Patents

Literature

1425 results about "Cyclohexanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cyclohexanol is the organic compound with the formula HOCH(CH₂)₅. The molecule is related to cyclohexane ring by replacement of one hydrogen atom by a hydroxyl group. This compound exists as a deliquescent colorless solid with a camphor-like odor, which, when very pure, melts near room temperature. Billions of kilograms are produced annually, mainly as a precursor to nylon.

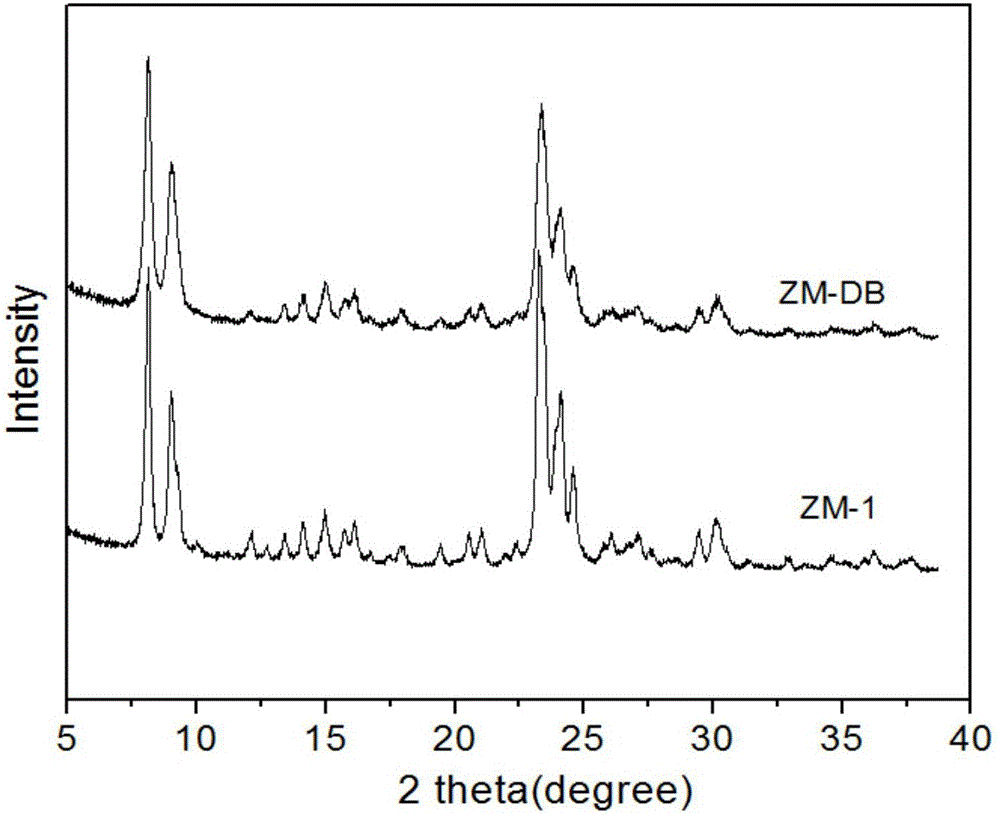

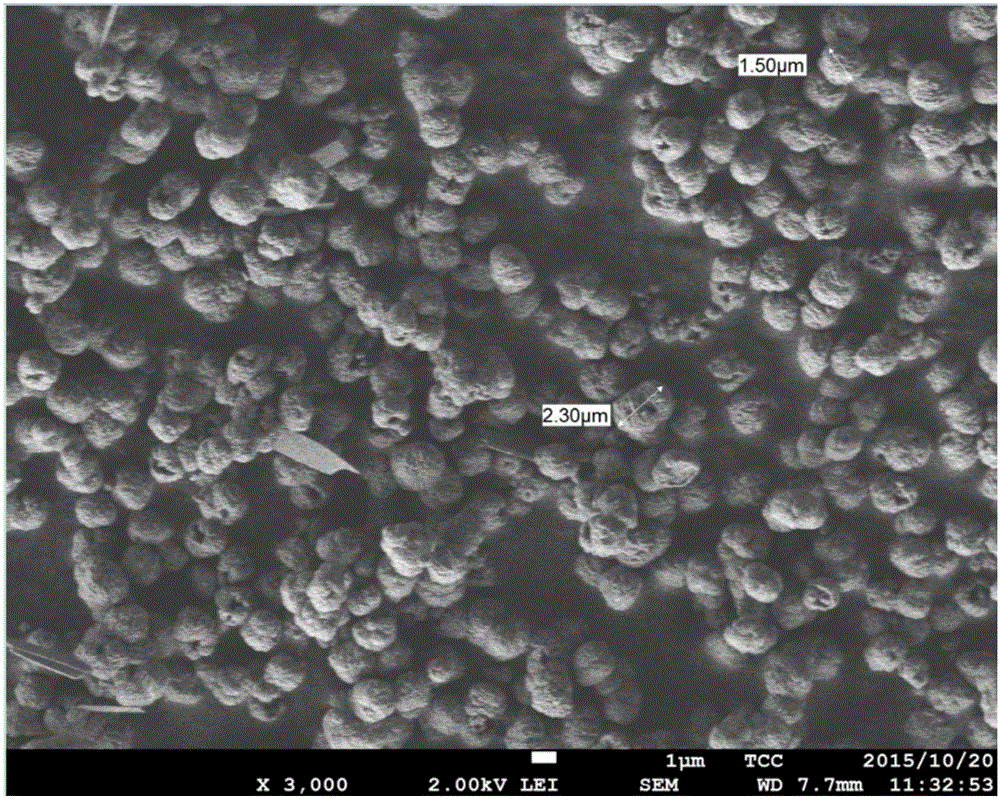

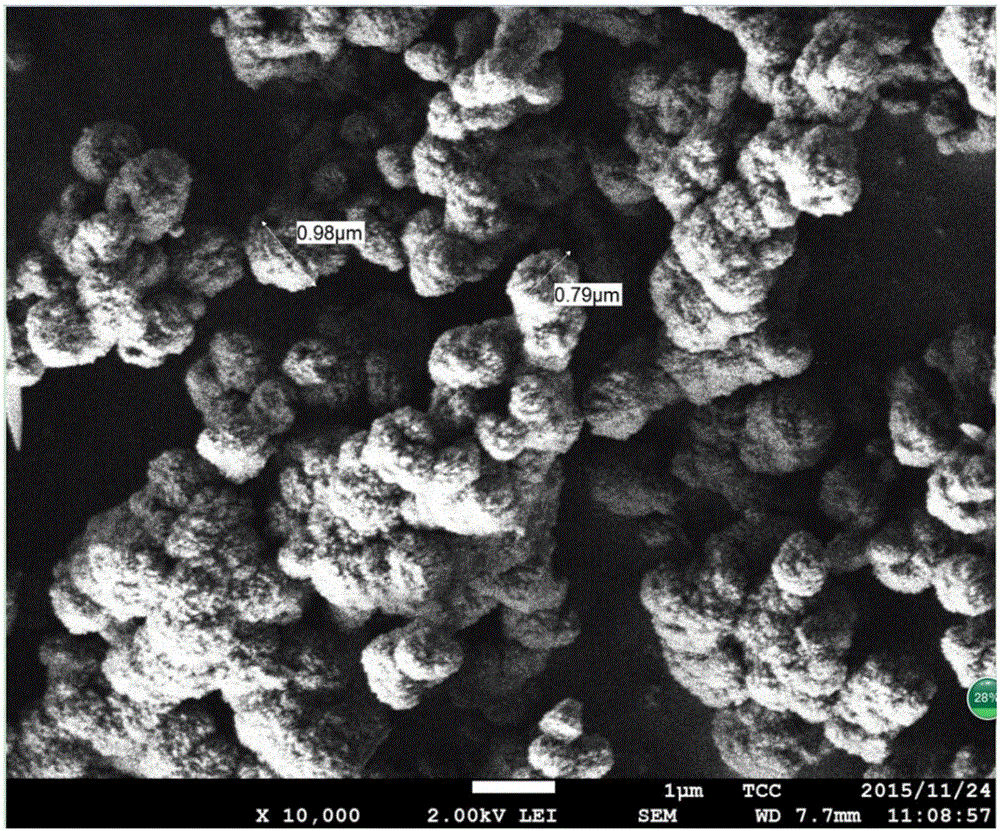

Process for preparing small crystal ZSM-5 zeolite

The preparation process of small crystal grain ZSM-5 zeolite includes the following steps: mixing alumino sillica gel grain in SiO2 / Al2O3 molar ratio of 20-600 and granularity of 20-300 mesh and water solution of organic template agent, and hydrothermal crystallization of the mixture with or without ZSM-5 zeolite crystal seed; and once filtering, drying and roasting. The said process can preparing ZSM-5 zeolite product with Si / Al molar ratio of 15-200 and initial crystal granularity of 0.1-0.5 micron. The process uses no sodium ion material, needs no ammonium exchange, filtering and roasting process, and thus has high zeolite product yield and simplified production process. The zeolite product is used in the catalyst for hydrolyzing cyclohexene to prepare cyclohexanol and has high cyclohexanol converting rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

