Patents

Literature

1561 results about "Oxygen barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

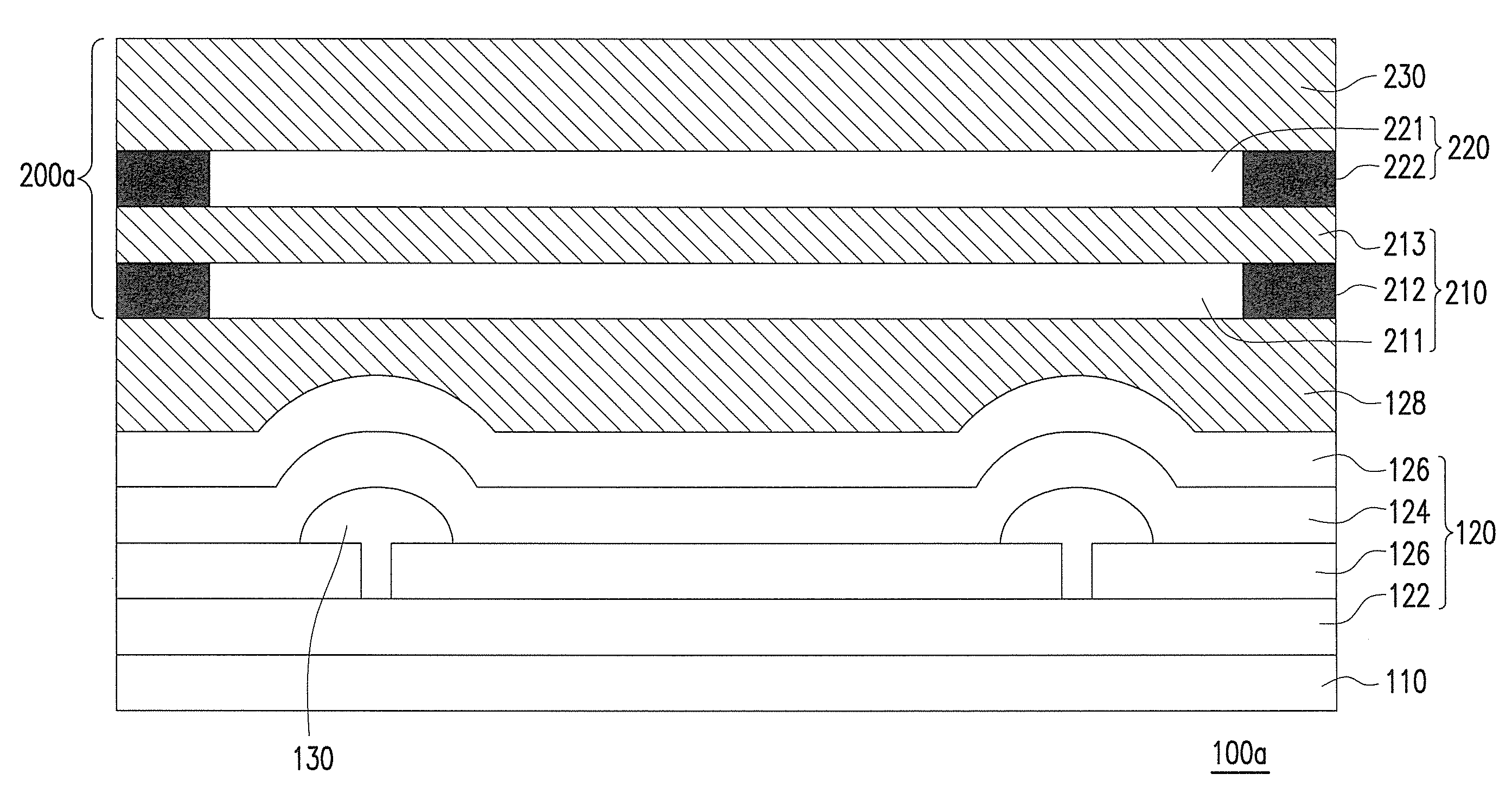

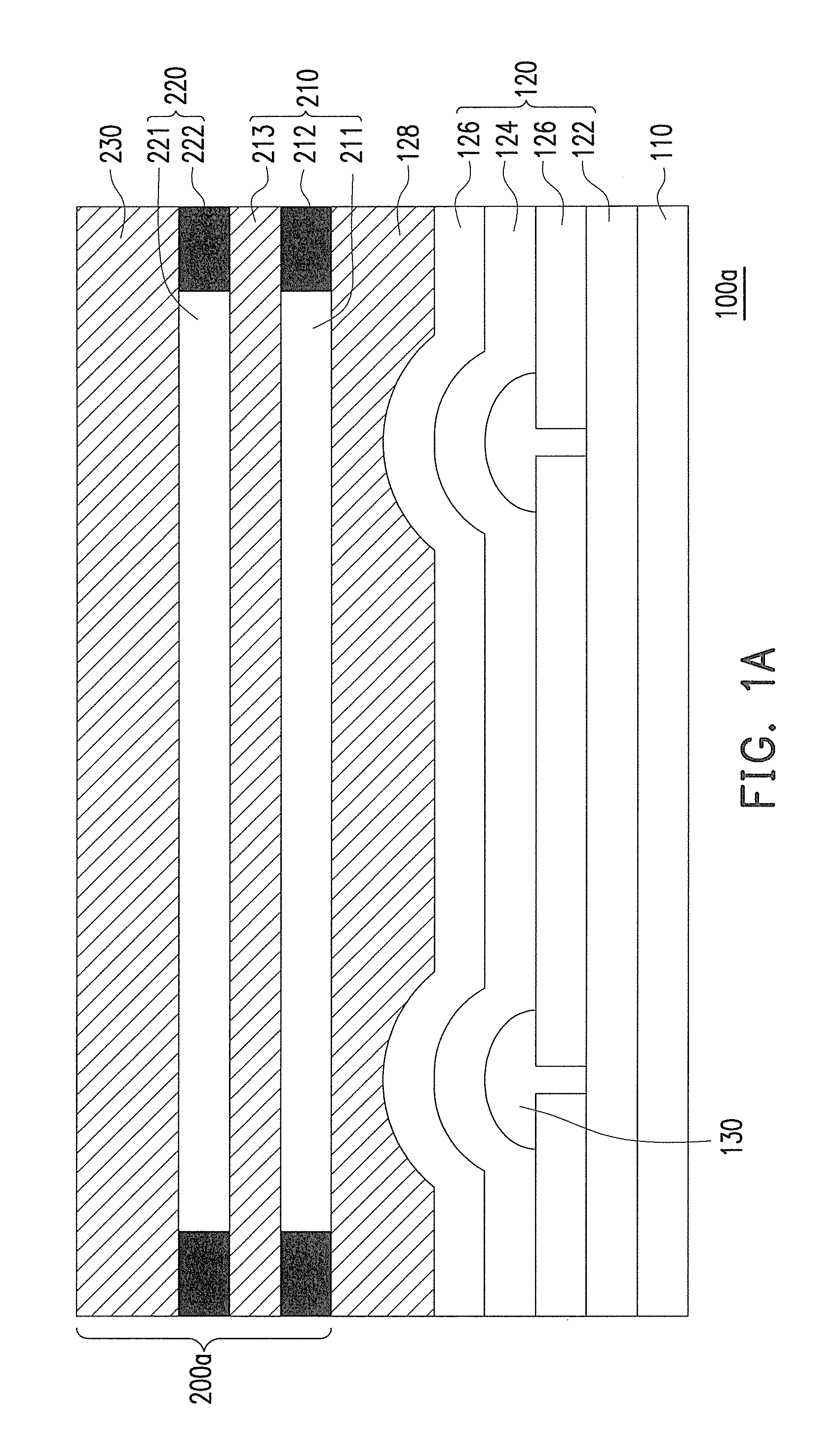

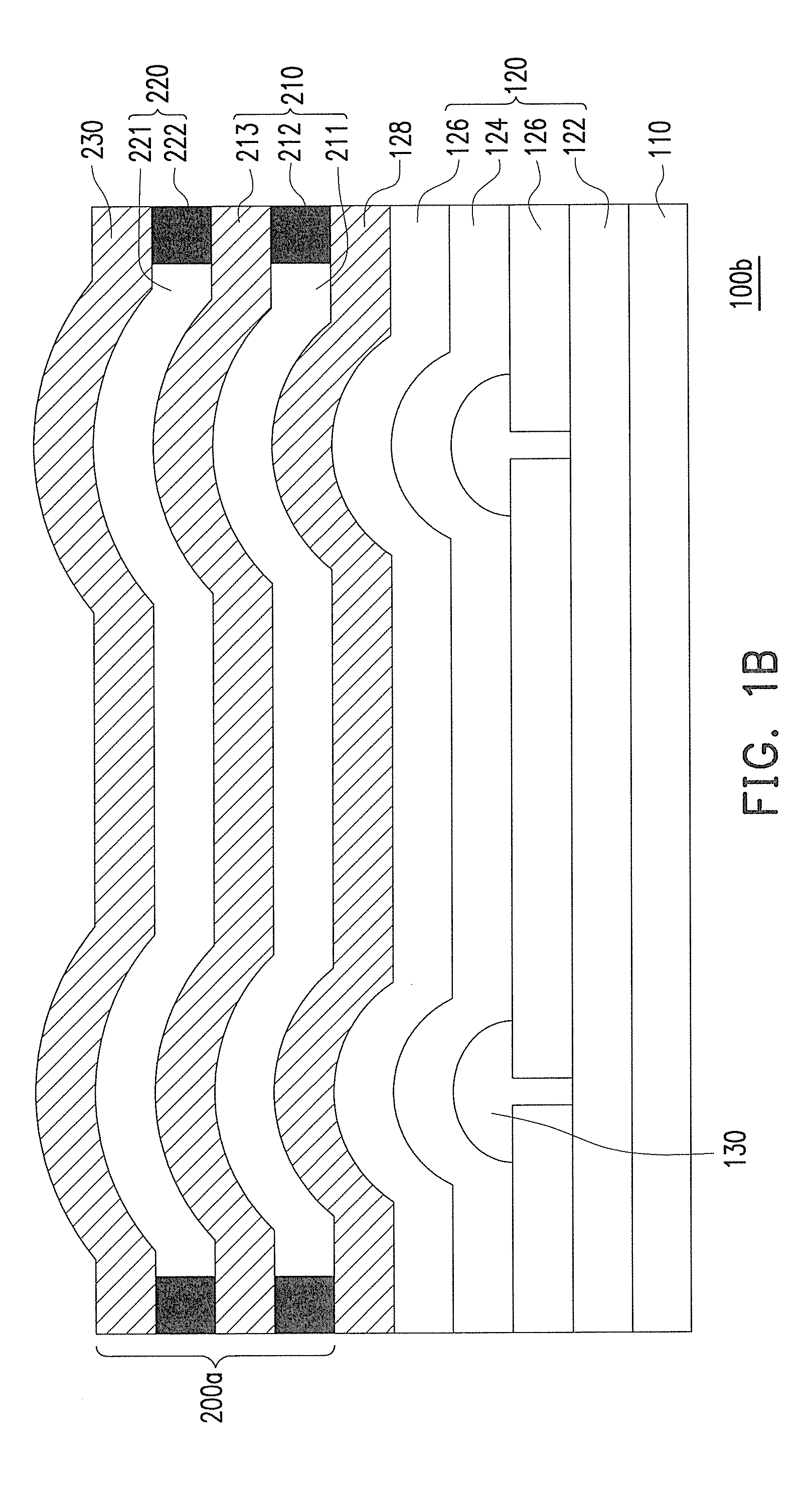

Touch-sensing display apparatus and fabricating method thereof

ActiveUS20100265206A1Static indicating devicesSolid-state devicesTouch SensesElectromagnetic interference

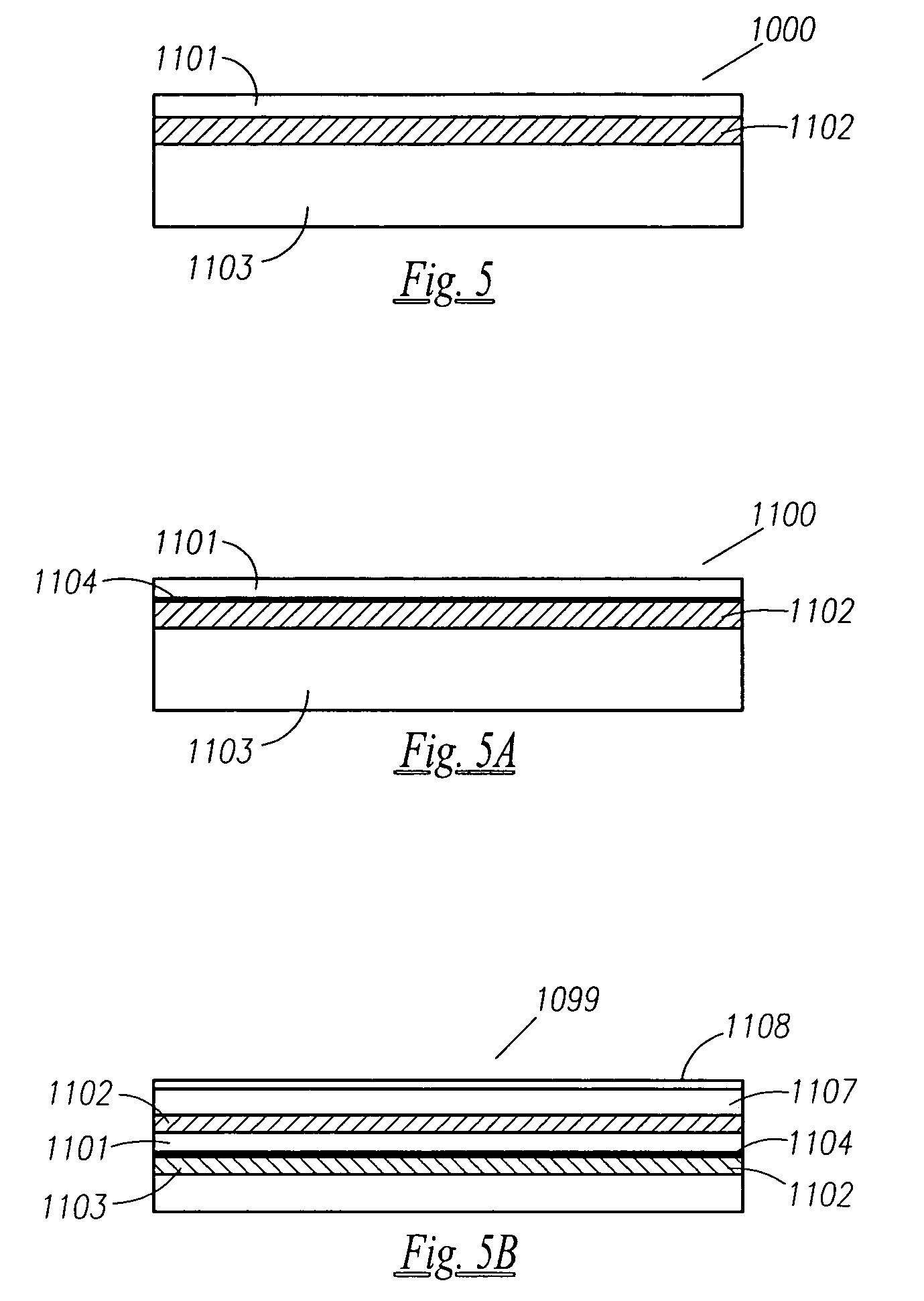

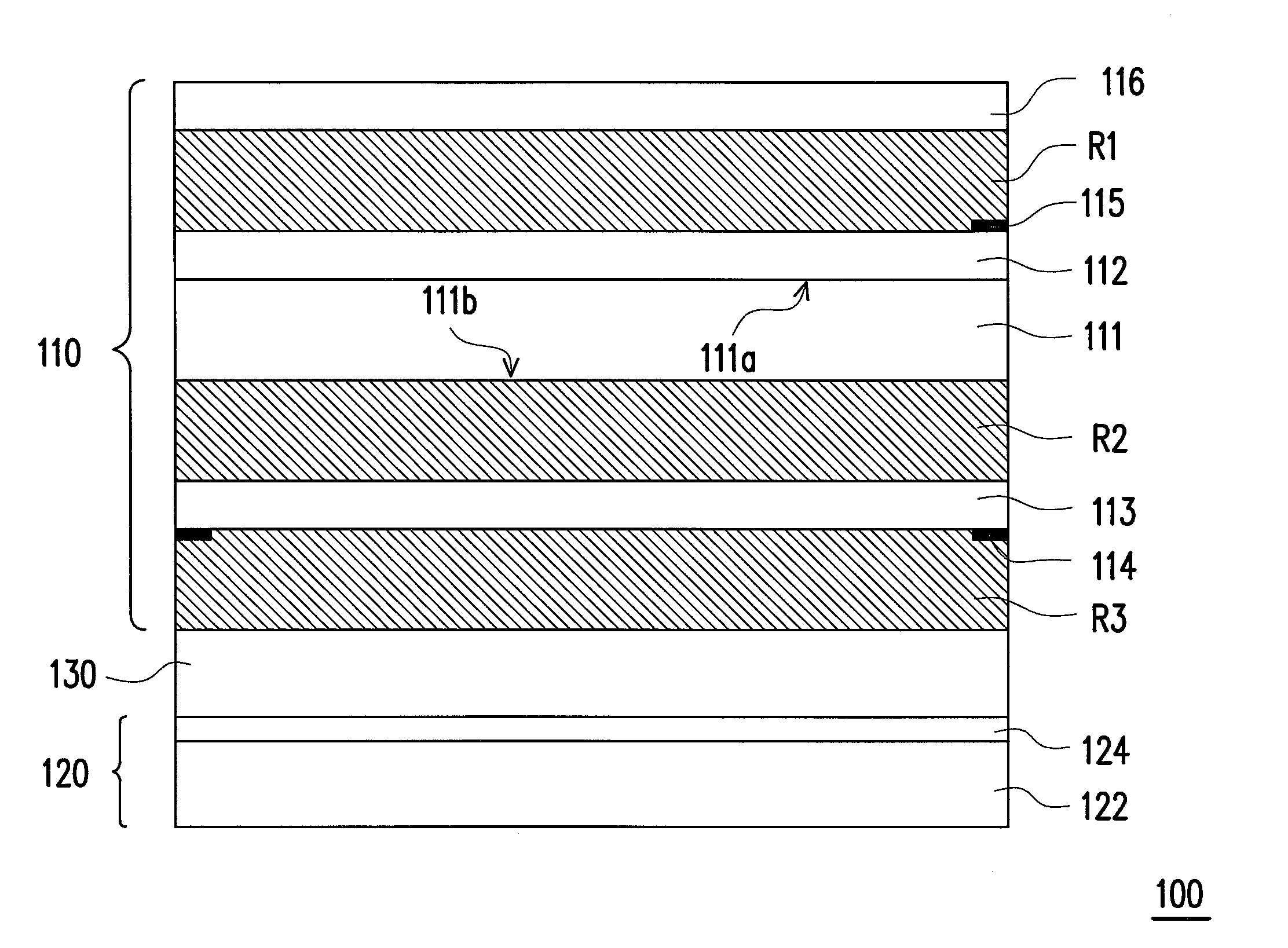

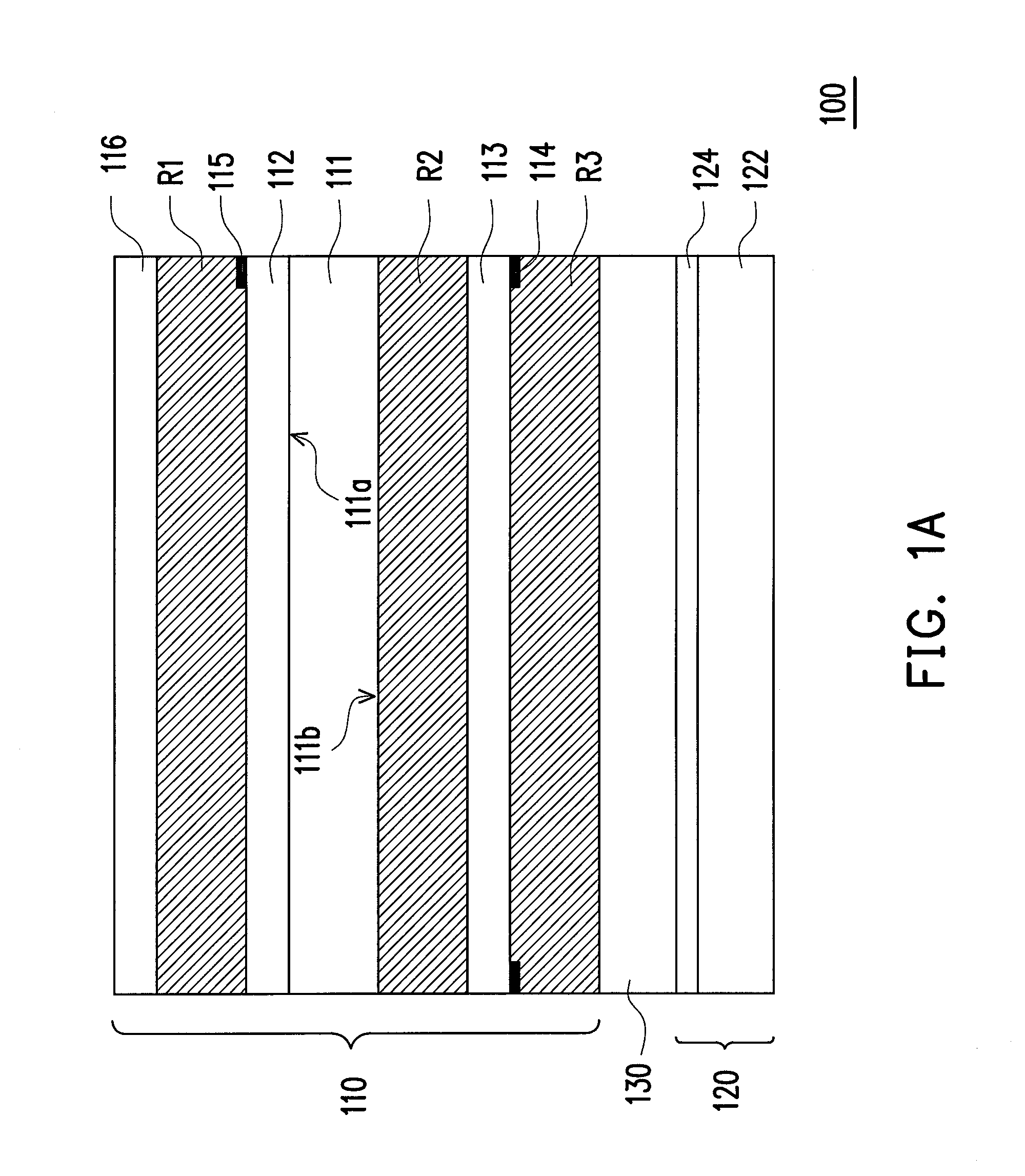

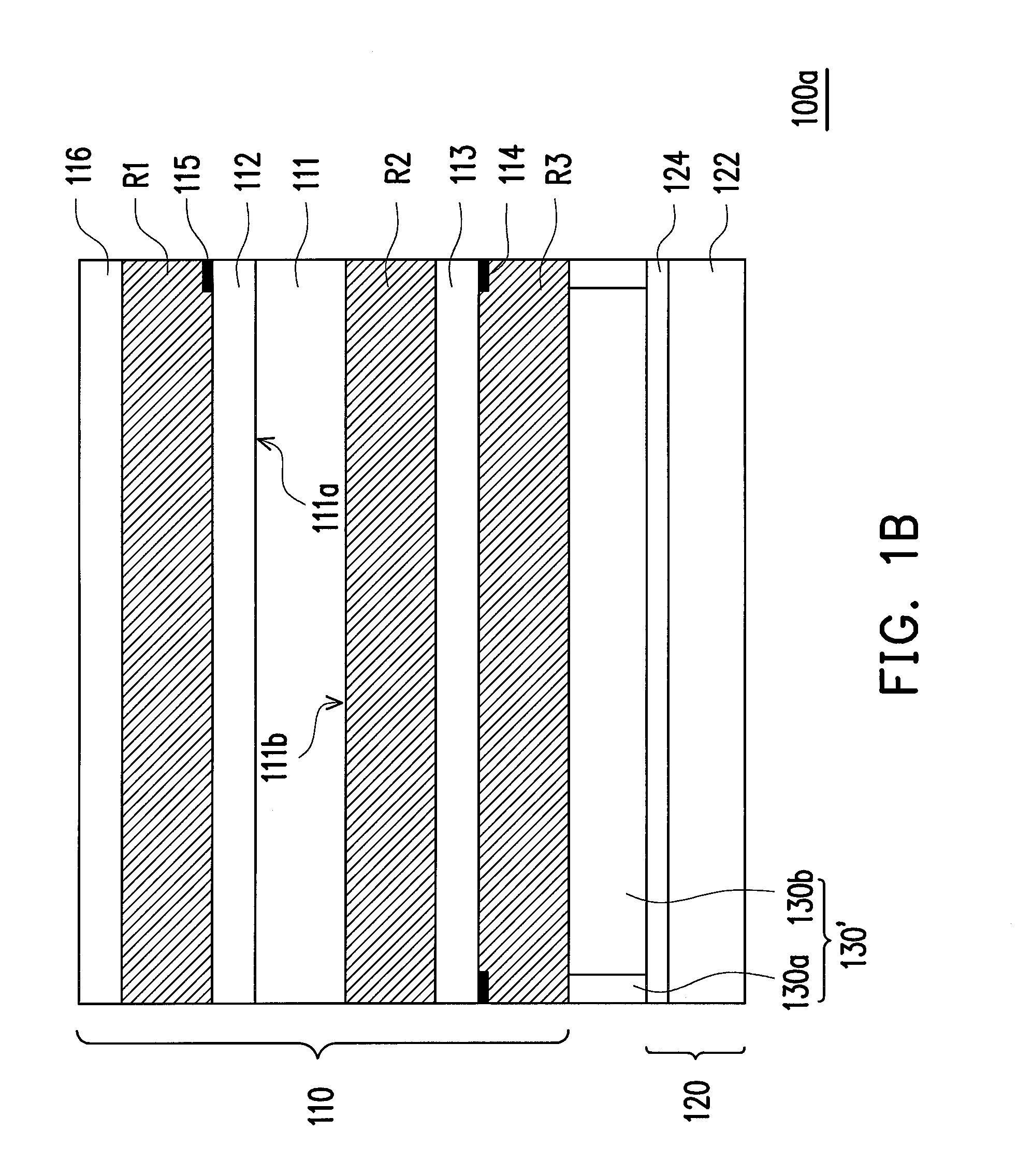

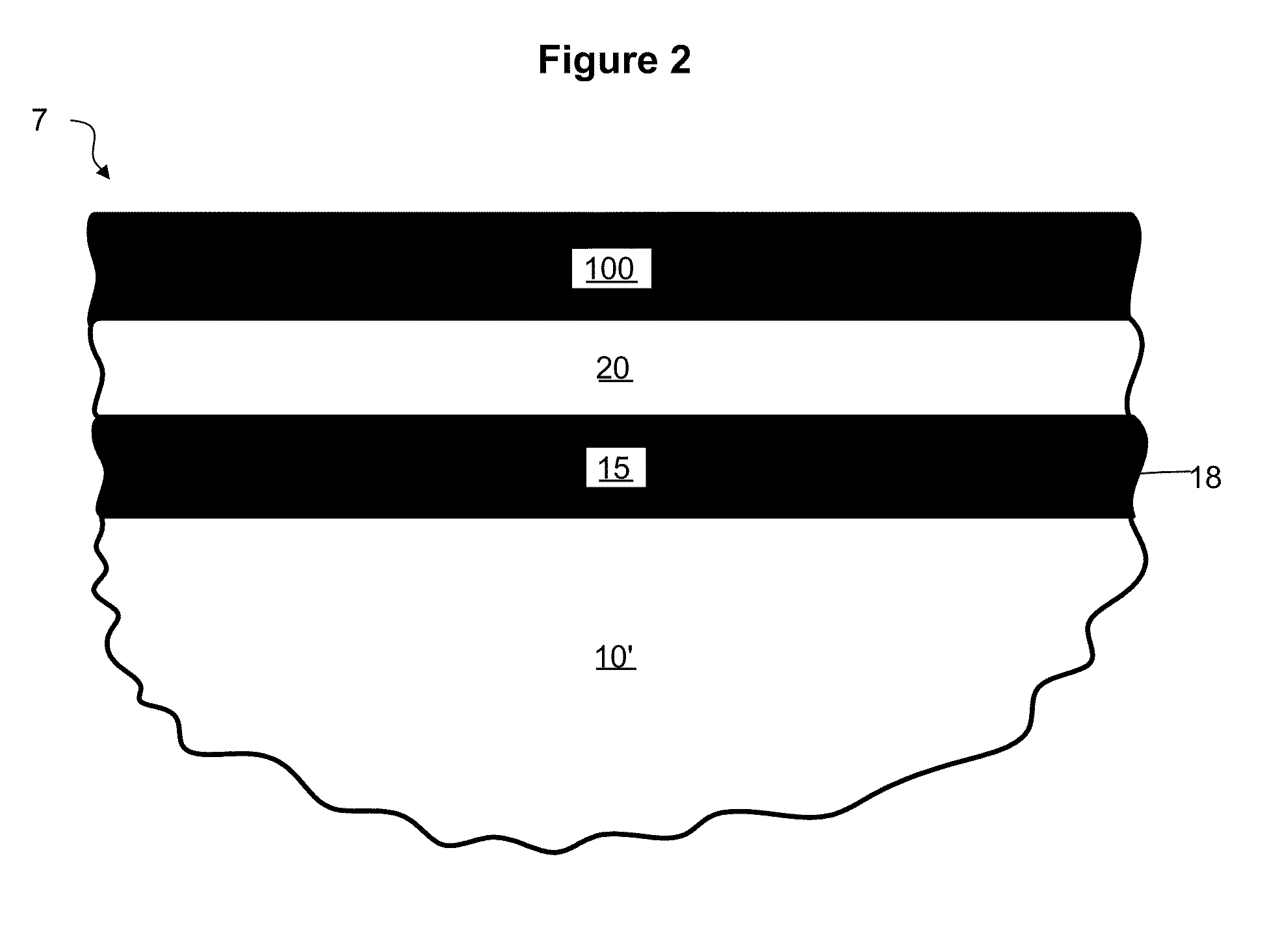

A touch-sensing display apparatus and a fabricating method thereof are provided. The touch-sensing display apparatus includes a substrate, an organic light emitting diode (OLED) display layer, and a touch structure. The OLED display layer is between the substrate and the touch structure apparatus and directly contacts with the touch structure. The touch structure includes a first water / oxygen barrier layer, an electromagnetic interference (EMI) shielding layer, a sensing circuit layer, and a second water / oxygen barrier layer. The first water / oxygen barrier layer is located on the OLED display layer. The EMI shielding layer is located on the first water / oxygen barrier layer. The sensing circuit layer is located on the EMI shielding layer. The second water / oxygen barrier layer is located on the sensing circuit layer.

Owner:IND TECH RES INST

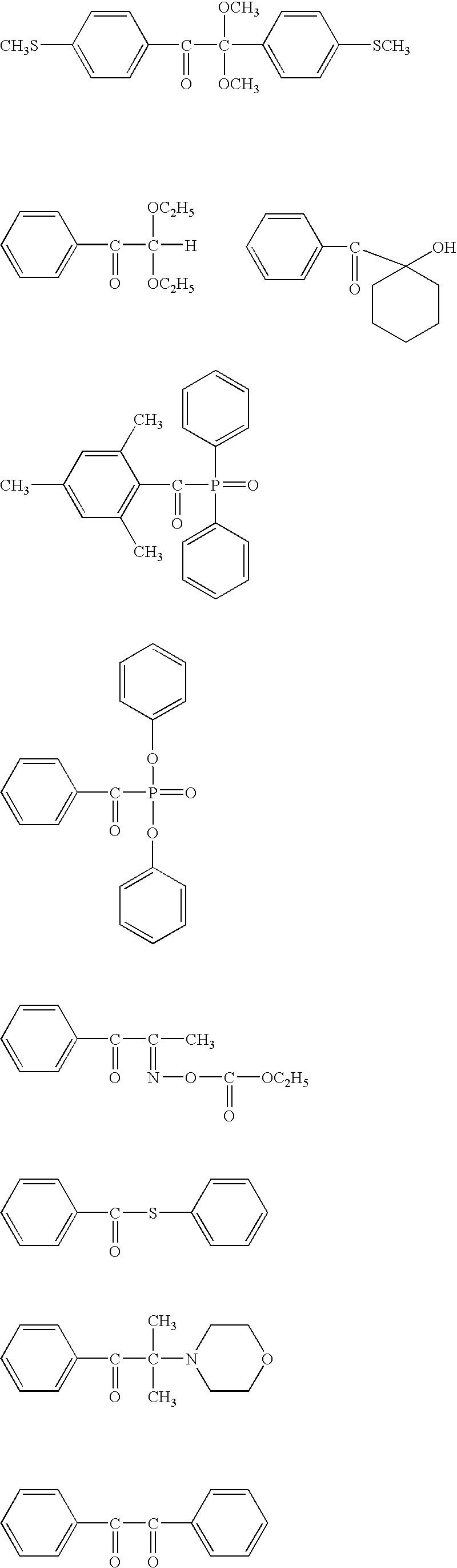

Methods for eyeglass lens curing using ultraviolet light

InactiveUS6022498AControl generationControl releaseOther chemical processesOptical articlesUV curingRadiation pulse

Method and apparatus for making [and coating] a plastic lens is provided. [Oxygen barrier containing photoinitiator is used to cure incompletely cured lens portions. Radiation pulses are used to control lens curing rate. Lens is postcured while in a mold cavity using a conductive heat source.] More particularly, the invention relates to applying alternating periods of ultraviolet light to lens forming composition. Such composition is cured while controlling the rate of heat generation and / or dissipation via manipulation of the duration of the radiation or the cooling in the curing chamber. The ultraviolet light is directed toward the lens forming composition which is preferably disposed in a mold cavity formed by two mold members. The ultraviolet light may be directed in pulses or continuously.

