Patents

Literature

1635results about "Vacuum distillation separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

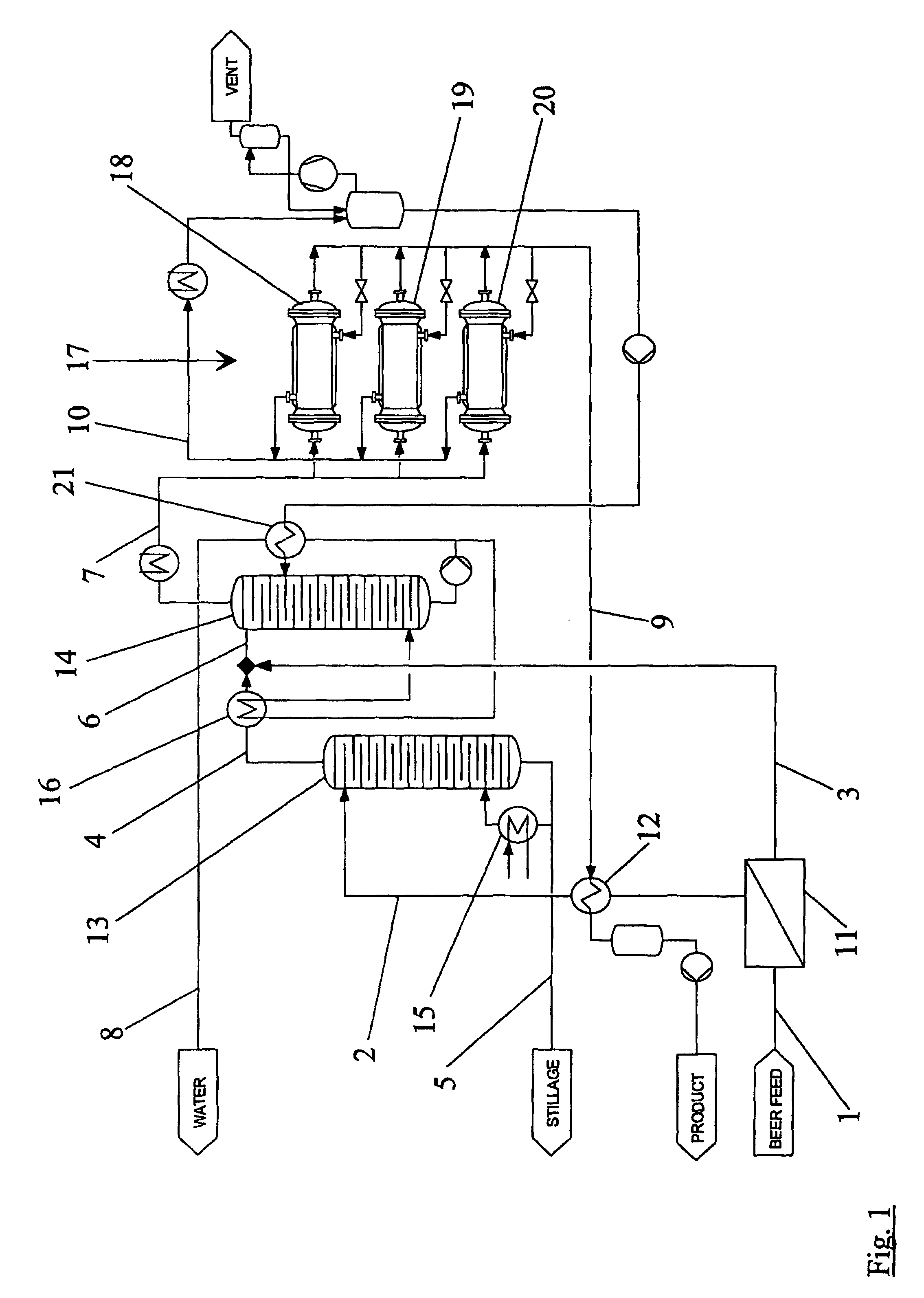

Ethanol distillation process

InactiveUS7297236B1Avoid insufficient heatingShorten the timeFermented solutions distillation/rectificationDistillation in boilers/stillsDistillationEvaporation

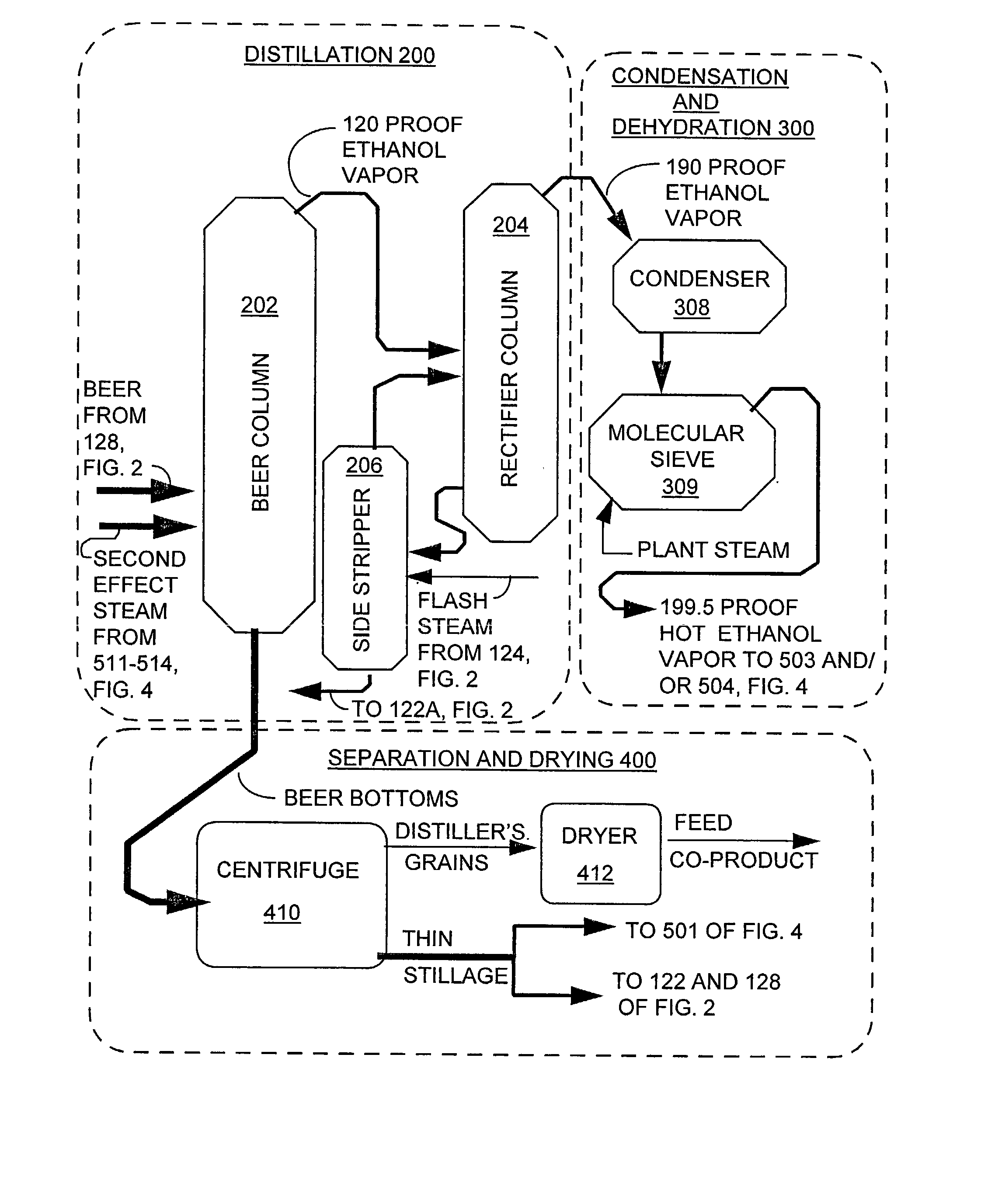

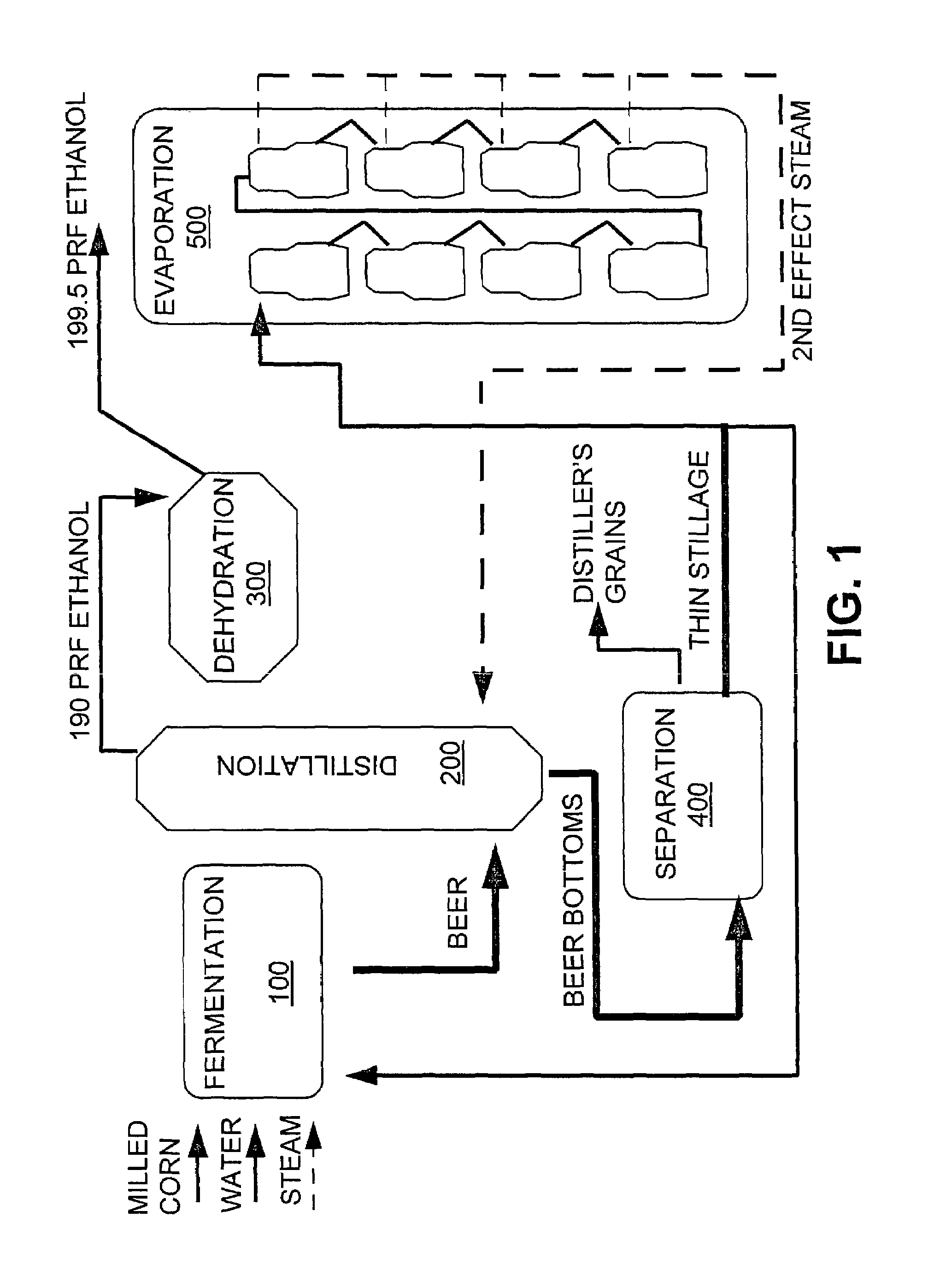

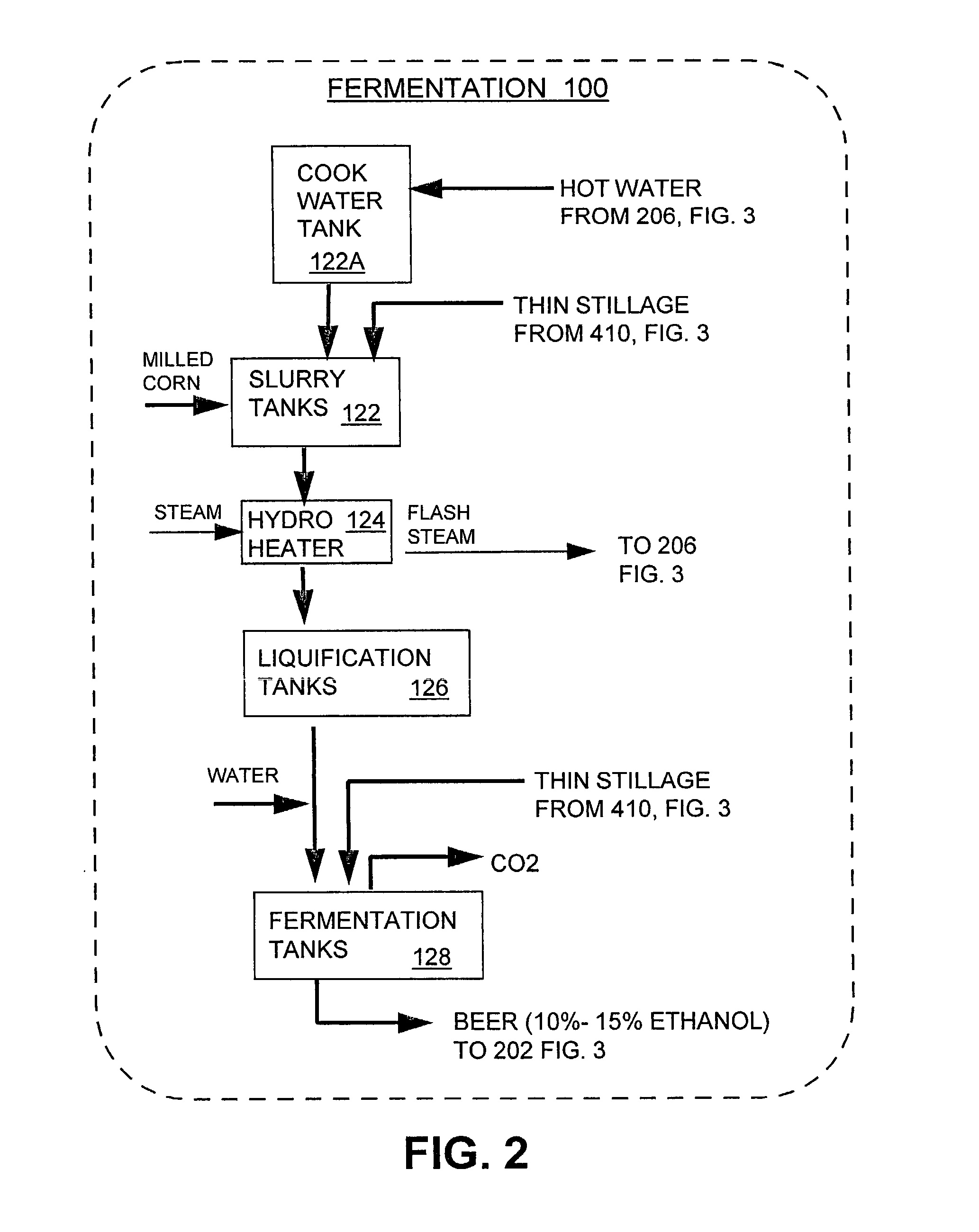

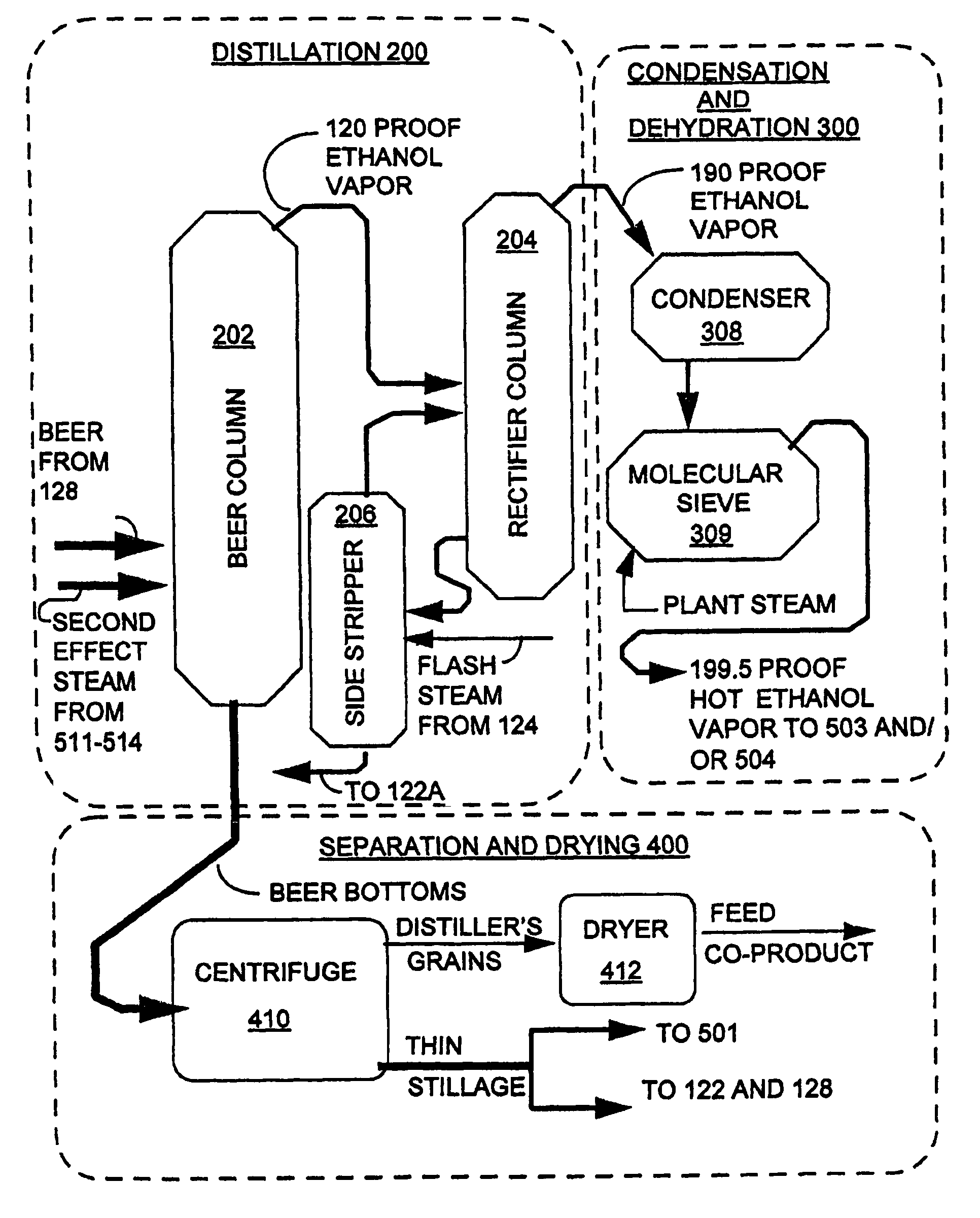

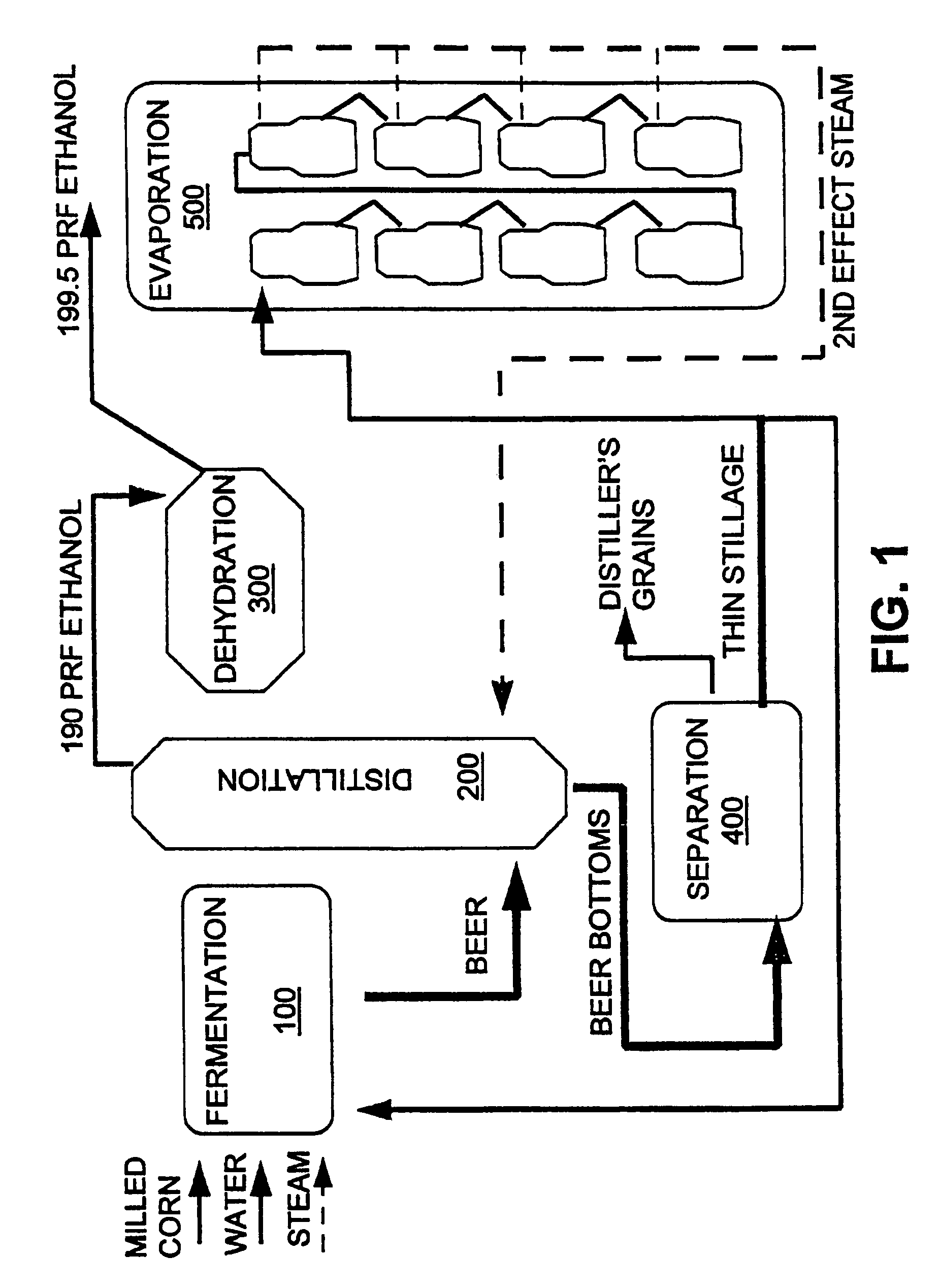

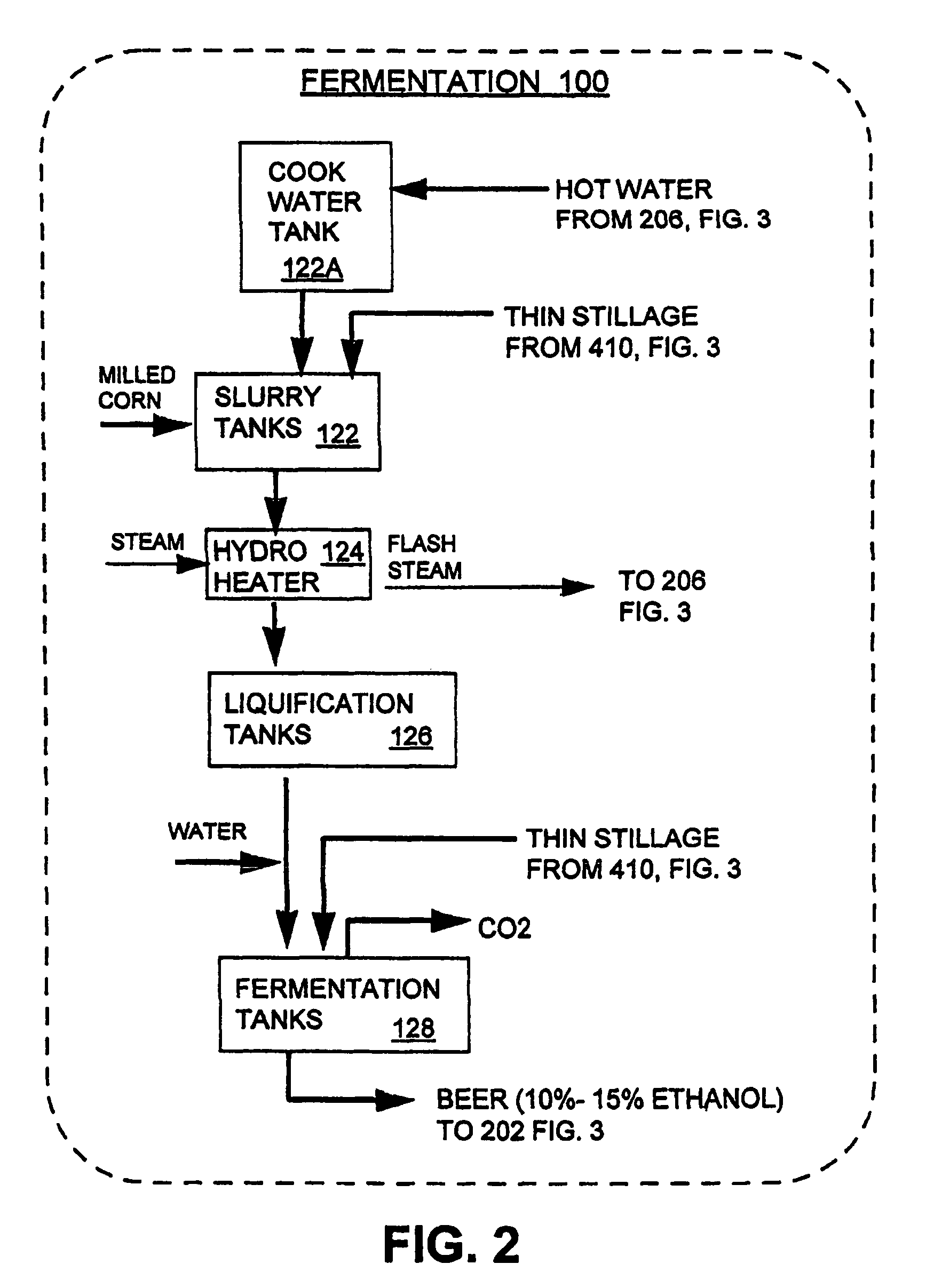

A process arrangement for distilling fuel grade ethanol includes a fermentation portion, a distillation portion, a condensation and dehydration portion, a separation and drying portion and an evaporation portion. The fermentation portion produces beer. The distillation portion, the condensation and dehydration portion and the separation and drying portion receives beer from the fermentation portion and produces hot ethanol vapor and thin stillage. In the evaporation portion, a set of first effect evaporators which are heated either by plant steam or hot ethanol vapor, concentrate thin stillage into mid stillage while producing first effect steam. The first effect steam from the first effect evaporators provides heat to a set of second effect evaporators which concentrate the mid stillage into a syrup for further drying. The second effect evaporators produce second effect steam which is used to heat the distillation portion of the process arrangement. The multiple evaporators of the first and second effects of the evaporation portion can be selectively taken off-line for maintenance while the evaporation portion and the remainder of the process arrangement continue to operate at full capacity.

Owner:ICM

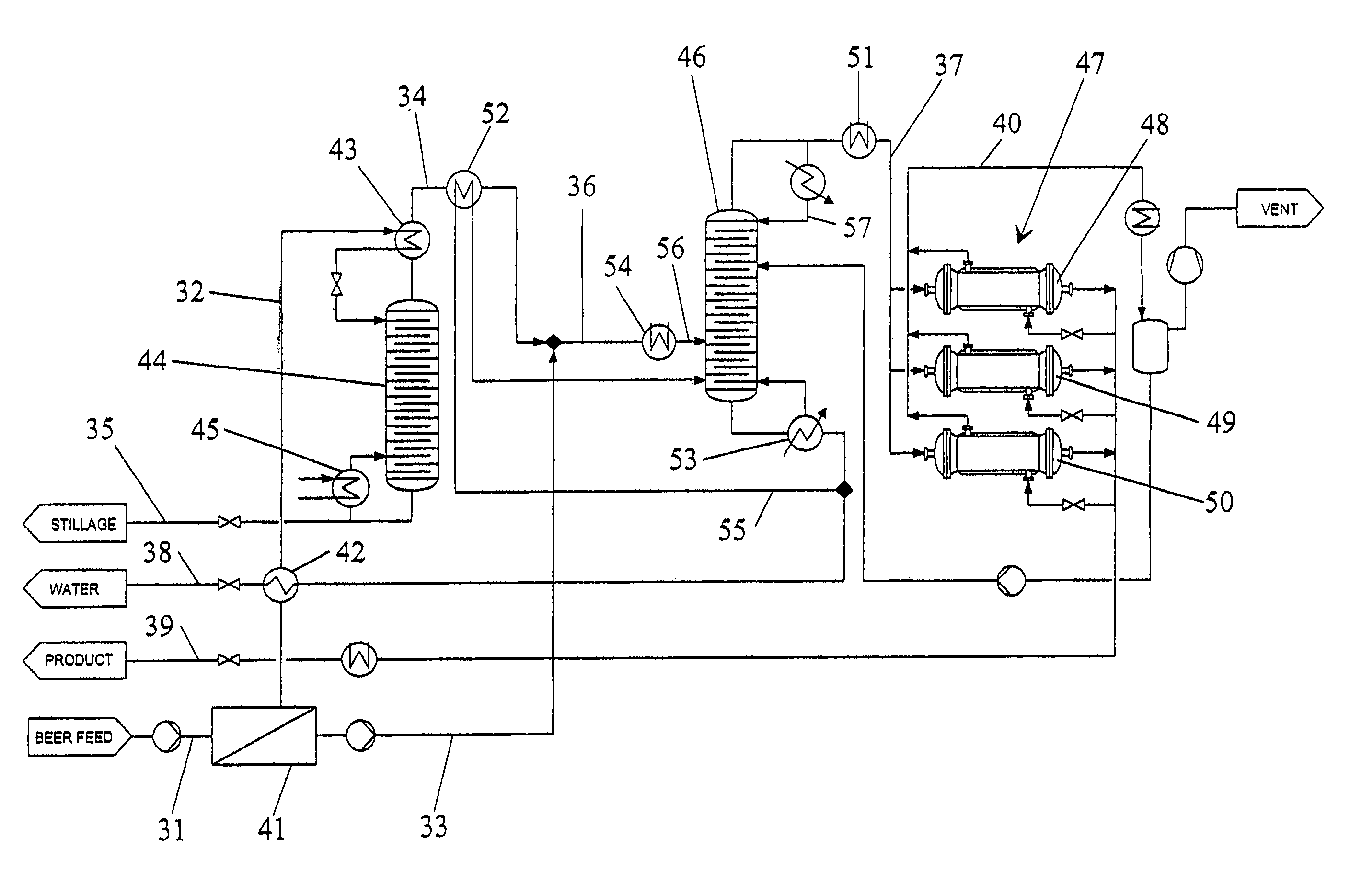

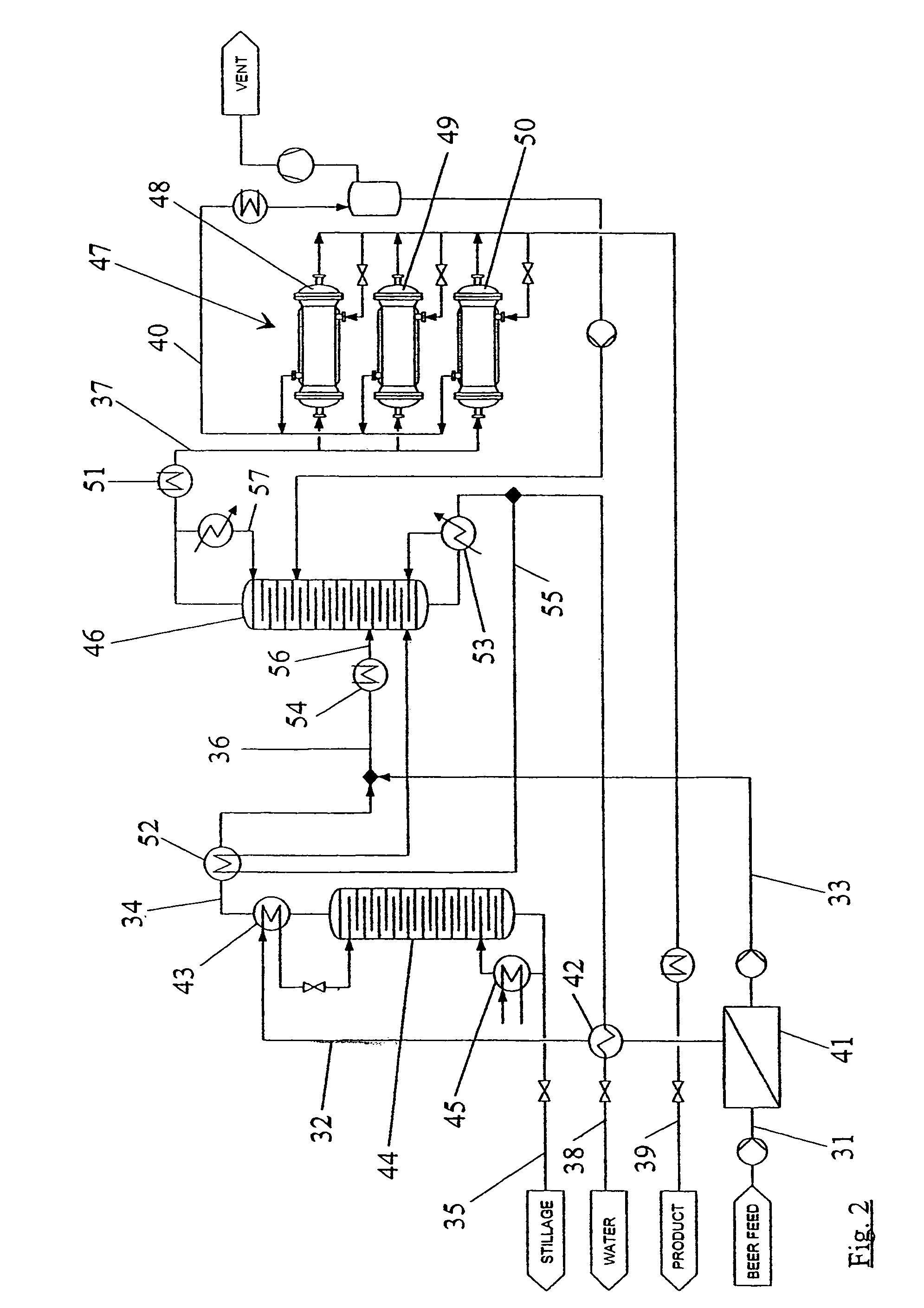

Ethanol distillation process

InactiveUS7572353B1Shorten the timeLess rapidlyFermented solutions distillation/rectificationOrganic compound preparationDistillationEvaporation

Owner:ICM

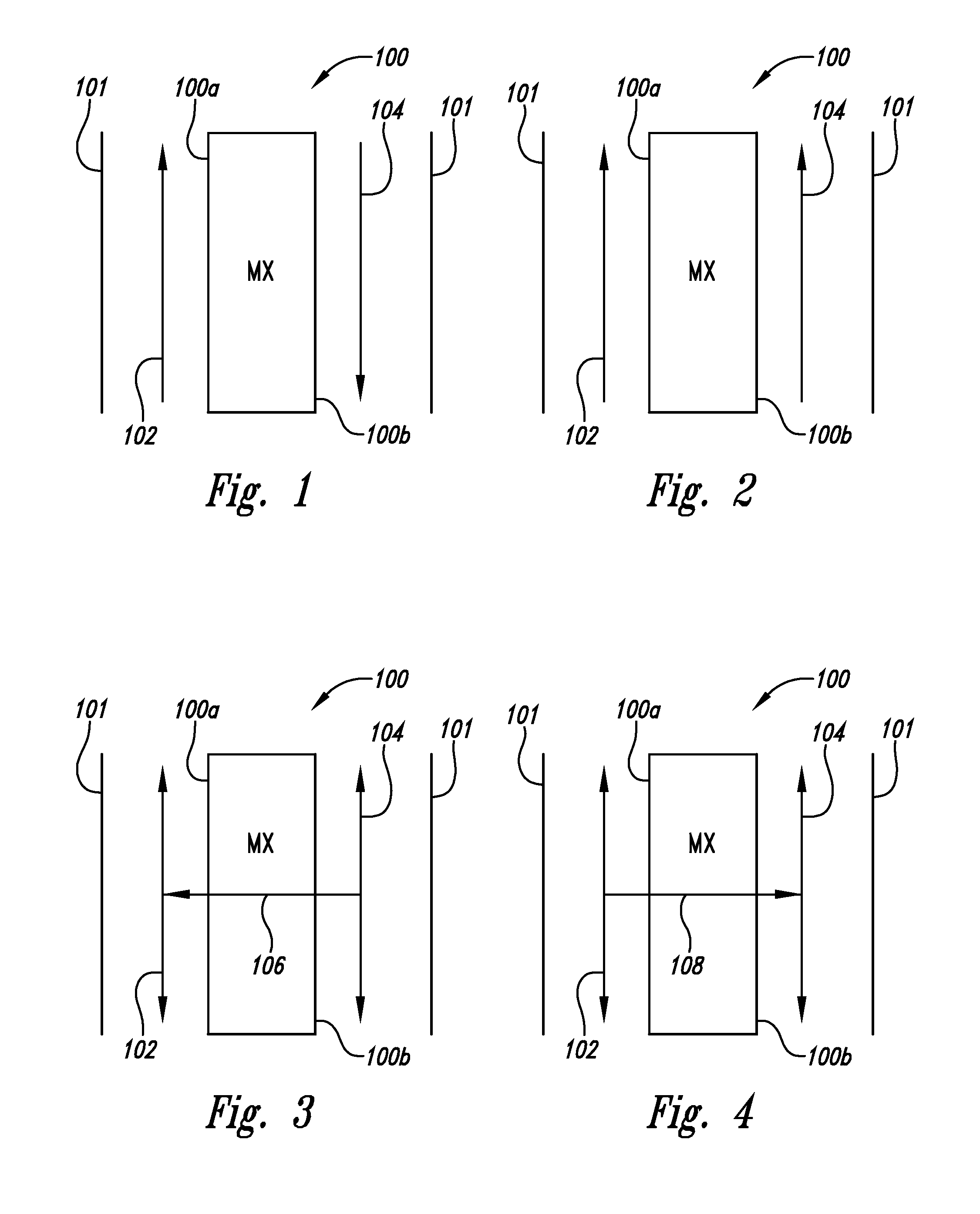

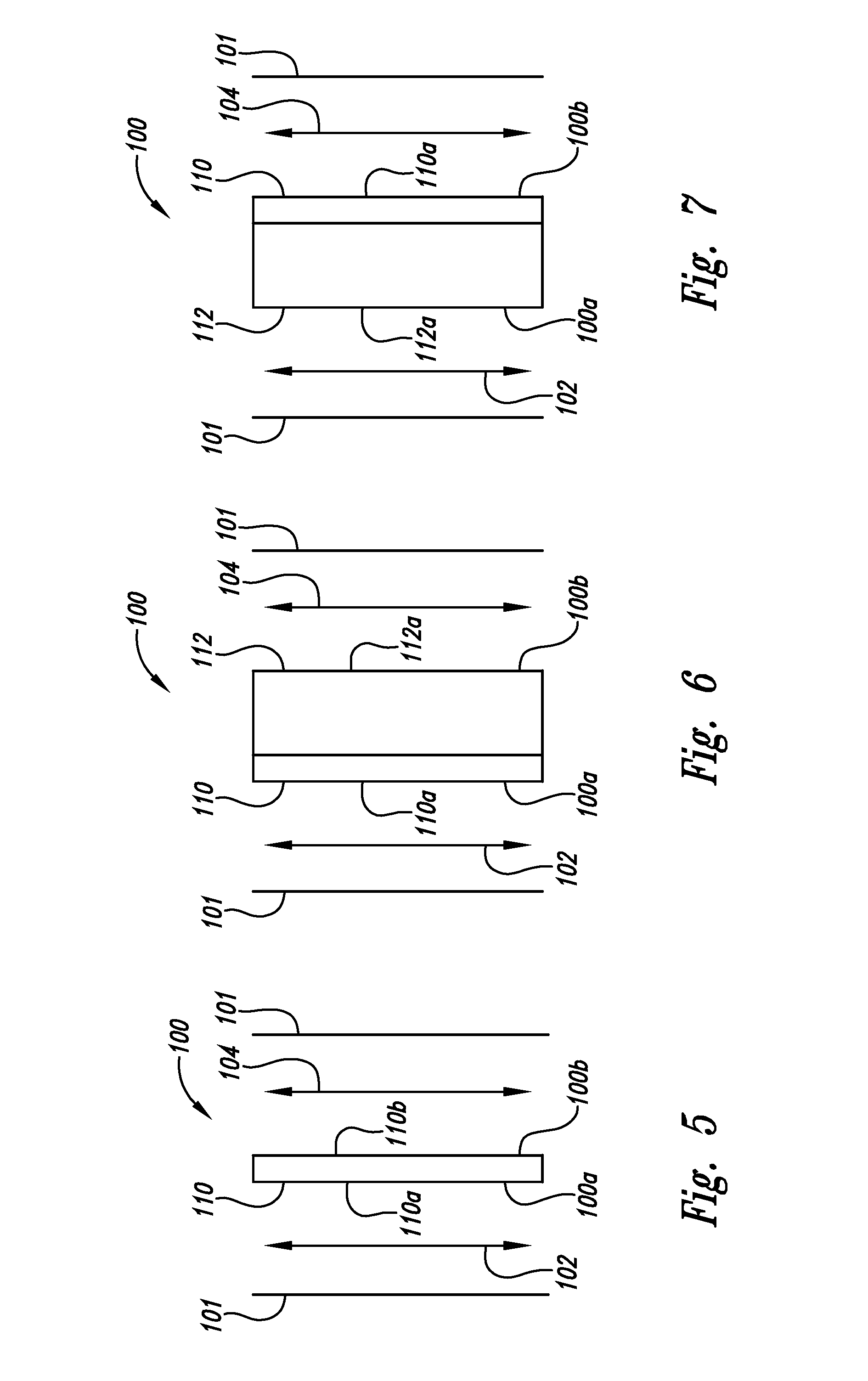

Multi-phase selective mass transfer through a membrane

Disclosed herein are embodiments relating to particular systems comprising a selective transfer membrane that can be utilized in material separation. In certain embodiments, the membrane assembly comprises part of a desalination, distillation, liquid purification, and / or heating and cooling system. Other particular embodiments allow for a high rate of thermal capture by way of the system utilizing a selective transfer membrane. Certain preferred embodiments include a selective transfer membrane comprising an ionomeric polymer that is permeable to high dipole materials.

