Patents

Literature

363 results about "Methyl cyclohexane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methylcyclohexane is an organic compound with the molecular formula is CH3C6H11. Classified as saturated hydrocarbon, it is a colourless liquid with a faint odor. Methylcyclohexane is used as a solvent.

Aqueous polyurethane dispersoid for coating yellowing-resistant leather and preparation method thereof

InactiveCN102924683AGood yellowing resistanceEasy to preparePolyurea/polyurethane coatingsLeather surface finishingPolyurethane dispersionPolymer science

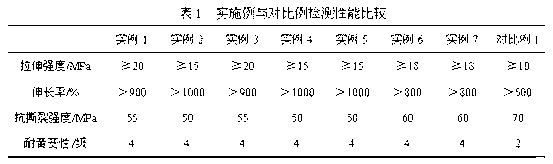

The invention discloses an aqueous polyurethane dispersoid for coating yellowing-resistant leather. The aqueous polyurethane dispersoid is prepared through the following steps: performing reaction on polyalcohol, a diisocyanate mixture and a crosslinking agent to generate a prepolymer with -NCO terminal group, wherein the diisocyanate mixture consisting of dicyclohexylmethane diisocyanate and isophorone diisocyanate is taken as a starting material; adding a hydrophilic chain extender into the prepolymer, further reacting and extending the chain by micromolecular dihydric alcohol; and neutralizing by using triethylamine and dispersing into water to obtain the aqueous polyurethane dispersoid. According to the aqueous polyurethane dispersoid prepared by the method, the yellowing-resistant level can reach more than level 4, the tensile strength is more than or equal to 15 MPa, the elongation ratio is more than or equal to 800 percent and the tearing strength is more than or equal to 50 MPa. The coated leather has soft and natural luster and plump and moist handfeel.

Owner:山西省应用化学研究所

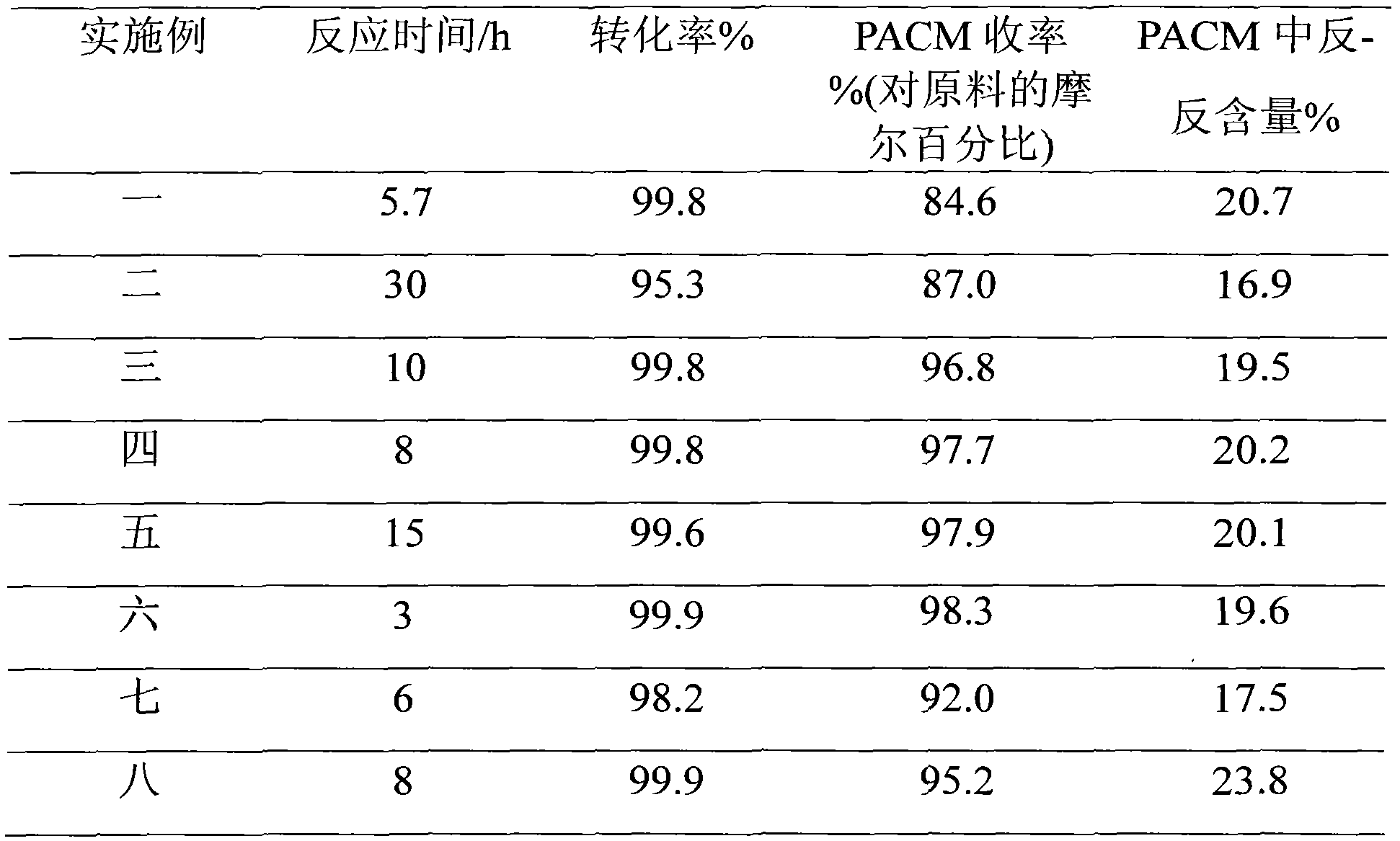

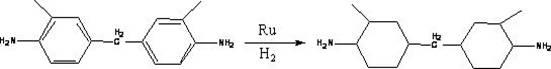

Method for producing H12MDA through hydrogenation reaction

ActiveCN101050184ALower conversion rateReduce contentOrganic compound preparationAmino compound preparationDiphenylmethaneNano catalyst

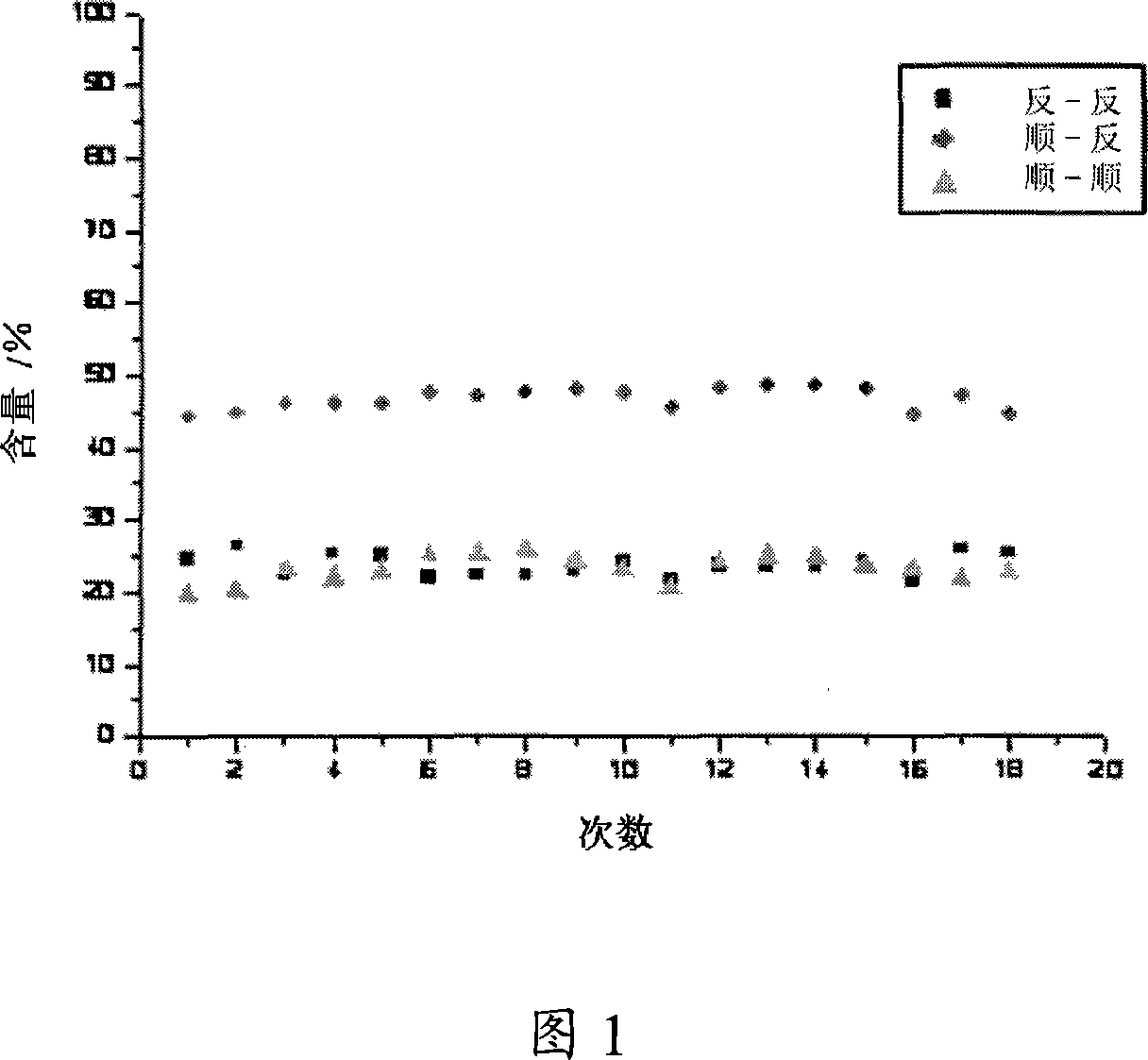

This invention discloses a method for preparing 4, 4'-diamino dicyclohexylmethane (H12MDA) from 4, 4'-diamino diphenylmethane (MDA) via hydrogenation catalyzed by supported nanoscale Ru catalyst. The method comprises: performing stereoselective hydrogenation on MDA at 100-180 deg.C and 4-10 MPa in an intermittent autoclave for 1-9 h to obtain H12MDA. The MDA conversion rate is near 100%, the H12MDA weight yield is near 100%, and the trans-H12MDA content is below 25%. After the supported nanoscale Ru catalyst is continuously reused for above 30 times without supplementation, the MDA conversion rate is still near 100%, and the trans-H12MDA content is below 27%.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD

Golf ball

ActiveUS20090143169A1Excellent abrasion-resistanceImprove spin performanceSolid ballsEngineeringMethyl cyclohexane

A golf ball which has excellent abrasion-resistance and spin performance is provided. The golf ball of the present invention includes a core and a cover covering the core. The cover contains, as a resin component, polyurethane which is obtained using, as a polyisocyanate component constituting the polyurethane, 4,4′-dicyclohexylmethane diisocyanate having a mole ratio ((B) / (A)) of non-cis-structure molecule (B) to cis-structure molecule (A) in a range from 3 / 7 to 9 / 1.

Owner:SUMITOMO RUBBER IND LTD

Waterborne polyurethane grouting material and preparation method thereof

InactiveCN102093537AConvenient sourceAvoid poisoningOther chemical processesIsophorone diisocyanatePolymer chemistry

The invention discloses a preparation method of a waterborne polyurethane grouting material. The method is as follows: isocyanate, retarding agent and hydrophilic polyether polyol are mixed to react and obtain the finished product, wherein isocyanate is selected from diphenylmethane diisocyanate, liquefied diphenylmethane diisocyanate, polymethylene polyphenyl isocyanate isophorone diisocyanate, dicyclohexylmethylmethane-4,4'-diisocyanate, hexamethylene diisocyanate and polymethylene polyphenyl isocyanate or the mixture of toluene diisocynate and the isocyanates; and the degree of functionality of hydrophilic polyether polyol is 2-6, the ratio of ethylene oxide to propylene oxide is 99 / 1-60 / 40 and the molecular weight is 1000-20000. The invention also relates to the hydrophilic polyurethane grouting material prepared by the method. The preparation method of the invention is simple and convenient and has wide raw material sources; the prepared hydrophilic polyurethane grouting material does not contain organic solvent, thus avoiding the damage on the health of the constructor and promoting environmental protection; and the grouting material can have lower viscosity and good permeability and waterproof and leaking stoppage effect.

Owner:SHANGHAI DONGDA CHEM

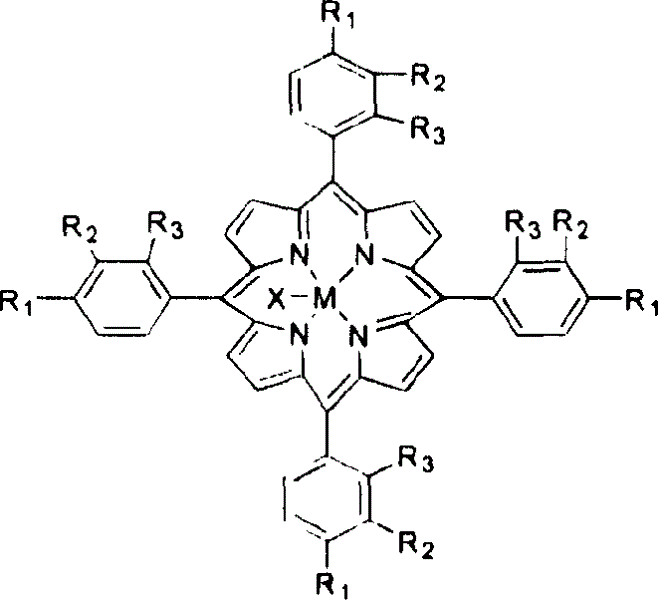

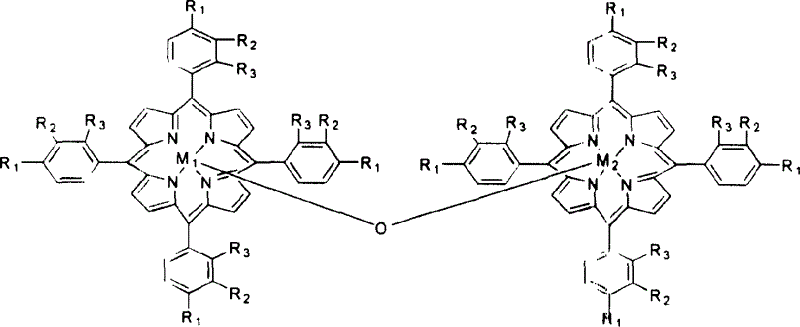

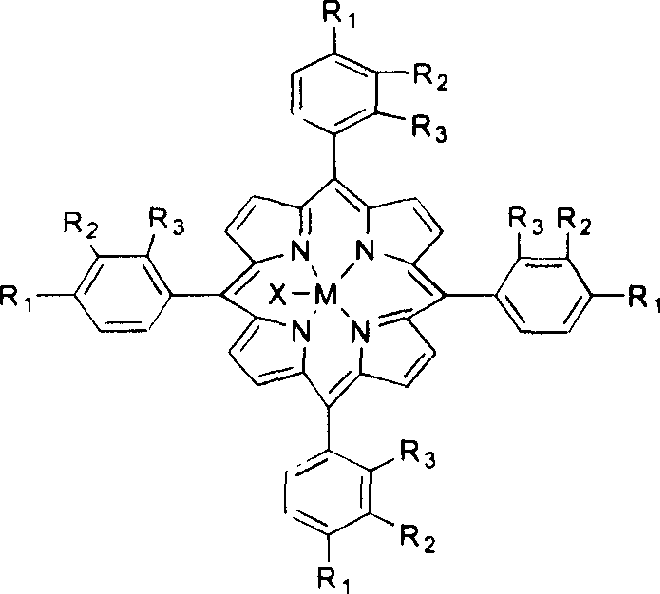

Method for catalytic conversion of alkyl cyclohexanol and alkyl cyclohexanone from air oxidized alkyl cyclohexane

InactiveCN1530357AControl deep oxidationReduce manufacturing costPreparation by oxidation reactionsOrganic compound preparationIsopropylcyclohexaneCyclohexanone

A process for selectively oxidizing alkyl cyclohexane by air under the catalysis of mu-oxygen bimetal porphyrin, single-metal porphyrin, or their solid carried substance to become alkyl cyclohexanol and alkyl cyclohexanone is disclosed. Said alkyl cyclohexane may be methyl cyclohexane, ethyl cyclohexane, isopropyl cyclohexane, etc. Its advantages are low cost, high catalytic performance, low reaction temp (less than 200 deg.C) and high transform rate.

