Patents

Literature

763results about How to "Lower conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

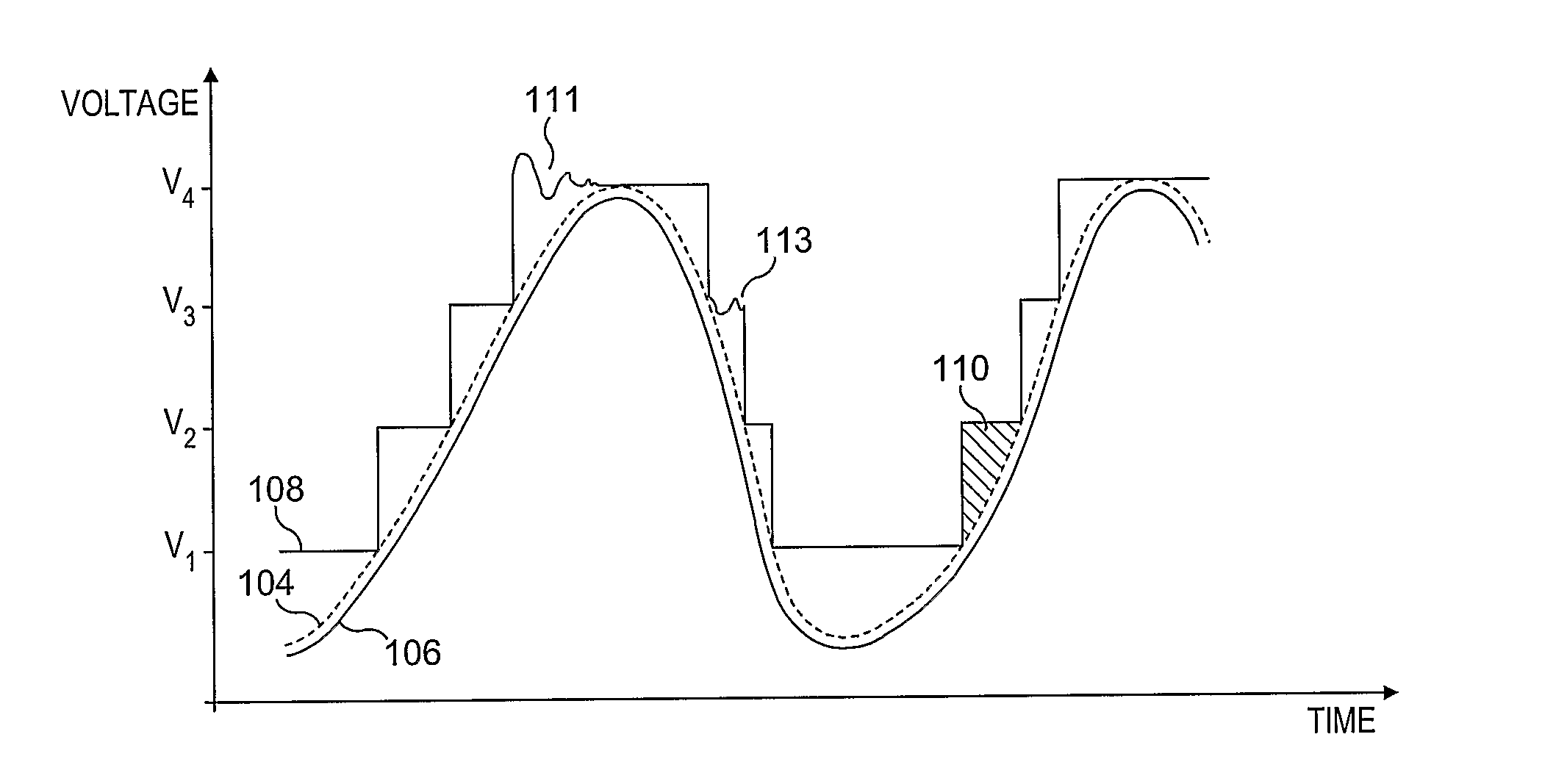

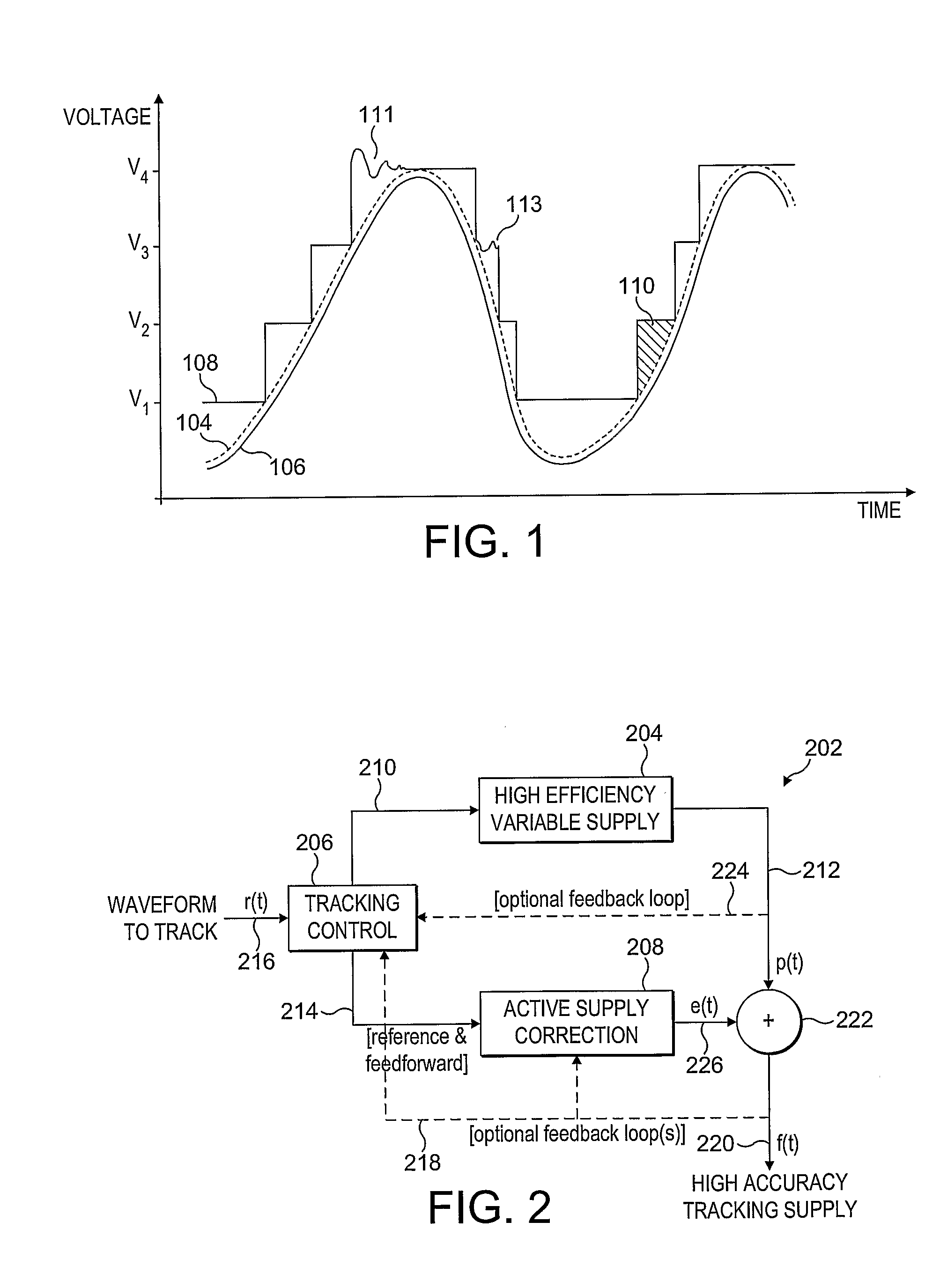

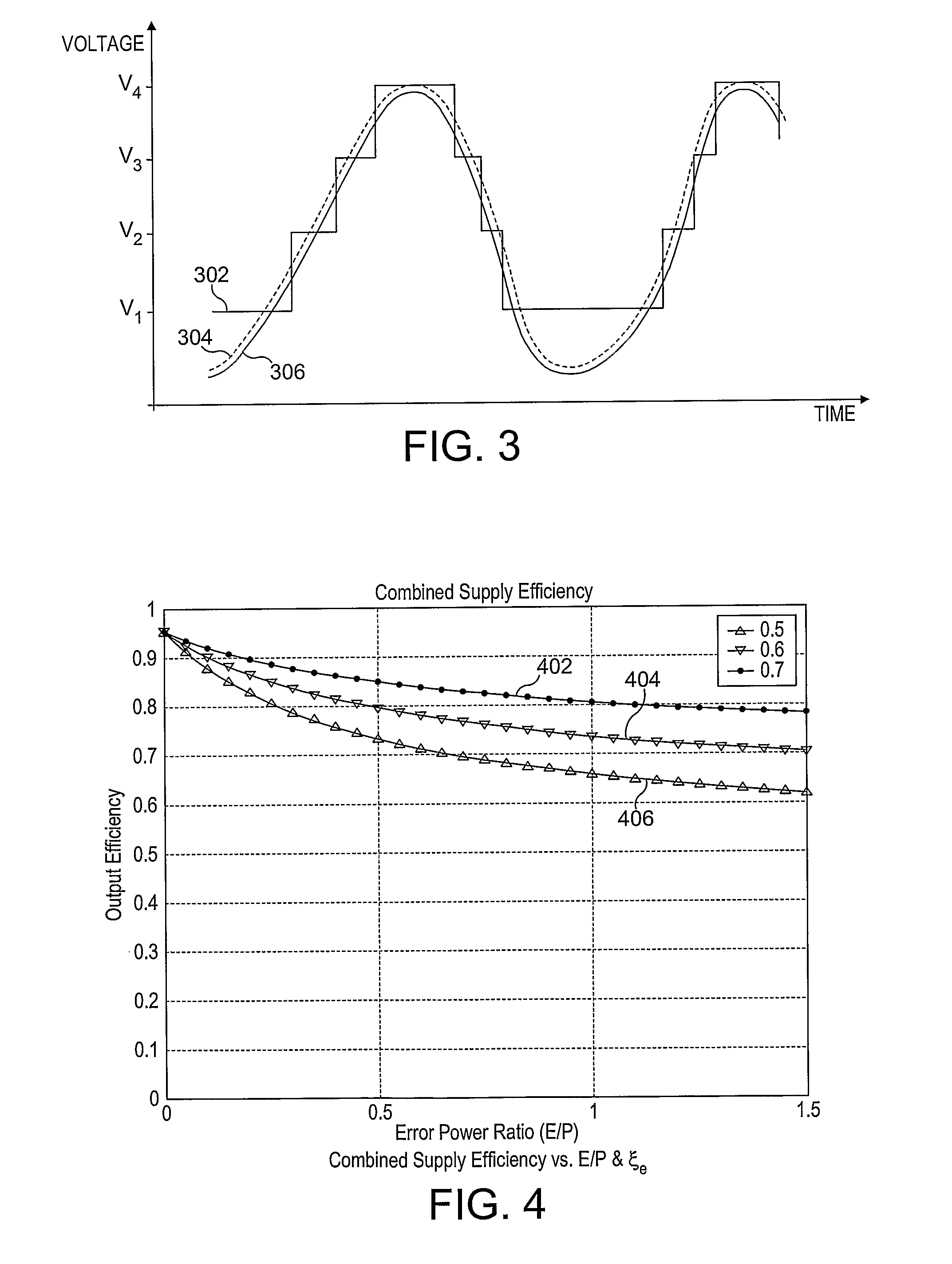

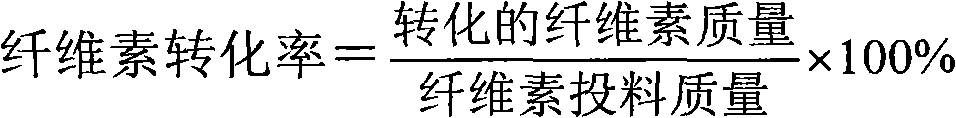

High efficiency variable voltage supply

InactiveUS20070210771A1Minimising peak amplitudeMinimising slew rateHigh frequency amplifiersAmplifier modifications to raise efficiencyEngineeringVariable-voltage power supply

There is disclosed a power supply stage (202), comprising: generating means for generating a power supply voltage from a high efficiency variable voltage supply (204) in dependence on a reference signal; adjusting means for receiving the generated power supply voltage (220), and adapted to provide an adjusted selected power supply voltage tracking the reference signal (216) in dependence thereon.

Owner:SNAPTRACK

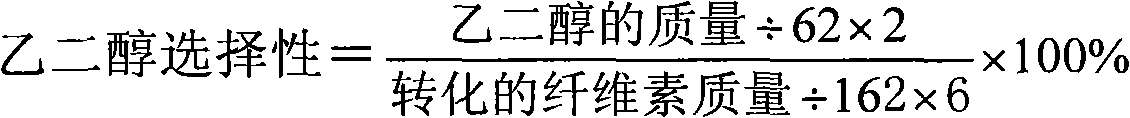

Method for preparing ethylene glycol and 1,2-propylene glycol

ActiveCN101768050ASimple processRapid responseOrganic compound preparationPreparation by OH group eliminationIsopropylene glycolPropylene glycol

The invention discloses a method for preparing ethylene glycol and 1,2-propylene glycol. In the method, fiber is placed into water to react under the action of a catalyst at the temperature of 200-250 DEG C to obtain the ethylene glycol and the 1,2-propylene glycol. In the method, the fiber is hydrolyzed in hot water; on one hand, the WO3 catalyst, the load WO3 catalyst and the Ru / C catalyst are led into for providing acidity for promoting the acid hydrolysis of the fiber, on the other hand, the intermediate products in the hydrolysis can be inverted into low-carbon matters, and hydrogenationis carried out, so as to obtain the ethylene glycol and the 1,2-propylene glycol. The method has simple process, quick reaction, high efficiency and less energy and is easy for industrialization; no liquid acid is added, and no waste acid is discharged, therefore, the method is environmentally friendly. The method has low requirement on equipment, can not cause the corrosion of the equipment and has small investment; moreover, the inversion rate of the fiber is 100% high, the yield of the ethylene glycol can reach 35%, and the yield of the 1,2-propylene glycol can reach 31%; therefore, the method has significant application value.

Owner:PEKING UNIV

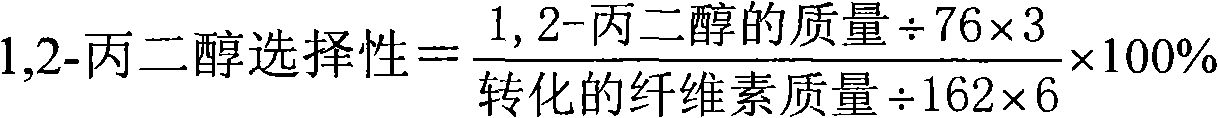

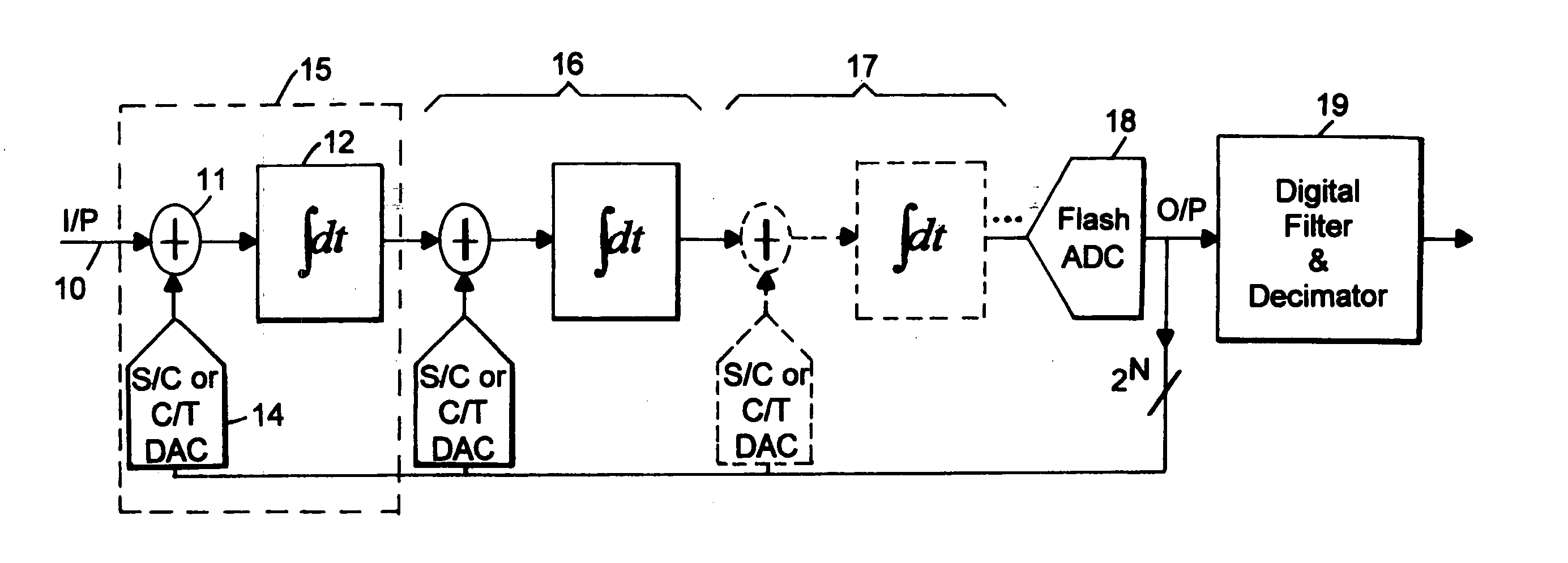

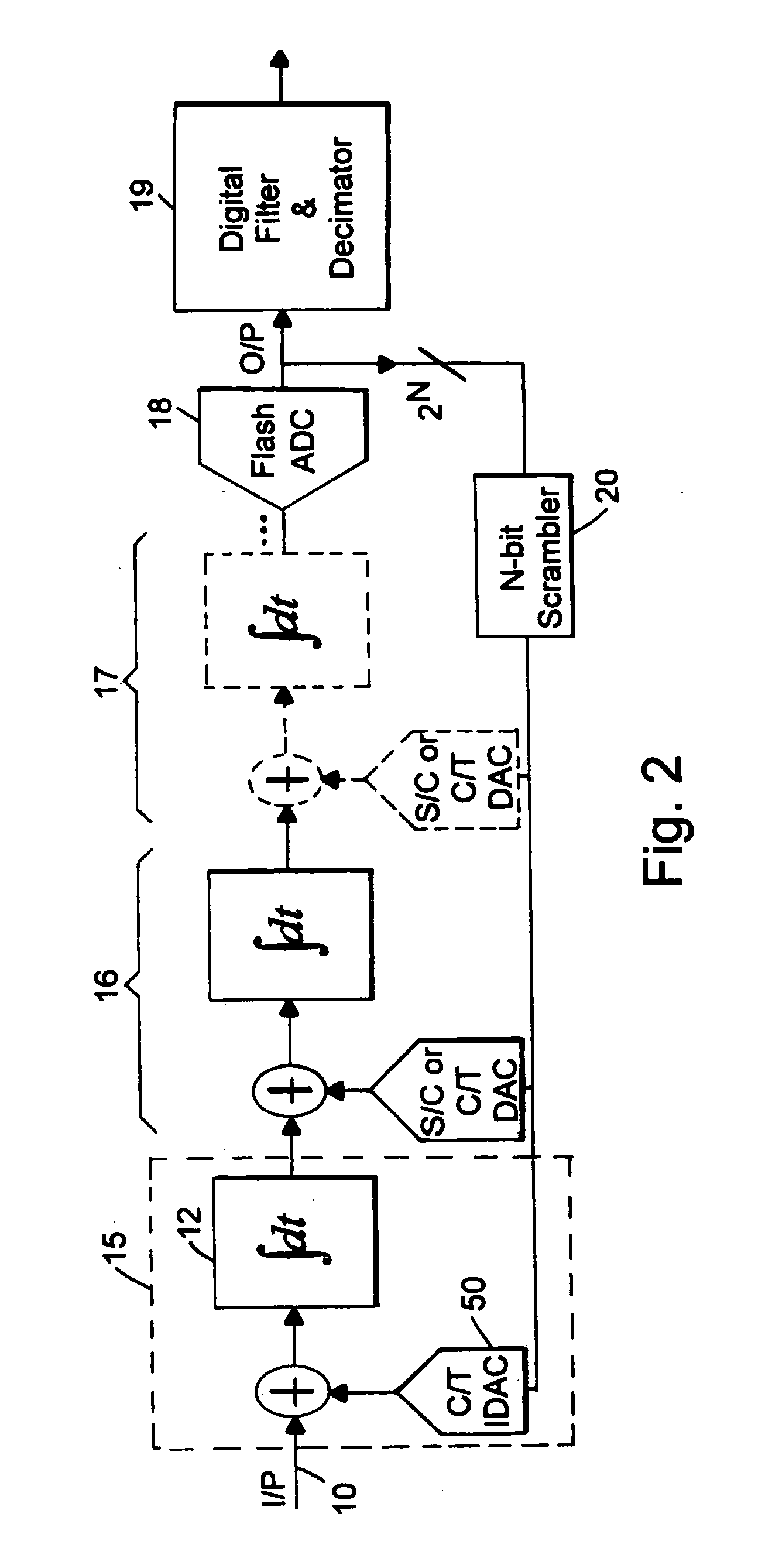

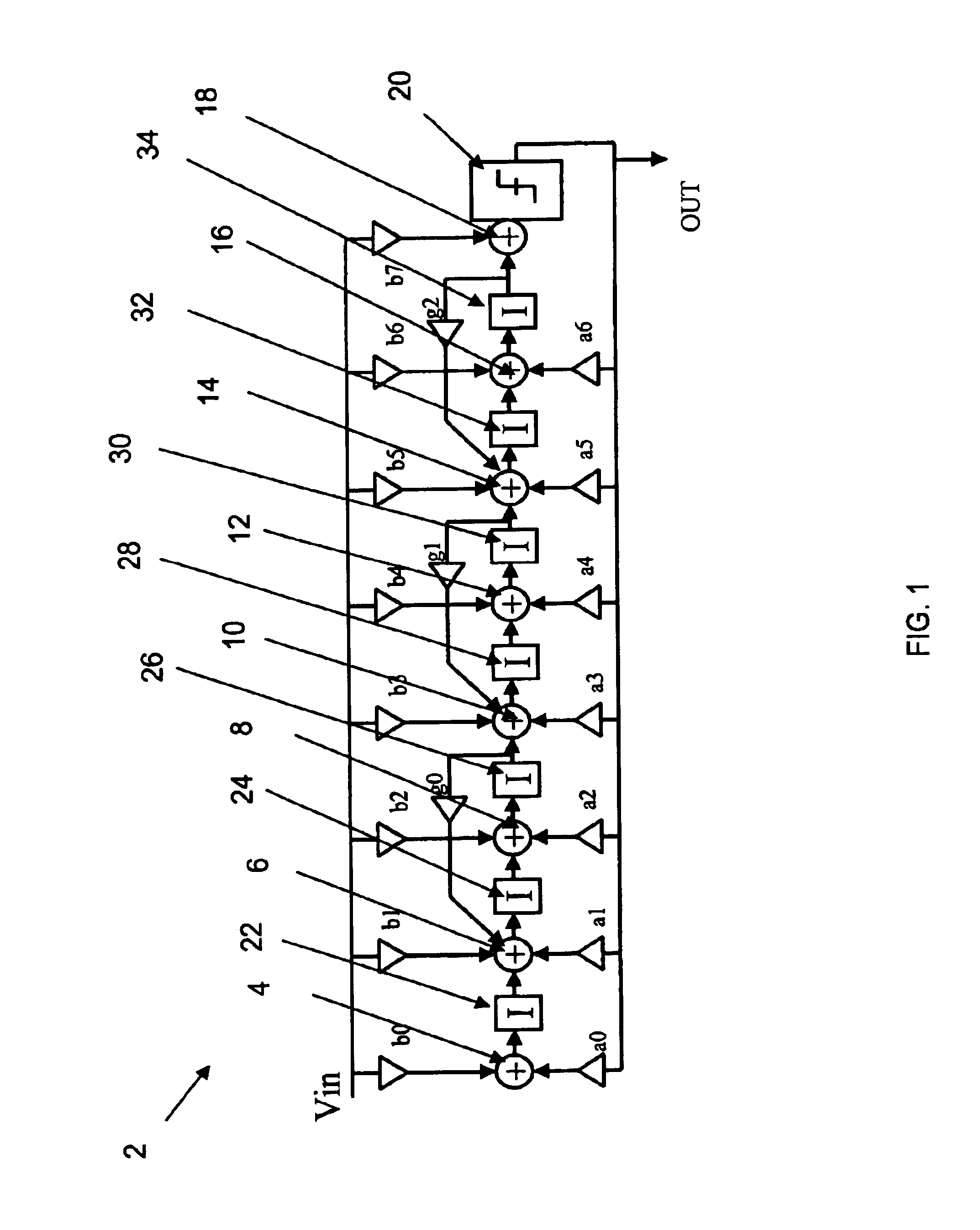

Differential front-end continuous-time sigma-delta ADC using chopper stabilisation

ActiveUS20060139192A1Less sensitive to substrate noiseReduce thermal noiseAnalogue/digital conversionElectric signal transmission systemsIntegratorDigital feedback

A multi-bit continuous-time sigma-delta analog-to-digital converter (ADC) has a differential input stage which receives an analog input signal current. A multi-bit feedback current digital-to-analog converter (IDAC) generates a multi-level feedback current depending on a digital feedback signal from a flash ADC. An integrator has a differential input that integrates the difference of the generated current by the multi-bit IDAC and the input signal current on a continuous-time basis. The input stage further comprises a first biasing current source and a second biasing current source which bias the input stage in a mid-scale condition. A first summing node connects to the first differential input line, a first differential input of the integrator and the first output branch. A second summing node connects to the second differential input line, a second differential input of the integrator and the second output branch. A set of chopping switches alternately connect the biasing current sources to the summing nodes in a first configuration and a second, reversed, configuration. The converter receives a modulator clock signal at a frequency FS and the chopping switches can operate at FS or a binary subdivision thereof. The integrator amplifier can also be chopper-stabilized.

