Patents

Literature

1145 results about "Silanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

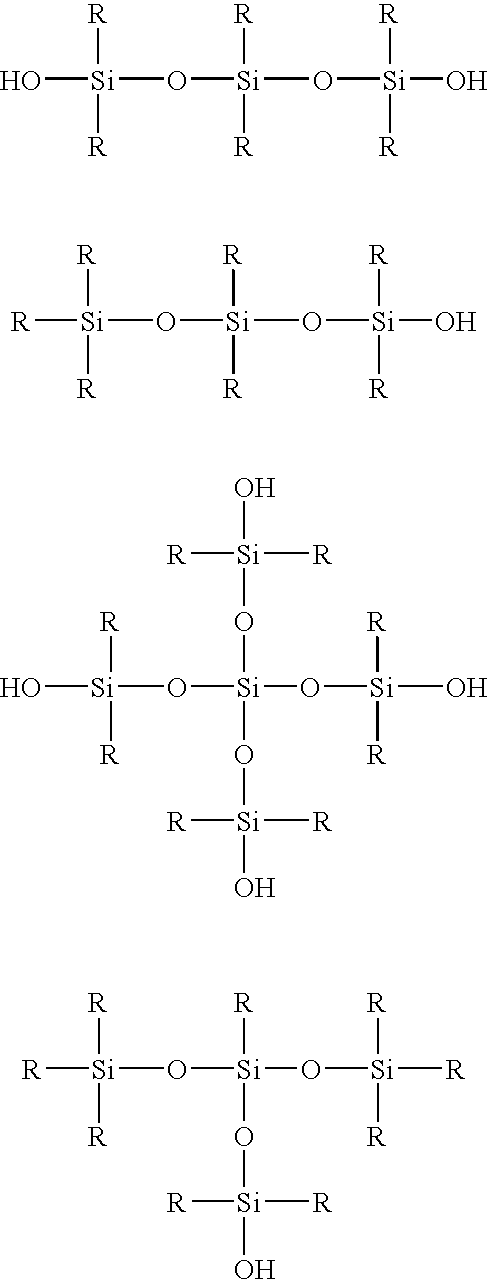

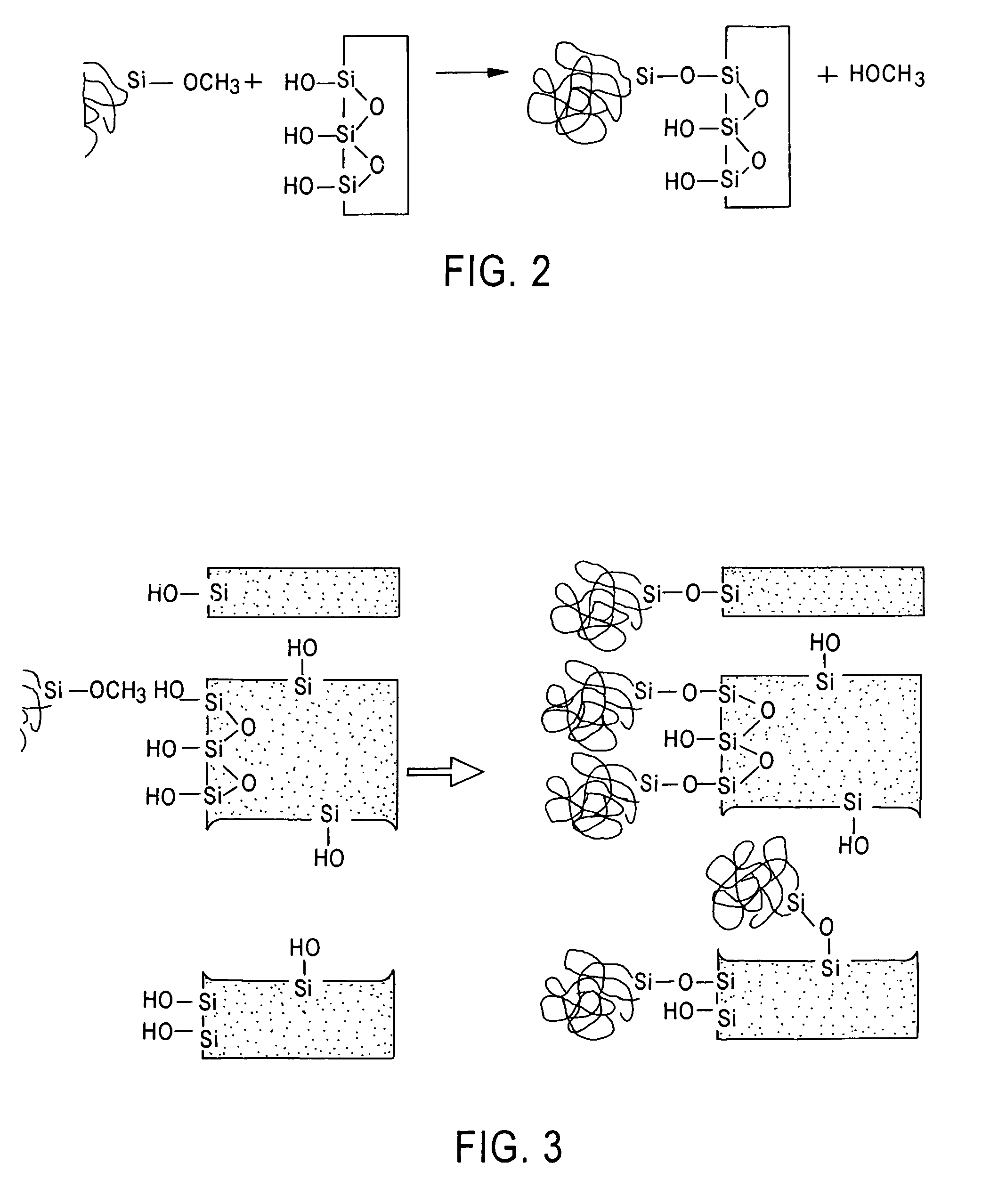

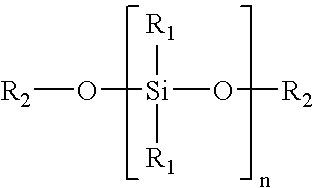

A silanol is a functional group in silicon chemistry with the connectivity Si–O–H. It is related to the hydroxy functional group (C–O–H) found in all alcohols. Silanols are often invoked as intermediates in organosilicon chemistry and silicate mineralogy. If a silanol contains one or more organic residue, it is an organosilanol.

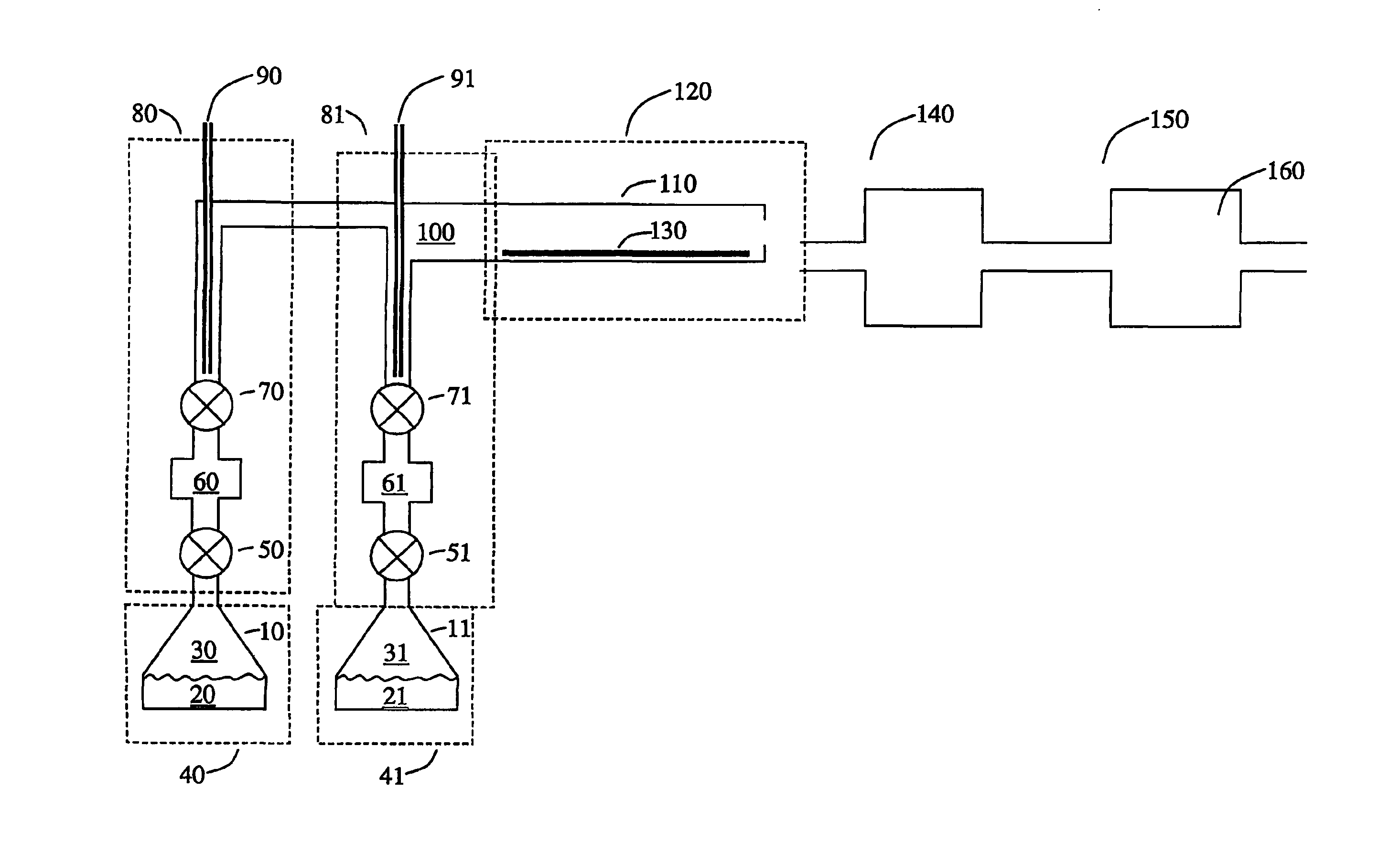

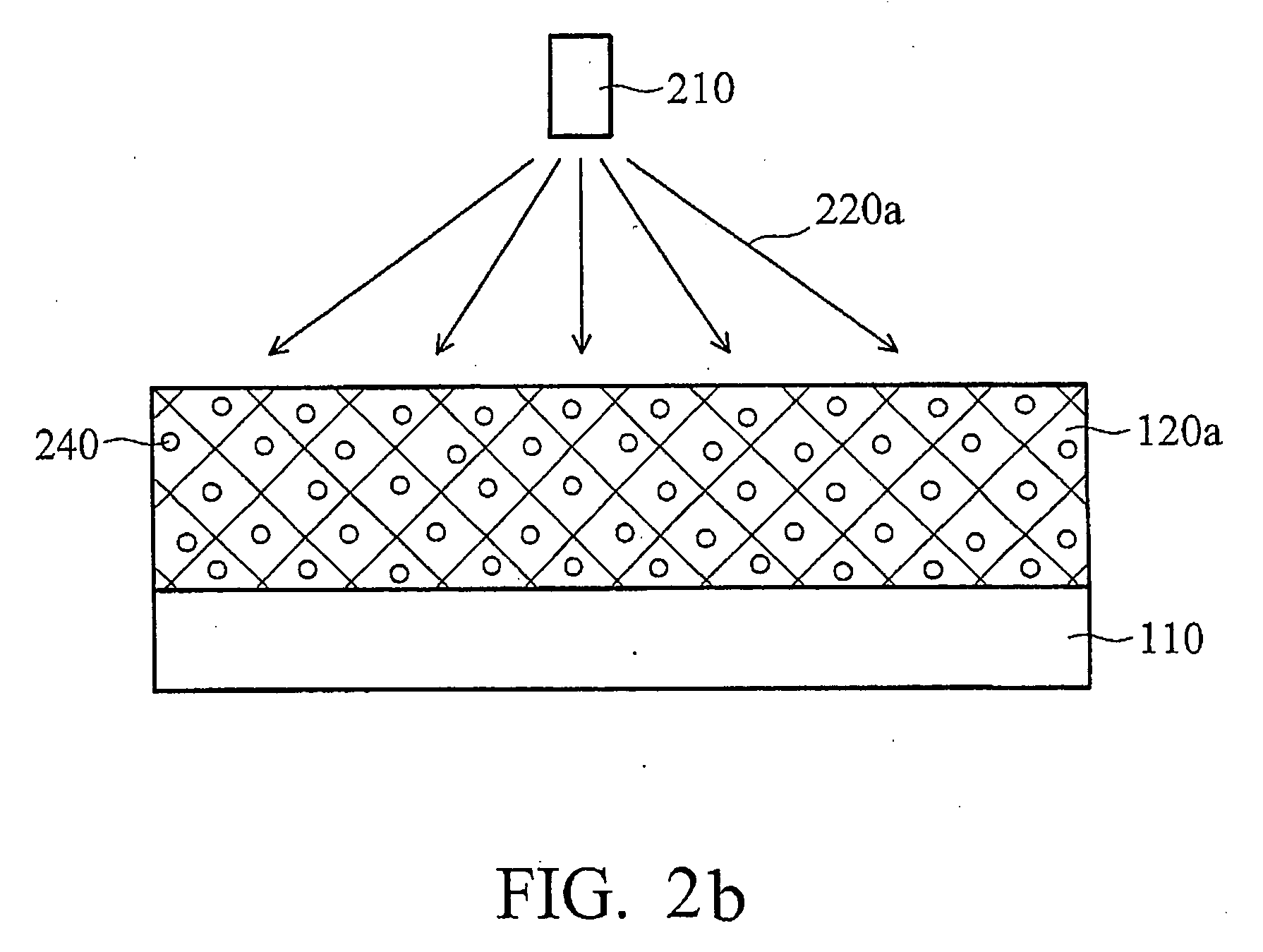

Deposition of silicon dioxide on hydrophobic surfaces

InactiveUS20120263876A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanolSilicon dioxide

