Patents

Literature

329 results about "ETFE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene tetrafluoroethylene (ETFE) is a fluorine-based plastic. It was designed to have high corrosion resistance and strength over a wide temperature range. ETFE is a polymer and its source-based name is poly(ethene-co-tetrafluoroethene). ETFE has a relatively high melting temperature, excellent chemical, electrical and high-energy radiation resistance properties. When burned, ETFE releases hydrofluoric acid.

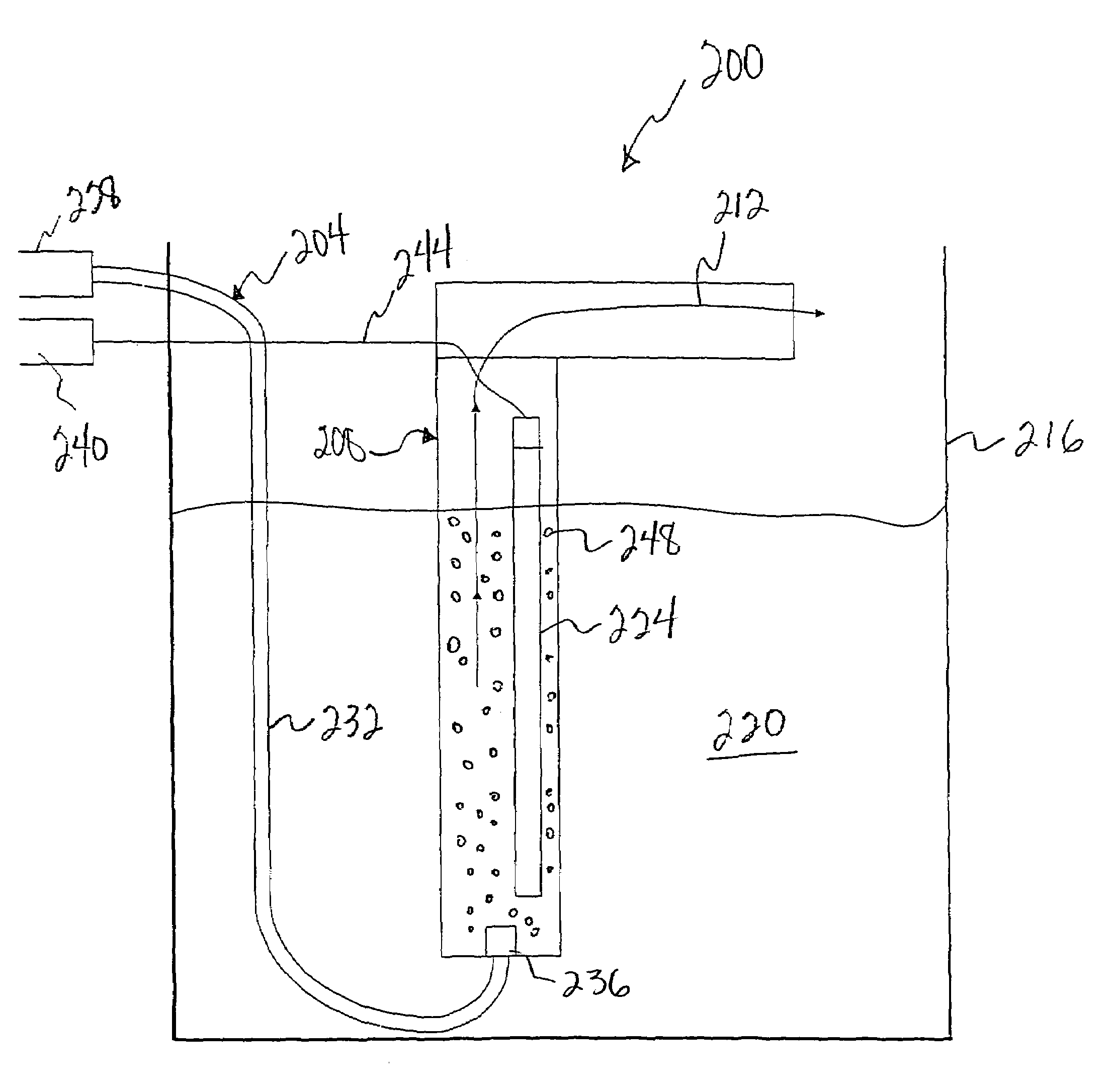

Methods and apparatus for disinfecting and sterilizing fluid using ultraviolet radiation

InactiveUS7081225B1Increase lethalitySterilizing of disinfecting aspect of the apparatus more effectiveWaste water treatment from animal husbandryScattering properties measurementsUltraviolet radiationUltraviolet lights

An apparatus for sterilizing or disinfecting fluids, which comprises a fluid conduit, an ultraviolet light source, which is at least partially within the fluid conduit, and an air drive unit coupled to the fluid conduit. The ultraviolet light source generates an ultraviolet light, which kills microorganisms in the fluid, thus sterilizing or disinfecting the fluid. The air dive unit creates air bubbles in the fluid, such as for fish tanks, fish hatchery ponds, or the like. In accordance with one embodiment of the present invention, the ultraviolet light source comprises an ultraviolet light bulb being surrounded by a protective sleeve. The protective sleeve preferably comprises a UV transmissive material, which may comprise a fluoropolymer material, such as PTFE, FEP, PFA, AF and Tefzel ETFE.

