Patents

Literature

332 results about "Polyoxyethylene castor oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Omega-3 fatty acid self-emulsifying composition

InactiveUS20180015038A1Reduce the amount requiredImprove compatibilityNervous disorderAntipyreticPolyoxyethylene castor oilEmulsion

A pharmaceutical composition comprising, in relation to 100% by weight of a total amount of a self-emulsifying composition, 70 to 90% by weight of eicosapentaenoic acid ethyl ester as a first medicinal component, 0.5 to 6% by weight of water, 1 to 29% by weight of polyoxyethylene sorbitan fatty acid ester (optionally further comprising polyoxyethylene castor oil) as an emulsifier, 1 to 25 parts by weight of lecithin in relation to 100 parts by weight of the eicosapentaenoic acid ethyl ester, and pitavastatin, rosuvastatin, or a salt thereof as a second medicinal component. The composition is excellent in any one of self-emulsifying property, dispersibility of the composition, emulsion stability, absorbability, and storage stability of the medicinal components and a preparation.

Owner:MOCHIDA PHARM CO LTD

Novel membrane spraying preparation for skin trauma and preparation method

InactiveCN101879283AAvoid profuse bleedingPromote healingHydroxy compound active ingredientsAerosol deliveryPolyoxyethylene castor oilPolyvinyl alcohol

Owner:ARMY MEDICAL UNIV

Pesticidal emulsifiable concentrate composition

InactiveUS6878674B2Improve emulsion stabilityGood low temperature stabilityBiocideDead animal preservationPolyoxyethylene castor oilPhenyl Ethers

There is provided a novel pesticidal emulsifiable concentrate composition that contains a phenoxypropionate herbicide (e.g., quizalofop-p-ethyl), a polar solvent (e.g., N-methyl-2-pyrrolidone), non-polar solvent (e.g., aromatic or aliphatic hydrocarbon) and a surfactant (e.g., polyoxyethylene castor oil ether, polyoxyethylene styryl phenyl ether), and that is improved in low-temperature stability and emulsion stability.