Owner:HUNAN UNIV

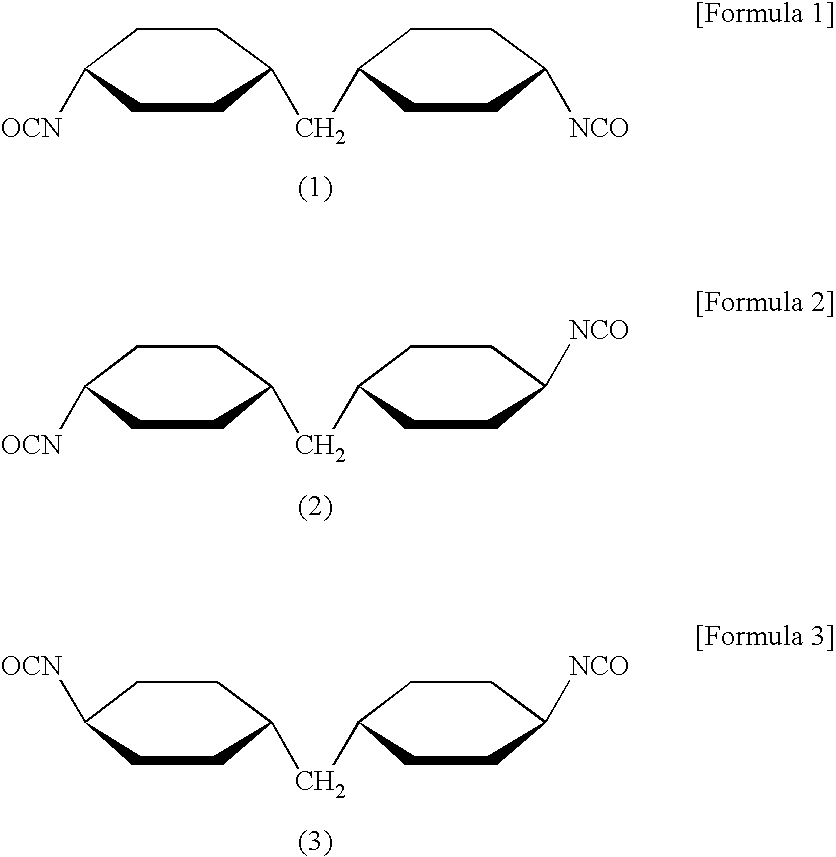

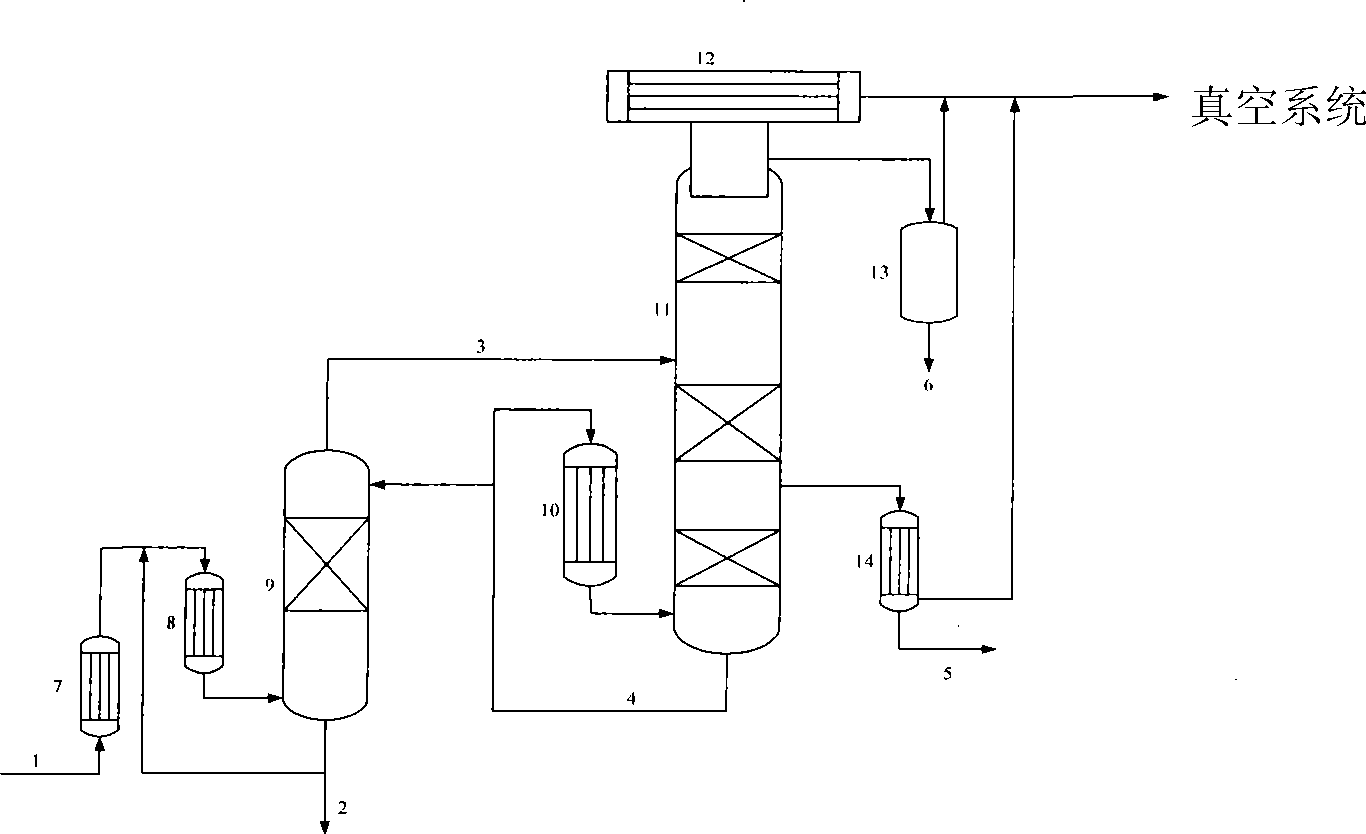

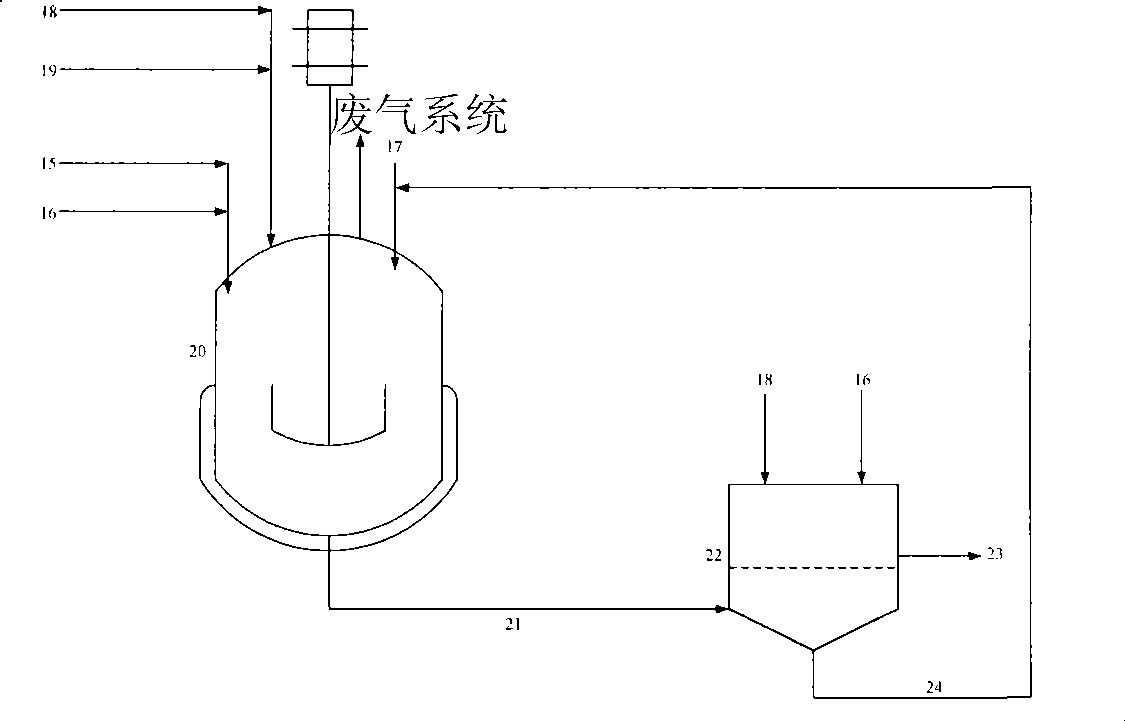

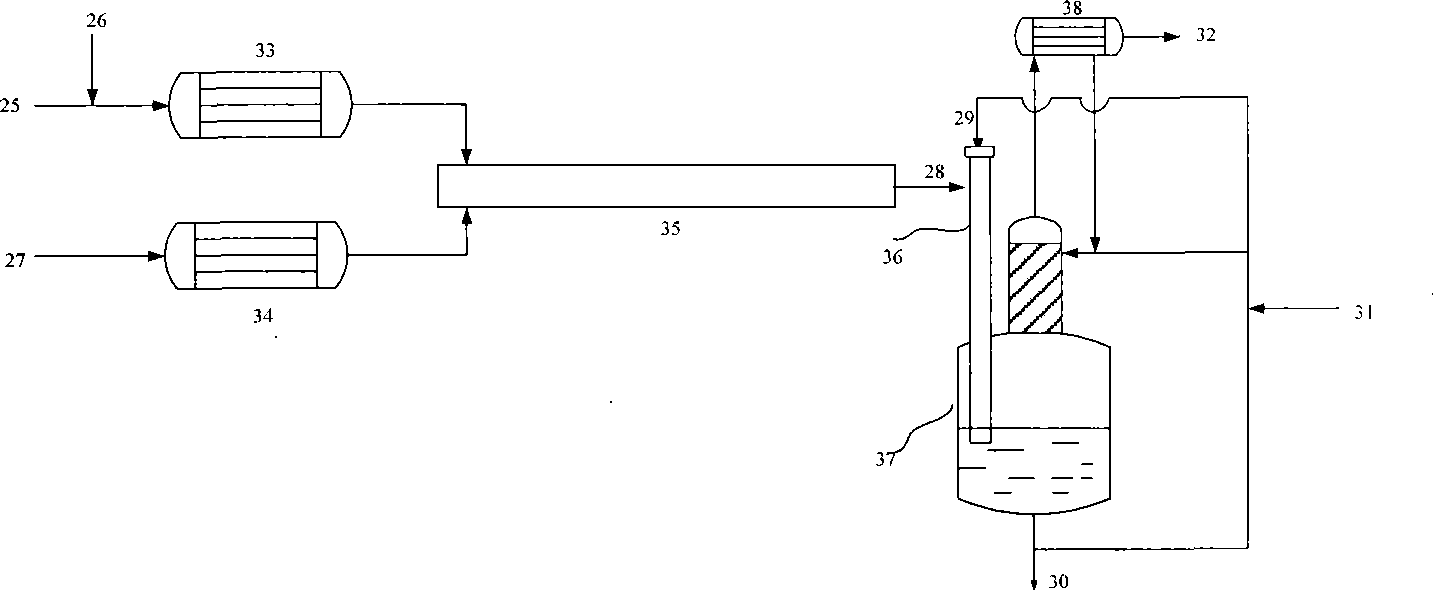

Process for producing dicyclohexyl methyl hydride diisocyanate and its midbody

ActiveCN101429139AReduce poisonExtended service lifeIsocyanic acid derivatives preparationOrganic compound preparationOrganic solventHydrogen pressure

The invention discloses a method for preparing dicyclohexyl methane diisocyanate. The method comprises the following steps: a) a diamino diphenylmethane isomer mixture reacts in an organic solvent at a reaction temperature between 90 and 200 DEG C, under the hydrogen pressure between 3.0 and 12.0 MPa and under the action of a catalyst, so as to obtain a diamino dicyclohexyl methane isomer mixture; and b) the diamino dicyclohexyl methane isomer mixture obtained in the step a) and phosgene are heated to 330 to 400 DEG C so as to be gasify respectively and then are sent into a reactor with a mixing device to be mixed and react, have hydrogen chloride and phosgene removed, and are distilled, so as to obtain the dicyclohexyl methane diisocyanate. The method has the advantages of prolonging the life span of the catalyst and reducing cost. The invention also provides a complete technological process for preparing the dicyclohexyl methane diisocyanate.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD

Hydrogenation catalyst and preparation method of 4,4'-diamino-dicyclohexyl methane

InactiveCN101966456ALow costEasy to prepareOrganic compound preparationAmino compound preparationDiphenylmethaneActive component

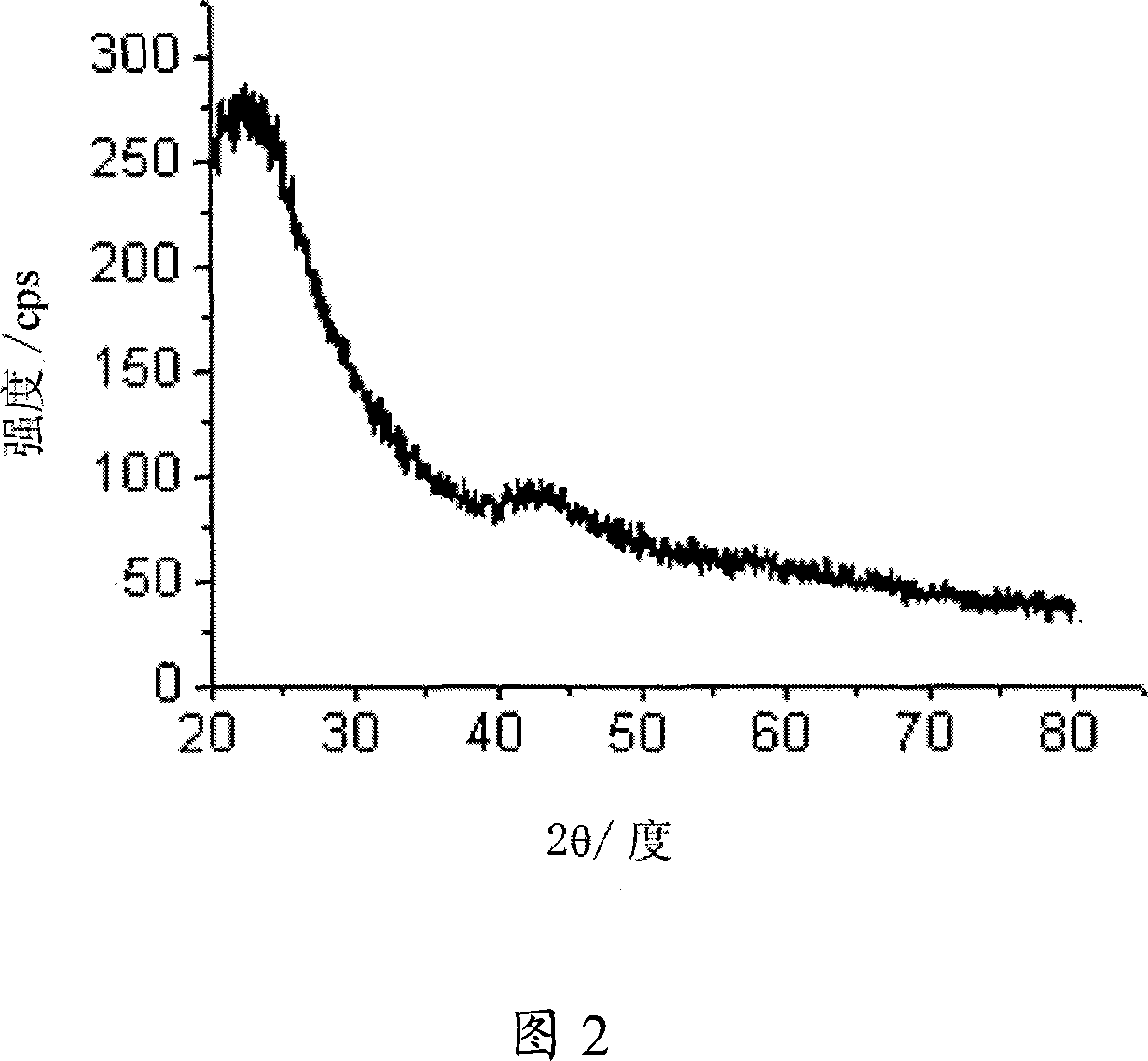

The invention discloses a hydrogenation catalyst and a preparation method of 4,4'-diamino-dicyclohexyl methane. The hydrogenation catalyst comprises a carrier used as mesoporous carbon and an active component used as ruthenium, wherein the load capacity of the active component is 0.5-10 percent by mass of the hydrogenation catalyst. in the preparation method of low transisomer 4,4'-diamino-dicyclohexyl methane, the catalyst of the invention is adopted to selectively hydrogenate and generate a target product under the conditions of solvents and hydrogenation. In the invention, the catalyst and the method reduce the generation of byproducts while the higher conversion ratio of the 4,4'-diamino-diphenylmethane is remained, and decrease the content of the transisomer of the 4,4'-diamino-dicyclohexyl methane. Meanwhile, the catalyst is low in cost and simple and convenient in preparation and is suitable for industrial application.

Owner:CHANGZHOU UNIV +1

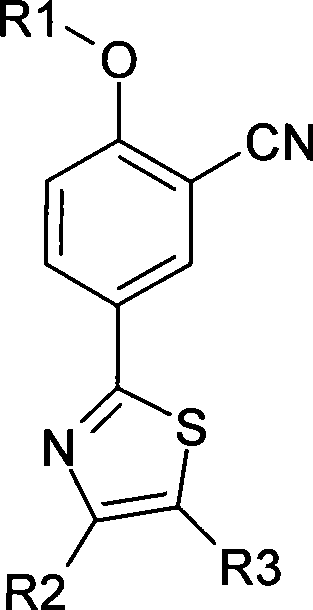

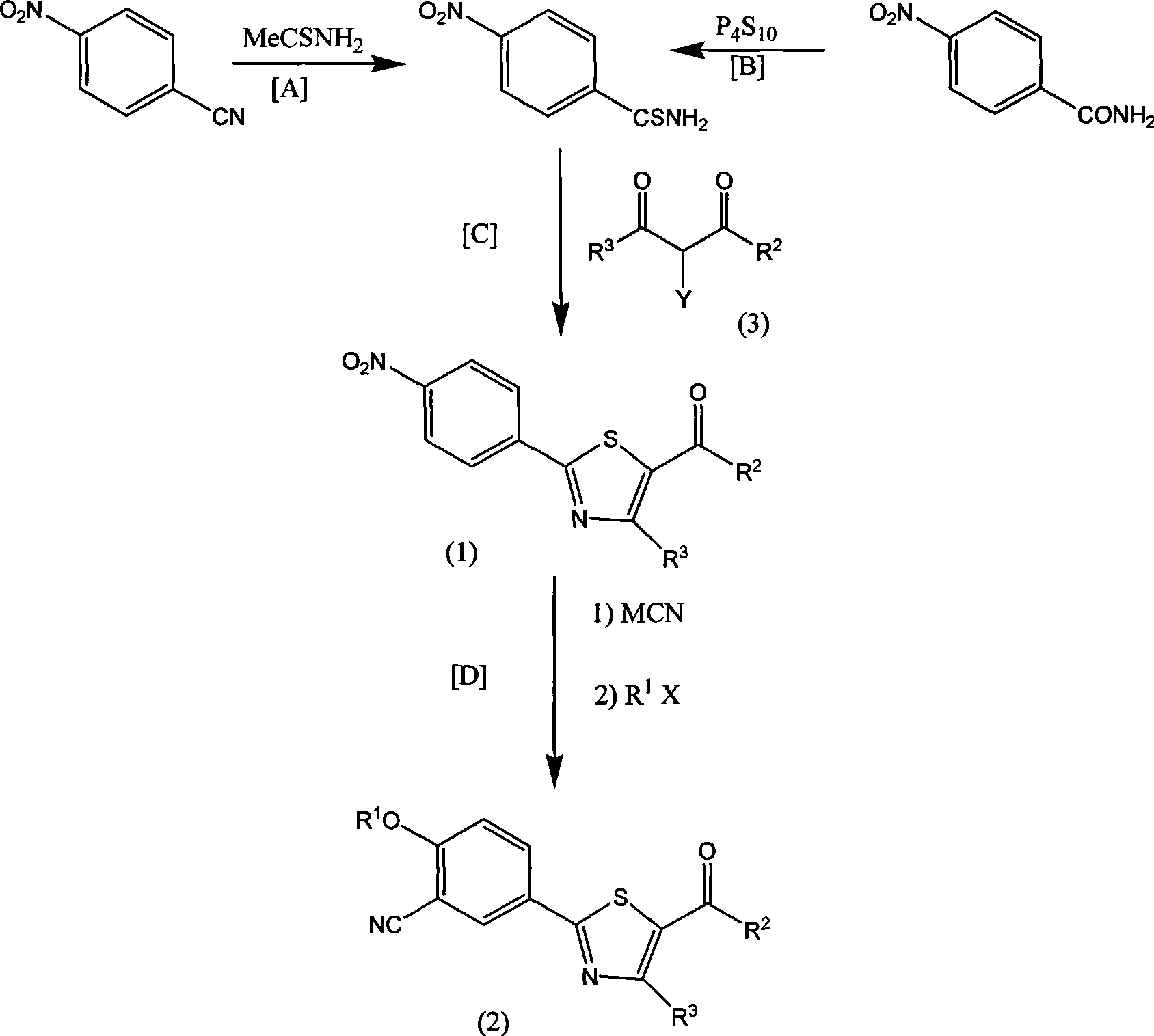

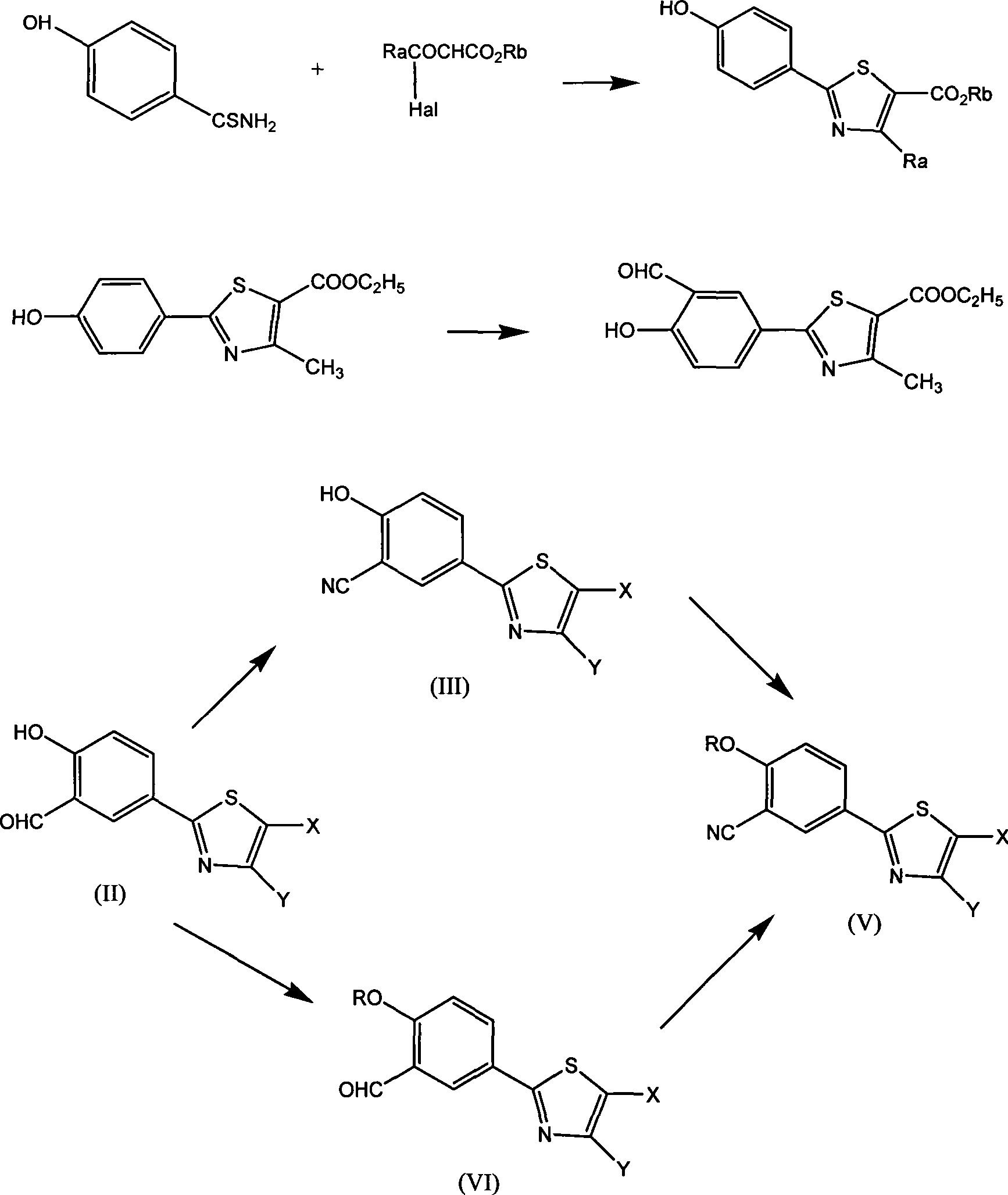

Aromatic nitrile-base thiazole derivatives for inhibiting xanthine oxidase activity, preparation method and application