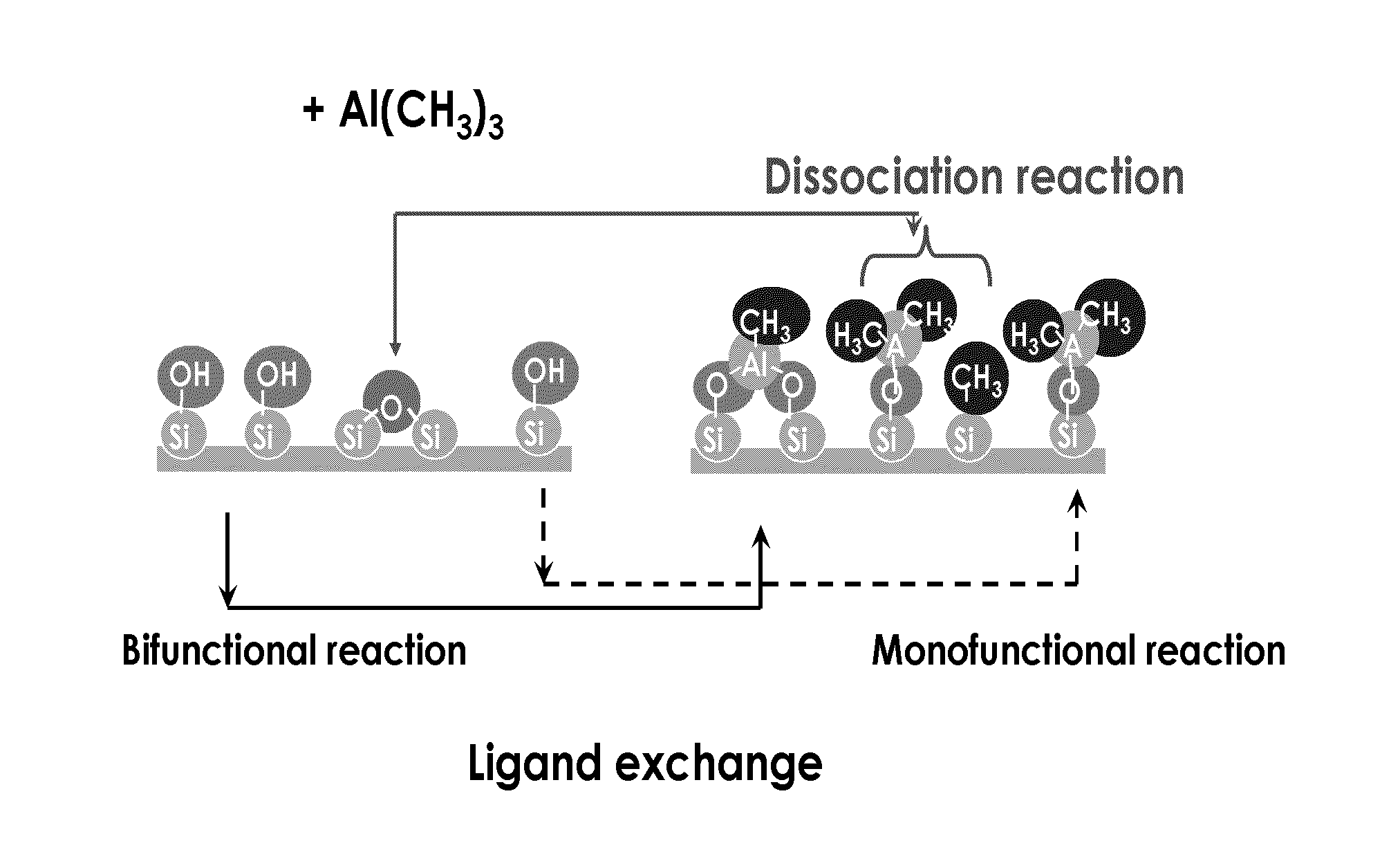

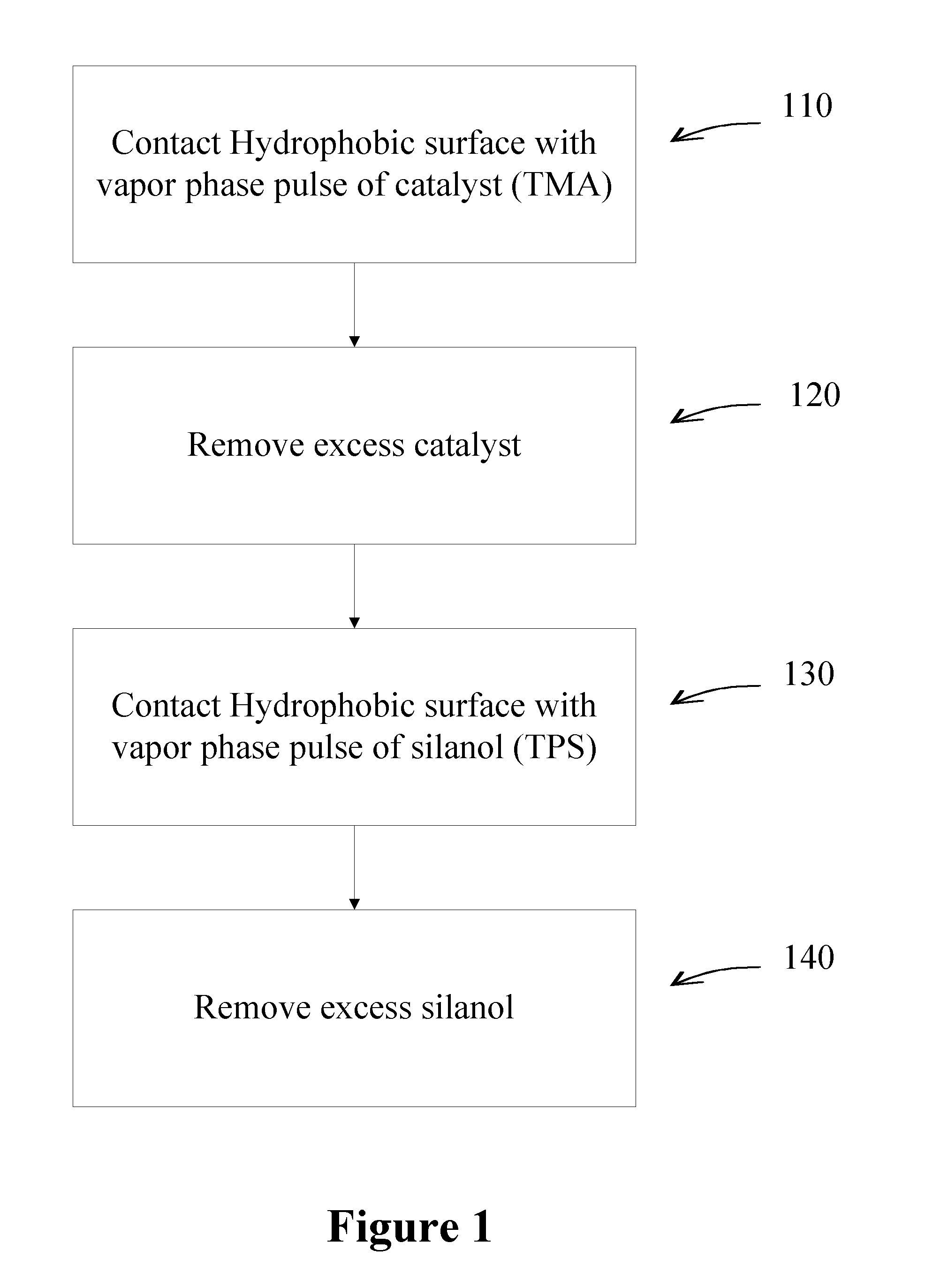

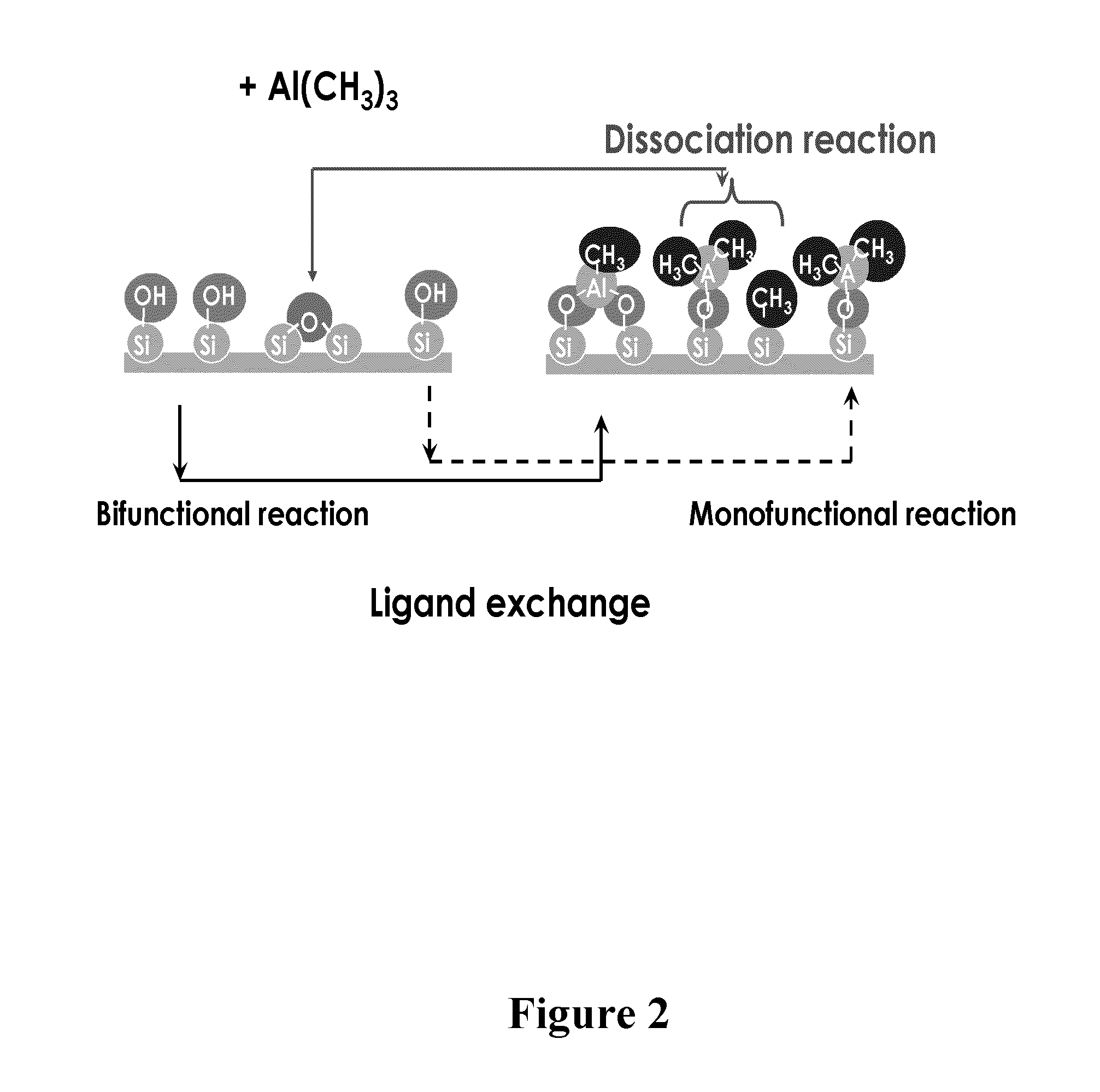

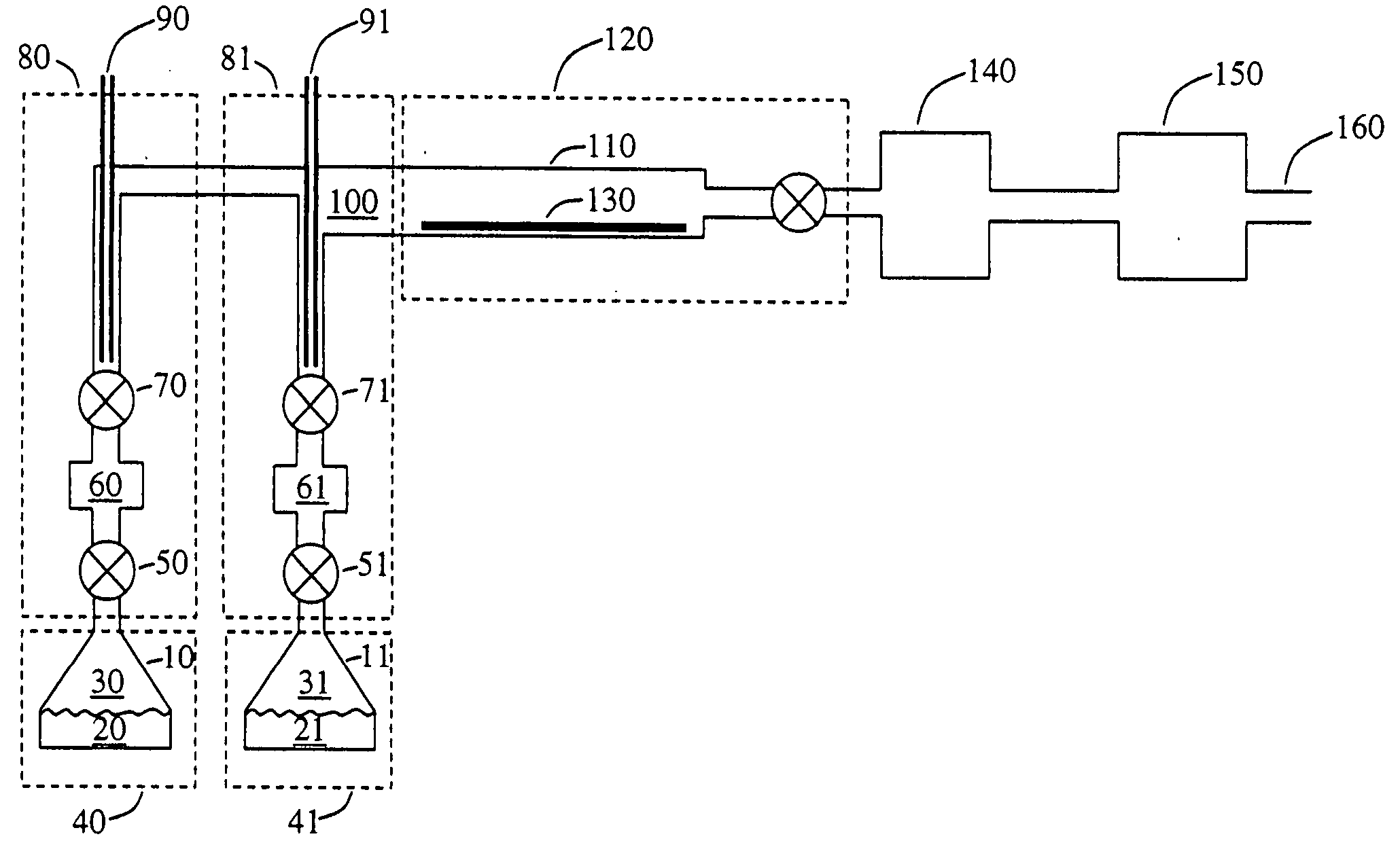

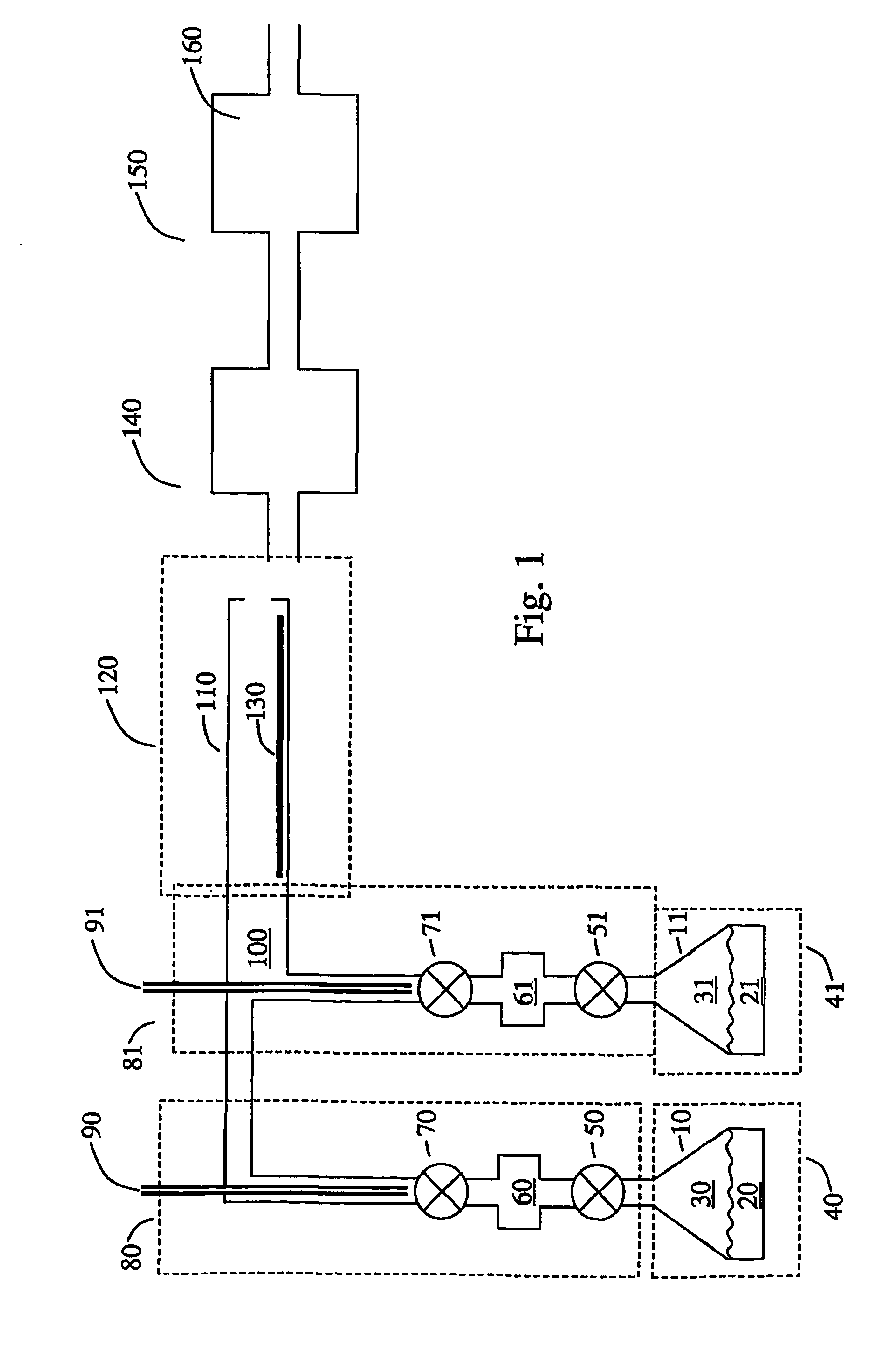

Methods for forming silicon dioxide thin films on hydrophobic surfaces are provided. For example, in some embodiments, silicon dioxide films are deposited on porous, low-k materials. The silicon dioxide films can be deposited using a catalyst and a silanol. In some embodiments, an undersaturated dose of one or more of the reactants can be used in forming a pore-sealing layer over a porous material.

Owner:ASM IP HLDG BV

Vapor deposition of silicon dioxide nanolaminates

ActiveUS20050112282A1Easy to produceUniform thicknessMaterial nanotechnologySemiconductor/solid-state device manufacturingPorosityElectrical conductor

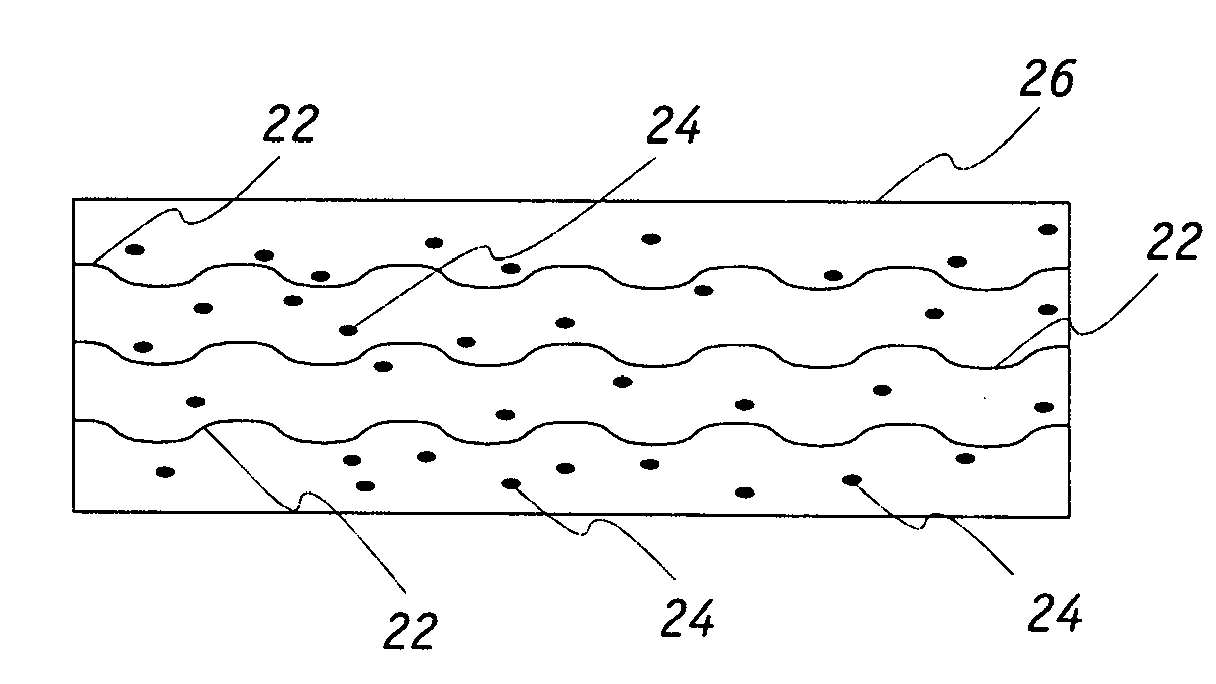

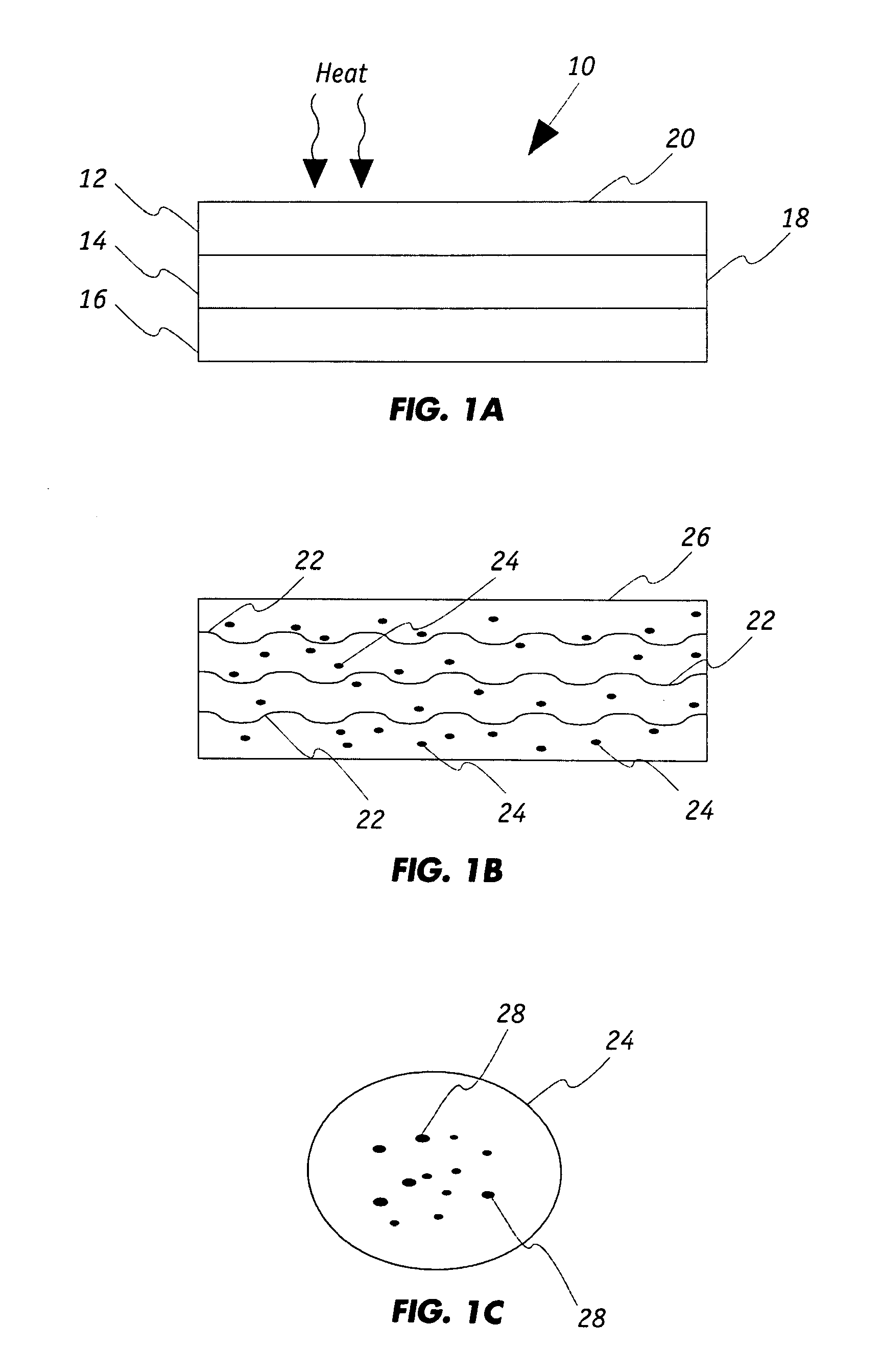

This invention relates to materials and processes for thin film deposition on solid substrates. Silica / alumina nanolaminates were deposited on heated substrates by the reaction of an aluminum-containing compound with a silanol. The nanolaminates have very uniform thickness and excellent step coverage in holes with aspect ratios over 40:1. The films are transparent and good electrical insulators. This invention also relates to materials and processes for producing improved porous dielectric materials used in the insulation of electrical conductors in microelectronic devices, particularly through materials and processes for producing semi-porous dielectric materials wherein surface porosity is significantly reduced or removed while internal porosity is preserved to maintain a desired low-k value for the overall dielectric material. The invention can also be used to selectively fill narrow trenches with low-k dielectric material while at the same time avoiding deposition of any dielectric on the surface area outside of the trenches.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

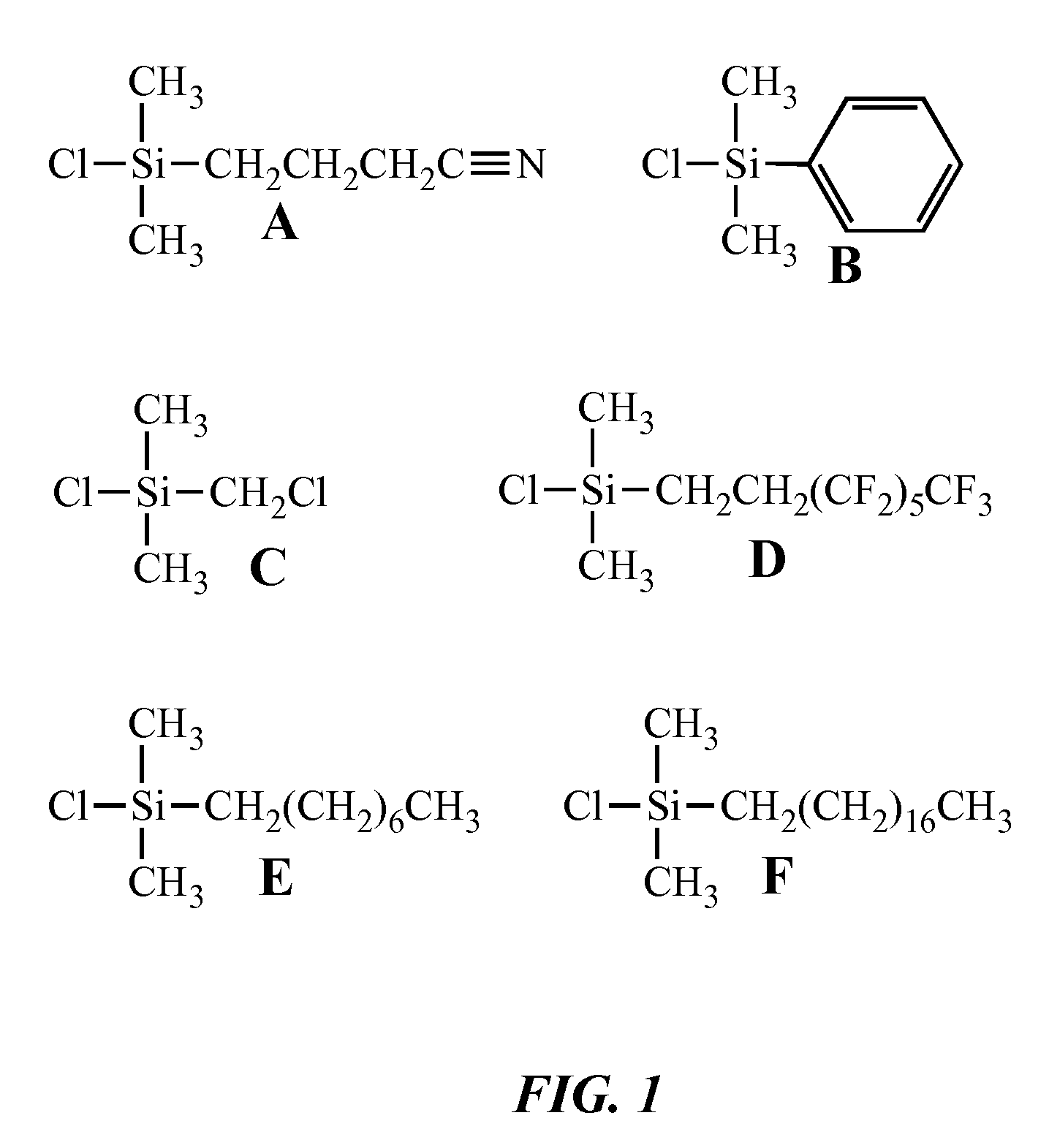

Recovery of hydrophobicity of low-k and ultra low-k organosilicate films used as inter metal dielectrics

InactiveUS20050106762A1Low costHigh mechanical strengthSolid-state devicesSemiconductor/solid-state device manufacturingChemical treatmentSilylation

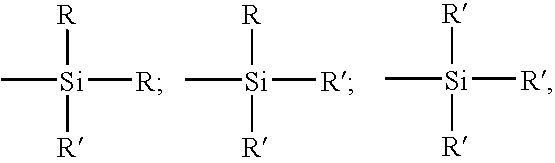

Often used to reduce the RC delay in integrated circuits are dielectric films of porous organosilicates which have a silica like backbone with alkyl or aryl groups (to add hydrophobicity to the materials and create free volume) attached directly to the Si atoms in the network. Si—R bonds rarely survive an exposure to plasmas or chemical treatments commonly used in processing; this is especially the case in materials with an open cell pore structure. When Si—R bonds are broken, the materials lose hydrophobicity, due to formation of hydrophilic silanols and low dielectric constant is compromised. A method by which the hydrophobicity of the materials is recovered using a novel class of silylation agents which may have the general formula (R2N)XSiR′Y where X and Y are integers from 1 to 3 and 3 to 1 respectively, and where R and R′ are selected from the group of hydrogen, alkyl, aryl, allyl and a vinyl moiety. Mechanical strength of porous organosilicates is also improved as a result of the silylation treatment.

Owner:GLOBALFOUNDRIES INC

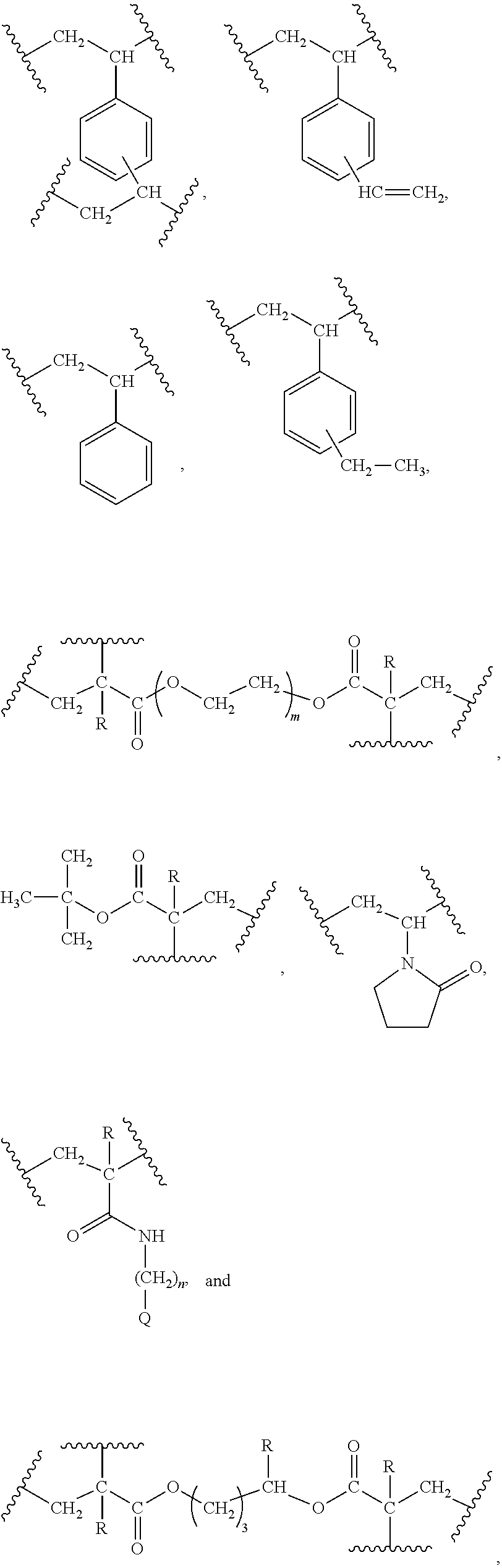

Silanol-functionalized compounds for the preparation of polyurethane foams

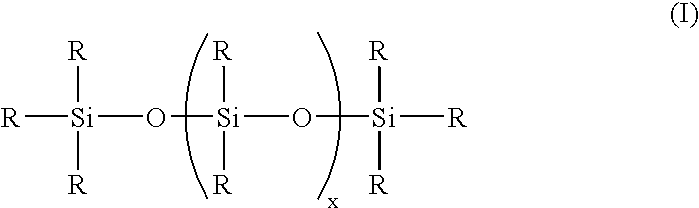

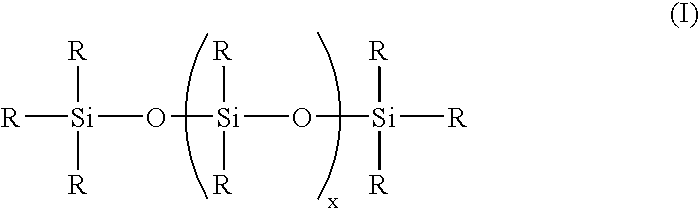

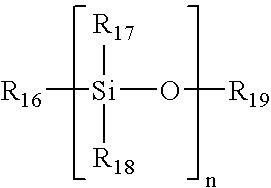

Methods for preparing polyurethane flexible foam are described, wherein an organic polyisocyanate is reacted with an active hydrogen-containing component such as an organic polyol, in the presence of a urethane catalyst, a blowing agent, optionally a cell opener, and a siloxane-based surfactant composition as a stabilizer for the foam. The siloxane-based surfactant composition comprises a silanol-functionalized organosiloxane having general formula (I), wherein: the R groups are independently a C1-C3 alkyl, phenyl, or —OSi(R)3; provided that at least one R group is a hydroxyl (—OH) bonded directly to any silicon atom and X is an integer from 0-200.

