Patents

Literature

334 results about "Solution state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stabilized human monoclonal antibody preparation

InactiveUS6165467ASufficient stabilizationImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsD-mannitolSolution state

A stabilized human monoclonal antibody preparation containing 1 to 20 mg of D-mannitol per 1 mg of a human monoclonal antibody. This preparation is excellent in stability in a solution state, a freeze drying state and a freezing state, particularly stability against aggregation and precipitation of the human monoclonal antibody at the time of redissolution after freeze drying.

Owner:HAGIWARA HIDEAKI

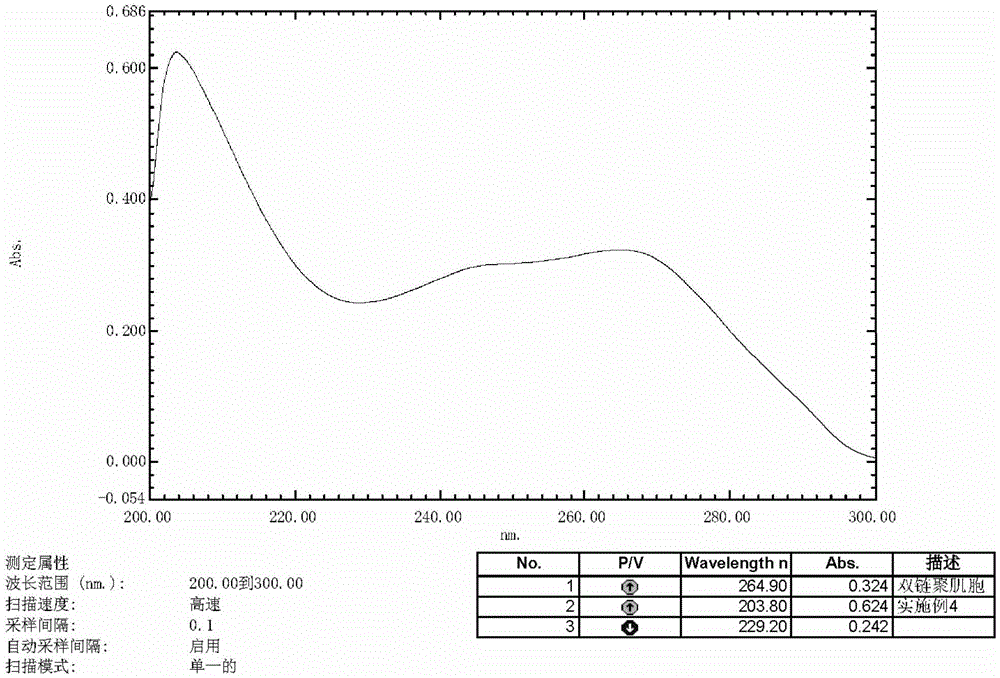

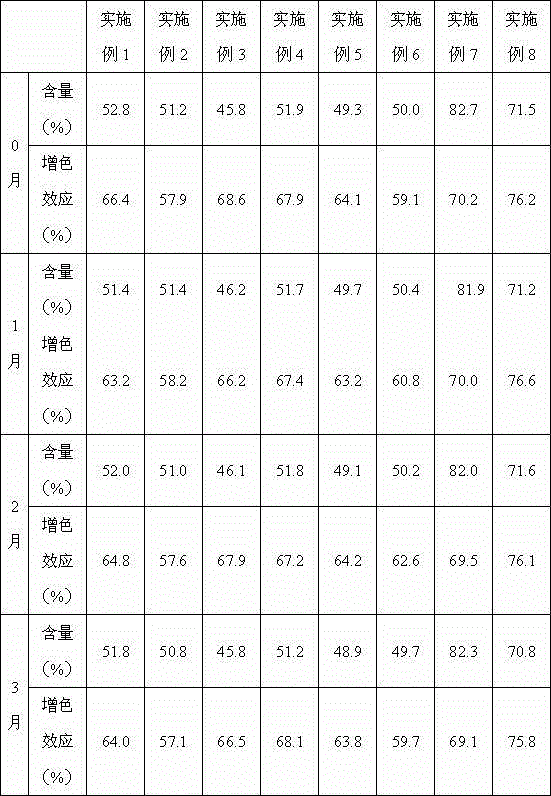

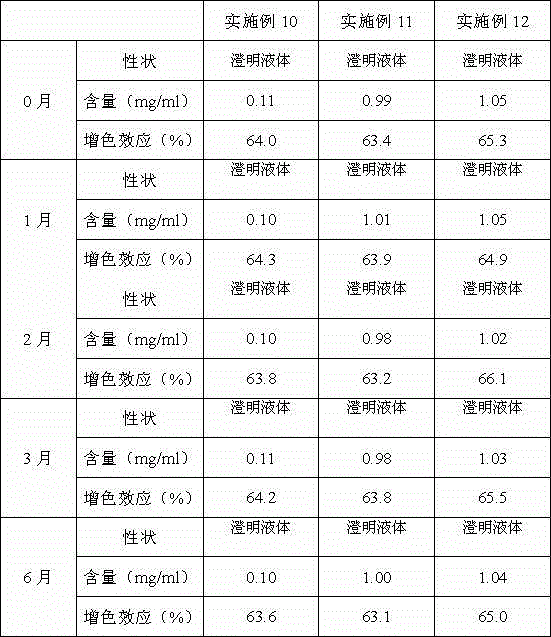

Preparation method of polyinosinic-polycytidylic acid dry powder

ActiveCN103599071AEasy to makeEasy to operatePowder deliveryCosmetic preparationsBiological bodyOrganic solvent

The invention provides a preparation method of polyinosinic-polycytidylic acid dry powder. The method comprises the following steps: (1) respectively dissolving polyinosinic acid and polycytidysic acid in a phosphate buffer solution, mixing the solution, adding a stabilizer, uniformly mixing the stabilizer and the solution, and performing heat preservation on the mixture at the temperature of 40-100DEG C; (2) naturally cooling the reaction liquid obtained in the step (1), mixing the reaction liquid with an organic solvent, standing for precipitating, and drying the precipitate, thereby obtaining the polyinosinic-polycytidylic acid dry powder. The preparation method has the beneficial effects that the prepared polyinosinic-polycytidylic acid dry powder has a complete double-helix structural features and physiological activity, the quality and the stability are better than those of the polyinosinic-polycytidylic acid at a solution state, a stronger enzymolysis-resisting performance can be achieved compared with the bare polyinosinic-polycytidylic acid after entering a living body, so that the curative effect can be enhanced. The polyinosinic-polycytidylic acid is purified in the process for making the polyinosinic-polycytidylic acid solution into the dry powder, a plurality of small-molecular-weight substances and impurities can be removed, the toxic and side effects can be reduced, and the quality of the polyinosinic-polycytidylic acid can be improved.

Owner:美亚药业海安有限公司

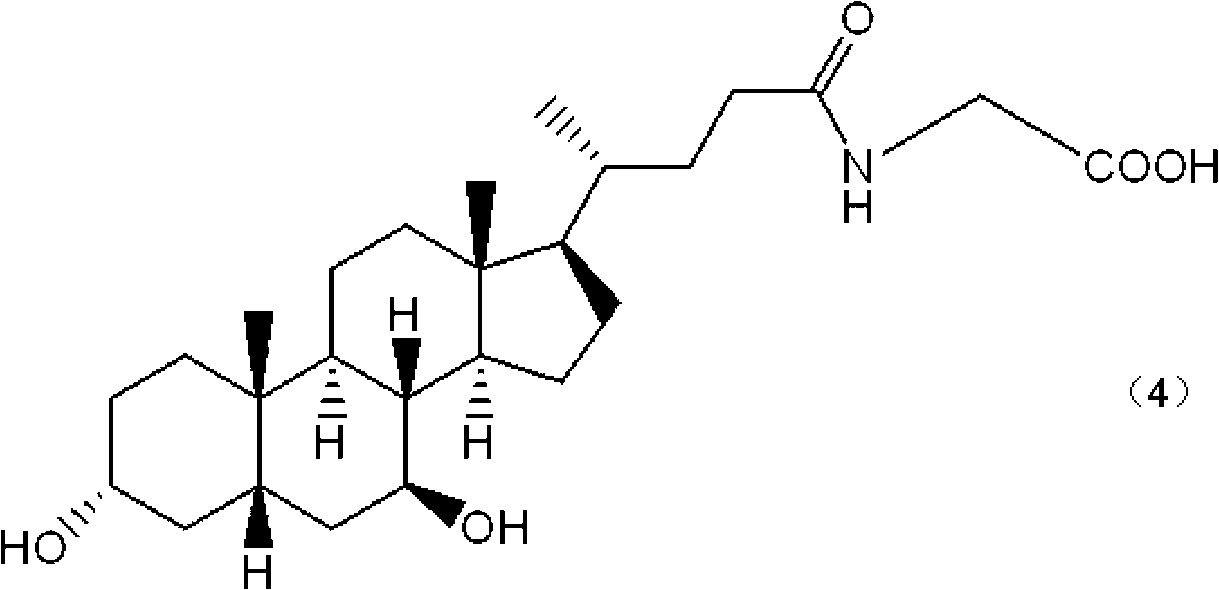

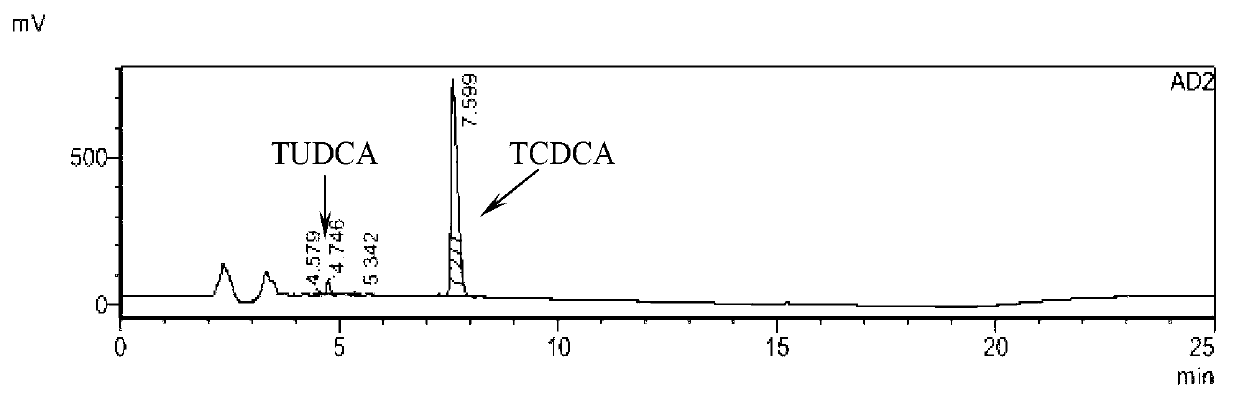

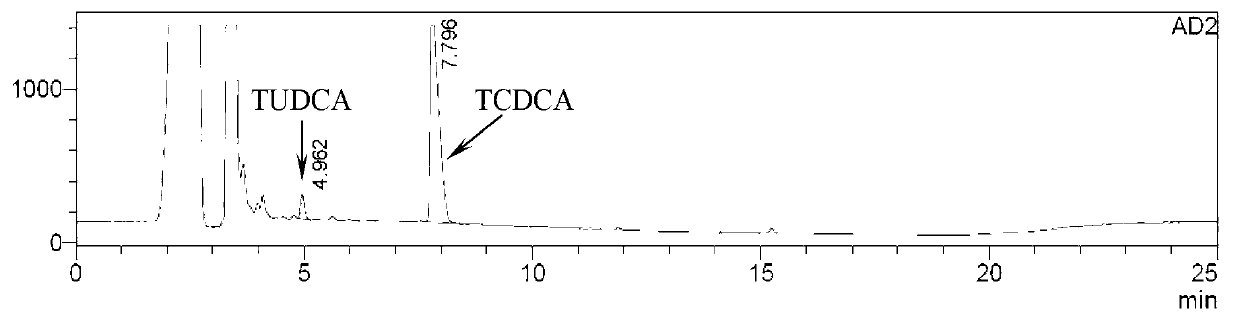

Method for preparing binding-form ursodesoxycholic acid by two-step enzymatic method

ActiveCN102994604ASimple preparation processImprove conversion rateFermentationChenodeoxycholic acidSolution state

The invention relates to a method for preparing binding-form ursodesoxycholic acid by a two-step enzymatic method, belonging to the field of biotechnology. Under the water solution state, a substrate, namely binding-form chenodeoxycholic acid, is converted into the binding-form ursodesoxycholic acid in the presence of 7alpha-HSDH and 7beta-HSDH, the separation is not needed in the intermediate step, thus the method disclosed by the invention is very simple, and furthermore, the conversion efficiency is very high. Especially chicken bile, duck bile or goose bile in a mixture form can be subjected to reaction without separating and purifying the binding-form chenodeoxycholic acid. The preparation process is simple and easy to implement, and the new, simple and convenient preparation method is provided for the binding-form ursodesoxycholic acid.

Owner:SHANGHAI KAIBAO PHARMA

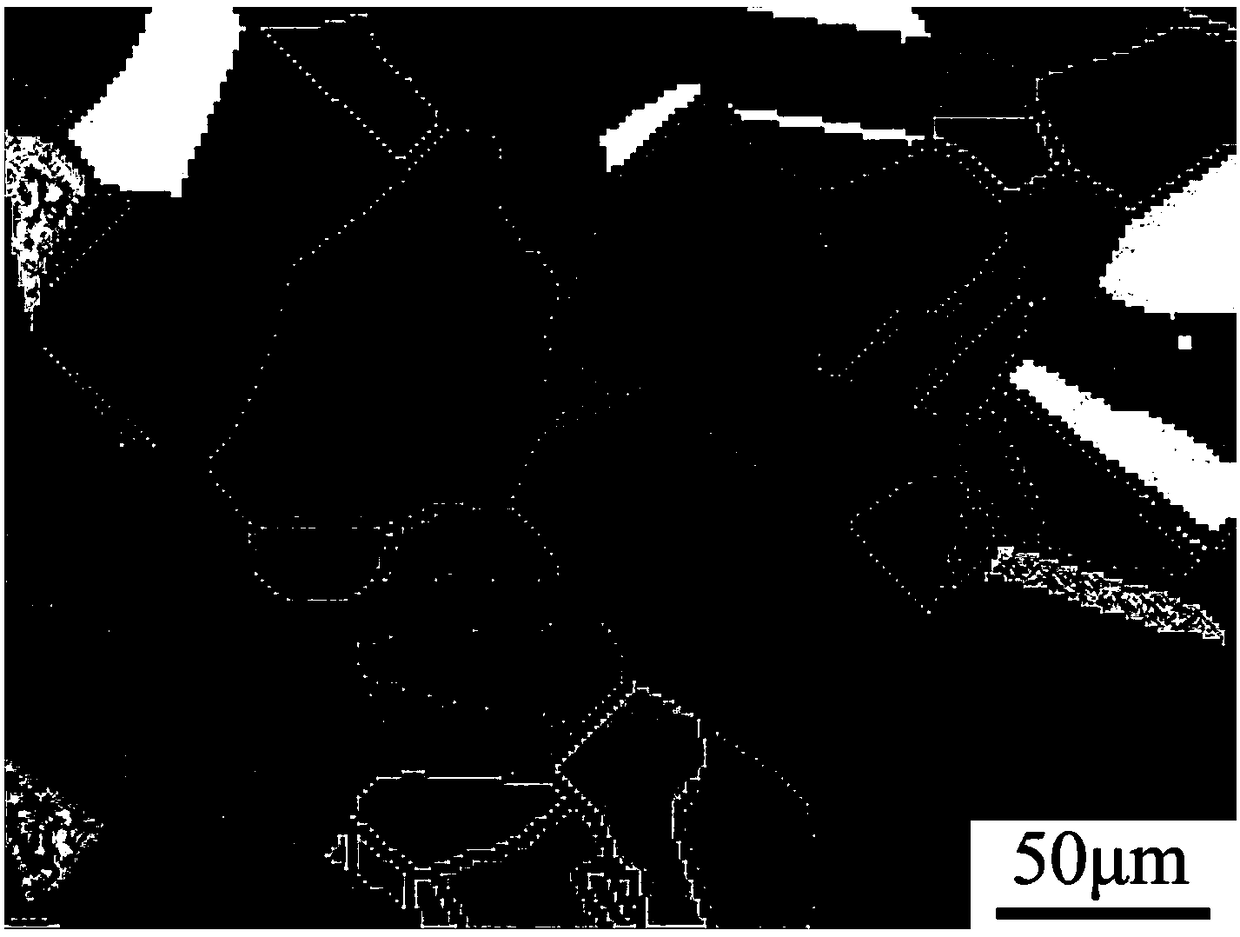

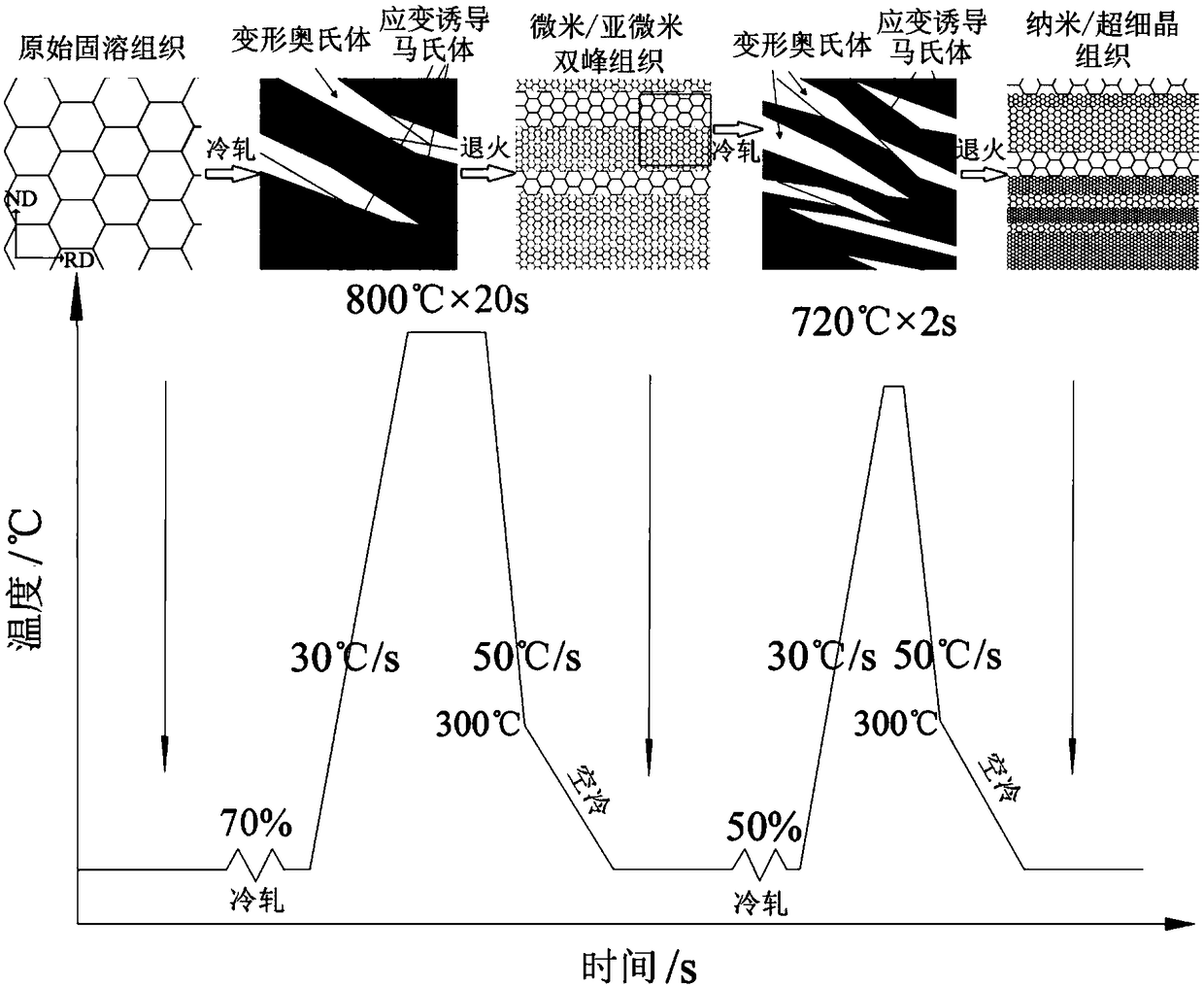

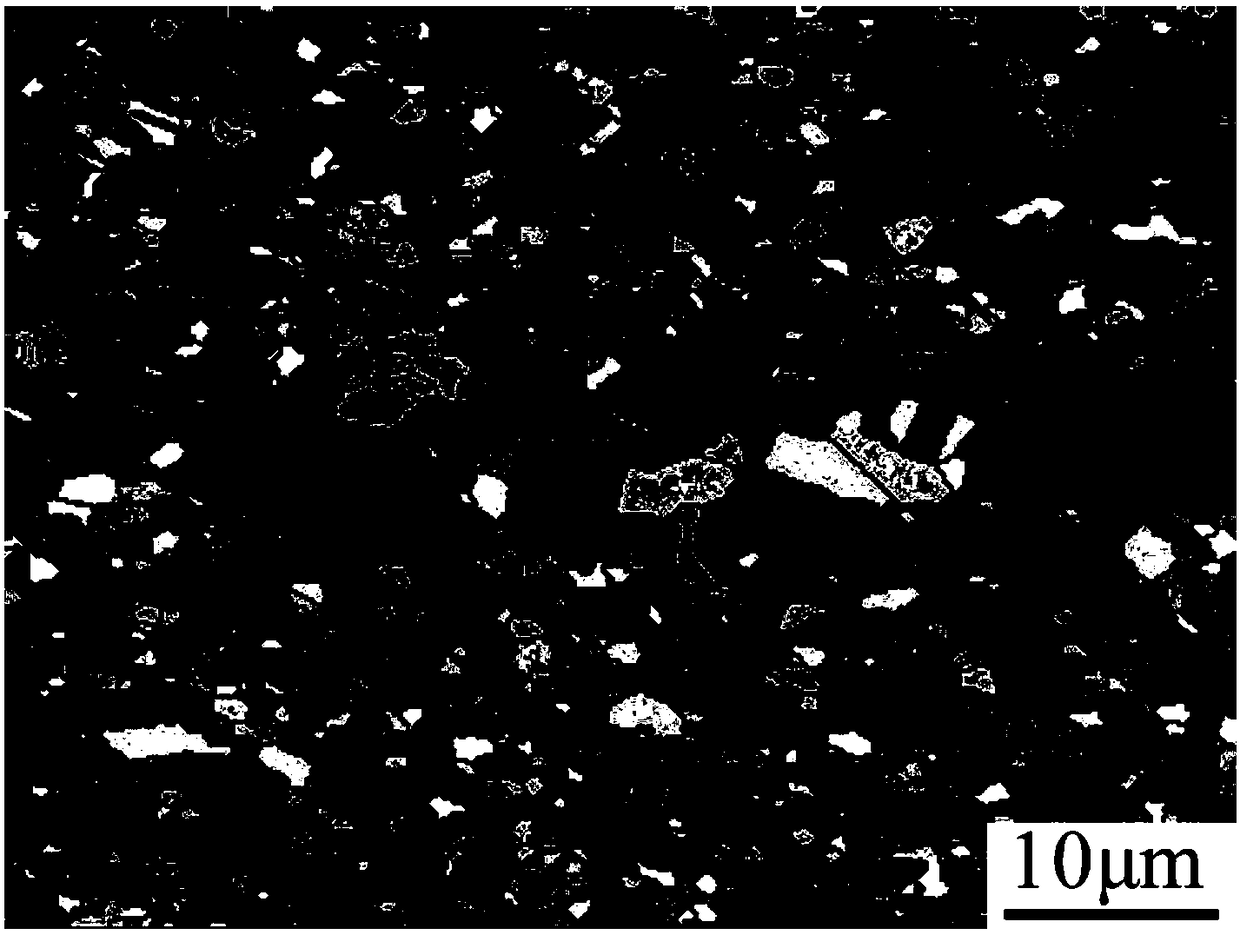

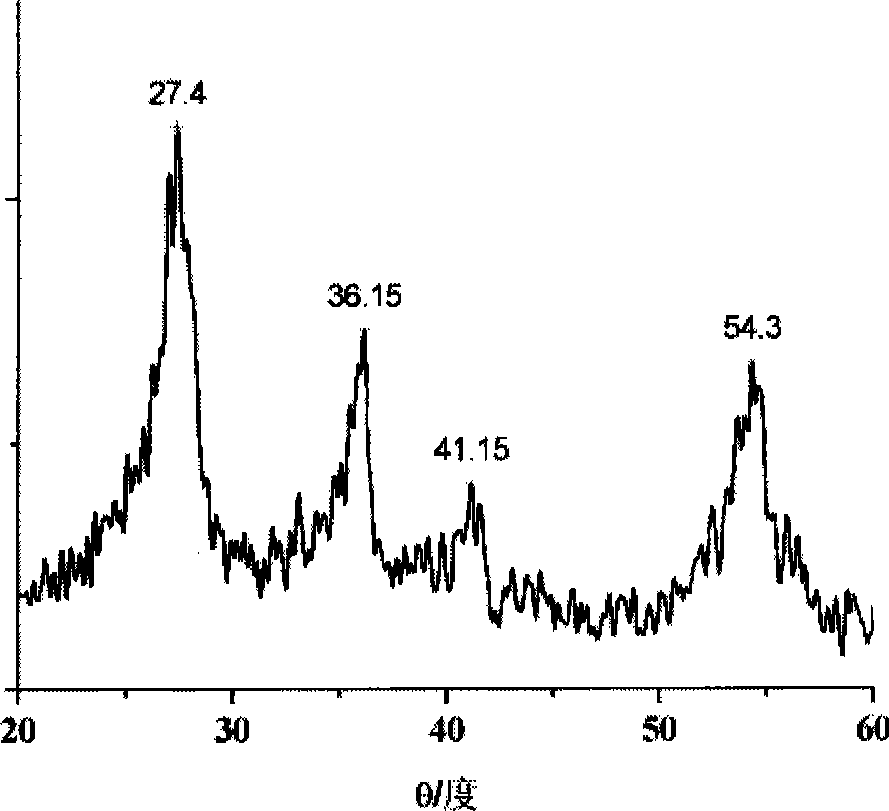

Nanometer/ultrafine crystal structure ultrahigh-strength plasticity austenitic stainless steel and preparation method

The invention discloses nanometer / ultrafine crystal structure ultrahigh-strength plasticity austenitic stainless steel and a preparation method, and belongs to the field of ultrahigh-strength plasticity alloy steel production. Raw materials comprise the following chemical components: 0.08-0.15% of C, 0.35-0.75% of Si, 7.5-10% of Mn, 0.5-0.9% of Cu, 1-1.5% of Ni, 14-16% of Cr, 0.1-0.25% of N, P notmore than 0.06%, S not more than 0.03%, and the balance of iron and inevitable impurities. After smelting by a vacuum induction furnace, a casting blank is forged, and a forging is hot rolled; twicecold rolling annealing is performed after the solid solution treatment; a nanometer / ultrafine crystal composite structure is obtained by using reversion of strain induction martensite and recrystallization of deformation austenite. The ultrahigh-strength plasticity of stainless steel is realized through fine crystal strengthening, back stress reinforcement, deformation induction twins effect and deformation induction martensite effect. The prepared stainless steel is prominent in comprehensive mechanical performance; the yield strength reaches 1150-1320 MPa, and is 3.2-4.5 times in an originalsolid solution state; the tensile strength reaches 1350-1440 MPa; the ductility still achieves a higher level of 39.2-47.3%; the cost is lower; and the preparation method is simple and feasible.

