Patents

Literature

251results about "Silicon halogen compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

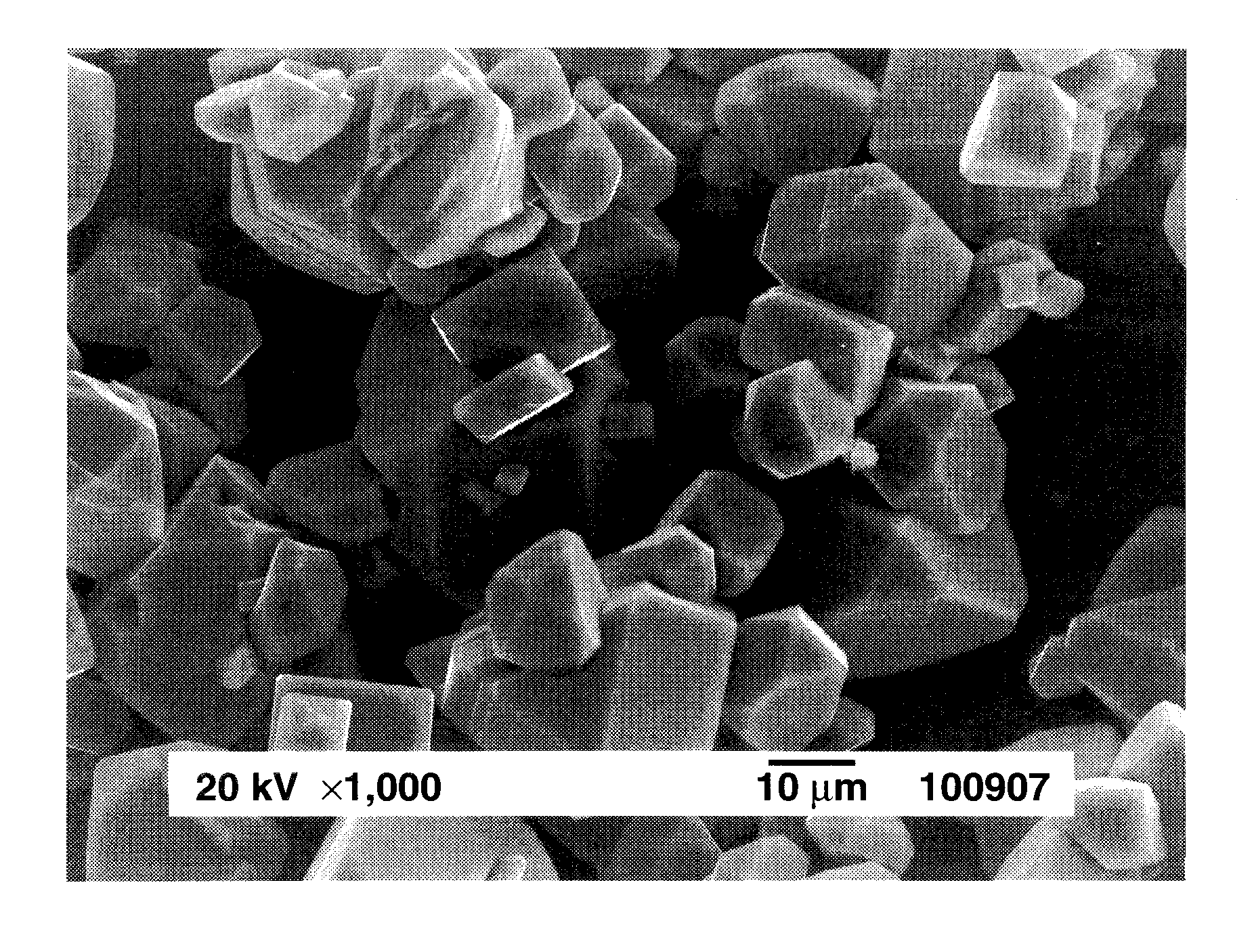

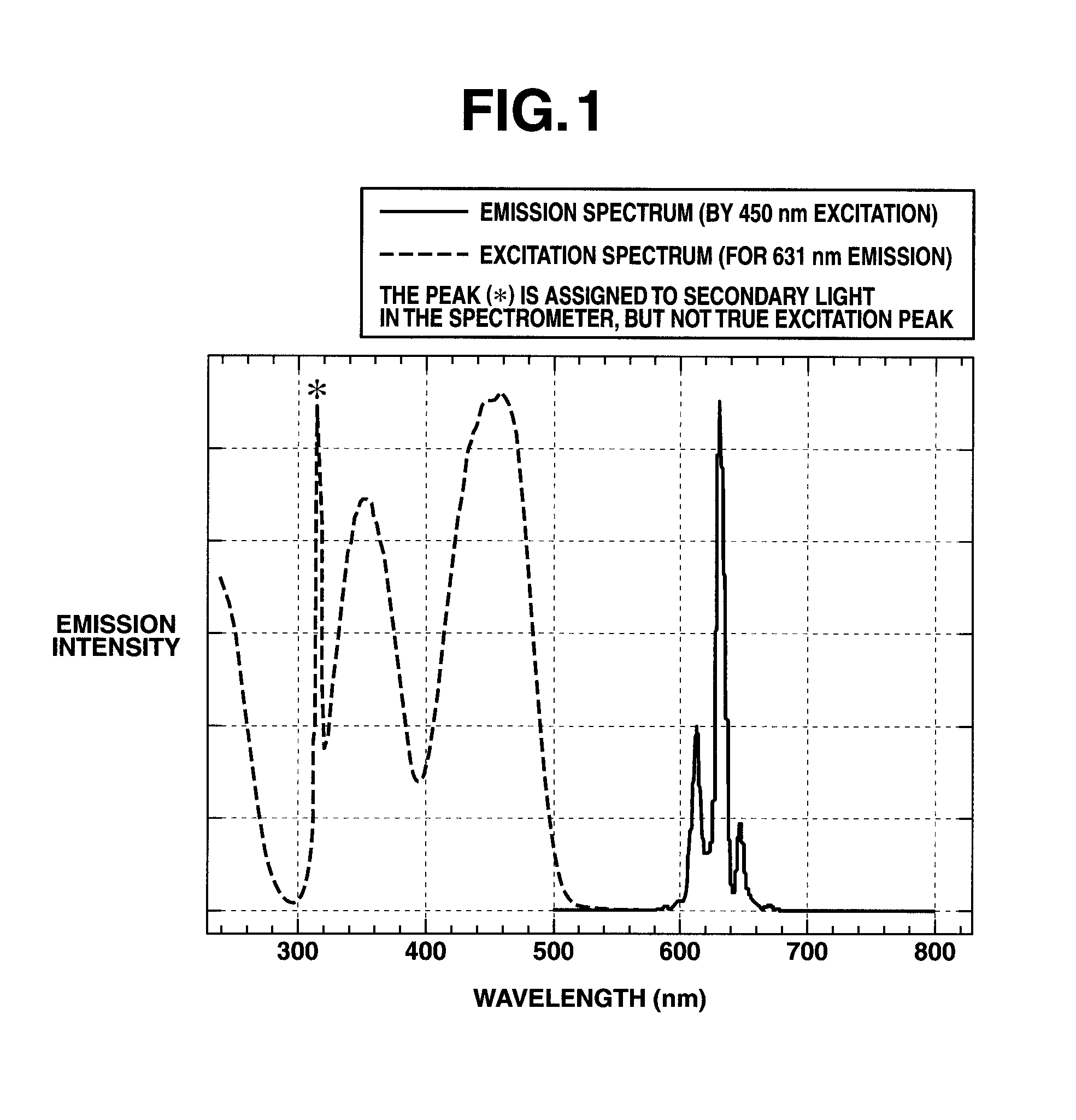

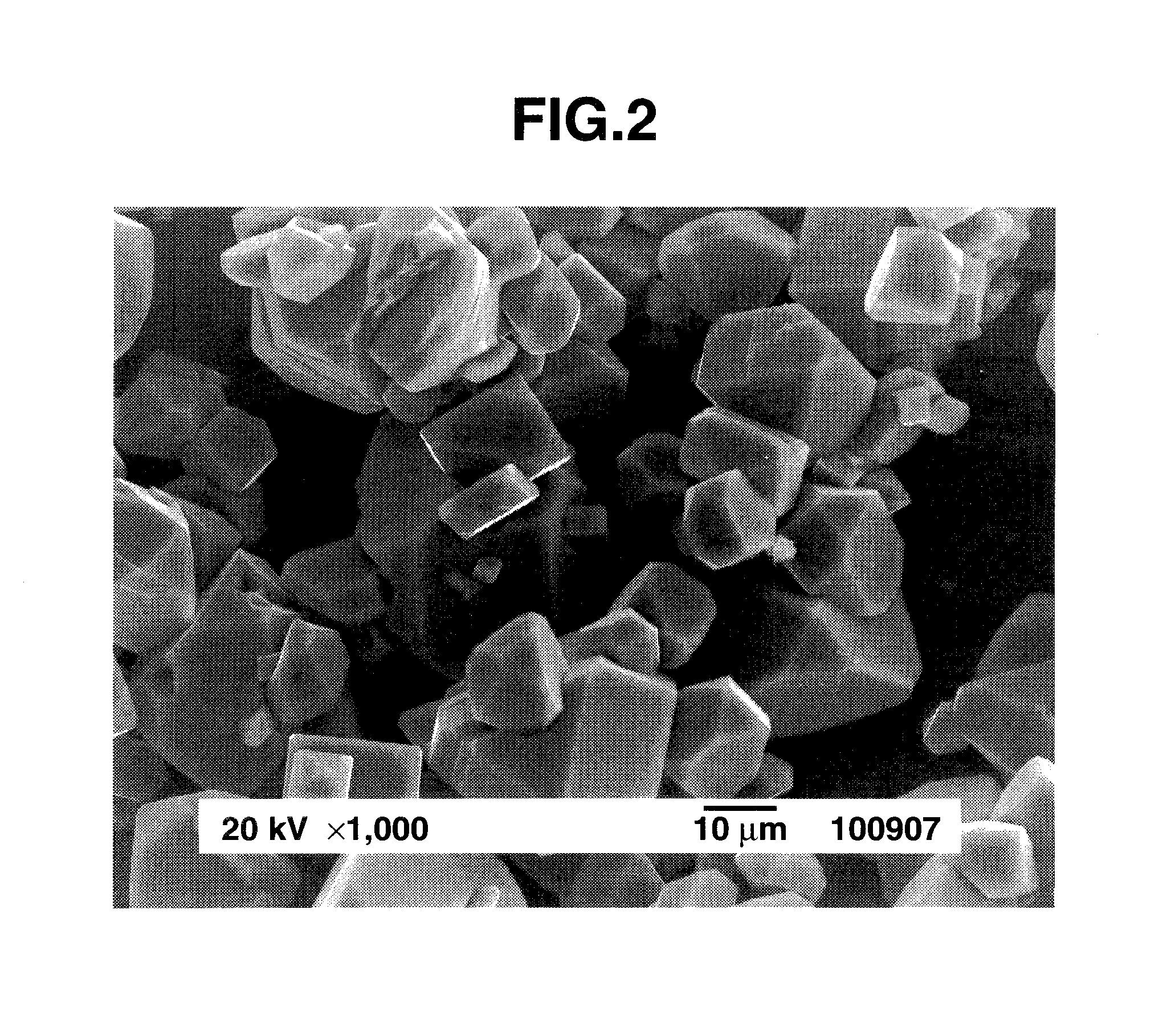

Preparation of complex fluoride and complex fluoride phosphor

ActiveUS20120256125A1Uniform sizeSatisfactory emissive propertyTin compoundsSilicon halogen compoundsPhysical chemistryFluoride

A complex fluoride A2MF6 wherein M is a tetravalent element Si, Ti, Zr, Hf, Ge or Sn, A is an alkali metal Li, Na, K, Rb or Cs is prepared by providing a first solution containing a fluoride of M, providing a second solution containing a compound of A and / or the compound of A in solid form, mixing the first solution with the second solution and / or the solid for reacting the fluoride of M with the compound of A, and recovering the resulting solid product via solid-liquid separation.

Owner:SHIN ETSU CHEM IND CO LTD

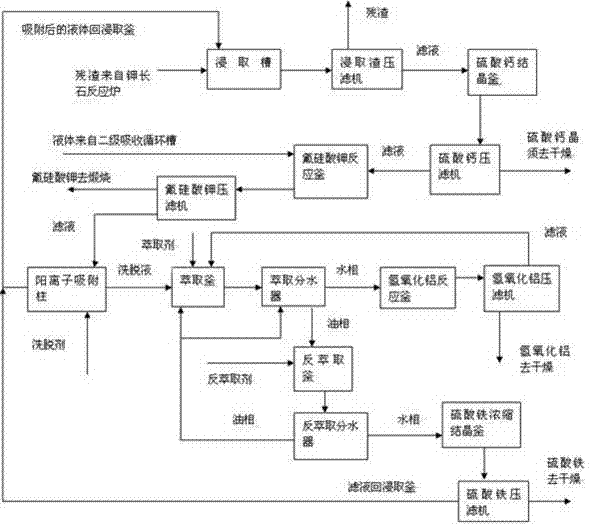

Process for decomposing potassium feldspar by adopting low-temperature semidry method for comprehensive utilization

ActiveCN103172074AAvoid wastingLower requirementSilicon halogen compoundsSilicaAluminium hydroxideDecomposition

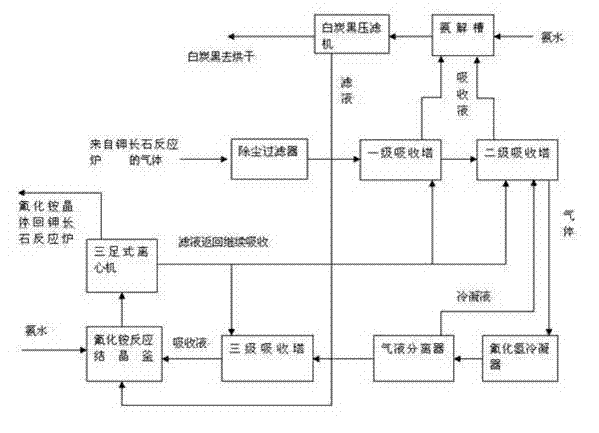

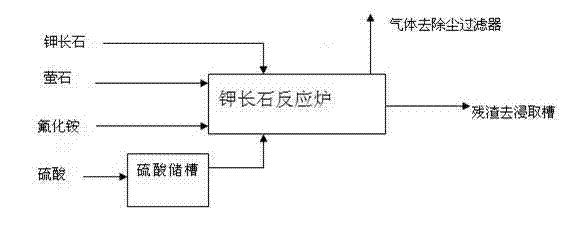

The invention relates to potassium feldspar decomposition and comprehensive utilization technology and in particular relates to a process for decomposing potassium feldspar by adopting a low-temperature semidry method for comprehensive utilization. The process comprises the steps of fully mixing potassium feldspar, fluorite and sulfuric acid, then adding the mixture to a converter reactor to react at 180-250 DEG C, separating SiF4 and HF generated through a reaction from a system under the condition of negative pressure, carrying out absorption with ethanol and water solution to prepare white carbon black, recovering fluorine resources in the process from the solution in the forms of ammonium fluoride and other aids by adopting the method of adding ammonia water and applying the recovered fluorine sources to decomposition of potassium feldspar and carrying out a series of processes such as extraction on the solids after a reaction to obtain calcium sulfate whisker, potassium fluosilicate, aluminium hydroxide and ferric sulfate products. Compared with the method for decomposing potassium feldspar by a high temperature method, the process has the advantages that the reaction conditions are mild and the requirements for equipment are lower; the white carbon black is directly prepared through gas hydrolysis, thus avoiding the tedious course from solid phase separation; and the fluorine resources introduced to the decomposition course are recycled by adopting the mode of ammonium fluoride, thus avoiding waste of the fluorine resources.

Owner:LUOYANG FLUORIDE & POTASSIUM TECH +1

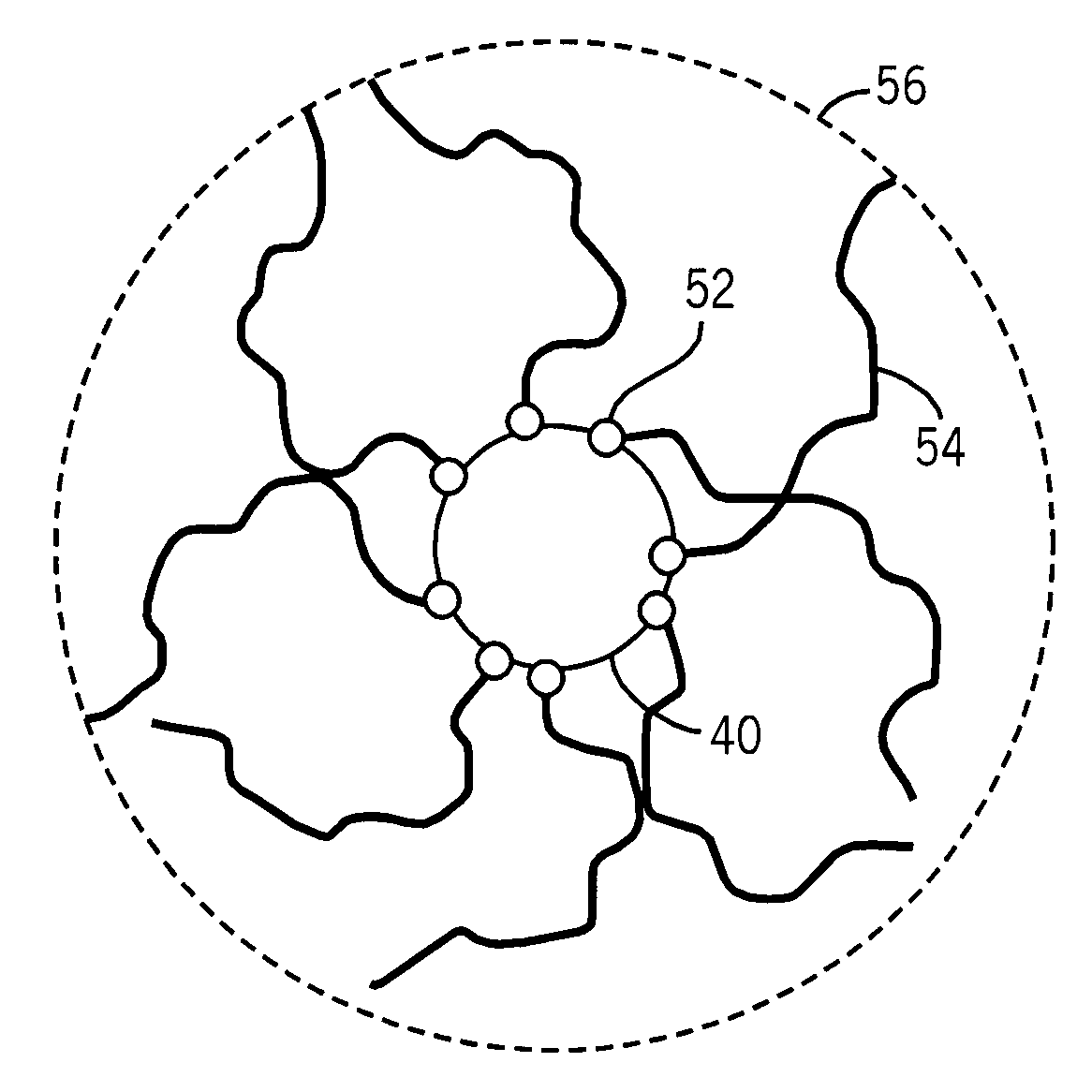

Semiconductor having large volume fraction of intermediate range order material

A high quality non-single-crystal silicon alloy material including regions of intermediate range order (IRO) silicon alloy material up to but not including the volume percentage required to form a percolation path within the material. The remainder of the material being either amorphous or a mixture of amorphous and microcrystalline materials. The materials were prepared by CVD using differing amounts of hydrogen dilution to produce materials containing differing amounts of IRO material. Preferably the material includes at least 8 volume percent of IRO material.