Owner:EVONIK OPERATIONS GMBH

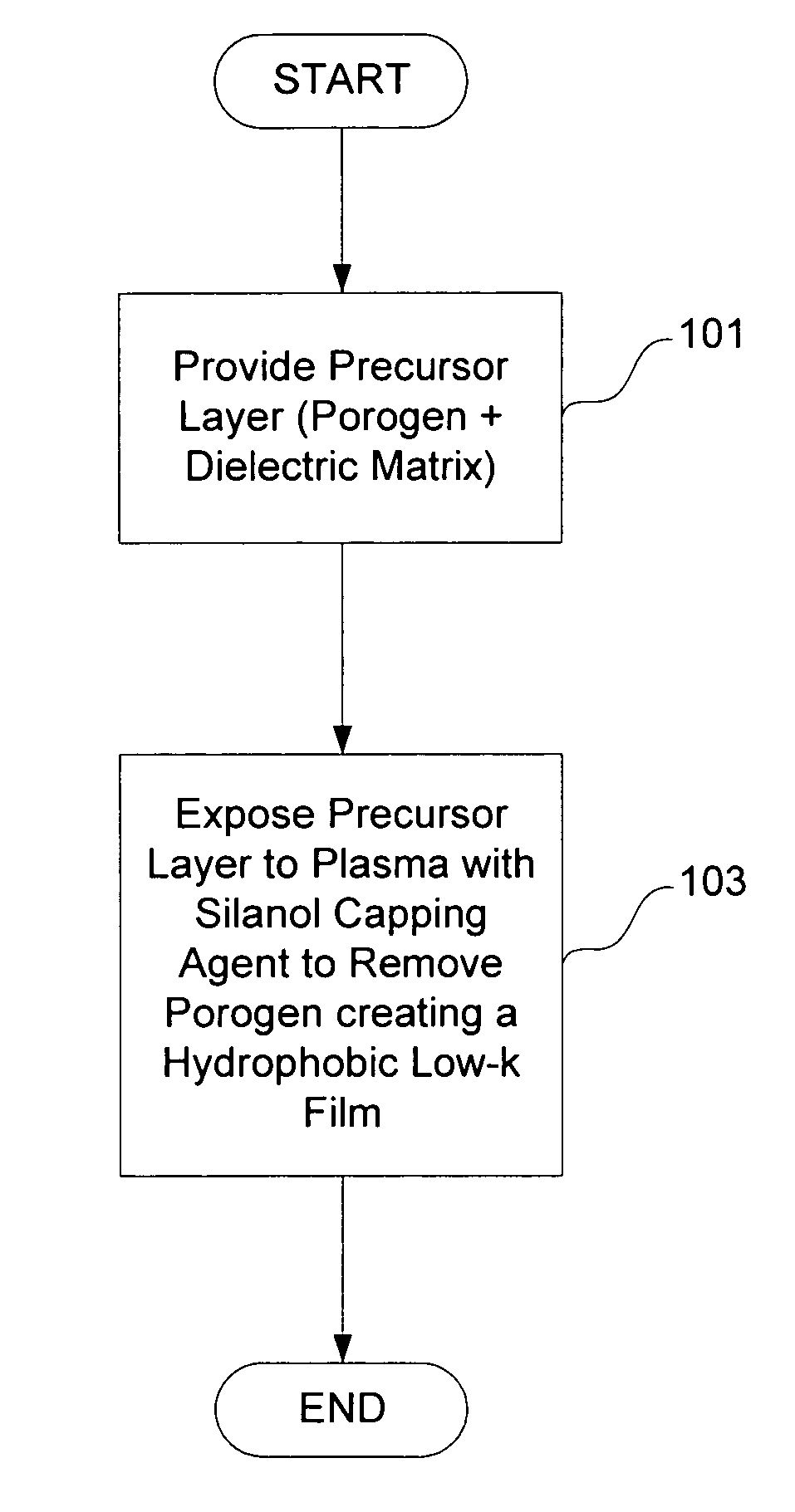

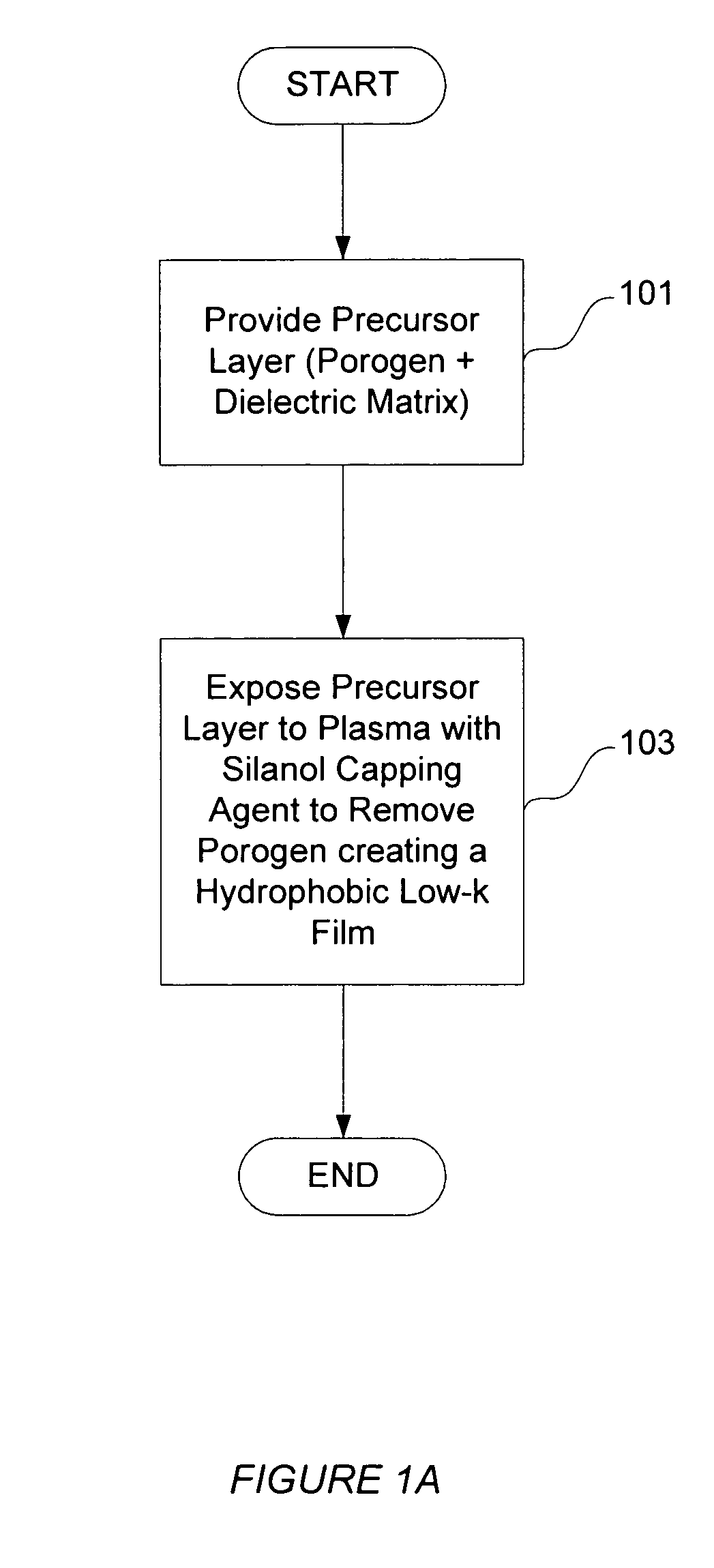

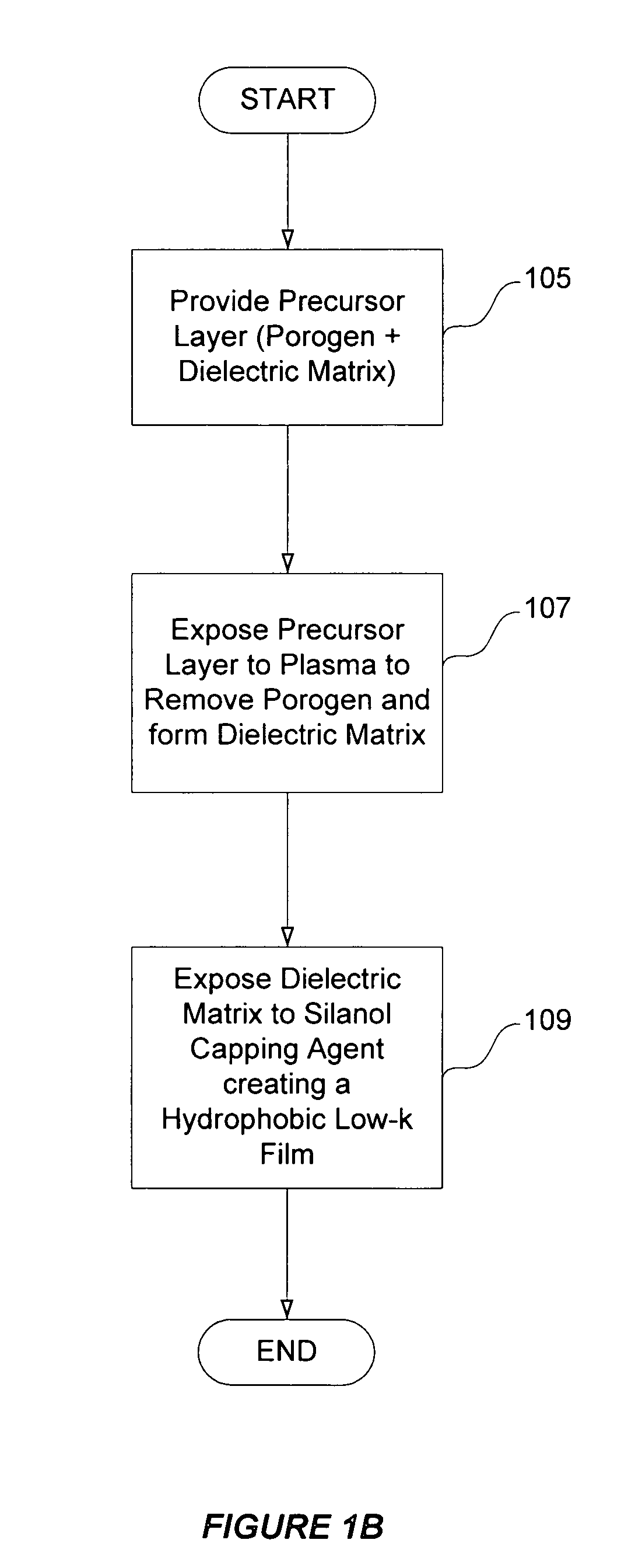

Plasma detemplating and silanol capping of porous dielectric films

InactiveUS7176144B1Creating voidSemiconductor/solid-state device manufacturingDielectric matrixSilanol

Methods of preparing a low-k dielectric material on a substrate are provided. The methods involve using plasma techniques to remove porogen from a precursor layer comprising porogen and a dielectric matrix and to protect the dielectric matrix with a silanol capping agent, resulting in a low-k dielectric matrix. Porogen removal and silanol capping can occur concurrently or sequentially. If performed sequentially, silanol capping is performed without first exposing the dielectric matrix to moisture or ambient conditions.

Owner:NOVELLUS SYSTEMS

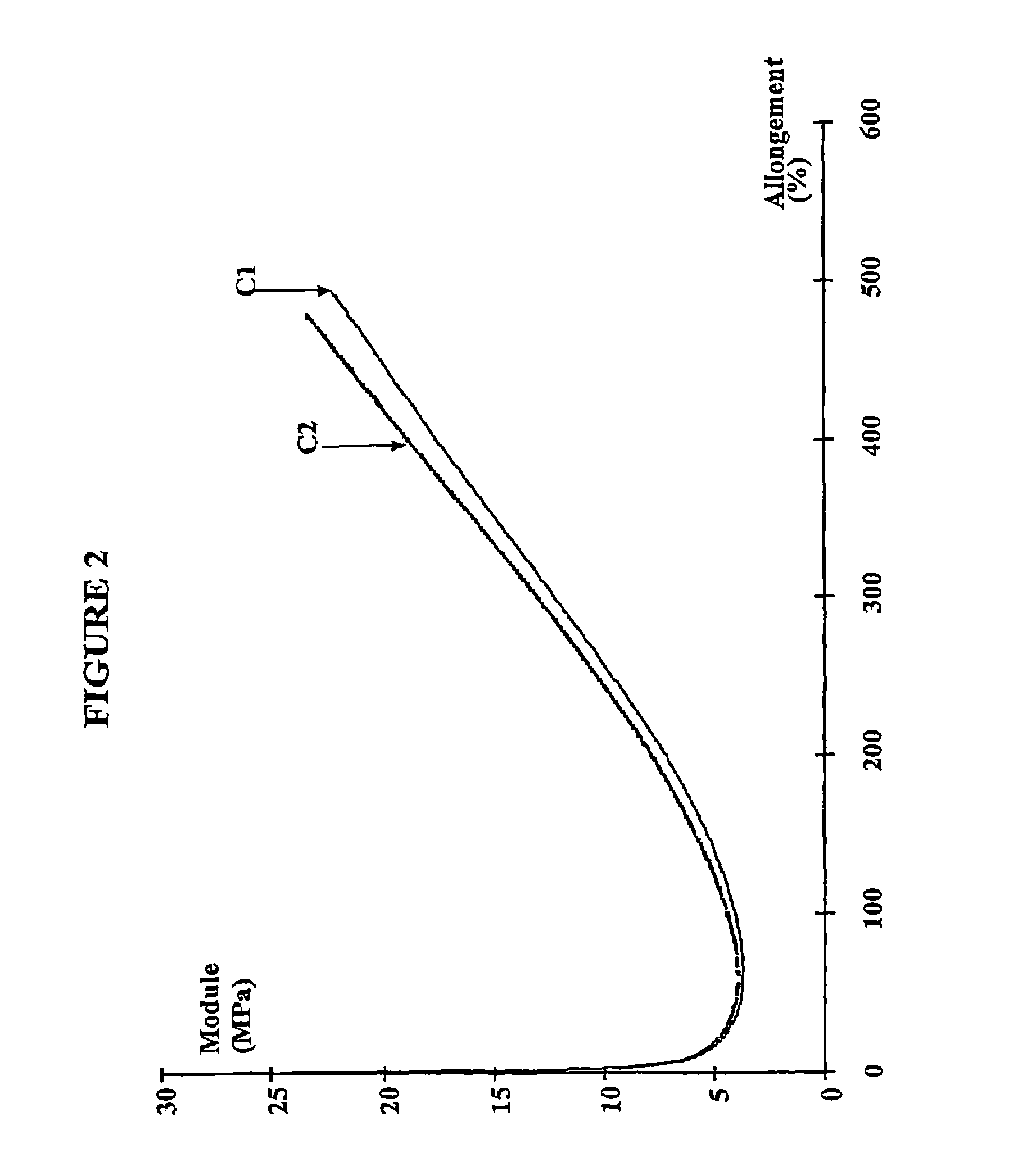

Diene rubber composition for tire comprising a specific silica as reinforcing filler

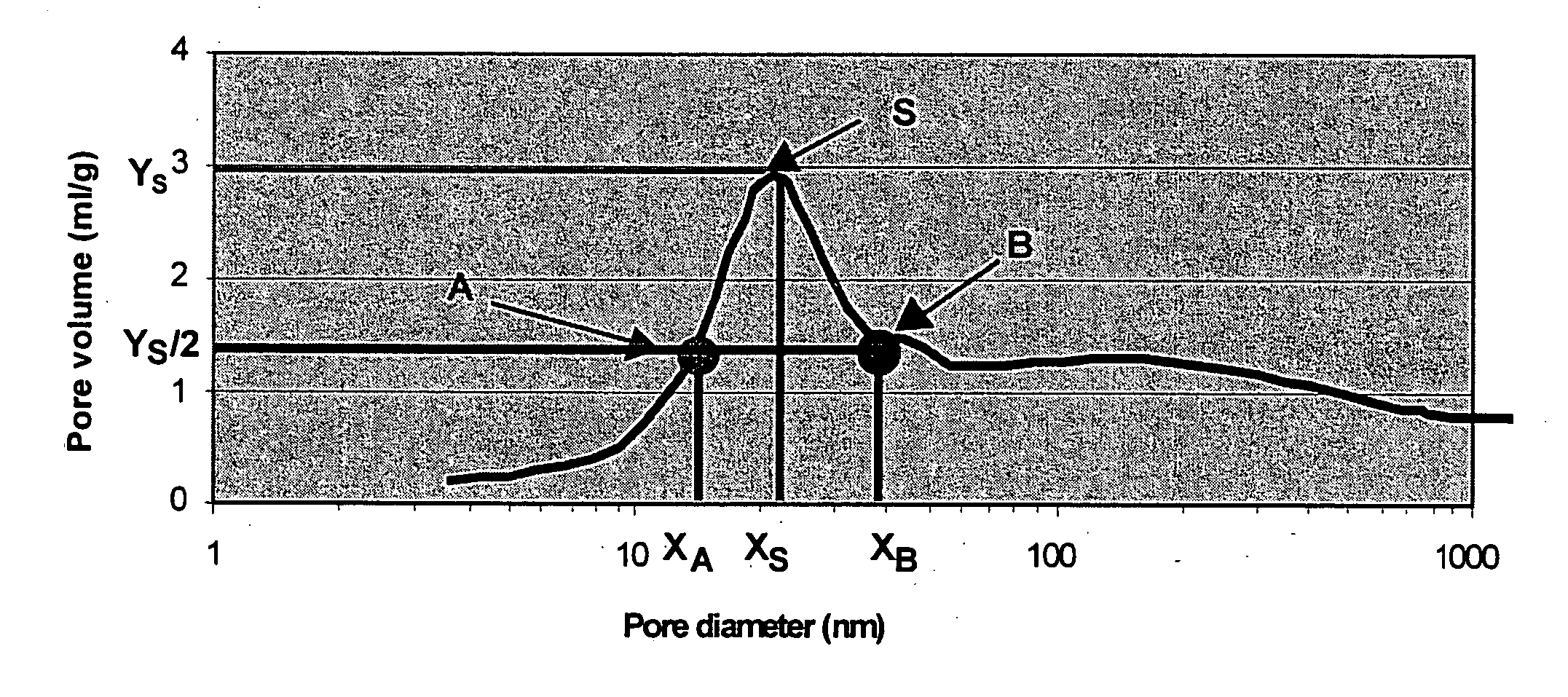

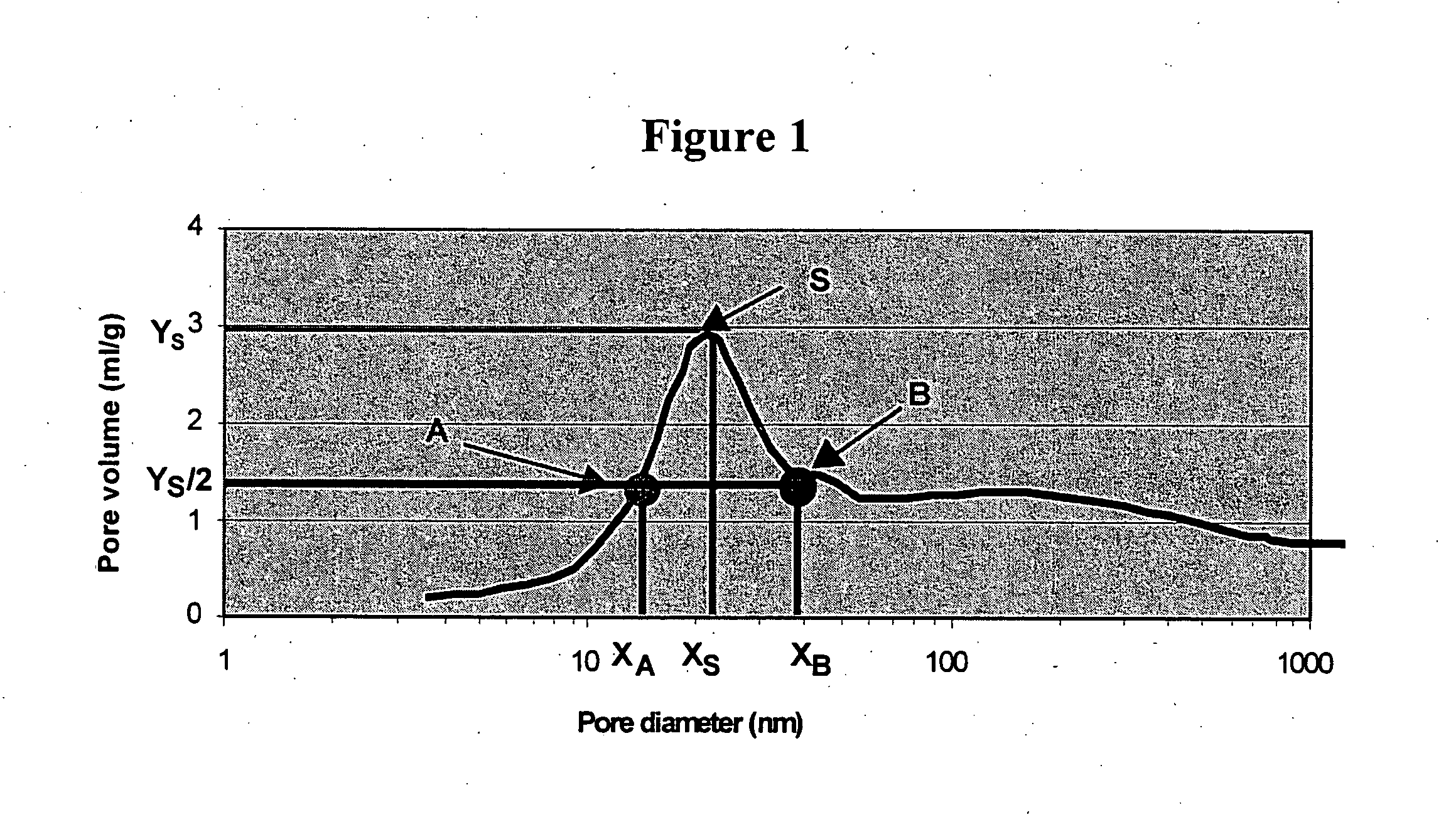

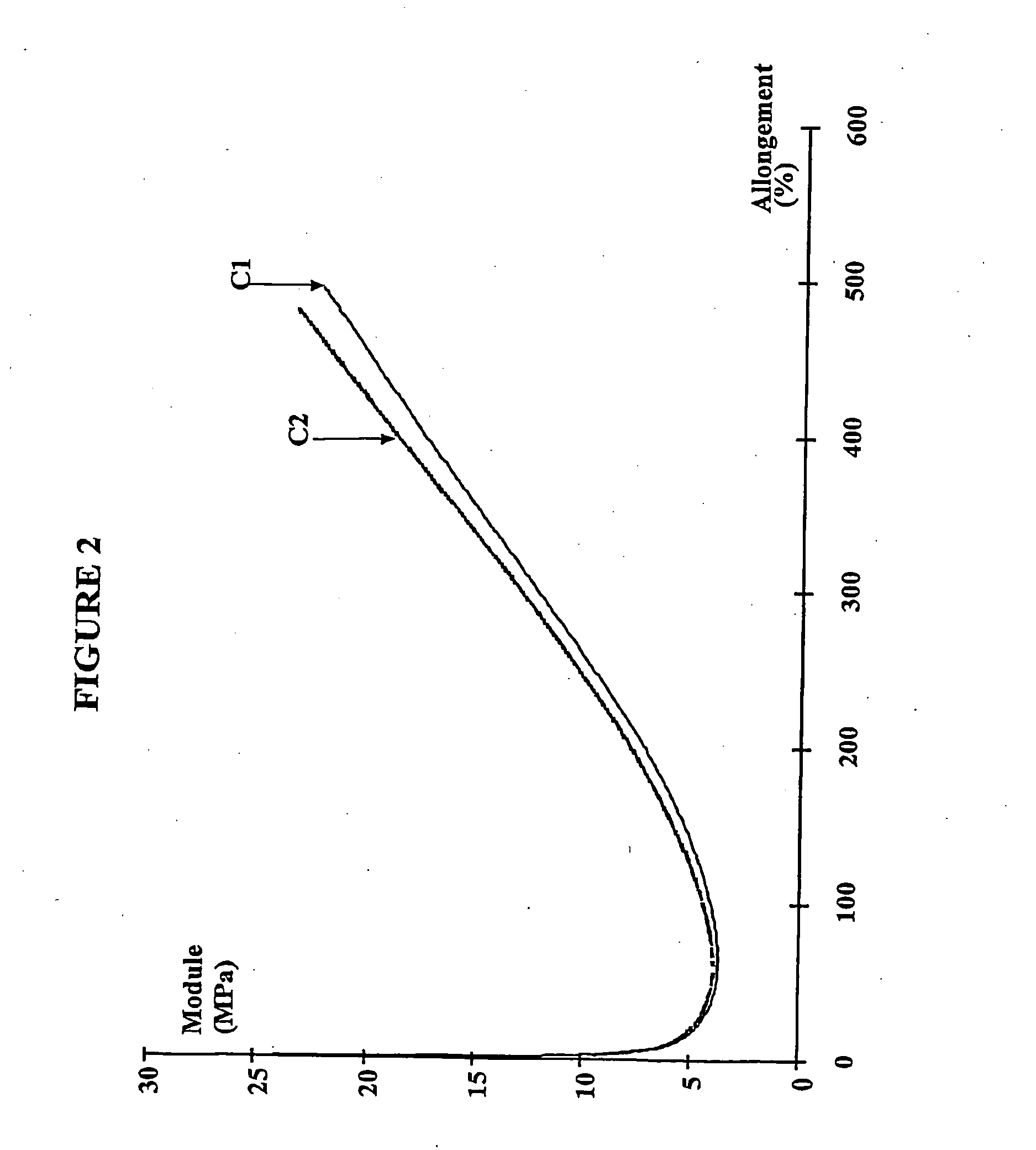

InactiveUS20050004297A1Less-difficult to processReduce hysteresisMaterial nanotechnologySpecial tyresElastomerPorosity