Owner:NISSAN CHEM IND LTD

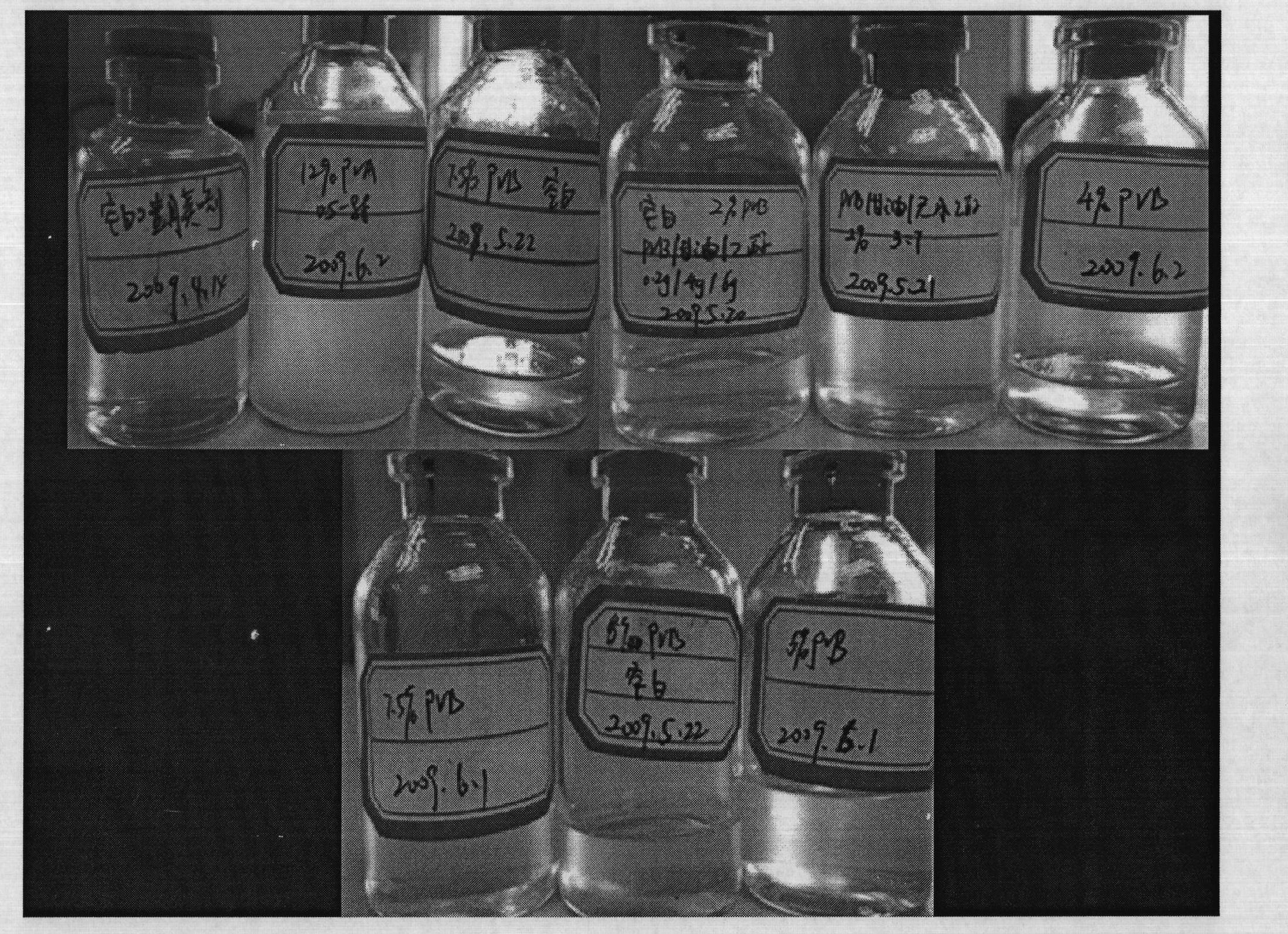

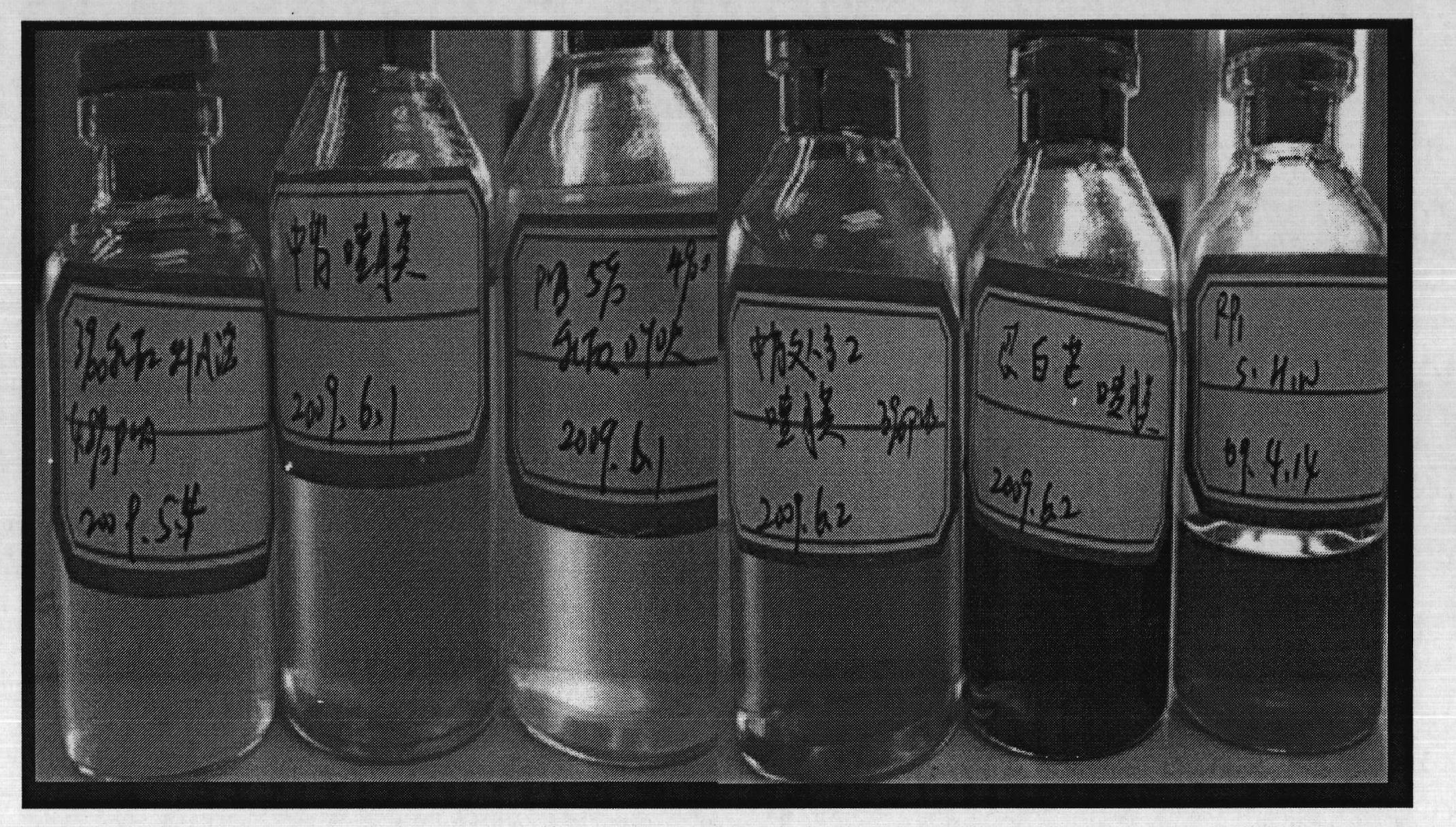

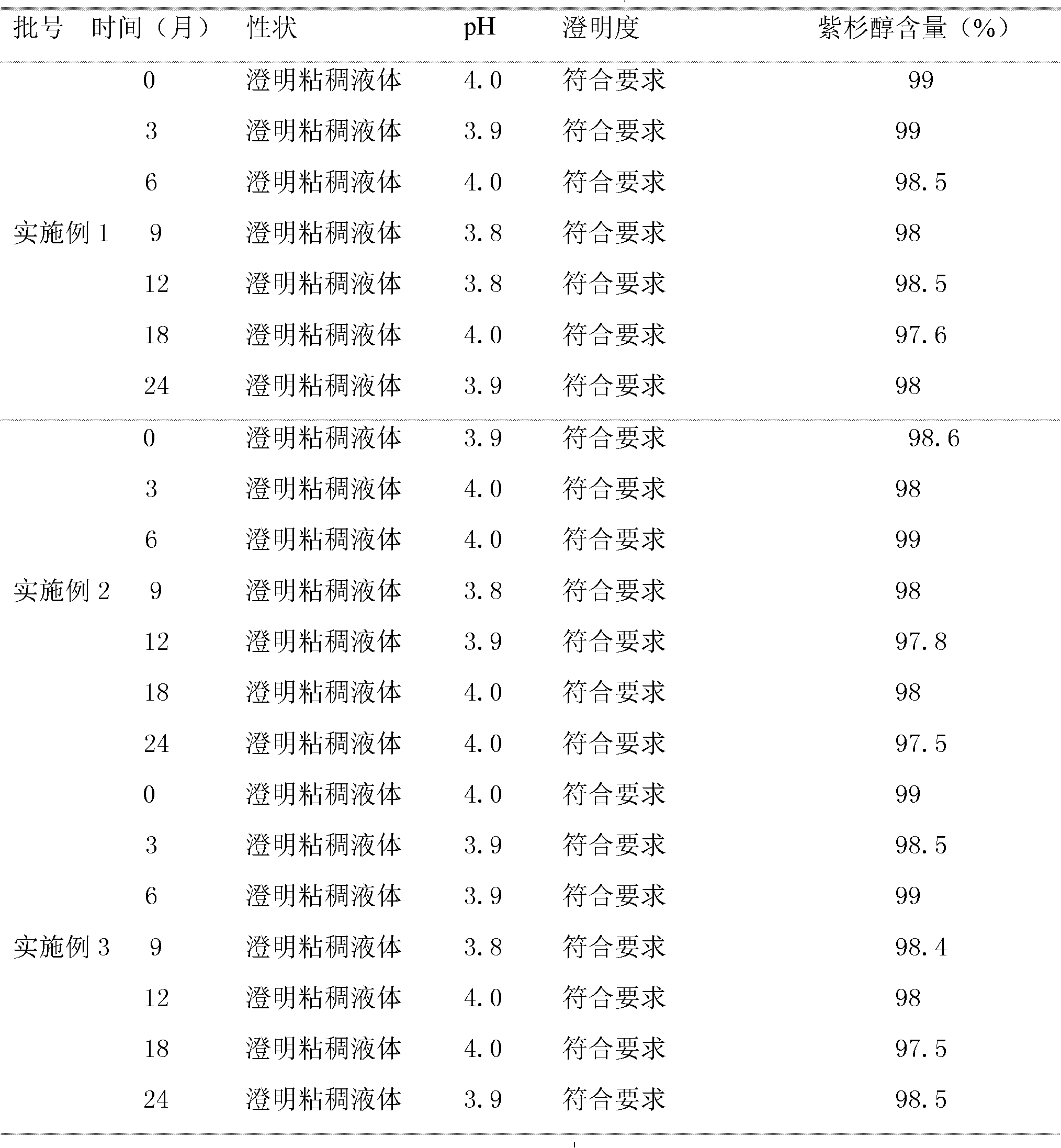

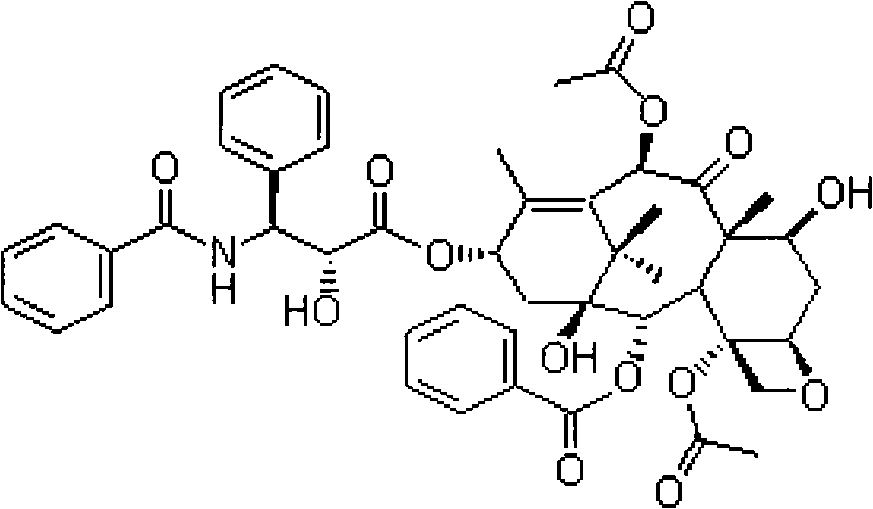

Paclitaxel mixed micelle preparation, and preparation method thereof

InactiveCN102198084AReduce toxic and side effectsImprove securityOrganic active ingredientsPharmaceutical delivery mechanismSolubilityPolyoxyethylene castor oil

The invention discloses a paclitaxel mixed micelle preparation, comprising 100 to 300 milligram of tocopherol polyethylene glycol succinate 1000 (TPGS), 0 to 50 milligram of phosphatide, 0.5 milliliter of anhydrous ethanol and 6 milligram of paclitaxel. The preparation method is as follows: the TPGS is dissolved in the anhydrous ethanol, or the TPGS and the phosphatide are dissolved in the anhydrous ethanol; the paclitaxel is added and dissolved under stirring; the mixture is filtered with a millipore filtration of 0.22 micrometer so as to obtain the paclitaxel mixed micelle preparation. In the invention, the TPGS and the phosphatide are used to form mixed micelles which have good stability and little toxic and side effects; the preparation method is simple and practicable, having a good application prospect. Compared to the prior art, polyoxyethylene castor oil in conventional prescription is substituted in the invention, thereby reducing toxic side effects of paclitaxel injections and greatly enhancing the safety of the injections on condition that solubility is guaranteed.

Owner:SHANDONG UNIV

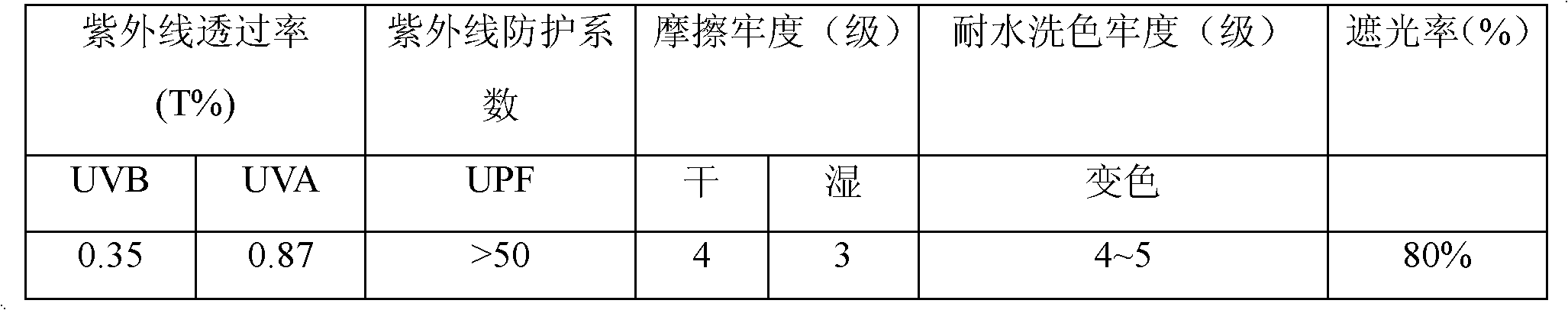

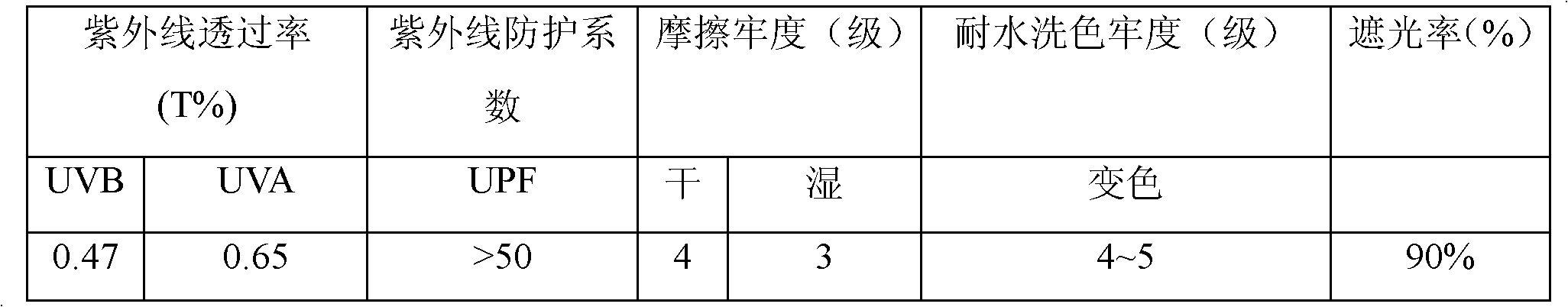

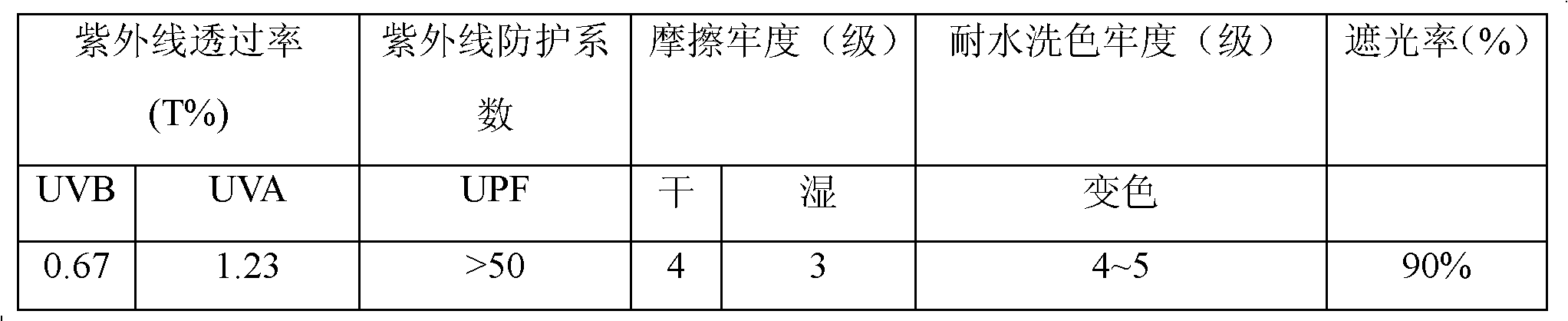

A kind of anti-ultraviolet and light-resistant finishing liquid and its preparation and application on fabrics

InactiveCN102277740AShort processEasy to implementFibre treatmentDyeing processMicro nanoPolyoxyethylene castor oil

The invention relates to an anti-ultraviolet and photostable finishing liquid, a preparation method thereof, and an application thereof on fabrics. The finishing liquid is prepared from materials of: 35 to 60g / L of a paint, 2 to 4g / L of a white paint, 15 to 30g / L of an acrylic ester adhesive, 10 to 20g / L of urea, 2 to 3g / L of glycerin, 55 to 80g / L of an organic softening agent, 2.5 to 15g / L of micro-nano oxide, 2 to 5g / L of polyoxyethylene castor oil ether, 0.5 to 1g / L of a penetrant, and balance of water. The materials are mixed, such that a target product is obtained. According to the invention, a window curtain is processed from a one-bath one-step process of dying, ultraviolet resisting, and shading. The method has characteristics of short technical process and convenient application.Also, the method is water saving, energy saving and discharging reducing.

