Patents

Literature

1014 results about "Forced circulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A forced circulation boiler is a boiler where a pump is used to circulate water inside the boiler. This differs from a natural circulation boiler which relies on current density to circulate water inside the boiler. In some forced circulation boilers, the water is circulated twenty times the rate of evaporation.

Adhesives for vehicle body manufacturing

InactiveUS20040079478A1Significant production advantageHigh strengthLamination ancillary operationsAdhesive processes with adhesive heatingCross-linkEngineering

Two-component systems are described which are suitable for underlining, adhesive bonding of the crimped fold and sealing of auto body sections, particularly for crimped fold sealing of add-on vehicle parts. The two-component systems attain the requisite grip strength for mounting the add-on parts on the body as well as the requisite strength and dimensional stability for the production process up to and with the CIP passage, within the predetermined cycle time, on the basis of cross-linking of the sealant composition twice. In one embodiment, the surface of the two-component system is pre-cross-linked by a UV-induced reaction and by the cross-linking of the two-component system to the extent of portability. In addition, two-component systems are described which cross-link intentionally only partially up to a consistency that permits a rugged course of the process through cleaning baths and which harden completely only by means of a further hardening process, for instance in the CIP forced circulation oven.

Owner:SIKA AG VORMALS KASPAR WINKLER

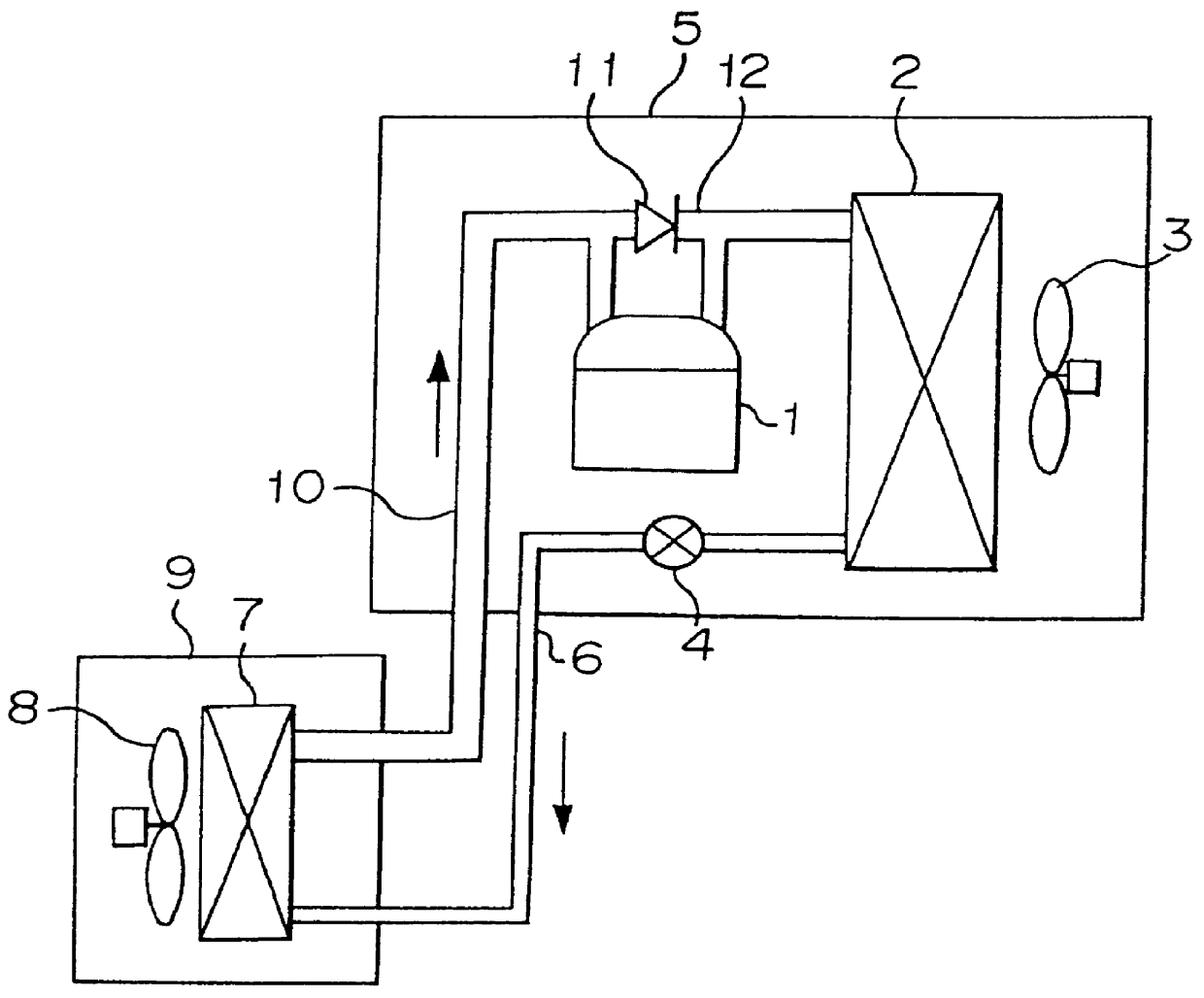

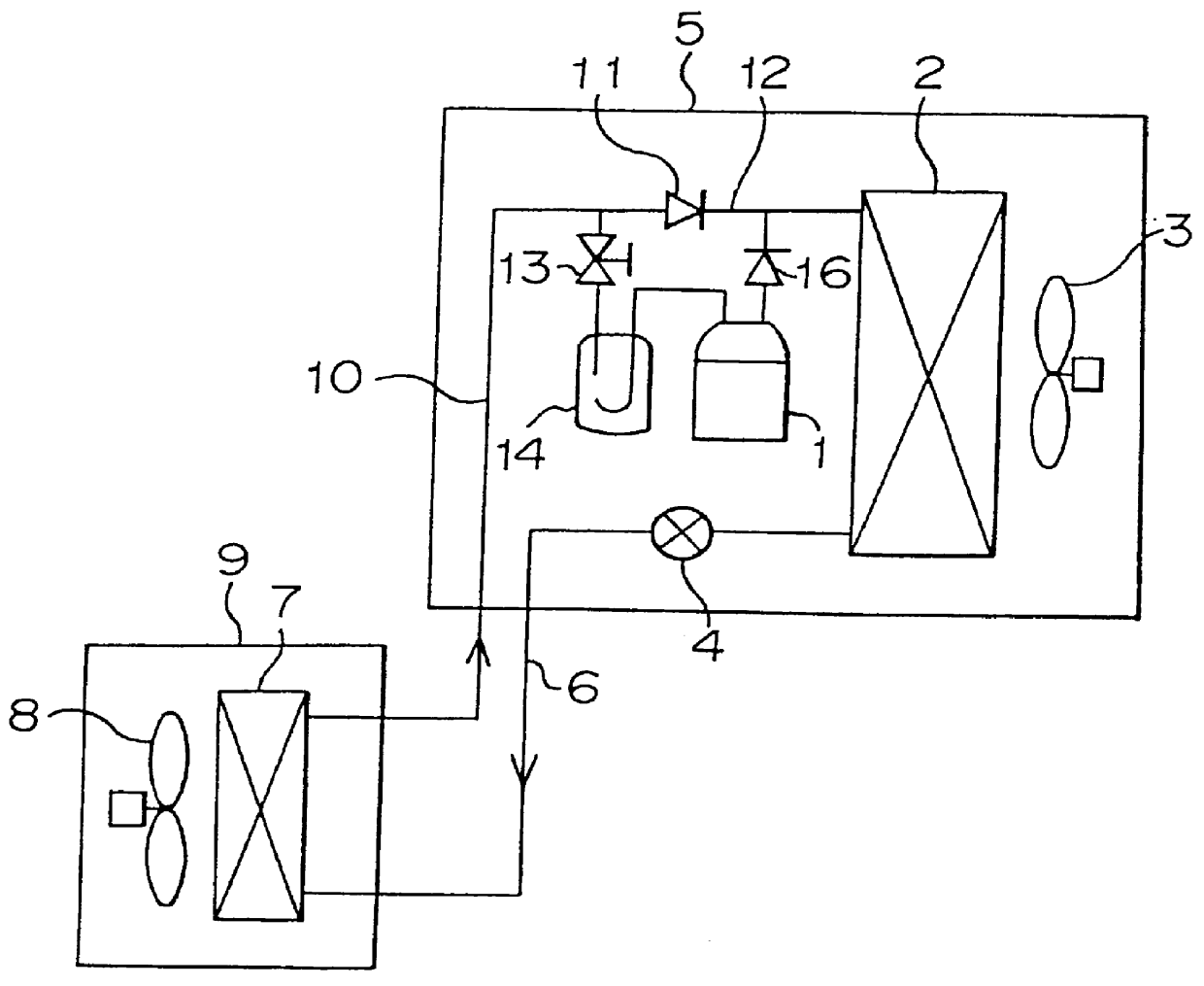

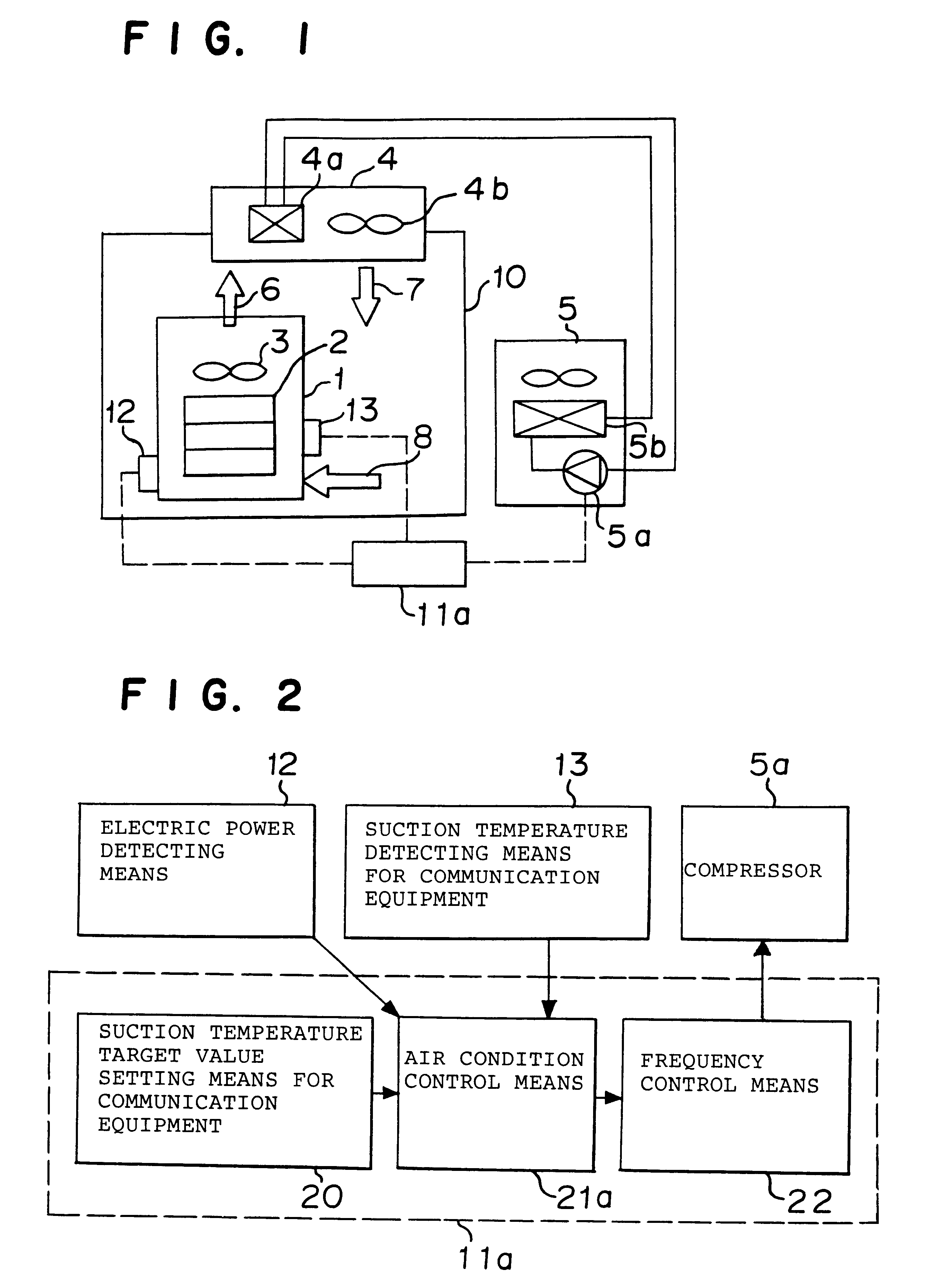

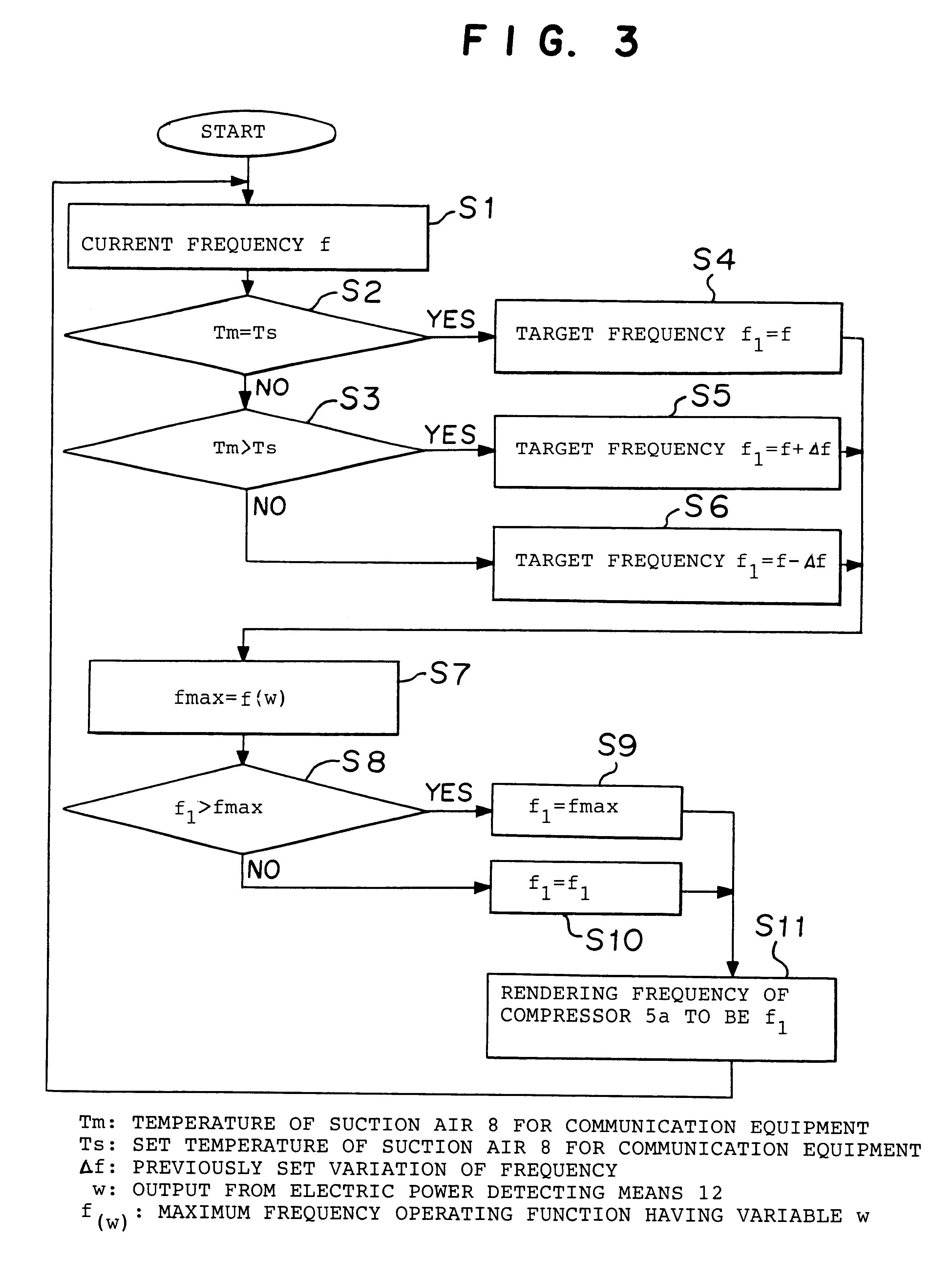

Air conditioner

InactiveUS6023935ACompression machines with non-reversible cycleEvaporators/condensersEngineeringRefrigeration

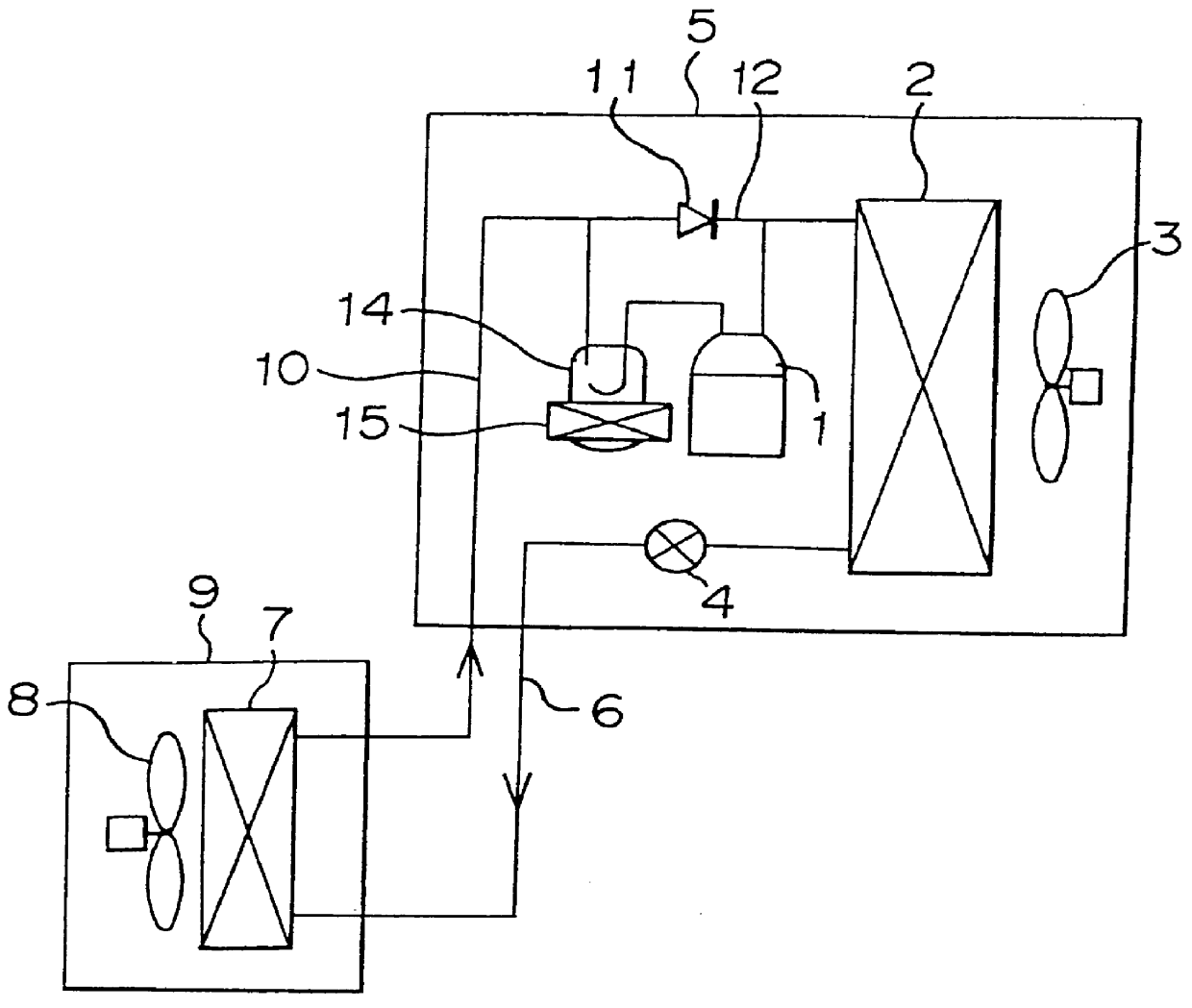

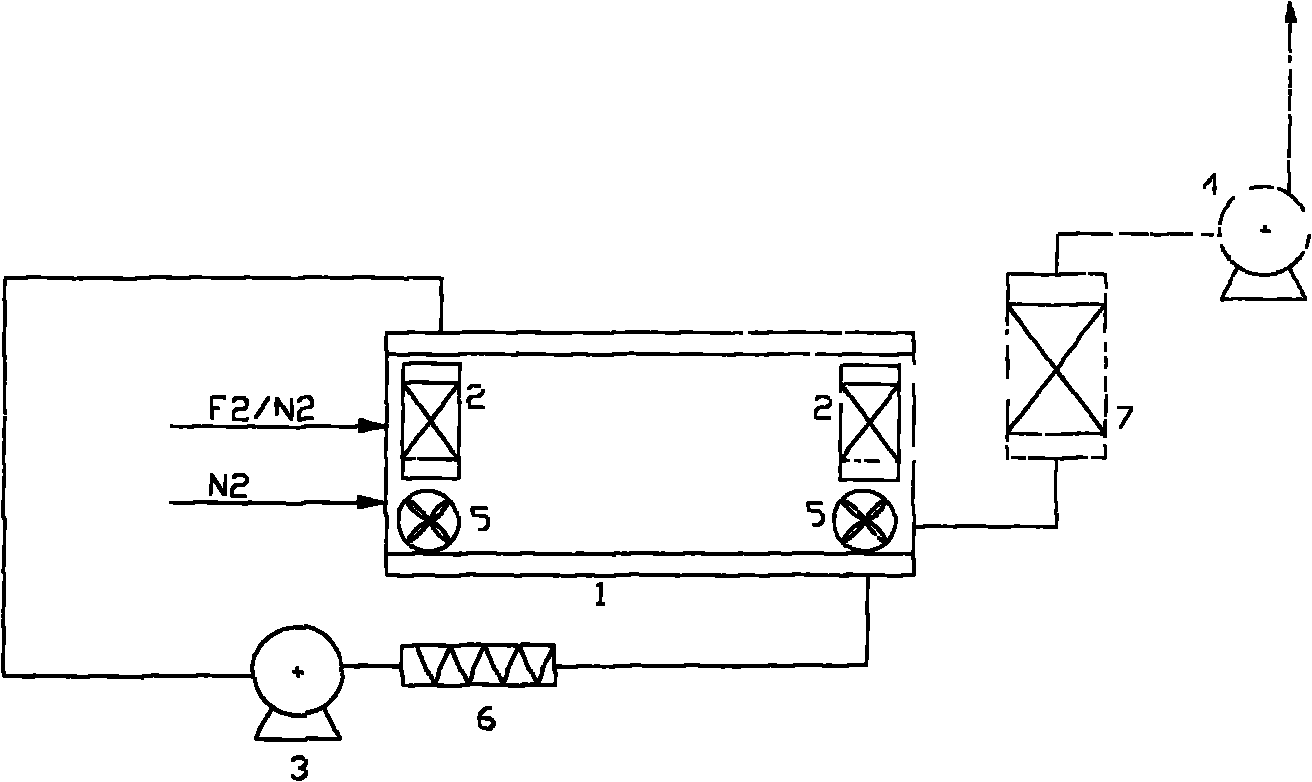

An air conditioner has a refrigeration circuit formed by sequentially connecting a compressor 1, a condenser 2, an electronic expansion valve 4 and an evaporator 7 by pipes (6, 10). A compressor bypass pipe 12 is provided to connect an outlet of the evaporator 7 with an inlet of the condenser 2. A first on-off valve 11 is located in the bypass pipe 12. The air conditioner is controlled to switch to either a forced circulation operation or a natural circulation operation. In the forced circulation operation, the first on-off valve 11 is closed, the expansion valve 4 is opened to a first degree to allow refrigerant to pass therethrough, and the compressor 1 is operated in a running state. In the natural circulation operation, the first on-off valve 11 is opened, the expansion valve 4 is opened to a second degree, different from the first degree, to allow refrigerant to pass therethrough, and the compressor 1 is stopped.

Owner:MITSUBISHI ELECTRIC CORP

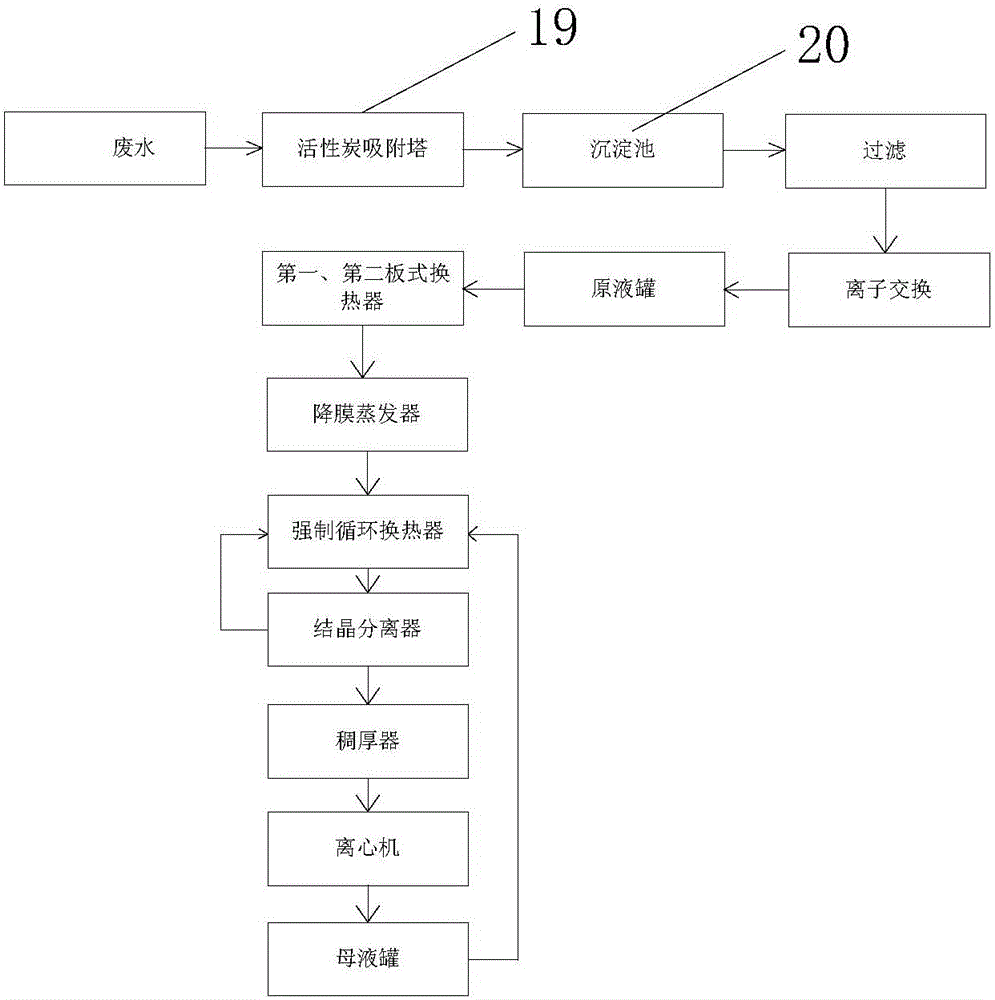

Process method for recovering ammonium chloride and sodium chloride from waste water containing ammonium chloride and sodium chloride

