/vegetable preservation by coatingSodium ascorbateSodium erythorbate

The invention discloses an edible compound coating antistaling agent for drupes. The edible compound coating antistaling agent belongs to the field of fresh preservation and treatment of fruits and vegetables and is characterized in that chitosan and other auxiliaries are dissolved in a water solution prepared in an acetic acid solution with low concentration. According to the invention, glycerylmonostearate and Tween 80 are added in chitosan coating, thus the connecting strength of antibacterial components is enhanced and, the toughness and air permeability of the coating are improved; and meanwhile, other components in the fresh preservation agent, such as sodium ascorbate, sodium chloride, and the like, have greater bacterial resistance and fresh preservation effects. The edible compound agent, after being applied to coating the drupes, can form a layer of shiny transparent film on the surface of each drupe and achieves the functions of preserving water, reducing bacterial contamination, preventing the growth of microorganisms, resisting oxidation and inhibiting the fruit respiration. The edible compound agent can be widely applied in the storage and fresh preservation of the drupes and achieves greater fresh preservation effects than other methods. The edible compound agent is convenient to prepare and use, requires small equipment investment, occupies a small operation area, and is suitable for industrial batch production.

Owner:SICHUAN AGRI UNIV

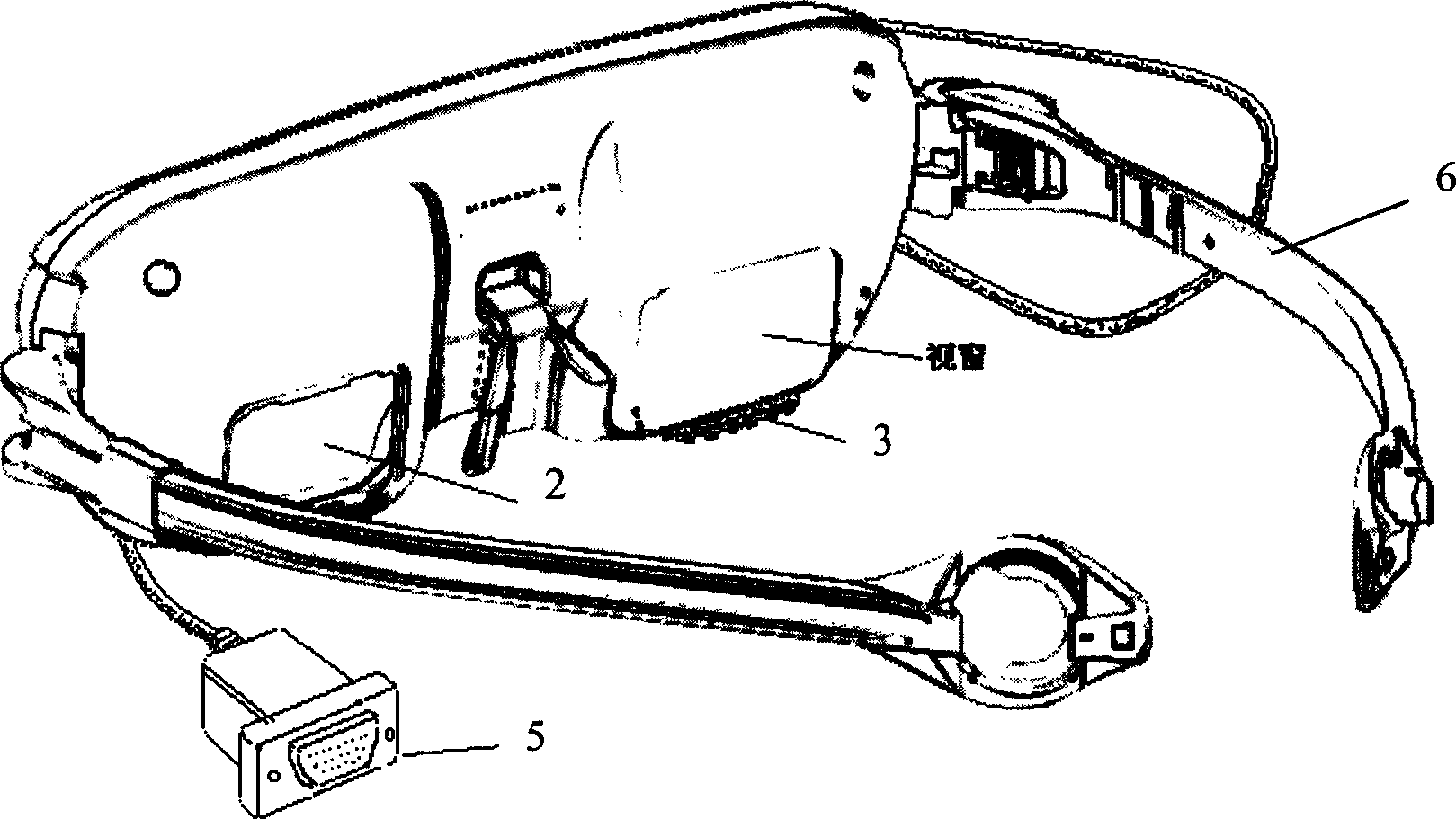

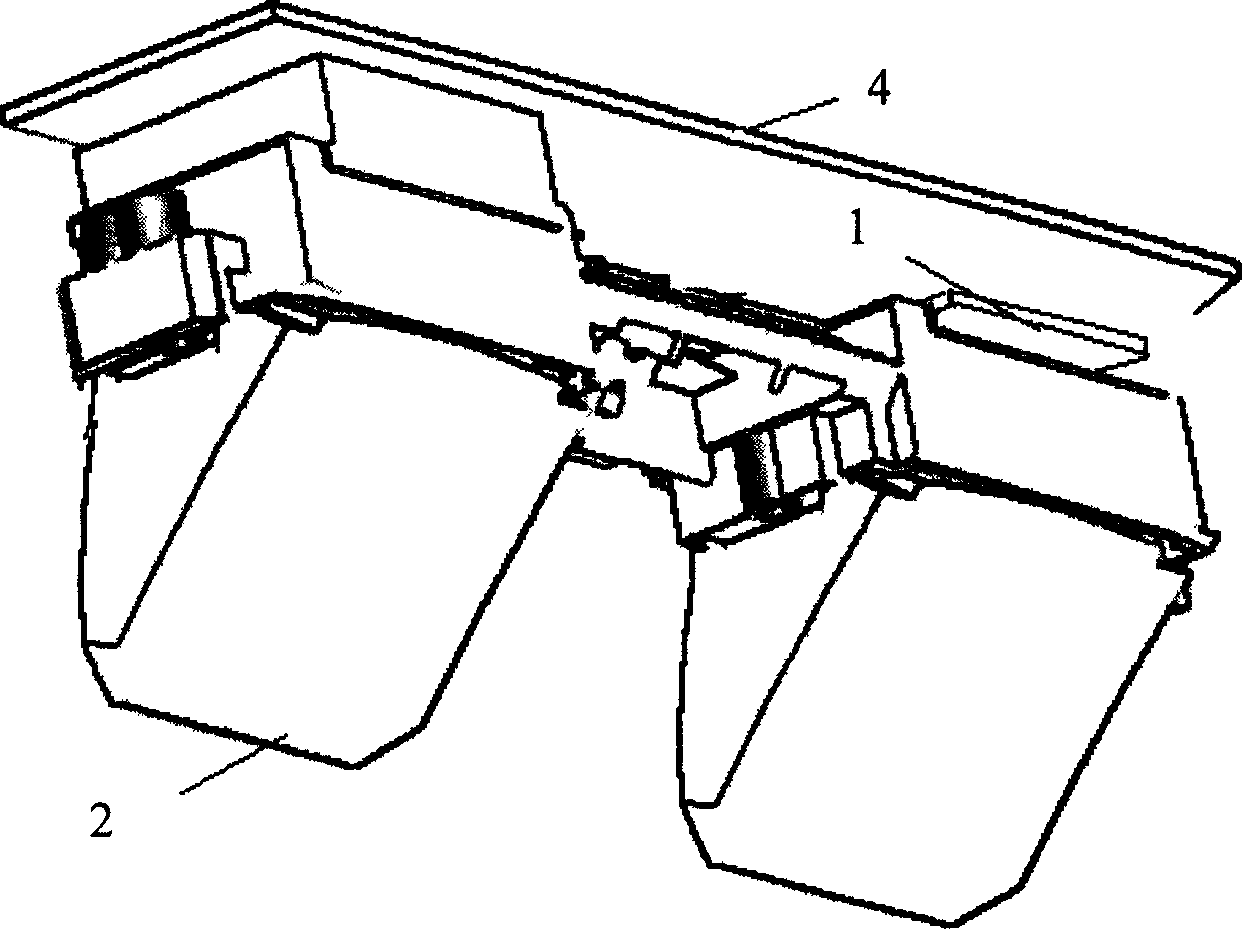

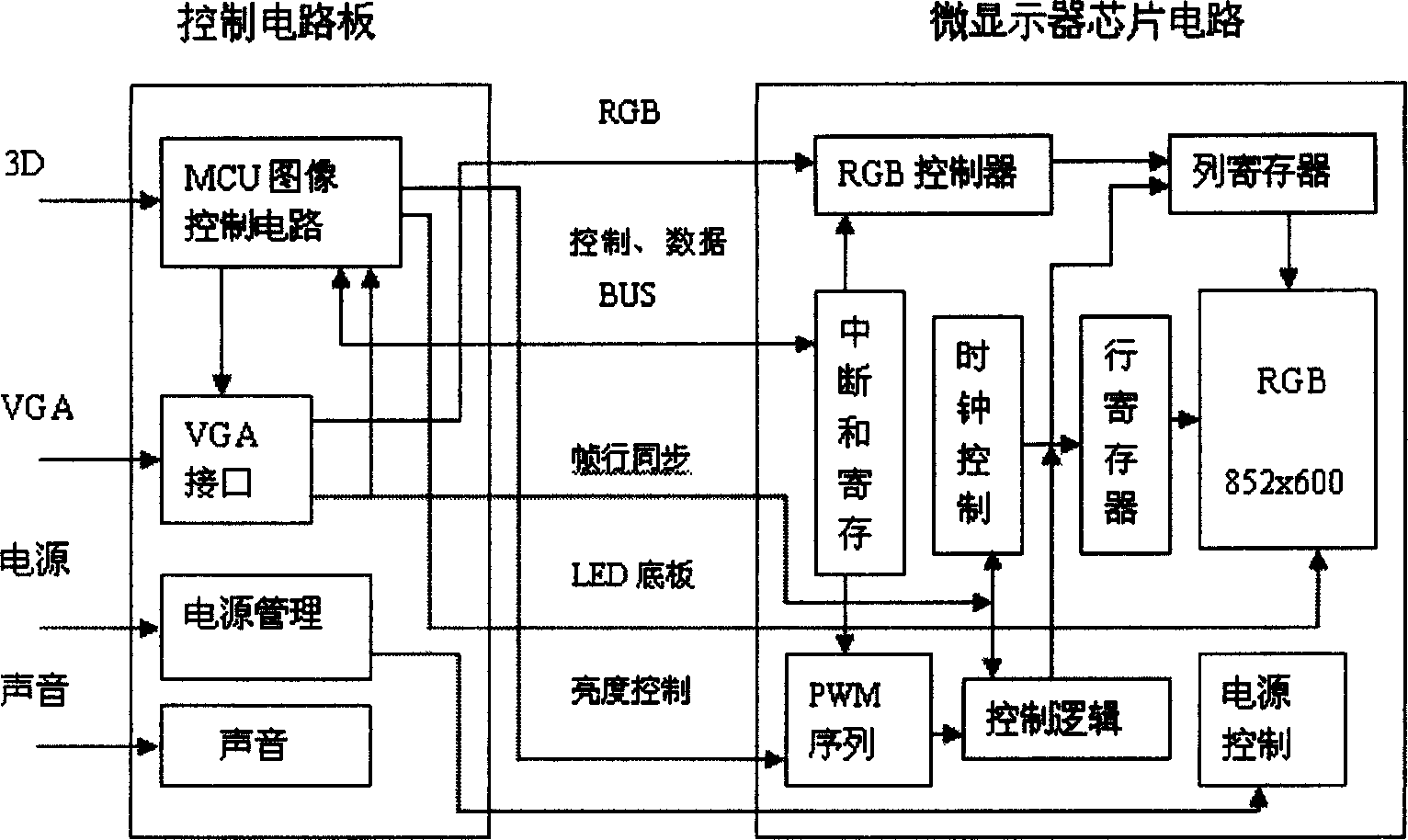

Spectacle type display device

InactiveCN1611988AHigh frame refresh rateProduce stereoscopic effectTelevision system detailsPrismsDisplay devicePrism