Owner:ANALOG DEVICES INC

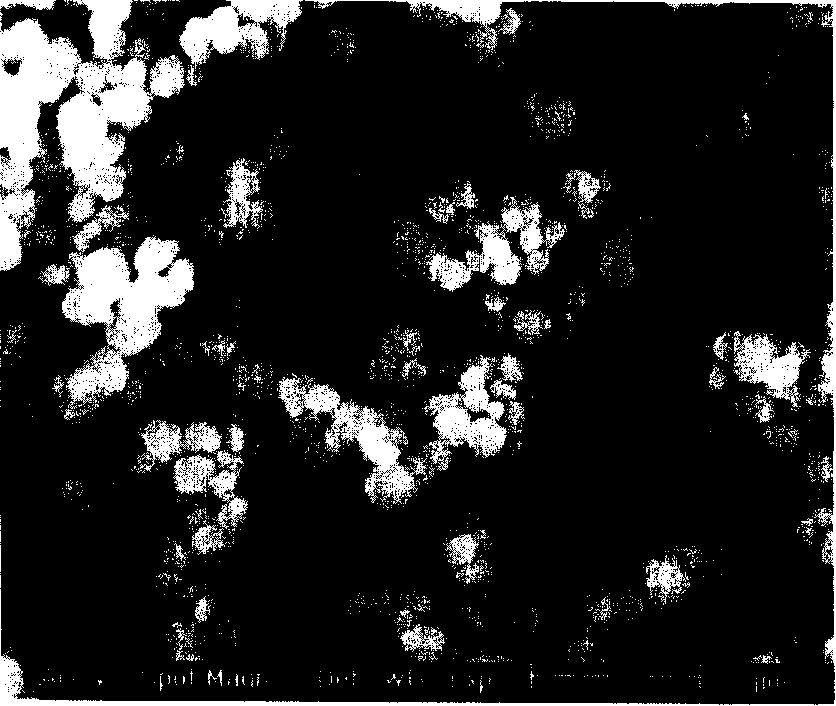

Ultrasound contrast agents and process for the preparation thereof

InactiveUS20070128117A1Low viscosityMinimal numberUltrasonic/sonic/infrasonic diagnosticsEchographic/ultrasound-imaging preparationsOrganic solventEmulsion

Method for preparing a lyophilized matrix and, upon reconstitution of the same, a respective injectable contrast agent comprising a liquid aqueous suspension of gas-filled microbubbles stabilized predominantly by a phospholipid and comprising a ligand agent. The method comprises preparing an emulsion from an aqueous medium, comprising a phospholipid and a water immiscible organic solvent. A suspension of a compound comprising the ligand agent or a precursor thereof is then added to emulsion. The emulsion is then freeze-dried and subsequently reconstituted in an aqueous suspension of gas-filled microbubbles.

Owner:BRACCO SUISSE SA

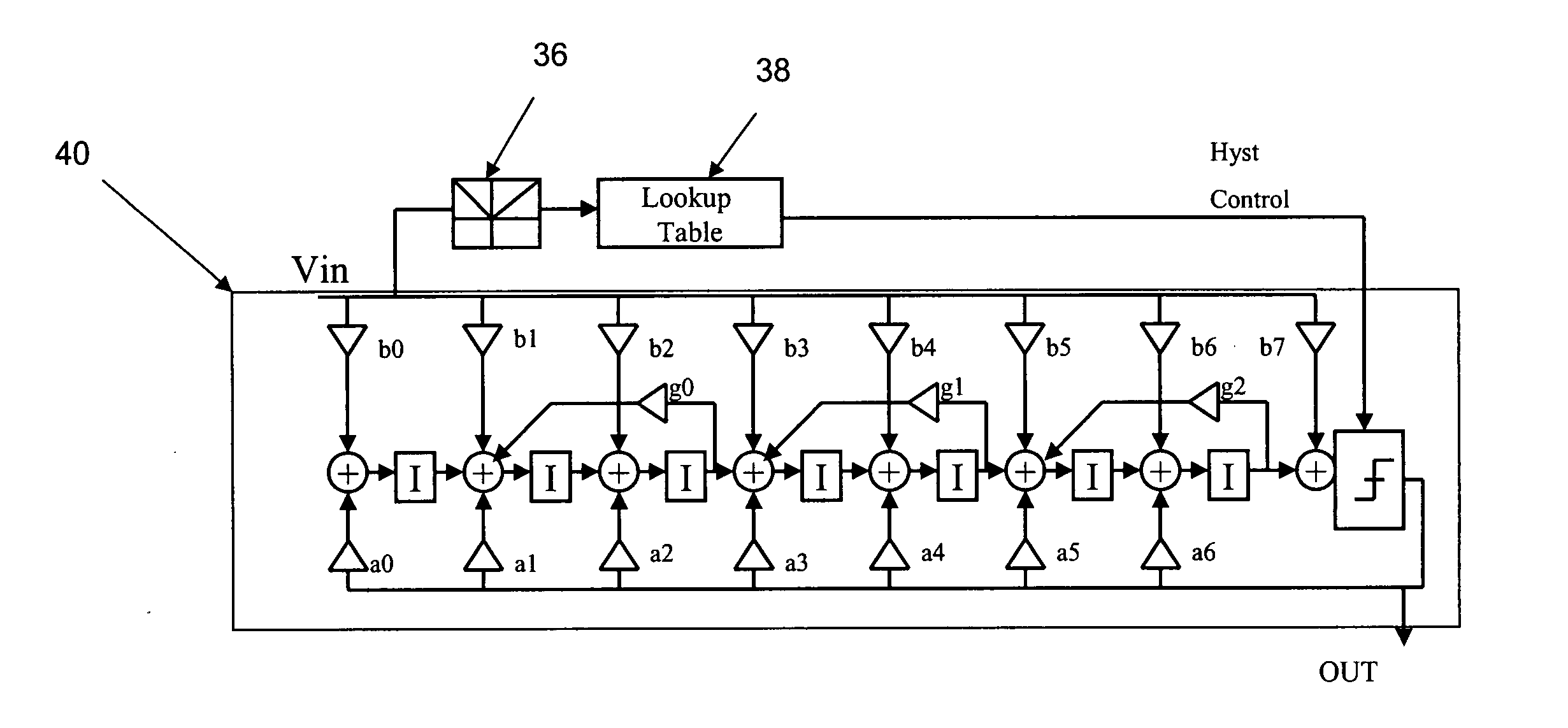

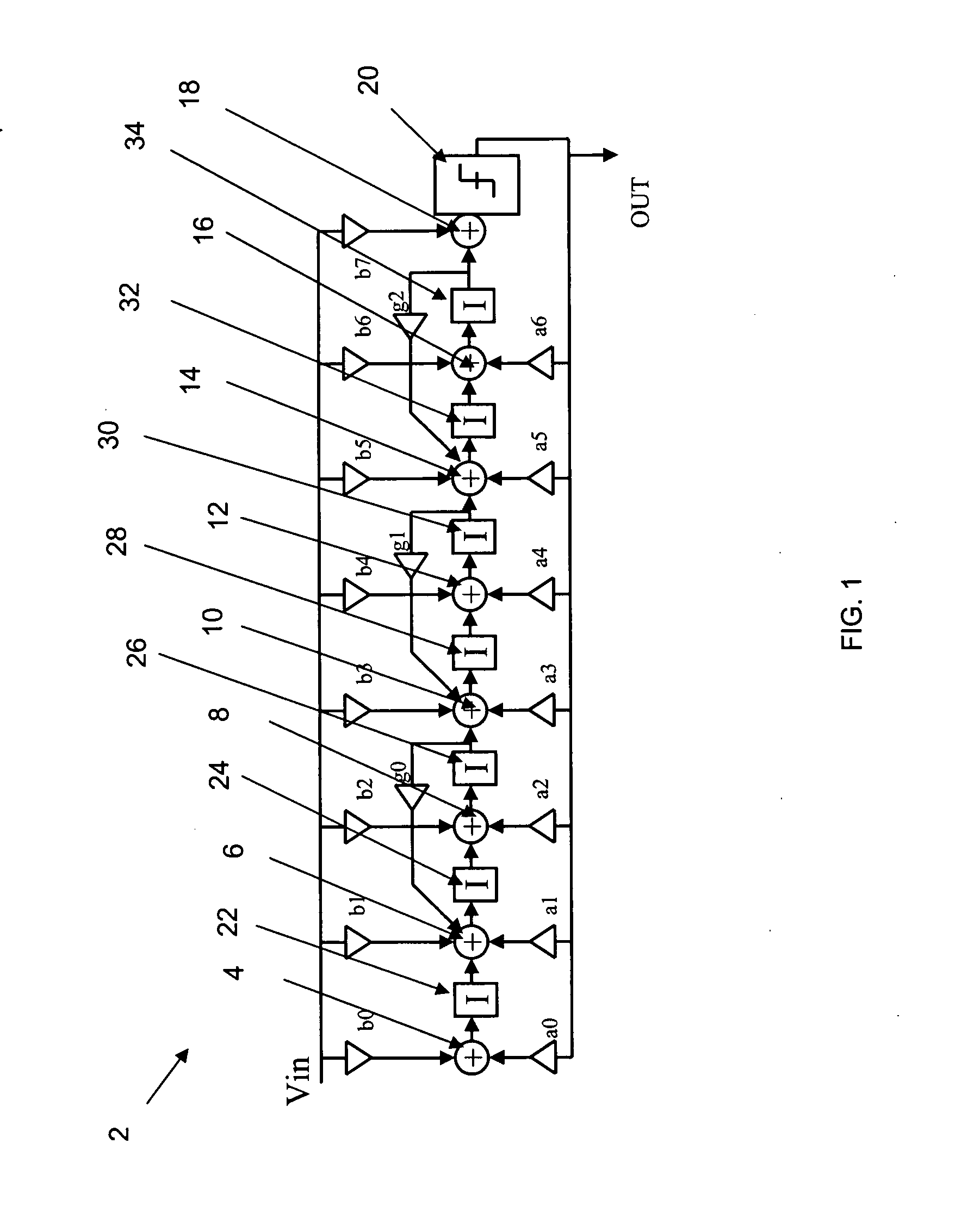

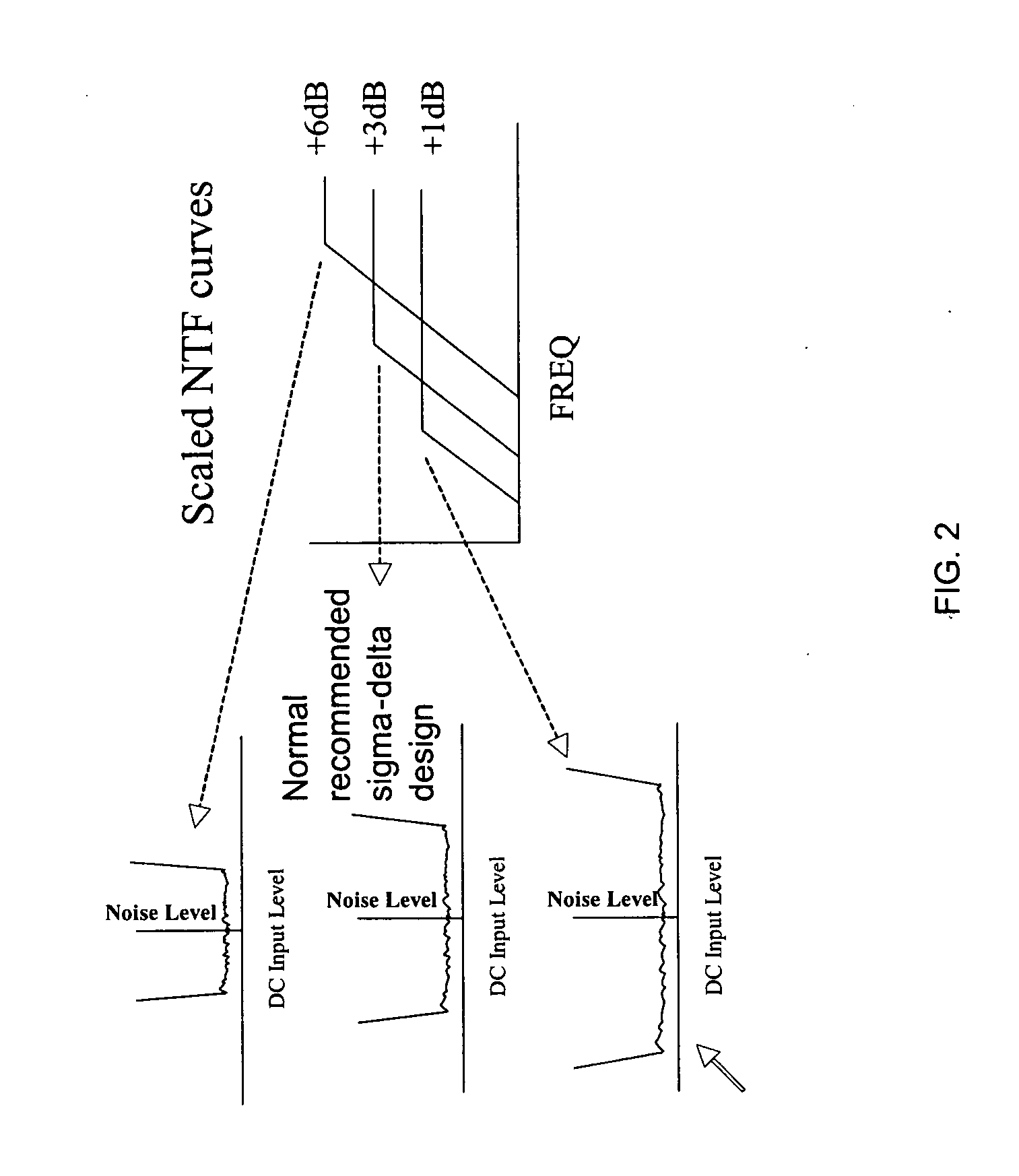

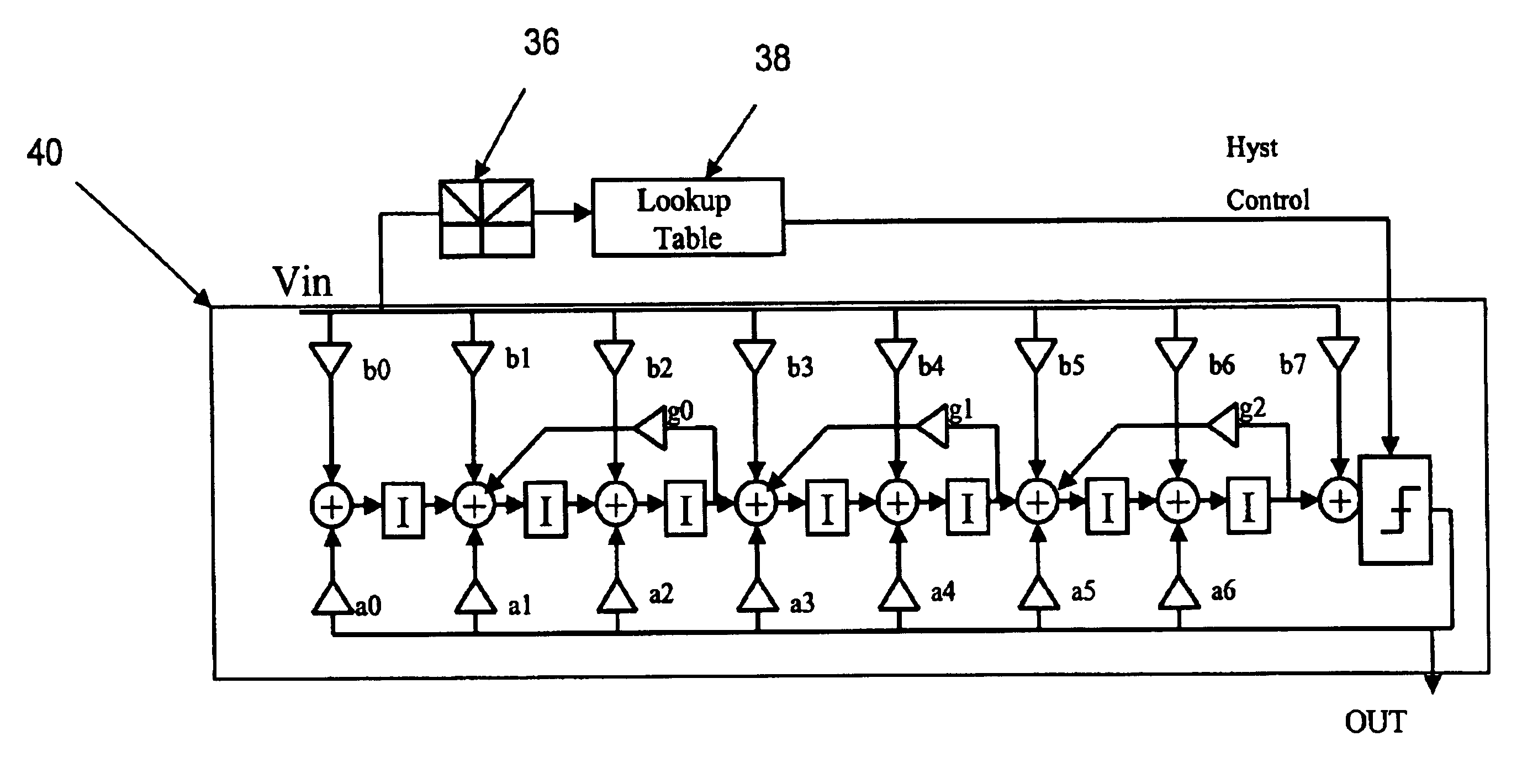

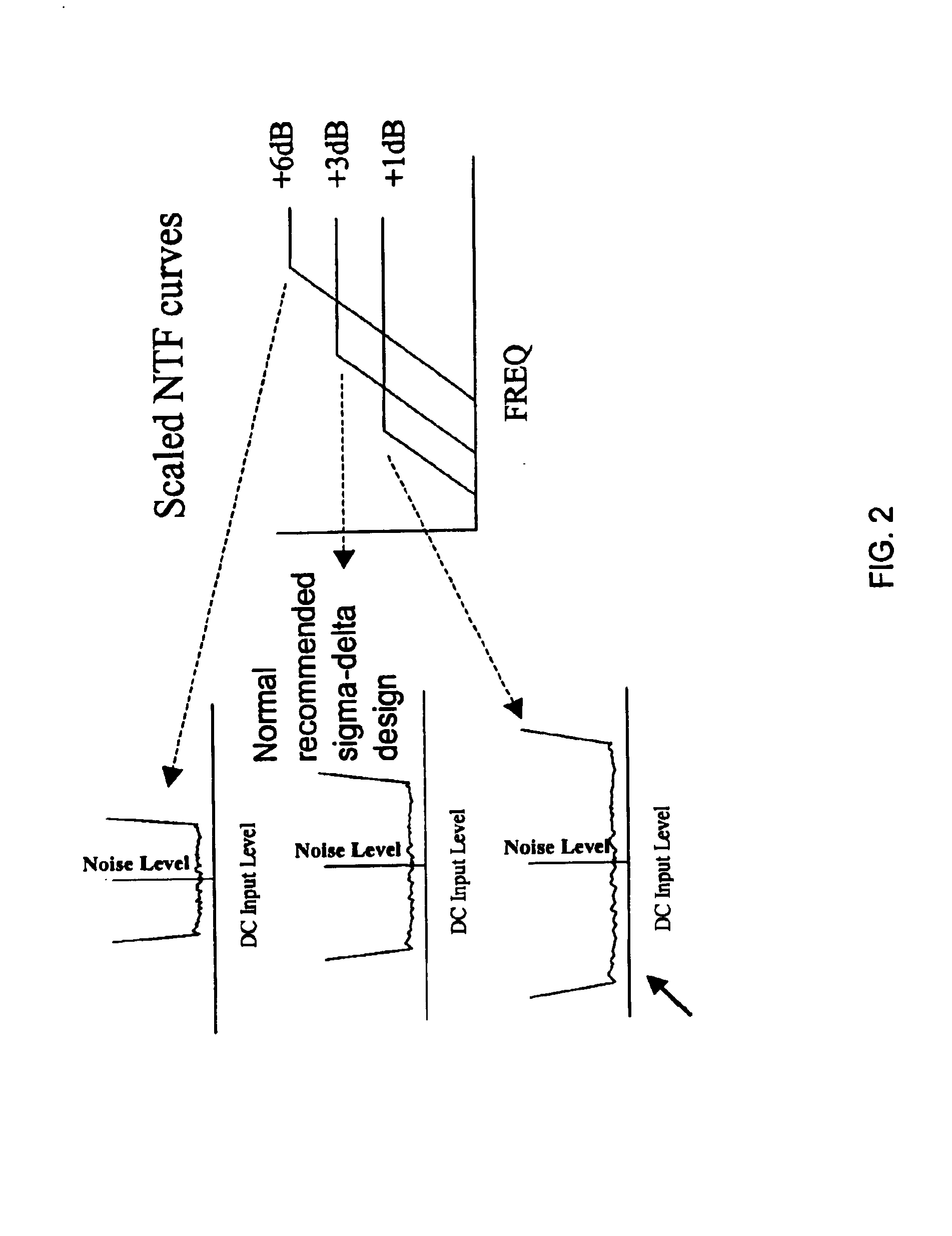

Sigma-delta modulator with reduced switching rate for use in class-D amplification

ActiveUS20050012649A1Lower conversion rateElectric signal transmission systemsAmplifier with semiconductor-devices/discharge-tubesHysteresisGreek letter sigma

A sigma delta modulator includes a modulator module that includes a quantizer with variable hysteresis, which receives an input signal to perform necessary modulation operations. A non-linear mapping module receives a signal associated with said input signal and tabulates the necessary hysteresis control information so as to reduce the transition rate of the modulator module.