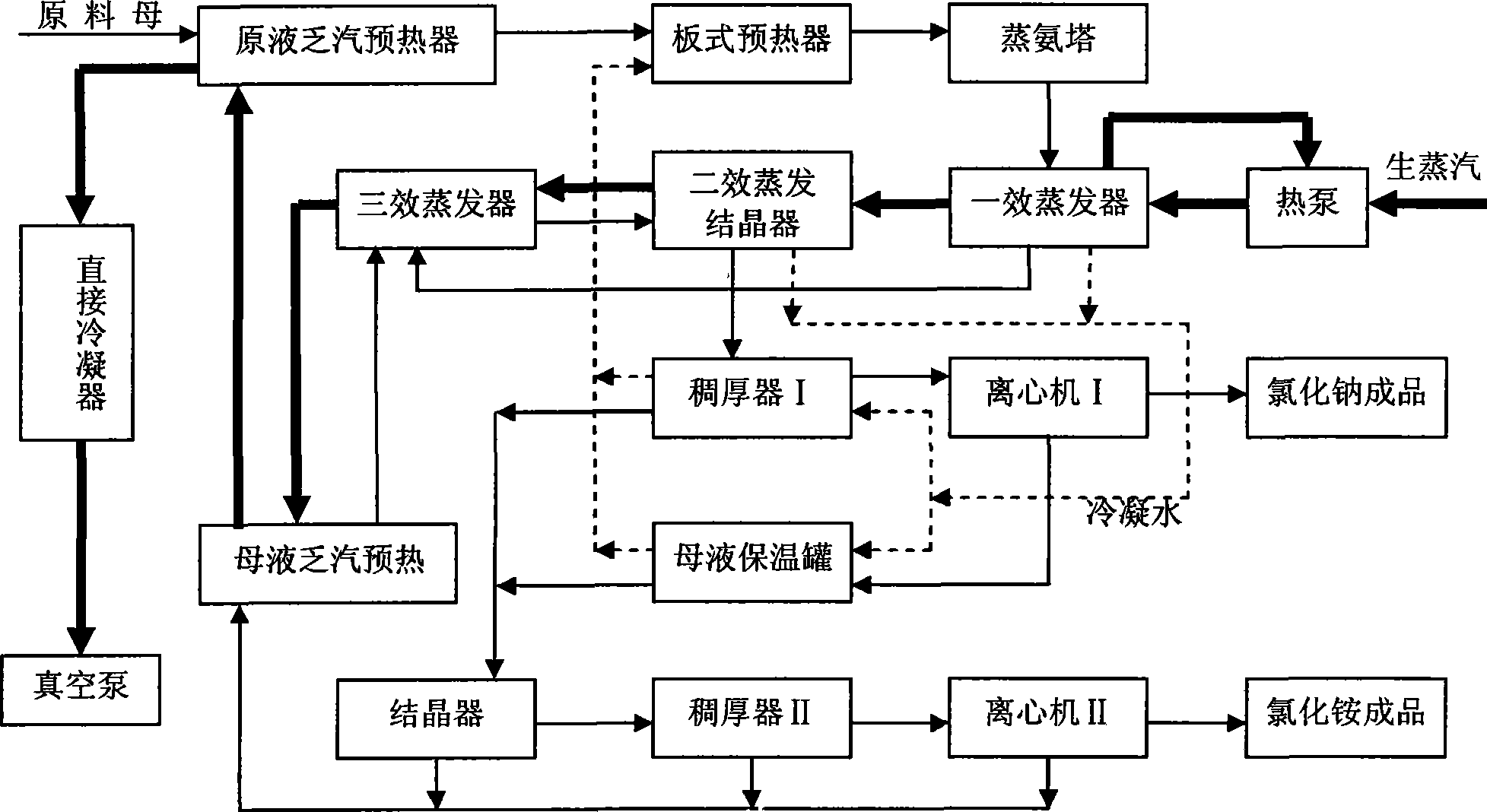

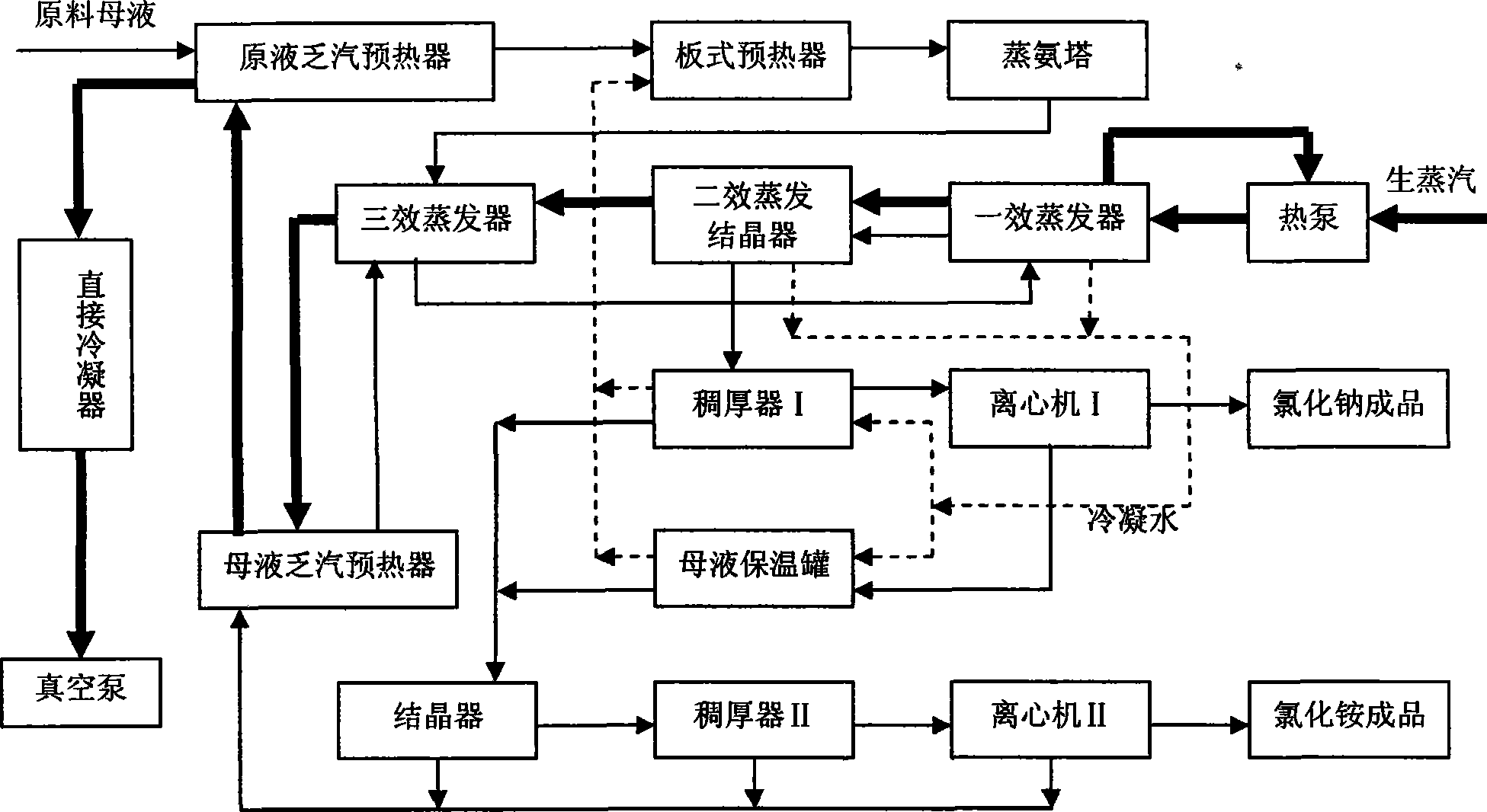

InactiveCN101544437AFully recycleReduce energy consumptionEnergy inputSolution crystallizationSodium bicarbonateDecomposition

The invention relates to a process method for recovering ammonium chloride and sodium chloride from waste water containing the ammonium chloride and the sodium chloride, which produces the ammonium chloride and the sodium chloride by using mother solution which is generated in a process for producing sodium bicarbonate by natural bittern double decomposition reaction and contains the ammonium chloride and the sodium chloride as raw materials. The method adopts ammonium still, evaporation, crystallization and separation process to treat, wherein the evaporation adopts multiple-effect, a heat pump and a vacuum evaporation process, and selects a falling film evaporator and a forced circulation type evaporator to perform triple-effect mixed-flow procedure, so that sodium chloride is crystallized and separated in the evaporation; and the ammonium chloride is crystallized and separated by cooling after the evaporation. The method effectively reduces the operation temperature of the equipment, can repeatedly use secondary steam and condensed water, reduces erosion of the ammonium chloride solution to the equipment, saves the energy, reduces the cost, improves the production efficiency, and reduces environmental pollution.

Owner:HEBEI UNIV OF TECH +1

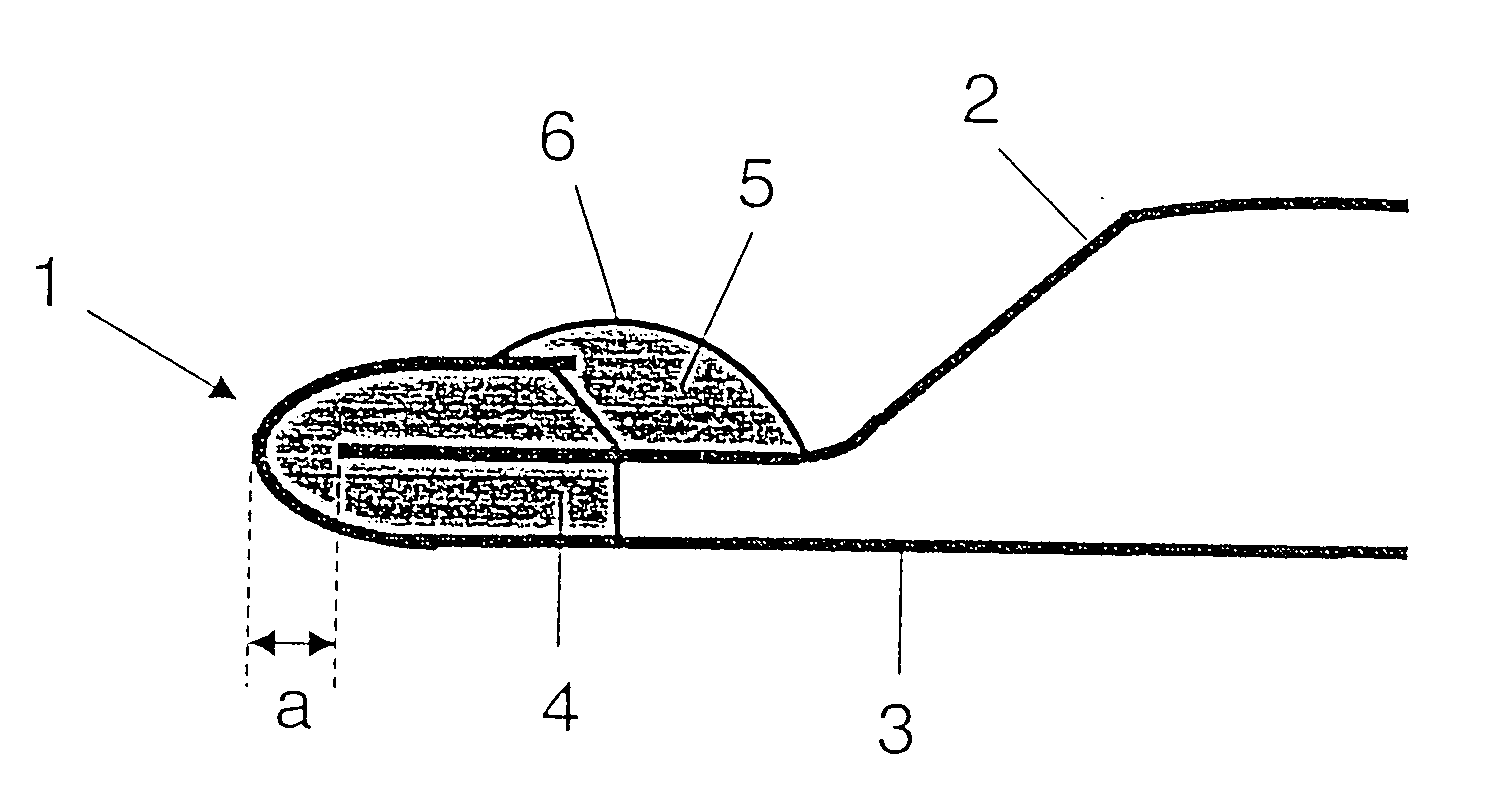

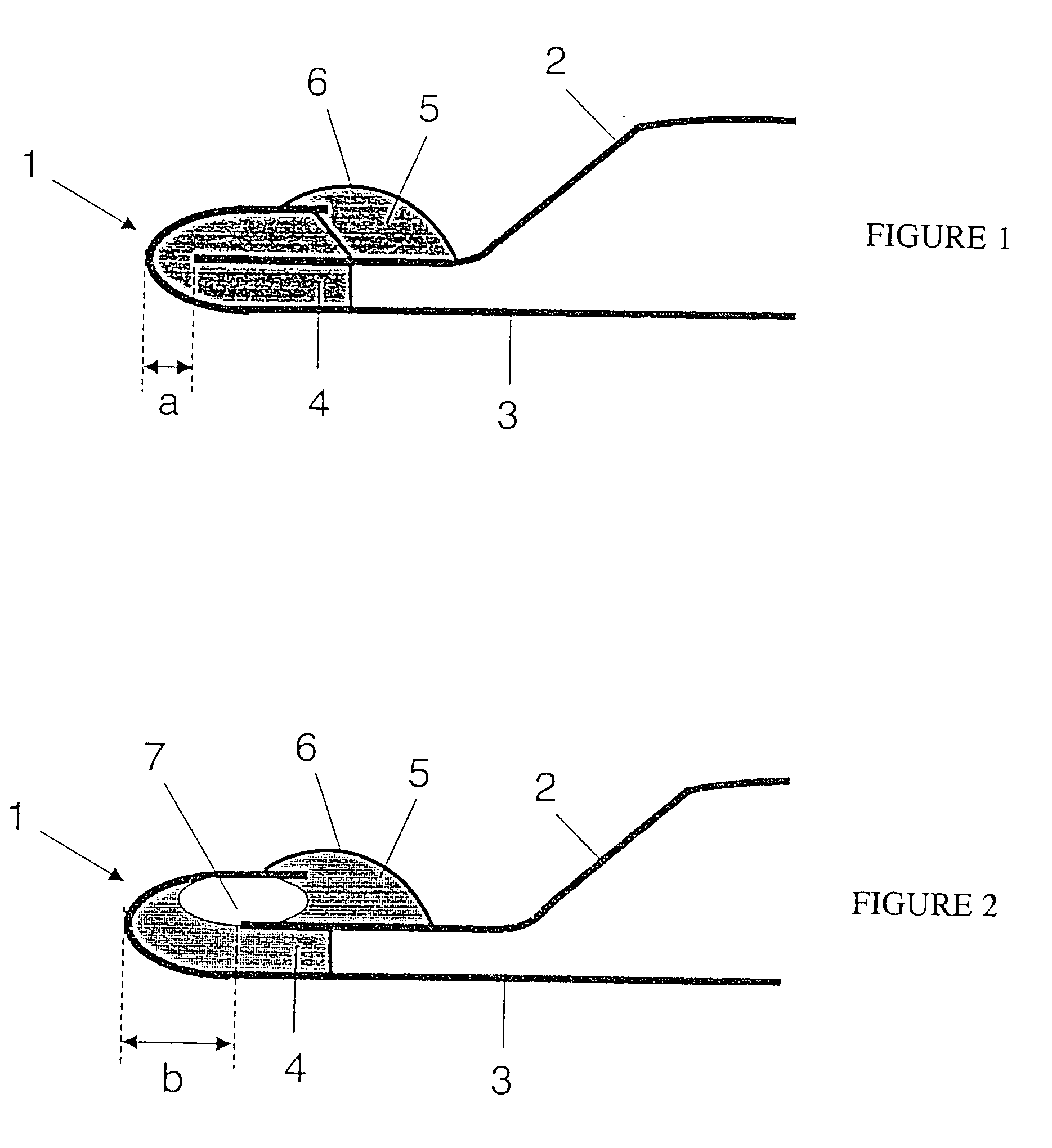

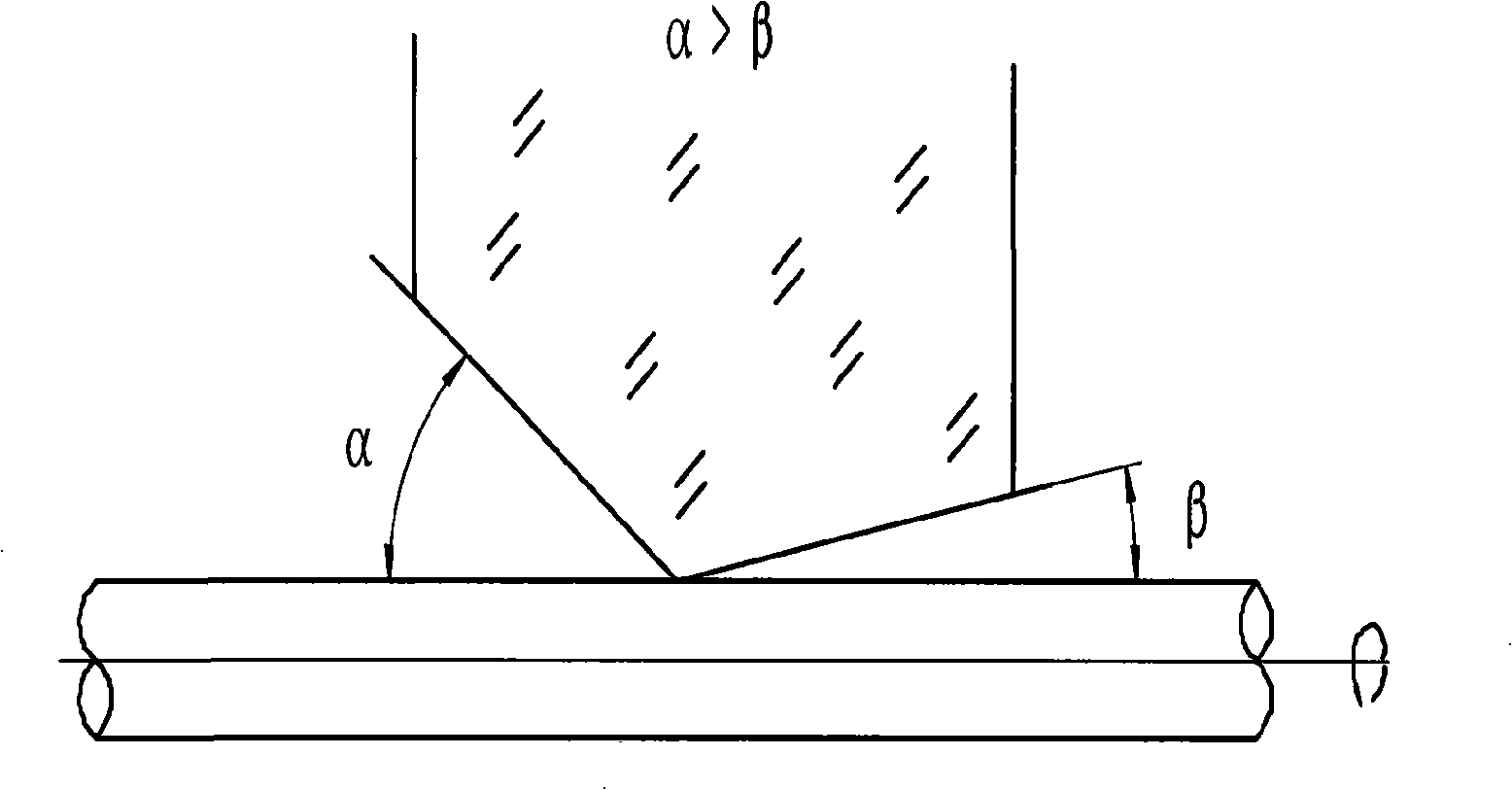

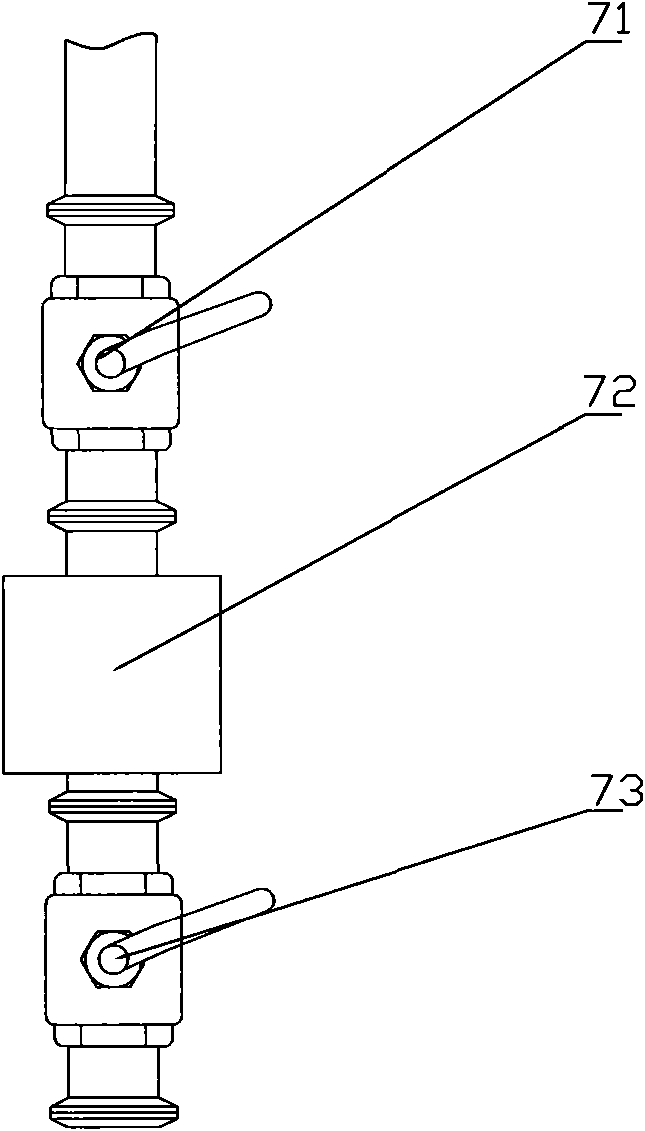

Integrated pin tool for friction stir welding and composite method of resistance-friction stir welding thereof

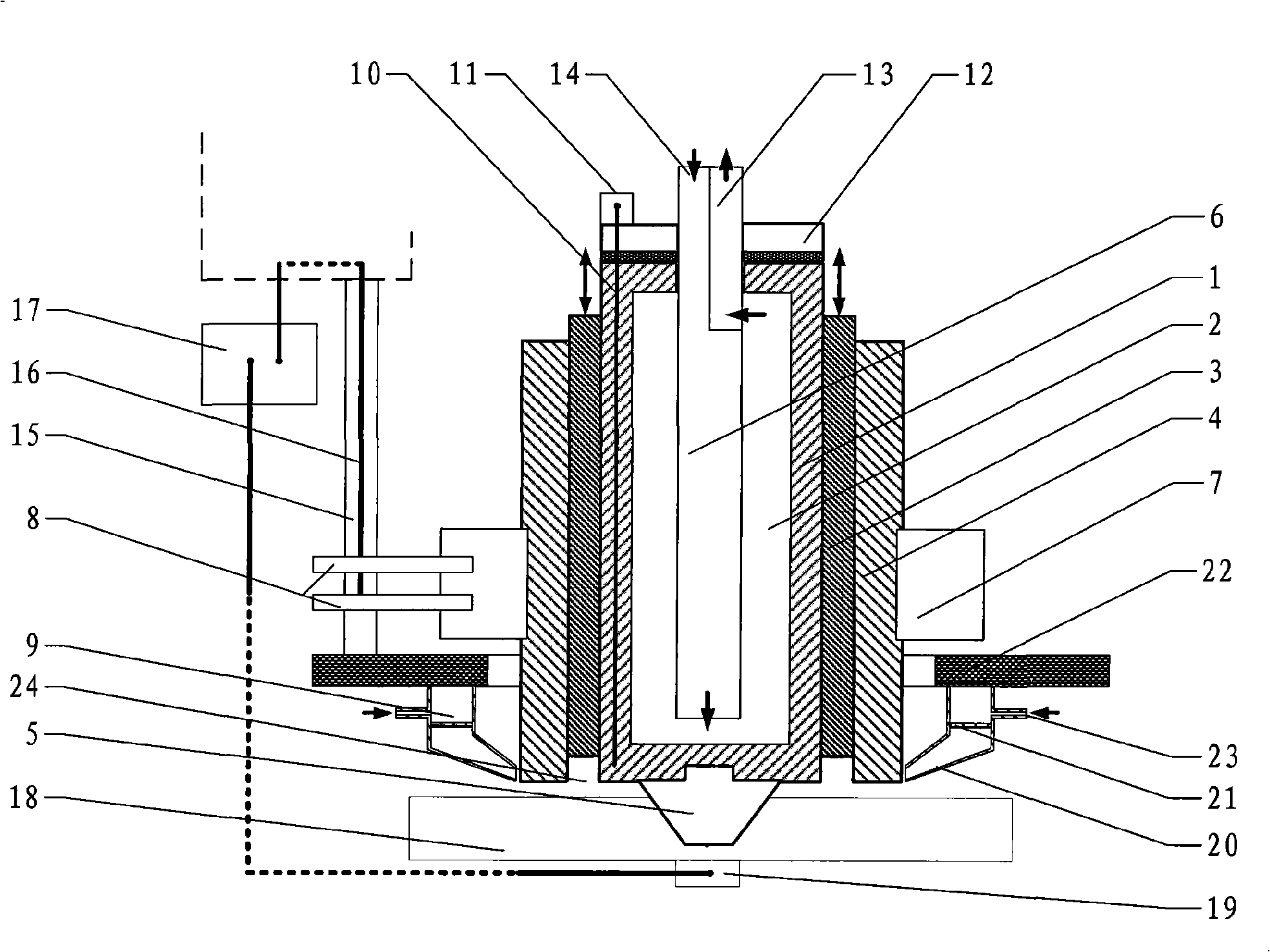

InactiveCN101537538AReduce wearExtended service lifeEngine sealsWelding/cutting media/materialsElectrical resistance and conductanceFriction welding

The invention discloses an integrated pin tool used for friction stir welding and a composite method of resistance-friction stir welding thereof. The pin tool comprises a pin tool body arranged on a friction welder and a tool pin arranged at the lower part of the tool pin body which is connected with the welder in a clamping and insulating manner; the pin tool also comprises a forced cooling system, a current carrying system, a gas shielding system, a temperature sensing and detecting system, a sealing and insulation system, an inner shaft shoulder and the tool pin, and is an integrated pin tool which has the functions of gas shielding, forced circulation cooling of internal liquid medium, automatic temperature sensing and detection, tool pin changing and composite non-keyhole resistance-friction stir welding. The invention overcomes the difficulty of friction stir welding of the high melting point metal and meets the harsh technical requirements of the friction stir welding of the low melting point metal, improves the quality of welding joints, prolongs the service life of the pin tool and realizes the friction stir welding of high melting point metal and low melting point light alloy, with low cost, high efficiency and excellent quality.

Owner:CHONGQING UNIV

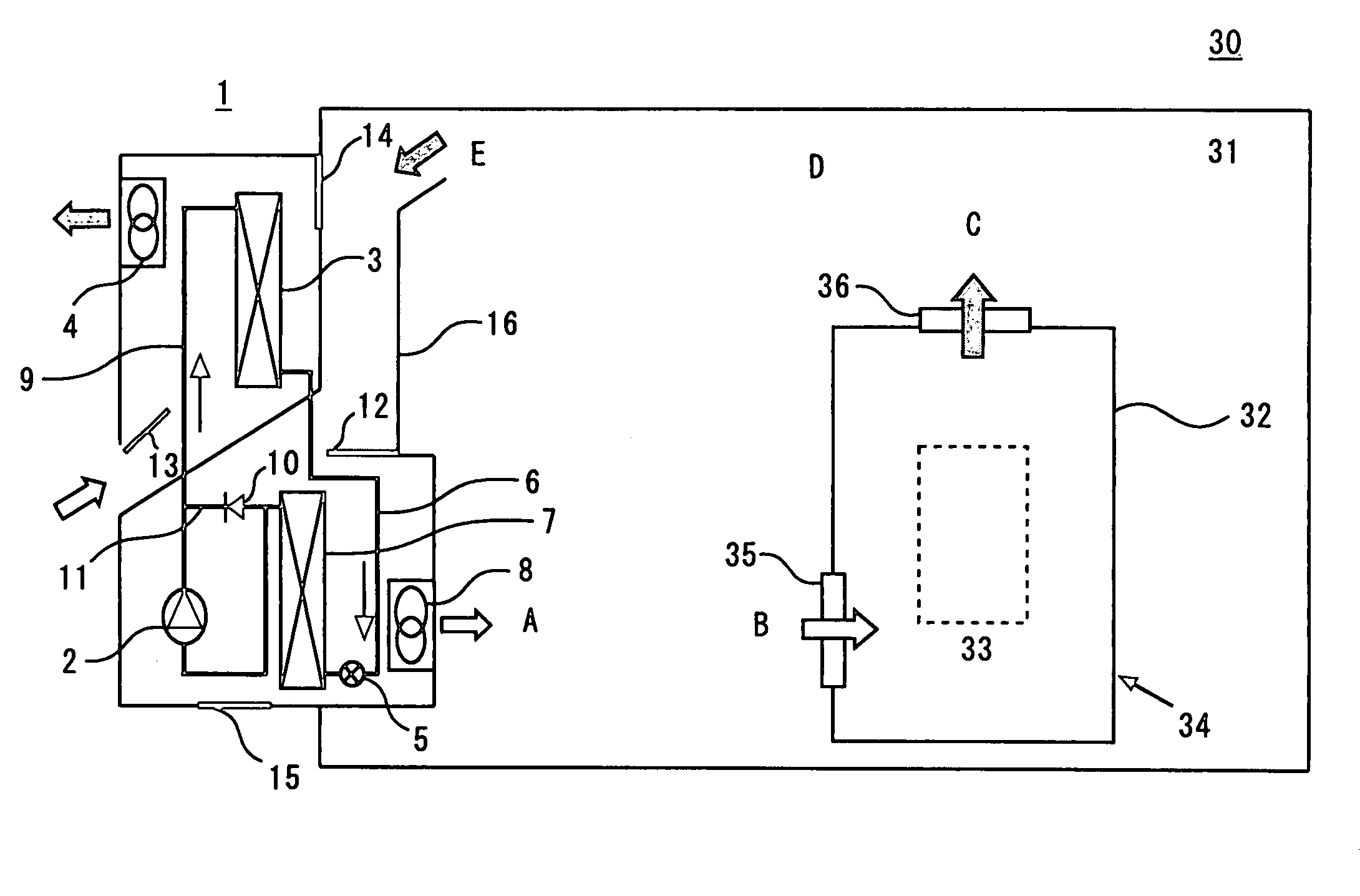

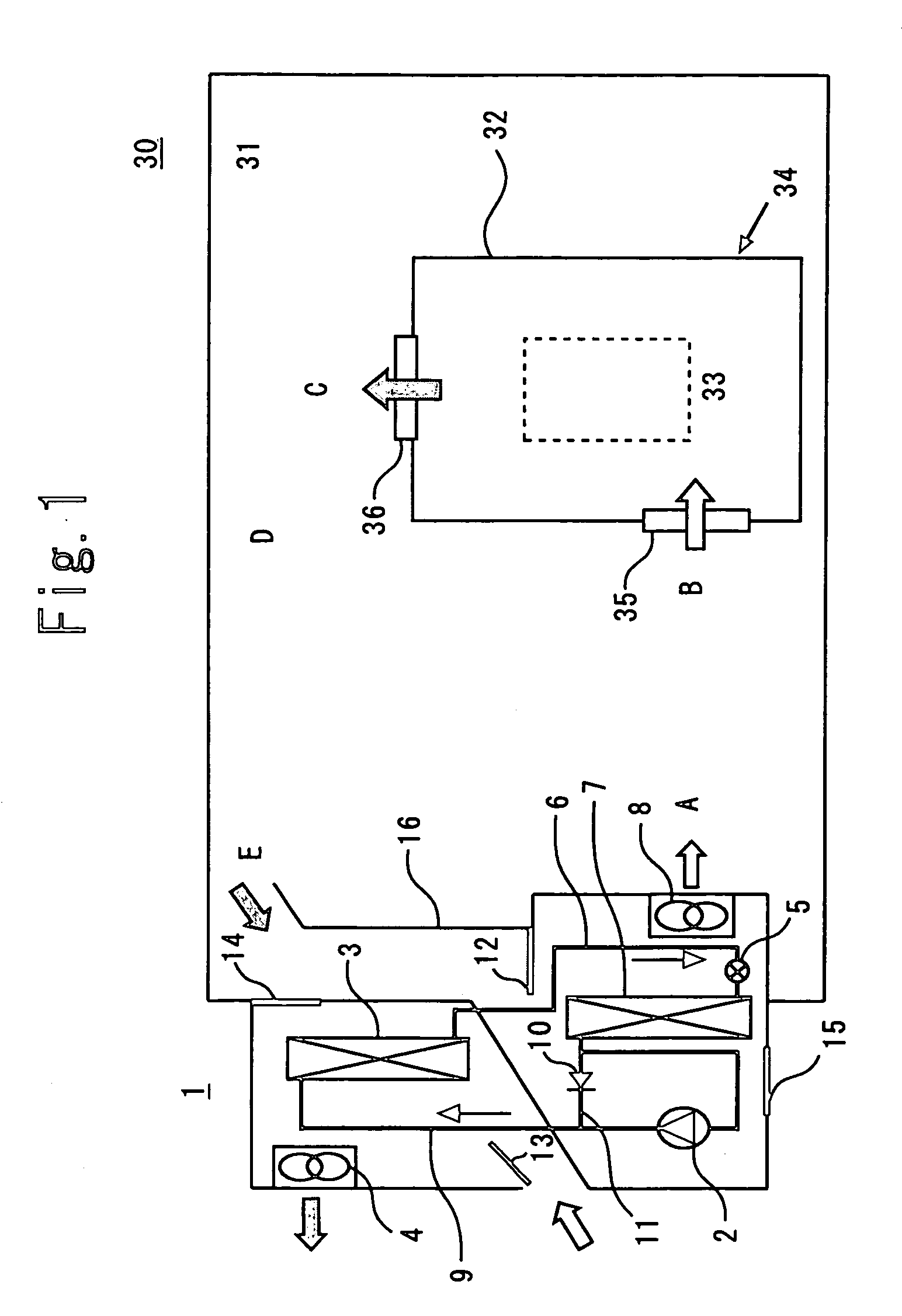

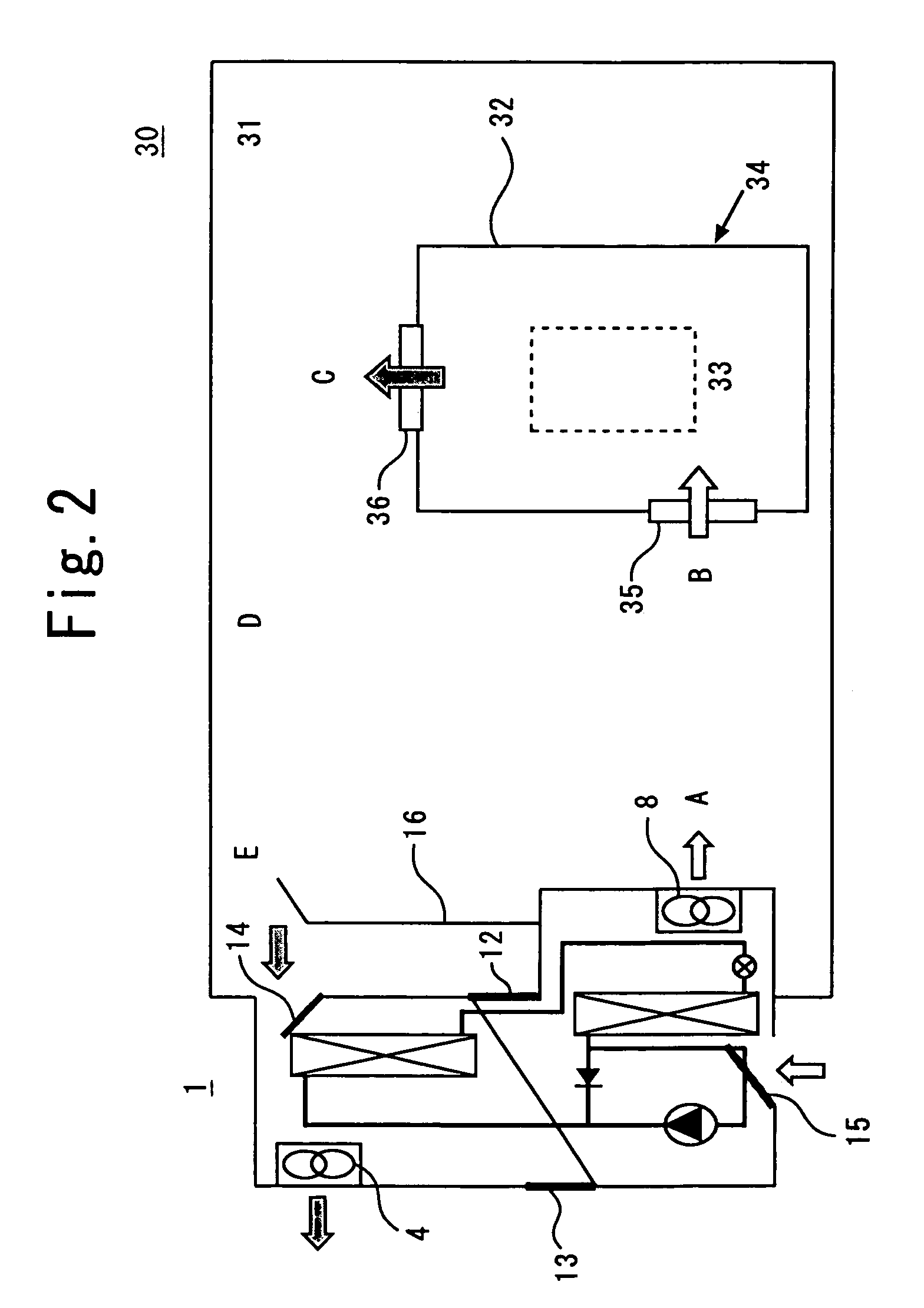

Cooling device

InactiveUS6997006B2Reduce in quantitySimplification of setting workCompression machines with cascade operationRefrigeration devicesPlate heat exchangerEngineering