Owner:TANGREDI PATRICIA

Distillation method

A method for distilling ethanol from a mash includes feeding a fluid to a first distillation column. The fluid and a distillate of the first distillation column are delivered to a second distillation column. The fed fluid and / or distillate of the second distillation column is / are purified in a first and / or last step of the method by a membrane separation process.

Owner:WHITE FOX TECH LTD

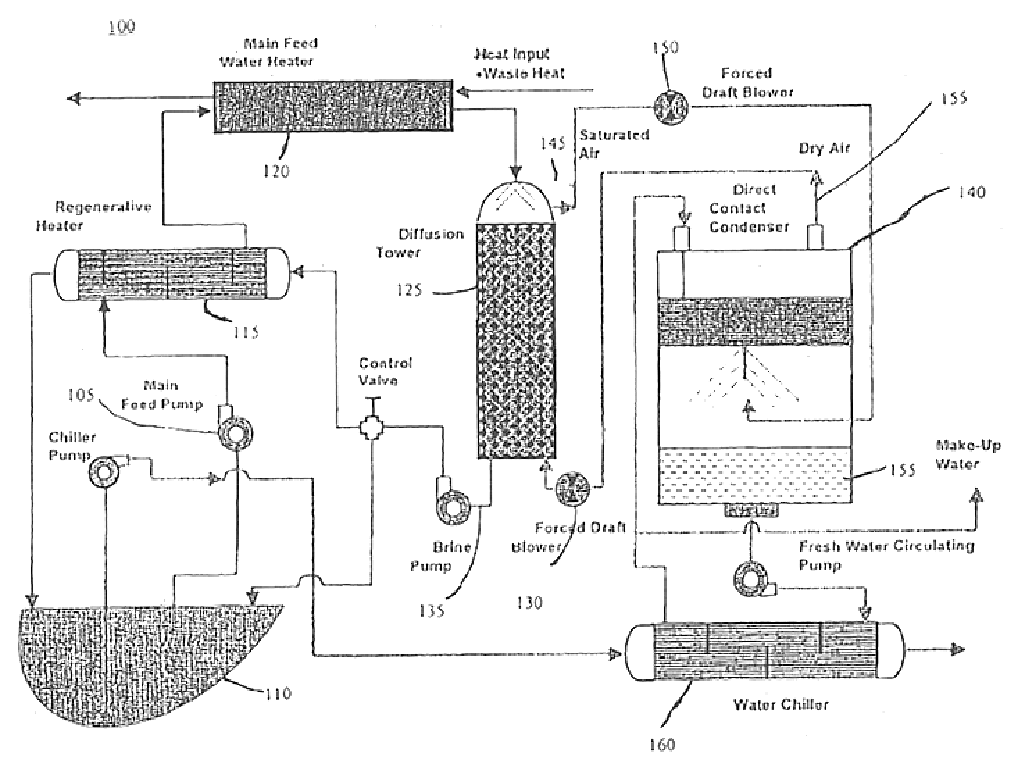

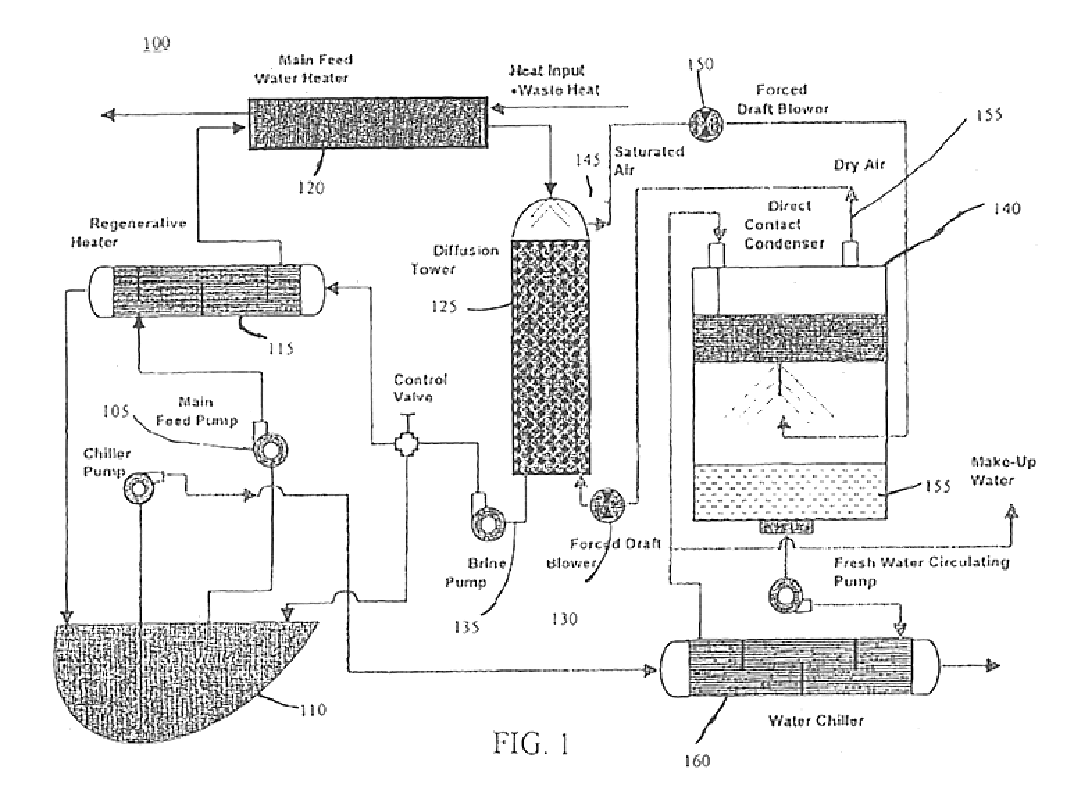

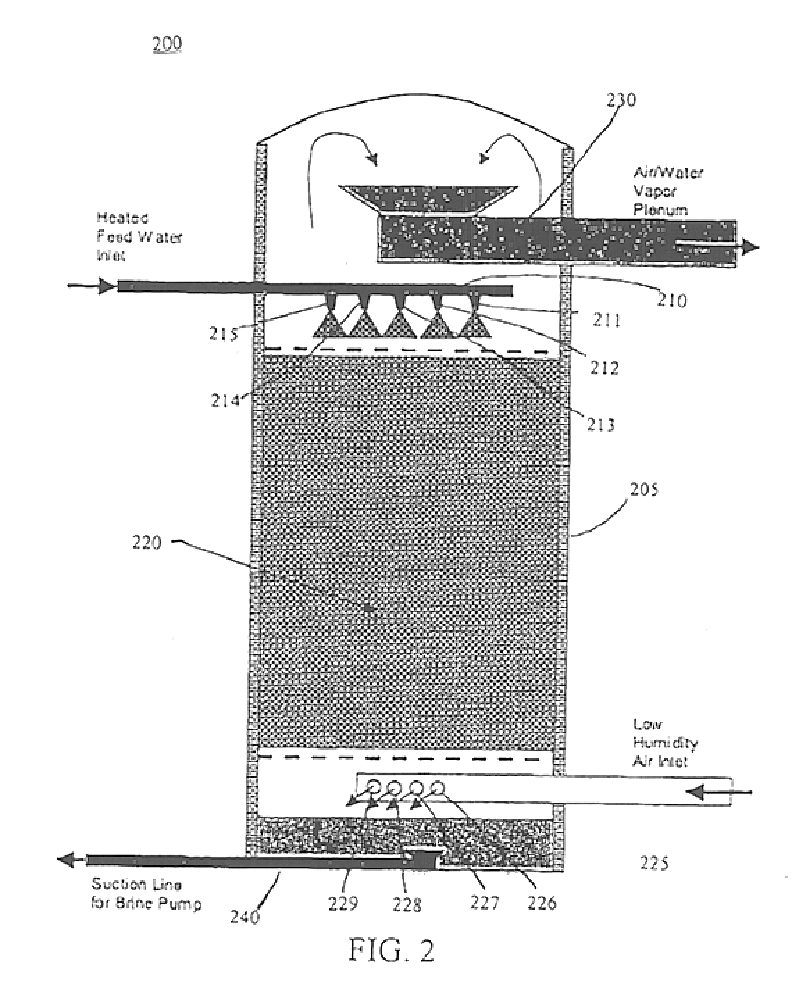

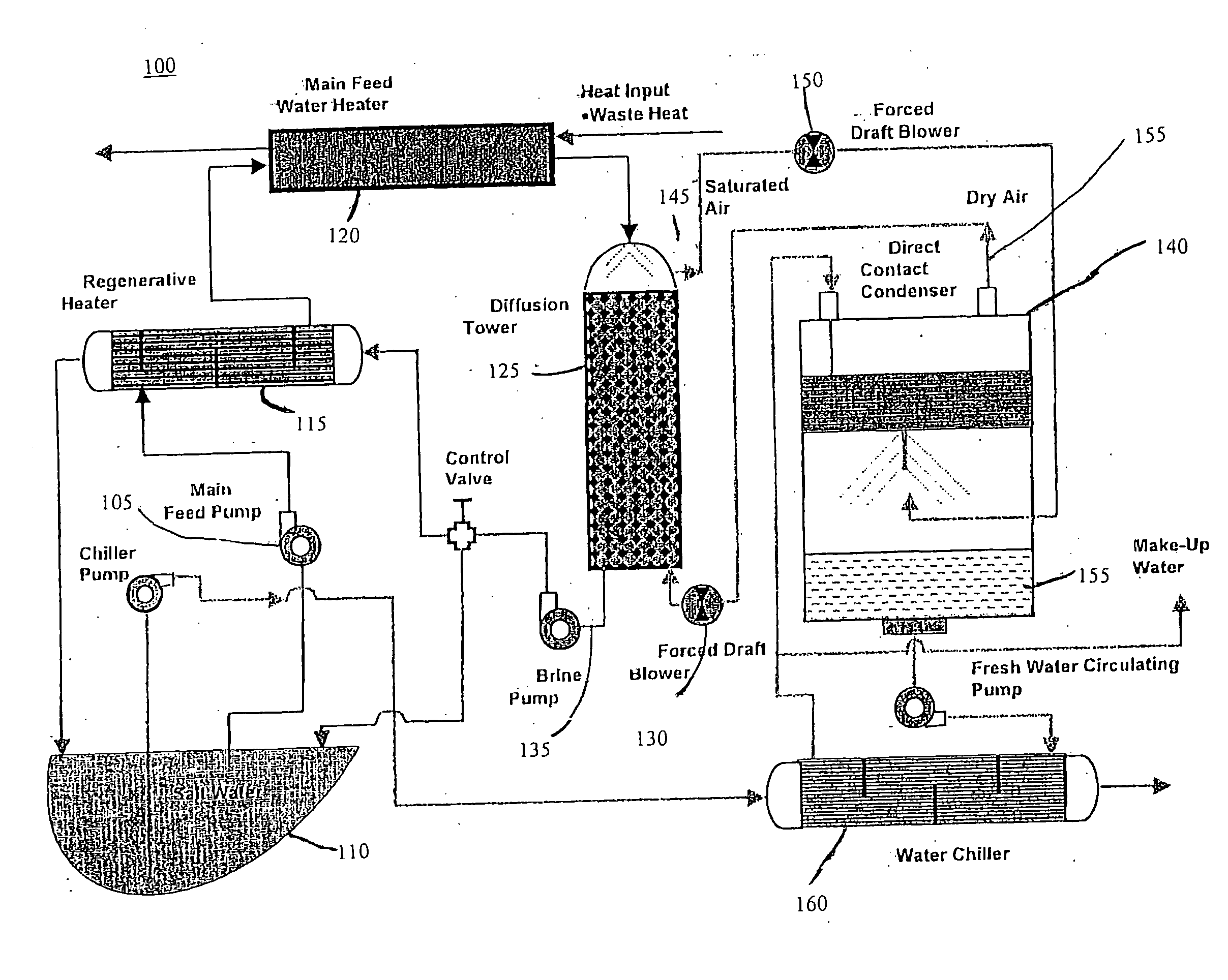

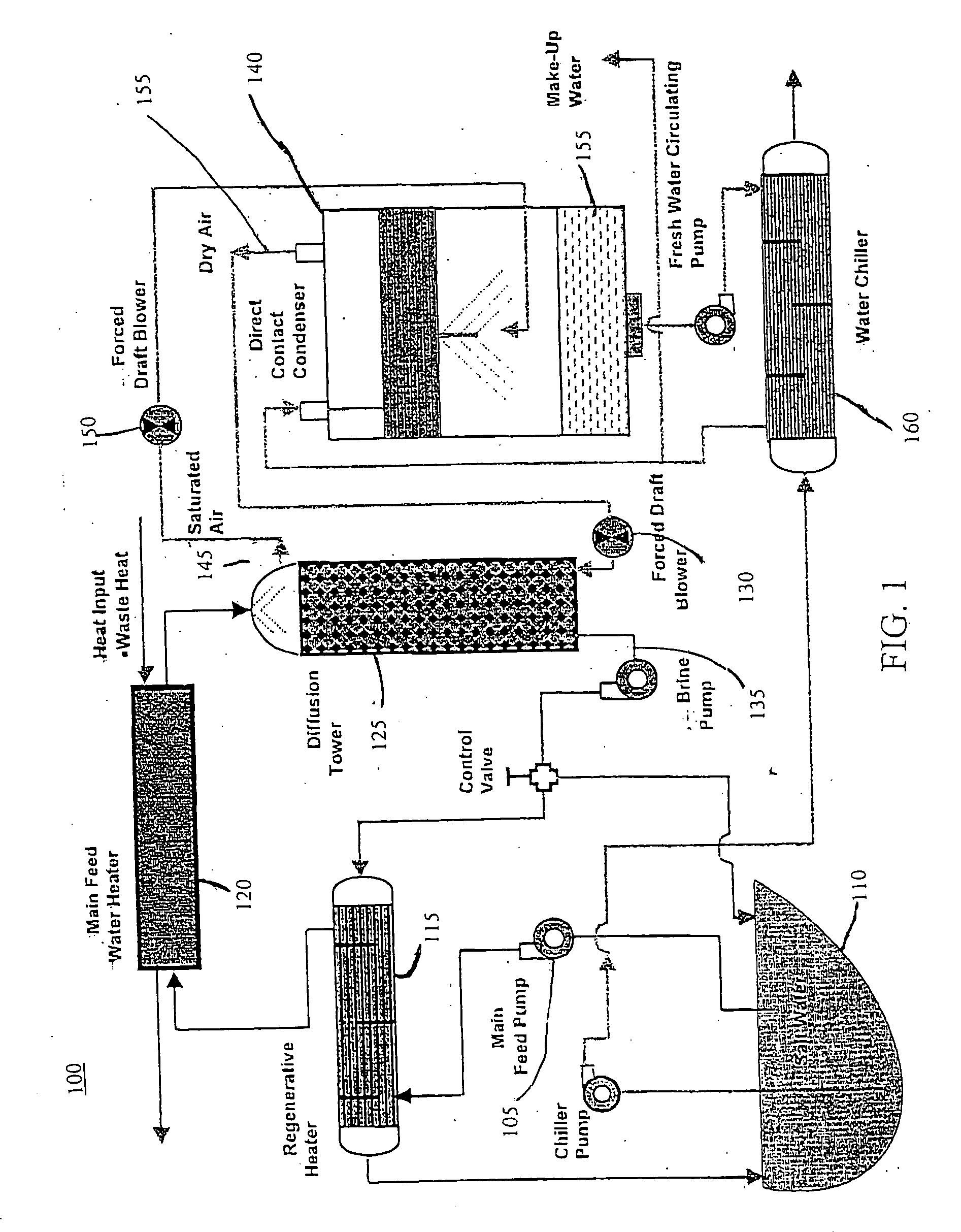

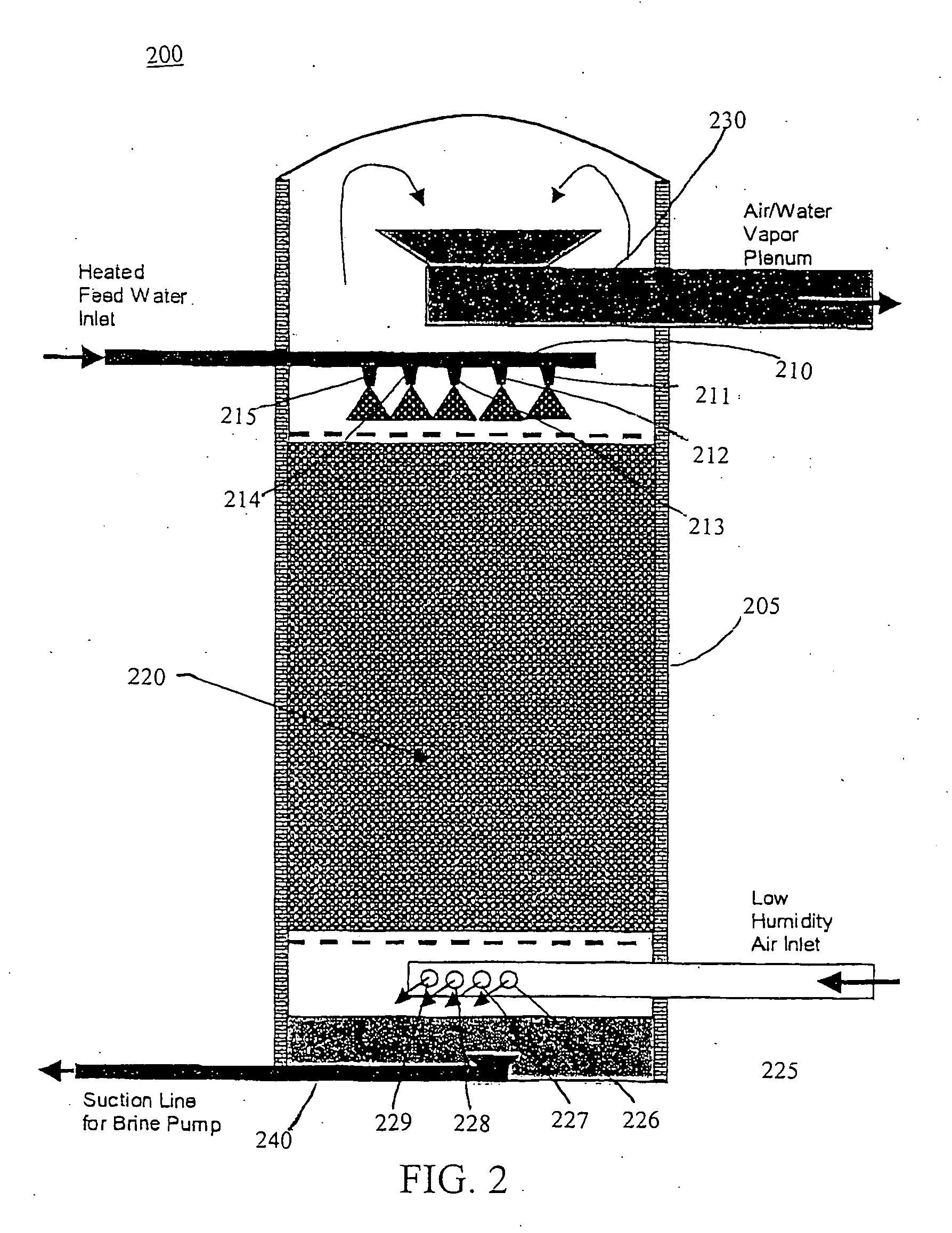

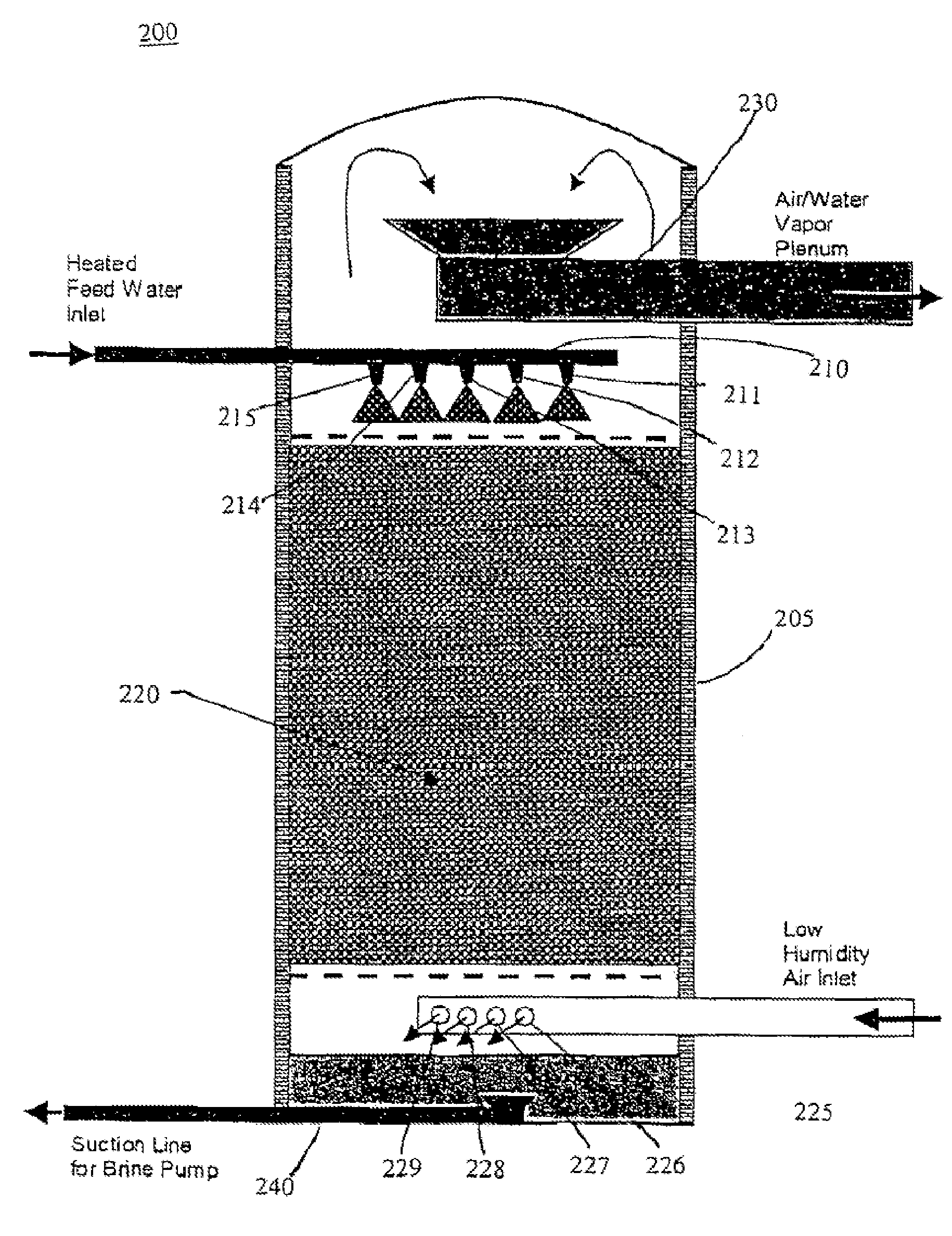

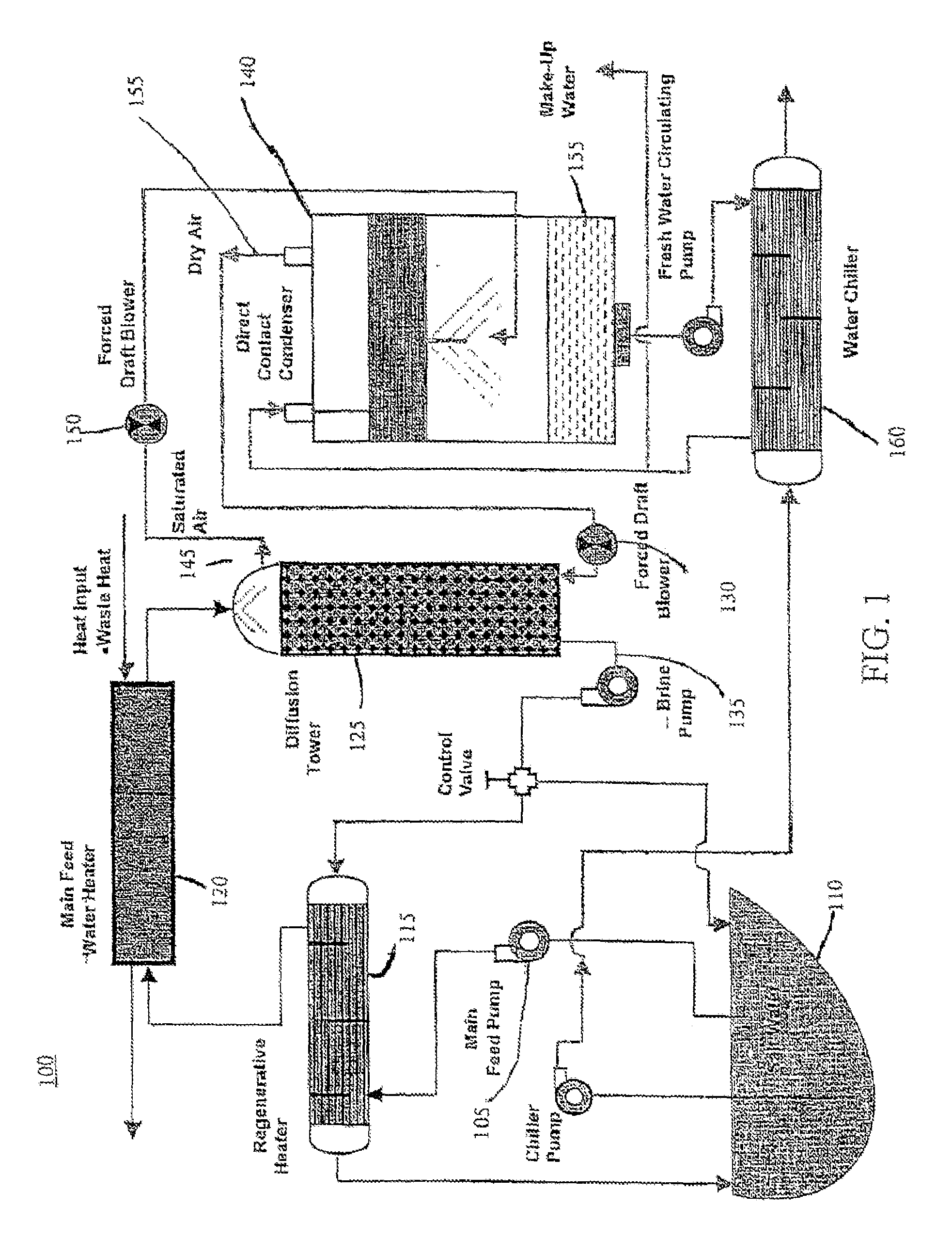

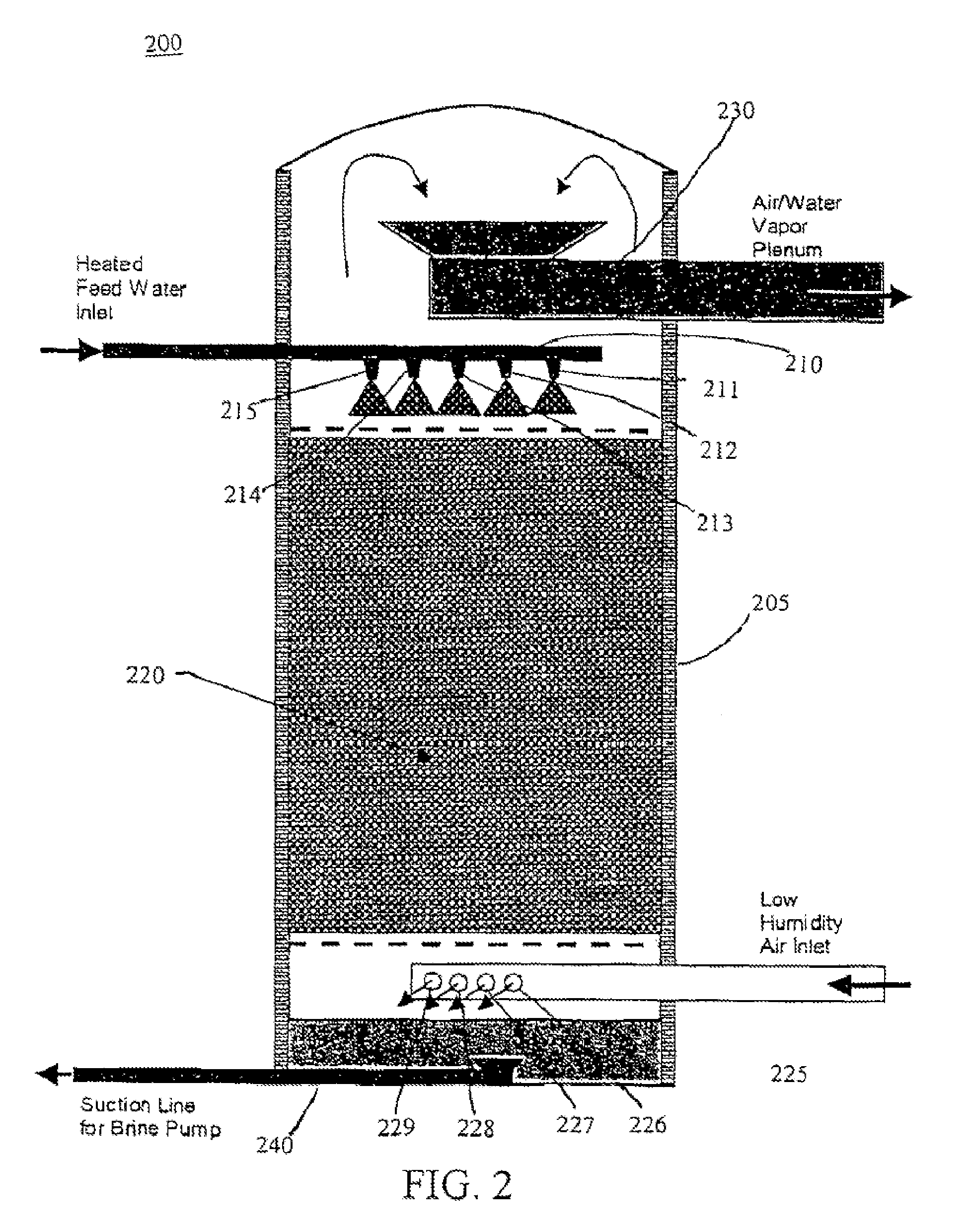

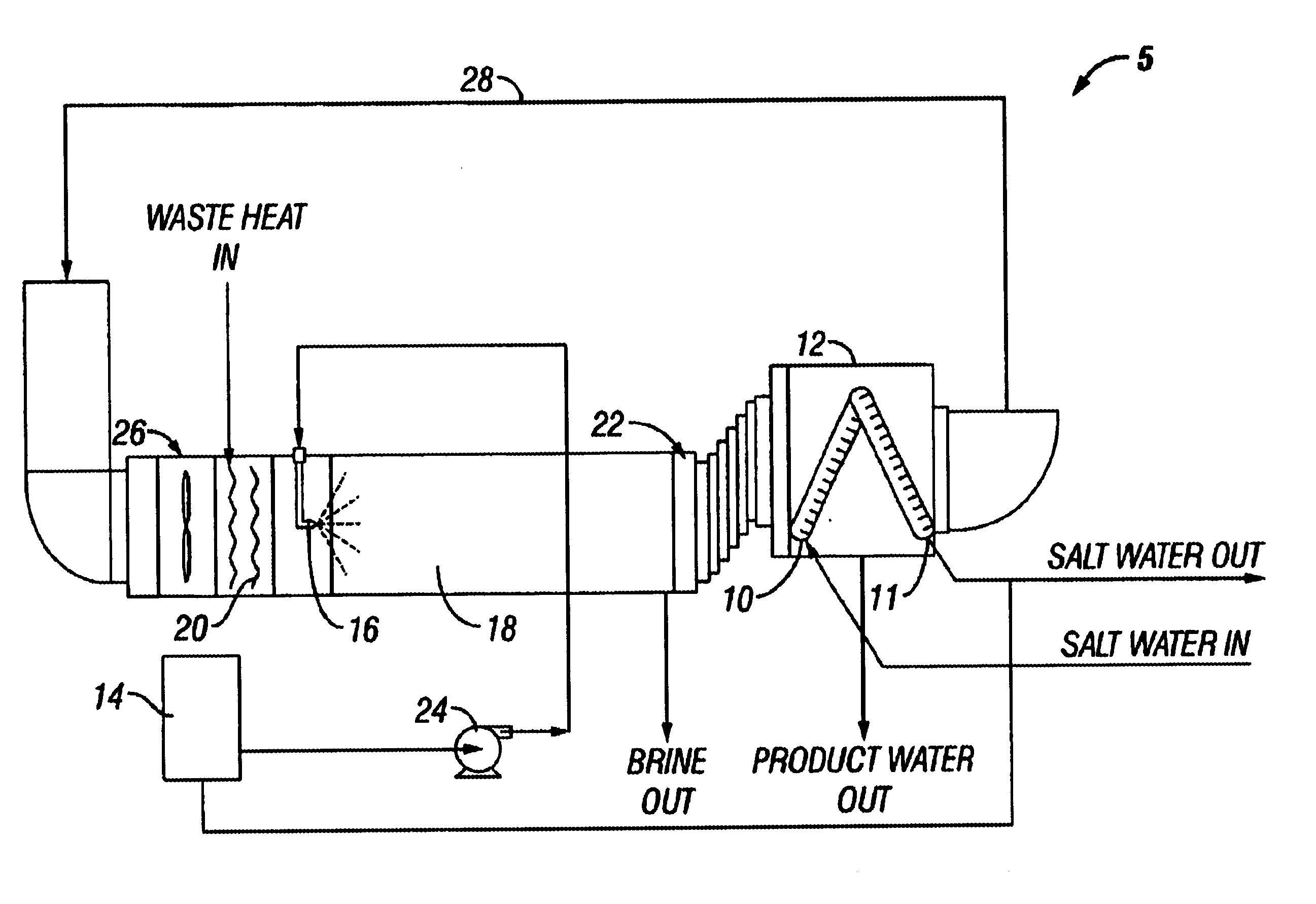

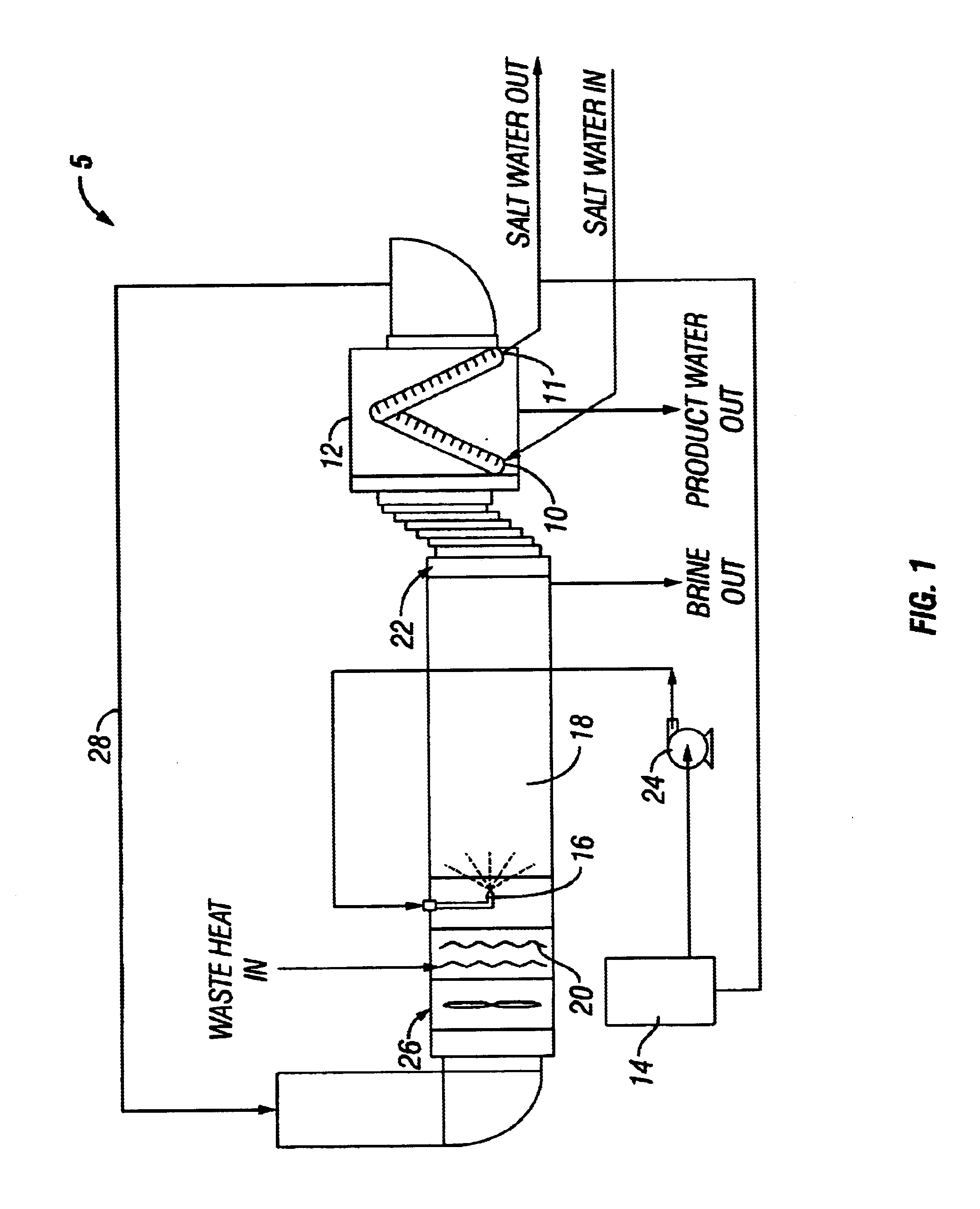

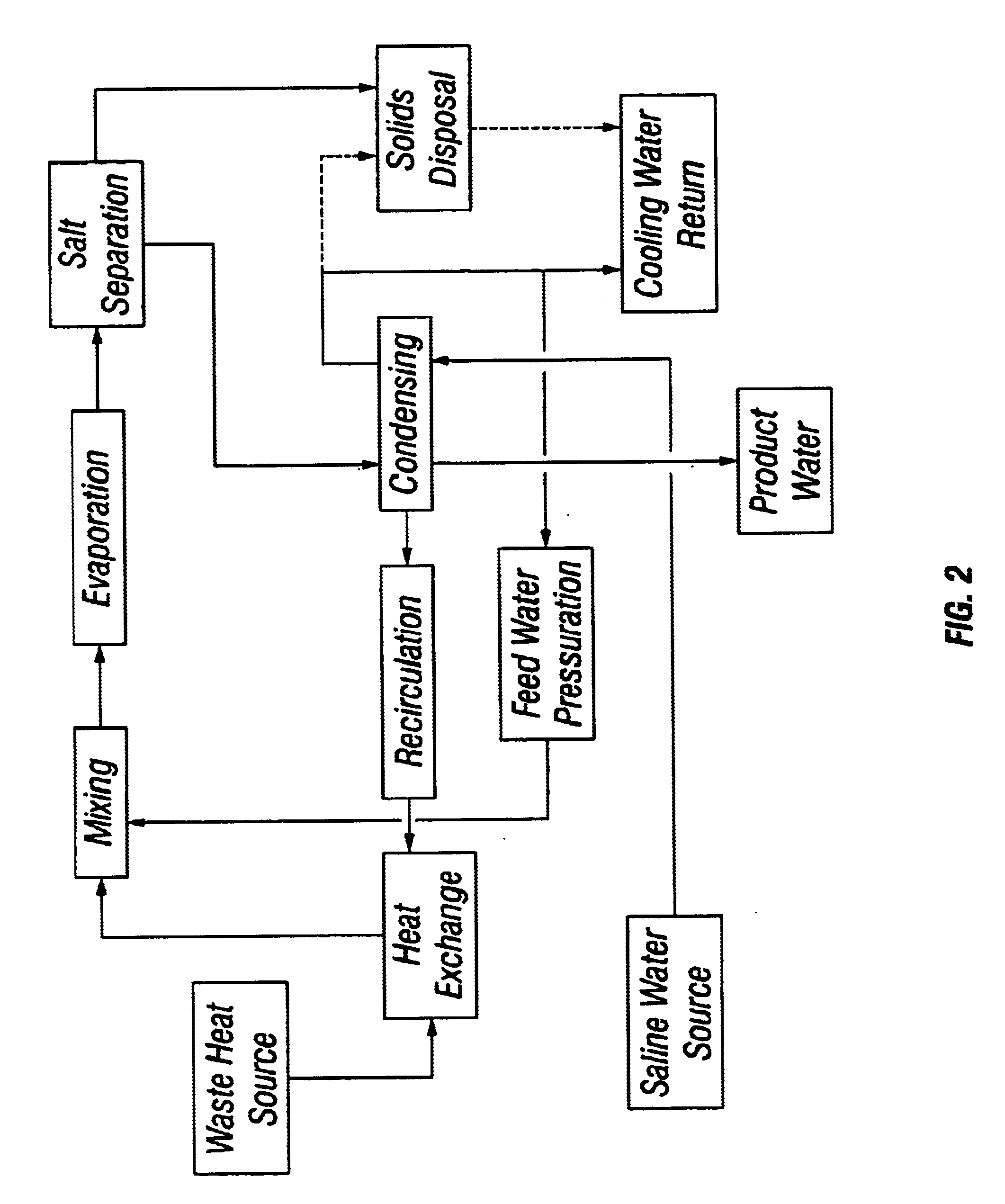

Diffusion driven desalination apparatus and process

A diffusion driven desalination apparatus and related method includes structure for receiving a heated water stream and creating at least one region having a thin film of water and structure for forcing a low humidity air stream over the thin film of water, wherein water from the thin film of water evaporates and diffuses into the air stream to create a humidified air stream. A diffusion tower including at least one plenum can be used to create and transfer the humidified air stream. At least one condenser, such as a direct contact condenser, condenses the humidified air stream, wherein purified water is produced. Waste heat from a power plant can be used to provide the heated water stream and power plants can use the waste heat generated to inexpensively provide purified water.