Owner:BEKAERT ECD SOLAR SYST

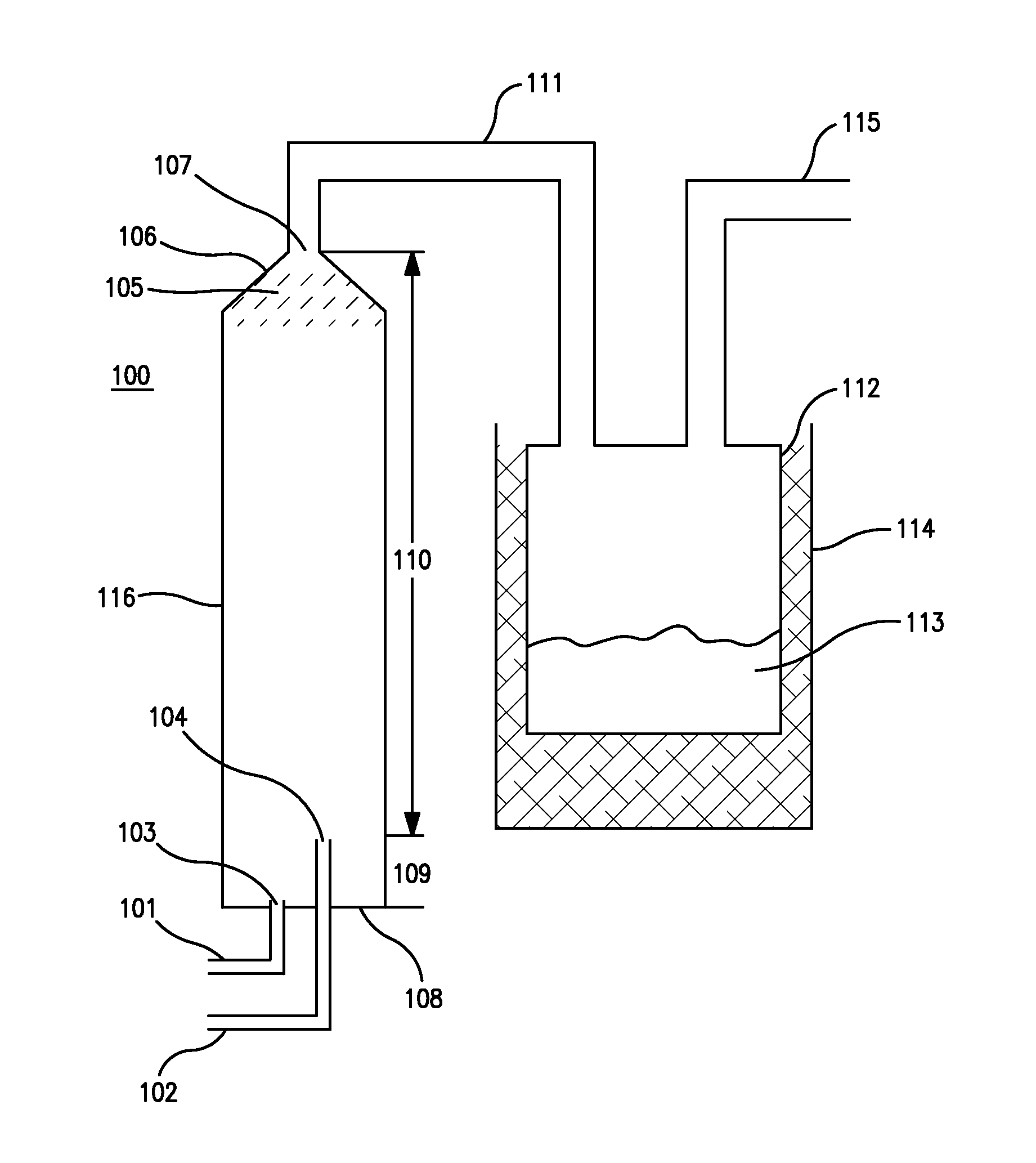

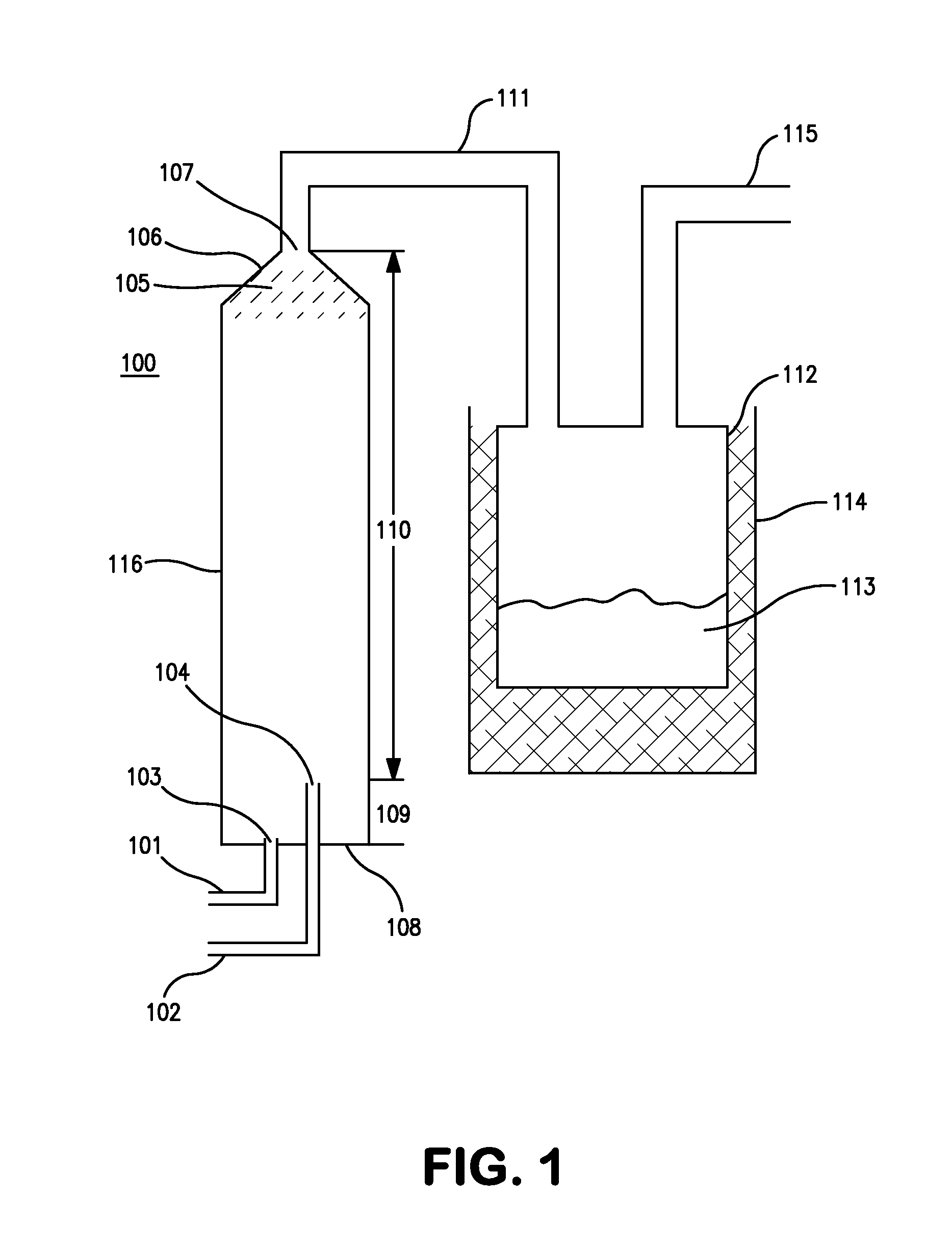

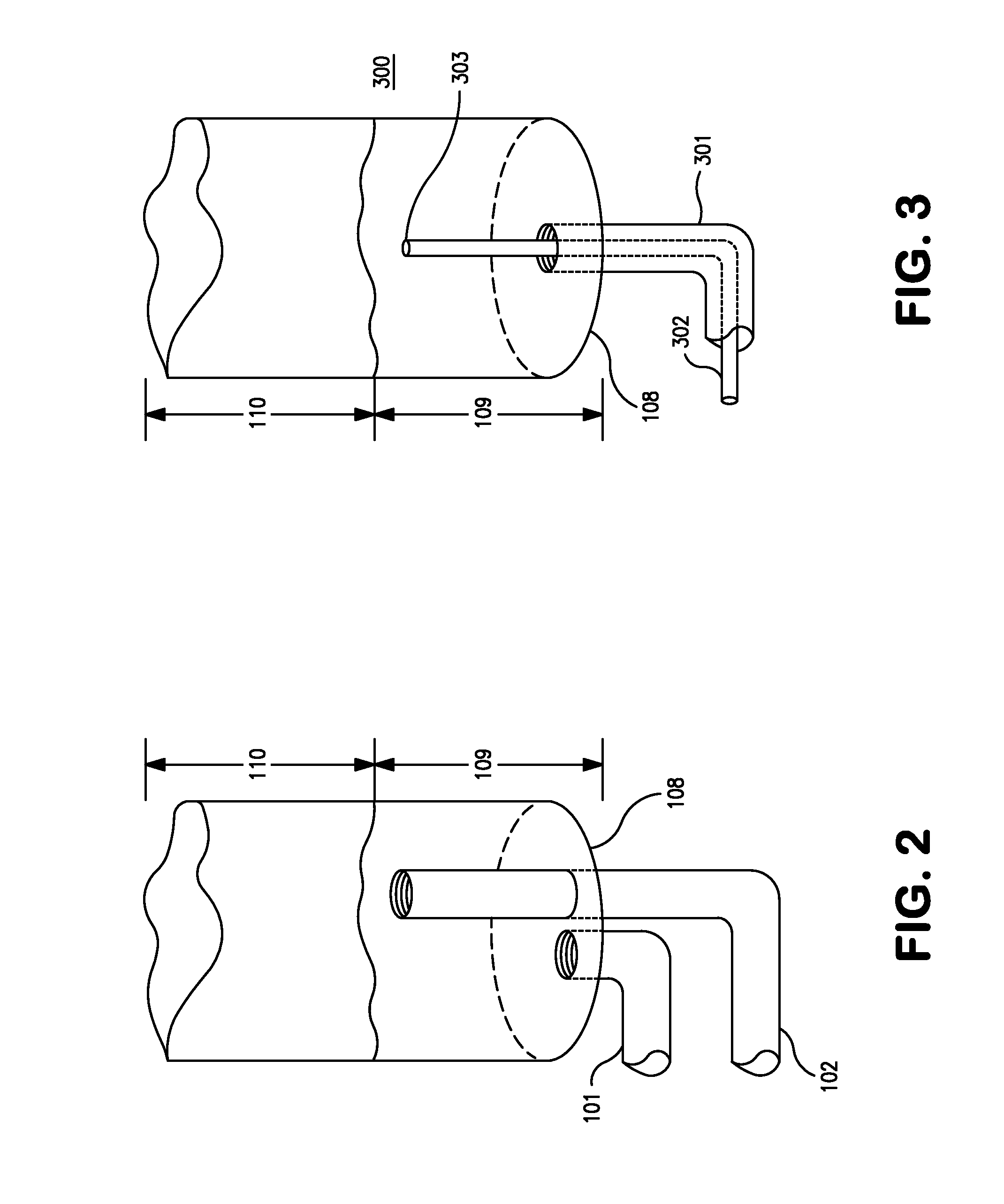

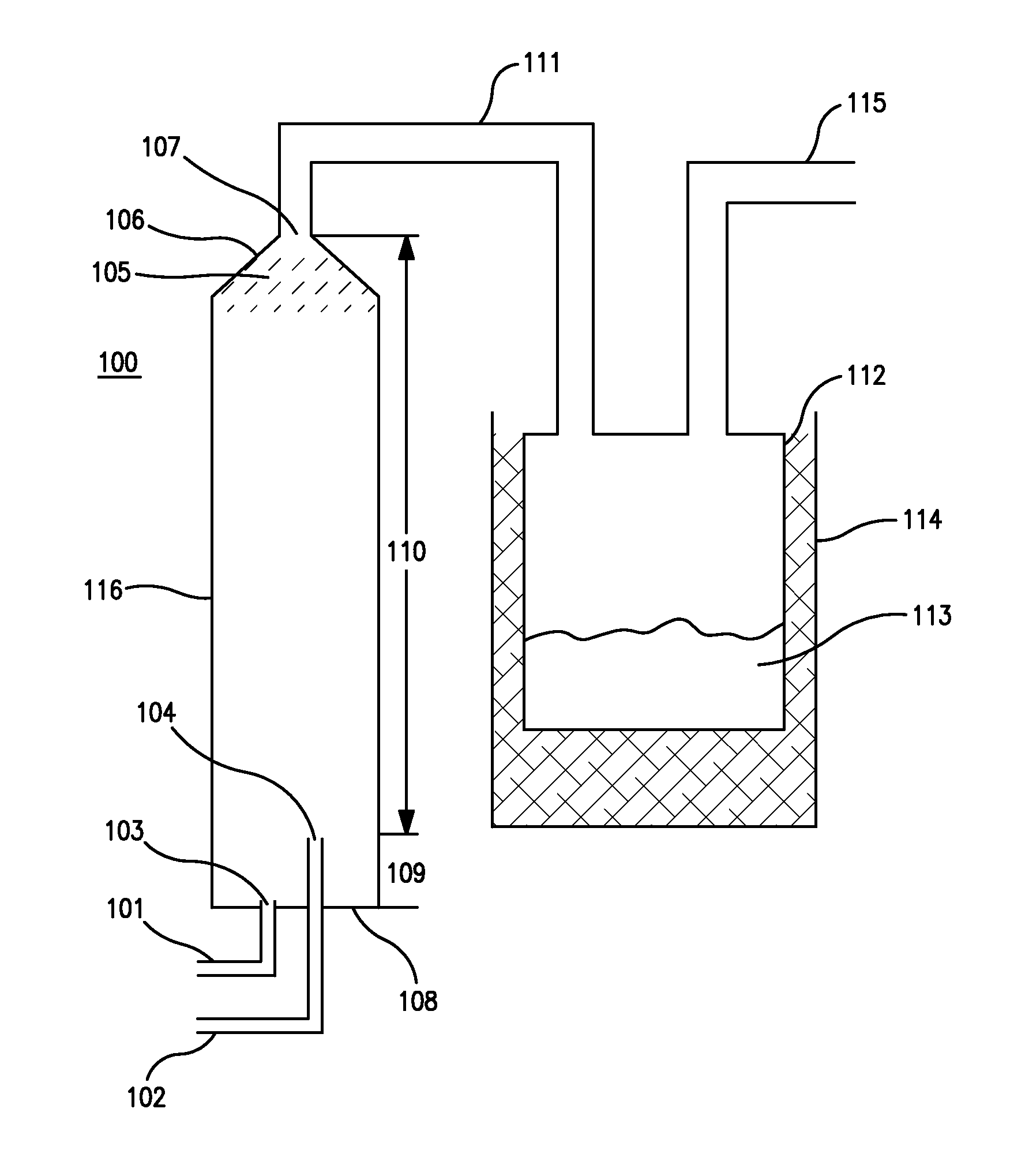

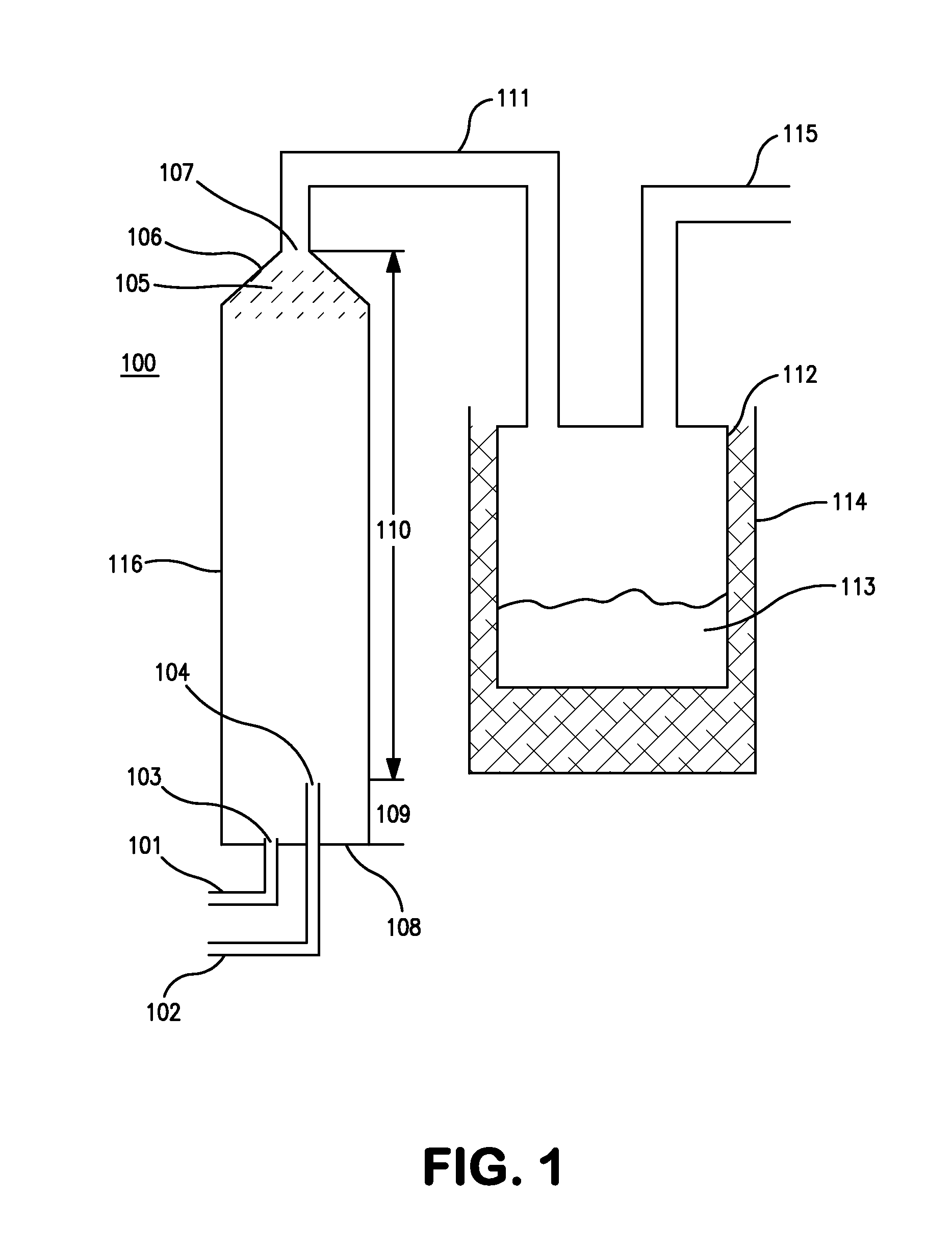

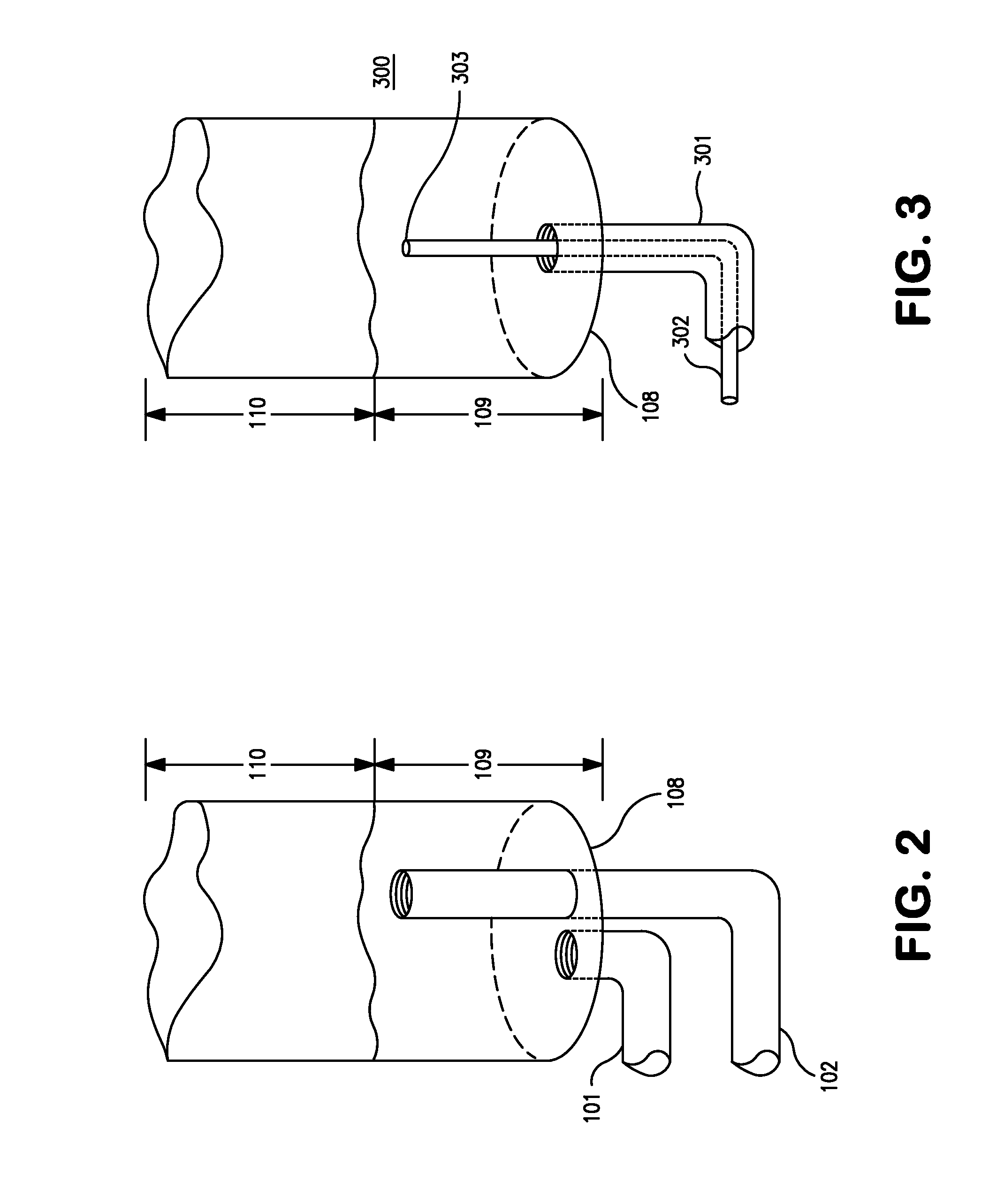

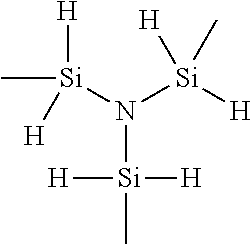

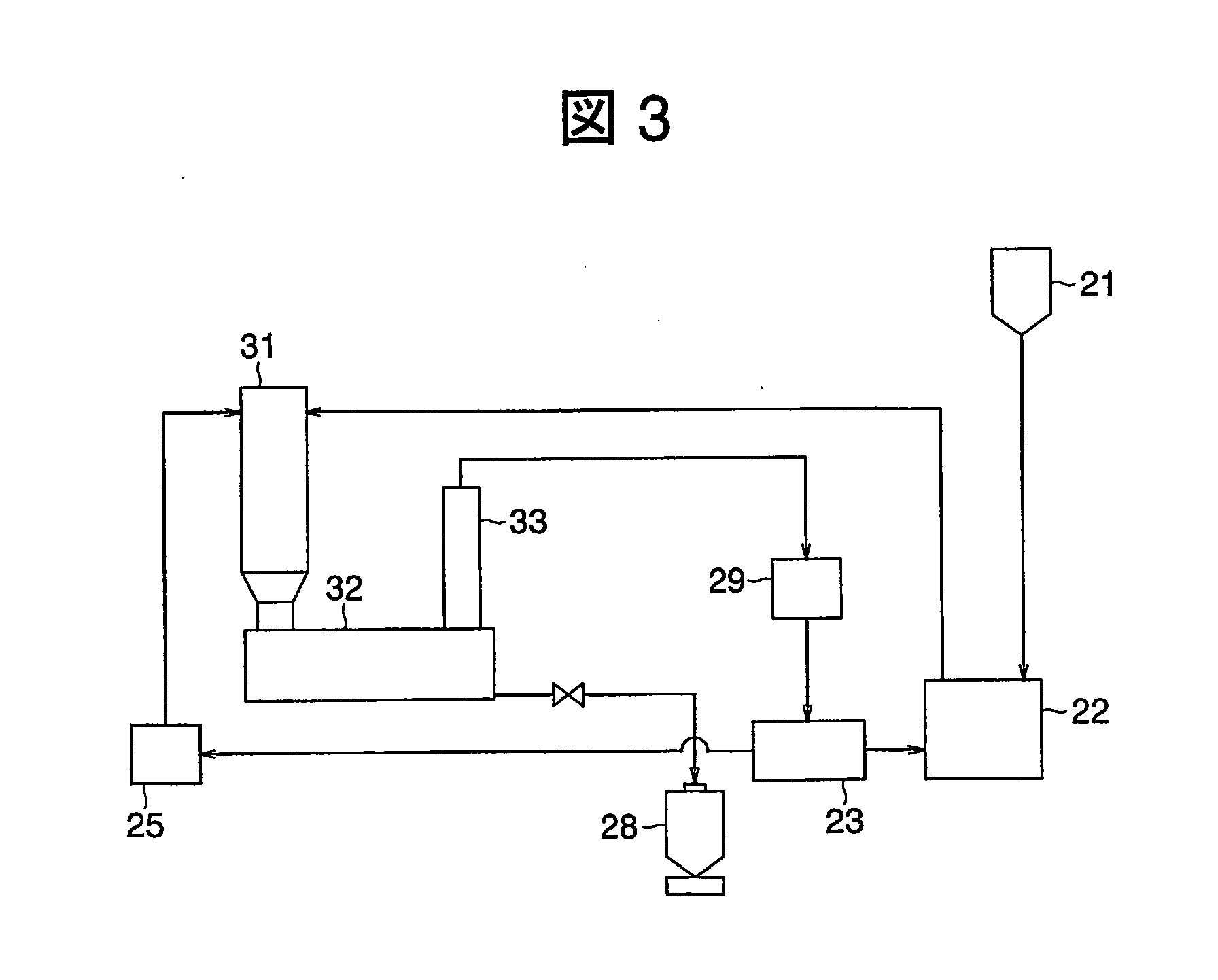

Apparatus and method for the production of trisilylamine

ActiveUS20100310443A1Increase volumeHigh volume high efficiency synthesisGroup 4/14 element organic compoundsPressurized chemical processReaction zoneProduct gas

There is described an apparatus, a tubular laminar flow, plug flow reactor, for making silylamines and particularly trisilylamine (TSA) in high yields from ammonia gas and a monohalosilane gas. The apparatus can be a tubular flow reactor comprising a first portion of the reactor defining a gas entry zone, a second portion of the reactor defining a reaction zone and a third portion of the reactor defining a separation zone, the reaction zone providing a reactant contacting region. Trisilylamine can be recovered in the separation zone in a cold trap collection vessel.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