A cooling system that has a heat exchanger which is housed in one enclosure and is constituted of a plurality of heat exchange modes, and the heat exchanger includes a refrigerant forced circulation mode, a refrigerant natural circulation mode, and a ventilation mode. A temperature detector performs switching to an optimal mode, to thereby cool the inside of the enclosure of a housing accommodating equipment including a heat-generating component.

Owner:MITSUBISHI ELECTRIC CORP

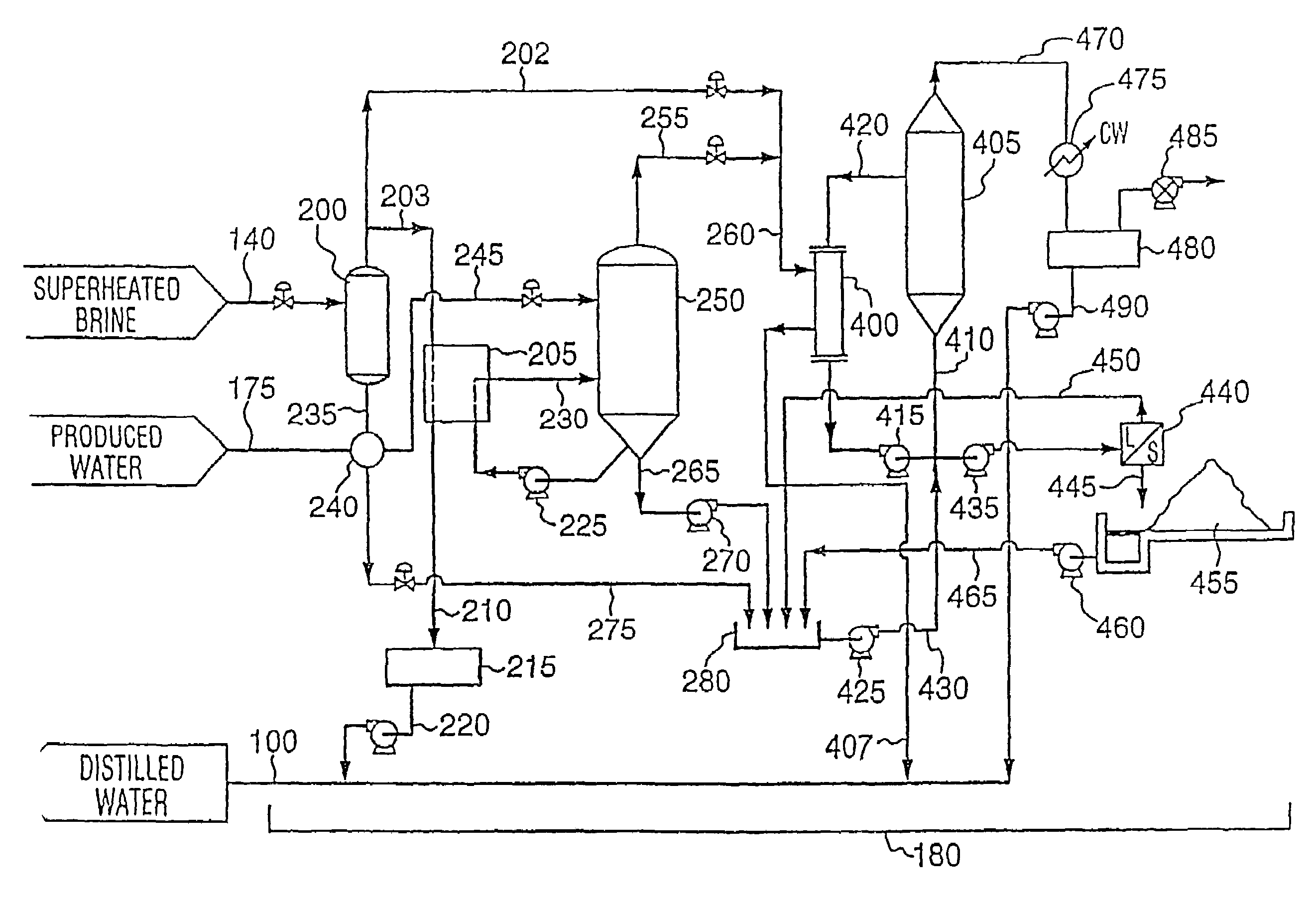

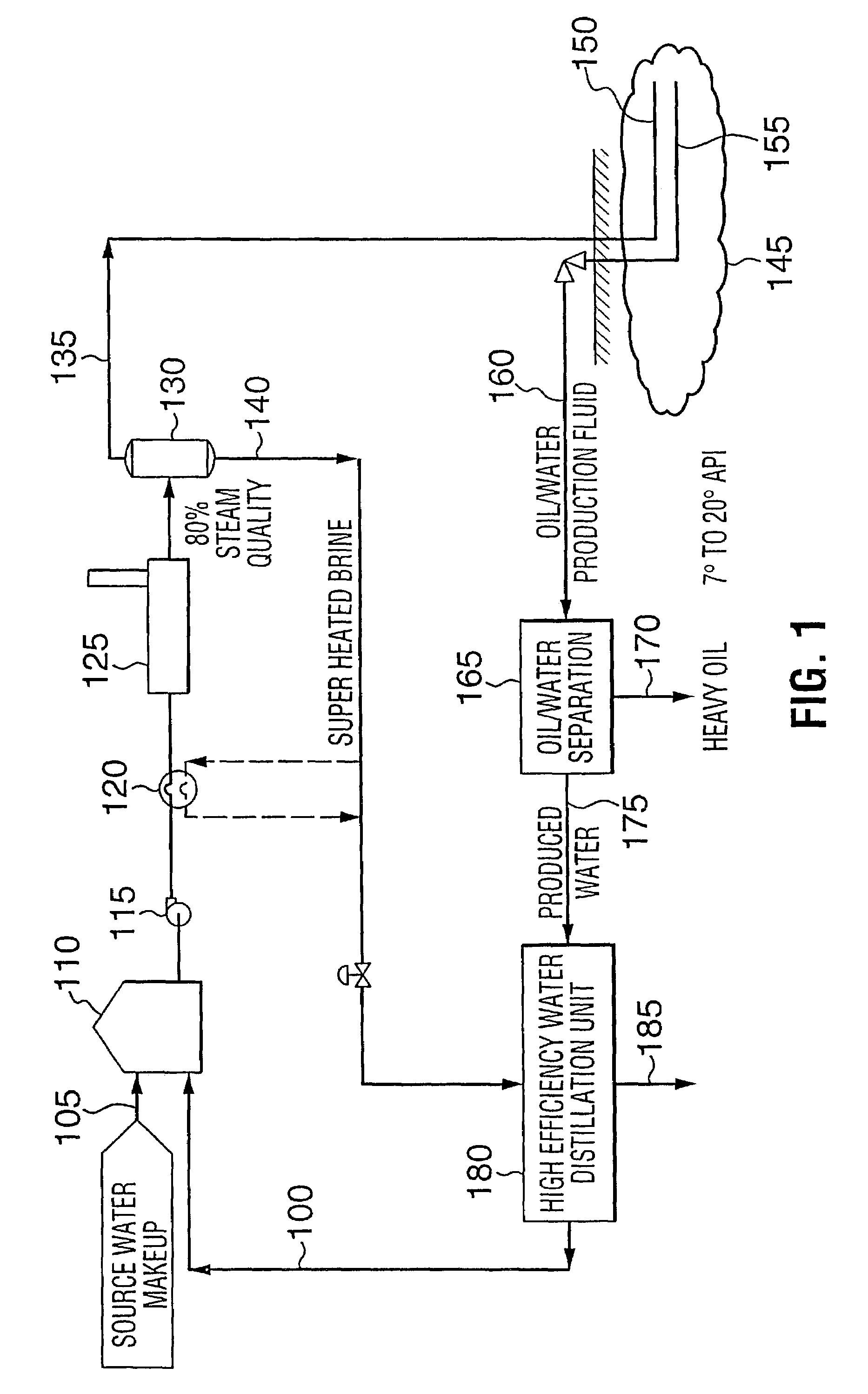

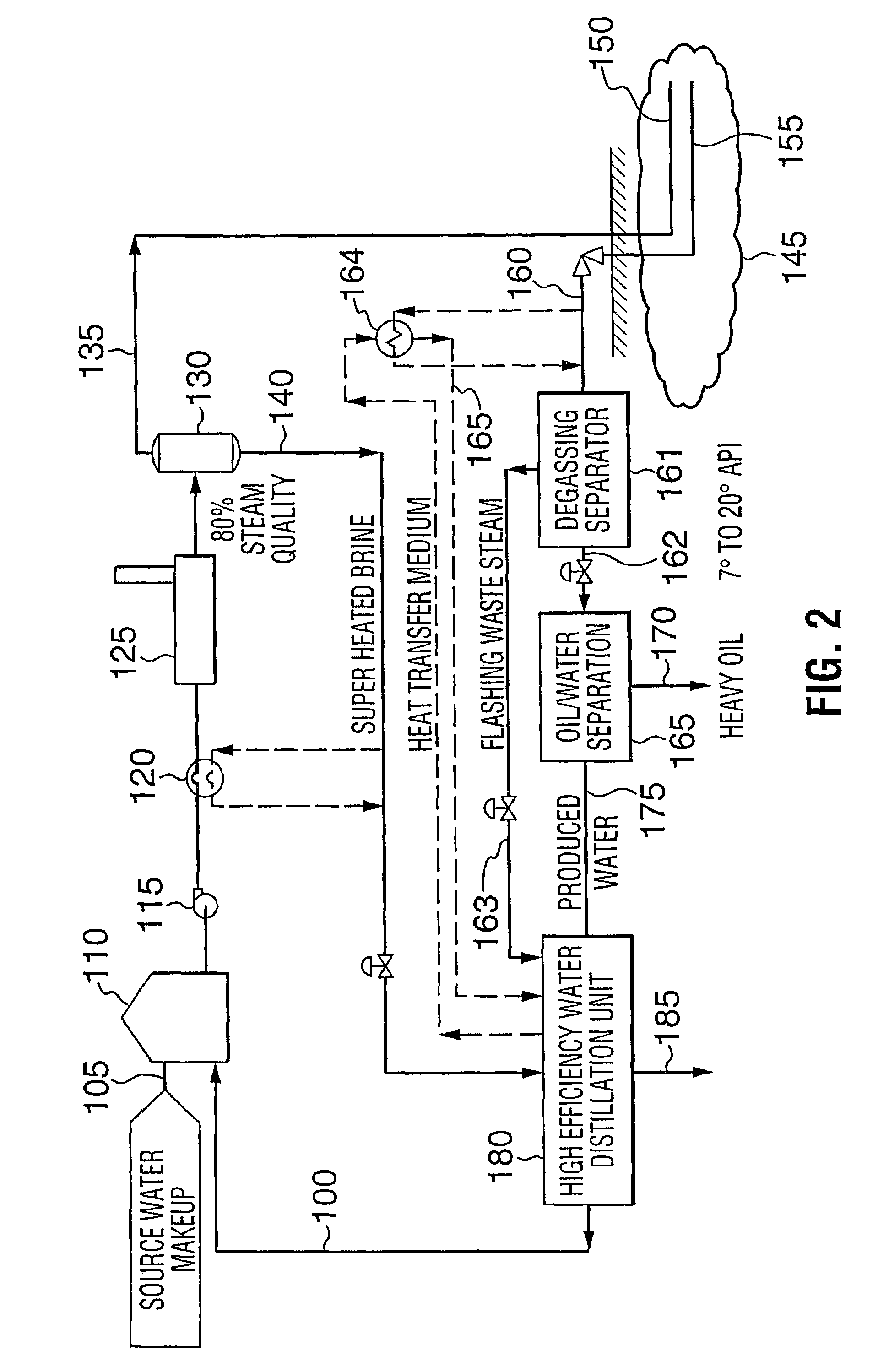

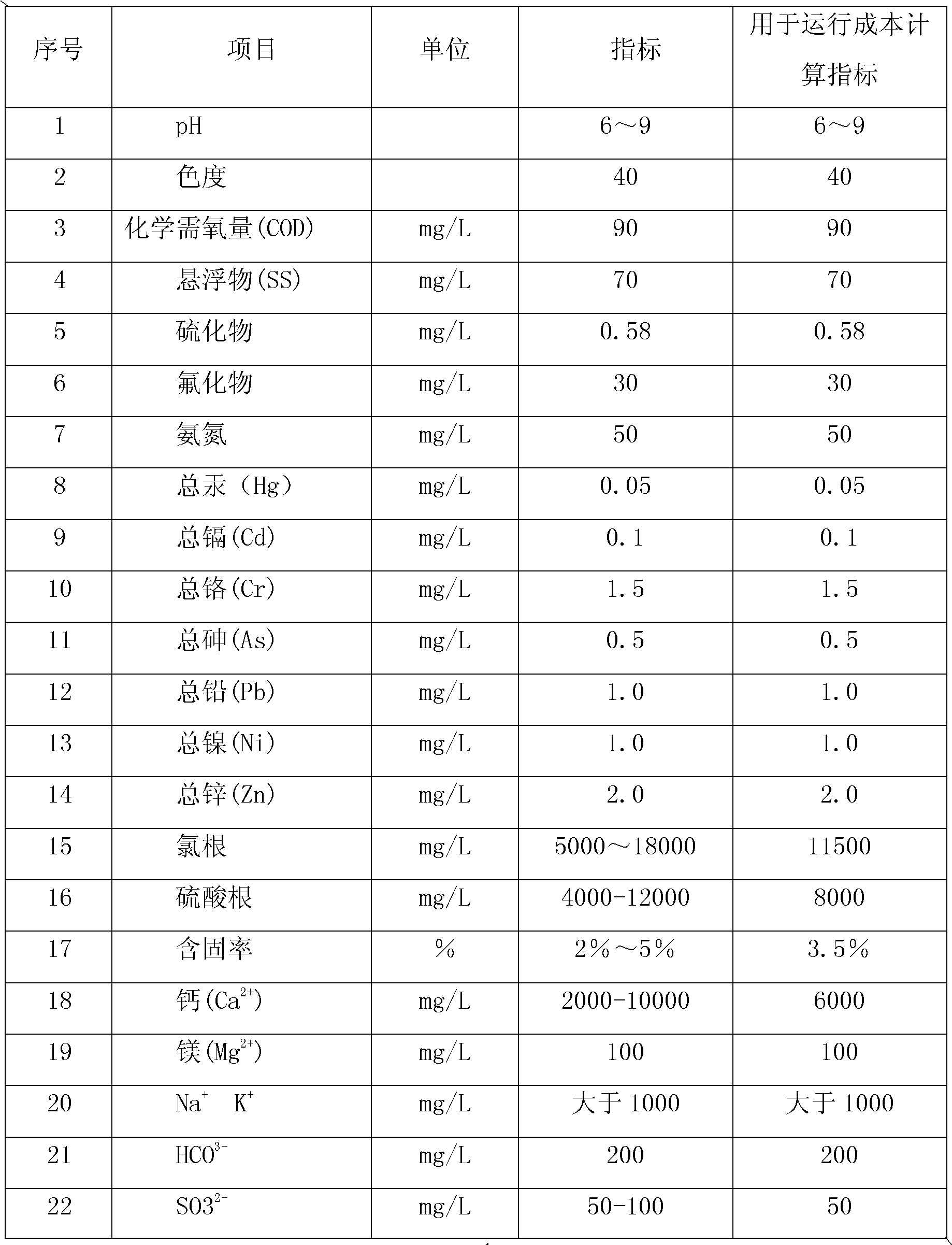

Water treatment process for thermal heavy oil recovery

There is disclosed a method and apparatus for treating produced water from a heavy oil thermal recovery unit to achieve water recovery and recycle levels of greater than 80% and as high as 100% to achieve zero discharge criteria. The method includes the initial steps of capturing the waste heat energy from the high pressure steam separator located downstream of the steam generators. Further, transferring the heat energy into a heated separator and reboiler exchanger to distill oil reservoir produced water and recover distilled water and a concentrated brine or solid product. The heated separator concentrated stream is circulated through the reboiler exchanger to maintain from 1% to about 50% mass vapour in the stream returning to the heated separator and prevent fouling and scaling. The apparatus includes a low pressure waste energy separator, heated separator and vapour compressor in combination with a forced circulation circuit to generate the distilled water.