Owner:UNIV OF FLORIDA RES FOUNDATION INC +1

Diffusion driven water purification apparatus and process

An apparatus for purifying water, such as for desalinization, includes a source of a heated air stream, the heated air stream having a temperature above an ambient temperature. A diffusion tower having high surface area material therein receives a water stream including at least one impurity and creates at least one region having thin films of water therein from the water stream. The heated air stream is directed over the thin films of water to create a humidified air stream that is at least substantially saturated. At least one direct contact condenser is in fluid communication with the humidified air stream for condensing the humidified air stream, thus producing purified water. A power plant can include the apparatus for purifying water, where energy to heat the air stream is provided by low pressure condensing steam.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

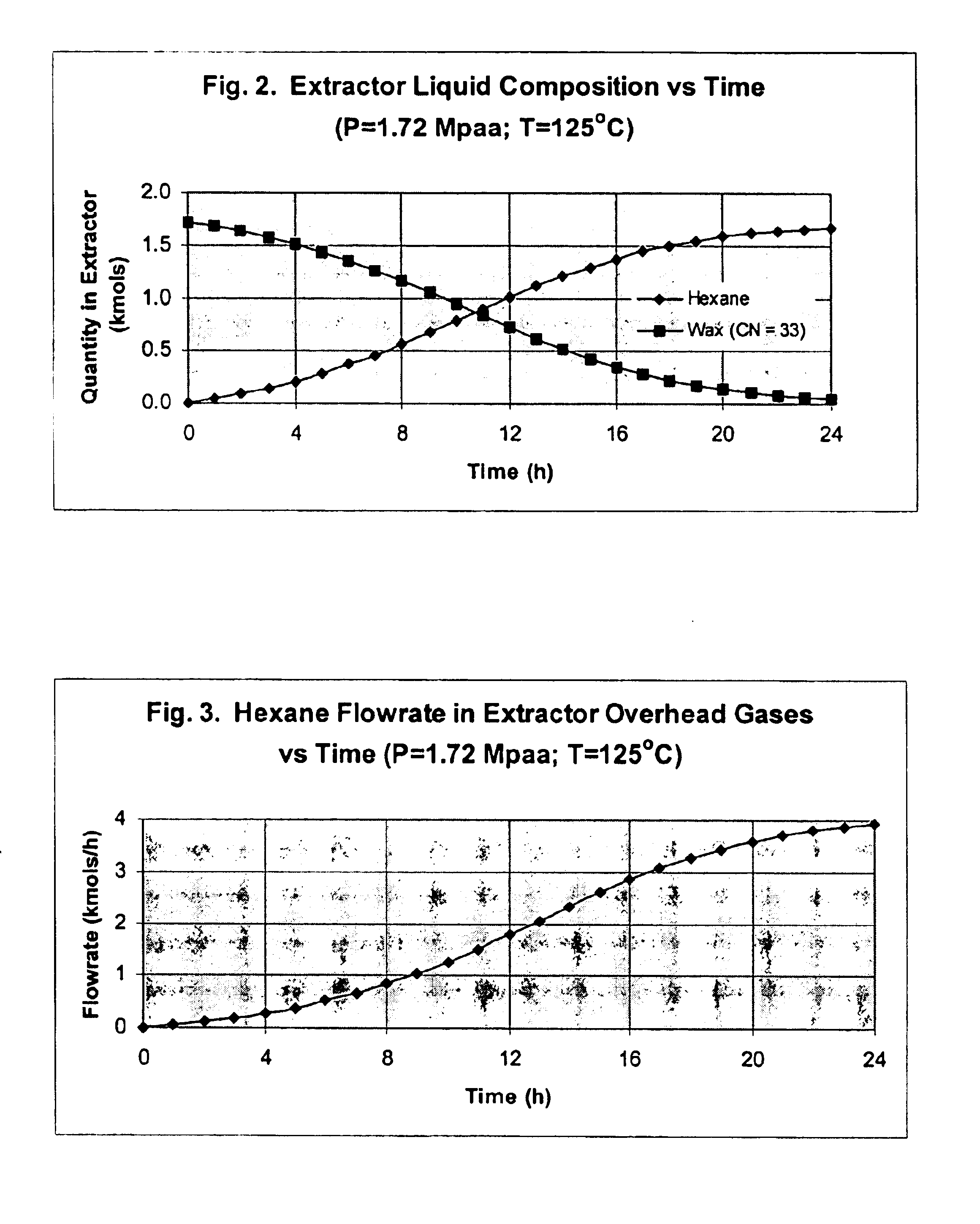

Method and apparatus for regenerating an iron-based Fischer-Tropsch catalyst

ActiveUS6838487B1Reduce concentrationMaintain standardOrganic compound preparationOther chemical processesWaxContinuous flow

Solvent extraction is used to remove wax and contaminants from an iron-based Fischer-Tropsch catalyst in a natural circulation continuous-flow system. The wax-free catalyst is then subjected to controlled oxidation to convert the iron to its initial oxidized state, Fe2O3. Reactivation of the oxide catalyst precursor is carried out by addition of synthesis gas.

Owner:RES USA LLC

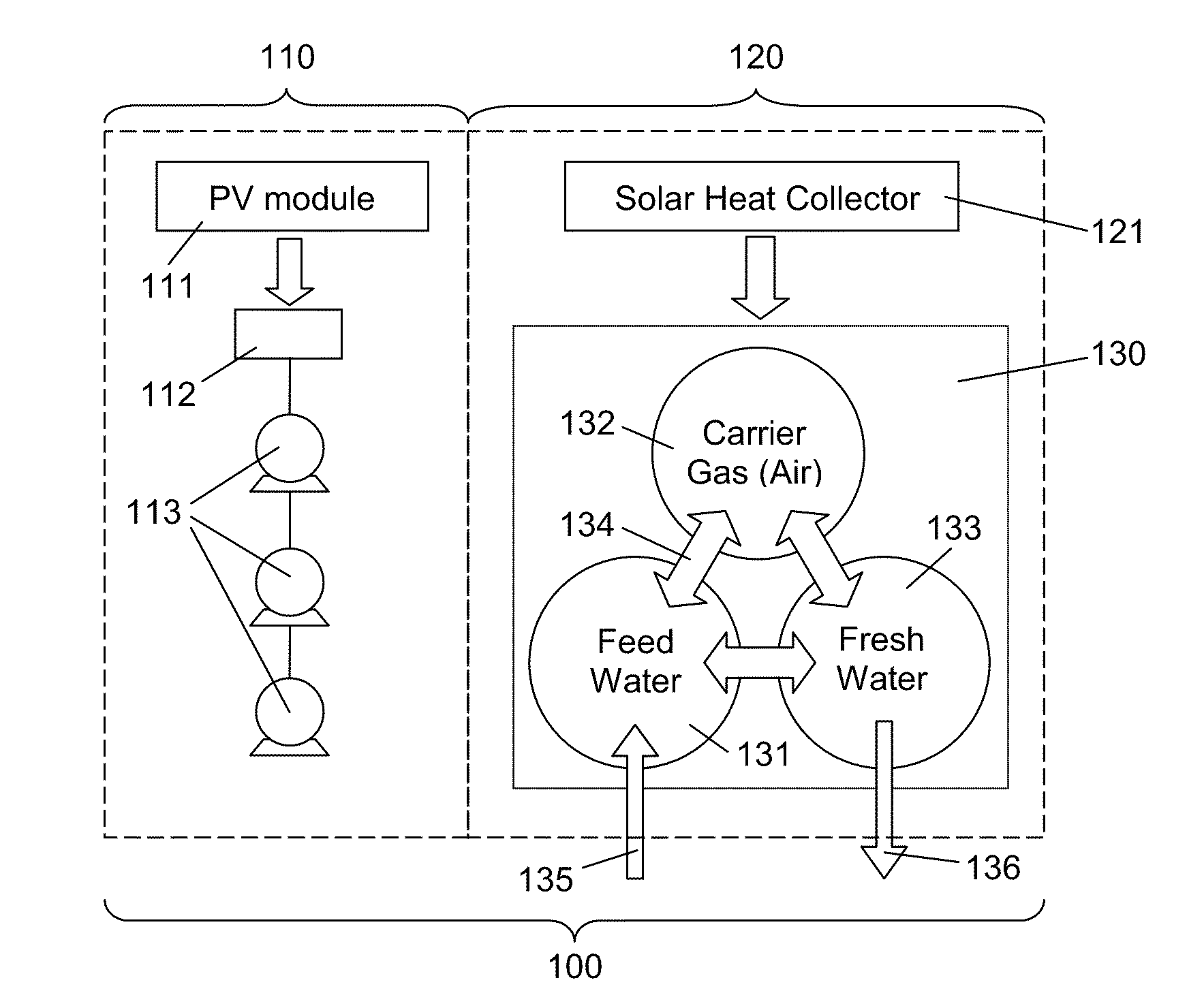

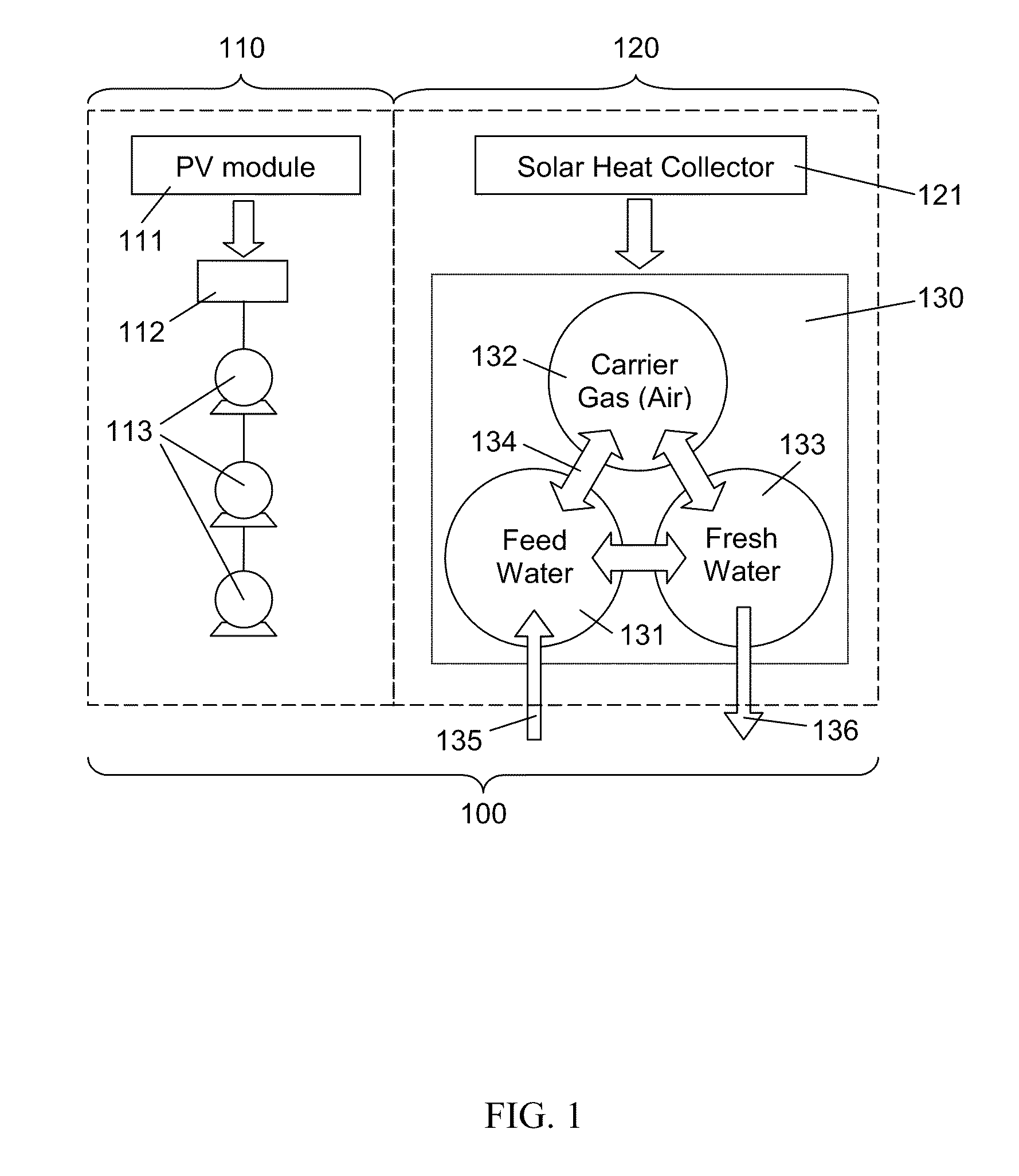

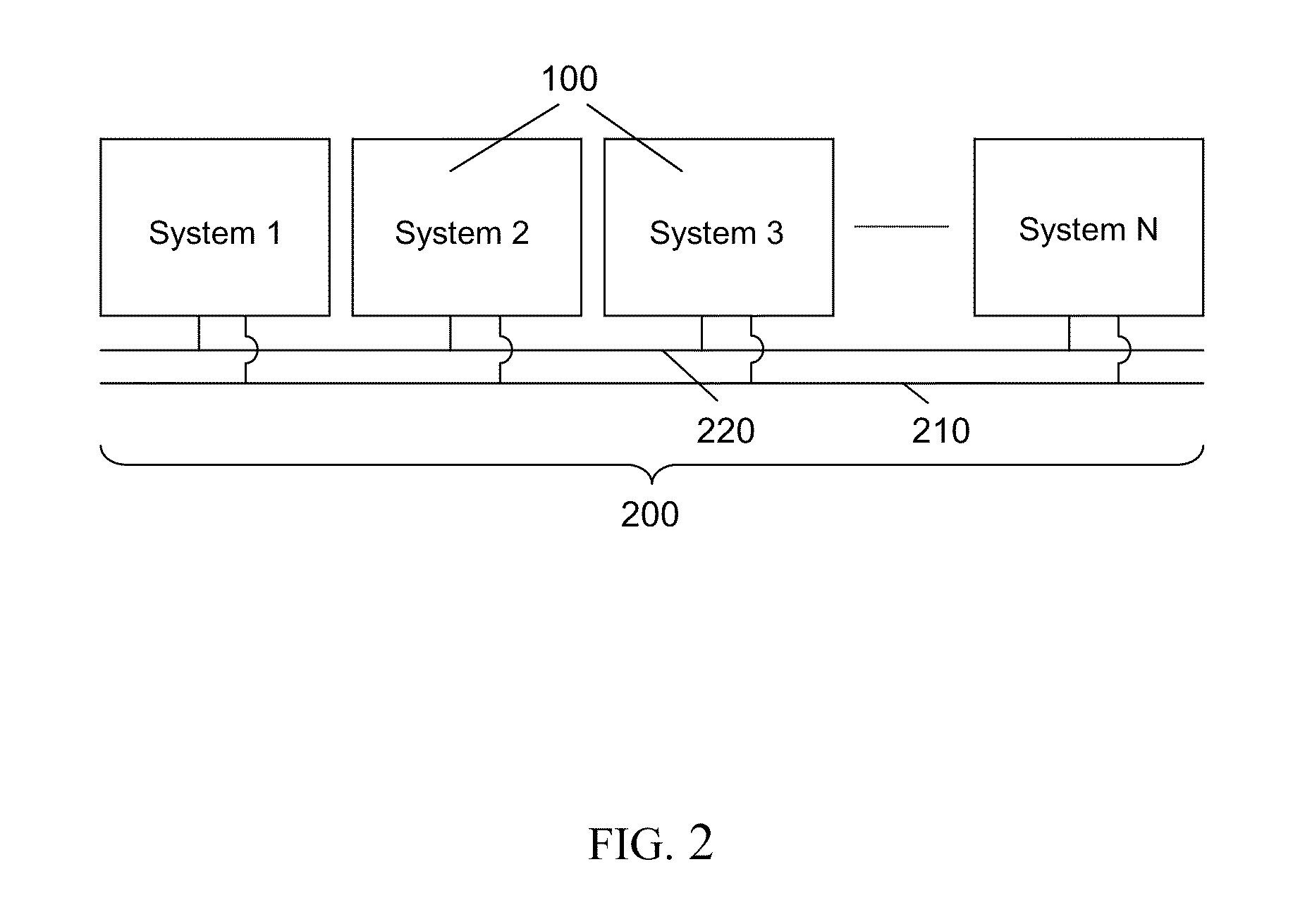

Hybrid solar desalination system

A hydro-thermal exchange unit (HTEU) for desalinating feed water in accordance with a humidification-dehumidification includes feed water, fresh water and gas conduit circuits for transporting feed water, fresh water, and gas, respectively. The unit also includes an evaporator through which a portion of the feed water conduit and the gas conduit pass. The evaporator causes evaporation of a portion of the feed water to produce vapor that is transported through the gas conduit. The unit also includes a condenser through which a portion of the gas conduit and the fresh water conduit pass. The condenser has input and output ports for coupling the gas and fresh water conduit circuits. The condenser extracts moisture from the vapor transported therethrough by the gas conduit. The extracted moisture is discharged through the fresh water conduit. The unit also includes a heat exchanger through which a portion of the fresh water conduit and the feed water conduit pass to thereby extract residual heat from the fresh water such that the residual heat heats the feed water.

Owner:SUNLIGHT PHOTONICS

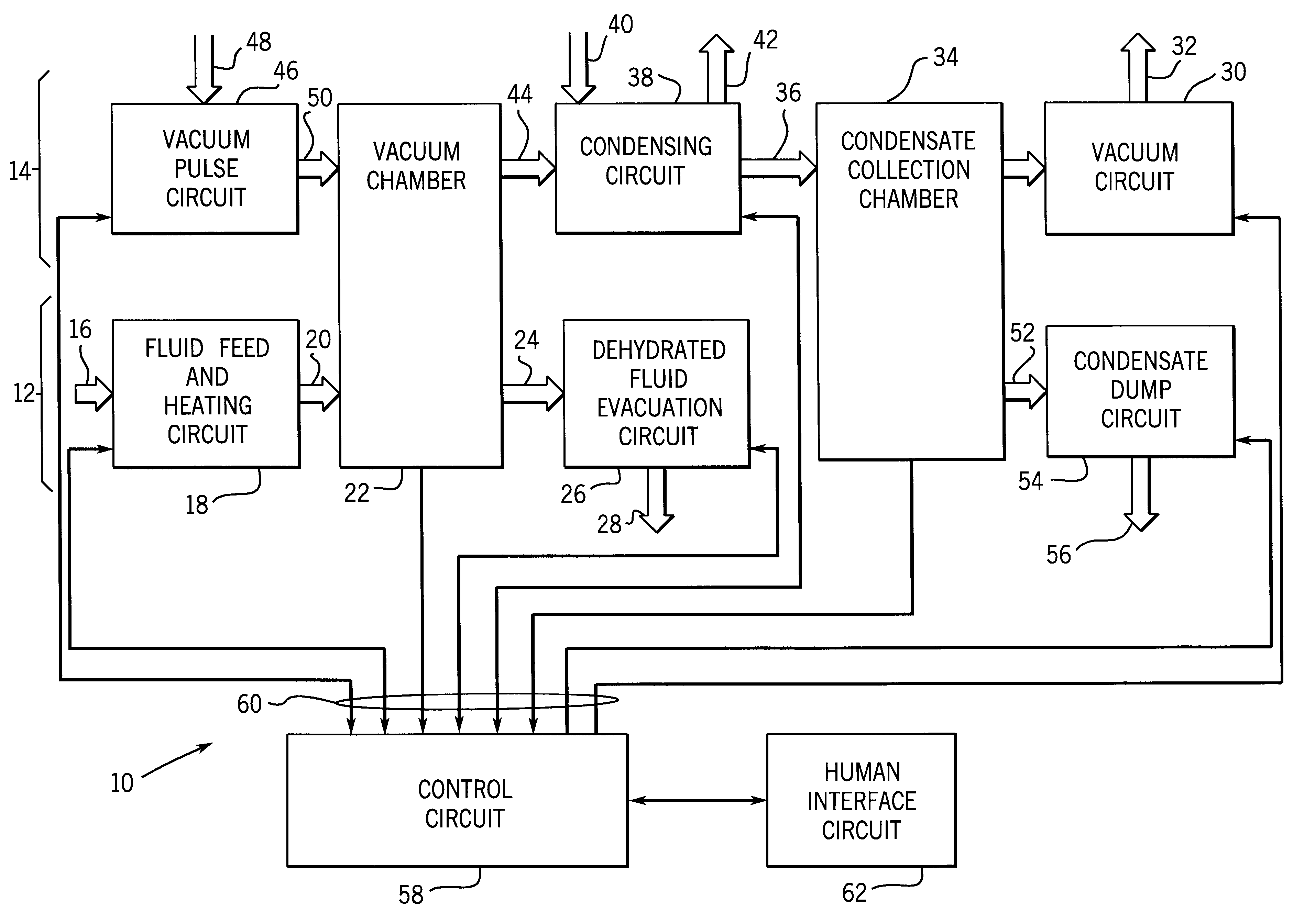

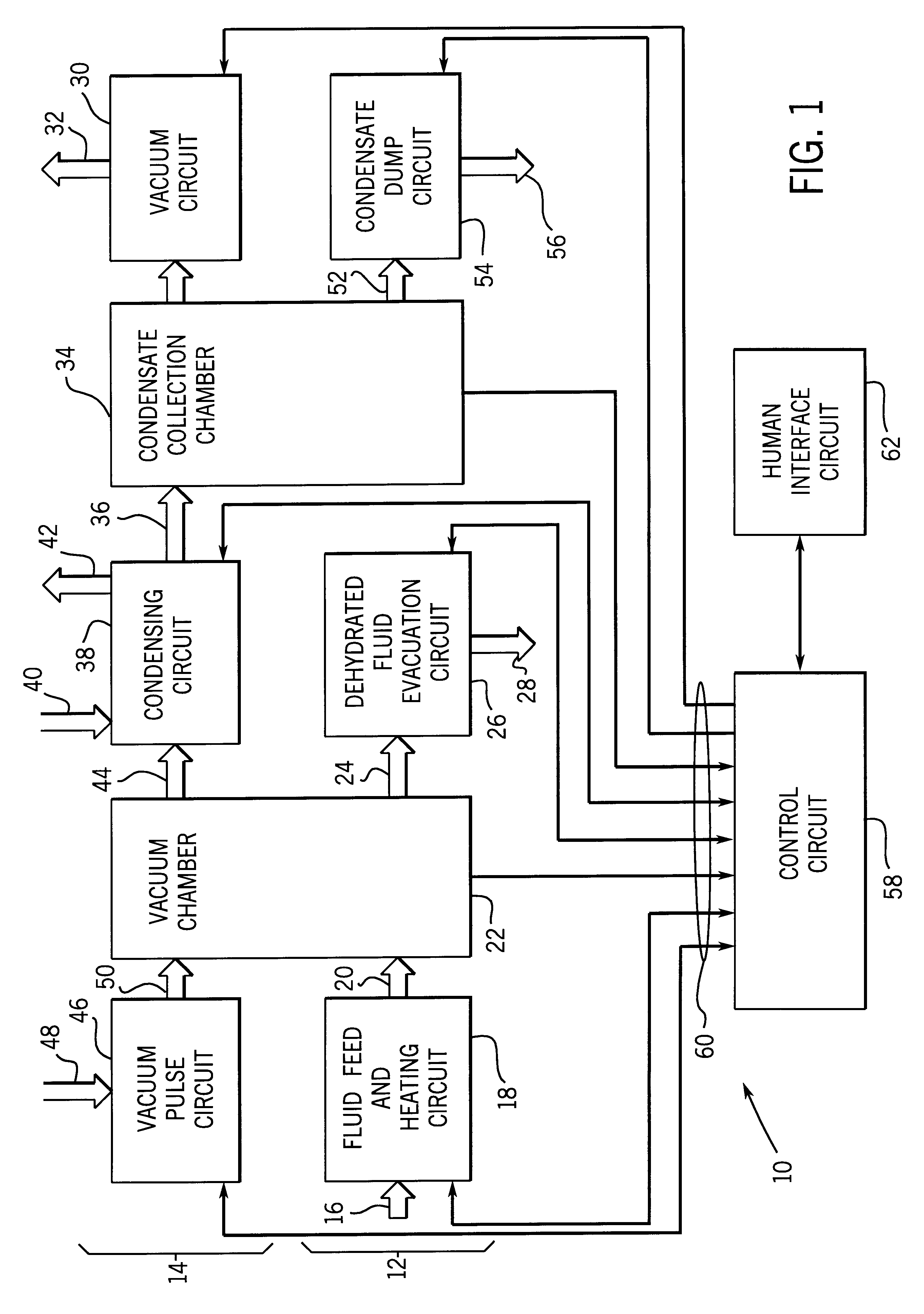

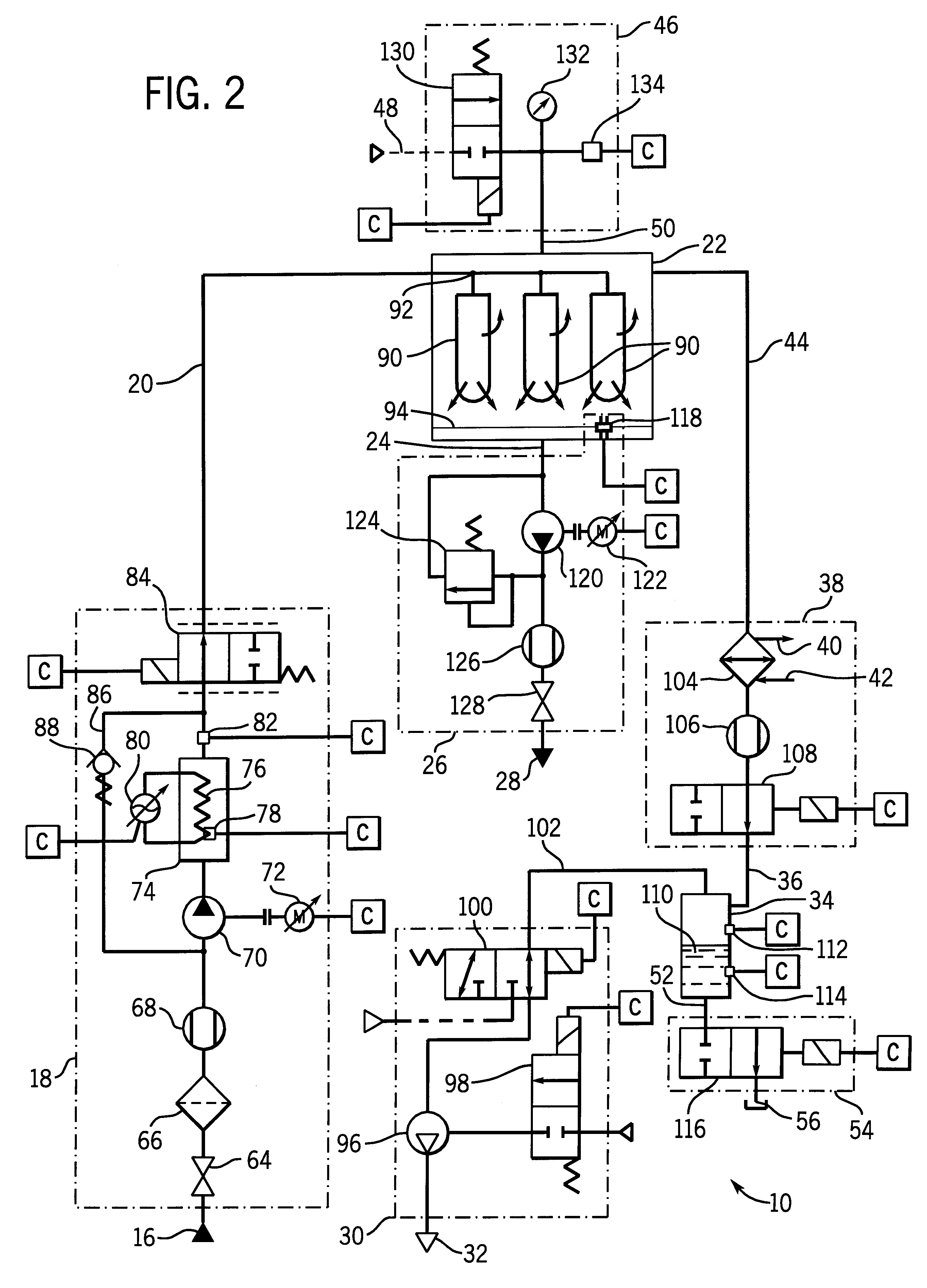

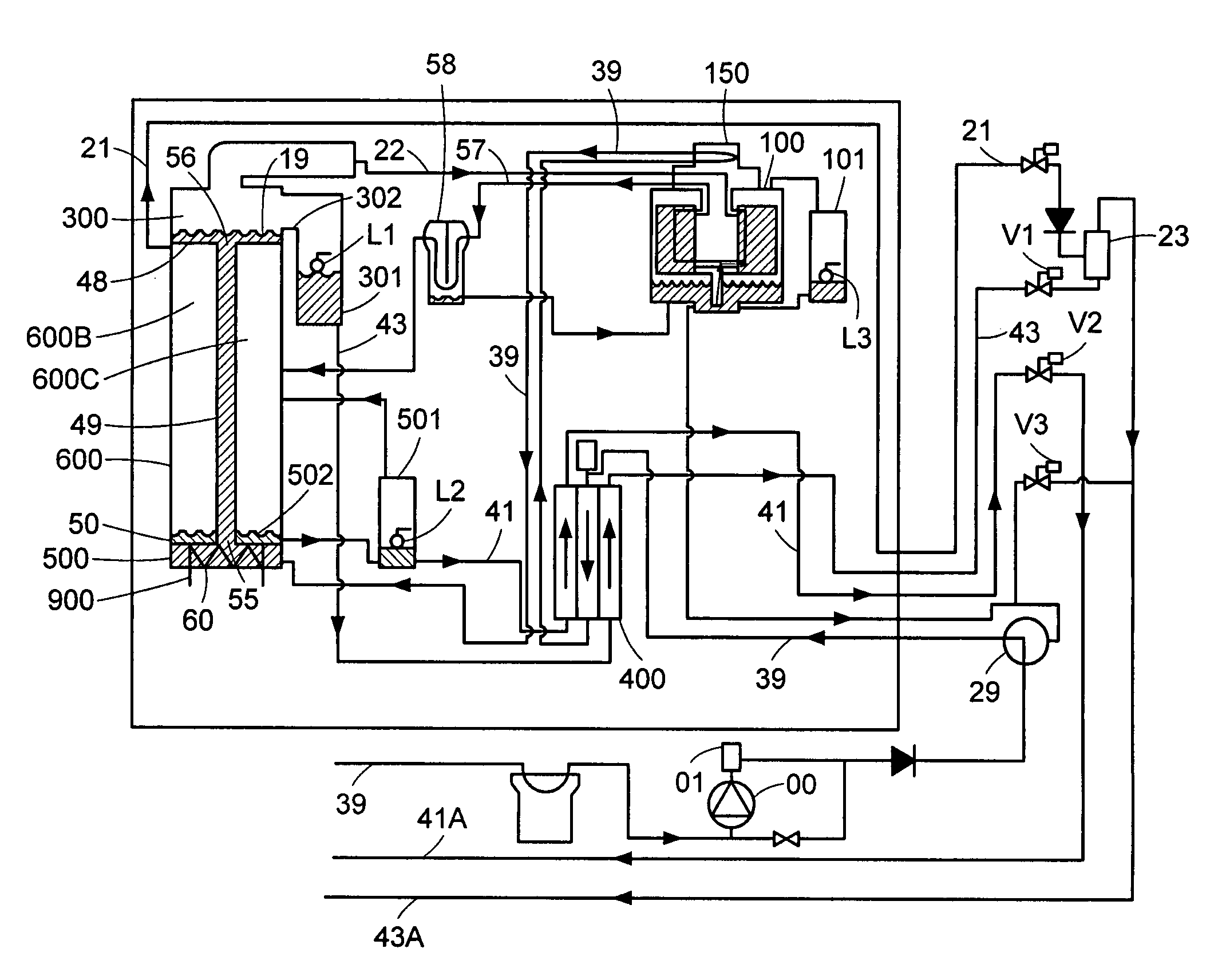

Apparatus for dehydrating oil

InactiveUS6224716B1Distillation regulation/controlEvaporation with vapour compressionVacuum pressureClosed loop

A system for dehydrating lubricating and hydraulic fluids includes a heating circuit and circuitry for creating a vacuum. The heating circuitry introduces a stream of heated fluid into a vacuum chamber in which a partial vacuum is drawn by the vacuum circuit. Aqueous components of the fluid stream are flashed in the vacuum chamber by virtue of the elevated temperature and reduced pressure. Dehydrated fluid is then collected and evacuated from the vacuum chamber. Vapor from the vacuum chamber, including the aqueous components of the fluid stream are collected, condensed and separately evacuated. The heating circuit limits surface temperature of a heating element in a closed-loop manner to avoid degradation of the fluid. The fluid stream is introduced into the vacuum chamber or is recirculated through the heating circuit to maintain a desired level of fluid temperature in a closed-loop manner. The system includes circuits for evacuating dehydrated fluid in a closed-loop manner and for automatically discharging condensate. The technique avoids undesirable foaming of dehydrated fluid within the vacuum chamber. A vacuum pulsing circuit is provided for periodically pulsing vacuum pressure within the vacuum chamber to aid in flashing aqueous components from the heated fluid stream.

Owner:OILQUIP

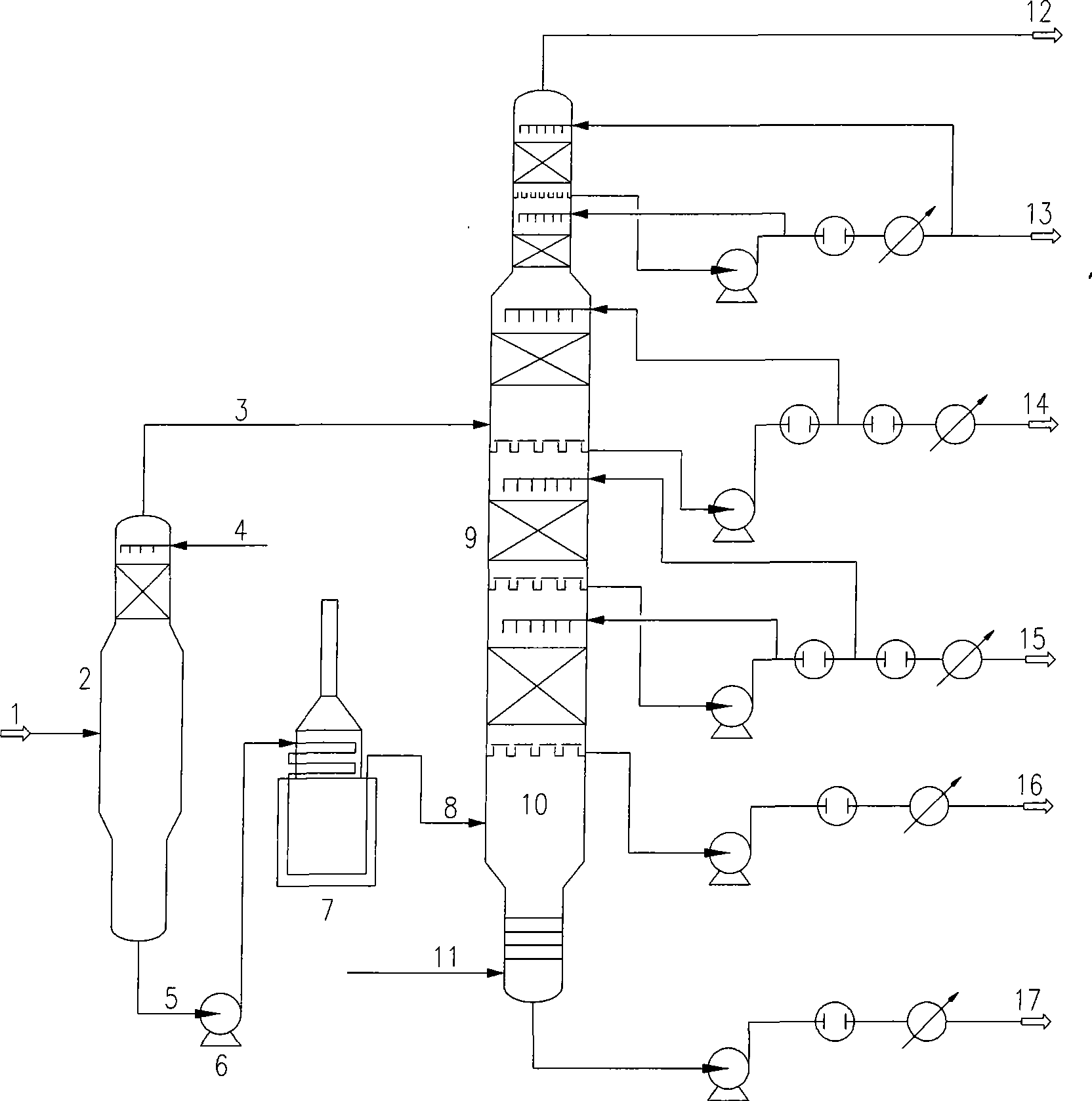

Atmospheric vacuum distillation method and apparatus with vacuum flash vaporizer

InactiveCN101376068AReduce the amount of feedEasy to handleVacuum distillation separationVacuum distillationVaporizationPulp and paper industry

The invention relates to an atmospheric and vacuum distillation device with a vacuum flash tower and a method thereof. The atmospheric and vacuum distillation device with a vacuum flash tower is characterized in that the vacuum flash tower arranged in front of a vacuum furnace is connected with the vacuum furnace and a vacuum tower through a pump and a pipeline. Constant bottom oil (1) is introduced into the vacuum flash tower (2)at first, and the operation pressure at the top part of the vacuum flash tower is higher than the operation pressure at the top part of the vacuum tower (9) by10 to 200mmHg; Flash cap gas (3) is introduced into the upper part or the lower part of an outlet for a side product which is similar to Flash cap gas fraction; flash bottom oil (5) is introduced into the vacuum furnace (7) through a flash bottom oil pump (6); when the flash bottom oil is heated to 350 to 430 degrees, air-liquid mixing vacuum tower feed material is obtained through partial vaporization and is introduced into a flash evaporation segment (10) of the vacuum tower through a transfer line (8); and products with different fractions are drawn from the side of the vacuum tower and vacuum residue is drawn from the bottom of the vacuum tower. Through adding the vacuum flash tower to improve the working process of the atmospheric and vacuum distillation device, the invention achieves the advantages of increasing treatment capacity, increasing vacuum distillation yield, and reducing energy consumption.

