Patents

Literature

1925results about "Distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

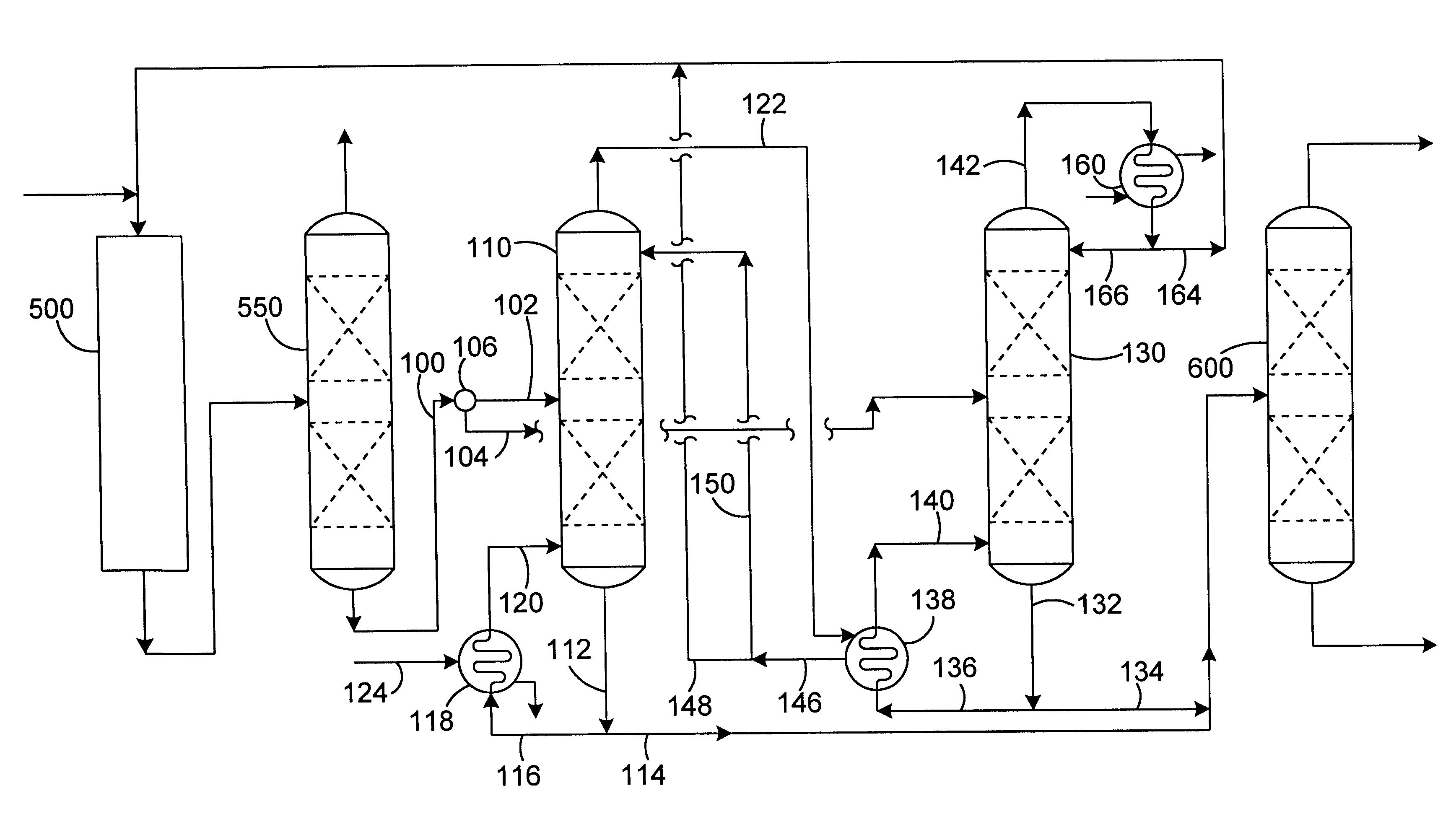

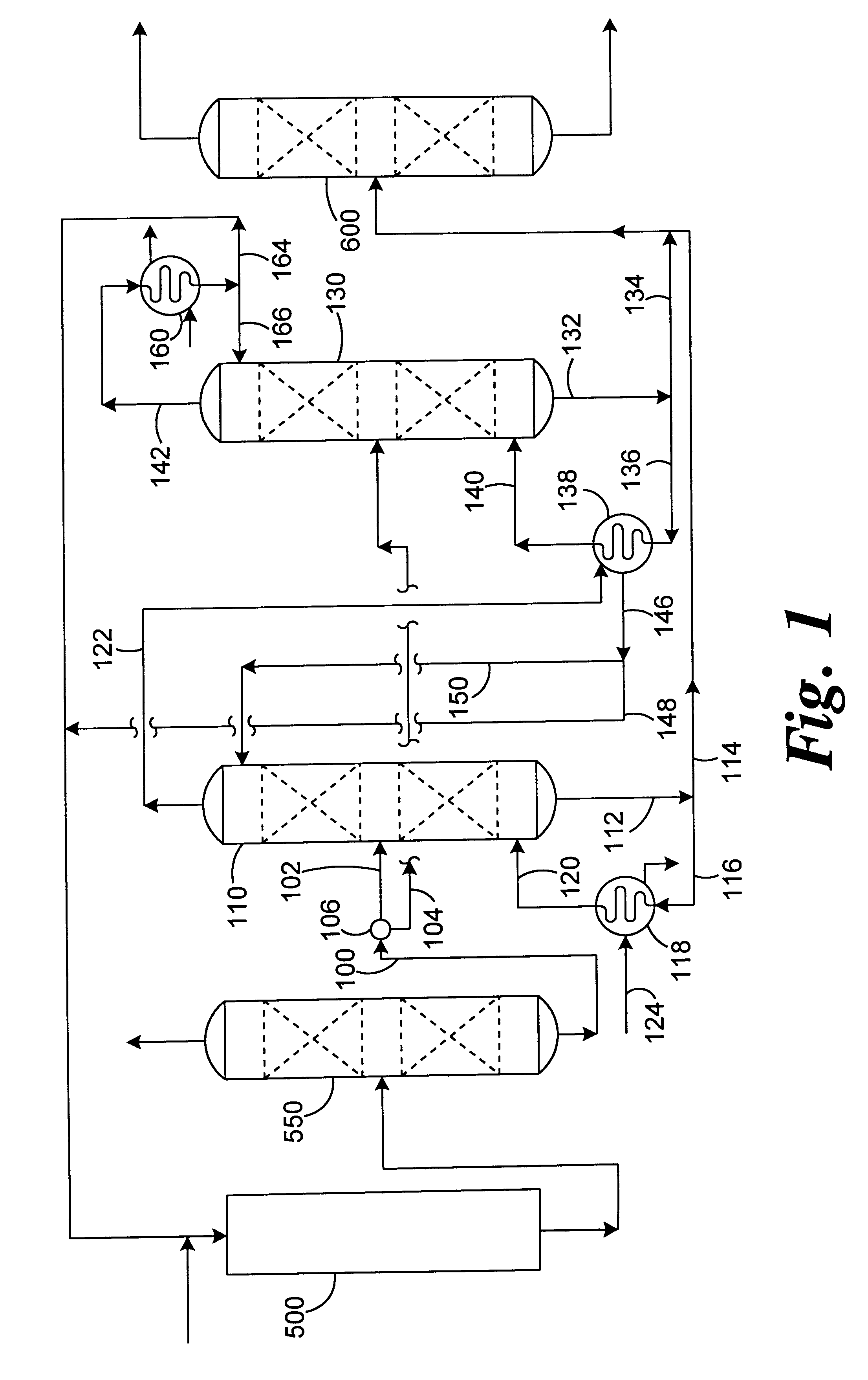

Ethanol distillation process

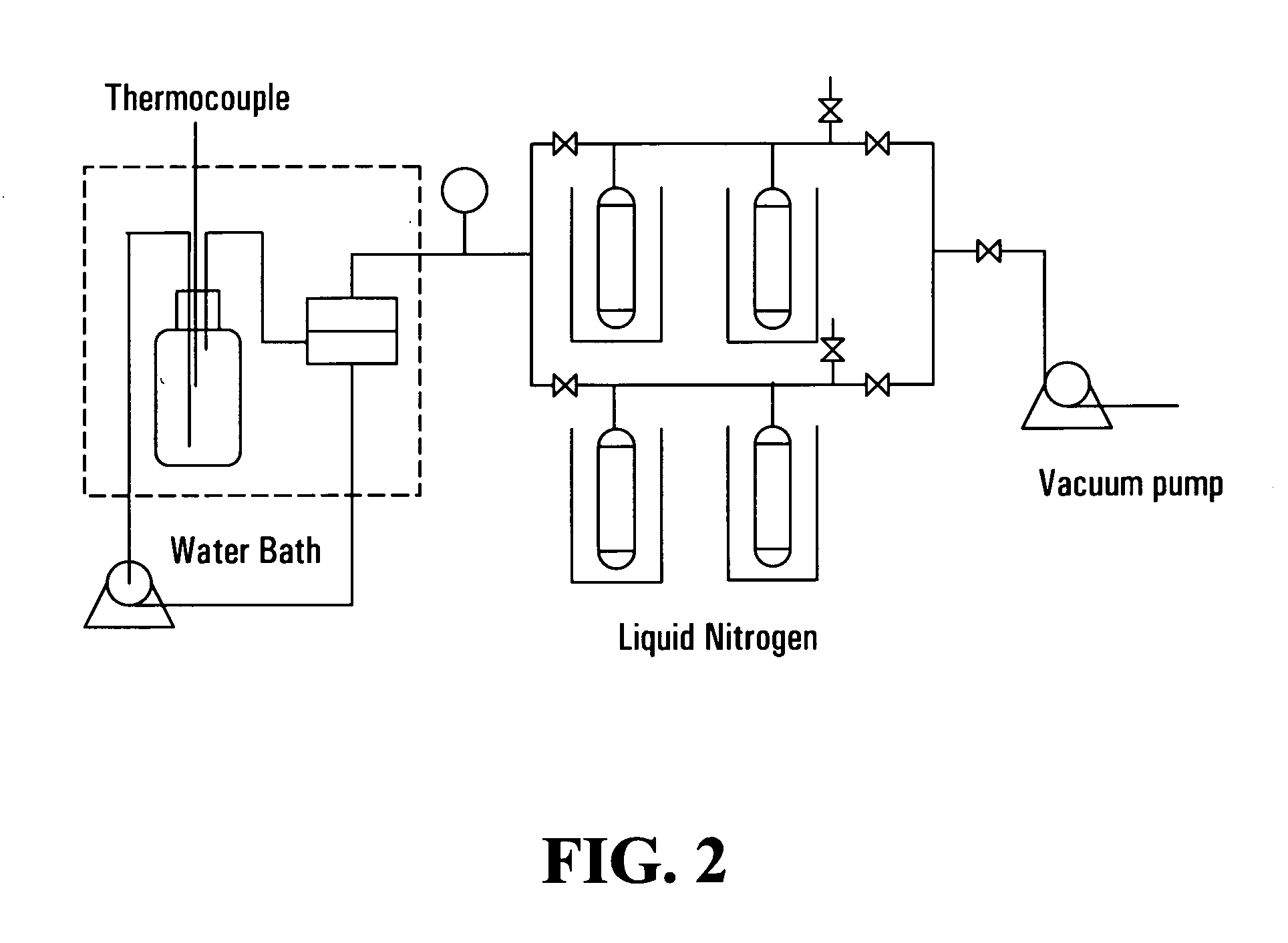

InactiveUS7297236B1Avoid insufficient heatingShorten the timeFermented solutions distillation/rectificationDistillation in boilers/stillsDistillationEvaporation

