Patents

Literature

58373results about How to "Improve product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

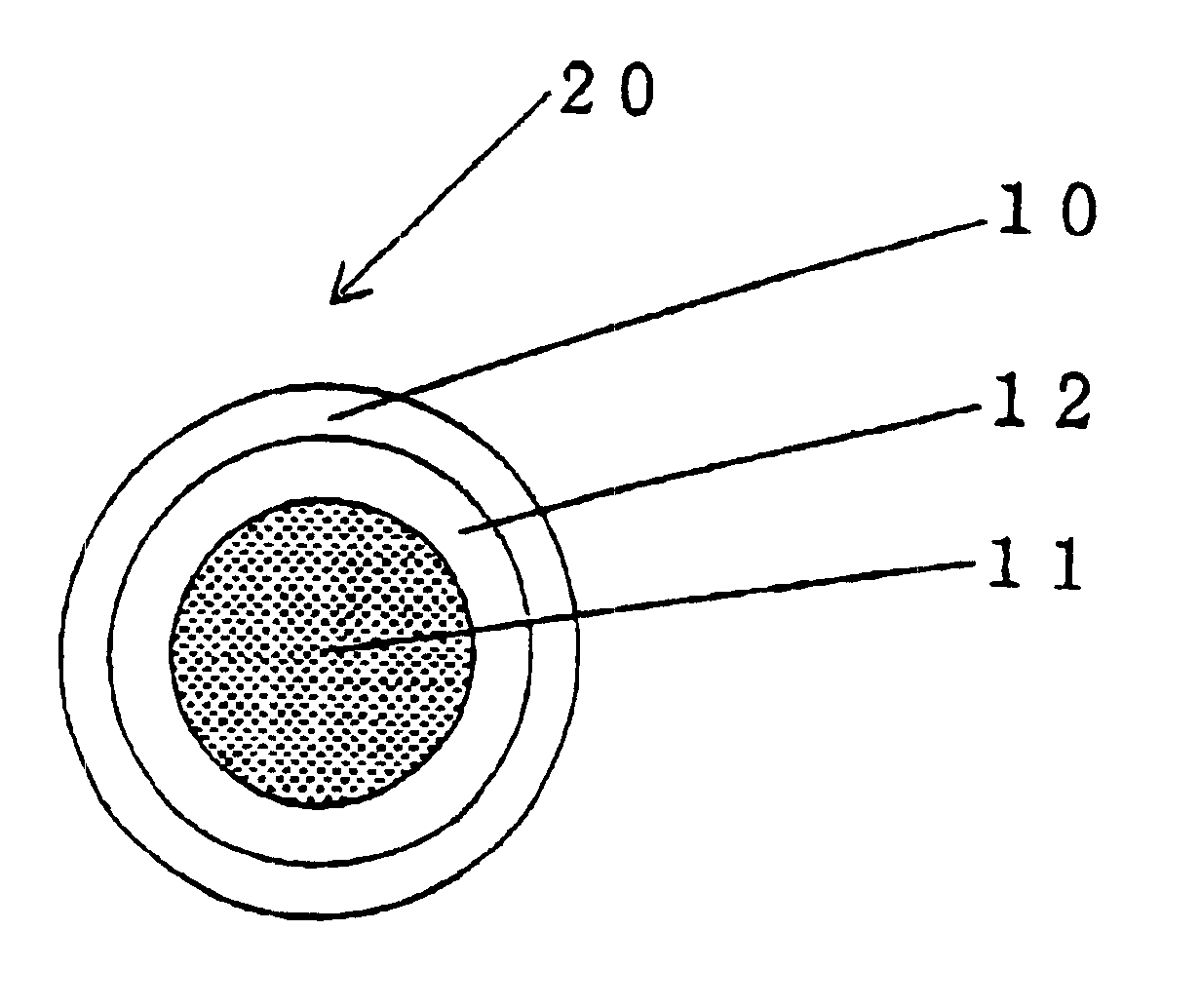

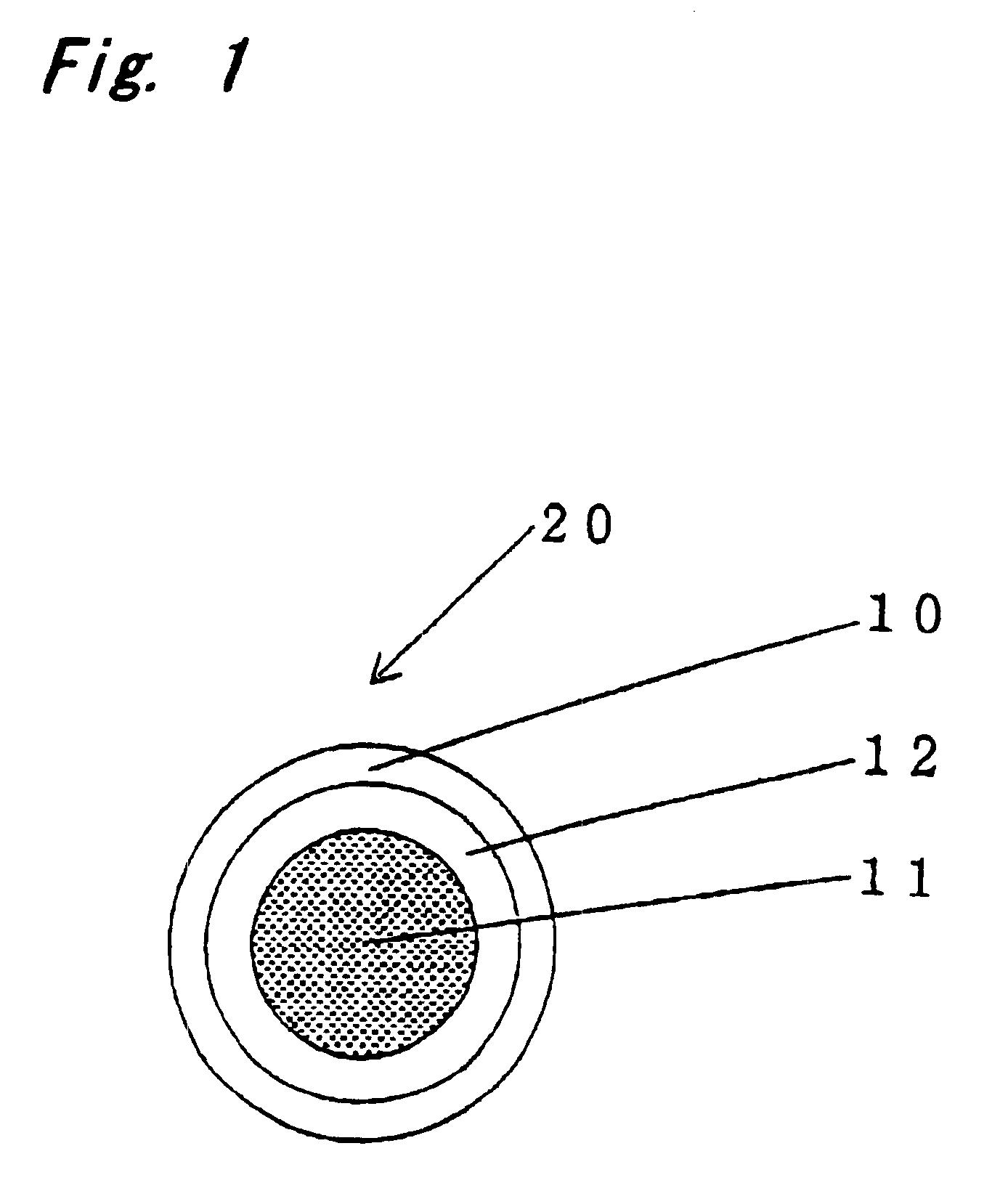

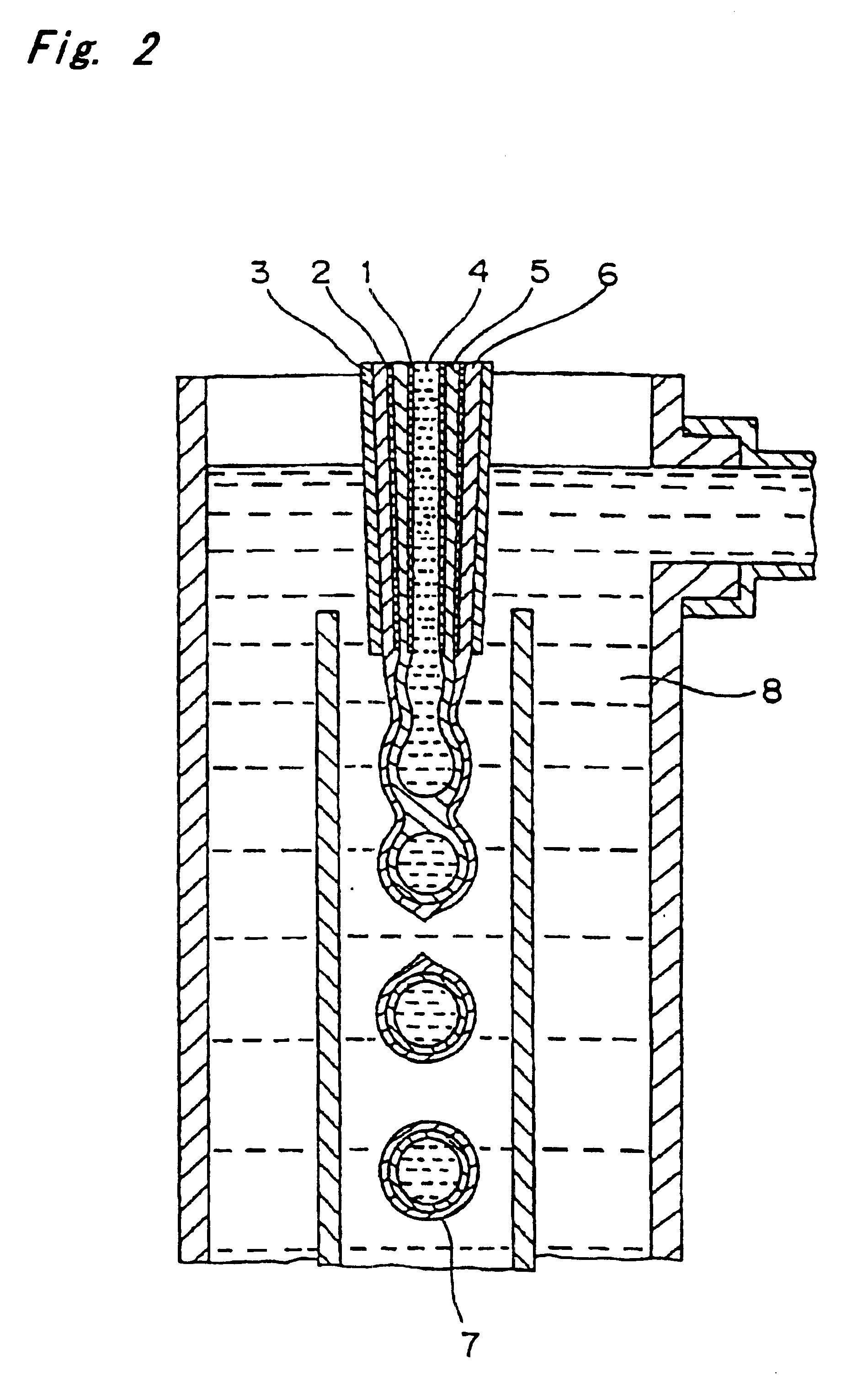

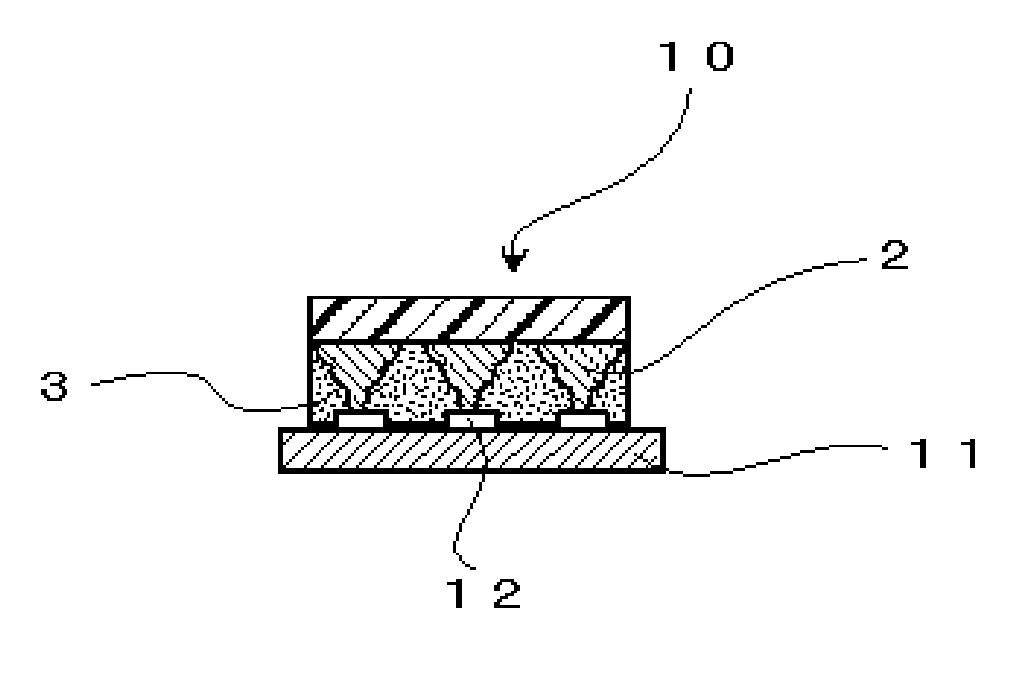

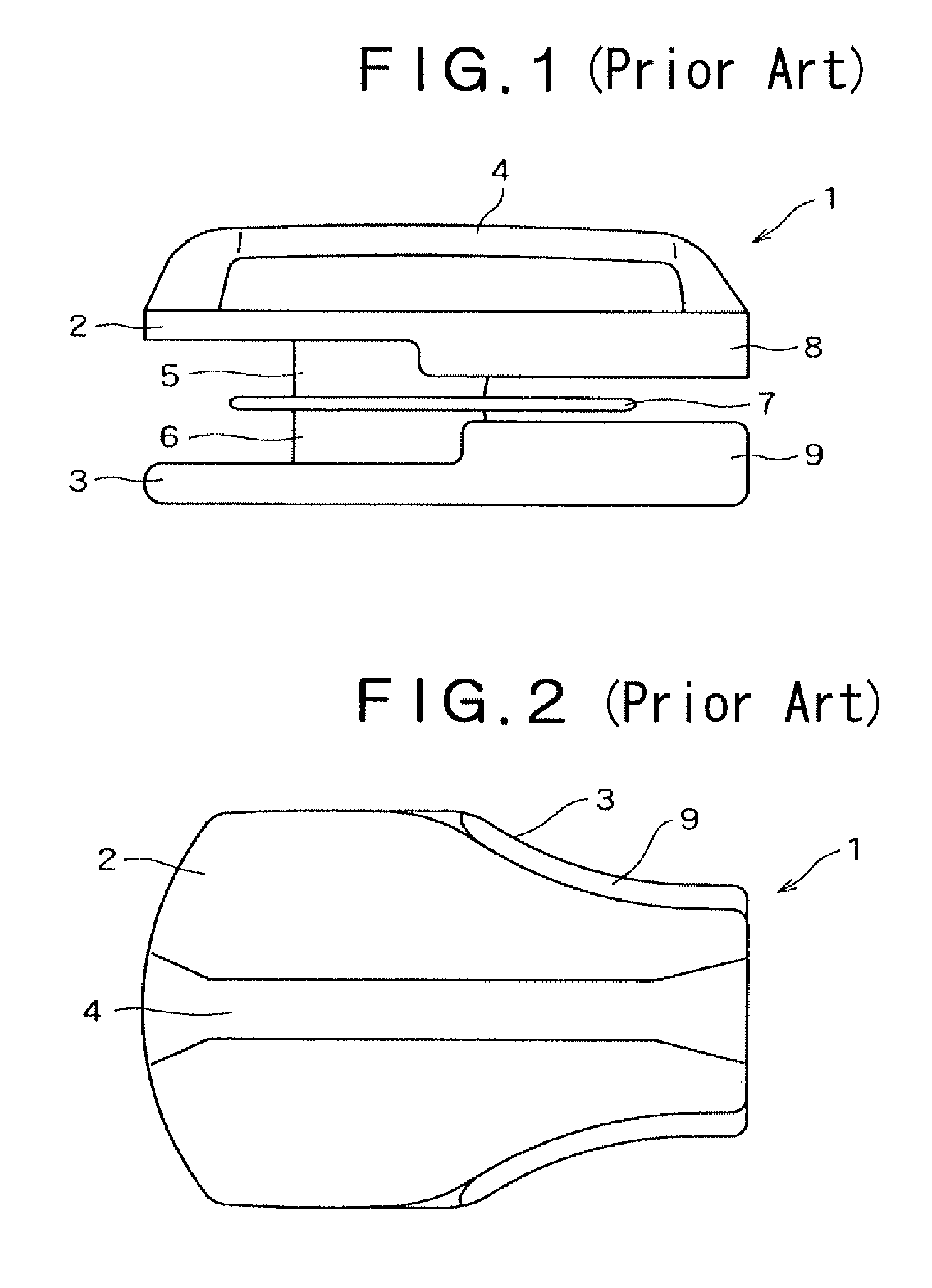

Encapsulated unsaturated fatty acid substance and method for producing the same

InactiveUS6531150B1Improve product qualityInhibit oxygen-permeabilityPowder deliveryGranular deliveryWater solubleGelatin

The present invention relates to an encapsulated unsaturated fatty acid substance in a form of a three-layered capsule, comprising an unsaturated fatty acid or a derivative thereof (11) as a content and a coating layer (10) mainly containing gelatin, encapsulating the content (11), wherein a water-soluble gel layer (12) containing an acid or an acid salt thereof is present between the coating layer (10) and the content (11). The encapsulated unsaturated fatty acid substance of the present invention is characterized by that it has neither insolubility nor deterioration with time, and that it is enteric.

Owner:MORISHITA JINTAN CO LTD

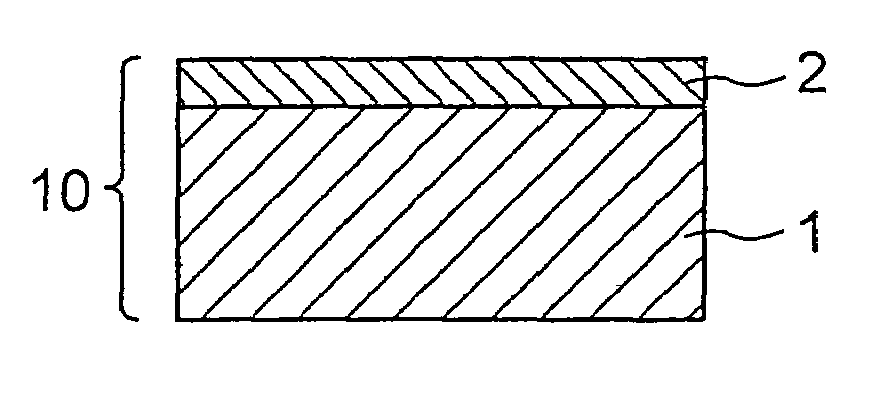

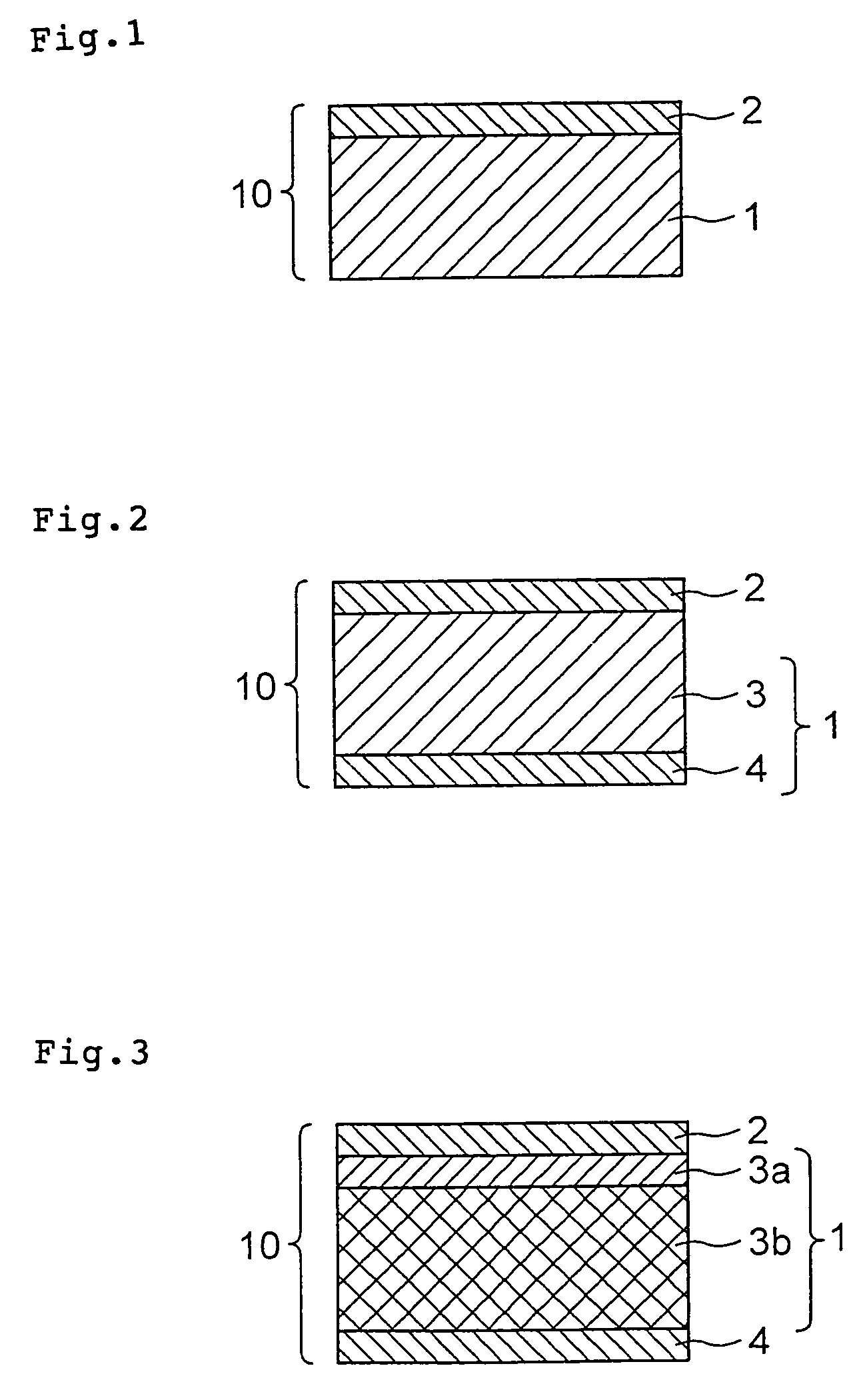

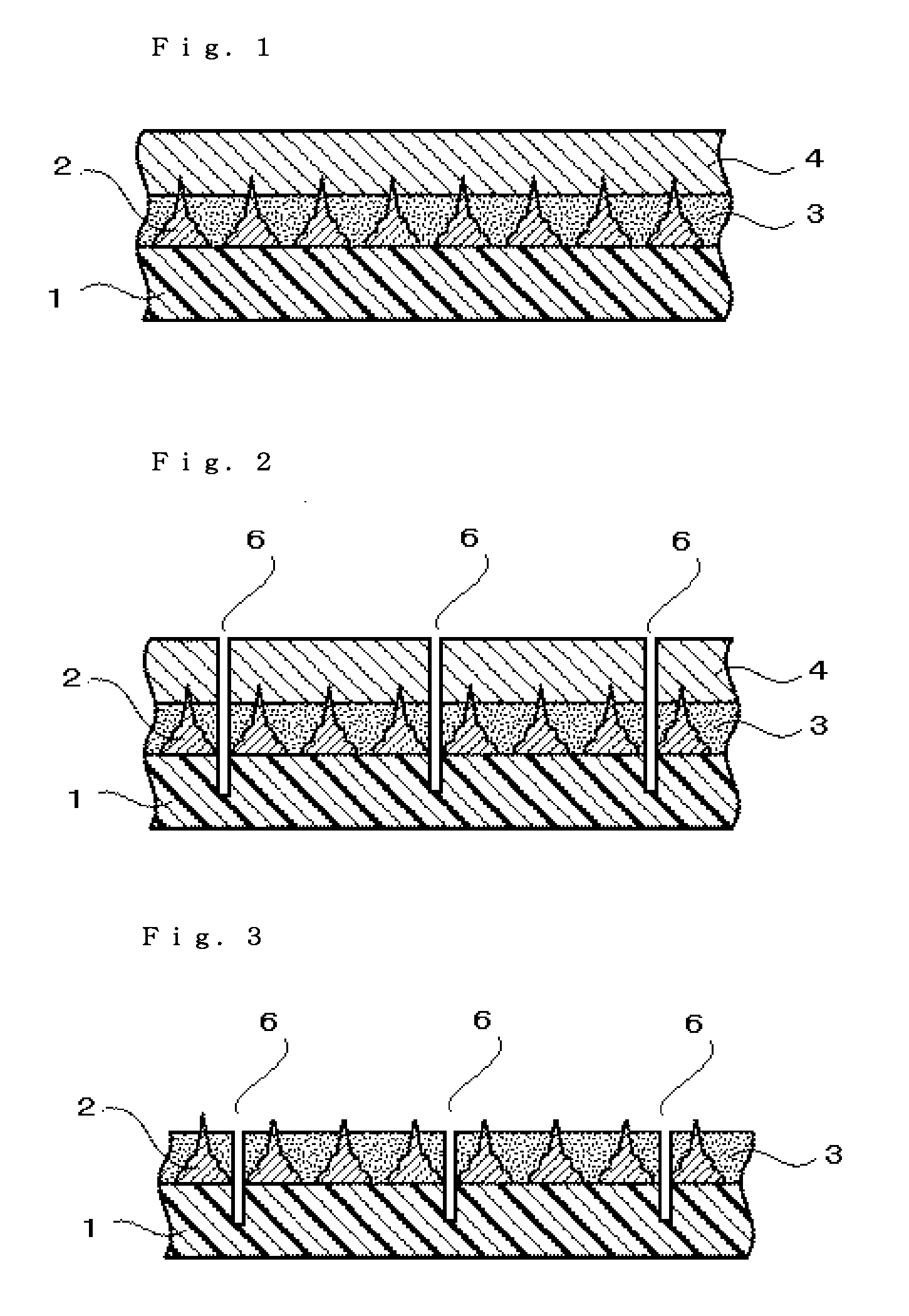

Wafer machining adhesive tape, and its manufacturing method and using method

InactiveUS7358158B2Reduce crackingSmall sizeSynthetic resin layered productsSolid-state devicesEngineeringSilicon

An adhesive tape having an adhesive layer formed on one side of a substrate layer, which renders it possible to minimize the extent of development of chipping or fragmentation (nicks) or crack in chip when the silicon wafer, to which this tape is adhered, is cut into chips using a dicer. The adhesive layer of the tape has a storage modulus G′ of 1 MPa or more at a temperature of 15 to 35° C., and preferably tan δ as represented by the ratio of a loss modulus G″ to the storage modulus G′ is 0.05 or less. The adhesive layer is preferably constructed principally of an olefin polymer.

