Condensation production process and special device of N-long-chain acyl amino acid salt

A technology for long-chain acyl amino acid salts and long-chain acyl amino acids, which is applied in the field of production technology and special equipment for the condensation process of N-long-chain acyl amino acid salts, and can solve the problems of increasing acid chloride addition time, prolonging production cycle, and increasing dripping time, etc. , to achieve the effect of increasing conversion rate, improving product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

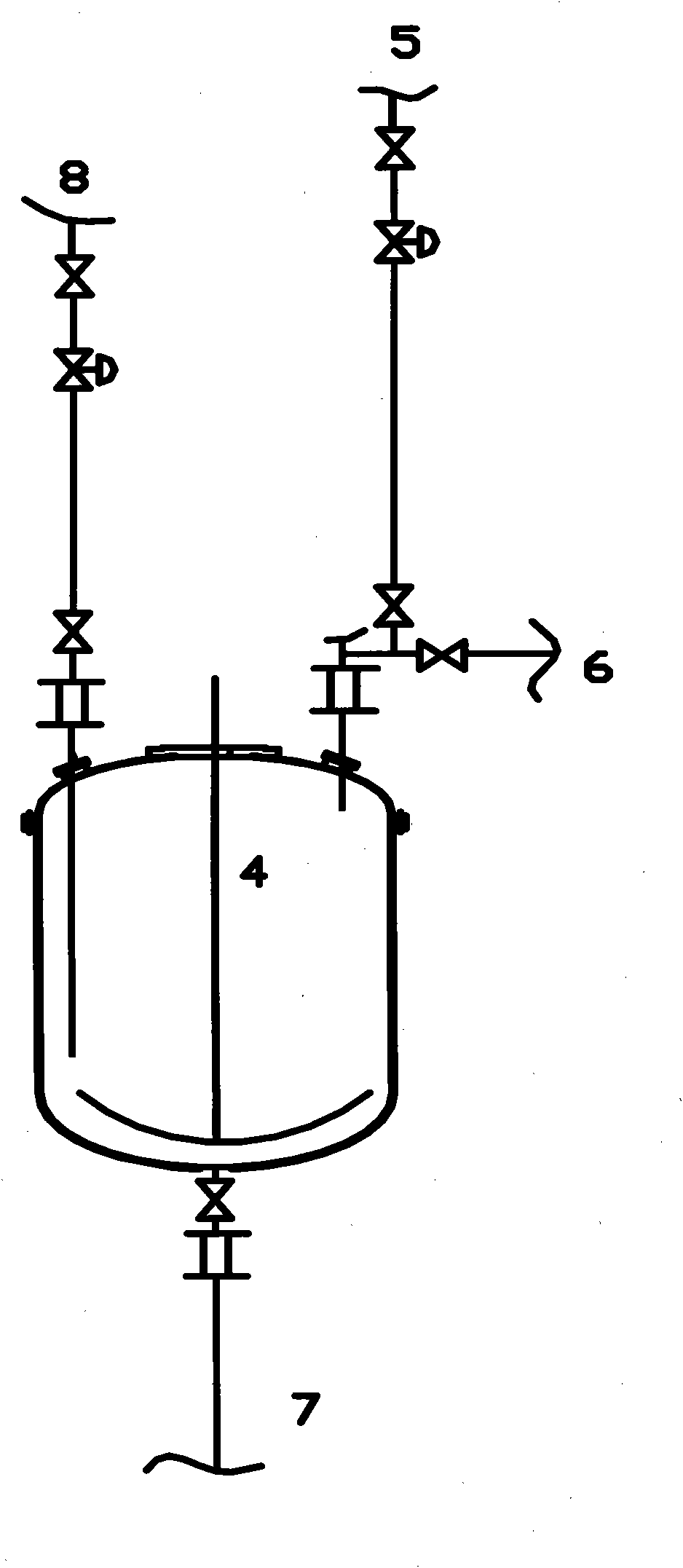

[0032] with attached figure 1 The single-pot reaction process shown in the synthesis of sodium lauroyl sarcosinate, the process is as follows: add sodium sarcosinate and pure water to the reactor 4' through the pipeline 6 (the specific consumption is determined by the volume of the reactor 4 '), so that the muscle The initial concentration of sodium phosphate is 12%-15% (w / w). Under the temperature condition of 10-15°C, the acid chloride is slowly added dropwise from the pipeline 8, and the stirring rate is increased as far as possible. During the process of adding lauroyl chloride , add sodium hydroxide dropwise from pipeline 5 to maintain the pH of the reaction solution at 9.5-10.5 until the addition of the acid chloride is completed and the material is discharged.

[0033]In the whole single-pot process, the molar ratio of sodium sarcosinate and lauroyl chloride is 1.05: 1.00. The average dropping time of 99% lauroyl chloride of 570kg is 8-12, and the average content of sod...