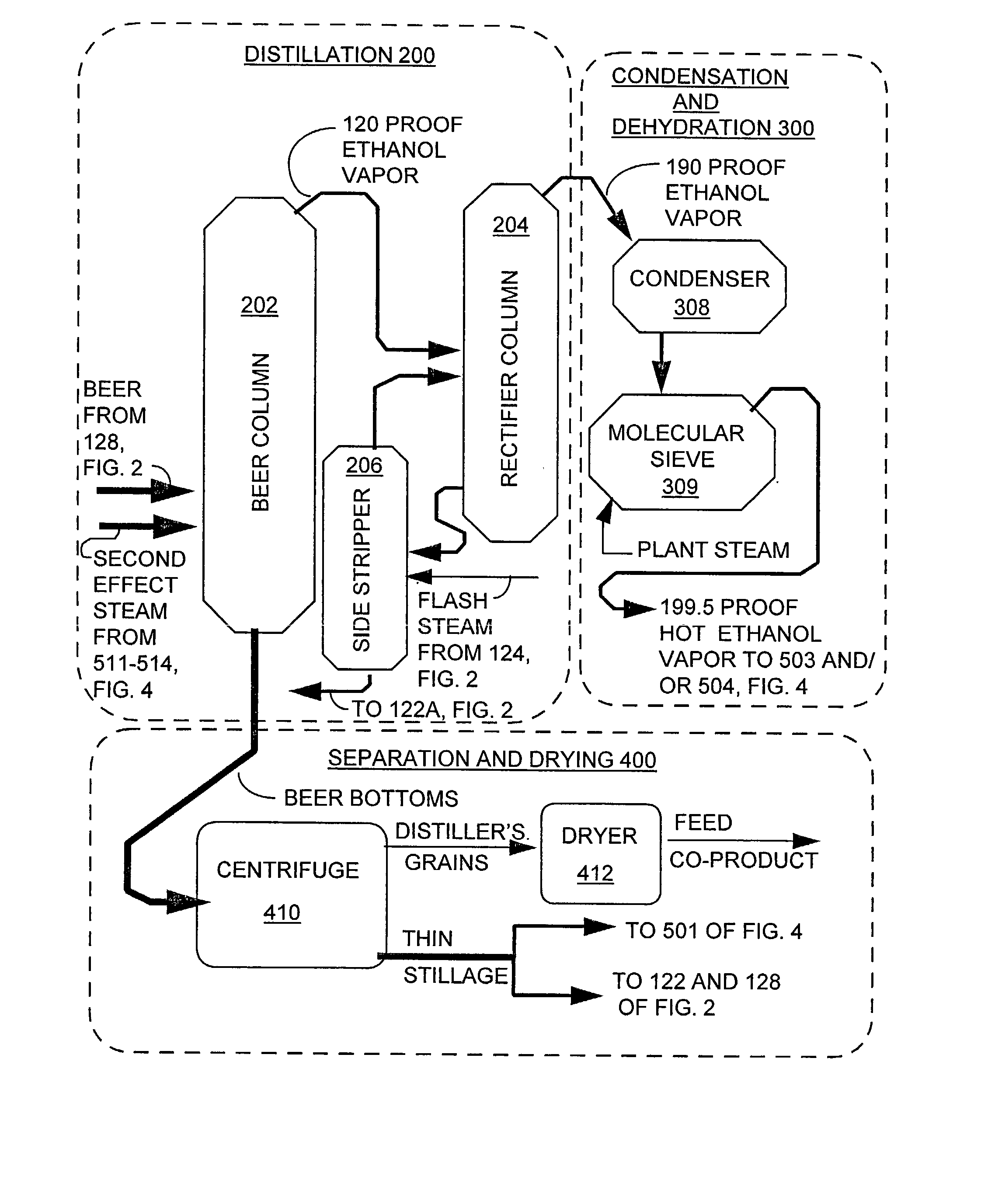

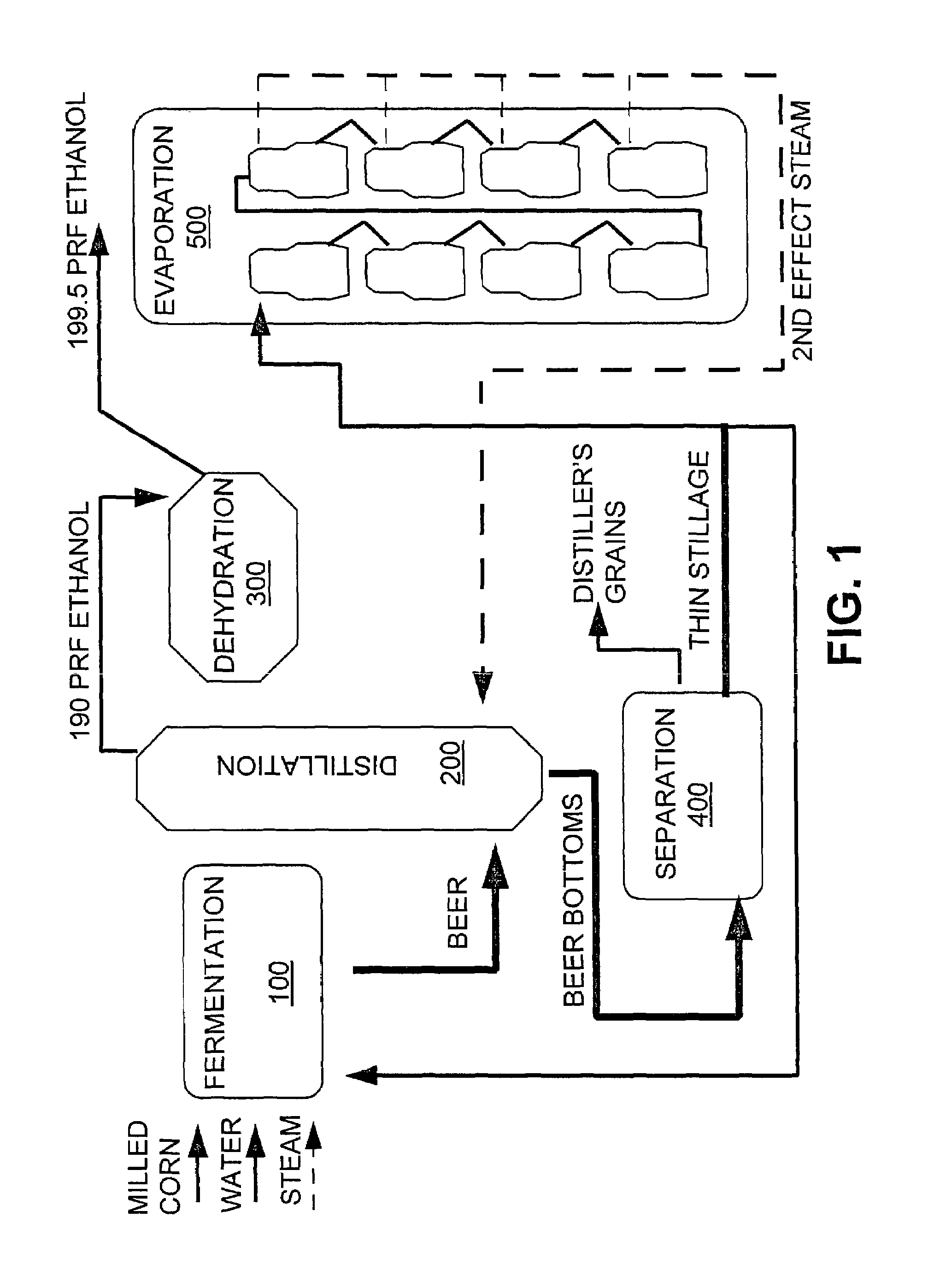

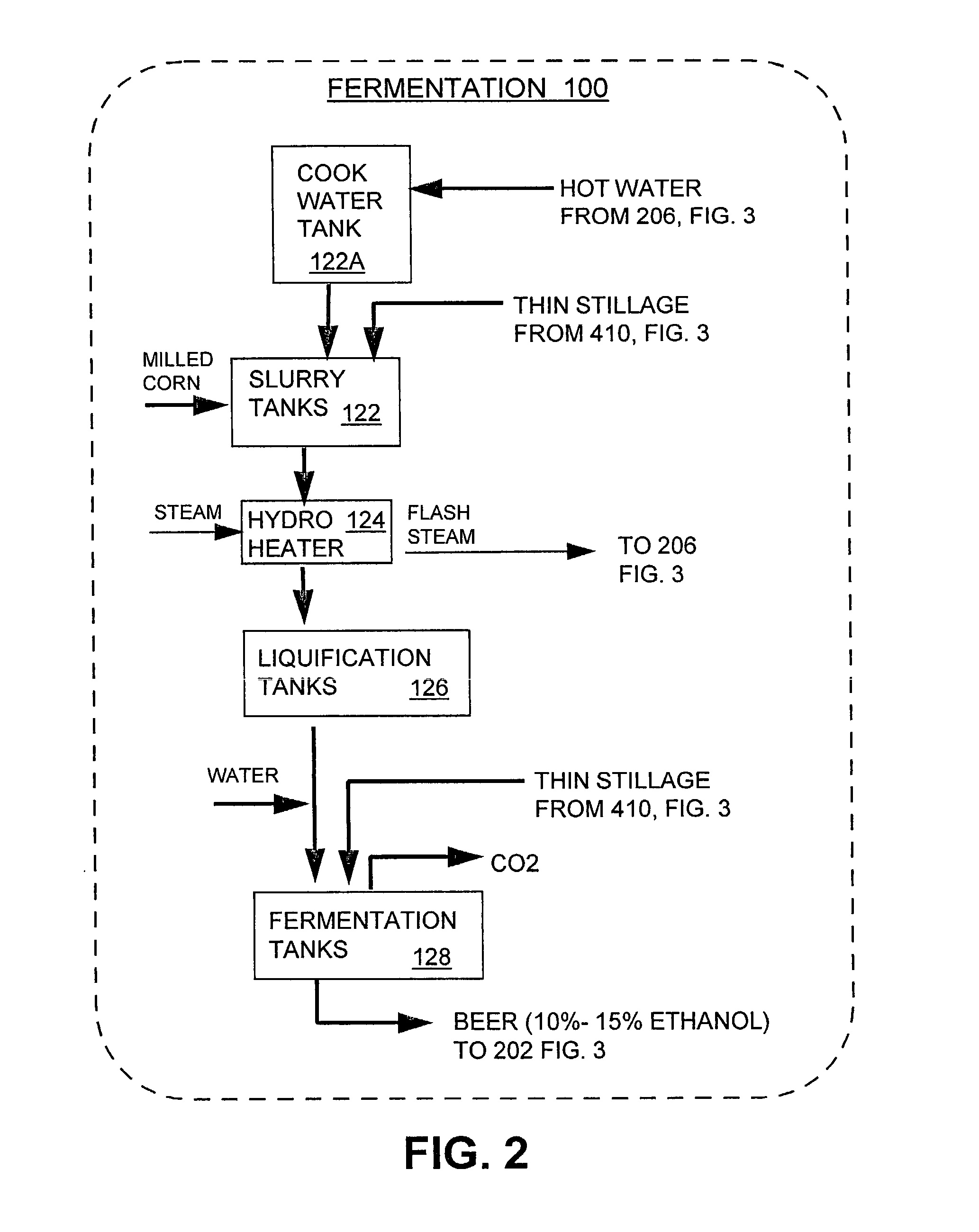

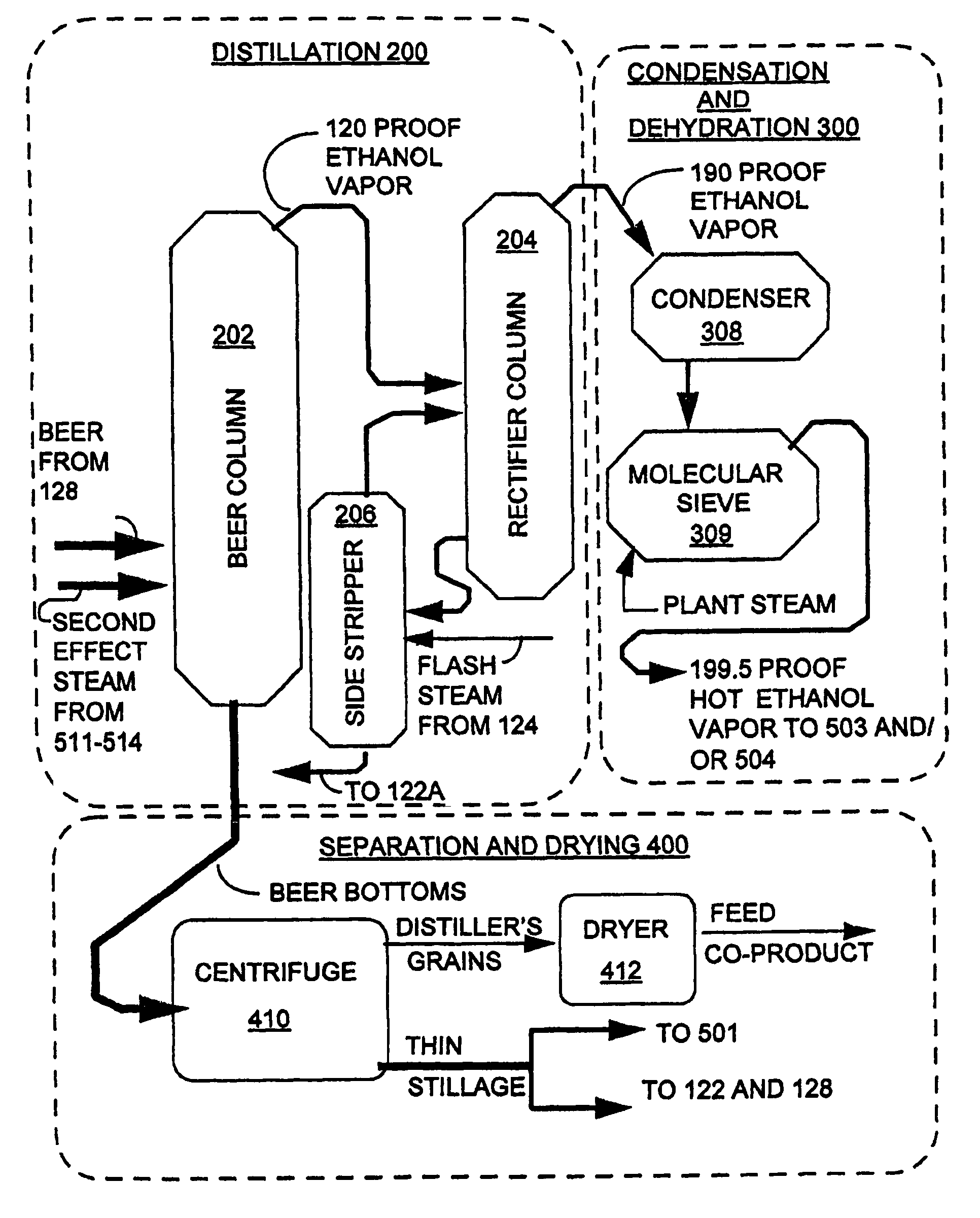

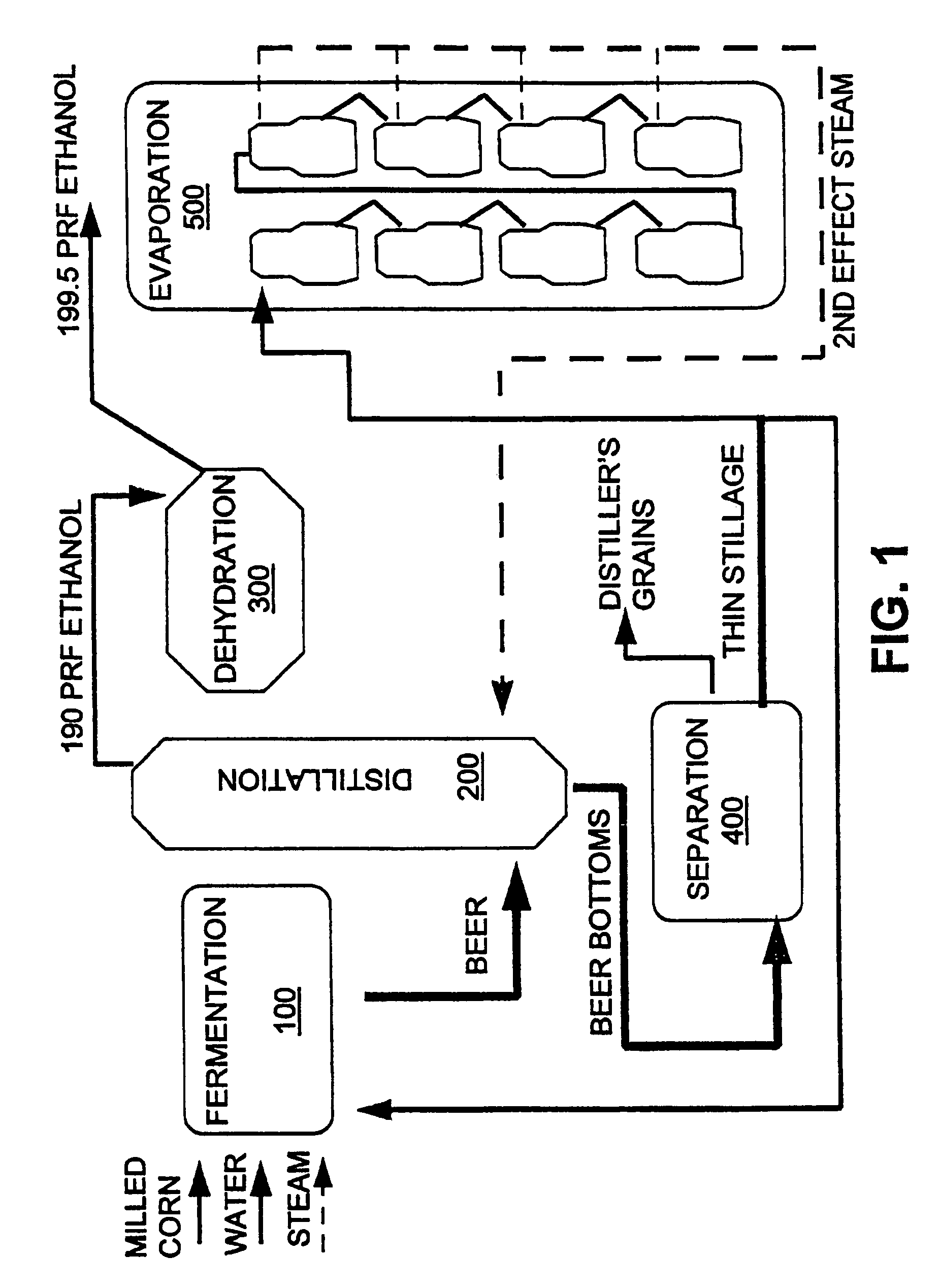

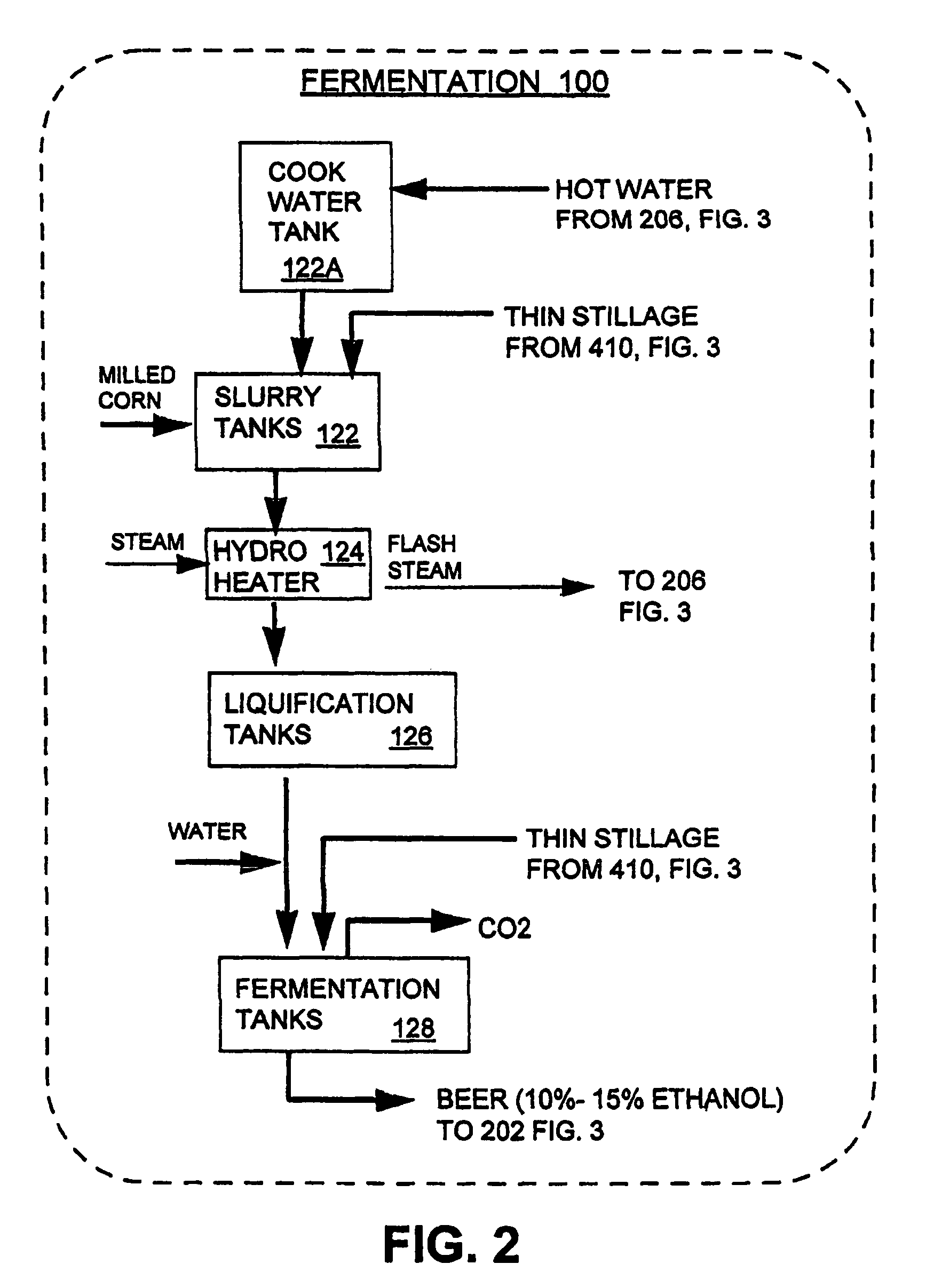

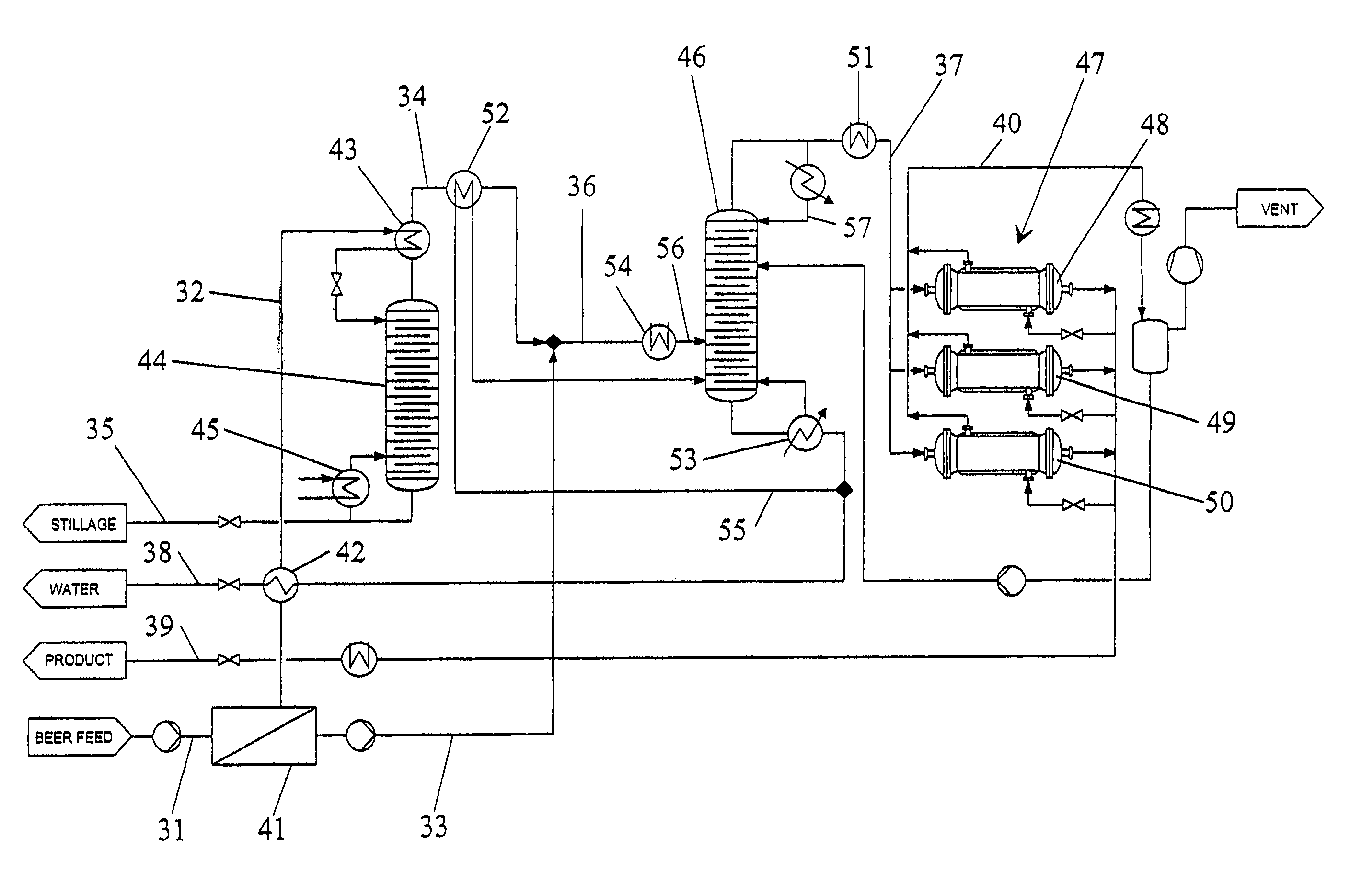

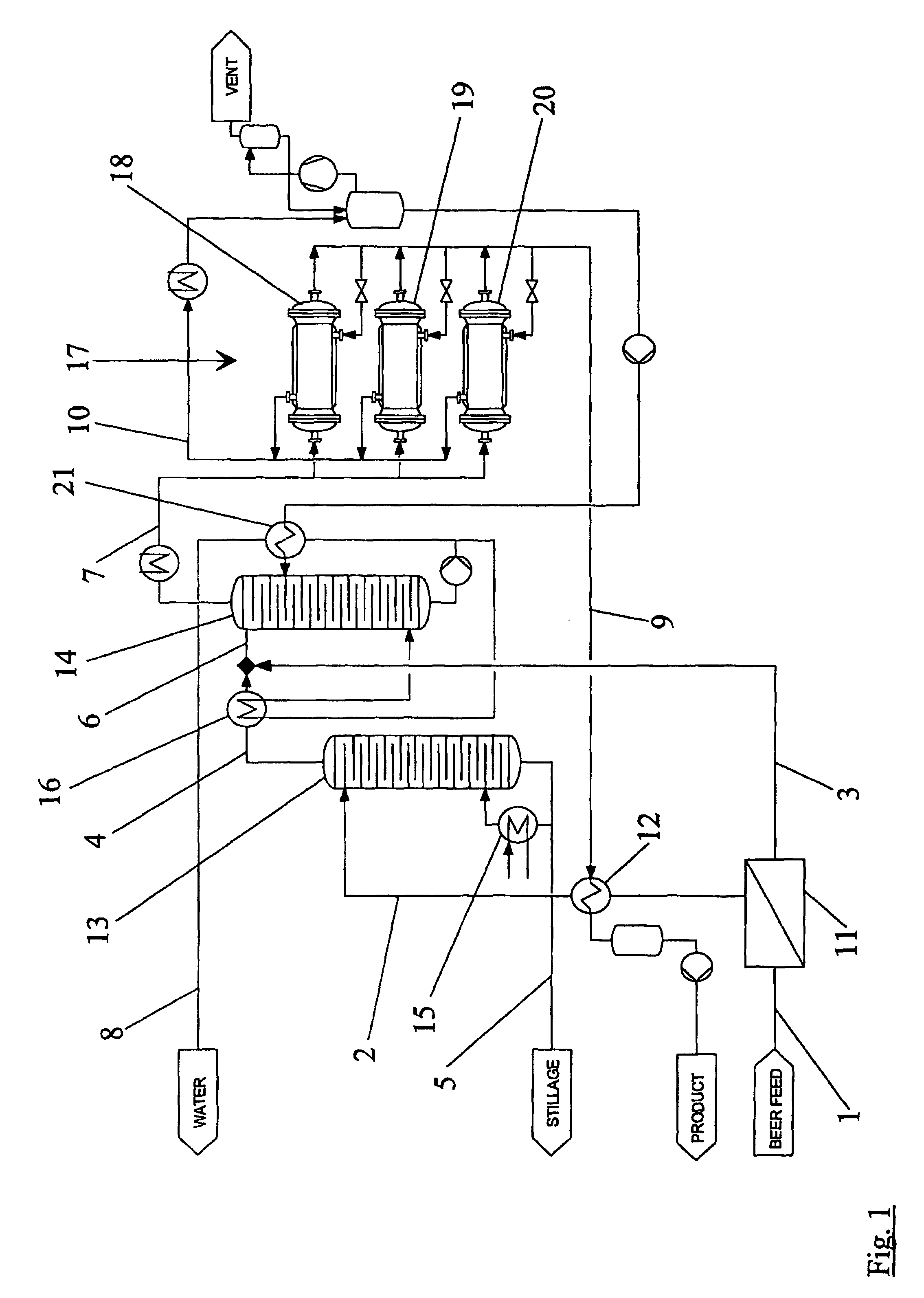

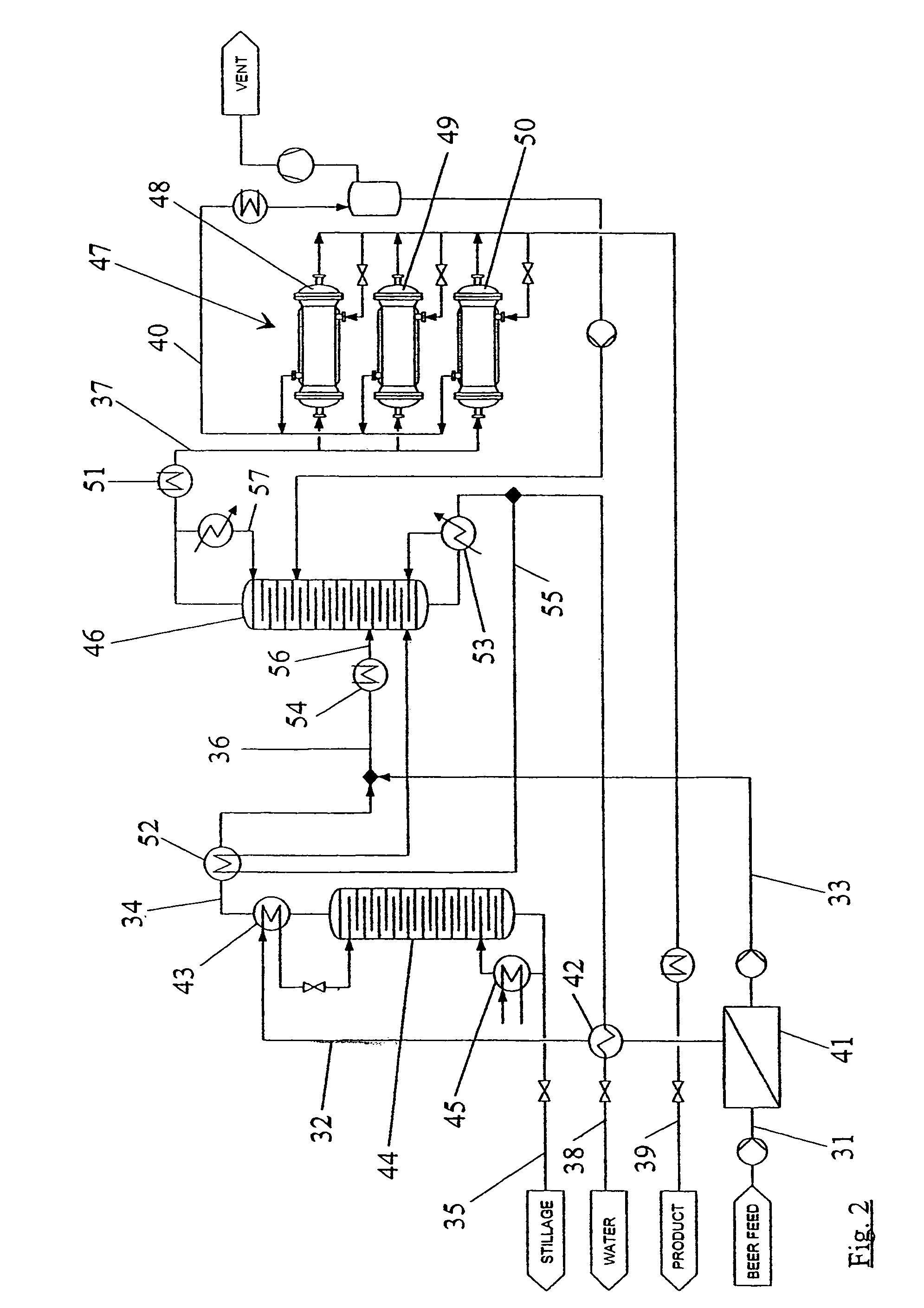

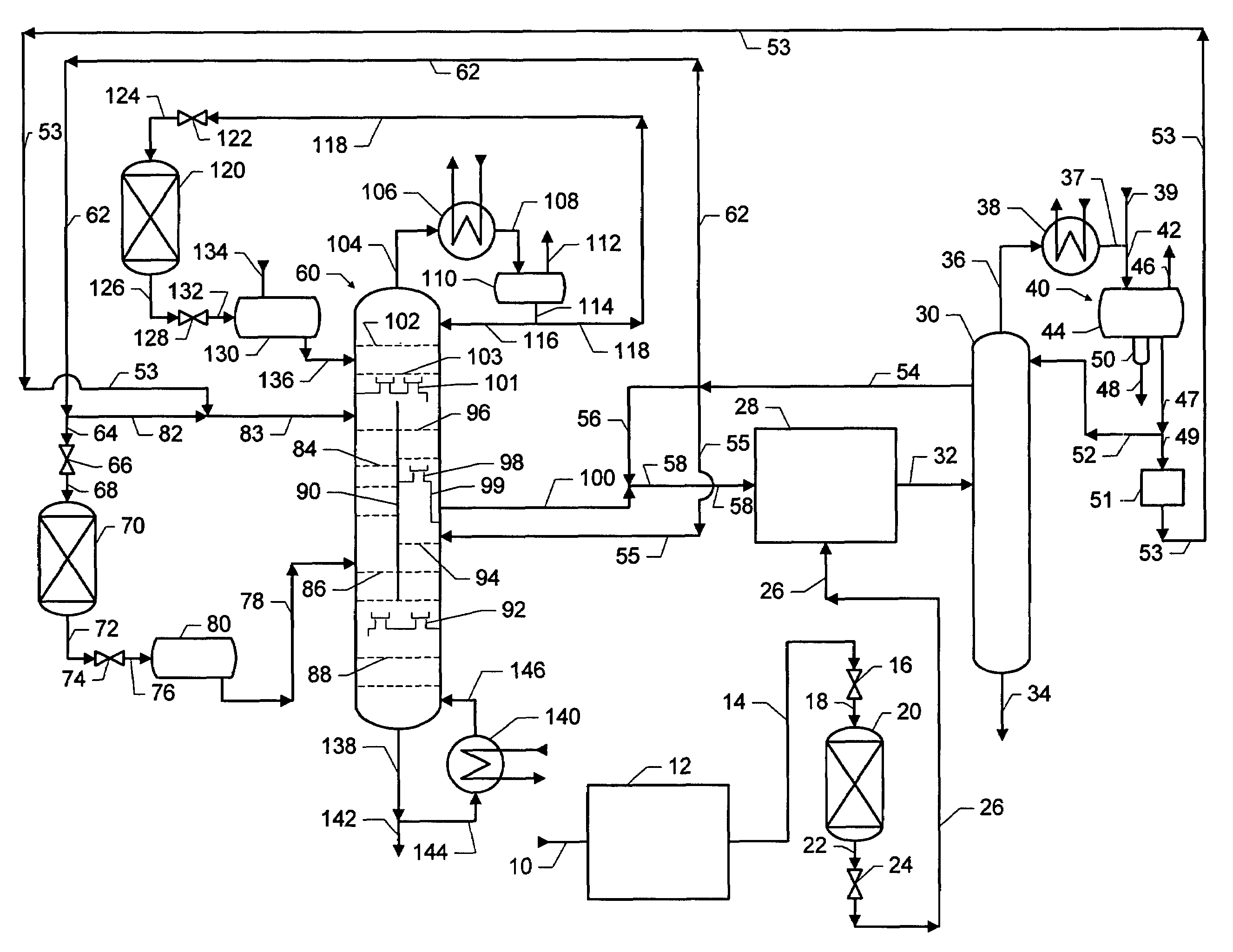

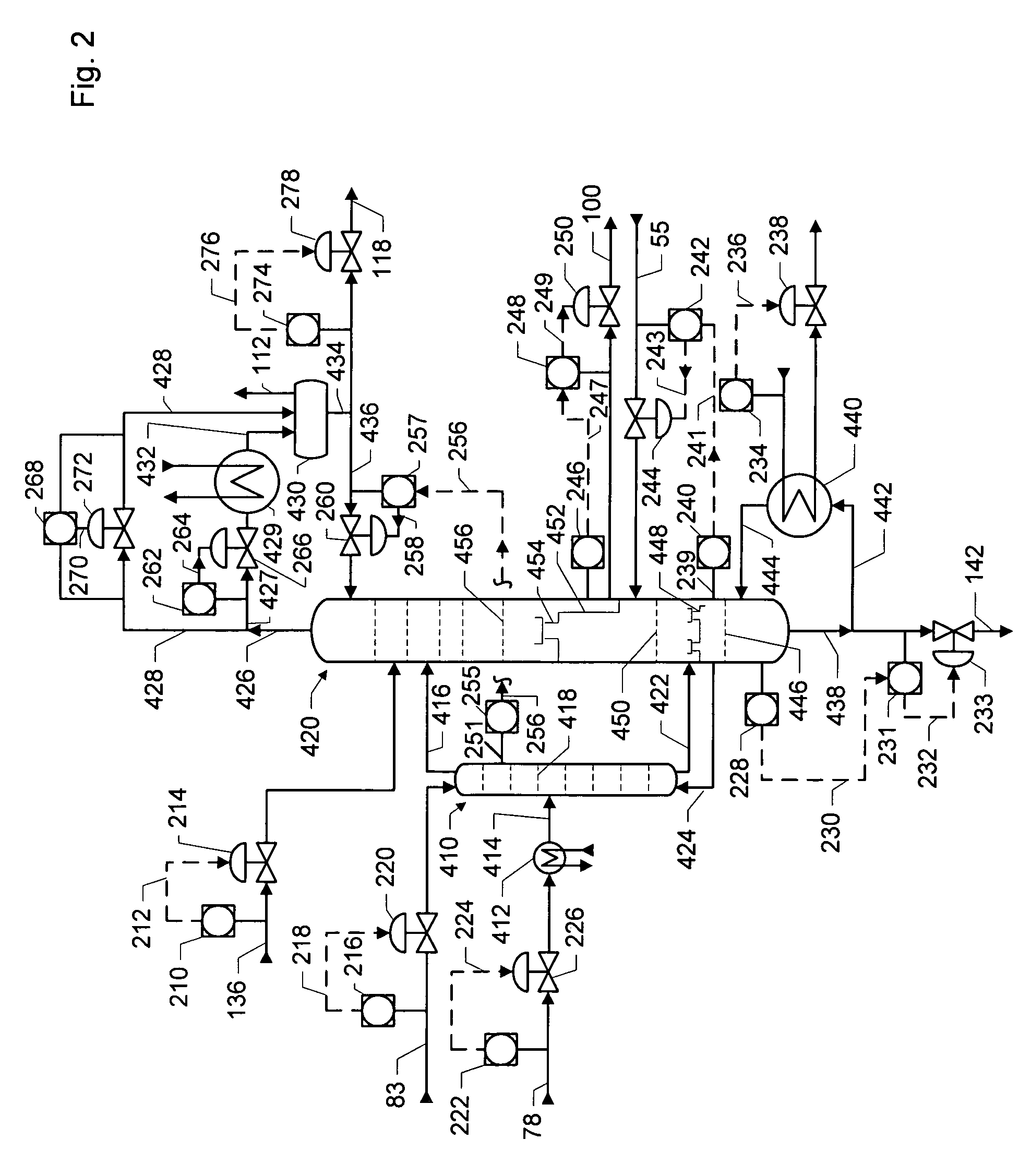

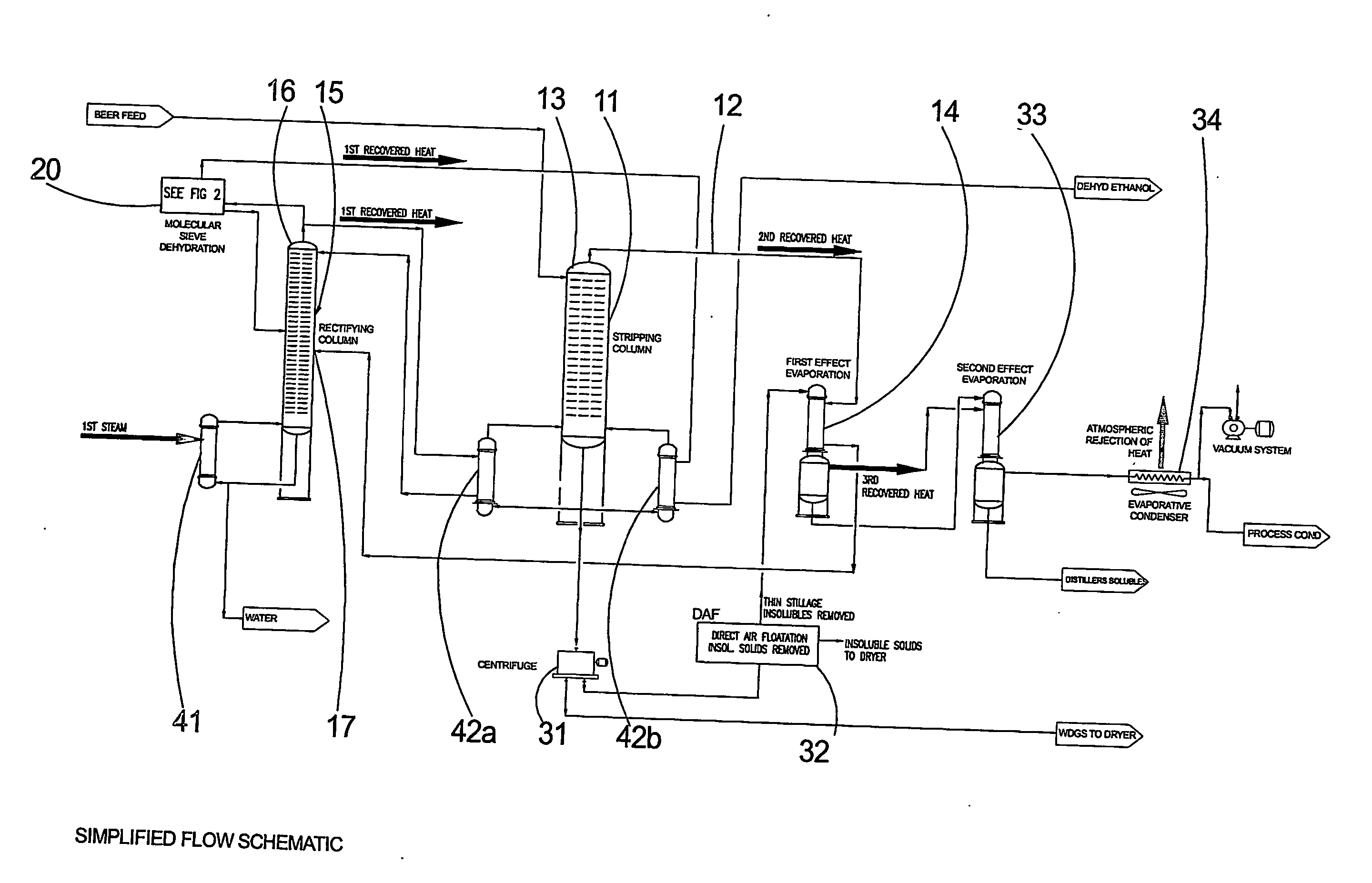

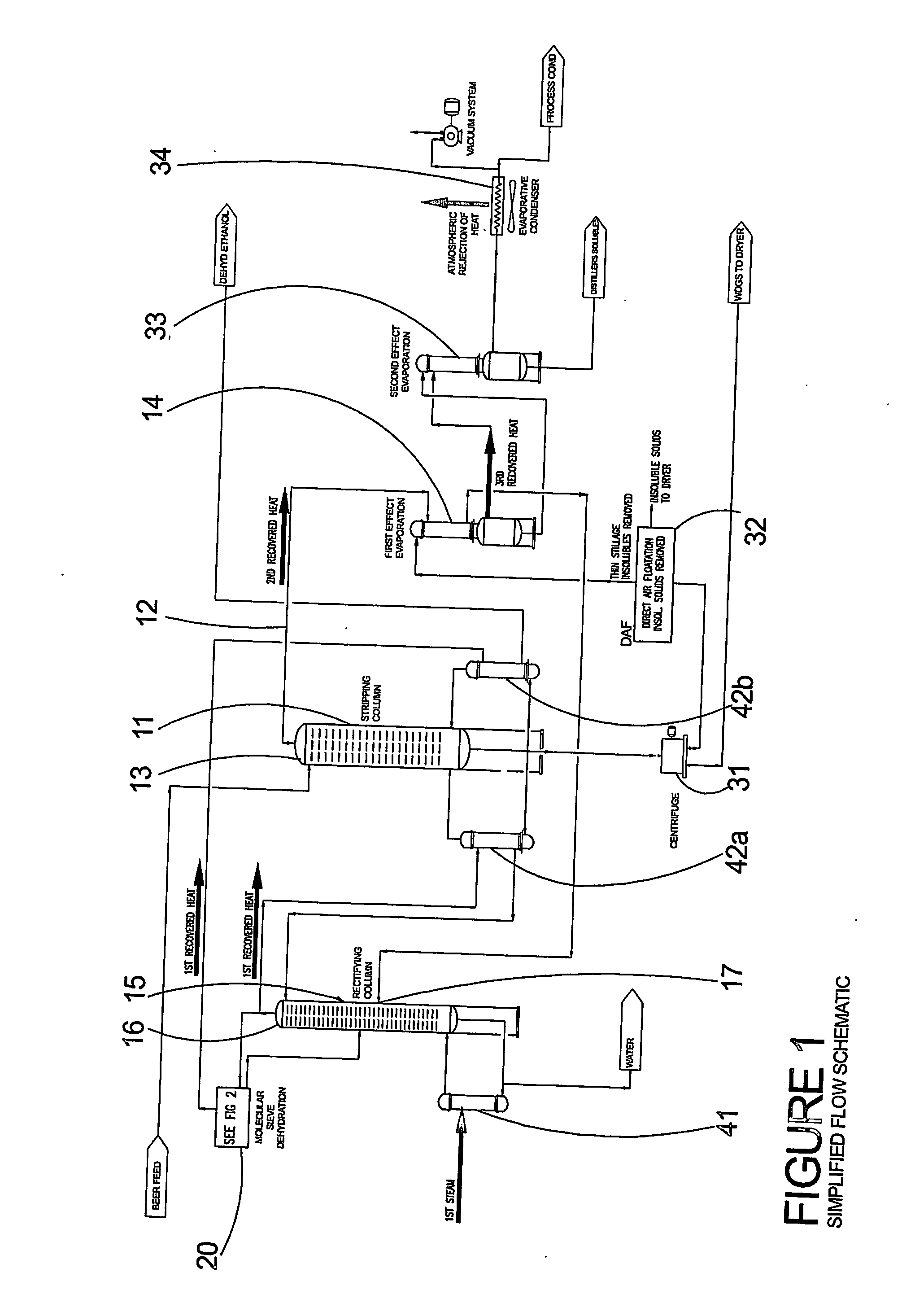

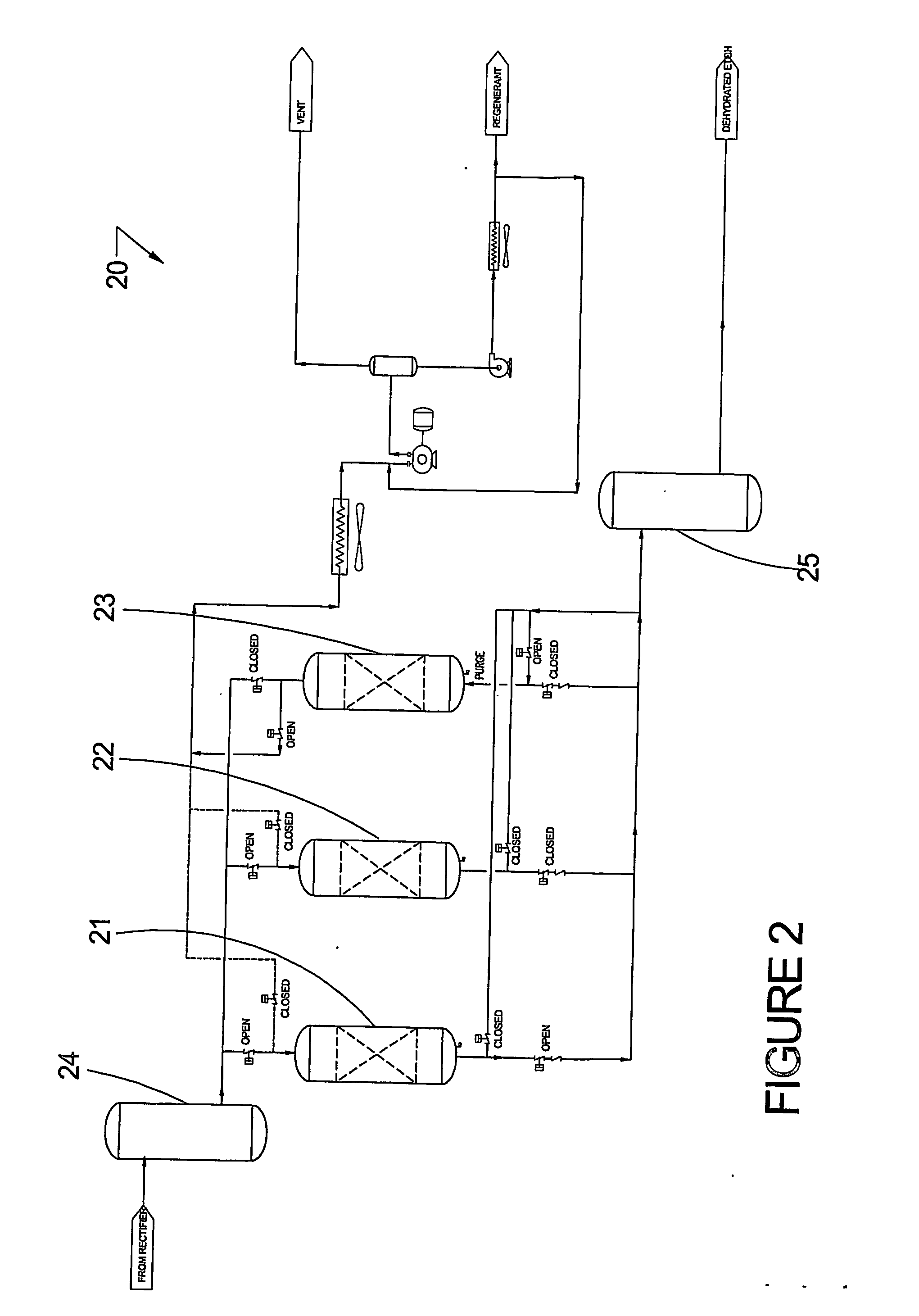

A process arrangement for distilling fuel grade ethanol includes a fermentation portion, a distillation portion, a condensation and dehydration portion, a separation and drying portion and an evaporation portion. The fermentation portion produces beer. The distillation portion, the condensation and dehydration portion and the separation and drying portion receives beer from the fermentation portion and produces hot ethanol vapor and thin stillage. In the evaporation portion, a set of first effect evaporators which are heated either by plant steam or hot ethanol vapor, concentrate thin stillage into mid stillage while producing first effect steam. The first effect steam from the first effect evaporators provides heat to a set of second effect evaporators which concentrate the mid stillage into a syrup for further drying. The second effect evaporators produce second effect steam which is used to heat the distillation portion of the process arrangement. The multiple evaporators of the first and second effects of the evaporation portion can be selectively taken off-line for maintenance while the evaporation portion and the remainder of the process arrangement continue to operate at full capacity.

Owner:ICM

Ethanol distillation process

InactiveUS7572353B1Shorten the timeLess rapidlyFermented solutions distillation/rectificationOrganic compound preparationDistillationEvaporation

Owner:ICM

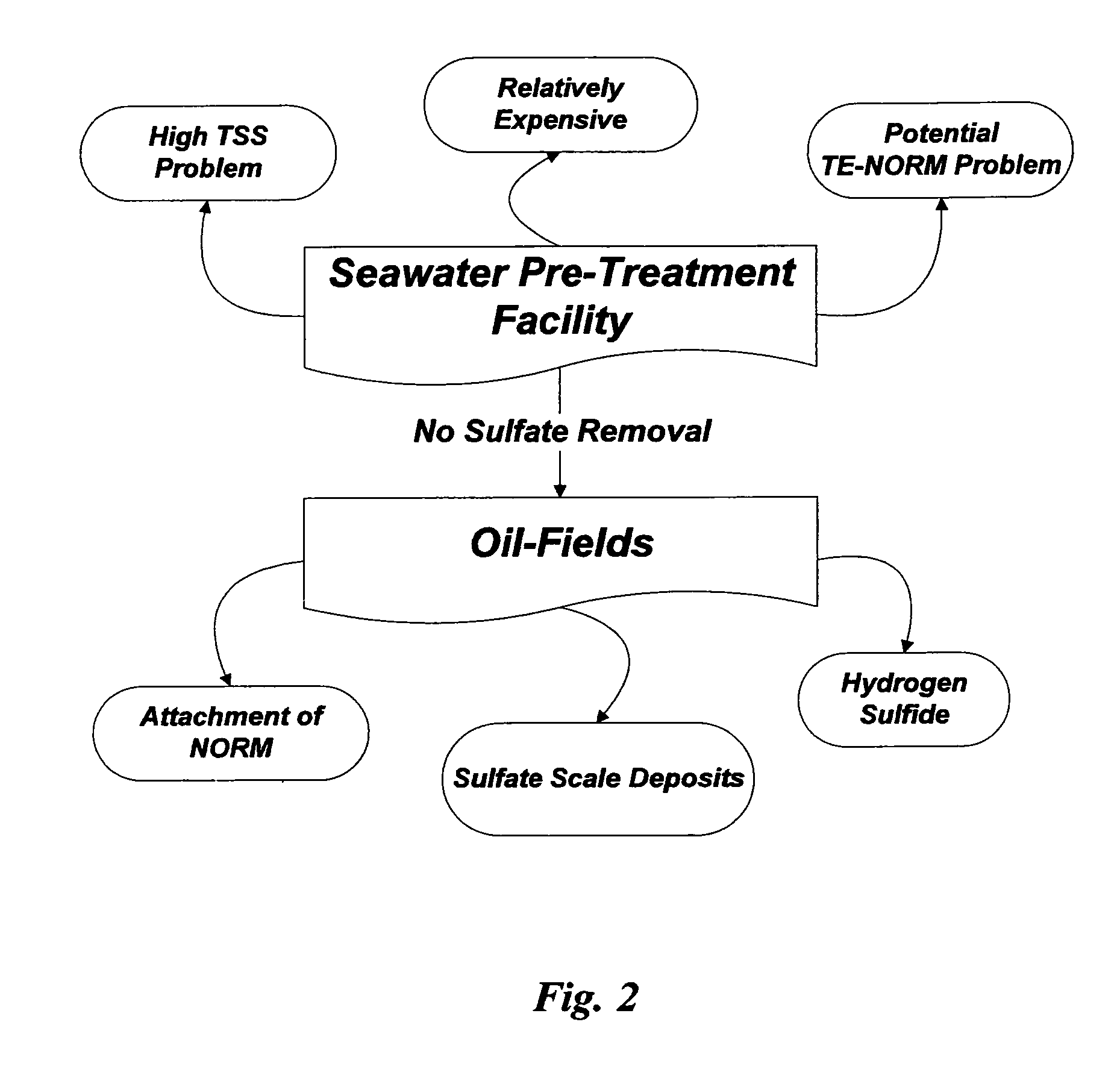

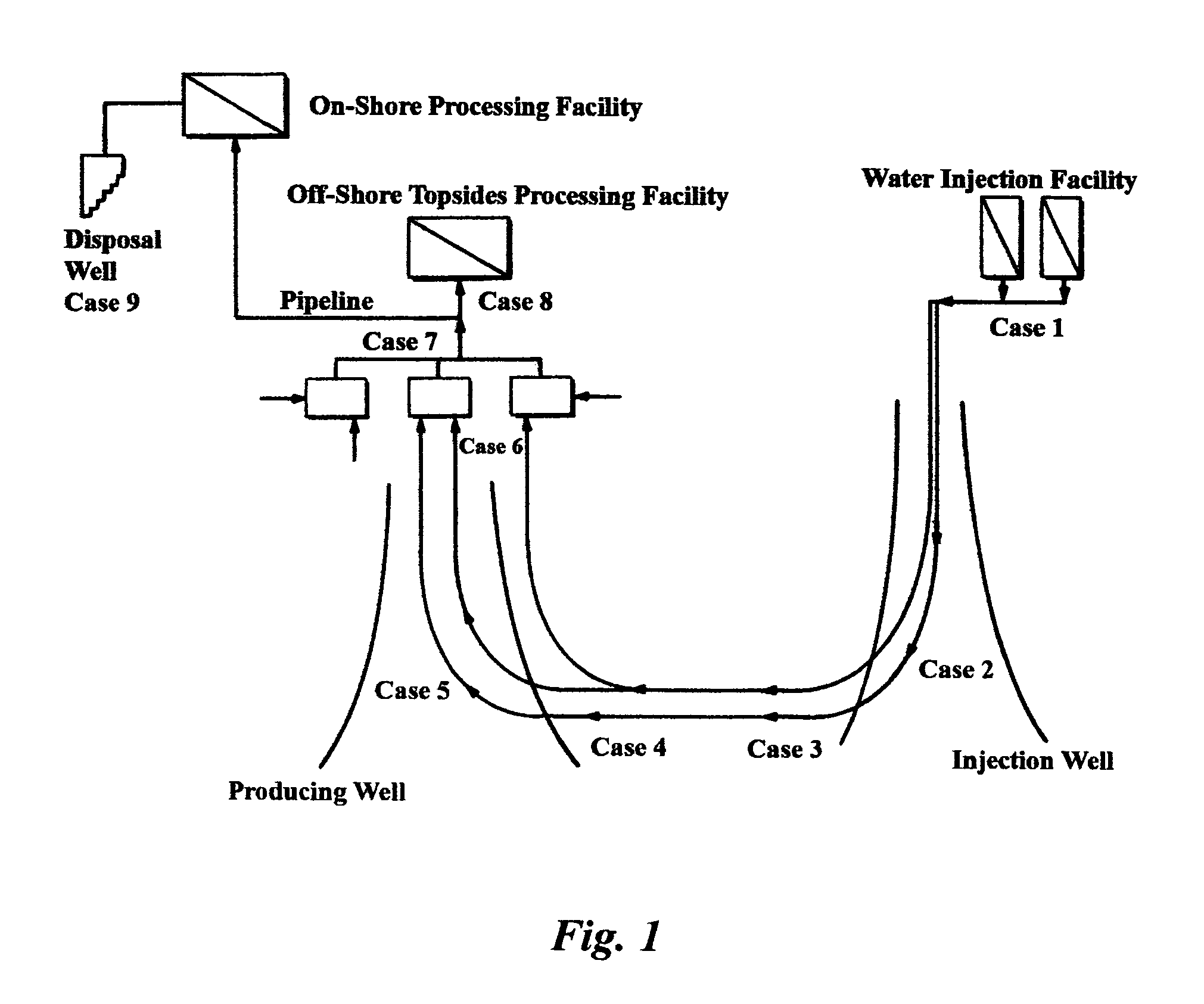

Methods to de-sulfate saline streams

ActiveUS7789159B1Avoid pollutionWaste water treatment from quariesSludge treatmentSaline waterInorganic materials

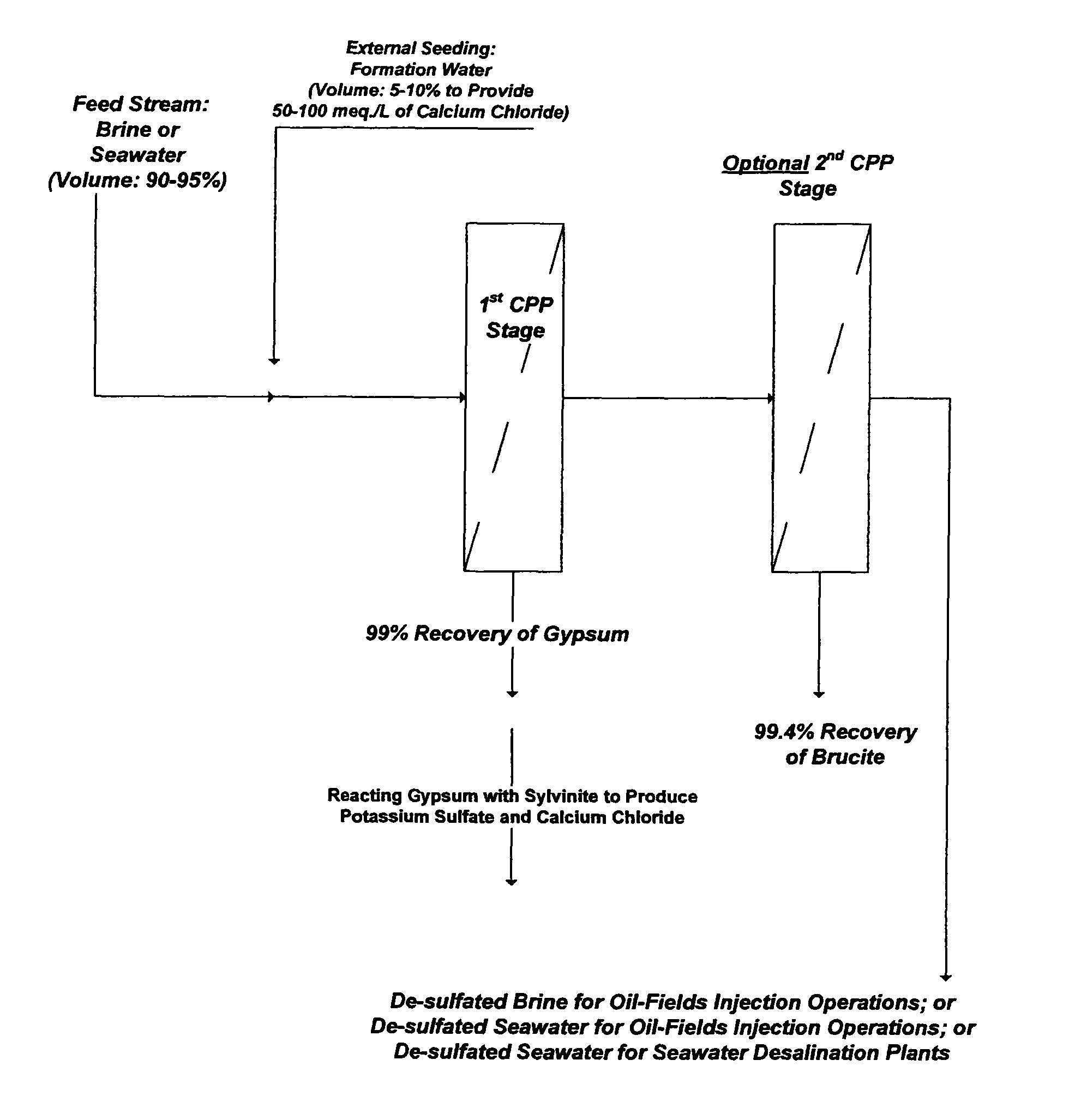

Methods are disclosed to de-sulfate saline streams such as seawater, brine from seawater desalination plants, and the like. The disclosed methods can also co-produce de-ionized water and inorganic materials from such de-sulfated saline streams.