Owner:MITSUI CHEM INC

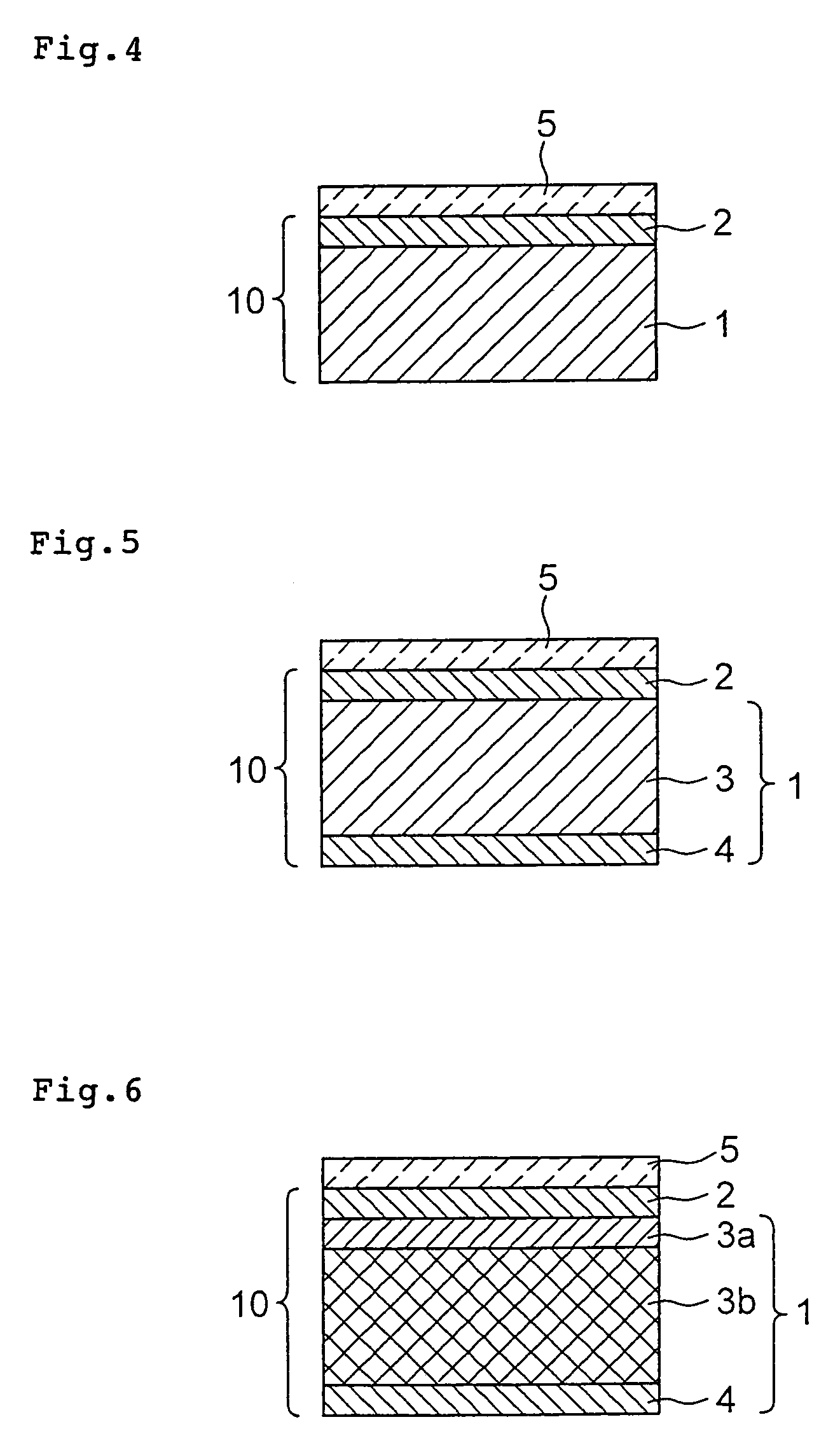

Package structure fabrication method

ActiveUS7934313B1Prevent conventional drawbackImprove qualityPrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringSealant

A fabrication method of a package structure includes: preparing a metal plate having first and second surfaces and defined with an active region; forming a wiring layer with conductive traces and first electrical contact pads on the first surface; forming third electrical contact pads corresponding to the first electrical contact pads on the second surface; forming a first encapsulant on the first surface; forming on the second surface an open area to penetrate the metal plate, wherein the metal plate form conductive posts between the first and third electrical contact pads; mounting in the open area a chip electrically connected to the wiring layer; forming a second encapsulant in the open area, the wiring layer and the third electrical contact pads; forming first and second openings in the first and second encapsulants to expose the third electrical contact pads, respectively; and cutting the metal plate to remove the metal layer.

Owner:SILICONWARE PRECISION IND CO LTD

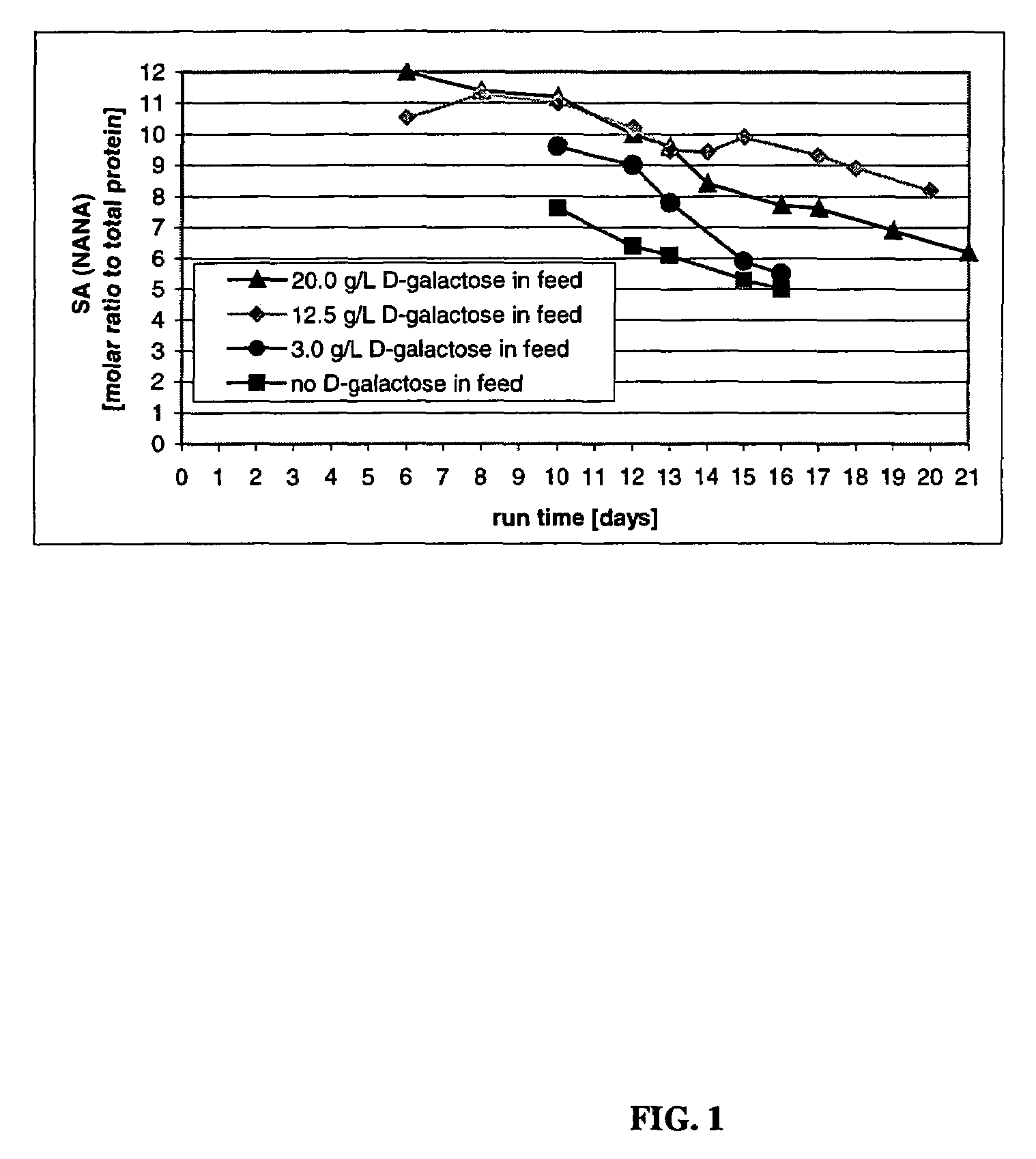

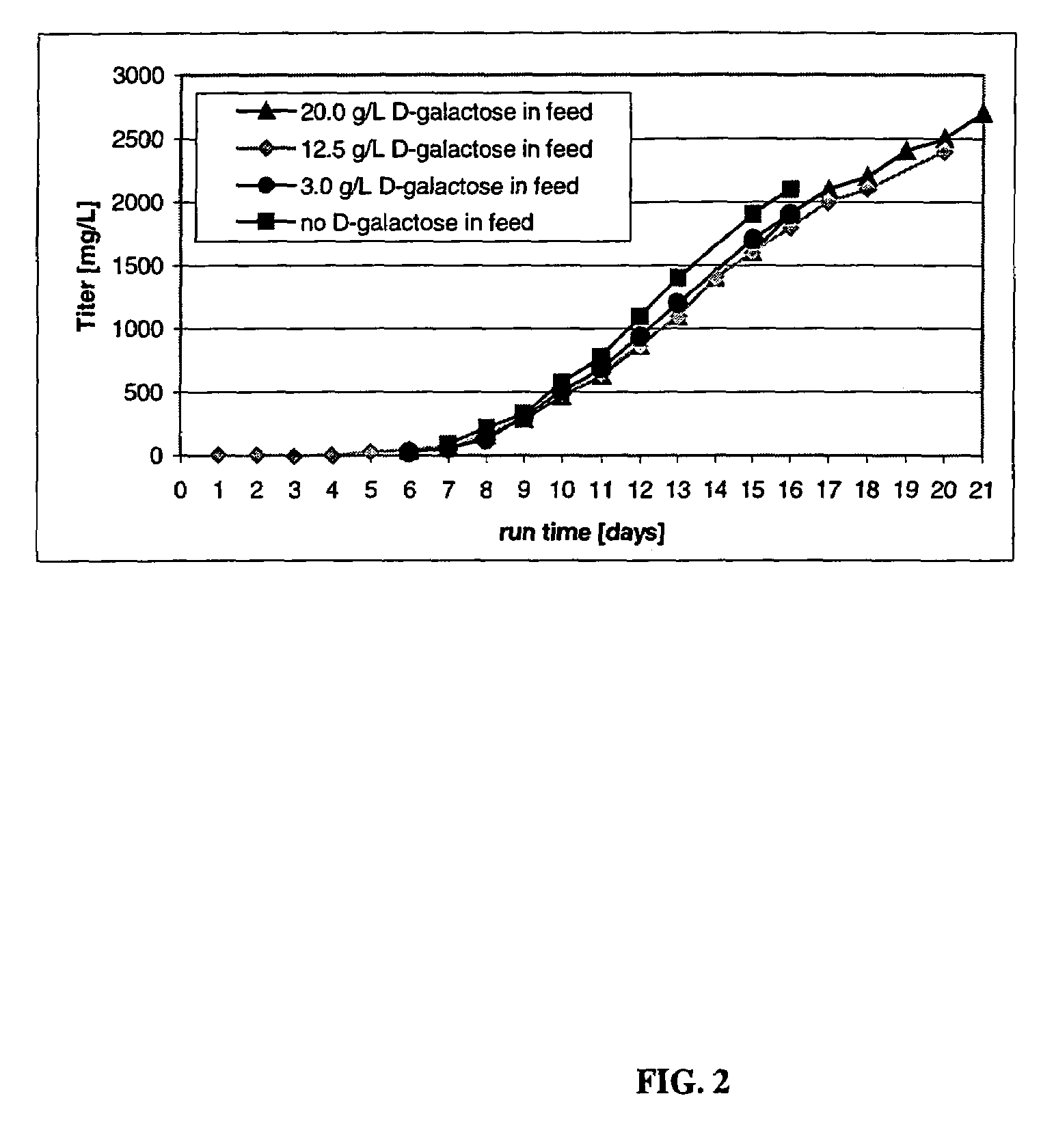

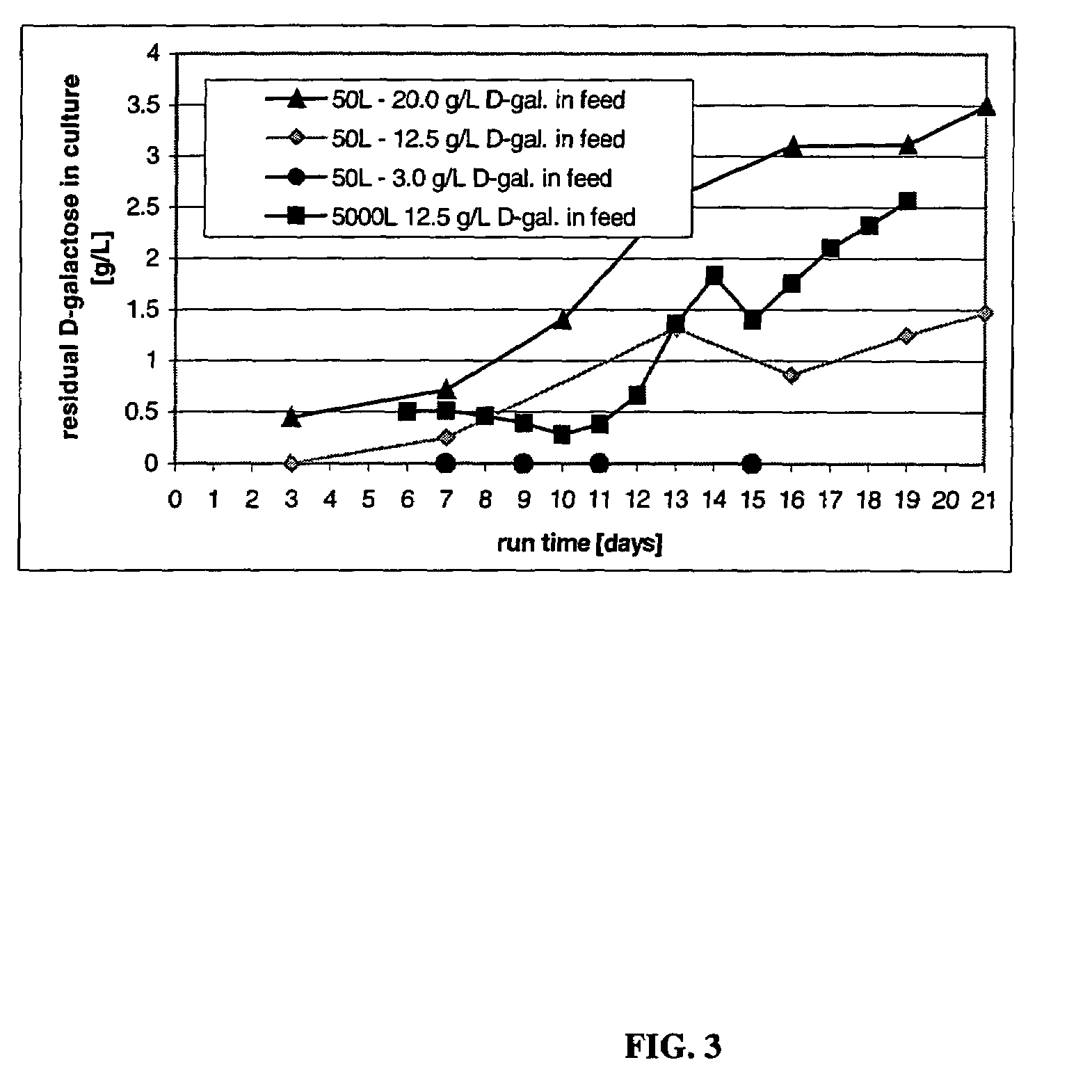

Product quality enhancement in mammalian cell culture processes for protein production

ActiveUS7332303B2Low production costQuality improvementAnimal cellsCell receptors/surface-antigens/surface-determinantsHigh cellBiotechnology

Owner:BRISTOL MYERS SQUIBB CO

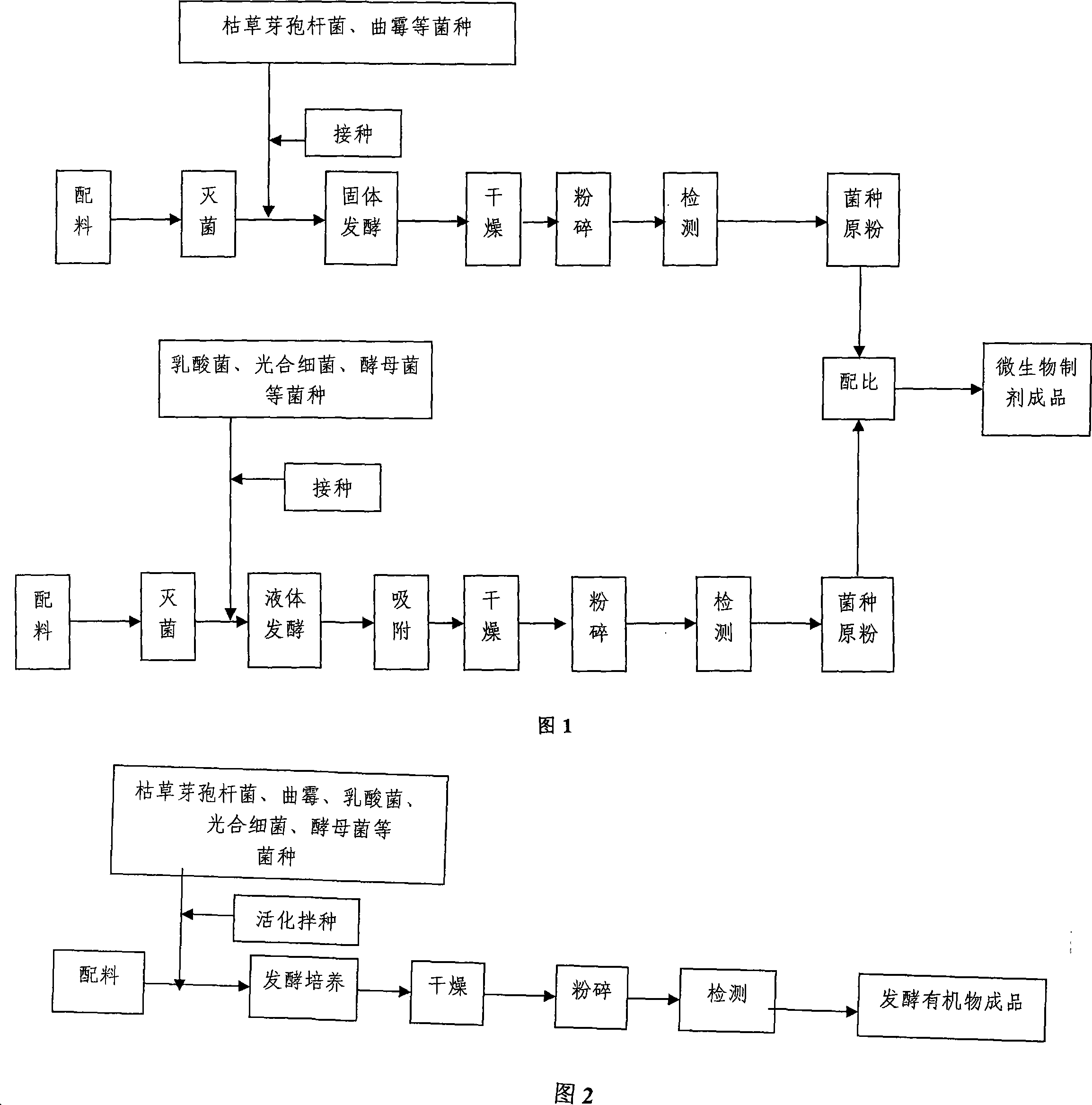

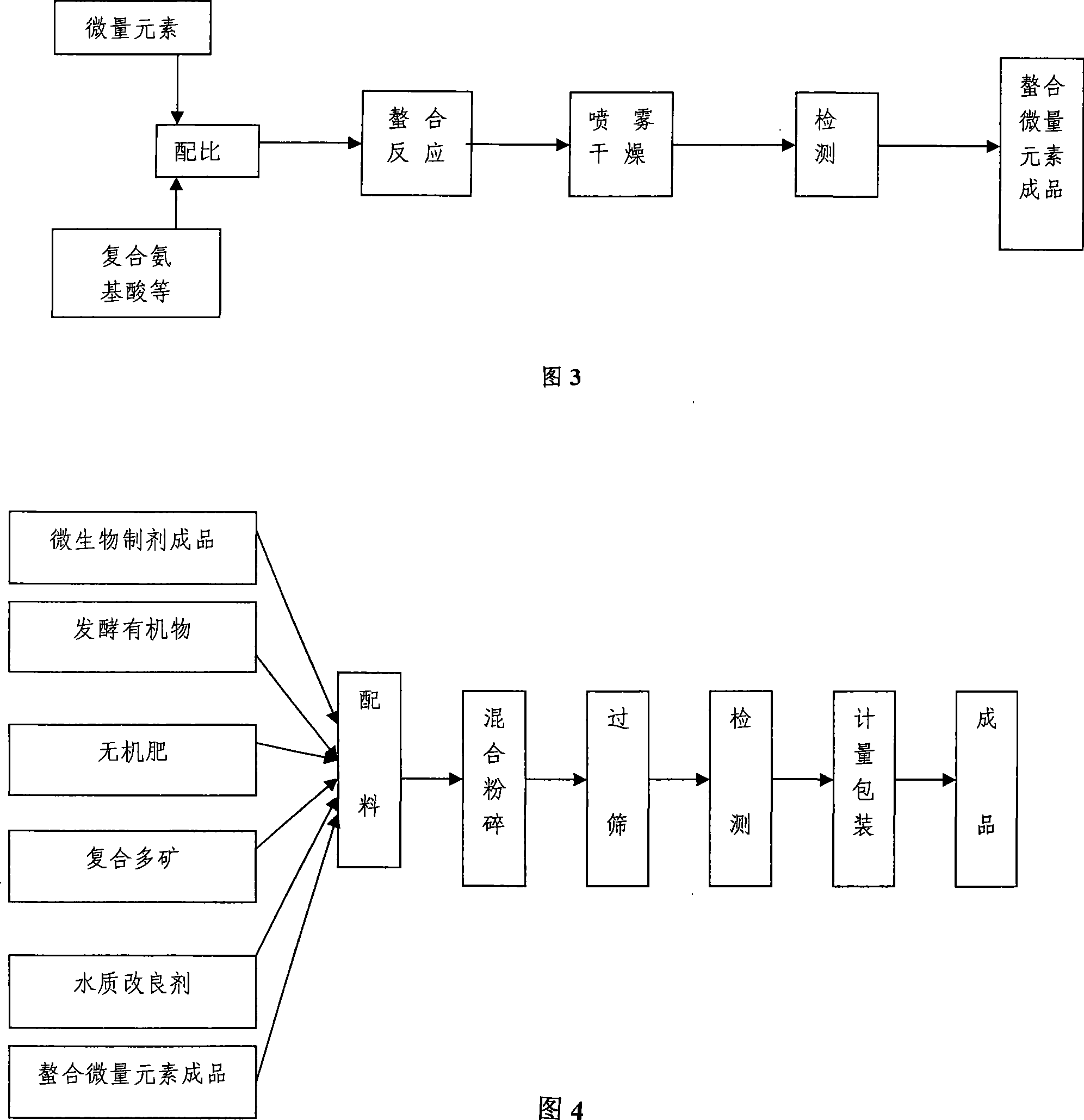

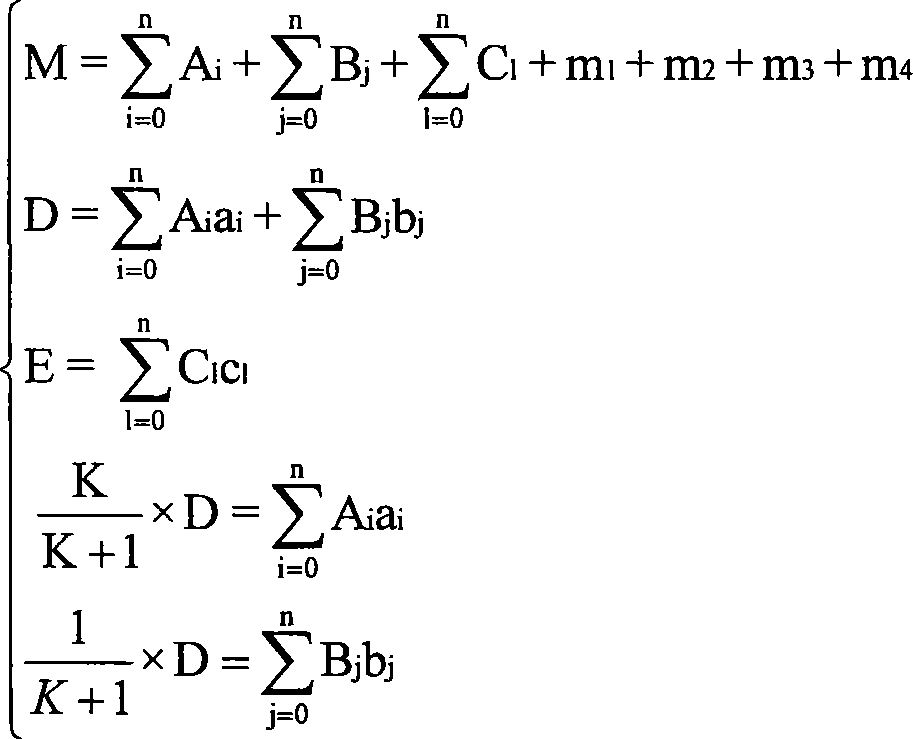

Special biological fish-fertilizer for aquaculture and preparation method thereof

ActiveCN101225007AMatching scienceIncrease profitClimate change adaptationPisciculture and aquariaDiseaseWater quality

The invention discloses a special biological fish fertilizer and a preparation method for the fertilizer used in aquiculture; wherein, the biological fish fertilizer mainly comprises raw materials as follows: microbiological preparation, inorganic fertilizers, fermentation organics, micro-mineral amino acid chelate, mineral composites, and water quality improver. The preparation method for the special biological fish fertilizer in aquiculture comprises steps as follows: microbiological preparation is produced; fermentation organics is then produced, and the micro-mineral amino acid chelate is produced, eventually the finished products are made. The special biological fish fertilizer has the advantages of limiting the growth and reproduction of the harmful algae, promoting the large-scale growth and reproduction of the suitable food for fish, effectively improving the water quality and purifying the water environment, strengthening the fish immunity, reducing the diseases, reducing cost due to the small use level, convenient use, mild odor, no pollution to the water, and environment protection. By combining the modern bioengineering technique, low-temperature drying technique, spray-drying technique, and super-fine crushing techniques, the preparation method has the advantages of stable quality for the fish fertilizers and lower overall cost.