Owner:UNIV OF SCI & TECH BEIJING

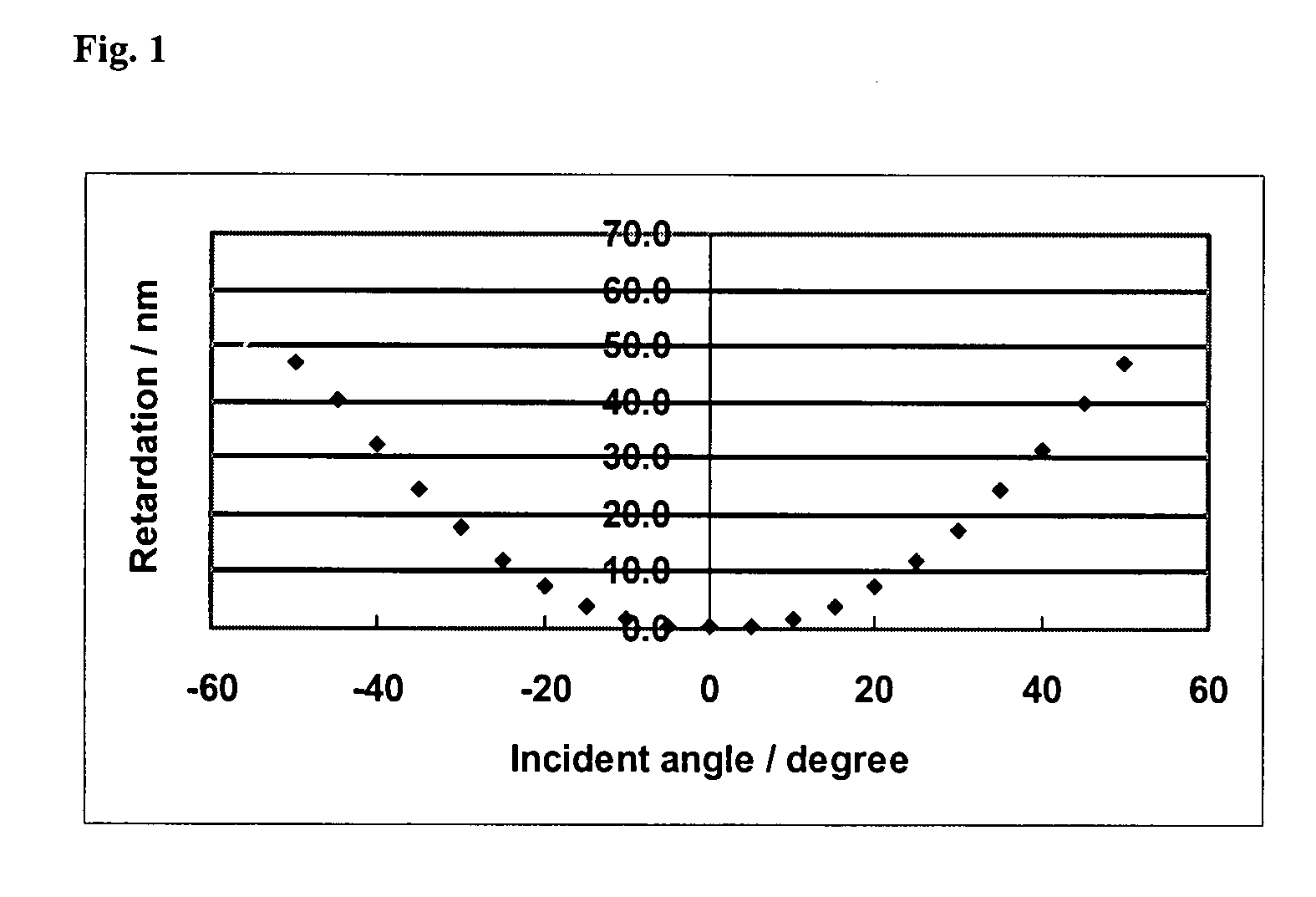

Polymerizable liquid crystal composition

InactiveUS20080014374A1Uniform thicknessPrevent productivity being deterioratedLiquid crystal compositionsThin material handlingSolution stateBisphenol

The invention is to provide such a polymerizable liquid crystal composition that is excellent in stability in a solution state, shows good coating property on a supporting substrate, and has uniform homeotropic alignment property. The polymerizable liquid crystal composition of the invention contains an acrylate compound and a bisphenol fluorene compound. The bisphenol fluorene compound is effective for controlling uniform homeotropic alignment of the polymerizable liquid crystal composition.

Owner:JNC PETROCHEM +1

Gold nanorod-silicon dioxide core-shell structure nanometer material, preparation method and application

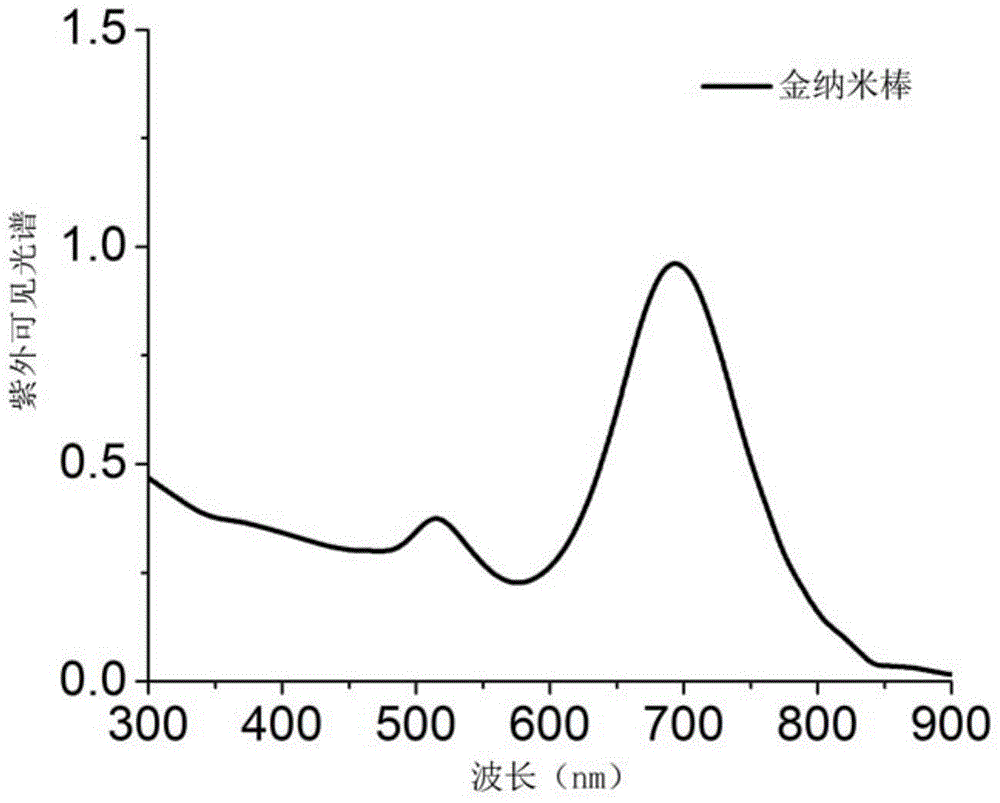

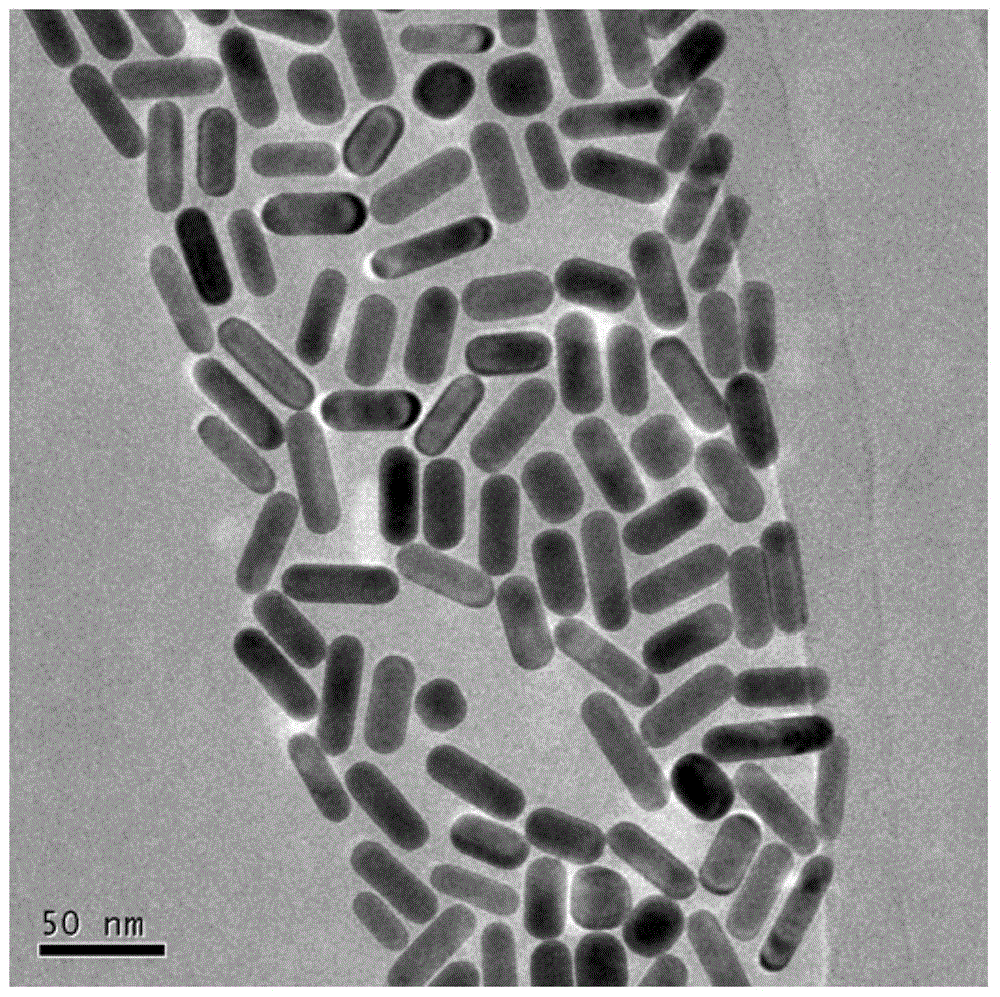

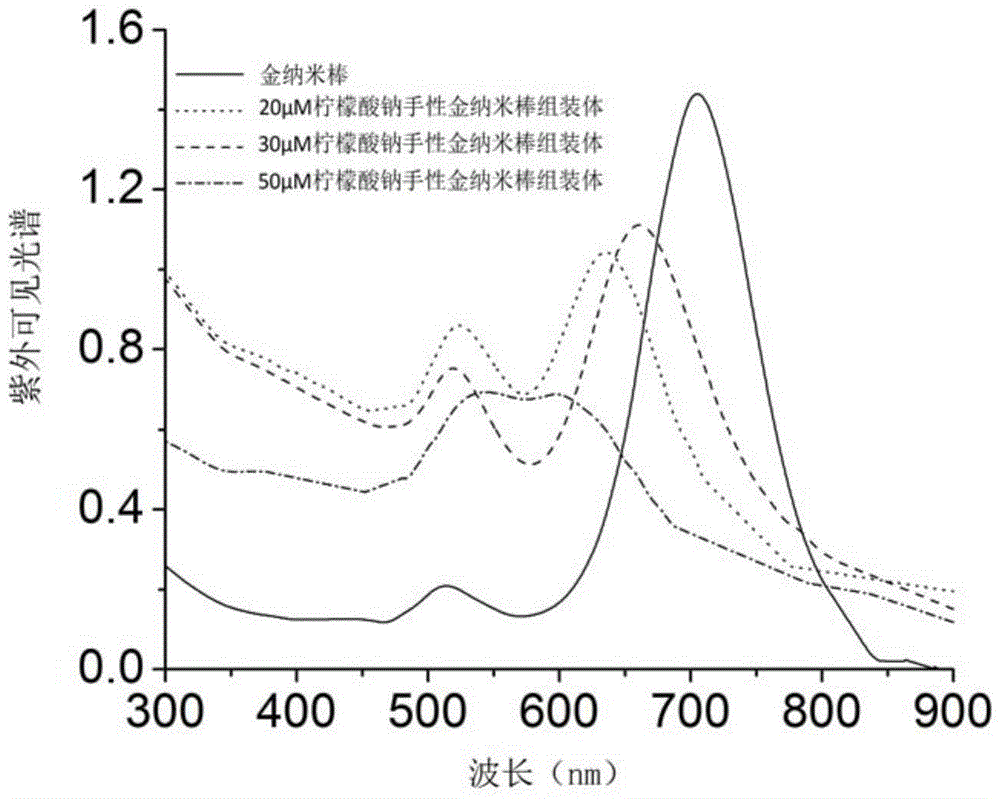

ActiveCN105036070AStrong circular dichroism optically activeCircular dichroic optical activity does not affectMaterial nanotechnologyIndividual molecule manipulationGold nanorodSolution state

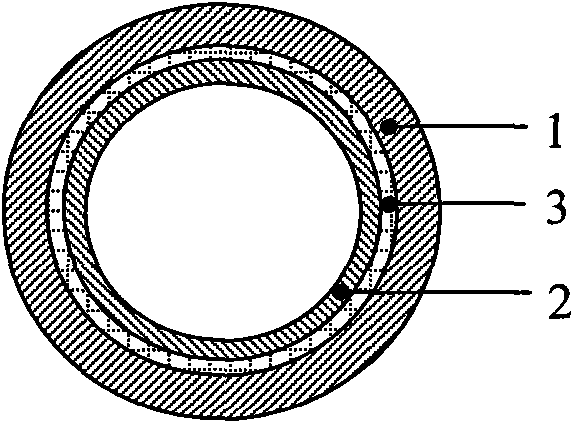

The invention discloses a gold nanorod-silicon dioxide core-shell structure nanometer material. The core structure of the core-shell structure nanometer material is a chiral gold nanorod side-by-side assembly with the circular dichroism optical activity. The shell structure of the core-shell structure nanometer material is silicon dioxide. The core of the chiral gold nanorod side-by-side assembly is coated with the silicon dioxide shell layer, so that the nanometer material with the circular dichroism optical activity is obtained. According to the nanometer material, the side-by-side assembly structure is stable, the solution state is stable, and the circular dichroism optical activity is obviously improved, wherein the circular dichroism optical activity is improved by 4-6 times compared with a pure chiral gold nanorod, and the stability is kept as long as 6 months. A preparation method of the gold nanorod-silicon dioxide core-shell structure nanometer material is simple and low in cost. The obtained chiral gold nanorod side-by-side assembly-silicon dioxide core-shell structure nanometer material has various compositions and properties, is wide in application range and has the large development space.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

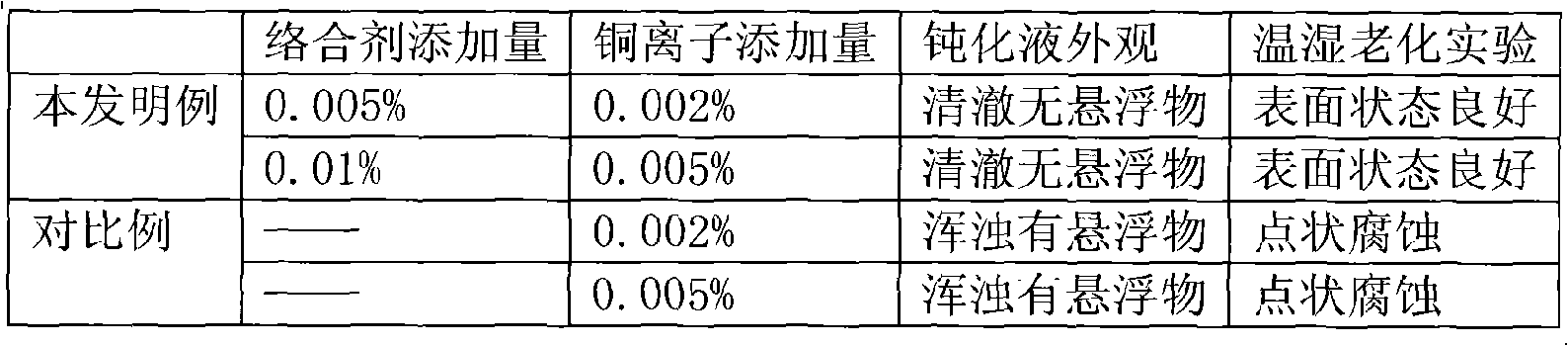

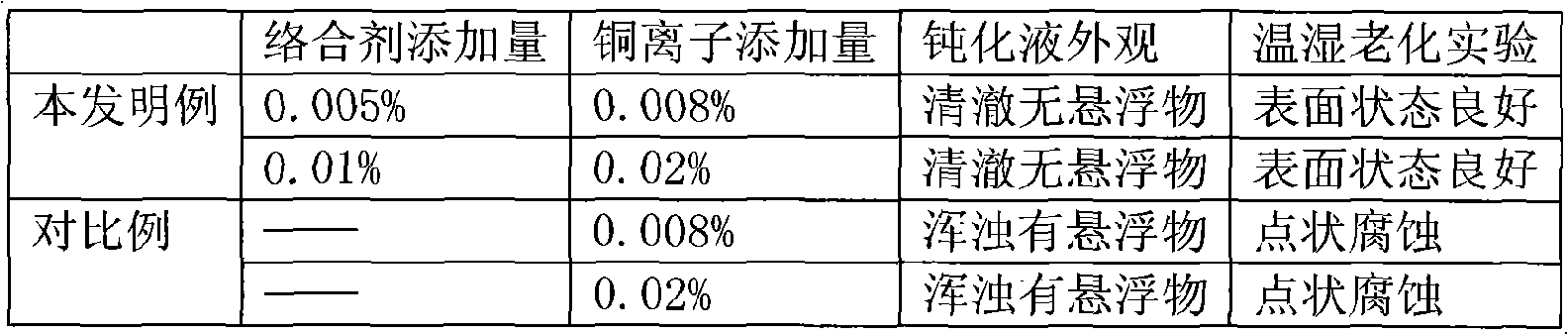

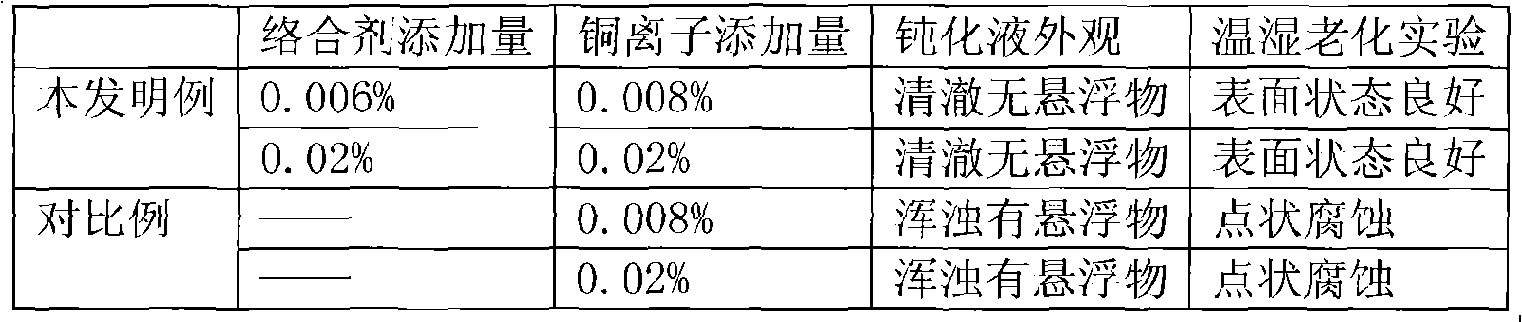

Method for continuously cleaning and passivating copper and copper alloy

InactiveCN101538710AImprove surface qualityExtend your lifeMetallic material coating processesChemical treatmentBenzotriazole

The invention relates to a method for continuously cleaning and passivating copper and copper alloy, belonging to the technical field of metal surface chemical processing. The method comprises the steps of: scrubbing and degreasing, rinsing with cold water, acid cleaning, scrubbing with cold water, rinsing with hot water, passivating and drying, and is characterized in that in the passivation, passivation solution adopts aqueous solution of benzotriazole or benzotriazole derivatives, and copper ion complexing agent is added in the passivation solution. The method for continuously cleaning and passivating copper and copper alloy adds the copper ion complexing agent in the passivation solution in an adding way, and the copper ion complexing agent preferably complexes with copper ions to lead the passivation solution to be in a solution state for a longer time, thus slowing down the reaction between the effective component benzotriazole and benzotriazole derivatives of the passivation solution and the copper ions. The method has reasonable design, simple operation and less pollution to the environment, saves the cost and improves the service life of the passivation solution, and the obtained copper and copper alloy have good surface quality.