ActiveCN101386604AEasy to operateHigh yieldOrganic active ingredientsOrganic chemistryCyclobutaneLithium formate

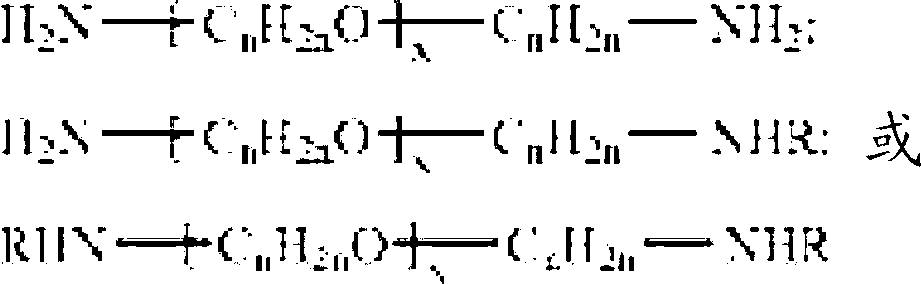

The invention disclosed an aryl nitrile group thiazole derivative for inhibiting the activity of xanthine oxidase, a method for preparing the same and application thereof. In the aryl nitrile group thiazole, R1 is methyl, ethyl, propyl, isopropyl, isobutyl, methyl cyclopropane, methyl cyclobutane, isoamyl, methyl cyclopentane, methyl cyclohexane or aromatic ring methyl, R2 is methyl or trifluoromethyl, and R3 is formic acid, sodium formate, potassium formate, lithium formate, methyl formate, or ethyl formate. Simultaneously, the invention discloses a method for synthesizing the aryl nitrile group thiazole derivative by using inexpensive raw materials, which has the advantages of simple operation, high yield, easy purification of products, application to industrial production and the like, and can obtain an efficient compound with low toxicity through screening; besides, the effective compound is expected to be widely applied to inhibit the activity of the xanthine oxidase required on animals and humans, and to become a new generation of antigout drugs and hyperuricemia drugs with special effect.

Owner:HANGZHOU ADAMERCK PHARMLABS INC

Polyurethane compositions having improved impact resistance and optical properties

A thermoset polyurethane composition having excellent impact and optical properties is prepared from a formulation comprising at least a prepolymer and a chain extender. The prepolymer includes an isocyanate component, containing 1,3-bis(isocyanatomethyl)cyclohexane and at least (20) percent by weight of 1,4-bis(isocyanatomethyl)cyclohexane, and an isocyanate-reactive component, containing hydroxyl, amine or thiol functionality. The isocyanate-reactive component includes from (70) to (95) percent by weight of a compound having a molecular weight from 150 to less than 950 Daltons, and from (5) to (30) percent by weight of a compound having a molecular weight from 2,000 to 4,500 Daltons. The chain extender is an aromatic, aliphatic, or cycloaliphatic polyamine compound containing at least one hydroxyl and / or thiol group. Articles that may be prepared include ophthalmic lenses, vehicle glazings, aircraft canopies, and the like.

Owner:DOW GLOBAL TECH LLC

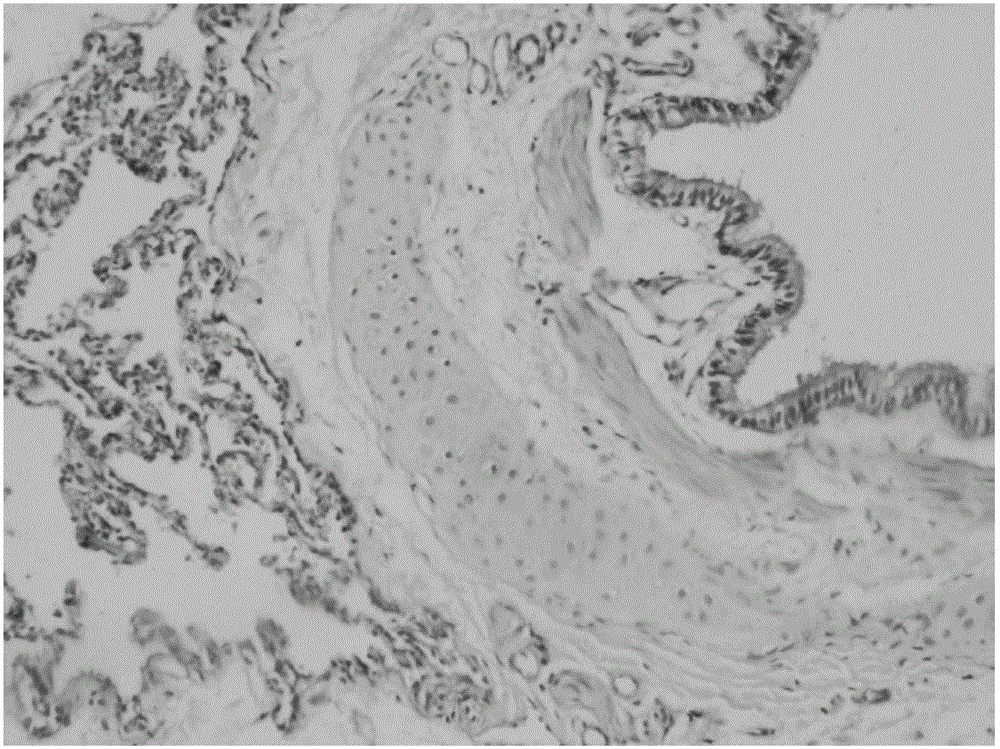

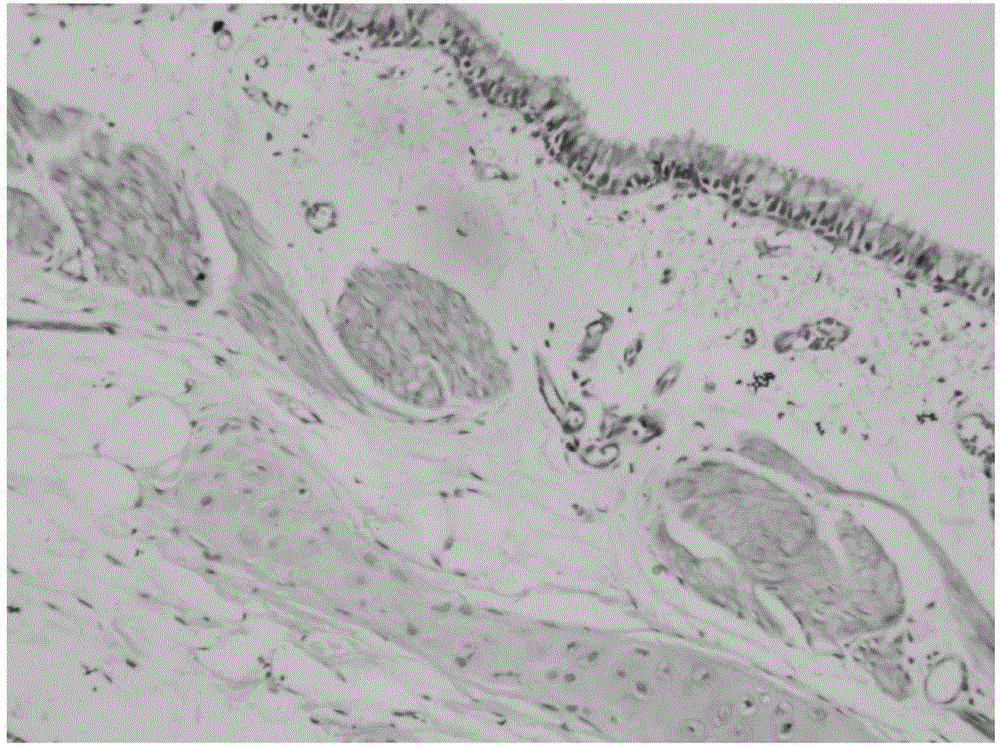

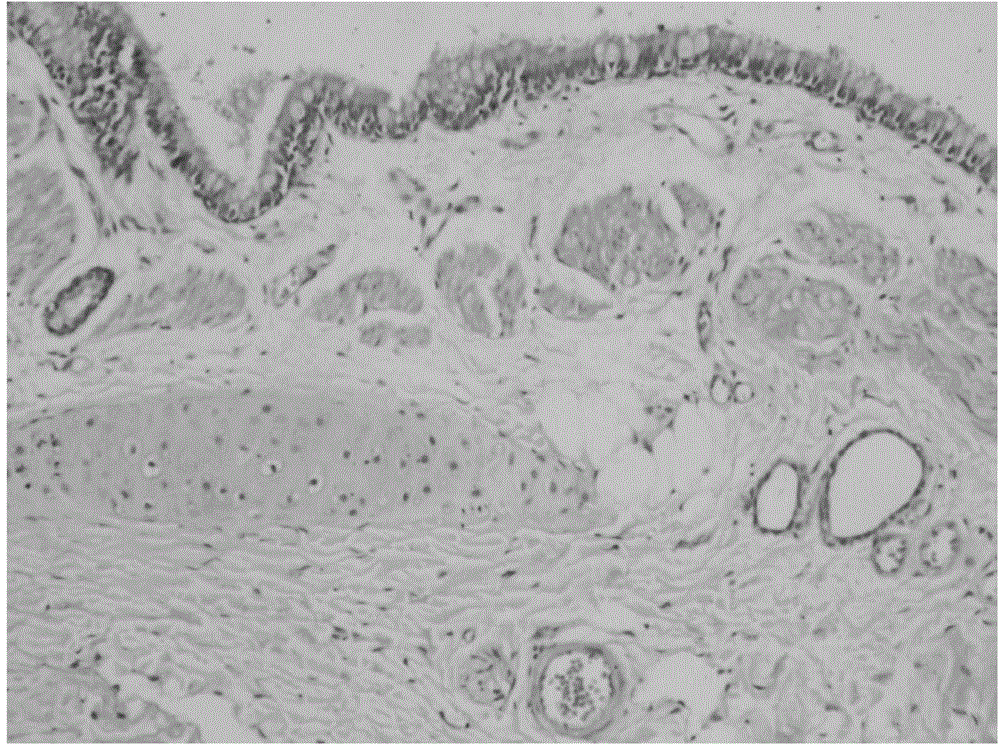

Tissue dewaxing transparent agent free of benzene

InactiveCN104155160ASoft effectNot easy to shrink and deformPreparing sample for investigationLiquid base cytologyStaining

The invention relates to a tissue dewaxing transparent agent free of benzene, which is used in biological histology, histopathology or forensic science, can make a tissue transparent, and can make the tissue dewaxed. The tissue dewaxing transparent agent belongs to the technical field of in vitro diagnostic reagents. The tissue dewaxing transparent agent mainly contains 95%-100% of alicyclic hydrocarbon, and the balance of accessories; the alicyclic hydrocarbon is a monocyclic alicyclic hydrocarbon or a bicyclic alicyclic hydrocarbon. The tissue dewaxing transparent agent free of benzene has the advantages of being non-toxic, soft in effect, and not easy to cause shrinkage, deformation, hardening and embrittlement of a tissue material, capable of improving the section intact rate, insensitive to the humid environment, not easy to muddy due to absorption of moisture in the air, and the like; not only can be used for liquid based cytology, immunohistochemistry, biological histology, routine pathological diagnosis, and immunohistochemical diagnostic techniques, is also suitable for special staining method and histochemical techniques. The refractive index of used alicyclic hydrocarbon transparent agent (cyclohexane) is 1.42, the (methyl cyclohexane) refractive rate is 1.42, and is basically consistent with the tissue refractive index (1.418), and the transparent effect is better.