Owner:HOLLANDER BRAD C

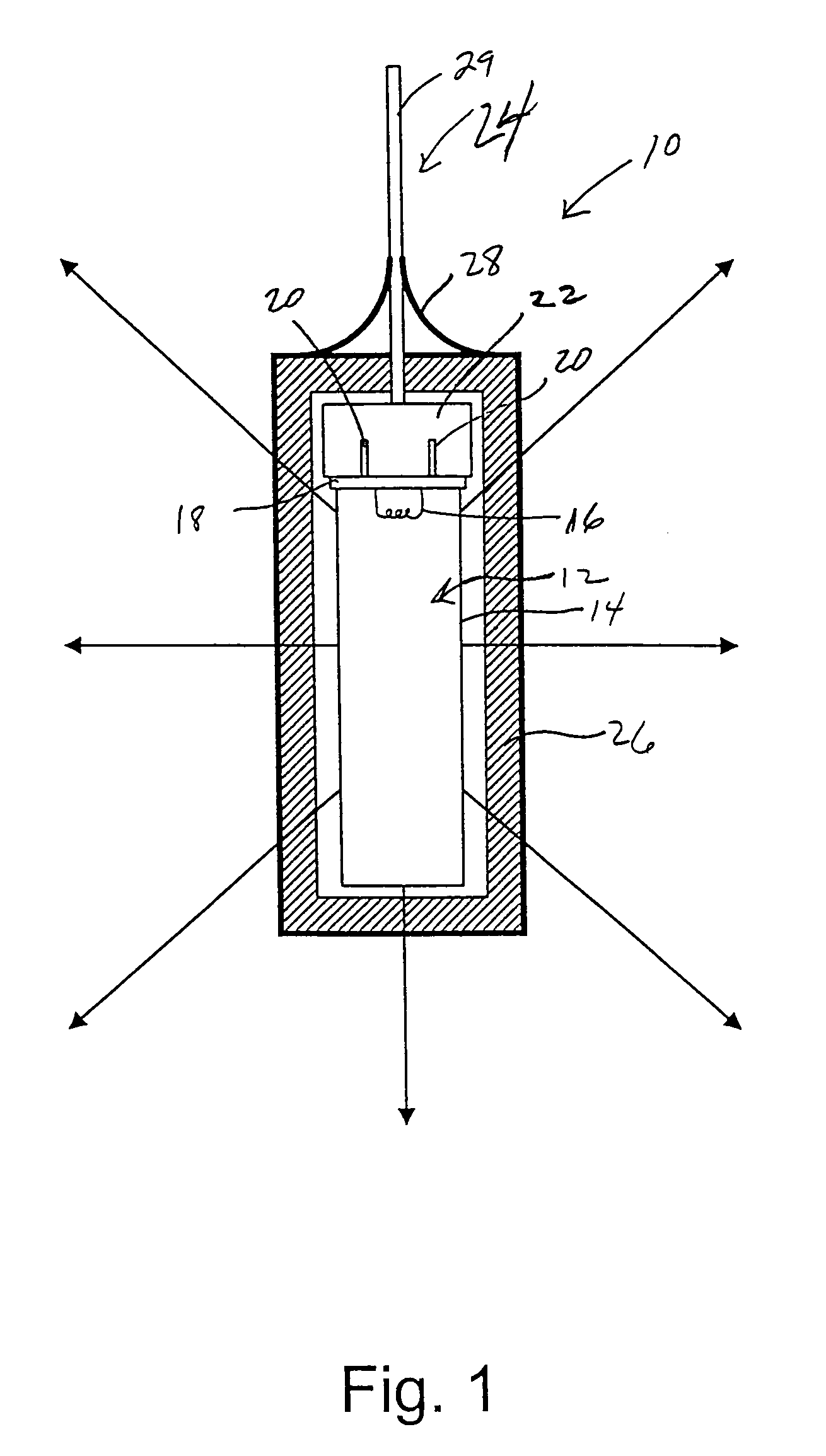

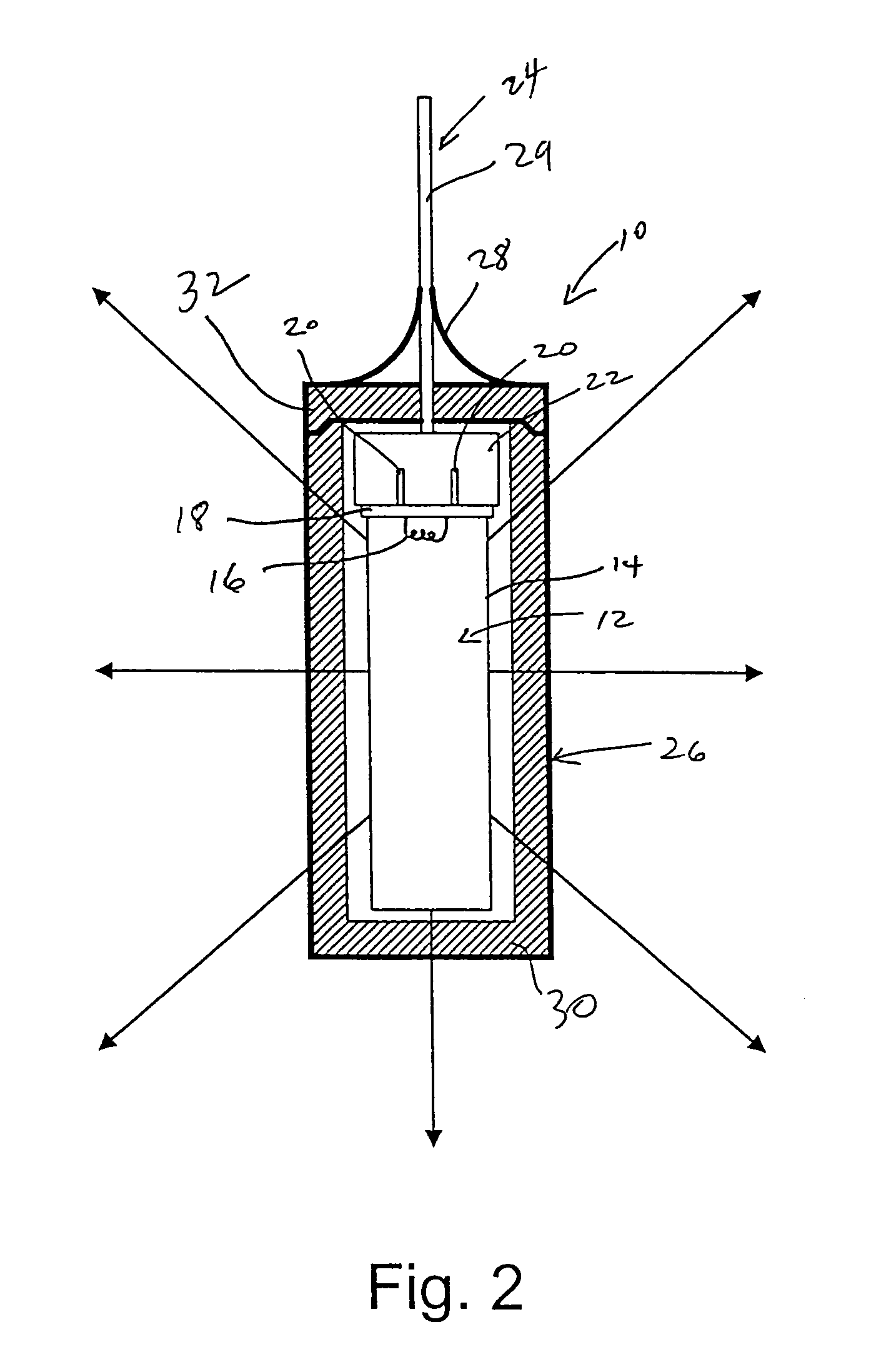

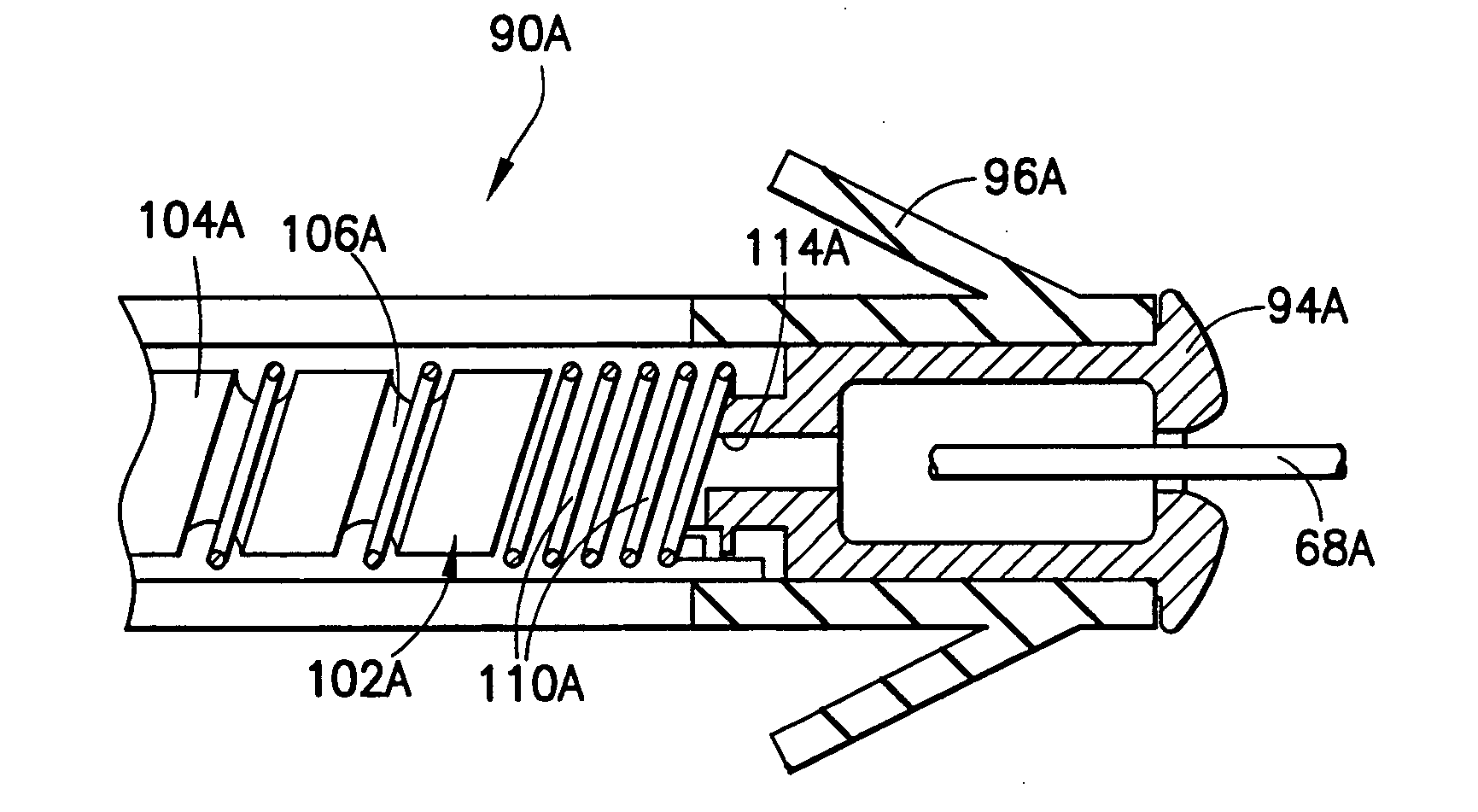

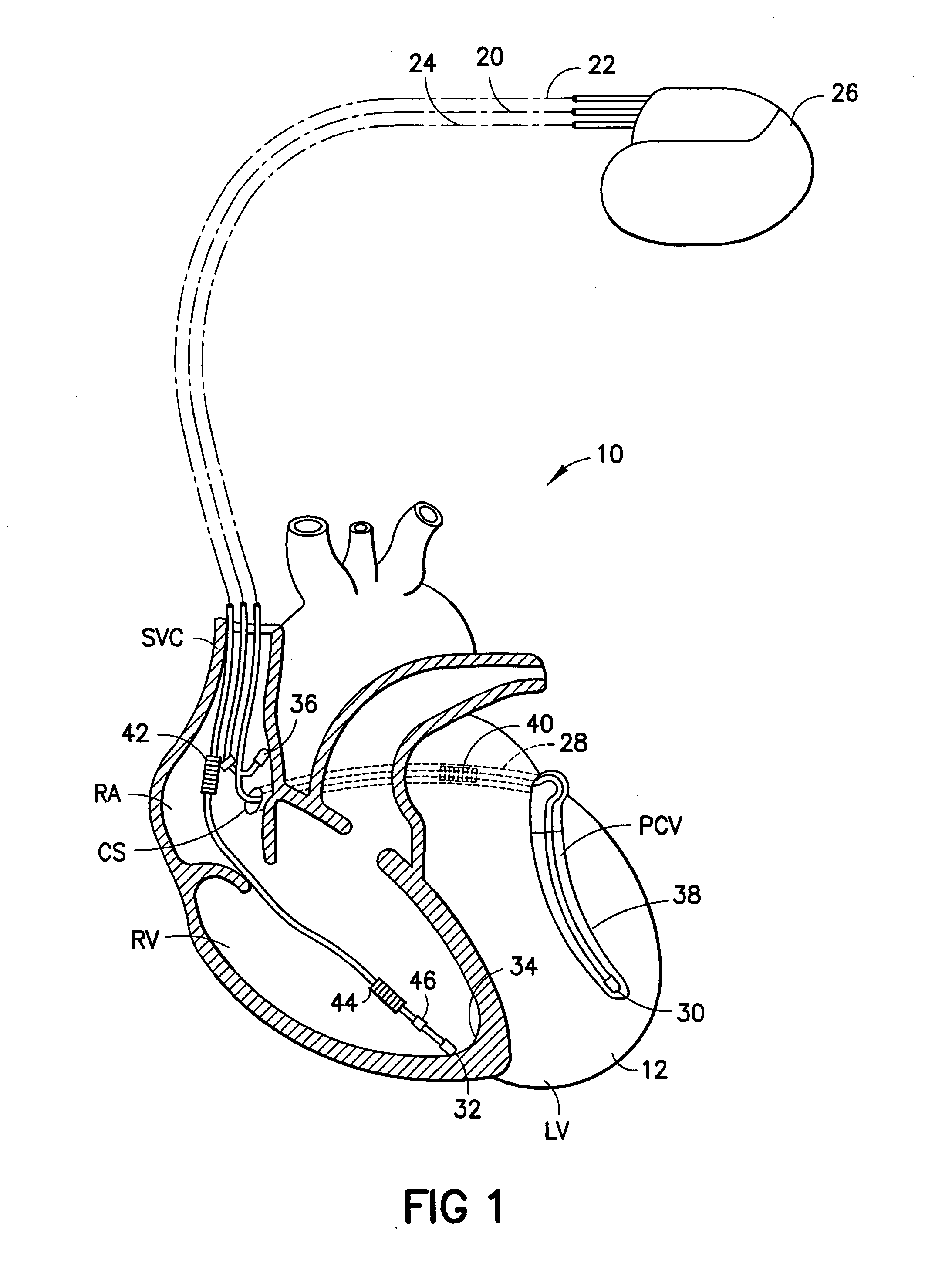

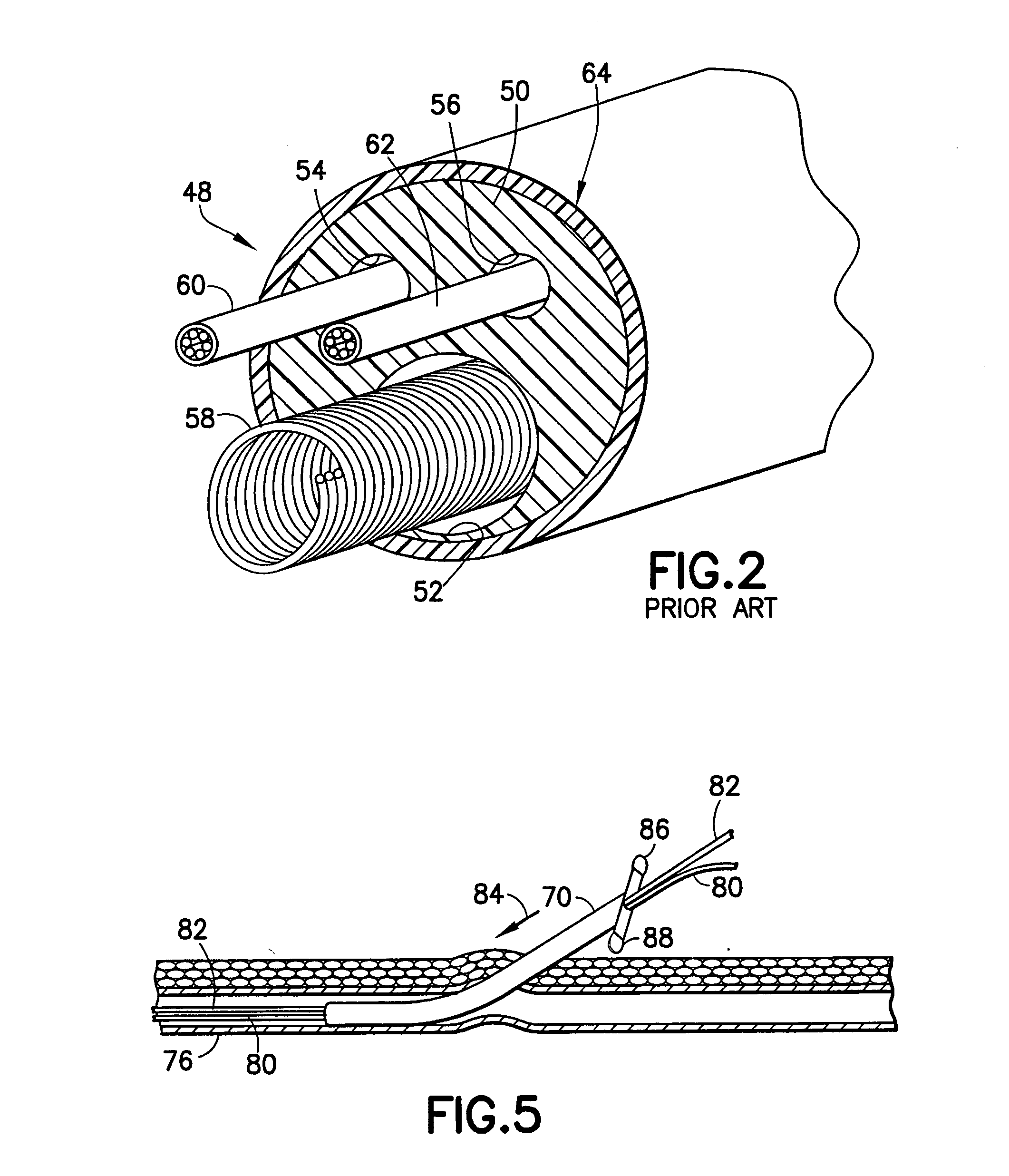

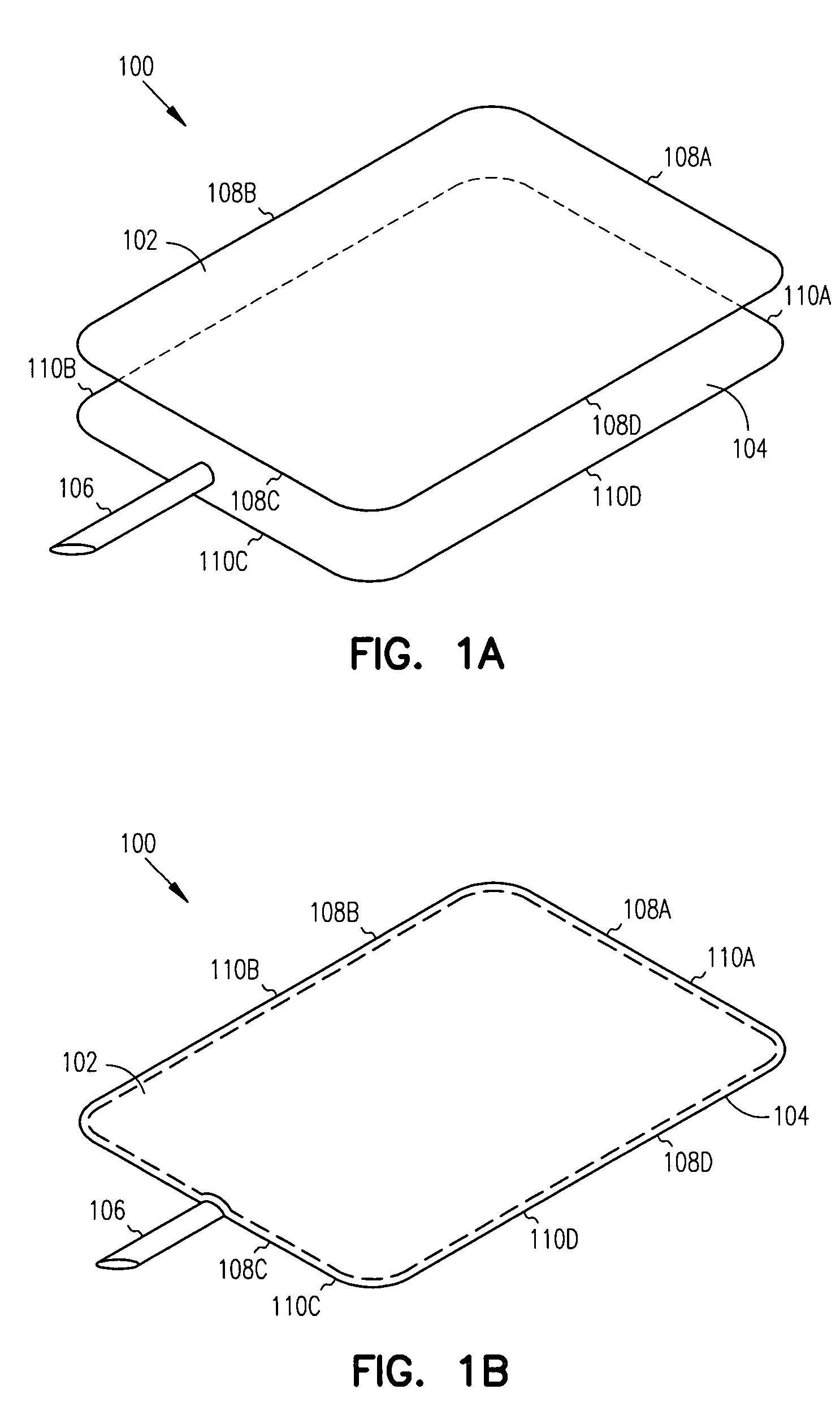

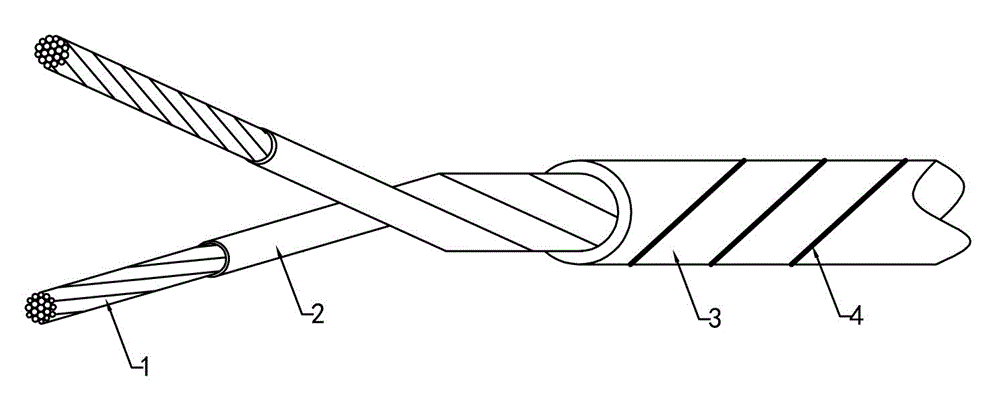

Lead body construction

InactiveUS20050080471A1Alleviate “ whip-like ” actionStiffnessTransvascular endocardial electrodesExternal electrodesElectrical conductorYoung's modulus

An implantable cardiac stimulation lead system for use with a stimulation device includes a lead body preferably having an outer diameter of less than 4 French and formed of a biocompatible material having a Young's modulus of at least 20,000 pounds per square inch. In the lead body, an inner insulator is composed of a suitable polymer such as PTFE or ETFE with an outer peripheral surface formed with a helical groove containing a conductor extending between a proximal connector and a distal tip electrode, and an outer insulator composed of polyurethane or silicone rubber or a combination thereof is positioned around the inner insulator. The lead system may be formed with a lumen for receiving a guidewire longitudinally through the lead body. A pair of insulated conductors may be received in the helical groove, one extending to the distal tip electrode, the other extending to a ring electrode proximally spaced from the distal tip electrode.

Owner:PACESETTER INC

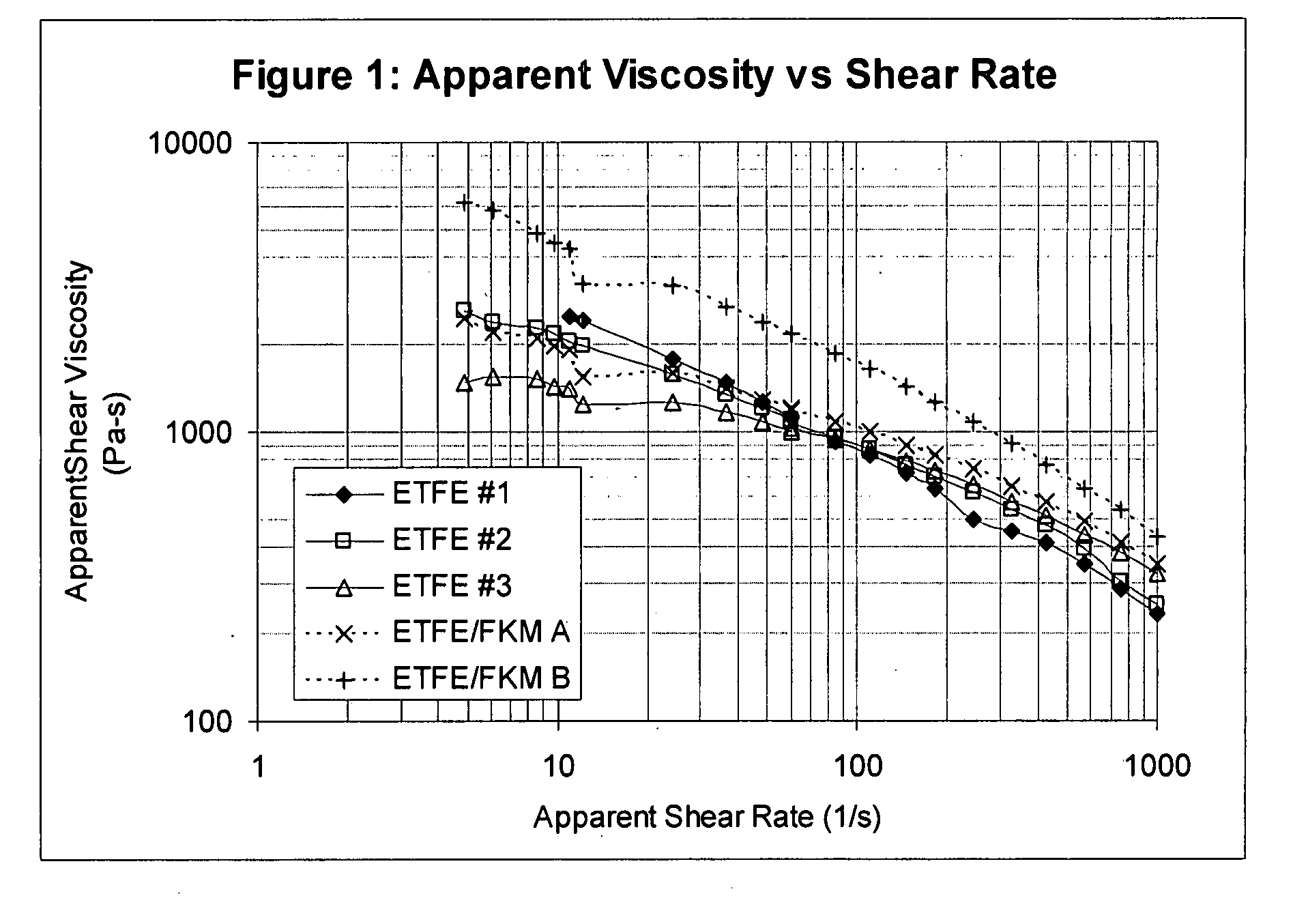

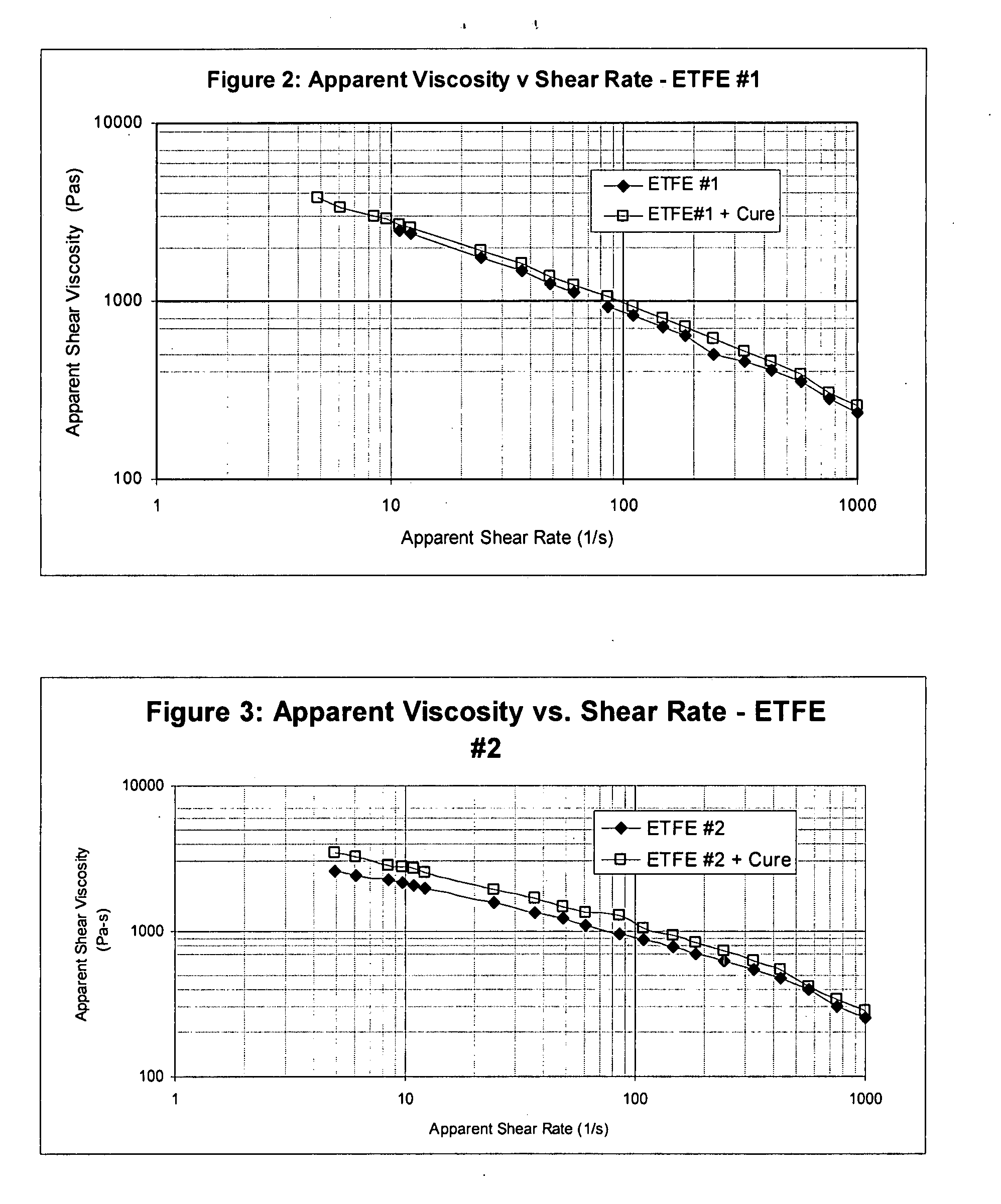

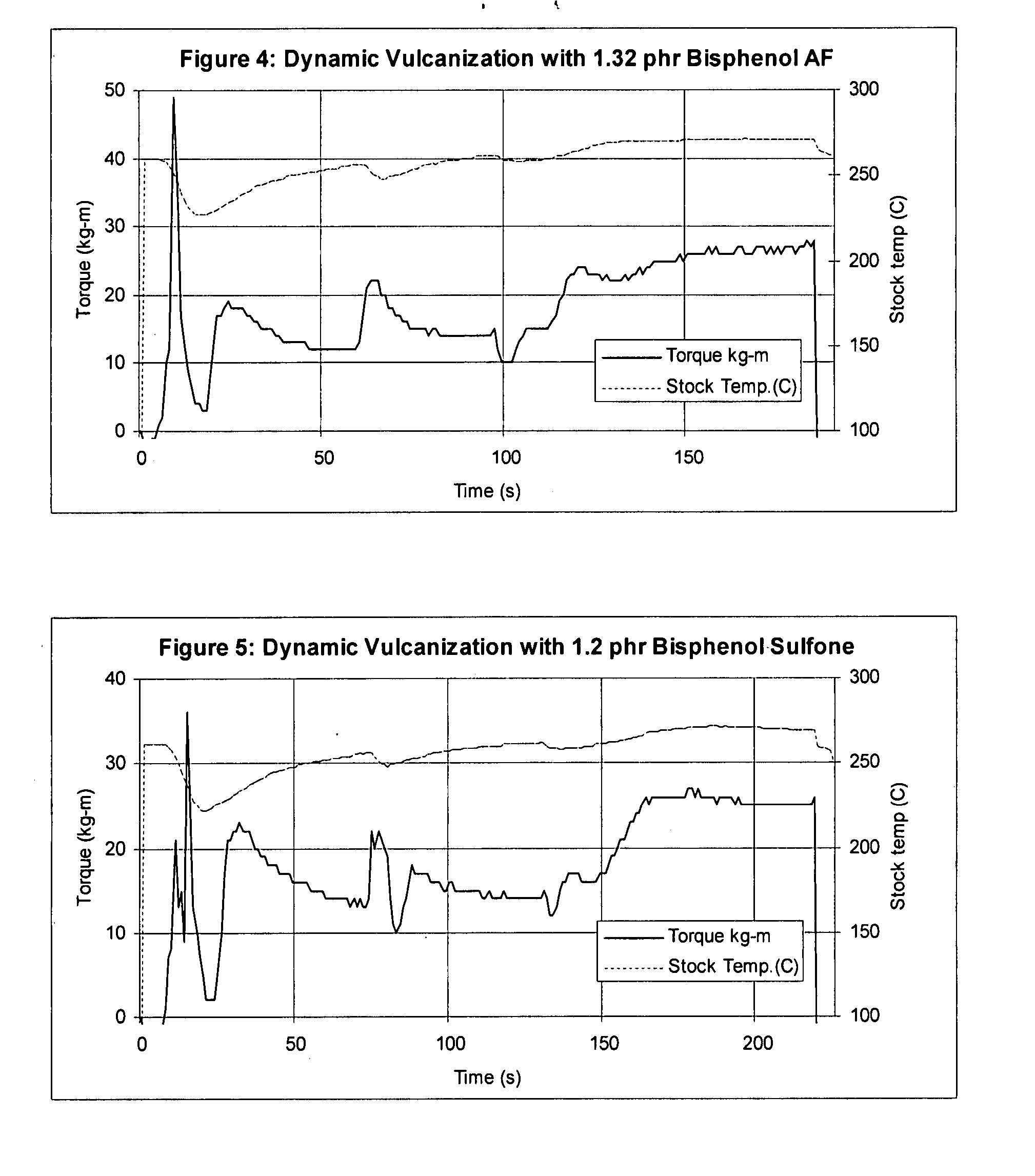

Thermoplastic, moldable polymer composition and dynamic vulcanizates thereof

InactiveUS20080032080A1Good chemical resistanceExcellent fuel barrier propertyEngine sealsOther chemical processesTetrafluoroethylenePolymer science

A thermoplastic, moldable, millable, extrudable composition of matter involving at least three polymeric components: a fluoroelastomer, an ETFE (ethylene / tetrafluoroethylene alternating copolymer, which may optionally contain one or more comonomers in minor amounts to alter crystallinity and melting temperature) fluoroplastic, and a block fluoropolymer containing at least one fluoroelastomer block and at least one ETFE block. The fluoroelastomer component and optionally the fluoroelastomer portion of the block fluoropolymer are crosslinked in a dynamic vulcanization process. Also disclosed are multilayer articles in which the aforesaid fluoro-TPV is adhered to an ETFE plastic layer. These bonded multilayer objects may include injection-molded parts that are either co-injected with both ETFE and fluoro-TPV layers, or insert molding jobs in which a previously molded ETFE insert is placed into a mold and surrounded by fluoro-TPV; and also multilayer co-extruded products such as hoses in which a fluoro-TPV layer is extruded against an ETFE layer.