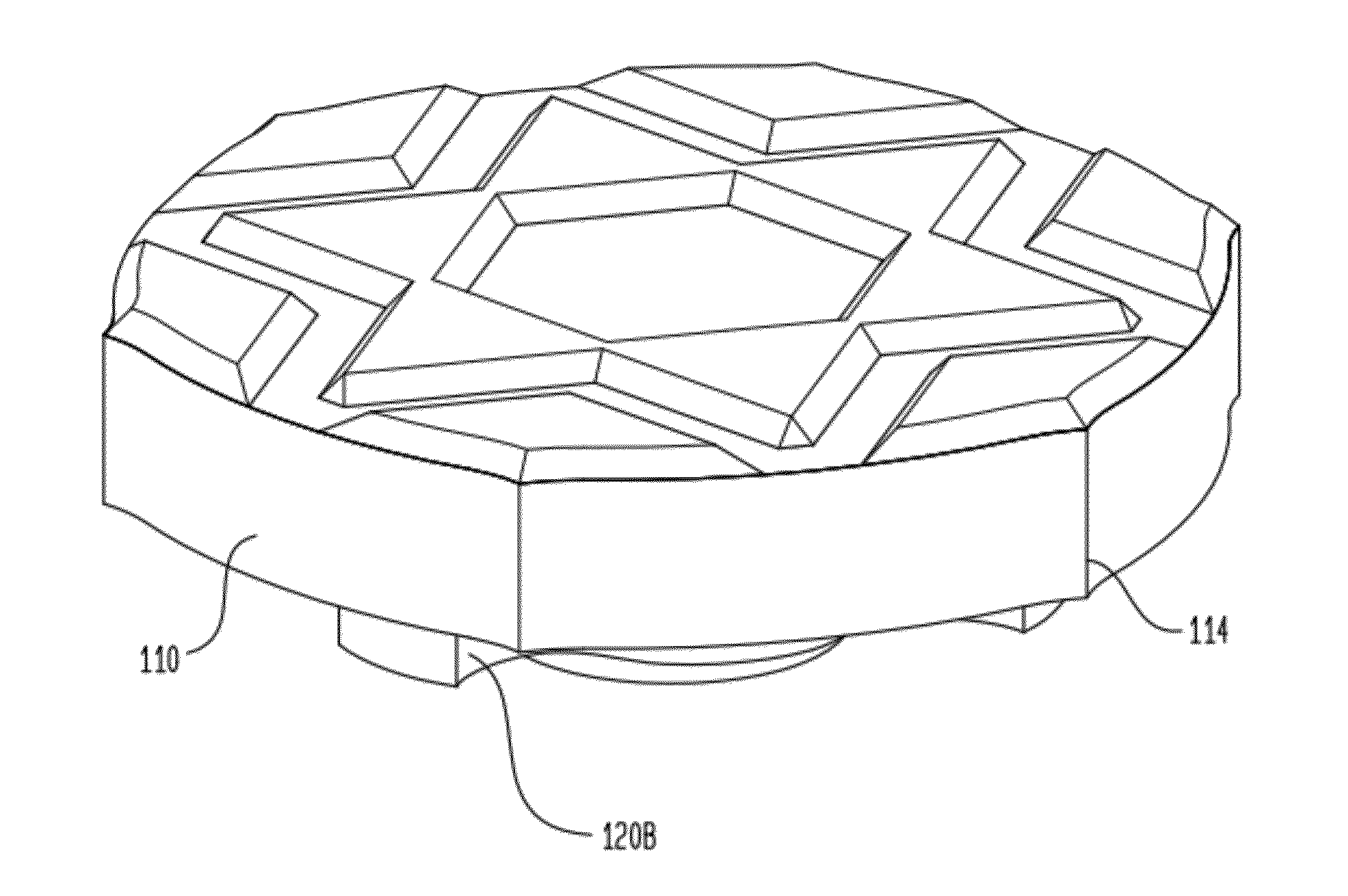

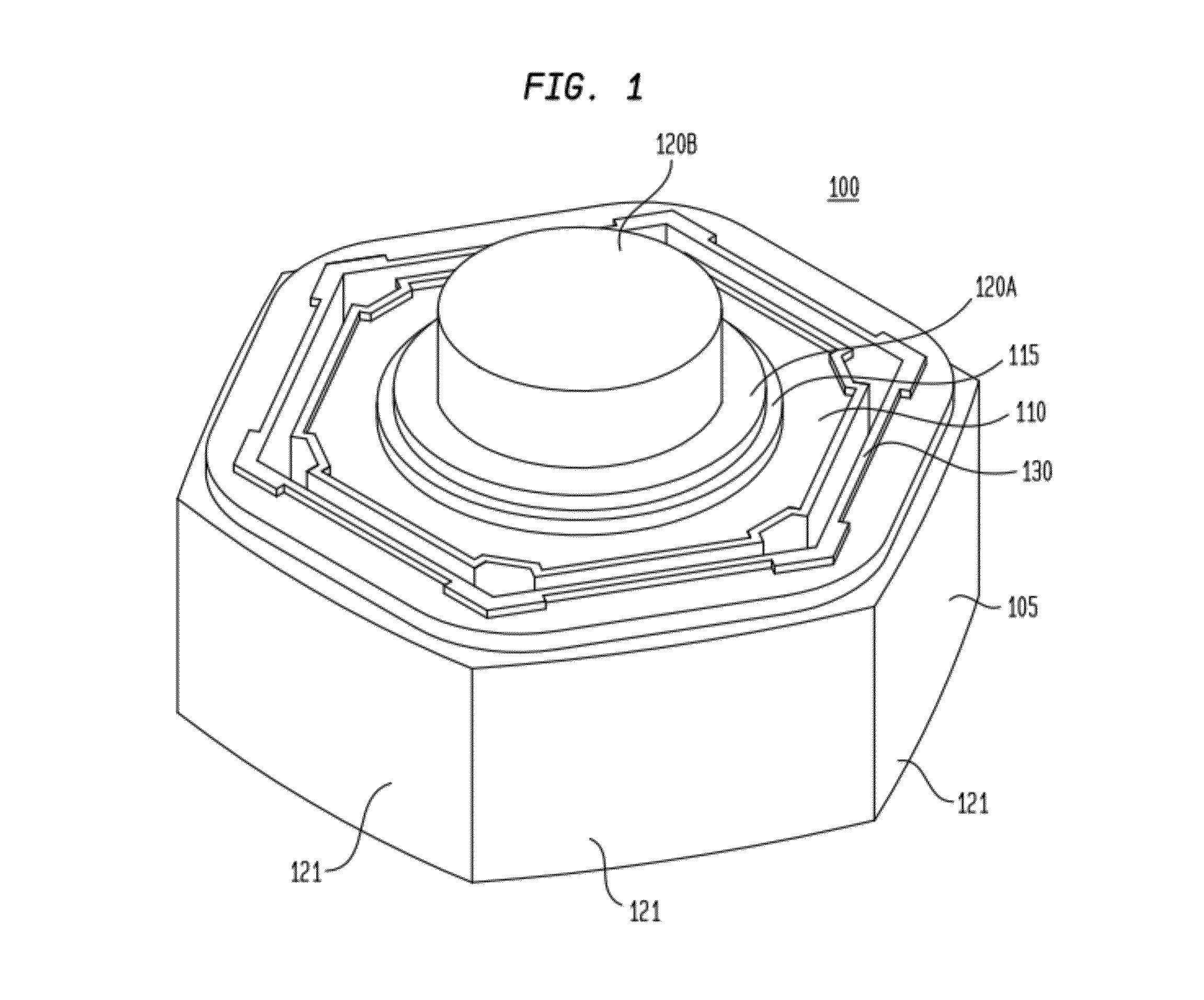

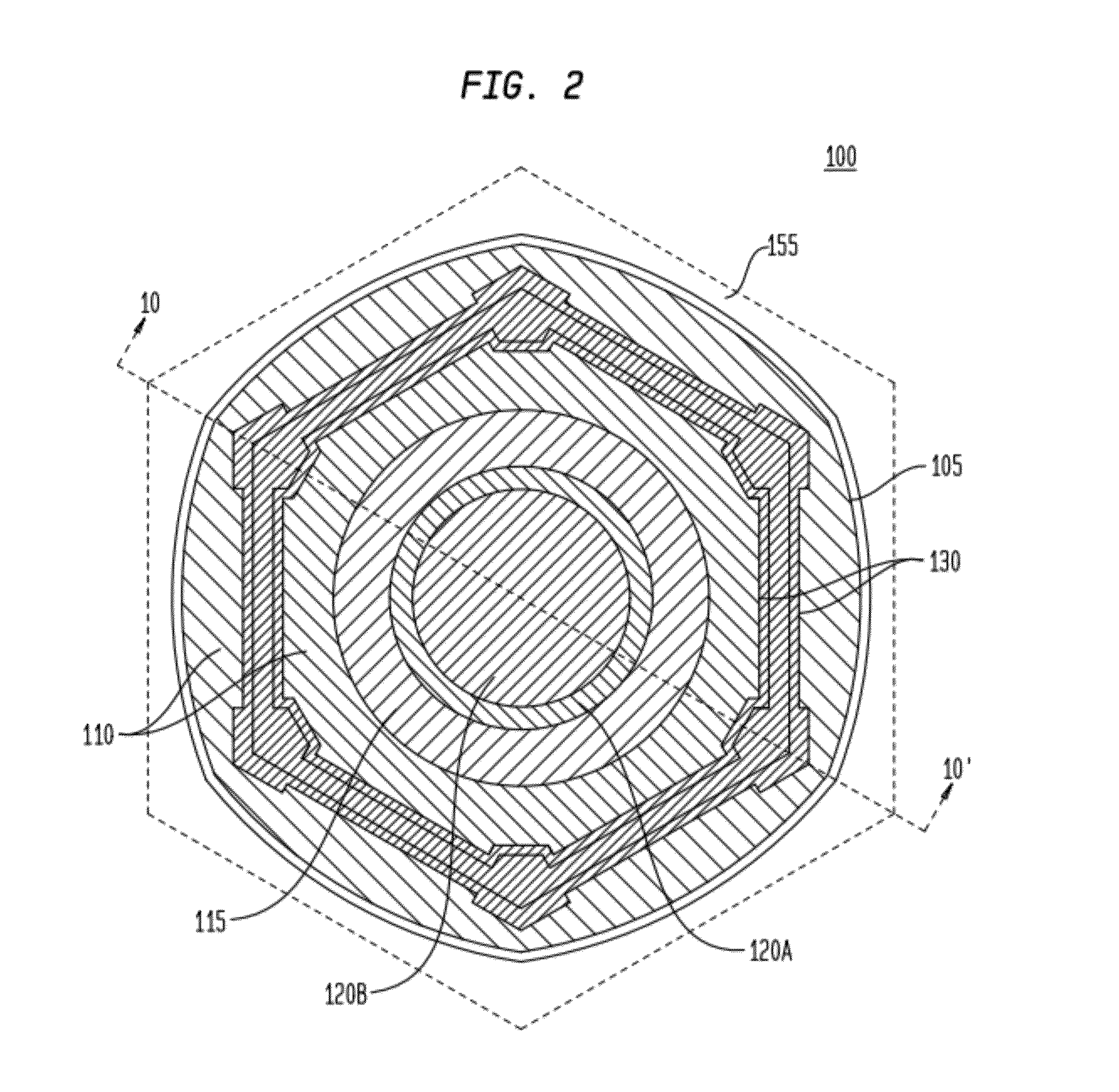

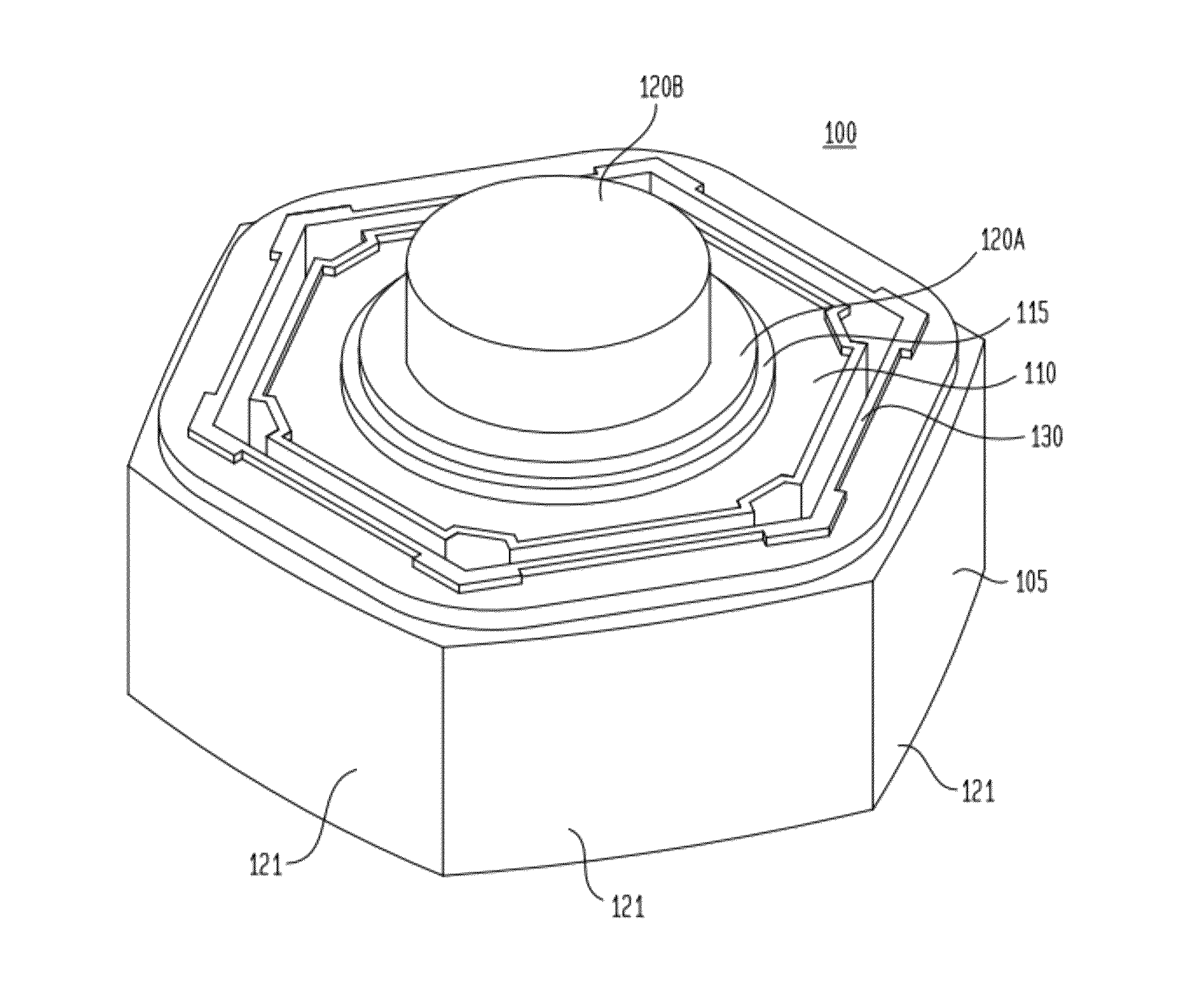

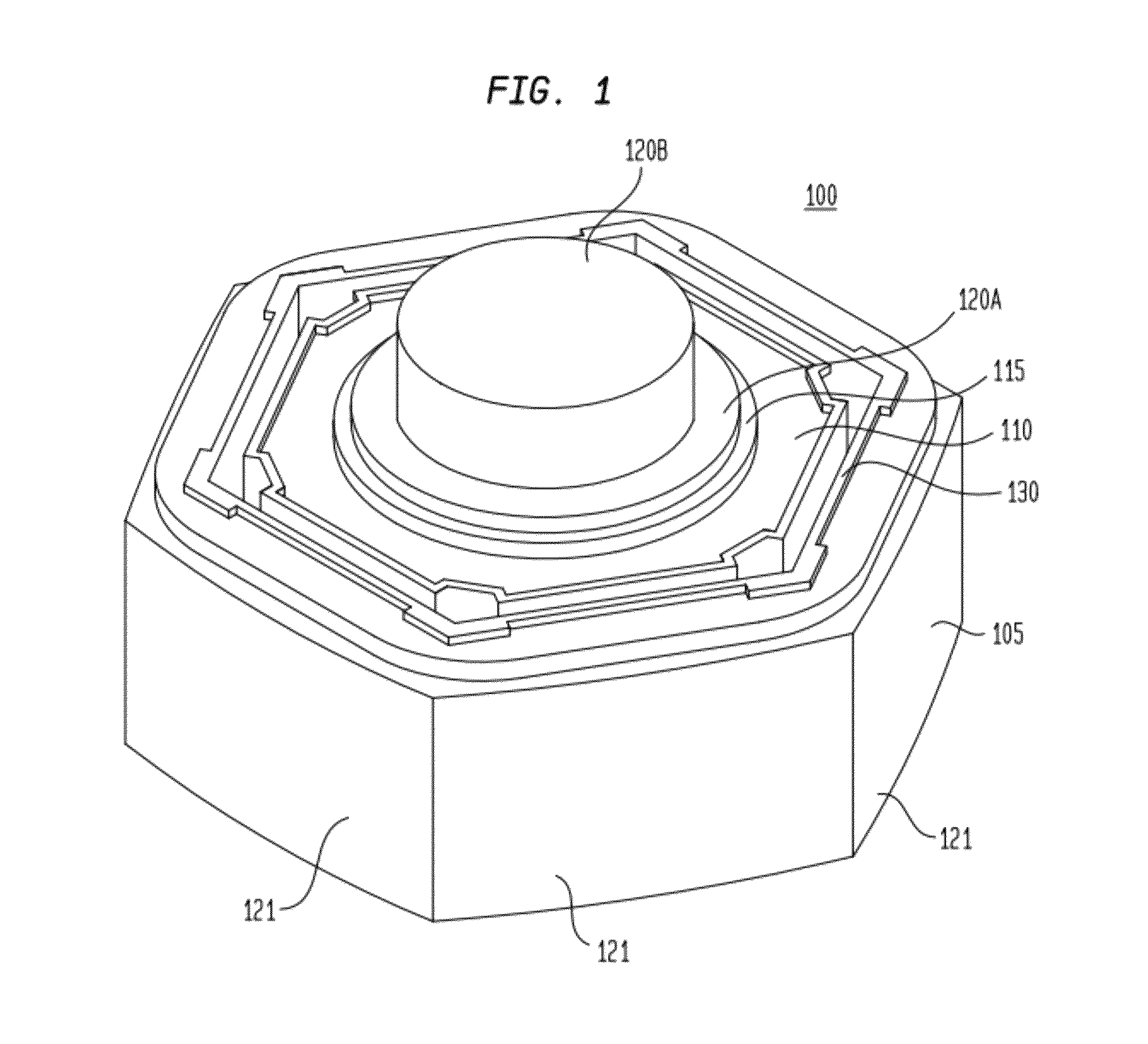

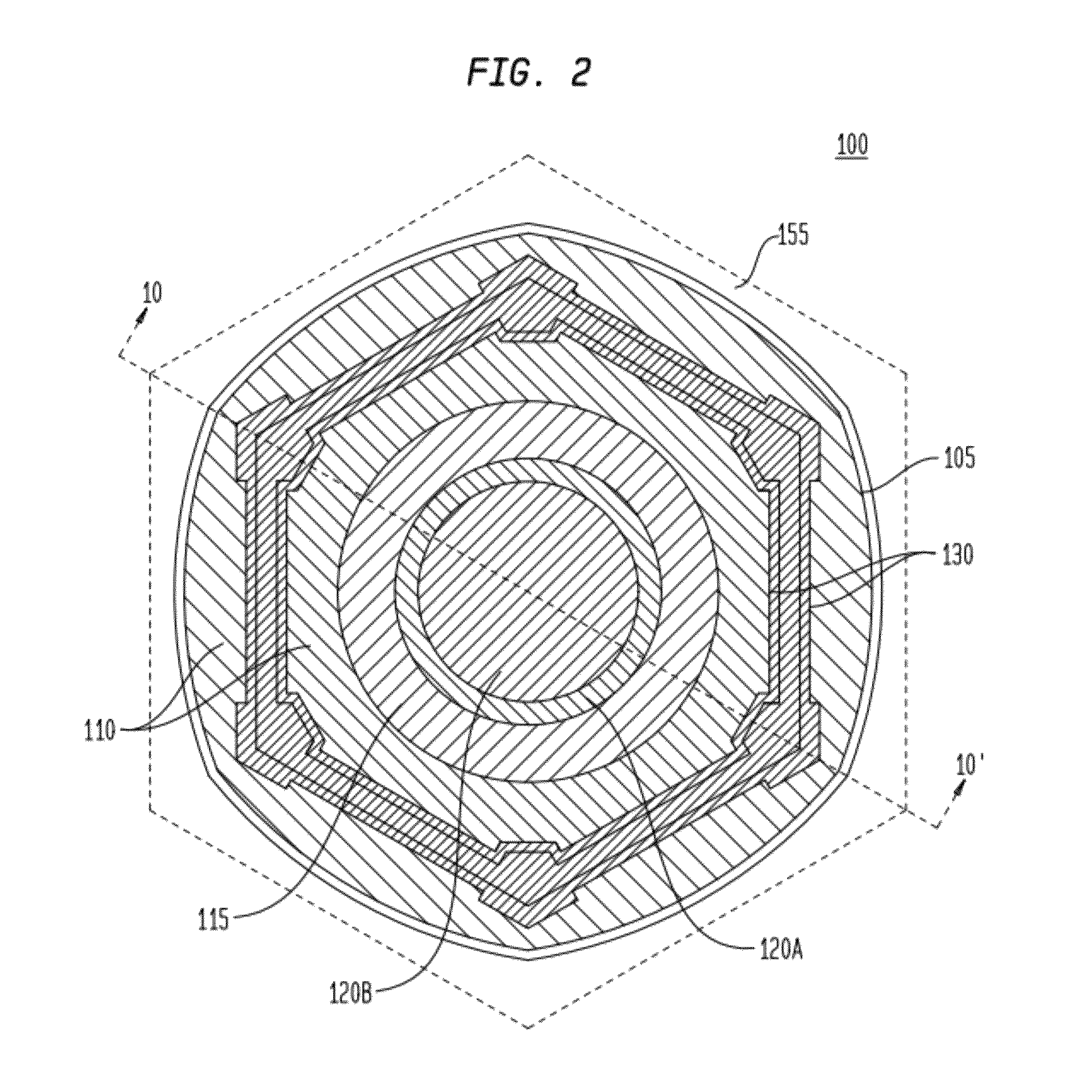

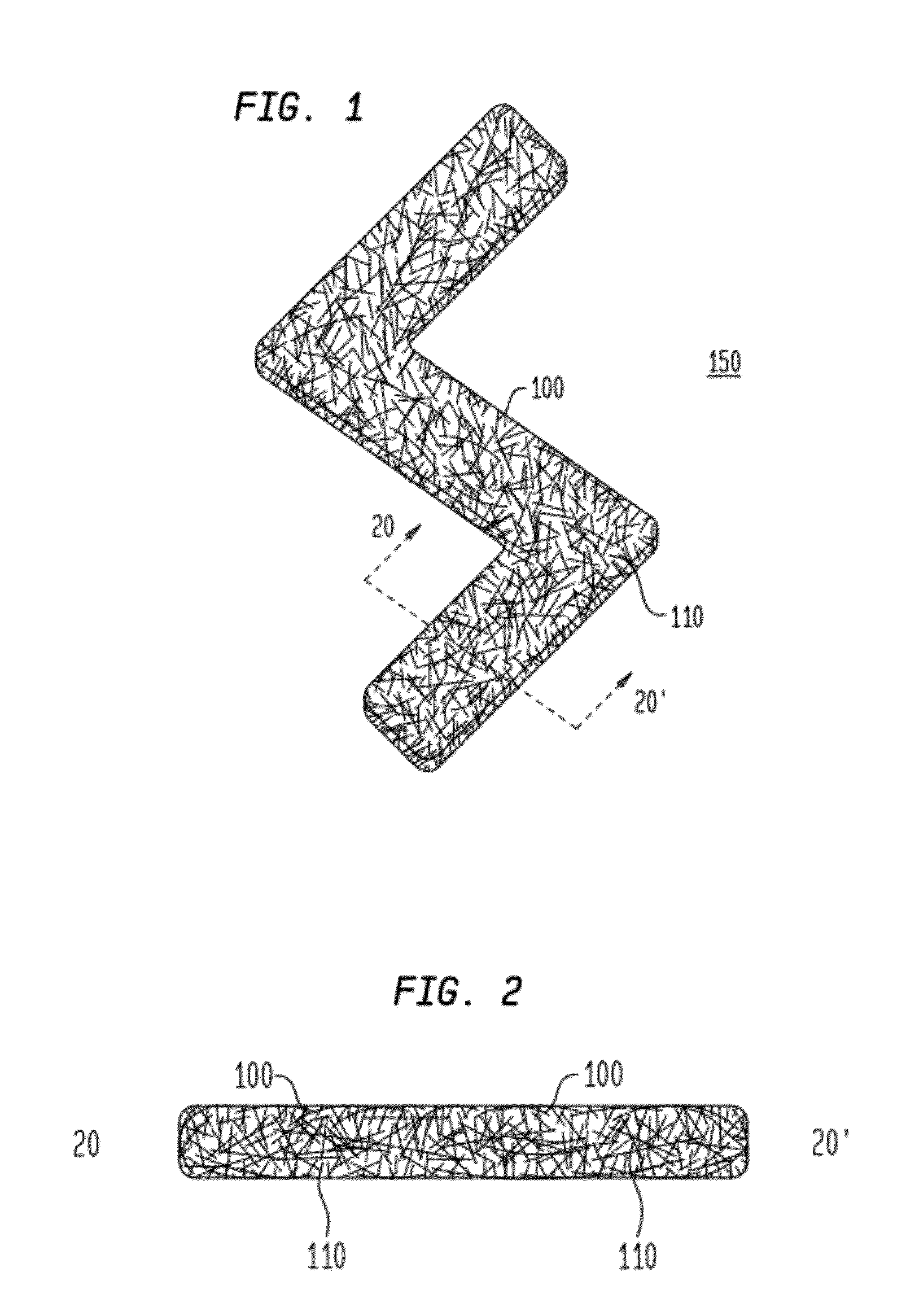

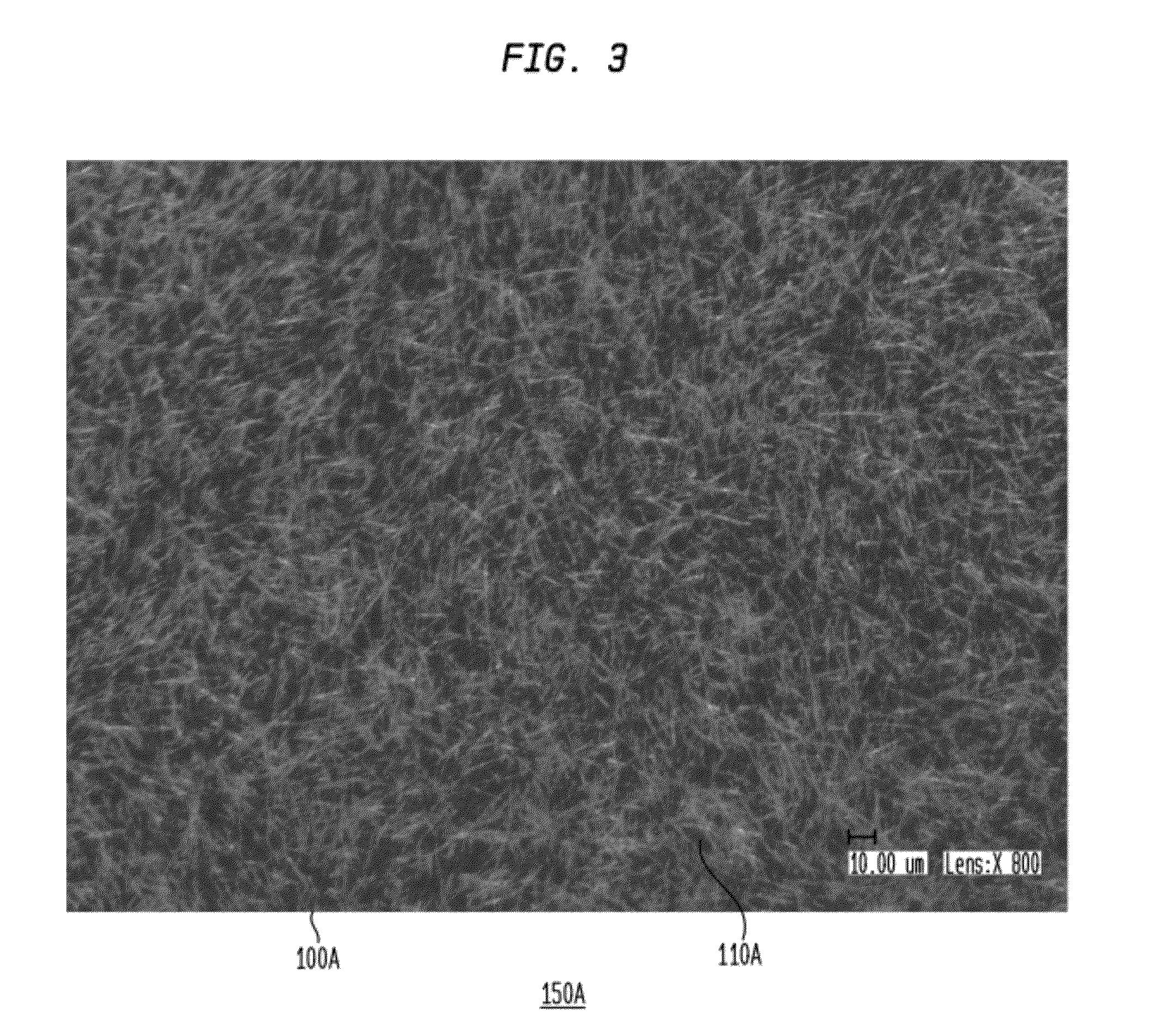

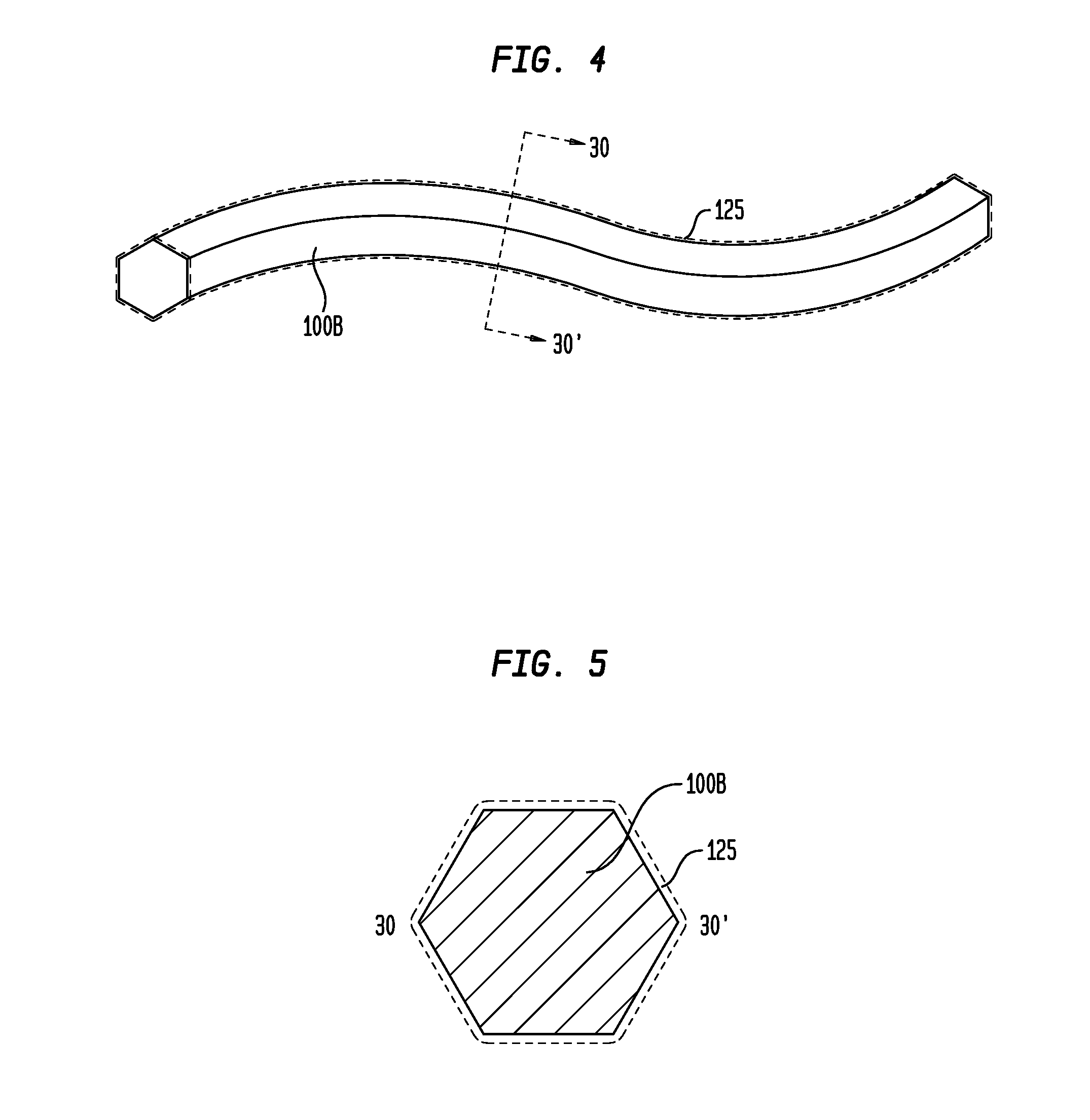

Printable Composition of a Liquid or Gel Suspension of Diodes

ActiveUS20120161195A1Solid-state devicesSemiconductor/solid-state device manufacturingOctanolSolvent

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. In other exemplary embodiments a second solvent is also included, and the composition has a viscosity substantially between about 100 cps and about 25,000 cps at about 25° C. In an exemplary embodiment, a composition comprises: a plurality of diodes or other two-terminal integrated circuits; one or