Owner:DONGHUA UNIV +1

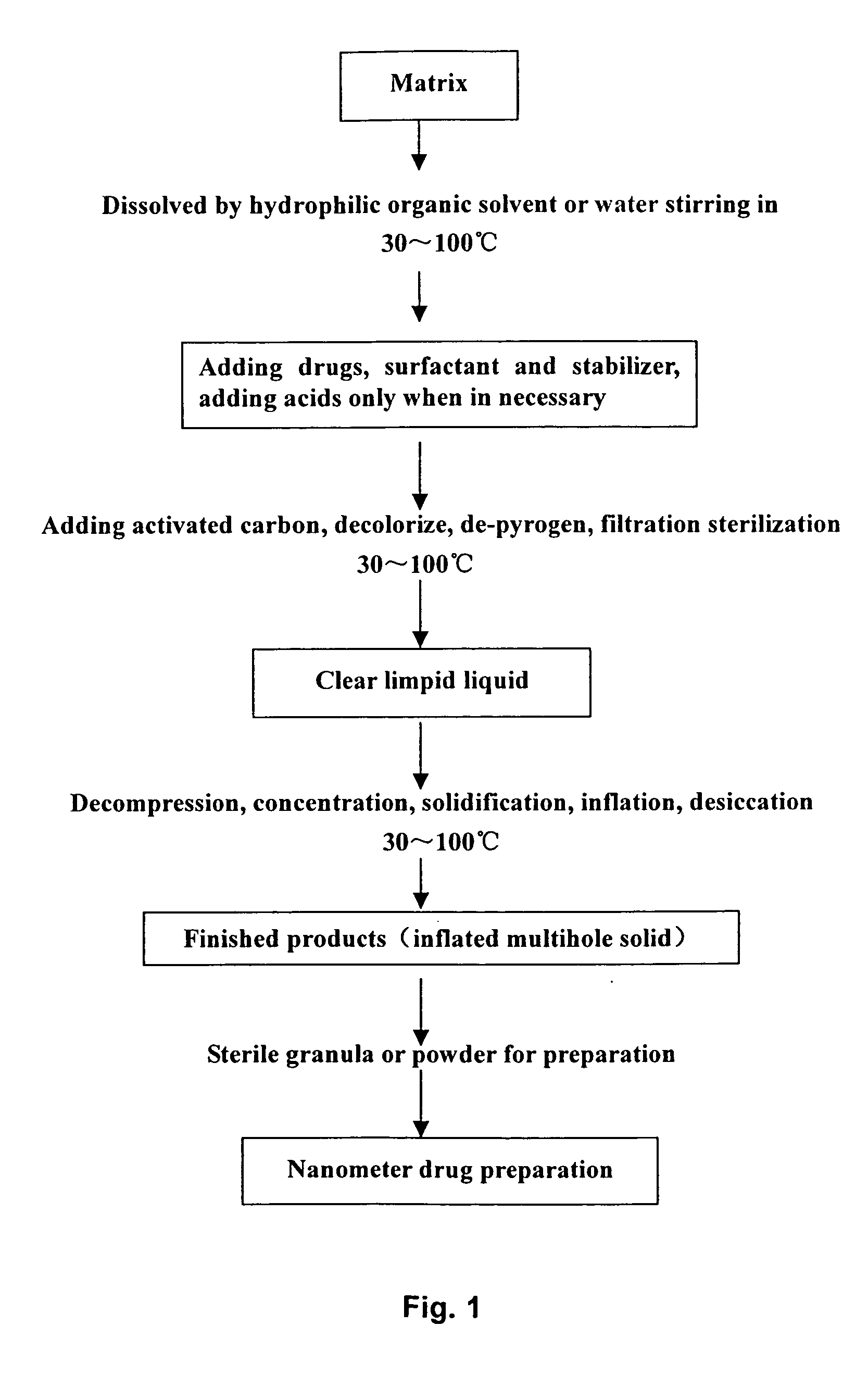

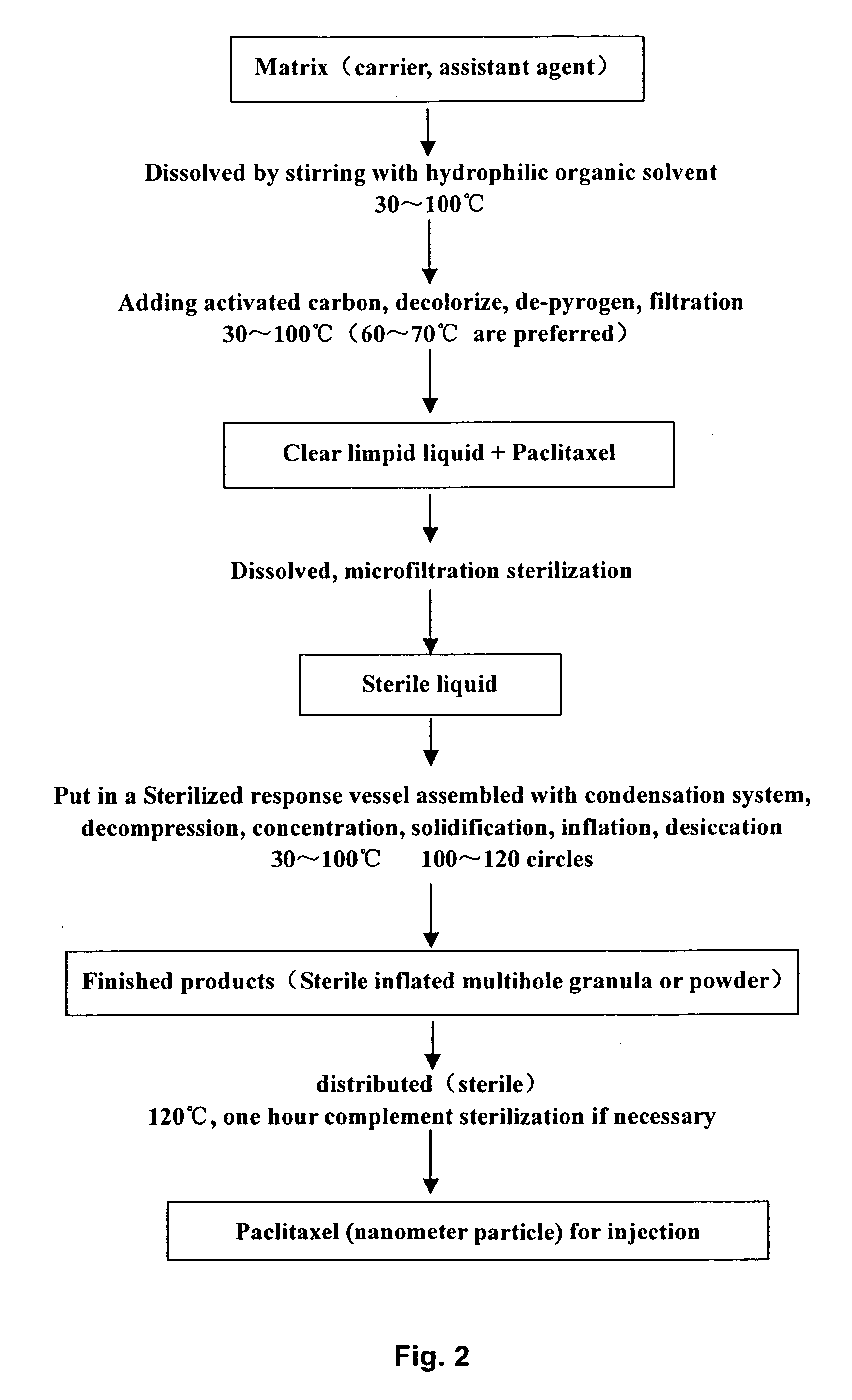

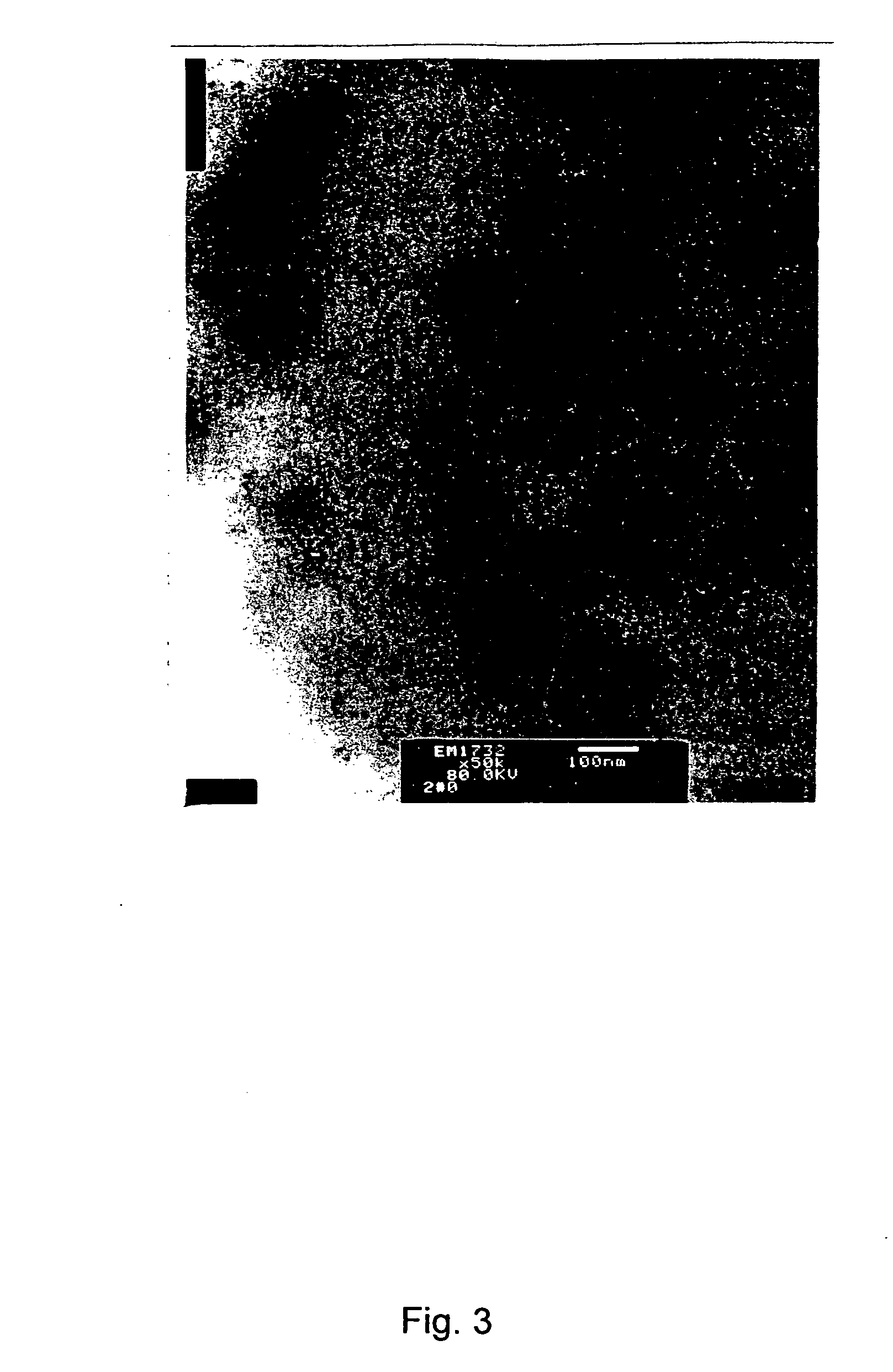

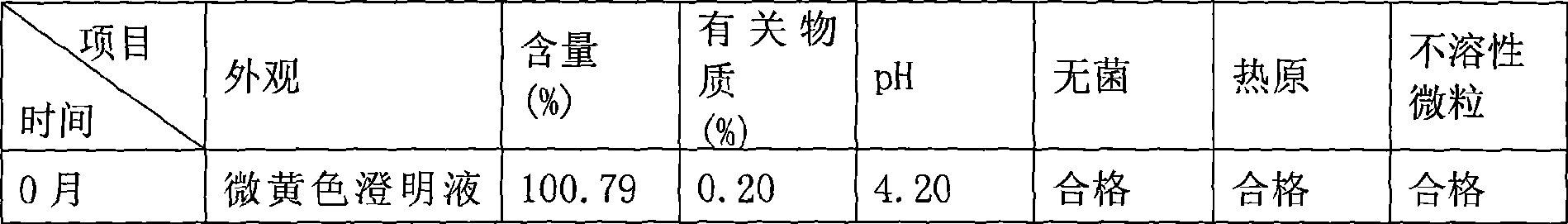

Solid nano pharmaceutical formulation and preparation method thereof

A method of preparing low water-soluble medicine into solid nanometer pharmaceutical formulation is disclosed. According to the characters of molecular aggregates such as supramolecular chemical micelles and vesicles, the formulation, which based on the hydroxypropyl-beta-cyclodextrin and phospholipid, is prepared under the condition of hyperthermia sterilization and decompression. Such nanometer formulation is sterile particle or powder with loose porosity. For directly intravenous use, the formulation has targeting activity, sustained release and long circulating characters. While as a solid oral product, it is fast-release, fast-effective, and improved bioavailability characters, and is readily melted in mouth. The formulation utilizes secure accessories, traditional equipments and methods, thus, it is suited to be used and manufactured widely. Also disclosed is intravenous formulation of anticancer paclitaxel, which characterized that there has no polyoxyethylenated castor oil in it. Such intravenous formulation is nonallergic so that it has higher security and efficiency compared to present commercially available paclitaxel formulations.

Owner:LIU YUNGING +3

Coenzyme Q10 pharmaceutical composition

InactiveCN101480381AOvercoming easily turbid precipitationOvercoming qualityOrganic active ingredientsPowder deliveryPolyoxyethylene castor oilMonoglyceride

The invention discloses a coenzyme Q10 pharmaceutical composition which mainly comprises components: (1) coenzyme Q10 is active ingredient; (2) one or multiple of polyethylene 15-oxhydryl glycol stearate (Solutol HS 15), polysorbate, PEG, poloxamer, and polyoxyethylene castor oil derived products are solubilizer; (3) one or multiple of midchain monoglyceride and derived products thereof, medium saturated or unsaturated fatty acid are oil component; and (4) injection water is solvent. One or multiple of excipient, chemical inhibitor, and osmotic pressure regulator are added for preparing injection and freeze drying agent. Compared with the traditional coenzyme Q10 pharmaceutical composition, the injection administration coenzyme Q10 pharmaceutical composition has better storage and transportation stability and higher clinical application safety and patient compliance. The injection has simple preparation process, convenient quality control, lower production cost and convenient industrial production.

Owner:郑微

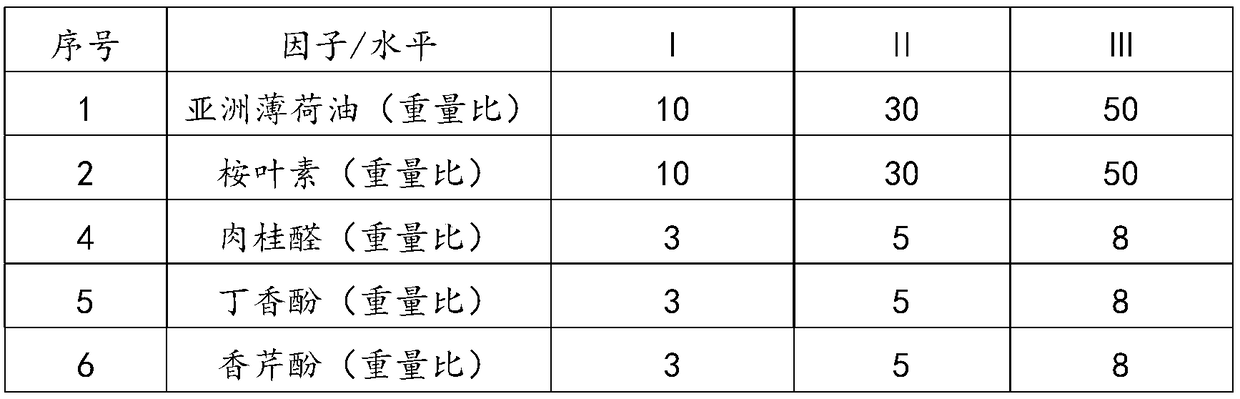

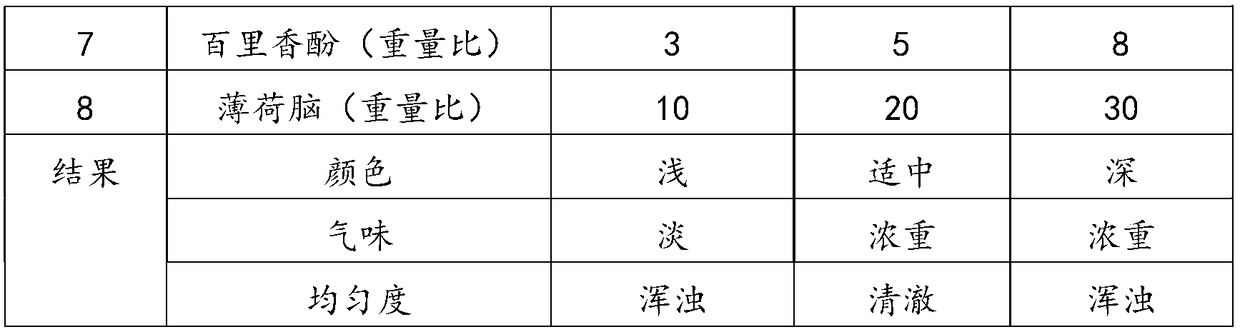

Mint-scented compound essential oil and feed additive containing mint-scented compound essential oil and application thereof