Owner:ANALOG DEVICES INC

Sigma-delta modulator with reduced switching rate for use in class-D amplification

ActiveUS6924757B2Lower conversion rateElectric signal transmission systemsAmplifier with semiconductor-devices/discharge-tubesHysteresisSignal correlation

Owner:ANALOG DEVICES INC

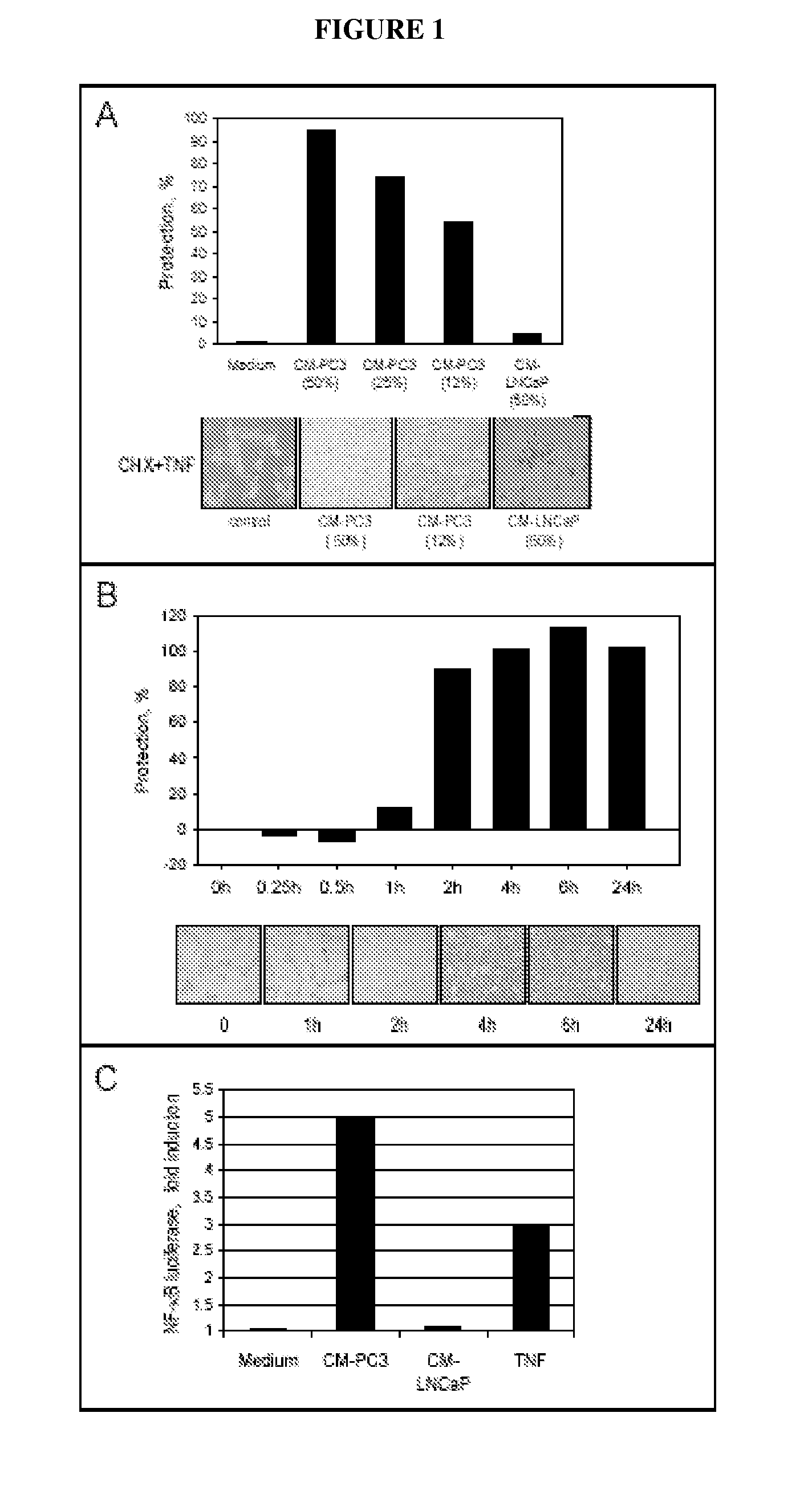

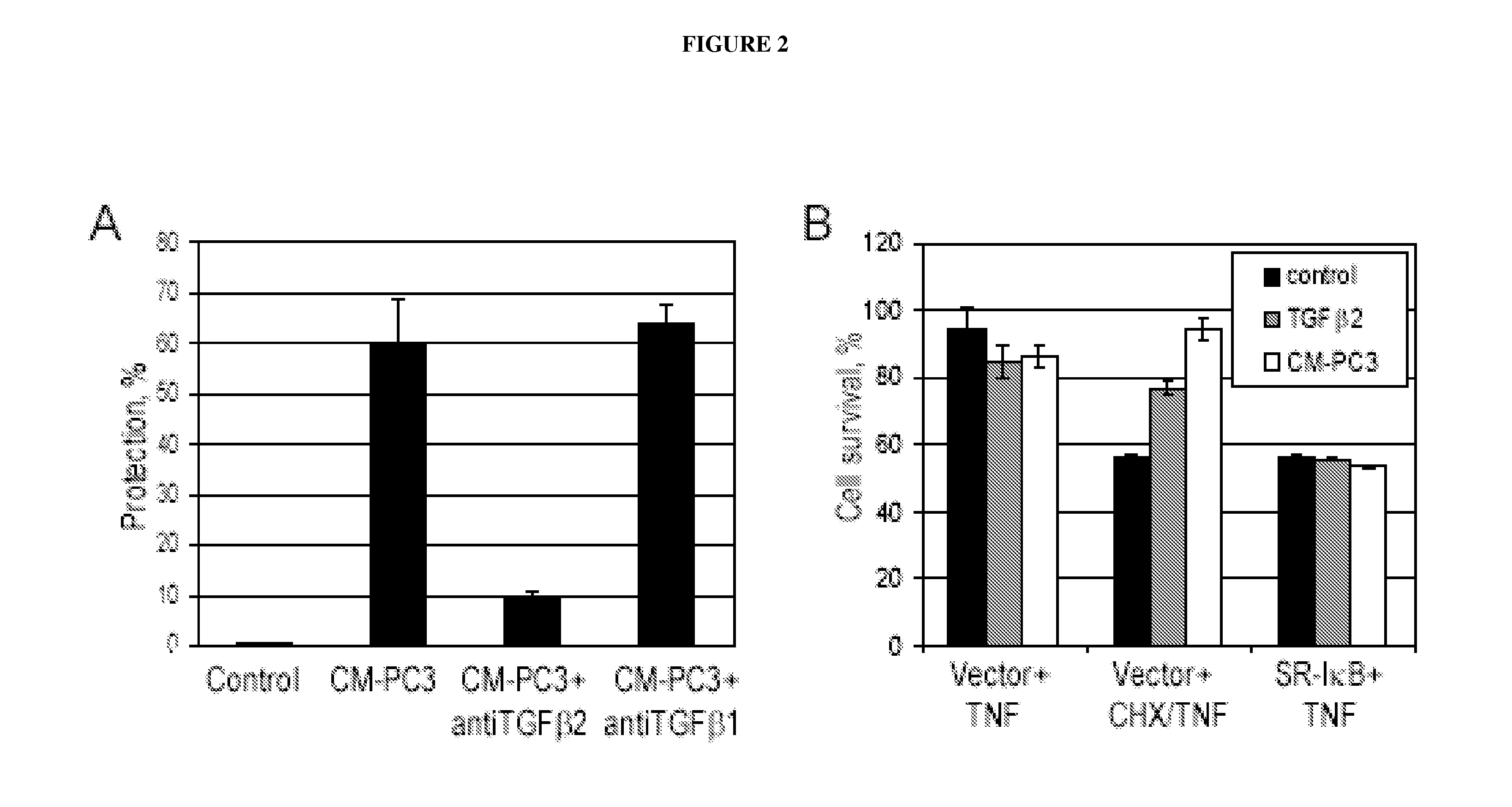

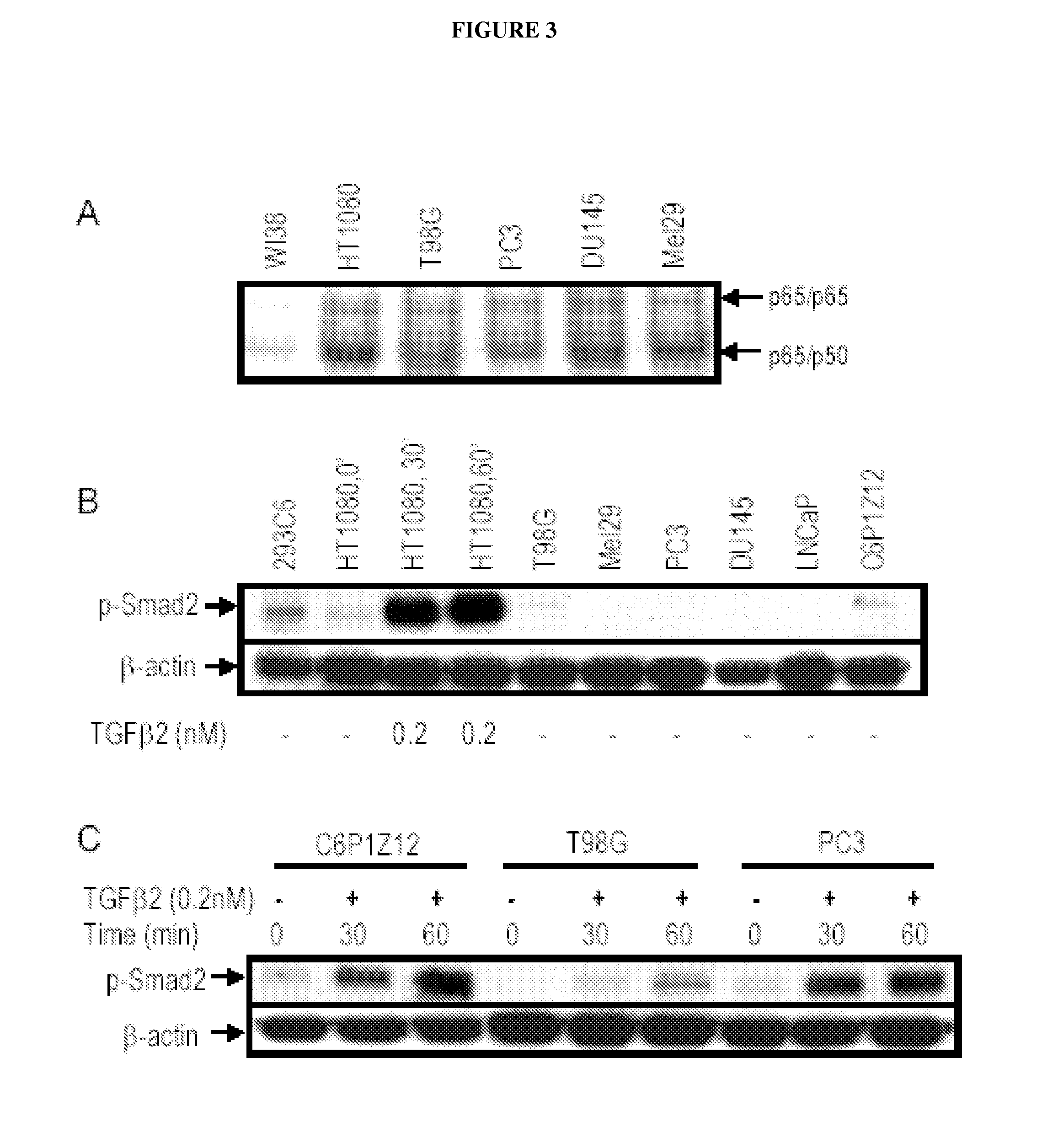

TGFBeta

InactiveUS20070202551A1Lower conversion rateCompound screeningApoptosis detectionAbnormal tissue growthApoptosis

Owner:THE CLEVELAND CLINIC FOUND

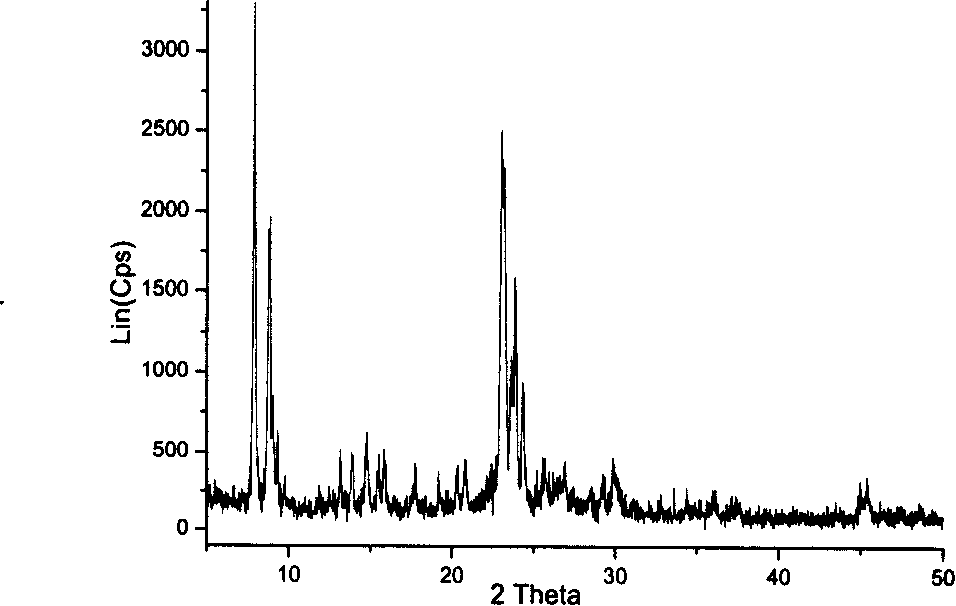

Method for preparing fine grain ZSM-5/mordenite composite molecular sieve

ActiveCN101190418ALarge specific surface areaSmall specific surface areaMolecular sieve catalystsBulk chemical productionNaphthaMordenite

The invention relates to the preparation method of a small crystal ZSM-5 / mordenite composite molecular sieve, mainly solving the problems in the existing preparation process of ZSM-5 / mordenite composite molecular sieve of bigger crystal of the composite molecular sieve, low catalytic activity and fast activity loss in the reaction in which ethene and propylene are prepared by the catalyzing and cracking of naphtha. The invention well resolves the problems by adopting the technical proposal that the ZSM-5 with decent silica alumina ratio and the crystal seed of mordenite is added in the synthetic process of the molecular sieve and the PH value of the molecular sieve raw material solution system is adjusted to 9-14 in the preparation process. The ZSM-5 / mordenite composite molecular sieve prepared by the method can be applied in the industrial production, in which ethene and propylene are prepared by the catalyzing and cracking of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

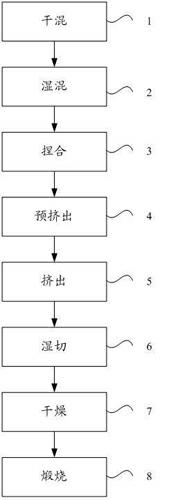

Preparation method of high-strength and antioxidant rare-earth-based smoke denitration catalyst

ActiveCN104209117AReduce escape rateReduce productionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumGlass factory

The invention discloses a preparation method of a high-strength and antioxidant rare-earth-based smoke denitration catalyst. The preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst comprises the following steps: by taking titanium dioxide and montmorillonite as carriers and ammonium metatungstate, cerous nitrate and lanthanum nitrate as active components, mixing, ageing, kneading, forming, drying and roasting with the accompanying of auxiliary materials. The auxiliary materials comprise ammonia water, lactic acid, citric acid, stearic acid, glass fiber, wood pulp, hydroxypropyl methyl cellulose, polyoxyethylene, monoethanolamine and water. The product prepared by the method is separated under a high SO2 smoke condition, nitric oxide in the smoke can be decomposed; meanwhile, the purpose of removing mercury and dioxin can be achieved. According to the preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst, the rare earth elements, namely cerium and lanthanum are used as the active components, so that the addition amount of vanadium is reduced, the toxicity of the product is reduced or the product is non-toxic product, the pressure of the post treatment of the product is reduced; the environmental protection pressure is reduced; the product is environmentally friendly; the product can be widely used in the field of thermal power plants, glass factories and chemical plants.

Owner:山东信义汽车配件制造有限公司

Catalytic agent for denitrating smoke and preparation technology thereof

ActiveCN102166516AGuaranteed denitrification effectImprove denitrification performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSurface-active agentsCoal

The invention provides a catalytic agent for denitrating smoke and a preparation technology thereof. The catalytic agent for denitrating the smoke comprises the raw materials based on parts by weight as follows: 60%-90% of titanium dioxide, 3%-9% of tungsten trioxide, 0.5-3% of vanadium pentoxide, 2%-5% of organic binder, 10%-20% of inorganic binder, 7%-10% of glass fiber, 2%-4% of plasticizer, 20%-40% of water, 2%-4% of lubricant, 0.1%-1% of surface active agent and 3%-9% of neutralizer. After the content of the tungsten trioxide is reasonably proportioned, on the premise of guaranteeing thedenitration performance of the catalytic agent for denitrating the smoke, the absorption to sulfur dioxide is reduced, the SO2 / SO3 conversion percentage is reduced, and the high-sulfur and high-ash use requirement of the coal quality in China is met.