Owner:Q2100

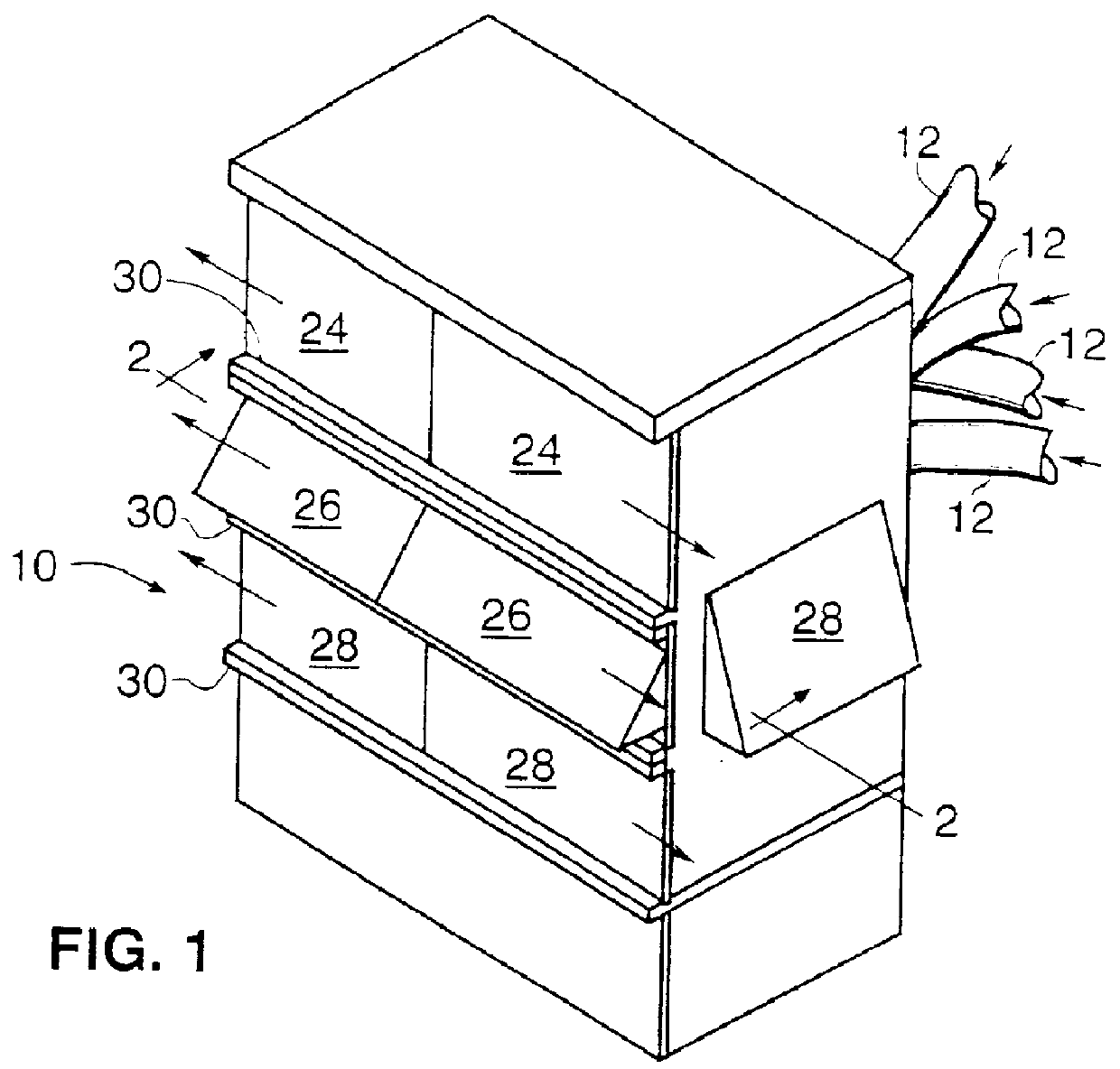

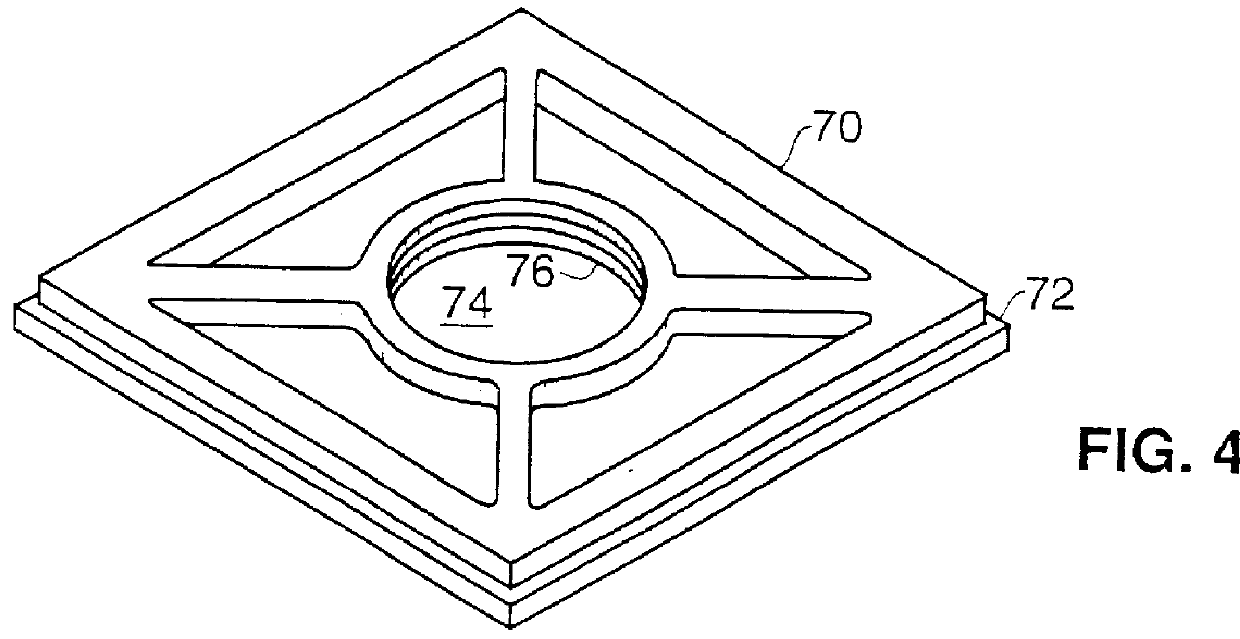

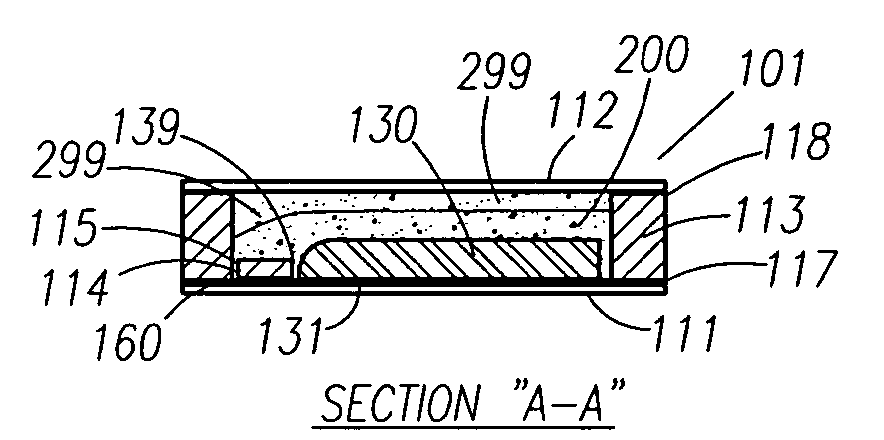

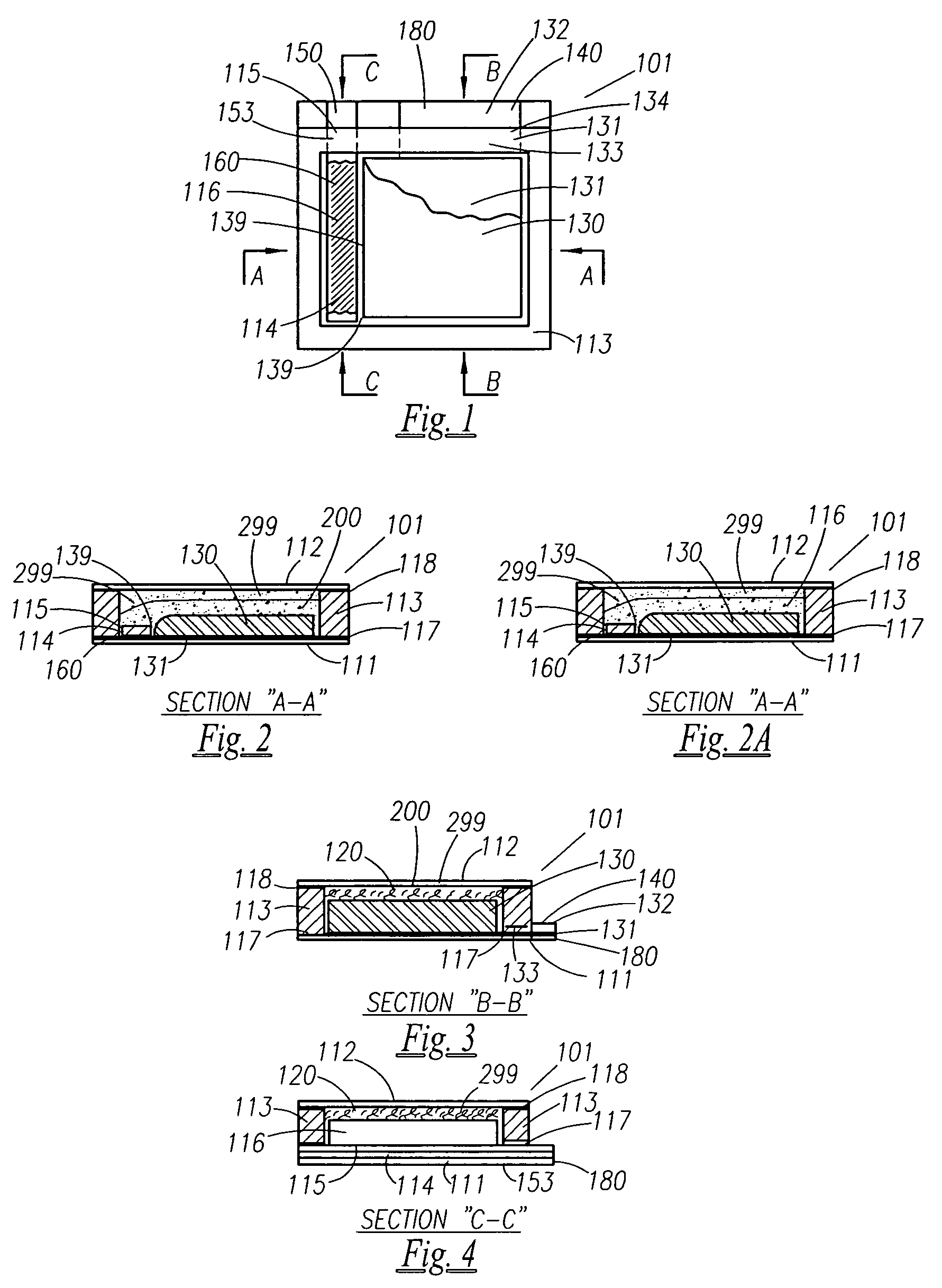

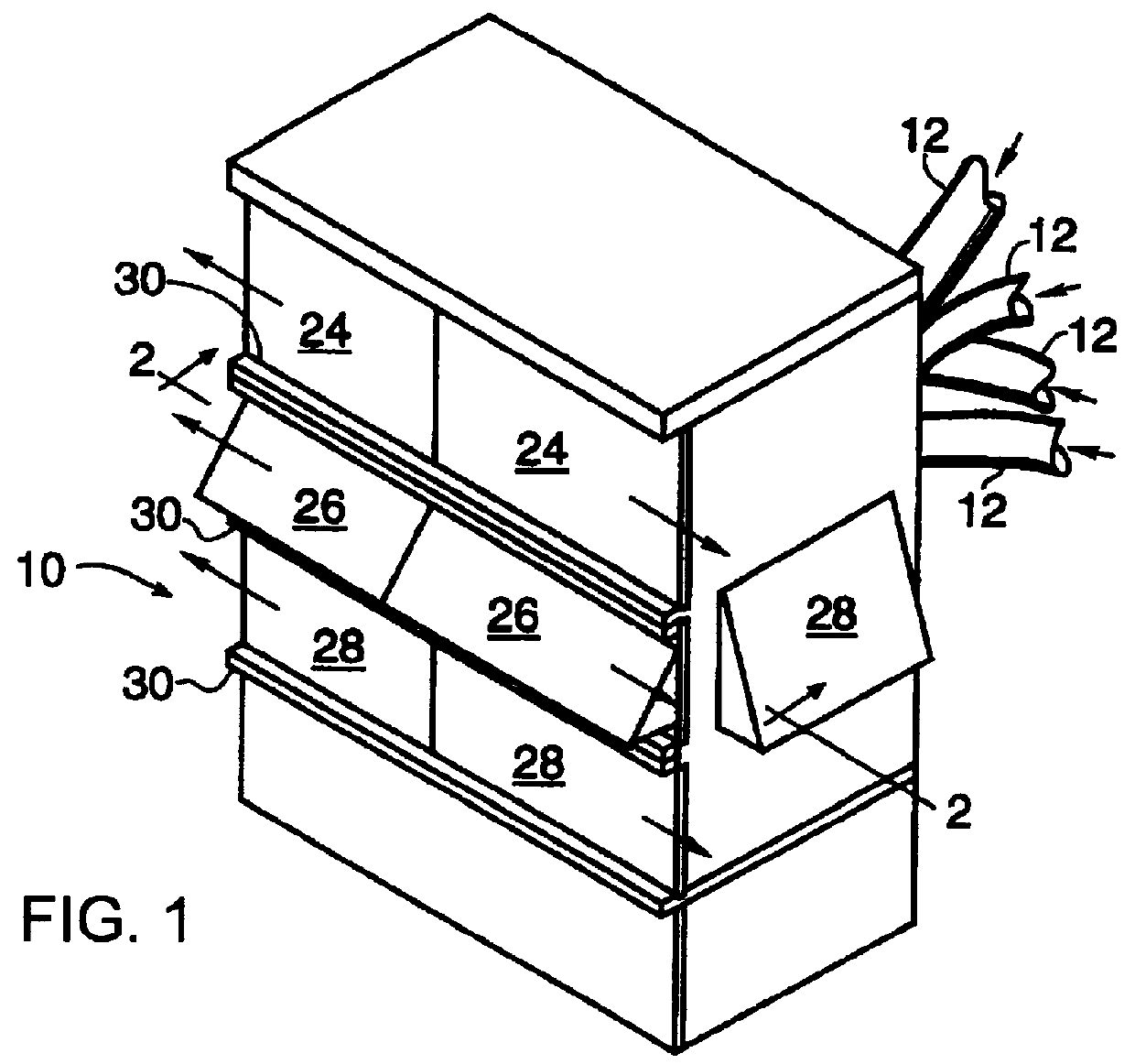

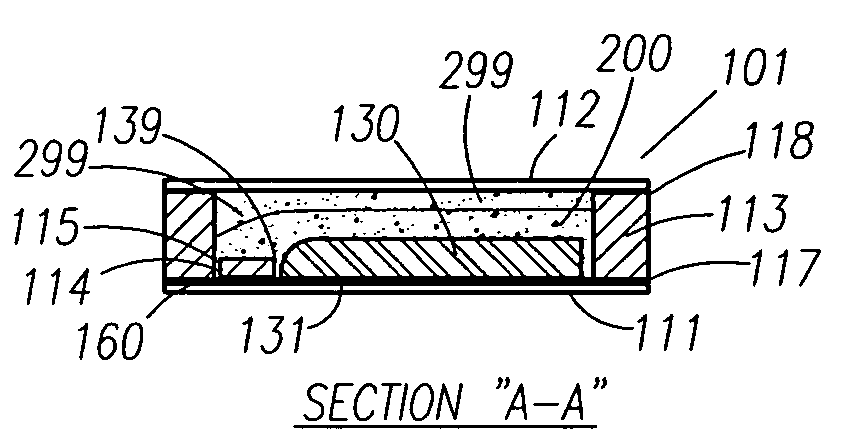

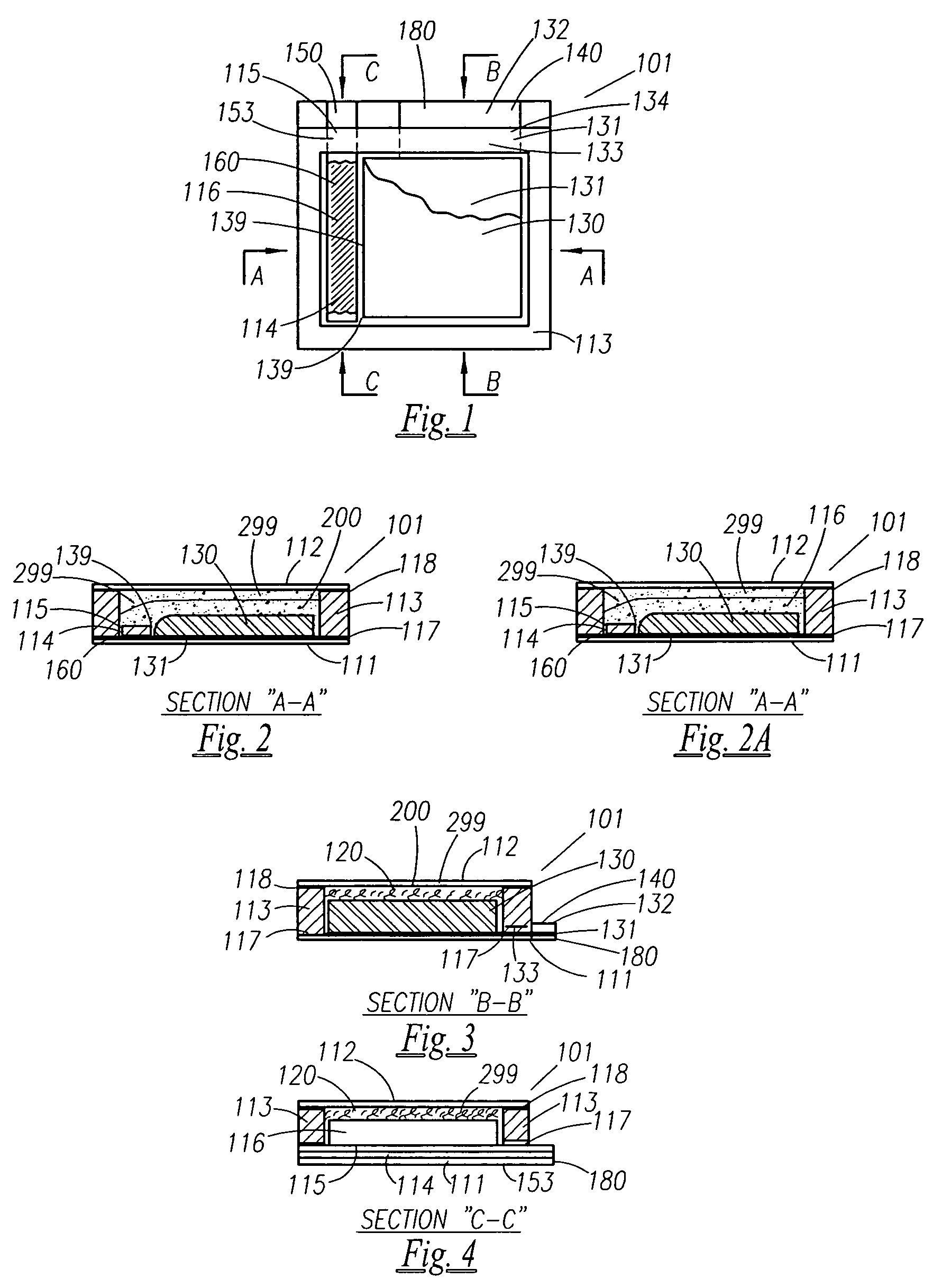

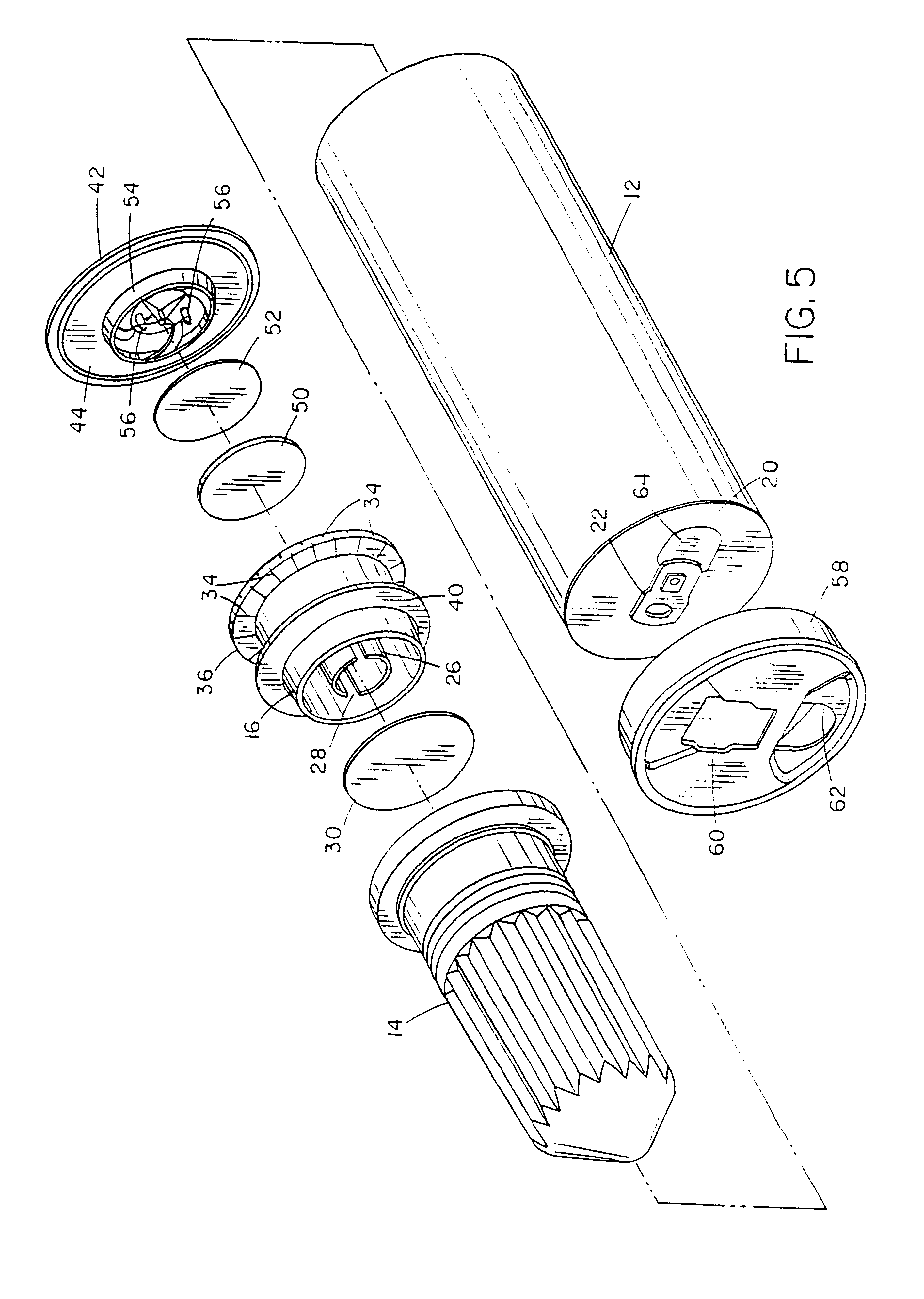

Thin printable electrochemical cell utilizing a "picture frame" and methods of making the same

A thin printed flexible electrochemical cell, and its method of manufacture, using a “picture frame” structure sealed, for example, with a high moisture and oxygen barrier polymer film and featuring, for example, a printed cathode deposited on an optional, highly conductive carbon printed cathode collector with a printed or a foil strip anode placed adjacent to the cathode. A viscous or gelled electrolyte is dispensed and / or printed in the cell, and a top laminate can then be sealed onto the picture frame. Such a construction could allow the entire cell to be made on a printing press, for example, as well as gives the opportunity to integrate the battery directly with an electronic application, for example.

Owner:BLUE SPARK INNOVATIONS LLC

Touch-sensing display apparatus and fabricating method thereof

ActiveUS20100265207A1Water/oxygen blocking abilitySolid-state devicesVessels or leading-in conductors manufactureTouch SensesOxygen

A touch-sensing display apparatus including a touch panel, an environmentally sensitive electronic device and an adhesive layer is provided. The water / oxygen vapor transmission rate of the touch panel is lower than 10−1 g / m2*day, and the touch panel includes a first substrate, a sensing circuit and at least one water / oxygen barrier layer. The first substrate is a first flexible substrate. The sensing circuit and the water / oxygen barrier layer are disposed on the first substrate. The environmentally sensitive electronic device includes a second substrate and a pixel array. The pixel array is disposed on the second substrate and between the first substrate and the second substrate. The adhesive layer is disposed between the touch panel and the environmentally sensitive electronic device. Moreover, a fabricating method of the above-mentioned touch-sensing display apparatus is also provided.

Owner:HANNSTAR DISPLAY CORPORATION

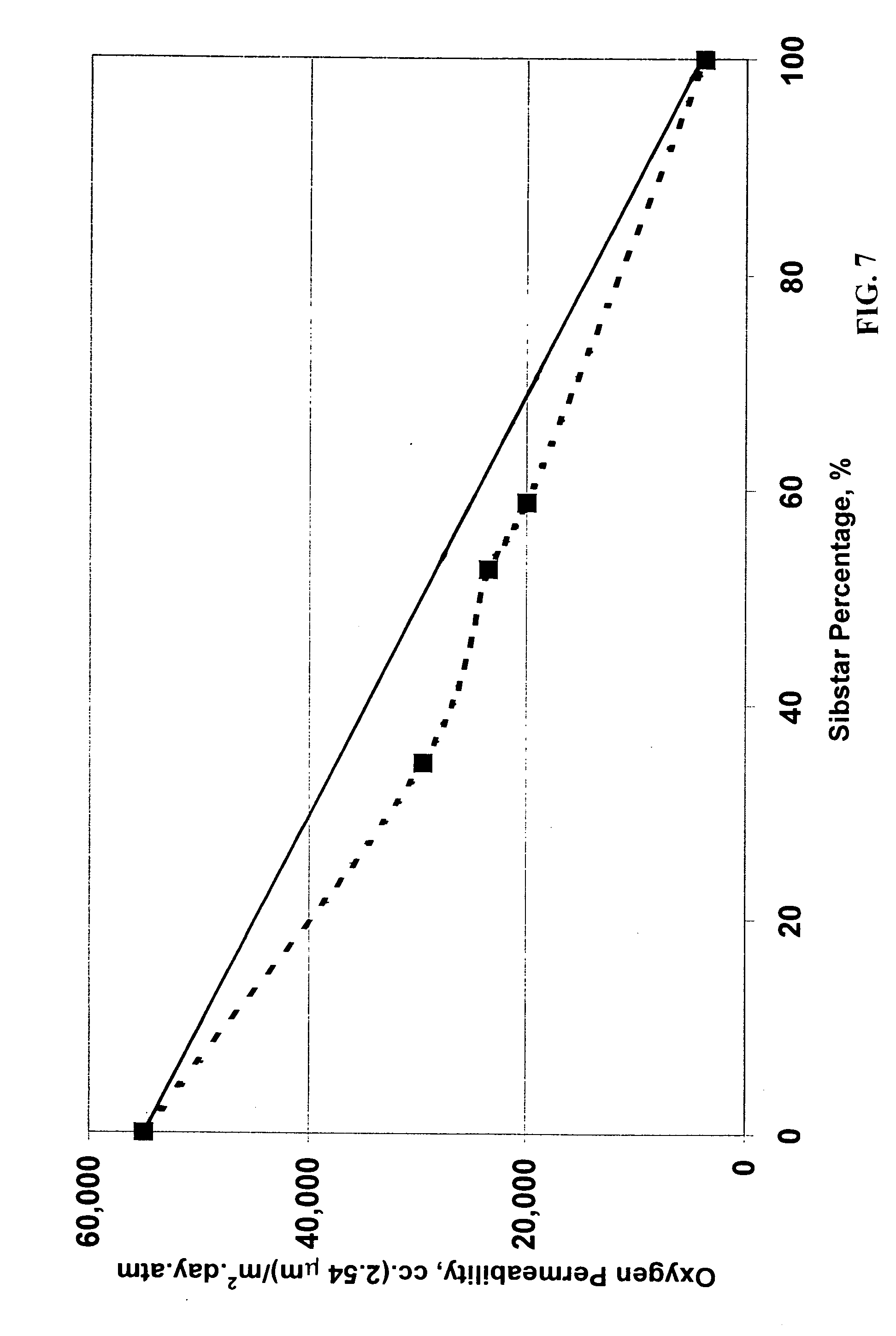

Polypropylene composition useful for making solid state oriented film

Disclosed is a polypropylene composition useful for making solid state oriented film. The composition comprises two predominantly isotactic polypropylenes with the melting point temperature of one of the polypropylenes being substantially lower than the melting point temperature of the other. In one embodiment of the composition the higher melting point polypropylene is made by Ziegler-Natta catalysis, while the lower melting point polypropylene is made by metallocene catalysis. Compared to polypropylene with similar melt flow rate and made by Ziegler-Natta catalysis, and solid state oriented film thereof, the composition provides a better balance of elevated temperature draw characteristics and physical properties of oriented film made therefrom. Thus, at the same or lower elevated temperature yield stress, oriented film of the composition exhibits improved properties such as stiffness, elongation-at-break, dimensional stability, and oxygen barrier. Also disclosed is a method for the manufacture of oriented, flexible packaging film. In the method a cast sheet is melt extruded from the composition, and, after cooling until it is solid, the cast sheet is stretched to the desired extent of orientation at a temperature which the sheet does not break while being stretched, but below the Tm of the composition. The resulting film then is cooled to at least the crystallization temperature of the lower melting point polypropylene.