Owner:DAIKIN AMERICA INC

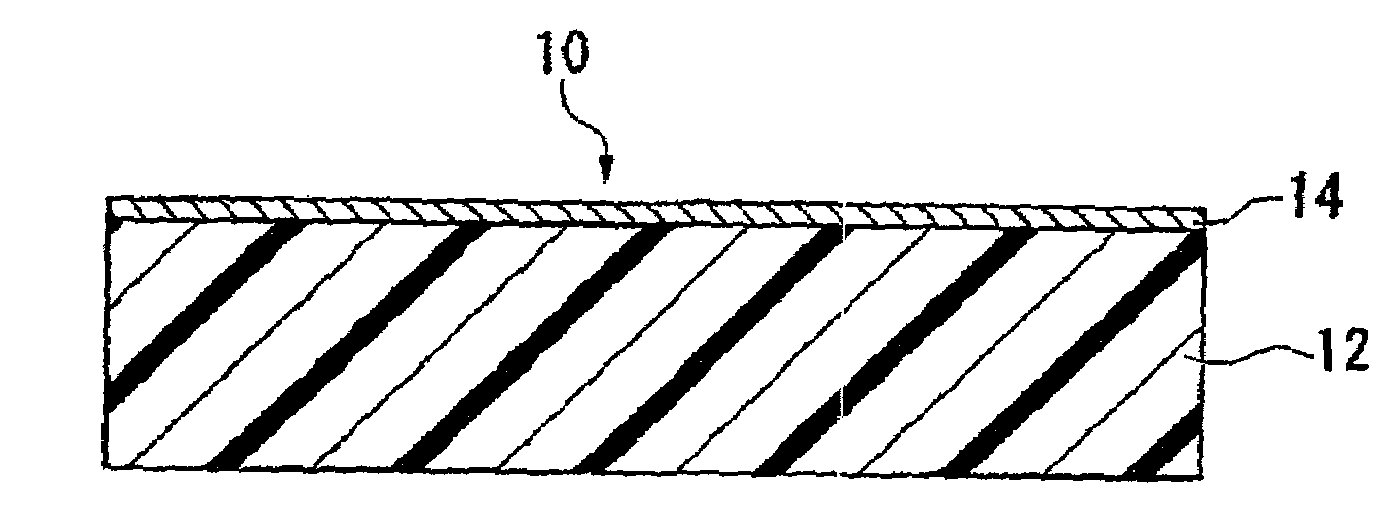

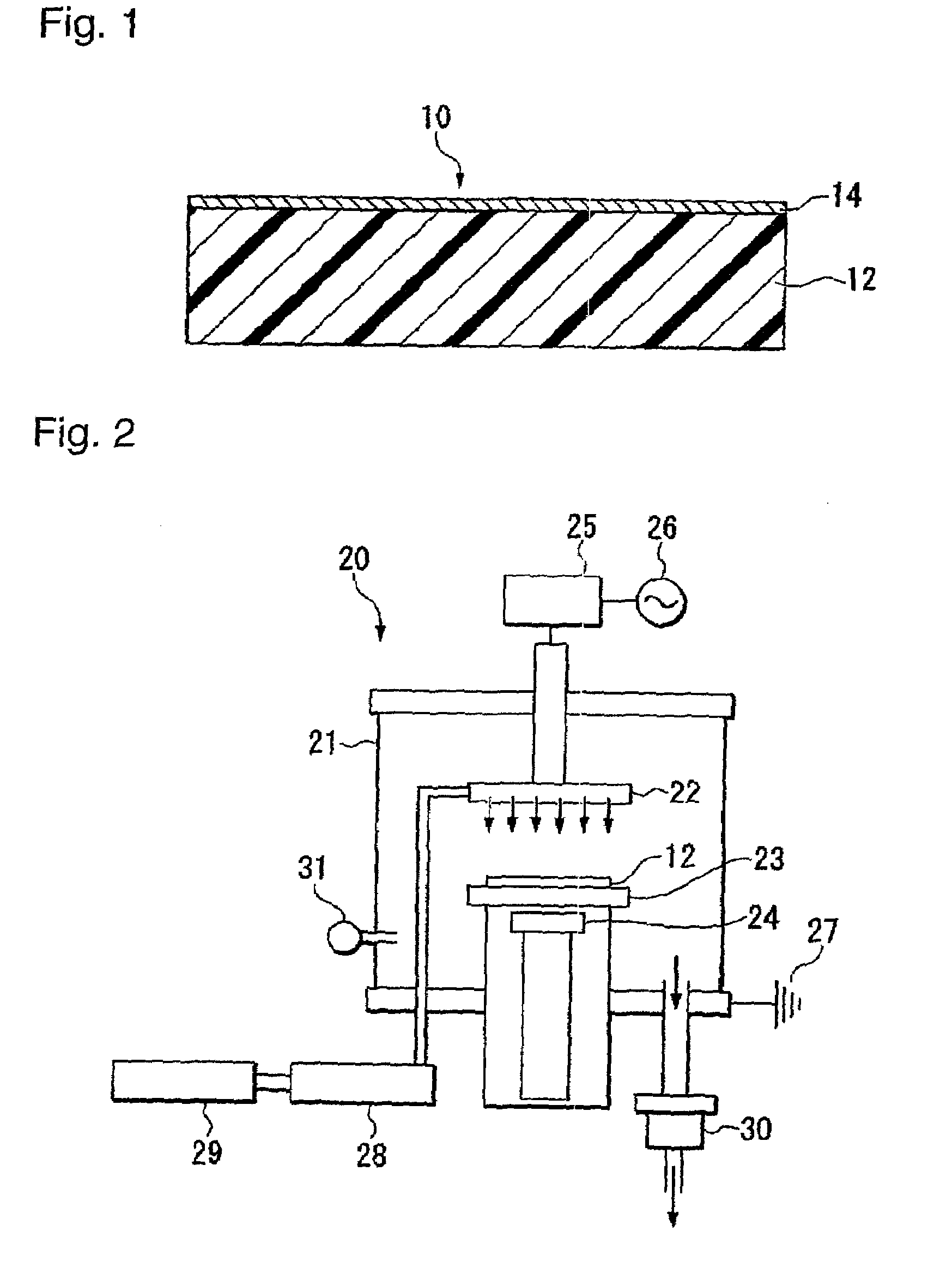

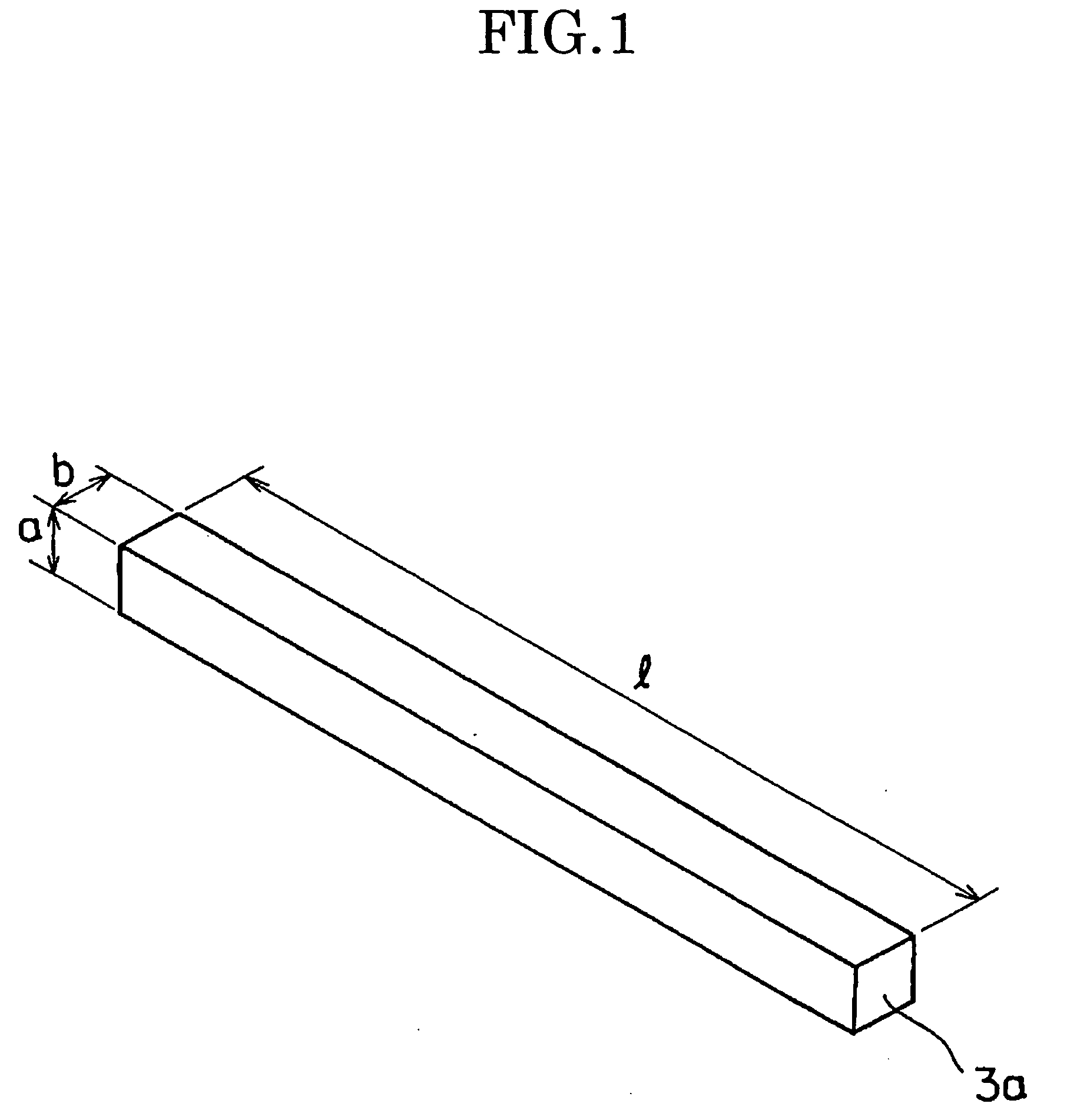

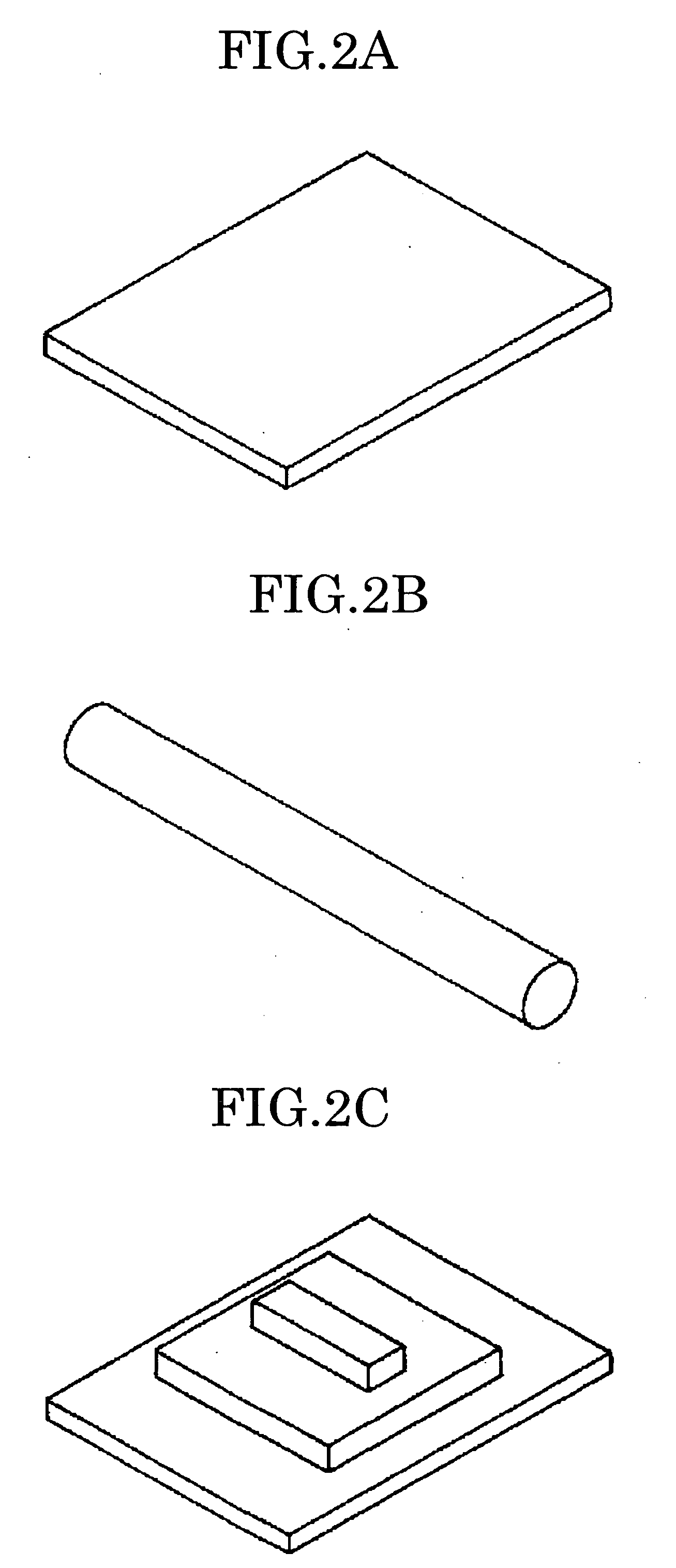

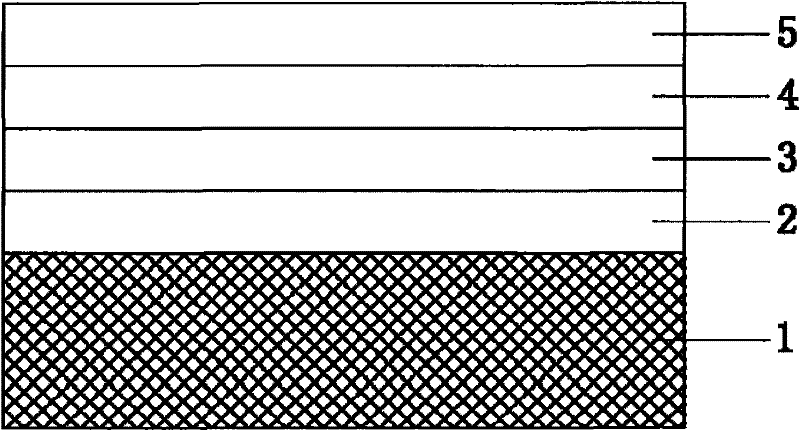

Ethylene/tetrafluoroethylene copolymer molded product and method for its production

ActiveUS20090214801A1Highly hydrophilic surfaceGood light transmissionLiquid surface applicatorsChemical vapor deposition coatingSilicon tetrafluorideSilicon oxide