more solvents comprising about 15% to 99.9% of any of N-propanol, isopropanol, dipropylene glycol, diethylene glycol, propylene glycol, 1-methoxy-2-propanol, N-octanol, ethanol, tetrahydrofurfuryl alcohol, cyclohexanol, and mixtures thereof; a viscosity modifier comprising about 0.10% to 2.5% methoxy propyl methylcellulose resin or hydroxy propyl methylcellulose resin or mixtures thereof; and about 0.01% to 2.5% of a plurality of substantially optically transparent and chemically inert particles having a range of sizes between about 10 to about 50 microns.

Owner:NTHDEGREE TECH WORLDWIDE

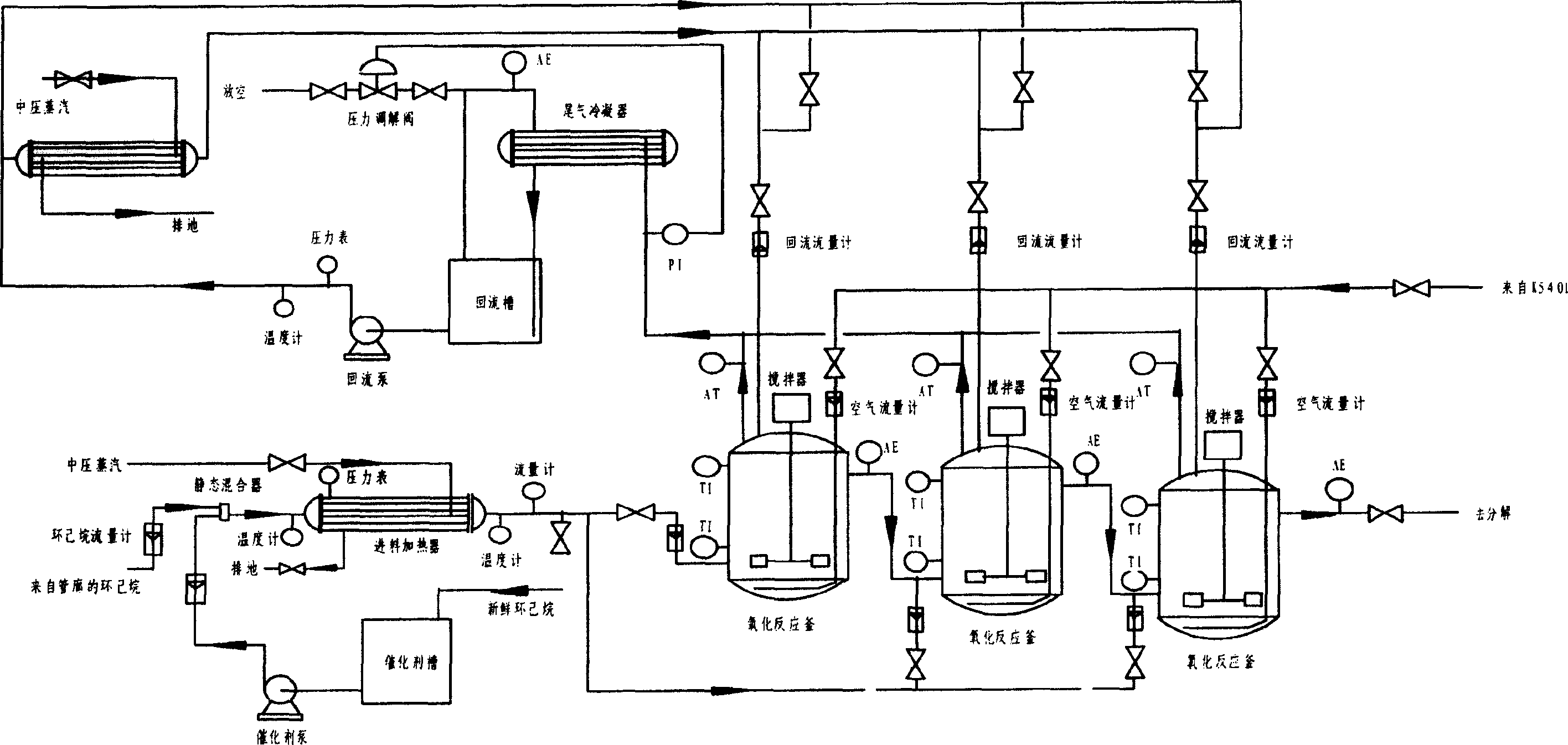

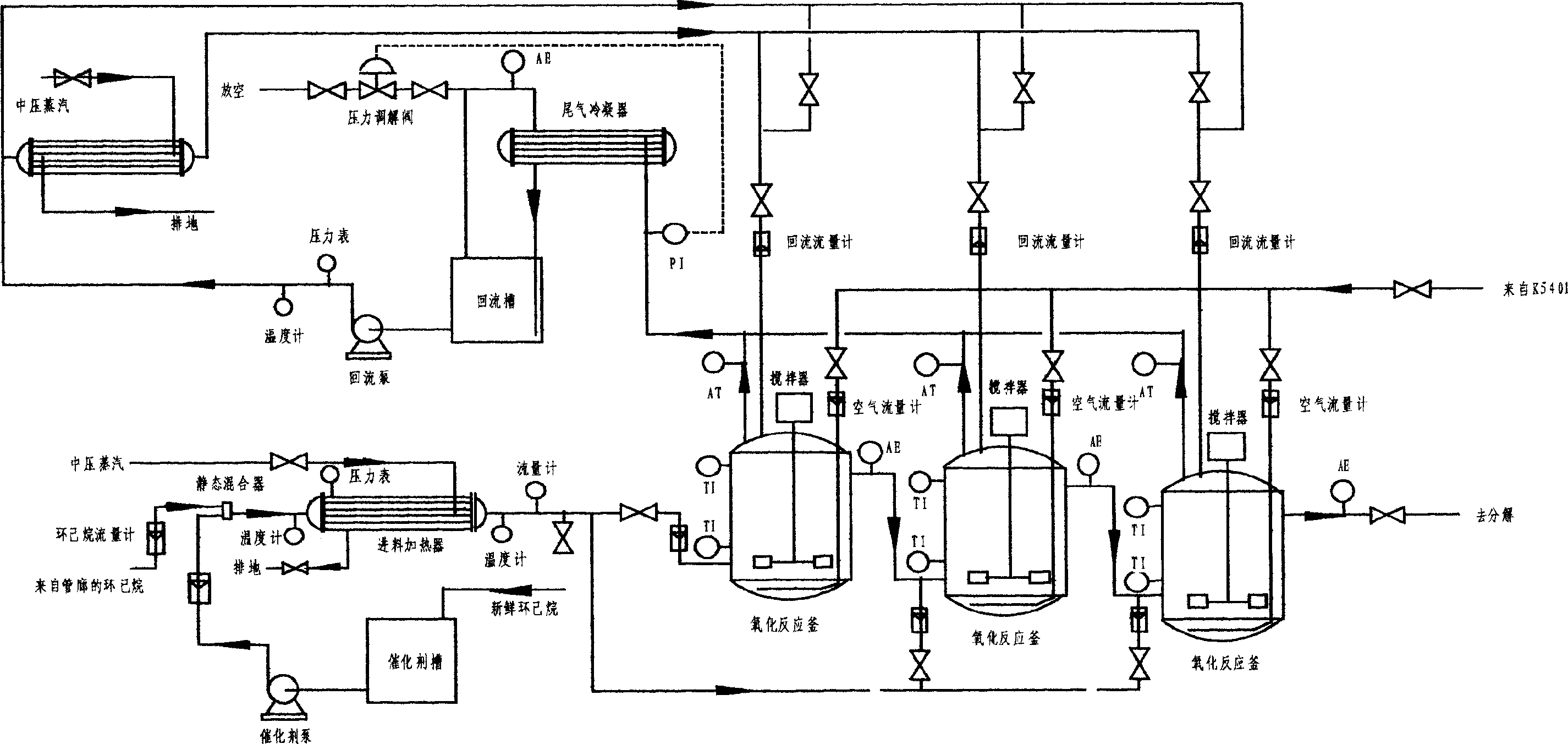

Process and equipment for preparing adipic acid by catalyzing air and oxidizing cyclohexane

InactiveCN101337879AImprove conversion rateHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCyclohexanoneBoiling point