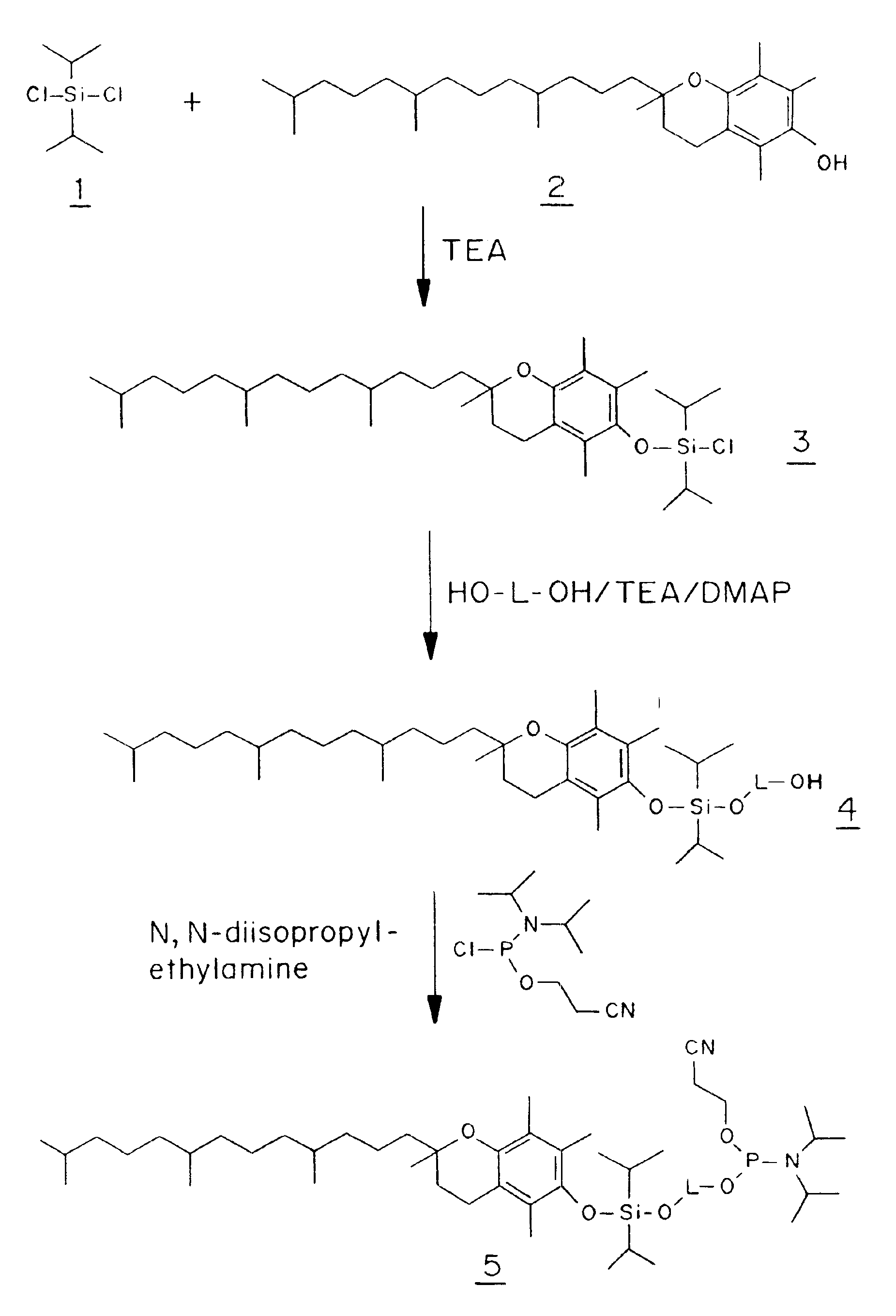

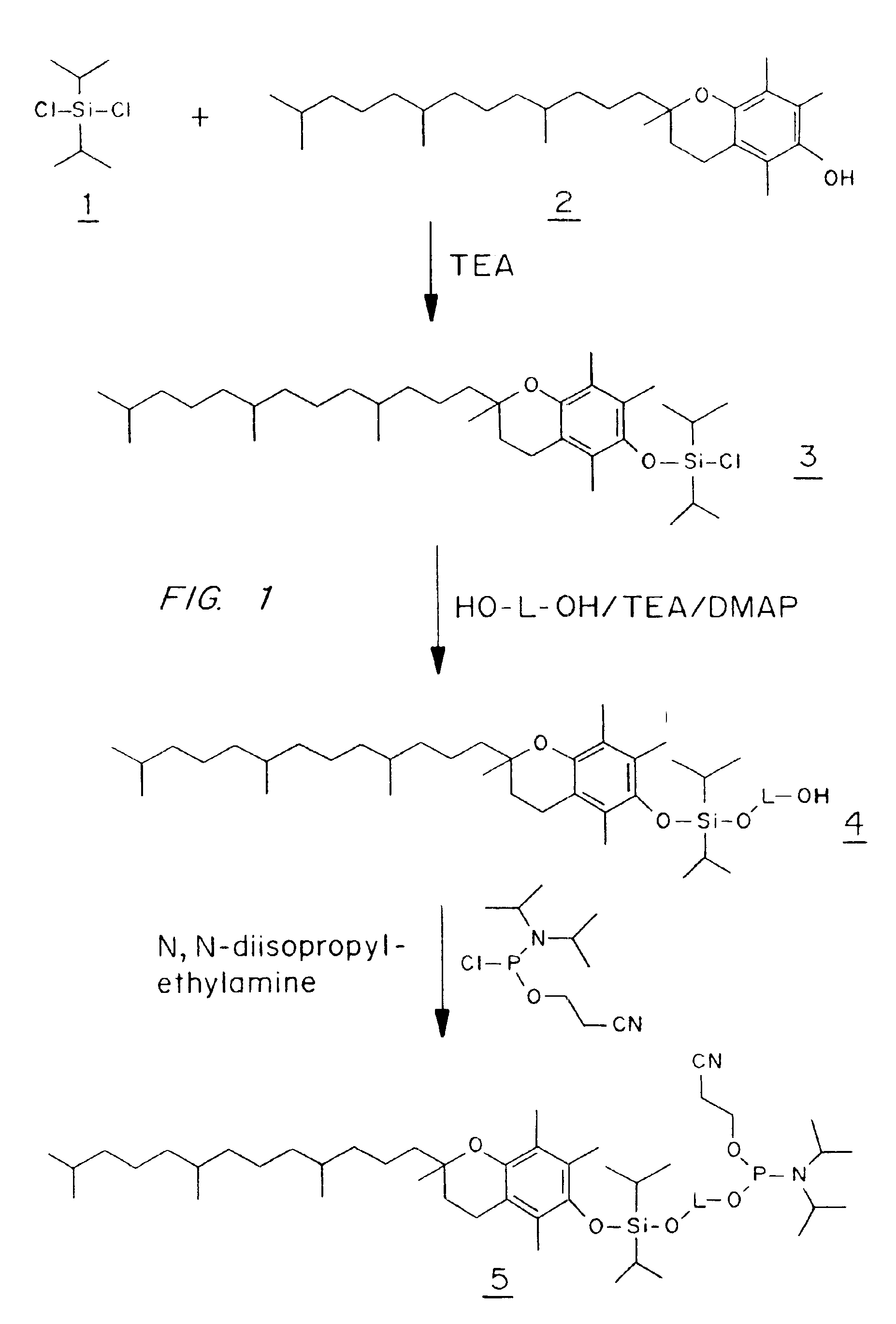

Purification of oligomers

InactiveUS6921818B2Easy to separateEfficient purificationSilicon organic compoundsSilicon halogen compoundsChromatographic separationSilylene

Compositions and methods are disclosed which facilitate purification of oligomers and other compounds. The disclosed compositions are silyl compositions that can be directly coupled, or coupled through a linking group, to a compound of interest, preferably to an oligomer at the end of oligomer synthesis. The silicon atom includes between one and three sidechains that function as capture tags. In one embodiment, the capture tags are lipophilic, which allows a derivatized oligomer to be separated from failure sequences by reverse phase chromatography. In another embodiment, the capture tags are compounds with a known affinity for other compounds, which other compounds are preferably associated with a solid support to allow chromatographic separation. Examples include haptens, antibodies, and ligands. Biotin, which can bind to or interact with a streptavidin-bound solid support, is a preferred capture tag of this type.

Owner:YALE UNIV

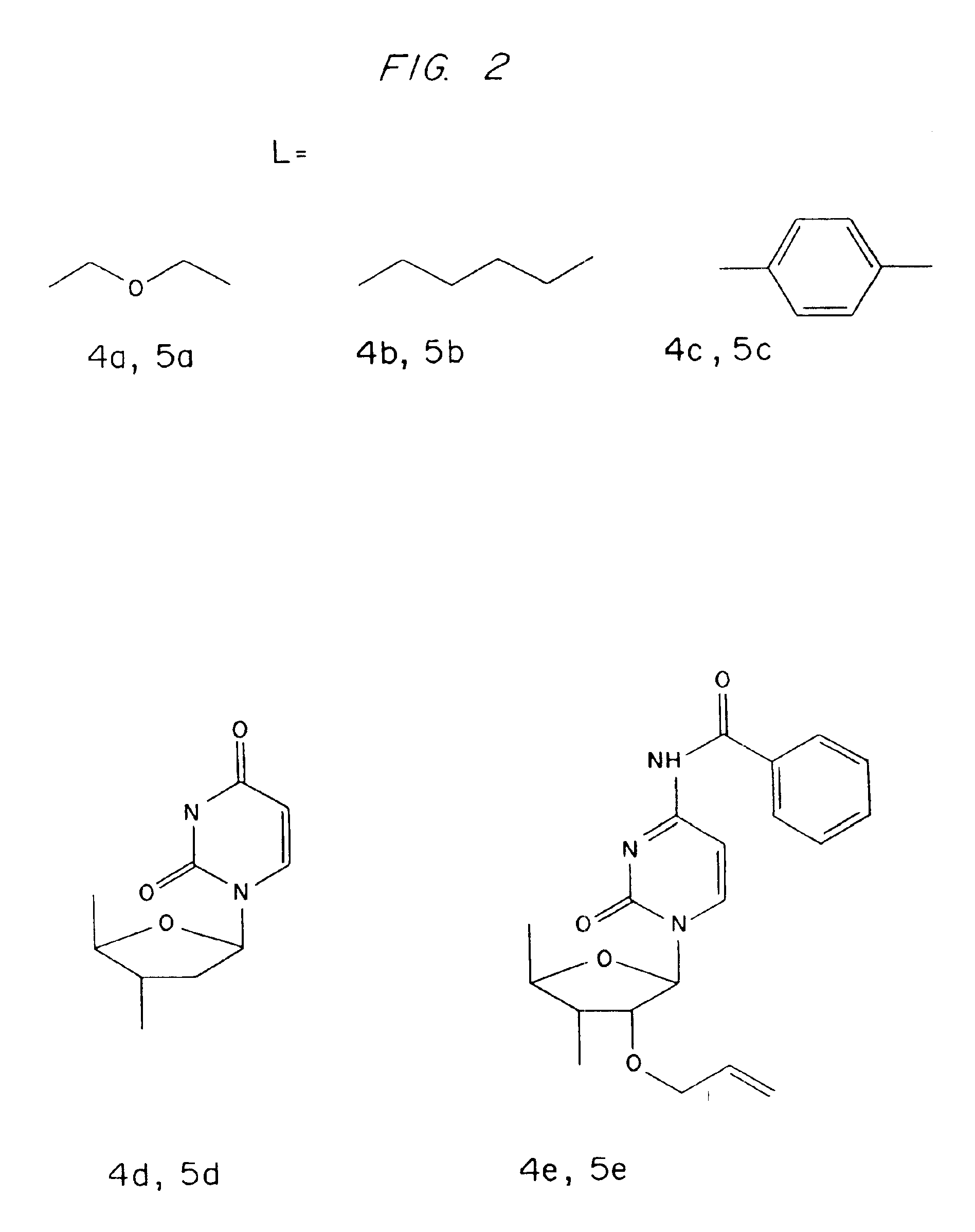

Method for absorbing and extracting phosphor and fluorin from phosphoric acid produced in kiln method

InactiveCN101049920AImprove separation rateHigh puritySilicon halogen compoundsPhosphoric acidHigh concentrationAbsorption column

This invention discloses a method for separating phosphorus and fluorine of kiln process phosphoric acid by absorption. The method comprises: sending relatively high temperature phosphoric acid after hydration in primary and secondary hydration columns to a circulation tank for cooling, pumping into the hydration columns for circulation, sending gases after primary and secondary absorption to a Venturi absorber for re-absorption, collecting the residual acid mist by a collector, sending the absorbed gas and tail gas after fluorine absorption together to a chemical absorption column, and exhausting the tail gas. Besides, qualified fluosilicic acid can be obtained from the fluorine-containing diluted H3PO4 in the collector. The method utilizes the air with residual heat in the kiln, and has such advantages as no extra energy consumption, high phosphorus and fluorine separation efficiency, high concentration and low fluorine content in obtained H3PO4, and low P2O5 content in obtained fluosilicic acid. The obtained fluosilicic acid has a wide concentration range and a high purity, and is easy to utilize.

Owner:HUBEI SANXIN PHOSPHORIC ACID

Nano-scale metal halide scintillation materials and methods for making same

Crystalline scintillator materials comprising nano-scale particles of metal halides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In these methods, ionic liquids are used in place of water to allow precipitation of the final product. In one method, the metal precursors and halide salts are dissolved in separate ionic liquids to form solutions, which are then combined to form the nano-crystalline end product. In the other methods, micro-emulsions are formed using ionic liquids to control particle size.

Owner:GENERAL ELECTRIC CO

Apparatus and method for the production of trisilylamine

There is described an apparatus, a tubular laminar flow, plug flow reactor, for making silylamines and particularly trisilylamine (TSA) in high yields from ammonia gas and a monohalosilane gas. The apparatus can be a tubular flow reactor comprising a first portion of the reactor defining a gas entry zone, a second portion of the reactor defining a reaction zone and a third portion of the reactor defining a separation zone, the reaction zone providing a reactant contacting region. Trisilylamine can be recovered in the separation zone in a cold trap collection vessel.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

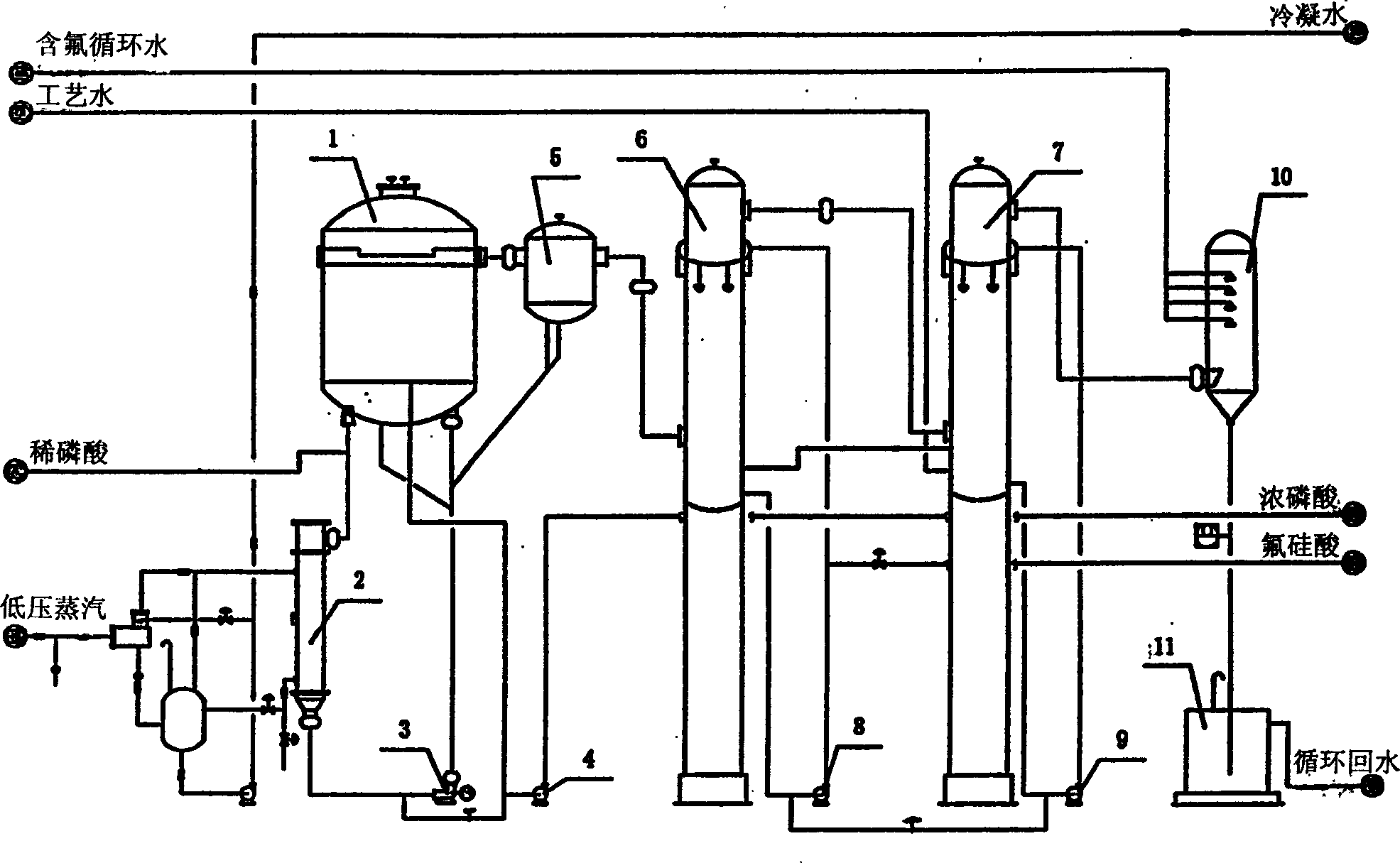

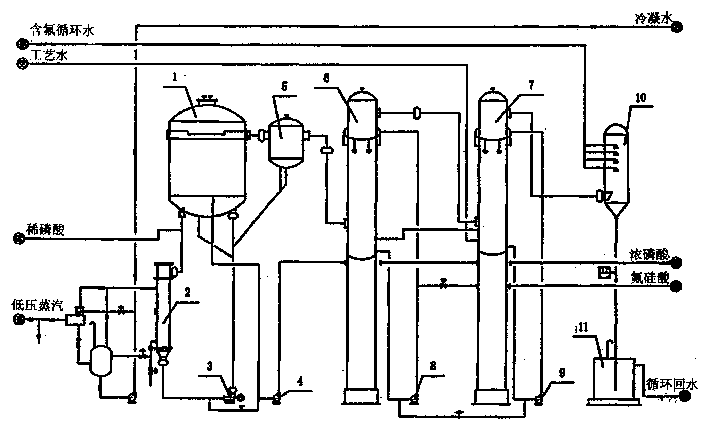

Method for producing phosphoric acid by adopting steam heating forced circulation concentration wet process and its equipment

InactiveCN1460636ALess process equipmentCompact layoutSilicon halogen compoundsPhosphorus compoundsGas phasePhosphoric acid

The phosphoric acid can be circularly heated and concentrated in a circulating loop formed from flash chamber, graphitic heat exchanger and axial-flow circulating pump, the diluted phosphoric acid can be added into the circulating loop from outlet pipe of graphitic heat exchanger, and the evaporated steam can be passed through the entrainment eliminator to remove entrained acid foam, then the steam is more passed through two-stage fluorine absorbing tower, sprayed and washed so as to recover fluoride in the gas phase. The vacuum required for flash chamber is provided by atmosphere condenser. Said invention can make wet phosphoric acid be concentrated to 48-50% P2O5 from 20-25% P2O5.

Owner:EAST CHINA ENG SCI & TECH

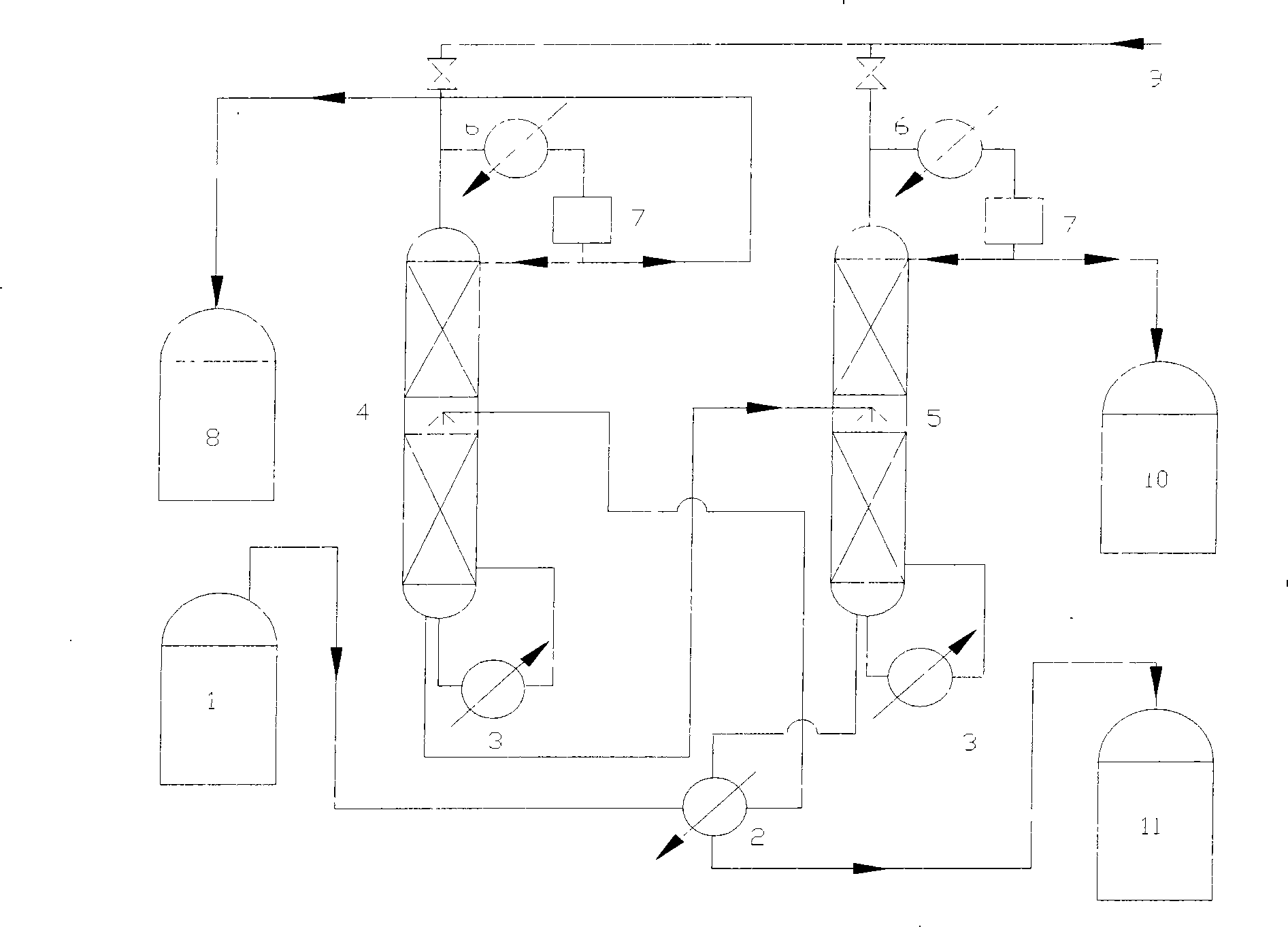

Separation apparatus and method of high precision rectification purify trichlorosilane

InactiveCN101249312AHigh boiling pointImprove heat transfer efficiencySilicon halogen compoundsFractional distillationDistillationSeparation technology

The invention relates to a separation device which adopts the pressurized continuous high-precision distillation for extracting trichlorosilane and method thereof, including a low-boiling-point compound separation tower, a high-boiling-point compound separation tower and a hydrogen or argon pressurizing system, wherein, the feeding materials enter the middle part of the low-boiling-point compound separation tower after passing by a raw material pre-heating heat exchanger, the low-boiling-point products are separated at the tower top of the low-boiling-point compound separation tower, and a trichlorosilane forerunning product discharge pipe line at the tower bottom is connected to enter the middle part of the high-boiling-point compound separation tower. The high-purity trichlorosilane product is obtained at the tower top. The purity of the purified trichlorosilane product by the process reaches more than 99.999 percent, wherein, the content of boron, phosphorous, iron and other impurities is all less than 10ppb, the content of the impurities of the mixture of the trichlorosilane and other low-boiling-point compounds and high-boiling-point compounds is less than 5.0ppm, the recovery rate of the process is larger than 98.0 percent, meanwhile, the pressurized continuous high-precision thermal coupling distillation and separation technology of the entire invention has simple process flow and lower energy consumption.