Owner:WUHAN KEYANG BIOTECH

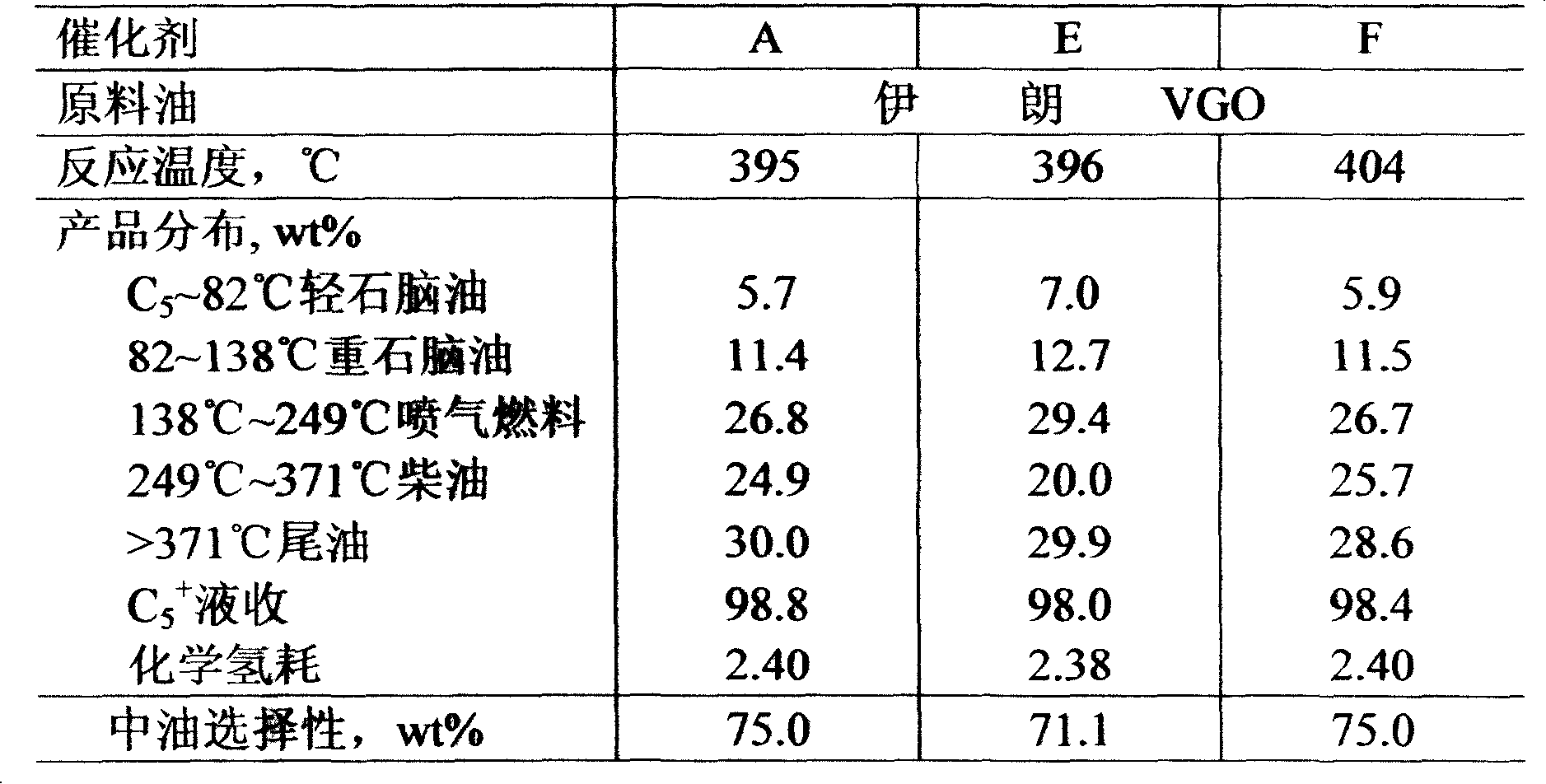

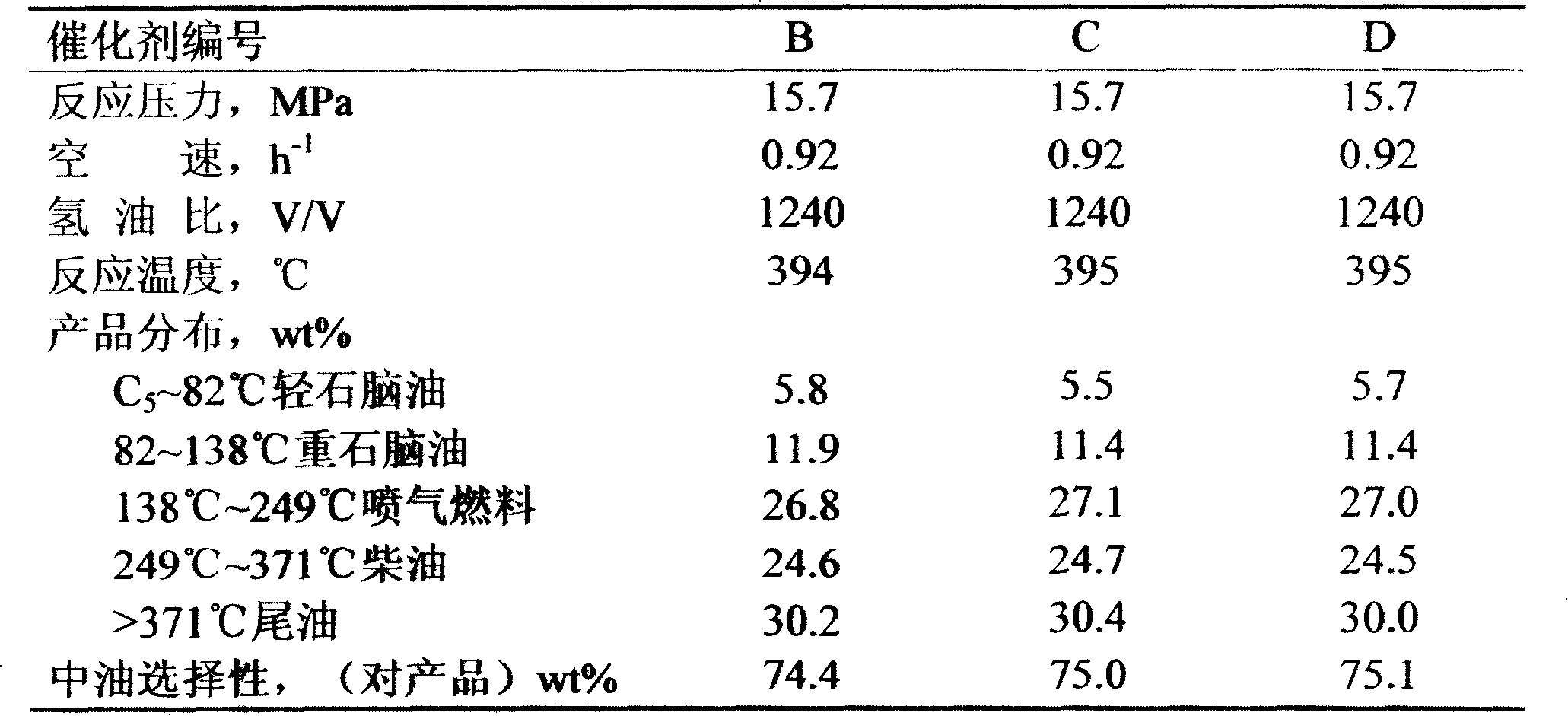

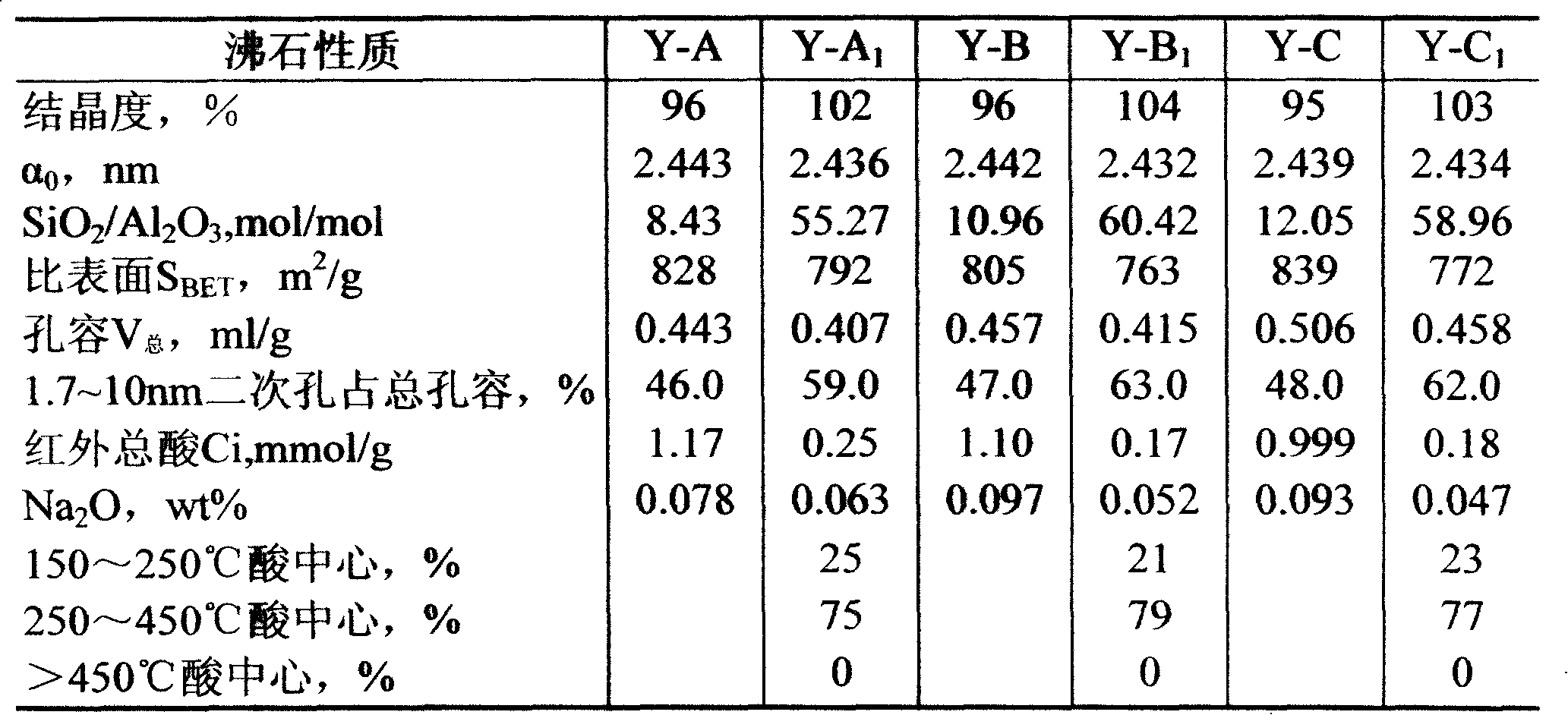

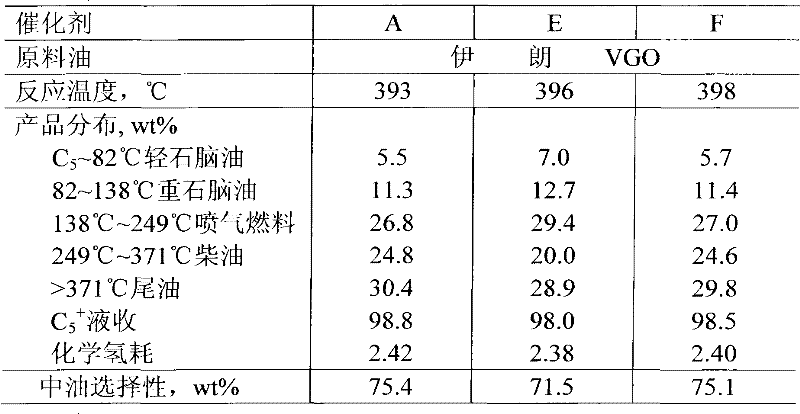

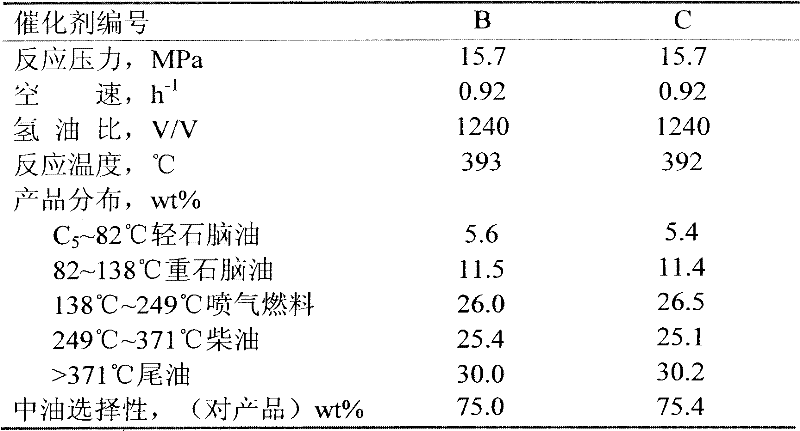

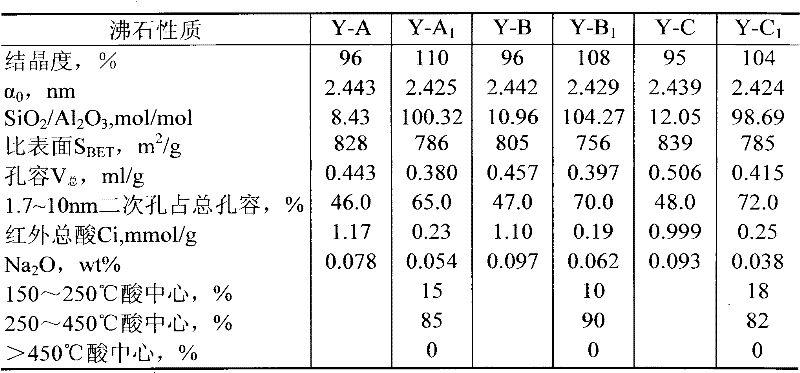

High active high medium oil selective hydrocracking catalyst and preparation thereof

ActiveCN101239324AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The present invention provides a hydrocracking catalyst having high activity, high medium oil selectivity, catalyst constitute uses amorphous silica-alumina as a carrier, Y type molecular sieve processed by special modification is an acidity component, the molecular sieve has a high crystallinity and a lower cell parameter, a plenty quadric hole, larger surface, in addition, has a small acid center, even distribution, no strong acid center, 70-80% is moderate intensity acid center, 20-30% is weak acid center, and the molecular sieve also has a strong anti-nitrogen ability and better damaging ability, the hydrocracking catalyst using the molecular sieve has a better hydrocracking activity, and a higher medium oil selectivity, and a strong anti-nitrogen ability at the same time. The invention uses heavy hydrocarbon single stage or single stage serial hydrocracking process generate midbarrel oil product, and has better activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

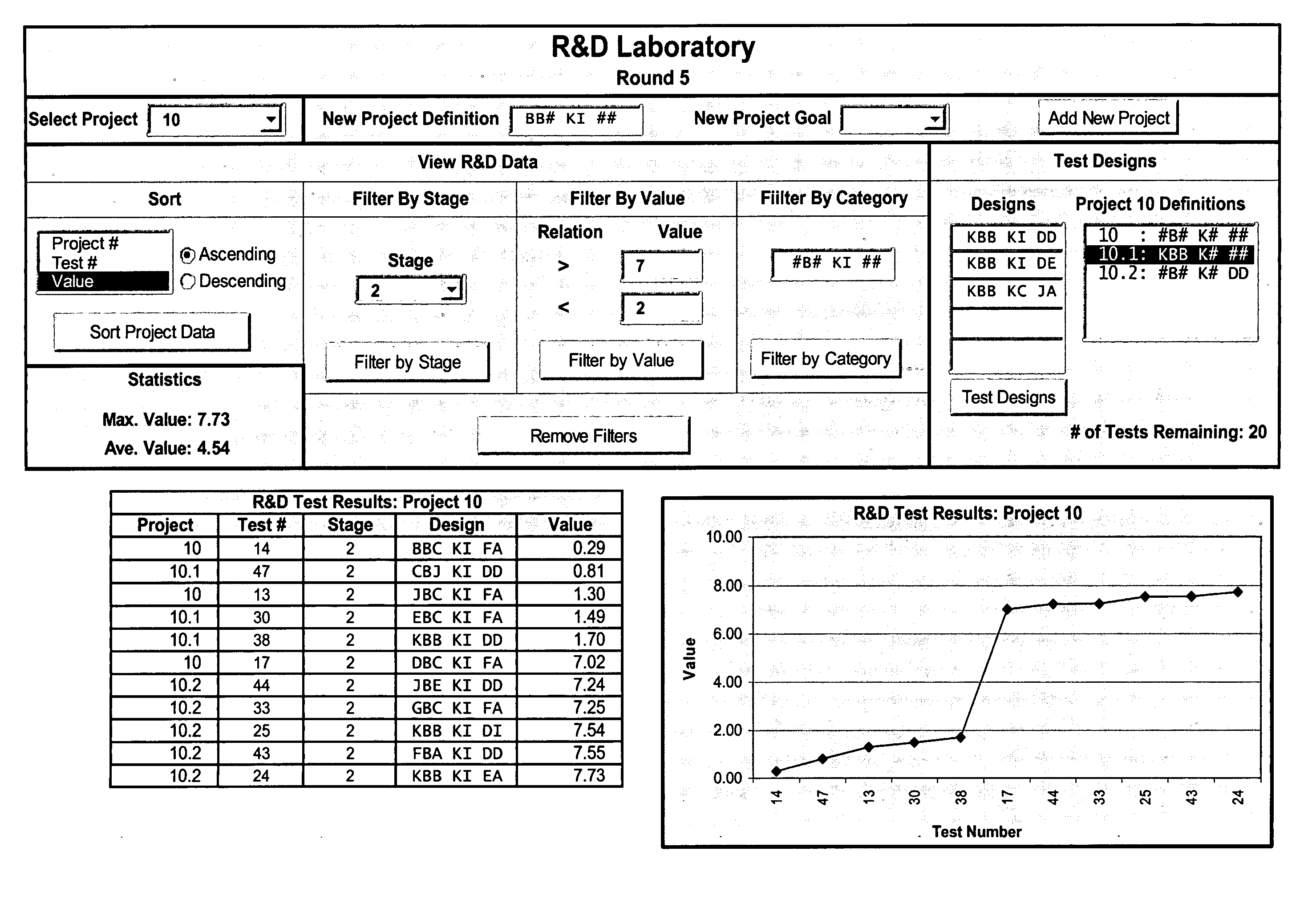

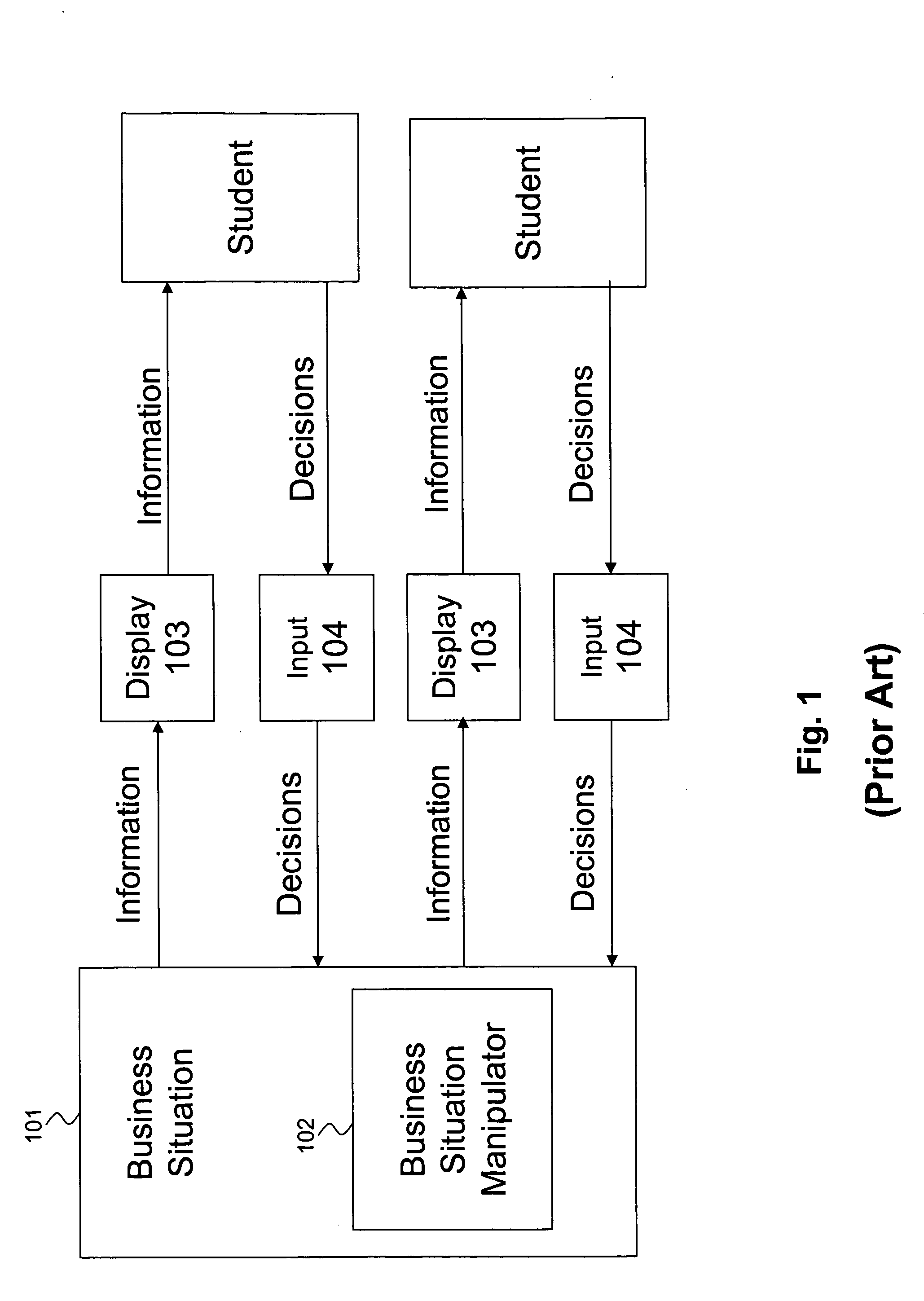

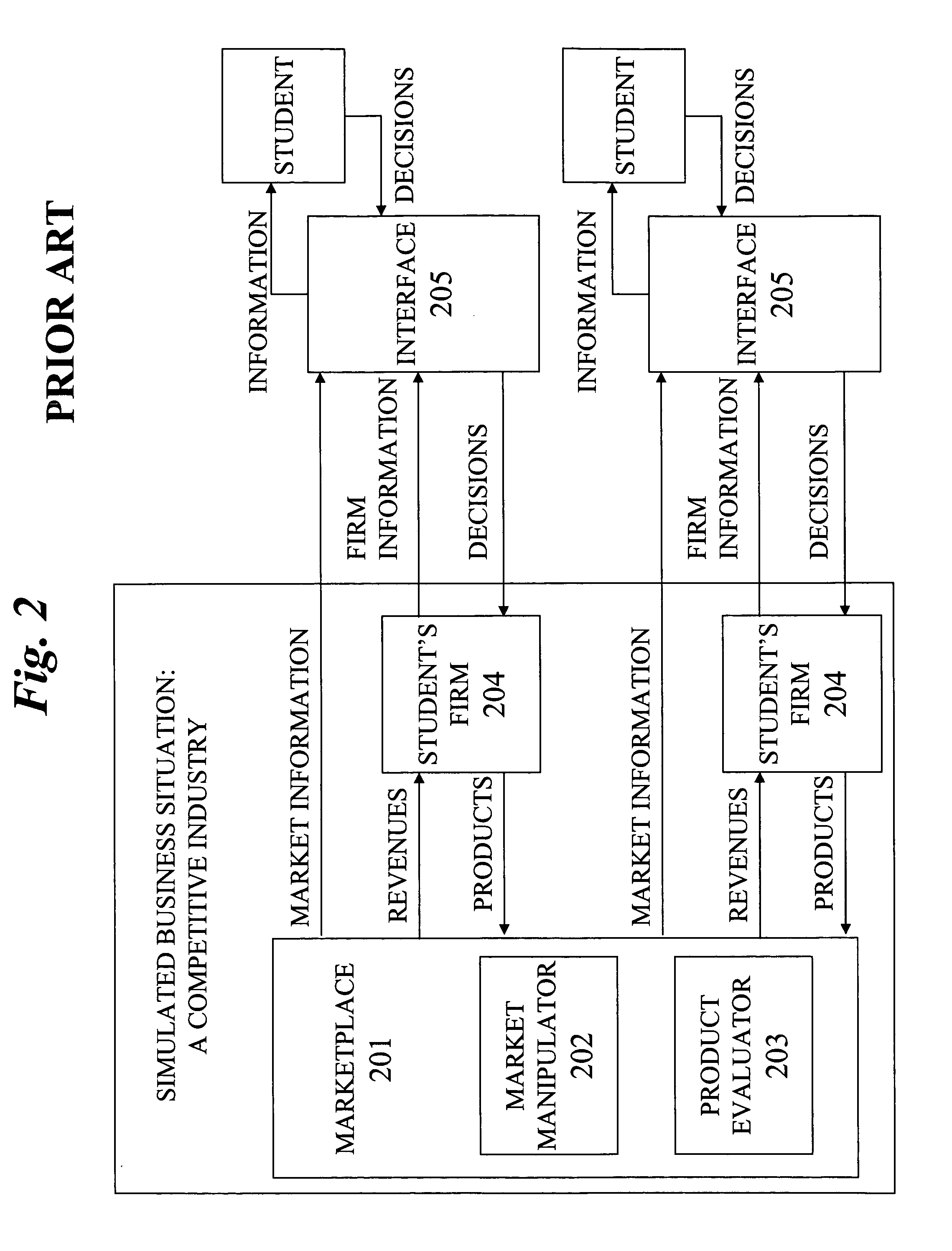

Management training simulation method and system

InactiveUS20050004789A1Reduce labor inputLow production costCosmonautic condition simulationsAnalogue computers for electric apparatusTelecommunications linkCommunication link

Developing decision-making skills of a user through practice in a simulated environment comprises defining a simulated situation to be influenced by the user including a set of objects that are represented by an attribute-characteristic representation, presenting information concerning a current state of the simulation, obtaining decisions from the user that at least partially determine object designs to be evaluated, evaluating an object design using a value function having multiple optima, updating the simulation with the results from the evaluation, and permitting continued practice by selectively repeating several of these steps. A system executes simulation software that simulates such a situation on a processor, and includes evaluation software for selecting and evaluating design objects by applying a value function having multiple optima. At least one terminal and communication links are provided for information transfer and implementation of the simulated situation. Diagnosis of the user's cognitive approach is also disclosed.

Owner:TUMBLEWEED HLDG LLC

Continuous long fiber reinforced fire-retardant thermoplastic resin and its prepn

ActiveCN1810862ASimple recipeSimple process controlLong-fiber-reinforced thermoplasticPolymer chemistry

The present invention discloses one kind of continuous long fiber reinforced fire-retardant thermoplastic resin and its preparation process. It is prepared through mixing continuous long fiber reinforced thermoplastic resin agglomerate, which has reinforcing fiber content of 30-80 wt% and agglomerate length of 3-30 mm, and fire-retardant agglomerate, which has thermoplastic resin as carrier, fire retardant in 20-60 wt%, fire-retarding synergist 5-20 wt% and other additive 0-5 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has continuous long fiber content of 5-60 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has excellent mechanical performance, especially impact resistance, and excellent fire-retarding performance.