The present invention relates to a spectacle type display device which is composed of a micro-display device chip, an optical prism and a display device control circuit. The micro-display device chip is a made of OLED material, the image light emitted by the micro-display device is introduced to the optical prism through a transmission surface. The display device control circuit provides various required logic control signal for the micro-display device. The micro-display device of the invention is made of OLED material, its vision field angle can reach 120 degrees, the frame fresh rate can reach 120 Hz, and the display device can generate vision effect of big screen and can generate stereo vision effect. The invention adopts VGA interface compatible with VESA standard, and can be connected to any video apparatus having VGA interface. The invention also has focusing function and can be used by short sighted human. The second curved surface and the third curved surface of the optical prism of the invention are both ball surfaces, so the design and manufacturing method is simple and useful.

Owner:深圳国际技术创新研究院

Temperature and salt-resistant AM/ACD/AE copolymer and its preparation method

InactiveCN102229692AThe preparation method is simple and feasibleMild reaction conditionsDrilling compositionPotassium persulfatePolymer science

The invention relates to a temperature and salt-resistant AM / ACD / AE copolymer used as an oil displacement agent in the petroleum exploitation and a preparation method thereof. The temperature and salt-resistant AM / ACD / AE copolymer can meet the requirements of the injected liquid viscosity with the incessant increasing of the oil reservoir temperature and the stratum mineralization. The technical scheme of the invention is characterized in that the mole ratio of the raw materials used in the preparation of the copolymer comprises, by mole percentage, 88.2-91.4% of an AM monomer, 8-11% of an ACD monomer, 0.6-0.8% of an AE monomer, an oxidizing agent potassium persulphate which accounts for 0.3-0.5% of the total weight of the monomers, and a reducing agent sodium bisulfite which accounts for0.35-0.45% of the total weight of the monomers. The preparation method provided by the invention comprises the following steps of: adding AM, ACD and AE into a container, adding water to produce a solution at the concentration of 15%, dissolving with stirring, adding the oxidizing agent and the reducing agent with uniformly blending, deoxygenizing by filling nitrogen, reacting at the temperature of 40-50 DEG C for 4-5 hours, washing and drying to obtain the AM / ACD / AE copolymer. The preparation method provided by the invention is simple and feasible with mild reaction conditions; the product prepared by the method has inclusion and aggregation functions as well as temperature and salt-resistant performance, and can be used in tertiary oil extraction.

Owner:SOUTHWEST PETROLEUM UNIV

Smoke denitration catalyst by catalytic oxidation, and preparation method thereof

ActiveCN102188979AHigh catalytic oxidation activityGood tolerance to sulfuric waterDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationCopper nitrate

The invention discloses a smoke denitration NO (Nitric Oxide) oxidation catalyst by catalytic oxidation, and a preparation method thereof. The NO oxidation catalyst is prepared from titanium crosslinking clay as a carrier and copper oxide and vanadium oxide as active ingredients, wherein the titanium crosslinking clay carrier is prepared by taking acetone as a dispersing agent and crosslinking and aging titanic acid butyl acetate and sodium base montmorillonite turbid liquid under an acid condition. Copper nitrate and ammonium metavanadate solutions are used as the precursors of the active ingredients, are fixed on the carrier by an immersion method, and are dried and calcined by program heating to obtain the smoke denitration catalyst by catalytic oxidation. In the catalyst, the copper capacity is 2-10%, and the vanadium capacity is 0.5-5%. The smoke denitration catalyst by catalytic oxidation has the advantages of good sulfur and water tolerance, good reproducibility and good denitration effect.

Owner:BEIJING UNIV OF CHEM TECH

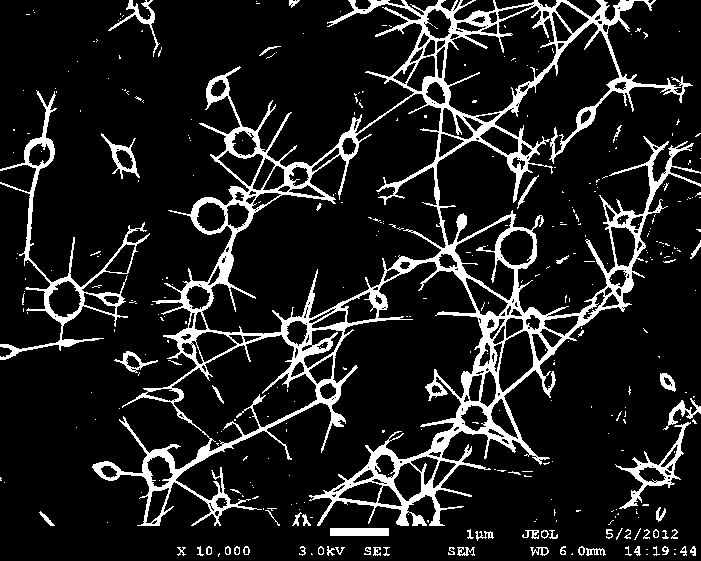

Collagen/polyvinyl alcohol composite microspheres as well as preparation method and application thereof

ActiveCN103276472AImprove adhesionPromote migrationConnective tissue peptidesConjugated cellulose/protein artificial filamentsFiberPolymer science

The invention provides collagen / polyvinyl alcohol composite microspheres as well as a preparation method and application thereof, belonging to the field of high polymer composite materials. The microsphere diameter of the collagen / polyvinyl alcohol composite microspheres is 100-1000nm, and the microspheres are connected into the shape of a string of beads by using collagen / polyvinyl alcohol composite nano-fibers, or are connected into the shape of a net by taking the microspheres as nodes and using the composite nano-fibers. The preparation method of the collagen / polyvinyl alcohol composite microspheres comprises the following steps of: (1) dissolving collagen into an acetic acid aqueous solution to prepare a collagen solution of which the concentration is 7-25g / L; and (2) uniformly mixing the collagen solution with a polyvinyl alcohol aqueous solution of which the concentration is 6-12wt% in a weight ratio of (1-9):1, and performing electrostatic spinning, wherein the distance between a spinning needle head and a receiving plate is 8-30cm, the voltage is 8-30kV, the spinning flow rate is 0.1-10mL / h, and the spinning temperature is 25-35 DEG C. The collagen / polyvinyl alcohol composite microspheres provided by the invention can be used as a scaffold material for biological tissue engineering or used as a medicament slow-release material.

Owner:ZHENGZHOU UNIV

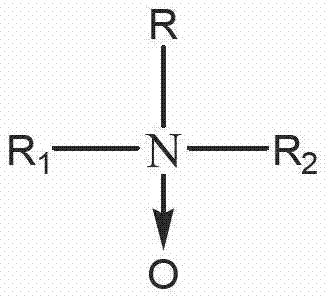

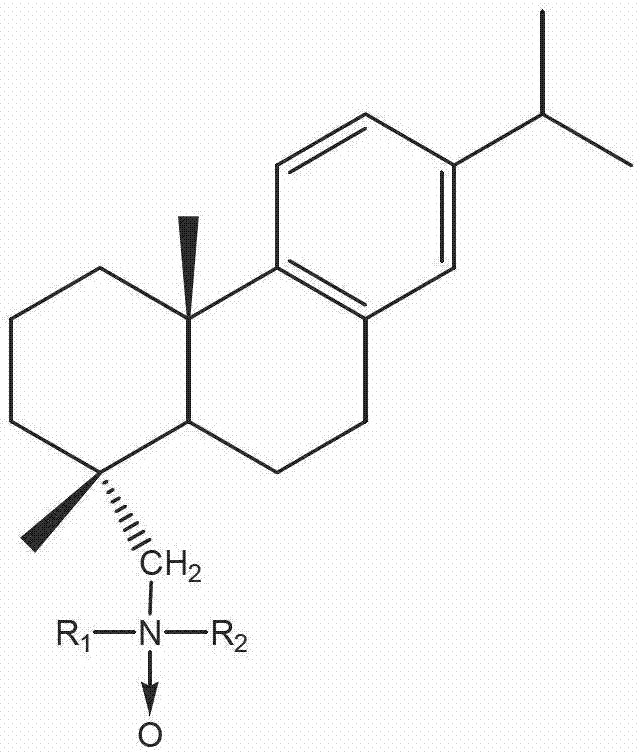

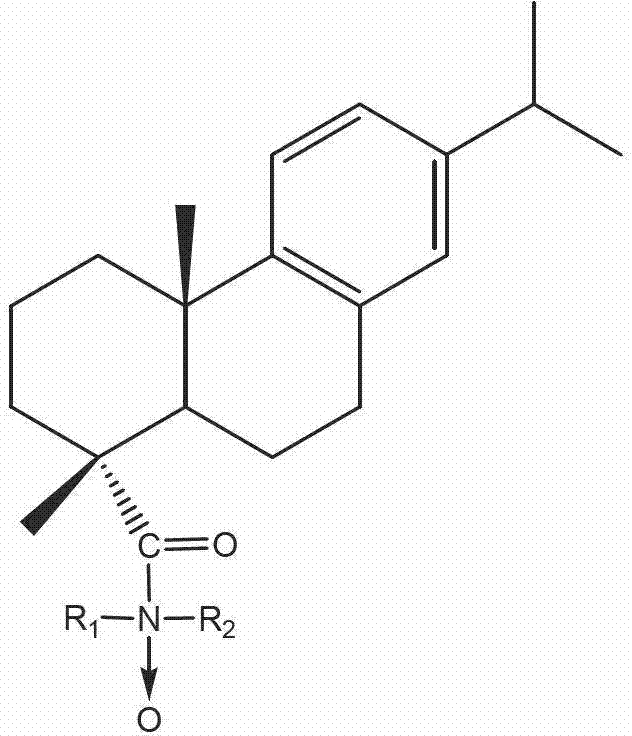

Tertiary amine oxide with rosinyl three-membered phenanthrene ring structure and preparation method of tertiary amine oxide

The invention discloses a tertiary amine oxide with a rosinyl three-membered phenanthrene ring structure and a preparation method of the tertiary amine oxide. The preparation method comprises the following steps of: (1) dissolving, namely mixing tertiary amine, an alcoholic solution or water and catalysts, heating the mixture to 50-60 DEG C, stirring and dissolving the mixture to obtain an alcoholic solution or an aqueous solution of the tertiary amine; (2) oxidizing reaction, namely mixing the alcoholic solution of the tertiary amine and hydrogen peroxide in a mole ratio of the tertiary amine to the hydrogen peroxide 1:(1-1.5), reacting the mixture for 12-25 hours at 65-80 DEG C, then adding disulfate and excess hydrogen peroxide to the mixture for reacting for 0.5-1 hour; and (3) separating and drying, namely steaming reaction products in a spinning manner, and drying the products in vacuum to obtain the tertiary amine oxide with the rosinyl three-membered phenanthrene ring structure. The tertiary amine oxide disclosed by the invention is high in electrolyte resistance and good in defoaming capability, has a good effect in hard water, and has good wetting and emulsifying performance. The preparation method is simple and practicable and is high in yield.