Owner:TIANJIN UNIV

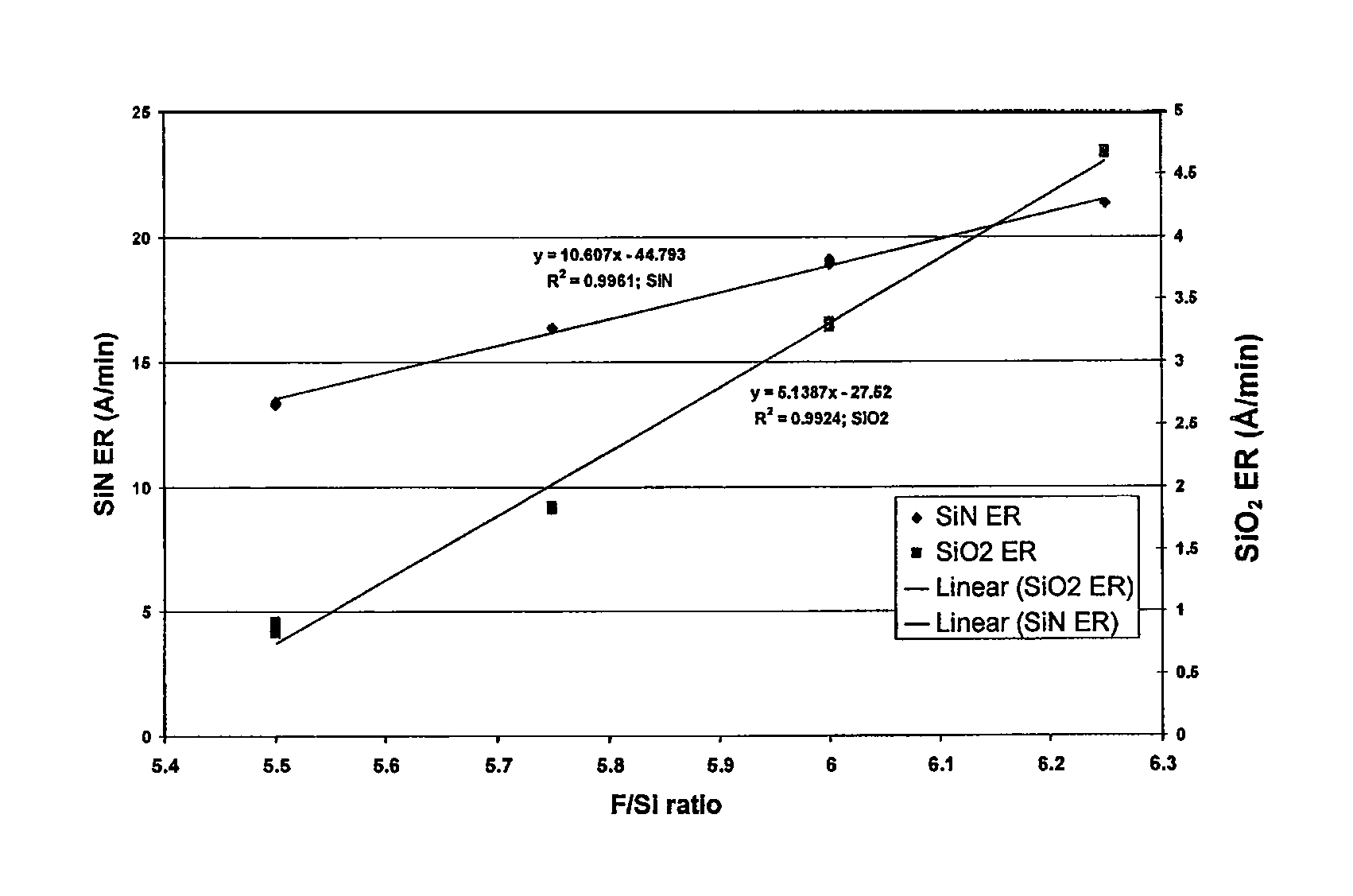

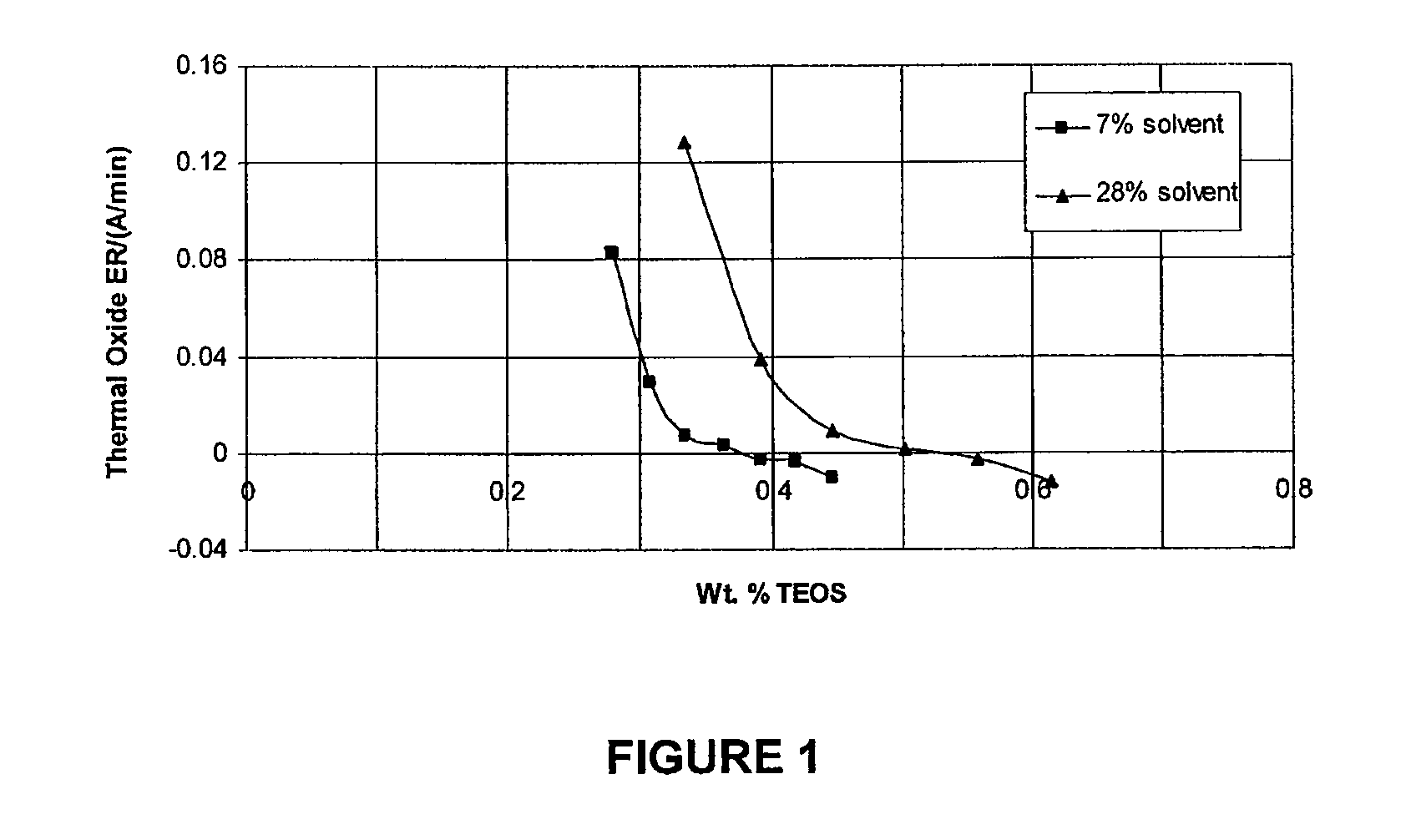

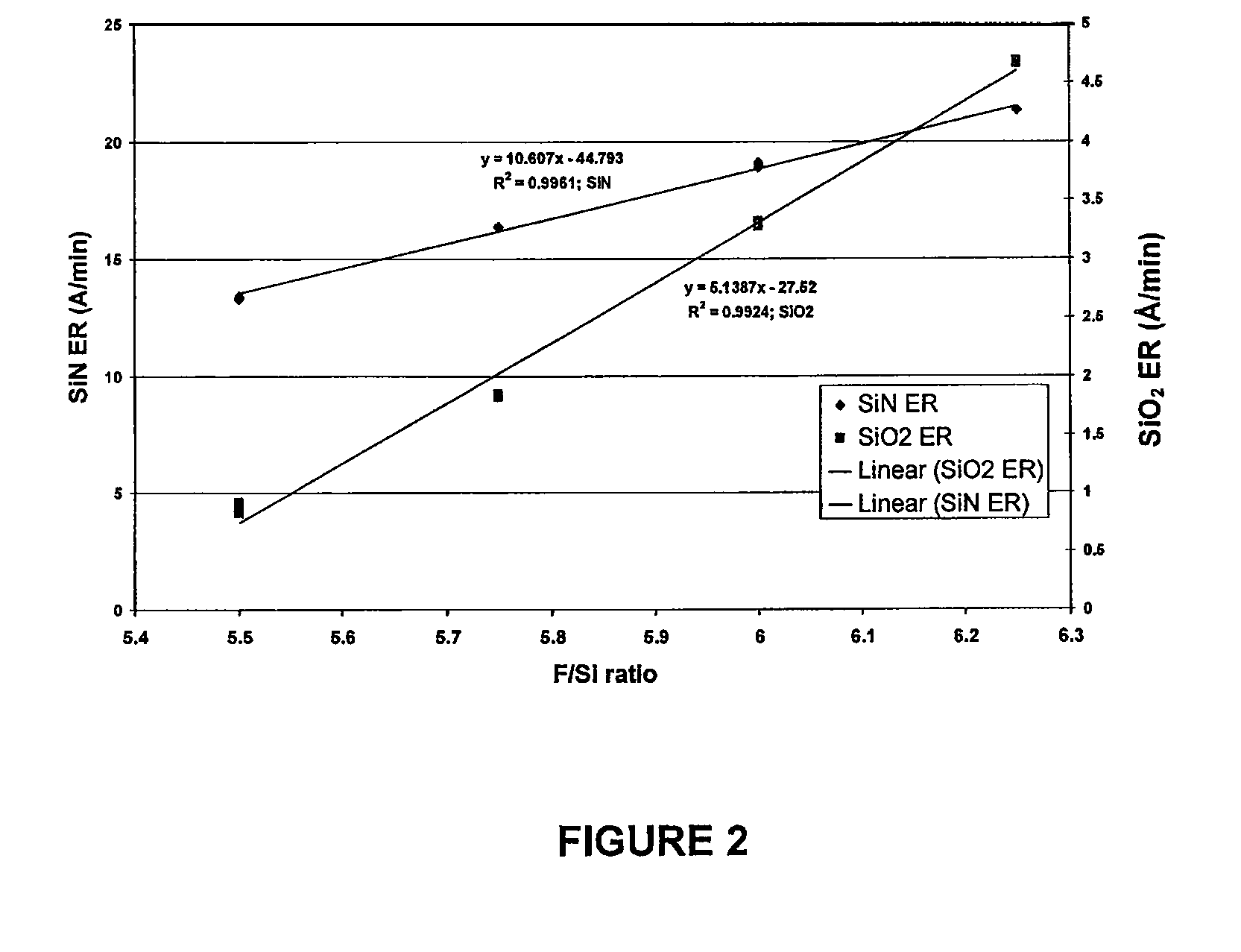

Compositions and methods for the selective removal of silicon nitride

ActiveUS8778210B2Effectively and efficiently etching a layerIncrease etch rateSilicon halogen compoundsDecorative surface effectsSilicic acidSilicon oxide

Compositions useful for the selective removal of silicon nitride materials relative to poly-silicon, silicon oxide materials and / or silicide materials from a microelectronic device having same thereon. The removal compositions include fluorosilicic acid, silicic acid, and at least one organic solvent. Typical process temperatures are less than about 100° C. and typical selectivity for nitride versus oxide etch is about 200:1 to about 2000:1. Under typical process conditions, nickel-based silicides as well as titanium and tantalum nitrides are largely unaffected, and polysilicon etch rates are less than about 1 Å min−1.

Owner:ENTEGRIS INC

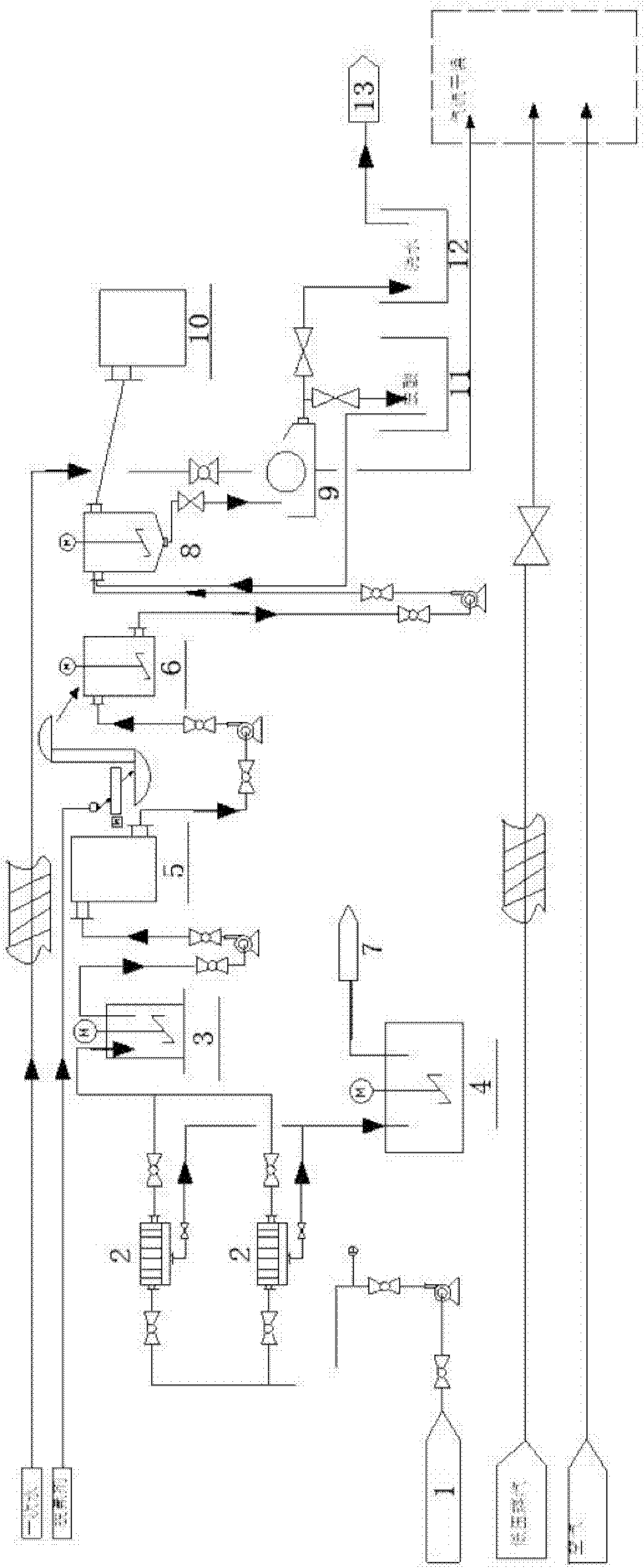

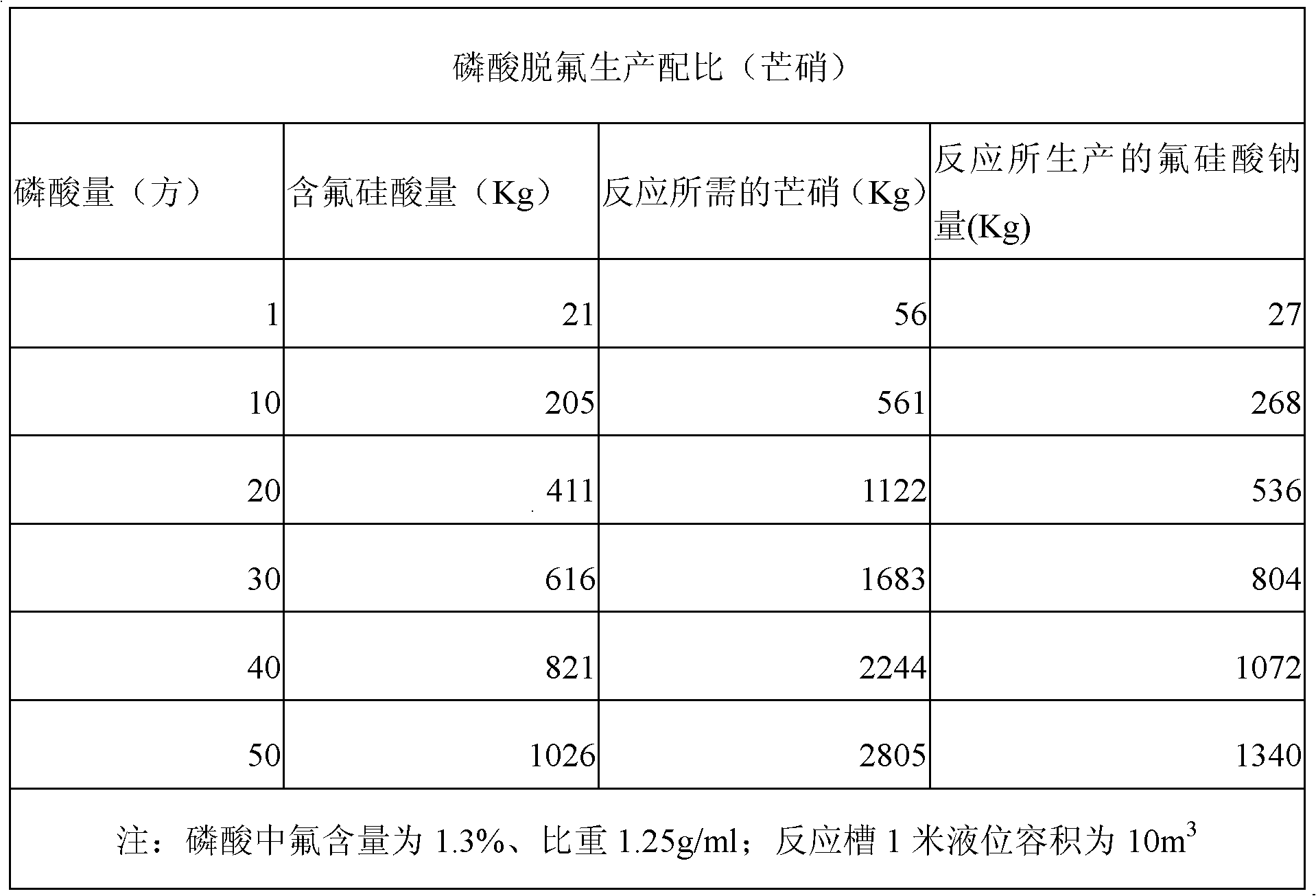

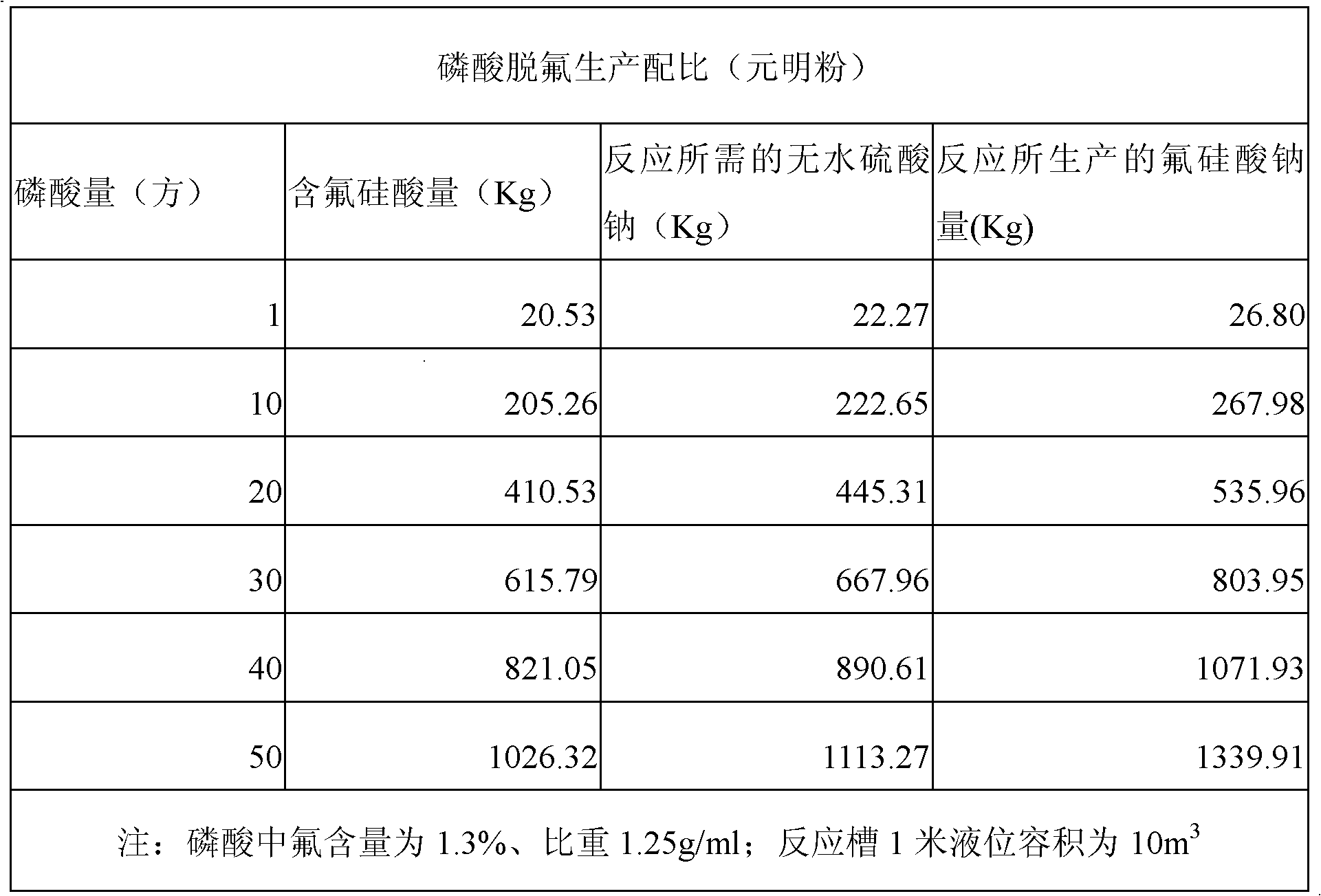

Production method of sodium fluosilicate

InactiveCN102153091AQuality improvementReduce or eliminate hazardsSilicon halogen compoundsPhosphoric acidEconomic benefits

The invention relates to a production method of sodium fluosilicate. The method comprises the following steps: adding a phosphoric acid purification device to purify the phosphoric acid produced in a phosphoric acid workshop; injecting the purified phosphoric acid in a filtrate receiver, injecting in a reaction tank by using a variable frequency pump; injecting fluorine-removing agent in the reaction tank at a ratio according to the fluorine content of phosphoric acid, reacting by utilizing the stirring action of the reaction tank; injecting the obtained mixture in a settling tank by using a pump after the reaction in the reaction tank, centrifuging the settled precipitate, and drying to obtain a sodium fluosilicate product and obtain the defluorinated phosphoric acid on the upper layer. In the method, after wet-process phosphoric acid is purified, fluorine-removing agent is used to remove about 2% of fluorine in phosphoric acid and form insoluble fluosilicate, and the fluosilicate is precipitated, washed, separated and dried to obtain a sodium fluosilicate product, thus the rational utilization of resource can be realized and the economic benefit of the enterprise can be increased. By adopting the method, fluorine resource can be fully recycled in the production process of compound fertilizer, high quality fluorine-free compound fertilizer can be produced and the damages to soil can be reduced or eliminated.

Owner:山东聊城鲁西化工第四化肥有限公司

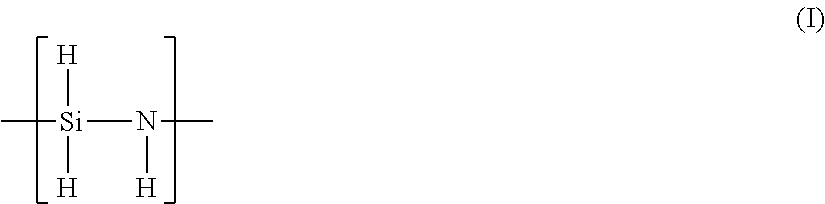

Inorganic polysilazane resin

InactiveUS20150004421A1Small shrinkageSmall residual stressSilicon halogen compoundsLayered productsOligomerSilazane

An inorganic polysilazane resin of the present invention has a Si / N ratio (i.e. a ratio of contained silicon atoms to contained nitrogen atoms) of 1.30 or more. The inorganic polysilazane resin having such a high Si content can be produced by, for example, a method in which an inorganic polysilazane compound containing both Si—NH and Si—Cl is heated to react NH with Cl, a method in which a silazane oligomer (polymer) that leaves no Si—Cl bond is synthesized and a dihalosilane is added to the synthesized silazane oligomer (polymer) to perform a thermal reaction, and the like. A siliceous film can be formed by, for example, applying a coating composition containing the inorganic polysilazane resin onto a base plate and then dried and the dried product is then oxidized by bringing the dried product into contact with water vapor or hydrogen peroxide vapor and water vapor under heated conditions.