Owner:TIANJIN UNIV +2

Diffusion driven water purification apparatus and process

Owner:UNIV OF FLORIDA RES FOUNDATION INC

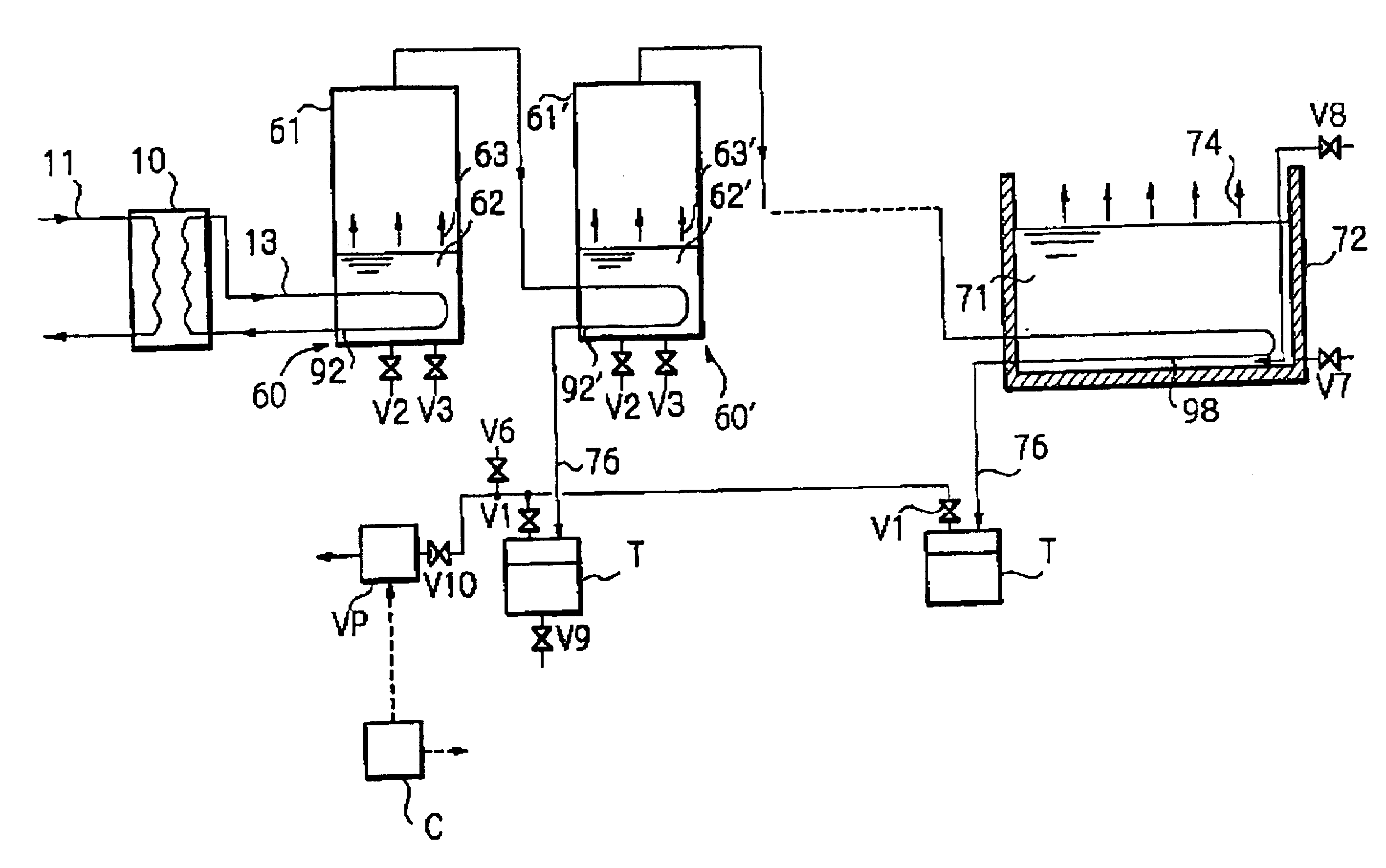

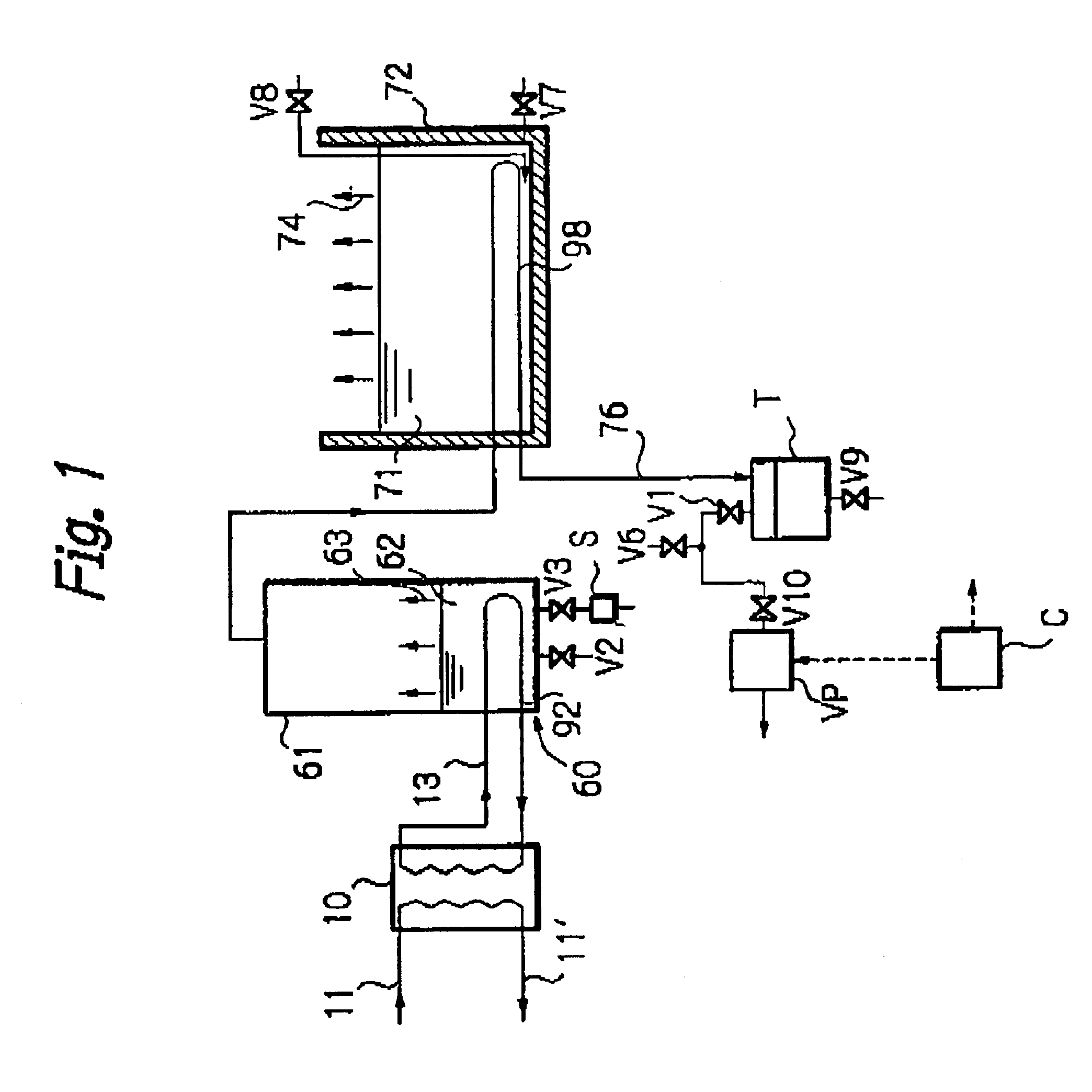

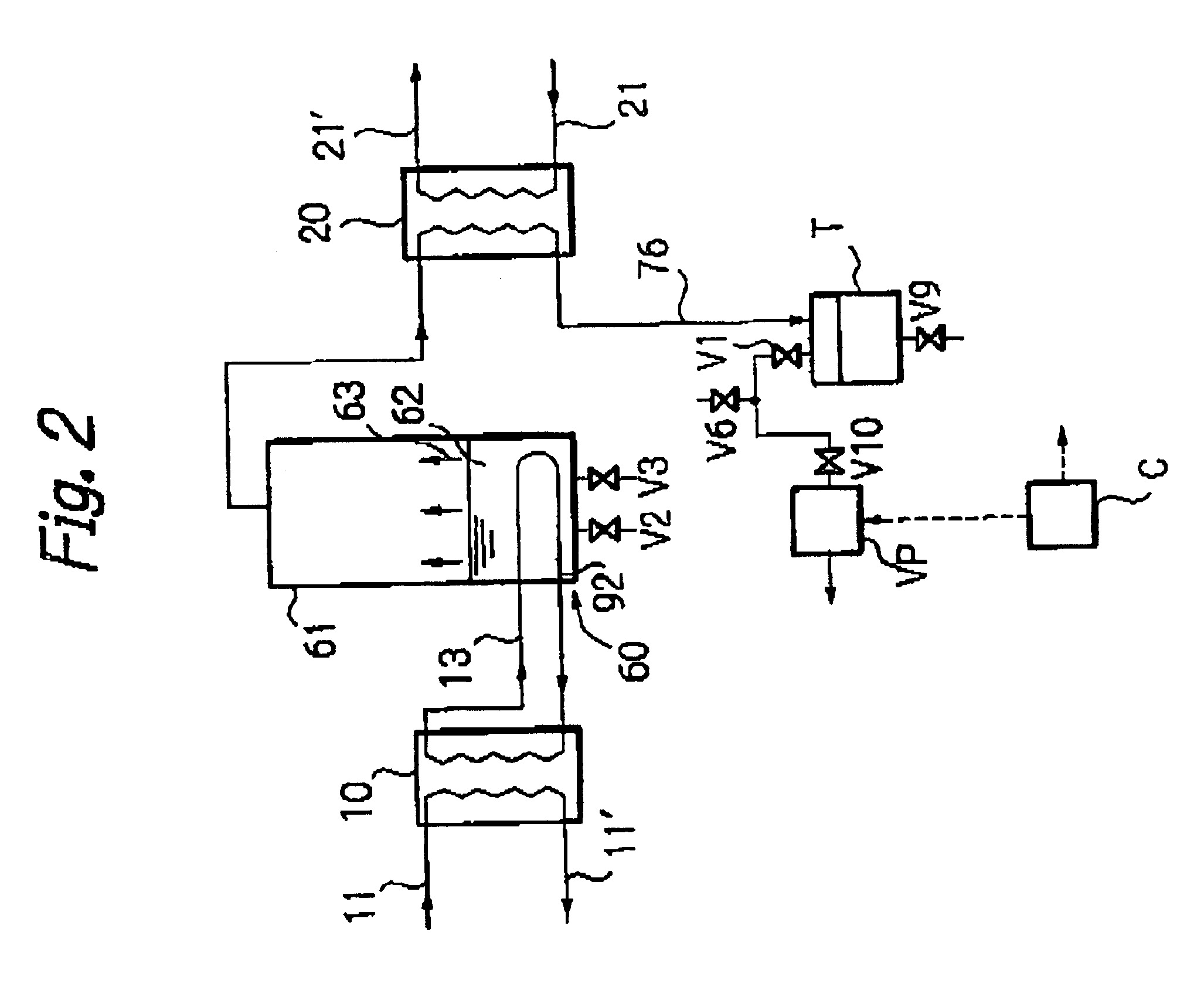

Desalination method and desalination apparatus

InactiveUS6833056B1Number of stage increasingIncrease the number ofAuxillariesGeneral water supply conservationDesalinationDistilled water

A desalination apparatus capable of obtaining fresh water stably at low cost by utilizing low-temperature waste, wherein the desalination apparatus including a heat exchanger 92 cooperating with an evaporation can 60 so as to subject a low-temperature waste heat 11 and raw water 62 in the evaporation can 60 to heat exchange and generate water vapor 63 in the evaporation can 60; a condenser 98 cooperating with a raw water tank 72 so as to receive the water vapor 63 from the evaporation can 60, cool the water vapor 63 by subjecting the water vapor 63 and raw water 71 in the raw water tank 72 to heat exchange and obtain distilled water 76; a distilled water tank for storing the distilled water 76; vacuum means for evacuating the evaporation can 60 and depressurizing the inside thereof so as to promote generation of water vapor 63 in the evaporation can 60; and raw water supply means for supplying raw water to the evaporation can.

Owner:EBARA CORP

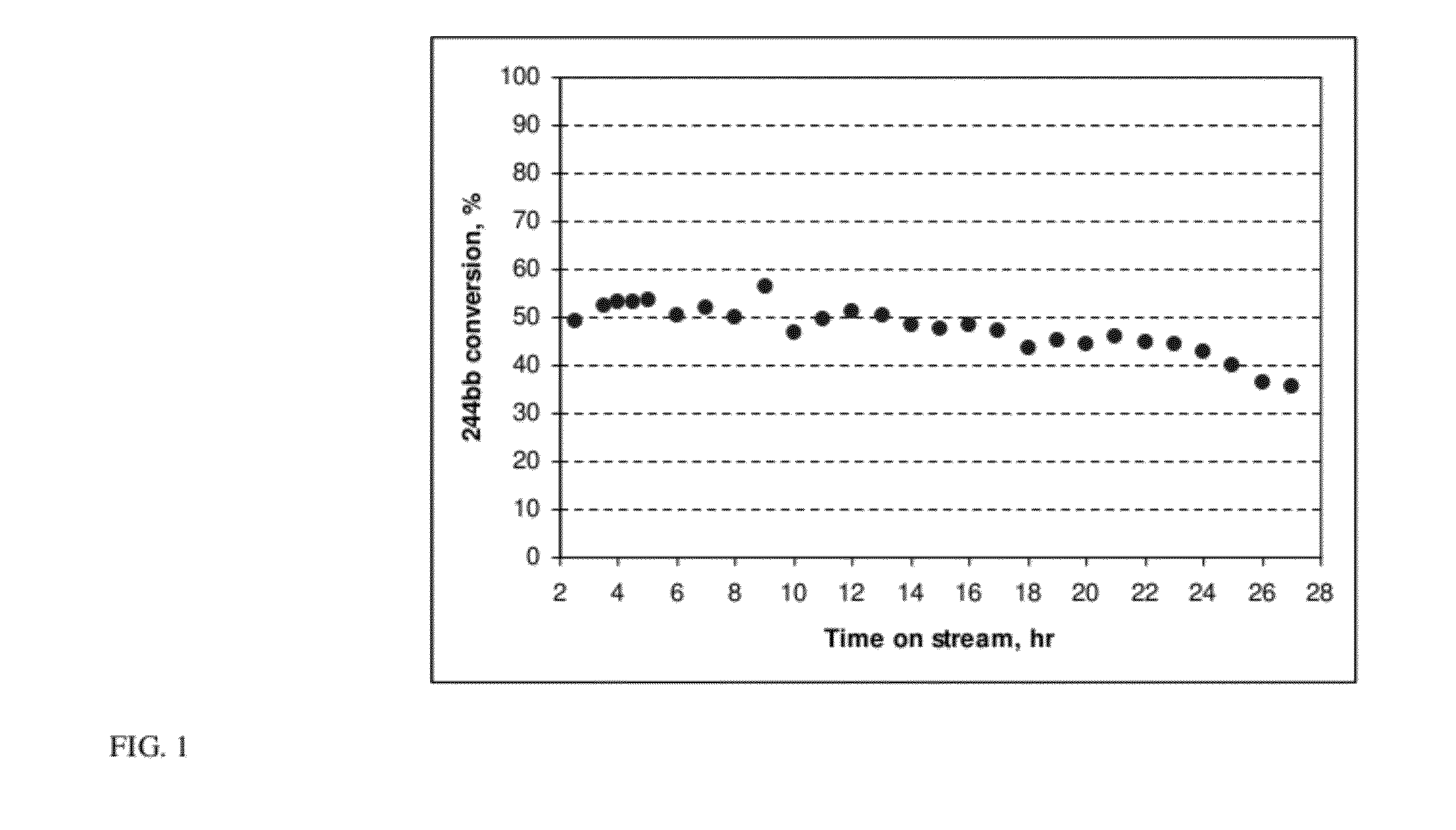

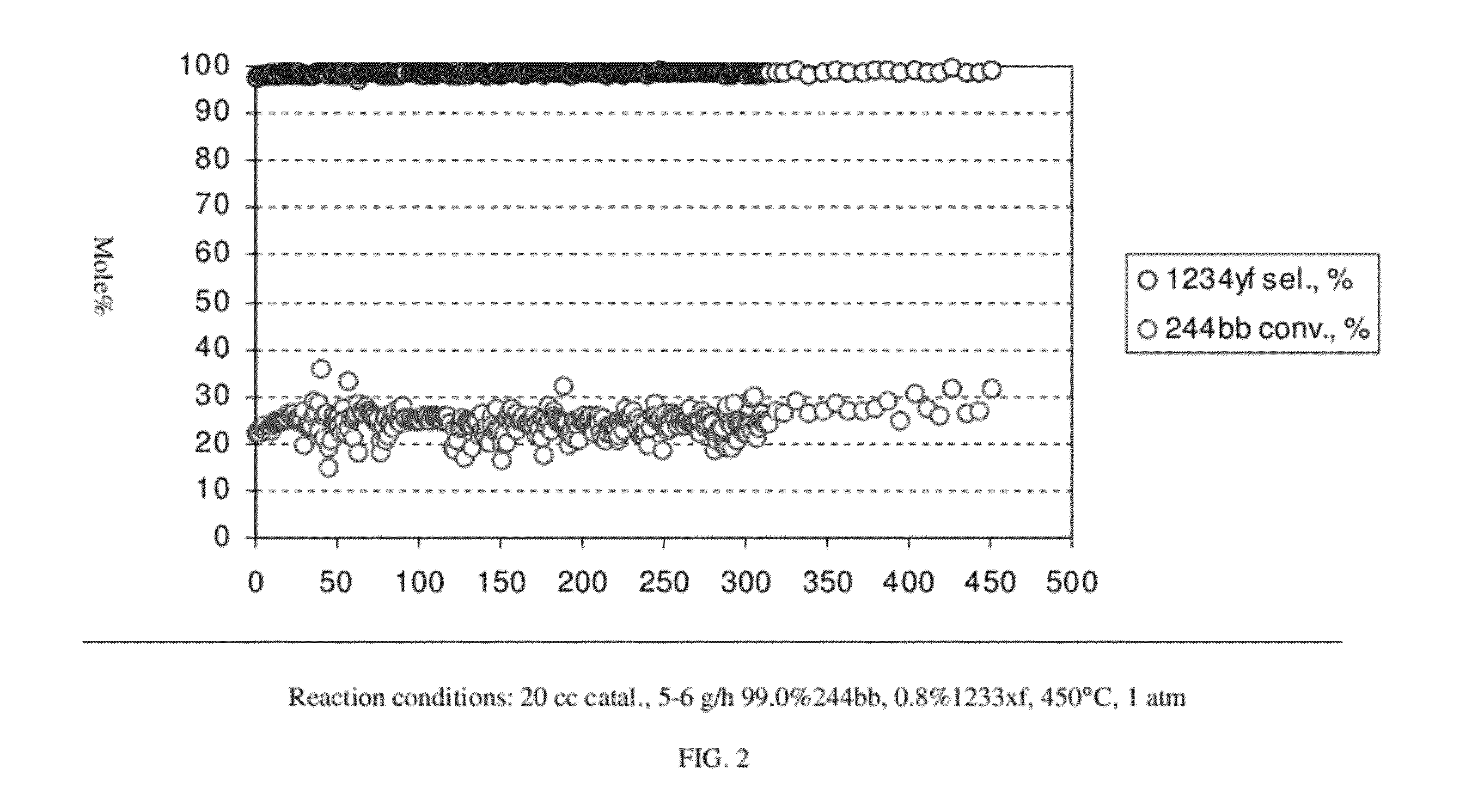

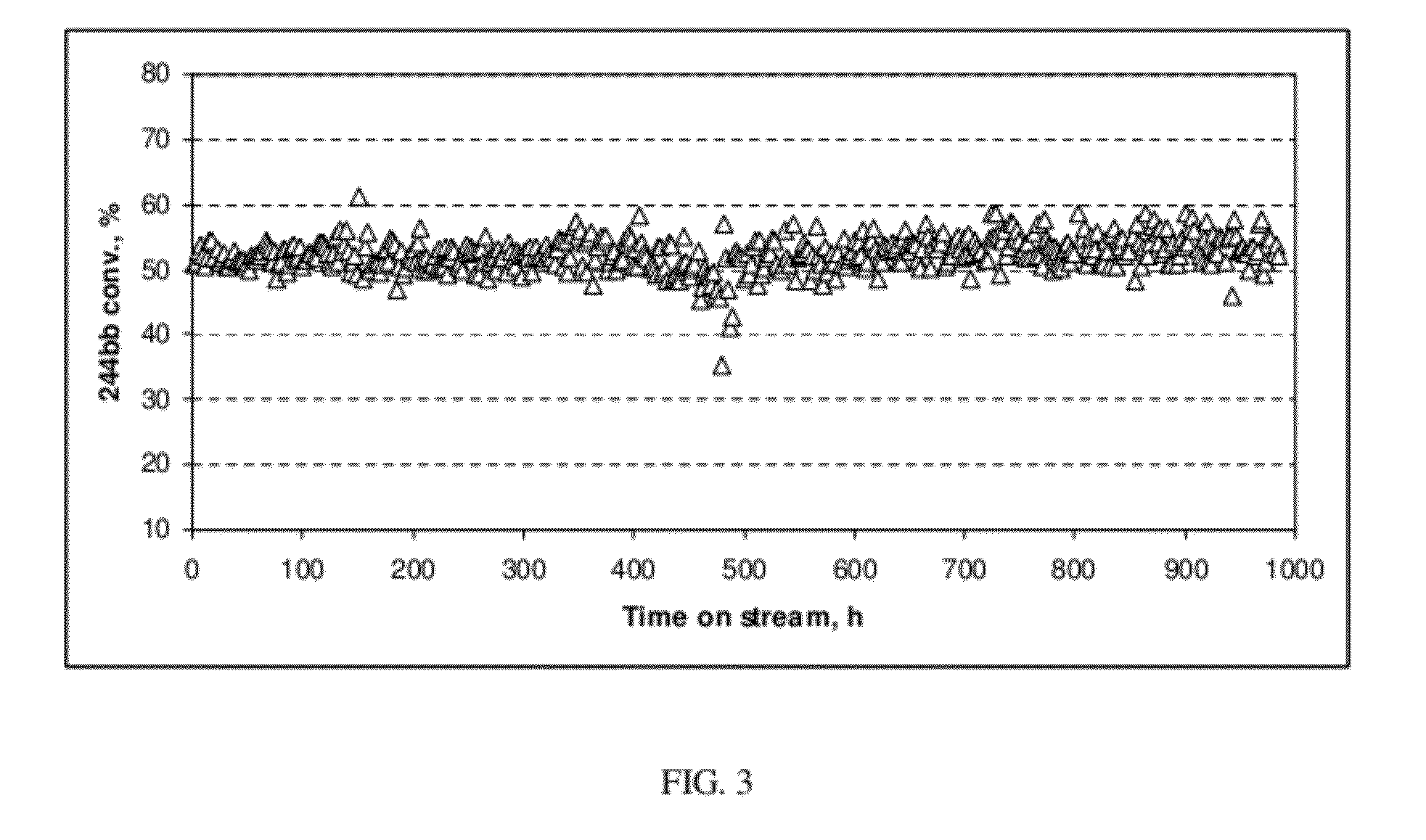

Process for producing 2,3,3,3-tetrafluoropropene

ActiveUS20120065437A1Increase productionPreparation by hydrogen halide split-offHalogenated hydrocarbon separation/purificationImpurity2,3,3,3-Tetrafluoropropene

The instant invention relates to a process and method for manufacturing 2,3,3,3-tetrafluoropropene by dehydrohalogenating a reactant stream of 2-chloro-1,1,1,2-tetrafluoropropane that is substantially free from impurities, particularly halogenated propanes, propenes, and propynes.

Owner:HONEYWELL INT INC

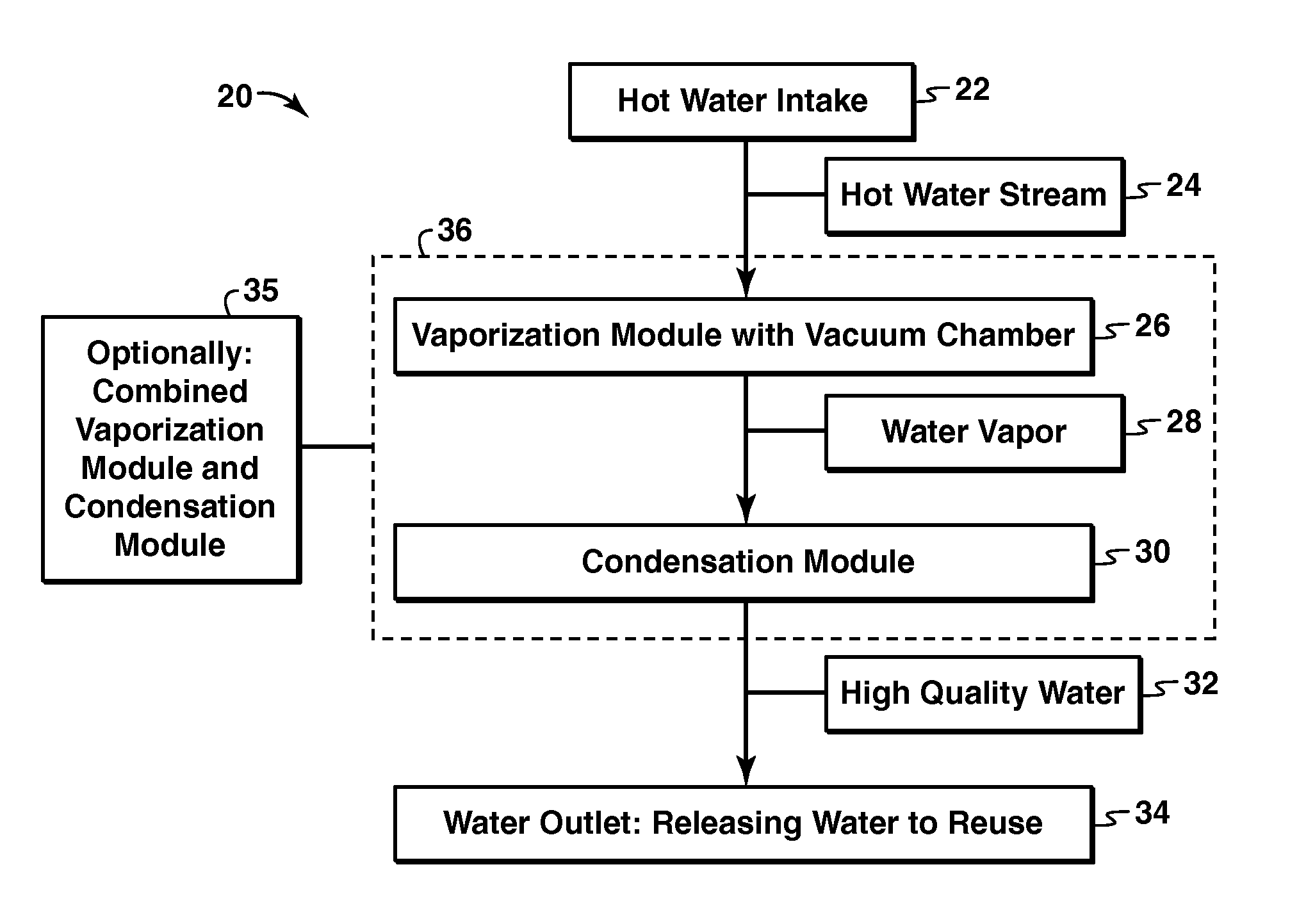

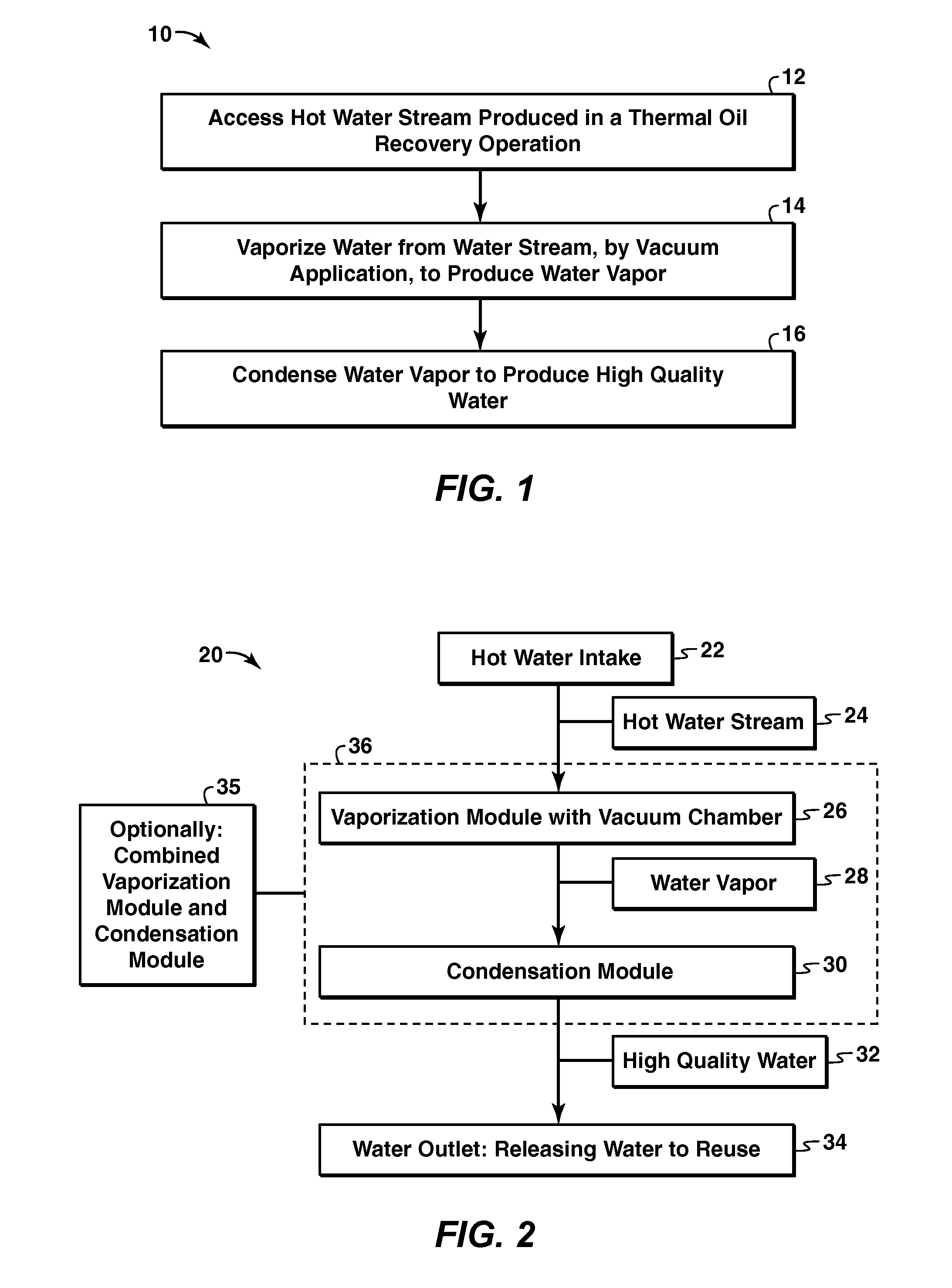

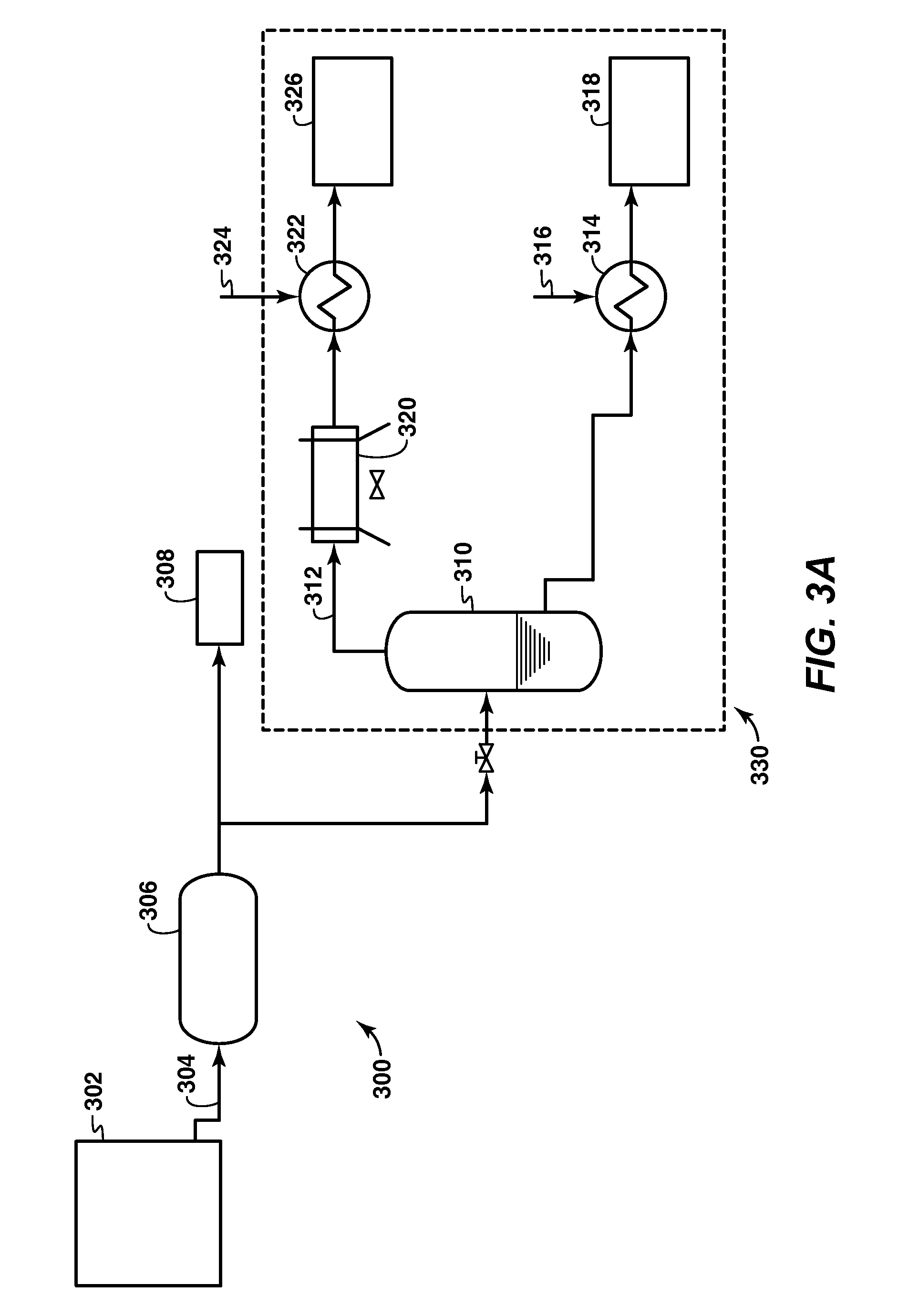

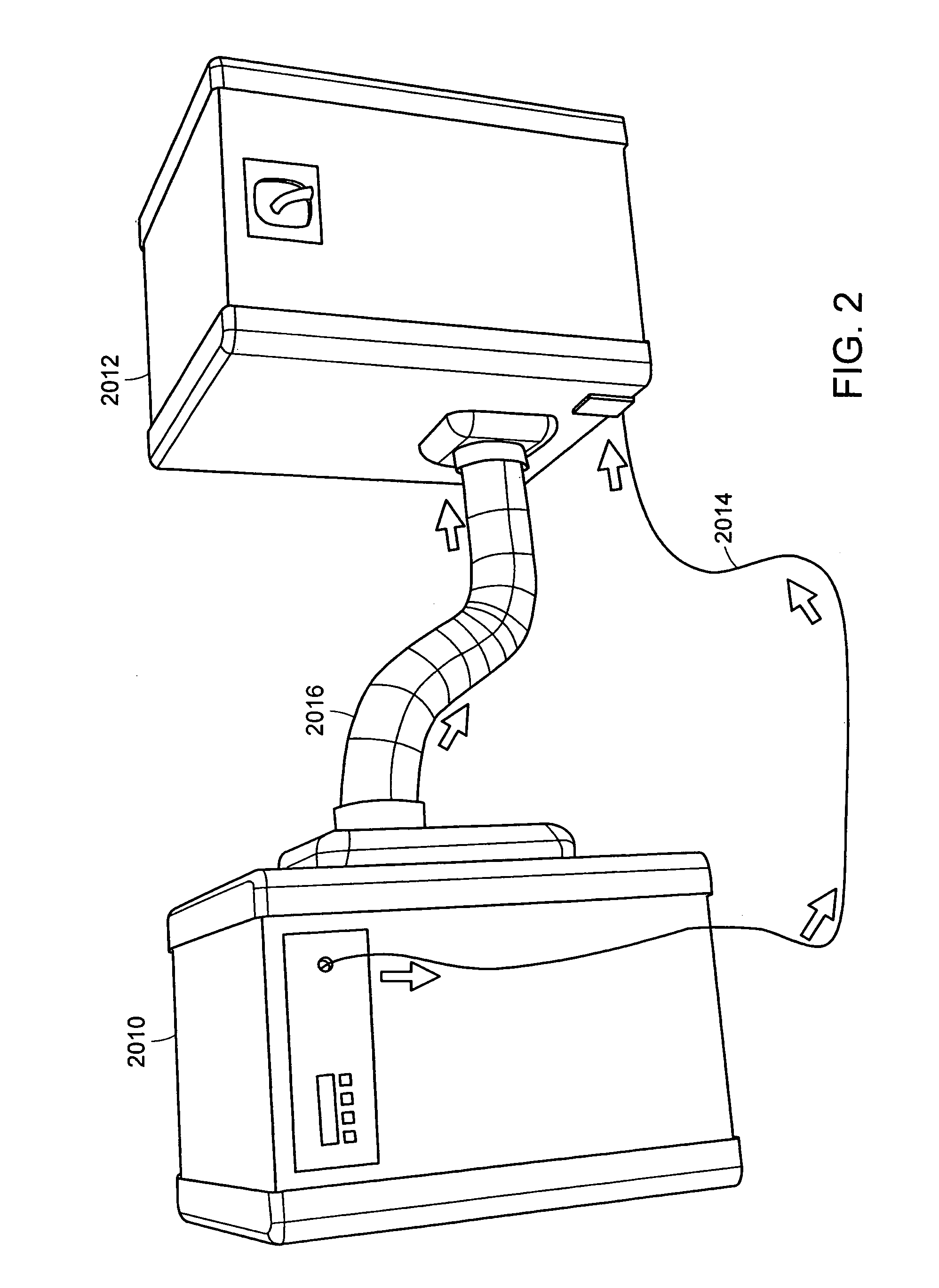

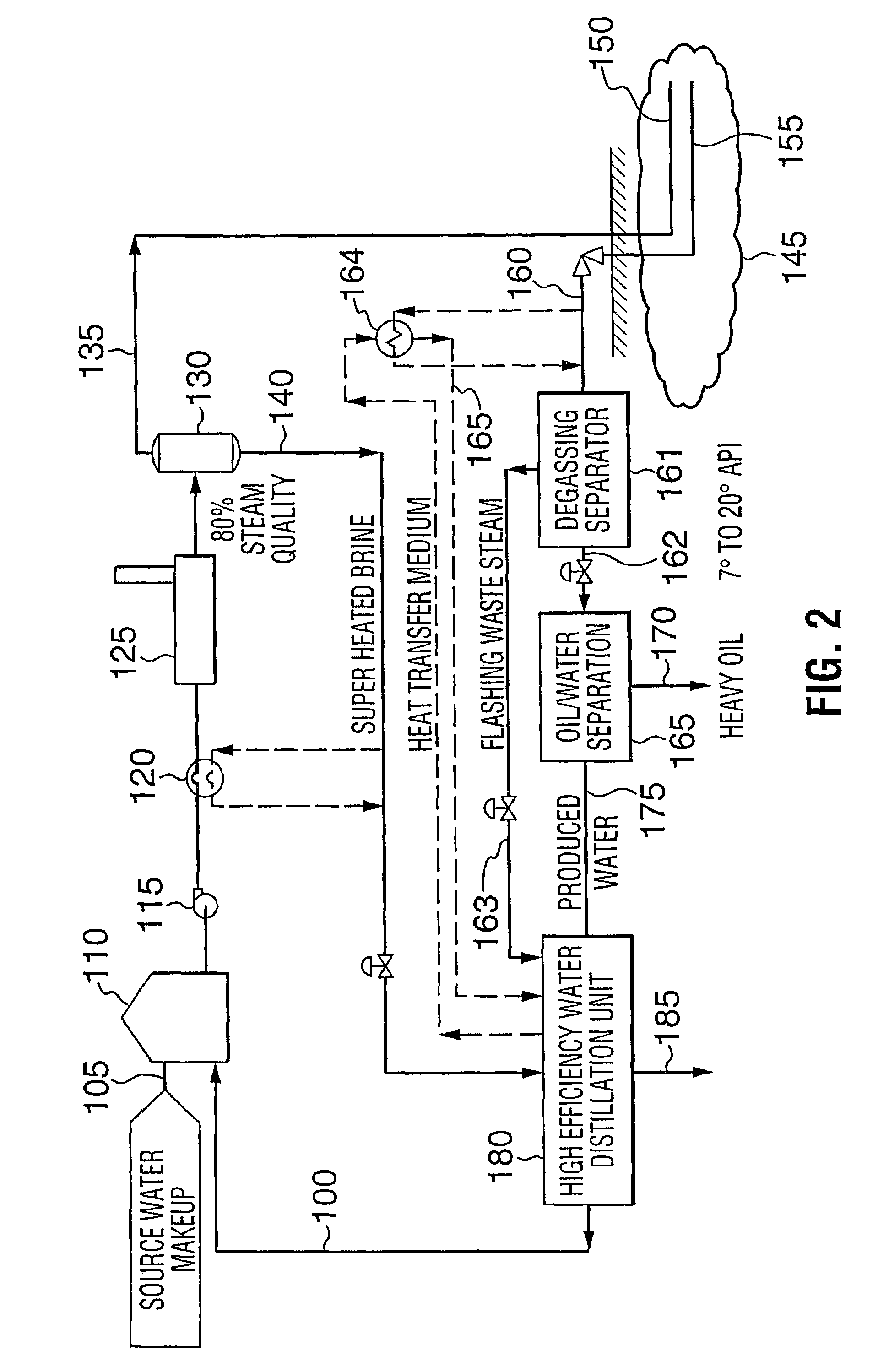

Recovery of high water from produced water arising from a thermal hydrocarbon recovery operation using vaccum technologies

InactiveUS20100282593A1High purityImprove purification effectAuxillariesEvaporation with vapour compressionWater flowVaporization

A method for reducing and re-using waste heat and water resulting from thermal hydrocarbon recovery operations involving accessing a hot water stream produced in a thermal hydrocarbon recovery operation; vaporizing water from the water stream by applying a vacuum, thereby producing water vapor; and condensing the water vapor to produce high quality water. A system is described including a hot water intake interfacing with a hot water stream from a thermal hydrocarbon recovery operation; a vaporization module receiving the hot water stream from the hot water intake, comprising a vacuum chamber in which a vacuum is applied to produce water vapor from the hot water stream; a condensation module in which water vapor produced in the vaporization module is condensed to form high quality water; and a water outlet for releasing the high quality water from the condensation module for re-use within the thermal hydrocarbon recovery operation.