Owner:GUANGXI UNIV FOR NATITIES

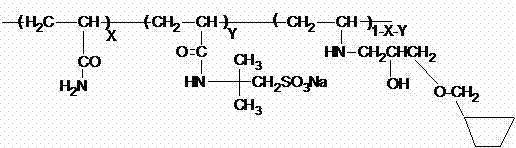

Acrylamide/2-acrylamido-2-methylpropane sulfonic acid sodium/cyclodextrin modified acrylamide (AM/AMPS-Na/MAM) copolymer and preparation method thereof

InactiveCN102199251AControl vectorThe preparation method is simple and feasibleDrilling compositionEthylenediamineAcetic acid

The invention discloses acrylamide / 2-acrylamido-2-methylpropane sulfonic acid sodium / cyclodextrin modified acrylamide (AM / AMPS-Na / MAM) copolymer serving as a fluid loss reducer for drilling fluid in oilfield, and a preparation method thereof, which can solve the problems of short cement paste thickening time, failure of an additive and high filter loss due to strata pressure and temperature rise. The technical scheme is that: the copolymer is prepared by polymerizing 83 to 85 percent of acrylamide AM, 15 to 16 percent of 2-acrylamido-2-methylpropane sulfonic acid sodium AMPS-Na and 1 to 2 percent of cyclodextrin modified acrylamide MAM. The preparation method comprises the following steps of: adding aqueous solution of the AM, solution of the MAM and solution of the AMPS-Na into a reaction container; adding ethylene diamine tetraacetic acid, potassium peroxydisulfate and sodium hydrogensulfite; and stirring uniformly, and reacting at the temperature of between 40 and 50DEG C for 5 to 6 hours under the protection of nitrogen to obtain the AM / AMPS-Na / MAM copolymer. The AM / AMPS-Na / MAM copolymer serving as a drilling fluid treating agent has high thermal stability, high temperature resistance, and better fluid loss reducing effect; the preparation method is simple and practicable, and the reaction conditions are mild; and the AM / AMPS-Na / MAM copolymer is used as the drilling fluid treating agent in the oilfield.

Owner:SOUTHWEST PETROLEUM UNIV

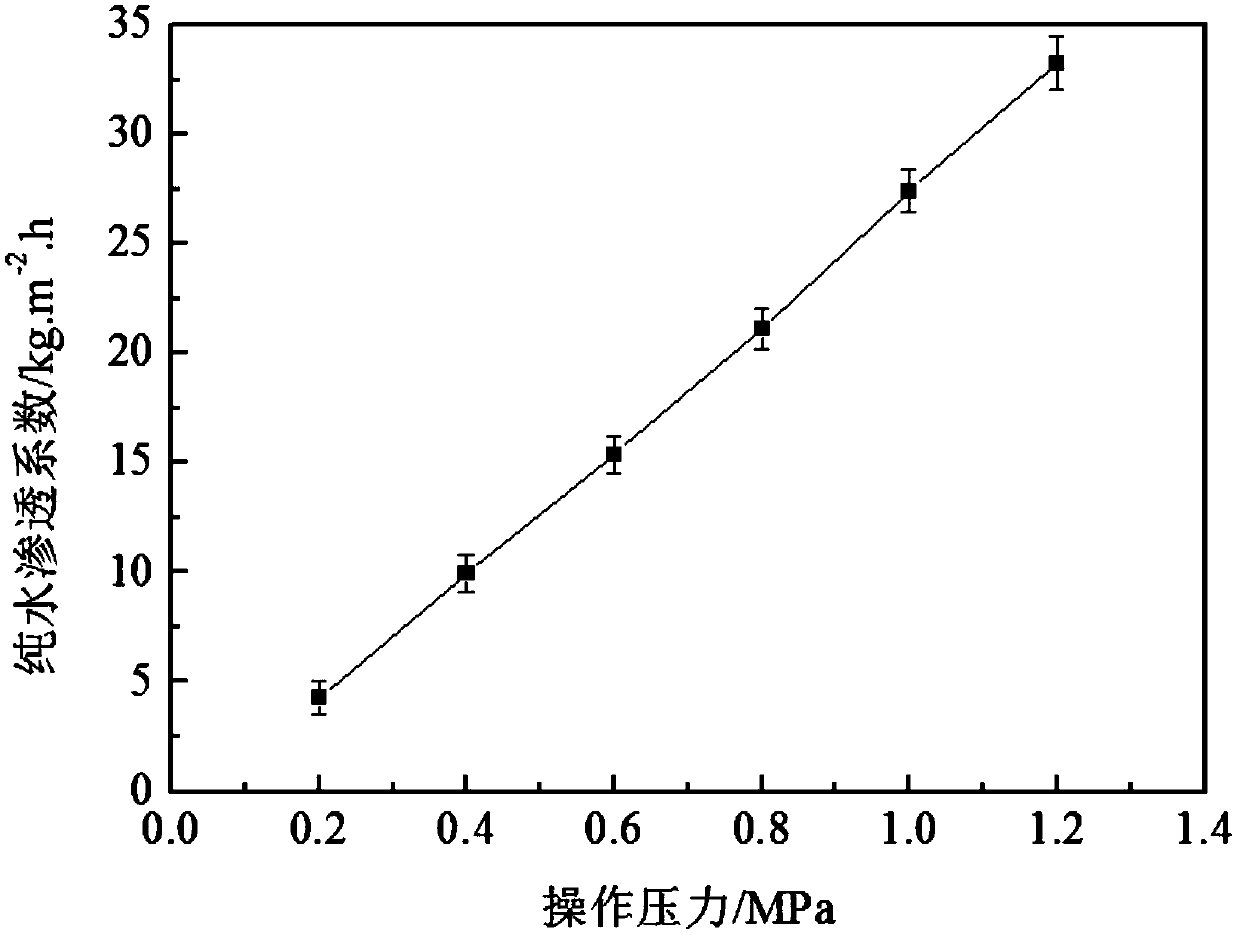

Preparation method of modified polyether sulfone functional gradient separating films

ActiveCN107715705ARealize Gradient DisposalEffectively display disposal efficiencyMembranesSemi-permeable membranesEthylenediamineEnvironmental resistance

The invention discloses a preparation method of modified polyether sulfone functional gradient separating films. The preparation method includes preparing and crushing aminated polyether sulfone separating films; subjecting aminated polyether sulfone separating film scraps, methyl acrylate and ethanediamine to Michael addition and amidation, loading arborization polyamide-amine function groups into the film scraps, and preparing modified polyether sulfone functional separating films with the arborization polyamide-amine function groups by a phase transfer technique; taking chitosan acetic acidliquor and trimesoyl chloride normal hexane liquor as a water phase and an organic phase respectively, and forming nanofiltration aromatic amide ultrathin layers on the surfaces of the modified polyether sulfone functional separating films through interfacial polymerization to obtain the modified polyether sulfone functional gradient separating films. The preparation method has the advantages that the method is simple and convenient to operate, and the coating process of the nanofiltration ultrathin layers is green and environment friendly; the prepared separating films effectively integratetreatment effects of micro ultrafiltration chelating film adsorption and nanofiltration film interception, and direct discharge and reuse of waste water containing high-concentration heavy metal and phosphate pollutants after treatment are guaranteed.

Owner:YANSHAN UNIV

Collagen/chitosan composite sponge biological dressing and preparation method thereof

ActiveCN105031711AImprove antibacterial propertiesGood biocompatibilityAbsorbent padsBandagesWound dressingBiological dressing

The invention provides a collagen / chitosan composite sponge biological dressing, and belongs to the field of medical polymer materials. The biological dressing is compounded by collagen, chitosan and nano-titanium dioxide; the nano-titanium dioxide accounts for 1-5% of the total weight of the collagen and the chitosan; and weight percentage of the collagen is 50-70%, and the weight percentage of the chitosan is 30-50%. The wound dressing has good mechanical property; toxin residues caused by utilization of cross-linking agents and structure collapse caused by secondary freeze-drying are avoided; the problem of bacterial infection in a wound healing process can be solved effectively; and a sterile environment can be provided in a wound healing process.