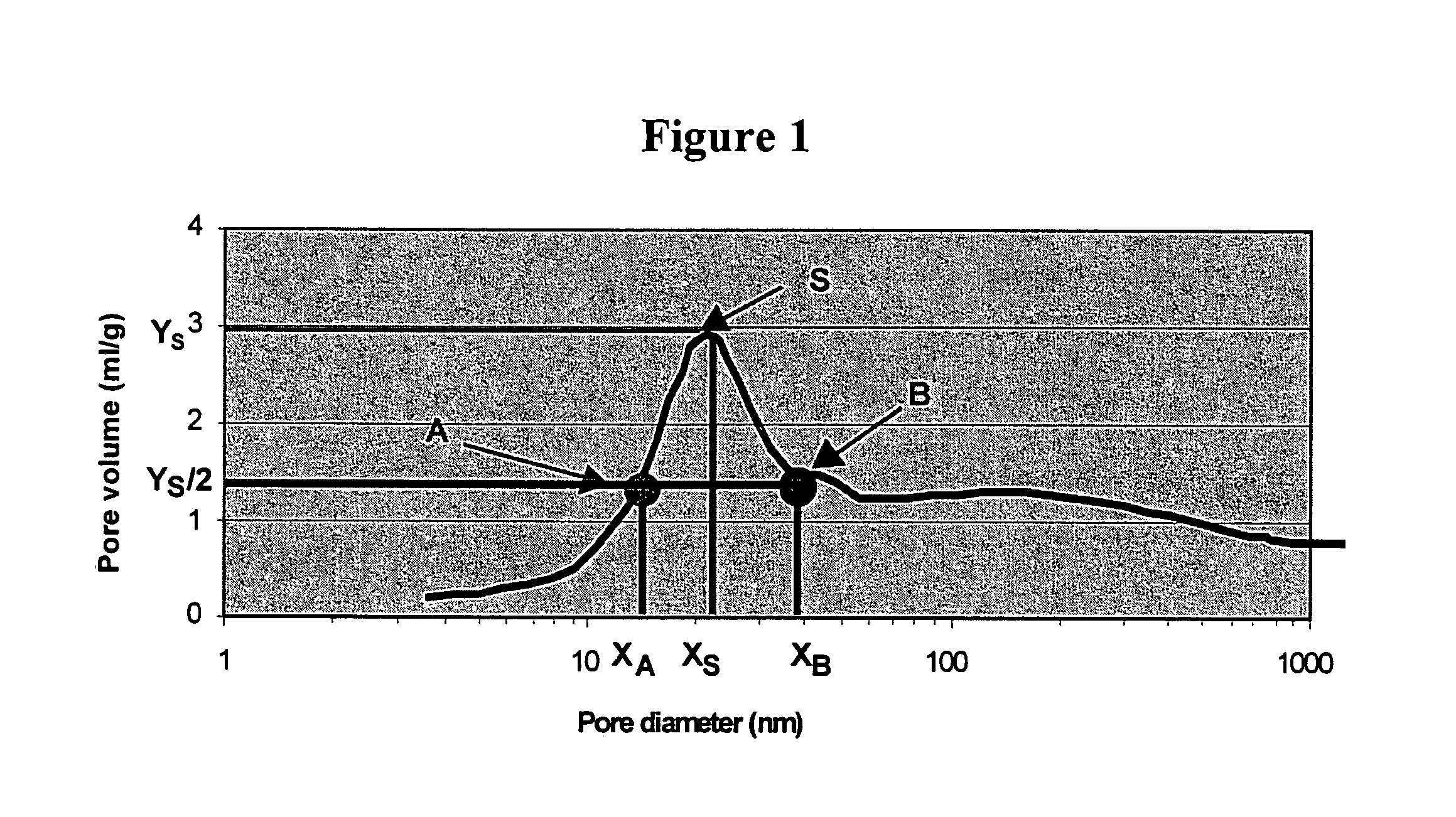

Diene rubber compositions are described containing a diene elastomer, a reinforcing inorganic filler, and a coupling agent wherein the inorganic filler includes a silica having the following characteristics: (a) a BET specific surface area between 45 and 400 m2 / g; (b) a CTAB specific surface area between 40 and 380 m2 / g; (c) an average particle size (by mass), dw, of 20 to 300 nm; and at least one of the following characteristics, preferably two and more preferably all three: (d) a particle size distribution such that dw≧ / CTAB)−30; (e) a porosity which meets the criterion L / FI≧−0.0025 CTAB+0.85; (f) an amount of silanols per unit of surface area, NSiOH / nm2; NSiOH / nm2≦−0.027 CTAB+10.5. These diene rubber compositions can be used for the manufacture of tires or of semi-finished products intended for tires.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

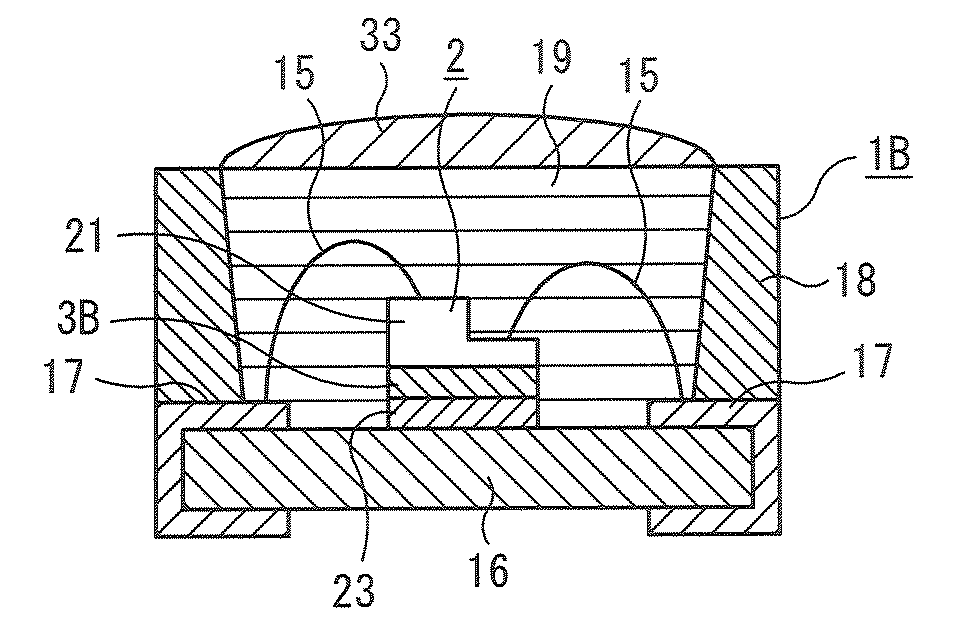

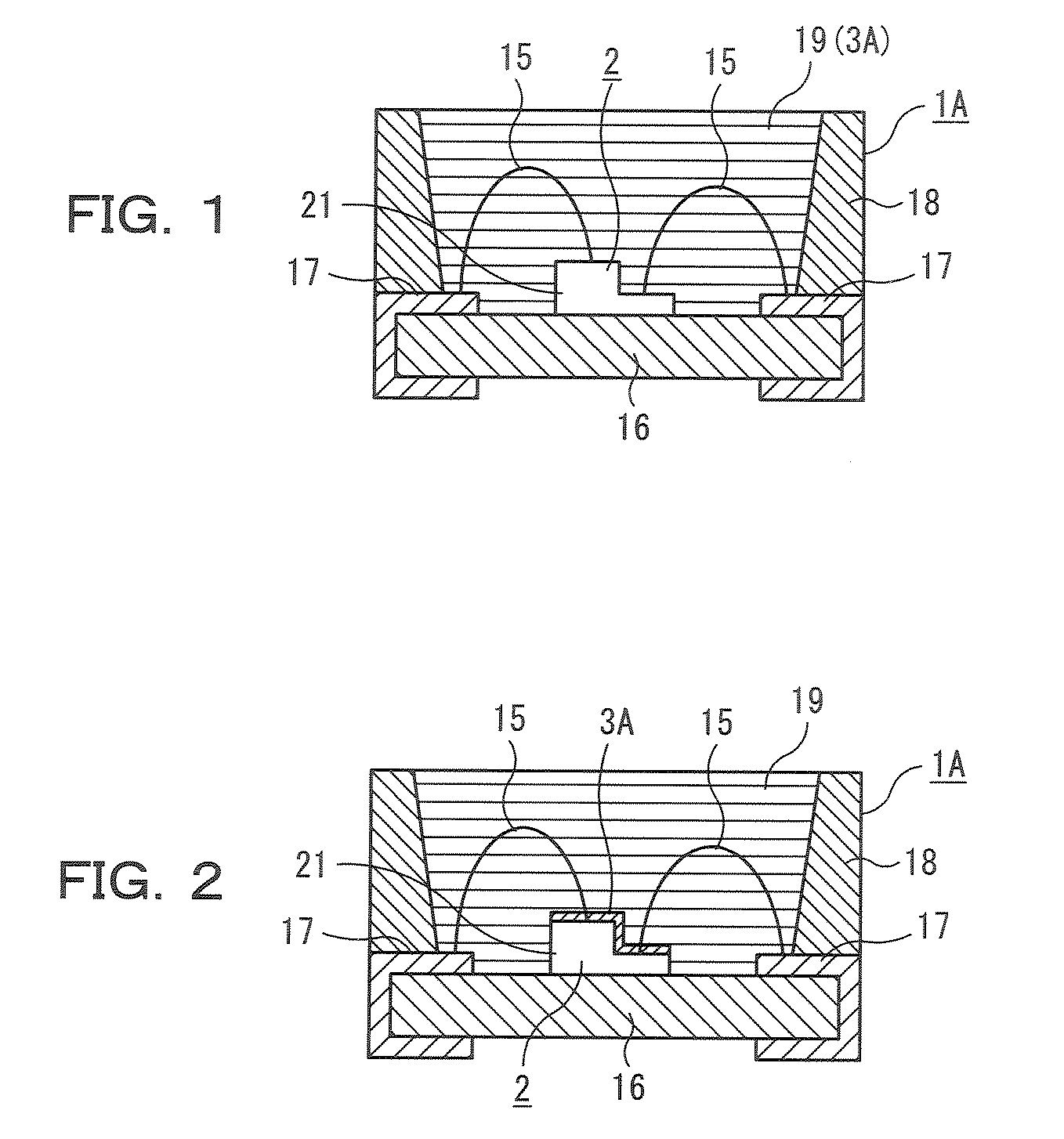

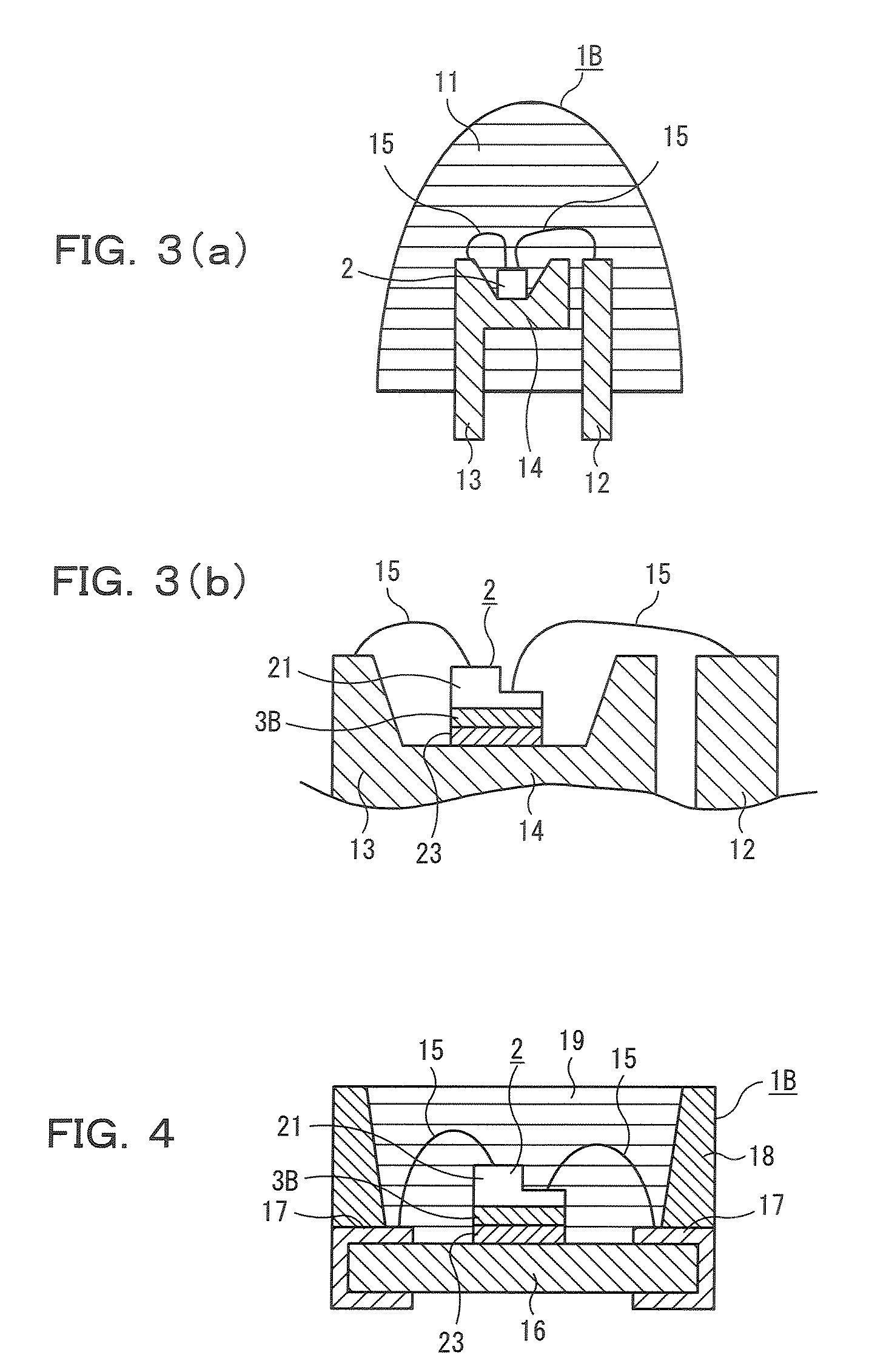

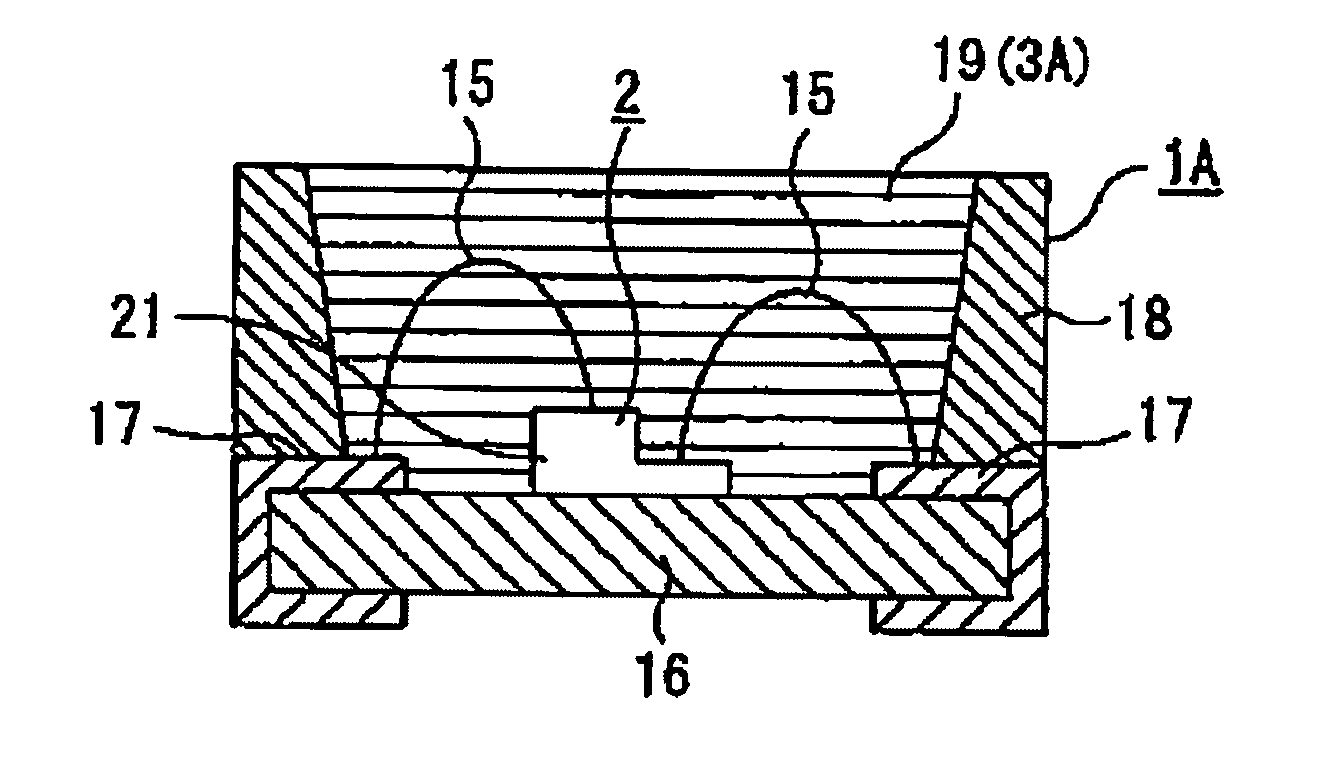

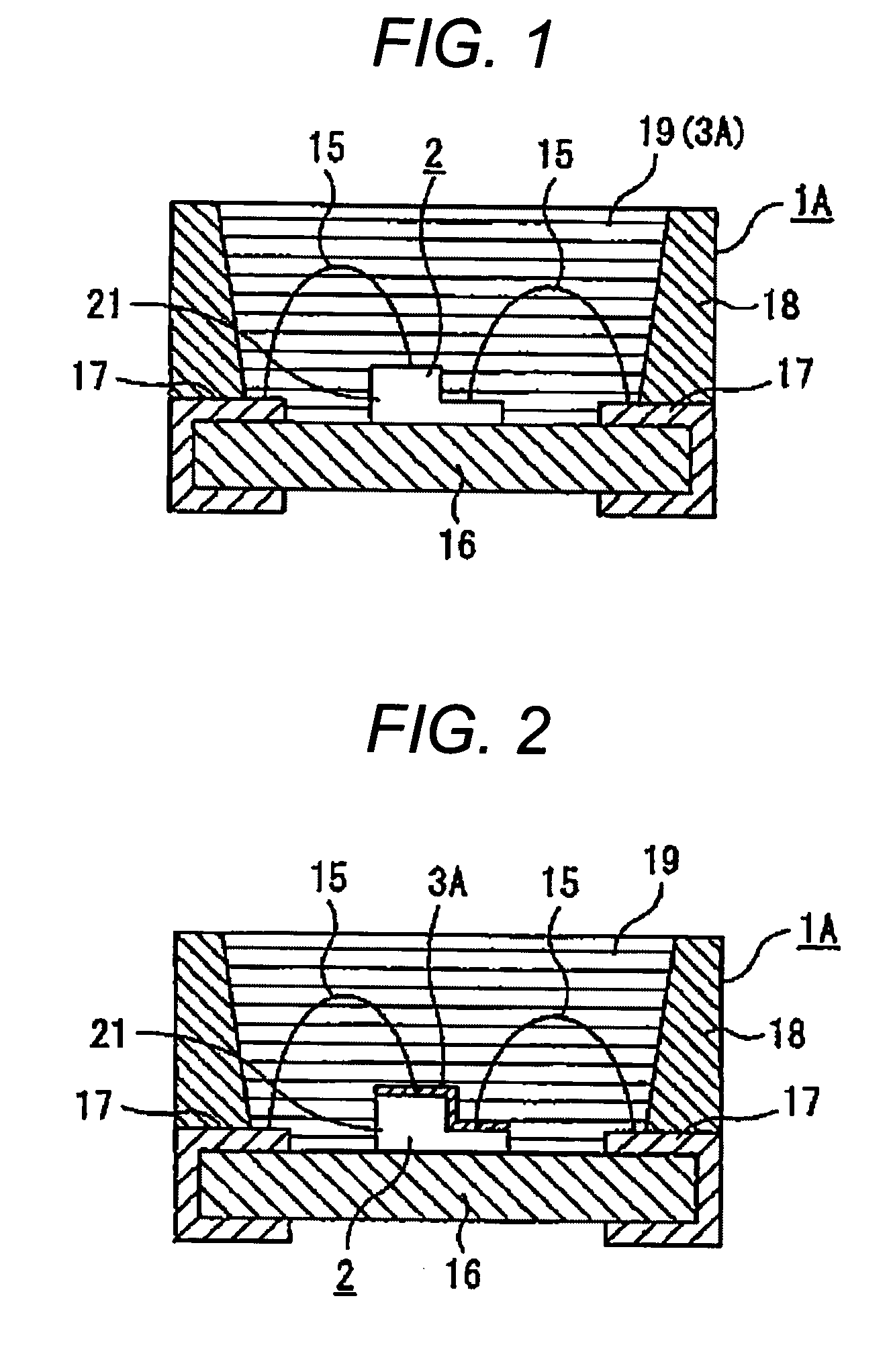

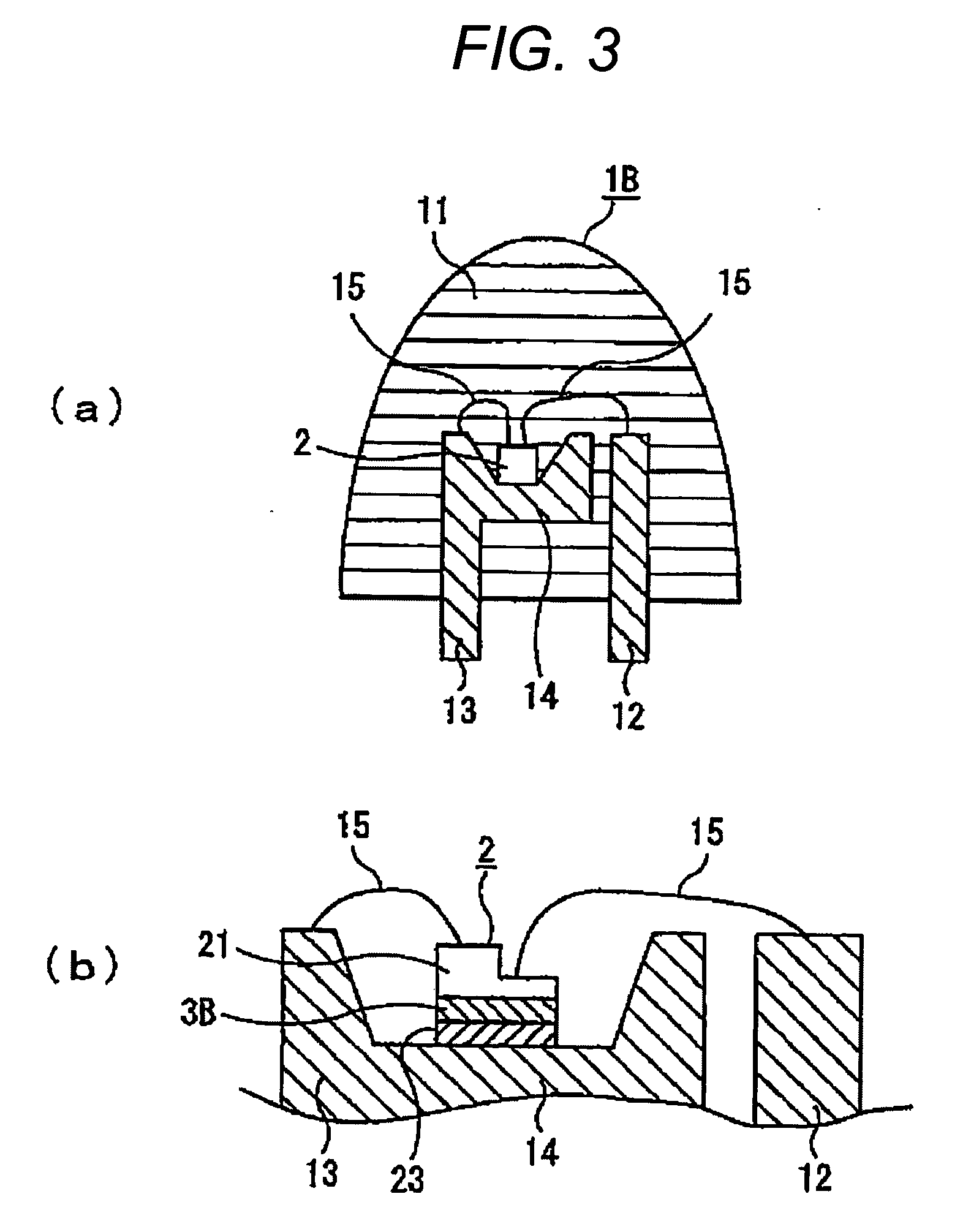

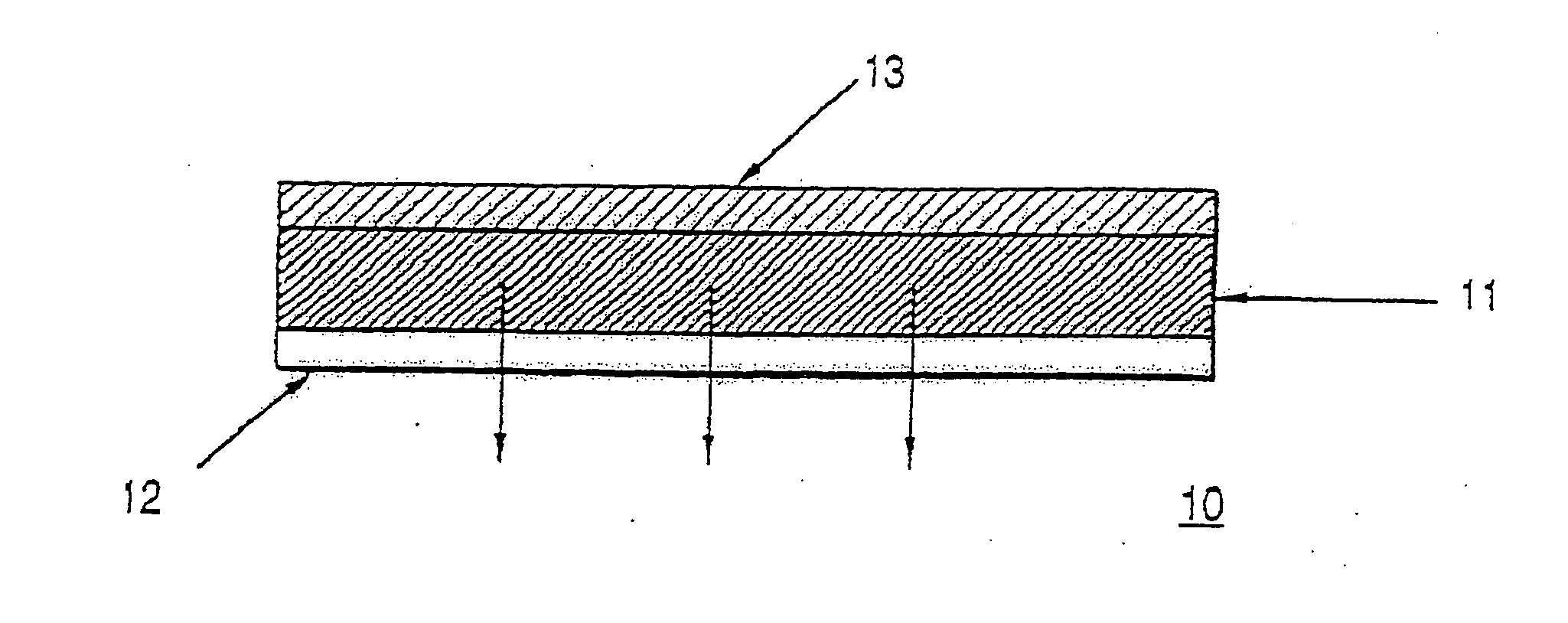

Semiconductor Light Emitting Device Member, Method for Manufacturing Such Semiconductor Light Emitting Device Member and Semiconductor Light Emitting Device Using Such Semiconductor Light Emitting Device Member