Owner:KINGFA SCI & TECH CO LTD +1

System for visually detecting workpiece appearance defects based on image processing

ActiveCN106053479AFast positioningHigh precisionImage enhancementImage analysisDiffuse reflectionVisual perception

The invention discloses a system for visually detecting workpiece appearance defects based on image processing, comprising an industrial personal computer, a coaxial light source, a CCD (charge coupled device) industrial camera, an image acquisition card and a rejecting mechanism; both the coaxial light source and the rejecting mechanism are connected with the industrial personal computer; the CCD industrial camera is connected with the industrial personal computer through the image acquisition card; wherein the coaxial light source is used for providing a diffuse reflection light source for a workpiece to be detected; the CCD industrial camera is used for taking an image of the workpiece at a detection station; the rejecting mechanism is used for rejecting from a production line, workpieces detected to be defective; the industrial personal computer has a defect detection module based on image processing; the system is high in detection efficiency and easy to implement.

Owner:XIANGTAN UNIV

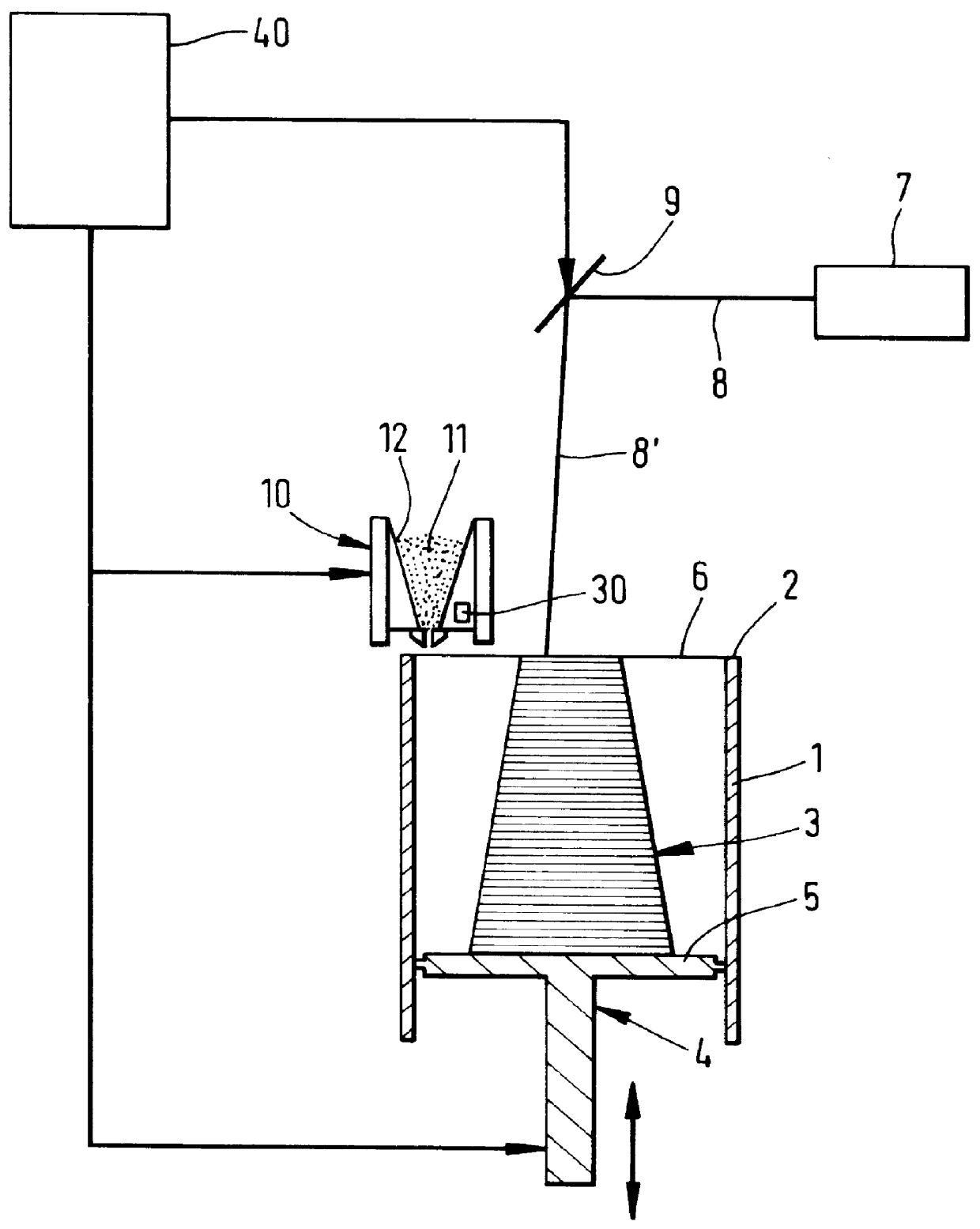

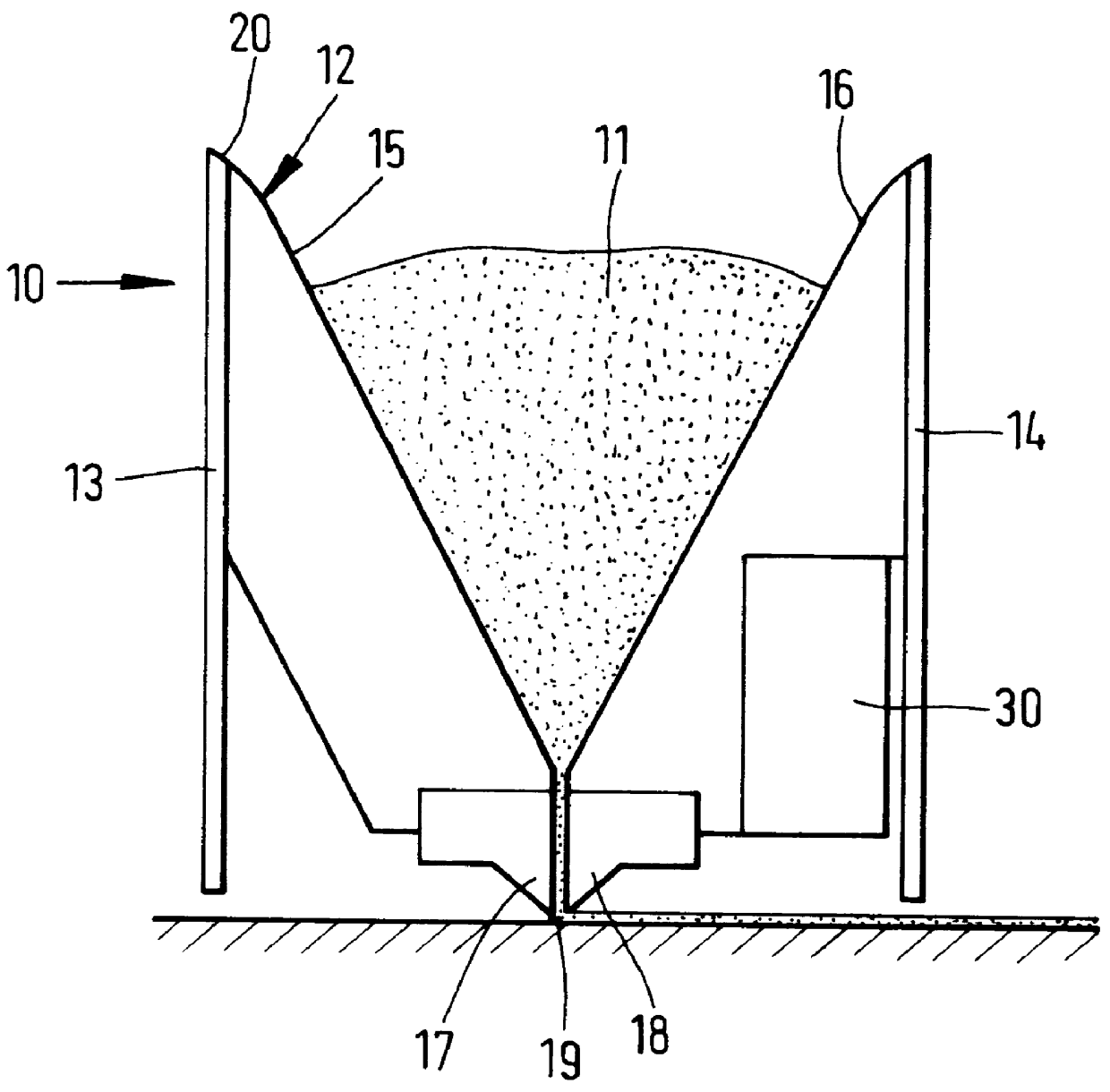

Apparatus and method for producing a three-dimensional object and for applying a layer of a powder material to a surface

InactiveUS6136257AShorten production timeImprove product qualityElectric discharge heatingPretreated surfacesElectromagnetic radiationMaterials science

An apparatus is described for producing a three-dimensional object from a powder material which includes powder particles and which is solidifiable by exposure to electromagnetic radiation. The apparatus includes a support having a substantially plane support surface for supporting said object, an applying device for applying a layer of the powder material to the support surface, a radiation device for selectively exposing the powder material to electromagnetic radiation at places corresponding to the object and a discharge electrode for generating an electric field for reducing charge differences on the powder particles.

Owner:EOS ELECTRO OPTICAL SYST

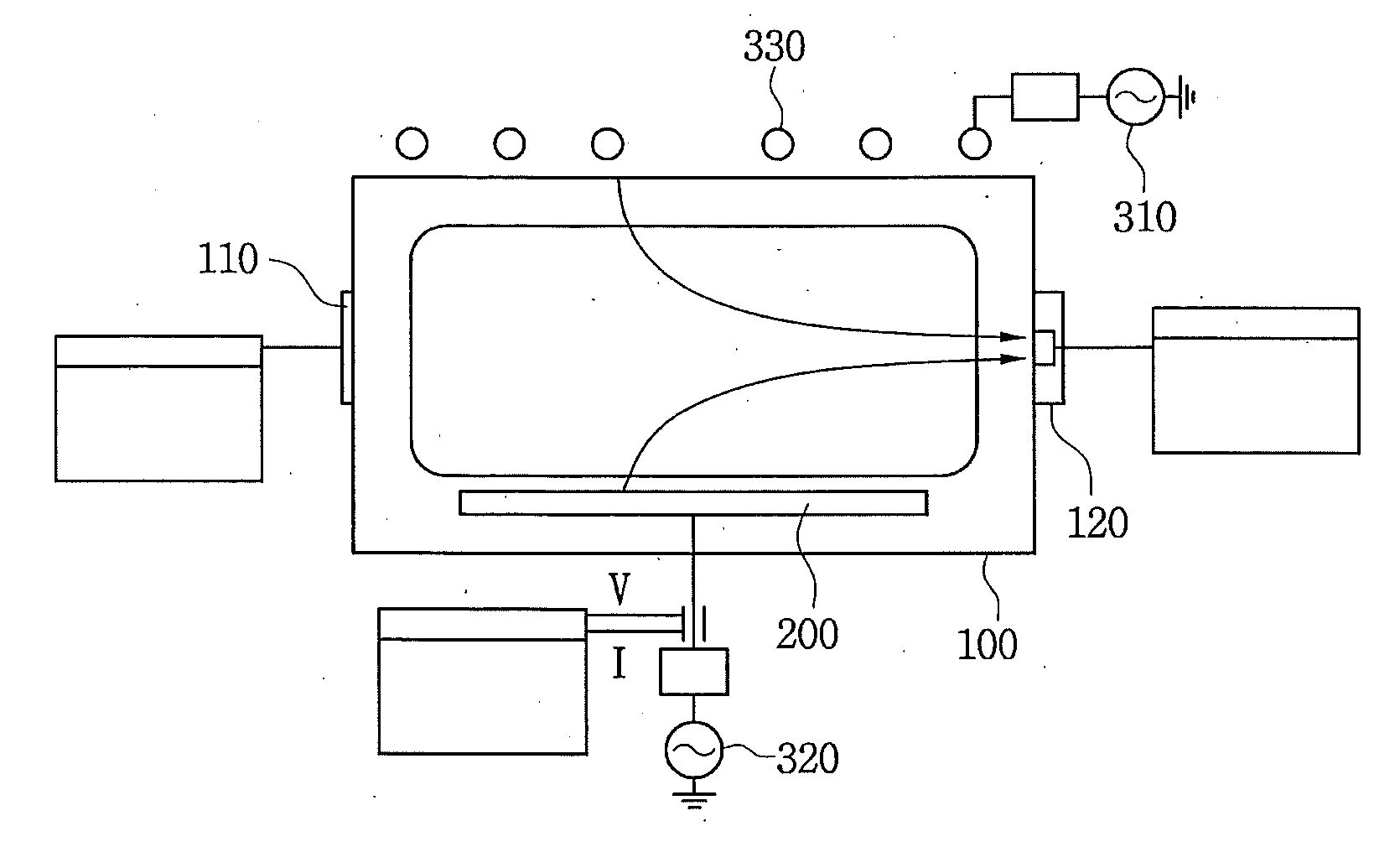

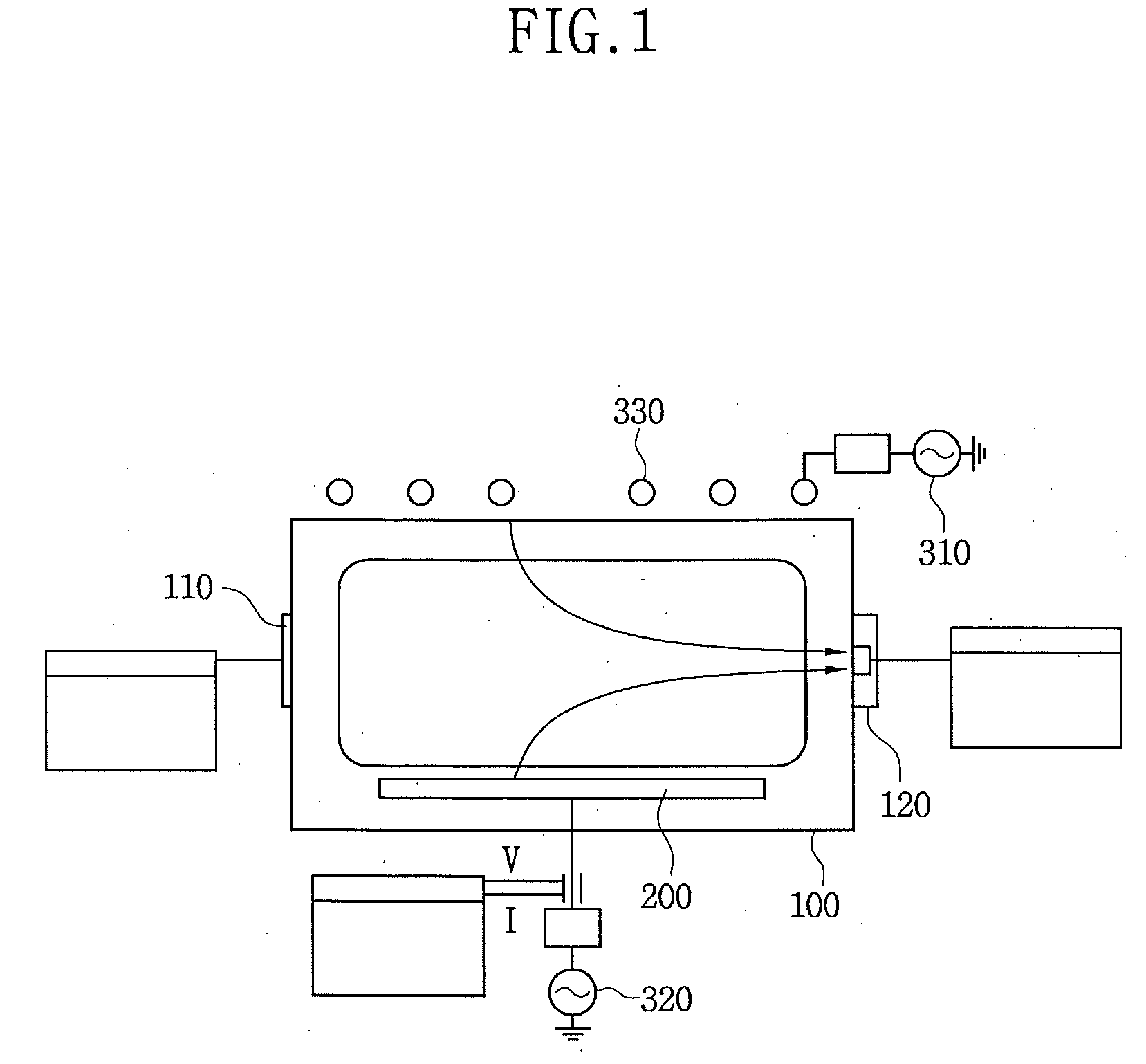

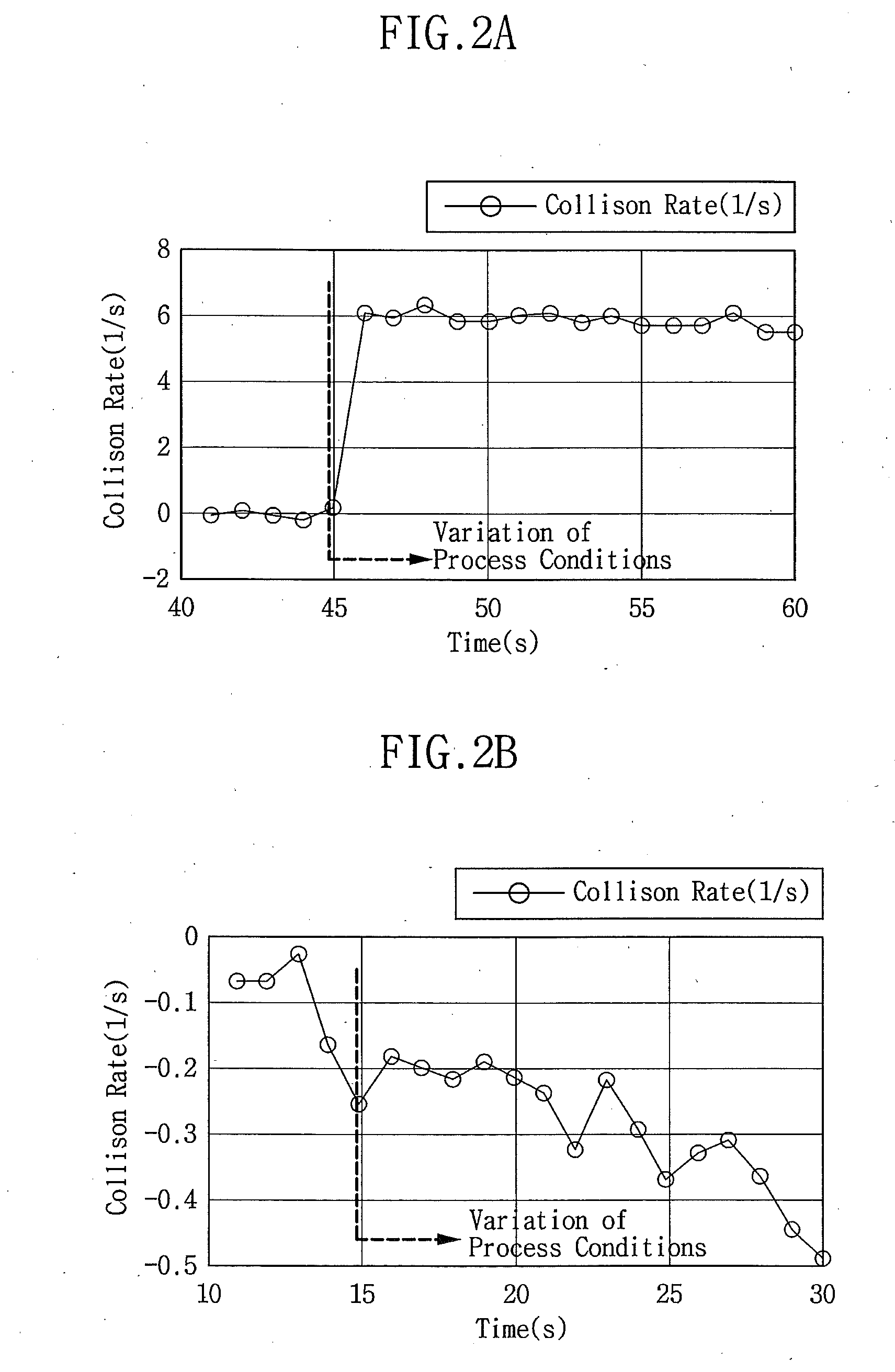

Methods of Selecting Sensors for Detecting Abnormalities in Semiconductor Manufacturing Processes

InactiveUS20100262398A1Improve product qualityAccurate detectionProgramme controlSemiconductor/solid-state device manufacturingDevice materialMultiple sensor

A method of selecting a sensor in a semiconductor manufacturing process is provided. The method includes measuring responses of a plurality of sensors when a first of a plurality of process conditions is varied, identifying one or more of the sensors having a steady state response after the first of the process conditions is varied, and selecting a sensor having a highest value within a response range from among the sensors having the steady state response for the first process condition that is varied. This methodology may be performed for multiple different process conditions. Thus, when process conditions in multiple processes of manufacturing a semiconductor device are varied, sensors having a steady state response can be selected from among multiple sensors for detecting abnormalities in the processes.

Owner:SAMSUNG ELECTRONICS CO LTD

Process for producing sodium sulfate and sodium chloride in Na2SO4-NaCl-H2O system

InactiveCN1944256AIncrease profitReduce energy consumptionAlkali metal sulfite/sulfate purificationAlkali metal halide purificationInorganic saltsSeparation technology

The process of producing sodium sulfate and sodium chloride in a Na2SO4-NaCl-H2O system belongs to the field of mixed inorganic solution evaporating separation technology. Mixed solution of sodium sulfate and sodium chloride as material is first evaporated and then separated to obtain sodium sulfate, sodium chloride and evaporated mother liquor; the evaporated mother liquor is low temperature evaporated and separated to obtain sodium chloride and salt-making mother liquor; and the salt-making mother liquor is evaporated and separated to obtain sodium sulfate and saltpeter-making mother liquor. The present invention has the features of high main and side product quality, high material adaptability, low cost, low cost, no waste draining, etc.