Owner:AZ ELECTRONICS MATERIALS LUXEMBOURG R L

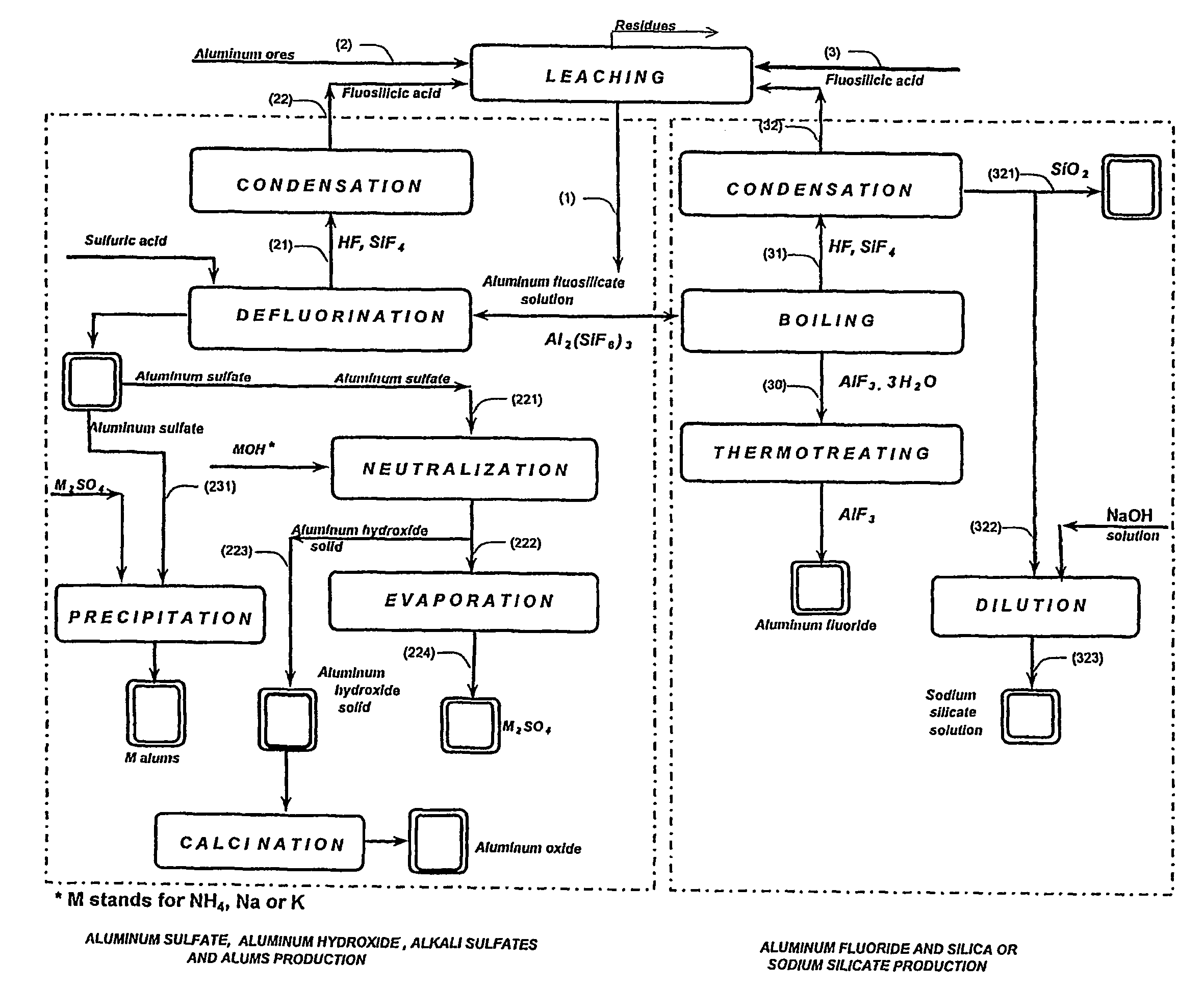

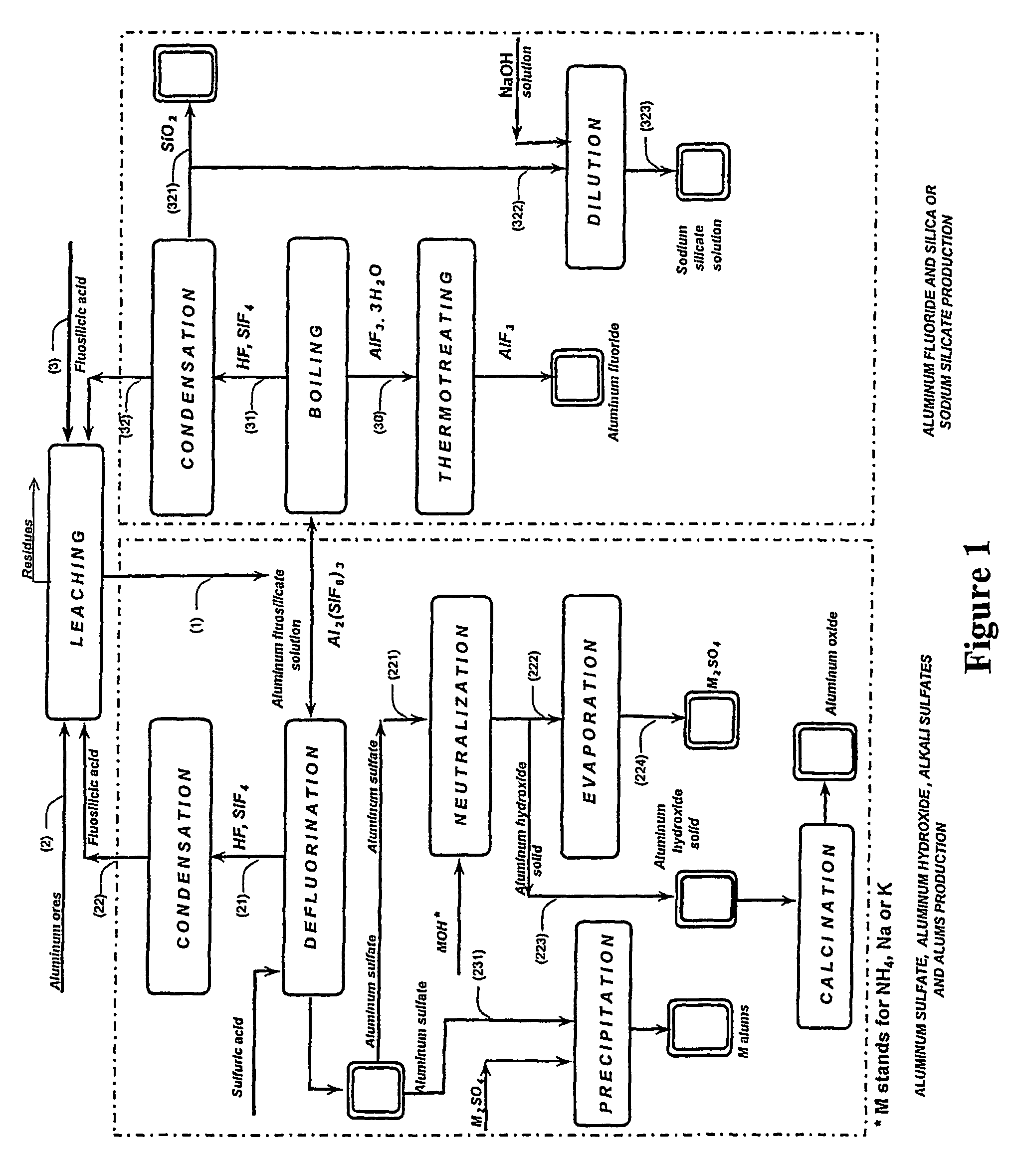

Production of aluminum compounds and silica from ores

A method for the production of inorganic aluminum substances and amorphous silica from aluminum oxide containing ores, comprising: (a) leaching of said ores with fluorosilicic acid to obtain aluminum fluosilicate solution; (b) filtering said leached solution from insoluble materials; and (c) washing said insoluble materials.

Owner:ATI ALUMINUM TECH ISRAEL

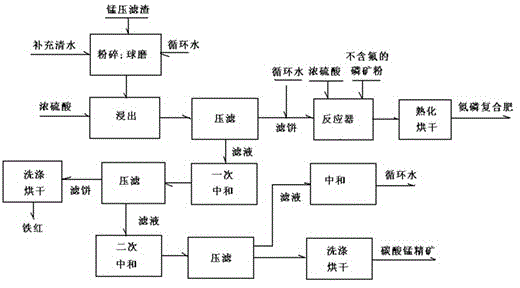

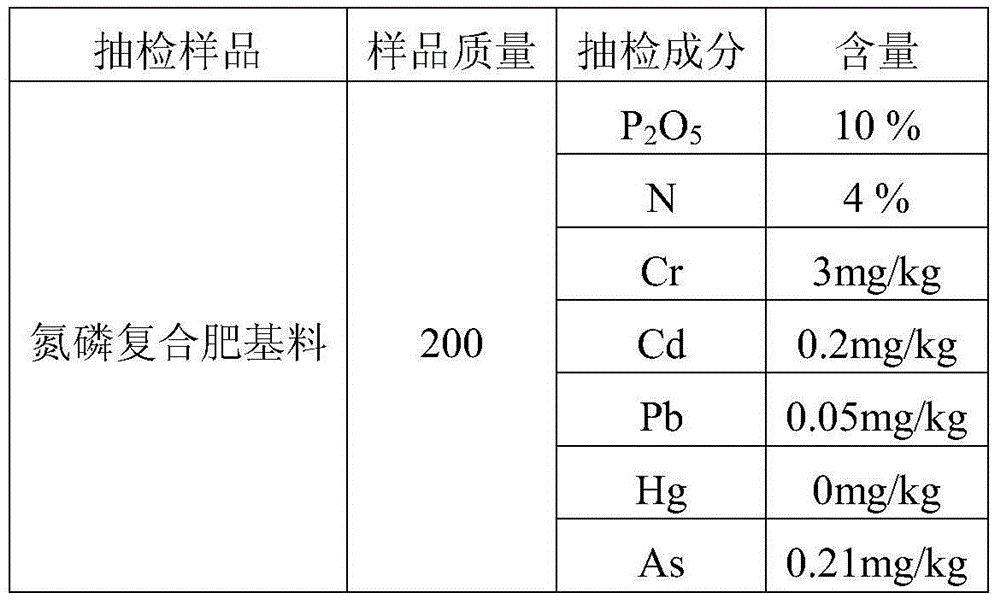

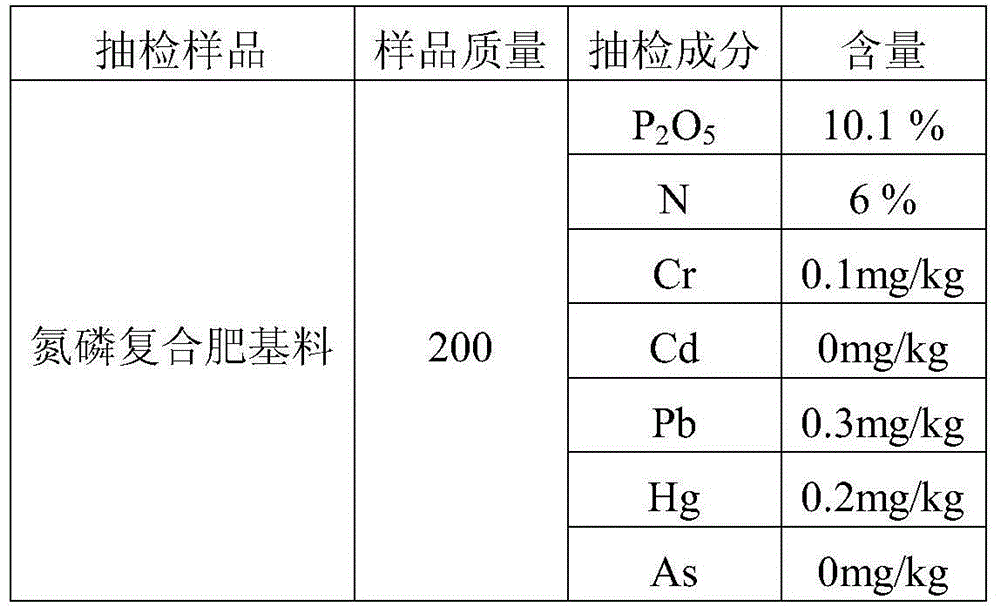

Method for recycling waste residue in manganese industry production

InactiveCN104480314AEfficient recyclingAvoid churnSilicon halogen compoundsProcess efficiency improvementWastewaterManganese

The invention relates to a method for recycling waste residue in manganese industry production. The method comprises the specific following steps: (1) pre-processing filter residue; (2) adding acid and leaching; (3) carrying out filtering and solid-liquid separation on ore slurry; (4) recovering hematite powder; (5) recovering manganese carbonate concentrate; and (6) preparing a nitrogen-phosphorus compound fertilizer base material. By the method, hematite powder, manganese carbonate concentrate and the nitrogen-phosphorus compound fertilizer base material can be recovered from leached press-filtered residue, the process is simple and is easy to achieve industrialization and meanwhile, the content of the heavy metal ingredients is in completely in conformity with national associated standards, treated wastewater and waste residue are free of harmful ingredients such as heavy metals, the environmental pressure is alleviated and the method has great promotional values.