Owner:BADER MANSOUR S

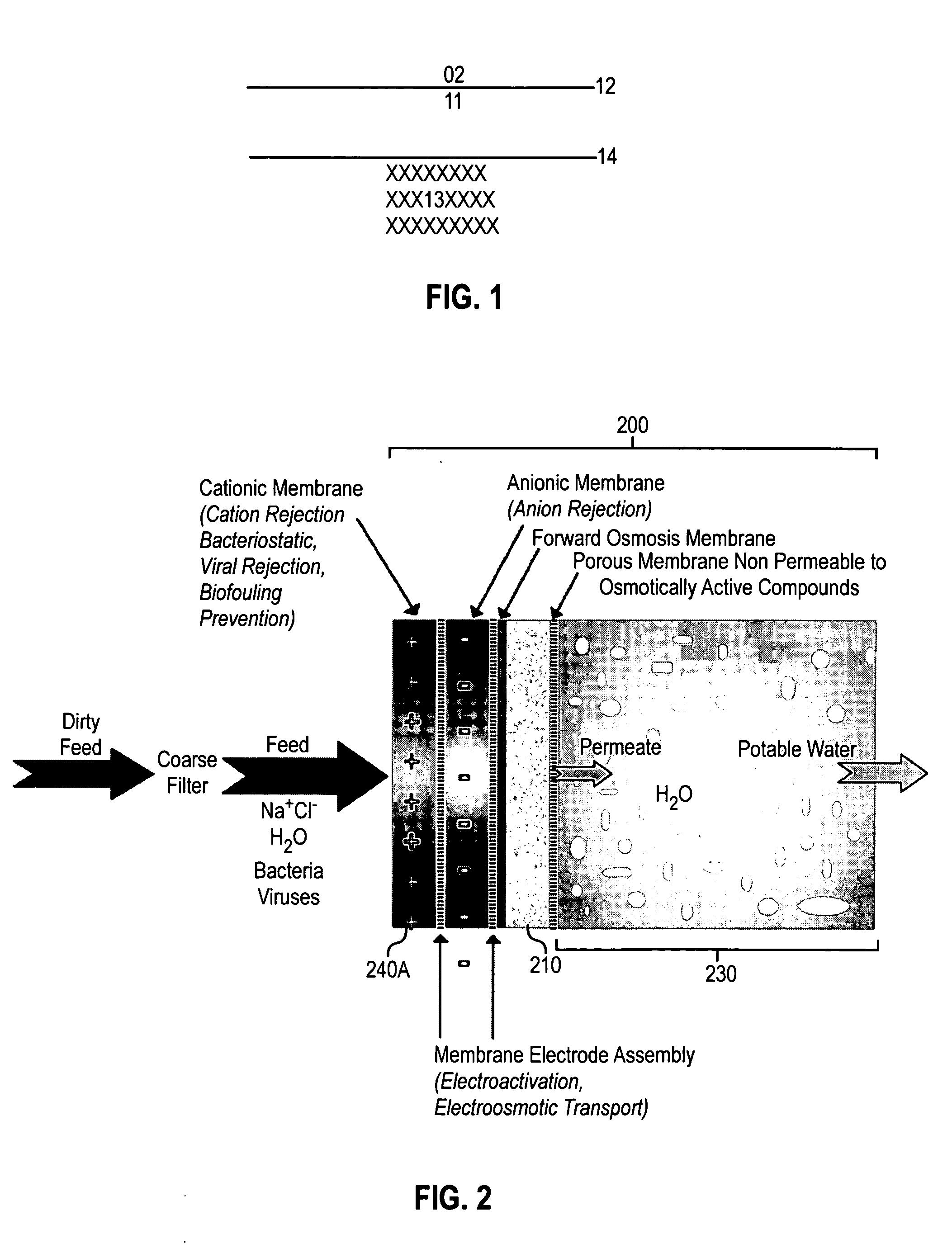

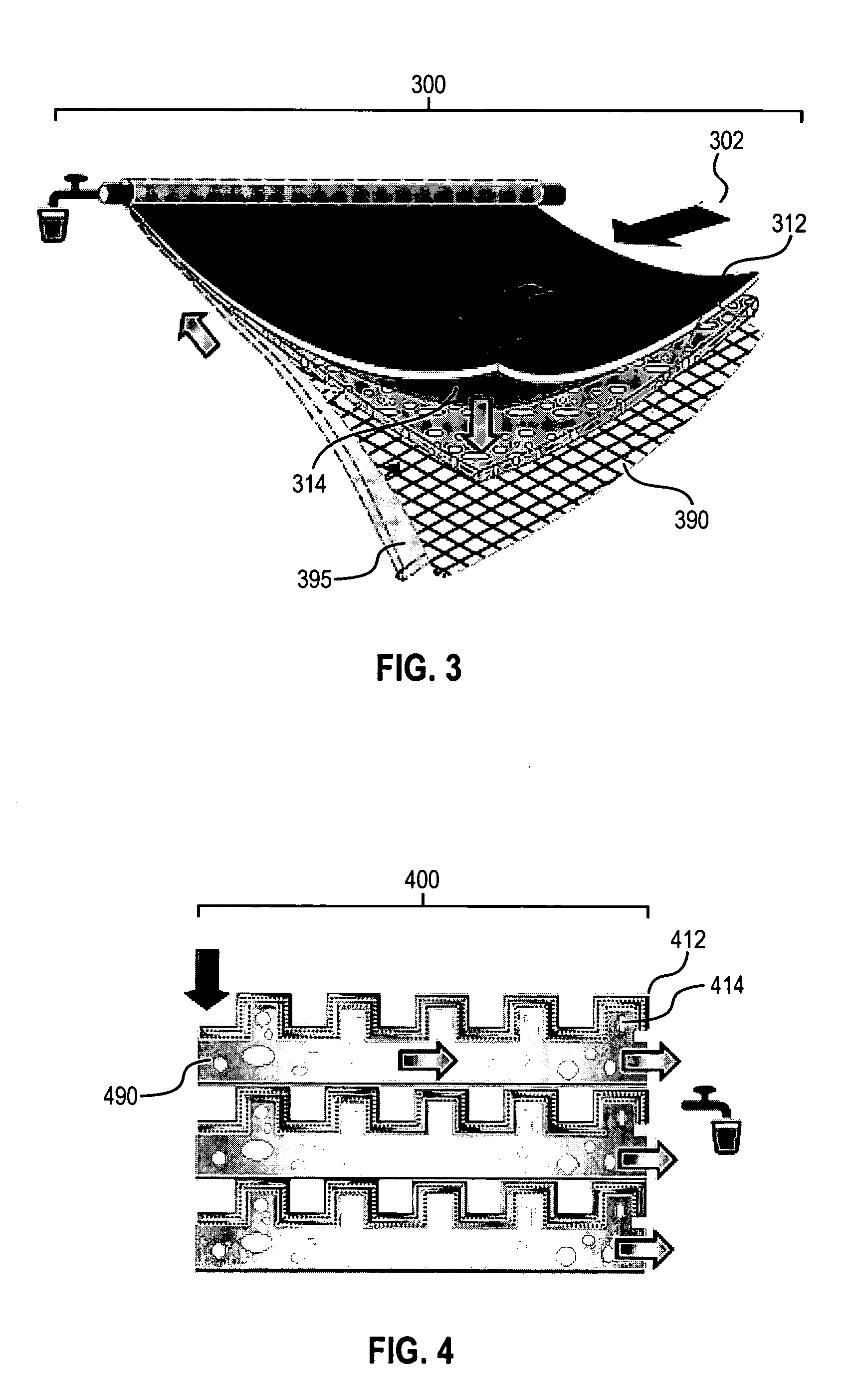

Membrane purification system

Owner:SRI INTERNATIONAL

Pressurized vapor cycle liquid distillation

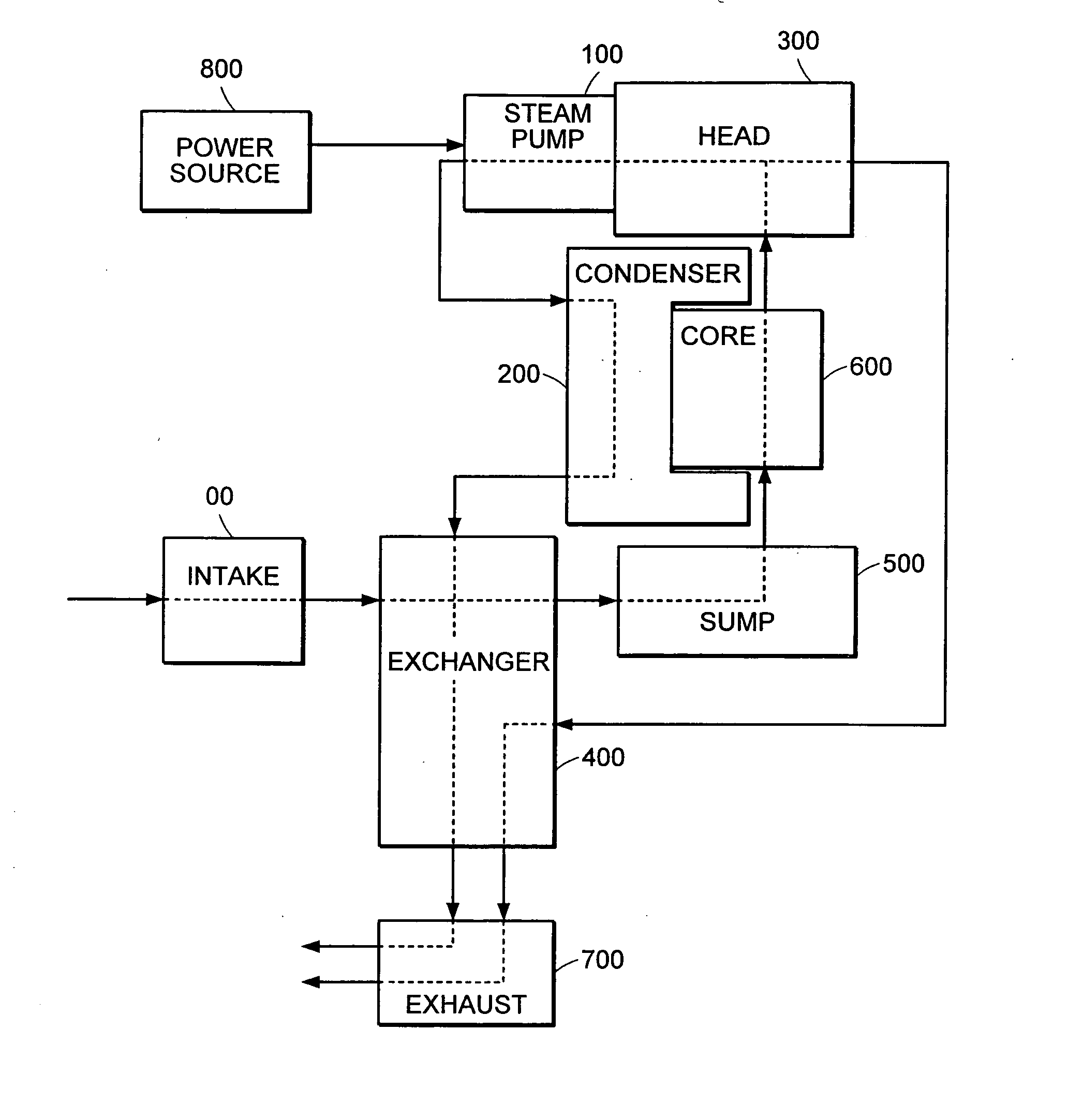

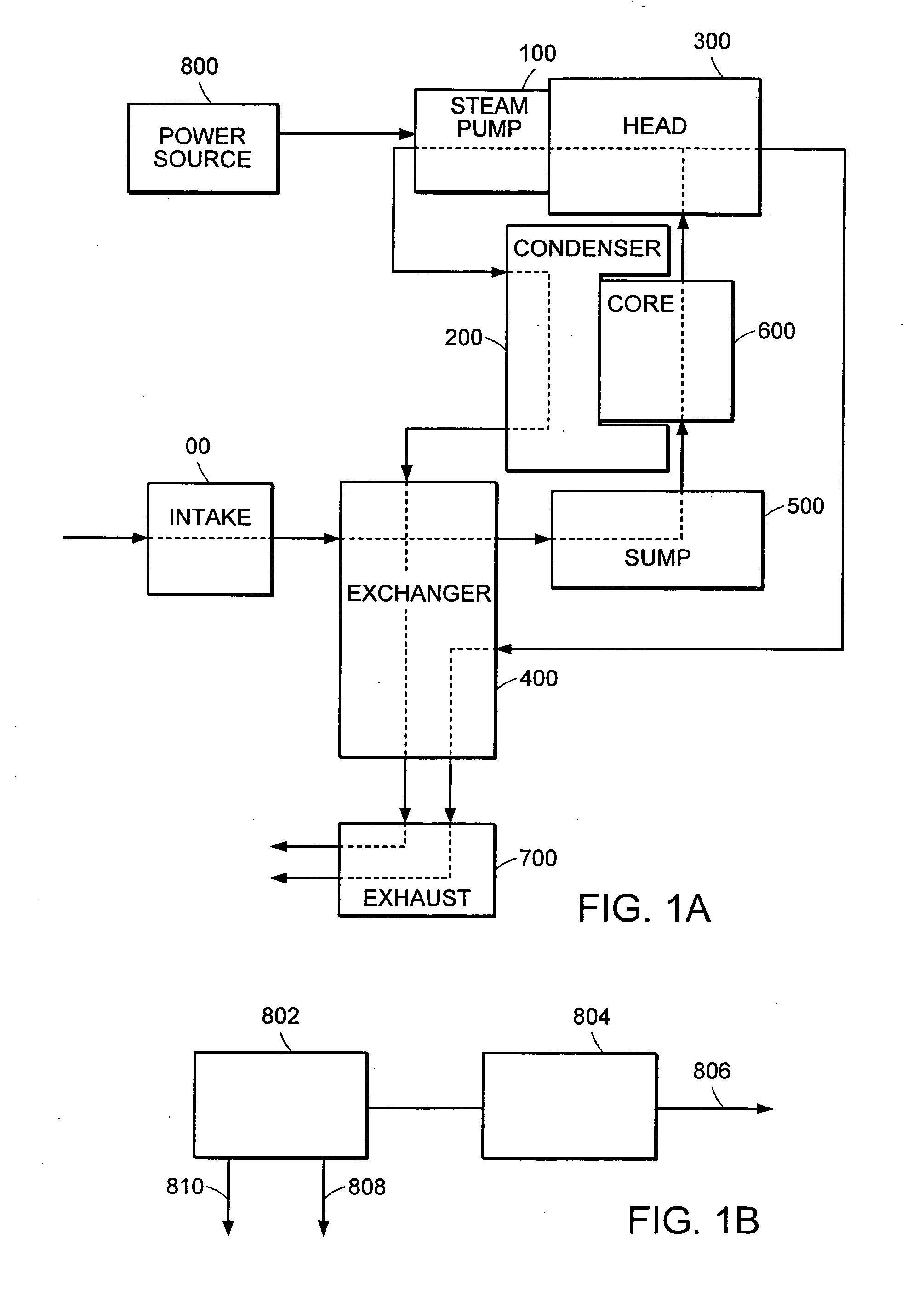

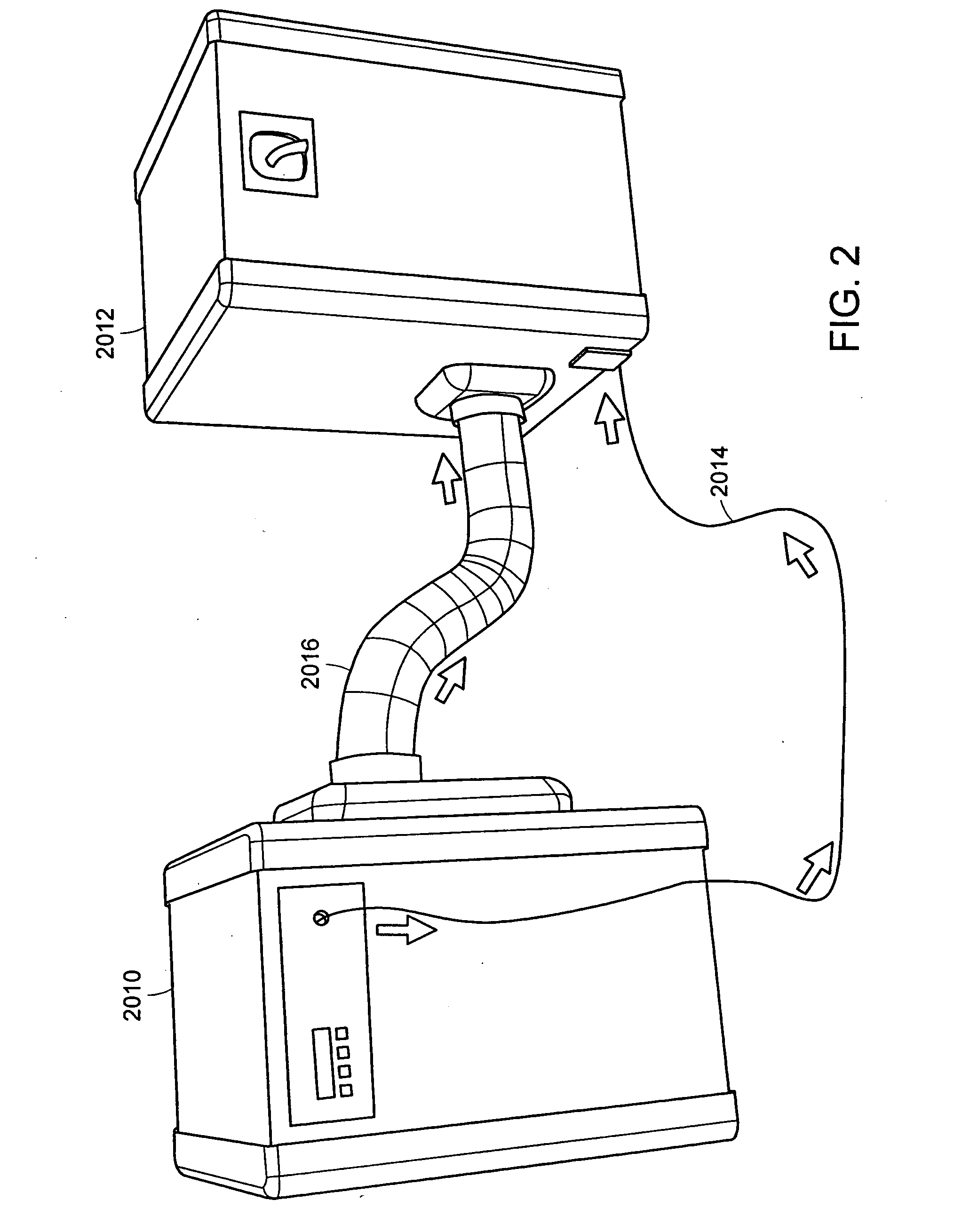

ActiveUS20050016828A1Easy maintenanceMaximize energy efficiencyDistillation regulation/controlUsing liquid separation agentHeat managementDrive shaft

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

Distillation method

A method for distilling ethanol from a mash includes feeding a fluid to a first distillation column. The fluid and a distillate of the first distillation column are delivered to a second distillation column. The fed fluid and / or distillate of the second distillation column is / are purified in a first and / or last step of the method by a membrane separation process.

Owner:WHITE FOX TECH LTD

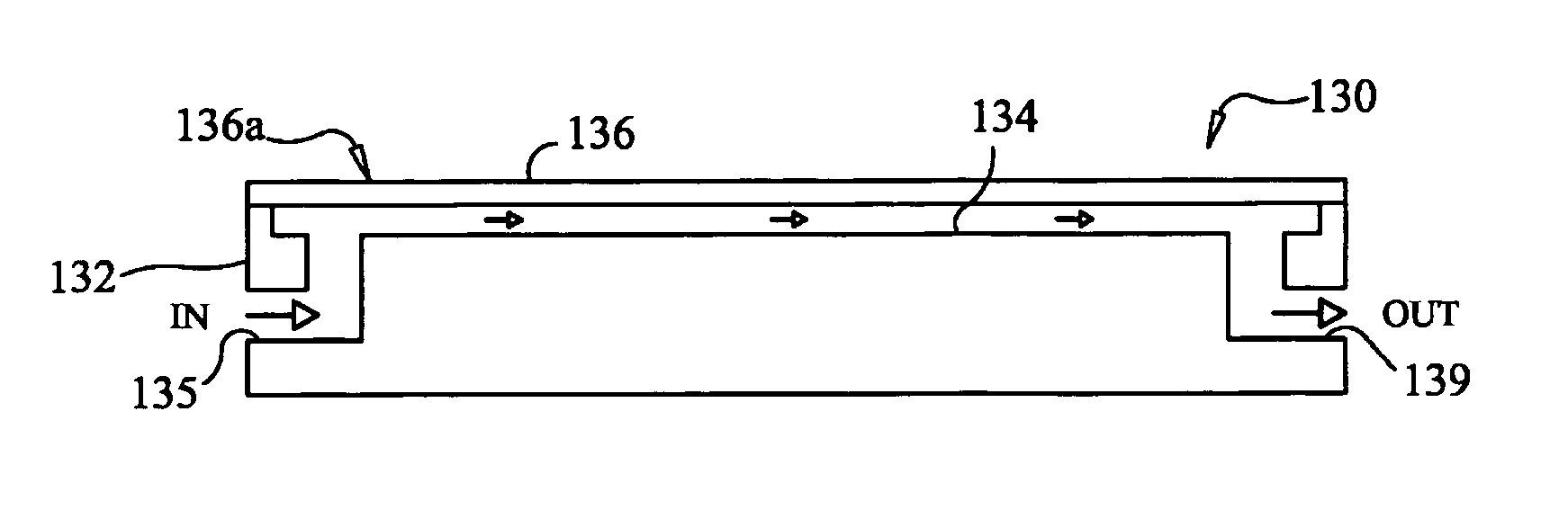

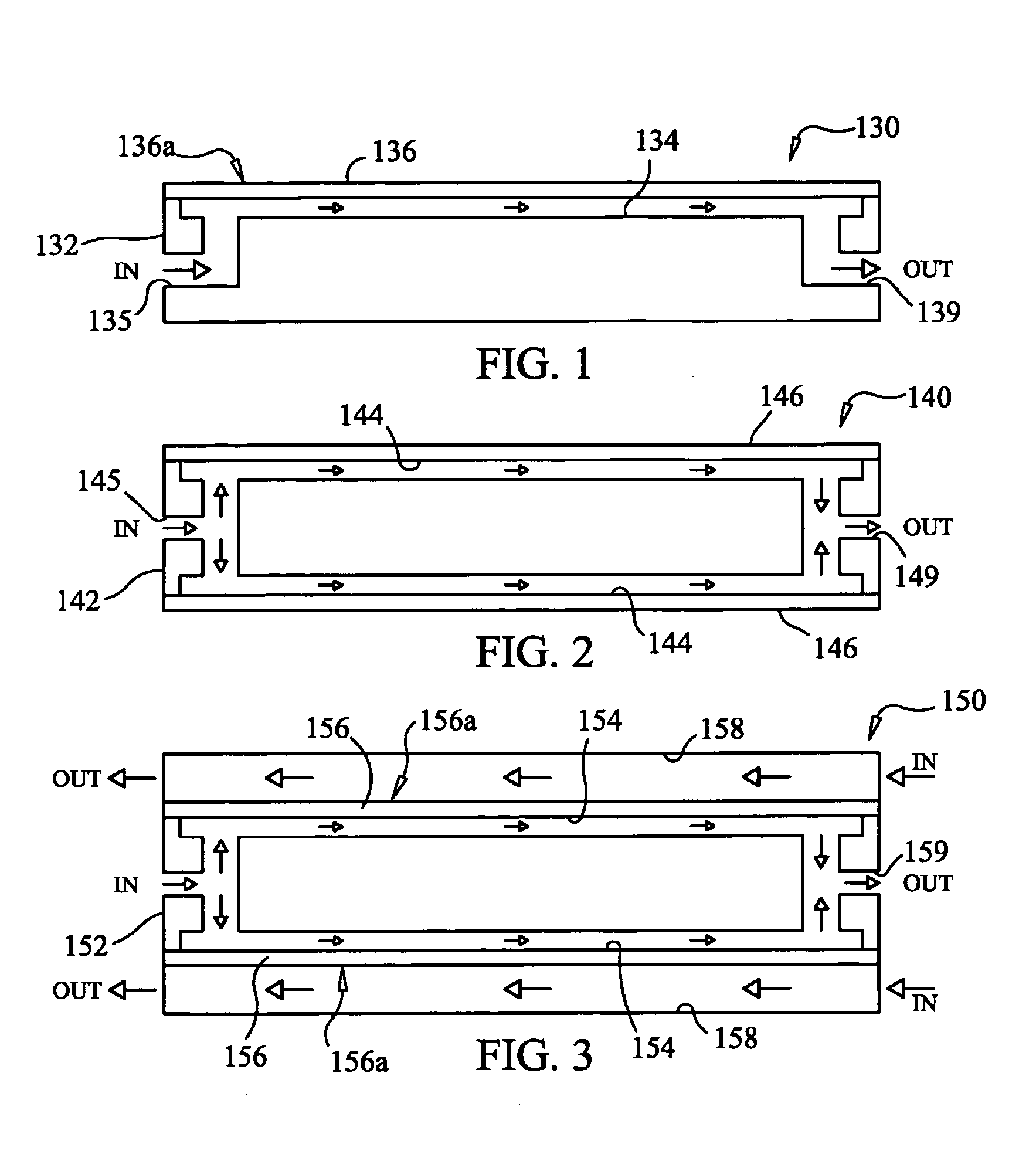

Water transport method and assembly including a thin film membrane for the addition or removal of water from gases or liquids

A water transport assembly, is provided including a housing having a first chamber therein, which is accessible through an opening in the housing. The housing additionally includes a sample inlet port and a sample outlet port, both of which are in fluid communication with the first chamber. A flat ion exchange membrane is attached to the housing in a plane over the opening in the housing, to seal the opening in a vapor tight seal. Water will pass through the membrane based upon the vapor pressure on each side of the membrane, to either dry or humidify sample passing through the first chamber. When the flat ion exchange membrane is a flat, thin ion exchange membrane it is preferable that the thin ion exchange membrane have a thickness of between about 0.1 and about 3.0 mils.

Owner:GOLDSTEIN JAY

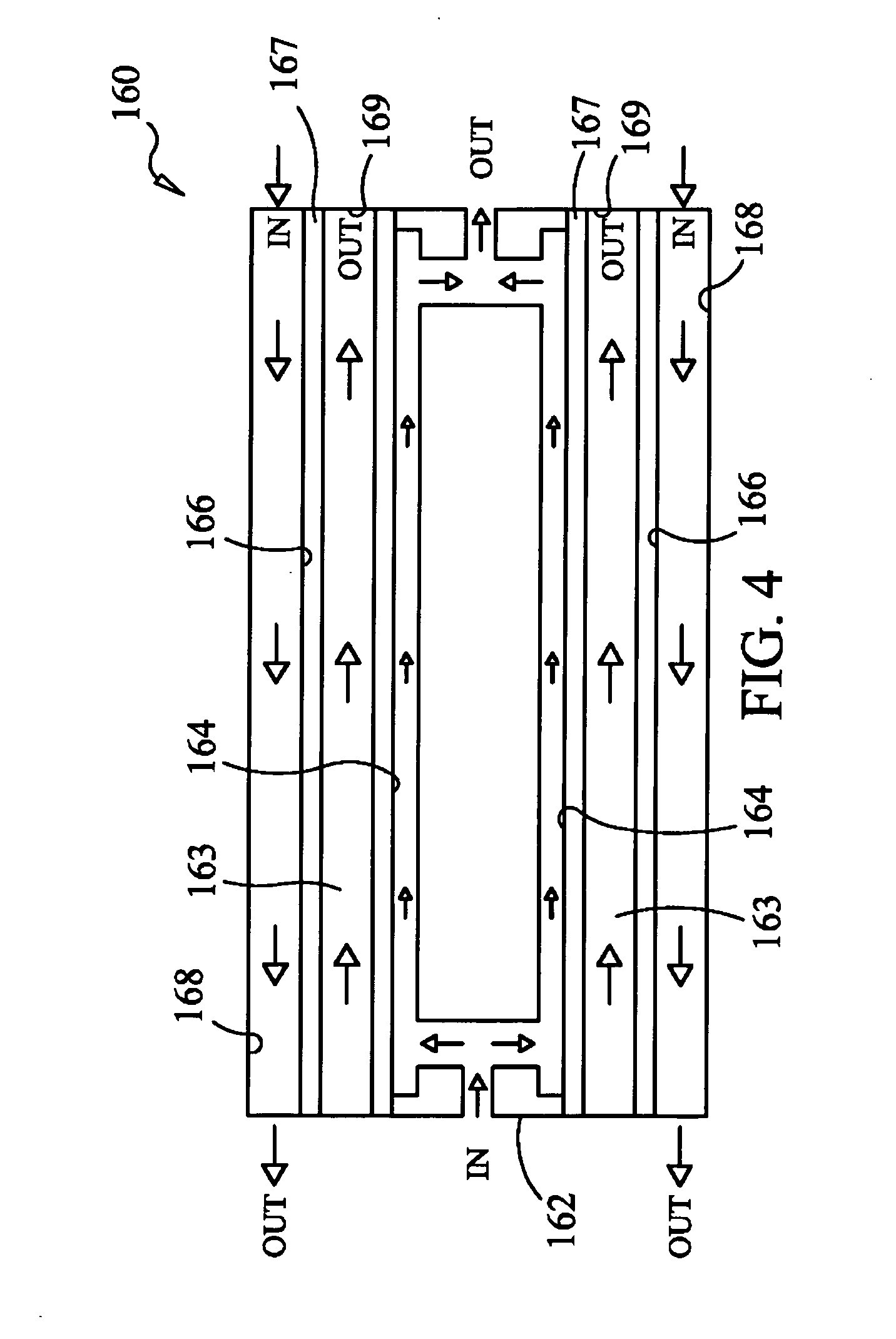

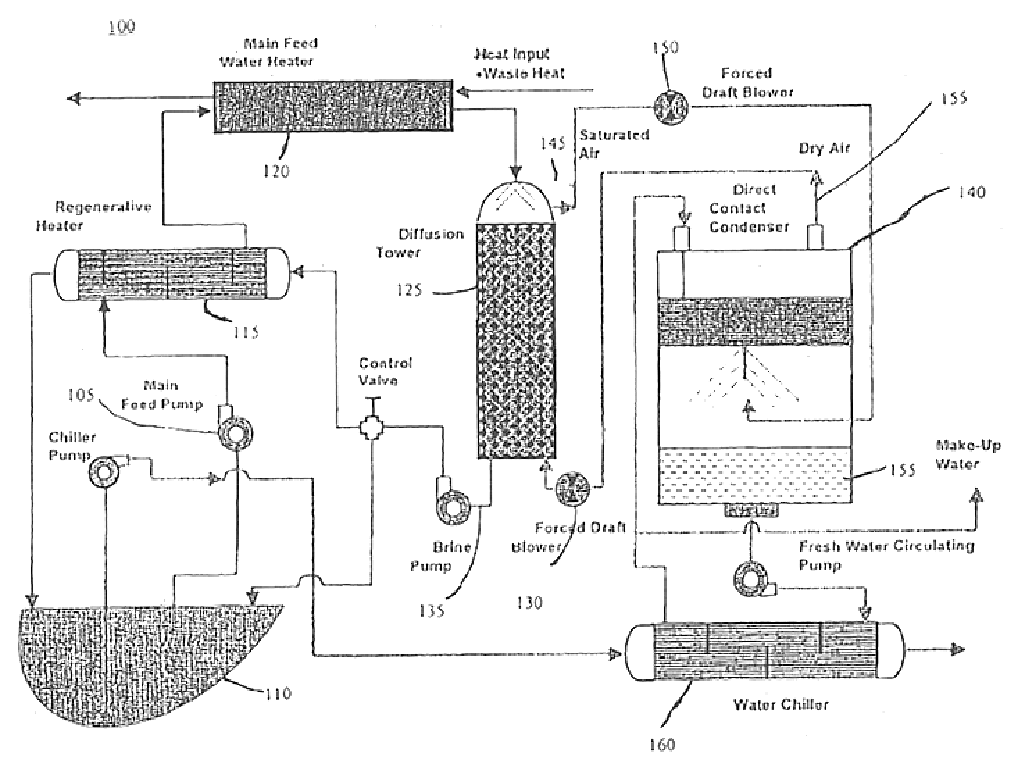

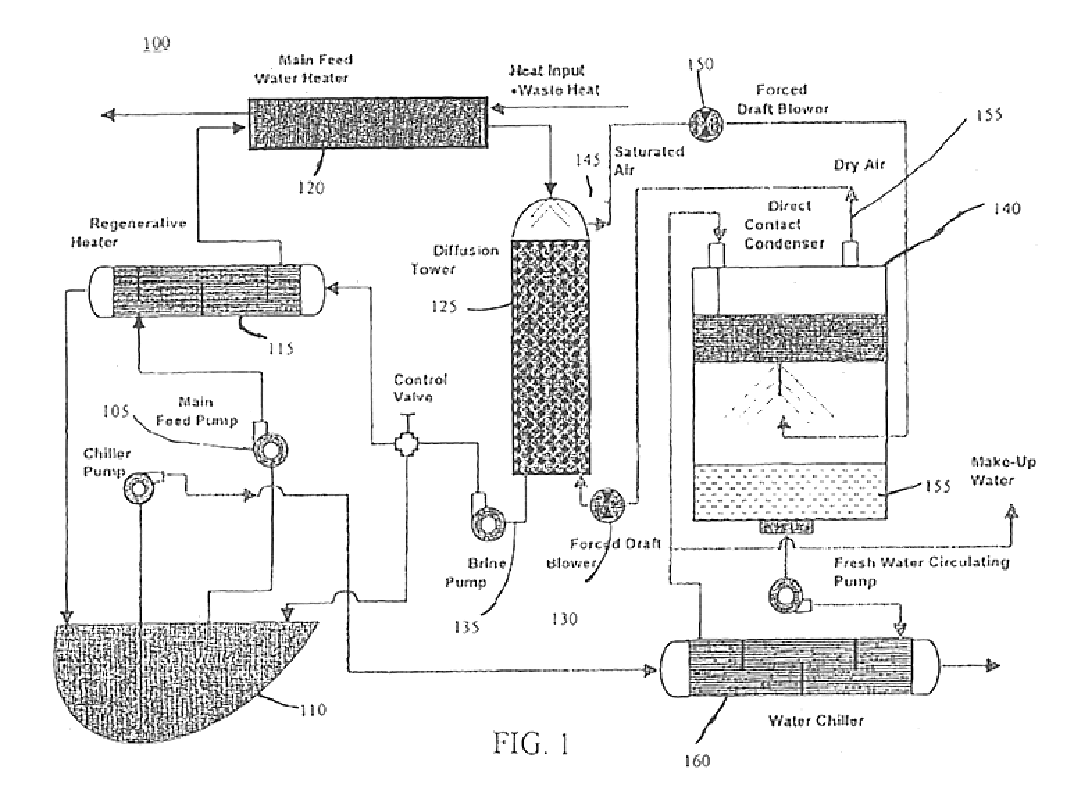

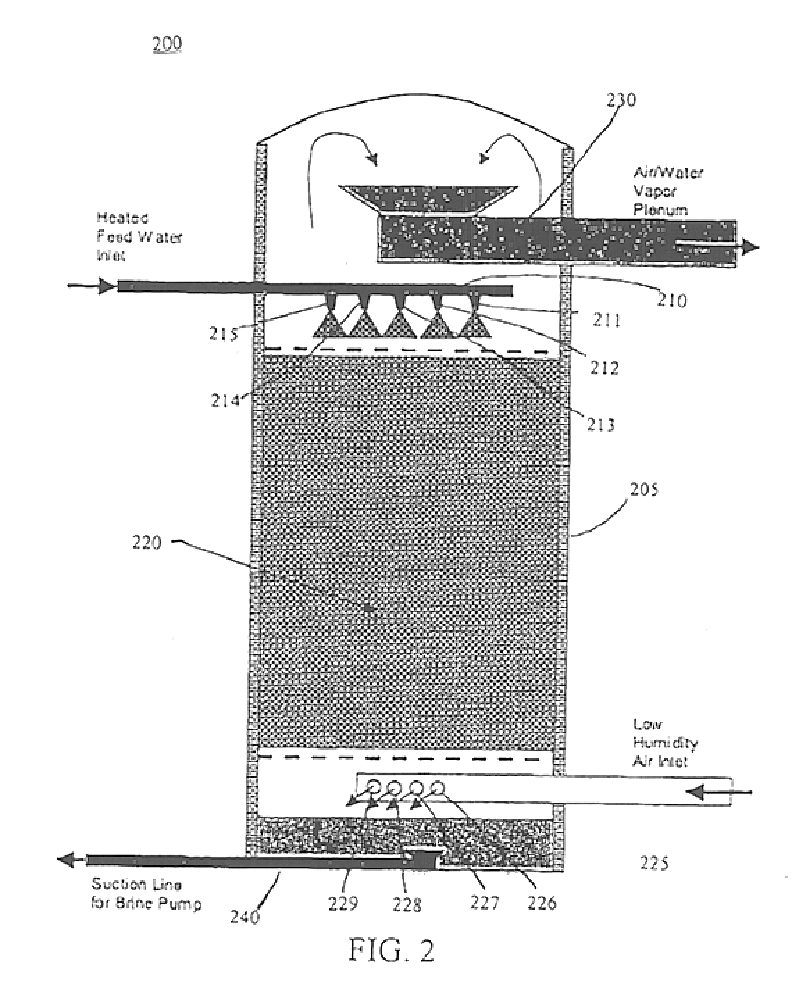

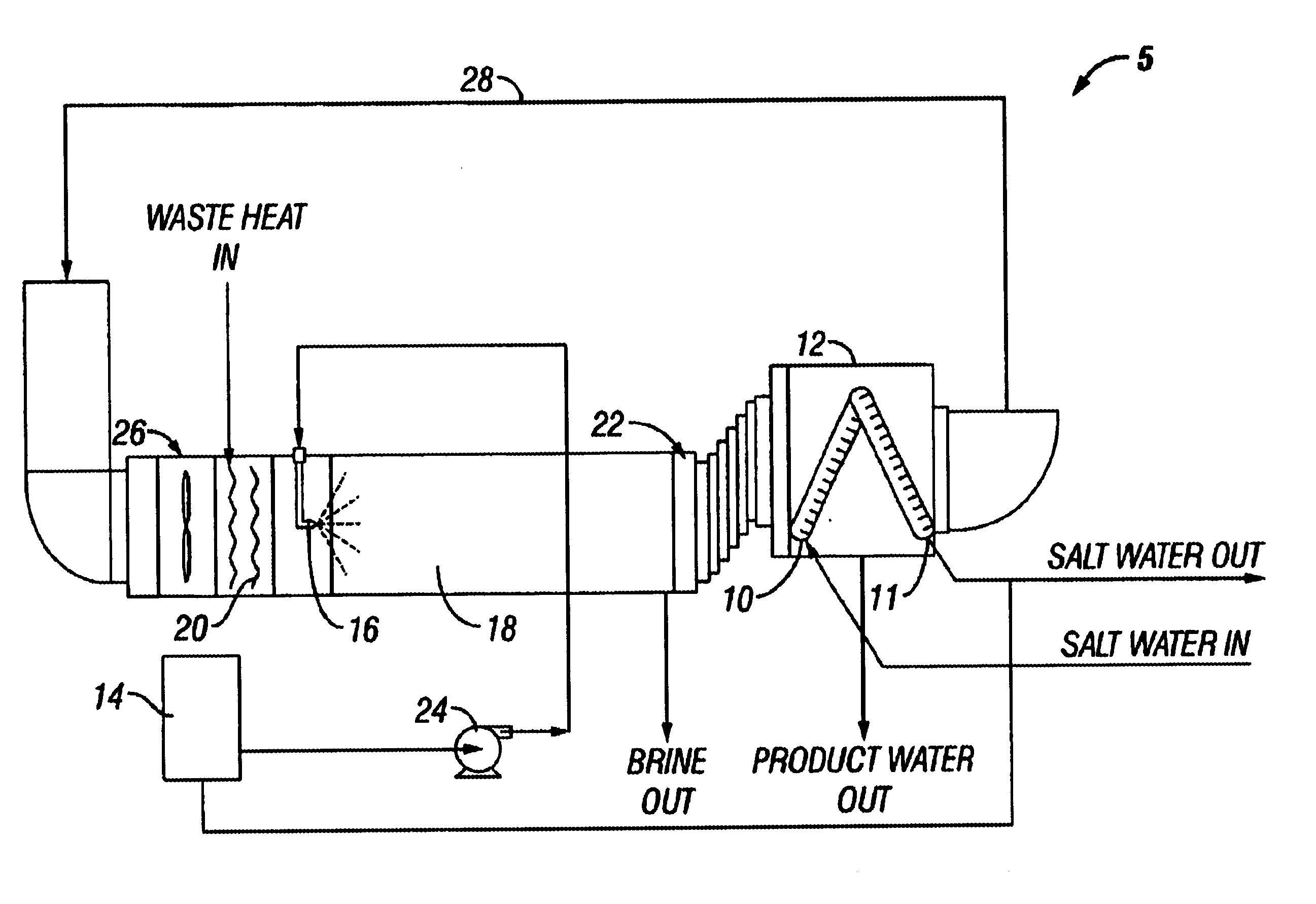

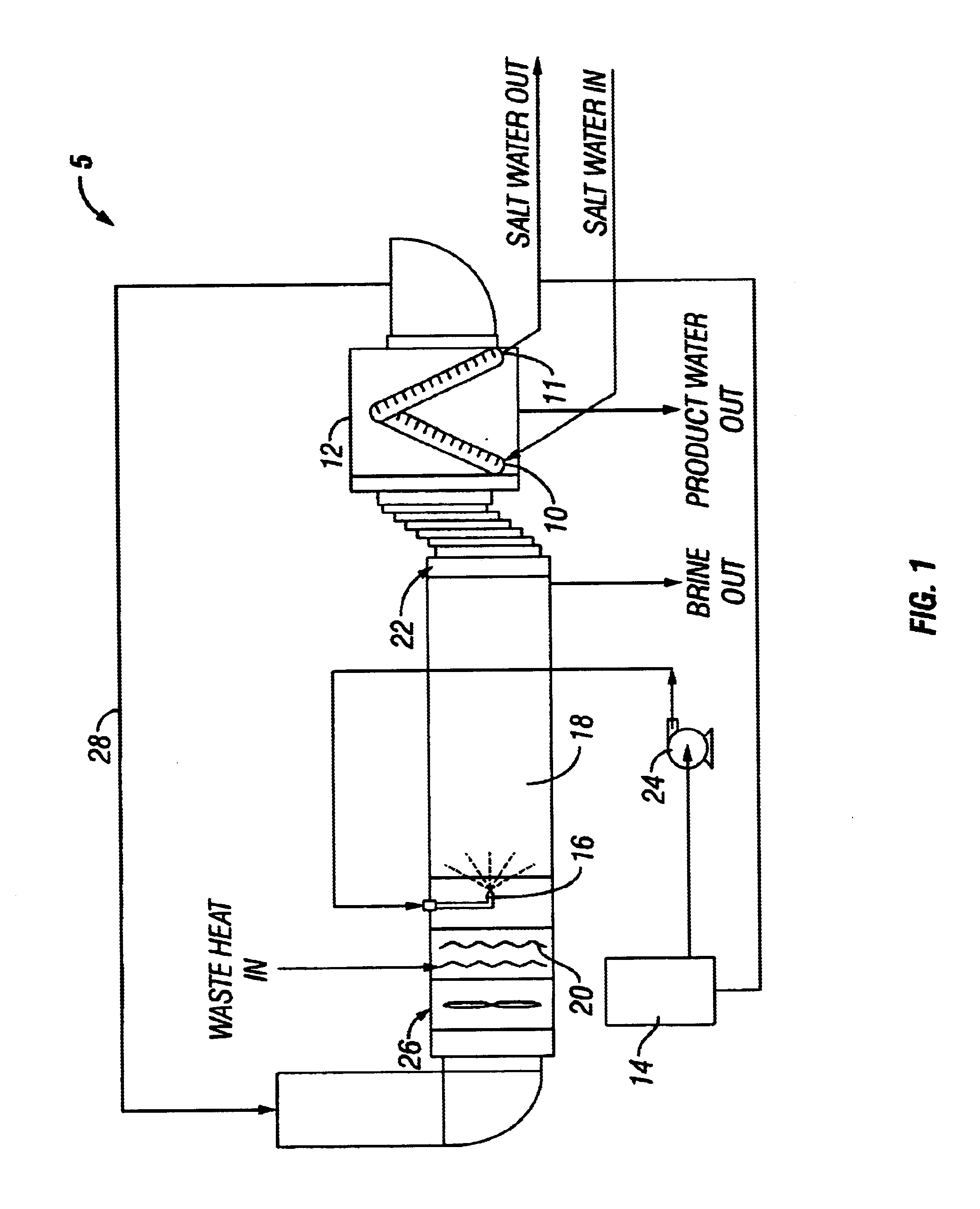

Diffusion driven desalination apparatus and process

A diffusion driven desalination apparatus and related method includes structure for receiving a heated water stream and creating at least one region having a thin film of water and structure for forcing a low humidity air stream over the thin film of water, wherein water from the thin film of water evaporates and diffuses into the air stream to create a humidified air stream. A diffusion tower including at least one plenum can be used to create and transfer the humidified air stream. At least one condenser, such as a direct contact condenser, condenses the humidified air stream, wherein purified water is produced. Waste heat from a power plant can be used to provide the heated water stream and power plants can use the waste heat generated to inexpensively provide purified water.