Owner:HUADIAN QINGDAO ENVIRONMENTAL TECHNOLOCY CO LTD

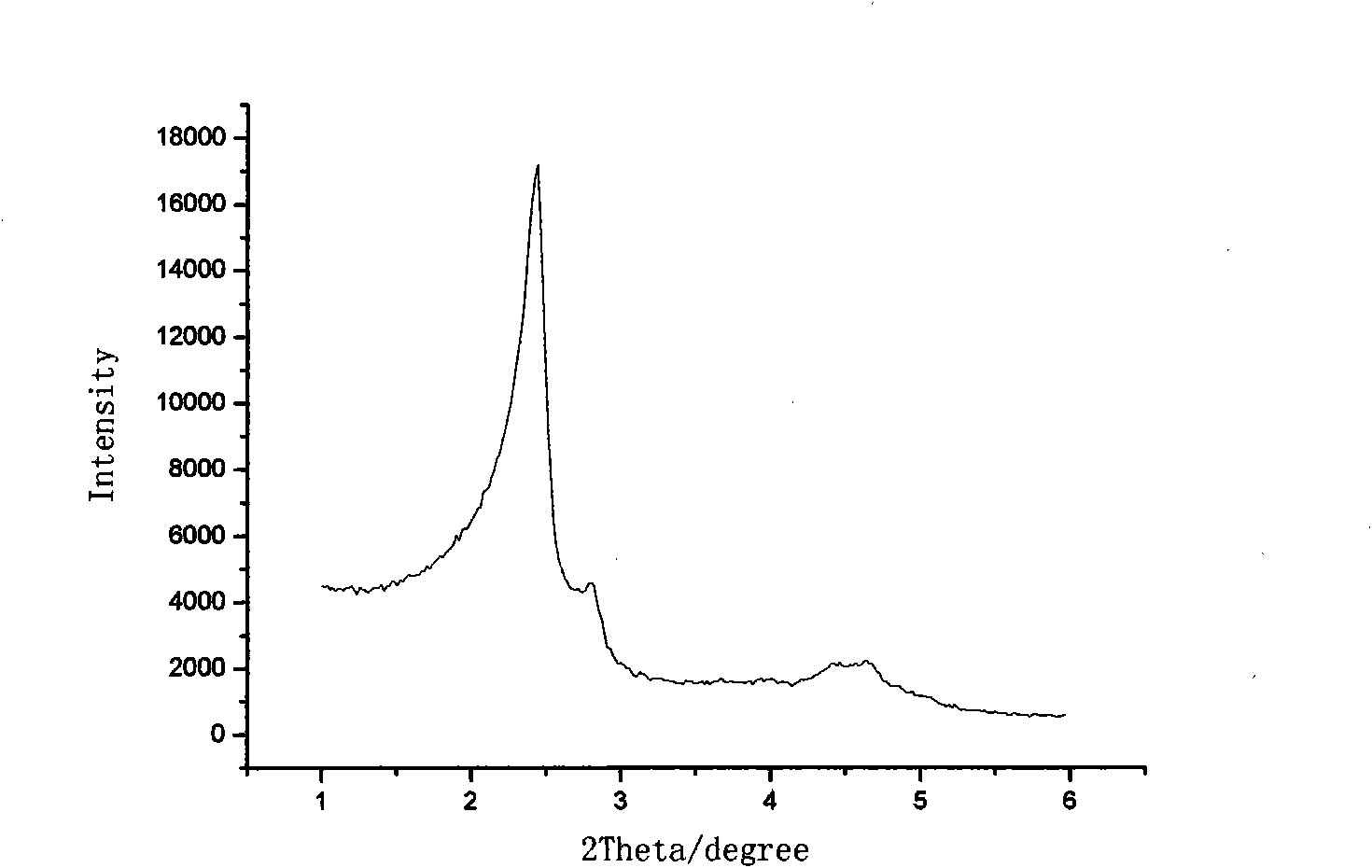

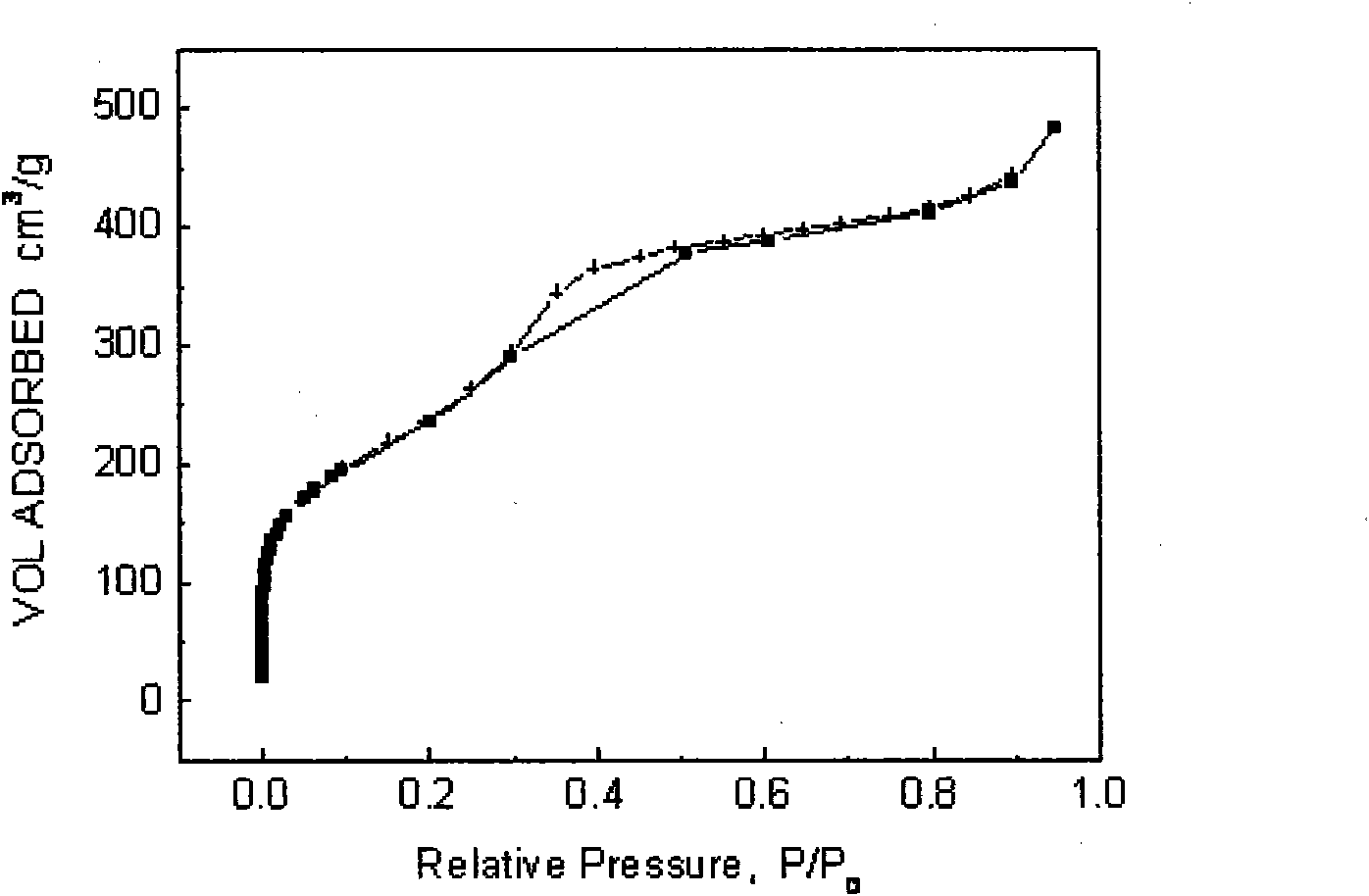

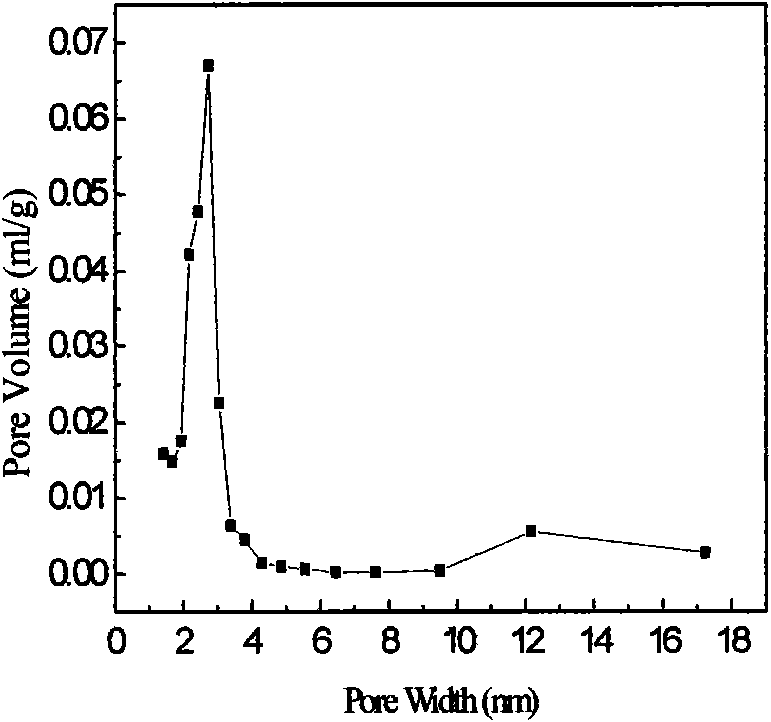

Cubic mesoporous molecular sieve catalyst with micropore canals, preparation method and use thereof

InactiveCN101683620AHigh catalytic activityGood choiceMolecular sieve catalystsHydrocarbonsMicrowaveSynthesis methods

The invention relates to a cubic mesoporous molecular sieve catalyst with micropore canals, a preparation method and use thereof. The catalyst comprises the raw materials of an aluminium source, a silicon source, sodium hydroxide, a template, surfactant and de-ionized water, and is prepared through the following steps: firstly preparing a silicon-aluminium precursor; and then utilizing a self-assembly function between the precursor and the surfactant to obtain stable molecular sieve materials. The preparation method comprises two methods of hydro-thermal synthesis and microwave synthesis. Dueto the adoption of the microwave synthesis method, the cubic mesoporous molecular sieve catalyst in the invention has the advantages of shortening the crystallization time, obtaining a synthesized molecular sieve with a cubic mesoporous structure, having micropore canals, having acid strength similar to that of a ZSM-5 molecular sieve, and having relatively higher catalytic activity when used forthe catalytic cracking reaction of 1,3,5-tri-isopropyl benzene.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