Owner:MONTELL TECH CO BV

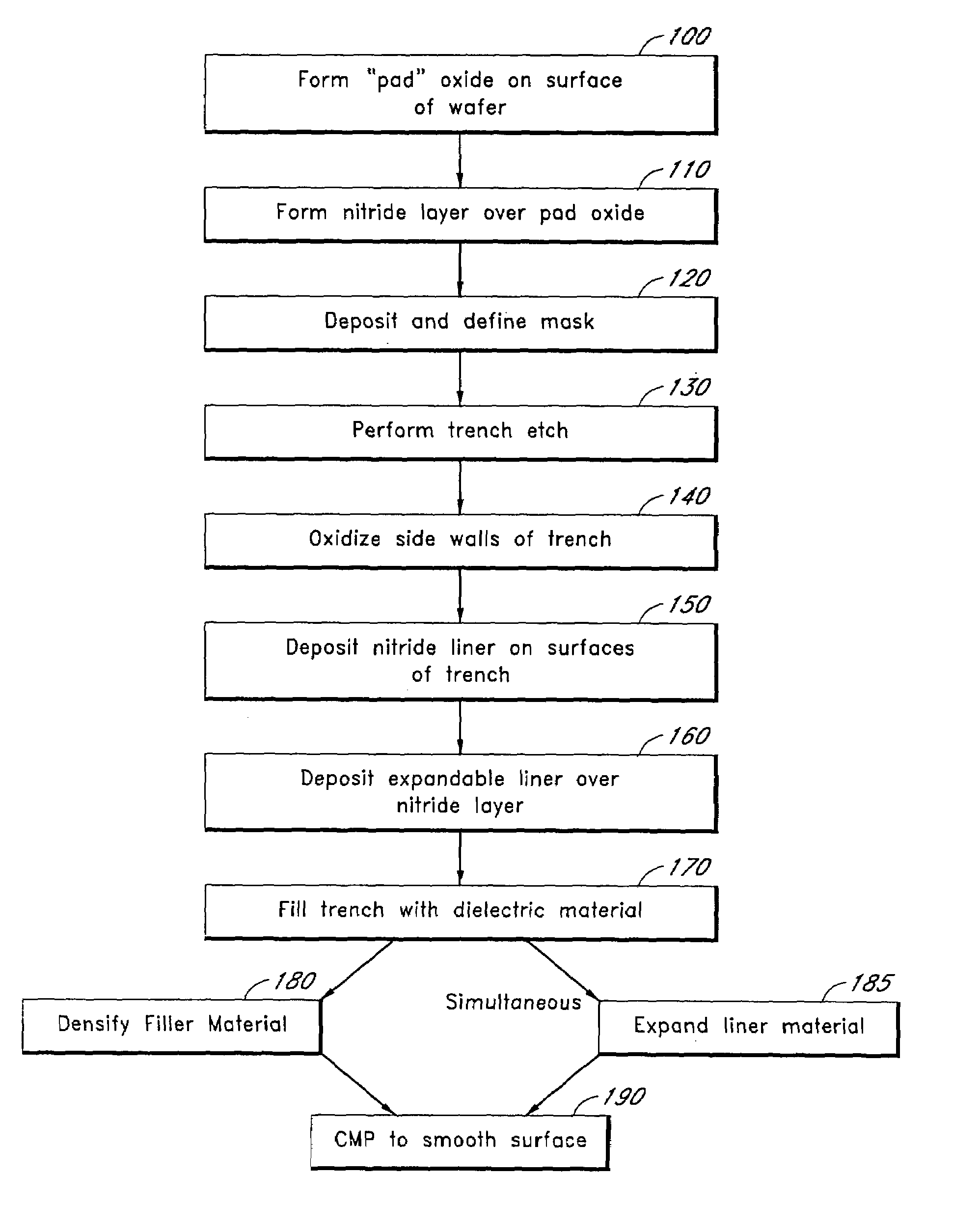

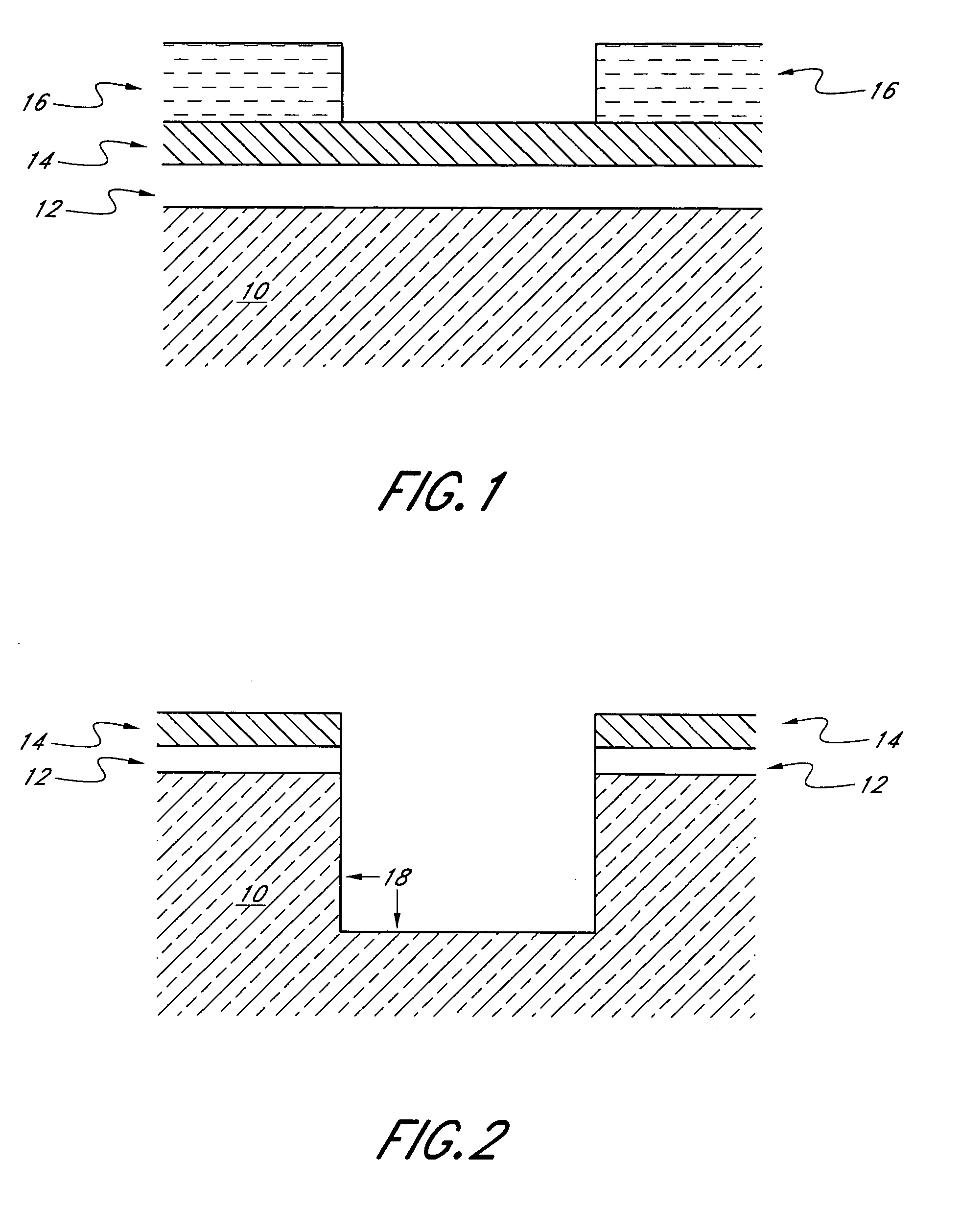

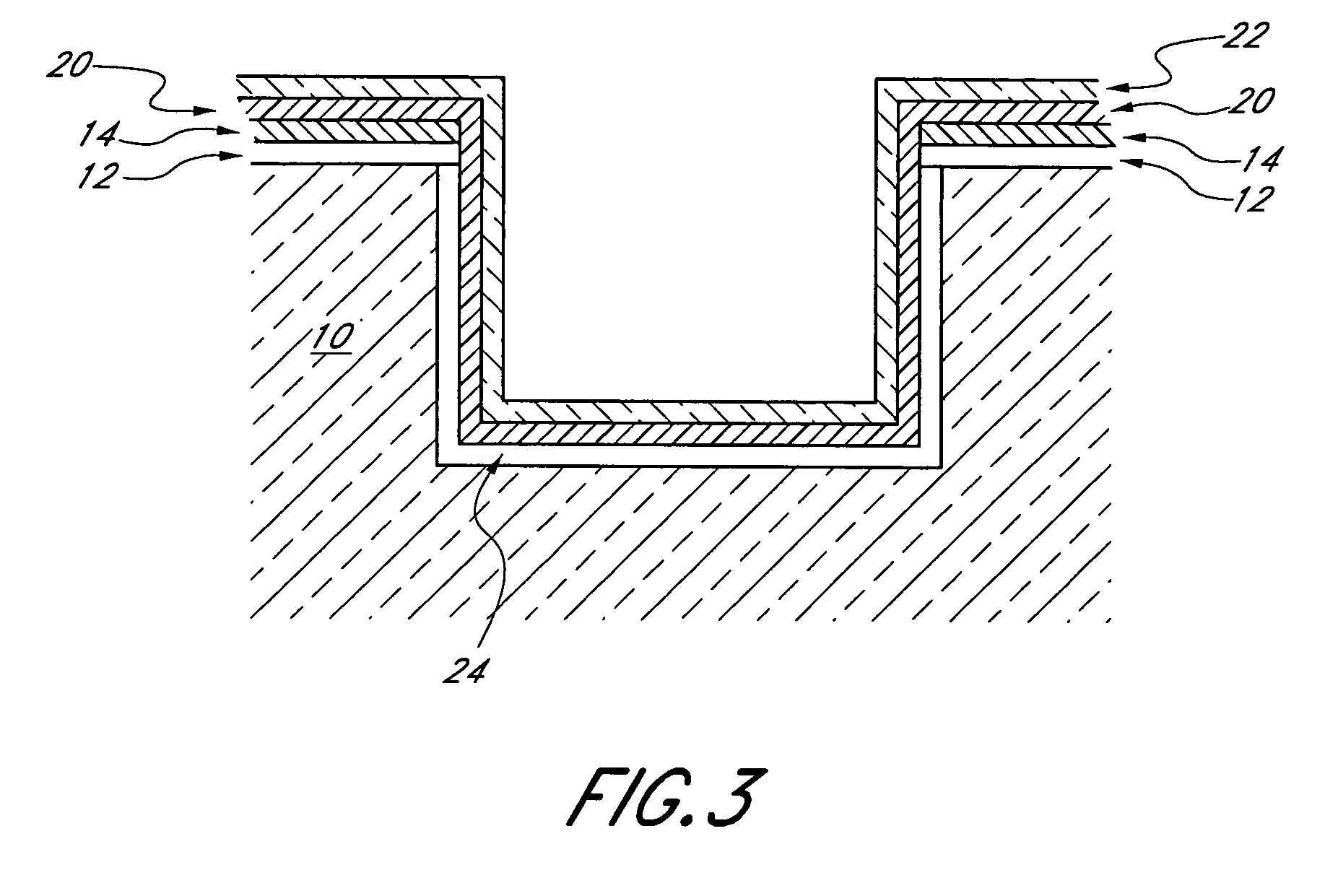

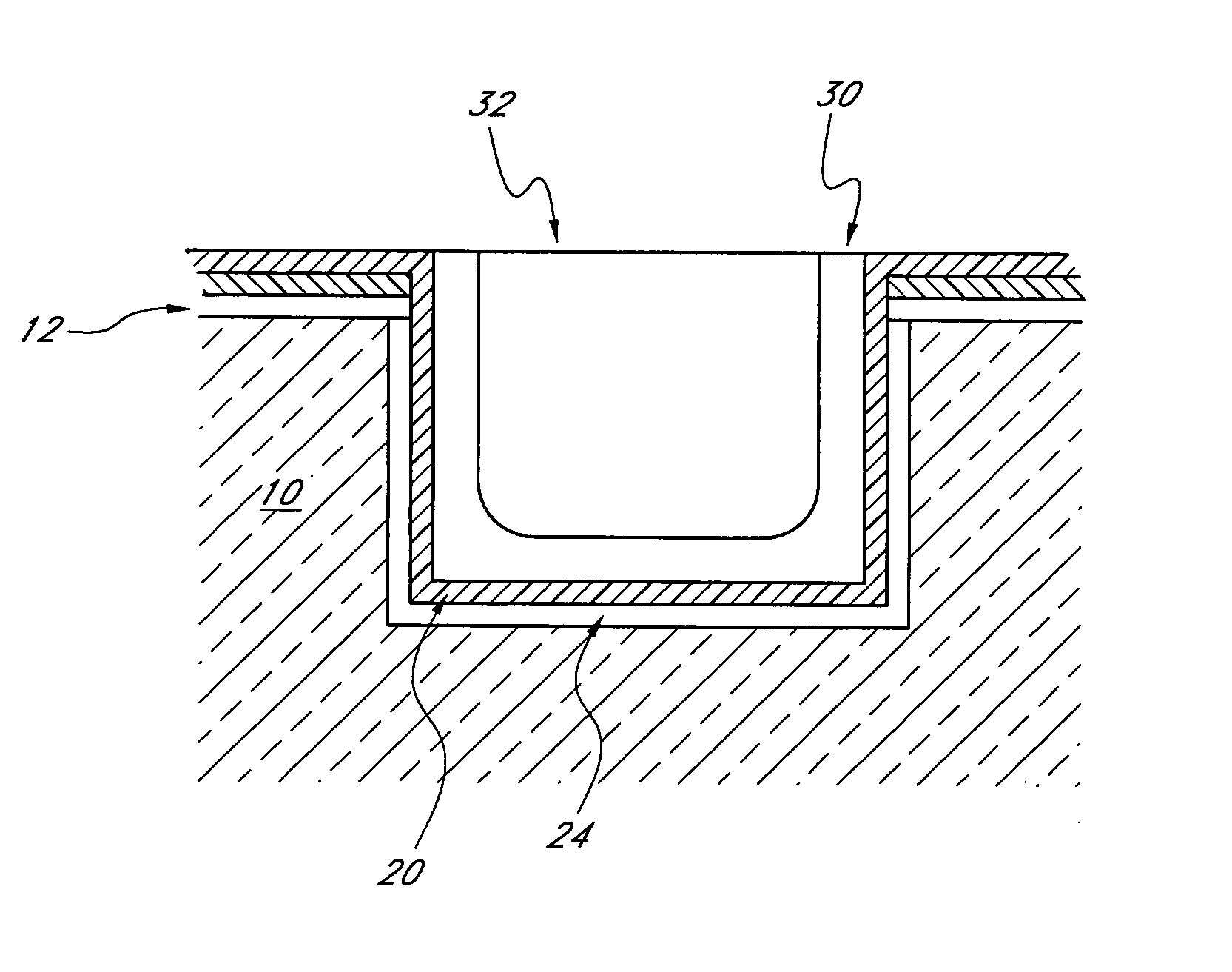

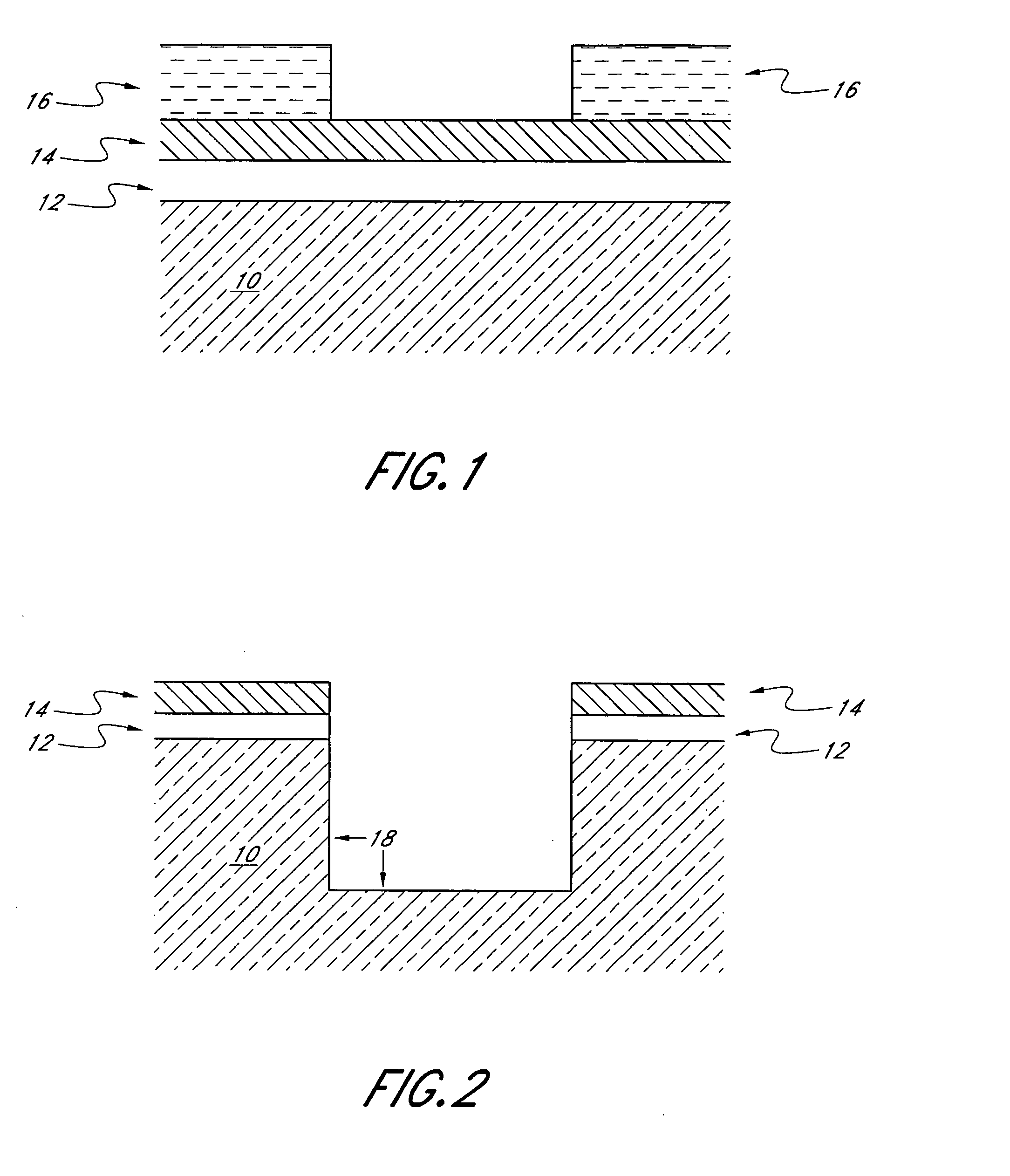

Sub-micron space liner and densification process

A method of depositing dielectric material into sub-micron spaces and resultant structures is provided. After a trench is etched in the surface of a wafer, an oxygen barrier is deposited into the trench. An expandable, oxidizable liner, preferably amorphous silicon, is then deposited. The trench is then filled with a spin-on dielectric (SOD) material. A densification process is then applied, whereby the SOD material contracts and the oxidizable liner expands. Preferably, the temperature is ramped up while oxidizing during at least part of the densification process. The resulting trench has a negligible vertical wet etch rate gradient and a negligible recess at the top of the trench.

Owner:MICRON TECH INC

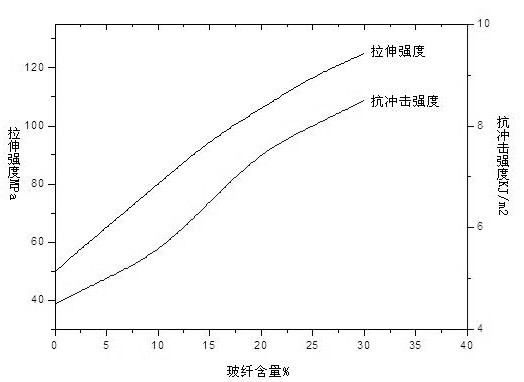

Flame-retardant polyester material with high glow wire ignition temperature and preparation method thereof

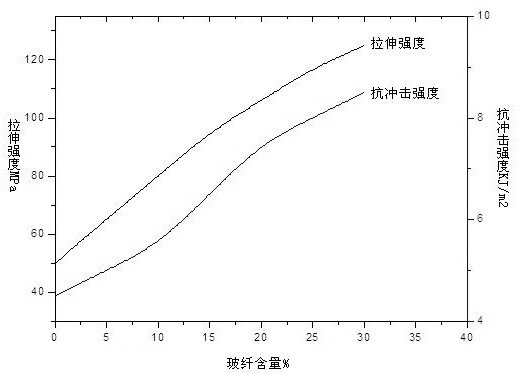

ActiveCN102250450AGWIT performance improvementsMeet performance requirementsPolyester resinUltimate tensile strength

The invention discloses a fame-retardant polyester material with a high glow wire ignition temperature and a preparation method thereof. The flame-retardant polyester material with a high glow wire ignition temperature is composed of the following components in parts by weight: 100 parts of polyester resins, 15-50 parts of bromine-series flame retardant, 5-20 parts of synergistic flame retardant, 0-20 parts of toughening agent, 0-80 parts of carbon forming agent, 5-40 parts of hot oxygen barrier agent, 0-120 parts of fibrous reinforcing agent and 0-10 parts of processing aid. The preparation method of the flame-retardant polyester material with a high glow wire ignition temperature comprises: drying the polyester resins, mixing with other components to obtain a premixed material, then feeding the premixed material into a twin-screw extruder, melting and plasticizing, kneading and mixing, extruding, drawing, cooling, pelletizing, drying and finally packaging. The flame-retardant polyester material with a high glow wire ignition temperature has the advantages of low cost, high glow wire ignition temperature, similar mechanical strength to ordinary flame-retardant polyester and wide application range.

Owner:KINGFA SCI & TECH CO LTD +1

Methods and apparatus for eyeglass lens curing using ultraviolet light and improved cooling

InactiveUS6086799AControl generationControl releaseOther chemical processesOptical articlesUltraviolet lightsRadiation pulse

Method and apparatus for making and coating a plastic lens. Oxygen barrier containing photoinitiator is used to cure incompletely cured lens portions. Radiation pulses are used to control lens curing rate. Lens is postcured while in a mold cavity using a conductive heat source. Air may be directed toward the mold cavity to help remove heat from the lens. An in-mold scratch resistant coating may be formed from two separate material which both contain a photoinitiator.

Owner:Q2100

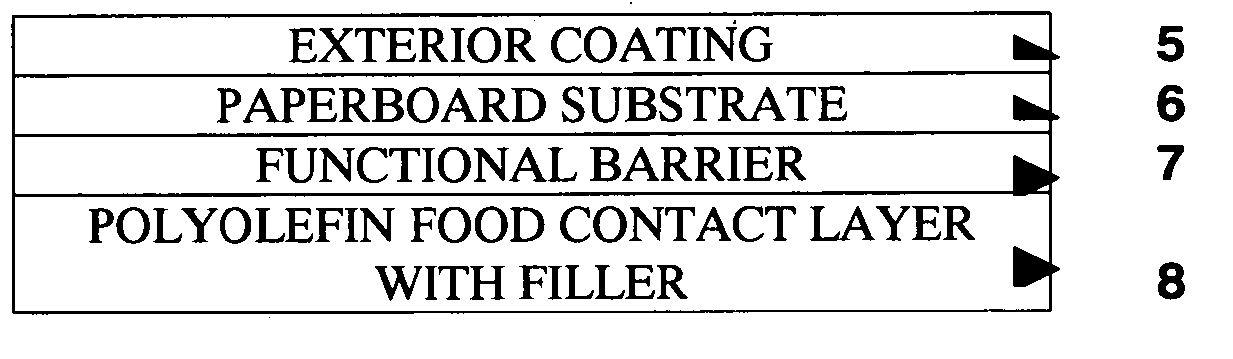

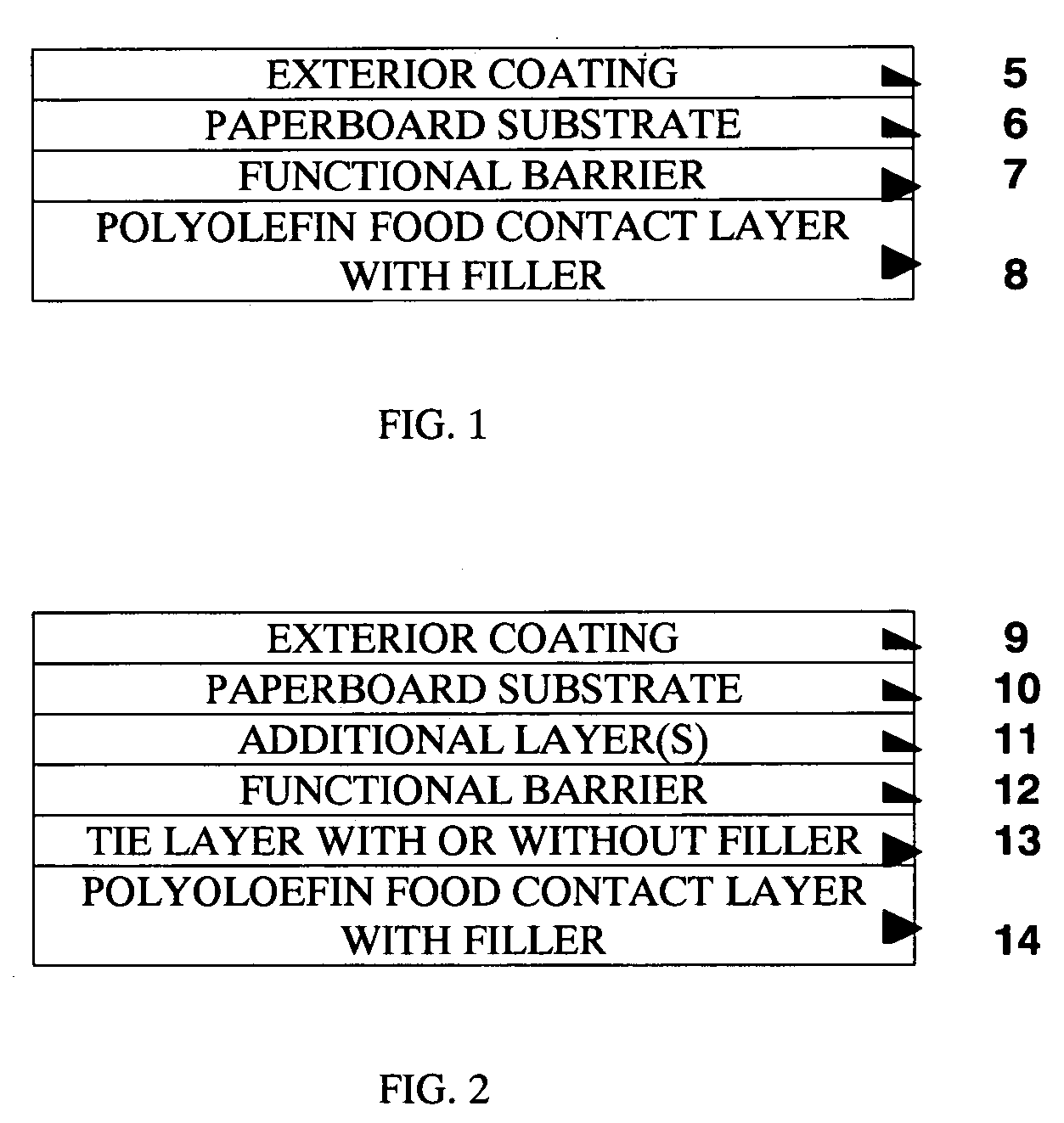

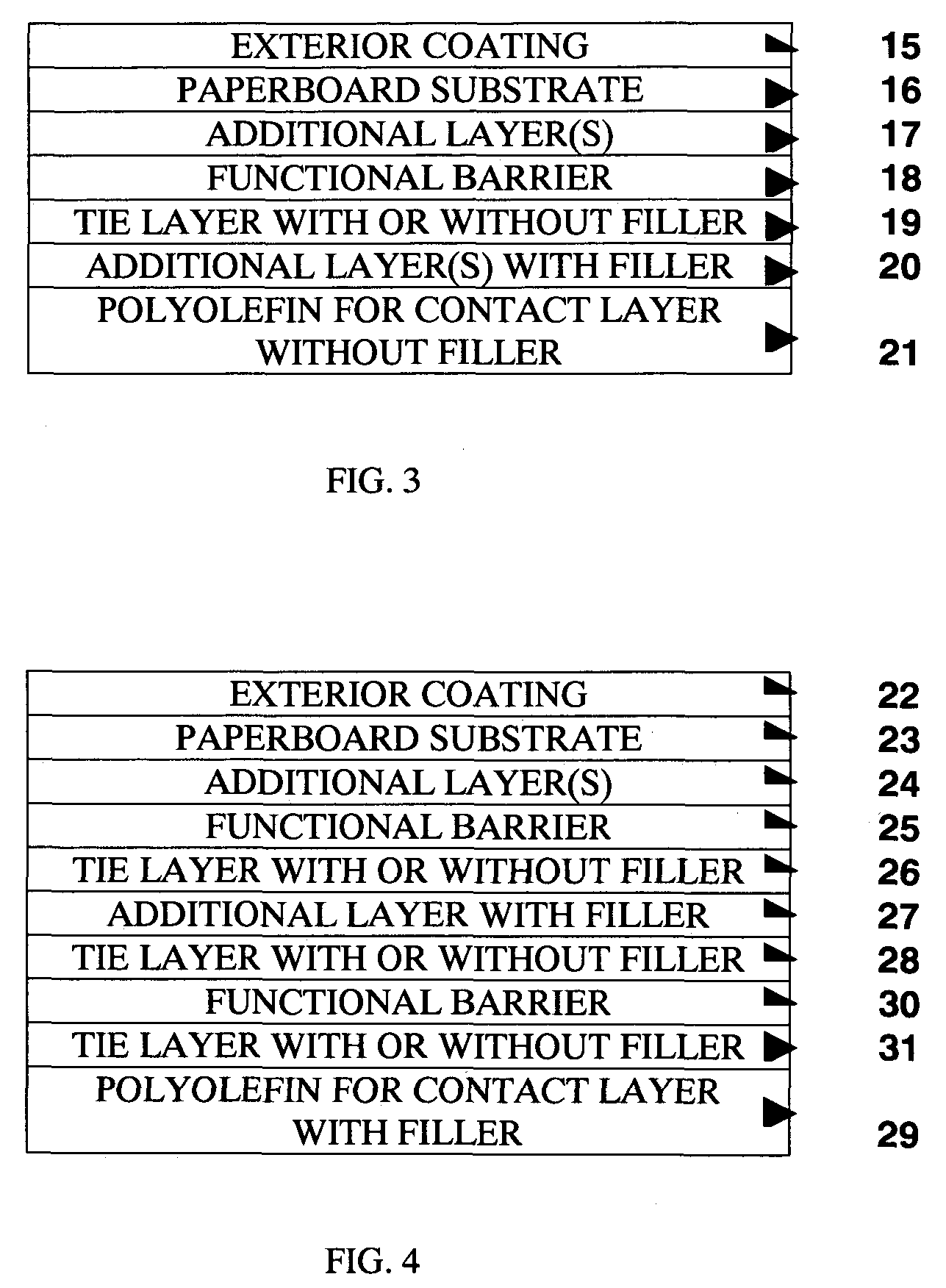

Paperboard laminate for food packaging applications

A laminate structure having improved resistance to the migration of essential oils, aromas and flavors and improved oxygen barrier characteristics for beverage packaging comprising an exterior coating of polyethylene applied onto the outer surface of paperboard substrate, a barrier layer of aluminum foil, EVOH, polyamide or PET applied directly or indirectly onto the paperboard and tie and other sublayers which may or may not contain inorganic filler applied intermediate the barrier layer and the innermost food contact layer which may or may not contain filler. The containers or cartons prepared from the laminate structures are characterized by minimized scalping and preserved product quality.

Owner:INT PAPER CO

Essentially gas-impermeable thermoplastic sealant

InactiveUS20060229402A1Improve barrier propertiesExtended shelf lifeCapsClosure using stoppersThermoplasticPolymer science

A thermoplastic essentially oxygen-impermeable plasticized sealant is formed by melt-blending a hydrogenated styrene-conjugated diene-styrene (SMS) block copolymer rubber with a polystyrene-polyisobutylene-polystyrene (SIBS) block copolymer rubber and a polyolefin plastic with a liquid polyisobutylene (PIB) oil plasticizer provided the PIB oil is present (i) in the range from 5% to less than 50% by weight of the sealant and (ii) in relation to total rubber, in the range from 0.3 to 0.8. The required minor amount of PIB oil, relative to total rubber, in combination with SIBS present in a minor amount relative to the amount of plasticized sealant, provides the sealant with unexpectedly better oxygen barrier properties and load bearing at 82° C. (180 ° F.) than a comparable blend of SIBS with mineral oil; the sealant is also essentially free of tack, adhesive properties and oil-bleed, with essentially no detackifier present. The PIB-oil plasticized SIBS sealant has a haze of less than 15%; a composite made by melt-bonding a core layer between polyC2-C3olefin sheets, maintains a haze less than 14%. The plasticised sealant is particularly useful for sealing elements for containers in which foods, beverages and medical products must be preserved for a long period.

Owner:GLS

High Quality Emission Control Coatings, Emission Control Glazings, and Production Methods

ActiveUS20120021149A1Layered productsWindows/door improvementIndium tin oxideTransparent conducting film

Owner:CARDINAL CG

Selectively self-assembling oxygen diffusion barrier

ActiveUS20100237442A1Semiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricMonomer

A shallow trench isolation structure is formed in a semiconductor substrate adjacent to an active semiconductor region. A selective self-assembling oxygen barrier layer is formed on the surface of the shallow trench isolation structure that includes a dielectric oxide material. The formation of the selective self-assembling oxygen barrier layer is selective in that it is not formed on the surface the active semiconductor region having a semiconductor surface. The selective self-assembling oxygen barrier layer is a self-assembled monomer layer of a chemical which is a derivative of alkylsilanes including at least one alkylene moiety. The silicon containing portion of the chemical forms polysiloxane, which is bonded to surface silanol groups via Si—O—Si bonds. The monolayer of the chemical is the selective self-assembling oxygen barrier layer that prevents diffusion of oxygen to a high dielectric constant material layer that is subsequently deposited as a gate dielectric.