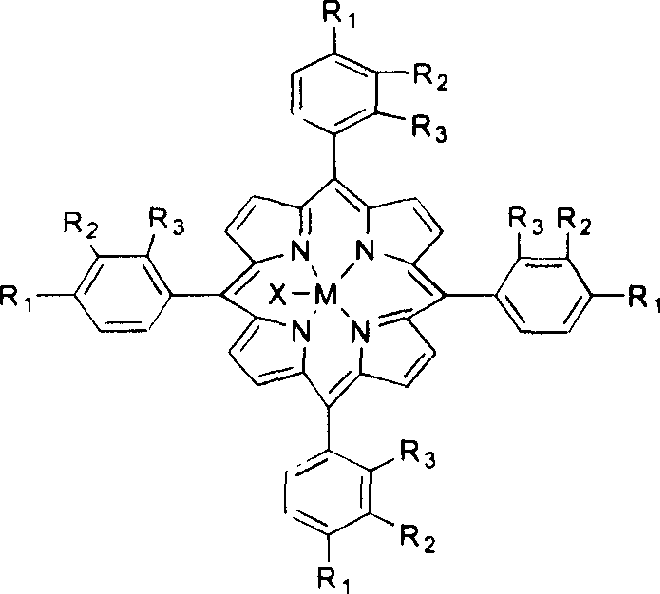

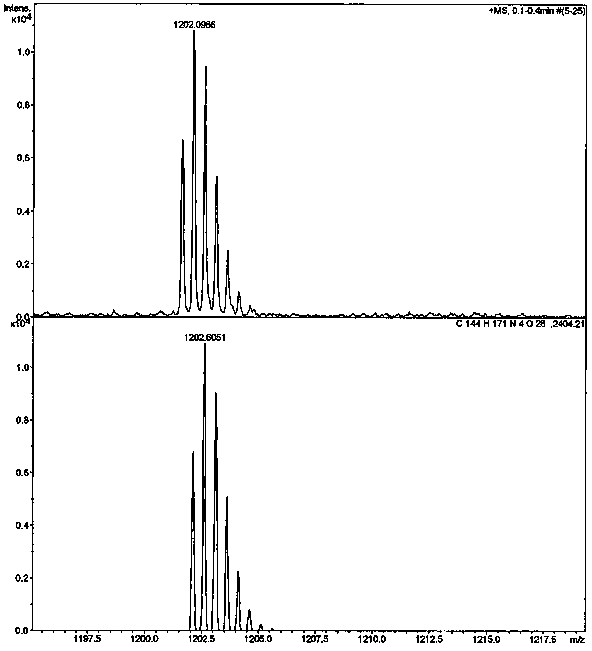

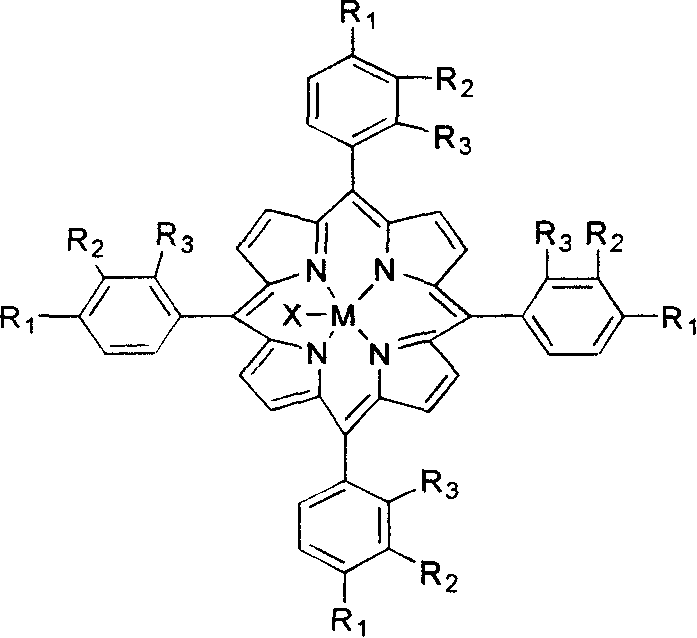

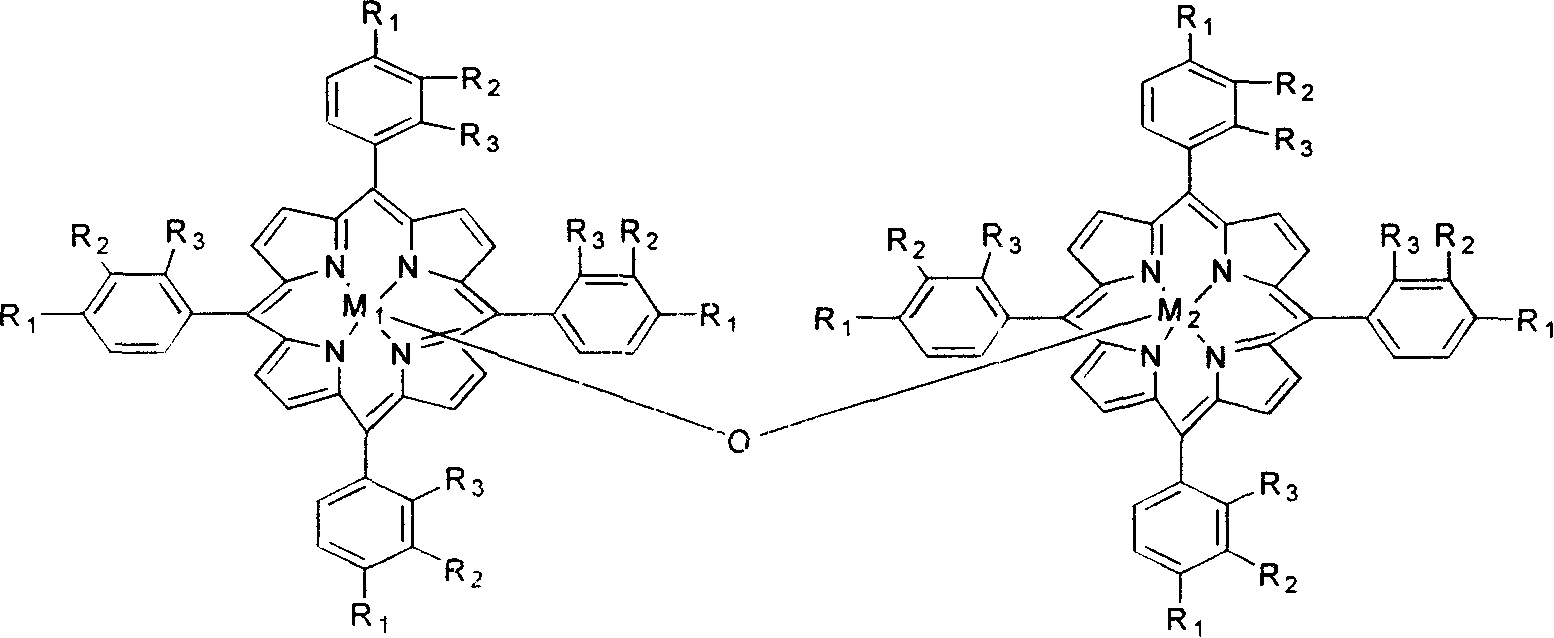

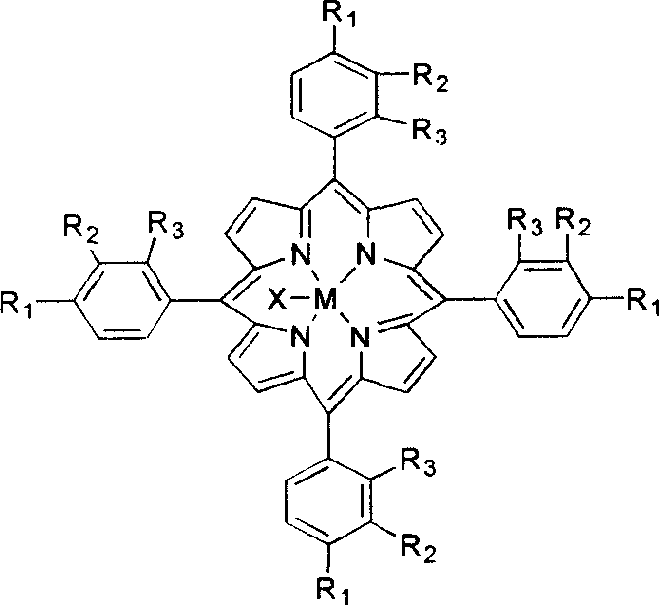

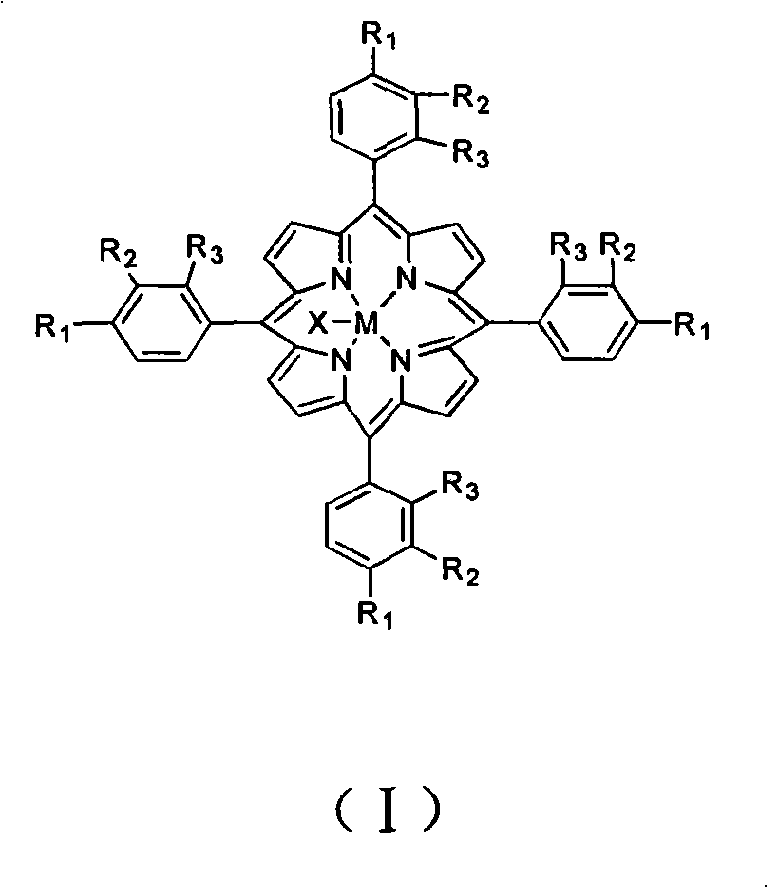

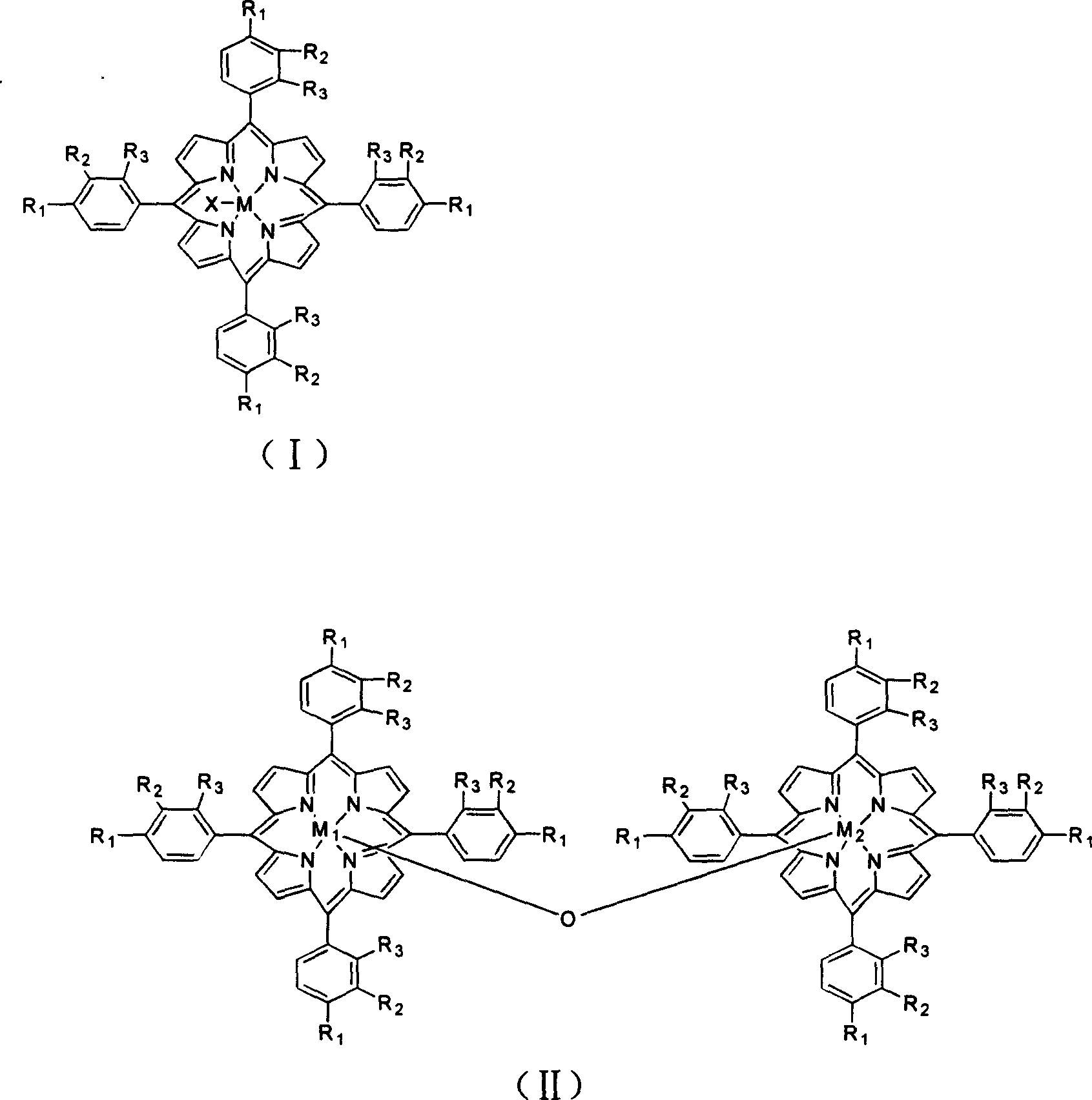

The invention discloses a process and a plant for preparing adipic acid by catalytically aerobically oxidizing cyclohexane. The process comprises the following steps: dissolving 1 to 50 PPM of a catalyst including single metalloporphyrin or mu-oxo bimetallic porphyrin or a mixture of single metalloporphyrin, mu-oxo bimetallic porphyrin and transition metal salt or oxide in cyclohexane; introducing 5 to 12 atm of air or oxygen-rich or oxygen-poor air into a multi-stage oxidation reactor with a gas distributor; controlling the reaction temperature at 140 to 160 DEG C; oxidizing cyclohexane for 45 to 120 min; feeding the mixture of the oxidation reaction into a flash separator to carry out flash evaporation at the temperature of 78 to 155 DEG C and under the pressure of 0.1 to 1.0 atm, so that the low-boiling-point products such as cyclohexane, cyclohexanol and cyclohexanone change to gas and are separated from adipic acid with the content above 80%; continuously circularly oxidizing the low-boiling-point products to separate and purify the high-boiling-point oxidation product; and purifying and separating by the existing technique to obtain fine adipic acid product. The process can directly prepare adipic acid by aerobically oxidizing cyclohexane, wherein the conversion rate of cyclohexane is up to 95%, and the yield of adipic acid is up to 70%.

Owner:HUNAN UNIV

Printable composition of a liquid or gel suspension of diodes

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. In other exemplary embodiments a second solvent is also included, and the composition has a viscosity substantially between about 100 cps and about 25,000 cps at about 25° C. In an exemplary embodiment, a composition comprises: a plurality of diodes or other two-terminal integrated circuits; one or more solvents comprising about 15% to 99.9% of any of N-propanol, isopropanol, dipropylene glycol, diethylene glycol, propylene glycol, 1-methoxy-2-propanol, N-octanol, ethanol, tetrahydrofurfuryl alcohol, cyclohexanol, and mixtures thereof; a viscosity modifier comprising about 0.10% to 2.5% methoxy propyl methylcellulose resin or hydroxy propyl methylcellulose resin or mixtures thereof; and about 0.01% to 2.5% of a plurality of substantially optically transparent and chemically inert particles having a range of sizes between about 10 to about 50 microns.

Owner:NTHDEGREE TECH WORLDWIDE

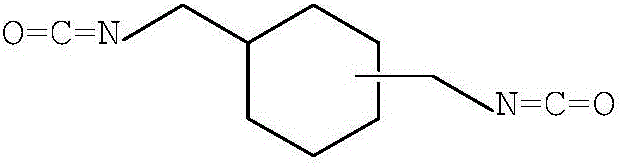

Preparation method of hydrogenated xylylene diisocynate

ActiveCN106674056AGood dispersionImprove liquidityOrganic compound preparationIsocyanic acid derivatives purification/separationXylyleneN dimethylformamide

The invention discloses a preparation method of hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate comprises the following steps: (1) performing salt forming reaction on 1,3-cyclohexanol dimethylamine and concentrated hydrochloric acid in a two-phase reaction solvent to obtain amine salt, wherein the two-phase reaction solvent consists of water and an inert organic solvent insoluble in water ; (2) performing photochemical reaction on the ammonium salt obtained in the step (1) and phosgene in an inert solvent by taking N,N-dimethylformamide or N,N-dimethylacetamide as a catalyst to obtain reaction liquid, and performing aftertreatment on the reaction liquid to obtain the hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate has the advantages of complete ammonium salt formation, small grain size of the ammonium salt, low viscosity of the ammonium salt, high space-time conversion rate of photochemical reaction, simple process, low cost and the like.

Owner:HUNAN HAILI CHEM IND

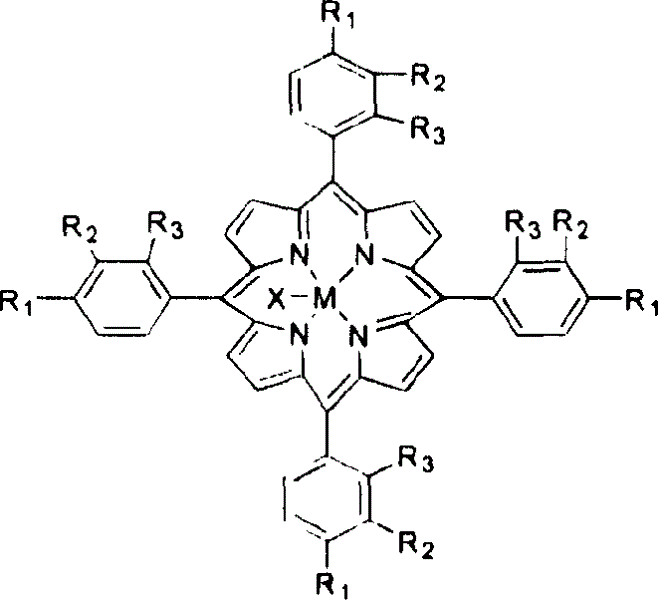

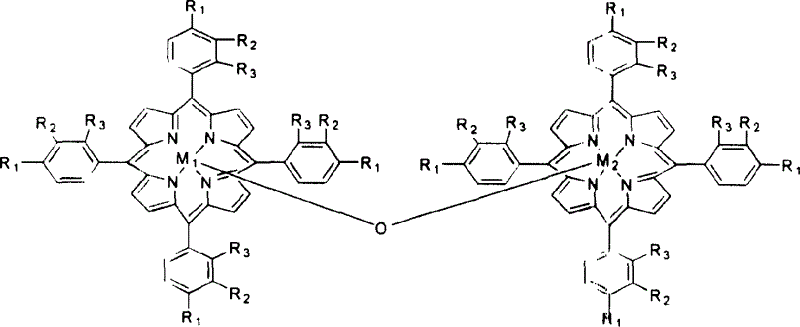

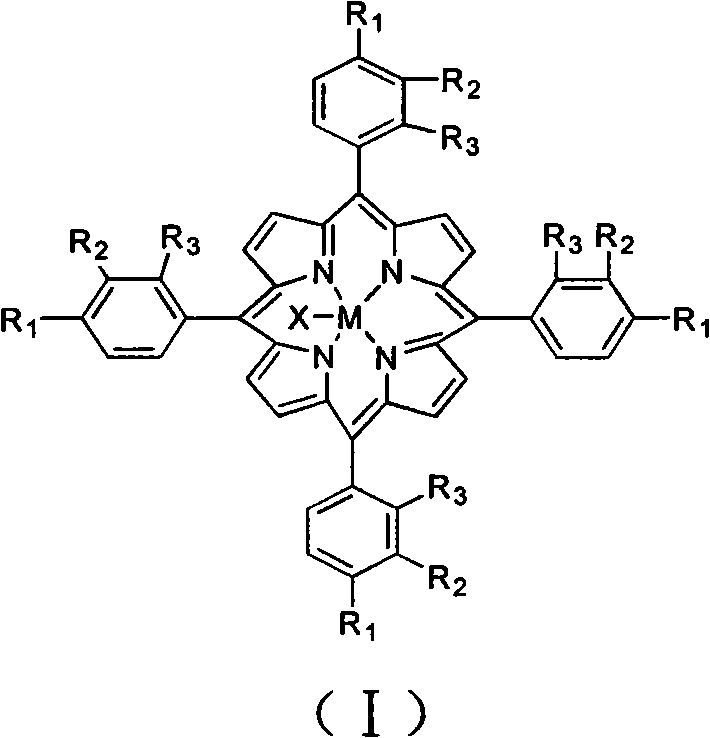

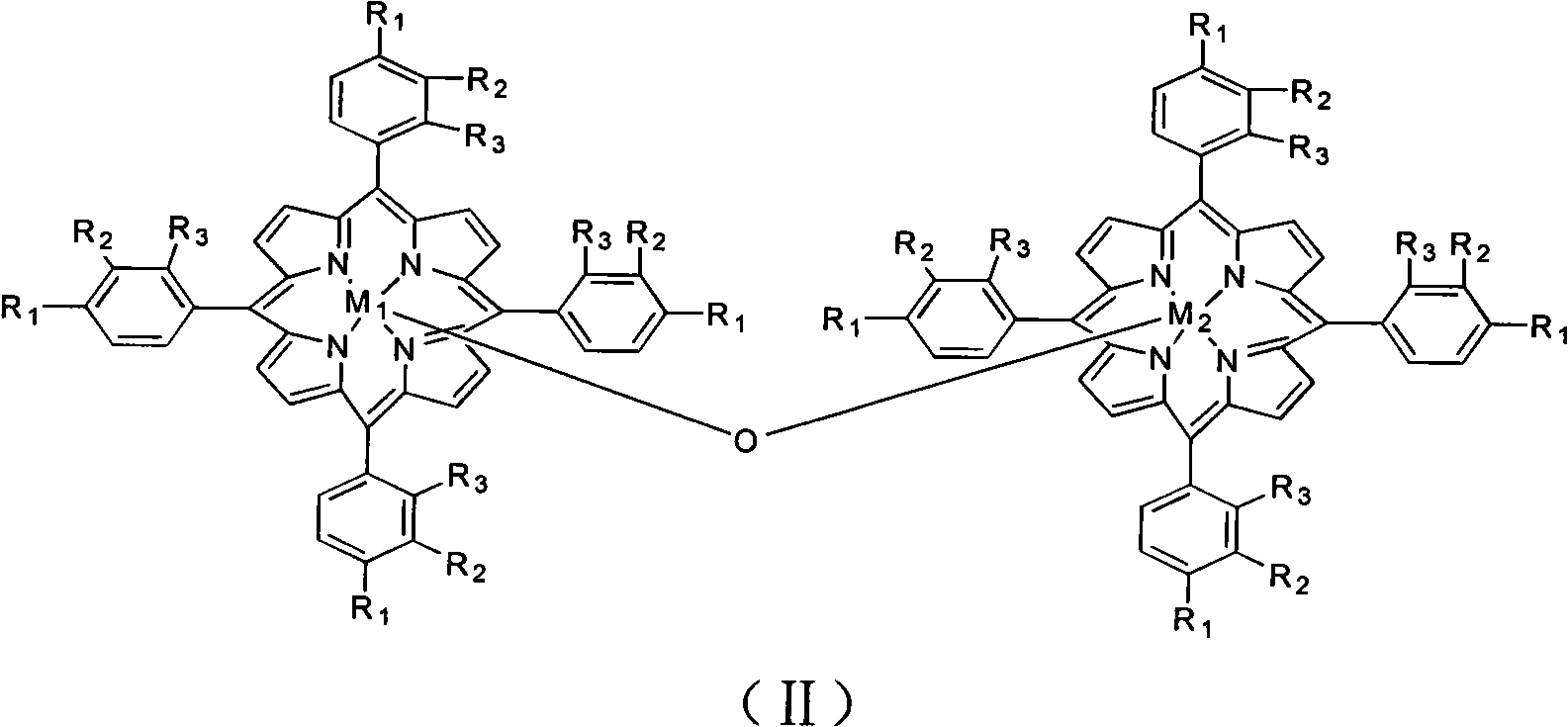

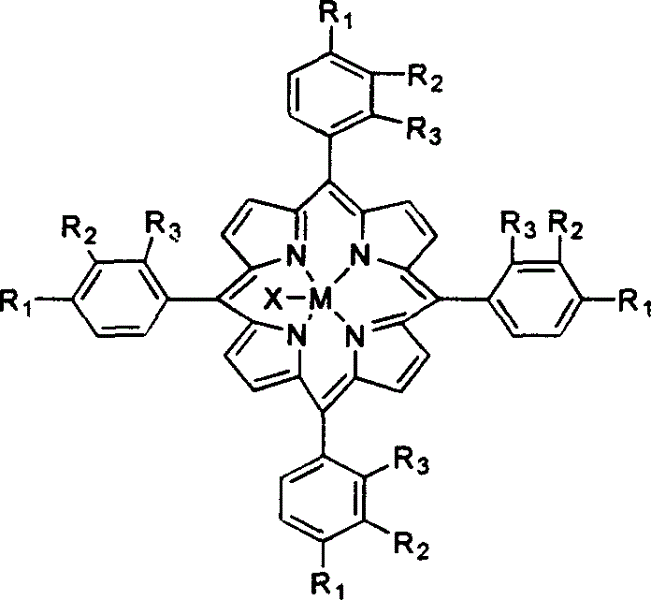

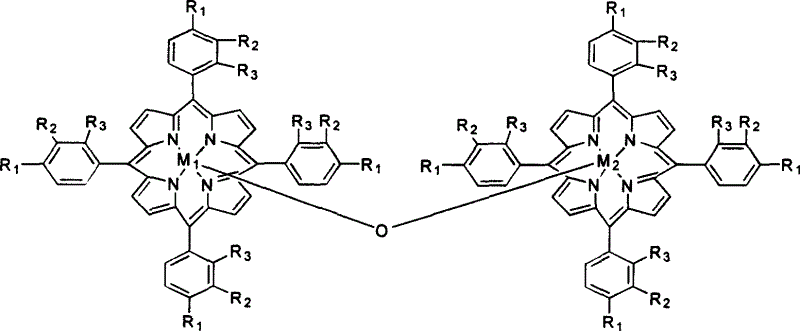

Method for atmospheric catalytic oxidation of cyclohexane by metalloporphyrin

InactiveCN1405131APreparation by oxidation reactionsOxygen compounds preparation by hydrocarbon oxidationCyclohexanoneReaction temperature

The invention relates to a new process in which under the catalytic action of metal porphyrin the cyclohexane can be selectively oxdated by air and made into cyclohexanol and cyclohexanone. Under the condition of 2-10 atm air, reaction temp. is 125-150 deg.C, it selects and uses micro-oxo double metal porphyrin and single metal porphyrin or their solid carrier as main catalyst, and uses transition metal salt or oxide as co-catalyst, the metal porphyrin can high-effectively and high-selectively catalyze oxidation of cyclohexane by using air in the biological concentratino as biological enzyme. The dose of metal porphyrin is small and said metal porphyrin can be repeatedly used, and said catalyst dose also is small, its catalystic effect is good, said catalyst can be used for making homogeneous catalysis, and after it is solid-carried, it also can be used for making heterogeneous catalysis.