Owner:FOUNTAIN QUAIL WATER MANAGEMENT LLC +1

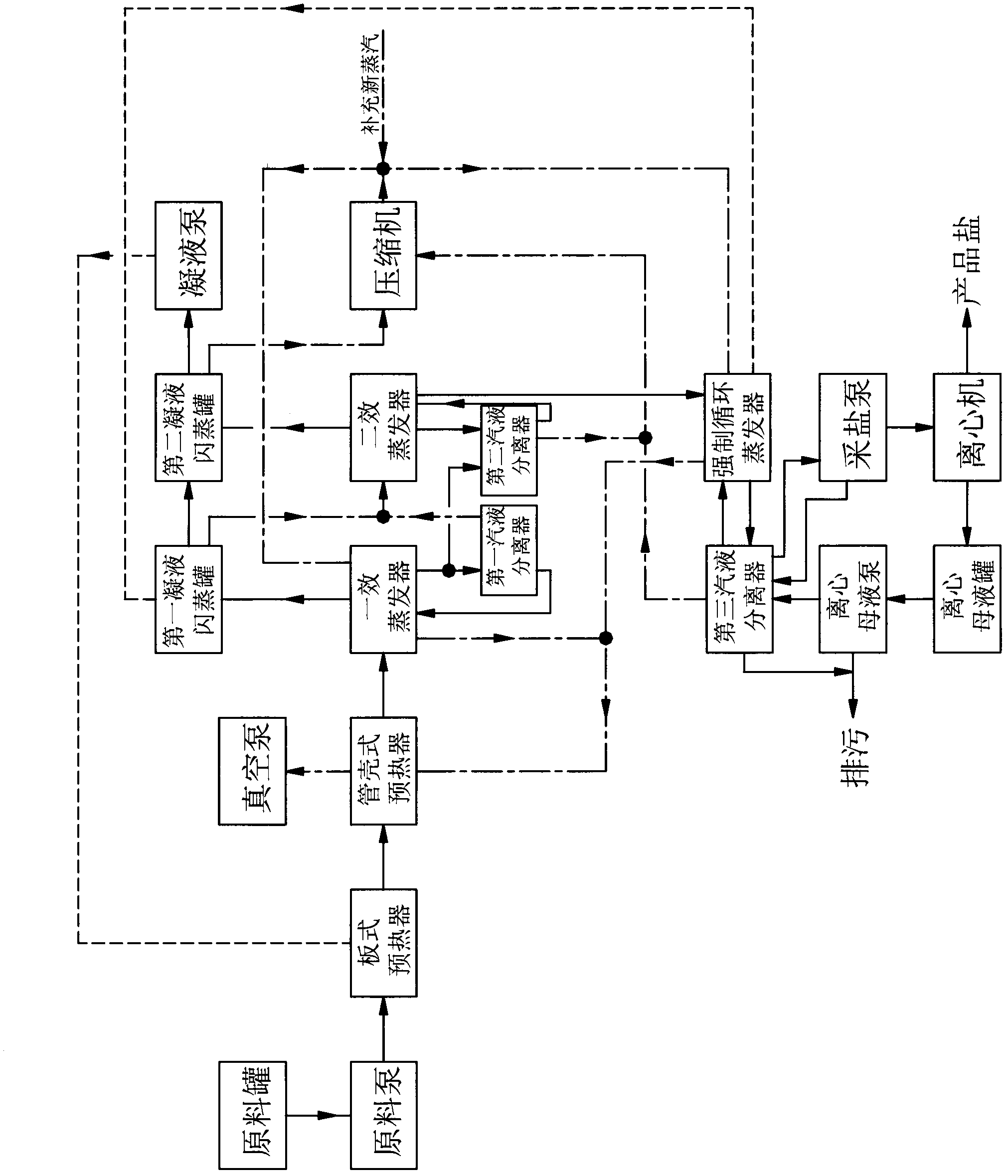

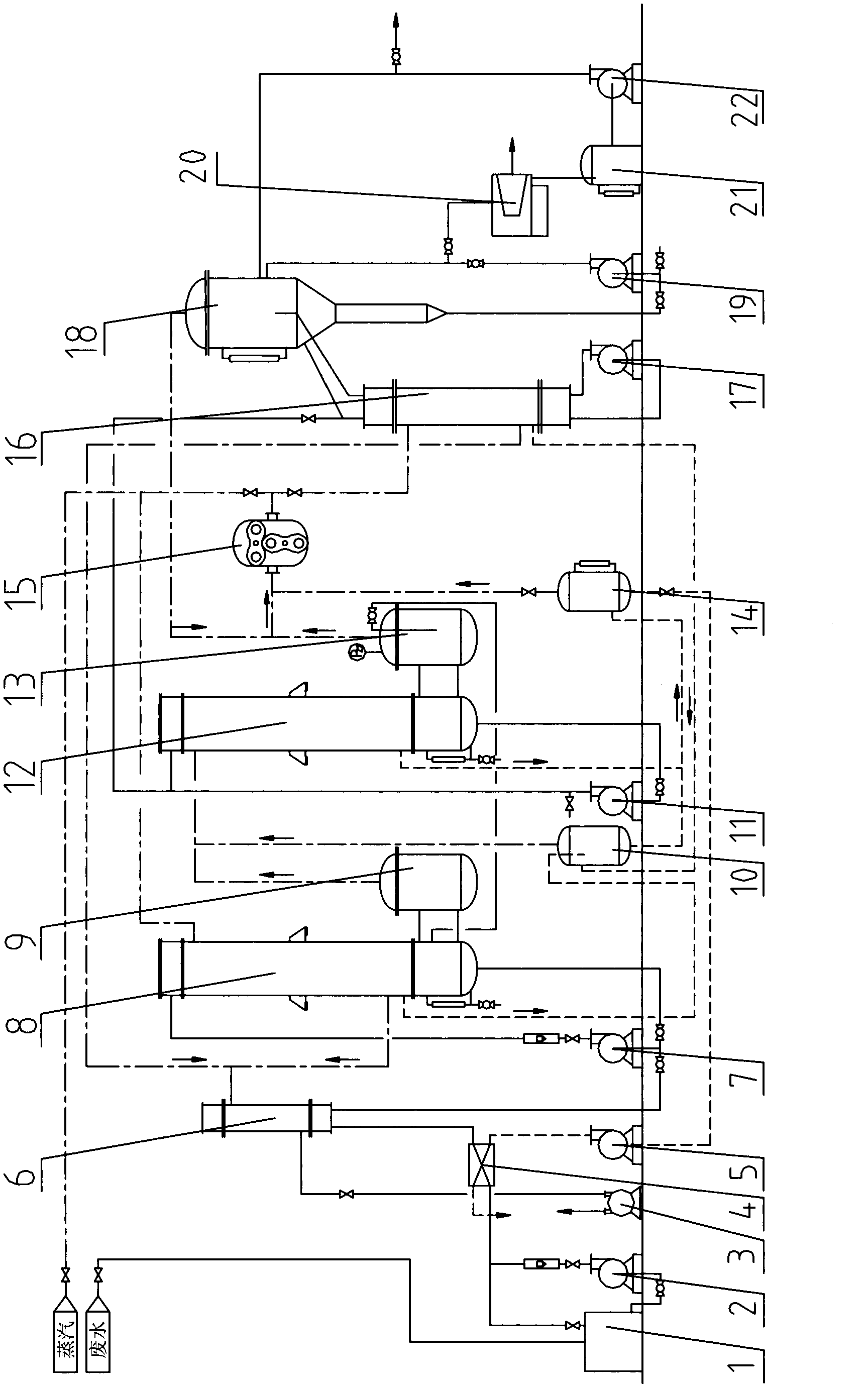

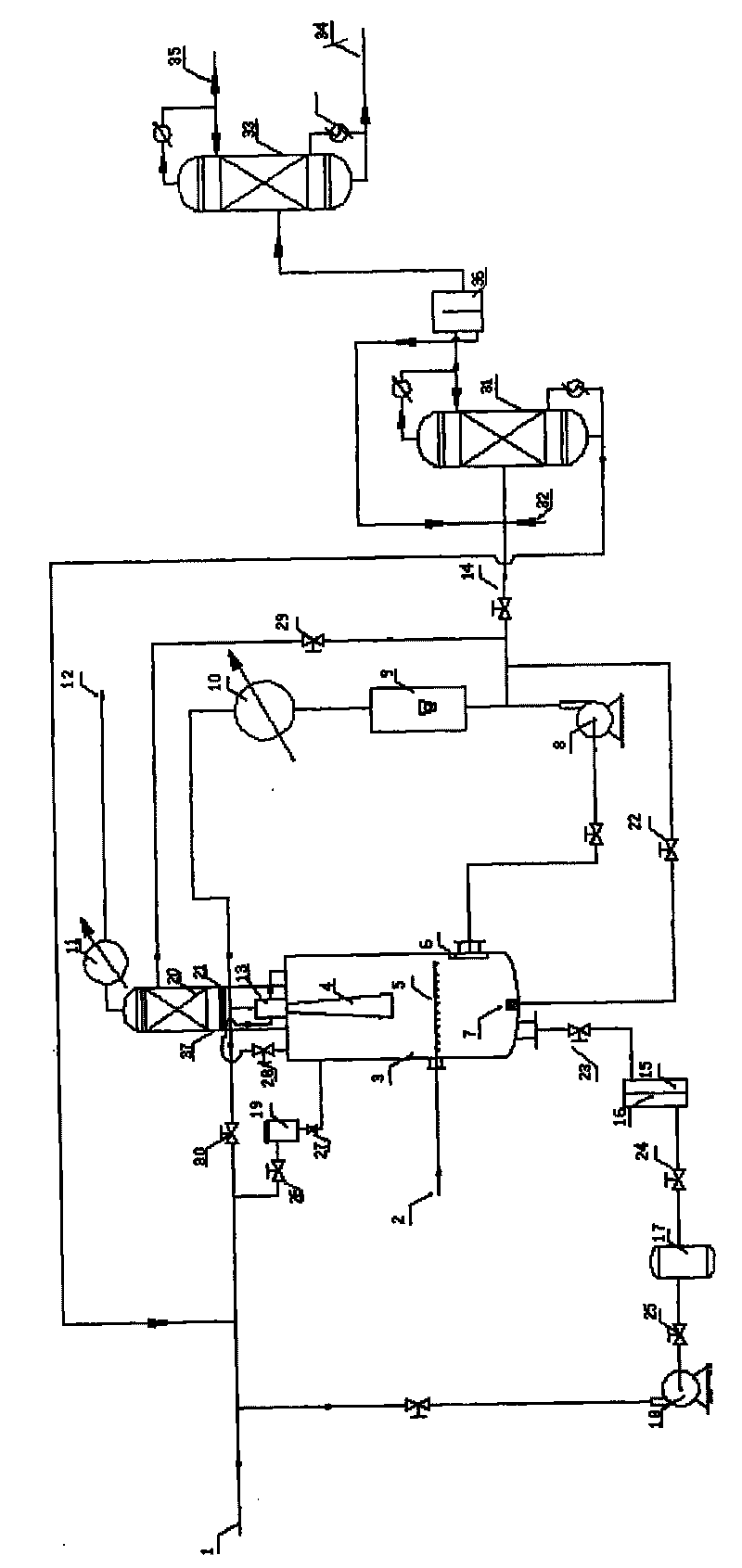

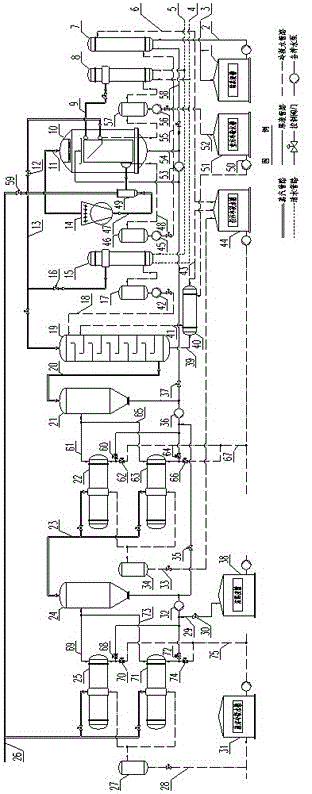

Wastewater evaporating process and device system

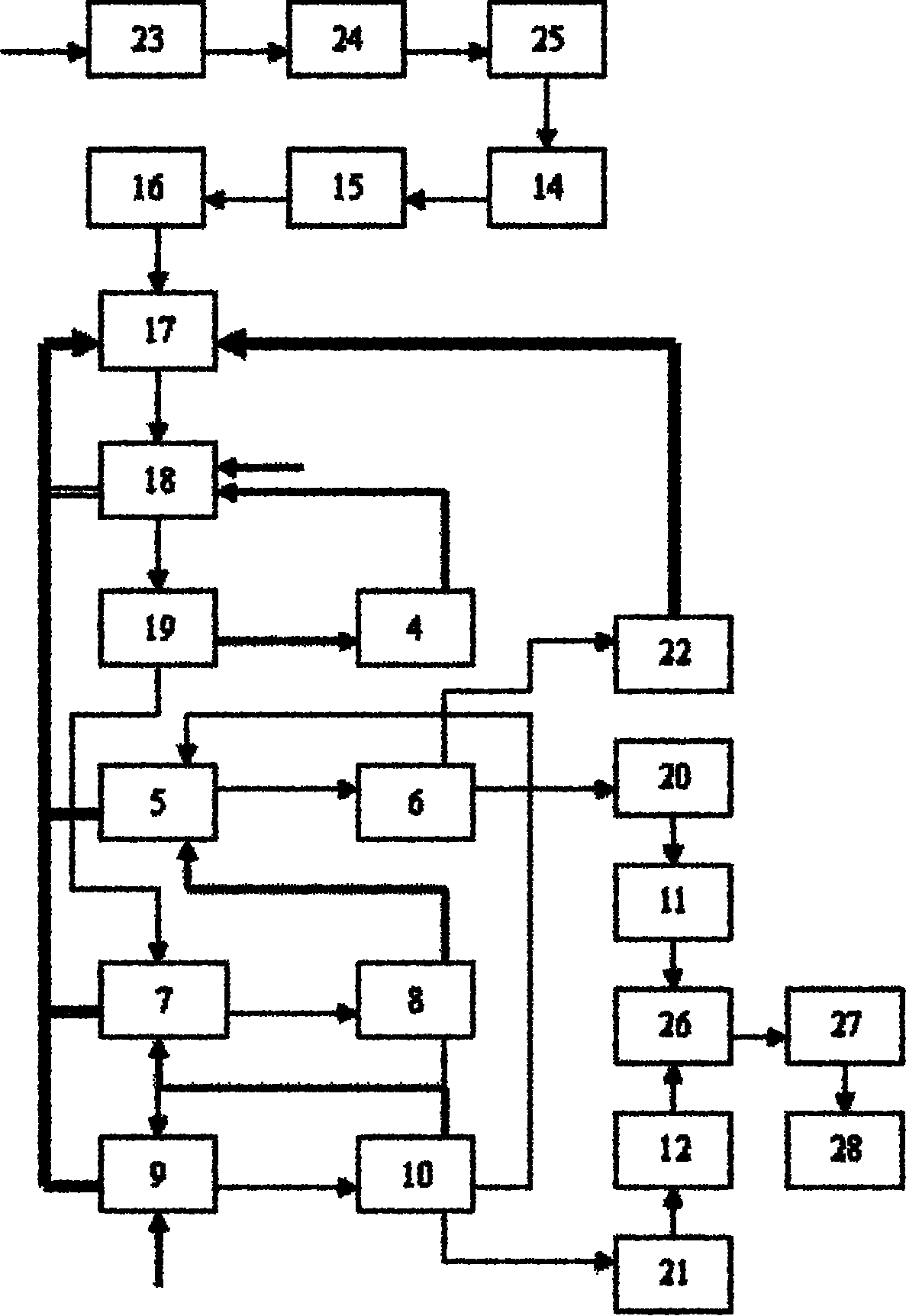

ActiveCN102060408AAvoid shockAvoid easy cloggingMultistage water/sewage treatmentProcess systemsTriple effect

The invention discloses a wastewater evaporating process and device system. The wastewater evaporating process comprises the following steps: the wastewater to be treated firstly enters a pretreatment softening system for softening treatment and secondly enters a mechanical vapor recompression (MVR) system for evaporation concentration; the generated secondary steam is compressed and enters an evaporator for recycling; the concentrated solution enters a triple effect flow-mixing forced circulation evaporation and crystallization system for evaporation and crystallization; the generated secondary steam is reused by the evaporation and crystallization system; the concentrated solution and crystalline grains obtained through crystallization are subject to solid-liquid centrifugal separation; the separated mother solution is sent back to a raw liquor tank or evaporated continuously for crystallization; and the separated crystals enter a centrifugal drying and packaging system for weighting and packaging. After the process disclosed by the invention is adopted to soften, evaporate and crystallize wastewater and dry and package the obtained crystals, wastewater is not discharged to the water bodies of the surface of earth and the aim of zero wastewater discharge can be realized; the process system is low-carbon and environmentally friendly; the material can be recycled, the thermal efficiency is high, the energy consumption is low, the energy can be saved, the operating cost can be greatly reduced, the range of temperature is small, the corrosion is low and the service life of the equipment is long, and the scaling has small possibility of occurrence.

Owner:华电水务工程有限公司 +1

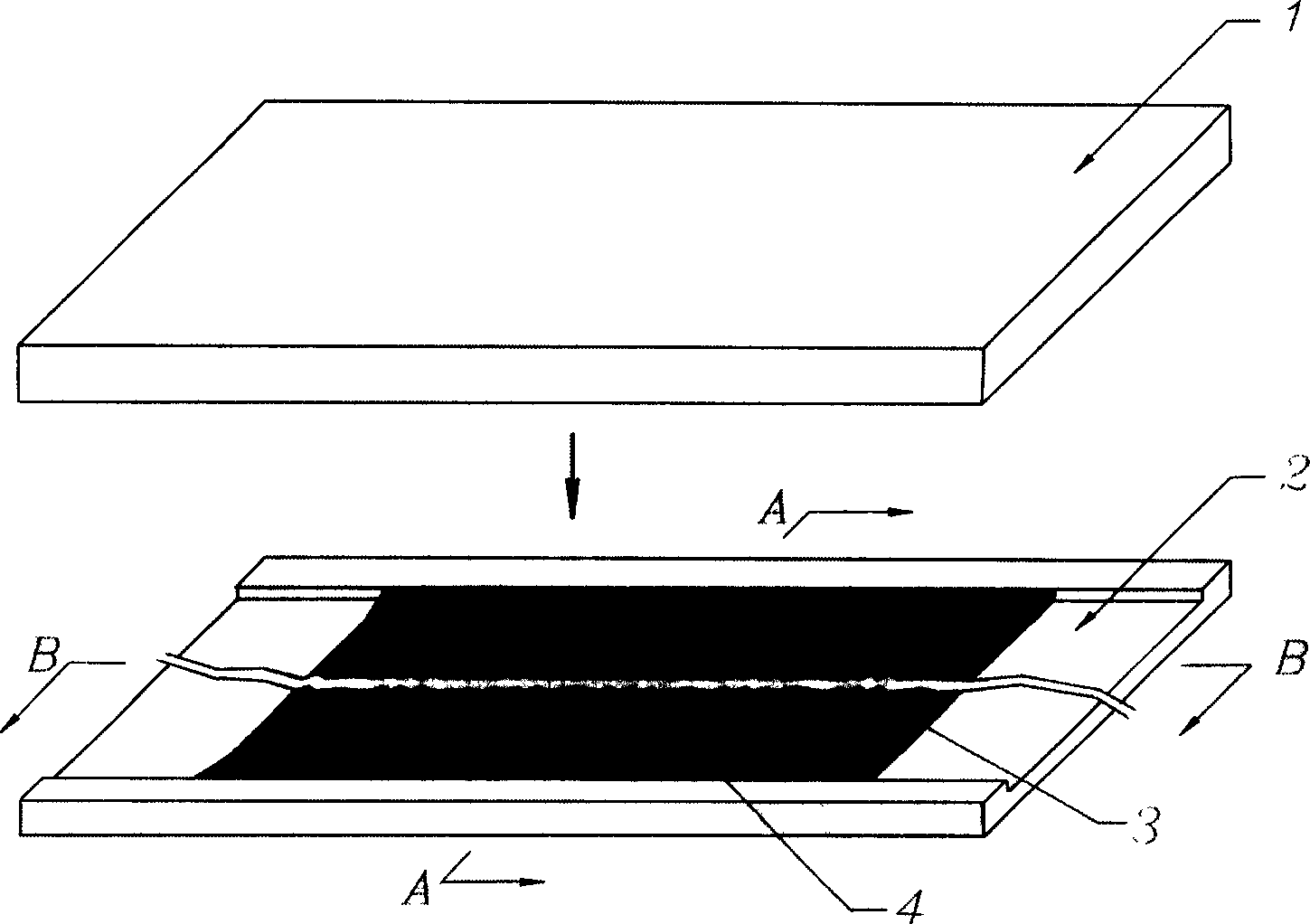

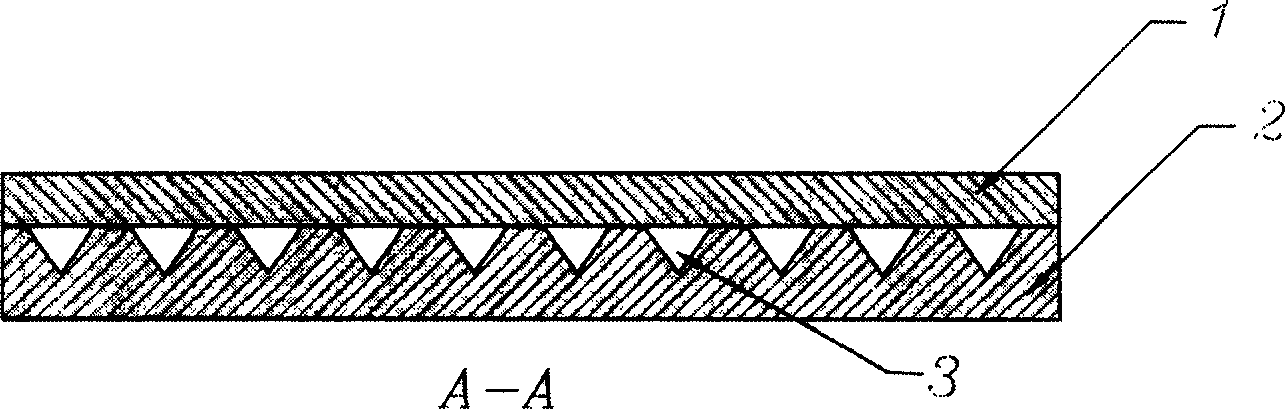

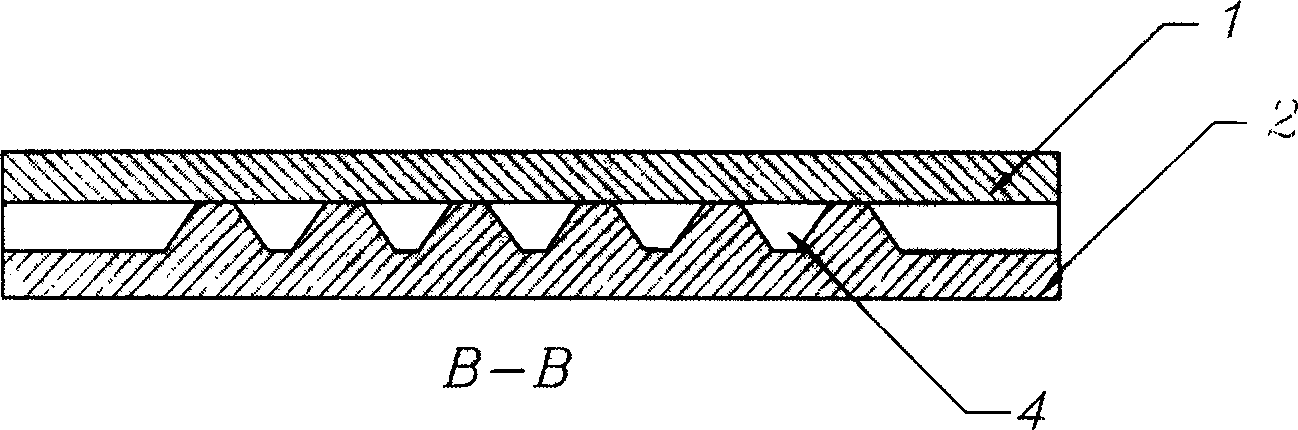

Silicon based micro passage heat exchanger

InactiveCN1558448AImprove heat transfer performanceReduce resistanceSemiconductor/solid-state device detailsSolid-state devicesNuclear engineeringHeat sink

The invention discloses a silicon based micro passage heat exchanger for the heat-sink cooling of high heat flow density electronic components, wherein a plurality of micro passages composed of multiple longitudinal passages along the cooling liquid flow direction and multiple transverse micro passages spaced by a predetermined distance along the direction perpendicular to the flow direction are etched on the silicon substrates of the semiconductor, the longitudinal micro passages and the transverse passages forming crossing micro passage array, and packaging the micro passages with heat resistant glass. The invention can be applied to link the micro pump, connecting pipe with the silicon based micro passage heat exchanger so as to form a forced-circulation return circuit.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

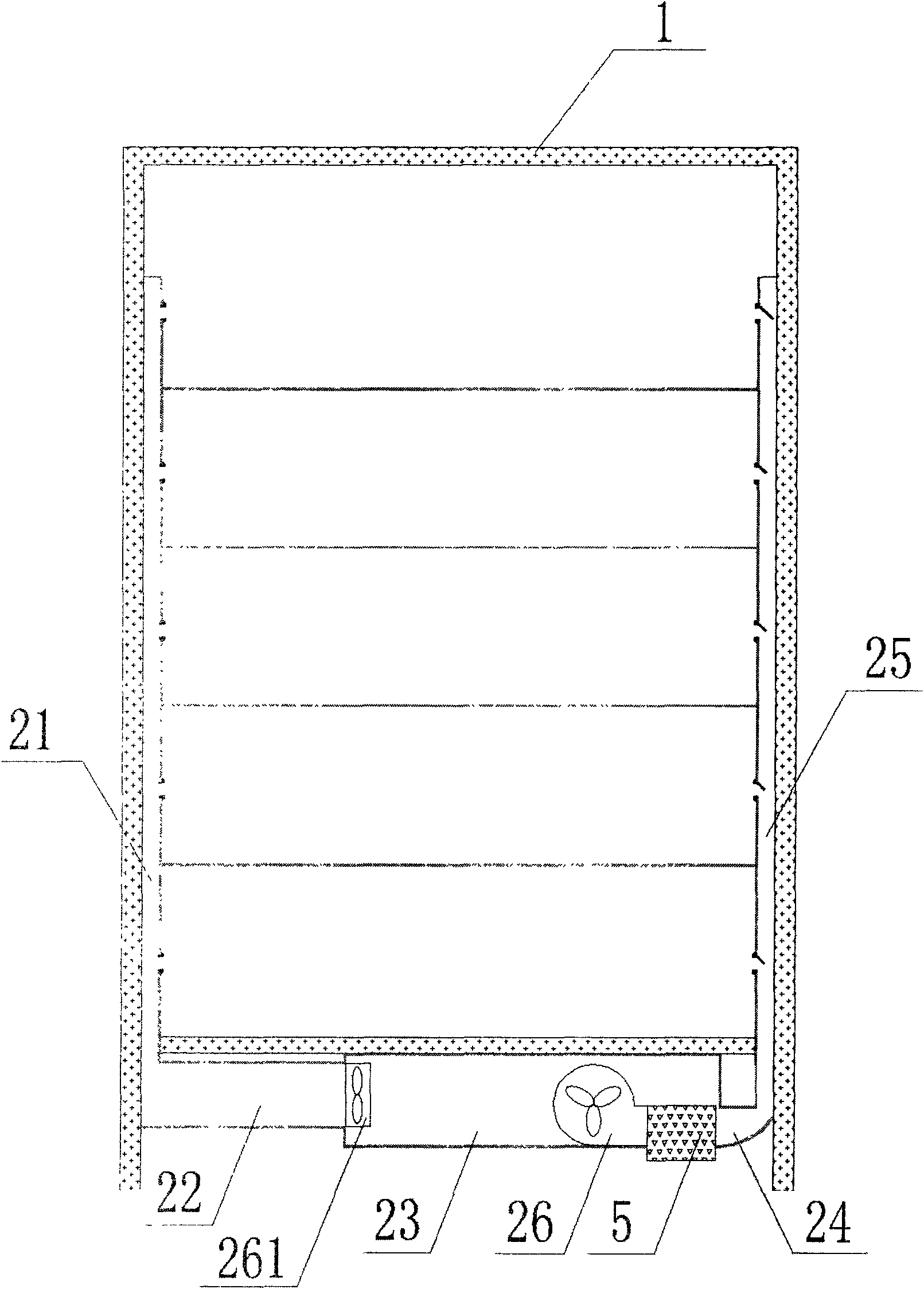

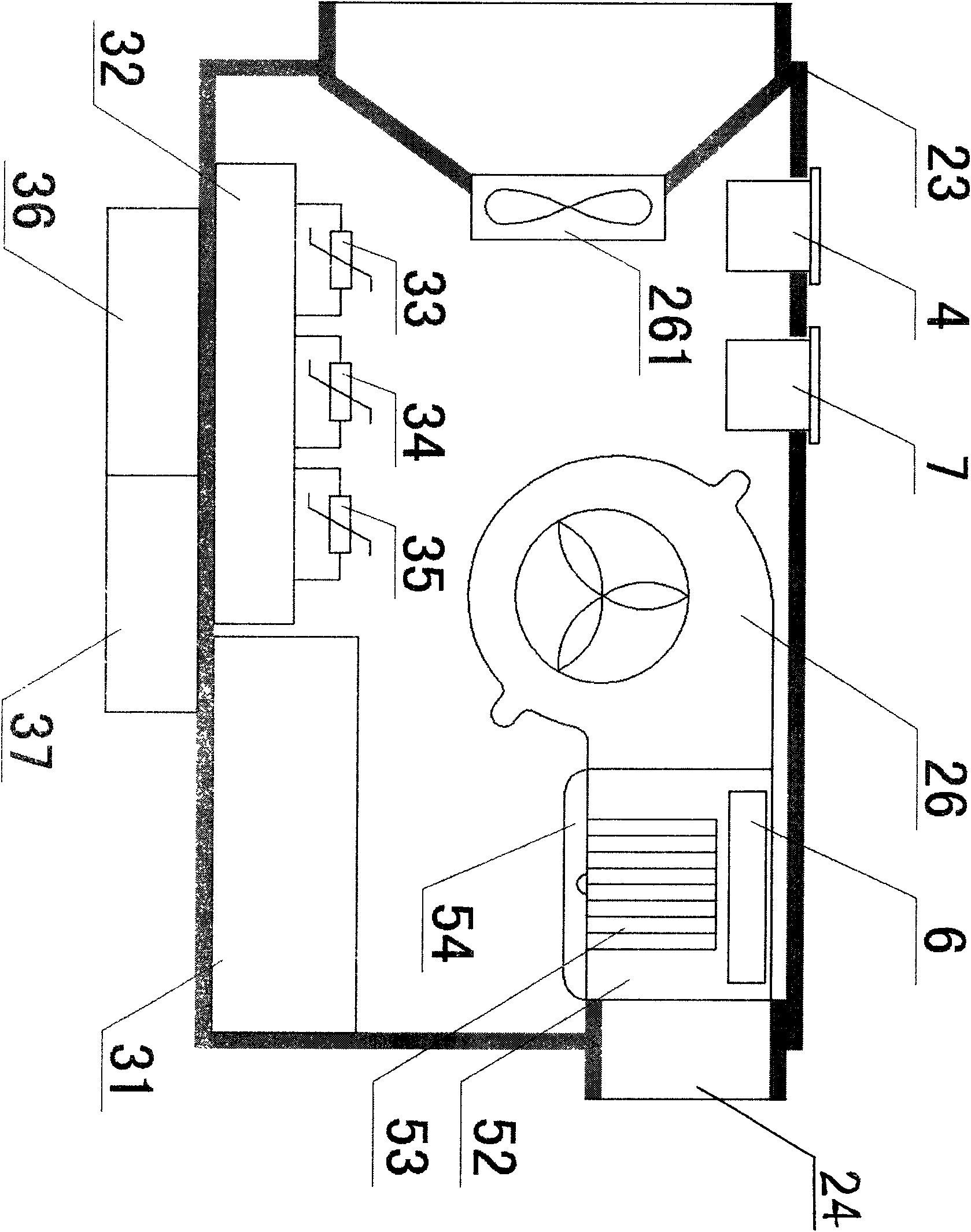

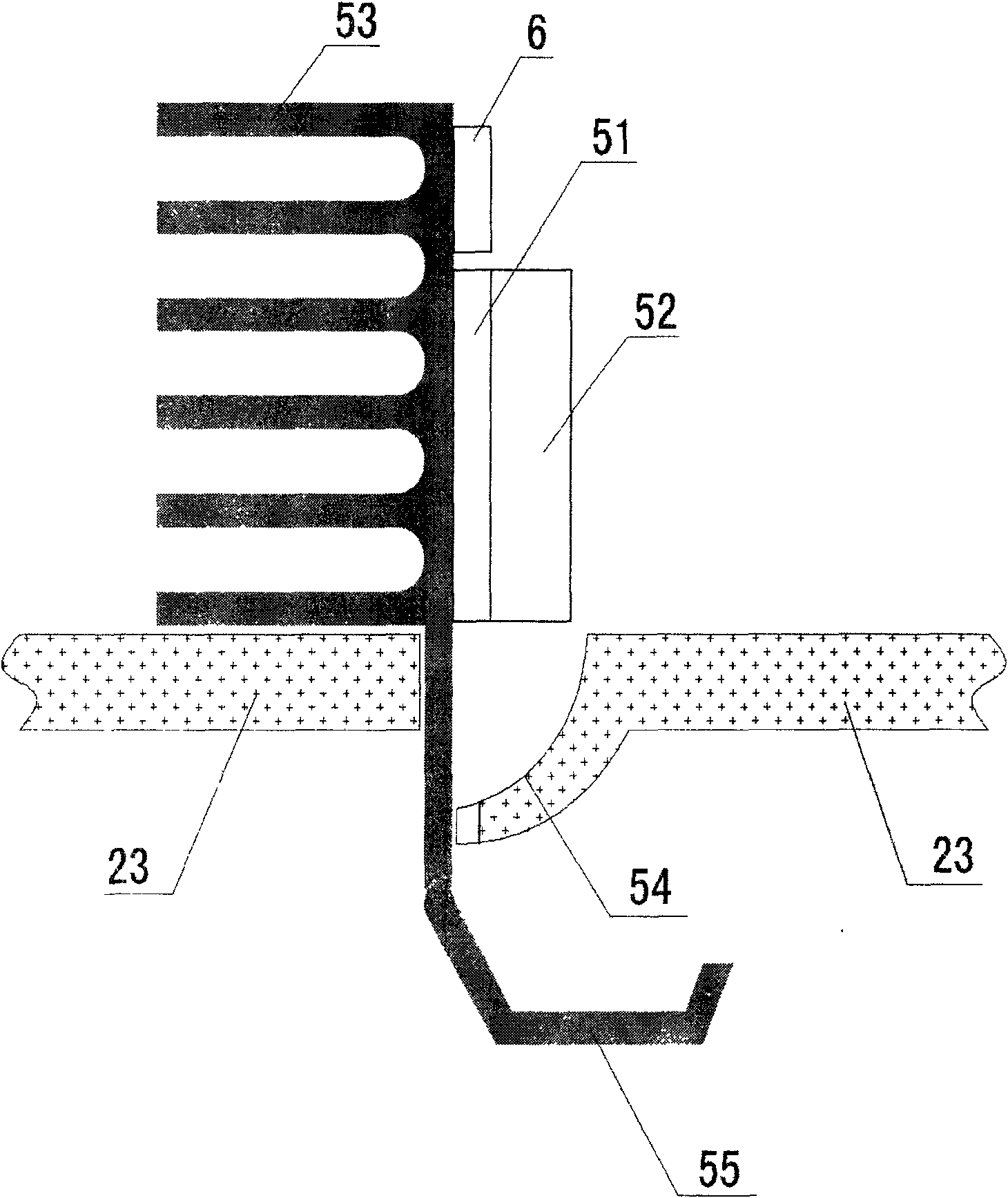

Intelligent electric shoe cabinet and automatic monitoring, dehumidifying and sterilizing method

InactiveCN101627858AWith sterilizationWith dehumidificationWardrobesLavatory sanitoryElectricityEngineering

The invention provides an intelligent electric shoe cabinet and an automatic monitoring, dehumidifying and sterilizing method. The intelligent electric shoe cabinet comprises a cabinet body 1, an air forced circulation device 2, an intelligent control system 3, a sterilization device 4, a dehumidifying device 5, a heater 6 and an air purifying device 7, wherein, the air forced circulation device is used to combine with the dehumidifying device and the intelligent control system, so that the intelligent electric shoe cabinet can determine whether sterilization or dehumidifying sterilization is started / closed or not automatically according to whether electricity is electrified initially or not and according to a switching order, a set sterilization frequency, a set dehumidifying sterilization frequency and temperature and humidity change in the cabinet so as to automatically sterilize as well as dehumidify and sterilize for stored shoes and socks.