Owner:陆可望 +1

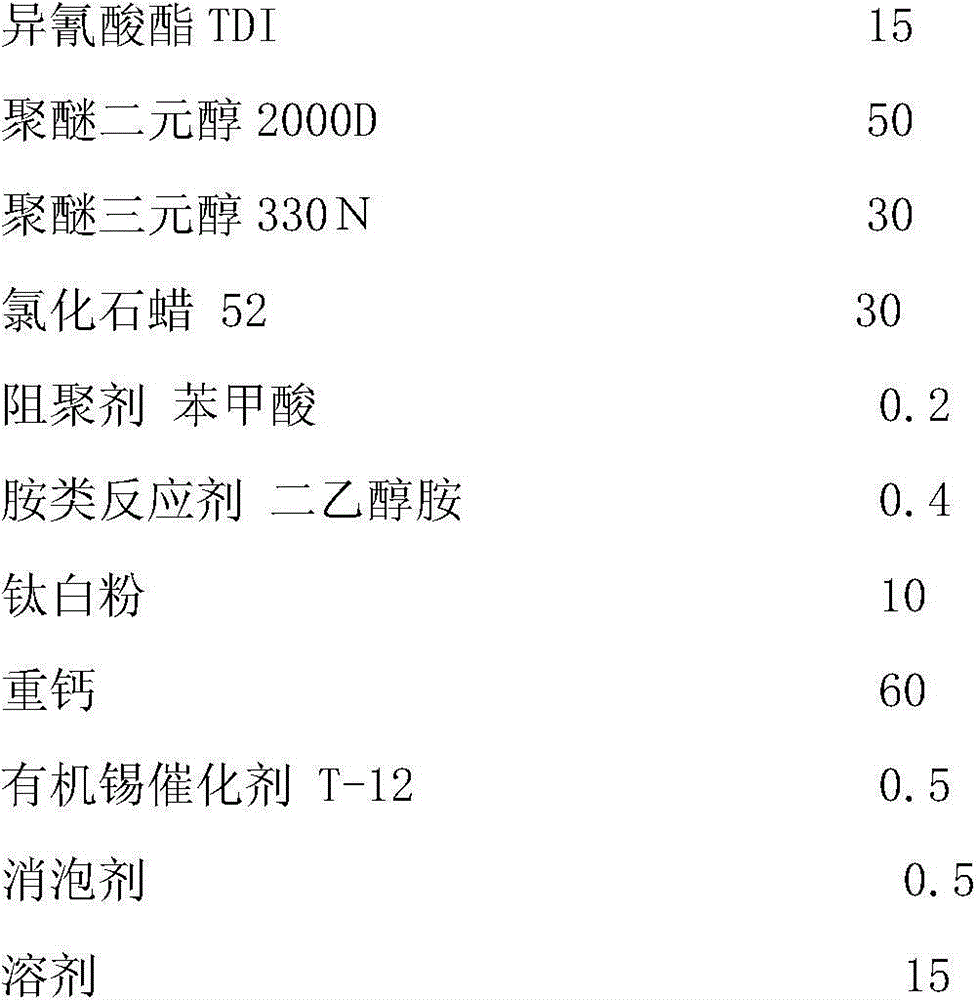

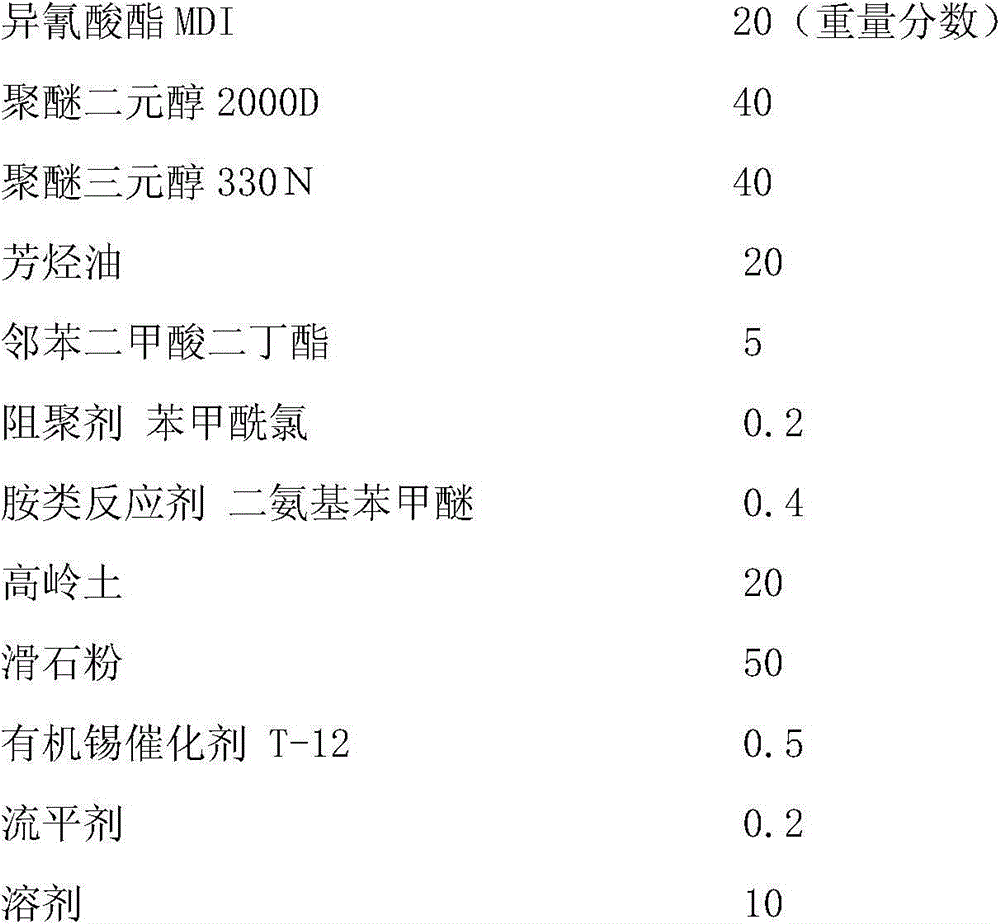

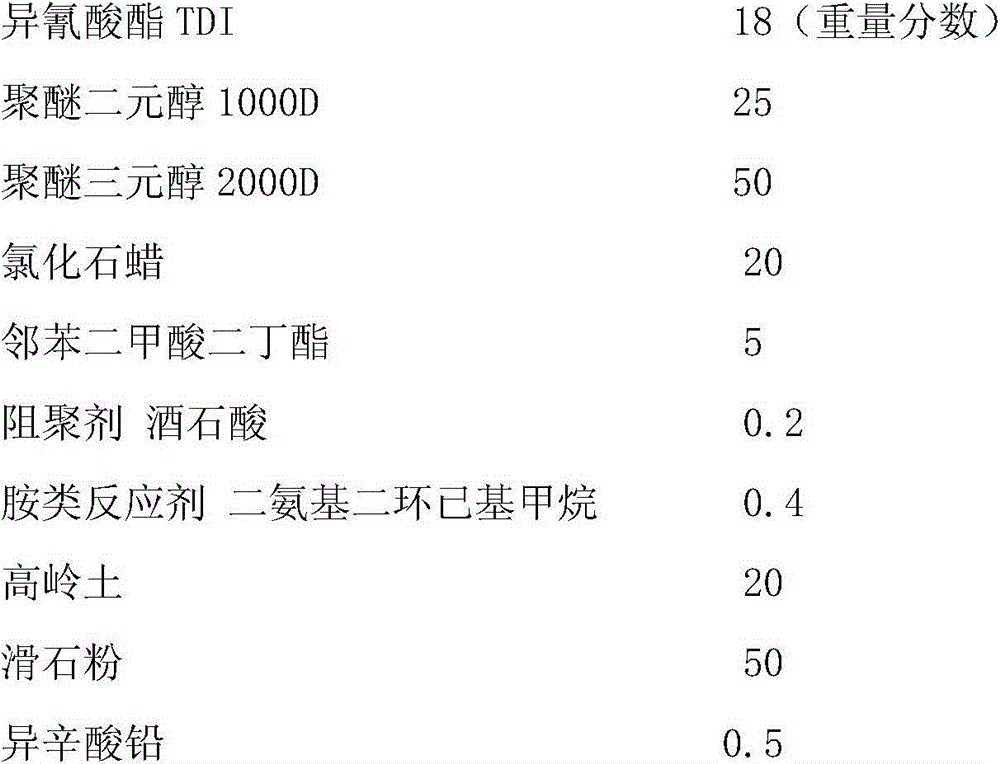

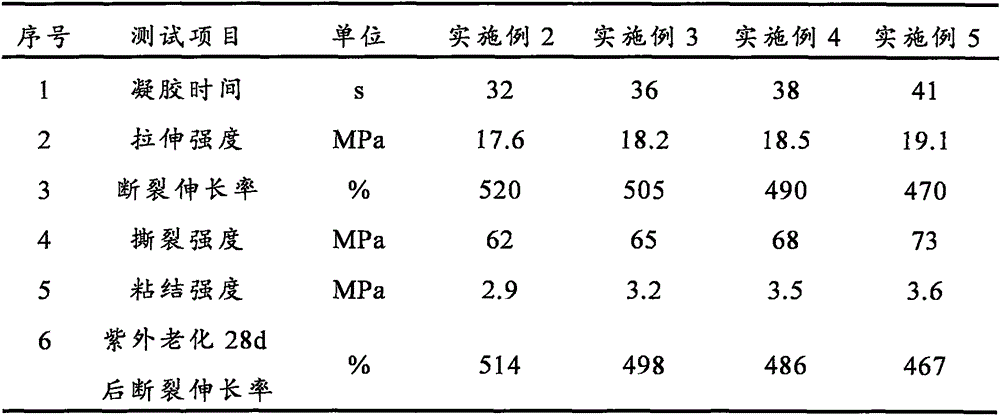

Single-component reactive thixotropic polyurethane waterproof paint and preparation method thereof

ActiveCN104559735ASolve the problem of particularly serious flowImprove constructabilityPolyurea/polyurethane coatingsDiaminodiphenyl etherPlasticizer

The invention discloses a single-component reactive thixotropic polyurethane waterproof paint which comprises the following components in parts by weight: 10-25 parts of isocyanate, 60-100 parts of polyether, 20-40 parts of plasticizer, 0.1-1 part of polymerization inhibitor, 0.1-1 part of amine reactant, 0.2-1 part of catalyst, 20-80 parts of pigment and filler, 5-20 parts of solvent and 0.1-1 part of high-performance assistant. The amine reactant is one or mixture of more of diaminodiphenyl ether, diamidodicyclohexyl methane, dialkylol amine and the like. The polyurethane waterproof paint has favorable thixotropic properties, and basically does not flow when being applied 2-3 times into a 1.5-2 mm coating in facade construction, thereby solving the problems of severe flow and difficulty in thickness increase in facade construction of the existing single-component polyurethane waterproof paint, effectively reducing the waste of materials and enhancing the operating efficiency and operating quality.

Owner:XUZHOU WONIUSHAN NEW WATERPROOF MATERIALS

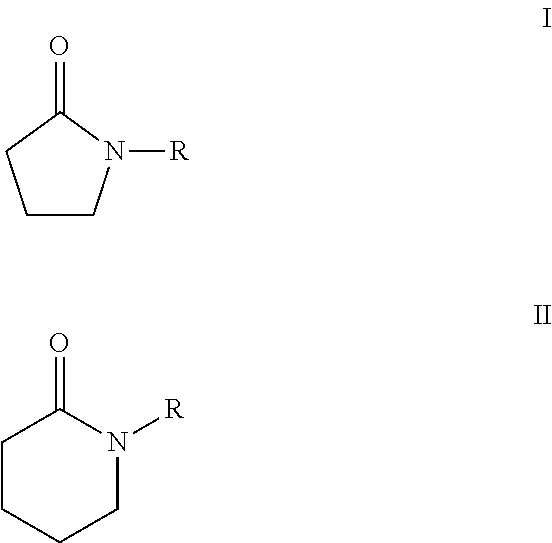

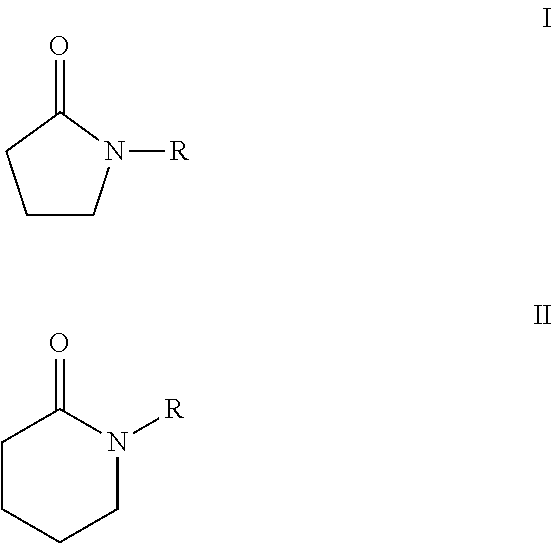

N-methyl pyrrolidone-free polyurethane dispersions based on dimethylol propionic acid

InactiveCN1865312ALiquid surface applicatorsPolyureas/polyurethane adhesivesPropanoic acidPolymer science

The present invention relates to aqueous polyurethane dispersions that are free from N-methylpyrrolidone and other solvents and wherein the polyurethanes are the reaction products of A) a mixture of 25% to 90% by weight of 1-isocyanate-3,3,5,-trimethyl-5-isocyanatomethylcyclohexane (IPDI) and 10% to 75% by weight of 4,4'-diisocyanatodicyclohexylmethane, wherein the preceding percentages are based on the weight of component A), with B) one or more polyols having average molarcular weights (Mn) of 500 to 6000, C) one or more compounds which have at least one OH- or NH-functional group and contain a carboxyl and / or carboxylate group, wherein at least 50 mol % of the acid groups, based on the total moles of acid incorporated into the polyurethane, are incorporated by dimethylolpropionic acid, D) one or more polyols and / or polyamines having average molecular weights (Mn) of below 500, and E) optionally one or more monoalcohols and / or monoamines. The present invention also relates to a process for preparing the aqueous polyurethane dispersions and to the use of the polyurethane dispersions for preparing coatings or adhesives.

Owner:BAYER MATERIALSCIENCE AG

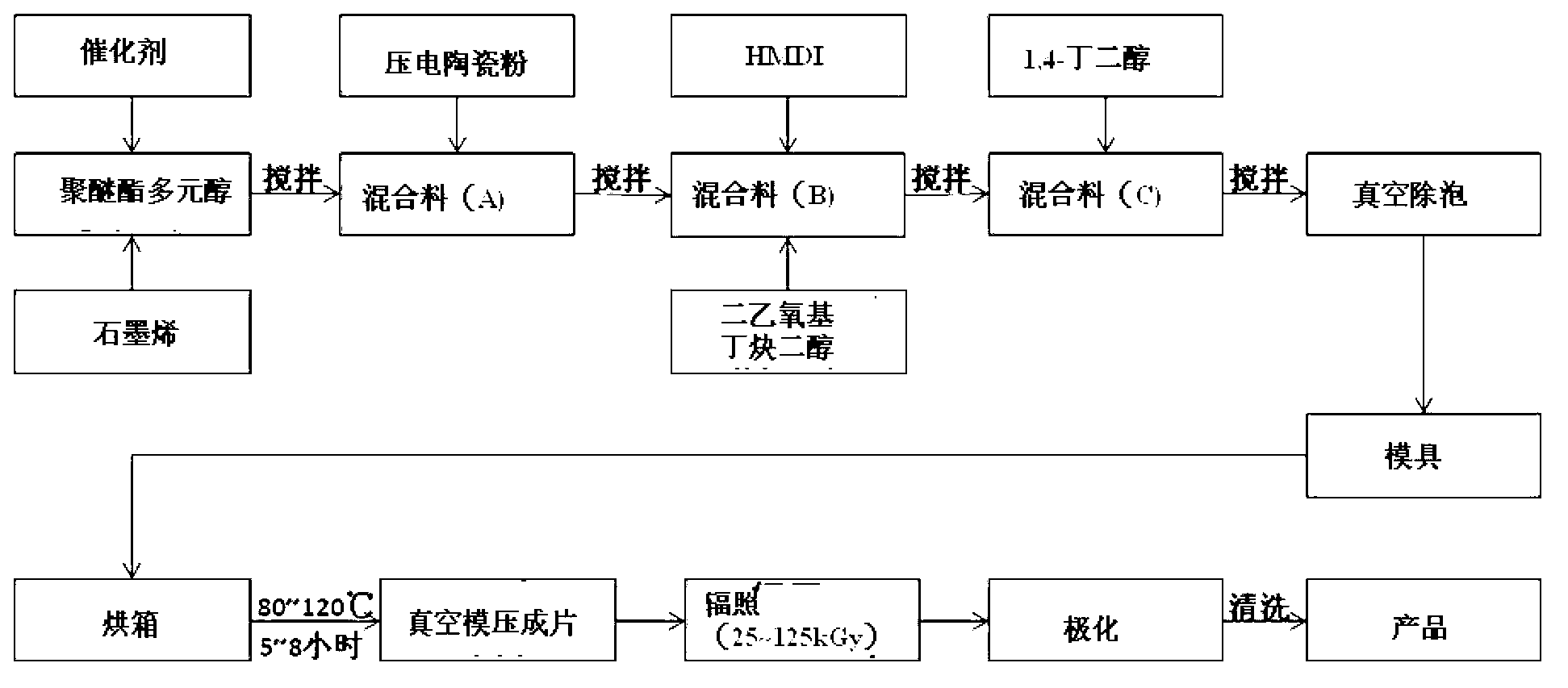

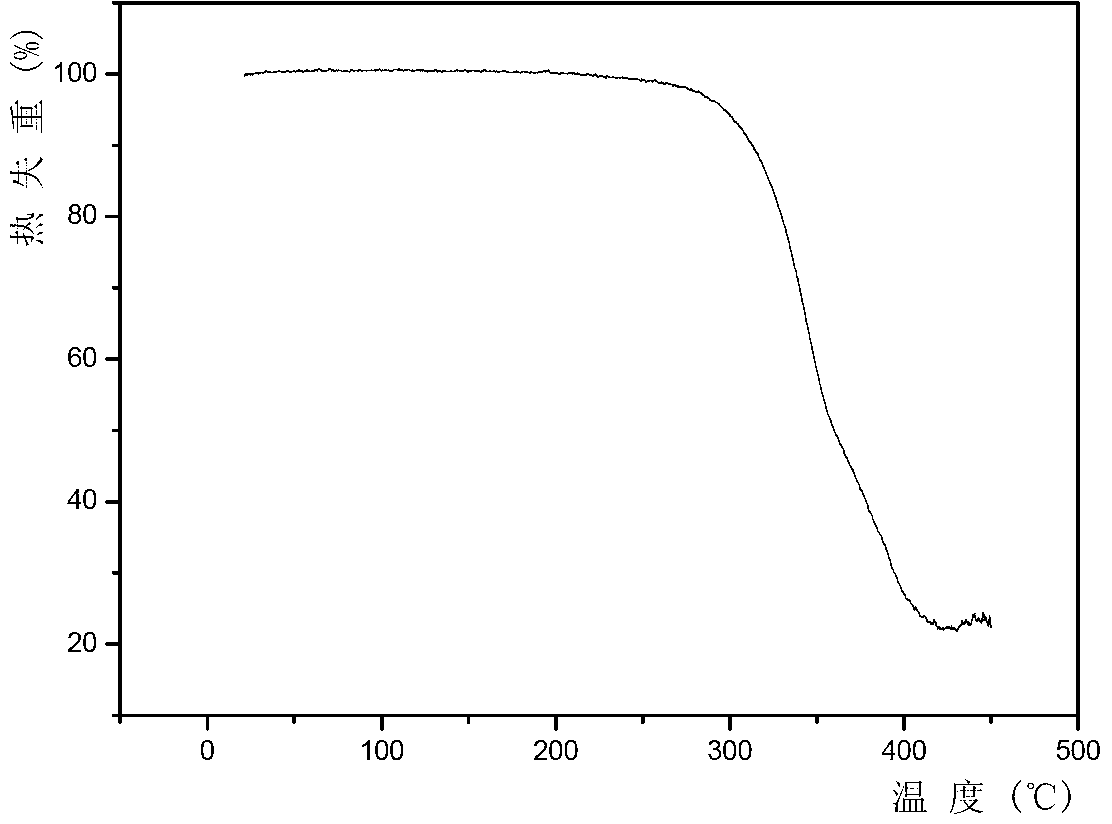

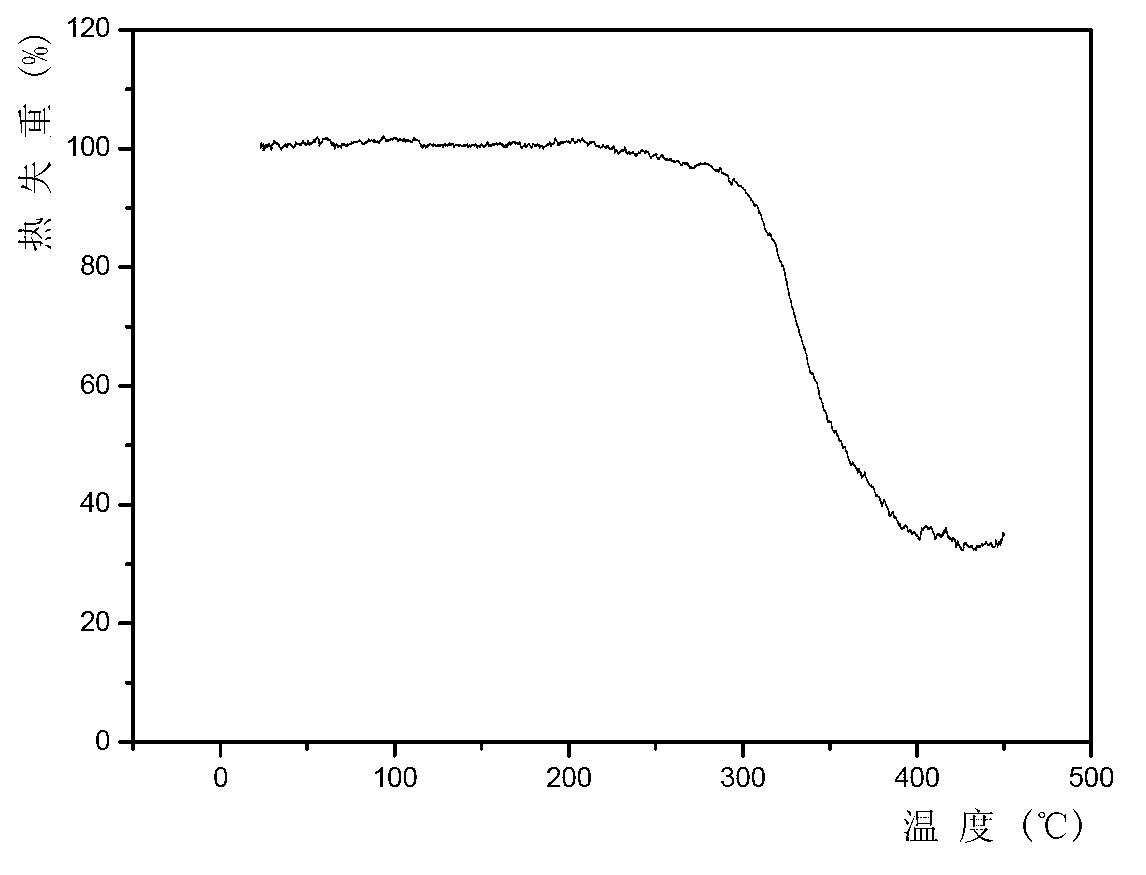

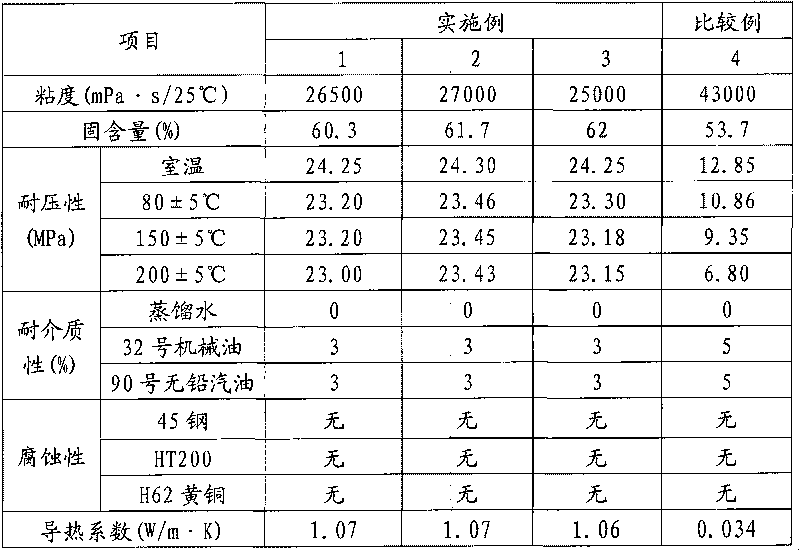

Irradiation-modified polyurethane piezoelectric damping material with conductive channel prepared from graphene and preparation method for same

The invention discloses an irradiation-modified polyurethane piezoelectric damping material with a conductive channel prepared from graphene and a preparation method for the same. The method comprises the following steps of: (1) mixing polyether ester polyol, 4,4'-dicyclohexyl methylene diphenyl diisocyanate, a catalyst, graphene, piezoelectric ceramic powder, dioxethyl butynediol and 1,4-butanediol to obtain a mixed material, performing vacuum defoaming on the mixed material, then pouring the mixed material in a mould, and sheeting via tape-casting to obtain sheets; (2) thermally curing the sheets, and then performing vacuum mould pressing to obtain a plate; and (3) irradiating the plate, and then performing electric polarization treatment to obtain the product. According to the method disclosed by the invention, via the introduction of the graphene conductive channel, the dielectric constant of the material is greatly increased, and the damping performance of the material is greatly improved. According to the method disclosed by the invention, crosslinking treatment is performed on the material via irradiation, so that the mechanical performance of the material is improved under the action of irradiation; and simultaneously, the post-curing time of the material is reduced, the production process is simplified, and the damping performance of the material is good.