Owner:杭州百木表面技术有限公司

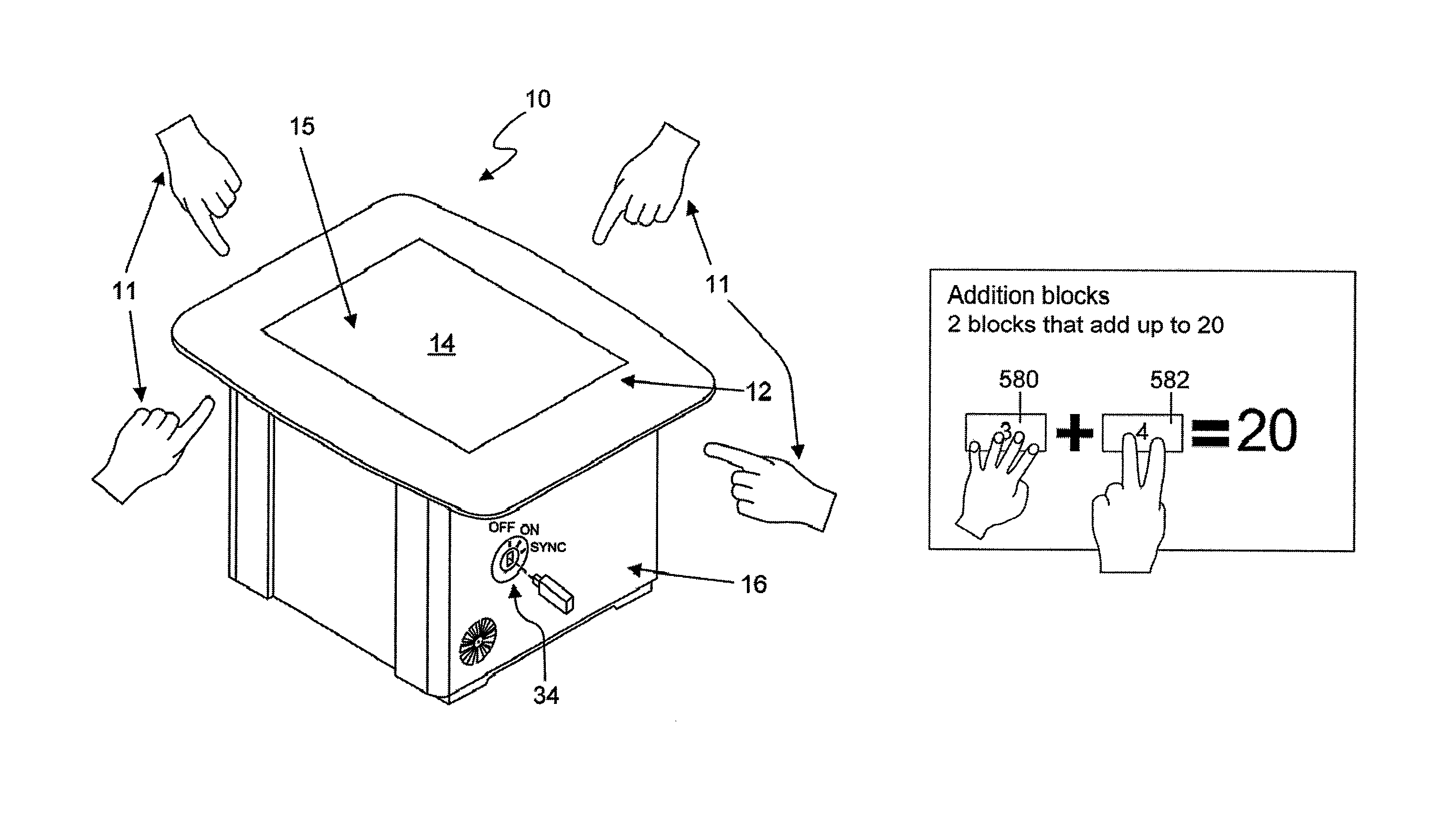

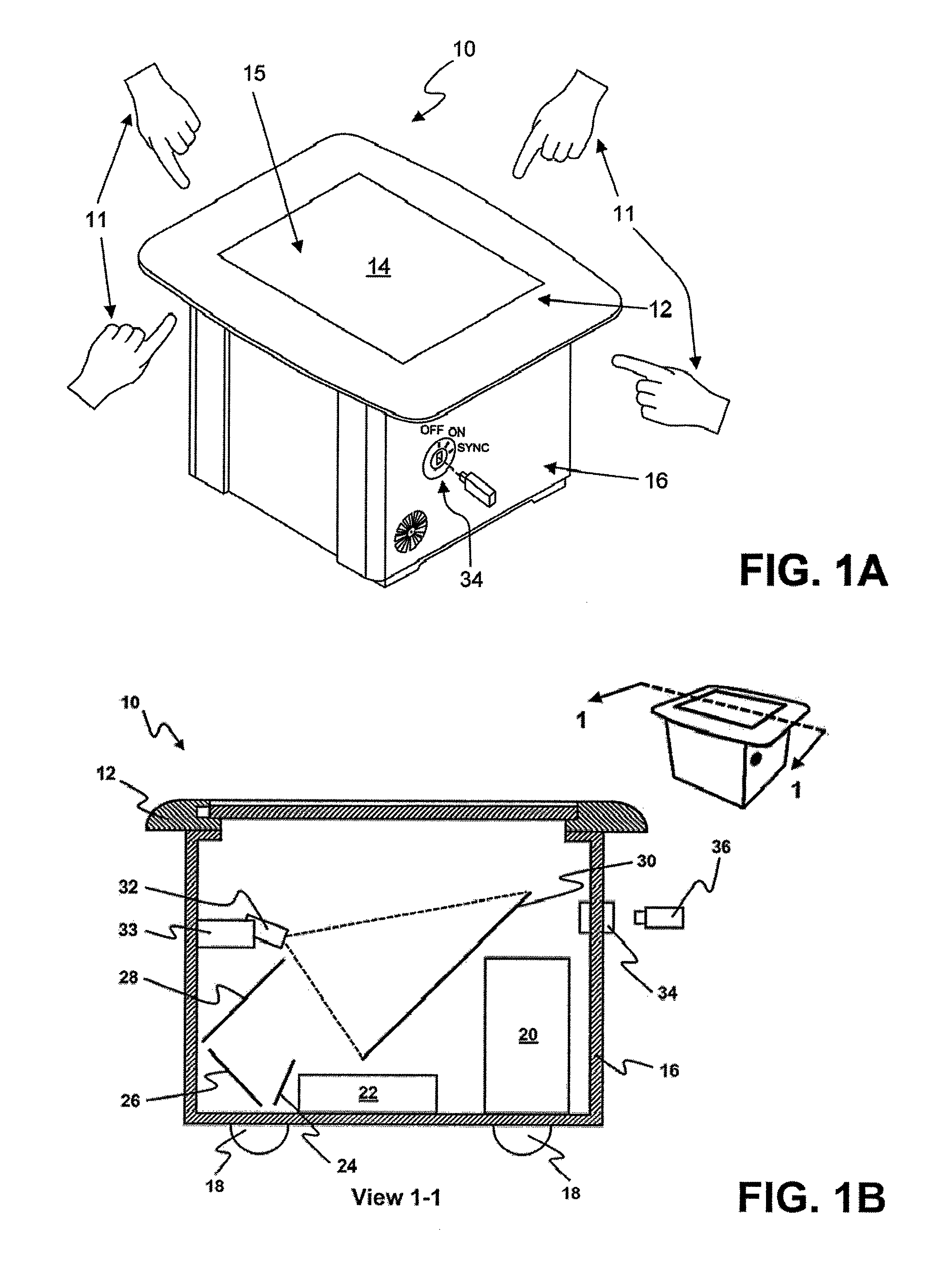

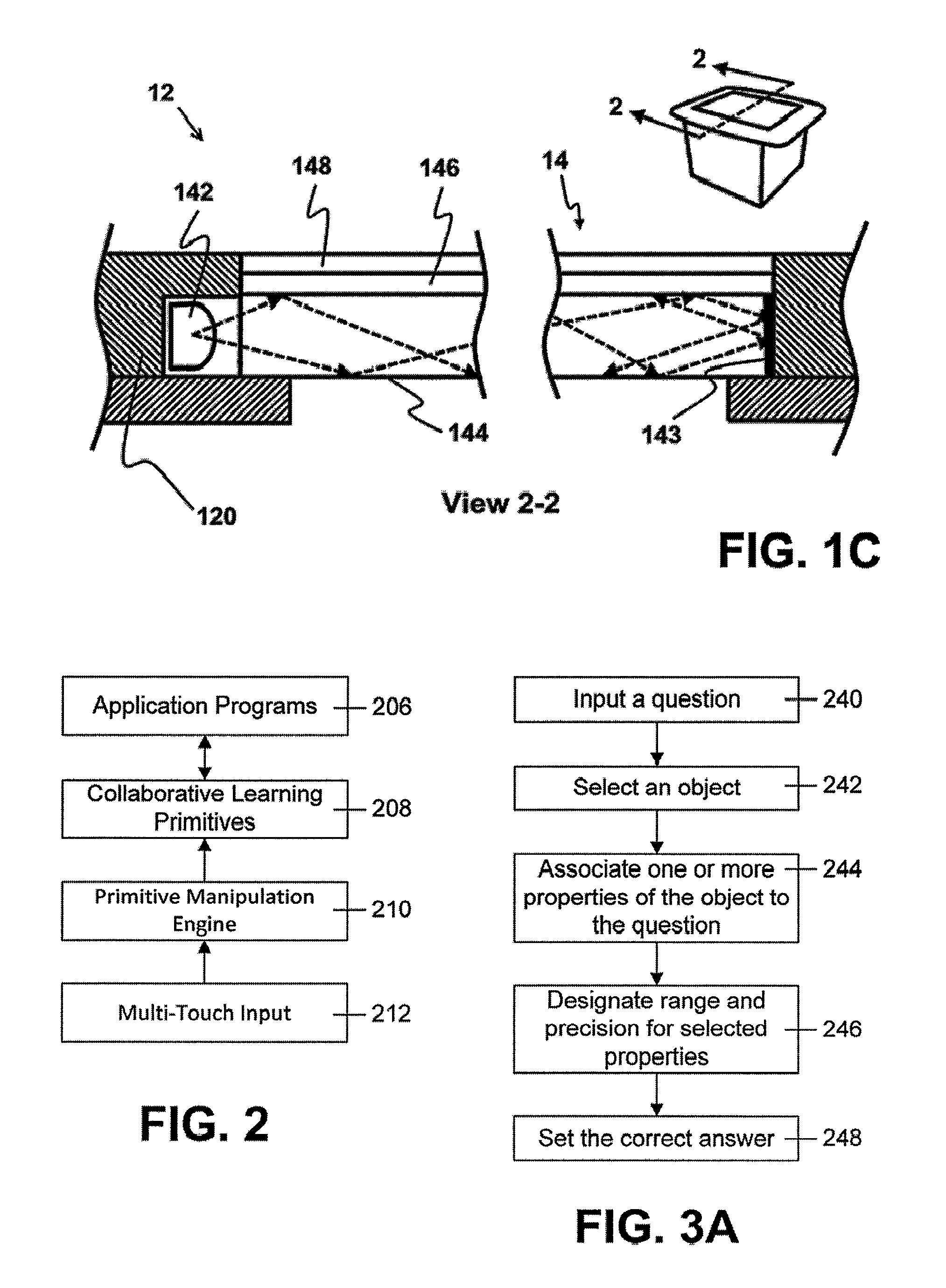

Method for handling user input in an interactive input system, and interactive input system executing the method

An interactive input system comprises a display surface and processing structure communicating with the display surface. The processing structure presents on the display surface at least one graphic object, the graphic object having properties and a respective solution state comprising a value of at least one property. The processing structure in response to gesture input manipulates the value of the at least one property, and provides an indication as to whether the graphic object is in its solution state in response to the application of a predetermined amount of pressure against the display surface in association with the graphic object. A method and computer readable medium are also provided.

Owner:SMART TECH INC (CA)

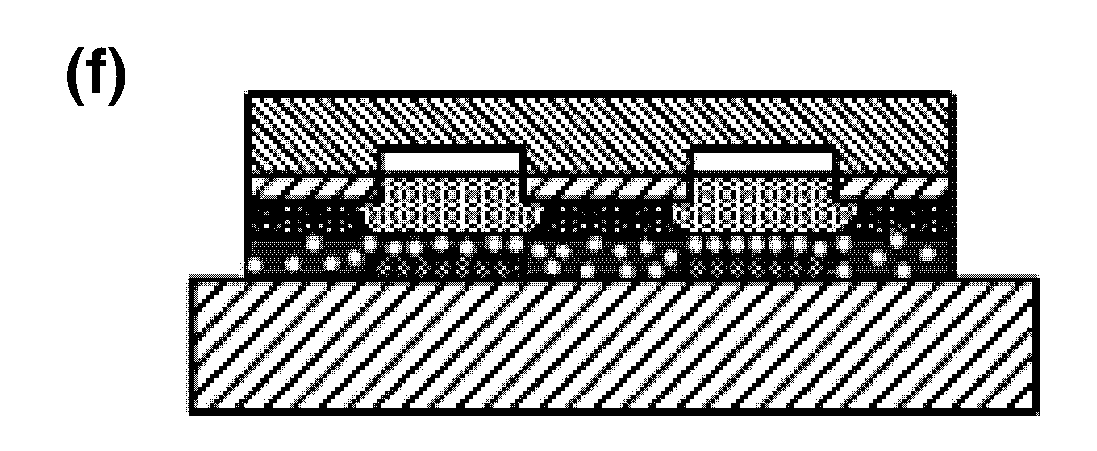

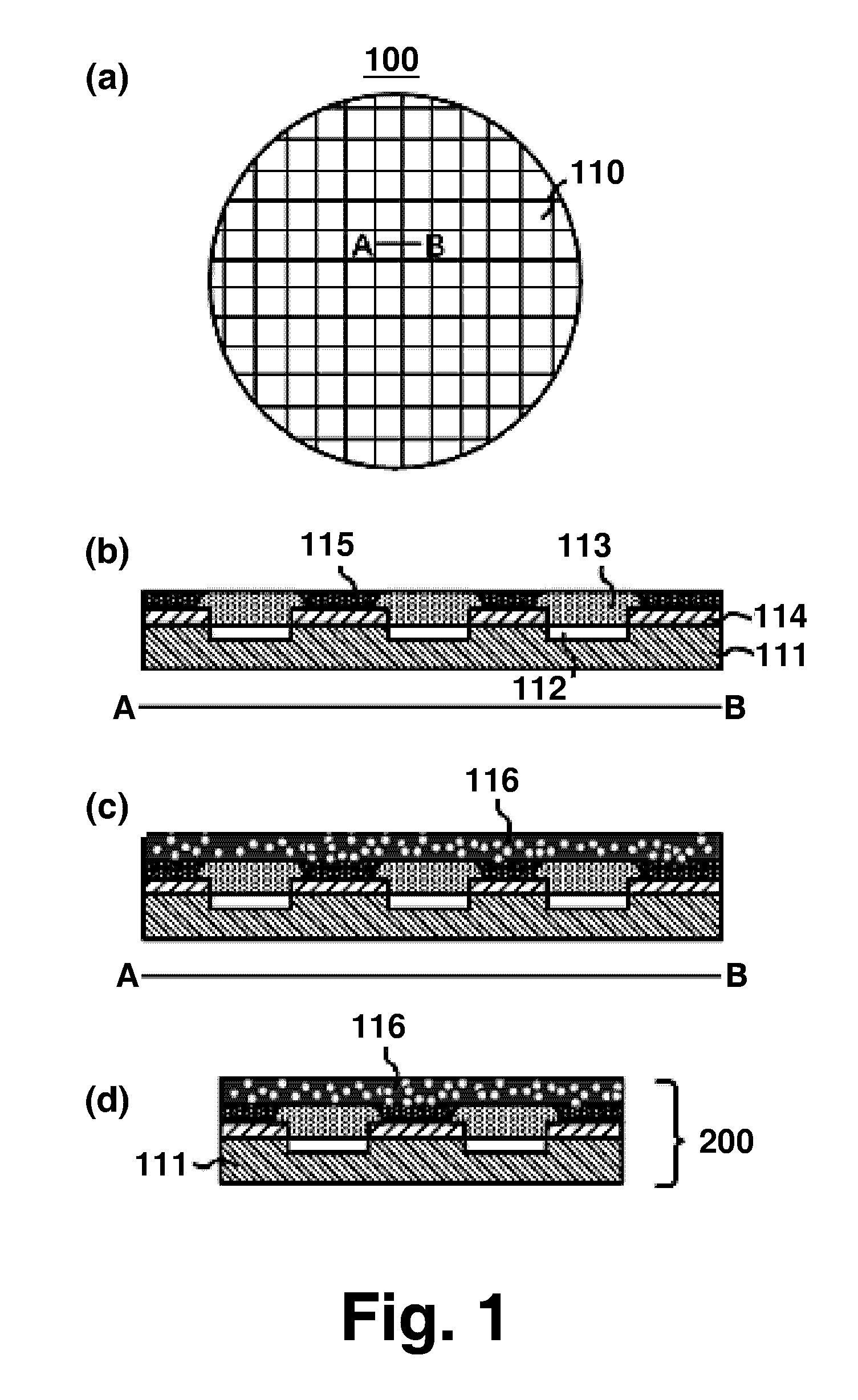

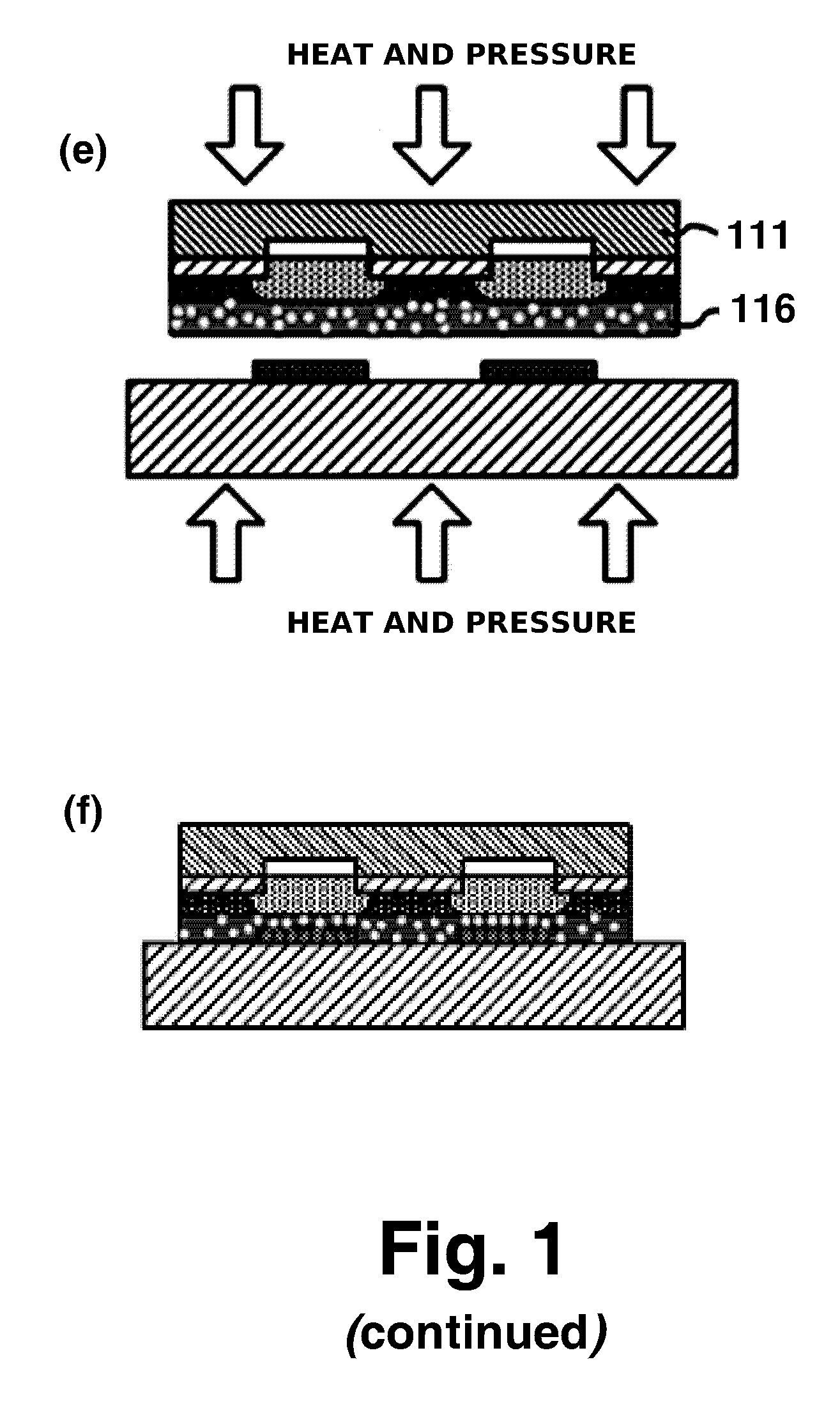

Wafer-level aca flip chip package using double-layered aca/nca

InactiveUS20090029504A1Reduce shadowing effectHigh selectivitySolid-state devicesSemiconductor/solid-state device manufacturingAnisotropic conductive adhesiveEngineering

A method of manufacturing a wafer-level flip chip package is capable of being used to produce a flip chip package by directly coating a flip chip package using anisotropic conductive adhesives (ACA) and non conductive adhesives (NCA) in a solution state as a double layer on a wafer. The method can be used to manufacture a non-conductive mixed solution and a conductive mixed solution and directly coat them on a substrate, such that it is possible to: increase productivity; simplify a manufacturing process; suppress a shadow effect; easily perform thickness control that is difficult with the anisotropic conductive adhesive paste or the non-conductive adhesive paste; and obtain the non-conductive layer and the anisotropic conductive layer in an initial state of a B-stage with a level not losing latent of hardening through a simple drying process to volatilize an organic solvent. Above all, the non-conductive layer and the anisotropic conductive layer is sequentially stacked on the substrate formed with the non-solder bump, making it possible to make the selectivity of electrical conduction and the stability of a connection process excellent, shorten process time and costs, and dramatically reduce consumption of the conductive particles which account for a large portion of total production costs.

Owner:KOREA ADVANCED INST OF SCI & TECH

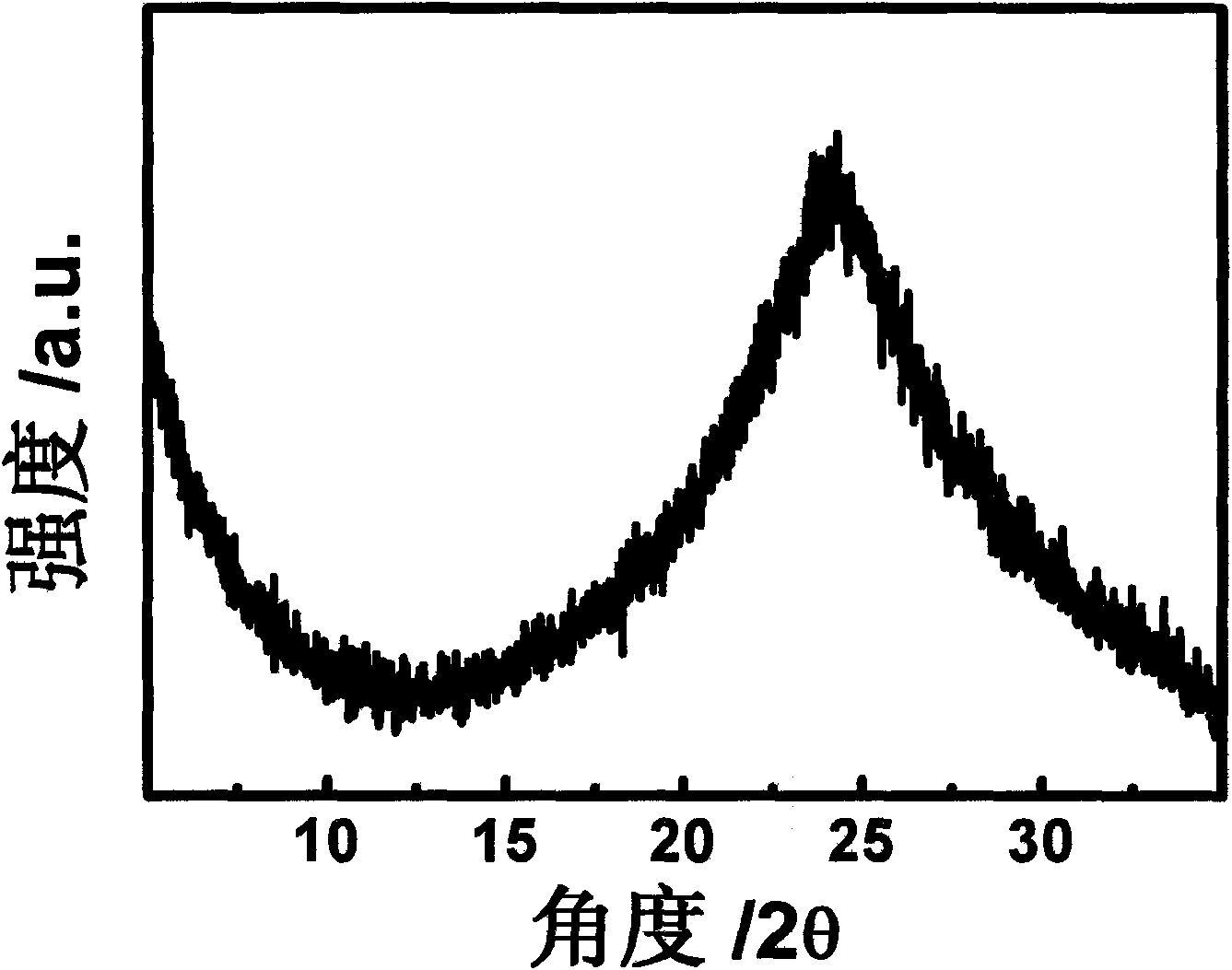

Method for preparing graphite alkenyl nanometer materials by electron beam irradiation method

InactiveCN101559941AHigh reversible lithium storage capacityImprove performanceNanostructure manufactureSolution stateCvd graphene

The invention relates to a method for preparing graphite alkenyl nanometer materials by an electron beam irradiation method. The method comprises the following steps: firstly, oxidizing natural graphite to obtain oxidized graphite; secondly, realizing the stripping between layers of the oxidized graphite by ultrasonic sound at the state of solution; and finally reducing the oxidized graphite through certain dosage of electron beam irradiation, and obtaining the graphite alkenyl nanometer materials. The method has simple preparation process, short preparation period and high yield, can be operated at normal temperature, does not add any catalyst and chemical initiator, and can be applied on a large scale.