Owner:ZHENGZHOU UNIV

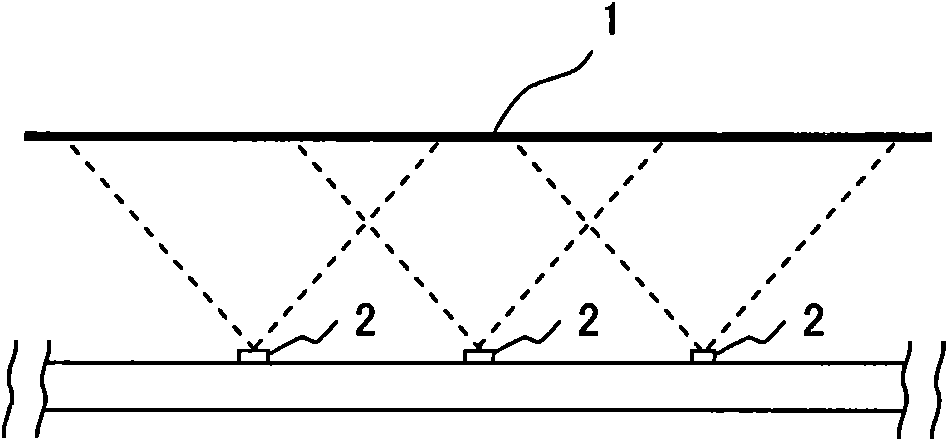

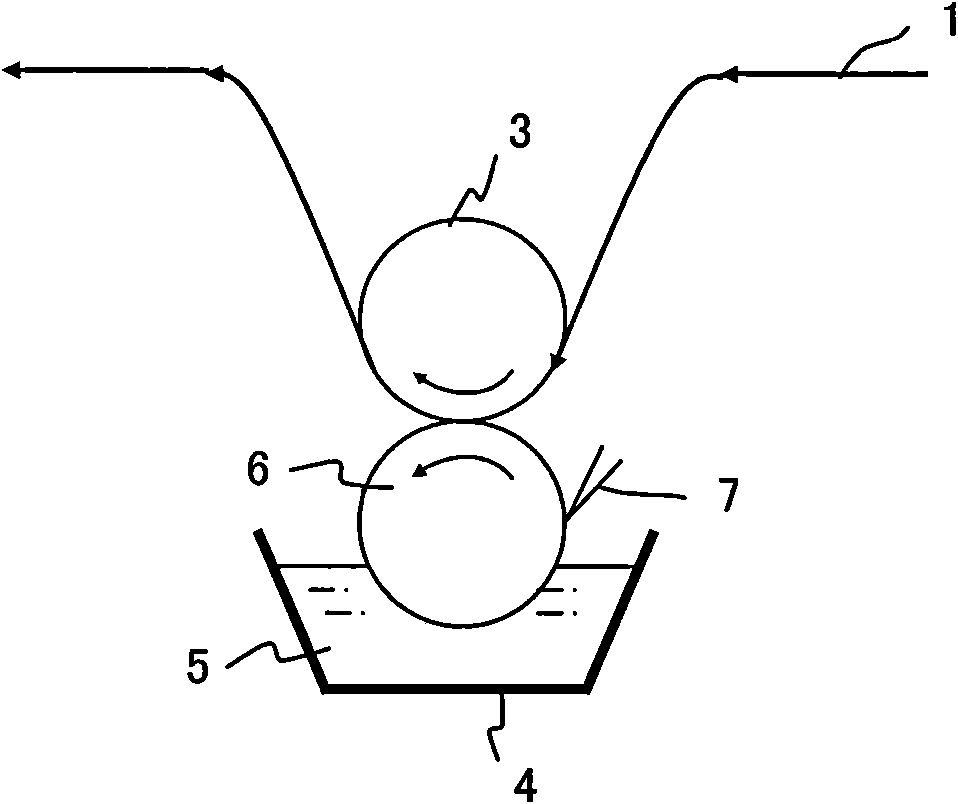

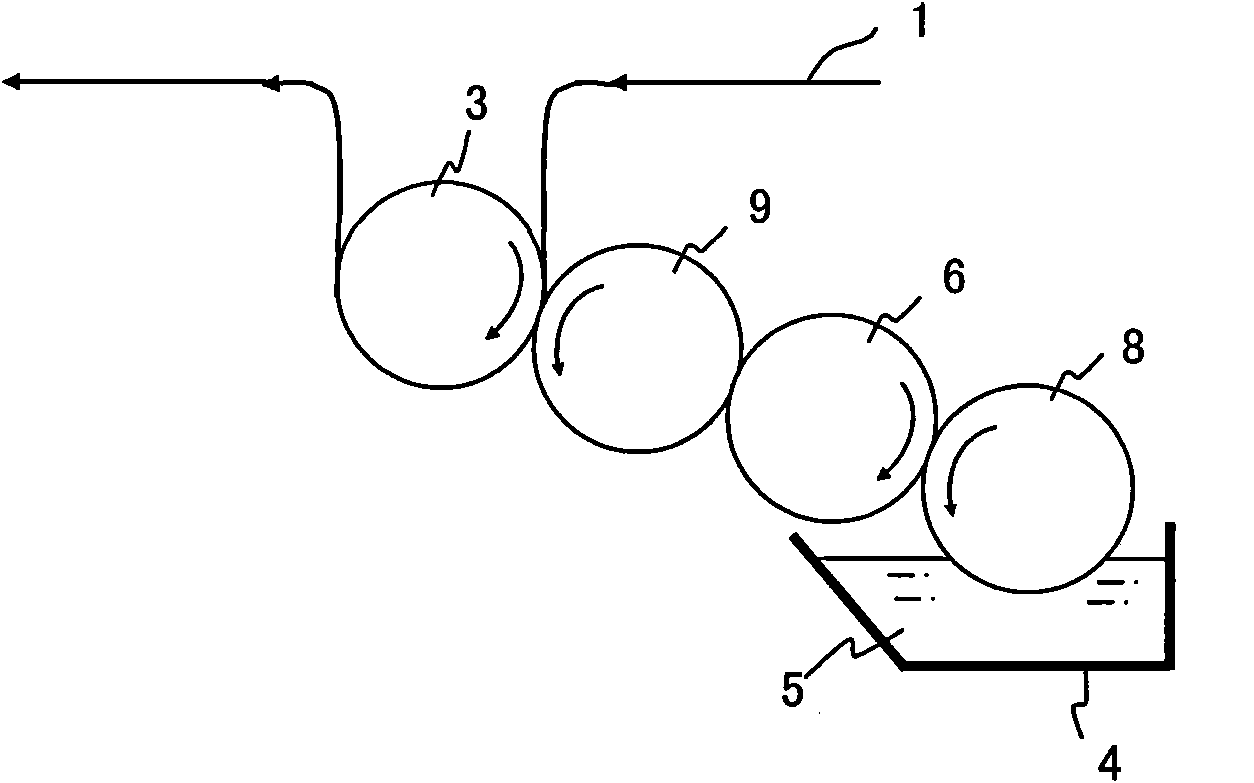

Flexible fiber paper and manufacturing method thereof

InactiveCN101922130AImprove securityImprove performanceNon-macromolecular organic additionPaper coatingPolyolPaper dust

The invention relates to a flexible fiber paper and a manufacturing method thereof. The flexible fiber paper is made by the way that fiber paper blank with the basis weight of 12.5-15g / m2 is wound on the impression cylinder of a conventional coating device under normal temperature and normal humidity (standard: temperature is 20 DEG C, and humidity is 65%RH), the fiber paper blank is coated with medicine solution containing the following main components: 0-15wt% of oiling agent, 60-90wt% of polyalcohol, 3-20wt% of saccharides and 3-5wt% of non-ionic surfactant, and antibacterial agent can be added into the medicine solution, so that the flexible fiber paper has antibacterial function. By utilizing the transfer printing manner or atomizing manner of the coating device, the medicine solution is coated by the proportion of 15-30wt%, thus obtained the flexible fiber paper. The flexible fiber paper of the invention has high safety on skin, soft handfeel and obvious moistness, and less paper dust is produced, thus being especially applicable to face tissues for sensitive skin, children or women.

Owner:가부시키가이샤하야시쇼지

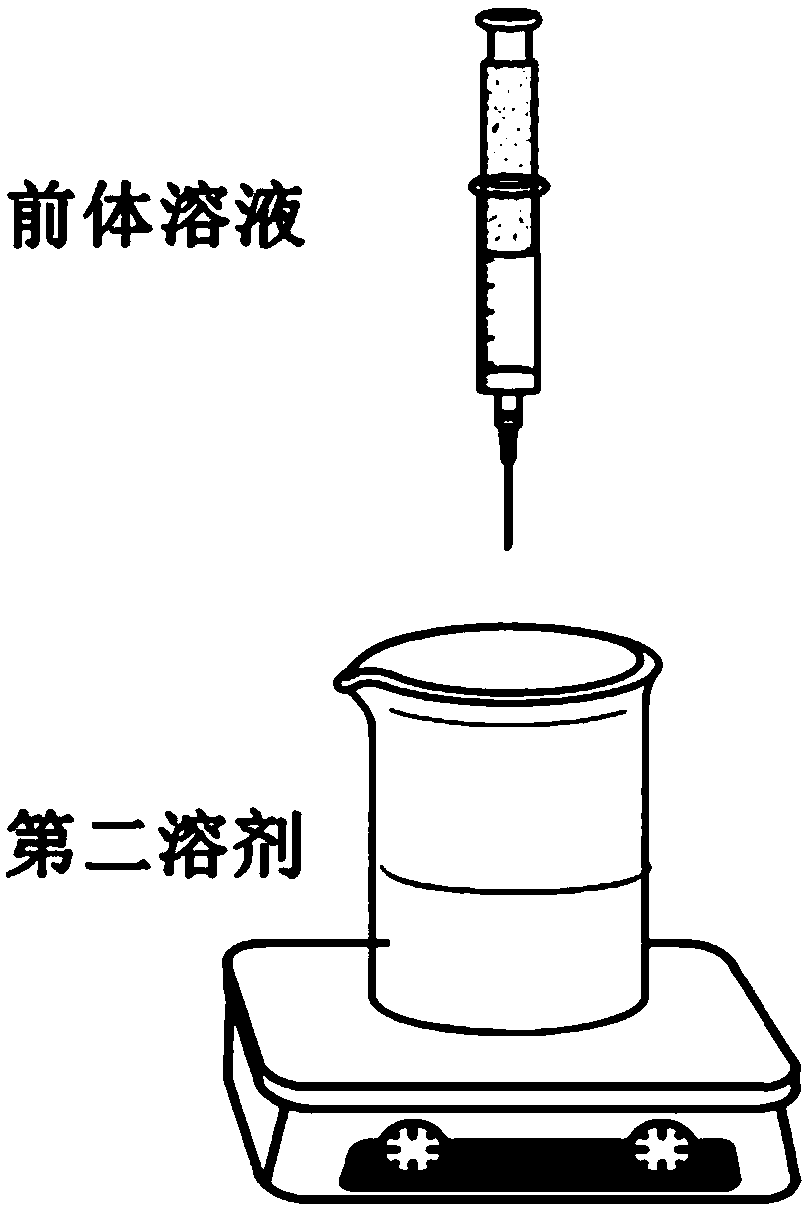

Preparation methods for organic-inorganic hybridized perovskite quantum dots and thin film

InactiveCN108690601AImprove luminous efficiencyThe preparation method is simple and feasibleOrganic compound preparationSolid-state devicesSolventOrganic inorganic

The invention relates to a preparation method of luminescent materials and particularly relates to a preparation method for organic-inorganic hybridized perovskite quantum dots. The method includes steps of: 1) dissolving organic amine in anhydrous ethanol with stirring, and dropwise adding haloid acid to the solution, washing the organic amine haloid acid thick liquid with ethyl ether, and filtering and drying the liquid to obtain organic amine haloid acid powder; 2) mixing inorganic halide salt with the organic amine haloid acid powder at molar ratio of 1:1-3, and adding short-chain organicamine haloid acid; 3) quickly stirring a second solvent on a magnetic stirrer, and at the same time, dropwise adding the precursor solution into the second solvent by a microsyringe with stirring, andcontinuously stirring the mixture to obtain an organic-inorganic hybridized perovskite quantum dot solution. In the invention, the short-chain amine haloid acid, instead of conventional long-chain amine or long-chain acid as a surface coating agent for the nano-particles, is used for synthesizing the quantum dots in various hybridized perovskite structures as the surface coating agent. The preparation method is simple and available. The quantum dots are high in luminous efficiency, and can be produced in a large scale.