Owner:BEIJING RADIATION APPL RES CENT

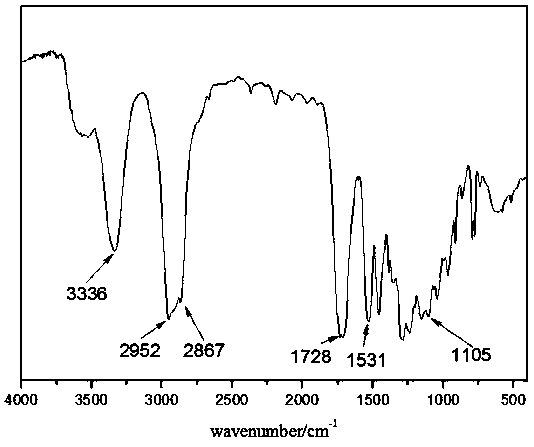

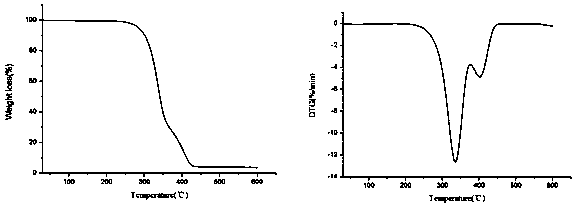

Mesoporous adsorbent resin with uniform pore size and large specific surface area and preparation method and application thereof

InactiveCN102600810ALarge specific surface areaExcellent adsorption kinetic propertiesOther chemical processesSolid sorbent liquid separationBenzoyl peroxideDivinylbenzene

The invention relates to mesoporous adsorbent resin with a uniform pore size and a large specific surface area, which has a brown spherical structure. The particle size is 0.3-1.0mm, and the pore size is 5-10nm. The preparation method comprises the steps of: dissolving polyvinyl alcohol in water to prepare an aqueous phase; mixing benzoyl peroxide as an initiator, a total monomer phase made via mixing of styrene and divinylbenzene as a crosslinking agent, a pore making agent with mixture of methyl cyclohexane and toluene to prepare an oil phase; and adding the aqueous phase into the oil phase to prepare matrix resin; adding xylene dichloride (XDC) and ferric chloride for reaction after swelling, filtering to obtain resin, cleaning and drying to obtain the target product. The invention has the advantages that: the specific surface area of the adsorbent resin is large, the pore size is concentrated in the mesoporous area, resin holes are distributed uniformly and have the single peak characteristics, the capacity for adsorption of relatively large dye molecules is high, and the equilibrium of adsorption can be achieved faster. The process of the preparation method is simple, the cost is low, and the preparation method has broad prospects for application in dye wastewater treatment.

Owner:NANKAI UNIV

High-temperature-resistant liquid sealant

ActiveCN101704965ALong-term useImprove aging resistanceOther chemical processesPolymer scienceGas phase

The invention discloses a high-temperature-resistant liquid sealant, which comprises the following main components: hydrogenated nitrile rubber compound, methyl cyclohexane, butyl acetate, terpene phenolic resin, gas-phase silica, aluminum powder, plasticizers and coupling agents. The sealant has the following advantages of: 1, adopting hydrogenated nitrile rubber as base material and having capability of long-term use at a high temperature and good aging resistance; 2, adding high-temperature-resistant fillers to improve the heat resistance of the sealant; 3, adding the aluminum powder to improve the thermal conductivity of the sealant; 4, adopting an environment-friendly solvent system, taking the methyl cyclohexane and the butyl acetate as mixed solvent, having little smell and low toxicity and meeting requirements of environmental protection; and 5, adopting a preparation process high in solid content and low in viscosity and having construction convenience and suitability for injection and extrusion processes.

Owner:GUANGDONG SANVO CHEM IND TECH

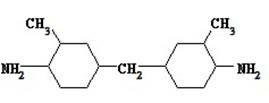

Synthesizing method of 3,3'-dimethyl-4,4'-diamido-dicyclohexyl methane

InactiveCN102030657AReduce processing costsAvoid separationOrganic compound preparationAmino compound preparationAlkaline earth metalHydrogenation reaction

The invention relates to a synthesizing method of 3,3'-dimethyl-4,4'-diamido-dicyclohexyl methane (MACM), belonging to the technical field of fine chemical synthesis. The synthesizing method comprises the following steps of: placing the MACM and 3,3'-dimethyl-4,4'-diamido-diphenyl methane (MDT) in a hydrogenation kettle according to the ratio of 1.0:(1.0-4.0), adding a Ru compound catalyst, adding trace alkaline earth metal assistant, performing hydrogenation reaction at the temperature of 120-190 DEG C and the pressure of 2.0-10.0MPa, cooling, discharging and filtering and rectifying to obtain pure MACM product. The invention has the advantages of low reaction temperature, low pressure, low requirement for devices, easy and simple operation, good product purity, high yield, good economical efficiency of reaction atom and no process waste water and gas in the whole technical process, technically and greatly reduces the generation source of three wastes, is environmental-friendly and has better industrial application prospect.

Owner:JIANGSU QINGQUAN CHEM CO LTD +1

Waterproof polyurea coating and preparation method thereof

ActiveCN105176343AImprove photostabilityGood weather resistanceAntifouling/underwater paintsPaints with biocidesPhotocatalytic reactionSilanes

The invention provides a waterproof polyurea coating and a preparation method thereof. The waterproof polyurea coating comprises a component A and a component B, wherein the component A comprises 3,3-dimethyl- 4,4-diisocyanatodicyclohexylmethane, polyether glycol and a solvent; and the component B comprises aminopolyether, an amine chain extender, a plasticizer and silane-modified nanometer lithopone. According to the waterproof polyurea coating, 3,3-dimethyl-4,4-diisocyanatodicyclohexylmethane is used as the raw material, so that the light stability and weather resistance of the waterproof polyurea coating are improved, the problem that a coating prepared by taking an aromatic compound as a raw material is easily aged is solved, the coating is kept to have long enough gelling time and curing time, and the coating is relatively good in permeation and combination with a substrate. The silane-modified nanometer lithopone is adopted, so that the corrosion resistance and ageing resistance of the coating are improved; and ultraviolet is effectively absorbed, and a photocatalytic reaction is carried out, so that the coating has antibacterial property, and the pollution resistibility of the coating is improved.

Owner:上海恩缔实业有限公司

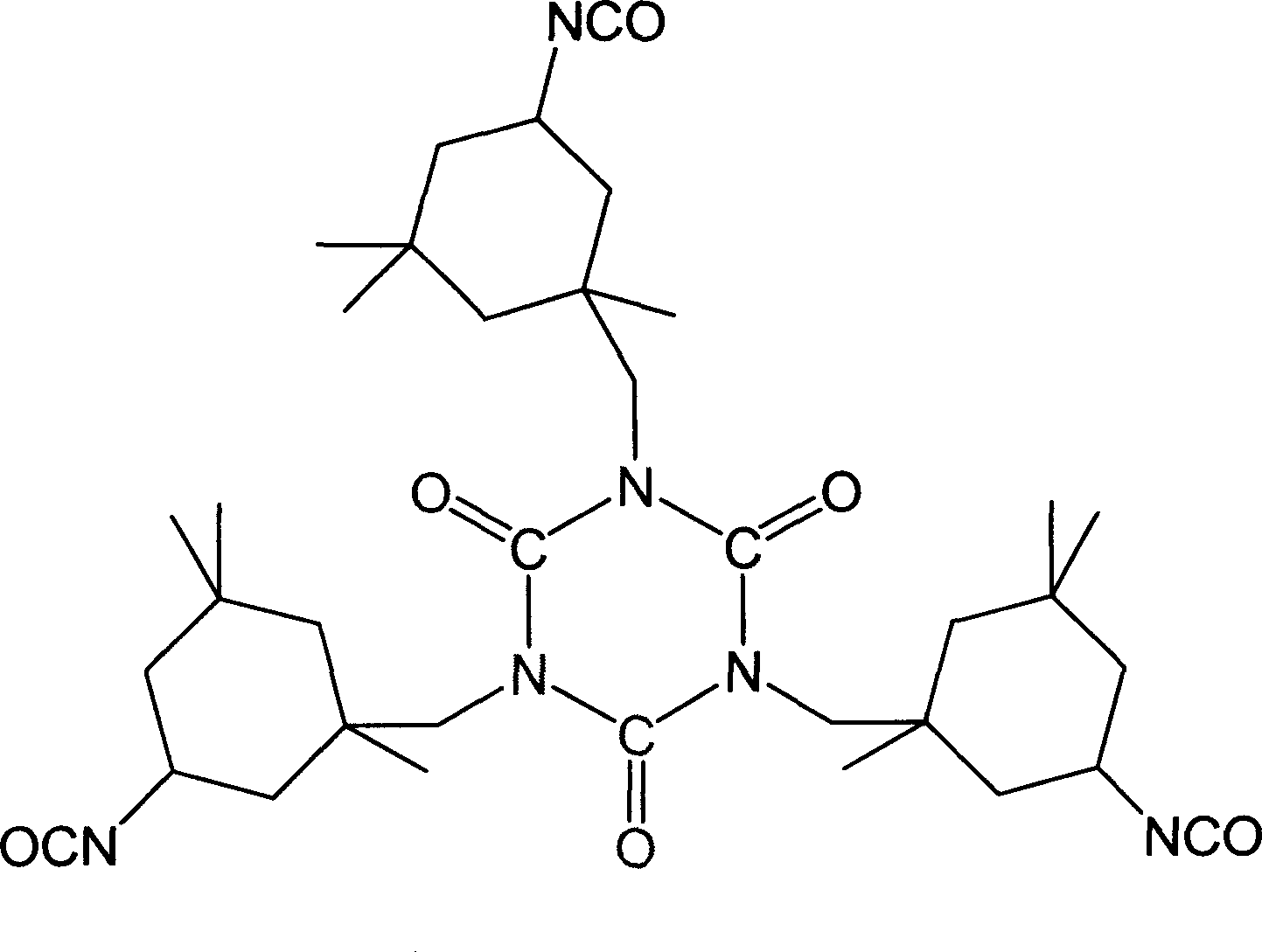

Method for preparing polyurethane acrylic resin

The invention discloses a manufacture method for urethane acrylate that makes isocyanate tripolymer contacting with hydroxy acrylic acid ester under the existence of catalyst, solvent and polymerization inhibitor. The isocyanate tripolymer could be one or several from IPDI tripolymer, HMDI tripolymer, and HTDI tripolyer. The invention has strong rigidity, and good wear resistance.

Owner:广东中科建设科技有限公司

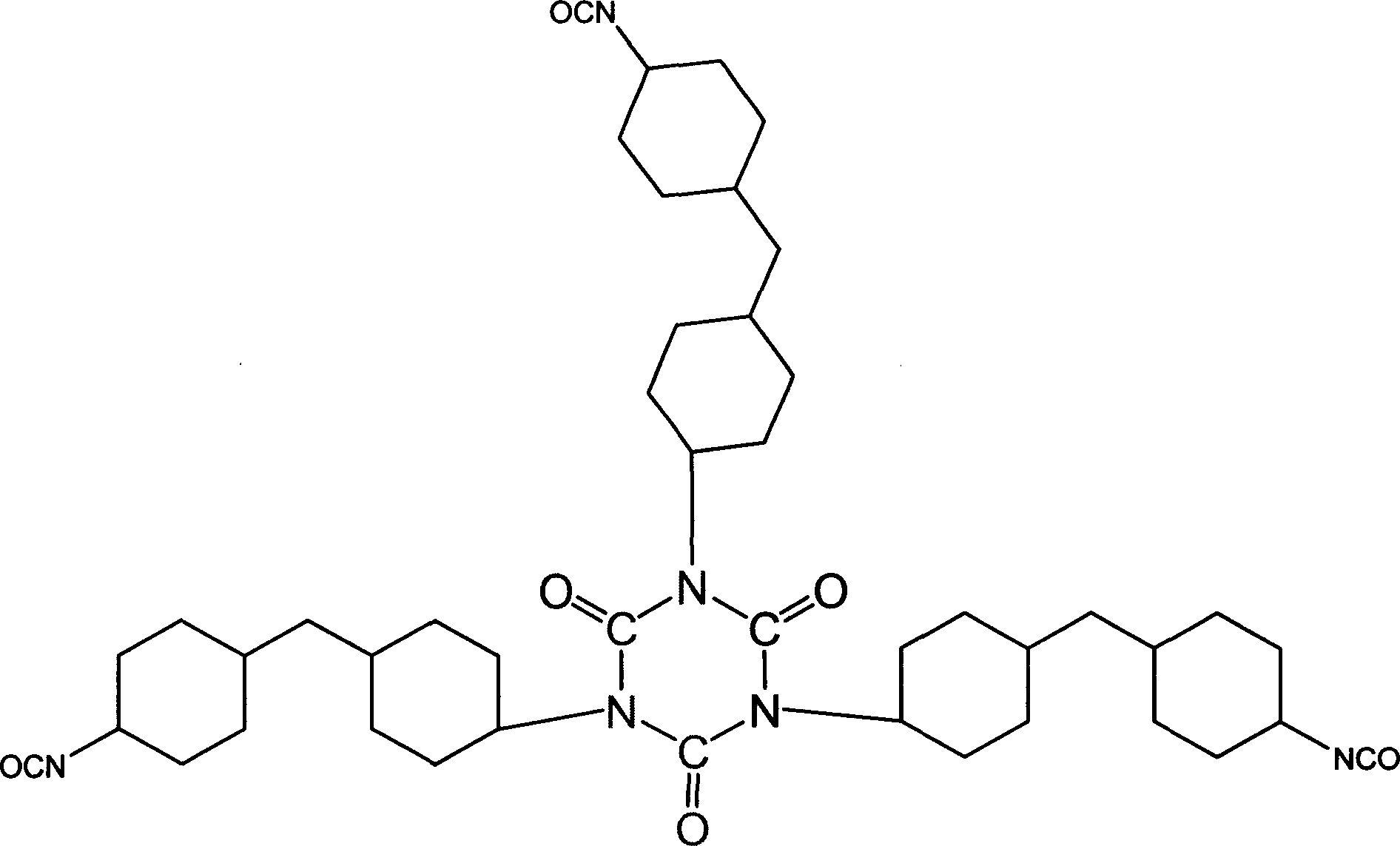

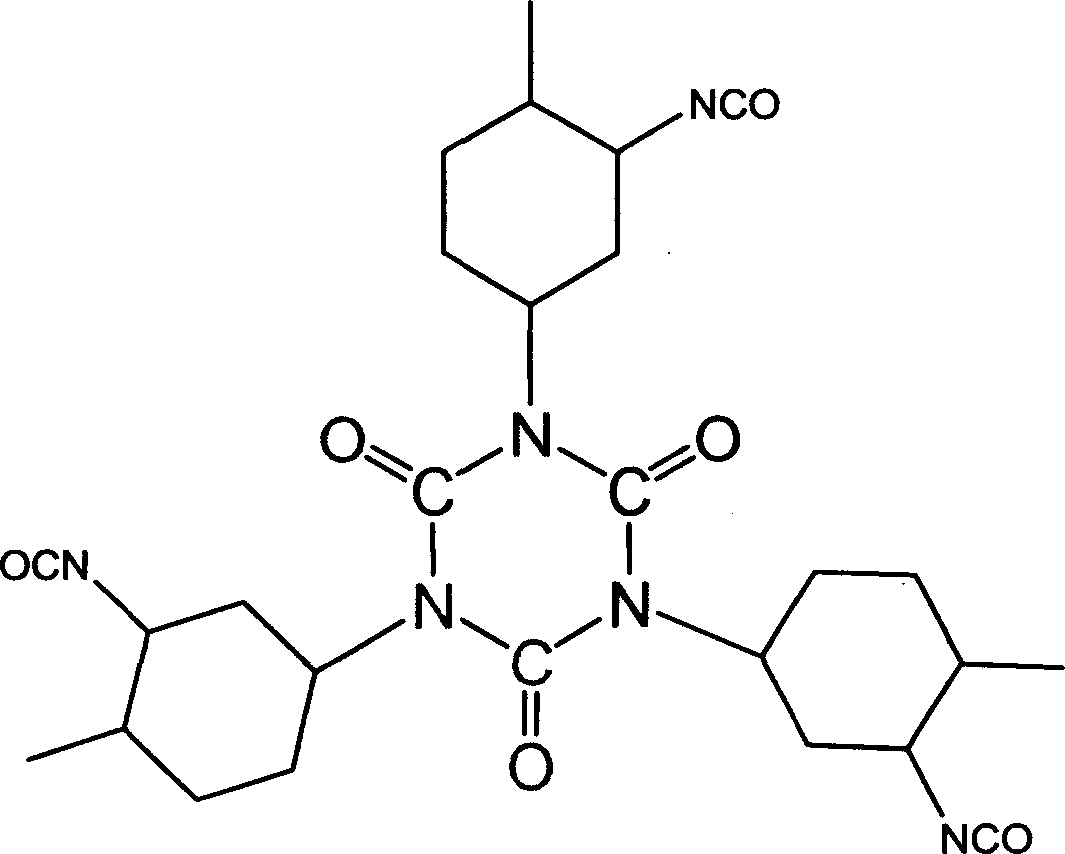

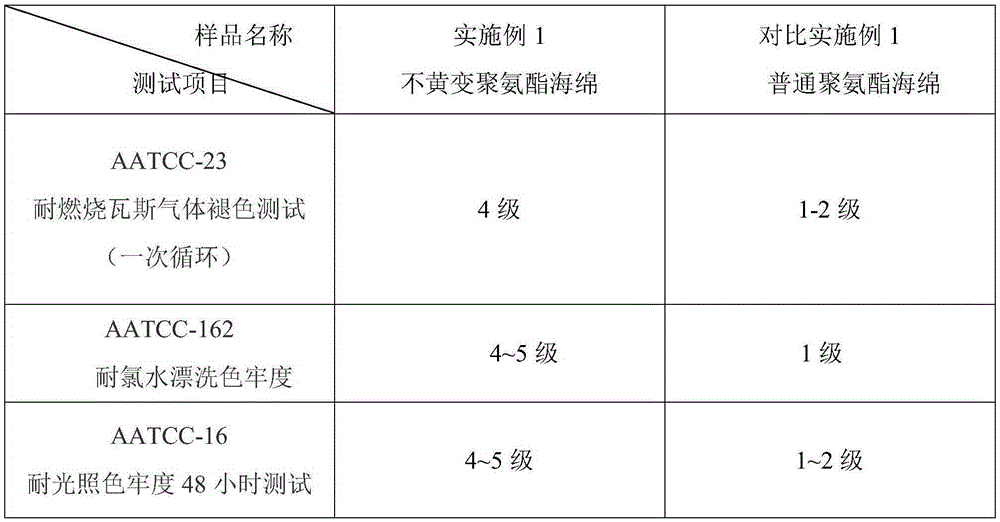

Method for preparing no-yellowing polyurethane sponge capable of being foamed at normal temperature

The invention discloses a method for preparing no-yellowing polyurethane sponge capable of being foamed at normal temperature. 4,4'-dicyclohexylmethane diisocyanate or a prepolymer thereof and polyether polyol serve as main raw materials; an environment-friendly catalyst and other auxiliary materials are added, the reaction and foaming are performed through a conventional polyurethane sponge production line at normal temperature, and the no-yellowing polyurethane sponge is obtained through a curing stage. The no-yellowing sponge can be obtained through the conventional polyurethane sponge production line at normal temperature, the raw materials do not need to be heated, existing equipment does not need to be modified, and the method has the advantages of small equipment investment and low energy consumption. In addition, since 4,4'-dicyclohexylmethane diisocyanate does not contain a benzene ring structure, obtained polyurethane sponge does not yellow, is excellent in aging resistance, oxidization resistance and illumination resistance and can be widely applied to the fields of shoe materials, furniture, electronics, printing supplies, aviation, automobiles, medical beauty, packaging, sports goods and articles for daily use.