Owner:HUNAN UNIV

Catalyst oxdie cyclohexane process

ActiveCN1530358AIncrease conversion rate per passImprove one-way yieldOxygen compounds preparation by hydrocarbon oxidationCyclohexanonePorphyrin

A process for preparing cyclohexanol, cyclohexanone and adipic acid by catalytic oxidization of cyclohexane under existance of metallic porphyrin catalyst and a certain temp and pressure through combination of different reactors is disclosed. Its advantages are high single-pass conversion rate of cyclohexane and total output rate, low energy consumption and cost, and no need of cyclohexanol or acetone solvent and cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP

Method of preparing adipic acid by air-oxidating hexacarbocyclic compound

InactiveCN1535947AReduce dosageHigh catalytic efficiencyOrganic compound preparationCarboxylic compound preparationCyclohexanoneCyclohexene

The present invention relates to a new process for preparing adipic acid by air oxidating cyclohexane, cyclohexanol, cyclohexanone and cyclohexene or mixture of cyclohexanol and cyclohexanone under the catalysis of metal porphyrin. Under the condition of 1-20 atm air and reaction temp. is 50-200 deg.C it can select and use mu-oxidized metal porphyrin and monometal porphyrin or their fixed carrier material as catalyst independently, also can select and use metal porphyrin or their fixed carrier material as main catalyst, and use transition metal salt or oxide as co-catalyst. The metal porphyrin like biological-enzyme can high-effectively and high-selectivity catalyze air under the biologicae concentration to directly oxidate the cyclohexane into adipic acid. Said invented dose of metal porphyrin is less, and its catalytic effect is good, it can make homogeneous catalysis, also can make heterogeneous catalysis after the carrier is fixed.

Owner:HUNAN UNIV

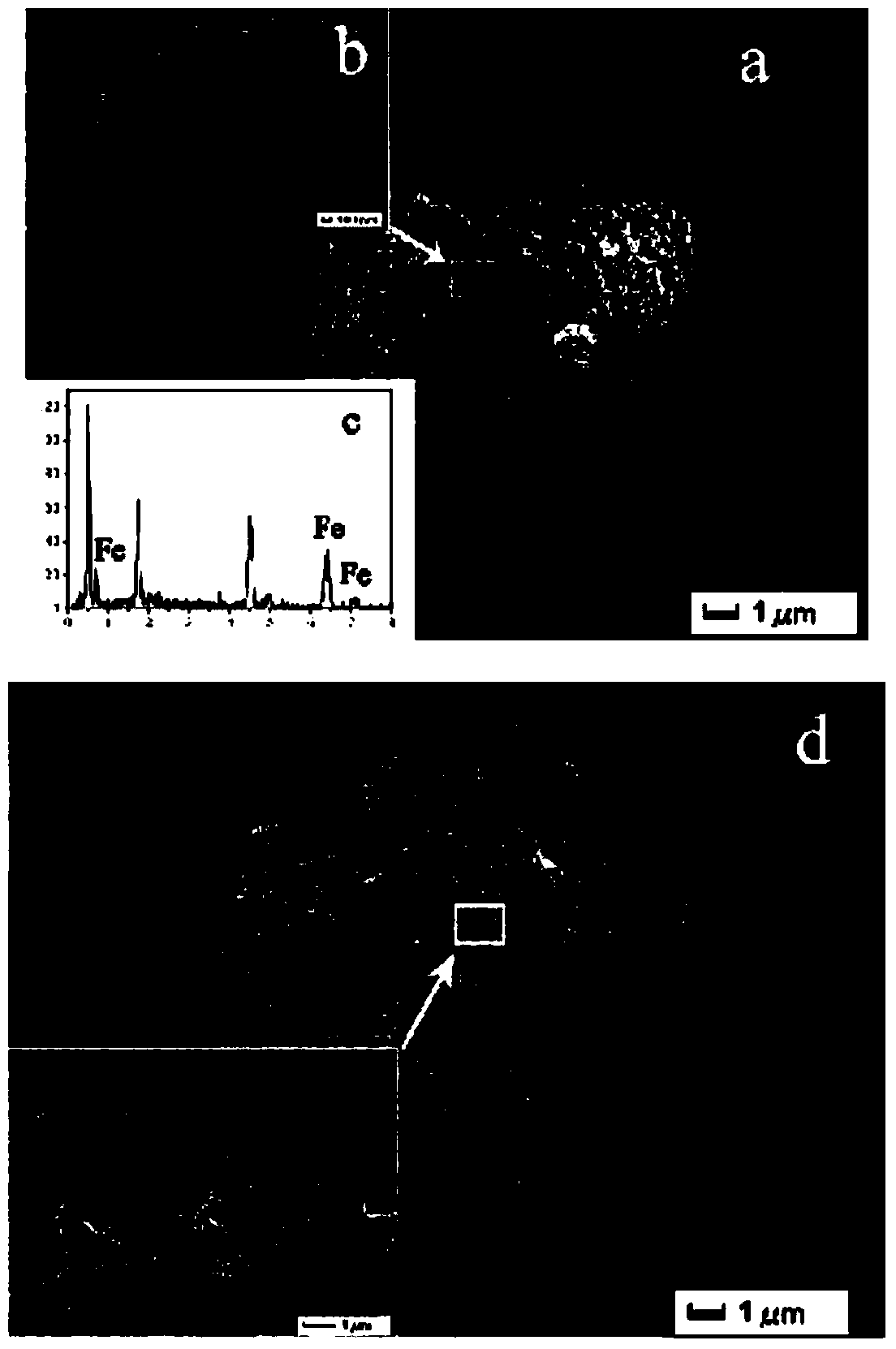

Supported nano Au catalyst and method for preparing the same

InactiveCN1827213AEvenly dispersedEasy to adjust particle sizeCatalyst carriersOxygen compounds preparation by hydrocarbon oxidationActive componentGold particles

The invention discloses a carrier nanometer gold catalyst gold catalyst and relative preparing method. Said invention is formed by Au, Al, and Ti / Si, Ag, Cu, Ce, Fe, or Zn. Wherein, Au is the main active component of catalyst, whose mass percentage is 0.1-4.0%; Al is the carrier of catalyst, whose mass percentage is larger than 90%; Ti or Si is the agent of catalyst carrier, whose mass percentage is 0.01-1.0%; Ag, Cu, Ce, Fe, or Zn is used as the auxiliary active component of catalyst, whose mass percentage is 0.1-5.0%. The invention has the advantages that: the gold is distributed uniformly, and the graininess of attained gold particle can be adjusted easily; the catalyst has high stability; and it can apply the oxide carrier for carrying gold whose isoelectric point pH is less than 6 and made by coprecipitation method. The invention has be used to apply the cyclohexane to prepare the nadone and cyclohexanol, with better activity and selectivity, less used amount and recycle support.

Owner:ZHEJIANG UNIV

ZSM-5 structure zeolite, preparation and use thereof

InactiveCN1530322ATroubleshooting FiltrationImprove conversion rateMolecular sieve catalystsPentasil aluminosilicate zeoliteCyclohexeneSilicon oxide

A ZSM-5 zeolite with 15-200 for the mole ration of silicon oxide to aluminium oxide, 0.5-10 microns for diameter, and 25-250 sq.m / g for mesopore surface area is prepared from the large-grain zeolite through treating in alkaline aqueous solution, ammonium ion exchanging, drying, and calcining. Said zeolite can be used to prepare cyclohexanol from cyclohexene by hydrating with high conversion rate, easy separation from liquid phase and easy filter.

Owner:CHINA PETROLEUM & CHEM CORP +1

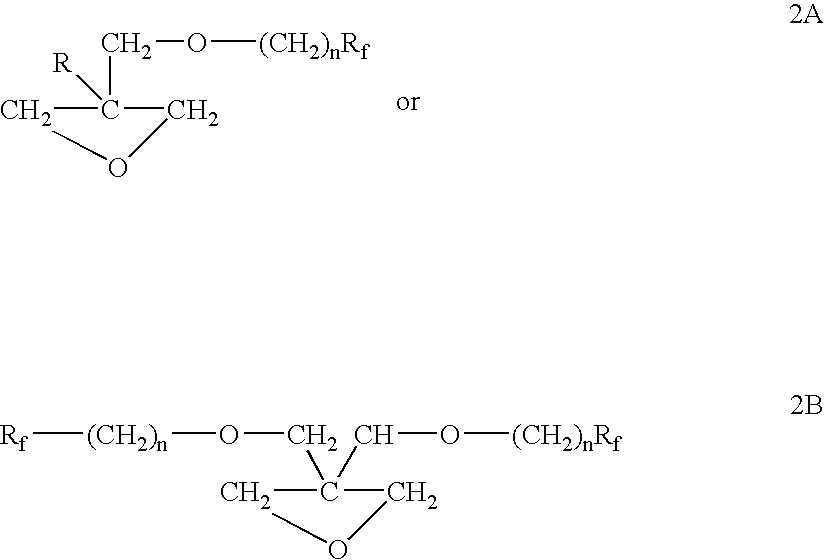

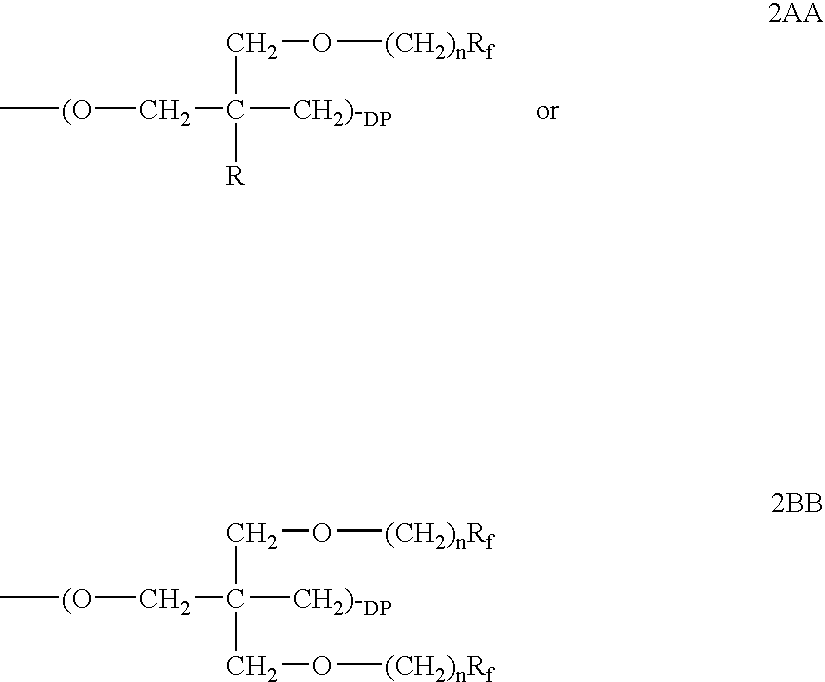

Polymeric surfactants derived from cyclic monomers having pendant fluorinated carbon groups

InactiveUS20040048957A1Good optical performanceHigh glossNon-fibrous pulp additionPaper/cardboardPolymeric surfaceCyclic ether

PURPOSE: To easily obtain the titled alcohol wherein one of both terminals is quantitatively capped, at a low cost, by polymerizing THF in the presence of an active hydrogen-containing compound using a Lewis acid and a cyclic ether as polymerization initiators. CONSTITUTION: A polyether monoalcohol is produced by polymerizing tetrahydrofuran in the presence of a compound containing one active hydrogen atom in one molecule using a Lewis acid and a 3-4-membered cyclic ether. The active hydrogen-containing compound is a compound having hydroxyl group, carboxyl group or thiol group, e.g. methanol, cyclohexanol, etc., and the ether is selected from epoxides or oxetanes.

Owner:OMNOVA SOLUTIONS INC

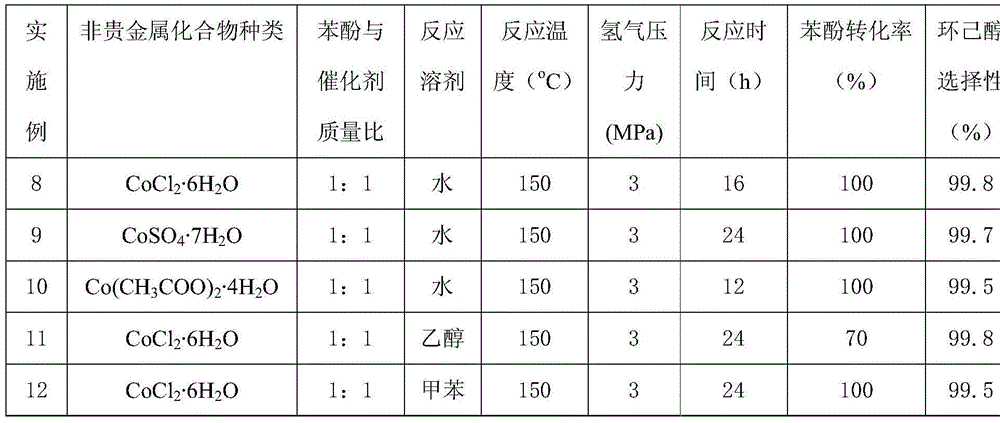

Method for preparing cyclohexanol by catalyzing by base metal catalyst

InactiveCN104447209AReduce use costLow costPreparation by hydrogenationHeterogenous catalyst chemical elementsFiltrationPorous carbon

The invention discloses a method for preparing cyclohexanol by catalyzing phenol hydrogenation by taking a porous carbon material loaded base metal as a catalyst. The synthetic route of the traditional two-step method comprises phenol hydrogenation and cyclohexanol dehydrogenation, and the catalysis of phenol hydrogenation in preparing cyclohexanol is mainly completed through metals, namely nanometer noble metal Pd, Ni radical and the like which have higher activated cracked hydrogen molecules. The method is characterized in that cyclohexanol is prepared in the presence of a solvent by using the porous carbon material loaded base metal as the catalyst, taking phenol or a phenol derivative as a raw material and catalyzing hydrogenation; a general formula of the catalyst is aM@CXy, wherein a indicates the weight percentage content of the metals contained in the catalyst, M indicates the base metal, C indicates carbon, X indicates a doped mixed element, and y indicates the weight percentage content of the mixed element. The method disclosed by the invention can be used for reducing the usage cost of the catalyst by recovering the catalyst by adopting a simple filtering method, and can obtain cyclohexanol by directly concentrating filter liquor obtained through filtration.

Owner:ZHEJIANG UNIV +1

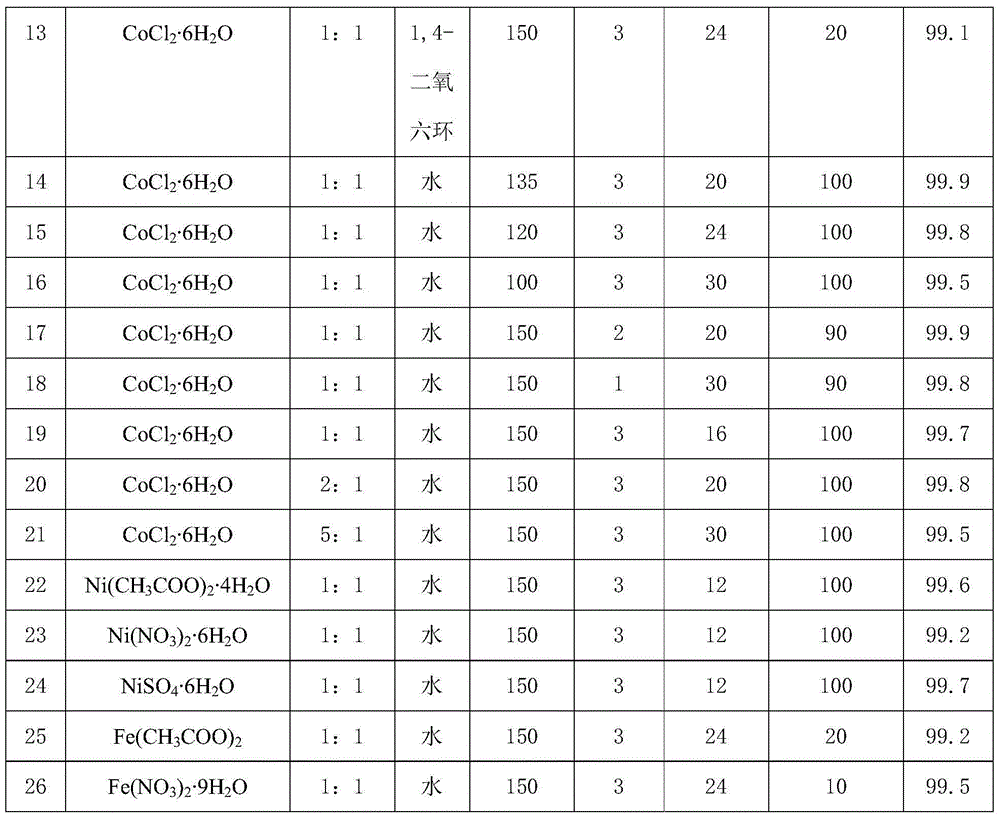

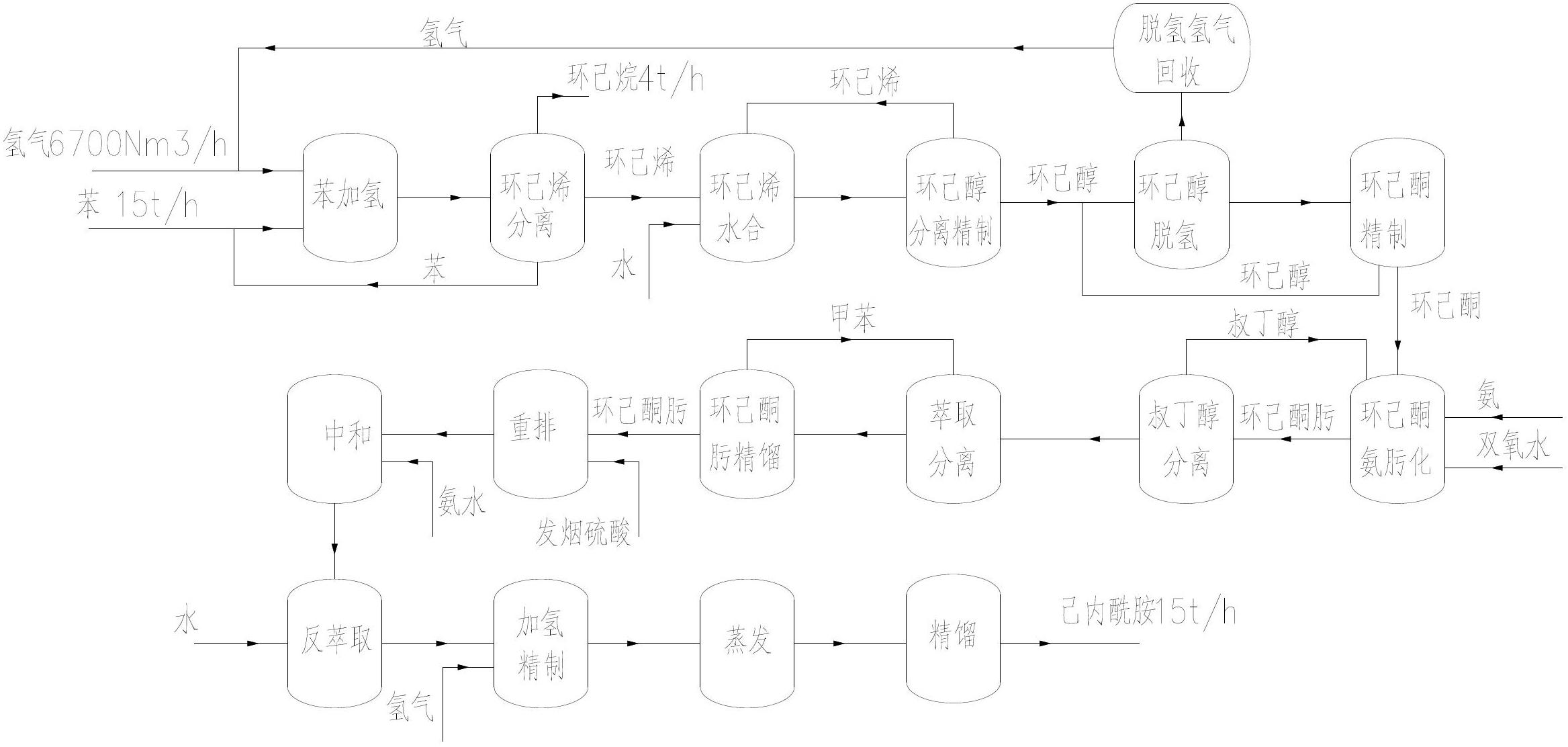

Method for producing caprolactam by taking high-purity benzene as raw material

ActiveCN102675176AAvoid it happening againQuality improvementLactams preparationHydration reactionCyclohexene