Owner:GLOBALFOUNDRIES US INC

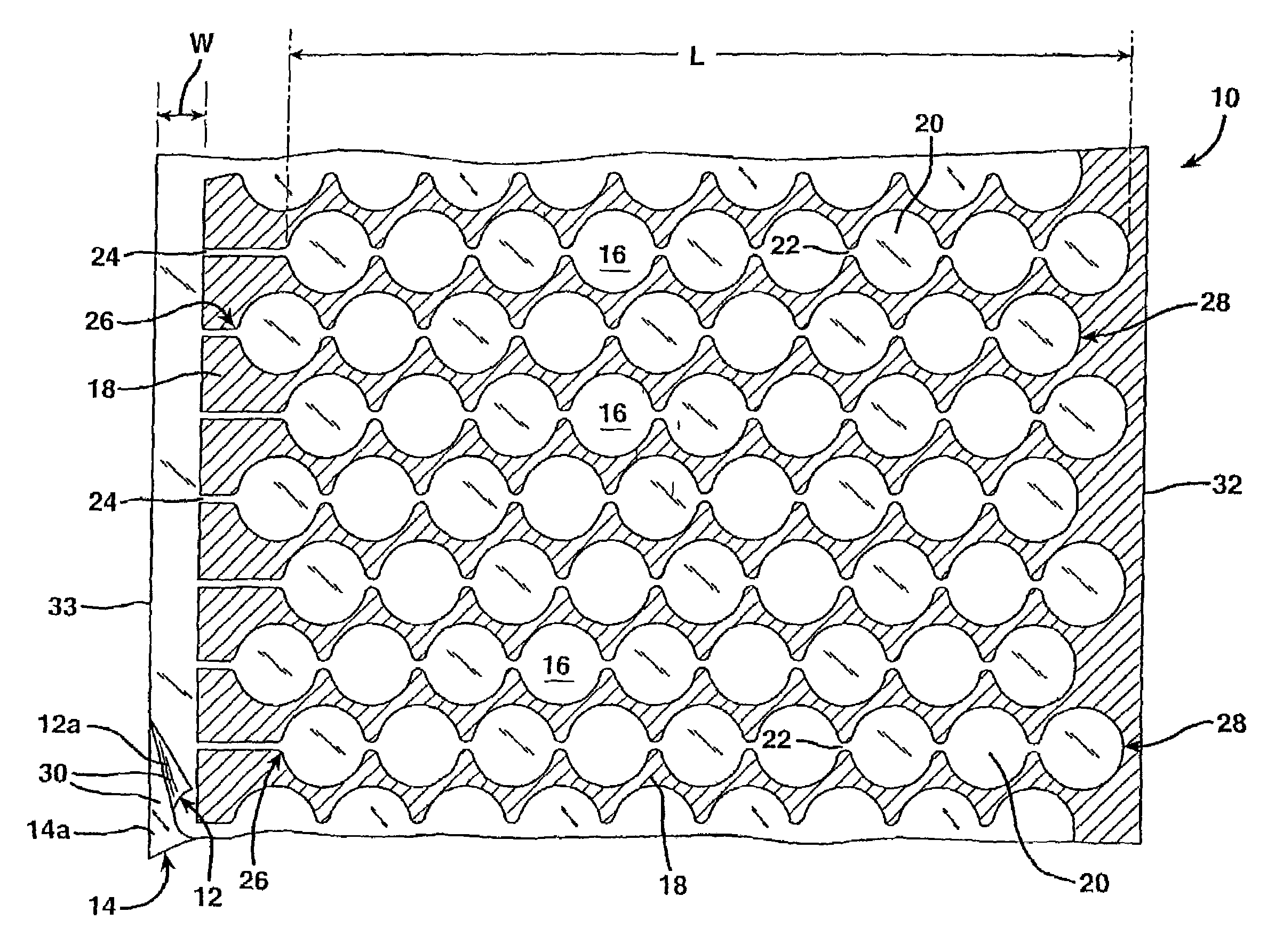

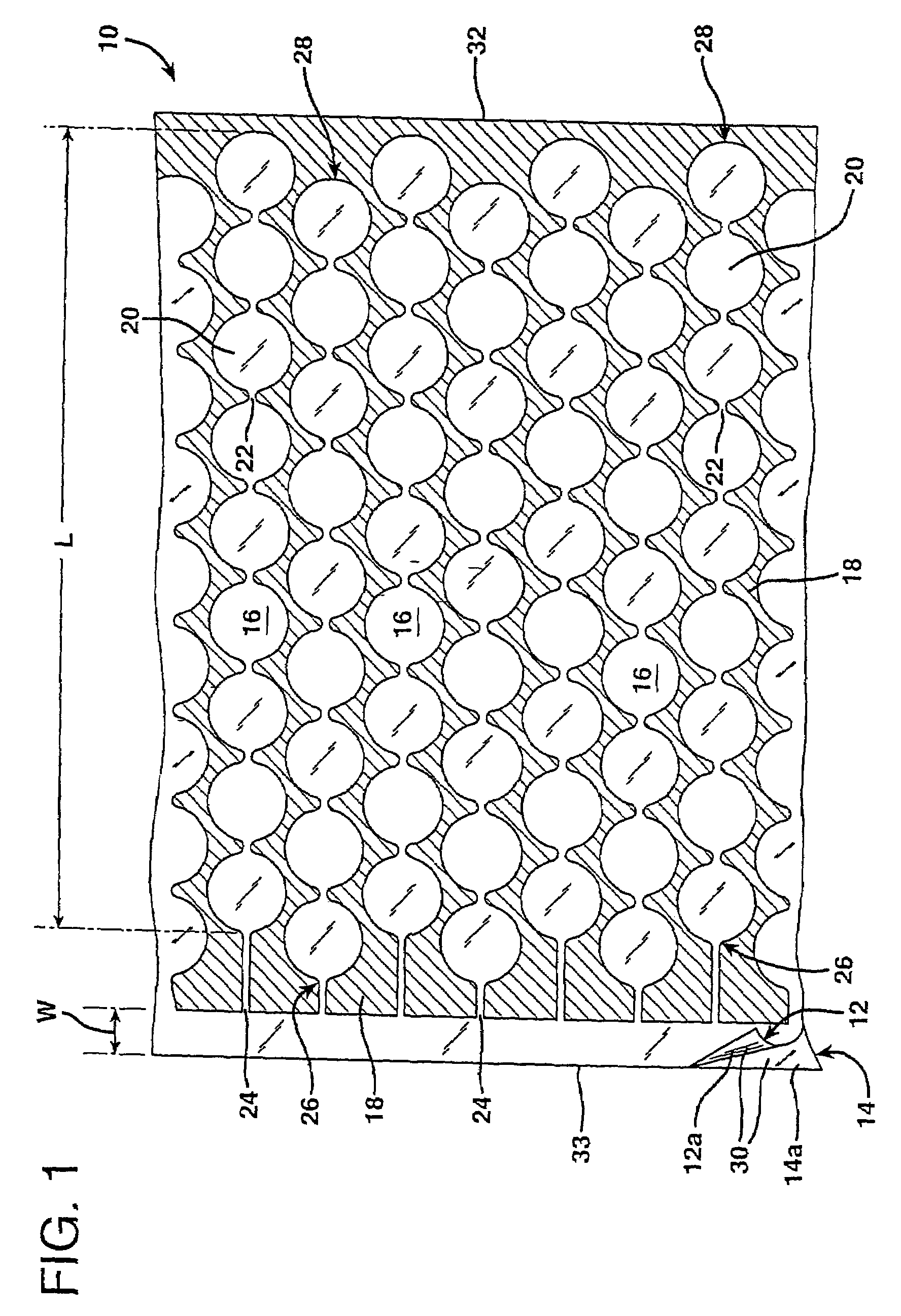

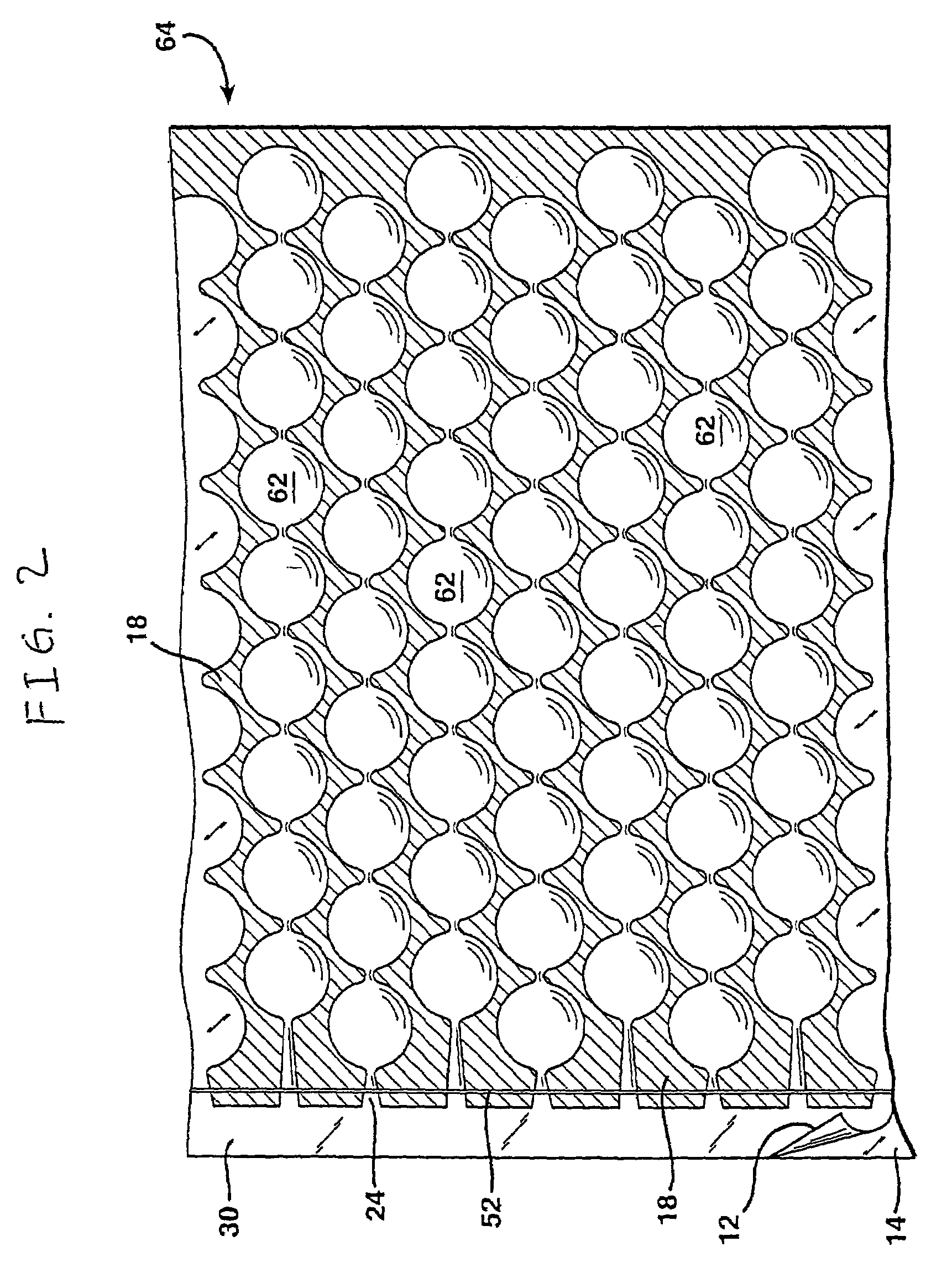

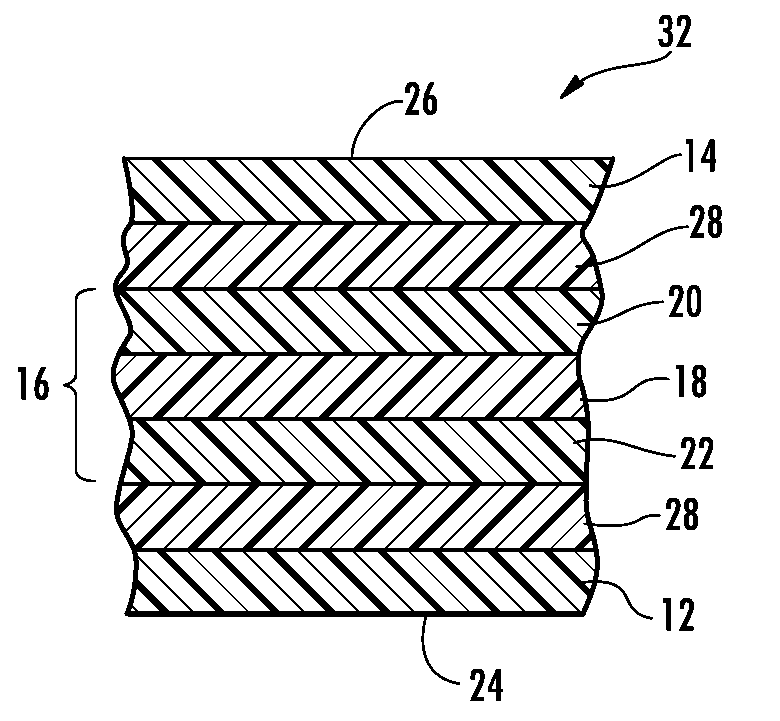

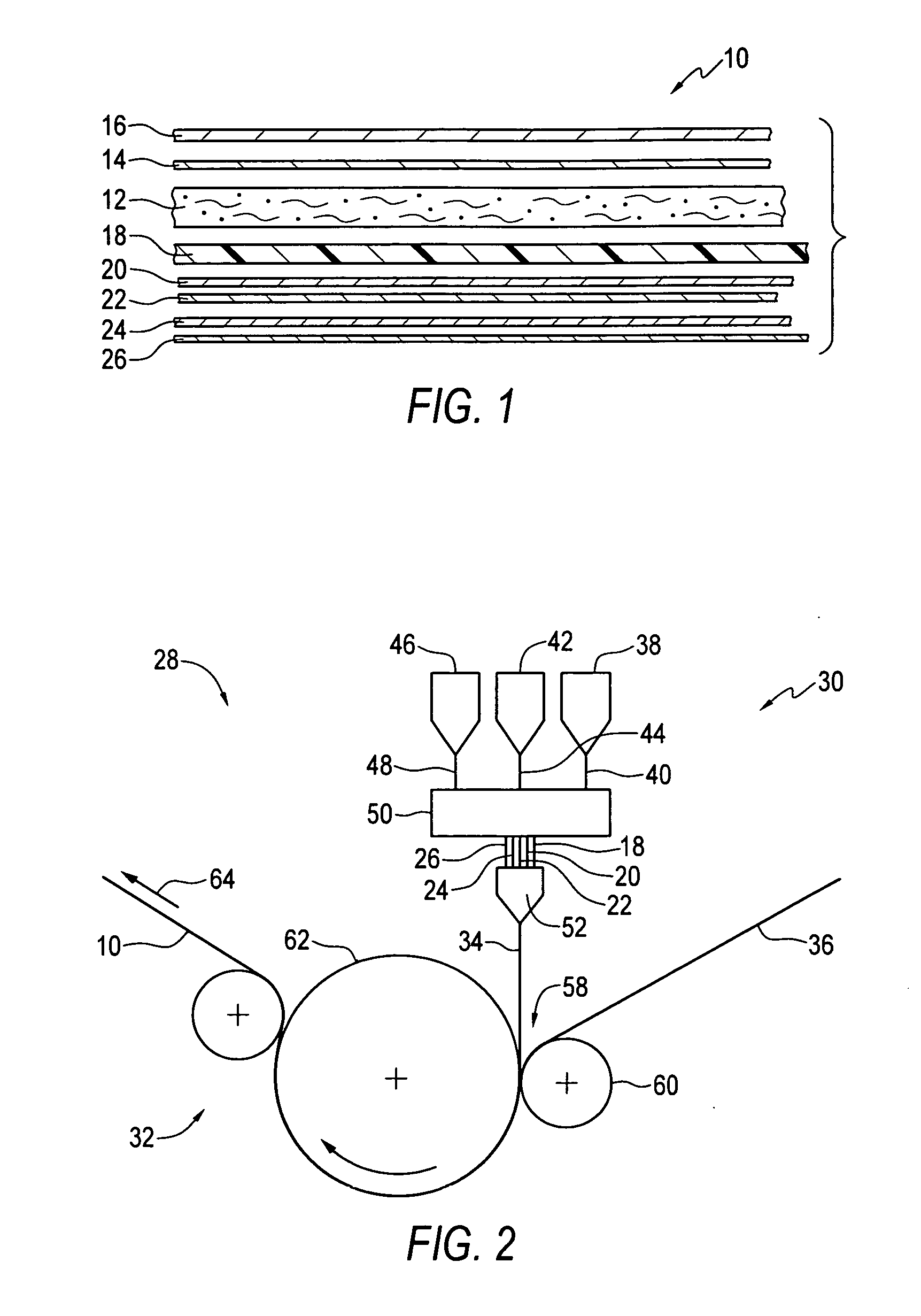

Process for making and aging high strength high gas barrier cellular cushioning product

ActiveUS7018495B2Reduce and eliminate film delaminationLower bursting pressurePaper/cardboard articlesHollow inflatable ballsPolyesterPolymer science

An inflatable cushioning article is made by a process of extruding two multilayer films (or extruding one film which is either annular or folded over) each having (a) a seal layer, (b) a tie layer containing an anhydride modified olefin polymer containing anhydride at a level of at least 150 ppm, based on the weight of the modified olefin polymer, and (c) an oxygen barrier layer comprising crystalline polyamide, crystalline polyester, ethylene / vinyl alcohol copolymer, polyacrylonitrile, and / or crystalline polycycloolefin. Selected portions of the films are heat sealed to one another in a selected area providing a heat seal pattern which leaves inflatable chambers between the films, whereby an inflatable cellular cushioning article is produced. At some point after extrusion, at least one of the multilayer films are aged for a time and at a temperature in accordance with at least one member selected from the group consisting of: (i) 141° F. to 250° F. for a period of at least 1 second; (ii) 101° F. to 140° F. for a period of at least 10 minutes; (iii) 61° F. to 100° F. for a period of at least 1 hour; and (iv) 30° F. to 60° F. for a period of at least 1 day. After aging, the cellular cushioning article is inflated. Preferably, the article is inflated to an internal pressure of at least 1.5 psi.

Owner:SEALED AIR U S

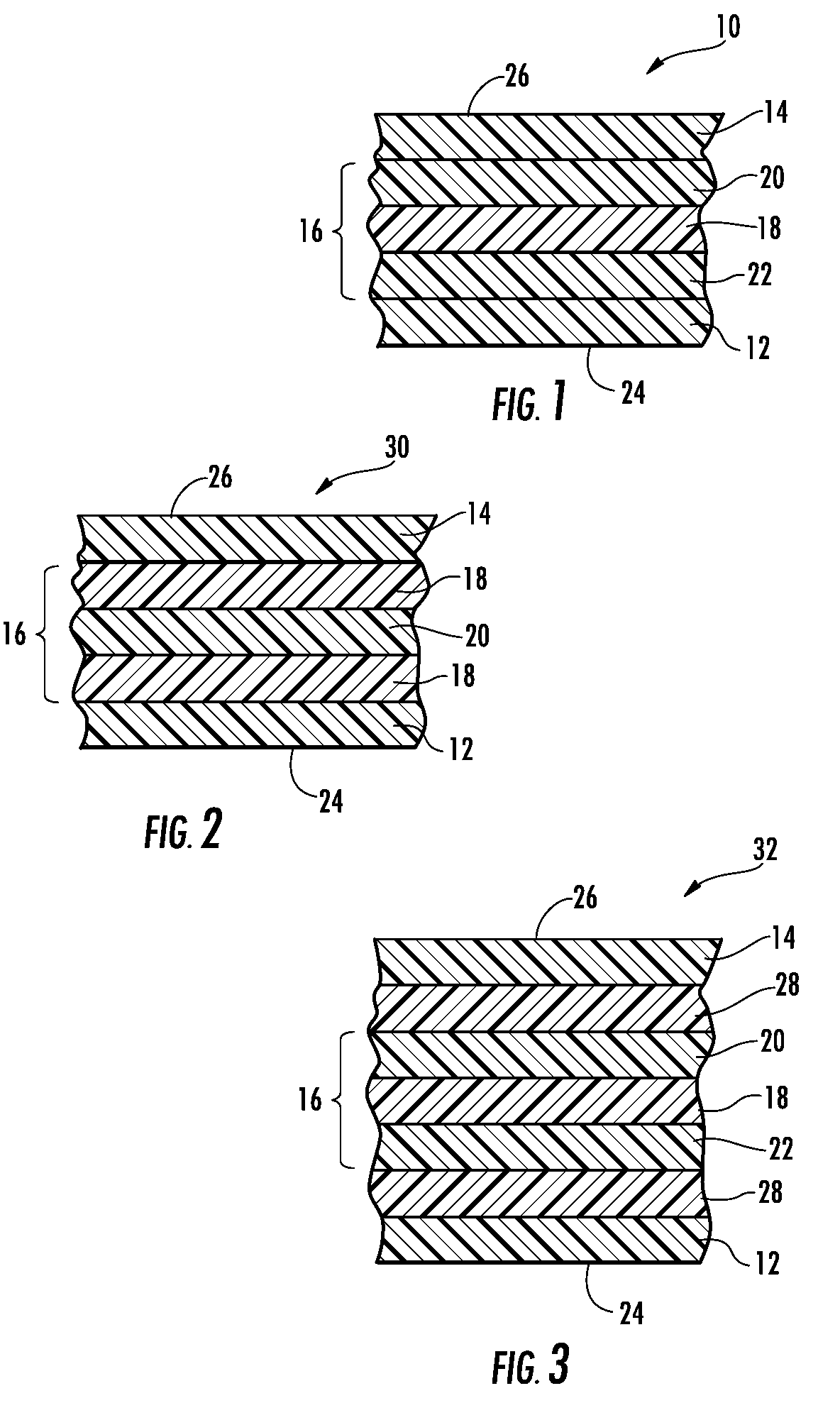

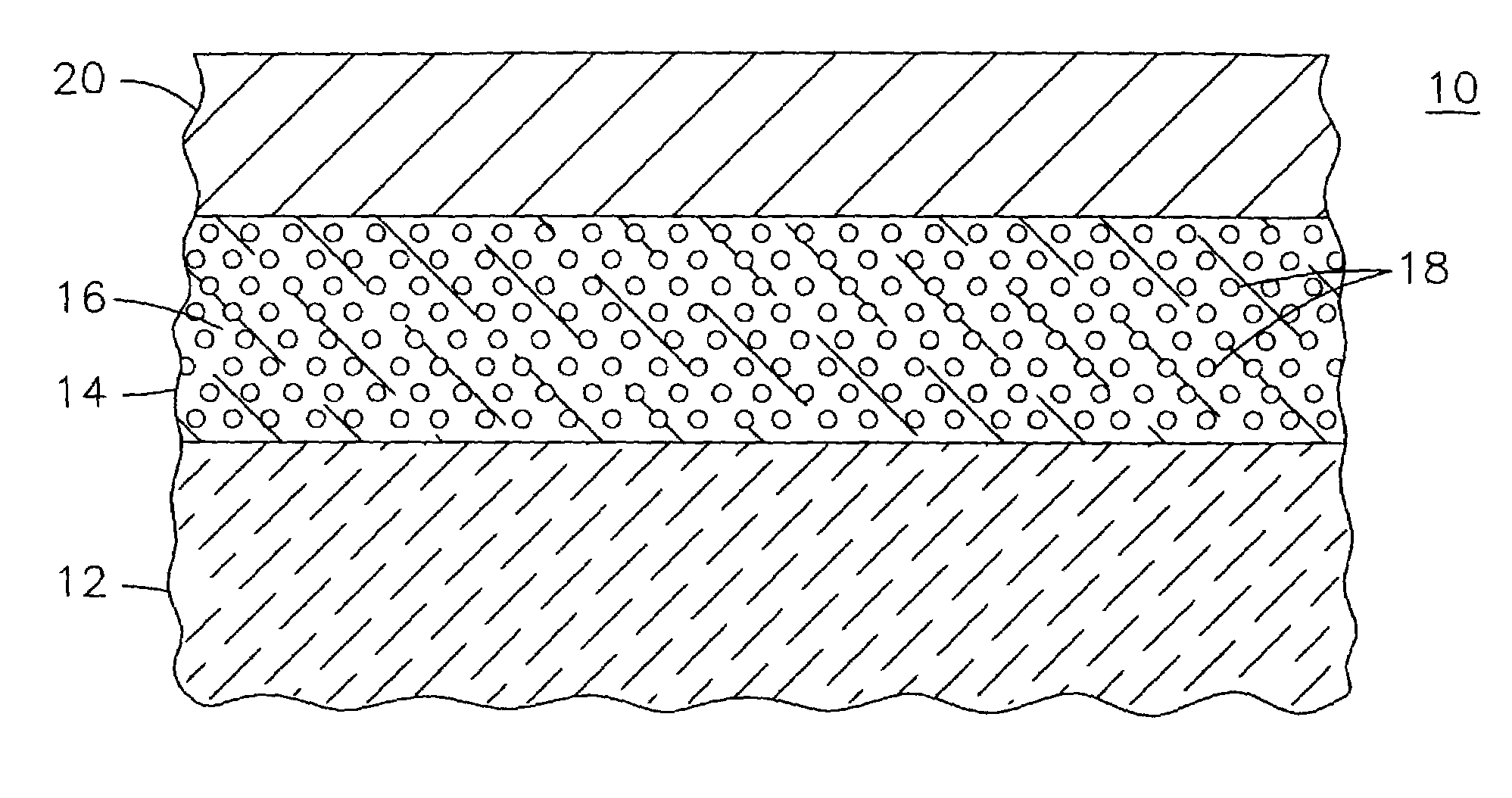

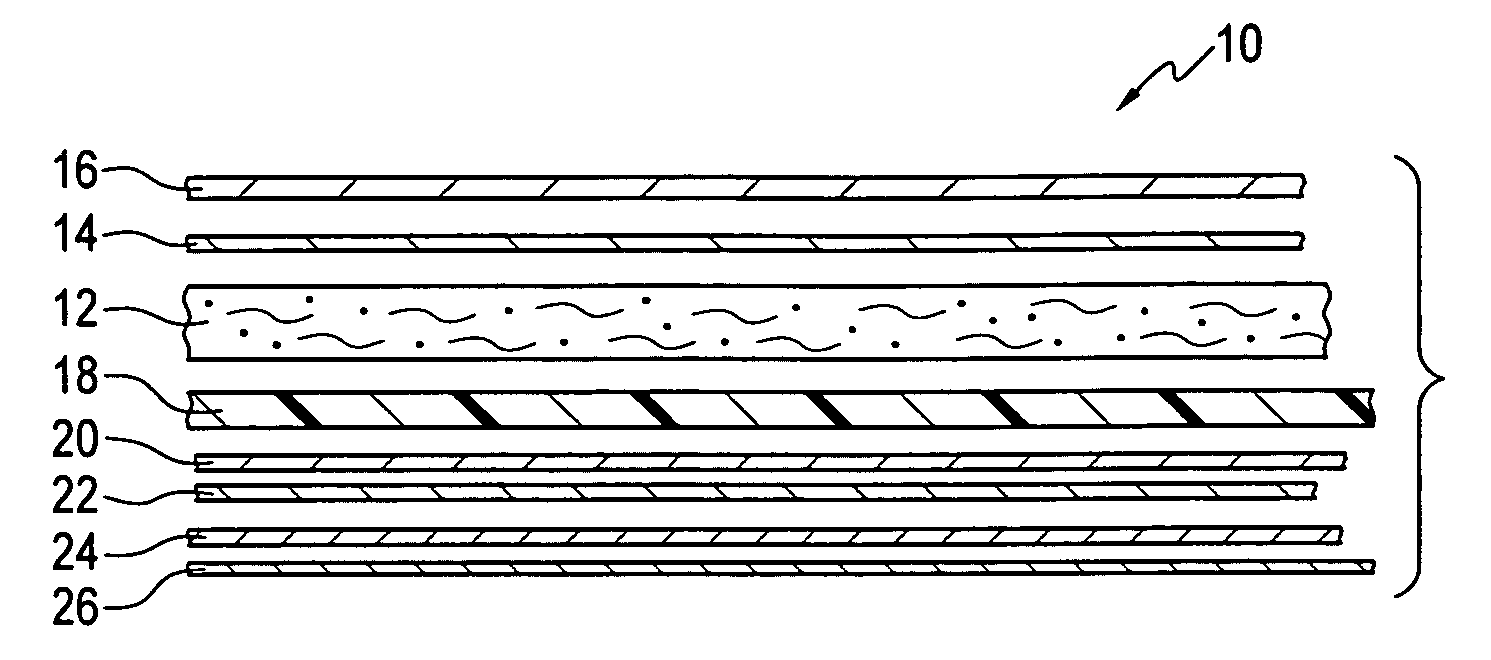

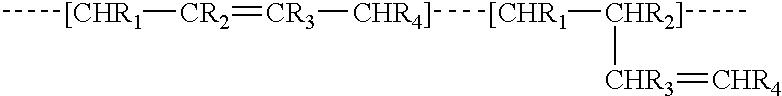

Multilayer Film Having Passive and Active Oxygen Barrier Layers

ActiveUS20090061061A1Reduce capacityLower their oxygen barrier propertyFlexible coversWrappersDouble bondOxygen

The present invention provides a multilayer film having an active oxygen barrier multilayer core comprising at least one of 1) an active oxygen barrier layer is sandwiched between two passive oxygen barrier layers, or 2) a passive oxygen barrier layer is sandwiched between two active oxygen barrier layers. In one embodiment, the active barrier layer comprises a composition that is a blend of a thermoplastic resin (A) having carbon-carbon double bonds substantially in its main chain, a transition metal salt (B), and an oxygen barrier polymer (C). In some embodiments the active barrier layer may also include a compatibilizer (D). The passive oxygen barrier layers help to maintain the oxygen barrier properties of the multilayer film after the oxygen absorbing capacity of the active barrier layer has been exhausted. As a result, the useful shelf life of the film can be extended.

Owner:CRYOVAC INC

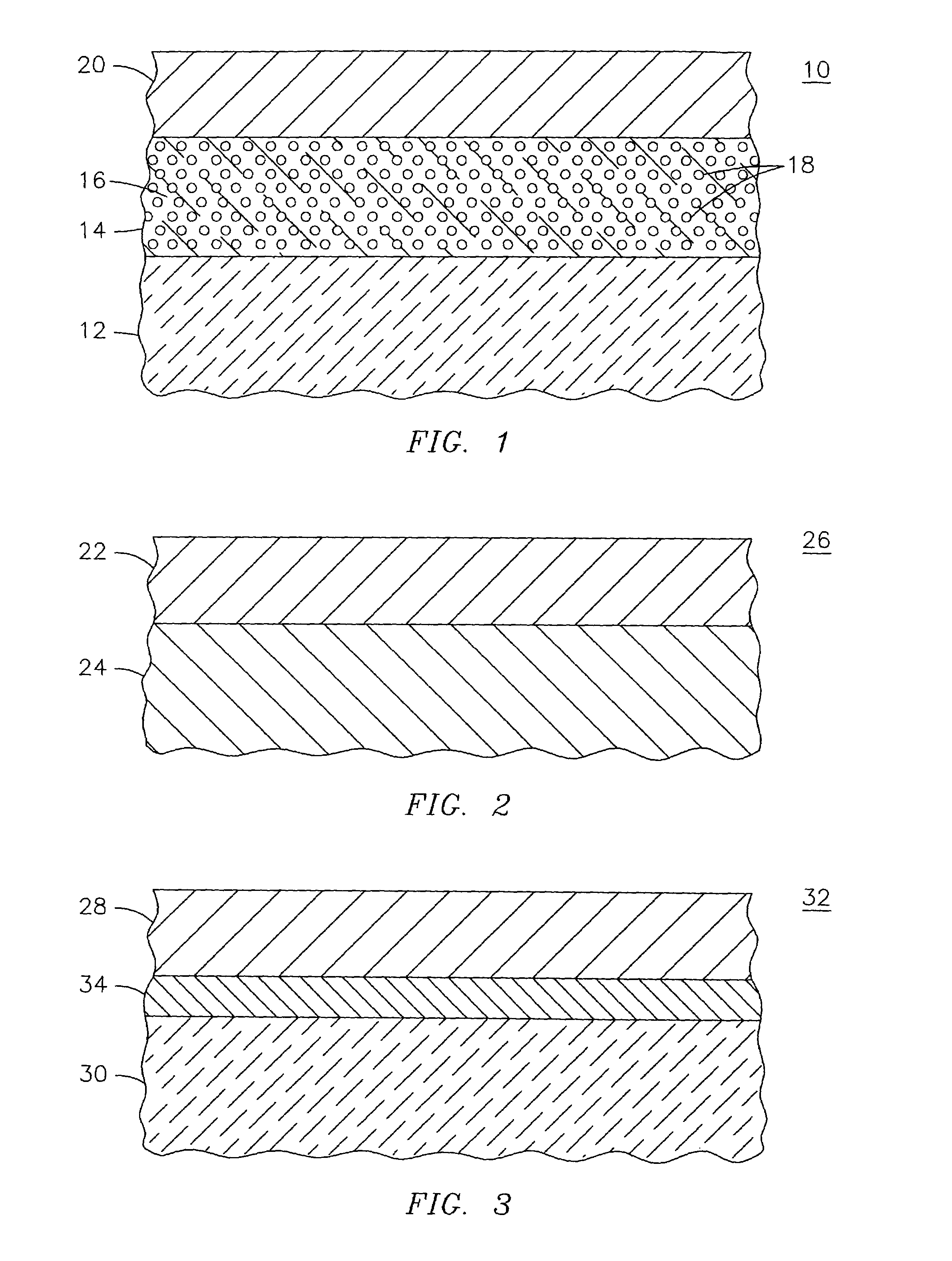

Protective overlayer for ceramics

A xenotime phosphate protective overlayer (22) for protecting a ceramic material (24) from a high temperature, moisture-containing environment. Yttrium phosphate may be used as a protective overlayer to protect an underlying mullite layer to temperatures in excess of 1,500° C. The coating may have porosity of greater than 15% for improved thermal shock protection. To prevent the ingress of oxygen to an underlying ceramic non-oxide material, such as silicon carbide or silicon nitride, an oxygen barrier layer (34) is disposed between the xenotime phosphate coating and the non-oxide material. Such a protective overlayer may be used for an article having a ceramic matrix composite substrate.