Owner:CHANGZHOU SHUNXIANG NEW MATERIAL TECH CO LTD

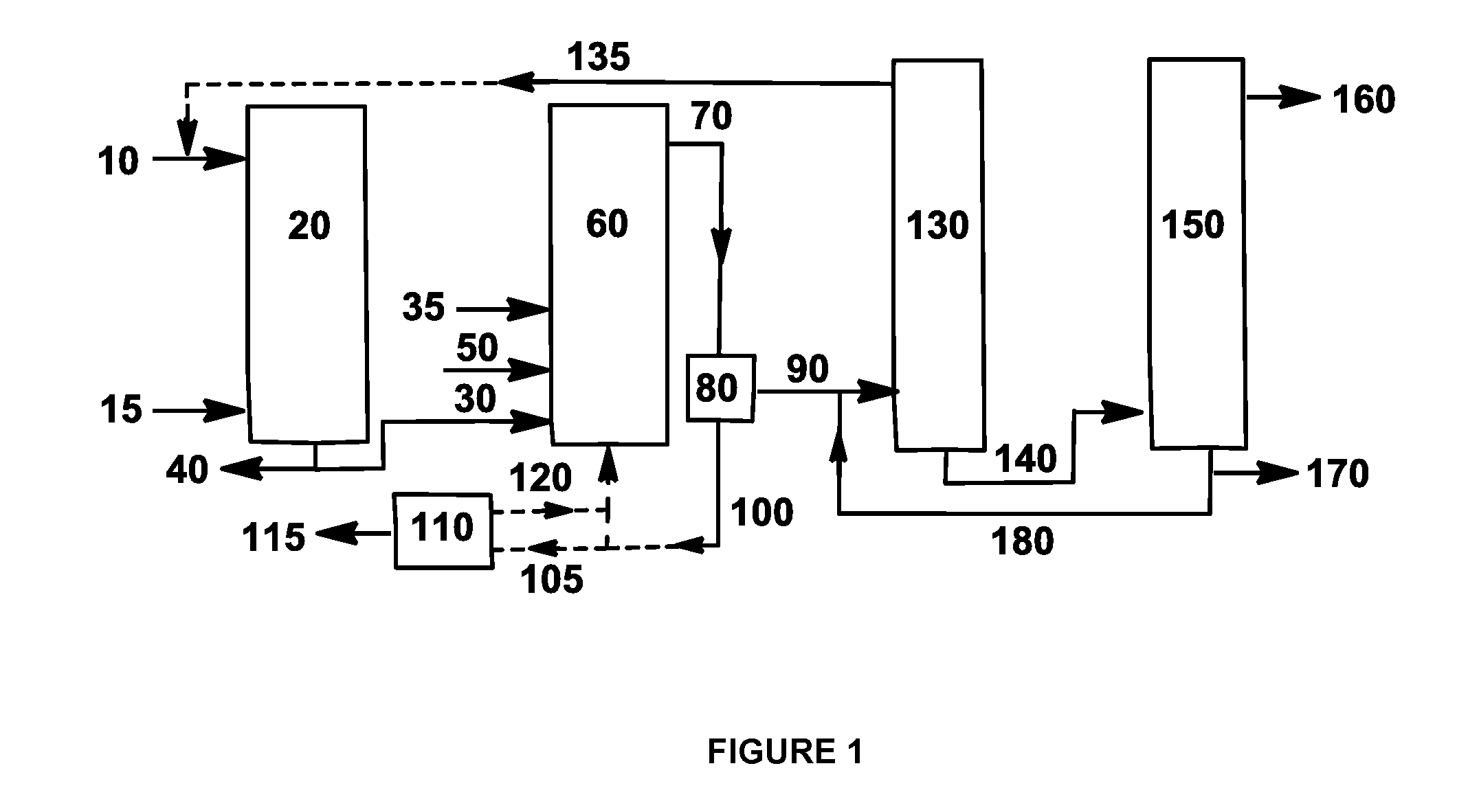

Processes for making cyclohexane compounds

ActiveUS20150183699A1Promote resultsOther chemical processesOrganic compound preparationCyclohexanecarboxylic acidHydrogenation process

This invention relates to hydrogenation processes for making cyclohexane compounds. More specifically, this invention relates to hydrogenation processes in the presence of tertiary amide solvent compounds, as well as compositions that can result from such processes. The invention thus provides processes for making cyclohexanecarboxylic acid compounds and processes for making hydroxymethylcyclohexane compounds.

Owner:EASTMAN CHEM CO

Aromatic hydrocarbon-free environment-protection chloroprene rubber adhesive with high adhesive strength

InactiveCN101177599AHigh bonding strengthWide range of usesMineral oil hydrocarbon copolymer adhesivesConjugated diene hydrocarbon adhesivesThermoplasticMethyl carbonate

The invention discloses aromatic hydrocarbon-free neoprene adhesive with high adhesive strength, which is characterized in that graft adhesive is firstly prepared according to the following formula: 10 percent-40 percent of methyl cyclohexane, 5 percent -30 percent of ethyl acetate, 0 percent-10 percent of butanone, 5 percent -30 percent of dimethyl carbonate, 8 percent-15 percent of chlorobutadiene rubber, 0 percent-2.5percent of SBS (thermoplastic styrene-butadiene rubber), 7 percent-15 percent of MMA (methyl methacrylate), 0.1percent-0.2 percent of initiator and 0.1 percent-0.5percent of antioxidant; then the invention is prepared by 100 portions of the graft adhesive prepared according to the formula, 0-10 portions of tackifying resin, 0-3 portions of strengthening agent , 0-3 portions of plasticizers and 0-20 portions of diluents. The product of the invention has the advantages of environmental protection, and high adhesive strength, etc.

Owner:GOOD CHEM SCI & TECH

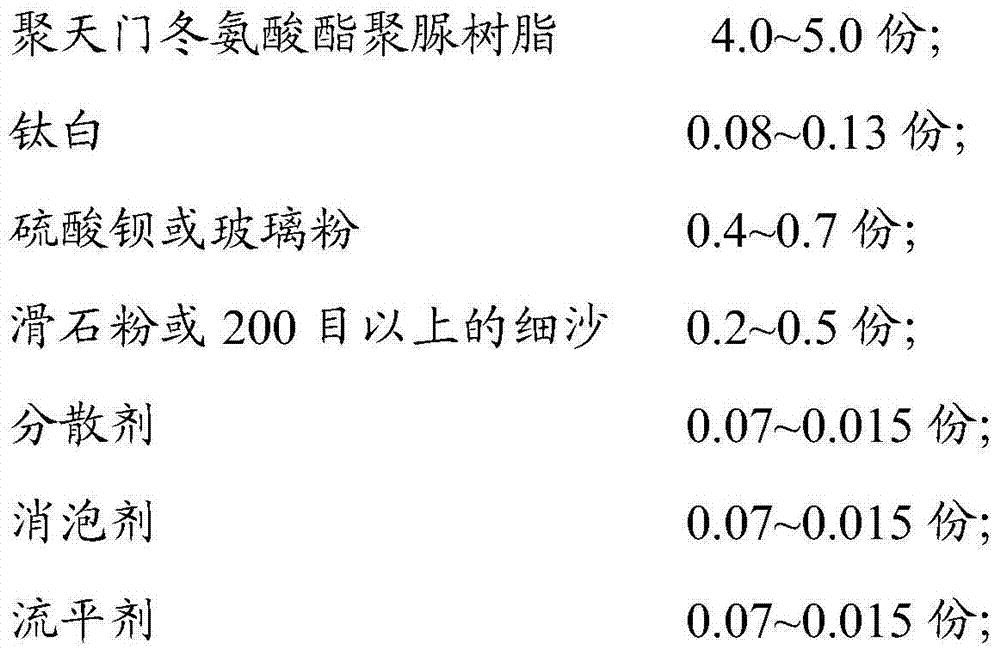

Polyurea floor coating and preparation and application methods thereof as well as carbamide resin

InactiveCN104497824AImprove wear resistanceImprove aging resistancePolyurea/polyurethane coatingsPolyaspartic acidAging resistance

The invention discloses a polyurea floor coating and preparation and application methods thereof as well as carbamide resin. The carbamide resin is polyaspartic acid ester carbamide resin; the polyaspartic acid ester carbamide resin is prepared by reacting diethyl maleate and 3,3-dimethyl-4,4-methylenebis(cyclohexylamine) as raw materials at 60-80 DEG C for 70-74 DEG C, with the weight ratio of the diethyl maleate to the 3,3-dimethyl-4,4-methylenebis(cyclohexylamine) is 1.0 to (1.55-1.60). The polyaspartic acid ester carbamide resin can stably exist at a room temperature; the polyaspartic acid ester carbamide resin is taken as a base component; and packing, an assistant and the like are added, so as to prepare the polyurea floor coating disclosed by the invention. The polyurea floor coating and an HDI curing agent are mixed to use at a certain ratio, so that the polyurea floor coating has the advantages of good abrasive resistance, ageing resistance, waterproofness, controllable elasticity and high-strength shock resistance.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

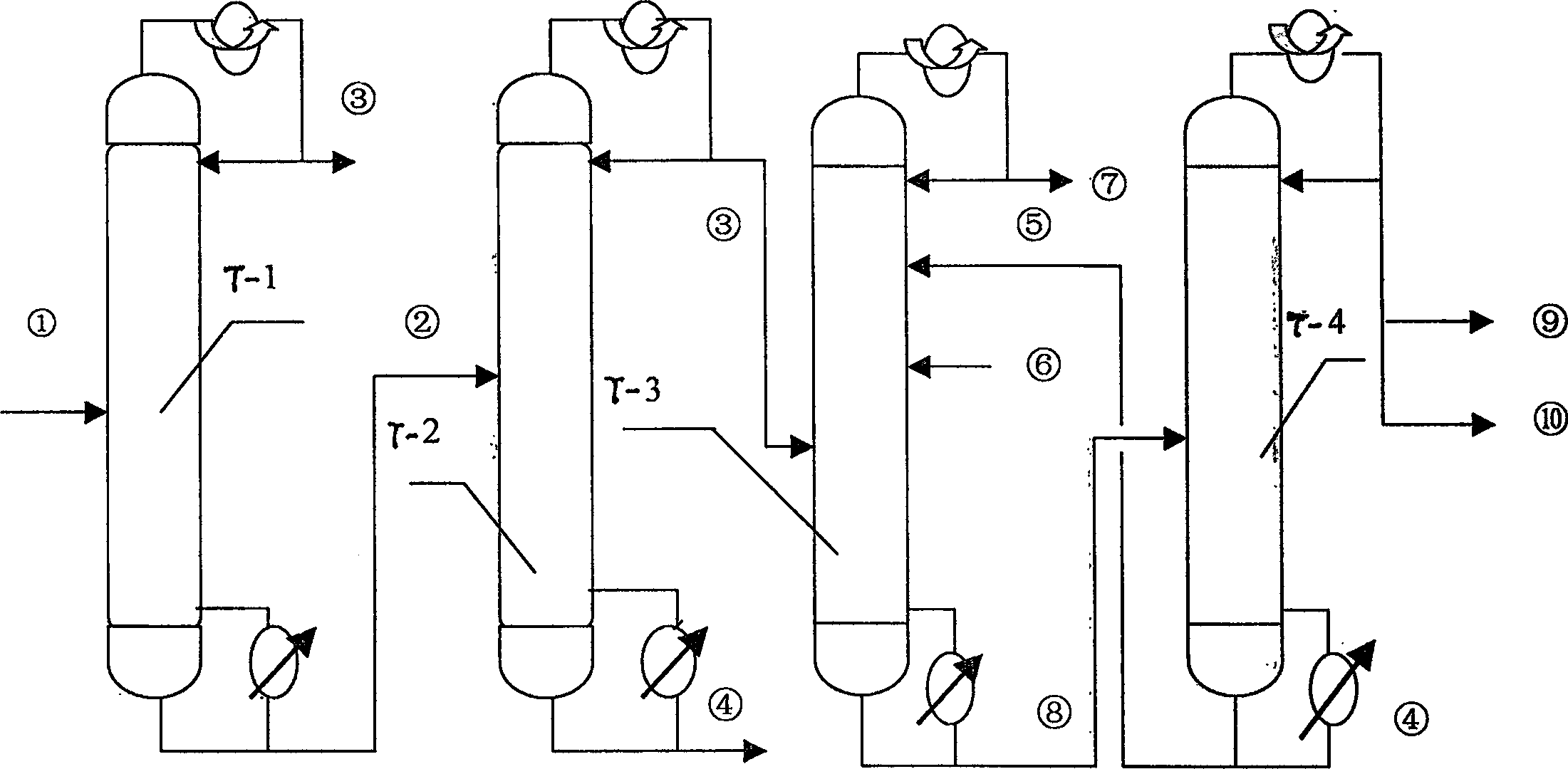

Method for distilling normal heptane and methyl - cyclohexane by using combination of rectification and compound extracted rectification

InactiveCN1872820AIncrease concentrationSimple processDistillation purification/separationMethyl cyclohexaneSolvent

This invention relates to a method for rectification and extraction of n-heptane and methyl cyclohexane. The method comprises: (1) pretreating 120# solvent oil in a primary rectification column to obtain a material containing more than 63% of n-heptane and methyl cyclohexane; (2) rectifying the material in a rectification column to obtain an overhead material containing more than 51% of n-heptane and more than 44% of methyl cyclohexane; (3) extracting the overhead material by a composite extractant at an overhead temperature of 98-100 deg.C to obtain an overhead material containing more than 98.9% of n-heptane and a mixed liquid, and discharging the mixed liquid; (4) treating the mixed liquid in a regenerating column to obtain a fraction containing 67% of n-heptane and more than 98.5% of methyl cyclohexane; (5) recycling the other fractions and the extractant. In this invention, the concentrations of n-heptane and methyl cyclohexane are both higher than 98%. The yield of n-heptane is up to 87.5%, and the energy consumption is only 55% that of hydrogenation and rectification method.

Owner:NANJING NORMAL UNIVERSITY

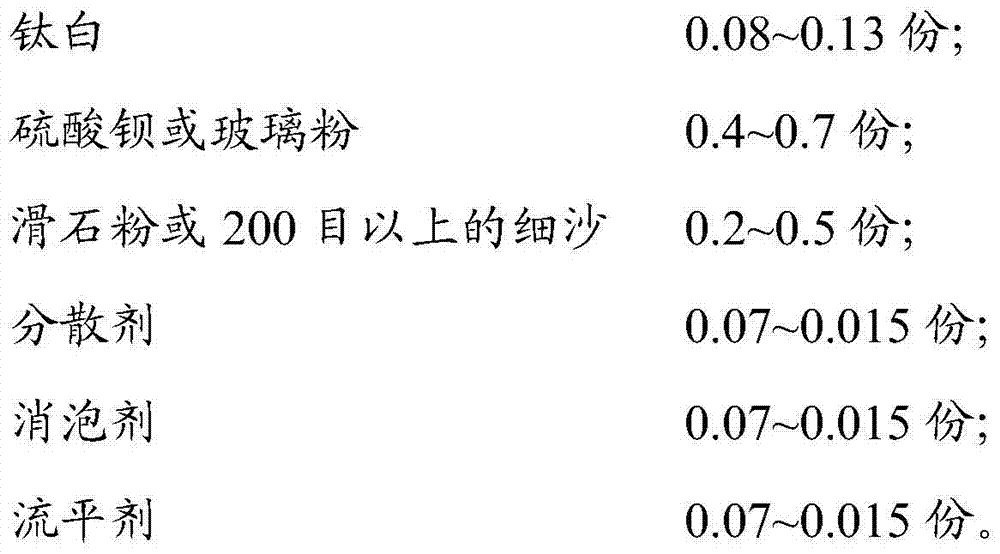

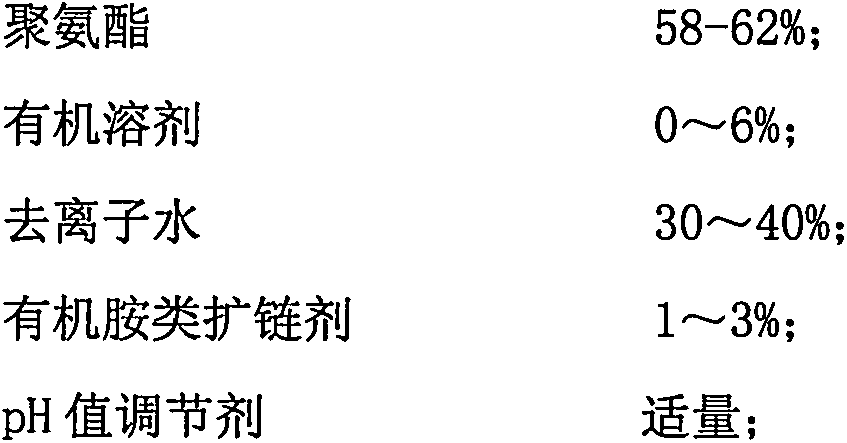

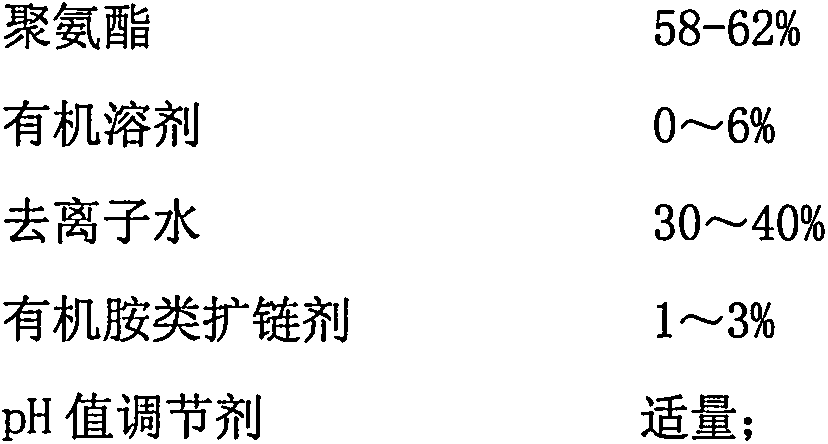

Waterborne polyurethane with solid content of 60%

The invention relates to preparation of waterborne polyurethane with the solid content of 60%. The waterborne polyurethane comprises the following components in parts by weight: 58-62 parts by weight of polyurethane, 0-6 parts by weight of an organic solvent, 30-40 parts by weight of deionized water, 1-3 parts by weight of an organic amine chain extender, and a proper amount of a pH value regulator. The preparation has the advantage that the high-solid-content waterborne polyurethane with the solid content of 60% is prepared through adopting of a specially-designed composite polyester polyol and a specially-designed composite isocyanate monomer. The composite polyester polyol comprises the following components in parts by weight: 20-40 parts by weight of a polyester polyol containing a sulfonate group, and 60-80 parts by weight of a polyester polyol having a highly branched structure. The composite isocyanate monomer comprises the following components in parts by weight: 20-70 parts by weight of isophorone diisocyanate (IPDI), and 30-80 parts by weight of dicyclohexyl methane diisocyanate (HMDI).