Owner:INNER MONGOLIA NORMAL UNIVERSITY

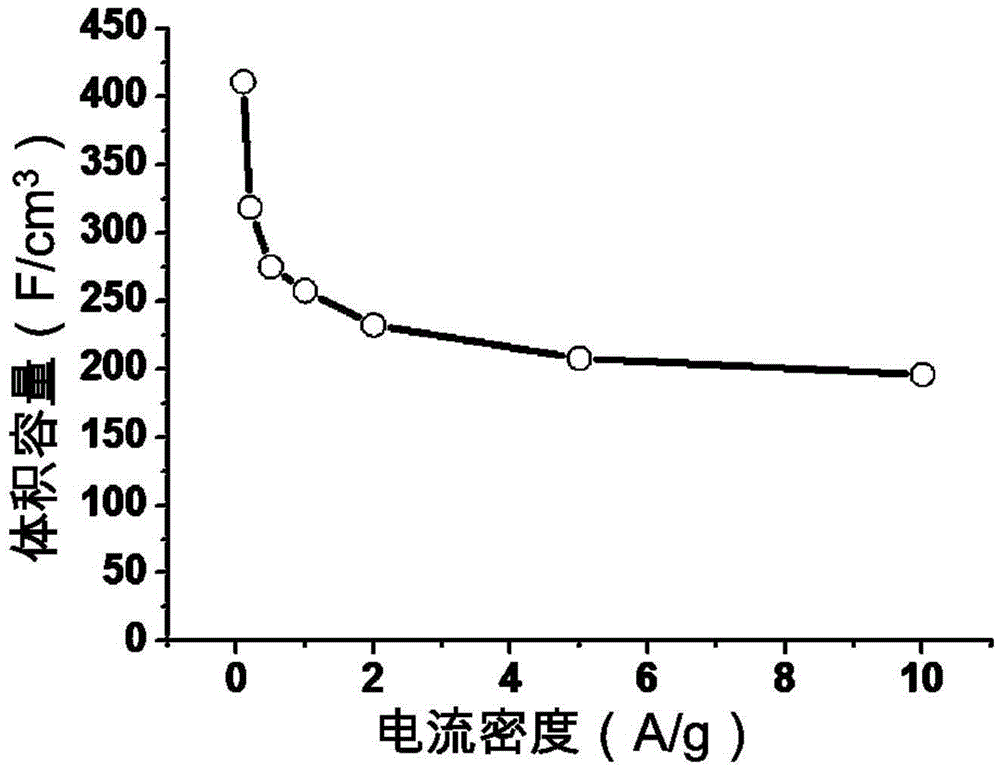

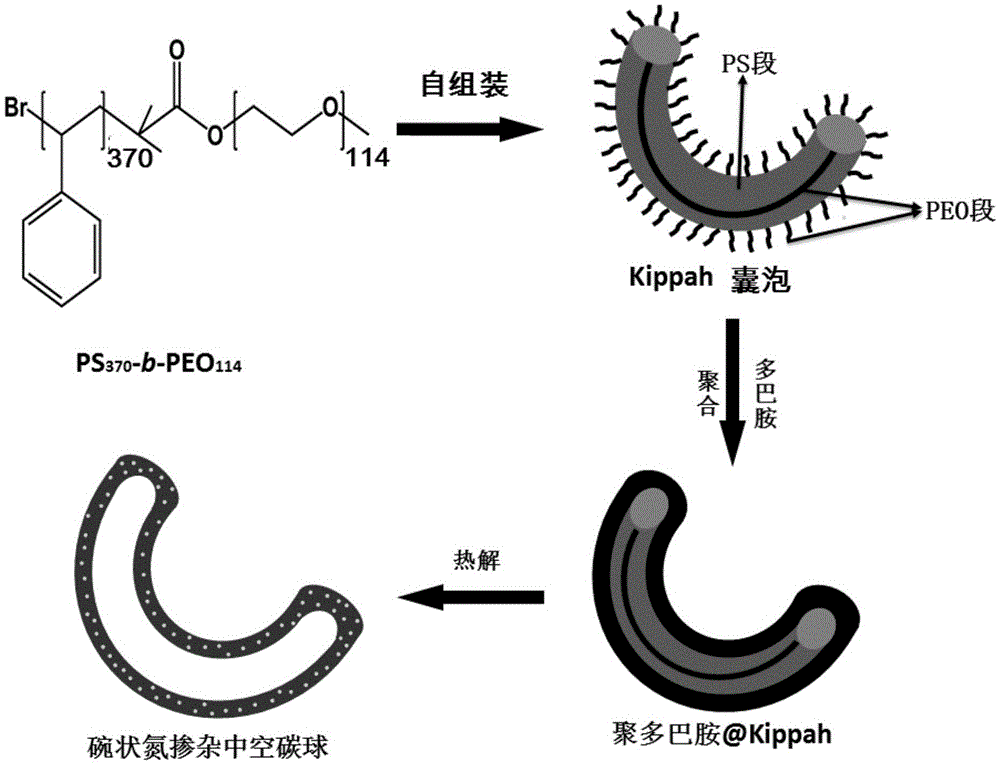

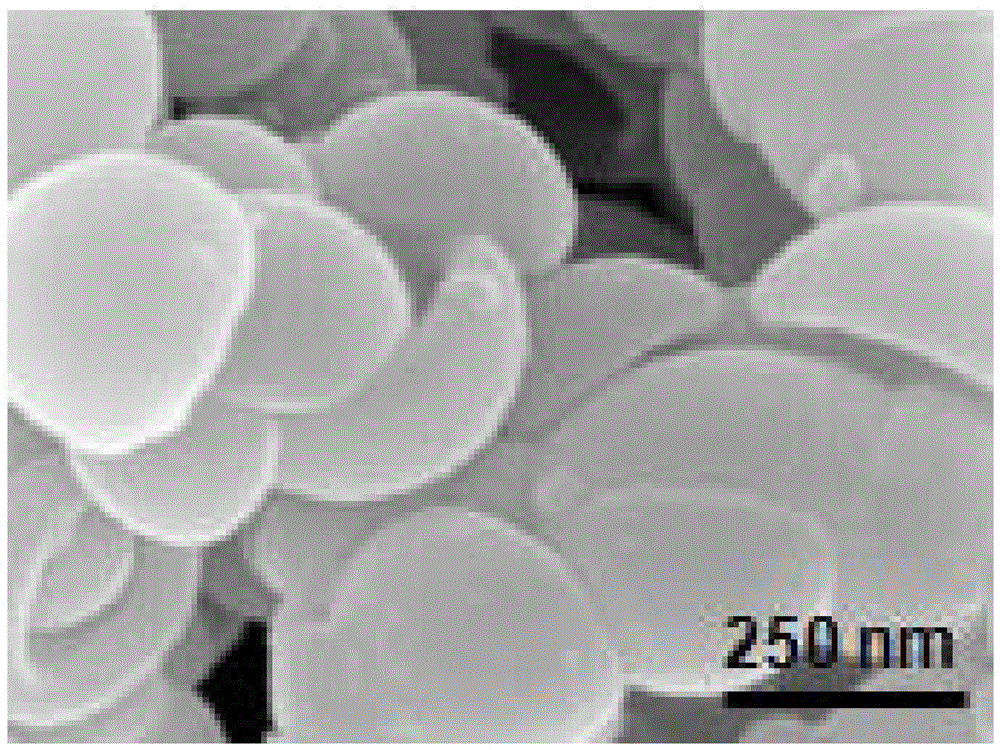

Preparation method and application of bowl-like nitrogen-doped carbon hollow particle

ActiveCN105551831AThe preparation method is simple and feasibleIncrease success rateHybrid capacitor electrodesHybrid/EDL manufactureNitrogen gasHigh capacitance

The invention discloses a preparation method of a bowl-like nitrogen-doped carbon hollow particle, comprising the following steps of forming a completely collapsed bowl-like vesicle through self assembling of an amphipathic PS-b-PEO segmented copolymer in solution; taking the bowl-like vesicle as a template to support dopamine to polymerize on a PEO chain segment, thereby obtaining a bowl-like polydopamine @Kippah vesicle particle; roasting the bowl-like polydopamine @Kippah vesicle particle with two steps in a nitrogen flow, and obtaining the bowl-like nitrogen-doped carbon hollow particle. The preparation method provided by the invention is simple, convenient and feasible, has high success rate and conversion rate, and can effectively reduce preparation cost. The invention also discloses an application of the bowl-like nitrogen-doped carbon hollow particle. According to the invention, the bowl-like nitrogen-doped carbon hollow particle is applied to super capacitors as an electrode material for the first time, and extremely high capacitance, good capacity retention ratio and outstanding cycling stability are realized.