InactiveCN109329609AHigh purityLower body temperatureAntibacterial agentsDigestive systemPolyoxyethylene castor oilEugenol

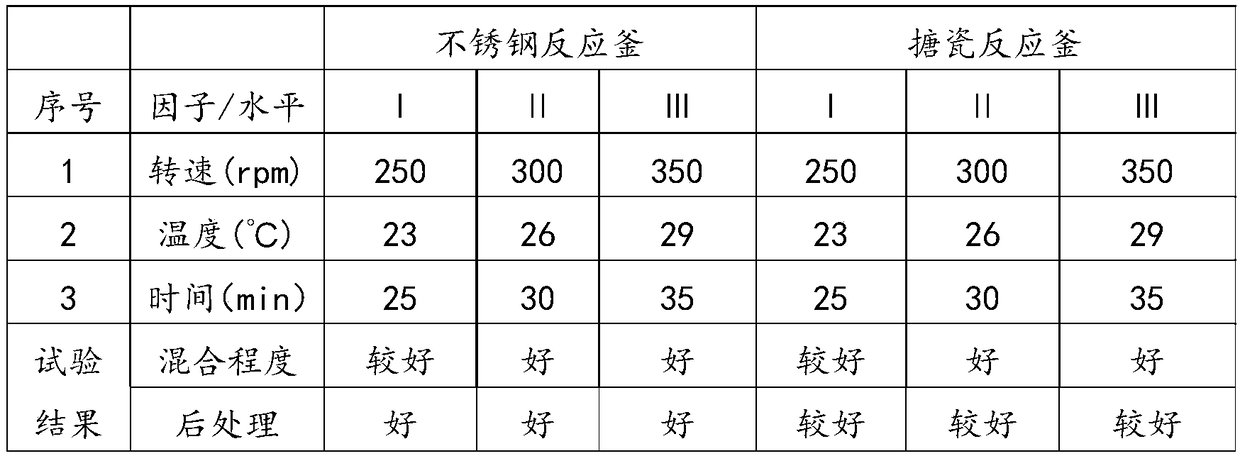

The invention discloses mint-scented compound essential oil and a feed additive containing mint-scented compound essential oil and production and application thereof, and relates to the technical field of feed nutrition and feed additive production. The mint-scented compound essential oil is prepared by using Asian mint oil, cineole, cinnamaldehyde, eugenol, carvacrol, menthol and thymol as raw materials, putting the above raw materials into an enamel reaction kettle or a stainless steel reaction kettle sequentially, and evenly stirring and mixing the above raw materials. Preparation method 1:stirring and mixing the compound essential oil and anhydrous alcohol or propylene glycol in the stainless steel reaction kettle according to a weight ratio, with the addition of polyoxyethylene castor oil emulsifiers, thereby obtaining a feed additive containing liquid mint-scented compound essential oil. Preparation method 2: stirring and mixing the compound essential oil and dry starch in a high-speed mixer according to a weight ratio, thereby obtaining a feed additive containing solid mint-scented compound essential oil. Preparation method 3: stirring and mixing the compound essential oiland beta-cyclodextrin or soluble starch in the high-speed mixer according to a weight ratio, with the addition of Tween-80 emulsifiers, thereby obtaining a feed additive containing water-soluble mint-scented compound essential oil.

Owner:辽宁威兰生物技术有限责任公司

Amino acid surfactant-based transparent solid soap

InactiveCN104312747AStrong alkalinityKeep dryOrganic detergent compounding agentsNon-ionic surface-active compoundsPolyoxyethylene castor oilD-Glucose

The invention relates to amino acid surfactant-based transparent solid soap. The amino acid surfactant-based transparent solid soap comprises, by weight, 55-75 parts of an amino acid surfactant, 3-13 parts of pure water, 3-10 parts of polyoxyethylene castor oil (15-40EO), 3-8 parts of glycerin, 3-10 parts of glucose, 2-8 parts of ethanol, 0.1-3 parts of a pH balance agent and 0.2-0.5 parts of essence. Through compounding of high-content amino acid surfactants having different structures, the pH value of the amino acid surfactant-based transparent solid soap is controlled to weak acidity and is the same to or close to a human body pH value. Through the amino acid surfactant-based transparent solid soap, skin feel is completely improved after cleaning. The amino acid surfactant-based transparent solid soap has the advantages of high transmittance of light and good durability.

Owner:YANTAI ANSHI PERSONAL CARE SUPPLIES

Drug formulation containing a solubilizer for enhancing solubility, absorption, and permeability

InactiveUS20070021325A1Promote absorptionImprove permeabilityOrganic active ingredientsPeptide/protein ingredientsSolubilityBenzoic acid

Solubility, absorption, and permeability of drugs upon oral administration are improved when the drugs are mixed and / or complexed with water-miscible organic solvents. Illustratively, the absorption of a heparin-deoxycholic acid conjugate upon oral administration is increased by mixing and / or complexing this conjugate with dimethyl sulfoxide. Other illustrative water-miscible organic solvents include N-methylpyrrolidone, polyoxyl 35 castor oil, diethylene glycol monoethyl ether, and benzoic acid.

Owner:MEDIPLEX CORP

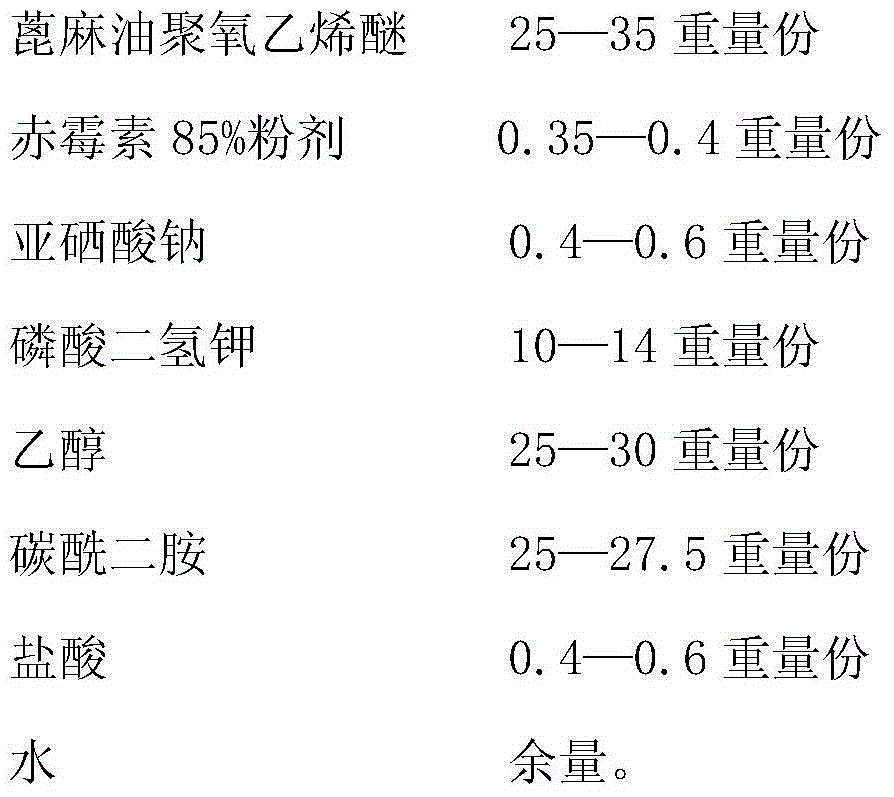

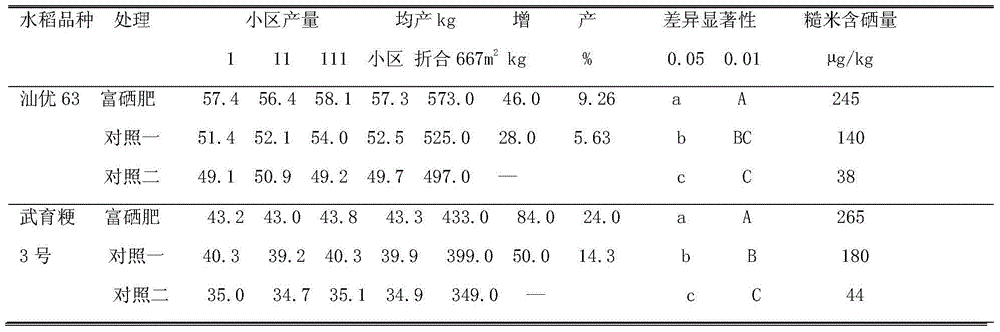

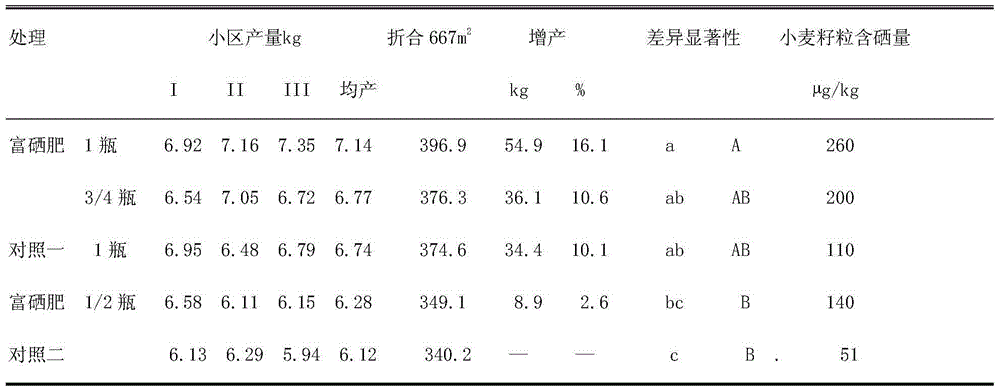

Selenium-rich foliar fertilizer, preparation method and application thereof

InactiveCN104151078AImprove adsorption capacityHigh strengthFertilising methodsFertilizer mixturesPolyoxyethylene castor oilPhosphate

The invention relates to a selenium-rich foliar fertilizer, a preparation method and an application thereof. Per 500 parts by weight of the selenium-rich foliar fertilizer is prepared by mixing following components including, by weight, 25-35 parts of polyoxyethylene castor oil, 0.35-0.4 parts of 85% powder of gibberellins, 0.4-0.6 parts of sodium selenite, 10-14 parts of potassium dihydrogen phosphate, 25-30 parts of ethanol, 25-27.5 parts of carbamide, 0.4-0.6 parts of hydrochloric acid and the balance water. The selenium-rich foliar fertilizer is reasonable and economical in formula, is low in cost, is durable in effect and has a significant intuitive effect, a significant yield-increasing effect and a significant selenium-rich effect. The preparation method is a conventional mixing and stirring method which is simple in technology and less in required equipment. The application of the selenium-rich foliar fertilizer is that the selenium-rich foliar fertilizer is diluted by 150-250 time with water and is directly sprayed onto leaf surfaces of a plant. The selenium-rich foliar fertilizer is simple in application method and is strong in applicability.

Owner:安徽富村微量元素科技有限公司

Production process of textile fiber color modifier

The invention relates to a production process of a textile fiber color modifier. The textile fiber color modifier is prepared from the following raw materials in percentage by weight: 52%-68% of swelling agent, 10%-30% of emulsifying and dispersing agent, and 8%-20% of solvent, wherein the swelling agent is one or more of propylene glycol monomethyl ether, phenoxy-1-propanol, cyclohexanol methyl ether, N-normal-butyl-phthalimide, and N-isopropyl-phthalimide; the emulsifying and dispersing agent is one or more of styrylphenol polyoxyethylene ether sulfonate, polyoxyethylene castor oil, iso-tridecanol polyoxyethylene ether, fatty amine polyoxyethylene ether, polyoxyethylene (60) sorbitan monostearate (namely Tween-60), polyoxyethylene (80) sorbitan monostearate (namely Tween-80), and pesticide emulsifier No.600; and the solvent is one or more of water, ethanol, isopropyl alcohol, ethylene glycol, and ethylene glycol monobutyl ether. The production process comprises the following steps of adding all the materials into a reaction kettle and stirring the materials at 30 DEG C to 50 DEG C for 60 to 90 minutes, thereby obtaining the textile fiber color modifier. The textile fiber color modifier can be used for overcoming the dyeing defects of polyester and blended fabrics of the polyester in dyeing, and the dyed fabrics can meet environmental protection standards.