The invention provides a method for producing caprolactam by taking high-purity benzene as a raw material, and the method comprises the following steps of: A. preparing cyclohexene from the raw material benzene through hydrogenation; B. separating and purifying cyclohexene; C. carrying out hydration on the cyclohexene for preparing cyclohexanol; D. separating and purifying cyclohexanol; E. carrying out dehydrogenation on cyclohexanol for preparaing cyclohexanone; F. refining cyclohexanone; G. carrying out oximation on cyclohexanone so as to prepare cyclohexanone-oxime; H. refining cyclohexanone-oxime; I. carrying out rearrangement on refined cyclohexanone-oxime so as to prepare caprolactam; and J. refining caprolactam, wherein the high-purity benzene is adopted as a raw material, so that the purity of benzene is more than 99.95%, the sulphur content is less than 5ppm, and the methylbenzene is not more than 100ppm. The method has the beneficial effects that the high-purity benzene is adopted as a raw material, so that the impurity is less, and the product quality is high; the raw material is high in comprehensive utilization rate and low in hydrogen consumption; and the mass of the raw material and intermediate products generated in all the steps of reaction can be strictly controlled, so that the direct commercial value of the intermediate products is fully exerted, and the optimal quality of the product caprolactam can be reached.

Owner:CHINA TIANCHEN ENG +3

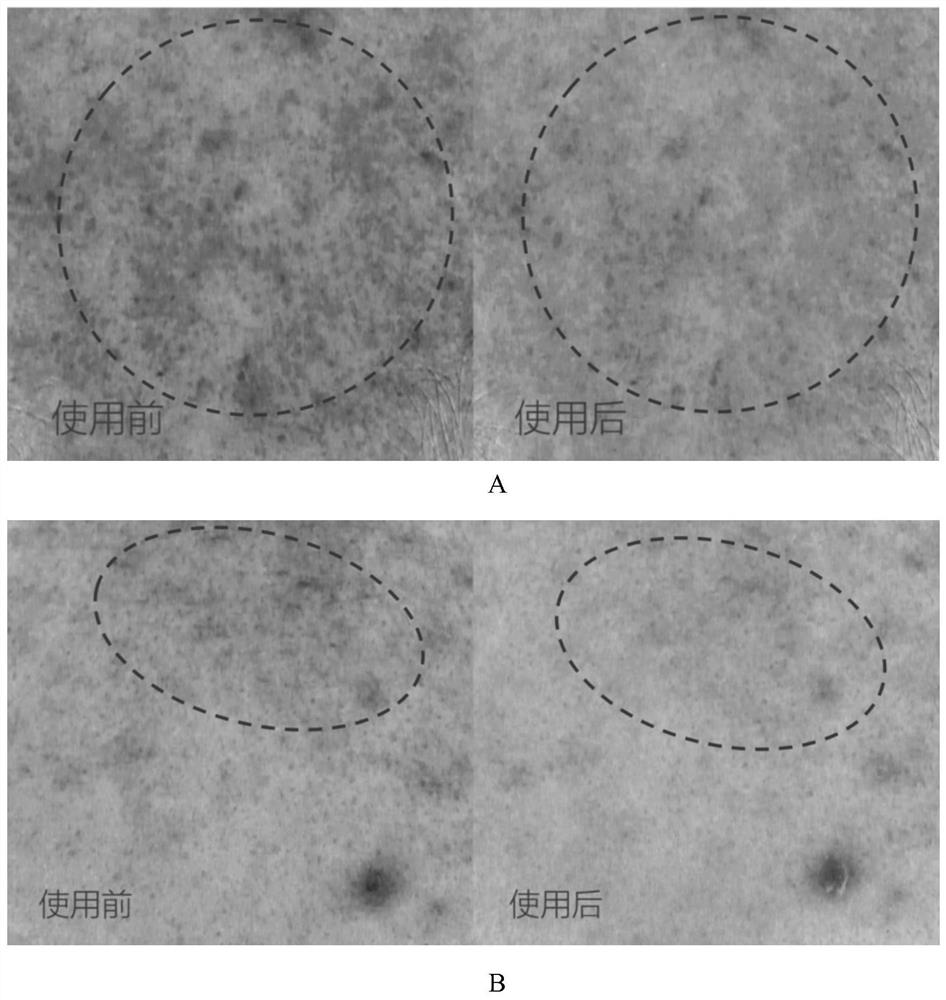

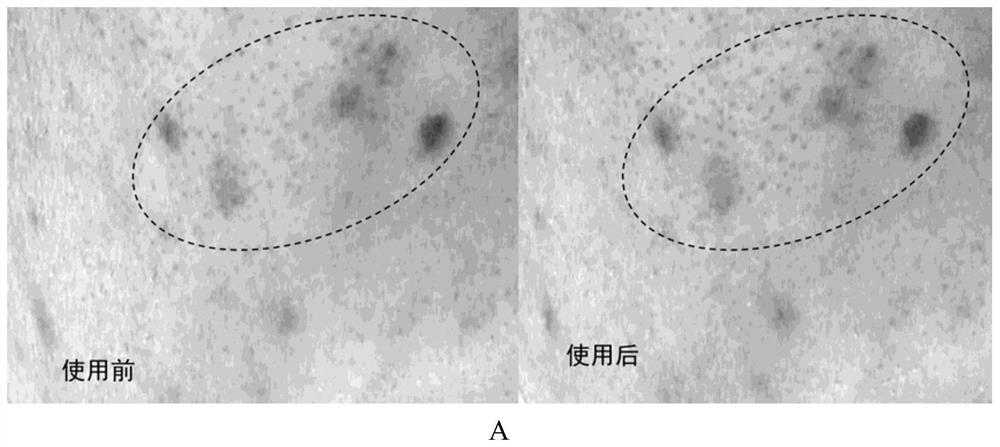

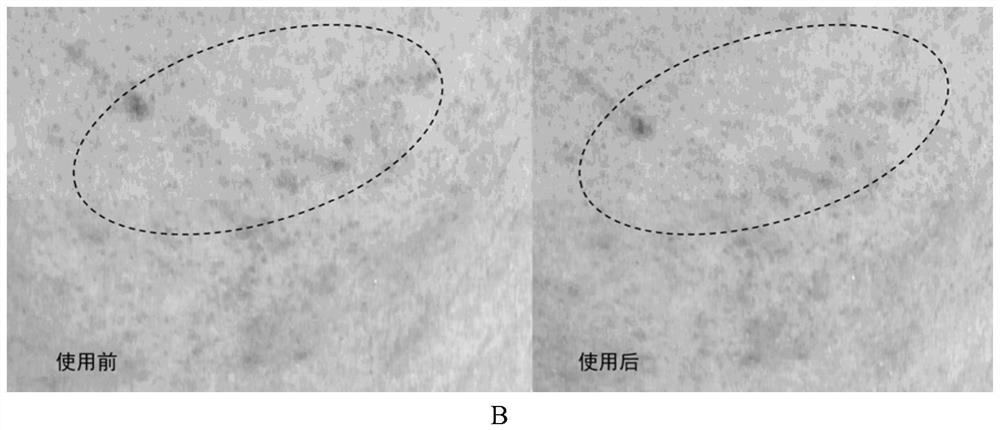

Soothing, repairing and moisturizing face cream and preparation method thereof

ActiveCN112315882ASoothing and repairingSoothing, repairing and moisturizingCosmetic preparationsToilet preparationsCyclohexanolAntiinflammatory Effect

The invention discloses soothing, repairing and moisturizing face cream and a preparation method thereof. The face cream is mainly prepared by compounding bisabolol, 4-tert-butyl cyclohexanol, a plantsoothing component, a skin conditioner and a moisturizer, wherein the plant soothing component and the bisabolol have instant itching relieving and anti-inflammatory effects; the 4-tert-butyl cyclohexanol can immediately relieve the burning feeling and the pricking feeling, and the skin conditioner can repair the skin; and the moisturizer has moisturizing and moistening effects, and can soften the skin and lock the skin moisture. The face cream is mild, non-irritant, safe, free of toxic and side effects, can effectively moisturize and repair skin and repair couperose skin, and is suitable forbeing used by crowds with partial sensitive skin and more sensitive skin.

Owner:山东福瑞达生物股份有限公司

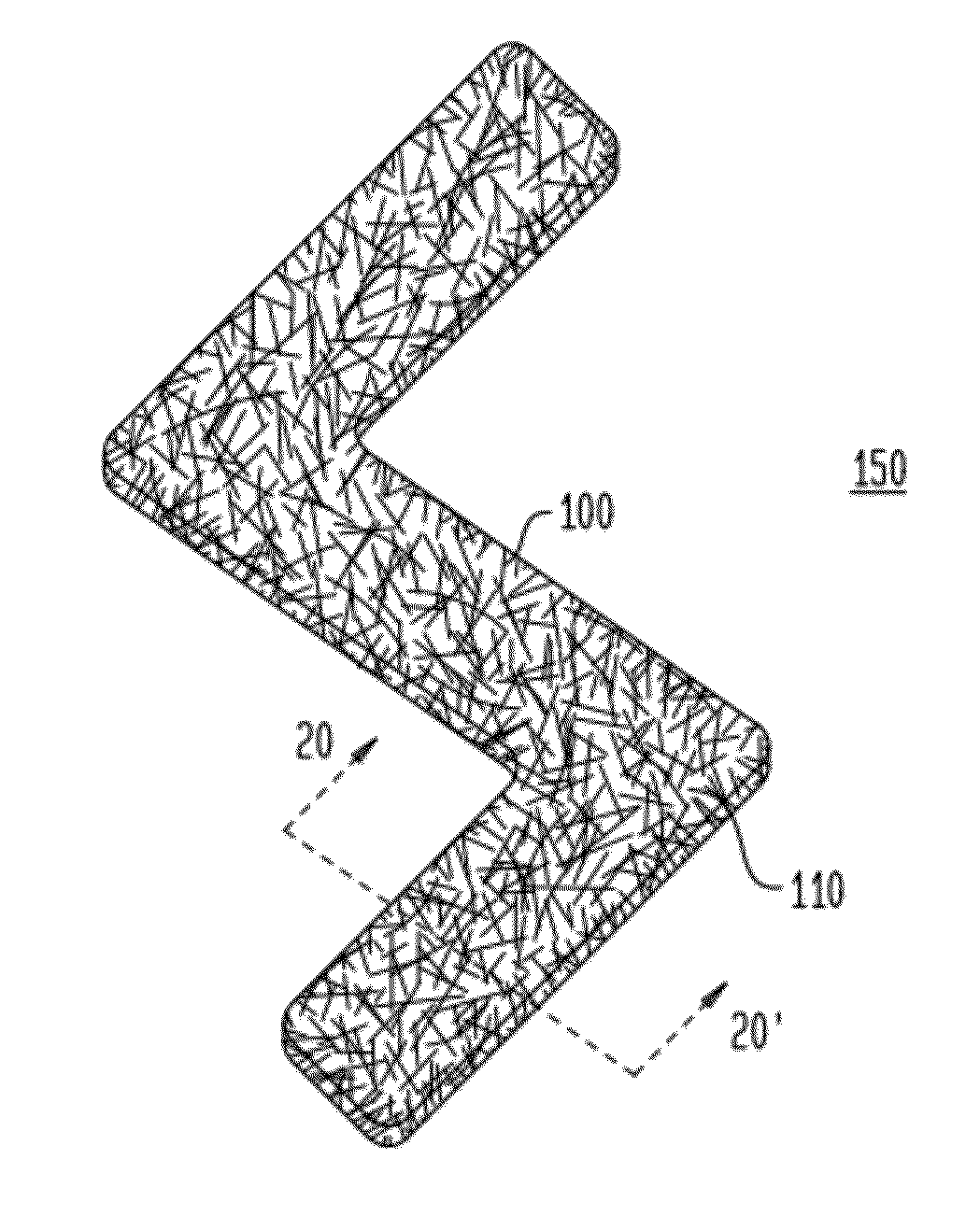

Metallic Nanofiber Ink, Substantially Transparent Conductor, and Fabrication Method

An exemplary printable composition comprises a liquid or gel suspension of a plurality of metallic nanofibers; a first solvent; and a viscosity modifier, resin, or binder. In various embodiments, the metallic nanofibers are between about 10 microns to about 100 microns in length, are between about 10 nm to about 120 nm in diameter, and are typically functionalized with a coating or partial coating of polyvinyl pyrrolidone or a similar compound. An exemplary metallic nanofiber ink which can be printed to produce a substantially transparent conductor comprises a plurality of metallic nanofibers; one or more solvents such as 1-butanol, ethanol, 1-pentanol, n-methylpyrrolidone, cyclohexanone, cyclopentanone, 1-hexanol, acetic acid, cyclohexanol, or mixtures thereof; and a viscosity modifier, resin, or binder such as polyvinyl pyrrolidone or a polyimide, for example.

Owner:NTHDEGREE TECH WORLDWIDE

Metallic Nanowire Ink Composition for a Substantially Transparent Conductor

An exemplary printable composition comprises a liquid or gel suspension of a plurality of metallic nanofibers or nanowires; a first solvent; and a viscosity modifier, resin, or binder. In various embodiments, an exemplary metallic nanowire ink which can be printed to produce a substantially transparent conductor comprises a plurality of metallic nanowires at least partially coated with a first polymer comprising polyvinyl pyrrolidone having a molecular weight less than about 50,000; one or more solvents such as 1-butanol, ethanol, 1-pentanol, n-methylpyrrolidone, cyclohexanone, cyclopentanone, 1-hexanol, acetic acid, cyclohexanol, and mixtures thereof; and a second polymer or polymeric precursor such as polyvinyl pyrrolidone or a polyimide, having a molecular weight greater than about 500,000.

Owner:NTHDEGREE TECH WORLDWIDE

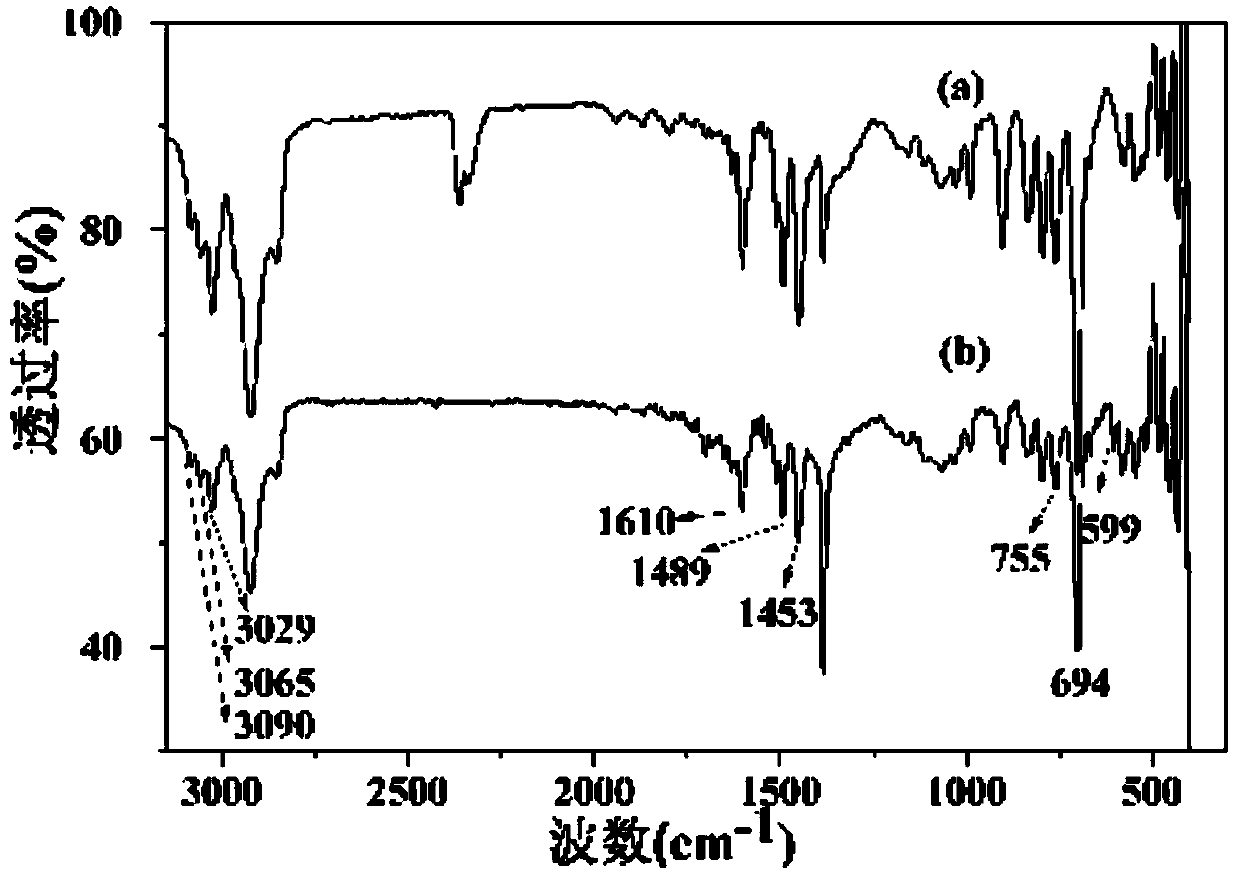

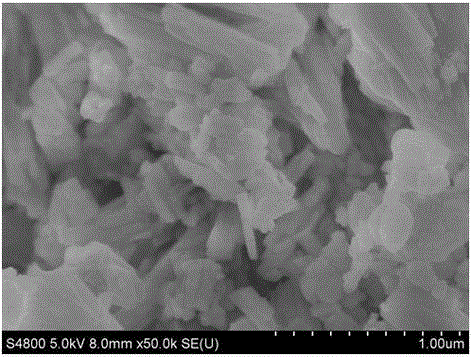

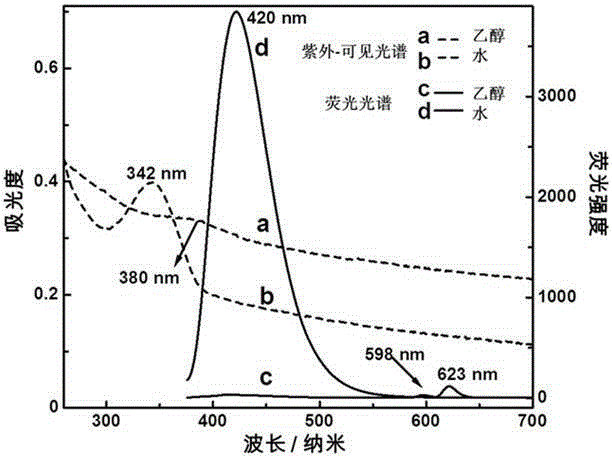

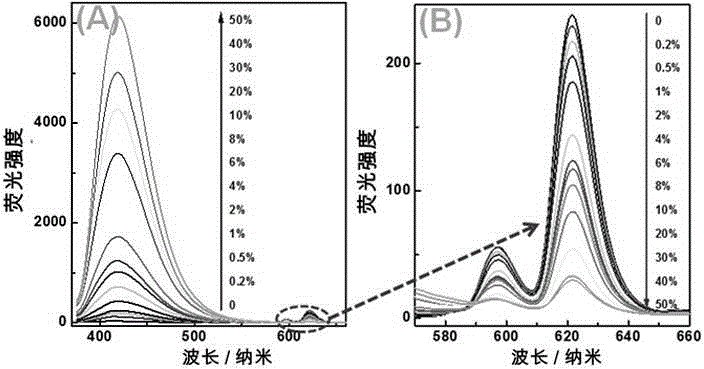

Bicolor Eu-MOFs/CDs fluorescent material as well as preparation and application thereof