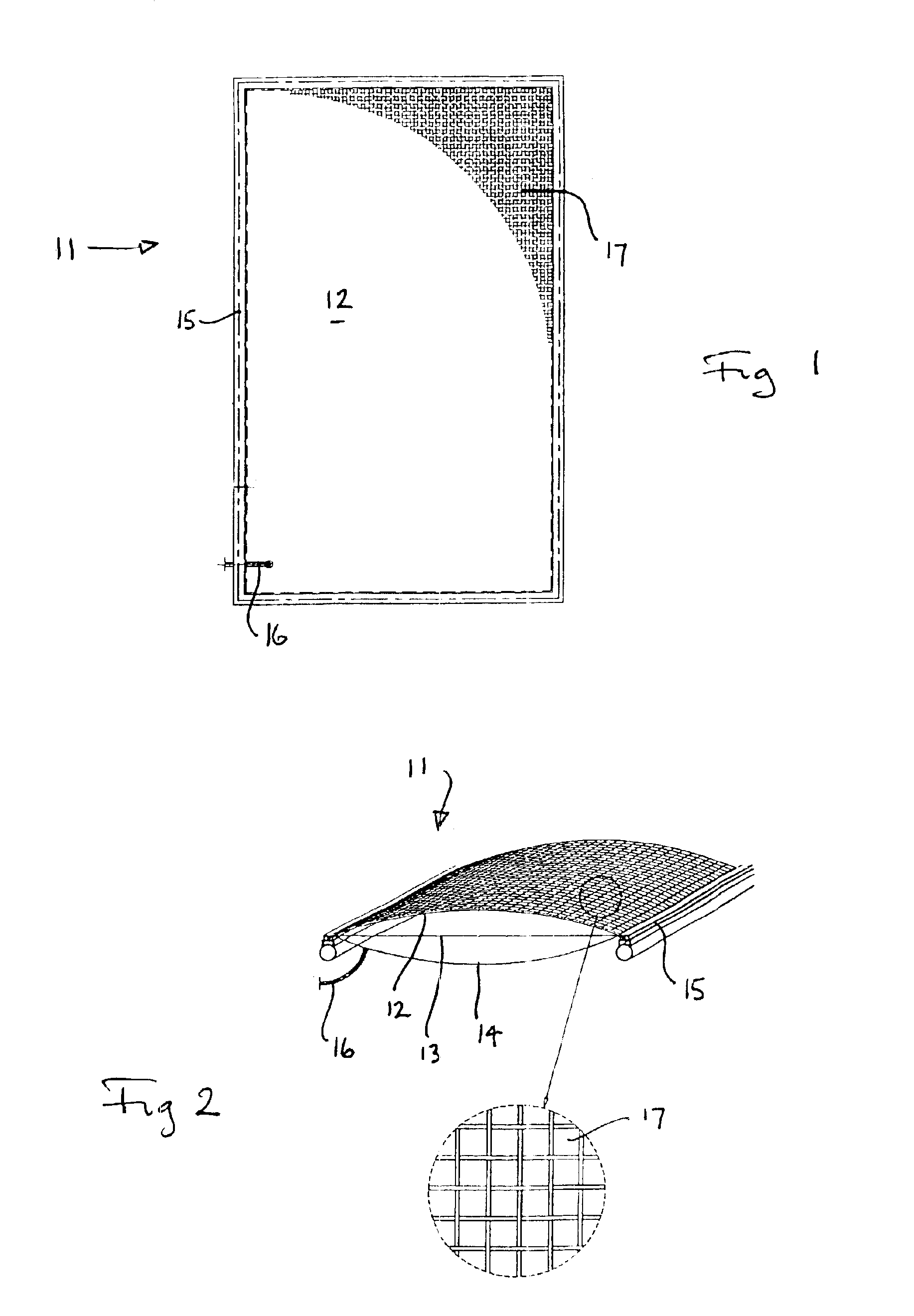

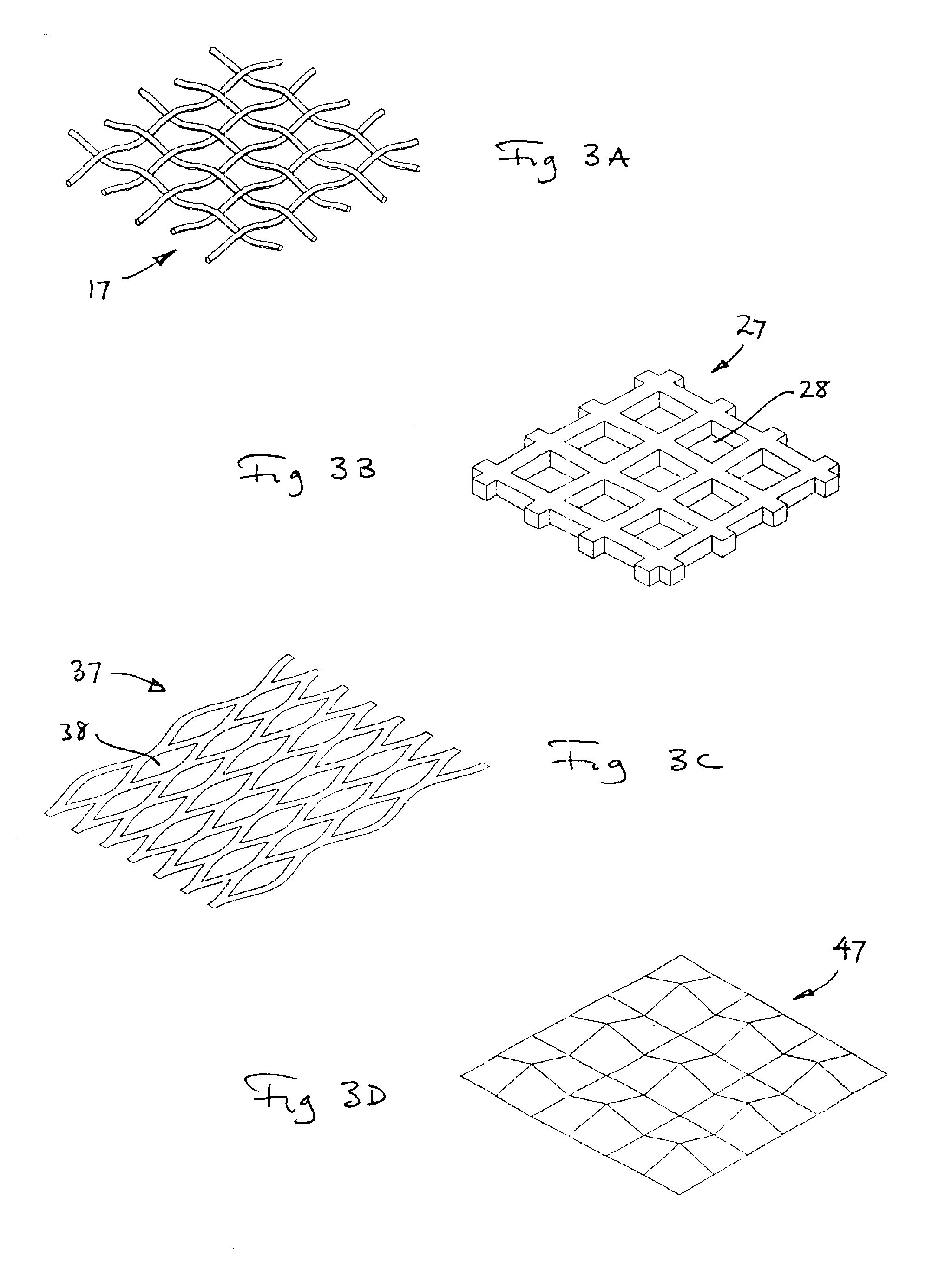

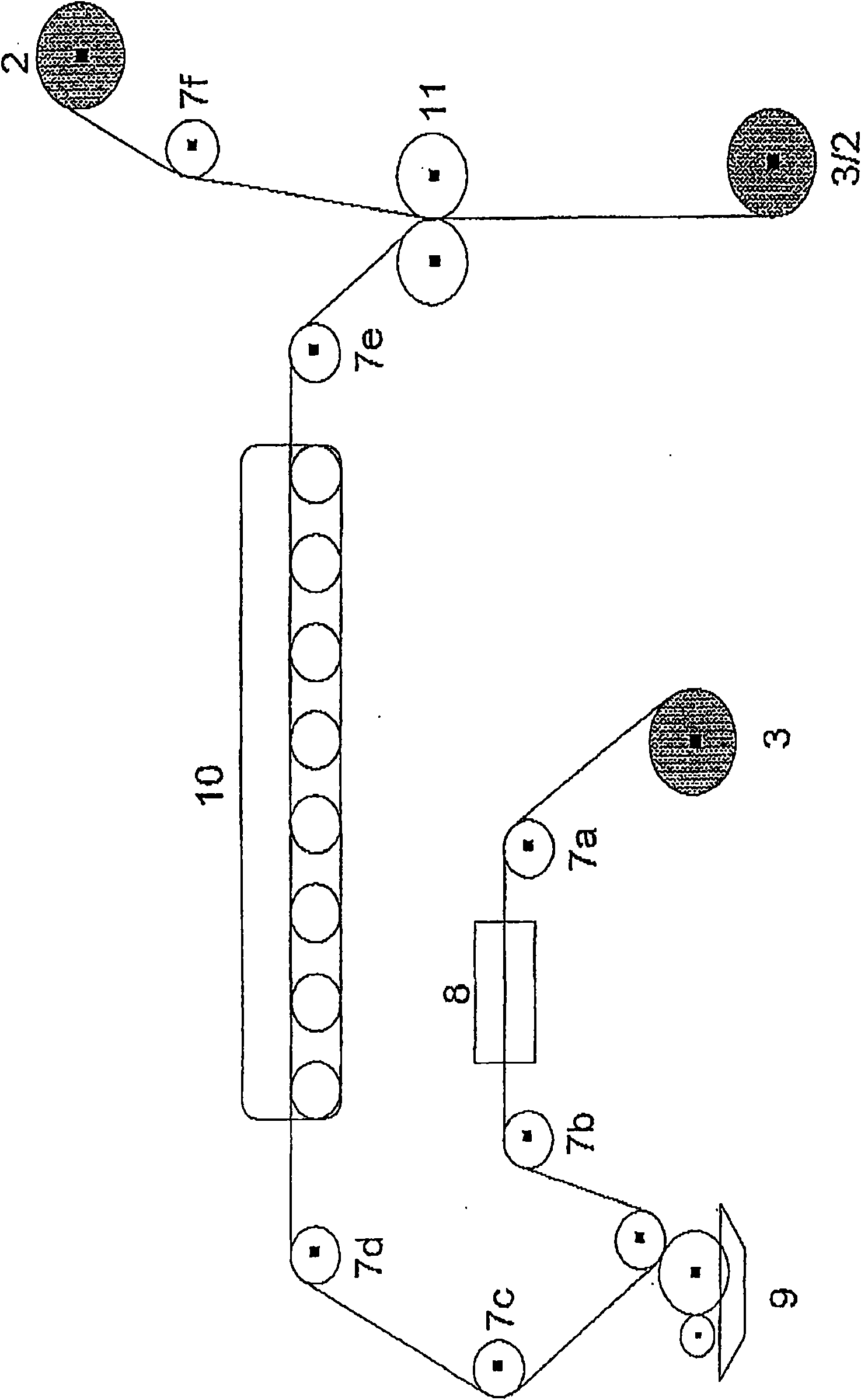

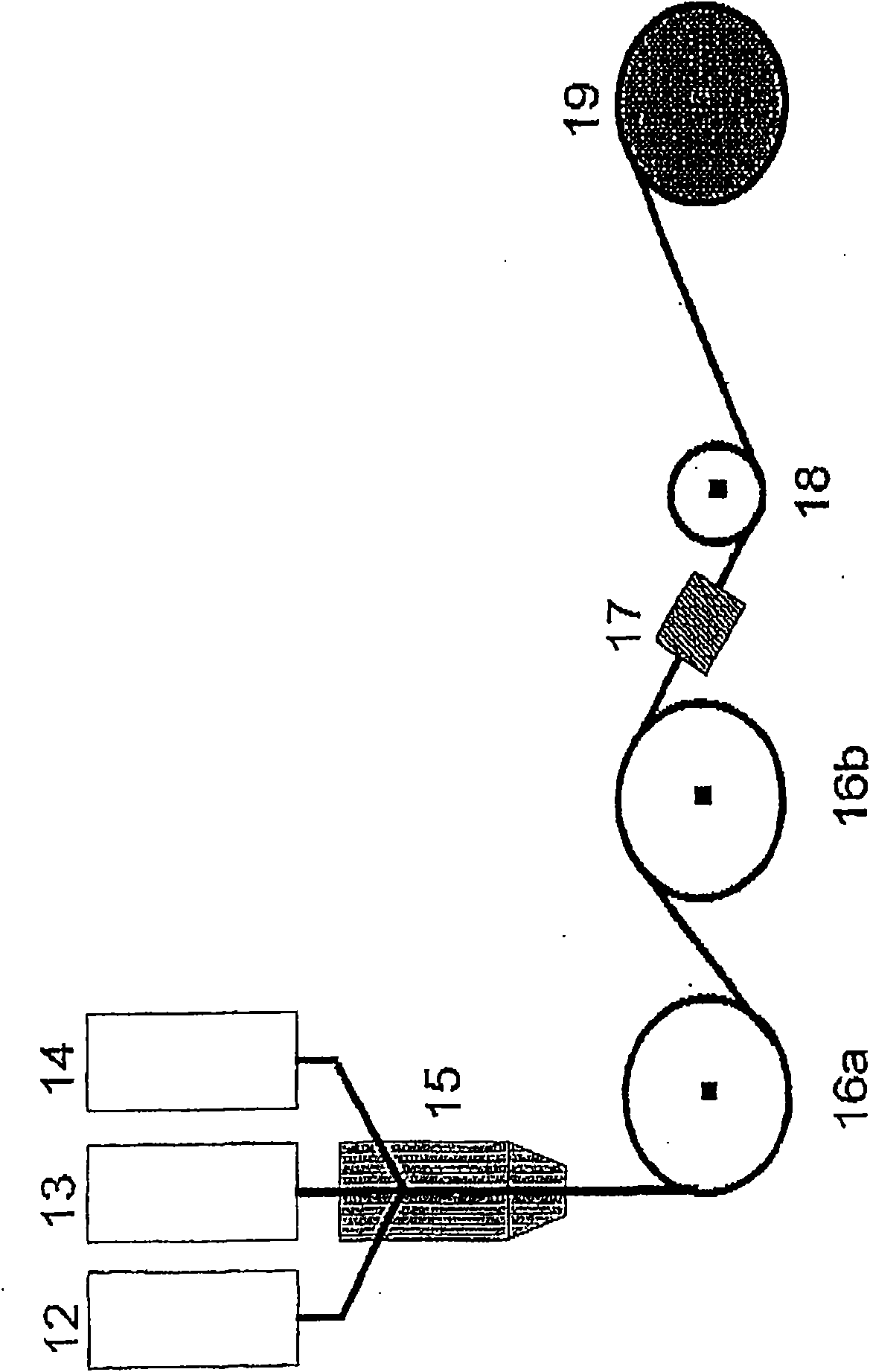

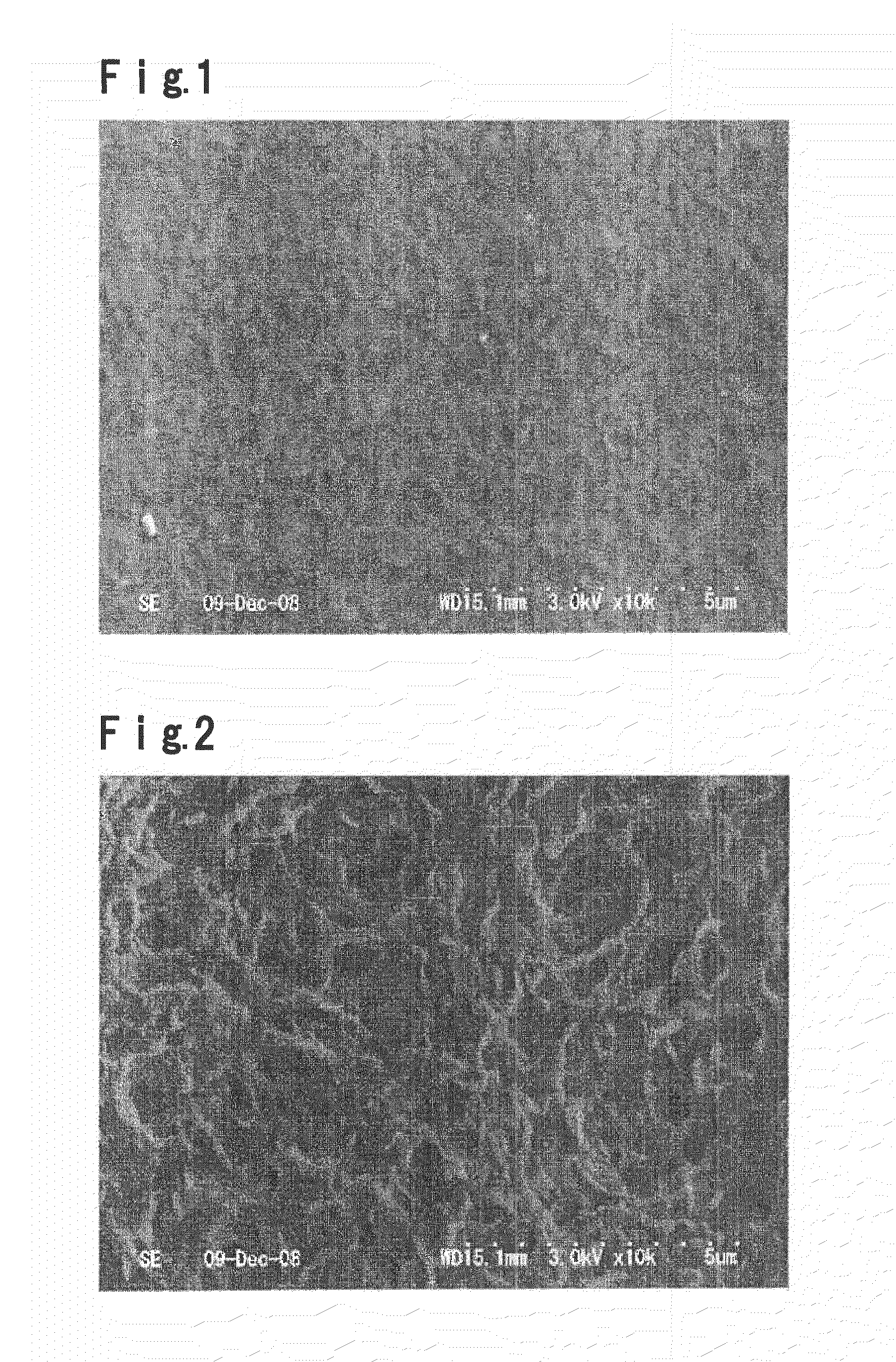

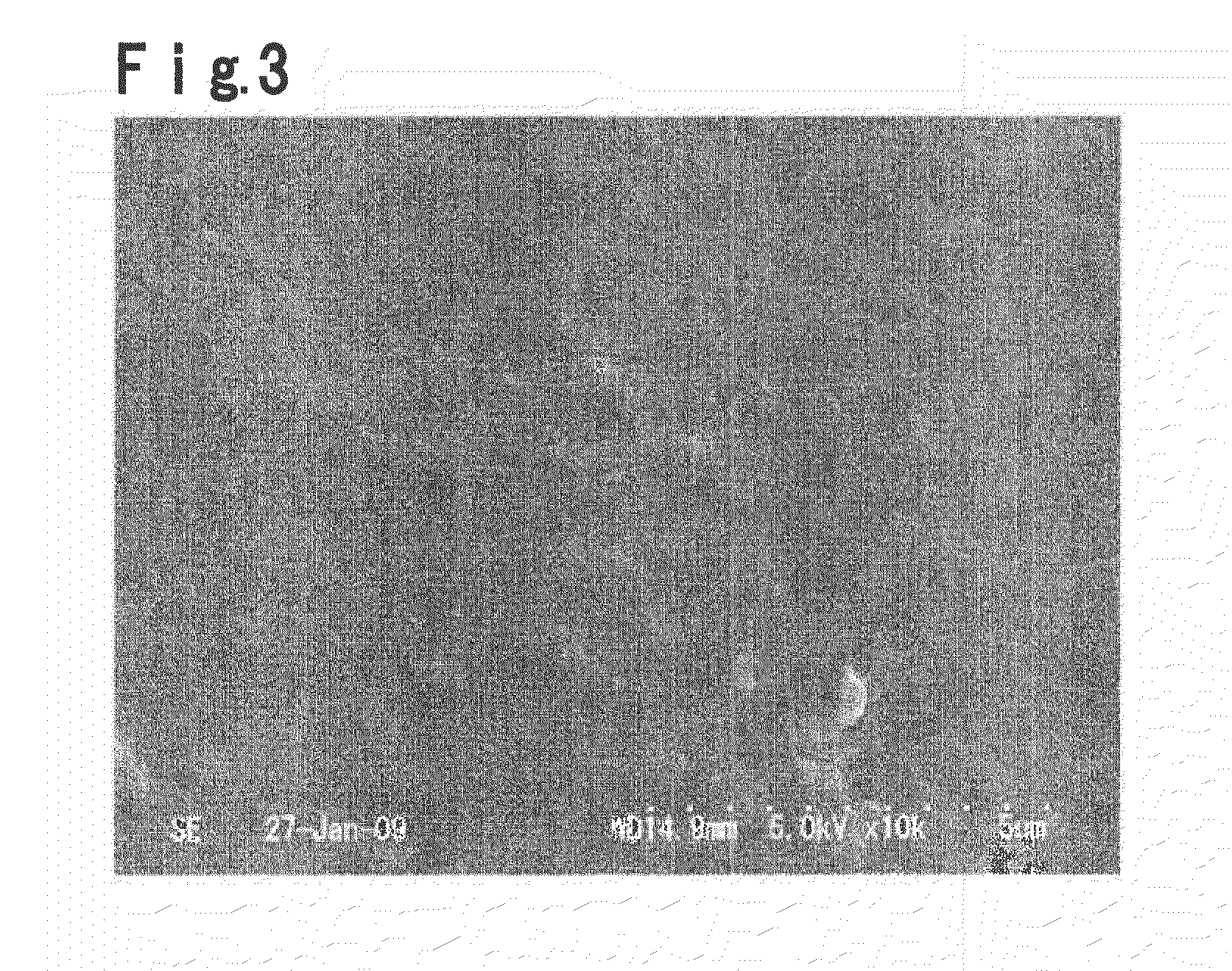

To provide an ethylene / tetrafluoroethylene (ETFE) copolymer molded product of which the surface has a high hydrophilicity and which is excellent in the light transmission property; and a method for producing the molded product.A method for producing an ETFE copolymer molded product comprising a substrate 12 made of a material containing at least 50 mass % of an ETFE copolymer, and a fluorine-doped silicon oxide film 14 formed on the surface of the substrate 12, characterized by supplying electric power between electrodes so that the electrical power density between the electrodes becomes from 0.5 to 1.1 W / cm3 to cause discharge and thus to plasmatize the following mixed gas so as to form the silicon oxide film 14 on the substrate 12: Mixed gas comprising silicon tetrafluoride, oxygen and a hydrocarbon, wherein the atomic ratio of oxygen atoms to carbon atoms (O / C) is from 1 to 10, and the atomic ratio of oxygen atoms to silicon atoms (O / Si) is from 1.7 to 25.

Owner:ASAHI GLASS CO LTD

Ethylene-tetrafluoroethylene copolymer composition

PCT No. PCT / JP98 / 02637 Sec. 371 Date Feb. 18, 1999 Sec. 102(e) Date Feb. 18, 1999 PCT Filed Jun. 16, 1998 PCT Pub. No. WO98 / 58018 PCT Pub. Date Dec. 23, 1998A composition which contains ETFE and PAS in a weight ratio of 5-95 / 5-95, and which further contains an organic onium compound in such a proportion that the weight ratio of the total amount of the above two component polymers and the organic onium compound is 80-99.99 / 0.01-20.

Owner:ASAHI GLASS CO LTD

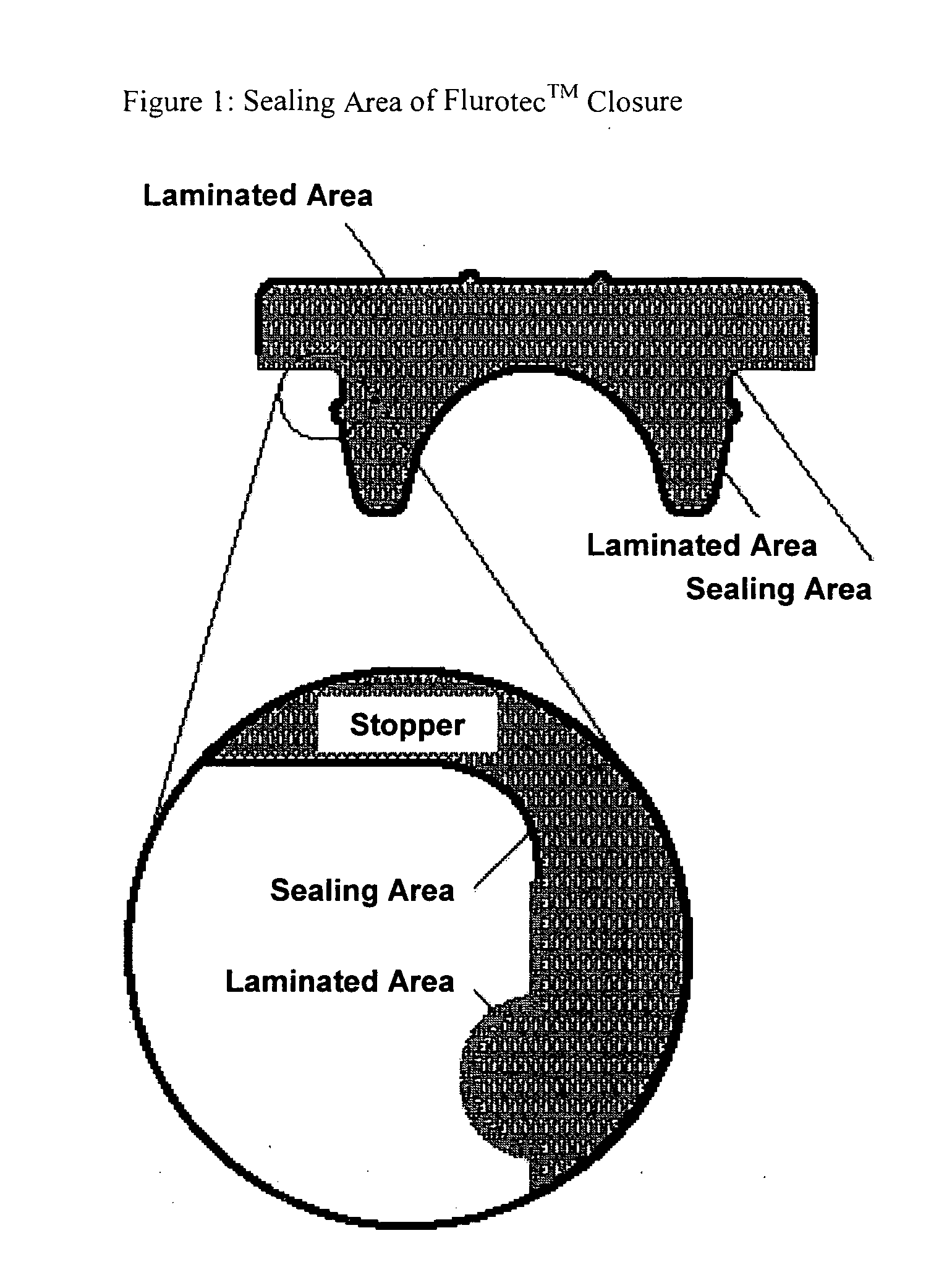

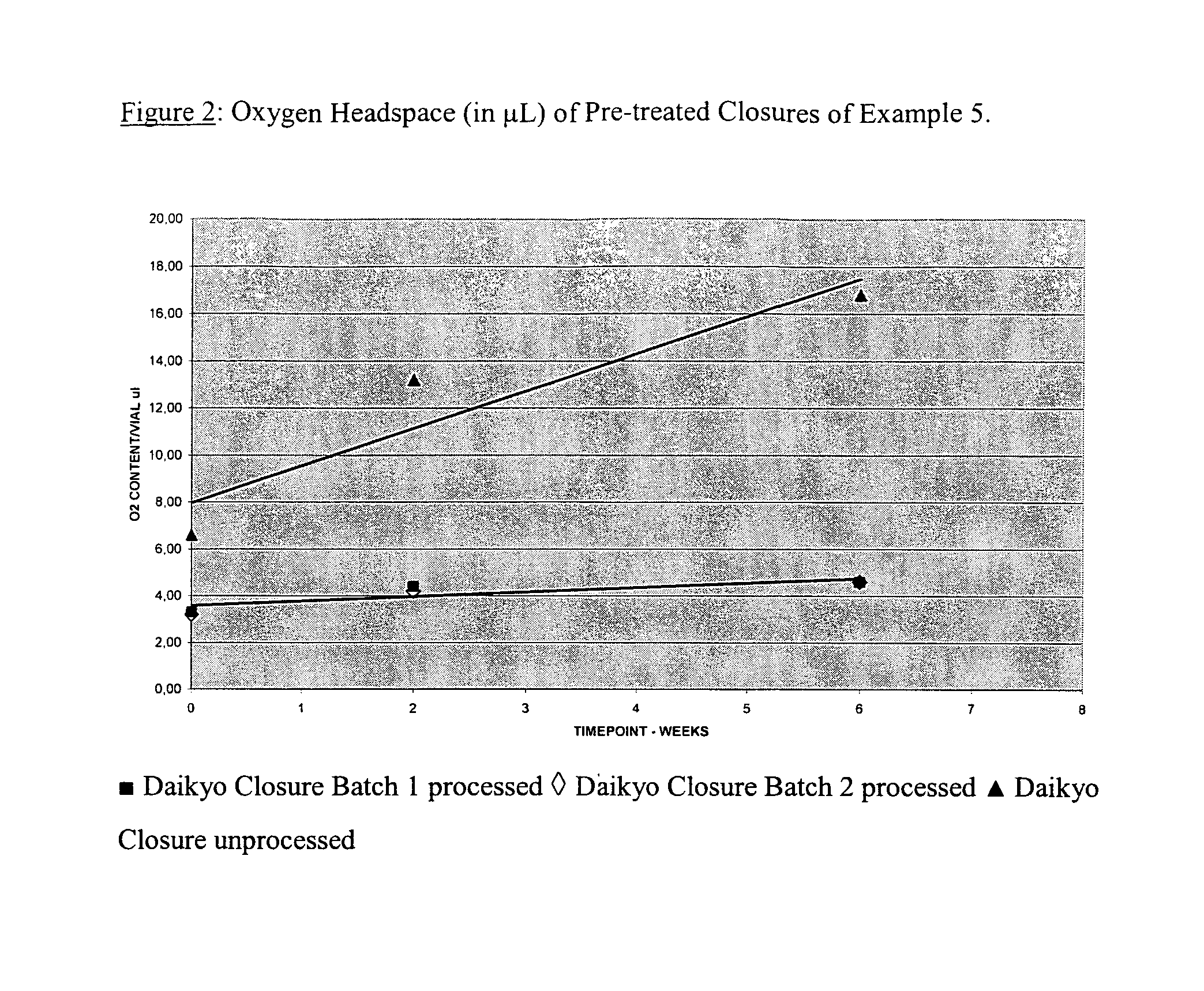

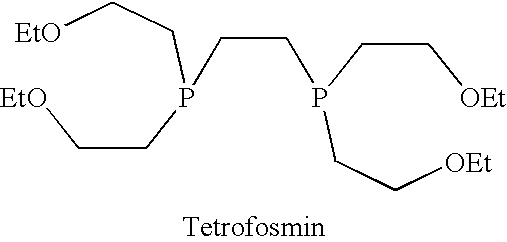

Radiopharmaceutical products

The present invention relates to improved radiopharmaceutical compositions in sealed containers, where the container closure has an ETFE (ethylene-tetrafluoroethylene copolymer) coating. Also disclosed are kits for radiopharmaceutical preparation using the sealed containers, as well as methods of preparation of radiopharmaceuticals using the sealed containers.

Owner:GE HEALTHCARE LTD

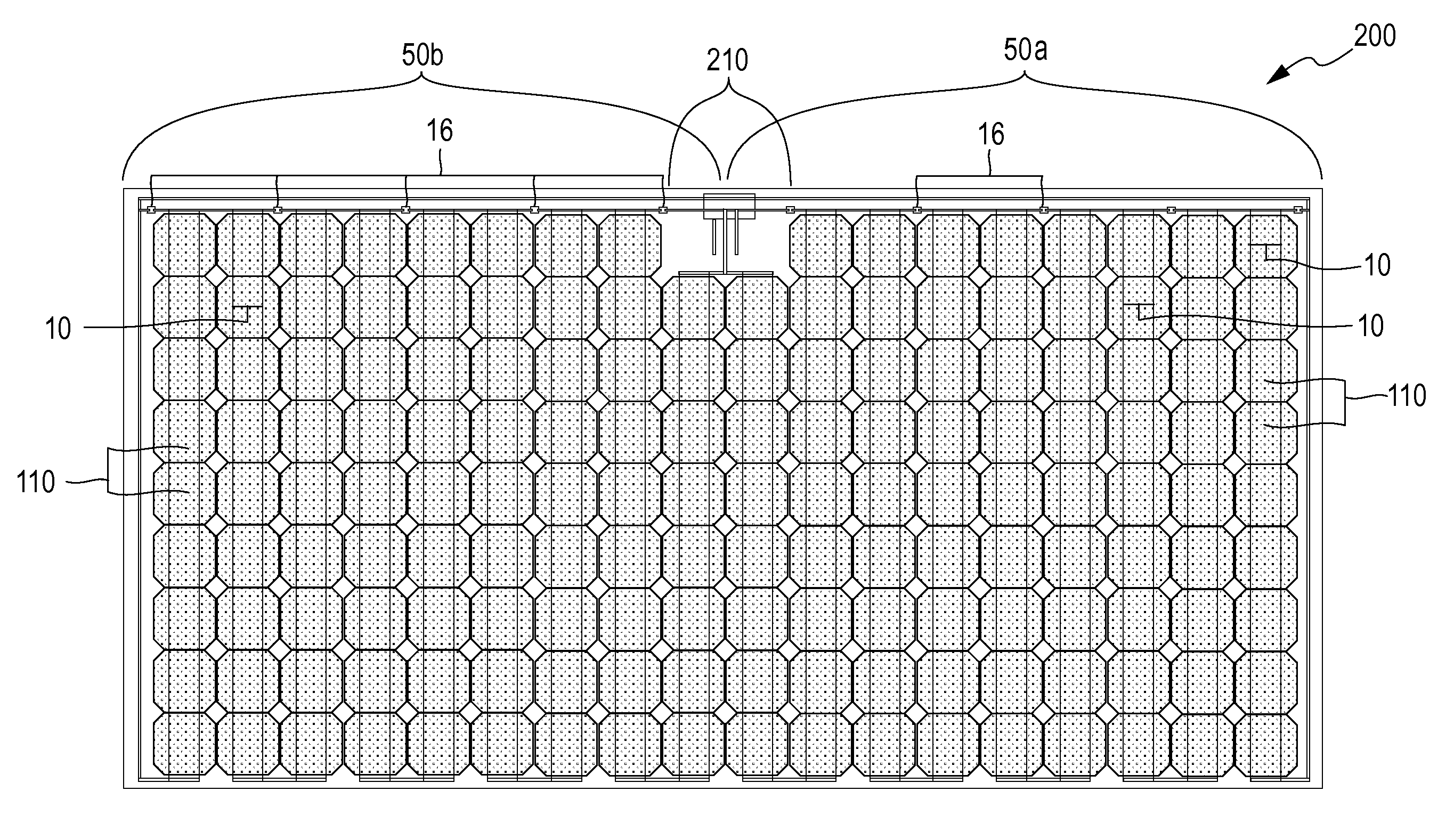

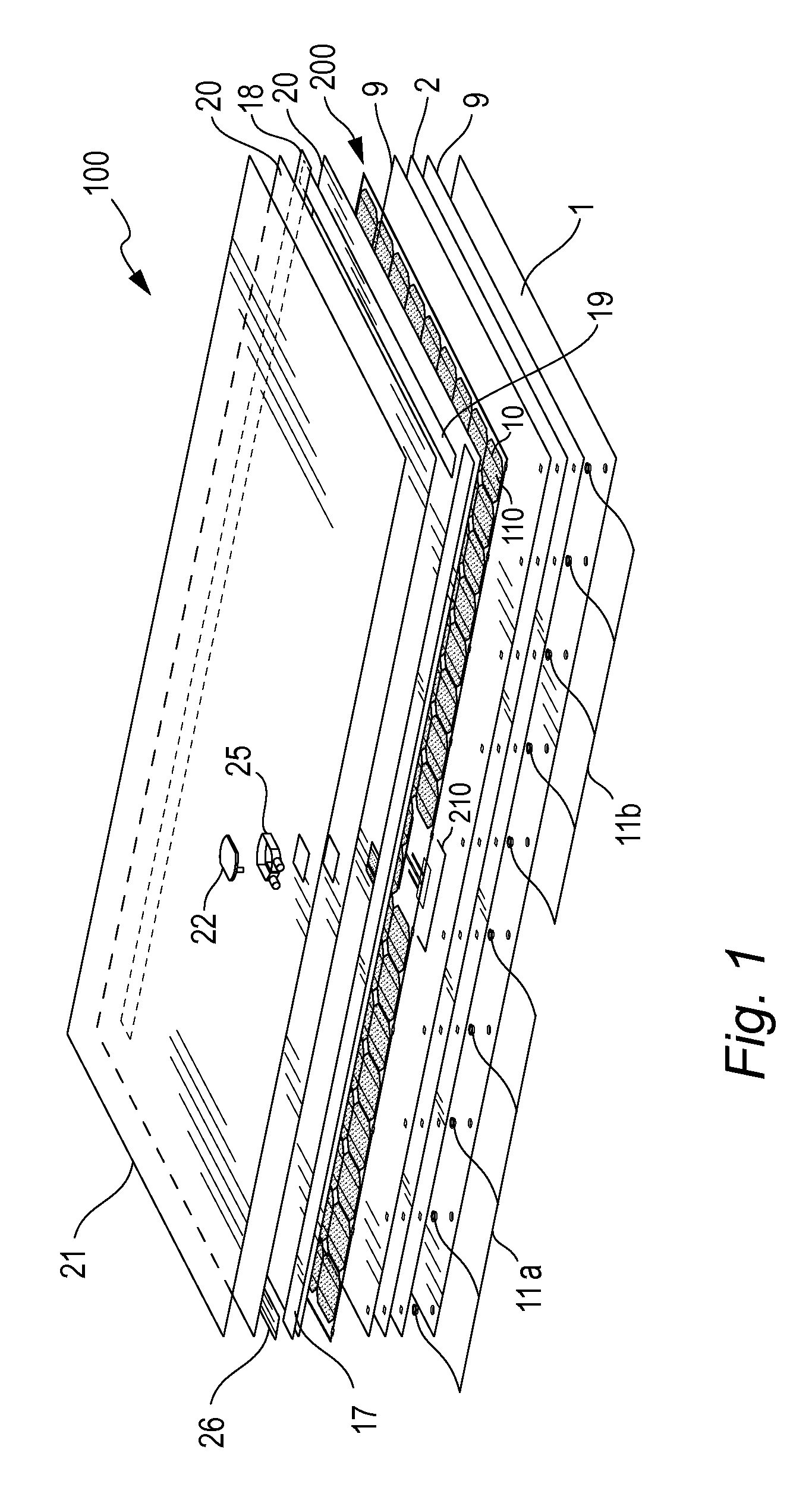

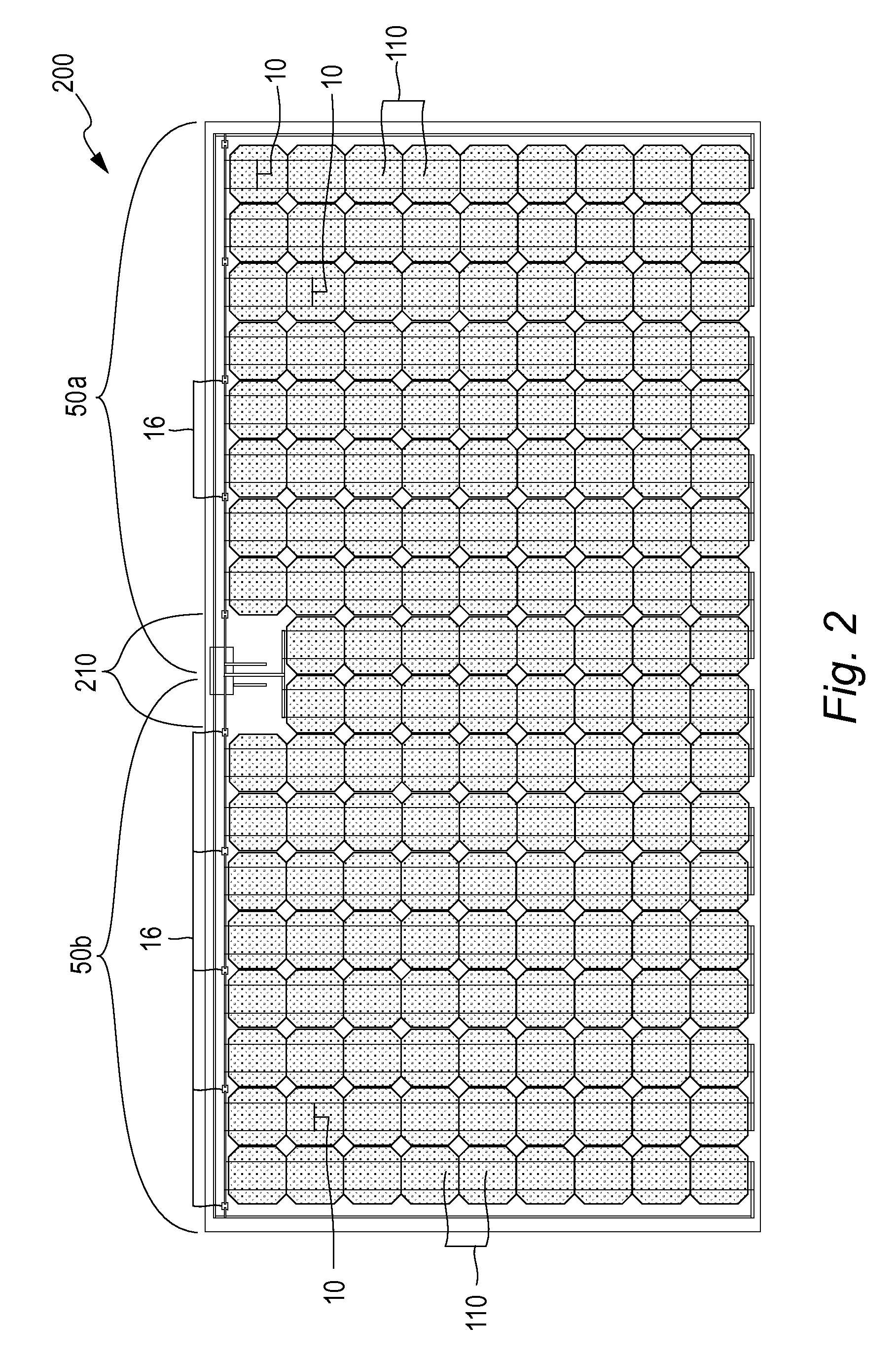

Photovoltaic modules and methods of manufacturing

Photovoltaic (PV) crystalline silicon modules and methods of manufacturing wherein the modules contain a non-glass front sheet, upper and lower encapsulate layers, a PV cell layer, an insulating sheet, and a structural back plane comprising an aluminum composite. The front sheet can be comprised of ETFE, the encapsulate layers comprise EVA, and the back plane preferably comprises APA. This particular configuration results in a lightweight PV module that still retains a high power density, and can be readily installed onto rooftops without traditional heavy racking. The PV module may be adhered to the roof using a double sided pressure sensitive adhesive or heat welded.