Owner:SHANGHAI UNIV

Method for preparing chitosan porous microsphere sorbent by metal ion imprinting and crosslinking methods as well as use

InactiveCN101347720AEfficient selection of separation functionsOther chemical processesWater/sewage treatment by sorptionHigh resistanceCrosslinked chitosan

The invention discloses a preparation method of a metallic ion blotting crosslinked chitosan porous spherical adsorbent and the application thereof; the method is as follows: the chitosan in solution state and metallic ions jointly form a composition which is prepared into microspheres with diameters from 1.0mm to 10.0mm, the prepared microspheres are treated with pre-crosslinking reaction and then crosslinking reaction in water solution, after crosslinking reaction, the metallic ions and pre-crosslinking agent used for blotting are removed and the metallic ion blotting crosslinked chitosan porous spherical adsorbent is obtained. The method of the invention jointly applies metallic ion blotting and the formaldehyde pre-crosslinking method and matches the technique of solidification and granulation in alkali solution to prepare the metallic ion blotting crosslinked chitosan porous spherical adsorbent with the diameter of 1.0-10.0mm. The spherical adsorbent has large size and high specific surface area, and can be applied to efficient selective separation of heavy metal ions; furthermore, the spherical adsorbent can solve the problems that the existing chitosan microsphere is mostly powder, and has small size and high resistance to water flows, and the speed of sewage treatment is affected, etc.

Owner:SOUTH CHINA NORMAL UNIVERSITY

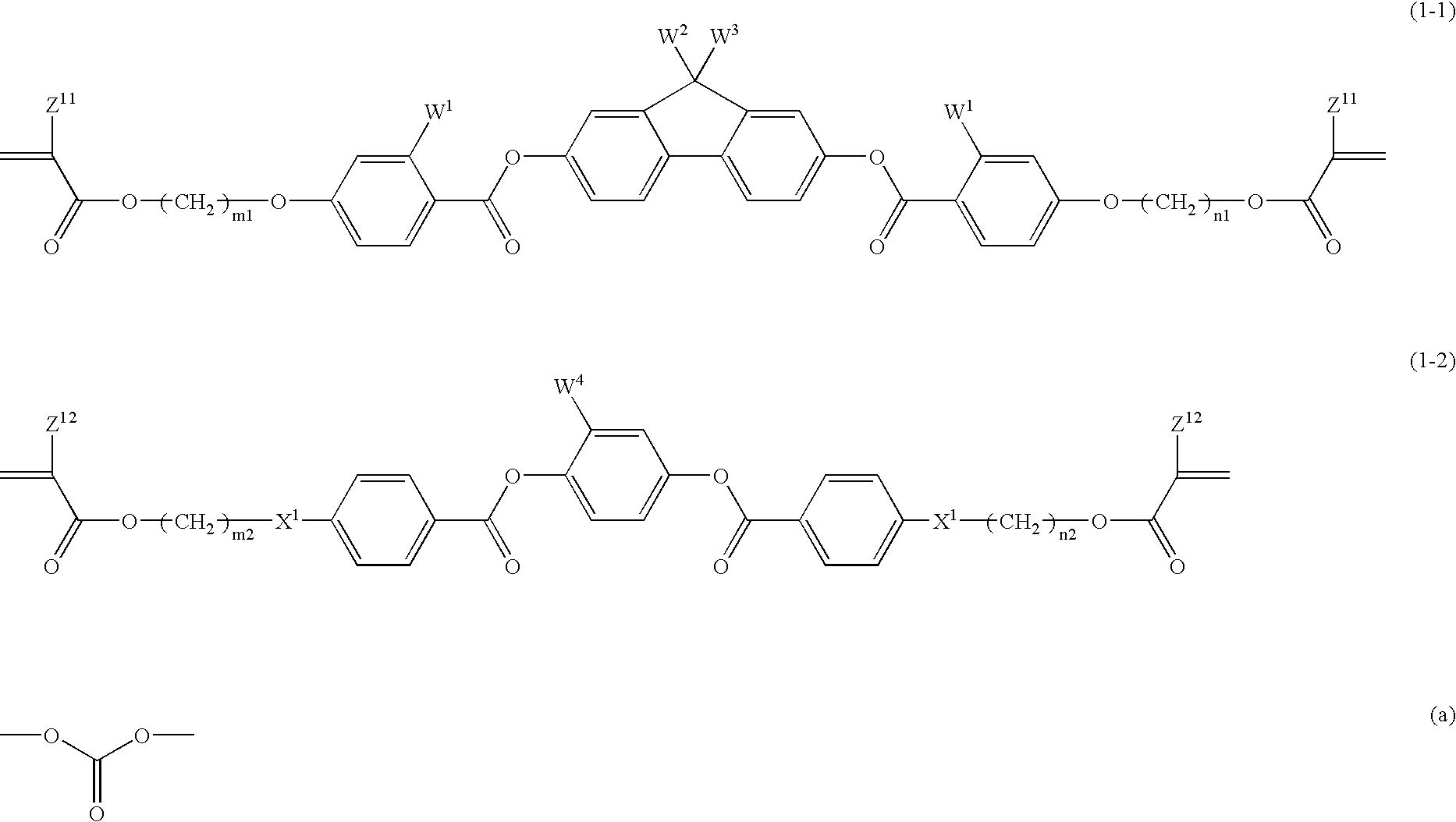

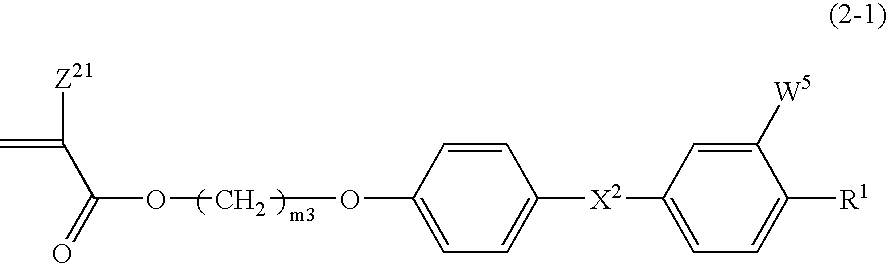

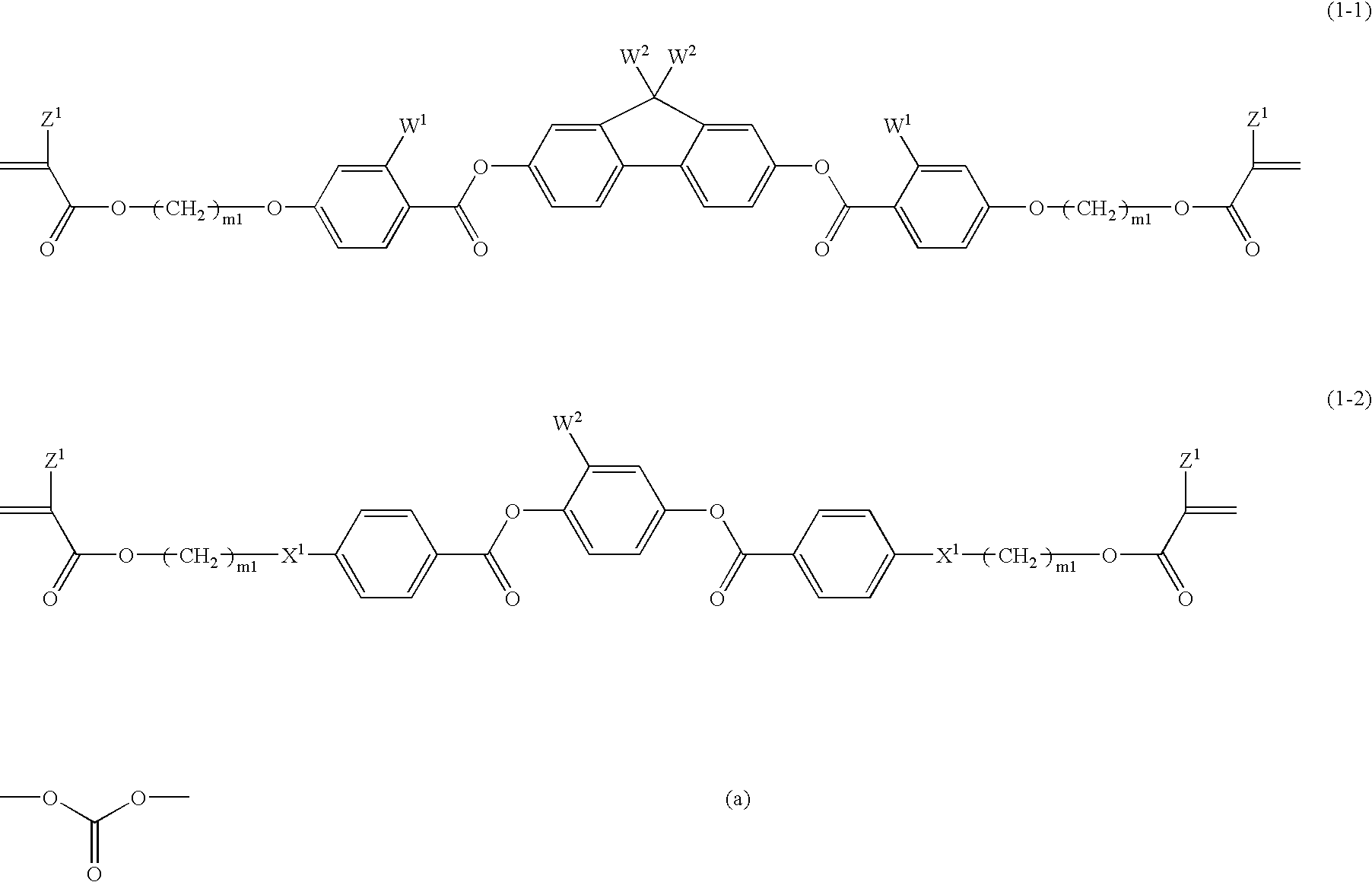

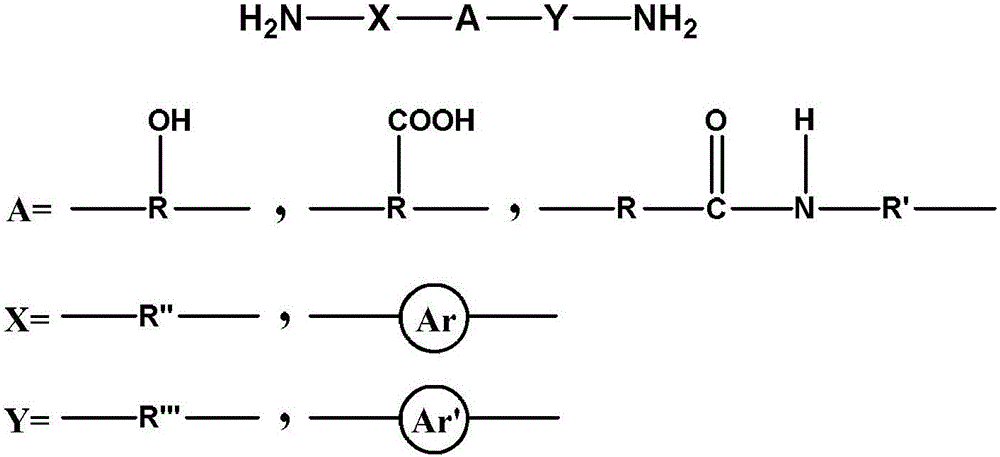

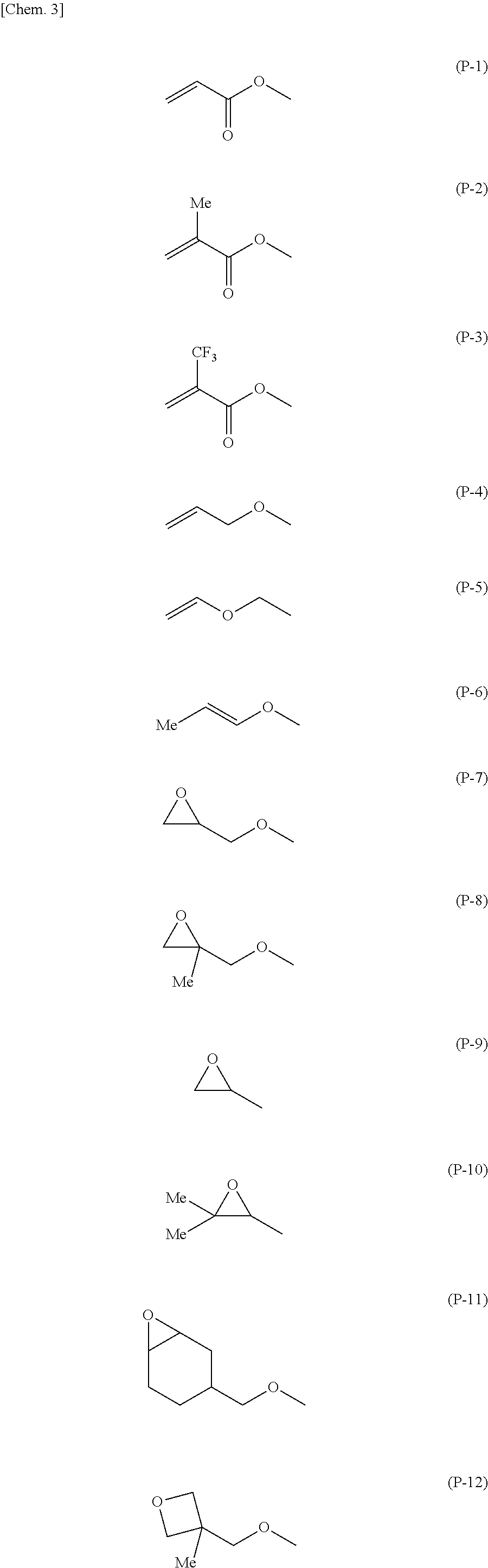

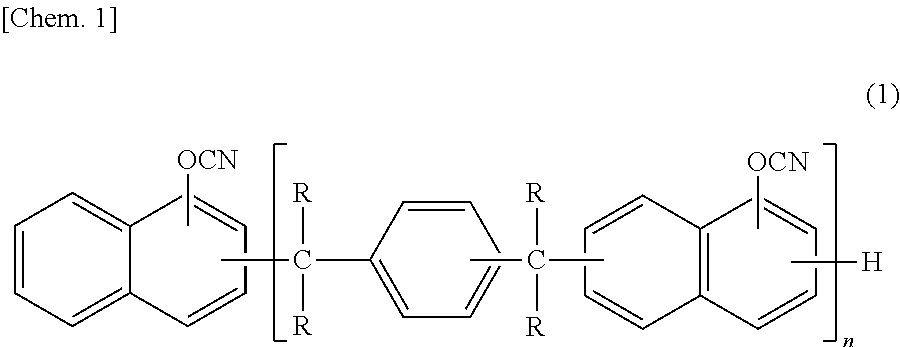

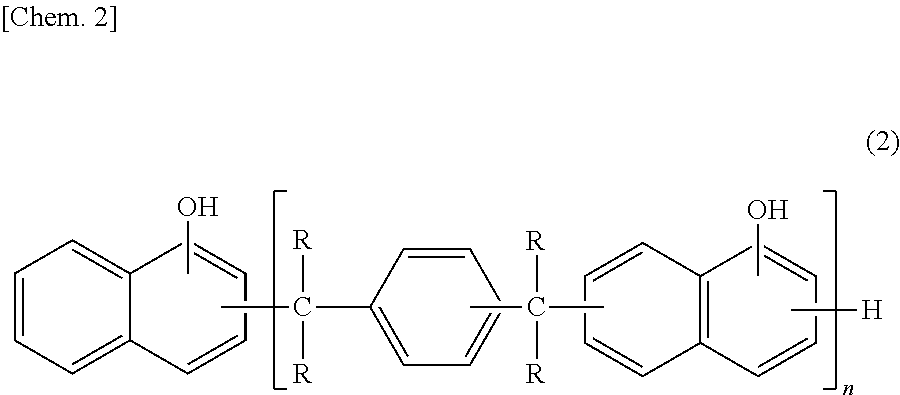

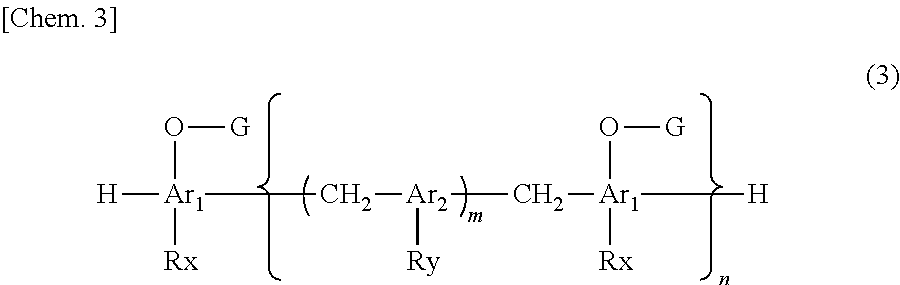

Polymerizable liquid crystal composition

ActiveUS20080241431A1Improve stabilityImprove adhesionLiquid crystal compositionsThin material handlingSolution stateOrganic chemistry

Such a polymerizable liquid crystal composition is to be provided that is excellent in stability in a solution state, shows good coating property on a supporting substrate, and has a uniform homeotropic alignment property. The polymerizable liquid crystal composition contains an acrylate compound, an epoxy compound and a bisphenol fluorene compound. The polymerizable liquid crystal composition contains a compound selected from a group of compounds represented by formulae (1-1) and (1-2) as a component (A), a compound selected from a group of compounds represented by formula (2) as a component (B), a compound selected from a group of compounds represented by formulae (3-1) to (3-3) as a component (C) and a compound selected from a group of compounds represented by formulae (4-1A), (4-1B), (4-2), (4-3), (4-4) and (4-5) as a component (D), and may optionally contain a compound selected from a group of compounds represented by formulae (5-1) and (5-2) as a component (E). The bisphenol fluorene compound is effective for controlling a uniform homeotropic alignment of the polymerizable liquid crystal composition.

Owner:JNC CORP +1

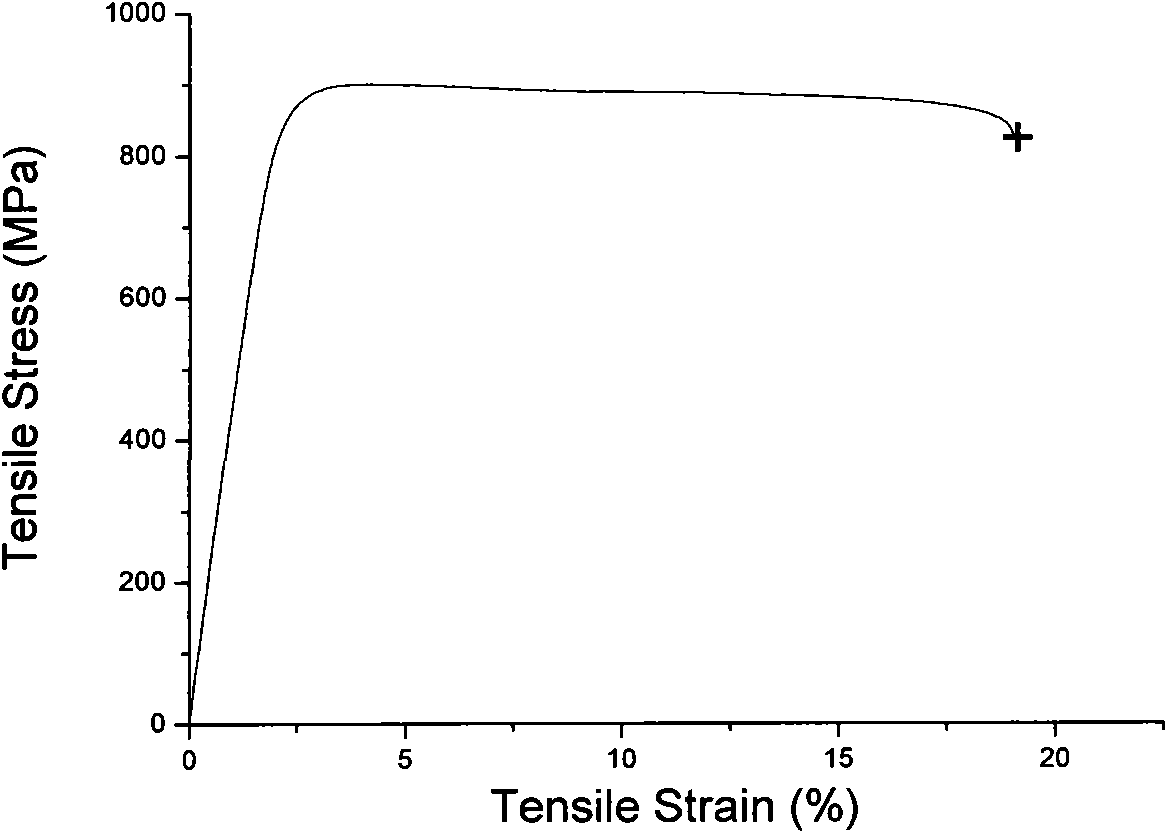

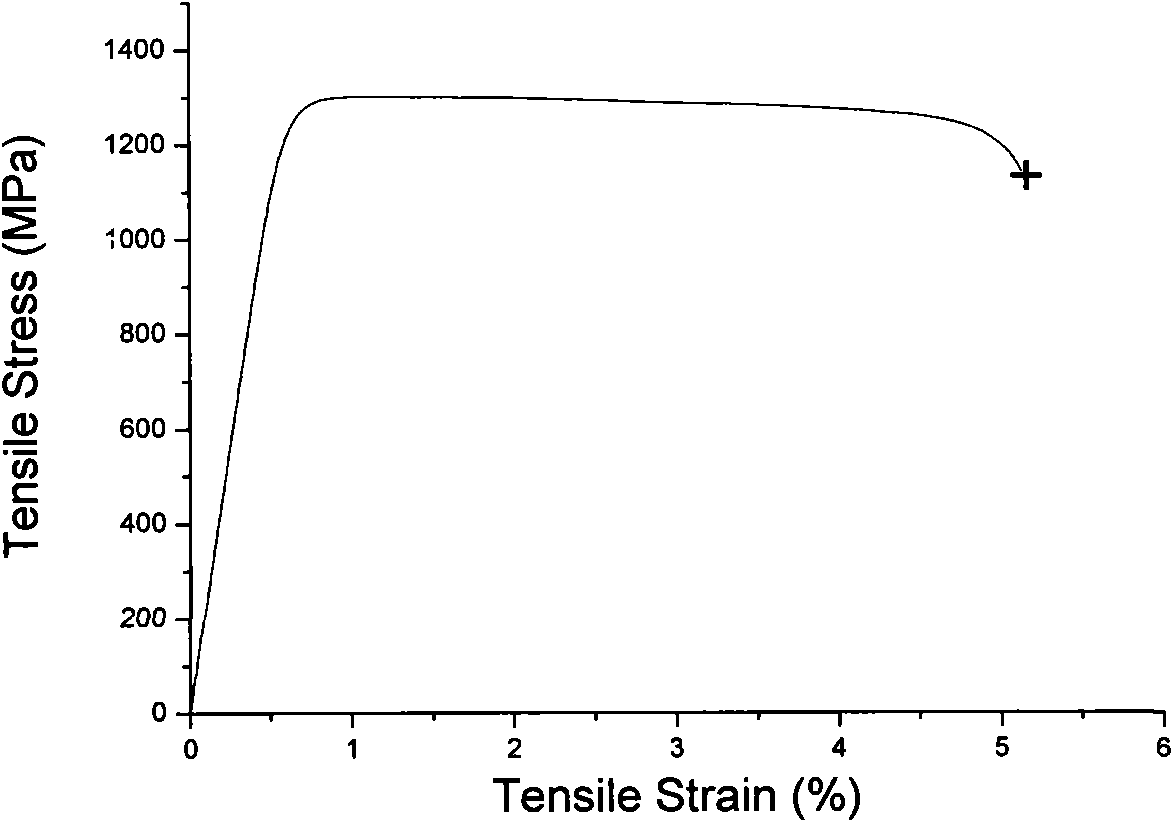

Beta titanium alloy and preparation method thereof

The invention relates to a beta titanium alloy, in particular to a beta titanium alloy with low cost and high strength and a preparation method thereof. The beta titanium alloy comprises the following components in mass percentage: 0.5%-2.5% of ferrum, 1.5%-3.5% of aluminum, 2%-4% of chromium, 6%-11% of niobium and the balance of titanium. The preparation method comprises the following steps of: smelting sponge-state titanium and then smelting the smelted titanium with ferrum, aluminum, chromium and niobium to obtain a beta titanium alloy ingot; and cooling the beta titanium alloy ingot along with a furnace after uniform heat treatment, hot rolling the cooled beta titanium alloy ingot into a sheet alloy material, cutting the sheet alloy material into samples, carrying out ice water quenching after solution treatment and then carrying out ageing treatment to obtain the beta titanium alloy with high strength. The results of stretching experiments indicate that the room-temperature tensile strength of the beta titanium alloy in the solution state is above 850 MPa, and the elongation is above 15%; and the room-temperature tensile strength of the beta titanium alloy in the ageing state is above 1300 MPa, the elongation is above 4%, the strength of the beta titanium alloy can achieve above 1300 MPa, and meanwhile, the beta titanium alloy keeps a certain plasticity.