Owner:冯祥茂

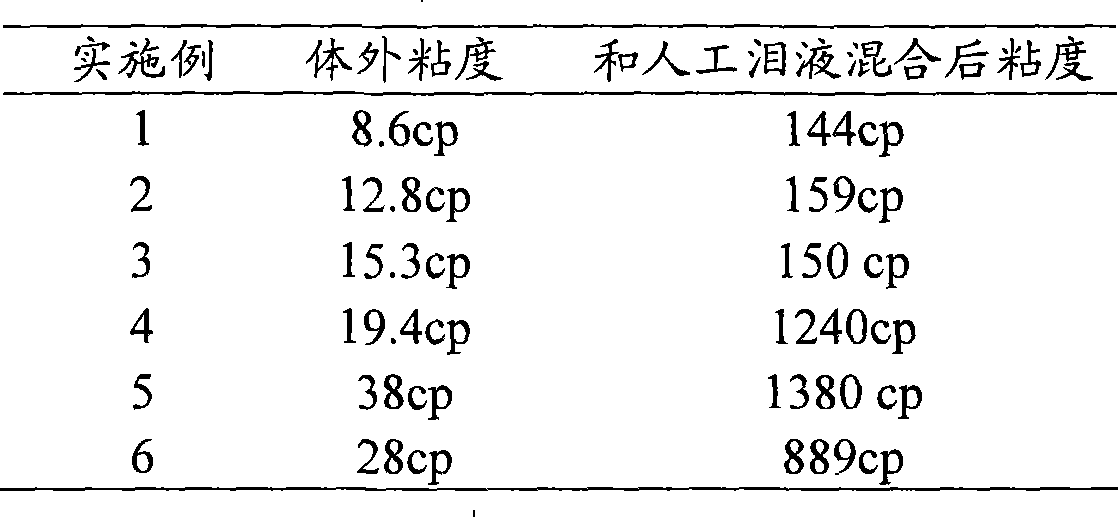

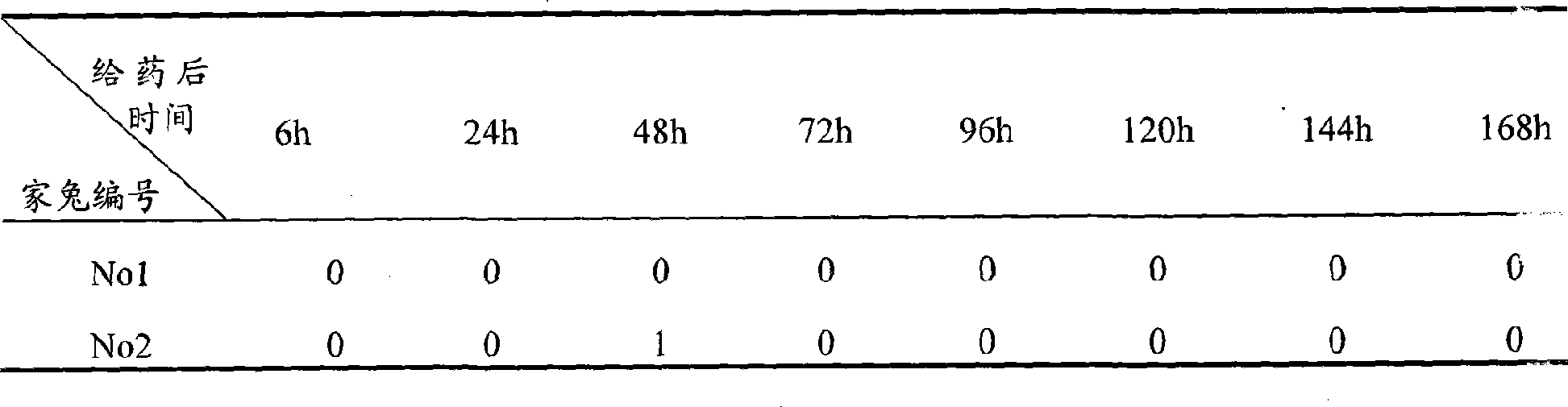

Flurbiprofen axetil eye nano-emulsion in-situ gel preparation and preparation method thereof

InactiveCN101385697AIncrease system viscosityNon-irritatingOrganic active ingredientsSenses disorderGel preparationPolyoxyethylene castor oil

The invention relates to an ophthalmic flurbiprofen ester nano emulsion-in situ gel preparation and a preparation method thereof. The ophthalmic flurbiprofen ester nano-emulsion in situ gel preparation is made from oil, an emulsifier, a thickener, an osmoregulator, a bacteriostatic agent and purified water; and is characterized in that one or a plurality of safe and non-irritating lecithin, Tween60, Tween80, polyoxyethylene castor oil and polyoxyethylene hydrogenated castor oil are taken as the emulsifier; and a high molecular material with ion sensitivity characteristic is taken as the thickener. The ophthalmic flurbiprofen ester nano emulsion-in situ gel preparation is low-viscosity fluid with good fluidity in vitro, and rapidly forms hydrogel after being dropped in eyes. The ophthalmic flurbiprofen ester nano emulsion in-situ gel preparation has the advantages of increasing the residence time of the drug in eyes and increasing bioavailability, has no irritability or other toxic side effect to eyes, and has good biocompatibility and the like.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

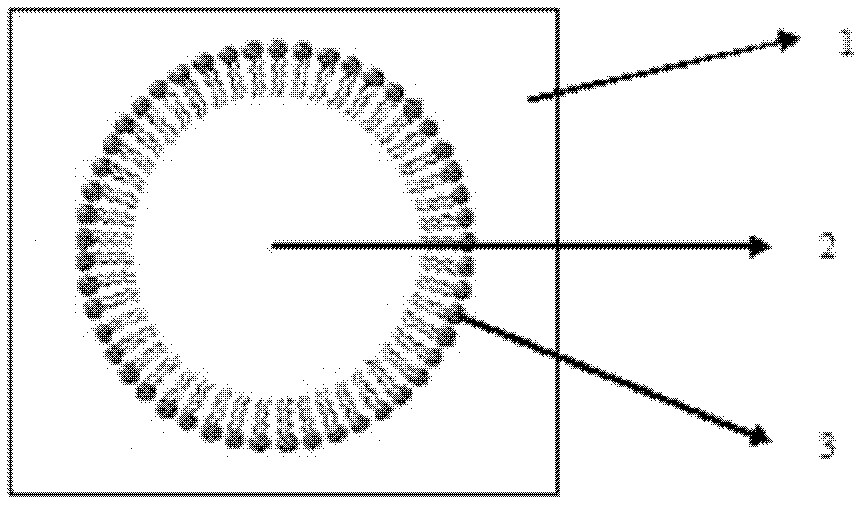

Novel vaccine adjuvant and application

ActiveCN102370977AAdjustable affinityAdjustable specificityGenetic material ingredientsEmulsion deliveryPolyoxyethylene castor oilVaccination

The invention discloses a novel vaccine adjuvant (also called as SPO1 vaccine adjuvant) and a preparation method thereof. The vaccine adjuvant disclosed by the invention mainly comprises squalane, polyoxyethylene castor oil and polyether, and can realize immunization through injection or nasal spray, transdermal non-injection and other approaches; and the vaccination through non-injection has the characteristics of low cost, convenience for administration, avoidance of cross infection and high safety. The SPO1 vaccine adjuvant disclosed by the invention can be used for preparing vaccines along with inactivated whole pathogens, extracted components of cracked pathogen, bacterial vesicles and capsular polysaccharide or polysaccharide-binding protein, recombinant protein, recombinant VLP (Virus-like Particle), DNA (Deoxyribonucleic Acid) or RNA (Ribonucleic Acid) and other different types of antigens, can be suitable for people in different age groups and preparation of different animal vaccines and immunization, has the advantages of no complex structure, simple process, convenience for preparation and sterilization, low cost and suitability for mass production and industrialization.

Owner:MICROBE EPIDEMIC DISEASE INST OF PLA MILITARY MEDICAL ACAD OF SCI +1

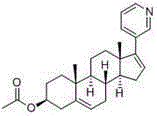

Abiraterone oral spray and use and preparation methods thereof

InactiveCN105055314ACorrectly designedTake a small doseOrganic active ingredientsAerosol deliveryPolyoxyethylene castor oilMetabolite

The invention relates to the technical field of pharmaceutical preparations and particularly relates to an abiraterone oral spray. The abiraterone oral spray comprises the following components in percent by weight: abiraterone acetate, an oil phase, a surfactant, a co-surfactant and the balance of water, wherein the oil phase is used as a carrier for prompting system micro-emulsification, and the oil phase is medium chain triglyceride, ethyl oleate or oleic acid; the surfactant is used for improving the performance of the abiraterone oral spray, expanding the range of application and realizing solubilization, and the surfactant is polyoxyethylene 40 hydrogenated castor oil or polyoxyethylene 35 castor oil; and the co-surfactant is used for reducing the surface tension of liquid and enhancing the emulsifying, moistening and blistering effects, and the co-surfactant is ethanol, n-butyl alcohol or propylene glycol. The spray has the advantages that the taking dose is reduced, so that the manufacturing cost is lowered; the formation of invalid metabolites is reduced, so that adverse reactions are effectively reduced; and the drug effect of the spray is longer than that of an oral drug.

Owner:HANGZHOU ANDE TECH CO LTD

Novel taxol lipid microsphere injection and preparation method thereof

InactiveCN102302447ARapid coolingImprove physical stabilityOrganic active ingredientsSolution deliveryPolyoxyethylene castor oilMicrosphere

The invention discloses a novel taxol lipid microsphere injection containing amphiphilic polyamino acid and a preparation method thereof. The injection contains taxol, amphiphilic polyamino acid, oil for injection, an emulsifying agent, an auxiliary emulsifying agent, a potential regulator, an antioxidant, a metal chelating agent, an iso-osmotic adjusting agent and water for injection, wherein the amphiphilic polyamino acid is a segmented copolymer consisting of a hydrophilic chain segment and racemic hydrophobic polyamino acid. The novel taxol lipid microsphere injection represents a microscopic structure different from that of a traditional lipid microsphere preparation, therefore the injection has excellent stability superior to that of the traditional lipid microsphere preparation. Inthe preparation, polyoxyethylene castor oil is not contained, VE (vitamin E) is not used massively, and no organic solvent is introduced; in addition, the injection can tolerate thermal pressure sterilization, has the advantages of no irritation, low toxicity, good stability and low cost, and is suitable for industrial production in large scale.

Owner:SHENYANG PHARMA UNIVERSITY

Paclitaxel lipid microspheres injection and preparation method thereof

InactiveCN101204373ALess irritatingNot easy to precipitateOrganic active ingredientsSolution deliveryLipid formationPolyoxyethylene castor oil

The invention relates to a paclitaxel lipid microsphere injection and a manufacturing method thereof. In the invention, a paclitaxel lipid microsphere injection that does not contain polyoxyethylene castor oil is prepared. The medicine 90-98 per cent paclitaxel is coated in the oil phase and the oil-water interfacial film of the lipid microsphere. Thus the toxicity and stimulation of paclitaxel in clinic use are largely reduced, and the adverse reaction resulted from the excipient in the existing paclitaxel injection is prevented. With low stimulation, low toxicity and high efficiency, the preparation as a antineoplastic drug is administrated by intravenous injection.

Owner:李时海 +1

Preparation method of taxol injection

ActiveCN101574318AInhibitory concentrationAvoid low overall contentOrganic active ingredientsPharmaceutical delivery mechanismMolecular sievePolyoxyethylene castor oil

The invention provides a preparation method of taxol injection, comprising the following steps: (1) blending polyoxyethylene castor oil and molecular sieve, and filtering and degerming; (2) removing trace moisture in taxol, and filtering and degerming; (3) blending, filtering and degerming solutions obtained in step (1) and step (2),. The method avoids overlarge local concentration or low whole content caused by overlong time used for blending solutions or incomplete solution of materials, thus solving the uniformity problem of solution of materials and the stability problem of the taxol injection in the process of blending solutions.

Owner:HAIKOU PHARMA FACTORY +1

Novel composite metal polishing fluid and preparation method thereof

A disclosed novel composite metal polishing fluid is characterized by being prepared from the following raw materials in parts by weight: 11-13 parts of cerium oxide, 2-4 parts of graphene oxide, 7-9 parts of rapeseed oil, 1-2 parts of stannous octoate, 4-6 parts of polyoxyethylene sorbitan fatty acid ester, 3-5 parts of polyoxyethylene castor oil, 4-6 parts of urea, 2-4 parts of citric acid, 4-6 parts of emulsified silicone oil, 5-7 parts of an auxiliary agent, and 300 parts of deionized water. The prepared mixed polishing fluid is safe, non-toxic and reasonable in formula. Through the cooperation of the added surfactant and the abrasive, the polishing effect is improved, preferential adsorption is realized, and a long-term easily-cleaned physical adsorption surface is formed. By adding the auxiliary agent, the polishing fluid has good dispersity, lubricity and film-forming property, and is capable of forming an air-obstructing layer on a workpiece surface to prevent air from corroding a metal surface. The polishing fluid is capable of satisfying the polishing processing requirements of various products and parts, and helps to improve the polishing efficiency, cleaning effect, surface precision and the like.