Embodiment 2

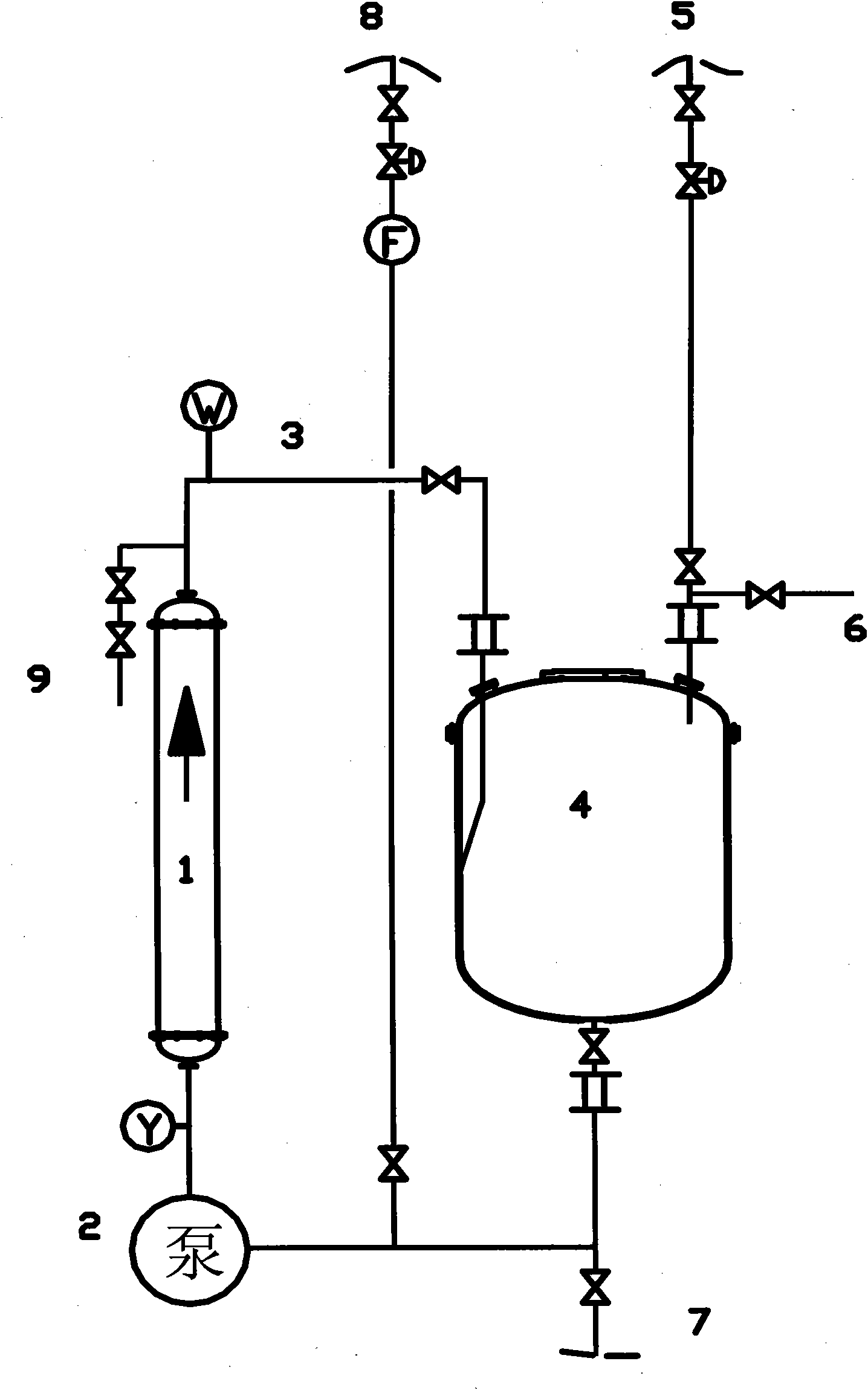

[0035] with attached figure 2 Shown process of the present invention produces sodium lauroyl sarcosinate, and process is as follows: inject a certain amount of 25% sodium sarcosinate and a certain amount of pure water into storage tank 4 by pipeline 6 (concrete consumption is determined by the volume of storage tank 4 ), make the initial concentration of sodium sarcosinate aqueous solution be 12%-15% (w / w), under the temperature condition of 15-20 ℃, open storage tank 4 bottom valves and the upper circulation valve that connects pipeline reactor, open Pump, so that the mixed solution of sodium sarcosinate and water flows out from the bottom valve through the storage tank 4, passes through the pipeline reactor 1, and enters the storage tank 4 at a flow rate of 25m 3 / h. The purpose of this process is to mix the sodium sarcosinate and pure water evenly. After sodium sarcosinate and pure water are mixed evenly, lauroyl chloride is added to the circulation system of sodium sarc...

Embodiment 3

[0042] with attached figure 1 The single-pot reaction process shown in the synthesis of sodium lauroyl methyl taurate, the process is as follows: add sodium methyl taurate and the pure water of an equivalent amount of sodium methyl taurate to the reaction kettle 4' through the pipeline 6, the temperature Control the temperature at 5-10°C, slowly add acid chloride dropwise from pipeline 8, and at the same time increase the stirring rate as much as possible, add sodium hydroxide dropwise from pipeline 5 during the reaction, and maintain the pH of the reaction solution at 9.0-10.0. Until the dropwise addition of the acid chloride is completed, the material is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com