Owner:CHINA LIGHT IND INT ENG CO LTD +1

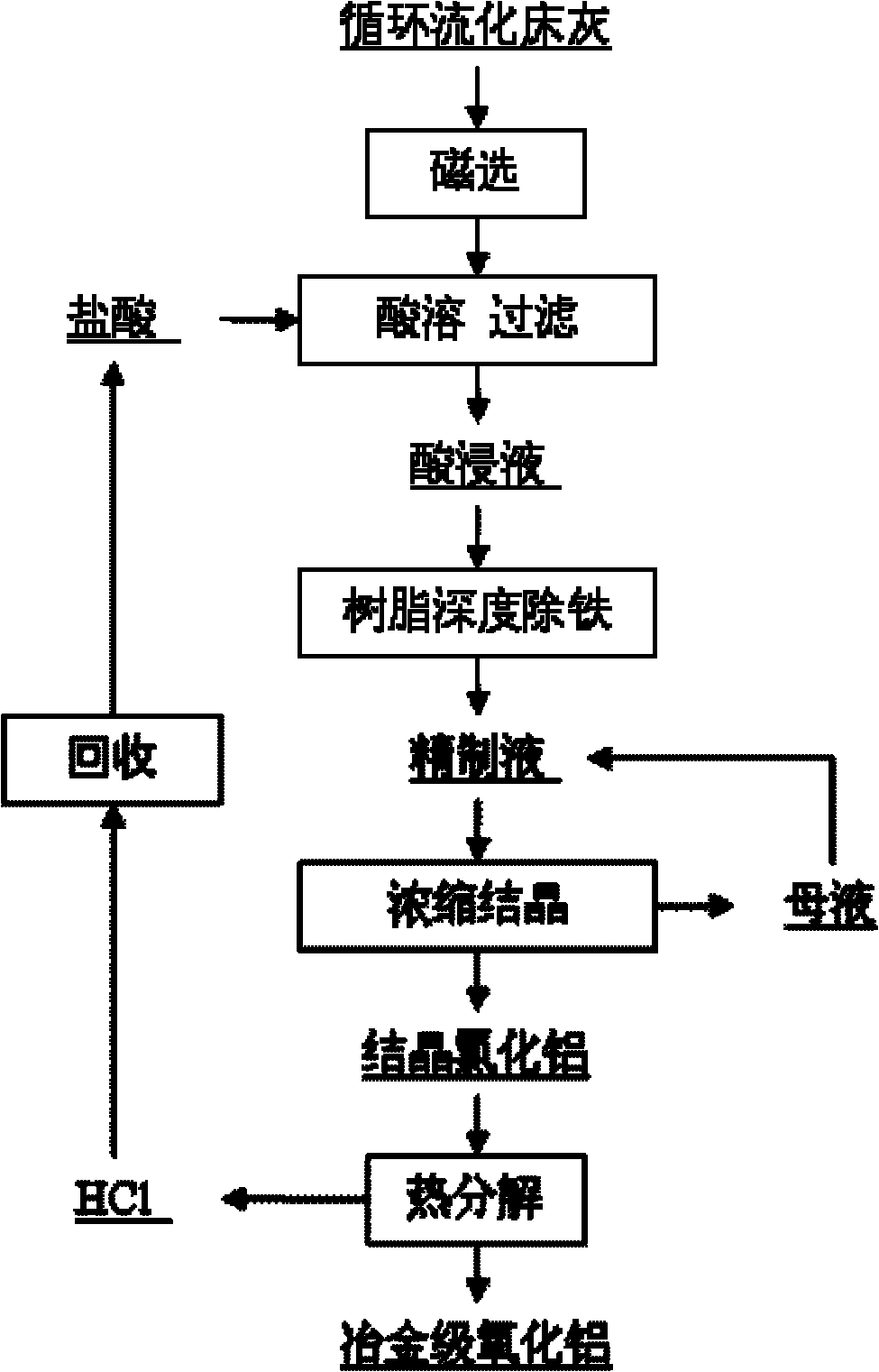

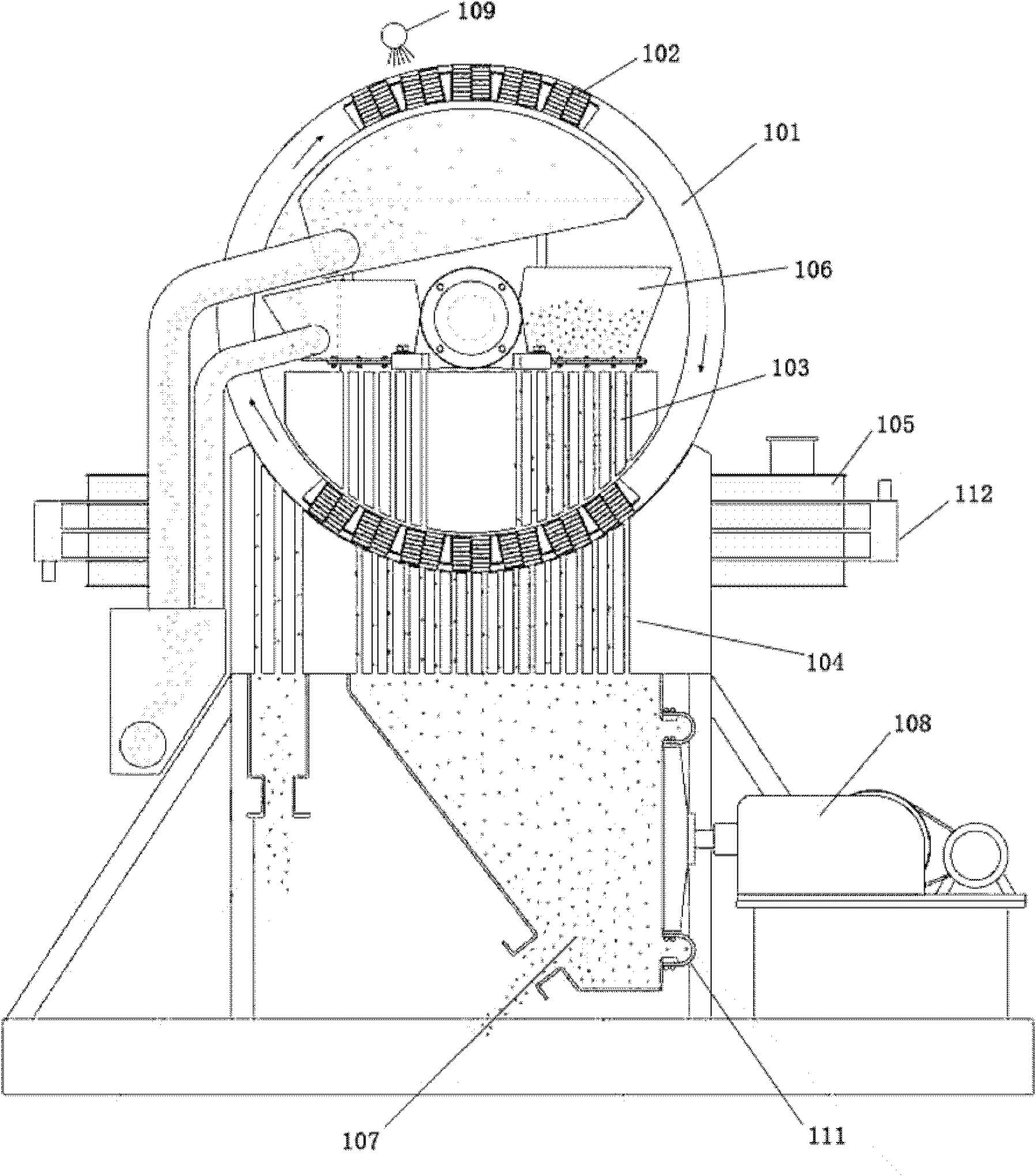

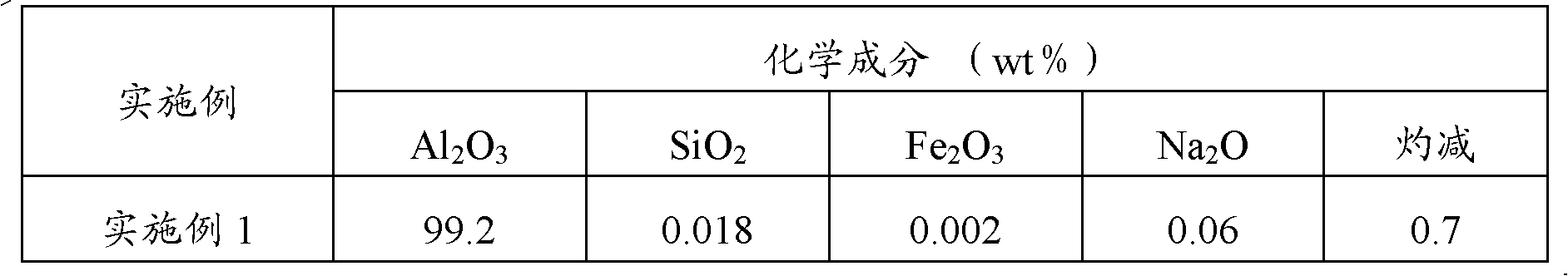

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

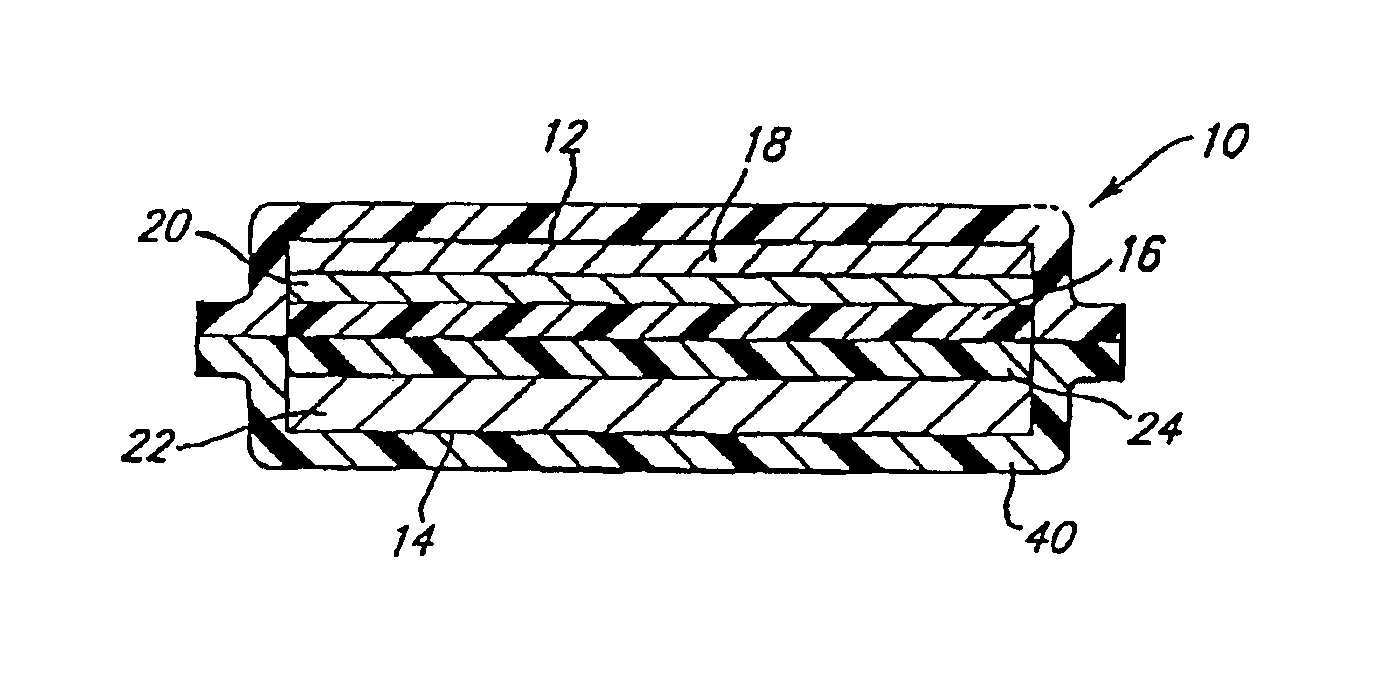

Echogenic devices and methods of making and using such devices

InactiveUS7014610B2Improve propertiesHigh practical echogenicityUltrasonic/sonic/infrasonic diagnosticsPreparing sample for investigationPorous particleMedical device

Owner:MEDTRONIC INC

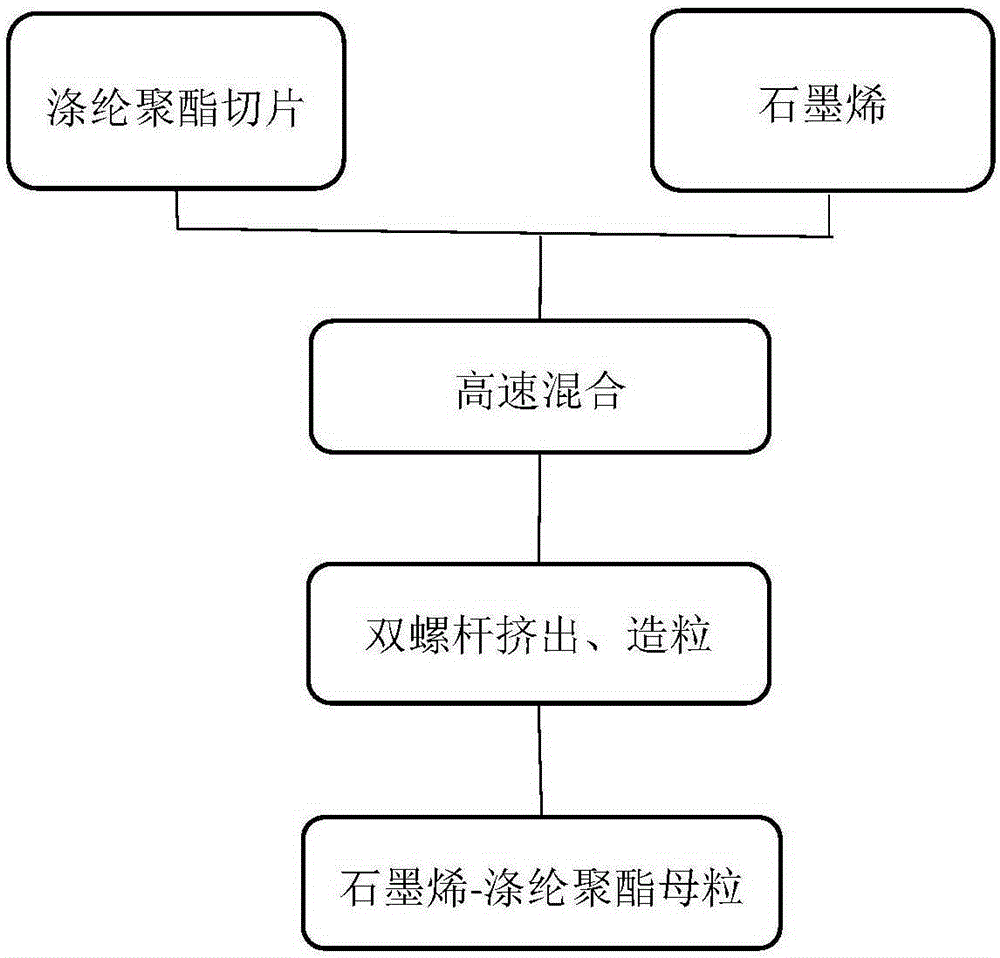

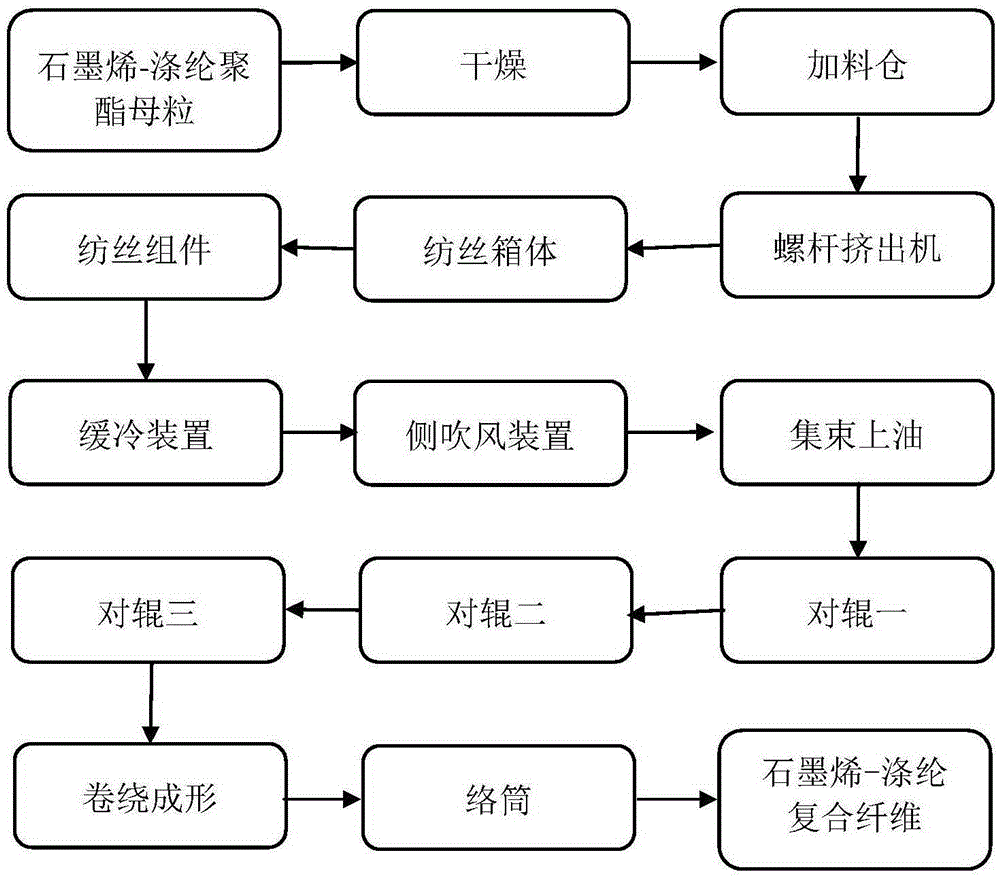

Preparation method of graphene-polyester nano-composite fiber

ActiveCN105200547AHigh breaking strengthEasy to prepareElectroconductive/antistatic filament manufactureFilament/thread formingNanometreSurface modification

The invention discloses a preparation method of graphene-polyester nano-composite fiber. The preparation method comprises the step of preparing graphene-terylene polyester composite master batch and the step of preparing the graphene-polyester nano-composite fiber from the composite master batch. Compared with other conventional methods, the preparation method has the advantages that the technology is extremely simple, the reinforcing material is excellent in performance and low in cost; besides, excellent mechanical property and functional characteristics of graphene self endow the nano-composite fiber with functionalities like high strength and antistatic property, surface-modified and modified graphene has good dispersity and perfect interfacial compatibility in terylene polyester polymer matrix, which enables graphene to be effectively and uniformly compounded with a terylene polyester chip base material.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

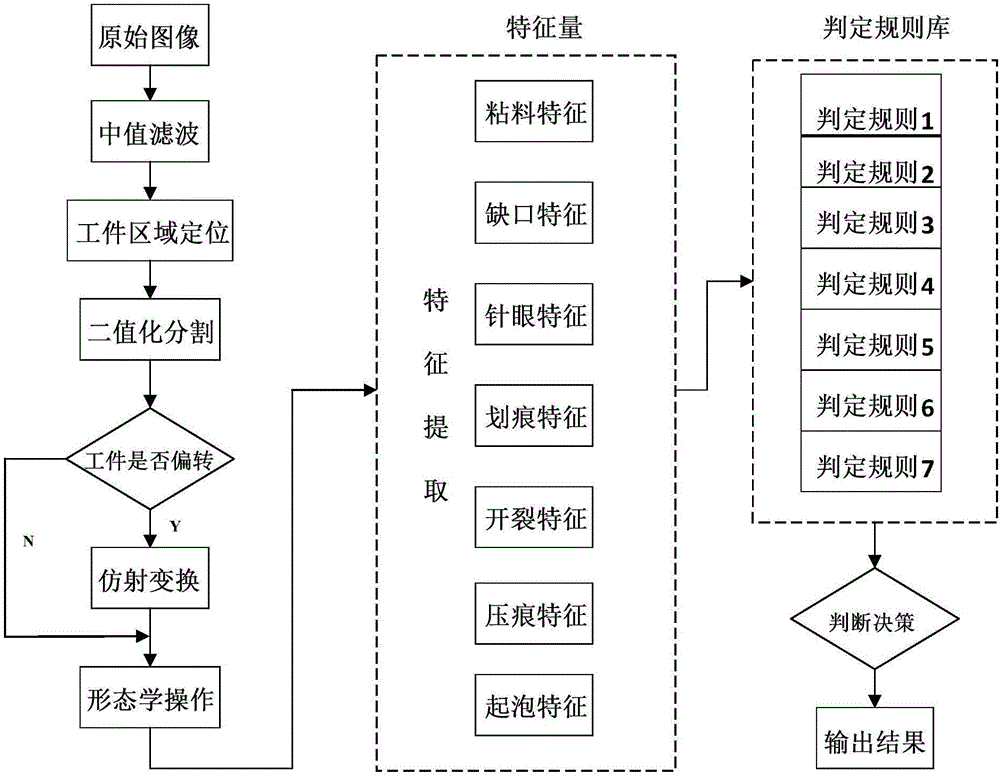

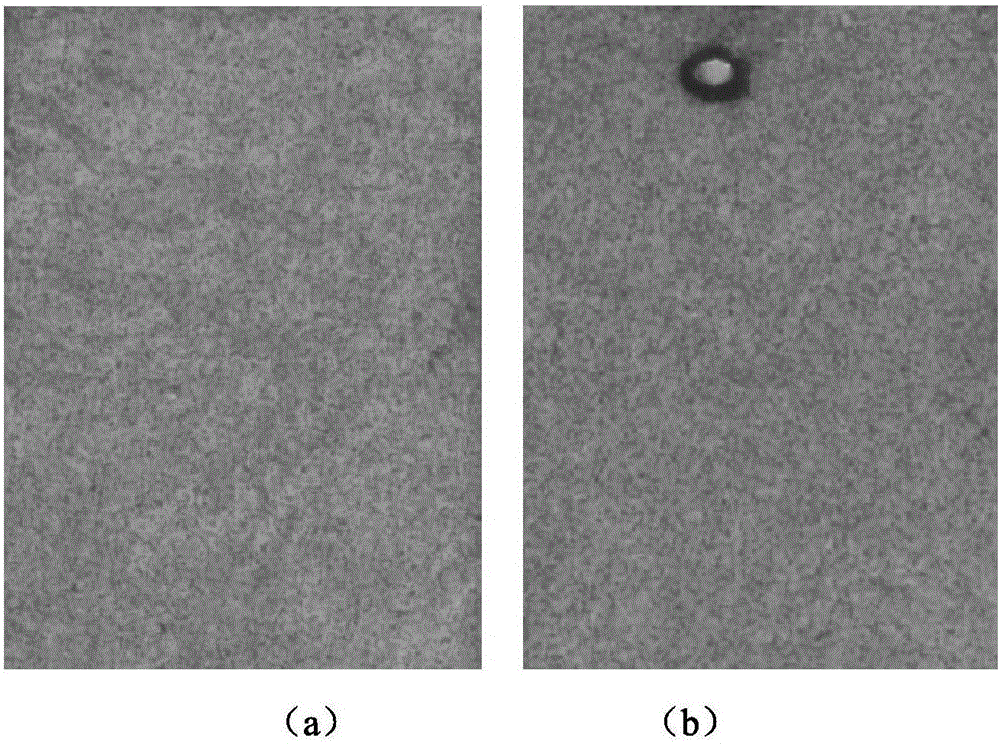

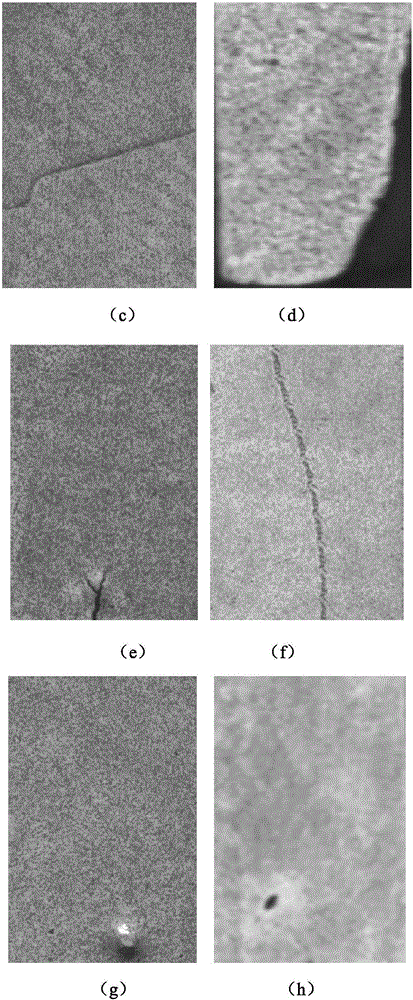

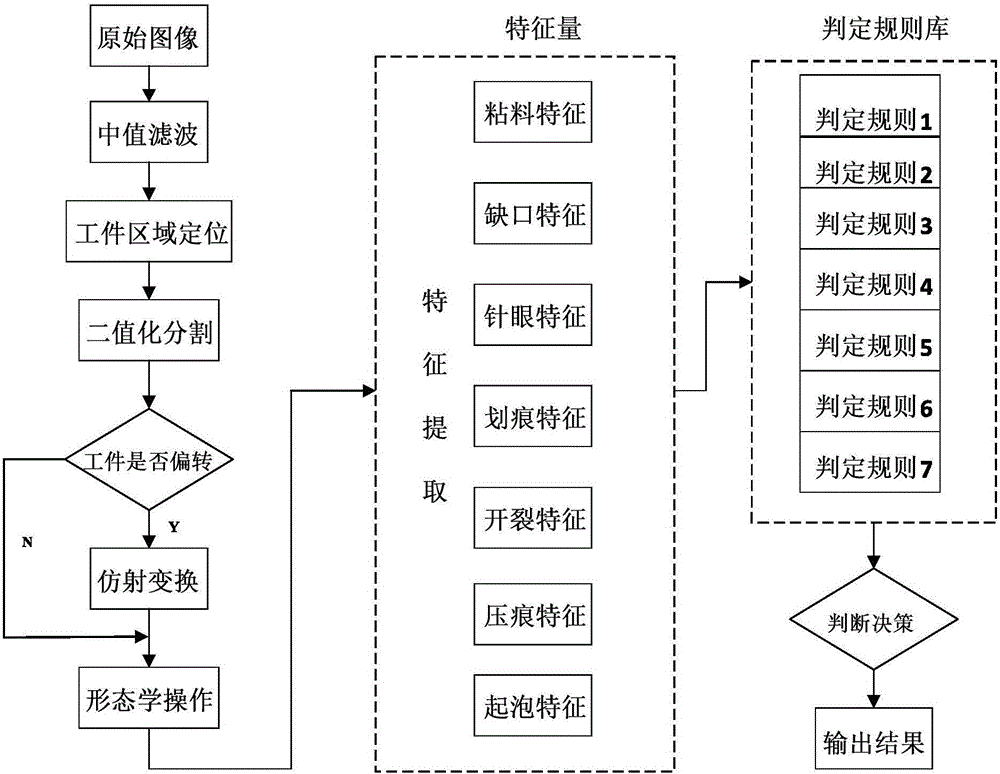

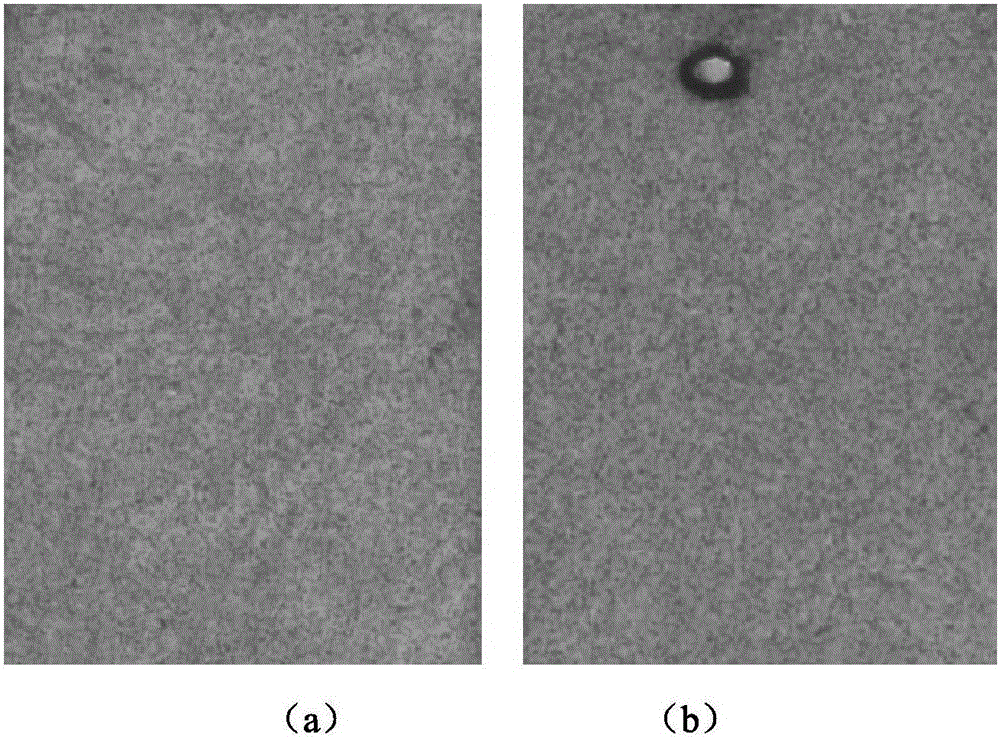

Workpiece apparent defect detection method based on machine vision

ActiveCN106204614AFast positioningHigh precisionImage enhancementImage analysisTemplate matchingVisual system

The invention discloses a workpiece apparent defect detection method based on machine vision. Firstly, a visual system is used for guiding a robot, the pose of a target workpiece is precisely positioned according to a template matching algorithm based on a gray value, and then workpiece apparent defect detection is carried out and comprises the steps that firstly, a workpiece image is acquired and pretreated through median filtering; secondly, the target workpiece is divided through a global threshold value, and workpiece pose correction is carried out; thirdly, burr interference of the edge of the workpiece is removed through mathematical morphology open operation; fourthly, notches, material sticking, cracking, indentation, needle eyes, scratches and foaming apparent defects are detected. The method solves the problems that the artificial detection speed is slow, the efficiency is low and precision is poor; the problems that according to current vision detection, defect types are singular, the imaging quality is poor, and the false drop rate is high are solved, and the automation degree of precise workpiece production and product quality are improved.