Owner:UNIV OF FLORIDA RES FOUNDATION INC +1

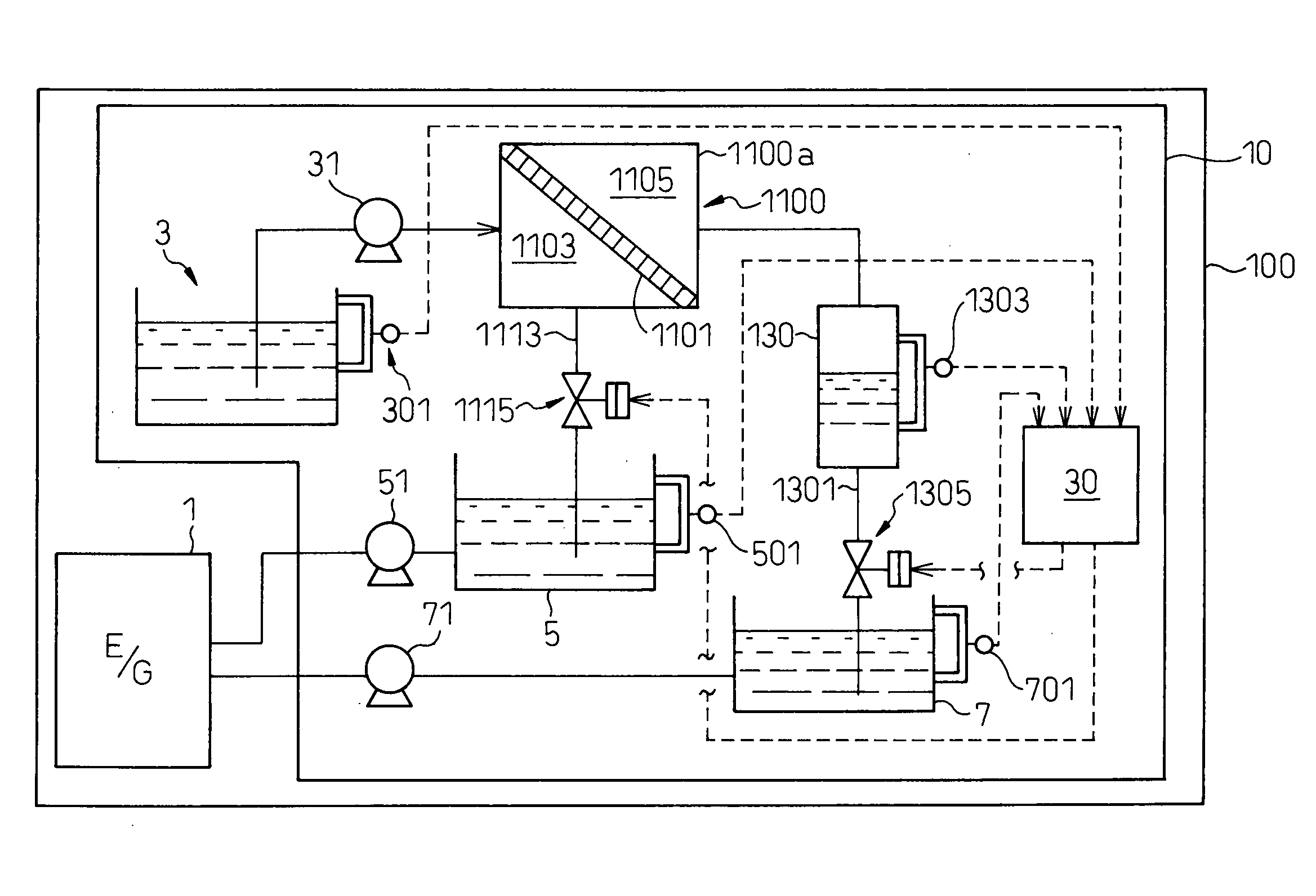

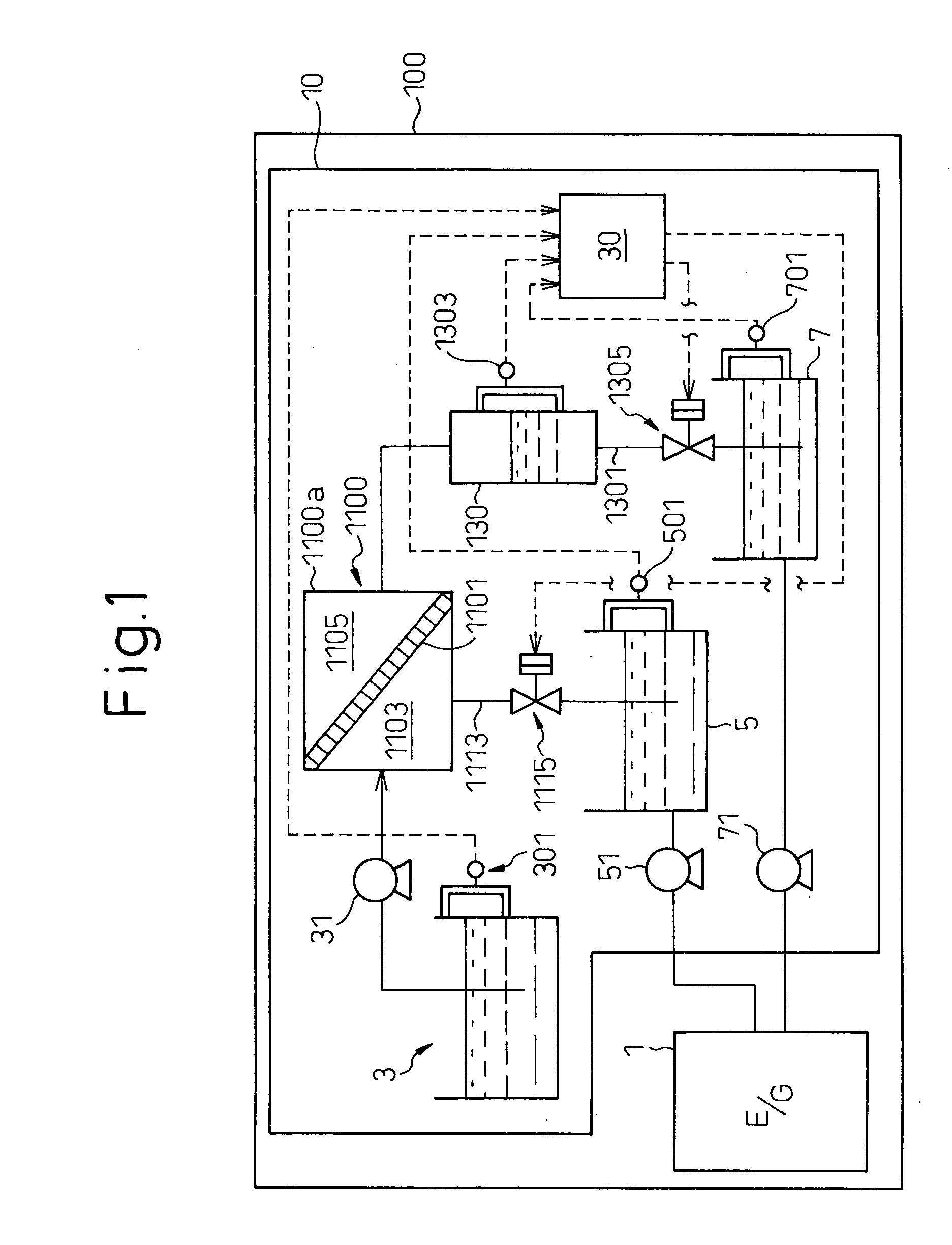

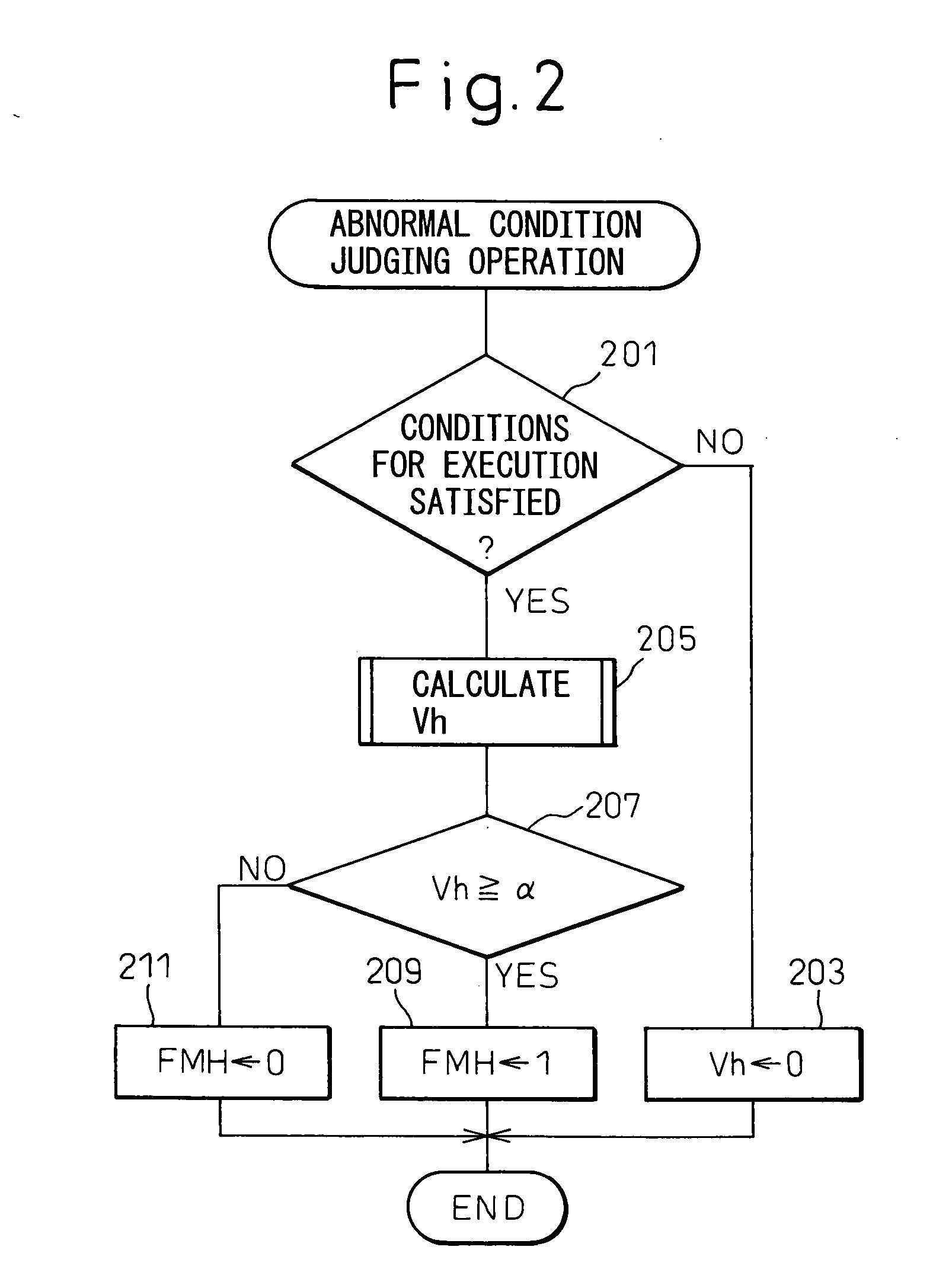

Onboard fuel separation apparatus for an automobile

A fuel separation apparatus includes a fuel tank storing the material fuel fed to a separation membrane, a fuel tank storing a separated low-octane fuel, and a fuel tank storing a separated high-octane fuel. An electronic control unit of the separation apparatus calculates the flow rate (amount of formation) of the high-octane fuel flowing into the high-octane fuel tank based on a change in the liquid level in the tank and on the amount of fuel fed to an engine from the tank, and so judges that an abnormal condition is occurring due to the breakage of the separation membrane when the amount of forming the high-octane fuel is larger than a predetermined upper limit value and that an abnormal condition is occurring due to a drop in the function of the separation membrane when the amount of formation is smaller than a predetermined lower limit value.

Owner:TOYOTA JIDOSHA KK

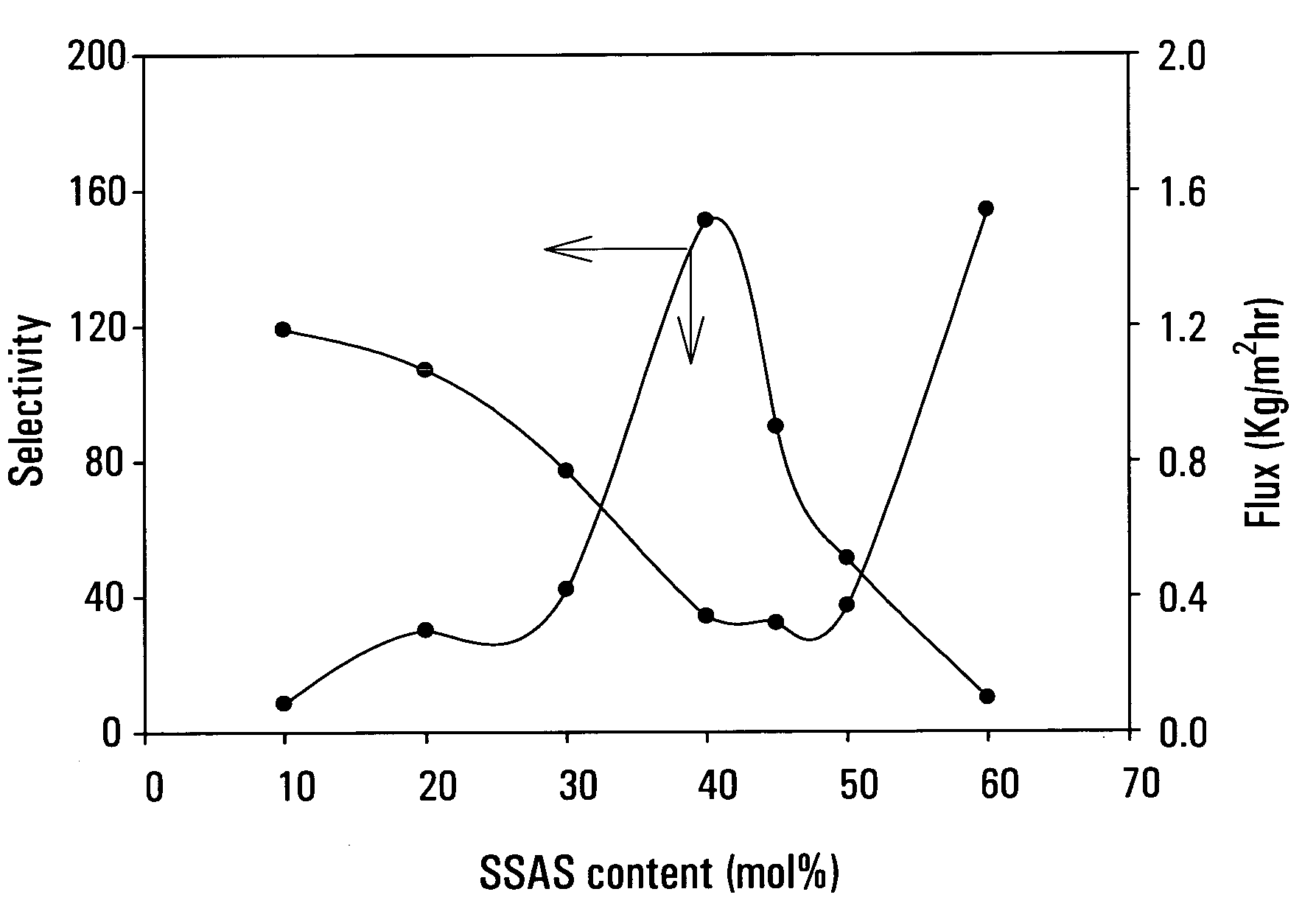

Pervaporation composite membranes

The present application discloses a composite membrane comprising (a) a support member that has a plurality of pores extending through the support member and (b) a cross-linked copolymer comprising (i) a cationic monomer and an anionic monomer and / or (ii) a zwitterionic monomer, which cross-linked copolymer fills the pores of the support member, the cross-linked copolymer having a permeability for a fluid that is dependent on the polarity of the fluid, wherein the permeability increases with increasing polarity.The present application also discloses a process for the preparation of the composite membrane, a pervaporation apparatus comprising the composite membrane, and methods for the use of the composite material in separation and dehydration processes.

Owner:MCMASTER UNIV

Dividing wall distillation column control apparatus

InactiveUS7267746B1Low costThermal non-catalytic crackingDistillation regulation/controlDistillationEngineering

A control apparatus and control method for controlling the separation in a dividing wall distillation column of at least two feeds into at least three products is disclosed. The apparatus uses a temperature measuring device to measure the temperature of fluid in the column, a controller, and a means for adjusting the temperature of fluid in the column. The temperature measuring device may be on either side of the dividing wall or above or below the dividing wall, and more than one such device may be used. The apparatus and method may be used in the production of alkylaromatic hydrocarbons by alkylating aromatic hydrocarbons with olefinic hydrocarbons.

Owner:UOP LLC

Fuel composition supply means for driving cycle conditions in spark ignition engines

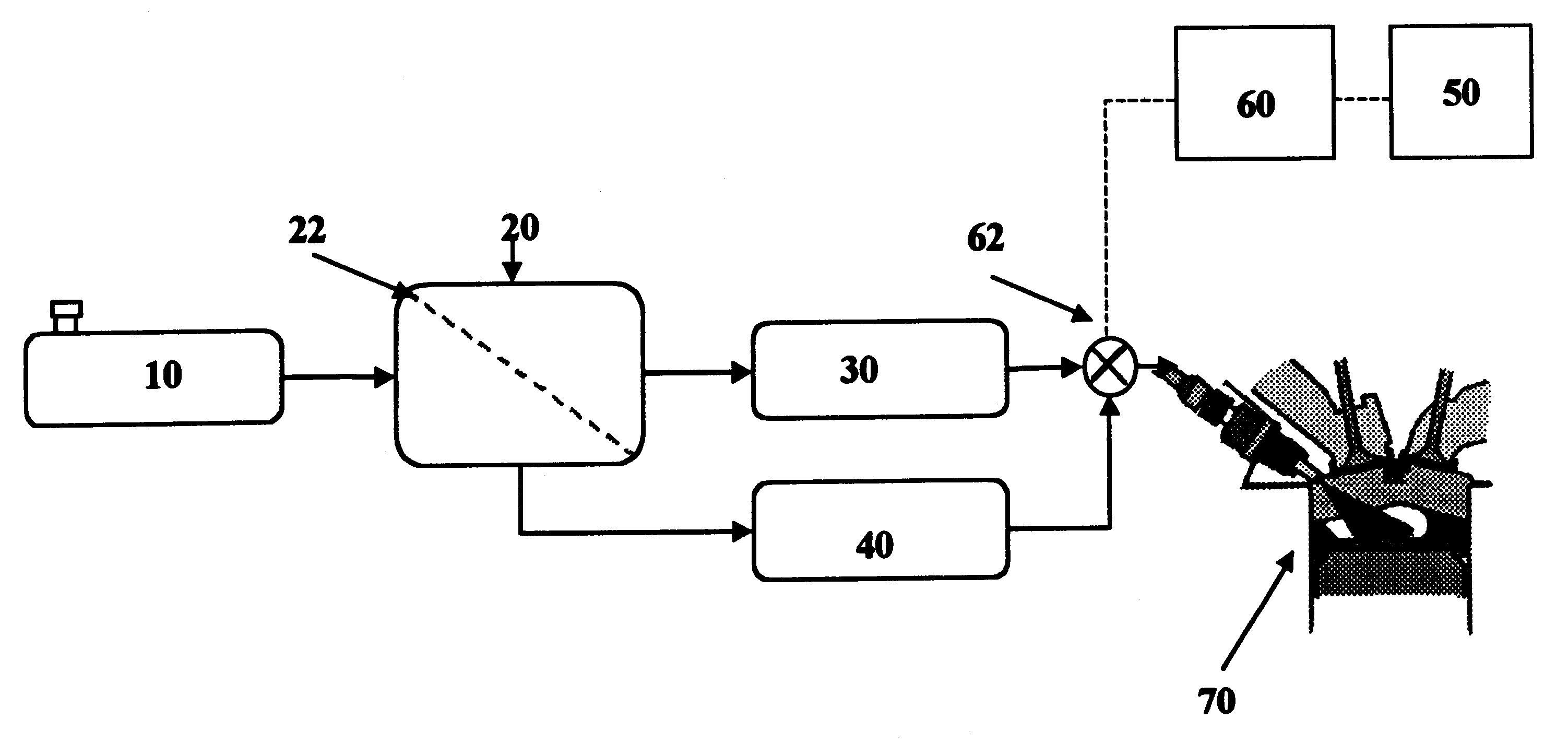

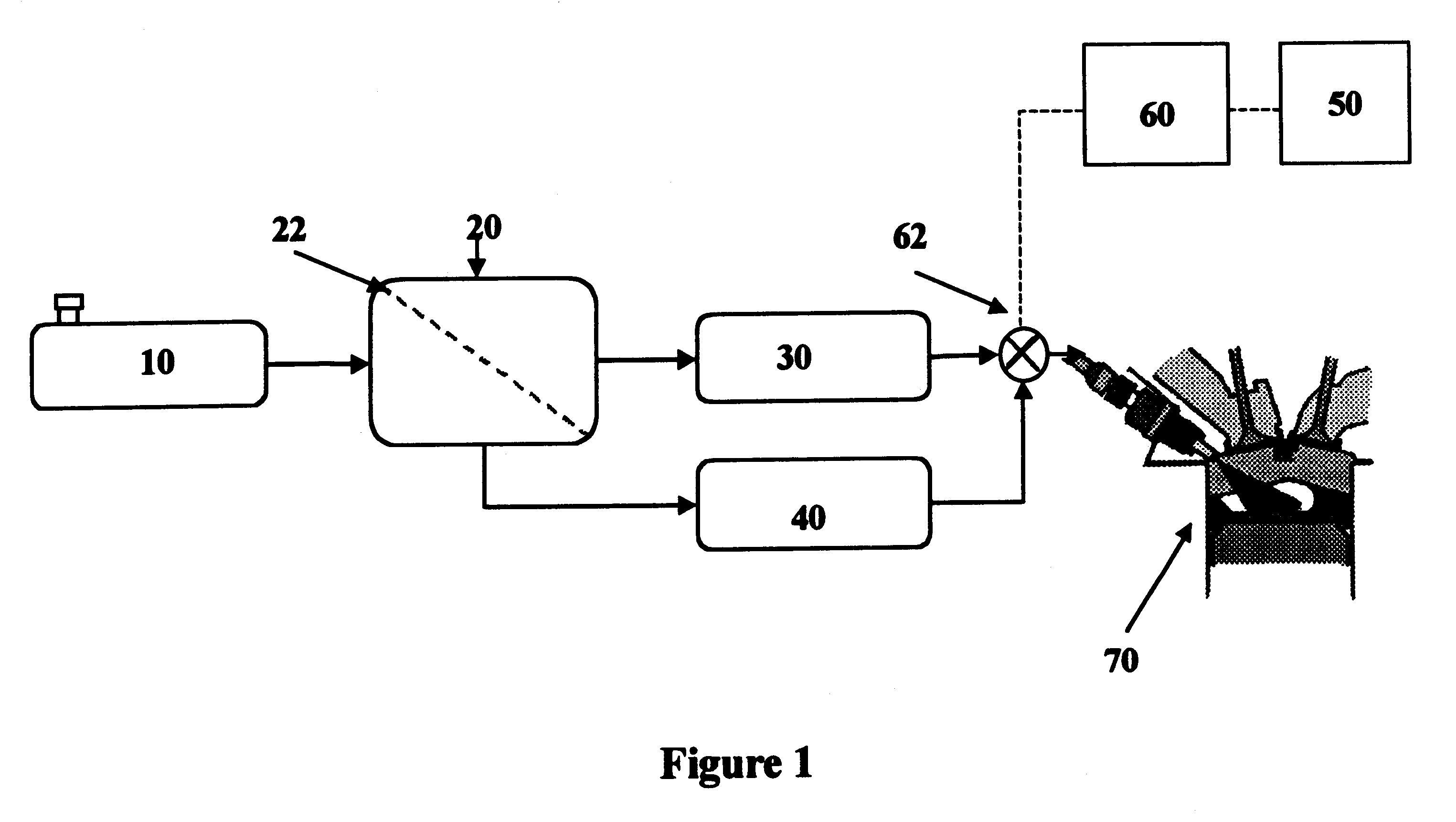

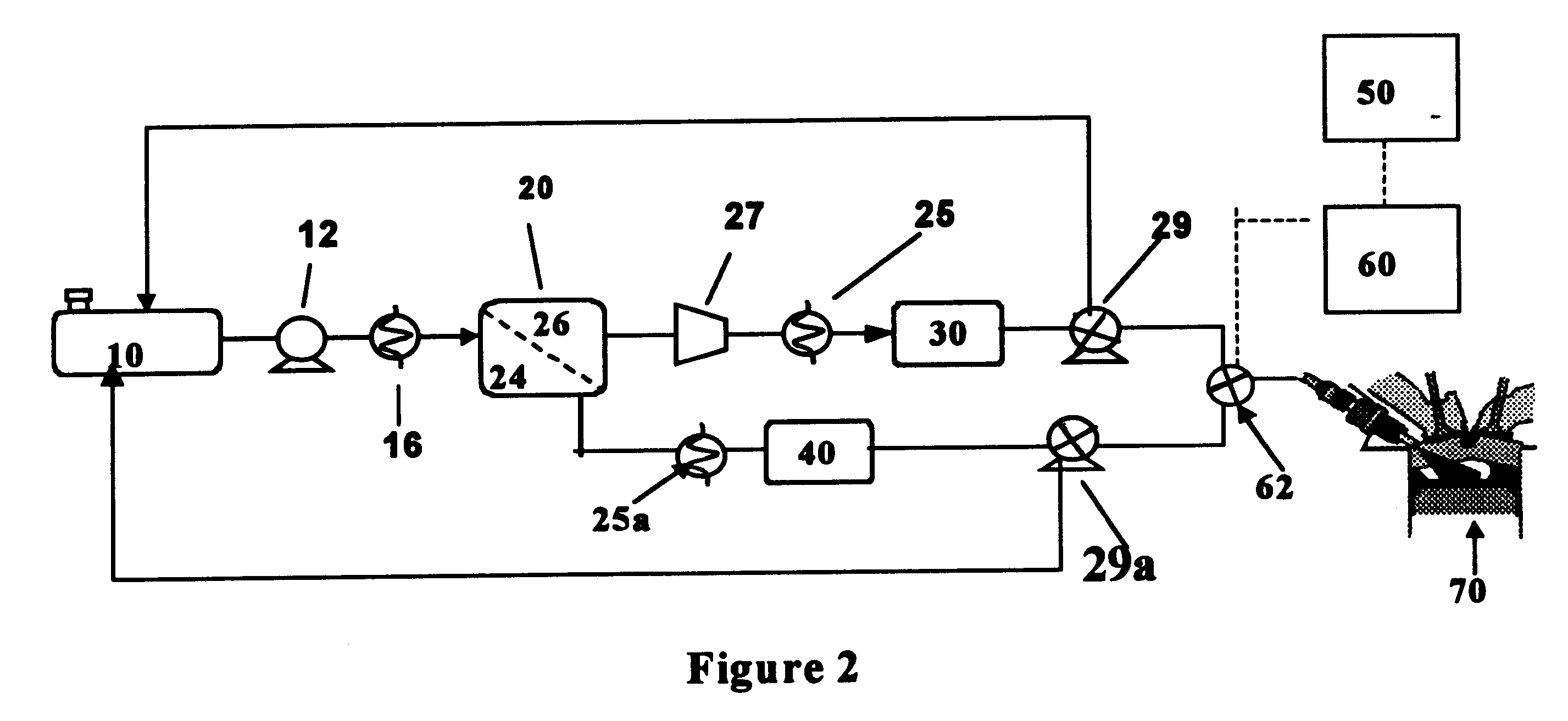

InactiveUS6622663B2More of efficiencyMore of emissionsInternal combustion piston enginesNon-fuel substance addition to fuelOn boardMotor fuel

A fuel system for on-board vehicle fuel separation to supply engine fuel compositions formulated as a function of driving cycle conditions. The invention results in improvements in one or more of feed efficiency and combustion emissions.

Owner:EXXON RES & ENG CO

Desalination method and desalination apparatus

InactiveUS6833056B1Number of stage increasingIncrease the number ofAuxillariesGeneral water supply conservationDesalinationDistilled water

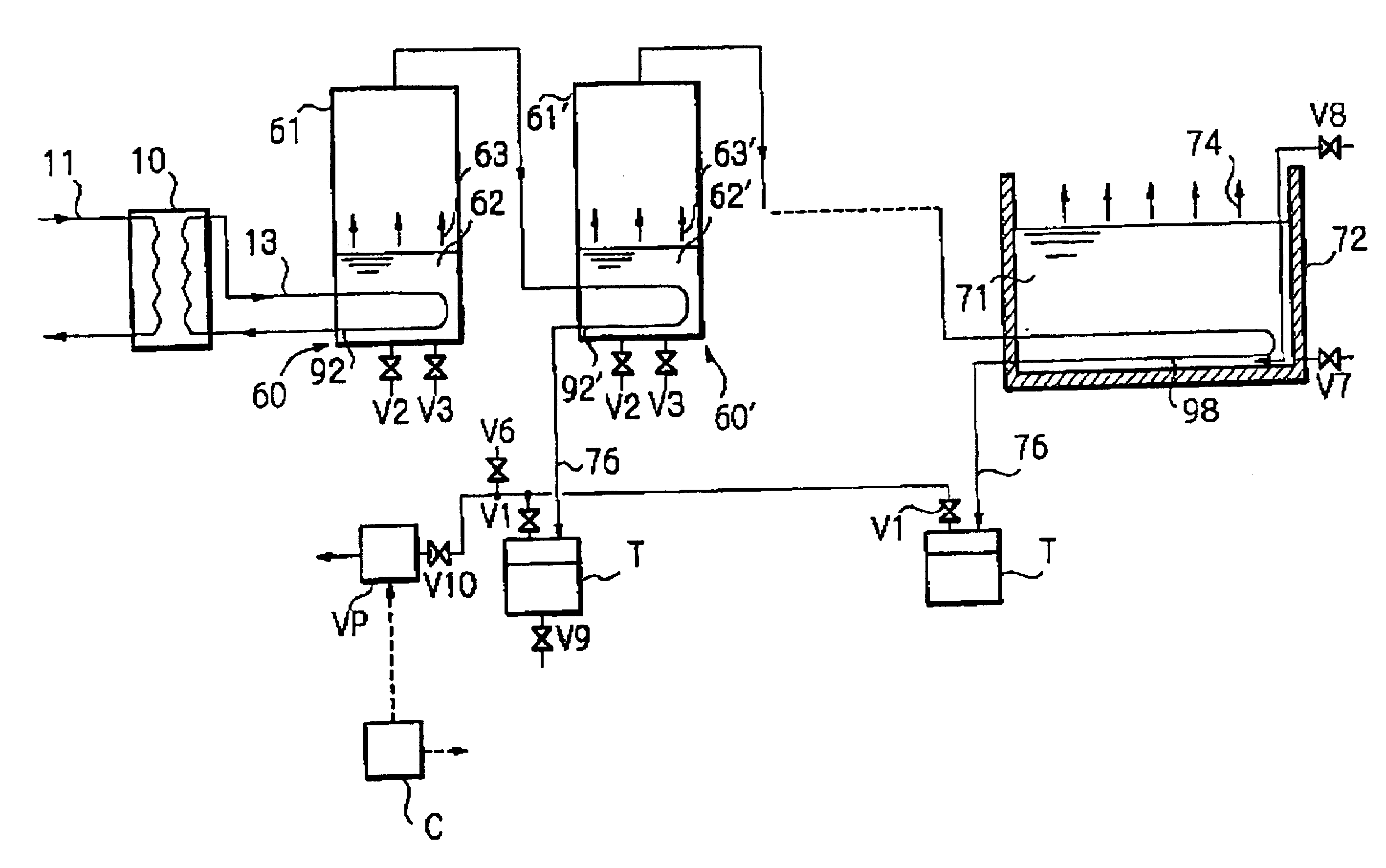

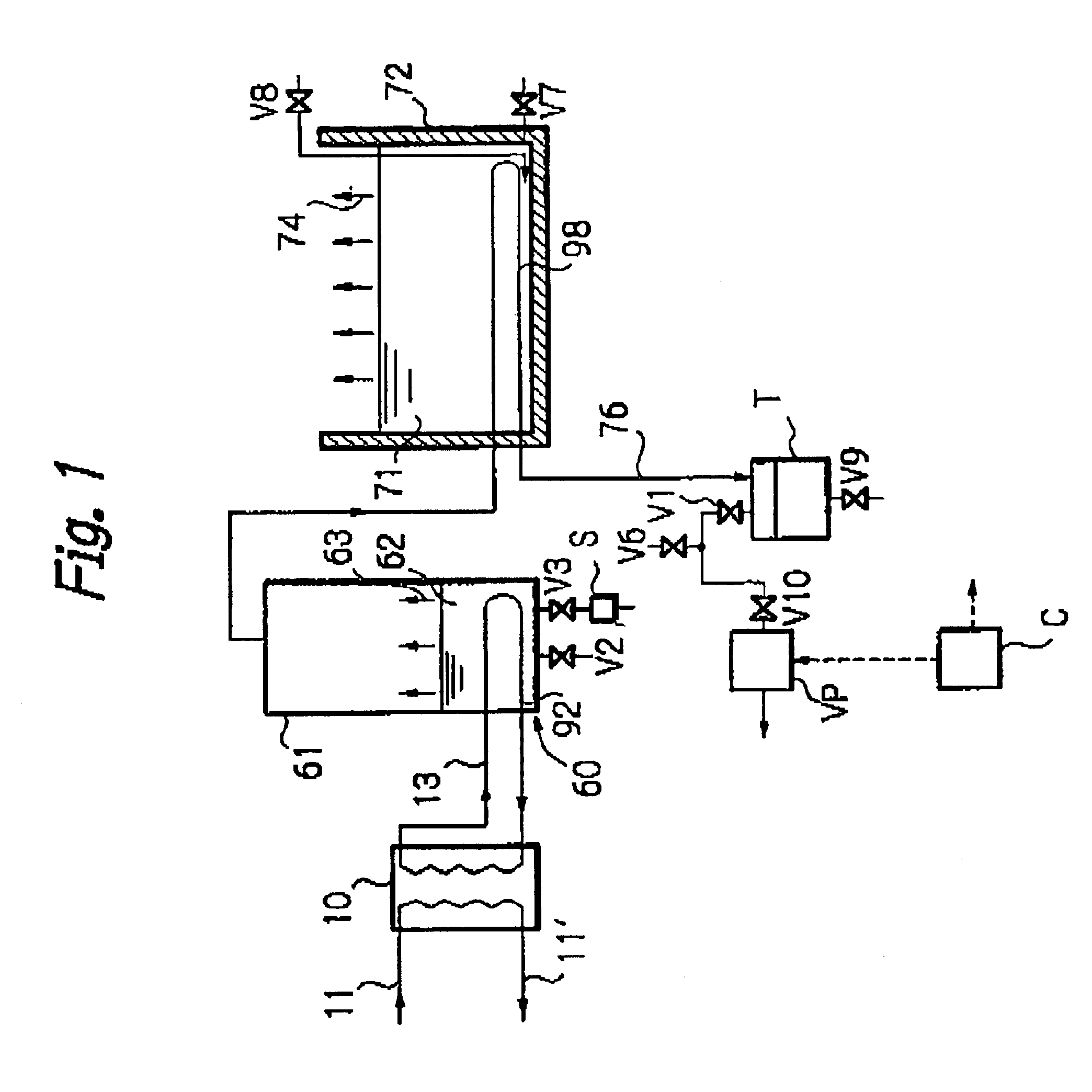

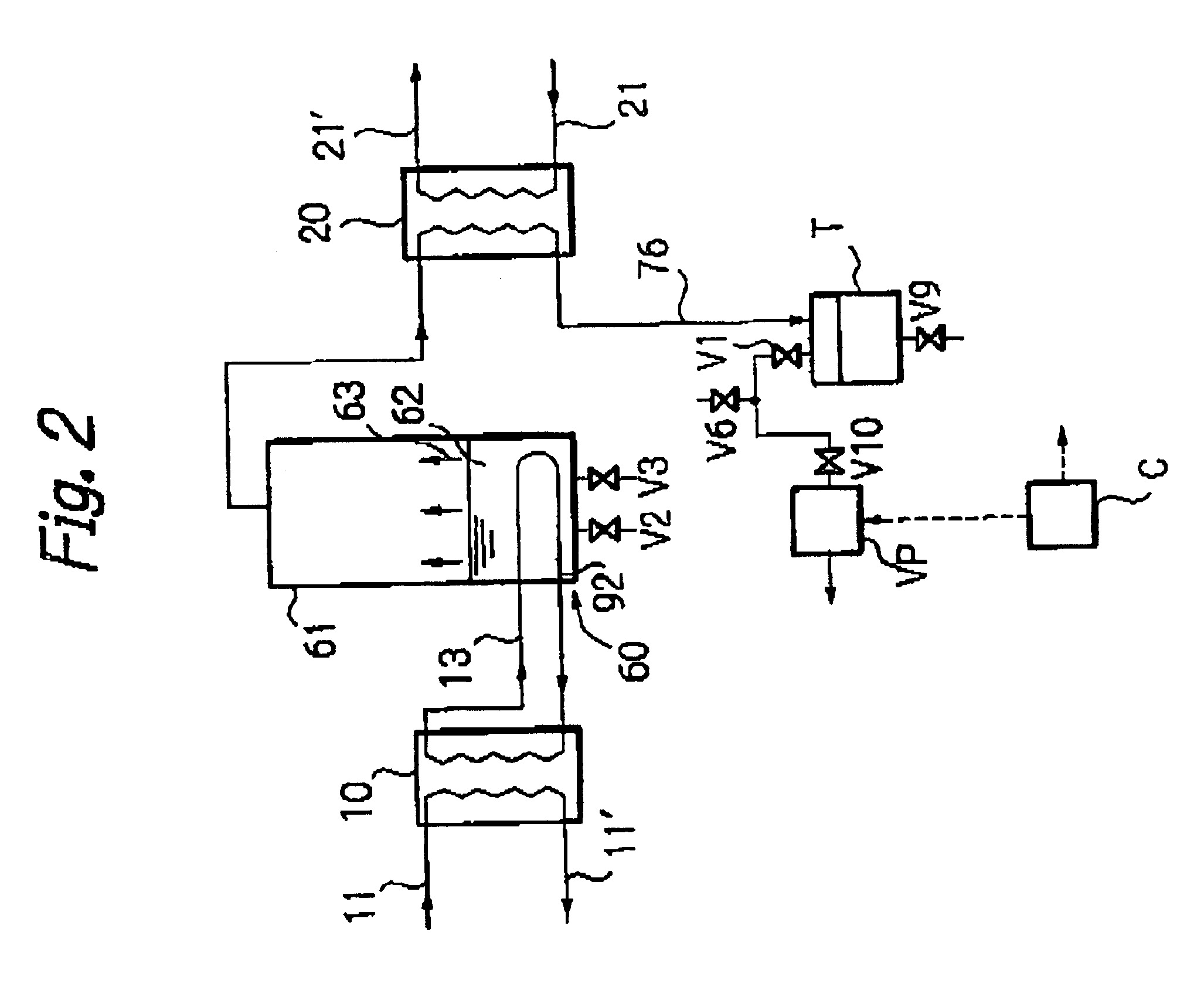

A desalination apparatus capable of obtaining fresh water stably at low cost by utilizing low-temperature waste, wherein the desalination apparatus including a heat exchanger 92 cooperating with an evaporation can 60 so as to subject a low-temperature waste heat 11 and raw water 62 in the evaporation can 60 to heat exchange and generate water vapor 63 in the evaporation can 60; a condenser 98 cooperating with a raw water tank 72 so as to receive the water vapor 63 from the evaporation can 60, cool the water vapor 63 by subjecting the water vapor 63 and raw water 71 in the raw water tank 72 to heat exchange and obtain distilled water 76; a distilled water tank for storing the distilled water 76; vacuum means for evacuating the evaporation can 60 and depressurizing the inside thereof so as to promote generation of water vapor 63 in the evaporation can 60; and raw water supply means for supplying raw water to the evaporation can.