Owner:EXXONMOBIL UPSTREAM RES CO

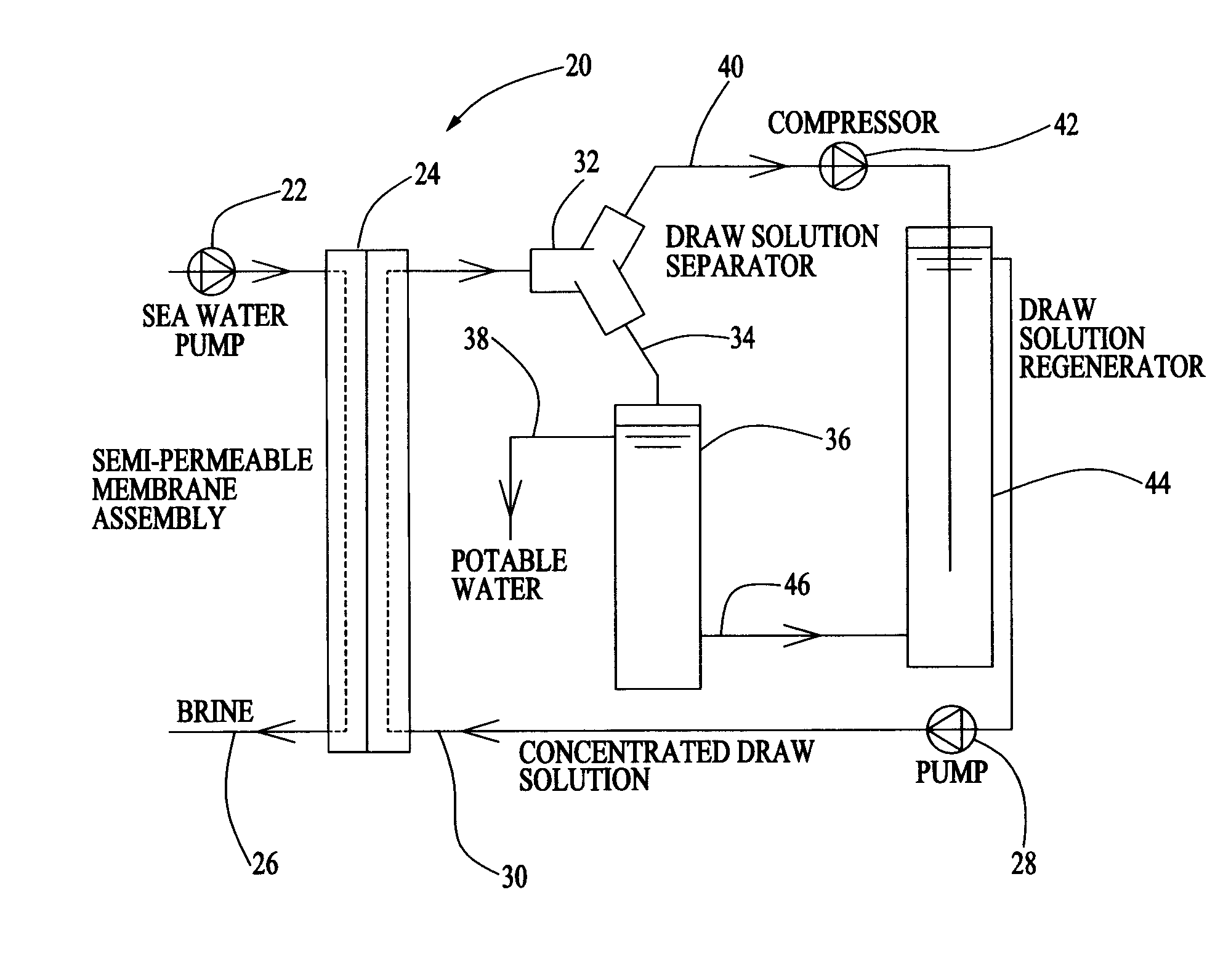

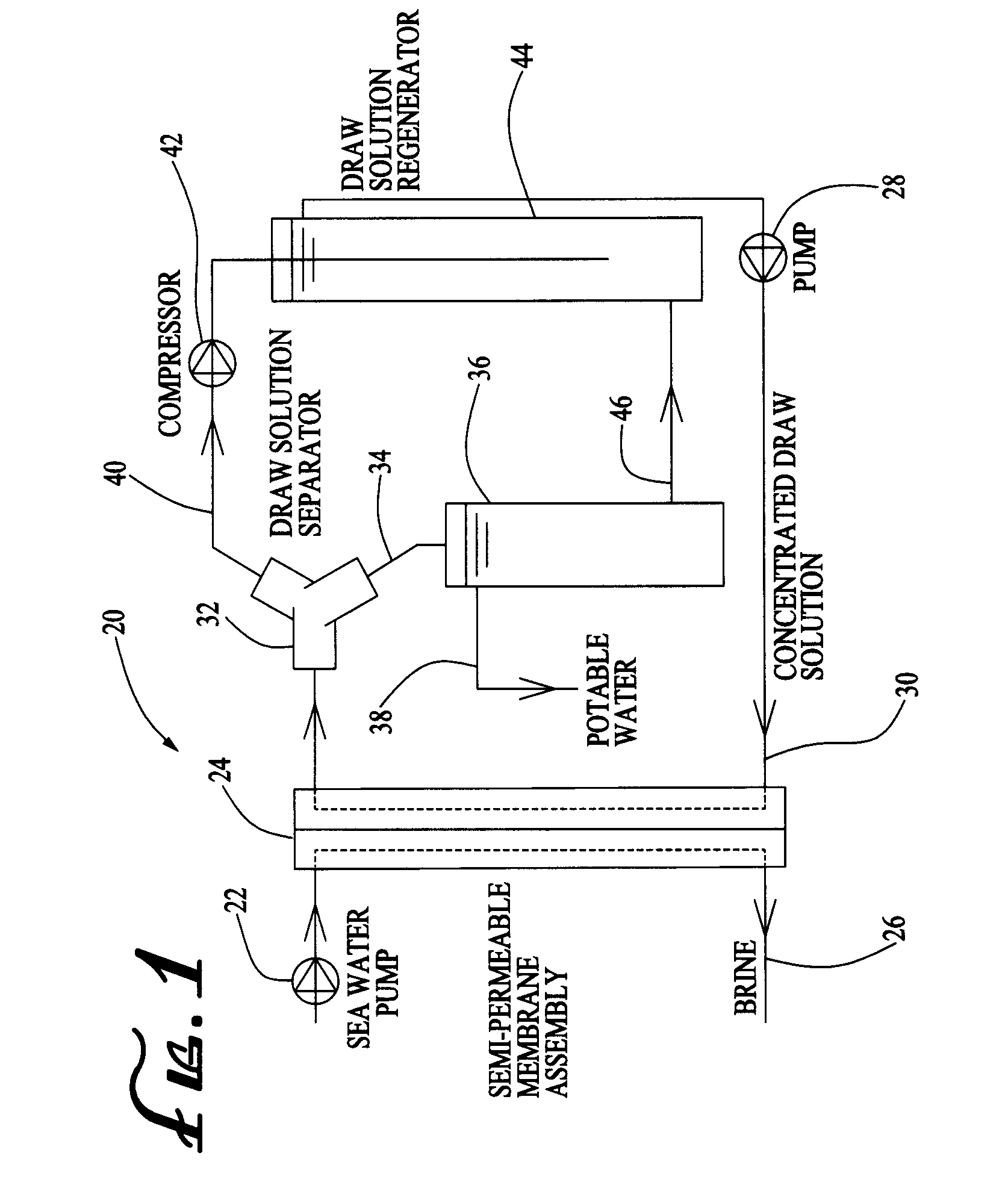

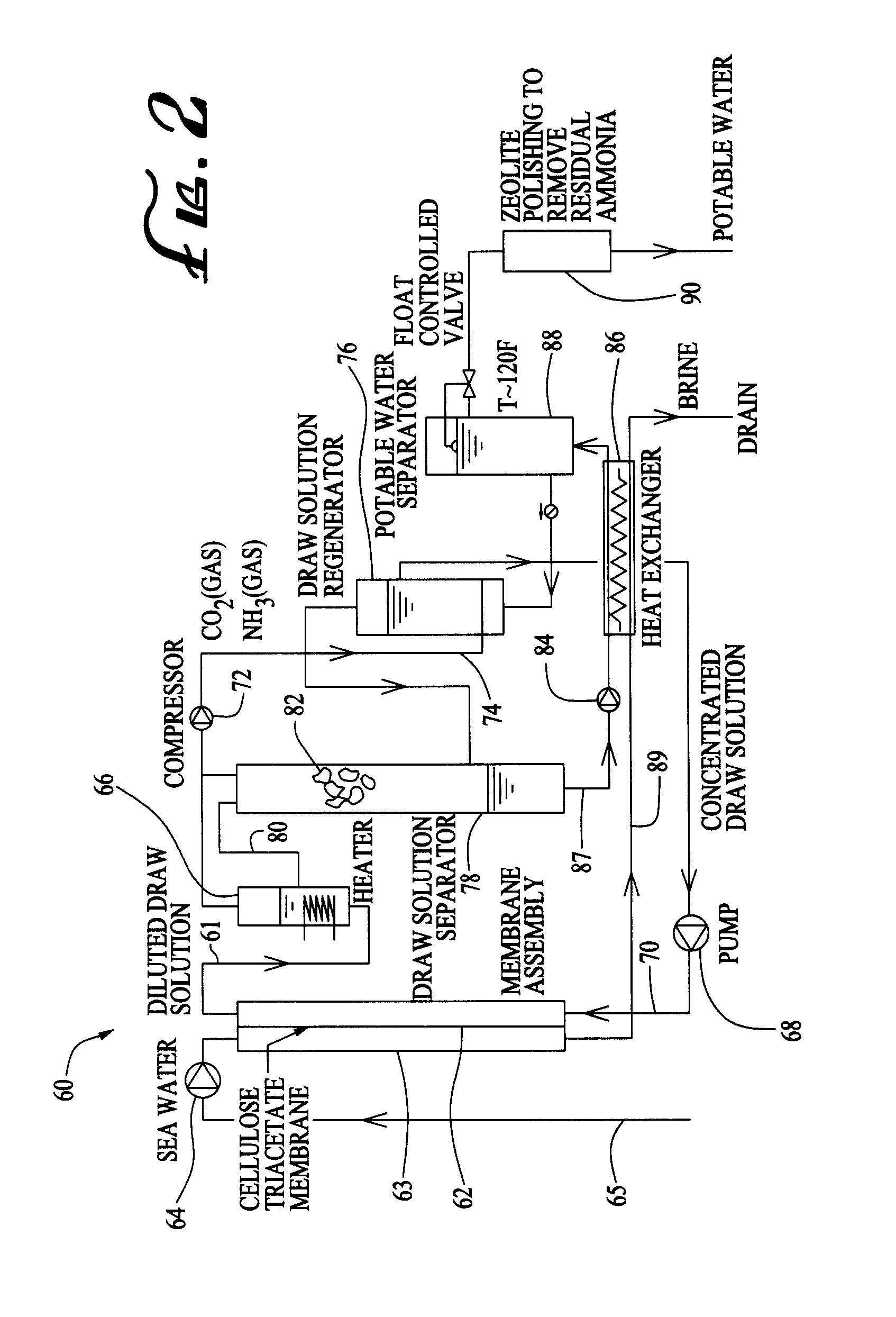

Method and Apparatus for Producing Potable Water from Seawater Using Forward Osmosis

ActiveUS20090308727A1Efficient and effectiveAuxillariesGeneral water supply conservationDesalinationPotable water

A method and apparatus for desalinating seawater which uses an ammonia bicarbonate forward osmosis desalination process. Seawater is pumped through one side of a membrane assembly. A draw solution is pumped through the other side of the membrane assembly. The draw solution withdraws water molecules from the seawater through the membrane into the draw solution. A draw solution separator receives a heated draw solution which then decomposes into ammonia, carbon dioxide and water. Potable water is separated from ammonia has and carbon dioxide gas. The ammonia gas and carbon dioxide gas are recombined with a portion of the potable water stream to reform the ammonium bicarbonate draw solution.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

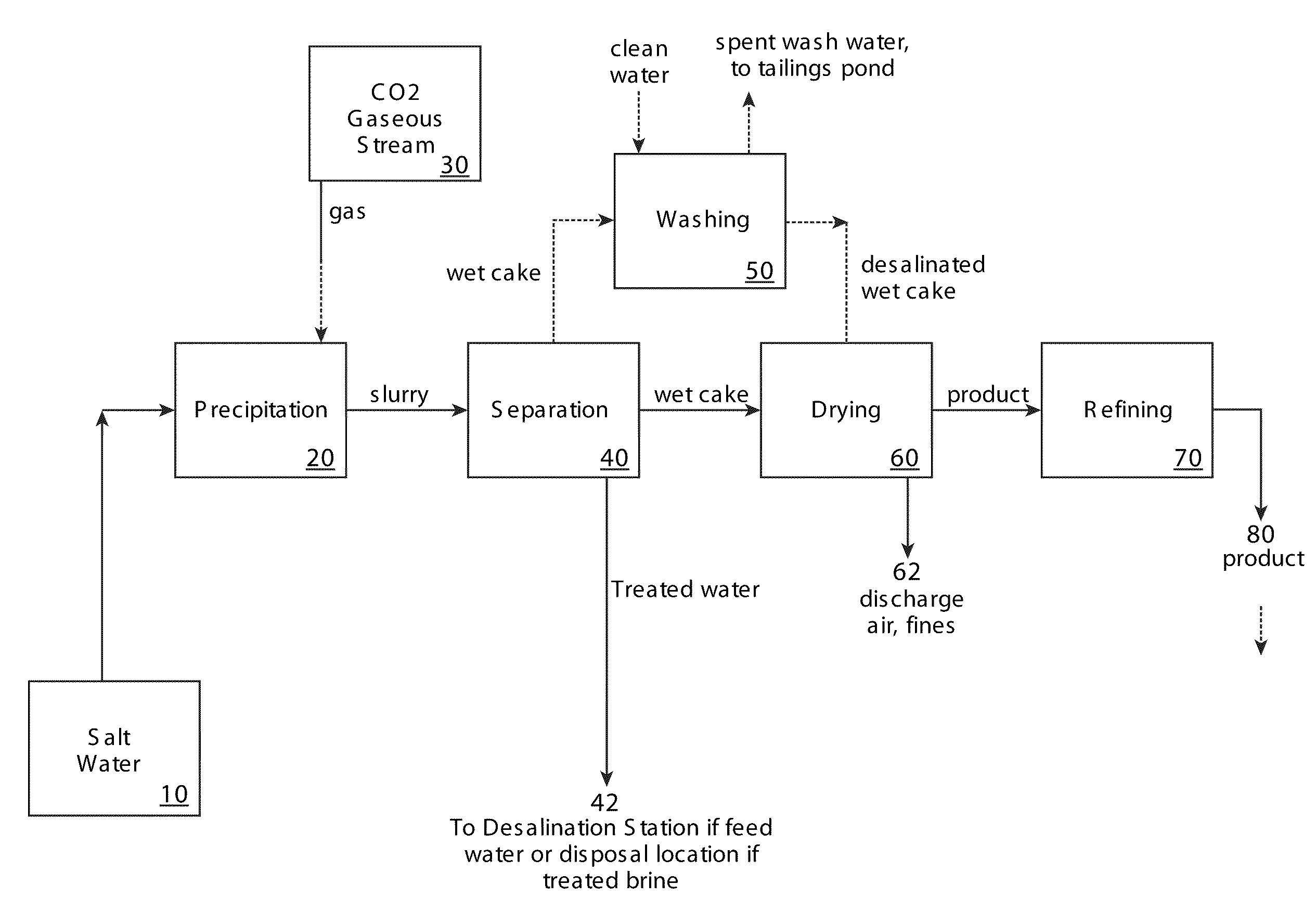

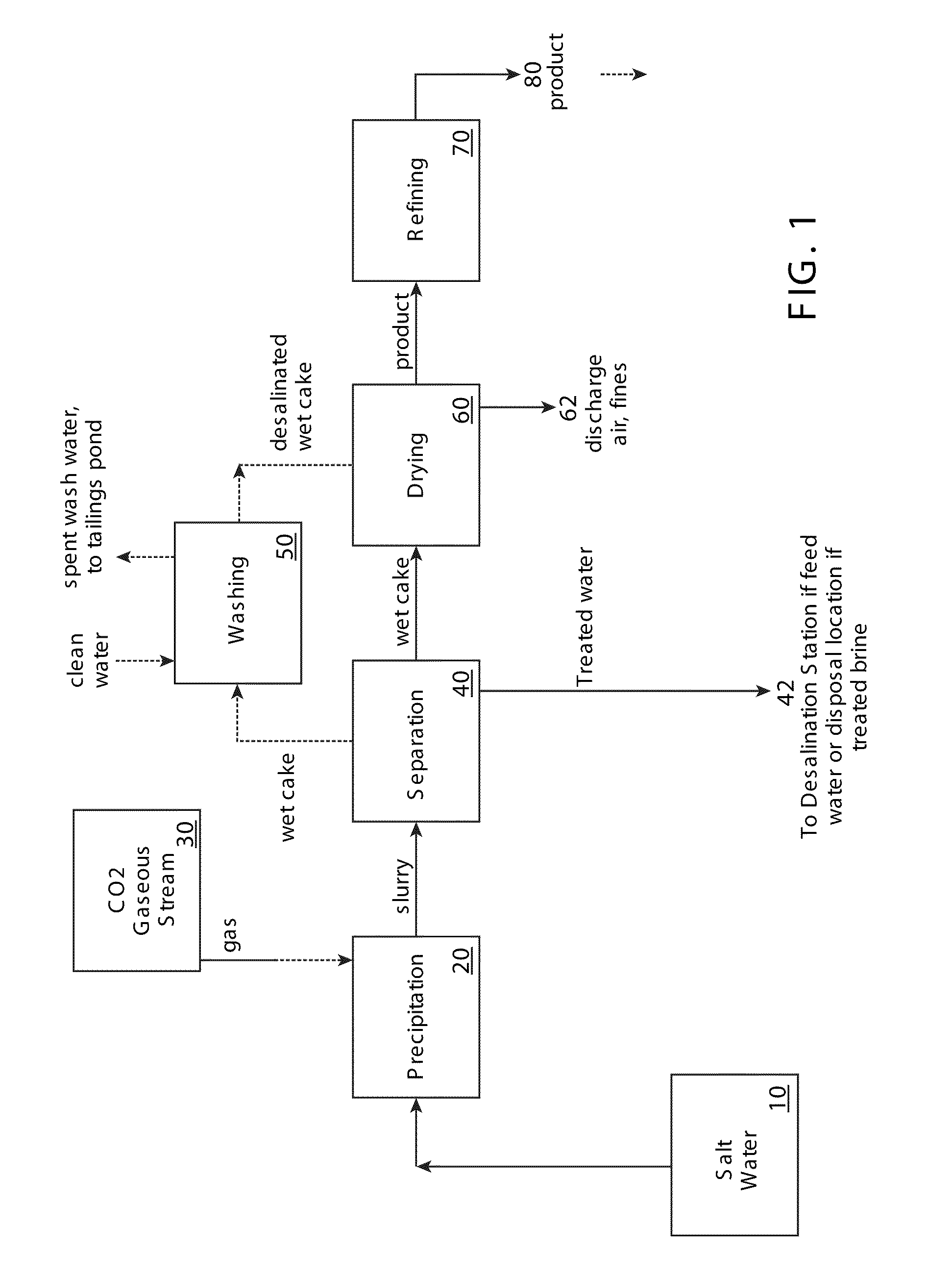

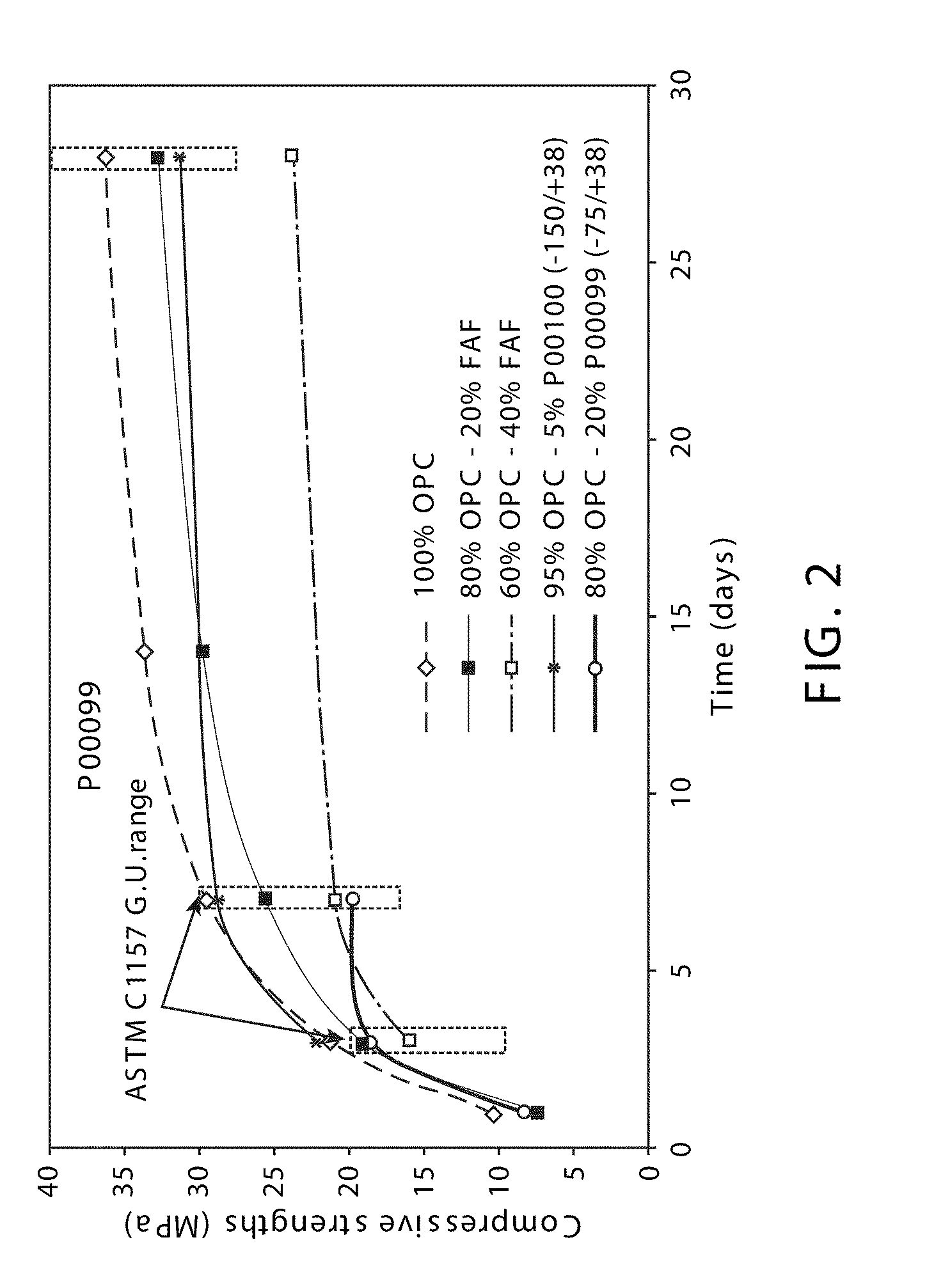

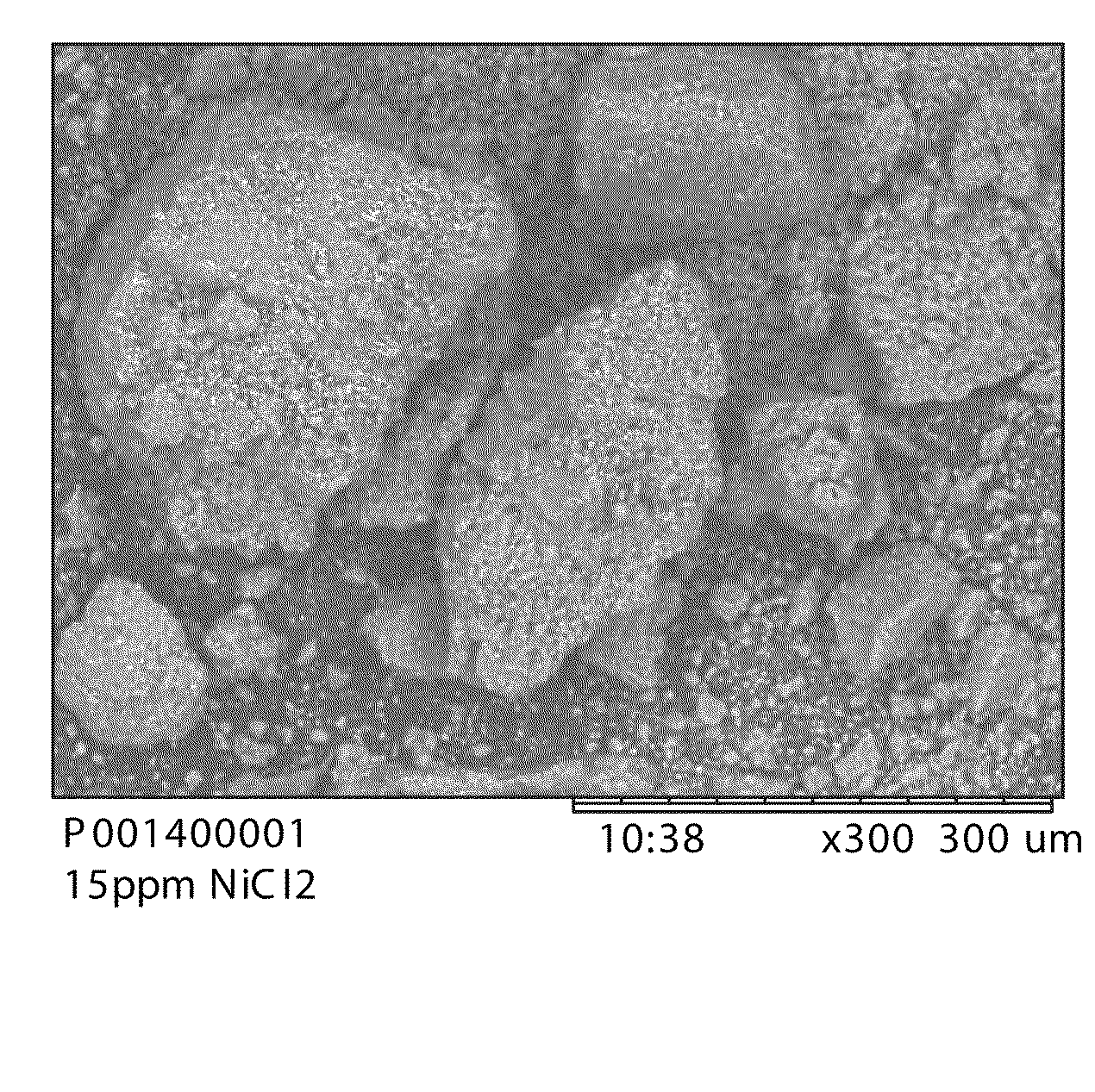

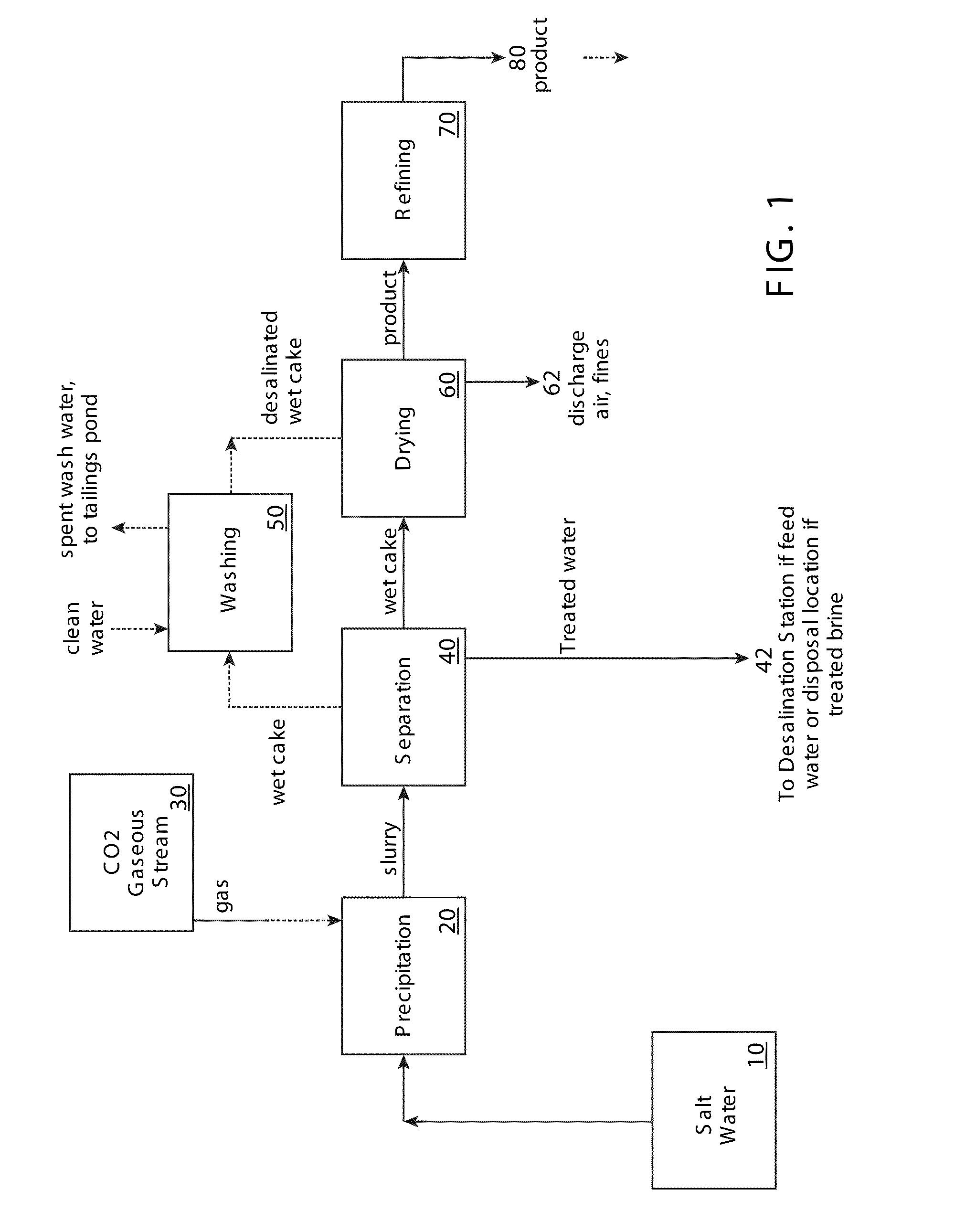

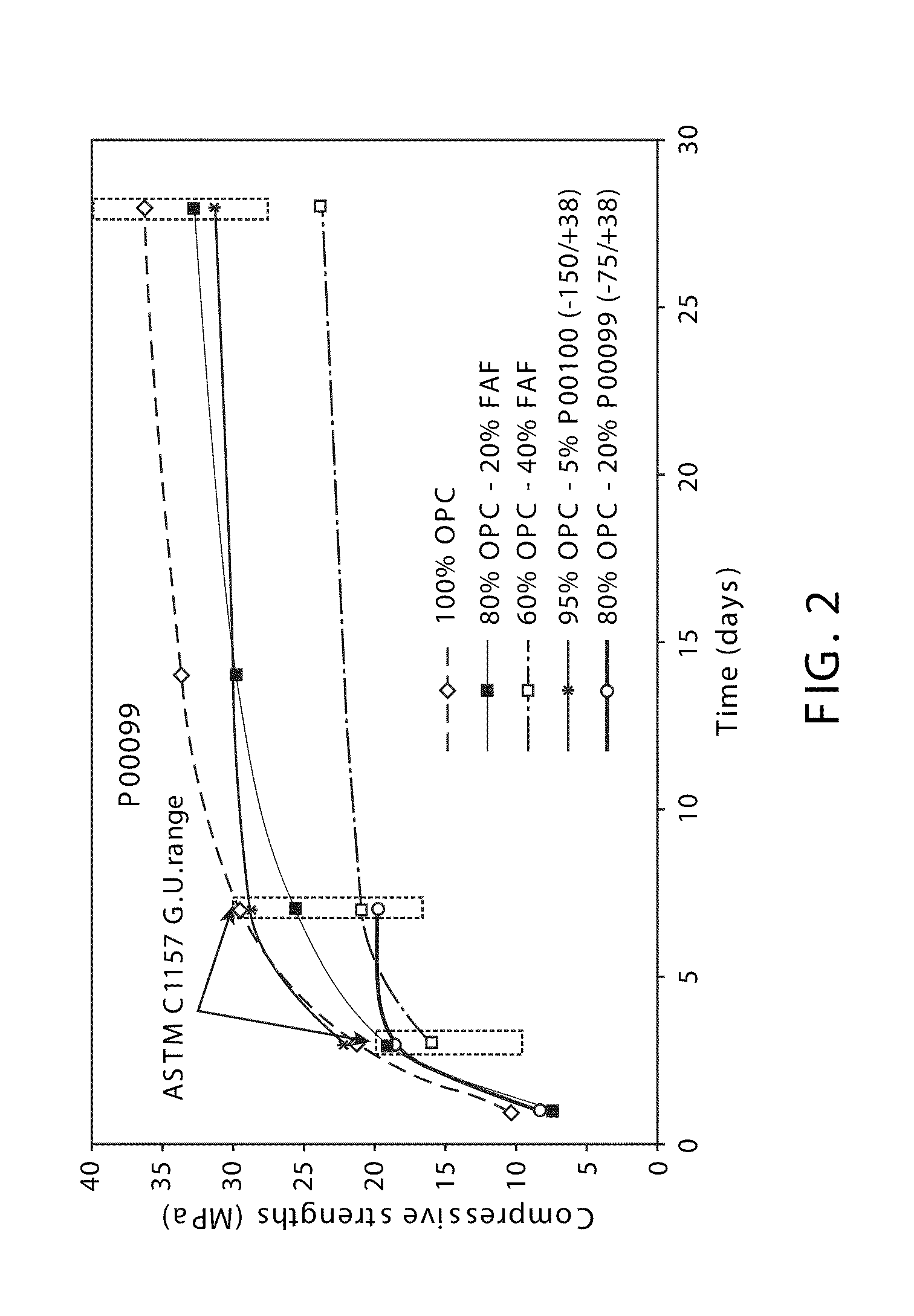

Desalination methods and systems that include carbonate compound precipitation

InactiveUS20100154679A1Easy complianceImprove desalination efficiencyAuxillariesGeneral water supply conservationSaline waterDesalination

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbon dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:CALERA CORP