InactiveCN105219376AThe synthetic route is simpleReduce cost inputFluorescence/phosphorescenceLuminescent compositionsN dimethylformamideUltraviolet

The invention discloses a bicolor Eu-MOFs / CDs fluorescent material as well as preparation and an application thereof. Europium ions, trimesic acid and carbon quantum dots are used as raw materials, and the bicolor fluorescent material is prepared through heat treatment in a solvent prepared by mixing N,N-dimethylformamide, distilled water and cyclohexanol. Under irradiation of ultraviolet lamps, the material can emit red fluorescence when dispersed in organic solvents and can emit blue fluorescent when dispersed in water, so that fluorescent colorimetric sensors for measuring water content in organic solvents can be prepared from the material, the prepared sensors are high in sensitivity, good in stability and low in cost and have higher population value and brighter application prospect.

Owner:FUZHOU UNIV

Treatment and resource technology for organic waste water

InactiveCN101074120AReduce processing costsSimple processWater contaminantsWater/sewage treatmentAnilinePhenol

A technology for treating organic waste water and resources is carried out by taking one or two or above organic waste water of phenol, aniline, toluene, butylenes oxide, cyclohexanol, N,N-dimethyl-formamide, methyl cyanide, methanol, methanol, methane acid etc. as raw materials, reform reacting organic substance with water at 180-350 degree under action of ranikel catalyst and 1-16 M pa and generating hydrogen, methane, carbon dioxide and carbon monoxide. It's cheap and efficient and has continuous or intermittent production.

Owner:ZHEJIANG UNIV OF TECH

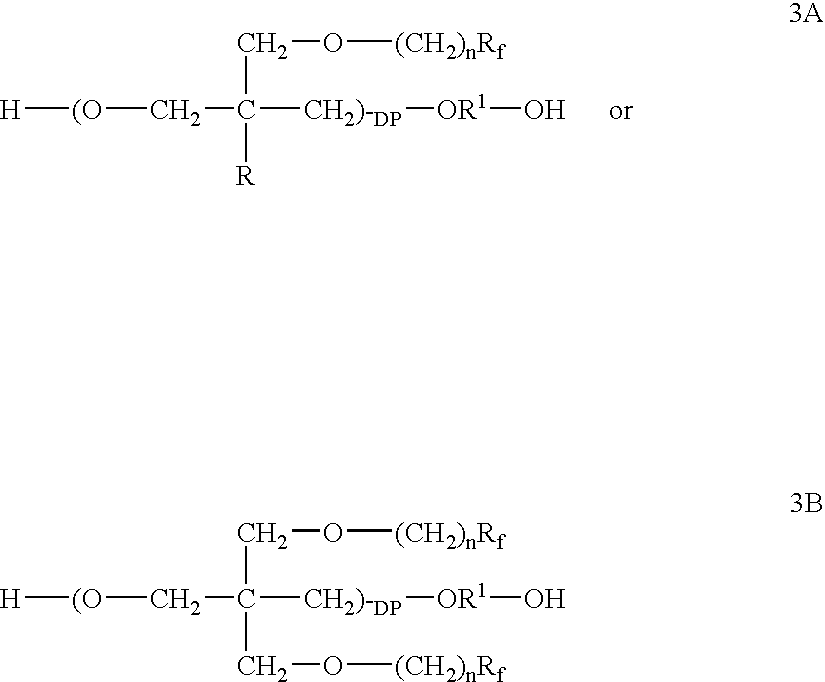

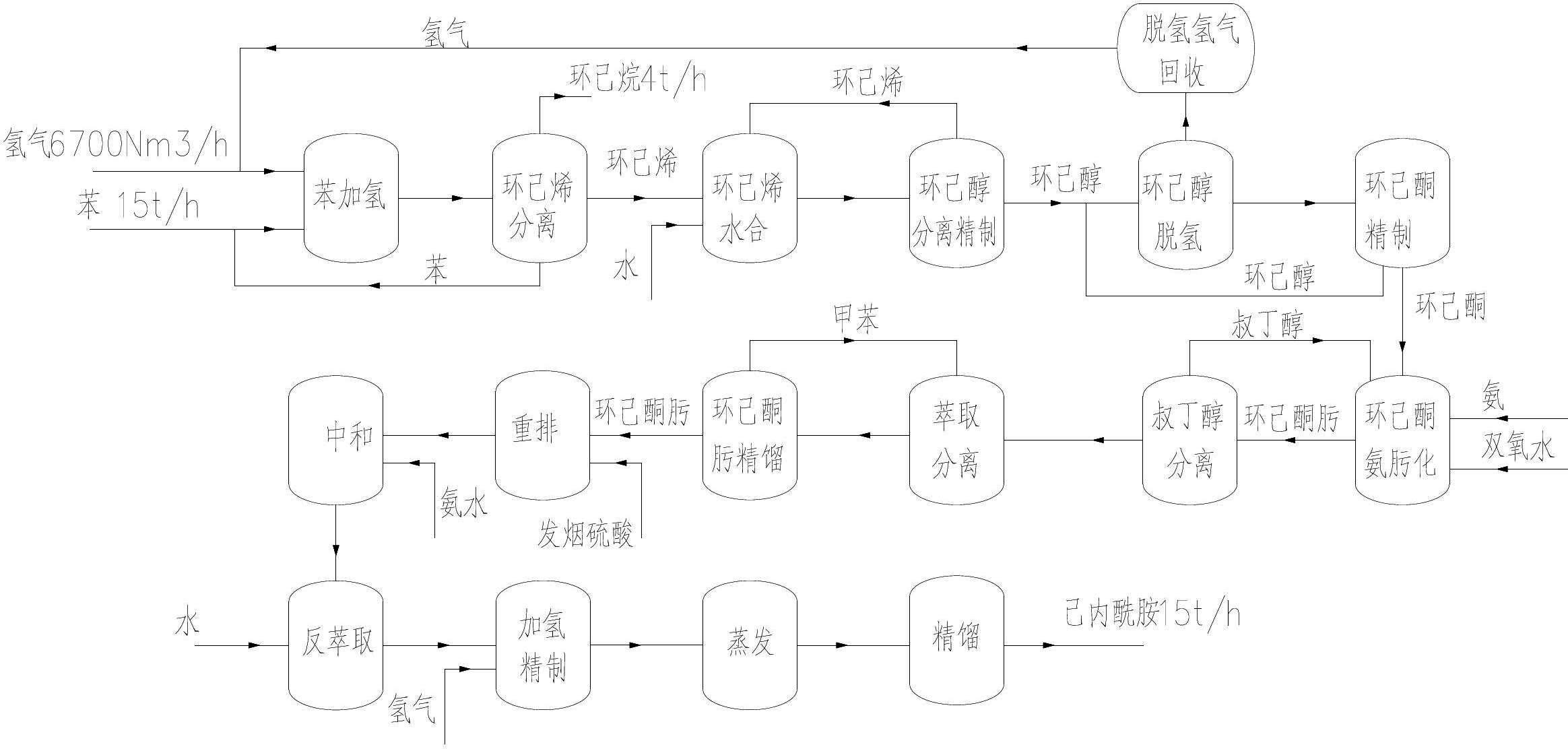

One pot process for the preparation of 1-[2-dimethylamino-(4-methoxyphenyl)-ethyl]cyclohexanol

InactiveUS6350912B1Easy to optimizeOrganic compound preparationAmino-hyroxy compound preparationFiltrationCyclohexanol

A process for the preparation of 2-[dimethylamino-(4-methoxyphenyl)ethyl]-cyclohexanol of formula 1 by reducing 1-[cyano(4-methoxyphenyl)-methyl]cyclohexanol of formula 2with a formylating agent in a protic solvent in the presence of a catalyst, removing the catalyst by filtration, isolating and purifying the compound of formula 1 is disclosed.

Owner:COUNCIL OF SCI & IND RES

Load type nano-au catalyst and the preparing method

InactiveCN101036887AEasy to manufactureLow costPreparation by oxidation reactionsCatalyst carriersCyclohexanoneKetone

The present invention discloses a supported gold nano-particles catalyst and the preparation method of the same, which comprises Au, Ce, Zr, Al and Si; wherein Au is the main active component and has a mass percent of 0.1~4.0%; Ce and Zr are the assistant active component and has a mass percent of 3~57%, wherein the mol ratio of Ce to Zr is 1~10; Al and Si are the carrier and has a mass percent of 40~97%. The catalyst is prepared by a sequential immersion method, wherein the alumina or silicon oxide carrier is firstly impregnated by an aqueous liquid containing cerous nitrate and zirconium nitrate and then the gold component is impregnated. The present invention has the advantages of that: the preparation method is simple, the stability is excellent and the cost is low. For the reaction of preparing cyclohexanone and cyclohexanol by cyclohexane oxygenation, the catalyst of the present invention can obtain high ketone alcohol selectivity even under the condition of a high conversion, besides the peroxide content in the product is very low. For example, when the conversion of cyclohexane is 12.8%, the ketone alcohol selectivity is up to 92.6% and the peroxide content is only 0.7%.

Owner:ZHEJIANG UNIV

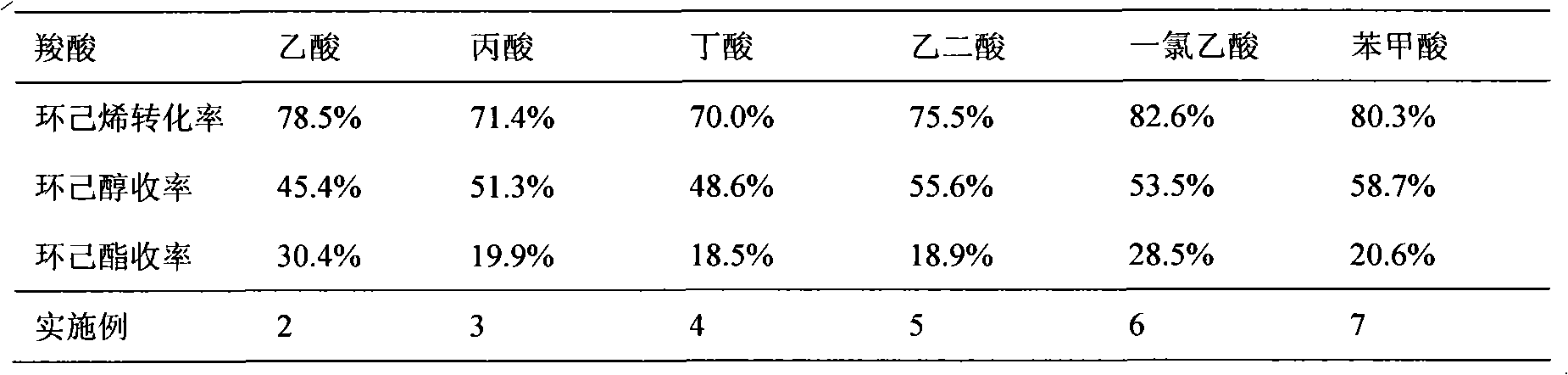

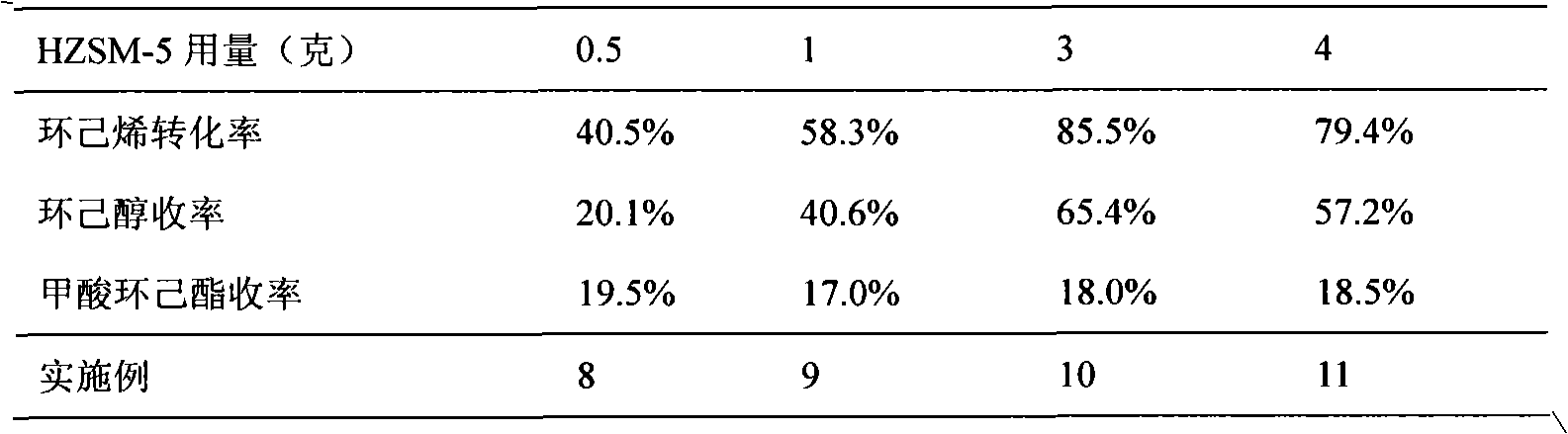

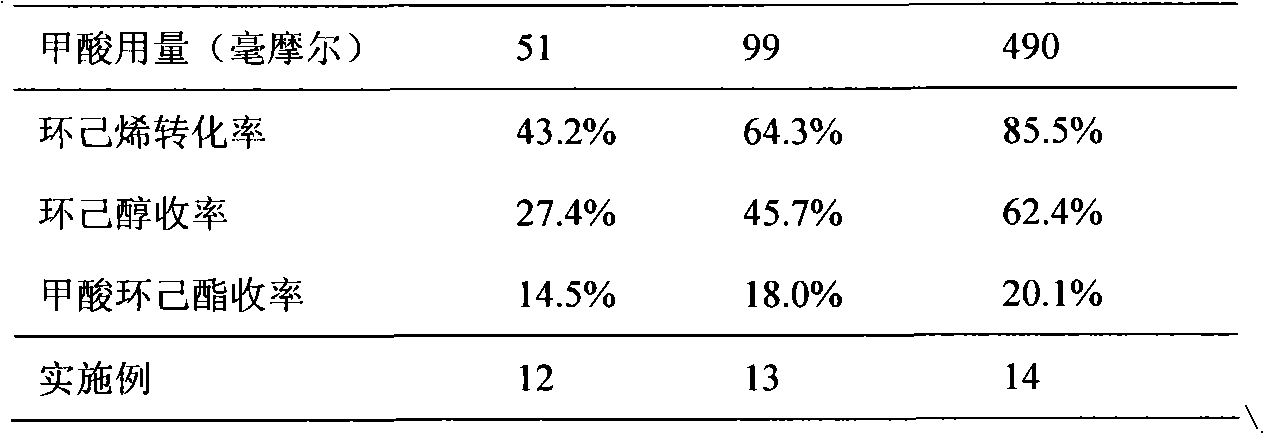

Method for preparing cyclohexanol by using cyclohexene

InactiveCN101851151AImprove conversion rateHigh yieldOxygen-containing compound preparationOrganic compound preparationGramReaction temperature

The invention discloses a method for preparing cyclohexanol by using cyclohexene. The method comprises the following steps of: (1) adding cyclohexene, carboxylic acid and catalyst into a reactor, heating the mixture to 100 to 150 DEG C and keeping the temperature to perform a reaction for 0.5 to 8 hours, wherein the mole ratio of the cyclohexene to the carboxylic acid is 1: 0.5-10, the use amountof the catalyst is 0.05 to 0.5 grams of catalyst per millimeter carboxylic acid, and the system pressure is the system self-generated pressure at the reaction temperature; and (2) after step (1) finishes, adding de-ionized water into the reactor, heating the mixed solution to 150 to 200 DEG C and continuously performing a reaction for 0.5 to 8 hours to obtain the cyclohexanol, wherein the volume ratio of the added de-ionized water to the original cyclohexene is 1 to 20: 1. In the invention, a simple intermittent reactor is adopted and the two reaction steps are completed in one reactor, so the equipment investment is small, the operation is simple and the cost is low. Besides, the catalyst used is easy to separate and can be repeatedly used, so the production cost is reduced.