Owner:XIAMEN UNIV

Selenium sustained-release edible fungus additive for selenium-rich culturing of edible fungus and preparation method thereof

InactiveCN102498950AAchieve growthTo achieve the effect of broad-spectrum nutritional fortificationHorticultureFertilizer mixturesBiotechnologyHydrogen

The invention discloses a selenium sustained-release edible fungus additive for selenium-rich culturing of edible fungus. The selenium sustained-release edible fungus additive is characterized by comprising the following components in parts by weight: 1-20 parts of selenium source, 950-1000 parts of attapulgite clay or modified attapulgite clay and 5-40 parts of beta-cyclodextrin, wherein the modified attapulgite clay is one-dimensional nano-state attapulgite clay which is modified by hydrogen type ion source (H<+>) irradiation. The composition achieves a stable release condition after 2-3 hours in a solution state, the selenium concentration in the solution state can achieve 40-60% of the original selenium concentration in the selenium sustained-release additive, and the stable release condition can be sustained for 90-120 days.

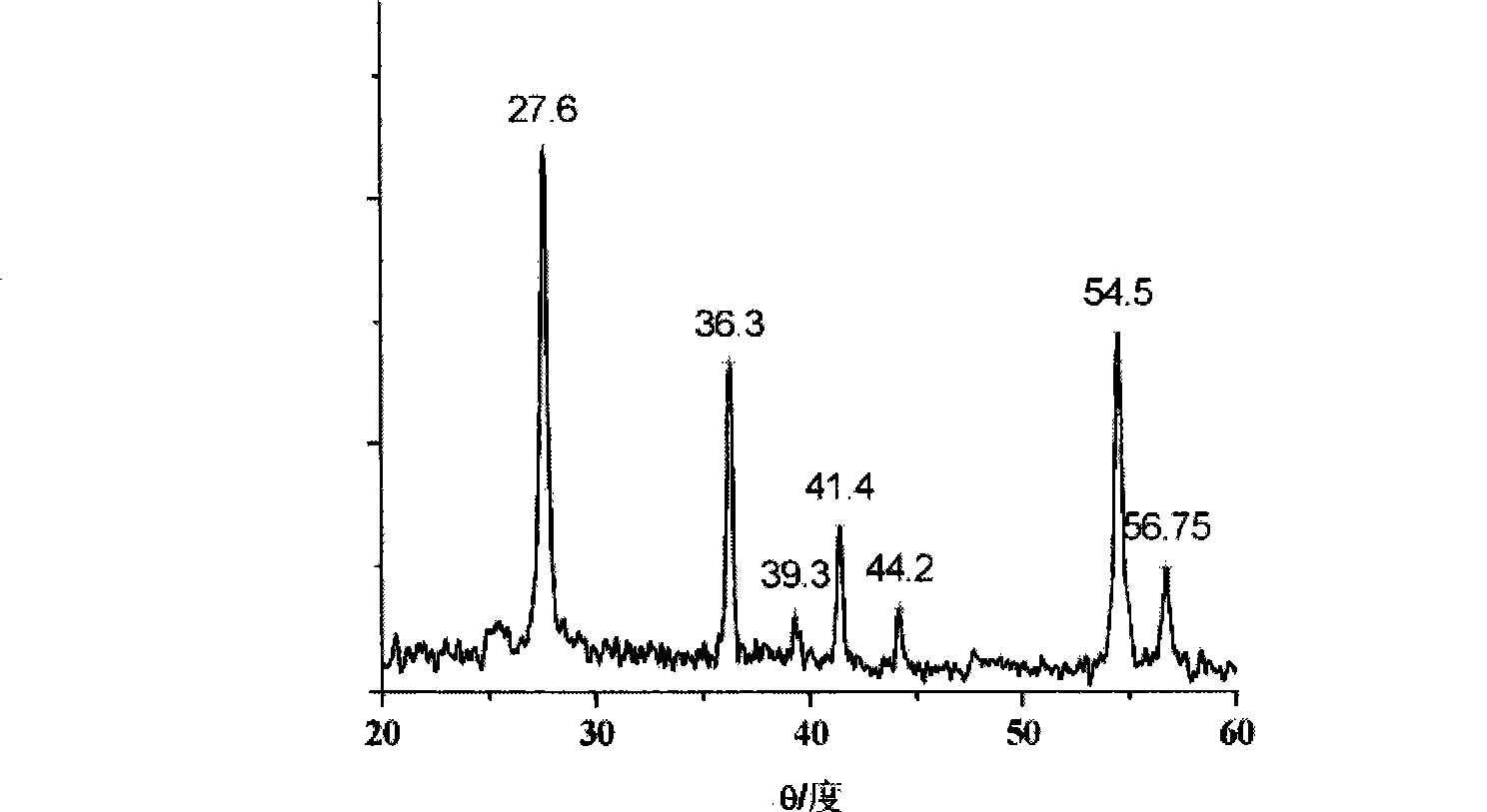

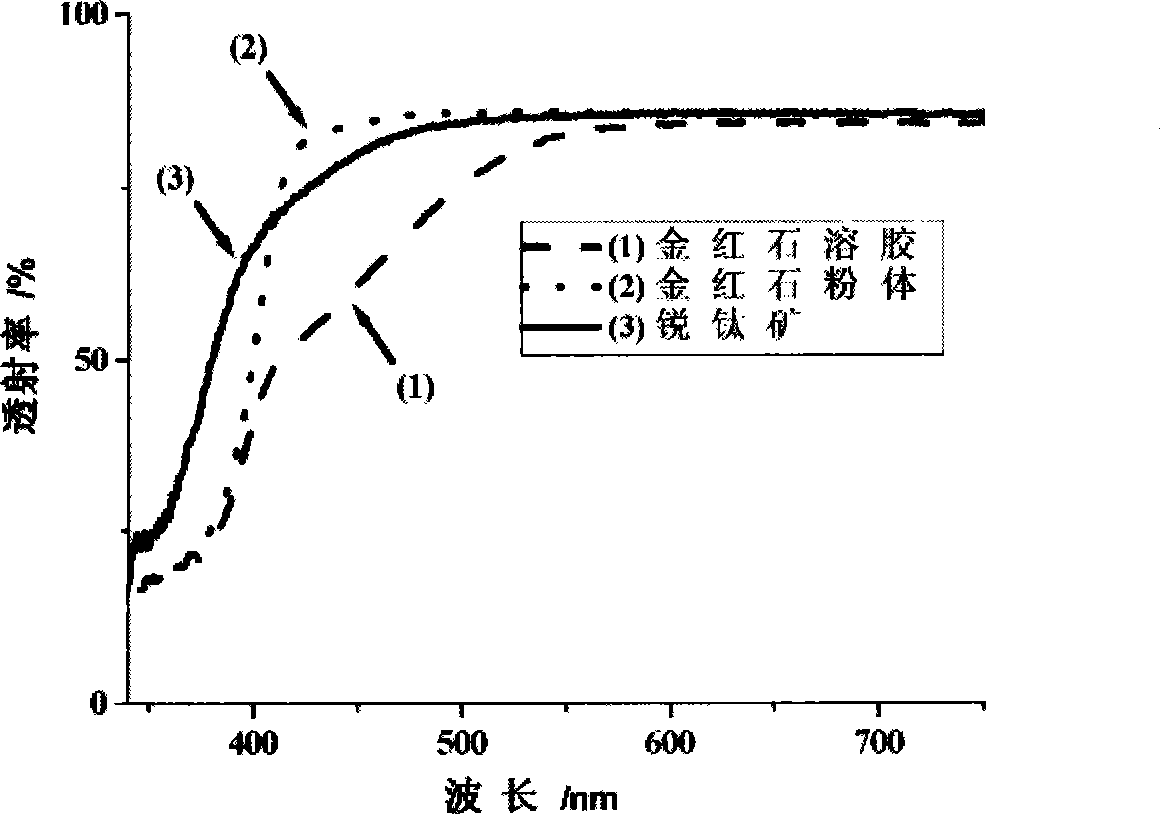

Synthetic method for preparing rutile type nano titanic oxide sol or powder at low temperature

The invention belongs to a synthesis method for preparing nano-titania sol and powder, and in particular relates to a synthesis method for preparing rutile nano-titania sol or powder at a low temperature. The synthesis method comprises: dissolving a mineralizer into an aqueous solution containing titanium salt, obtaining the mineralizer-doped aqueous solution containing the titanium salt, using inorganic alkali to adjust the pH value of the solution to be between 5 and 11 or using water to dilute the mineralizer-doped aqueous solution containing the titanium salt or heating the mineralizer-doped aqueous solution containing the titanium salt, and obtaining composite titanate deposit; using superoxol to disperse the composite titanate deposit into solution state, and adjusting the pH value of the composite titanate solution; adjusting the pH value to be more than 1 in order to obtain the sol; adjusting the pH value to be less than or equal to 1 in order to obtain the powder; heating the solution; obtaining the yellow orange transparent or semitransparent nano titania sol when the pH value is more than 1; and obtaining white deposit when the pH value is less than or equal to 1, and obtaining the nano titania powder after centrifugation or filtration. The synthesis method greatly reduces the cost and simplifies the technology.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

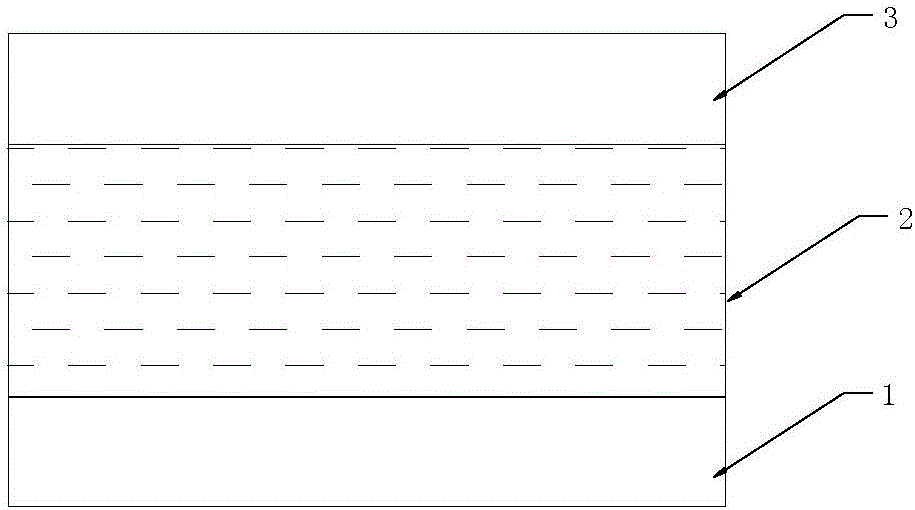

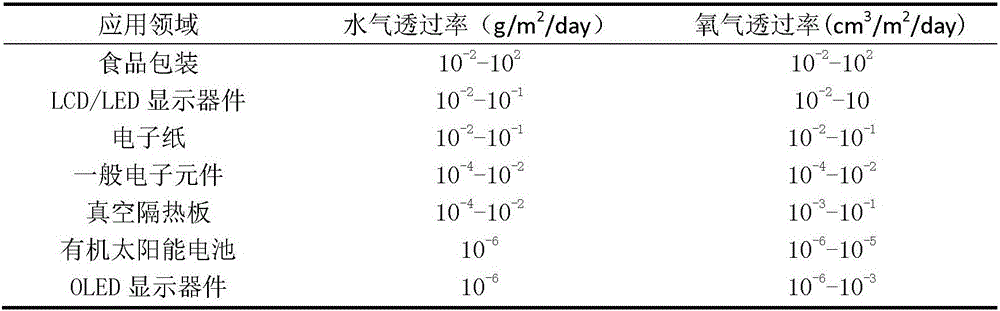

Water/oxygen barrier polymer-based composite material as well as preparation method and application thereof

The invention discloses a water / oxygen barrier polymer-based composite material. The water / oxygen barrier polymer-based composite material is formed by enabling inorganic matter layered filler to react with a surface modification agent and an intercalation agent and dispersing reaction products into a polymer base material, wherein the polymer base material is an organic polymer which contains an amido bond, hydroxyl or carboxyl. The water / oxygen barrier polymer-based composite material has the advantages that a water / oxygen barrier layer is simple in structure and effective; a preparation method of the composite material is a solution-state production process, and a vacuum process is not involved in the preparation process, so that the preparation method is simple; the water / oxygen barrier polymer-based composite material is low in preparation cost and wide in application scope.

Owner:SUN YAT SEN UNIV

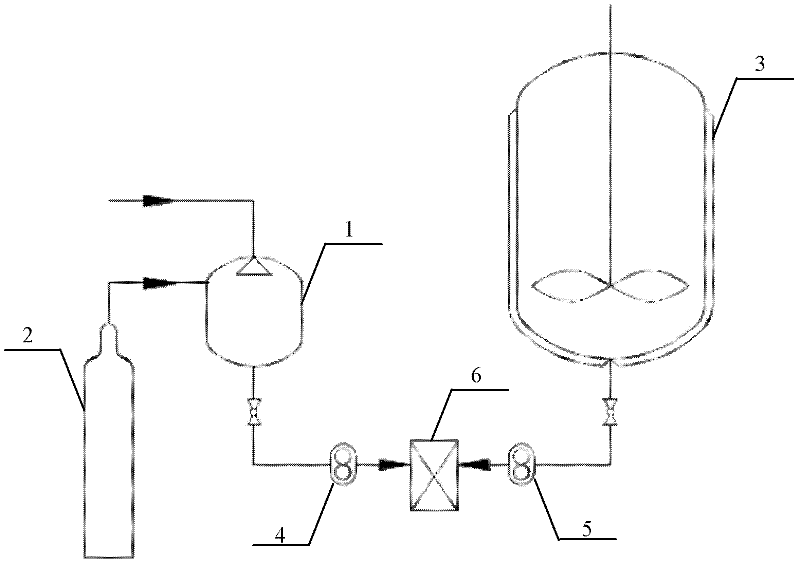

Ammonification method of polyacrylonitrile polymerization liquid and device for realizing same

InactiveCN102336865AAdvantages of ammoniation methodOvercoming Difficult MeasurementsFibre chemical featuresAcrylonitrileSolution state

The invention discloses an ammonification method of polyacrylonitrile polymerization liquid and a device for realizing the same. The method comprises the following steps: (1) dissolving acrylonitrile, copolymerization monomers and an initiator in a solvent in a polymerization kettle by adopting a solution polymerization process, and carrying out copolymerization reaction in a solution state to obtain the polyacrylonitrile polymerization liquid; (2) adding a certain amount of solvent to a container, and introducing ammonia gas to the solvent to obtain NH3 solution, wherein the solvent is same as that used in the step (1); and (3) adding a proper amount of the polyacrylonitrile polymerization liquid obtained in the step (1) and a proper amount of the NH3 solution obtained in the step (2) toa mixer, and uniformly mixing to realize uniform ammonification of the polyacrylonitrile polymerization liquid. Compared with the existing ammonia gas bubbling method, the ammonification method overcomes the defects that ammonia gas is difficult to meter and mix and generates pollution to the polymerization kettle, improves the ammonification controllability and uniformity, and lays a foundation for production of stable and high-performance PAN (polyacrylonitrile) protofilament.

Owner:ZHEJIANG TAIXIAN NEW MATERIAL

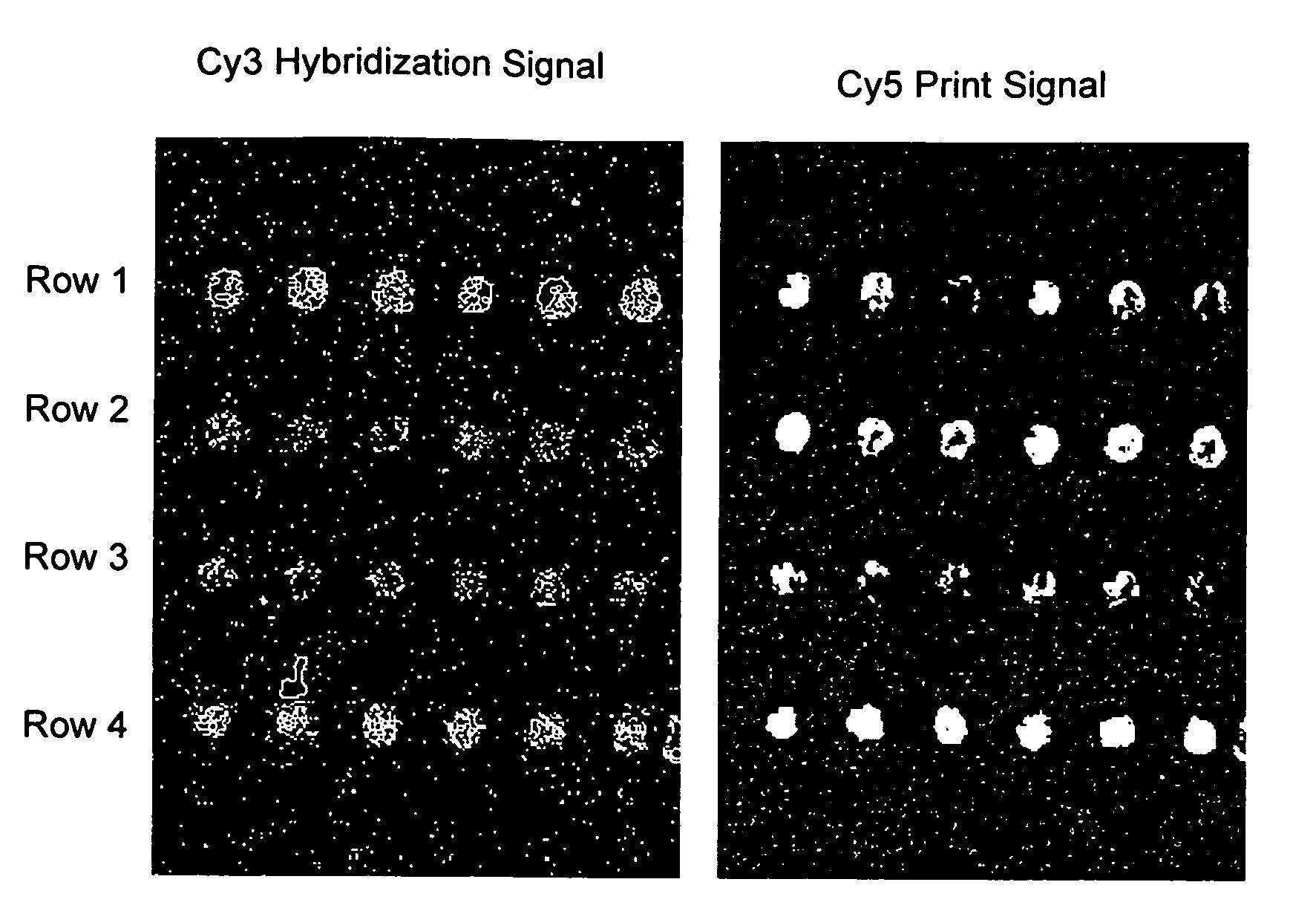

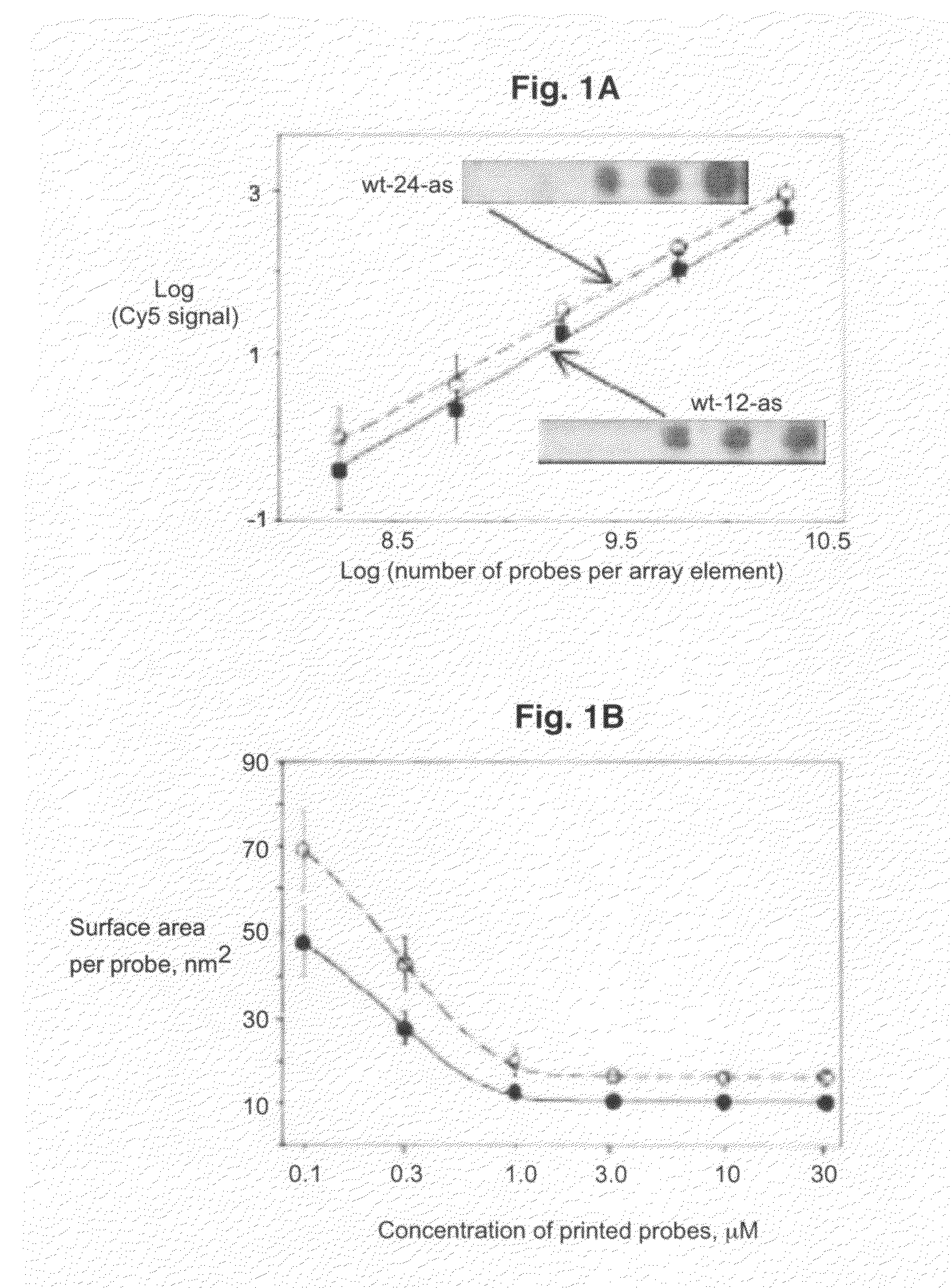

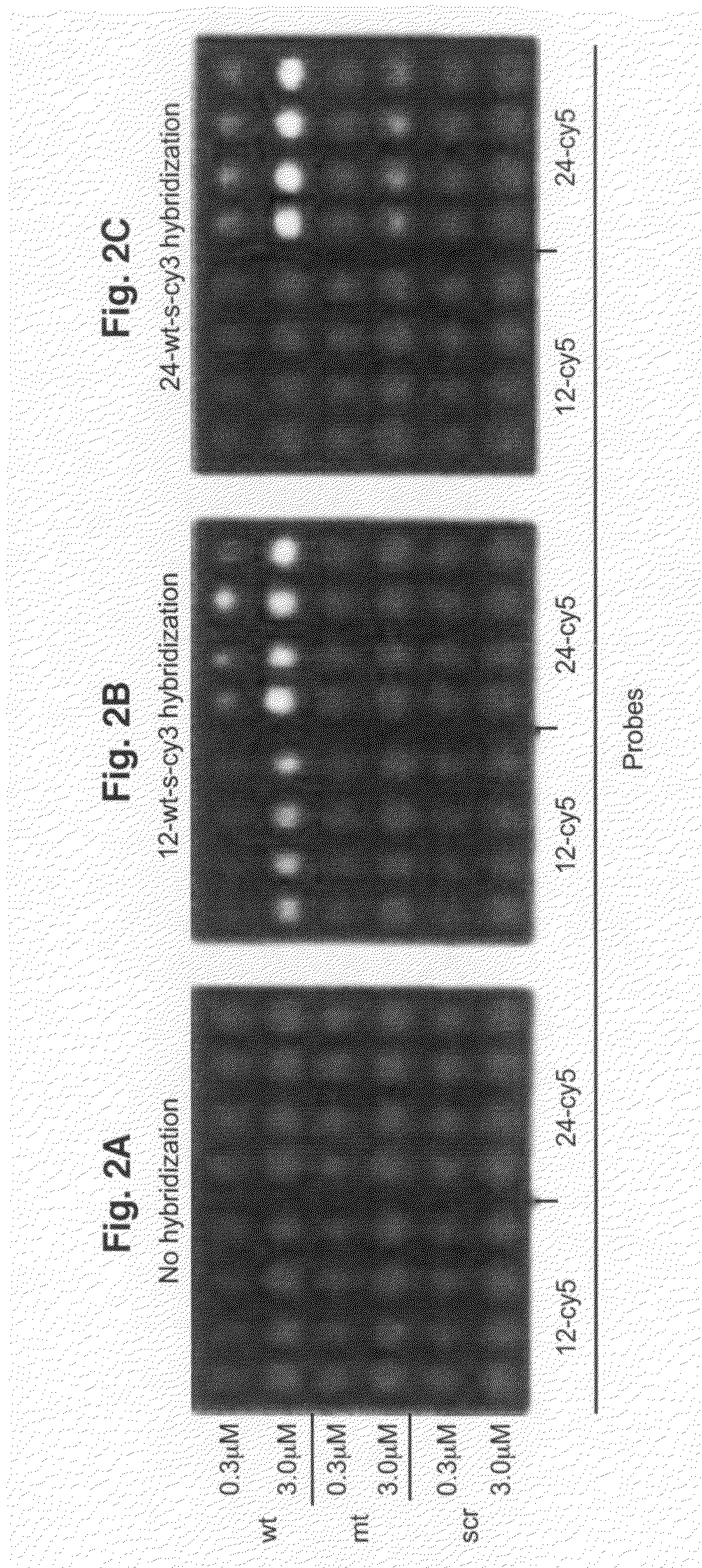

Methods and devices based upon a novel form of nucleic acid duplex on a surface

InactiveUS20090011949A1Easy to manufactureCapacity retentionSequential/parallel process reactionsNucleotide librariesPhosphateNucleotide

Provided herein are biomolecular hybridization devices comprising a substrate with a permanently and covalently attached surface of functional groups and an adsorbed monolayer of unmodified, single-stranded oligonucleotides all of which are 10 to about 24 bases in length as a saturated film of constrained oligonucleotides on the surface via direct non-covalent phosphate-surface adsorptive contact of substantially all phosphate groups of each oligonucleotide. The constrained oligonucleotides are effective to dissociably hybridize to a complementary single-stranded nucleic acid with asymmetric, non-helical base pairing and without oligonucleotide dissociation from the surface of the device. Also, provided are methods for hybridizing solution-state target nucleic acids to probe nucleic acids and for identifying a nucleotide sequence to which a nucleotide-binding protein binds using the biomolecular hybridization devices.