Owner:EBARA CORP

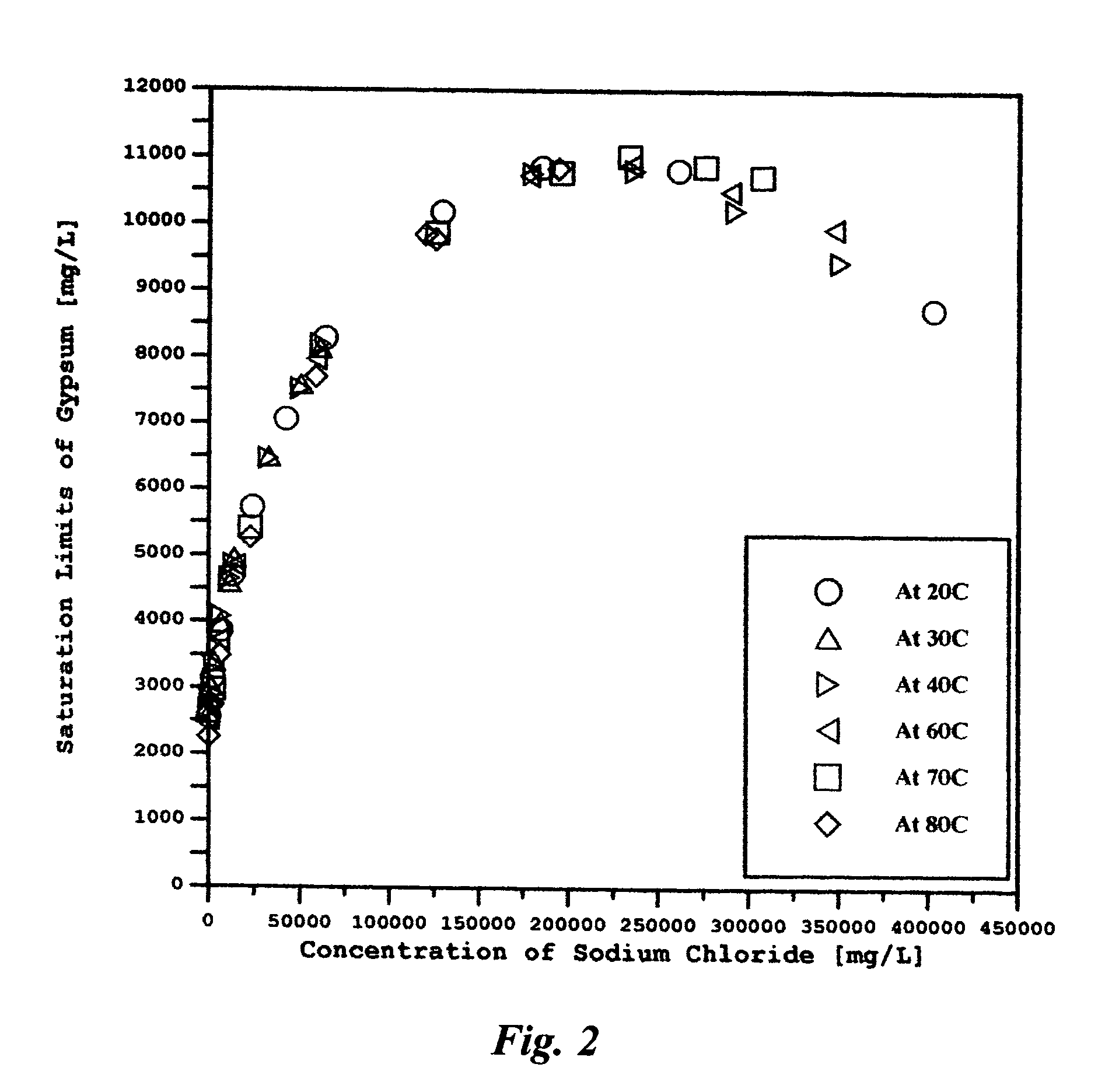

Methods to produce sulfate-free saline water and gypsum

ActiveUS7392848B1Avoid pollutionWaste water treatment from quariesSludge treatmentSaline waterSulfate

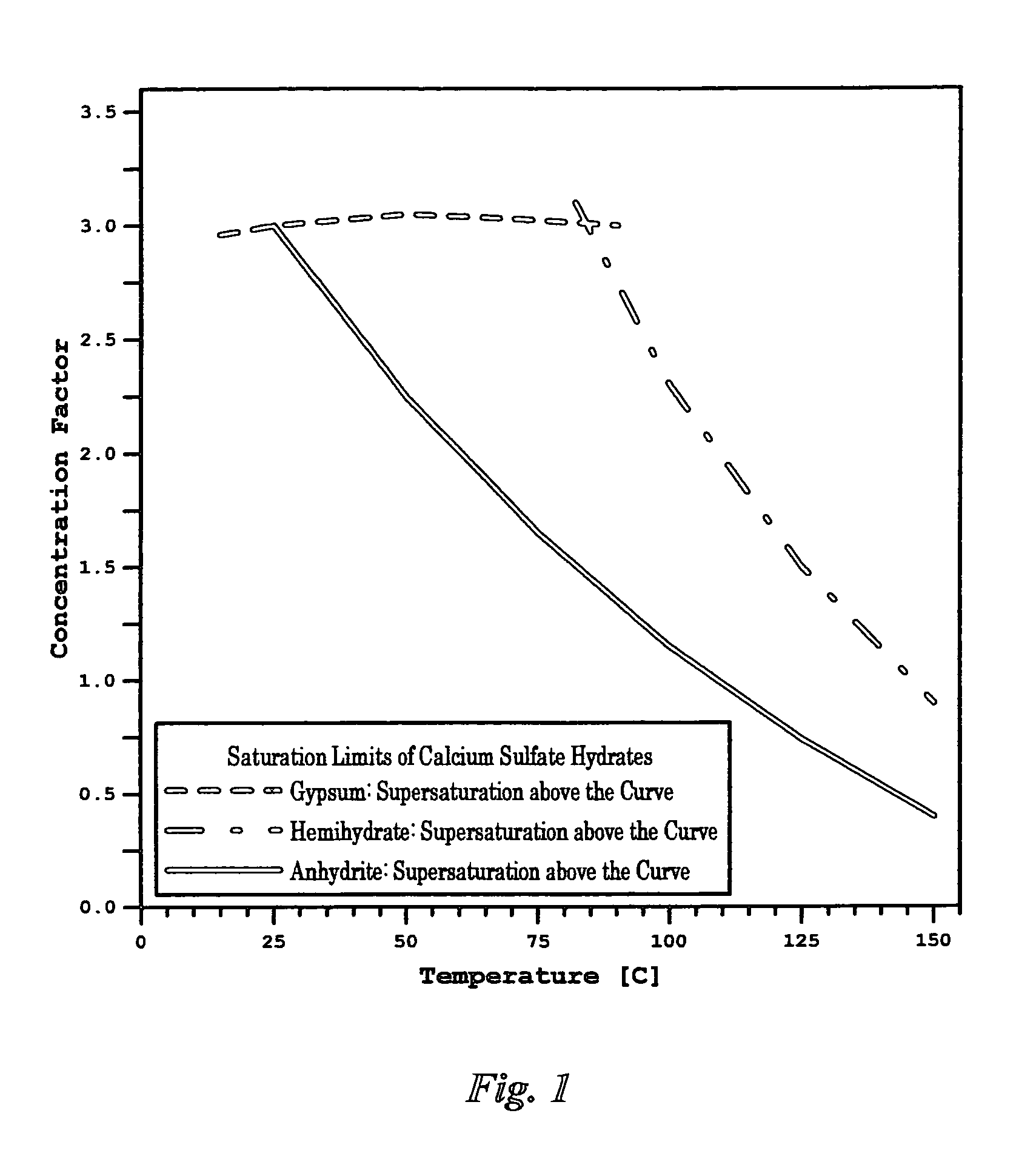

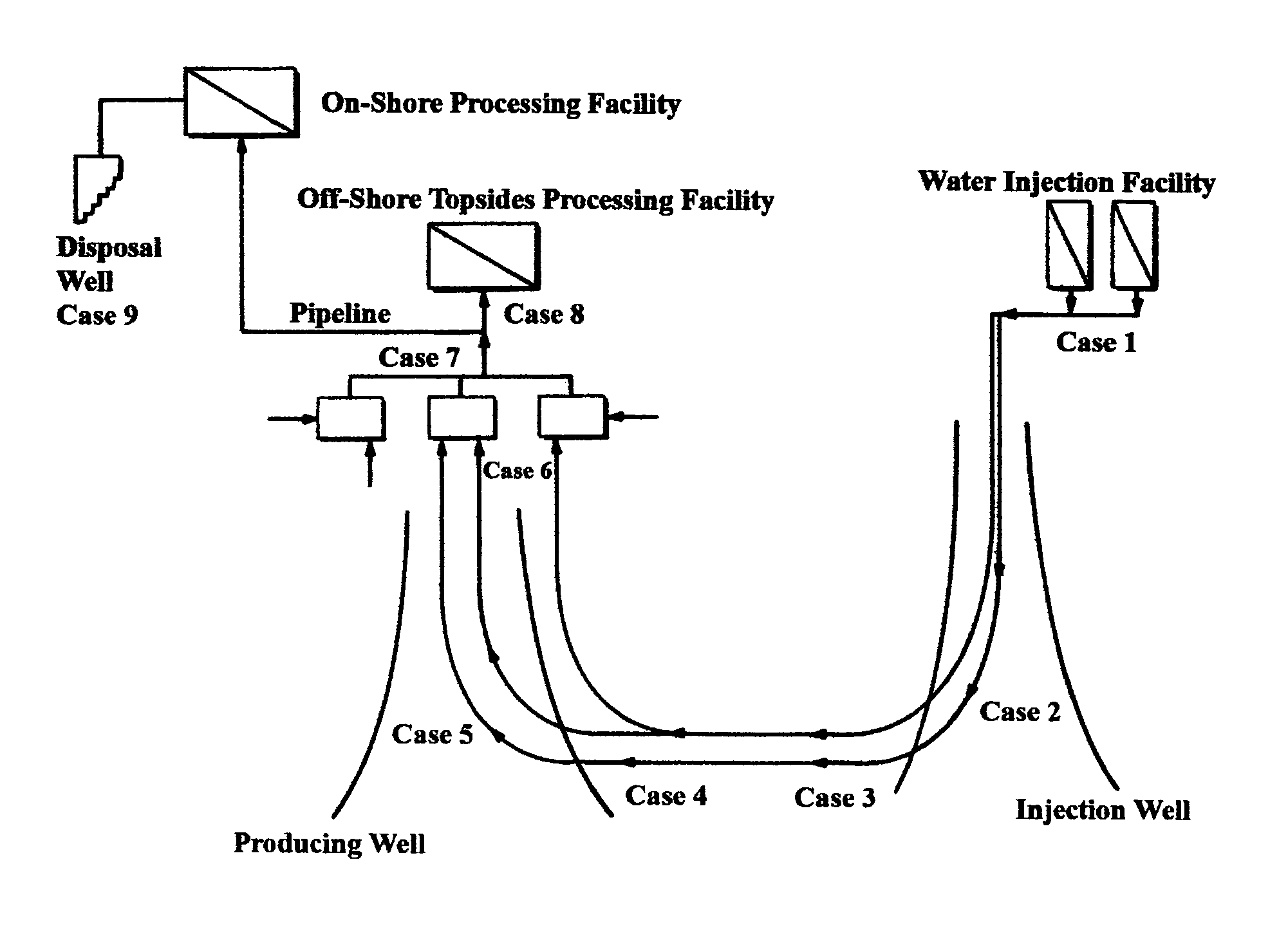

Methods are disclosed for the selective separation of sulfate from a saline stream such as seawater to produce nearly sulfate-free saline stream for oil-fields water injection operations. The separated sulfate in the form of gypsum from the treated saline stream can be used in different applications.

Owner:BADER MANSOUR S

Cascade reboiling of ethylbenzene/styrene columns

InactiveUS6171449B1Reduce use costEfficient and economical approachDistillation regulation/controlDistillation in boilers/stillsCascadeEngineering

Apparatus and process are disclosed for the distillation separation of styrene monomer from ethylbenzene utilizing a split feed to two distillation columns in conjunction with cascade reboiling utilizing thermal energy from the overhead of one column to supply heat to the second.

Owner:STONE & WEBSTER PROCESS TECH

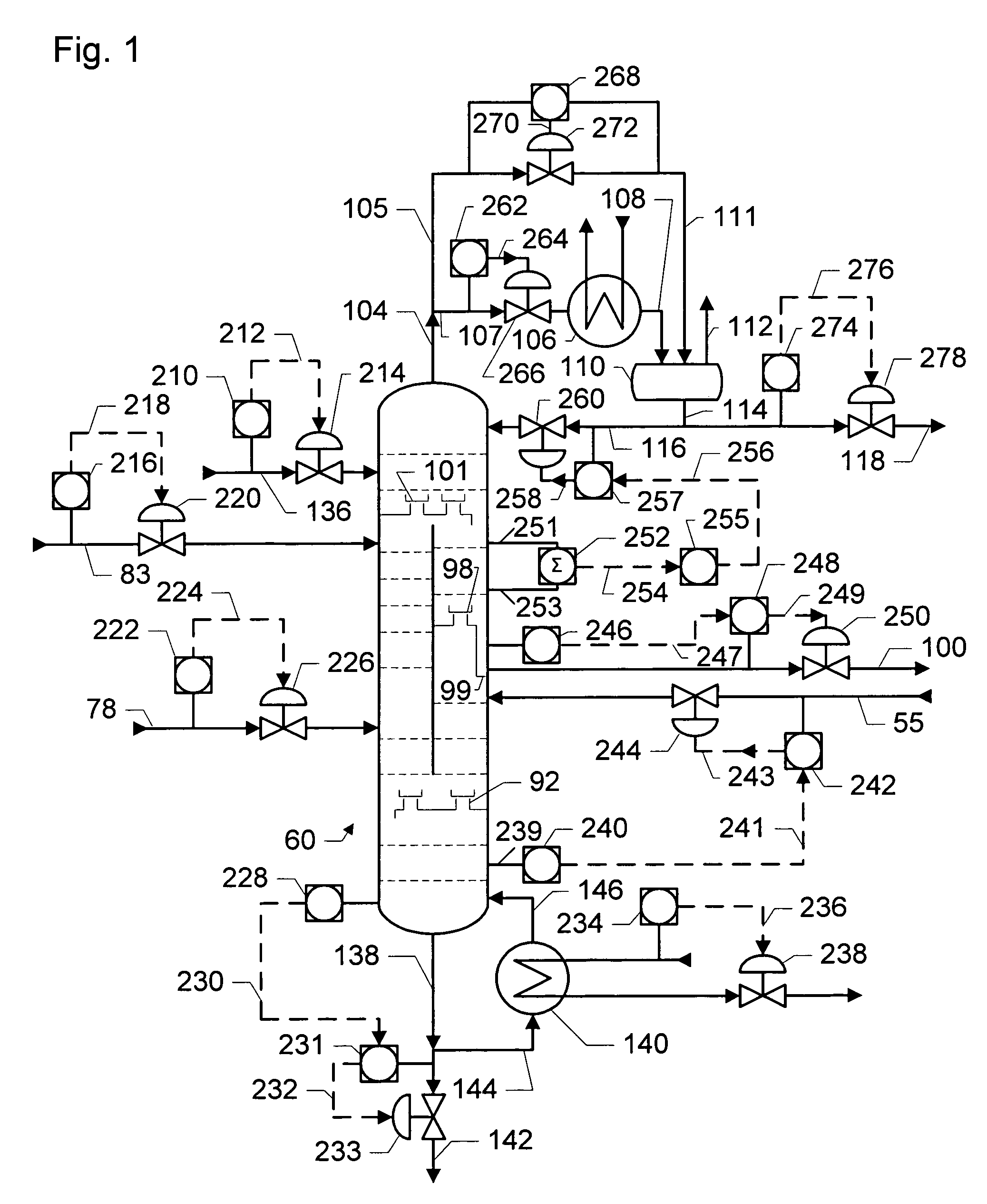

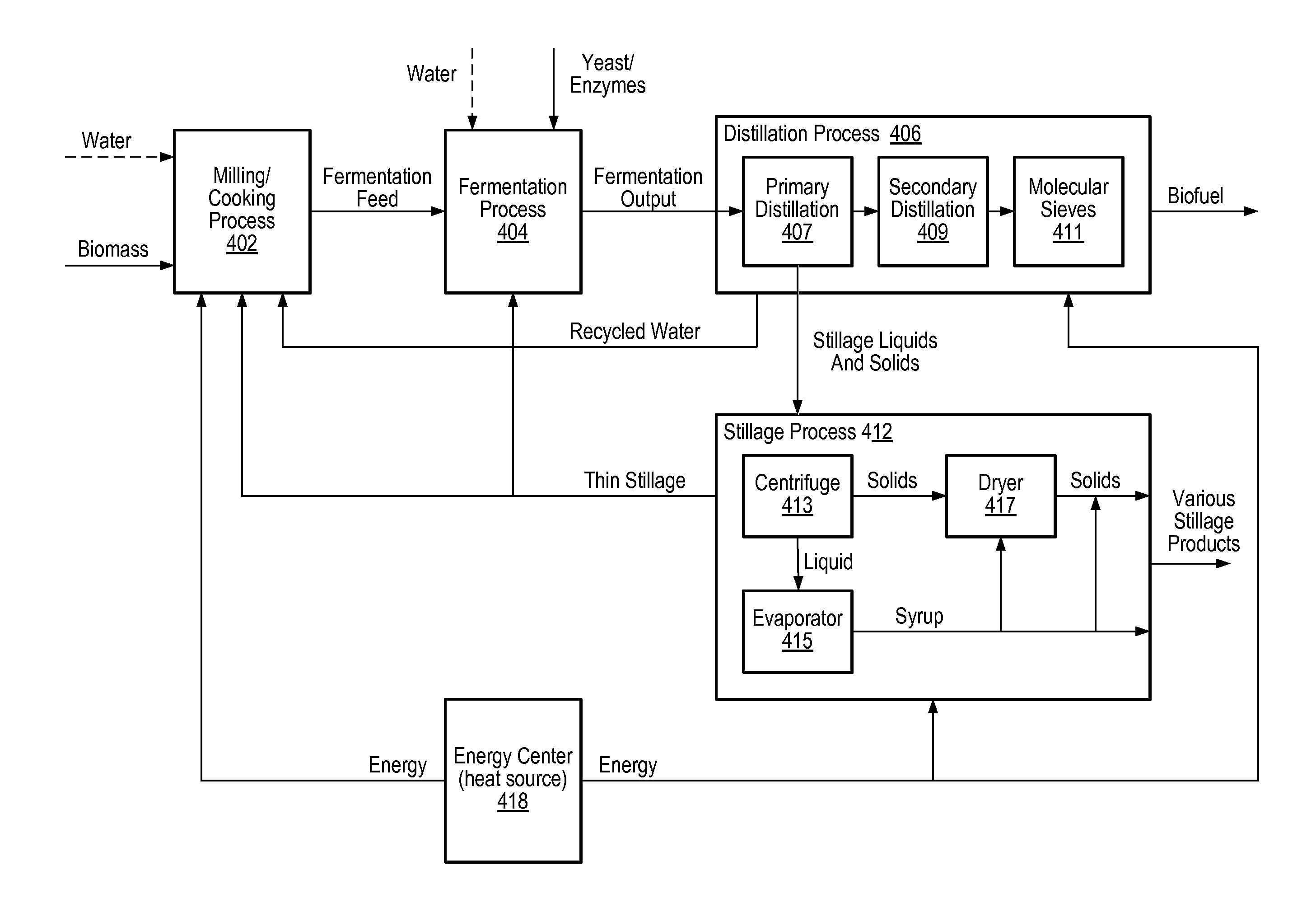

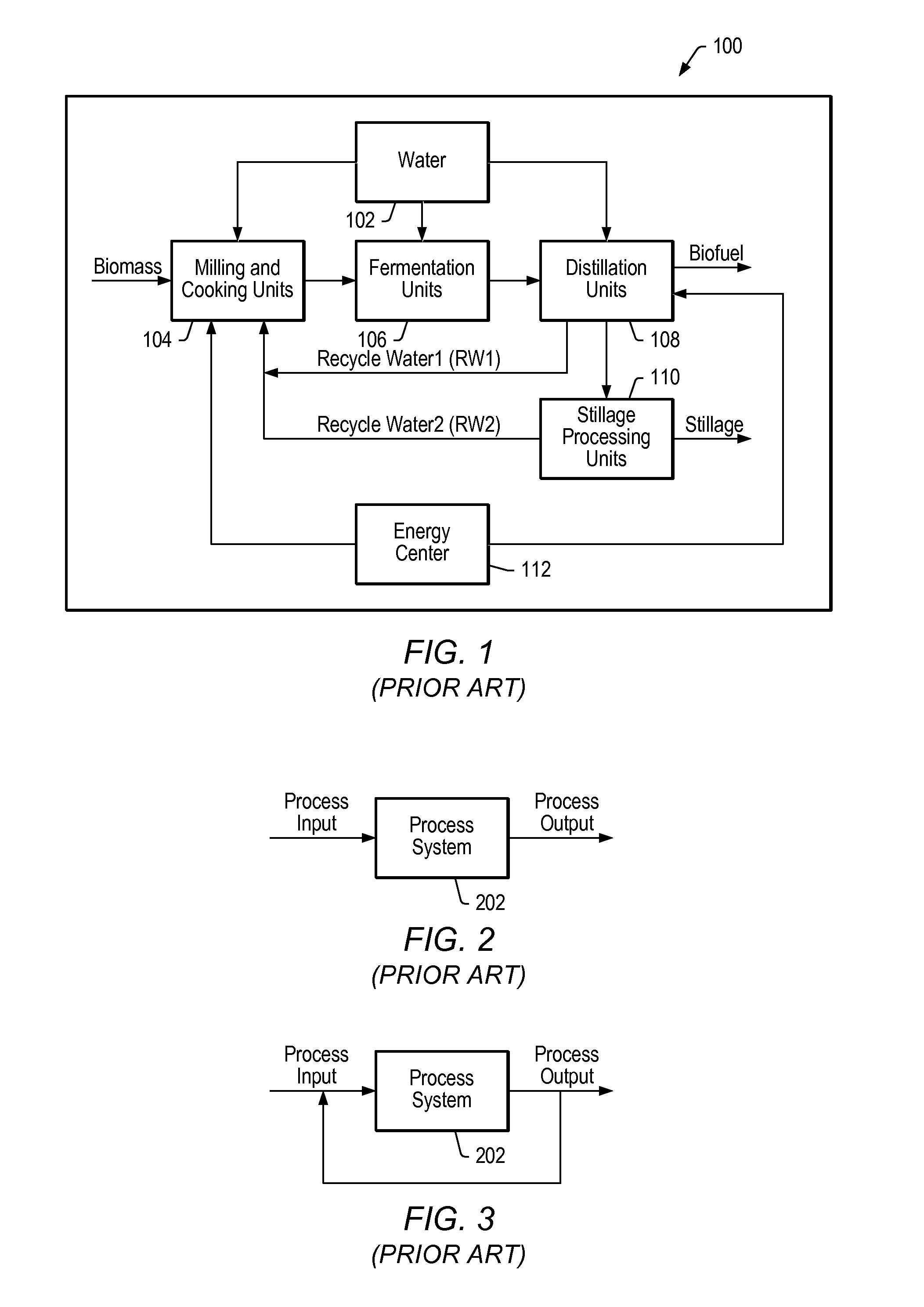

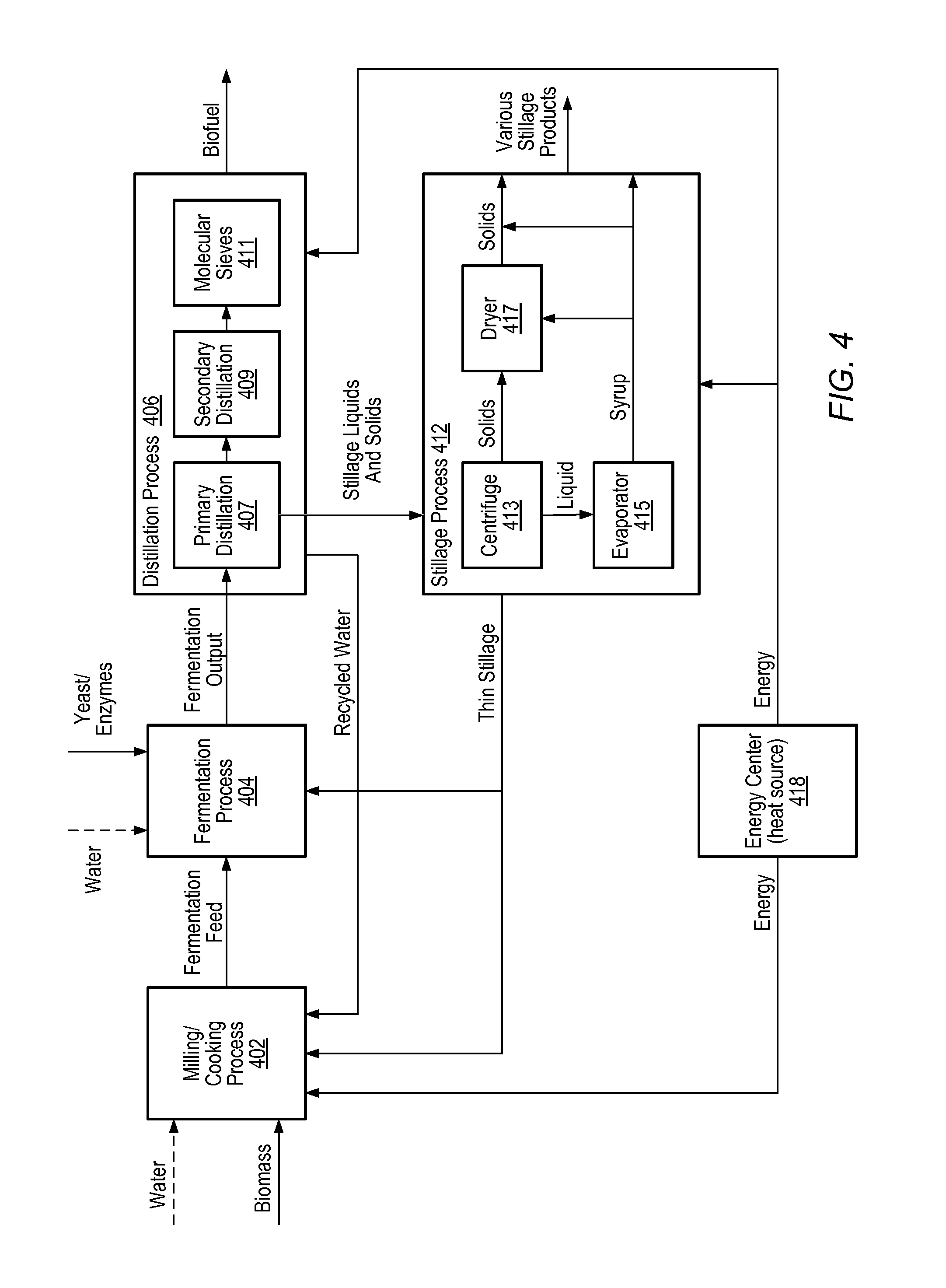

Integrated model predictive control of distillation and dehydration sub-processes in a biofuel production process

ActiveUS20080103748A1Efficiently manipulatedBioreactor/fermenter combinationsAnalogue computers for chemical processesProcess systemsProduction rate

System and method for integrated management of a biofuel distillation process and a biofuel dehydration process of a biofuel production process, comprising a dynamic multivariate model-based controller coupled to a dynamic multivariate predictive model. The model is executable to: receive distillation and dehydration process information including biofuel compositions, receive an objective for biofuel production output from the distillation and dehydration processes, e.g., target product composition, production rate, and / or feed rate, and generate model output comprising target values for a plurality of manipulated variables related to the distillation and dehydration processes in accordance with the objective. The controller is operable to dynamically control the biofuel production process by adjusting the plurality of manipulated variables to the model-determined target values in accordance with the objective for biofuel production.

Owner:ROCKWELL AUTOMATION TECH

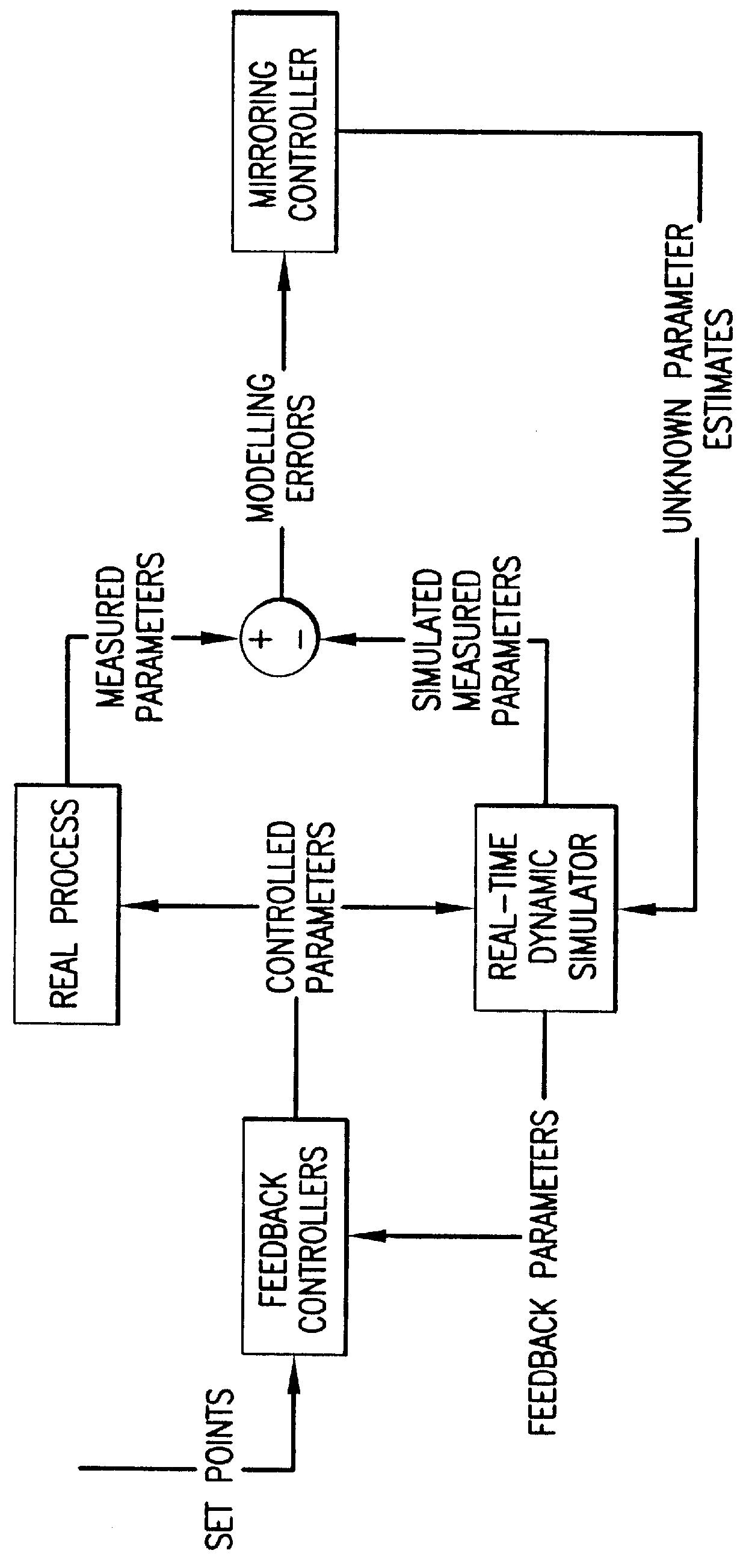

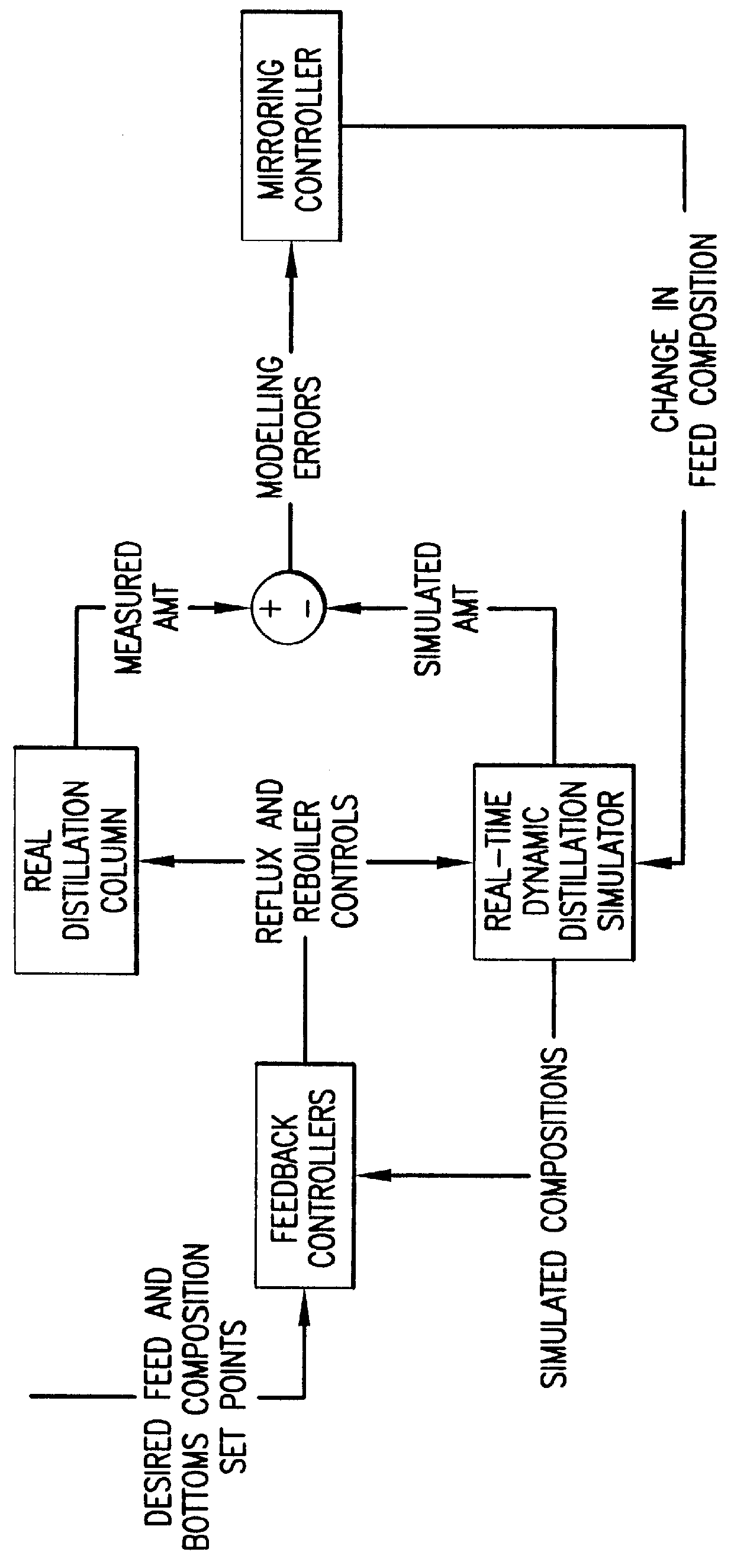

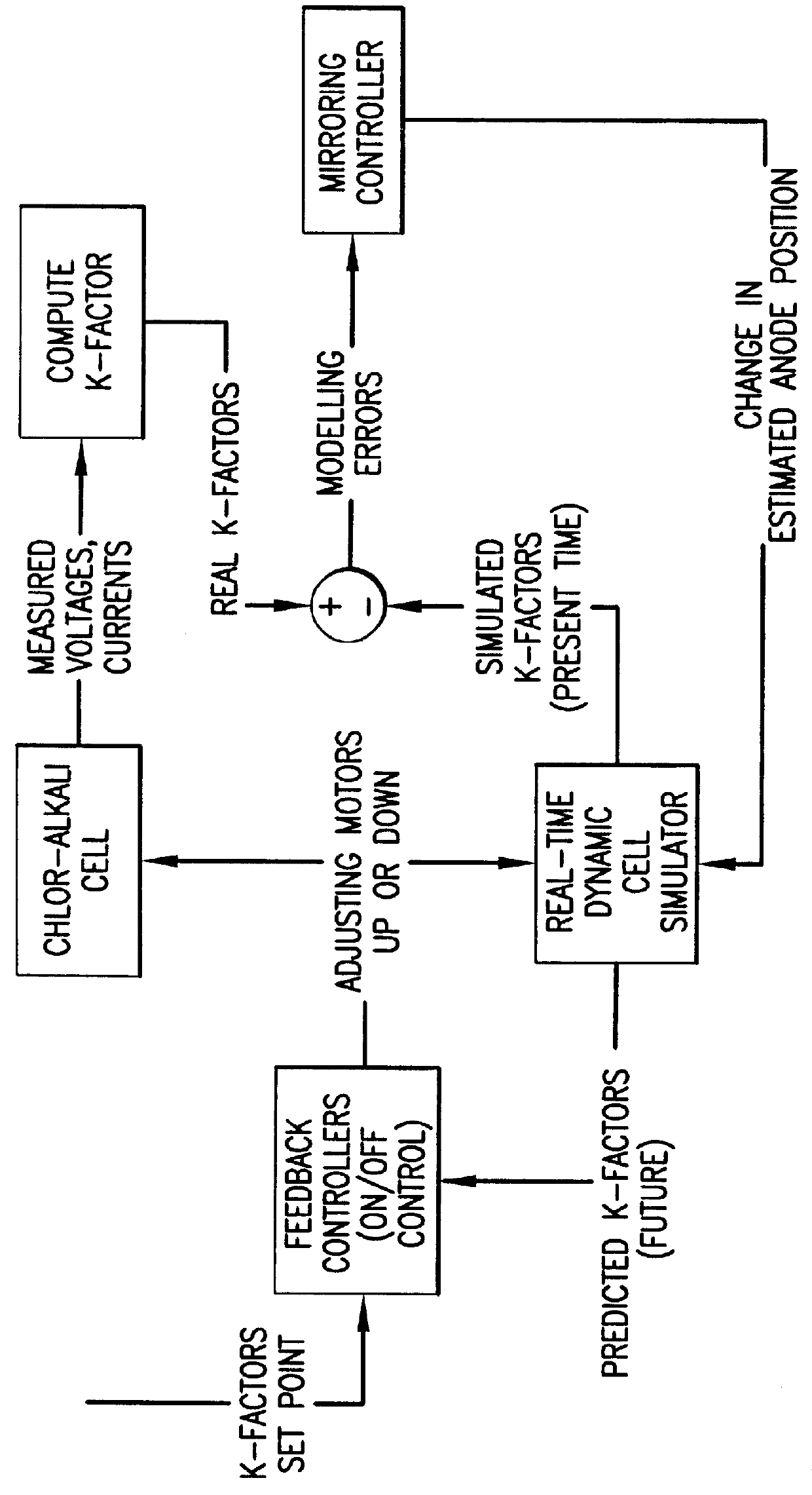

Automatic control system for unit operation

InactiveUS6088630AImprove stabilityAccurate predictionSampled-variable control systemsPhotography auxillary processesAutomatic controlAutomatic train control

Automatic control systems, and corresponding processes, for controlling either an anode adjuster in a chlor / alkali cell or at least one average middle temperature of a distillation column wherein the combination of feedback control from at least one real unit operation variable and an embedded real-time dynamic simulation of that variable are used.