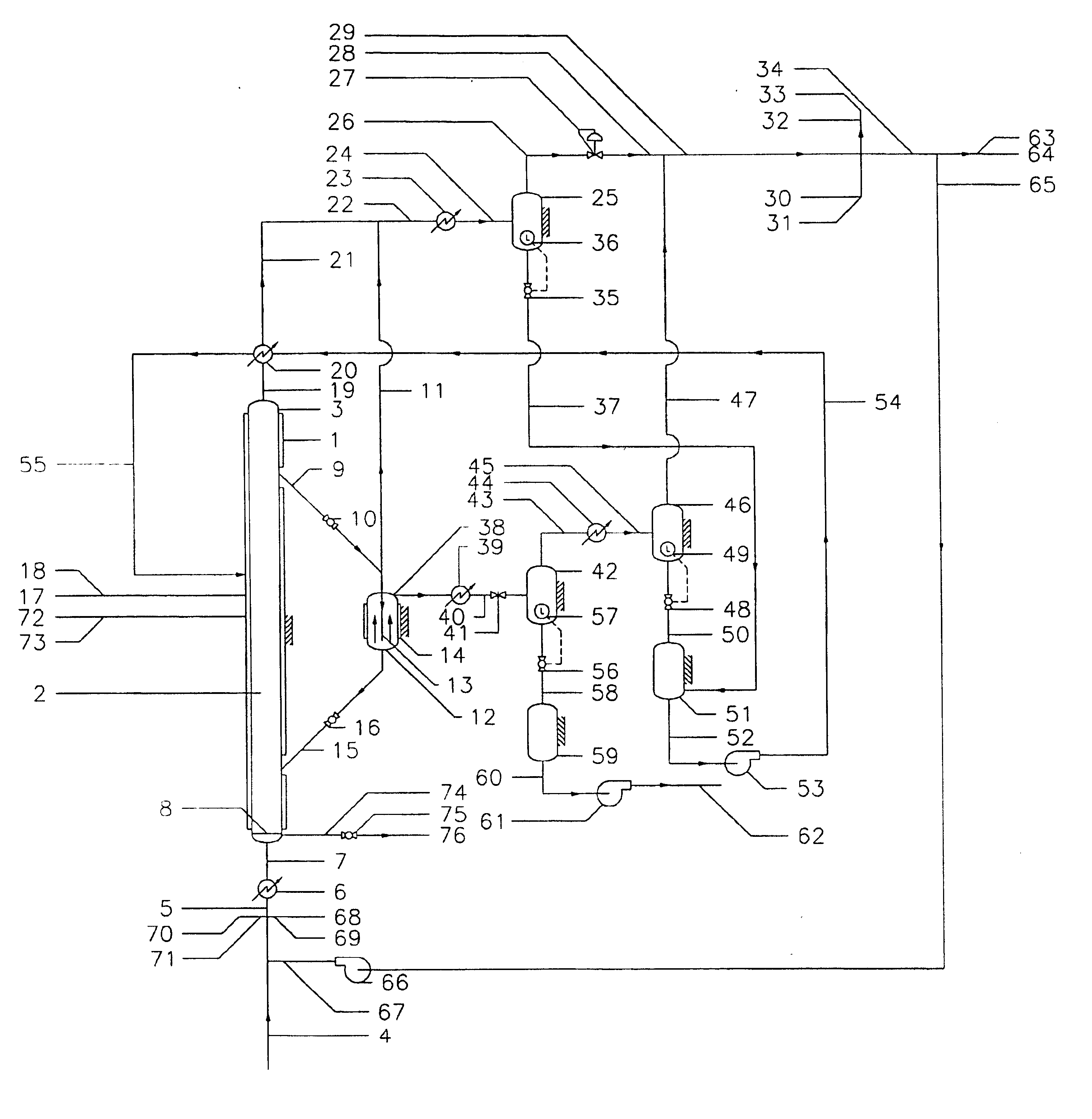

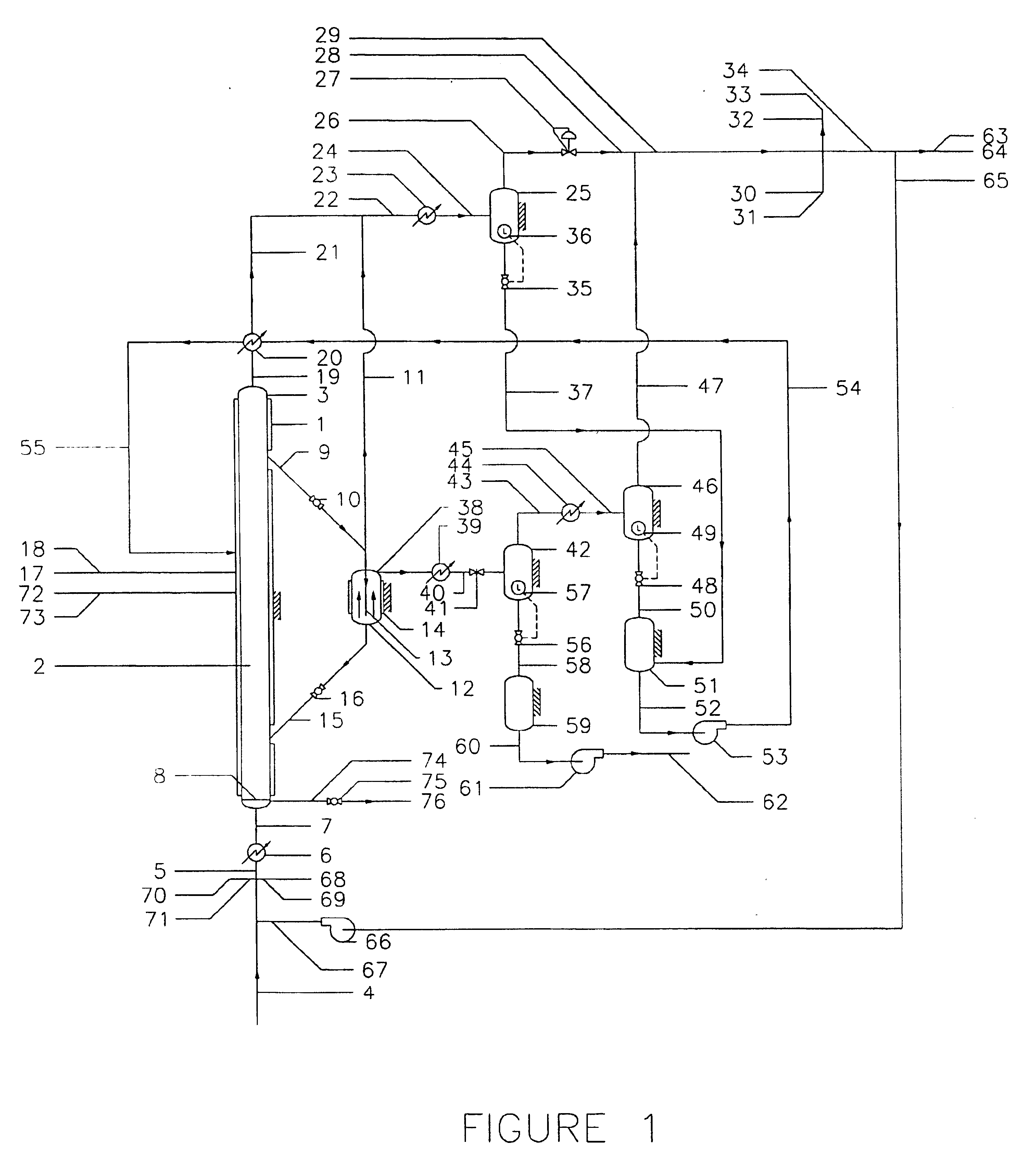

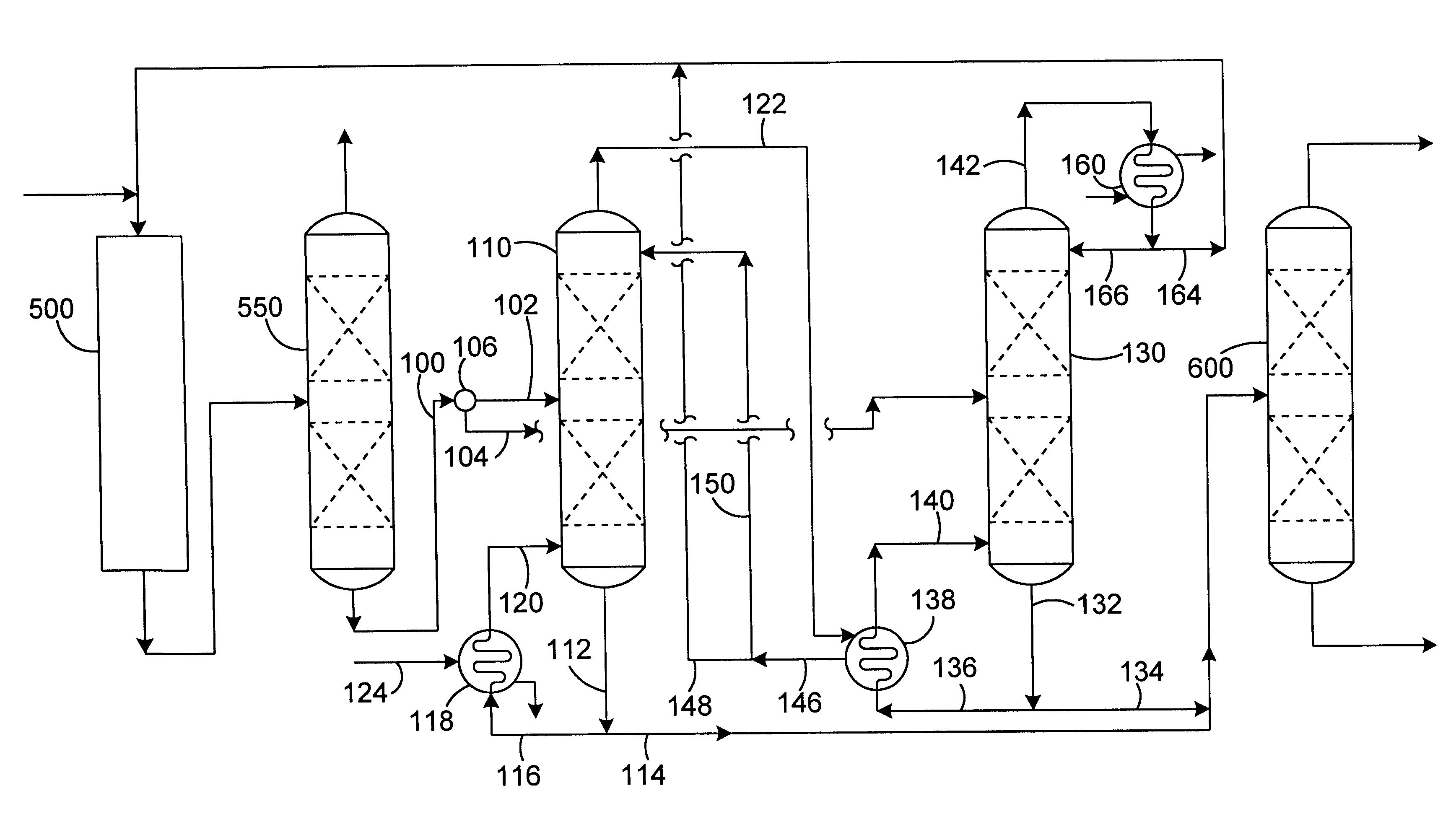

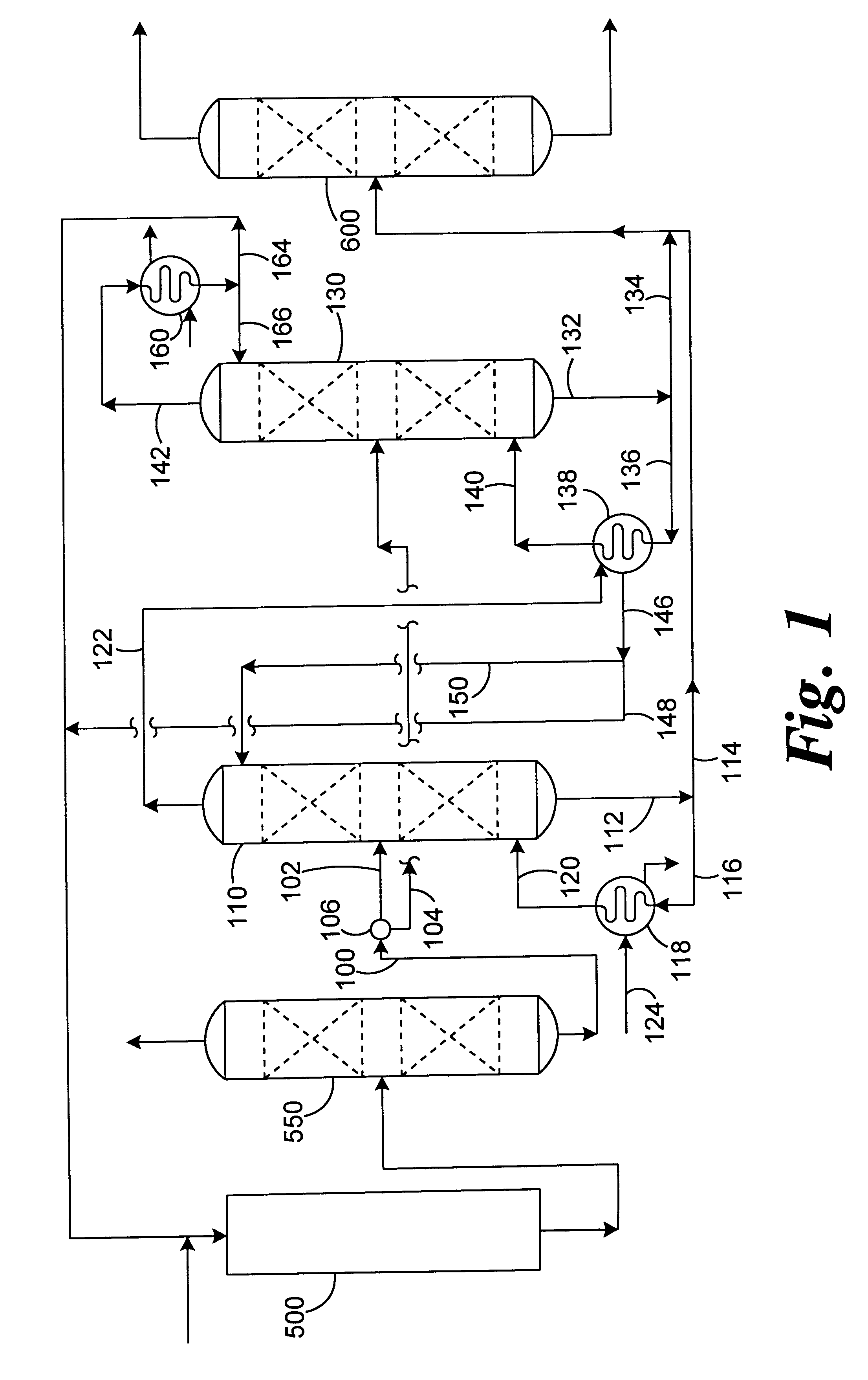

Cascade reboiling of ethylbenzene/styrene columns

InactiveUS6171449B1Reduce use costEfficient and economical approachDistillation regulation/controlDistillation in boilers/stillsCascadeEngineering

Apparatus and process are disclosed for the distillation separation of styrene monomer from ethylbenzene utilizing a split feed to two distillation columns in conjunction with cascade reboiling utilizing thermal energy from the overhead of one column to supply heat to the second.

Owner:STONE & WEBSTER PROCESS TECH

Desalination methods and systems that include carbonate compound precipitation

ActiveUS20100158786A1Easy complianceImprove desalination efficiencyCalcium/strontium/barium carbonatesAuxillariesSaline waterDesalination

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbone dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:ARELAC INC

Apparatus and method for thermal desalination based on pressurized formation and evaporation of droplets

A method for removing dissolved solids, particularly salts, from water. An apparatus for performing the inventive method is disclosed. The aqueous solution to be treated, for example sea water, is atomized using special non-pneumatic nozzles, and sprayed into an evaporation chamber through which air, heated by waste heat, is blown. The micro-droplets undergo rapid evaporation in the chamber, resulting in the separation of the salt solids from the vapor phase of the water. The mixture of suspended solids and water vapor is filtered to remove and collect the salts, and the water vapor is condensed to collect the salt-free water.

Owner:AQUASONICS RSE INC

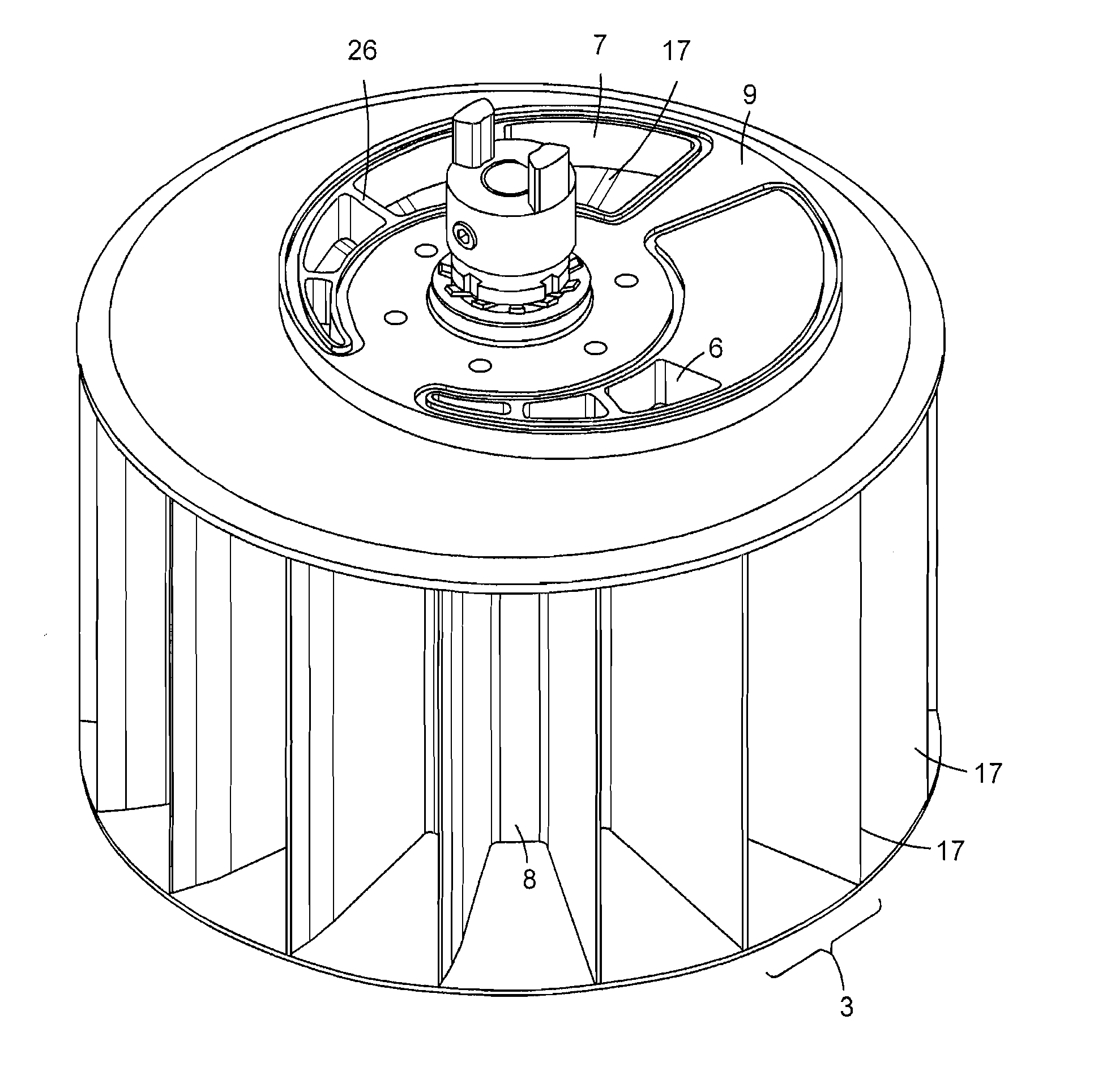

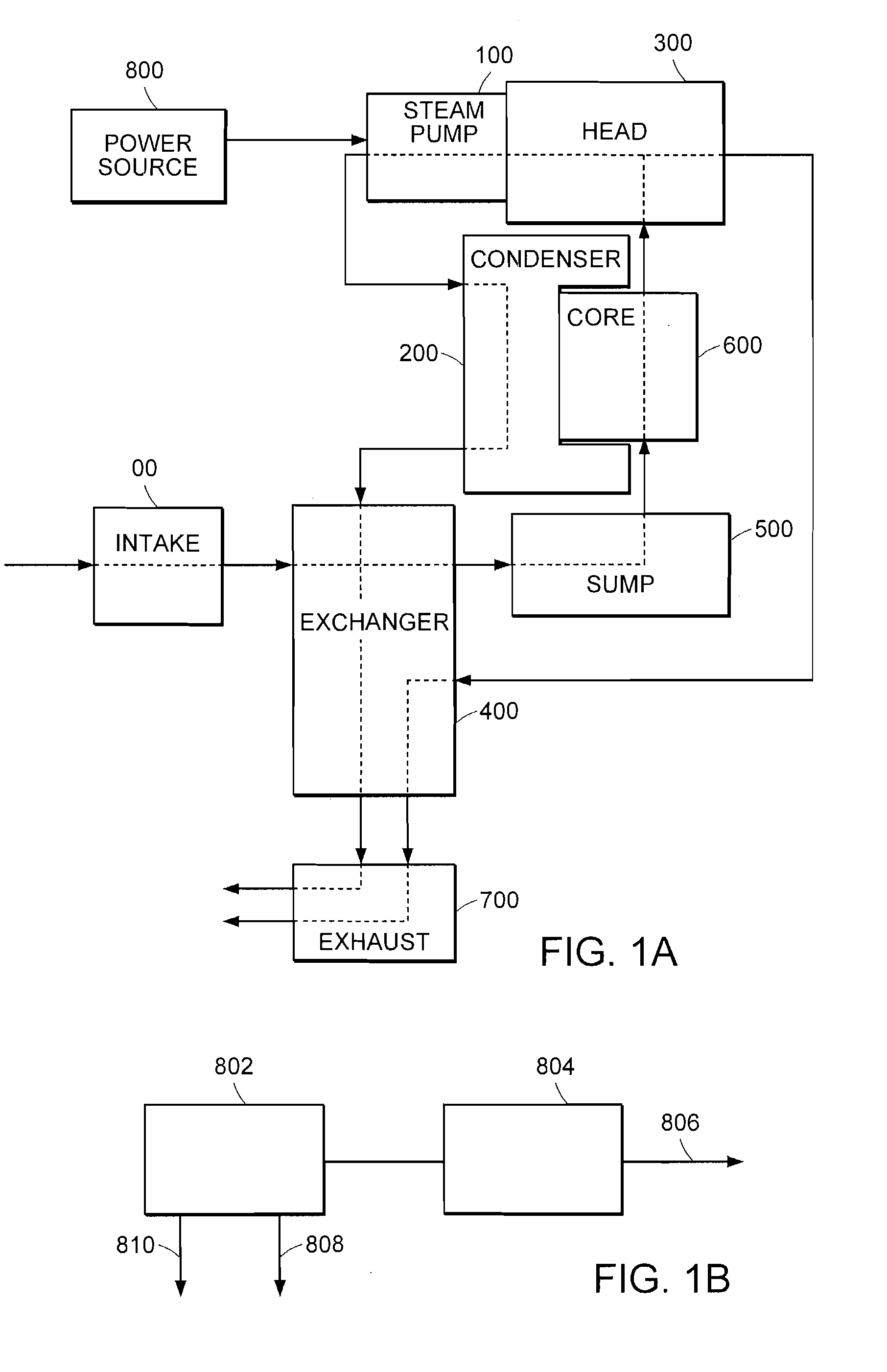

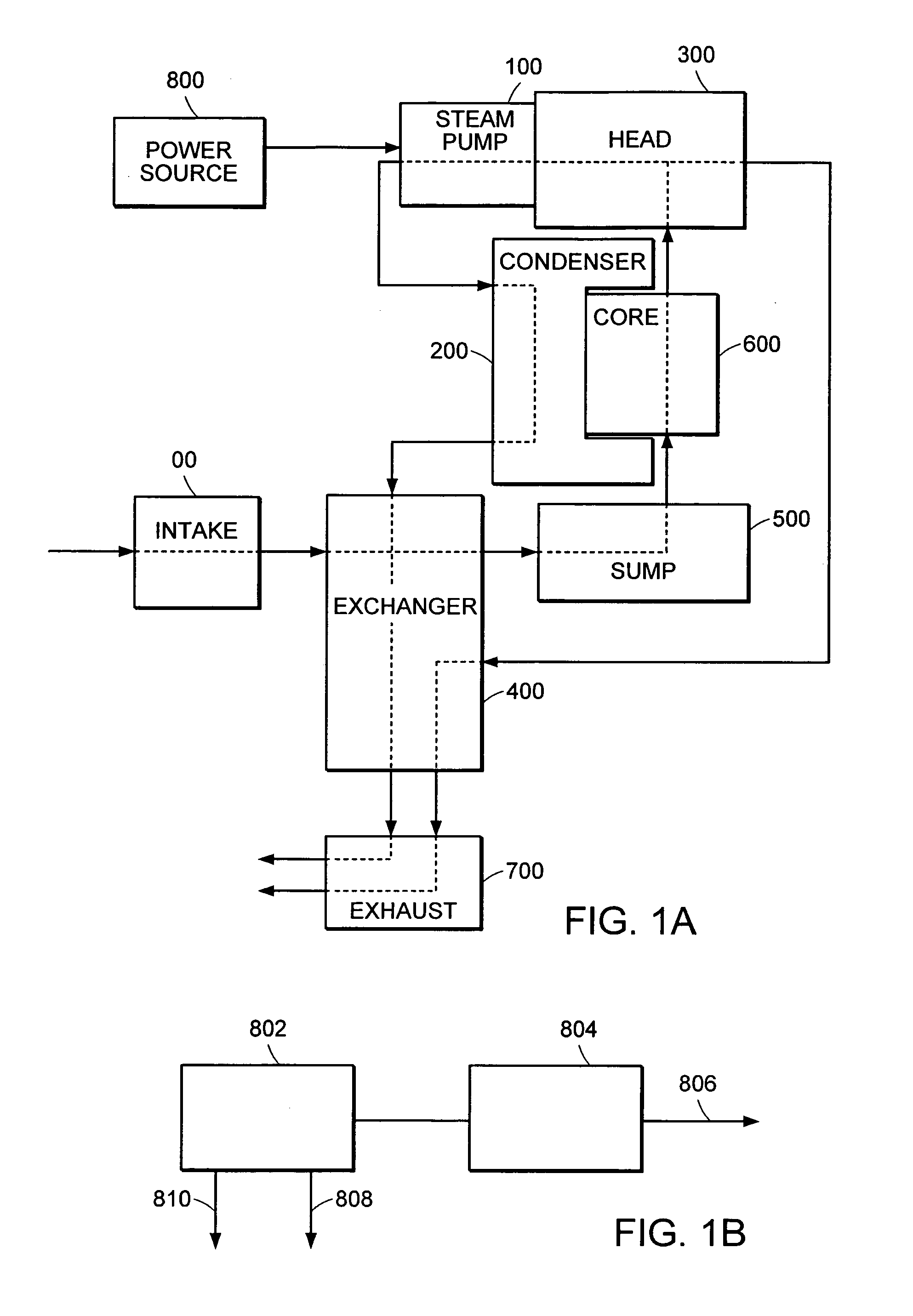

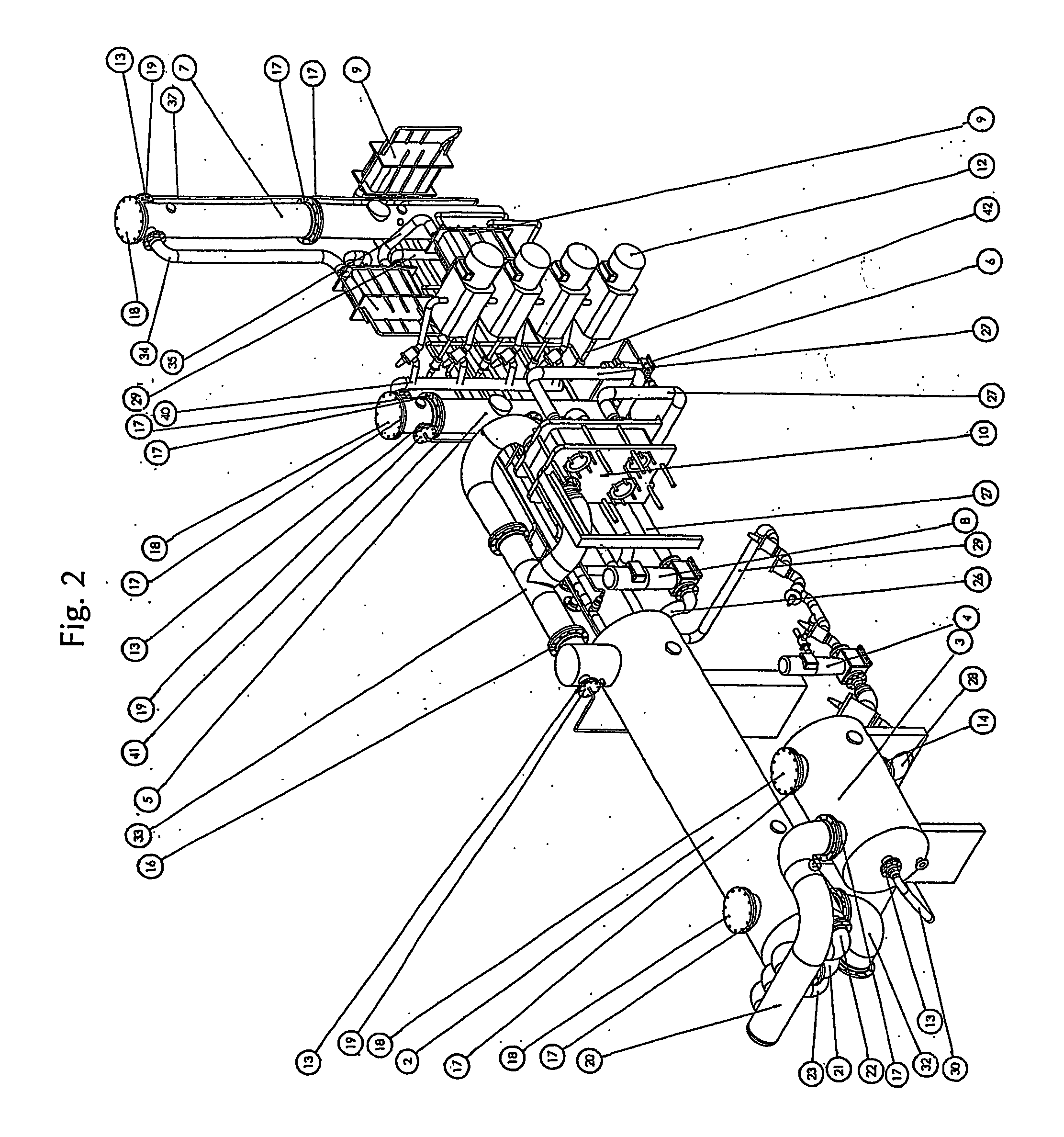

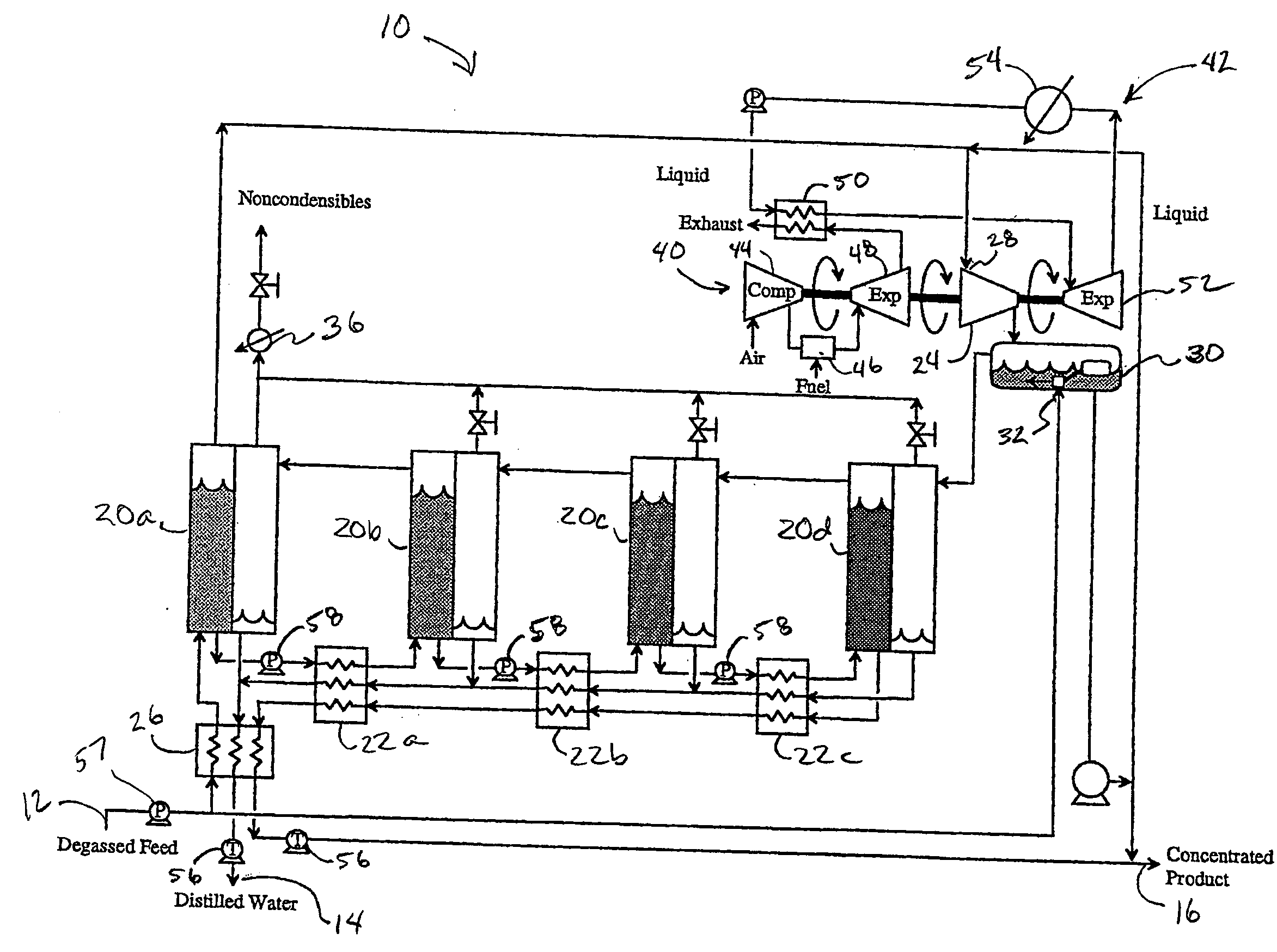

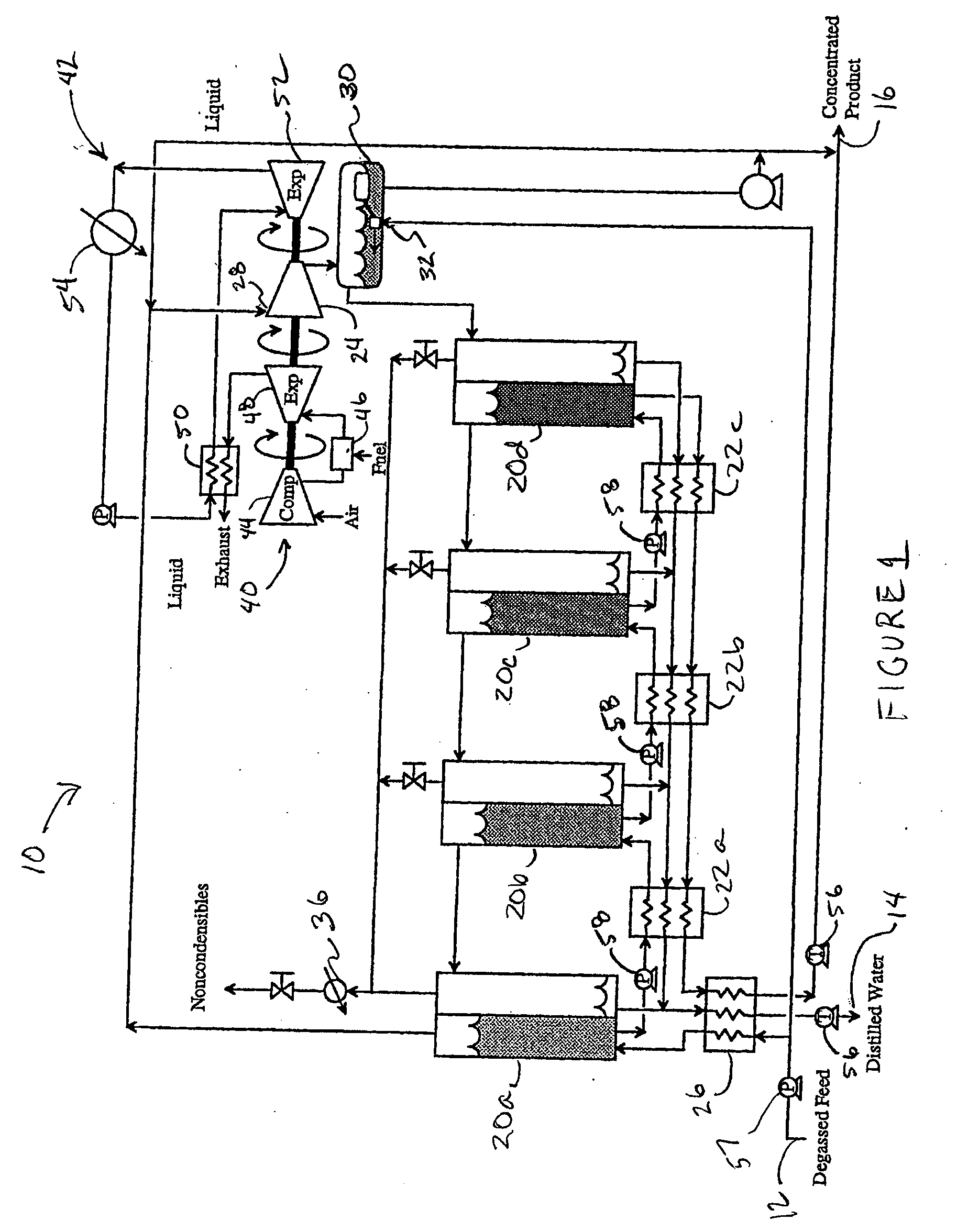

Pressurized vapor cycle liquid distillation

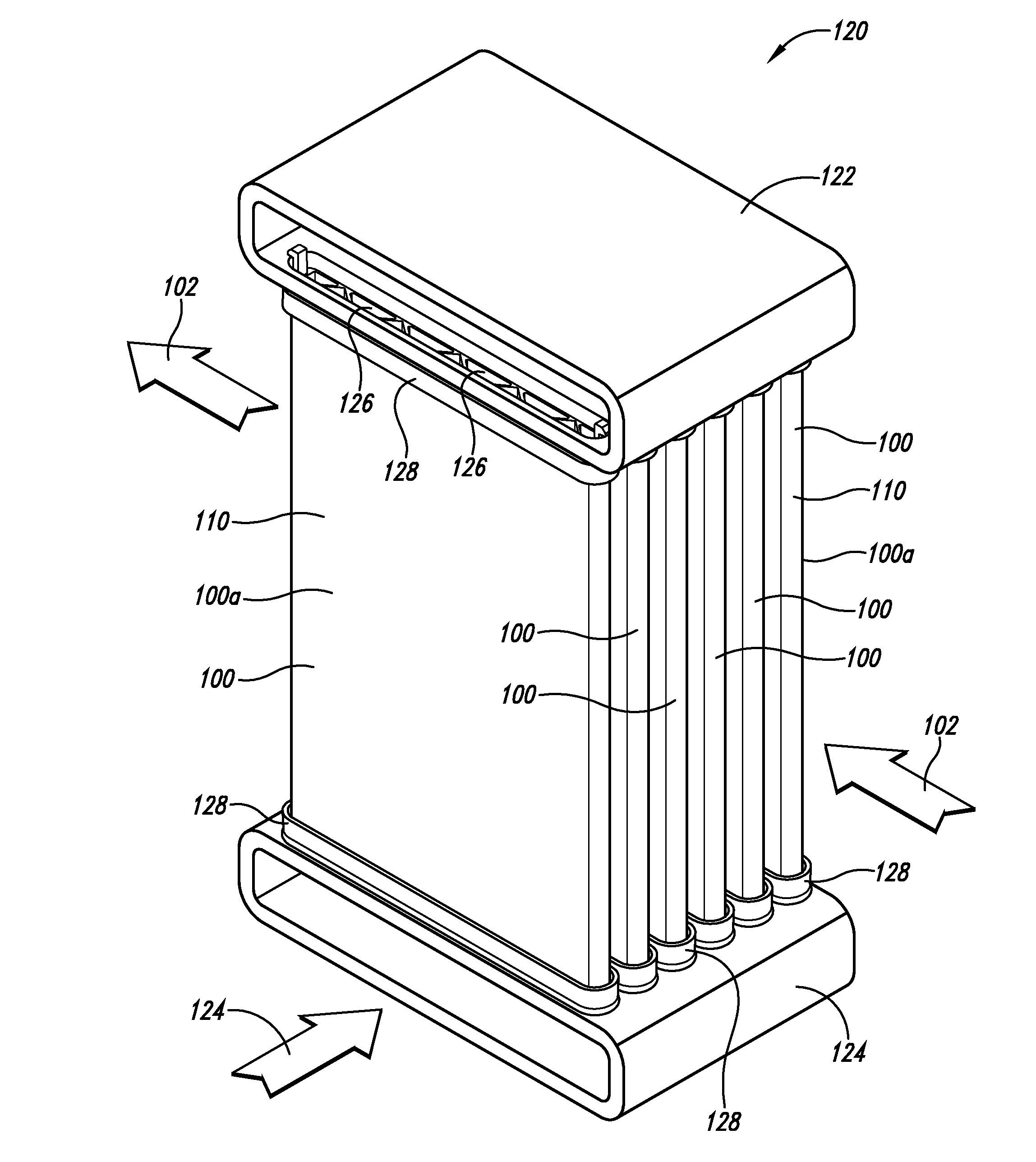

ActiveUS20070017192A1Easy maintenanceImprove efficiencyCombination devicesDrying using combination processesHeat managementDistillation