Owner:SHANGHAI JIAO TONG UNIV

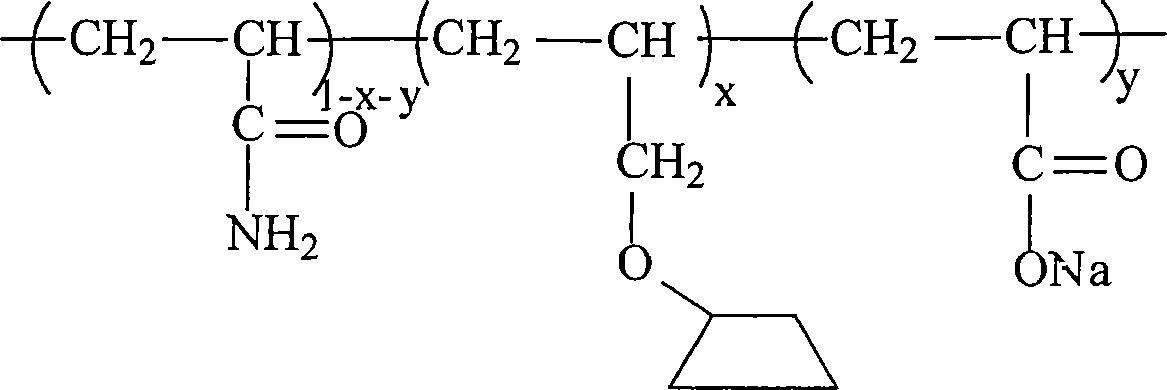

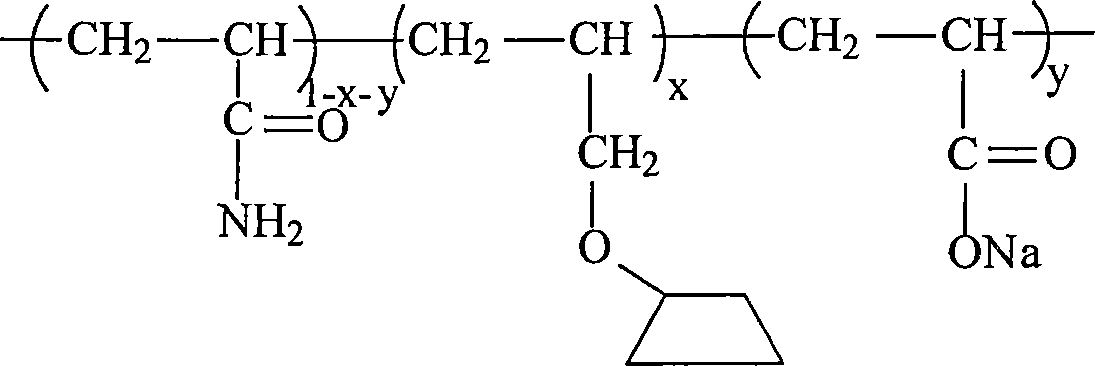

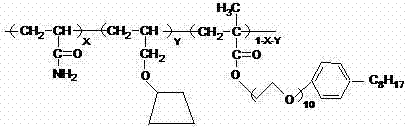

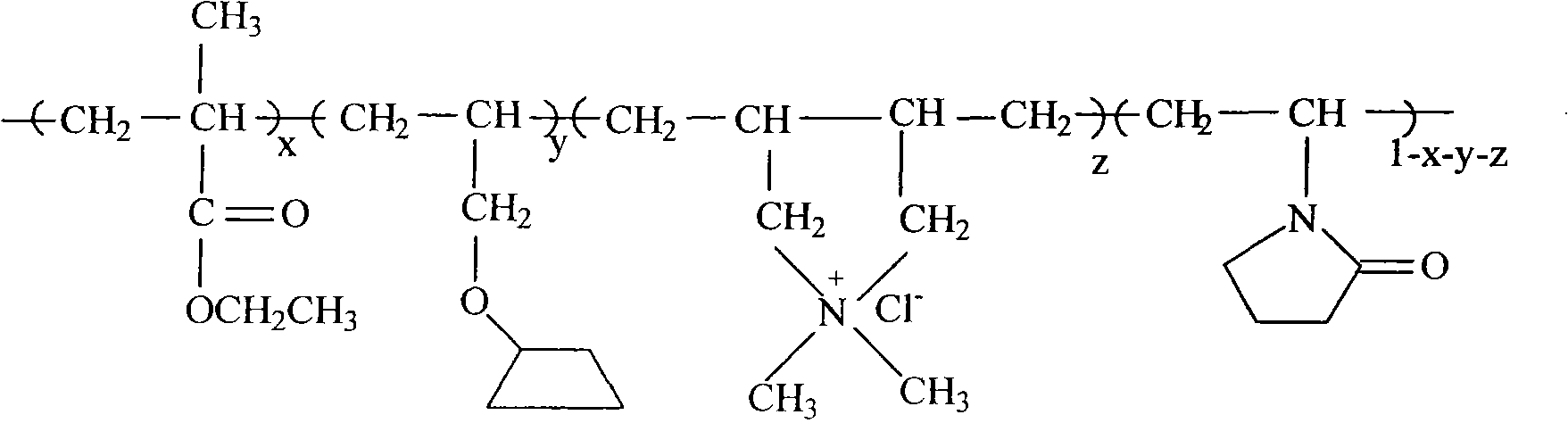

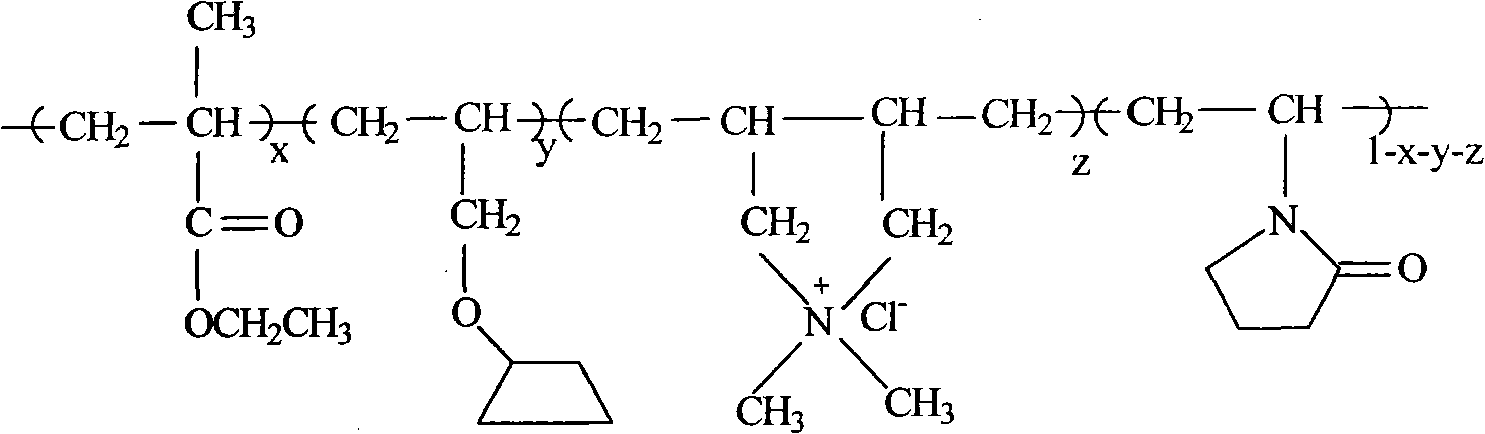

Hydrate inhibitor polymer and preparation method

InactiveCN101817909AThe preparation method is simple and feasibleMild reaction conditionsDrilling compositionDeoxygenationEmulsion

The invention relates to a hydrate inhibitor polymer used in petroleum marine deep water drilling fluid and a preparation method. The hydrate inhibitor polymer for the petroleum marine deep water drilling fluid can capture natural gases permeated in the drilling fluid to form super molecular combinations and achieve effect of high effectively inhibiting the hydrates. The technical scheme is that the hydrate inhibitor is a polymer consisting of ethyl methacrylate (EM), allylcyclodextrin (ACD), dimethyldiallylammonium chloride (DMDAAC) and N-Vinylpyrrolidone (NVP); EM is added into the DMDAAC aqueous solution while stirring, high speed stirring is carried out for 10-20 min to form an emulsion, and the emulsion and the NVP solution are added in the ACD aqueous solution; a chelating agent, an oxidant and a reductant are added in turn; at last, nitrogen is charged for 20-40 min after evenly stirring and mixing for deoxygenation, and the reaction is carried out for 6-12 h at a temperature of 30-60 DEG C to obtain the hydrate inhibitor polymer product. The polymer has the advantages of simple and feasible preparation method, moderate reaction condition and good hydrate inhibiting effect. The polymer is used in the petroleum marine deep water drilling fluid.

Owner:SOUTHWEST PETROLEUM UNIV

Barium strontium calcium scale remover and preparation method thereof

InactiveCN106147735AThe preparation method is simple and feasibleLower synthesis costDrilling compositionSulfatePotassium hydroxide

The invention provides a barium strontium calcium scale remover. The barium strontium calcium scale remover is prepared from, by weight, 20%-35% of a metal chelator, 10%-20% of a solubilizer, 0.5%-5% of a dispersing agent, 5%-15% of potassium hydroxide and 40%-60% of deionized water. Compared with the prior art, the barium strontium calcium scale remover has the good performance, can effectively remove organic composite scale such as barium sulfate, strontium sulfate and calcium sulfate, has the advantages of being high in scale removal efficiency, harmless to the natural environment, safe in use, non-corrosive to equipment and the like and has an important practical significance for increasing the oil and gas recovery rate.