Owner:大新县信锰矿业有限公司

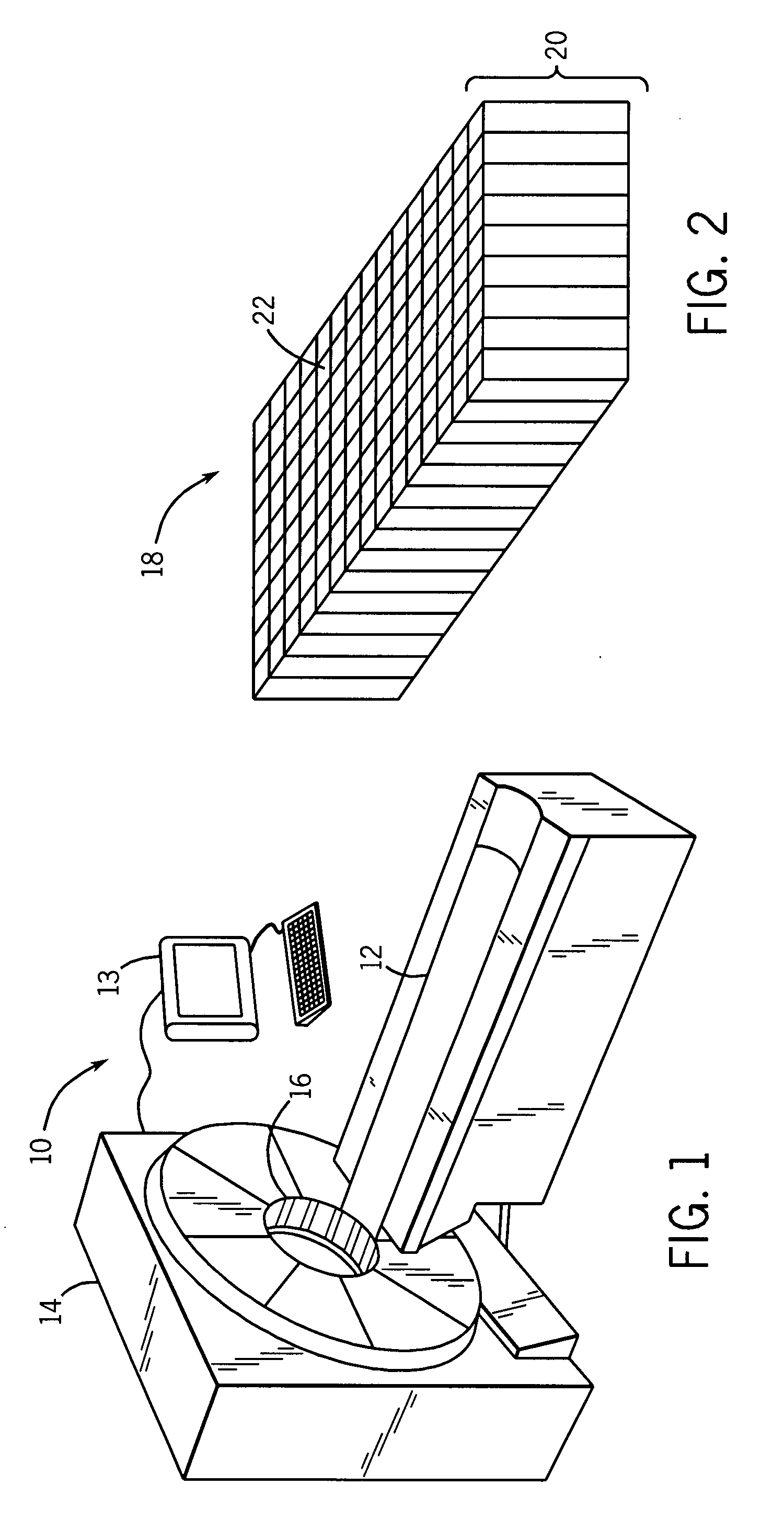

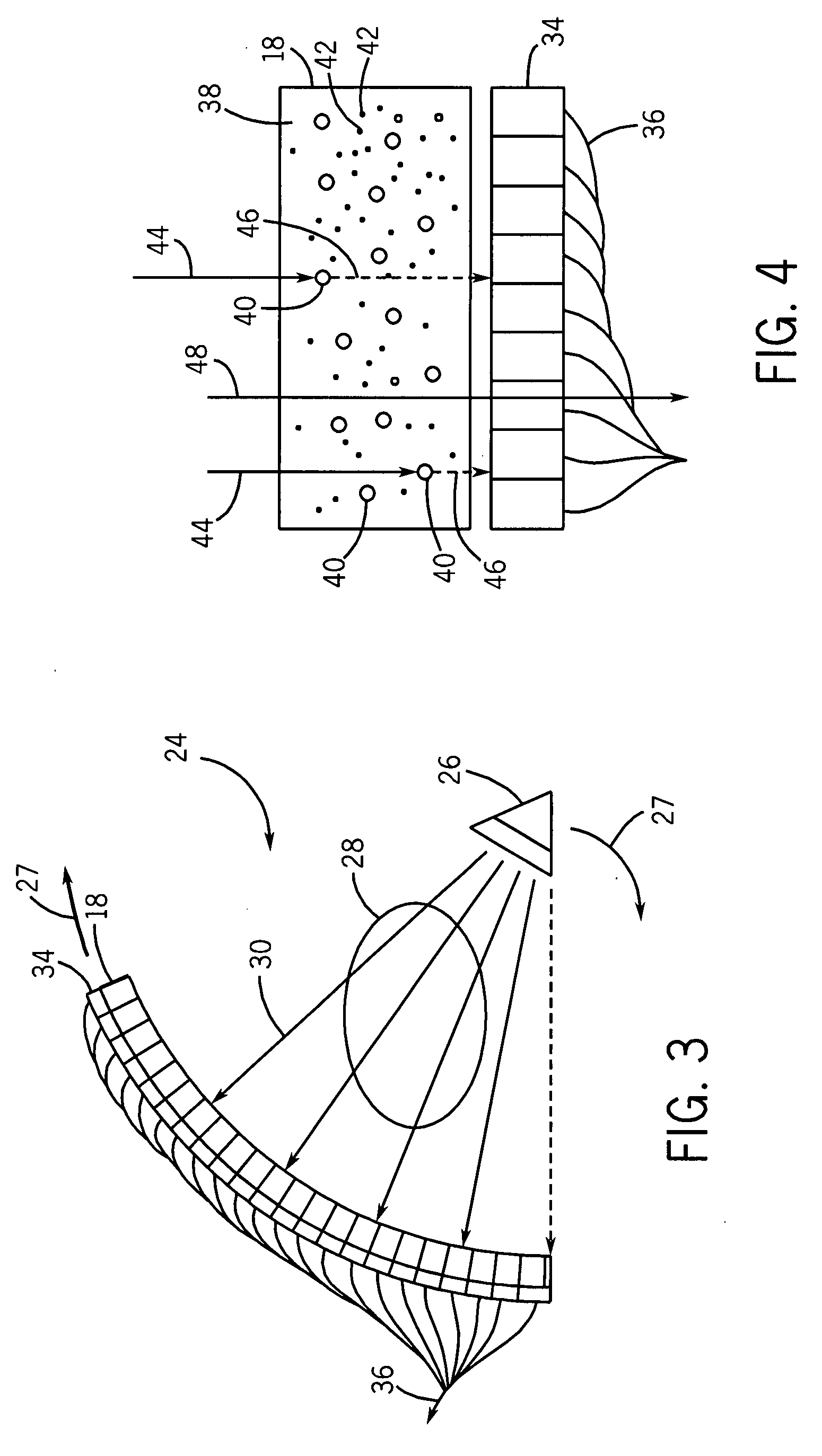

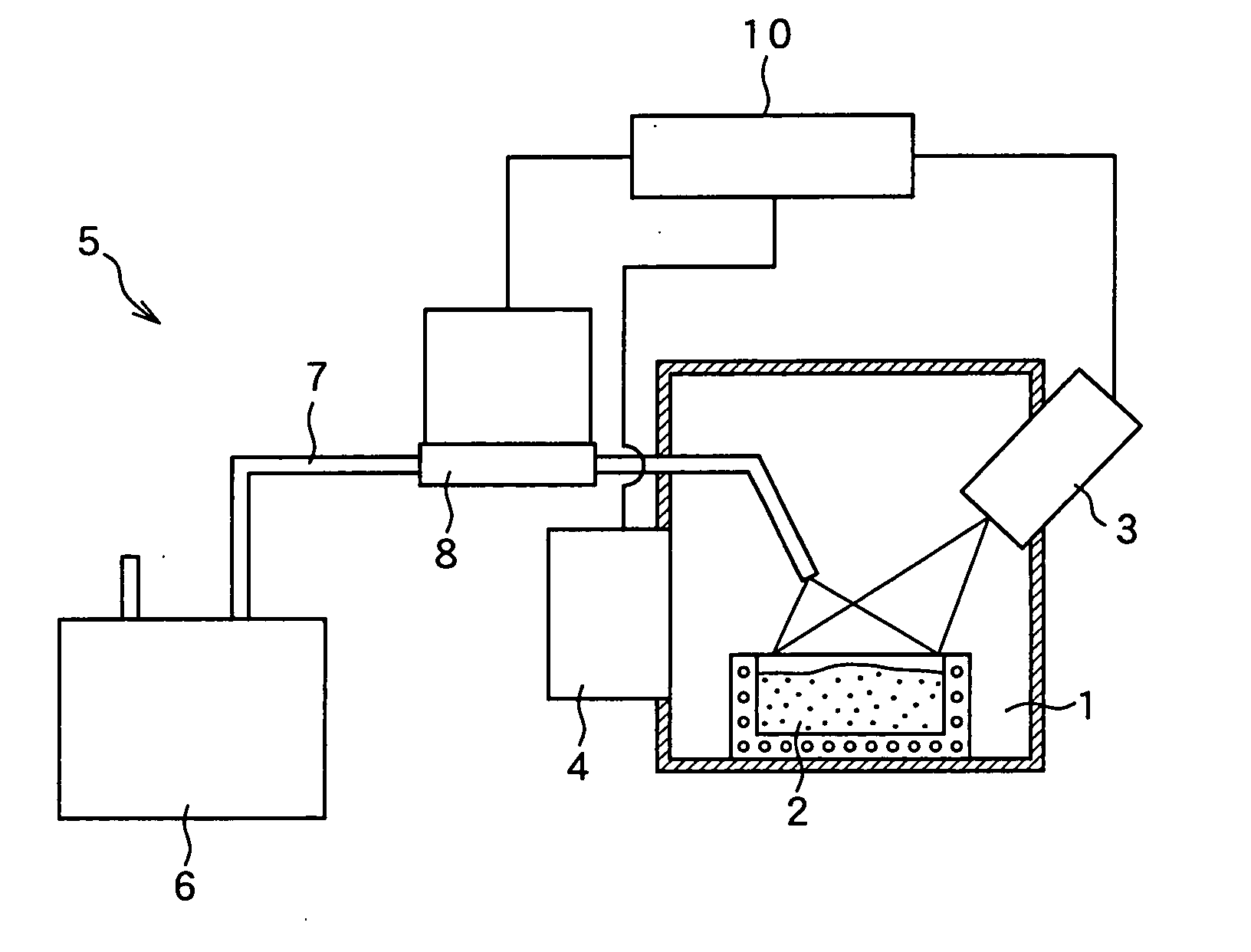

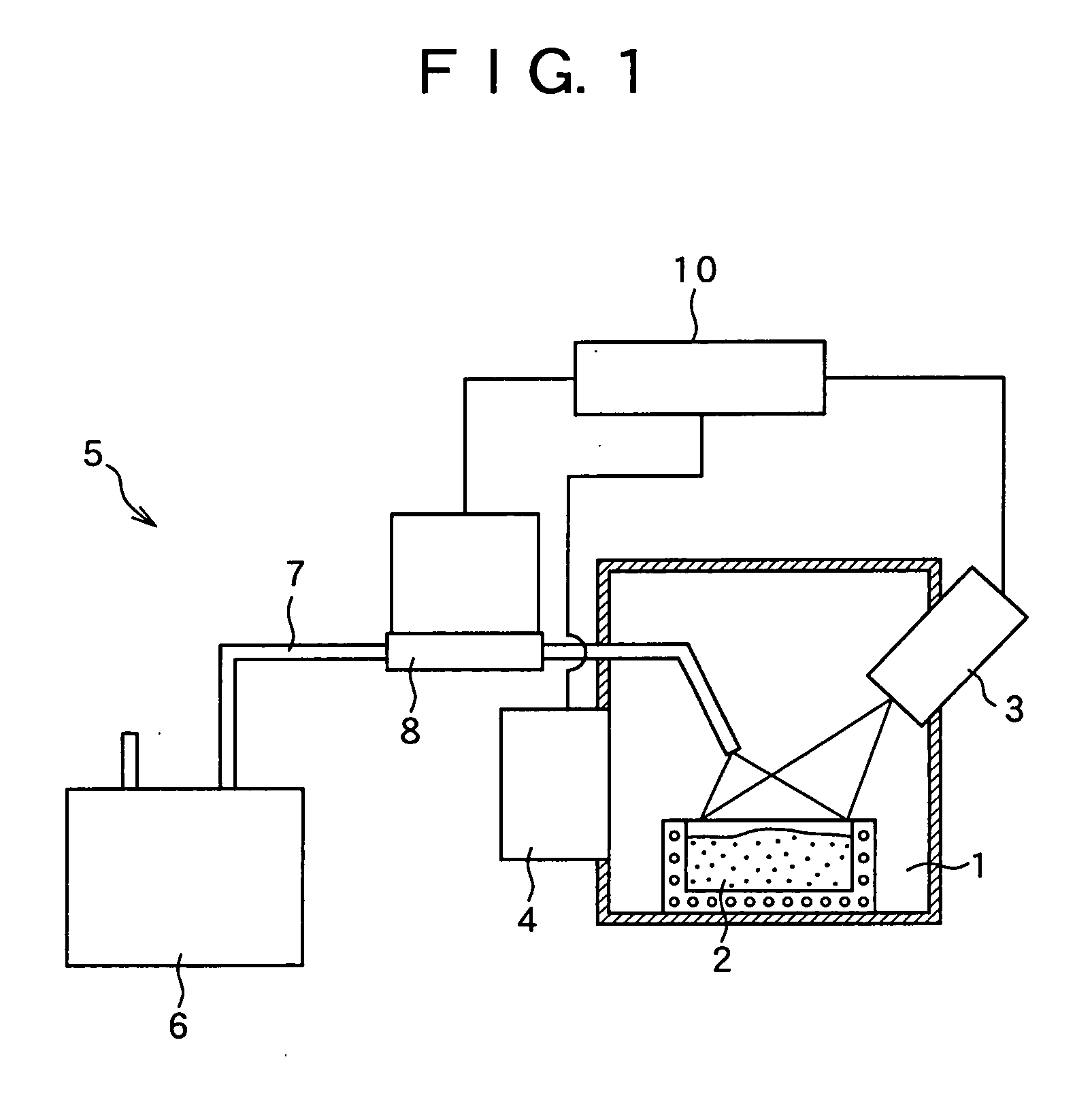

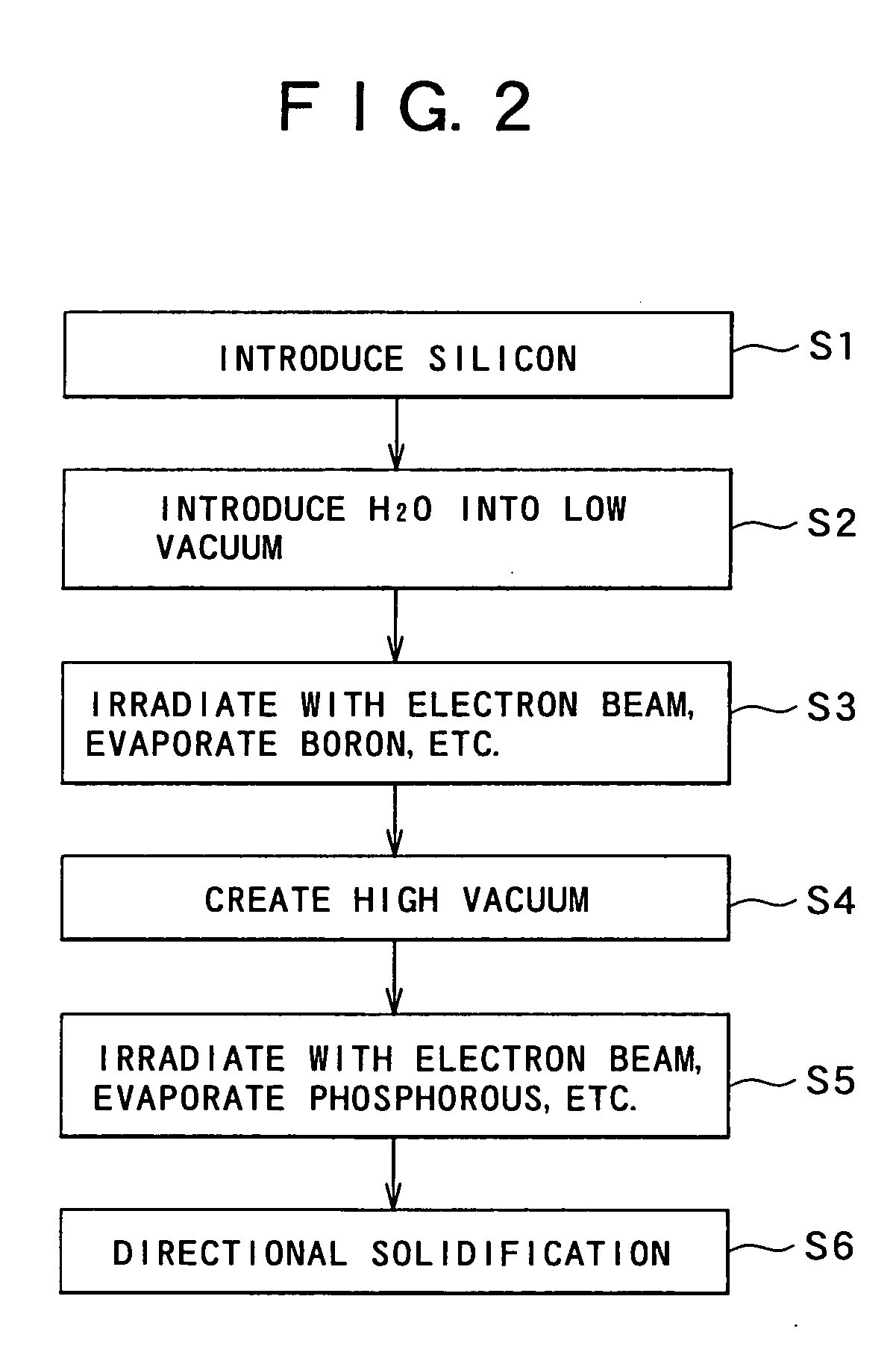

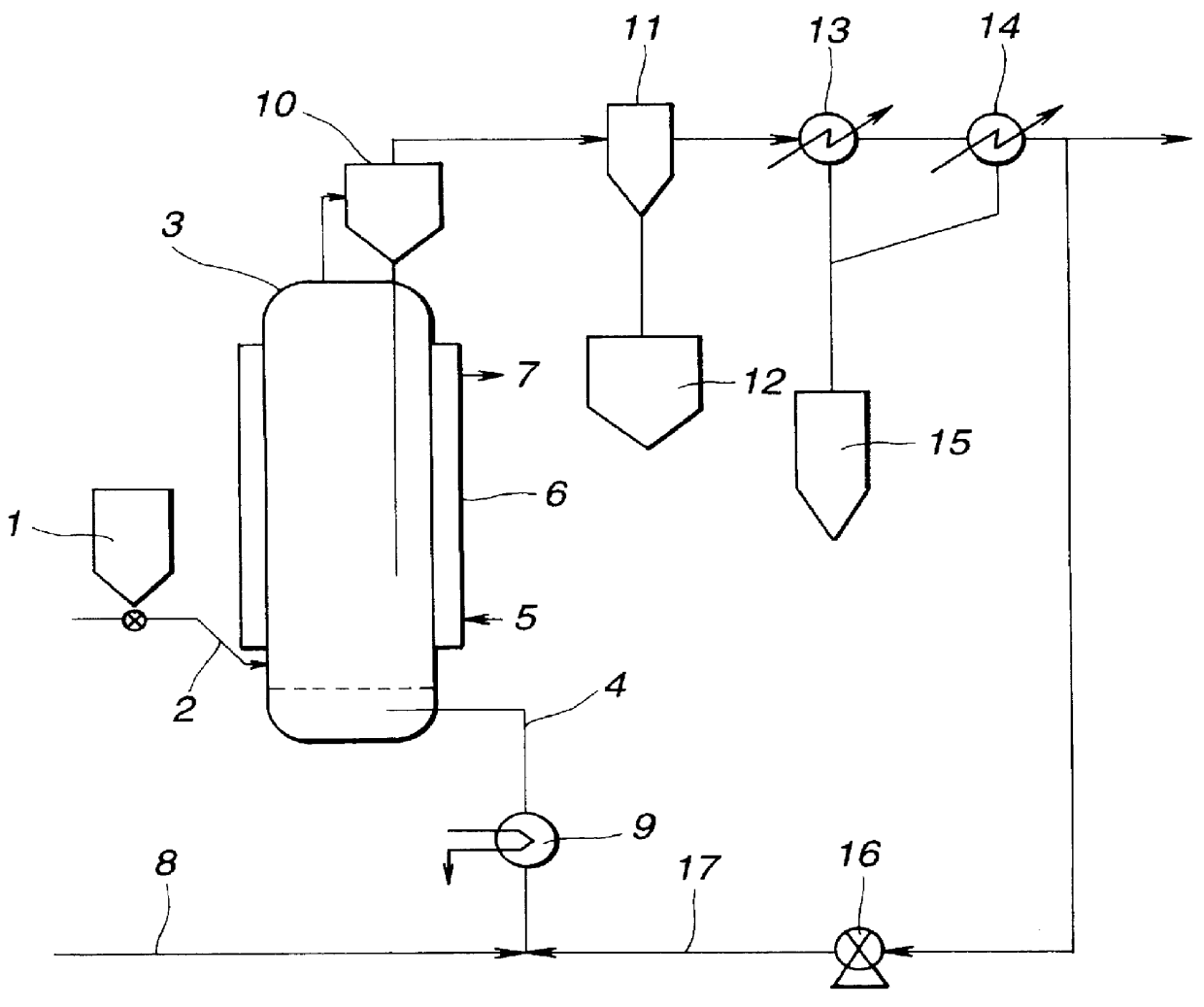

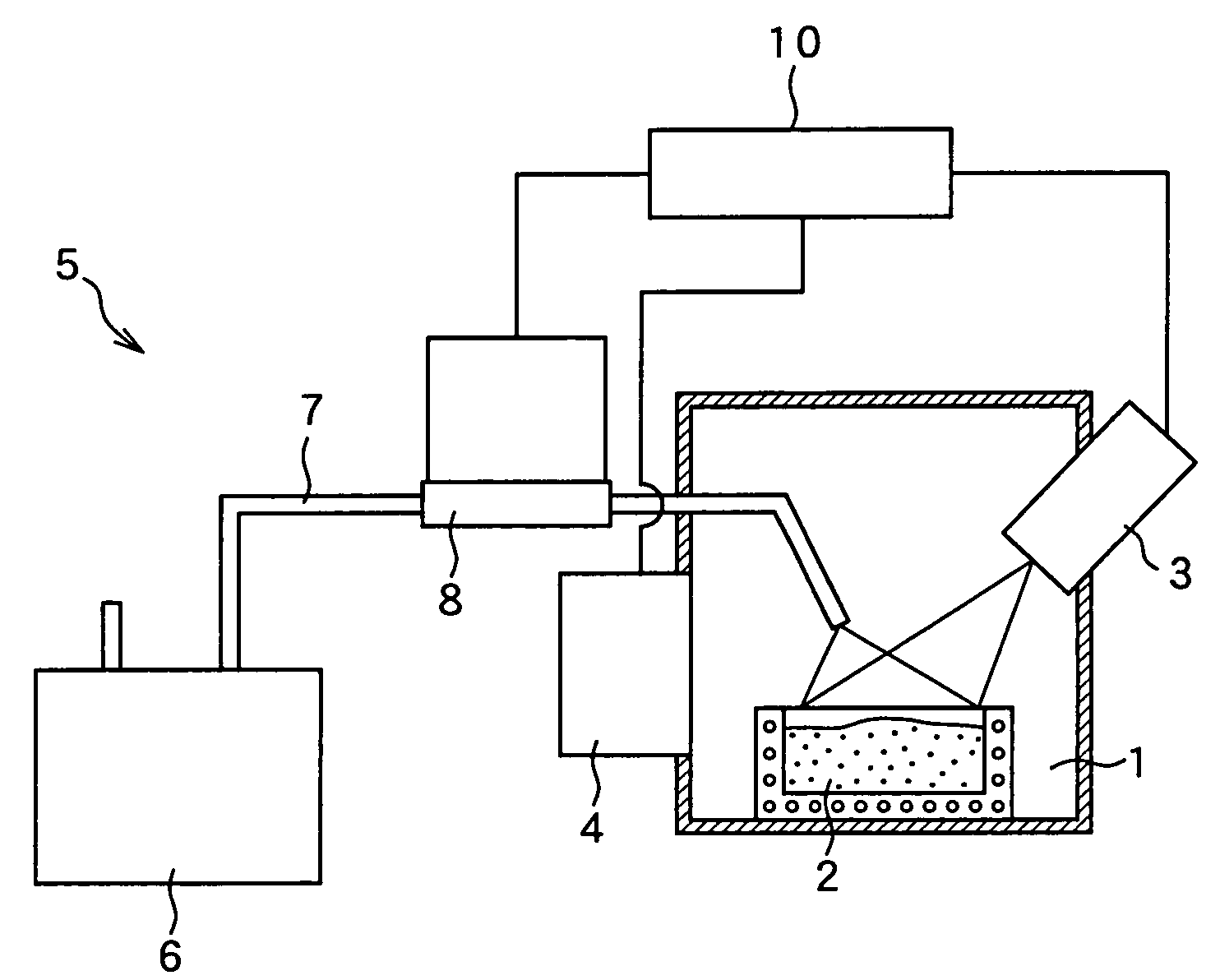

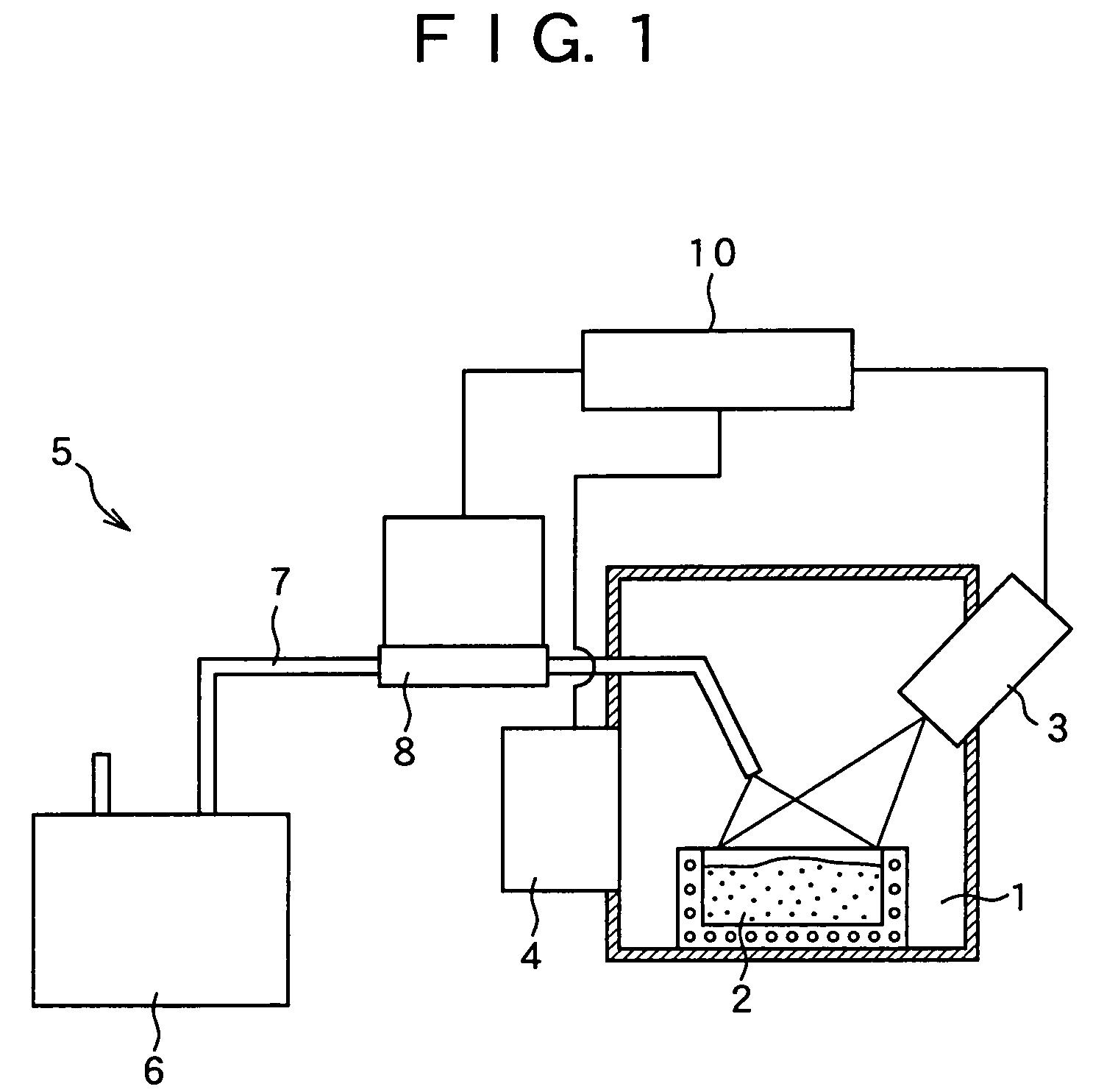

Method and apparatus for refining silicon using an electron beam

InactiveUS20070077191A1Avoid damageLife is preservedSilicon halogen compoundsSiliconCompound (substance)Low vacuum

A method and apparatus for refining silicon which can remove impurity elements such as phosphorus and antimony as well as impurity elements such as boron and carbon using an electron beam in the same vacuum chamber are provided. Silicon is irradiated and melted with an electron beam in a low vacuum inside a vacuum vessel, a compound-forming substance such as H2O which reacts with boron or the like in the molten silicon and forms a vaporizable oxide is introduced into the vacuum chamber, and impurity elements such as boron having a low vapor pressure in a vacuum are evaporated from the molten silicon as part of the vaporizable compound. Silicon in the vacuum vessel is then irradiated with an electron beam in a high vacuum in the vacuum vessel, and impurity elements contained in the silicon having a high vapor pressure in a vacuum such as phosphorus are removed.

Owner:YAMAUCHI NORICHIKA +2

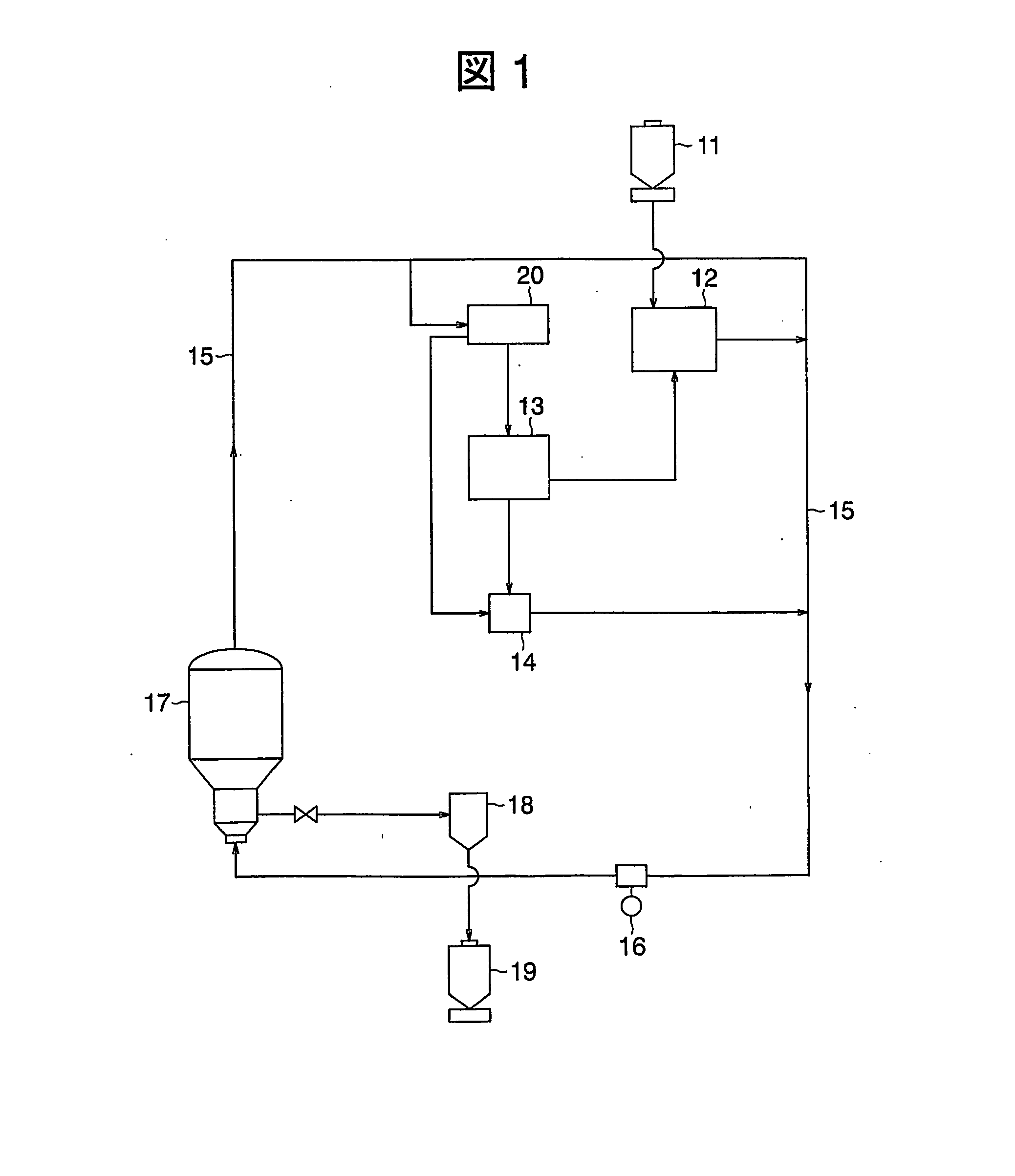

Process for producing high-purity silicon and apparatus

InactiveUS20060270199A1Crystal fineImprove reaction efficiencyPolycrystalline material growthSilicon halogen compoundsMolten stateGas phase

When high purity silicon is produced through a gas-phase reaction between silicon tetra-chloride and zinc in a reaction furnace, the produce silicon is obtained as block or molten state. after the reaction in which the silicon is not in contact with air and reaction temperature is maintained at melting point of the silicon or less.

Owner:ASAHI GLASS CO LTD

Method for producing sodium fluosilicate by utilizing waste water containing sodium sulfate

ActiveCN102020281AQuality impactLow costSilicon halogen compoundsIndustrial waste waterWater resources

The invention discloses a method for producing sodium fluosilicate by utilizing waste water containing sodium sulfate. The method is as follows: generating the sodium fluosilicate by adopting the waste water containing sodium sulfate and fluosilicic acid as a side product for producing hydrofluoric acid as a raw material; and obtaining a sodium fluosilicate product by curing, filtering, cleaning and pneumatic drying. The dilute sulphuric acid as a side product is used for a production line of sodium dichromate. The method provided by the invention has the advantages that the industrial sodium sulfate waste water is utilized to produce the sodium fluosilicate, and the materials are all industrial waste water. The industrial waste water of the sodium sulfate is from waste water obtained by washing chromium sesquioxide produced by sodium dichromate or waste water generated for producing chromium salt, the fluosilicic acid is from waste water in the process for producing the hydrofluoric acid, the produced sodium fluosilicate is used as a commodity for sales, the dilute sulphuric acid as a side product is used for the production line of the sodium dichromate. By utilizing the method, the cost for treating the waste water treatment of the industrial sodium sulfate in the chromium salt industry is reduced, and the reutilization of water resources is realized.

Owner:GANSU JINSHI CHEM

Preparation of contract mass for alkylhalosilane production and process for producing alkylhalosilanes

InactiveUS6090966AHigh selectivityEliminate the problemGroup 4/14 element organic compoundsSilicon halogen compoundsReaction temperatureCopper

Alkylhalosilanes are produced by first fluidizing a metallic silicon powder with an inert gas, preheating the silicon powder at a temperature between 200 DEG C. and a steady reaction temperature while keeping the silicon powder fluidized, adding a copper catalyst to the preheated silicon powder to form a contact mass, and feeding an alkyl halide into the contact mass whereby the alkylhalosilanes are formed by direct synthesis. This process prevents the copper catalyst from being sintered by thermal hysteresis and activates a high catalysis on the contact mass at the start of reaction. The desired dialkyldihalosilane can be produced at a high selectivity.