Owner:李耀强

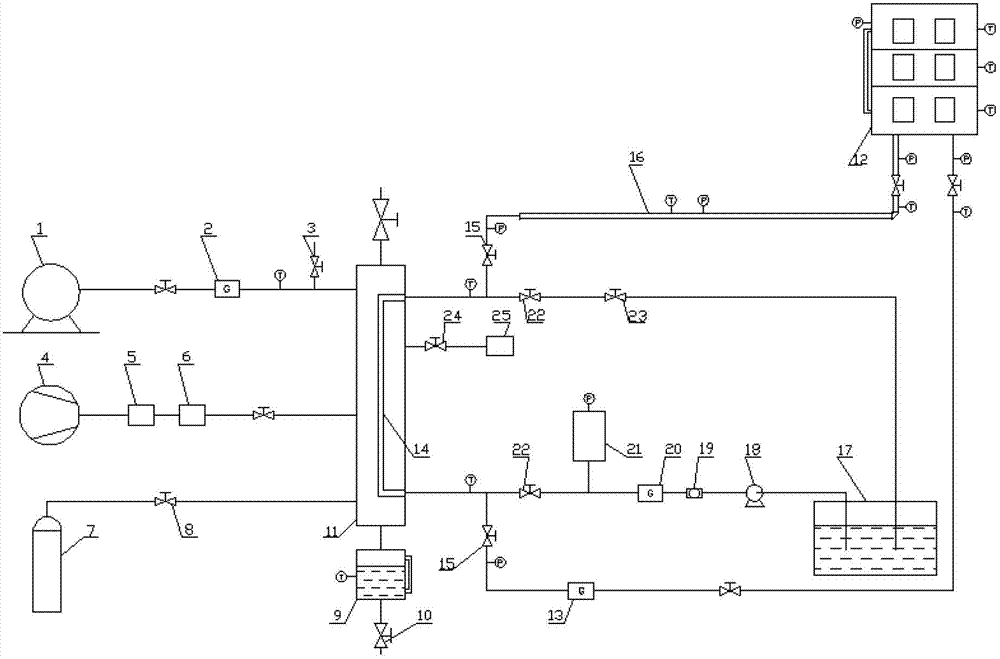

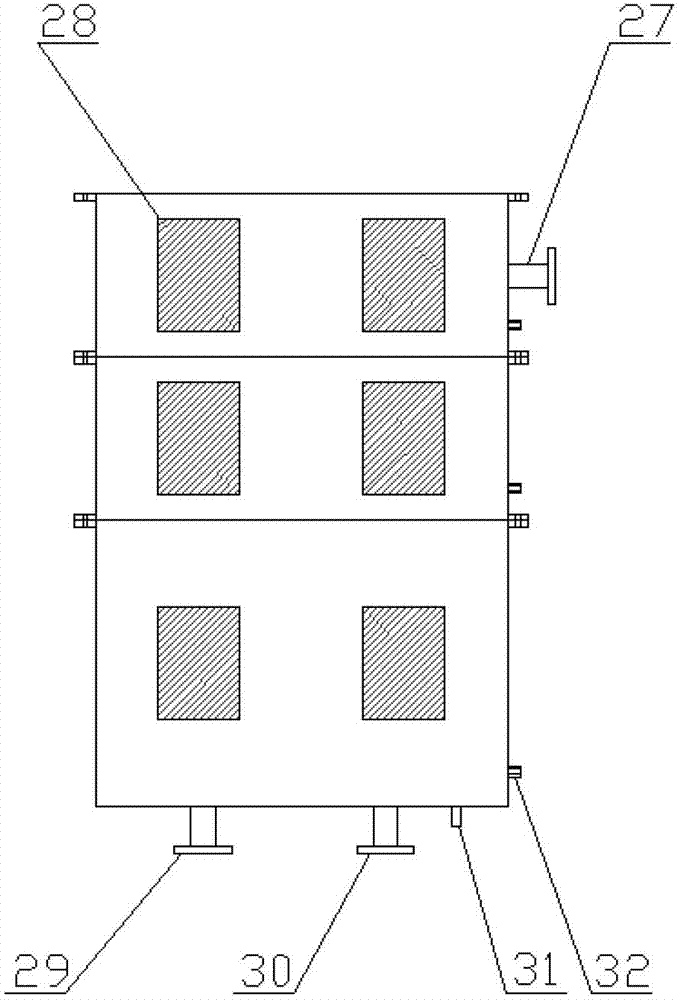

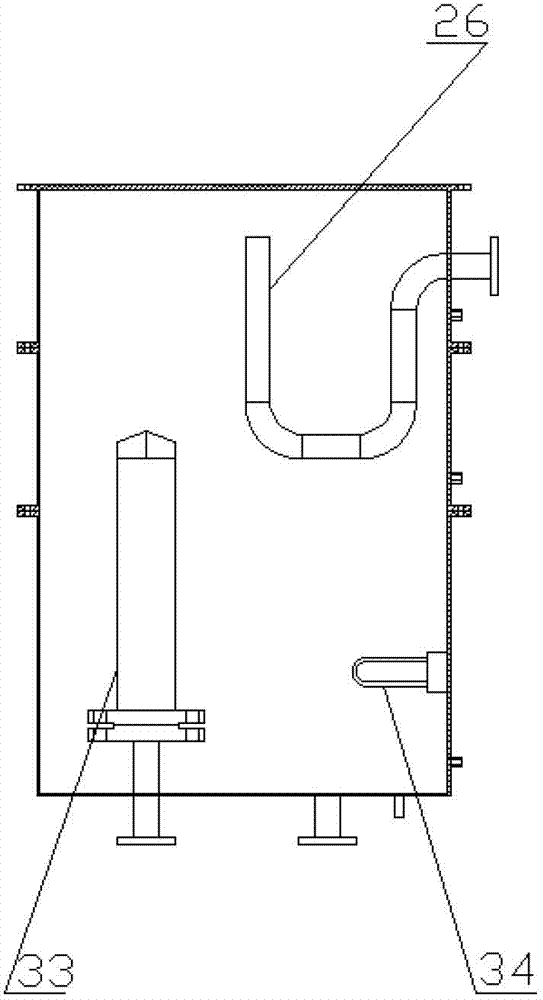

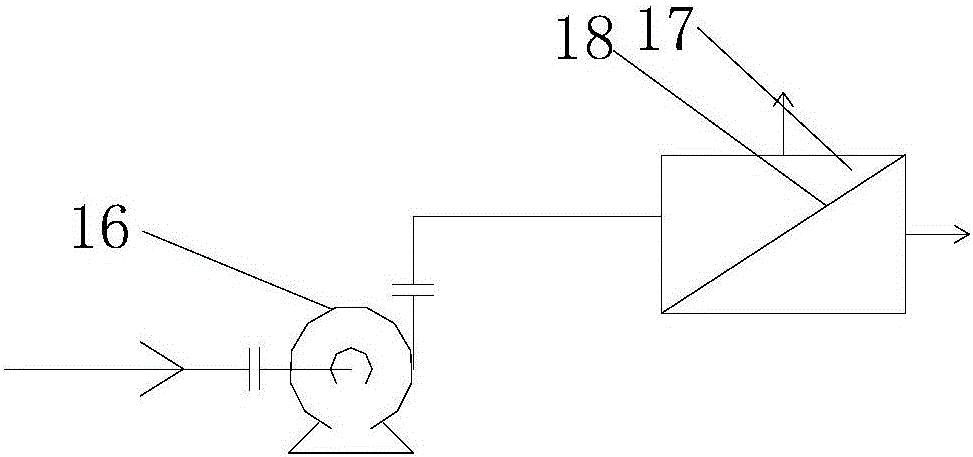

Condensation heat-transfer experiment device capable of realizing coupling of natural circulation and forced circulation

InactiveCN103196945AImprove accuracyObserve the water qualityMaterial heat developmentVisibilityCoupling

The invention provides a condensation heat-transfer experiment device capable of realizing the coupling of natural circulation and forced circulation. The condensation heat-transfer experiment device mainly comprises a steam supply system, an air supply system, a helium gas supply system, a natural circulation cooling system, a forced circulation cooling system, a condensing experiment body and a data measurement and acquisition system. The non-condensable gas containing extra-steam-pipe external condensation heat transfer experiment research under natural circulation and forced circulation cooling conditions and the experiment research on the heat extraction and flow characteristics of a natural circulation system under the conditions that the heating power is stable and changed can be realized. The device can monitor the experiment data in real time and continuously measure the condensation characteristics under different mixed gas compositions, and therefore, the device carries out measurement accurately and carries out data processing rapidly. In addition, the degree of visibility of a whole system is extremely high; and through the observation on experimental phenomena, the understanding on experimental processes and the in-depth study on heat transfer and flow mechanisms are facilitated.

Owner:HARBIN ENG UNIV

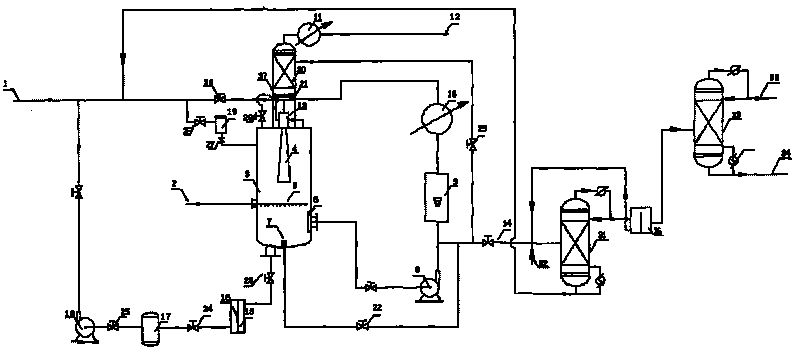

Method and device for processing high-saline organic wastewater

ActiveCN102616973ASmall volumeSimple processMultistage water/sewage treatmentWater/sewage treatment by heatingEvaporationEconomic benefits

The invention relates to a method for processing high-saline organic wastewater. A mechanical vapor recompression vaporization (MVR) system is adopted to process the wastewater, and the method comprises the following steps of: (1) preheating of the wastewater; (2) primary vaporization; (3) primary vapour-liquid separation; (4) secondary vaporization; (5) secondary vapour-liquid separation; (6) forced-circulation evaporation; (7) discharging; (8) secondary vapor recompression; and (9) circulation evaporation. Due to the adoption of the MVR system, the economic benefit can be improved remarkably, and enterprises can be helped to realize the aim of energy conservation and emission reduction.

Owner:常州中源工程技术有限公司

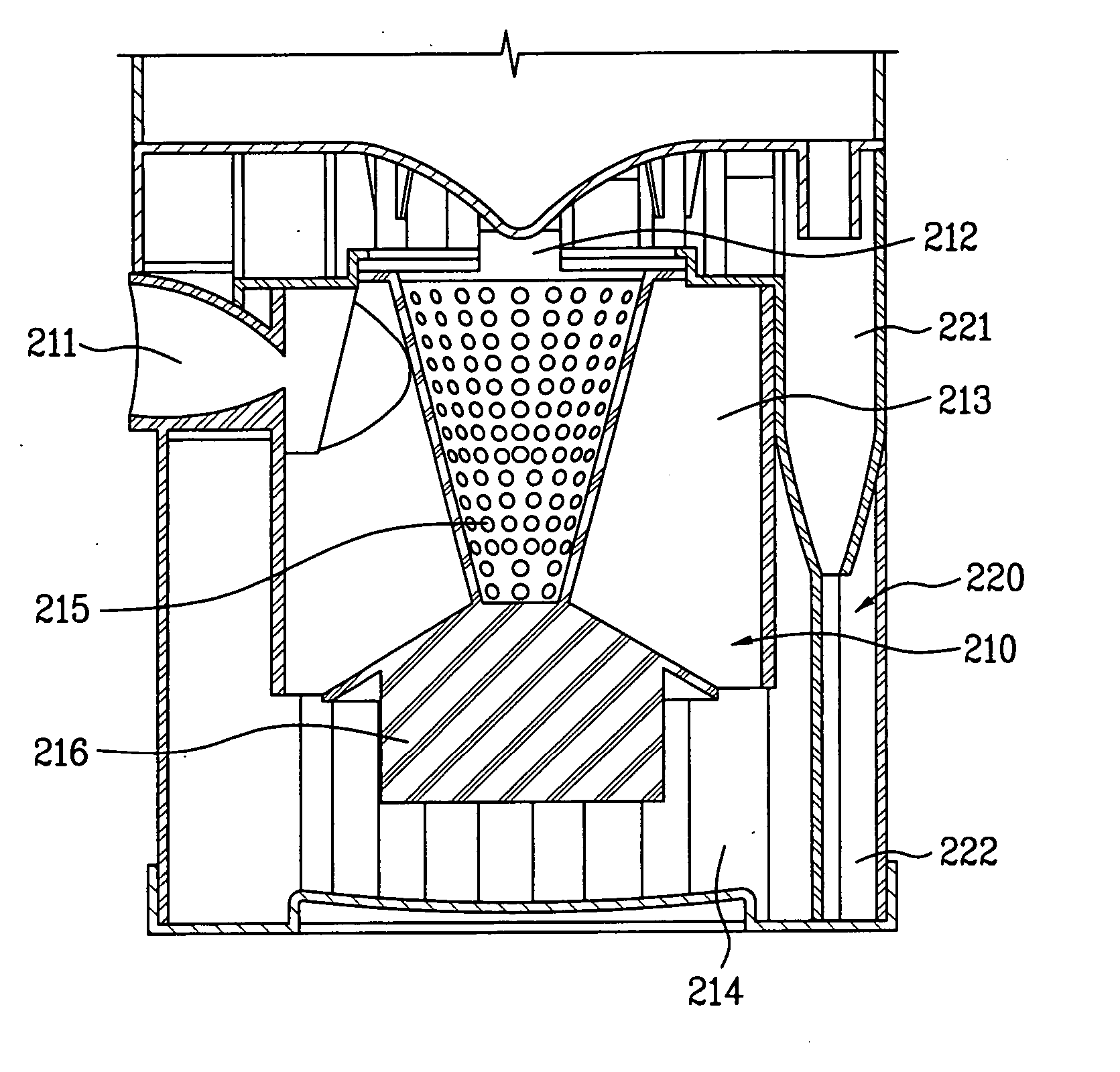

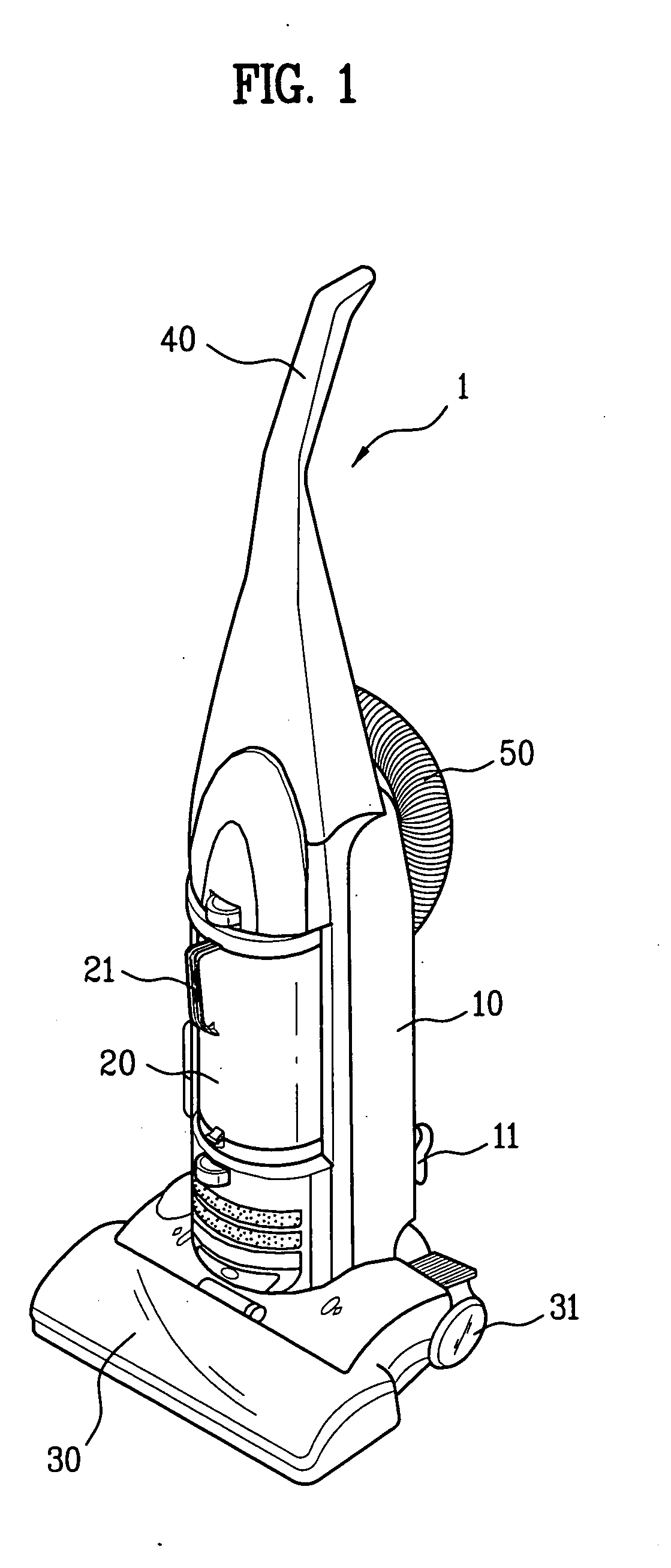

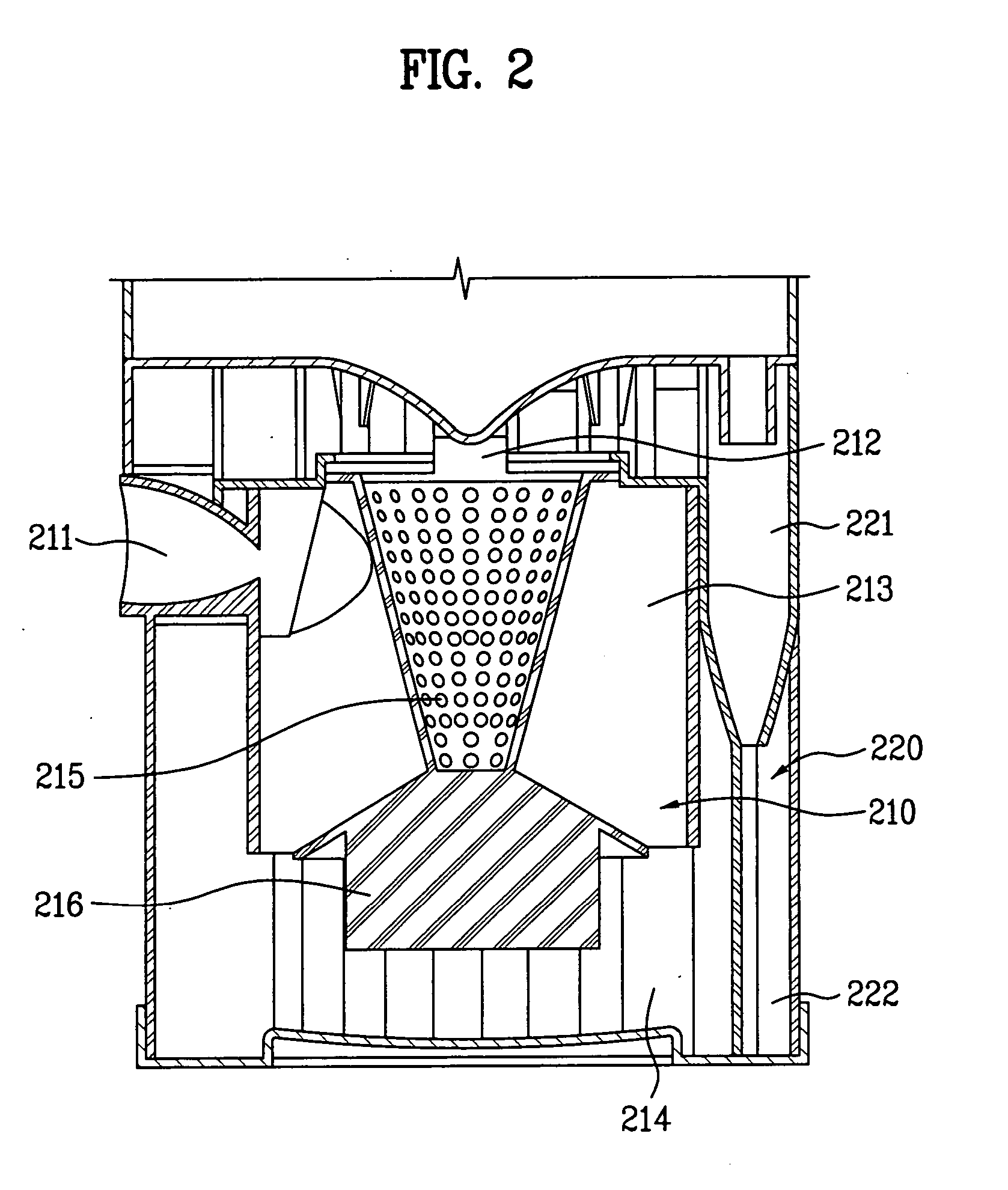

Vacuum cleaner

InactiveUS20060277712A1Prevent leakageEasy to receiveCleaning filter meansSuction filtersForeign matterCyclone

An object of the present invention is to provide a dust collecting device in a vacuum cleaner replacement of which dust collecting filter is easy. To achieve this, the present invention provides a vacuum cleaner including a cleaner body having a body suction opening, and a fan-motor assembly for forced circulation of air introduced through the body suction opening, a dust collecting device in communication with the body suction opening, the dust collecting device having a main cyclone unit for separating foreign matters from the air introduced thereto by a cyclone principle, and at least one supplementary cyclone unit around the main cyclone for separating foreign matters from the air discharged from the main cyclone unit, a suction unit having an air suction opening in communication with the body suction opening, for drawing external air through the air suction opening, and a filter assembly having a dust collecting filter in a flow passage through which the air from the supplementary cyclone unit flows for separating the foreign matters from the air, and a filter housing in the dust collecting device for housing the dust collecting filter therein and drawing out of the dust collecting device assembly in a sliding fashion, thereby permitting easy mounting / dismounting of the dust collecting filter on / off the dust collecting device, enabling convenient washing or replacement of the dust collecting filter.

Owner:LG ELECTRONICS INC

Supercritical fluid dyeing machine

ActiveCN101760914ASave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

The invention discloses a supercritical fluid dyeing machine. A horizontal type cylindrical dyeing kettle, a magnetomotive cloth lifting wheel, a spray cavity, a wave-shaped cloth guide passage in the dyeing kettle, a heat exchanger, a dye kettle or / and an entrainer kettle and a circulating pump are used as main components to form a dyeing circulation system; and both ends of a fan are respectively connected with fluid outlets under the spray cavity and the dyeing kettle and form a cloth feeding system together with the magnetomotive cloth lifting wheel, the spray cavity and an operating opening. A rope-shaped fabric realizes circulated dyeing under the common action of the fluid in the magnetomotive cloth lifting wheel and the spray cavity, and the fluid in the dyeing kettle carries out forced circulation by the circulating pump. The dye and the fluid can realize recycling by a separating and recycling system after dyeing, and the whole dyeing circulation system and the separating and recycling system are clean to achieve the requirement during color changing and dyeing. The supercritical fluid dyeing machine can realize anhydrous dyeing processing on the fabric in a loosening type tension-free state without the production and discharge of pollutants, and has the characteristics of ecology, environmental pollution, wide adaptability of fabric variety, and the like.

Owner:SUZHOU UNIV +2

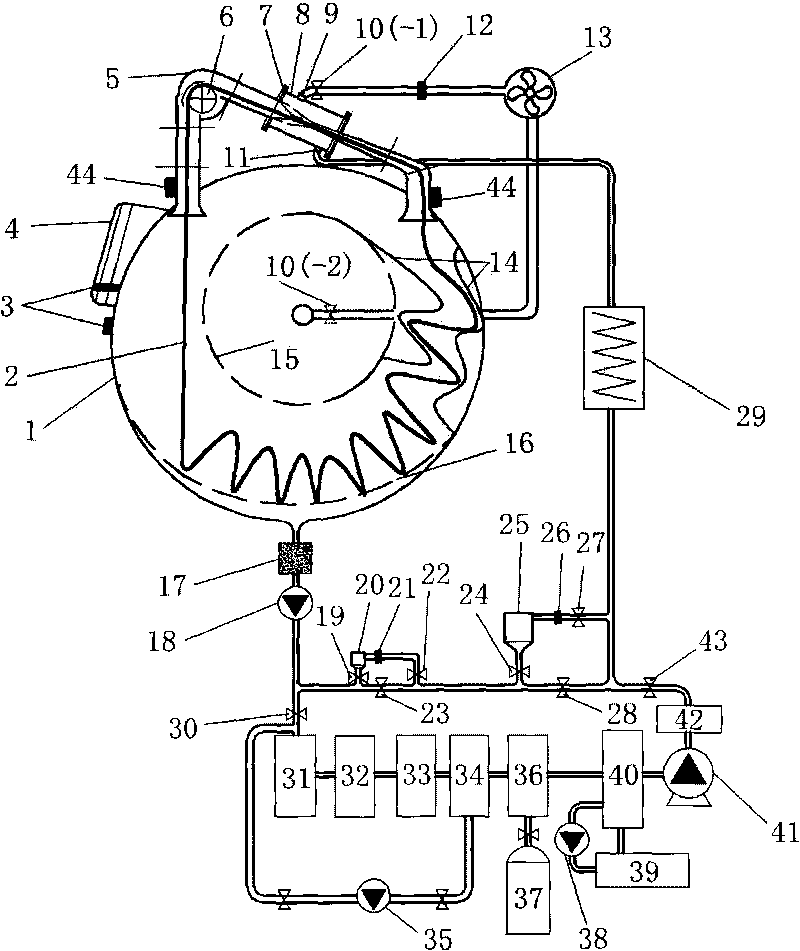

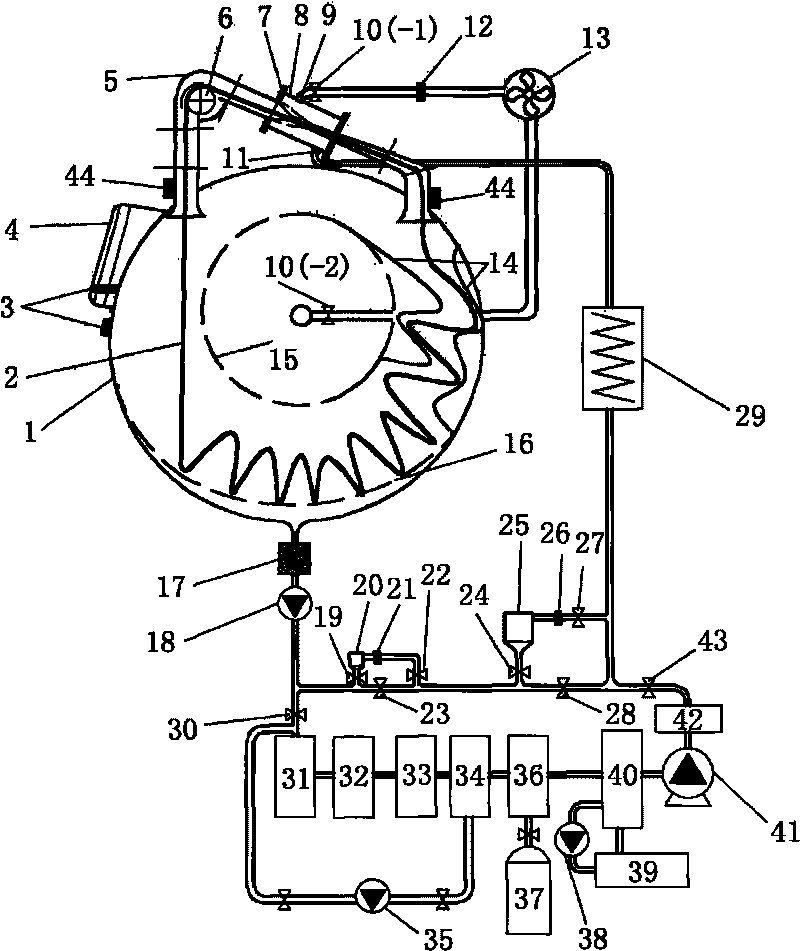

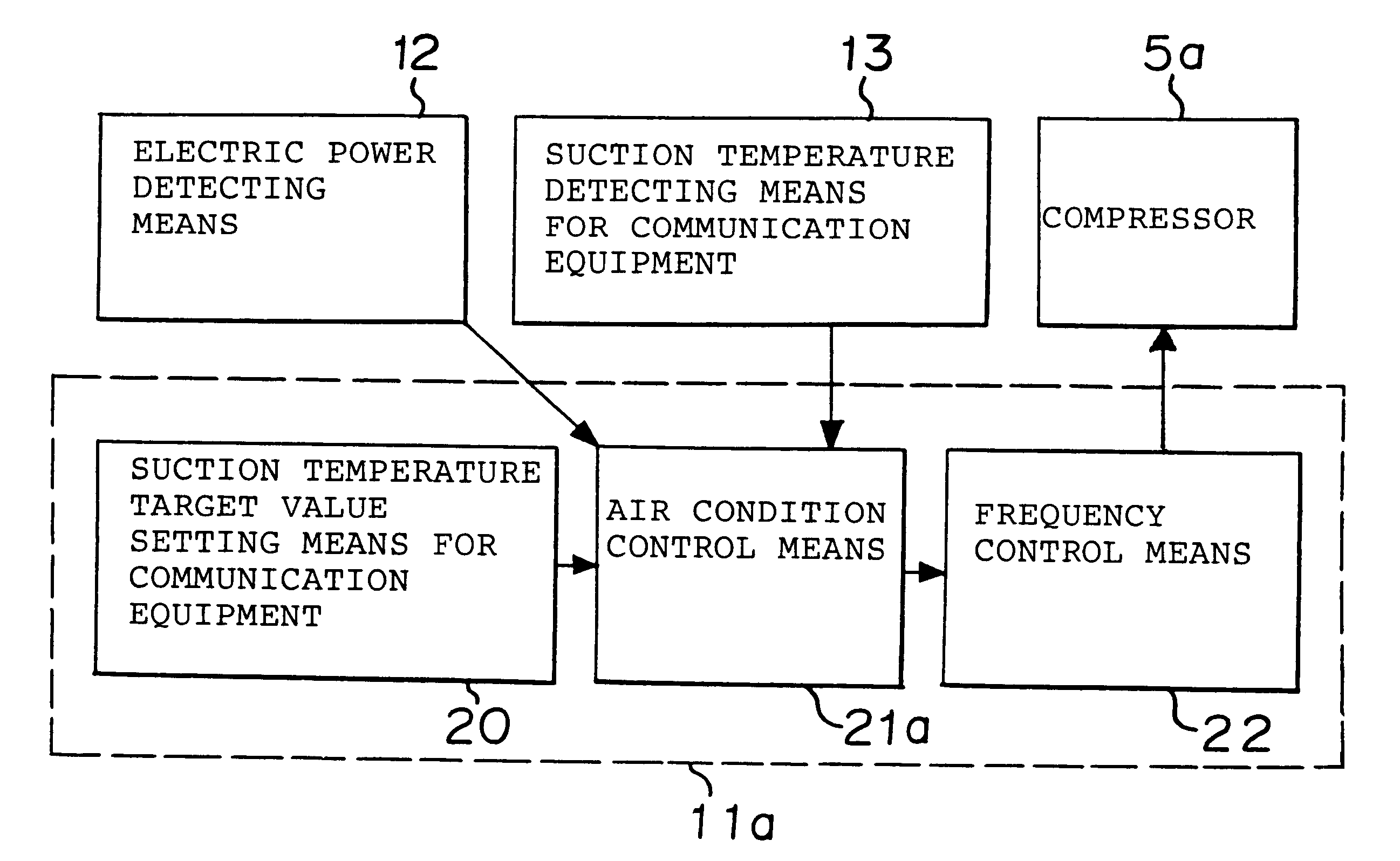

Method for controlling to cool a communication station

InactiveUS6539736B1Lower capability requirementsMechanical apparatusSpace heating and ventilation safety systemsTelecommunicationsForced circulation

A cooling system for a communication station for cooling a casing of the communication relay station, accommodating communication equipments including heat components, by a boiling-type cooler in a natural circulation refrigerating circuit and an evaporator in a forced circulation refrigerating circuit, activated by a compressor comprising:a common airflow path having a heated air intake port for taking a heated air in the casing; anda common fan for sending an air to the boiling-type cooler and the evaporator,wherein the boiling-type cooler, the evaporator, and the common fan are built in a common airflow path.