Owner:OLIN CORP

Apparatus and method for thermal desalination based on pressurized formation and evaporation of droplets

A method for removing dissolved solids, particularly salts, from water. An apparatus for performing the inventive method is disclosed. The aqueous solution to be treated, for example sea water, is atomized using special non-pneumatic nozzles, and sprayed into an evaporation chamber through which air, heated by waste heat, is blown. The micro-droplets undergo rapid evaporation in the chamber, resulting in the separation of the salt solids from the vapor phase of the water. The mixture of suspended solids and water vapor is filtered to remove and collect the salts, and the water vapor is condensed to collect the salt-free water.

Owner:AQUASONICS RSE INC

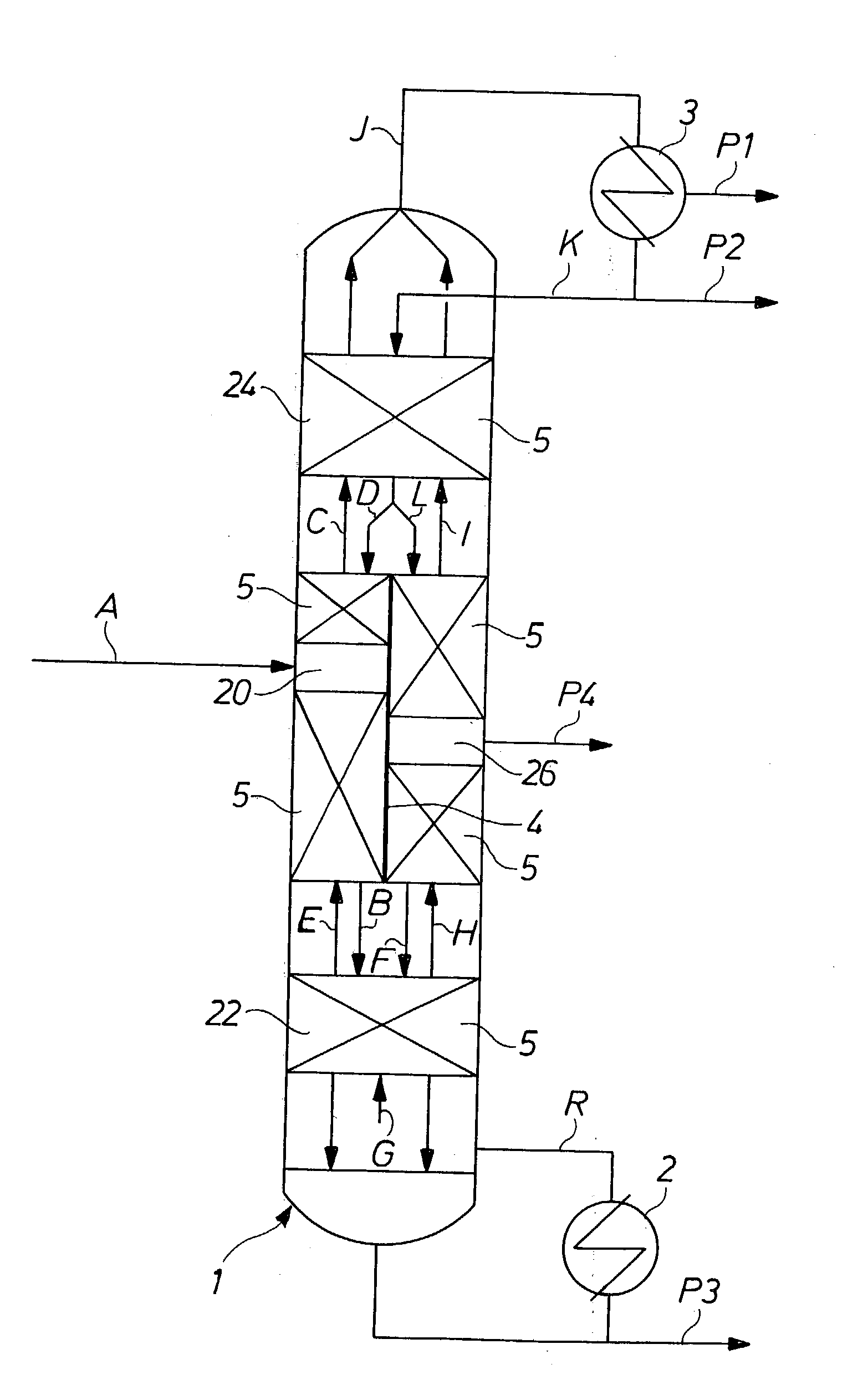

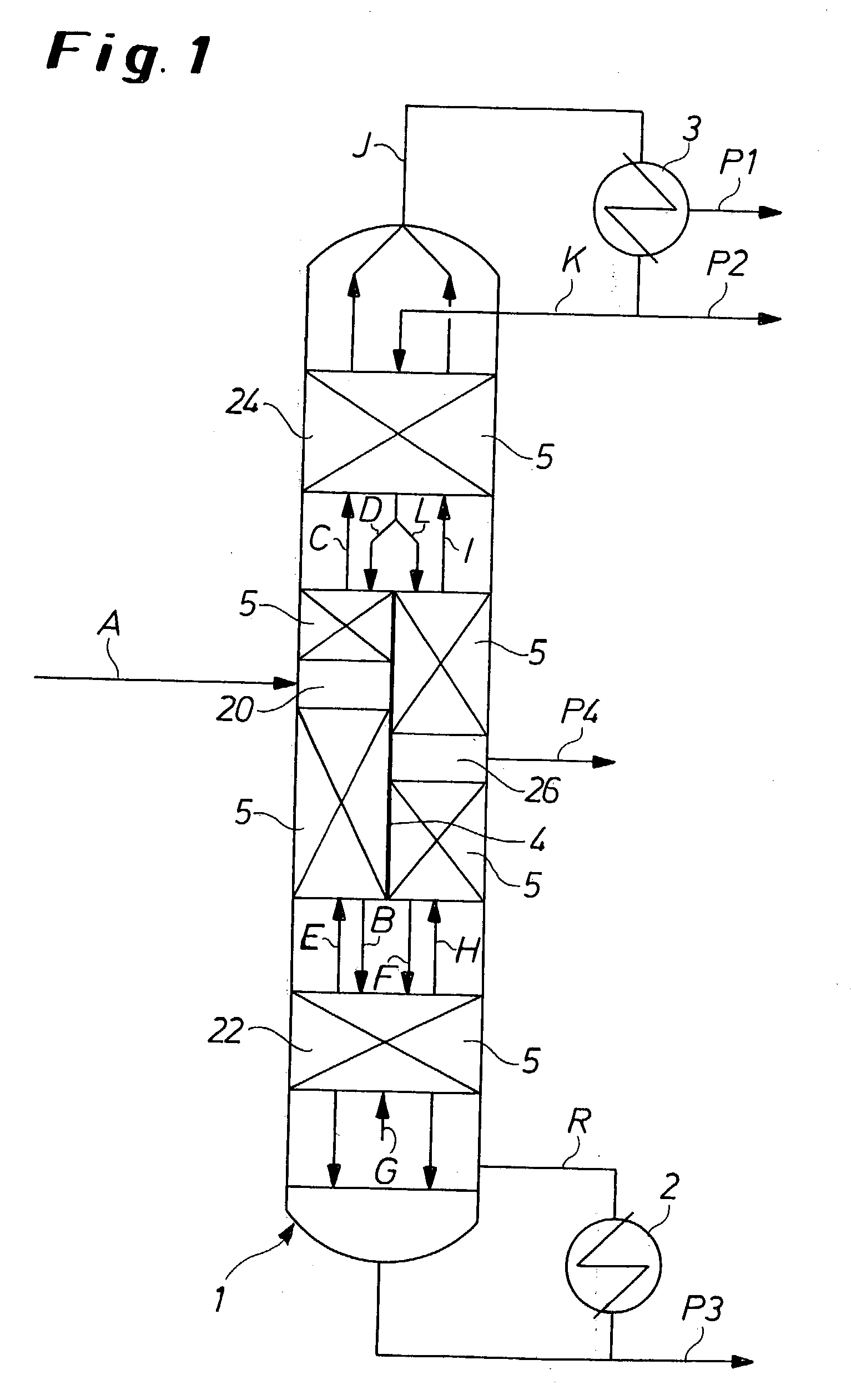

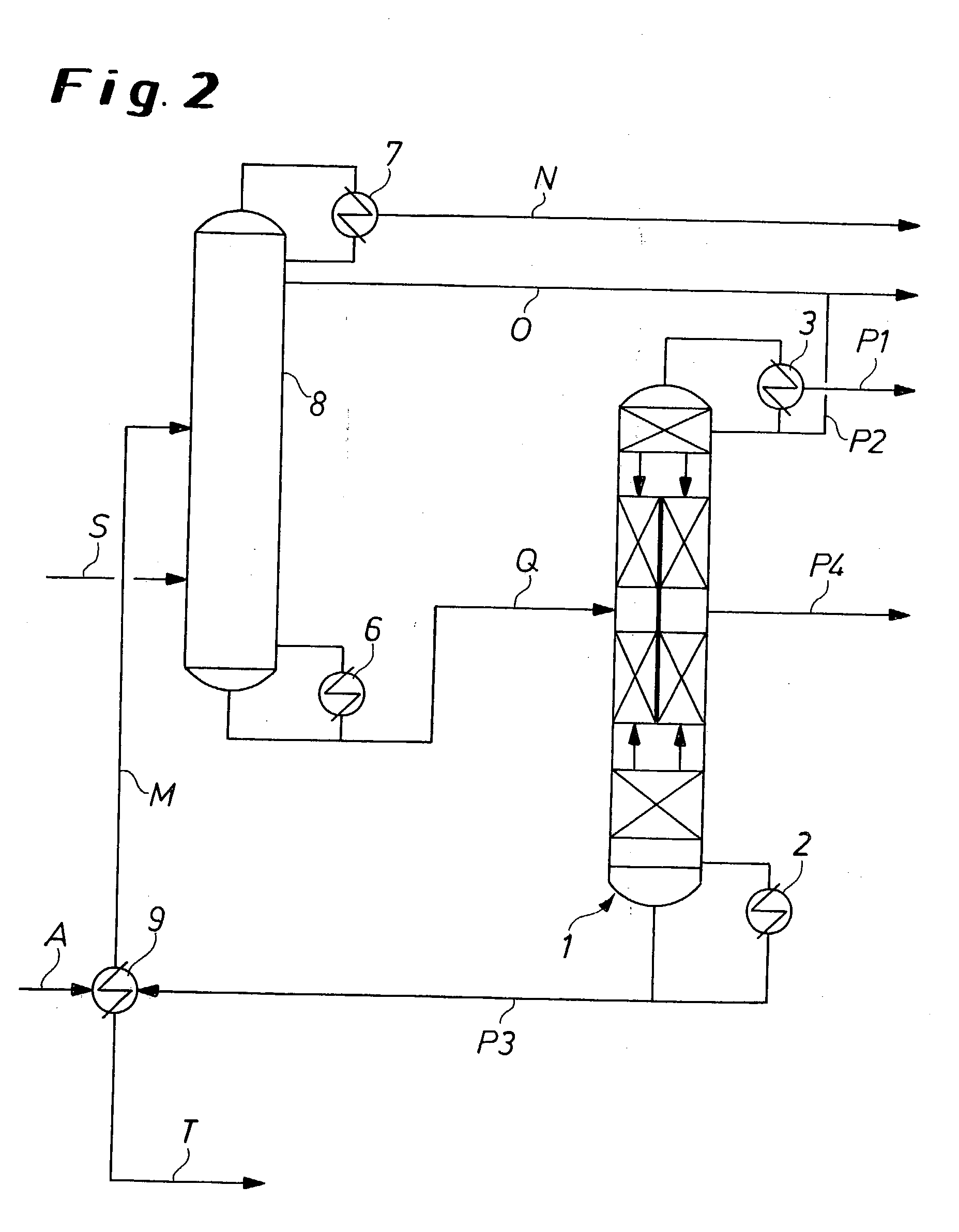

Process for the purification of mixtures of toluenediisocyanate incorporating a dividing-wall distillation column

InactiveUS20030230476A1Weaken energyLow investment costThermal non-catalytic crackingOrganic compound preparationPurification methodsOrganic solvent

Process for the purification of toluenediisocyanate from a crude distillation feed comprising toluenediisocyanate, an organic solvent and less than 2% by weight phosgene by separating the crude distillation feed in a dividing-wall distillation column into at least four product fractions P1-P4. P1 is a phosgene enriched low-boiler product, P2 is a solvent-enriched product, P3 is a high boiler enriched bottoms and P4 is a toluenediisocyanate product stream.

Owner:COVESTRO DEUTSCHLAND AG

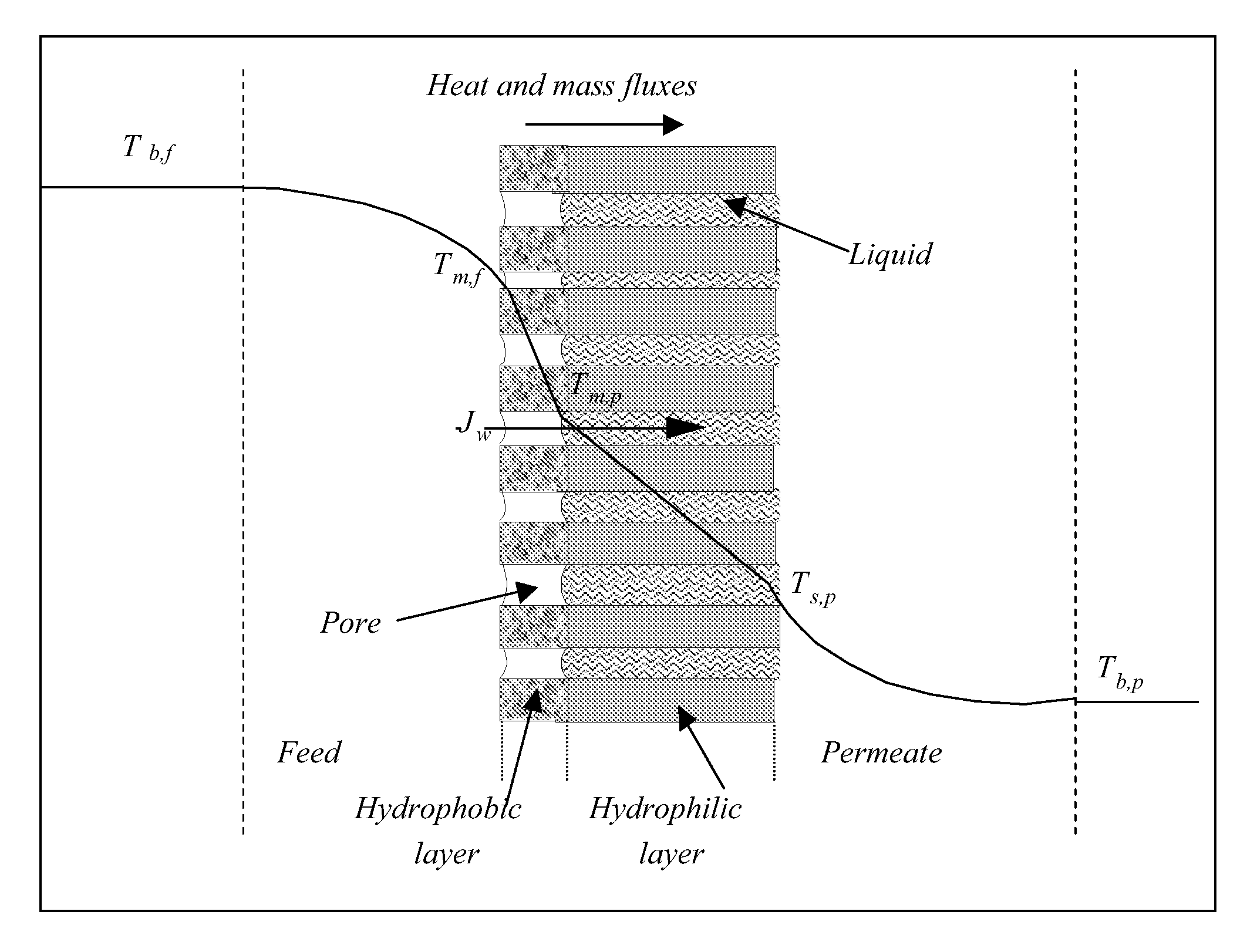

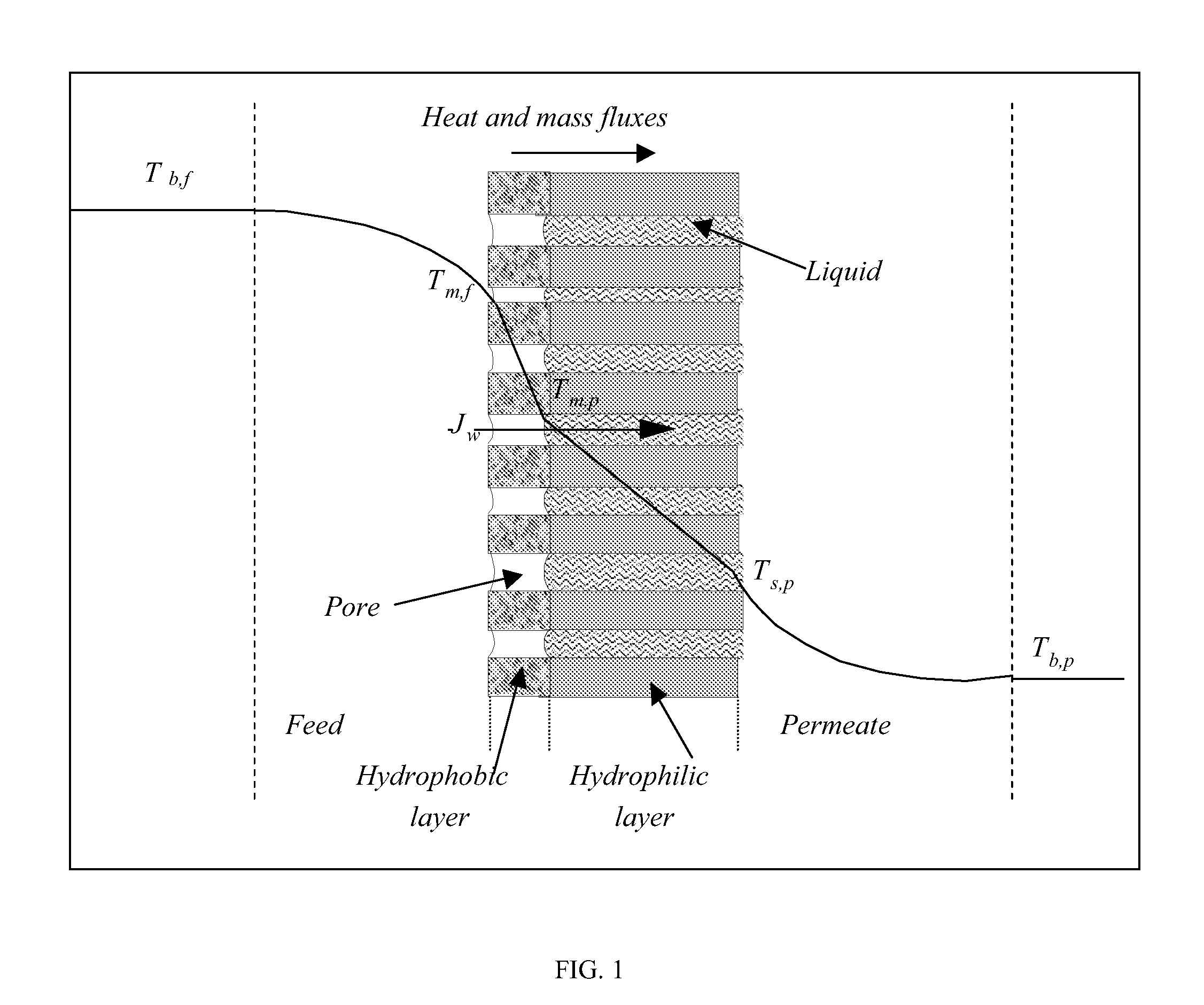

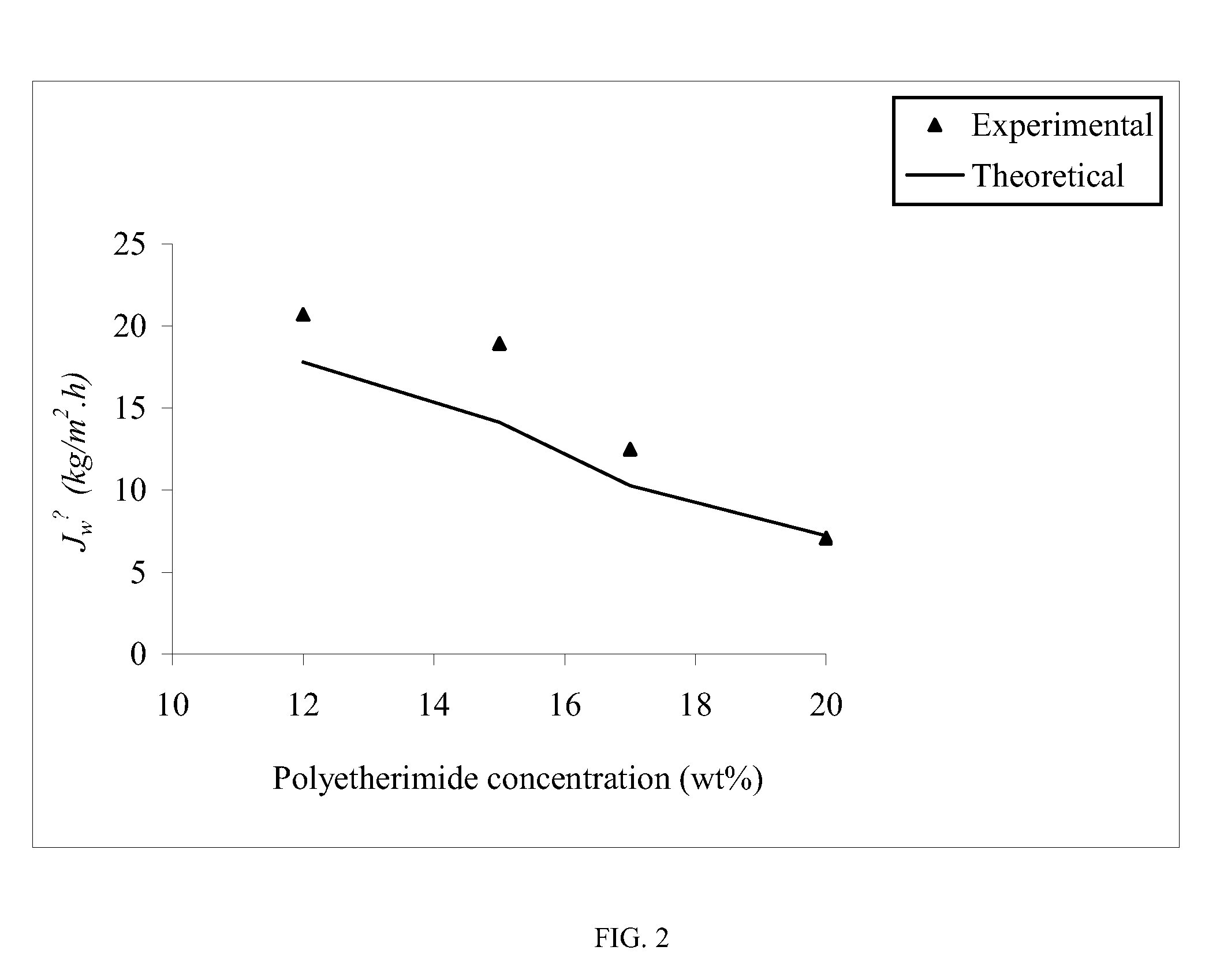

Composite membranes for membrane distillation and related methods of manufacture

ActiveUS20110031100A1Maximizing porosityThickness minimizationMembranesVacuum distillation separationPolymer scienceHydrophilic polymers

The present invention provides composite membranes for membrane distillation and related methods of manufacture. In particular, there is provided a composite hydrophilic / hydrophobic membrane comprising a hydrophilic polymer layer and a hydrophobic polymer layer comprising fluorinated surface-modifying macromolecules, wherein said composite membrane has a high vapour flux. Also provided herein are methods of manufacturing and optimizing the composite membranes and a membrane distillation system comprising the composite membranes.

Owner:MEMBRANE DISTILLATION DESALINATION LTD

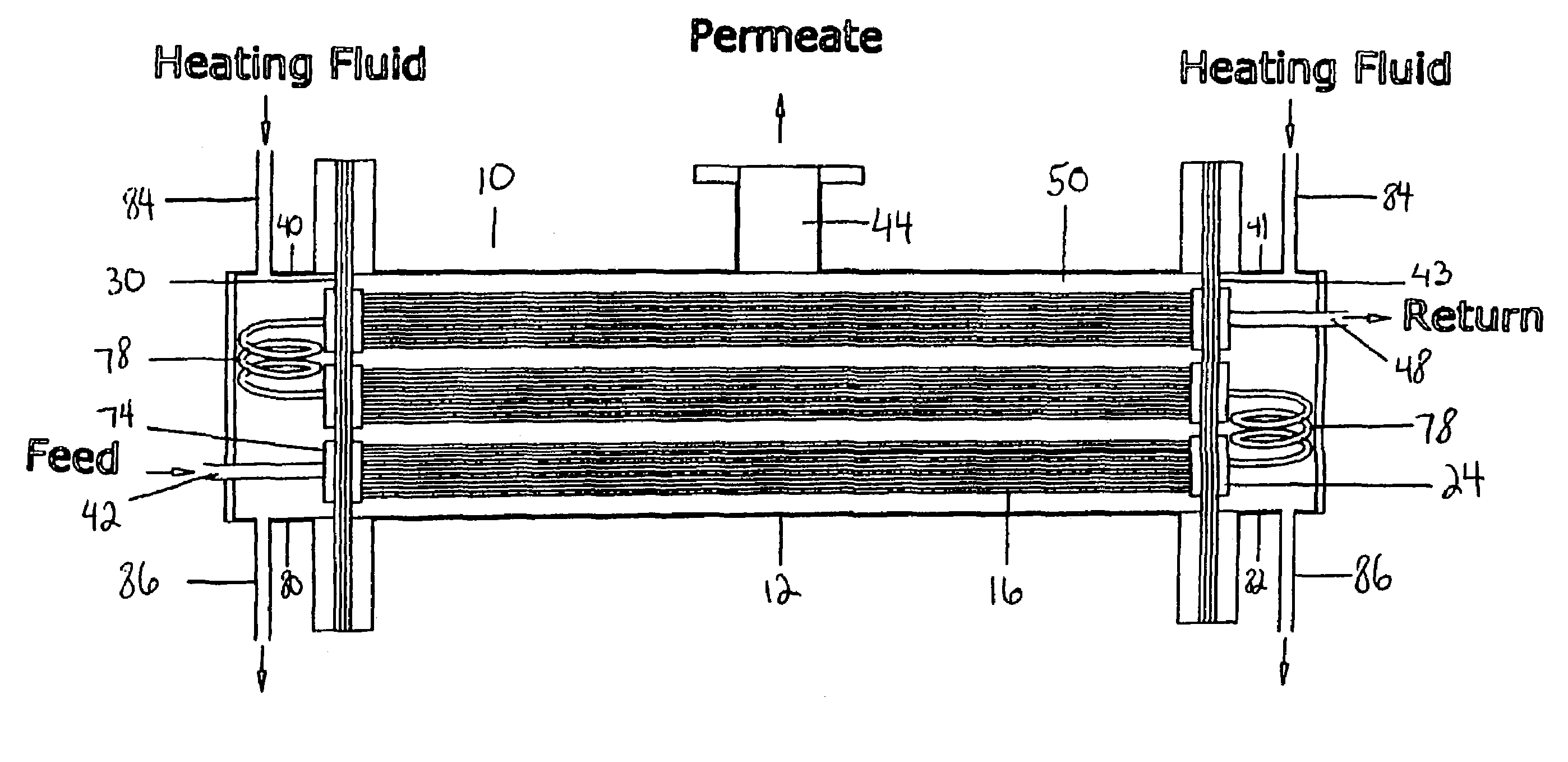

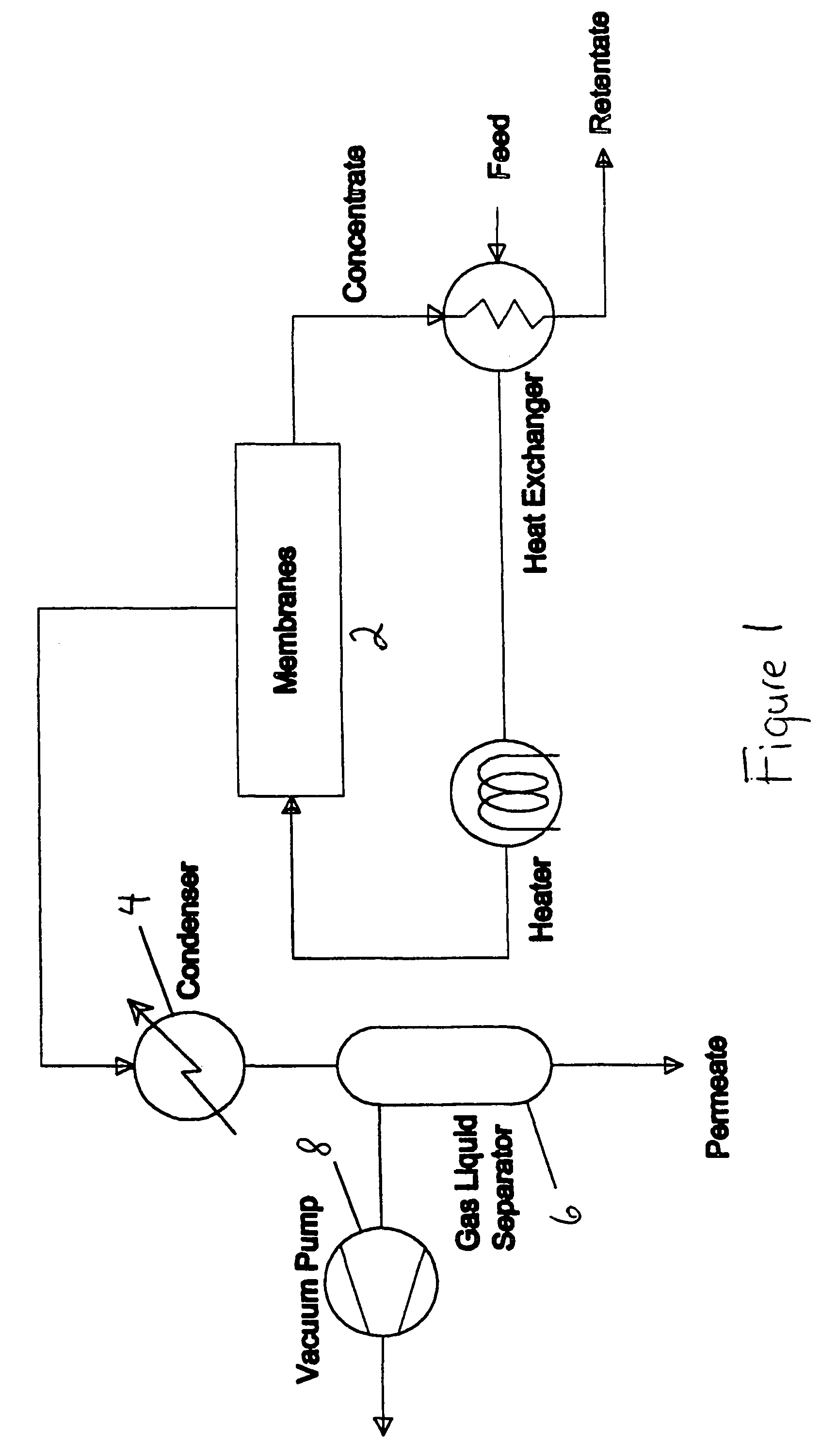

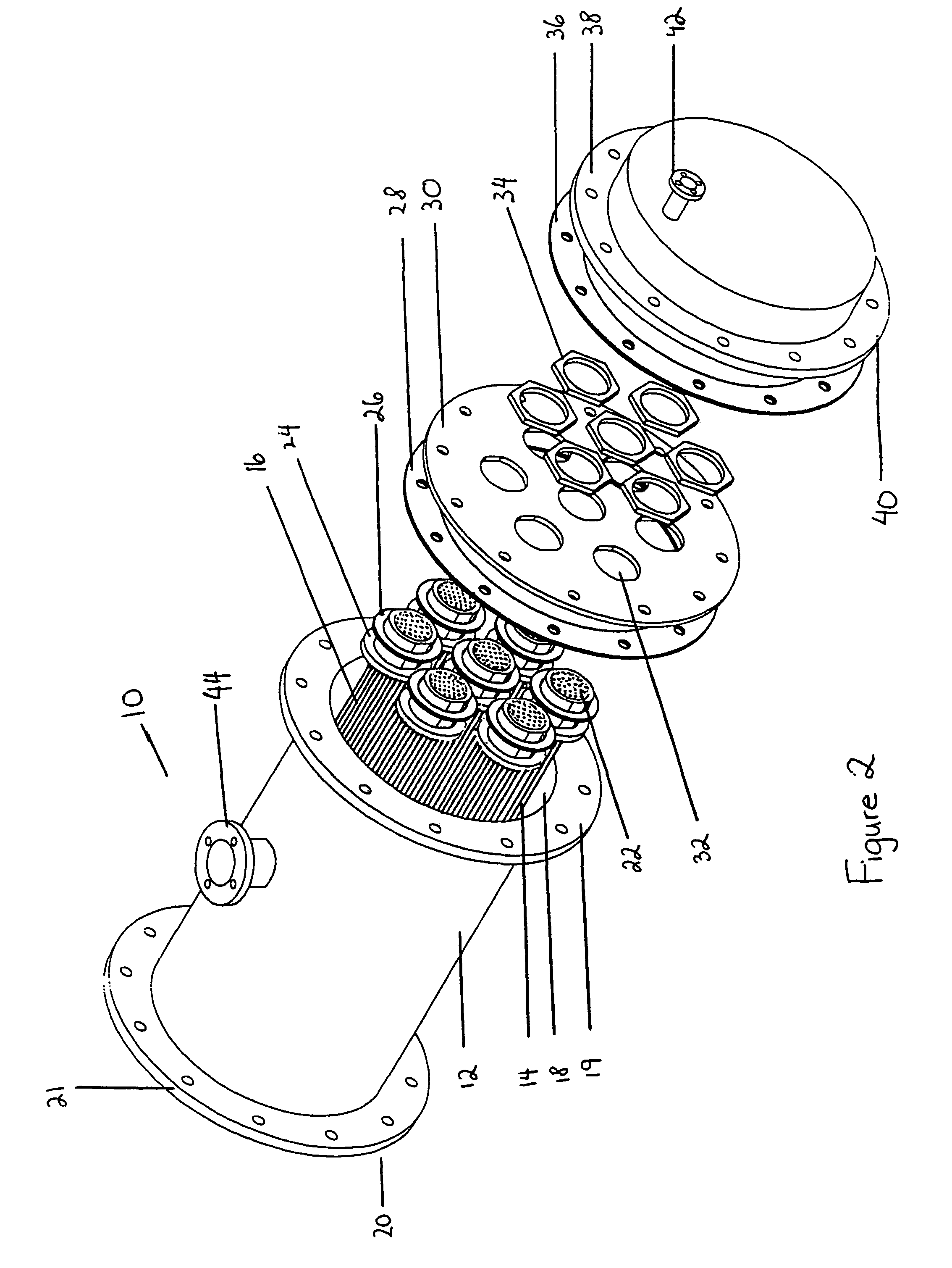

Membrane-assisted fluid separation apparatus and method

InactiveUS7459084B2Easy to disassembleReduce complexityMembranesGeneral water supply conservationFiberHigh concentration

This present invention relates to a fluid separation module adapted to separate a given fluid mixture into permeate and retentate portions using bundles of hollow fiber membranes. The membranes may be composed of different kinds of membranes depending on the application being used to separate the fluid mixture. The fluid separation module may be used to separate fluid mixtures by a number of different processes, including but not limited to, pervaporation, vapour permeation, membrane distillation (both vacuum membrane distillation and direct contact membrane distillation), ultra filtration, microfiltration, nanofiltration, reverse osmosis, membrane stripping and gas separation. The present invention also provides an internal heat recovery process applied in association with those fluid separation applications where separation takes place by evaporation through the membrane of a large portion of the feed into permeate. Desalination and contaminated water purification by means of vacuum membrane distillation are just two examples where the internal heat recovery process may be applied. In these two examples, large portions of the feed are separated by membranes into a high purity water permeate stream by evaporation through the membranes and into a retentate stream containing a higher concentration of dissolved components than present in the feed. In this process the permeate vapour that is extracted from the fluid separation module is compressed by an external compressor to increase the temperature of the vapour higher than the temperature of the feed entering the separation module. Heat from the permeate vapour at the elevated temperature is transferred back to the incoming feed fluid mixture entering the fluid separation module in a condenser / heat exchange.