Owner:BENGBU GAOHUA ELECTRONICS

Anti-tritium glove and preparation method thereof

The invention provides an anti-tritium glove and a preparation method thereof. Compound latex adopted for the anti-tritium glove is prepared from, by weight, 200 parts of butyl rubber emulsion, 0.10-0.25 part of polyoxyethylated castor oil, 0-5 parts of potassium hydroxide and 20 parts of dispersoid. The butyl rubber emulsion is prepared from, by weight, 160 parts of butyl rubber, 1.0-1.5 parts of oleic acid, 4.0-7.2 parts of potassium hydroxide, 5.5-6.4 parts of monopotassium phosphate, 35-50 parts of polyvinyl alcohol, 0.8-1.0 part of polyoxyethylene castor oil potassium soap and 94-100 parts of soft water. The dispersoid is prepared from, by weight, 4 parts of sulphur, 5 parts of accelerant Px, 10 parts of accelerant ZDC, 8 parts of zinc oxide, 2 parts of antiager DBH, 0.4 part of green pigment, 5 parts of dispersant NF, 0.8 part of stabilizer KOH, 0.1 part of carbon black, 1.5-5.0 parts of anti-tritium material and 50 parts of water. Compared with the prior art, the anti-tritium glove has the advantages that the tritium permeability coefficient, air tightness, mechanical performance, hot air aging resistance, sulfuric acid solution resistance and sodium hydroxide solution resistance are excellent, and the requirements of relevant military units are met.

Owner:GUANGZHOU DOUBLE ONE LATEX PROD CO LTD

Developing solution as well as preparation method and application thereof

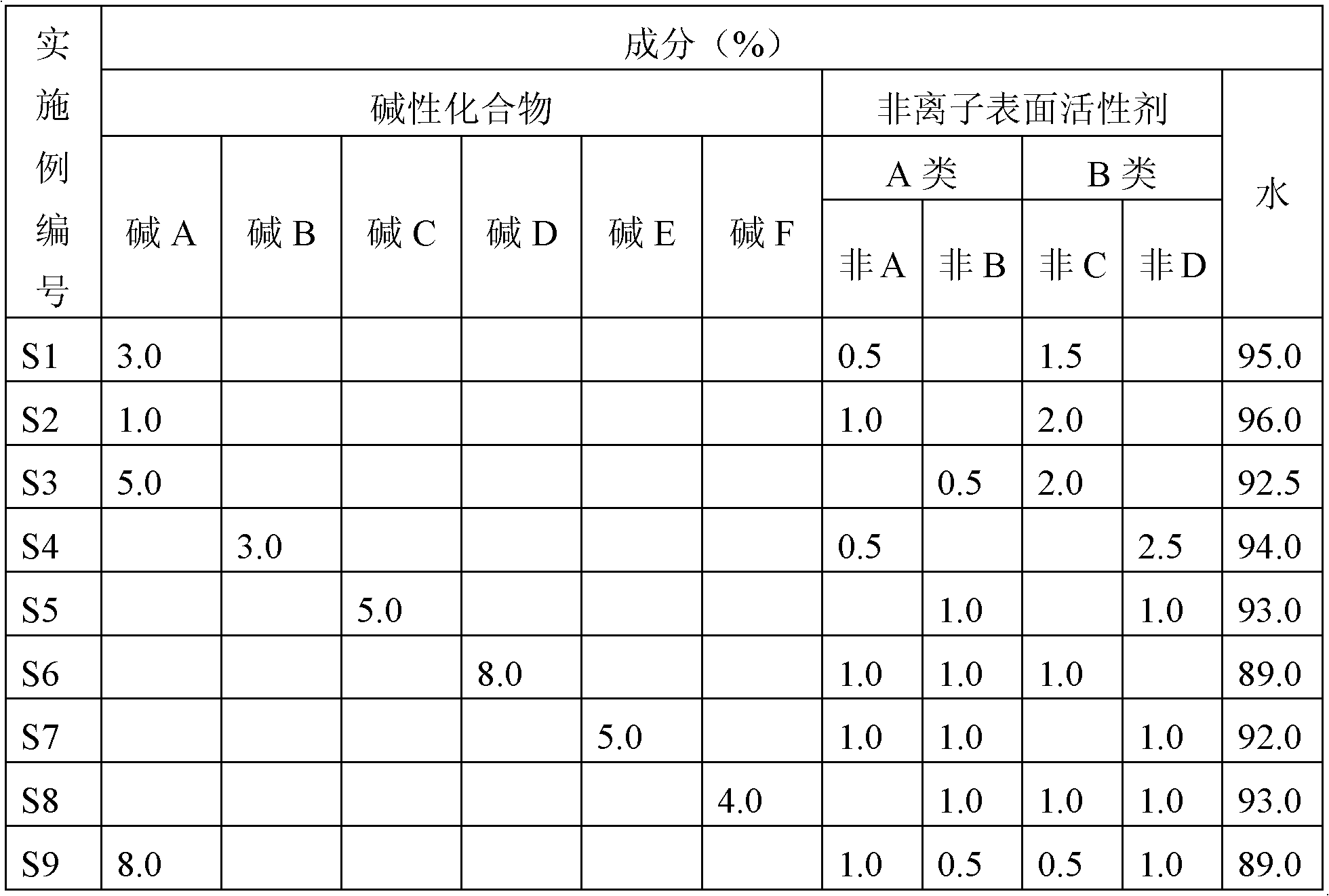

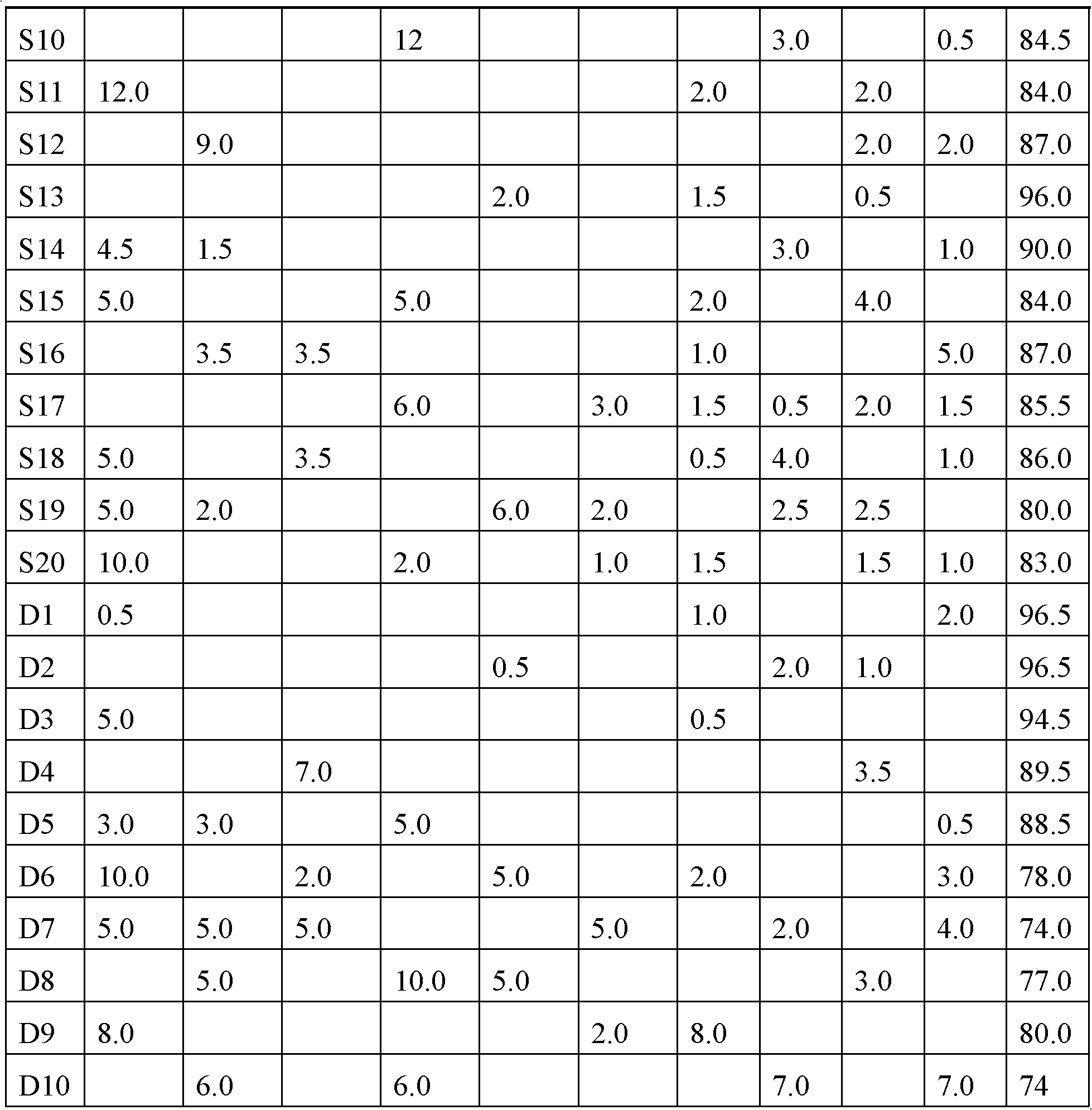

ActiveCN102096344AOvercoming the inability to take developability into account at the same timeOvercome defoamingPhotosensitive material processingPhotosensitive materials for photomechanical apparatusPolyoxyethylene castor oilTetramethylammonium hydroxide

The invention discloses a developing solution as well as a preparation method and application thereof. The developing solution comprises the following components in percentage by weight: 1-15% of an alkaline compound, 0.5-6% of a non-ionic surface active agent and the balance of water, wherein the alkaline compound is preferably selected from at least one of tetramethylammonium hydroxide, tetraethyl ammonium hydroxide and tetrapropylammonium hydroxide. The non-ionic surface active agent is selected from at least one of coconut monoethanol amide, cocoanut fatty acid diethanolamide, polyoxyethylene castor oil (10) ether and polyoxyethylene castor oil (30) ether. In the developing solution provided by the invention, the water solution formed by the alkaline compound and the non-ionic surfaceactive agent has good intersolubility, the developing solution has the characteristics that the developing performance is good, no residue is left, the operating temperature range is wide, and the environmental pollution is less and the like, and has wide application in a development preparation process of photosensitive resin.

Owner:HEFEI MAOTENG ENVIRONMENTAL PROTECTION TECH CO LTD

Building glass cleaner

InactiveCN104087432AEffective decontamination and decontaminationAvoid pollutionOrganic detergent compounding agentsNon-ionic surface-active compoundsPolyoxyethylene castor oilMonoglyceride

The invention discloses a building glass cleaner. The building glass cleaner consists of the following raw materials in parts by weight: 3-5 parts of dodecylbenzene sulfonic acid, 2-5 parts of sodium dodecyl sulfate, 3-4 parts of polyoxyethylene castor oil, 2-5 parts of fatty alcohol-polyoxyethylene ether, 8-10 parts of methyl parahydroxybenzoats, 6-8 parts of monoglyceride, 5-10 parts of glycerin monostearate, 2-5 parts of sodium carboxymethylcellulose, 2-5 parts of sodium lauryl sulfate, 2-5 parts of lauryl alcohol, 2-5 parts of triethanolamine, 5-10 parts of phenoxyethanol, 3-5 parts of 2-hydroxyethylamine, 3-10 parts of nanosilicon dioxide, 5-10 parts of talcum powder, 5-10 parts of ethyl acetate and 80-100 parts of deionized water. The building glass cleaner is capable of effectively removing and cleaning pollution and effectively preventing the glass from being polluted again, good in hydrophilicity and free from track on the surface of the glass after scrubbing.

Owner:陈新棠

Wool lubricant

InactiveCN102071571AMeet environmental protection production standardsImprove permeabilityFibre treatmentPolyoxyethylene castor oilOleic Acid Triglyceride

The invention relates to a wool lubricant which is mainly used for wool textile technique; the wool lubricant needs to be diluted into emulsion when in use. The wool lubricant comprises mineral oil, oleate, anion surfactant, non-ion surfactant, emulsion, organic alcohol amine and organic acid; the weight percentage of the constituents is as follows: 55% of the mineral oil, 18% of the oleic acid methanol ester, 5% of the oleic acid butanol ester, 5% of the sodium oleate, 6% of polyoxyethylene castor oil (EO=15), 6% of nonylphenol ethoxylates (EO=10), 2% of triethanolamine, and 3% of oleic acid. The method for preparing the wool lubricant comprises the following steps of: in a reaction kettle with temperature control, orderly adding 55kg of the mineral oil, 18kg of the oleic acid methanol ester, 5kg of the oleic acid butanol ester, 5kg of the sodium oleate, 6kg of the polyoxyethylene castor oil, 6kg of the nonylphenol ethoxylates, 2kg of the triethanolamine, 3kg of the oleic acid and a certain amount of essence. The composite product is transparent yellow oily liquid and can be diluted by water into stable emulsion liquid with a pH value of 6-8.

Owner:TIANJIN BOLAIEN TECH DEV

Method for determining nickel content in soil by microwave digestion-flame atomic absorption spectrometry

InactiveCN103558173AImprove atomization efficiencyHigh measurement sensitivityPreparing sample for investigationColor/spectral properties measurementsPolyoxyethylene castor oilTrace element

The invention provides a method for determining a nickel content in soil by microwave digestion-flame atomic absorption spectrometry, wherein the method is characterized by: pretreating a soil sample by combining long-time immersion and stepedly heated microwave digestion, using polyoxyethylene castor oil glycerin ether as an activator, raising atomization efficiency of nickel atoms in flame, raising determination sensitivity, thereby raising sensitivity; based on linear relation of absorbance and nickel content determined by a flame atomic abserption spectrometer by a standard solution, measuring and calculating to obtain the content of nickel atoms in soil. The method provided by the invention solves problems that a method for determining trace elements by traditional atomic absorption spectrometry has disadvantages long time consumption, low sensitivity, large solvent consumption amount, and severe environment pollution caused by a solvent, and the method provided by the invention has advantages of good precision, high recovery rate, accuracy, reliability, rapidness and convenience.