ActiveUS20090008673A1Improve sealingImprove heat resistanceSolid-state devicesSemiconductor/solid-state device manufacturingNMR - Nuclear magnetic resonanceHeat resistance

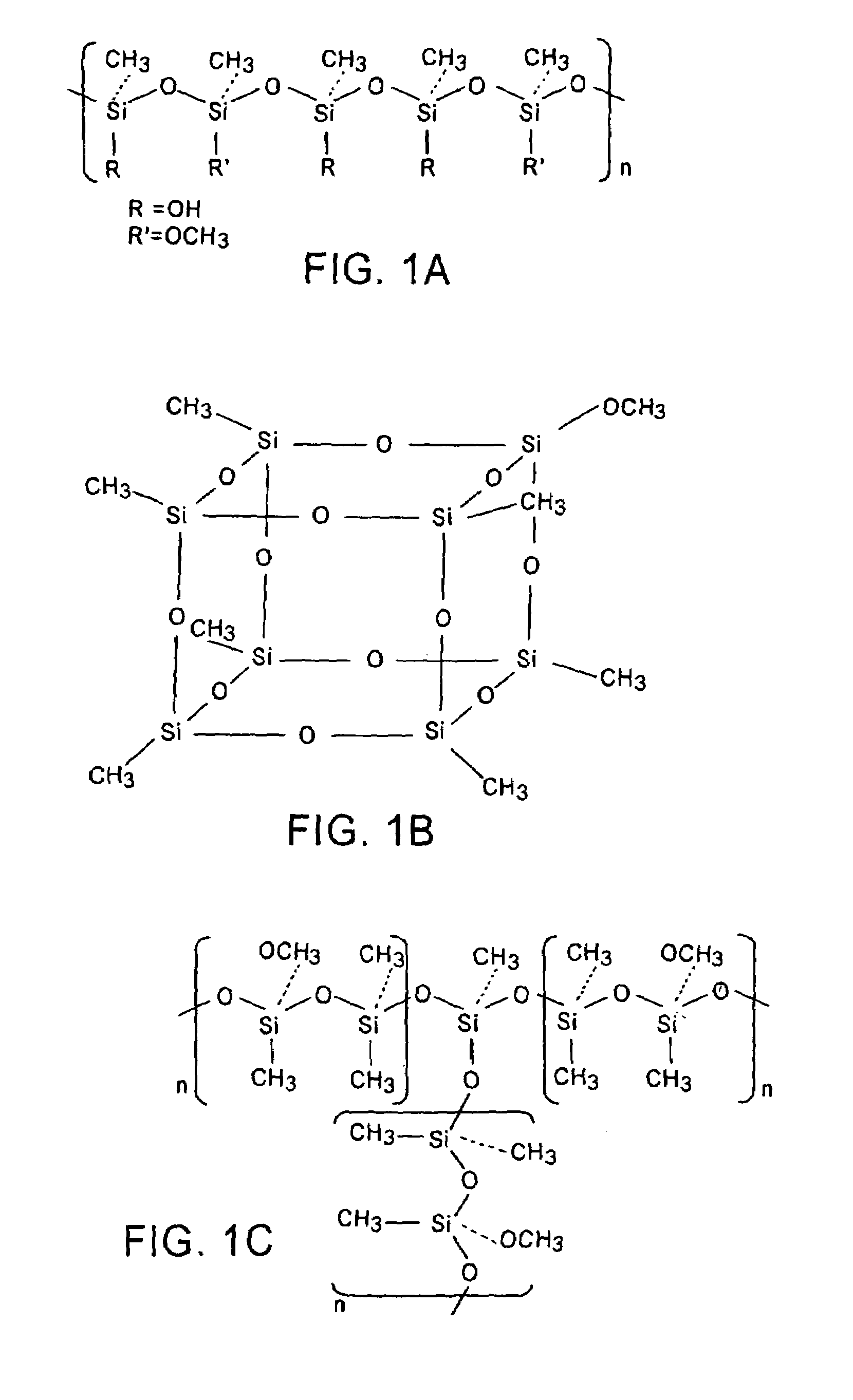

A semiconductor light-emitting device member excellent in transparency, light resistance, and heat resistance and capable of sealing a semiconductor light-emitting device without causing cracks and peeling even after a long-time use is provided. Therefore, a semiconductor light-emitting device member that comprises (1) in a solid Si-nuclear magnetic resonance spectrum, at least one peak selected from a group consisting of (i) peaks whose peak top position is in an area of a chemical shift of −40 ppm to 0 ppm inclusive, and whose full width at half maximum is 0.3 ppm to 3.0 ppm inclusive, and (ii) peaks whose peak top position is in an area of the chemical shift of −80 ppm or more and less than −40 ppm, and whose full width at half maximum is 0.3 ppm to 5.0 ppm inclusive, wherein (2) silicon content is 20 weight % or more and (3) silanol content is 0.1 weight % to 10 weight % inclusive is used.

Owner:MITSUBISHI CHEM CORP

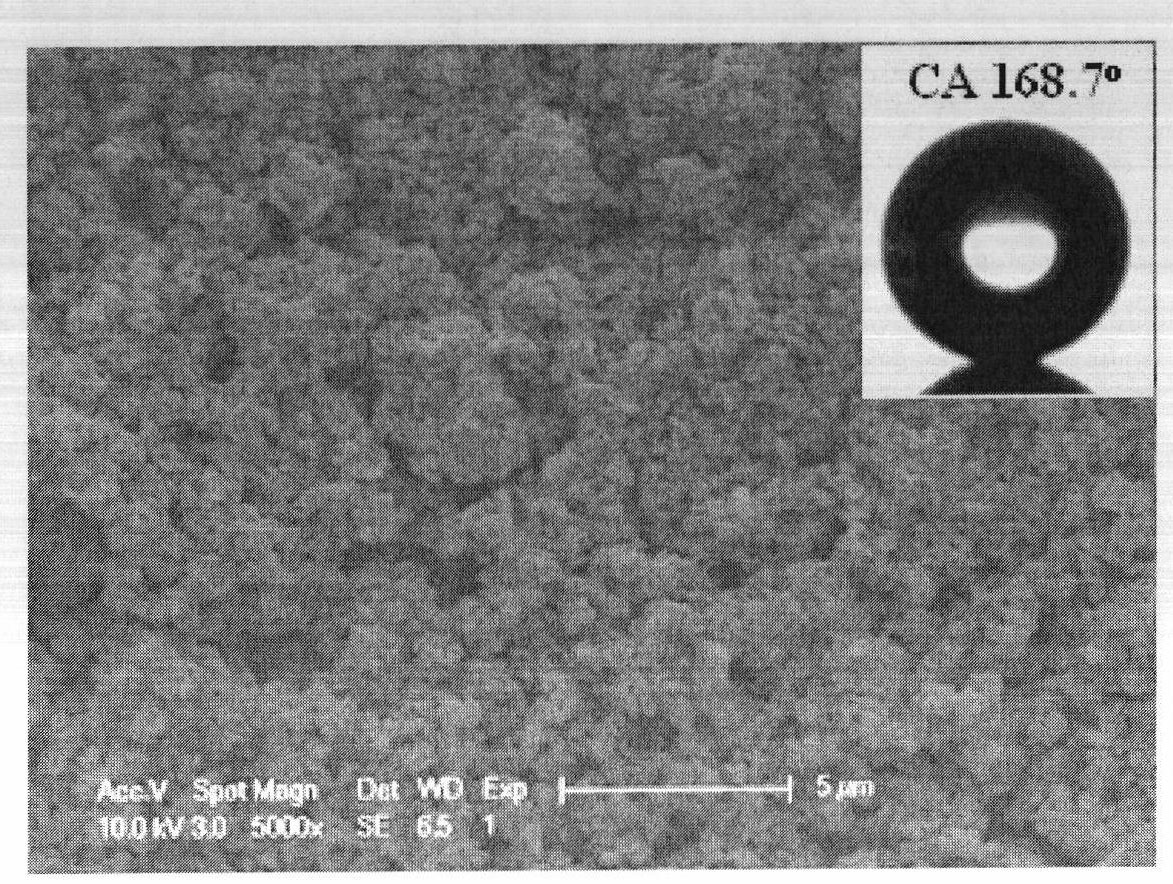

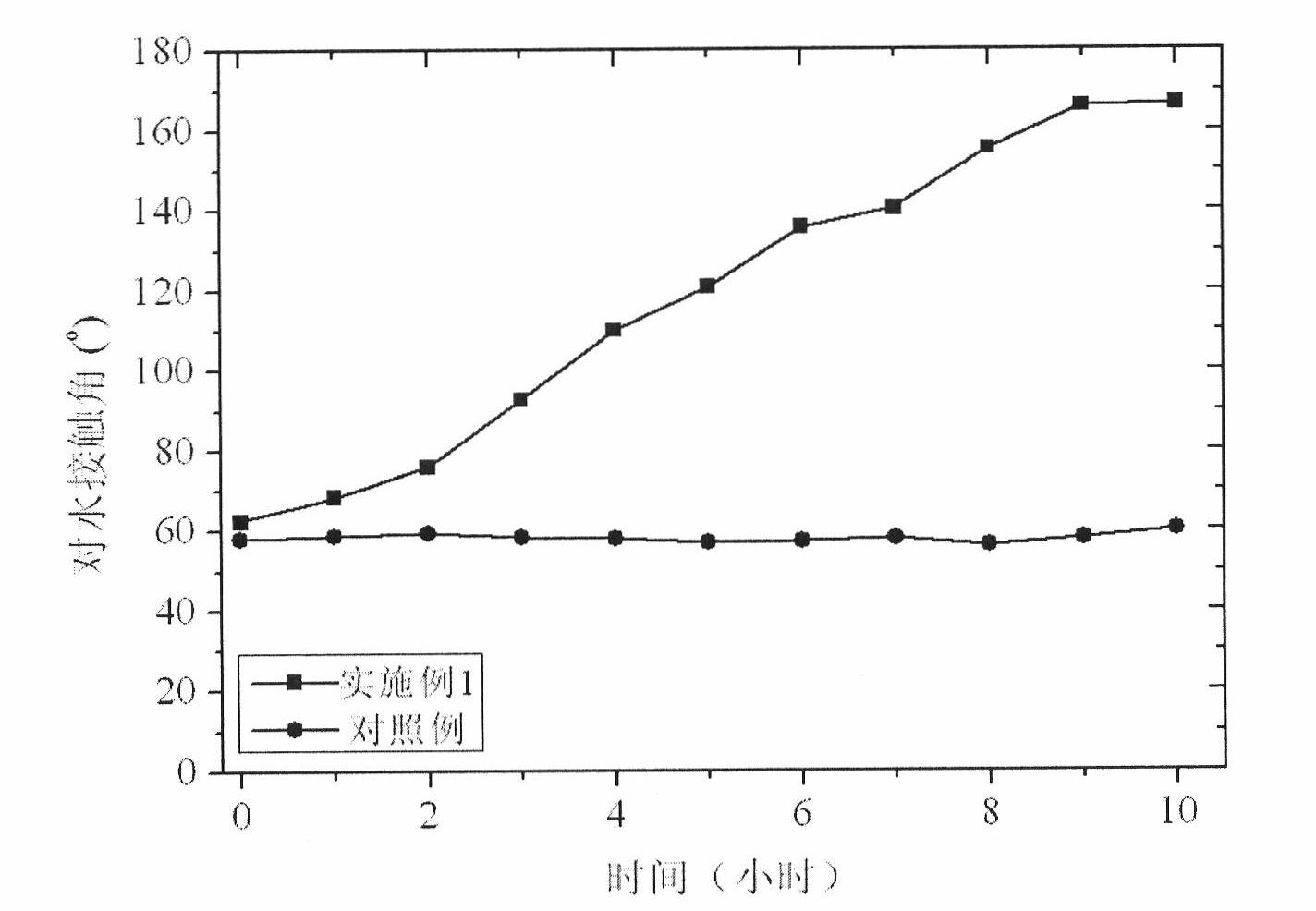

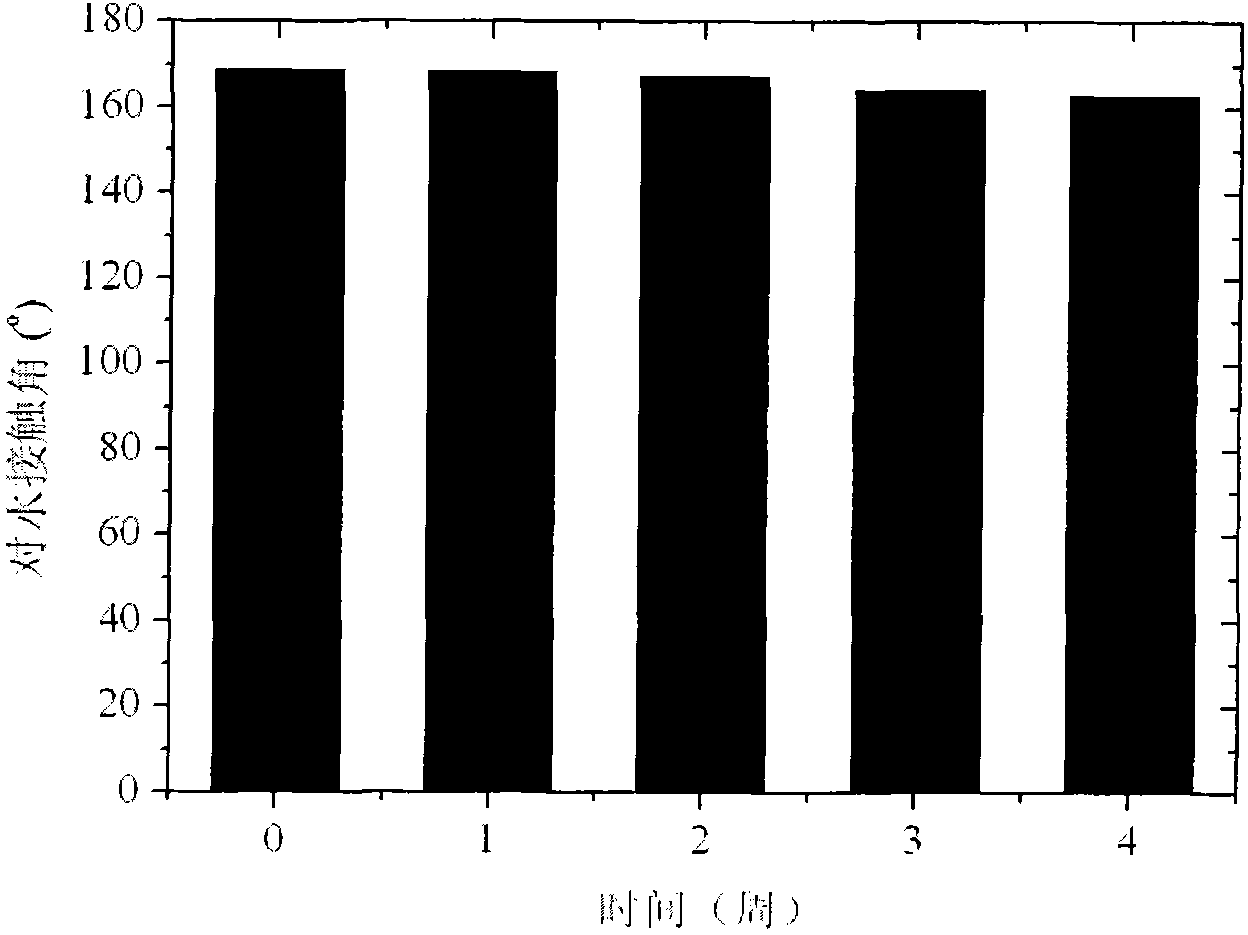

High-durability super-hydrophobic self-cleaning coating material and preparation method thereof

InactiveCN101962514AHas the following advantages: (1) cleanlinessHas the following advantages: (1) has the functionAntifouling/underwater paintsPaints with biocidesDouble bondDimethyl siloxane

The invention belongs to the technical field of a new chemical material, and in particular relates to a high-durability super-hydrophobic self-cleaning coating material and a preparation method thereof. The coating material of the invention is prepared by curing and drying nanoparticles with photo-catalytic activity, a low-surface-free-energy polymer and a cross-linking agent at the room temperature, wherein the low-surface-free-energy polymer consists of one or more of polysiloxane fluoride, dimethyl silicone polymer and polyphenylene methyl siloxane, which contain active groups, such as hydroxyl alkoxy group, carbon-carbon double bond, silanol group, siloxy group, and the like; the cross-linking agent is hydrogen-containing silicone oil or aminosilane; and the mass content of the photo-catalytic nanoparticles in the coating ranges from 10 to 60 percent. The coating is formed into a micro-nanostructure by nanoparticle self-organization; a super-hydrophobic self-cleaning coating with lotus effect is prepared from the coating and a cross-linked filming matrix with low surface energy; the persistence of a lotus-shaped super-hydrophobic characteristic of the coating is realized by using the photo-catalytic decomposition characteristic of an organic pollutant for the nanoparticles; and thus the material is suitable for large-area construction and has high weathering resistance andprominent self-cleaning characteristic.

Owner:FUDAN UNIV

Diene rubber composition for tire comprising a specific silica as reinforcing filler

InactiveUS7250463B2Less-difficult to processReduce hysteresisMaterial nanotechnologySpecial tyresPorosityElastomer

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Vapor deposition of metal oxides, silicates and phosphates, and silicon dioxide

InactiveUS6969539B2Good step coverageNarrow structureOxygen/ozone/oxide/hydroxideAluminium silicatesAlkylphosphatePhosphate

Metal silicates or phosphates are deposited on a heated substrate by the reaction of vapors of alkoxysilanols or alkylphosphates along with reactive metal amides, alkyls or alkoxides. For example, vapors of tris-(ter-butoxy)silanol react with vapors of tetrakis(ethylmethylamido)hafnium to deposit hafnium silicate on surfaces heated to 300° C. The product film has a very uniform stoichiometry throughout the reactor. Similarly, vapors of diisopropylphosphate react with vapors of lithium bis(ethyldimethylsilyl)amide to deposit lithium phosphate films on substrates heated to 250° C. supplying the vapors in alternating pulse produces these same compositions with a very uniform distribution of thickness and excellent step coverage.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Curable composition

InactiveUS20090182091A1Less discolorationGood adhesivenessOther chemical processesEster polymer adhesivesSilylenePlasticizer

The present invention has its object to provide a curable composition which comprises a guanidine compound as a non-organotin type catalyst, is less discolored, has good surface curability, depth curability, strength rise and adhesiveness, and can retain the curability even after storage; the above object can be achieved by a curable composition which comprises: (A) an organic polymer containing a silyl group capable of crosslinking under siloxane bond formation, the silyl group being a group represented by the general formula (1): —SiX3 (1) (wherein X represents a hydroxyl group or a hydrolyzable group and the three X groups may be mutually the same or different), (B) a guanidine compound (B-1) as a silanol condensation catalyst, and (C) a plasticizer, wherein the content of the component (B-1) is not lower than 0.1 part by weight but lower than 8 parts by weight per 100 parts by weight of the component (A), and a non-phthalate ester plasticizer accounts for 80 to 100% by weight of the (C) component plasticizer.

Owner:KANEKA CORP

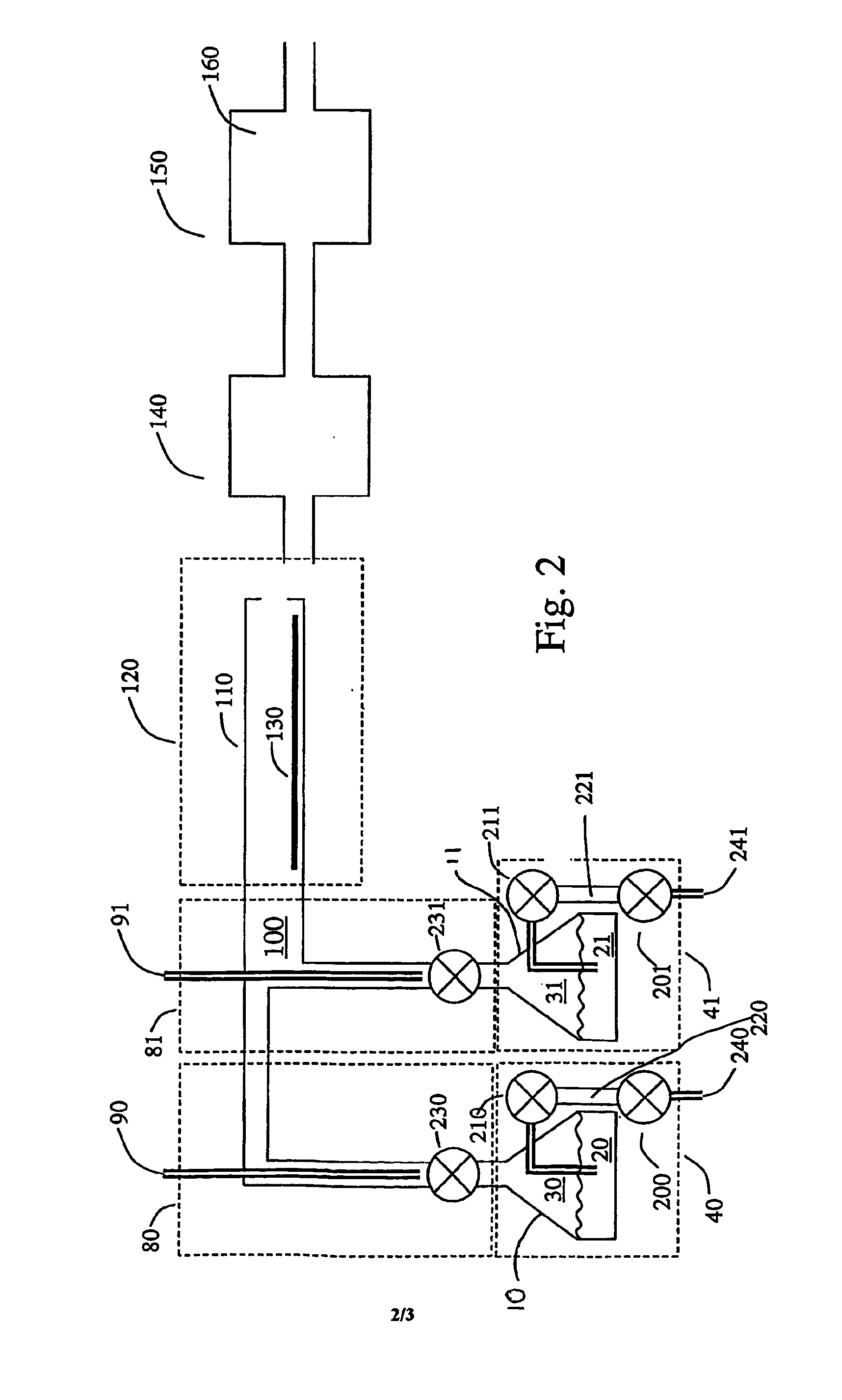

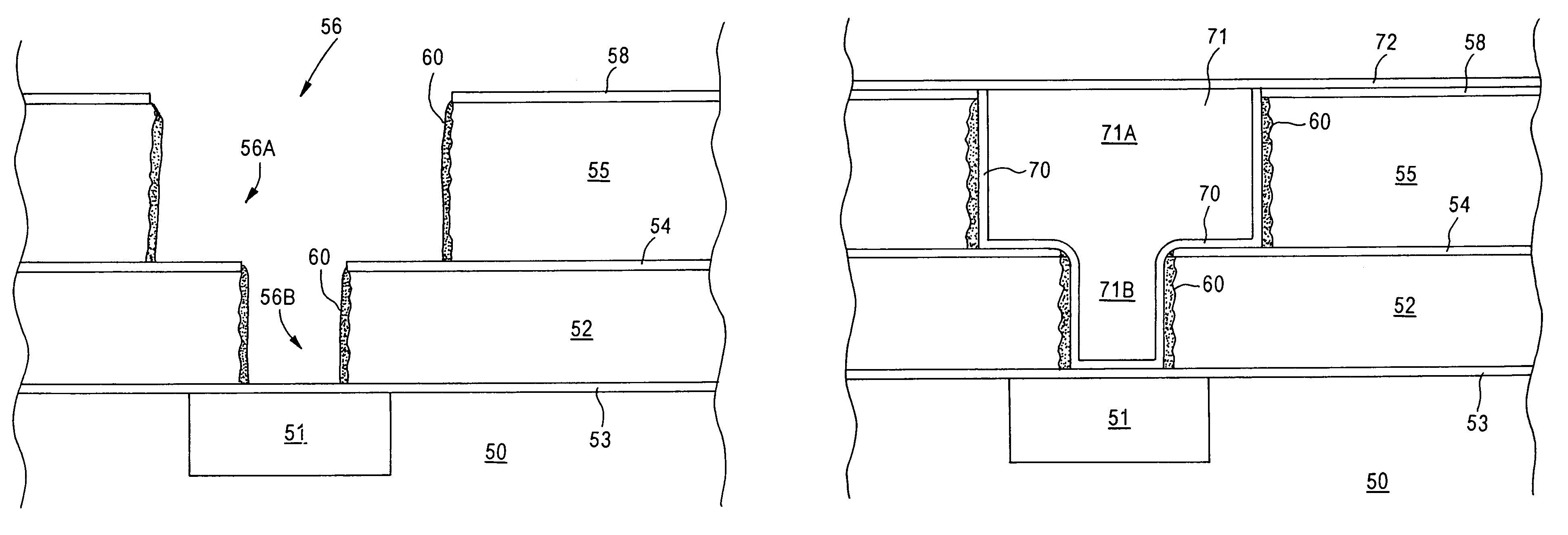

Interconnects with a dielectric sealant layer

ActiveUS6919636B1Reduced parasitic RxC time delayReduce time delaySemiconductor/solid-state device detailsSolid-state devicesCapacitanceAlloy

Leakage, capacitance and reliability degradation of interconnects fabricated in low-k dielectric materials, particularly porous low-k dielectric material, due to penetration by a barrier metal and / or barrier metal precursor during damascene processing is prevented by depositing a conformal, heat stable dielectric sealant layer on sidewalls of the low-k dielectric material defining the damascene opening. Embodiments include forming a dual damascene opening in a porous, low-k organosilicate layer, the organosilicate having a pendant silanol functional group, depositing a siloxane polymer having a silylating functional group which bonds with the pendant silanol group to form the sealant layer, depositing a Ta and / or TaN barrier metal layer by CVD or ALD and filling the opening with Cu or a Cu alloy.