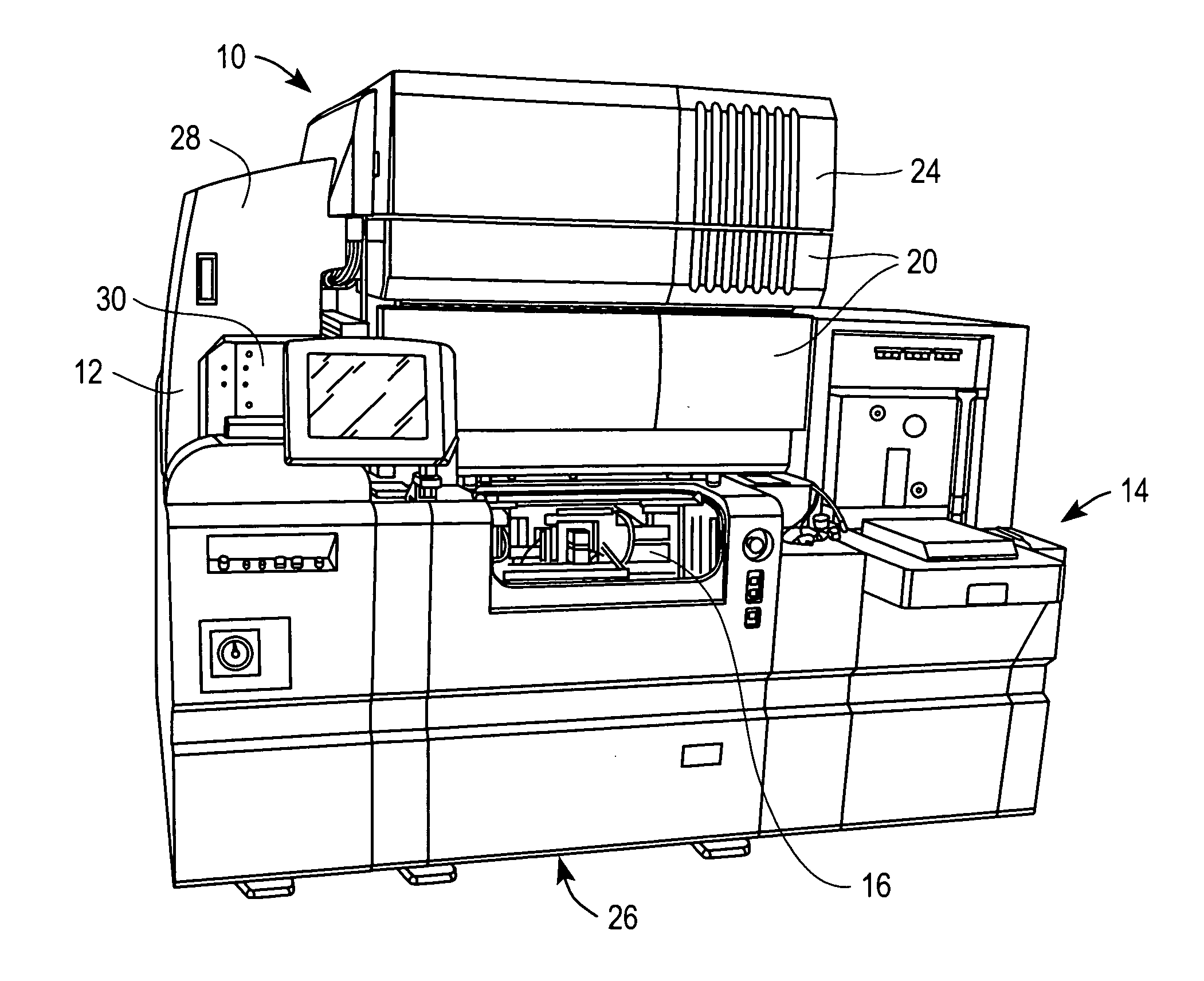

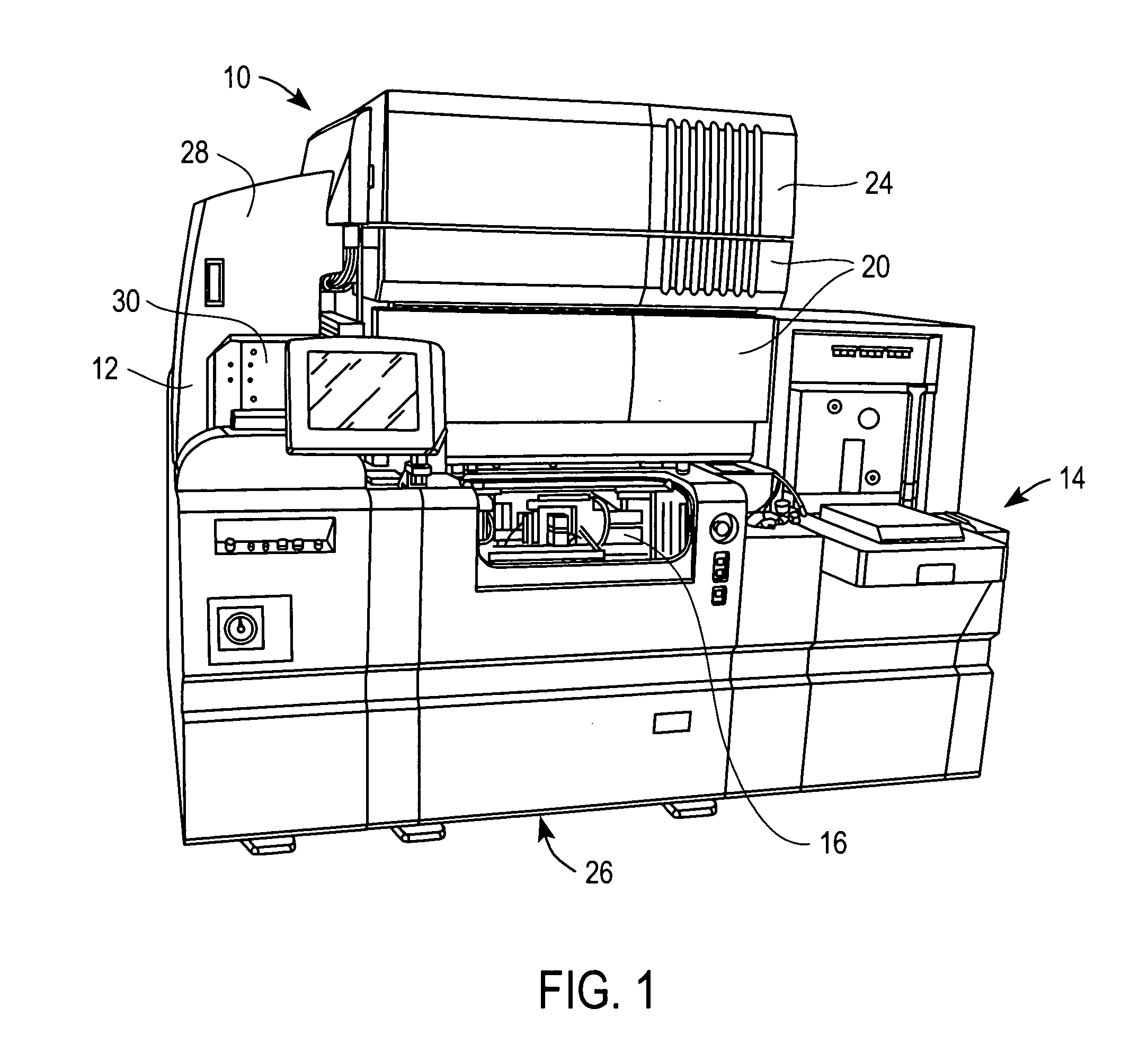

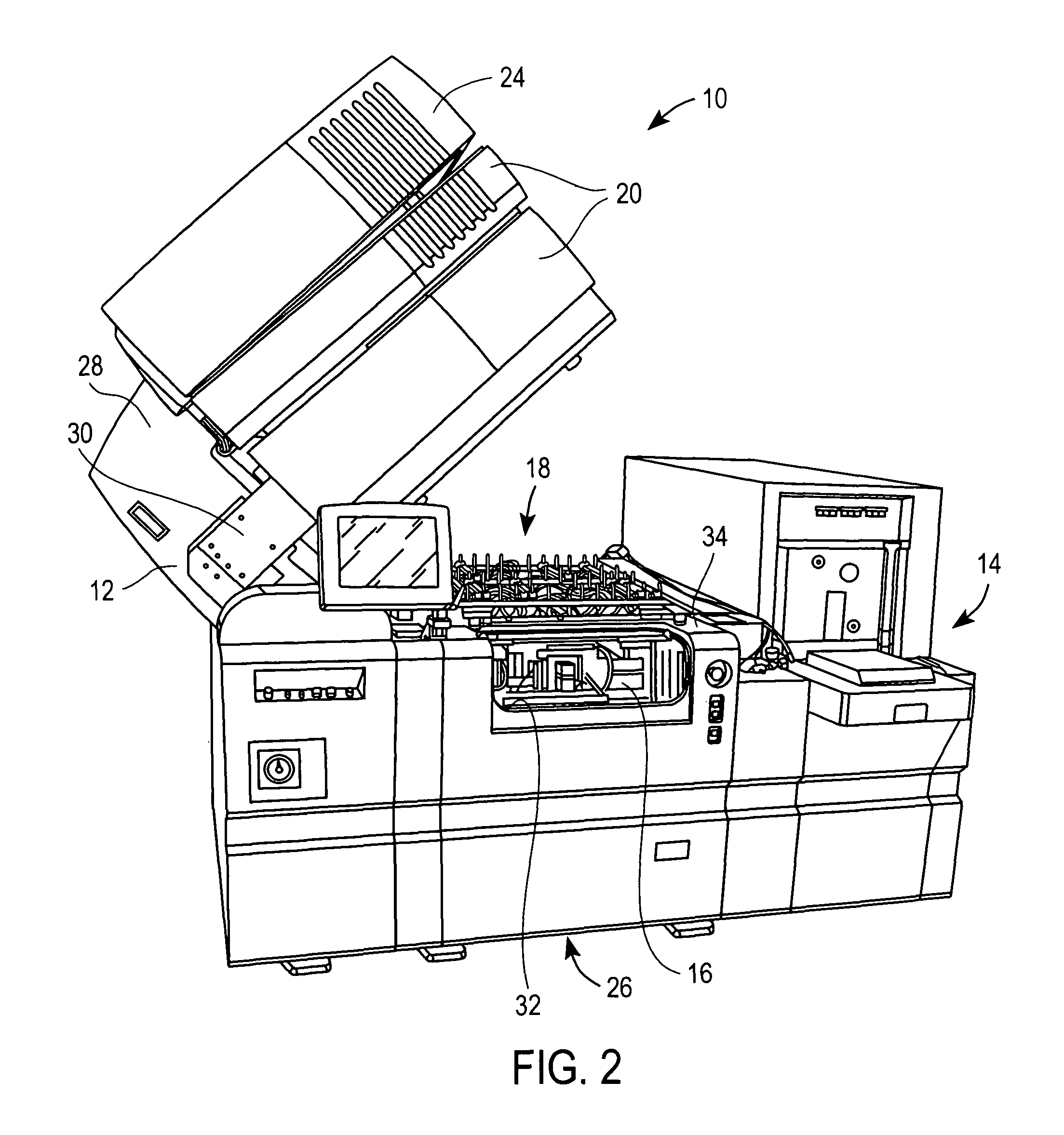

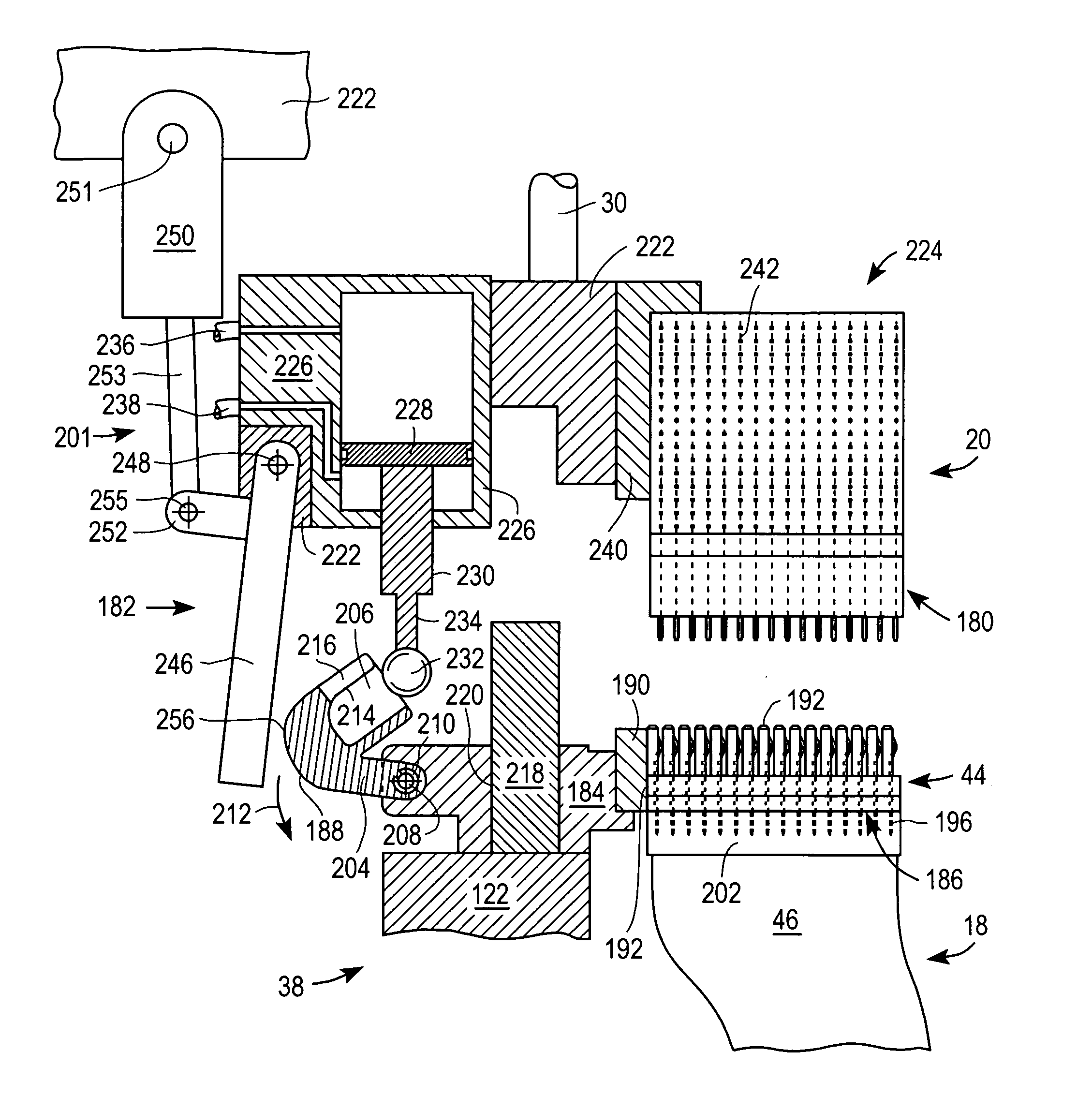

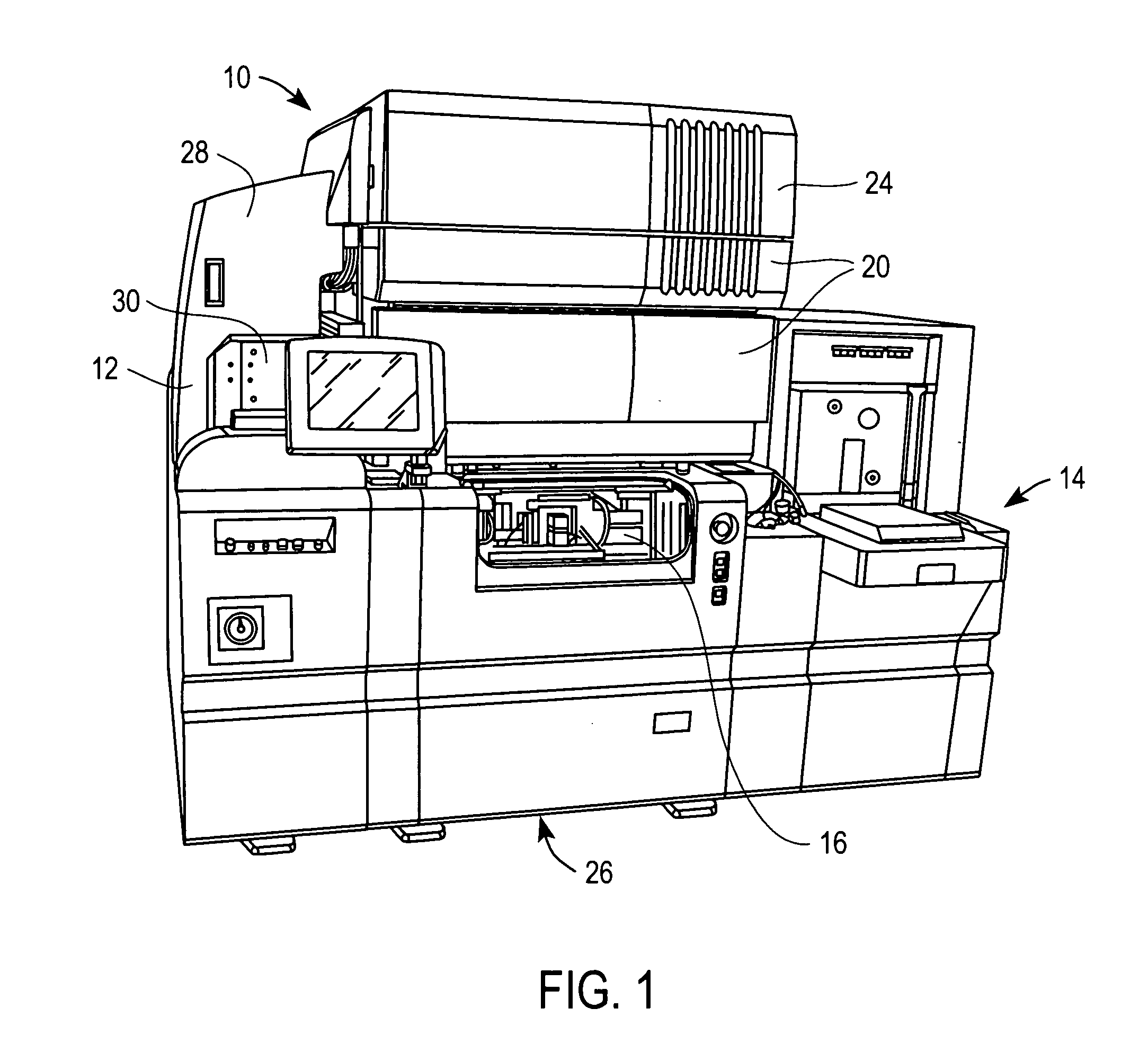

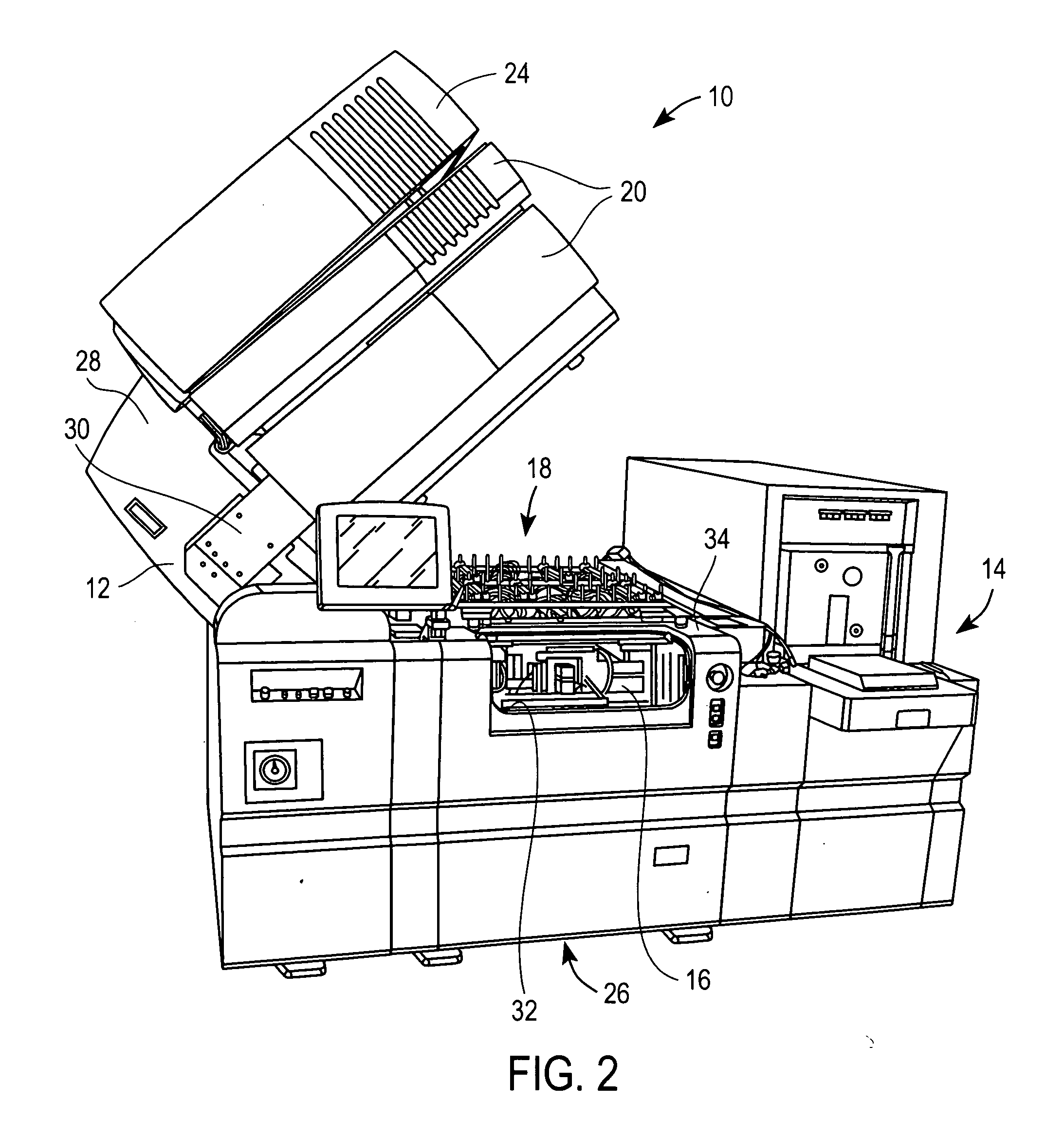

Apparatus for testing electronic devices

ActiveUS7826995B2Lower conversion rateResistance/reactance/impedenceError detection/correctionEngineeringInterconnection

Owner:AEHR TEST SYST

Apparatus for testing electronic devices

ActiveUS20080079451A1Lower conversion rateResistance/reactance/impedenceError detection/correctionEngineeringInterconnection

The invention provides an apparatus for testing an integrated circuits on devices including a plurality of electrical subassemblies including a plurality of pattern generator, driver, and power boards divided into physical zones with each physical zone including one pattern generator board, at least one driver board, and at least one power board connected to one another; and a configuration file having information representing flow of current through the electrical subassemblies connected to one another in an interconnection scheme, wherein the electrical subassemblies are organized into at least one logical zone, and wherein the logical zone comprises a plurality of pattern generators.

Owner:AEHR TEST SYST

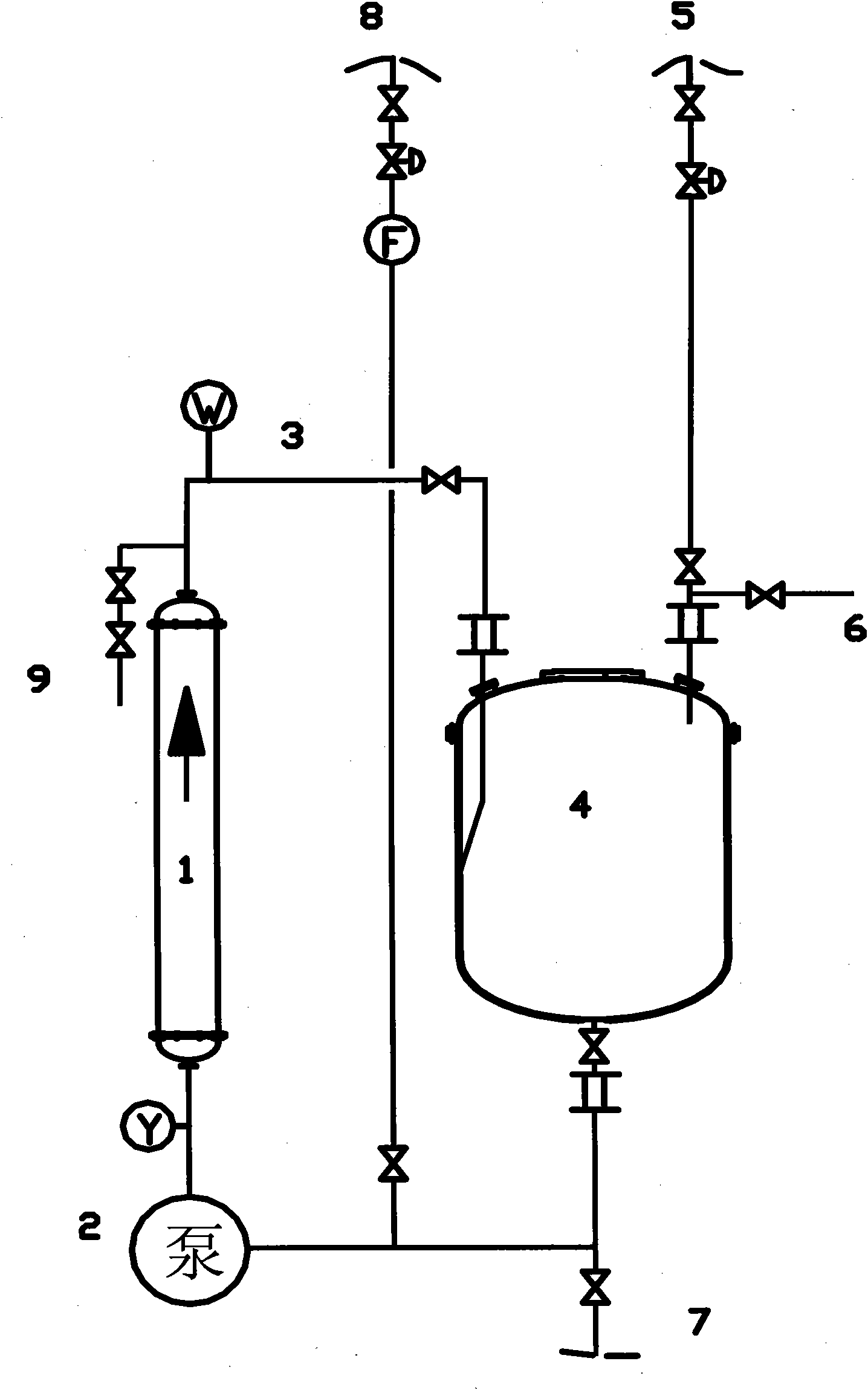

Condensation production process and special device of N-long-chain acyl amino acid salt

ActiveCN102126984AReduce contentSolve the inhibition problem of acid chloride hydrolysisOrganic compound preparationSulfonic acids salts preparationCondensation processN acylaminoacid

The invention relates to a production process and special device of the condensation process of N-long-chain acyl amino acid salt. By adopting the process and special device, the hydrolysis of acyl chloride can be inhibited and the content of the by-product fatty acid salt can be reduced in the condensation process of acyl amino acid type surfactant. Therefore, the weight of the surfactant can be increased, the content of fatty acid salt can be reduced by 50%-75% compared with the single-pot reaction, the conversion rate can be increased to more than 99%, the feeding ratio can be reduced, the condensation time can be shortened and the production efficiency can be increased.

Owner:SHANGHAI OLI ENTERPRISES CO LTD

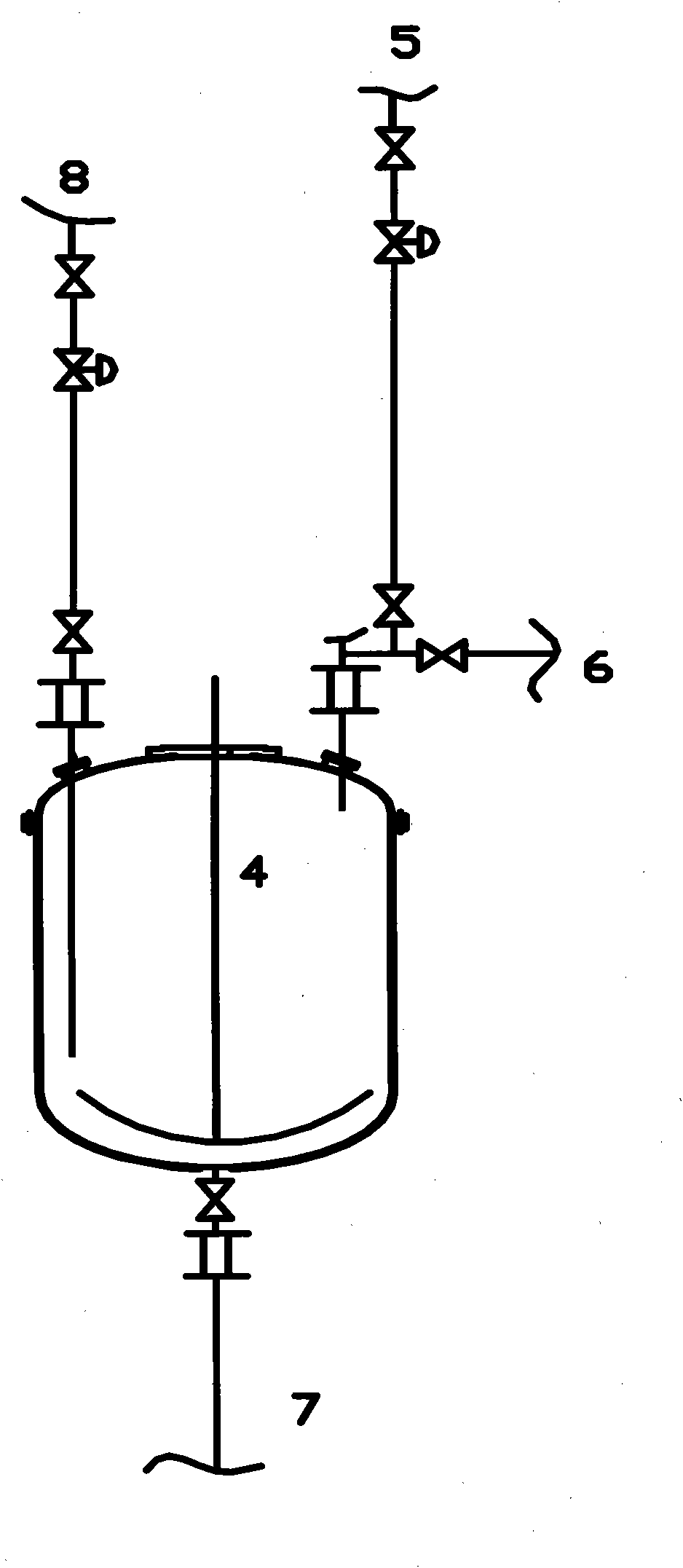

Process for producing bisphenol a

InactiveUS6429343B1Lower conversion rateIncrease the molar ratioOrganic chemistryOrganic compound preparationThiolIon-exchange resin

The present invention provides a process for producing bisphenol A which is capable of prolonging the life of an acid-type ion exchange resin partially modified with a sulfur-containing amine compound as catalyst, and increasing the yield of bisphenol A per unit quantity of the catalyst. There is disclosed a process for producing bisphenol A by reacting acetone with phenol in the presence of an acid-type ion exchange resin partially modified with a sulfur-containing amine compound as catalyst and alkylmercaptan as co-catalyst, said process comprising:conducting said reaction using a multi-stage reaction apparatus comprising at least two individual reactors connected in series to each other, wherein the molar ratio of total alkylmercaptan to total acetone and the molar ratio of total acetone to phenol are increased as the conversion rate of the phenol is decreased.