Owner:GMSBIOTECH INC +1

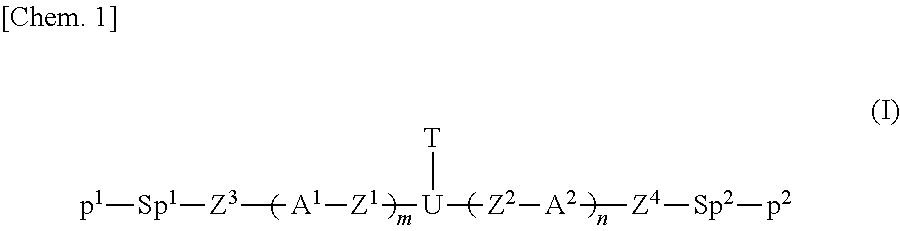

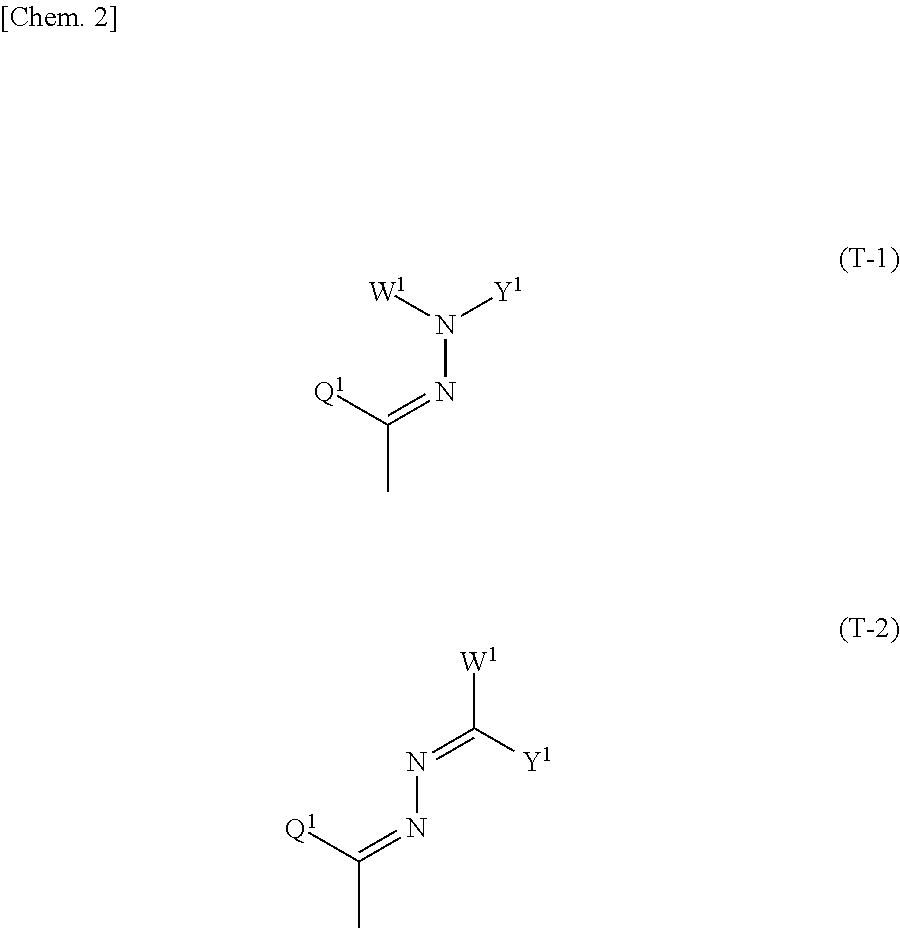

Polymerizable compound, composition, polymer, optically anisotropic body, liquid crystal display element, and organic el device

ActiveUS20170260150A1Good optical performanceWiden perspectiveOrganic chemistrySolid-state devicesSolubilityLiquid-crystal display

It is an object of the present invention to provide a polymerizable compound having a good liquid crystal property, a good alignment property, sufficient solubility in solvents, high preservation stability in a solution state, and high optical stability; a composition including the polymerizable compound; a polymer produced by polymerizing the polymerizable compound, such as a resin produced using the polymerizable compound; an optically anisotropic body including the polymer; and a liquid crystal display element and an organic EL device that include the optically anisotropic body. As a result of conducting intensive studies in order to achieve the above object, the compound represented by General Formula (I) is developed.

Owner:DAINIPPON INK & CHEM INC

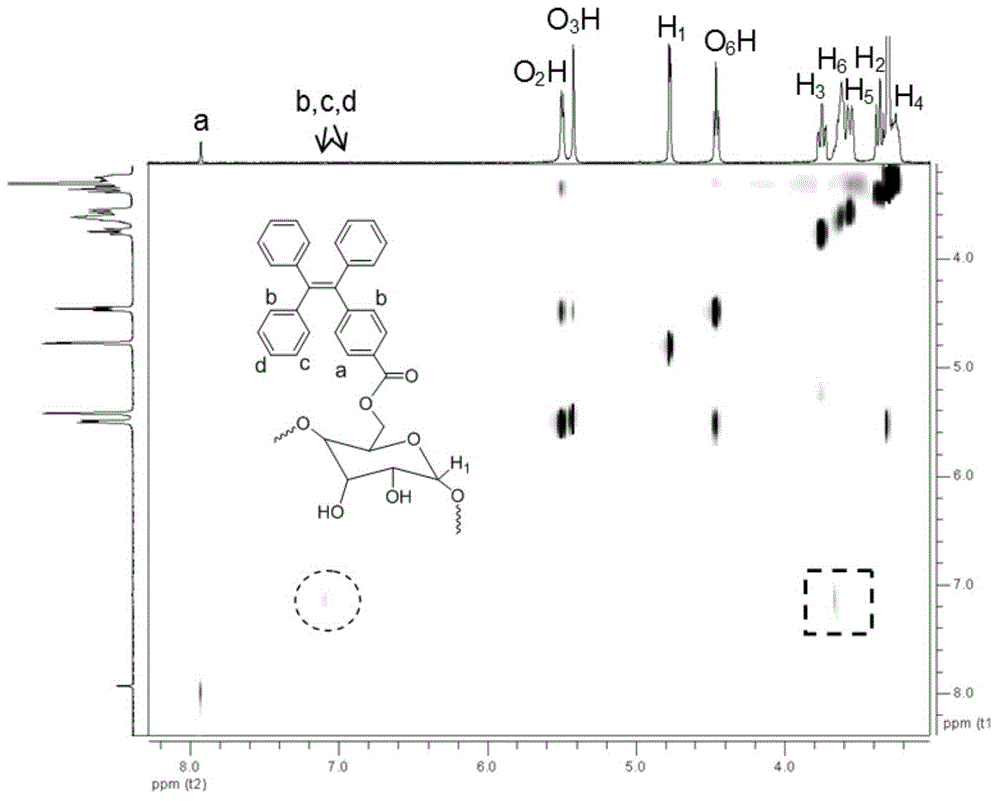

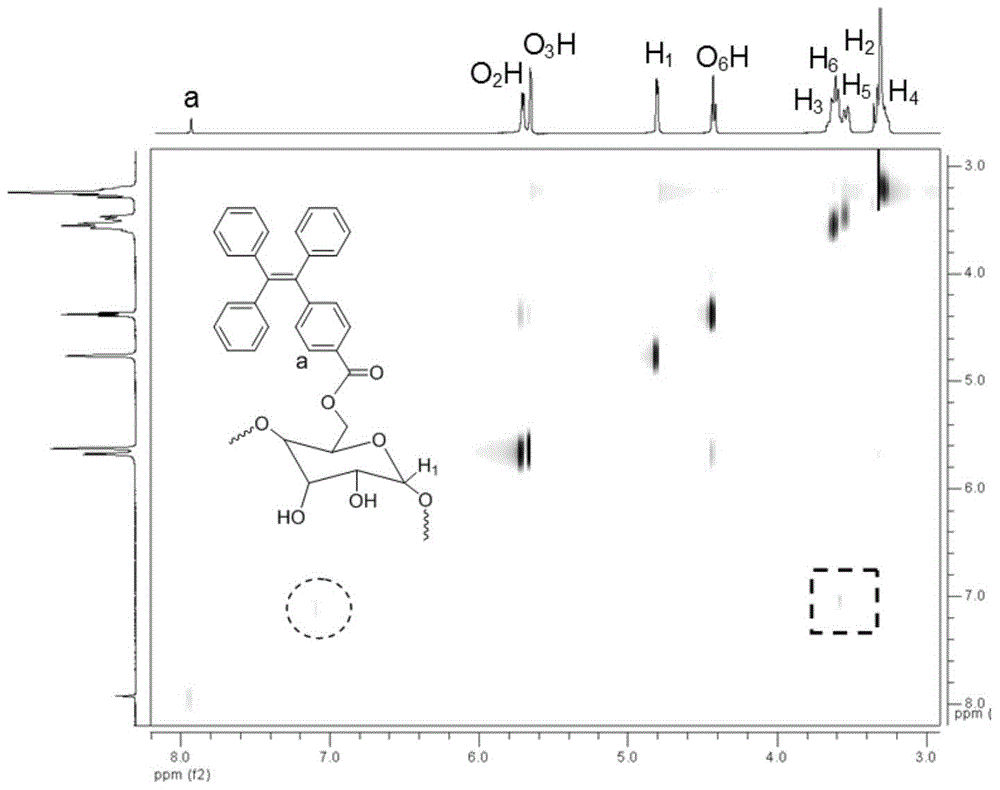

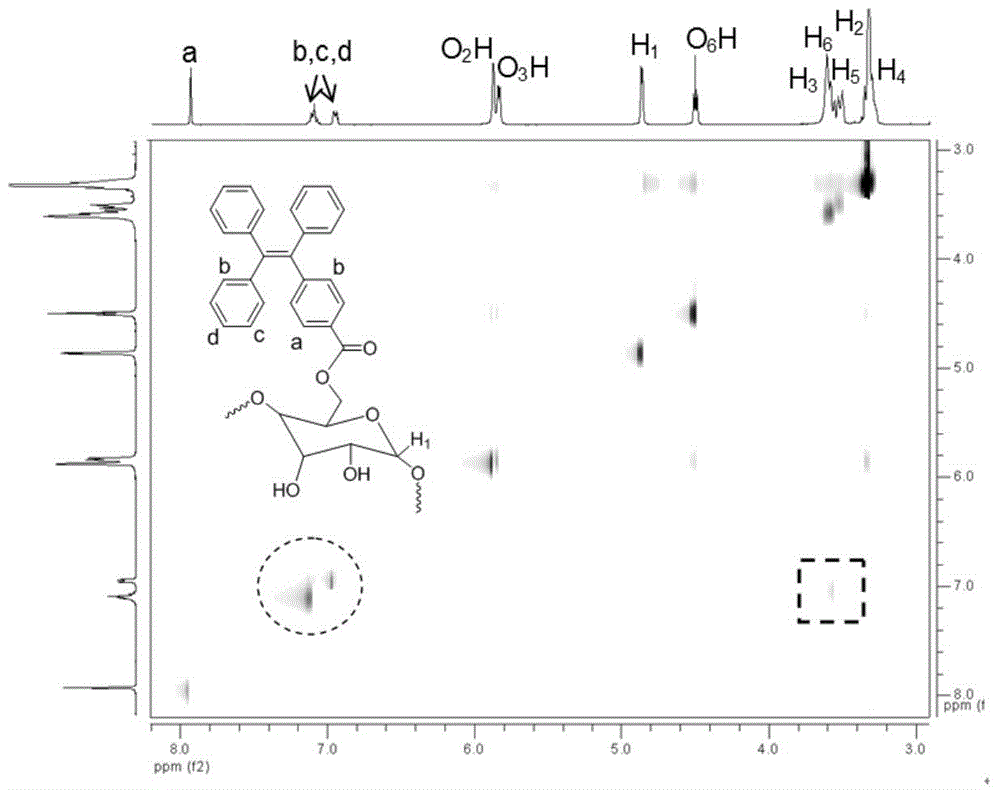

An activated luminescence material and a method for preparing the same

ActiveCN104673275AGood biocompatibilityHigh fluorescence quantum yieldBiological testingFluorescence/phosphorescenceQuantum yieldBiocompatibility Testing

The invention relates to the technical field of fluorescent material, specifically to an activated luminescence material and a method for preparing the same. Different biomolecules are combined to tetraphenyl ethylene through condensation reaction, so the biocompatible activated luminescence material having AIE / AEE features can be obtained. The biomolecules contain water soluble activated luminescence molecules with high fluorescent quantum yield, which have excellent biocompatibility in a solution state and a solid state, and crystalline polymer which can form nanosheets in a water-soluble medium. The obtained activated luminescence material can be applied to living cell fluorescence staining, sensitive explosive detecting and the like.

Owner:HKUST SHENZHEN RES INST +1

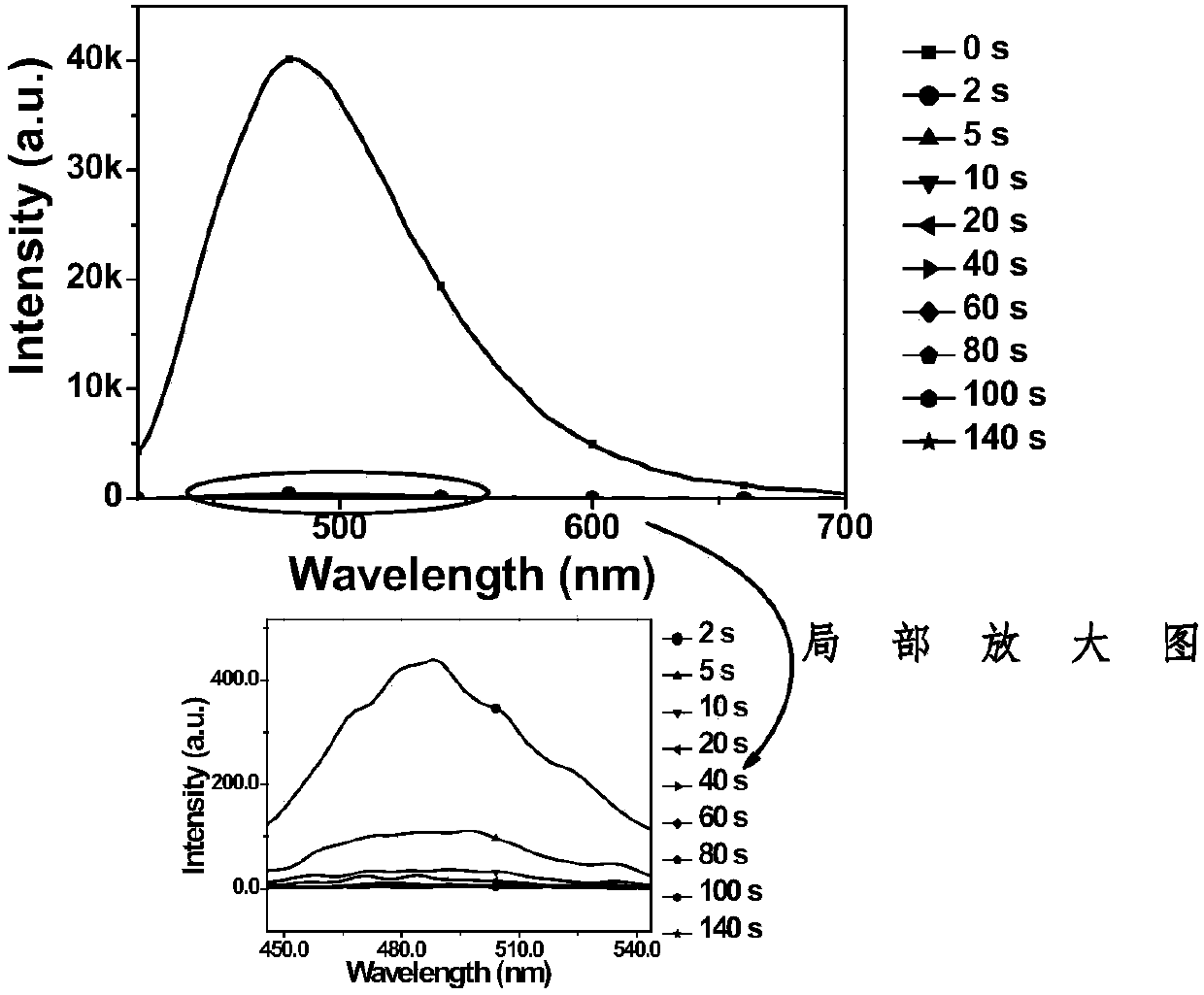

Fluorescent compound with aggregation-induced luminescence properties and application thereof to cell fluorescence imaging field

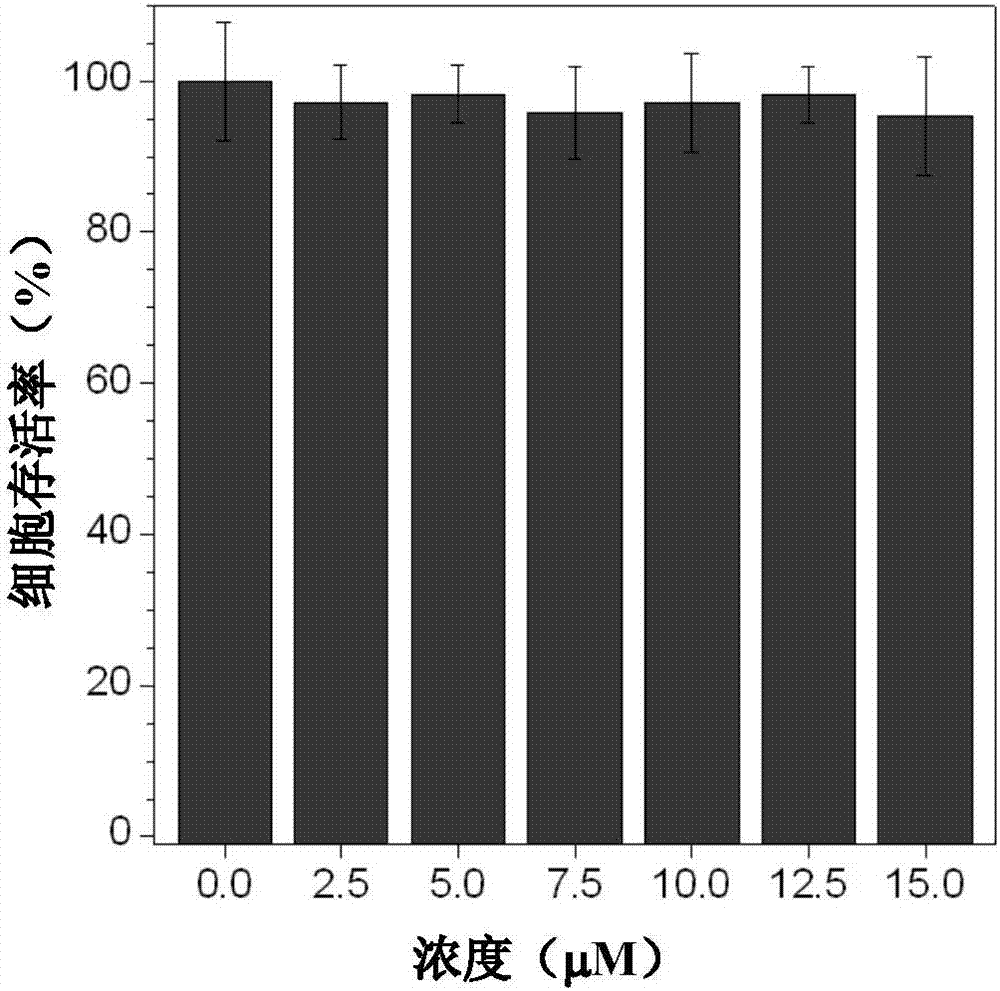

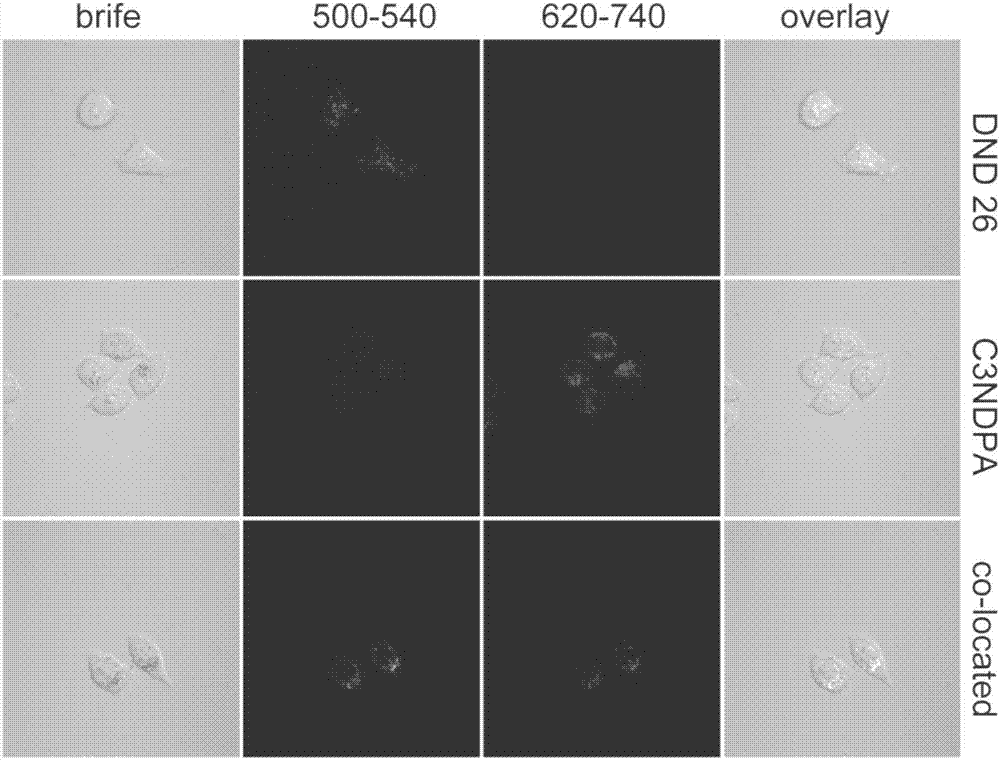

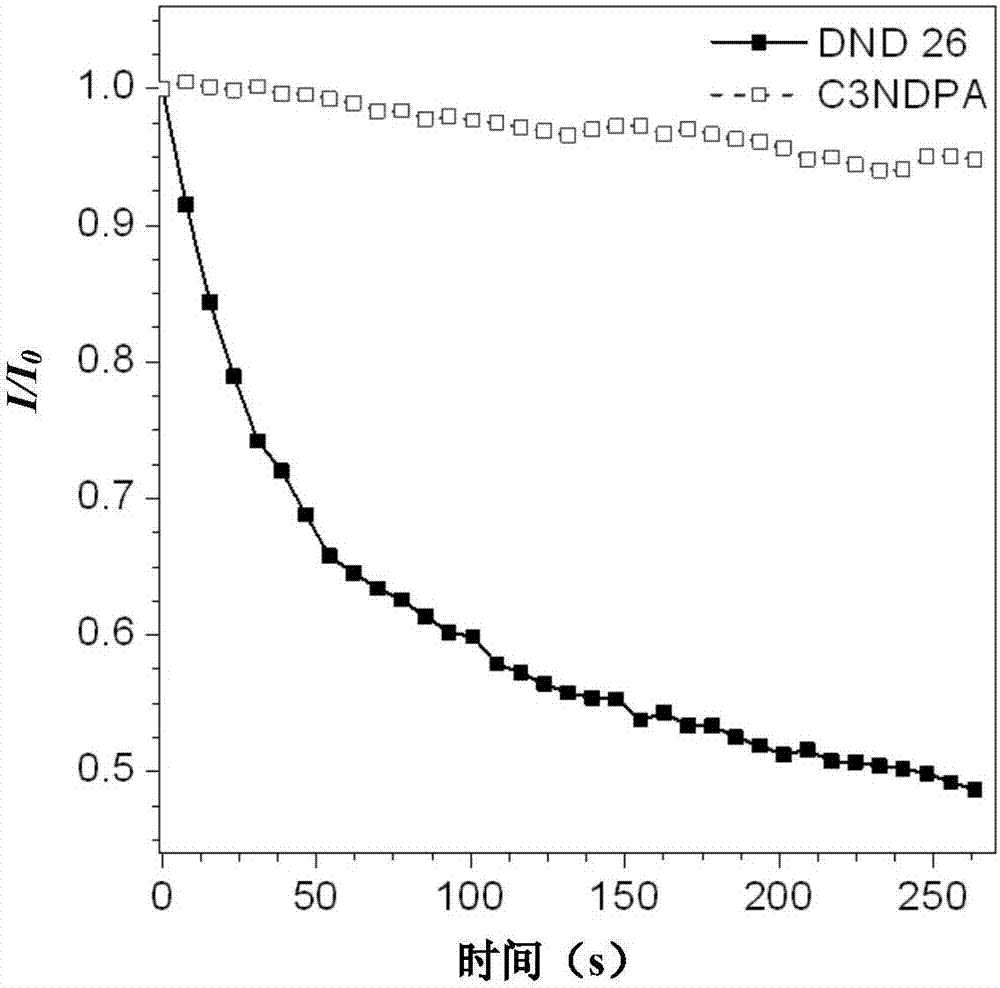

ActiveCN107200709AEasy to makeWide range of luminescence spectrumCarboxylic acid nitrile preparationOrganic compound preparationCytotoxicityRoom temperature