Owner:XIANGTAN UNIV

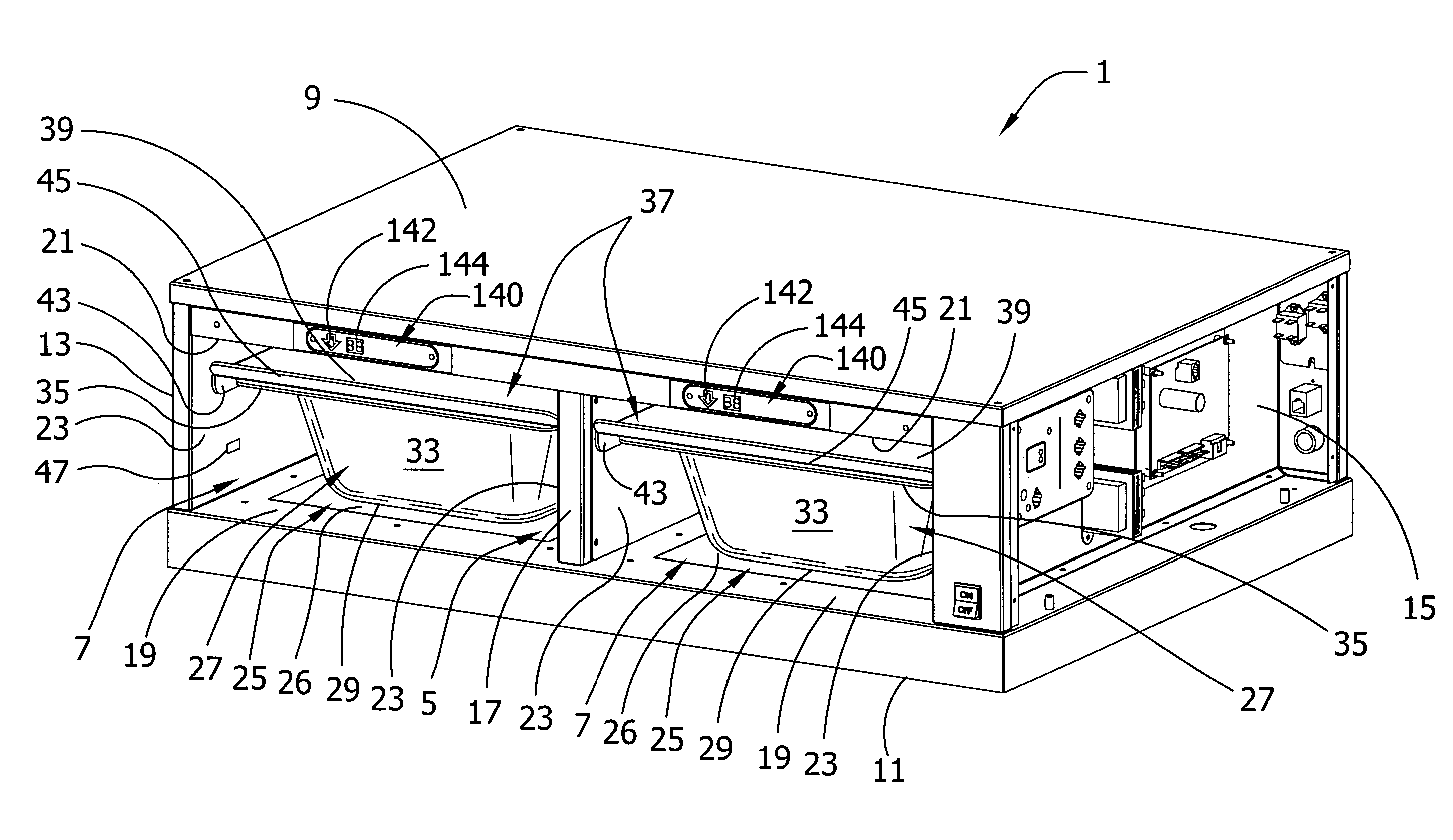

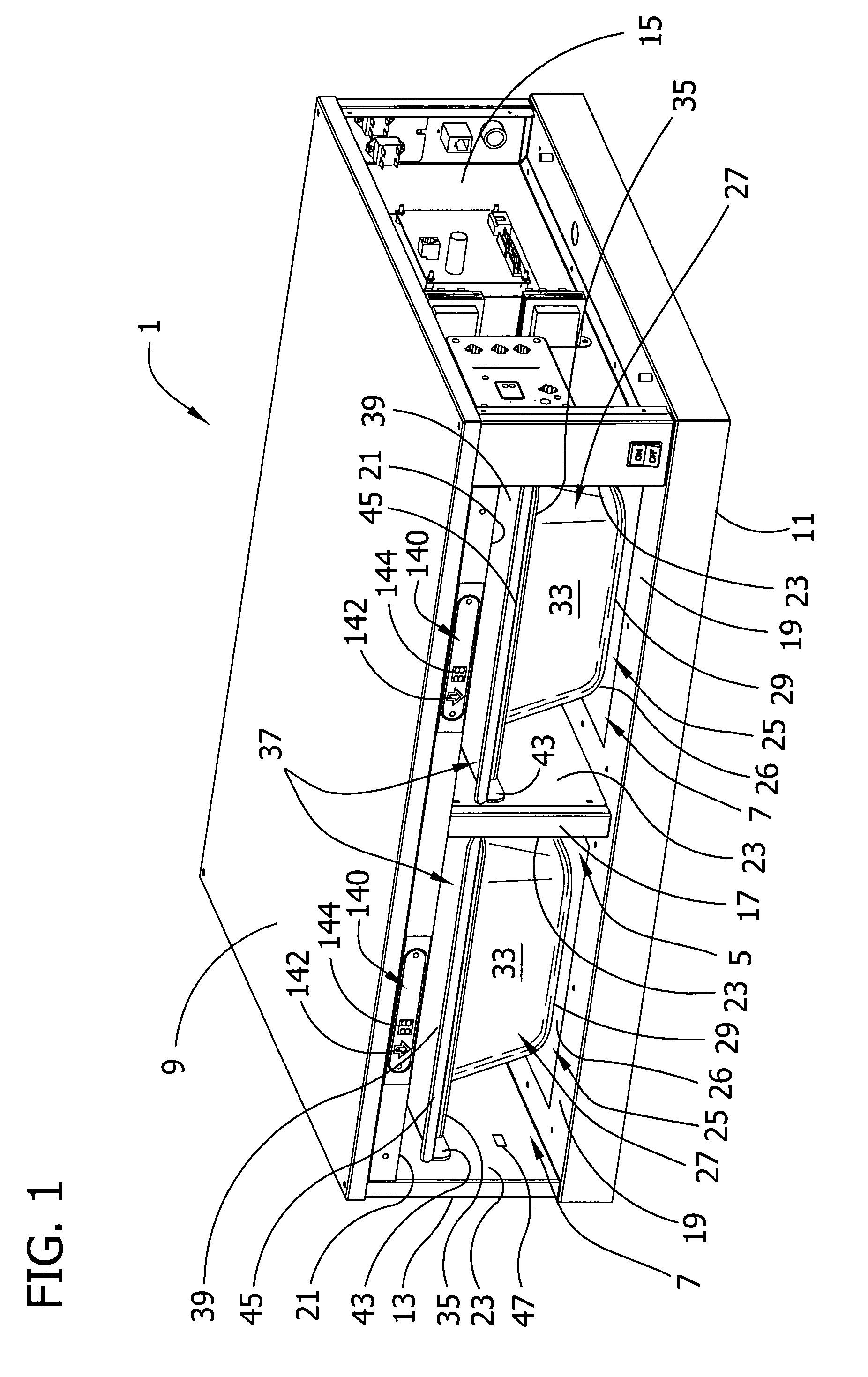

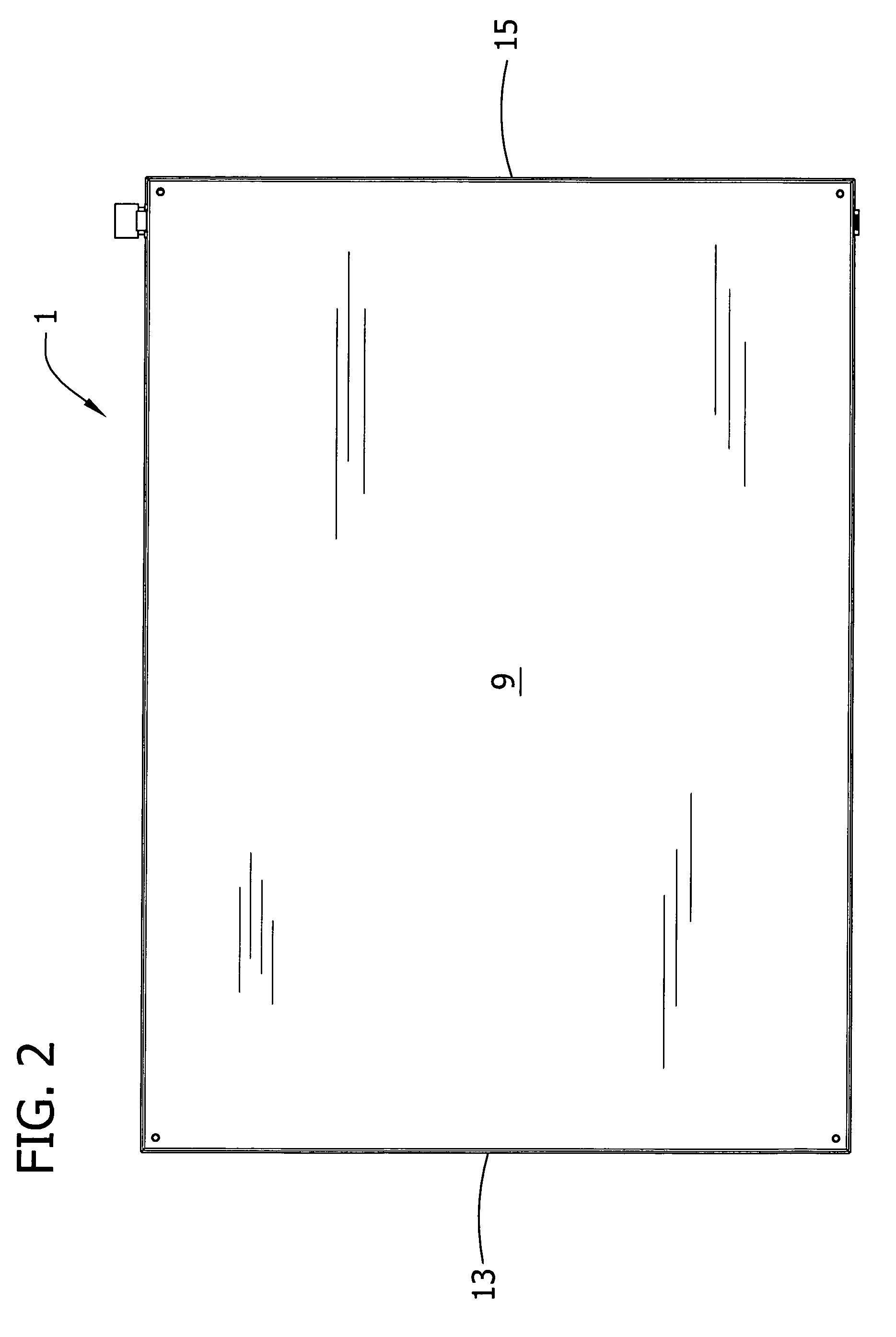

Food warming apparatus

InactiveUS7328654B2Improve product qualityHeating up fastDomestic stoves or rangesElectrical heating fuelEngineering

Owner:DUKE MANUFACTURING COMPANY

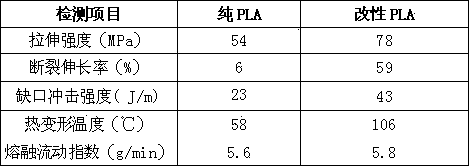

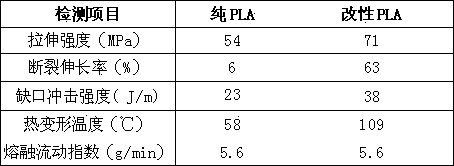

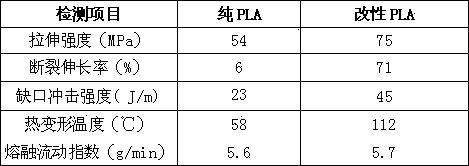

3D printing modified polylactic acid material and preparation method thereof

InactiveCN103467950AIncrease profitSelf-performance has not declinedMonocomponent polyesters artificial filamentArtifical filament manufactureHeat deflection temperaturePolymer science

A 3D printing modified polylactic acid material comprises, by weight, 70-85 parts of polylactic acid, 1-5 parts of chain extenders, 1-5 parts of cross-linking agents, 0.5-1 part of nucleating agents, 5-10 parts of polymers with low molecular weights, 5-10 parts of flexibilizers, 1-5 parts of fortifiers and 0.3-0.8 part of antioxidants. According to the 3D printing modified polylactic acid material, a low-temperature smashing hybrid reaction technology is utilized, modified processing is carried out on polylactic acid, toughness, impact strength and the heat distortion temperature for the polylactic acid are improved to a large extent, and the polylactic acid can have wider application prospects in 3D printing materials.

Owner:佛山市斯太克科技有限公司

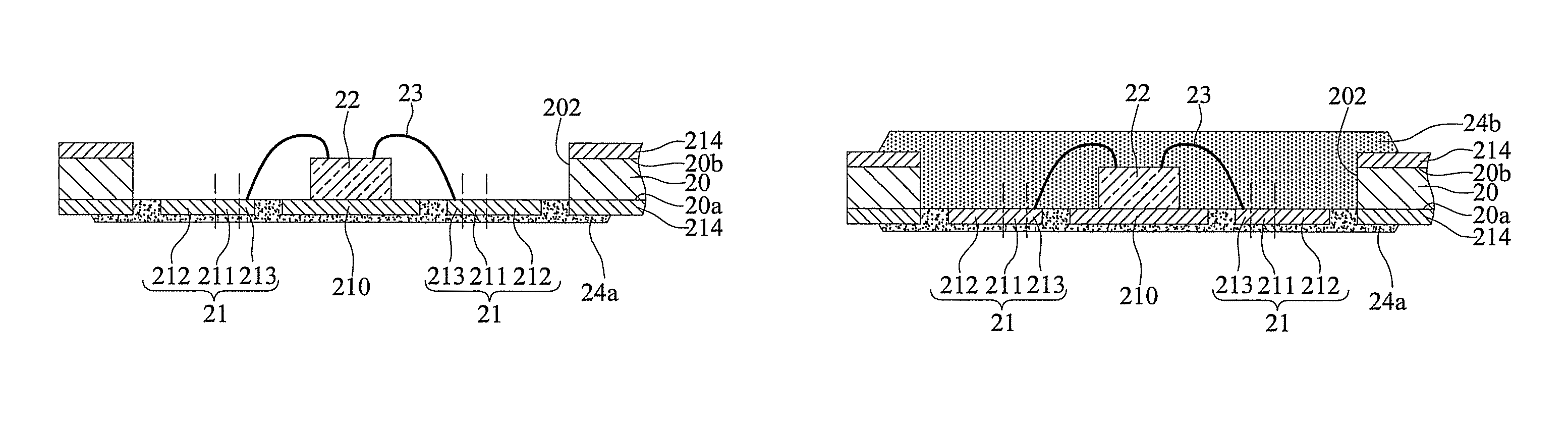

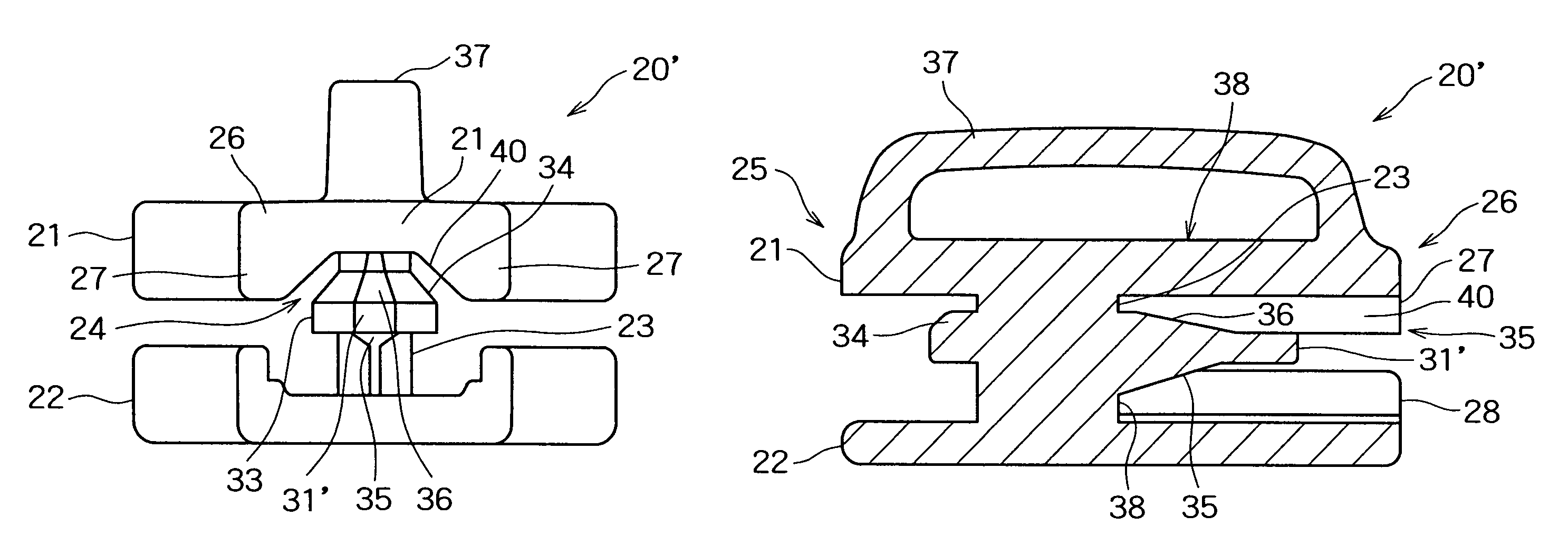

Manufacturing Method of Semiconductor Device

ActiveUS20100190293A1Improve reliabilitySimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingAmbient pressureEngineering

The present invention has been achieved reflecting such situation, and its object is to provide a manufacturing method of a semiconductor device capable of continuously performing the mounting process which applies a so-called DBG process and a flip chip bonding method, and can contribute to simplify the manufacturing process and to improve the reliability with no void in the product. The manufacturing method of a semiconductor device according to the present invention comprises:laminating a surface protective sheet to a circuit surface side of a wafer formed with grooves which divide each circuit wherein an adhesive film is adhered on the circuit surface of the wafer;reducing the thickness of the wafer and finally dividing the wafer into individual chips by grinding a back face of the wafer;picking up individual chips together with the adhesive film;die-bonding said individual chip to predetermined position of a chip mounting substrate via said adhesive film;fixing the chip to the chip mounting substrate by heating the die-bonded chip having the adhesive film; andapplying a static pressure larger than an ambient pressure by 0.05 MPa or more to a stacked body including the adhesive film one or more times, at any point between adhering the wafer to the adhesive film and fixing the chip to the chip mounting substrate.

Owner:LINTEC CORP

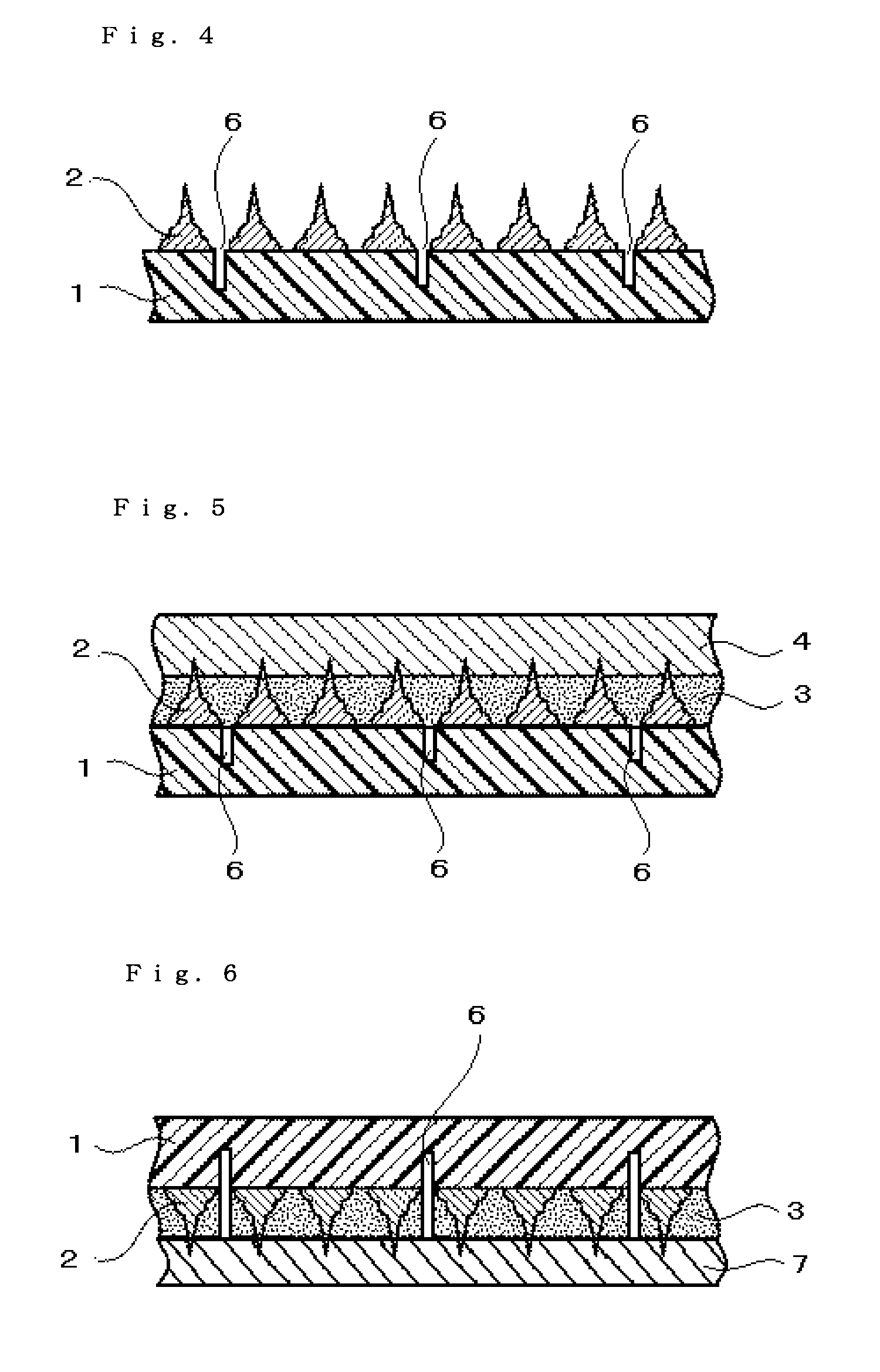

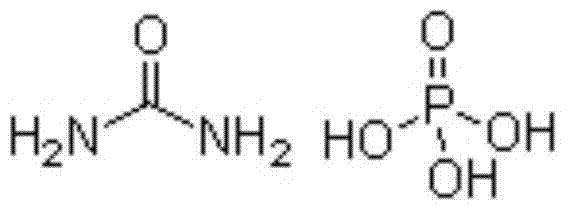

Method for preparing sodium dihydrogen phosphate by utilizing phosphoric acid by wet process

InactiveCN103787293AReduce manufacturing costShort process routePhosphorus compoundsHigh energyPhosphoric acid

The invention discloses a method for preparing sodium dihydrogen phosphate by utilizing phosphoric acid by wet process. The method comprises the steps of carrying out reaction on carbamide and the phosphoric acid by the wet process to obtain intermediate, and then carrying out a reaction on the intermediate and sodium hydroxide to obtain the sodium dihydrogen phosphate product. The method is short in process route, low in energy consumption, stable in product quality, low in production cost, convenient to operate and safe in production; the by-product slurry can be completely recycled; the whole production process is environment-friendly, clean and free from pollution as well as emission of waste gas, waste water and waste residue; therefore, the method responses to the policy of energy conservation and emission reduction as well as clean production, and solves the problems of complicated technology, unstable product quality, high energy consumption, environmental pollution and the like in the prior art; the obtained sodium dihydrogen phosphate product has the purity of more than or equal to 98%.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

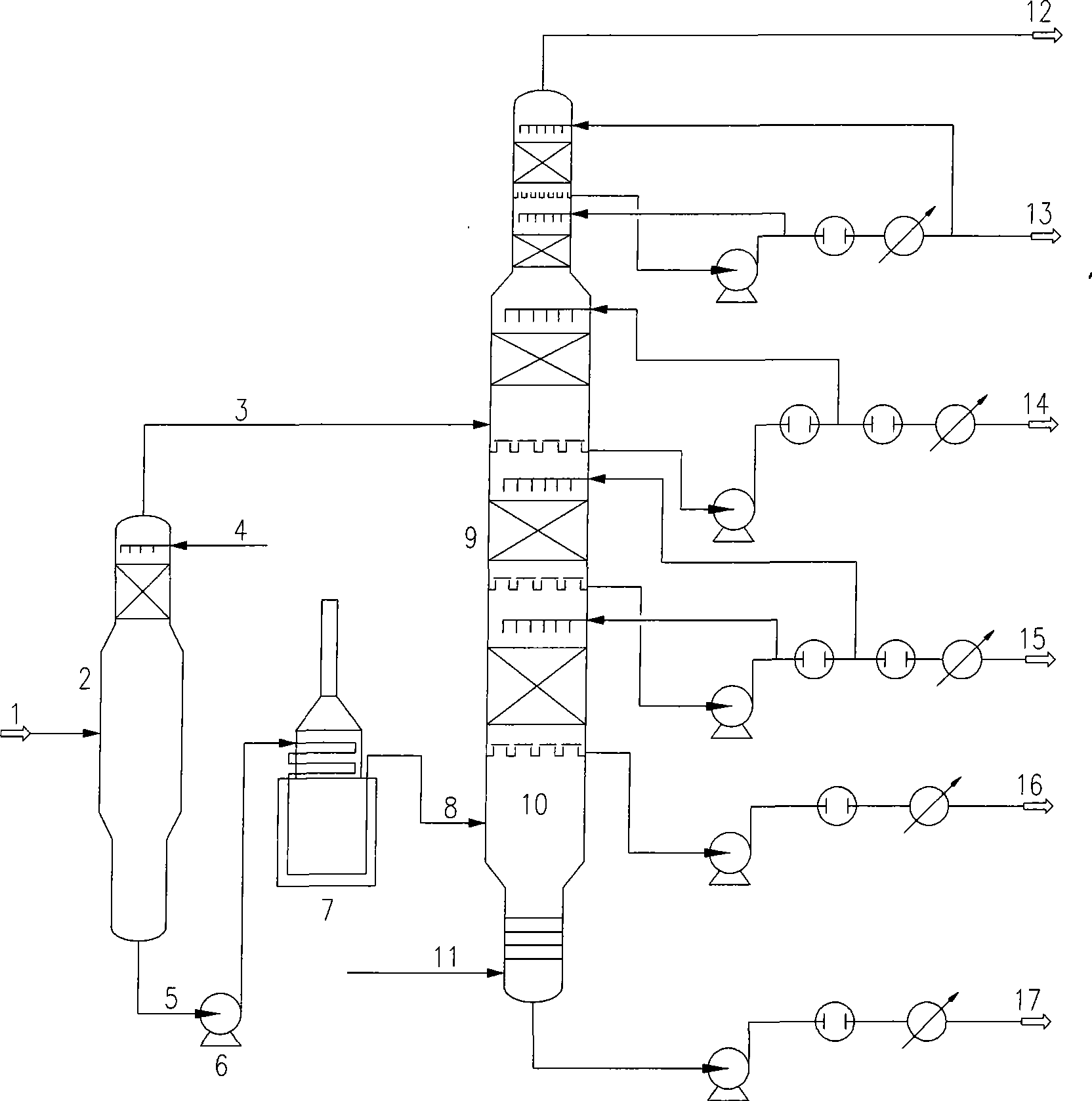

Atmospheric vacuum distillation method and apparatus with vacuum flash vaporizer

InactiveCN101376068AReduce the amount of feedEasy to handleVacuum distillation separationVacuum distillationVaporizationPulp and paper industry

The invention relates to an atmospheric and vacuum distillation device with a vacuum flash tower and a method thereof. The atmospheric and vacuum distillation device with a vacuum flash tower is characterized in that the vacuum flash tower arranged in front of a vacuum furnace is connected with the vacuum furnace and a vacuum tower through a pump and a pipeline. Constant bottom oil (1) is introduced into the vacuum flash tower (2)at first, and the operation pressure at the top part of the vacuum flash tower is higher than the operation pressure at the top part of the vacuum tower (9) by10 to 200mmHg; Flash cap gas (3) is introduced into the upper part or the lower part of an outlet for a side product which is similar to Flash cap gas fraction; flash bottom oil (5) is introduced into the vacuum furnace (7) through a flash bottom oil pump (6); when the flash bottom oil is heated to 350 to 430 degrees, air-liquid mixing vacuum tower feed material is obtained through partial vaporization and is introduced into a flash evaporation segment (10) of the vacuum tower through a transfer line (8); and products with different fractions are drawn from the side of the vacuum tower and vacuum residue is drawn from the bottom of the vacuum tower. Through adding the vacuum flash tower to improve the working process of the atmospheric and vacuum distillation device, the invention achieves the advantages of increasing treatment capacity, increasing vacuum distillation yield, and reducing energy consumption.