Owner:IDEMITSU KOSAN CO LTD

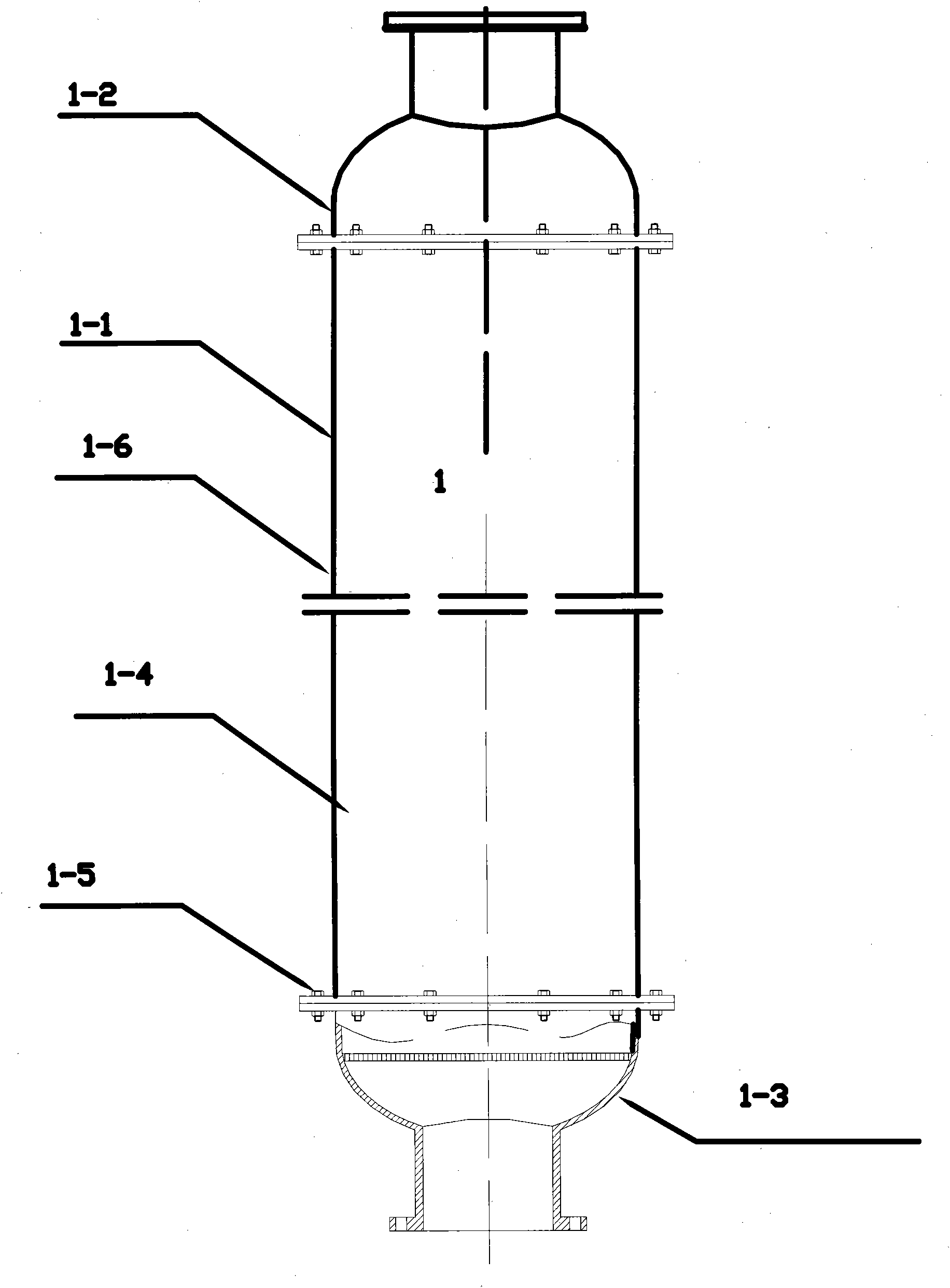

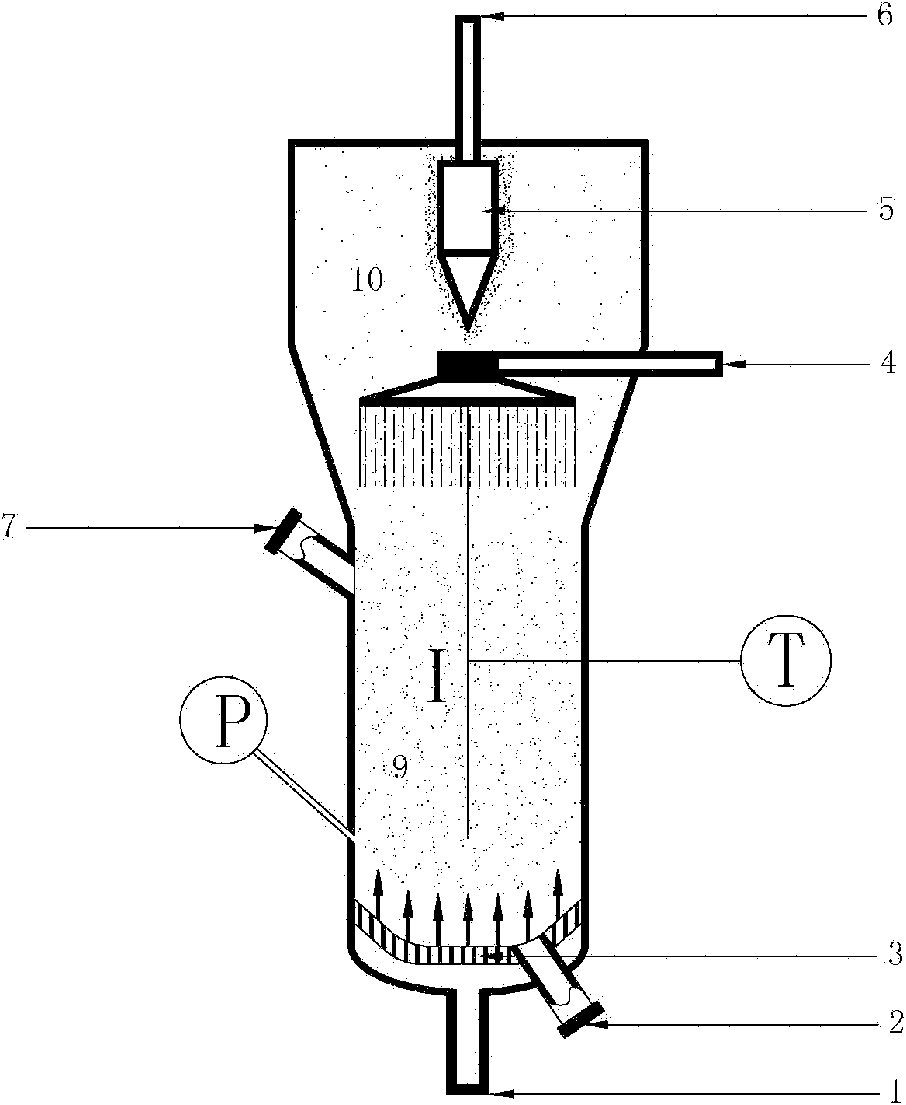

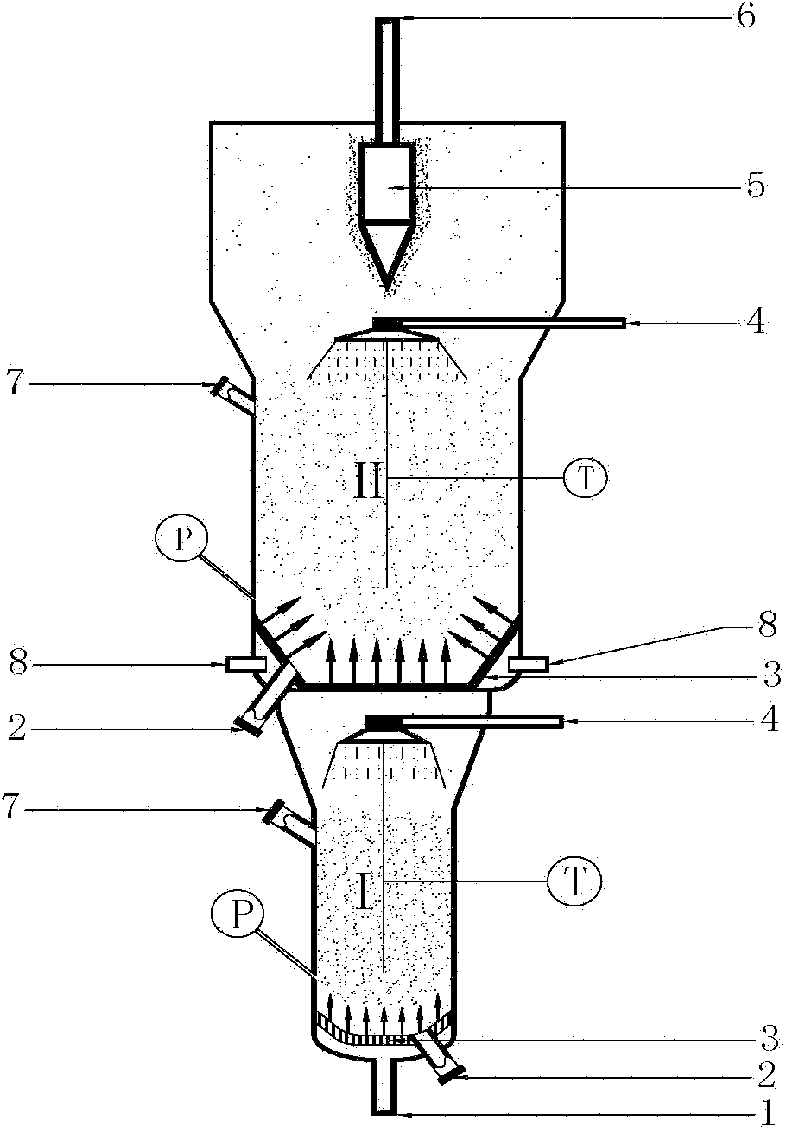

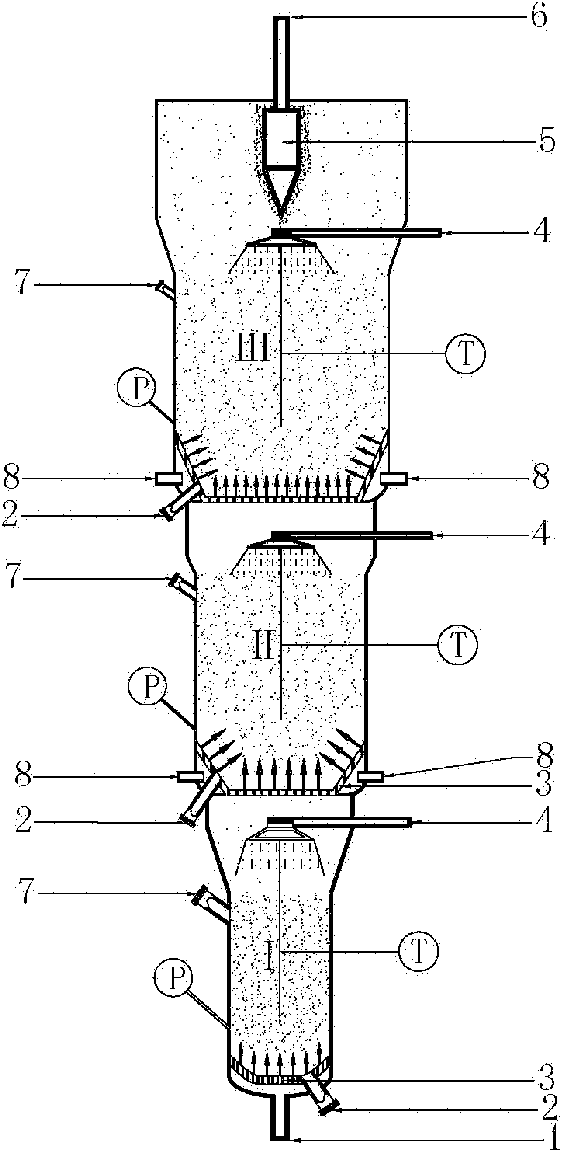

Fluidized bed reactor and method for methanation of gas mixture containing H2 and CO

ActiveCN102600771AReduce the numberExtend your lifeHydrocarbon from carbon oxidesChemical/physical processesGas solidContact high

The invention relates to a fluidized bed reactor and a method for methanation of gas mixture containing H2 and CO. The fluidized bed reactor of the invention comprises a material gas inlet 1, a catalyst outlet 2, a gas-solid separator 5, a product gas outlet 6, a catalyst inlet 7 and a material gas lateral line inlet, wherein one or more gas distribution plate 3 is arranged in the fluidized bed reactor in order to divide the reactor into several fluidized bed layers to form several catalyst dense-phase zones; a cooling water spraying device 4 is arranged above each layer of the catalyst dense-phase zone in order to control temperature of the reactor. Because the circulating cooling water directly contacts high-temperature product gas, the reactor of the invention strengthens heat transfer, is easy to control reaction temperature, reduces heat loss during the heat transfer and improves heat utilization rate during the reaction. The reactor has the advantages of large production flux, big operation elasticity, high CO conversion rate, high selectivity of produced methane, less catalyst dosage, high utilization rate of heat quantity and so on, so that the reactor has good industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Solid catalyst for preparing epoxy phenylethane by epoxidation of styrene and preparation method

InactiveCN1557553ANo significant decrease in conversion rateLower conversion rateOrganic chemistryMolecular sieve catalystsBenzoic acidIon exchange

The catalyst is VIII metal oxide or VIII metal oxide loaded on silica carrier, and has the composition of MOx or nMOx / SiO2, where SiO2 is mesoporous silica of pore size 1.5-30 nm, MOx is the oxide of VIII metal Fe or Co, and n=0.5 %-8 % is the weight percentage of metal oxide in the catalyst. The catalyst is prepared through ion exchange process or soaking process. Under proper reaction condition, the styrene converting rate within 4 hr may reach 40 %, epoxide selectivity may reach 60 %, and the side product is benzaldehyde mainly except small amount of phenylacetaldehyde and benzoic acid. The catalyst has no obviously lowered styrene converting rate and epoxide selectivity after repeated use.

Owner:XIAMEN UNIV

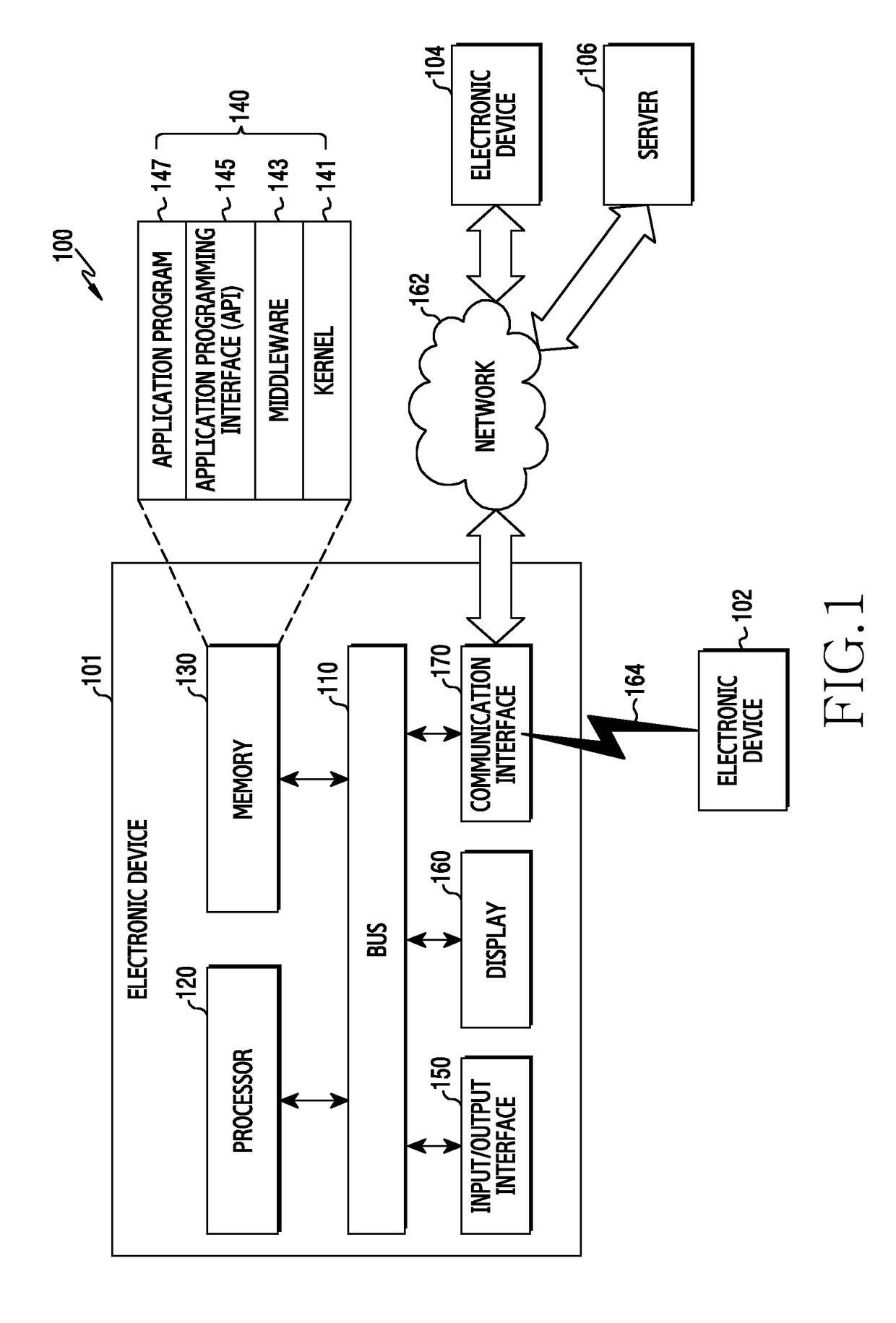

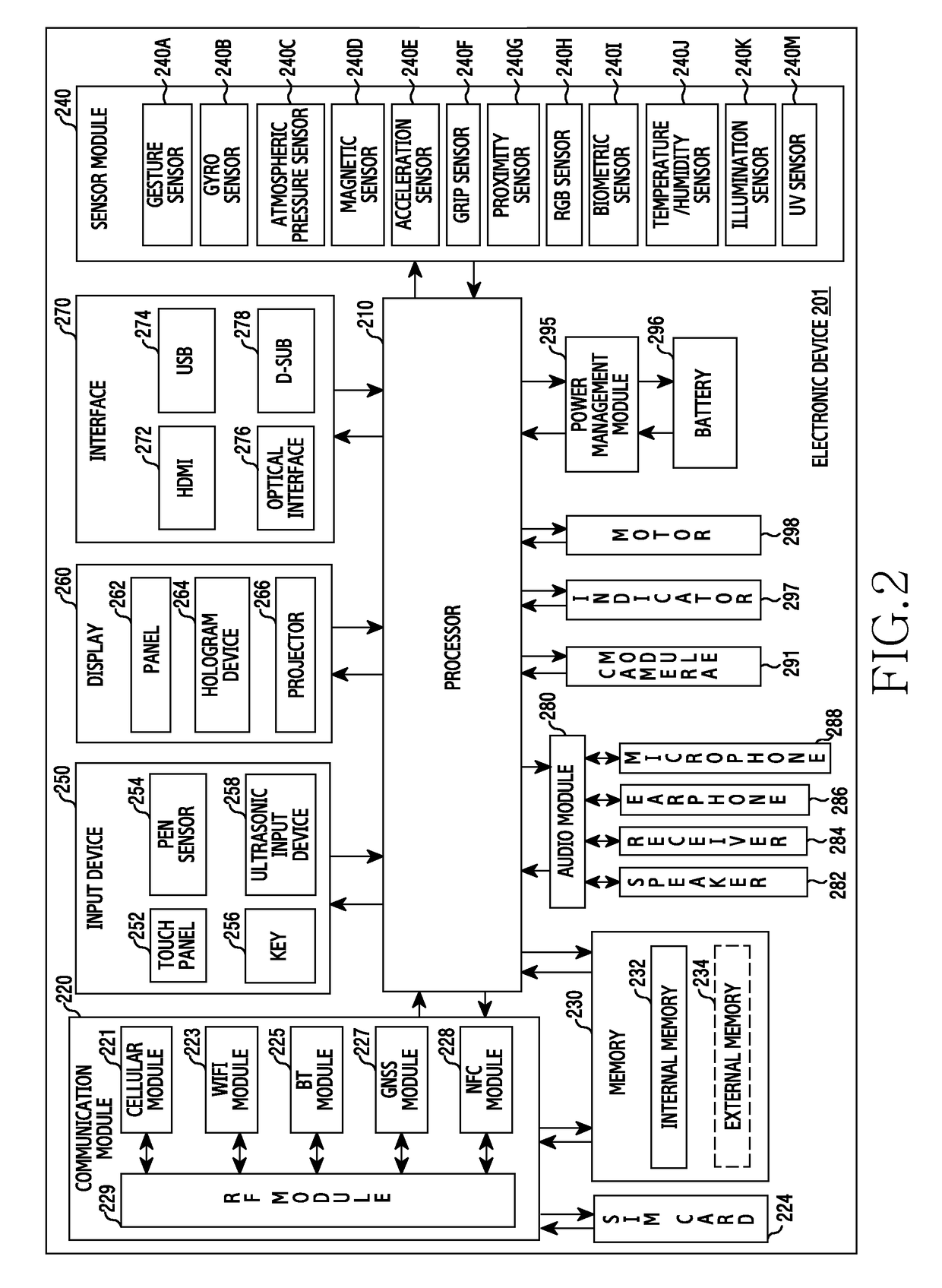

Method for controlling charge for improving receive sensitivity and electronic device for the same

ActiveUS20170346306A1Lower conversion rateImprove receiver sensitivityElectric powerTransmissionElectricityCharge control

An electronic device and a method thereof are provided. The electronic device includes a memory, a battery, a charging circuit for charging the battery using current supplied from a power supply device, a slew rate variable circuit electrically connected to the charging circuit, and a processor electrically connected to the memory, the battery, the charging circuit, and the slew rate variable circuit. The processor is configured to control the charging circuit to control the charging of the battery, to monitor a state of the electronic device during battery charging, and to control the slew rate variable circuit based on the state of the electronic device to change a slew rate related to the battery charging.

Owner:SAMSUNG ELECTRONICS CO LTD

Oxygen-enriched tail gas nitrogen oxide purifying catalyst

InactiveCN1509813AEfficient purificationHigh reducing activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitrogen oxidesMonoxide

A catalyst of removing the NOx, residual organic substance and CO from the oxygen-enriched tail gas from engine contains the porous inorganic carrier, silver, noble metal chosen from Au, Pt, Pd, Ph, Ir and Ru, and other metal chosen from Fe, Cu, Ti, Zr, Ba, Sn, W, Zn, Mo, Ce, Cs, La and Ca.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