Owner:APPLIED SOLAR

Fluorine-containing coating composition, primer for ETFE-based coatings, and coated article

InactiveUS7192638B2Improve adhesionEasy to processSynthetic resin layered productsOrganic dyesTetrafluoroethyleneCompound a

A fluorine-containing coating composition obtainable by compounding a macromolecular material with an ethylene-tetrafluoroethylene copolymer having an average particle diameter of 1 to 30 μm. The macromolecular material is one occurring as a liquid or in a state dissolved in a solvent at below the melting initiating temperature of the ethylene-tetrafluoroethylene copolymer. Furthermore, a volume ratio between the ethylene-tetrafluoroethylene copolymer and the macromolecular material is 35:65 to 95:5.

Owner:DAIKIN IND LTD

Apparatus for removing halogen hydracids from biomass hydrolysates

ActiveUS20110070131A1Inexpensive materialsSilicon halogen compoundsMaterial heat developmentHydrogen halidePolymer science

An apparatus for removing hydrogen halide and water from hydrolysates that were obtained by way of halogen-acid hydrolysis from vegetable biomasses, characterized in that: —said apparatus comprises two containers, which are connected to each other by a tube, —at the inlet of the first container two flows are fed, one representing the hydrolysates and the other a heat transfer medium, which dissolves in the hydrolysate only to an economically justifiable extent (no additional process steps due to potential contamination during mixing), or enriches matter therefrom, —both flows are sprayed together in the first container, thereby producing a homogeneous mixing of the two flows, including heat transfer, which subsequently results in complete evaporation of water and the hydrogen halide dissolved in the hydrolysates, —the evaporation produces a mixture of granular solid bodies and heat transfer medium droplets, which is pulled from the first container into the second container via the connecting tube by way of a pressure gradient, —the second container is configured as a cyclone or centrifugal force precipitator, and a separation of liquid (heat transfer medium droplets) and solid constituents (granular solid bodies) from the gas flow takes place. An apparatus, characterized in that the second container (here: cyclone) on the inside wall may be lined with polyvinylchloride [PVC] (hard), PVC (chlorinated), polyethylene (PE), polypropylene (PP), polybutylene (PB), polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF), polyvinyl fluoride (PVF), ethylene-propylene-diene rubber (EPDM), ethylene-propylene copolymer, ethylene-tetrafluoroethylene (ETFE), perfluoro-ethylene-propylene plastic (FEP), fluoropolymer plastics (FPM and FKM=group designation), perfluoro trifluoroethylene (PCTFE), perfluorinated rubber (FFPM and FFKM), butyl robber (HR), isoprene rubber (IR), chlorinated polyethylene (PE-C) and rubber (collective term for rubbers containing sulfur) and copolymers and mixtures thereof from said polymers, or comprises them.

Owner:GREEN SUGAR AG

ESP Power Cables

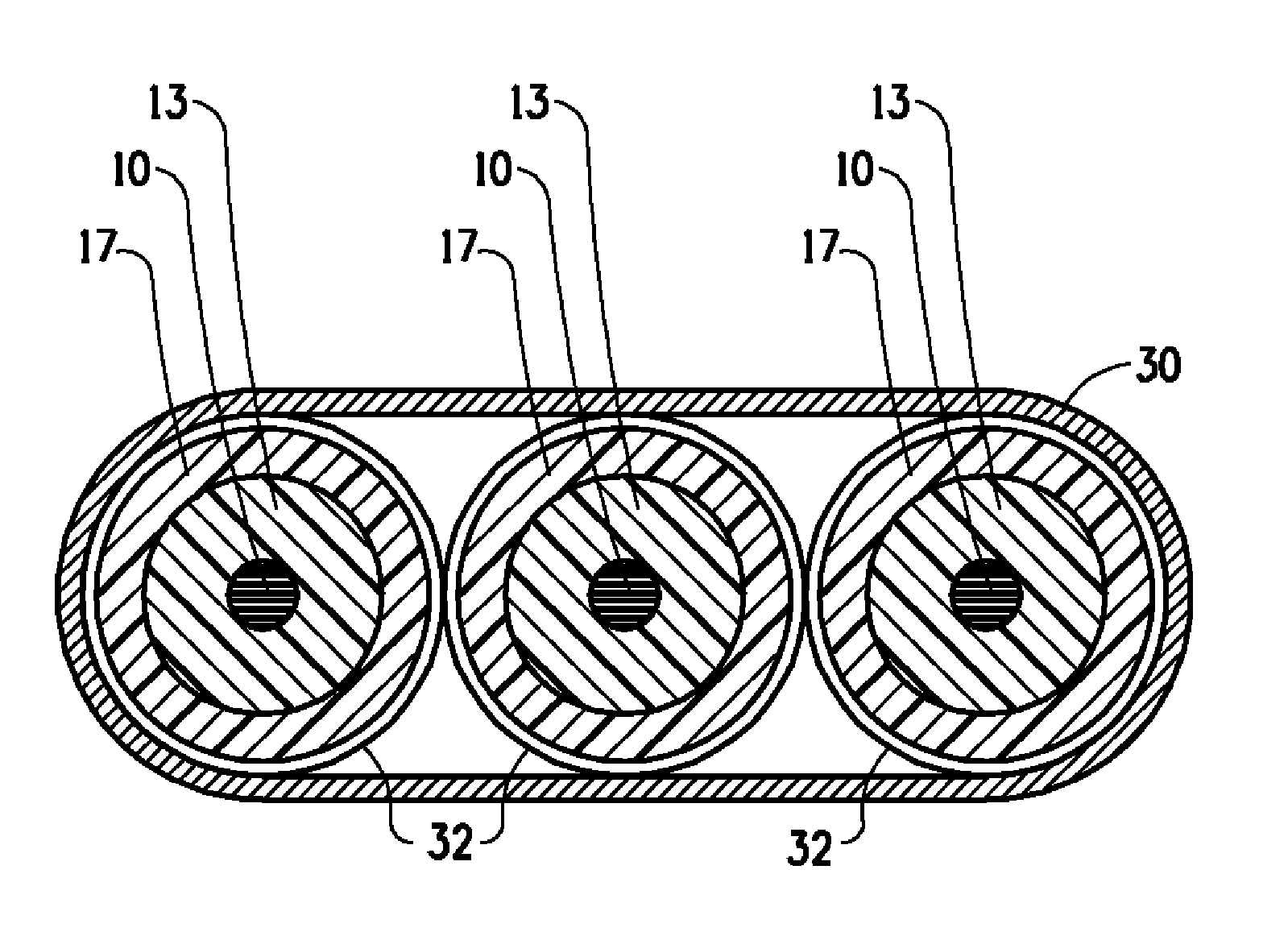

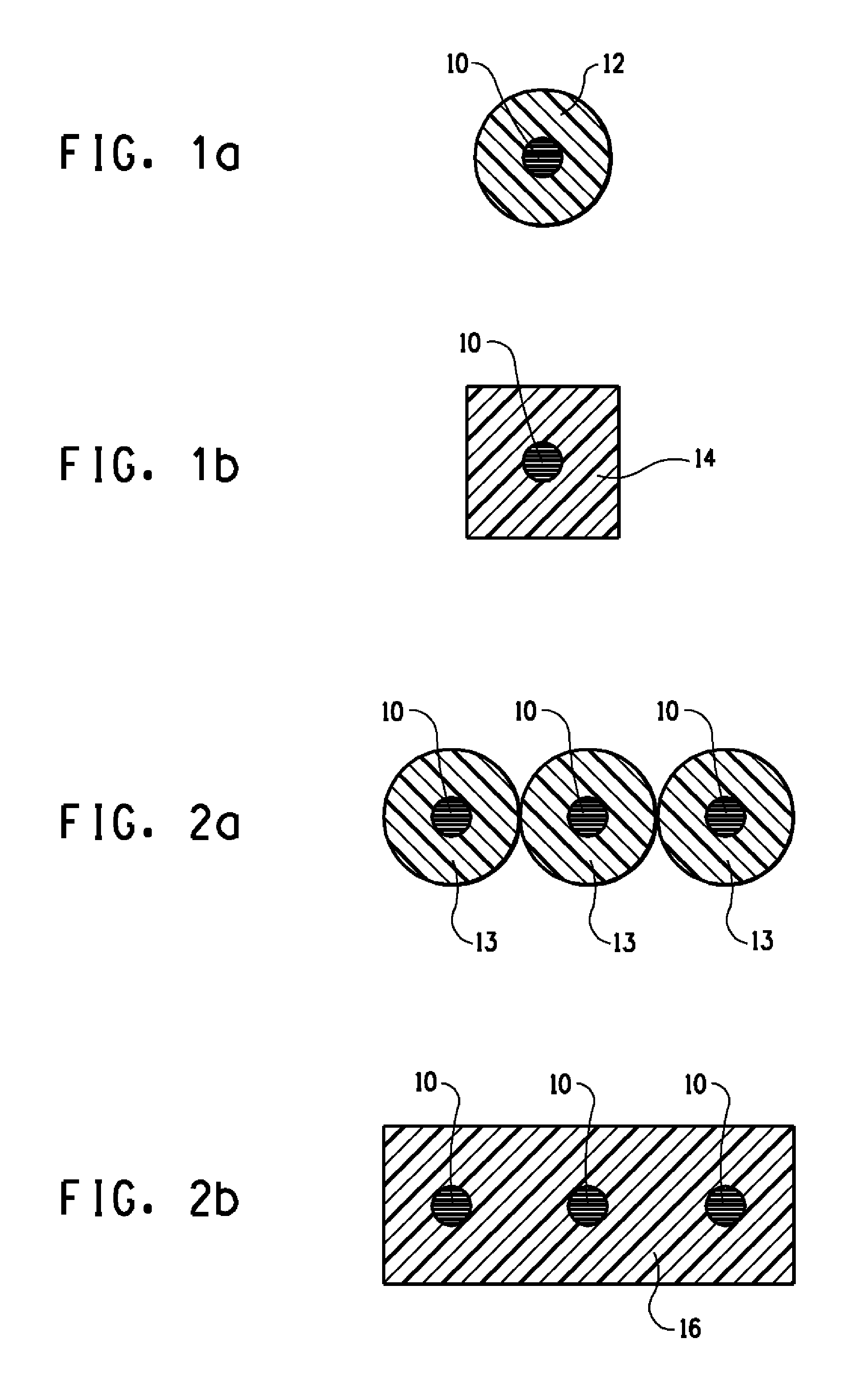

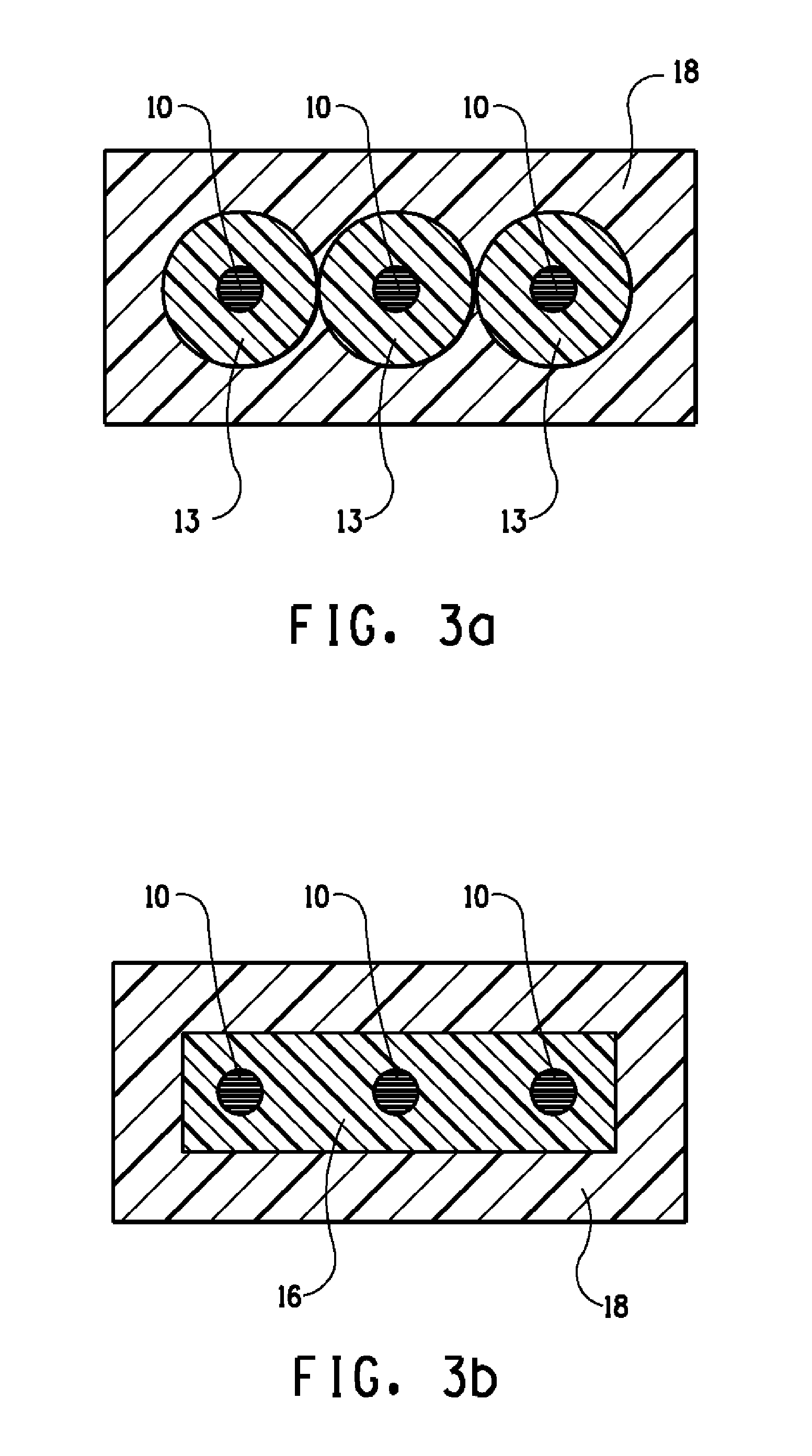

InactiveUS20130153260A1Small sectionReduce spacingPower cables with screens/conductive layersInsulated cablesTetrafluoroethyleneElectrical conductor

An electrical submersible pump (ESP) power cable for use in oil wells is provided, comprising at least two electrical conductors, a first fluoropolymer layer surrounding each of the at least two electrical conductors, an outer metal armouring, wherein the first fluoropolymer layer surrounding each of the at least two electrical conductors is composed of at least one fluoropolymer chosen among ETFE (ethylene tetrafluoroethylene copolymer), PFA (perfluoroalkoxy copolymer), FEP (fluorinated ethylene propylene copolymer) and / or mixtures thereof.

Owner:EI DU PONT DE NEMOURS & CO

Sterile, pyrogen-free, polymeric film-based heating bag

In one embodiment, there is a method for storing fluids in a bag that has an inner lining that is essentially sterilized and essentially free of pyrogen. The method comprises heating the bag that is comprised of a polymeric film to at least approximately 253° Celsius. The polymeric film includes a polymer selected from the group of poly(oxy-1,4-phenylene-oxy-1,4-phenylene-carbonyl-1,4-phenylene) (PEEK); polytetrafluoroethylene (PTFE); a perfluoroalkoxy (PFA) polymer; poly(tetrafluoroethylene-co-perfluoromethyl vinyl ether) (MFA); polyperfluoro(ethylene-co-propylene) (FEP); poly(ethylene-alt-chlorotrifluoroethylene) (ECTFE); poly(ethylene-co-tetrafluoroethylene) (ETFE); poly(vinylidene fluoride) (PDVF); tetrafluoroethylene-co-hexafluoropropylene-co-vinylidene fluoride terpolymer (THV); ultra-high molecular weight polyethylene (UHMW PE); (poly(bisphenol A-co-4-nitrophthalic anhydride-co-1,3-phenylenediamine) (PEI); poly(4-methyl-1-pentene) (PMP); and suitable mixtures thereof.

Owner:ADVANCED TECH MATERIALS INC +1

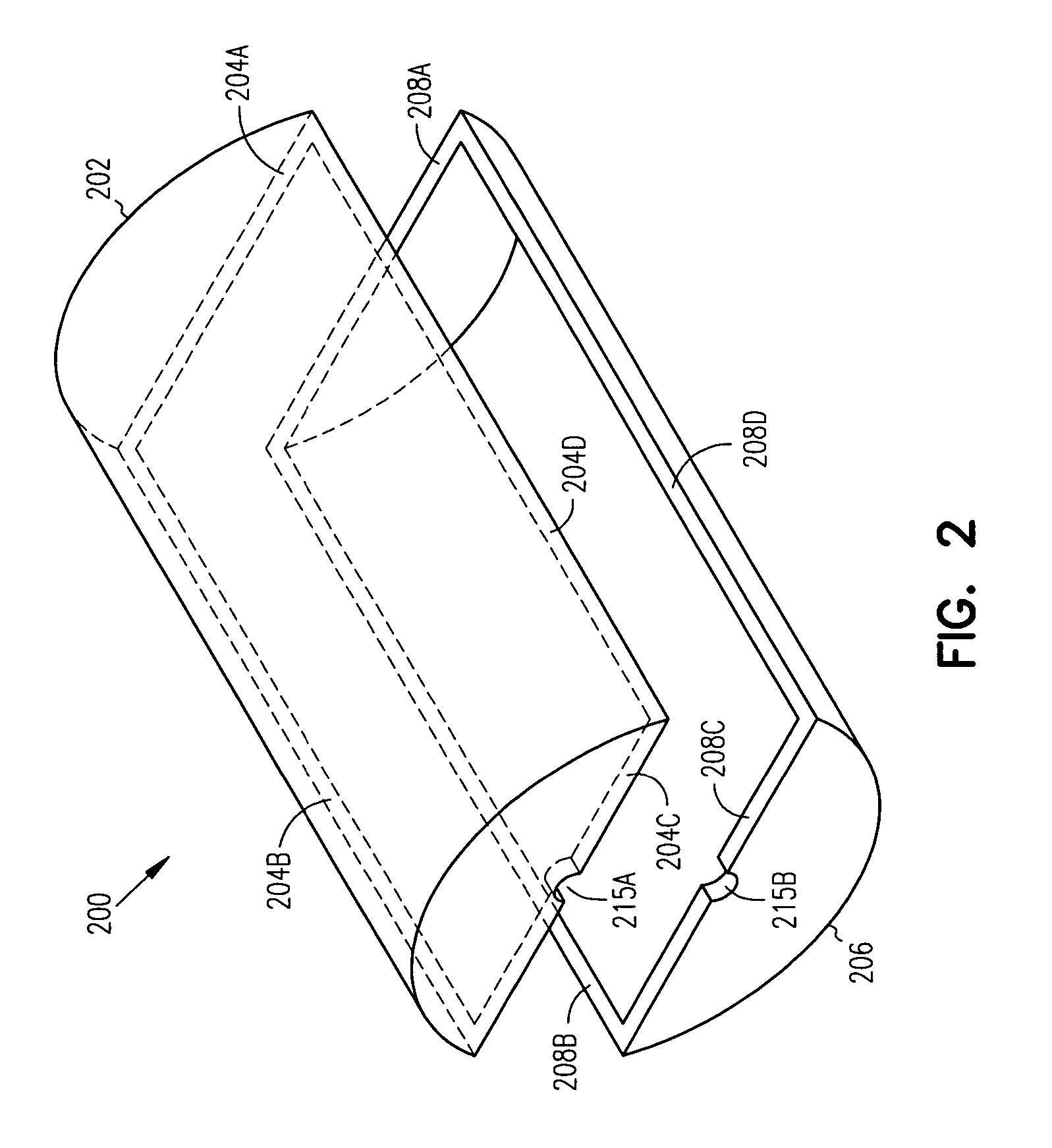

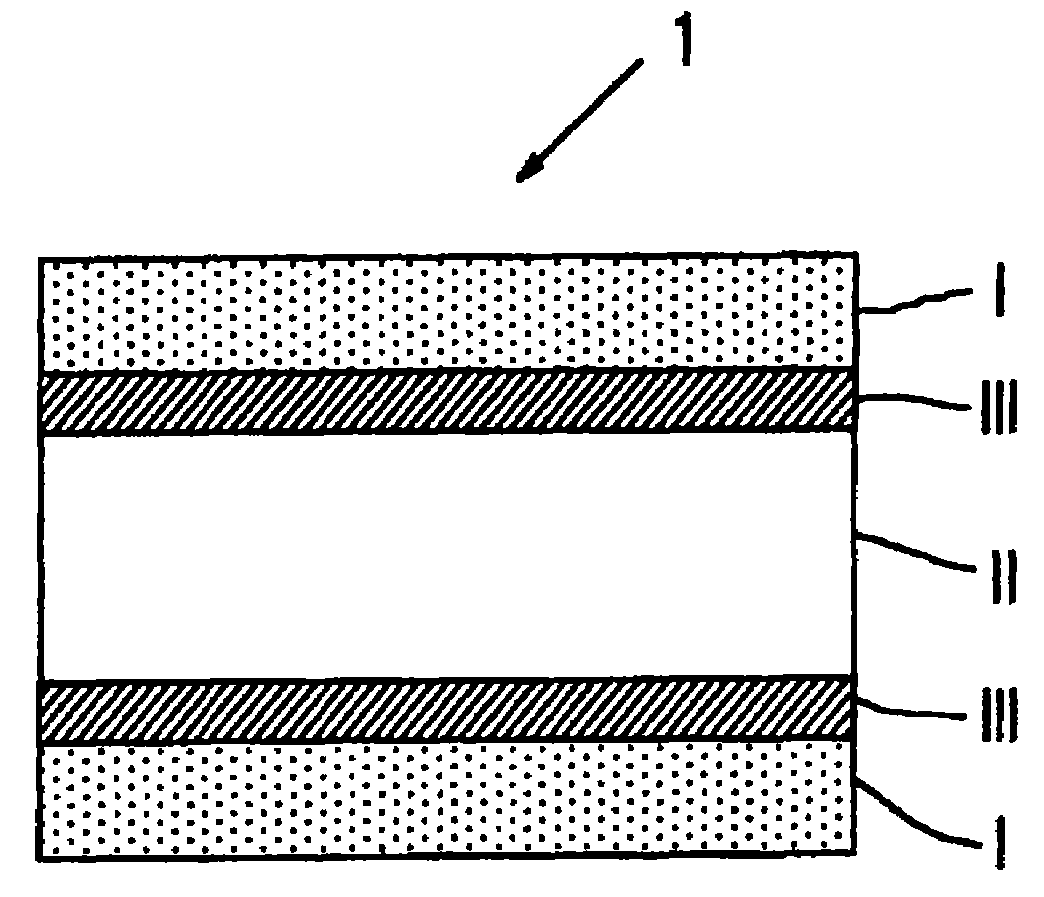

Release film for semiconductor resin molds

InactiveUS20090053528A1Low gas permeabilityExcellent in mold obsequence propertySynthetic resin layered productsSolid-state devicesMagnesiumOxide