Owner:CNPC BOHAI DRILLING ENG

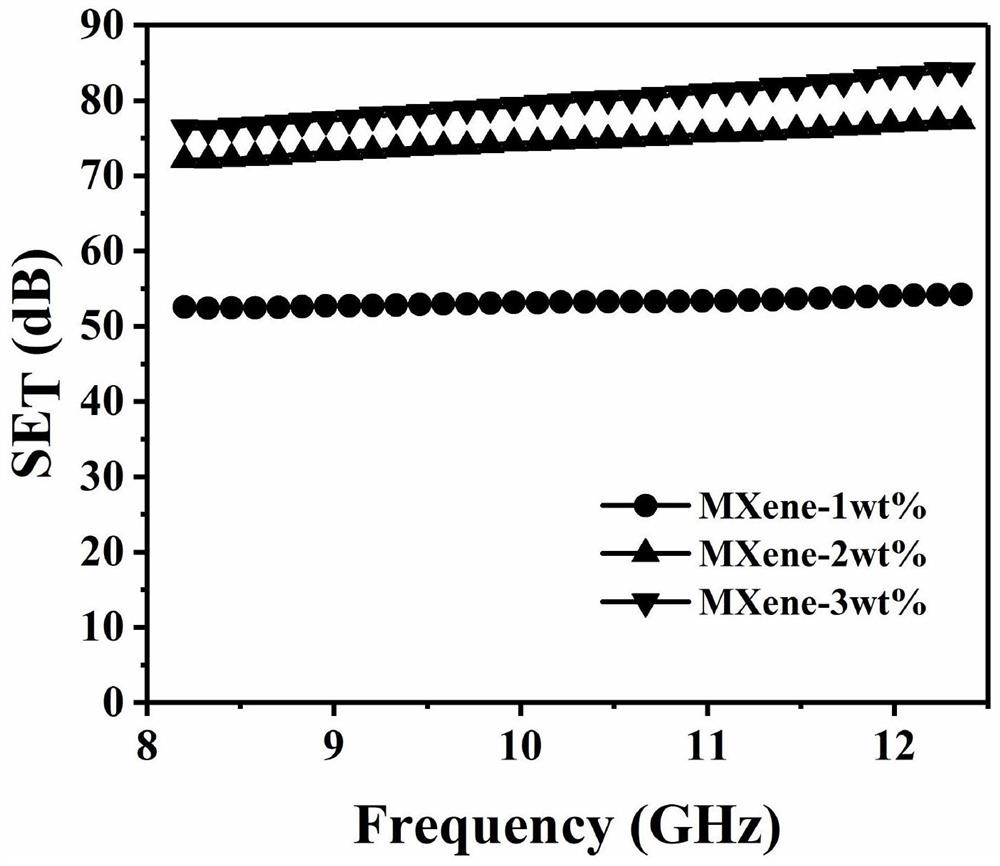

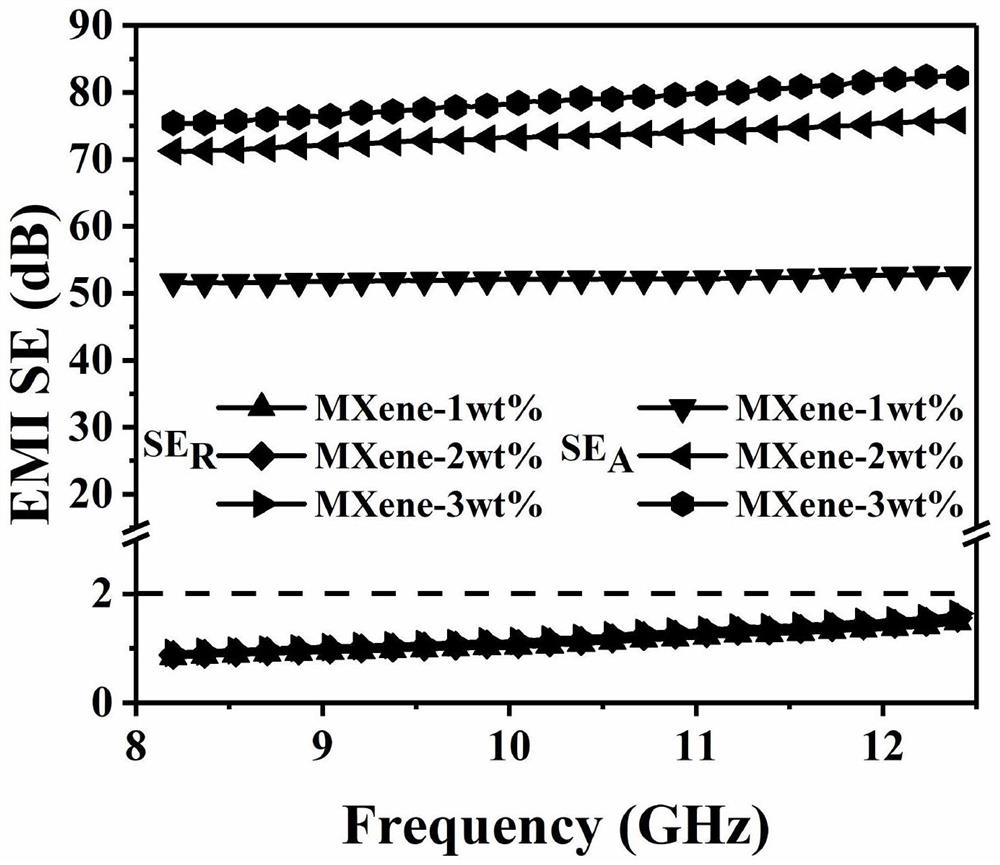

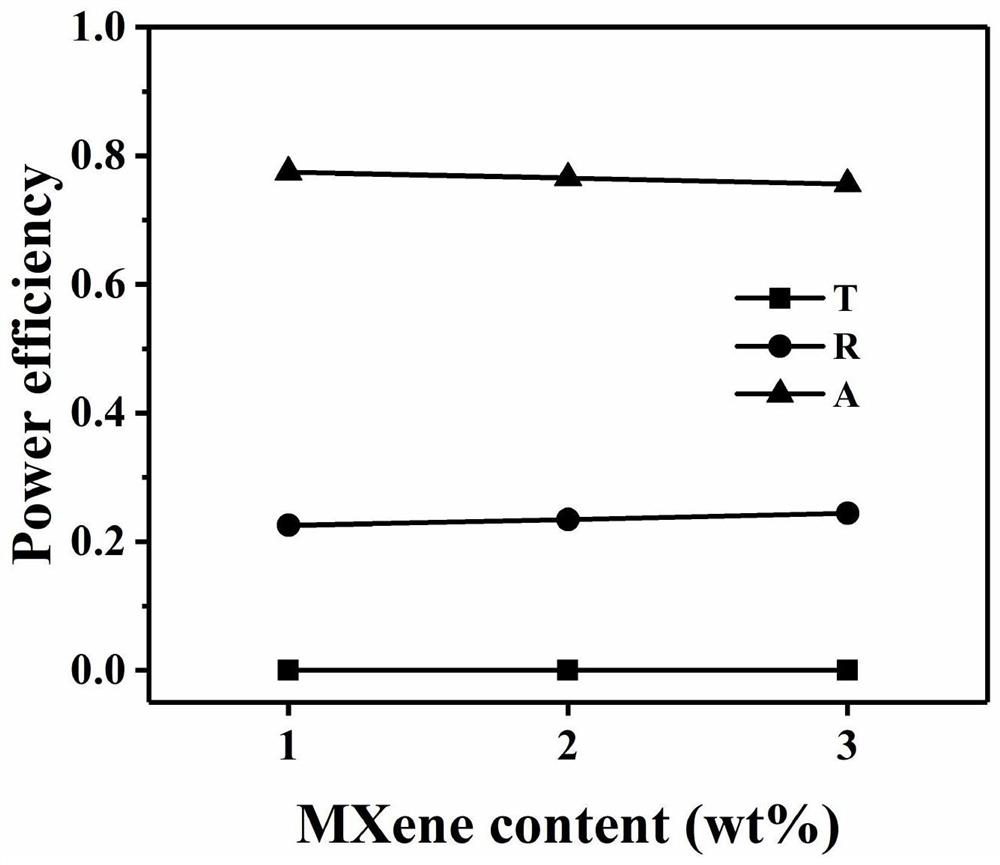

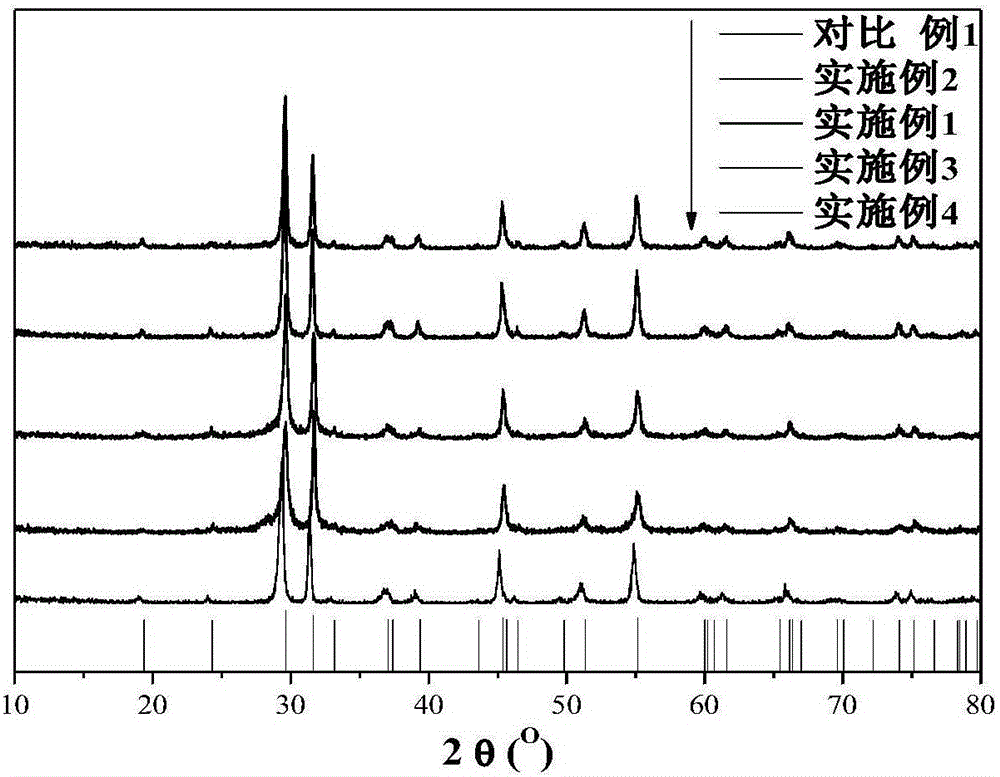

Preparation method of MXene-carbon aerogel/TPU composite material

ActiveCN112911920ASave fillerReduce absorptionMagnetic/electric field screeningCelluloseElectromagnetic shielding

The invention discloses a preparation method of an MXene-carbon aerogel / TPU composite material. The method specifically comprises the following steps: firstly, etching an MAX phase precursor by LiF / HCl to prepare a few-layer MXene solution; preparing an MXene-cellulose aerogel by using a few-layer MXene solution; then, putting the MXene-cellulose aerogel into a tubular furnace to be carbonized, and obtaining MXene-carbon aerogel; and finally, preparing a MXene-carbon aerogel / TPU composite material from the MXene-carbon aerogel and TPU particles. According to the composite material prepared by the method, the unique design of a three-dimensional structure enables electromagnetic waves to enter more easily, and incident waves are attenuated through multiple reflections and scattering in the porous structure, so that excellent electromagnetic shielding performance is obtained, and the application requirements in the fields of aerospace, electronic packaging and the like can be met.

Owner:ZHEJIANG HUANLONG NEW MATERIAL SCI & TECH

Preparation method and application of BiOI-reduced graphene oxide composite photocatalyst

ActiveCN106040269AReduced band gapEasy transferBiocidePhysical/chemical process catalystsDispersityOxide composite

The invention relates to the field of photocatalytic materials, in particular to a method using supercritical alcohol-heating technology to prepare a BiOI-reduced graphene oxide (RGO) visible-light-driven photocatalyst and application of the BiOI-RGO visible-light-driven photocatalyst to pollutant degradation and bacteria inhibiting and killing. The method uses ethanol as the reducing agent to simply and fast prepare the BiOI-RGO through a supercritical alcohol-heating process. The preparation method has the advantages that the method is simple and easy in raw material obtaining, low in cost, simple and practicable and capable of avoiding polluting byproducts and lowering cost, and the prepared BiOI-RGO visible-light-driven photocatalyst is good in catalyst dispersity, shows quite good photocatalytic activity, and is good in stability, recyclable and promising in actual application prospect.

Owner:SHANGHAI NORMAL UNIVERSITY

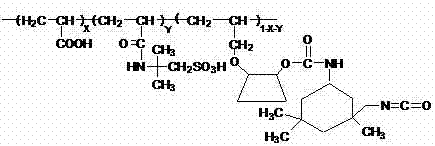

Acrylic acid(AA)/sodium 2-acrylamide-2-methylpro panesulfonic acid(AMPS-Na)/diisocyanate-modified allyl cyclodextrin (MACD) copolymer

InactiveCN102241801AThe preparation method is simple and feasibleMild reaction conditionsOther chemical processesDrilling compositionPolymer sciencePeroxydisulfate

The invention relates to acrylic acid(AA) / sodium 2-acrylamide-2-methylpro panesulfonic acid(AMPS-Na) / diisocyanate-modified allyl cyclodextrin (MACD) copolymer. The copolymer can effectively adsorb organic molecules in wastewater and has higher fluid loss effect. The technical scheme is that: the copolymer is prepared by polymerizing three monomers, namely acrylic acid (AA), sodium 2-acrylamide-2-methylpro panesulfonic acid (AMPS-Na) and diisocyanate-modified allyl cyclodextrin (MACD); and the copolymer comprises 0.7 molar percent of AA, 15 to 50 molar percent of AMPS-Na and 49.3 to 84.3 molarpercent of MACD. A preparation method comprises the following steps of: adding an aqueous solution of AA, a solution of AMPS-Na and a solution of MACD; adding disodium ethylene diamine tetraacetate, potassium peroxydisulfate and sodium hydrogensulfite; and uniformly stirring and mixing, and reacting at the temperature of between 30 and 70DEG C for 5 to 8 hours under the protection of nitrogen to obtain the AA / AMPS-Na / MACD copolymer. The copolymer has good decontamination effect when treating the organic molecules in the wastewater, has good fluid loss effect in drilling fluid and can resist temperature higher than 250DEG C.

Owner:SOUTHWEST PETROLEUM UNIV

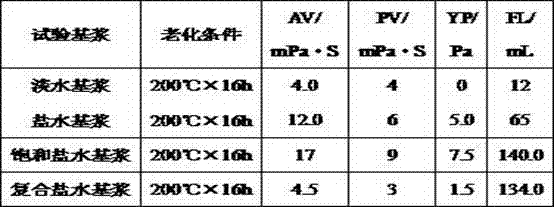

Broad-spectrum composite microbial fungicide and preparation method thereof

The invention discloses a broad-spectrum composite microbial fungicide and a preparation method thereof. Original composite conidial powder consists of the following three microorganisms: bacillusthuringiensis GSICC32807, bacillus amyloliquefaciens GSICC32826 and pythiumoligandrum GSICC61615. Two types of bacterial spore powder and a type of fungal spore powder are mixed according to the weight ratio of 1:1:1 to prepare a broad-spectrum composite microbial fungicide product. The broad-spectrum composite microbial fungicide product provided by the invention can be quickly planted around the root of a plant to obviously prevent, resist and kill microbial diseases of various crops by competing infection sites with pathogenic bacteria, implementing the hyperparasitism action, secreting auxin, promoting nutrient absorption of the plant and the like; furthermore, the road-spectrum composite microbial fungicide has the effects of promoting the growth of the crops, increasing the yield and improving the quality.