Owner:SUZHOU GUOHUAN ENVIRONMENT DETECTION

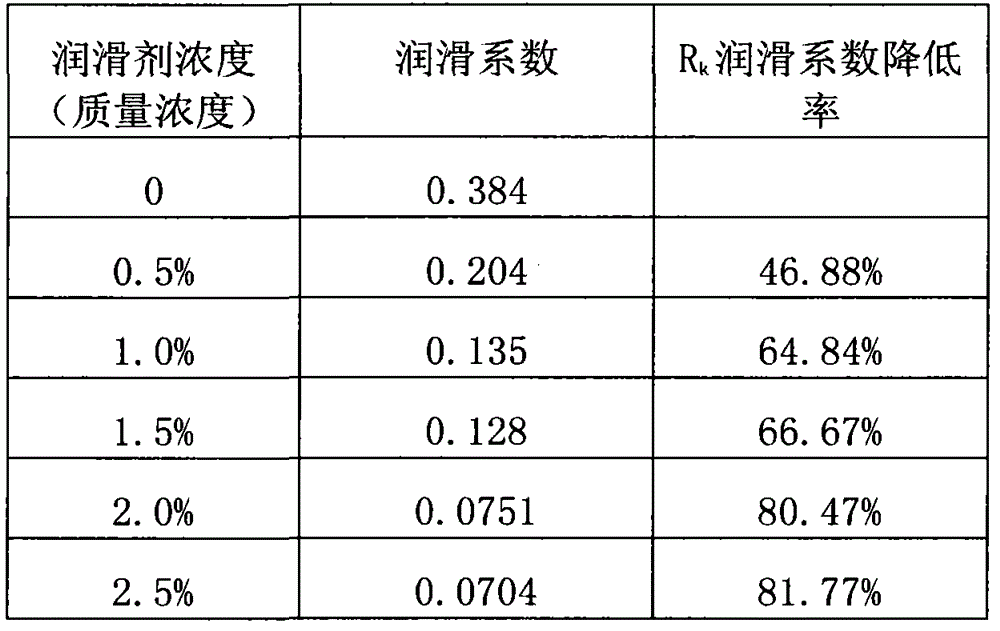

Environmental-friendly drilling fluid lubricant

ActiveCN105694826AImprove wear resistancePromote degradationDrilling compositionLoss ratePolyoxyethylene castor oil

The invention belongs to the field of oilfield chemistry, and relates to a drilling fluid lubricant prepared by taking biodiesel, a polyether compound and esters oil as base oil, adding a proper antiwear additive and surfactants and blending, and a preparation method thereof. The lubricant provided by the invention comprises the components by the weight percentage: 20%-30% of the biodiesel, 20%-30% of polyether, 20%-30% of esters base oil, 5-20% of Span-80 sorbitan oleate, 5-20% of EL-40 polyoxyethylene castor oil, 2-10% of an extreme pressure antiwear agent, and 0.5-1% of a defoaming agent. The drilling fluid lubricant provided by the invention is formed by taking the biodiesel, the polyether, esters and other good-biodegradability compounds as the base oil, adding the anionic surfactant, the non-ionic surfactant, the extreme pressure antiwear agent and the defoaming agent and blending; the drilling fluid lubricant has excellent wear resistance and biodegradability, has no significant effect on other drilling fluid properties, such as the viscosity, the water loss rate and the like, and is an environmental-friendly drilling fluid lubricant.

Owner:BEIJING XINXIANGYUAN CHANGSHUN LUBRICATING OIL CO LTD

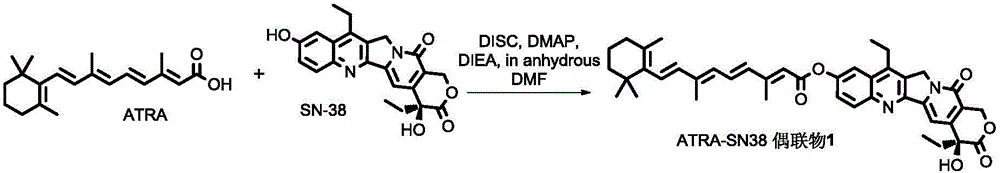

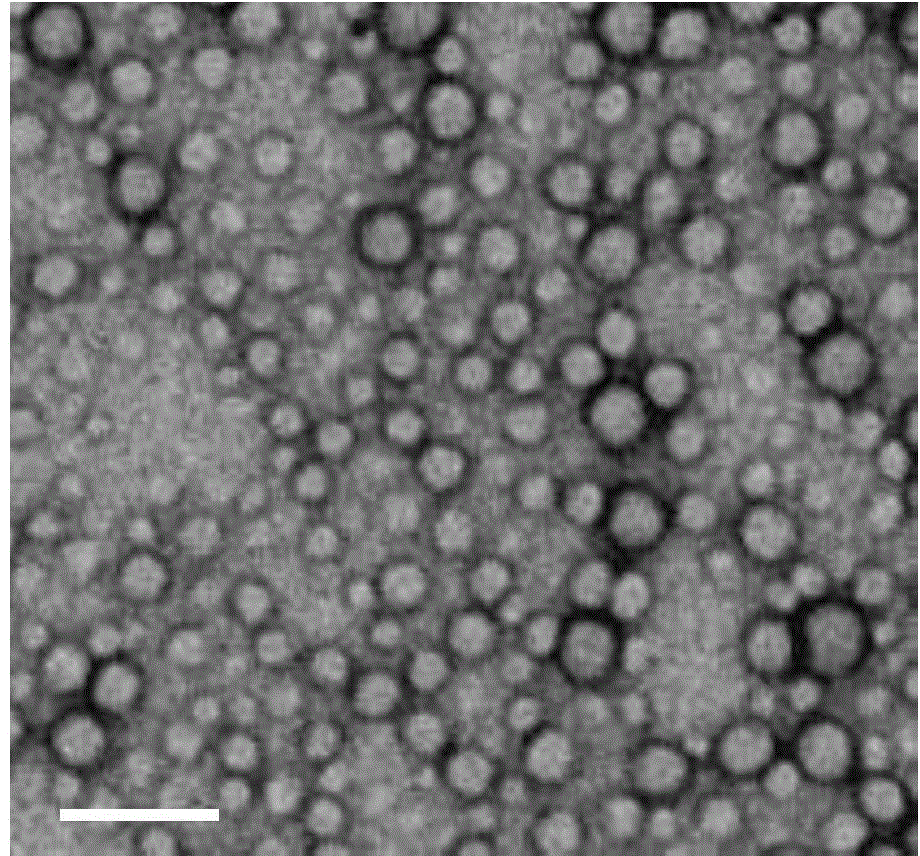

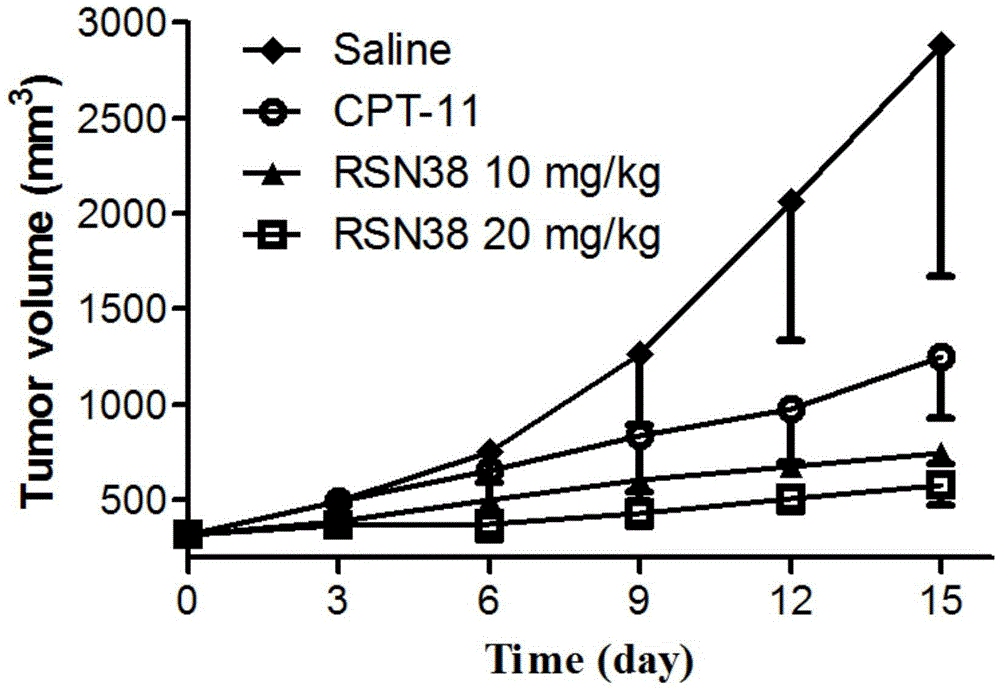

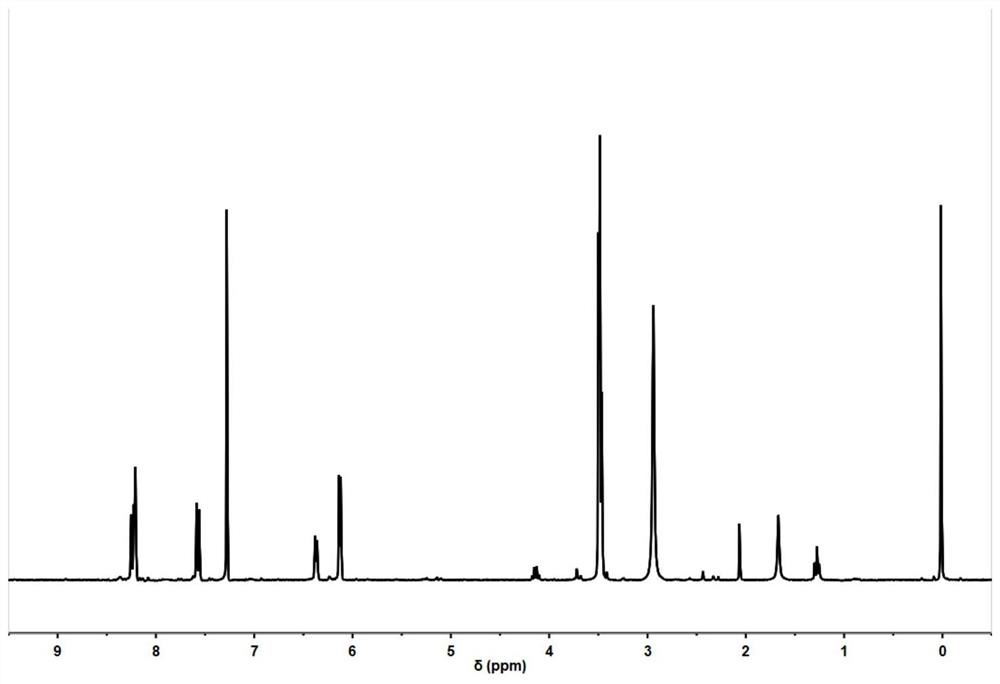

All-trans retinoic acid-camptothecin anticancer drug conjugate as well as preparation method and application thereof

ActiveCN104478890AImprove solubilityExpand the scope of clinical applicationOrganic active ingredientsOrganic chemistryPolyoxyethylene castor oilSolubility

The invention discloses an all-trans retinoic acid-camptothecin anticancer drug conjugate as well as a preparation method and application thereof. The structural formula of the all-trans retinoic acid-camptothecin anticancer drug conjugate is shown in a formula (I), (II), (III), (IV), (V) or (VI). The all-trans retinoic acid-camptothecin anticancer drug conjugate has good solubility in Tween, polyoxyethylene castor oil, a Poly(ethylene adipate)-polylactic acid copolymer and a Poly(ethylene adipate)-poly (lactic acid-glycollic acid) copolymer, can be self assembled into nanometer grains in water, can be directly injected or taken orally or processed into other dosage forms. According to the all-trans retinoic acid-camptothecin anticancer drug conjugate disclosed by the invention, as all-trans retinoic acid and SN-38 or camptothecin take synergistic effect, compared with a conjugate only containing one of irinotecan, SN-38 and all-trans retinoic acid, the all-trans retinoic acid-camptothecin anticancer drug conjugate has good tumor suppression effect.