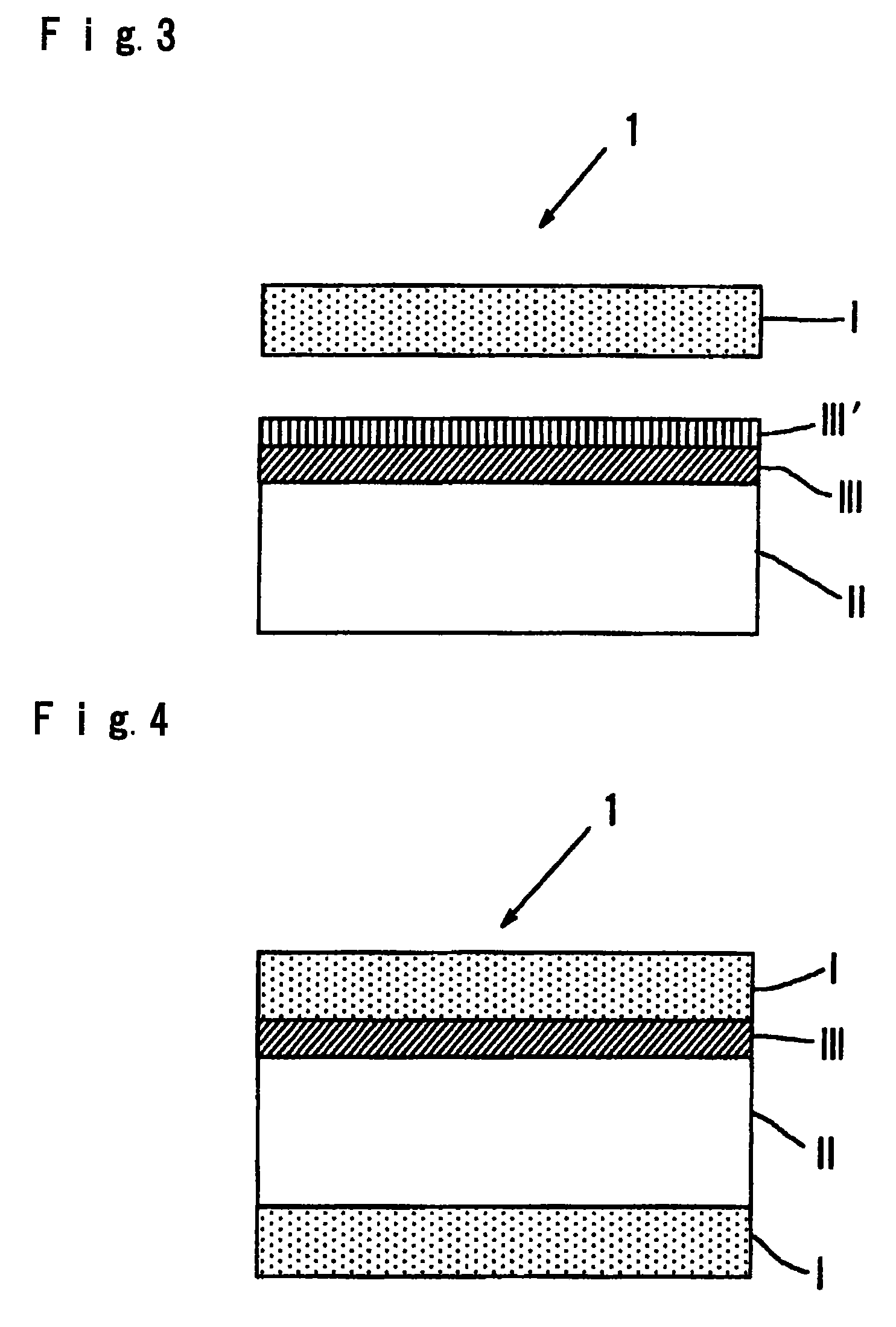

To provide a release film which has an extremely low gas permeability, an enormously small mold contamination by a mold resin and a high releasability.A gas barrier release film for semiconductor resin molds, comprising a release layer (I) having excellent releasability, a plastic support layer (II) supporting the release layer, and a gas restraint layer (III) made of a metal or a metal oxide, formed between the release layer and the support layer, and having a xylene gas permeability of at most 10−15 (kmol m / (s·m2·kPa)) at 170° C. The release layer (I) is preferably formed from a fluororesin such as an ethylene / tetrafluoroethylene copolymer, and a metal oxide layer is preferably a layer of an oxide such as an aluminum oxide, a silicon oxide or a magnesium oxide.

Owner:ASAHI GLASS CO LTD

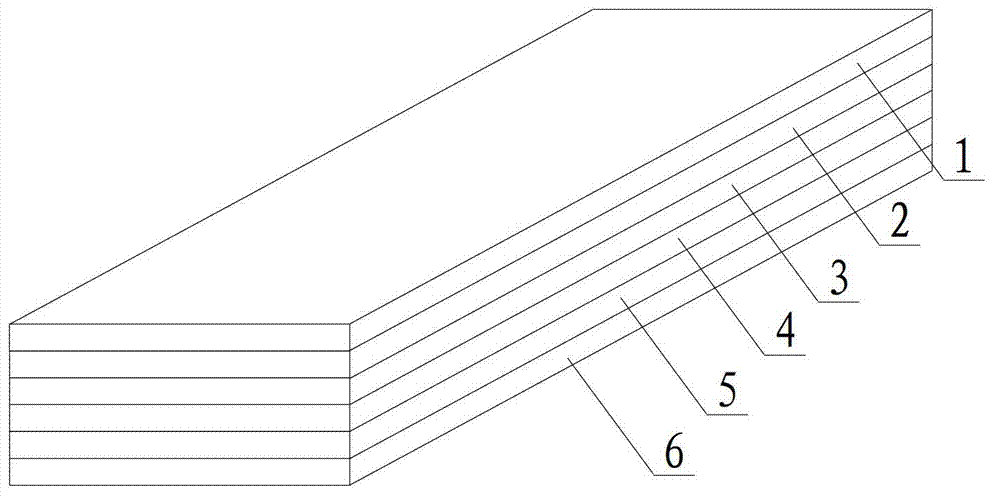

Lithium-ion battery diaphragm with high melting temperature as well as preparation method thereof

InactiveCN103811700AGood extrusion processing performanceImprove mechanical propertiesCell component detailsTetrafluoroethyleneBoPET

The invention discloses a lithium-ion battery diaphragm with high melting temperature as well as a preparation method thereof. The diaphragm is formed by compounding an ETFE (ethylene-tetrafluoroethylene) microporous membrane and a PE (polyethylene) microporous membrane. The preparation method comprises the following steps: preparing a diaphragm from ETFE and PE respectively by a thermally induced phase separation method, and extracting a diluent by A / B / A three-layer coextrusion curtain coating and compounding as well as bidirectional stretching, thereby preparing the lithium-ion battery diaphragm, wherein the layer A is the ETFE microporous membrane; the layer B is a PE microporous membrane. The lithium-ion battery diaphragm provided by the invention is high in melting temperature and mechanical intensity, is low in obturator temperature, and can practically and effectively improve the safety of the lithium ion battery.

Owner:INST OF CHEM CHINESE ACAD OF SCI

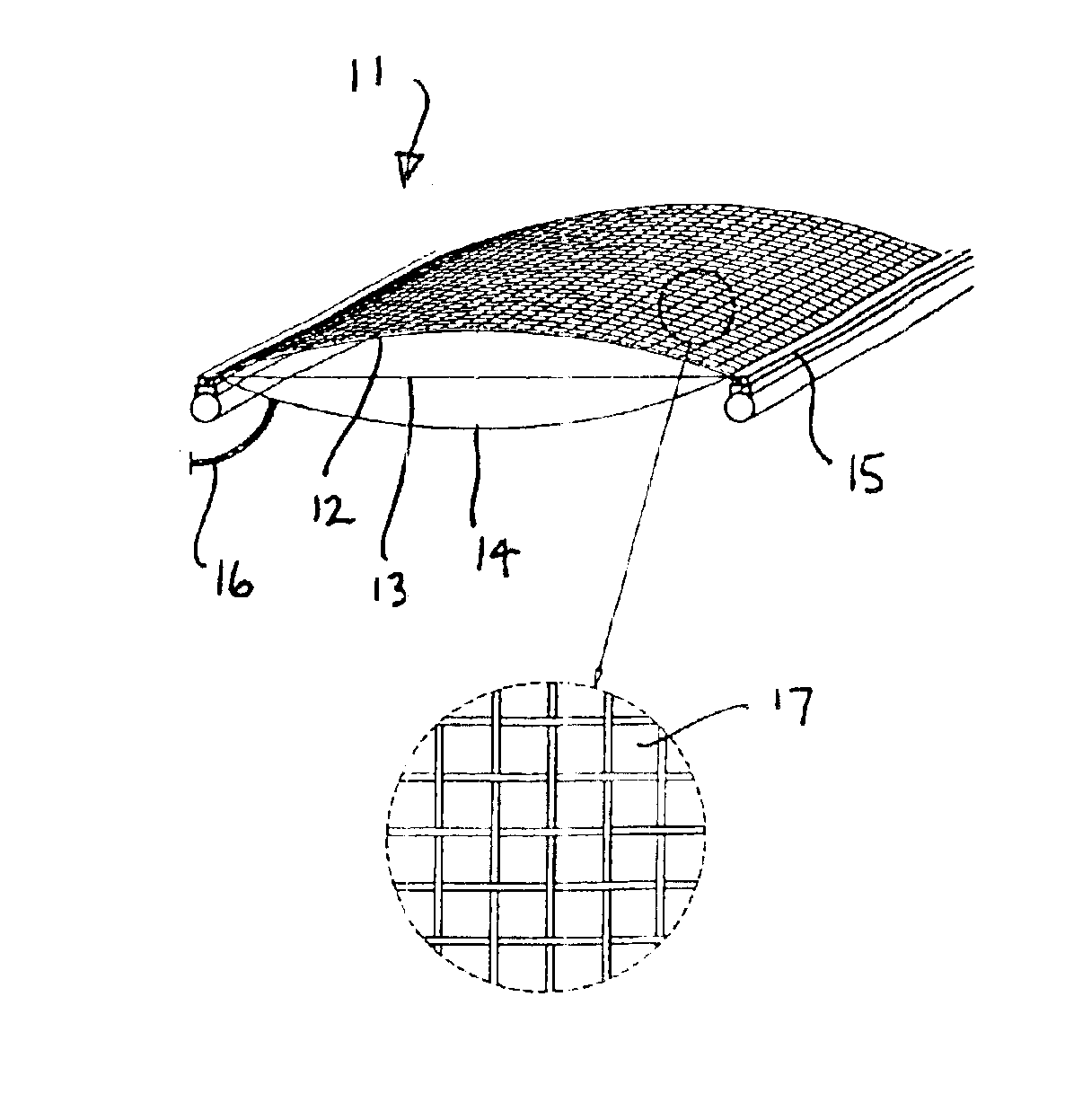

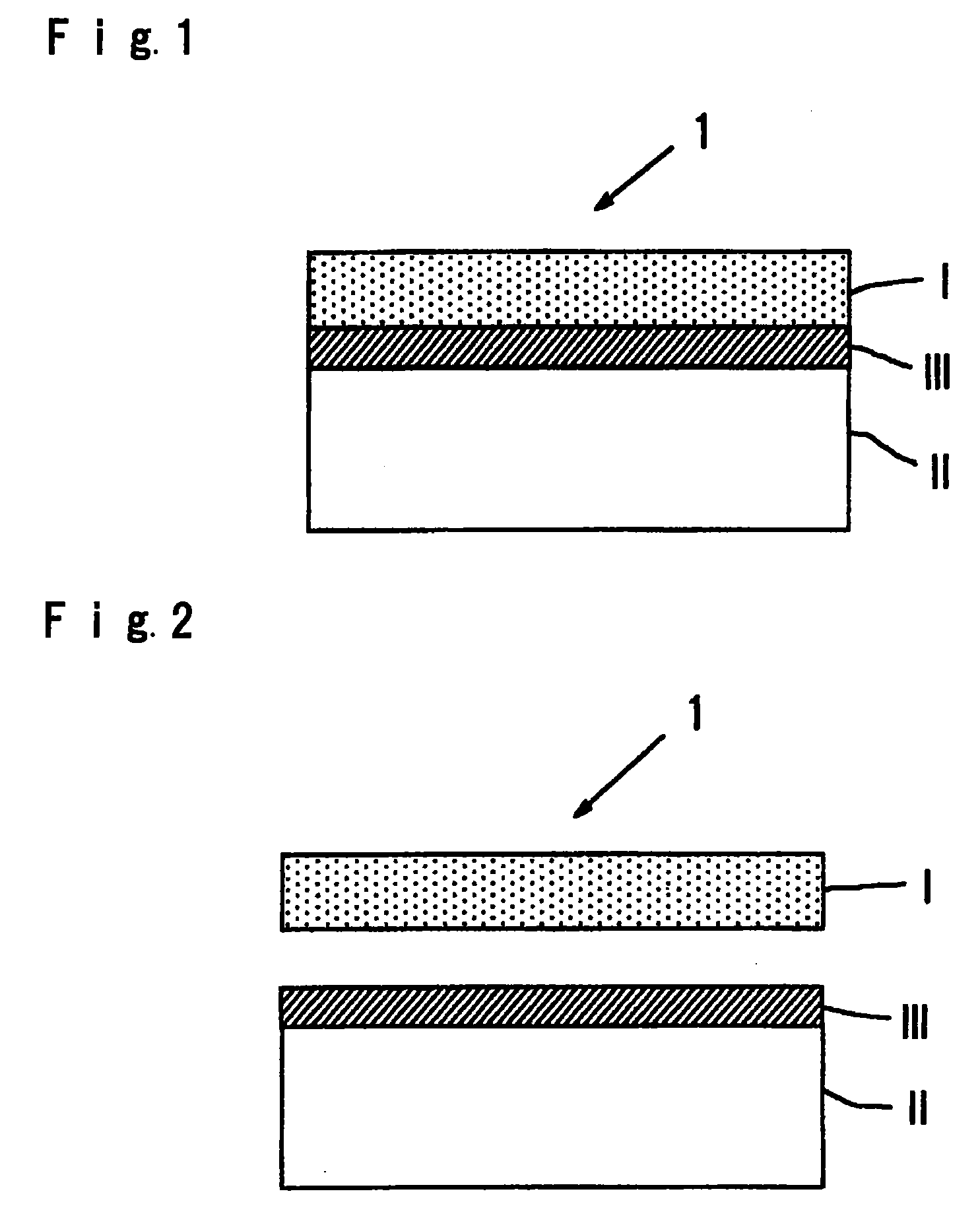

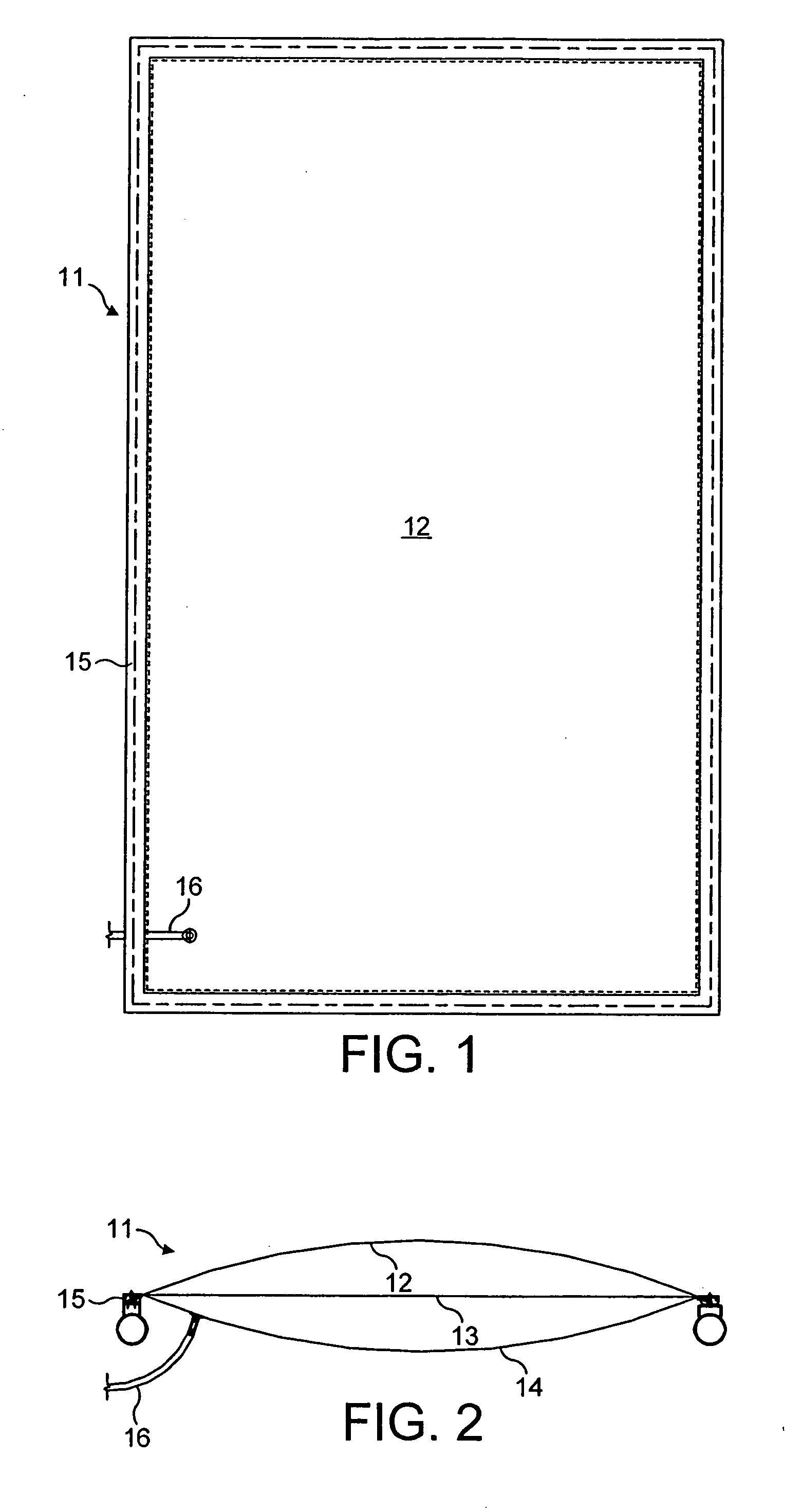

Fluororesin film and its use

InactiveUS20110220184A1Reduce transmittanceDeterioration of the fluororesin is suppressedPigmenting treatmentRoof covering using sealantsUltraviolet lightsSolar cell

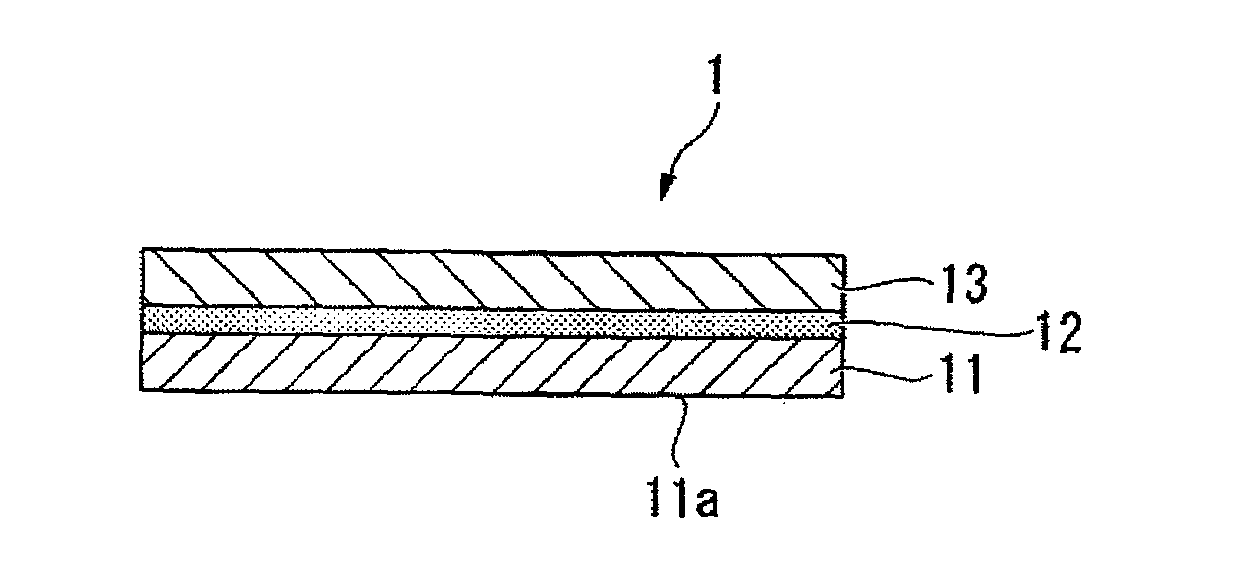

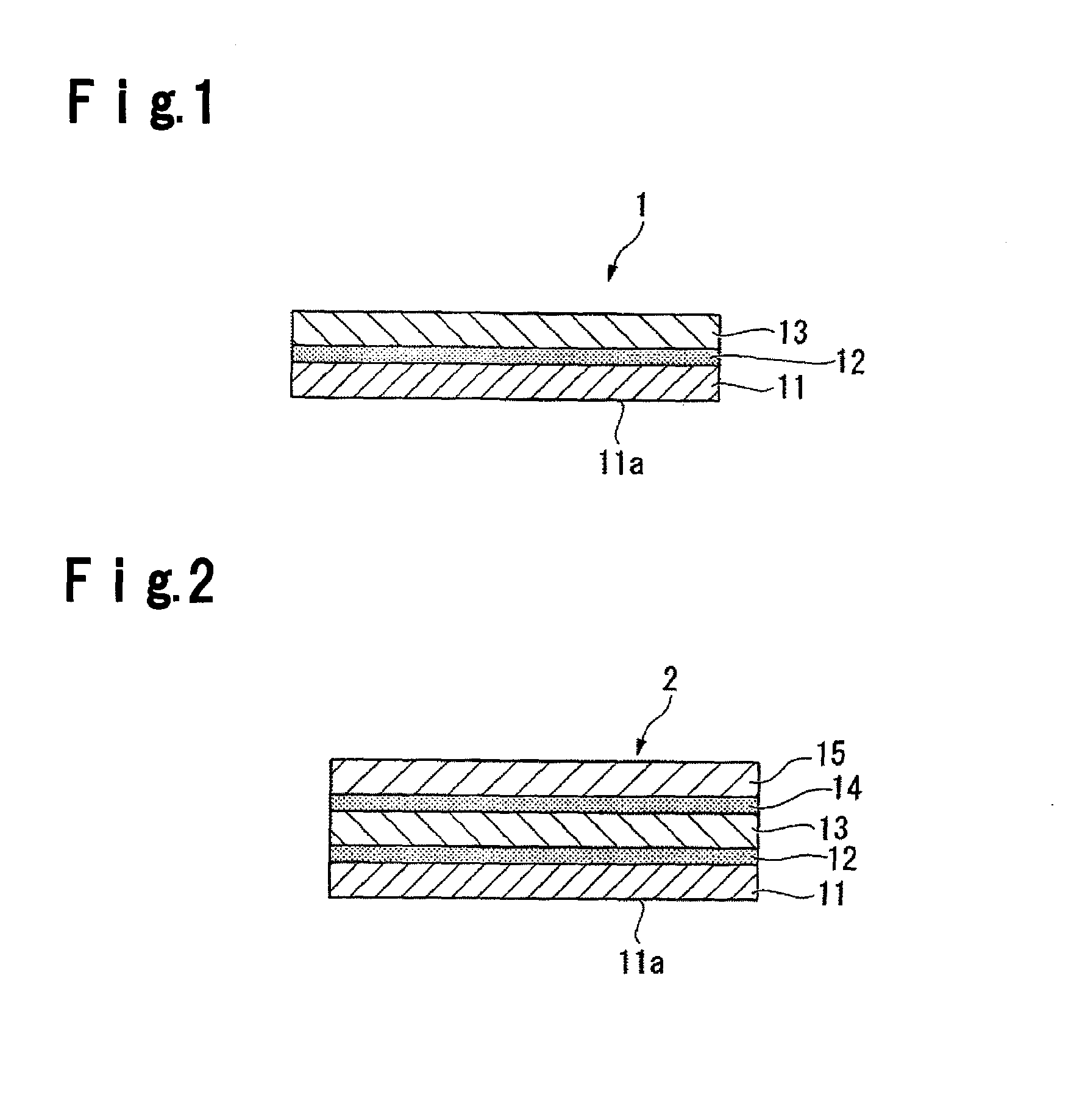

To provide a fluororesin film on which no bubble streaks are formed even when it contains a sufficient amount of titanium oxide, in which deterioration of the fluororesin is suppressed, and which has a low transmittance of ultraviolet light at a wavelength of at most 360 nm and has excellent weather resistance and heat resistance, a method of its use, a backsheet for a solar cell module, and a solar cell module.A fluororesin film containing an ethylene / tetrafluoroethylene copolymer as the main component, to be used for an outermost layer of a backsheet of a solar cell module, which contains specific titanium oxide composite particles and has an arithmetic mean roughness Ra of the film surface to be in contact with the air of at most 3 μm, and a method of its use. Further, a backsheet 1 comprising a laminate having a fluororesin film 11, and a solar cell module comprising the backsheet.