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

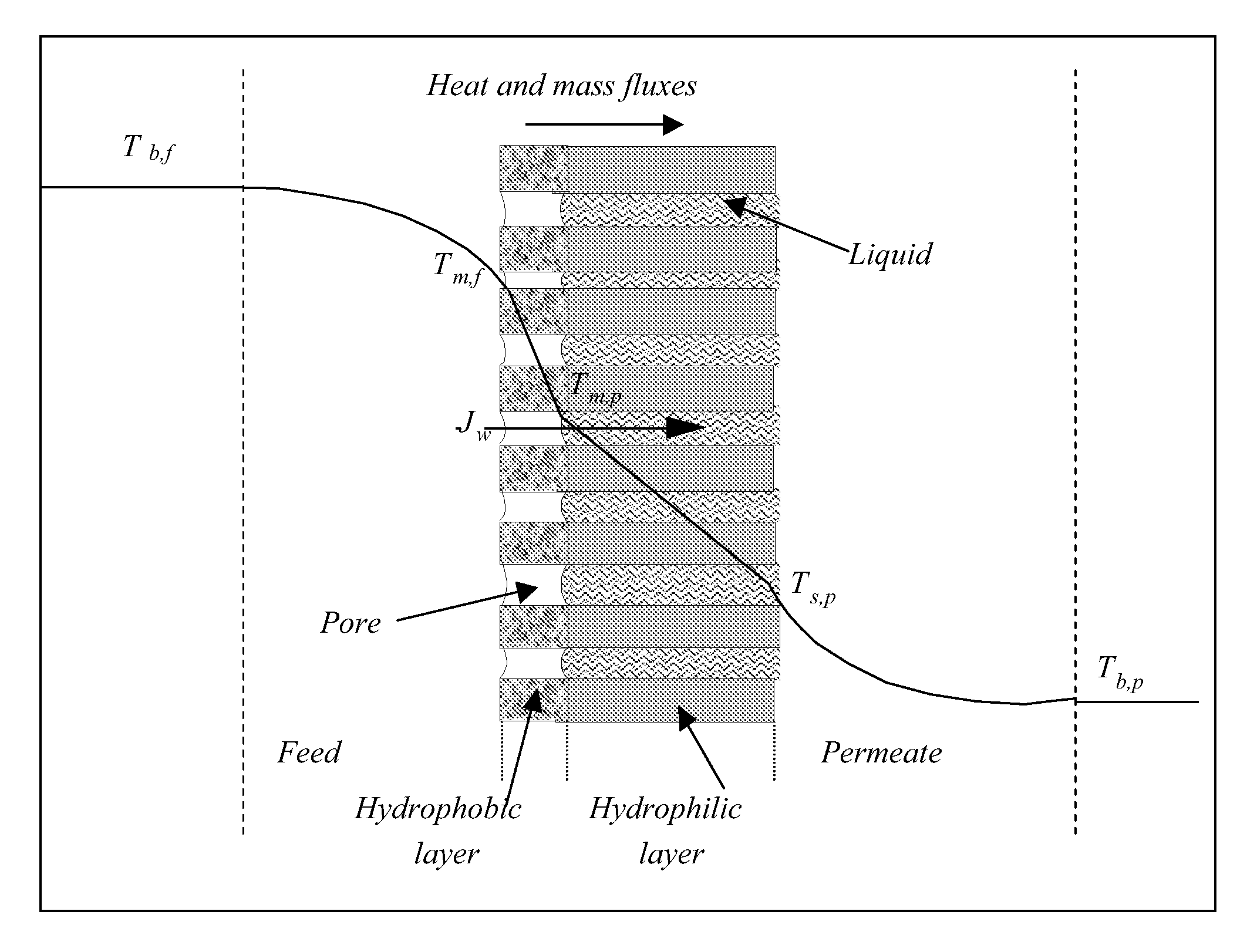

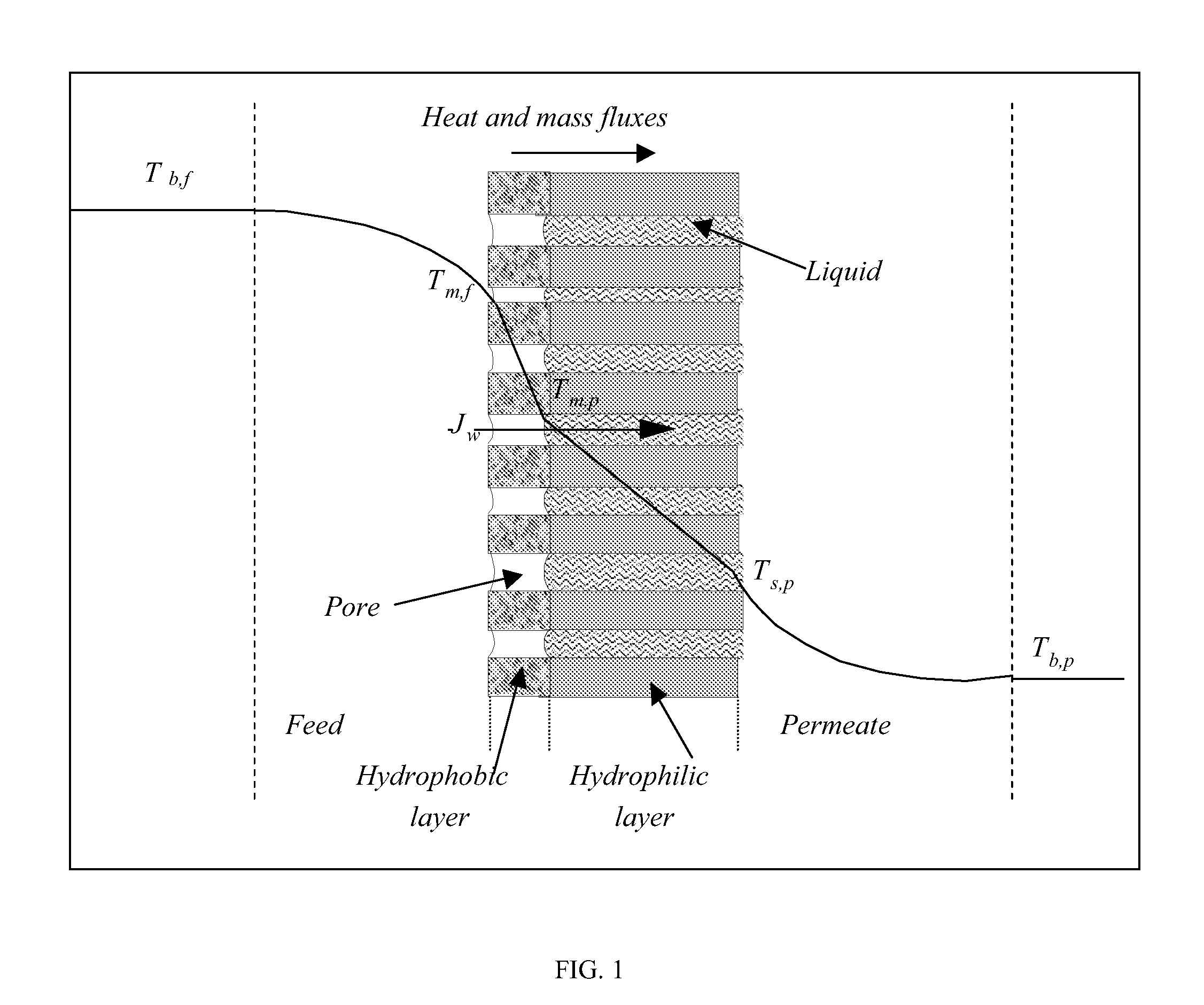

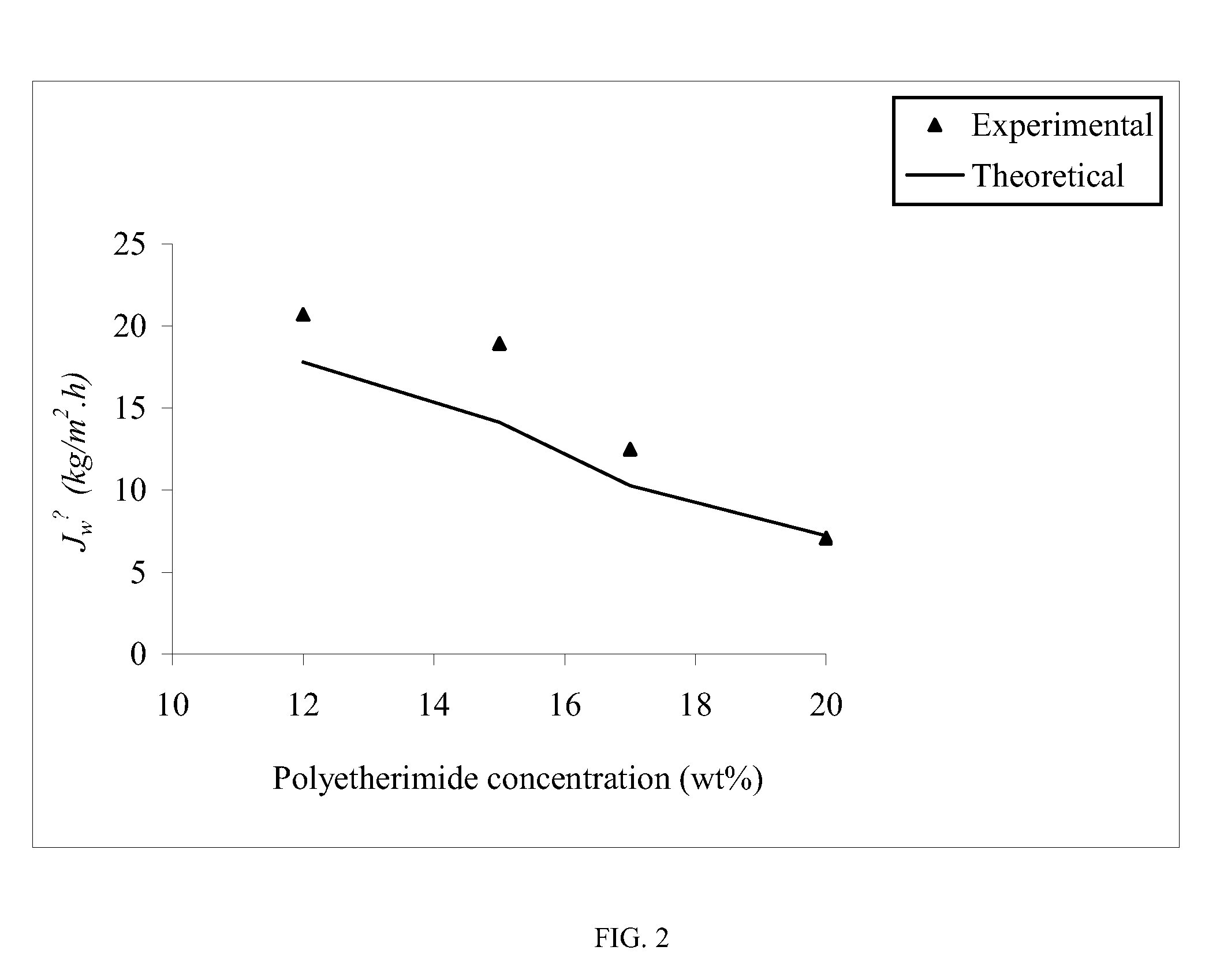

Composite membranes for membrane distillation and related methods of manufacture

ActiveUS20110031100A1Maximizing porosityThickness minimizationMembranesVacuum distillation separationPolymer scienceHydrophilic polymers

The present invention provides composite membranes for membrane distillation and related methods of manufacture. In particular, there is provided a composite hydrophilic / hydrophobic membrane comprising a hydrophilic polymer layer and a hydrophobic polymer layer comprising fluorinated surface-modifying macromolecules, wherein said composite membrane has a high vapour flux. Also provided herein are methods of manufacturing and optimizing the composite membranes and a membrane distillation system comprising the composite membranes.

Owner:MEMBRANE DISTILLATION DESALINATION LTD

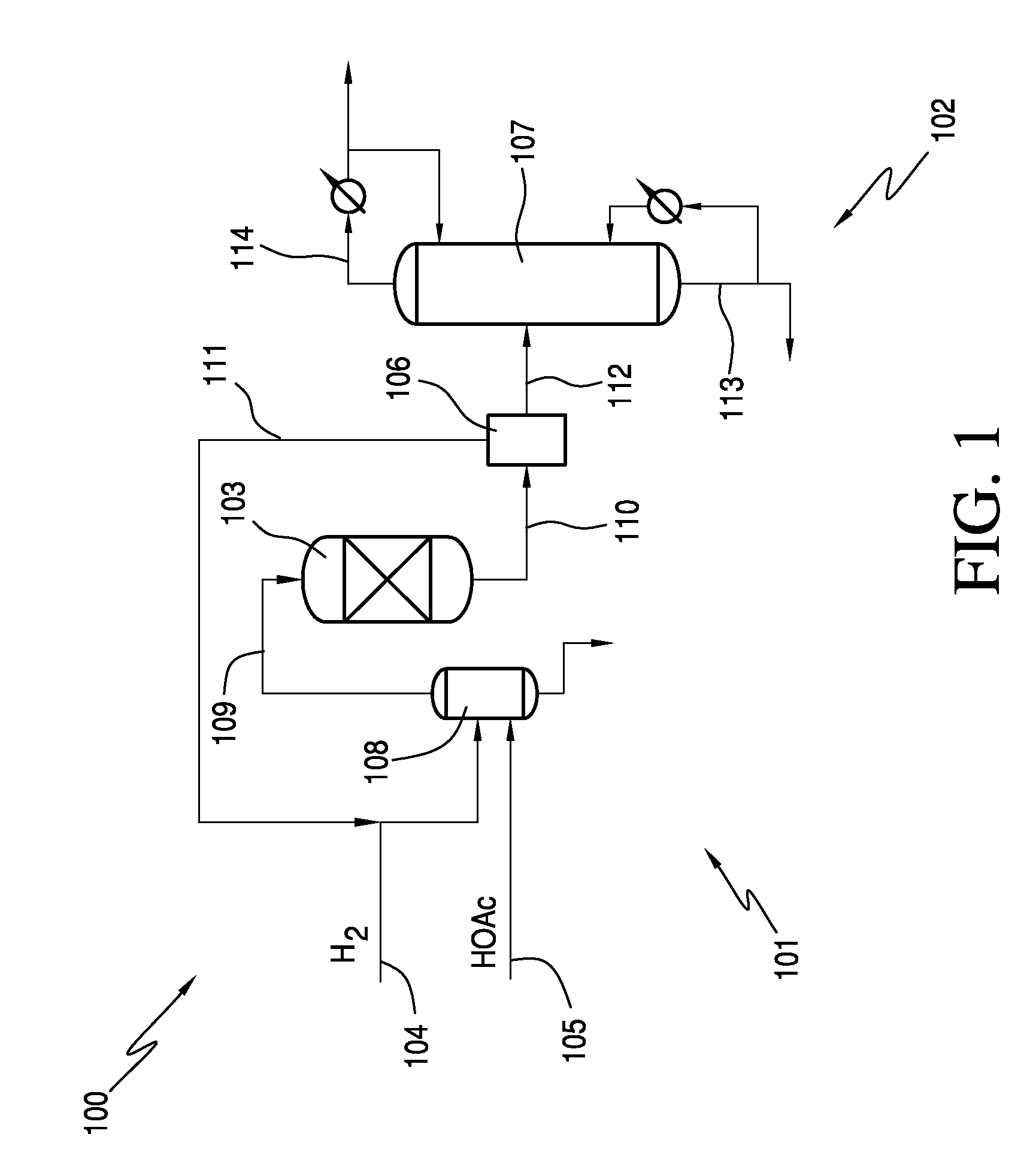

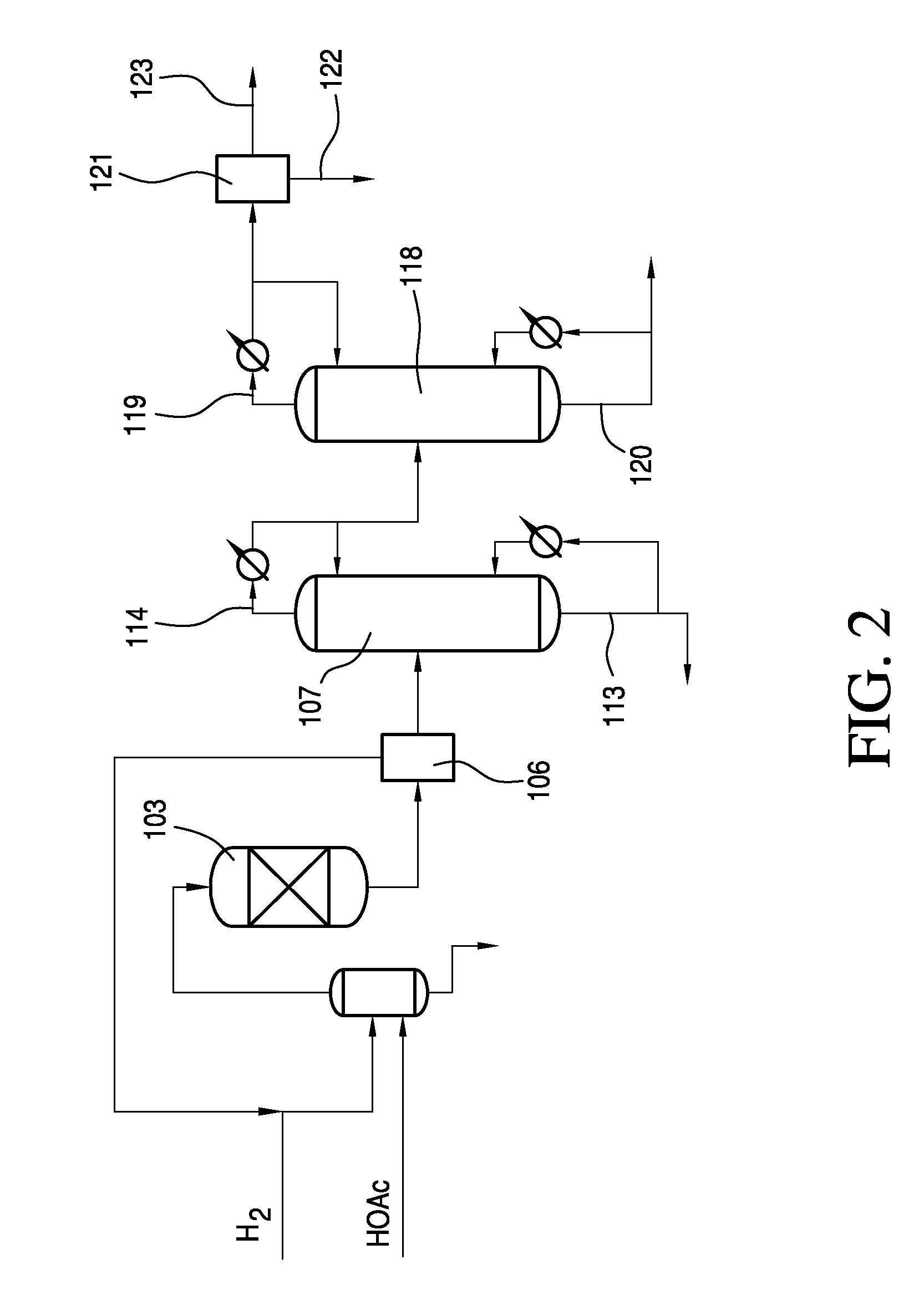

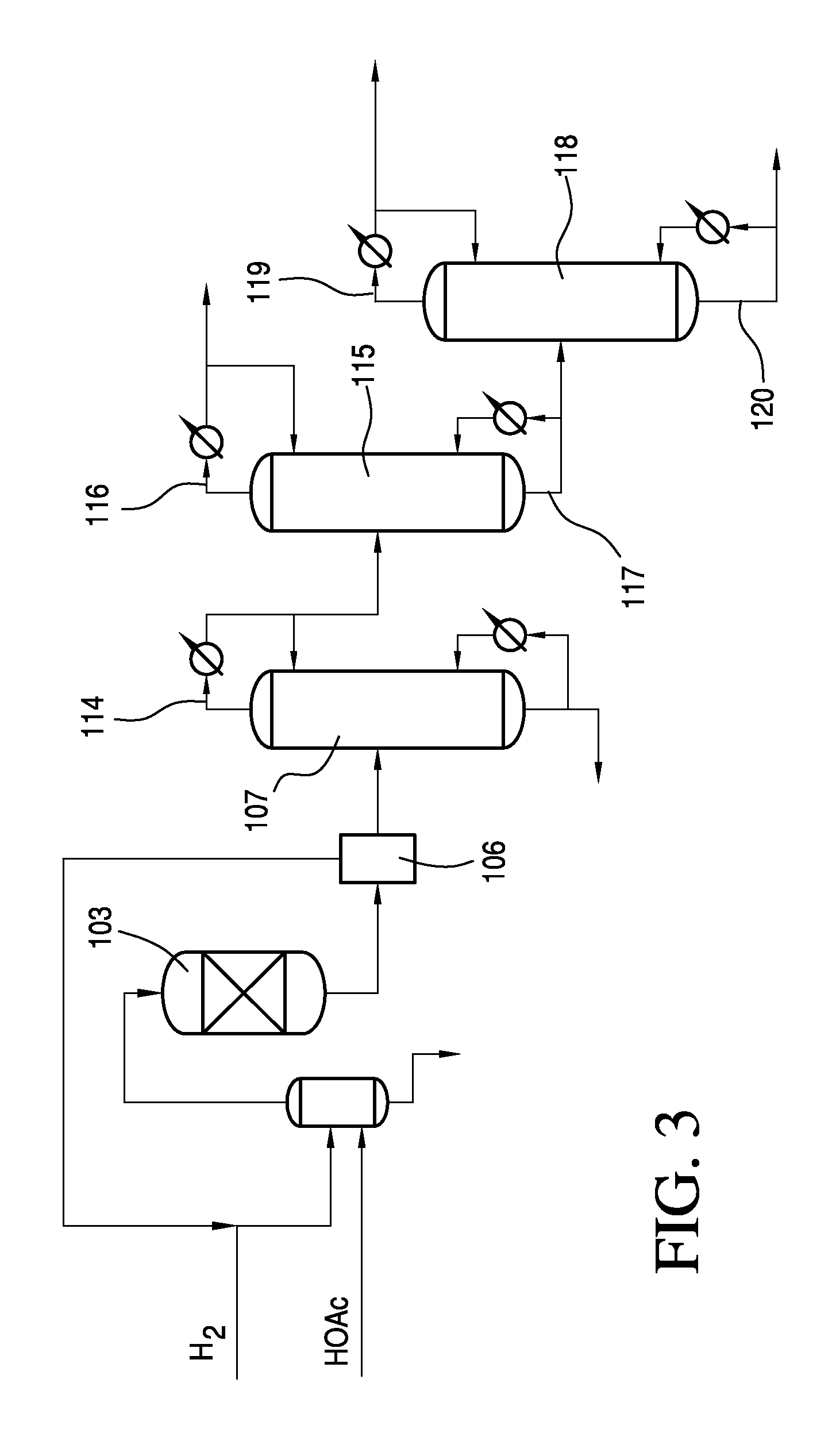

Reduced Energy Alcohol Separation Process

InactiveUS20120010438A1Fermented solutions distillation/rectificationOrganic compound preparationAcetic acidAqueous alcohol

Recovery of alcohols, in particular ethanol, from a crude ethanol product obtained from the hydrogenation of acetic acid using a reduced energy process. The crude ethanol product may be fed to a distillation column in which a substantial portion of the water is removed with the acetic acid in the residue. The ethanol product is obtained from the distillate.

Owner:CELANESE INT CORP

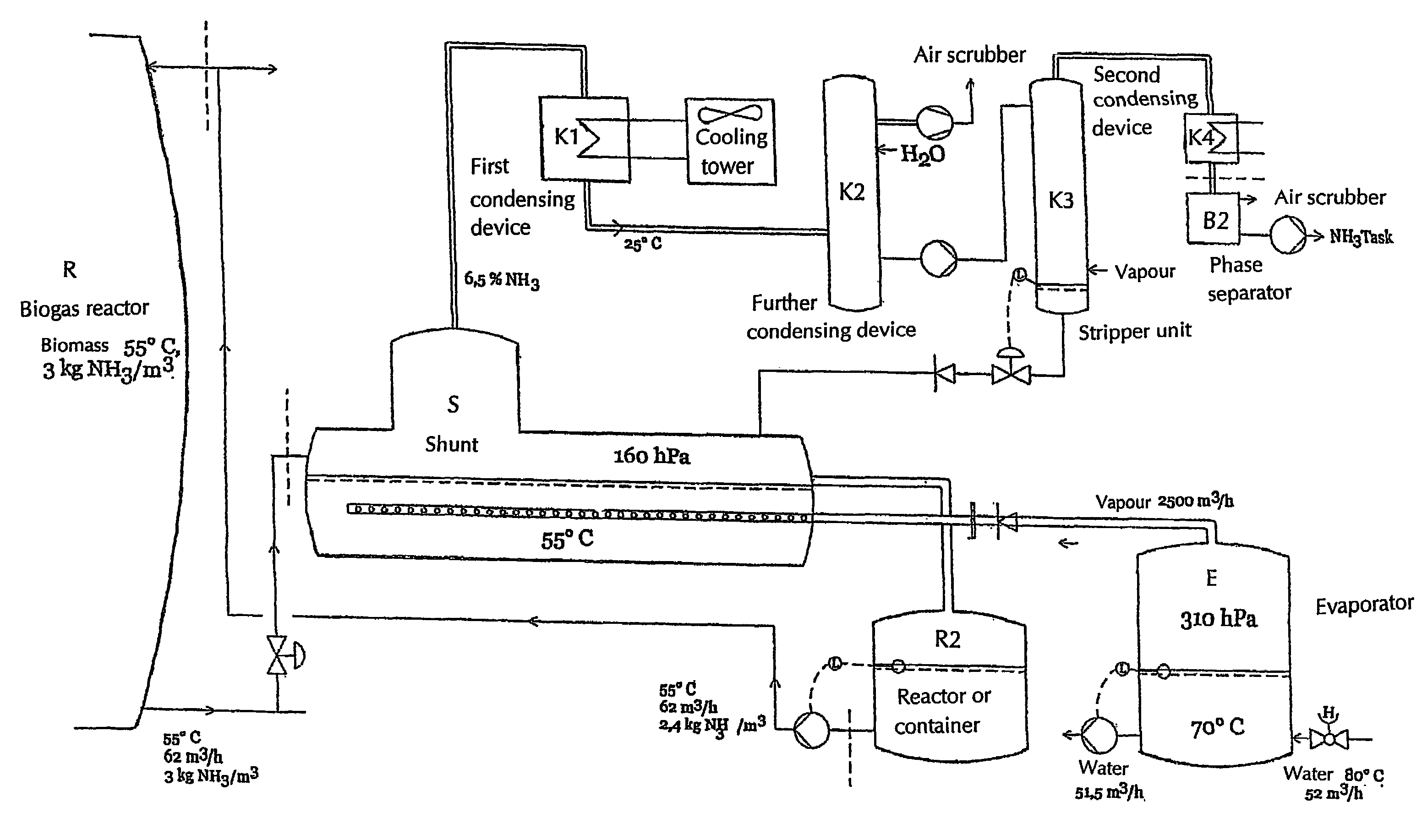

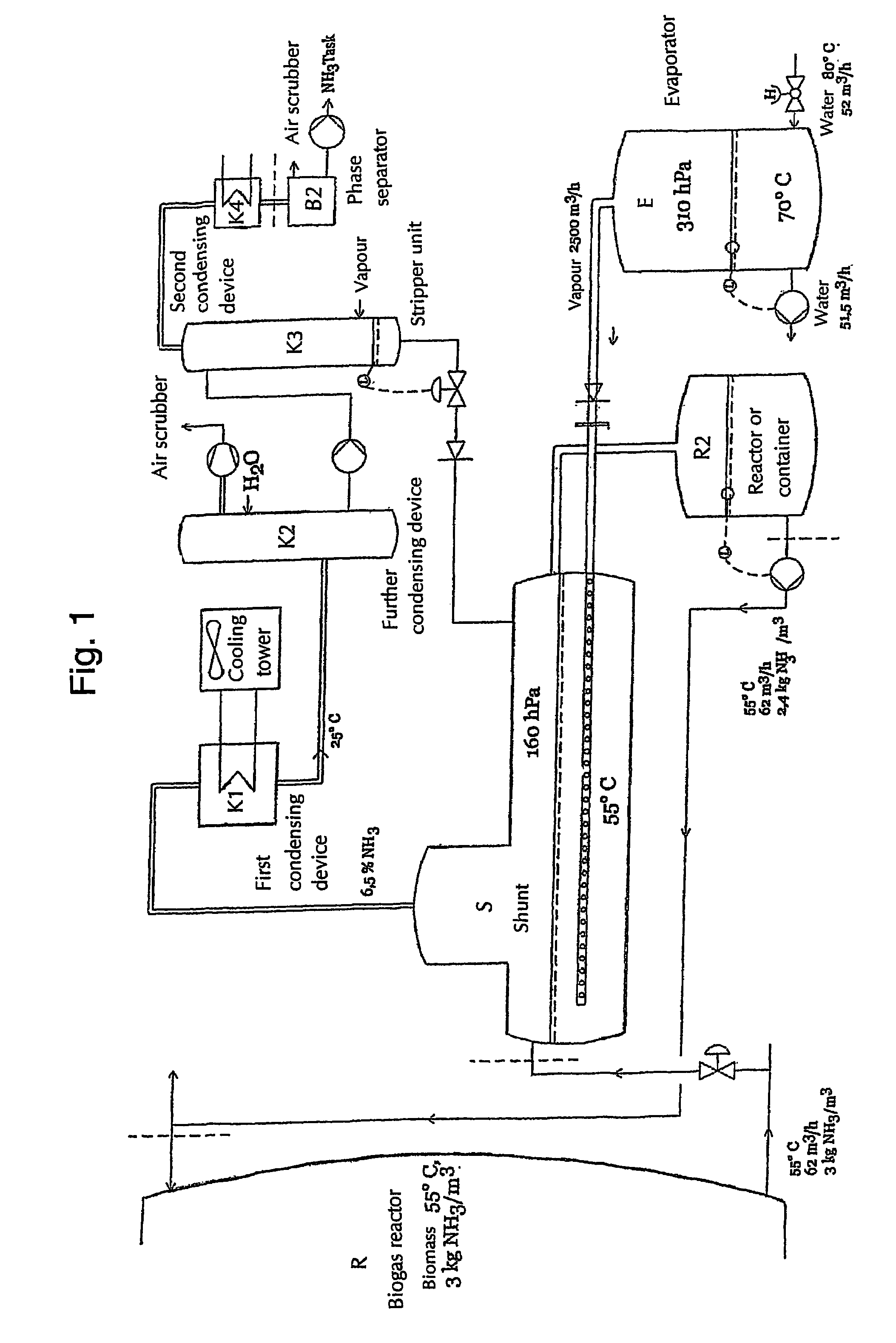

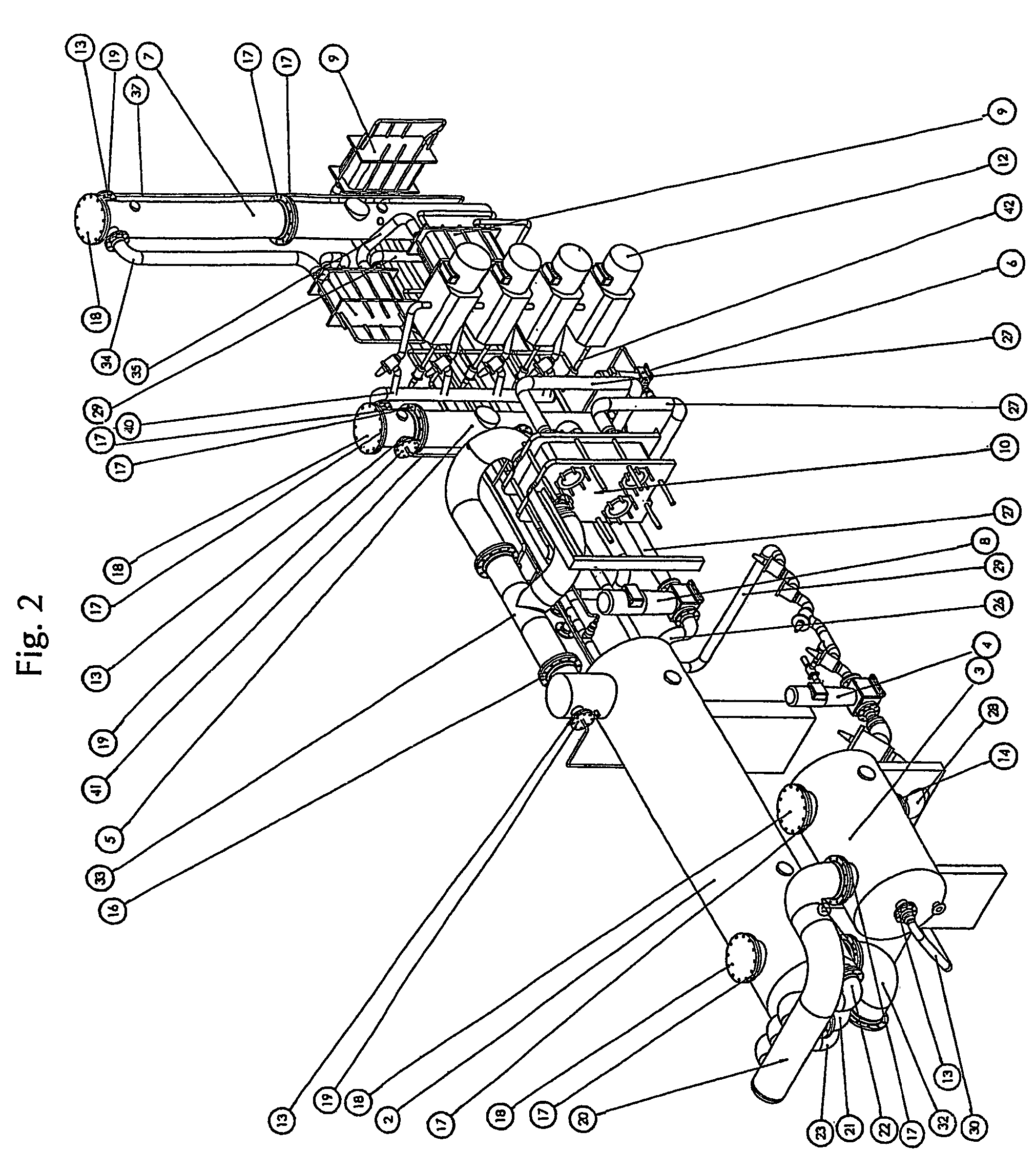

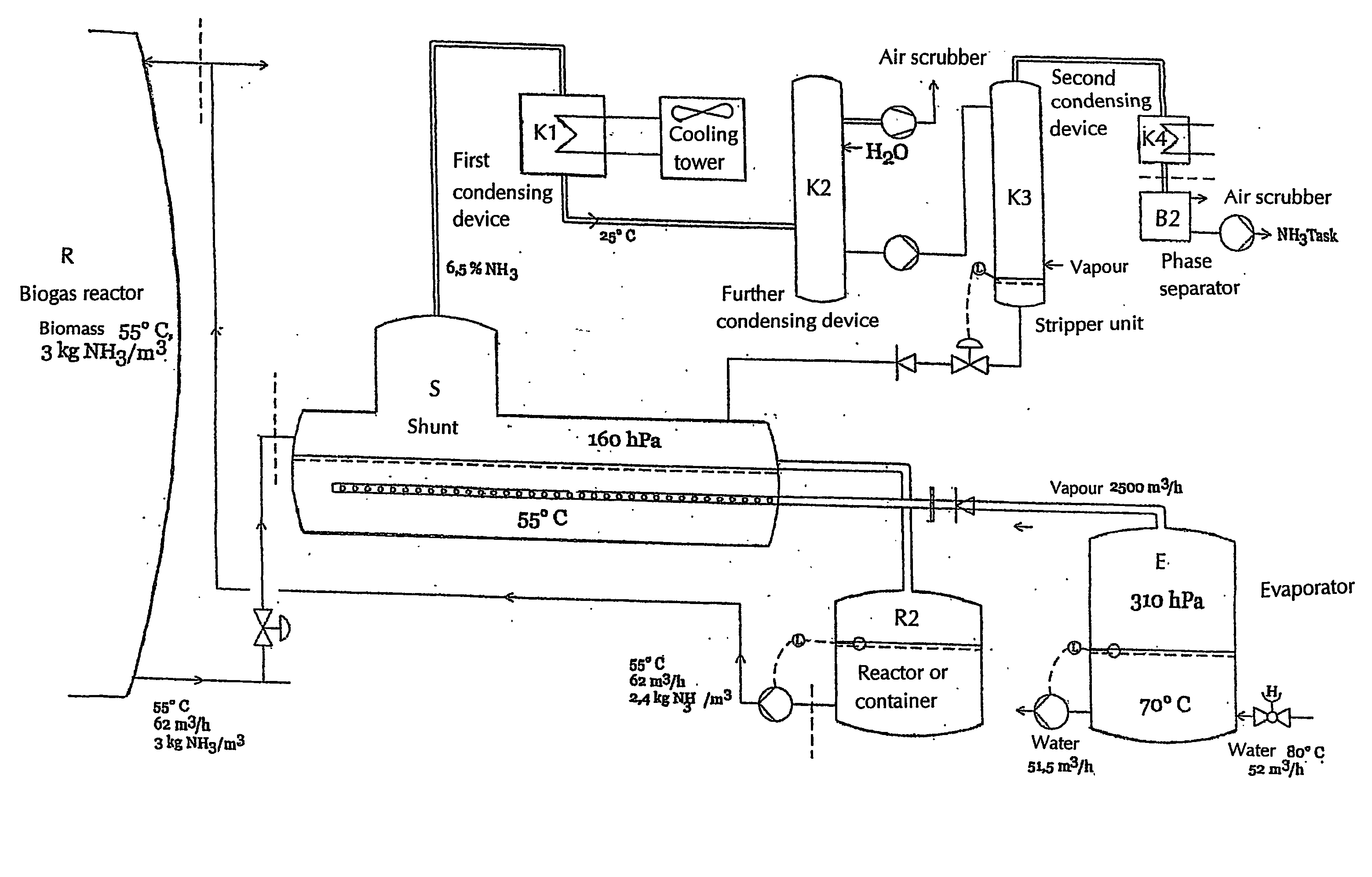

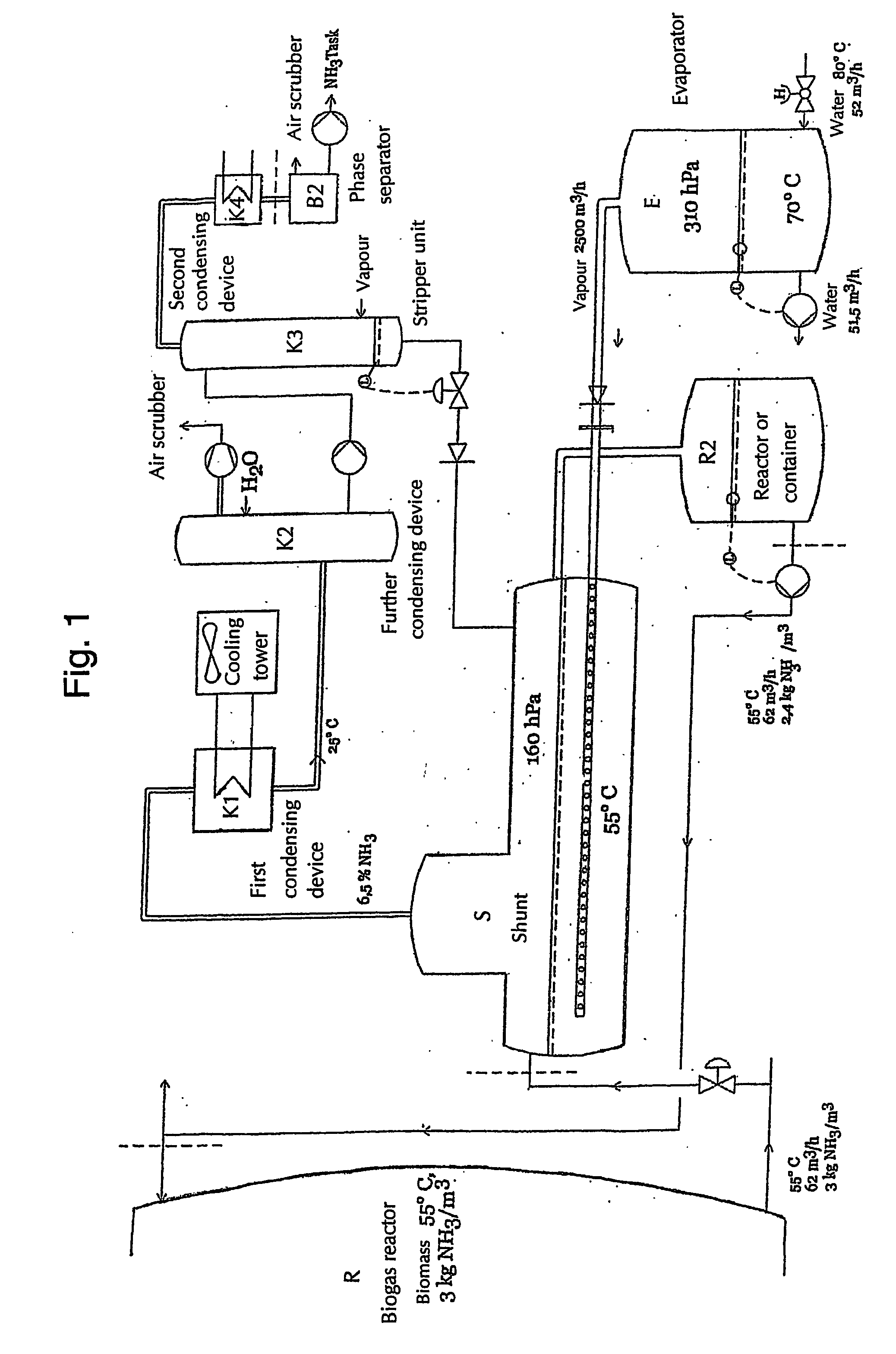

Method and device for stripping ammonia from liquids

InactiveUS7416644B2Simple and economic in operationLow-valuedBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumHigh pressure