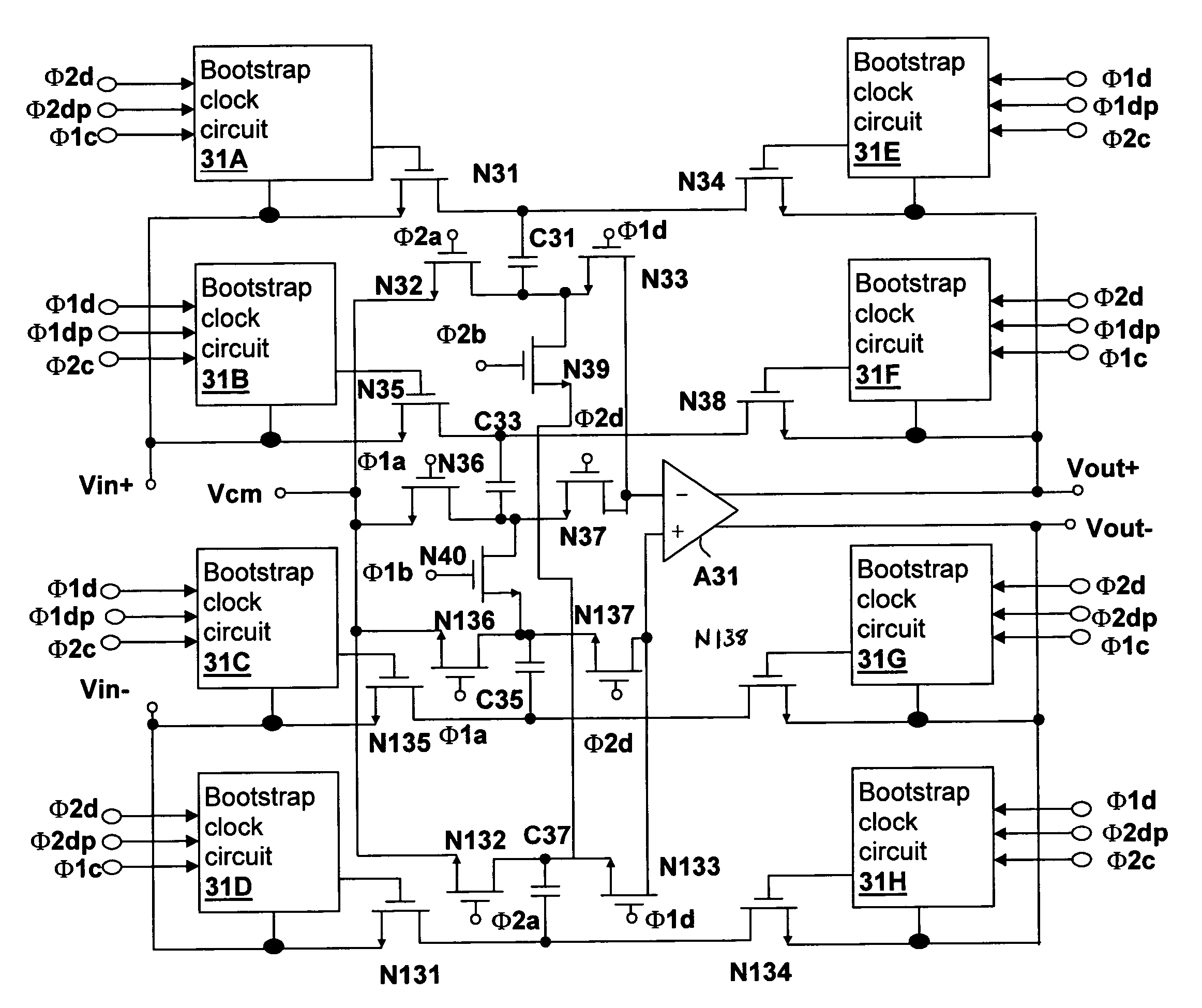

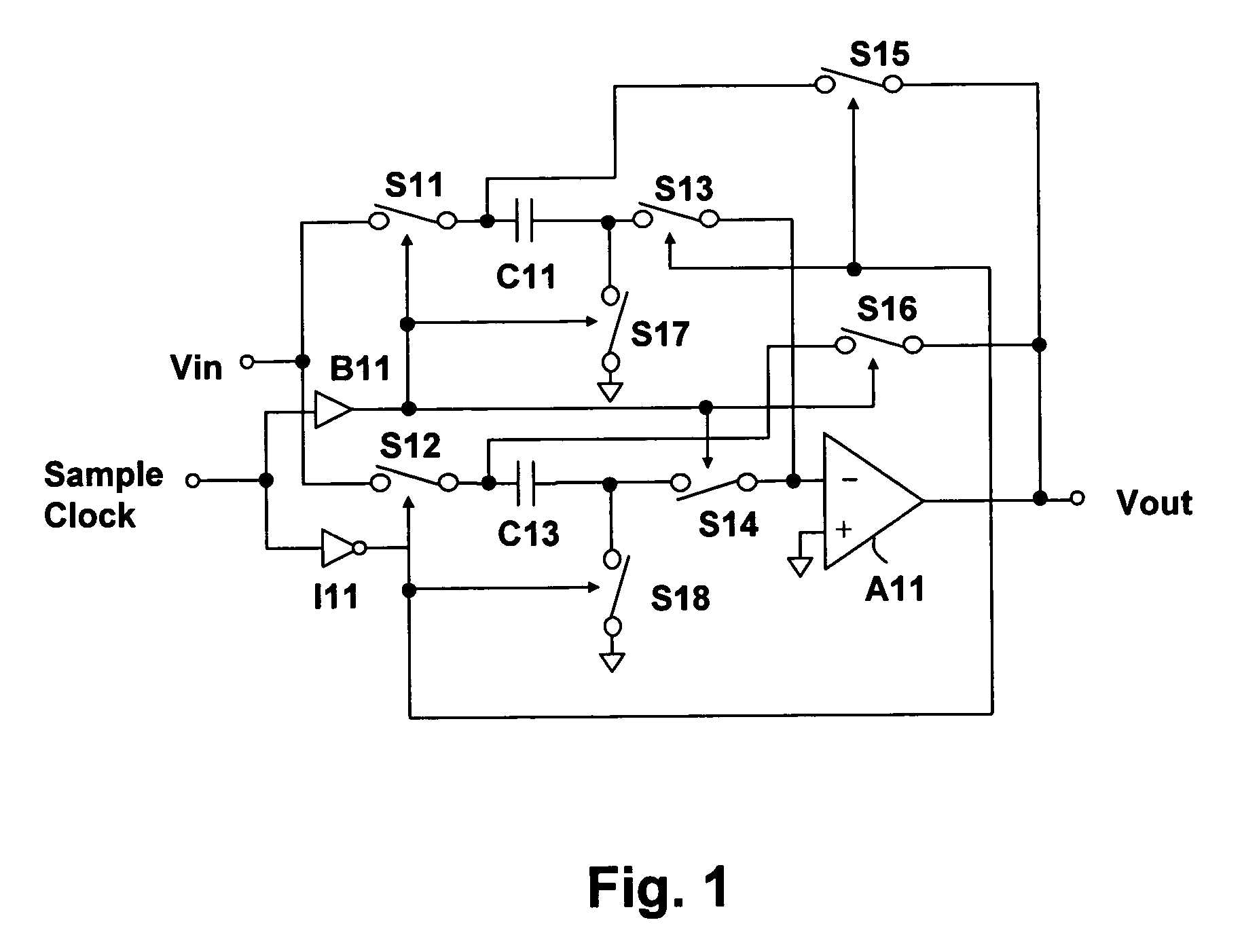

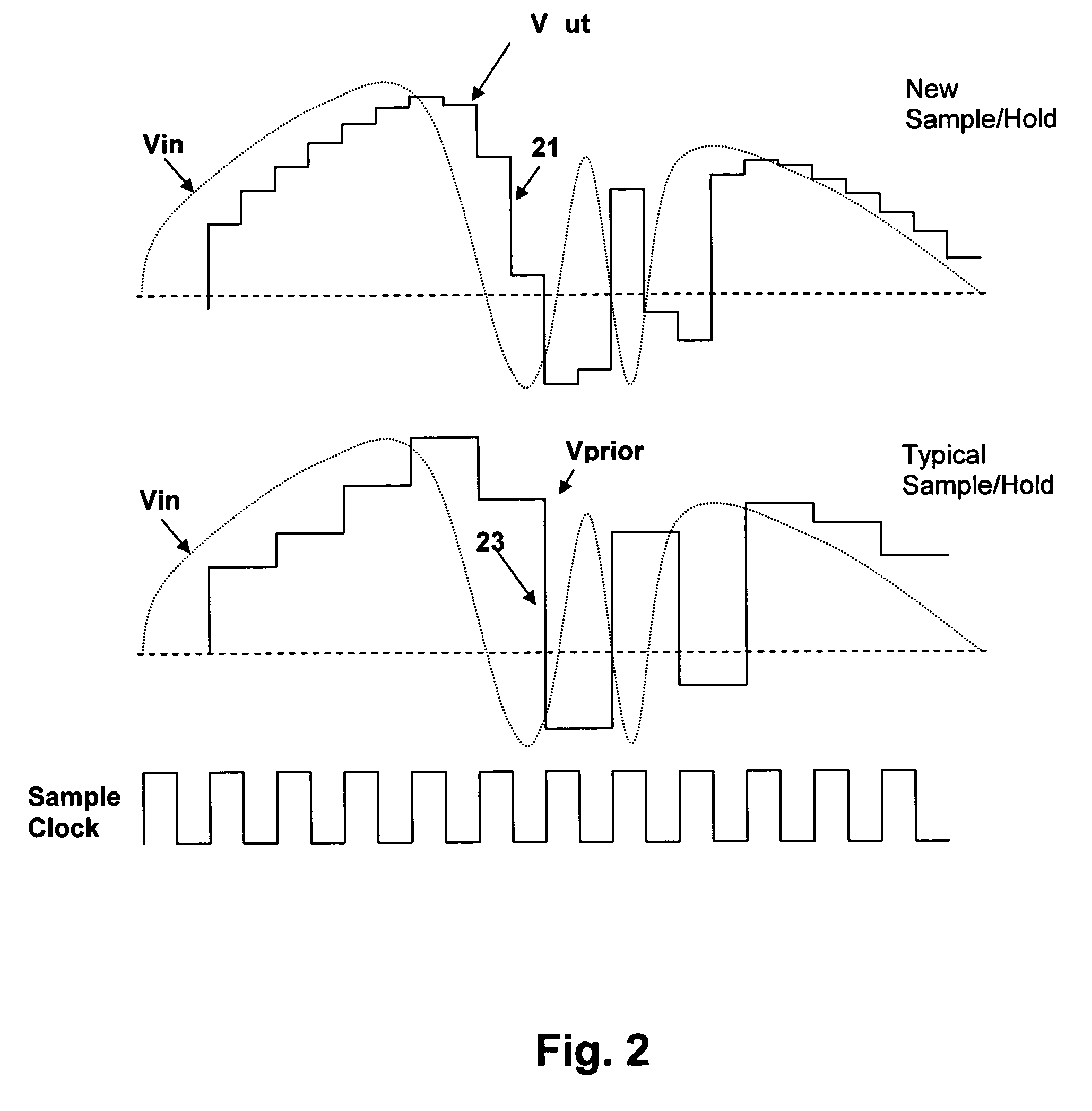

Switched-capacitor sample/hold having reduced amplifier slew-rate and settling time requirements

InactiveUS6992509B2Lower conversion rateReduce errorsAnalogue/digital conversionComputing operations for integral formationCapacitanceCharge injection

A switched-capacitor sample / hold circuit and method having reduced slew-rate and settling time requirements provides for lower-cost and / or lower-power implementation of sample / hold circuits and / or reduced error due to amplifier characteristics. The switched-capacitor sample / hold circuit incorporates a pair of capacitors that are alternatively and mutually-exclusively switched between an input sample position and an amplifier hold position, providing a dual sampled amplifier output signal that has reduced transitions at each sample interval. An alternative embodiment of the sample / hold circuit incorporates a fully-differential amplifier having a differential input and a differential output. Four capacitors are employed forming two of the dual sampled switched-capacitor circuits, one in each negative feedback path (inverted output to non-inverting input, non-inverted output to inverting input) of the amplifier. The two dual sampled switched-capacitor circuits are referenced to each other, providing fully differential operation and cancellation of error due to charge injection.

Owner:MICROCHIP TECH INC

Catalyst having a zeolitic core and zeolitic layer and the use of the catalyst for olefin oligomerization

InactiveUS6300536B1Raise the ratioLow degree of branchingMolecular sieve catalystsMolecular sieve catalystMolecular sieveSurface layer

A molecular sieve comprising a core having deposited thereon a surface layer, wherein the core is a zeolite containing silicon and at least one element selected from gallium and iron and the surface layer has a higher Si:Al ratio than that of the silicon:selected element ratio of the core, provides for lower branching in olefin oligomerization products.

Owner:EXXONMOBIL CHEM PAT INC

Auto-sexing breeding method of early-maturing excellent type yellow-shank partridge chickens

The invention provides an auto-sexing breeding method of early-maturing excellent type yellow-shank partridge chickens. The method comprises the steps that a Qingyuan partridge chicken rapid-feathering line which grows fast in early stage, a Qingyuan partridge chicken slow-feathering line which has prominent reproductive performance and a Guangxi partridge chicken rapid-feathering line are adopted, the grandparent generation selects cocks and hens of the Qingyuan partridge chicken rapid-feathering line, the paternal line selects cocks of the Qingyuan partridge chicken slow-feathering line, and the maternal line selects hens of the Guangxi partridge chicken rapid-feathering line; the parent generation selects cocks of the Qingyuan partridge chicken slow-feathering line, and the female parent selects yellow-shank slow-feathering hens produced by hybridizing the cocks of the Qingyuan partridge chicken slow-feathering line with the hens of the Guangxi partridge chicken rapid-feathering line; for slow-type early-maturing excellent yellow-shank partridge chickens, the cocks are slow-feathering cocks, the hens are rapid-feathering hens, and autosexing is achieved according to the feathering speed. Compared with traditional Qingyuan partridge chickens, commercial generation autosexing according to the feathering speed is achieved, the market age of the hens is 10 days ahead of schedule, the egg laying performance of the parental generation can be improved by 15% or above, the feed conversion rate is decreased by 0.2, and the breeding profit is increased.

Owner:李华

Method for preparing sodium aescinate

ActiveCN102659897AReduce extractionReduce the conversion rate of impuritiesSugar derivativesSteroidsChemistryOrganic solvent

The invention provides a method for preparing sodium aescinate. The method can be used for solving the problem that a traditional method for preparing sodium aescinate is low in yield and purity and long in purification cycle, remaining organic solvents can be effectively decreased, the content of sodium aescinate A and sodium aescinate B is increased, accordingly, environmental pollution is decreased, and clinical application effects of the sodium aescinate are improved. The method includes the steps: firstly, performing extraction; secondly, performing purification; and finally, performing baking and drying. The method is characterized in that buckeye powder and ethanol solution are mixed and soaked according to the liquid ratio of 1:(3-12) kilograms per liter, and then are extracted, wherein the liquid ratio is preferably 1:9 kilograms per liter.

Owner:WUXI KAIFU PHARMA

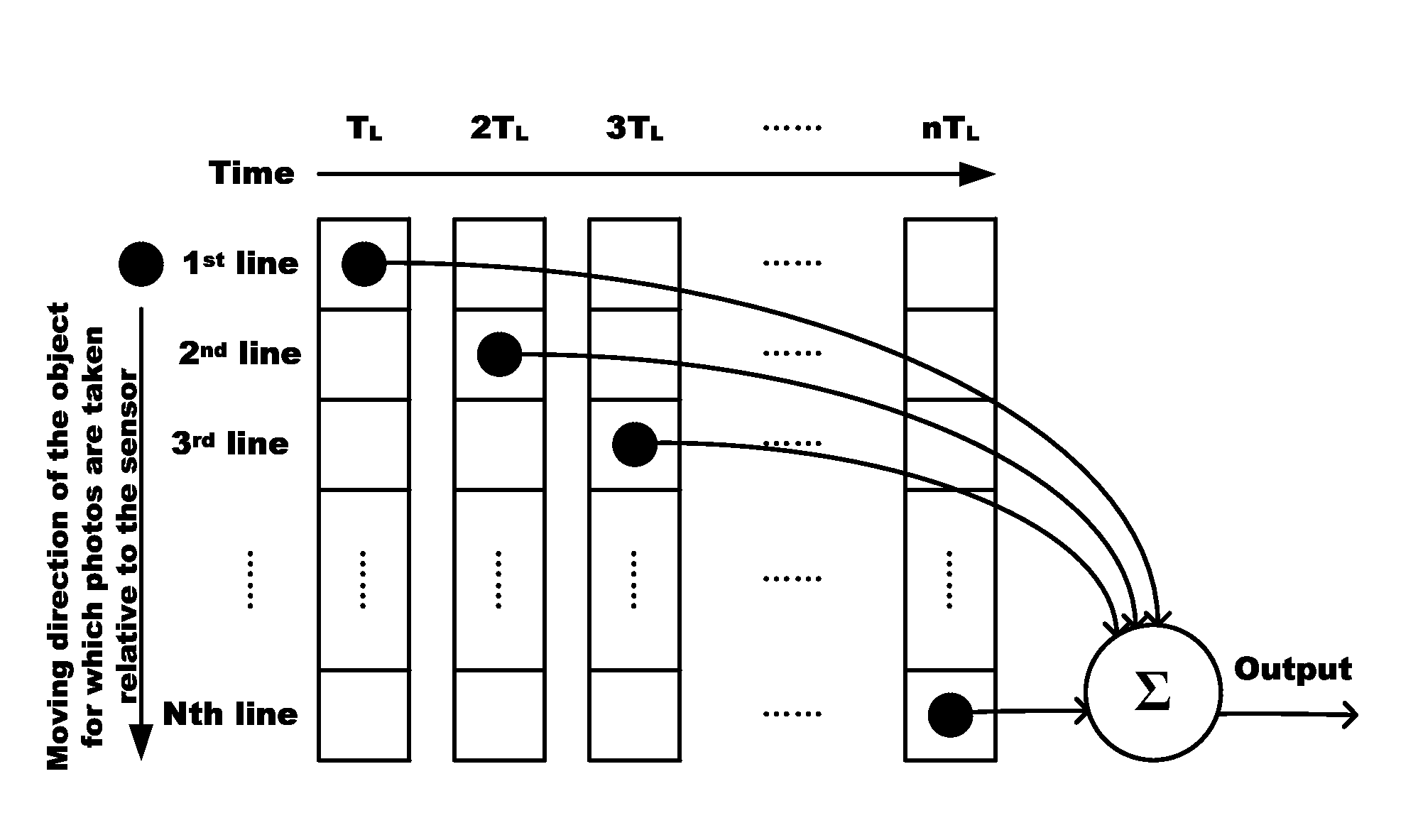

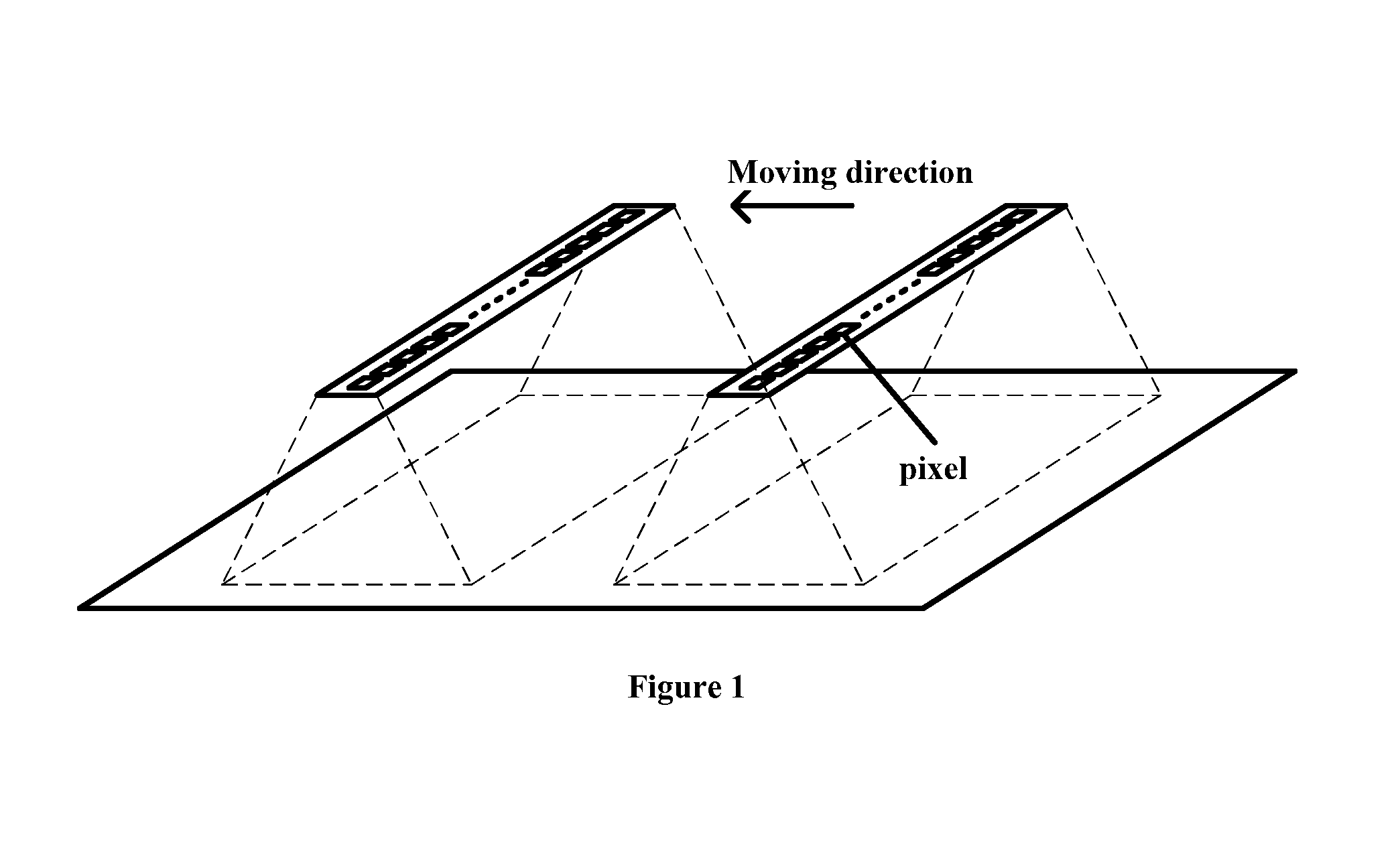

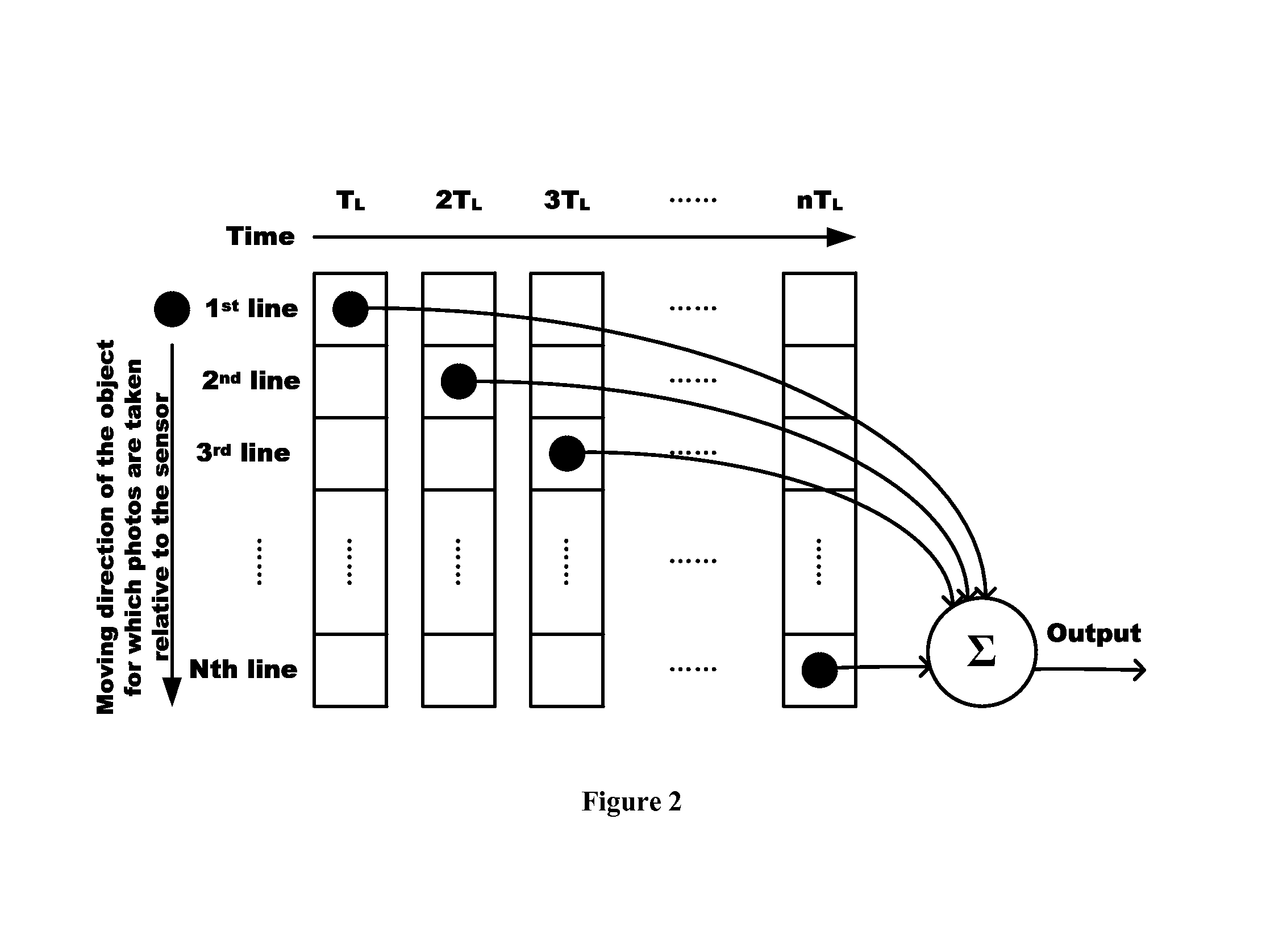

Digital domain accumulative cmos-tdi image sensor with low power consumption

ActiveUS20140368703A1Reduce riskDecrease in conversion rateTelevision system detailsTelevision system scanning detailsCMOSHybrid integrated circuit

The present invention relates to the field of design of analog digital hybrid integrated circuit. The object of the invention is to reduce ADC conversion rate thus further reducing power consumption of the sensor while not reducing line frequency of the CMOS-TDI. To this end, a digital domain accumulative CMOS-TDI image sensor with low power consumption is provided. It includes a pixel array of n+k lines multiplied m columns, a column parallel signal pre-processing circuit, a column parallel successive approximation (SAR) ADC, a column parallel digital domain accumulator, a column parallel divider, a timing control circuit and an output shift register, wherein n+k+1 coarse quantification memory units are provided to the column parallel digital domain accumulator for storage of coarse quantification results; and memory units for storage of n times of fine quantification results are also provided, thus realizing n stages of TDI signal accumulation after accumulation of n times of fine quantification results. The invention is generally used in hybrid integrated circuit design.

Owner:QUANTRON

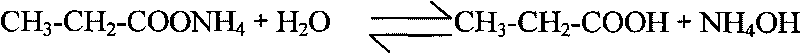

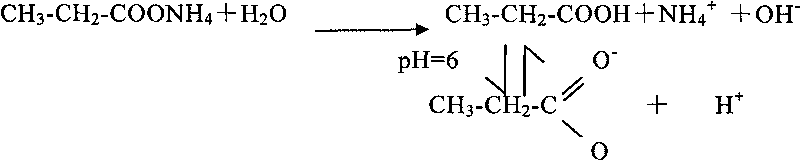

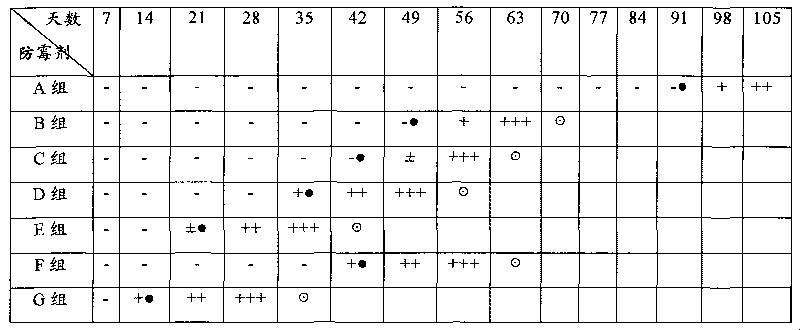

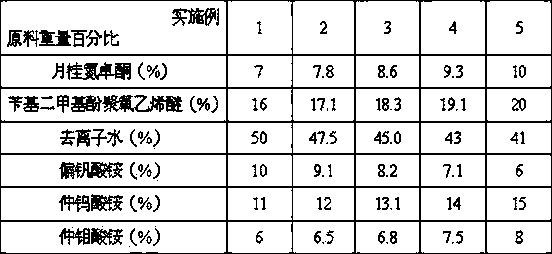

Compound mouldproof agent with acidizing effect and preparation method thereof

ActiveCN101731451ALower conversion rateGood antibacterial effectAnimal feeding stuffDehydroacetic acidAcetic acid

The invention provides a compound mouldproof agent with the acidizing effect and a preparation method thereof. The compound mouldproof agent comprises the following components in parts by weight: 20-50 parts of propionic acid-ammonium propionate-ammonium dipropionate mixture, 5-15 parts of glacial acetic acid-ammonium acetate-ammonium diacetate mixture, 2-10 parts of benzoic acid, 1-3 parts of dehydroacetic acid and / or sorbic acid and 37-55 parts of vectors. The invention also provides the preparation method of the compound mouldproof agent, which is characterized by evenly stirring the mixture of the 20-50 parts of propionic acid-ammonium propionate-ammonium dipropionate mixture, the 5-15 parts of glacial acetic acid-ammonium acetate-ammonium diacetate intermediate product components, the 2-10 parts of benzoic acid, the 1-3 parts of dehydroacetic acid and / or sorbic acid and the 37-55 parts of vectors, filtering, inspecting and packaging, thus obtaining the compound mouldproof agent. The compound mouldproof agent has double functions of mould proofing and acidizing, is synergistic, avoids antagonism and is simple in preparation, low in cost and high in application value.