Owner:ASAHI GLASS CO LTD

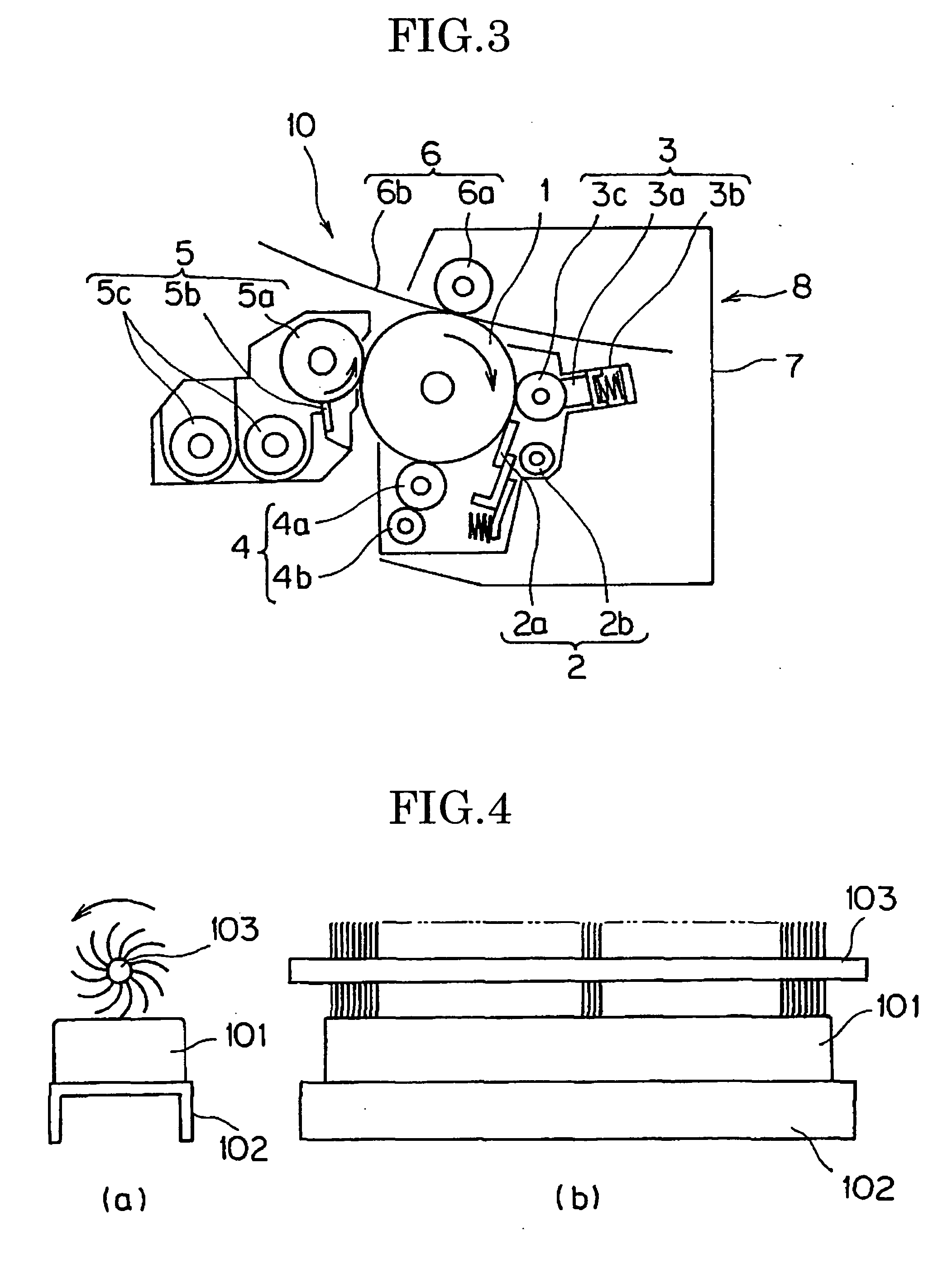

Lubricant molded body, lubricant application apparatus, process cartridge, and image forming apparatus

ActiveUS20070123435A1Low costFew cracking and cuttingFibre treatmentSynthetic resin layered productsCarbon numberAluminum Stearate

A lubricant molded body, which is to be applied to a surface of a photosensitive layer for electrophotography in an image forming apparatus, for example, is composed of at least two kinds of higher fatty acid metallic salts having respectively different carbon numbers. As the higher fatty acid metallic salt that forms lubricant molded body, compounds such as zinc stearate, calcium stearate, barium stearate, aluminum stearate, zinc laurate, calcium laurate, etc. may be recited. The higher fatty acid metallic salts may contain at least one kind of fillers selected from the group consisting of silica, alumina, tungsten disulfide, molybdenum disulfide, graphite fluoride, graphite, boron nitride, polytetrafluoroethylene (PTFE), ethylene tetrafluoroethylene (ETFE), and polyvinylidene fluoride (PVDF).

Owner:RICOH KK

Preparation of ethylene-tetrafluoroethylene copolymer

The invention discloses a method for making ethylene-tetrafluoroethylene copolymer. The method adopts a microemulsion system, and the microemulsion comprises deionized water, perfluoro ether oil, perfluoro dispersant and an auxiliary agent. The obtained ethylene-tetrafluoroethylene copolymer has thermal cracking resistance at high temperature, excellent chemical corrosion resistance and outstanding mechanical property.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

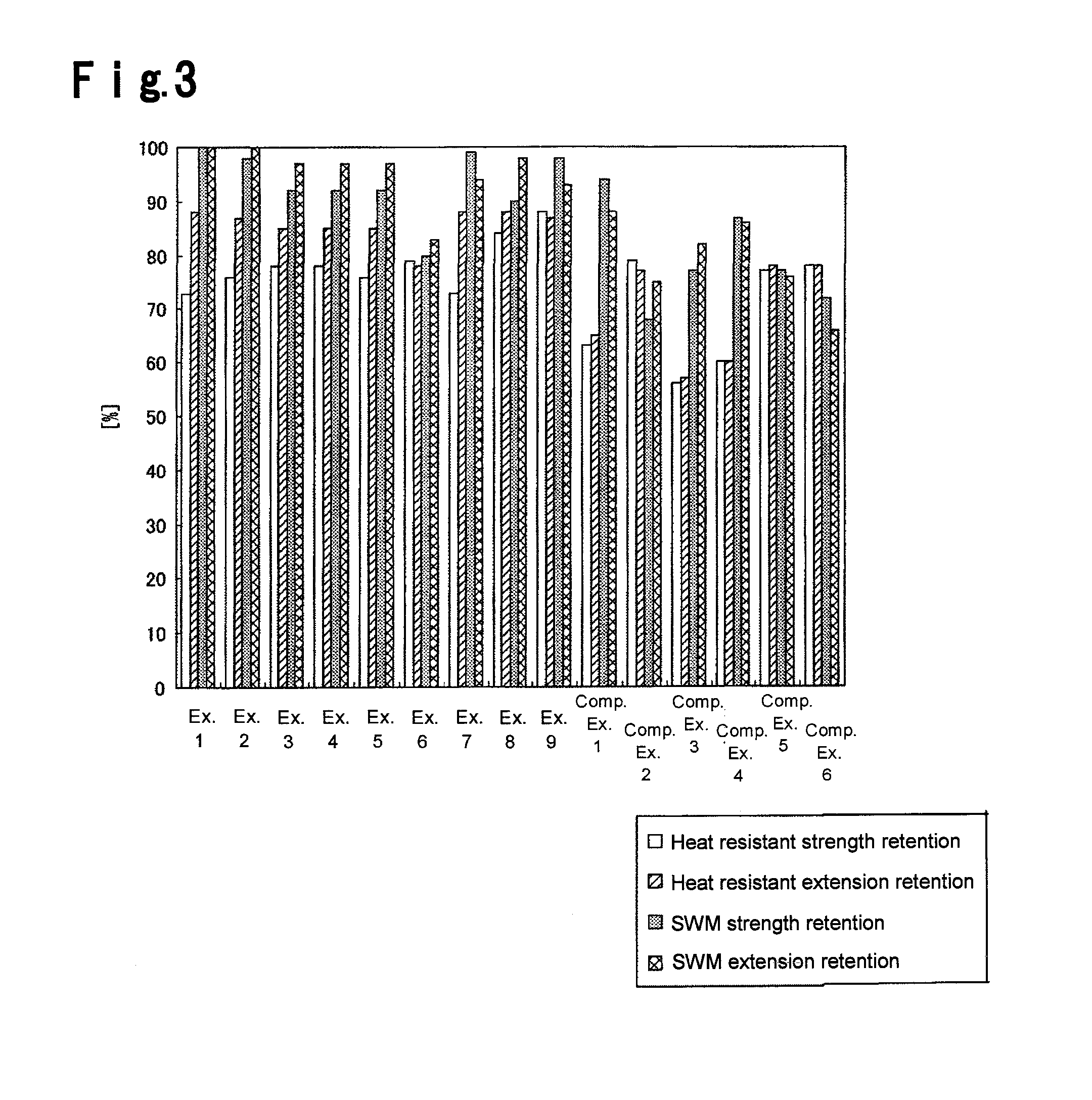

Ethylene/tetrafluoroethylene copolymer and method for its production

InactiveUS20090301752A1Improve heat resistanceNot adversely influencedPlastic/resin/waxes insulatorsSynthetic resin layered productsTetrafluoroethyleneOrganic solvent

To provide an ethylene / tetrafluoroethylene copolymer excellent in the thermal resistance, and a method for its production.The ethylene / tetrafluoroethylene copolymer is produced by polymerizing ethylene with tetrafluoroethylene in an organic solvent containing no chlorine atoms as a polymerization medium, in the presence of a chain transfer agent containing no chlorine atoms and a polymerization initiator containing no chlorine atoms, and further in the substantial absence of a chain transferable compound having a carbon-chlorine atomic bond in the reaction system.

Owner:ASAHI GLASS CO LTD

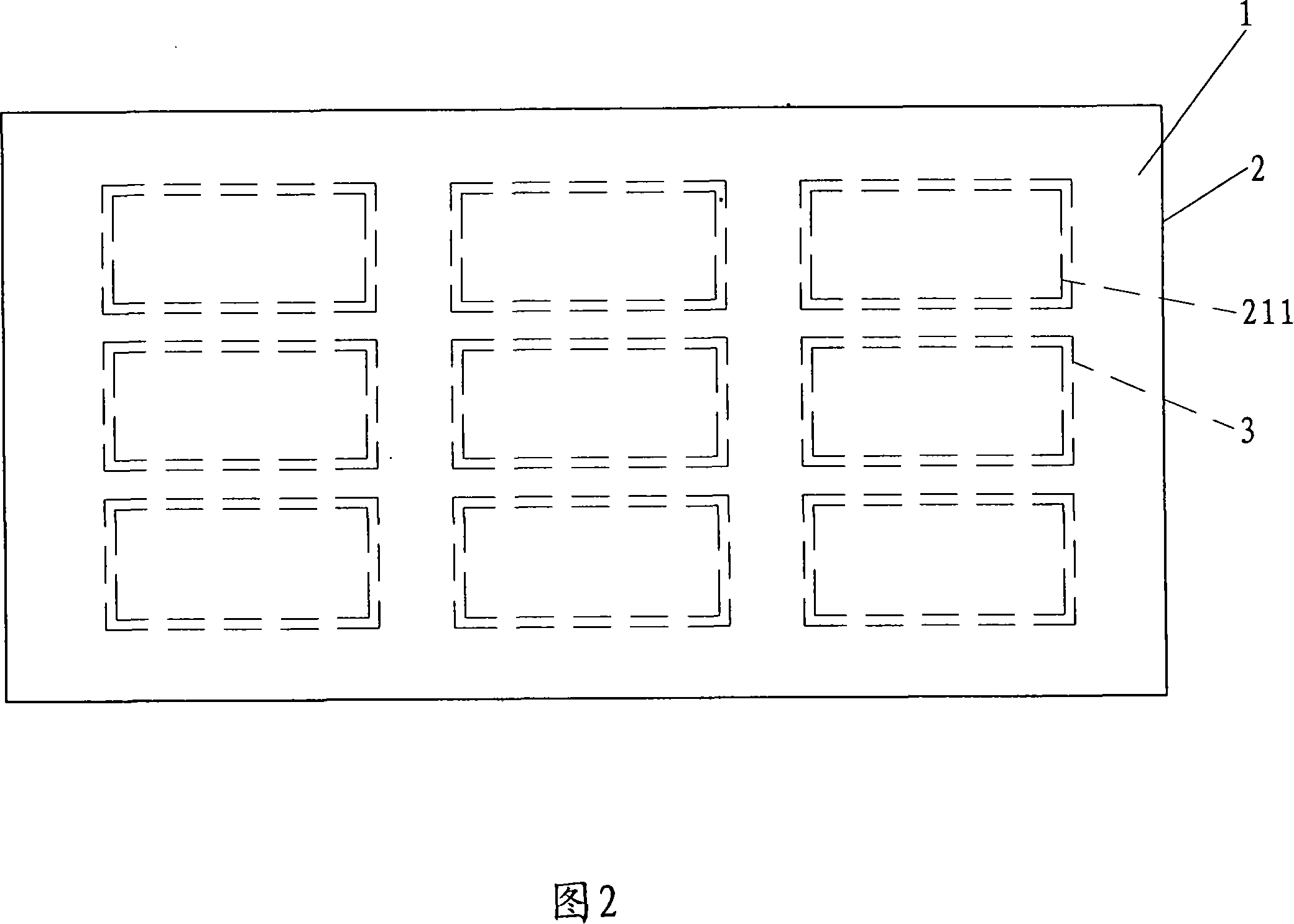

Manufacturing method for flexible solar cell unit

ActiveCN101132031AEasy to operateSolve the shortcomings of not being portable and not being able to be used anytime, anywhereFinal product manufactureSemiconductor devicesEngineeringBandage

Owner:XIAMEN TOPUNIVE TECH

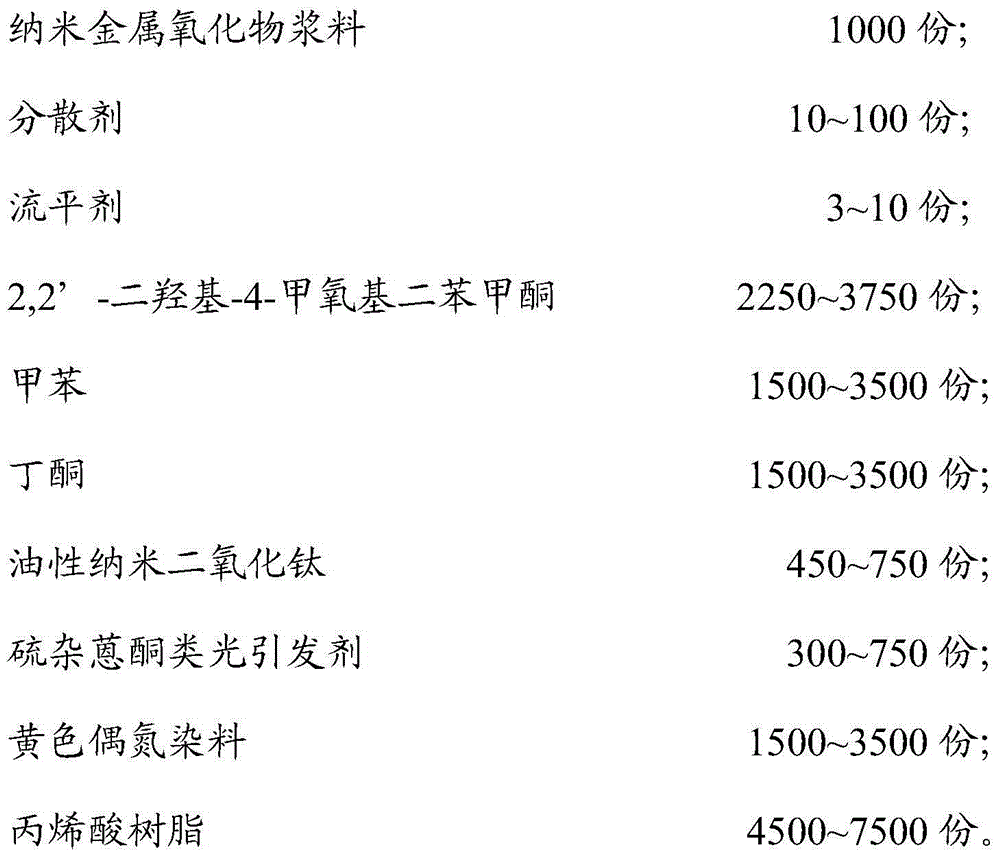

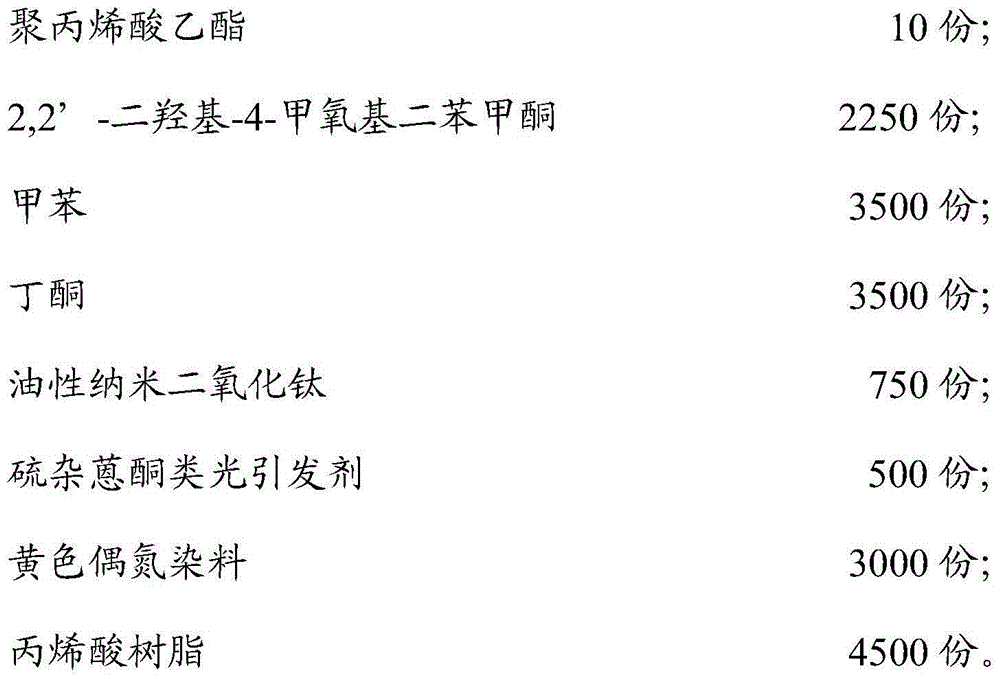

Anti-ultraviolet heat insulation car film

InactiveCN104149451AWith UV protection functionWith heat insulation functionSynthetic resin layered productsCoatingsComposite filmAdditive ingredient

The invention discloses an anti-ultraviolet heat insulation car film which comprises a PET composite film and an ETFE film layer, wherein the part between the PET composite film and the ETFE film layer is coated with anti-ultraviolet heat insulation slurry, and the parts between the anti-ultraviolet heat insulation slurry and the two layers of films are coated with adhesive. The anti-ultraviolet heat insulation slurry contains an ultraviolet absorbent and heat insulation ingredients such as nanoscale metal oxides, both the PET film and the ETFE film are transparent materials, and the ETFE film has heat preservation performance, so that the anti-ultraviolet heat insulation car film can absorb ultraviolet light and prevent external temperature from influencing in-car temperature.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

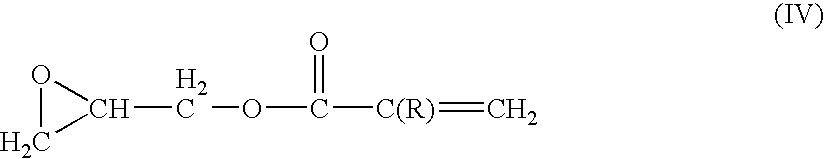

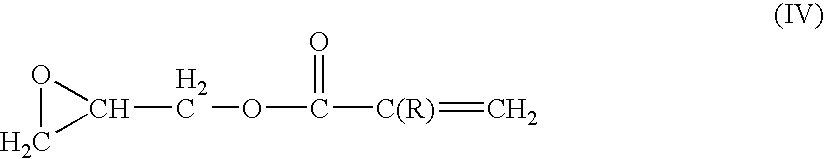

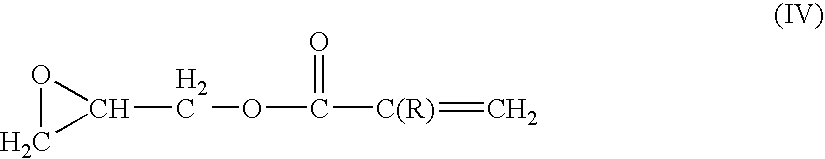

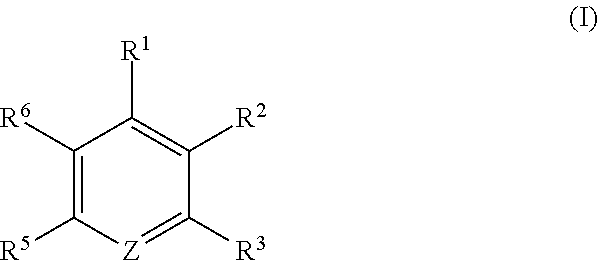

Ethylene tetrafluoroethylene (meth)acrylate copolymers

A copolymer composition comprising monomers copolymerized in the following percentages by weight:(a) from about 20% to about 95% of a monomer, or mixture of monomers, of formula (I):CnF2n+1(CH2)x[(CF2CF2)y(CH2CH2)z]m-L-C(O)—C(R)═CH2 (I)whereinR is H, Cl, F or CH3,L is O, S, NH, S—(CH2)rO, S—(CH2)rNH, OC(O)NH—CH2CH2O, NHC(O)NHCH2CH2O, S—(CH2)rOC(O)NHCH2CH2O, or S(CH2)rNHC(O)NHCH2CH2O, and(b) from about 5% to about 80% of at least one of:(i) an alkyl (meth)acrylate monomer having a linear, branched or cyclic alkyl group of from about 6 to about 18 carbons; or(II) a monomer of formula (II)(R2)2N—R3—O—C(O)—C(R)═CH2 (II)whereinR is H, Cl, F or CH3,each R2 is independently a C1 to C4 alkyl; andR3 is a divalent linear or branched C1 to C4 alkylene; and wherein the nitrogen is from about 40% to 100% salinized; or(iii) a mixture thereof.

Owner:EI DU PONT DE NEMOURS & CO

ETFE (Ethyl Tetra Fluoro Ethylene) thin film as well as preparation method and application thereof

The invention discloses an ETFE (Ethyl Tetra Fluoro Ethylene) thin film as well as a preparation method and an application thereof. The thin film is made of ETFE and a functional addition agent, and the processing temperature is 170-235 DEG C, wherein the use amount ratio of the ETFE to the functional addition agent is 1: (0.1-30%) in weight percentage; the melt index of the ETFE is 7-30; and the functional addition agent comprises more than any one of a regular fluoroplastic addition agent and a regular engineering addition agent. The ETFE thin film disclosed by the invention has excellent stretchability, non-sticky performance, adsorption, non-toxicity and heat insulation, which reach, and even exceed common indexes of industries; and the ETFE thin film can be used for the fields of LED (Light Emitting Diode) release packages, semiconductor release packages, flexile solar cell packages, electronic release films, medical packages, agricultural thin films and the like.