Owner:SIEMENS ENERGY INC

Thin printable electrochemical cell utilizing a “picture frame” and methods of making the same

Owner:BLUE SPARK INNOVATIONS LLC

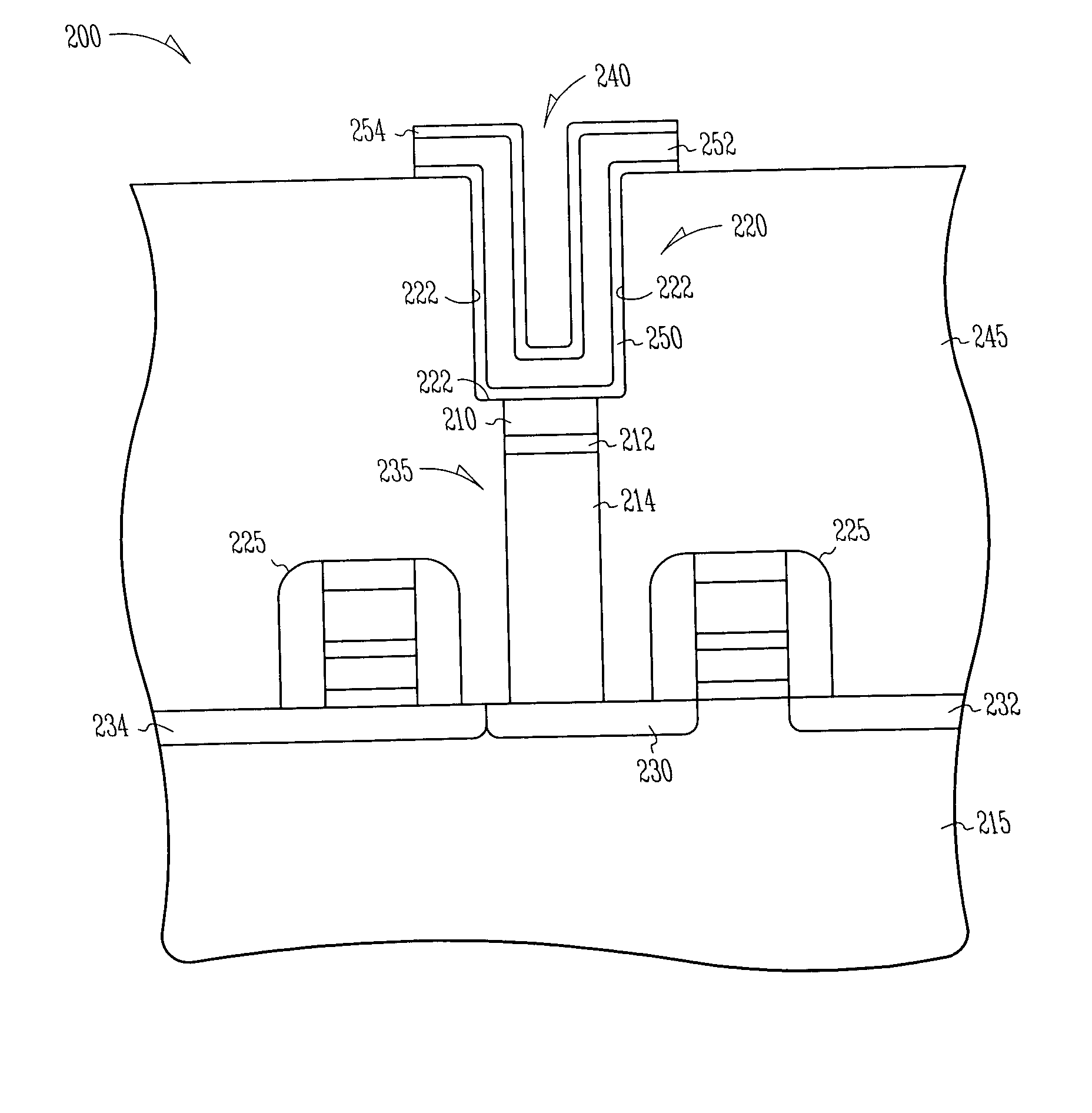

Sub-micron space liner and densification process

A method of depositing dielectric material into sub-micron spaces and resultant structures is provided. After a trench is etched in the surface of a wafer, an oxygen barrier is deposited into the trench. An expandable, oxidizable liner, preferably amorphous silicon, is then deposited. The trench is then filled with a spin-on dielectric (SOD) material. A densification process is then applied, whereby the SOD material contracts and the oxidizable liner expands. Preferably, the temperature is ramped up while oxidizing during at least part of the densification process. The resulting trench has a negligible vertical wet etch rate gradient and a negligible recess at the top of the trench.

Owner:MICRON TECH INC

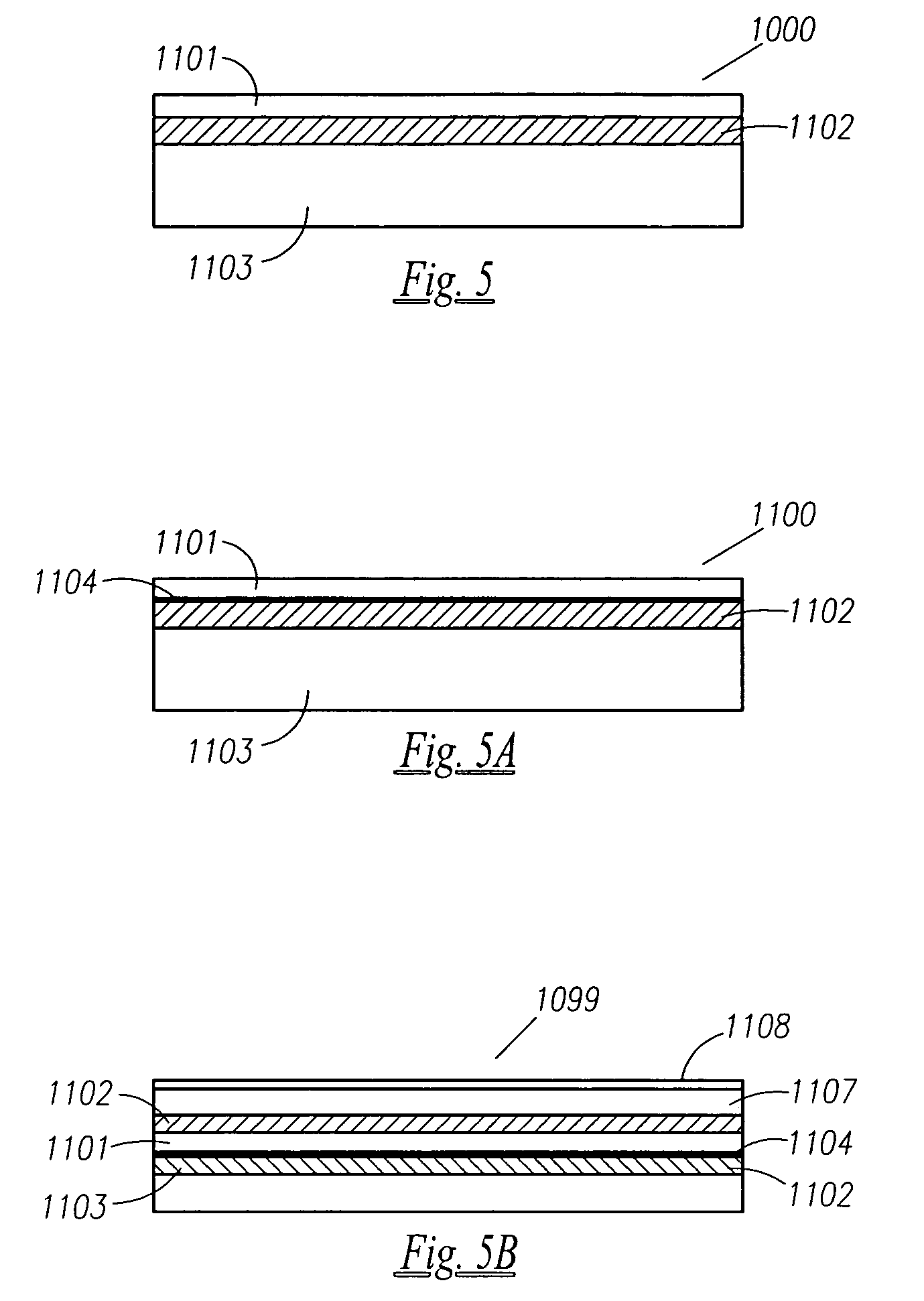

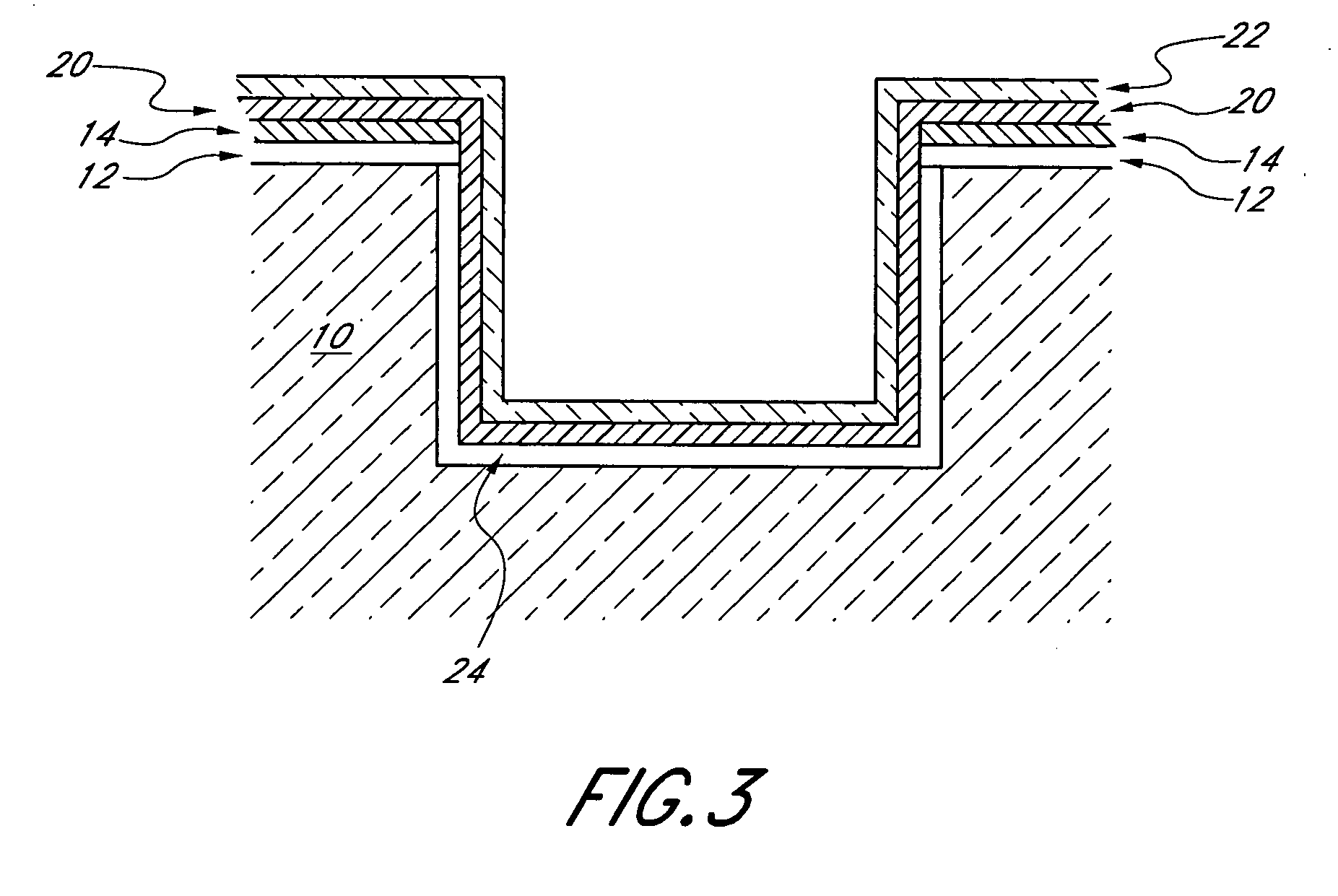

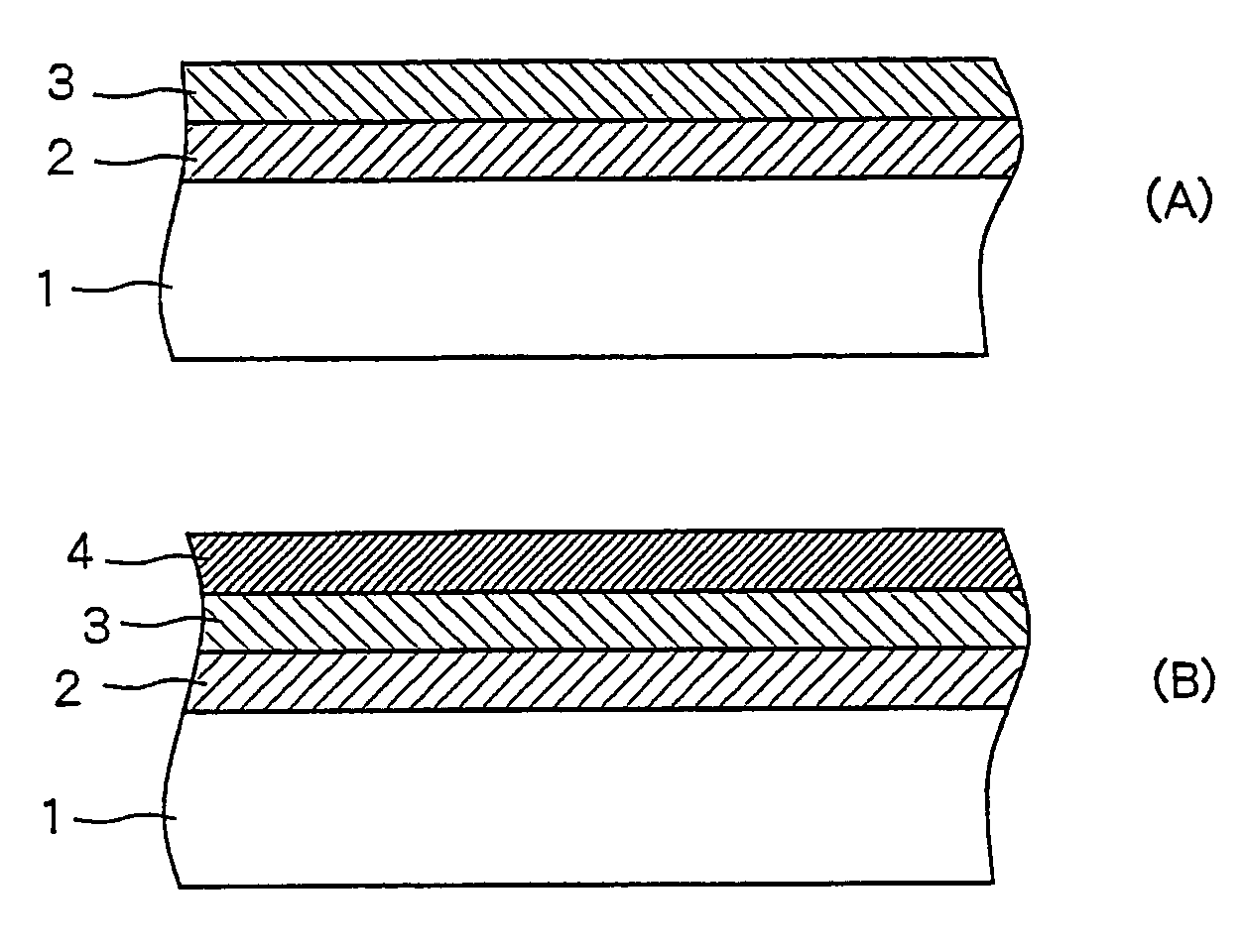

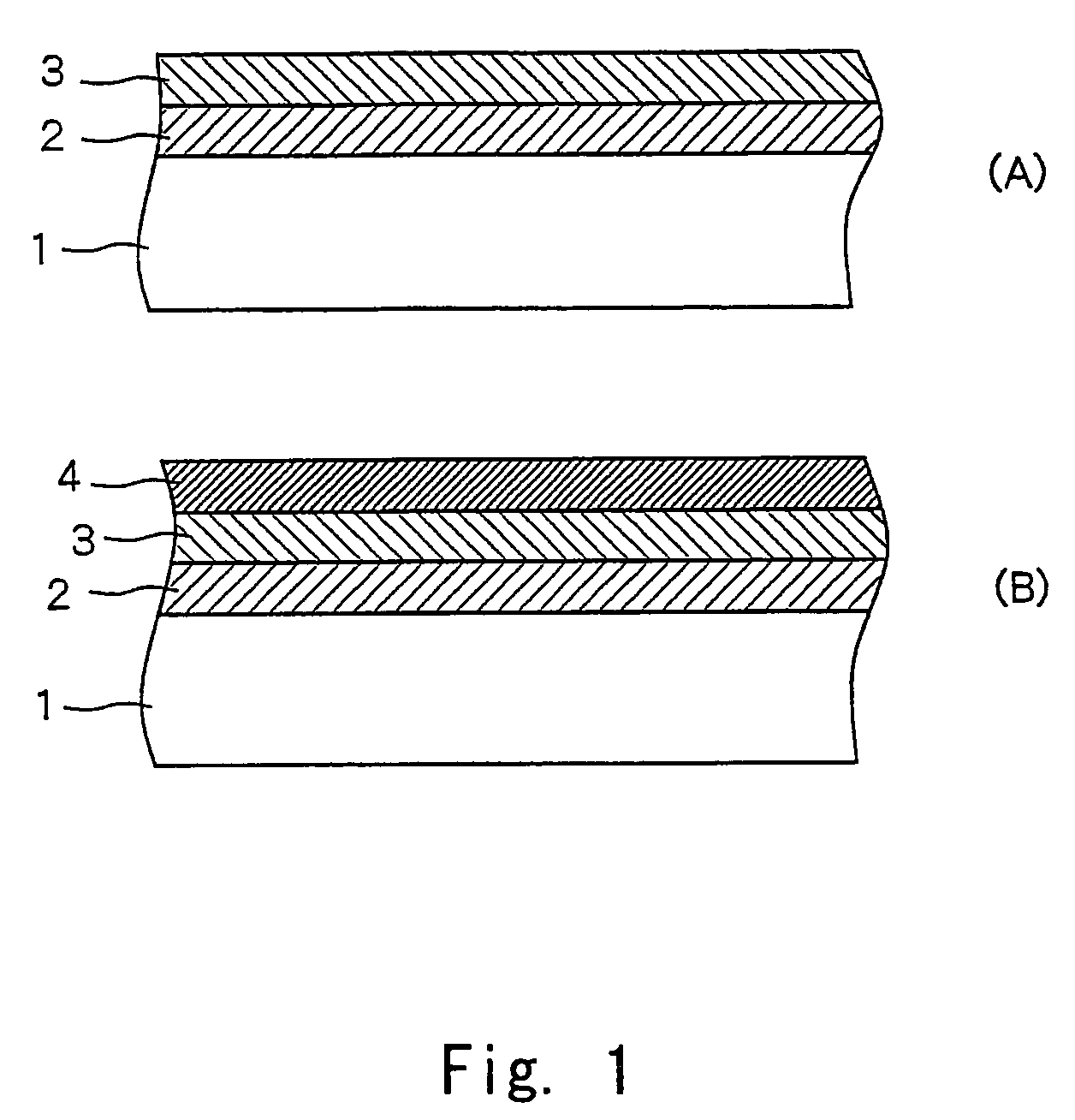

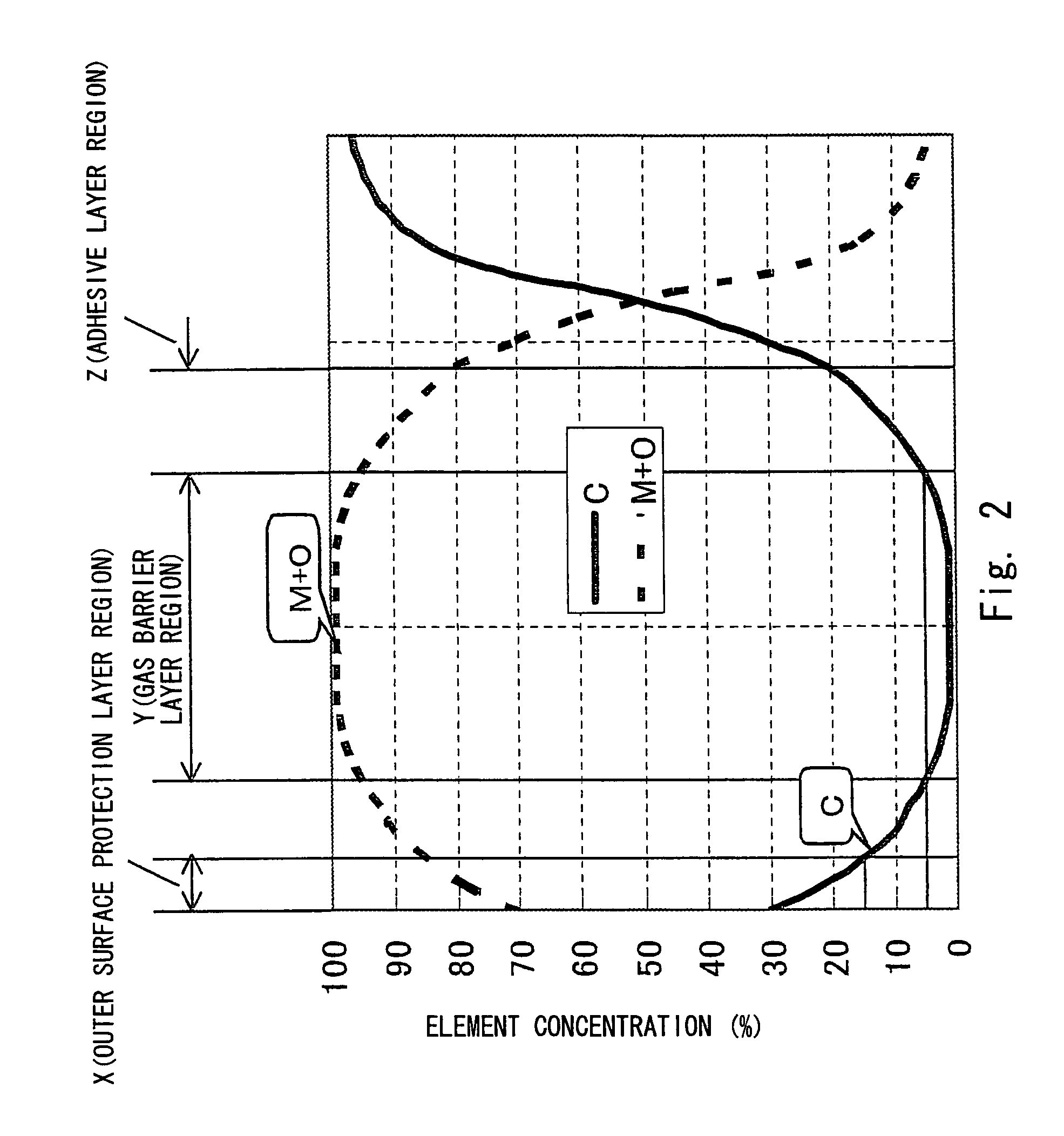

Chemical vapor deposited film based on a plasma CVD method and method of forming the film

InactiveUS7488683B2Liquid surface applicatorsSemiconductor/solid-state device manufacturingFilm baseSilicon oxide

A method of forming a vapor deposited film of a silicon oxide on the surface of a substrate by holding the substrate to be treated in a plasma-treating chamber, and effecting the treatment with a chemical plasma by feeding an organosilicon compound and an oxidizing gas into the treating chamber, wherein the rate of feeding the oxidizing gas is varied while maintaining constant the rate of feeding the organosilicon compound gas into the plasma-treating chamber during the formation of the vapor deposited film. A chemical vapor deposited film is formed featuring excellent adhesiveness, softness, flexibility, oxygen-barrier property and water-barrier property.

Owner:TOYO SEIKAN KAISHA LTD

Multi-layer, high barrier packaging materials

InactiveUS20070087212A1Provide moisture resistanceProvide anti-wicking propertySynthetic resin layered productsCellulosic plastic layered productsPaper basedEngineering

A multi-layer, high barrier packaging lid material is adapted for releasably sealing to a plurality of containers including a first container comprised of one polymer and a second container comprised of another polymer. The packaging lid material comprises a paper base with an internal wet strength agent and an anti-wicking agent and having interior and exterior surfaces. A polymer oxygen barrier layer is bonded on the interior surface of the base. A tie layer is on the barrier layer, and a seal-peel layer is on the tie layer. The seal-peel layer is comprised of a blend of a first polymer and a second polymer. When the lid material is heat sealed to a first container the first polymer in the seal-peel layer bonds with the first container while the second polymer in said seal-peel layer functions as a contaminant to provide easy peeling. When the lid material is heat sealed to a second container the second polymer in the seal-peel layer bonds with the second container while the first polymer in the seal-peel layer functions as a contaminant to provide easy peeling.