Owner:ZHEJIANG UNIV

Insecticidal composition containing fipronil for corps

InactiveCN101133738AGood spreadabilityImprove permeabilityBiocideAnimal repellantsPolyoxyethylene castor oilFipronil

The present invention relates to a composite pesticide containing fipronil. Its composition includes (by wt%) 0.1%-30% of effective component A, 0.2%-10% of fipronil, 0.1%-3% of organic silicon synergistic agent, 5.0%-20% of emulsifying agent and 50%-90% of solvent, in which the described effective component is one of abamectin or profenofos or phoxim or more than one of them; the described emulsifying agent is one of sodium alkylbenzenesulfonate, polyoxyethylene castor oil ether, fatty alcohol-polyoxyethylene ether and polyoxyethylene nonylphenol ether or more than one of them; and the described solvent is one of methyl alcohol, ethyl alcohol, dimethyl benzene, dimethyl sulfoxide, dimethyl formamide, rapeseed oil, soybean oil and cotton seed oil or more than one of them.

Owner:湖南万家丰科技有限公司

Self-lubricating wear-resistant ceramic for cutting tools and preparation method thereof

ActiveCN104387071AImprove high temperature resistanceImprove carrying capacityPolyoxyethylene castor oilWear resistant

The invention relates to a self-lubricating wear-resistant ceramic for cutting tools, which is prepared from the following raw materials in parts by weight: 2-3 parts of bismuth sulfide, 2-3 parts of diethanolamine, 2-3 parts of ammonium sulfate, 2-3 parts of magnesium chloride, 2-3 parts of calcium carbide sludge, 2-3 parts of graphene oxide, 0.6-0.8 part of KOH, 0.2-0.3 part of polyoxyethylene castor oil, 3-4 parts of magnesium oxide, 36-40 parts of titanium boride, 4-5 parts of nano tungsten trioxide, 30-35 parts of titanium carbide, 3-5 parts of beryllium oxide, 1-2 parts of silver powder, a right amount of ethanol, a right amount of deionized water, 1-1.5 parts of polyacrylic acid, 1.2-1.6 parts of polyethyleneglycol and 4-5 parts of antiwear assistant. The added nano tungsten trioxide enhances the high temperature resistance of the ceramic. The ceramic has the characteristics of high temperature resistance, high carrying capacity, self lubrication, thermal shock resistance, high wear resistance and the like, and is suitable for manufacturing cutting tools. The antiwear assistant can enhance the wear resistance and heat resistance of the ceramic.

Owner:枣庄科顺数码有限公司

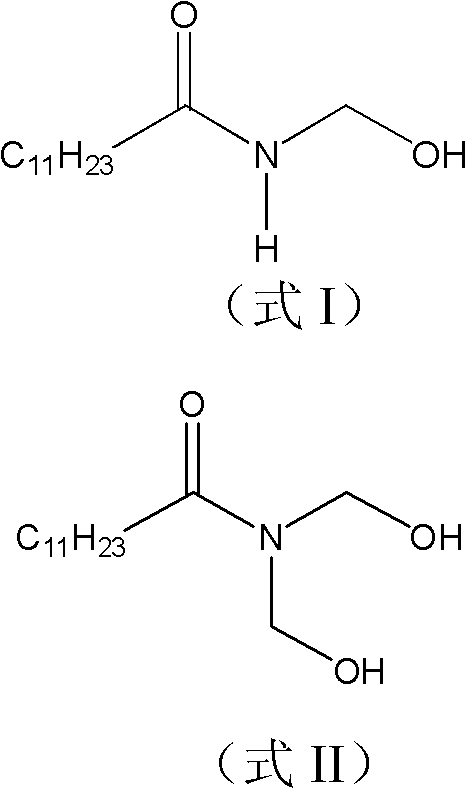

Albumin hydrogel as well as preparation method and application thereof

ActiveCN111621038ASolve the shortcomings of poor solubilityEvenly distributedOrganic active ingredientsAerosol deliveryPolyoxyethylene castor oilEnd-group

The invention provides albumin hydrogel. The albumin hydrogel is prepared by mixing albumin, a cross-linking agent and a solvent, the cross-linking agent comprises a repeating unit having a structureof formula (I) and an end group having a structure of formula (II). The invention develops the albumin hydrogel which is rapid in crosslinking, low in gelatinization concentrating and free of biotoxicity, and the albumin hydrogel is applied to the fields of cell culture, tissue engineering and drug delivery. Besides, as a good paclitaxel topical treatment drug carrier, the albumin hydrogel overcomes the defect of poor paclitaxel solubility, polyoxyethylene castor oil with biotoxicity is not introduced, and compared with a systemic preparation, the albumin hydrogel has the advantages that the administration frequency is effectively reduced, the drug concentration at a tumor is increased, and the systemic toxicity is reduced. Nanoparticles wrapping paclitaxel are used as gel forming components of the gel, so that uniform distribution of the paclitaxel in the gel can be realized, and stable and continuous release is realized.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

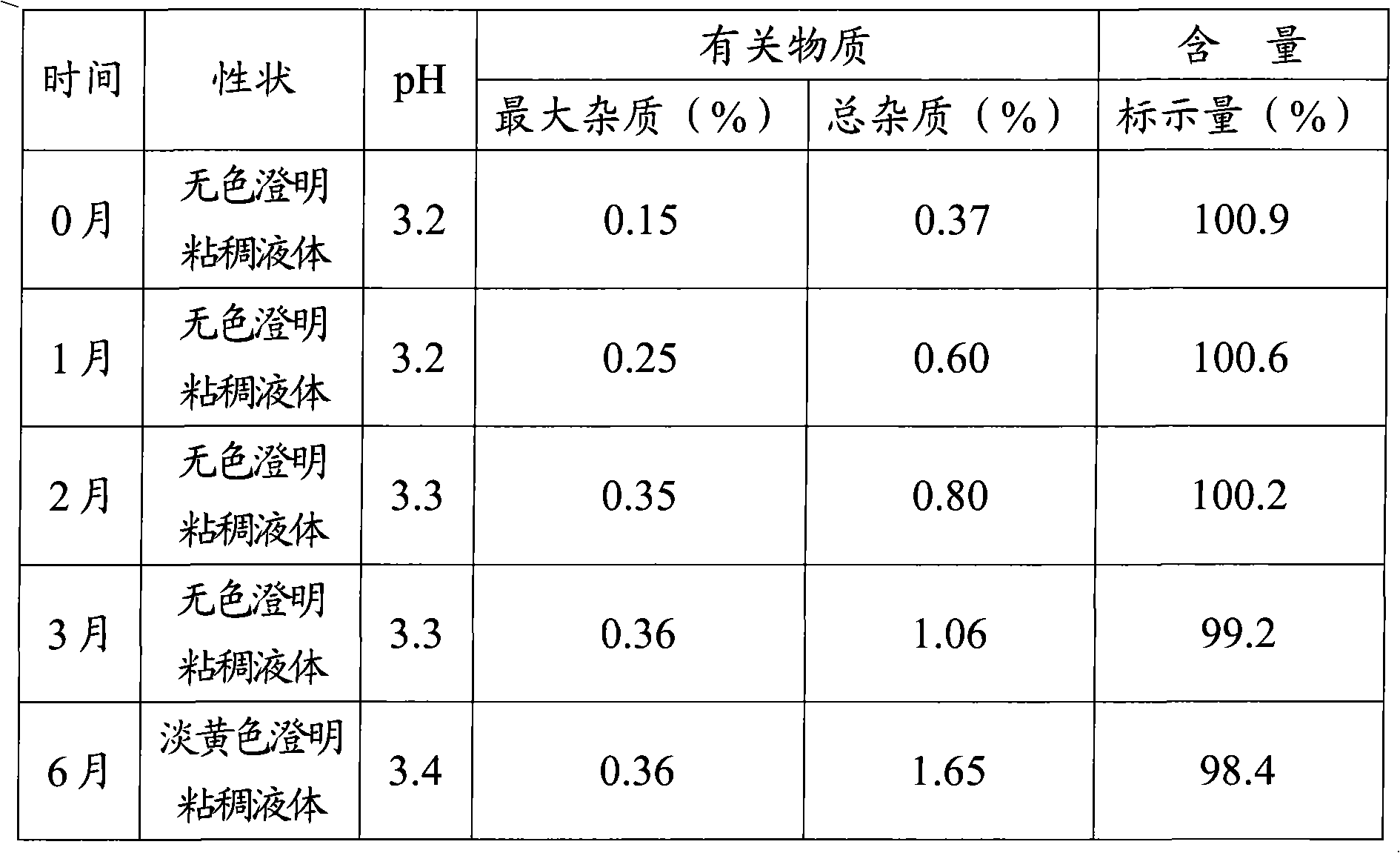

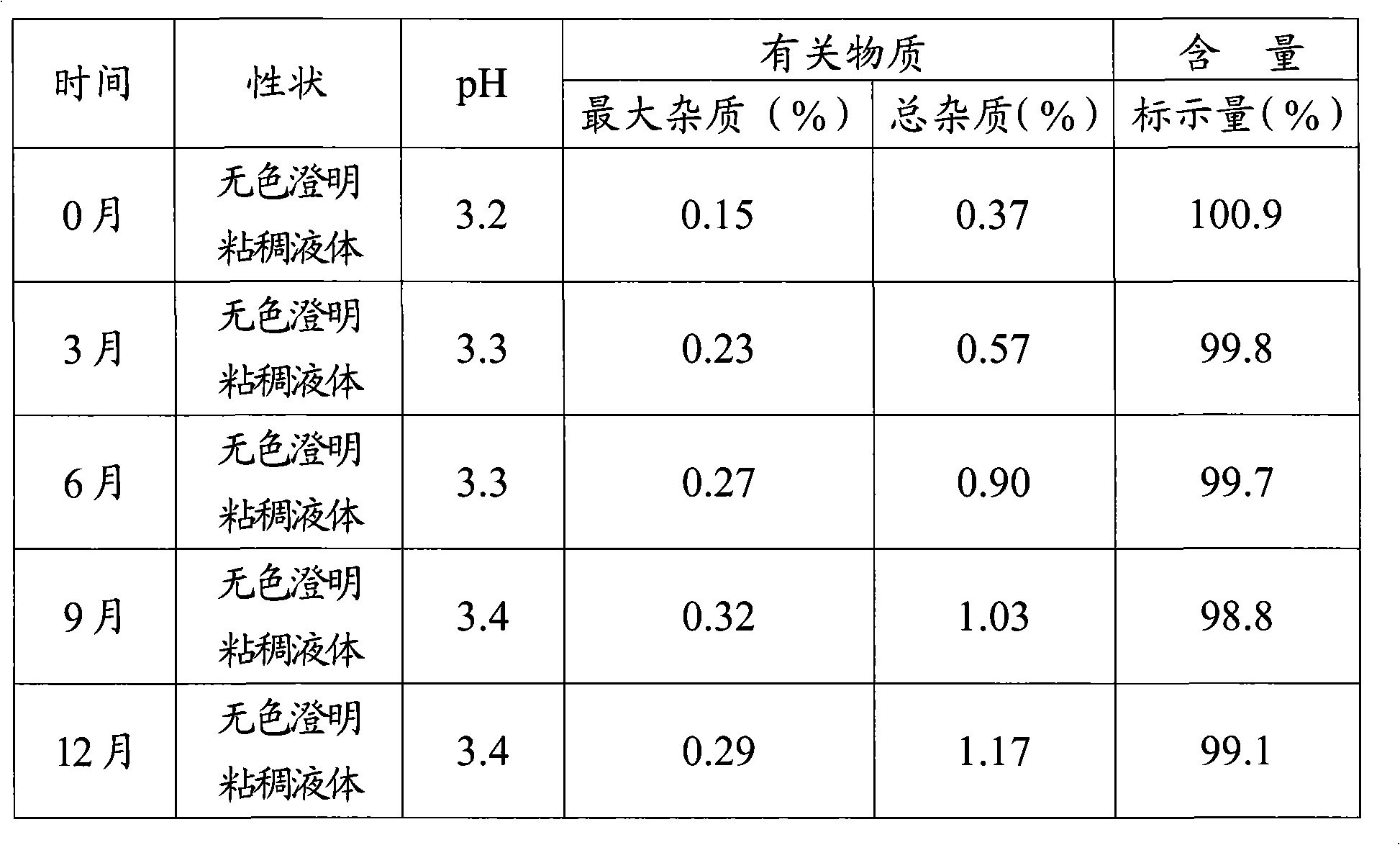

Paclitaxel composition for injection and preparation method thereof

InactiveCN102552123AImprove securityLow content of related substancesOrganic active ingredientsPharmaceutical delivery mechanismPolyoxyethylene castor oilEngineering

The invention provides a paclitaxel composition for injection. The composition comprises the following components in percentage by weight: 0.200-1.087% of paclitaxel, 95.000-99.200% of polyoxyethylenated castor oil and ethanol as well as 0.200-1.500% of organic acid. The paclitaxel composition for injection, provided by the invention, can be directly administrated after being diluted by an infusion solution. By using the paclitaxel composition for injection, provided by the invention, the damage caused by terminal sterilization of the product to the main component is avoided because a sterile production process is adopted in the preparation process; meanwhile, the sterile level of the product is more preferably guaranteed because an polyoxyethylenated castor oil sterilizing process is additionally increased in the process. Compared with the prior art, the paclitaxel composition for injection, provided by the invention, has the advantages of reducing the content of the preparation related substances, improving the product stability, reducing the occurring rate of the adverse reaction and improving the safety in clinical use.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com