Owner:LOEB INVESTORS CO 166 LP +1

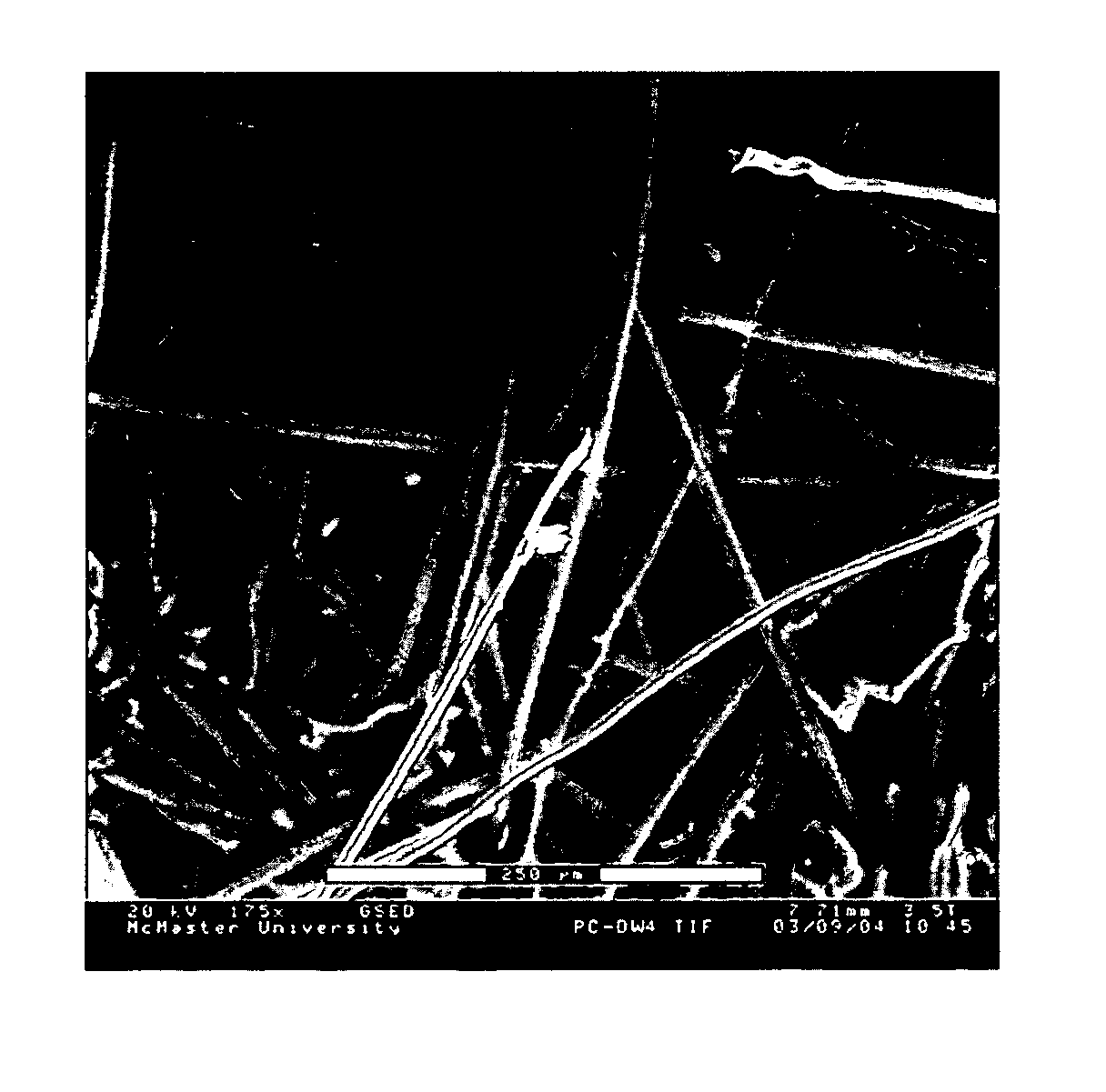

Pervaporation composite membranes

The present application discloses a composite membrane comprising (a) a support member that has a plurality of pores extending through the support member and (b) a cross-linked copolymer comprising (i) a cationic monomer and an anionic monomer and / or (ii) a zwitterionic monomer, which cross-linked copolymer fills the pores of the support member, the cross-linked copolymer having a permeability for a fluid that is dependent on the polarity of the fluid, wherein the permeability increases with increasing polarity. The present application also discloses a process for the preparation of the composite membrane, a pervaporation apparatus comprising the composite membrane, and methods for the use of the composite material in separation and dehydration processes.

Owner:MCMASTER UNIV

Ethanol distillation with distillers soluble solids recovery apparatus

ActiveUS20070000769A1High operating temperatureReduce drying loadDistillation regulation/controlBiofuelsMolecular sieveAnhydrous ethanol

The present invention relates to a system for producing ethanol from an organic source and that operates to purify and dry ethanol from a beer source. The system for producing substantially anhydrous ethanol comprises: (a) a first distillation stripping column that operates between 160 to 220 degrees F.; (b) a second distillation rectifying column having a higher operating temperature than said stripping column; (c) a molecular sieve dehydration means in fluid communication with said rectifying column; and (d) an energy control means.

Owner:RCM TECH USA INC

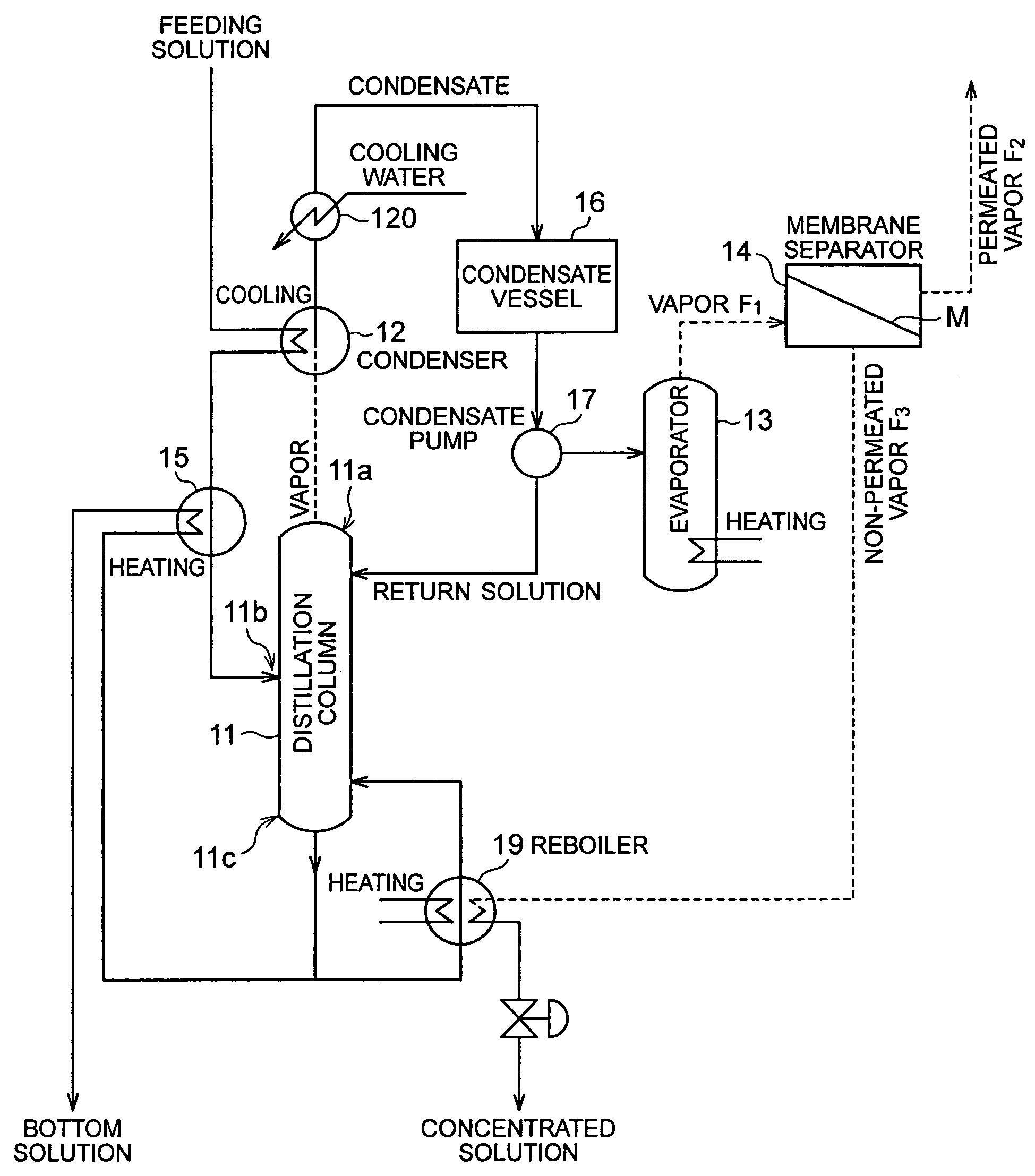

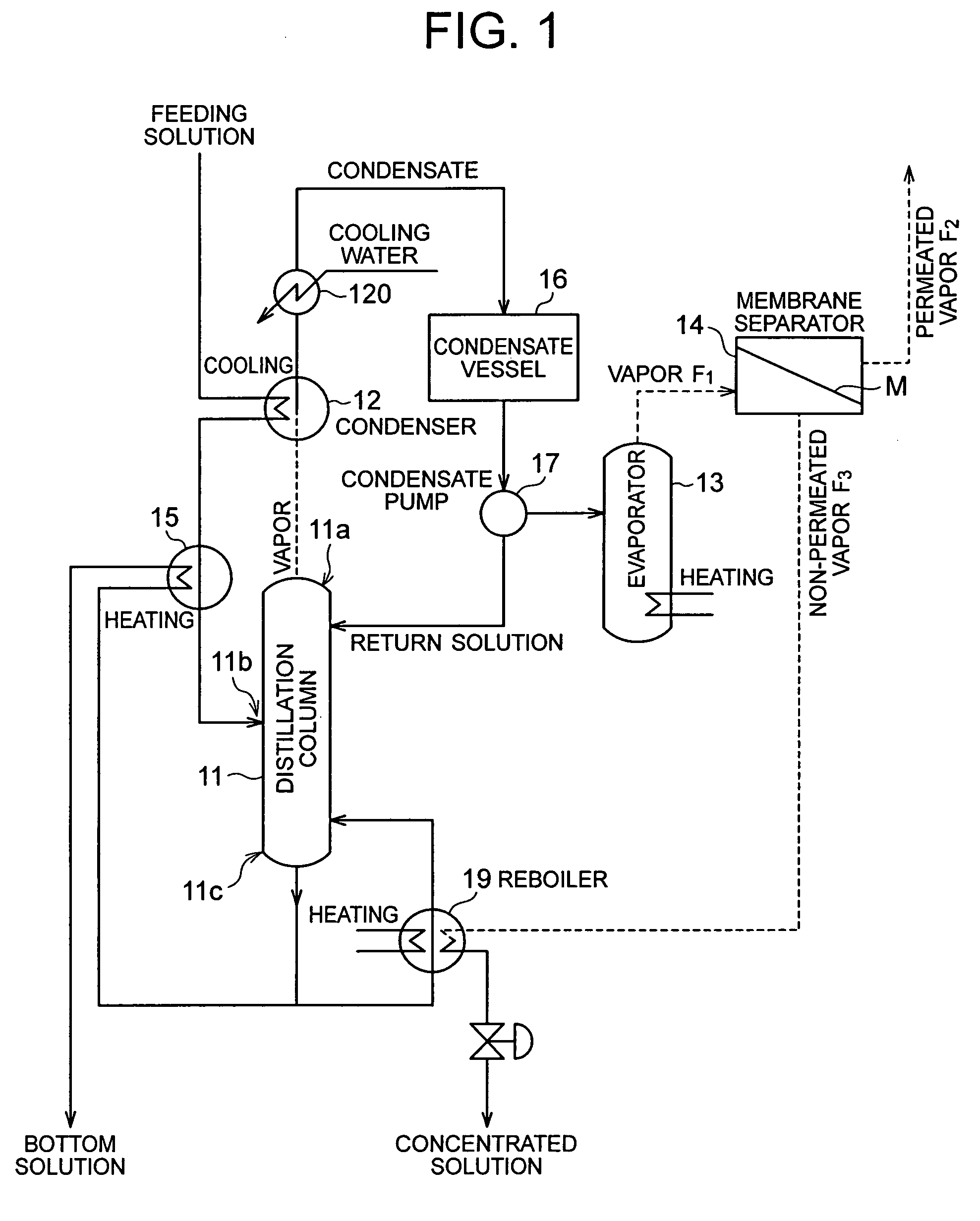

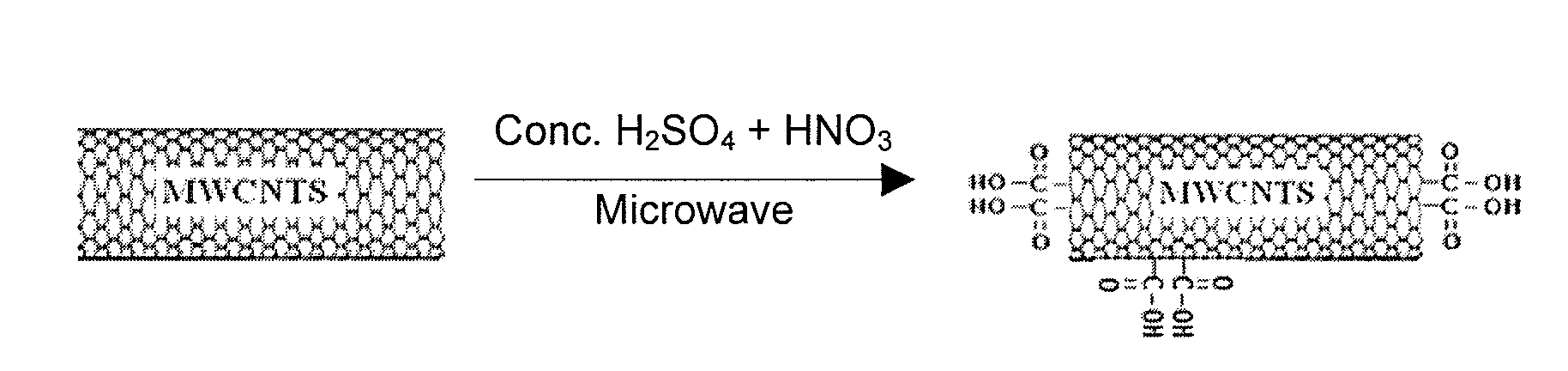

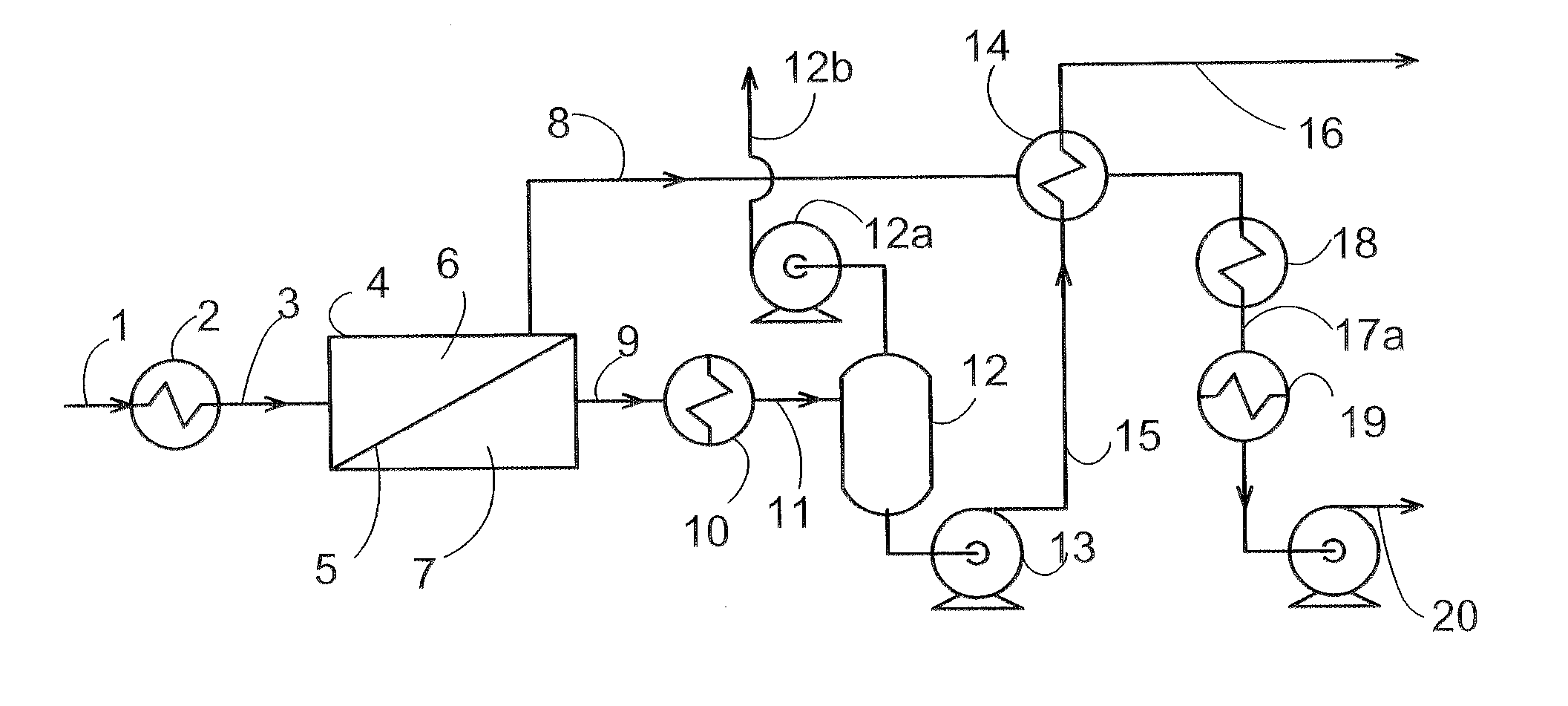

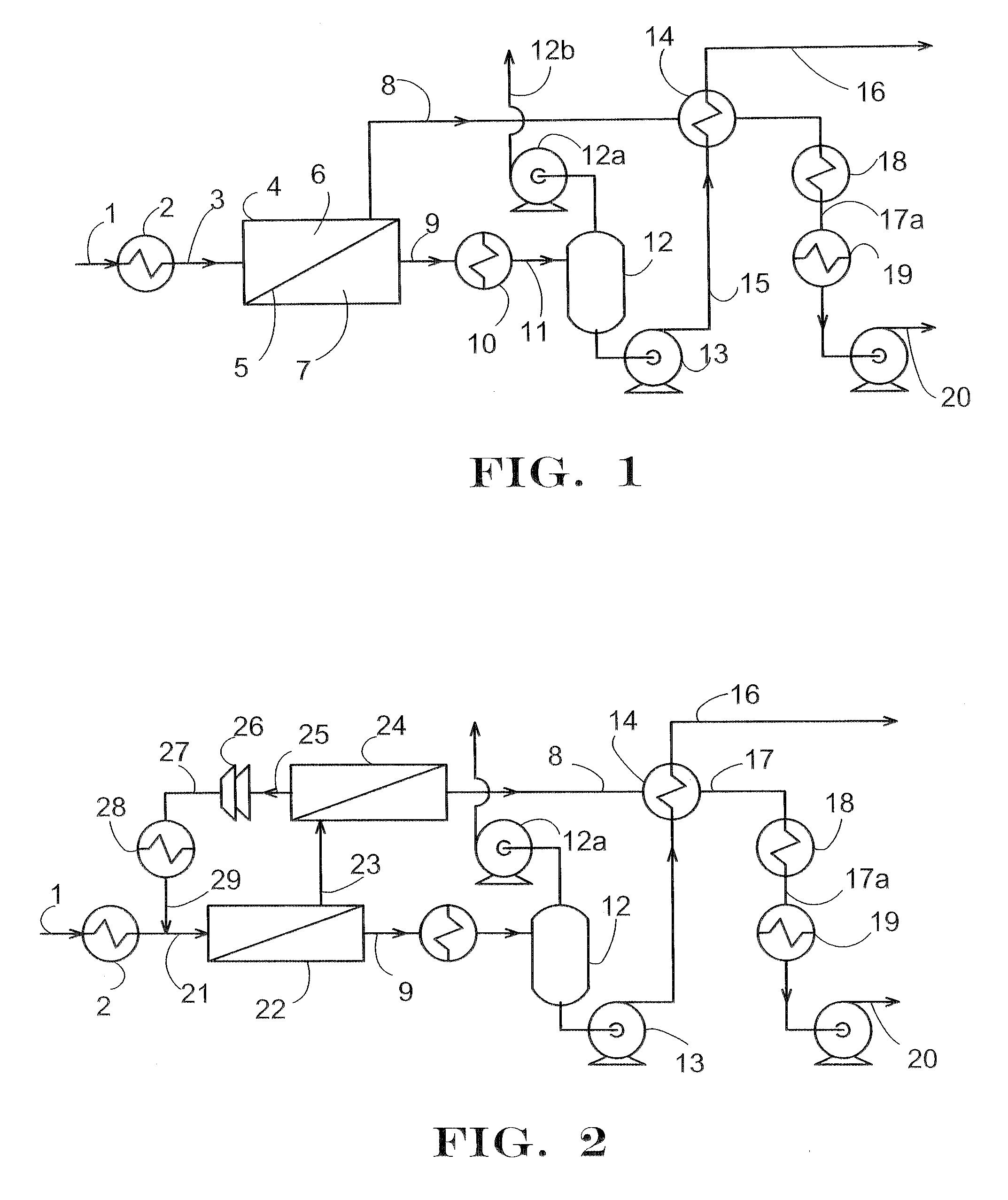

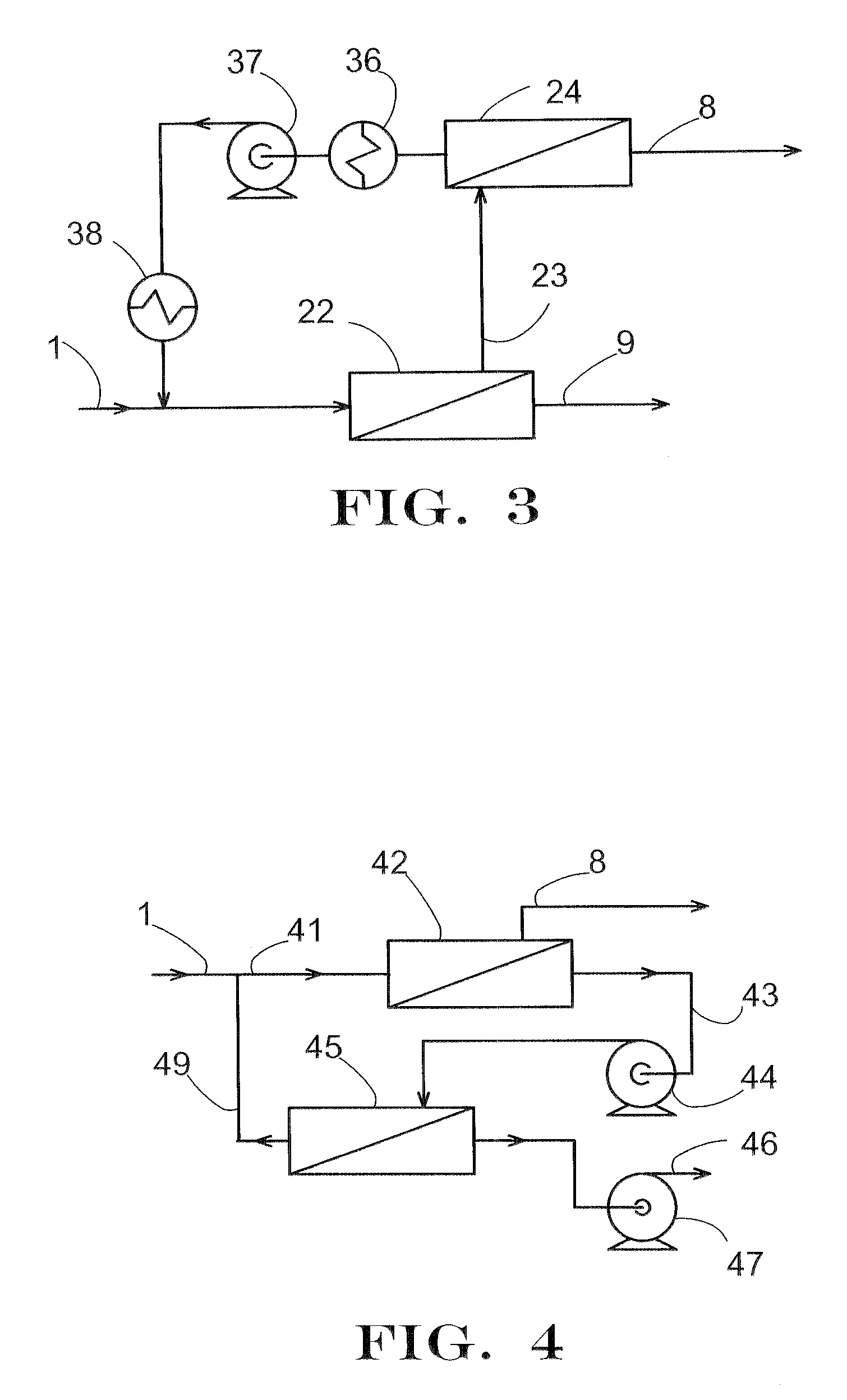

Method for concentrating water-soluble organic material

InactiveUS7594981B2Improve permeabilityIncrease operating pressureOrganic compound preparationDispersed particle separationDistillationWater soluble

A method for concentrating a water-soluble organic material wherein a mixture of the water-soluble organic material with water is distilled in a distillation column (11), and the fraction from the top (11a) of the distillation column (11) is separated by the use of a membrane separator (14) into a permeated vapor (F2) and a non-permeated vapor (F3), which comprises once condensing the fraction to form a condensate, heating the condensate in an evaporator (13) to generate a vapor (F1) having a pressure higher than the operation pressure for the distillation column (11), and introducing the vapor (F1) to the membrane separator (14), thereby separating water from the mixture.

Owner:MITSUBISHI CHEM CORP

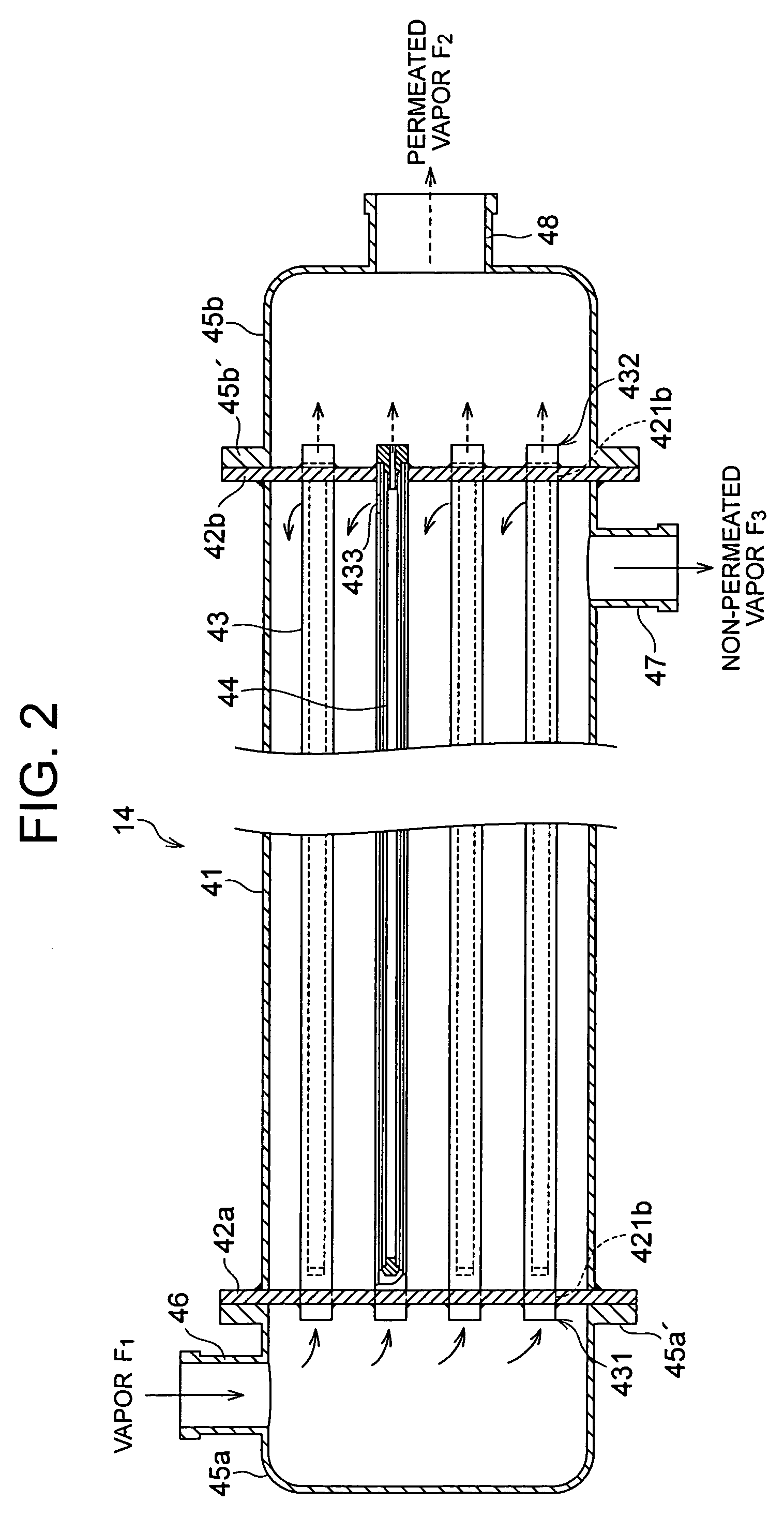

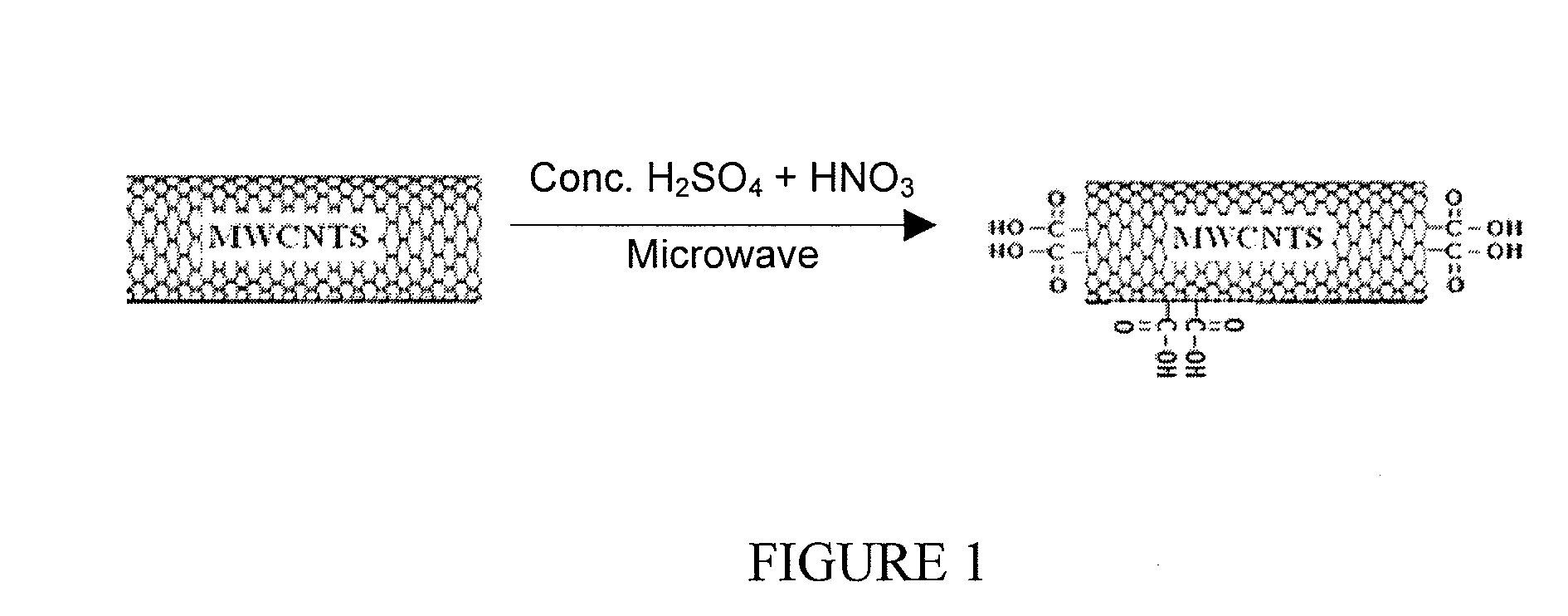

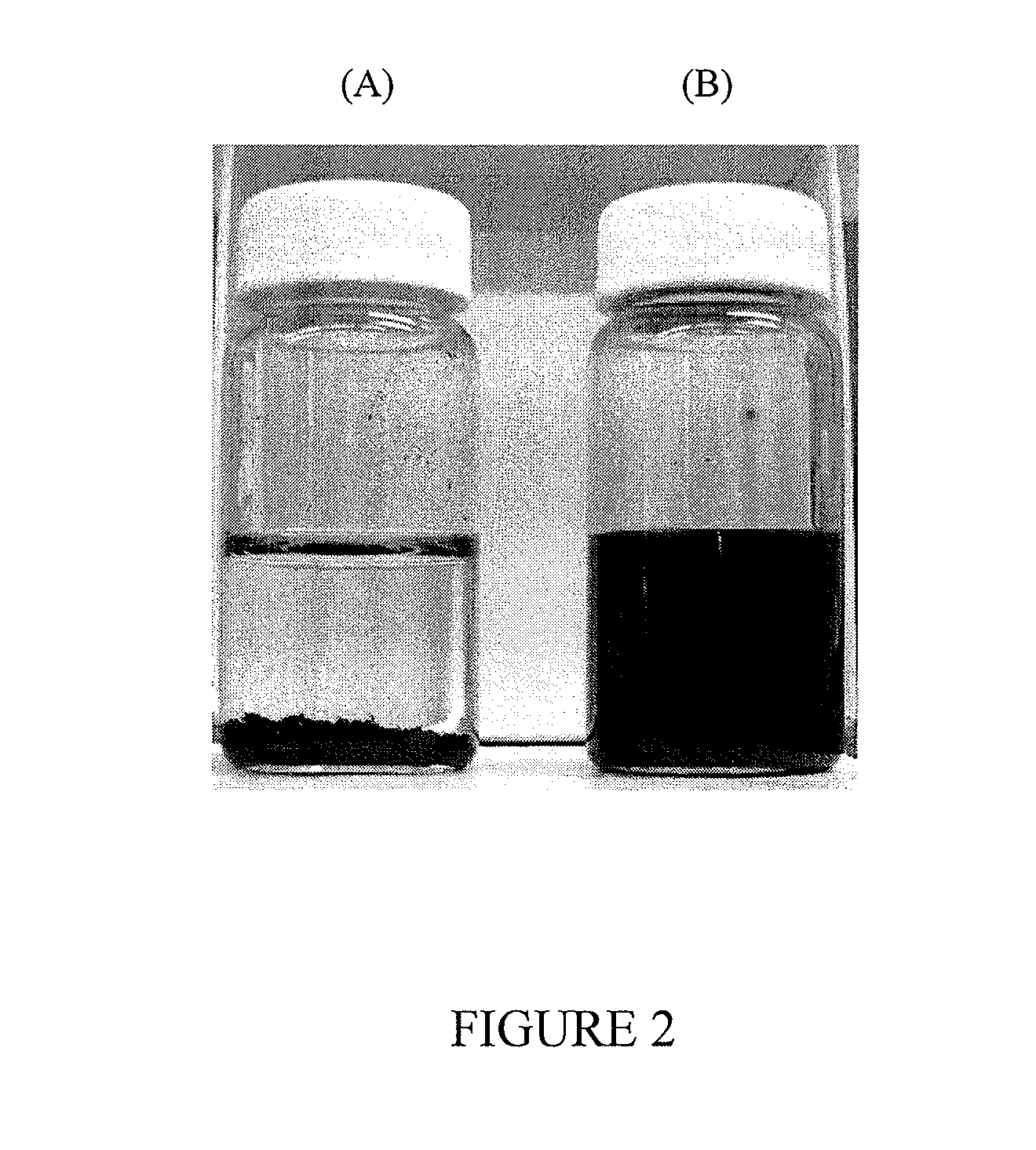

Carbon Nanotube Mediated Membrane Extraction

ActiveUS20090283475A1Improve performanceSimple systemMaterial nanotechnologySolvent extractionImproved methodNanotube

The present disclosure provides an improved membrane or substrate having carbon nanotubes introduced and / or immobilized therein, and an improved method for introducing and / or immobilizing carbon nanotubes in membranes or substrates. More particularly, the present disclosure provides for improved systems and methods for fabricating membranes or substrates having carbon nanotubes immobilized therein. In one embodiment, the present disclosure provides for systems and methods for introducing and / or immobilizing functionalized carbon nanotubes into the pore structure of a polymeric membrane or substrate, thereby dramatically improving the performance of the polymeric membrane or substrate. In exemplary embodiments, the present disclosure provides for systems and methods for the fabrication of nanotube immobilized membranes by incorporating CNTs in a membrane or substrate.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