Owner:MITSUBISHI ELECTRIC CORP

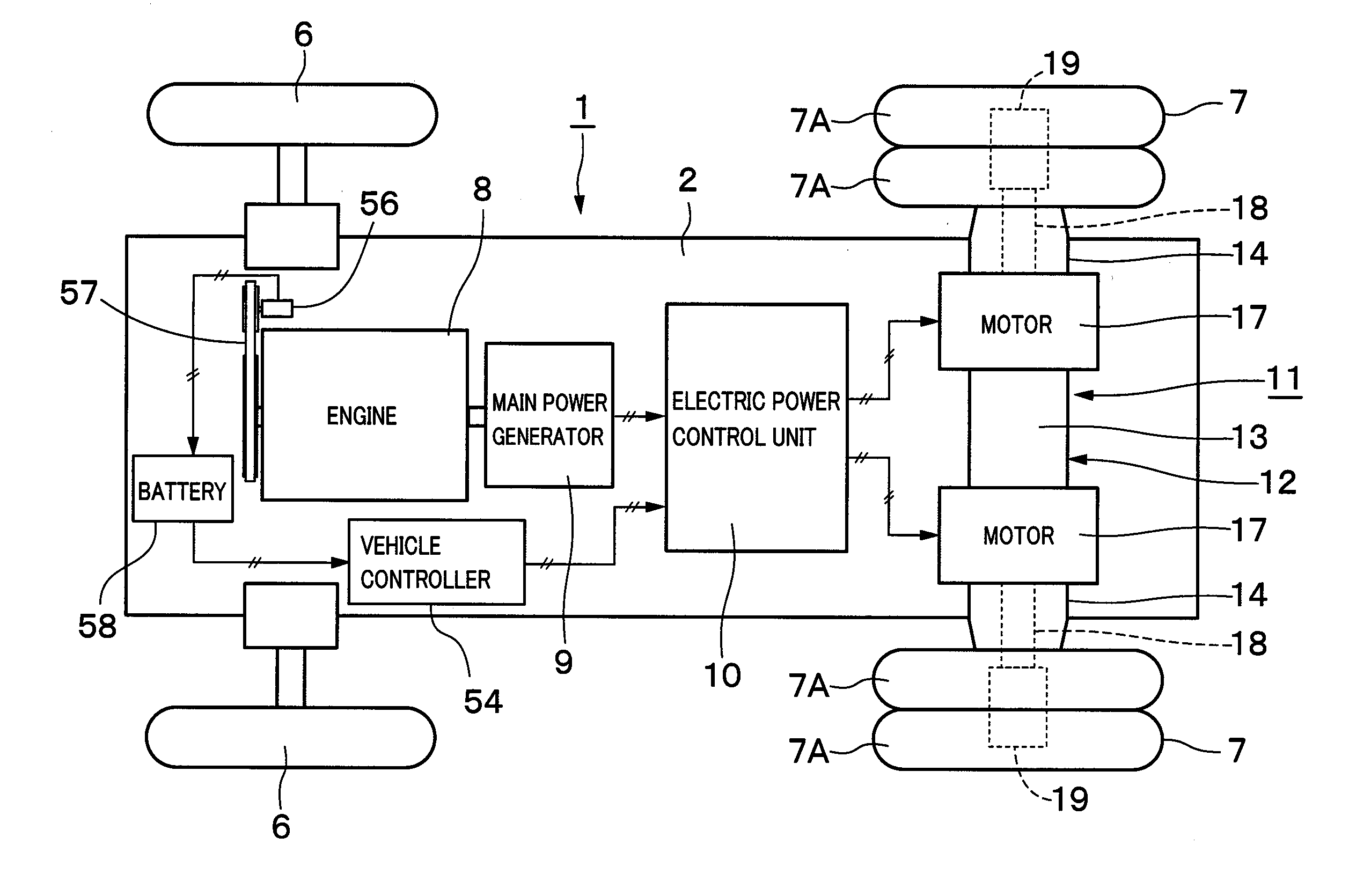

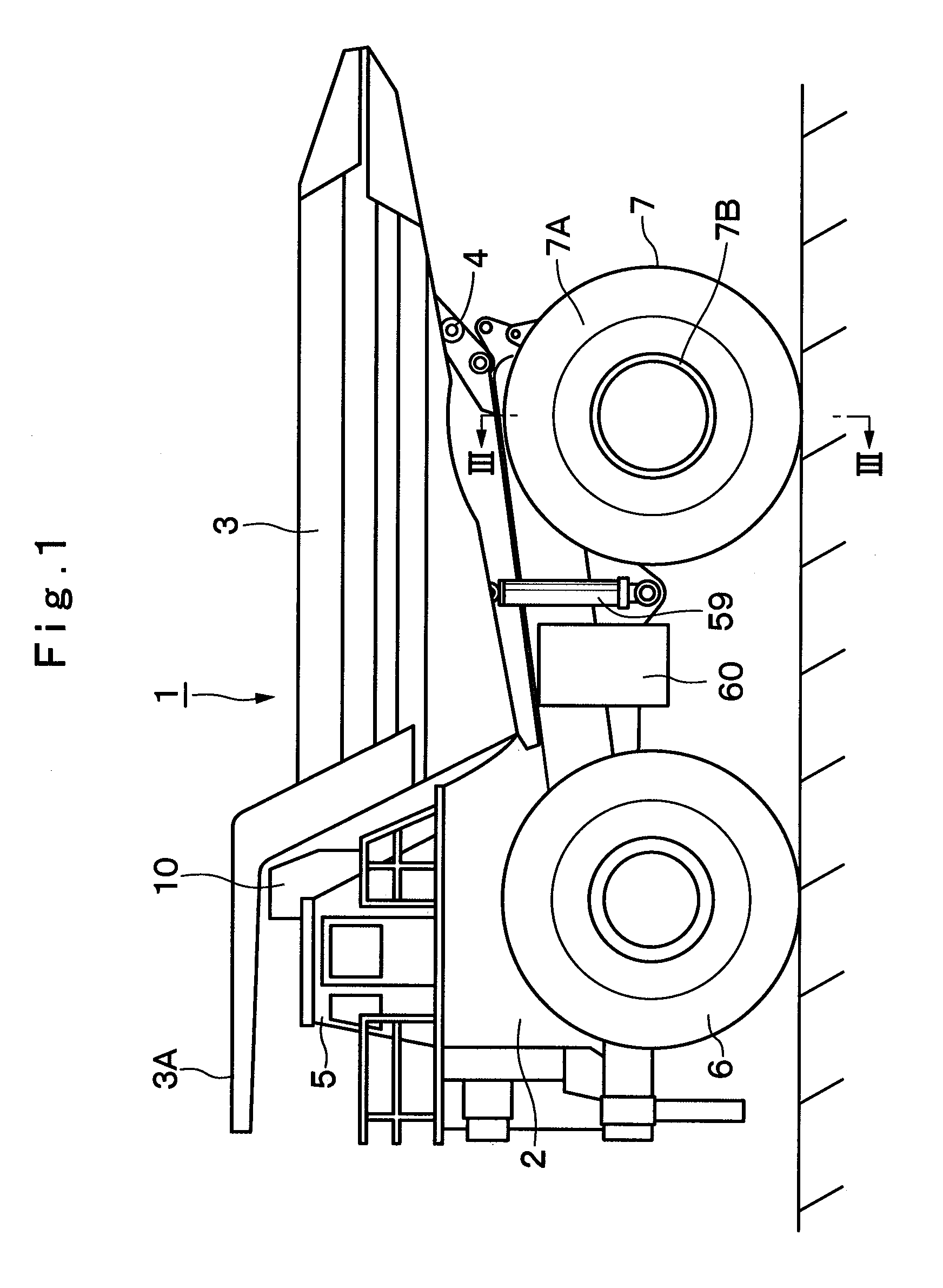

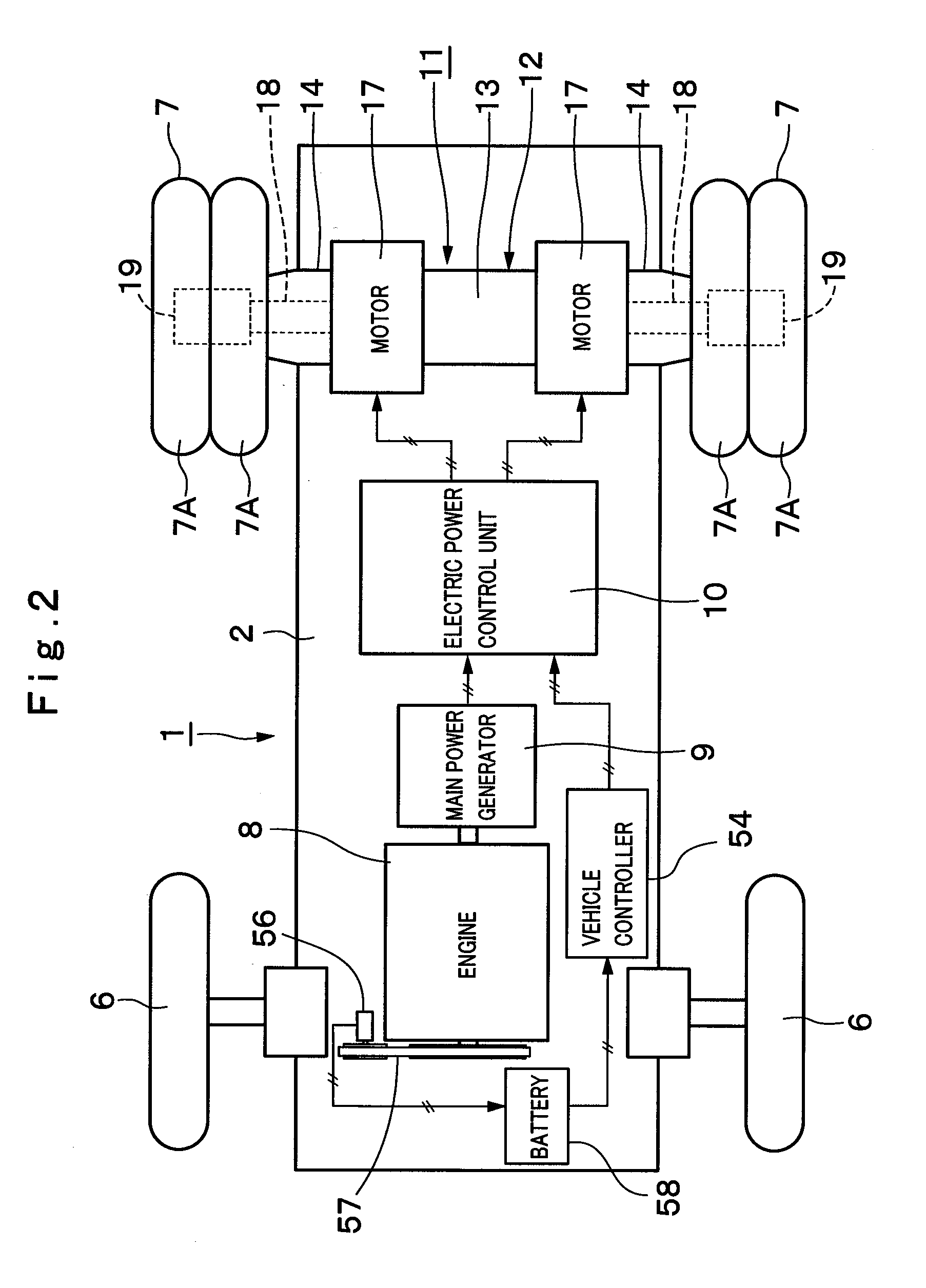

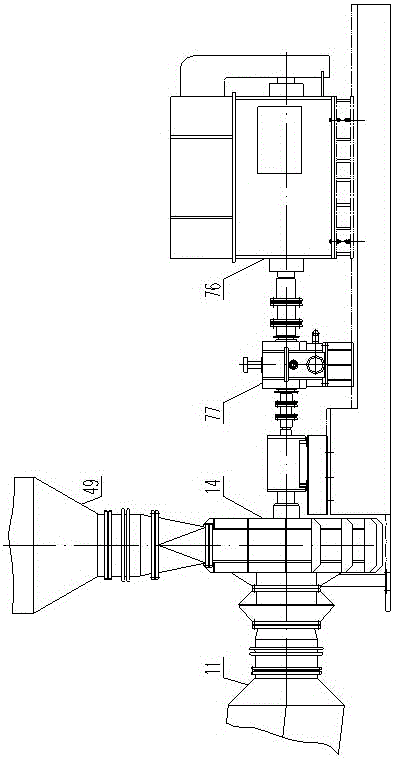

Travel drive apparatus for a working vehicle

ActiveUS20100187044A1Improve the lubrication effectImprove cooling effectHybrid vehiclesAnalogue computers for trafficEngineeringDrive motor

In case a temperature (T) of a lubricant oil (G) cannot be detected by an oil temperature sensor (51) provided on an output side of a lubricant pump (46), the temperature (Tm) of a wheel drive motor (17) is detected by using a motor temperature sensor (53) provided on the wheel drive motor (17). By estimating the temperature (T) of the lubricant oil (G) from the temperature (Tm) of the wheel drive motor (17), monitoring is carried out as to whether or not the temperature (Tm) has risen to a predetermined temperature (Tms) at which the cooling of the lubricant oil (G) by forced circulation is deemed necessary. The drive of a lubricant pump (46) by a pump drive motor (47) is stopped until the motor temperature (Tm) rises to a level exceeding the predetermined temperature (Tms).

Owner:NIHON KENKI CO LTD

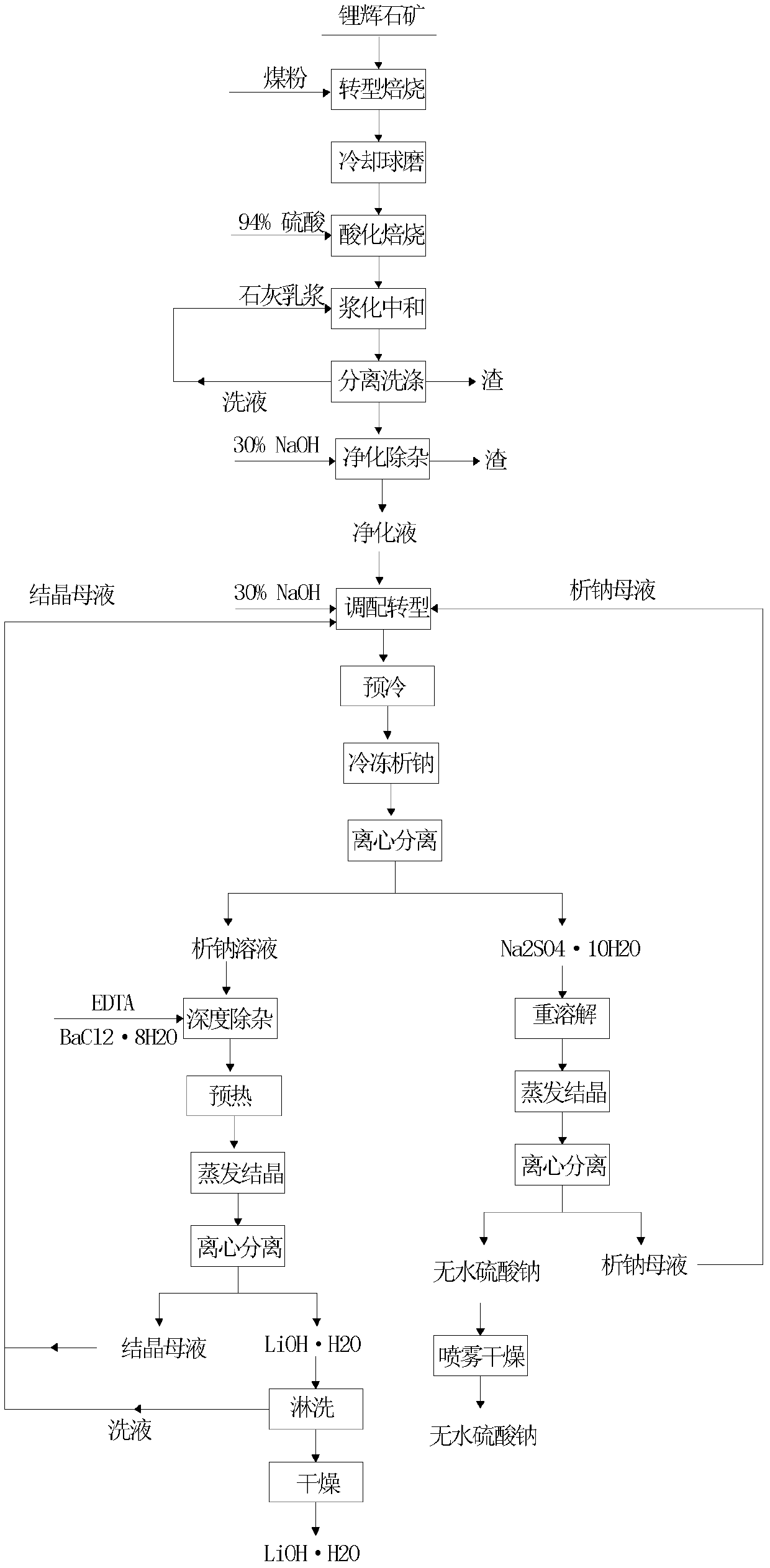

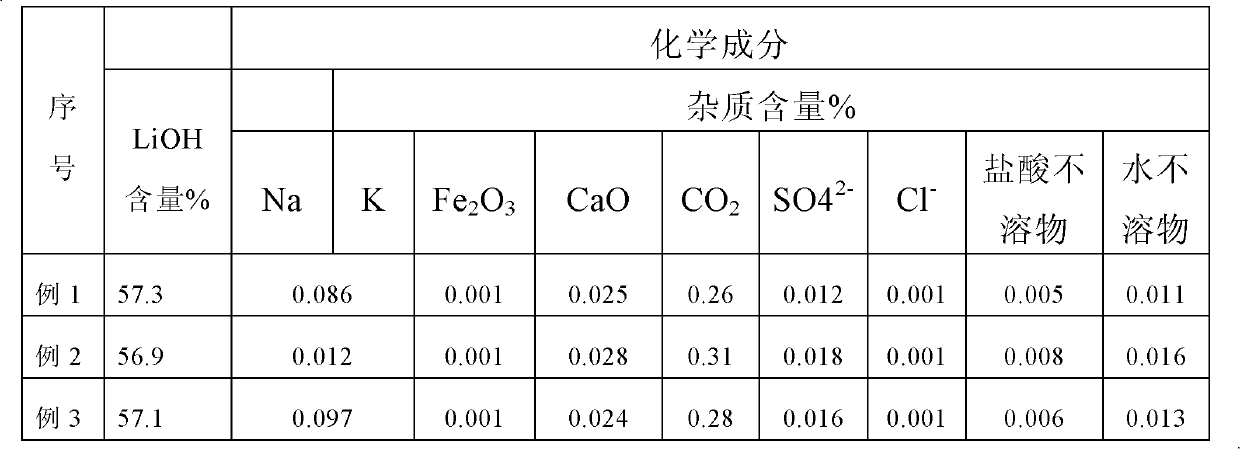

Method for preparing lithium hydroxide monohydrate by extracting lithium from spodumene

ActiveCN102701239AAchieve coolingAchieve evaporative crystallizationLithium oxides/hydroxidesResource utilizationPhysical chemistry

The invention discloses a method for preparing lithium hydroxide monohydrate by extracting lithium from spodumene. The method includes steps of transformation roasting, cooling, ball milling, acidification roasting, pulping, neutralizing, separation washing, purifying, blending for transformation, freezing for sodium precipitation, deep decontaminating, evaporative crystallization, centrifugal separation, drip washing and drying. By means of a DTB (draft tube baffle) type crystallizer, an FC (forced circulation) crystallizer or an OSLO crystallizer, continuous cooling crystallization and evaporative crystallization are realized, equipment yield is increased by more than 50%, and equipment utilization rate is increased. Therefore, the method is simple and practical in process, high in equipment yield, low in production cost, high in resource utilization rate, low in energy loss and low in three wastes (waste gas, waste water and waste residues).

Owner:GANFENG LITHIUM CO LTD

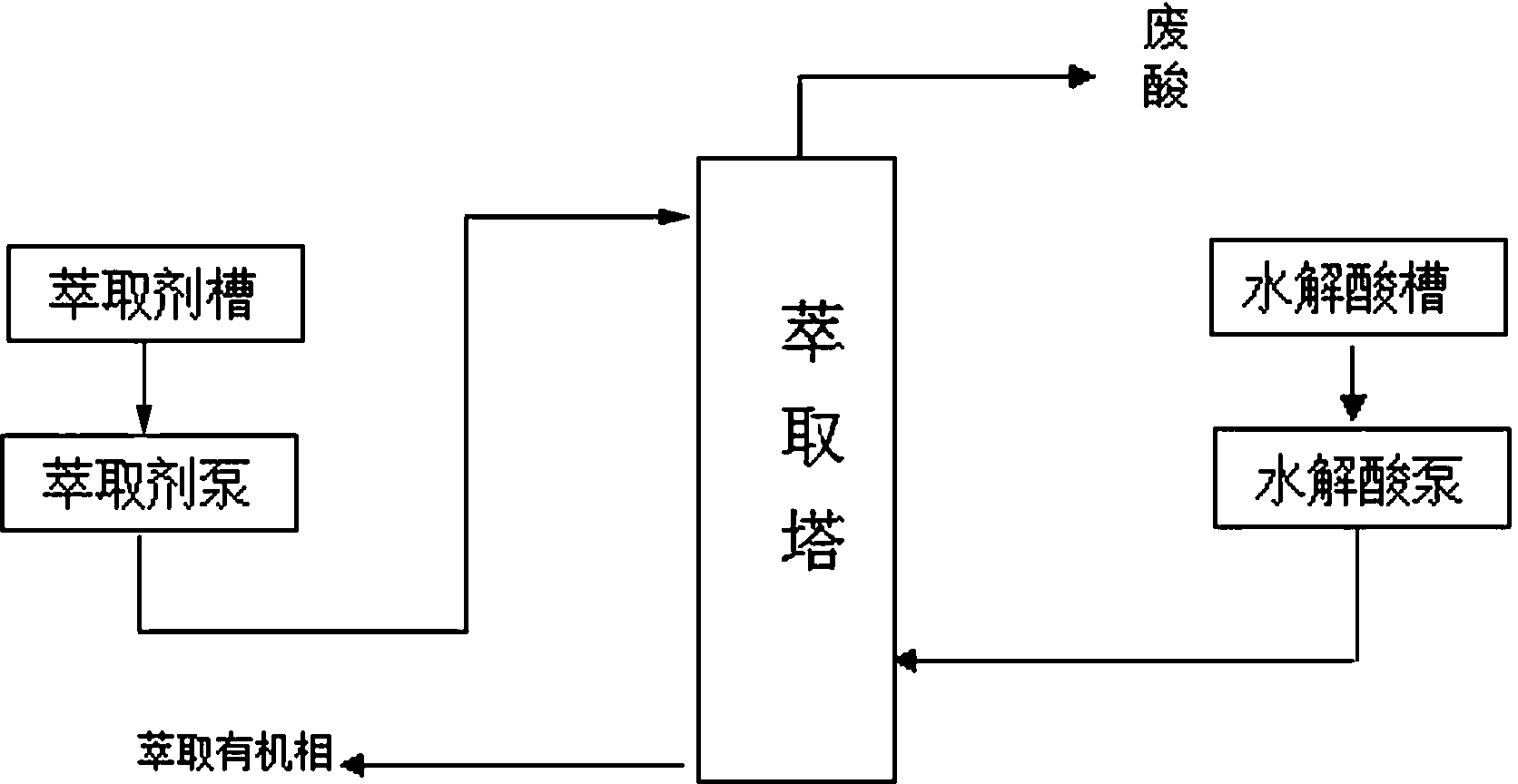

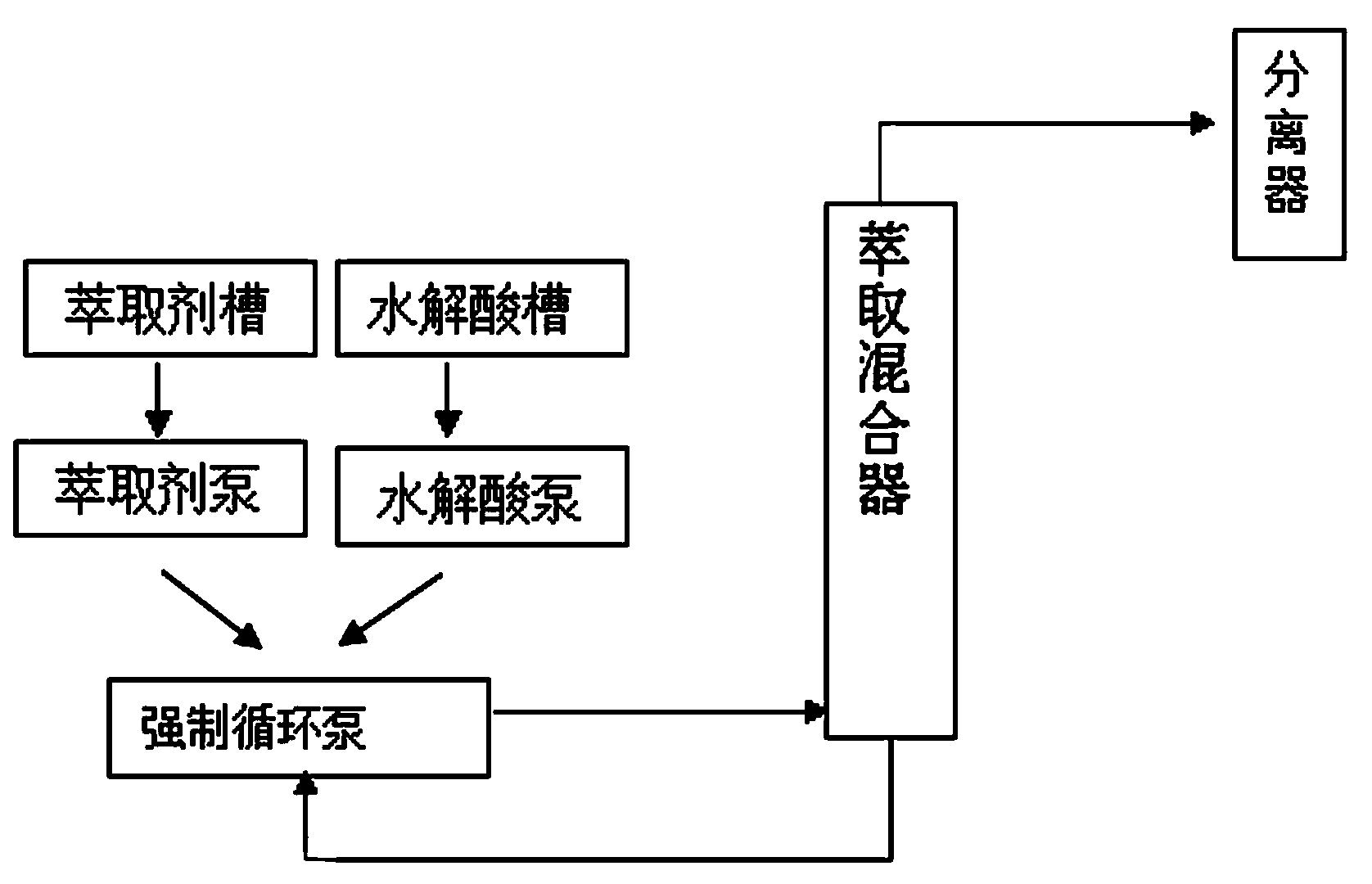

Forced circulating extraction method in production of acesulfame

ActiveCN104225956AImprove cycle stabilityIncrease mixing intensityOrganic chemistryLiquid solutions solvent extractionOrganic matterUltimate tensile strength

The invention relates to a forced circulating extraction method in production of acesulfame. The forced circulating extraction method comprises the following steps: injecting an extraction agent to an extraction mixer through an extraction pump, starting a forced circulation pump to enable the extraction agent to be circulated in the mixer, starting a hydrolytic acid pump, pumping the hydrolytic acid to the extraction mixer, adjusting the flow of the extraction agent, enabling the ratio of the hydrolytic acid to the extraction agent to be 1:2 to 1:4, in an overflow port at the topmost end of the mixer, with increase of feedstock in the extraction agent pump and the hydrolytic acid pump, overflowing a part of material out of the extraction mixer, feeding the overflown material to a separator to be separated, extracting the separated acid again in the extraction agent, and feeding the organic phase to an organic phase slot for neutralization. The forced circulating extraction method disclosed by the invention has the advantages that the forced circulating extraction is high in stability, the mixing intensity is increased, and the product yield is increased; the extraction effect of the hydrolytic acid is improved, the content of the organic matters in the waste acid can be effectively lowered, the processing difficulty can be reduced, and the contamination can be reduced; the method can be used to simplify production operation and reduce the labor intensity of workers.