Owner:日氟荣高分子材料(上海)有限公司

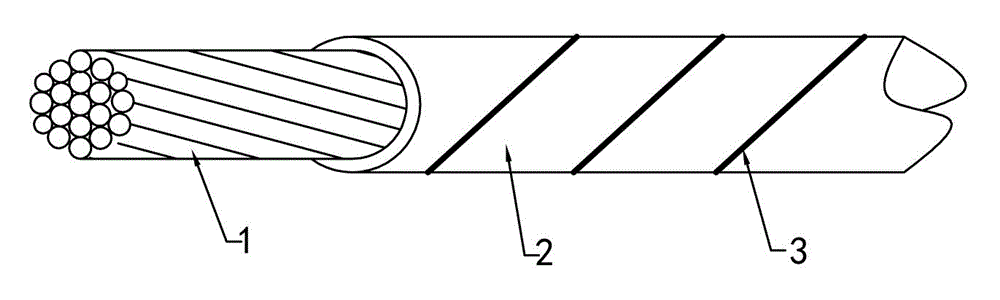

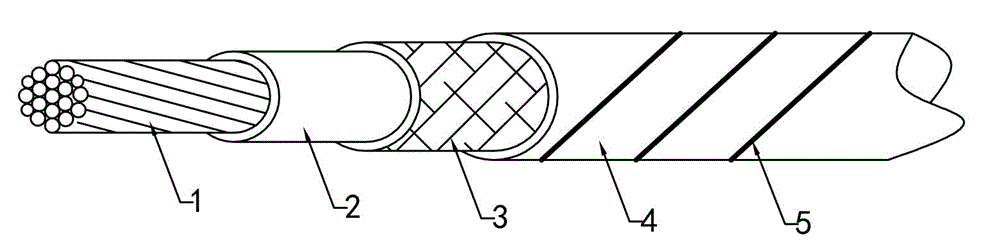

X-ETFE (crosslinked ethylene-tetrafluoroethylene) insulating wire or cable with spiral stripe identifications for aerospace and preparation process for insulating wire or cable

InactiveCN102723135AQuick distinctionAccurate distinctionInsulated cablesConductor/cable markingTetrafluoroethyleneWire rod

The invention discloses an X-ETFE (crosslinked ethylene-tetrafluoroethylene) insulating wire or cable with spiral stripe identifications for aerospace and a preparation process for the insulating wire or cable. The preparation process for the insulating wire or cable includes steps of: printing spiral stripe identifications on an insulating layer of an X-ETFE insulating wire directly formed by a single insulating core wire; printing spiral stripe identifications on a sheath layer of an X-ETFE insulating cable formed by a single insulating core wire, a shielding layer and the sheath layer; printing spiral stripe identifications on an insulating layer and / or a sheath layer of an X-ETFE insulating cable formed by a plurality of insulating core wires, the shielding layer and the sheath layer; and printing spiral stripe identifications on an insulating layer and / or a sheath layer of an X-ETFE insulating cable formed by a plurality of insulating core wires and the sheath layer. The insulating core wires consist of conductors and the insulating layers which wrap the conductors. The X-ETFE insulating wire or cable with the spiral stripe identifications for aerospace is easy to be distinguished and identified, convenient to trace back and rapid in checking, and is beneficial to waste wire recovery. In addition, the X-ETFE insulating wire or cable with the spiral stripe identifications for aerospace has excellent high-temperature resistance, low-temperature resistance and radiation resistance, and the mechanical performance of the insulating layer is quite good.

Owner:GUANGZHOU KAIHENG SPECIAL WIRE & CABLE

Preparation method of solar cell assembly and prepared solar cell assembly by utilizing preparation method

InactiveCN102456766AEliminate wrinklesControl flowFinal product manufacturePhotovoltaic energy generationFiberAging resistance

The invention relates to the solar cell manufacture field, specifically relating a preparation method of a solar cell assembly and a prepared solar cell assembly by utilizing the preparation method. Since in the preparation method of the invention, tetrafluoro cloth is provided on a panel glue film, then lamination technology is carried out, a surface of the tetrafluoro cloth has uniform consistent fiber lines and particles, thus in a lamination process of laminated layers, the tetrafluoro cloth can effectively control flow of a second layer packaging glue film (which is an upper packaging glue film), a problem that fold is generated on the panel glue film (such as an ETFE film) is eliminated, and a problem that a bubble is generated in the solar cell assembly is avoided. The prepared solar cell assembly by utilizing the preparation method has no fold on a surface, thus appearance and aging resistance properties of the assembly are in accordance with requirements of standards of IEC61215, IEC61730, UL1703 and the like.

Owner:WUXI SUNTECH POWER CO LTD

Fluoropolymer gas separation films

The invention relates to a novel film, membrane or powder media made from fluoropolymers, especially PVDF-based and ETFE-based polymers, which are suitable for separating gases, especially carbon dioxide, from a gas mixture. The novel film has good selectivity, high permeance, good mechanical properties, and exhibits a high resistance to oxidant and acid attack. The separation film is especially useful in harsh and corrosive environments.

Owner:ARKEMA INC

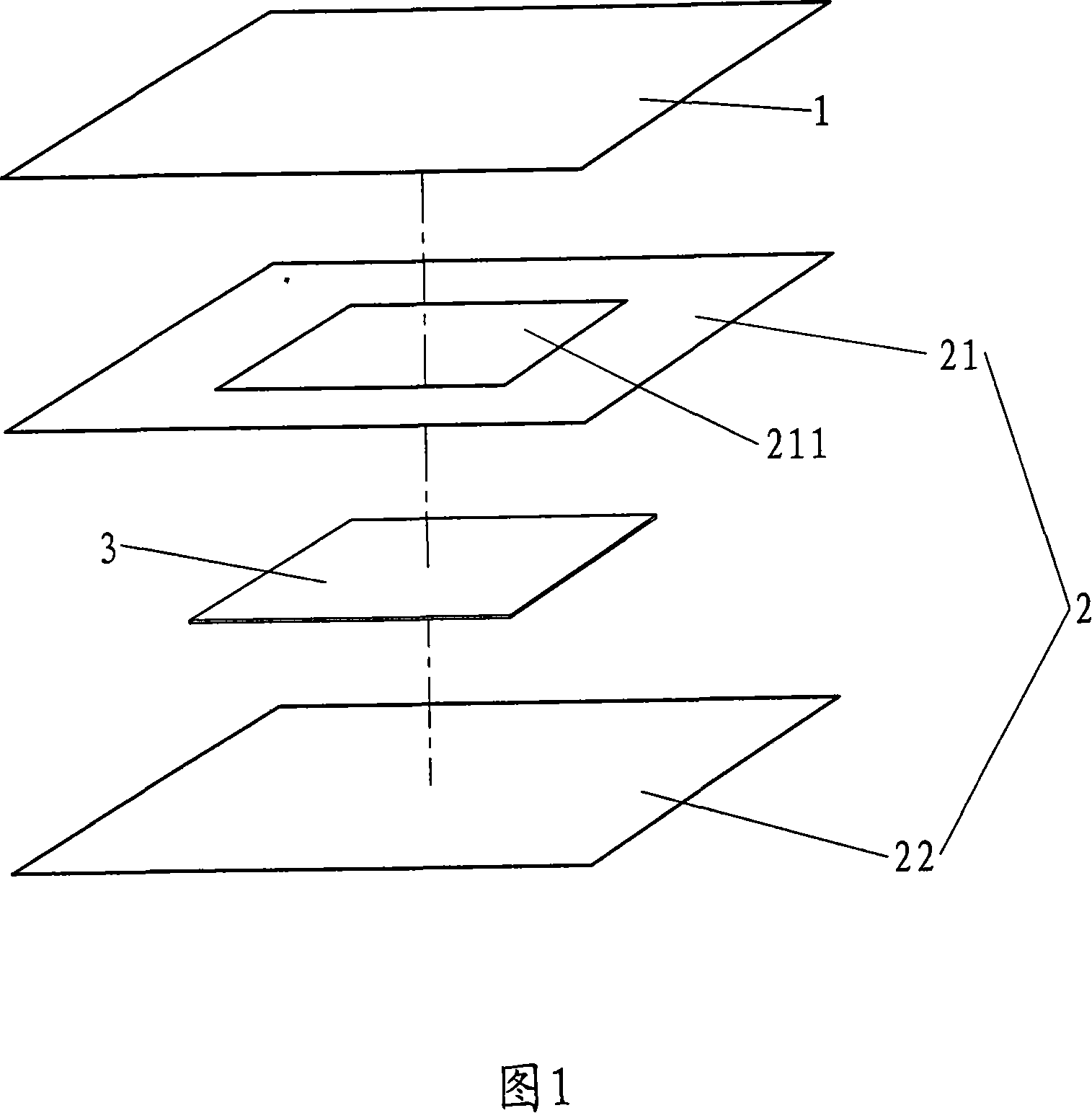

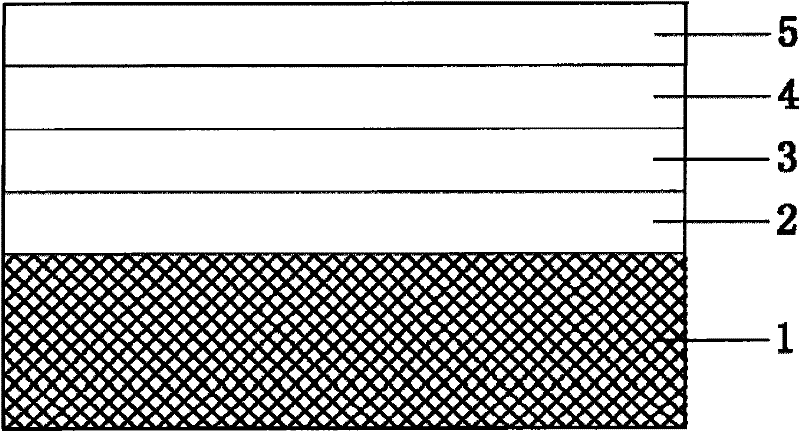

Use of a polymer composite for the production of photovoltaic modules

InactiveCN101669214ASynthetic resin layered productsPhotovoltaic energy generationTetrafluoroethyleneNylon 12

The invention relates to the use of a polymer composite (1, 1'), comprising a backing material (3, 3'), selected from the group made up of polyethylene terephthalate (PET), polyethylene naphthenate (PEN) and ethylene-tetrafluoroethylene copolymer (ETFE), and layers of nylon 12 (2, 2', 4, 4') adjacent to the backing material on both sides, for producing photovoltaic modules.

Owner:ISOVOLTA OSTE ISOLIERSTOFFWERKE AG

Fluorocopolymer composition and its production process

To provide a composition comprising a fluorocopolymer such as an ethylene / tetrafluoroethylene copolymer which can be produced at a relatively low temperature, and its production process.A fluorocopolymer composition which comprises a fluorocopolymer such as an ethylene / tetrafluoroethylene copolymer and a fluorinated aromatic compound having a melting point of at most 230° C. and having a fluorine content in the compound of from 5 to 75 mass %, and is in a solution state at a temperature of at most the melting point of the fluorocopolymer, and a process for producing the fluorocopolymer composition, which comprises a step of dissolving the fluorocopolymer in a solvent containing the fluorinated aromatic compound at a temperature of at most the melting point of the fluorocopolymer.

Owner:ASAHI GLASS CO LTD

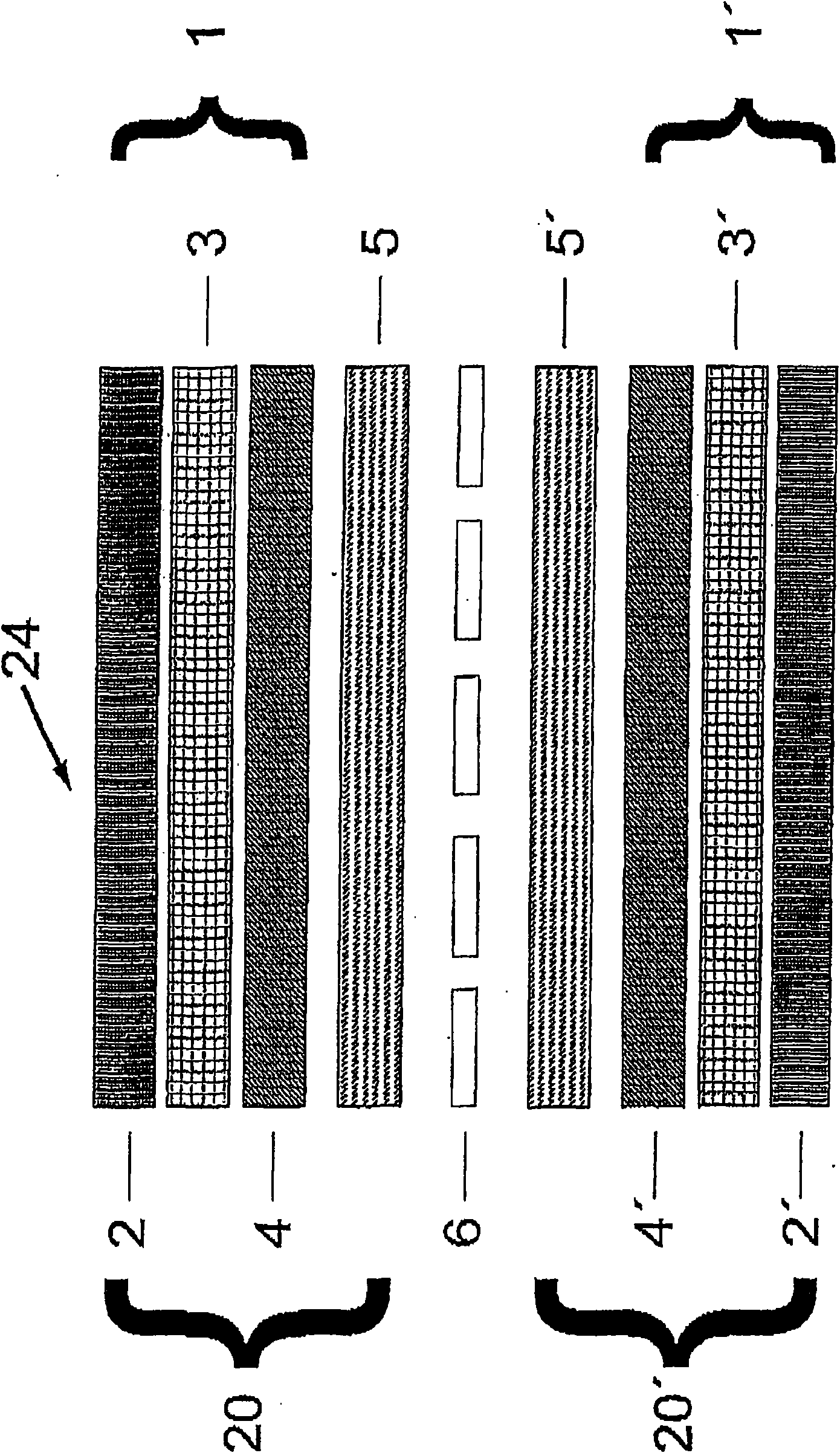

Front plate packaging structure of solar module

InactiveCN102738283AGood optical matching characteristicsImprove conversion efficiencySynthetic resin layered productsPhotovoltaicsSpectral responseEngineering

The invention relates to a front plate packaging structure of a solar module. An ETFE (Ethylene Tetra Fluoro Ethylene) fluoroplastic film (5), a first EVA (Ethylene-Vinyl Acetate) film (4), a cell slice (3), a second EVA film (2) and a back plate (1) are sequentially arranged on the upper surface of the solar cell module (6) from bottom to top. Compared with conventional tempered glass, the packaging structure disclosed by the invention has a better optical matched characteristic and not only has an excellent adsorption effect on main spectral response light of the cell slice, but also has a good light transmitting effect on light of which the wavelength is in the range of 320 to 1,200nm, so that the conversion efficiency of the solar module is improved and the packaging loss is reduced.

Owner:DONGFANG ELECTRIC YIXING MAGI SOLAR POWER TECH

ETFE lining member

InactiveUS7208227B2Improve adhesionReduce coatingSynthetic resin layered productsCeramic layered productsSurface layerMaterials science

The present invention provides a lining member in which an ETFE is used and which shows good adhesion and can show a reduction in coating film defects. An ETFE-lining member comprising a substrate, a primer layer and a surface layer laminated in this order, wherein said substrate comprises a metal or a ceramic, said primer layer comprises an ETFE (A) and a binder component, and said surface layer comprises an ETFE (B) having fluorine content higher than that of the ETFE (A).

Owner:DAIKIN IND LTD

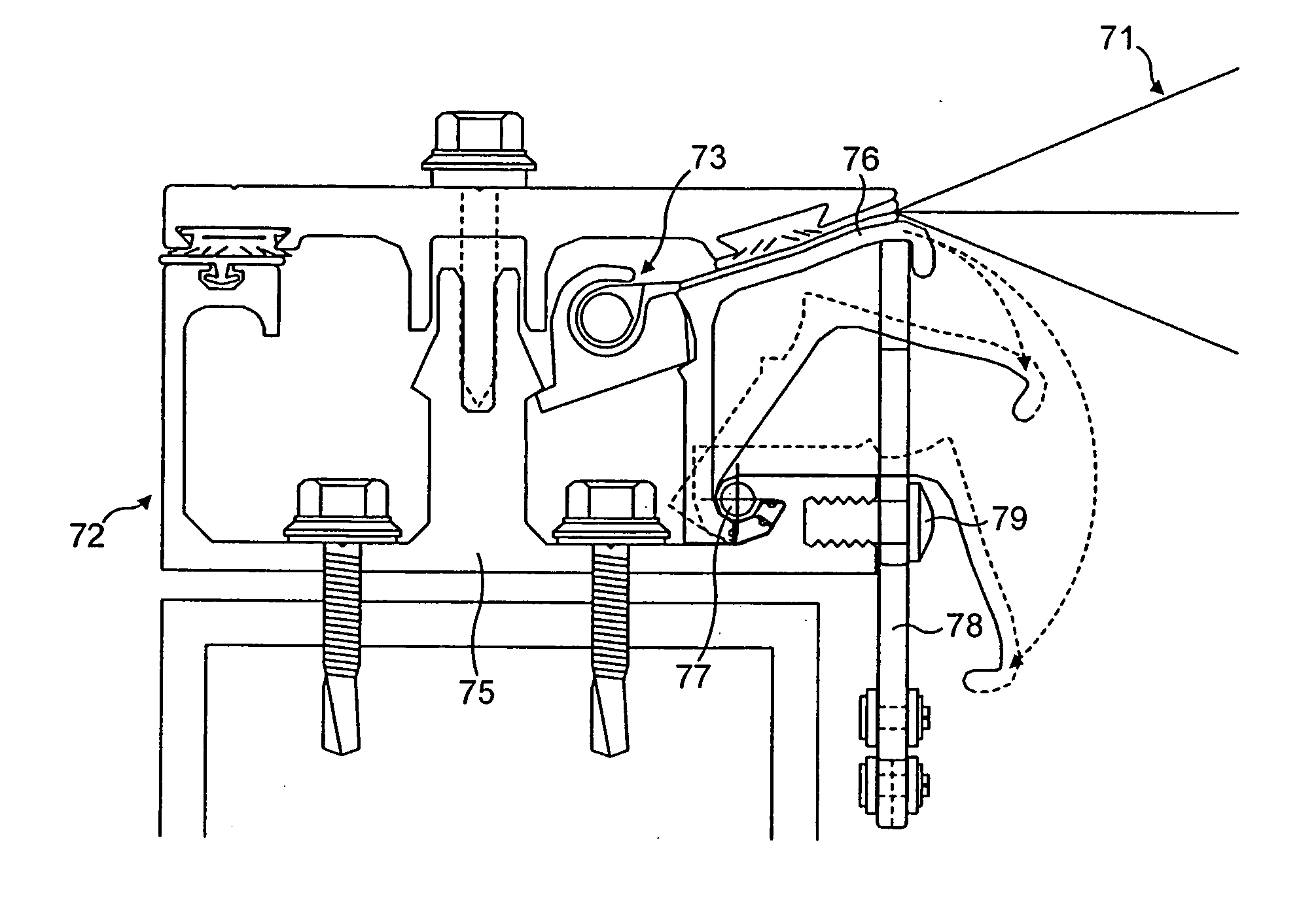

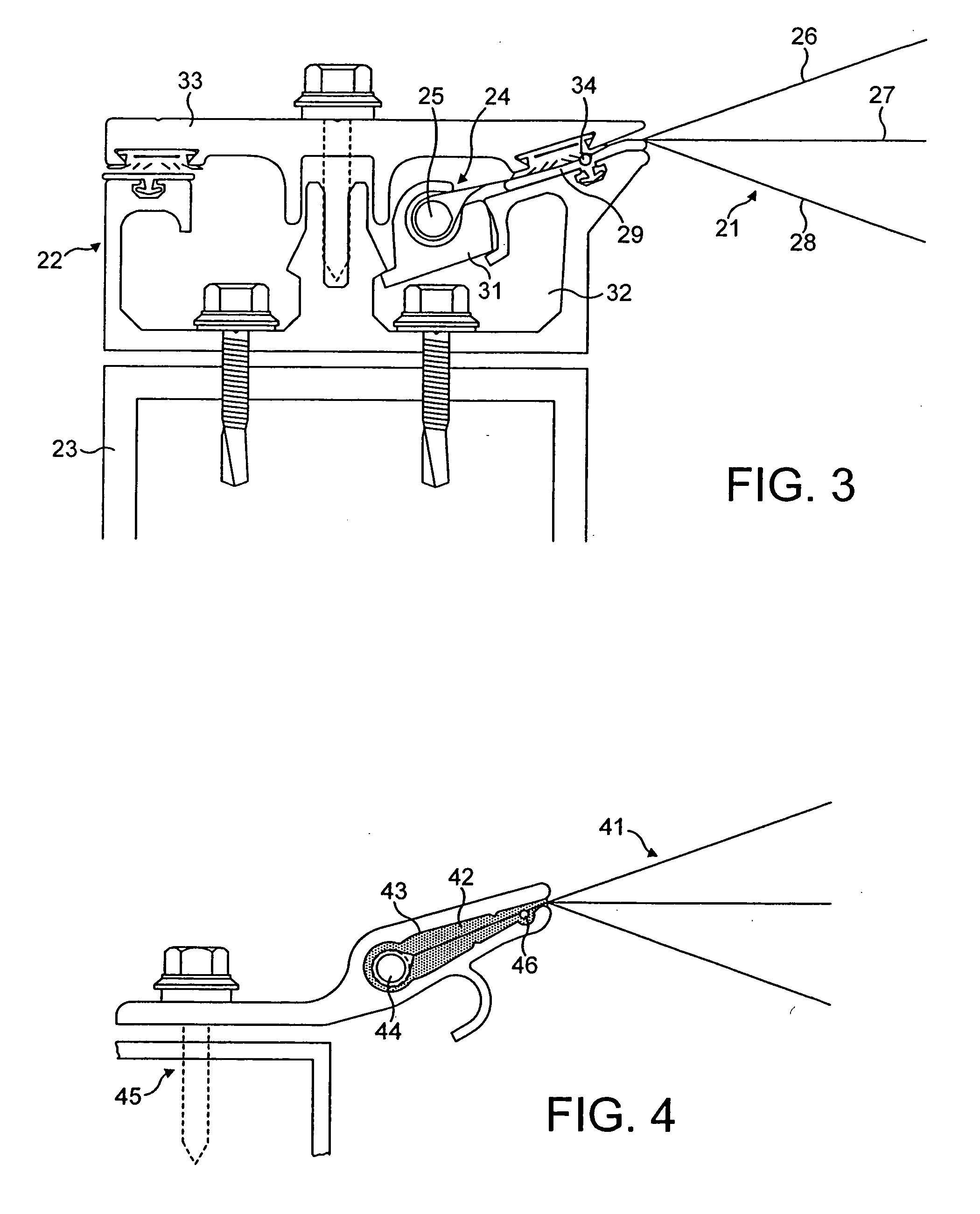

Building component

A building component for forming a roof. The component includes an ETFE foil cushion comprising sheets of ETFE foil which are held in a frame about their periphery, and which are inflated. The frame includes a release mechanism for releasing the cushion from the frame, for example, in the event of a fire.

Owner:MORRIS BENEDICT GEORGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com