Owner:SHIN ETSU CHEM IND CO LTD

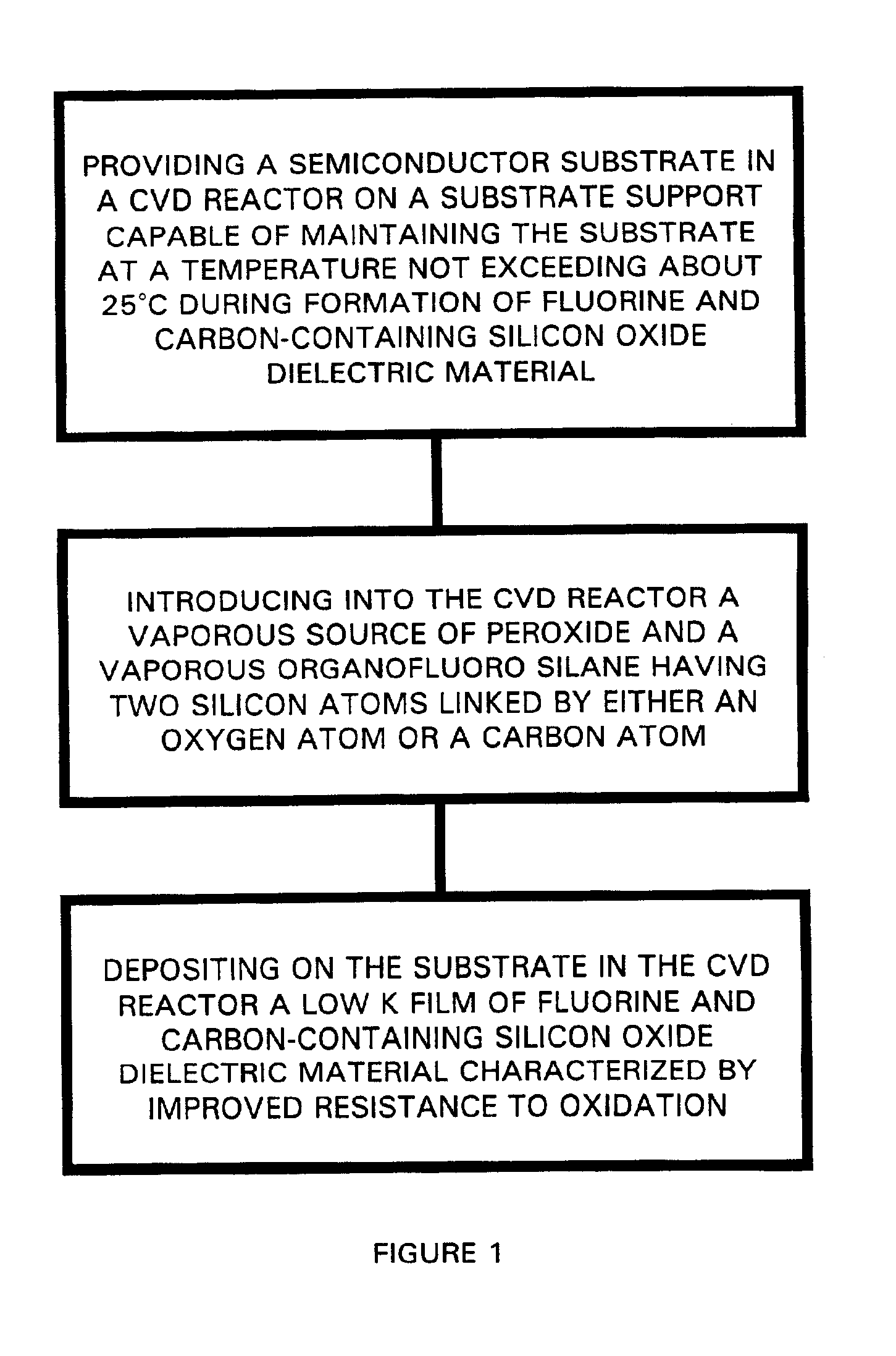

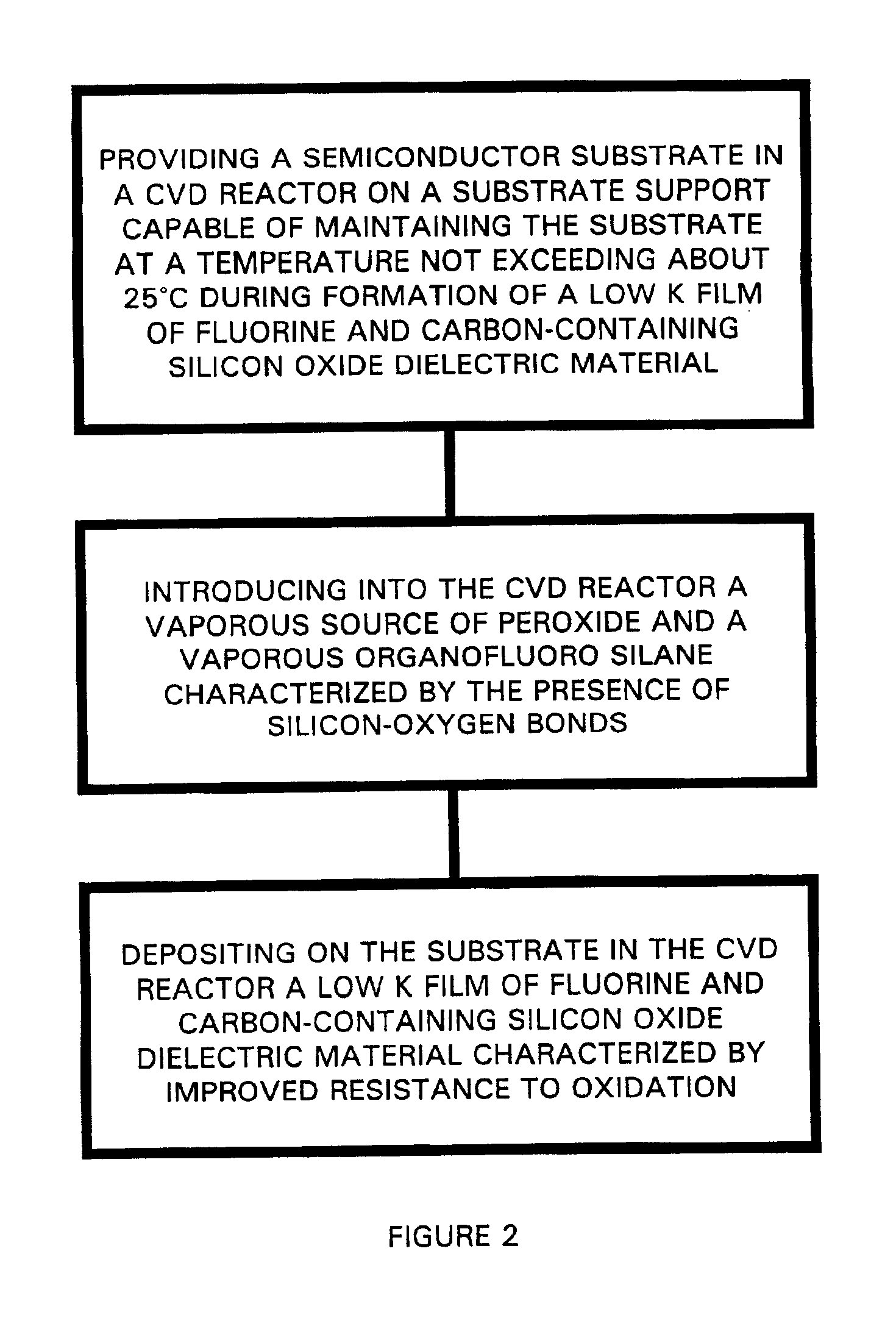

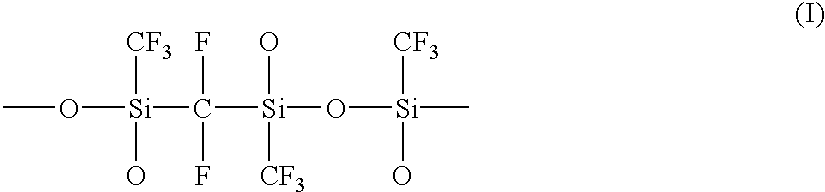

Process for forming a low dielectric constant fluorine and carbon-containing silicon oxide dielectric material

The invention provides a process for forming a low k fluorine and carbon-containing silicon oxide dielectric material by reacting with an oxidizing agent one or more silanes that include one or more organofluoro silanes selected from: (a) an organofluoro silane containing two silicon atoms linked by one oxygen atom; (b) an organofluoro silane containing two silicon atoms linked by one or more carbon atoms, where the one or more carbon atoms each are bonded to one or more fluorine atoms, or to one or more organofluoro moieties, or to a combination thereof; and (c) an organofluoro silane containing a silicon atom bonded to an oxygen atom. The invention also provides a process for forming a low k fluorine and carbon-containing silicon oxide dielectric material by reacting with an oxidizing agent one or more silanes that include one or more organofluoro silanes characterized by the presence of Si—O bonds.

Owner:BELL SEMICON LLC

Treatment method for multi-crystalline silicon texturization etching waste liquid

InactiveCN104986771ASilicon halogen compoundsFluoride preparationAlkaline earth metalEconomic benefits

The invention relates to a treatment method for multi-crystalline silicon texturization etching waste liquid. The treatment method comprises the following steps: (a) under the stirring condition, adding an alkali metal compound in the waste liquid for reaction till precipitates are not generated any more, and filtering to obtain a first precipitate and first filtrate; (b) under the stirring condition, adding an alkaline earth metal compound in the first filtrate for reaction till precipitates are not generated, and filtering to obtain a second precipitate and second filtrate; (c) conducting condensation crystallization on the second filtrate to obtain a nitrate solid. The treatment method has the advantages that the alkali metal compound is added in the waste liquid for reaction till the precipitates are not generated any more, filtering is conducted, the alkaline earth metal compound is added in the another filtrate, filtering is conducted again, and finally, concentration is conducted, so that fluosilicic acid radical ions and fluorinions in the waste liquid can be removed, a fluosilicate solid, a fluoride salt solid and the nitrate solid can be obtained, and not only can the environment be protected, but also new economic benefits can be generated.

Owner:SUZHOU KZONE EQUIP TECH

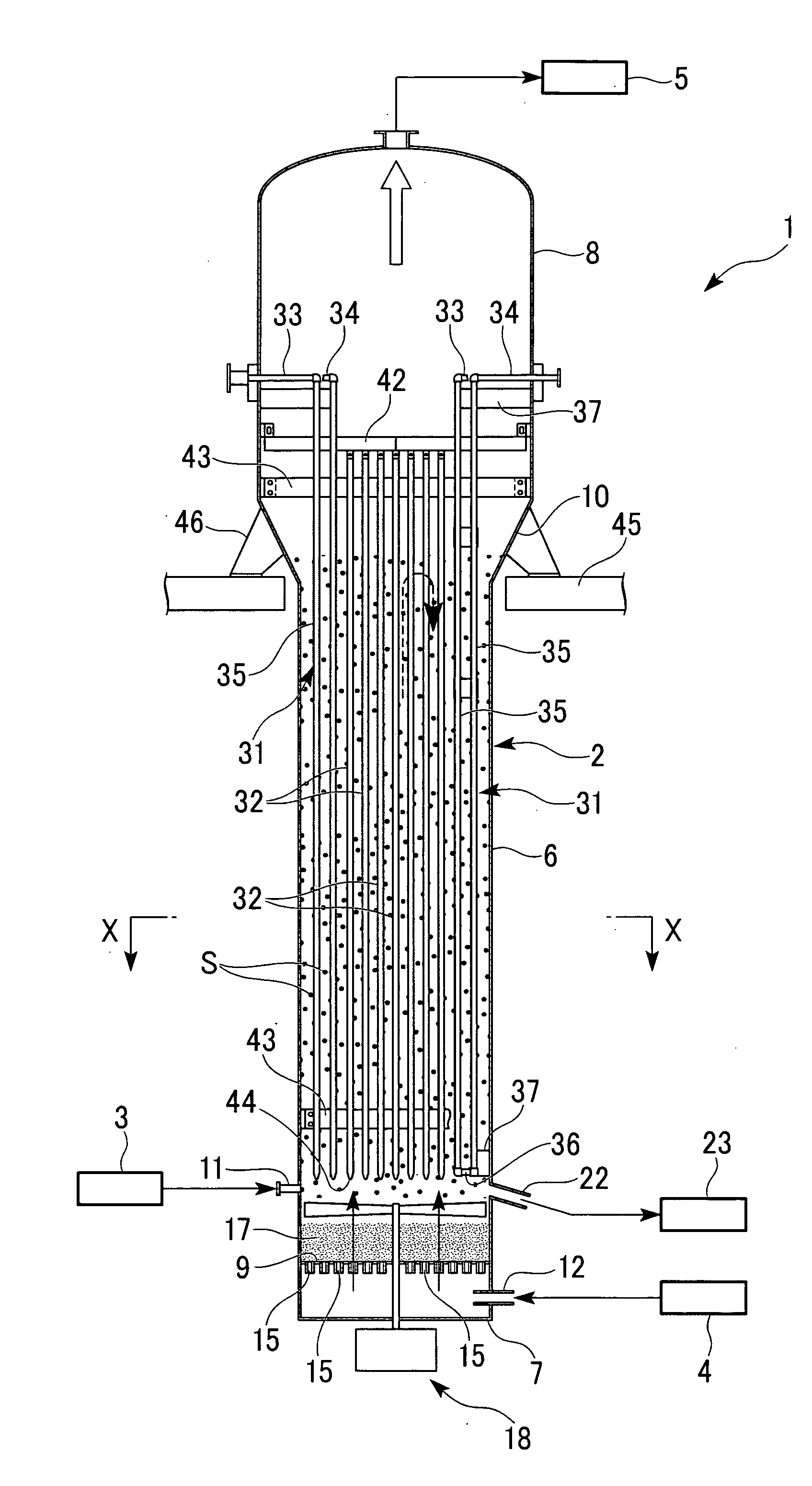

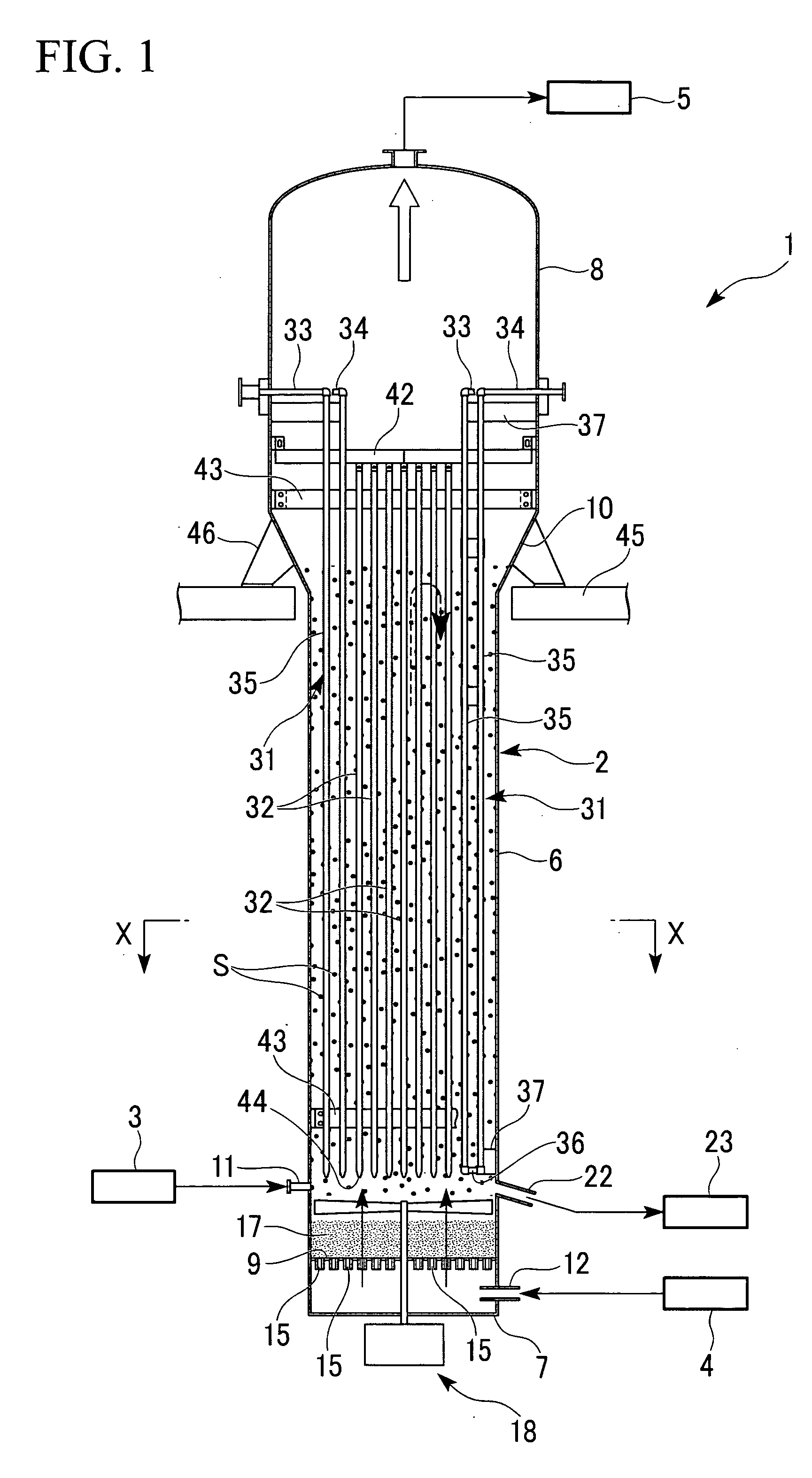

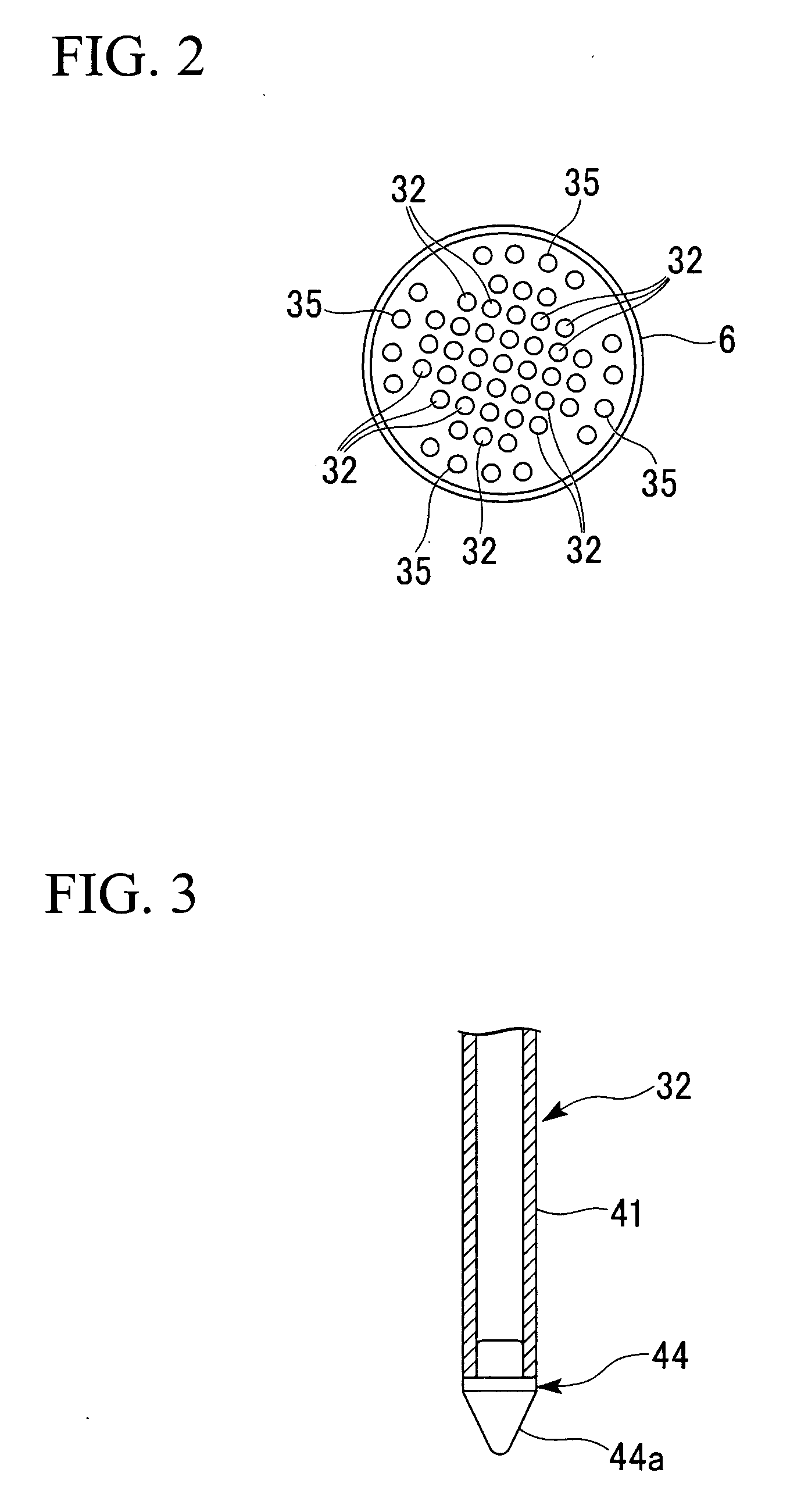

Apparatus for producing trichlorosilane and method for producing trichlorosilane

ActiveUS20090104104A1Increase contact areaImprove reaction efficiencySilicon halogen compoundsFluidised-bed furnacesProduct gasHydrogen chloride

In the apparatus for producing trichlorosilane in which metal silicon powder supplied into the reactor is reacted with hydrogen chloride gas while being fluidized by the gas, thereby taking out trichlorosilane generated by the reaction from the upper part of the reactor, and a plurality of gas flow controlling members are installed at the internal space of the reactor along the vertical direction.

Owner:HIGH-PURITY SILICON CORP

Industrial fluosilicic acid purification and white carbon black co-production method

ActiveCN104843712ALow costEasy to controlSilicaSilicon halogen compoundsSilicon tetrafluorideProduct gas

An industrial fluosilicic acid purification and white carbon black co-production method belongs to the technical field of inorganic acid chemical production and purification. The method comprises the following steps: contacting an industrial fluosilicic acid solution with silica powders and carrying out heating, and collecting silicon tetrafluoride gas obtained after heating; absorbing the obtained silicon tetrafluoride gas directly by absorption liquid, and carrying out hydrolysis reaction to obtain a mixture of a fluosilicic acid solution and hydrated silicon dioxide solid; and separating the mixture to obtain the fluosilicic acid solution and the hydrated silicon dioxide solid. The method does not waste fluorine atoms in the purification process, and thus application range and additional value of the industrial fluosilicic acid are improved.

Owner:BEIJING UNIV OF CHEM TECH

Process for making silicon tetrachloride

The present invention provides a way to obtain SiCl4 with high activity and selectivity by allowing metal Si or a chlorosilane having HSi bond in the molecule to react with HCl in the coexistence of a specific metal and a specific single substance of an element. Metal Si or a chlorosilane having HSi bond in the molecule and HCl are react with each other in the coexistence of one or more metals of group VIII elements in periodic table and one or more single substances of group VB elements of the 3rd and succeeding period.

Owner:TOKUYAMA CORP

Method for preprocessing biomass

The present invention relates to a method for pretreating biomass instead of sodium hydroxide, fulfuric acid and vapor explosion. Said invention is characterized by that it adopts the following steps: pulverizing cellulose-live biomasses of crop straw and stalk, grass and wood, etc., removing impurity, making acid hydrolysis, separating and extracting cellulose, using cellulose to hydrolyze cellulose, using saccharomycetes to make fermentation to produce ethyl alcohol and recover silicon fluoride. The above-mentioned acid is hydrofluoric acid.

Owner:SHAANXI UNIV OF SCI & TECH

Apparatus for removing halogen hydracids from biomass hydrolysates

ActiveUS20110070131A1Inexpensive materialsSilicon halogen compoundsMaterial heat developmentHydrogen halidePolymer science

An apparatus for removing hydrogen halide and water from hydrolysates that were obtained by way of halogen-acid hydrolysis from vegetable biomasses, characterized in that: —said apparatus comprises two containers, which are connected to each other by a tube, —at the inlet of the first container two flows are fed, one representing the hydrolysates and the other a heat transfer medium, which dissolves in the hydrolysate only to an economically justifiable extent (no additional process steps due to potential contamination during mixing), or enriches matter therefrom, —both flows are sprayed together in the first container, thereby producing a homogeneous mixing of the two flows, including heat transfer, which subsequently results in complete evaporation of water and the hydrogen halide dissolved in the hydrolysates, —the evaporation produces a mixture of granular solid bodies and heat transfer medium droplets, which is pulled from the first container into the second container via the connecting tube by way of a pressure gradient, —the second container is configured as a cyclone or centrifugal force precipitator, and a separation of liquid (heat transfer medium droplets) and solid constituents (granular solid bodies) from the gas flow takes place. An apparatus, characterized in that the second container (here: cyclone) on the inside wall may be lined with polyvinylchloride [PVC] (hard), PVC (chlorinated), polyethylene (PE), polypropylene (PP), polybutylene (PB), polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF), polyvinyl fluoride (PVF), ethylene-propylene-diene rubber (EPDM), ethylene-propylene copolymer, ethylene-tetrafluoroethylene (ETFE), perfluoro-ethylene-propylene plastic (FEP), fluoropolymer plastics (FPM and FKM=group designation), perfluoro trifluoroethylene (PCTFE), perfluorinated rubber (FFPM and FFKM), butyl robber (HR), isoprene rubber (IR), chlorinated polyethylene (PE-C) and rubber (collective term for rubbers containing sulfur) and copolymers and mixtures thereof from said polymers, or comprises them.