Owner:ANHUI JINGHE IND

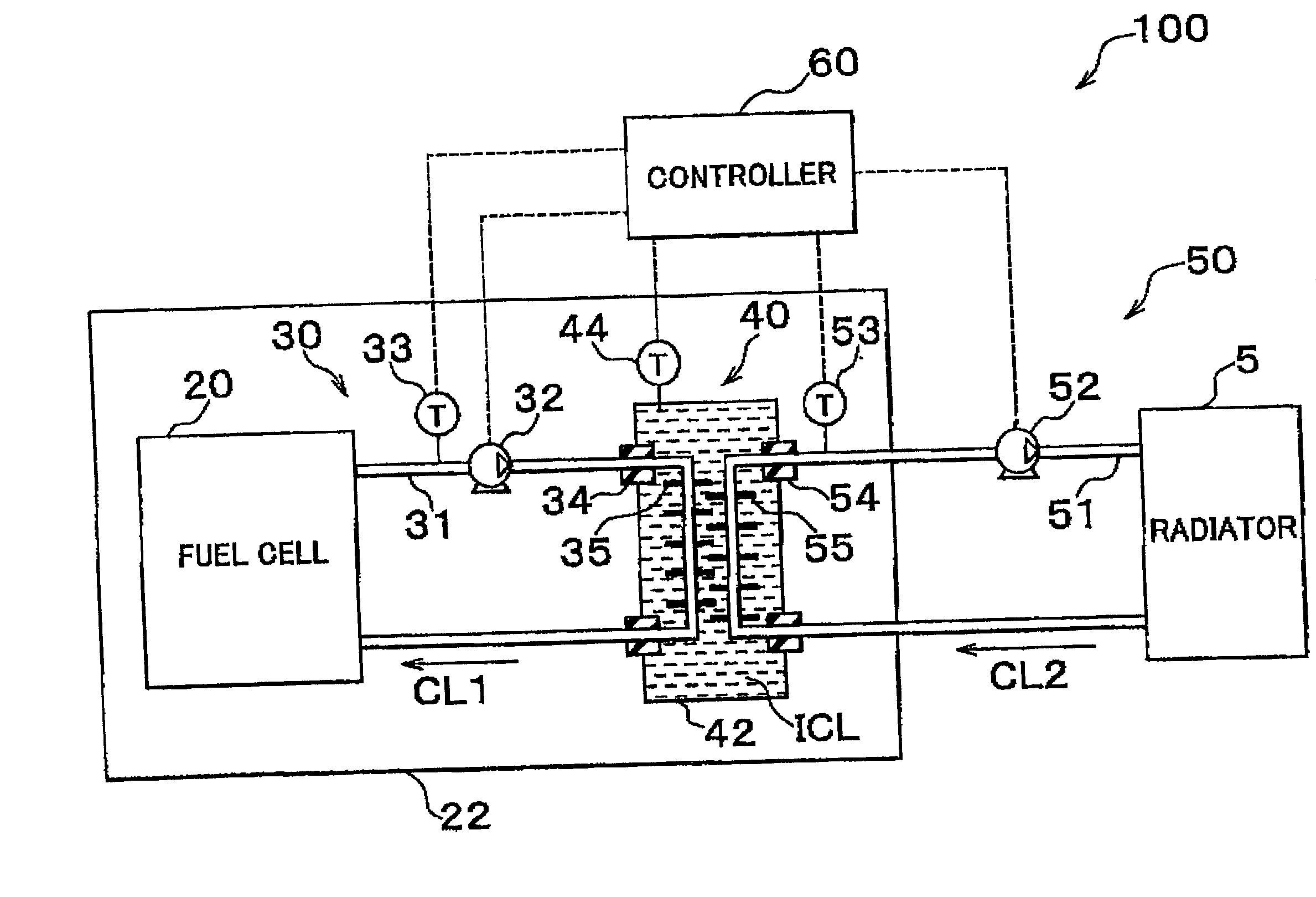

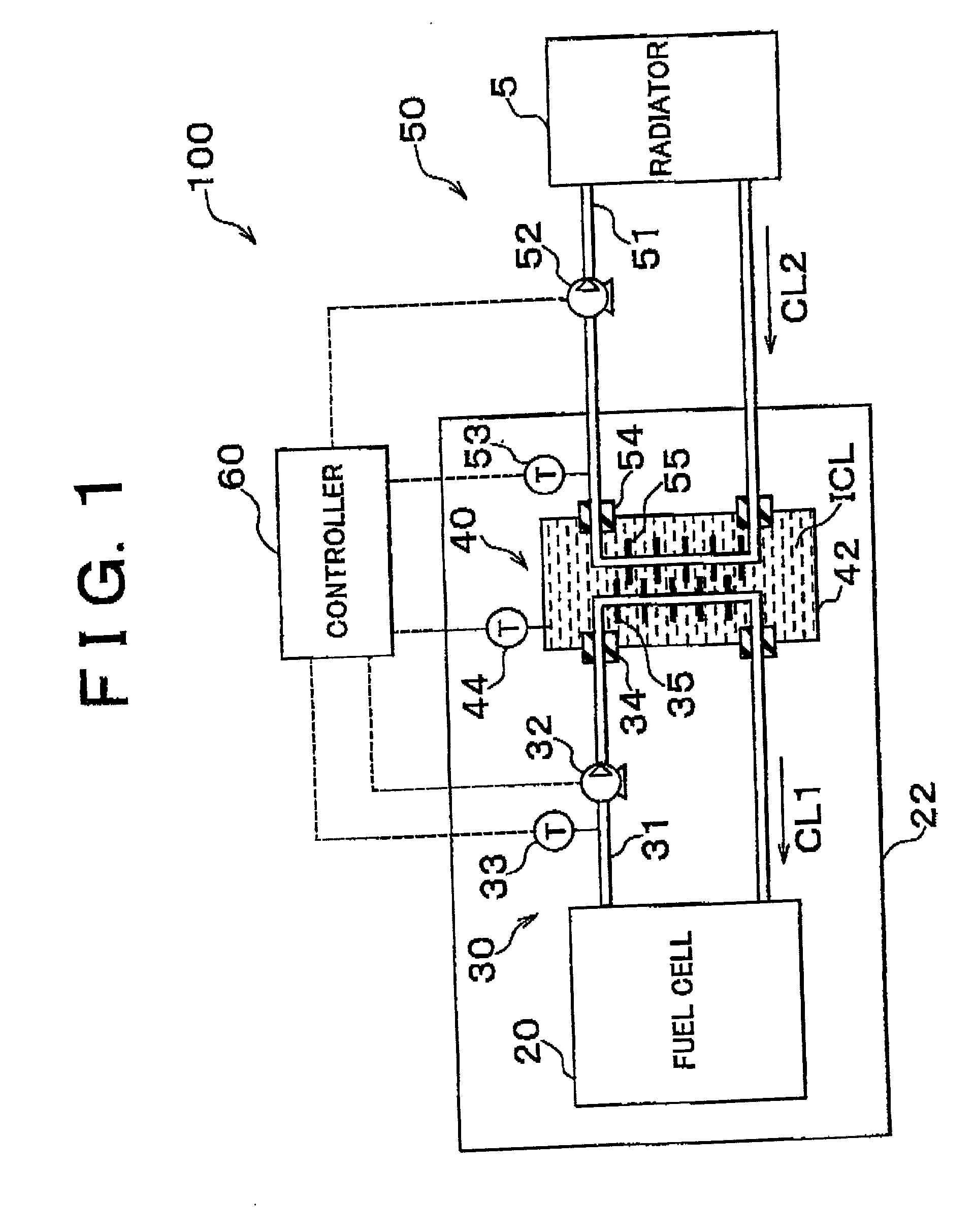

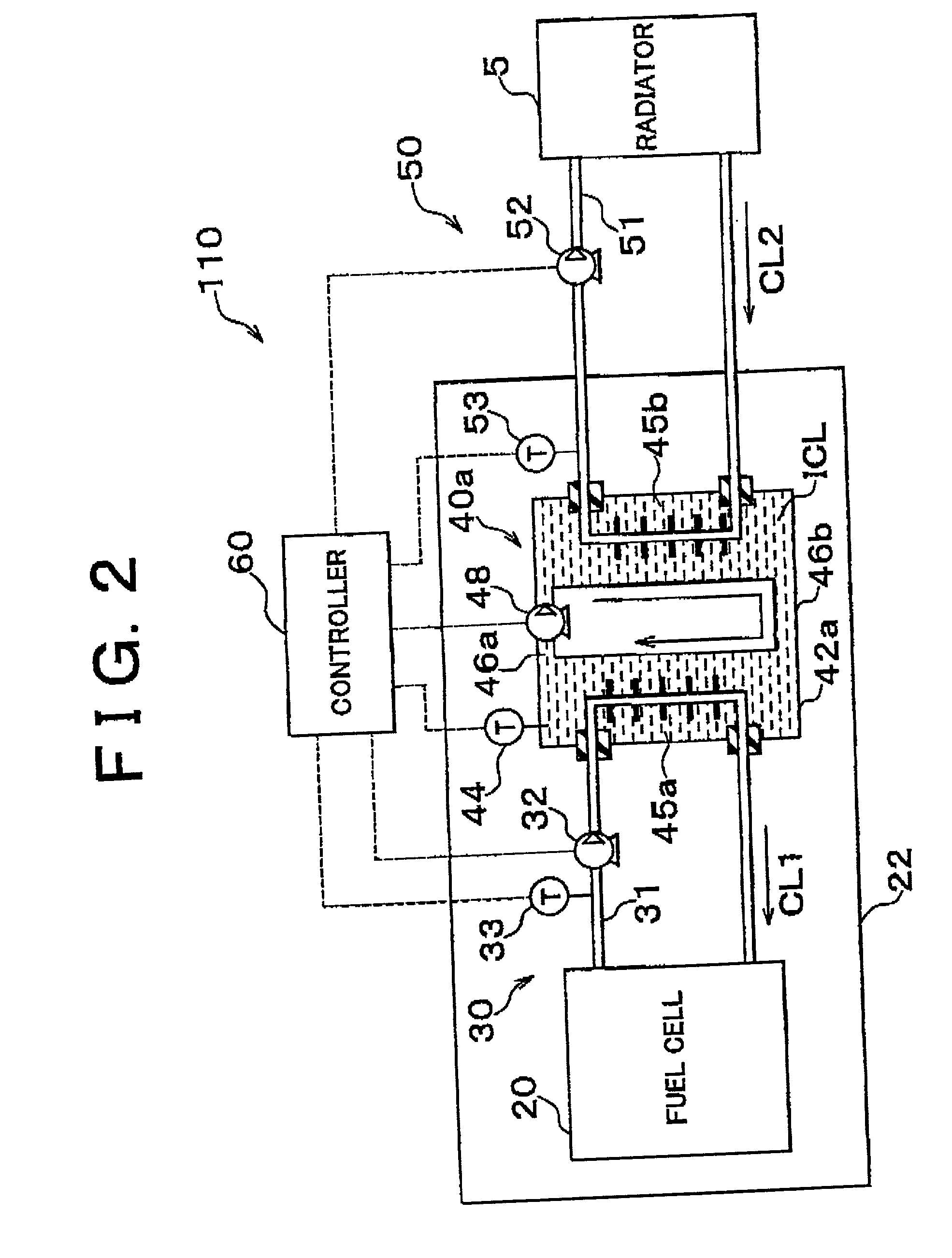

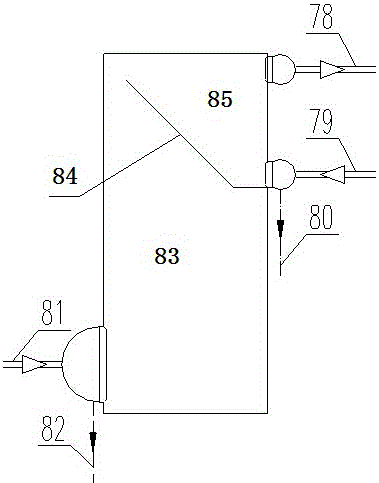

Fuel cell system having cooling apparatus

InactiveUS20020031693A1Improve insulation performanceExtended temperature rangeFuel cell auxillariesFuel cell detailsFuel cellsNuclear engineering

A cooling apparatus that cools a fuel cell has a first forced circulation cooling system that directly cools the fuel cell, a second forced circulation cooling system that is independent of the first forced circulation cooling system, and an intermediate cooling system that exchanges heat with each of the first and second forced circulation cooling systems. A container provided in the intermediate cooling system contains an electrically insulating liquid as a coolant.

Owner:TOYOTA JIDOSHA KK

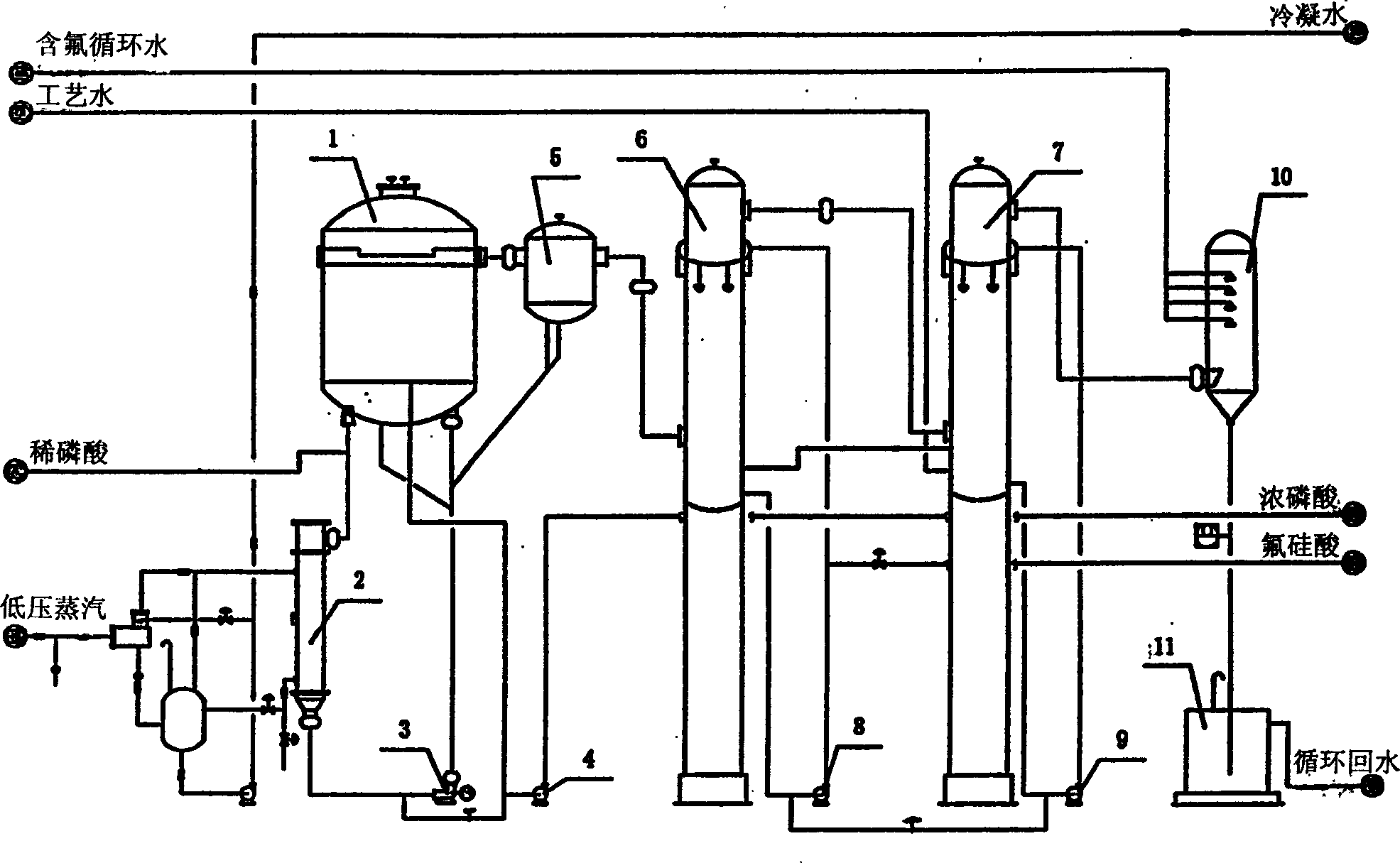

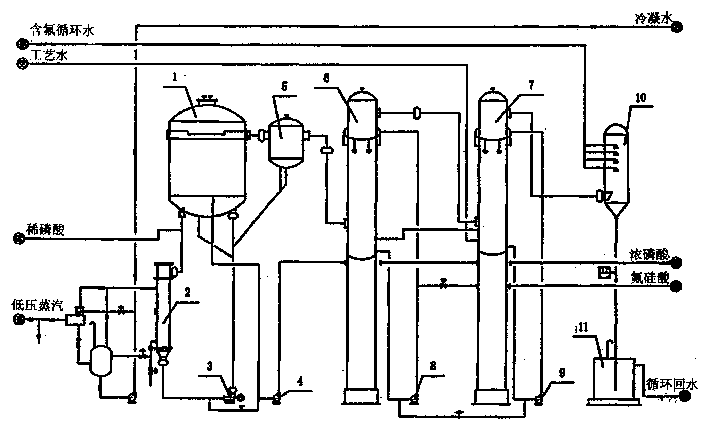

Method for producing phosphoric acid by adopting steam heating forced circulation concentration wet process and its equipment

InactiveCN1460636ALess process equipmentCompact layoutSilicon halogen compoundsPhosphorus compoundsGas phasePhosphoric acid

The phosphoric acid can be circularly heated and concentrated in a circulating loop formed from flash chamber, graphitic heat exchanger and axial-flow circulating pump, the diluted phosphoric acid can be added into the circulating loop from outlet pipe of graphitic heat exchanger, and the evaporated steam can be passed through the entrainment eliminator to remove entrained acid foam, then the steam is more passed through two-stage fluorine absorbing tower, sprayed and washed so as to recover fluoride in the gas phase. The vacuum required for flash chamber is provided by atmosphere condenser. Said invention can make wet phosphoric acid be concentrated to 48-50% P2O5 from 20-25% P2O5.

Owner:EAST CHINA ENG SCI & TECH

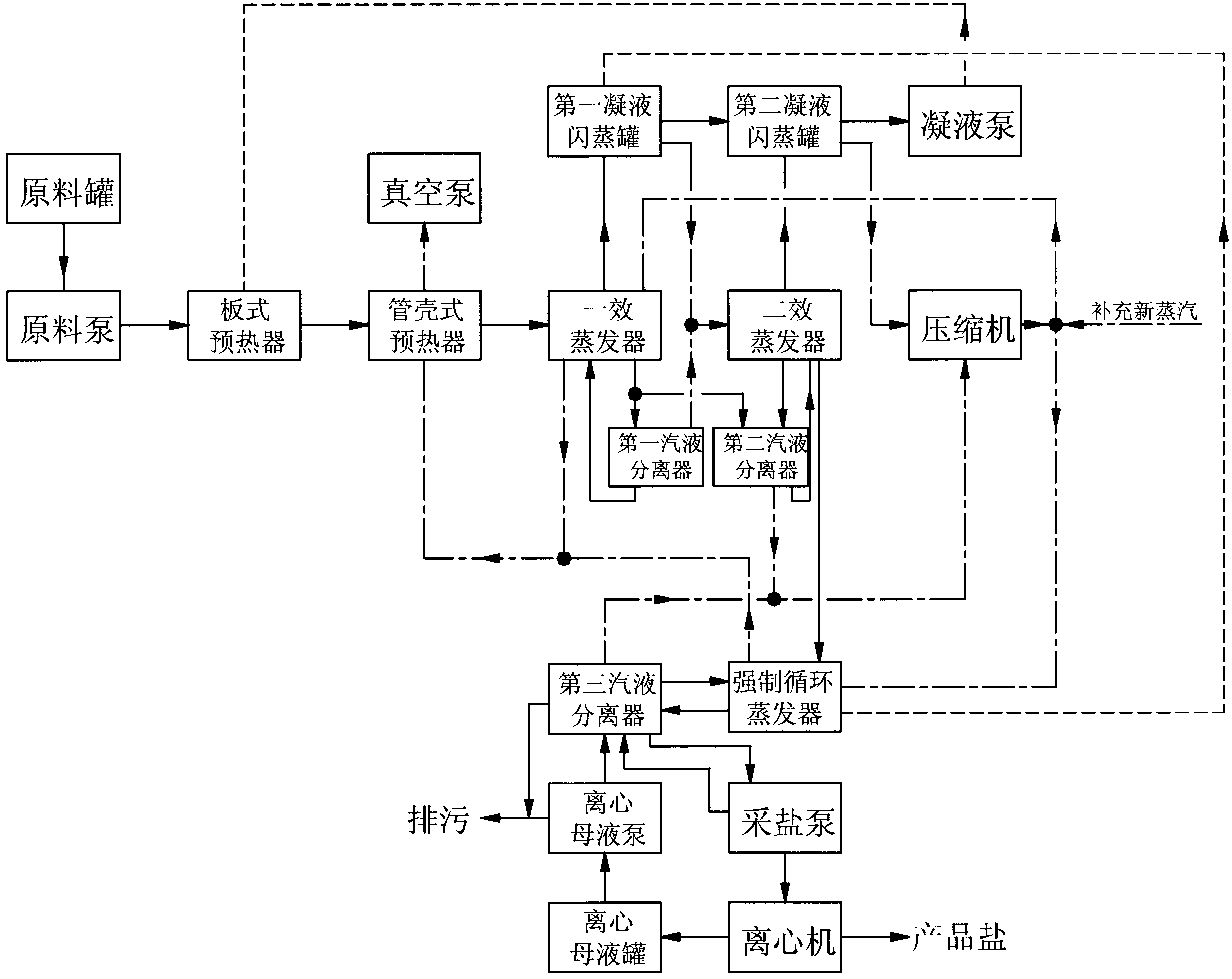

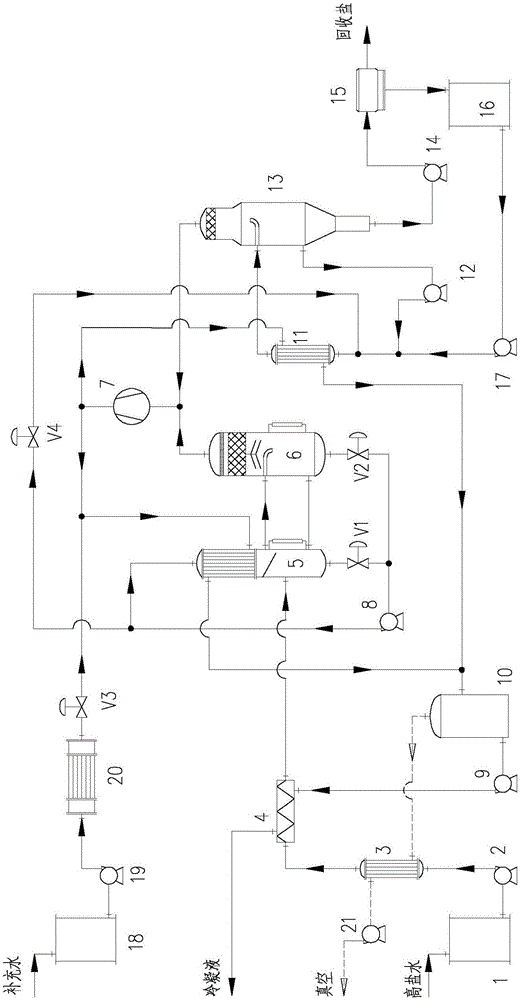

MVR (mechanical vapor recompression) evaporation crystallization system and method for high-salinity wastewater

PendingCN106669207ATake advantage ofAchieve recyclingEvaporator accessoriesEvaporators with forced circulationVapor–liquid separatorEvaporation

The invention discloses an MVR (mechanical vapor recompression) evaporation crystallization system and method for high-salinity wastewater[0]. The system comprises a raw material tank, a first preheater, a second preheater, an MVR evaporator, a gas-liquid separator, a compressor, a first circulating pump, a condensate tank, a forced circulation evaporator, a second circulating pump, a crystallizer, a centrifuge and a vapor generator. The full utilization of secondary vapor is realized after high-salinity wastewater is treated with the system, and the system has the advantages that the cost is low, the continuity and the energy saving effect are good, and the crystal salt quality is high.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

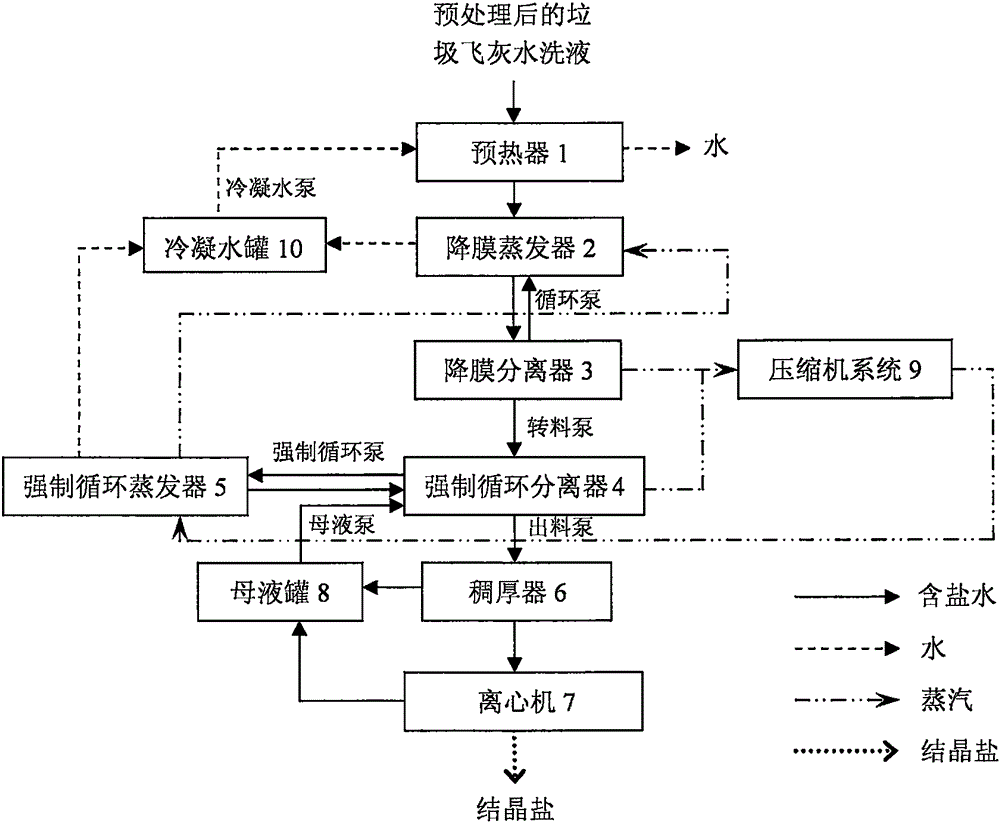

Garbage fly ash water washing liquid evaporation desalination system and method

InactiveCN105016555AInnovativeImprove energy savingMultistage water/sewage treatmentDesalinationEnvironmental engineering

The invention discloses a garbage fly ash water washing liquid evaporation desalination system and method. The system comprises two individual evaporative concentration and evaporation crystallization units. A compressor provides desired heat energy for the units and keeps heat energy balance. The evaporative concentration unit comprises a preheater, a falling film evaporator and a falling film separator. Through garbage fly ash water washing liquid pre-heating and repeated evaporation, the material is concentrated. The evaporation crystallization unit comprises a forced circulation separator and a forced circulation evaporator. Through further evaporation of the concentrate, the material is in a saturated or oversaturated state and salt crystals are precipitated. Through settlement condensation adopting a thickener and separation adopting a centrifuge, the salt in the garbage fly ash water washing liquid can be separated finally. The system adapts to the garbage fly ash water washing liquid characteristics of complex components and high salt content, has the characteristics of large evaporation capability, operation stability and smooth desalination and guarantees large scale stable treatment on the garbage fly ash water washing liquid.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