Owner:惠州市昕昊实业有限公司

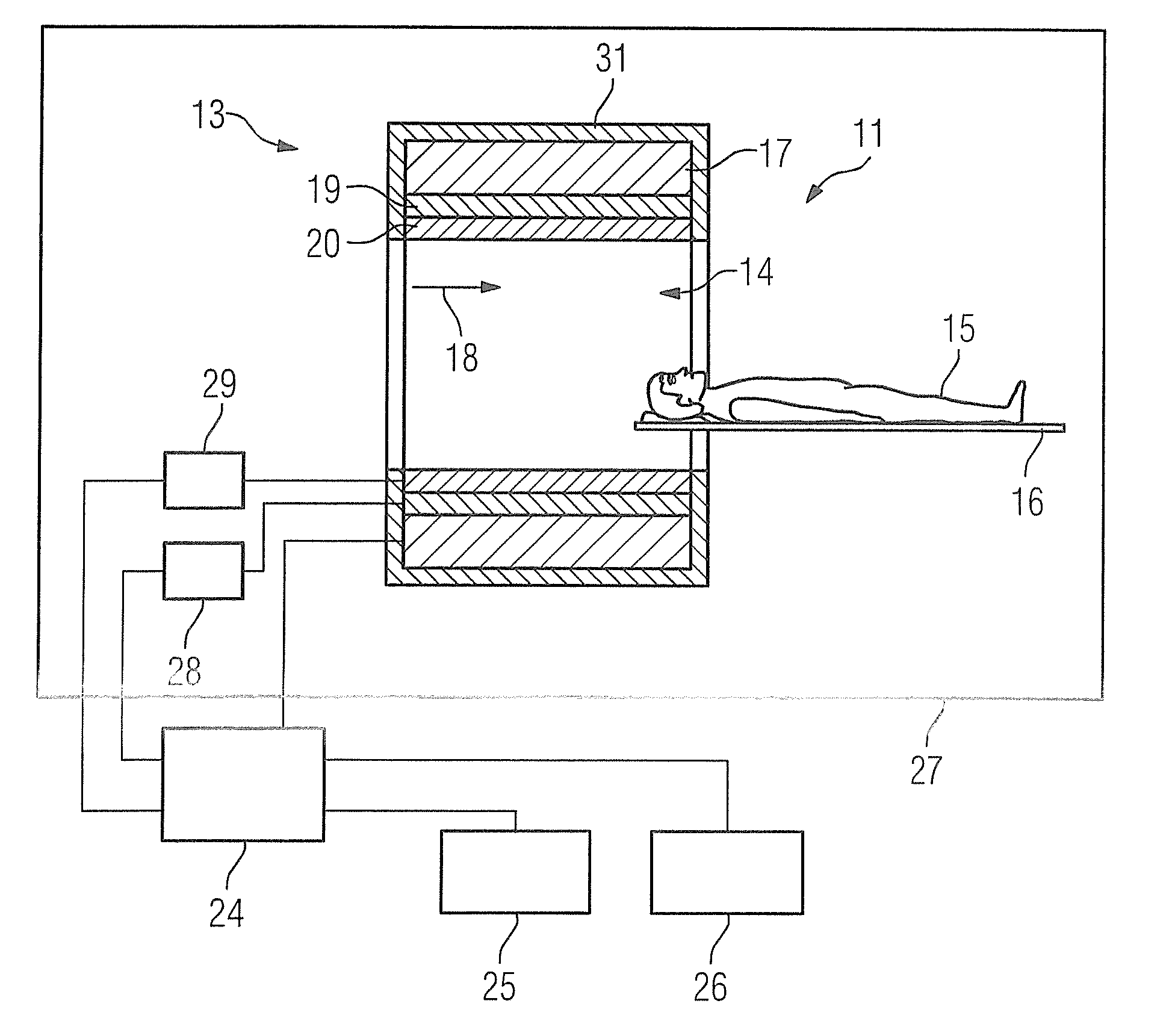

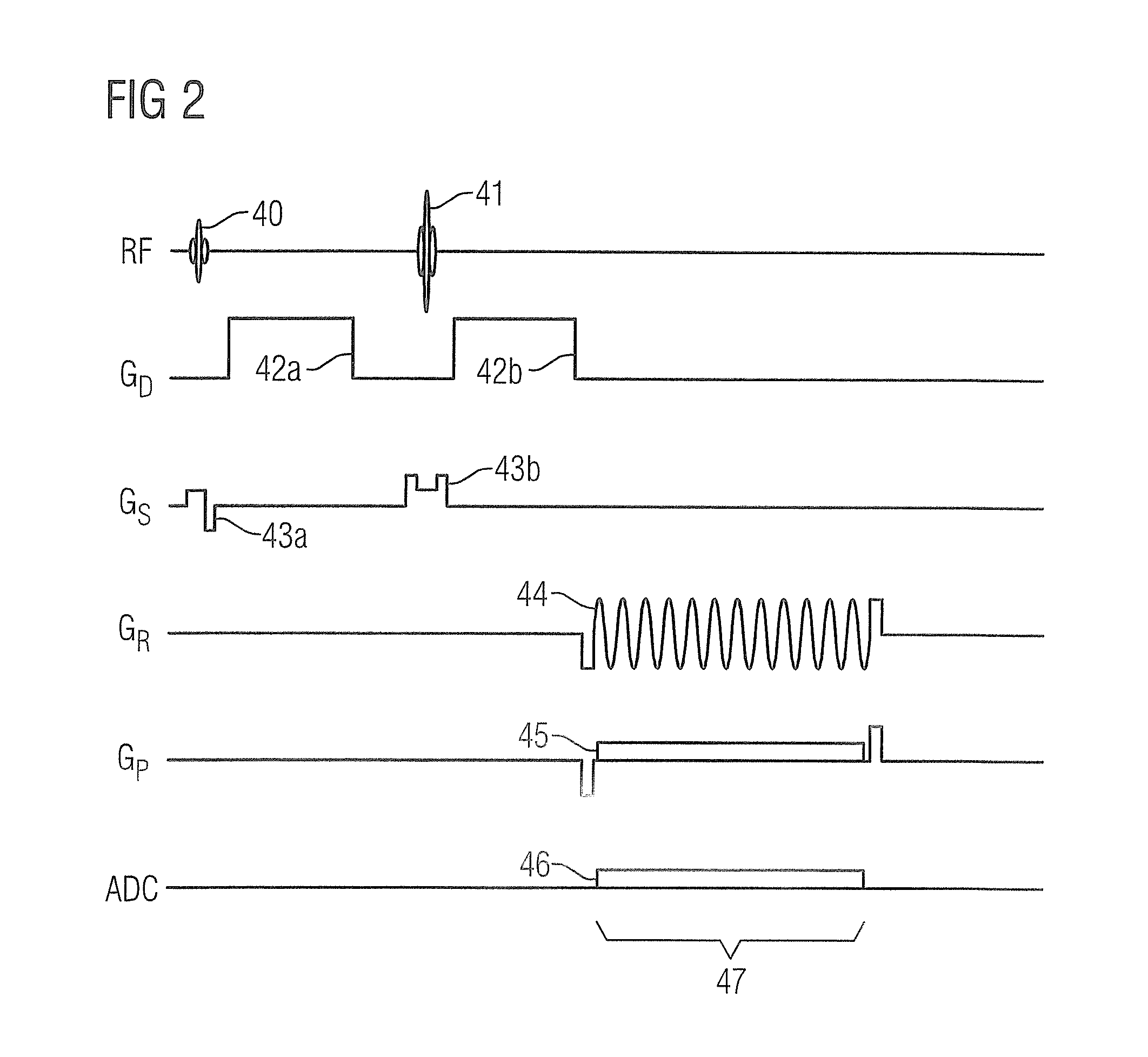

Method and apparatus for magnetic resonance imaging

ActiveUS20150253408A1QuietAttenuation bandwidthMeasurements using NMR imaging systemsElectric/magnetic detectionResonanceSlew rate

In a method and apparatus for magnetic resonance imaging, a particularly quiet magnetic resonance sequence, uses echo-planar imaging with at least one gradient switching in a readout direction, wherein the at least one gradient switching in the readout direction has a slew rate that is less than a maximum slew rate defined by system specification parameters of the magnetic resonance apparatus.

Owner:SIEMENS HEALTHCARE GMBH

Method for preparing high oil absorption resin

A process for preparing the resin with high oil absorptivity from styrene and long-chain olefin monomer CnH2n, where n is equal to or greater than 4, includes such steps as preparing the low-cross-linked polystryrene or styrene copolymer, immersing it in solvent or long-chain olefin monomer or their mixture, and alkylating reaction. Its advantages are high content of gel and oil absorptivity, and low cost.

Owner:NANJING UNIV OF SCI & TECH

Double-treatment cleaning and regenerating method for vanadium-titanium based denitration catalyst

InactiveCN103386313AImprove redox abilityToxic substance reductionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsTitaniumMixed gas

The invention discloses a double-treatment cleaning and regenerating method for a vanadium-titanium based denitration catalyst and aims to solve the technical problem that the regenerating effect of the traditional vanadium-titanium based denitration catalyst is not so good. According to the technical scheme, the double-treatment cleaning and regenerating method comprises the following steps of: introducing air-ozone mixed gas into a catalyst regenerating reactor, and carrying out oxidation treatment to obtain a regenerated vanadium-titanium based denitration catalyst; then, placing the regenerated vanadium-titanium based denitration catalyst into a catalyst activity liquid, dipping the regenerated vanadium-titanium based denitration catalyst for 4-6h, then, taking out the regenerated vanadium-titanium based denitration catalyst, drying the regenerated vanadium-titanium based denitration catalyst in dry air at 50-60 DEG C for 1-3h, and then, repeating the operation once; and then, roasting the regenerated vanadium-titanium based denitration catalyst at the temperature of 160-200 DEG C for 1-3h, and then, roasting the regenerated vanadium-titanium based denitration catalyst at the temperature of 300-400 DEG C for 1-3h to obtain the cleaned and regenerated vanadium-titanium based denitration catalyst. The double-treatment cleaning and regenerating method has the beneficial effects that the denitration ratio of the regenerated vanadium-titanium based denitration catalyst can be up to 87%, so that efficient regeneration is realized, meanwhile, the conversion ratio of SO2 / SO3 is effectively reduced, and the denitration cost is greatly reduced.

Owner:HEBEI MILSON TITANIUM DIOXIDE

Liquid acidifier and preparation method

InactiveCN101120758AImprove digestibilityIncrease production capacityOrganic active ingredientsAntiinfectivesOrganic acidMortality rate

The present invention disclosed a liquid acidifier and making method. The present invention comprises organic acids and relevant soluble salts. After the organic acids and the relevant soluble salts are treated by the following procedures of heating, melting, mixing, removing bacteria, filtrating and so on, the liquid acidifier is made. The content of organic acids is over 70percent, which can reduce the pH value of drinking water and intestine, can prevent the harmful flora, can restrain the growth of the salmonella, at the same time can improve the stress ability of the animals, can reduce the death rate and promote the growth rate, and can enhance the absorption rate and conversion of feed. The present invention provides a new idea for developing a compound acidifier.

Owner:CHENGDU FENGLAN SCI & TECH

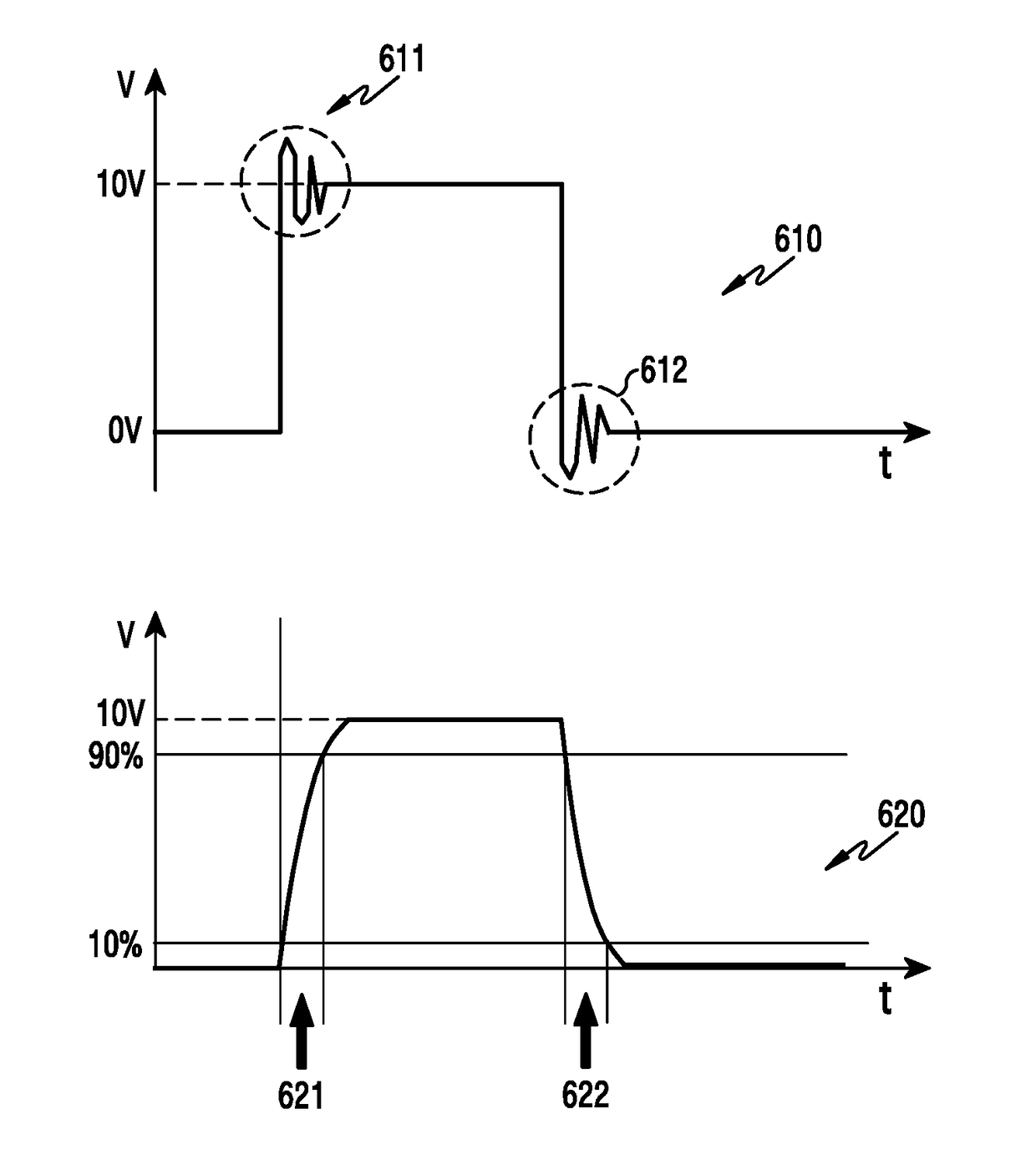

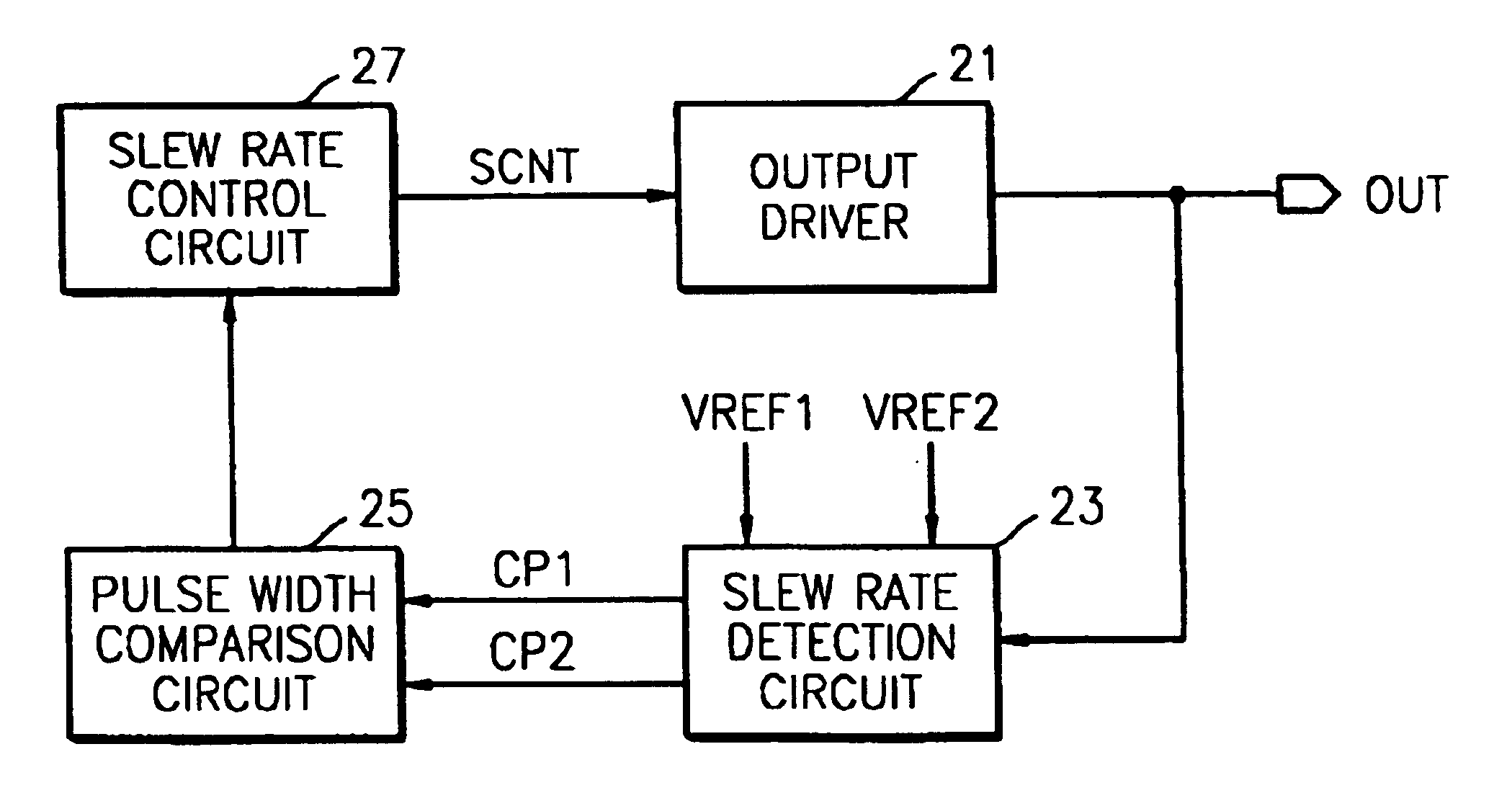

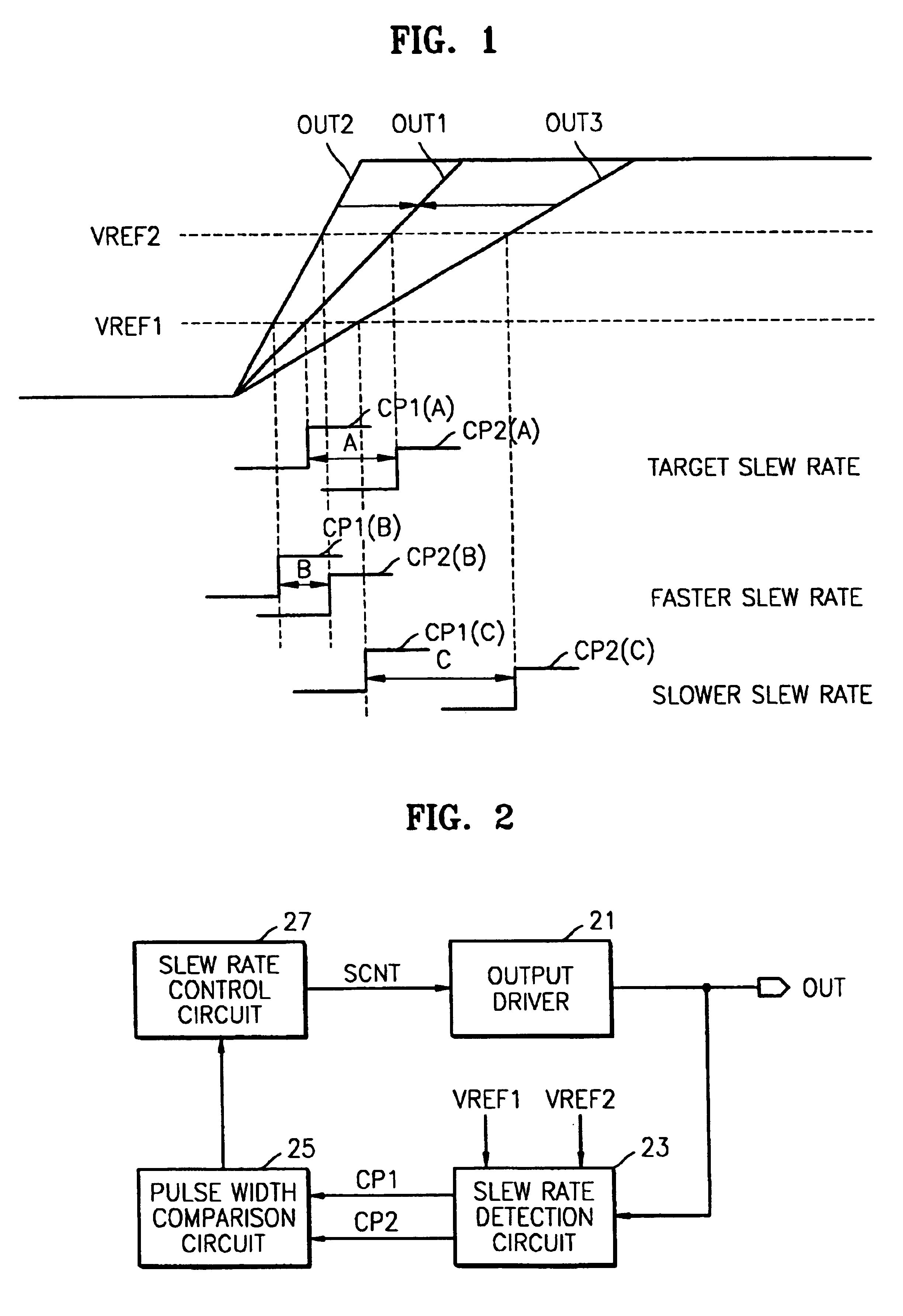

Output driver circuit with automatic slew rate control and slew rate control method using the same

InactiveUS6903589B2Lower conversion rateIncrease conversion rateElectronic switchingDigital storageDriver circuitVoltage reference

The output signal from an output driver is compared with first and second reference voltages. A first comparison output signal is generated which exhibits a voltage transition when the output signal reaches the first reference voltage, and a second comparison output signal is generated which exhibits a voltage transition when the output signal reaches the second reference voltage. First and second pulse widths values are then compared. The first pulse width value corresponds to a time delay difference between the voltage transition of the first comparison output signal and the voltage transition of the second comparison output signal, and the second pulse width value corresponds to a target slew rate of the output signal from the output driver. The slew rate of the output signal is decrease when the first pulse width value is smaller than the second pulse width value, and the slew rate of the output signal is increased when the first pulse width value is larger than the second pulse width value.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com