The invention belongs to the technical field of bio-analytical detection and discloses a fluorescent compound with aggregation-induced luminescence properties and application thereof to the cell fluorescence imaging field. The fluorescent compound with the aggregation-induced luminescence properties adopts one of structures shown as a formula 1 to a formula 4. The fluorescent compound with the aggregation-induced luminescence properties almost does not emit light or emit weak fluorescence in a solution state, can obtain the strong fluorescence emission aggregation-induced luminescence properties in solid state and aggregation states, has room temperature phosphorescent emission properties in a crystalline state, is simple to prepare and wide in luminous spectrum range, is applied to cell fluorescence imaging, biological analysis and other fields, has the characteristics of being sensitive and quick in cell dyeing, small in cytotoxicity, excellent in fluorescence signal anti-photobleaching properties and capable of in-situ real-time monitoring, and has practical application values.

Owner:SOUTH CHINA UNIV OF TECH +1

Stainless steel composite steel pipe and manufacturing method thereof

InactiveCN101566256AImprove corrosion resistanceCombined with good qualityRigid pipesSolution stateHeating temperature

The invention discloses a stainless steel composite steel tube and a manufacturing method thereof. The method overcomes the technical prejudices in the prior manufacture of brazing stainless steel composite steel tube, adopts a brass foil with lower price as a brazing material, and avoids the problems of environmental pollution, high cost, large energy consumption and the like in the prior art which uses a nickel-based brazing material coated layer; and a method for performing diffusion brazing by air-cooling a composite tube blank from bottom to top according to a temperature reducing gradient of between 100 and 200 DEG C per minute so as to solidify a brazing solder in sequence from bottom to top not only sufficiently fills the brazing material in the inner and outer tube gaps but also forms diffusion with a distance of a few microns with inner and outer layer materials, wherein an inner layer stainless steel tube and an outer layer carbon steel tube form good metallurgical bonding through a diffusion brazing layer; and simultaneously, the heating temperature, the soaking time and the cooling speed can make carbon steel in a normalized condition to obtain fine textures, and the strength matches well with the plasticity and the stainless steel which is in a solution state and has optimal corrosion resistance at the same time.

Owner:大连合生科技开发有限公司

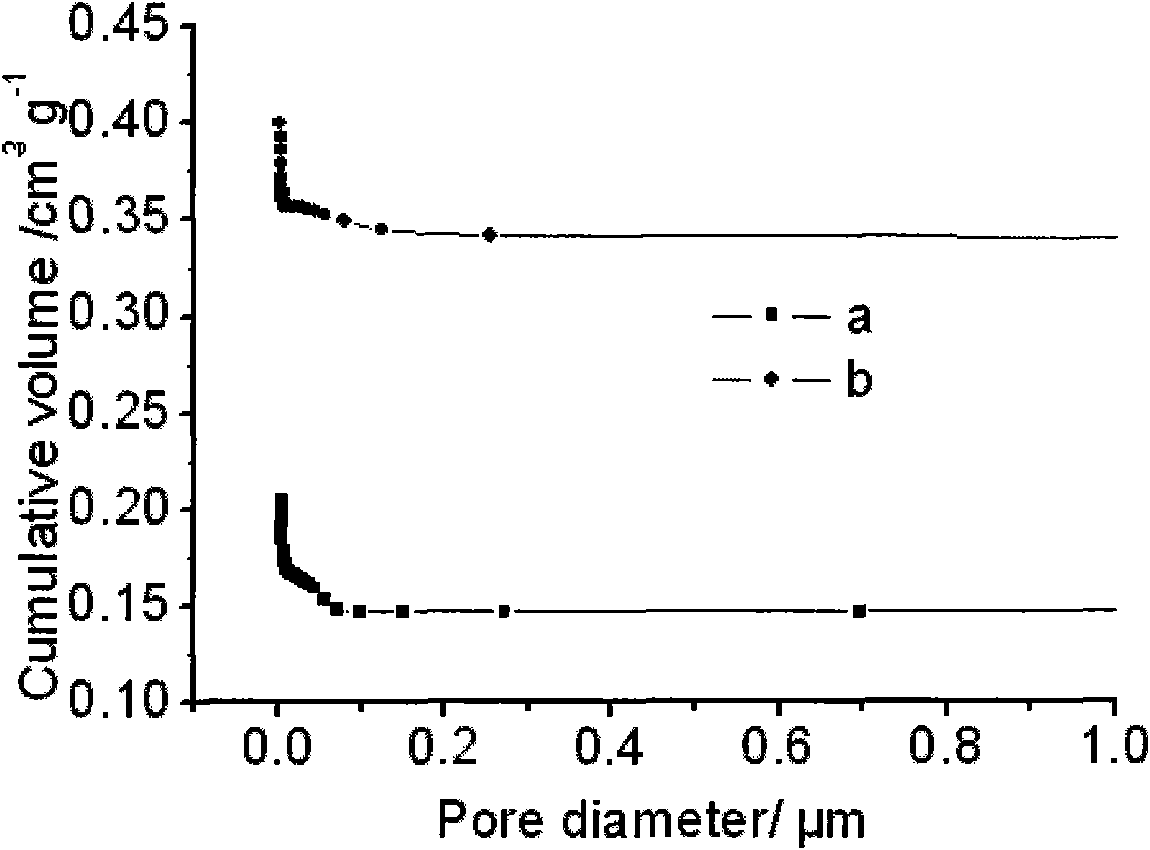

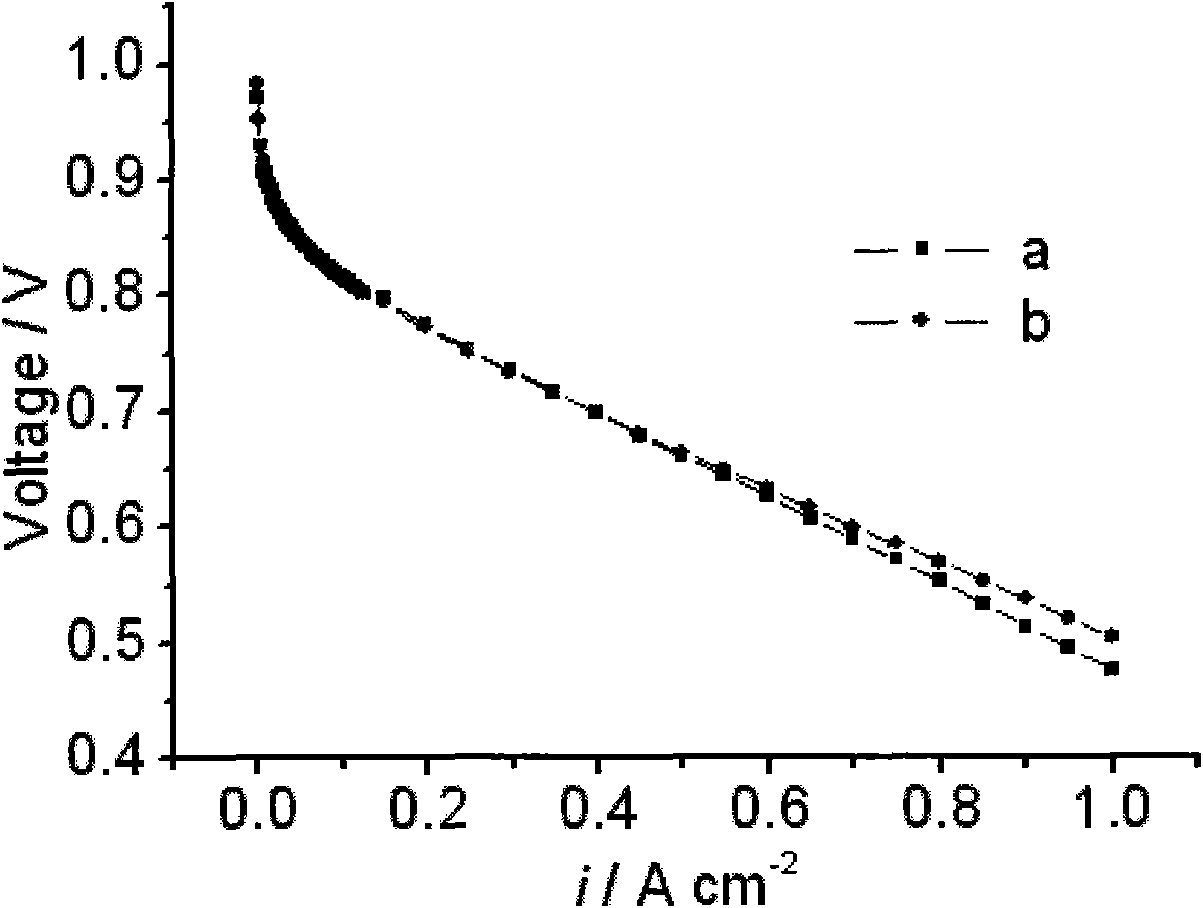

Catalyst sizing agent for preparing catalytic membrane electrode of fuel cell and preparation thereof

ActiveCN102255085ASimple methodIncrease profitCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPorosityElectrical conductor

The invention relates to a catalyst sizing agent for preparing a catalytic membrane electrode of a proton exchange membrane fuel cell. The catalyst sizing agent consists of an electric catalyst, proton conductor polymer distilled water and an organic solvent. The catalyst sizing agent is controlled in a colloid state, so that the pore structure of a prepared catalytic layer of a catalytic membrane electrode is improved, and the cell performance is enhanced. The conventional sizing agent for preparing the catalytic membrane electrode is in a solution state, so that the utilization ratio of a prepared electrode catalyst is not high, the porosity of a catalytic layer is very low, and the gas diffusion process is suppressed. In the invention, the composition and adding sequence of organic solvents in the sizing agent are changed. A preparation method of the catalyst sizing agent comprises the following steps of: conditioning a solution-state catalyst sizing agent with isopropanol, ethanol, ethanediol and the like; and dropwise adding the formed sizing agent into butyl acetate under ultrasonic oscillation condition to form a colloid-state catalyst sizing agent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

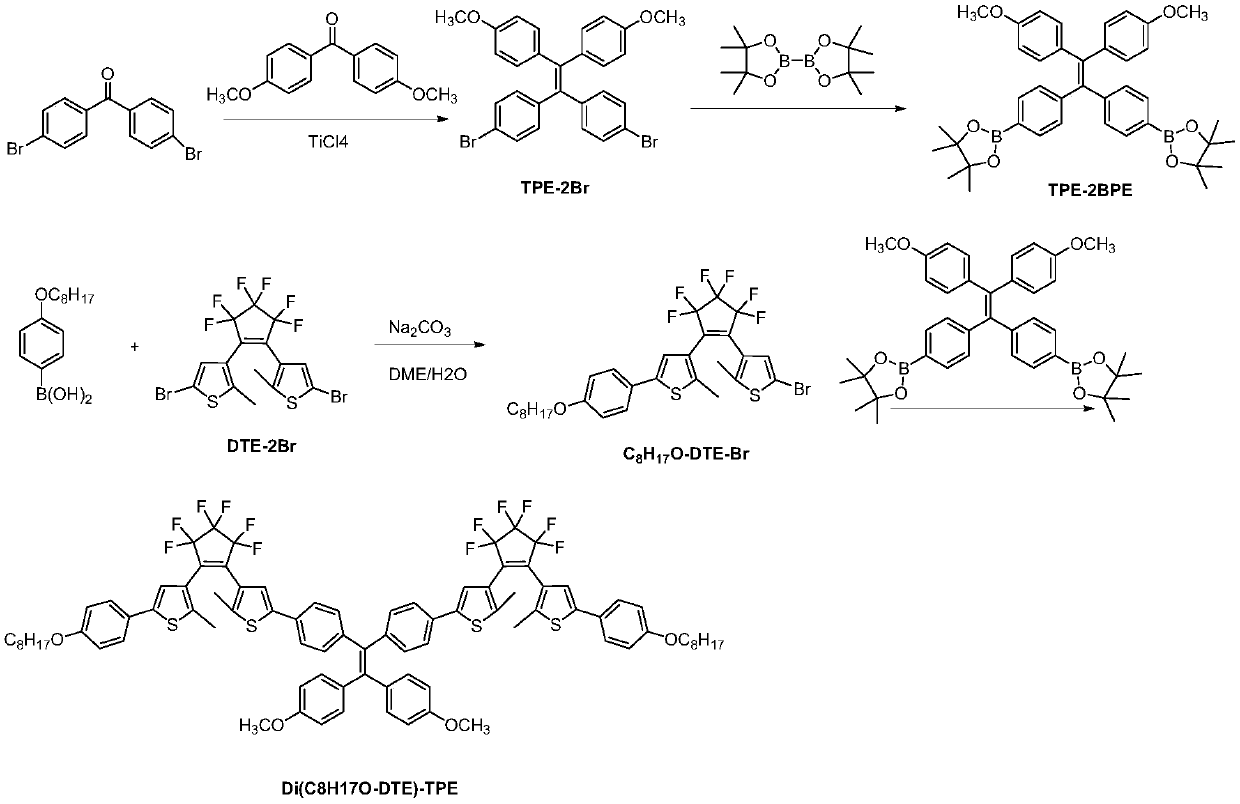

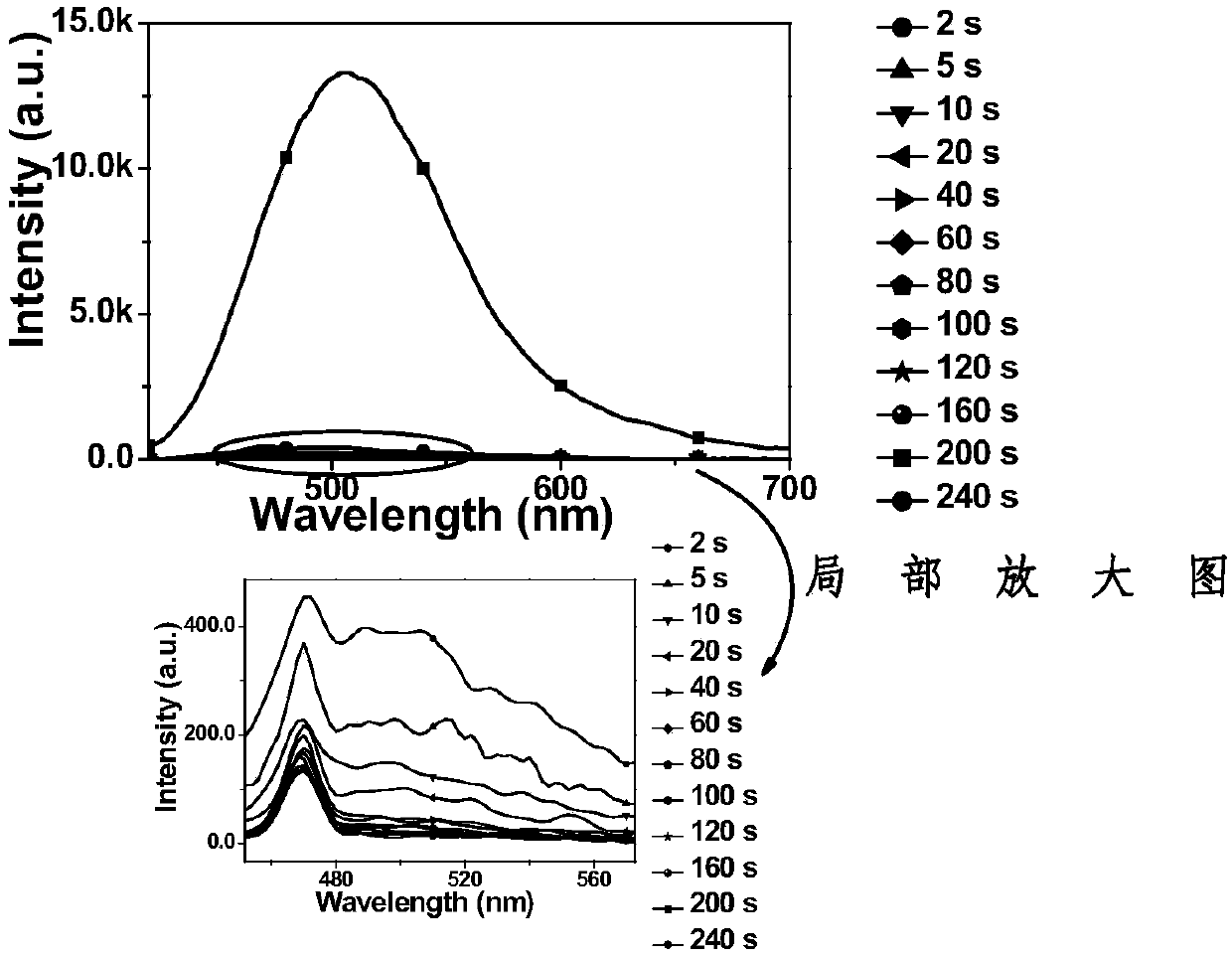

Diarylethene fluorescent molecular switch and preparation method and application thereof

ActiveCN107652279AEasy to synthesizeImprove thermal stabilityOrganic chemistryFluorescence/phosphorescenceAggregation-induced emissionMolecular switch

The invention discloses an aggregation-induced emission type diarylethene fluorescent molecular switch and a preparation method and application thereof. The aggregation-induced emission type diarylethene fluorescent molecular switch is characterized in that an AIE radical is introduced to gain solid or aggregation strong emission capacity; two diarylethene can be used for quickly quenching fluorescence of fluorescent radicals which aggregate in the surrounding under the irradiation of ultraviolet rays or visible light, thus achieving the purpose of high fluorescent switch ratio. According to the light control type AIE-effect fluorescent molecular switch, the limitation that traditional fluorescent chromophore leads to fluorescence quenching is broken; in addition, the fluorescent molecularswitch in solid and aggregation state has the advantages of being high in switch ratio and high in fluorescence quenching efficiency by being compared with the fluorescent molecular switch in solution state; the fluorescent molecular switch is applicable to information storage under solid state and photoelectric devices and has potential application in biosensing and fluorescence imaging.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method and application of super-molecular carbon dioxide adsorbent used in solid and liquid states

InactiveCN104437383AEasy to useEasy to storeOther chemical processesDispersed particle separationOrganic solventSorbent

The invention discloses a preparation method and application of a super-molecular carbon dioxide adsorbent used in solid and liquid states, and belongs to the technical fields of environmental chemistry and new materials. The method comprises the following steps: carrying out heating reaction on organic amine, a macrocyclic compound and a solvent according to a certain weight ratio; filtering insoluble substances or adding an organic solvent so as to enable sediments to be separated out; and washing solids, and drying in vacuum, so as to obtain a super-molecular complex of the organic amine and the macrocyclic compound. The super-molecular complex is used for adsorbing carbon dioxide in a solution state or a solid state; the carbon dioxide can be efficiently dissociated under the heating or acidifying condition; and the regeneration and the cyclic utilization of the adsorbent are achieved. The super-molecular carbon dioxide adsorbent disclosed by the invention is low in cost, simple in preparation flow, easy to recycle and regenerate, and long in circulating service life; the defects that the organic amine is easy to oxide and degrade, and strong in corrosivity are solved; and the super-molecular carbon dioxide adsorbent is relatively stable in property, and convenient to store and transport, can be used at high temperature, and is a carbon dioxide adsorbent with a wide application prospect.

Owner:DALIAN UNIV OF TECH

Pressure sensitive adhesive film for overlamination

InactiveUS20050064125A1Improve water resistanceImprove adhesionLayered productsEster polymer adhesivesEmulsionAlkoxy group

There is disclosed an overlaminating adhesive film comprising a transparent film, an adhesive layer and a release material successively laminated in this order, wherein said release material has a surface contacting with the adhesive layer, said surface having a centerline average surface roughness of 0.5 μm or lower; an adhesive forming said adhesive layer has a pH of 7.2 to 8.5 in a solution state before applied, and is an acrylic emulsion-type adhesive having an average particle size of 200 nm or smaller; and a monomer component used for production of said adhesive includes an alkoxysilane group-containing unsaturated monomer in which each alkoxy group has 1 to 4 carbon atoms, but includes no hydroxy-containing unsaturated monomer. The overlaminating adhesive film of the present invention exhibits a good water resistance and is free from deterioration in its transparency due to lifting or bubbles when laminated on an adherend, and further prevents an ink-jet printed surface over which the adhesive film is laminated, from suffering from ink bleeding even when the printed surface is allowed to stand under humidified conditions.