Owner:HEBEI UNIV OF TECH

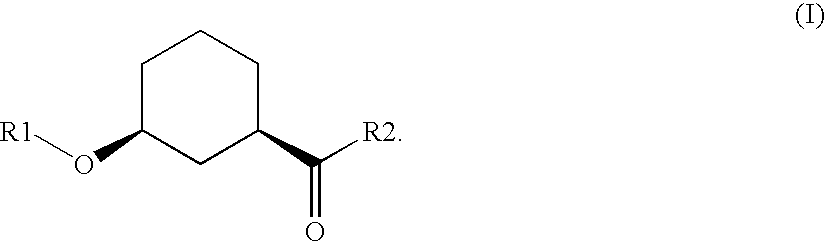

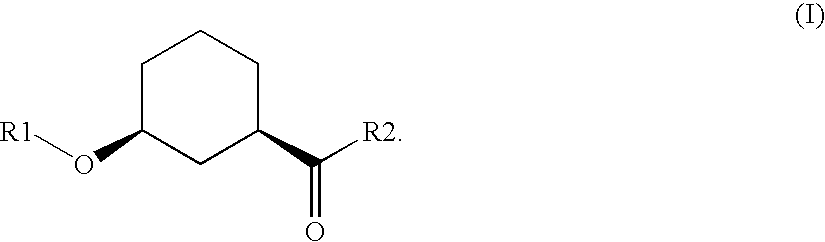

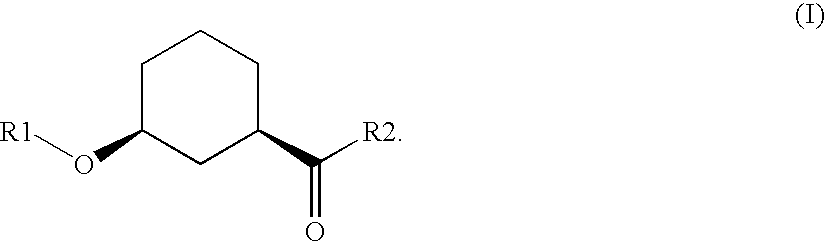

Method for the preparation of enantiomer forms of cis-configured 3-hydroxycyclohexane carboxylic acid derivatives using hydrolases

InactiveUS20070197788A1Silicon organic compoundsMetabolism disorderAcute hyperglycaemiaAcid derivative

The present invention relates to a process for preparing chiral non-racemic cis-configured cyclohexanols or cyclohexanol derivatives of the formula (I) Cis-configured hydroxyl-cyclohexane carboxylic acid derivatives of formula (I) are central building blocks or immediate precursors for the medicinally active compounds which allow a therapeutic modulation of the lipid and / or carbohydrate metabolism and are thus suitable for preventing and / or treating type II diabetes, hyperglycemia and artherosclerosis. The cis-configured hydroxyl-cyclohexane carboxylic acid derivatives of formula (I) are central building blocks or immediate precursors for the medicinally active compounds described in the prior art.

Owner:SANOFI AVENTIS DEUT GMBH

Method for catalytic conversion of alkyl cyclohexanol and alkyl cyclohexanone from air oxidized alkyl cyclohexane

InactiveCN1530357AControl deep oxidationReduce manufacturing costPreparation by oxidation reactionsOrganic compound preparationIsopropylcyclohexaneCyclohexanone

A process for selectively oxidizing alkyl cyclohexane by air under the catalysis of mu-oxygen bimetal porphyrin, single-metal porphyrin, or their solid carried substance to become alkyl cyclohexanol and alkyl cyclohexanone is disclosed. Said alkyl cyclohexane may be methyl cyclohexane, ethyl cyclohexane, isopropyl cyclohexane, etc. Its advantages are low cost, high catalytic performance, low reaction temp (less than 200 deg.C) and high transform rate.

Owner:HUNAN UNIV

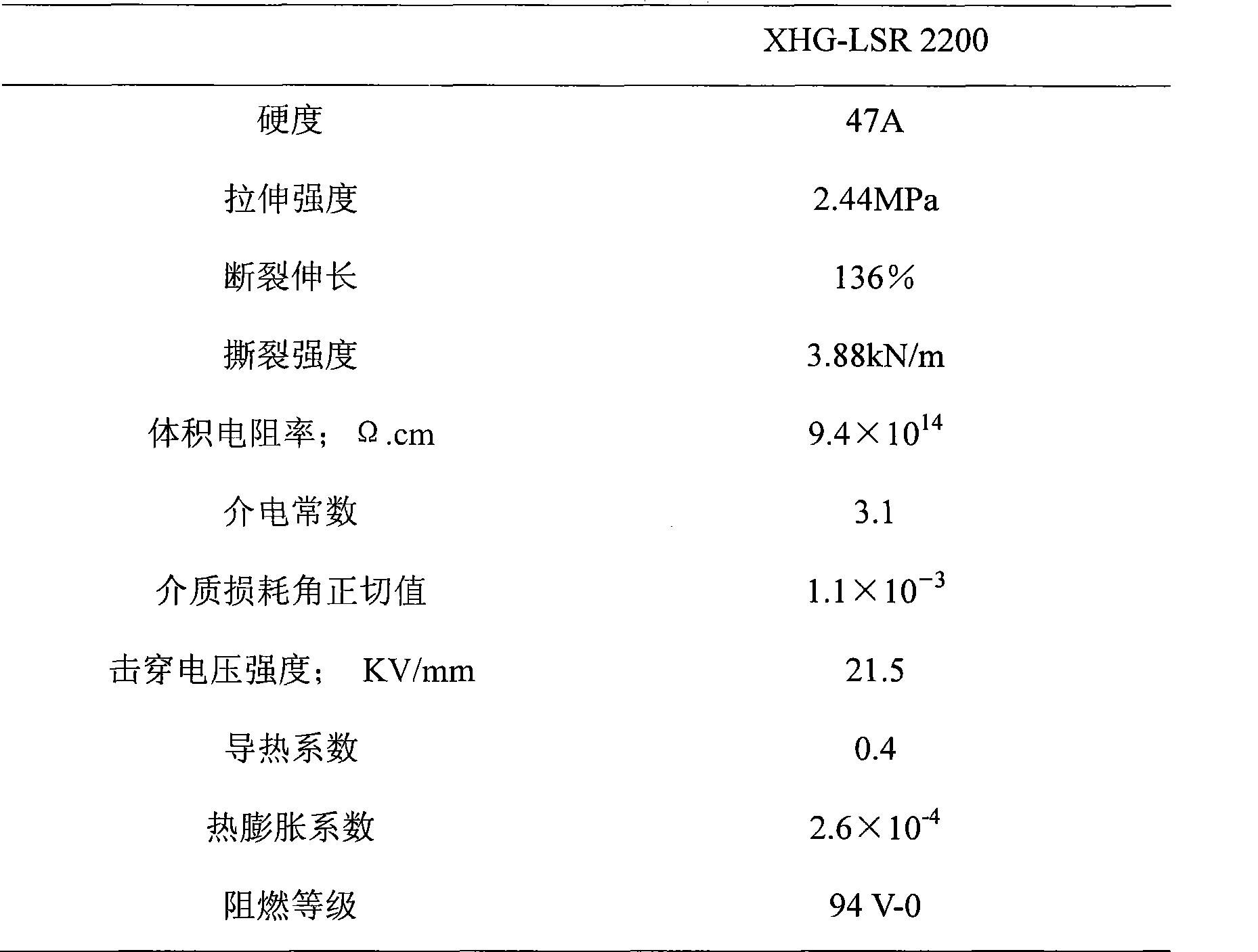

Liquid potting composite of dicomponent addition type silicone rubber and preparation

InactiveCN101418123ANo pollution in the processEasy to useOther chemical processesPolymer scienceAliphatic unsaturated hydrocarbon

The invention relates to a liquid filling and sealing composition for bi-component additive silicon rubber and a preparation method thereof. The composition comprises the following components from (A) to (F): (A) 100 mass portions of univalent unsaturated fatty hydrocarbon polysiloxane, wherein at least 2 or more than 2 bonds in each molecule are connected to a silicon atom; (B) 0.1 to 50 mass portions of hydrogen atomic hydrogenated polysiloxane, wherein at least 2 or more than 2 bonds in each molecule are connected to a silicon atom; (C) 10 to 70 mass portions of electronic grade quartz powder; (D) platinum based catalyst; (E) a triazole compound; and (F) 0.001 to 0.009 mass portion of acetylenyl cyclohexanol. The preparation method is as follows: the (A) component, the (B) component and the (C) component are mixed and milled by a kneader to prepare a basic composition; and the (D) component, the (E) component and the (F) component are added into the basic composition, and the mixture is subjected to vacuum defoamation and high-temperature solidification to obtain the silicon rubber. The liquid filling and sealing composition for the bi-component additive silicon rubber is convenient to use, is safe and reliable, does not pollute the environment, has stable service performance, can not be cracked at a low temperature, and has the characteristics of moisture protection, dust prevention, corrosion resistance, shock resistance and so on.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

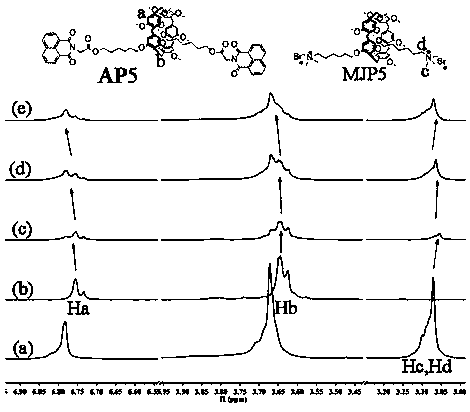

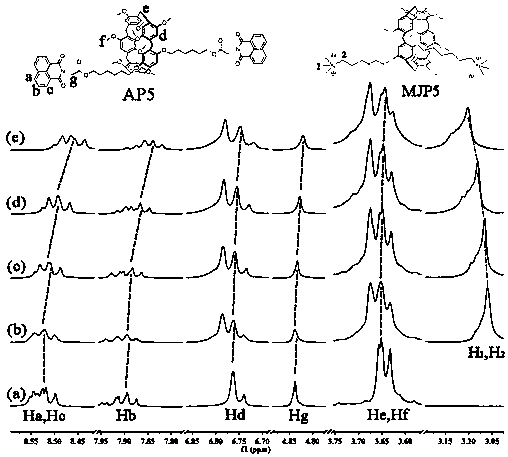

Preparation and application of supermolecule polymer framework material

InactiveCN107936262AAchieving Continuous ResponseRealize highly sensitive detectionFluorescence/phosphorescencePolymer scienceCyclohexanol

The invention designs and synthetizes a supermolecule polymer framework material. The supermolecule polymer framework material is formed through self assembly in cyclohexanol by using naphthalimide functionalized pillar [5] arene as a subject and bilateral quaternization pillar [5] arene as an object, wherein the mole ratio of the subject to the object is 1:1. Through competitive coordination mechanism, the supermolecule polymer framework material (SOF-AP5-MJP5) and a metal supermolecule polymer framework material (M-SOF-AP5-MJP5) can respectively realize continuous response and high-sensitivity detection to Fe<3+> and H2PO4<->; the recognition performance has important application values in the field of ion recognition.

Owner:NORTHWEST NORMAL UNIVERSITY

Method of preparing adipic acid by air-oxidating hexacarbocyclic compound

InactiveCN1218922CReduce dosageHigh catalytic efficiencyOrganic compound preparationCarboxylic compound preparationCyclohexanonePtru catalyst

The present invention relates to a new process for preparing adipic acid by air oxidating cyclohexane, cyclohexanol, cyclohexanone and cyclohexene or mixture of cyclohexanol and cyclohexanone under the catalysis of metal porphyrin. Under the condition of 1-20 atm air and reaction temp. is 50-200 deg.C it can select and use mu-oxidized metal porphyrin and monometal porphyrin or their fixed carrier material as catalyst independently, also can select and use metal porphyrin or their fixed carrier material as main catalyst, and use transition metal salt or oxide as co-catalyst. The metal porphyrin like biological-enzyme can high-effectively and high-selectivity catalyze air under the biologicae concentration to directly oxidate the cyclohexane into adipic acid. Said invented dose of metal porphyrin is less, and its catalytic effect is good, it can make homogeneous catalysis, also can make heterogeneous catalysis after the carrier is fixed.

Owner:HUNAN UNIV

Catalyst oxdie cyclohexane process

InactiveCN1247501CReduce loadReduce concentrationPreparation by oxidation reactionsOxygen compounds preparation by hydrocarbon oxidationCyclohexanonePorphyrin

A process for preparing cyclohexanol, cyclohexanone and adipic acid by catalytic oxidization of cyclohexane under existance of metallic porphyrin catalyst and a certain temp and pressure through combination of different reactors is disclosed. Its advantages are high single-pass conversion rate of cyclohexane and total output rate, low energy consumption and cost, and no need of cyclohexanol or acetone solvent and cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP

Synthesis process of cyclohexanone and cyclohexanol

InactiveCN1847206AImprove conversion rateFix security issuesOrganic compound preparationPreparation by hydrogenationCyclohexanonePalladium catalyst

The present invention relates to synthesis process of cyclohexanone and cycloexanol, especially through hydrogenating phenol. Phenol material, C1-C2 fatty alcohol and water in the weight proportion of 1 to 2.5-40 to 10-160 are reacted in one step at 100-300 deg.c temperature and 1-10 MPa pressure and in the action of Renny Ni catalyst or active carbon supported palladium catalyst to synthesize cyclohexanone and cycloexanol. The present invention features no need of outer hydrogen supply for hydrogenating phenol and the use of relatively cheap Renny Ni catalyst, and has the advantages of high safety, simplified technological process, low production cost, high phenol converting rate, high total cyclohexanone and cycloexanol selectivity near 100 %, no side product and easy product separation.

Owner:ZHEJIANG UNIV OF TECH

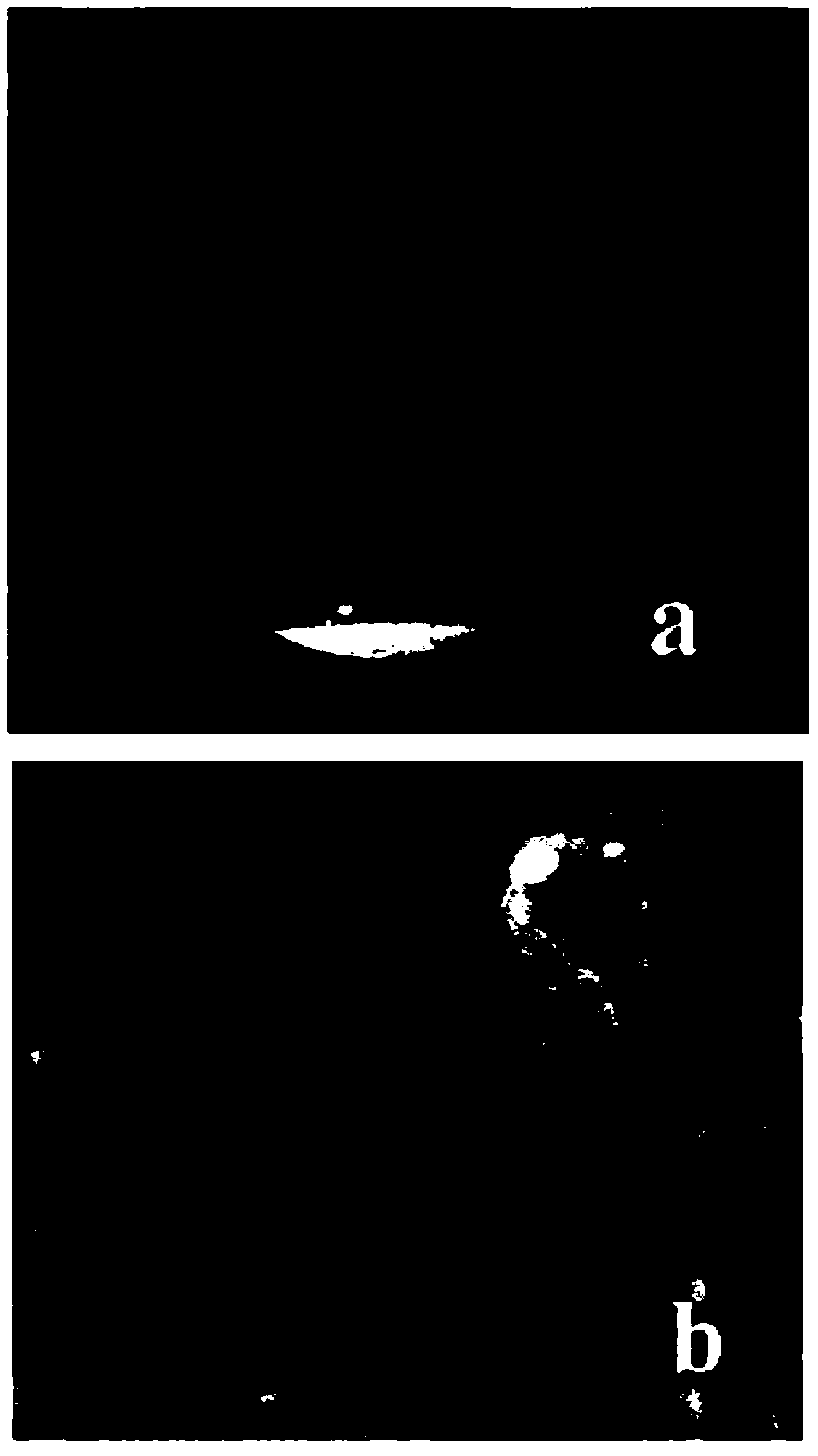

Method for preparing magnetic porous polystyrene microspheres on basis of suspension polymerization

InactiveCN103627022AIncrease productionHigh mechanical strengthOther chemical processesAlkali metal oxides/hydroxidesMagnetic stabilityPolymer science

The invention relates to a method for preparing magnetic porous polystyrene microspheres on the basis of suspension polymerization, belonging to the technical field of preparation of environmental functional materials. The method comprises the following steps: synthesizing Fe3O4 magnetic particles by a solvothermal process; and preparing magnetic porous polystyrene microspheres by suspension polymerization by using styrene and divinylbenzene as functional monomers, azodiisobutyronitrile as an initiator and toluene and cyclohexanol as pore-forming agents. The obtained microspheres have abundant pores on the surface, thereby being beneficial to enhancing adsorbability; and the Fe3O4 magnetic particles inside the microspheres have magnetic stability, and can be quickly separated under the action of an external magnetic field. The adsorbent is used in a water environment for selectively adsorbing 2,4-dichlorophenol and 2,6-dichlorophenol. The static adsorption experiment result indicates that the magnetic porous microspheres prepared by the method have the advantages of favorable adsorption capacity, quick adsorption kinetic property and favorable regenerability.

Owner:JIANGSU UNIV

Application and preparation method of ZSM-5 molecular sieve with mesopores and micropores

ActiveCN105728019ASimple stepsEven stepsMolecular sieve catalystsPreparation by hydroxy group additionCyclohexeneCyclohexanol

The invention provides an application and a preparation method of a ZSM-5 molecular sieve with mesopores and micropores. The preparation method includes steps of precursor preparation, silica-alumina gel preparation and preparation of the ZSM-5 molecular sieve with the mesopores and micropores.In a preparation process of a hierarchical porous catalyst, consumption of a microporous templating agent and a mesoporous templating agent can be substantially reduced, synthesis steps of the hierarchical porous catalyst are simple, and the synthesized molecular sieve is large in specific surface area, uniform in particle size and controllable in mesopore quantity and size, and intrinsic lipophilicity of the molecular sieve is enhanced due to abundant surface terminal hydroxide radicals. By adoption of the molecular sieve as the catalyst, a method for preparing cyclohexanol by direct hydration of cyclohexene is established, and the catalyst is high in cyclohexene conversion rate and cyclohexanol selectivity.

Owner:CHINA TIANCHEN ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![One pot process for the preparation of 1-[2-dimethylamino-(4-methoxyphenyl)-ethyl]cyclohexanol One pot process for the preparation of 1-[2-dimethylamino-(4-methoxyphenyl)-ethyl]cyclohexanol](https://images-eureka.patsnap.com/patent_img/7de068ff-172d-4c90-b316-a12cd2eed13b/US06350912-20020226-C00001.png)

![One pot process for the preparation of 1-[2-dimethylamino-(4-methoxyphenyl)-ethyl]cyclohexanol One pot process for the preparation of 1-[2-dimethylamino-(4-methoxyphenyl)-ethyl]cyclohexanol](https://images-eureka.patsnap.com/patent_img/7de068ff-172d-4c90-b316-a12cd2eed13b/US06350912-20020226-C00002.png)

![One pot process for the preparation of 1-[2-dimethylamino-(4-methoxyphenyl)-ethyl]cyclohexanol One pot process for the preparation of 1-[2-dimethylamino-(4-methoxyphenyl)-ethyl]cyclohexanol](https://images-eureka.patsnap.com/patent_img/7de068ff-172d-4c90-b316-a12cd2eed13b/US06350912-20020226-C00003.png)