Owner:TIANJIN UNIV +2

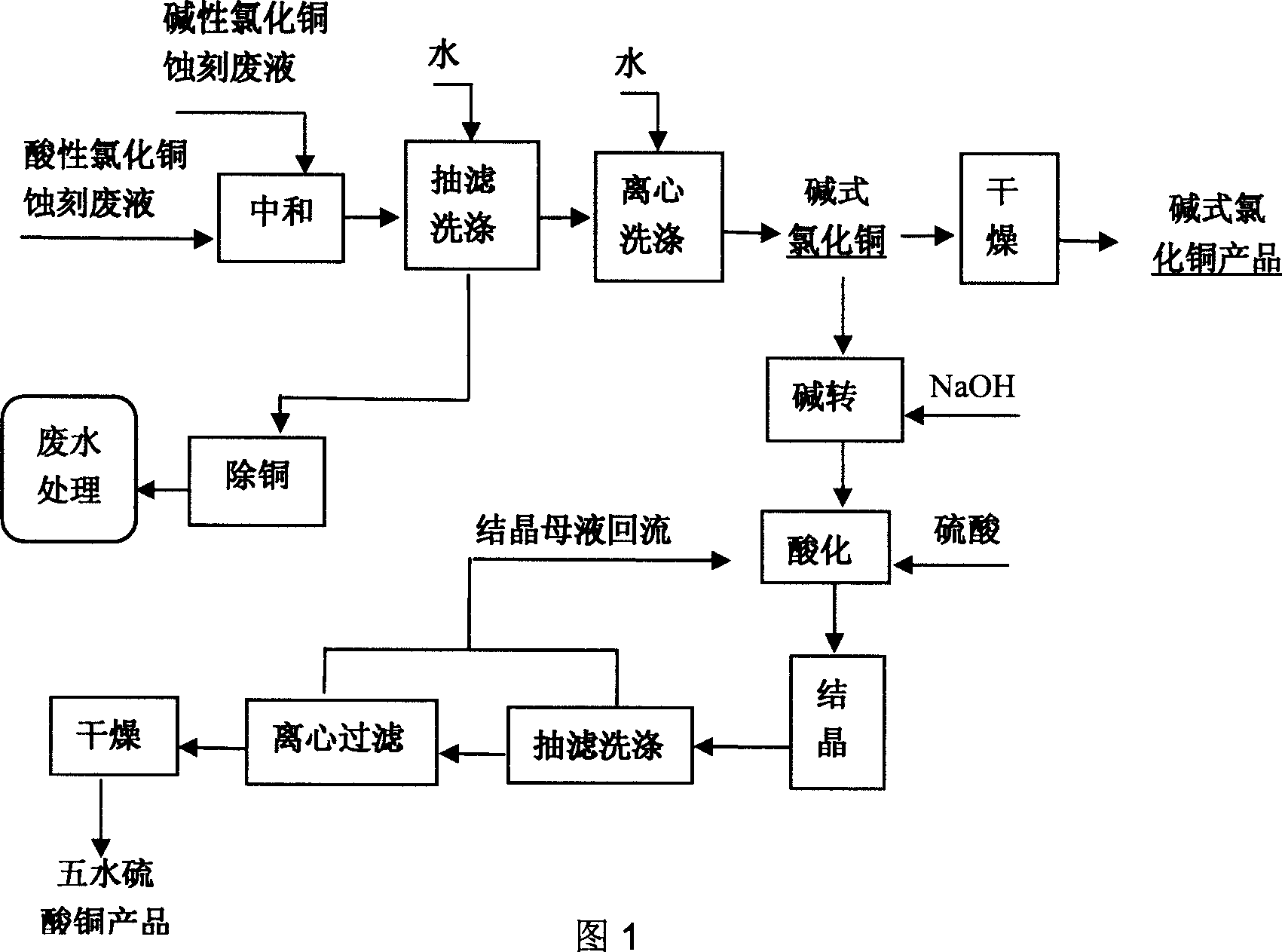

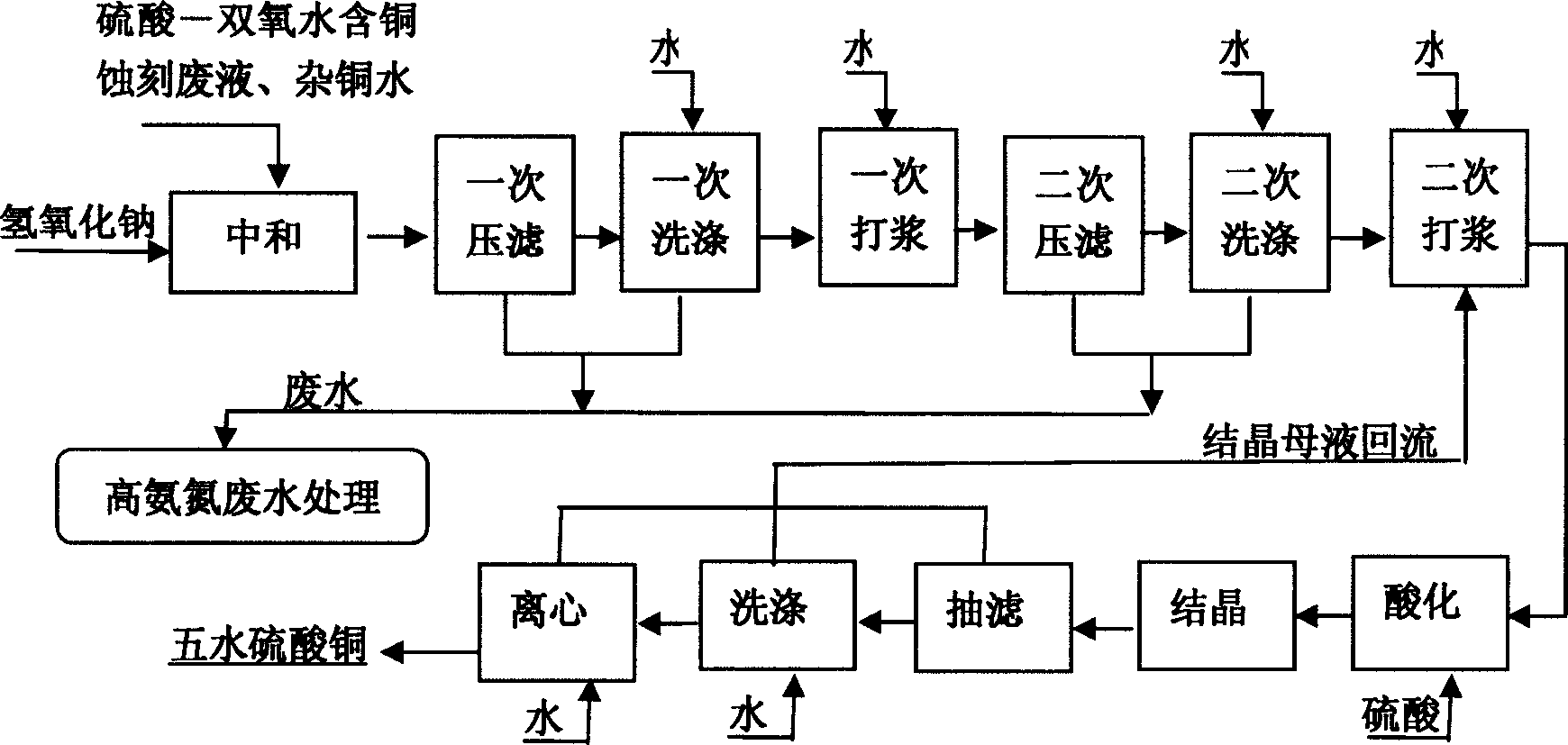

Method for producing basic copper chloride, cupric sulfate pentahydrate from copper-containing etching waste liquid

ActiveCN101391800AEfficient removalImprove product qualityCopper chloridesMultistage water/sewage treatmentCopper chlorideSulfate

The invention relates to a method for producing copper chloride hydroxide and blue vitriod by using cupriferous etching wastewater; the method comprises the following steps: acidic copper chloride etching wastewater and alkaline copper chloride etching wastewater are neutralized and crystallized to get acidic copper chloride crystal under the condition of strictly controlling filling liquid and the Ph range of a reaction kettle, and then pumped and filtrated, and centrifugated; part of the obtained alkaline copper chloride crystal is dried to obtain finished products while the other is added with NaOH solution for alkali conversion to obtain copper oxide, and then is acidulated by sulphuric acid, crystallized, washed, centrifugated, and dried to obtain blue vitriod products. The method for producing blue vitriod by directly using sulphuric acid-oxyful etching wastewater includes the following steps: sulphuric acid-oxyful etching wastewater and composition brass wasterwater in a PCB manufacture are blended together and added with NaOH to form cupric hydroxide precipitation which filtrated, washed, and then acidulated by sulphuric acid to obtain copper sulphate solution; after the copper sulphate solution is cooled, crystallized, centrifugated and dried, and the blue vitriod is obtained.

Owner:HUIZHOU DONGJIANG ENVIRONMENTAL PROTECTION TECH

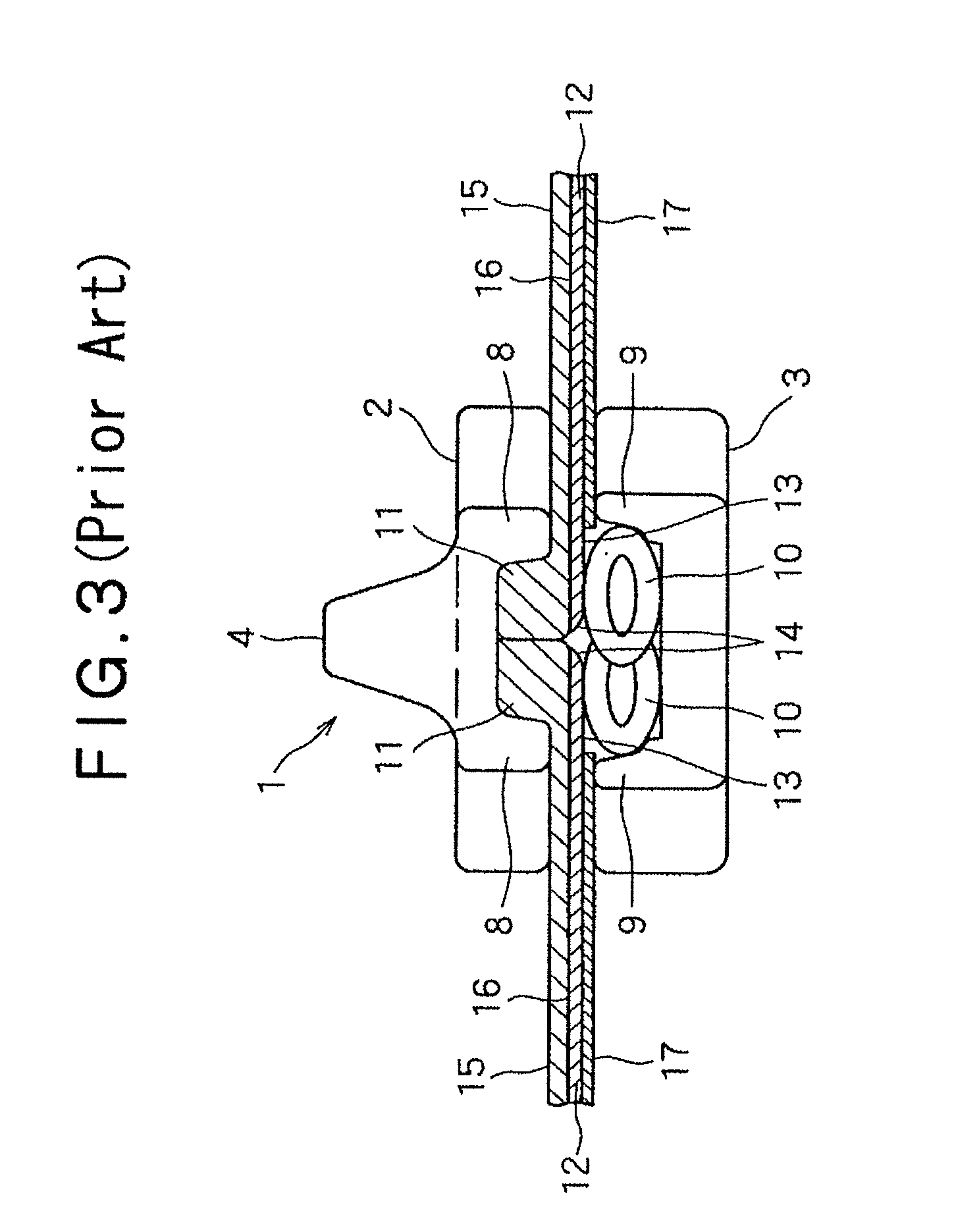

Slider for a fluid tight slide fastener

ActiveUS8112848B2Reduce manufacturing costImprove product qualitySnap fastenersSlide fastenersDie castingEngineering

Owner:YKK CORP

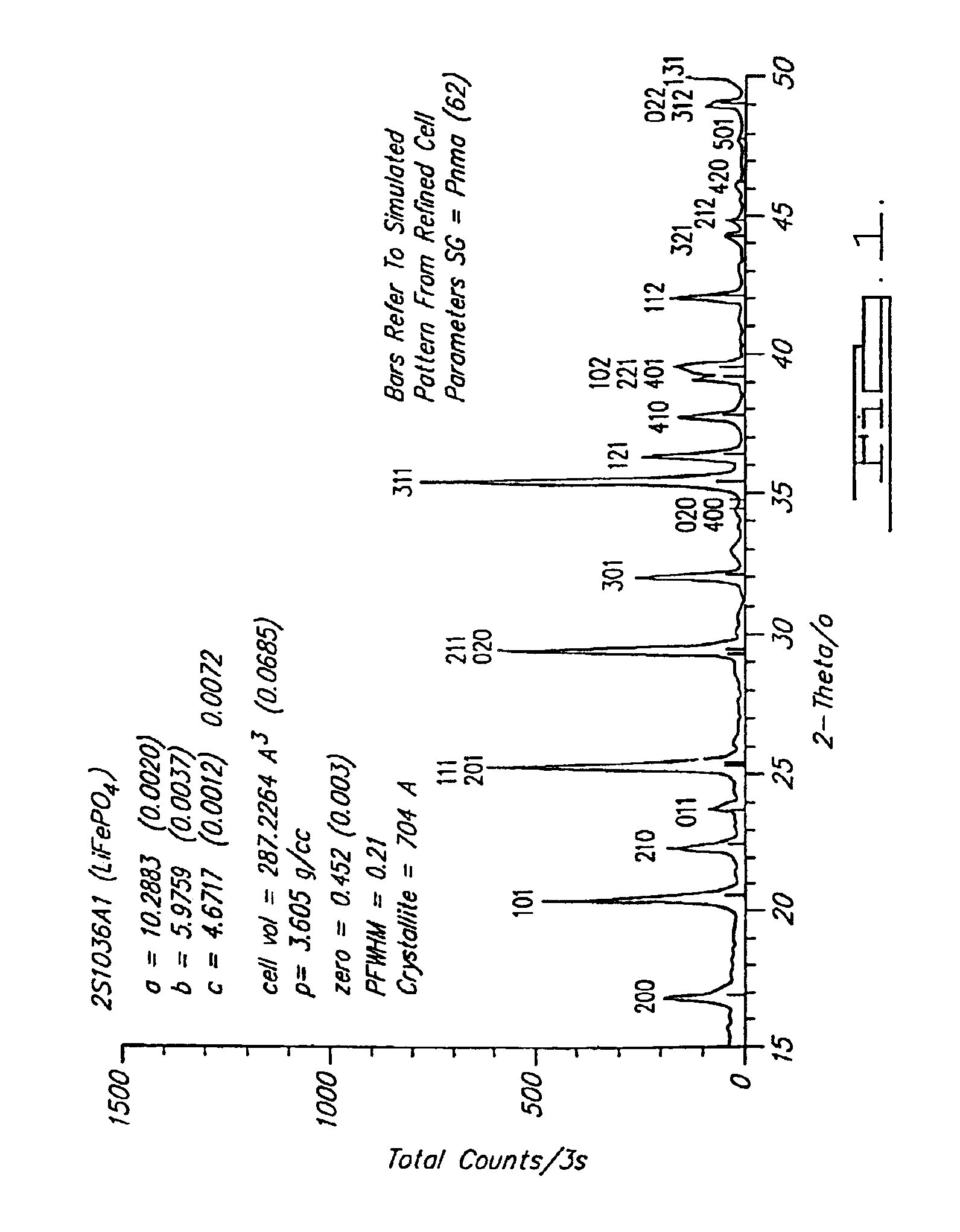

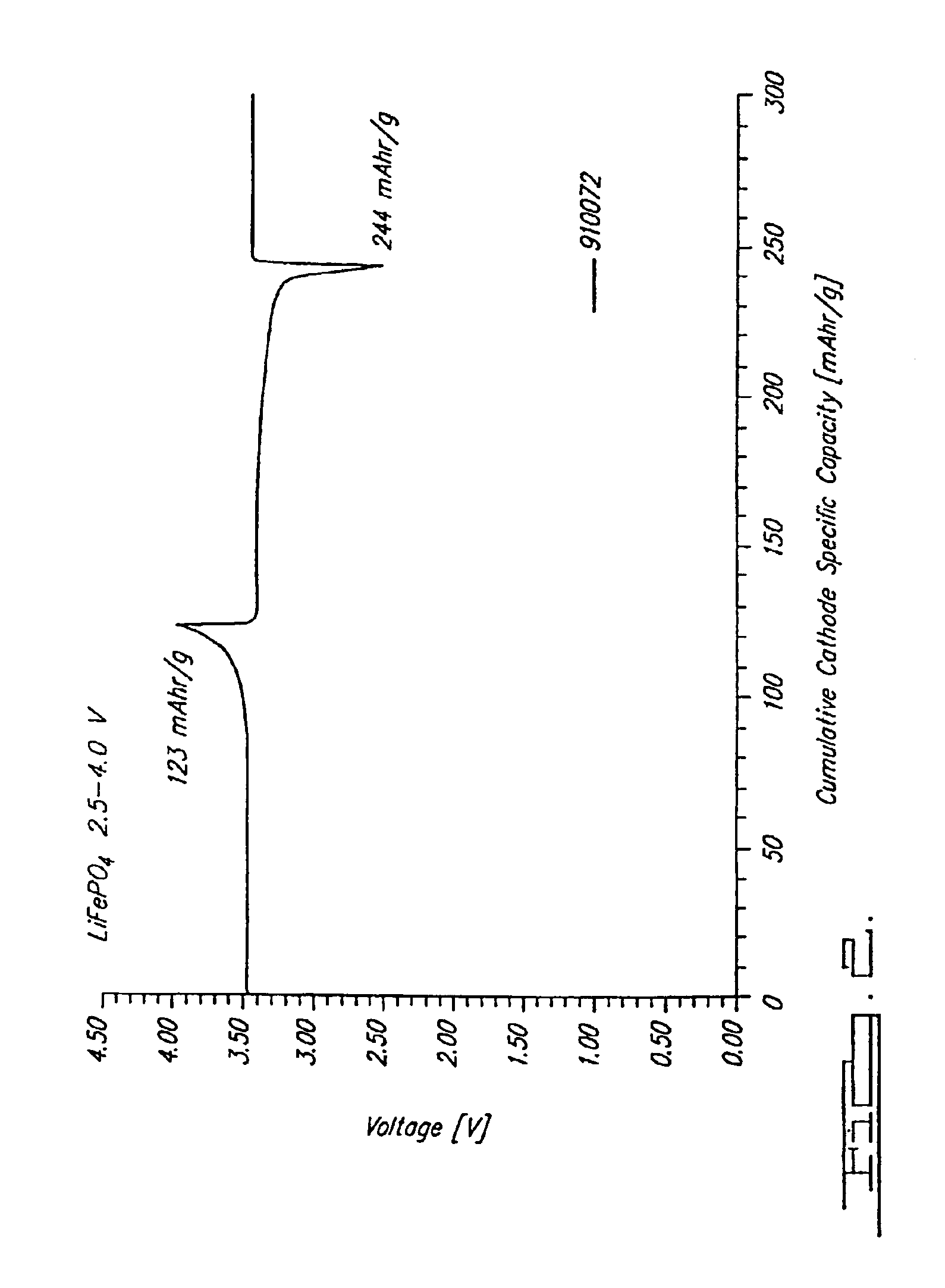

Lithium-based active materials and preparation thereof

InactiveUS6884544B2Easy to adaptHigh capacity retentionElectrode manufacturing processesPhosphatesElectrochemical cellChemistry

The invention provides novel active material represented by the general formula LiaMI1-yMIIyPO4, wherein MI is selected from the group consisting of Fe, Ni, Mn, V, Sn, Ti, Cr, and mixtures thereof; MII is selected from the group consisting of Zn, Cd, and a mixture thereof; a is about 1; and 0<y<1, which, upon electrochemical interaction, releases lithium ions, and is capable of reversibly cycling lithium ions. The invention provides a rechargeable lithium battery which comprises an electrode formed from the novel active material, wherein MI is selected from the group consisting of Fe, Co, Ni, Mn, Cu, V, Sn, Ti, Cr, and mixtures thereof. Methods for making the novel active material and methods for using such a material in electrochemical cells are also provided.

Owner:LITHIUM WERKS TECH BV

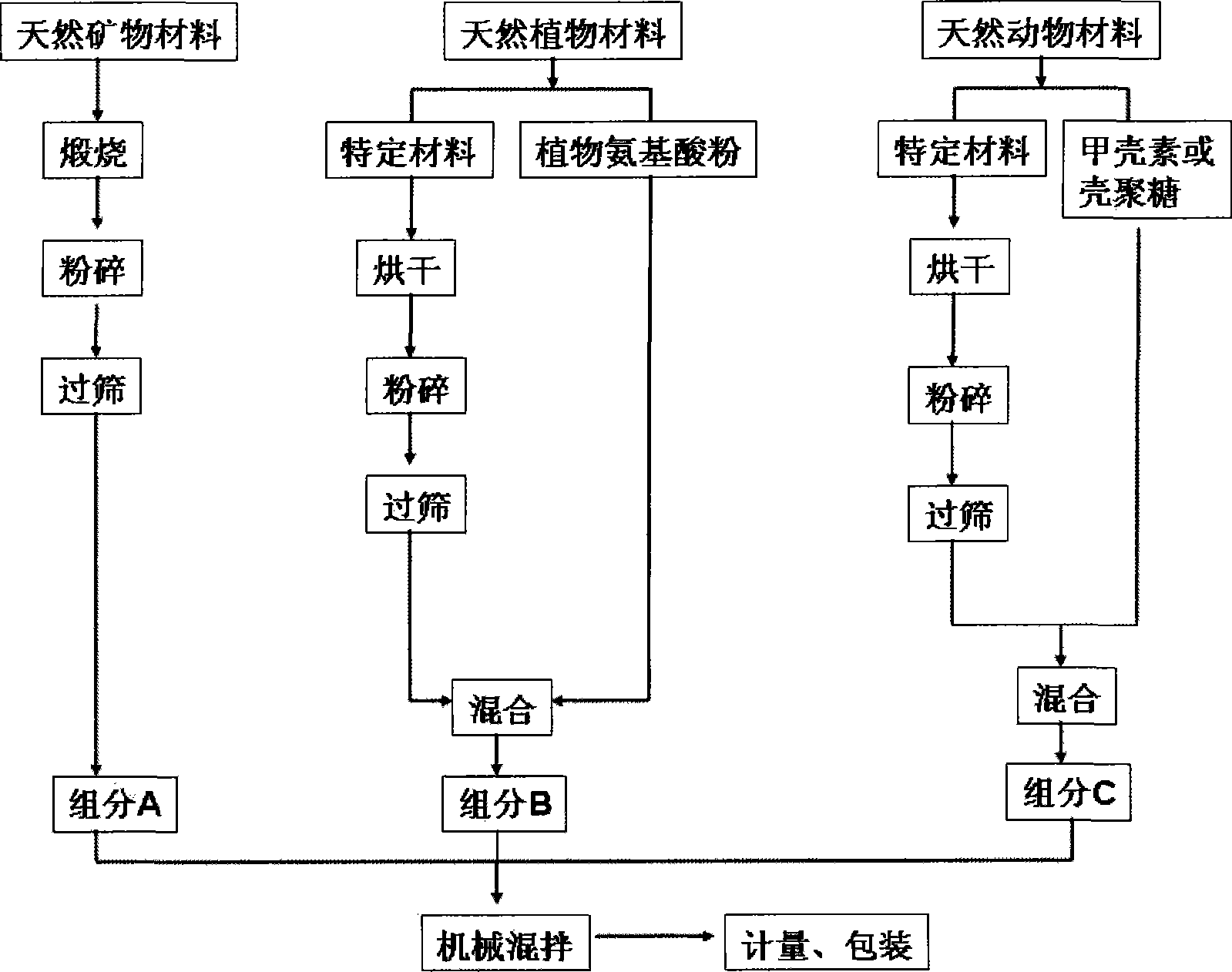

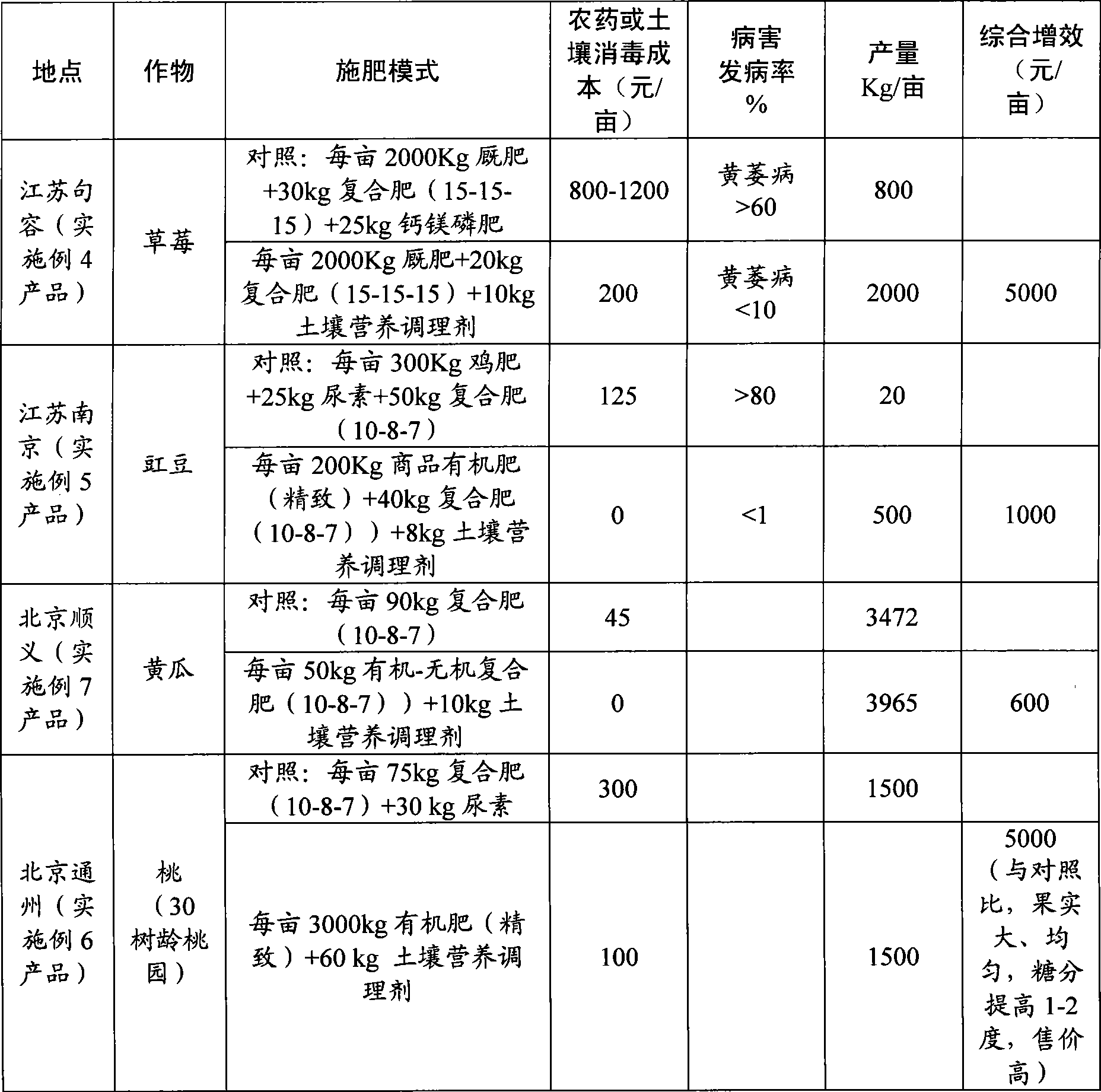

Soil fertility amendment and preparation method thereof

The invention provides a multifunctional soil nutrient conditioner formula with low cost, practicality and effectiveness and a preparation method thereof aiming at the technical problems. The production technology is simple, the production cost is low, and no harmful gas and sewage are generated during production. The product can effectively provide dozens of nutritive elements required for plant growth, is applied by being combined with a common fertilizer and an organic fertilizer, and can obviously improve the utilization rate of the fertilizer, so as to reduce the fertilizer input; and simultaneously the product can obviously stimulate action of beneficial floras of the soil, inhibit action of causal organisms, and increase the disease suppression of the soil and the resistance of plants, and then can effectively control generation of physiological diseases and soil-borne diseases, so as to reduce the pesticide input. The fertilizer input and the pesticide input can be reduced by more than 15 to 30 percent, and the yield can be increased by more than 15 to 30 percent, and simultaneously the product quality is obviously improved and cost conservation and synergism are obvious. Moreover, the soil improvement effect is obvious, and the sustainable utilization capacity can be obviously enhanced.