Owner:LINTEC CORP

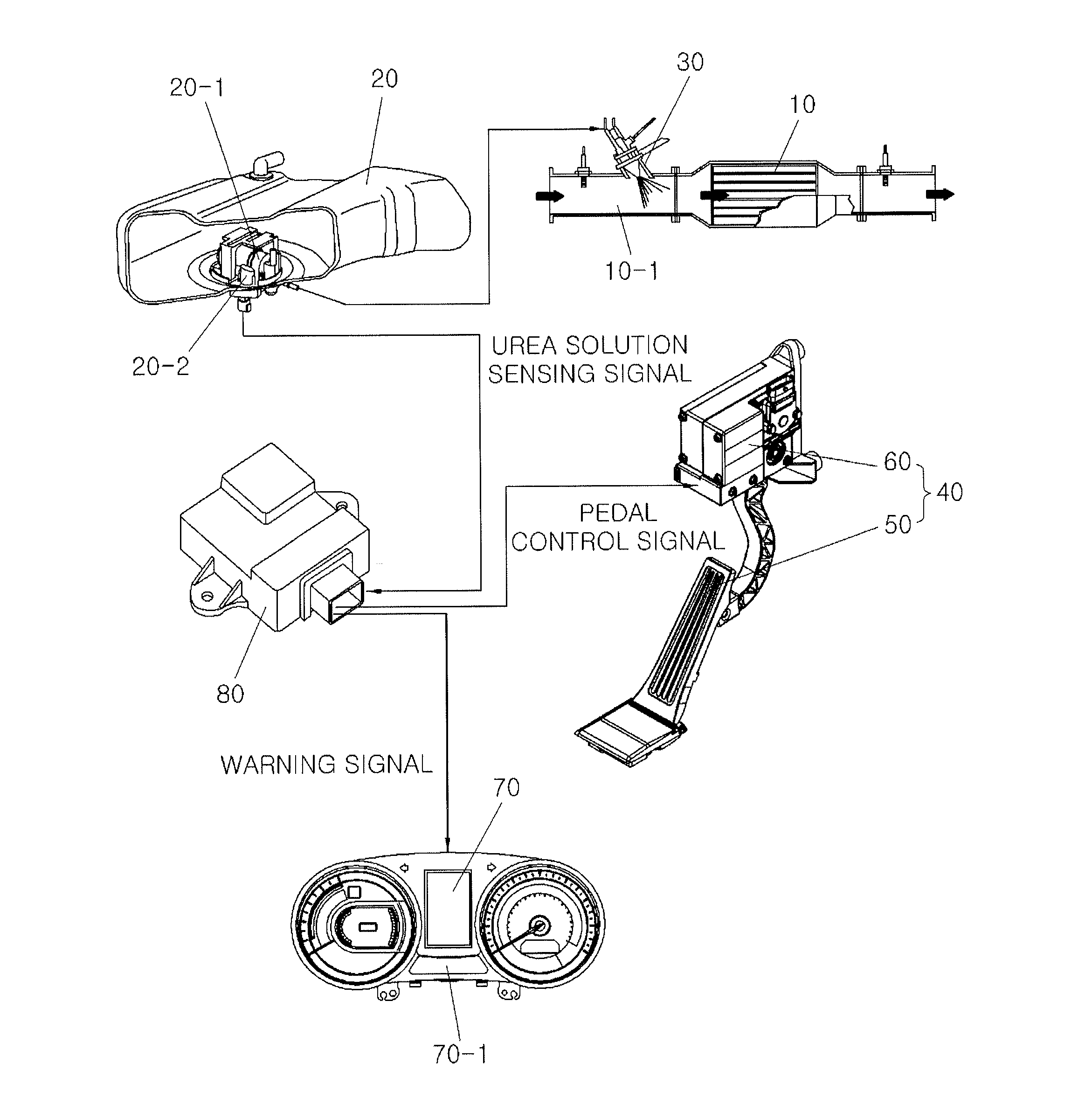

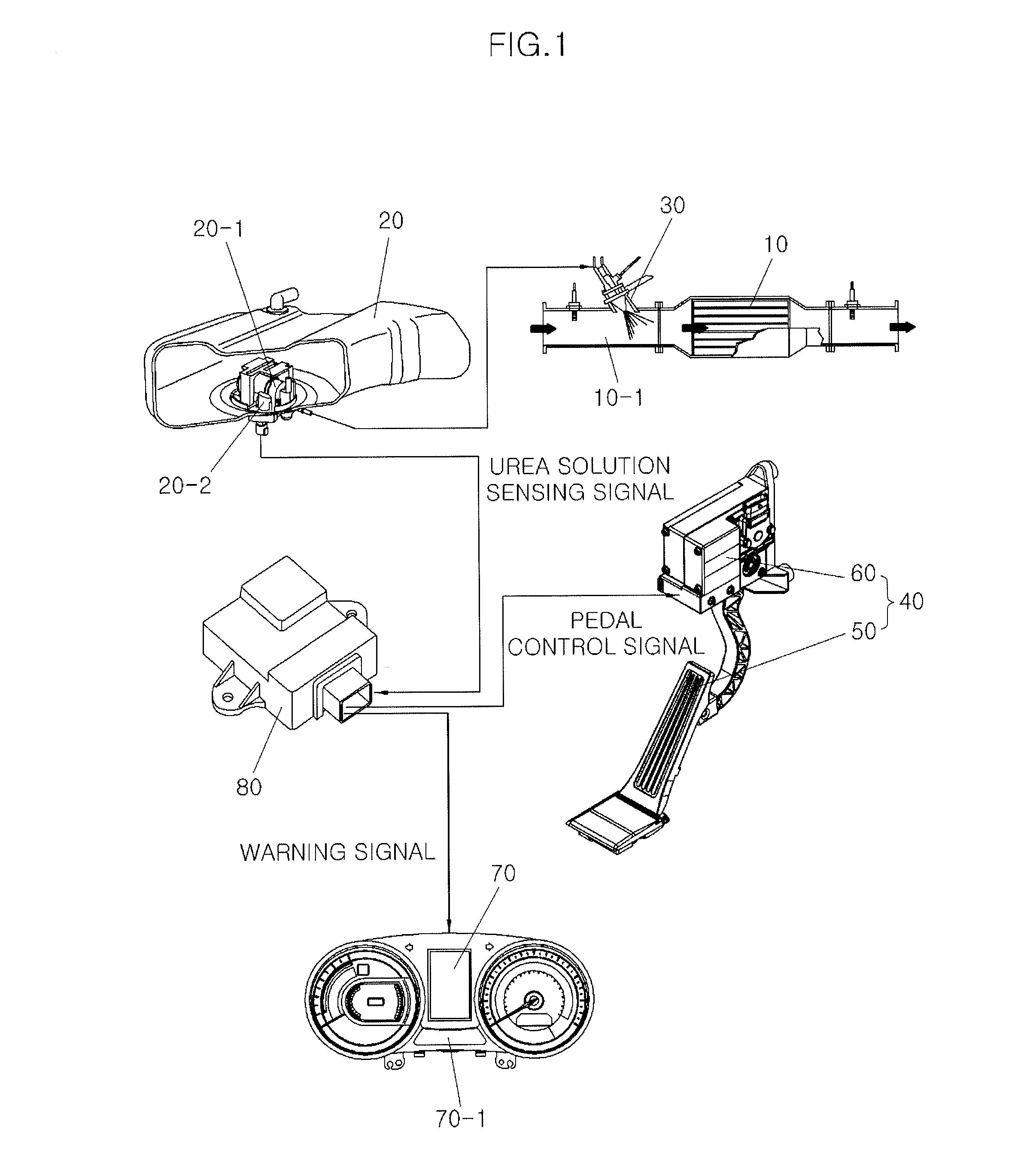

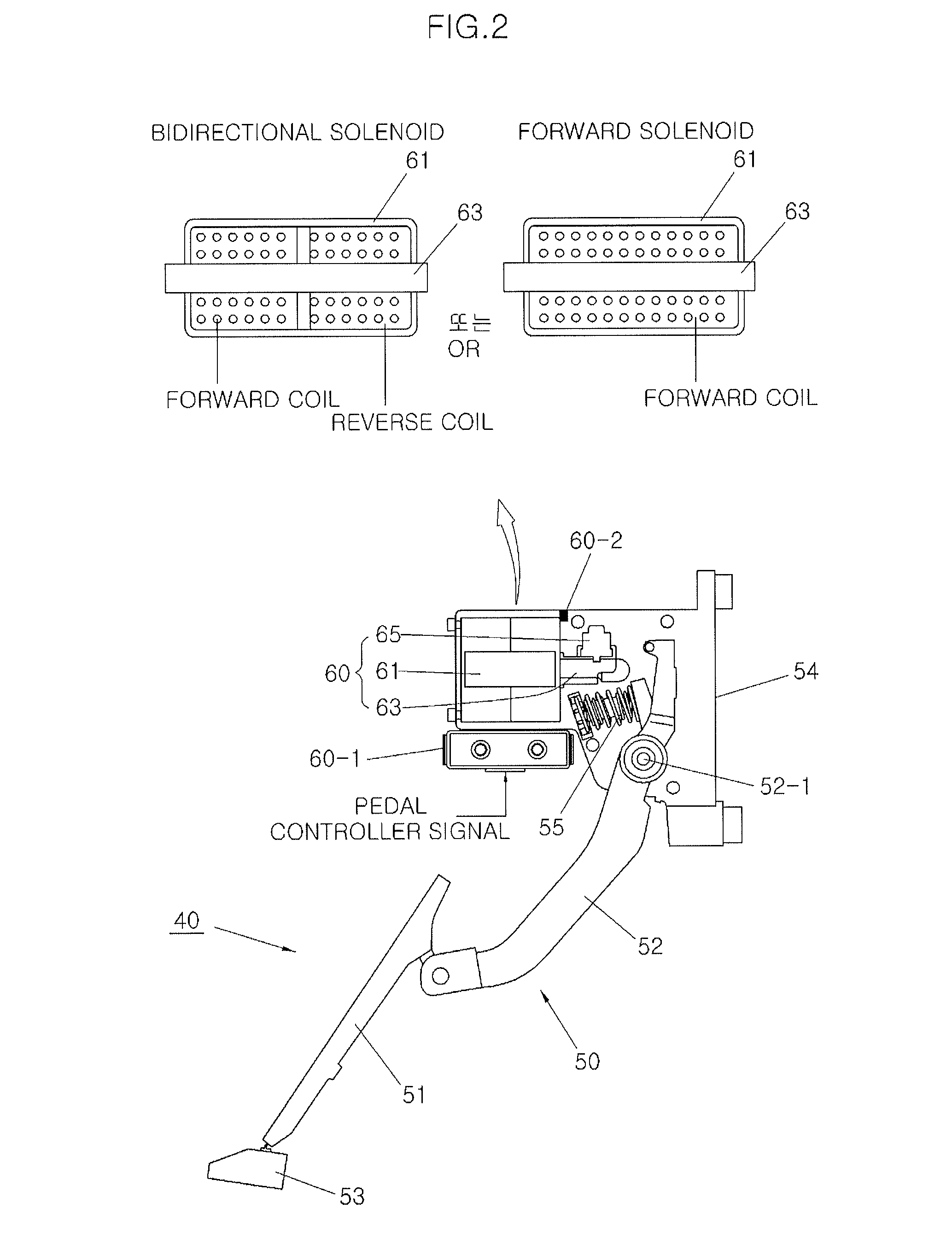

Urea solution after-treatment system, and method and controller for warning of urea solution state using touch

InactiveUS20150322835A1Improve fuel efficiencyReduce NOxVehicle testingInternal combustion piston enginesAfter treatmentSolution state

A urea solution after-treatment system may include a controller which receives urea solution detection information of a urea solution storage tank (20) storing a urea solution supplied to an SCR (Selective Catalytic Reduction) (10) for removal of NOx, the controller classifying the urea solution detection information into urea solution state information and then classifying the classified urea solution state information into output signals corresponding thereto, the controller outputting the classified output signals as pattern signals of urea solution shortage, urea solution exhaustion, and urea solution failure, and an accelerator pedal (40) which generates touch recognition patterns varying according to the pattern signals when the pattern signals are input, and transfers the touch recognition patterns using a touch felt by a driver's foot.

Owner:HYUNDAI MOTOR CO LTD

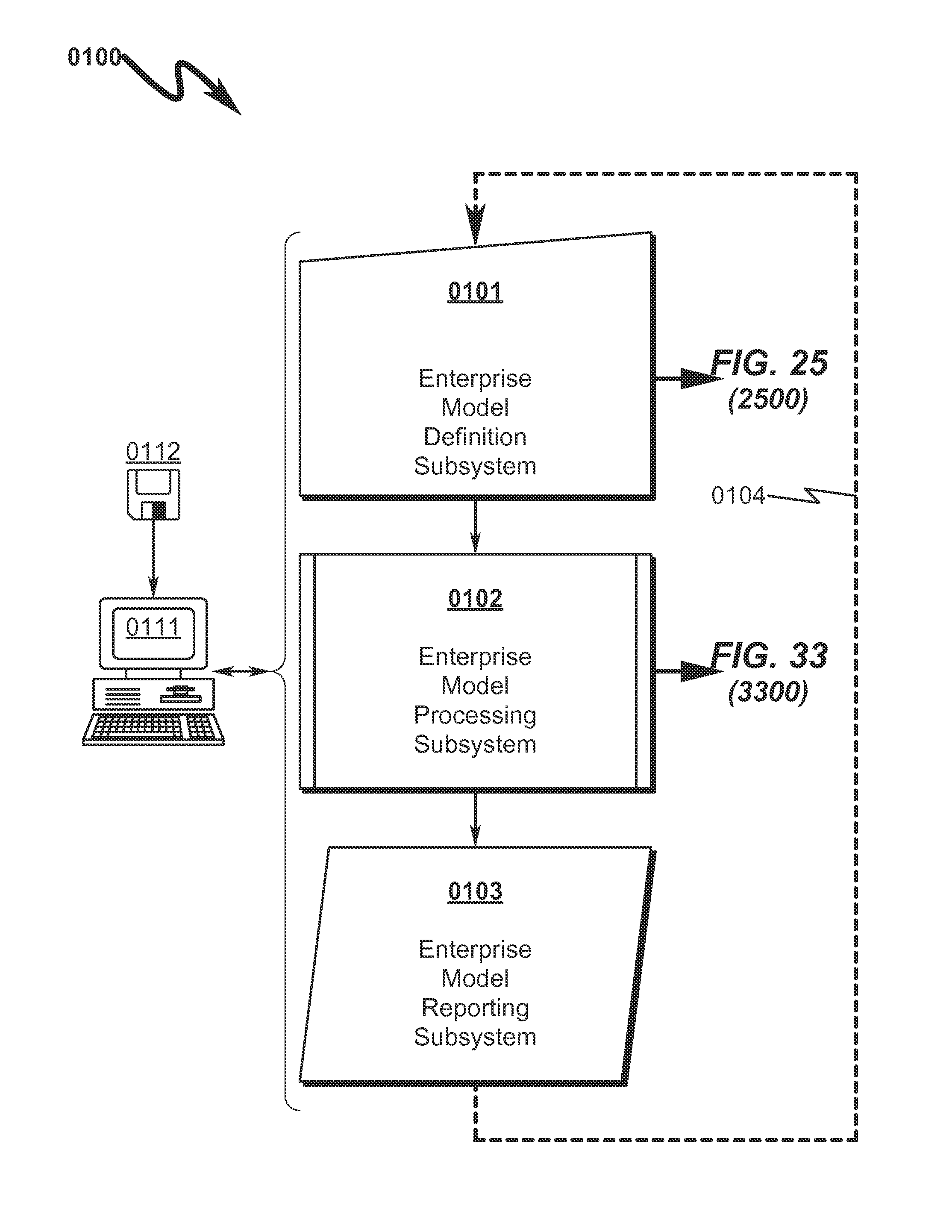

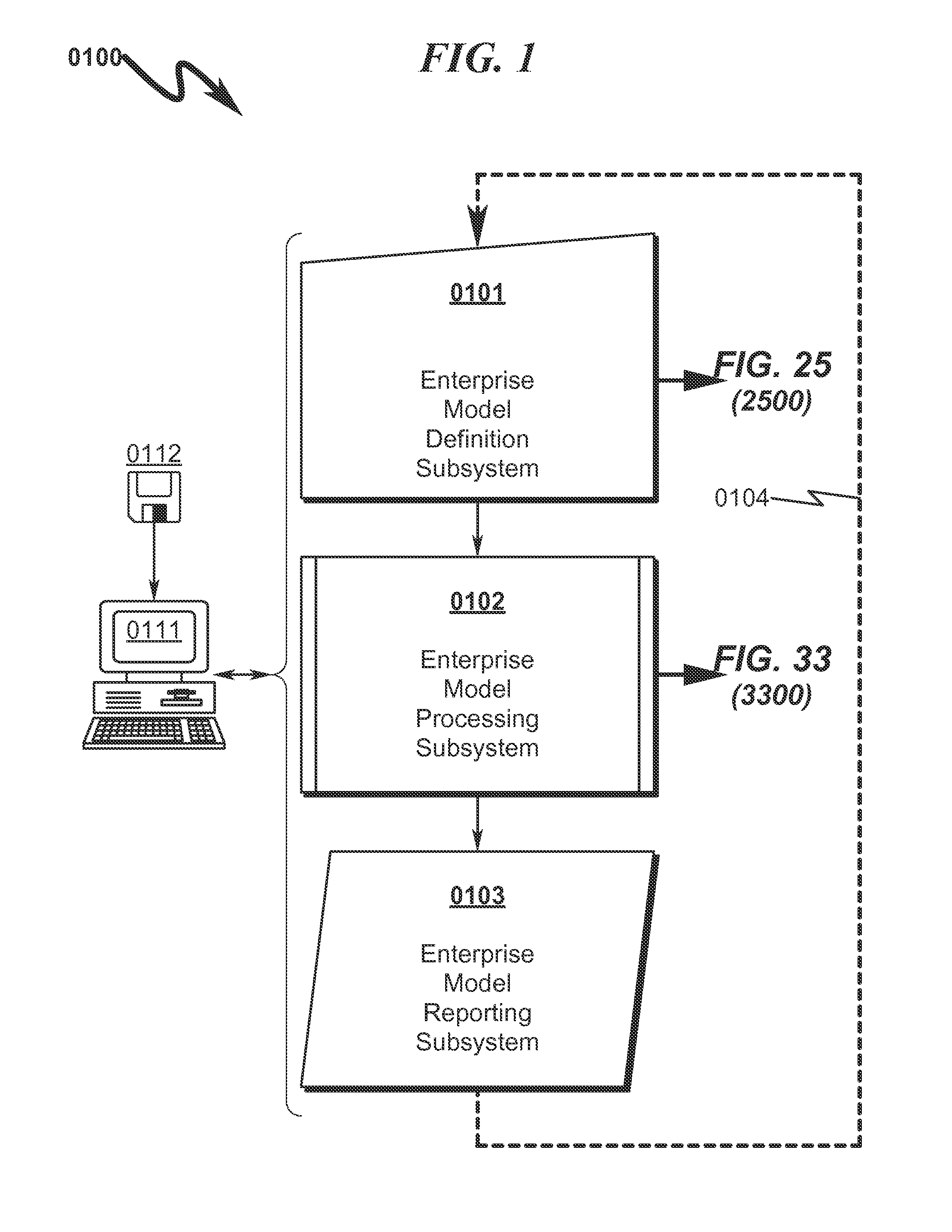

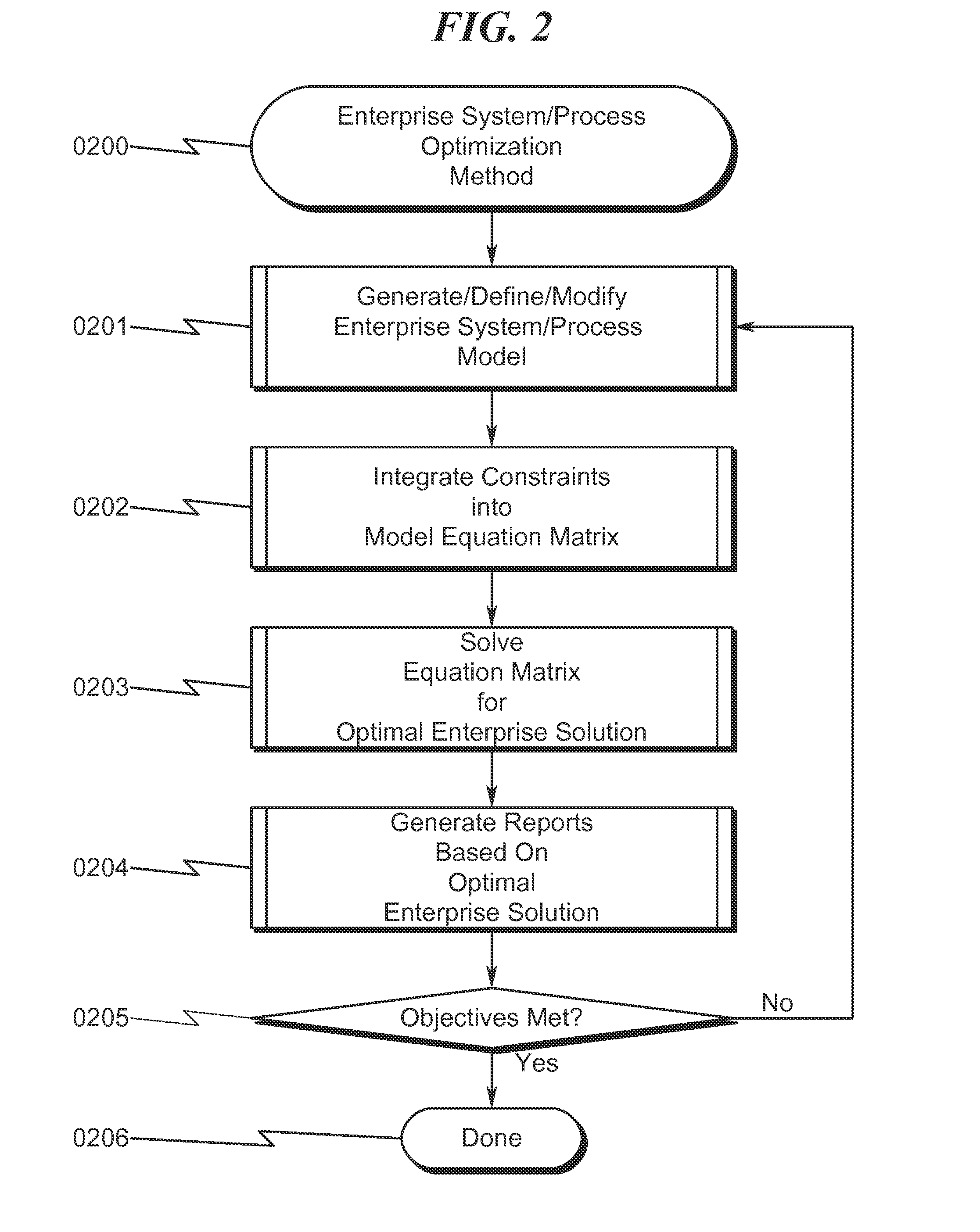

Enterprise System/Process Modeling System and Method

An enterprise system / process modeling (ESPO) system and method that permits efficient representation of enterprise systems / processes (ESP) and calculation of global solutions to models associated with these ESPs is disclosed. The system / method incorporates an enterprise system / process modeling definition subsystem (ESPD) in which an interconnected processes, resources, constraints, and objectives may be defined to describe a global enterprise system / process model (ESPO). This ESPO describes the enterprise to be modeled and the various boundaries within which enterprise modeling is to take place. This ESPO is translated and transformed into an intermediate indexed format by an enterprise global modeling subsystem (EGMS) for use in generating the coefficients of an equation matrix. The equation matrix is solved for a solution state space conforming to desired enterprise objectives and the results are presented for review by an enterprise model reporting subsystem (FSPR).

Owner:RIVER LOGIC

Method for storing resin solution, and method for producing prepreg and laminate

ActiveUS20120018072A1Improve heat resistanceSmall thermal expansionLaminating printed circuit boardsWood working apparatusSolventSolution state

This invention relates to a method for storing a naphthol aralkyl type cyanate ester resin solution, which is difficult to precipitate due to long term storage in a solution state, and particularly relates to a method for storing a naphthol aralkyl type cyanate ester resin solution (AB), which comprises: preparing (i) a naphthol aralkyl type cyanate ester resin solution (AB) comprising a naphthol aralkyl type cyanate ester resin (A), a maleimide compound (B) and a solvent, (ii) a naphthol aralkyl type cyanate ester resin solution (AB) comprising a prepolymer of a naphthol aralkyl type cyanate ester resin (A), a maleimide compound (B) and a solvent, or (iii) a naphthol aralkyl type cyanate ester resin solution (AB) comprising a prepolymer of a naphthol aralkyl type cyanate ester resin (A) and a maleimide compound (B), and a solvent, and; storing the resin solution (AB).

Owner:MITSUBISHI GAS CHEM CO INC

Compound medicine of ginkgo leaf extract and dipyridamole and preparing method thereof

InactiveCN1454596AReduce lossesAdvanced preparation technologyOrganic active ingredientsBlood disorderFiberDipyridamole

The invention is a manufacturing method for vein medicament of gingkgo leaves extraction materials and di-pyridine compound drug. It is based on that the stability of gingkgo flavone in low thickness aqueous solution is higher than in high thickness aqueous solution, the gingkgo leaves extraction materials and di-pyridine is dissolved at the same time, after the two are frozen and dried into even solid, the stability of gingko flavone is higher than the solid which is only frozen and dried from itself, and produces the infusion agent and powder pin agent. The manufacturing process doesn't use active carbon, but uses middle hole fiber film filtering new technology to wipe off impurities, enhances thep quality of the product. The method is simple, convenient, and good curative effect.

Owner:张哲峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com