Owner:GREEN SUGAR AG

Method for aminolysis of fluorosilicone compounds and separation of fluorine and silicon

InactiveCN1884077AOvercoming the disadvantages of separation methodsImprove conversion rateSilicon halogen compoundsAmmonium halidesPhosphoric acidSilicon tetrafluoride

The invention discloses a separating method of aminolysis and hydrofluosilicic element of silicofluoride, which comprises the following steps: 1. adding solid ammonium fluosilicate or silicon tetrafluoride gas in the saturated ammonium fluoride circulating reacting liquid; putting raw material amino to proceed aminolysis reaction; 2. reducing slurry temperature; screening the reacted slurry; 3. filtering the screened silica suspension and ammonium fluoride crystal slurry to obtain saturated ammonium fluoride solution, silica solid and ammonium fluoride crystal; returning to former procedures as the circulating reacting liquid; washing the ammonium fluoride crystal; drying through normal drying method to obtain high-purity product. The invention can improves technological and economical index, which is fit for wet-producing phosphoric acid, phosphate fertilizer and other phosphor businesses.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

Method and apparatus for refining silicon using an electron beam

A method and apparatus for refining silicon which can remove impurity elements such as phosphorus and antimony as well as impurity elements such as boron and carbon using an electron beam in the same vacuum chamber are provided. Silicon is irradiated and melted with an electron beam in a low vacuum inside a vacuum vessel, a compound-forming substance such as H2O which reacts with boron or the like in the molten silicon and forms a vaporizable oxide is introduced into the vacuum chamber, and impurity elements such as boron having a low vapor pressure in a vacuum are evaporated from the molten silicon as part of the vaporizable compound. Silicon in the vacuum vessel is then irradiated with an electron beam in a high vacuum in the vacuum vessel, and impurity elements contained in the silicon having a high vapor pressure in a vacuum such as phosphorus are removed.

Owner:YAMAUCHI NORICHIKA +2

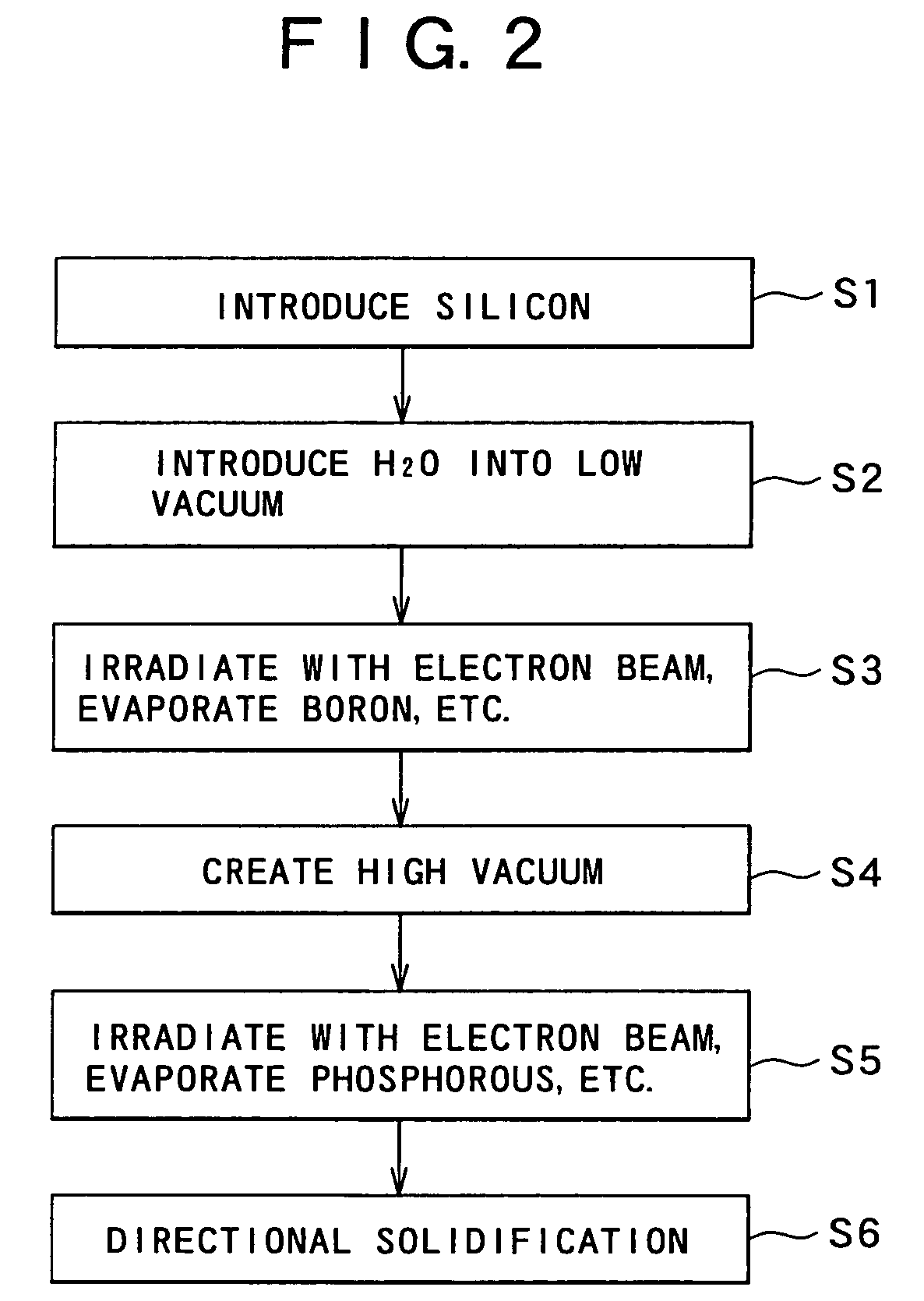

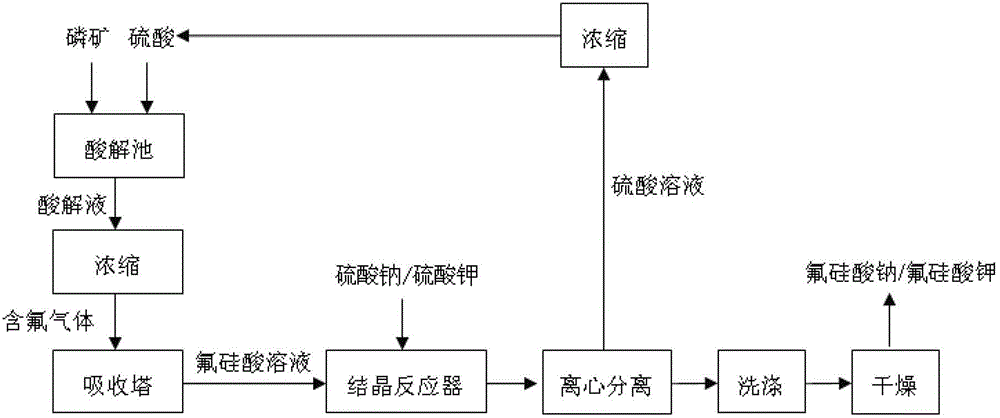

Resource comprehensive utilization method for recovering fluorine from wet-process phosphoric acid

InactiveCN103145131AQuality improvementReduce or eliminate hazardsSilicon halogen compoundsPotassium silicatePhosphoric acid

The invention relates to a resource comprehensive utilization method for recovering fluorine from wet-process phosphoric acid. The method comprises the following steps of: absorbing SiF4 and HF gases generated in the wet-process phosphoric acid by using water, and preparing the gases into a hydrofluosilicic acid solution of which the mass percent concentration is 10-35%; mixing one of four solids including solid sodium sulfate, solid potassium sulfate, solid sodium chloride and solid potassium chloride with the hydrofluosilicic acid solution, and reacting for 0.1-2 hours at 30-80 DEG C under stirring to obtain a mixture; centrifugally separating the obtained mixture to obtain a solid and a filtrate; and washing the solid with water, and drying for 1-3 hours at 100-120 DEG C to obtain a sodium fluorosilicate or potassium fluorosilicate crystal. According to the method, a byproduct hydrofluosilicic acid in the wet-process phosphoric acid and sodium (potassium) sulfates or chlorides which are abundant and easily-available are used as raw materials, so that the cost is low, two products including sodium fluorosilicate and potassium fluorosilicate can be produced at the same time by using one set of equipment, and the maximum utilization ratio of the hydrofluosilicic acid can reach over 99%.

Owner:KINGENTA NORSTERRA CHEM CO LTD

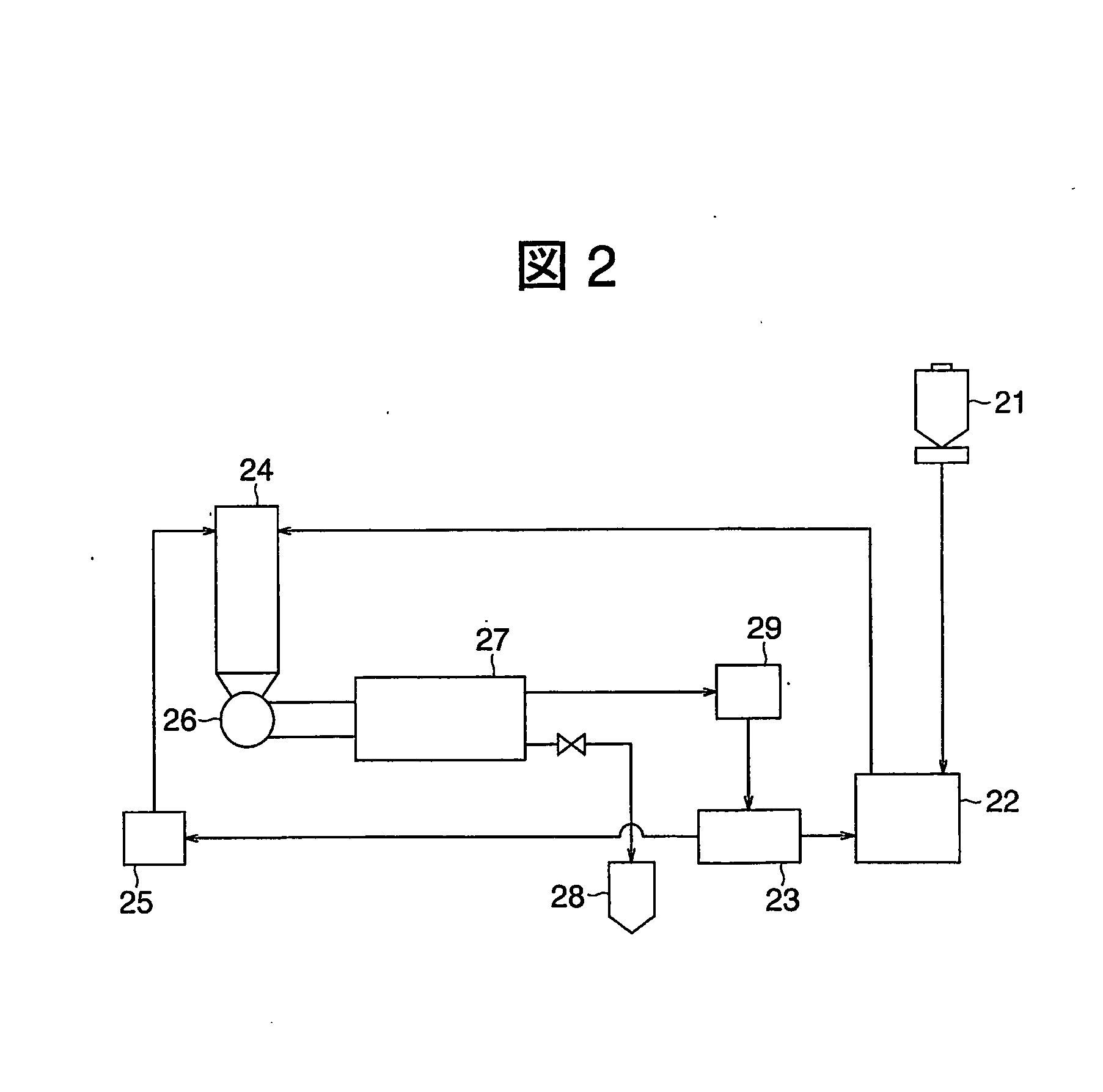

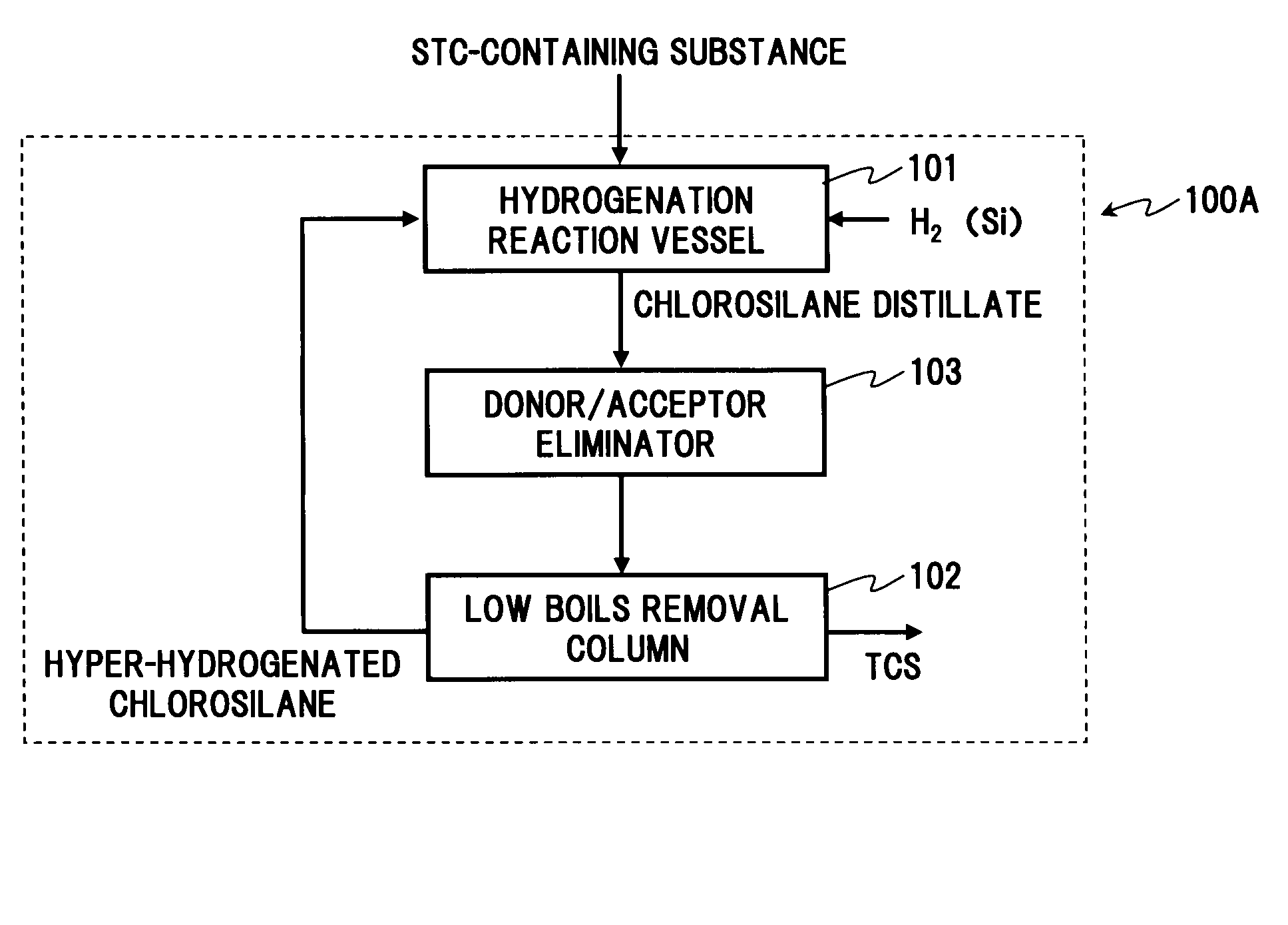

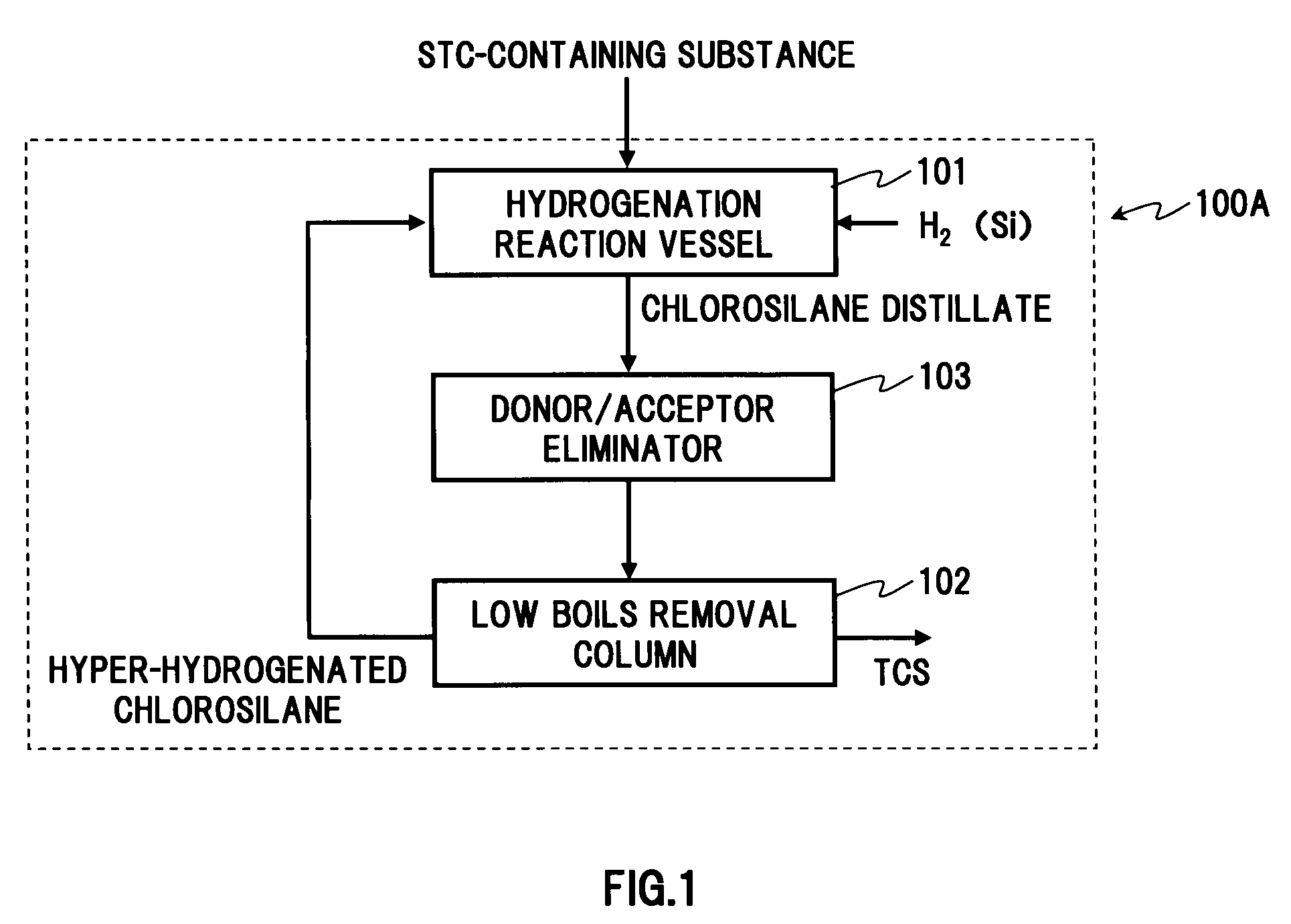

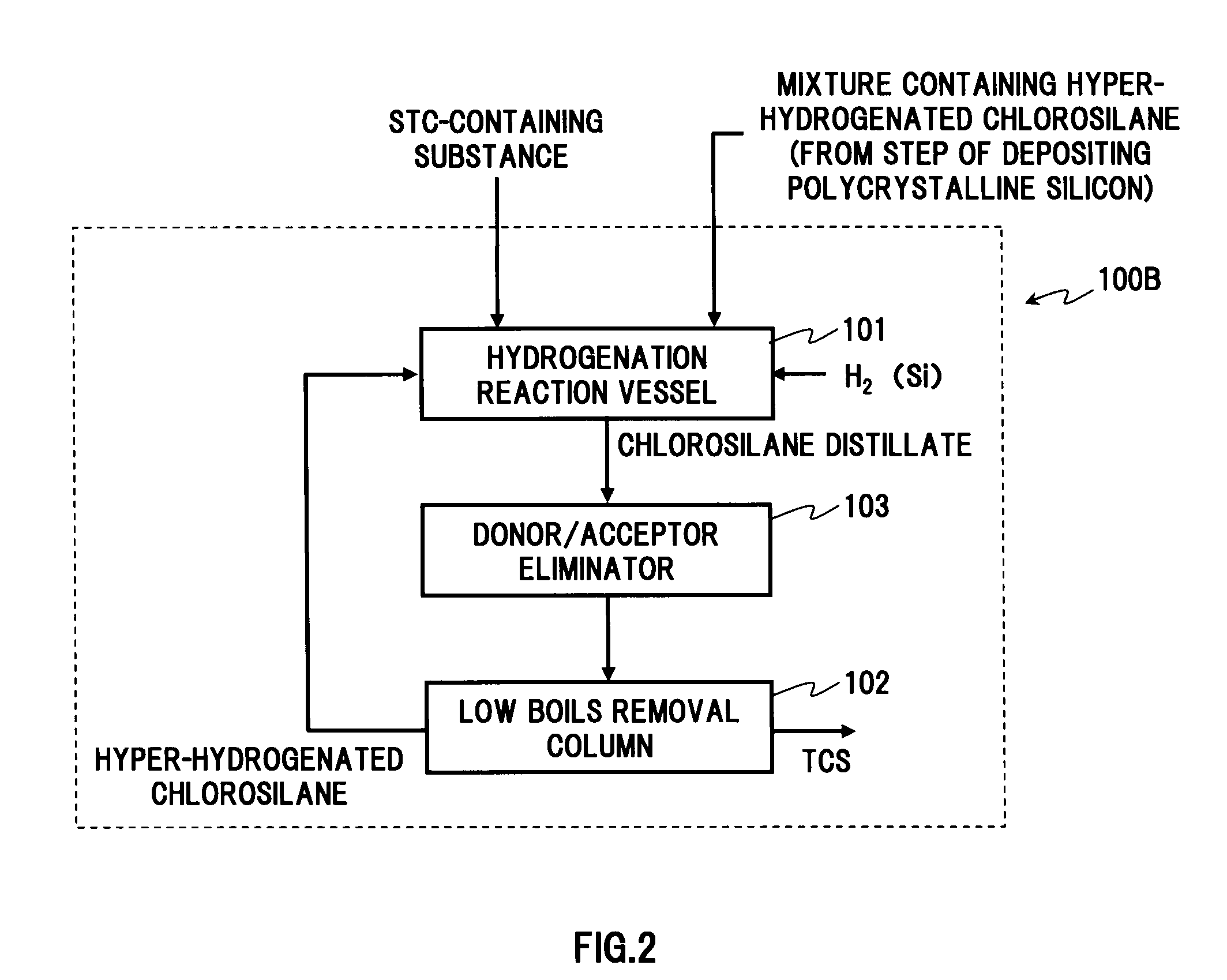

Method for producing trichlorosilane and method for producing polycrystalline silicon

ActiveUS8293076B2Improve processing efficiencyQuality improvementGroup 4/14 element organic compoundsSilicon halogen compoundsHydrogenSilanes

Methods for producing trichlorosilane, including: reacting a tetrachlorosilane containing substance with hydrogen at a temperature of 400° C. to 1,200° C. to obtain a mixture including silane, monochlorosilane, dichlorosilane, and trichlorosilane; removing impurities which are electrically active in a semiconductor crystal from the mixture; separating the trichlorosilane from the silane, monochlorosilane and dichlorosilane to obtain purified trichlorosilane; and circulating the silane, monochlorosilane and dichlorosilane obtained from the separating step into the reacting step.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com