Owner:ADVANCED MICRO DEVICES INC

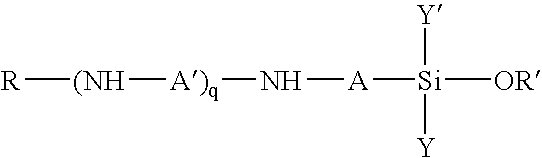

Fast-curing modified siloxane compositions

Fast-curing modified siloxane compositions comprise; (1) an alkoxy- or silanol-functional silicone intermediate, (2) at least one amine reactive ingredient selected from the group consisting of acetoacetate-functional ingredients, acrylate-functional ingredients, and mixtures thereof, (3) an epoxy-functional ingredient, (4) a curing agent selected from the group consisting of amines, aminosilanes, ketimines, aldimines and mixtures thereof, and (5) water. Other ingredients useful in forming fast-curing modified siloxane compositions of this invention include silanes, organometallic catalysts, solvents, pigments, fillers and modifying agents. The above-identified ingredients are combined and reacted to form a fully cured protective film comprising a cross-linked enamine polysiloxane and / or acrylate polysiloxane chemical structure in a reduced amount of time when compared to conventional epoxy siloxane compositions.

Owner:PPG IND OHIO INC

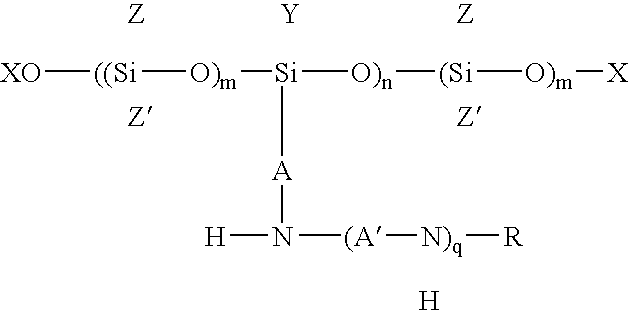

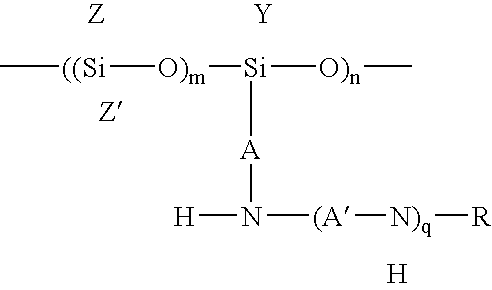

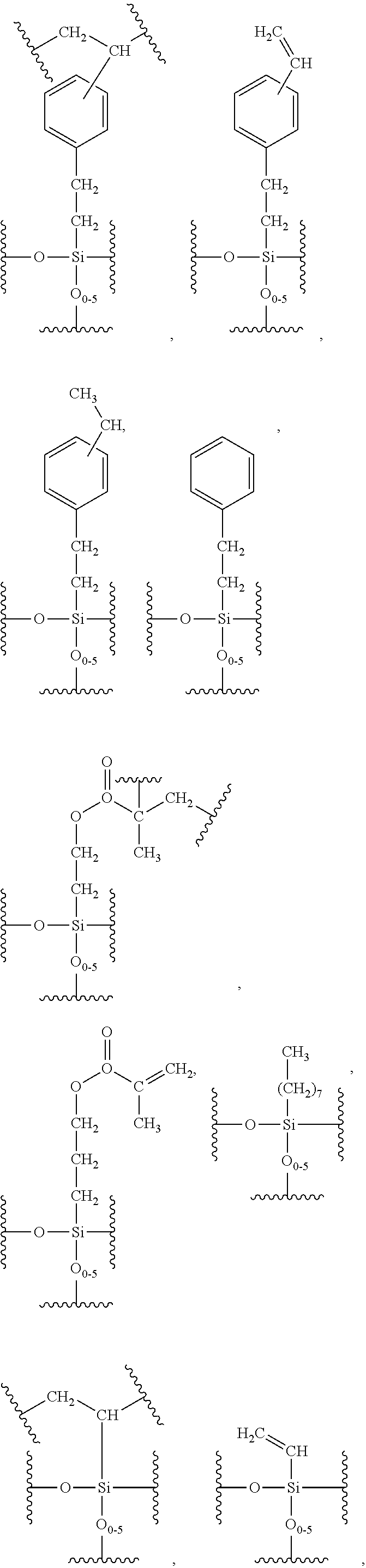

Polysiloxanes and their preparation

InactiveUS7238768B2Improve catalytic performanceCosmetic preparationsGroup 4/14 element organic compoundsPolymer sciencePtru catalyst

An amino-functional polysiloxane is prepared by reacting an aminosilane (A) which contains an aminoalkyl group and at least one alkoxy group bonded to Si with a carboxylic acid and a silanol-functional polysiloxane (B). The aminosilane (A) is partially converted into its carboxylate salt which acts as a catalyst for the siloxane condensation polymerization reaction between (A) and (B).

Owner:DOW SILICONES CORP

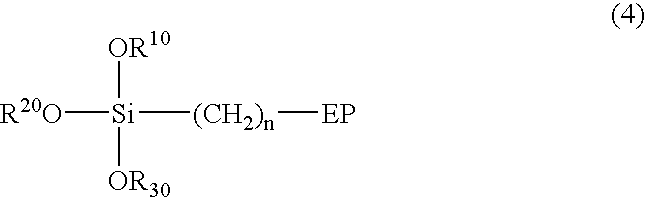

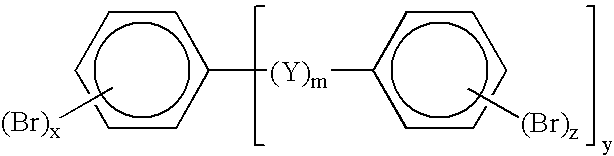

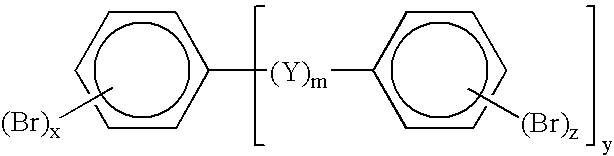

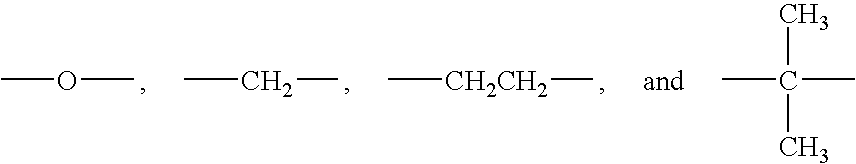

Antimicrobial coatings for medical applications

InactiveUS20050008763A1Broaden applicationEasy to preparePharmaceutical containersPretreated surfacesArylAdditive ingredient

The invention generally is related to preventing or inhibiting microbial infections on live tissues or in relation to the use of medical articles. In one embodiment, the invention is directed to a method for forming an antimicrobial coating on live tissue or a medical article, such as, for example, a catheter. The method includes applying to a live tissue or a surface of a medical article an aqueous or non-aqueous composition that includes at least one silane of the general formula R1nSi(OR2)4-n wherein, n is an interger of 1 or 2, R1 generally is a lower alkyl group, a C6-C8 aryl group, or a functional group, such as vinyl, acrylic, amino, mercapto, or vinyl chloride functional group, and R2 generally is a lower alkyl group. A partial condensate of a silanol of the formula R1Si(OH)3 also can be used. The composition includes one or more additional ingredients. The method also includes reacting and / or curing the silane, in the presence of the one or more ingredients, thereby forming the antimicrobial coating.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

Curable polysiloxane composition, and polysiloxane cured product, optical member, member for aerospace industry, semiconductor light-emitting device, illuminating device and image display device using the same

ActiveUS20110098420A1Improve heat resistanceImprove light resistanceSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceLight emitting device

The present invention provides a curable polysiloxane composition which is excellent in light resistance (particularly ultraviolet resistance) and adhesion and has a sufficient heat resistance / hydrothermal resistance and film-forming property and which generates little foaming at curing and does not generate cracks, peeling, coloring, and foaming even when used for a long period of time. A curable polysiloxane composition which comprises a specific hydrosilyl group-containing polysiloxane compound, a specific polysiloxane compound comprising two or more silanol groups in one molecule, and a dehydrogenative condensation reaction catalyst.

Owner:MITSUBISHI CHEM CORP

Swellable sol-gels, methods of making, and use thereof

The present invention relates to a method of making a swellable sol-gel composition that involves the use of a bridged silane precursor. The resulting sol-gel includes residual silanols, which are derivatized with a reagent having at least one silanol-reactive group and at least one alkyl group; and the sol-gel is then dried. Sol-gels of the invention are demonstrated to swell up to about 8-10 times their original volume in the presence of a non-polar sorbate. The sol-gel compositions can be used in a sorbate-activated actuator or in a detector for non-polar sorbates. The sol-gel compositions can further be used to take up non-polar sorbates for purposes of chemical remediation, extraction from aqueous systems or vapor, and chemical sensing.

Owner:WOOSTER TECH GRP +1

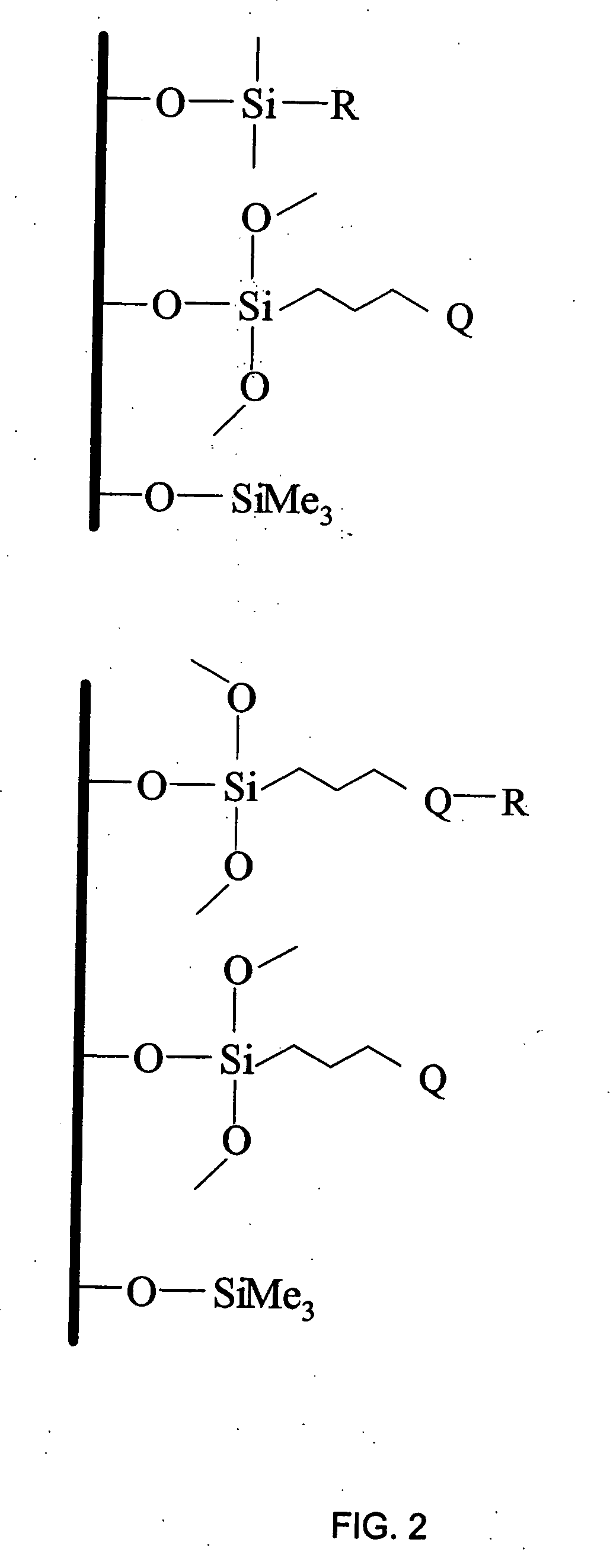

Polar-modified bonded phase materials for chromatographic separations

ActiveUS20050178730A1Good reproducibilityIon-exchange process apparatusOther chemical processesChromatographic separationStationary phase