Owner:仲元(北京)绿色生物技术开发有限公司 +1

Investment precision casting technology for producing automobile I-shaped front axle

InactiveCN101147954ALess investmentReduce manufacturing costFoundry mouldsFoundry coresSteelmakingWax

The present invention relates to a fusible pattern precision casting process for producing automobile H-shaped front axle. Said casting process includes the following steps; (1), preparing wax pattern; (2), applying coating material onto the wax pattern surface for several times, spreading sand and making the coating material hardened pattern shell be primarily formed, removing wax and forming pattern shell; (3), firing pattern shell; (4), pouring the molten steel into the pattern shell, before steel-smelting having to make analysis of charge mixture ratio, in the course of smelting steel having to make on-the-spot sample analysis and furnace rear analysis, adding required additive and deoxidant so as to make the molten steel be reached to the defined chemical components requirement; (5), removing pattern shell from obtained automobile H-shaped front axle casting, cleaning sand and cutting spure; (6), grinding, finishing and checking casting; (7), making quenching and tempering, heat treatment; (8), making correction and shot blasting treatment; and (9), making metalworking treatment.

Owner:NANPING AUTO FORGING & STAMPING FACTORY

Hydrocracking catalyst with high activity and high-medium oil selectivity and preparation method of hydrocracking catalyst

ActiveCN102441411AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNitrogen

The invention relates to a hydrocracking catalyst with high activity and high-medium oil selectivity. According to the hydrocracking catalyst, amorphous silicon aluminum is used as a carrier, and a specially-modified Y-type molecular sieve is used as acid component, the molecular sieve has high degree of crystallization and low cell parameters, rich secondary holes, large surface area, less uniformly-distributed acid sites, no strong acid center, and most of medium-strength acid centers, and also has strong nitrogen-resisting performance and better damage capacity; and the hydrocracking catalyst using the molecular sieve has high hydrocracking activity and high middle oil selectivity, and stronger nitrogen resisting capacity. The catalyst provided by the invention is used in the process of producing an intermediate distillate product by adopting a heavy hydrocarbon single-section or one-section hydrocracking process, and has better activity and middle oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

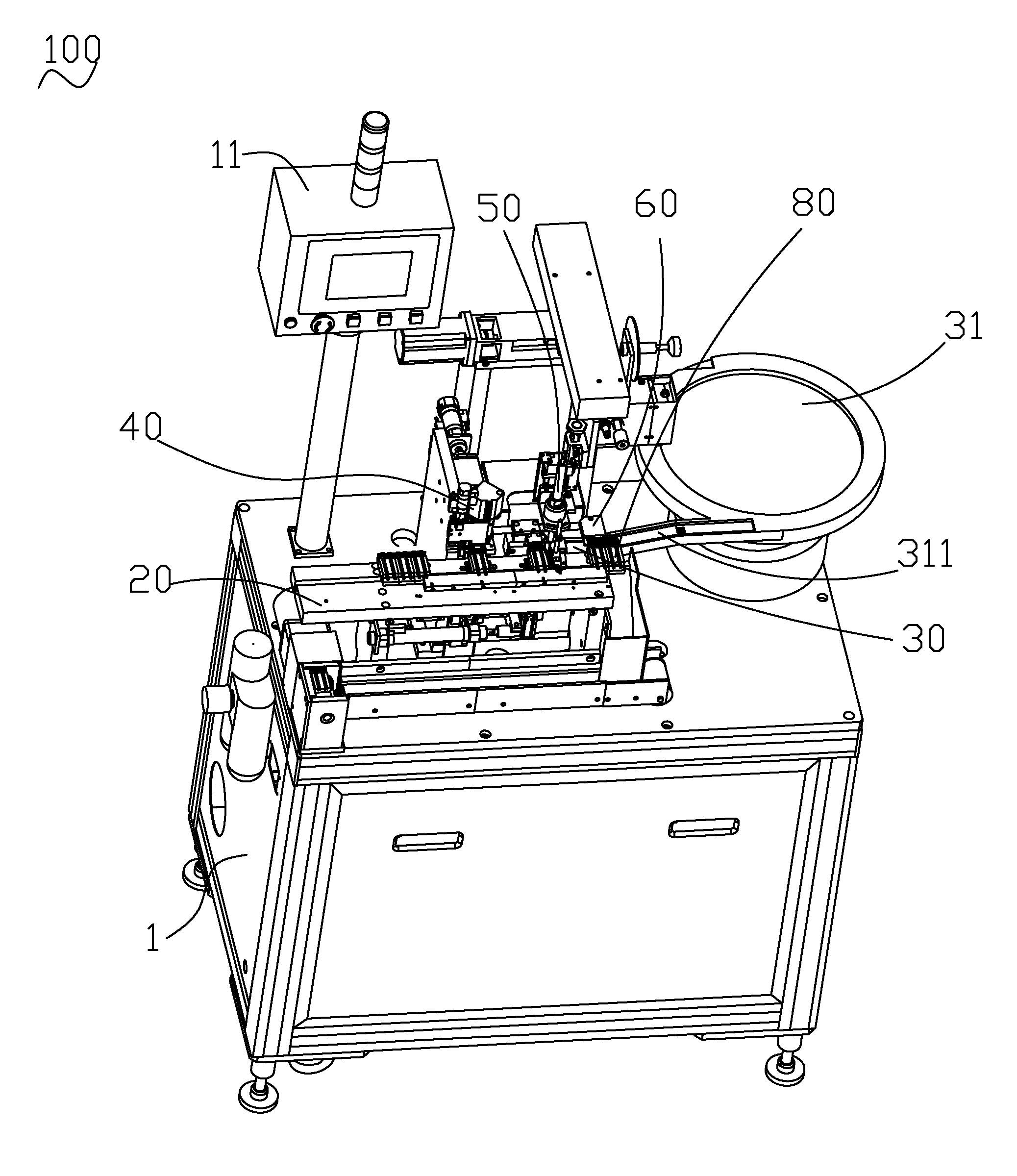

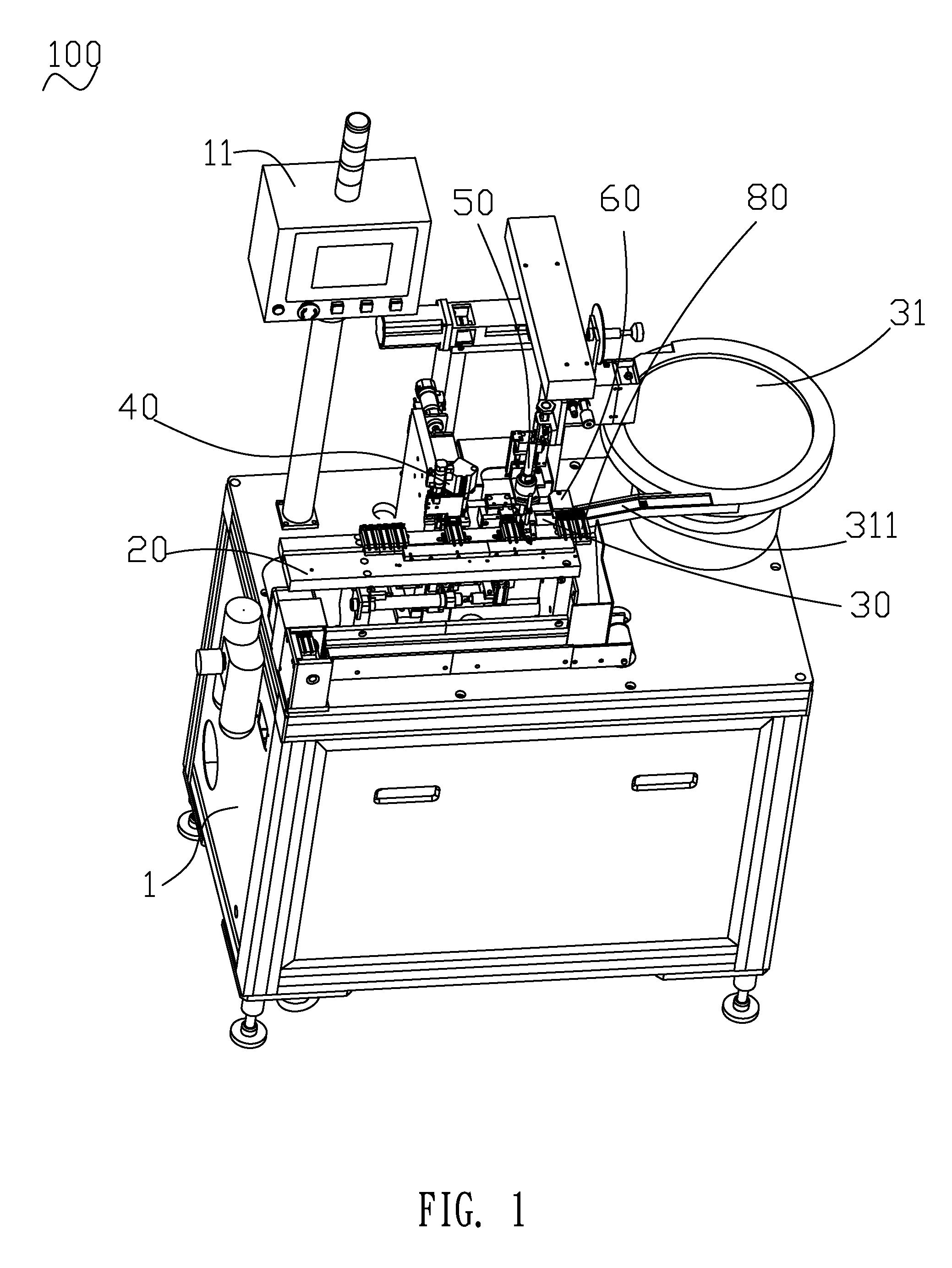

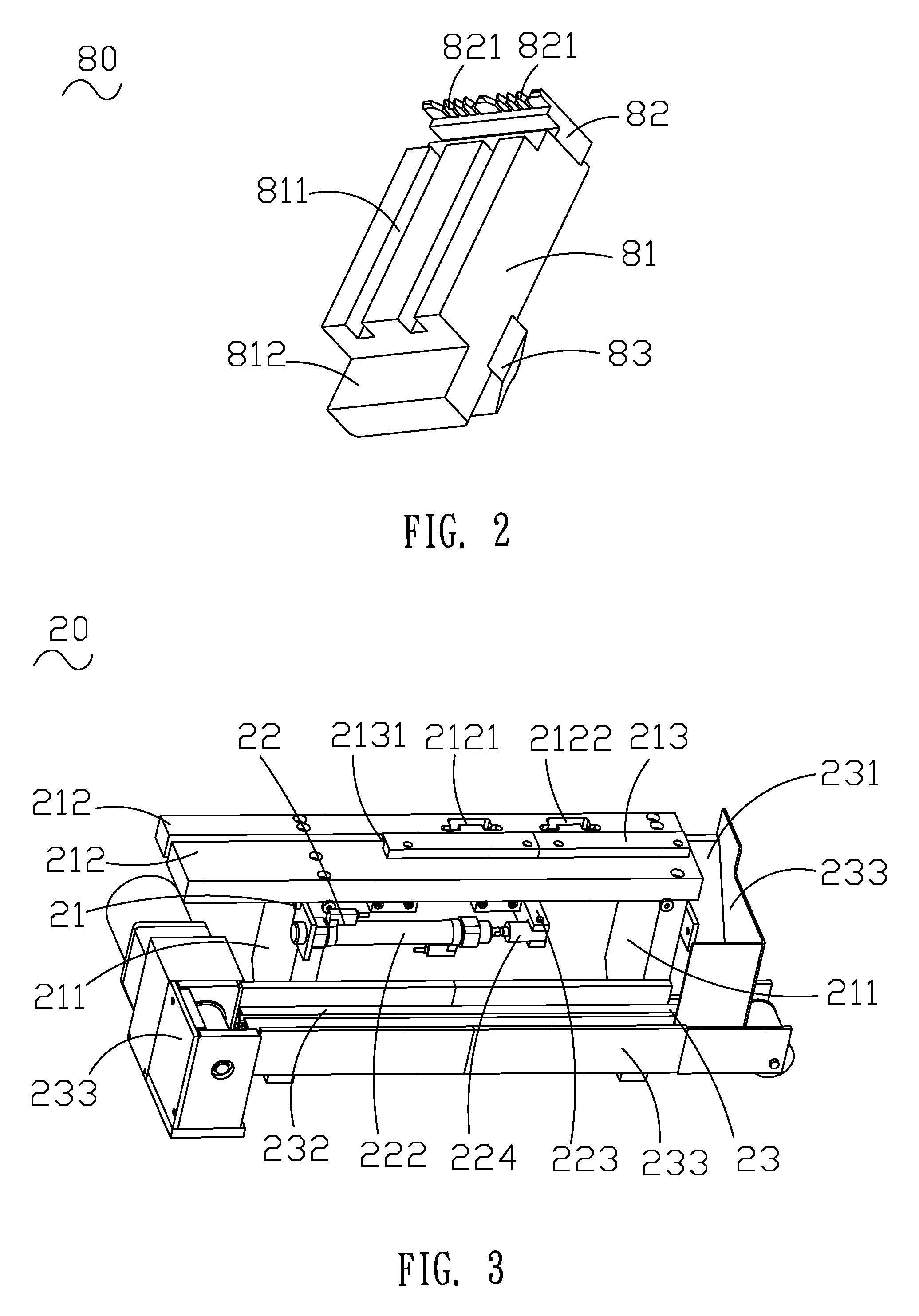

Automatic soldering machine

InactiveUS8011557B1High production efficacyImprove product qualityWelding/cutting auxillary devicesFeeding apparatusControl systemEngineering

An automatic soldering machine for soldering wires, each exposing at least one core wire and electronic components with at least one soldering portion respectively is disclosed. The automatic soldering machine comprises an equipment, a delivery mechanism, a plurality of clamps, a feeding mechanism, an insulation removing mechanism, a soldering mechanism, an unloading mechanism and a programmable control system. The delivery mechanism delivers the wires. The clamps locate the wires. The feeding mechanism conveys the electronic components. The insulation removing mechanism cuts the core wires and strips insulations at tops of the core wires. The soldering mechanism solders the core wires and the soldering portions of the electronic components. The unloading mechanism separates the soldered electronic components and core wires off from the clamps. The programmable control system is connect to the aforesaid mechanisms and controls thereof with high production efficacy and stable production quality.

Owner:CHENG UEI PRECISION IND CO LTD

Blackthorn pear fruit-juice solid product and its production

The invention is concerned with the solid product of roxburgh rose juice and the preparation method, it is: prepares the roxburgh rose juice or combined roxburgh rose juice to be granule, tablet, capsule or effervesce agent in order to improve the stability of vitamin C, vitamin p and superoxide dismutase in it, and reduce the nutritive value loss of roxburgh rose juice. The preparation method is: 1) prepares clear roxburgh rose juice; 2) prepares roxburgh rose condensing juice; 3) adds 1% -50% accessories into the clear roxburgh rose juice or roxburgh rose condensing juice; 4) gets grains by wet-process, or makes instant powder of roxburgh rose then gets grains by wet-process; 5) the above grains dry at the temperature of 30 centigrade - 70 centigrade in order to get the solid products.

Owner:SHANGHAI NORMAL UNIVERSITY

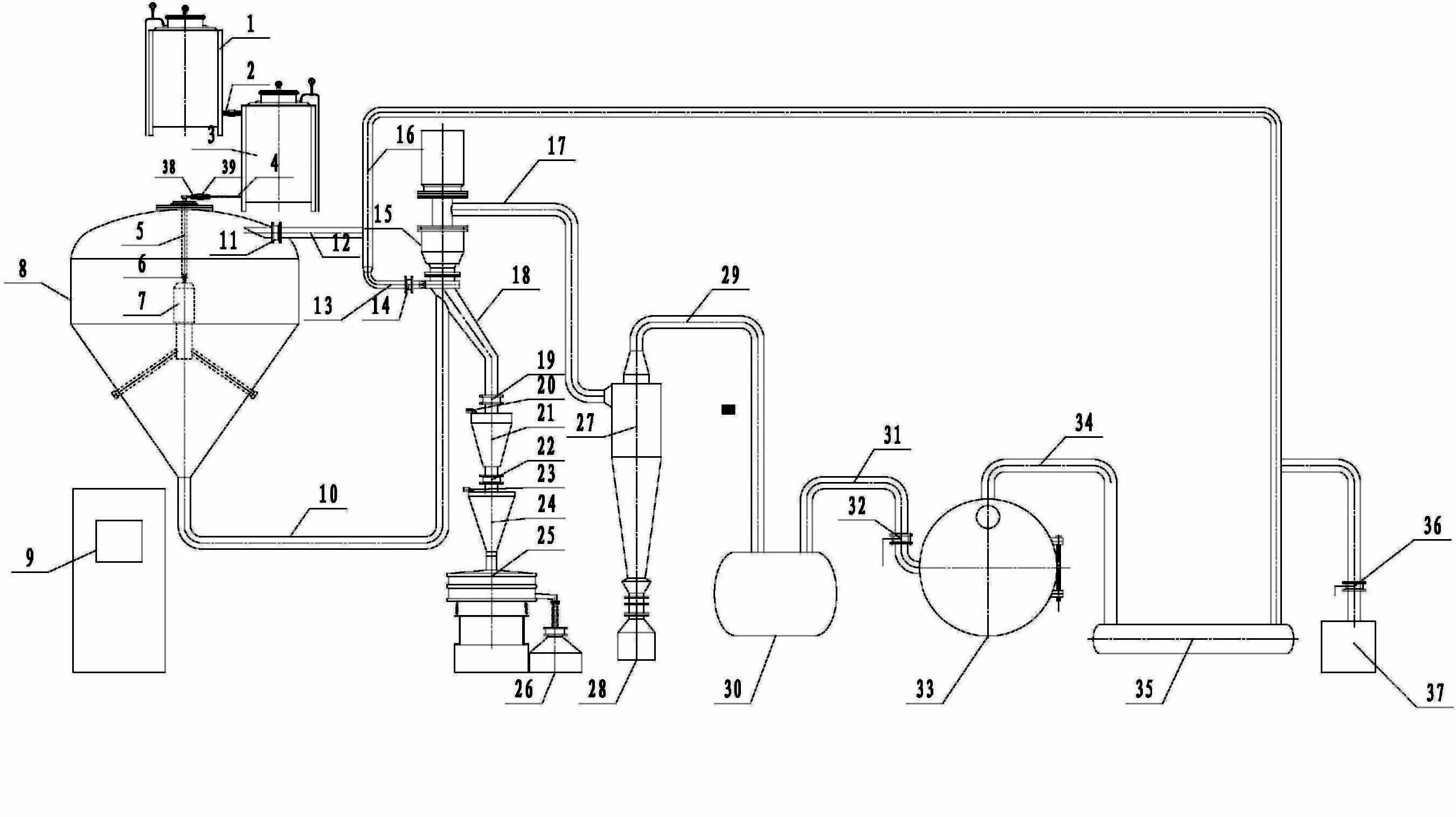

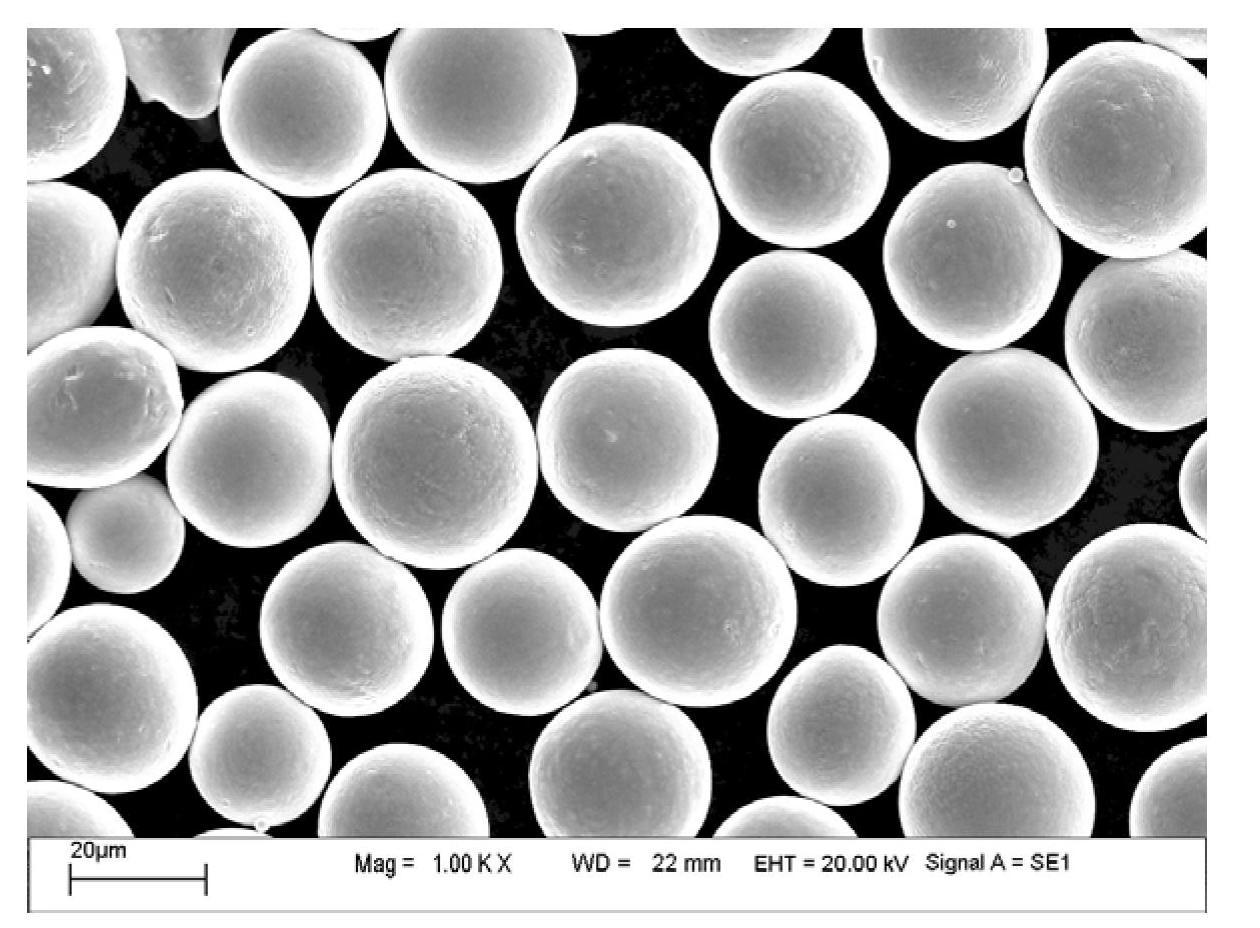

Metal powder preparation device and method therefor

The invention relates to a metal powder preparation device and method therefor. The device comprises an atomization furnace, a heater, a cooler, an atomization chamber, an atomizer, a pneumatic classifier, a middle bin, a sieving funnel, a screening machine, a deduster, a balance tank, a shell-and-tube heat exchanger, a vacuum obtaining device, a control system, an infusion tube, a conduit, a pipeline, a gas channel, a pneumatic butterfly valve, an electromagnetic valve and the like. The method comprises atmosphere preparation, metal smelting, infusion, centrifugal atomizing, pneumatic classification, mechanical screening, gas purification, cooling and the like, the metal is smelted and treated so as to be poured onto the atomizer for centrifugal atomization to form powder, the powder is classified by the pneumatic classifier, after classification, rough powder is screened by the mechanical screening so as to obtain the finished powder, fine powder is sent into the deduster by airflow for purification, the purified gas is driven by a high pressure centrifugal fan so as to be speeded up to be atomized and classified again after being subjected to heat exchange through the shell-and-tube heat exchanger. The device can be used for continuous production of spherical powder below -320 meshes, and the oxygen content is less than or equal to 80ppm.

Owner:BEIJING COMPO ADVANCED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com