Owner:SHANGHAI SISHENG POLYMER MATERIAL

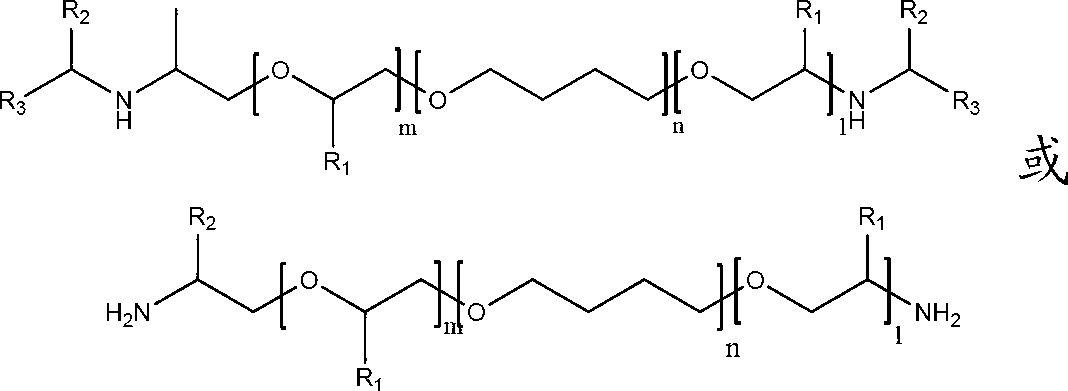

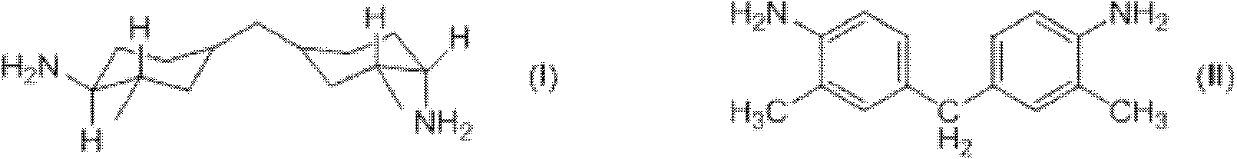

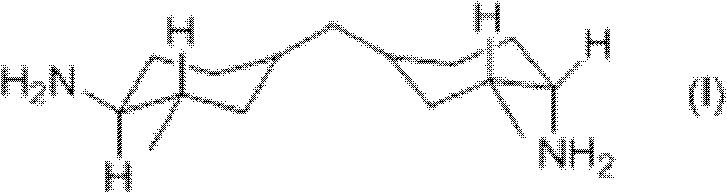

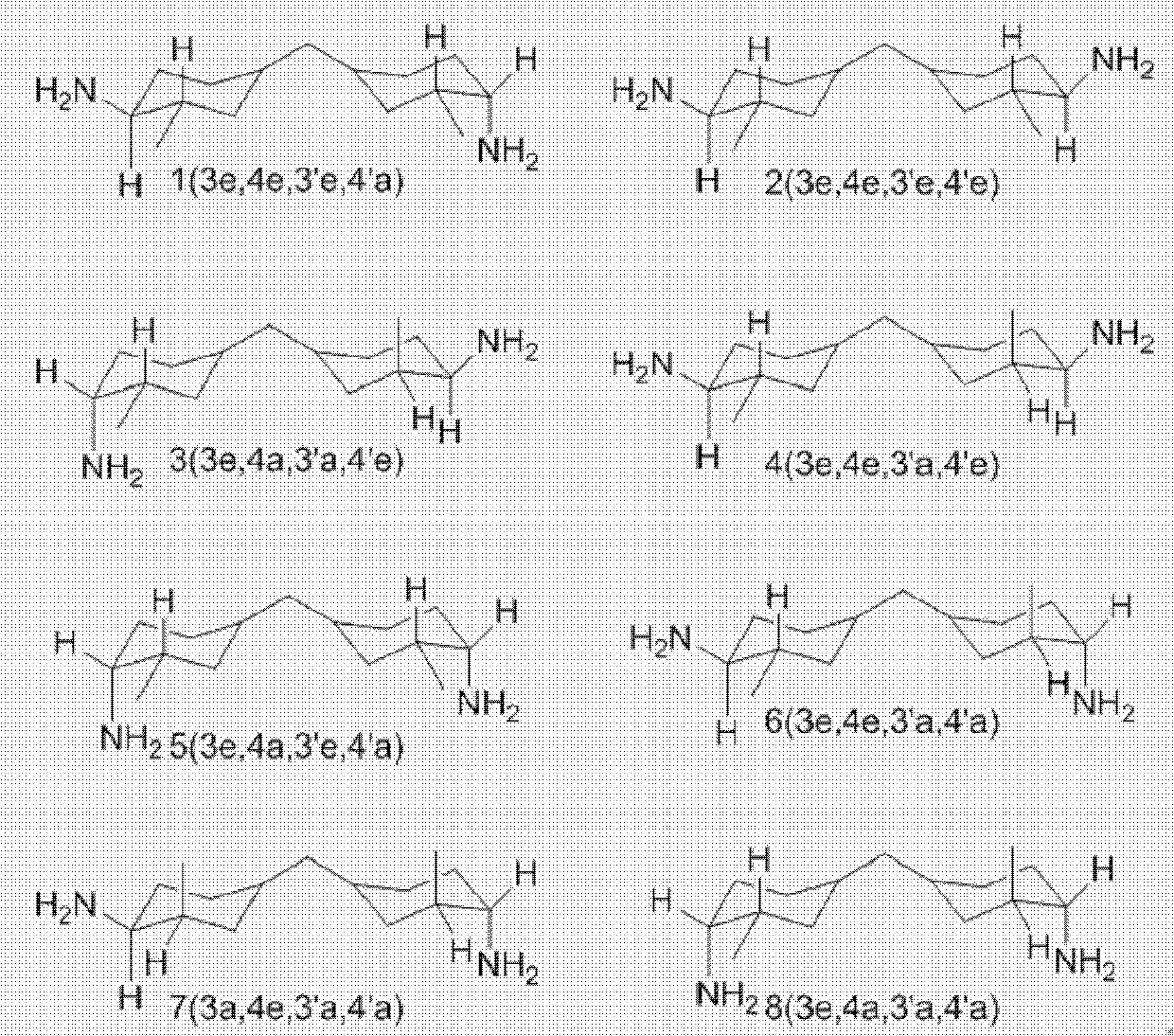

Method for synthesizing 3,3'-dimethyl-4,4'-diamino dicyclohexyl methane

ActiveCN102627569ALow first isomer contentQuality improvementOrganic compound preparationAmino compound preparationAlkaline earth metalReaction temperature

The invention relates to a method for synthesizing 3,3'-dimethyl-4,4'-diamino dicyclohexyl methane (MACM), comprising the following steps of: using 3,3'-dimethyl-4,4'-diamino dibenzyl methane (MDT) as a raw material, and performing catalytic hydrogenation to obtain the product MACM. In addition, the content of a first isomer as shown in the formula I in the MACM product is less than or equal to 26 wt%. Correspondingly, the invention also provides an MACM product composed of a plurality of isomers with the first isomer in the composition accounts for a specific proportion. During the preferred reaction, a noble metal catalyst is used and an alkaline earth metal auxiliary agent is added; the preferred reaction temperature is 50-150 DEG C, the reaction pressure is 8-30MPa, and the reaction time is 3-50 hours. The MACM is prepared at low temperature and at low pressure. The method provided by the invention has advantages of short reaction time, mild condition and simple technology. The MACM product has low freezing point, which is beneficial to production, storage and usage of the product. In addition, the quality of downstream products can be raised.