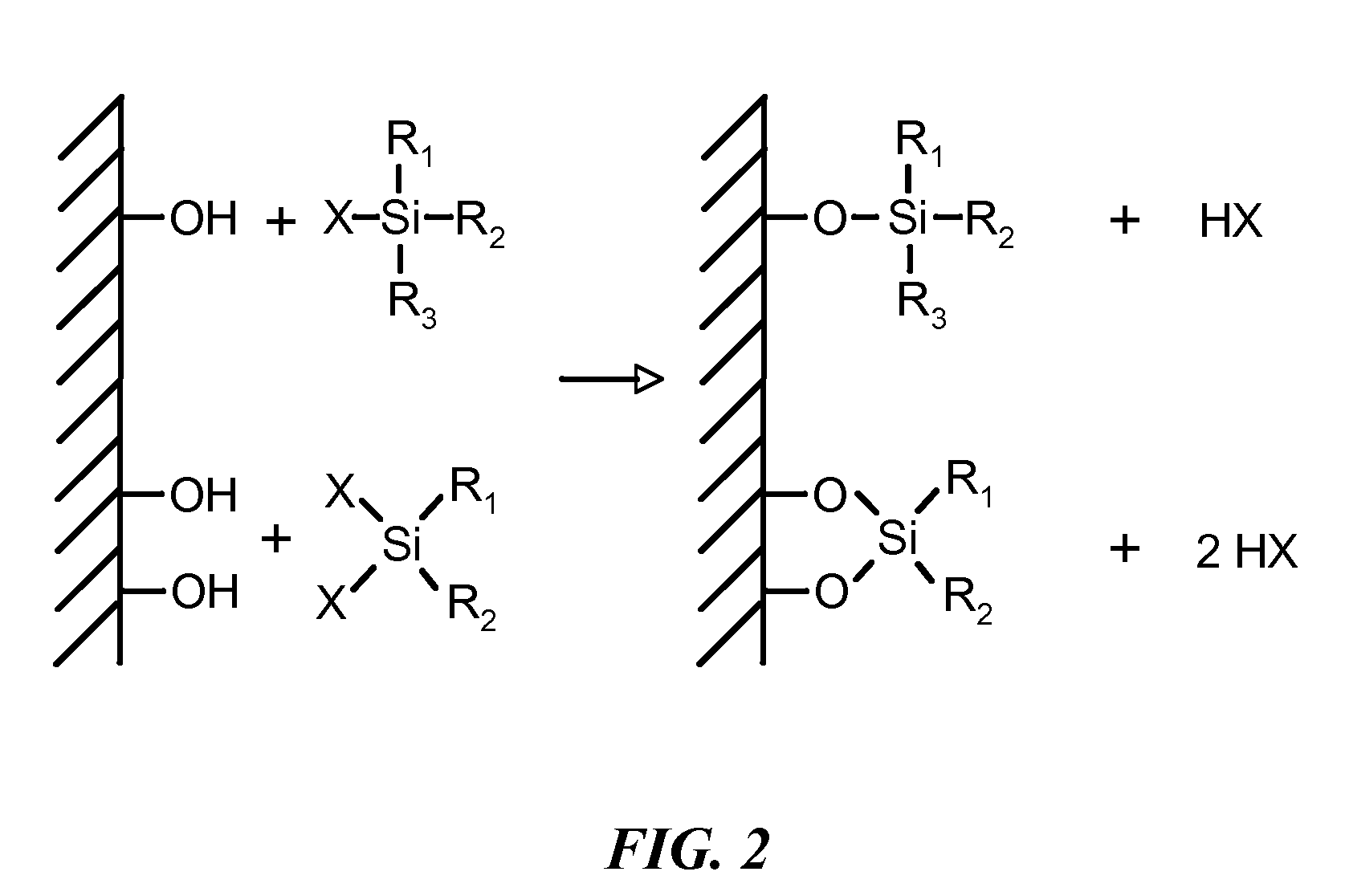

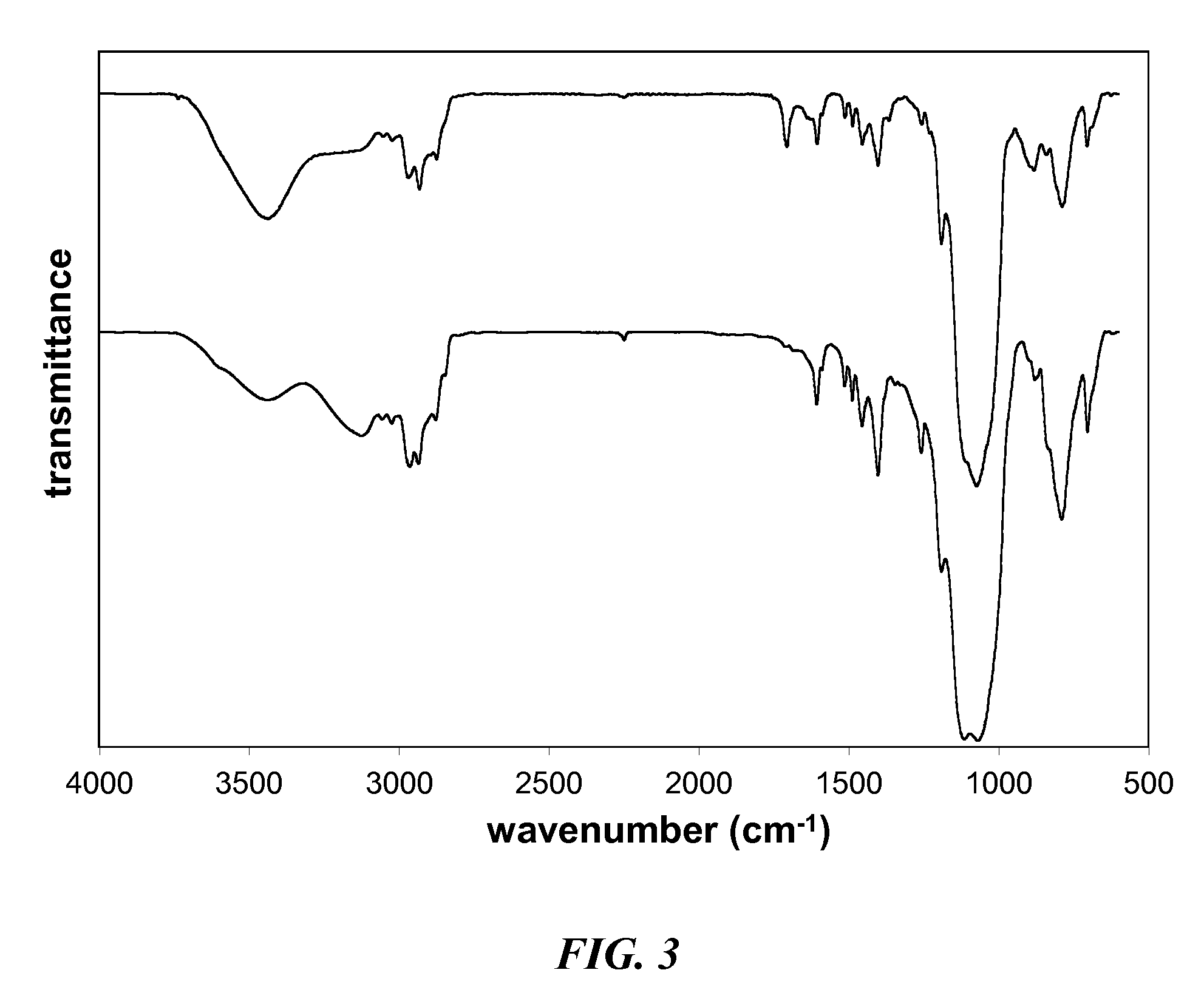

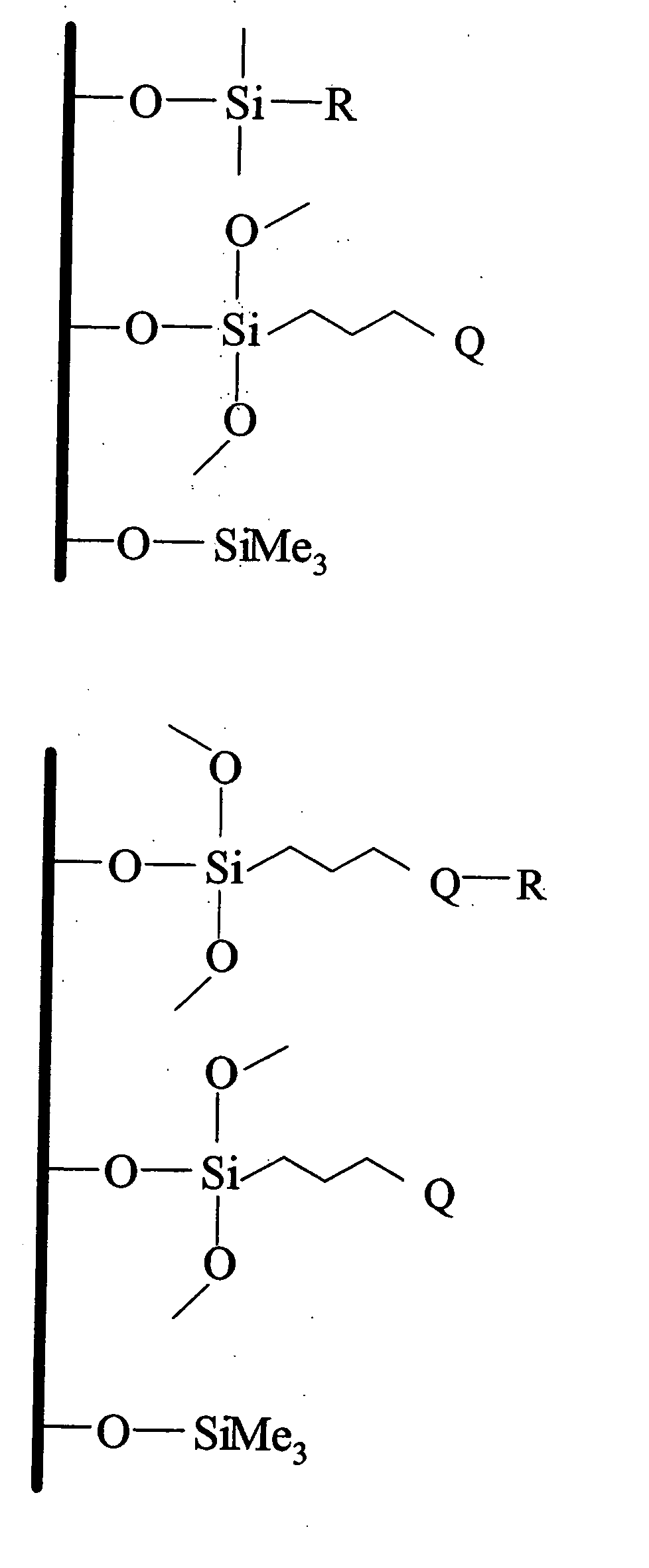

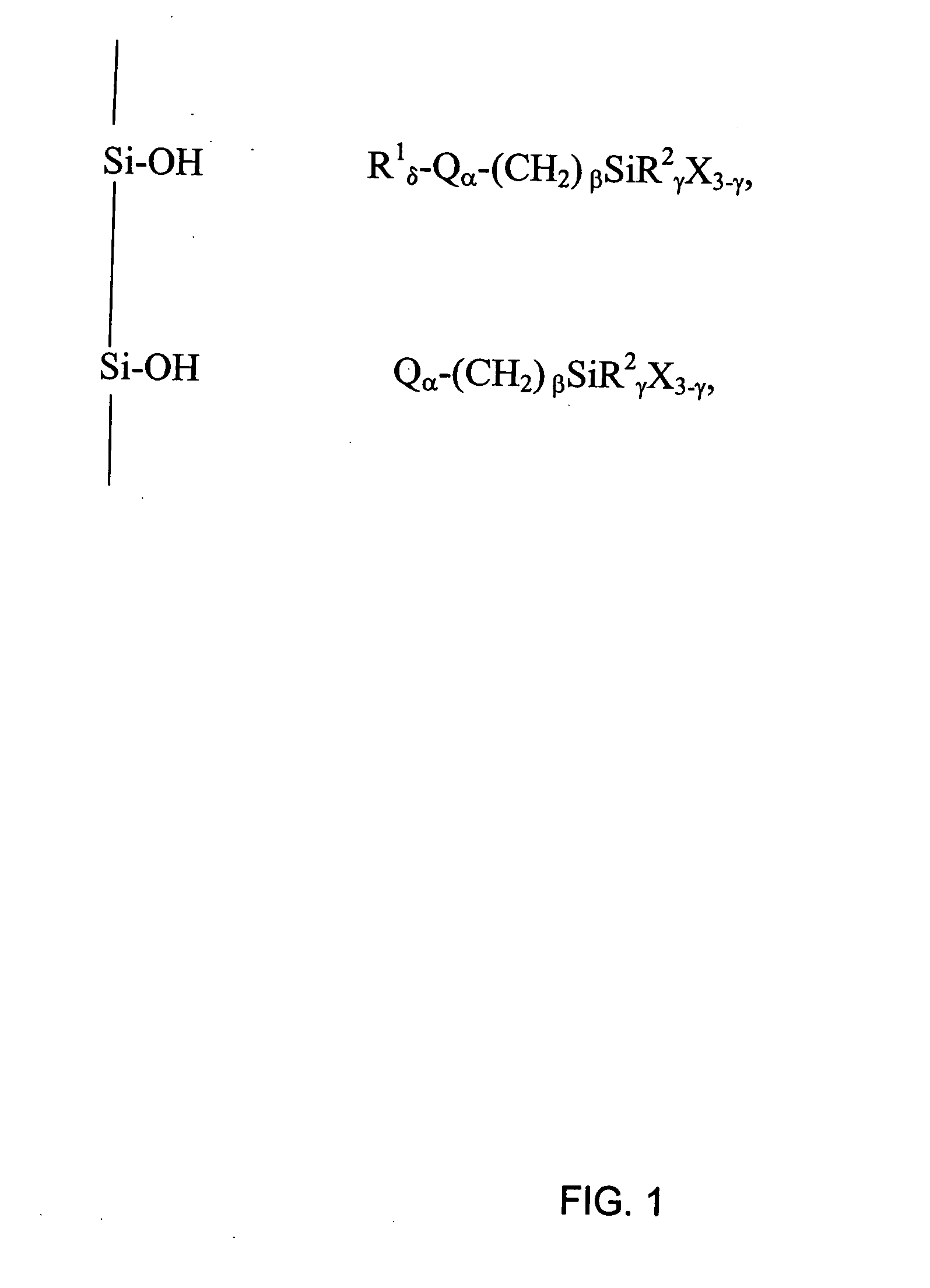

Novel compositions are disclosed for use as a stationary phase in chromatography comprising an inorganic substrate that is modified with at least one silane having the formula R1δ-Qα-(CH2)βSiR2γX3-γ. In a preferred embodiment, the inorganic substrate is silica gel and is modified with at least two silanes. Methods of preparation and use in chromatographic applications are disclosed. The novel compositions provide superior chromatographic performance, reduced silanol activity, enhanced stability, and reproducibility in preparation and performance.

Owner:AGILENT TECH INC

Silicon dioxide which bears partially or fully silylated polysilicic acid chains on its surface

InactiveUS6183867B1Improve rheologyImprove mechanical propertiesPigmenting treatmentSilicaSilanolSilylation

The invention relates to silicon dioxide which bears partially or fully silylated polysilicic acid chains on its surface, wherein the sum of silanol groups of the silicon dioxide surface (SiOH) and grafted-on silylating agent radicals (SiRa) is greater than the number of silanol groups on the surface of untreated silicon dioxide, where a can be 1, 2 or 3 and R can be identical or different and are each a substituted or unsubstituted hydrocarbon radical.

Owner:WACKER CHEM GMBH

Crosslinkable flame retardant wire and cable compositions having improved abrasion resistance

Moisture curable flame retardant wire and cable formulations having improved abrasion resistance are provided. The compositions are comprised of a high density silane-containing polyethylene base resin which can be a blend of a bimodal HDPE and ethylene-silane copolymer or silane-grafted bimodal HDPE in combination with a flame retardant and silanol condensation catalyst.

Owner:EQUSR CHEM LP

Antifouling coating composition

The antifouling composition of the present invention includes a glassy matrix formed by crosslinking a mixture of a silanol-terminated silicone and an alkoxy-functionalized siloxane to provide an interpenetrating polymer network of glass and silicone and at least two materials capable of microphase separation, at least one of which is graftable to the glassy matrix. A primer composition is also provided and is a mixture of an epoxy, an alkoxy-functionalized siloxane and a silane capable of compatabilizing the epoxy and the alkoxy-functionalized siloxane; a glassy matrix formed by crosslinking a mixture of a silanol-terminated silicone and an alkoxy-functionalized siloxane.

Owner:MICROPHASE COATINGS

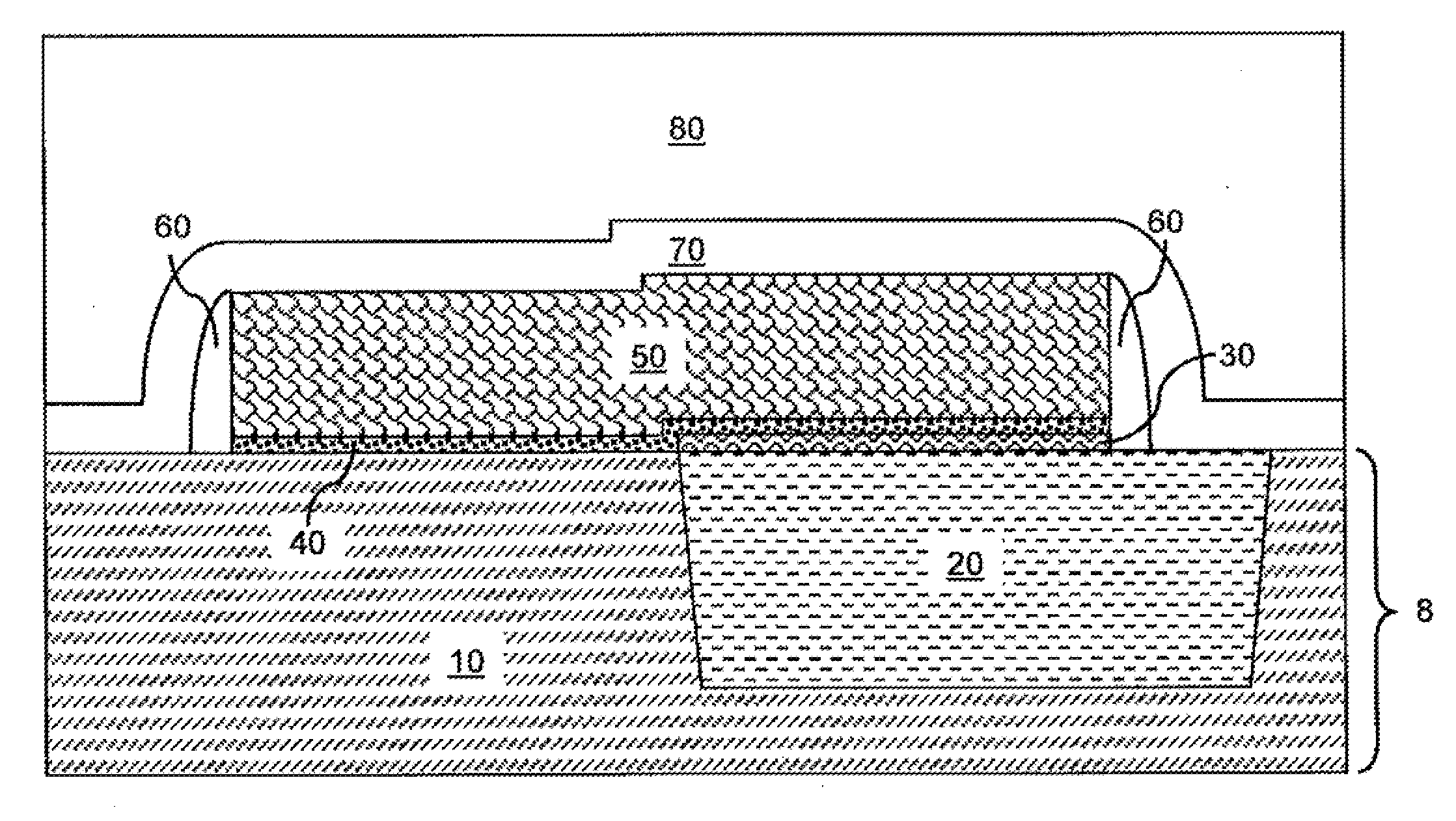

Selectively self-assembling oxygen diffusion barrier

ActiveUS20100237442A1Semiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricMonomer

A shallow trench isolation structure is formed in a semiconductor substrate adjacent to an active semiconductor region. A selective self-assembling oxygen barrier layer is formed on the surface of the shallow trench isolation structure that includes a dielectric oxide material. The formation of the selective self-assembling oxygen barrier layer is selective in that it is not formed on the surface the active semiconductor region having a semiconductor surface. The selective self-assembling oxygen barrier layer is a self-assembled monomer layer of a chemical which is a derivative of alkylsilanes including at least one alkylene moiety. The silicon containing portion of the chemical forms polysiloxane, which is bonded to surface silanol groups via Si—O—Si bonds. The monolayer of the chemical is the selective self-assembling oxygen barrier layer that prevents diffusion of oxygen to a high dielectric constant material layer that is subsequently deposited as a gate dielectric.

Owner:GLOBALFOUNDRIES US INC

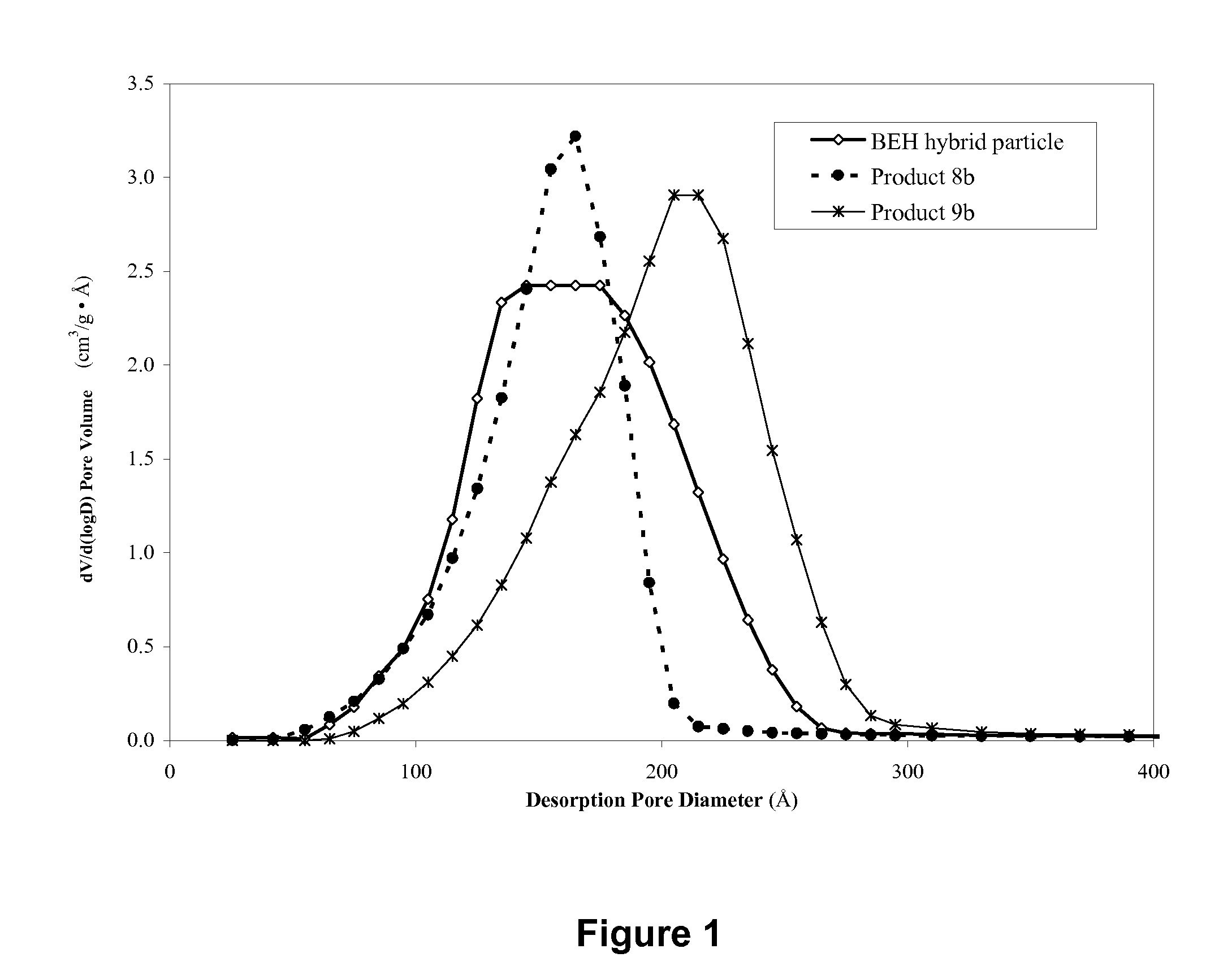

Hybrid inorganic/organic materials having novel surface modification; process for the preparation of inorganic/organic hybrid materials; and use of said particles for chromatographic separations

ActiveUS20120055860A1Enhancing oneMany of characteristicIon-exchange process apparatusSemi-permeable membranesChromatographic separationIon exchange

The present invention provides novel chromatographic materials, e.g., for chromatographic separations, processes for their preparation and separations devices containing the chromatographic materials. The preparation of the inorganic / organic hybrid materials of the invention wherein a surrounding material is condensed on a porous hybrid core material will allow for families of different hybrid packing materials to be prepared from a single core hybrid material. Differences in hydrophobicity, ion-exchange capacity, surface charge or silanol activity of the surrounding material may be used for unique chromatographic separations of small molecules, carbohydrates, antibodies, whole proteins, peptides, and / or DNA.

Owner:WATERS TECH CORP

Antifouling coating composition

The antifouling composition of the present invention includes a glassy matrix formed by crosslinking a mixture of a silanol-terminated silicone and an alkoxy functionalized siloxane to provide an interpenetrating polymer network of glass and silicone and at least two materials capable of microphase separation, at least one of which is graftable to the glassy matrix.

Owner:MICROPHASE COATINGS

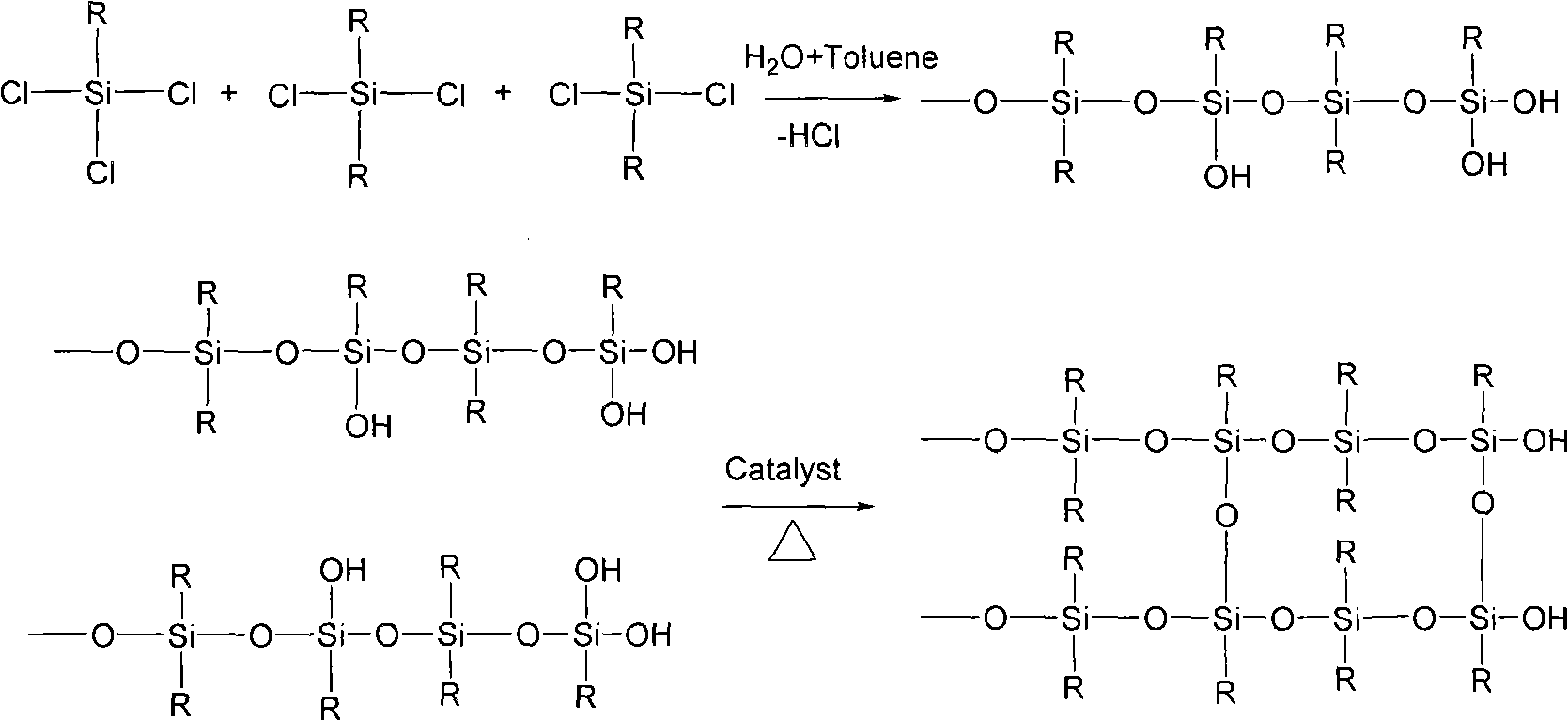

Preparation method for methyl phenyl vinyl polysiloxane for packaging LED

The invention discloses a preparation method for organosilicon, in particular relates to a preparation method of methyl-phenyl-vinyl silicone resin with high refractive index and high light transmission rate for packaging LED. The preparation method adopts the steps that the mixture of chlorosilane and toluene is added into the solvent which is composed of water and the toluene, the hydrolysis reaction is performed, then an amount of catalyzer is added into the silanol-toluene solution as hysrolysis product, the polycondensation reaction is performed, end capping reagent is finally added to perform the reaction, thus the objective product is obtained. The methyl-phenyl-vinyl silicone resin prepared by utilizing the method has the advantages of high refractive index, transparent clarification, radiation resistance, and high and low temperature resistance and weather resistance, thereby being especially suitable for the high modular basic glue in the packaging material for LED and expected to be applied in organosilicon material such as elastomeric sealant, pouring sealant, elastomoric adhesive and the like.

Owner:HANGZHOU NORMAL UNIVERSITY

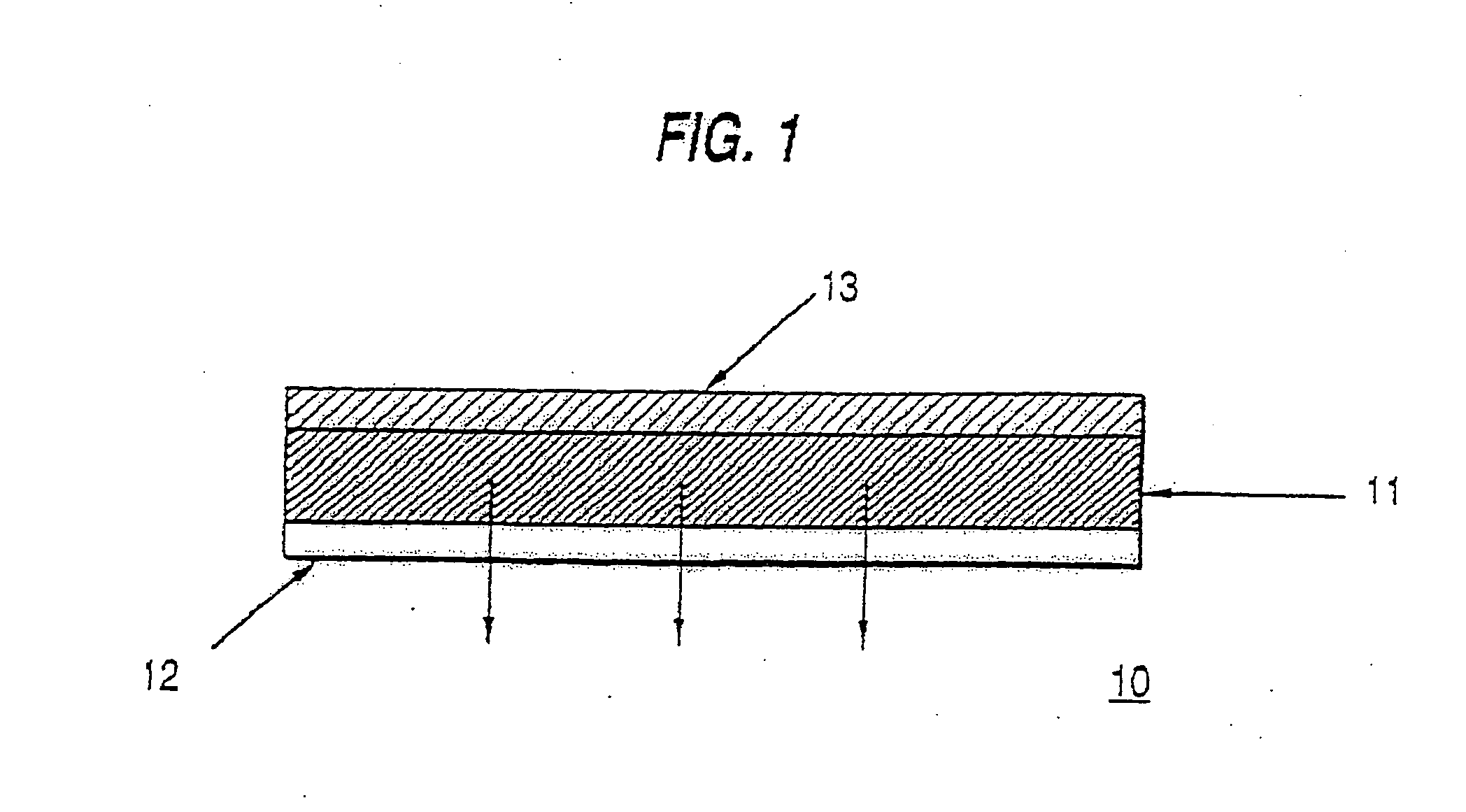

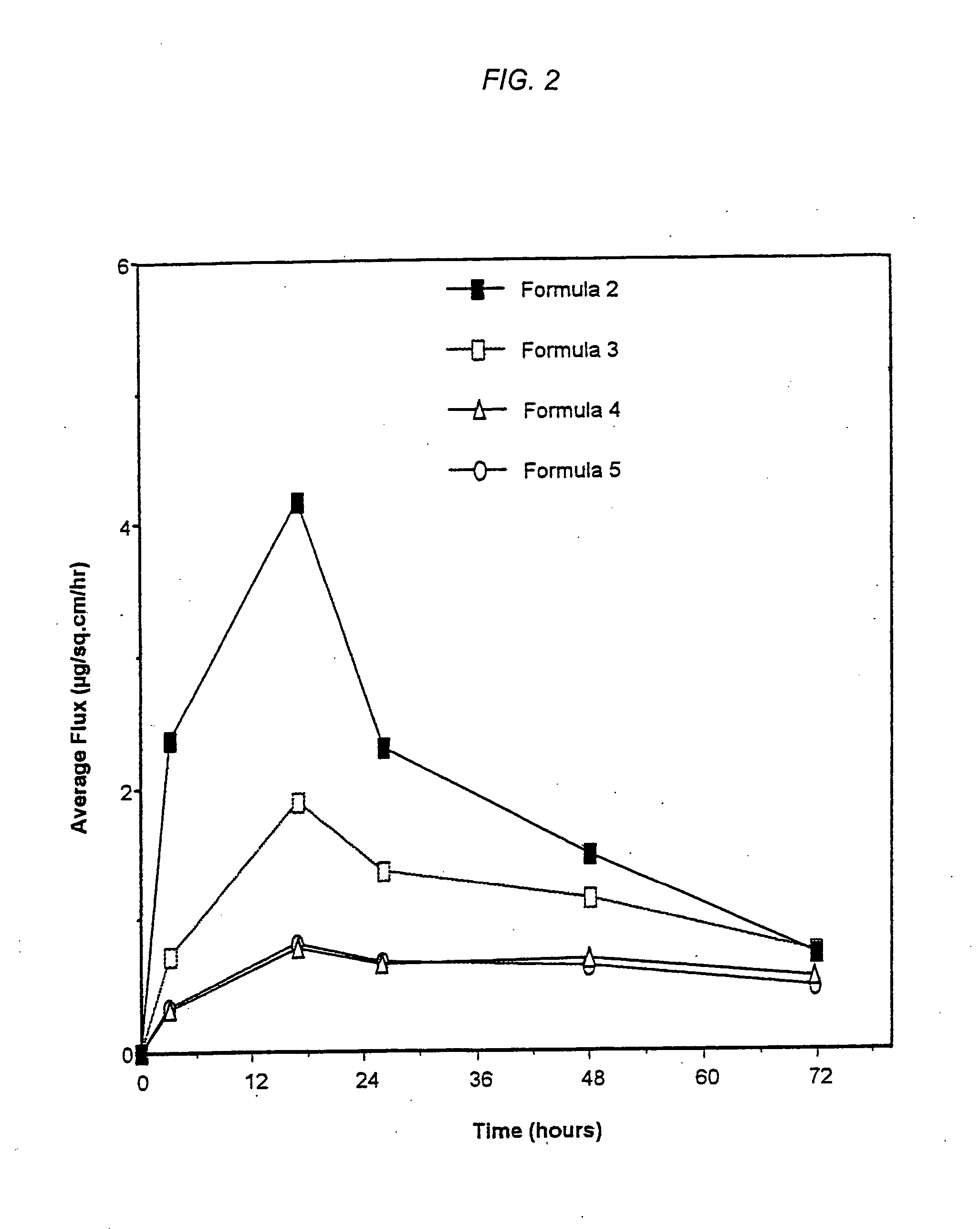

Composition and method for controlling drug delivery from silicone adhesive blends

InactiveUS20050019385A1Reduce concentrationPrevent/inhibit crystallizationSheet deliveryBandagesControlled drugsSolubility

Compositions and methods for controlling transdermal drug delivery, particularly of amine-functional and basic drugs, comprising a blend of a first silicone-based polymer having a reduced silanol concentration and a second silicone-based polymer have a substantial or high silanol concentration. The blend of such silicone-based polymers, particularly pressure-sensitive silicone adhesives, provides sufficient drug solubility and reduced initial drug delivery onset to permit a prolonged delivery duration at a substantially zero-order rate of delivery.