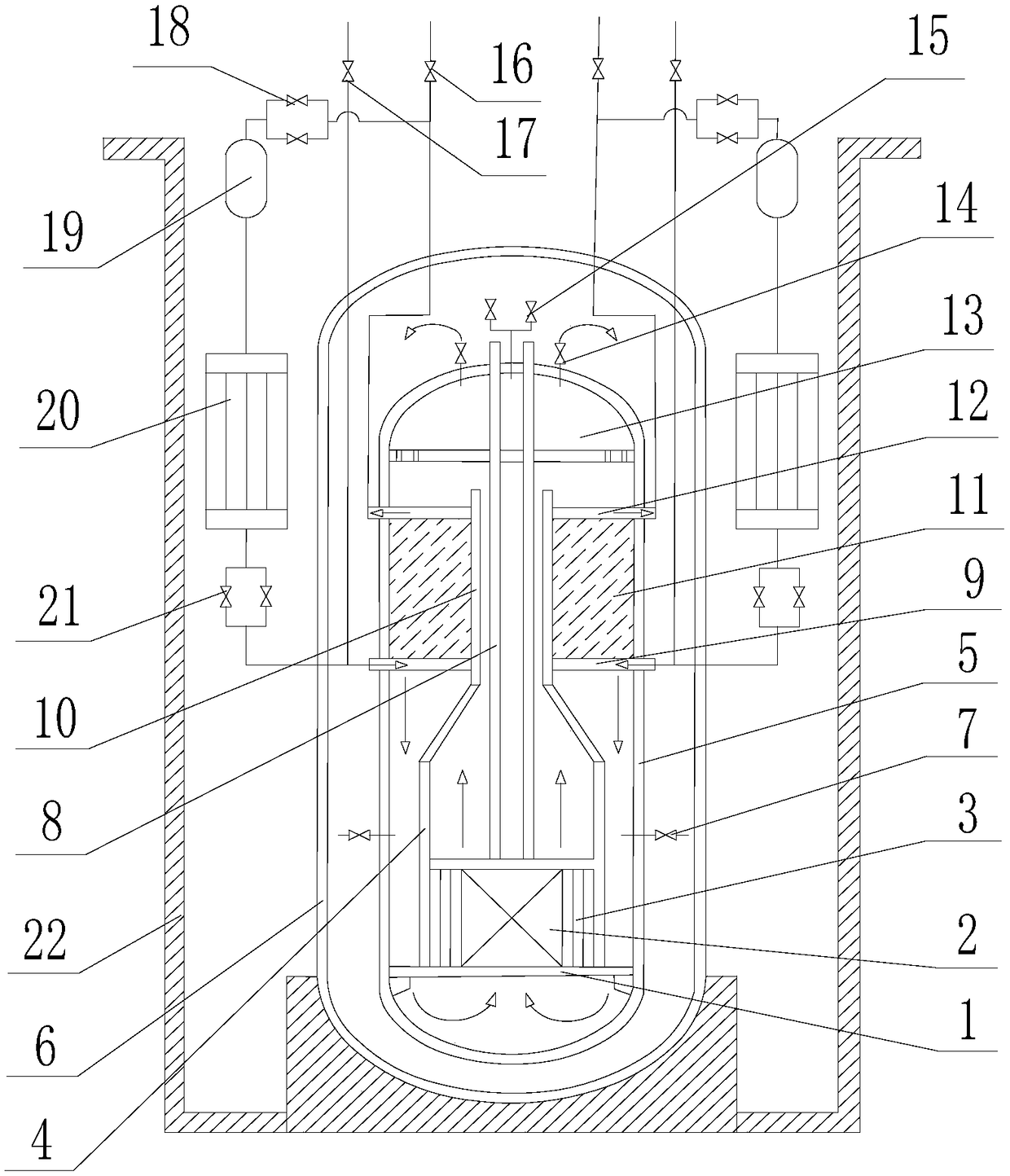

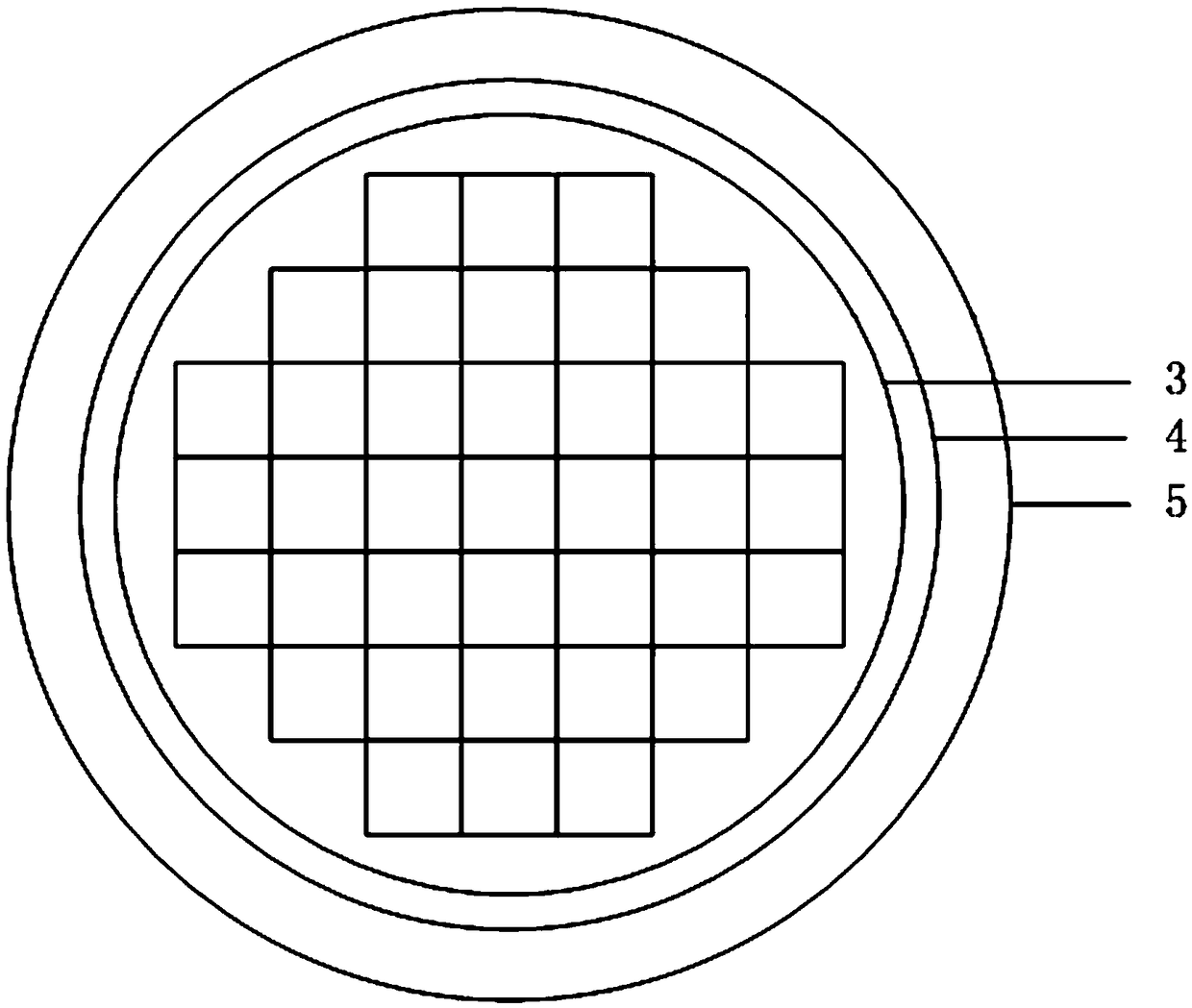

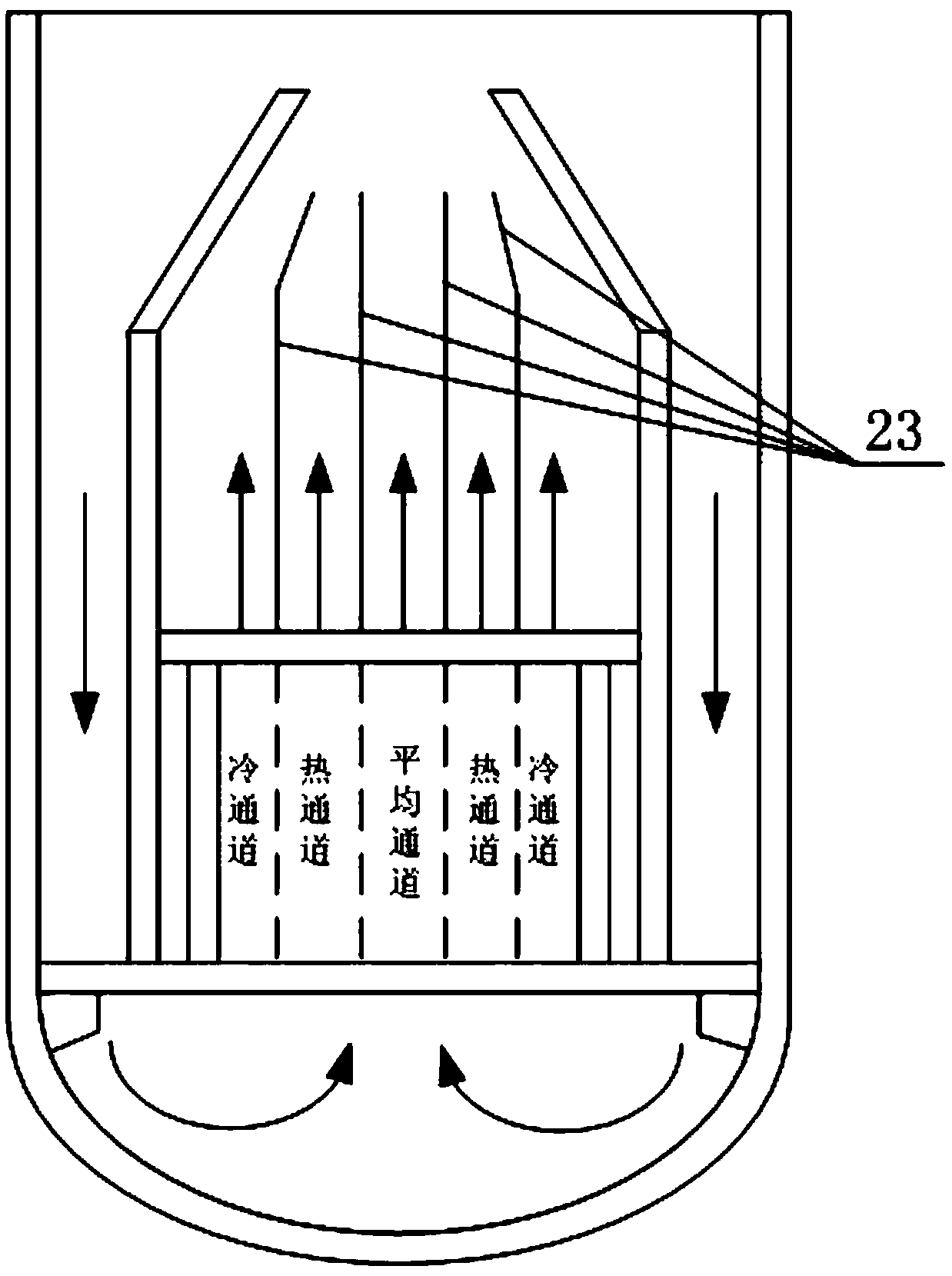

All natural circulation-type modular small reactor

ActiveCN108648837AReduce resistanceImprove natural circulationNuclear energy generationCooling arrangementPotential differenceHeat transmission

The invention discloses an all natural circulation-type modular small reactor. The all natural circulation-type modular small reactor comprises a reactor main body, a safe shell, a water tank and a passive safety system. The reactor main body comprises a pressure vessel. A reactor core, a direct current steam generator and a voltage stabilizer are orderly arranged in the pressure vessel from bottom to top. One end of a control rod driving mechanism matched with the reactor core is arranged at a top cover of the pressure vessel. The pressure vessel is arranged in the safe shell. The safe shellis immersed in the water tank. The passive safety system comprises a passive residual heat removal system and a passive safe shell heat transmission system. The reactor is free of forced circulation of a path of a cooling agent driven by a main pump, and utilizes density contrast of cooling agents between the direct current steam generator and the reactor core and cold and hot core potential difference to drive the cooling agents to all naturally circulate in the pressure vessel so that the reactor safety is improved. The passive safety system realizes a lasting submerged state of the reactorcore and carries out the residual heat of the reactor core to prevent core damage.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

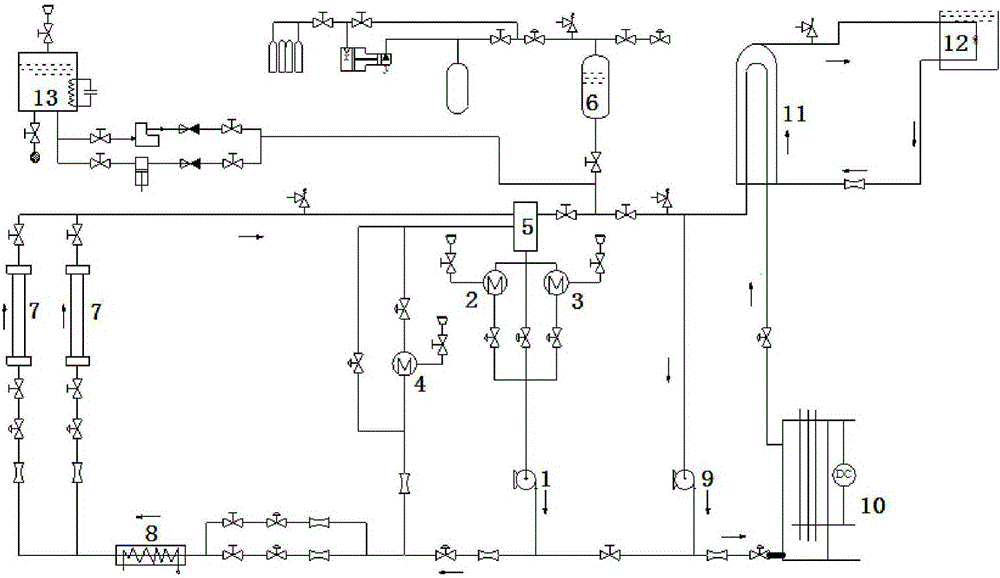

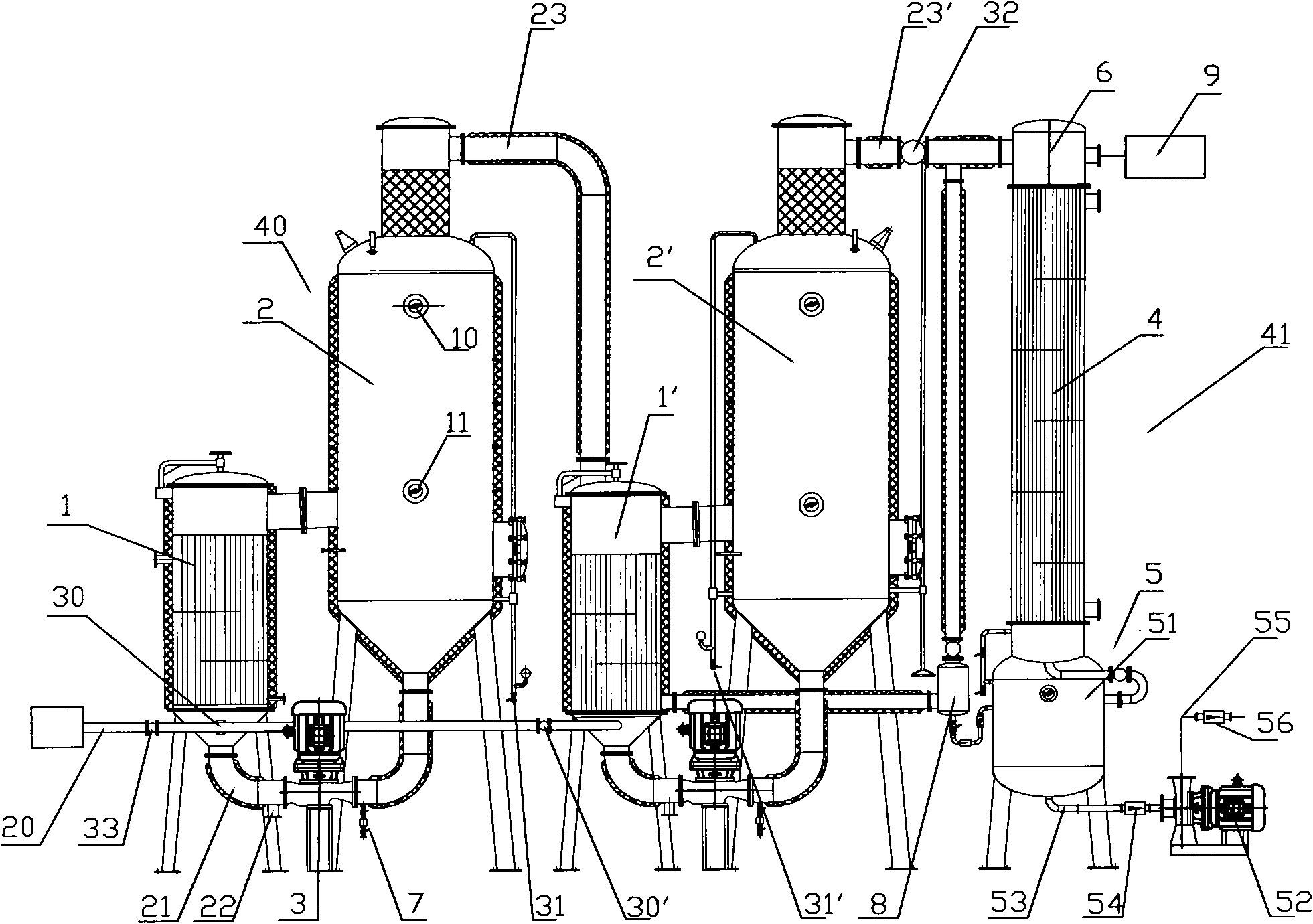

Natural circulation and forced circulation experiment loop system

InactiveCN105225708AAdd varietyImprove reliabilityNuclear energy generationNuclear monitoringMeasuring instrumentProcess engineering

The invention discloses a natural circulation and forced circulation experiment loop system. The system includes a forced circulation loop, a natural circulation loop 1 and a natural circulation loop 2; the forced circulation loop comprises a main circulating pump, a main heat exchanger, an auxiliary heat exchanger, a coagulation device, a voltage stabilizer, a test section, a preheater, a flowmeter and corresponding pipelines, valves and measuring instruments. The forced circulation experiment branch consists of a measuring section, a preheater, an experimental body, a coagulation device, a voltage stabilizer and corresponding pipelines and valves. The natural circulation loop 1 comprises a main circulating pump, a core simulator, a steam generator, a voltage stabilizer and corresponding pipelines, valves and measuring instruments. The natural circulation loop 2 comprises a steam generator, a heat exchanger, a heat-exchange water tank and corresponding pipelines and valves. The system improves the reliability of the measures set beyond design basis accident and the diversification of the nuclear power plant safety system, and has high engineering value.

Owner:SOUTHWEST PETROLEUM UNIV

Multi-effect vacuum forced circulation evaporation device and material concentrating method thereof

InactiveCN102008829AReduce manufacturing costReduce consistencyMultiple-effect evaporationOrganic solventEvaporation

The invention discloses a multi-effect vacuum forced circulation evaporation device, belonging to the field of evaporation devices. The multi-effect vacuum forced circulation evaporation device comprises at least two forced circulation evaporators, a condensate drain device and a vacuumizing device, wherein the vacuumizing device is communicated with the forced circulation evaporator and the condensate drain device through pipelines; and a feed valve is arranged on a feed pipeline of the forced circulation evaporator of each effect and is used for controlling the feeding of feed liquid. In the invention, the vacuumizing device is used for realizing the vacuum feeding process of the evaporators, and meanwhile, the feed valve and an emptying valve are arranged on each evaporator of one effect; by means of a mode of closing a vacuum pump, opening the feed valves of the double-effect evaporators and simultaneously opening the emptying valve of the evaporator of the secondary effect, materials of the secondary effect can be absorbed into the primary effect and then are continuously heated and evaporated, and the materials are discharged through a forced circulation pump after the material concentration meets requirements after circulation evaporation. The multi-effect vacuum forced circulation evaporation device is suitable for various evaporators and also suitable for concentrating equipment for various organic solvents.

Owner:温州市天龙轻工设备有限公司

Technology for continuously producing secbutyl acetate

InactiveCN101735047AThe replacement process is continuousFor quick replacementOrganic compound preparationCarboxylic acid esters preparationAcetic acidTower

The invention discloses a technology for efficiently and continuously producing secbutyl acetate. In the technology, acetic acid and 1-butylene serve as raw materials, solid-liquid mixed acid serves as catalyst and an integrated system composed of an injection collision stream tower reactor, a rectification system, an oil-water separator and the like is adopted. Wherein the injection collision stream tower reactor is mainly composed of an injection-collision stream reaction section, a tower plate / filler tower-type reaction section, a forced circulation and control part and a catalyst replacing part, which greatly improves conversion rate of acetic acid and use ratio of butylene. The method for efficiently and continuously producing secbutyl acetate has the comprehensive advantages of compact structure, safety and reliability, high conversion rate, high material use ratio, low operation cost and the like.

Owner:NANJING UNIV

Production method of cold-rolled steel strip for flux cored wire

InactiveCN102755992ASimple production processLow costWork treatment devicesRollsExtensibilityCarbide

The invention provides a production method of a cold-rolled steel strip for a flux cored wire. The production method comprises the following steps of: (1) selecting a raw material, to be specific, selecting an SPCE hot-rolled acid-washed raw material with thickness of 2.2-3.0 mm and width of 300-850 mm, wherein the raw material comprises the following components in percentage by weight: 0.01-0.025 percent of C, 0.002-0.010 percent of Si, 0.150-0.350 percent of Mn, not greater than 0.01 percent of S, not greater than 0.015 percent of P, not greater than 0.003 percent of N, not greater than 0.05 percent of Alt and the balance of iron element and inevitable impurities; (2) cold-rolling, to be specific, performing cold-rolling on the acid-washed raw material to be 0.5-1.2 mm and controlling total screw-down rate to be 700-85 percent; (3) performing recrystallization annealing, to be specific, holding a rolled steel strip in a forced circulation hood type annealing furnace, heating, preserving heat and cooling, wherein the holding temperature is 610-660 DEG C and the holding time is controlled to be 9-12 hours; (4) leveling; and (5) cutting to obtain the cold-rolled steel strip for the flux cored wire. The produced flux cored wire steel strip has a simple production process and is low in cost. The produced flux cored wire steel strip has stable performance; solid solution carbide is fully separated through staged slow cooling in the process of the hood type annealing furnace; the influence of time limitation on subsequent drawing is avoided; the hardness of the product is HV 90-110; and the extensibility A reaches 42-50 percent.

Owner:武钢集团有限公司

Polymer surface fluorination technique

The invention relates to a polymer surface fluorination technique, which comprises the steps of: putting polymer product and adsorbent into a fluorination chamber, heating the gas and the polymer product in a fluorination furnace into 10-80 DEG C, and vacuumizing the fluorination furnace and using nitrogen for replacement; filling fluoride or nitrogen fluoride into the fluorination furnace, and controlling the fluoride concentration to be 5-50% and the pressure in a fluorination chamber to be -0.08 to 0.1MPa; and leading the gas in the fluorination furnace to have forced circulation, and controlling the temperature of the fluorination chamber to be 10-80 DEG C and the reaction time to be 20-120 min. The polymer surface fluorination technique effectively improves the polymer surface fluorination efficiency, and leads the surface of a fluorination layer to be deeper and more uniform.

Owner:洛阳森蓝化工材料科技有限公司

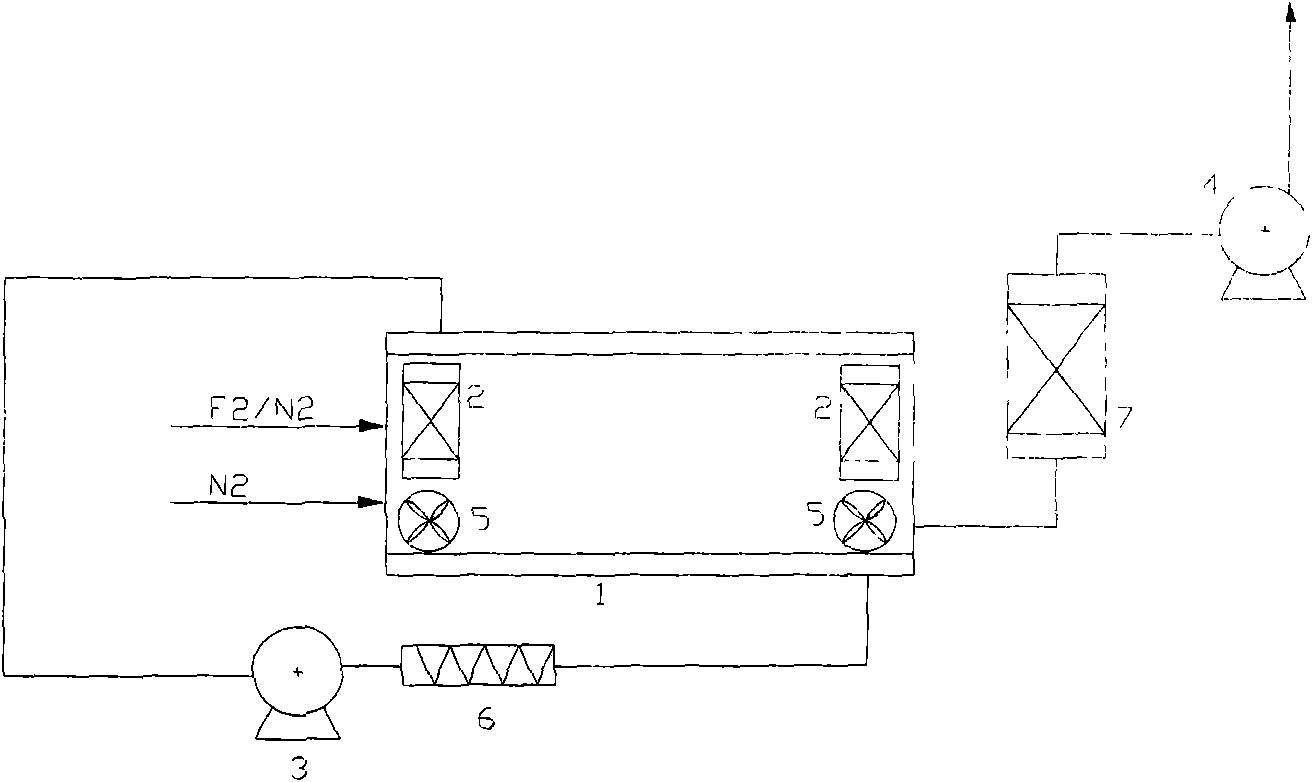

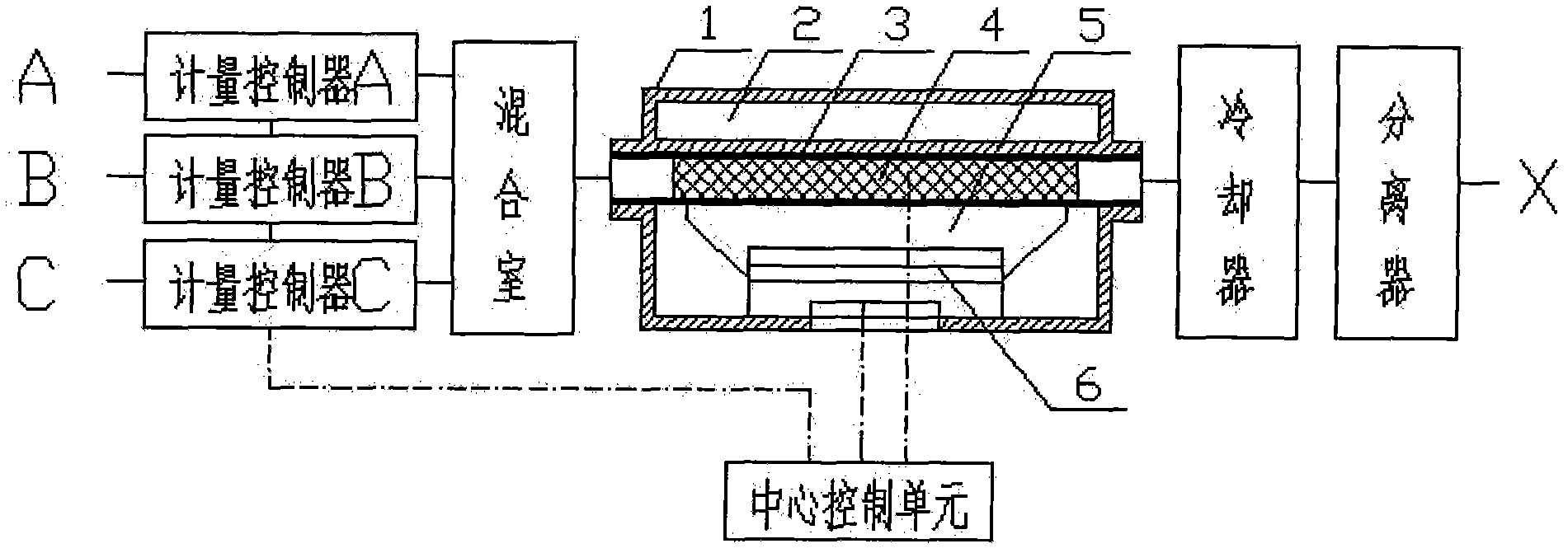

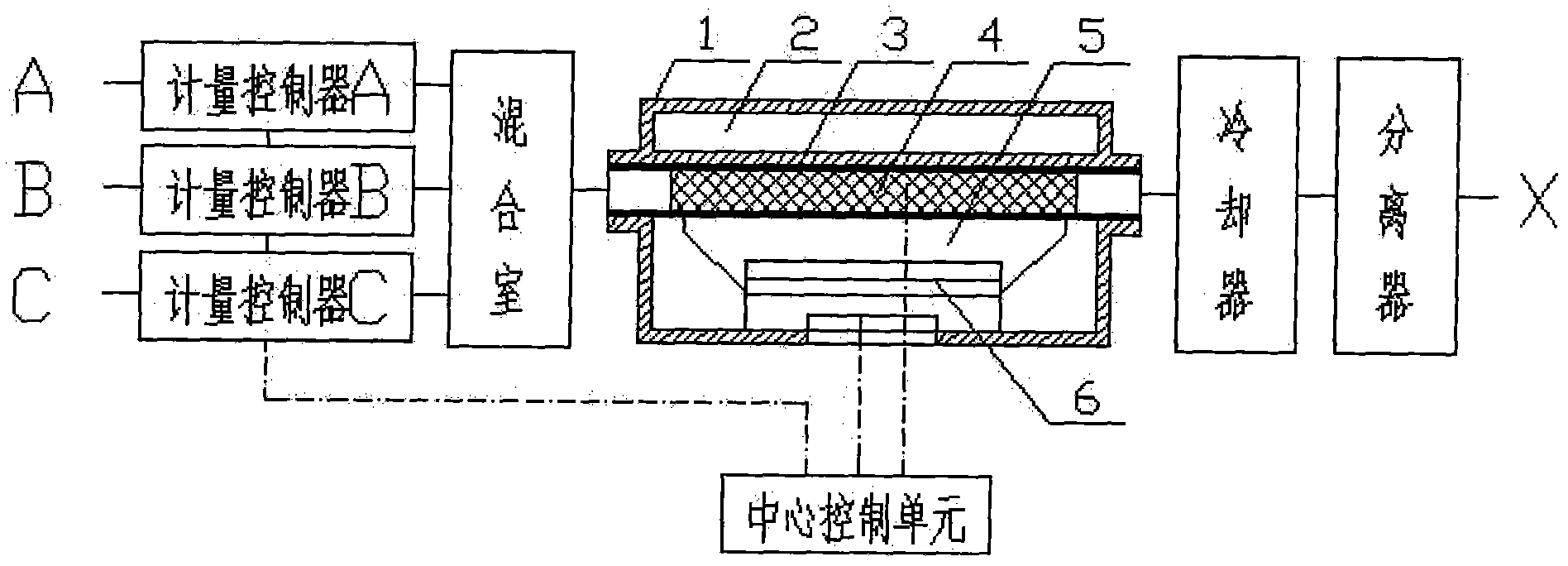

Microwave catalytic reactor system

InactiveCN102133516AScientific and reasonable structureEnergy based chemical/physical/physico-chemical processesMicrowave cavityReactor system

The invention relates to a microwave catalytic reactor system comprising a feeding hole, a measuring controller, a mixing chamber, a microwave reactor and a discharging hole which are sequentially connected, wherein a reaction tube (3) and a microwave cavity (5) are installed in a reactor body (1) of the microwave reactor; a microwave tube (6) is installed in the microwave cavity (5); a catalyst (4) with a microwave absorption characteristic is filled in the reaction tube (3); a temperature sensor is arranged in the catalyst (4); and the measuring controller, a control circuit of the microwave tube (6) and the temperature sensor are electrically connected with a central control unit. A forced circulation cooling water chamber (2) is arranged between the outer wall of the reaction tube (3) and the reactor body (1), a water tank for holding forced circulation cooling water is installed outdoors, and the cooling water chamber (2) and the water tank are connected with a water pump through pipelines. An outlet of the microwave reactor can be selectively connected with a cooler and a separator. The microwave catalytic reactor system can be used for continuous flowing air (liquid) and solid catalytic reaction, and can be used for treating waste water, waste gas and the like.

Owner:XIANGTAN UNIV

High-efficiency energy-saving sewage treatment method and device

ActiveCN105036223AAchieving zero emissionsLow investment costWater/sewage treatment by heatingWater resourcesWastewater

The invention discloses a method and device, which are used for harmlessly treating industrial sewage, can sufficiently utilize heat energy in the treatment process and can repeatedly utilize a water resource and other industrial products. The sewage treatment method comprises: first preheating to-be-treated sewage to a set temperature, then sending the sewage into an MVR evaporator, evaporating and concentrating the sewage to respectively obtain concentrated liquid and secondary steam, obtaining a treated solution when the concentration of concentrated liquid in the MVR evaporator reaches a predetermined value, introducing the treated solution into a forced circulating evaporator, and re-evaporating and concentrating the treated solution. By adopting the device, the method can be implemented, sewage can be effectively and efficiently treated, the off-line cleaning time of the device can be greatly shortened, the equipment is simpler to re-clean, and the equipment cost can be maximally reduced.

Owner:兰州节能环保工程有限责任公司 +1

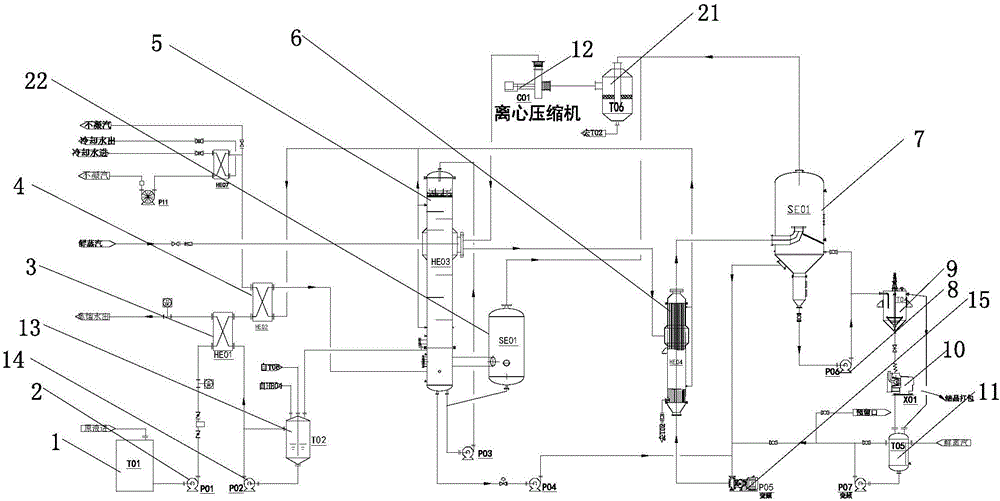

Treatment process and device of electroplating wastewater

ActiveCN105836951AExtended service lifeWater/sewage treatment by centrifugal separationSpecific water treatment objectivesTreatment effectCirculator pump

The invention relates to the technical field of sewage treatment equipment, in particular to a treatment process and device of electroplating wastewater. The treatment device comprises a stock solution tank, a feeding pump, a first plate heat exchanger, a second plate heat exchanger, a falling film evaporator, a falling film separator, a forced circulation heat exchanger, a crystallization segregator, a discharging pump, a thickener, a centrifuge and a mother liquor tank which are successively communicated, wherein the falling film separator and the top end of the crystallization segregator are communicated with the falling film evaporator through a centrifugal compressor; the falling film evaporator and the forced circulation heat exchanger are further communicated with a distilled water tank, and the distilled water tank is communicated with the first plate heat exchanger through a distilled water pump; the falling film separator, the falling film evaporator and the crystallization separator are all communicated with the input end of a forced circulation pump, and the output end of the forced circulation pump is communicated with the forced circulation heat exchanger. Therefore, the treatment process and device disclosed by the invention are low in production cost, and high in treatment effect.

Owner:JIANGSU RUISHENGHUA ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com