Owner:甘肃绿能农业科技股份有限公司

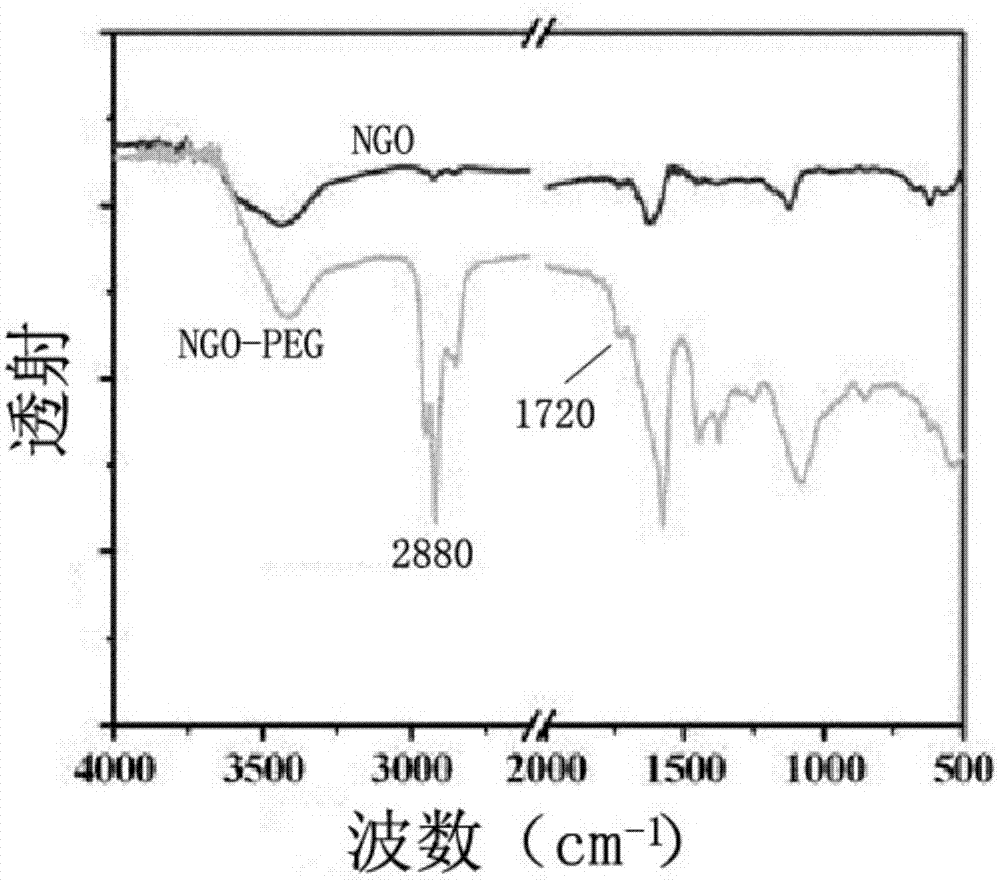

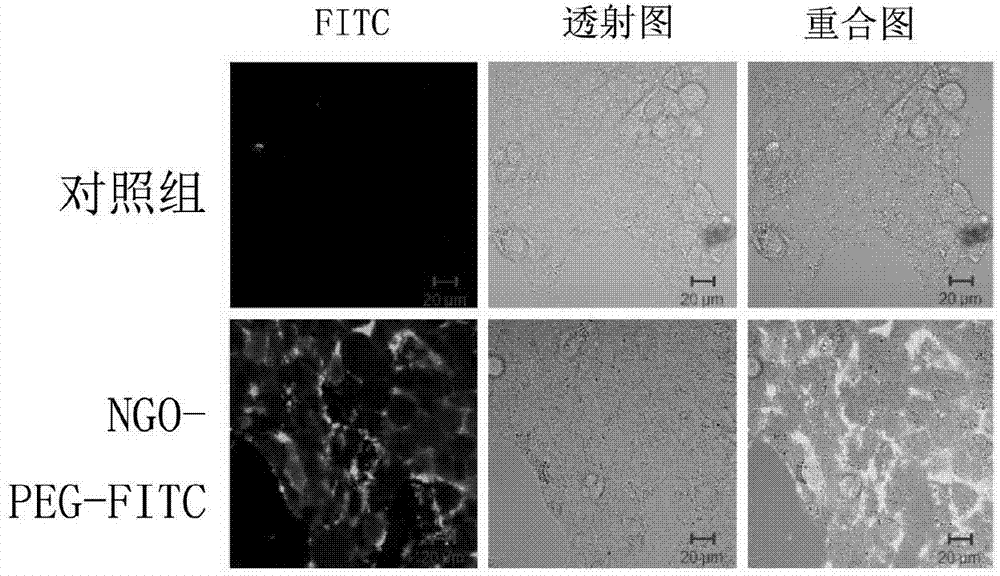

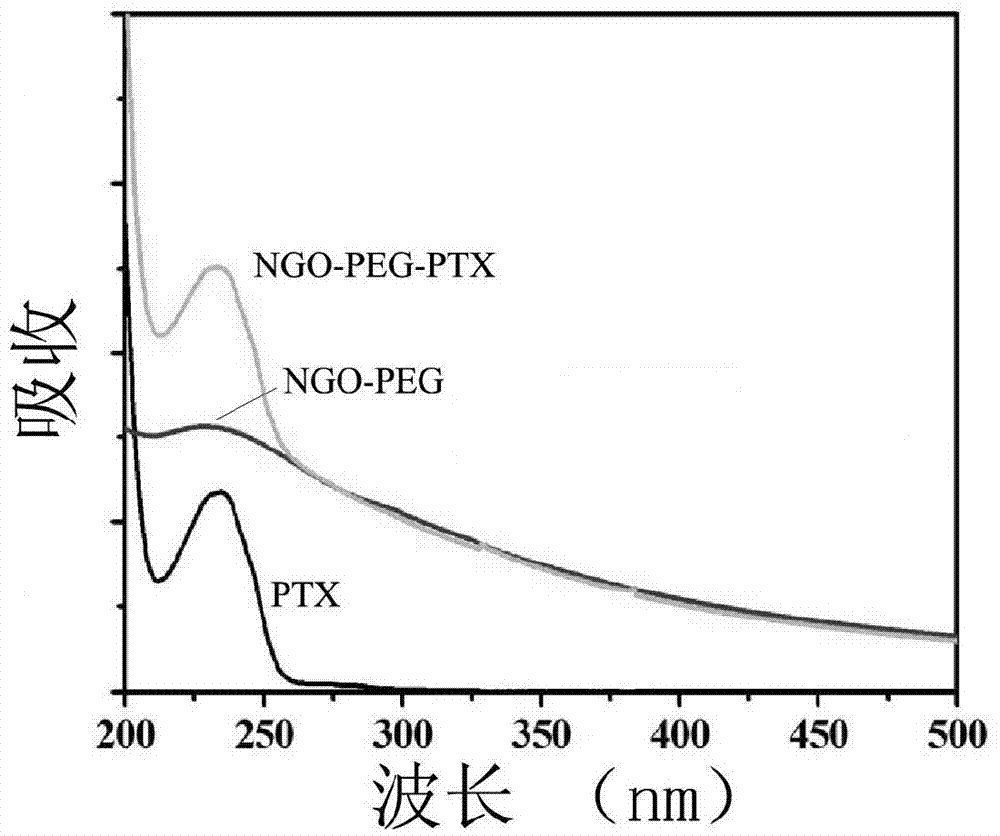

Nanometer drug complex loaded with paclitaxel and preparation method thereof

ActiveCN104758240AThe preparation method is simple and feasibleLow costOrganic active ingredientsPharmaceutical delivery mechanismSolventSolubility

The invention provides a nanometer drug complex loaded with paclitaxel. The nanometer drug complex comprises paclitaxel and a nanometer drug carrier, wherein the nanometer drug carrier is graphene oxide modified by amino polyethylene glycol. The invention also provides a preparation method for the nanometer drug complex loaded with paclitaxel. The method comprises the following steps: amino polyethylene glycol is modified on the surface of graphene oxide via an amide covalent bond so as to obtain the nanometer drug carrier, and paclitaxel is absorbed via pi-pi interaction so as to obtain the nanometer drug complex. The preparation method for the nanometer drug complex provided by the invention is simple and feasible, has low cost and solves the problems of great toxic and side effects and complex formulation preparation in conventional paclitaxel formulations using polyoxyethylene castor oil as a cosolvent; and the nanometer drug complex has good water-solubility, stability and biological compatibility, small toxic and side effects and good safety and is capable of effectively killing tumor cells and improving therapeutic effects of paclitaxel.

Owner:SHENZHEN INST OF ADVANCED TECH

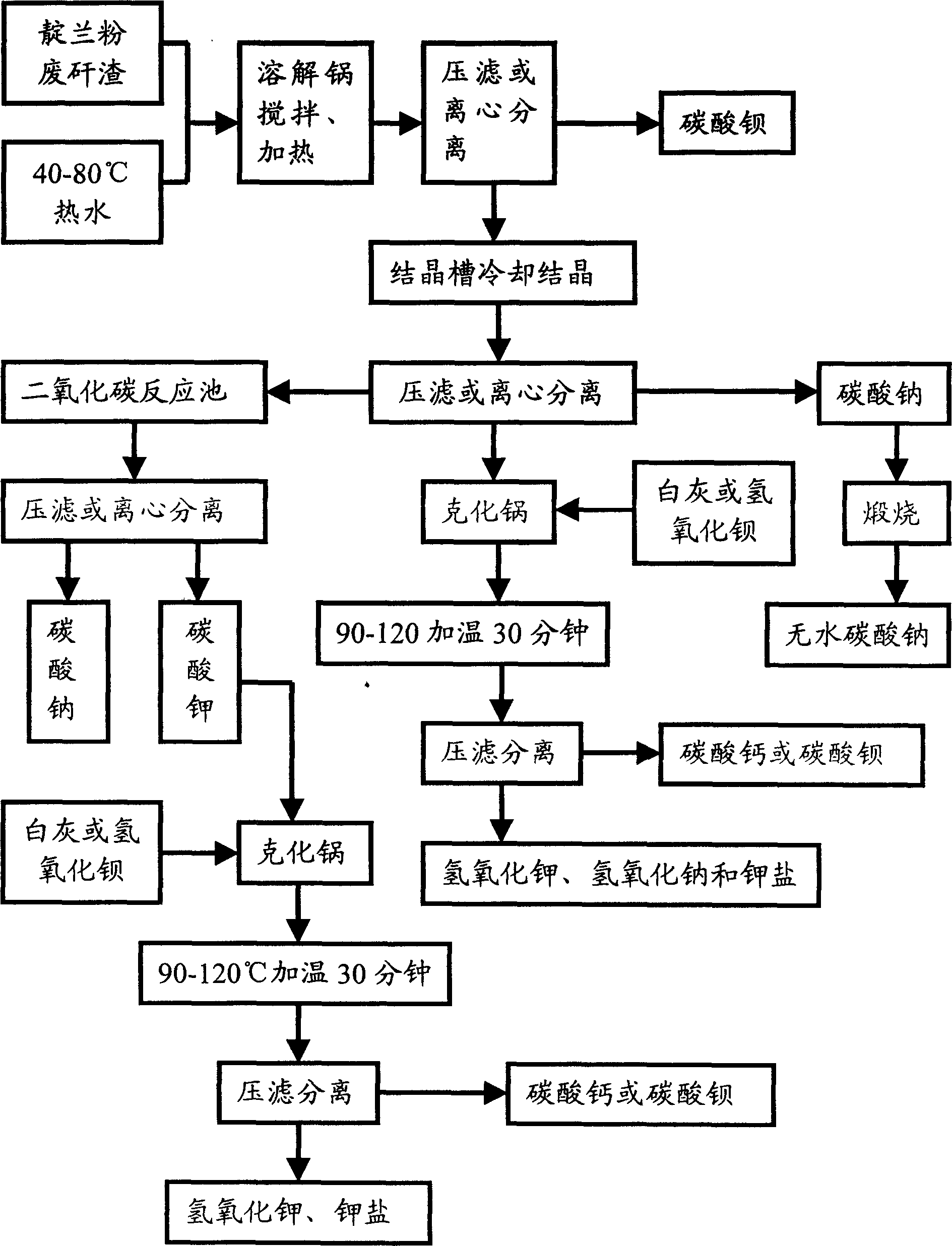

Comprehensive process for recovering and treating indigo blue powder waste slag

InactiveCN1557708AReasonable process designThe preparation method is simple and feasibleSolid waste disposalAlkali metal hydroxidesSlagPotassium hydroxide

The comprehensive indigo powder waste gangue slag recovering treatment process includes heating the mixture of waste gangue slag and water in a reactor to 4-80 deg.c for the waste gangue slag to dissolve fully; centrifugally separating to eliminate dreg and create mother liquid A; cooling mother liquid an in a crystallizing tank for 12-30 hr; press filtering or centrifuging to separate crystal as mixture of crystal carbonate and natron from crystallized liquid A; and calcining the crystal mixture to obtain anhydrous sodium carbonate. The said process can recover sodium hydroxide, potassium hydroxide, potassium carbonate, potassium salt and sodium carbonate in low cost and high yield.

Owner:贾升

Popular searches

Improve compatibility Improve physical and mechanical properties Good mechanical properties Good compatibility Good physical and mechanical properties Simple manufacturing method Improve mechanical properties Good high and low temperature resistance Good oil resistance Increase surface adsorption capacity

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com