Owner:NOVEN PHARMA

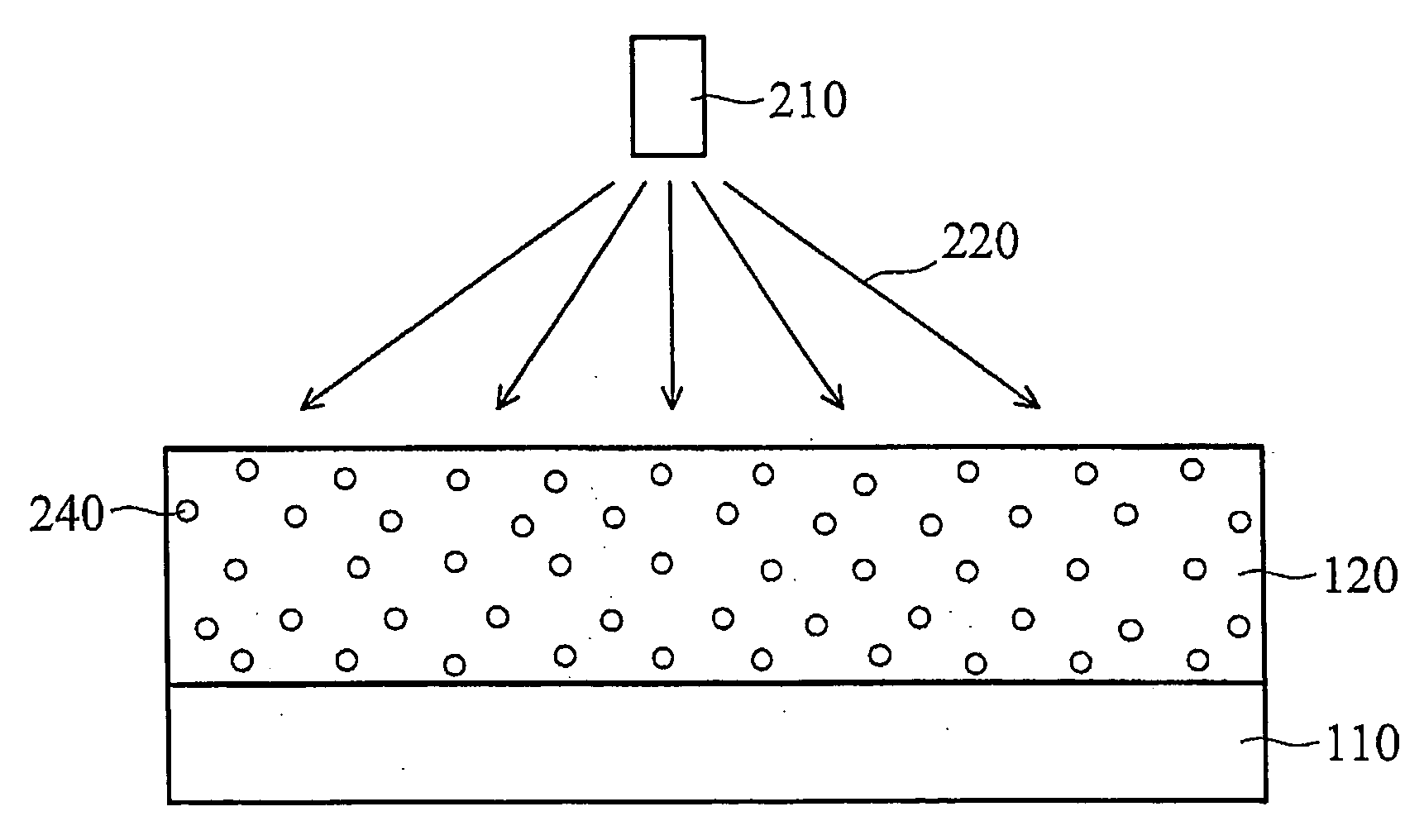

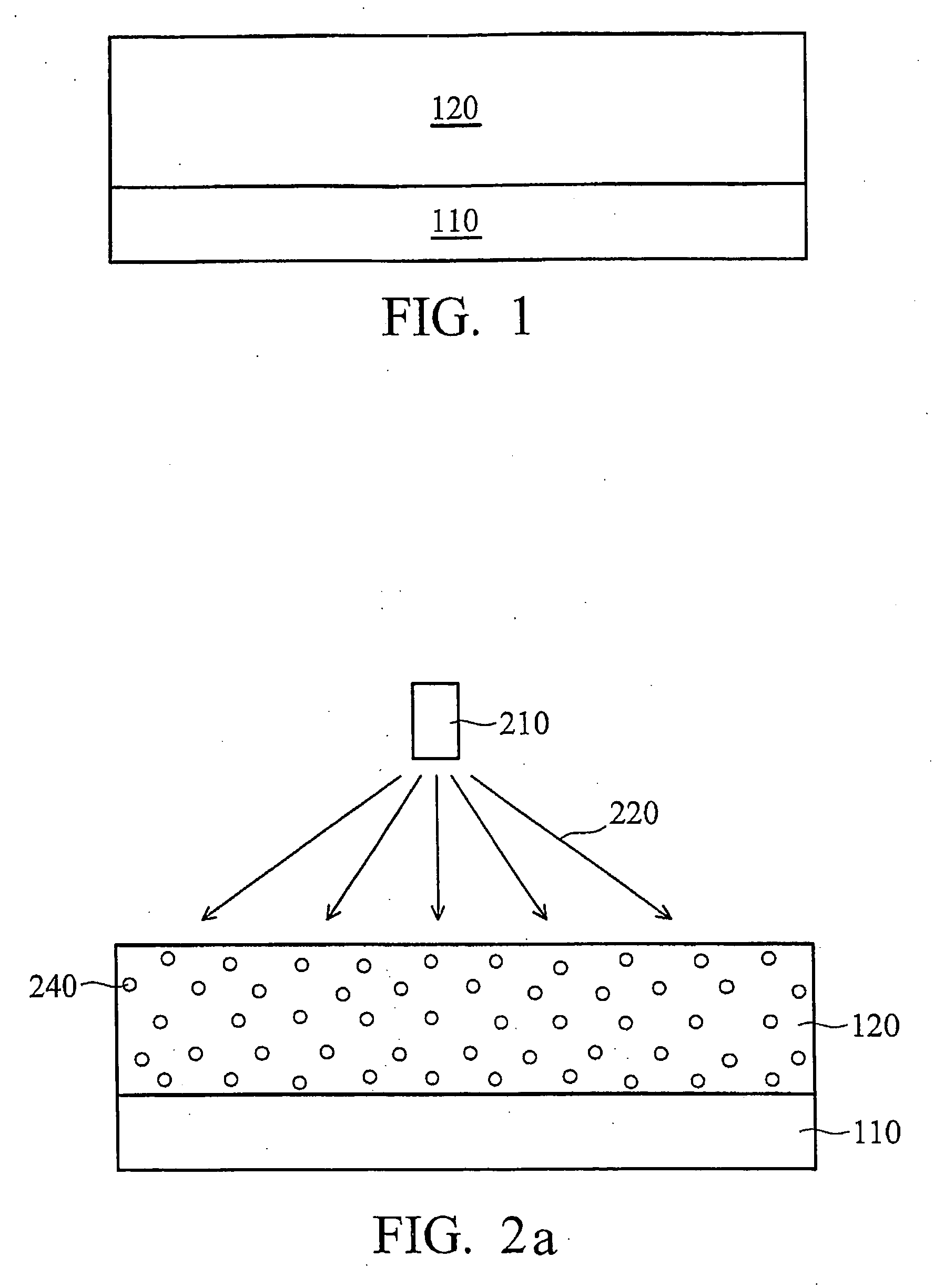

UV curing of low-k porous dielectrics

InactiveUS20070161230A1Solid-state devicesSemiconductor/solid-state device manufacturingCross-linkDevice material

A method of manufacturing a semiconductor device having a low-k dielectric layer is provided. An embodiment comprises forming a dielectric layer on a substrate, wherein the layer comprises a pore generating material dispersed in an uncured matrix. A second step comprises forming pores in the uncured matrix by irradiating the layer with radiation having a first wavelength. After pore forming, a third step comprises cross-linking the dielectric by irradiating it at a second wavelength, the second being less than the first. In an embodiment, the irradiating wavelengths comprise ultra-violet radiation. Embodiments may further include repairing processing damage wherein the damage includes dangling bonds or silanol formation. The repairing includes annealing in a carbon-containing ambient such as C2H4, C3H6, or hexamethyldisilazane (HMDS).

Owner:TAIWAN SEMICON MFG CO LTD

Erosion-resistant silicone coatings for protection of fluid-handling parts

ActiveUS7033673B2Improve adhesionEconomy in coatingPretreated surfacesLiquid/solution decomposition chemical coatingSilanesSilanol

Owner:SS IND TECH LLC

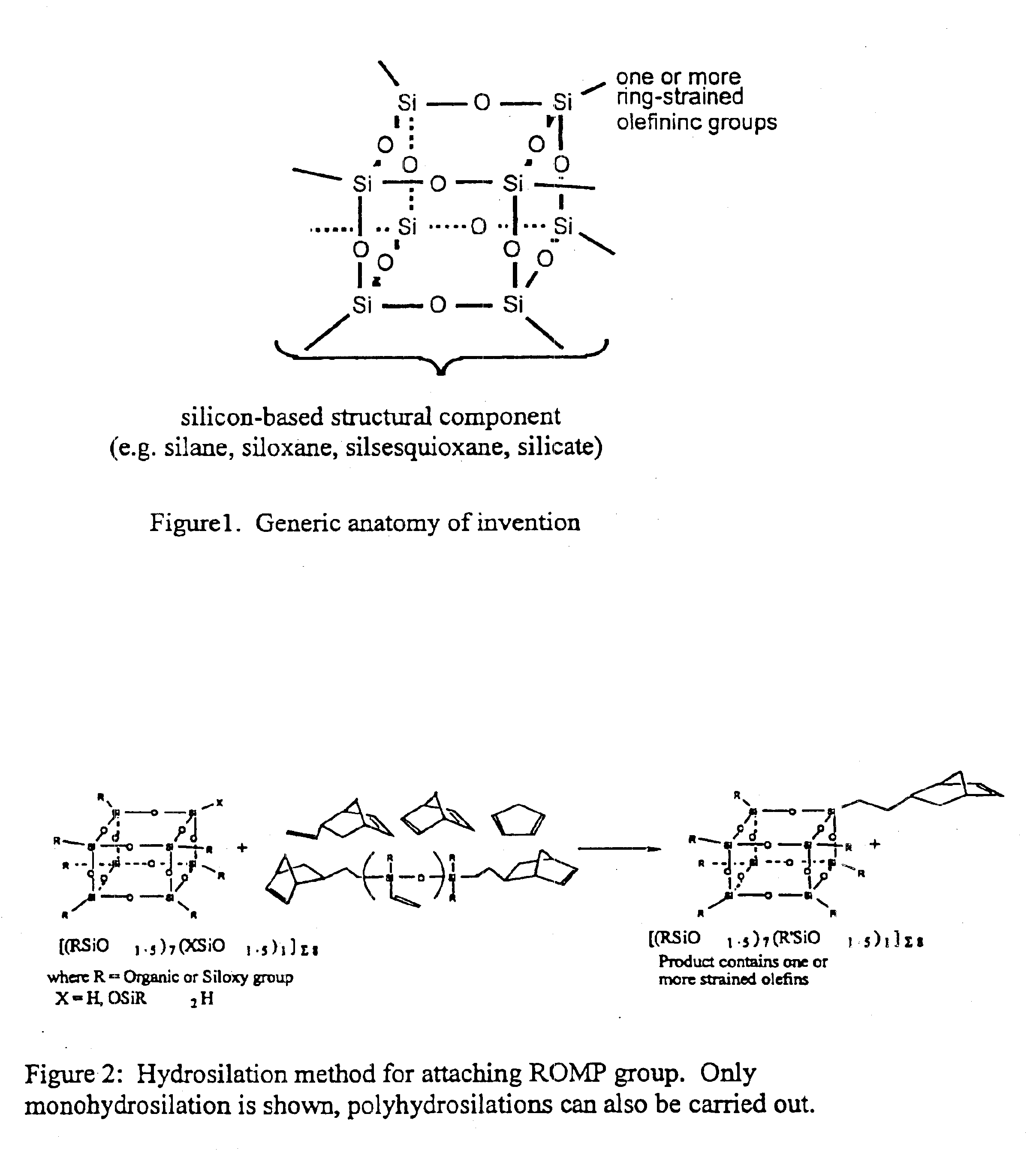

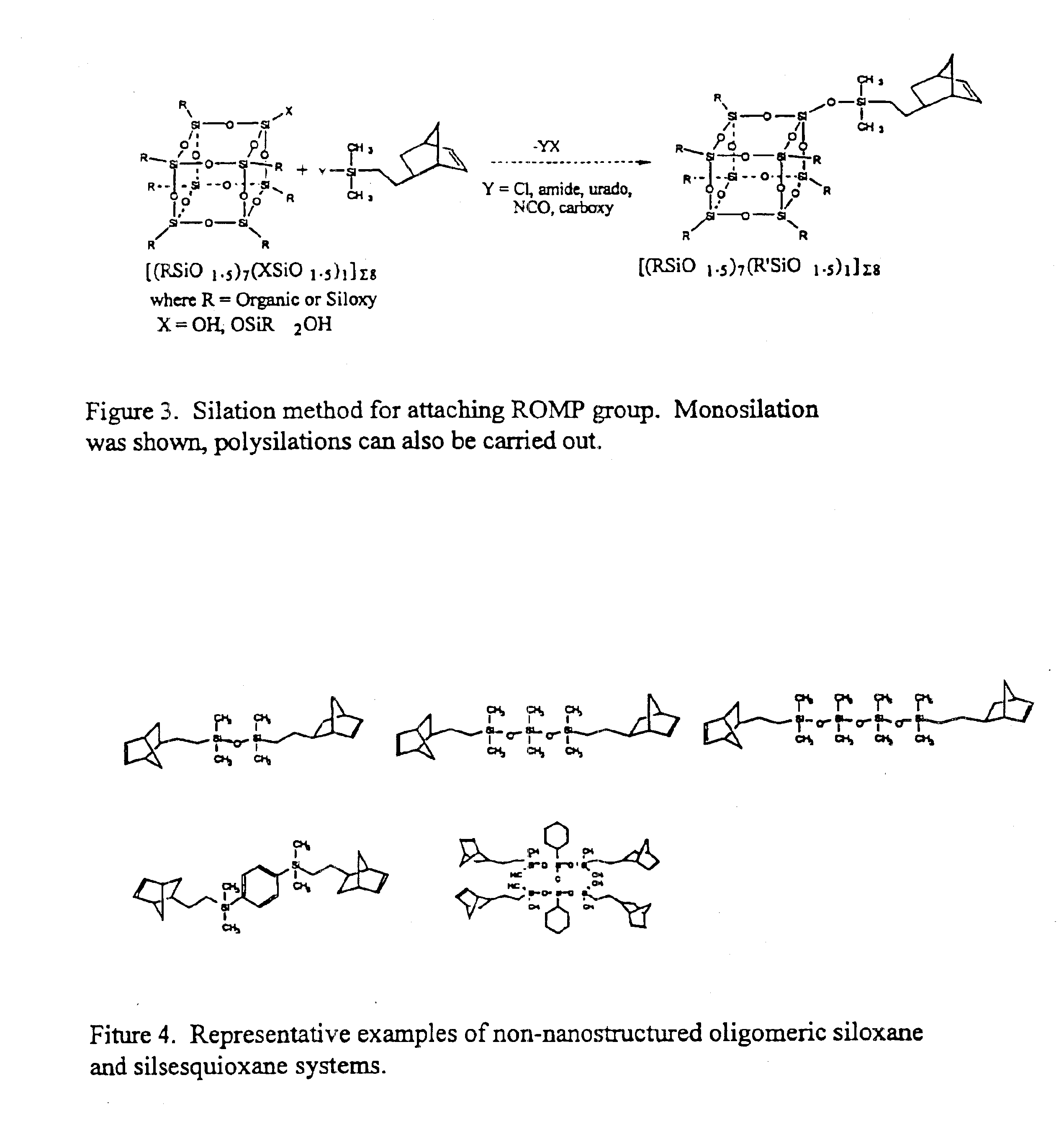

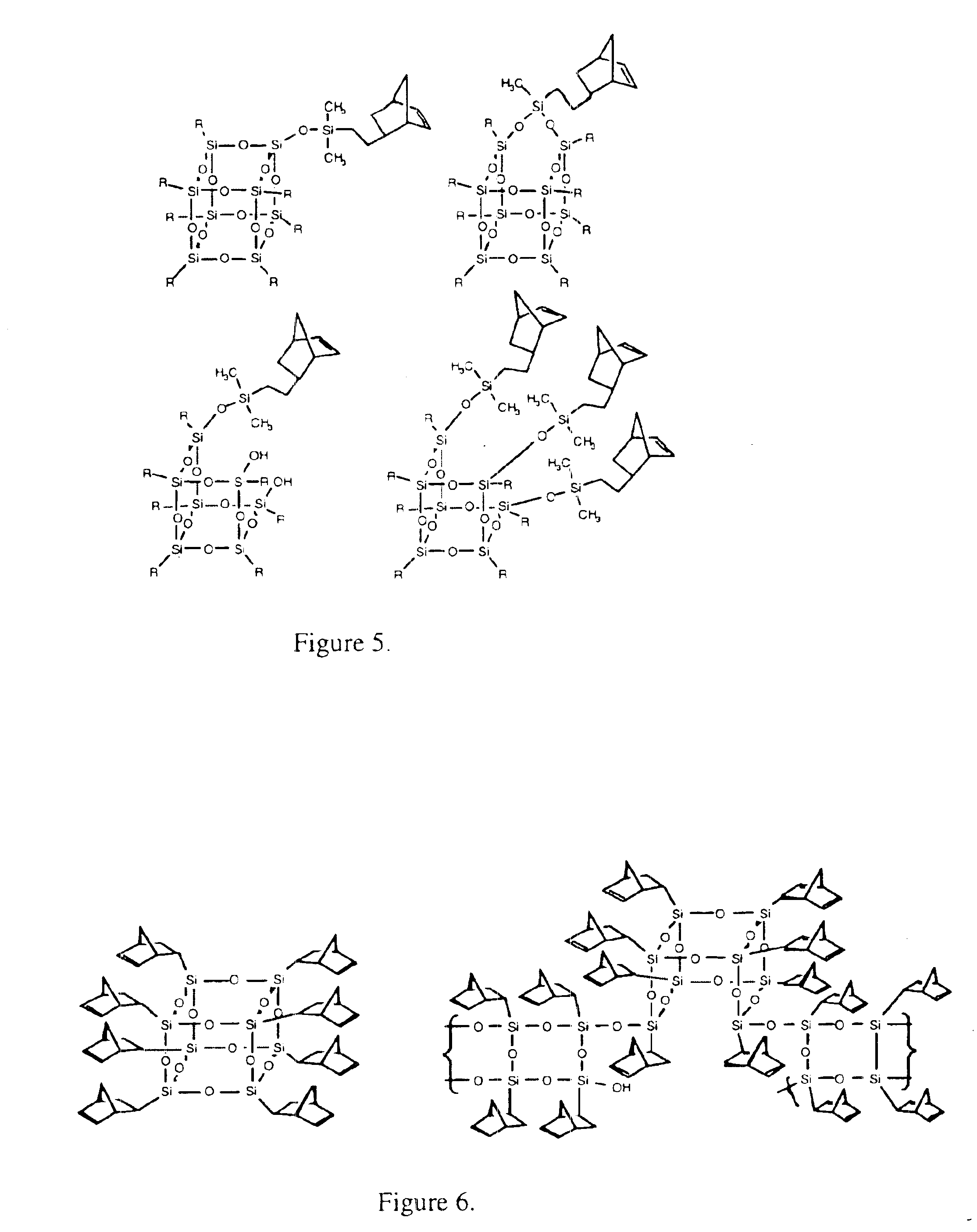

Polyhedral oligomeric -silsesquioxanes, -silicates and -siloxanes bearing ring-strained olefinic functionalities

InactiveUS6911518B2Improving biocompatabilityImprove fire resistanceSilicon organic compoundsGroup 6/16 organic compounds without C-metal linkagesAlkaline earth metalChemical reaction

Processes have been developed for the manufacture of polyhedral oligomeric silsesquioxanes (POSS), polysilsesquioxanes, polyhedral oligomeric silicates (POS), and siloxane molecules bearing reactive ring-strained cyclic olefins (e.g. norbornenyl, cyclopentenyl, etc. functionalities). The preferred manufacturing processes employ the silation of siloxides (Si—OA, where A=H, alkaline or alkaline earth metals) with silane reagents that contain at least one reactive ring-strained cyclic olefin functionality [e.g., X3-ySi(CH3)y(CH2)2 where y=1-2 and X=OH, Cl, Br, I, alkoxide OR, acetate OOCR, peroxide OOR, amine NR2, isocyanate NCO, and R]. Alternatively, similar products can be prepared through hydrosilation reactions between silanes containing at least one silicon-hydrogen bond (Si—H) with ring-strained cyclic olefin reagents [e.g., 5-vinyl, 2 norbornene CH2═CH, cyclopentadiene]. The two processes can be effectively practiced using polymeric silsesquioxanes [RSiO1.5]∞ where ∞=1-1,000,000 or higher and which contain unreacted silanol or silane groups at chain terminus or branch points, on POSS nanostructures of formulas [(RSiO1.5)n]Σ#, homoleptic, [(RSiO1.5)m(R′SiO1.5)n]Σ#, heteroleptic, and {(RSiO1.5)m(RXSiO1.0)n}Σ#, functionalized heteroleptic nanostructures, on silanes RSiX3, linear, cyclic, oligomeric and polymeric siloxanes (polymeric formula RX2Si—(OSiRX)m—OSiRX2 where m=0-1000, X=OH, Cl, Br, I, alkoxide OR, acetate OOCR, peroxide OOR, amine NR2, isocyanate NCO, and R). Each of the processes result in new chemical species bearing one or more ring strained olefins that can undergo polymerization, grafting, or other desirable chemical reactions to form polymeric products. These polymeric systems are most desirably utilized in polymerizations for the modification of properties of thermoplastic or thermoset resin systems or for the preparation of polymers with utility in electronics, medical devices, sporting goods, and aerospace as coatings and structural components.

Owner:HYBRID PLASTICS INC

Fire resistant flexible ceramic resin blend and composite products formed therefrom

InactiveUS20100304152A1Improve fire performanceConducive to lightweightSynthetic resin layered productsCellulosic plastic layered productsAdhesiveComposite laminates

High heat resistant elastic composite laminates, sealants, adhesives, and coatings developed from a resin blend. The resin blend is made up of methyl and optionally phenyl silsequioxane resins selected to produce silanol-silanol condensation silicone polymers formed in a slowly evolving reaction mass containing submicron boron nitride, silica and boron oxide fillers. The required ratio of submicron boron nitride to silica has been discovered for assuring the formation of a high temperature resistant elastic composite blend that will form intermediate flexible ceramic products up to 600 deg C., then continue to form preceramic then dense ceramic products from 600 to 1000 deg C. The thermal yield of the composite is generally greater than 90 wt. % at 1000 deg C. Composite products with different levels of heat transformation can be fabricated within the same product depending upon the thickness of the layers of reinforcement.

Owner:FLEXIBLE CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com