Owner:STORA ENSO NORTH AMERICA

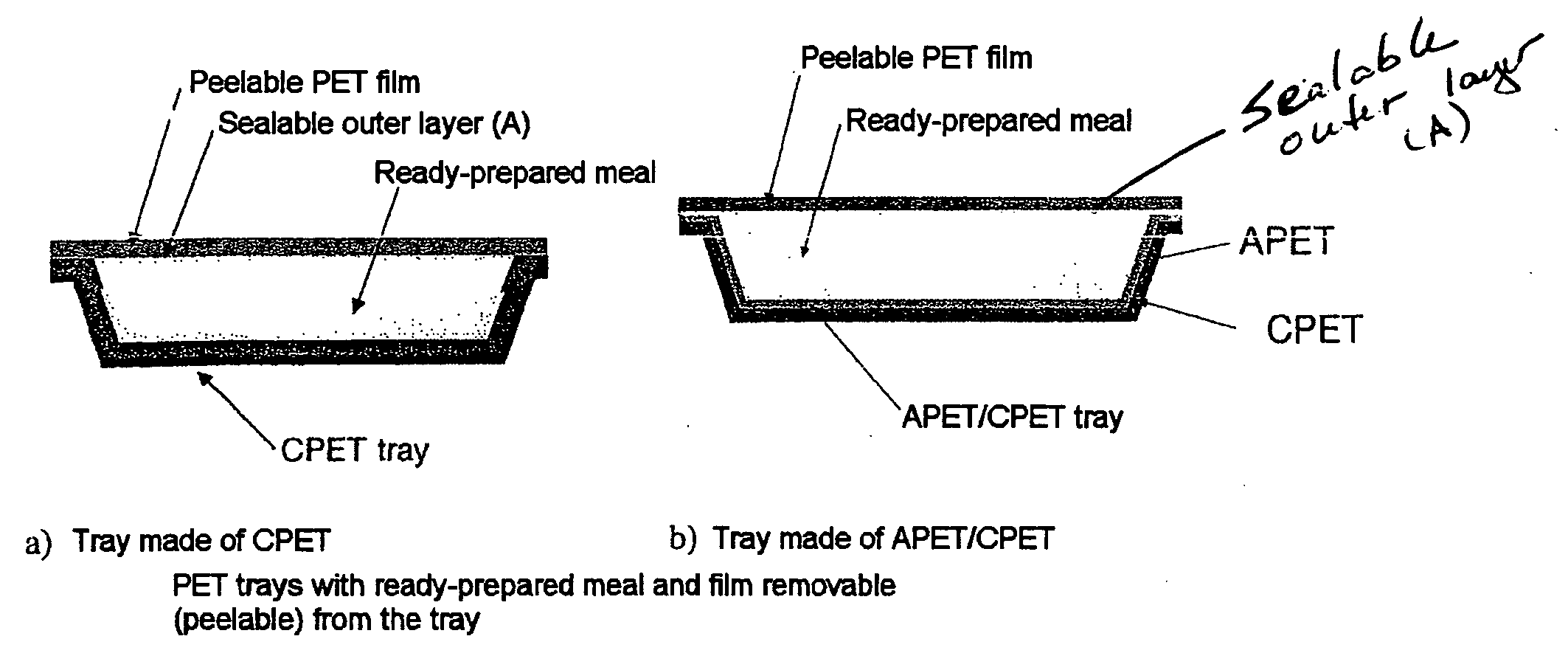

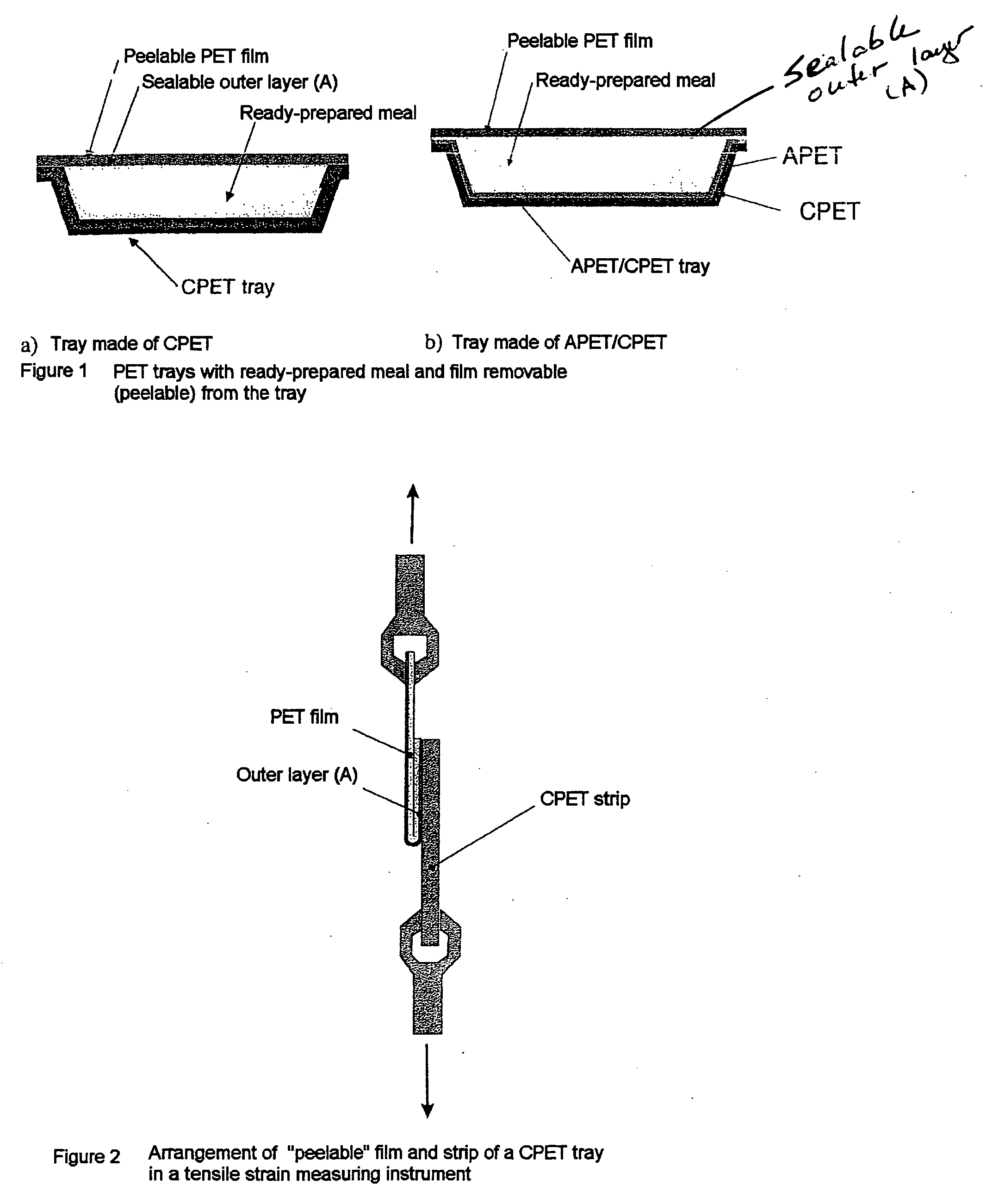

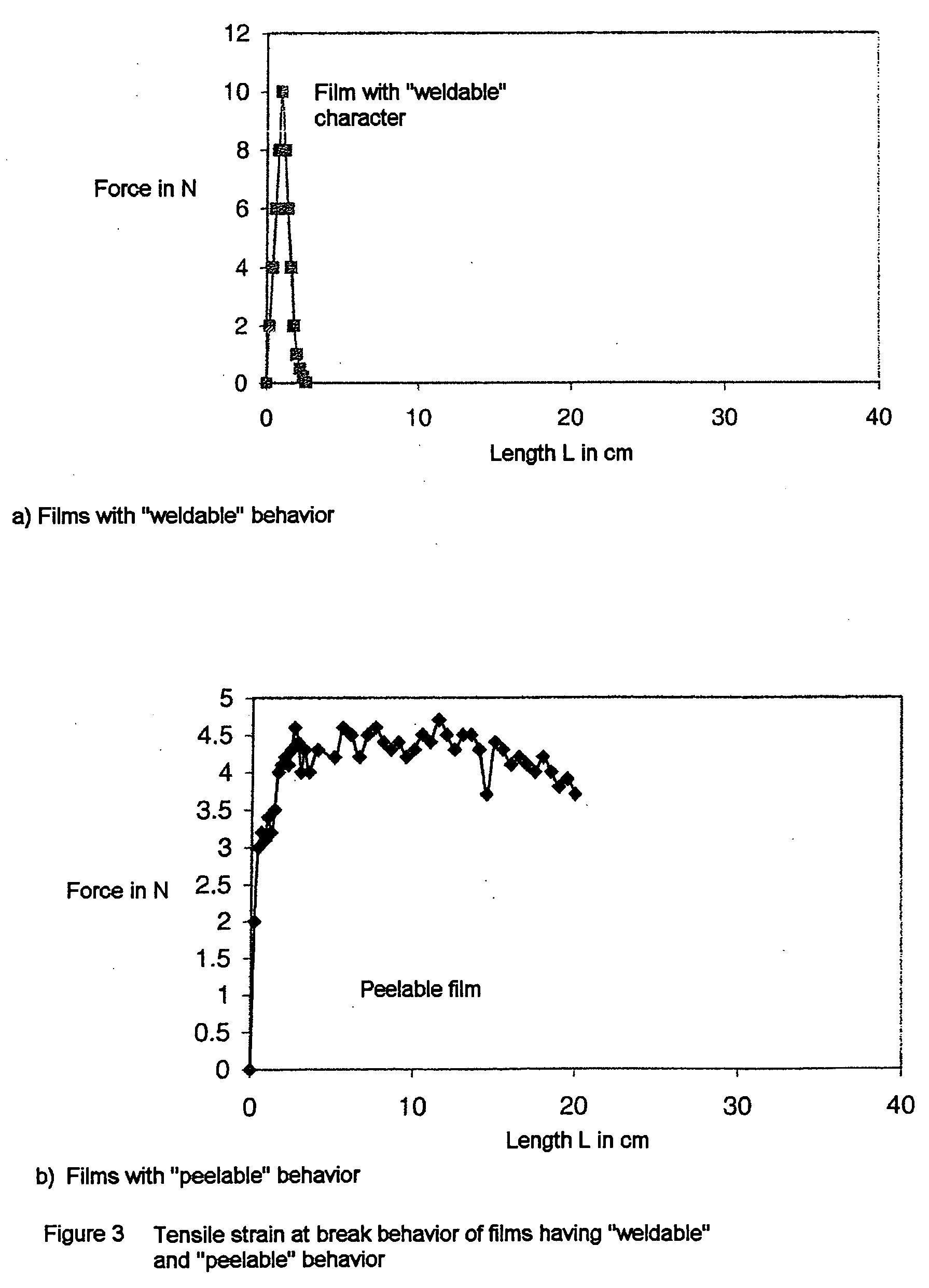

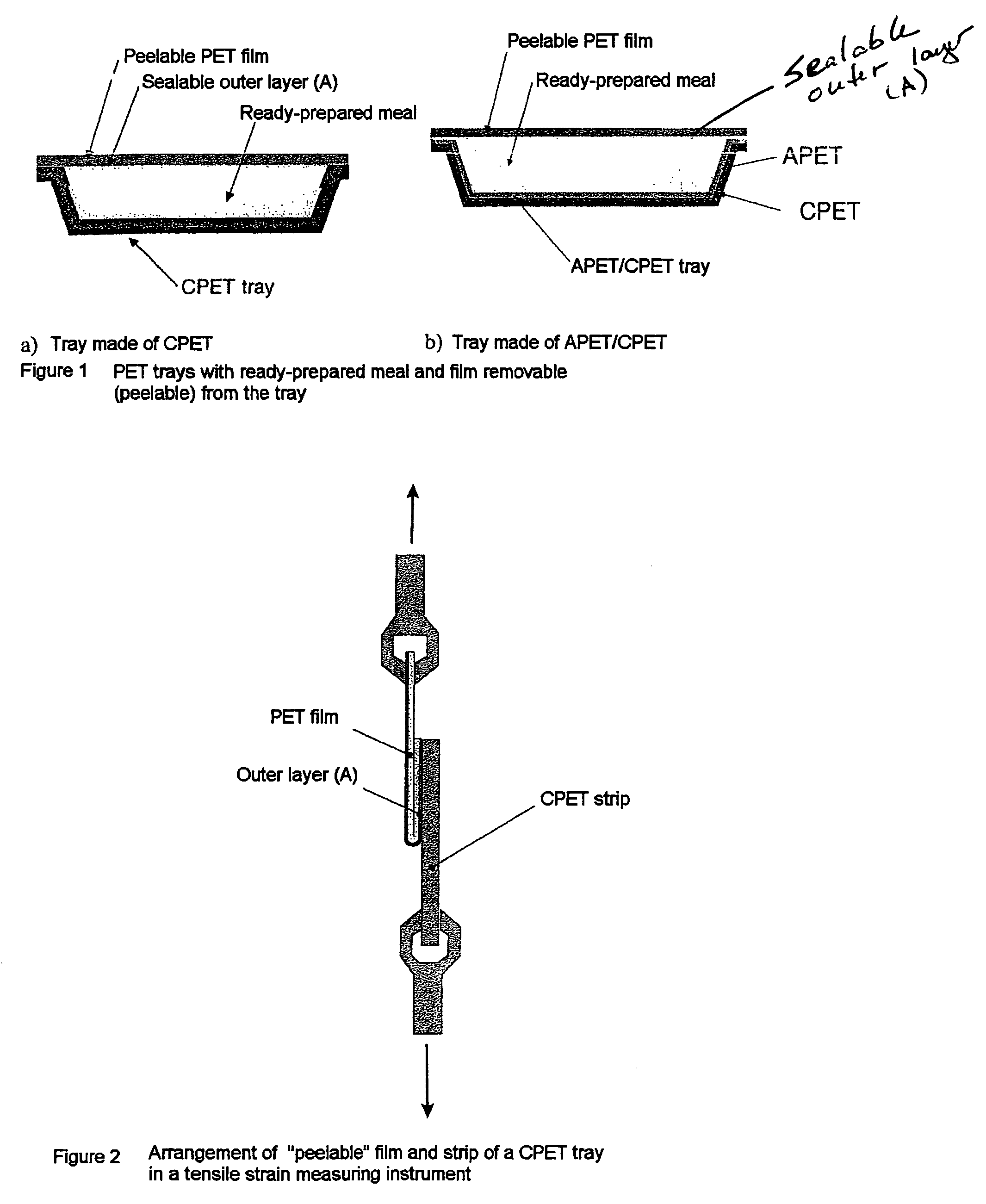

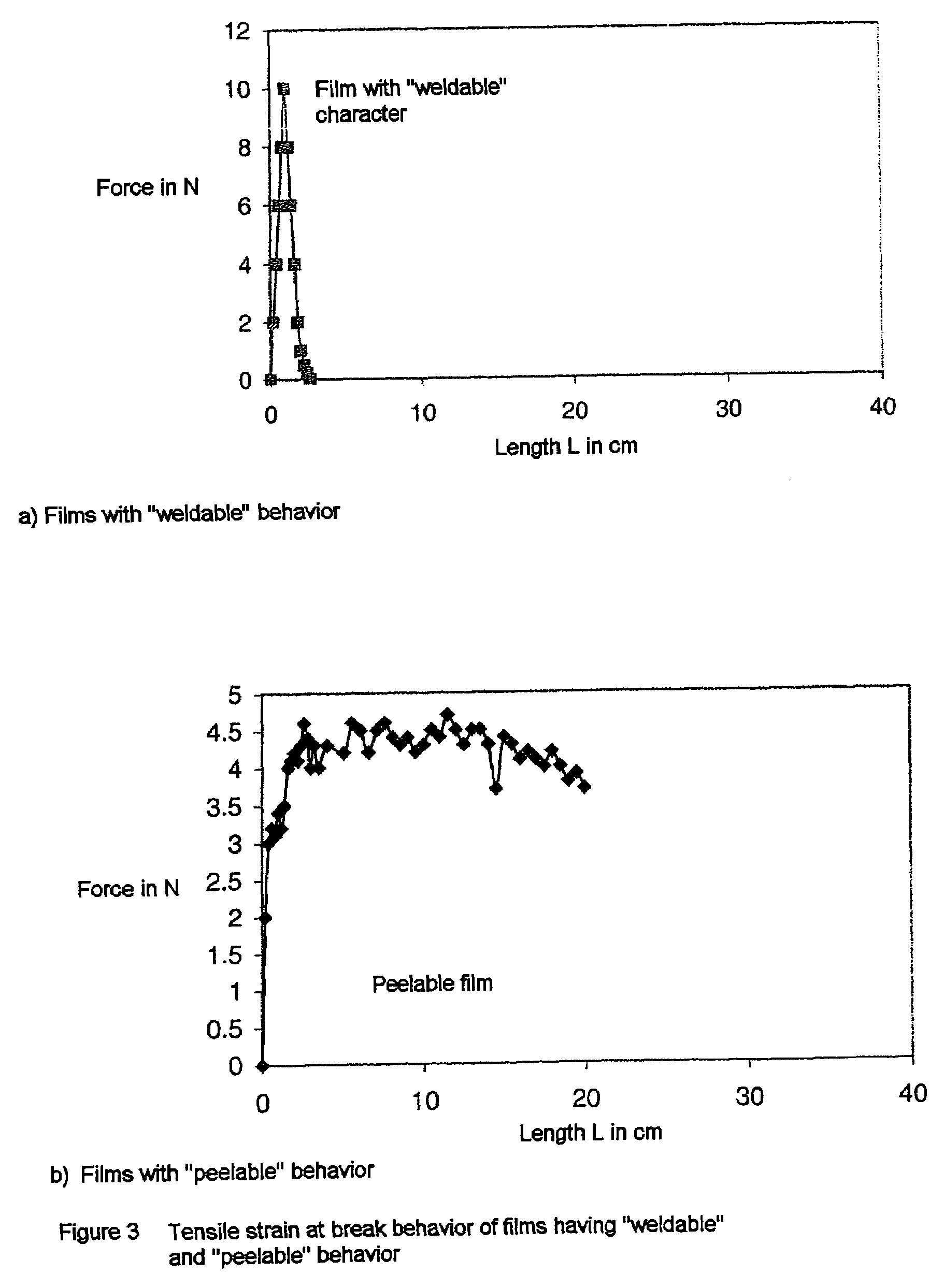

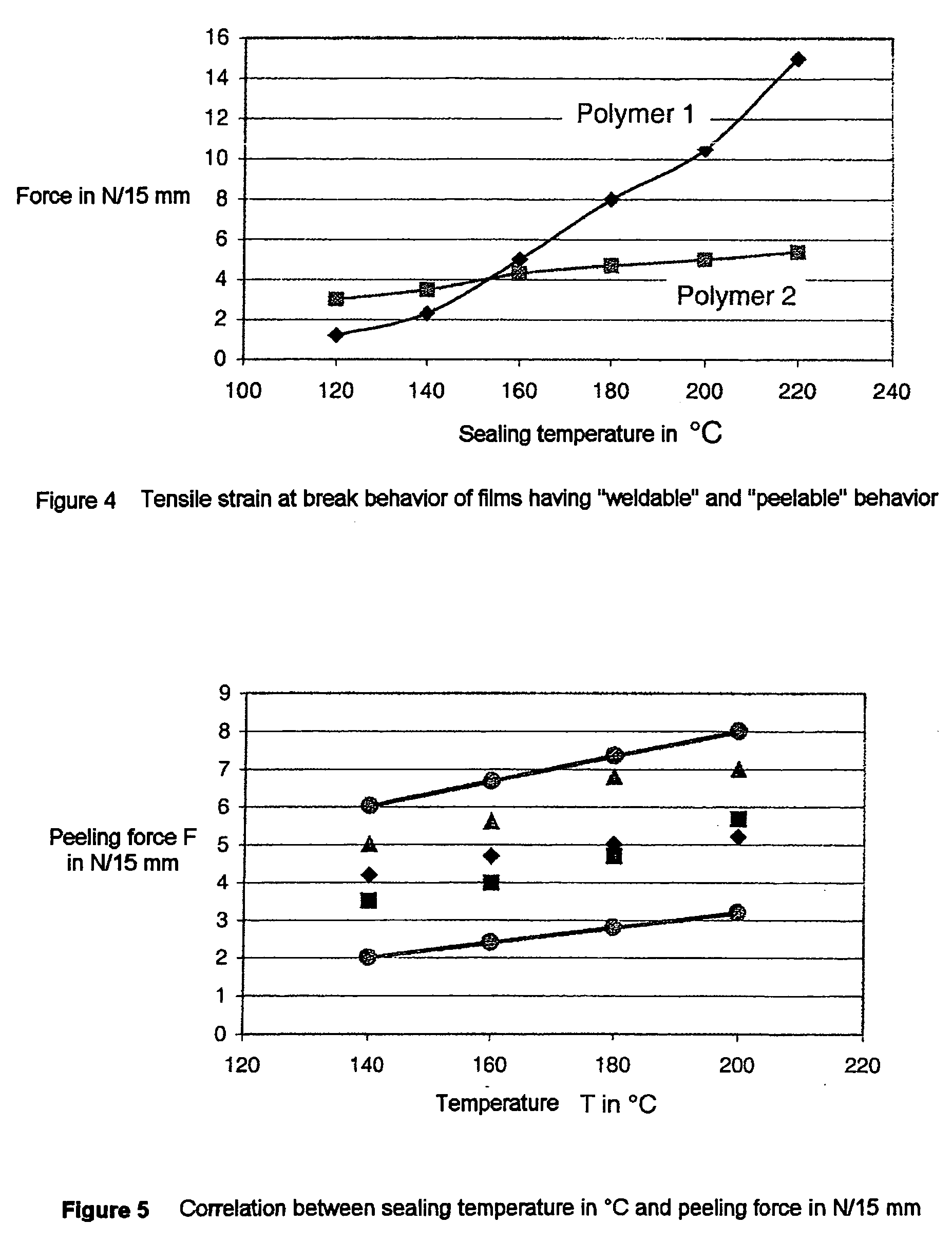

Peelable polyester film having improved oxygen barrier, process for its production and its use

InactiveUS20050100729A1Improve barrier propertiesWrappersRecord information storagePolyesterDicarboxylic acid

Coextruded, biaxially oriented polyester films which have a base layer (B) and have a heatsealable outer layer (A) that can be peeled from APET / CPET and from CPET, where the outer layer (A) comprises from 80 to 99% by weight of polyester and from 1 to 10% by weight of inorganic and / or organic particles with a median diameter d50 of from 2.5 to 12 μm, and where the polyester is composed of from 12 to 89 mol % of units derived from at least one aromatic dicarboxylic acid and of from 11 to 88 mol % of units derived from at least one aliphatic dicarboxylic acid, and the ratio calculated from the particle size d50 of the particles and the layer thickness dA of the outer layer (A) is ≧1, and the base layer (B) comprises poly(-xyleneadipamide). The films of the invention are suitable, owing to their increased oxygen barrier, as a packaging material for foods and other consumable goods or as a lid film for APET / CPET or CPET trays.

Owner:MITSUBISHI POLYESTER FILM

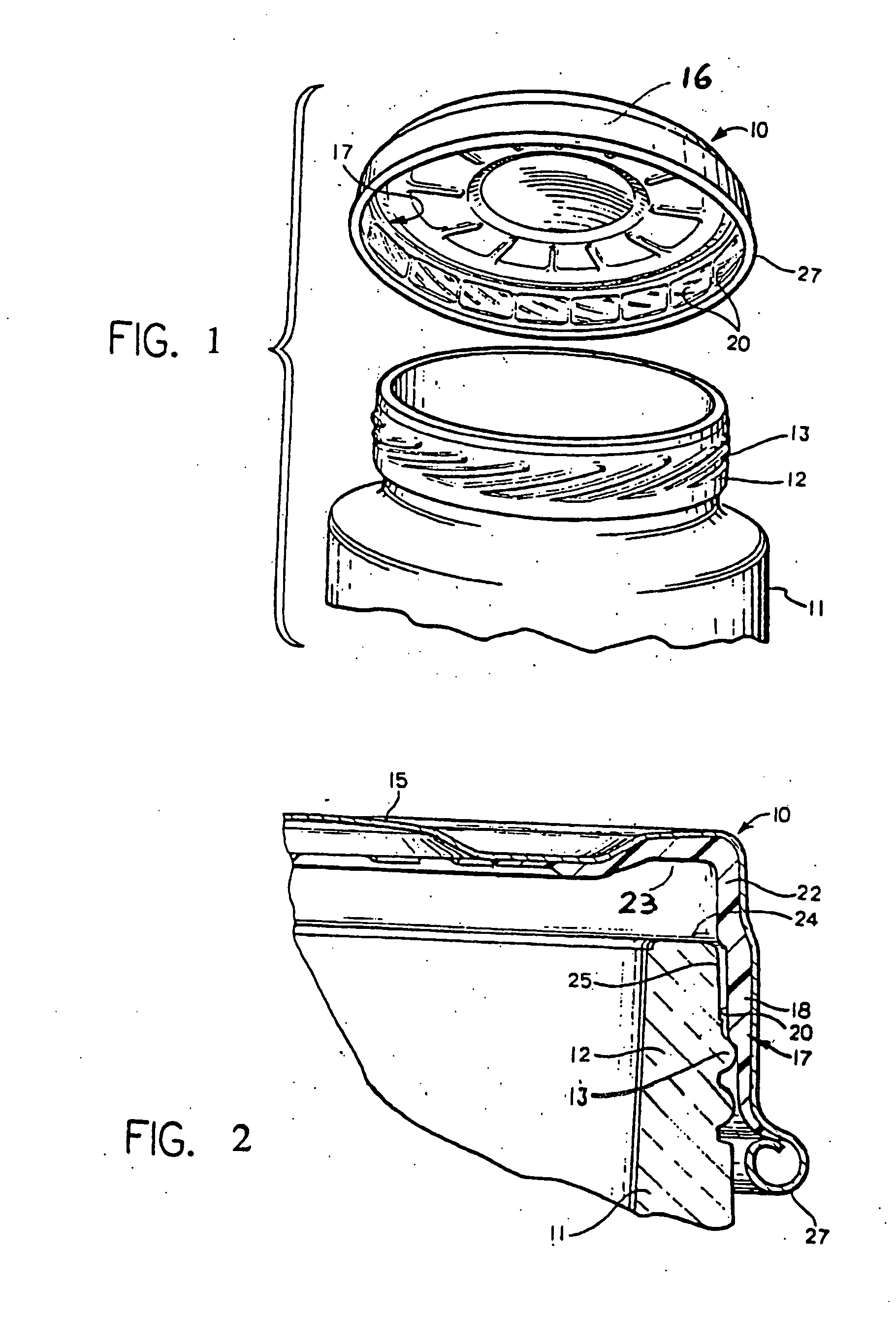

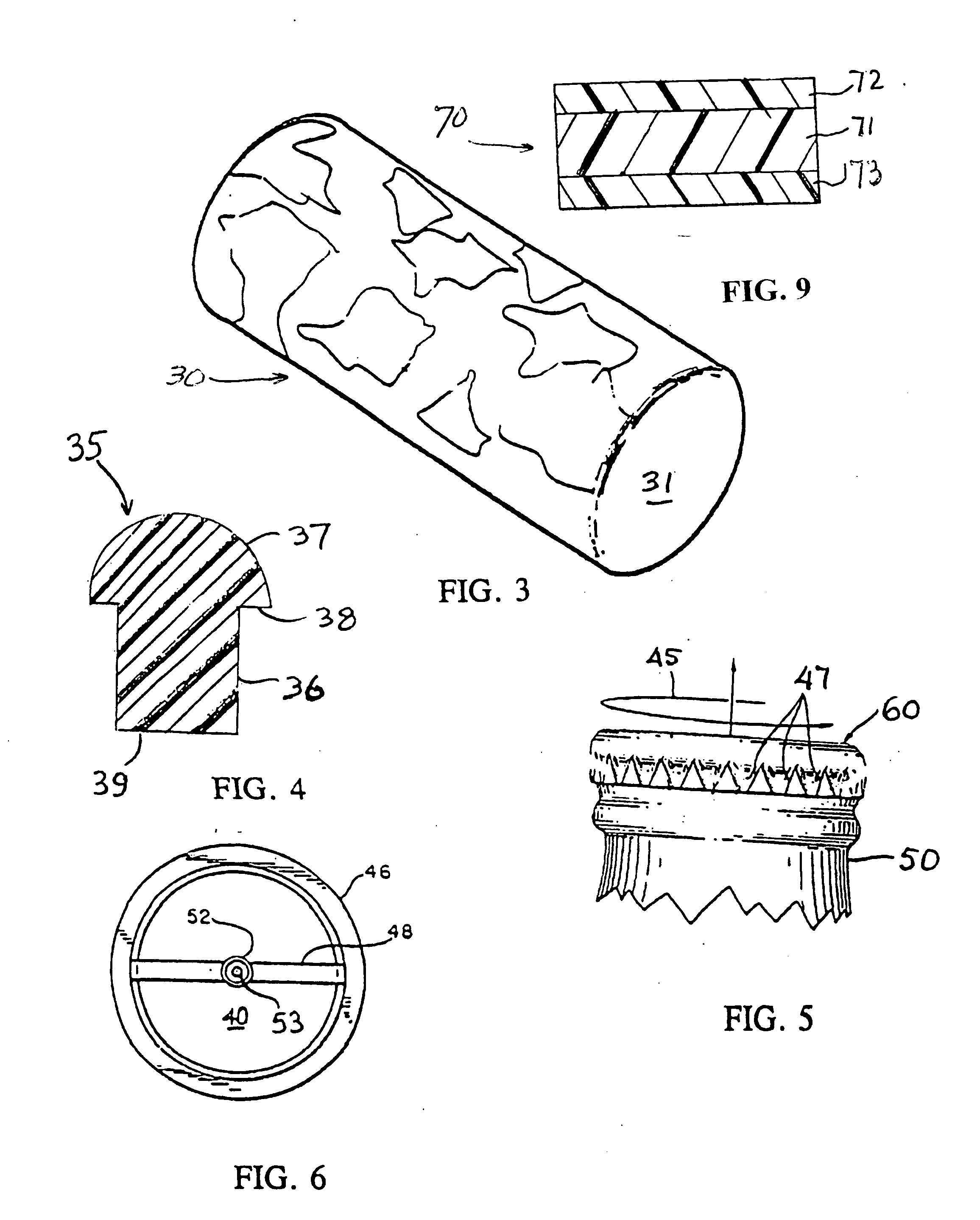

Retortable liners and containers

ActiveUS20100006532A1Improve sealingPrevent leakageSynthetic resin layered productsSealingPolyolefinPlastic packaging

Retort liners and containers including a container body such as a bottle or jar, a closure, and the retort liner, wherein the retort liners exhibit attractive properties such as low compression set under retort conditions, desirable adhesion to a polymeric closure such as a cap or lid, and beneficial oxygen barrier properties. In particular, the retort liners are thermoplastic elastomers formed from compositions including one or more styrenic block copolymers, one or more polyolefins and a softener. In a preferred embodiment, the retortable containers are all plastic packages, wherein the bottle or jar and the closure are thermoplastic compositions and the liner is a thermoplastic elastomer composition.

Owner:TEKNOR APEX

Multi-layer non-carbon metal-based anodes for aluminum production cells and method

InactiveUS6077415AImprove electrochemical activitySolution to short lifeMachining electrodesIsotope separationElectrical batteryOxygen ions

A composite, high-temperature resistant, non-carbon metal-based anode of a cell for the electrowinning of aluminium comprises a metal-based core structure of low electrical resistance, for connecting the anode to a positive current supply, coated with a series of superimposed, adherent, electrically conductive layers. These layers consist of at least one layer on the core structure constituting a barrier substantially impervious to monoatomic oxygen and molecular oxygen; one or more intermediate, protective layers on the oxygen barrier layer which remain inactive in the reactions for the evolution of oxygen gas; and an electrochemically active layer for the oxidation reaction of oxygen ions present at the anode / electrolyte interface into nascent monoatomic oxygen, as well as for subsequent reaction for the formation of gaseous biatomic oxygen. The active layer on the outermost intermediate layer is slowly consumable during electrolysis and protects the intermediate protective layer by inhibiting its dissolution into the electrolyte.

Owner:MOLTECH INVENT

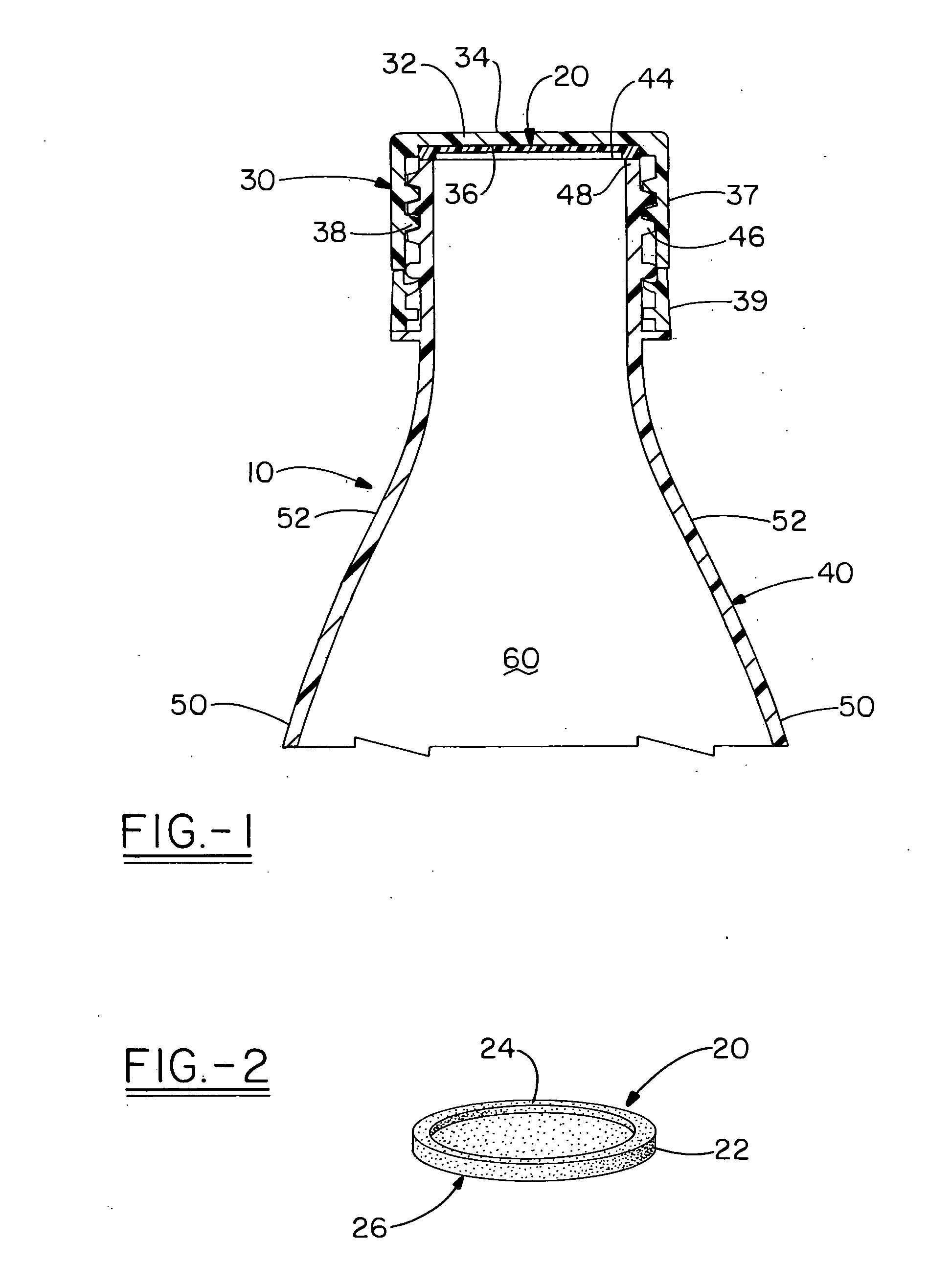

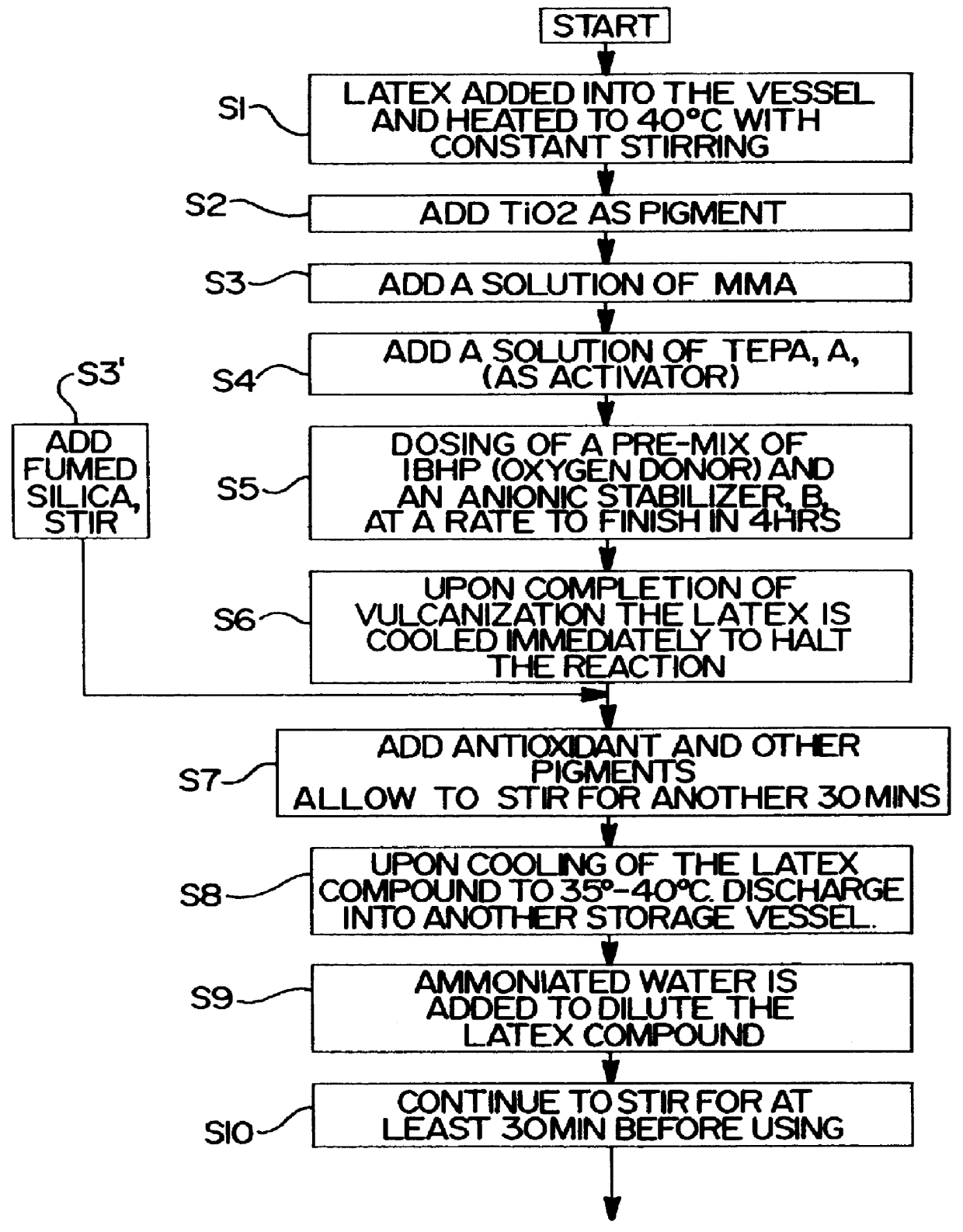

Thin-walled natural rubber latex material substantially free of sulfur and nitrosamines

InactiveUS6051320AEfficient processingEasy to useLayered productsGlovesMicrocrystalline waxGas phase

A thin walled natural rubber latex material is disclosed suitable for forming thin walled products including gloves, dental dams and shields, catheter tubing, penrose surgical drains, finger cots, coverings for body parts, and the like. The thin walled material is formed from a latex emulsion containing natural rubber, sulphur-free, oxygen-donating curing agents, and a strength enhancing agent which may be an inorganic substance such as fumed silica and / or an organic substance such as monomers and polymers of families of acrylics and esters. The emulsion also preferably includes microcrystaline wax as an oxygen barrier, and the material is also provided with a heat resistant and water resistant coating which blocks transfer of latex proteins from the material and enhances slip of the material.