Owner:JIANGSU QINGQUAN CHEM CO LTD

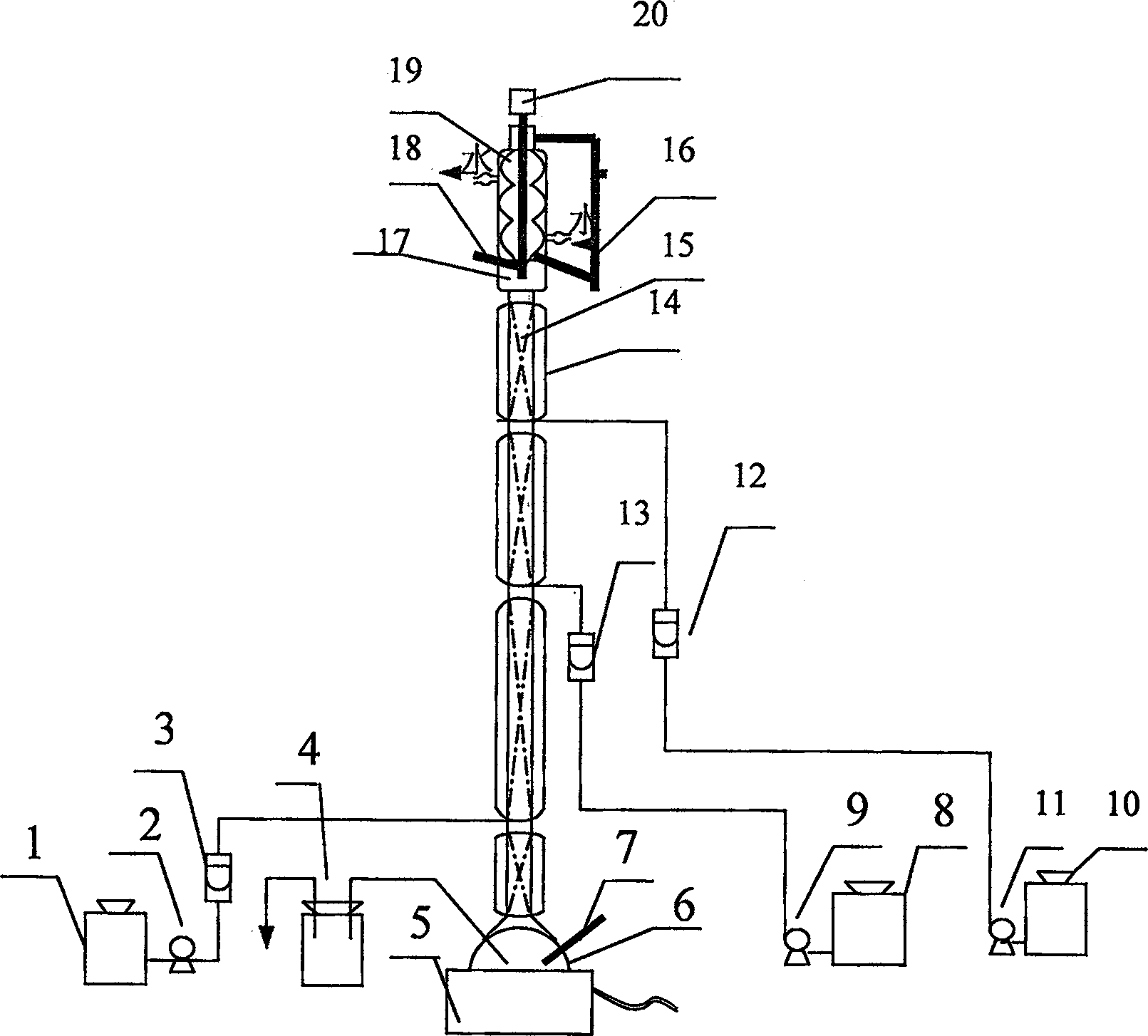

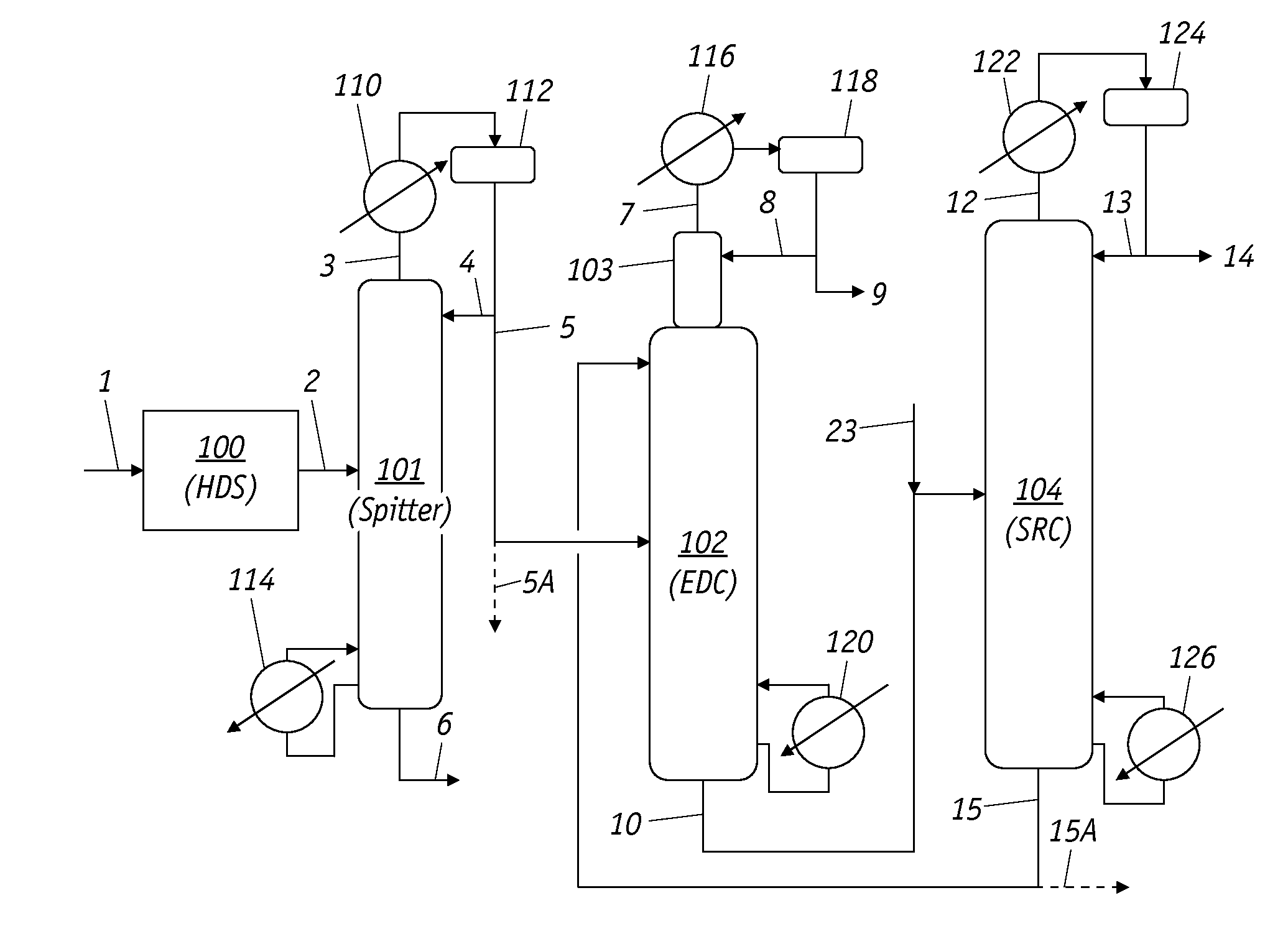

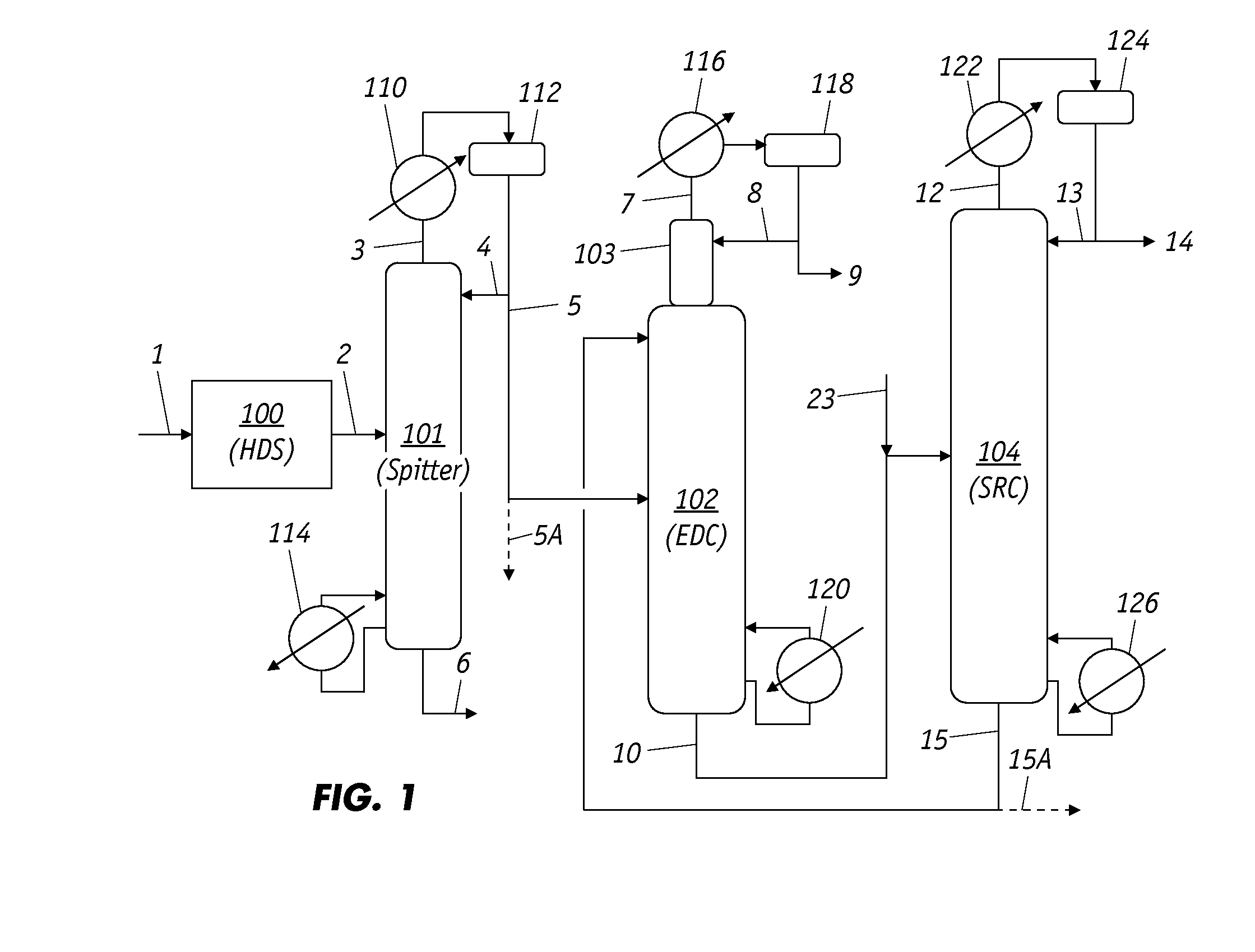

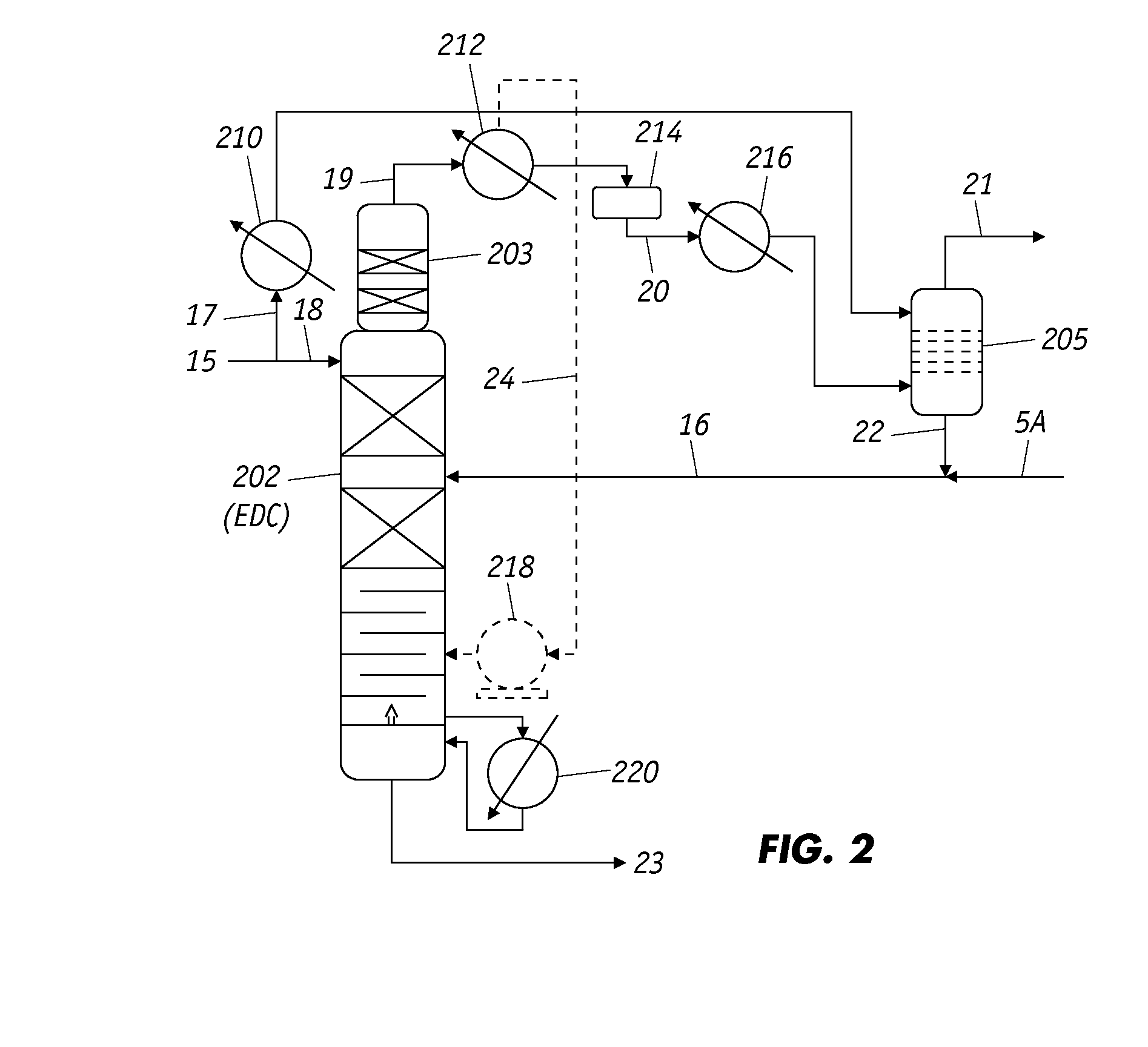

Extractive Distillation Process For Benzene Recovery

ActiveUS20130228447A1Easy to separateEasy to implementDistillation purification/separationExtractive distillationBenzeneHydrodesulfurization

Recovering high purity benzene from hydrocarbon feedstock containing aromatics and non-aromatics is implemented by simple and low-cost modifications to conventional extractive distillation columns (EDCs). Methyl cyclohexane (MCH) that is generated through non-selective hydrogenation of toluene in hydrodesulfurization (HDS) units is a major contaminant in benzene production. To meet MCH specifications, often times the extractive distillation (ED) process for recovering purified benzene is operated with excessive benzene loss to the overhead raffinate stream, producing a lower quality non-aromatic product. Novel techniques (1) remove operational constrictions of the HDS unit on MCH production, thus lengthening the catalyst life and (2) allow the EDC to drive essentially any amount of MCH away from the bottom benzene product without concerns with benzene loss to the overhead raffinate stream and (3) recover benzene from the overhead raffinate stream to upgrade the quality of non-aromatic product and increase the benzene product recovery.

Owner:CPC CORPORATION +1

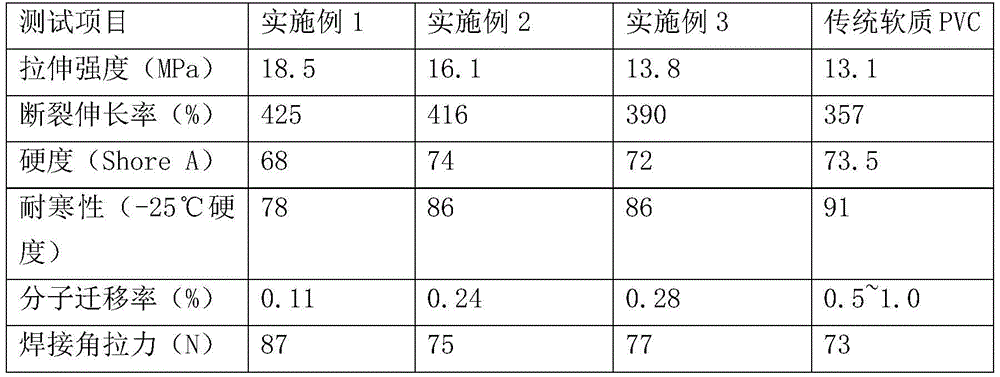

Modified polyvinyl chloride door seal and preparation method thereof

The invention belongs to the technical field of door seal materials, and relates to a modified polyvinyl chloride door seal and a preparation method thereof. The door seal is prepared from, by weight, 40-50 parts of polyvinyl chloride resin powder, 5-15 parts of anti-yellowing thermoplastic elastomer, 0-5 parts of 1,2-cyclohexane dicarboxylic acid di-isononyl ester, 5-20 parts of trioctyl trimellitate, 0-5 parts of dioctyl adipate, 5-10 parts of epoxidized soybean oil, 5-10 parts of polyester oligomer, 10-15 parts of filler, 1-3 parts of a stabilizer, 1-3 parts of a compatilizer, 1-3 parts of a lubricating agent and 0.1-1 part of pigment. Fat diisocyanate is two of hexamethylene diisocyanate (HDI), isophorone diisocyanate (IPDI) and hexamethylene diisocyanate (HMDI). The defects that the hardness of a traditional soft PVC door seal is sharply increased at low temperature and elasticity becomes poor are overcome, the tensile strength and the breaking elongation of the door seal are improved, the welding angle pull force of the door seal is increased, and the service life of the door seal is prolonged.

Owner:QINGDAO NEW MATERIAL TECH IND PARK DEV

Degradable polyurethane biological material and preparation method thereof

The invention discloses a degradable polyurethane biological material and a preparation method thereof. The degradable polyurethane biological material is prepared from the following components in parts by weight: 7.8 to 19 percent of poly epsilon-caprolactone (PCL), 3 to 15.6 percent of polyethylene glycol (PEG), 12.8 to 13.8 percent of isocyanate, 3.1 to 4.1 percent of a chain extender, 0.09 to0.11 percent of a catalyst and 57.6 to 63 percent of a green solvent, wherein isophorone diisocyanate (IPDI), hexamethylene diisocyanate (HDI), dicyclohexyl methane diisocyanate (HMDI) or mixed isocyanate of more than two of the above materials is adopted as the isocyanate. The preparation method comprises the following steps: blending according to the proportion of the raw materials, adding the vacuum-dried PCL and PEG into the isocyanate dropwise, reacting at 70 to 85 DEG C for 2 to 3 hours, adding the solvent and the catalyst, adjusting the temperature to be 55 to 65 DEG C, adding the chainextender, performing chain-extending reaction for 4 to 5 hours, casting the obtained polyurethane solution on a polytetrafluoroethylene mold, and naturally volatilizing the solvent in a ventilation kitchen to prepare a polyurethane film.

Owner:ZHENGZHOU UNIV

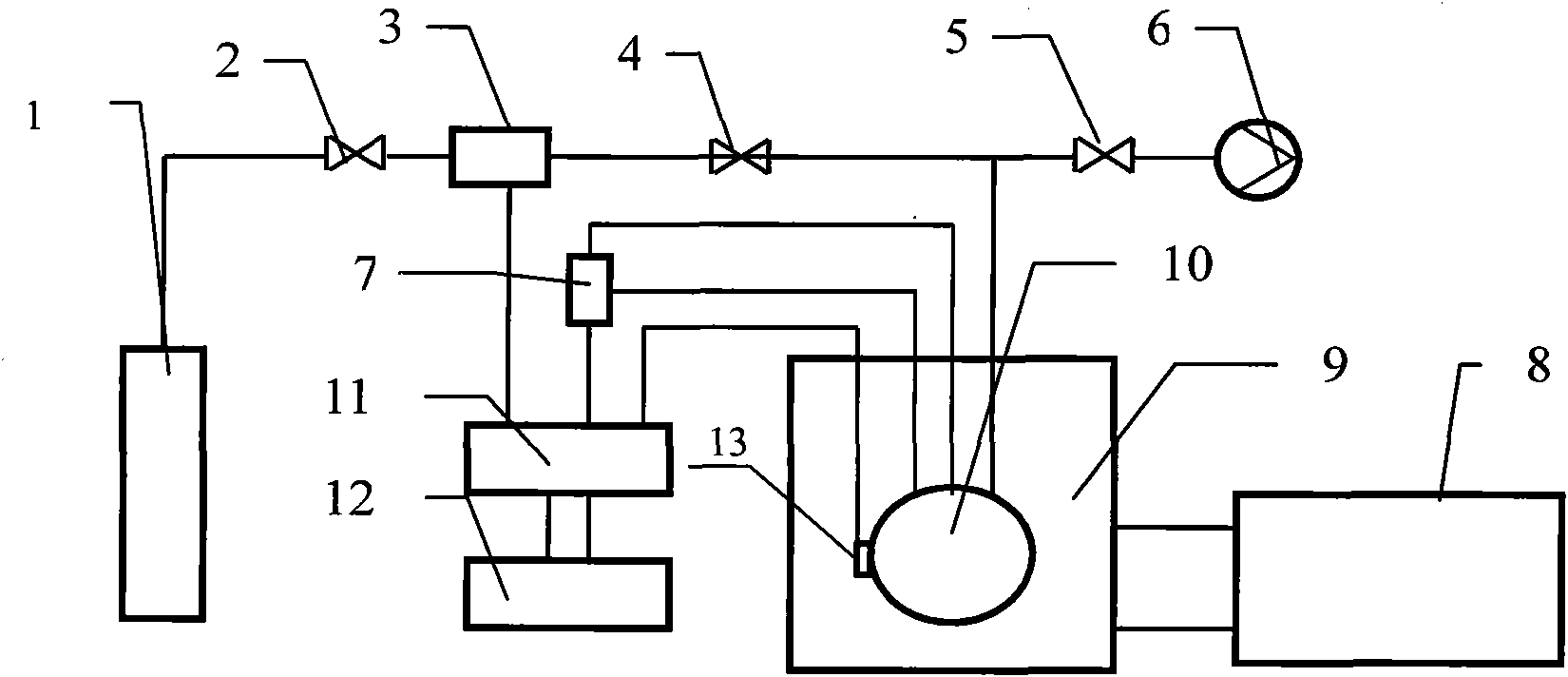

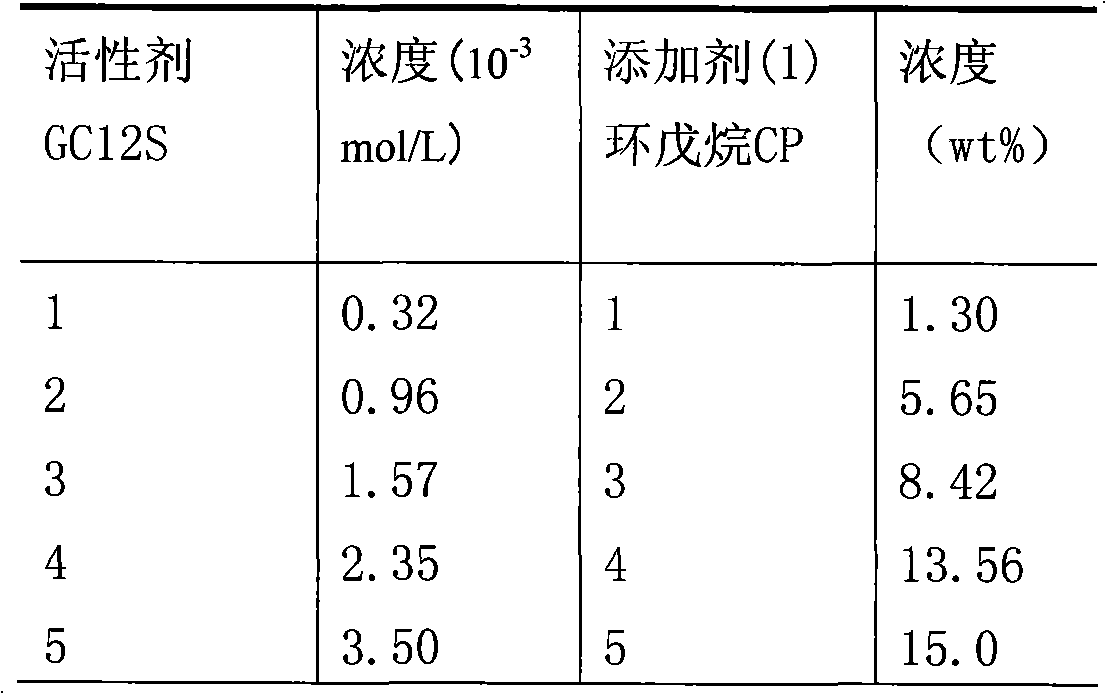

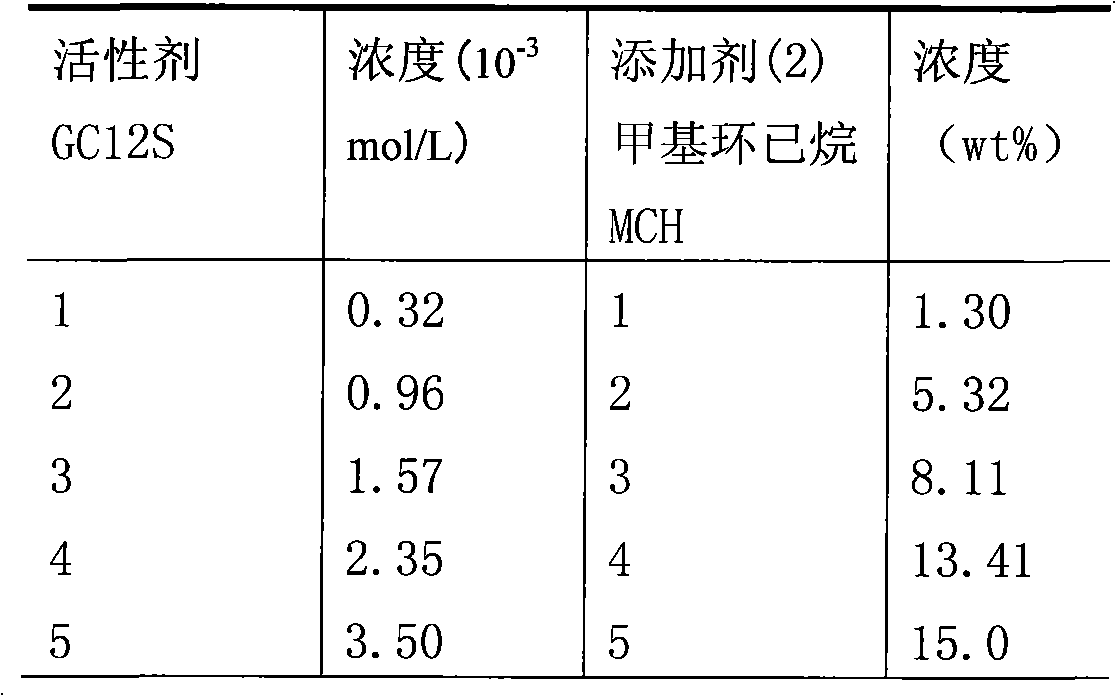

Method for preparing composite hydrate accelerant

The invention relates to a method for preparing a composite hydrate accelerant. The composite accelerant is characterized by being prepared by mixing cyclopentane or methyl cyclohexane serving as a kinetic accelerant and 2-butyl octyl sodium sulfate serving as a surfactant, wherein the percentage by mass of the cyclopentane or methyl cyclohexane in a solvent is 1.3 to 15.0, and the concentration of the surfactant 2-butyl octyl sodium sulfate in the solvent is 0.32*10<-3> to 9.5*10<-3> mol / L; and 0.02 to 0.78 mass percent of sodium chloride is added into the mixture. In the method, a high-pressure gas cylinder is taken as a gas source, a pressure is properly adjusted through a pressure adjustment valve, consumed gas is metered by a mass flow meter, a temperature and the pressure in a reactor are monitored by pressure and temperature transducers, and the temperature of liquid in a water tank is controlled by means of a thermostatic water bath, so that the temperature in the reactor is adjusted; and data is acquired by a data acquisition system and a computer, and the forming condition of a hydrate in the reactor is monitored by a photoelectric lens. The method for preparing the composite hydrate accelerant not only can reduce the forming condition of the hydrate, but also can shorten the formation time of the hydrate and improve the gas storage capacity of the hydrate.

Owner:溧阳常大技术转移中心有限公司

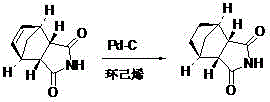

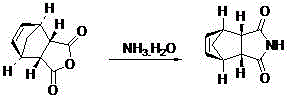

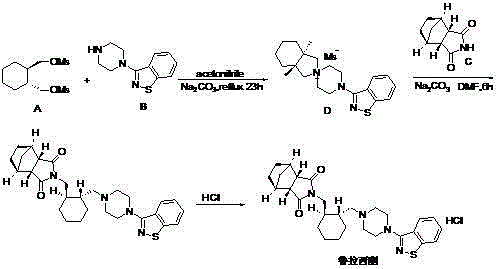

Preparation method of lurasidone

The invention provides a preparation method of lurasidone. On the basis of the existing preparation method of lurasidone, a one-pot method is adopted to replace the method including multiple steps and obtain a target product once. The preparation method comprises the following steps: adding 3-(1-piperazinyl)-1,2-benzisothiazole in toluene, stirring to dissolve; adding (1R,2R)-1,2-bis(methanesulfonyloxymethyl)cyclohexane and an inorganic alkali, heating and carrying out reflux reaction for 12-36 hours; adding (3alpha R,4S,7R,7alpha S)4,7-methano-1H-isoindole-1,3(2H)-dione; heating and refluxing; recycling toluene at reduced pressure; adding ethyl acetate in the residue, stirring to dissolve, washing for 2-3 times with 5% hydrochloric acid, separating out the organic layers, drying for 20-120 minutes, filtering to remove the drying agent, concentrating the obtained ethyl acetate solution, dropwise adding concentrated hydrochloric acid, precipitating the solid, and performing suction filtration to obtain crude lurasidone; and refining crude lurasidone to obtain pure lurasidone. By adopting the preparation method of lurasidone, the solvent can be recycled conveniently and the method is simple in operation.

Owner:SHANDONG BESTCOMM PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com