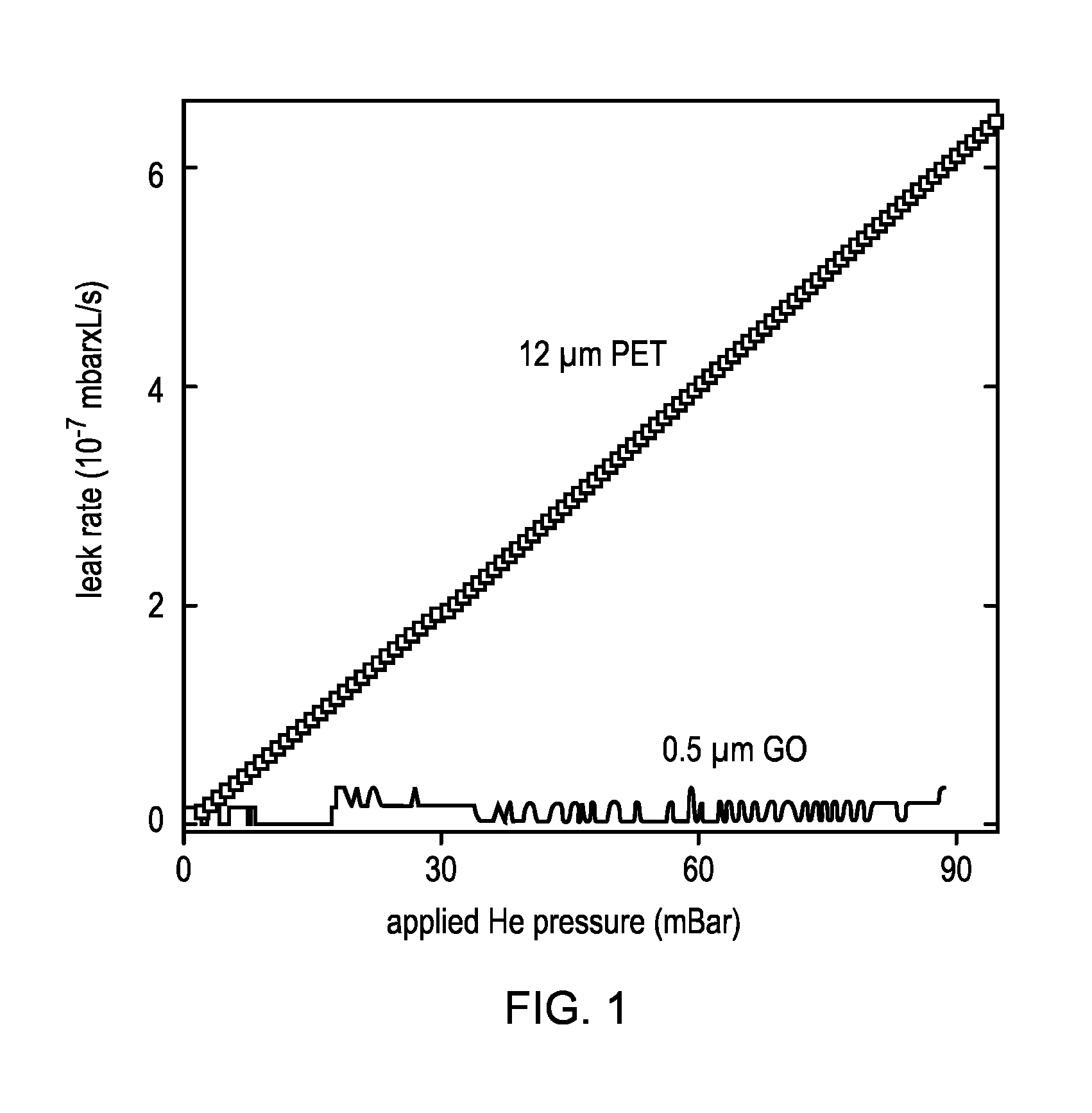

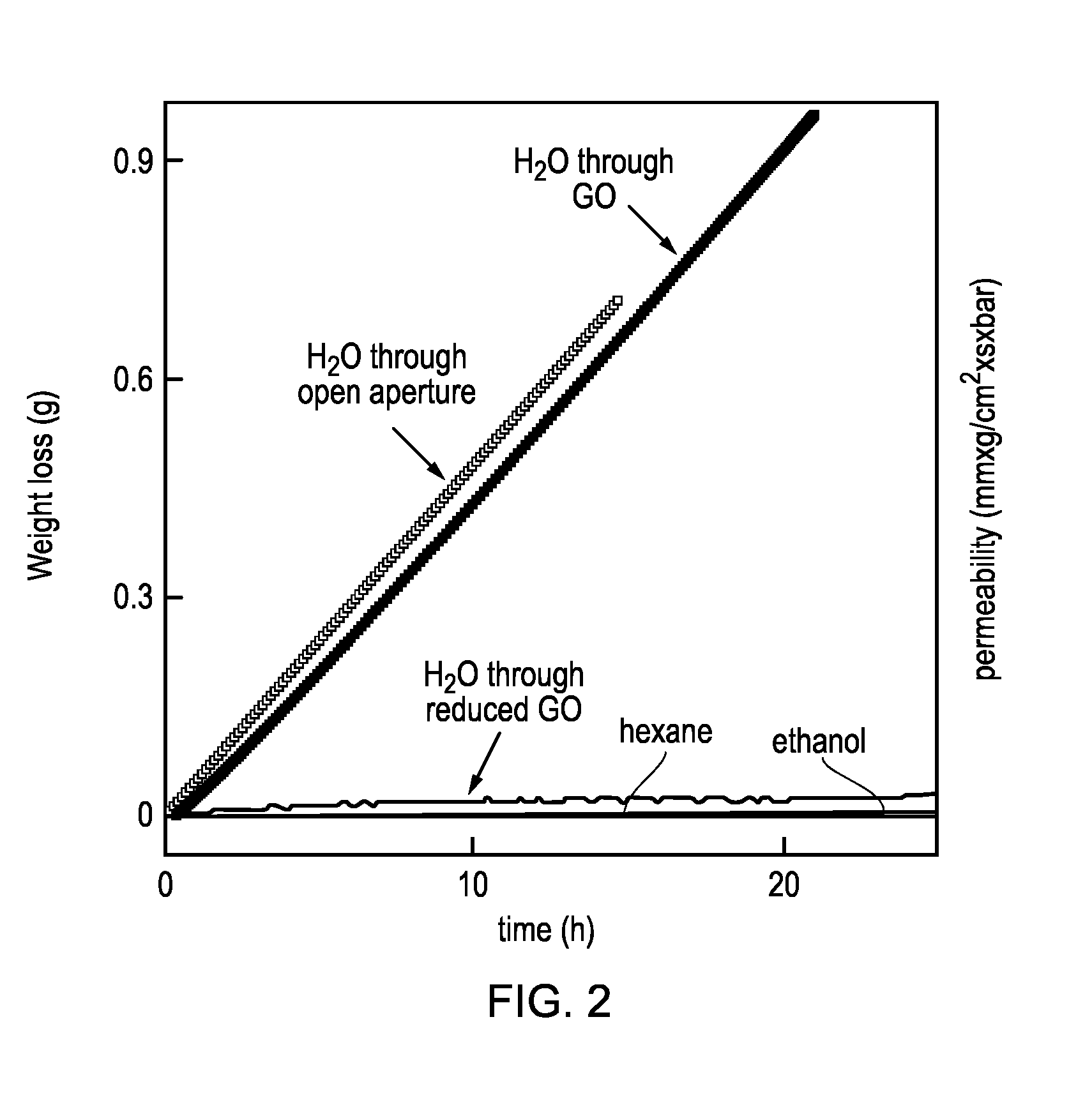

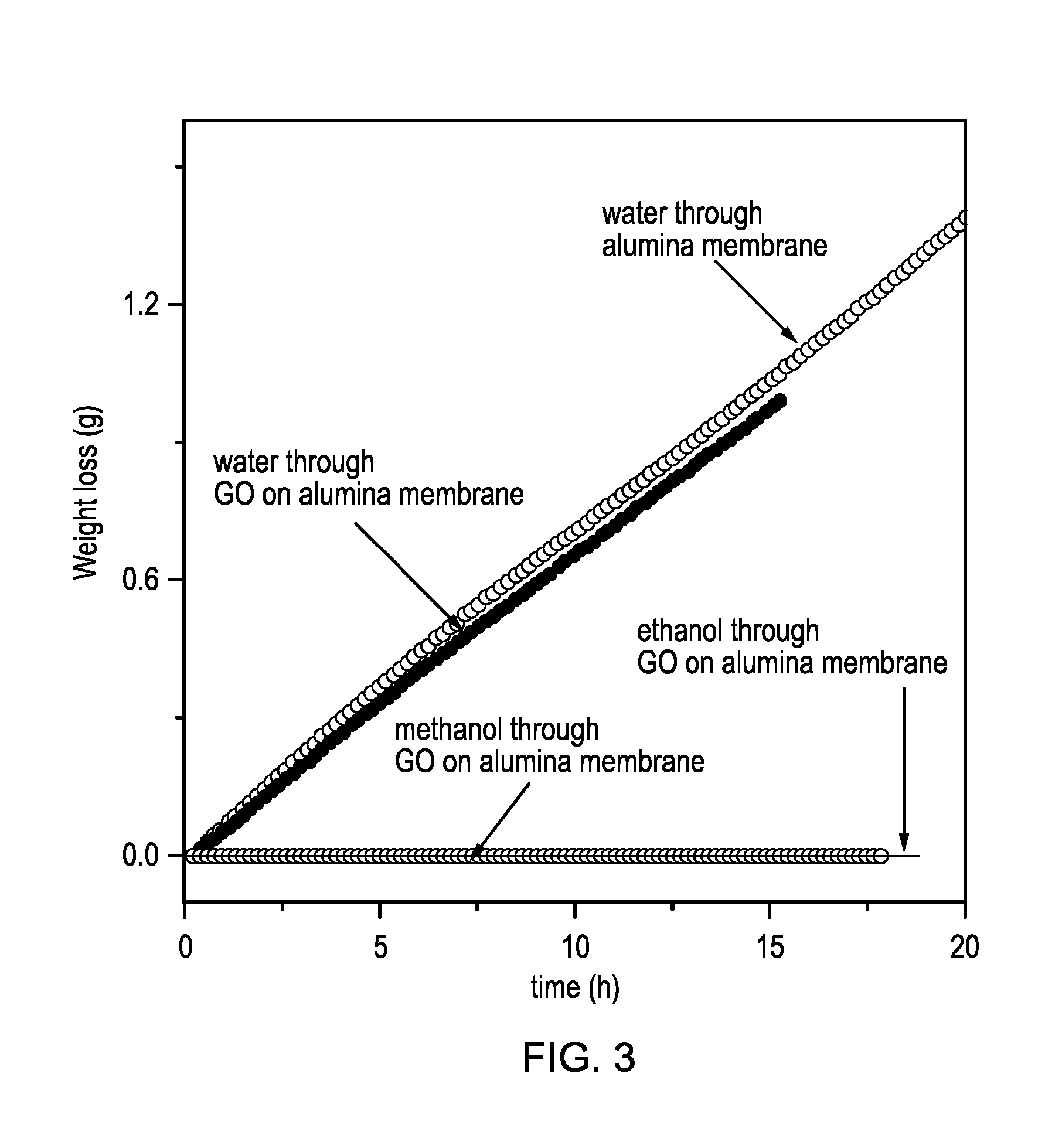

Separation of Water Using a Membrane

This invention relates to uses of graphene oxide, and in particular graphene oxide on a porous support, and a membrane comprising these materials. This invention also relates to methods of dehydration, which include vapour phase separation and pervaporation. Pervaporation is a method of separating mixtures of liquids using a membrane. Pervaporation consists of two basic steps: permeation of the permeate through the membrane and evaporation of the permeate from the other side of the membrane. Pervaporation is a mild which can be used to separate components which would not survive the comparatively harsh conditions needed for distillation (high temp, and / or low pressure).

Owner:UNIV OF MANCHESTER

Preparation method of electrostatic spinning hydrophobic nanofiber porous membrane for membrane distillation

The invention relates to a preparation method of an electrostatic spinning hydrophobic nanofiber porous membrane for membrane distillation. The method comprises the following steps of: dissolving a hydrophobic functional polymer material in the solvent to get a 1-35wt% polymer spinning solution, performing electrostatic spinning to get a hydrophobic nanofiber porous membrane, and further performing thermal treatment, thereby obtaining the electrostatic spinning hydrophobic nanofiber porous membrane for membrane distillation. The preparation method provided by the invention is simple and practicable, and can be used for conveniently and accurately controlling the thickness and uniformity of the nanofiber membrane and realizing operations of mass production more easily; the high-hydrophobicity nanofiber porous membrane prepared by the preparation method can be used for signally improving the defects of the conventional membrane for membrane distillation that the water flux is low and the membrane pores get wet easily, so that the membrane distillation technology can compete with a reverse osmosis technology in the seawater desalination field.

Owner:DONGHUA UNIV

Removal of Water and Methanol from Fluids

ActiveUS20080099400A1Efficient separationPowerfulMembranesUltrafiltrationChemical reactionInternal combustion engine

A method of removing water and / or methanol from fluid mixtures of the water or methanol with other compounds uses vapor permeation or pervaporation of the water or methanol, as the case may be, from the mixture through a membrane having an amorphous perfluoropolymer selectively permeable layer. The novel process can be applied in such exemplary embodiments as (a) removing water or methanol from mixtures of compounds that have relative volatility of about 1-1.1 or that form azeotropic mixtures with water or methanol, (b) the dehydration of hydrocarbon oil such as hydraulic fluid to concentrations of water less than about 50 ppm, (c) removing water and methanol byproducts of reversible chemical reactions thereby shifting equilibrium to favor high conversion of reactants to desirable products, (d) drying ethanol to less than 0.5 wt. % water as can be used in fuel for internal combustion engines, and (e) controlling the water content to optimum concentration in enzyme-catalyzed chemical reactions carried out in organic media.

Owner:COMPACT MEMBRANE SYST INC

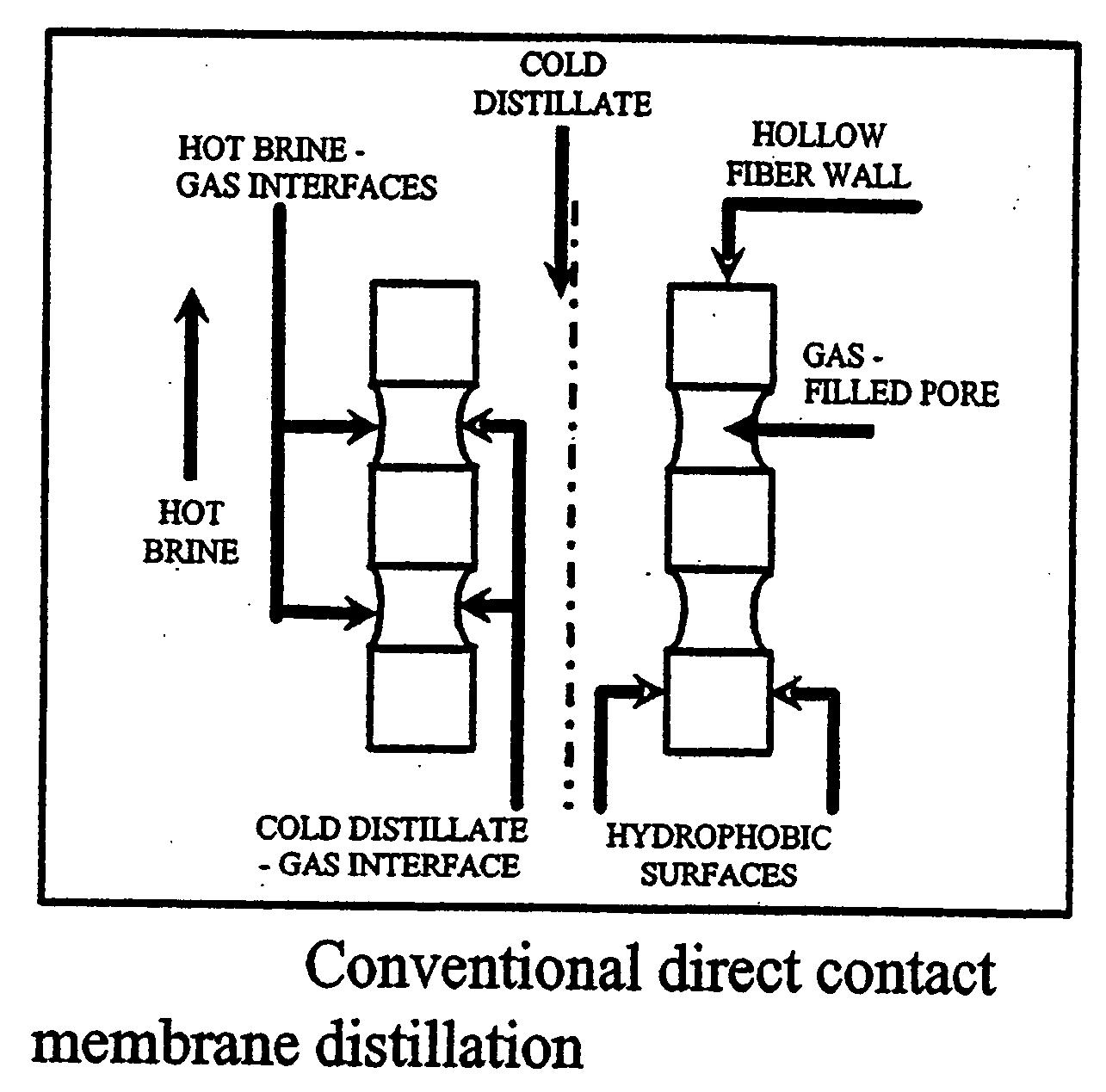

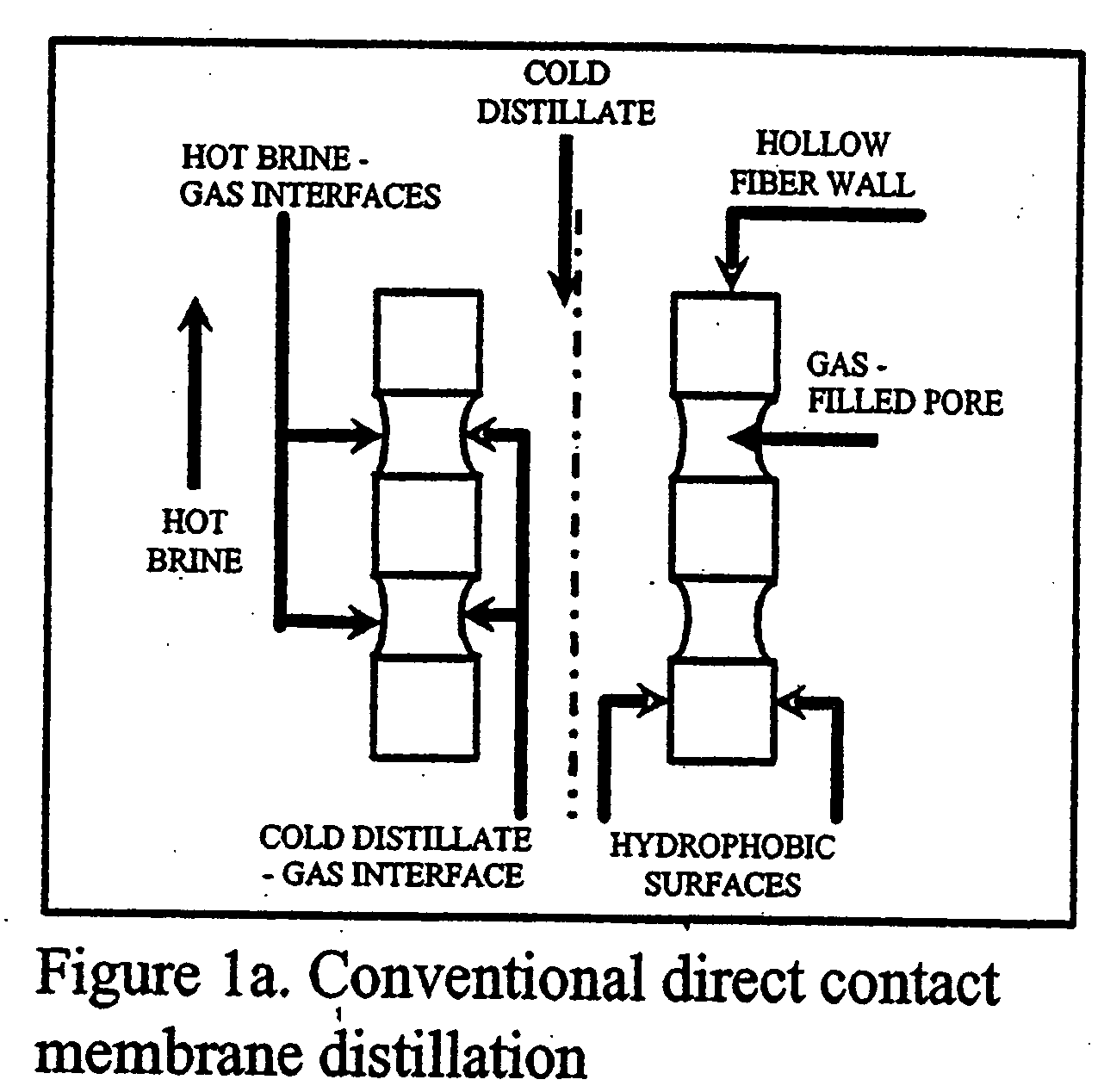

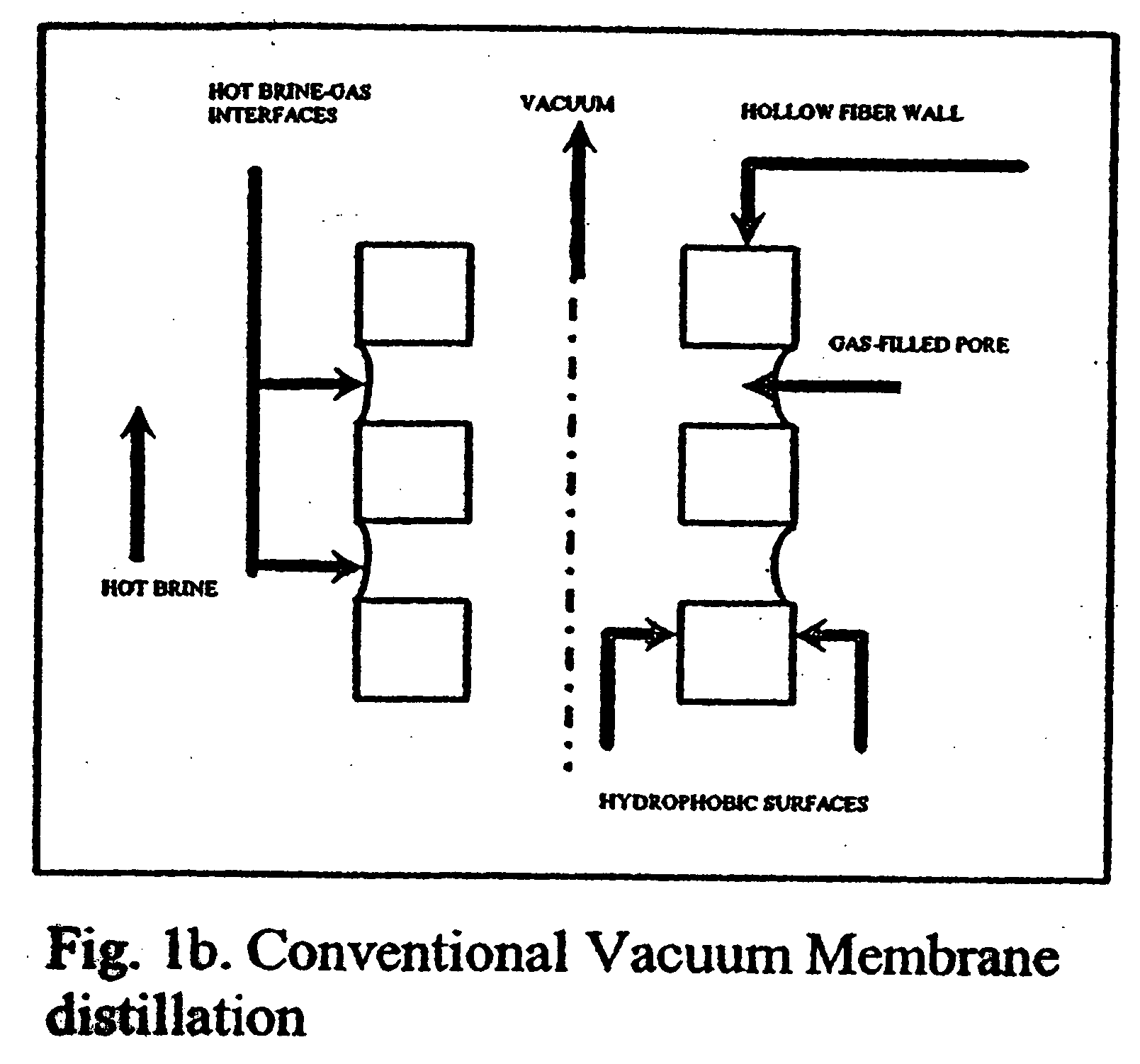

Devices and methods using direct contact membrane distillation and vacuum membrane distillation

ActiveUS20060076294A1Eliminate pore wettingReduce lossesGeneral water supply conservationSolid sorbent liquid separationFiberHollow fibre membrane

DCMD and VMD systems and methods for use in desalination applications are provided. The DCMD and VMD systems employ coated porous hydrophobic hollow fiber membranes. The coatings advantageously function to essentially eliminate pore wetting of the membrane, while permitting substantially unimpeded water vapor permeance through the fiber walls. The DCMD and VMD membranes are characterized by larger fiber bore diameters and wall thicknesses. The membranes substantially reduce the loss of brine sensible heat, e.g., heat loss via conductive heat flux through the membrane wall and the vapor space and, in exemplary embodiments, the brine-side heat transfer coefficient is dramatically enhanced by horizontal / vertical cross flow of brine over the outside surface of the coated fibers. Superior water vapor fluxes are achieved with the systems and methods.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

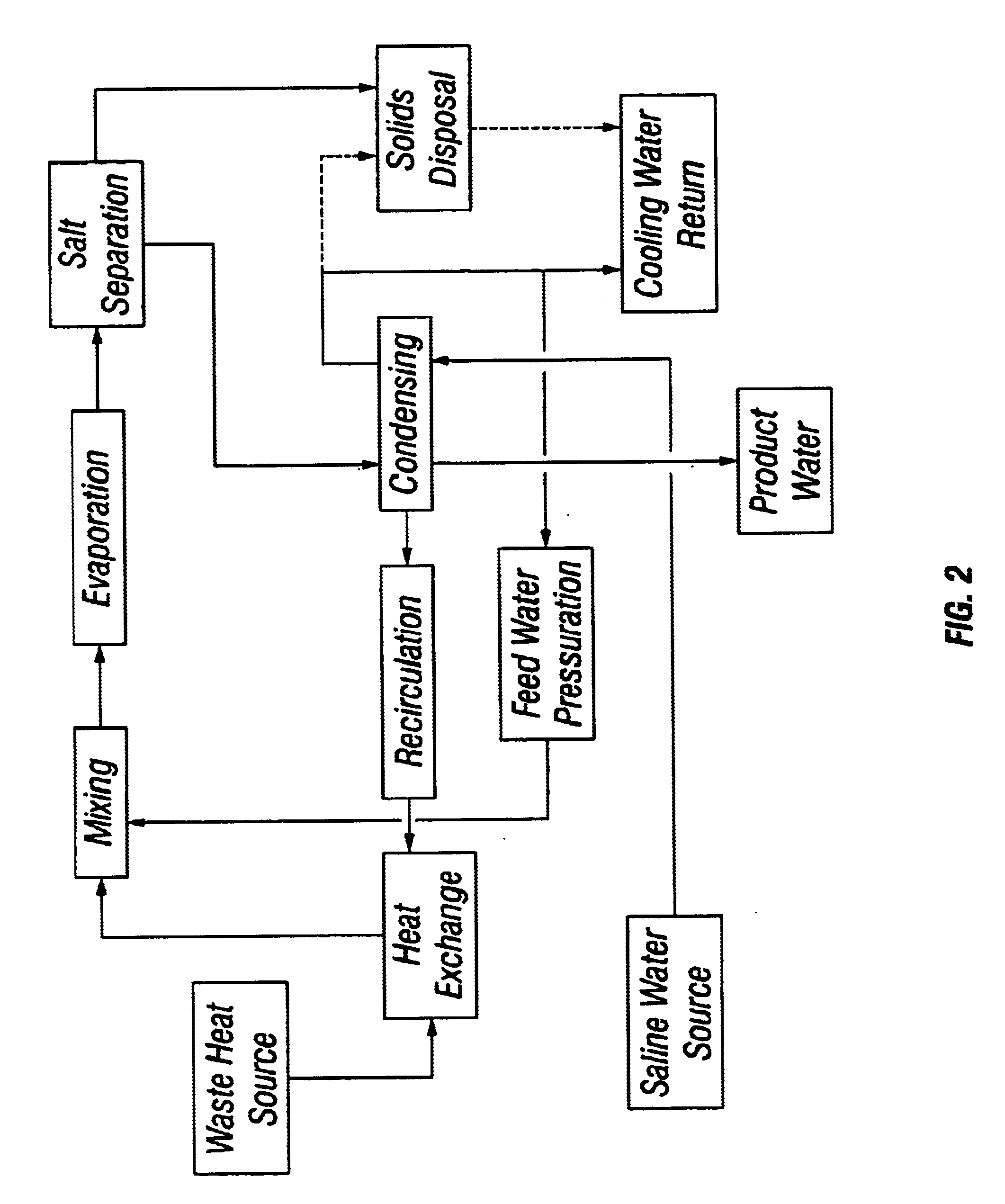

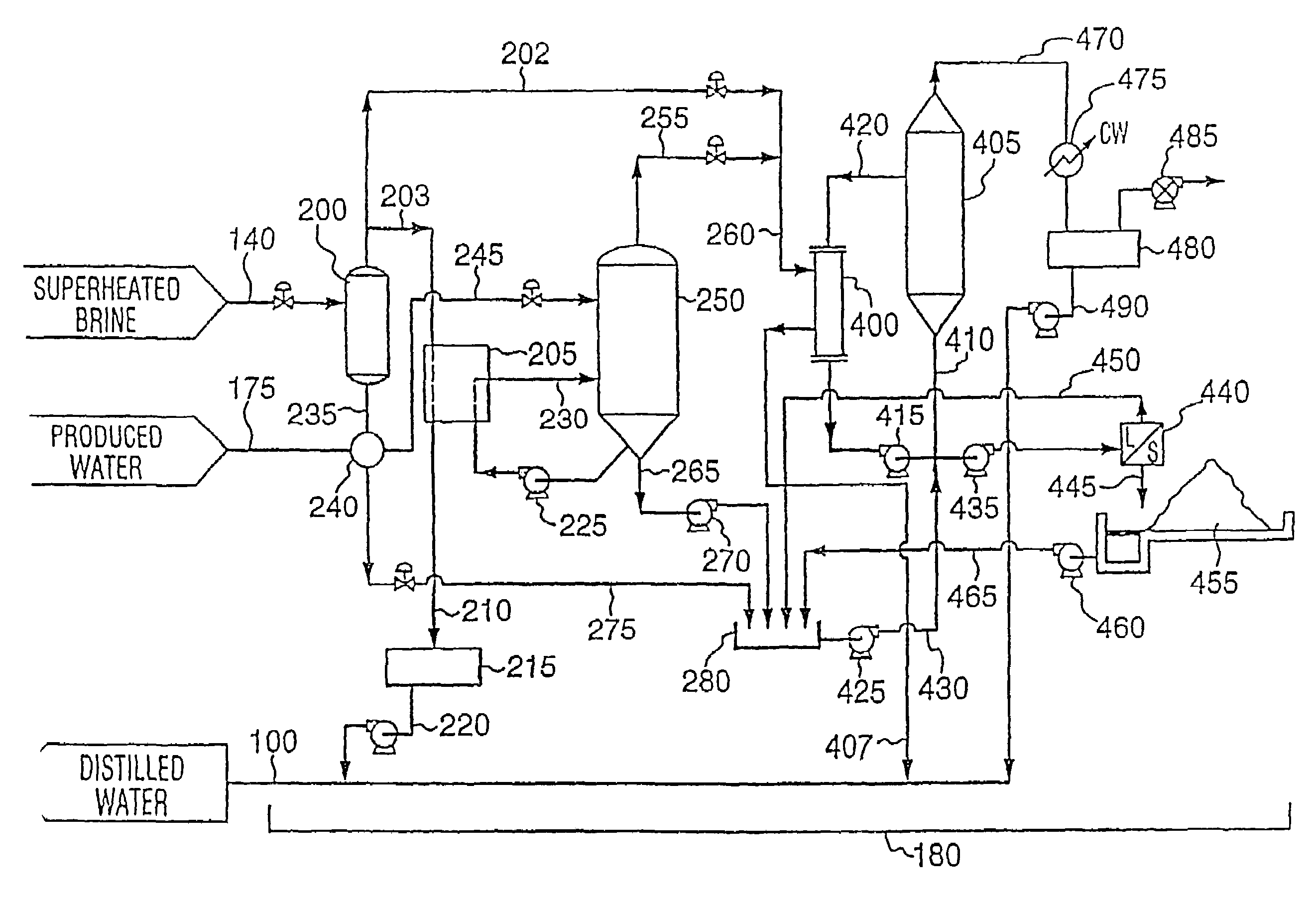

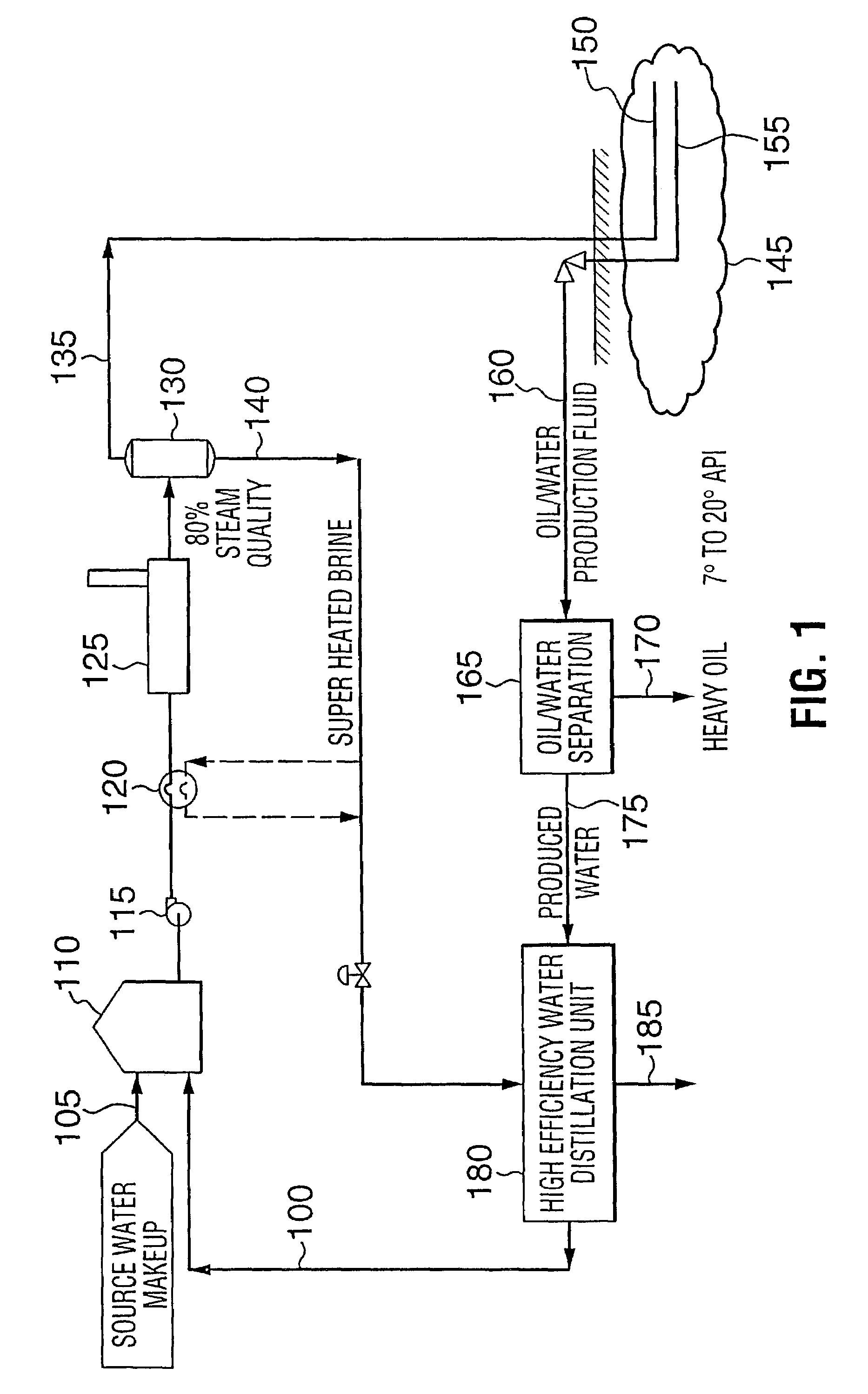

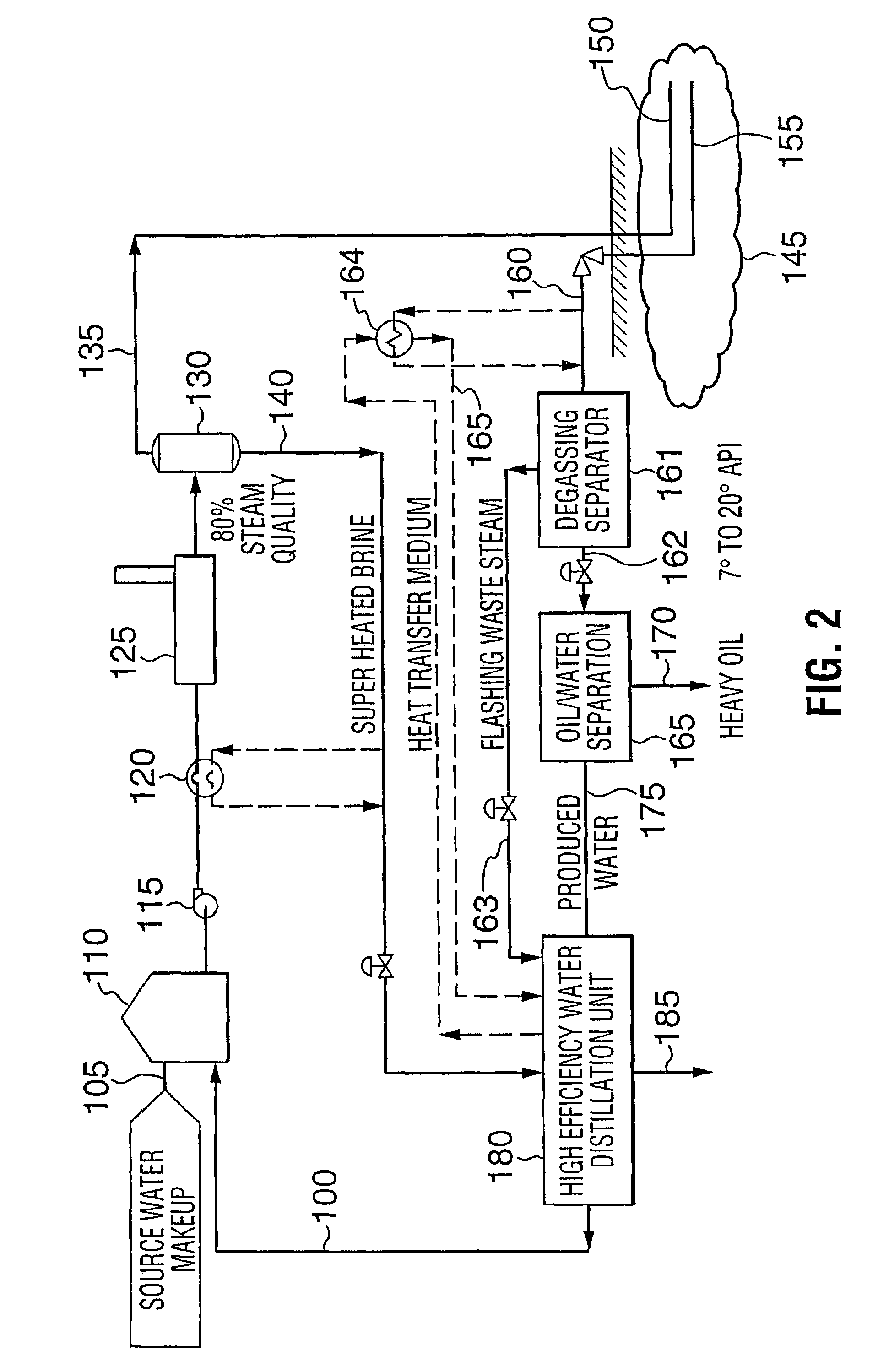

Water treatment process for thermal heavy oil recovery

There is disclosed a method and apparatus for treating produced water from a heavy oil thermal recovery unit to achieve water recovery and recycle levels of greater than 80% and as high as 100% to achieve zero discharge criteria. The method includes the initial steps of capturing the waste heat energy from the high pressure steam separator located downstream of the steam generators. Further, transferring the heat energy into a heated separator and reboiler exchanger to distill oil reservoir produced water and recover distilled water and a concentrated brine or solid product. The heated separator concentrated stream is circulated through the reboiler exchanger to maintain from 1% to about 50% mass vapour in the stream returning to the heated separator and prevent fouling and scaling. The apparatus includes a low pressure waste energy separator, heated separator and vapour compressor in combination with a forced circulation circuit to generate the distilled water.

Owner:FOUNTAIN QUAIL WATER MANAGEMENT LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com