Owner:HAU HO TEON +1

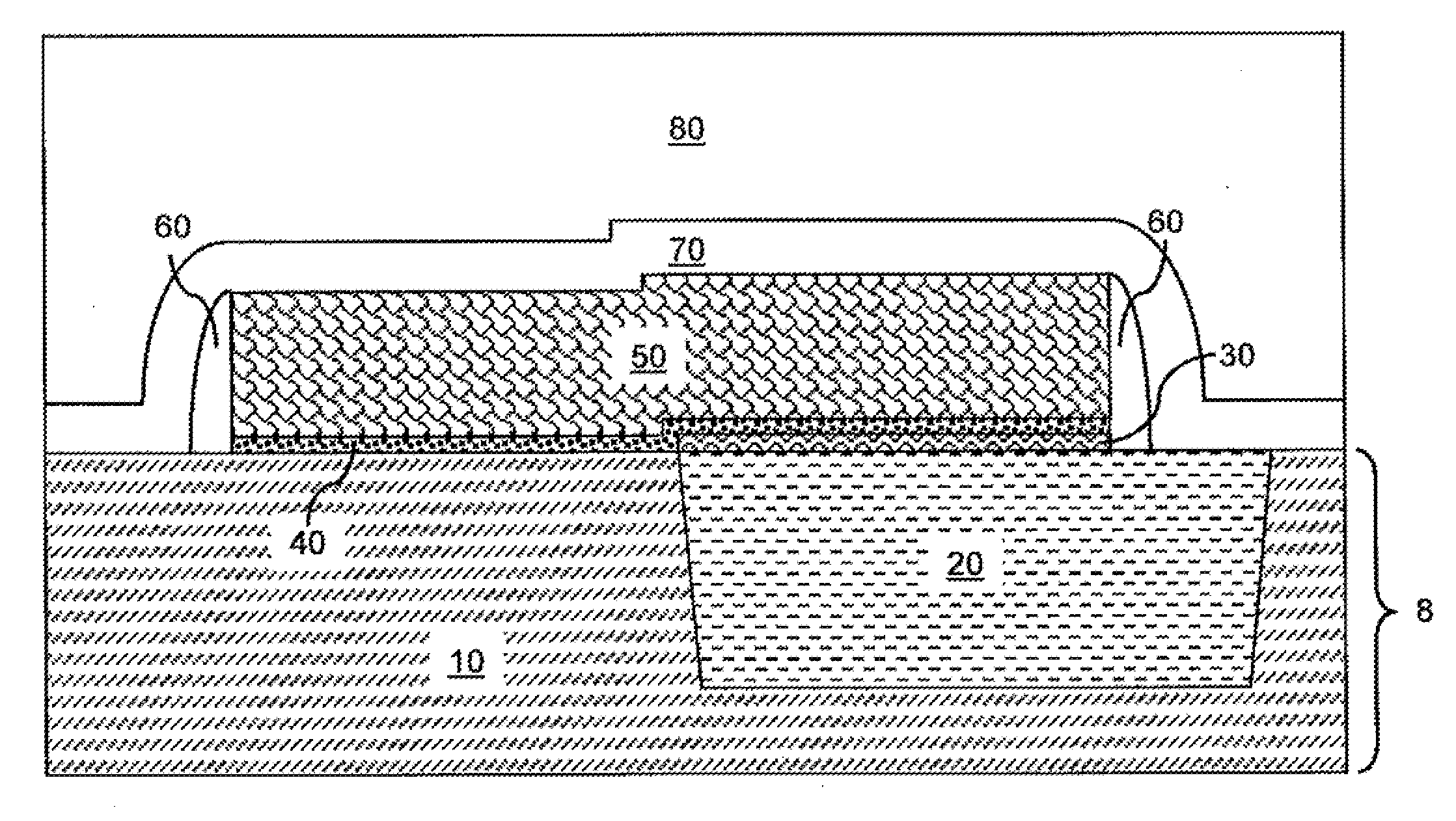

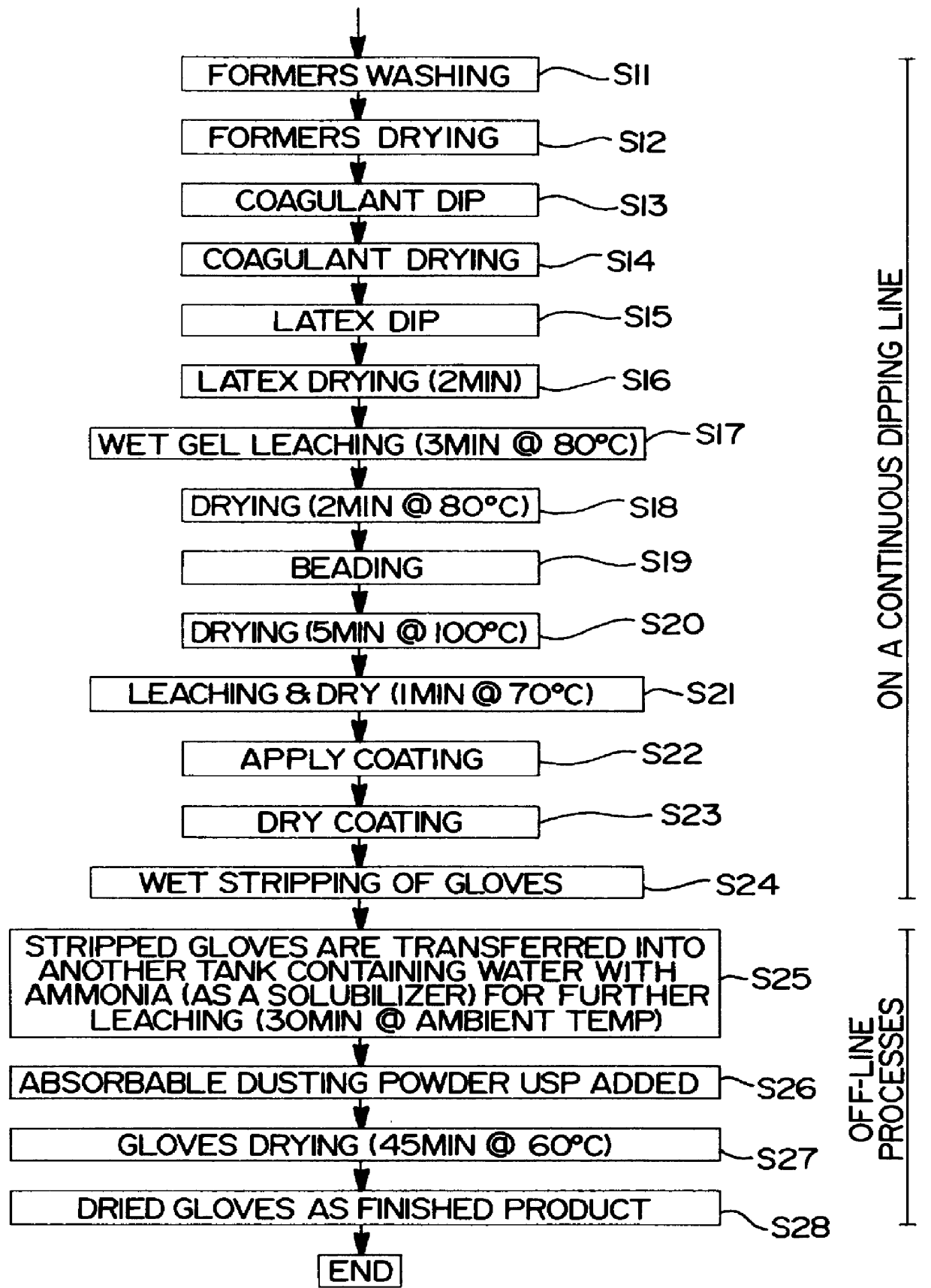

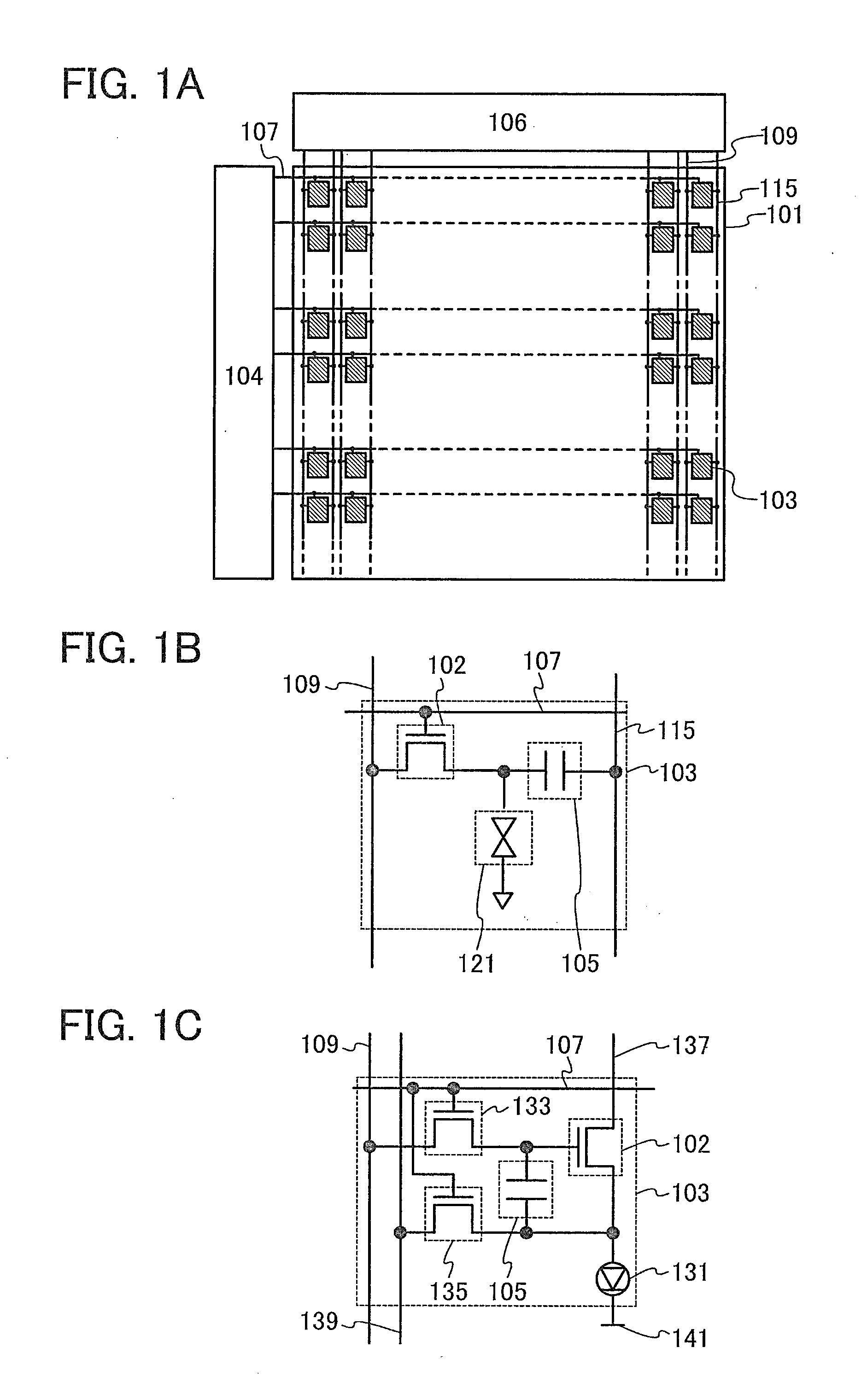

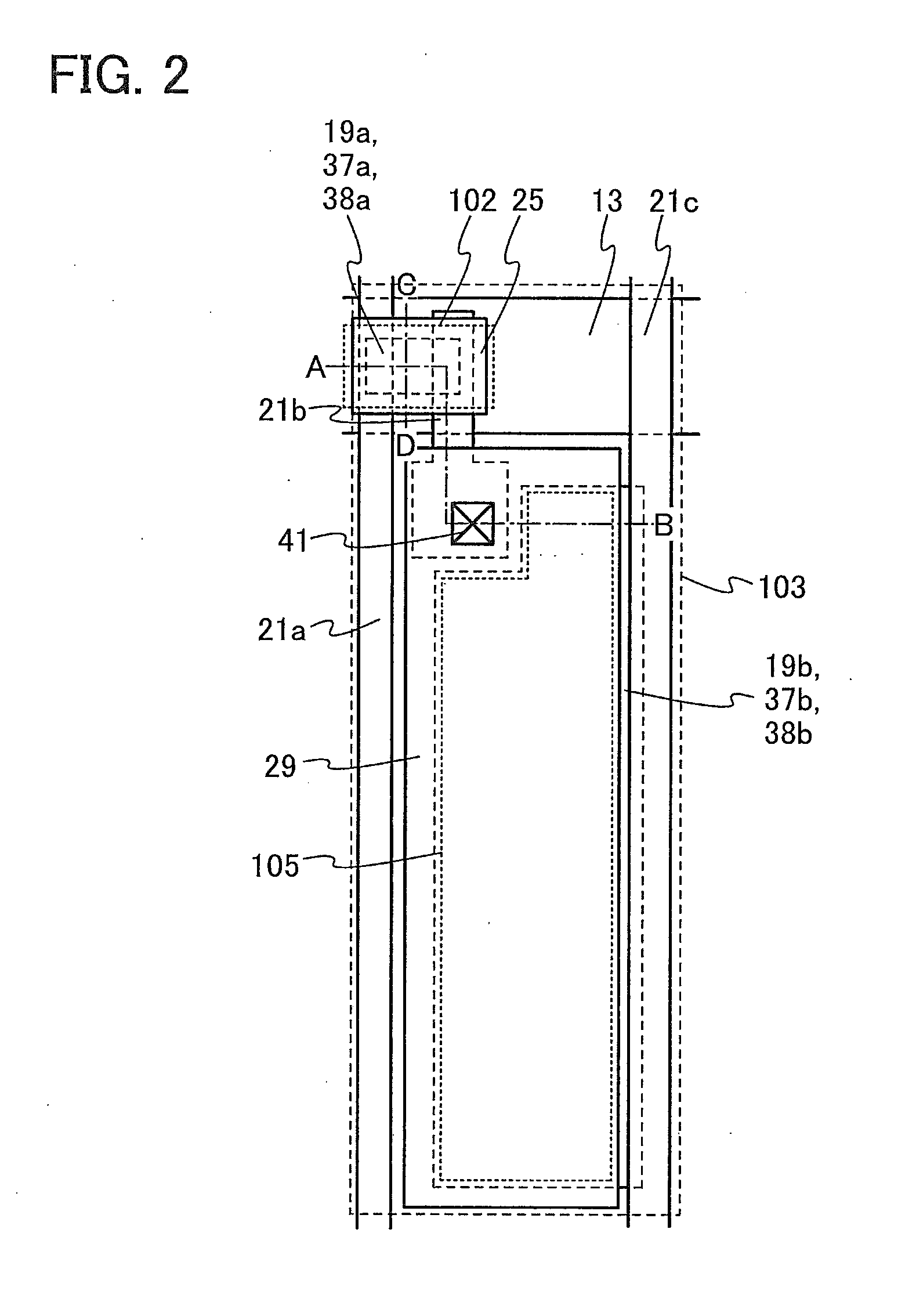

Semiconductor device

ActiveUS20140339539A1Reduce the number of stepsIncreasing area occupiedTransistorElectroluminescent light sourcesCapacitanceOxygen barrier

A semiconductor device including a transistor having excellent electrical characteristics is provided. Alternatively, a semiconductor device having a high aperture ratio and including a capacitor capable of increasing capacitance is provided. The semiconductor device includes a gate electrode, an oxide semiconductor film overlapping the gate electrode, an oxide insulating film in contact with the oxide semiconductor film, a first oxygen barrier film between the gate electrode and the oxide semiconductor film, and a second oxygen barrier film in contact with the first oxygen barrier film. The oxide semiconductor film and the oxide insulating film are provided on an inner side of the first oxygen barrier film and the second oxygen barrier film.

Owner:SEMICON ENERGY LAB CO LTD

Peelable polyester film having improved oxygen barrier, process for its production and its use

Coextruded, biaxially oriented polyester films which have a base layer (B) and have a heatsealable outer layer (A) that can be peeled from APET / CPET and from CPET, where the outer layer (A) comprisesfrom 80 to 99% by weight of polyester andfrom 1 to 10% by weight of inorganic and / or organic particles with a median diameter d50 of from 2.5 to 12 μm, and wherethe polyester is composed offrom 12 to 89 mol % of units derived from at least one aromatic dicarboxylic acid and offrom 11 to 88 mol % of units derived from at least one aliphatic dicarboxylic acid,and the ratio calculated from the particle size d50 of the particles and the layer thickness dA of the outer layer (A) is ≧1, and the base layer (B) comprises poly(-xyleneadipamide). The films of the invention are suitable, owing to their increased oxygen barrier, as a packaging material for foods and other consumable goods or as a lid film for APET / CPET or CPET trays.

Owner:MITSUBISHI POLYESTER FILM

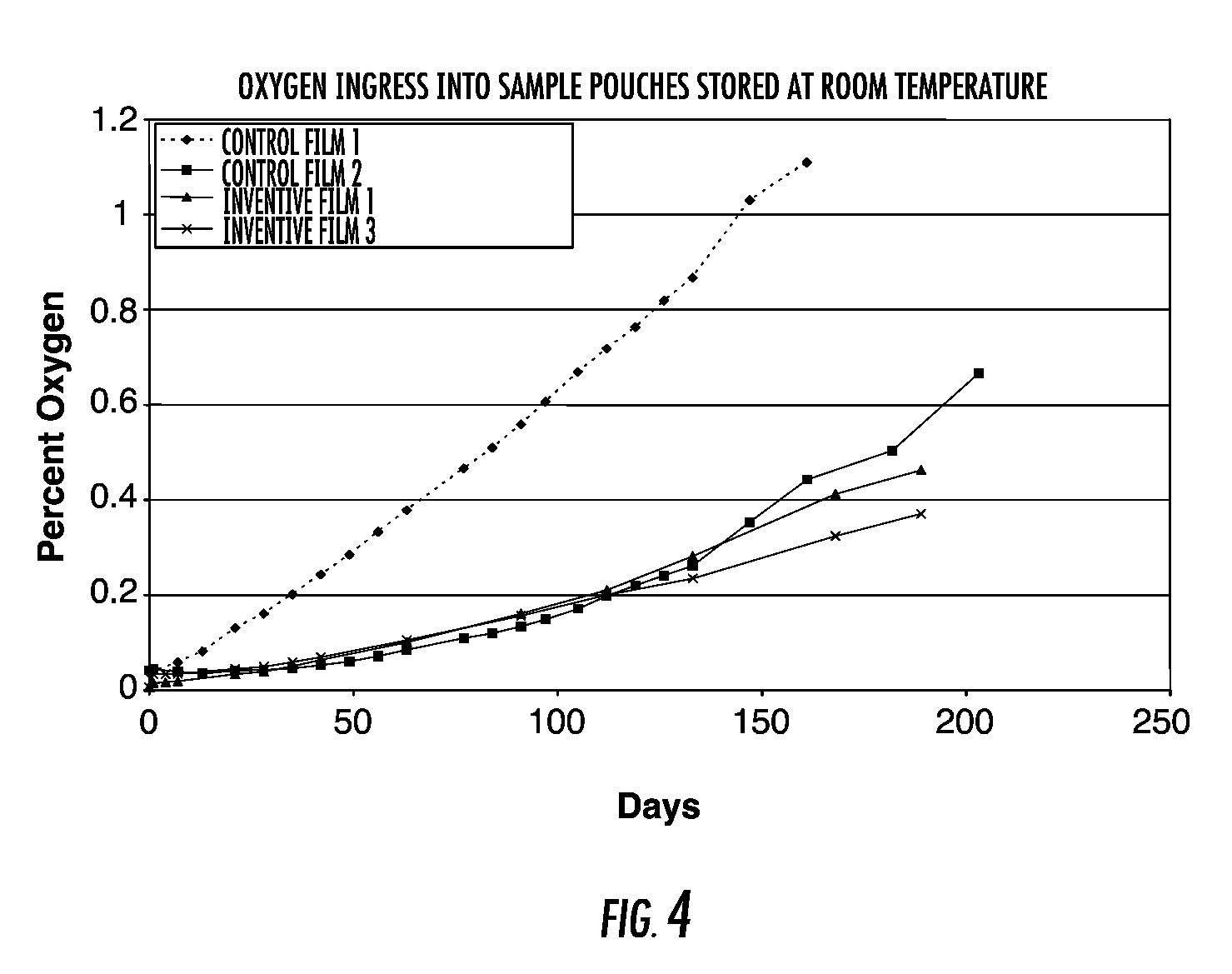

Ultra high oxygen barrier films and articles made therefrom

Oxygen barrier films exhibiting high oxygen scavenging capability suitable for extended shelf-life, packaging applications. These films comprise a polyamide homopolymer, copolymer, or blends thereof; an ethylene vinyl alcohol copolymer; an oxidizable polydiene; and at least one metal salt catalyst. These films are particularly suited to making high barrier, retortable packaging structures such as pouches, containers etc. Such articles are useful for packaging a variety of oxygen-sensitive foods, beverage, medical and health care products.