Owner:GFE PATENT AS

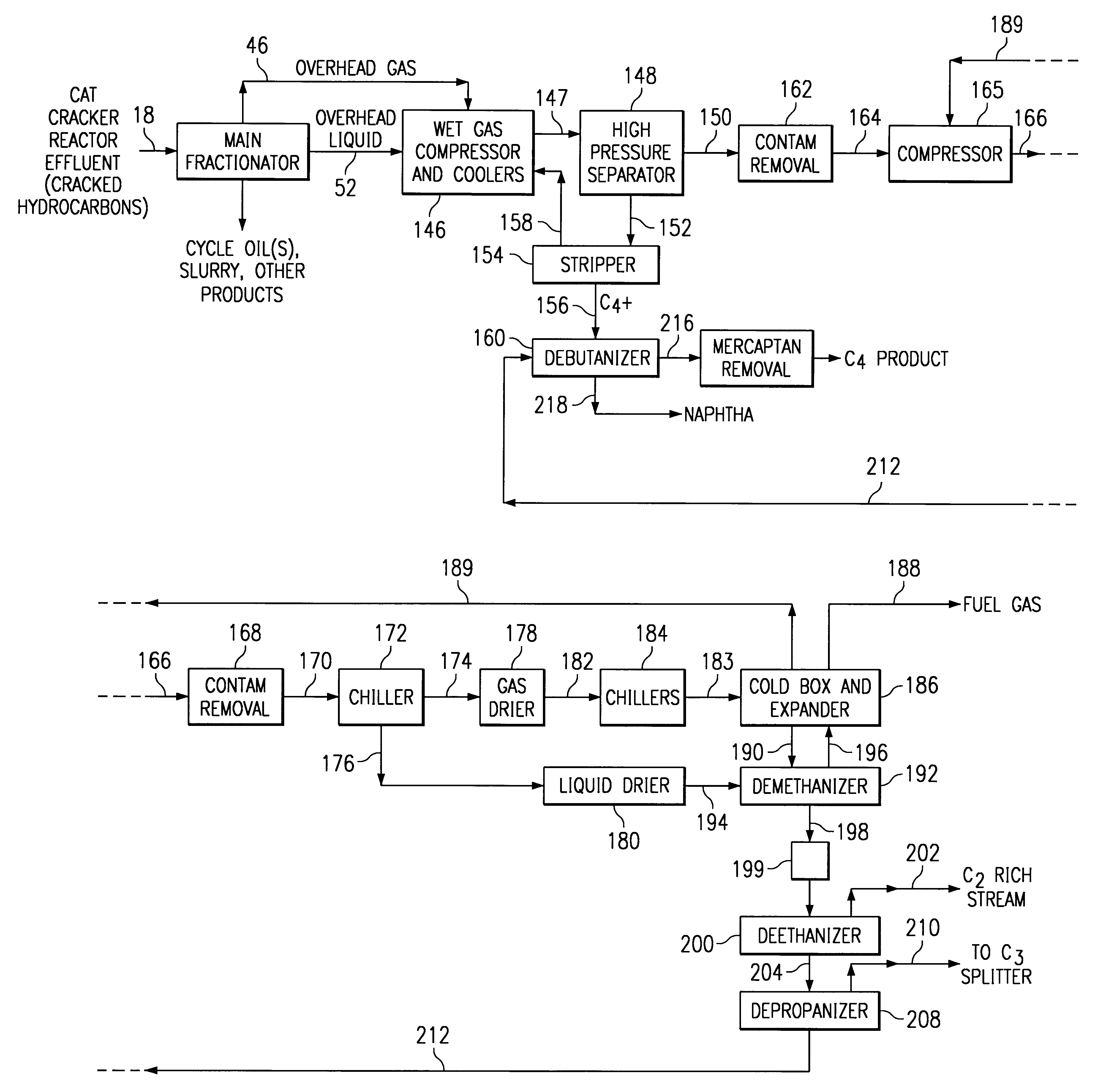

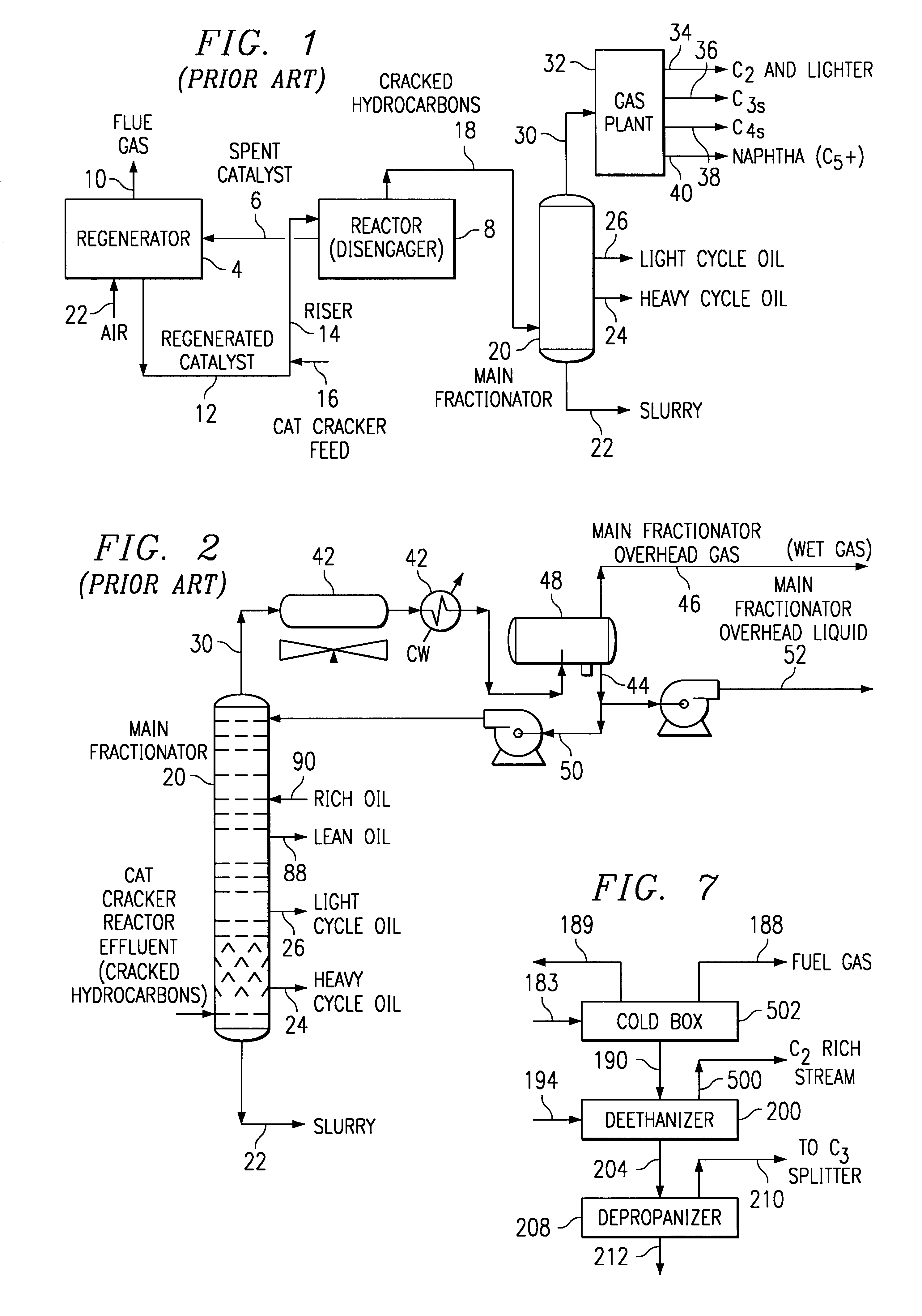

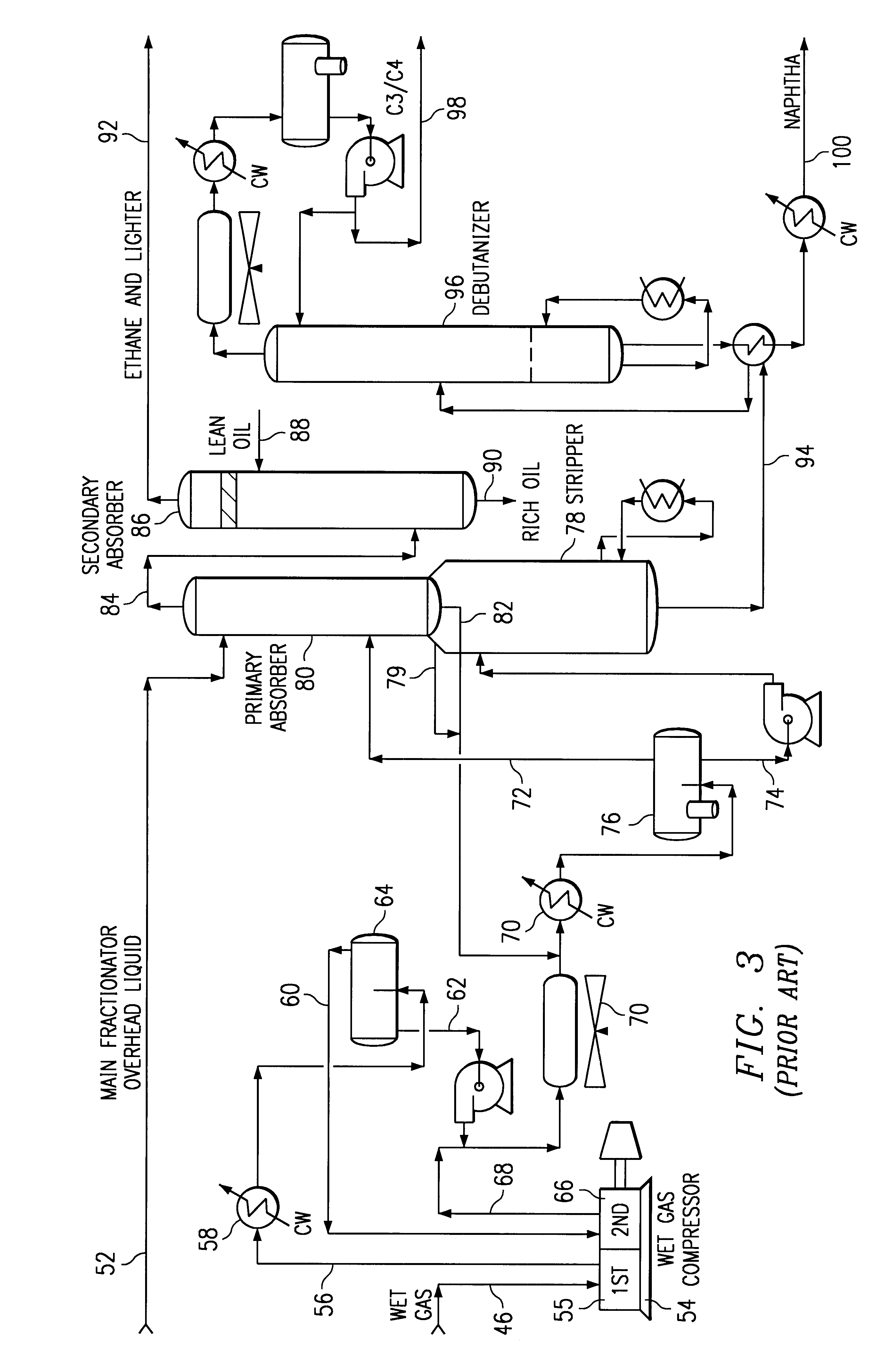

Cat cracker gas plant process for increased olefins recovery

The invention relates to a new process for more efficient separation and recovery of light olefins such as ethylene and propylene from a fluid catalytic cracking unit. The new process invention for recovering olefins from a mixture of cracked hydrocarbons from a fluid catalytic cracker comprises the steps of: (a) providing a mixture of cracked hydrocarbons including methane, ethylene, ethane, propylene, propane, butylene, butane and heavier hydrocarbons such as naphtha produced in a fluid catalytic cracker; (b) separating said mixture into (i) a first stream comprising substantially all of said ethane, ethylene, and methane and a major portion of said propane and propylene and (ii) a second stream comprising a portion of said butylene and butane, and a major portion of said heavier hydrocarbons; and (c) processing said first stream to recover the ethylene and propylene therefrom, and the details of such process described herein.

Owner:STONE & WEBSTER PROCESS TECH

Liquid ring pumps with hermetically sealed motor rotors

ActiveUS7465375B2Easy maintenanceMaximize energy efficiencyGeneral water supply conservationDistillation regulation/controlDrive shaftDistillation

Owner:DEKA PROD LLP

Method and device for stripping ammonia from liquids

InactiveUS20060006055A1Simple and economic in operationLow-valuedBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumHigh pressure

The present invention in a first aspect provides a method and a system for stripping volatile compounds such as ammonia from e.g. fermentation liquids. Part of the ammonia is stripped from the liquid in a stripper system comprising a shunt through which liquid such as e.g. fermentation medium comprising a biomass can be diverted in the form of a side stream in liquid contact with a main fermentor(s). The stripper system is connected to an evaporator. In the evaporator aqueous liquid is heated at a pressure below atmospheric pressure whereby vapour is developed at a temperature below 100° C. The vapour from the evaporator is directed to the liquid medium comprising ammonia and this results in ammonia being stripped from the liquid and transferred to the vapour phase. The vapour phase is condensed in a first condenser at a low pressure, e.g. a pressure well below 1 bar, and the liquid thus obtained is further treated in a stripper unit at a higher pressure, such as e.g. a pressure at or above 1 bar, to obtain a more concentrated solution of ammonia. When stripped for at least part of the ammonia the liquid initially obtained from the biogas reactor and diverted to the shunt can be returned to the reactor.

Owner:GFE PATENT AS

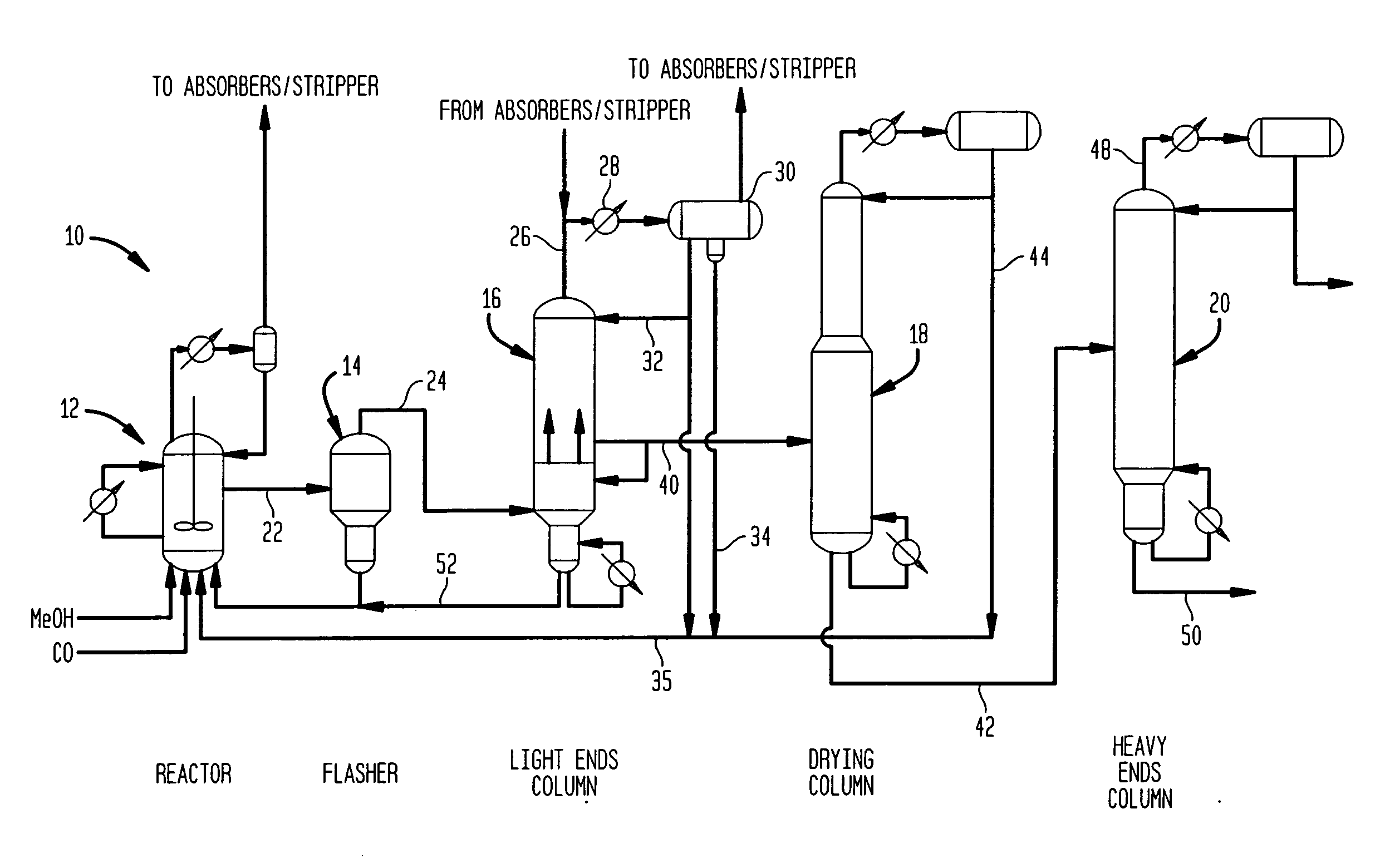

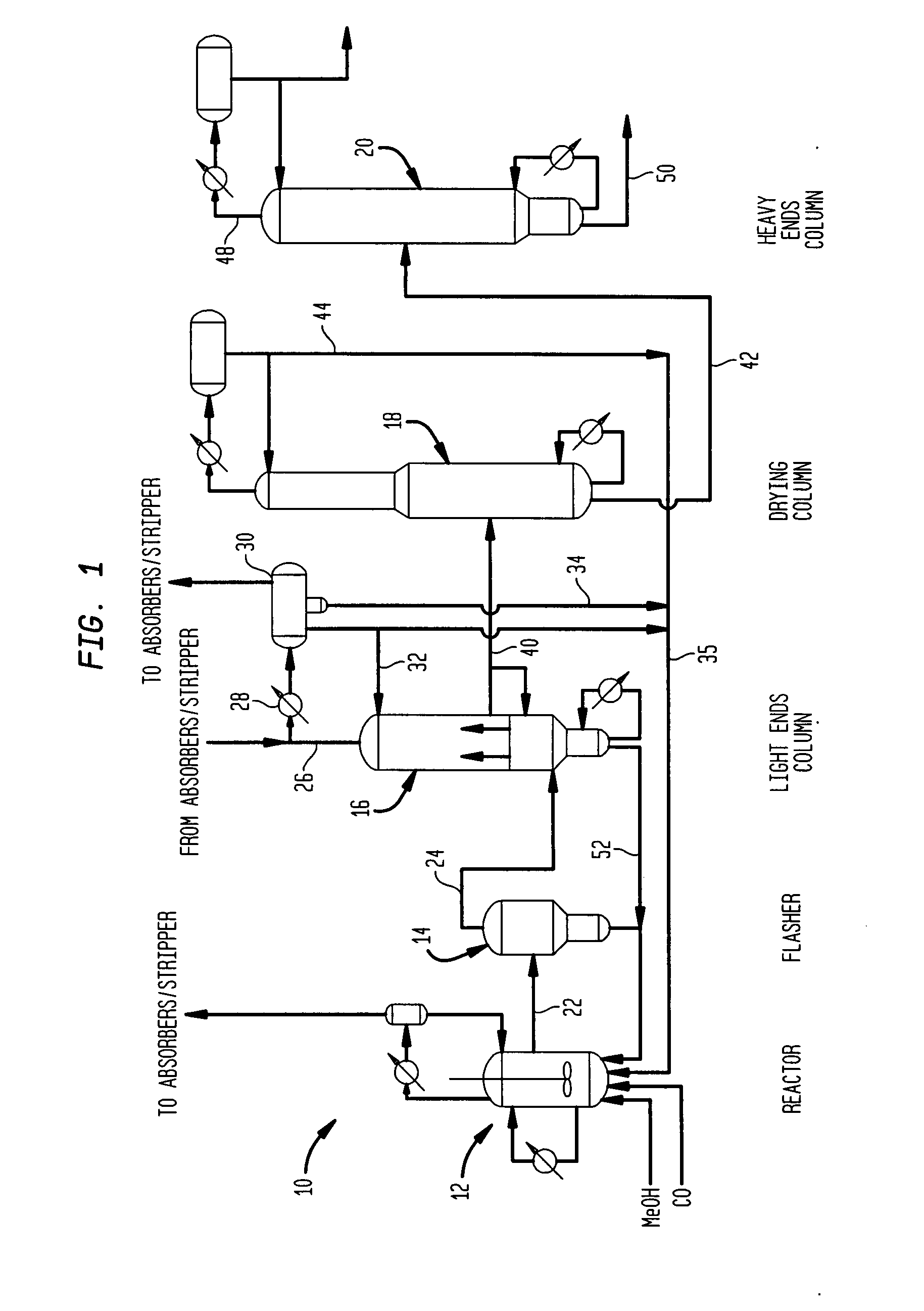

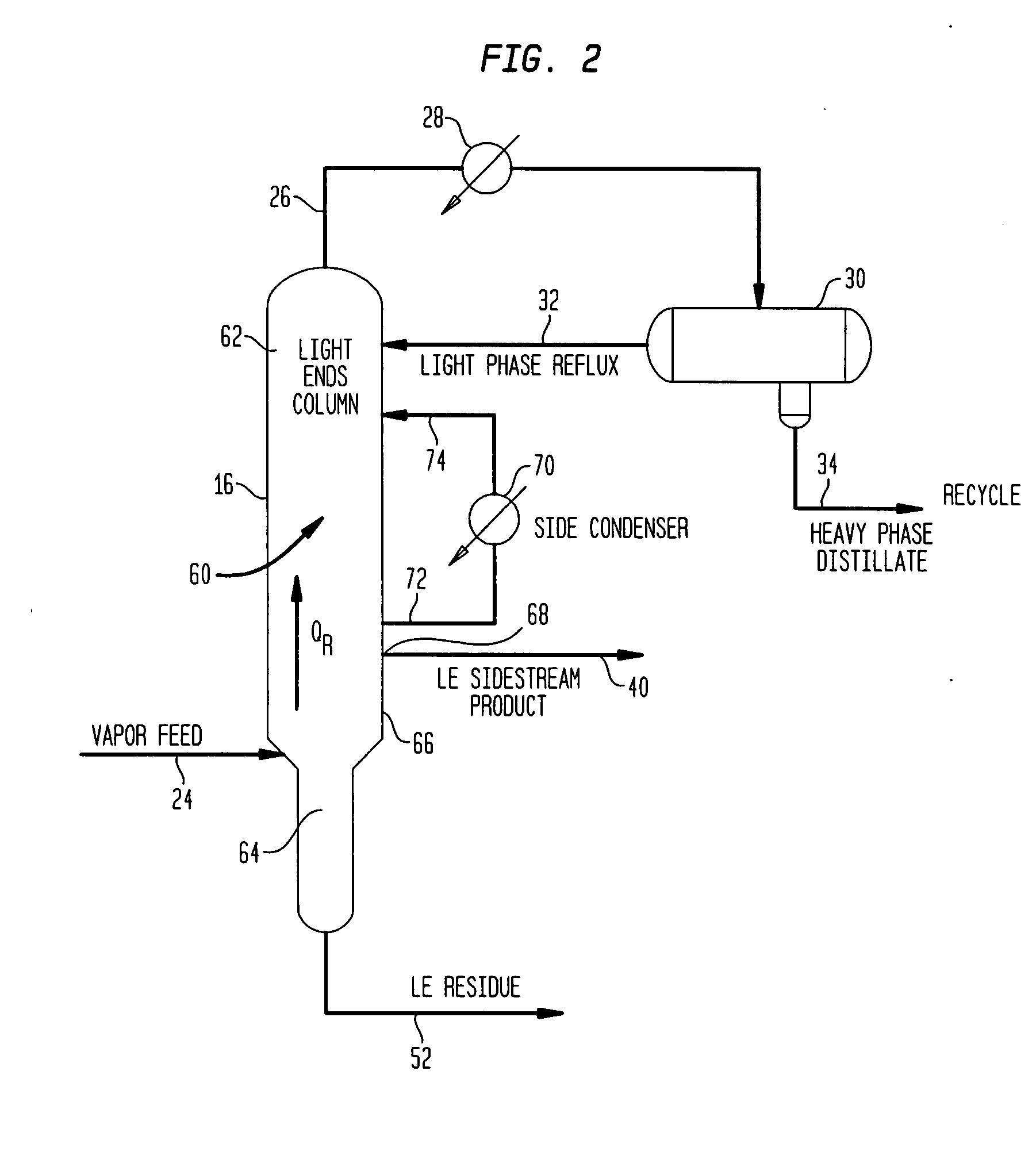

Method and apparatus for making acetic acid with improved light ends column productivity

ActiveUS20080287706A1Reduce hydraulic loadLight loadBacterial antigen ingredientsOrganic compound preparationAcetic acidProduction rate

An improved apparatus and method of producing acetic acid includes condensing overhead vapor to provide reflux to the light ends column as well as condensing vapor from a central portion of the light ends column to increase capacity. Throughput or load on the light ends column is substantially reduced without compromising product quality.

Owner:CELANESE INT CORP

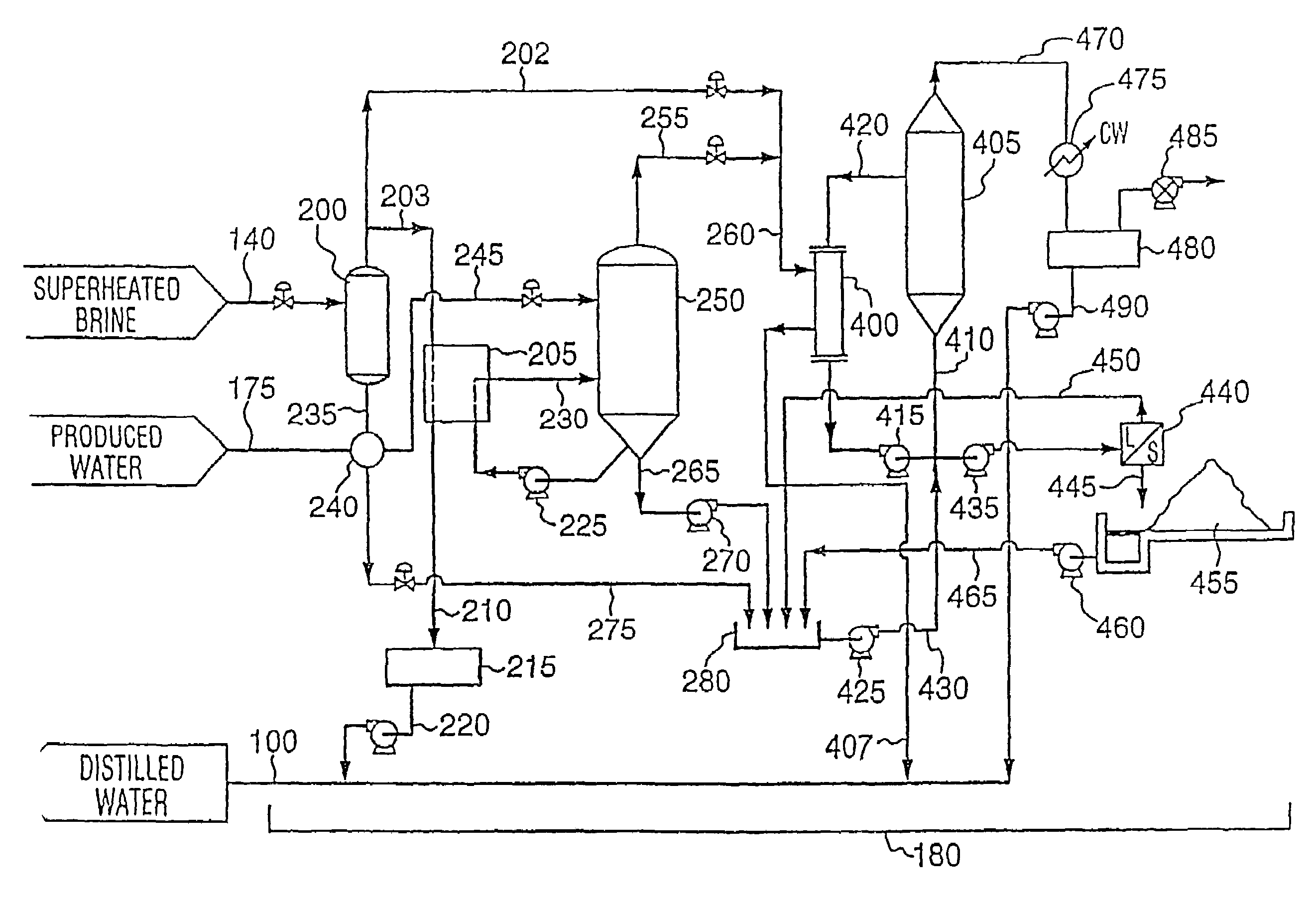

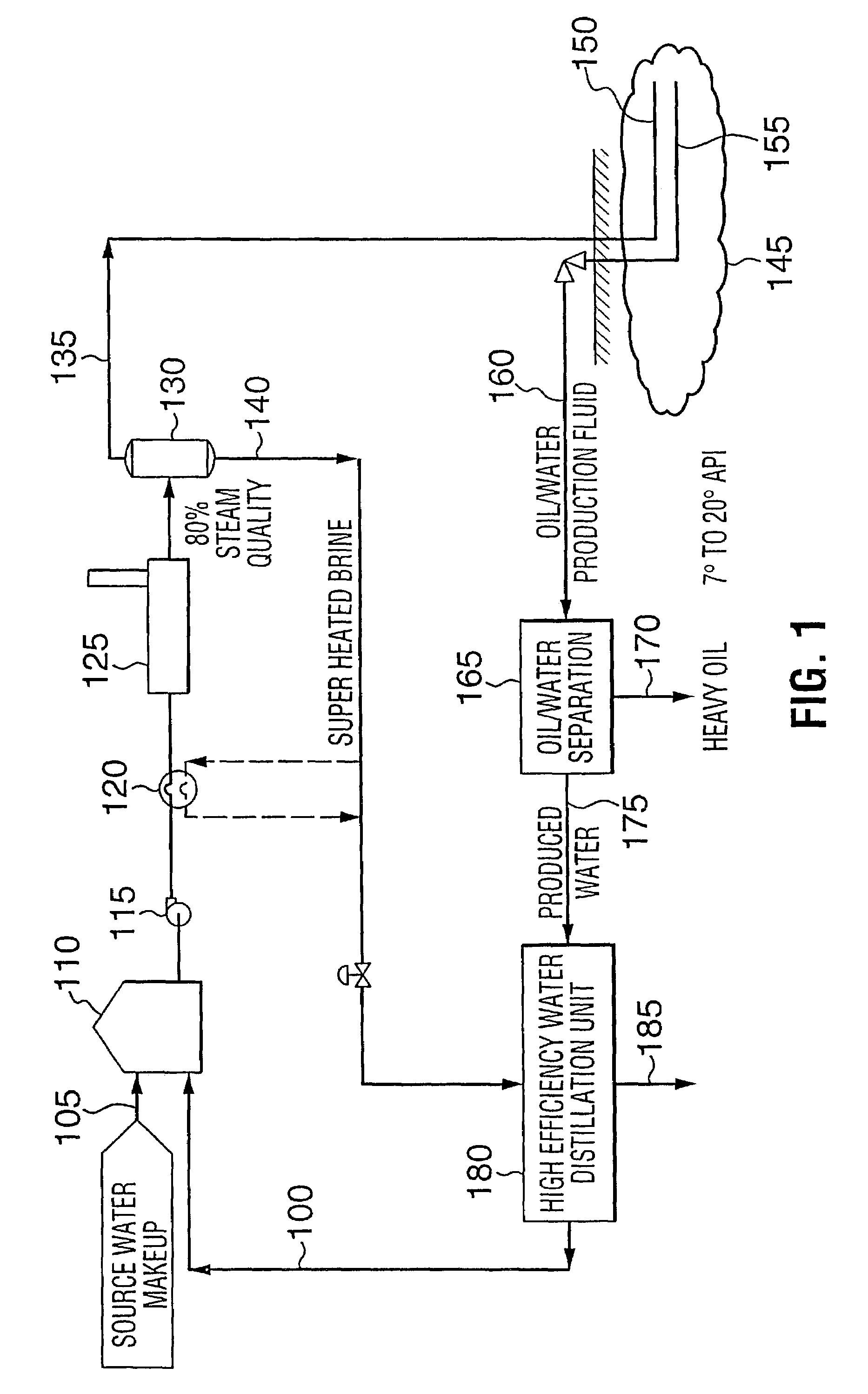

Water treatment process for thermal heavy oil recovery

There is disclosed a method and apparatus for treating produced water from a heavy oil thermal recovery unit to achieve water recovery and recycle levels of greater than 80% and as high as 100% to achieve zero discharge criteria. The method includes the initial steps of capturing the waste heat energy from the high pressure steam separator located downstream of the steam generators. Further, transferring the heat energy into a heated separator and reboiler exchanger to distill oil reservoir produced water and recover distilled water and a concentrated brine or solid product. The heated separator concentrated stream is circulated through the reboiler exchanger to maintain from 1% to about 50% mass vapour in the stream returning to the heated separator and prevent fouling and scaling. The apparatus includes a low pressure waste energy separator, heated separator and vapour compressor in combination with a forced circulation circuit to generate the distilled water.

Owner:FOUNTAIN QUAIL WATER MANAGEMENT LLC +1

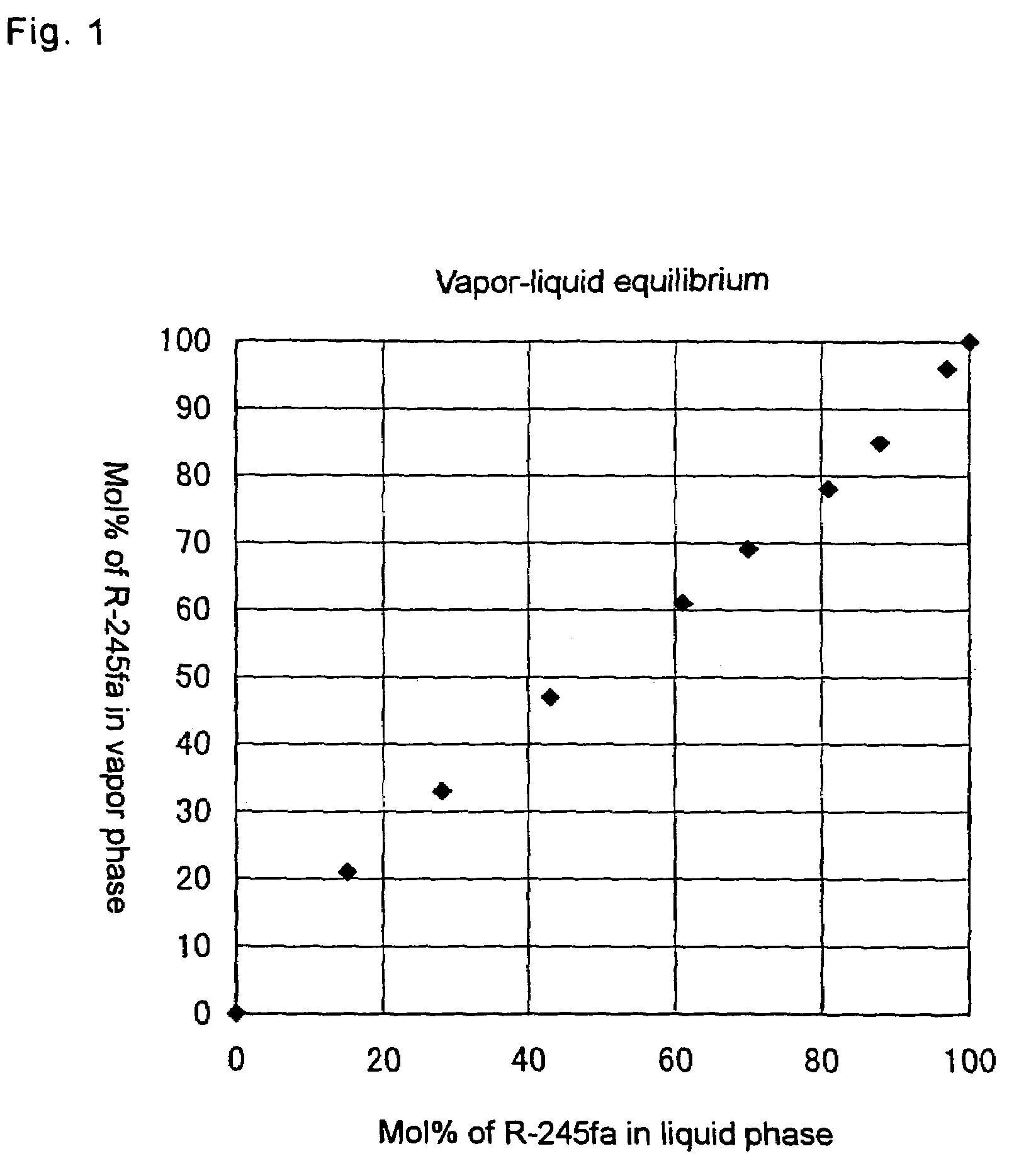

Azeotropic composition, comprising 1, 1, 1, 3,3-pentafluoropropane and 1, 1, 1-trifluoro-3-chloro-2-propene, method of separation and purification of the same, and process for producing 1, 1, 1,3,3-pentafloropropane and 1, 1, 1-trifluoro-3-chloro-2-propene

InactiveUS7183448B2Delayed recoveryIncrease production costPreparation by hydrogen halide split-offOther chemical processesDistillationPentafluoropropane

A mixture comprising at least 1,1,1,3,3-pentafluoropropane and 1,1,1-trifluoro-3-chloro-2-propene is subjected to a distillation operation, and thereby, a distillate comprising an azeotropic composition consisting substantially of 1,1,1,3,3-pentafluoropropane and 1,1,1-trifluoro-3-chloro-2-propene is obtained and a bottom product comprising 1,1,1,3,3-pentafluoropropane or 1,1,1-trifluoro-3-chloro-2-propene which each is separated and purified.

Owner:DAIKIN IND LTD

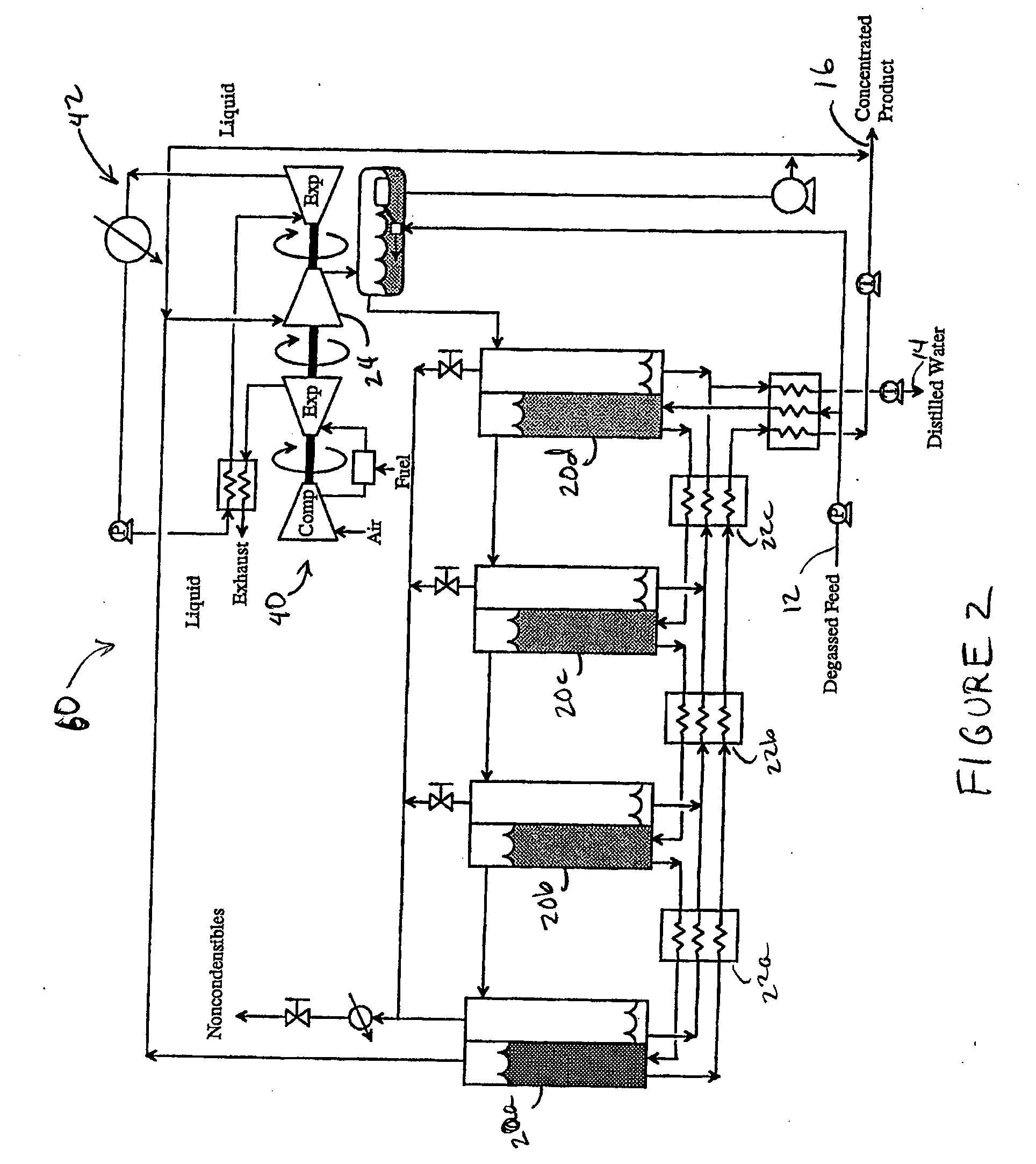

Desalination System

InactiveUS20080083605A1EfficientlyReduce workloadAuxillariesGeneral water supply conservationDesalinationEngineering

In accordance with particular embodiments, a desalination system includes a plurality of evaporators. The plurality of evaporators includes at least a first evaporator and a last evaporator. The plurality of evaporators are arranged in cascading fashion such that a concentration of salt in a brine solution increases as the brine solution passes through the plurality of evaporators from the first evaporator towards the last evaporator. The desalination system also includes a plurality of heat exchangers. An input of each evaporator is coupled to at least one of the plurality of heat exchangers. The system also includes a vapor source coupled to at least one of the plurality of evaporators.

Owner:TERRABON ADVE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com