Owner:ADVANSIX RESINS & CHEM LLC

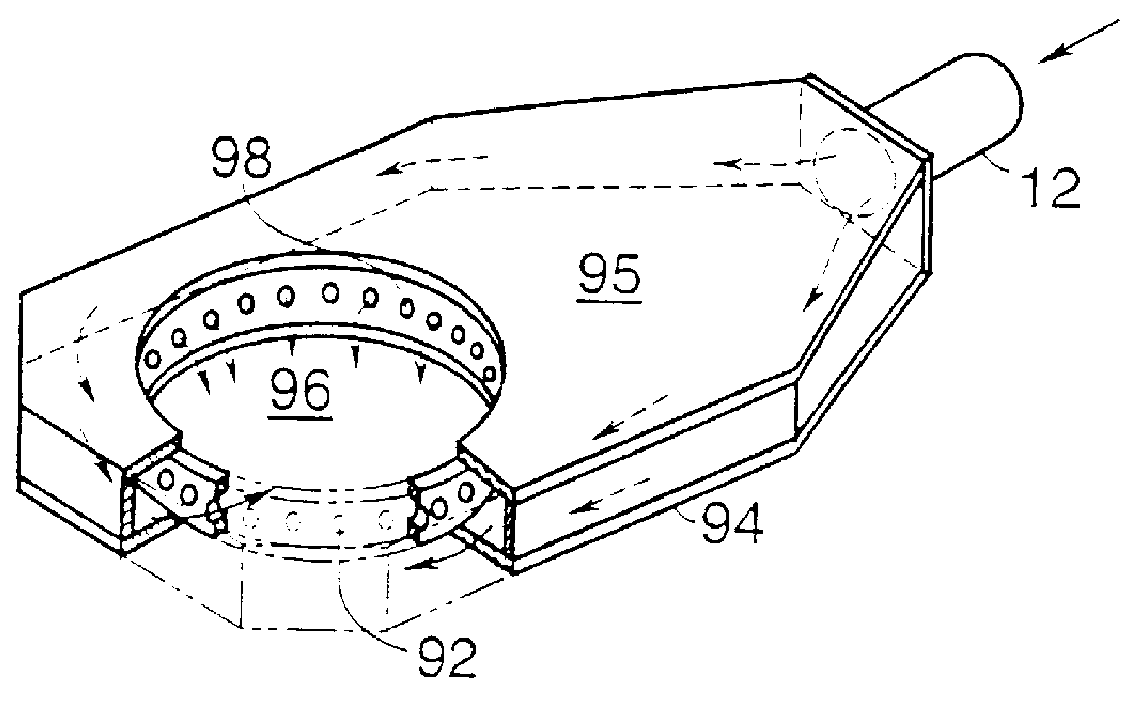

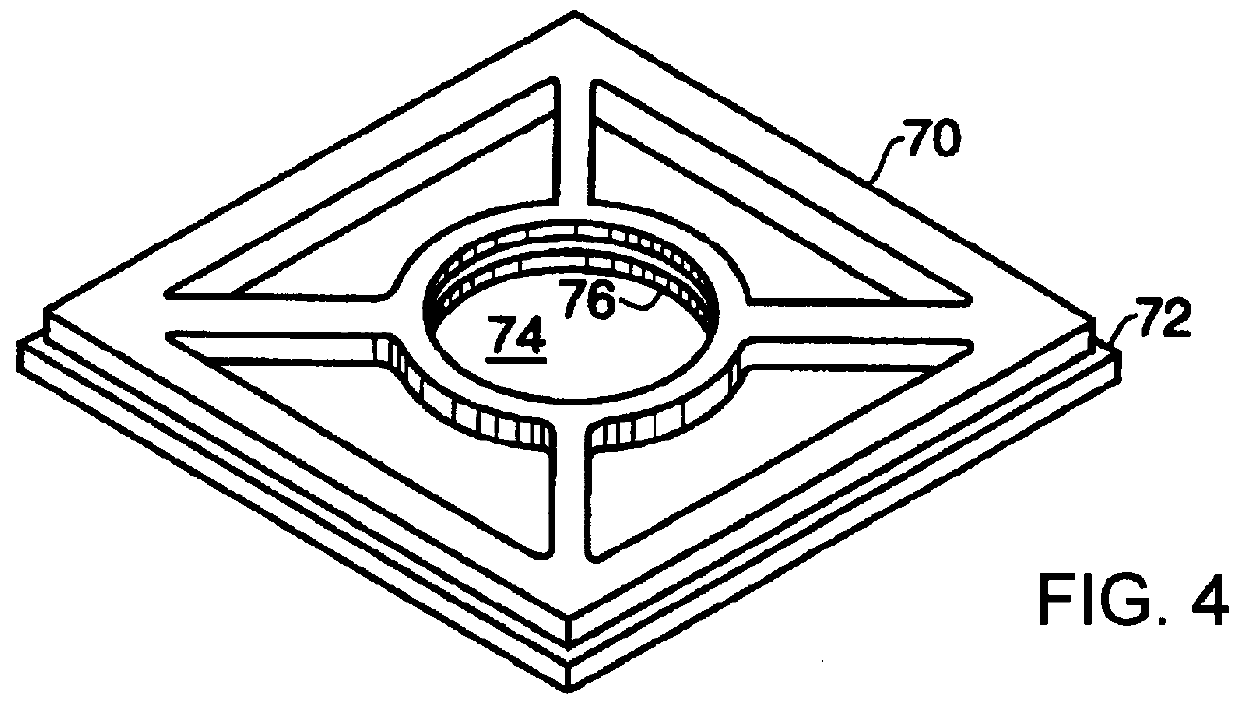

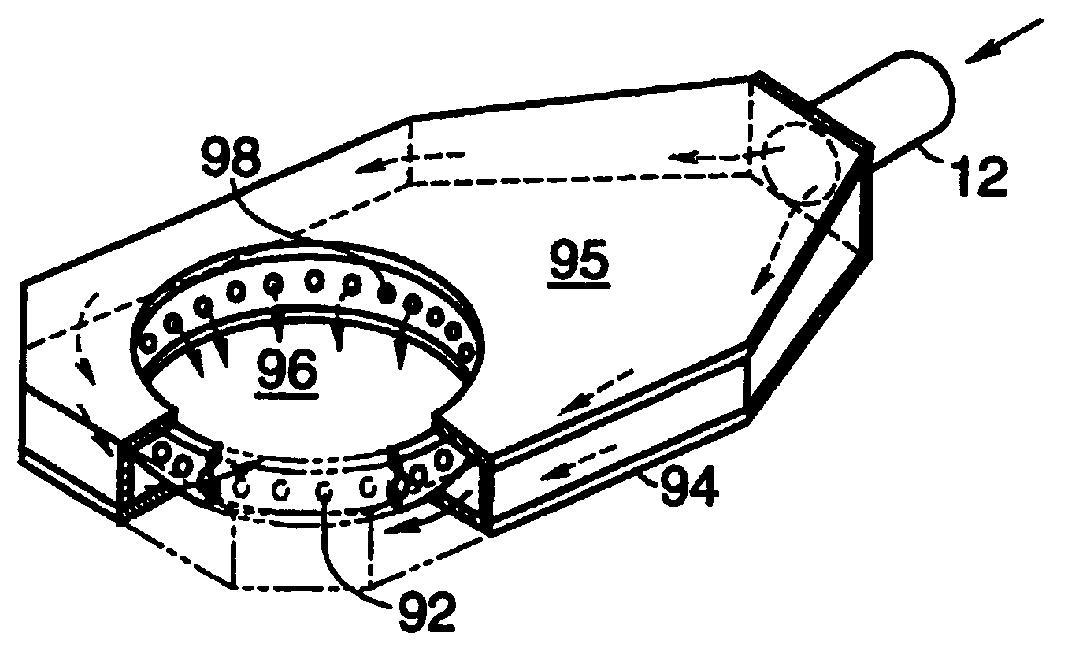

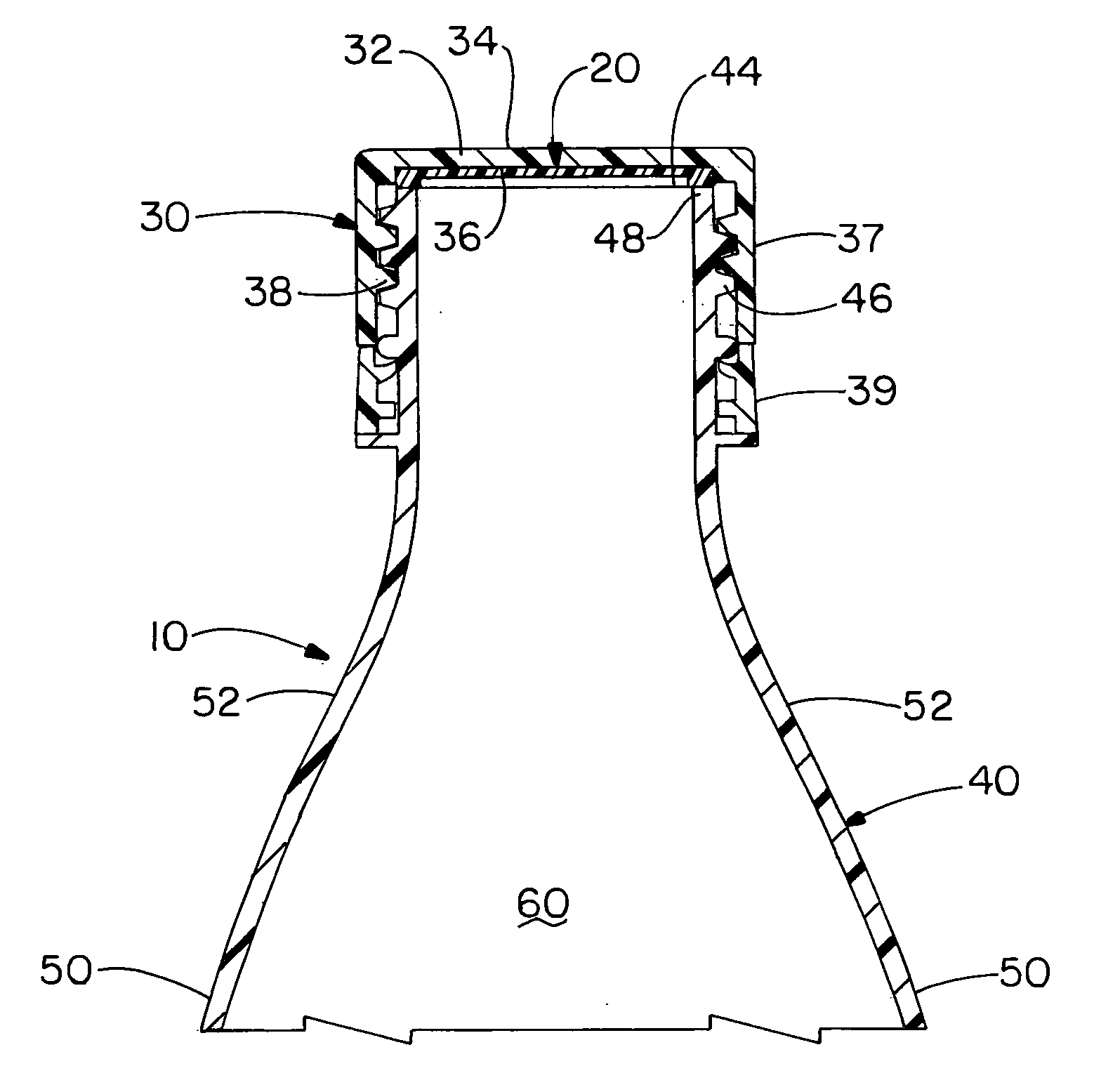

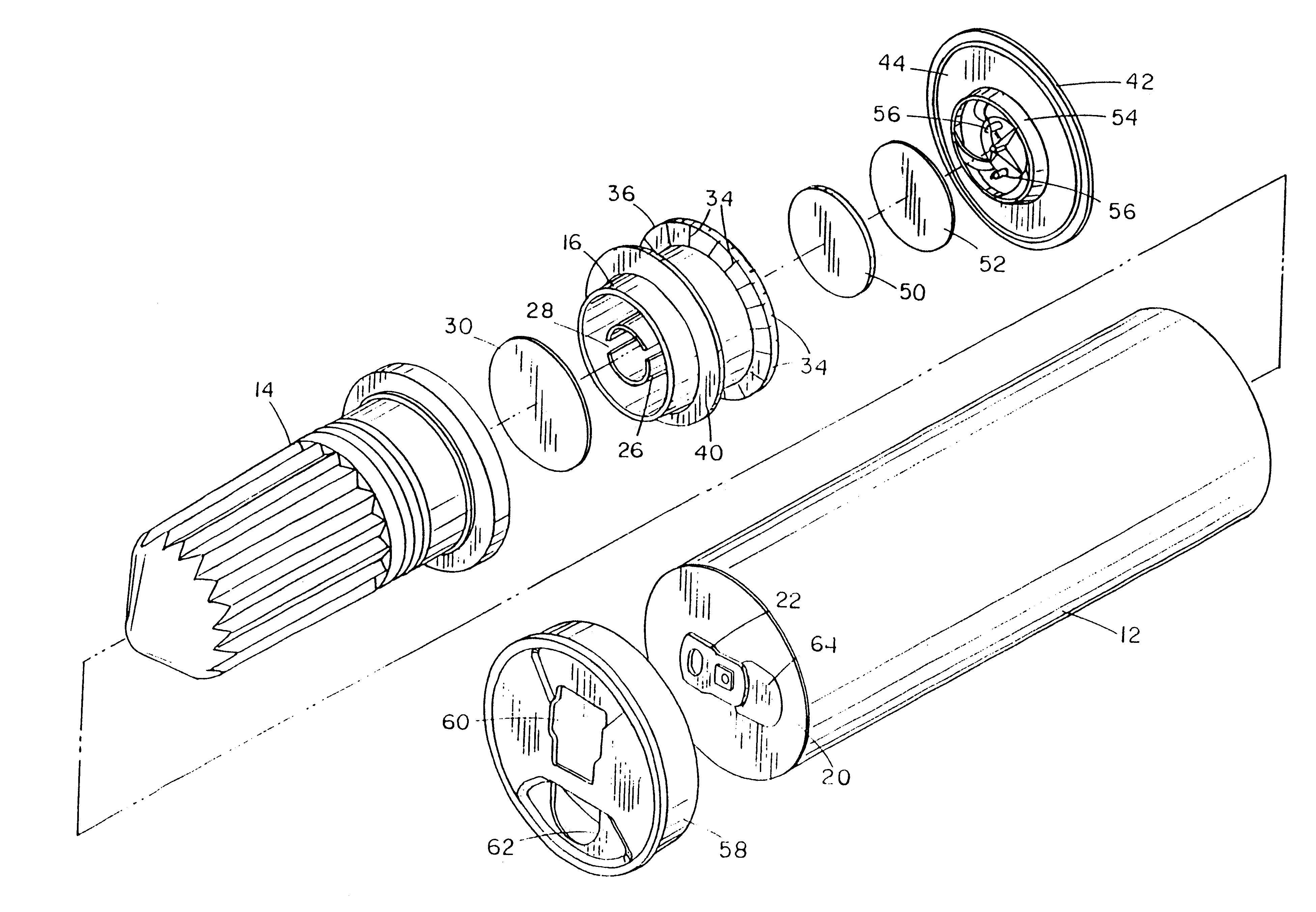

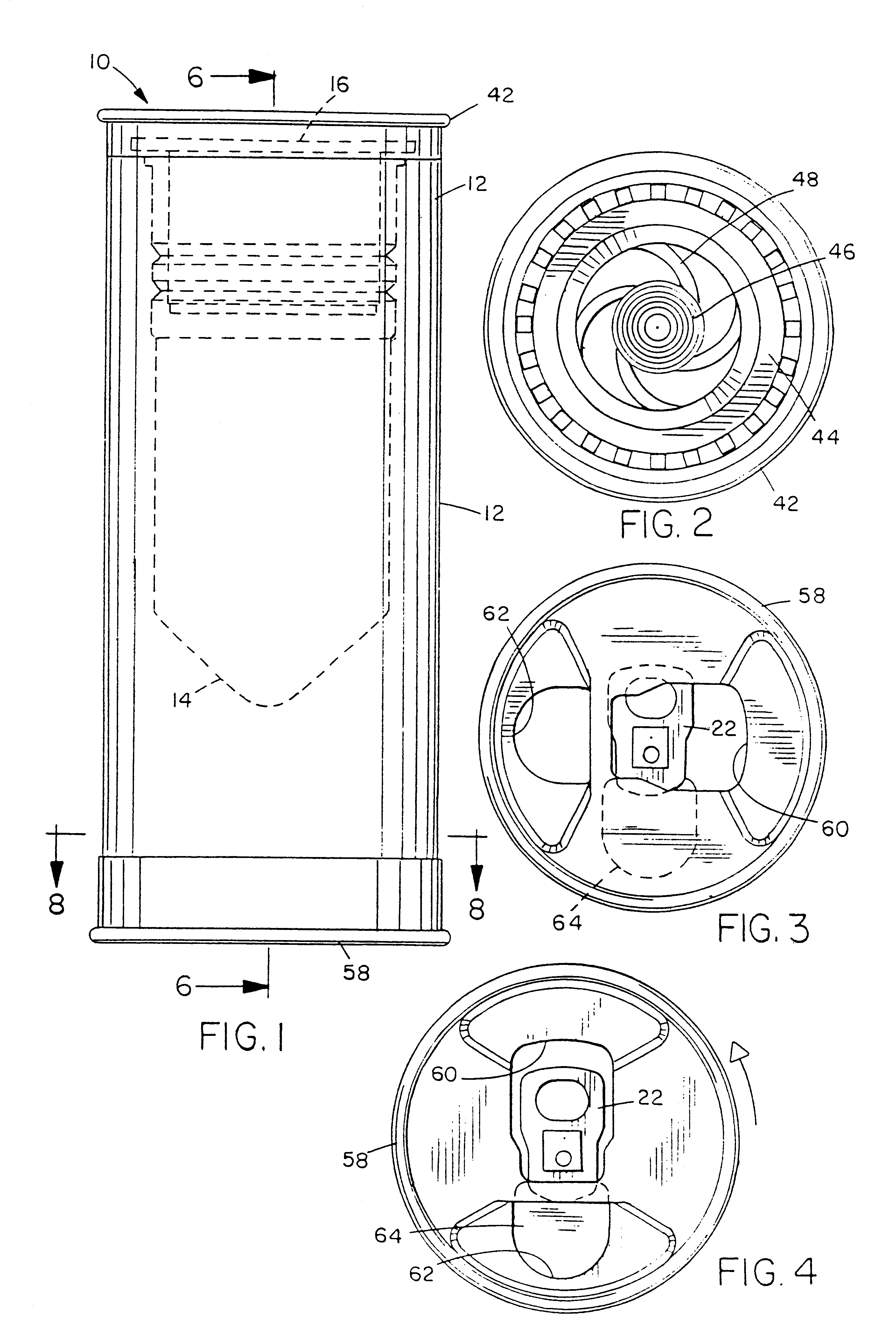

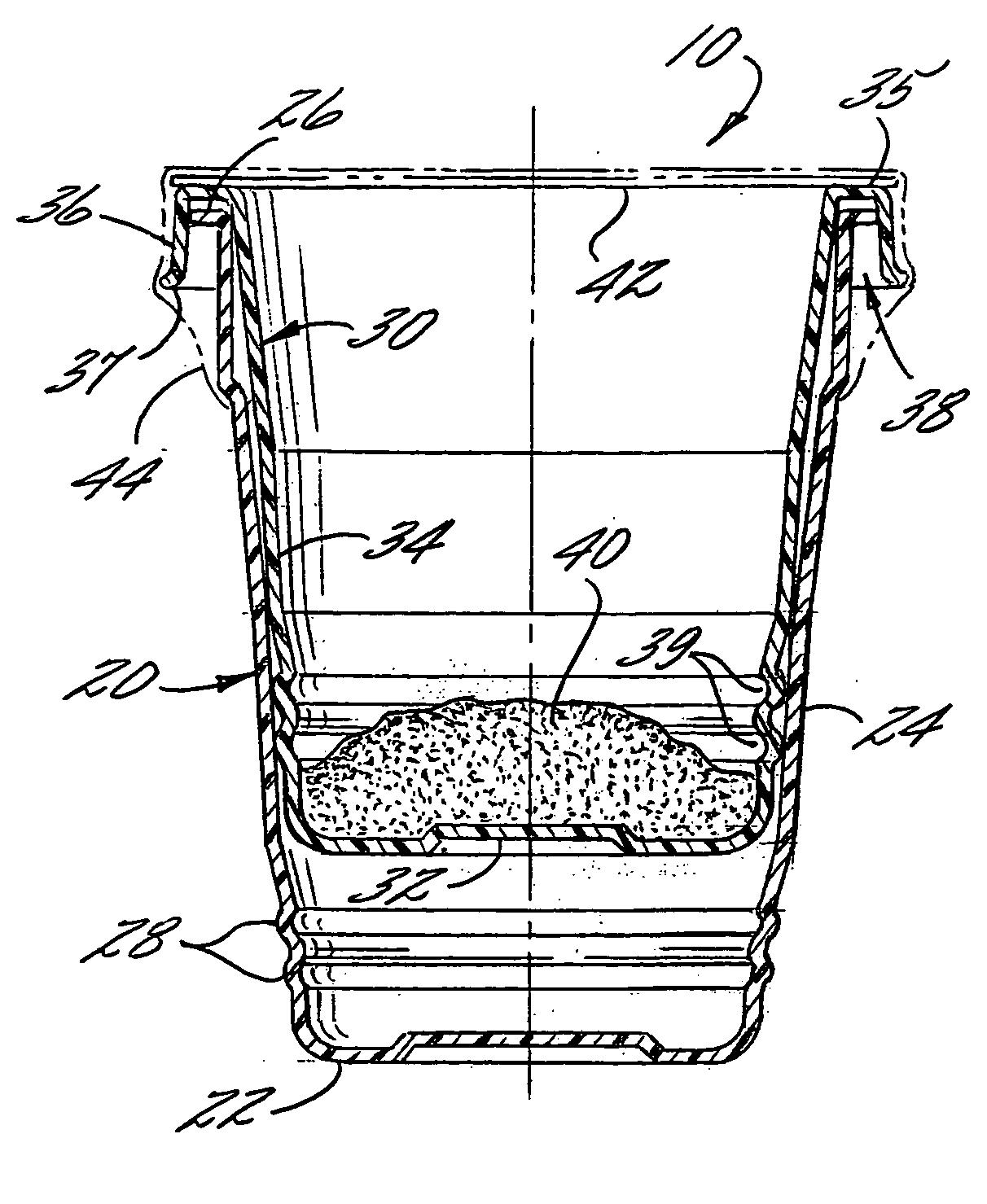

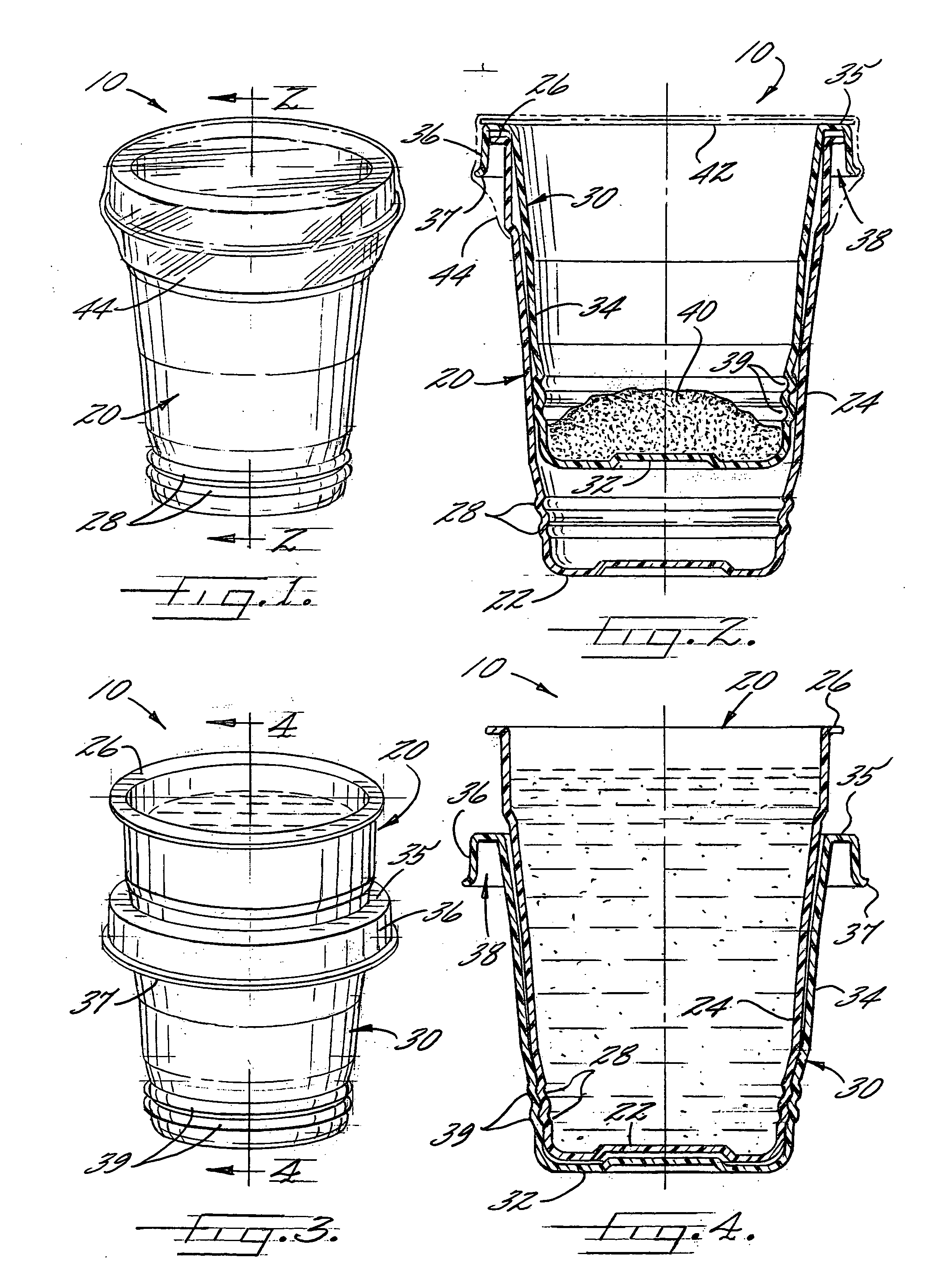

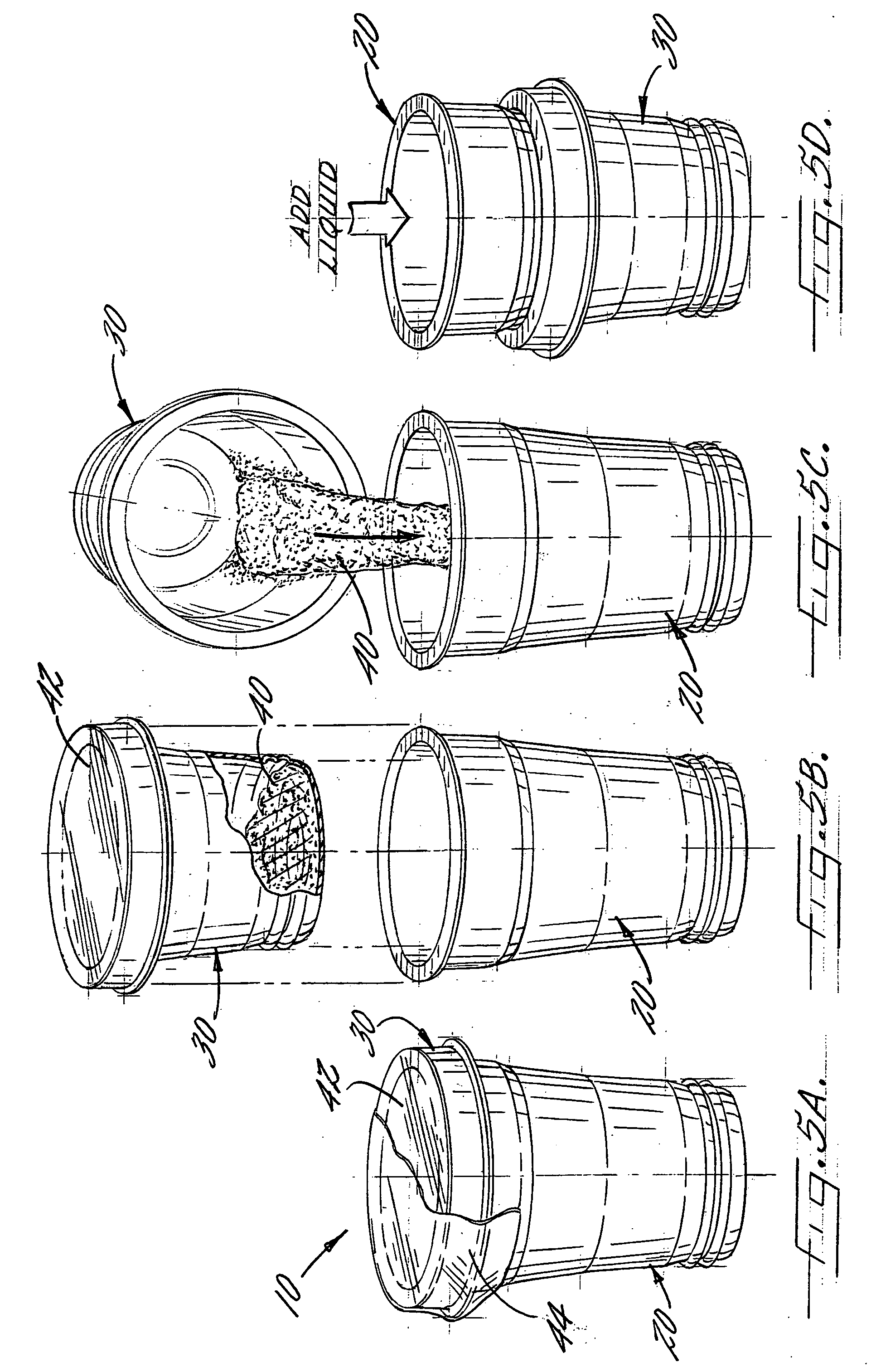

Container with integral module for heating or cooling the contents and method for its manufacture

InactiveUS6351953B1Exothermal chemical reaction heat productionOther heat production devicesSpin weldingChemical reaction

A container having a container body, a thermic module at one end of the body, and a closure at the other end of the body initiates an internal exothermic (or, alternatively, endothermic) chemical reaction to heat its contents when a user actuates the thermic module. A plastic thermic module body is spin-welded to a plastic container body by rotating one relative to and in contact with the other. The container body has multiple layers, including an inner layer such as a so-called oxygen barrier layer that inhibits oxidation and spoilage of the contents, and spin-welding the container body to the module body seals the otherwise-exposed oxygen barrier layer against air or moisture intrusion. The container includes a rotatable cover adhered to the container end over the closure with heat-sensitive adhesive that prevents a user from accessing the contents until a certain temperature is reached. The thermic module further includes a seal between an inner actuator button and an outer actuator button that seals the thermic module reactants against moisture intrusion prior to use, and is punctured when the thermic module is actuated. The thermic module may also include a filter disposed in interfering relation with the thermic module vents, including a portion between the inner and outer actuator buttons, to block egress of any particles of the solid reactant or the reaction product.

Owner:AURA LTD

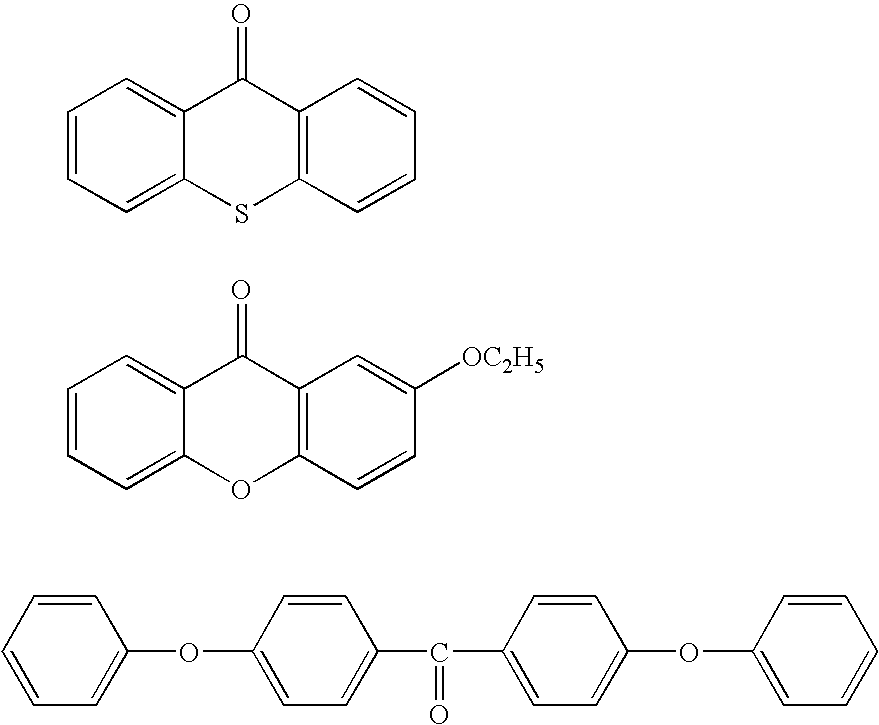

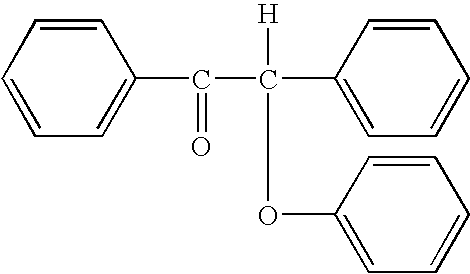

Planographic printing plate precursor and stack thereof

ActiveUS20070231740A1Maximize advantageous effectPhotosensitive materialsPhotomechanical apparatusCompound (substance)Engineering

The present invention provides a planographic printing plate precursor, including: a support; and a photosensitive layer containing a polymerizable compound; an oxygen barrier layer; and a protective layer containing a filler (preferably an organic resin particle), the layers being formed in this order on the support. The present invention also provides a stack of planographic printing plate precursors, produced by stacking the planographic printing plate precursors with the photosensitive layer side outermost layer and the support side rear surface of the adjacent plate precursor in direct contact with each other.

Owner:FUJIFILM CORP

Food product package having nested cup and cup holder

InactiveUS20050220939A1Prevent penetrationComfortable to holdClosuresPackaging foodstuffsEngineeringFood packaging

A package for a food product that is packaged in dry form and is prepared by adding liquid such as hot water, comprises a primary container formed as a tapered plastic drinking cup, and a cup holder also formed as a tapered plastic cup. The primary container and cup holder are configured so they are nestable inside each other. The package is convertible between a packaged configuration in which the cup holder is nested inside the primary container, and a serving configuration in which the primary container is nested inside the cup holder. The food product can be contained in the primary container or in the cup holder. A membrane can seal the cup holder closed. An outer wrapper such as a shrink band or label can hold the cup holder in the primary container and provide tamper evidence, and can also serve as a moisture and / or oxygen barrier.

Owner:SONOCO DEV INC

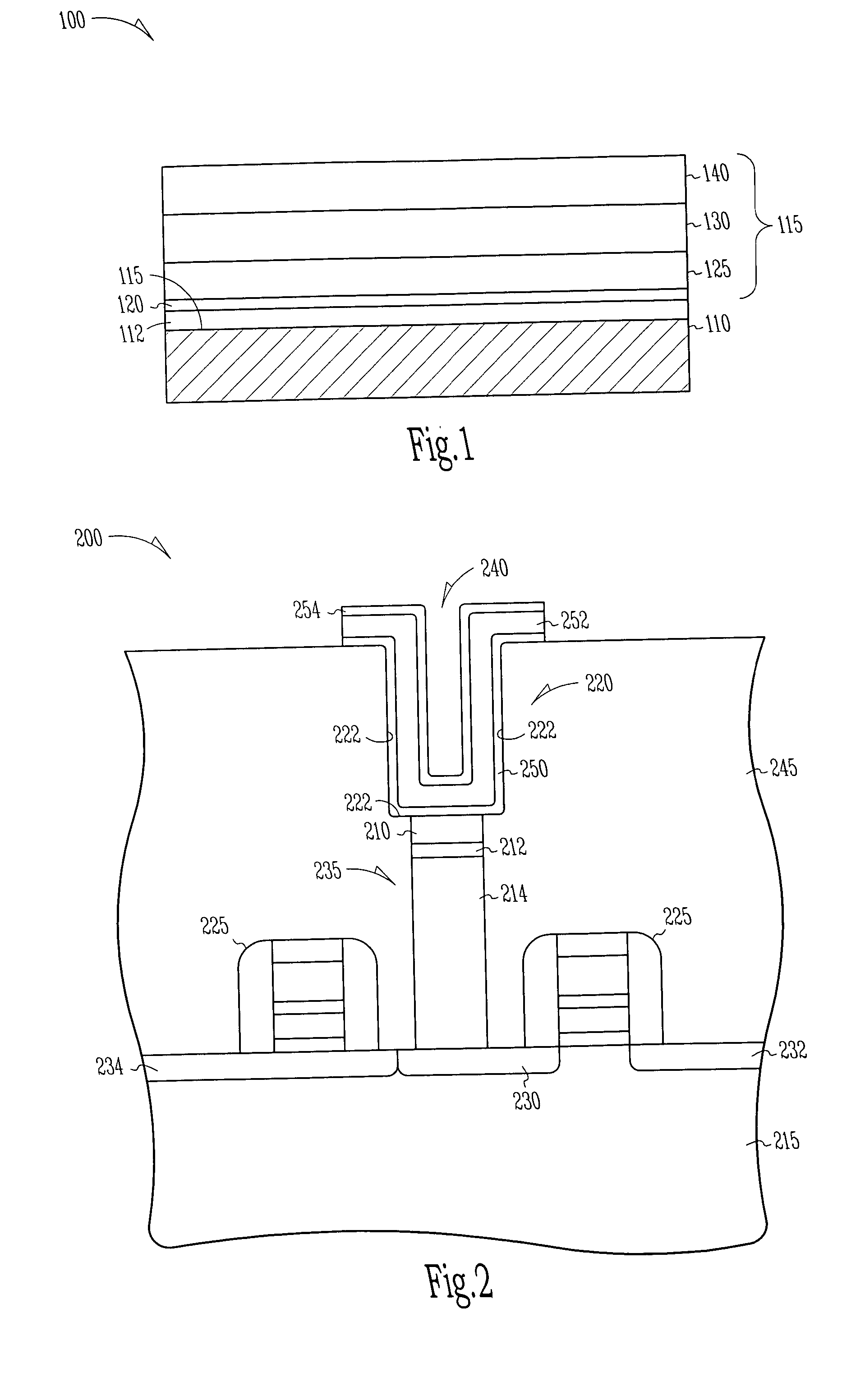

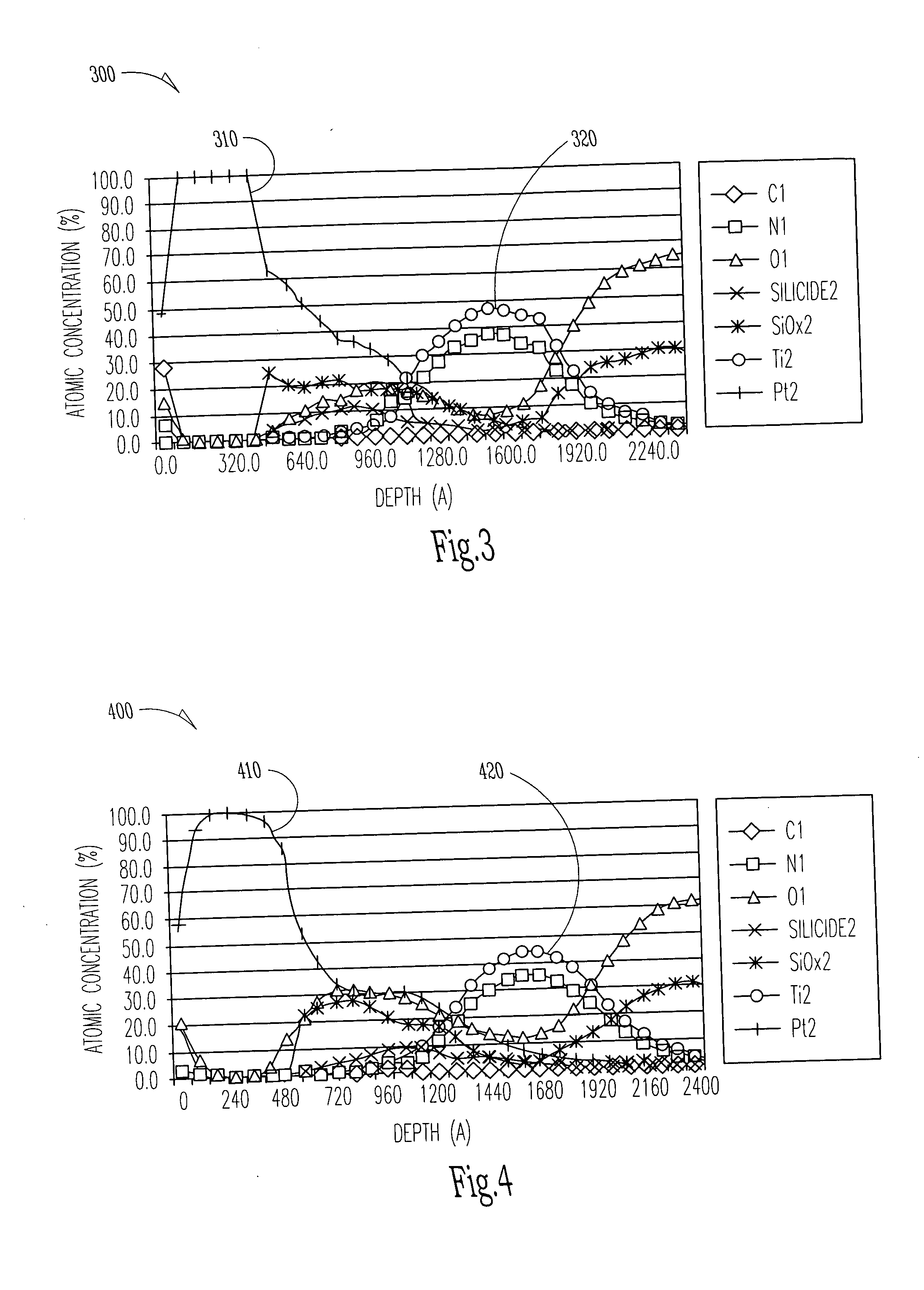

Platinum stuffed with silicon oxide as a diffusion oxygen barrier for semiconductor devices

The present invention provides techniques to fabricate high dielectric MIM storage cell capacitors. In one embodiment, this is accomplished by forming a silicon contact is then formed to electrically connect the formed bottom electrode layer in the container with the at least one associated transistor device. A titanium nitride barrier layer is then formed over the silicon contact. An oxygen barrier layer including platinum stuffed with silicon oxide is then formed over the titanium nitride layer and below the bottom electrode layer. A bottom electrode layer is then formed using platinum over interior surfaces of a container formed relative to at lest one associated transistor device on a silicon substrate. Further, a high dielectric insulator layer is formed over the bottom electrode layer. A top electrode layer is then formed over the high dielectric insulator layer.

Owner:MICRON TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com